Patents

Literature

2219 results about "Waste rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Products useful as roof shingles and a process for making such products

InactiveUS6194519B1ExpensePromote degradationRoof covering using tiles/slatesOther chemical processesElastomerRubber material

The present invention relates to low-cost, efficiently-manufactured, polymer-based products useful as roofing shingles and similar products. The inventive shingles are weatherproof, inexpensive to manufacture and durable, particularly as contrasted with conventional shingles in areas of the country subject to hail damage. The invention also includes a method of making such shingle products. In a preferred embodiment, products of this invention use rubber material as the polymer base in combination with specific types of polyolefins. The rubber material can be most efficiently provided by the use of crumb rubber particles from spent automobile tires and other recycled rubber debris which are readily available and of very low cost. The products will have an average life far greater than that of current commercial roofing shingles, which are made using fiberglass or asphalt.The products of the instant invention are produced by extrusion as a mixture of materials, which product and its materials can be summarized as follows as a roofing shingle product which comprises:a. one or more side-branched polyolefins as an elastomer;b. optionally a blend of additional synthetic polymers, such as ethylene and propylene, as a second elastomer; andc. a rubber fraction, preferably obtained in part from recycled spent automotive or truck tires, and similar sources of waste rubber (sometimes known as "crumb rubber"), ground or recycled into particles having a mesh size of from 10 to 30 (i.e., approximately from about 500 to about 1000 microns).

Owner:MONTY MCWILLIAMS +3

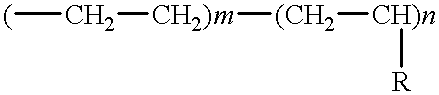

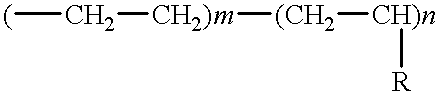

Wood plastic composite material

The invention relates to a wood plastic composite material comprising the following materials in parts by weight: 100 parts of wood meals, 20-80 parts of waste plastics, 5-50 parts of waste rubbers, 10-60 parts of high-melt index thermoplastic resins, 1-12 parts of surface active agents, 2-8 parts of lubricating agents, 0.1-4 parts of cross-linking agents, 0.1-4 parts of antioxygens and 0.05-1.5 parts of processing agents, wherein the grain diameter of the wood meals ranges from 10 meshes to 325 meshes; the flow velocity of the high-melt index thermoplastic resins is higher than 20 g / 10 minutes; the cross-linking agents are peroxides, thus the invention improves the dispersibility and the flowability of the wood meals contained in the composite and the compatibility of plastics by adding the high-melt index thermoplastic resins, can not only better utilize the resources, but also enhances the mechanical strength (such as tensile strength, bending strength, impact strength, and the like) of the composite material by adding the waste rubbers, has the advantages of good processing property, low water absorption rate, good stability of products, and the like and is suitable for injection moulding and beneficial to market promotion.

Owner:东莞市启原实业有限公司

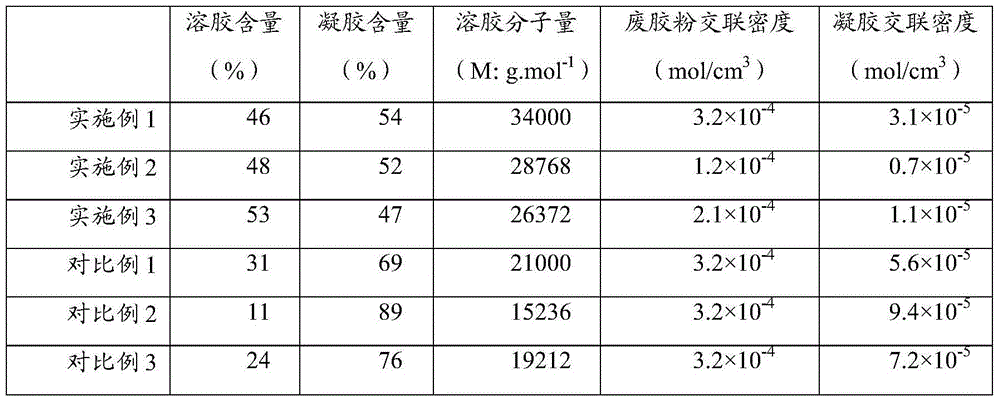

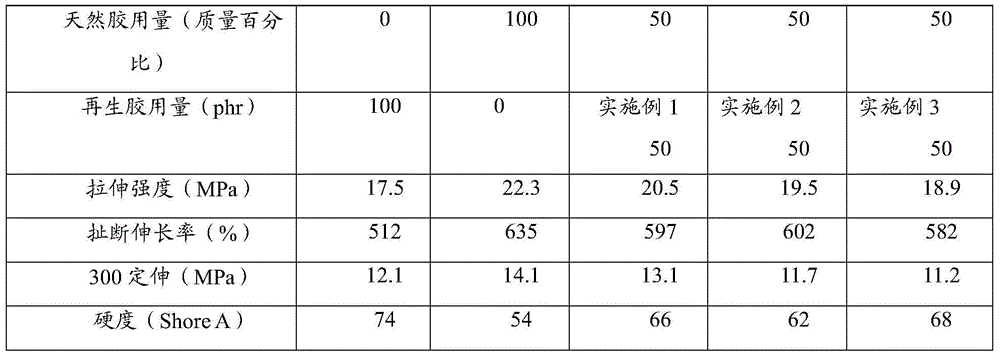

Method for continuously preparing liquid reclaimed rubber by aid of screw extruder

The invention relates to a method for continuously preparing liquid reclaimed rubber by the aid of a screw extruder, which belongs to the field of waste rubber recycling. The method is characterized in that a cross-linked network of pretreated waste rubber powder is crushed to obtain the liquid reclaimed rubber under the combined action of temperature, pressure, shearing and desulfurizer in the screw extruder by means of a physical and chemical linkage method and by the aid of the screw extruder. The method is simple in technical process and has the advantages of high desulfurization and depolymerization degree, energy conservation, environmental protection and continuity. The obtained liquid reclaimed rubber can be used with asphalt or replaces the asphalt for paving, and can be used with pure rubber to manufacture waterproof anticorrosion materials and the like.

Owner:宿迁绿金人橡塑机械有限公司

Devulcanization product consisting of scrap rubber, a devulcanization compound, a method for producing same, the reuse thereof in fresh mixtures and the use thereof for producing injection moulded parts

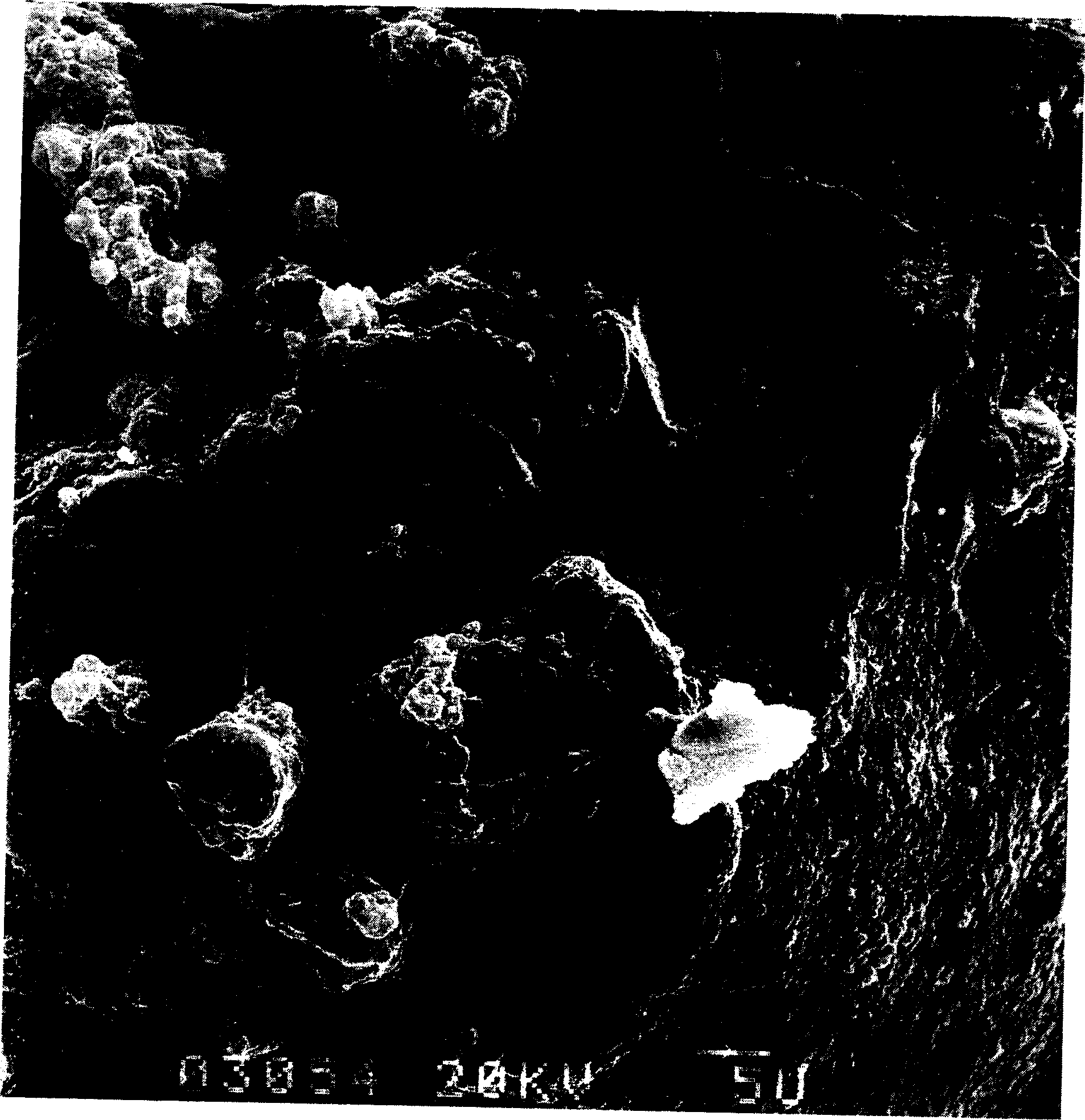

InactiveUS6924319B1High possible phase connectionImprove the level ofPlastic recyclingChemistryScrap

A devulcanization product of comminuted scrap rubber of rubber granules, in which the sulfur bridges of the rubber granule surface are broken and activated for a new vulcanization, is produced by treating the rubber granules to swell the rubber structure of the granule surface and by mixing the treated rubber granules with a devulcanization formulation, acting mechanically and chemically reductively on the rubber granules, in a heating and cooling mixer combination. The rubber granules and the devulcanization formulation are heated to a temperature of 105-150° C. and subsequently immediately cooled. A devulcanization compound is prepared by mixing the devulcanization product with vulcanization and binding agents so as to coat the rubber granules uniformly with them The devulcanization compound can also be prepared by coating the swelled rubber granules in layers by admixing vulcanization agents such as accelerators, activators, auxiliary agents, binding agents, oxygen radical donors and scavengers.

Owner:KRIEG GERHARD +1

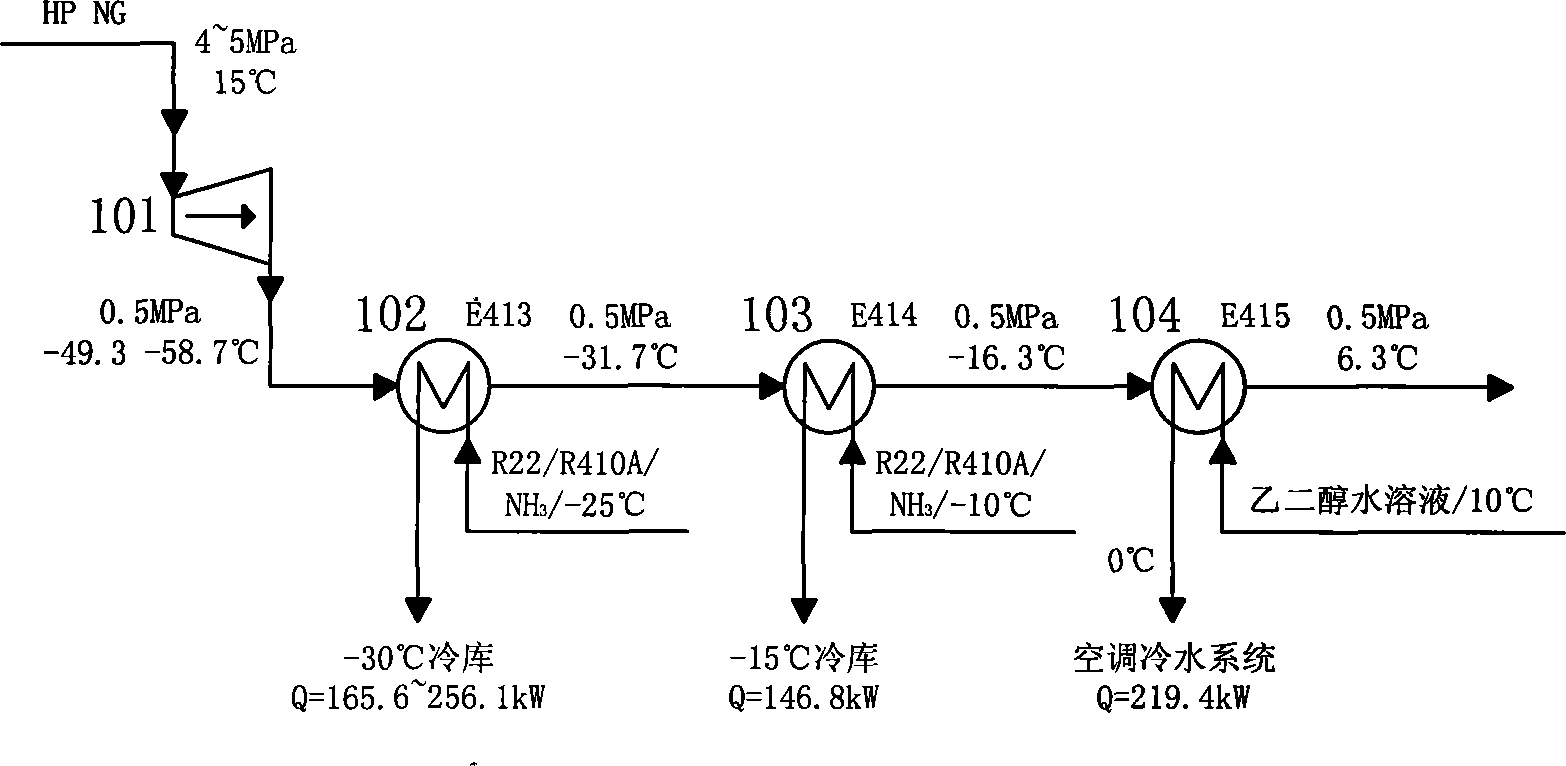

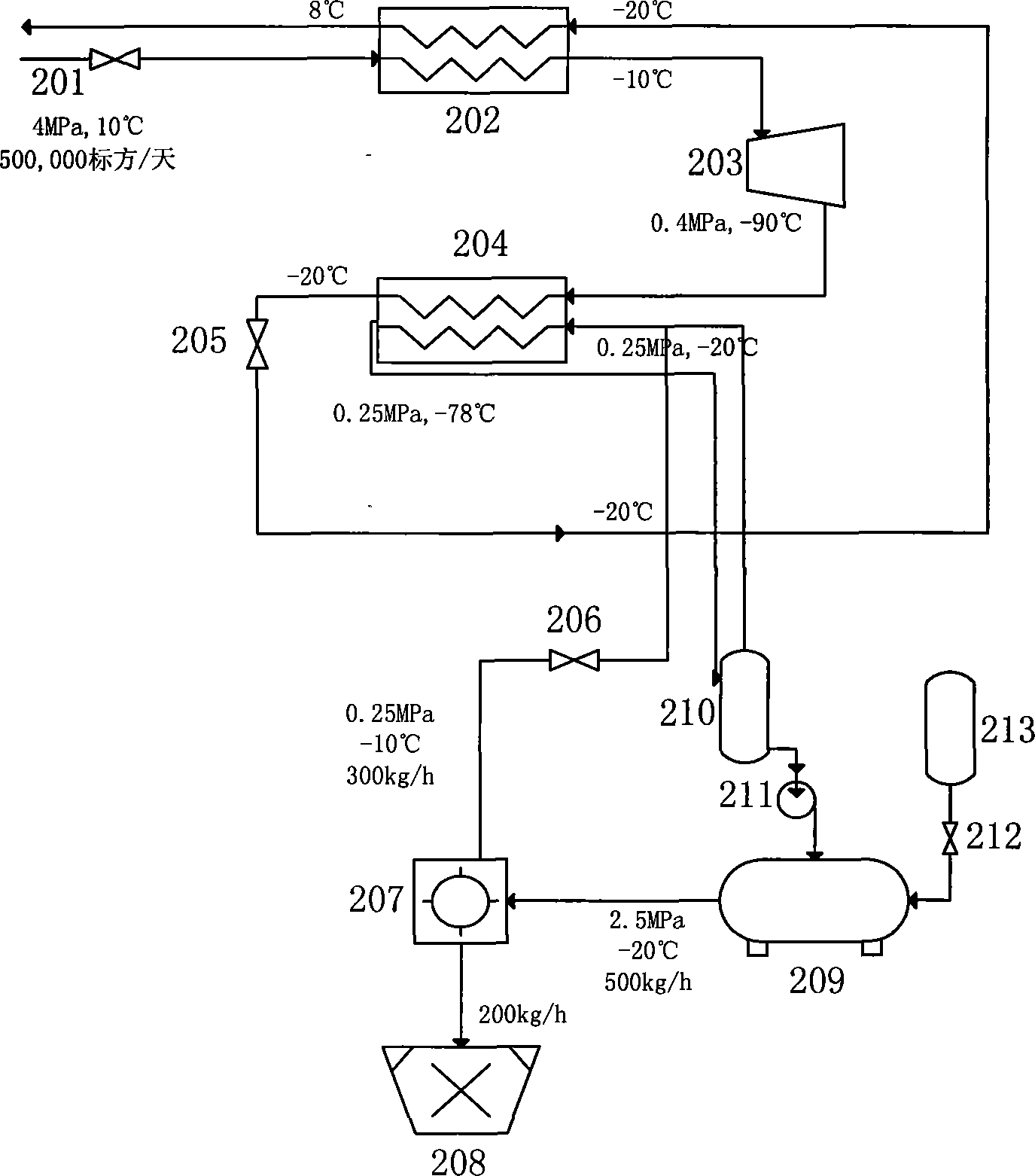

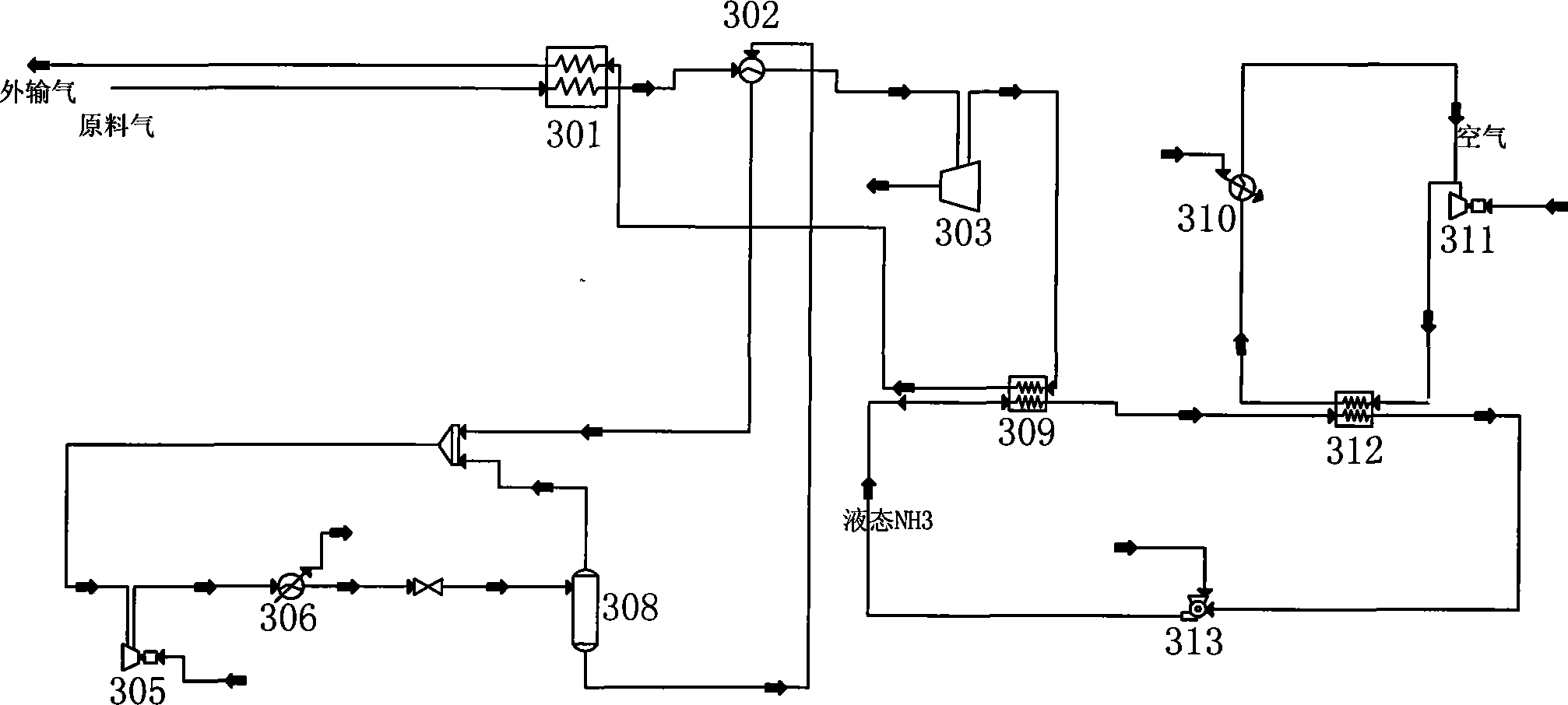

Method for utilizing pressure energy of natural gas

InactiveCN101245956AImprove utilization efficiencySimple processing technologyCompression machinesStationary plate conduit assembliesWaste rubberEngineering

The invention discloses a method which utilizes natural gas pressure energy; namely, the pressure and the temperature of the natural gas in a high pressure pipeline are reduced by a no-power refrigerator so as to gain low temperature natural gas which then exchanges the heat with a normal-temperature refrigerant which is sent by a normal-temperature tank; the low temperature refrigerant with temperature reduced enters a refrigerant storage tank for standby and is finally delivered to a cold energy user; the normal-temperature natural gas with temperature increased enters the pipeline. The method which utilizes natural gas pressure energy has convenient and practical whole process technique and high efficiency, spends little investment on the self-pressure energy in the pressure reduction process of the high pressure natural gas which is recovered by a pressure modulating station, converts the pressure energy into the cold energy with low operation cost, leads the cold energy to be used by cold quantity users of cold storages, cold water air conditioners, wasted rubber deep-cold crushing round the pressure modulating station by means of the refrigerant, etc., or to be made into ice blocks and dry ice products for abroad sale, etc., thus gaining huge economic benefits, improving the utilization ratio of the energy resource and eliminating the safe hidden trouble which is generated by sudden coolness of the equipment in the normal pressure modulating process.

Owner:GUANGZHOU GAS

Waste rubber tyre powder modified asphalt and its prepn process

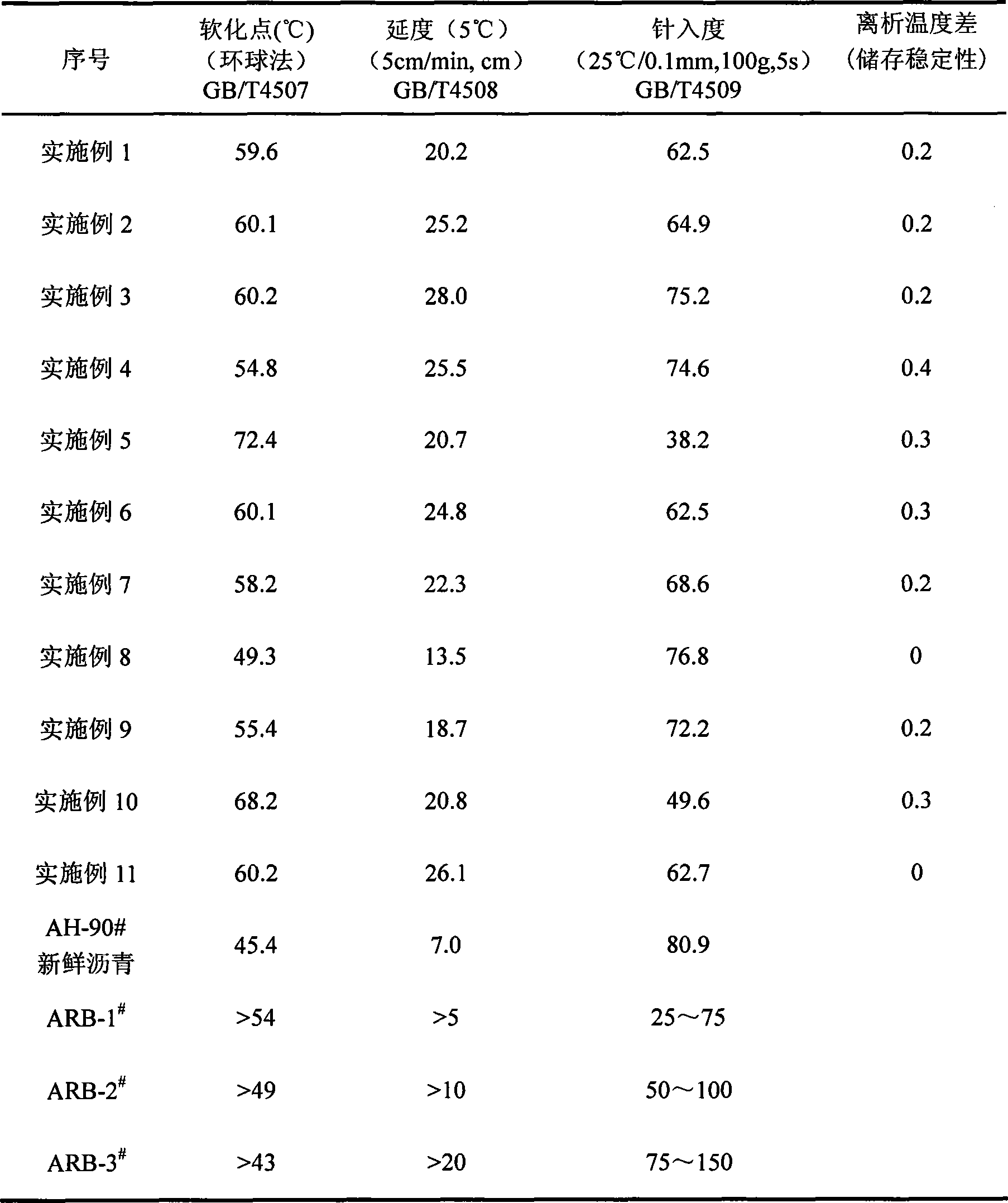

InactiveCN101089049AInhibition of segregationAvoid elastic recoveryBuilding insulationsPolymer scienceWaste rubber

The present invention relates to one kind of waste rubber tyre powder modified asphalt and its preparation process. The waste rubber tyre powder modified asphalt consists of asphalt matrix 100 weight portions, waste rubber tyre powder 10-30 weight portions, compatilizer 1-10 weight portions, dissolution promoter 0.5-30 weight portions, activating modifier 1-40 weight portions and emulsifier 0-5 weight portions. It is prepared through a chemical and physical process including the steps of degrading and activating the waste rubber tyre powder, vulcanizing and cross-linking, stirring and shearing. It is suitable for paving and repairing highway.

Owner:SHANGHAI MIRONGKE ELECTRICAL DIGITAL INTEGRATION

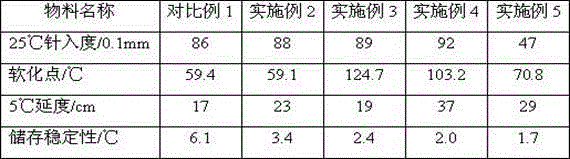

Ultraviolet aging-resistant compound modified asphalt and preparation method thereof

ActiveCN103146207AImprove anti-aging propertiesStop breakingTreatment with plural serial refining stagesBuilding insulationsPolymer modifiedPolymer science

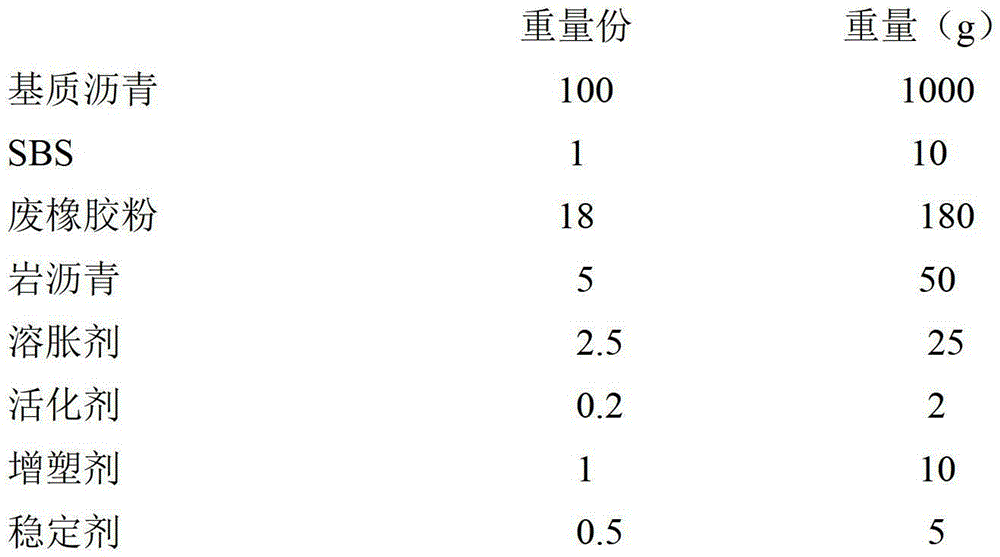

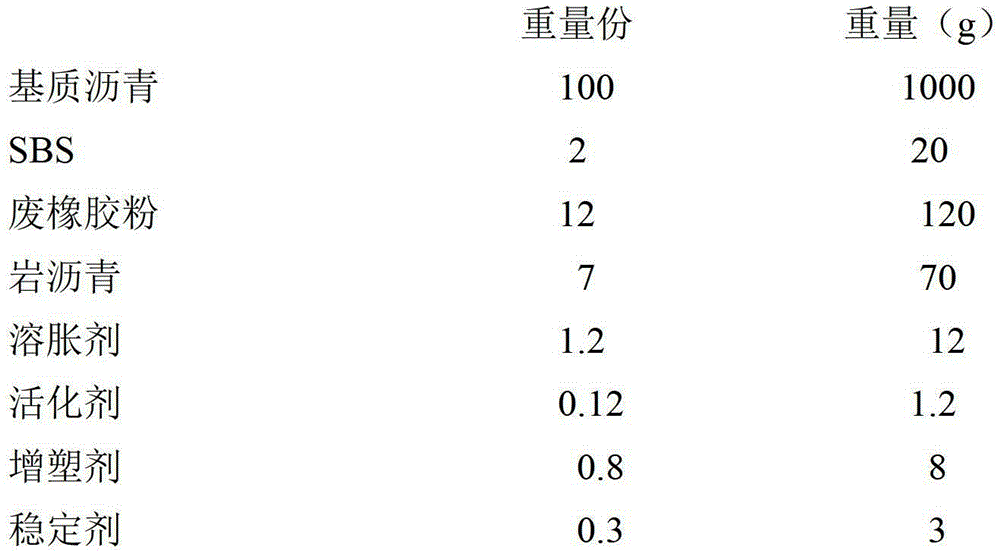

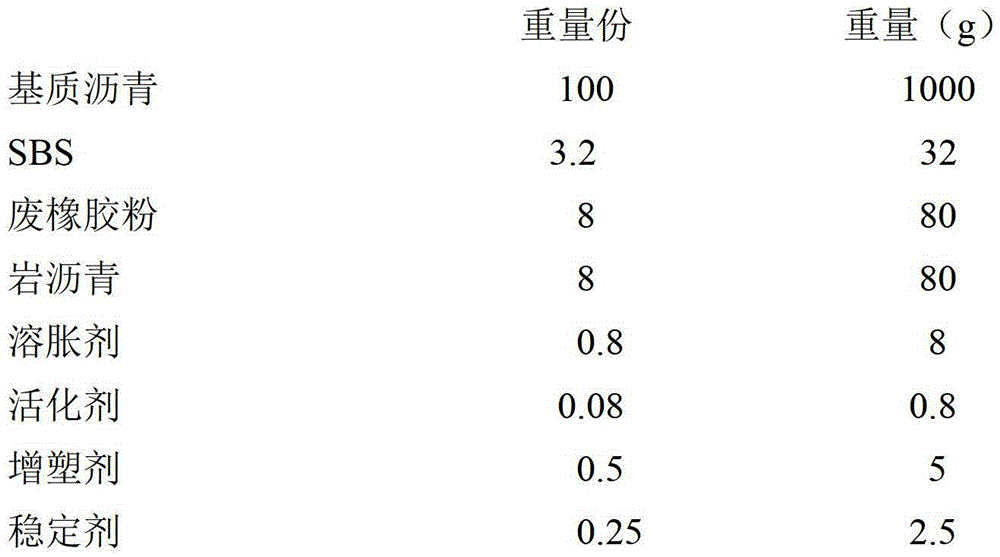

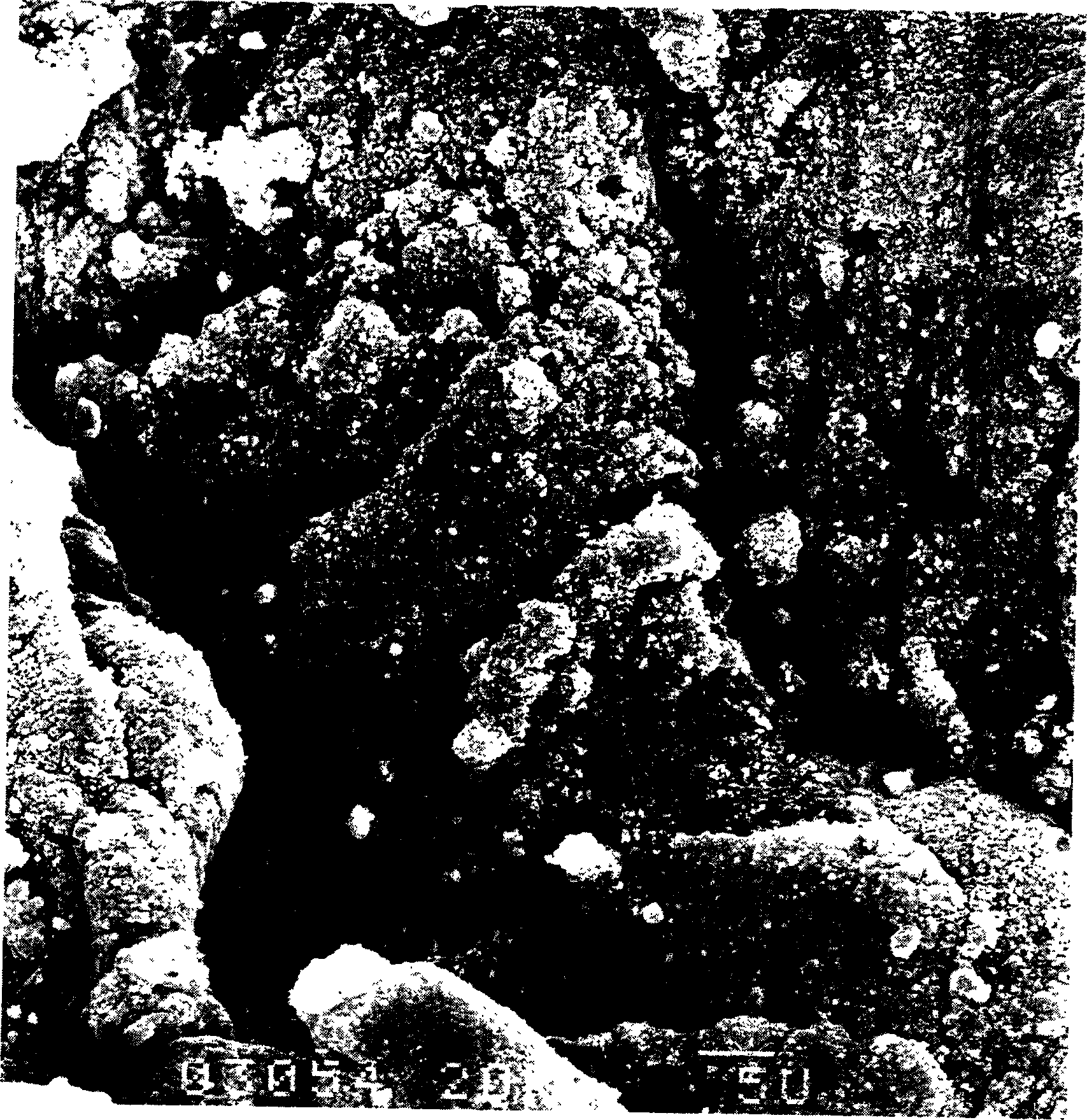

The invention belongs to the technical field of road asphalt modification and relates to an ultraviolet aging-resistant compound modified asphalt, wherein on the basis of 100 parts by weight of matrix asphalt, in parts by weight, 1-6 parts of styrene-butadiene-styrene block copolymer, 3-18 parts of waste rubber powder, 5-10 parts of rock asphalt, 0.3-2.5 parts of sweller, 0.03-0.2 part of activator, 0.1-1 part of plasticizer and 0.2-0.5 part of stabilizer are further added, wherein the sweller is furfural extract oil which is subjected to dewaxing treatment previously; the furfural extract oil contains 60wt%-88wt% of aromatic components which contain 40-65wt% of heavy aromatic hydrocarbon; and the waste rubber powder is waste rubber tire tread rubber powder having the content of carbon black between 28wt% and 58wt% and the grain diameter between 45 and 80 meshes. The ultraviolet aging-resistant compound modified asphalt provided by the invention is up to the standard of the polymer modified asphalt in performance, and the ultraviolet aging resistance of the asphalt is improved to a large extent; and waste resources are utilized.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

Composite of modified road asphalt by microwave radiating old rubber powder and its preparation process

InactiveCN1597782AGood dispersionGood physical and mechanical propertiesBuilding insulationsWaxMicrowave

The invention relates to a microwave-irradiated waste-rubber powder modified pitch combination and its preparing method, using higher-wax content pitch as a substrate, adding in powdery butadiene-styrene rubber and microwave-irradiated waste rubber powder, and making high-speed cutting and uniform commixing to make the modified pitch. The modified pitch has the characters of high-temperature stability, obviously increased low-temperature extensibility, good antiaging property, etc, has road performance synthetically improved and can act as high-grade road pitch for use.

Owner:NORTHWEST NORMAL UNIVERSITY

Activated waste rubber powder and preparation method thereof as well as modified asphalt and preparation method thereof

InactiveCN101817946AGood compatibilityGood storage stabilityBuilding insulationsPolymer scienceWaste rubber

The invention relates to activated waste rubber powder and a preparation method thereof. The activated waste rubber powder is prepared from a mixture containing waste rubber powder, a softener and / or a rubber activating agent. The invention also relates to a waste rubber powder modified asphalt and a preparation method thereof. The waste rubber powder modified asphalt is prepared from a mixture containing base asphalt and the activated waste rubber powder. The activated waste rubber powder and the base asphalt have favorable compatibility, and the modified asphalt containing the activated waste rubber powder can have favorable storage stability, high temperature property and ageing-resistant performance and lower cost. In addition, the preparation methods of the activated waste rubber powder and the modified asphalt are simple in process and convenient to operate.

Owner:RES INST OF HIGHWAY MIN OF COMM

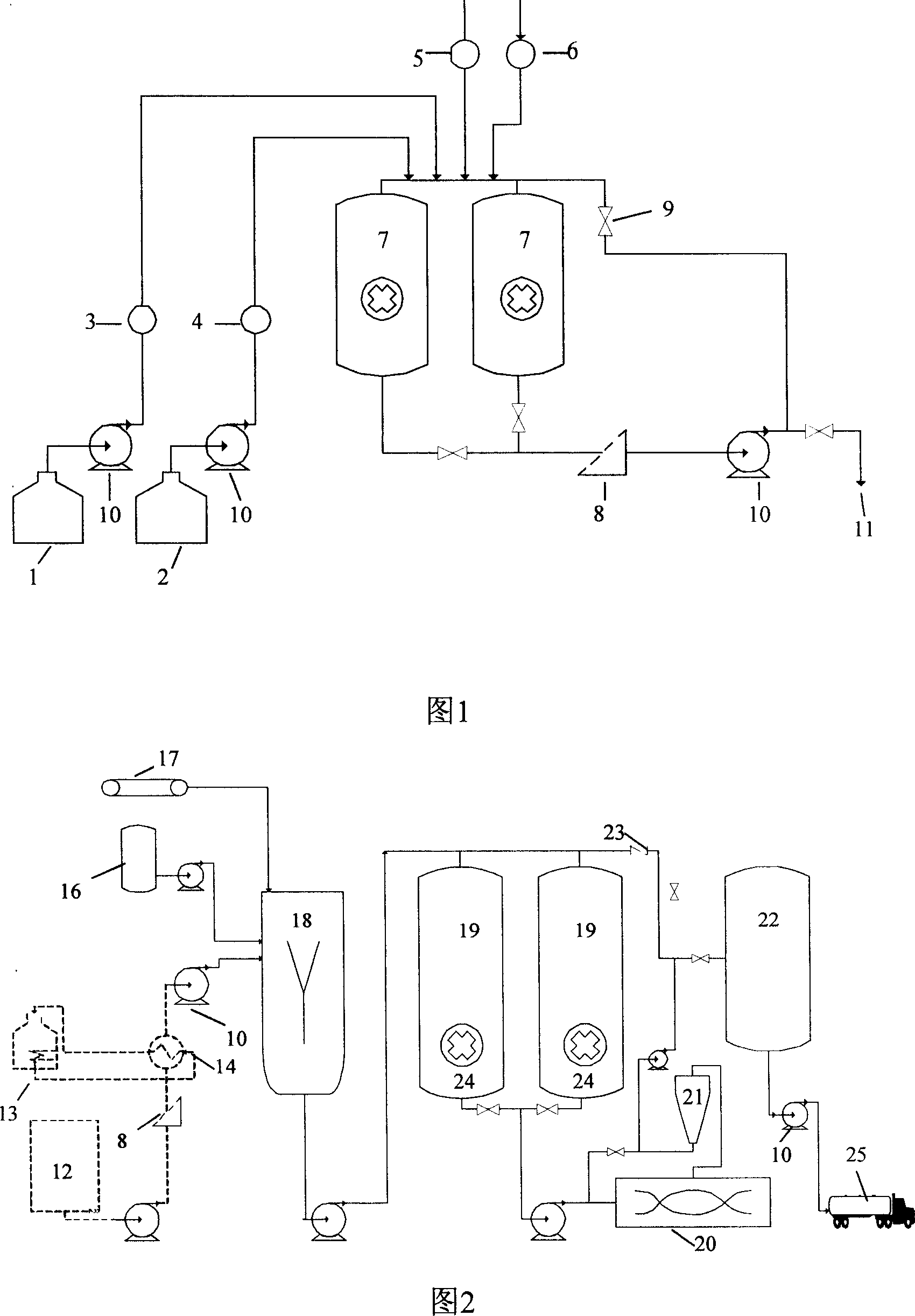

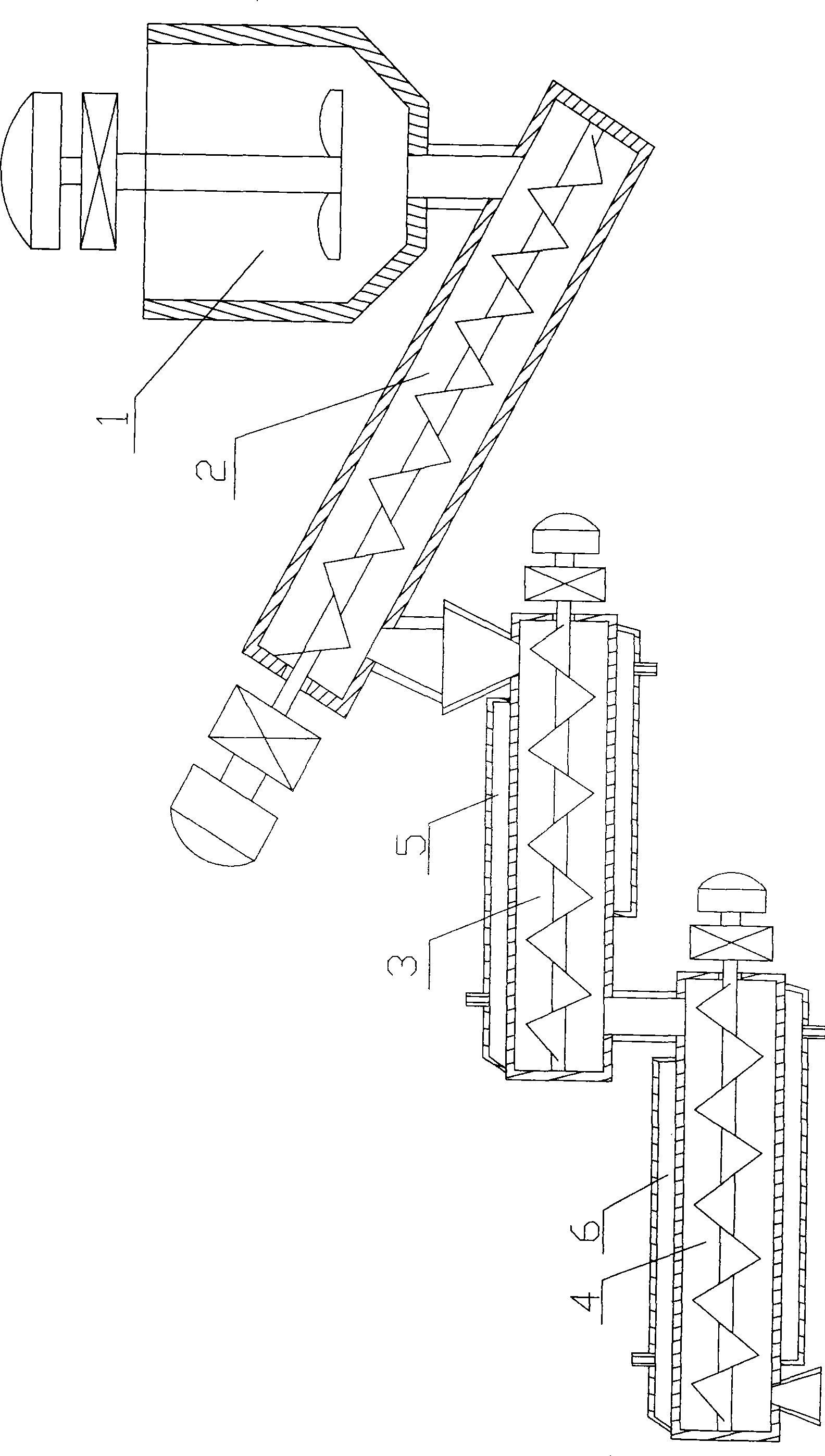

Automatic rubber powder plasticizing process and apparatus thereof

The invention relates to a technique of automatic rubber powder plasticization which carries out plasticization to the rubber powder in the recovery, processing and utilization of waste rubber. The waste rubber powder is smashed to 10 meshes to 40 meshes, added with an activator and a softer according to a weight ratio of 1:0.3-0.4 percent: 8-18 percent, evenly mixed, and heated to 180 DEG C to 320 DEG C with temperature preserved for 8min to 15min; then desulfurization and plasticizing are carried out, and plasticized rubber powder is obtained after being cooled. The invention also provides a device for plasticizing processing, which comprises a stirring device (1), a feeding device (2), a thermal reaction device (3) and a cooling device (4), which are all communicated with each other in sequence. The technique is simple, can realize automatic continuous production, has no pressure and no discharging of waste gas and no pollution, is safe and reliable, and has stable quality stable and easy control. The plasticized rubber powder processed can be directly used for the production of rubber products without dehydration, thereby saving energy, reducing consumption and having little investment and low cost. The device can realize automatic continuous production, and is simple in structure, easy and convenient in operation, easy to control and low in cost.

Owner:TAIAN JINSHAN RUBBER IND

Gelatine powder modified asphalt and processing method thereof

ActiveCN101104739AImprove stabilityReduce manufacturing costBuilding insulationsPolymer scienceWaste rubber

The invention discloses a modified asphalt and a processing method of the modified asphalt. The modified asphalt of the invention contains the following components in part by weight: 50 to 92 parts by weight of base asphalt, 8 to 50 parts by weight of rubber powder, 0.1 to 5 parts by weight of first cross-linking agent, 0 to 12 parts by weight of diluent and 0 to 6 parts by weight of second cross-linking agent. The invention develops a modified asphalt prepared through desulphurization degradation and recrosslinking and the processing method of the modified asphalt through the analysis of the conditions of selective degradation process of waste rubber powder in the asphalt, the recovery of macro molecules performance of the degraded waste rubber powder in the modified asphalt and the study on the preparation technique of the modified asphalt made of the waste rubber powder. The modified asphalt can form homogeneous mixing system, the viscosity of the asphalt is reduced and the storage stability is increased.

Owner:CHINA NAT OFFSHORE OIL CORP +2

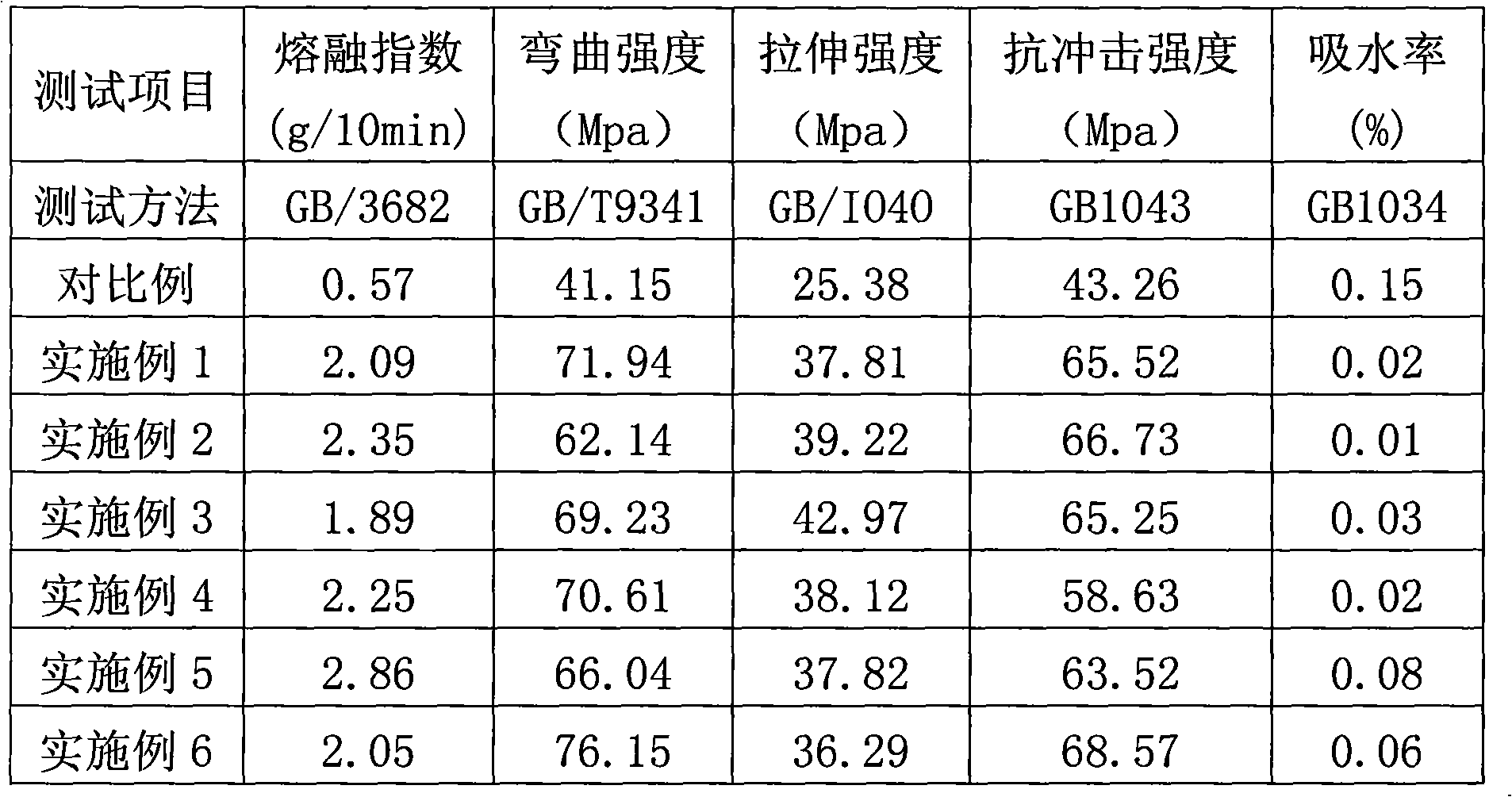

Environment-friendly method for regenerating waste rubber

ActiveCN104387611AImprove performanceFully qualitative regenerationPlastic recyclingBulk chemical productionCross-linkMicrowave

The invention discloses an environment-friendly method for regenerating waste rubber. The method comprises the following steps: 1) uniformly mixing waste rubber and an environment-friendly desulfurizing agent according to a mass ratio of 100:0.2-2; 2) guiding the mixed waste rubber into a first reaction chamber and then fully filling the first reaction chamber with supercritical CO2 fluid; 3) starting a microwave heating device of a second reaction chamber so as to desulfurize waste rubber powder; and 4) after the desulfurization is completed, cooling the waste rubber powder to be below 80 DEG C and refining into pieces after discharging. According to the method, supercritical CO2 fluid which has excellent swelling and permeating characteristics can be used for replacing a rubber softening agent so that a regenerant can permeate and disperse inside the waste rubber powder in a short time and the waste rubber can reach swelling balance; then, microwaves are utilized to selectively damage S-S and C-S cross-linked bonds of the rubber and the desulfurizing agent completely so that a main chain is protected from being damaged to the greatest extent.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

Self-adhesive waterproof material and preparation method thereof

The invention discloses a self-adhesive waterproof material and a preparation method thereof. The waterproof material is composed of the following materials: 25-50% of softening oil, 0-5% of a hot melt adhesive elastic body, 1-9% of a styrene-butadiene-styrene block copolymer, 0-5% of a tackifying rubber, 8-18% of a waste rubber elastomer, 0.1-0.5% of a UV resistant agent, 5-8% of a high temperature resin, 10-25% of a tackifier resin, 0.1-0.15% of an interfacial agent, and 4-44% of a pigment filler. The waterproof material provided by the invention has excellent weather-proof and ageing-proof performance to solve the problem that a traditional asphalt coiled material loses waterproof effect with time and seasons, and has super stripping performance 2-3 times of that of the traditional asphalt coiled material, and can closely combined with the concrete to form a skin-type waterproof barrier.

Owner:湖北蓝盾之星科技有限公司

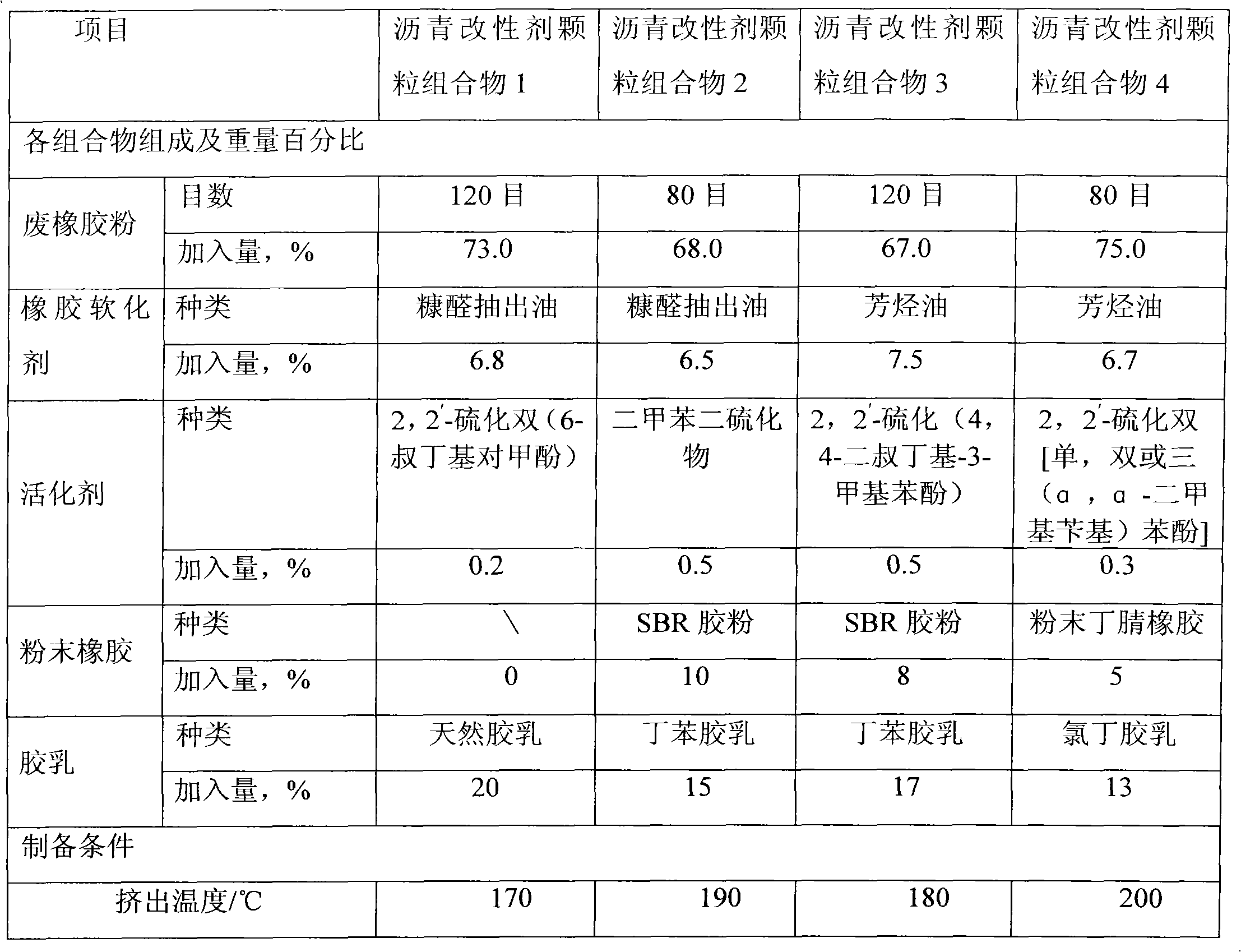

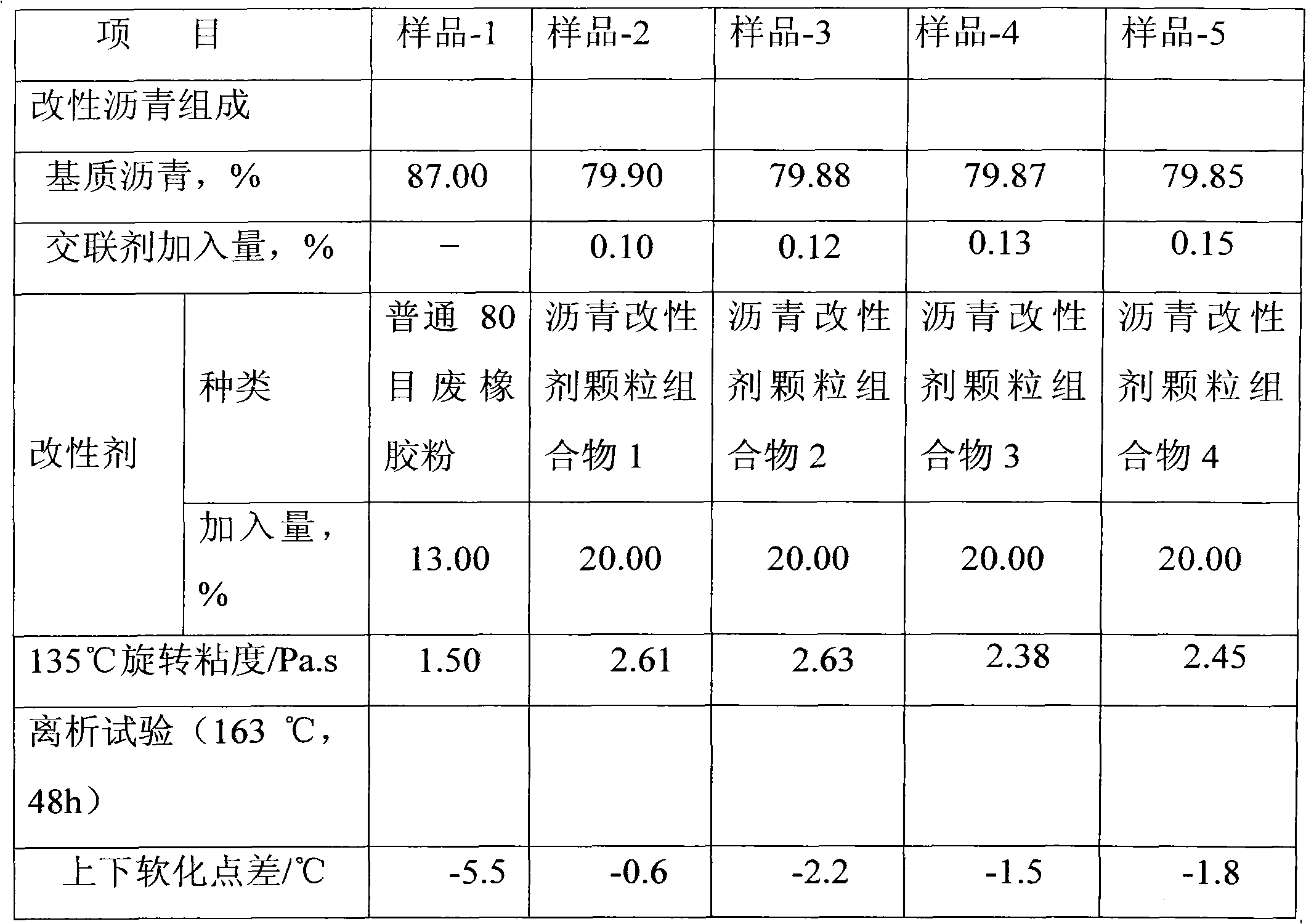

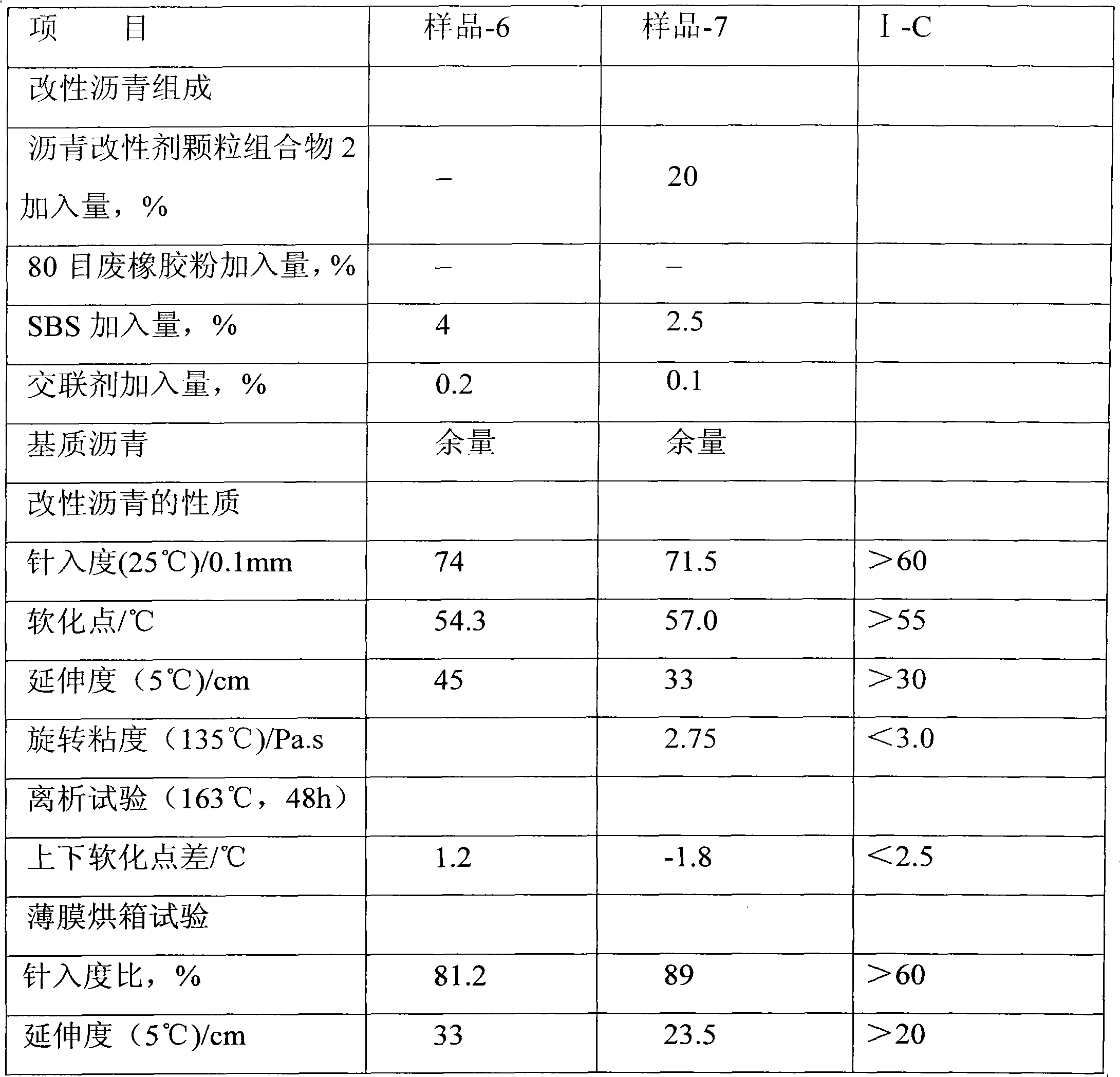

Asphalt modifier granule composition and preparation method thereof

ActiveCN102050965AStay flexibleImprove low temperature performanceBuilding insulationsCross-linkPolymer science

The invention discloses an asphalt modifier granule composition and a preparation method thereof. The composition comprises the following components by weight: 60 to 75 percent of waste rubber powder, 5 to 10 percent of rubber softening agent, 0.2 to 0.5 percent of active agent, 5 to 20 percent of latex and 0 to 10 percent of powdery rubber. The preparation method comprises the following steps of: mixing the latex and the waste rubber powder uniformly, mixing the active agent and the rubber softening agent, and simultaneously conveying the two mixtures into an extruder respectively to obtain the asphalt modifier granule composition. The asphalt modifier granules keep original certain elasticity of the waste rubber powder, and recover partial plasticity; and the surface of partial waste rubber powder is tightly adhered with certain powdery rubber or latex by blending extrusion, the powdery rubber or the latex adhered on the waste rubber powder added into the asphalt can be well cross-linked under the action of a cross-linker, and the waste rubber powder can be uniformly and stably dispersed in the asphalt by the 'bridge' effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waste rubber powder modified asphalt composition and its preparation method

ActiveCN1765998AUniform dispersion stabilityUniform storage stabilityBuilding insulationsWaste rubberDiluent

The invention provides a method to improve the storage stability for waste rubber powder modified asphalt. Wherein, the opposite compound comprises: 70~98.5% basic asphalt, 1~29.5% waste rubber, 0~10.0% diluent, and 0.1~5.0% coupling agent. The method comprises: adding the agents with given ratio into the waste rubber powder past 60-item screen to mix evenly; adding the treated rubber powder into asphalt to grinde for 30~190min by special device. As the alkoxy in coupling agent can form chemical bonding with inorganic filler to form organic active monomolecular layer between interfaces, this product can improve obviously the storage stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing solid refuse composite modified asphalt

InactiveCN101200597AMeet road requirementsSufficient sourceBuilding insulationsMetallurgyWaste rubber

The present invention belongs to the technical field of asphalt modification. The present invention relates to solid wastes comprising waste rubber, waste plastic and waste pyrolysis carbon black, the composing of which is 2 percent to 22 percent of waste rubber powder, 1 percent to 8 percent of the waste plastic, 0.5 percent to 6 percent of the waste pyrolysis carbon black, 1 percent to 6 percent of surfactant, 0.02 percent to 3 percent of crosslinking agent and 75 percent to 90 percent of asphalt. A preparation technology is finished by two steps that a first step is modifying the rubber powder, under the temperature condition of 70 DEG C to 100 DEG C, the rubber powder and the surfactant are mixed and stirred for 5 to 20 minutes at the speed of 20 to 100r / min and are mixed uniformly for using; the second step is to prepare modified asphalt, the asphalt is heated up to 120 DEG C to 160 DEG C, the waste plastic is added while being stirred at the speed of 200 to 1000r / min and then is stirred fast for 5 to 10 minutes at the speed of 600 to 3000r / min, the temperature is kept about 170 DEG C, modified rubber powder is added while being stirred, the crosslinking agent and the waste pyrolysis carbon black are added to be stirred fast for 10 to 20 minutes, and a system is processed for high-speed cutting or colloid mill grinding to prepare the modified asphalt.

Owner:NANKAI UNIV

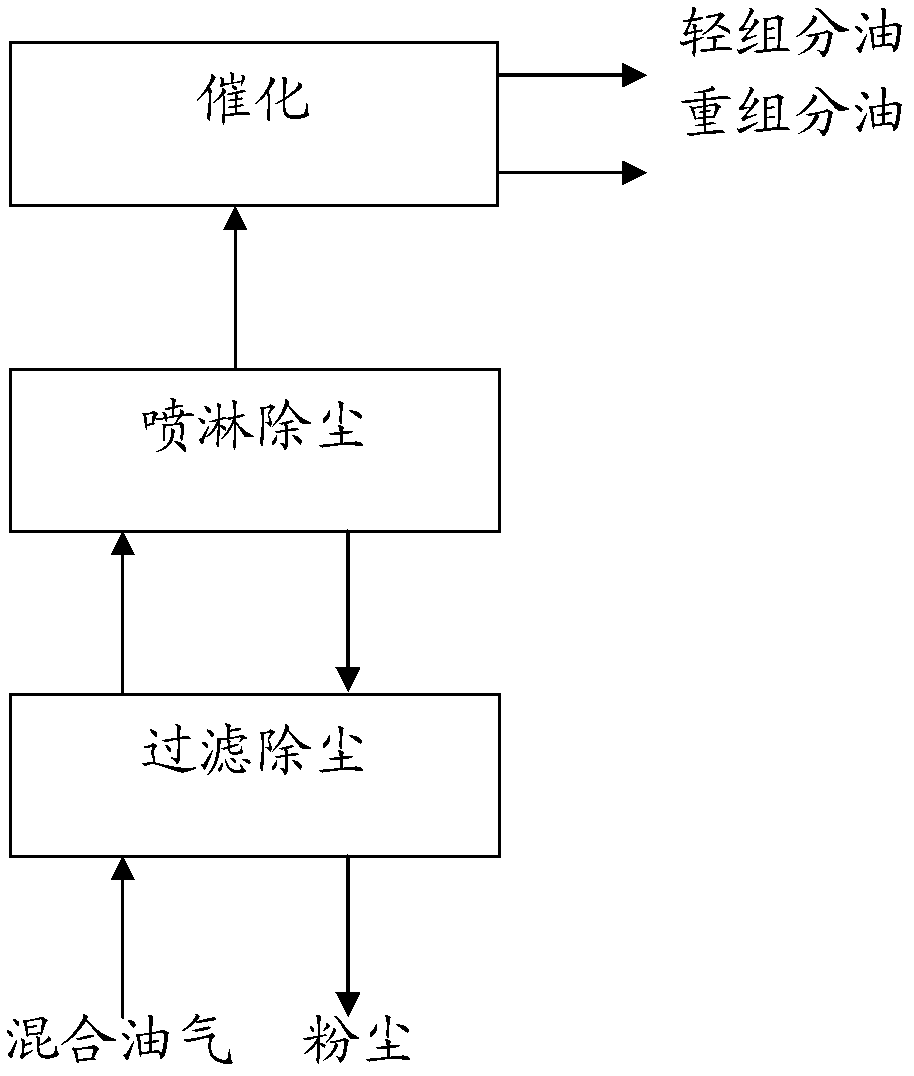

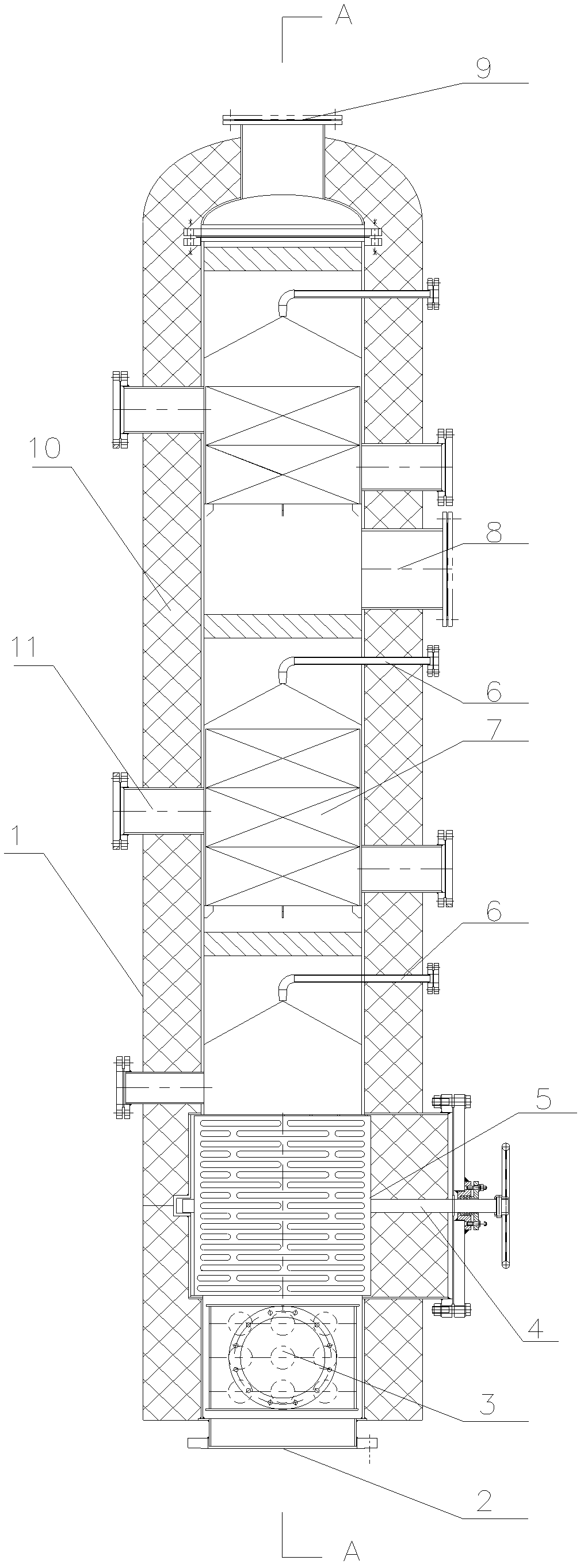

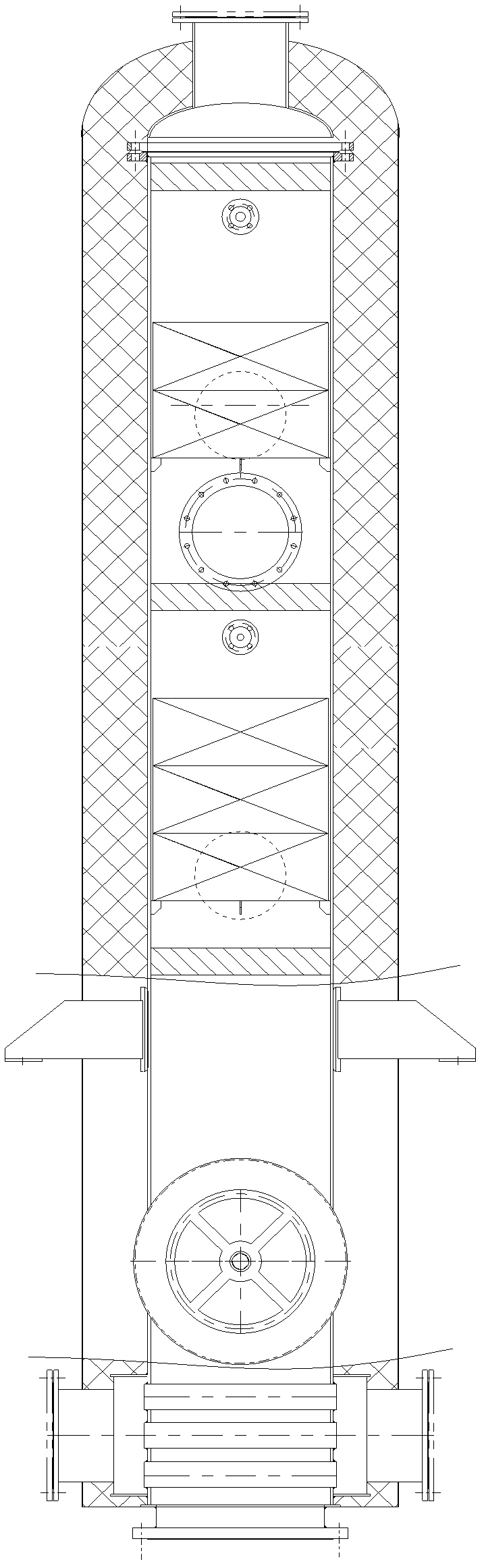

Technology and equipment for dedusting mixed oil gas

ActiveCN102210960AEasy to separateQuality improvementCombination devicesDispersed particle filtrationLiquid stateNatural state

The invention relates to a technology and equipment for dedusting mixed oil gas, in particular to the technology and the equipment for dedusting mixed oil gas formed by splitting waste rubber and waste plastic. The technology is characterized in that the oil gas is sprayed and dedusted by same type of oil after being filtered and dudusted; and when dust falls, and oil adhered on the dust is converted into gaseous state from liquid state. The equipment comprises a tower body of which the lower end is provided with an oil gas inlet, wherein the tower body is internally provided with a filteringand dedusting mechanism and a spraying device for same type of oil, and the spraying device is arranged above the filtering and dedusting mechanism; the filtering and dedusting mechanism comprises dedusting rotary cage controlled by a lateral shaft; and the total volume of the filler filled into the dedusting rotary cage under the natural state is smaller than the volume of the dedusting rotary cage. In the invention, the reasonable technology and the reasonable equipment are adopted for dedusting and purifying oil obtained by splitting waste rubber and waste plastic, oil discharging quality and carbon black quality are improved, environmental pollution is lightened, thus providing a new path for solving the increasingly serious energy crisis, so that the technology and the equipment can be widely popularized and used.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

Pyrolysis system for waste rubber

InactiveUS20090211892A1Indirect and direct heating destructive distillationHeat recoveryWaste rubberProduct gas

An apparatus for separating components of batches of waste rubber by pyrolysis comprises at least one heating chamber interconnected with a condenser by a conduit. The heating oven is provided with a plurality of cooperating heating elements, an inlet for receiving waster rubber, and an outlet for egress of pyrolyzed gaseous components. The condenser condenses and separates cooled liquid components from the gaseous components. Separated gaseous components are exhausted from the condenser. Cooled liquid components are conveyed from the condenser to a re-circulation tank. The conduit is provided with a pair of opposed injectors adjacent the outlet of the heating oven. A re-circulation line interconnects the re-circulation tank with the injectors and is provided with a pressurizing device for injecting cooled liquid components through the injectors into the conduit in the form of intersecting liquid laminar sheets thereby applying a vacuum draw on the egressing pyrolyzed gaseous components.

Owner:ANDERSEN DAN

High-efficiency and novel biological carrier for sewage biological treatment and preparation method thereof

InactiveCN101538083AHigh mechanical strengthAvoid deformationBiological water/sewage treatmentWastewaterWaste rubber

The invention relates to a high-efficiency and novel biological carrier for a sewage biological treatment and a preparation method thereof. The biological carrier is prepared by comprising the following steps of: blending, extruding or injection-molding the following components: PP, PE, and ethylene-propylene copolymer, compatilizer, inorganic materials, plant materials, magnetic particles, and waste rubber according to a certain proportion, thus providing a biological carrier with large specific surface area, high hydrophilicity and easy hanged membrane on surfaces. The shapes of the biological carriers can be spherical, fibrous and polyhedral or powdery with various forms. The chemical or physical methods such as grinding, acid base reaction, coating on surface and the like can also be carried out to prepare the biological carrier, thus further improving the specific surface area, strengthening the adhesive ability of the biological membrane on the carrier, and improving the microorganism concentration. The preparation method of the biological carrier provided by the invention is simple, has wide adjusting range of the carrier density, easy obtaining materials, low cost, high efficiency of eliminating COD and variety shapes, can be lighter or heavier than water, and is applicable to all biological wastewater treatments.

Owner:常州华钛化学有限公司

Waste and old rubber modified asphalt

The invention relates to waste rubber modified asphalt, which is prepared by reacting rubber powder which is recycled through desulfurizing with asphalt under the condition of existing vulcanizing components under 130 DEG C-250 DEG C. The invention uses rubber powder which is recycled through desulfurizing as modifier, and prepares modified asphalt (asphalt rubber) which has low cost and excellent stable property under the condition of existing small amount of vulcanizing components, which overcomes the weaknesses existing in the prior art of higher cost and poor dispersing stability of rubber in asphalt.

Owner:EAST CHINA UNIV OF SCI & TECH

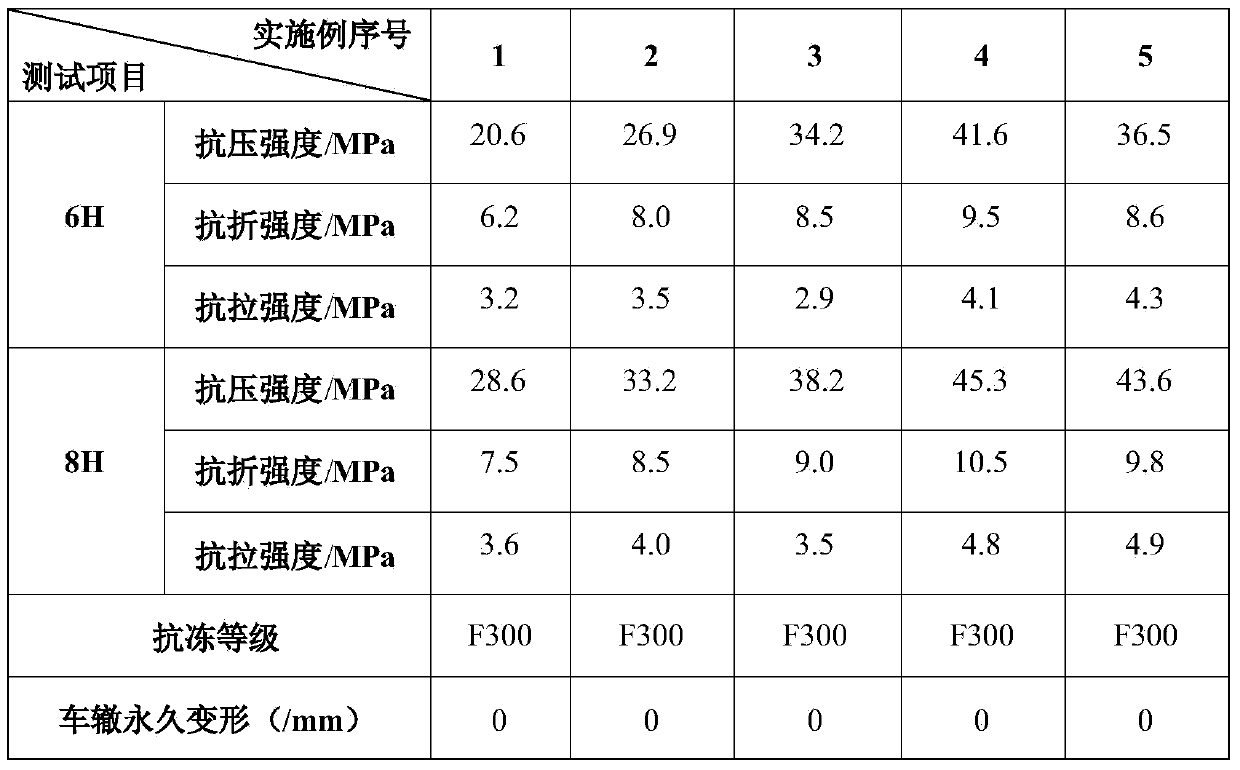

Concrete pavement material for heavy traffic roads and preparation method thereof

ActiveCN104193221AElastic modulus controllableHigh modulus of elasticitySolid waste managementMass ratioWaste rubber

The invention relates to a concrete pavement material for heavy traffic roads and a preparation method thereof. The material is composed of a component A, a component B and a component C in a mass ratio of 1:(0.2-0.6):(4-8). The component A comprises the following components in parts by mass: 40-80 parts of epoxy resin, 0-20 parts of epoxy reactive diluent, 10-50 parts of elastic modifier, 0.2 part of defoaming agent and 0.2 part of dispersing agent. The component B comprises the following components in parts by mass: 100 parts of curing agent, 0-10 parts of curing accelerator and 1 part of coupling agent. The component C comprises the following components in parts by volume: 100 parts of fine stone, 30-300 parts of fine sand, 130-800 parts of waste rubber particle, 50-100 parts of waste rubber powder and 10-20 parts of crystal whisker. Compared with the prior art, the concrete pavement material for heavy traffic roads has the advantages of high strength, favorable durability, favorable roadability, energy saving, environment friendliness and the like, and is convenient for construction.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Waste rubber powder modified asphalt composition and preparation method thereof

ActiveCN104559242AAdequate responseGood storage stabilityBuilding insulationsRoad engineeringWaste rubber

The invention discloses a waste rubber powder modified asphalt composition and a preparation method thereof. The waste rubber powder modified asphalt composition comprises the following components in percentage by weight: 60-94 percent of basic asphalt and 6-20 percent of activated waste rubber powder. The preparation method comprises the following steps: adding the activated waste rubber powder into the melted basic asphalt for fully mixing to obtain the waste rubber powder modified asphalt composition. The asphalt composition disclosed by the invention is high in storage stability and low in cost, and the raw materials are easily available; the asphalt component has a wide application prospect in the fields of road engineering, waterproof coiled materials and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environmental protection weeping plastic track

InactiveCN1552999AOvercome disadvantagesPolyureas/polyurethane adhesivesGround pavingsPolyurethane adhesiveWaste rubber

An environment protective and water penetrative plastic trick involves a polymer material, consisting of adhesive, pigment for spraying adhesive, catalyst for carboxylic salt, black waste rubber granules, and color EPDM granules. It is constructed by: making mono-component polyurethane as primary agent to bind recovered rubber granules; mixing with catalyst and stirring uniformly; mechanically spreading; curing at atmosphere - 70 deg.C to form a plastic layer with thickness of 4 - 10mm; and then spreading well-mixed polyurethane adhesive, color EPMD granules and catalyst to form a top plastic layer, finally curing to form the said trick with a plastic layer and a cement substrate. The construction are not only available for tricks, but also for other pavements with low cost, high strength, large extension rate, and good penetration. It can be constructed mechanically and effectively with good flatness.

Owner:上海康达新材料科技有限公司

Method for preparing waste rubber modified asphalt

InactiveCN101555354ANo pollution in the processGood value for moneyBuilding insulationsPolymer scienceWaste rubber

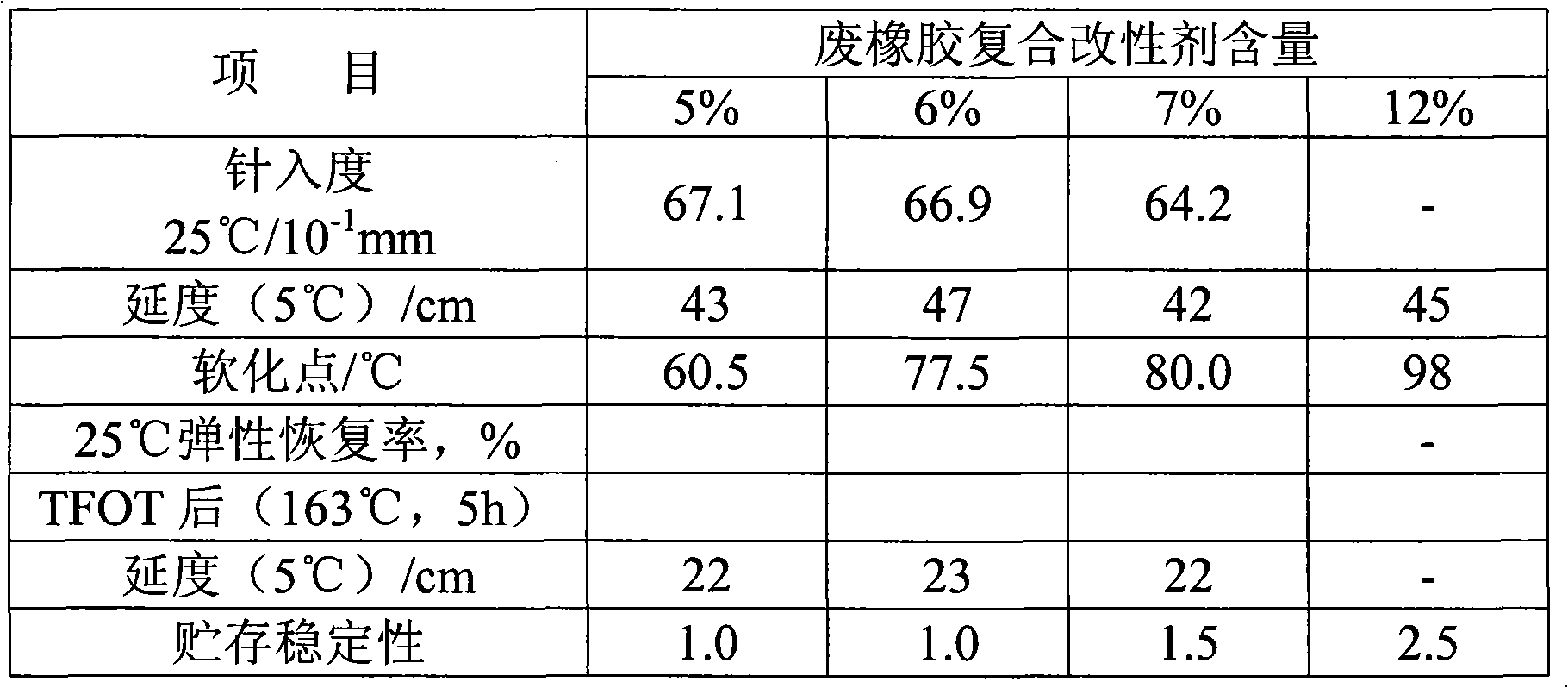

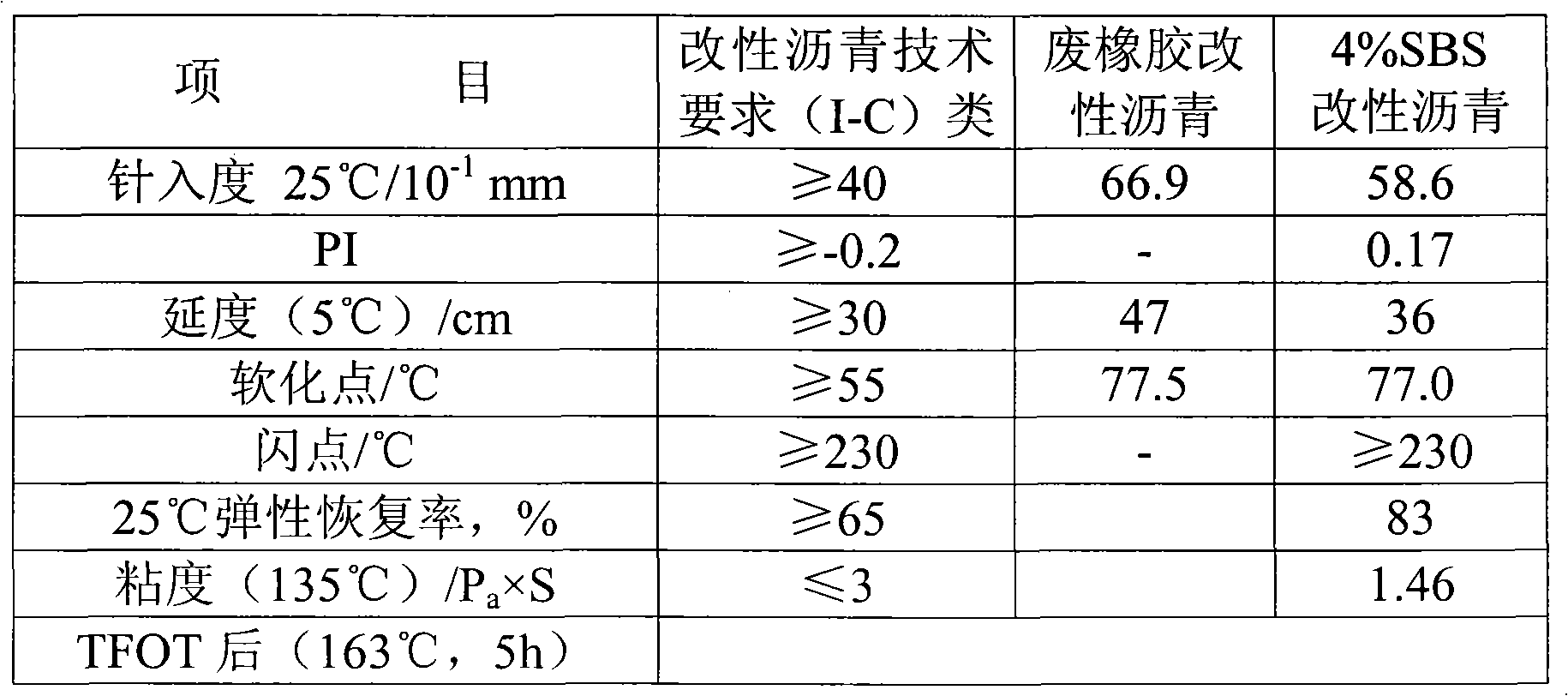

The invention discloses a method for preparing waste rubber modified asphalt, which comprises the following steps: A, 8-12 percent of SBS, 75-85 percent of rubber powder and 7-13 percent of PE are evenly stirred and mixed to prepare a waste rubber composite modifier, wherein the sum of the weight percentages of the SBS, the rubber powder and the PE is 100 percent, and the content of the waste rubber powder in the rubber powders is above 50 percent of the total rubber powder; and B, matrix asphalt is firstly heated to 150-165 DEG C, and the waste rubber composite modifier is added into the matrix asphalt to form asphalt mixture, wherein the content of the waste rubber composite modifier is 5-20 percent of the total waste rubber modified asphalt, the waste rubber composite modifier is sheared at a high speed through a high-speed shearing apparatus until the asphalt mixture is scattered evenly, a stabilizing agent is added into the waste rubber composite modifier, the temperature is kept at the temperature of 160-180 DEG C and the waste rubber composite modifier is sheared continuously for 20-30 minutes so as to make the waste rubber modified asphalt. The waste rubber modified asphalt prepared by the method has no pollution and high cost performance, and completely satisfies the technical specification requirement on SBS modified asphalt.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

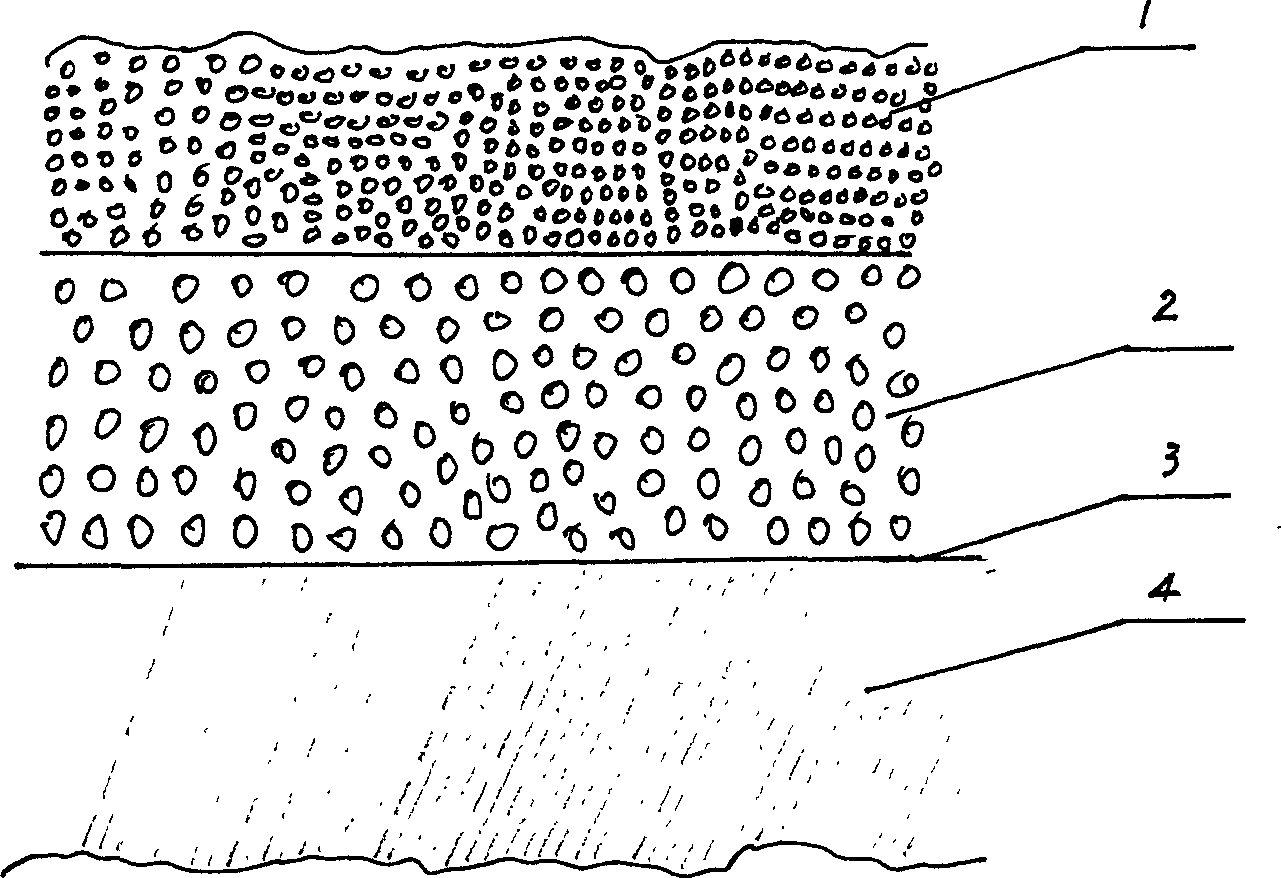

Novel environment-friendly water-based plastic track

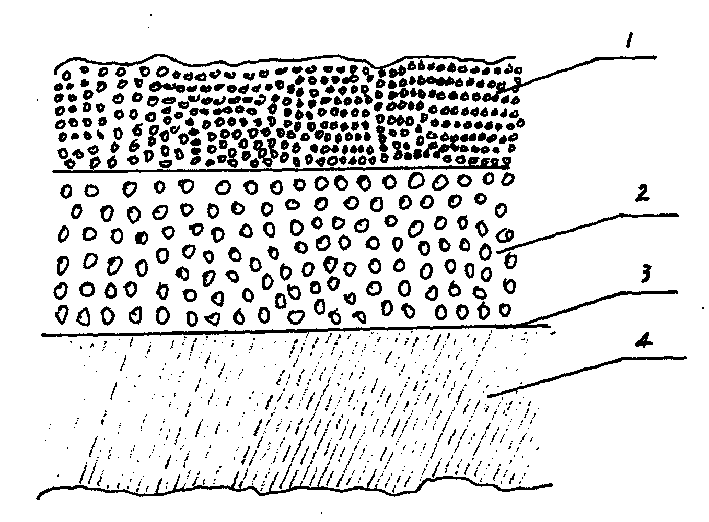

The invention relates to a novel environment-friendly water-based plastic track, which comprises three layers of structures such as a base surface layer, a plastic elastic layer and an antiskid surface layer, wherein the base surface layer is provided with a concrete or asphalt structure; the plastic elastic layer is formed by fully stirring cement, a water-based polymer emulsion, black waste rubber particles of which the particle size is 3 mm, water and an aid, paving the mixture on the base surface layer and solidifying the mixture at the normal temperature of -50 DEG C, and reaches the required thickness; and the antiskid surface layer is formed by fully stirring white cement, a water-based polymer emulsion, water, pigment and an aid to obtain a slurry, paving the slurry on the plastic elastic layer, spraying 30 to 40 mass parts of colorized EPDM particles of which the particle size is 2 to 4 mm, and performing solidification under the condition that the temperature is between the normal temperature and 50 DEG C. The novel environment-friendly water-based plastic track adopts building water-based polymer emulsion modified cement as a binding agent, is nontoxic and environment-friendly, can be used for construction in a moist environment with water, has a low cost, is simple and convenient to operate, is ventilate and hydro-ceramic, has high physical properties, and does not drop particles, and all properties of the novel environment-friendly water-based plastic track reach national standards.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Rubber modified asphalt mixture and preparation and construction methods thereof

The invention relates to a modified asphalt mixture and preparation and construction methods thereof, particularly relates to rubber modified asphalt and preparation and construction methods thereof and belongs to the technical field of engineering. The rubber modified asphalt and the methods solve the construction problem that the mixture is thick and sticky by adding trans-polyoctenamer rubber (TOR) into the asphalt mixture, further reduce the stirring temperature of the rubber asphalt mixture, reduce processing equipment, improve production process, and are favorable for preventing water damage by a design method of continuous dense gradation. The preparation process of the mixture improves the using performance of the rubber asphalt mixture. The rubber modified asphalt and the methodshave the advantages of promoting the comprehensive utilization of waste tires by paving asphalt pavements with waste rubber powder modified asphalt, reducing great environment stress brought by blackpollution, saving resources, improving the pavement performance of the asphalt mixture, improving the service quality of the pavement, prolonging the service life of the pavement, reducing cost, and improving performance of products. Compared with the conventional modified asphalt production process, the preparation and construction methods have the advantages of energy saving and environmental protection and are convenient for construction.

Owner:JIANGSU EASTTRANS INTELLIGENT CONTROL TECH GRP CO LTD

High-performance low-noise asphalt pavement conserving material and preparation method thereof

The present invention relates to a high-performance low-noise asphalt pavement maintaining material and the preparing method thereof, the maintaining material is mainly composed of conventional micro-surfacing asphalt concrete and waste rubber powder and polymer fiber, and the content of the waste rubber powder and polymer fiber respectively accounts for the gross weight of the micro-surfacing asphalt concrete 1-5% and 0.1-0.3%. The maintaining material preparing method is mixing the waste rubber power and the polymer fiber and the dry mixture of the prescribed grading aggregate to uniform, then adding filling agent, water and modified emulsified asphalt in sequence, and mixing to uniform. The material of the invention is improved with the bonding capacity to the original asphalt pavement because of the adding of the waste rubber powder and the polymer fiber, the capacity of the micro-surfacing asphalt concrete is increased, the excellent high-temperature-resisting track and low-temperature cracking capacity is facilitated to be possessed, has the advantages of excellent water-proofing and water-resisting property, excellent noise reducing, skid resistance, abrasion-proofing, impact resistance, cracking resistance and freeze-thaw resistance; and the material of the invention has the advantages of simple preparing method, low construction cost and less environmental pollution and the like.

Owner:WUHAN UNIV OF TECH

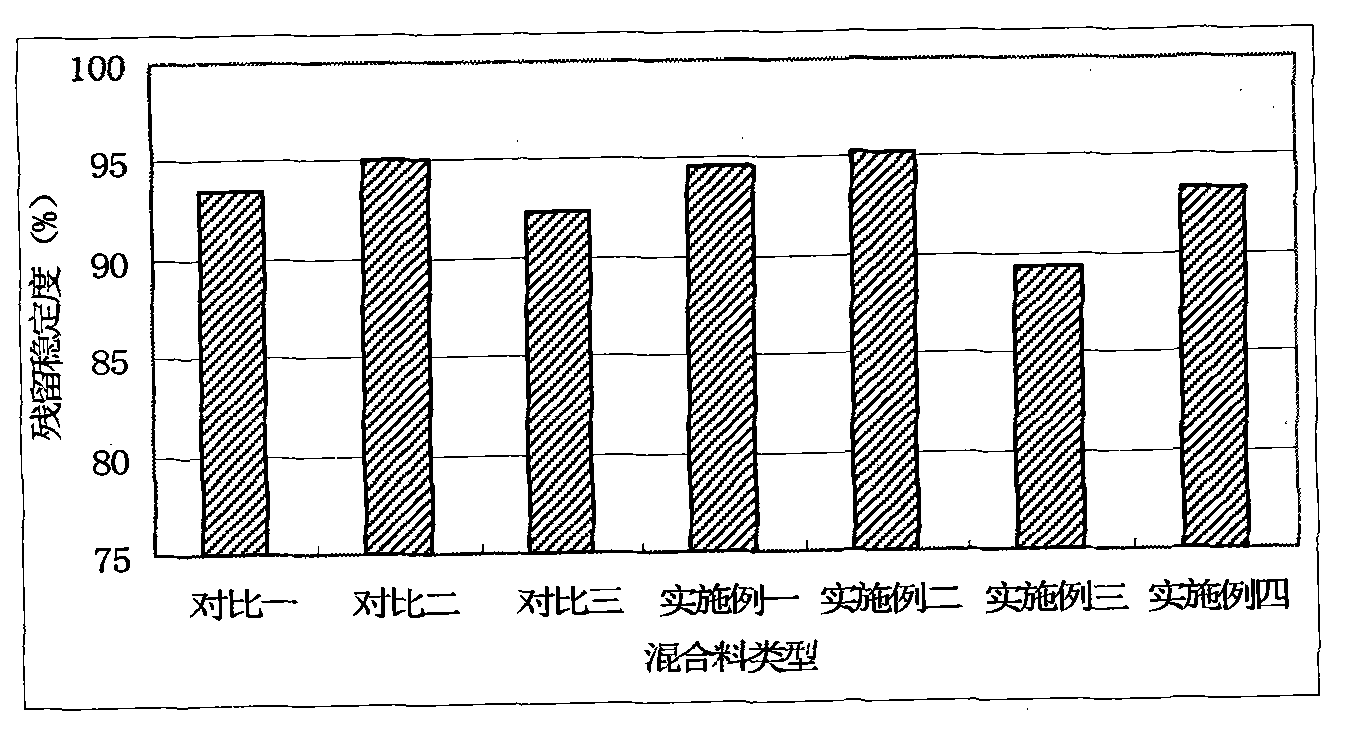

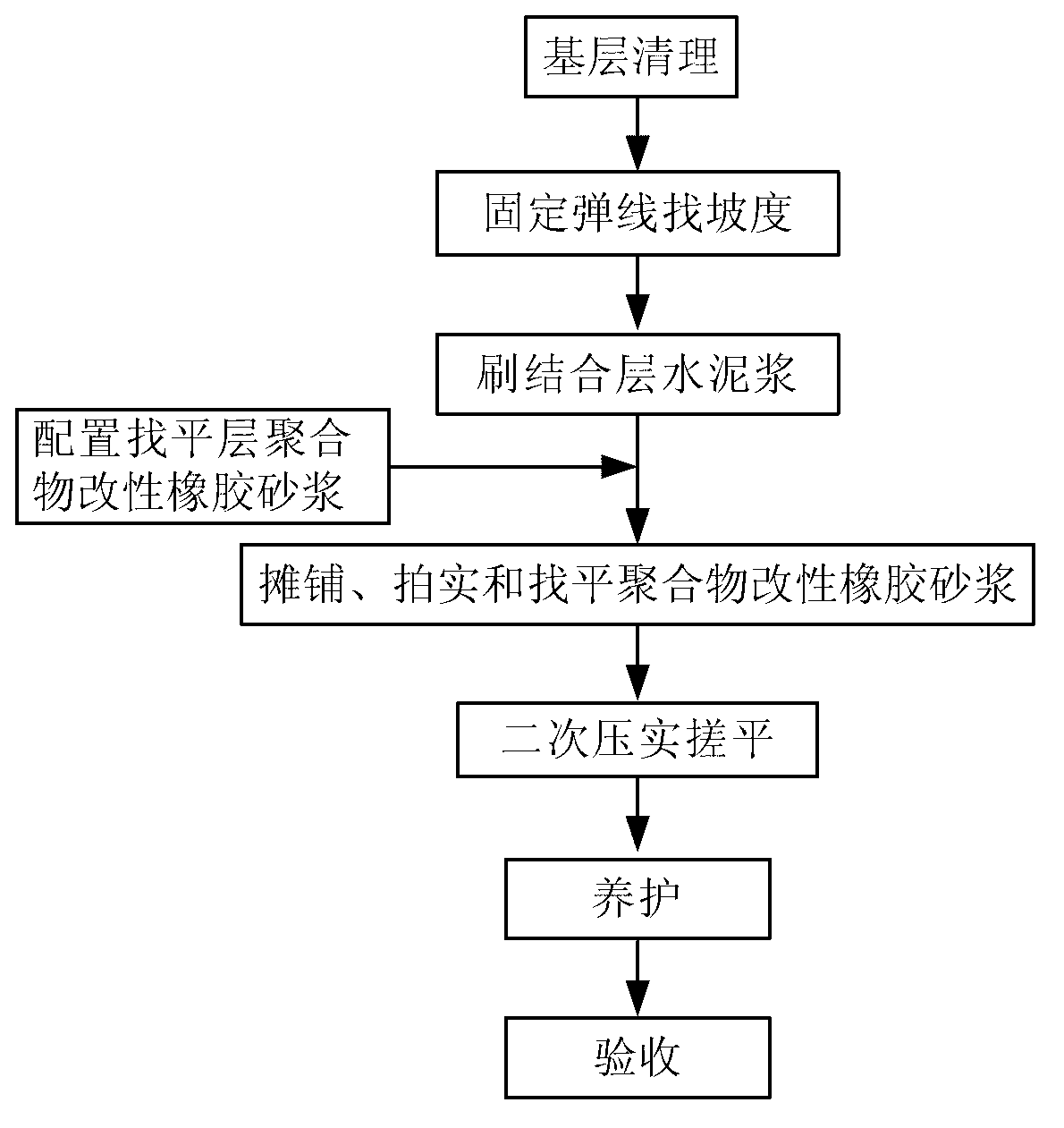

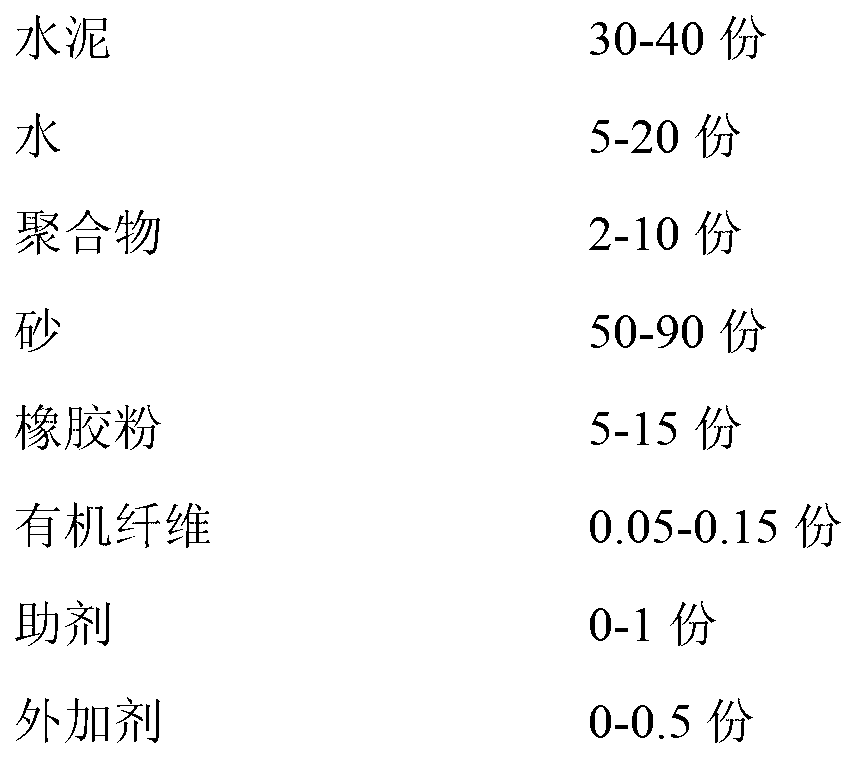

Polymer modified rubber mortar used for building leveling layer and construction method of polymer modified rubber mortar

ActiveCN103342520AGood flexibilitySignificant flexibility advantageCovering/liningsSolid waste managementFiberPolymer modified

The invention discloses polymer modified rubber mortar for a building leveling layer. The polymer modified rubber mortar is formed by doping three modified materials including rubber powder, a polymer and an organic fibre into modified cement mortar. The polymer modified rubber mortar is formed by mixing the following components in parts by weight: 30-40 parts of cement, 5-20 parts of water, 2-10 parts of the polymer, 50-90 parts of sand, 5-15 parts of the rubber powder, 0.05-0.15 part of the organic fibre, 0-5 parts of mineral admixtures, 0-1 part of an auxiliary, and 0-0.5 part of an additive. According to the freshly-mixed polymer modified rubber mortar, the thickness is controlled to be 7cm, during the curing period of 7 days, the compressive strength of the mortar is not less than 10 MPa, the rupture strength is not less than 3.5 MPa, during the curing period of 28 days, the compressive strength of the mortar is not less than 15 MPa, the rupture strength is not less than 5 MPa, the chloride ion permeation coefficient is not larger than 50*10<-14>m<2> / s, and the heat conductivity coefficient is not larger than 0.5W / m.k. The polymer modified rubber mortar disclosed by the invention can be used for effectively solving the problems of sugaring, peeling, crispiness, bulging, cracking and the like existing in the traditional cement mortar leveling layer, has the performance advantages of permeability resistance, crack prevention, thermal insulation, high tenacity and the like, can fully utilize waste rubber, can turn waste into wealth, and is suitable for various building leveling layers.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Preparation method for thermoset resin/waste rubber powder/waste tire fiber composite material

The invention discloses a thermoset resin / waste rubber powder / waste tire fiber environment-friendly composite material and a preparation method thereof. The thermoset resin is used as a base body and an adhesive, a waste tire fiber is used as a reinforcing and toughening material, and the waste rubber powder is used as a toughening and filling material. The surface of the waste rubber powder is processed by a monomer and the waste tire fiber is processed by a modifying agent, thereby effectively improving the interface combination of each component of the composite material. The environment-friendly composite material with the advantages of light weight, excellent mechanical property, wide temperature using range and low cost can be prepared by adopting the process of mould pressing or injection moulding and adjusting the proportion of each component.

Owner:SOUTH CHINA UNIV OF TECH

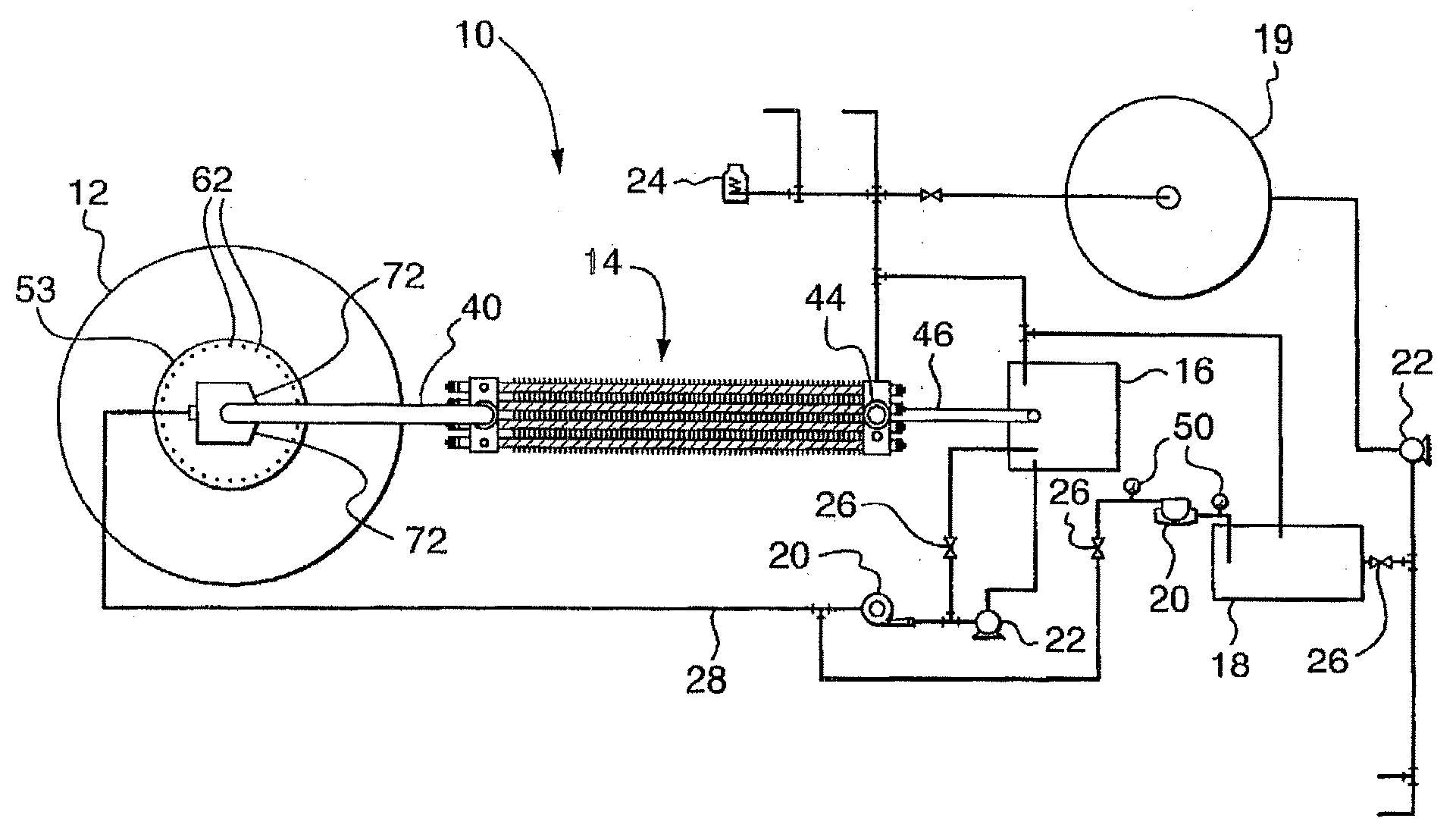

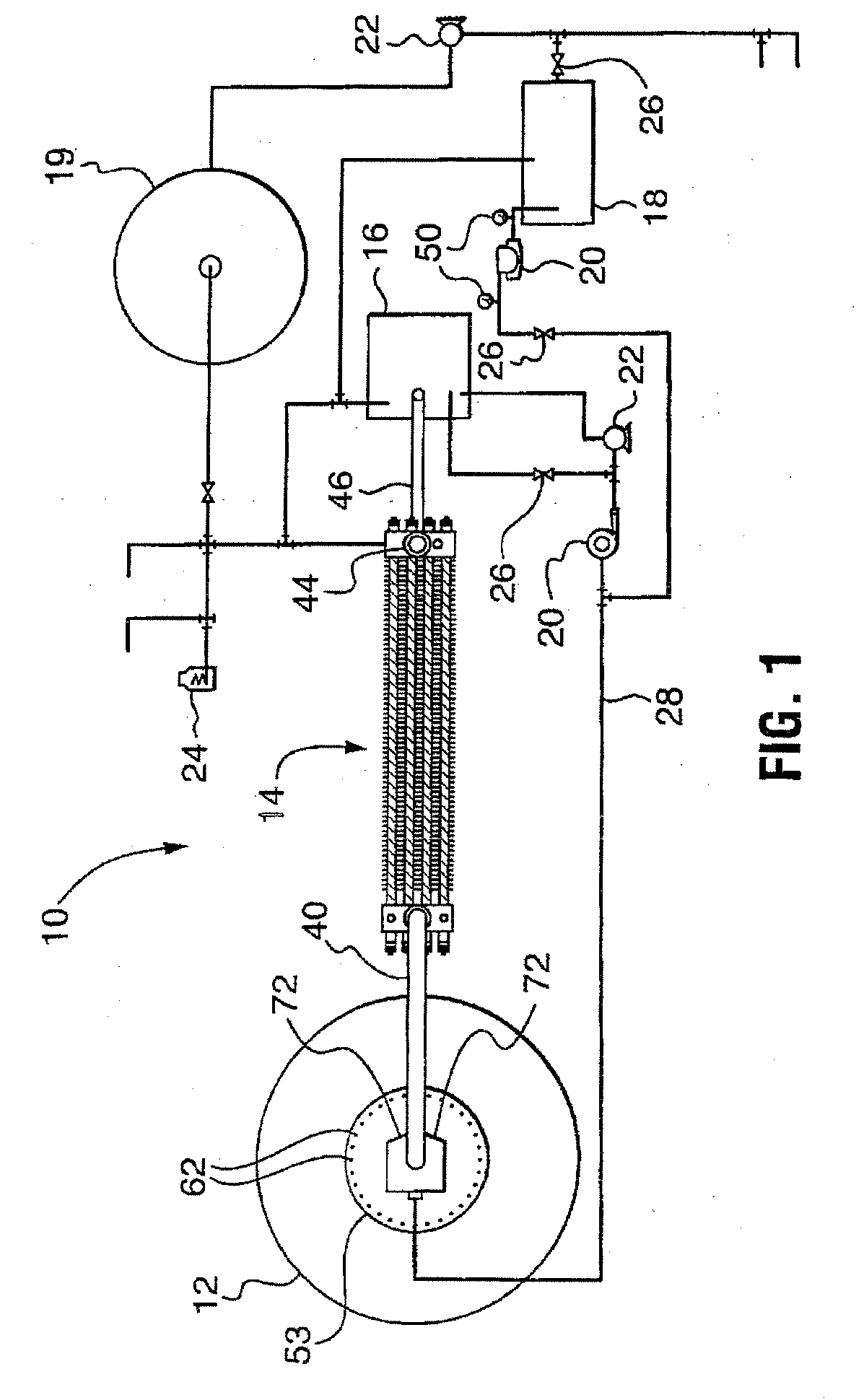

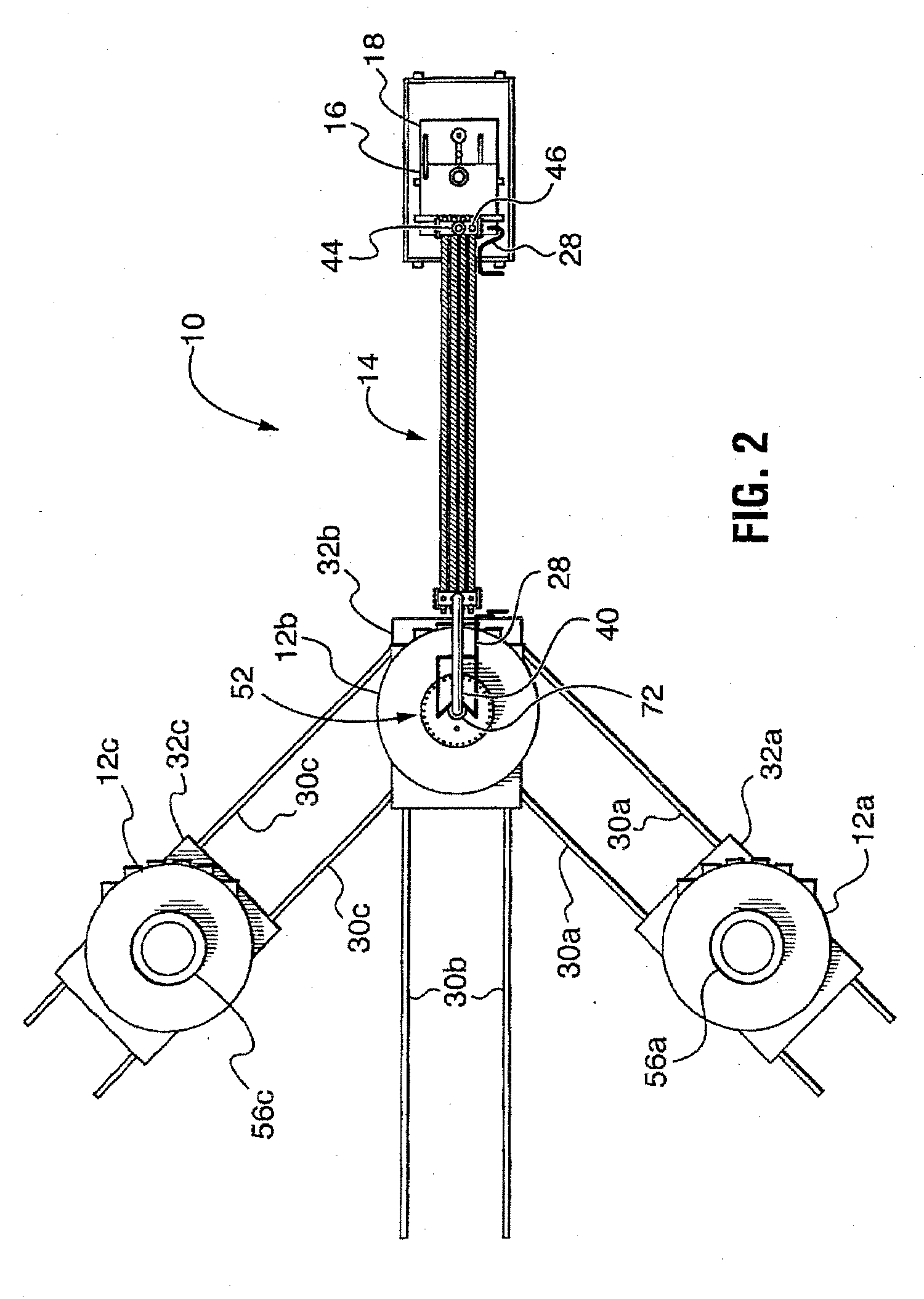

Apparatus and method for recovering marketable products from scrap rubber

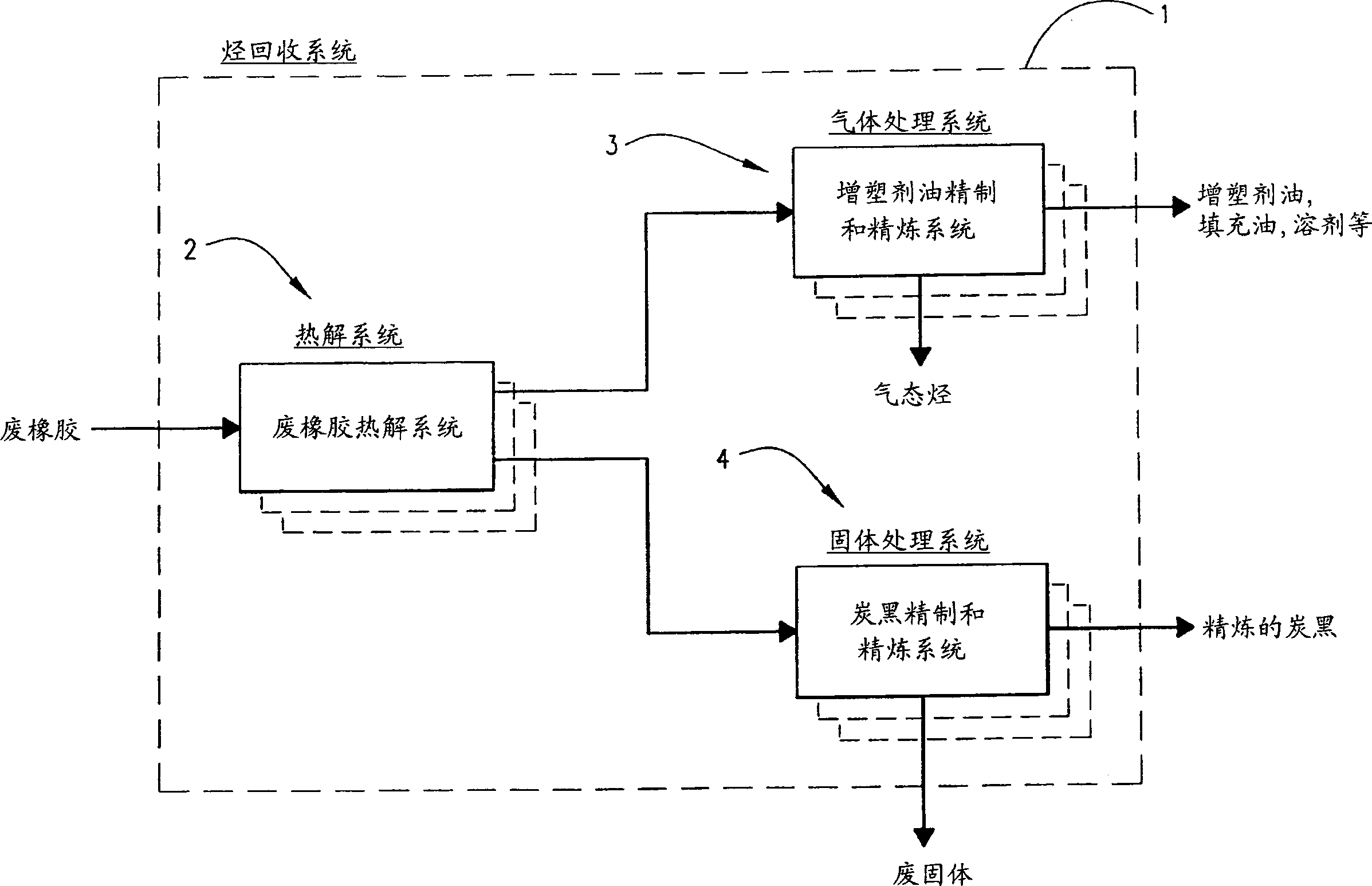

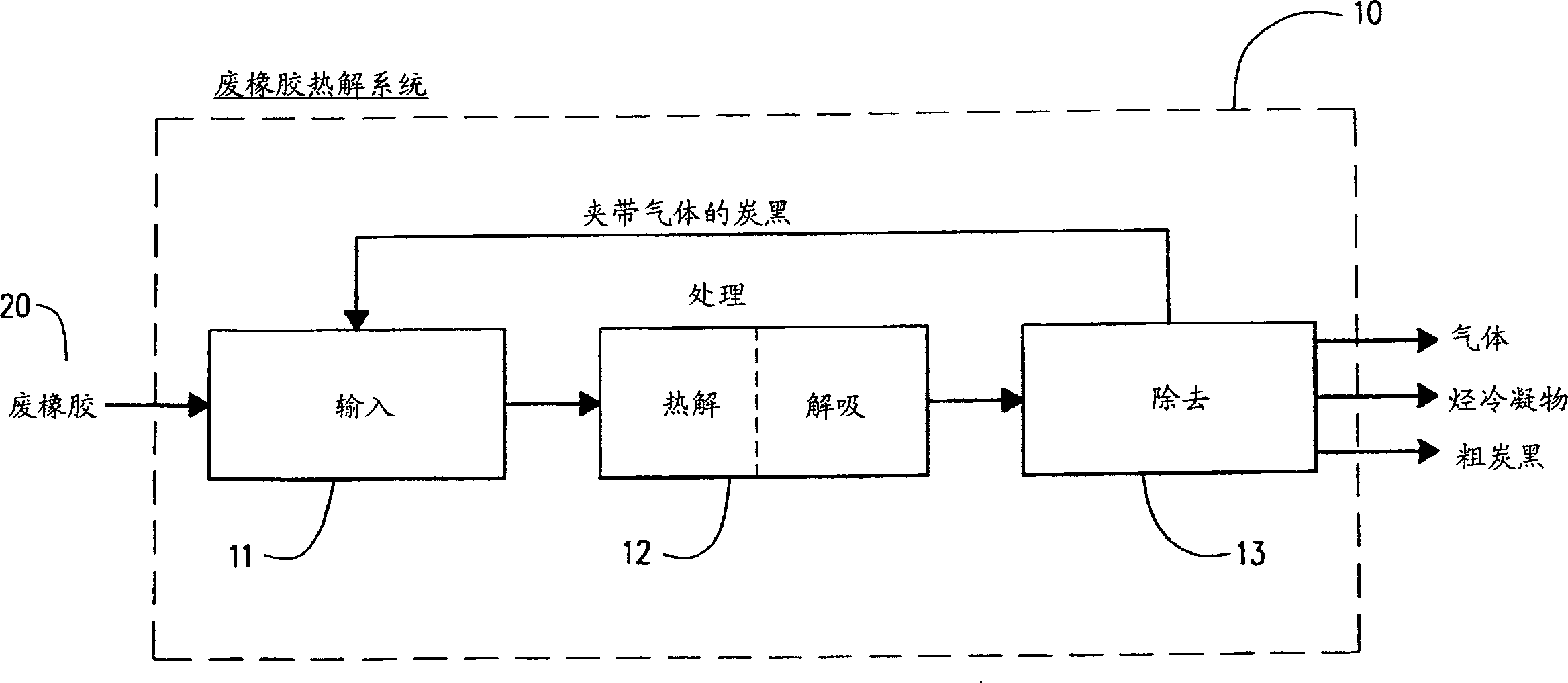

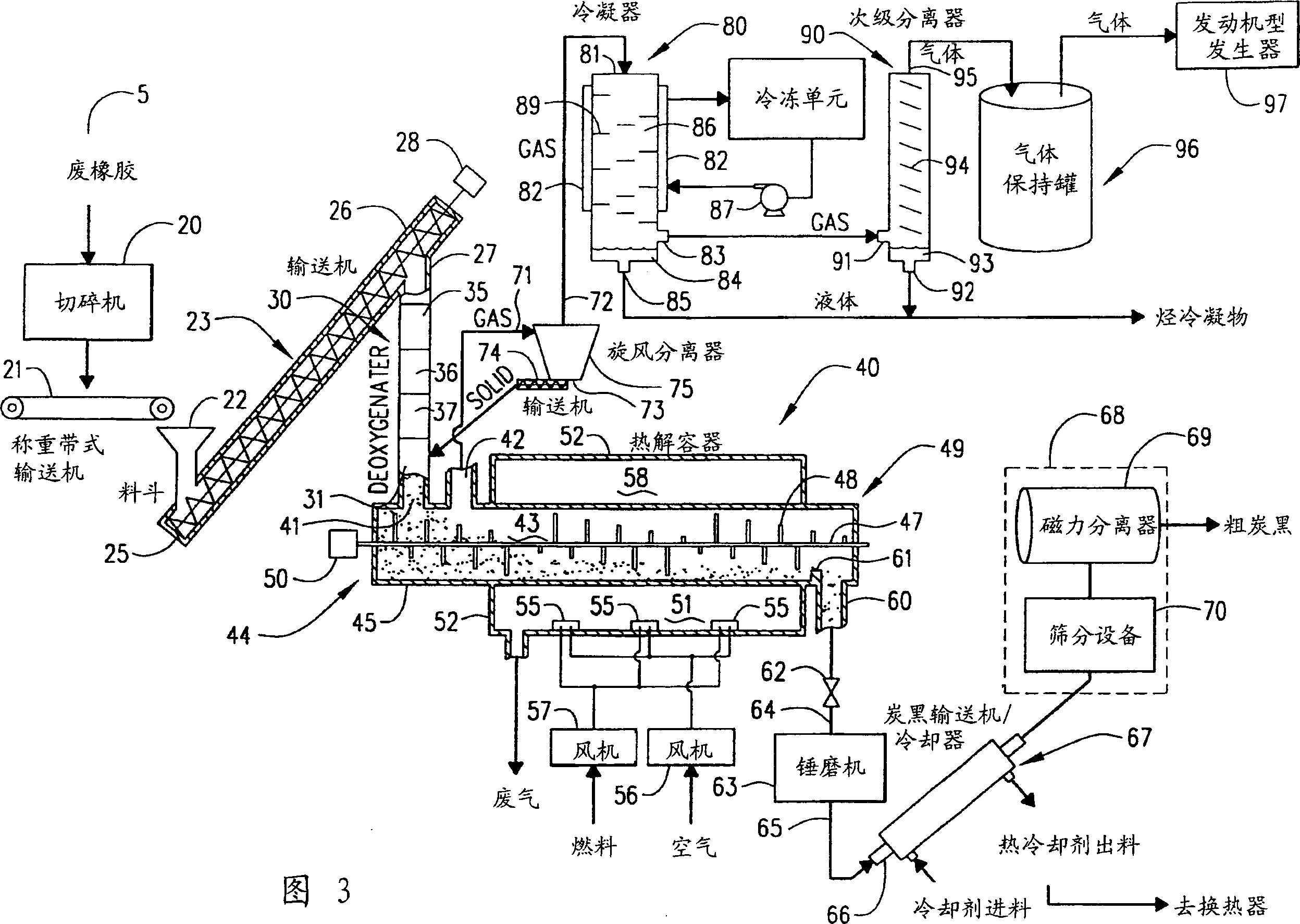

Tire pyrolysis systems and processes are provided which include feeding tire shreds to a pyrolysis vessel (40) and pyrolyzing the shreds in a pyrolysis vessel (40) to produce a pyrolysis gas and carbon black mixture. The pyrolysis gas processed by centrifugally separating entrained particles therefrom, separating the pyrolysis gas into a hydrocarbon condensate and a light vapor, removing entrained hydrocarbon condensate from the light vapor, and purifying and refining the hydrocarbon condensate. The carbon black mixture is processed by pulverizing the mixture to break up all strands and clumps of inorganic solids, cooling the carbon black mixture, separating the gross contaminants from the carbon mixture, and purifying and refining the carbon black. The hydrocarbon condensate is purified and refined by removing all remaining contaminants, removing any polycyclic aromatics to produce a clear, colorless plasticizer oil. The carbon black is purified and refined by pulverizing it into a powder, removing all remaining particulate contaminants, optionally pelletizing the carbon black, and bagging or packaging it for shipping.

Owner:FEDERAL RECYCLING TECH +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com