High-solid-content weather-proof bottom-face integrated anticorrosive paint containing polyaspartic acid ester

A technology of aspartic acid ester and anti-corrosion coatings, which is applied in the direction of anti-corrosion coatings, polyester coatings, polyamide coatings, etc., and can solve the problems of poor comprehensive performance, low non-volatile content of coatings, and poor storage stability of coatings, etc. problems, to achieve the effect of long-term anti-corrosion, large molecular weight and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

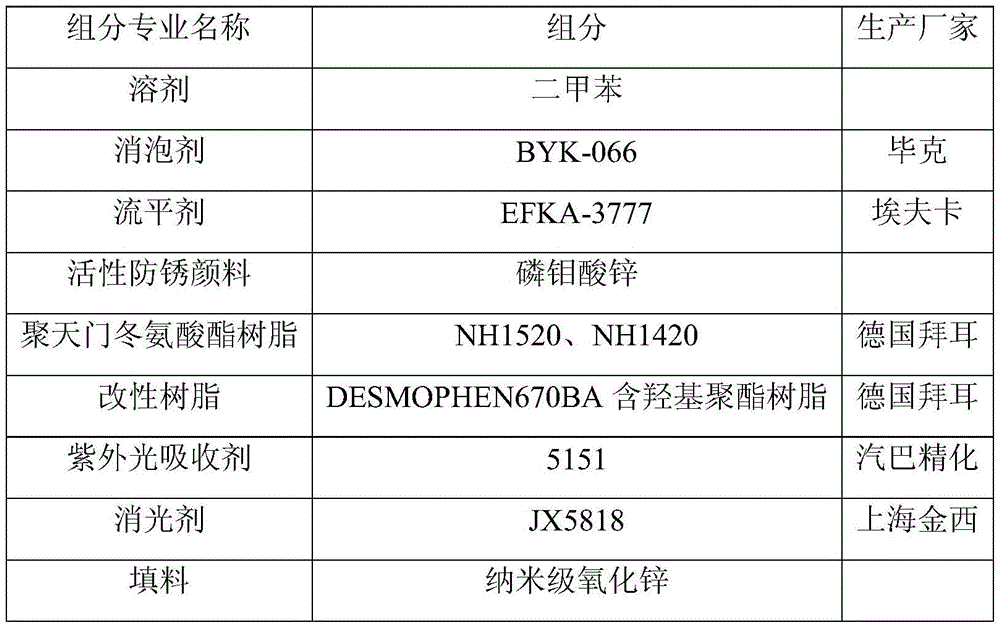

Method used

Image

Examples

Embodiment 1

[0032] (1) Pretreatment of pigments and fillers

[0033] Add 38 parts by weight of pigment and 10 parts by weight of filler to the aqueous solution of polyvinylpyrrolidone with a mass fraction of 10% solute. The total mass of the added pigment and filler is 8% of the mass of the aqueous solution of polyvinylpyrrolidone. Stir at 50°C for 4 hours. Filter and dry at 70°C;

[0034] (2) First, 9 parts by weight of solvent, 16 parts by weight of modified resin, pigments and fillers pretreated in step (1) are mixed and stirred for 25 minutes, and then polyaspartic acid ester (20 parts by weight of NH1520, 8 parts by weight of NH1420) is added. Parts by weight), 0.4 parts by weight of defoamer, 0.4 parts by weight of leveling agent, 1 part by weight of ultraviolet light absorber, and 3.5 parts by weight of matting agent, continue to mix and stir for 10 minutes, as component A;

[0035] (3) Divide 24.5 parts by weight of curing agent as component B.

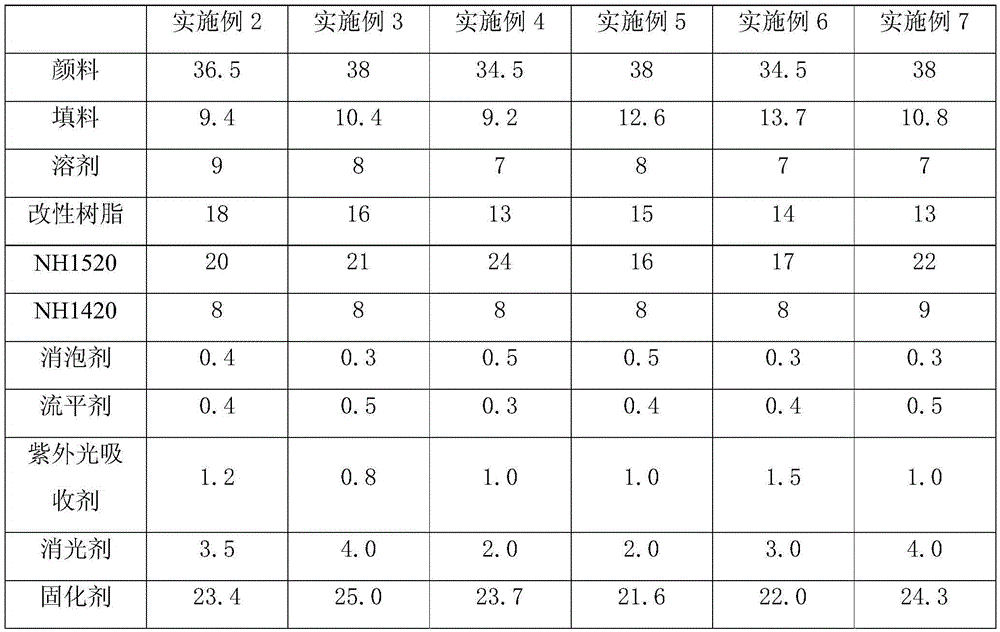

Embodiment 2 to 7

[0037] The preparation process is the same as in Example 1. The content of each component in the coating system is shown in Table 2 (calculated by weight):

[0038] Table 2

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com