Patents

Literature

108257results about How to "Reduce pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

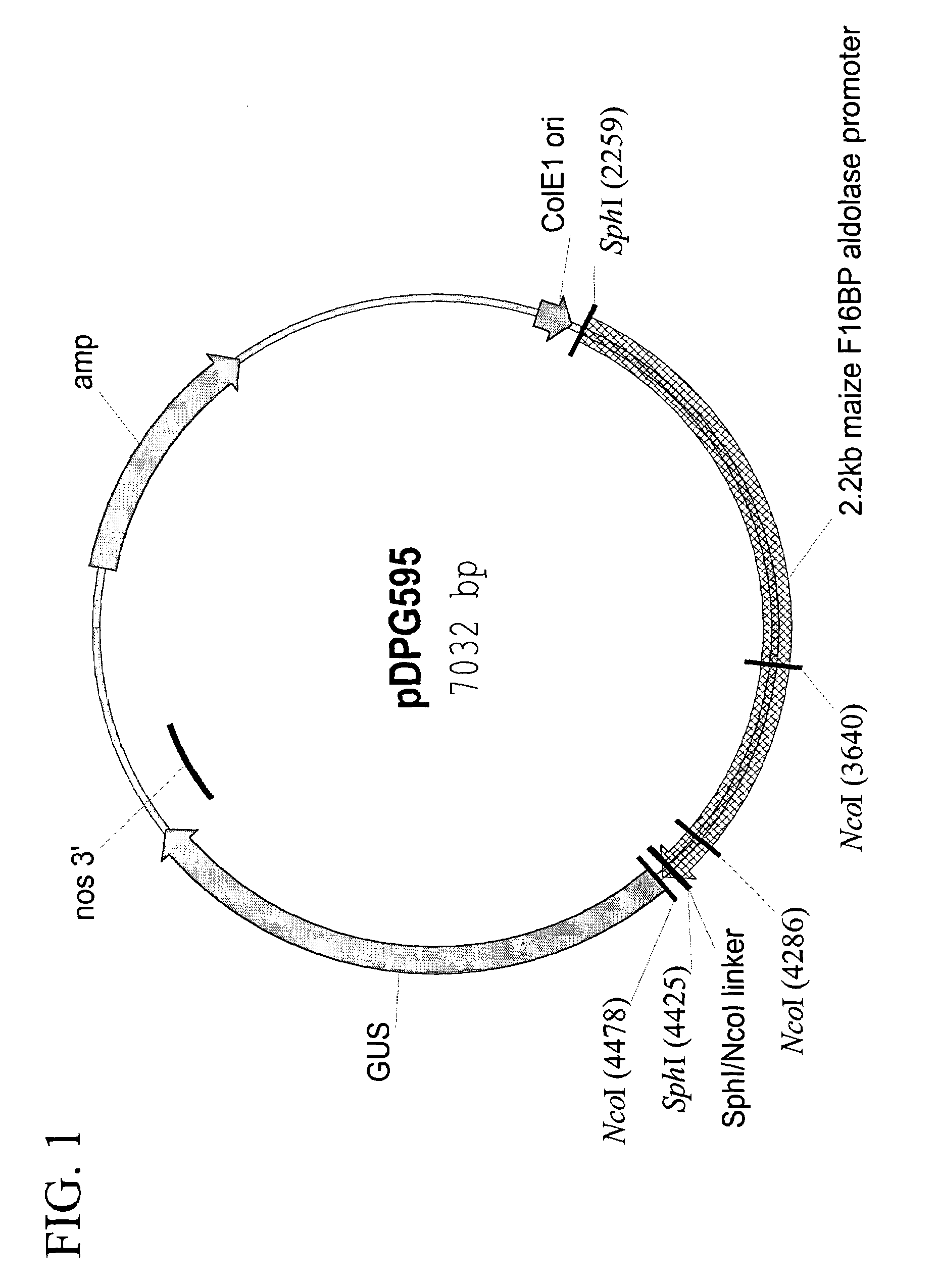

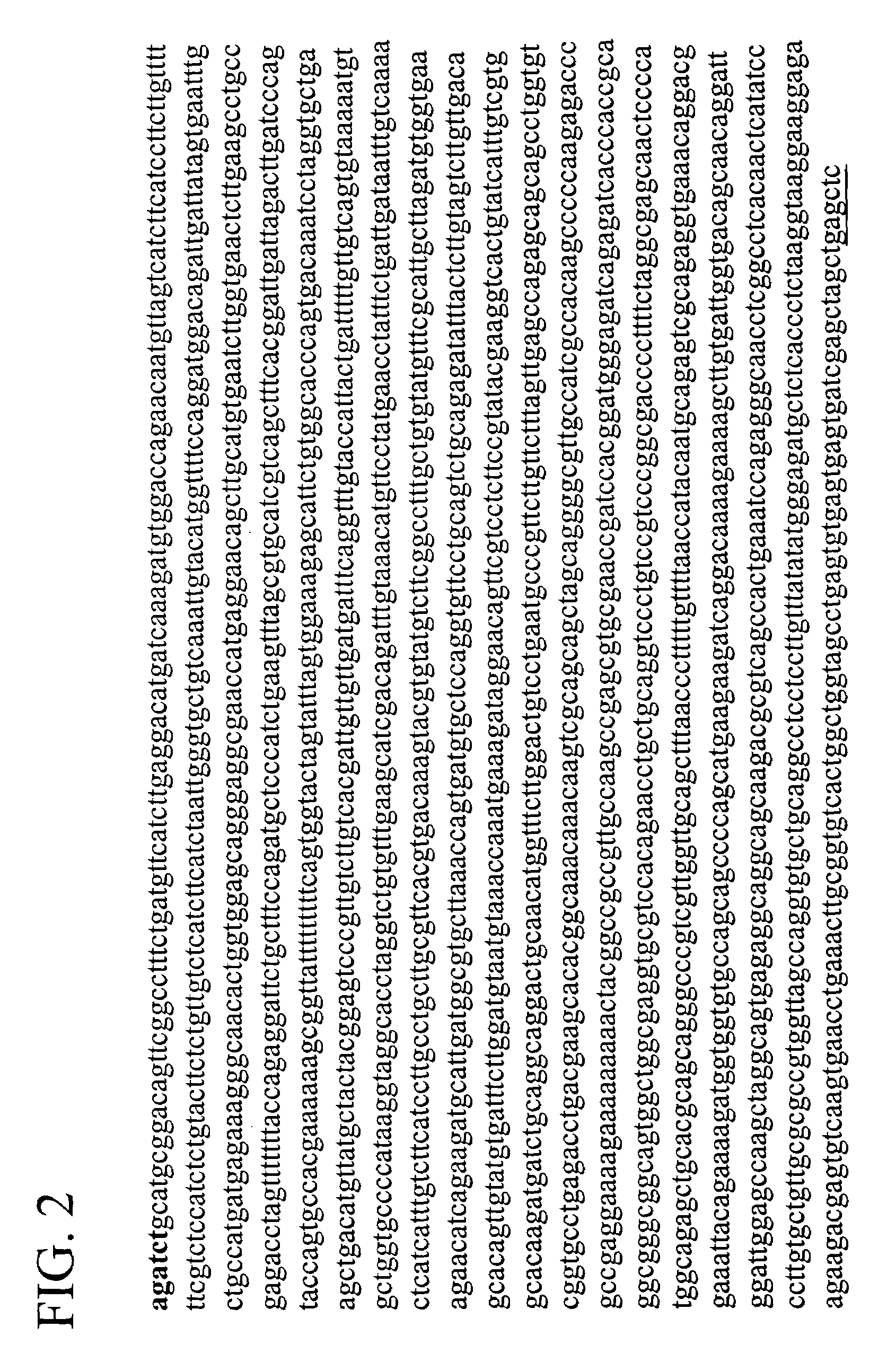

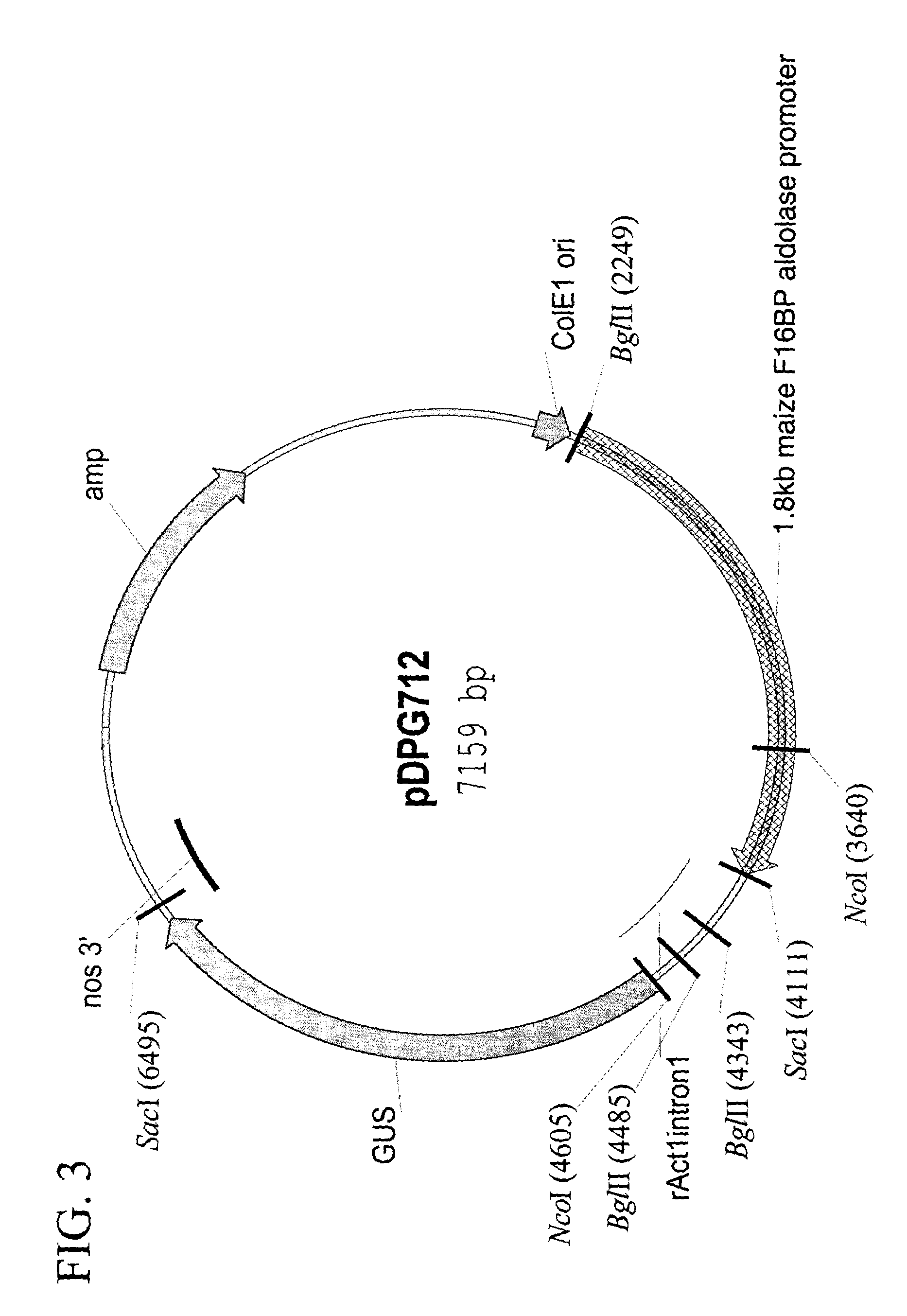

Maize chloroplast aldolase promoter compositions and methods for use thereof

ActiveUS7151204B2Simple compositionQuality improvementSugar derivativesOther foreign material introduction processesFructoseTransgene

The current invention provides the promoter of the Zea mays nuclear gene encoding chloroplast-localized fructose-1,6-bisphosphate (F16BP) aldolase. Compositions comprising this sequence are described, as are plants transformed with such compositions. Further provided are methods for the expression of transgenes in plants comprising the use of these sequences. The methods of the invention include the direct creation of transgenic plants with the chloroplastic F16BP aldolase promoter by genetic transformation, as well as by plant breeding methods. The sequences of the invention represent a valuable new tool for the creation of transgenic plants, preferably having one or more added beneficial characteristics.

Owner:MONSANTO TECH LLC

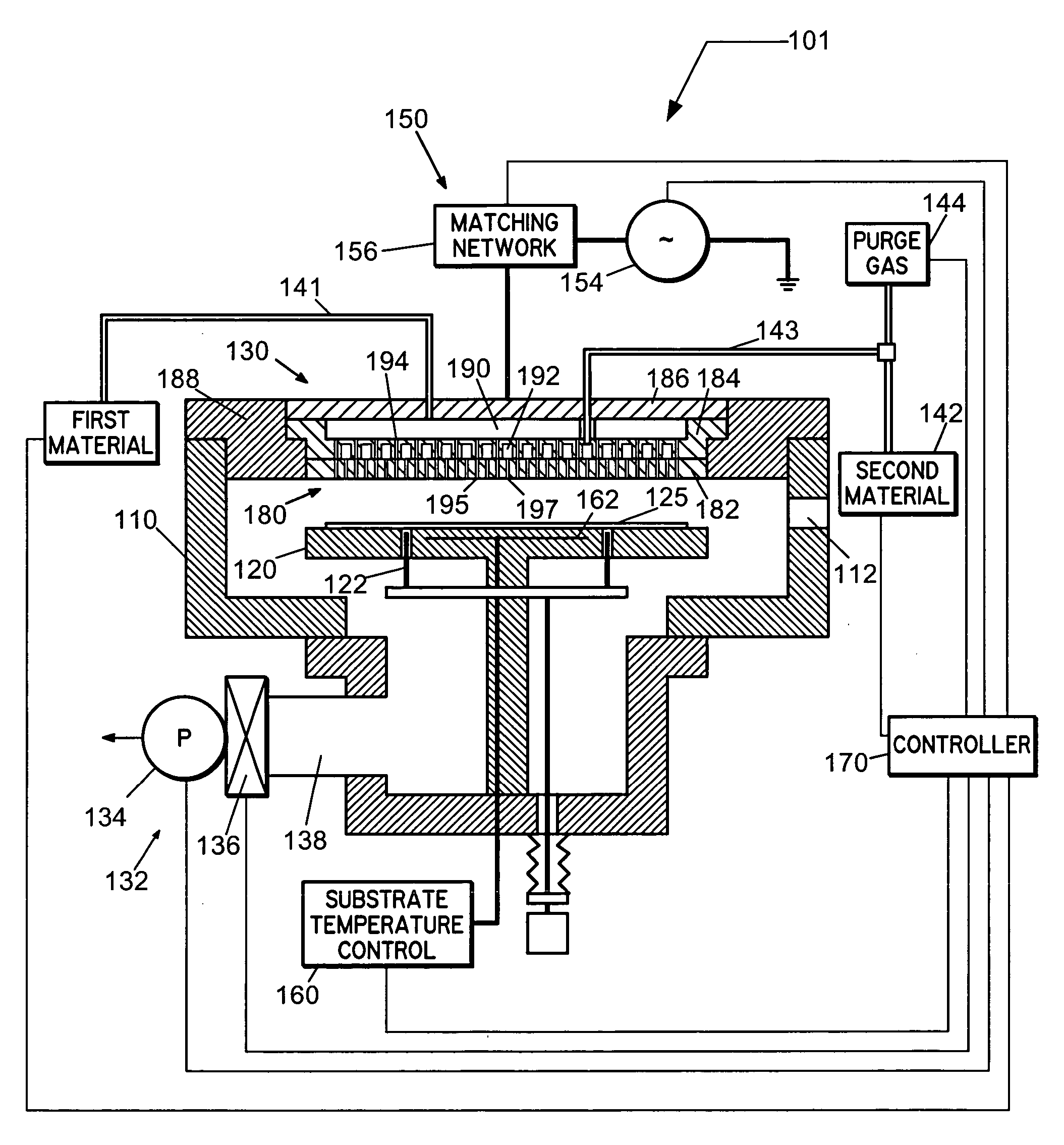

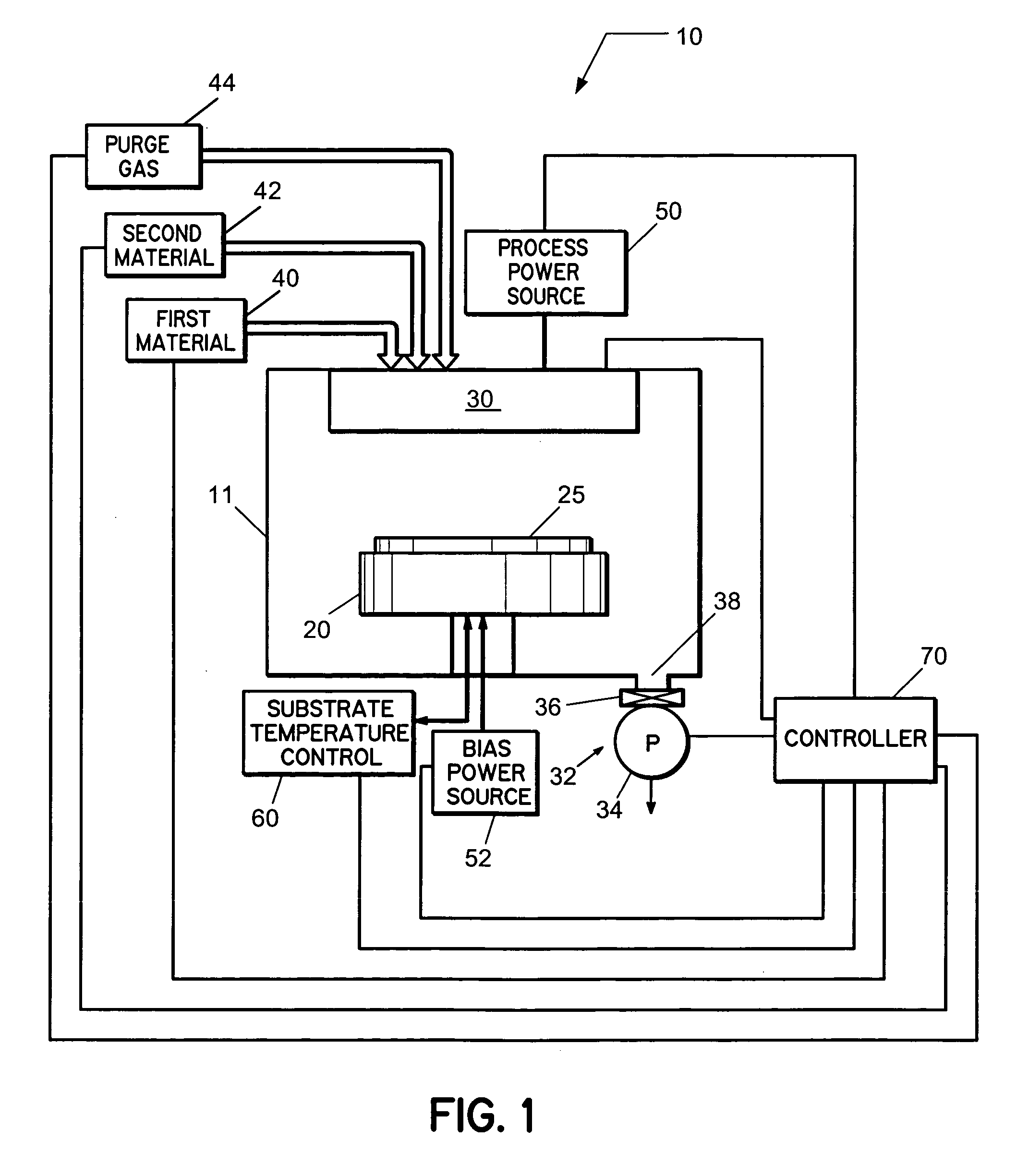

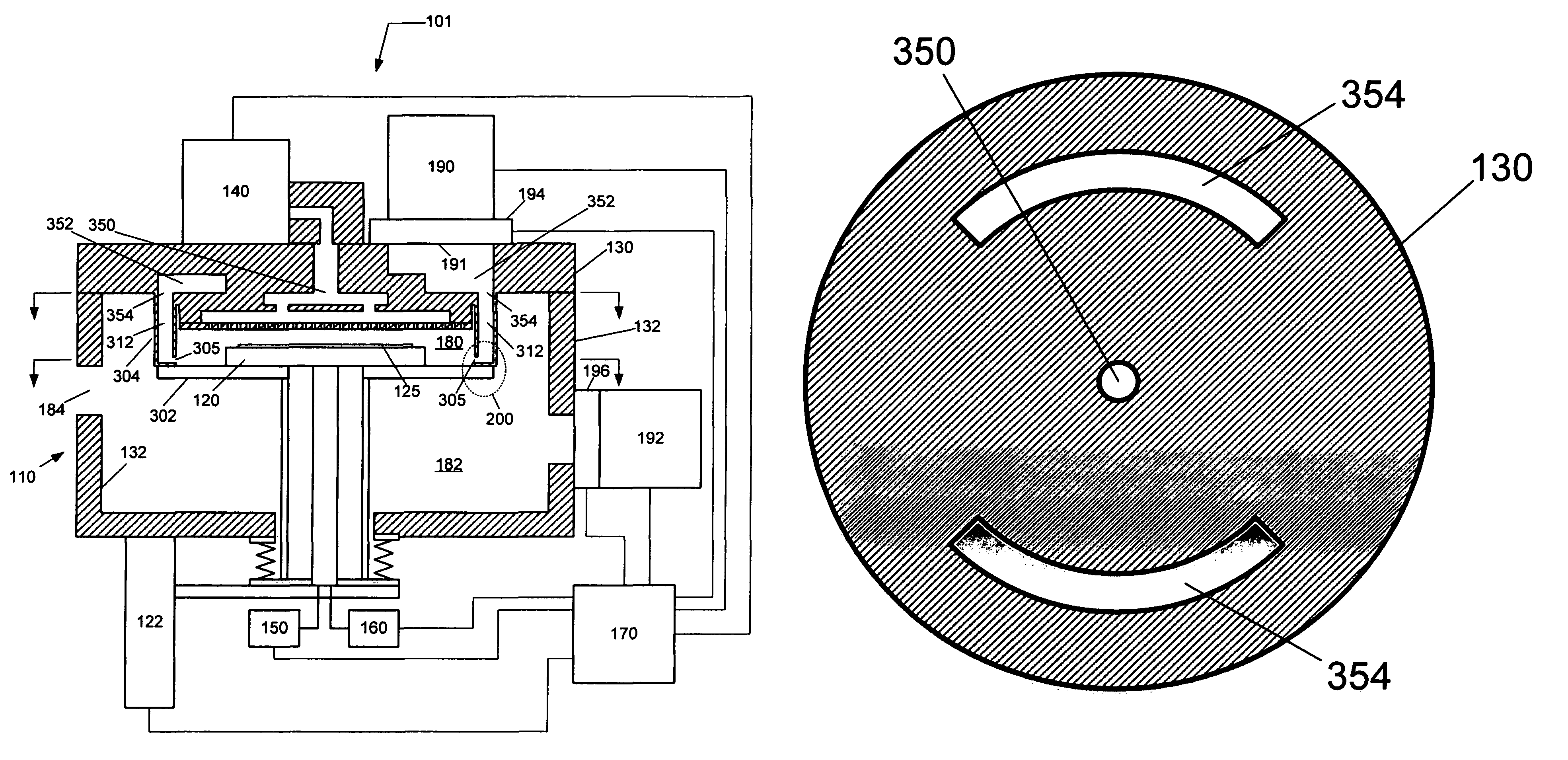

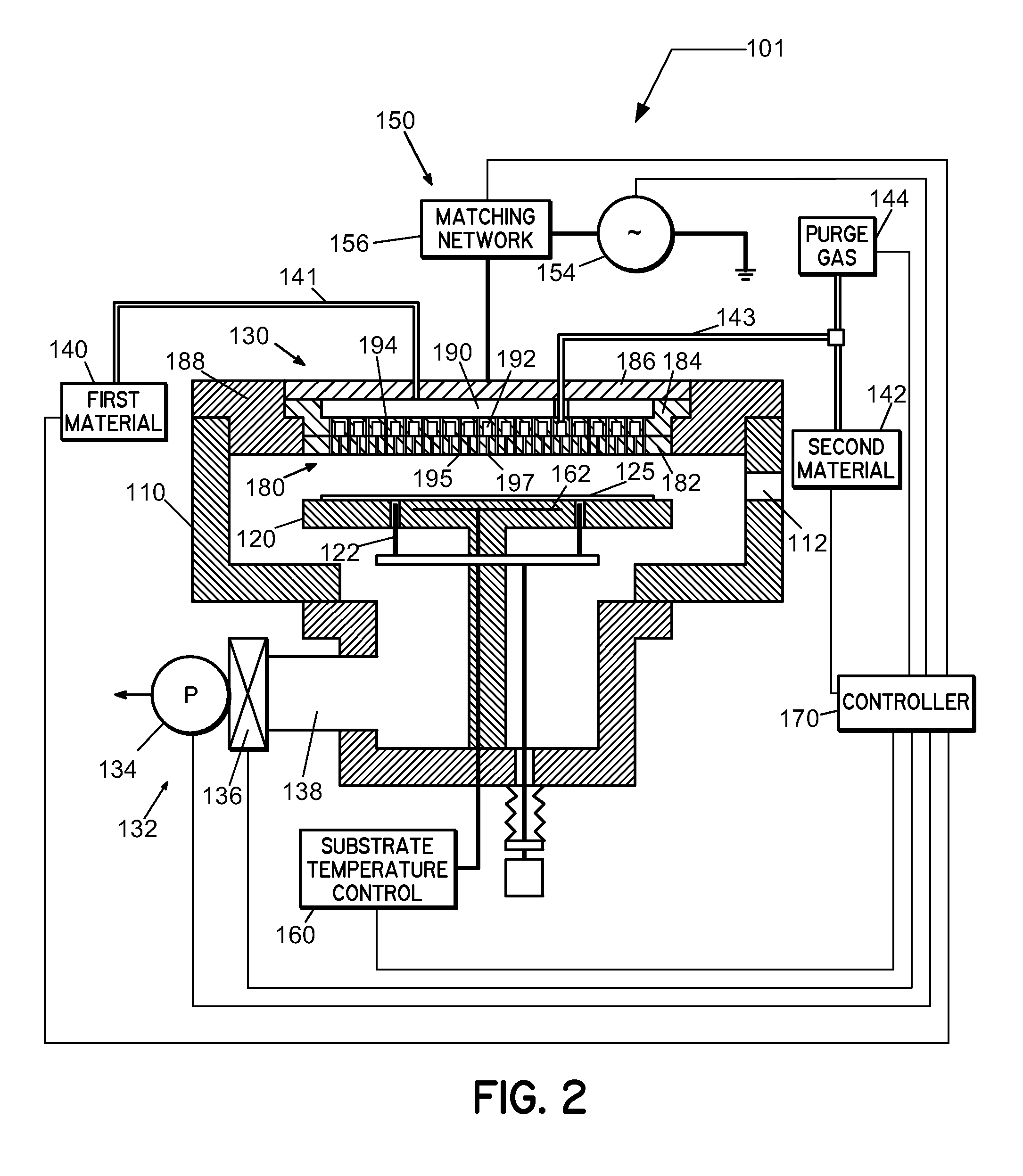

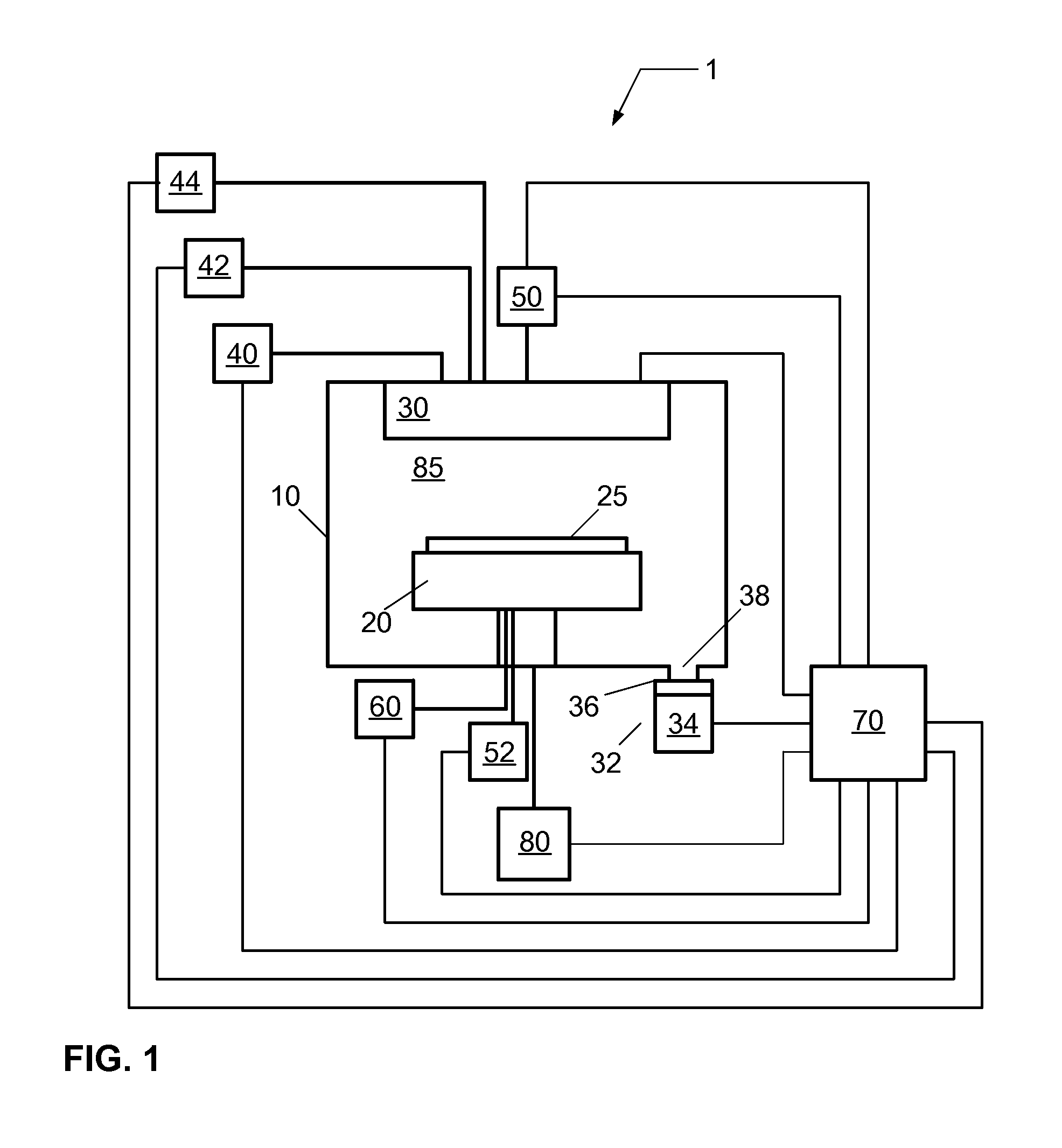

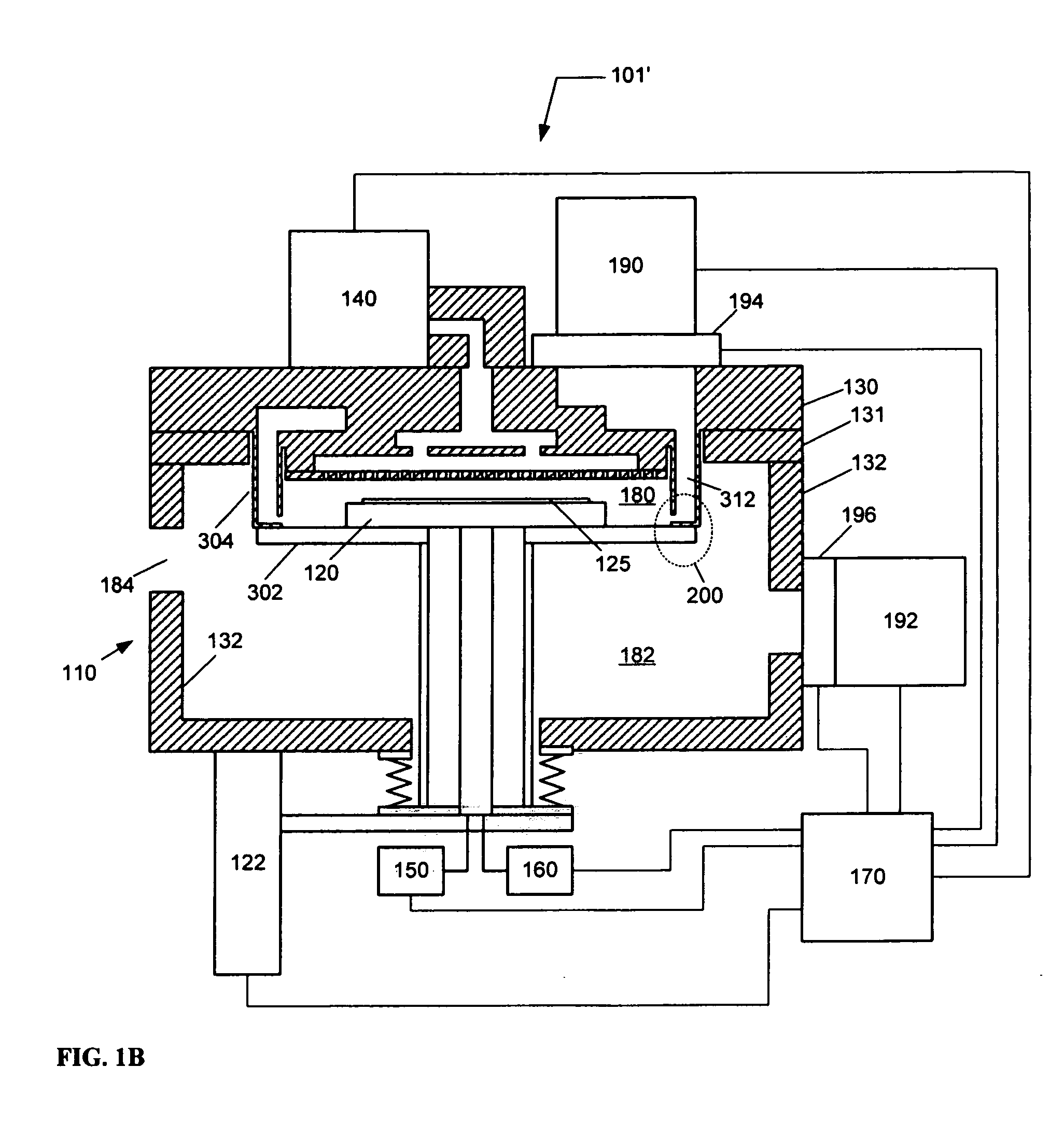

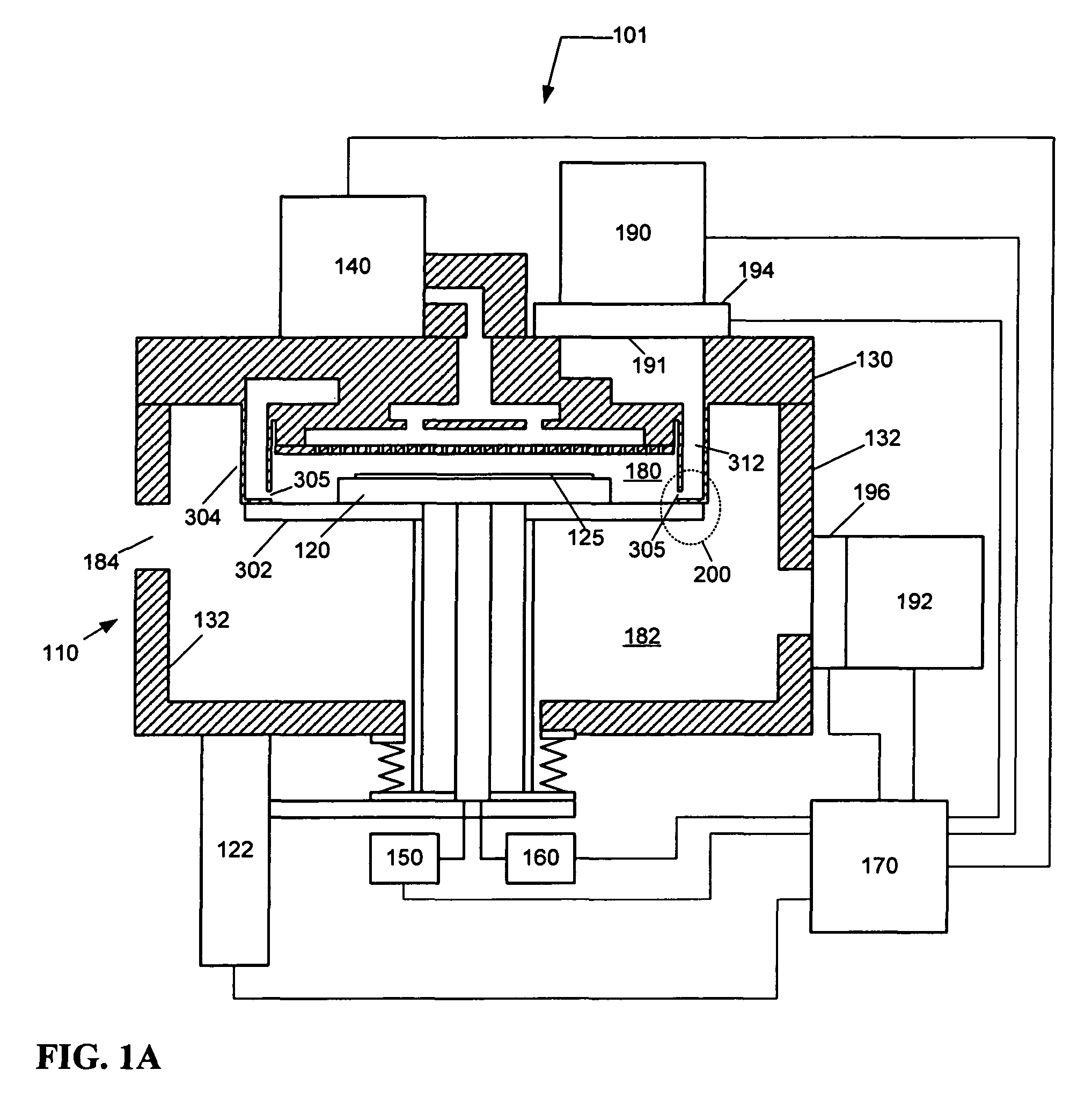

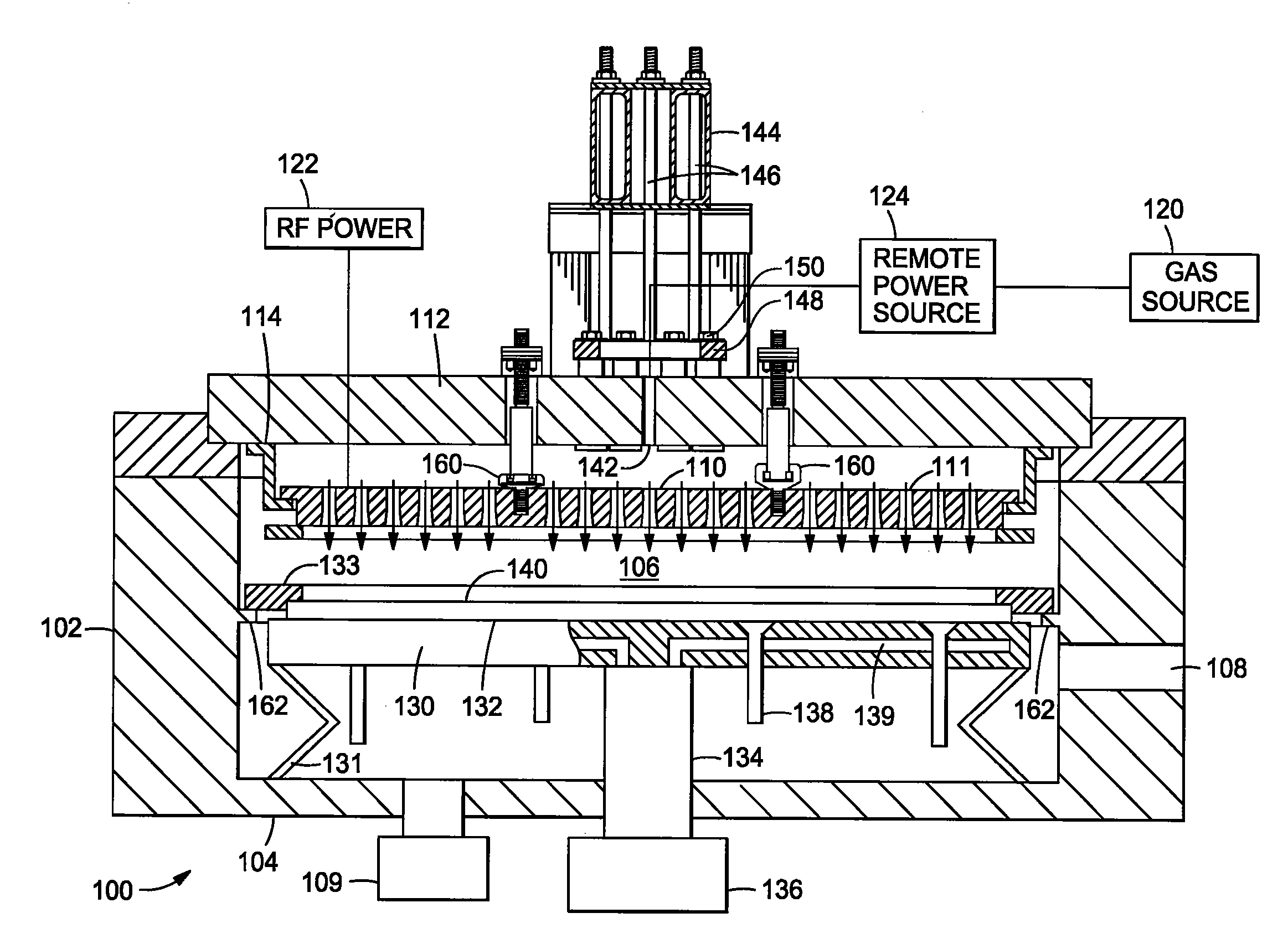

Plasma enhanced atomic layer deposition system having reduced contamination

ActiveUS20060213439A1Trend downThin film depositionLiquid surface applicatorsSemiconductor/solid-state device manufacturingAtomic layer depositionContamination

A plasma enhanced atomic layer deposition (PEALD) system is described, wherein the system comprises a processing space and a high vacuum, ultra-clean transfer space. During processing, the substrate to which the thin conformal film is formed is exposed to the processing space. During substrate transfer, the substrate is exposed to the high vacuum space. Processing gases are introduced sequentially and alternately to the process chamber and the pressures and gas flows within, to and from, and between the process chamber and the high vacuum transfer space are controlled to keep the transfer space ultra-clean.

Owner:TOKYO ELECTRON LTD

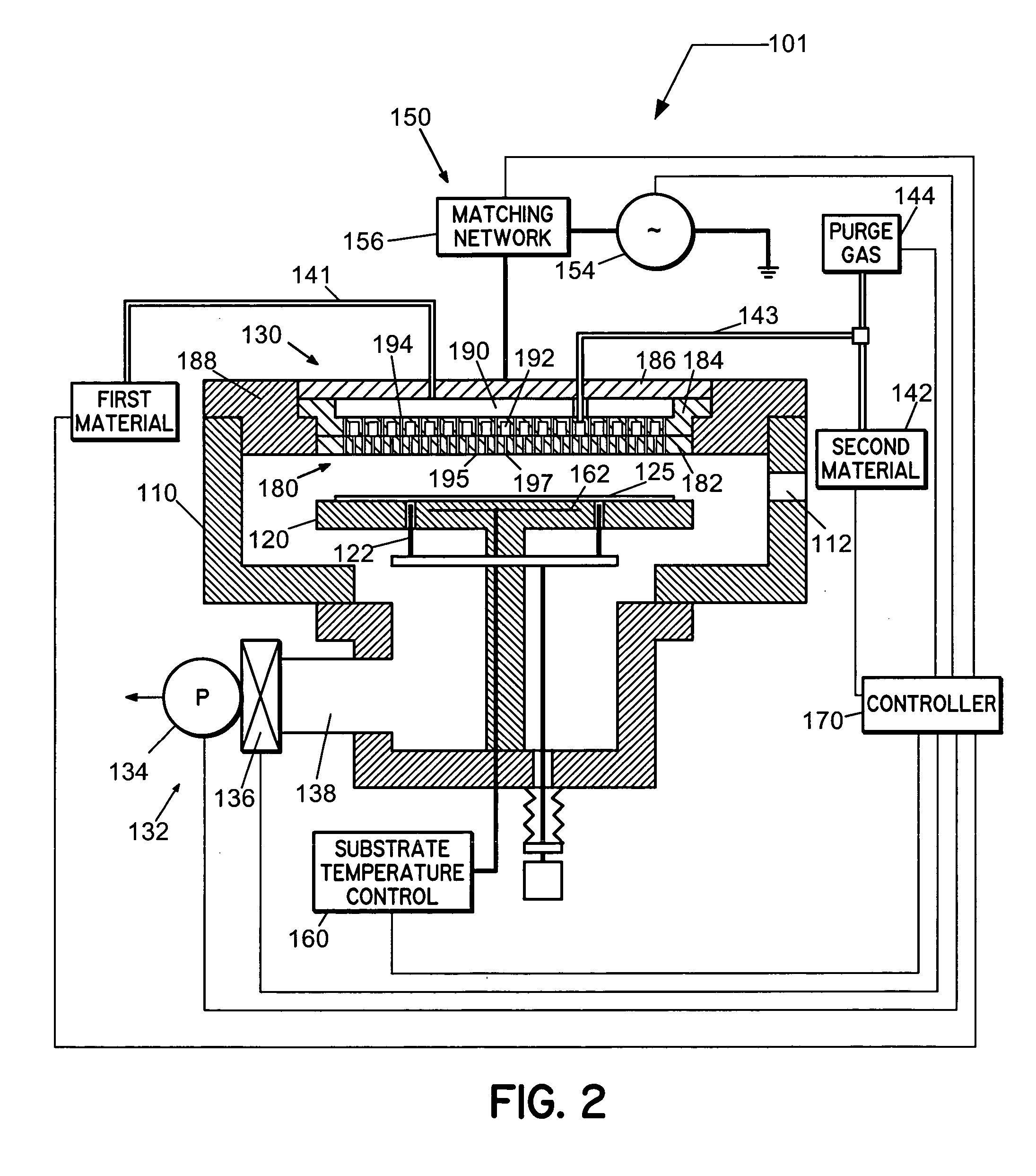

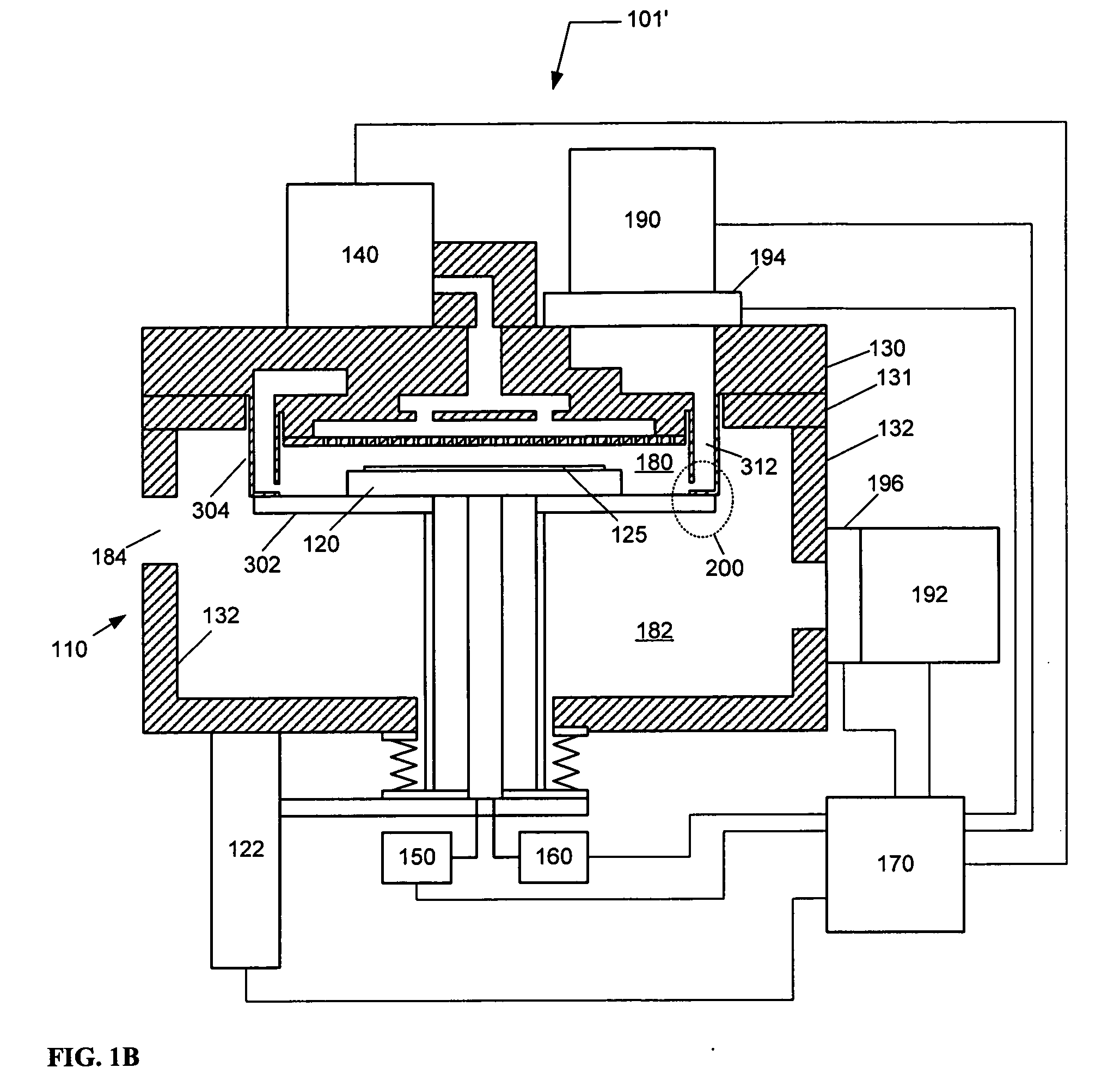

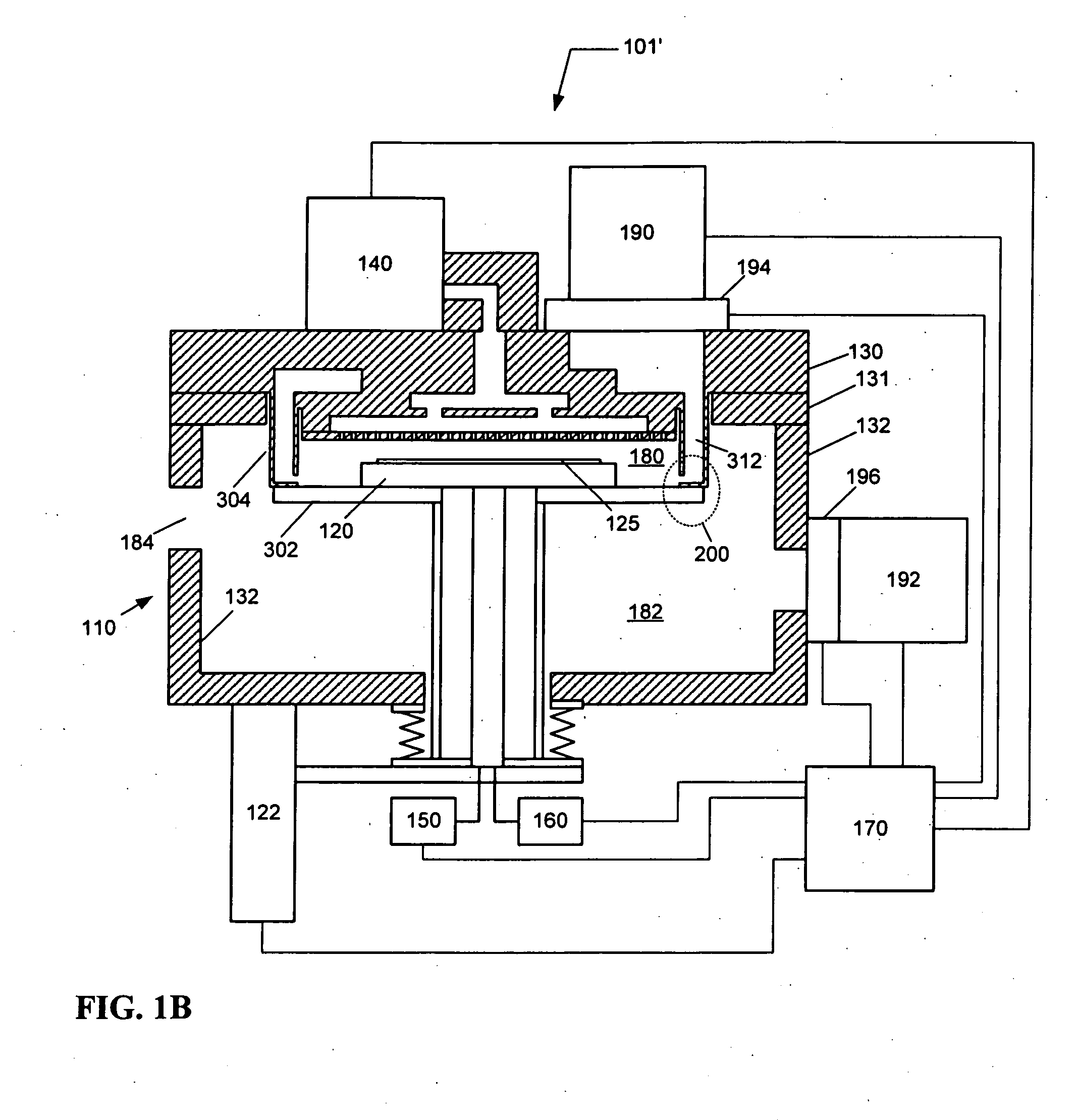

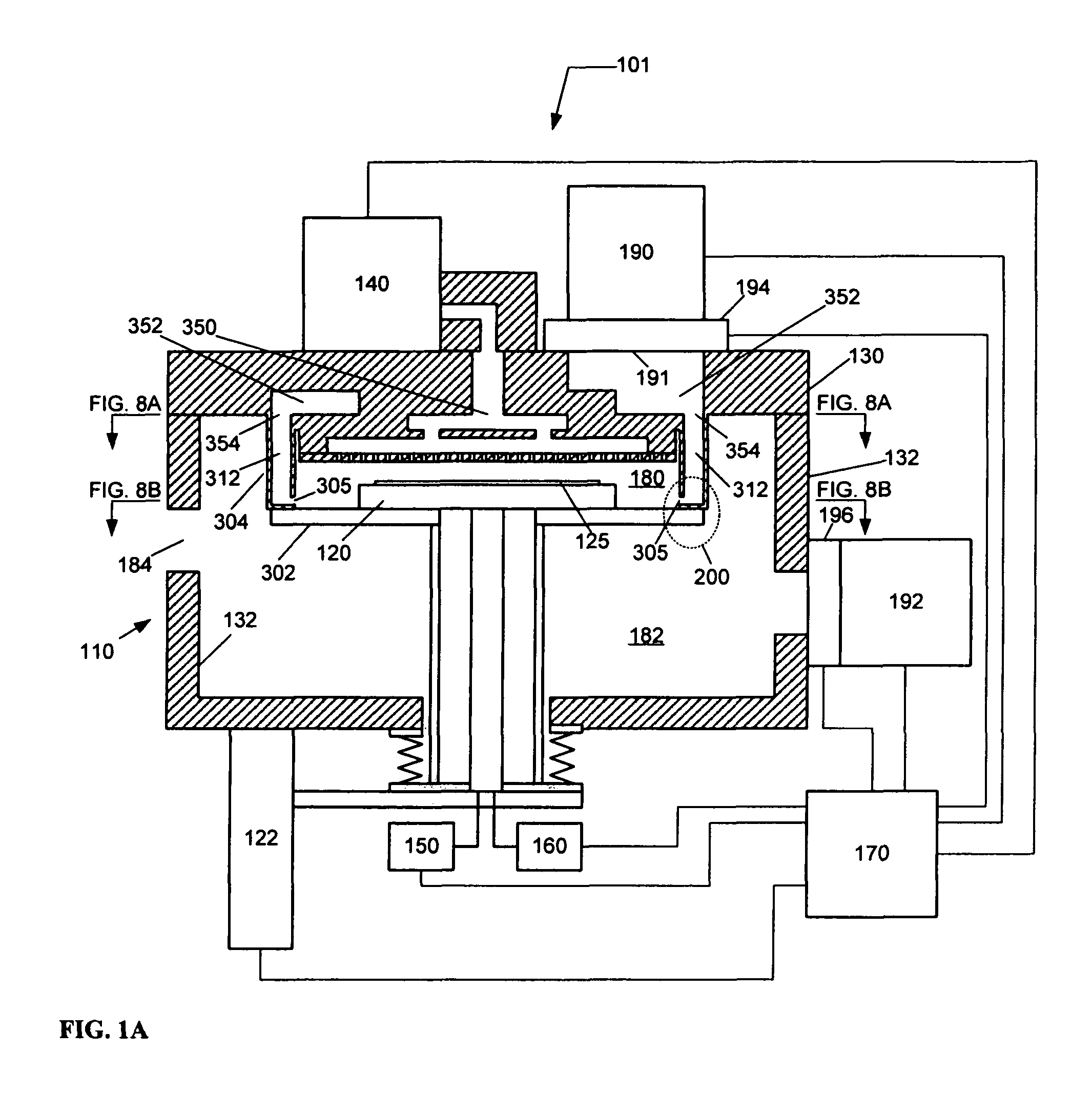

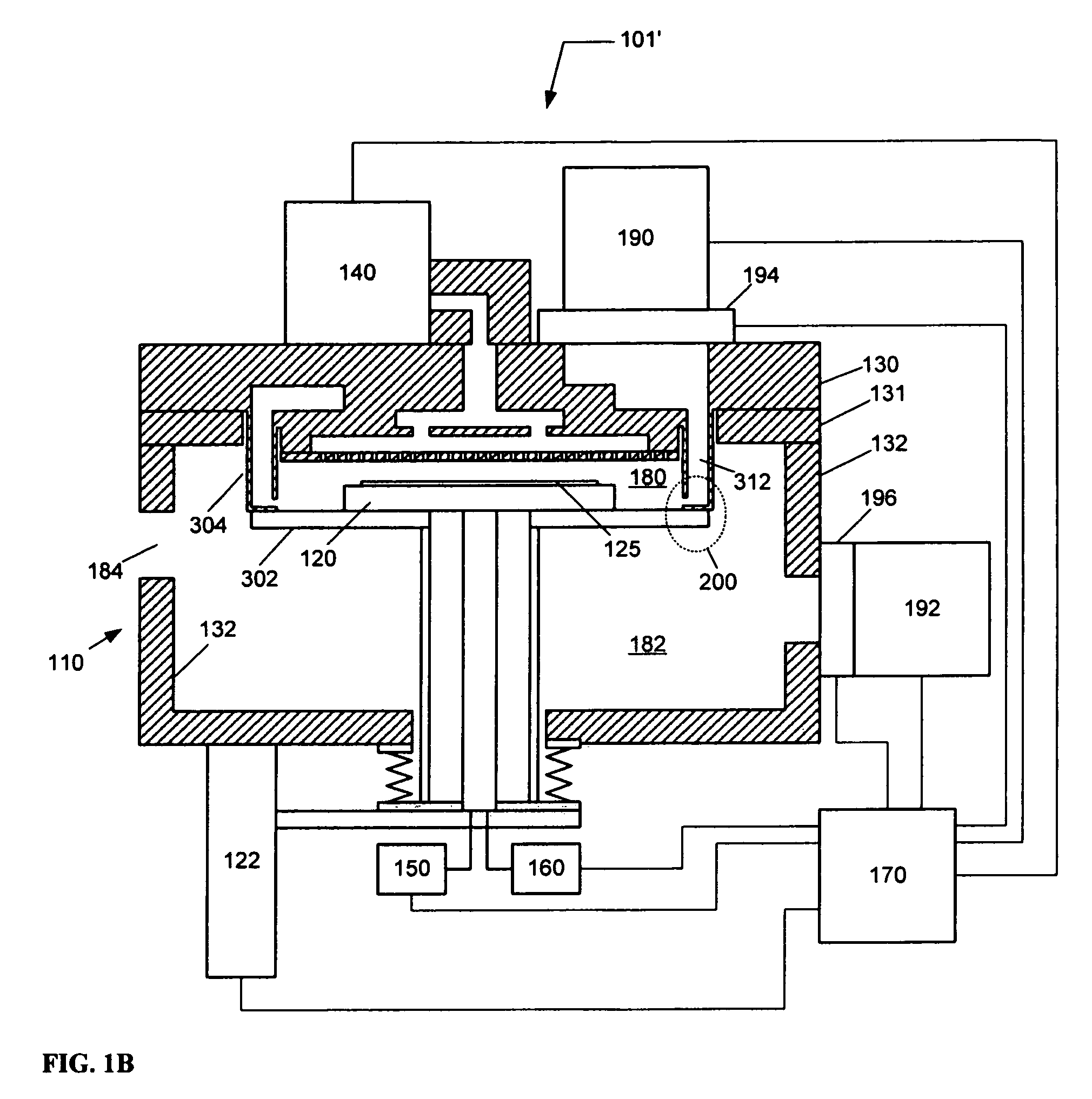

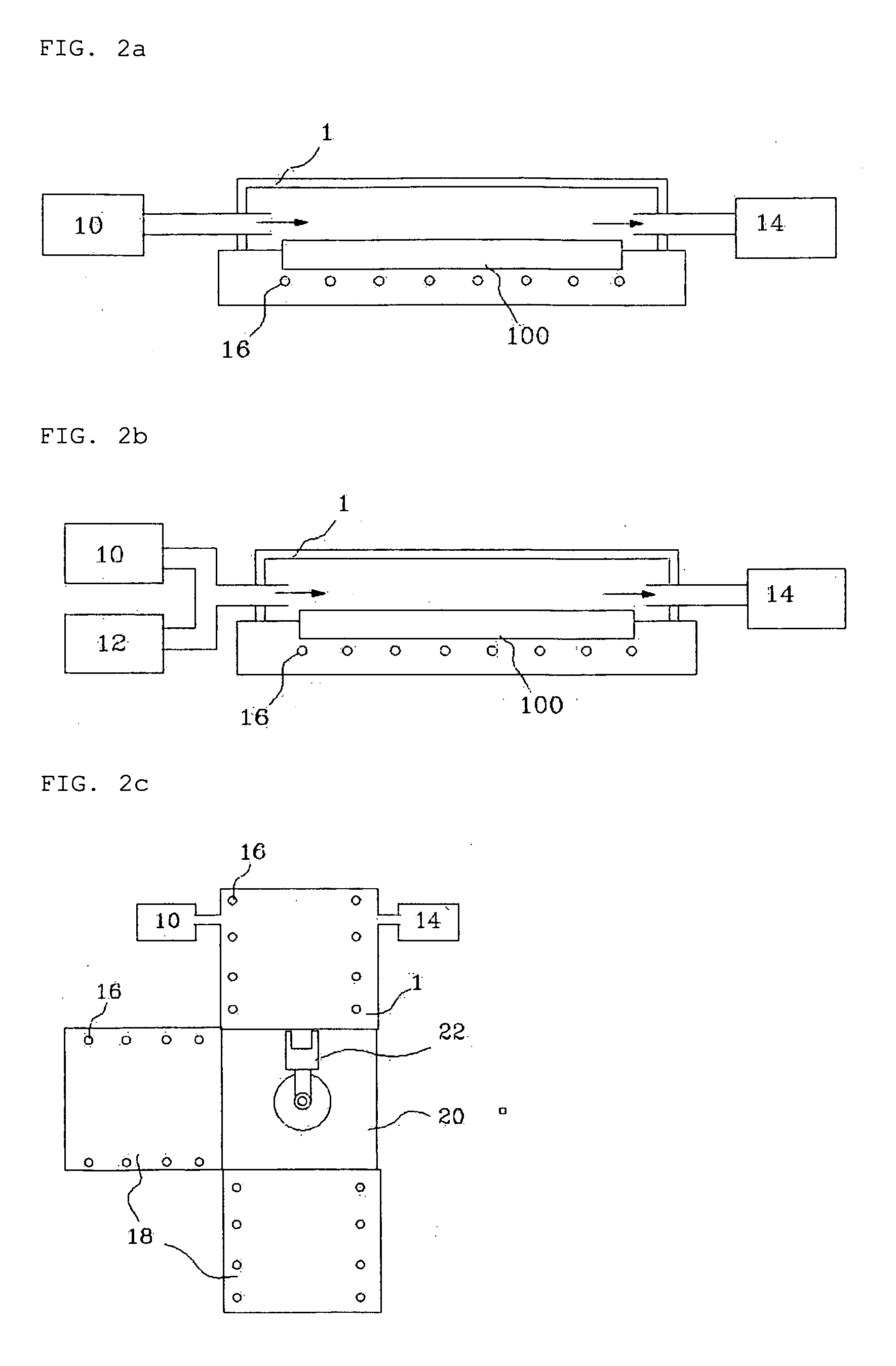

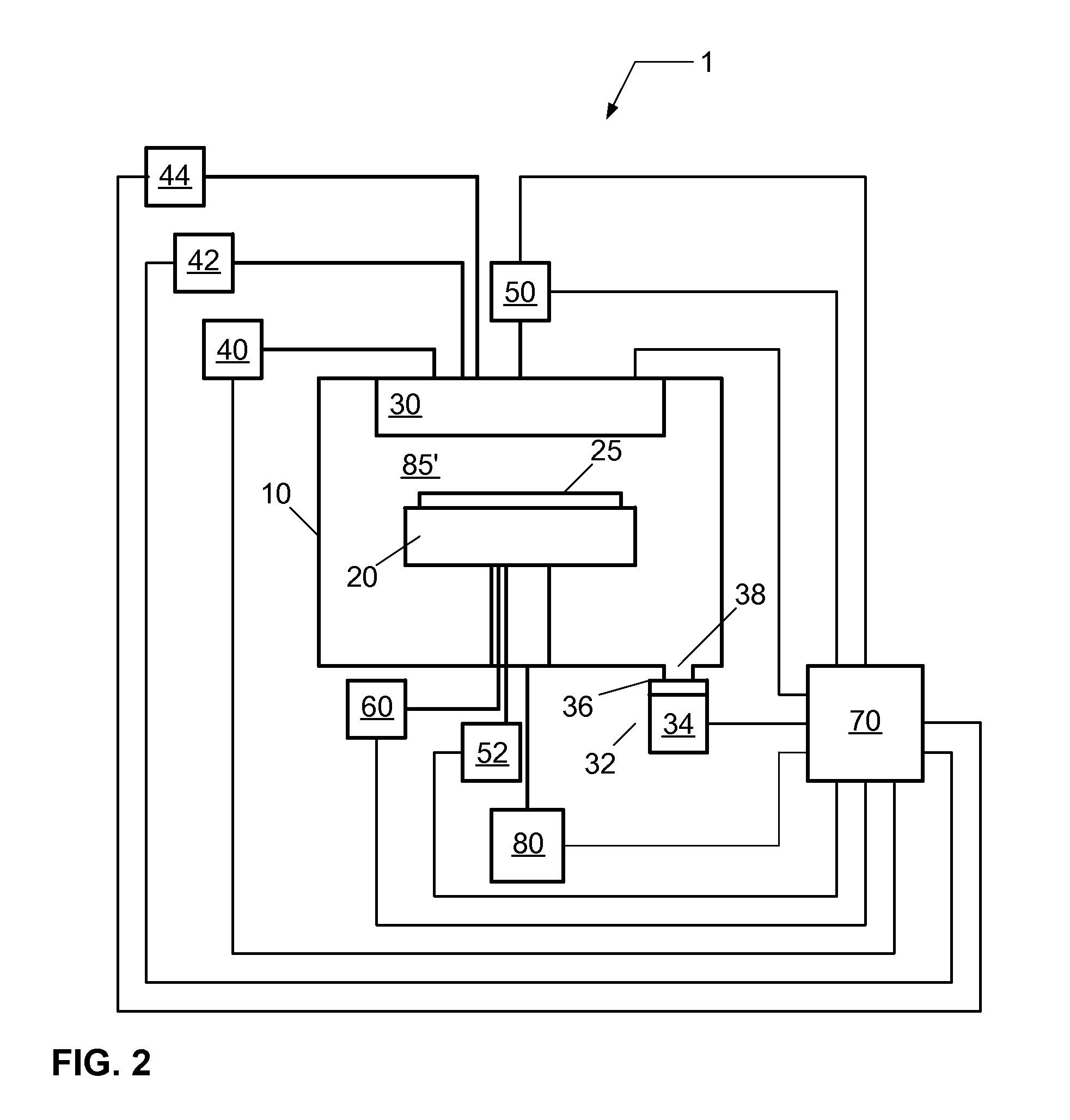

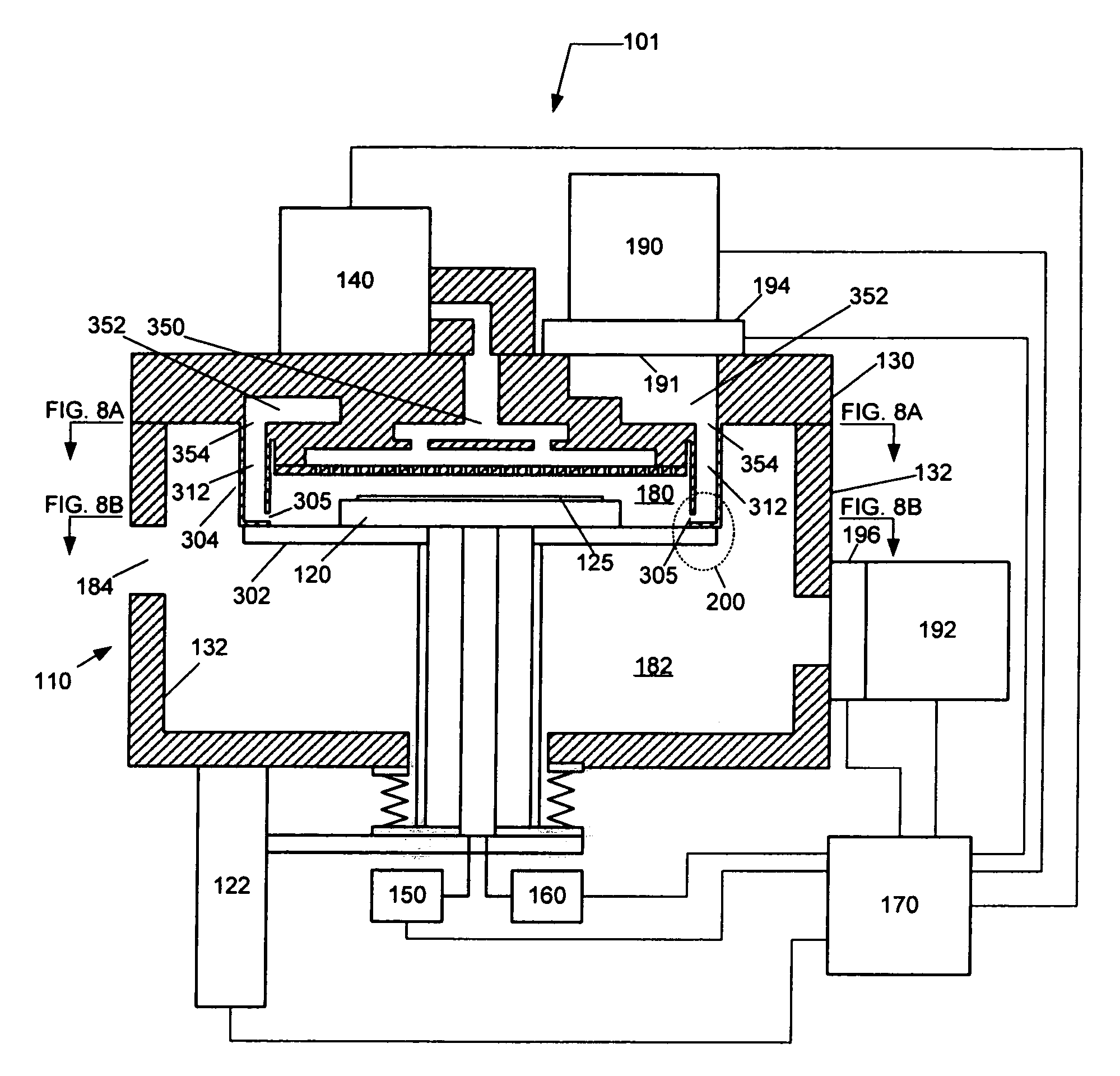

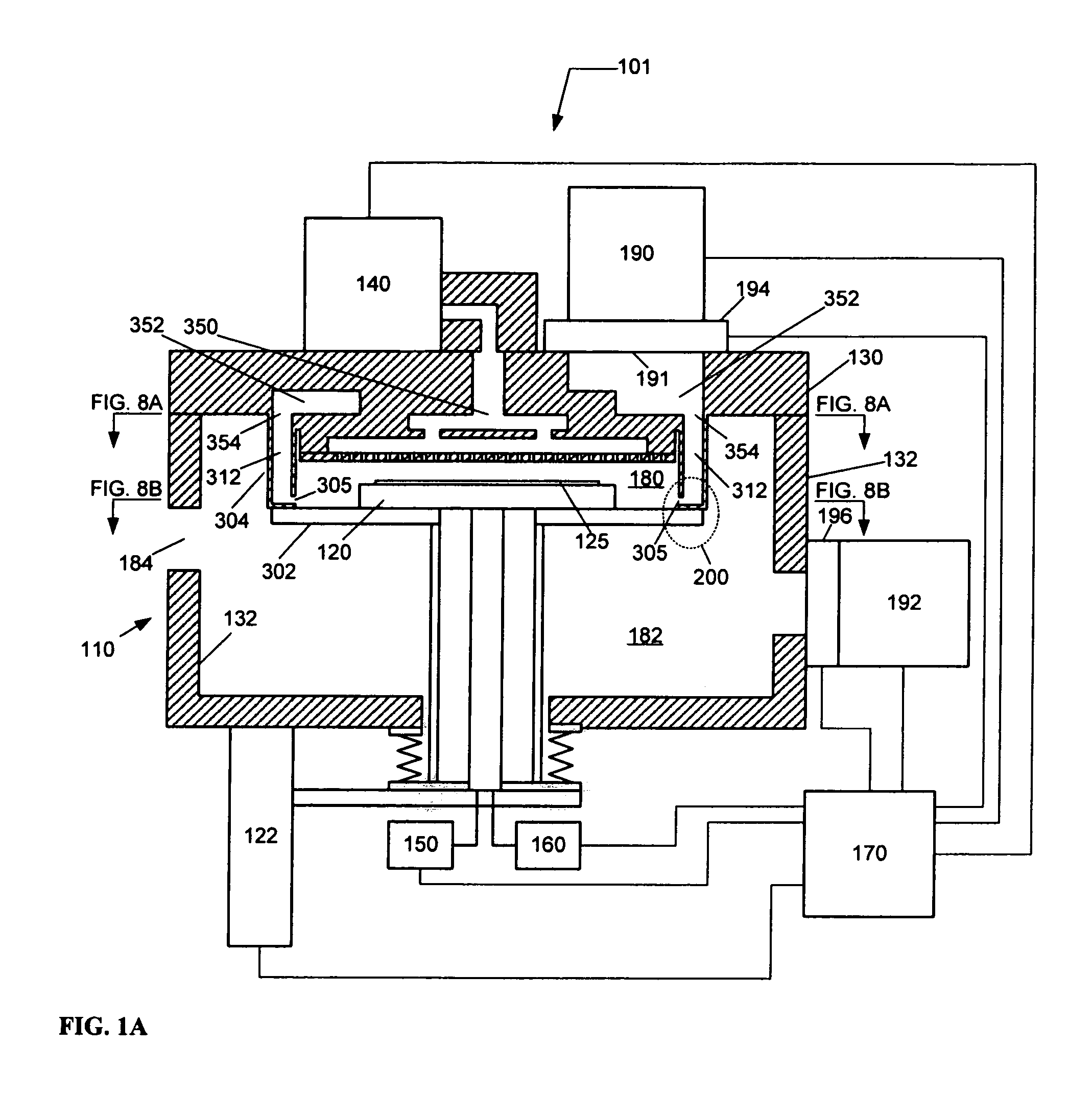

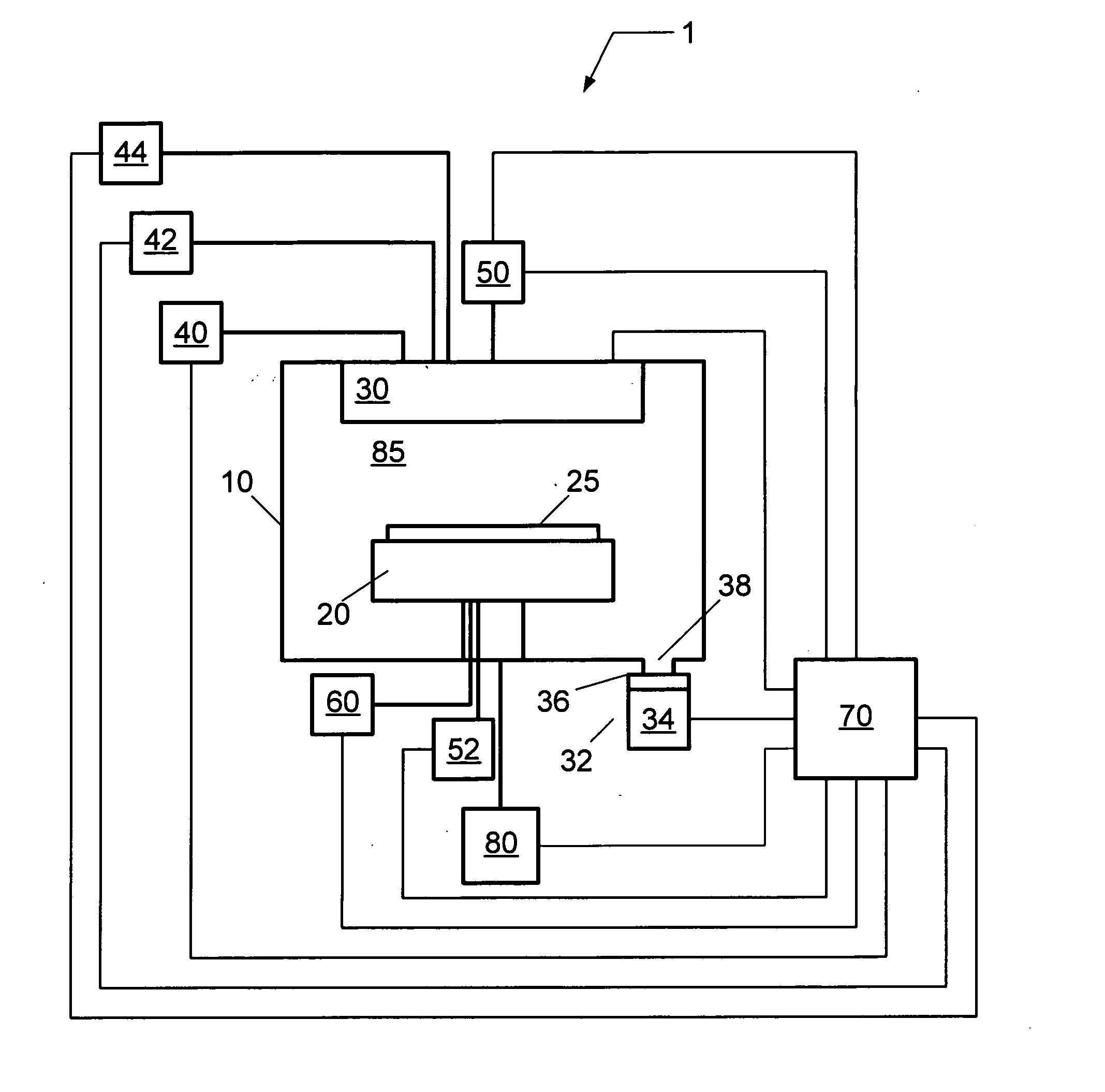

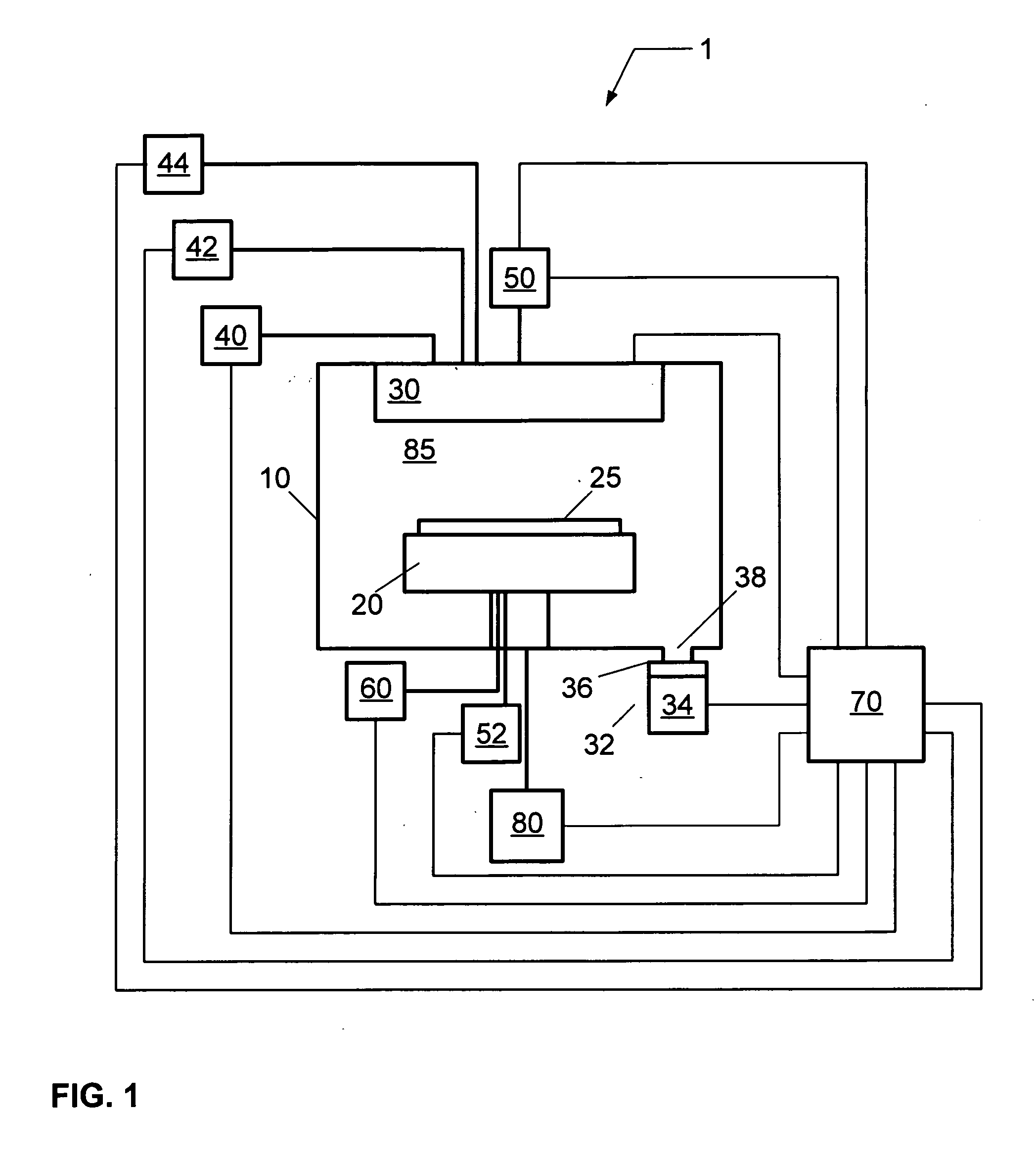

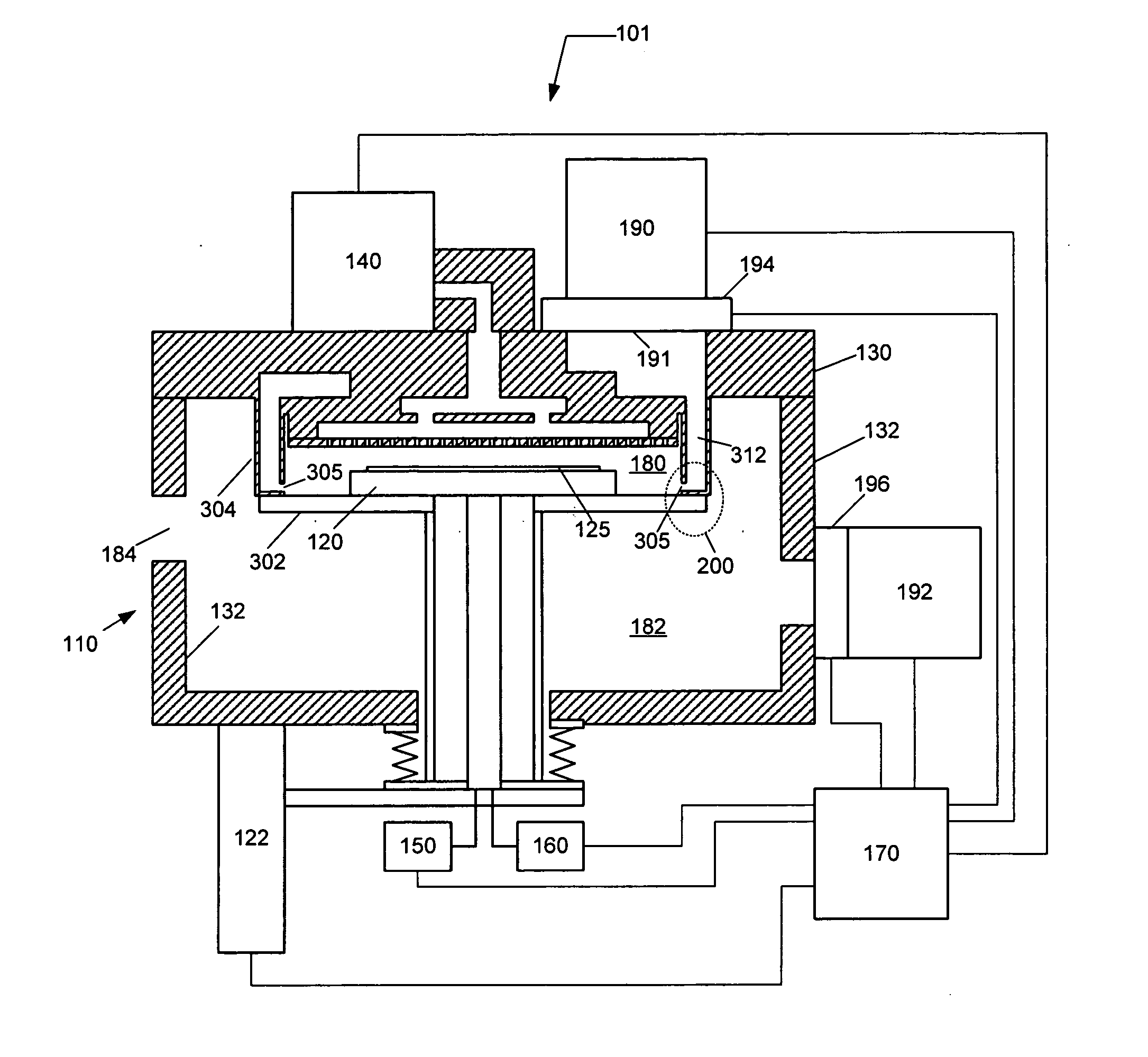

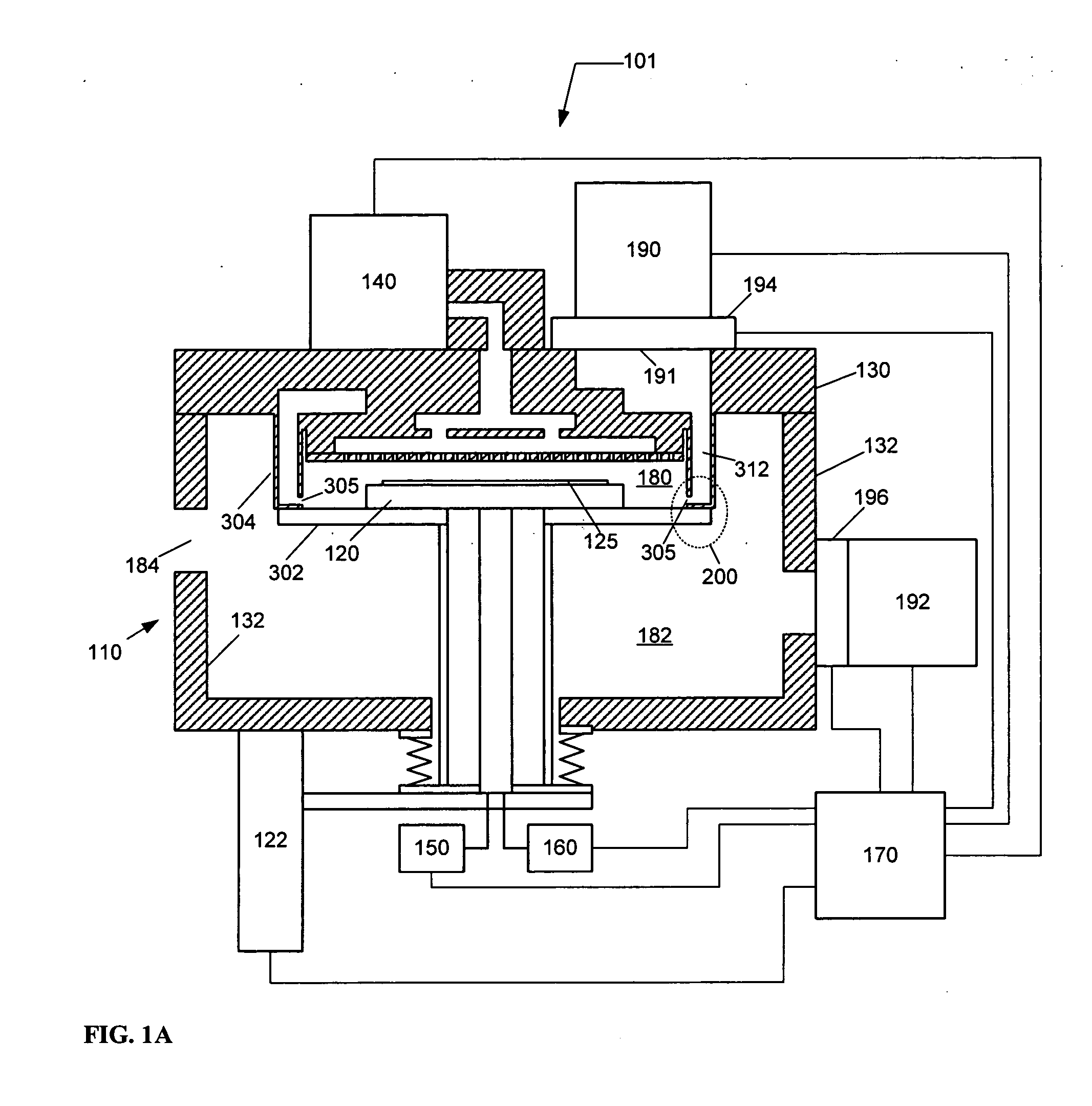

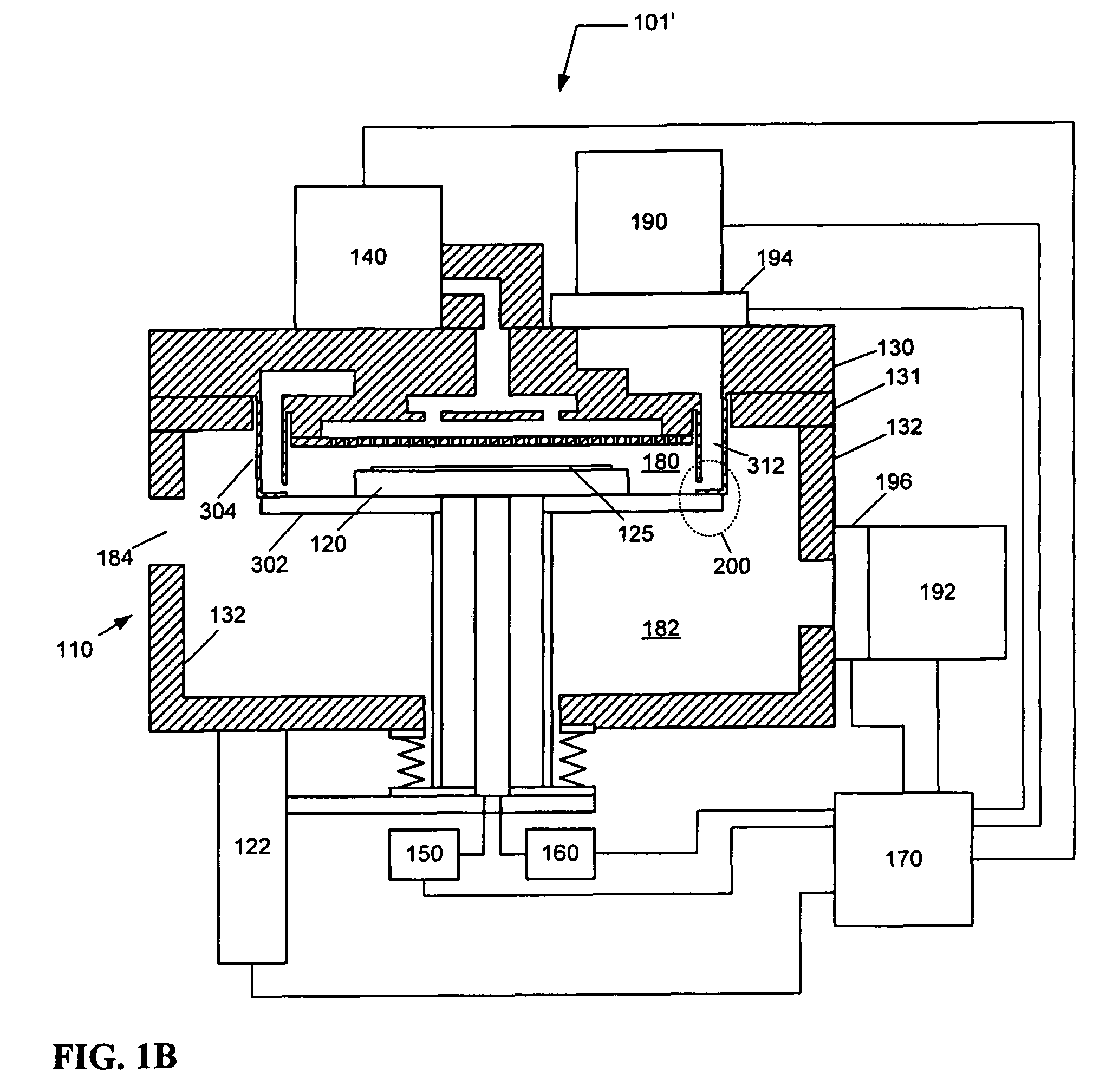

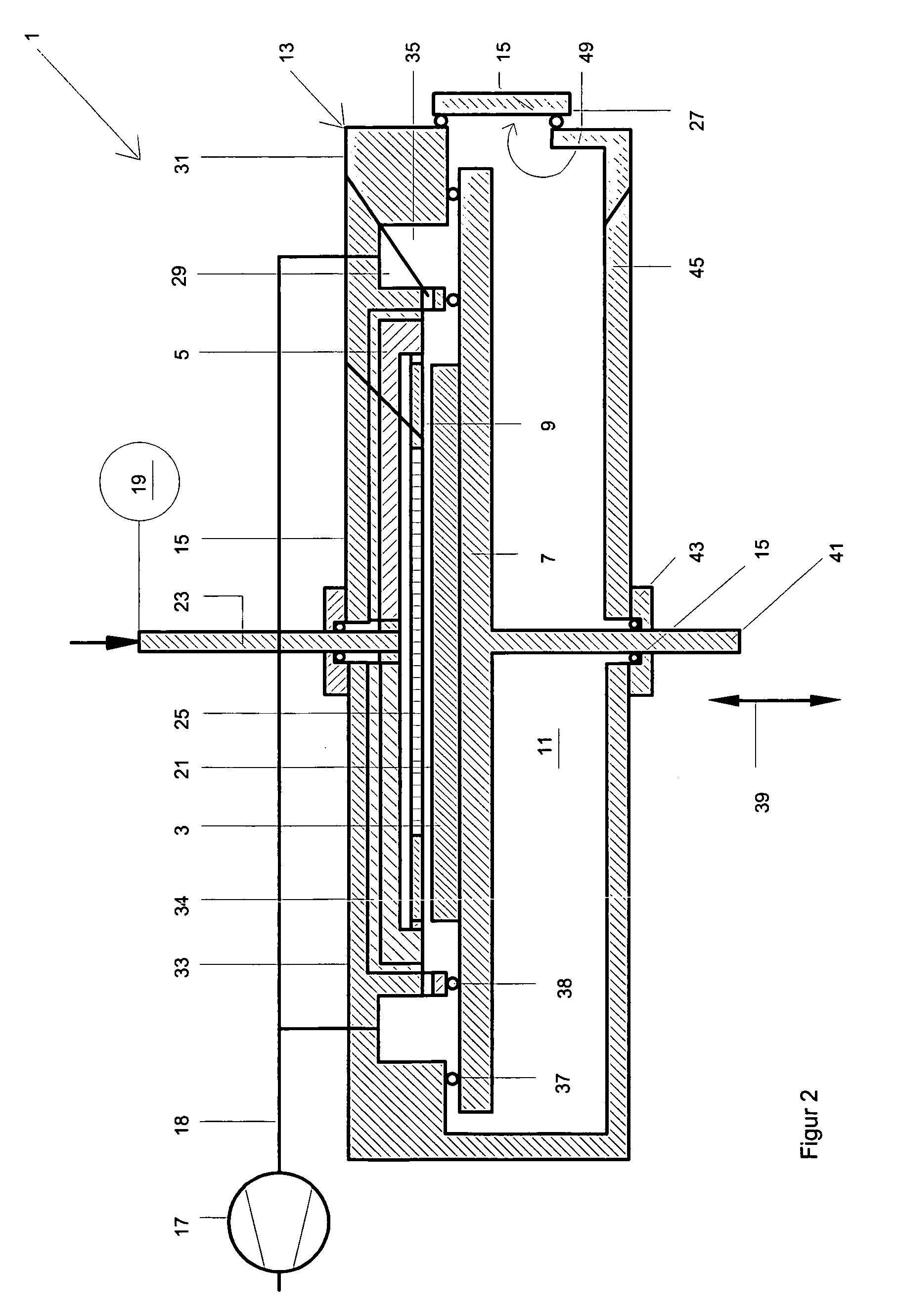

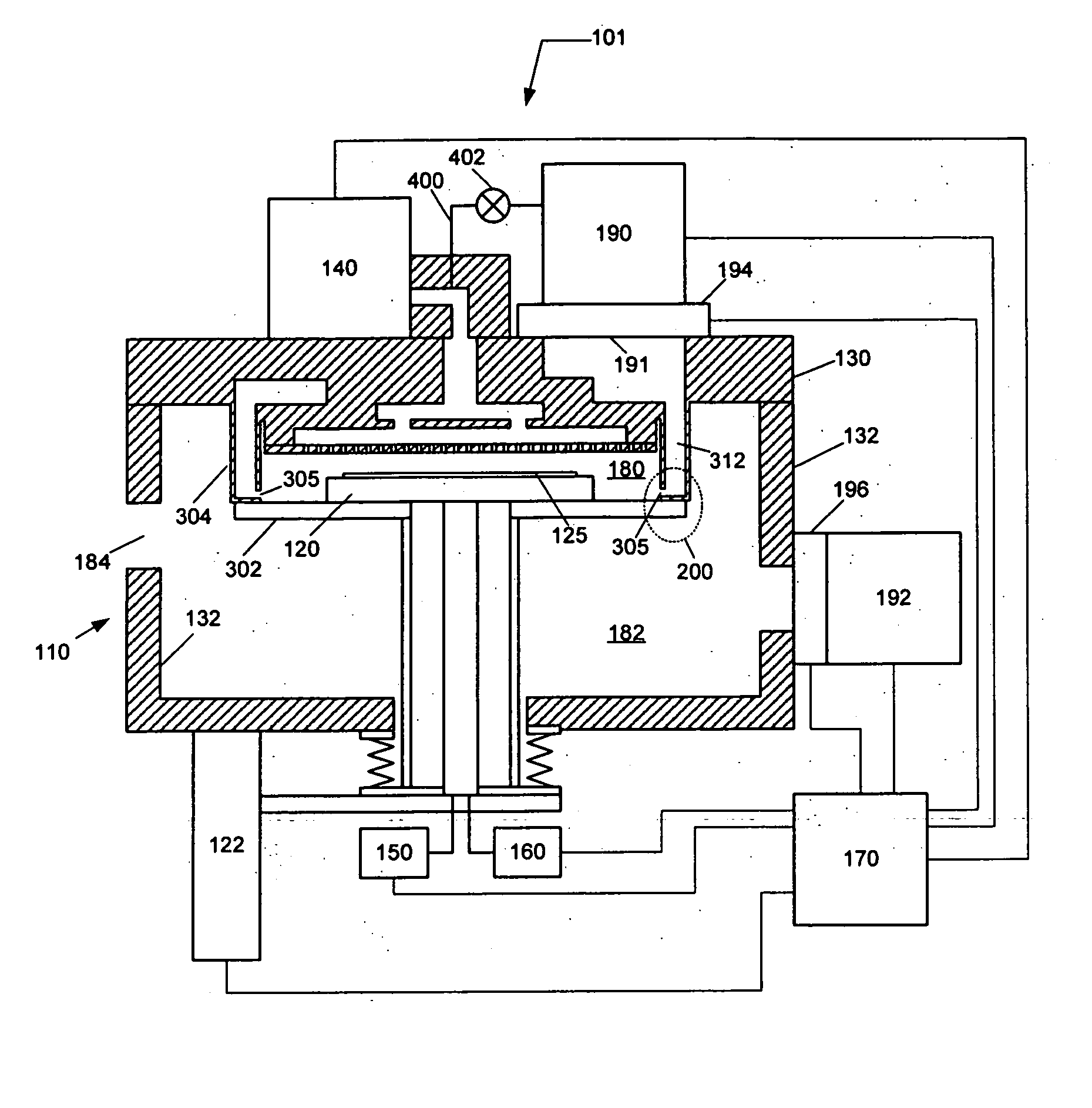

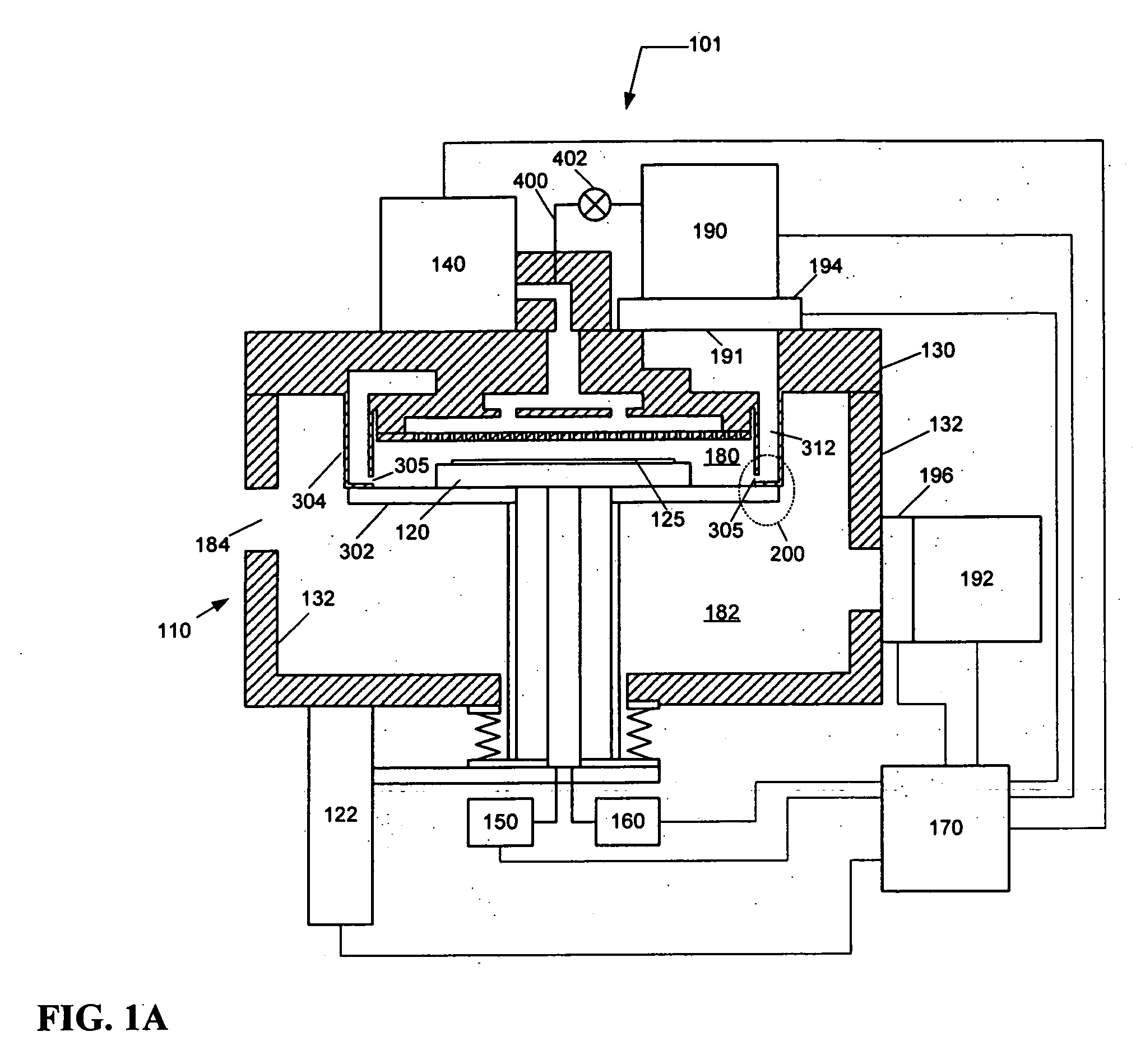

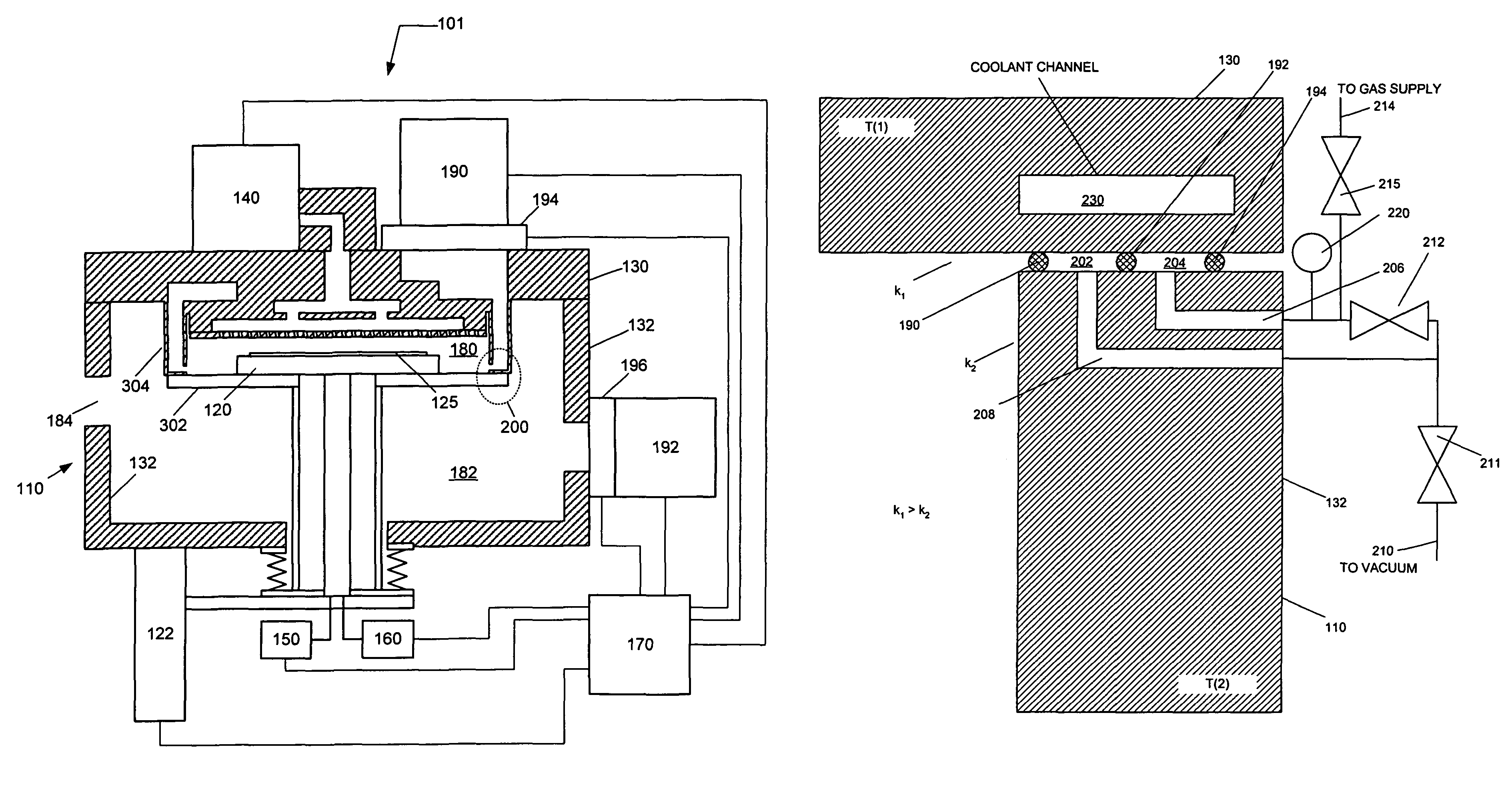

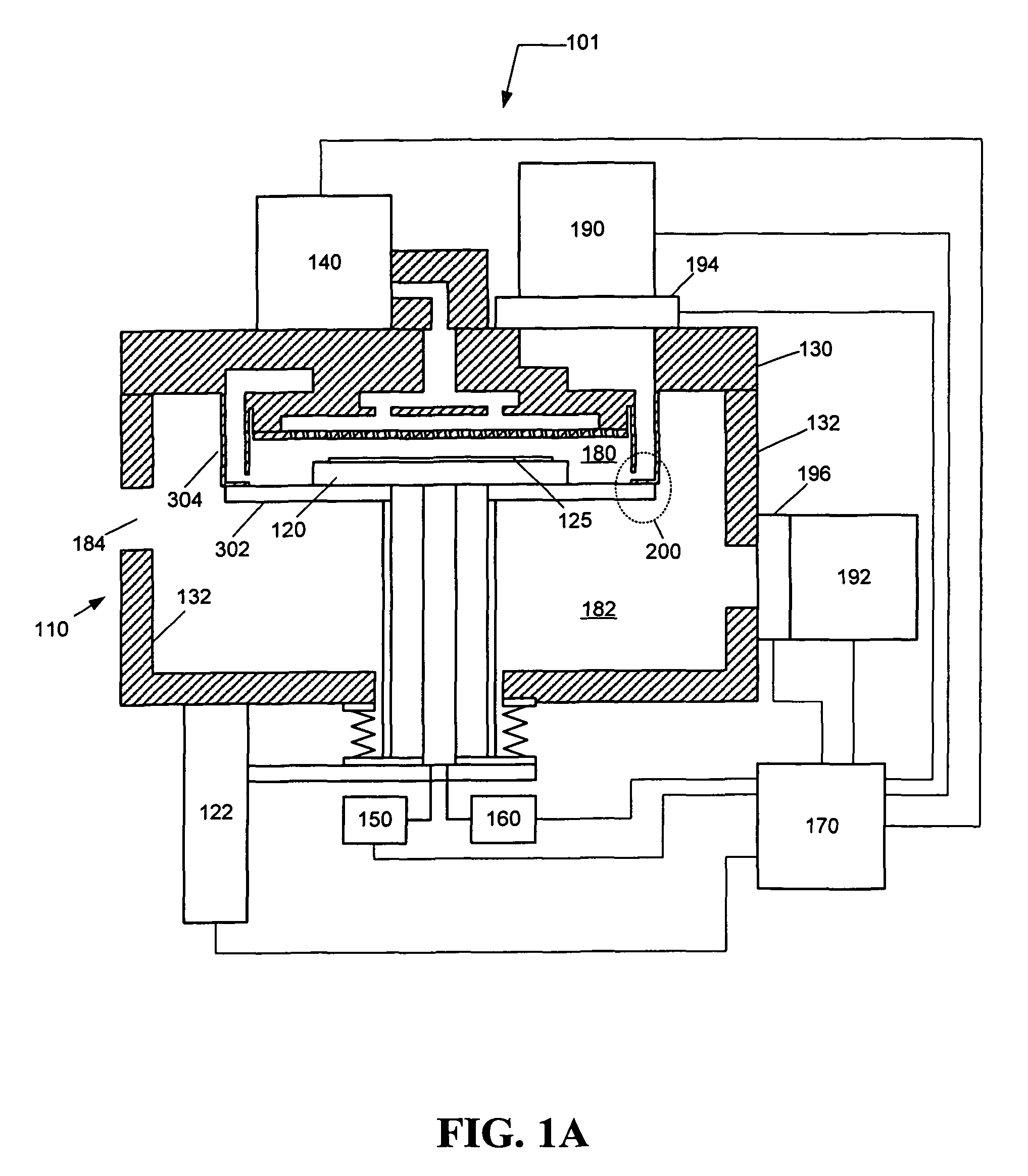

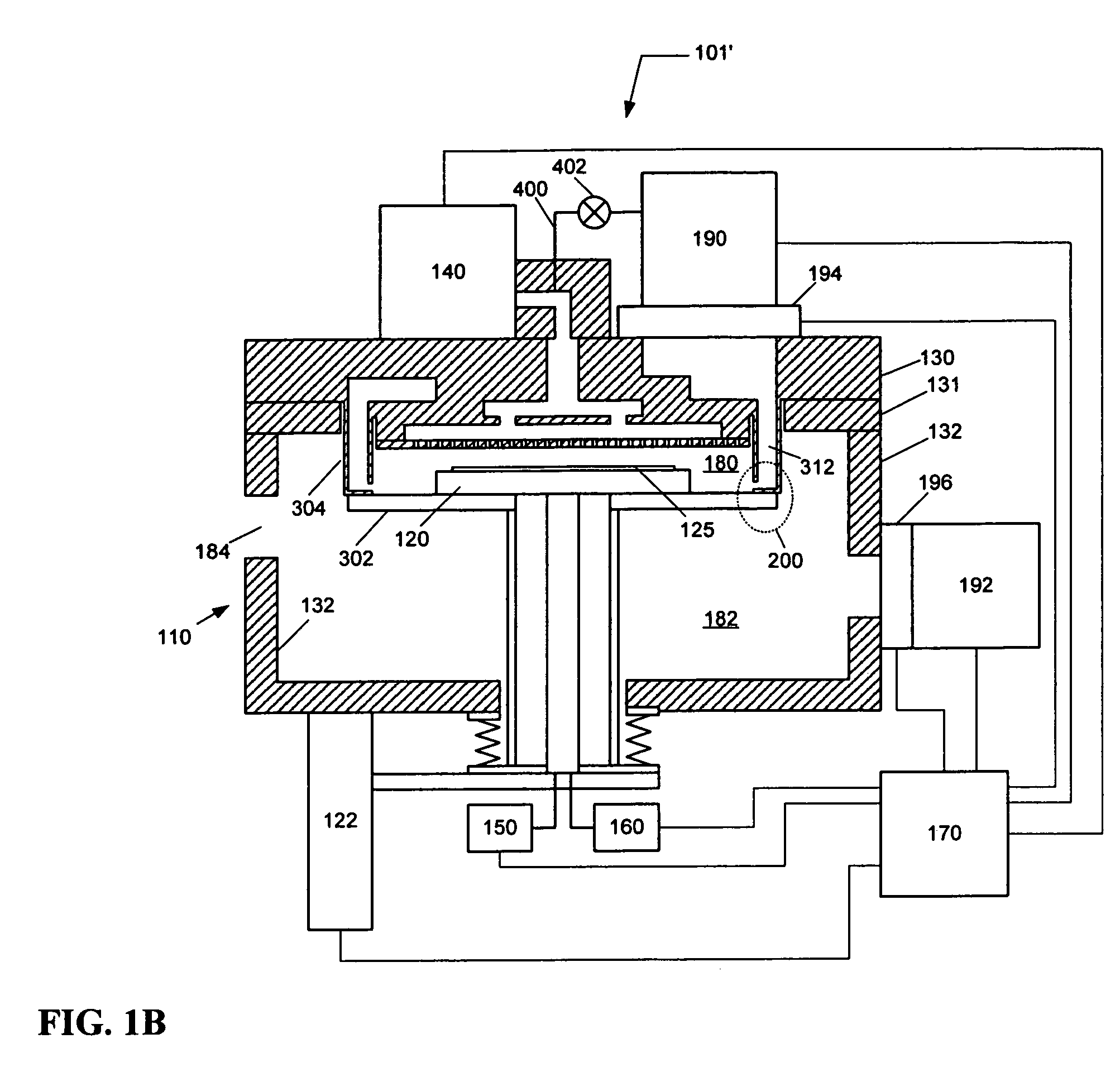

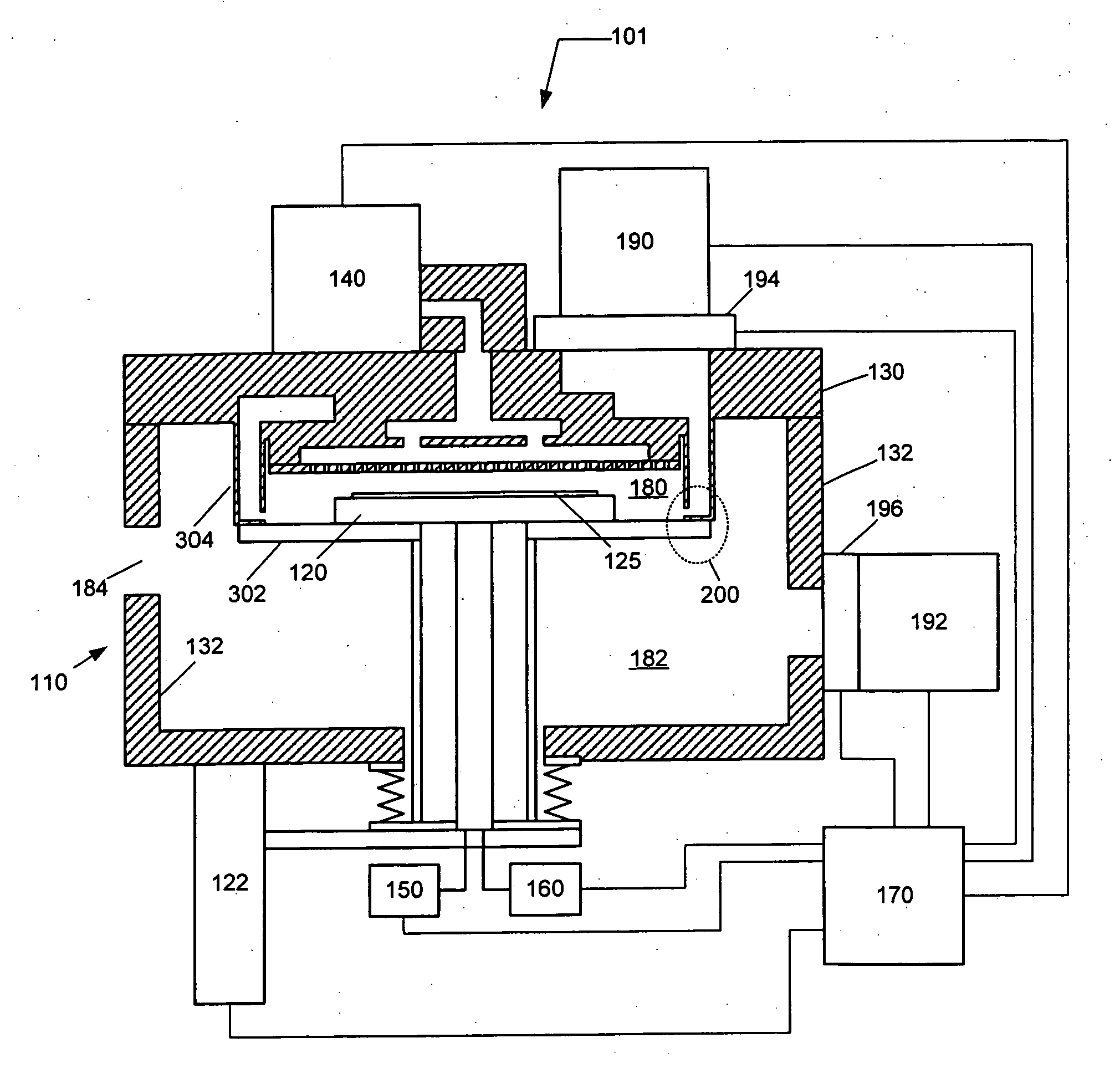

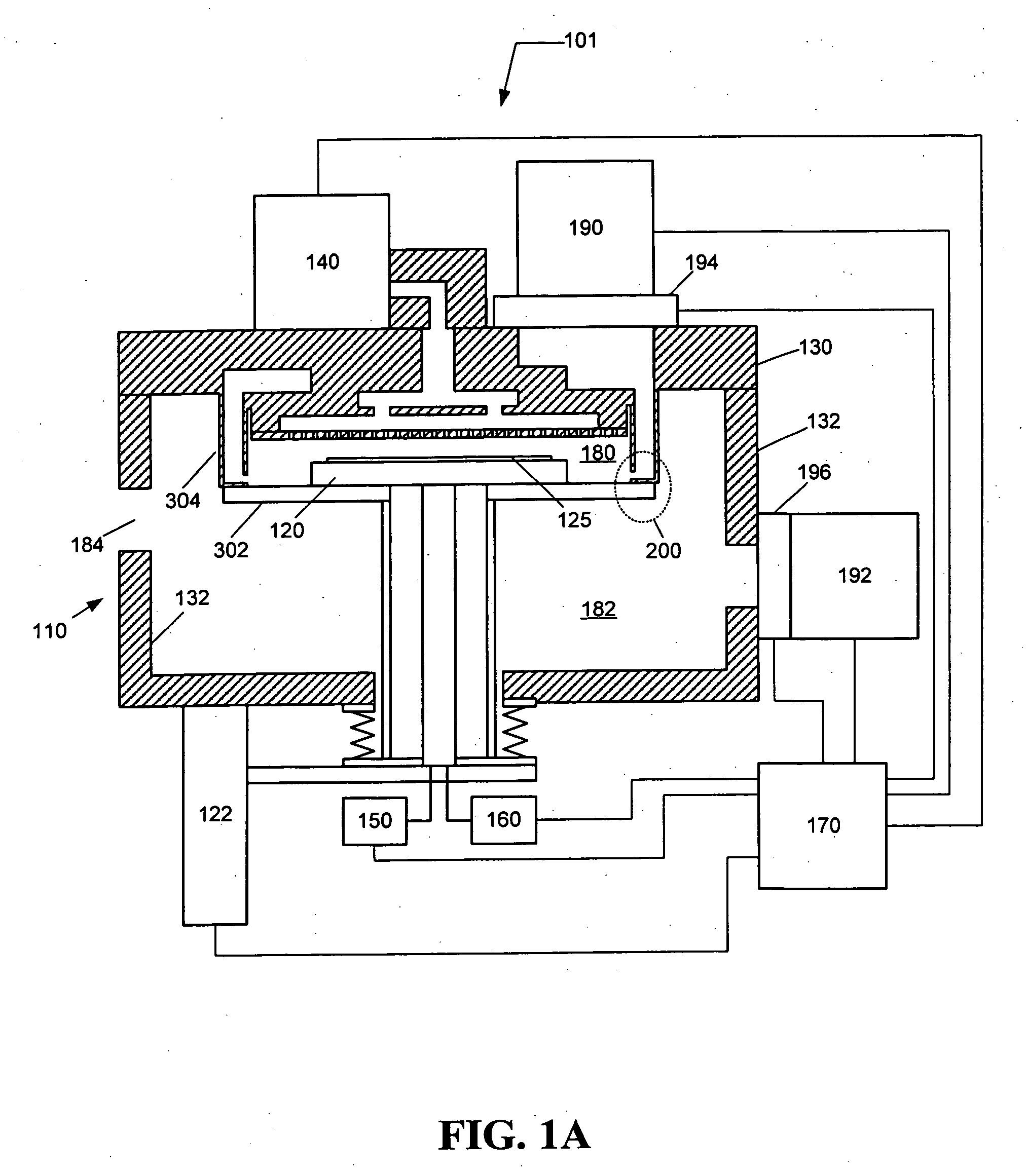

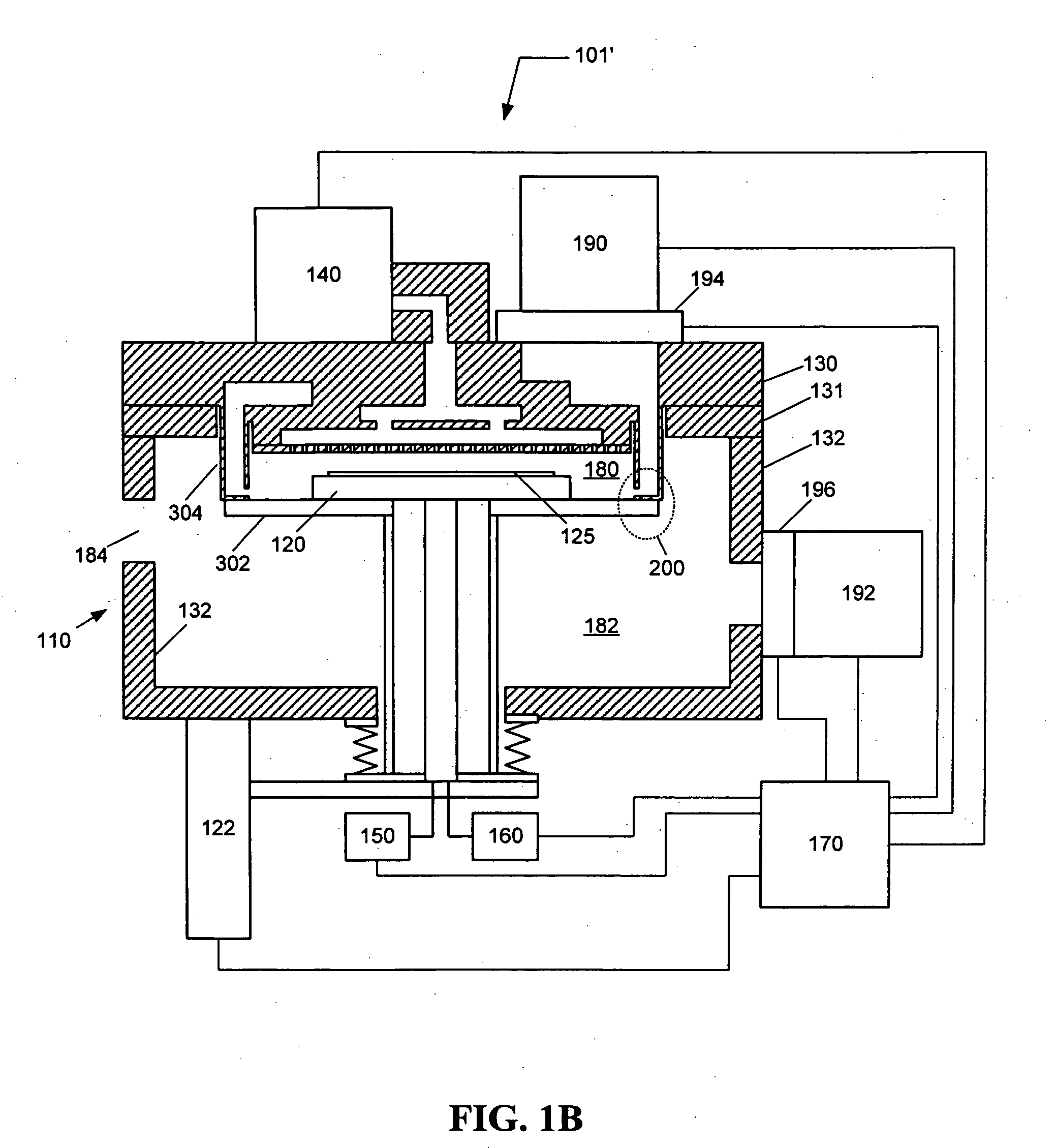

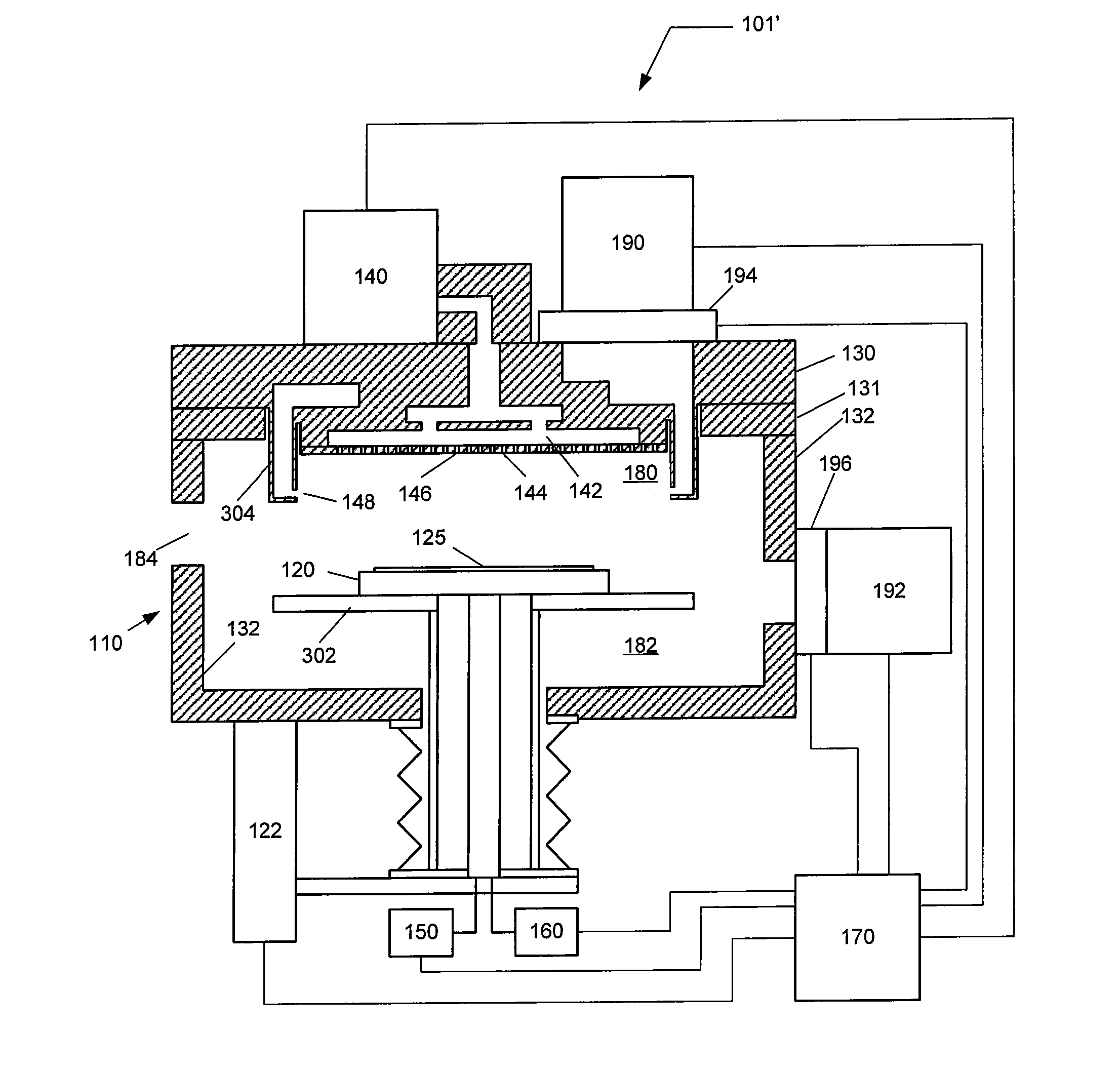

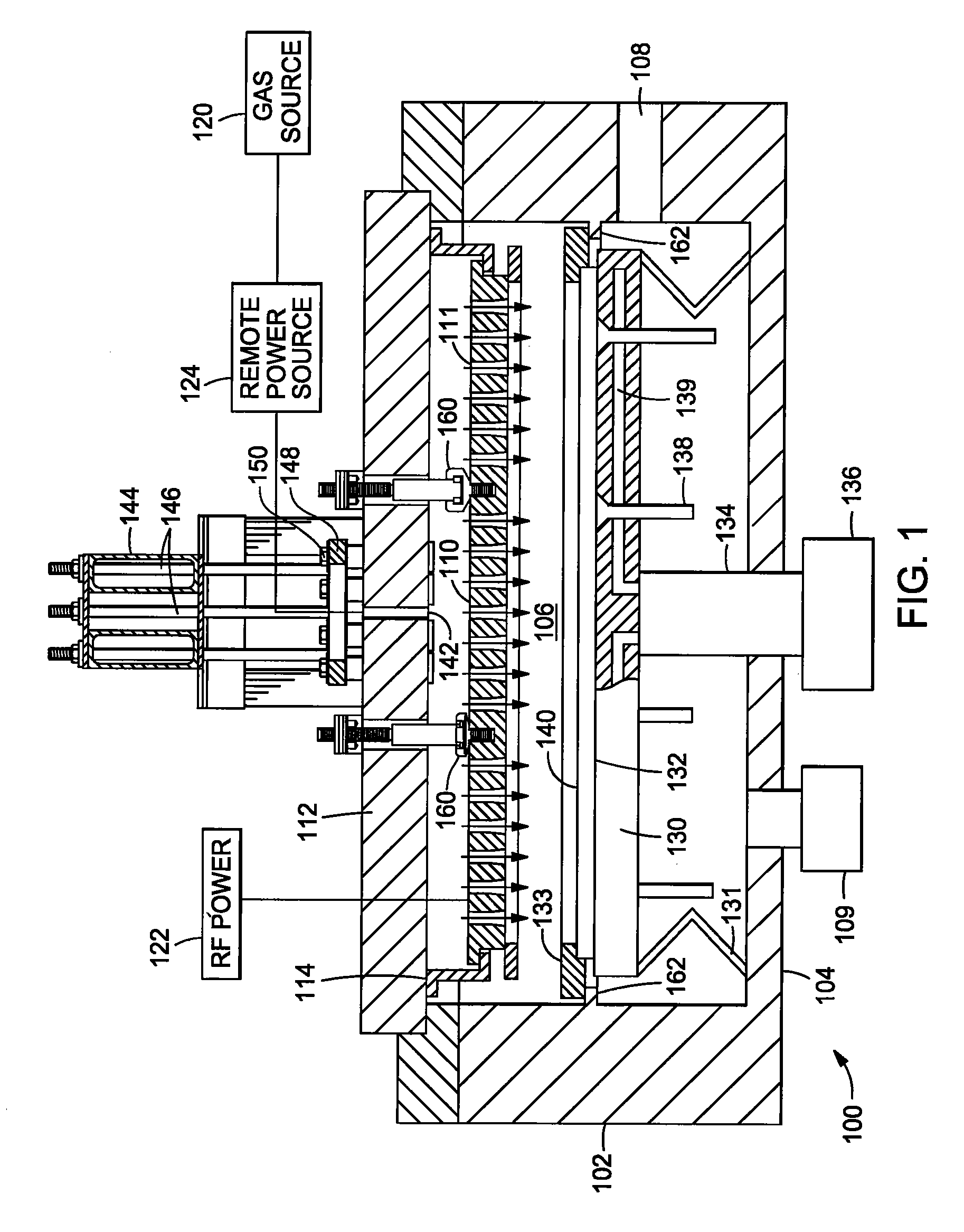

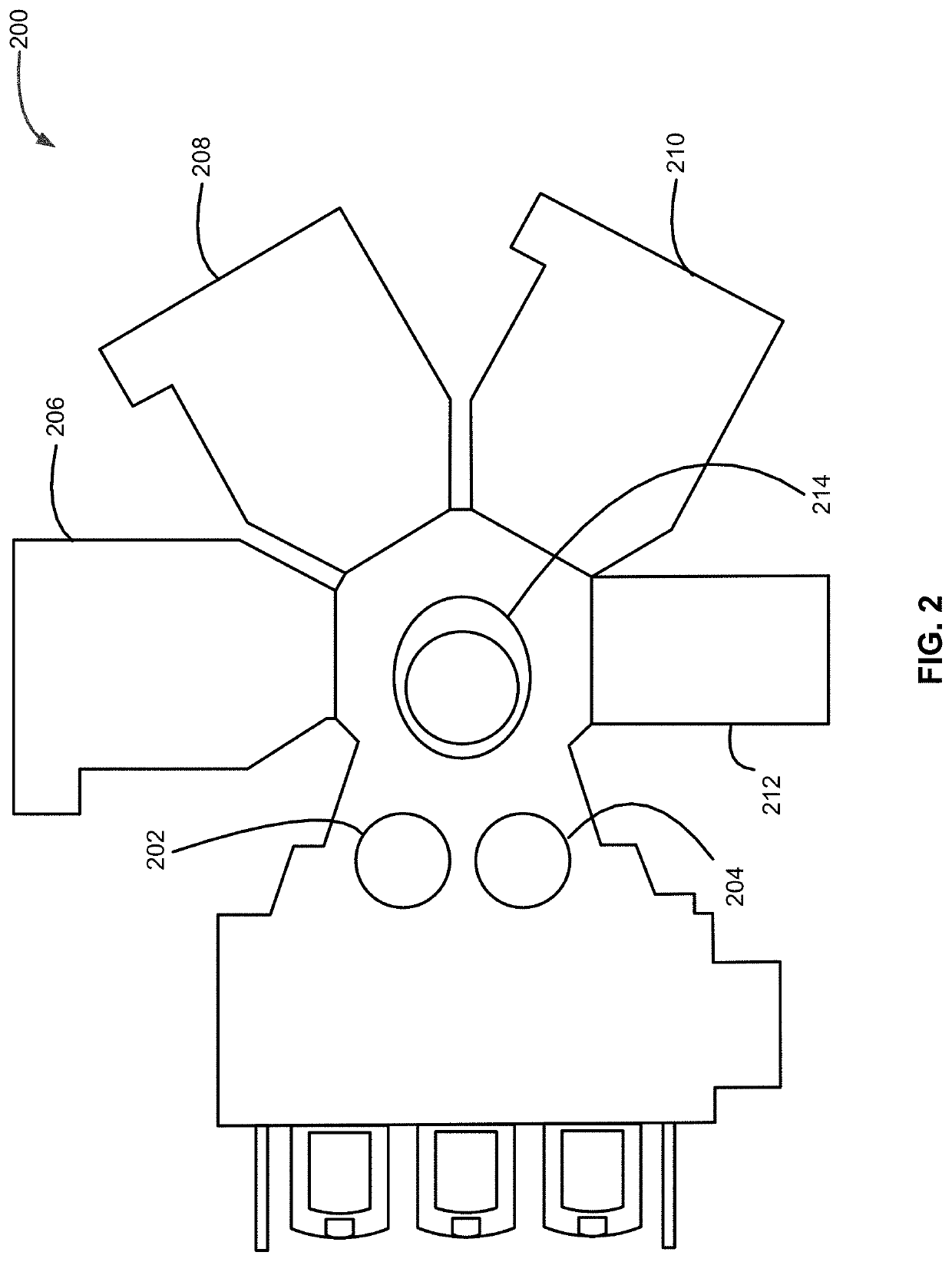

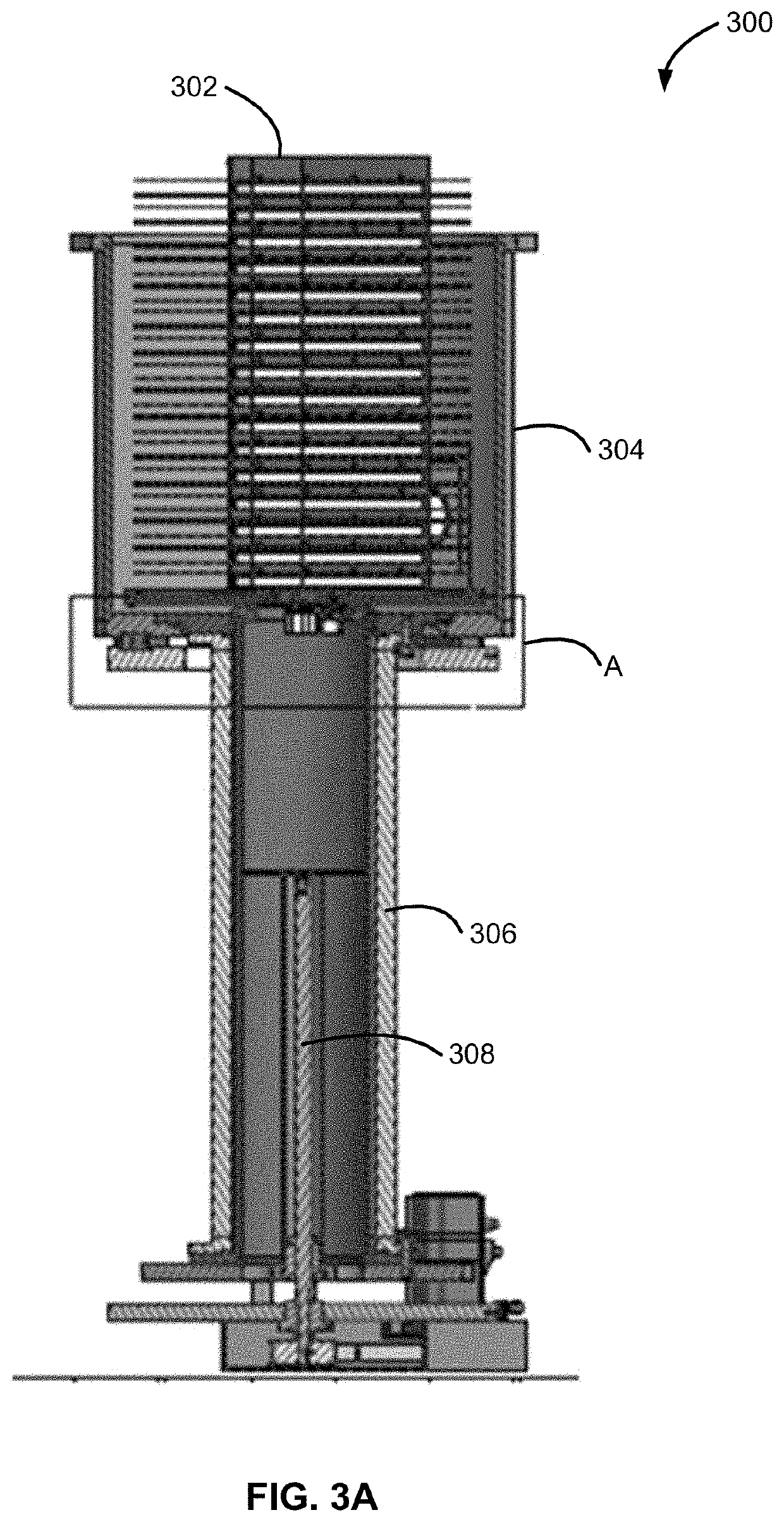

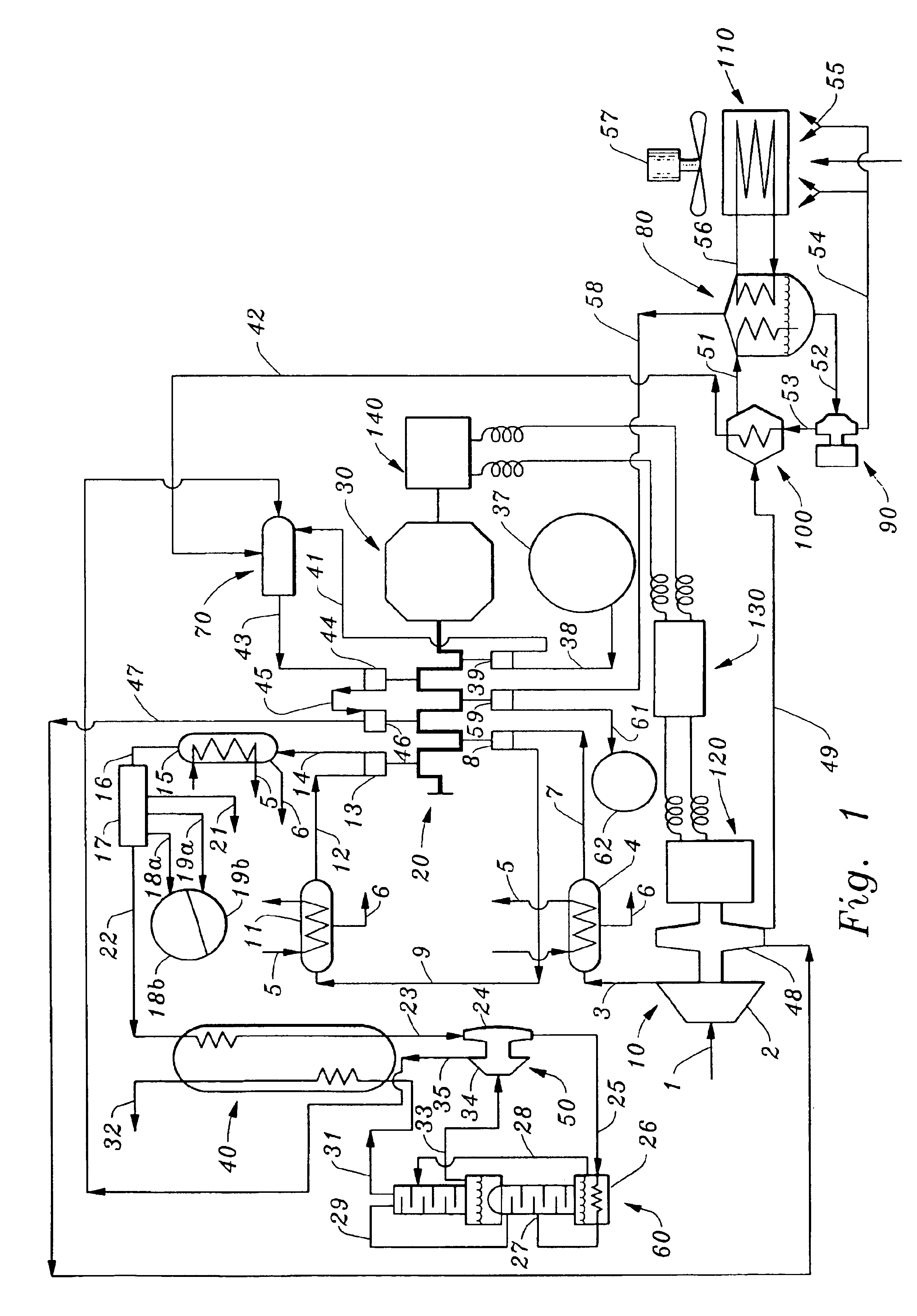

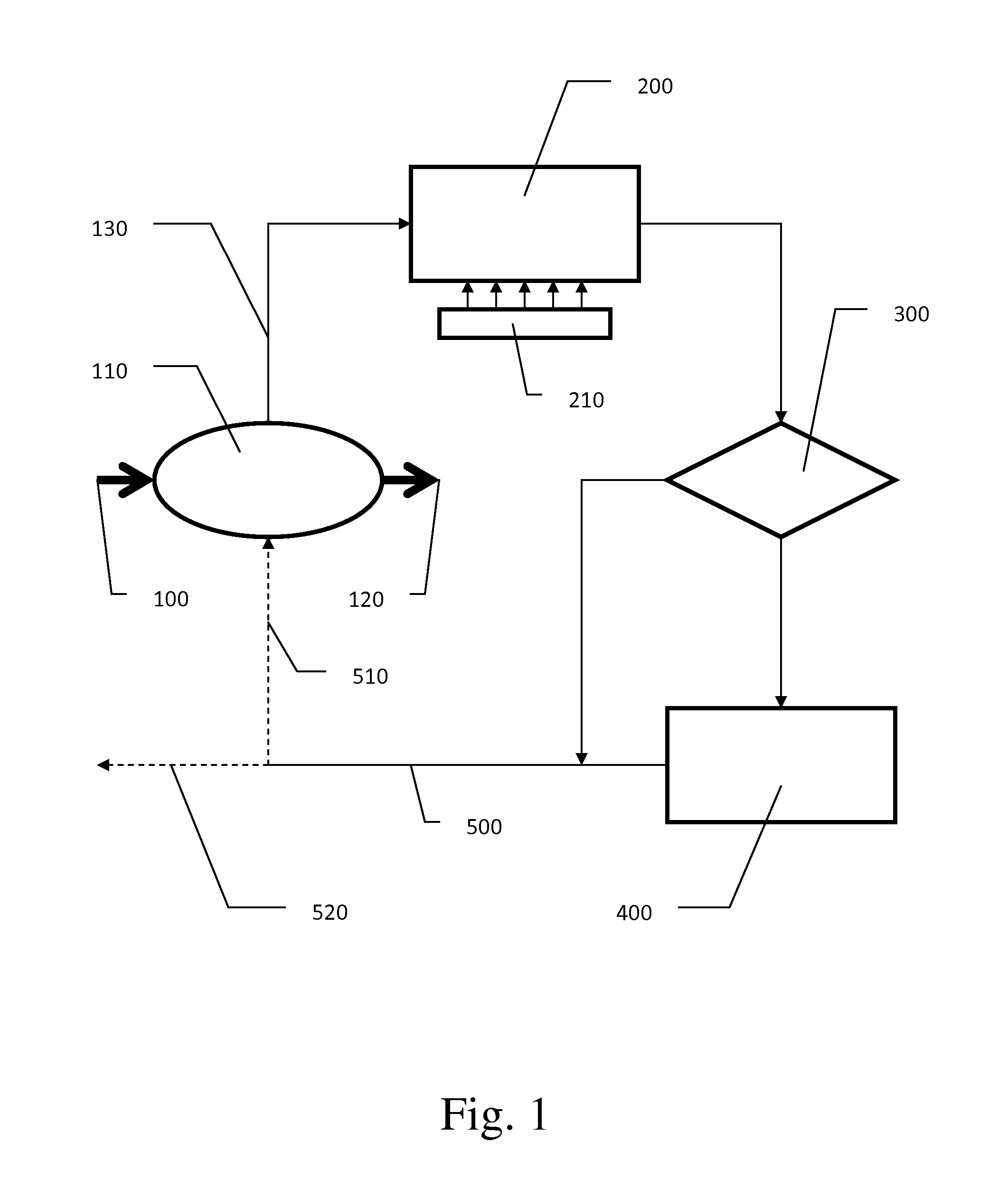

Apparatus for thermal and plasma enhanced vapor deposition and method of operating

InactiveUS20070116873A1Reduce pollutionElectric discharge tubesSemiconductor/solid-state device manufacturingGas phaseProcess engineering

A method, computer readable medium, and system for vapor deposition on a substrate that maintain a first assembly of the vapor deposition system at a first temperature, maintain a second assembly of the vapor deposition system at a reduced temperature lower than the first temperature, dispose the substrate in a process space of the first assembly that is vacuum isolated from a transfer space in the second assembly, and deposit a material on the substrate. As such, the system includes a first assembly having a process space configured to facilitate material deposition, a second assembly coupled to the first assembly and having a transfer space to facilitate transfer of the substrate into and out of the deposition system, a substrate stage connected to the second assembly and configured to support the substrate, and a sealing assembly configured to separate the process space from the transfer space. The first assembly is configured to be maintained at a first temperature and the second assembly is configured to be maintained at a reduced temperature lower than the first temperature.

Owner:TOKYO ELECTRON LTD

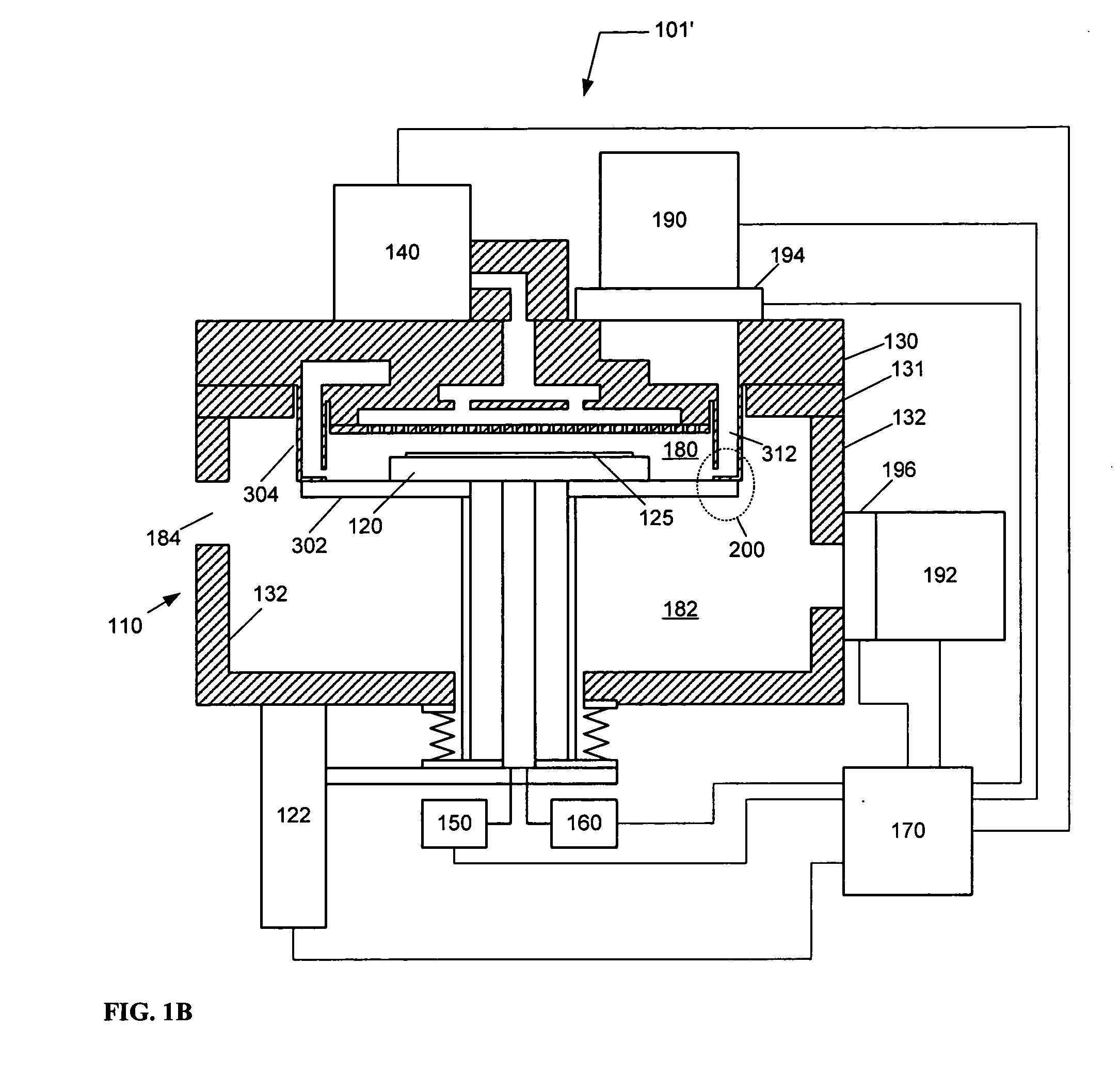

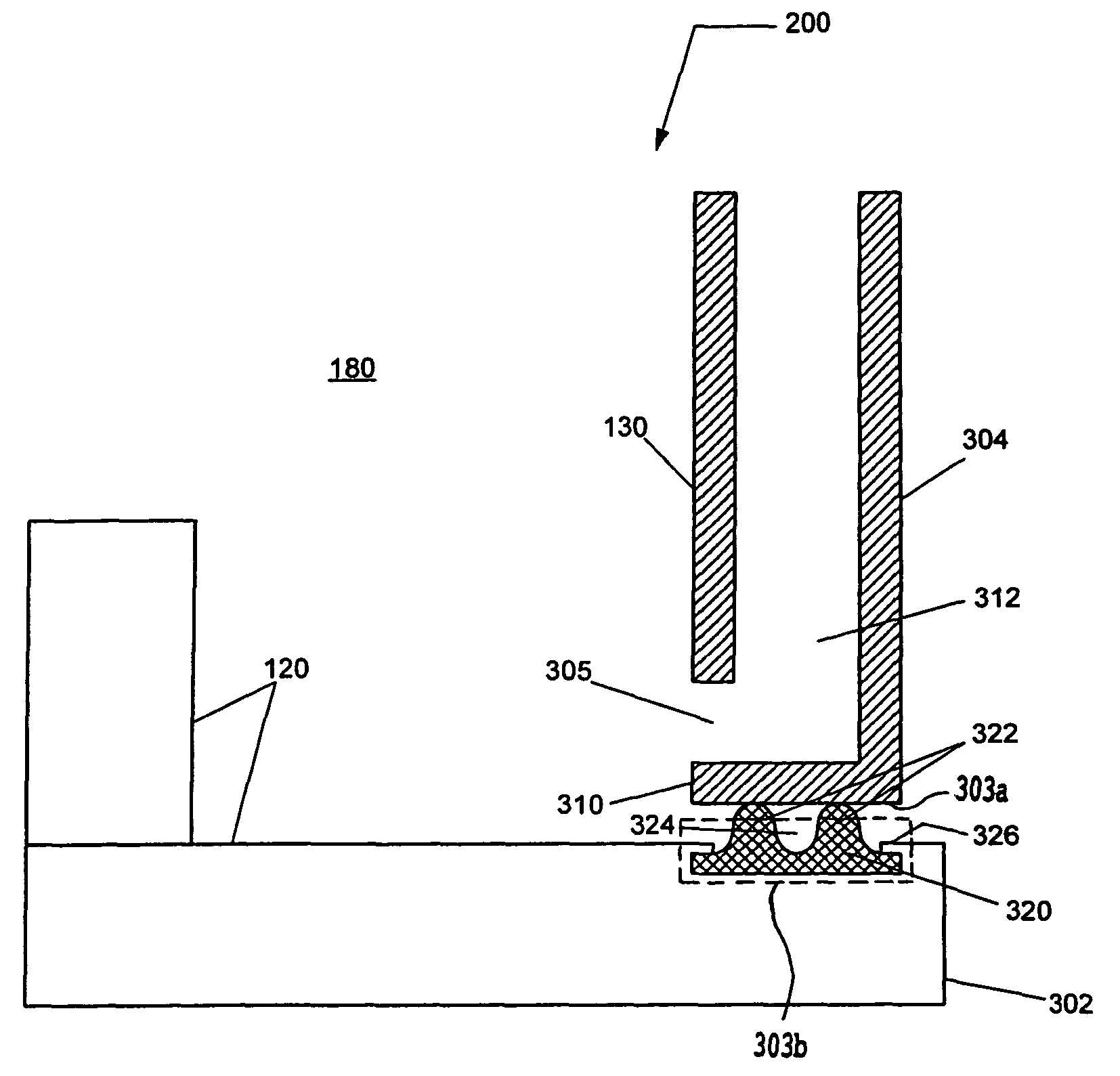

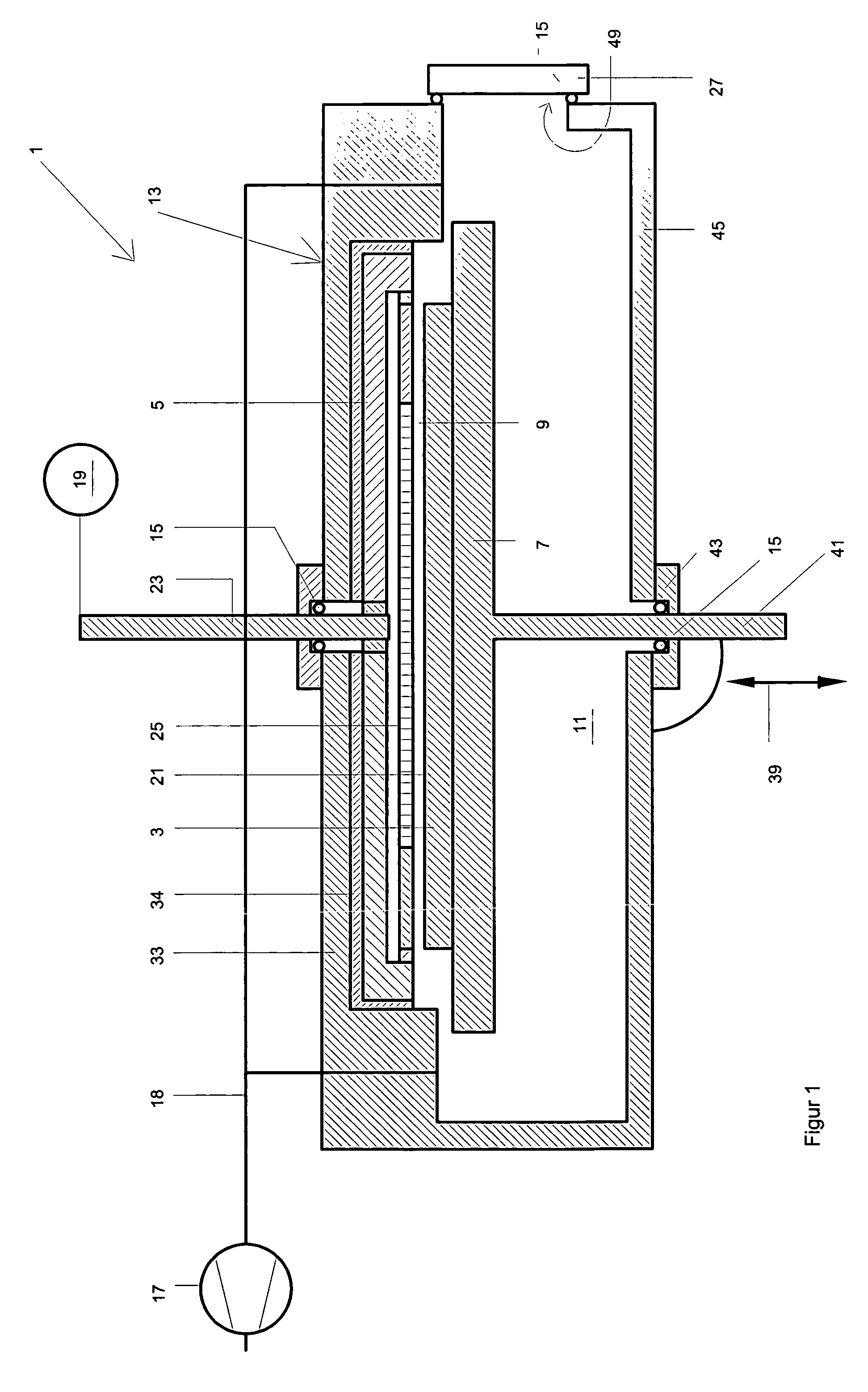

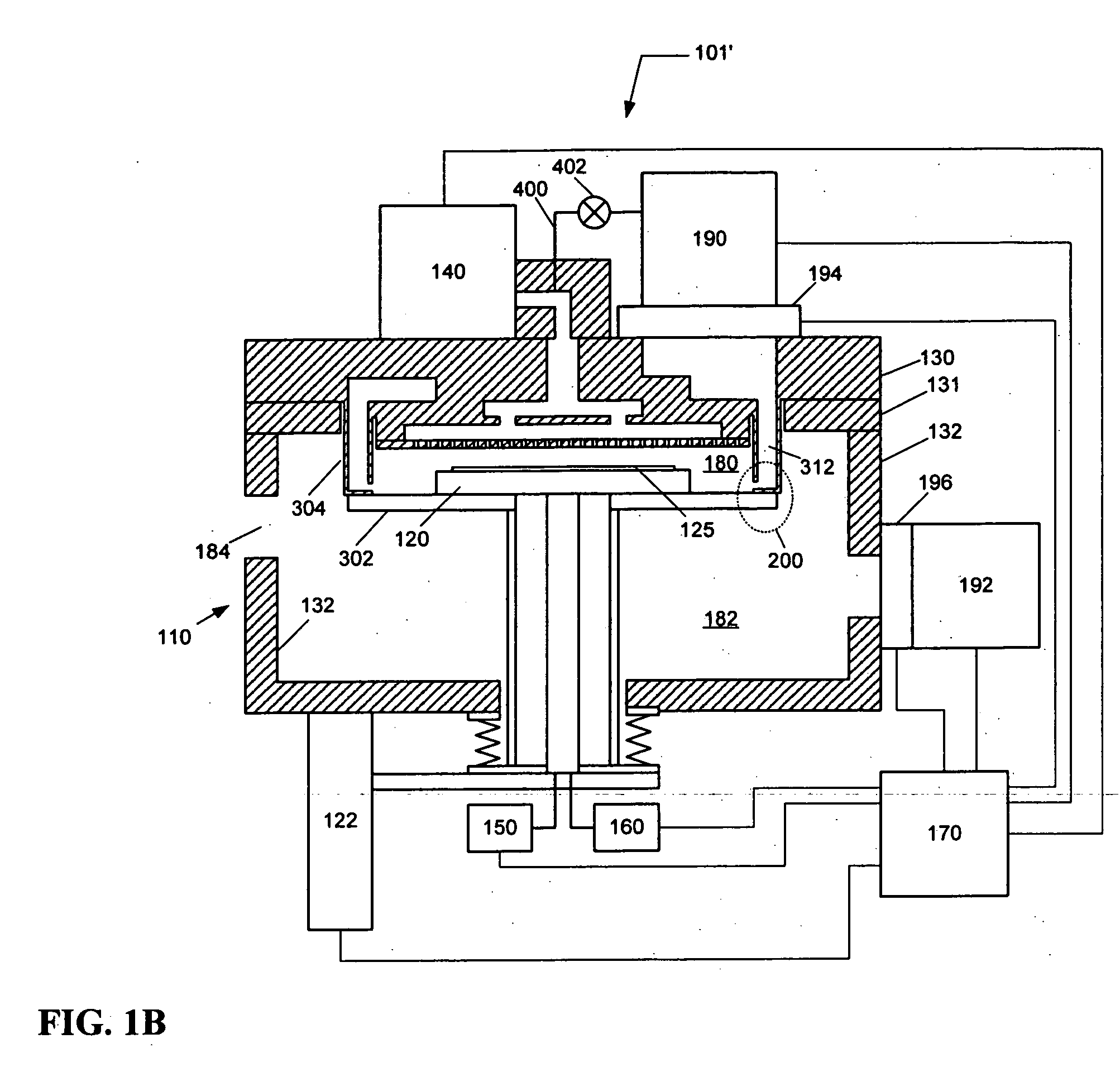

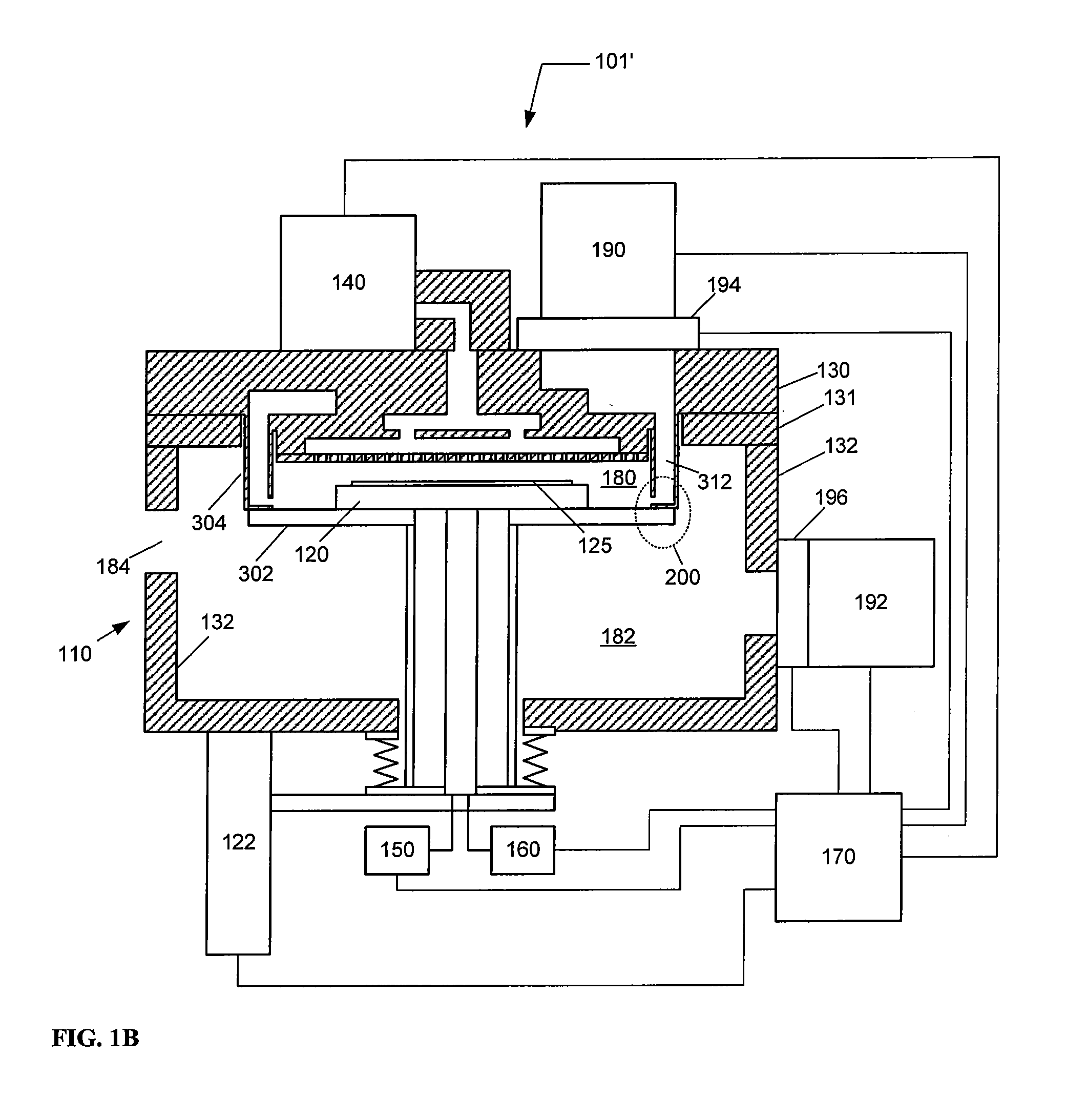

Sealing device and method for a processing system

InactiveUS20070209590A1Reduce pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

A method, computer readable medium, and system for treating a substrate in a process space of a processing system that is vacuum isolated from a transfer space of the processing system is described. A sealing device is disposed between a first chamber assembly configured to define the process space and a second chamber assembly configured to define the transfer space. When the sealing device is engaged, vacuum isolation is provided between the process space and the transfer space. The sealing device comprises two or more contact ridges with one or more pockets formed therebetween. When the sealing device is engaged between the first chamber assembly and the second chamber assembly, gas is trapped in the one or more pockets. This trapped gas assists the release of the sealing device upon disengagement of the sealing device between the first chamber assembly and the second chamber assembly.

Owner:TOKYO ELECTRON LTD

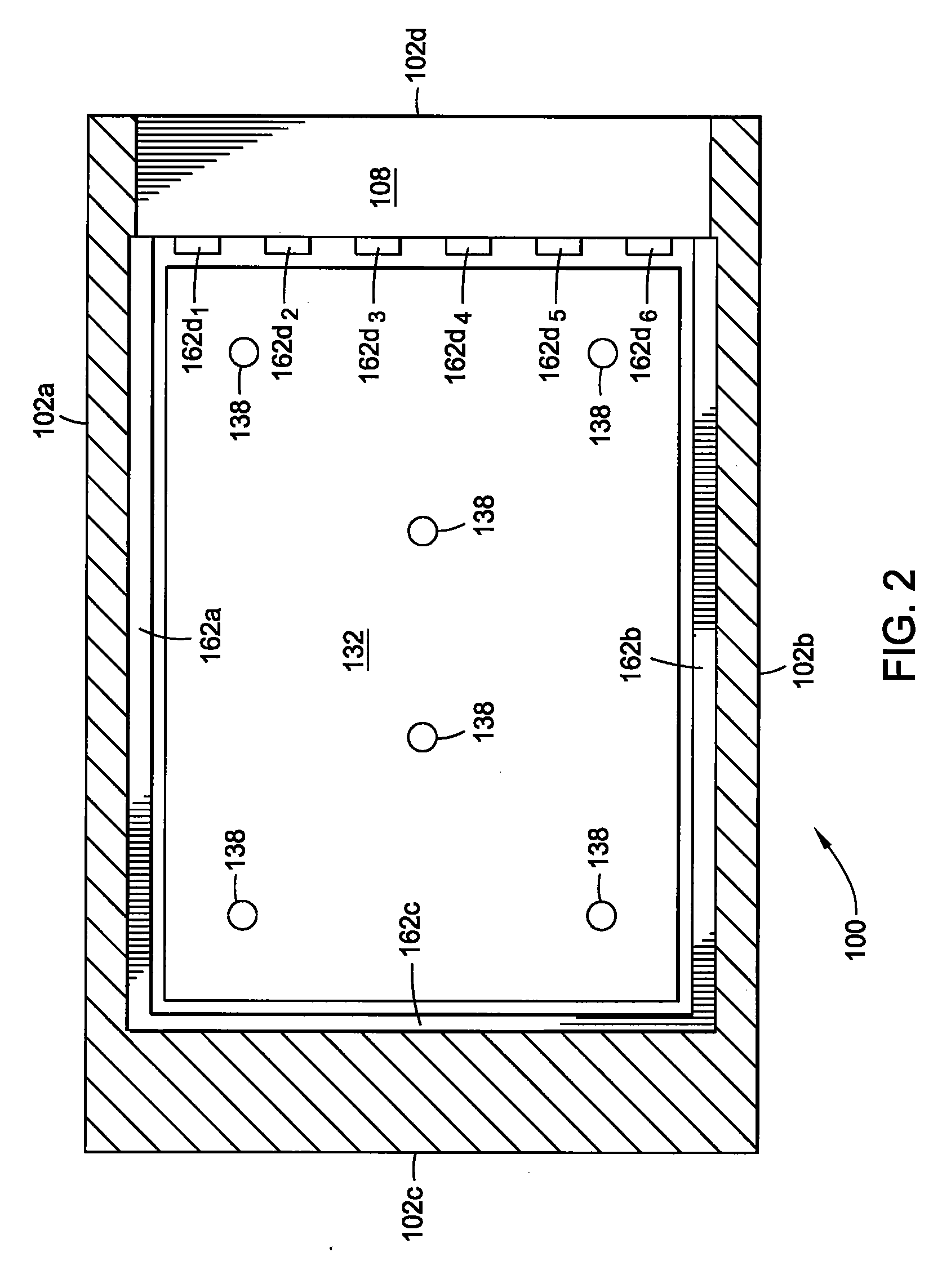

Exhaust apparatus configured to reduce particle contamination in a deposition system

InactiveUS7740705B2Reduce pollutionUniform processingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseEngineering

Owner:TOKYO ELECTRON LTD

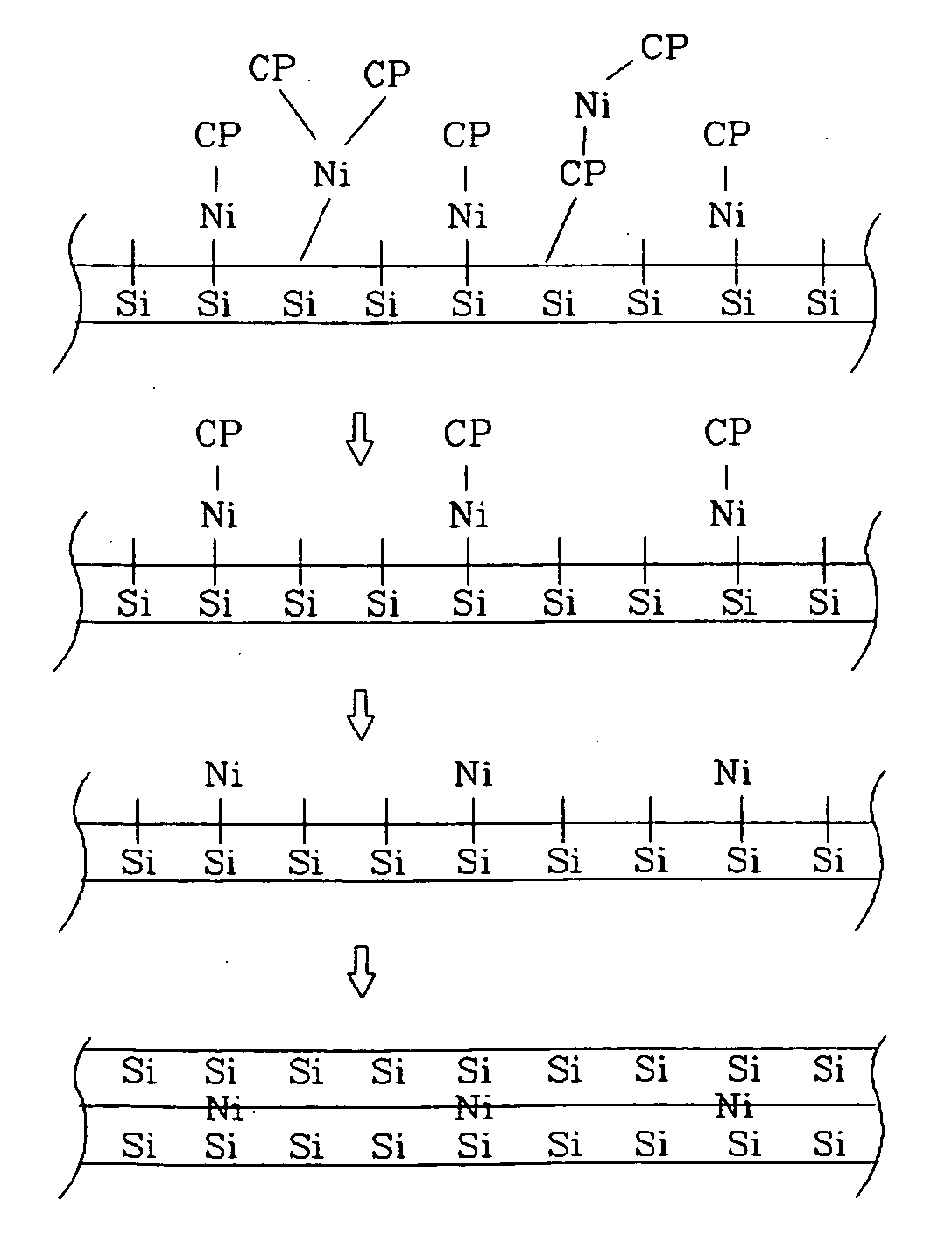

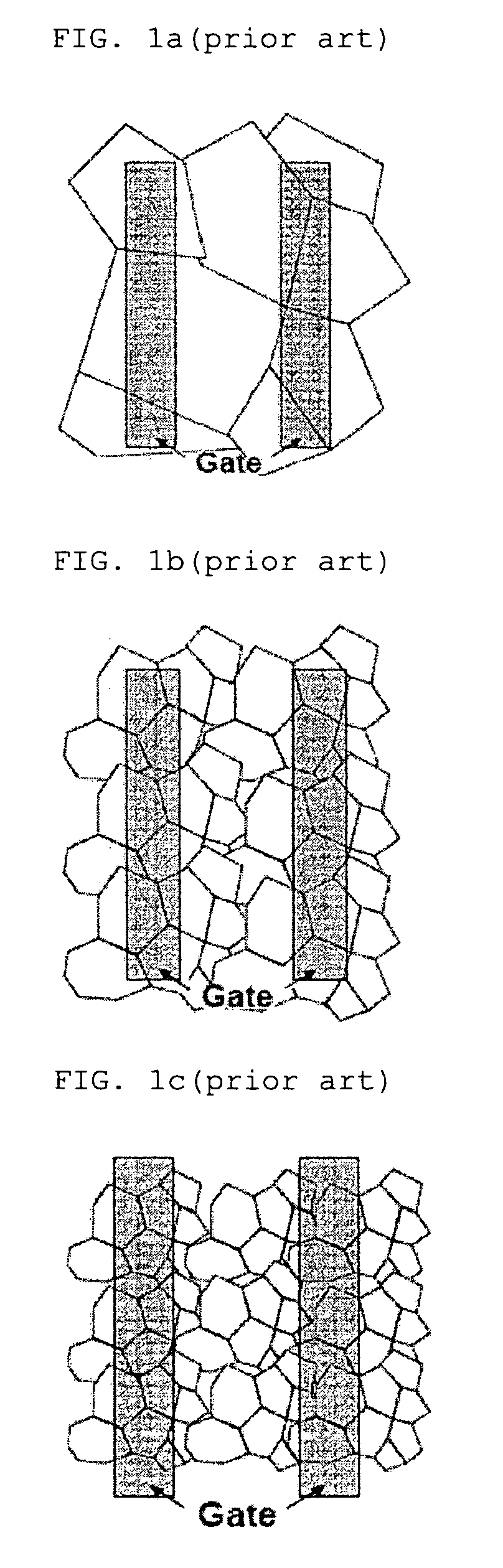

Apparatus and method for forming polycrystalline silicon thin film

ActiveUS20070054499A1Increase the rate of crystallizationDecrease in crystallization temperatureAfter-treatment apparatusSemiconductor/solid-state device manufacturingGas phaseAmorphous silicon

Apparatus and method for forming a polycrystalline silicon thin film by converting an amorphous silicon thin film into the polycrystalline silicon thin film using a metal are provided. The method includes: a metal nucleus adsorbing step of introducing a vapor phase metal compound into a process space where the glass substrate having the amorphous silicon formed thereon is disposed, to adsorb a metal nucleus contained in the metal compound into the amorphous silicon layer; a metal nucleus distribution region-forming step of forming a community region including a plurality of silicon particles every metal nucleus in a plane boundary region occupied by the metal compound by a self-limited mechanism due to the adsorption of the metal nucleus; and an excess gas removing step of purging and removing an excess gas which is not adsorbed in the metal nucleus distribution region-forming step.

Owner:WONIK IPS CO LTD

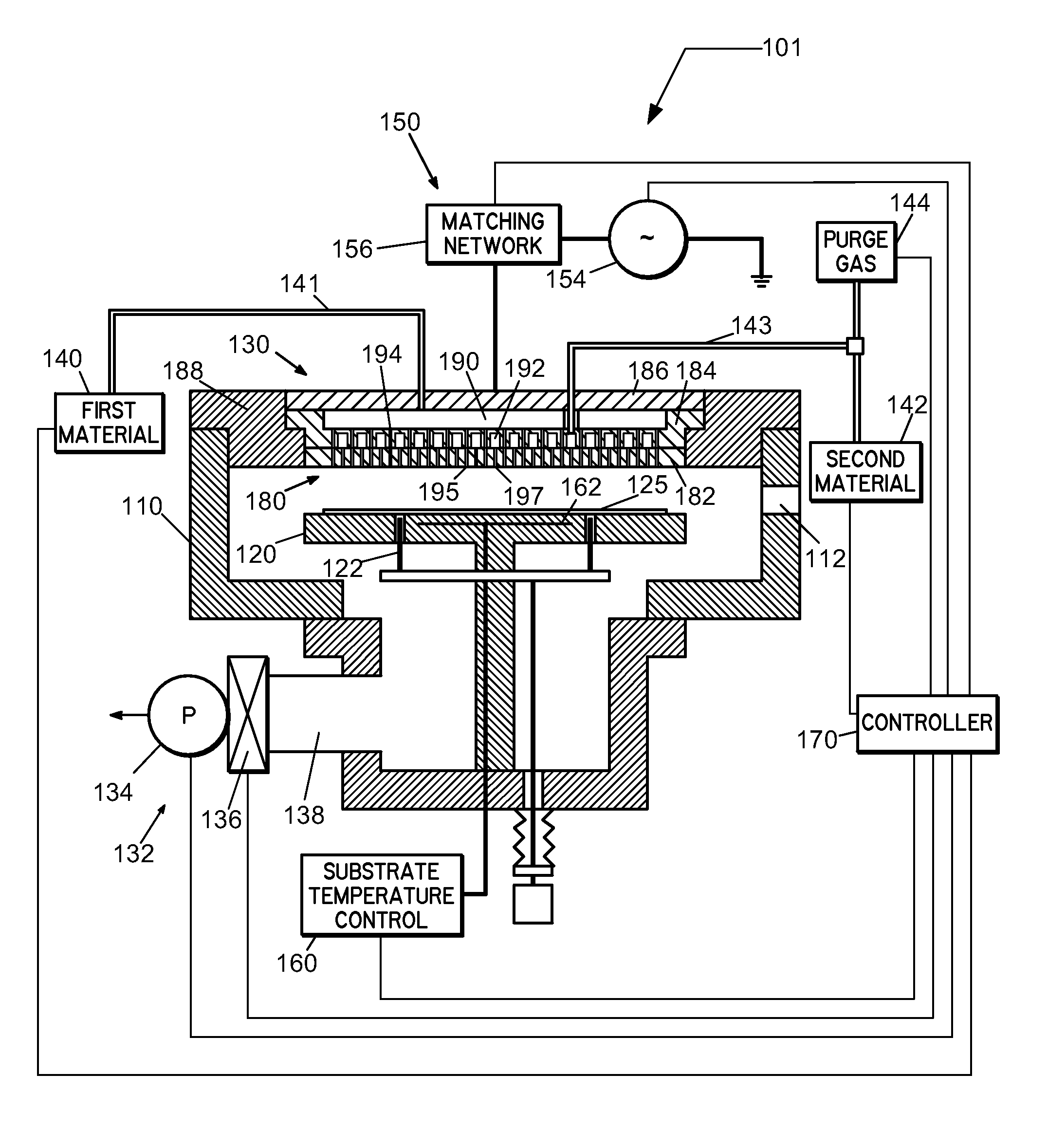

Plasma enhanced atomic layer deposition system having reduced contamination

ActiveUS7422636B2Reduce pollutionEnhance layeringLiquid surface applicatorsSemiconductor/solid-state device manufacturingAtomic layer depositionContamination

A plasma enhanced atomic layer deposition (PEALD) system is described, wherein the system comprises a processing space and a high vacuum, ultra-clean transfer space. During processing, the substrate to which the thin conformal film is formed is exposed to the processing space. During substrate transfer, the substrate is exposed to the high vacuum space. Processing gases are introduced sequentially and alternately to the process chamber and the pressures and gas flows within, to and from, and between the process chamber and the high vacuum transfer space are controlled to keep the transfer space ultra-clean.

Owner:TOKYO ELECTRON LTD

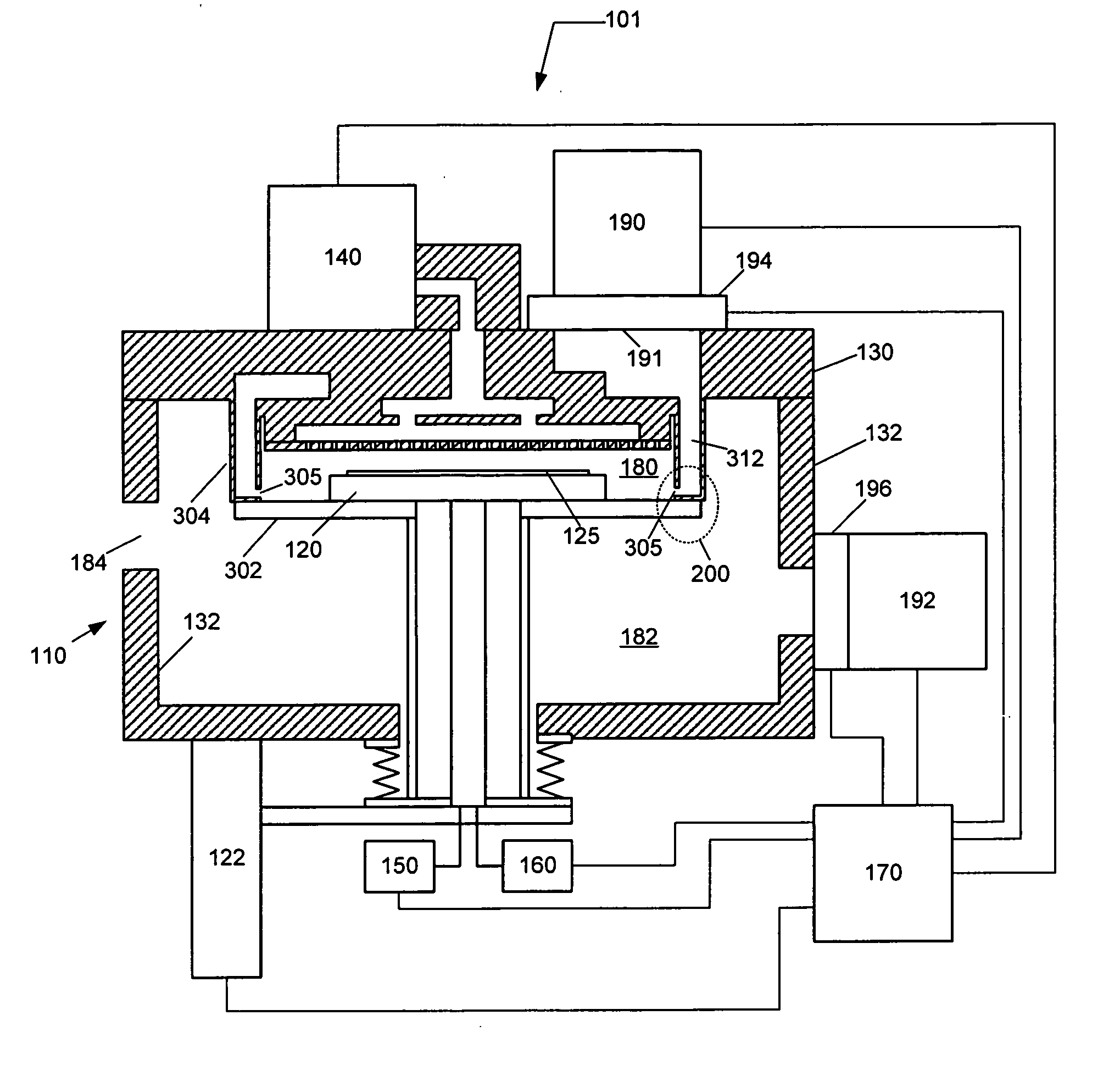

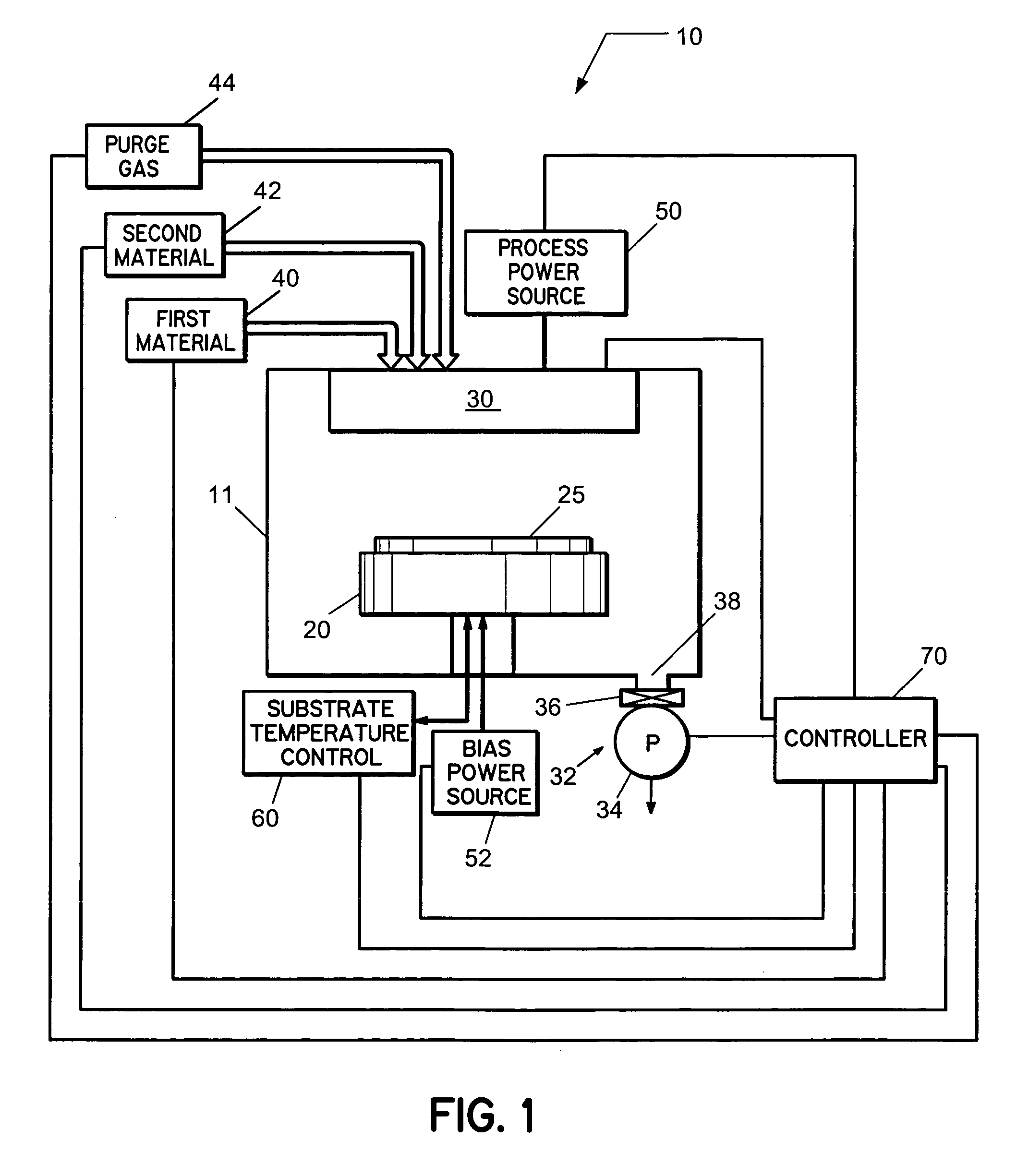

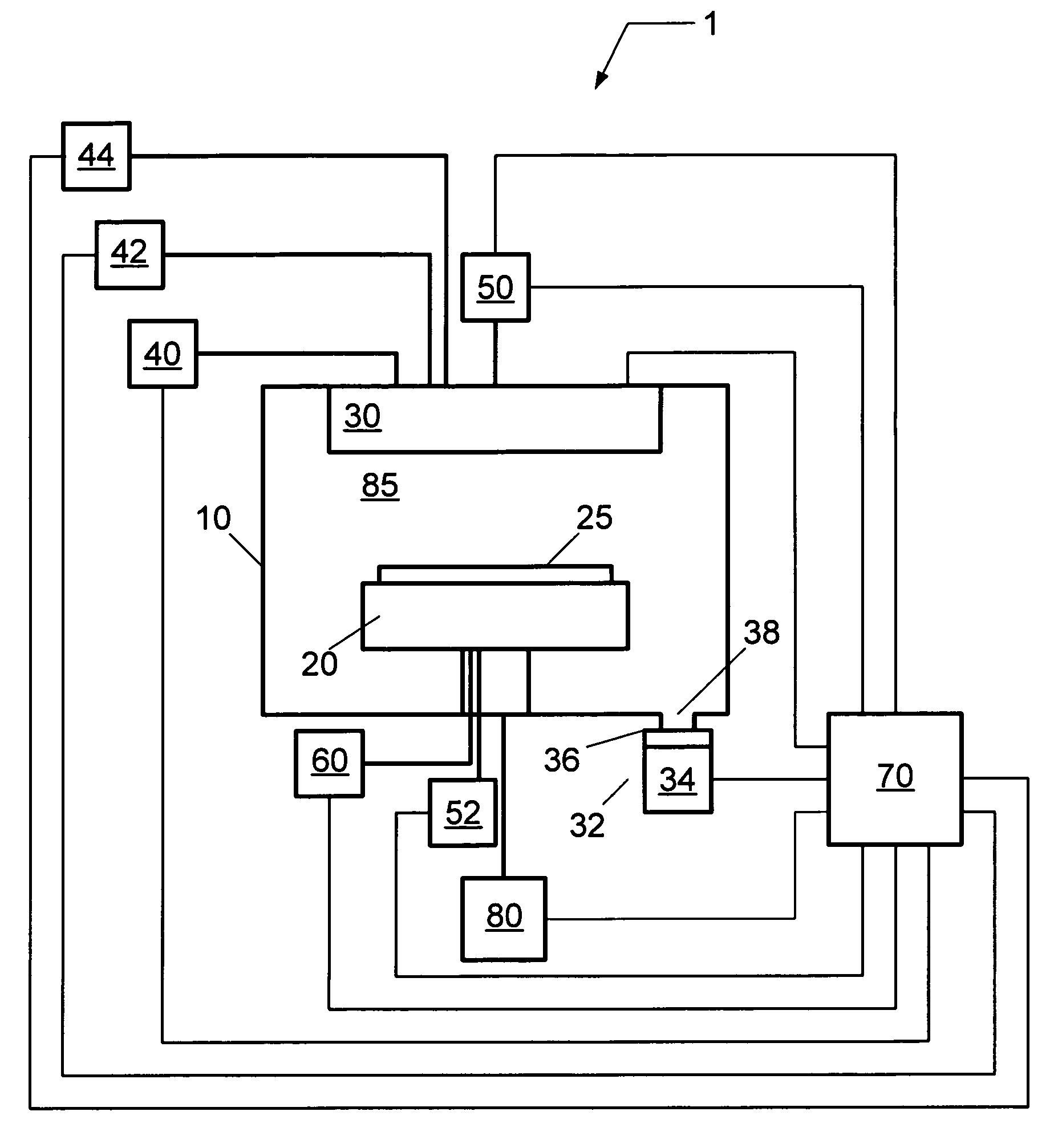

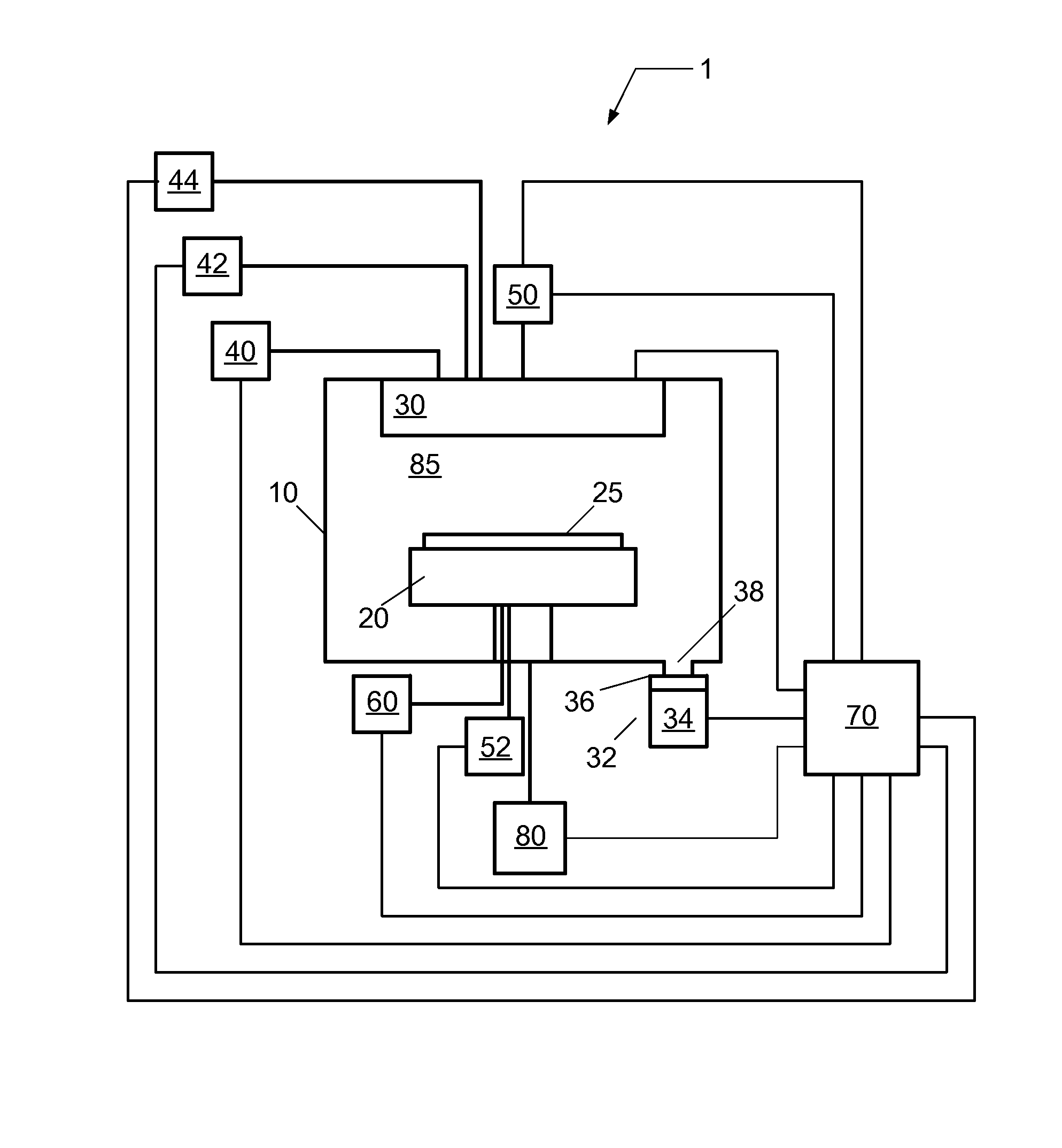

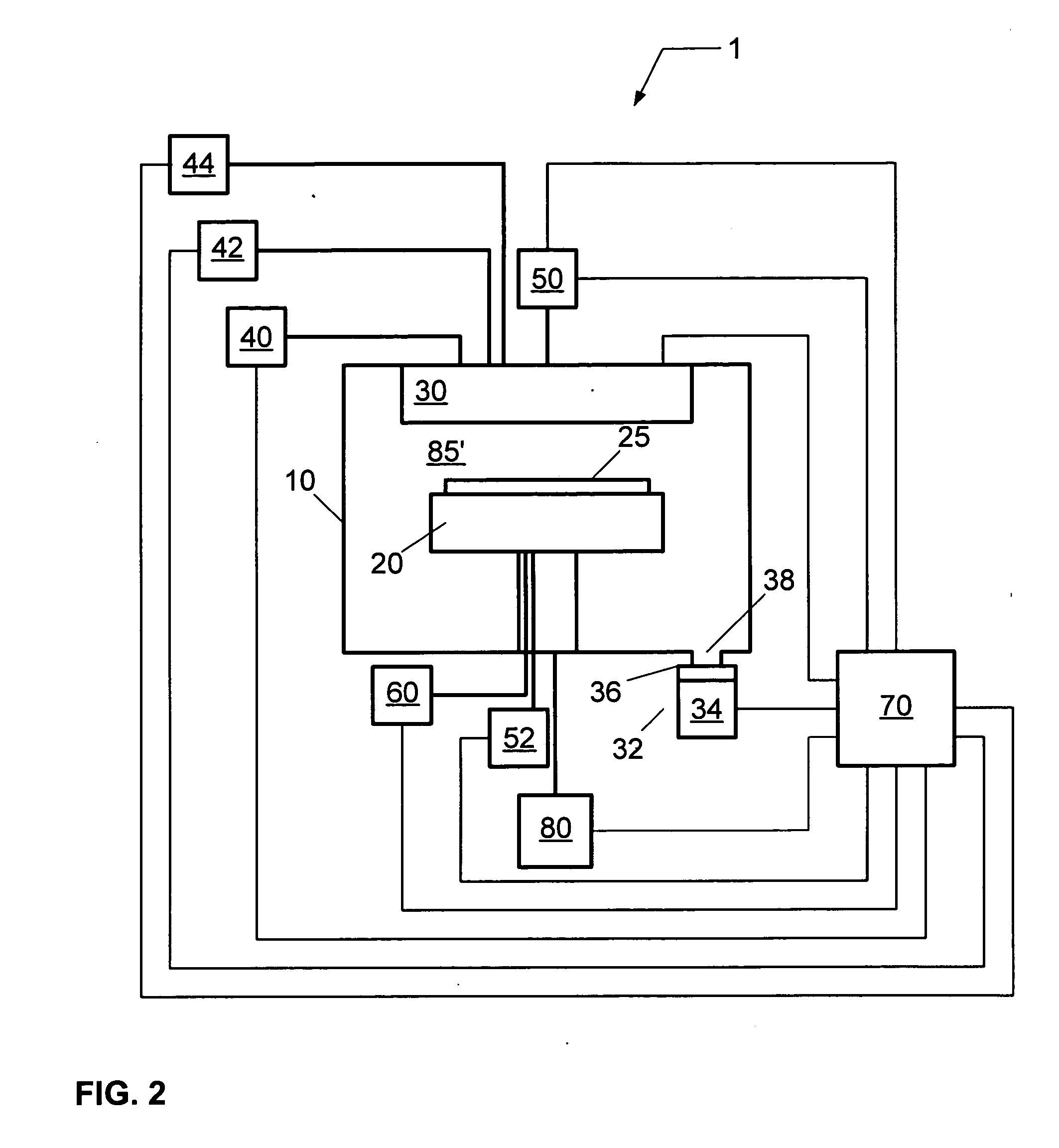

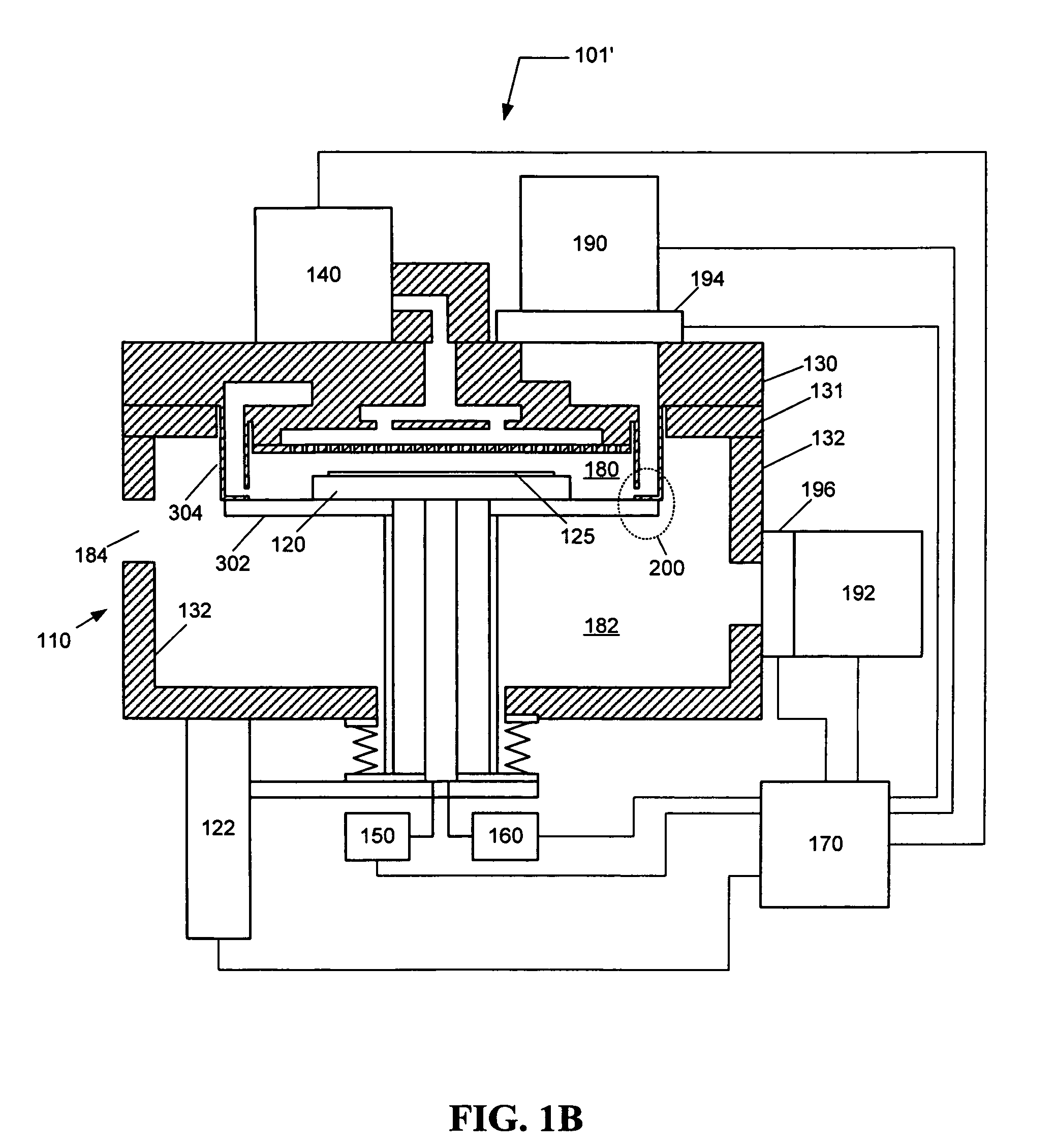

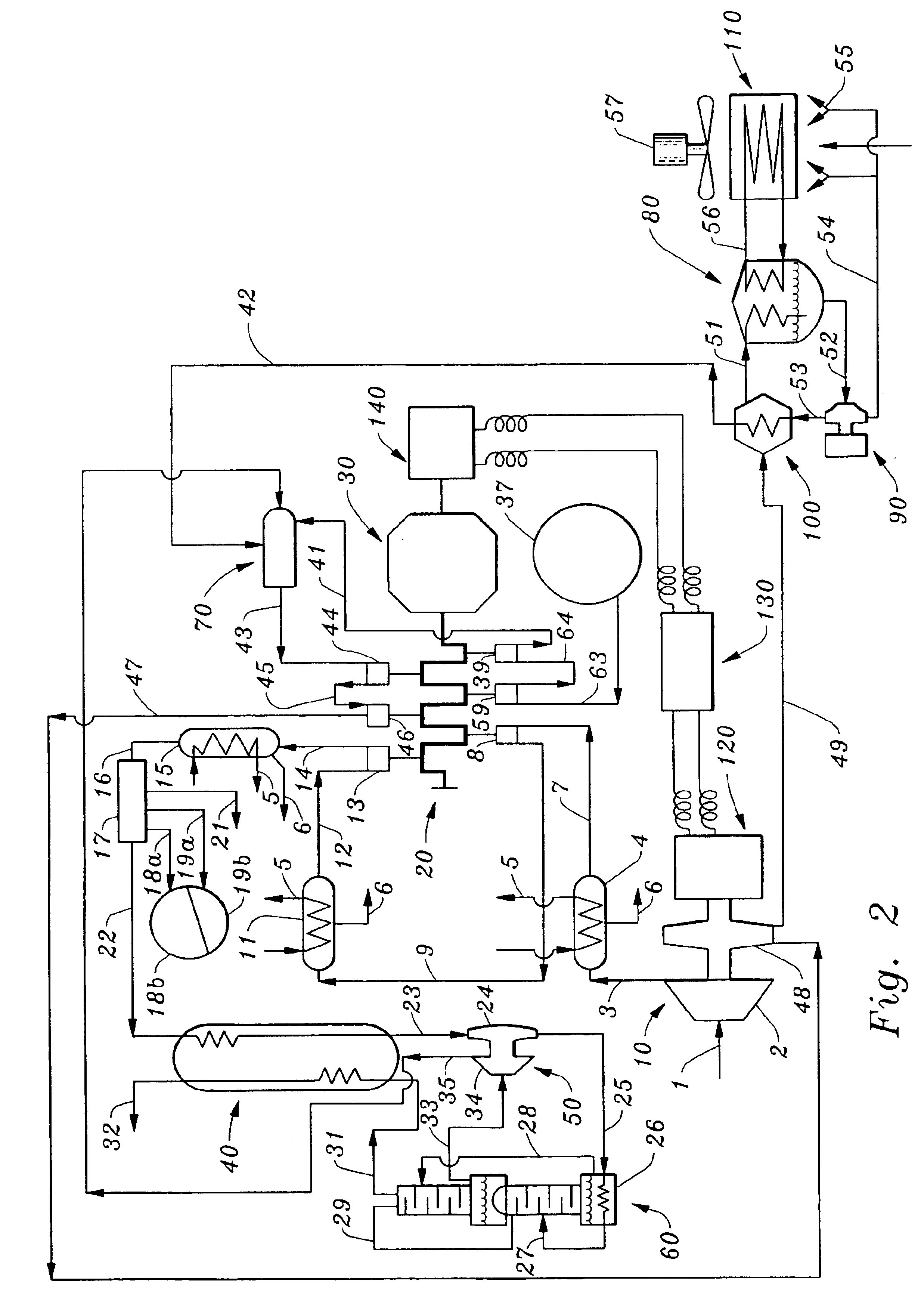

Method and system for performing plasma enhanced atomic layer deposition

InactiveUS7897217B2Reduce pollutionEnhanced reduction within the same systemElectric discharge tubesChemical vapor deposition coatingGas phaseProcess engineering

A method, computer readable medium, and system for vapor deposition on a substrate that introduce a gaseous film precursor to a process space, increase the volume of the process space from a first size to a second size to form an enlarged process space, introduce a reduction gas to the enlarged process space, and form a reduction plasma from the reduction gas. The system for vapor deposition includes a process chamber including a first process space and further including a second process space that includes the first process space and that has a second volume that exceeds the first volume. The first process space is configured for atomic layer deposition, and the second process space is configured for plasma reduction of a layer deposited in the first process space.

Owner:TOKYO ELECTRON LTD

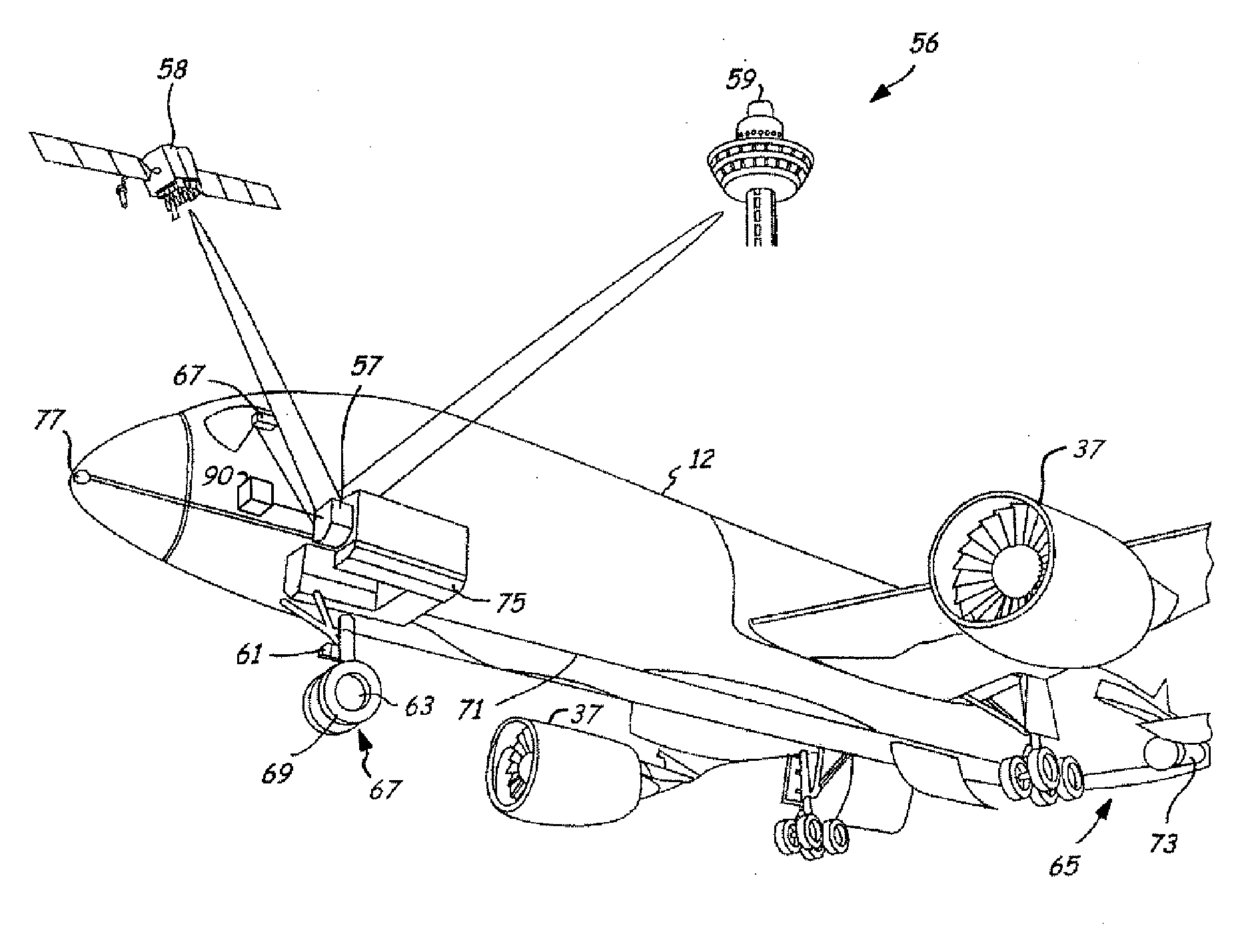

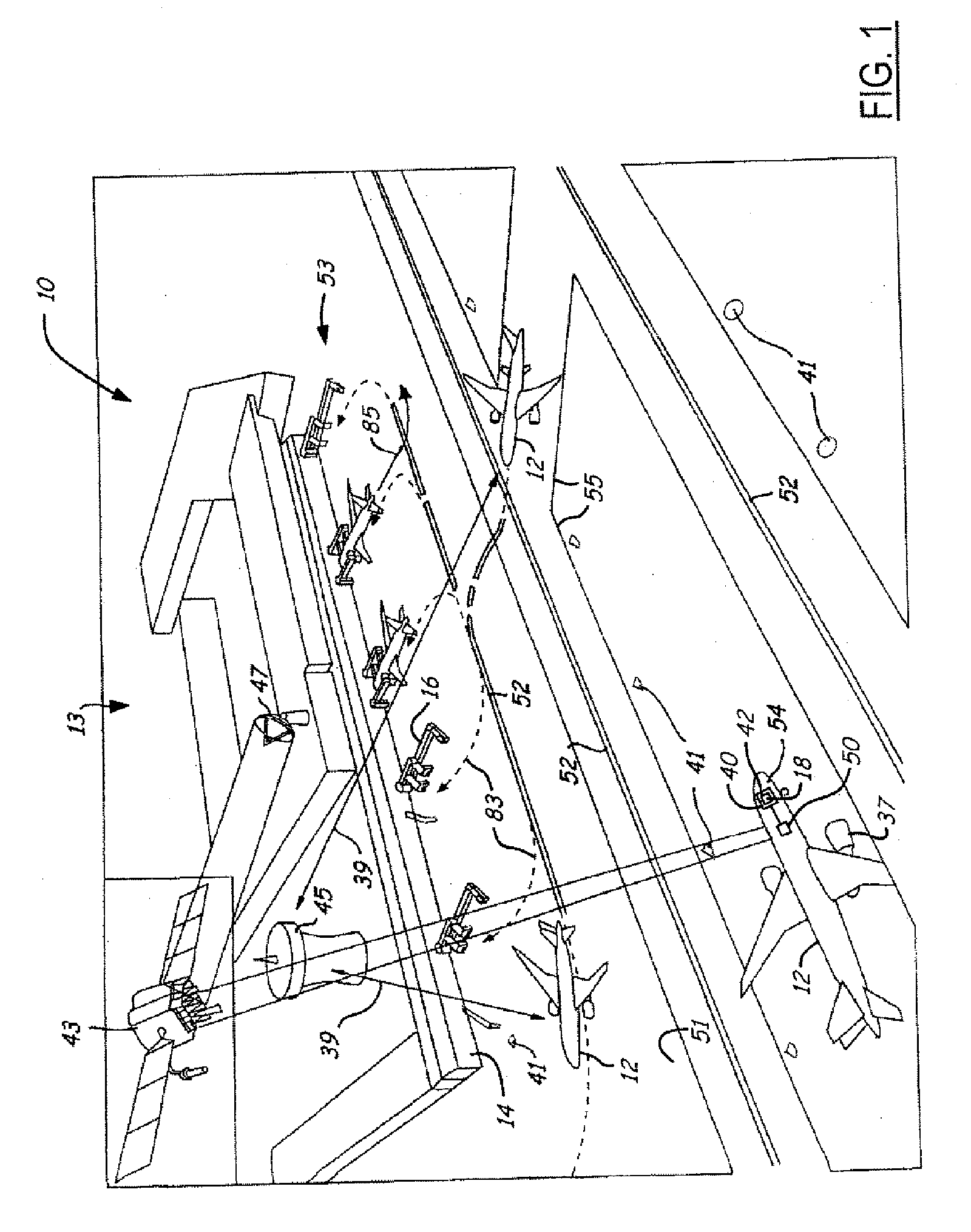

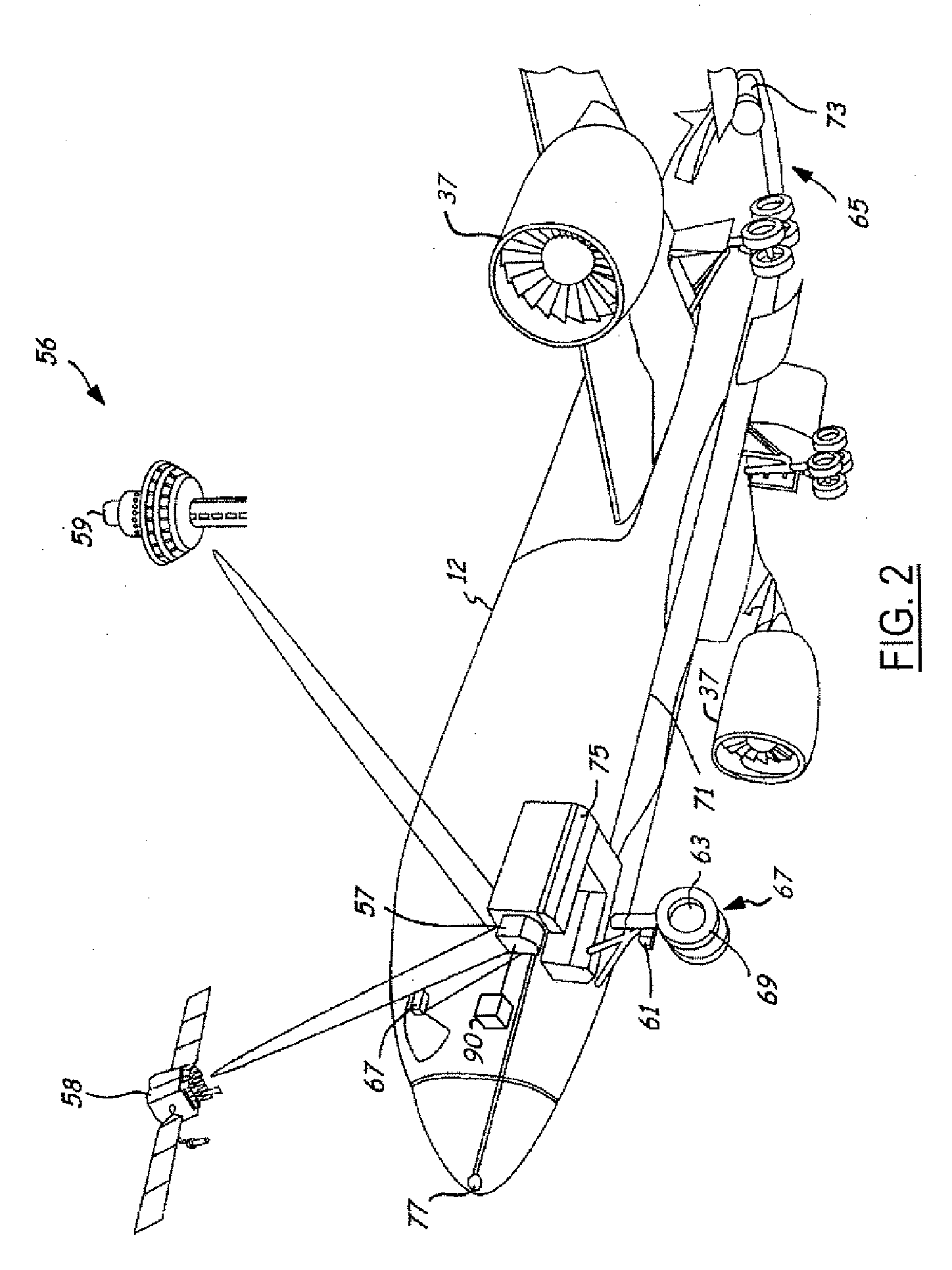

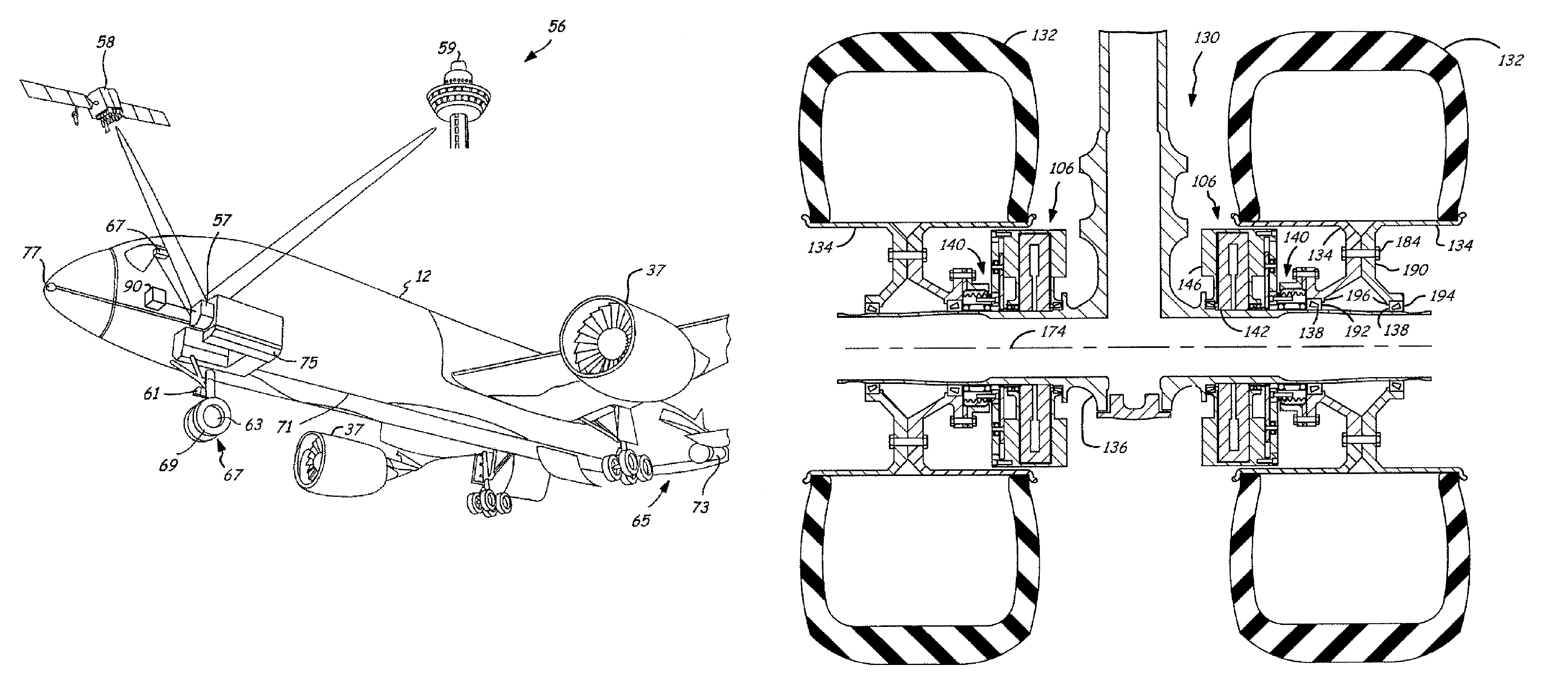

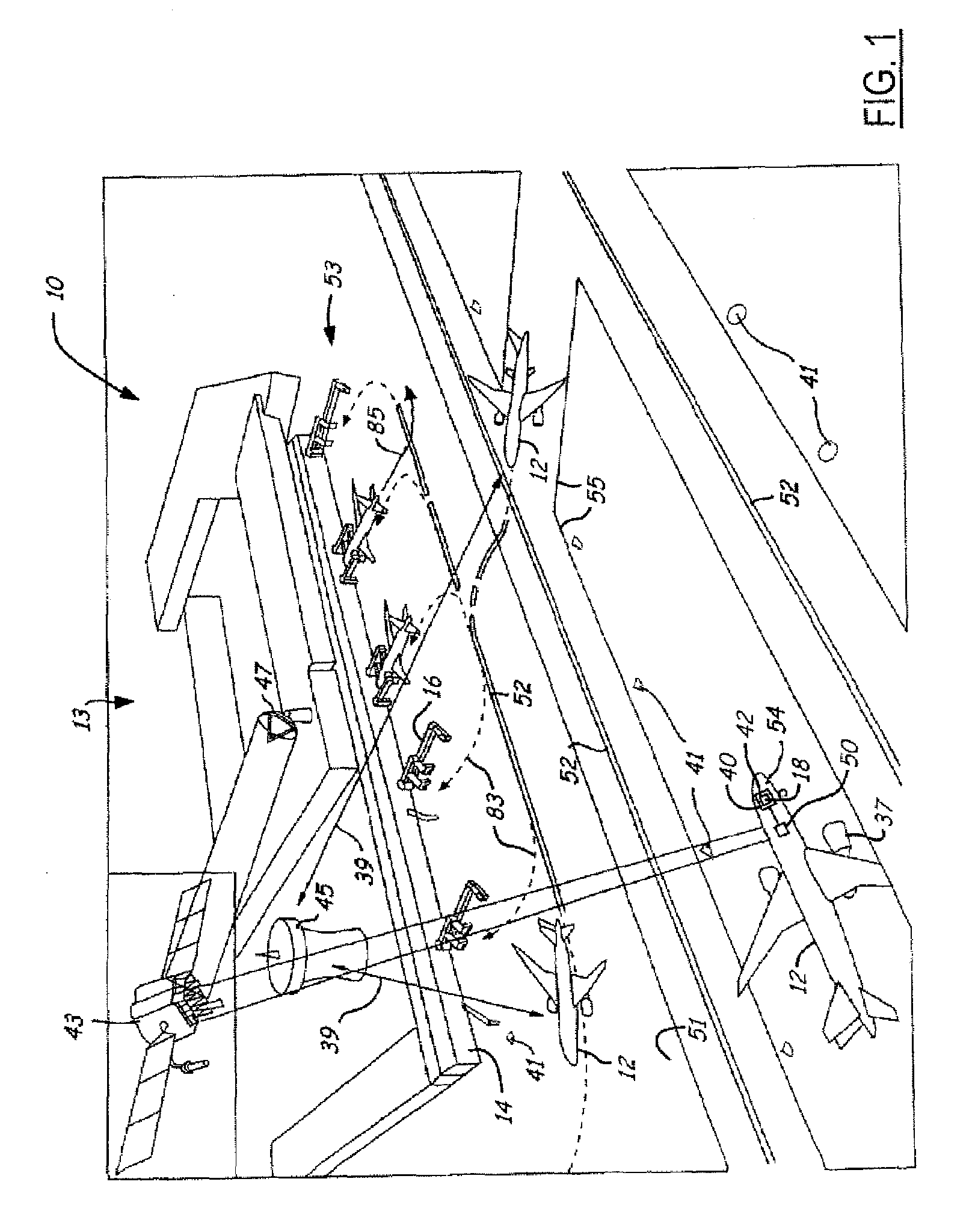

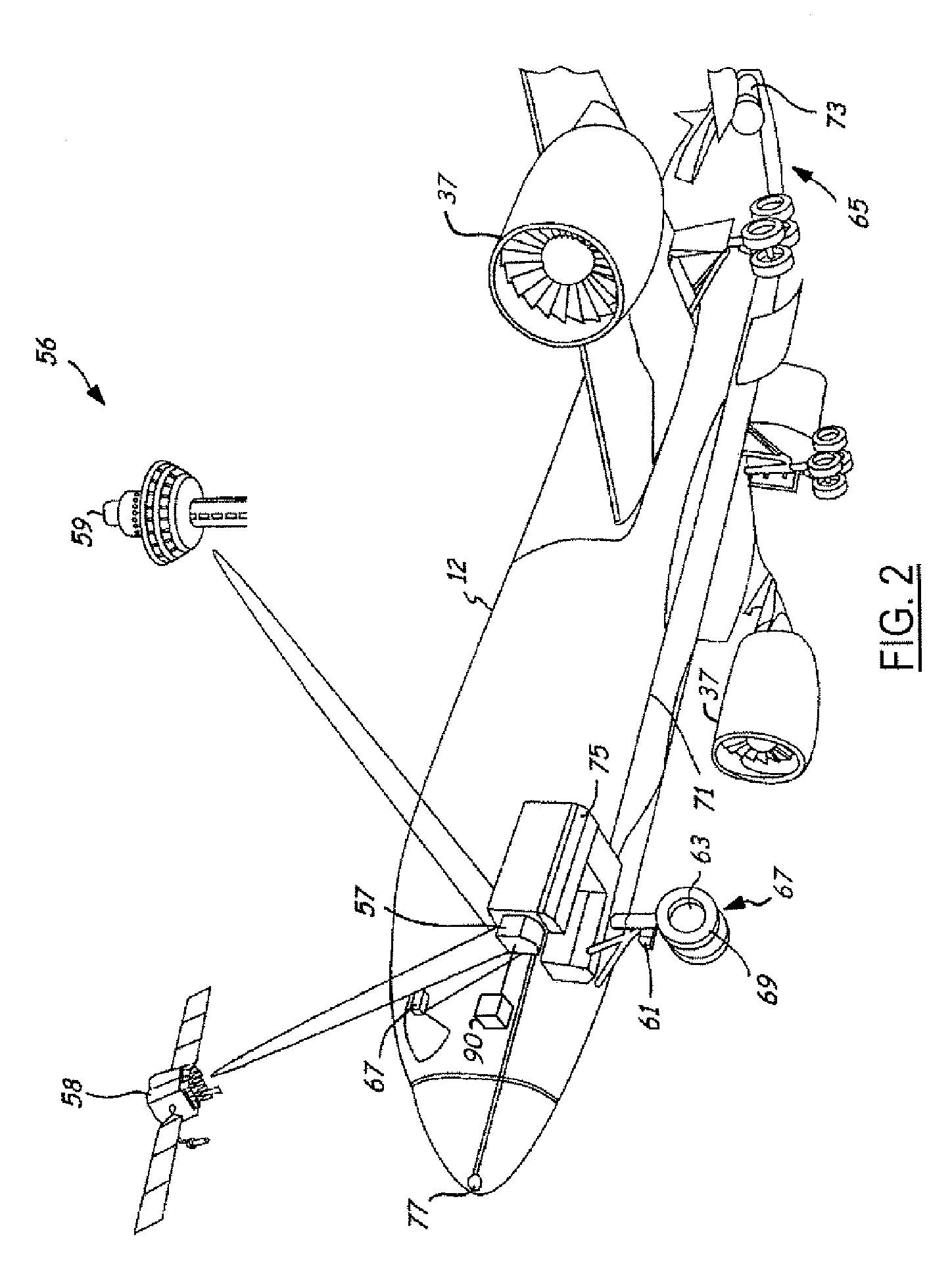

Powered nose aircraft wheel system

InactiveUS20060065779A1Improve productivityEfficiently useLiquid handling installationsEnergy efficient operational measuresAutomotive engineeringAirplane

A powered nose aircraft wheel system (130) for an aircraft (12) includes landing gear (104) that extends from the aircraft (12). A wheel axel (136) is coupled to the landing gear (104). A wheel (134) is coupled to the wheel axel (136). A wheel motor (106) is coupled to the wheel axel (136) and the wheel (134). A controller (120) is coupled to the wheel motor (106) and rotates the wheel (134). A method of taxiing an aircraft (12) includes permitting the wheel (134) of the aircraft (12) to freely spin during the landing of the aircraft (12). Power is transferred from an auxiliary power unit (73) of the aircraft (12) to the wheel motor (106). The wheel (134) is rotated via the wheel motor (106). The aircraft (12) is steered and the speed of the wheel (134) is controlled via one or more controllers selected from an onboard controller (18, 118, 120) and an offboard controller (45, 58, 59).

Owner:THE BOEING CO

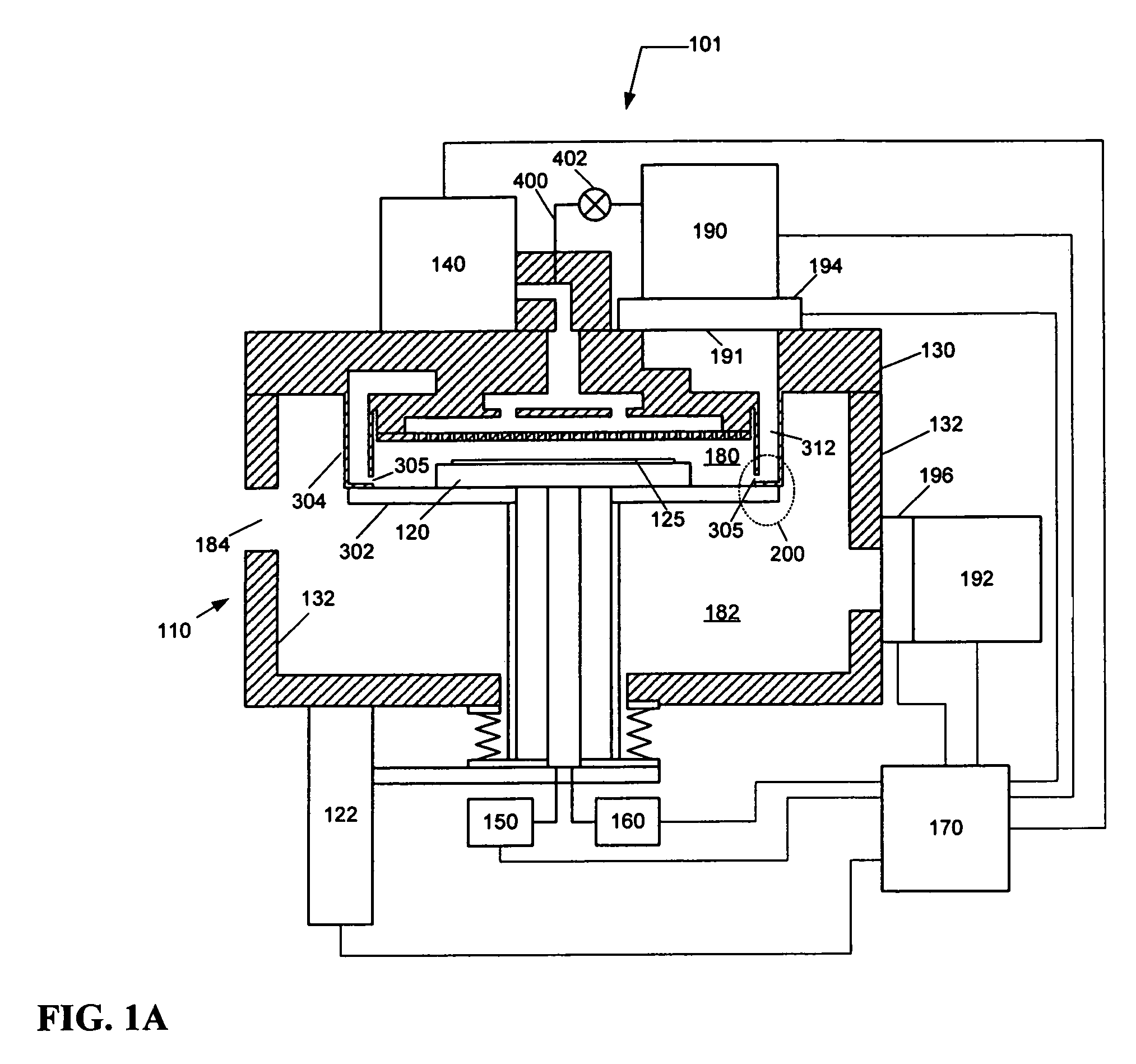

Method and system for performing different deposition processes within a single chamber

ActiveUS20110135842A1Reduce pollutionLiquid surface applicatorsElectric discharge tubesVacuum pumpingGas phase

A method and system for plasma-assisted thin film vapor deposition on a substrate is described. The system includes a process chamber including a first process space having a first volume, a substrate stage coupled to the process chamber and configured to support a substrate and expose the substrate to the first process space, a plasma generation system coupled to the process chamber and configured to generate plasma in at least a portion of the first process space, and a vacuum pumping system coupled to the process chamber and configured to evacuate at least a portion of the first process space. The system further includes a process volume adjustment mechanism coupled to the process chamber and configured to create a second process space that includes at least a part of the first process space and that has a second volume less than the first volume, the substrate being exposed to the second process space.

Owner:TOKYO ELECTRON LTD

Exhaust apparatus configured to reduce particle contamination in a deposition system

InactiveUS20070212484A1Reduce pollutionUniform processingPretreated surfacesSemiconductor/solid-state device manufacturingGas phaseEngineering

A method and system for vapor deposition on a substrate that disposes a substrate in a process space of a processing system that is isolated from a transfer space of the processing system, processes the substrate at either of a first position or a second position in the process space while maintaining isolation from the transfer space, and deposits a material on said substrate at either the first position or the second position. Furthermore, the system includes a high conductance exhaust apparatus configured to be coupled to the process space, whereby particle contamination of the substrate processed in the deposition system is minimized. The exhaust apparatus comprises a pumping system located above the substrate and an evacuation duct, wherein the evacuation duct has an inlet located below the substrate plane.

Owner:TOKYO ELECTRON LTD

Method and system for performing plasma enhanced atomic layer deposition

InactiveUS20070116887A1Reduce pollutionReduce depositionElectric discharge tubesChemical vapor deposition coatingGas phaseProcess engineering

A method, computer readable medium, and system for vapor deposition on a substrate that introduce a gaseous film precursor to a process space, increase the volume of the process space from a first size to a second size to form an enlarged process space, introduce a reduction gas to the enlarged process space, and form a reduction plasma from the reduction gas. The system for vapor deposition includes a process chamber including a first process space and further including a second process space that includes the first process space and that has a second volume that exceeds the first volume. The first process space is configured for atomic layer deposition, and the second process space is configured for plasma reduction of a layer deposited in the first process space.

Owner:TOKYO ELECTRON LTD

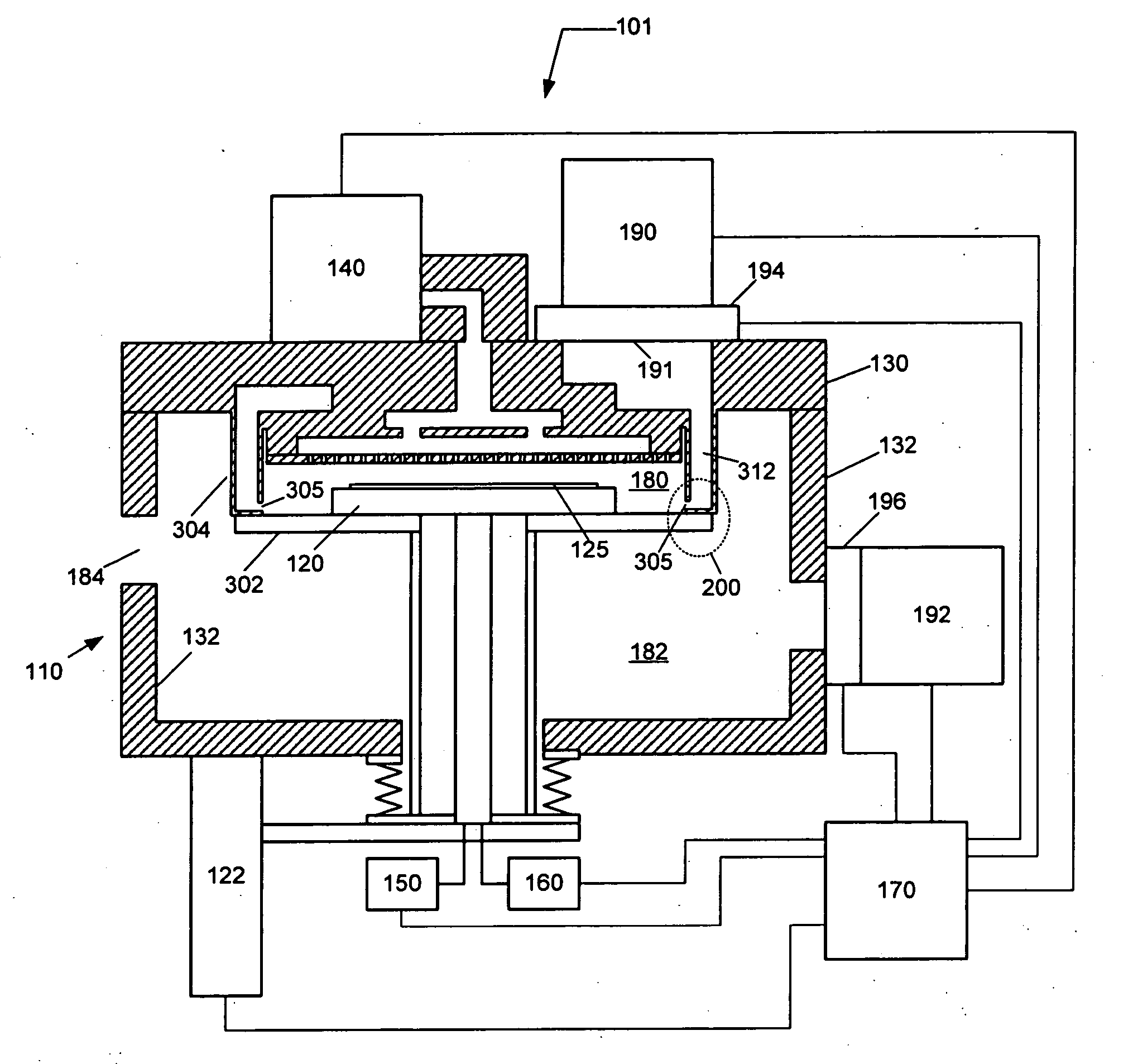

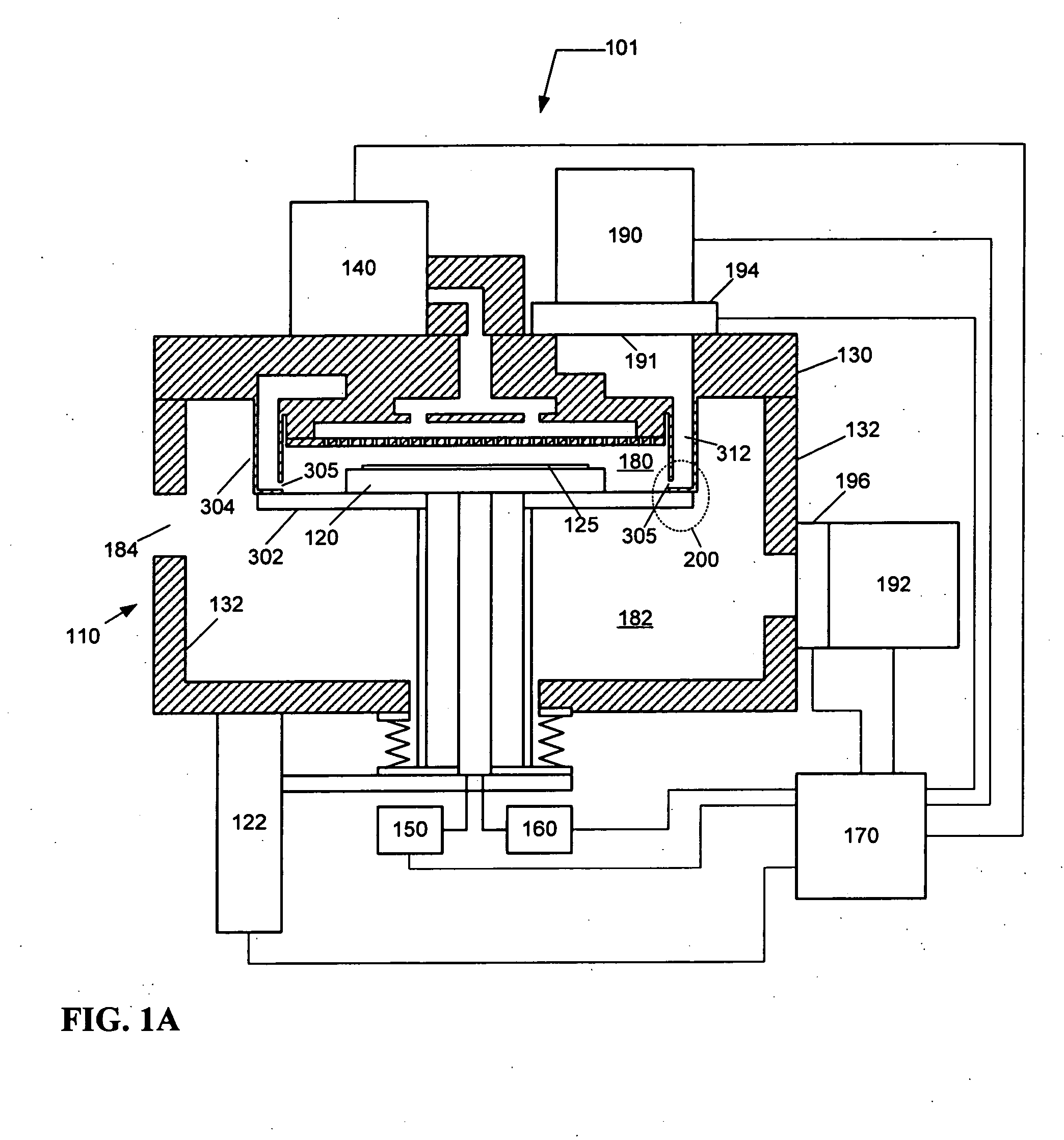

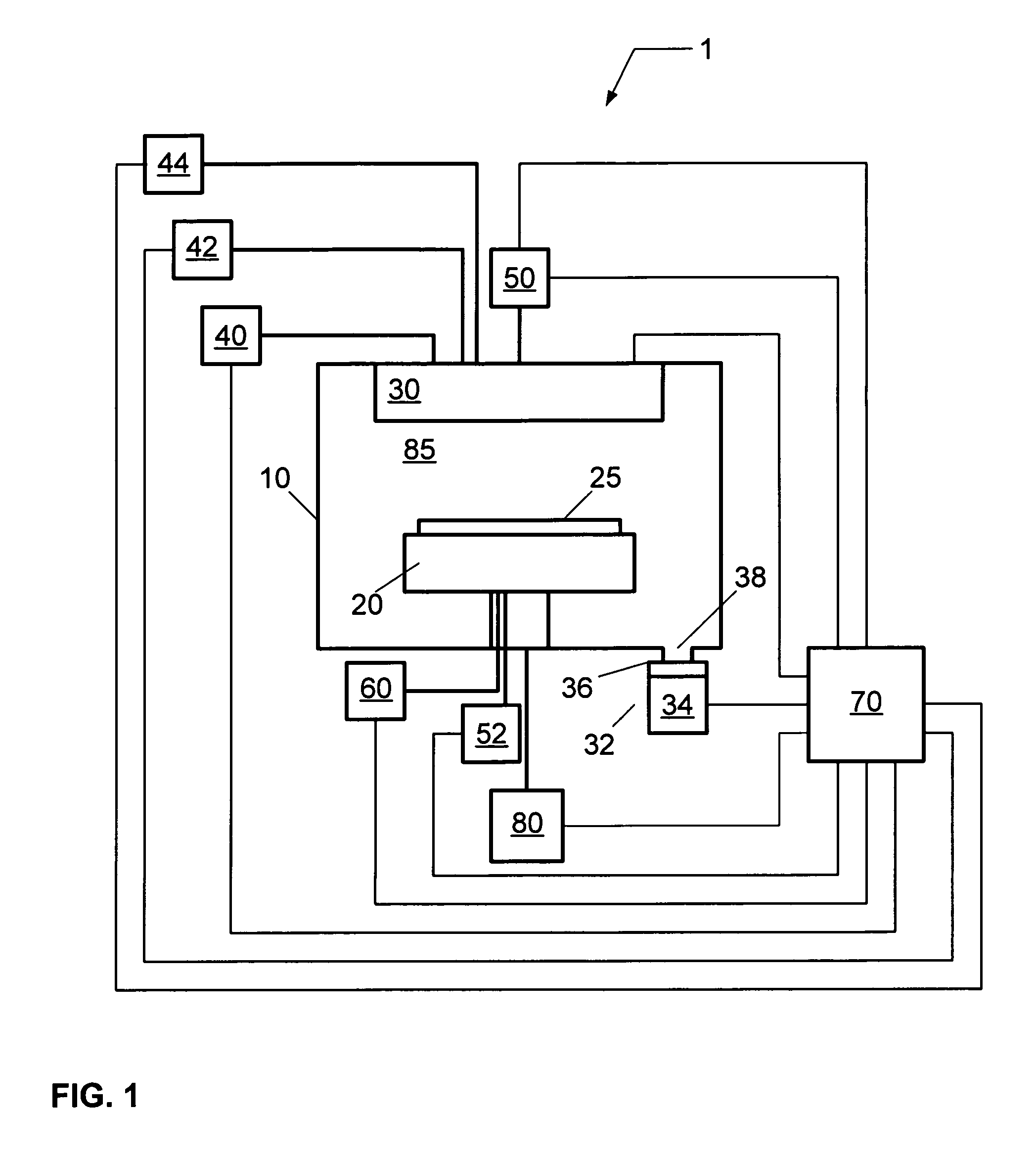

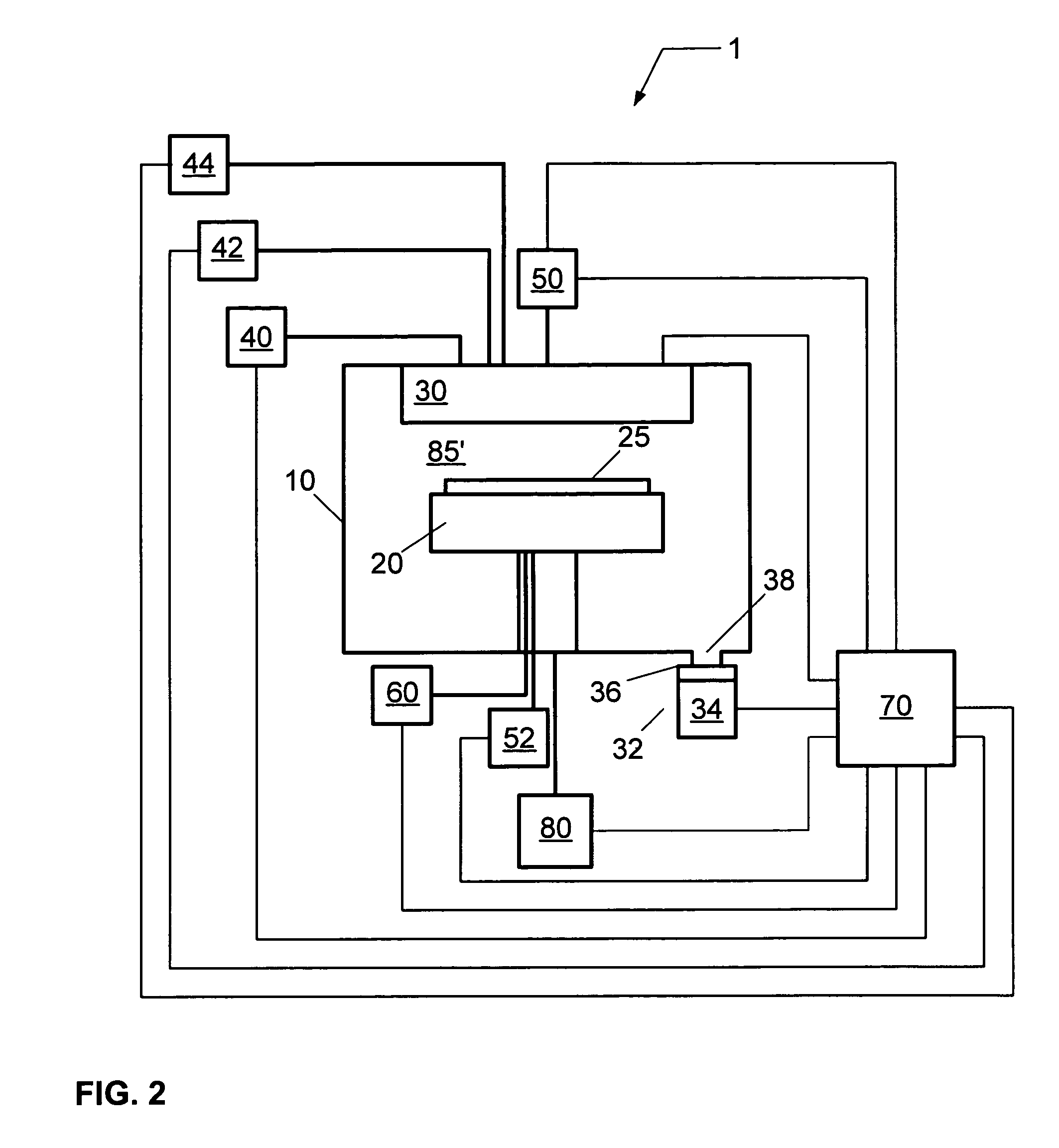

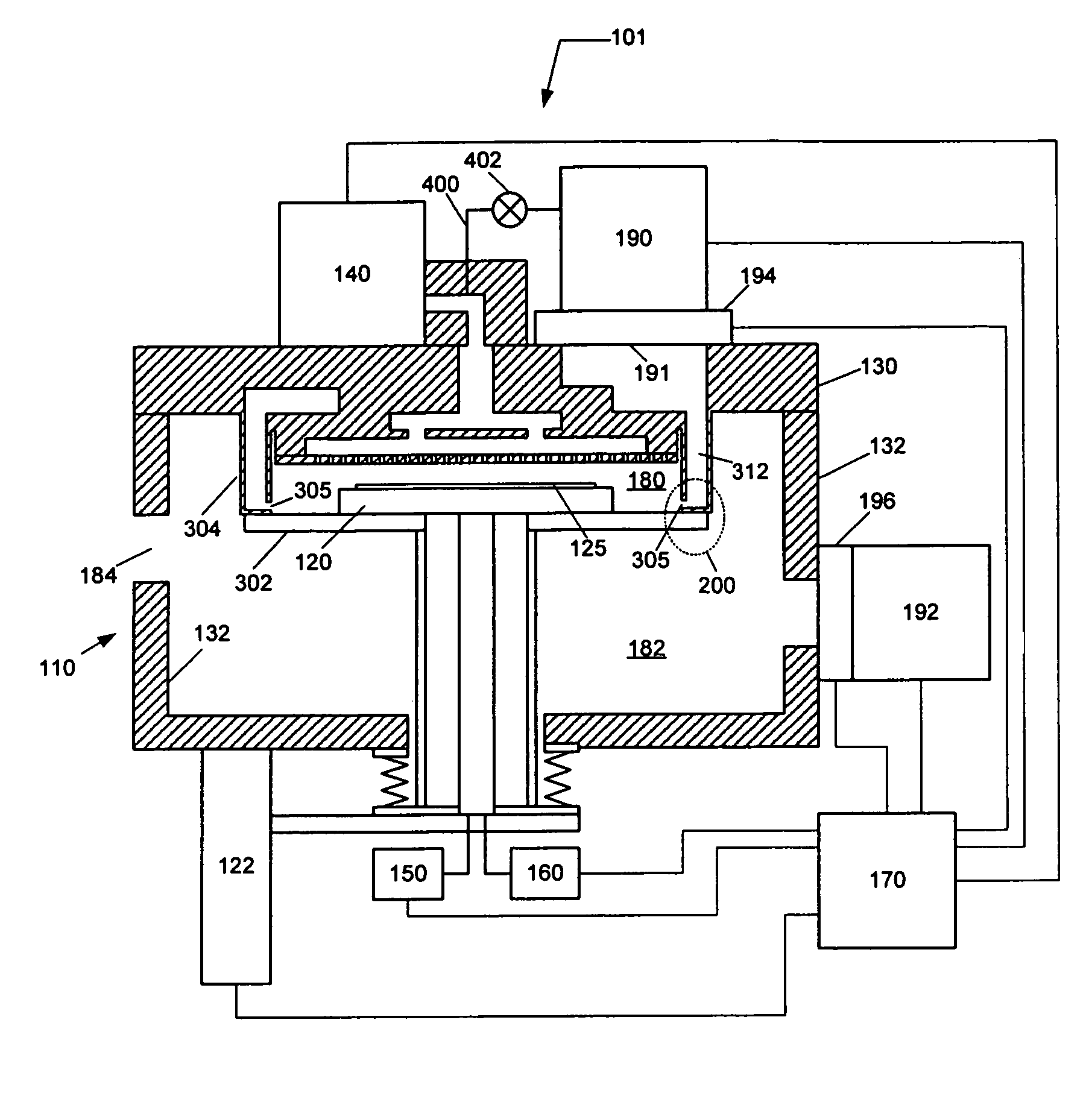

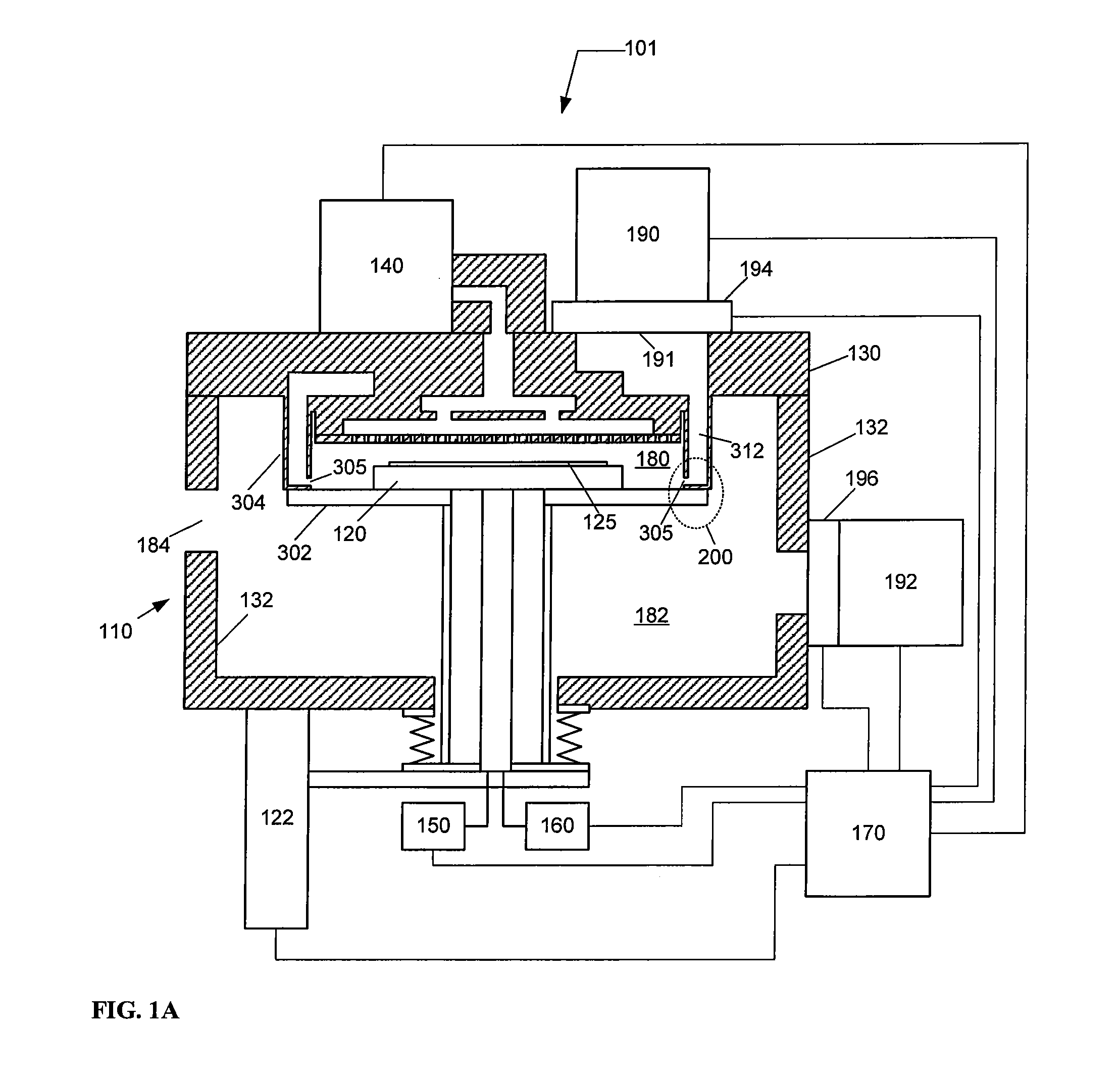

Apparatus for thermal and plasma enhanced vapor deposition and method of operating

InactiveUS20070116872A1Reduce contamination problemReduce pollutionElectric discharge tubesChemical vapor deposition coatingFree spaceEngineering

A method, computer readable medium, and system for vapor deposition on a substrate that disposes a substrate in a process space of a processing system that is vacuum isolated from a transfer space of the processing system, processes the substrate at either of a first position or a second position in the process space while maintaining vacuum isolation from the transfer space, and deposits a material on said substrate at either the first position or the second position. As such, the system includes a first assembly having a process space configured to facilitate material deposition, a second assembly coupled to the first assembly and having a transfer space to facilitate transfer of the substrate into and out of the deposition system, a substrate stage connected to the second assembly and configured to support and translate the substrate between a first position in the transfer space to a second position in the process space. The system includes a sealing assembly configured to impede gas flow between the process space and the transfer space during translation of the substrate within the process space.

Owner:TOKYO ELECTRON LTD

Sealing device and method for a processing system

InactiveUS7794546B2Reduce pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHandling systemMechanical engineering

A method, computer readable medium, and system for treating a substrate in a process space of a processing system that is vacuum isolated from a transfer space of the processing system is described. A sealing device is disposed between a first chamber assembly configured to define the process space and a second chamber assembly configured to define the transfer space. When the sealing device is engaged, vacuum isolation is provided between the process space and the transfer space. The sealing device comprises two or more contact ridges with one or more pockets formed therebetween. When the sealing device is engaged between the first chamber assembly and the second chamber assembly, gas is trapped in the one or more pockets. This trapped gas assists the release of the sealing device upon disengagement of the sealing device between the first chamber assembly and the second chamber assembly.

Owner:TOKYO ELECTRON LTD

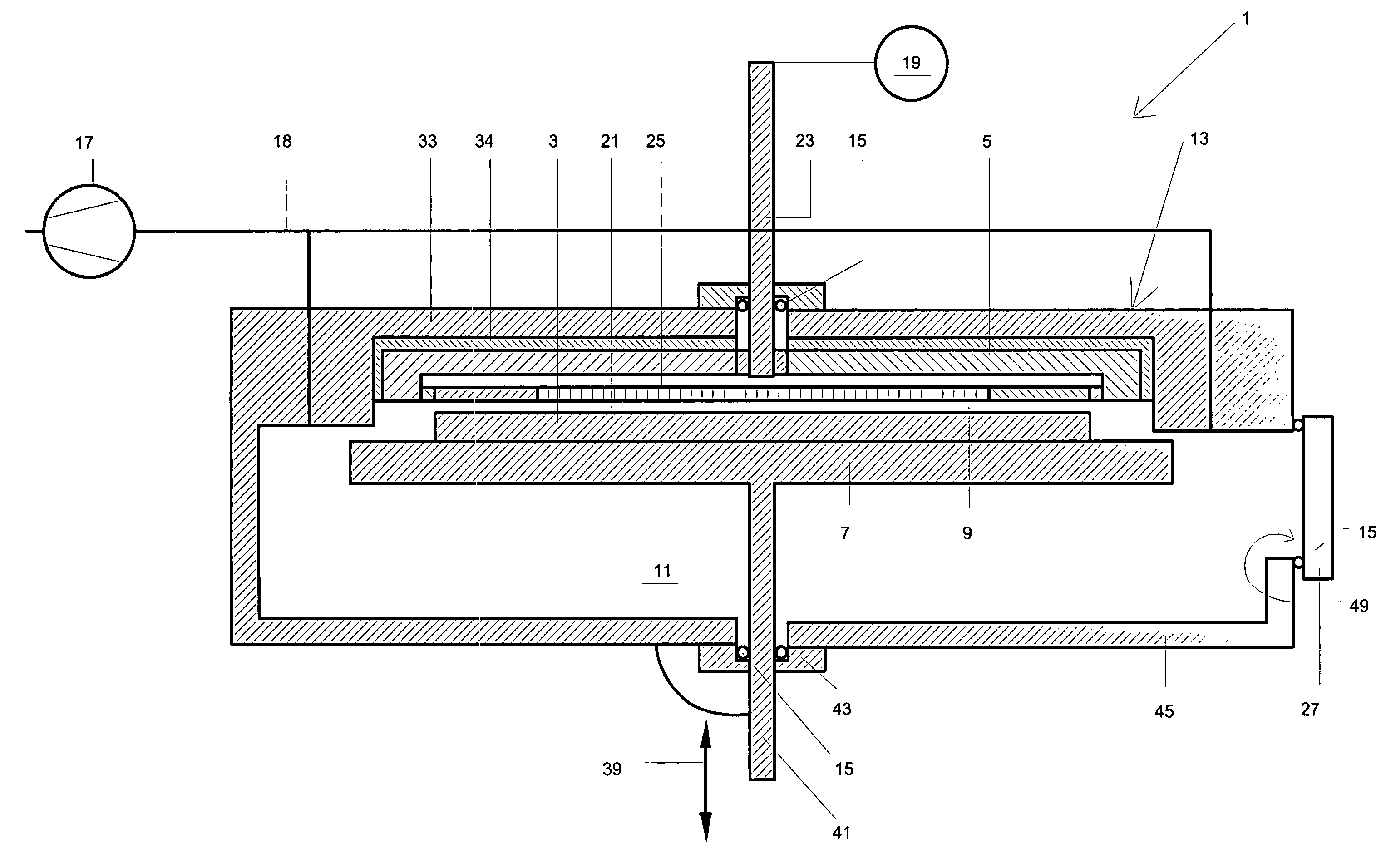

Treatment system for flat substrates

InactiveUS20100255196A1Effective plasma treatmentEasy to operateLiquid surface applicatorsElectric discharge tubesEngineeringVacuum chamber

A reactor for the treatment of flat substrates includes a vacuum chamber with a process space arranged therein. A first electrode and a counterelectrode generate a plasma for the treatment of a surface to be treated and form two opposite walls of the process space. The reactor further includes means for introducing and means for removing gaseous material into and out from the process space. At least one substrate is accommodated by a front side of the counterelectrode. The vacuum chamber includes an opening having a closure device. The reactor includes a device for varying the relative distance between the first electrode and the counterelectrode and a device assigned to the counterelectrode for accommodating substrates. At least one substrate is arranged at an angle alpha in a range of between 0° and 90° relative to a perpendicular direction at least during the performance of the treatment.

Owner:LEYBOLD OPTICS

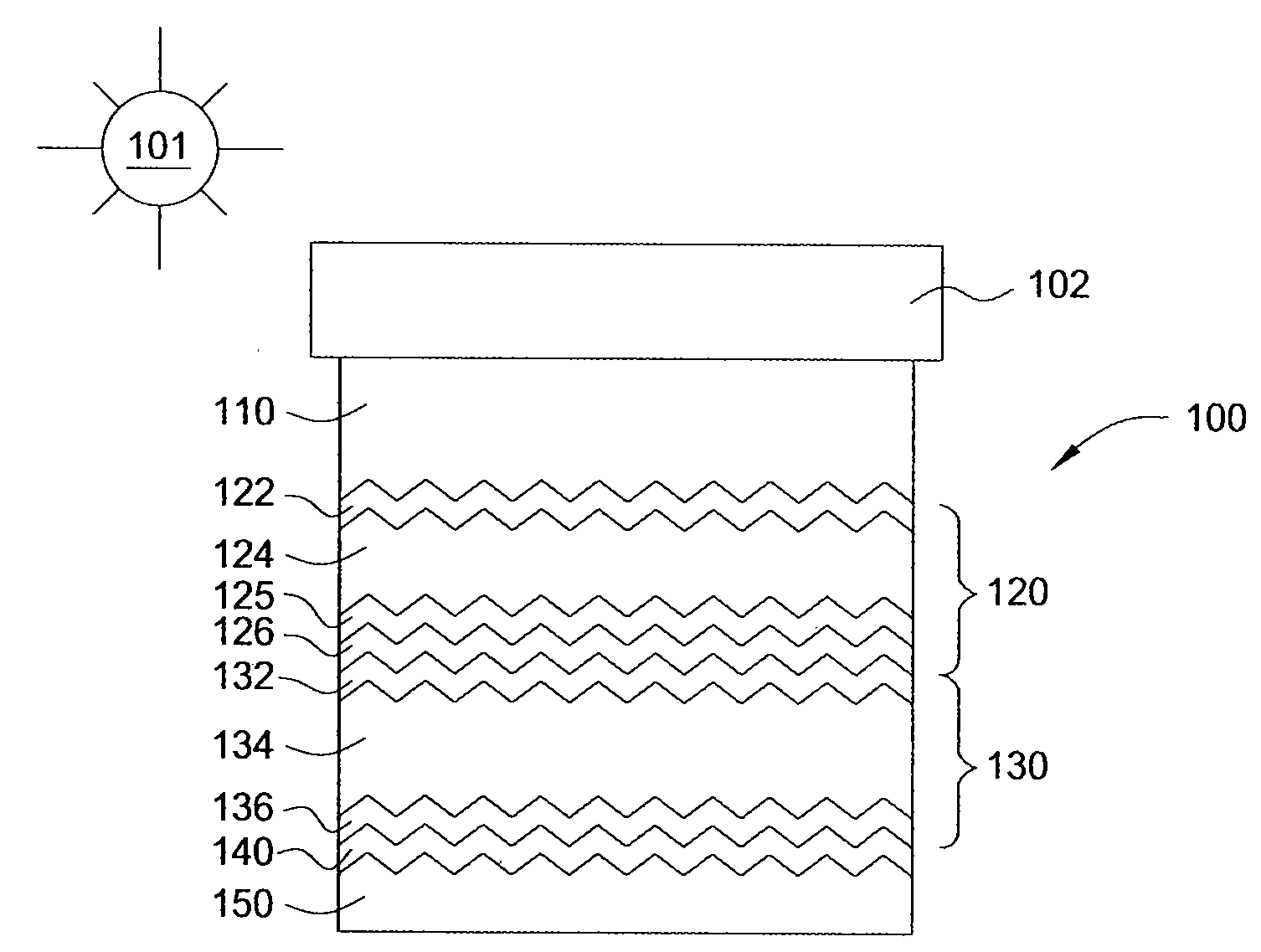

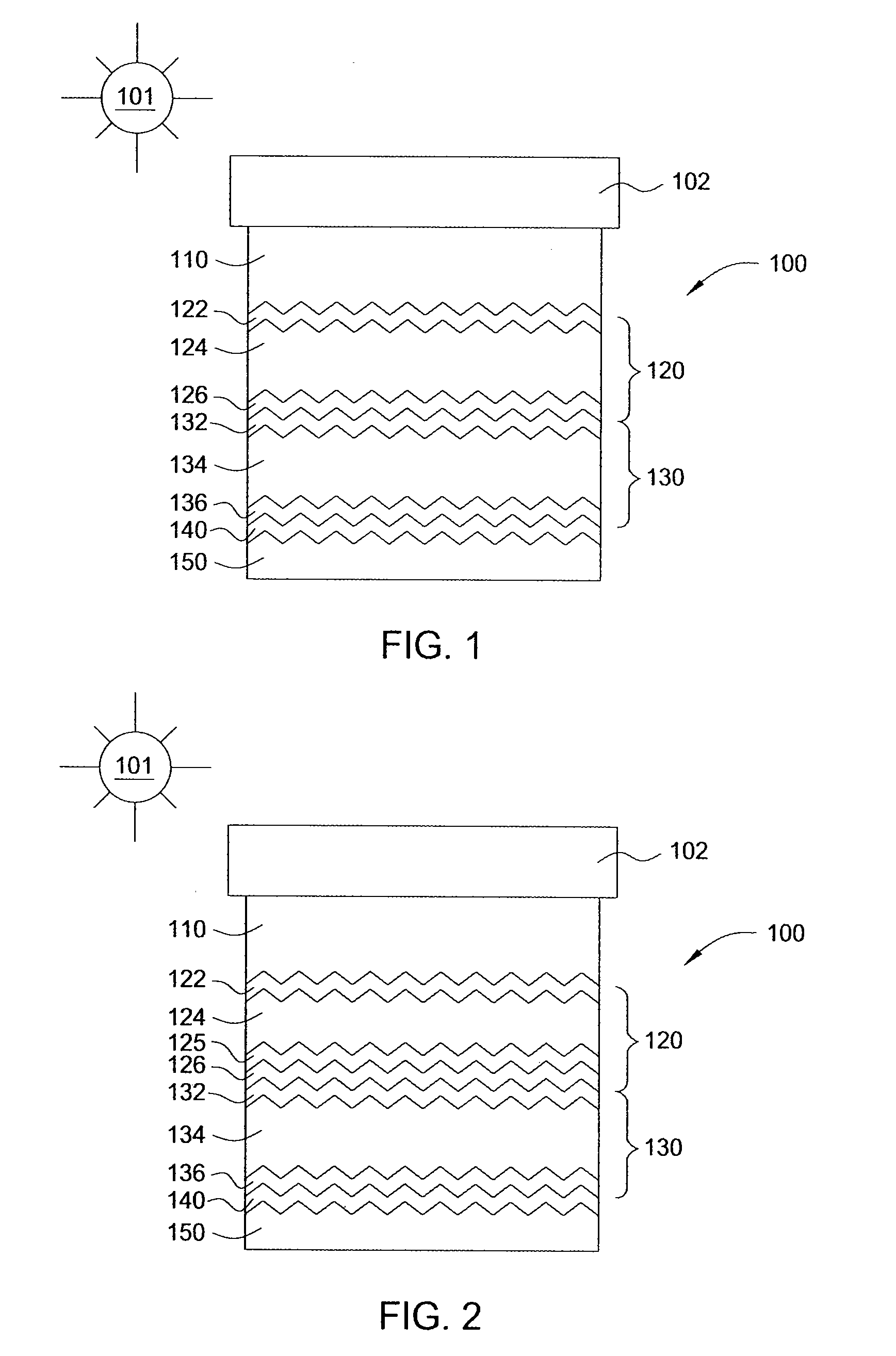

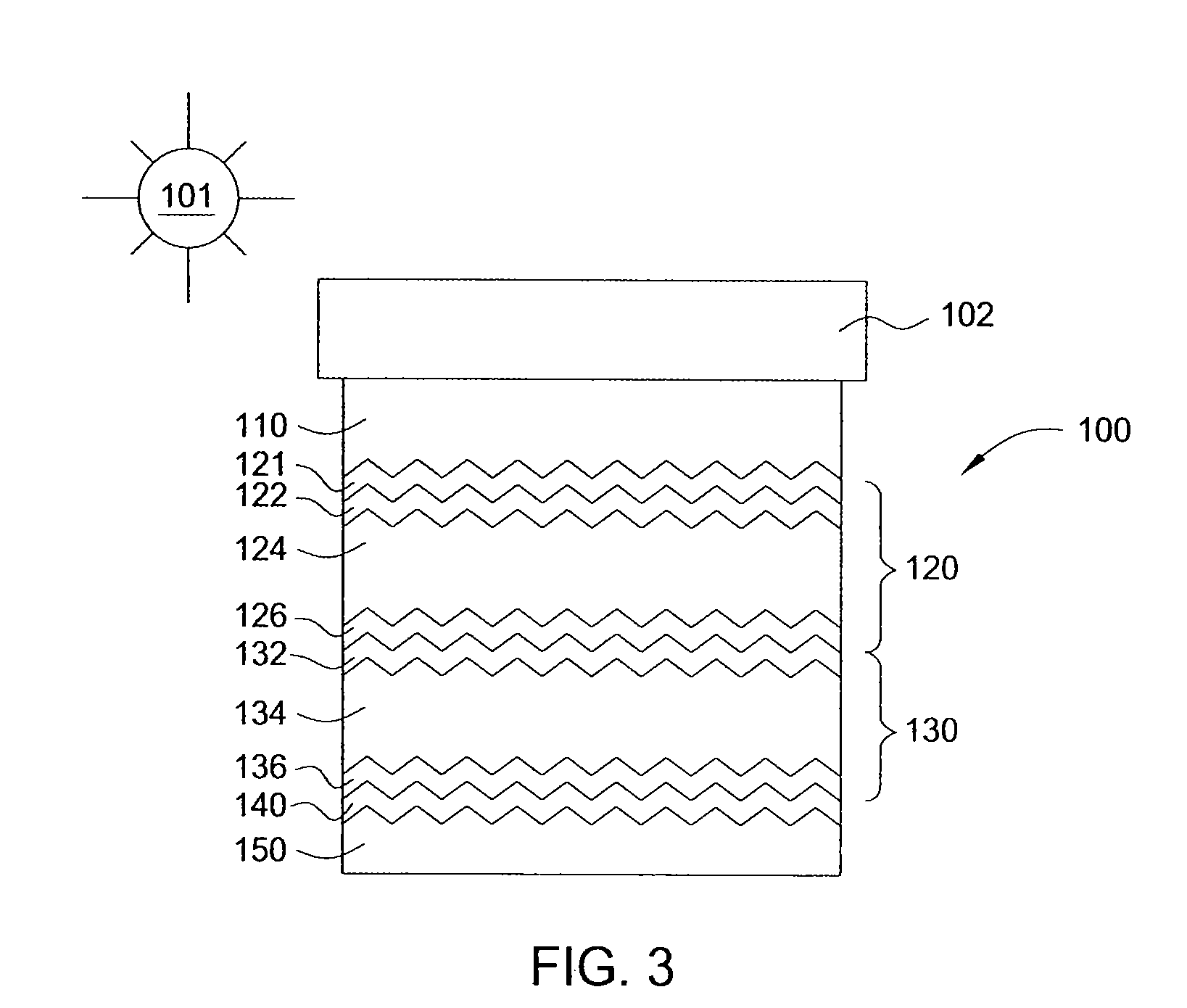

Solar cells and methods and apparatuses for forming the same including i-layer and n-layer chamber cleaning

InactiveUS20090093080A1Reduce pollutionFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringContamination

Embodiments of the present invention generally provide an apparatus and method for forming an improved thin film single or multi-junction solar cell in a substrate processing device. One embodiment provides a system that contains at least one processing chamber that is adapted to deposit one or more layers that form a portion of a solar cell device. In one embodiment, a method is employed to reduce the contamination of a substrate processed in the processing chamber by performing a cleaning process on the inner surfaces of the processing chamber prior to depositing the one or more layers on a substrate. The cleaning process may include depositing a layer, such as a seasoning layer or passivation layer, that tends to trap contaminants found in the processing chamber. Other embodiments of the invention may provide scheduling and / or positioning the cleaning processing steps at desirable times within a substrate processing sequence to improve the overall system substrate throughput.

Owner:APPLIED MATERIALS INC

Exhaust system for a vacuum processing system

InactiveUS20070209588A1Reduce contamination problemFacilitate transitionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingFree spaceProcess engineering

A method, computer readable medium, and system for treating a substrate in a process space of a vacuum processing system is described. A vacuum pump in fluid communication with the vacuum processing system and configured to evacuate the process space, while a process material supply system is pneumatically coupled to the vacuum processing system and configured to supply a process gas to the process space. Additionally, the vacuum pump is pneumatically coupled to the process supply system and configured to, at times, evacuate the process gas supply system.

Owner:TOKYO ELECTRON LTD

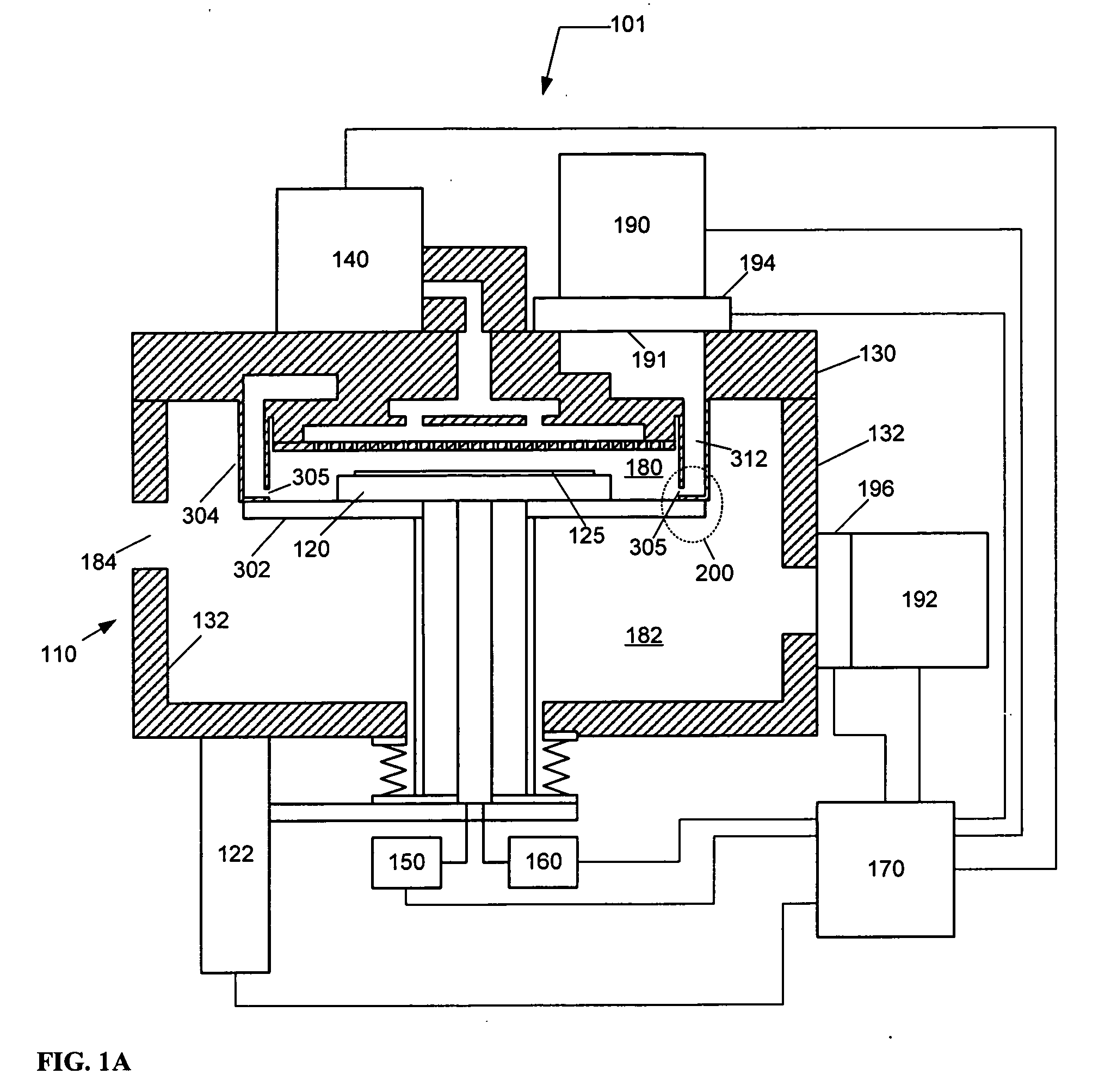

Method and system for sealing a first assembly to a second assembly of a processing system

ActiveUS8454749B2Reduce pollutionAnti-theft cycle devicesElectric discharge tubesEngineeringMechanical engineering

A method, computer readable medium, and system for vapor deposition on a substrate that maintain a first assembly of the vapor deposition system at a first temperature, maintain a second assembly of the vapor deposition system at a reduced temperature lower than the first temperature, dispose the substrate in a process space of the first assembly that is vacuum isolated from a transfer space in the second assembly, and deposit a material on the substrate. As such, the system includes a first assembly having a process space configured to facilitate material deposition, a second assembly coupled to the first assembly and having a transfer space to facilitate transfer of the substrate into and out of the deposition system, a substrate stage connected to the second assembly and configured to support the substrate, and a sealing assembly configured to separate the process space from the transfer space. The first assembly is configured to be maintained at a first temperature and the second assembly is configured to be maintained at a reduced temperature lower than the first temperature.

Owner:TOKYO ELECTRON LTD

Exhaust system for a vacuum processing system

InactiveUS7670432B2Reduce pollutionEasy transitionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasProcess engineering

A method, computer readable medium, and system for treating a substrate in a process space of a vacuum processing system is described. A vacuum pump in fluid communication with the vacuum processing system and configured to evacuate the process space, while a process material supply system is pneumatically coupled to the vacuum processing system and configured to supply a process gas to the process space. Additionally, the vacuum pump is pneumatically coupled to the process supply system and configured to, at times, evacuate the process gas supply system.

Owner:TOKYO ELECTRON LTD

Method and system for sealing a first assembly to a second assembly of a processing system

ActiveUS20070157683A1Reduce pollutionAnti-theft cycle devicesElectric discharge tubesGas phaseMechanical engineering

A method, computer readable medium, and system for vapor deposition on a substrate that maintain a first assembly of the vapor deposition system at a first temperature, maintain a second assembly of the vapor deposition system at a reduced temperature lower than the first temperature, dispose the substrate in a process space of the first assembly that is vacuum isolated from a transfer space in the second assembly, and deposit a material on the substrate. As such, the system includes a first assembly having a process space configured to facilitate material deposition, a second assembly coupled to the first assembly and having a transfer space to facilitate transfer of the substrate into and out of the deposition system, a substrate stage connected to the second assembly and configured to support the substrate, and a sealing assembly configured to separate the process space from the transfer space. The first assembly is configured to be maintained at a first temperature and the second assembly is configured to be maintained at a reduced temperature lower than the first temperature.

Owner:TOKYO ELECTRON LTD

Apparatus for thermal and plasma enhanced vapor deposition and method of operating

InactiveUS20120315404A1Reduce pollutionElectric discharge tubesChemical vapor deposition coatingGas phaseEngineering

A method for vapor deposition on a substrate in a vapor deposition system having a process space separated from a transfer space. The method disposes a substrate in a process space of a processing system that is vacuum isolated from a transfer space of the processing system, processes the substrate at either of a first position or a second position in the process space while maintaining vacuum isolation from the transfer space by way of a movement accommodating sealing material, and deposits a material on the substrate at either the first position or the second position.

Owner:TOKYO ELECTRON LTD

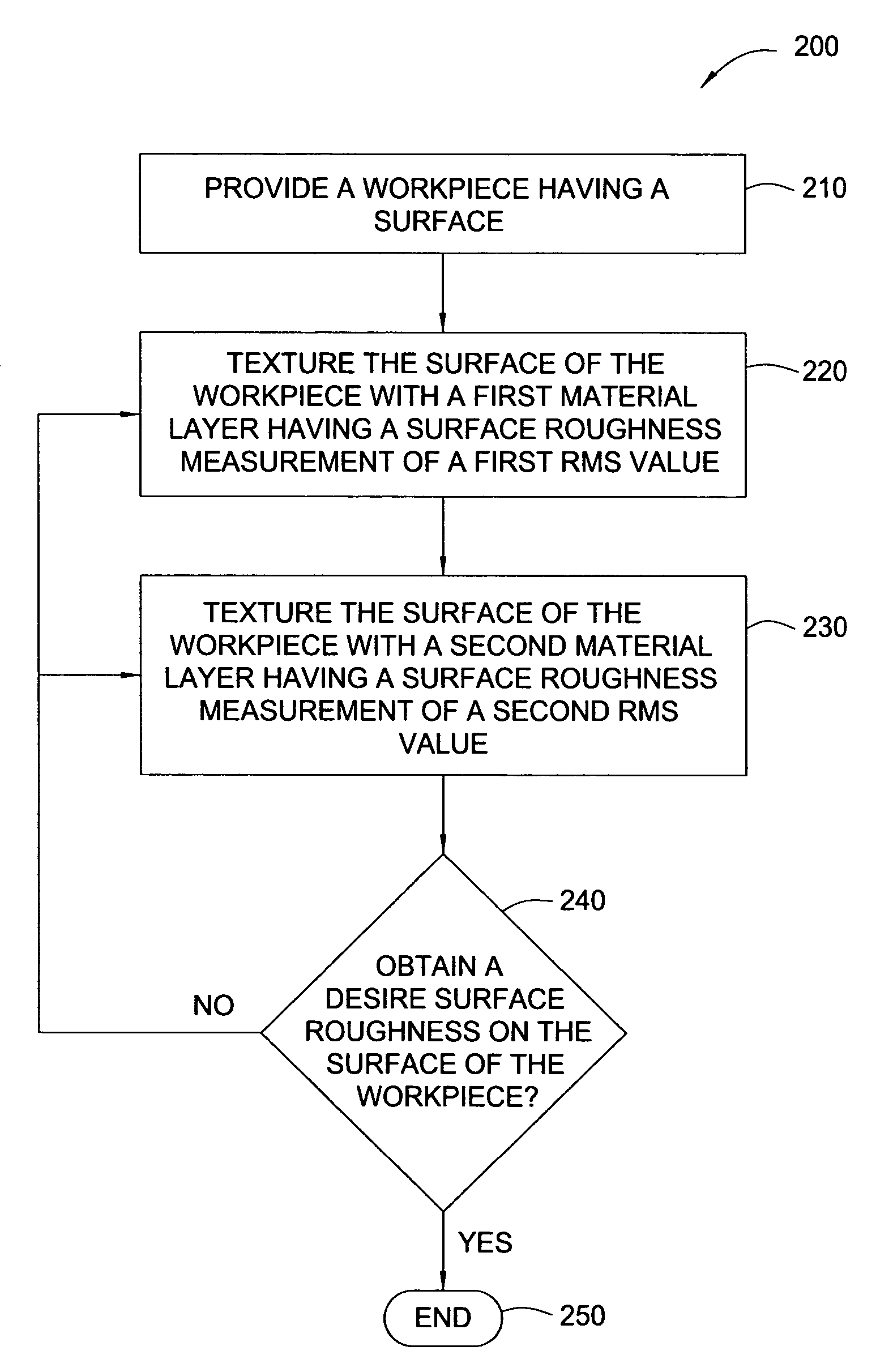

Process kit design to reduce particle generation

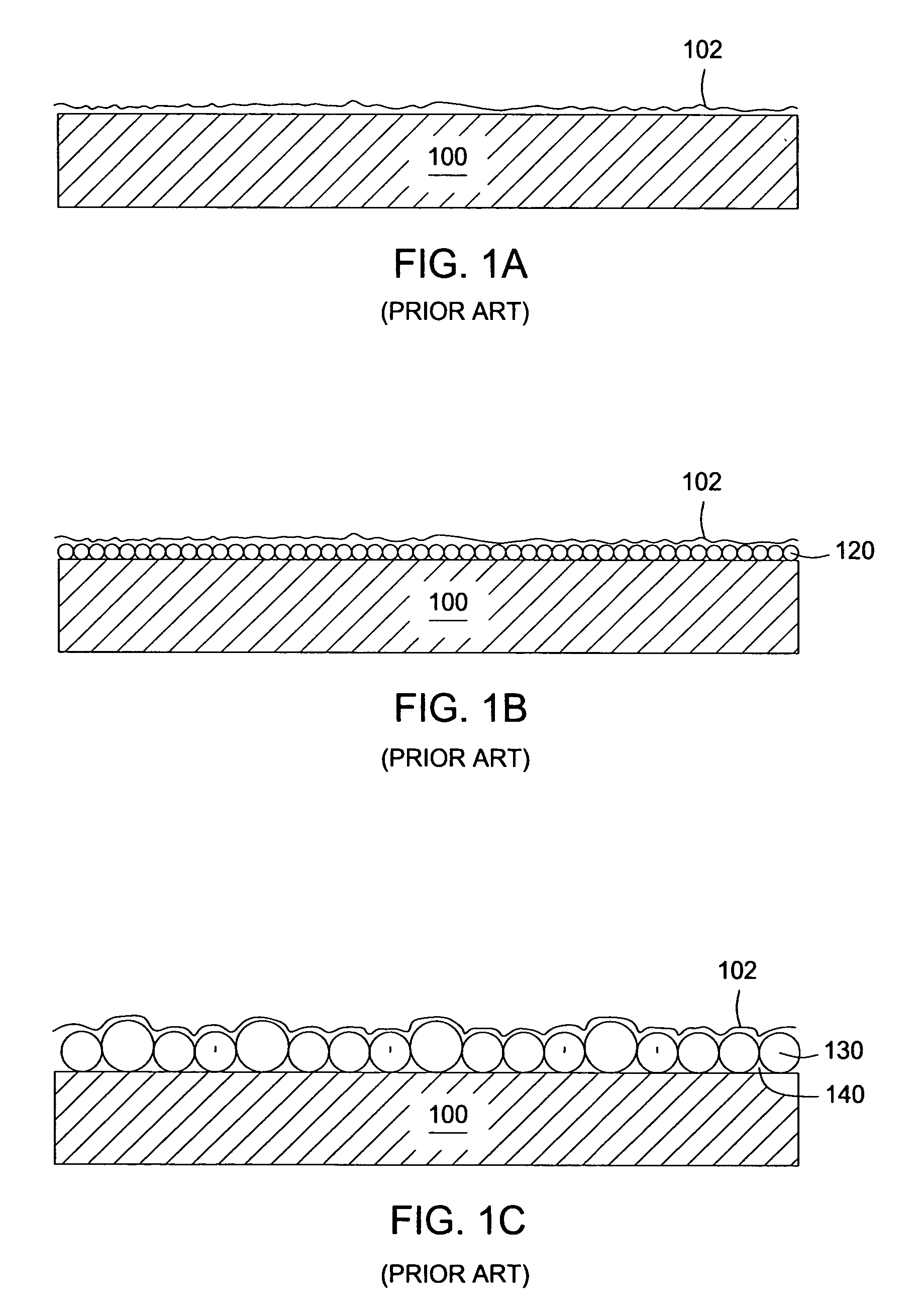

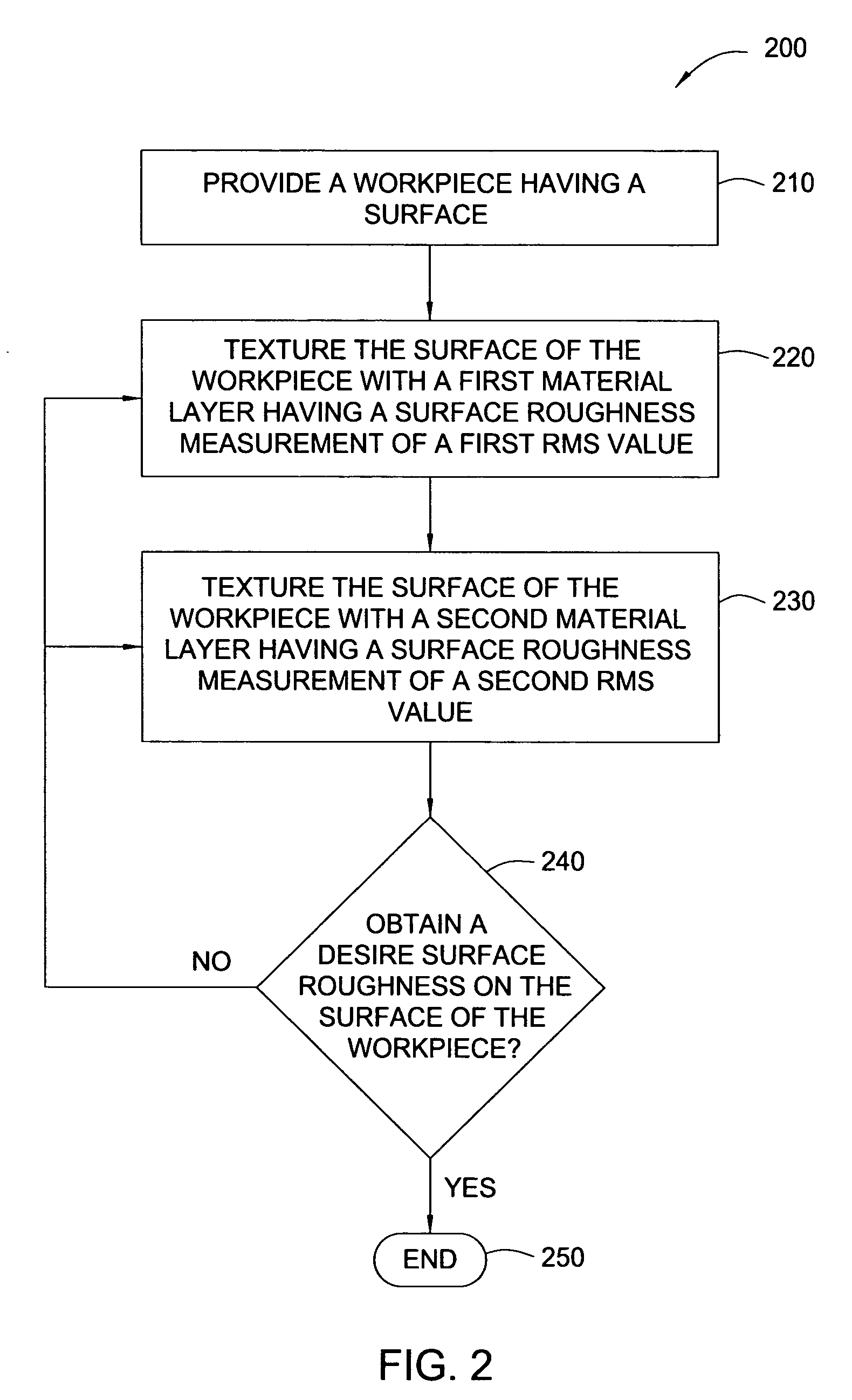

InactiveUS20060292310A1Reduce pollutionRough textureLiquid surface applicatorsMolten spray coatingThermal sprayingMetallurgy

A method for making a process kit and a process kit design which has reduced particle generation during substrate processing are provided. The internal surface of the process kit design are textured by coating its surface with a first material layer having a smaller RMS surface roughness measurement and arc spraying with a second material layer or additional material layers having a larger RMS value. The first material layer can be coated by bead blasting, plating, arc spraying, thermal spraying, or other processes. In addition, the invention also provides selective coating of internal surface of the process kit with a protective layer and arc spraying the surface pf the protective layer with another material layer, which may be of the same material as the material of the internal surface of the process kit.

Owner:APPLIED MATERIALS INC

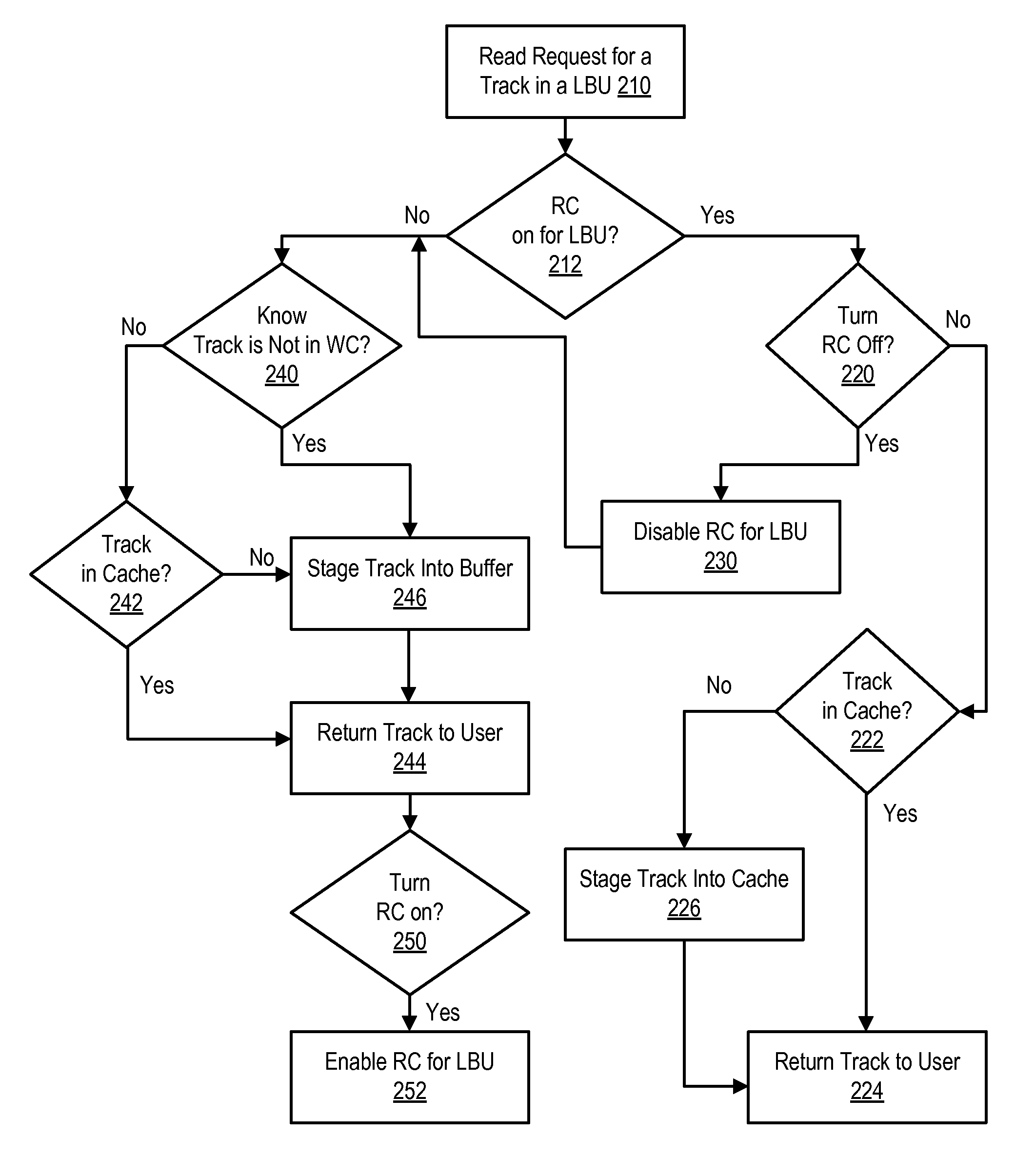

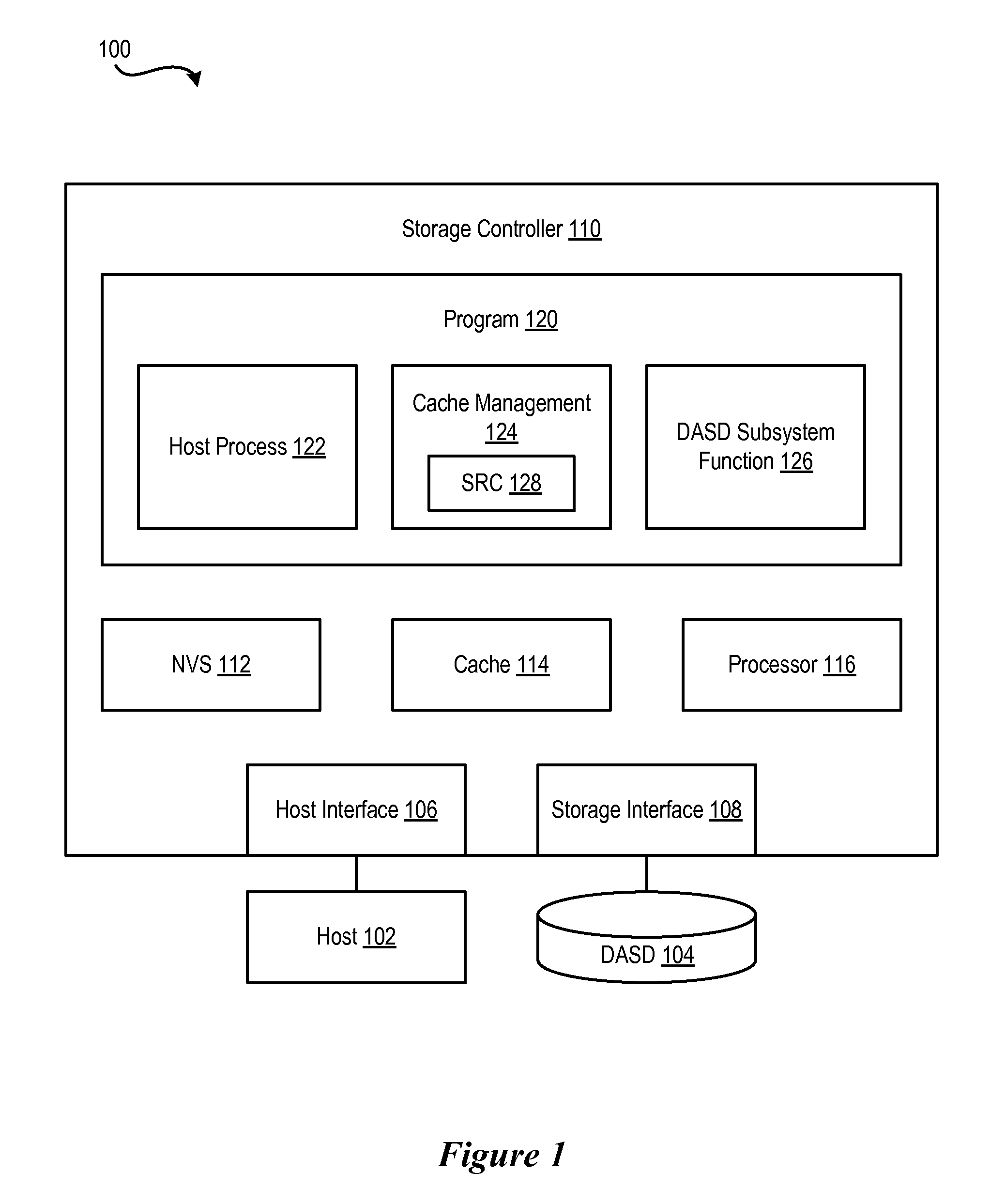

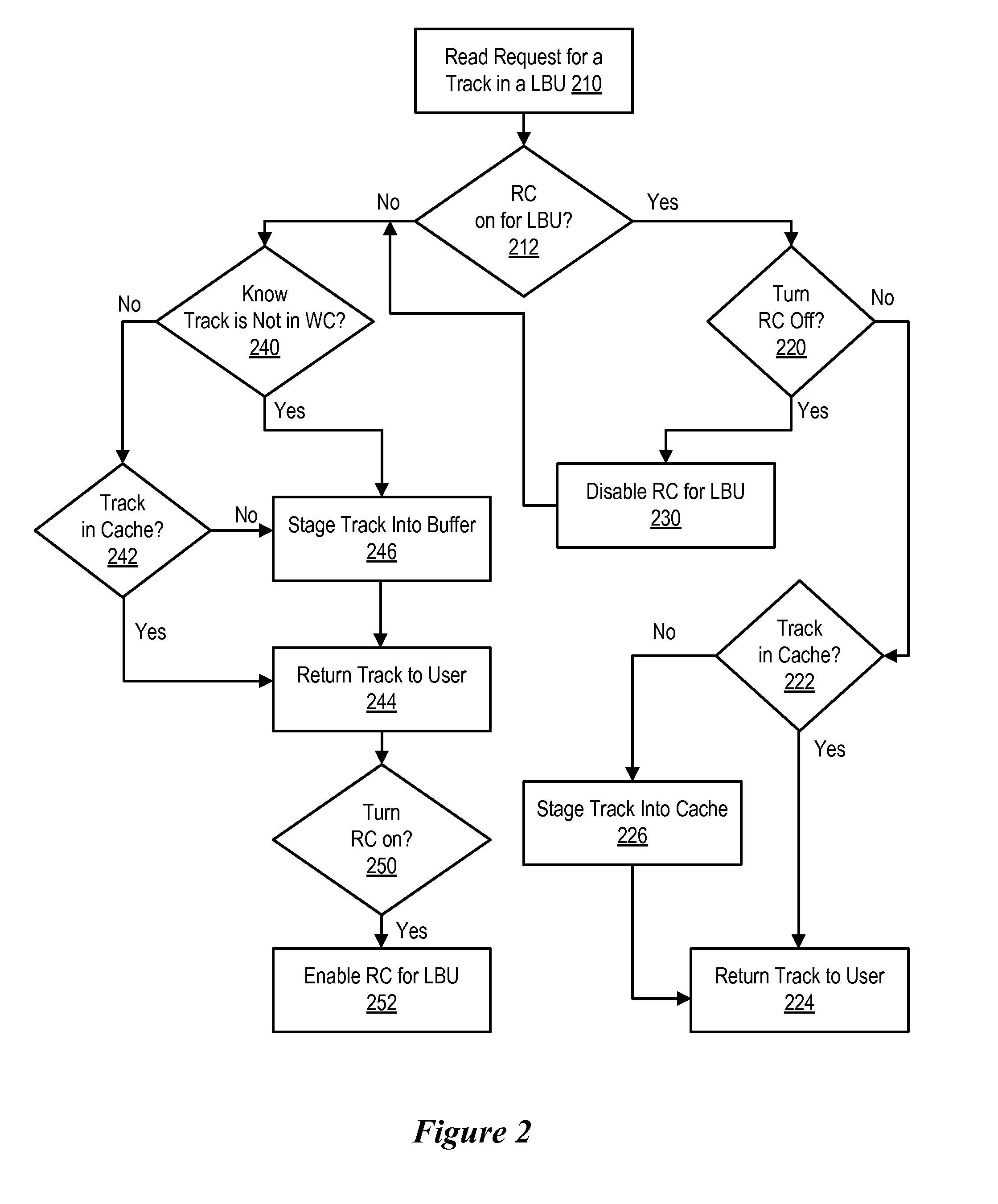

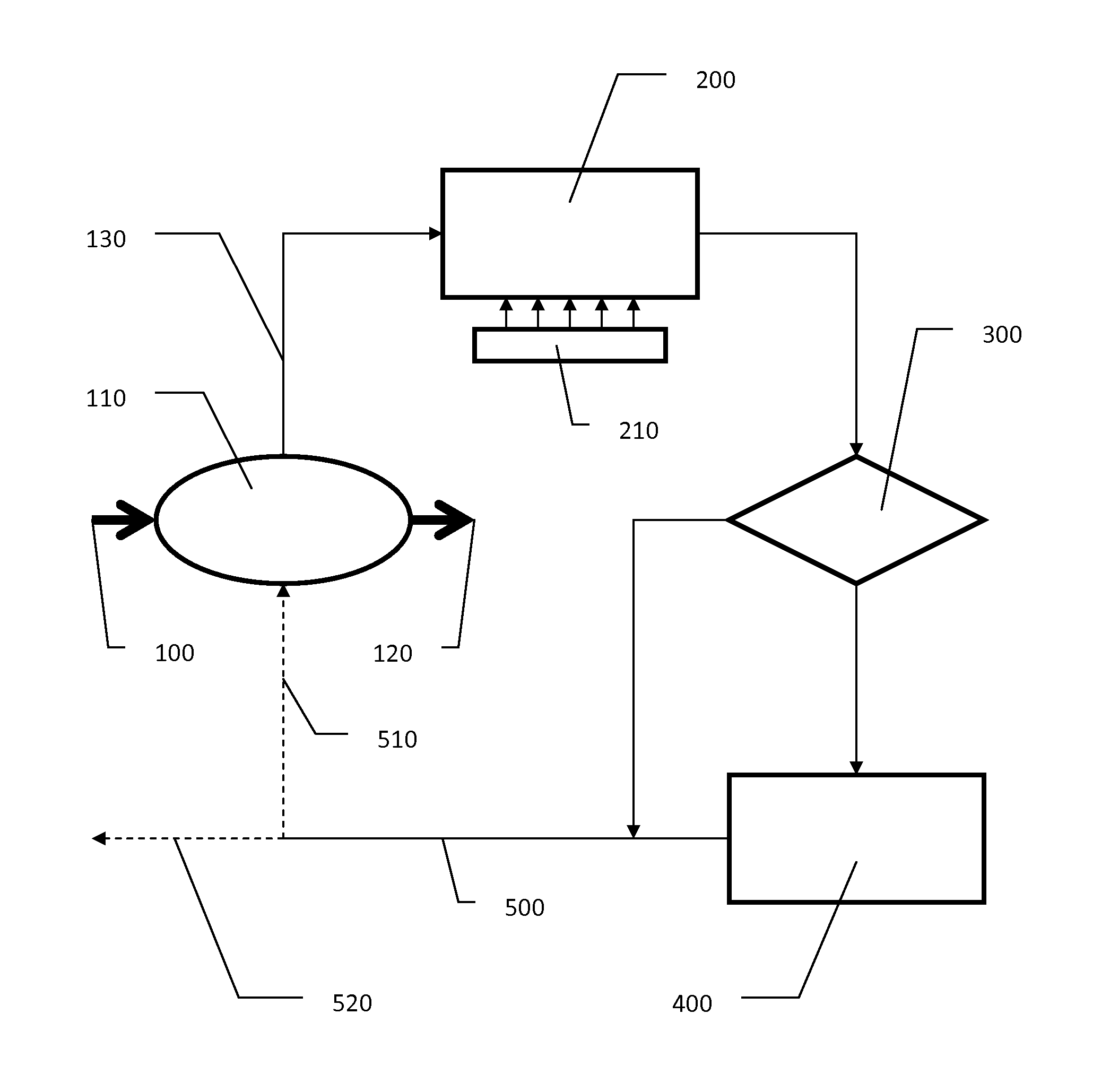

Method for Selectively Enabling and Disabling Read Caching in a Storage Subsystem

InactiveUS20090037662A1Improve performanceLow cache hit ratioMemory adressing/allocation/relocationCache hit rateWorkload

A mechanism for selectively disabling and enabling read caching based on past performance of the cache and current read / write requests. The system improves overall performance by using an autonomic algorithm to disable read caching for regions of backend disk storage (i.e., the backstore) that have had historically low cache hit ratios. The result is that more cache becomes available for workloads with larger hit ratios, and less time and machine cycles are spent searching the cache for data that is unlikely to be there.

Owner:IBM CORP

RF shutter

InactiveUS20080286463A1Reduce contaminationReduce amountElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma processingEngineering

The present invention generally comprises an RF shutter assembly for use in a plasma processing apparatus. The RF shutter assembly may reduce the amount of plasma creep below the substrate and shadow frame during processing, thereby reducing the amount of deposition that occurs on undesired surfaces. By reducing the amount of deposition on undesired surfaces, particle flaking and thus, substrate contamination may be reduced.

Owner:APPLIED MATERIALS INC

Substrate retaining apparatus, system including the apparatus, and method of using same

PendingUS20200102653A1Reduce pollutionDegradation of surface of substrateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCooling fluidHeat shield

A substrate retaining apparatus, a load lock assembly comprising the substrate retaining apparatus, and a system including the substrate retaining apparatus are disclosed. The substrate retaining apparatus can include at least one sidewall and one or more heat shields. One or more of the at least one sidewall can include a cooling fluid conduit to facilitate cooling of substrates retained by the substrate retaining apparatus. Additionally or alternatively, one or more of the at least one sidewall can include a gas conduit to provide gas to a surface of a retained substrate.

Owner:ASM IP HLDG BV

Powered nose aircraft wheel system

InactiveUS7445178B2Improves arrival and departure efficiency and productivityEasy to useLiquid handling installationsEnergy efficient operational measuresNoseAuxiliary power unit

A powered nose aircraft wheel system (130) for an aircraft (12) includes landing gear (104) that extends from the aircraft (12). A wheel axel (136) is coupled to the landing gear (104). A wheel (134) is coupled to the wheel axel (136). A wheel motor (106) is coupled to the wheel axel (136) and the wheel (134). A controller (120) is coupled to the wheel motor (106) and rotates the wheel (134). A method of taxiing an aircraft (12) includes permitting the wheel (134) of the aircraft (12) to freely spin during the landing of the aircraft (12). Power is transferred from an auxiliary power unit (73) of the aircraft (12) to the wheel motor (106). The wheel (134) is rotated via the wheel motor (106). The aircraft (12) is steered and the speed of the wheel (134) is controlled via one or more controllers selected from an onboard controller (18, 118, 120) and an offboard controller (45, 58, 59).

Owner:THE BOEING CO

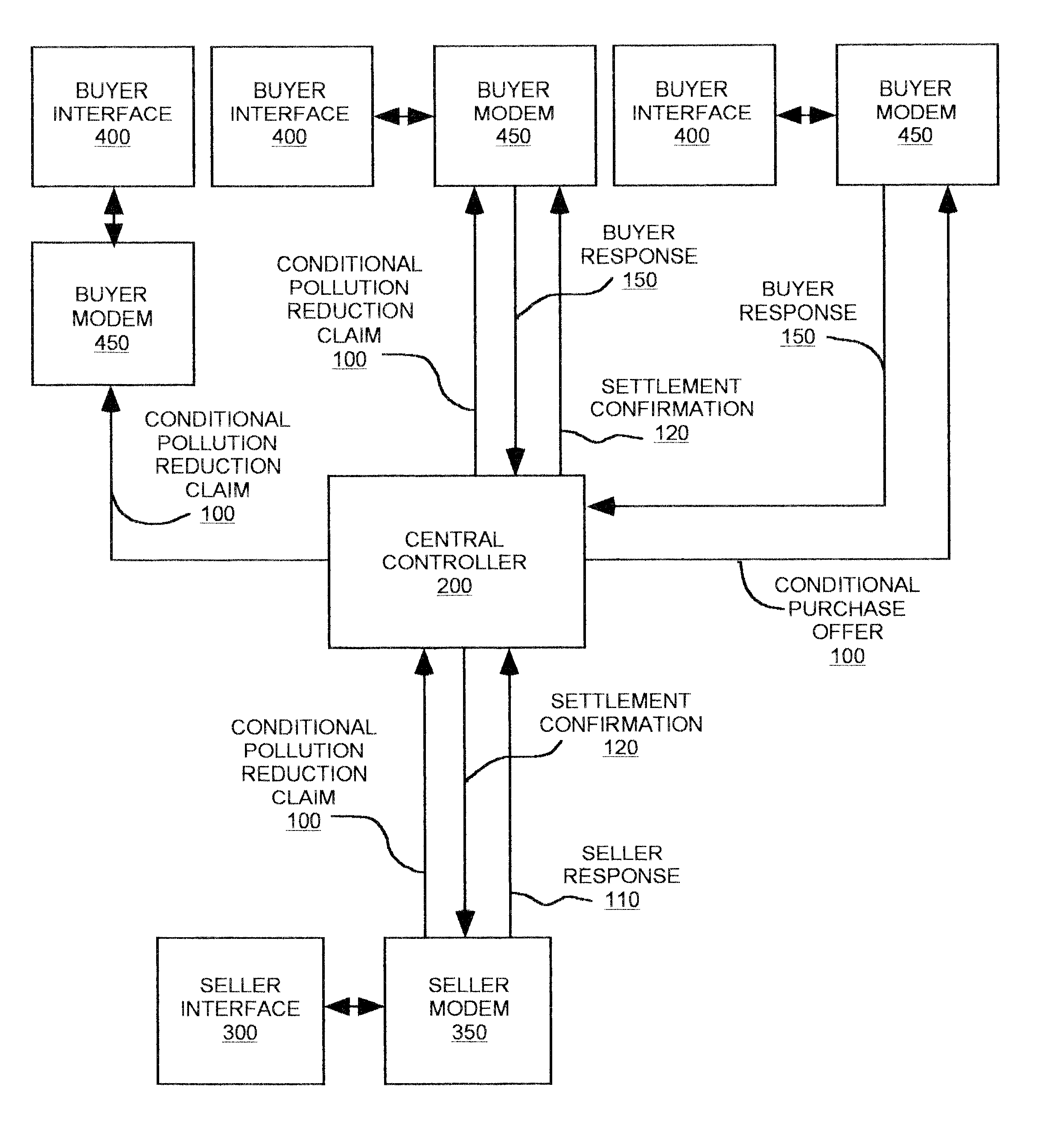

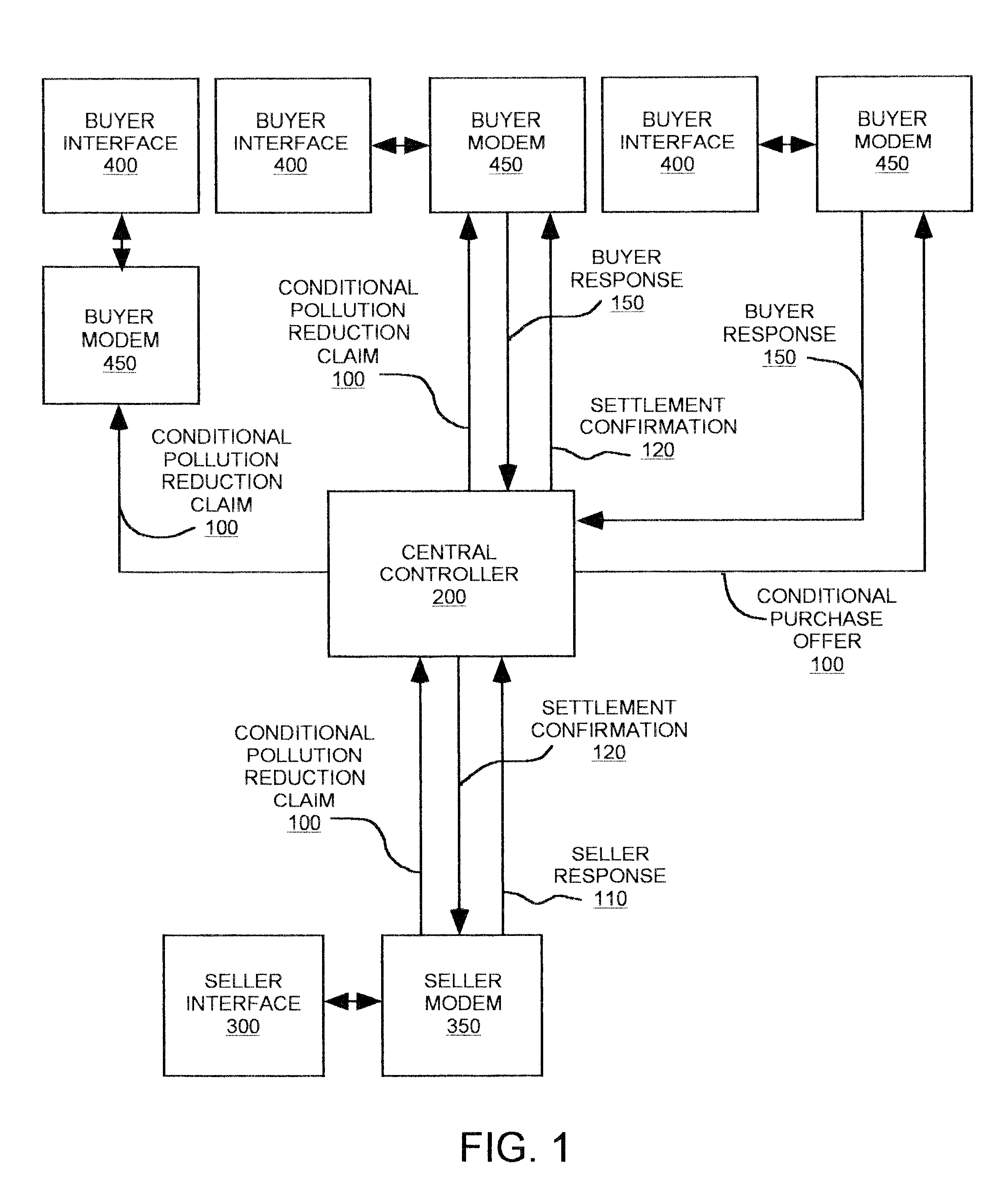

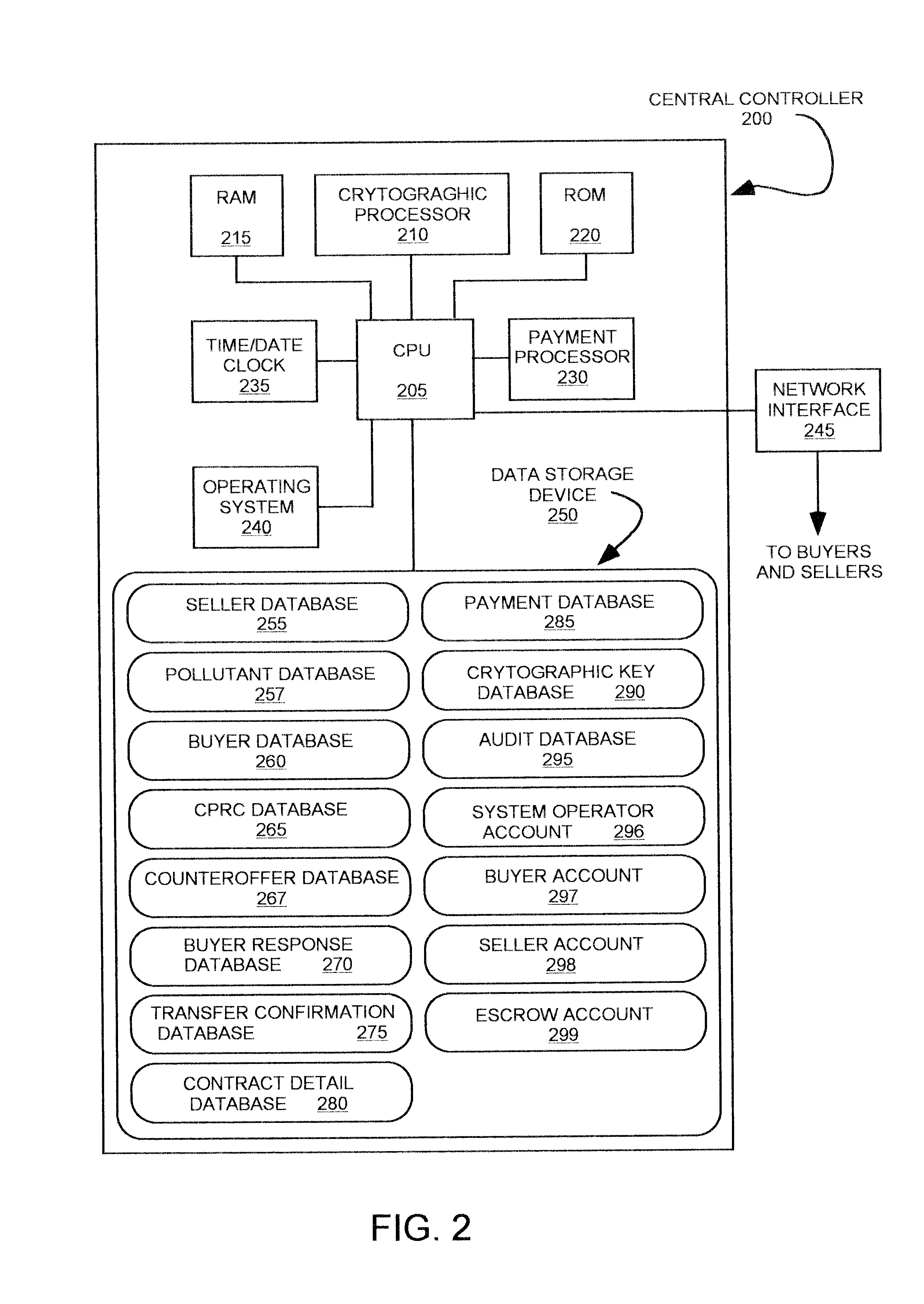

Pollution credit method using electronic networks

InactiveUS6601033B1Reduce pollutionReduce the valueSustainable waste treatmentFinanceThird partyEngineering

The present invention is a method and apparatus for effectuating commerce in claimant-driven individual pollution credits which allows gas utility consumers to claim pollution credit when reducing their pollution levels while employing energy efficiency measures, which has value. Such reduced pollution credit is given value by a third-party, thus, individuals, government agencies and related parties, working in concert with a third-party identify the need, establish ownership, calculate the pollution credit value, and create a new market that has economic value and environmental benefit.

Owner:SOWINSKI RICHARD F

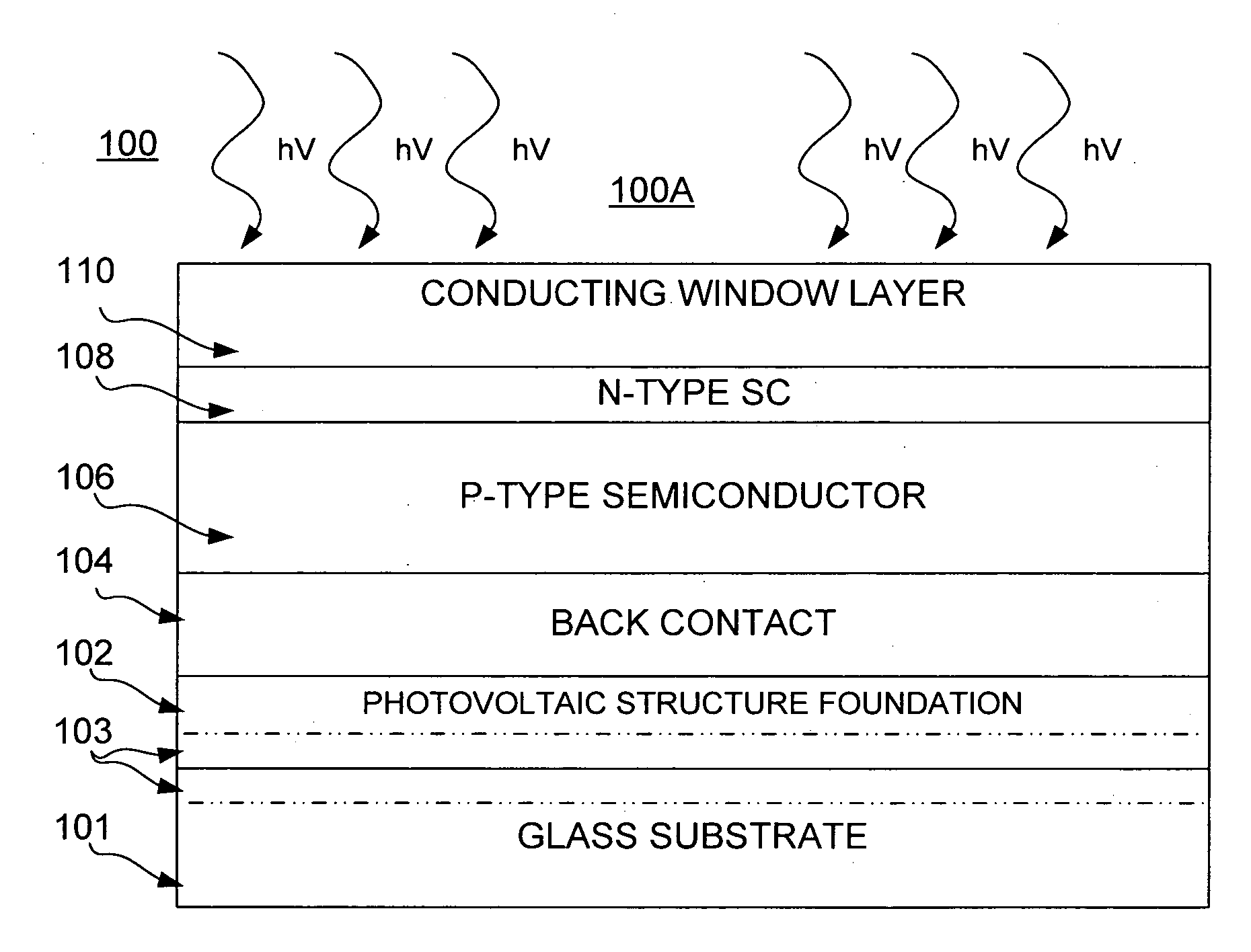

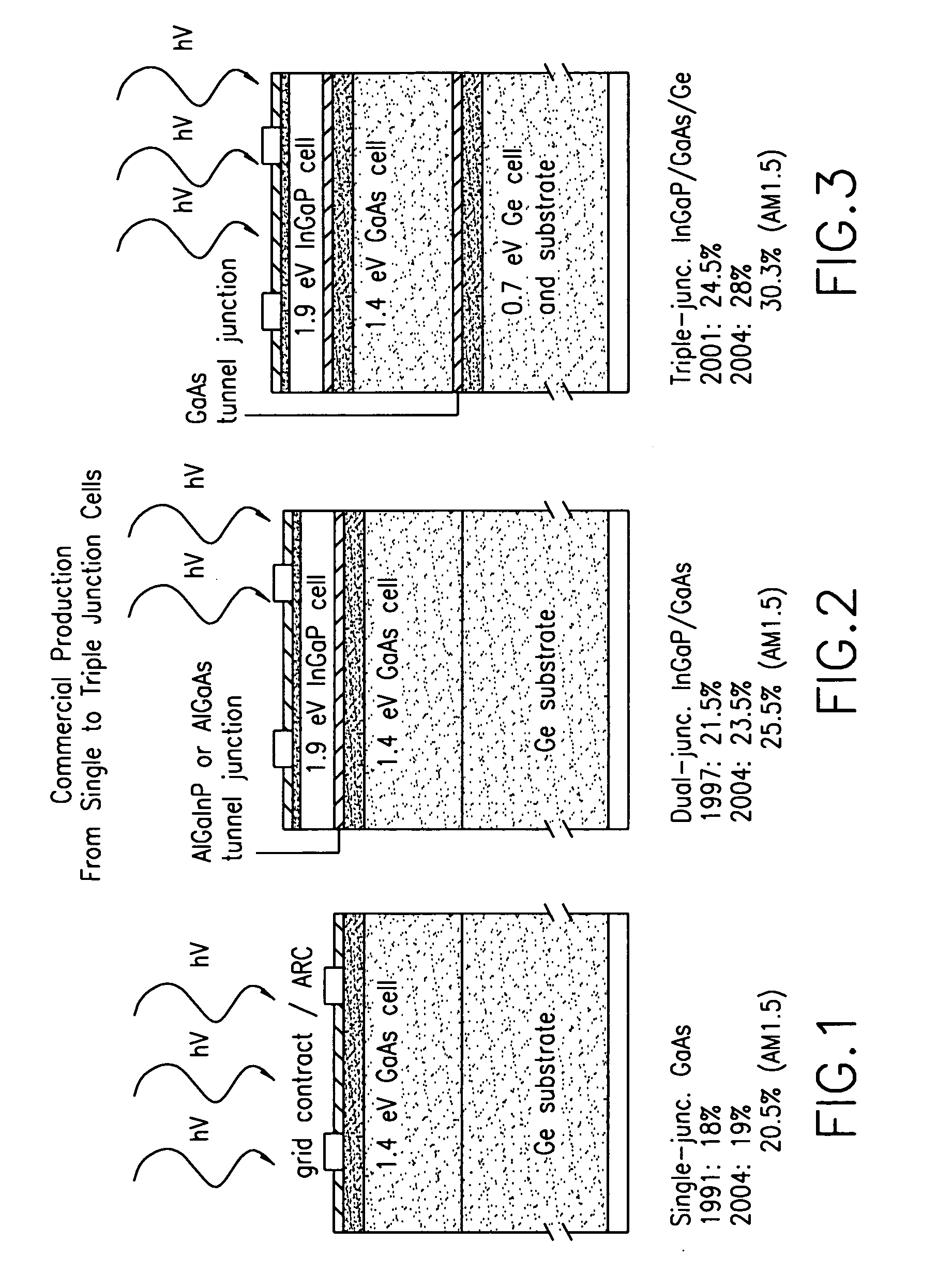

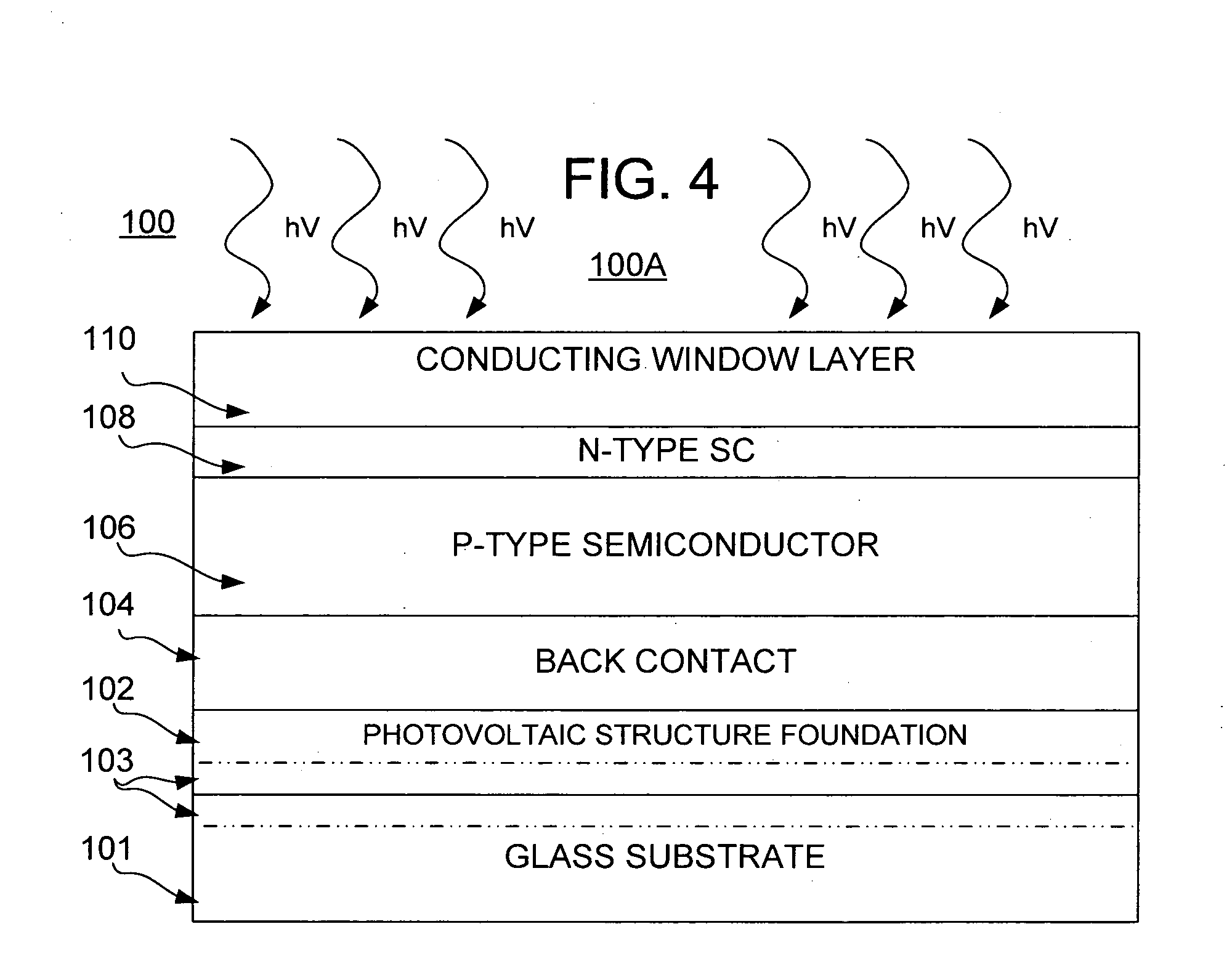

Thin film photovoltaic structure

InactiveUS20070277874A1Faster throughputReduce needSemiconductor/solid-state device manufacturingPhotovoltaic energy generationAnodic bondingVoltage

Systems and methods of production of a photovoltaic device include creating on a donor semiconductor wafer an exfoliation layer and transferring the exfoliation layer to an insulator substrate. One or more finishing processes may be performed before and / or after transferring the exfoliation layer, such as to create a plurality of photovoltaic structure layers. Production of the photovoltaic device further may include subjecting the donor semiconductor wafer to an ion implantation process to create the exfoliation layer, bonding the exfoliation layer to the insulator substrate, and separating the exfoliation layer from the donor semiconductor wafer. Transferring may include forming an anodic bond via electrolysis, such as through the application of heat, pressure and voltage to the exfoliation layer and the insulator structure.

Owner:CORNING INC

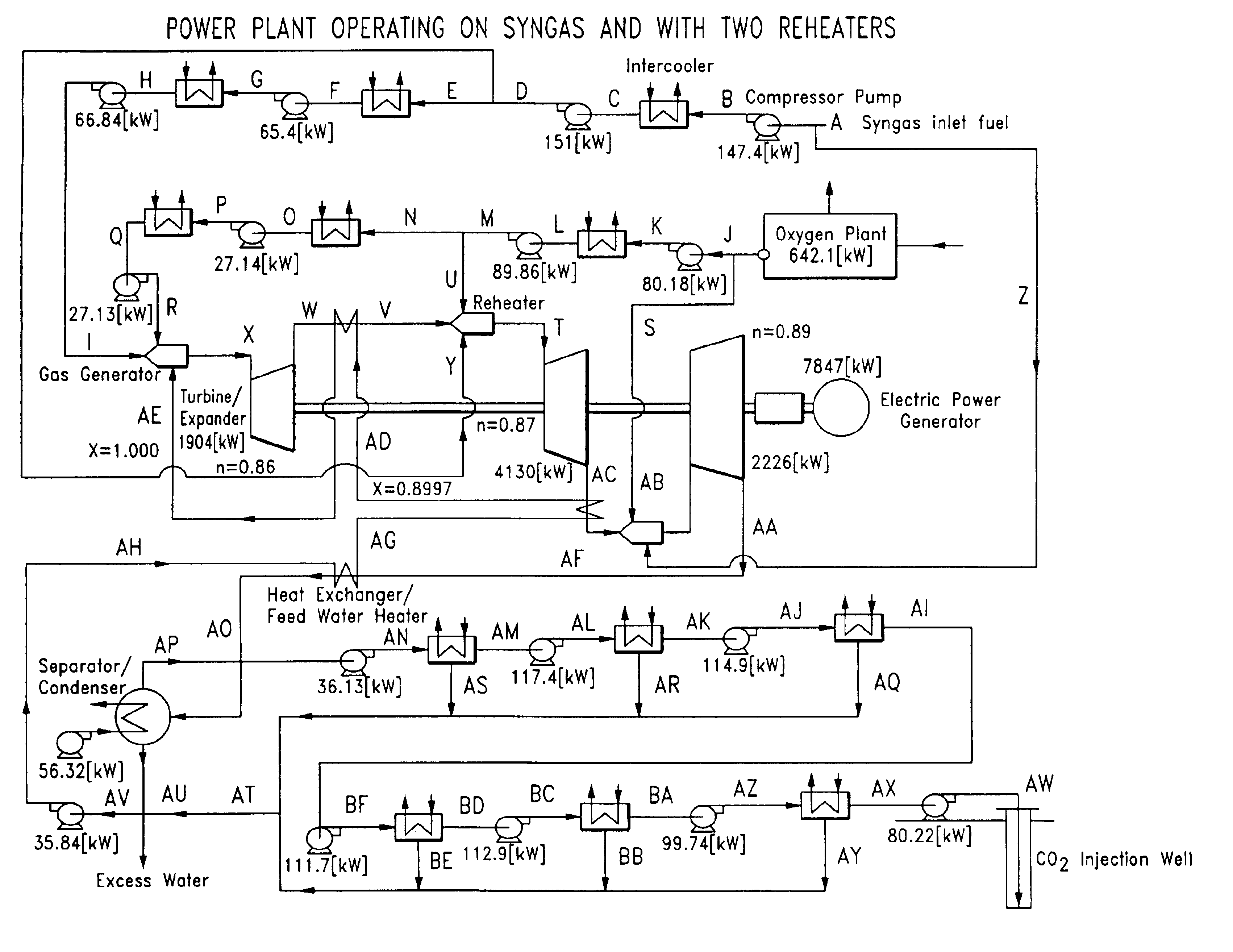

Low pollution power generation system with ion transfer membrane air separation

InactiveUS6945029B2Nitrogen oxideReduce electricity demandSolidificationLiquefactionPollutionCombustion products

A low or no pollution power generation system is provided. The system has an air separator to collect oxygen. A gas generator is provided with inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. Water or other diluents are also delivered into the gas generator to control temperature of the combustion products. The combustion products are then expanded through at least one turbine or other expander to deliver output power. The combustion products are then passed through a separator where the steam is condensed. A portion of the water is discharged and the remainder is routed back to the gas generator as diluent. The carbon dioxide can be conditioned for sequestration. The system can be optimized by adding multiple expanders, reheaters and water diluent preheaters, and by preheating air for an ion transfer membrane oxygen separation.

Owner:CLEAN ENERGY SYST

Ethanol plant process

InactiveUS20090166172A1Shorten process cycleIncrease ethanol productionOrganic compound preparationBeer fermentationEthanol fuelProcess engineering

The present invention conserves water by reducing the heat load placed on a cooling tower during the ethanol fuel production process. An air cooler is placed between the ethanol vapor condenser and the cooling tower thereby minimizing process temperature spikes before water enters the cooling tower. This, in turn, shortens the process cycle thereby increasing ethanol production. During certain climactic conditions, the cooling tower may be completely bypassed, thereby conserving more water and increasing ethanol production.

Owner:CASEY LEONARD RAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com