Absorption liquid for gas desulfurization and desulfurization method thereof

A technology for absorbing liquid and gas, applied in separation methods, sulfur preparation/purification, chemical instruments and methods, etc., can solve the problems of slow catalyst regeneration, many side reactions, fast degradation, etc. The effect of slow speed and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

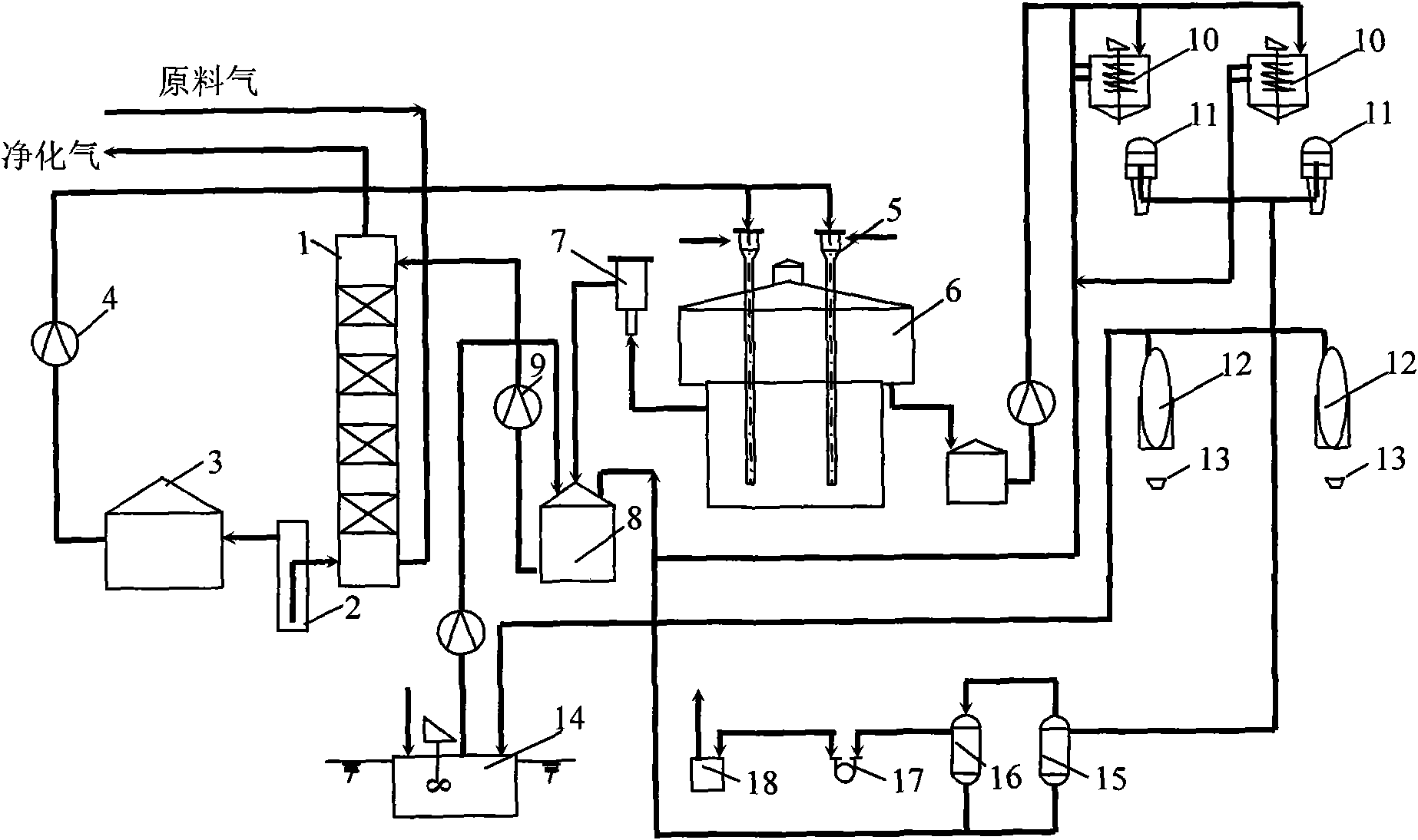

Method used

Image

Examples

Embodiment 2

[0043] Configure absorption solution, its composition and content are: sodium carbonate 1.5g / L, phenol: 0.1g / L, naphthoquinone: 0.25g / L, microbial enzyme: 0.005g / L, vanadium: 0.2g / L, NTA: 0.6 g / L, acetic acid: 0.05g / L, the balance is water, configuration method: simple stirring and mixing at a temperature of 35°C.

[0044] Adopt the same method as Example 1 to carry out desulfurization, the difference is that the feed gas contains 3g / m 3 H 2 S nitrogen, the gas flow rate is 5000L / h. Measure the sulfur content in the purified gas, and the results are as follows: the sulfur content in the purified gas is 25mg / m 3 .

Embodiment 3

[0046] Configure the absorption liquid, its composition and content are: potassium carbonate 1g / L, hydroquinone: 0.5g / L, naphthoquinone: 0.25g / L, microbial enzyme: 0.005g / L, vanadium: 0.4g / L, Diphenylcarbohydrazide: 0.5g / L, ethanol: 0.05g / L, the balance is water, and the preparation method: simple stirring and mixing at a temperature of 50°C.

[0047] Adopt the same method as Example 1 to carry out desulfurization, the difference is that the feed gas contains 300mg / m 3 H 2 S nitrogen, the gas flow rate is 3000L / h. Measure the sulfur content in the purified gas, and the results are as follows: the sulfur content in the purified gas is 2.5mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com