Method for removing hydrogen sulfide in gas phase through oxidization under high gravity field

A technology of supergravity field and hydrogen sulfide, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of huge sulfur separation equipment, huge regeneration equipment, long regeneration time, etc., and achieve shortening of sulfur settling time, Small footprint and reduced number of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

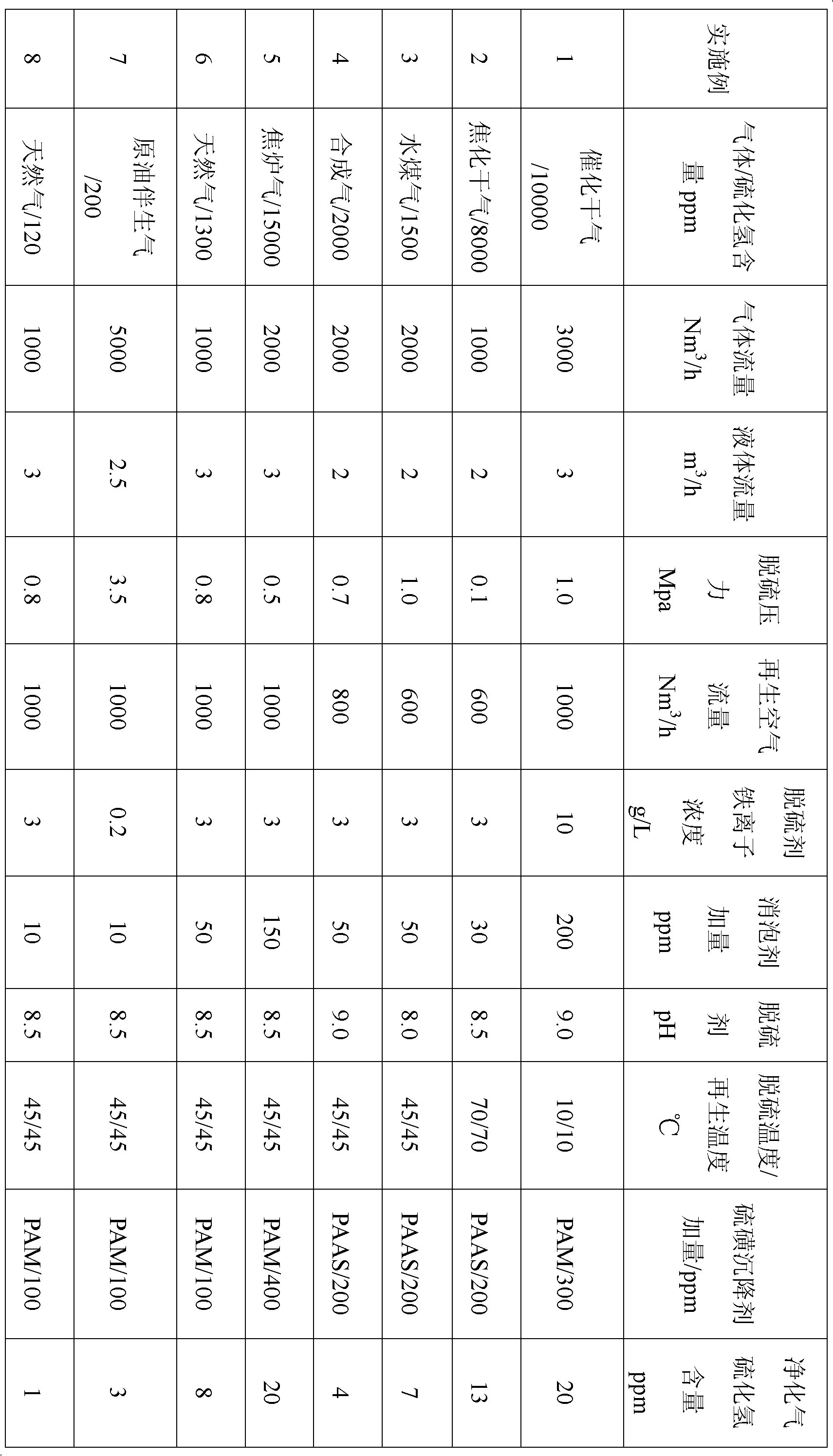

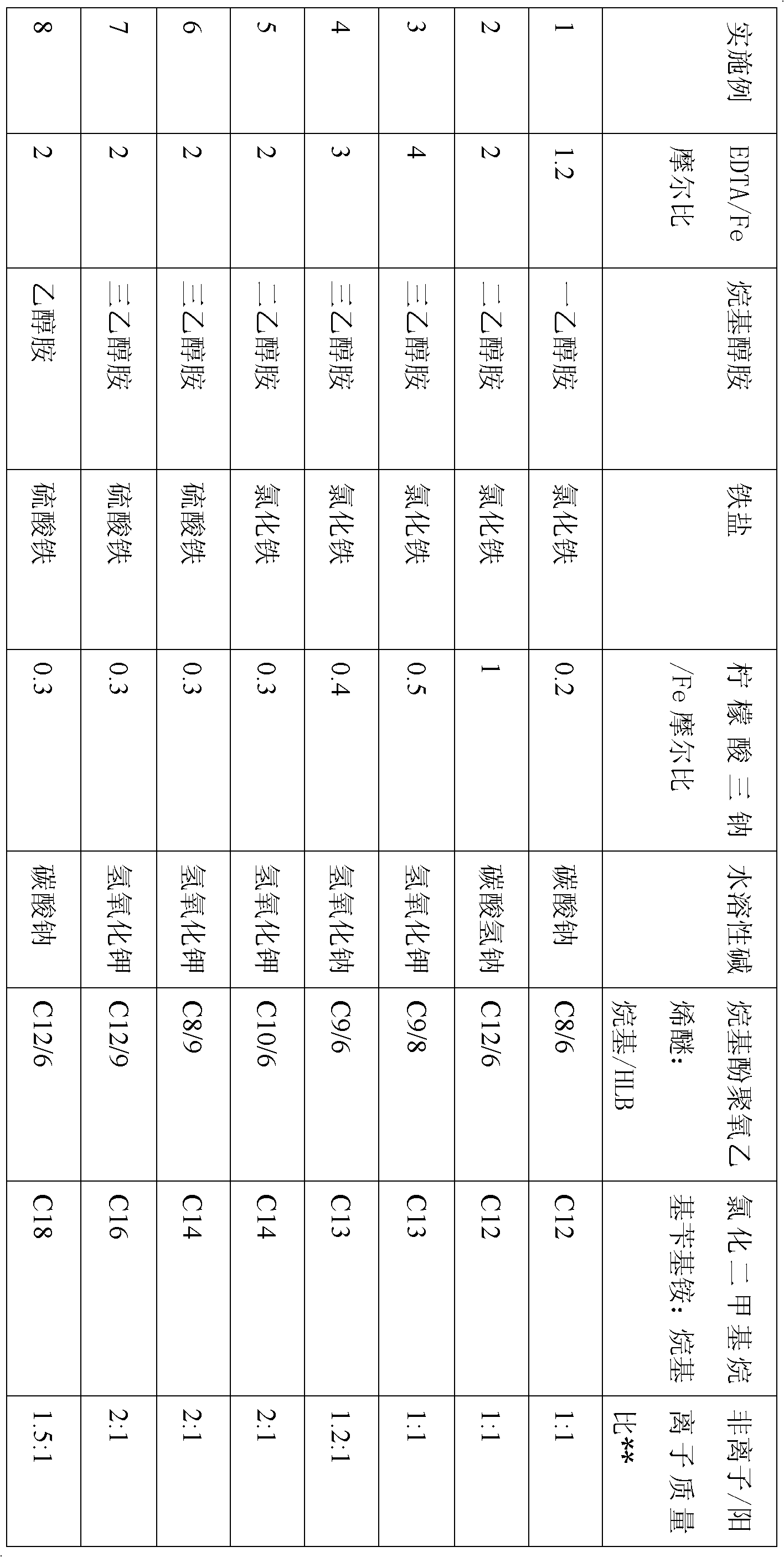

Examples

Embodiment Construction

[0011] The present invention is described further below by embodiment, and its purpose is in order to better understand content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

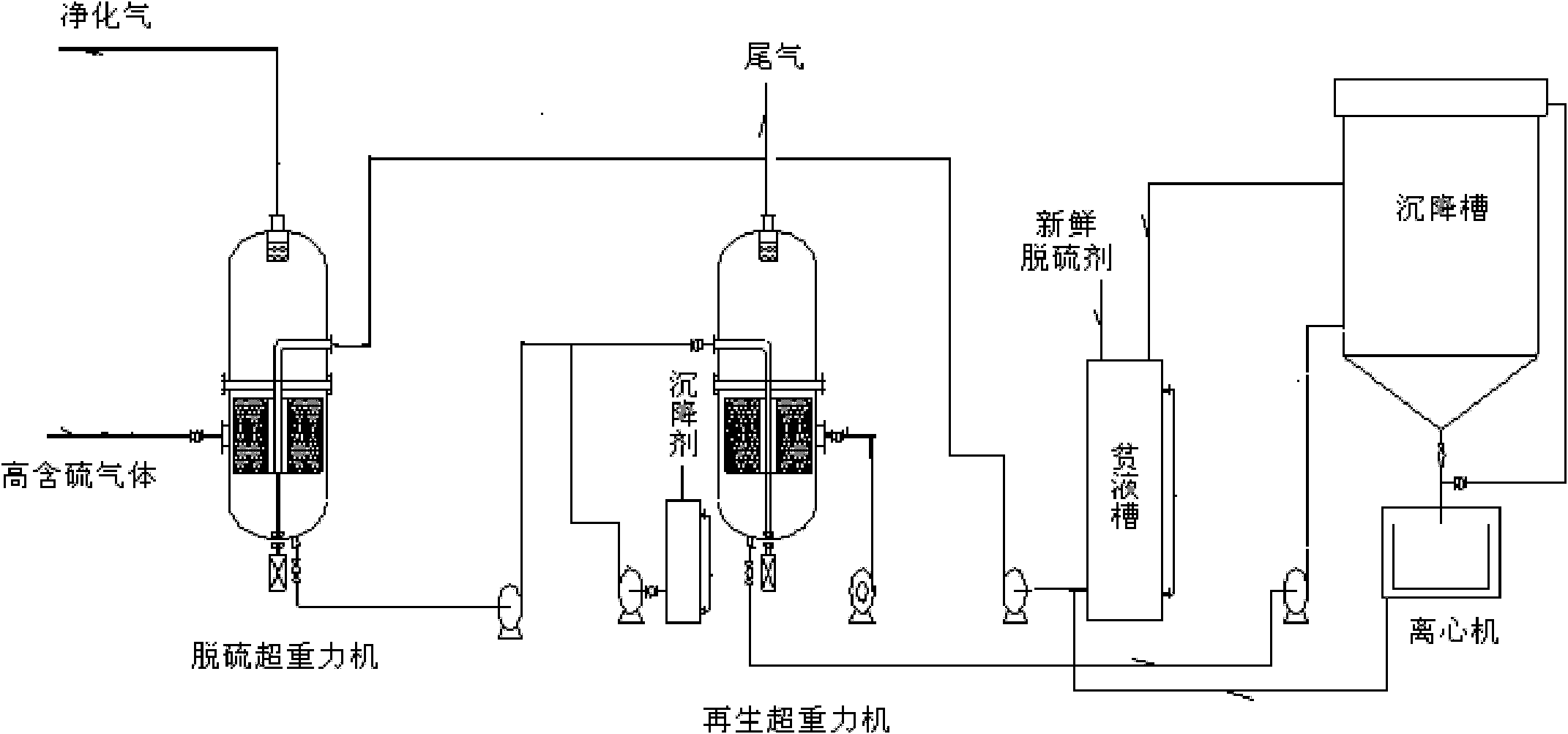

[0012] Such as figure 1 As shown, the present invention consists of a desulfurization supergravity machine, a rich liquid pump, a sedimentation agent pump, a sedimentation agent tank, a regenerative supergravity machine, an explosion-proof fan, a lean liquid pump, a lean liquid tank, a sedimentation pump, a sedimentation tank and a centrifuge; The lean desulfurization agent (solution containing complex iron) in the liquid tank enters the desulfurization supergravity machine through the lean liquid pump, and the high hydrogen sulfide gas from the production line is filled in the supergravity machine with the lean desulfurizer in the screen packing of the rotor Surface contact, hydrogen sulfide transfers to the liquid phase and is oxidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com