Patents

Literature

22323 results about "Defoaming Agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cast form water borne coating and technique for preparing the same

InactiveCN101497105AGood water dispersibilityGood suspensionFoundry mouldsFoundry coresDefoaming AgentsCorrosion

The invention relates to an auxiliary material for casting a mould, in particular to a casting mould water-based coating formulation for a sand mould or an expendable pattern casting (EPC), and a process for preparing the same. The casting mould water-based coating formulation consists of refractory powder, a suspending agent, a bonding agent, a surfactant, a defoaming agent, a corrosion remover and water. The process comprises the following steps: adding the suspending agent to the water directly, and mixing and dispersing the mixture in a high speed dispersion machine; adding auxiliary agents including the defoaming agent, the surfactant, the corrosion remover, and the like to the water, and mixing the auxiliary agents; adding the refractory powder to the mixture to be mixed; and adding the bonding agent to the mixture to be mixed, and then adding water to adjust the coating until the coating has the thickness in a using state to obtain the finished product. The coating prepared by the process has the effects that the coating ensures that a high-density low-viscosity coating has excellent suspension property and storage stability, a coating layer is not easy to crack after drying, the coating is advantageous to improve the capacity of the coating to resist high temperature metal corrosion, and the like.

Owner:深圳市景鼎现代科技有限公司

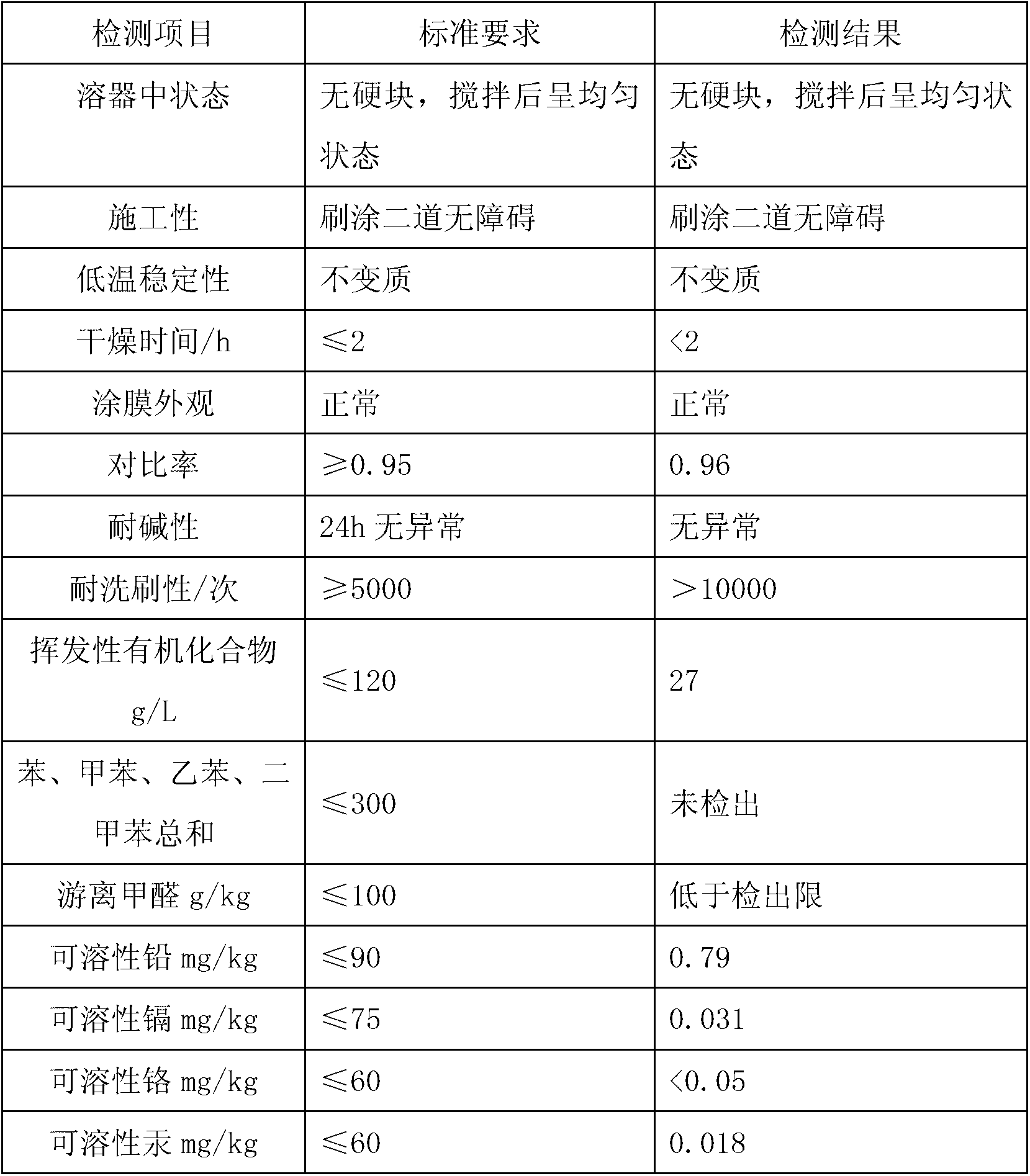

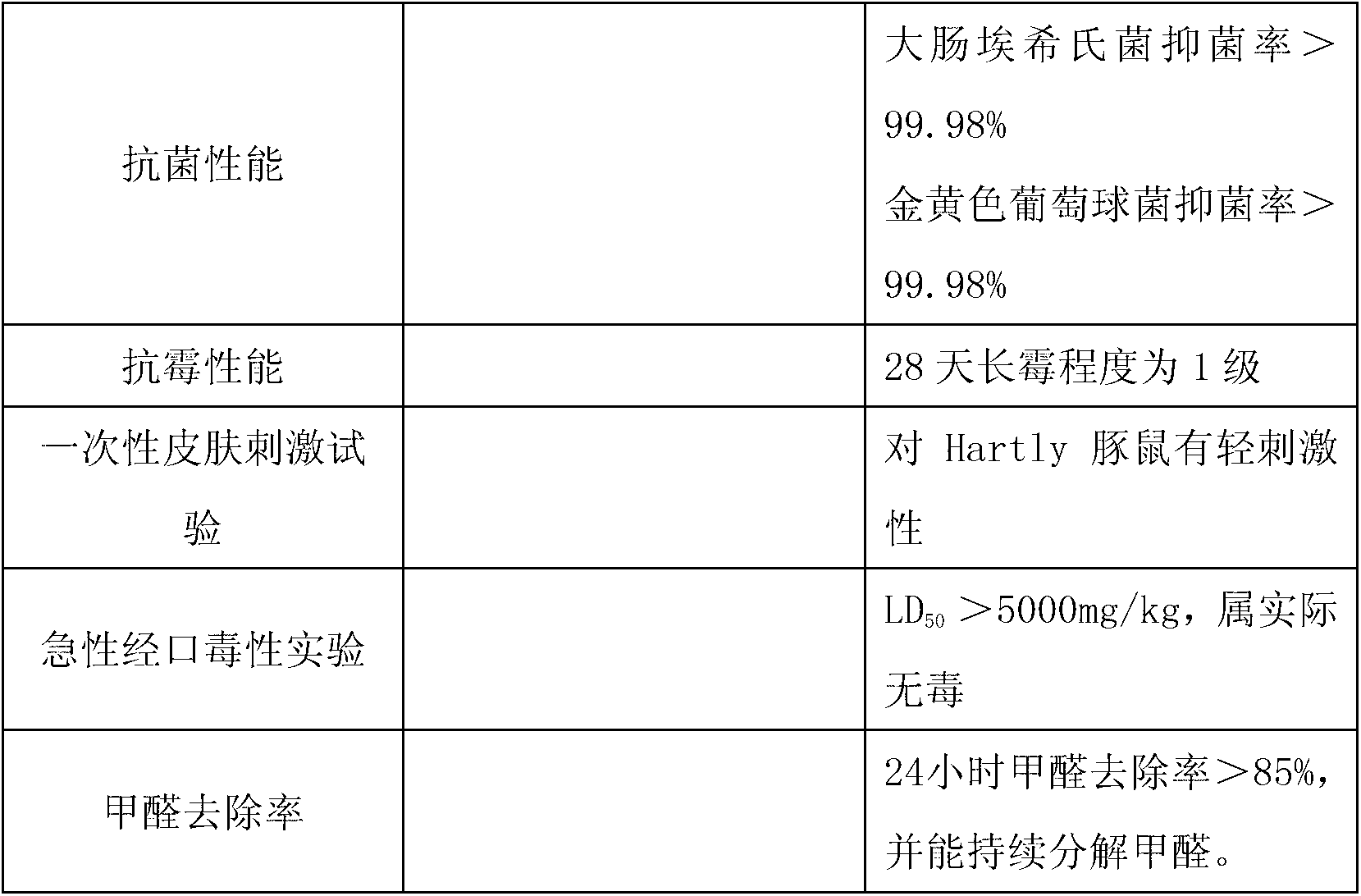

Odorless anti-formaldehyde environment-friendly internal wall latex paint and preparation method thereof

ActiveCN103059679AStrong absorption capacityStrong sustainable degradation abilityEmulsion paintsEmulsionSlurry

The invention discloses an odorless anti-formaldehyde environment-friendly internal wall latex paint and a preparation method thereof. The odorless anti-formaldehyde environment-friendly internal wall latex paint is prepared from the following components in percentage by weight: 1-15% of visible light induced nano titanium dioxide photocatalyst slurry, 15-35% of odorless emulsion, 1-15% of formaldehyde absorbent, 0.5-2% of dispersing agent, 0.2-3% of thickening agent, 0.2-1% of wetting agent, 0.1-1% of defoaming agent, 0.5-5% of film-forming assistant, 0.2-3% of anti-freeze agent, 20-40% of pigment and filler, 0.1-1% of pH regulator, 0.01-0.1% of anticorrosive bactericide and 15-40% of deionized water. The invention adopts an IPS+odorless technique, and the visible light induced nano titanium dioxide photocatalyst and the formaldehyde absorbent are added, thereby achieving the optimal effect of removing formaldehyde and other harmful substances through physical adsorption and chemical decomposition. The invention can be widely used for decorative spraying of various internal walls and other constructions.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

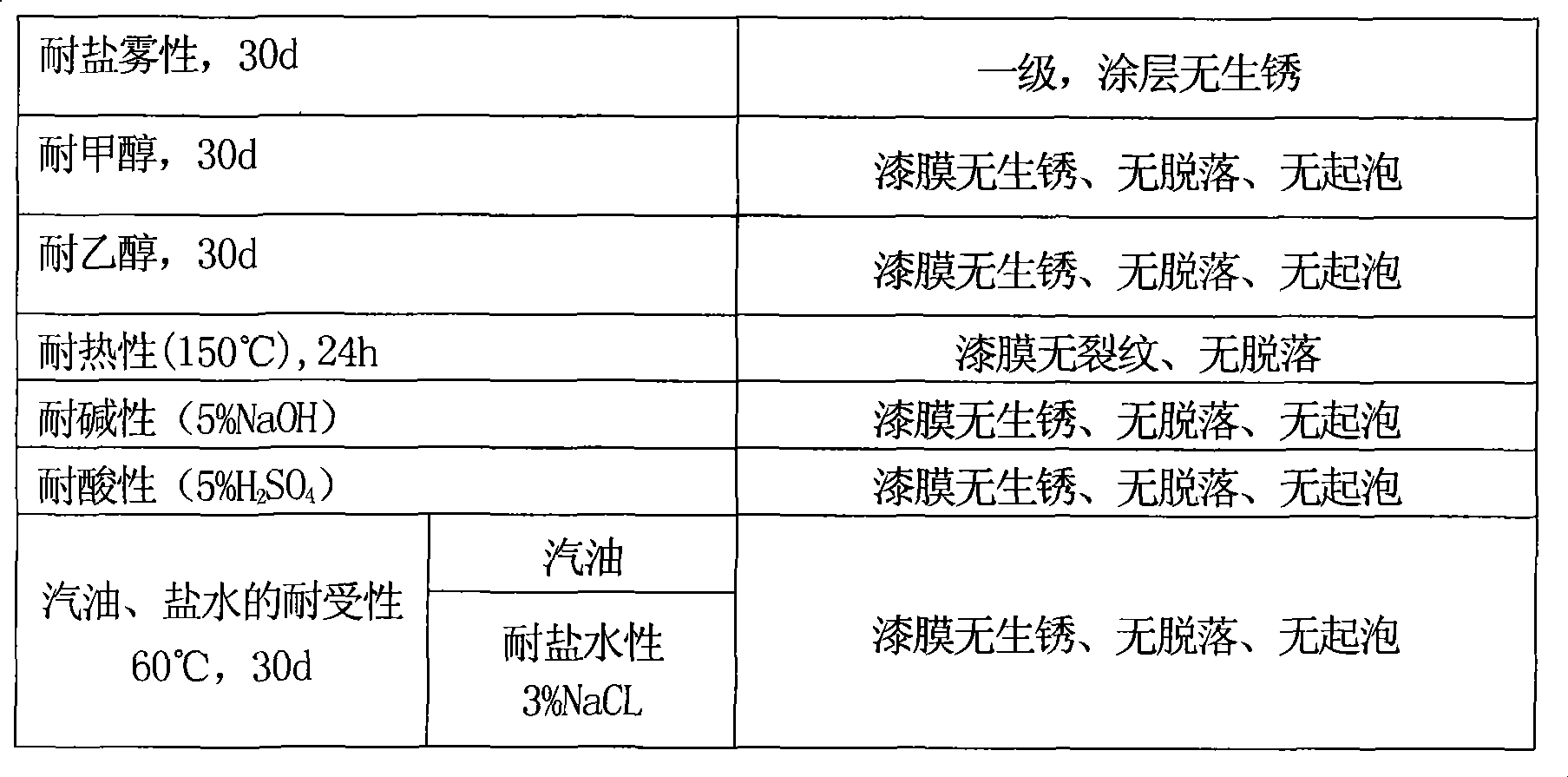

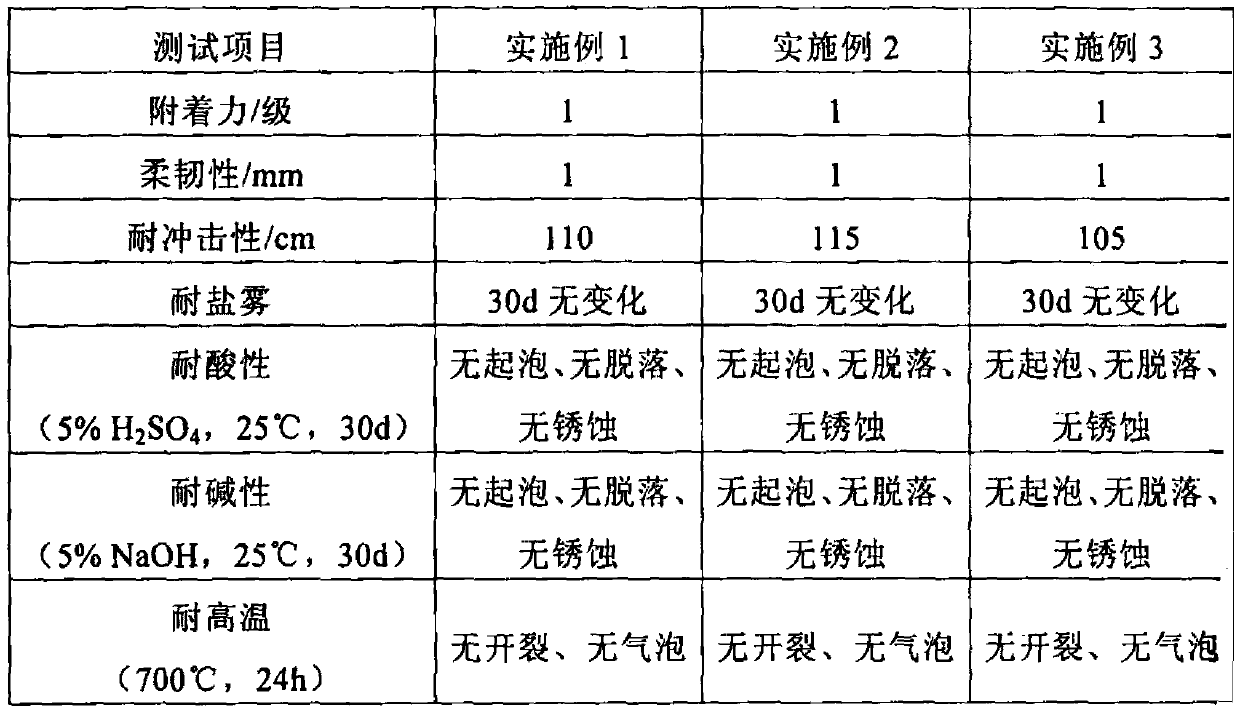

High-performance water-based anticorrosion paint and preparation method thereof

InactiveCN102134410AReduce heavy metal contentImprove heat resistanceAlkali metal silicate coatingsAnti-corrosive paintsAviationWater based

The invention relates to a preparation method of high-performance water-based anticorrosion paint. The high-performance water-based anticorrosion paint comprises 30-60 parts of inorganic material resin, 0.5-30 parts of polyaniline-based nano composite material, 0-30 parts of curing agent, 0.1-1 part of defoaming agent, 0.1-1 part of dispersant and 0.1-1 part of leveling agent. Since the high-performance water-based anticorrosion paint does not contain organic resin or organic solvent, the paint has the advantages of heat resistance, wear resistance, weather resistance, oil resistance, fire resistance and environmental protection; the paint also has the advantages of simple preparation technique, strong binding force with metal, and low cost, can be cured at normal temperature, and can be widely used for corrosion protection in the fields of aviation, navigation, chemical engineering, electronics and the like.

Owner:济宁市产品质量监督检验所

Waterborne conductive ink and preparation method thereof

The invention relates to waterborne conductive ink which comprises the following components in percentage by weight: 1-40 percent of polymer emulsion or dispersion liquid, 0.1-0.7 percent of dispersant, 0.1-0.3 percent of wetting agent, 0.2-1.8 percent of defoaming agent, 30-70 percent of conductive material, 0.5-3 percent of film-forming addition agent and 5-60 percent of water. The waterborne conductive ink disclosed by the invention has the advantages of no toxicity or odor, safety, environment friendliness, convenience in use, resource economization, favorable film forming performance and printing performance of ink, strong adhesive force and good weather resistance; the defects of toxicity, harm, inflammability and explosiveness of solvent ink are overcome; and water replaces organic solvent, so that a volatile organic compound (VOC) is reduced, and the production cost is also reduced.

Owner:SUZHOU NIUJIAN NEW MATERIAL

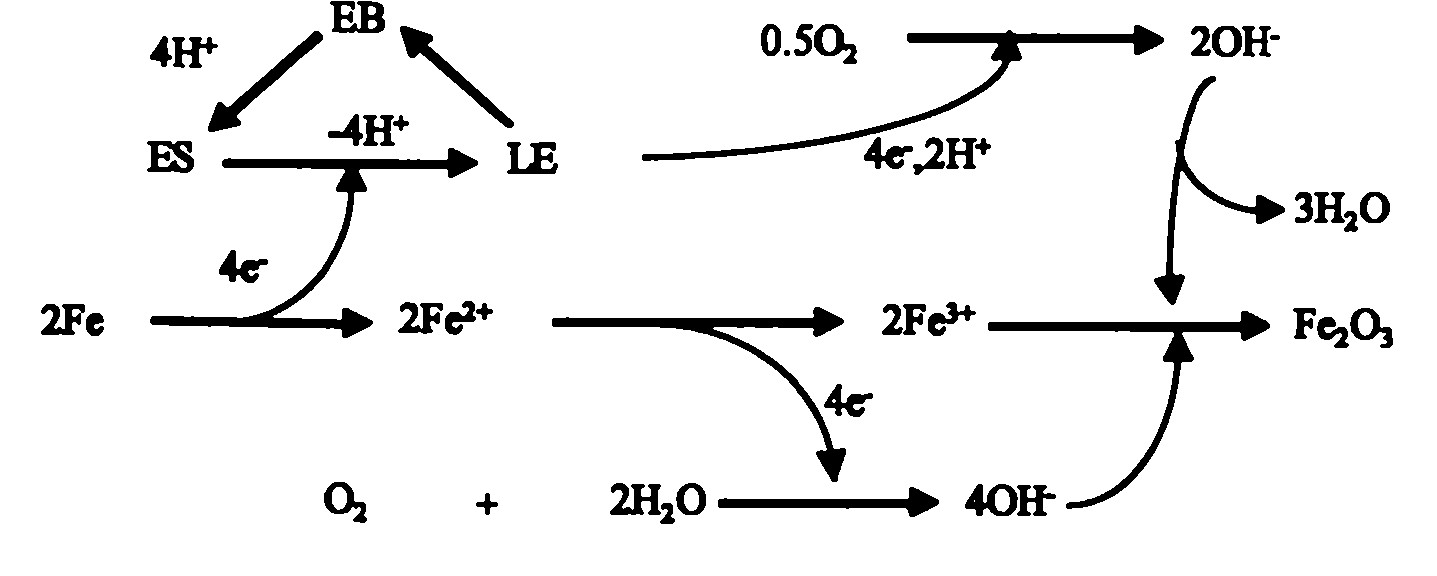

Nanometer compound water-based heat insulation anticorrosion paint used for metal and preparation method thereof

ActiveCN101665645AGood heat insulationImprove corrosion resistanceAnti-corrosive paintsReflecting/signal paintsWater basedAcrylic resin

The invention discloses a nanometer compound water-based heat insulation anticorrosion paint used for metal and a preparation method thereof. The raw materials of the paint consists of the following components: tap water, watercraft acrylic resin, rustproofing pigment, reflection pigment and filler, hollow micro-beads, watercraft nanometer size, anti-settling agent, wetting and dispersing agent A,wetting and dispersing agent B, film-forming assistant, defoaming agent, flatting agent, anti-flash rustproofing agent and thickening agent. Watercraft polyacrylic emulsion is styrene-crylic acid copolymerization emulsion, pure crylic acid polymerization emulsion or organic silicon-crylic acid copolymerization emulsion. The wetting and dispersing agent A is block macromolecule copolymer, multivalence carboxylate polymer and / or synthetic macromolecule copolymer, and the wetting and dispersing agent B is anion wetting agent and / or nonionic wetting agnet. The product contains no organic solvent,heavy metal and other harmful substances, is extremely excellent in environmental conservation, integrates the functions of anticorrosion and heat insulation as a whole and is simple and convenient for construction, safe in storage and stable in performance.

Owner:GUANGZHOU JOINTAS CHEM

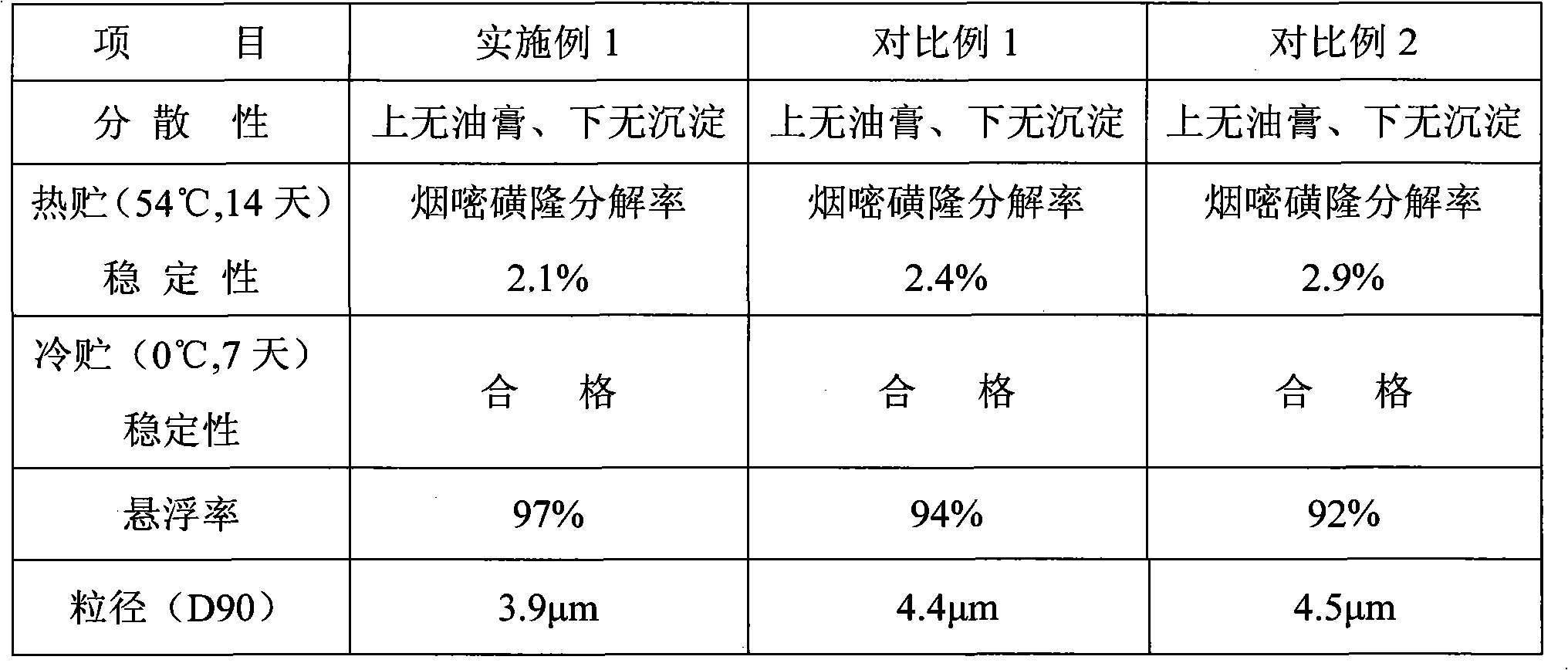

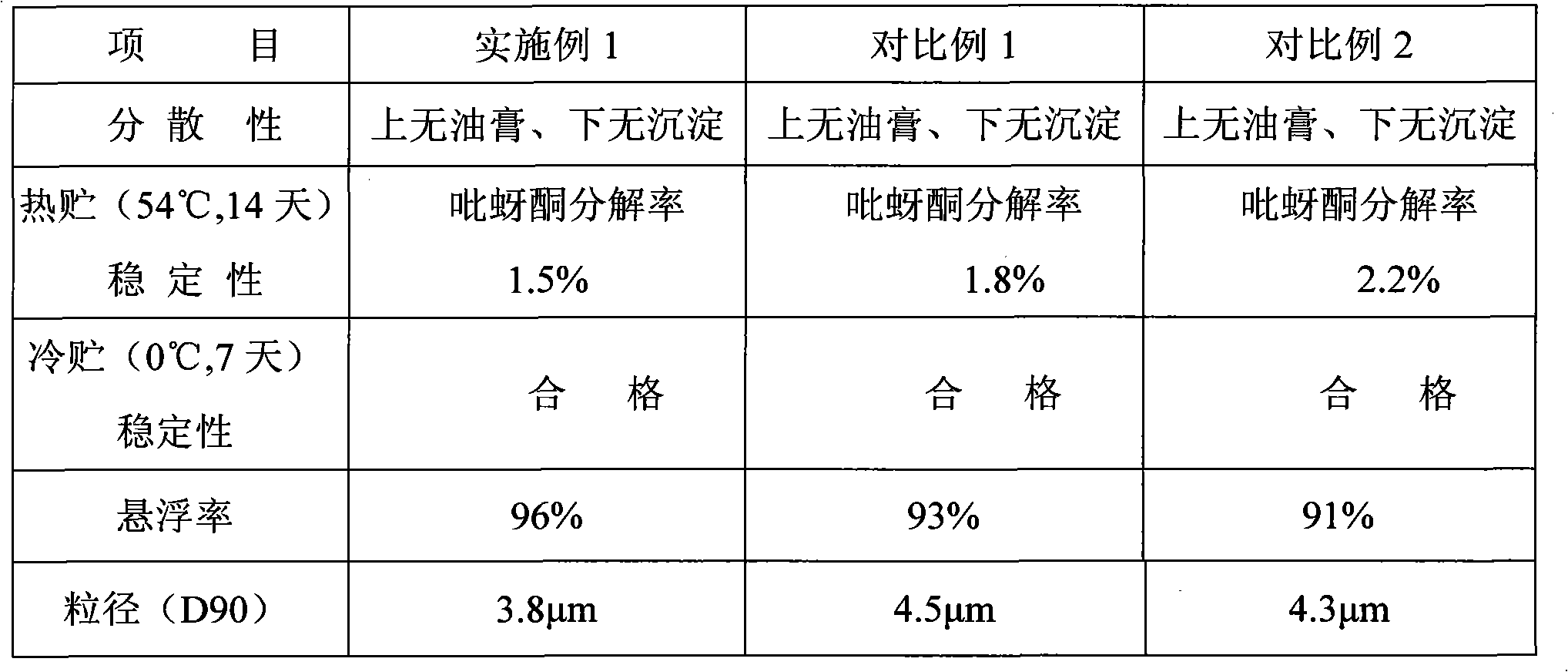

Oil suspension preparation using resin-based vegetable oil as carrier and preparation method thereof

ActiveCN101984809AGood cost advantageWide variety of sourcesBiocideFungicidesVegetable oilBULK ACTIVE INGREDIENT

The invention provides an oil suspension preparation using resin-based vegetable oil as a carrier and a preparation method thereof, and relates to a pesticide preparation. The oil suspension preparation using the resin-based vegetable oil as the carrier comprises the following raw material components in percentage by mass: 1 to 50 percent of pesticide active ingredient, 1 to 10 percent of emulsifying agent, 2 to 8 percent of wetting dispersant, 0 to 5 percent of suspension stabilizer, 0 to 0.2 percent of organic silicon defoaming agent and the balance of resin-based vegetable oil. After the pesticide active ingredient, the emulsifying agent, the wetting dispersant, the suspension stabilizer, the organic silicon defoaming agent and the resin-based vegetable oil are mixed uniformly, the mixture is put into a high-speed shearing ball milling device for ball milling so as to obtain the oil suspension preparation using the resin-based vegetable oil as the carrier.

Owner:FUJIAN NUODE BIOTECH

Zeolite colored coating powder having air-purifying function

InactiveCN105272114ASolving difficult-to-disperse reunionsImprove the bactericidal effectPorosityPyrophosphate

The invention discloses zeolite colored coating powder having an air-purifying function. According to the technical scheme, the zeolite colored coating powder having the air-purifying function is characterized in that ingredients include attapulgite pottery clay powder having the air-purifying function, acidified zeolite particles, colored portland cement, Paris plaster, white carbon black, calcium chloride, aerosil, expanded perlite, nanometer silver-loaded antibacterial powder, nanometer titanium dioxide, sodium pyrophosphate and powder defoaming agents. The ingredients of the zeolite colored coating powder having the air-purifying function are input three times into a stirring machine to be stirred evenly and packaged into the finished product. By the adoption of the colored coating, in indoor wall decoration, an artistic emboss effect of various embossed three-dimensional colored patterns can be achieved through spraying and manufacturing, after spraying, a coating is hard, the porosity is high, the specific surface area is large, adhesion is strong, indoor formaldehyde, ammonia nitrogen, benzene and other harmful substances can be adsorbed and decomposed, and the functions of automatic humidification, mould prevention, sterilization, deodorization and air purification are achieved.

Owner:蒋文兰

Oil resistant (solvent), heatproof static conducting anti-corrosive paint and preparation thereof

InactiveCN101372601AHigh solid contentReduce the number of coatsAnti-corrosive paintsPolyurea/polyurethane coatingsPlasticizerSolvent

The invention belongs to the corrosion protective coating technique field and provides an oil resistance (solvent) and temperature resistance electrostatic conducting corrosion protective coating and a preparation method thereof. The coating is mainly made by raw components by weight percentage of 20-35 percent of resinI which is used as basic material, 0-15 percent of modified resin II, 15-30 percent of conductive fillers, 1-3 percent of coupling agent, 8-20 percent of fillers, 10-15 percent of solvent, 2-10 percent of plasticizer, 0.5-1 percent of defoamer, 0.5-1 percent of flatting agent and 6-15 percent of curing agent. The coating is prepared according to the following steps: the resin I, the modified resin II, the coupling agent, the plasticizer, the flatting agent and the defoamer are put in a distributing tank. And part of mixed solvent is added to be stirred and distributed uniformly. The fillers are added proportionally and are put in a sand mill for sand milling after being dispersed and stirred uniformly at high speed, so as to obtain upper grinding pigment paste. The conductive fillers and the rest mixed solvent are added at low stirring speed. The conductive fillers are totally blended into the upper grinding pigment paste and stirring is carried out at middle speed, the viscosity is adjusted to be qualified and the fillers are filtered to obtain a qualified component A product. The curing agent is carried out subpackage according to proportion.

Owner:洛阳双瑞防腐工程技术有限公司

Oxidized graphene and graphene reinforced cement based composite material and preparation method thereof

The invention relates to an oxidized graphene and graphene reinforced cement based composite material and a preparation method thereof. The oxidized graphene and graphene reinforced cement based composite material comprises the oxidized graphene, the graphene, a dispersing agent, a thickening stabilizer, a water reducer, a defoaming agent and a cement matrix, the mass ratio of the total mass of the oxidized graphene and the graphene to the cement matrix is (0.0005-0.5):1, and the mass ratio of the total mass of oxidized graphene and the graphene to the dispersing agent to the water reducer to the thickening stabilizer to the defoaming agent is 1:(0.05-10):(0.1-20):(0.1-20):(0.05-5). In the composite material, the oxidized graphene and the graphene are dispersed in the cement matrix uniformly; compared with the traditional cement material, the tensile strength, rupture strength and conductivity of the composite material are all improved remarkably; and the composite material has more excellent mechanical property and electrical property, and is applicable to the field of multifunctional construction materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

High temperature resistant anticorrosion coating based on graphene and preparation method thereof

InactiveCN103589281AImprove high temperature resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to a high temperature resistant anticorrosion coating based on graphene and a preparation method thereof. The high temperature anticorrosion coating comprises the following components by the mass percentage: 5-60% of epoxy resin, 3-30% of polyphenylene sulfide resin, 3-30% of amino resin, 1-10% of a pigment, 1-20% of graphene, 3-50% of n-butyl alcohol, 0.1-0.3% of a defoaming agent, 0.1-10% of polyhydroxy acid sodium salt, 0.1-5% of benzenedicarboxylic acid dibutyl ester, 0.5-1.0% of bentonite, and 0.2-0.5% of a leveling agent. Compared with the prior art, the prepared coating has the advantages of quite excellent waterproof and anticorrosion performance, high temperature resistance, weather resistance, alkali resistance, impact resistance, artificial aging resistance and the like, and the preparation method has the advantages of good controllability, simple operation, low production cost, and easy industrialized production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

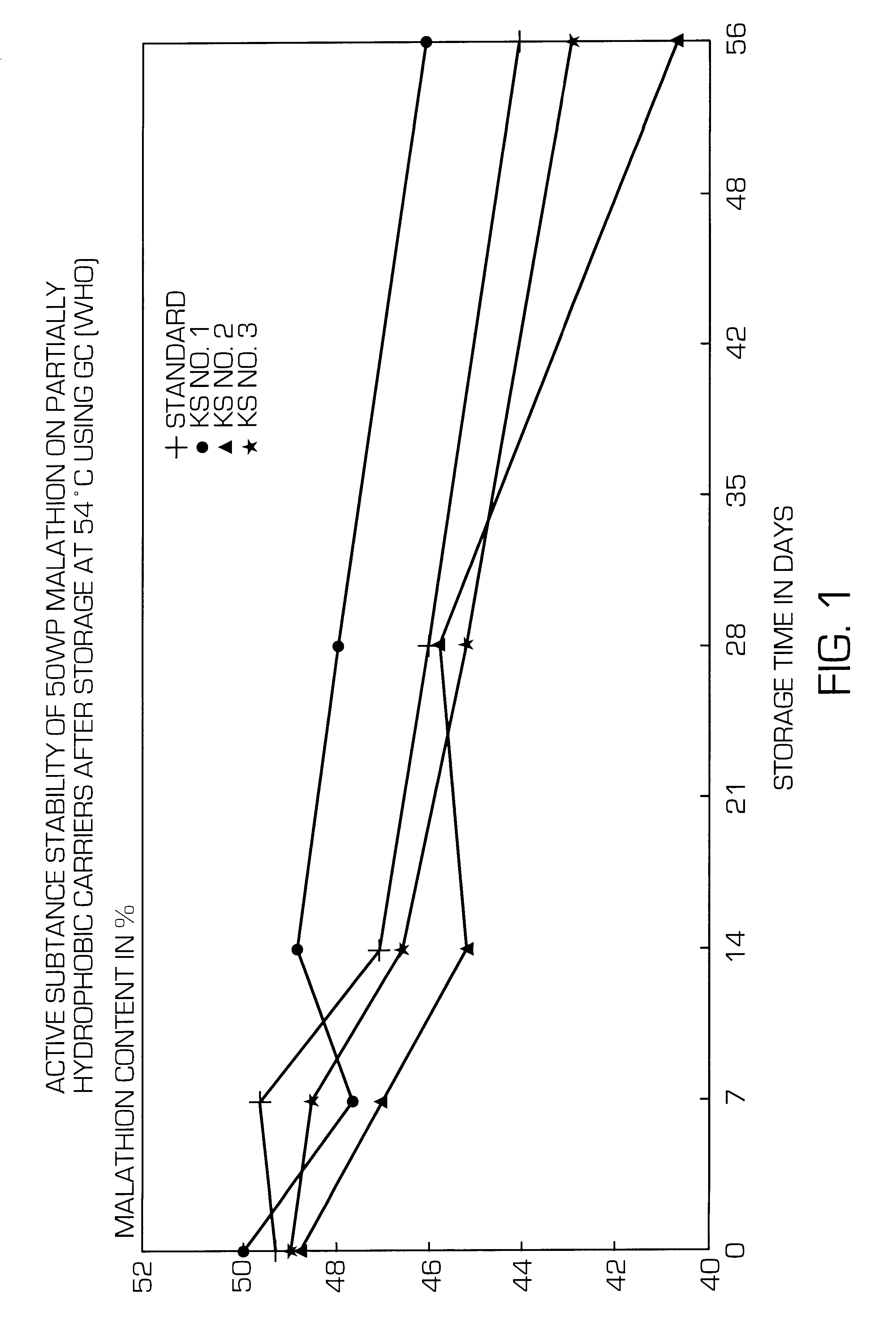

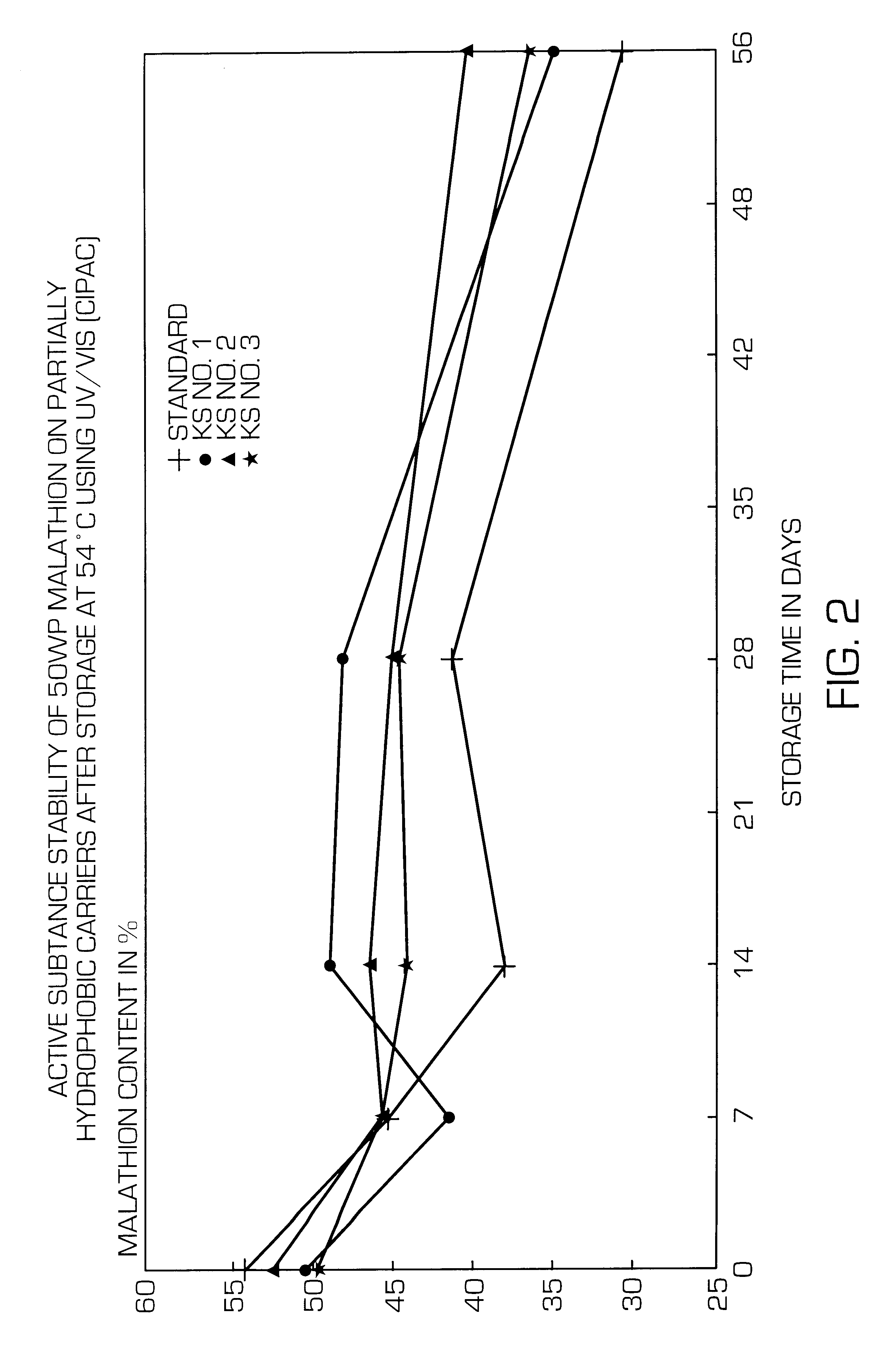

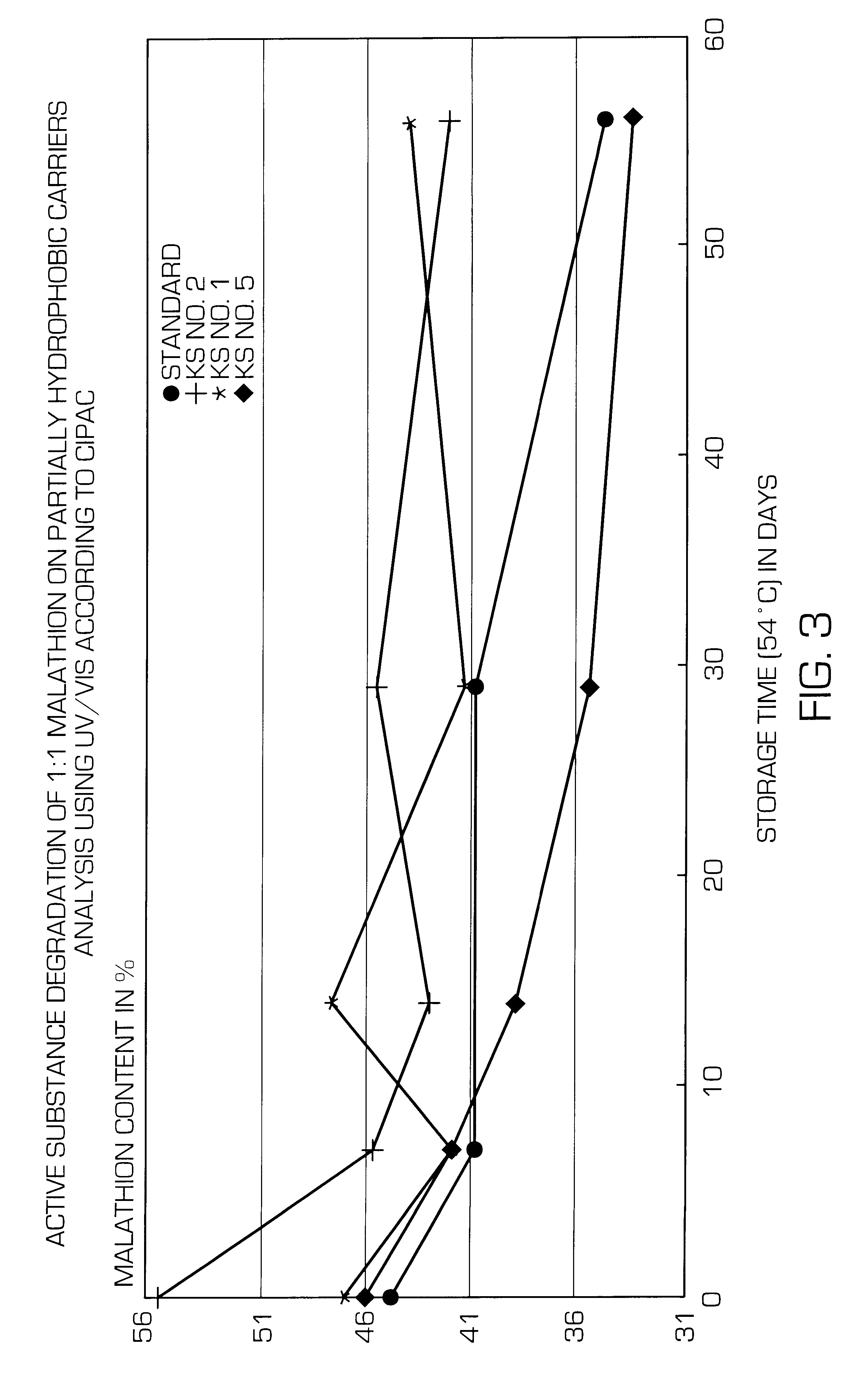

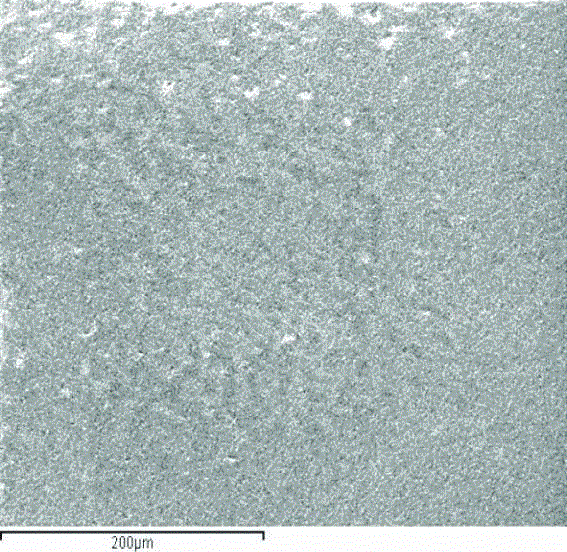

Partially hydrophobic precipitated silicas

A partially hydrophobic precipitated silica having a methanol wettability of 10 to 49%, in particular with a DBP uptake on a dry basis of greater than 250 g / 100 g and a mean particle size of 1 to 12 mum and / or a carbon content of 0.3 to 1.85% and / or a loss on drying of 2.6 to 10.0% and / or a pH value of 5.5 to 10.0, is prepared by mixing the amount of water-repellent agent with the precipitated silica suspension at very short residence time and low pH value, filtering off the solid substance, washing free of salt, drying, post-treating thermally and milling. The partially hydrophobic precipitated silica can be used in active substance formulations and active substance formulations of hydrolysis-sensitive substance and in defoaming agents.

Owner:EVONIK DEGUSSA GMBH

Composite coating electromagnetic shielding paint and composite coating electromagnetic shielding material prepared therefrom

ActiveCN102020899AReduce generationEnsure safetyPolyurea/polyurethane coatingsRadiation-absorbing paintsEmulsionDefoaming Agents

The invention relates to the field of electromagnetic wave shielding, in particular to a composite coating electromagnetic shielding paint and a composite coating electromagnetic shielding material prepared therefrom. The composite coating electromagnetic shielding paint comprises a conducting layer paint with a reflection function and a wave-absorbing layer paint with an absorption function, wherein the reflecting layer paint comprises the components of polymer emulsion, a conducting filler, a coupling agent, a defoaming agent, a wetting agent, a film forming assistant, a thickening agent and water; and the wave-absorbing layer paint comprises the components of polymer emulsion, a wave-absorbing filler, a coupling agent, a defoaming agent, a wetting agent, a film forming assistant, a thickening agent and water. The invention also discloses a composite coating electromagnetic shielding material prepared by coating the paint. The material is prepared by the steps of firstly coating the conducting layer paint on the surface of a base material, drying, then coating the wave-absorbing layer paint and the like. In the invention, the electromagnetic shielding material prepared by using the mode of compounding the wave-absorbing layer with the reflecting layer effectively reduces secondary pollution caused by the reflection of electromagnetic radiation and has wider shielding wave band in comparison to a pure wave absorbing coating; and the use of water emulsion reduces the production of harmful volatile matters and guarantees body safety.

Owner:ARMY MEDICAL UNIV +1

Prepn process of active defoaming agent composition

The present invention is one kind of active defoaming composition suitable for eliminating harmful foams under high temperature and strong alkaline condition in high efficiency, and may be used in washing paper pulp, treating metal surface and other fields. The active defoaming composition is prepared with organic siloxane, silicone resin, inorganic oxide particle, hydrophobic treating agent, catalyst and other material. The preparation process includes the following steps: 1. mixing organic siloxane, silicone resin and catalyst, and heating the mixture to 80-200 deg.c for controllable polymerization; 2. adding inorganic oxide particle and hydrophobic treating agent; and 3. further heating to reaction at 80-200 deg.c temperature and 0.01-0.08 MPa vacuum for 2-10 hr, and cooling to room temperature to obtain white polymer as the active defoaming composition.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Conducting paint

ActiveCN102977742AImprove conductivityGood adhesionEpoxy resin coatingsElectrically-conductive paintsEpoxySolvent

The invention provides a conducting paint which comprises 1-8 wt% of graphene, 0.1-1 wt% of functionalized graphene, 15-30 wt% of epoxy resin and curing agent, 0.2-1.5 wt% of wetting dispersant, 0.1-0.5 wt% of defoaming agent, 0-30 wt% of conducting filler and the balance of solvent. The functionalized graphene is amino-containing functionalized graphene or sulfhydryl-containing functionalized graphene. The functionalized graphene contains amino or sulfhydryl group, and therefore, can be better dispersed in the system, and the amino or sulfhydryl group can react with epoxy group in the epoxy resin, thereby enhancing the binding force of the coating; and besides, the graphene has a flake structure and a large radius-thickness ratio and is arranged as a plurality of layers in the coated film in parallel, and therefore, the conducting paint has favorable conductivity and adhesiveness.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

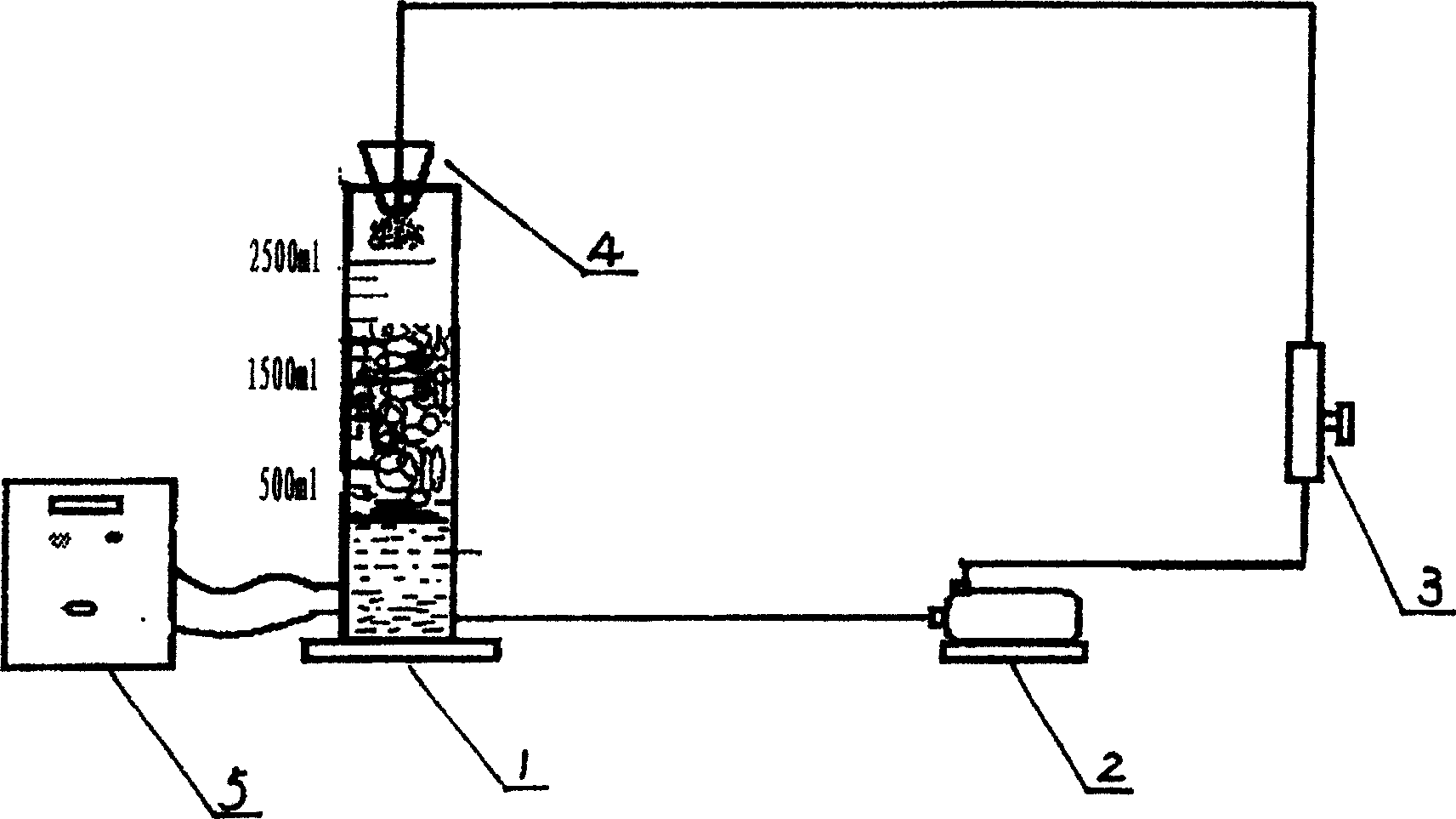

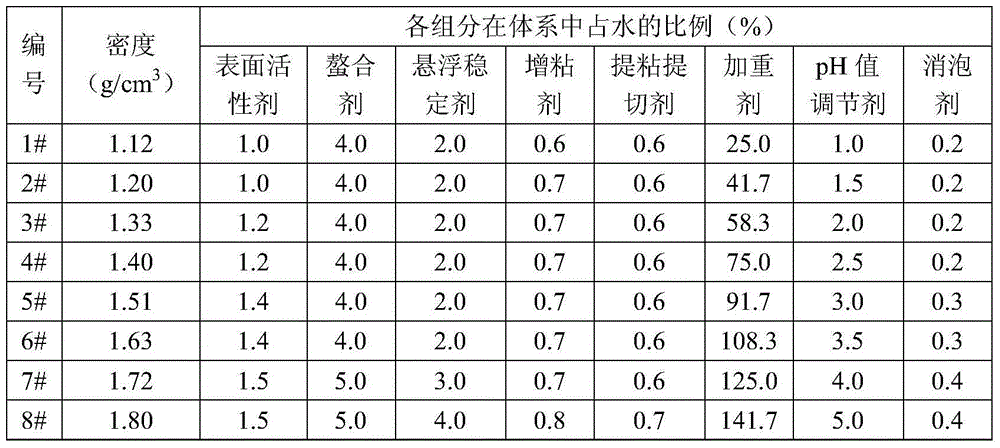

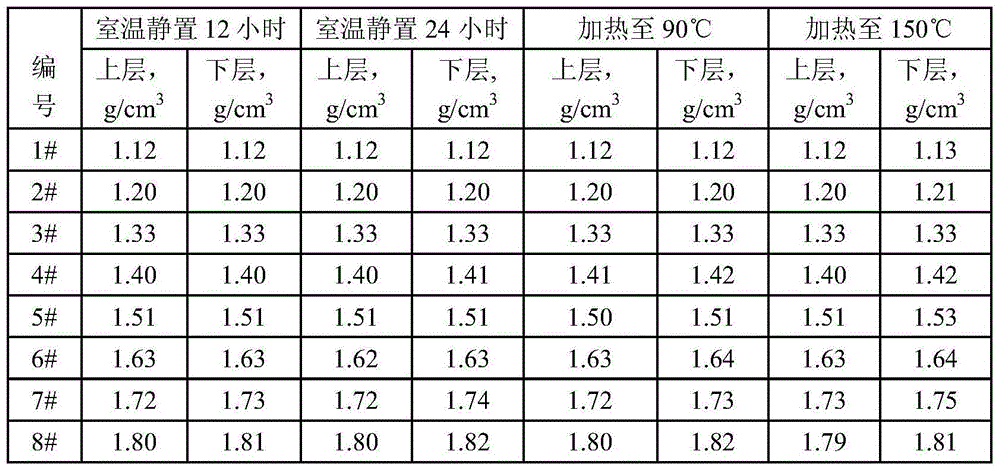

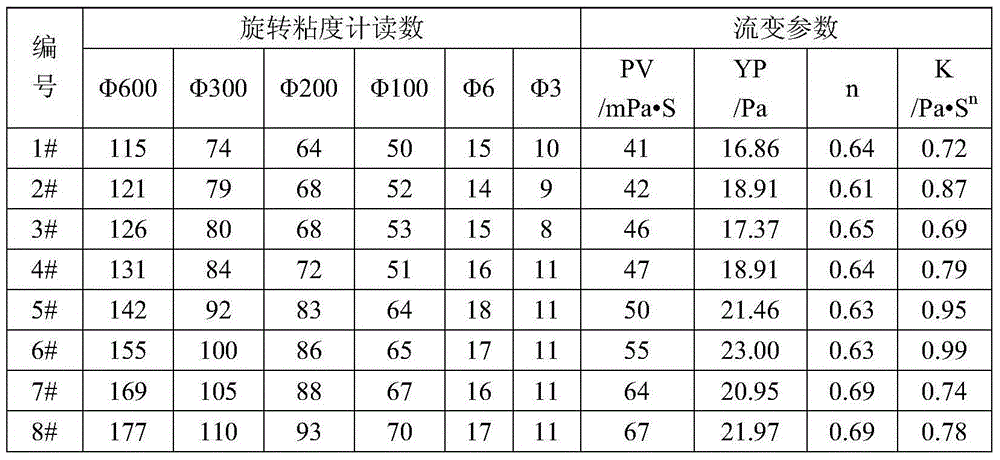

High-efficiency oil-based flushing spacer liquid and preparation method thereof

The invention relates to a high-efficiency oil-based flushing spacer liquid. The flushing spacer liquid is prepared from the following components in parts by weight: 100 parts of clear water, 1.0-1.5 parts of a surfactant, 4.0-5.0 parts of a chelating agent, 2.0-4.0 parts of a suspension stabilizer, 0.6-0.8 part of a tackifier, 0.5-0.75 part of a viscosity enhancer, 25-15 parts of a weighting agent, 1.0-5.0 parts of a pH regulator, and 0.2-0.4 part of a defoaming agent. The invention provides a special high-efficiency flushing spacer liquid for oil-based drilling fluid, which has dual functions of flushing and spacing, is high in flushing efficiency, wide in density adjusting range and good in suspension stability, and can effectively improve the conditions of interfacial cementation and improve the quality of well cementation.

Owner:SHENYANG POLYTECHNIC UNIV

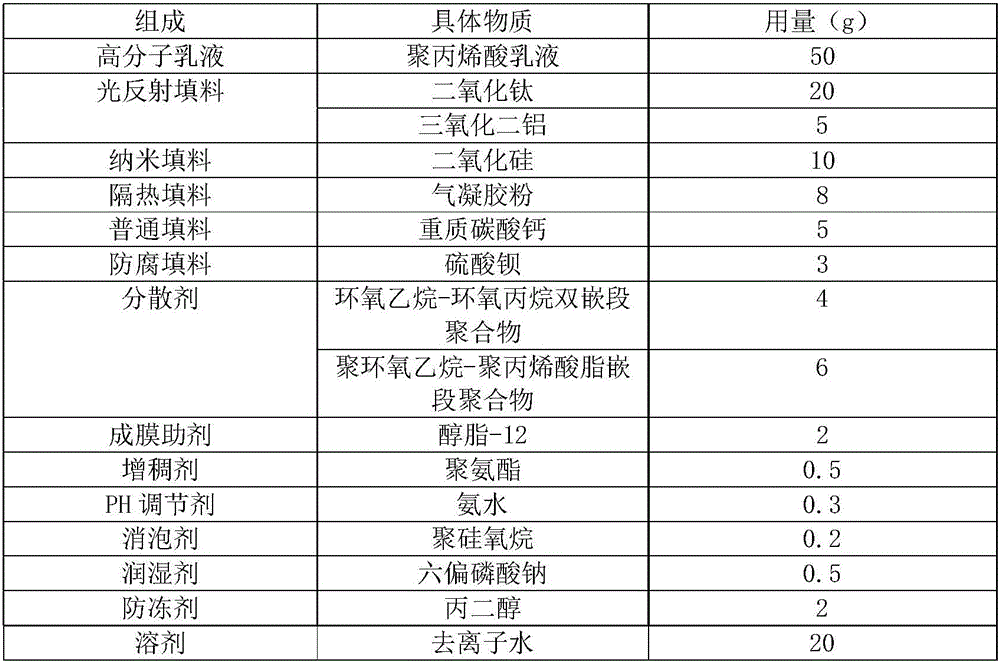

Water-based light reflex industrial insulation coating and preparation method thereof

ActiveCN106752526AGood compatibilityImprove thermal insulation performanceAnti-corrosive paintsReflecting/signal paintsWater basedDefoaming Agents

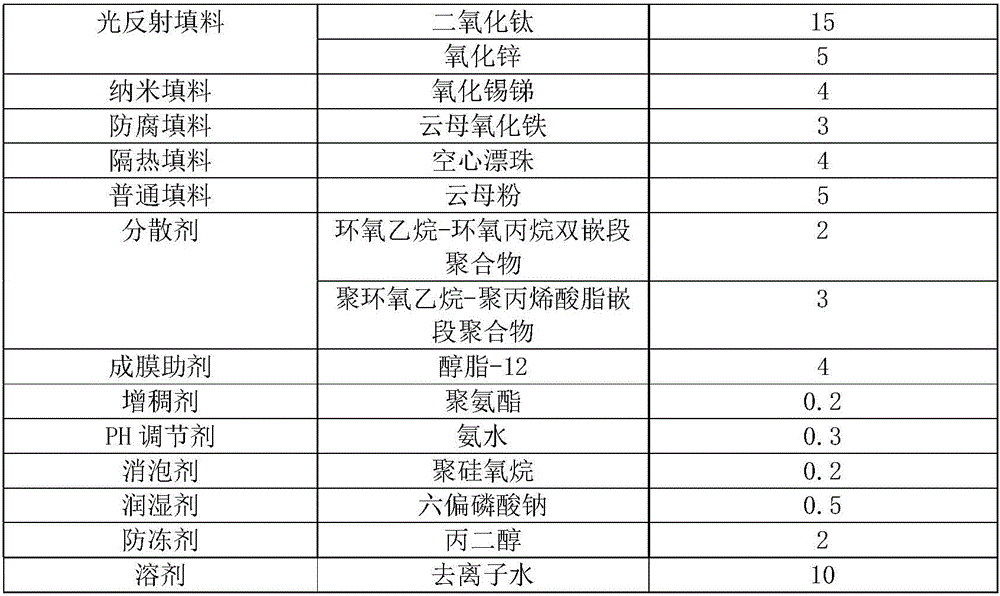

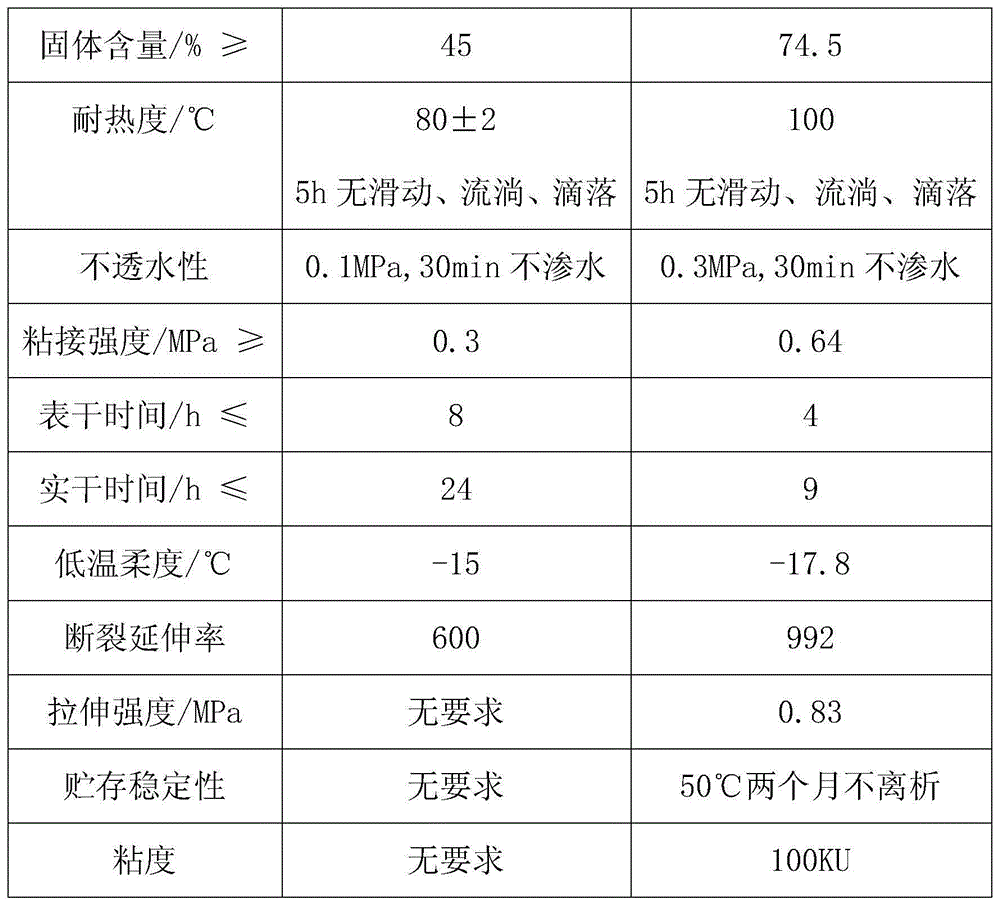

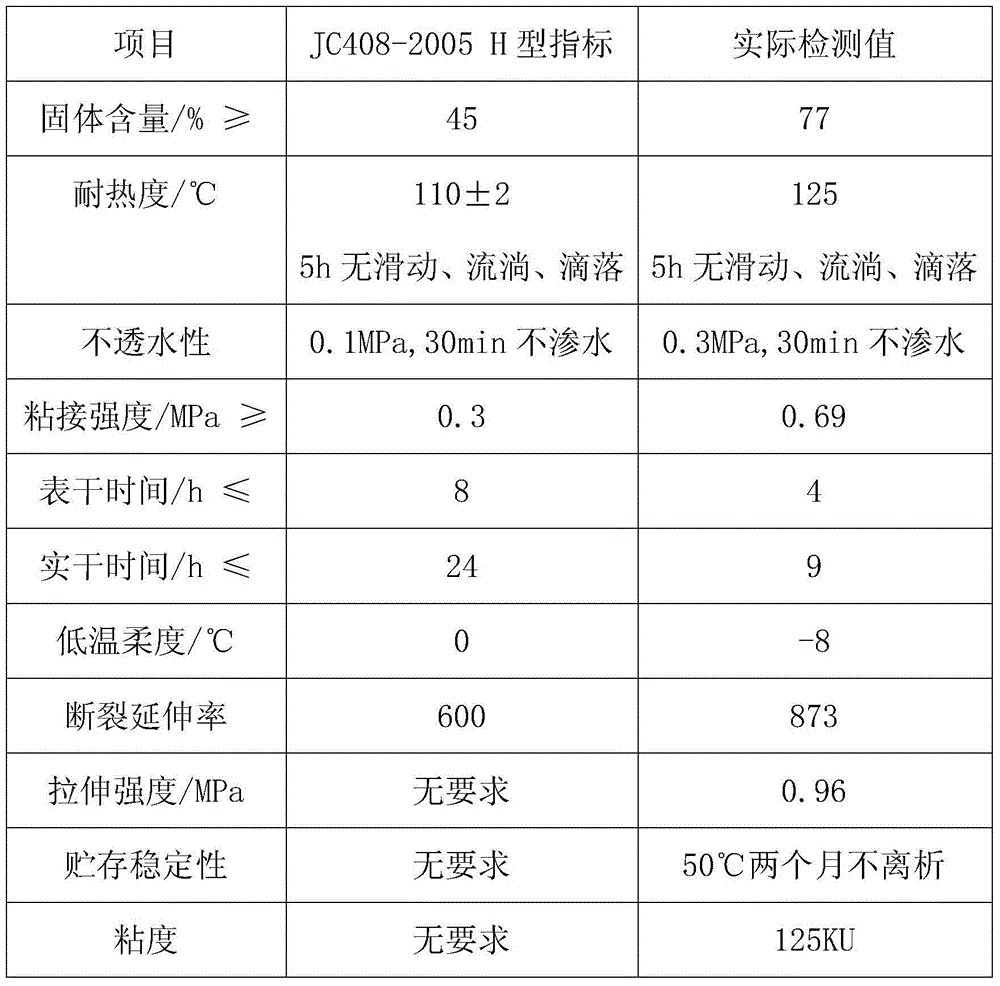

The invention relates to an industrial coating, in particular to a water-based industrial insulation coating with light reflection, heat insulation and corrosion protection effects and a preparation method thereof. The coating is prepared from the following components in percentage by weight: 25 percent to 50 percent of polymer emulsion, 5 percent to 30 percent of light reflective filler, 1 percent to 5 percent of nanofiller, 5 percent to 10 percent of heat-insulating filler, 5 percent to 10 percent of anti-corrosion filler, 5 percent to 8 percent of normal filler, 0 percent to 10 percent of curing agent, 1 percent to 5 percent of dispersing agent, 0.1 percent to 4 percent of coalescing agent, 0.1 percent to 2 percent of thickening agent, 0 percent to 1 percent of defoaming agent, 0.01 percent to 0.5 percent of PH (Potential Of Hydrogen) regulator, 0.1 percent to 2 percent of wetting agent, 0.5 percent to 1 percent of antifreezing agent, and the balance of deionized water. The coating provided by the invention has the effects on light reflection, heat insulation and corrosion protection at the same time, can be applied in the fields of storage tanks, pipelines, outdoor equipment, containers and the like, has the characteristics of safety, nontoxicity, environmental protection and pollution free, and has favorable weather fastness, stain resistance, salt fog resistance and scrubbing resistance.

Owner:SHENYANG RES INST OF CHEM IND

Composite emulsified asphalt waterproof coating and preparation method thereof

InactiveCN104449381AGood dispersionHigh viscosityConjugated diene hydrocarbon coatingsNatural rubber coatingsBituminous waterproofingEmulsion

The invention relates to a composite emulsified asphalt waterproof coating and a preparation method thereof. The composite emulsified asphalt waterproof coating is prepared from the following raw materials in parts by weight: 150-220 parts of emulsified asphalt, 50-105 parts of a polymeric emulsion, 70-130 parts of inorganic powder, 0.5-2 parts of a stabilizer, 6-10 parts of a dispersant, 2-5 parts of a wetting agent, 1-3 parts of a thickener I, 1-3 parts of a thickener II, 2-7 parts of a defoaming agent and 15-40 parts of water. The invention further relates to a preparation method of the composite emulsified asphalt waterproof coating. The viscosity, strength, application property, solid content and storage stability of the emulsified asphalt waterproof coating are remarkably improved, and the cost is lowered to a great extent.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

Bi-component cement based composite material for 3D printing as well as preparation method and application thereof

The invention discloses a bi-component cement based composite material for 3D (three dimensional) printing as well as a preparation method and application thereof. The bi-component cement based composite material for 3D printing comprises a component A and a component B, wherein the component A is prepared from 34 to 40 percent of sulphate aluminium cement, 0 to 6 percent of inorganic powder, 40 to 44 percent of tailing machine-made sand, 2.5 to 3 percent of high-molecular polymer and the balance of a retarder, a water reducer, a size stabilizer, a defoaming agent and water, the pumping performance can be well kept for a long time, an industrialized process of pre-stirring production in a mixing plant, transportation, and using in a construction site can be realized; the B component is prepared from a coagulate promoting agent, a thixotropic agent, a defoaming agent and water, the component is stable in form and can be stored for a long time or produced in a concentrated manner. After A and B are respectively pumped in a 3D printer, through high-speed stirring and being mixed by an extrusion head, the composite printing material can be extruded out, the time of coagulation is short, the strength is high, the adhesion is good, the stability is strong, the constructive continuity and building strength requirements of building 3D printing can be met, the industrial production and promotion of the cement based 3D printing material are facilitated, and the application of a 3D printing technology in buildings can be effectively promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

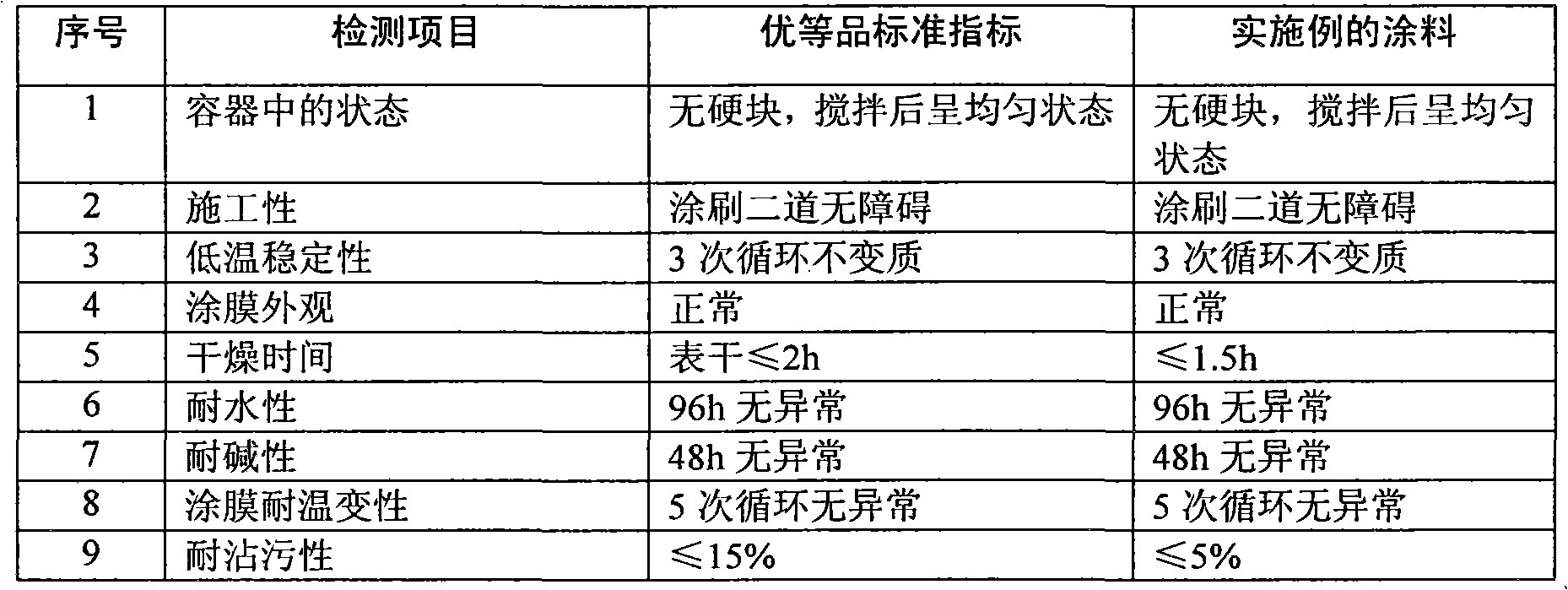

Exterior wall coating and preparation method thereof

InactiveCN101974273ASimple preparation processLow equipment requirementsAnti-corrosive paintsPolymer scienceDefoaming Agents

The invention discloses a multifunctional exterior wall coating with strong weather resistance, brushing resistance and high adhesion and a preparation method thereof. The exterior wall coating is prepared from the following raw materials in percentage by weight: 10-30% of silicone acrylic emulsion with a interpenetrating network structure, 10-40% of acrylic ester emulsion, 1-15% of hydrophobically modified inorganic nanoparticles, 10-40% of pigment and filler, 0.3-1% of a dispersing agent, 0.1-0.2% of a defoaming agent, 0.1-0.3% of a preservative, 0.3-0.6% of a flatting agent, 1-2% of a thickening agent, and the balance deionized water. The exterior wall coating of the invention has the advantages of strong weather resistance, brushing resistance, strong adhesion, long service life, simple and convenient preparation process and low equipment requirement, thus being easy for large-scale popularization and application. The exterior wall coating overcomes the defects of poor brushing resistance, poor ageing resistance and the like of the existing exterior wall coating.

Owner:广州市枫源化工有限公司

Monocomponent high elastic aqueous polyurethane/acrylate waterproof paint and process for preparing same

InactiveCN1670096AImprove performanceIncrease elasticityPolyurea/polyurethane coatingsEmulsion paintsEmulsionPolymer science

The invention discloses a monocomponent high elastic aqueous polyurethane / acrylate waterproof paint which comprises (by weight ratio) polyurethane / acrylic ester composite emulsion 30-90 parts, filling pigment 5-45 parts, dispersing agent 0.2-1.1 parts, film forming adjuvant 0.6-1.5 parts, levelling agent 0.05-0.35 part, defoaming agent 0.08-0.32 part, plasticizer 0.6-12 parts, thickening agent 0.01-1.0 part, pH stabilizing agent 0.01-5.0 parts, ultraviolet absorbent 0.5-1.0 part, water 1-15 parts. The preparation process is also disclosed.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Water-based primer-topcoat braking paint and preparation method thereof

The invention relates to a water-based primer-topcoat braking paint and a preparation method thereof. The braking paint comprises the following materials by weight percentage: 30-40 of water-based acrylic resin, 2-10 of amino resin, 1-3 of neutralizing agent, 2-5 of compound rustproofing pigment, 1-3 of tinting pigment, 10-20 of filling agent, 0.1-0.5 of defoaming agent, 0.1-0.5 of flatting agent and 25-40 of deionized water, wherein the water-based acrylic resin is a free radical polymerization resultant which comprises the following materials by weight percentage: 10-30 of monomer containing hydroxy acrylic acid, 5-20 of monomer containing carboxyl acrylic acid, 2-8 of internal crosslinking monomer, 20-40 of other acrylic acid monomer, 15-30 of phenyl ethylene monomer, 1-5 of evocating agent and 40-50 of alcohol ether latent solvent. When the paint is prepared, the dispersion and the abrading condition of the pigments and the filling agents are reasonably controlled to ensure that each component of the paint fully plays the respective function. The paint ensures the corrosion prevention effect and the decoration of a coating and realizes the combination of a primer and a topcoat.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

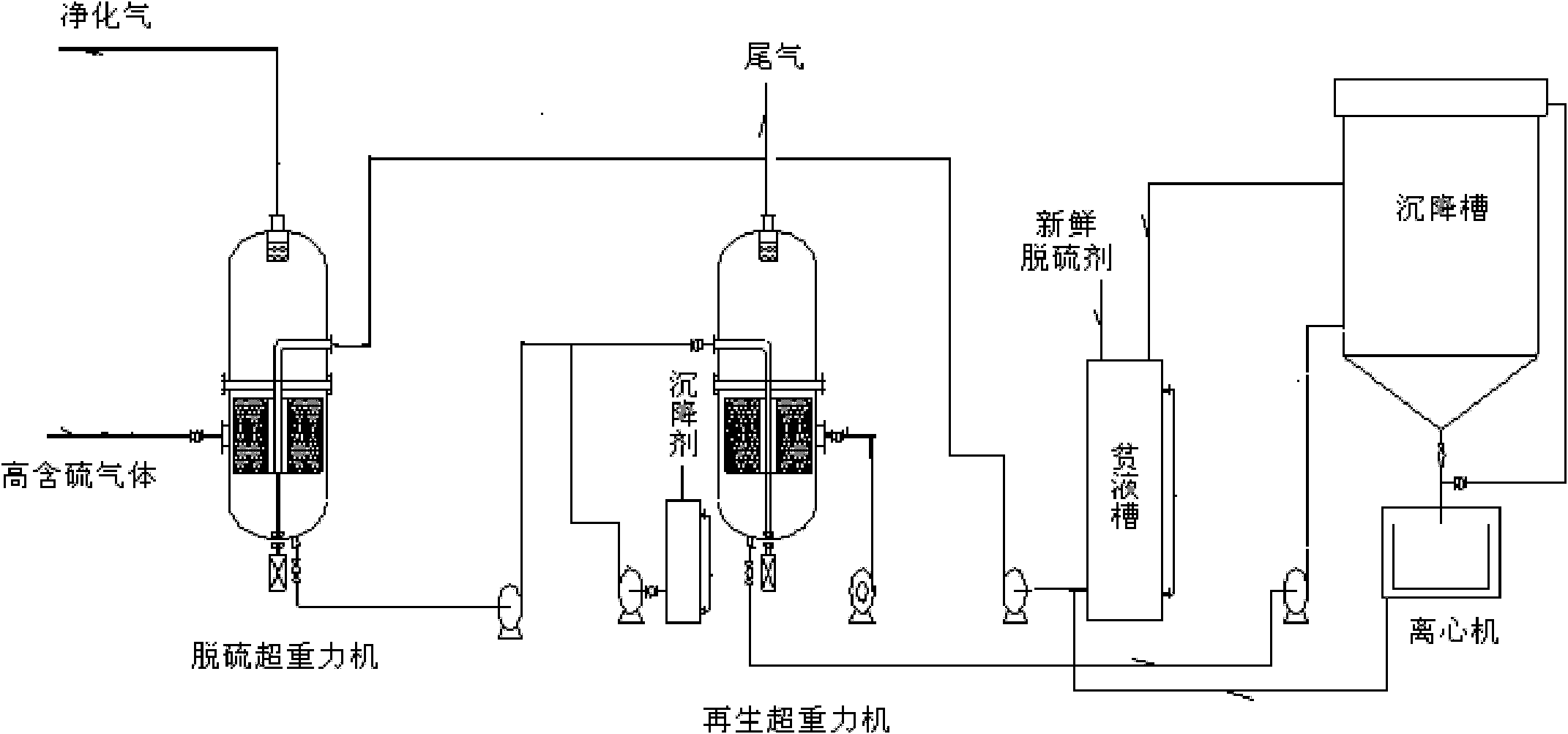

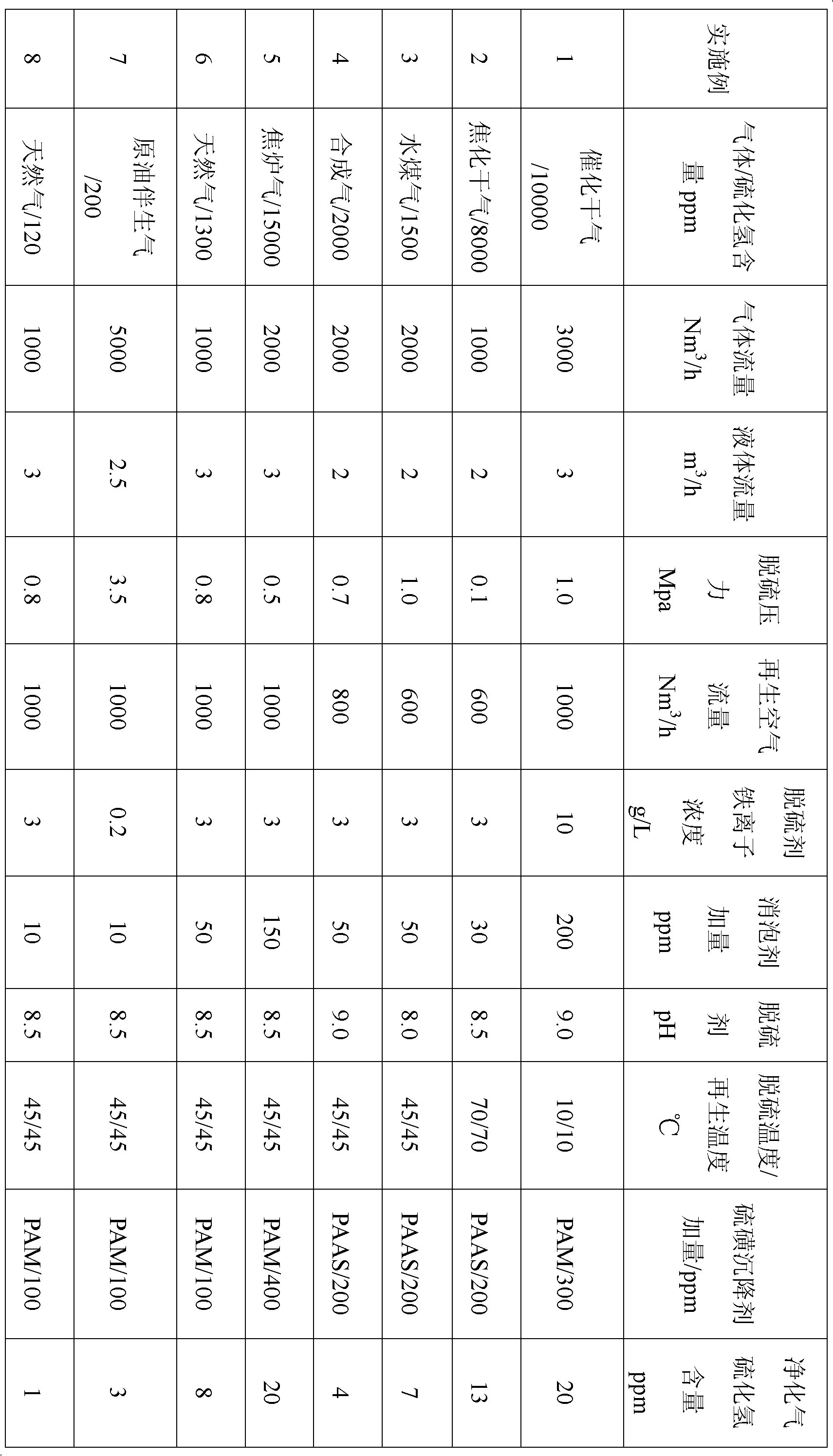

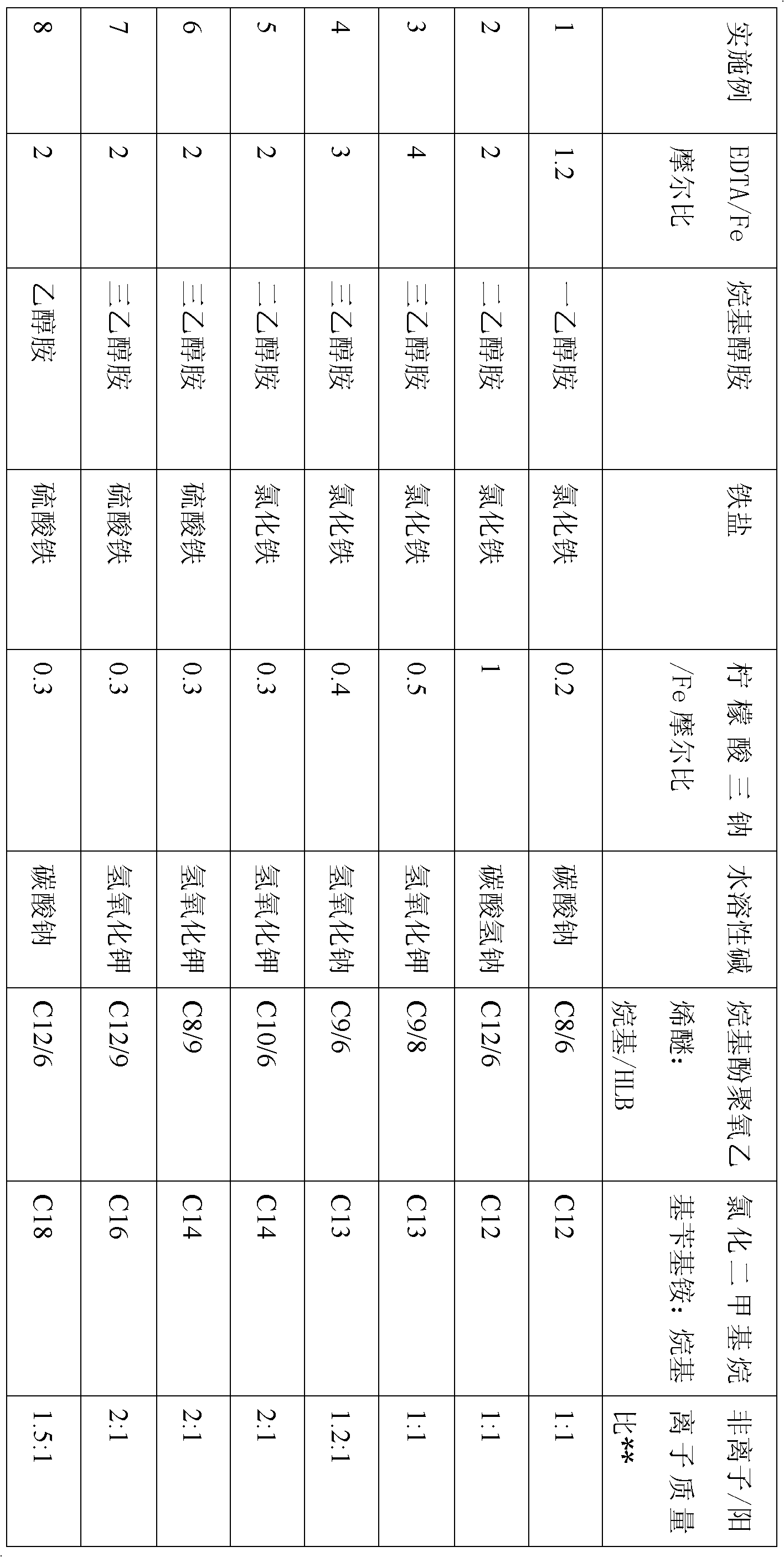

Method for removing hydrogen sulfide in gas phase through oxidization under high gravity field

InactiveCN102151476AShort regeneration timeSmall sizeDispersed particle separationGas phaseDefoaming Agents

The invention discloses a method for removing hydrogen sulfide in a gas phase through oxidization under a high gravity field, which comprises the steps of: enabling a desulfurizing agent to be in a countercurrent or cross current contact with a hydrogen sulfide containing gas in a desulfurizing high gravity machine; and then adding the desulfurizing agent rich in sulphur in a sulphur sedimentation agent and then enabling the desulfurizing agent added with the sulphur sedimentation agent to be in a countercurrent or cross current contact with air in a regeneration high gravity machine, whereinthe desulfurizing agent is a mixed solution consisting of complex iron, aqueous alkali, a sulphur modifying agent and a defoaming agent, and in the mixed solution, the concentration of iron ions is 0.1-10g / L, pH is 8.0-9.2, the concentration of the sulphur modifying agent is 10-200ppm, and the concentration of the defoaming agent is 5-50ppm. The high gravity machine is used for replacing the traditional low-transfer-efficiency reactor, and a high gravity rotary packed bed reactor is adopted during hydrogen sulfide oxidization and catalyst regeneration, thus process transfer efficiency is greatly strengthened, and time of oxidization desulfurization and regeneration of a desulfurizing agent is shortened; in addition, the sedimentation agent is adopted in a sulphur sedimentation stage and acts together with the sulphr modifying agent, thus the sulphur sedimentation time is also greatly shortened.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD +1

A novel masonry cement

The invention discloses a novel type of masonry cement, which comprises silicate cement clinker aggregate, mixed material, gypsum, cellulose ether, grinding aid, dispersant emulsion powder, water reducing agent, air-entrainer, quick-setting agent, retarders, instant coagulant, thixotropy lubricating agent, defoaming agent, hydrophobing agent, starch ether, plumping agent, shrinkage reduction agent, exciting agent, pigment and fabric.

Owner:SOUTH CHINA UNIV OF TECH

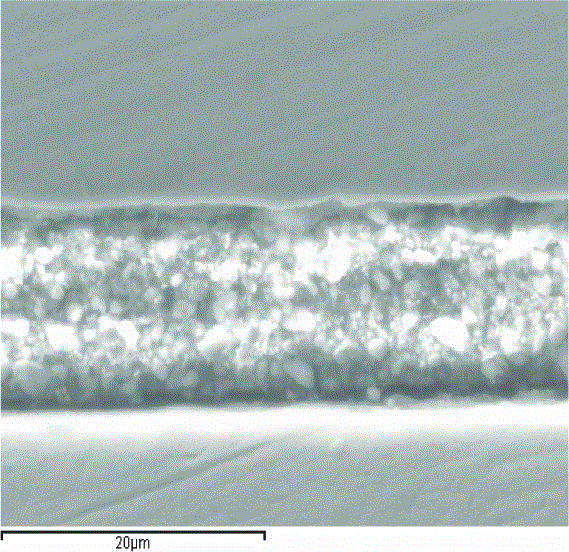

Graphene coating as well as preparation method and coating method thereof

The invention belongs to the technical field of materials and in particular relates to a graphene coating as well as a preparation method and a coating method thereof. The graphene coating is prepared from the components by weight: 5-95wt percent of less layer of grapheme, 5-95wt percent of adhesive, 0.01-50wt percent of dispersant and surfactant, 0.01-10wt percent of defoamer and the balance of solvent. With the adoption of the graphene coating, the thickness of an electricity and heat conductive coating can be controlled to be 100nm-20 microns; when the graphene coating is used on a plastic matrix, the volume resistivity can reach a range from 10<-2>ohm.cm to 10<-4>ohm.cm; while the graphene coating is used on a metal matrix, the volume resistivity can reach 10<-6>ohm.cm. The graphene coating can be applied to the metal surface so as to improve the cohesiveness, the electricity / heat conduction performance and the corrosion and oxidation resistance. When the graphene coating is coated on the plastic surface, the frictional resistance, the electricity and heat conduction performances and the static resistance can be lowered, and the graphene coating can be applied to the fields of printed circuits, electronic devices, radio frequency devices, touch screens, thin film solar energy, LEDs, magnetic shielding, radio frequency shielding and the like.

Owner:SUPERCDONGGUAN TECH

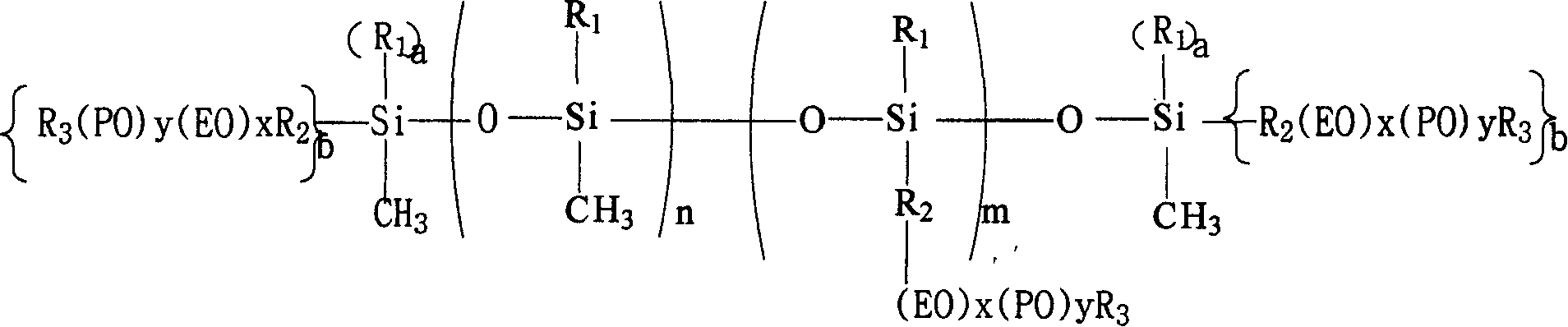

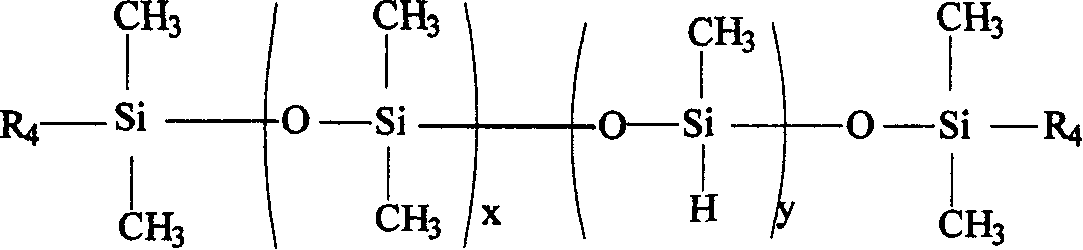

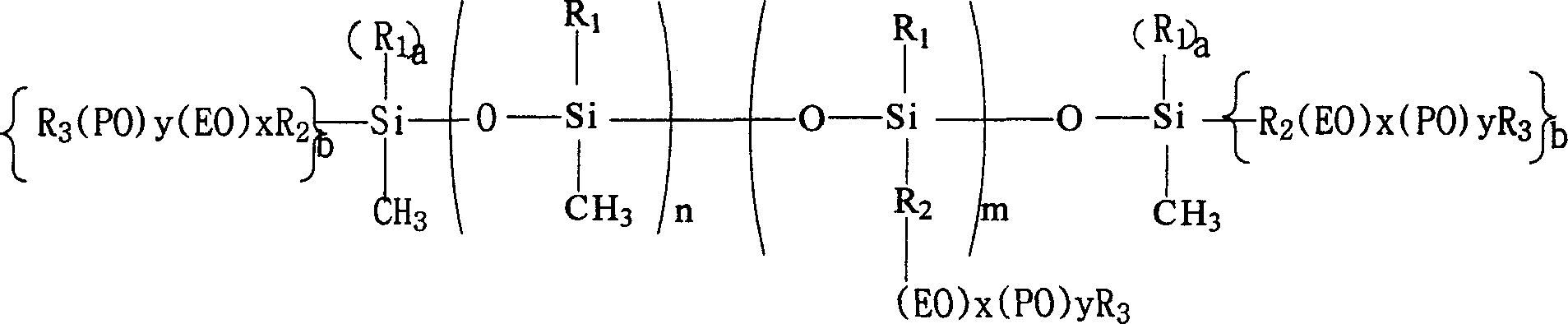

Organosilicon defoaming agent for water-based system and preparation method thereof

The invention discloses an organic silicon defoamer and preparing method in the hydraulic flexible ink and paint, which comprises the following parts: silicon polyether, silicone grease, emulsifier and thickener, wherein the active content is 10-50% corresponding to emulsion; the silicon polyether and silicone grease is 70-90% in the active content; the disperse dielectric adopts deionized water.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

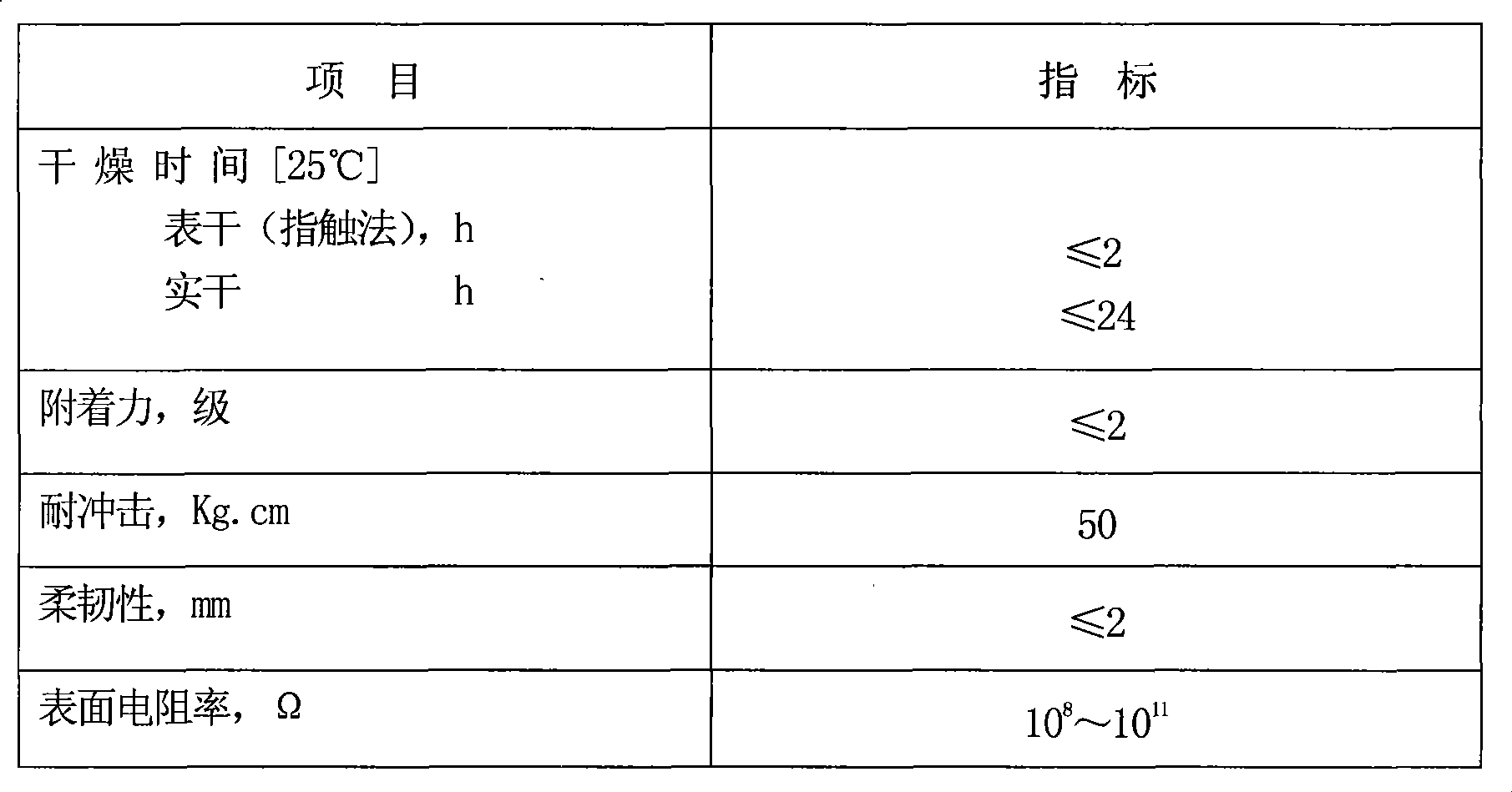

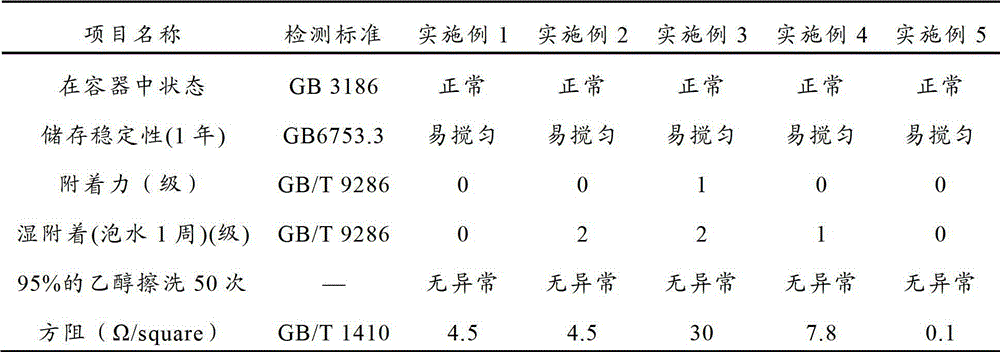

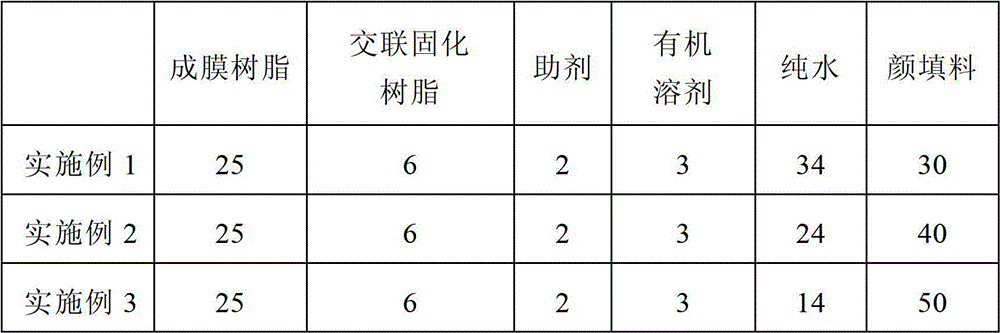

Silicon steel water-soluble environment-friendly super thick insulating coating and preparation method thereof

ActiveCN102746725AHigh solid contentGood heat resistancePolyurea/polyurethane coatingsEpoxy resin coatingsOrganic solventWater soluble

A silicon steel water-soluble environment-friendly super thick insulating coating and a preparation method thereof. The insulating coating comprises the following components, by weight percentage: 10-60% of organic resin containing film-forming resin and crosslinking curing resin; 0.1-5% of inorganic pigment; 28-60% of filler; additives including 0.1-4% of wetting agent, 0.1-4% of dispersing agent, 0.1-1% of defoaming agent in and 0.1-1% of pH regulator; 1-15% of organic solvent; and the balance of pure water. The present invention provides a chrome-free C6 water-soluble environment-friendly coating with low VOC emission. The coating has high solid content and inorganic filler content (solid no less than 60%, inorganic filler content no less than 40%, GB / T 1725-2007), excellent surface insulation performance no less than1500 ohm.cm<2> / tablet (ASTM A717), good attachment (grade class A, phi 10mm rod, GB / T 2522-2007), low lamination heat compression rate, and good corrosion resistance, and is suitable for silicon steel processed with clipping and stamping by large and medium-sized motors.

Owner:BAOSHAN IRON & STEEL CO LTD

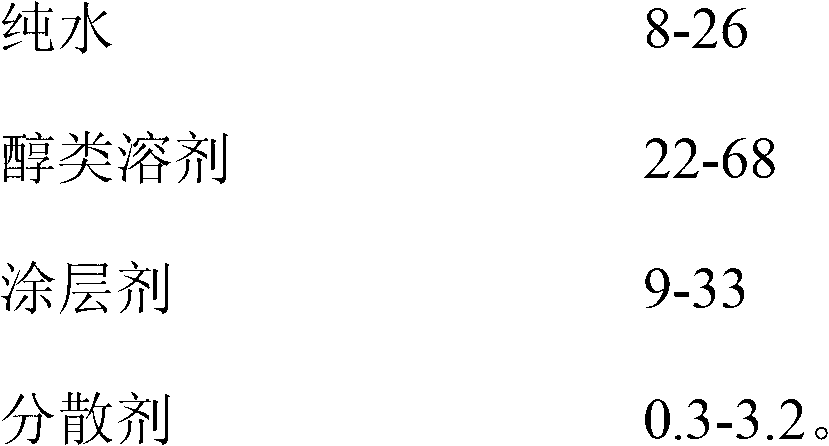

Waterborne digital ink-jet printing sublimation ink and preparation method thereof

ActiveCN101709177AAdjust surface tensionAdjust viscosityInksDyeing processDisperse dyeOrganic solvent

The invention provides waterborne digital ink-jet printing sublimation ink and a preparation method thereof. The ink comprises the following components in percentage by mass: 1 to 10 percent of disperse dye, 2 to 15 percent of dispersing agent, 10 to 60 percent of deionized water, 10 to 50 percent of water soluble organic solvent, 0.1 to 5 percent of surface active agent, 0.05 to 0.5 percent of germicide, and 0.05 to 0.5 percent of defoaming agent. The preparation method comprises the following steps of: mixing 1 to 20 percent of dispersing agent, 10 to 40 percent of water soluble organic solvent, 0.1 to 2 percent of germicide, 0.1 to 2 percent of defoaming agent, and 30 to 50 percent of deionized water, adding 1 to 20 percent of disperse dye while stirring, and grinding the mixed solution to obtain color paste; uniformly mixing 15 to 50 percent of color paste, 10 to 30 percent of water soluble organic solvent, 0.1 to 5 percent of surface active agent and 20 to 50 percent of deionized water and filtering the mixed solution to obtain the waterborne digital ink-jet printing sublimation ink. When the waterborne digital ink-jet printing sublimation ink is used in a large-sized ink-jet printer using waterborne ink, the good printing smoothness and the water retention of a printing head are achieved, and the preparation process is simple.

Owner:上海英威喷墨科技有限公司

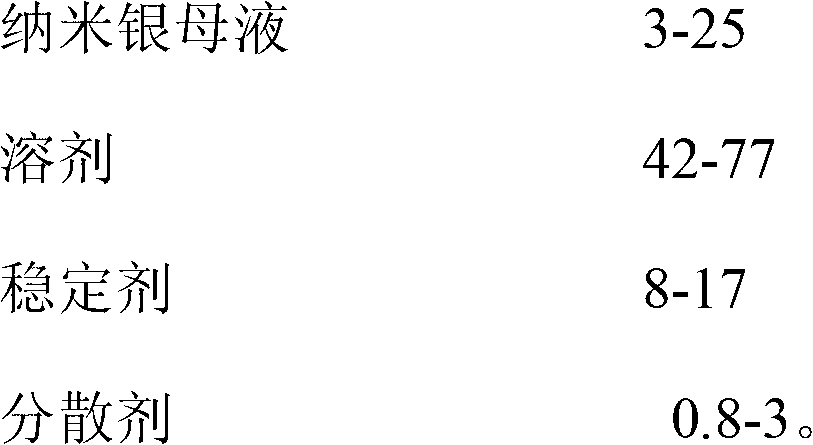

Anti-bacterial water-based paint and preparation method thereof

InactiveCN102702889AImprove aging resistanceImprove the pulverization performanceBiocideAntifouling/underwater paintsWater basedEscherichia coli

The invention relates to anti-bacterial water-based paint and a preparation method thereof. The paint comprises the following components in parts by weight: 0.2-11 parts of anti-bacterial agent, 8-33 parts of nano material, 23-64 parts of water-based resin dispersoid and 0.75-18 parts of adhesive resin or plasticizer. The preparation method comprises the following steps: firstly preparing a nano silver anti-bacterial agent; mixing deionized water, the anti-bacterial agent, a wetting agent, a dispersing agent and a defoaming agent and uniformly mixing, adding the nano material, uniformly dispersing to obtain the water-based dispersoid; adding the obtained water-based dispersoid to the mixed emulsion or water-based resin dispersoid, then adding the adhesive resin or plasticizer and various conventional assistants, stirring and dispersing evenly; adding pigments or colorant; and supplementing water to obtain the anti-bacterial water-based paint. The long-acting broad-spectrum antibacterial water-based paint has high fungicidal efficiency (more than 99%) on escherichia coli, staphylococcus aureus, black varietas of bacillus subtilis and the like and can reduce the high concentrate of organic matters of formaldehyde to the range of specified concentration index.

Owner:ANHUI JINDUN PAINT

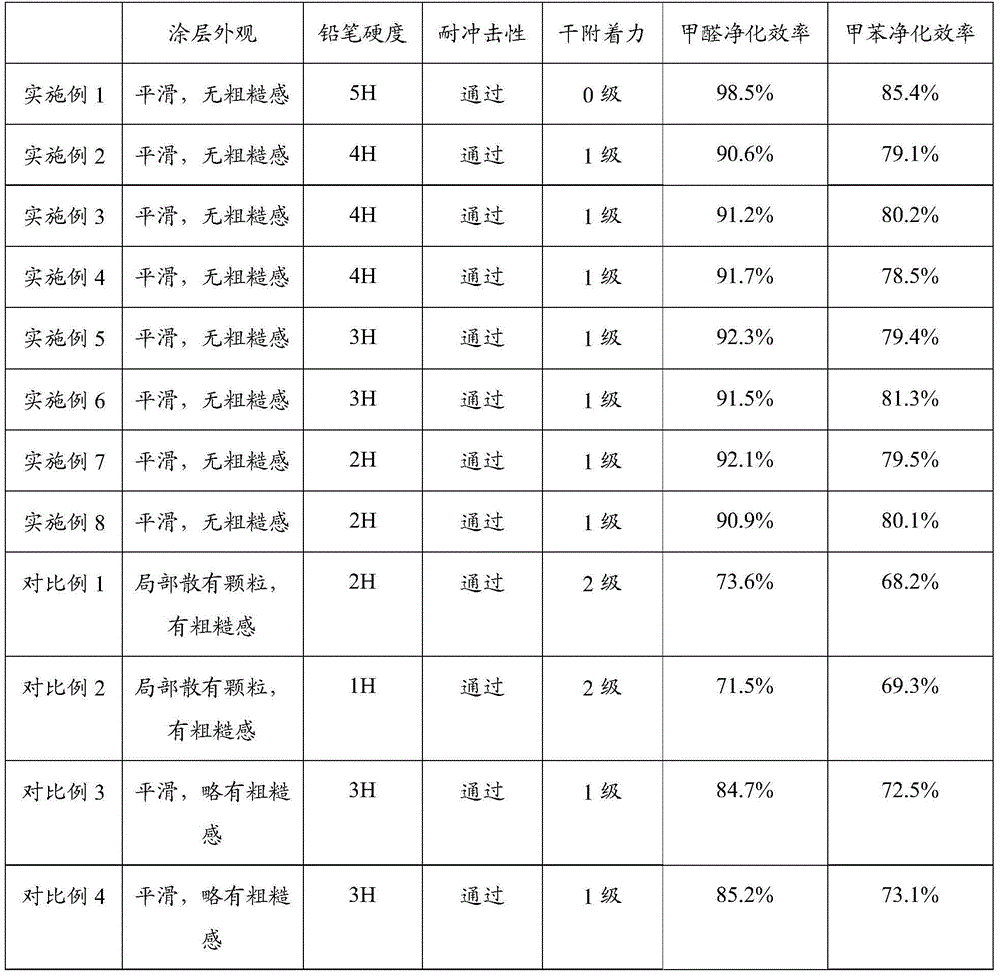

Powder coating with super-weathering resistance, preparation method and application thereof

InactiveCN101671518AWith super weather resistanceThe ratio is scientific and reasonablePowdery paintsPolyester coatingsPliabilityUltraviolet

The invention discloses powder coating with super-weathering resistance, a preparation method and an application thereof. The powder coating comprises the following raw materials in parts by weight: 40-90 parts of weather-resistant polyester resin, 3-30 parts of thermosetting fluorocarbon resin, 4-50 parts of curing agent, 0.1-1.5 parts of flatting agent, 0.2-0.8 part of degasifying agent, 0-4.5 parts of defoaming agent and 4-45 parts of pigment and filler. The powder coating with super-weathering resistance provided by the invention has scientific and reasonable proportioning in the aspects of raw material composition and raw materials, fine comprehensive properties such as flexibility, hardness, adhesive force and the like, stable chemical property, easy storage, performances of acid rain, ozone, ultraviolet ray and chemical medicine resistance and the like in long-term outdoor use, environment protection and wide application range. The preparation method provided by the invention has reasonable processes, strong operability, high qualified rate of finished products and capability of realizing industrialized production.

Owner:TIGER DRYLAC TAICANG

Multifunctional inorganic diatom ooze coating and preparation method thereof

InactiveCN104387816AStir wellNot easy to reuniteAntifouling/underwater paintsAlkali metal silicate coatingsCelluloseEmulsion

The invention relates to a multifunctional inorganic diatom ooze coating, which is prepared from the following components in percentage by mass: 10%-25% of water, 0.4%-0.8% of cellulose, 10-30% of a mixture of potassium metasilicate and silica sol, 0.2%-0.4% of a stabilizer, 0.1%-0.3% of a dispersing agent, 0.1%-0.3% of a silicon additive, 0.3%-0.5% of a defoaming agent, 0.1%-0.3% of an antibacterial agent, 0-20% of titanium dioxide, 5%-15% of nanometer kieselguhr, 10%-30% of coarse whiting, 2%-4% of talcum powder, 1%-3% of medical stone, 0-1.5% of anion, 0-2% of a nano-photocatalyst, 1%-2% of inorganic gel powder, 0-9% of an order-removing emulsion and 0-1.5% of pigment, wherein the sum of the components is 100%. The invention also provides a preparation method of the coating. The coating disclosed by the invention has the functions of sterilizing, preventing mold, purifying air and the like; and the preparation method disclosed by the invention is simple and easy to operate.

Owner:佛山市南海万磊建筑涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com