Technology and equipment for dedusting mixed oil gas

An oil and gas technology, applied in the field of oil and gas dedusting technology and equipment, can solve the problems of low quality and oil quality decline, and achieve the effects of reducing energy consumption, reducing environmental pollution, and improving oil quality and carbon black quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

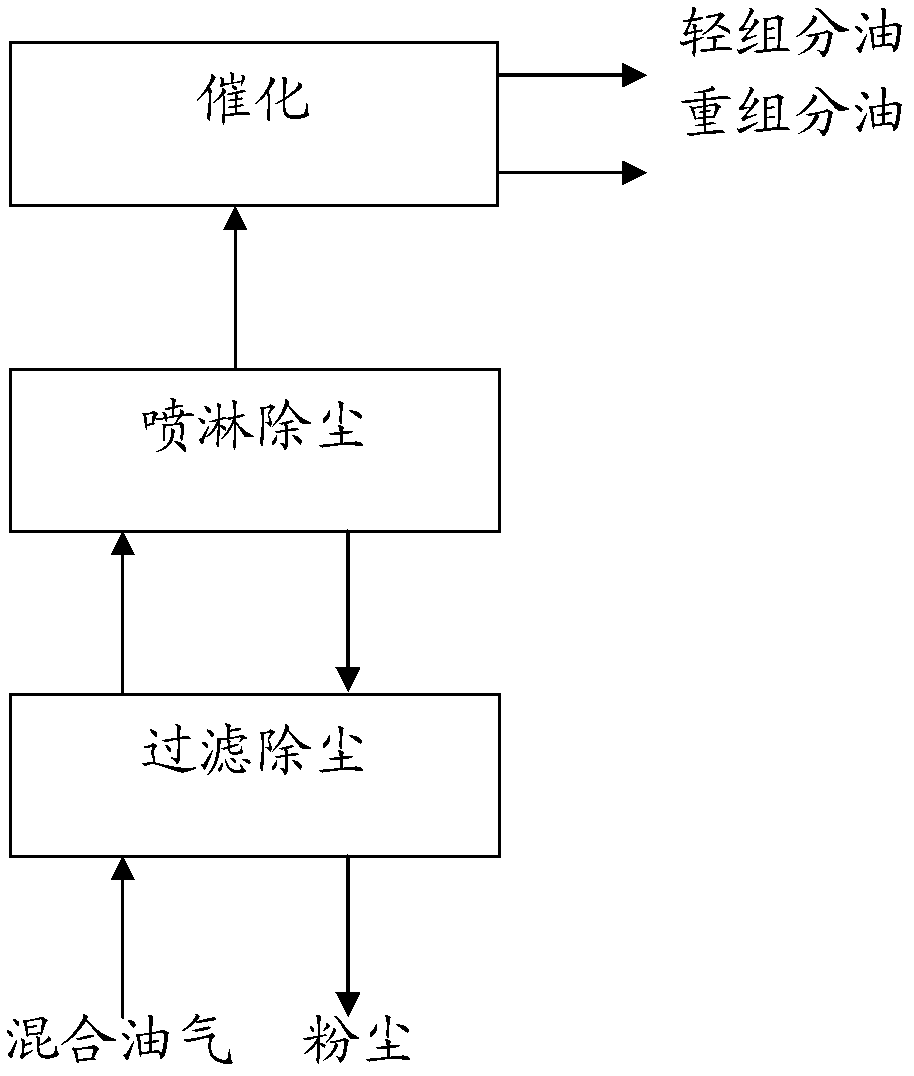

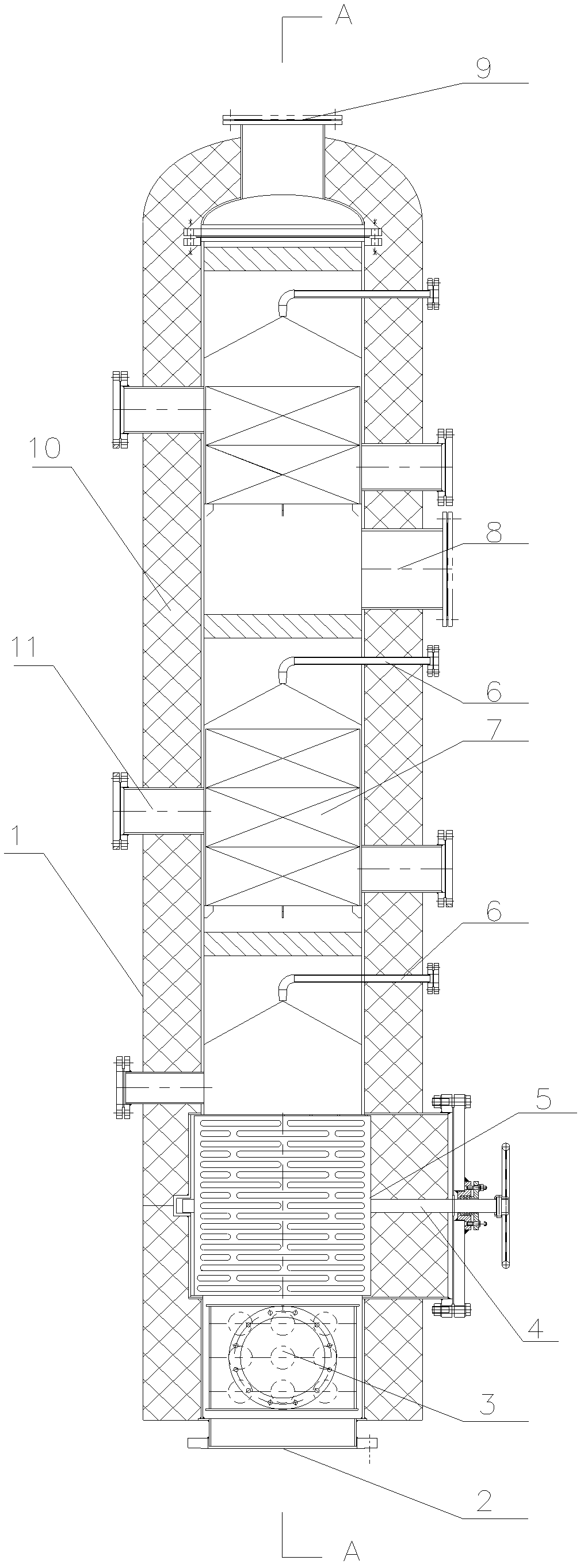

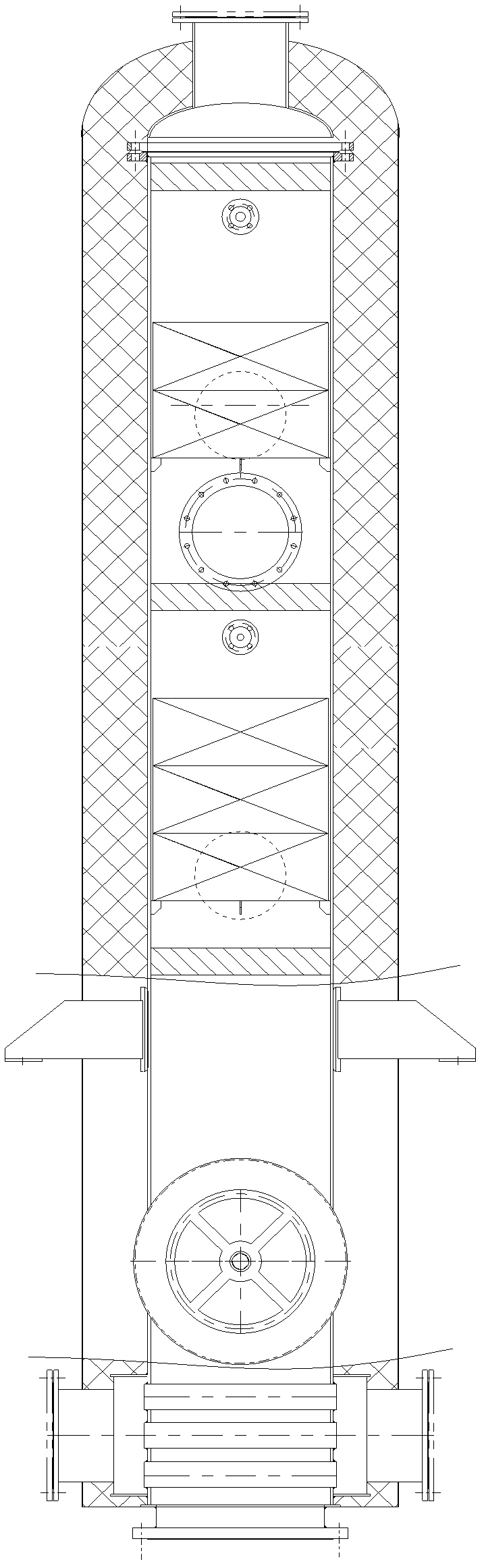

[0036] A dust removal process for mixed oil and gas. The oil and gas produced by the cracking of waste plastics enter from the oil and gas inlet. After filtering and dust removal, the same kind of oil is used to spray and remove dust. The incoming oil and gas is transformed into a gaseous state under the action of high temperature, and then rises under the action of the subsequent incoming oil and gas. After dust removal and spraying, the oil is discharged from the oil and gas outlet, and the settled dust is transported to the discharge port.

Embodiment 2

[0038] A dust removal process for mixed oil and gas. The oil and gas generated after the cracking of waste rubber enters from the oil and gas inlet at the lower end of the dust removal tower, and is heated to 450°C and kept warm. The oil and gas rise, and after passing through the Pall ring in the filter and dust removal mechanism, the oil and gas continue Rising to the bottom of the spray device, the same type of oil at 250°C is used for spraying and dust removal. When the dust falls to the filter and dust removal mechanism, the oil attached to it is transformed from liquid to gas under the influence of high temperature in the tower body. Under the action of subsequent entering oil and gas, it rebounded. The recovered oil and gas also contains a small amount of dust, which is filtered and catalyzed by the catalyst again, and then discharged from the corresponding oil and gas outlets after spraying and dust removal. mouth.

Embodiment 3

[0040] A dust removal process for mixing oil and gas. The oil and gas produced by the cracking of waste plastics enters from the oil and gas inlet at the bottom of the dust removal tower, heated to 420°C and kept warm, and the oil and gas rise. After the filler in the filter and dust removal mechanism, the oil and gas continue to rise to Under the spraying device, the same kind of oil at 300°C is used for spraying and dust removal. When the dust falls to the filter and dust removal mechanism, the oil attached to it is transformed from liquid to gas under the influence of the high-temperature oil and gas that enters later, and It rebounded under the action of subsequent oil and gas. The recovered oil and gas still contains a small amount of dust, and after a Pall ring filter and spray dust removal, the qualified oil is discharged from the oil and gas outlet; the remaining oil and gas continue to rise, and after being catalyzed by the catalyst and sprayed to remove dust, it is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com