Patents

Literature

7925 results about "Cooling tower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cooling tower is a heat rejection device that rejects waste heat to the atmosphere through the cooling of a water stream to a lower temperature. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or, in the case of closed circuit dry cooling towers, rely solely on air to cool the working fluid to near the dry-bulb air temperature.

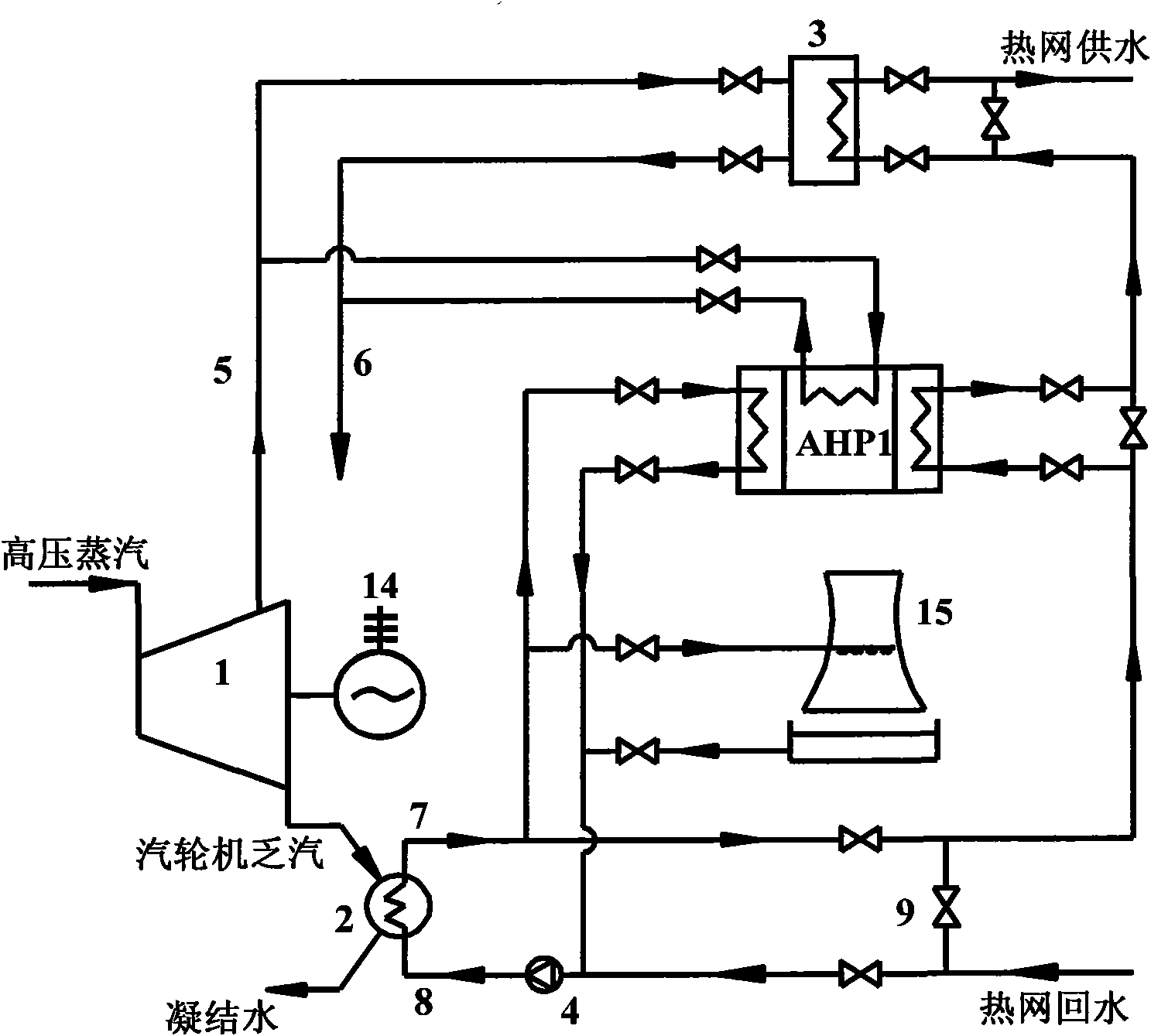

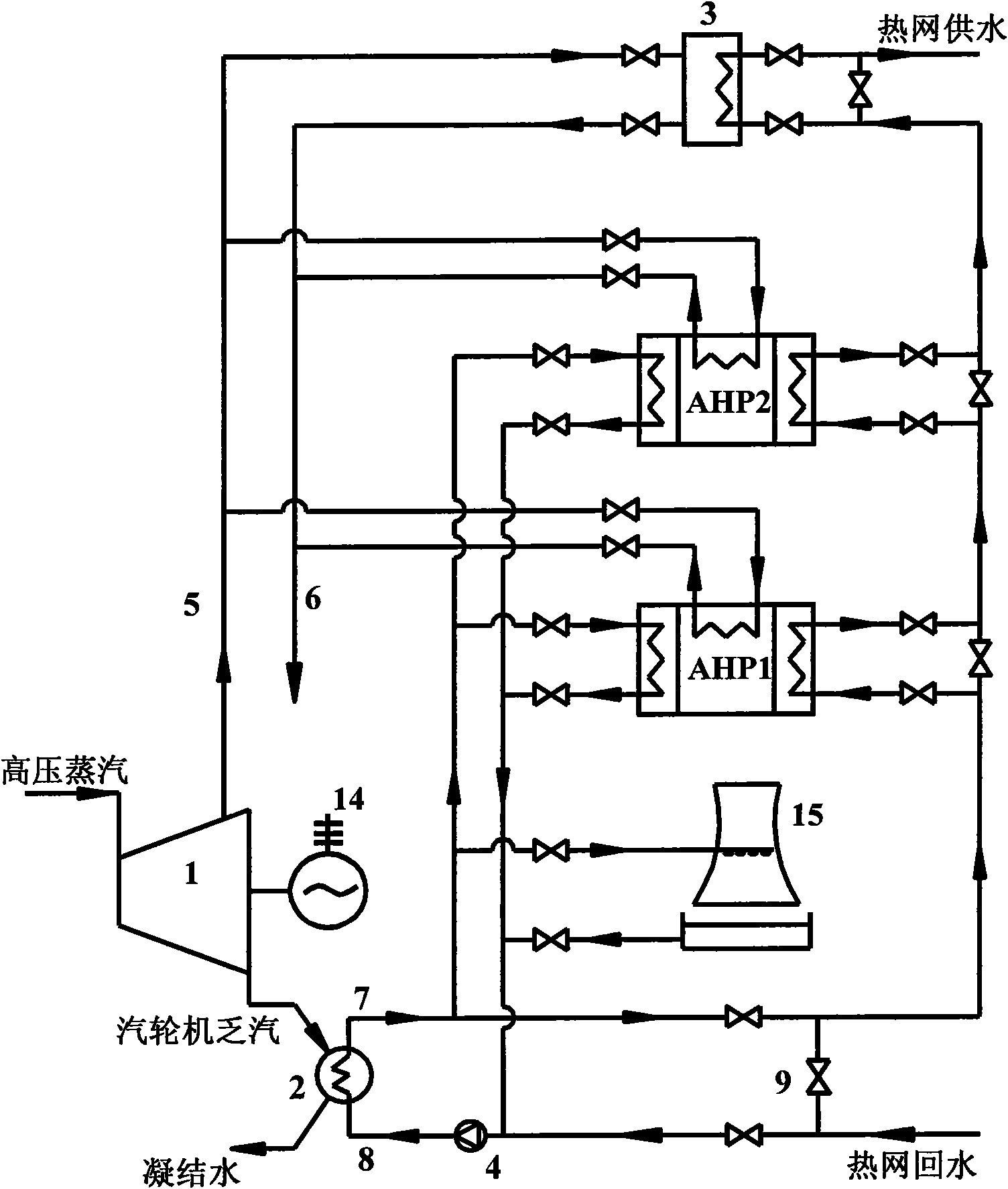

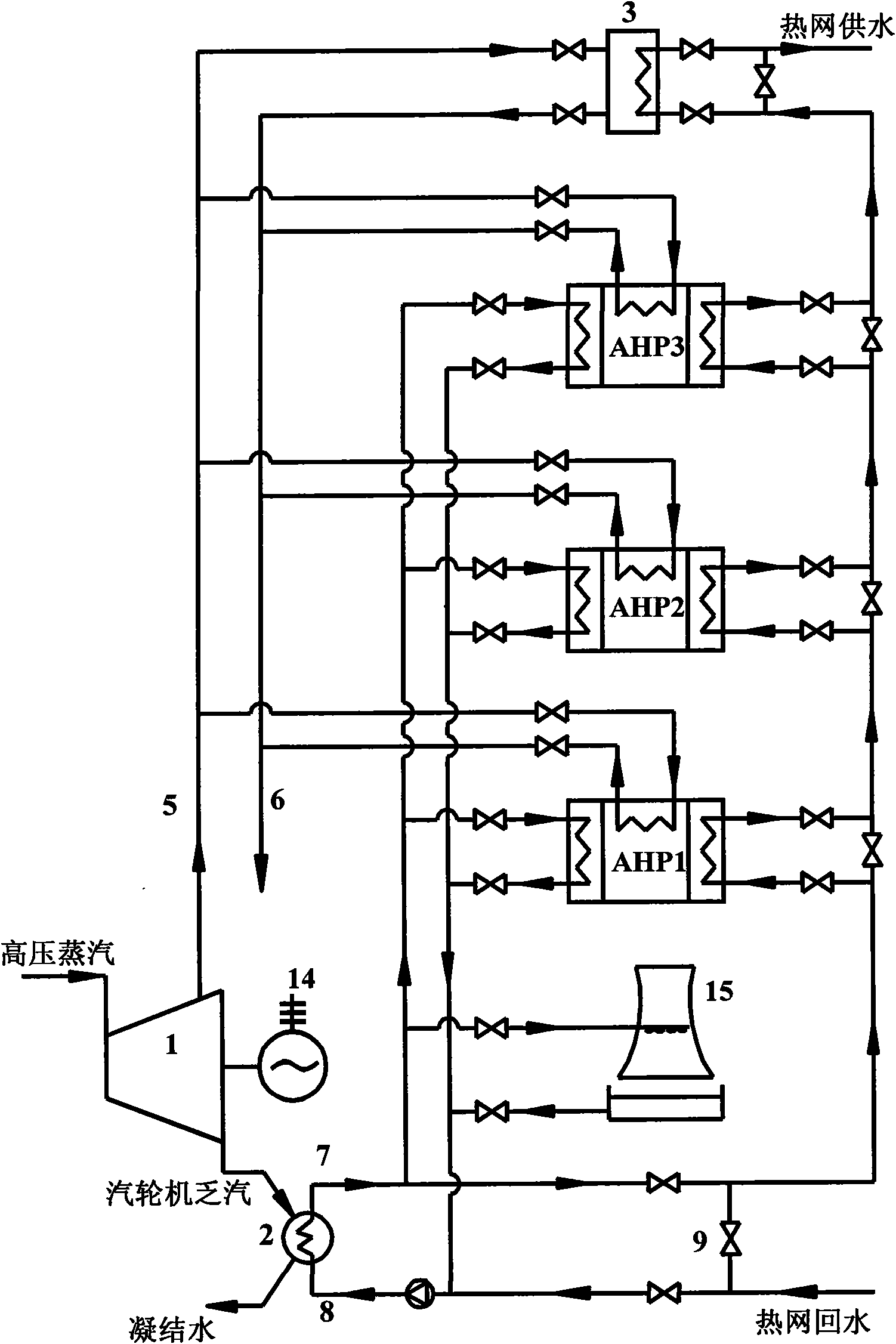

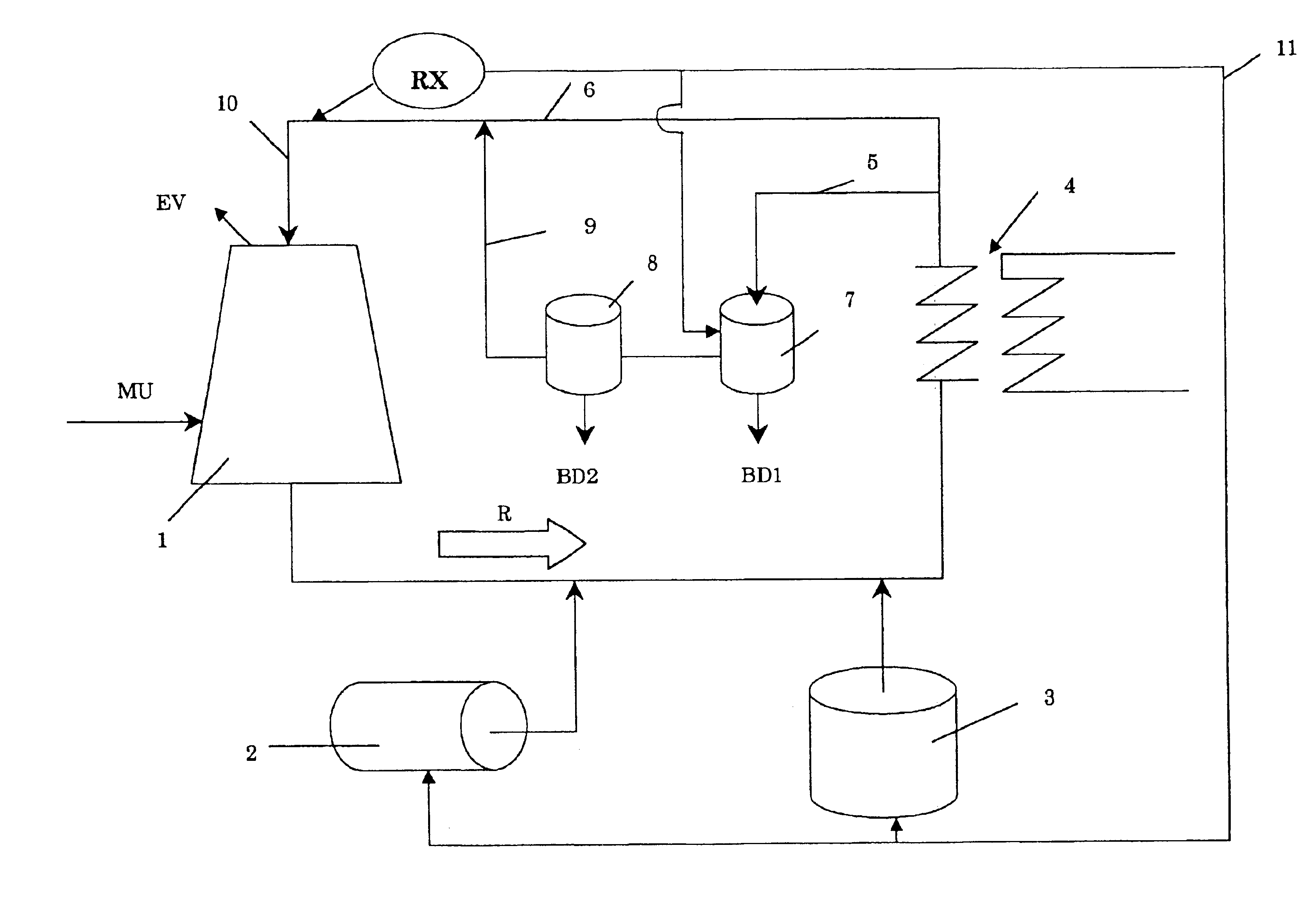

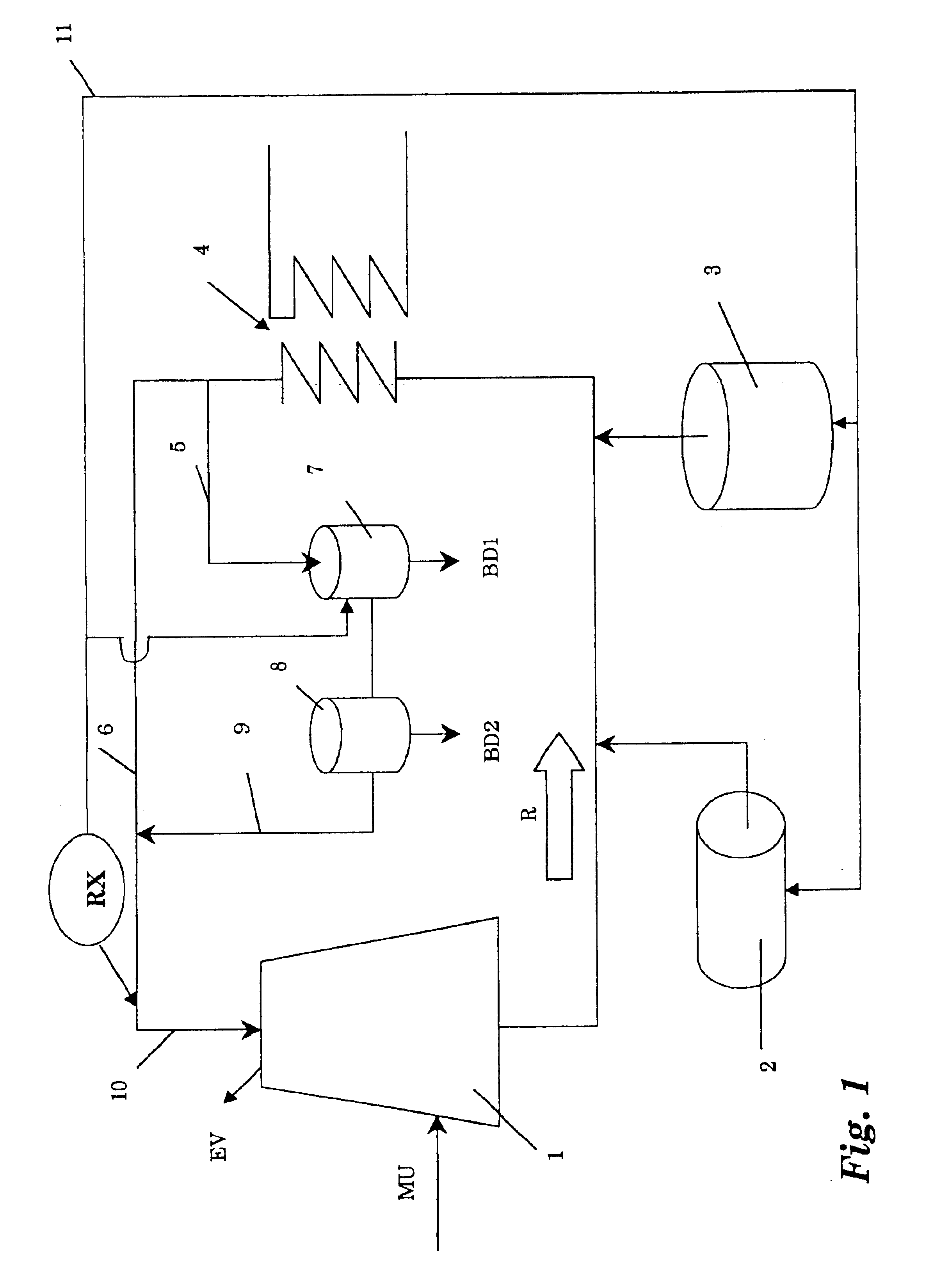

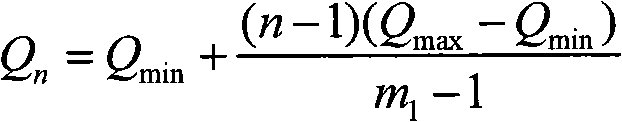

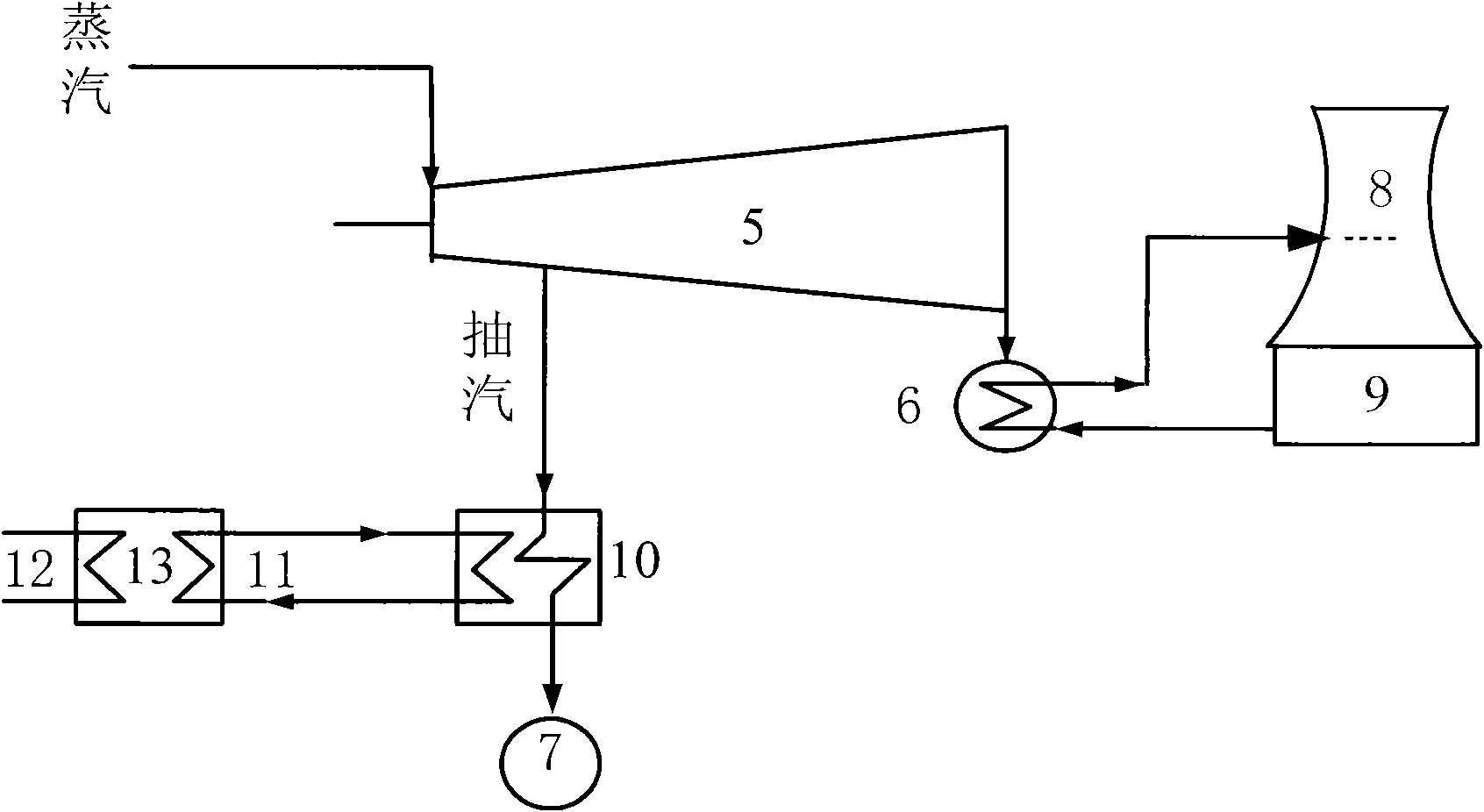

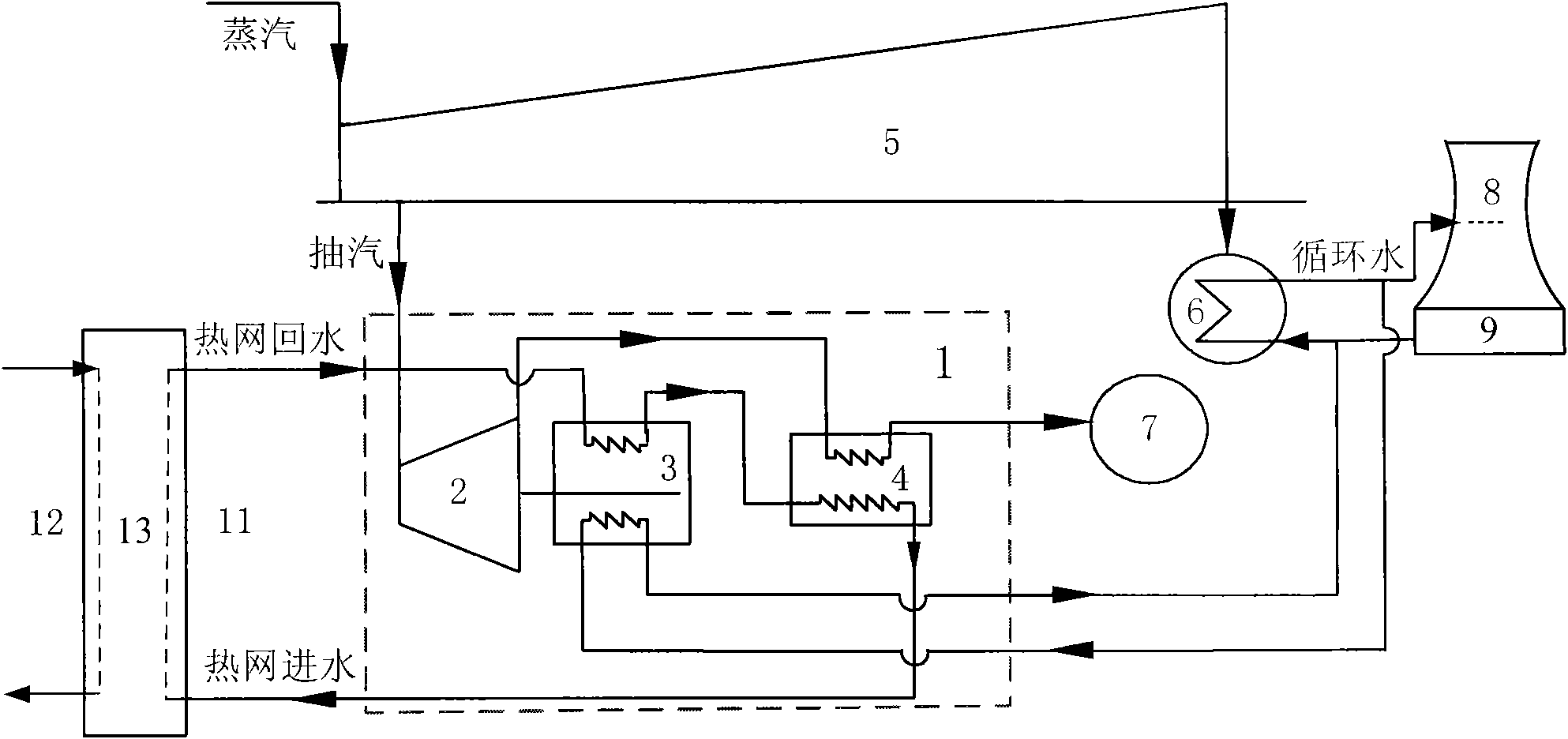

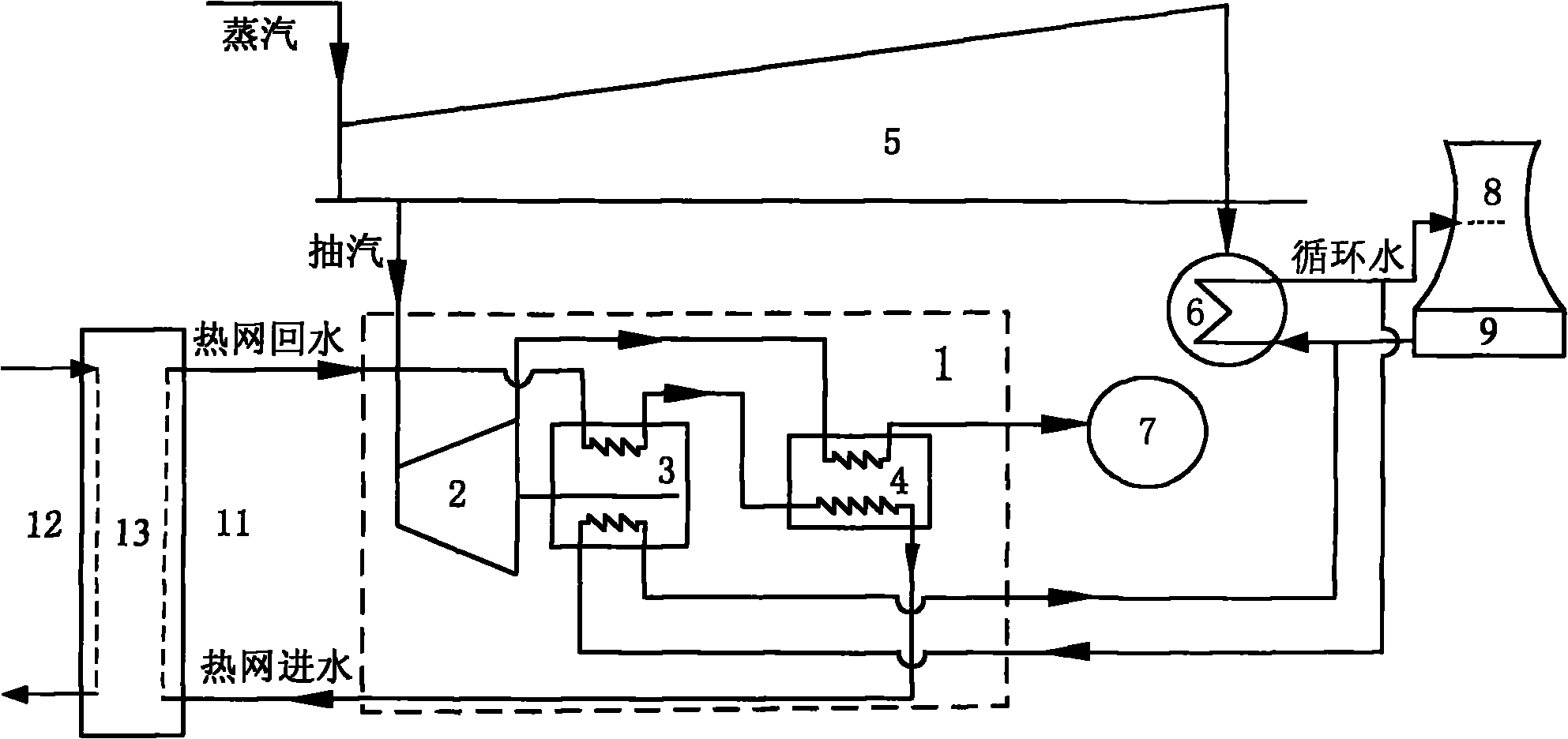

Method for recovering waste heat of thermal power plant and heating and supplying heat to hot water in a stepping way

ActiveCN101619662AImprove utilization efficiencyReduce exergy lossSteam useCombined combustion mitigationCooling towerSteam condensation

The invention discloses a method for recovering the waste heat of a thermal power plant and heating and supplying heat to hot water in a stepping way. In the method, low-temperature heat-net return water is firstly mixed with circulating cooling water positioned on an outlet of a cooling condenser or exchanges heat with the circulating cooling water positioned on the outlet of the cooling condenser to be increased in temperature and then sequentially delivered into an each-step vapour absorption type heat pump and a vapor-water heat exchanger in a series connection way to be gradually heated to be increased in temperature to heat supplying temperature and finally discharged through a water supplying pipeline; the circulating cooling water absorbs the waste steam condensation heat of a steam turbine in the cooling condenser, then one path of the circulating cooling water is directly mixed with the low-temperature heat-net return water or heats the low-temperature heat-net return water through the heat changer, the other path of the circulating cooling water is delivered into an each-step absorption type heat pump unit to be used as a low-order heat source of the absorption type heat pump unit, and the redundant heat of the circulating cooling water is discharged to the environment through a cooling tower. The invention uses the steam extraction of the steam turbine as a driving heat source of the absorption type heat pump so that the low-temperature heat-net return water is heated in a stepping way, thereby reducing the effective energy loss; the waste heat of the discharged steam of the steam turbine is sufficiently recovered in a direct heating way and an absorption type heat pump temperature increasing heating way, therefore, the comprehensive energy usage efficiency of the thermal power plant is enhanced.

Owner:TSINGHUA UNIV +1

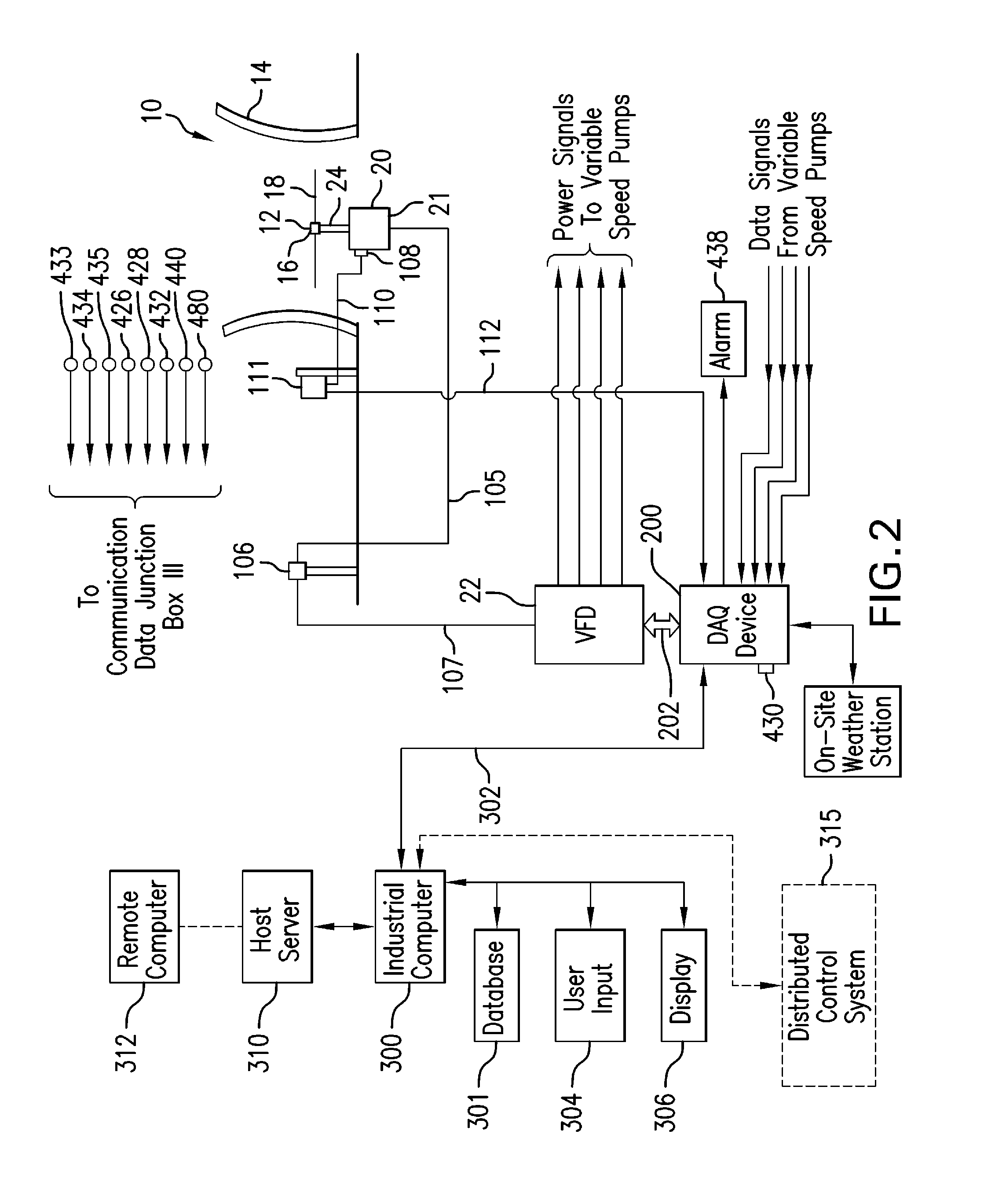

Optimized Control System For Cooling Systems

ActiveUS20090171512A1Reduce energy consumptionImprove energy efficiencySampled-variable control systemsMechanical apparatusCooling towerControl system

A cooling system for providing conditioned air to a facility includes a chiller or other cooling subsystem, a cooling tower subsystem and one or more air handling units or process cooling units. The cooling subsystem may advantageously include one or more chillers (e.g., variable speed chillers, constant speed chillers, absorption chillers, etc.) and chilled fluid pumps. The cooling tower subsystem includes one or more cooling tower units and condenser fluid pumps. In some implementations, the air handling unit has a cooling coil and a variable volume fan. In some implementations, direct expansion (DX) cooling systems comprise compressors, evaporators and air-cooled, water-cooled or evaporatively-cooled condensing systems. Such systems can be controlled to reduce energy waste, improve occupant comfort and / or improve the thermal characteristics of the process cooling unit. The cooling system further comprises a control system which is configured to evaluate a cooling load value at the air handling unit and use the cooling load value to calculate at least one operational setpoint. The operational setpoint may advantageously be selected to improve the energy efficiency of the overall cooling system.

Owner:YARDI SYST

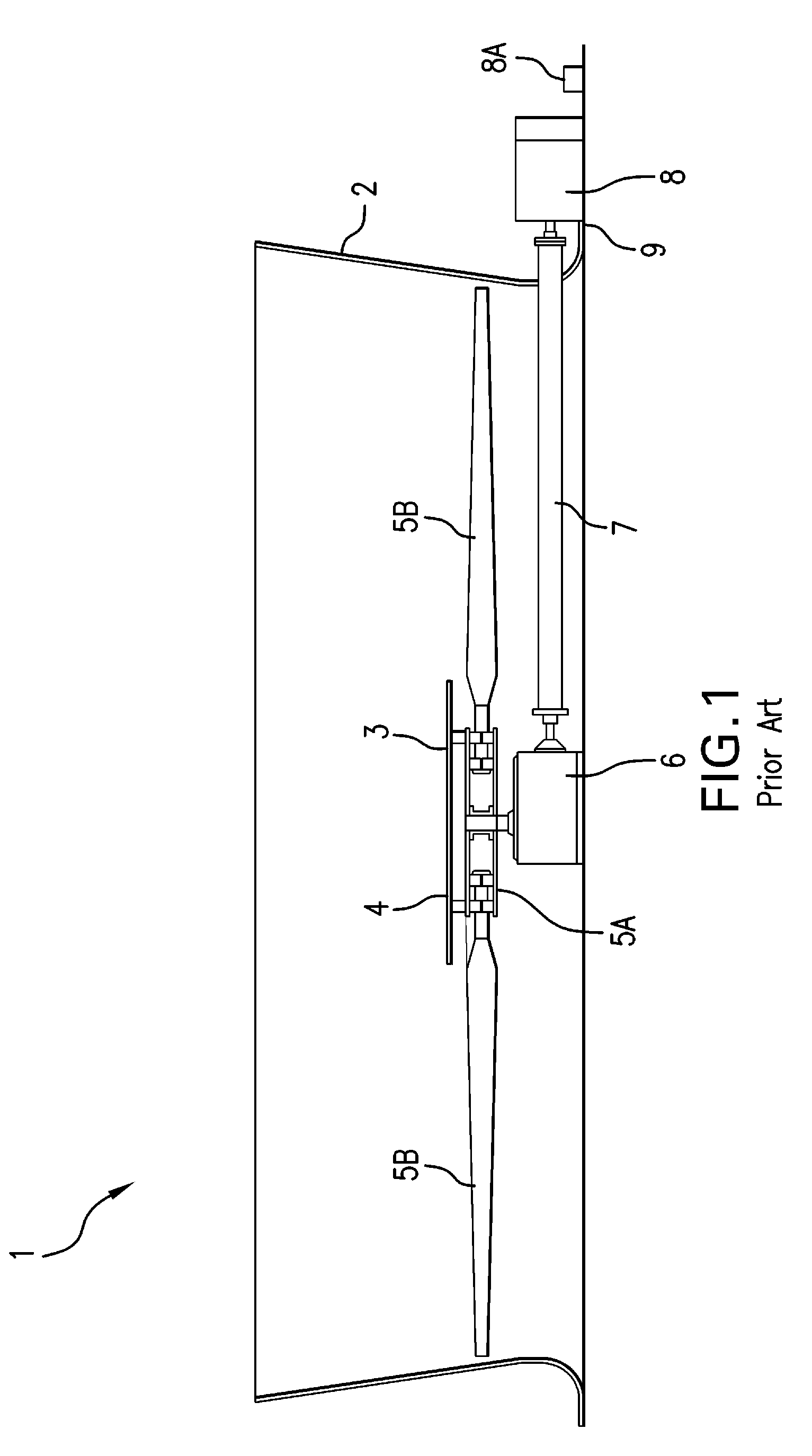

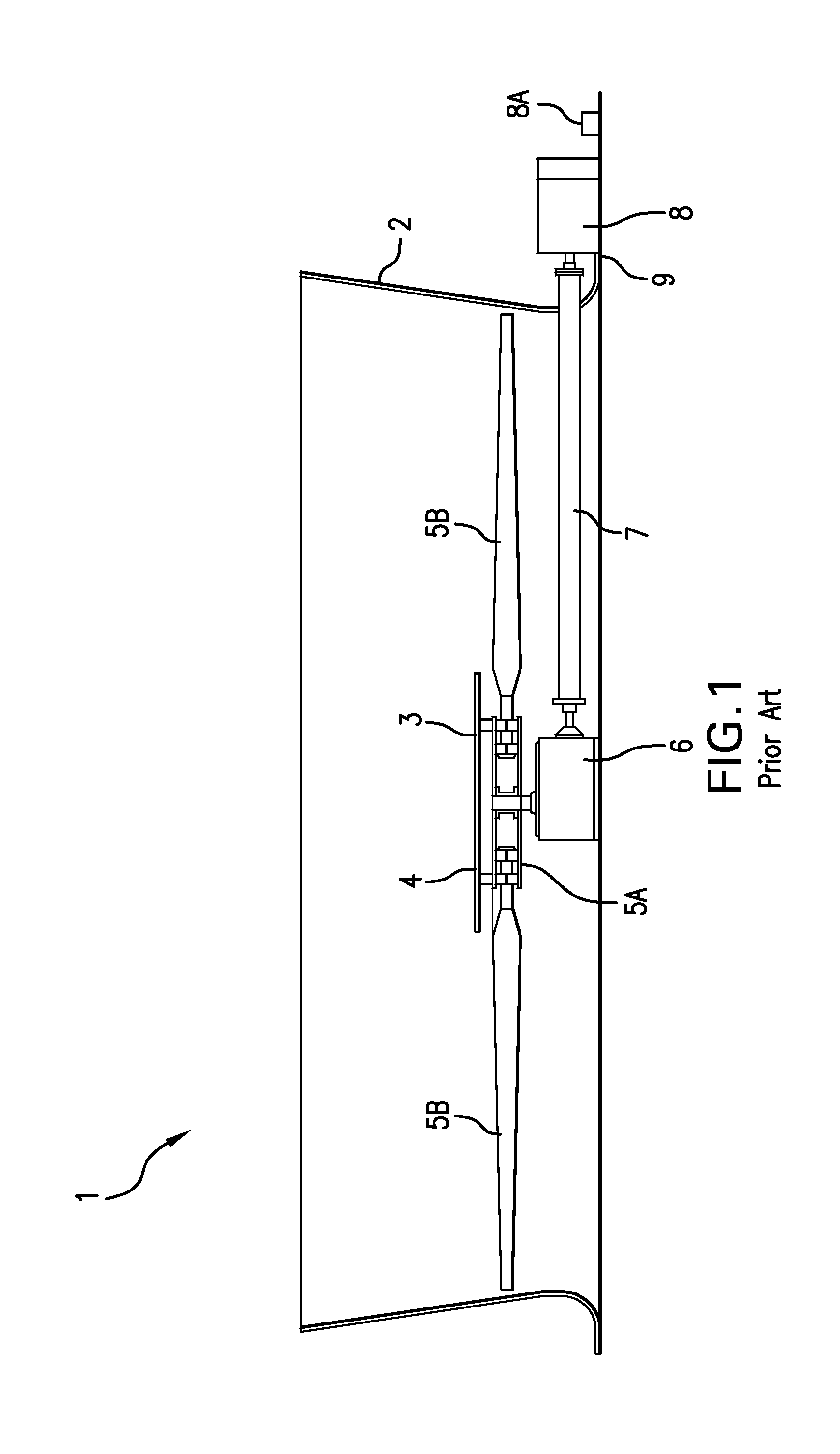

Direct drive fan system with variable process control

ActiveUS20140244051A1System smoothReduce vibrationTransportation and packagingEngine fuctionsCooling towerHigh torque

The present invention is directed to a direct-drive fan system and a variable process control system for efficiently managing the operation of fans in a cooling system such a as wet-cooling tower or air-cooled heat exchanger (ACHE), HVAC systems, mechanical towers or chiller systems. The present invention is based on the integration of key features and characteristics such as tower thermal performance, fan speed and airflow, motor torque, fan pitch, fan speed, fan aerodynamic properties, and pump flow. The variable process control system processes feedback signals from multiple locations in order control a high torque, variable speed, permanent magnet motor to drive the fan. Such feedback signals represent certain operating conditions including motor temperature, basin temperature, vibrations, and pump flow rates. Other data processed by the variable process control system in order to control the motor include turbine back pressure set-point, condenser temperature set-point and plant part-load setting. The variable process control system processes this data and the aforesaid feedback signals to optimize the operation of the cooling system in order to prevent disruption of the industrial process and prevent equipment (turbine) failure or trip. The variable process control system alerts the operators for the need to conduct maintenance actions to remedy deficient operating conditions such as condenser fouling. The variable process control system increases cooling for cracking crude and also adjusts the motor RPM, and hence the fan RPM, accordingly during plant part-load conditions in order to save energy.

Owner:PRIME DATUM

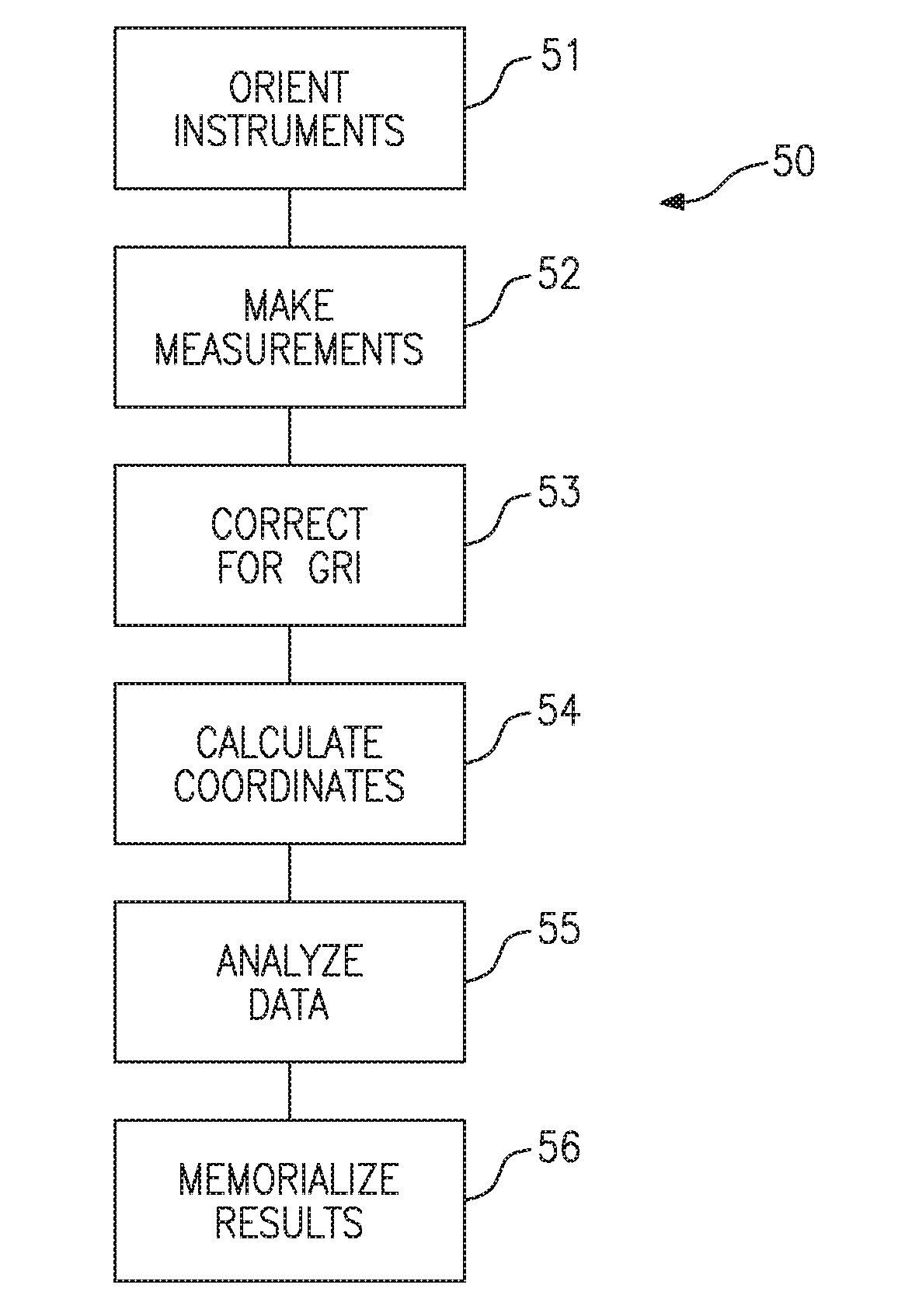

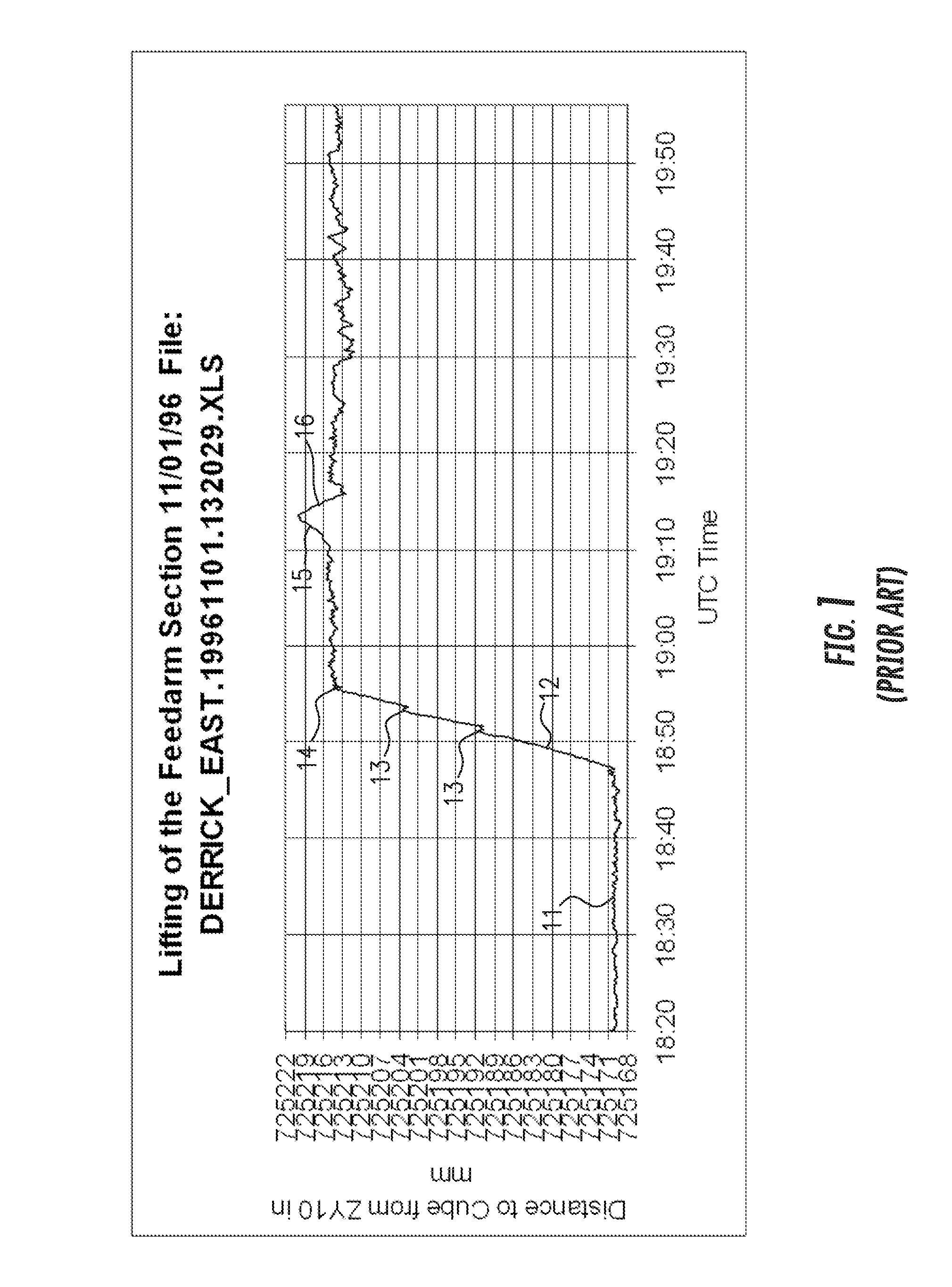

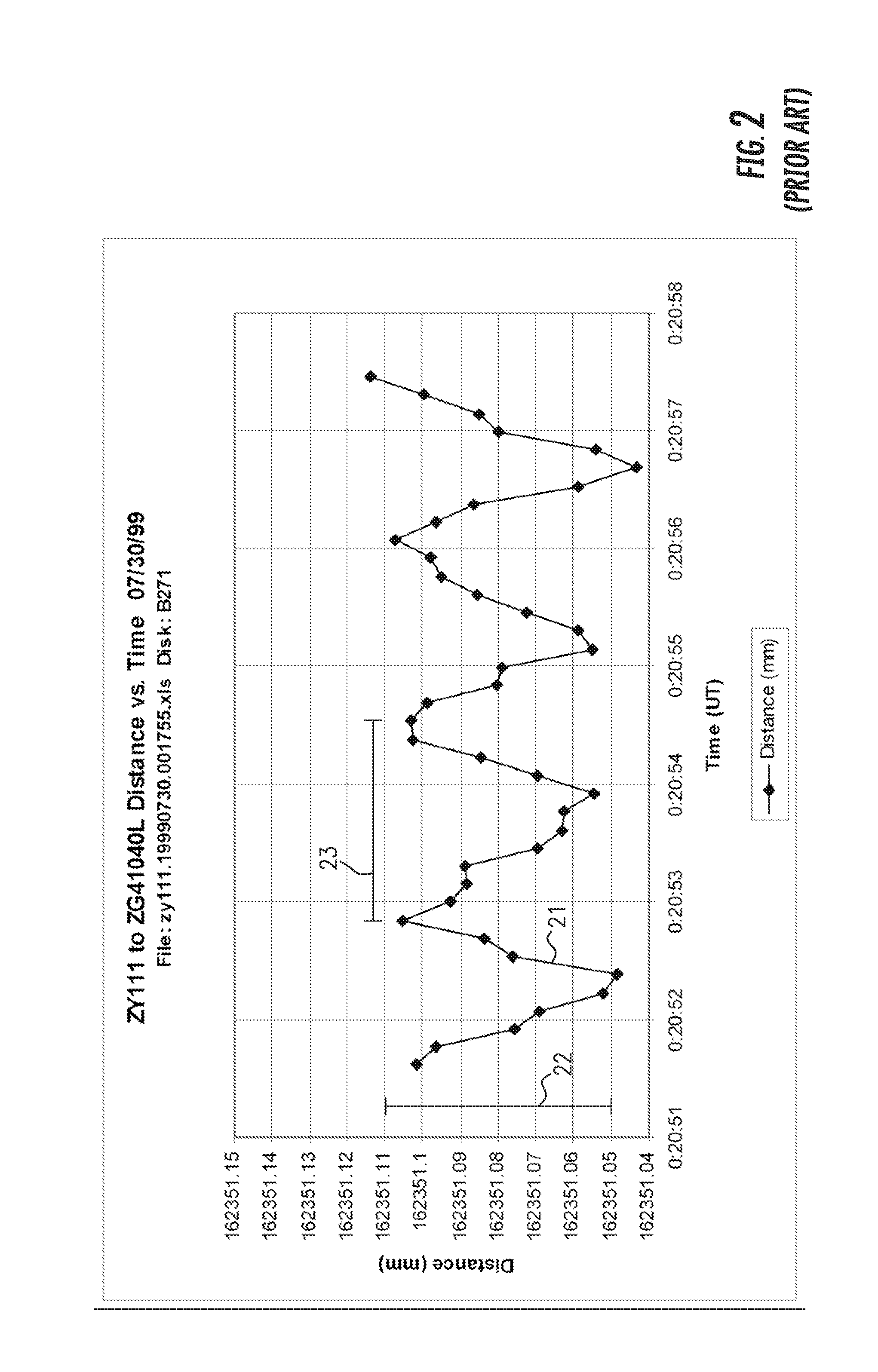

Methods for measuring and modeling the process of prestressing concrete during tensioning/detensioning based on electronic distance measurements

Methods are disclosed for nondestructive testing and measuring the structural health of prestressed concrete structures, such as slabs, columns, girders, bridges, towers, elevated storage tanks, silos, cooling towers, wind power generation towers, liquefied gas storage tanks, nuclear power containment buildings, and the like. Measurements are made as the structure undergoes tensioning and detensioning operations. By measuring actual movements of cardinal points on the structure, in an absolute three-dimensional coordinate system, and comparing the measurements to a model—as tension on a tendon is changed—a margin of safety is assured. High accuracy measurements are made by electronic distance measurement (EDM) instruments over hundreds of meters, which yield coordinates of cardinal points with an uncertainty of the order of one part per million. The methods are proposed as possible alternatives to prior failures of post-tensioned concrete, including the Las Lomas Bridge, the Kapiolani Interchange On-Ramp, Turkey Point Unit 3 Nuclear Power Plant, and Crystal River Unit 3 Nuclear Power Plant. An extensive review of the most closely related prior arts is included.

Owner:SOPHIE LIN TRUSTEE OF THE JOHN MICHAEL PAYNE FAMILY TRUST +1

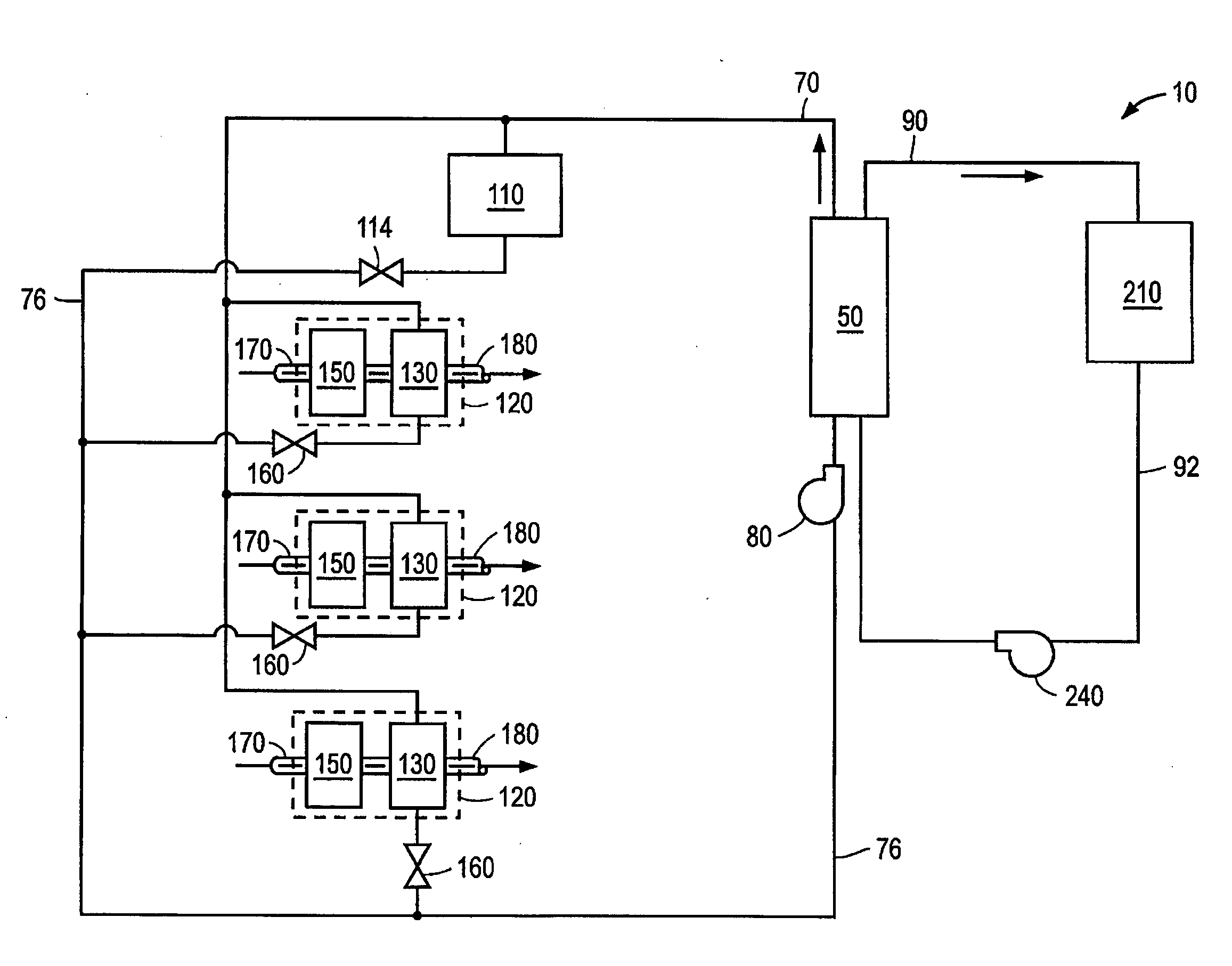

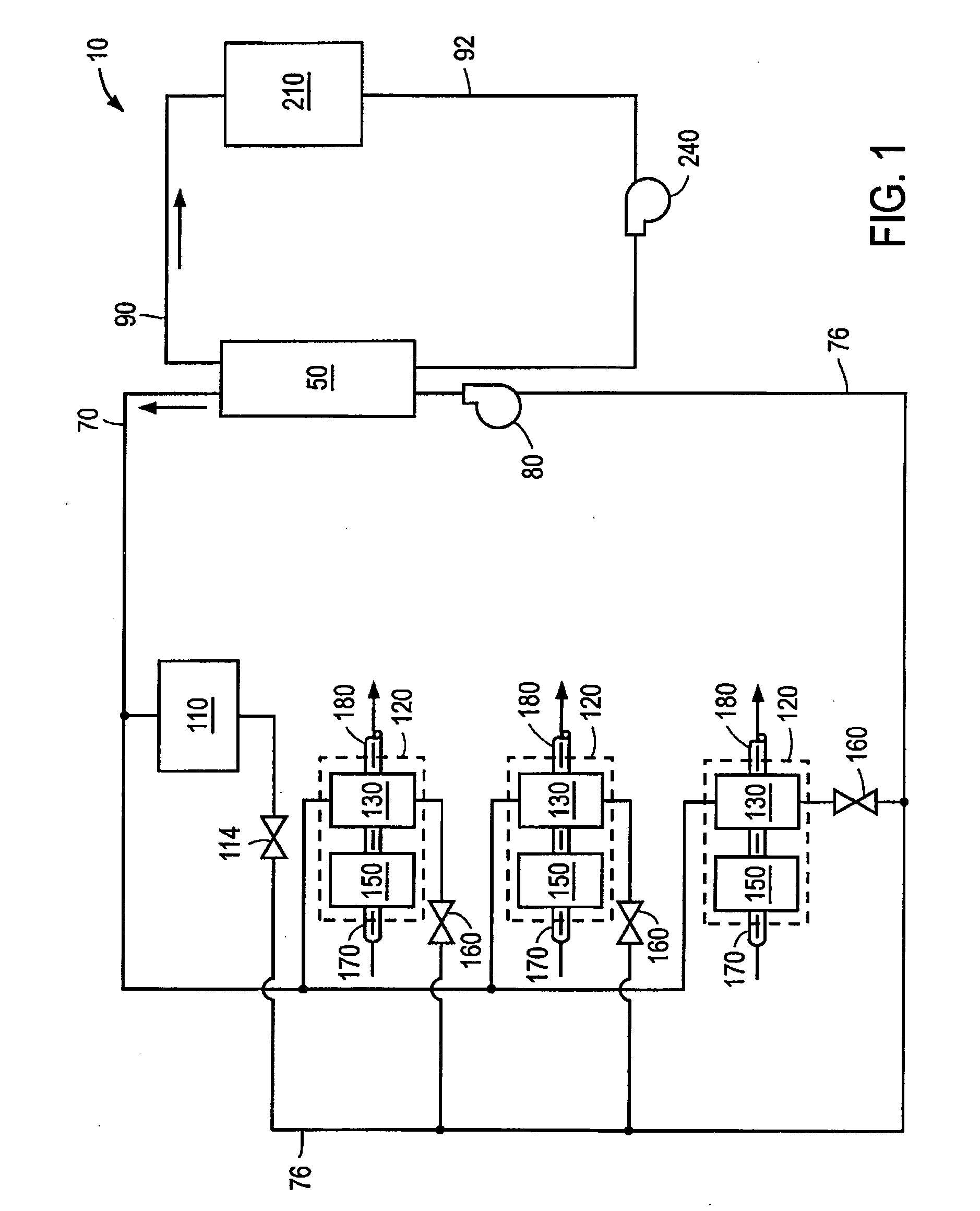

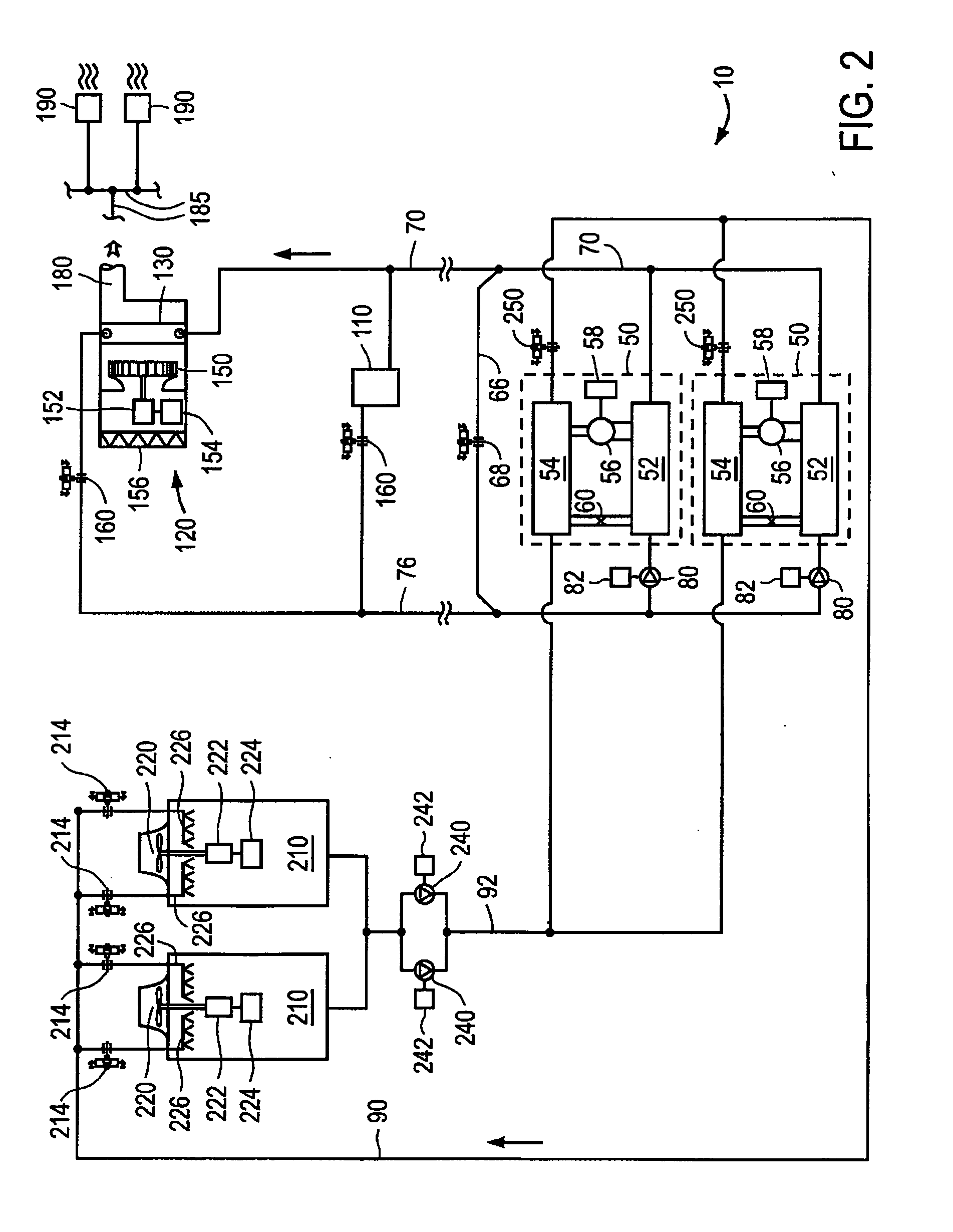

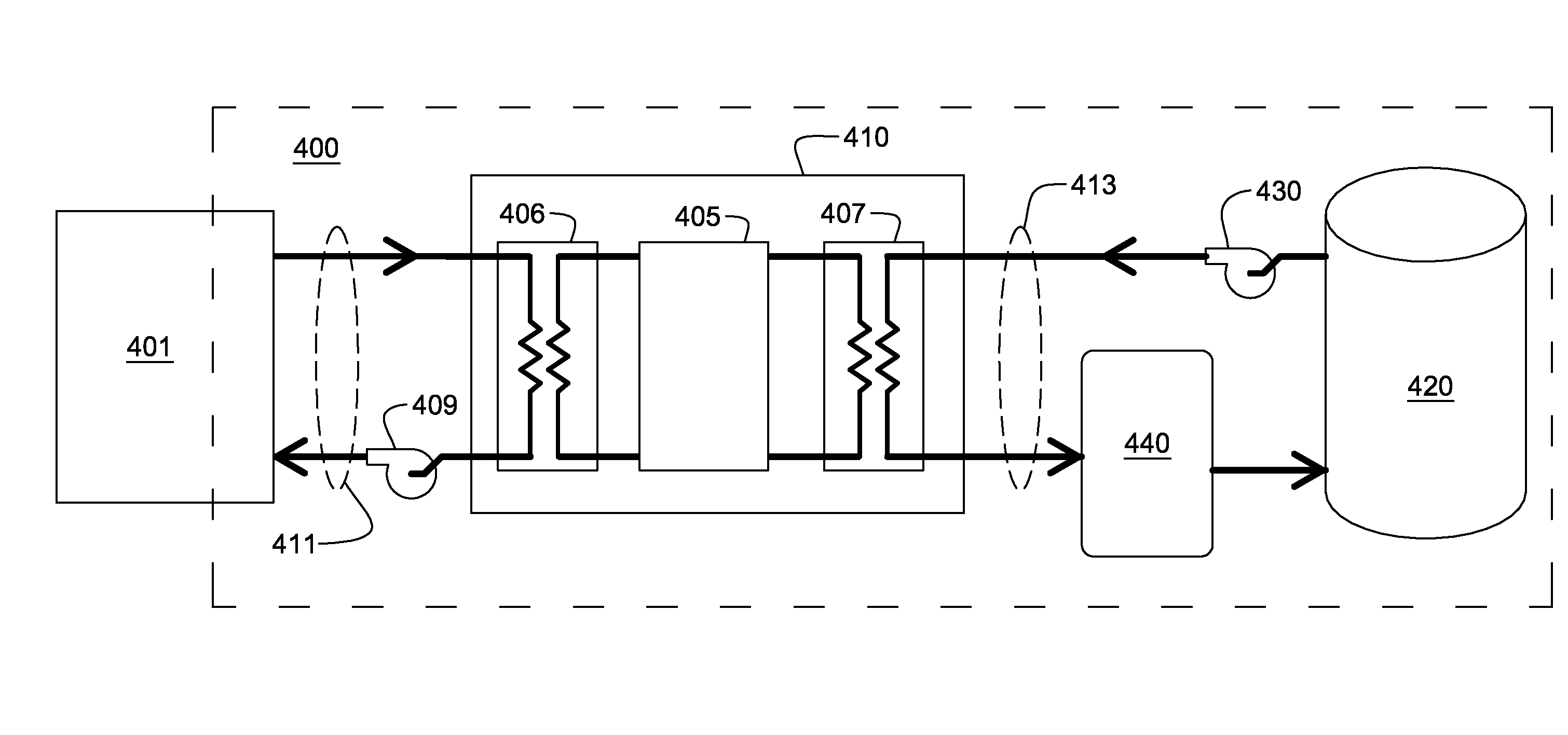

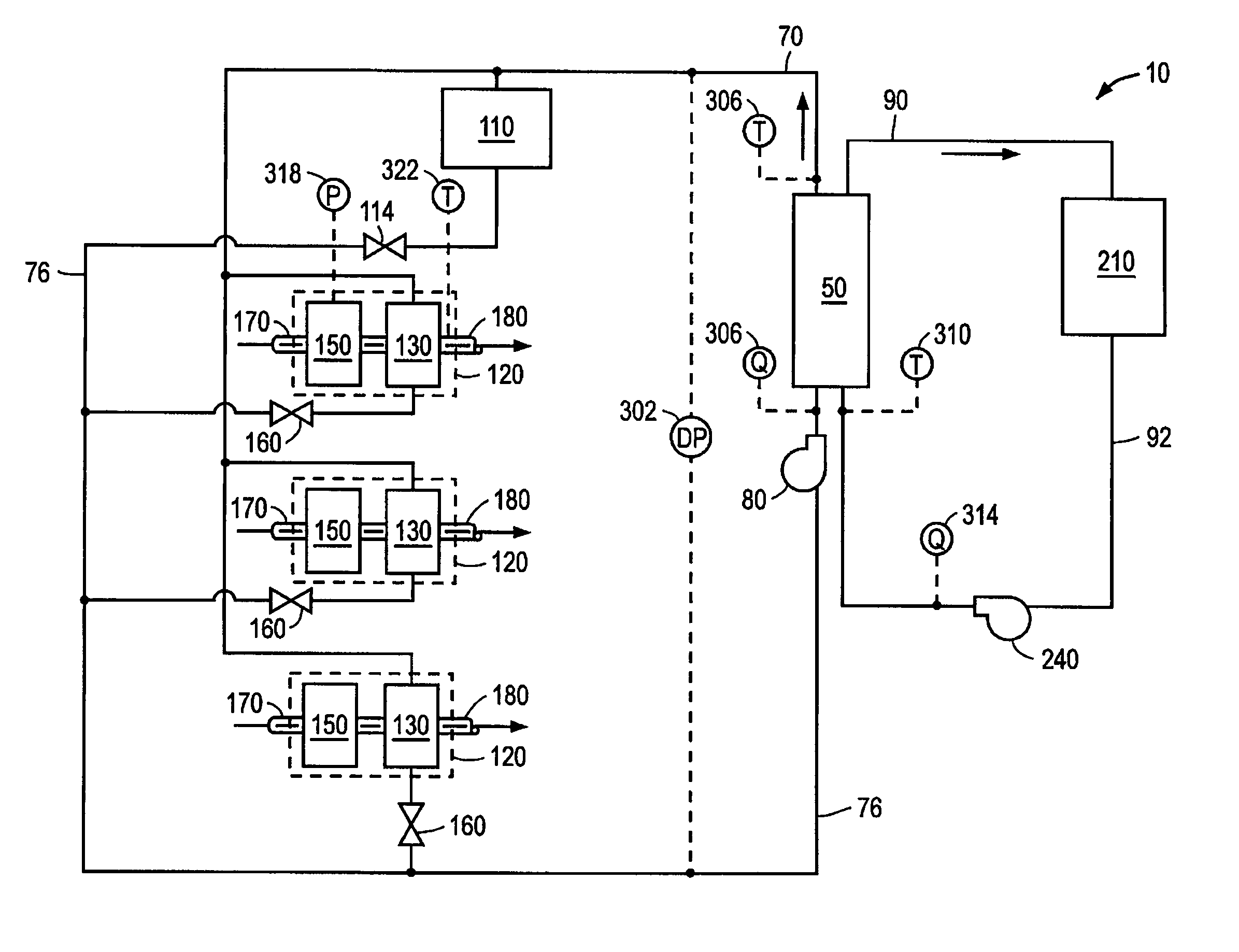

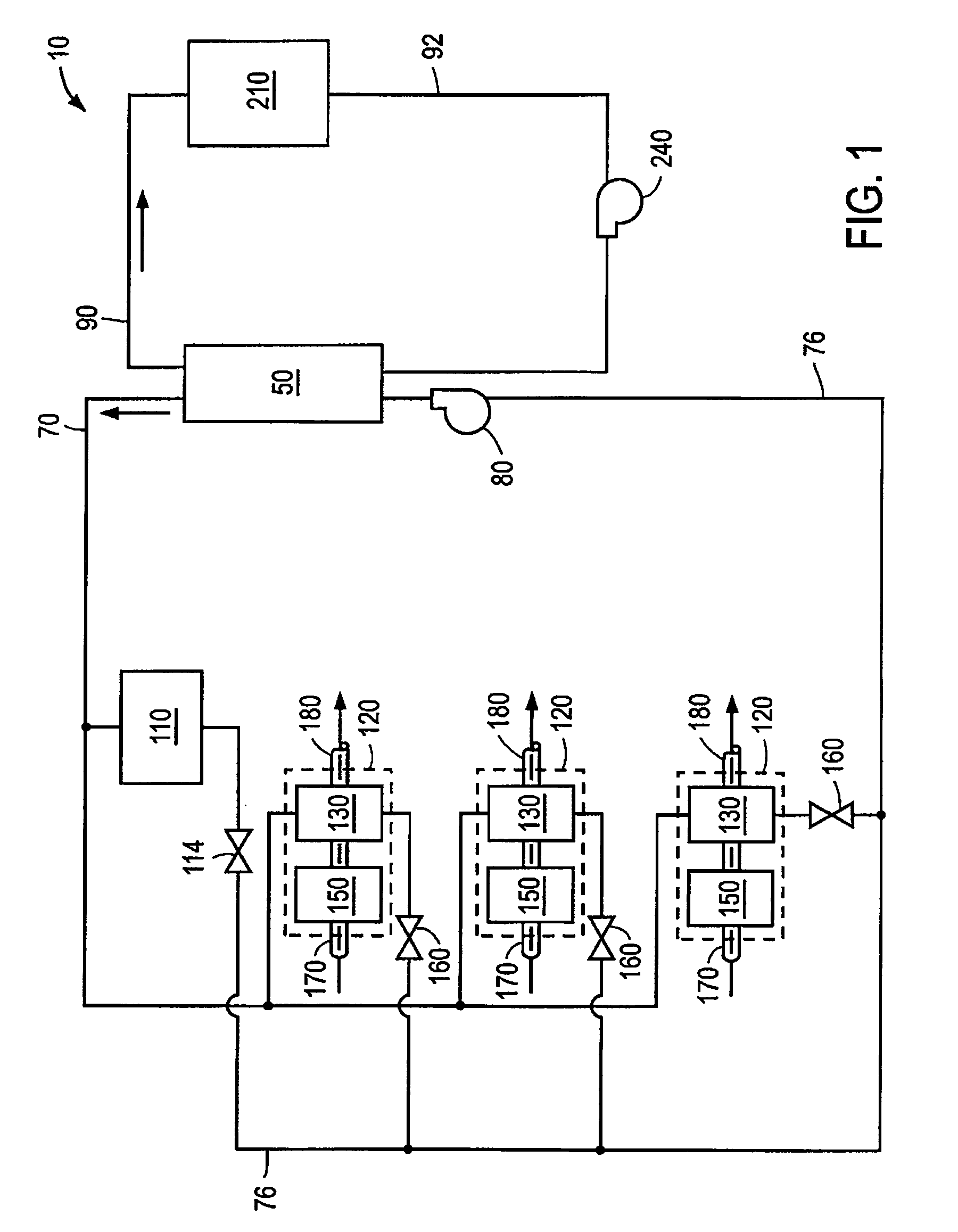

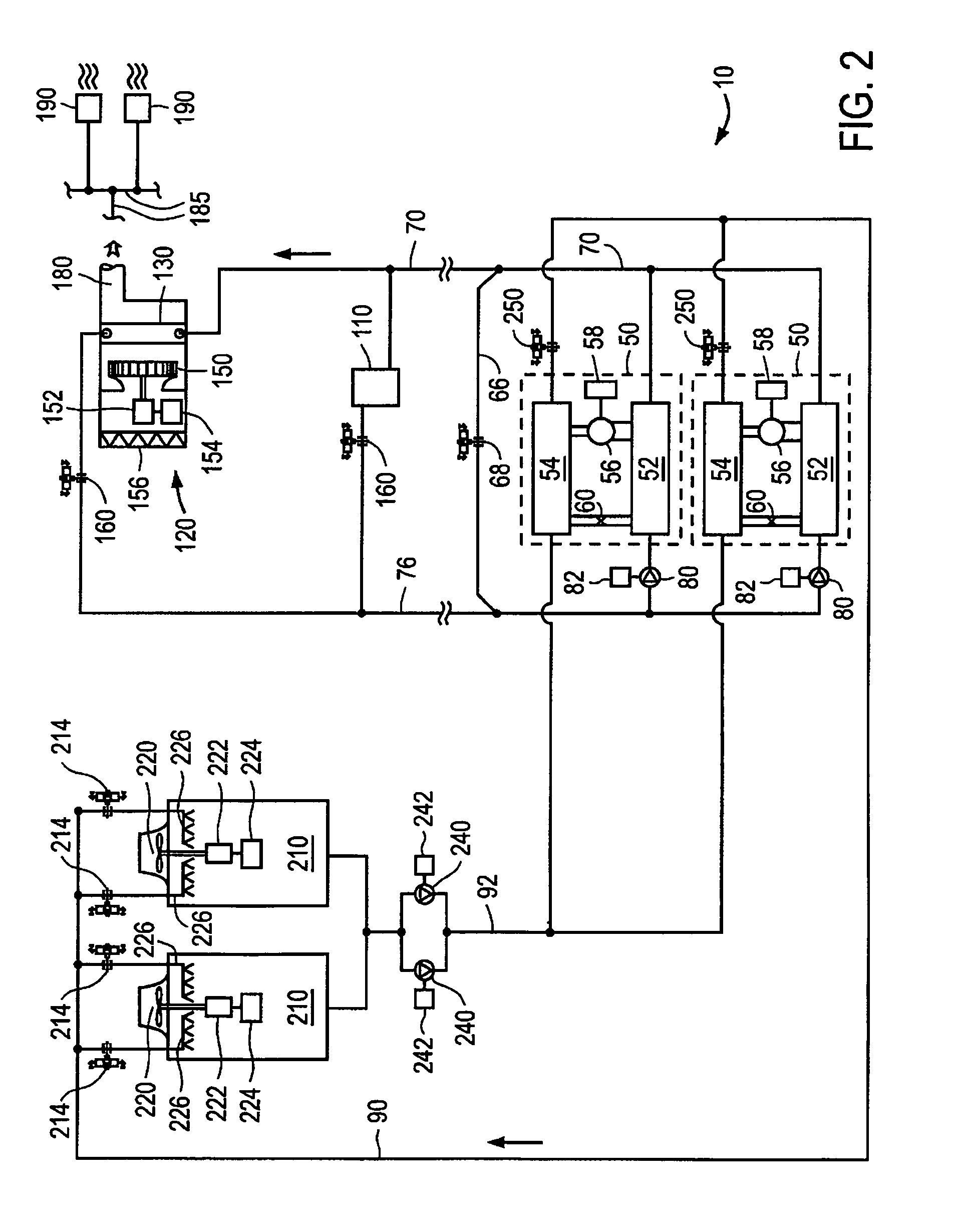

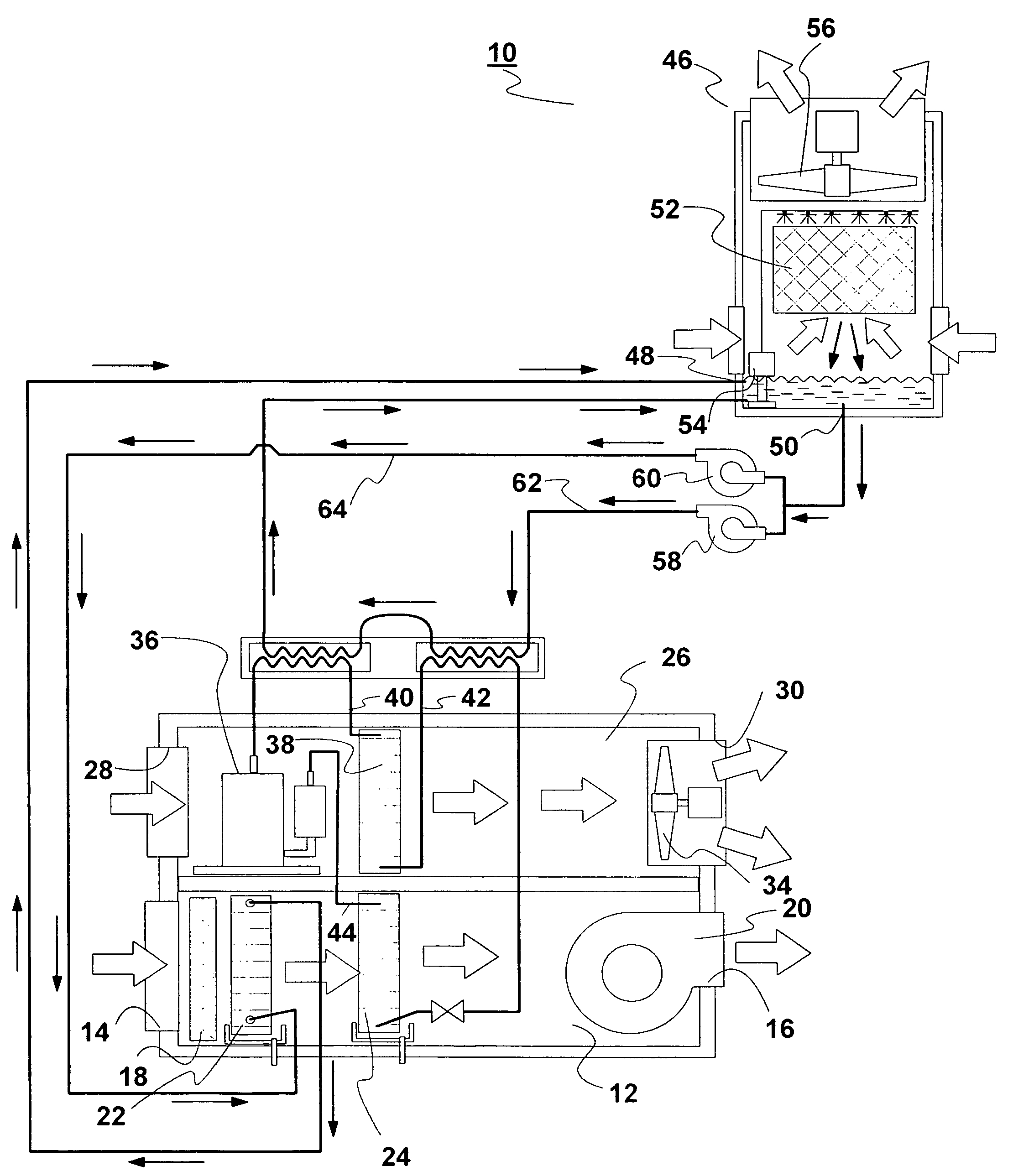

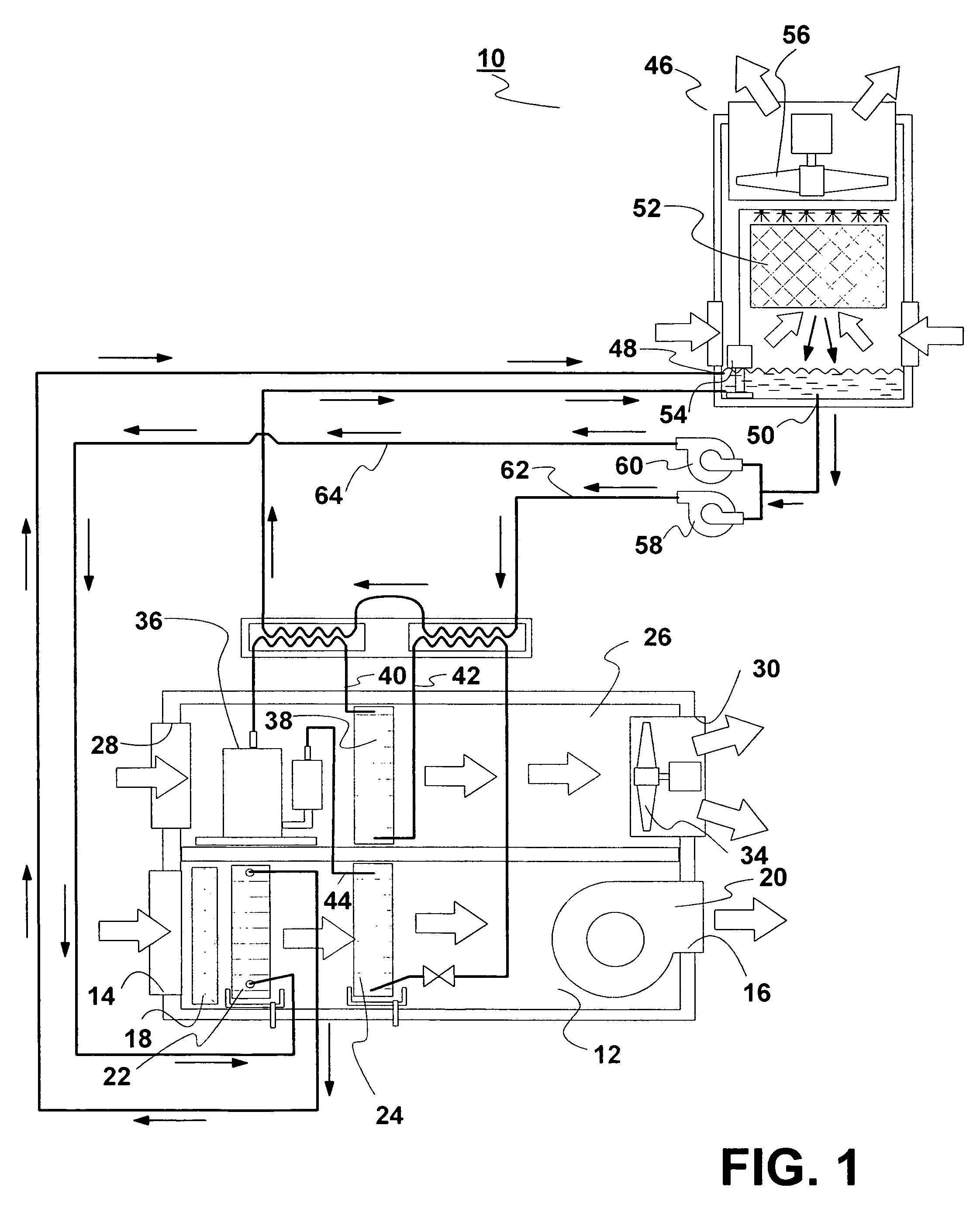

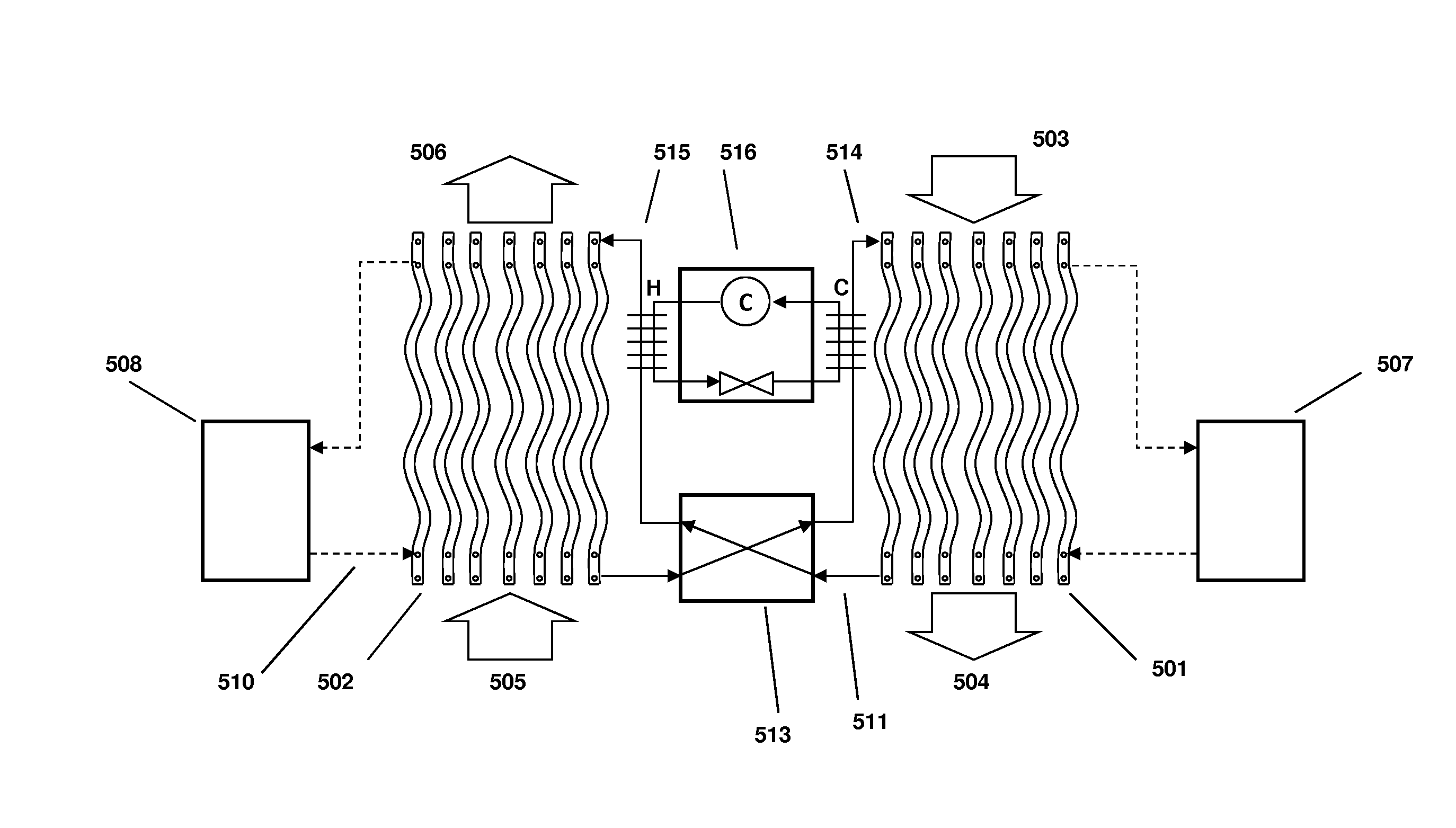

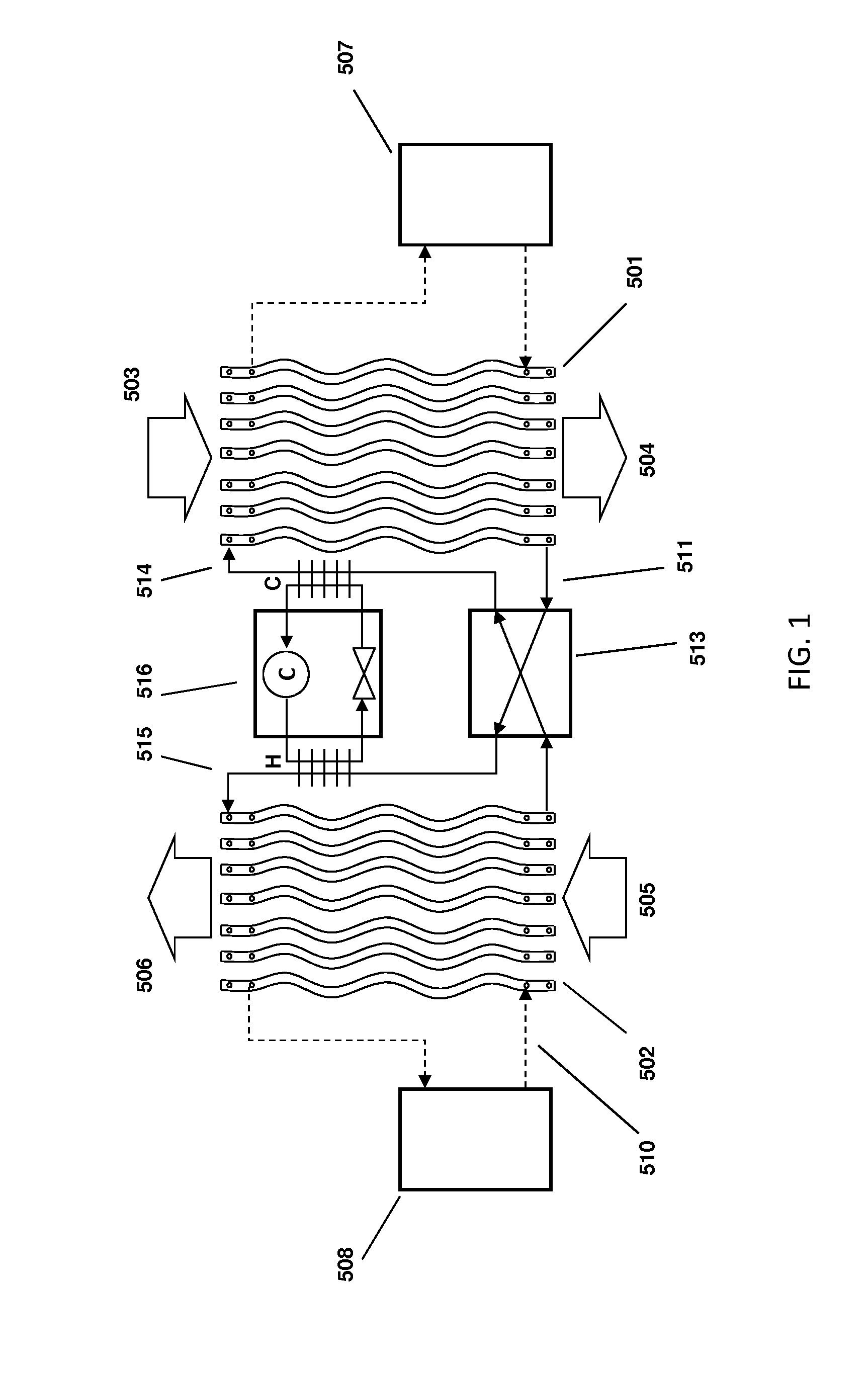

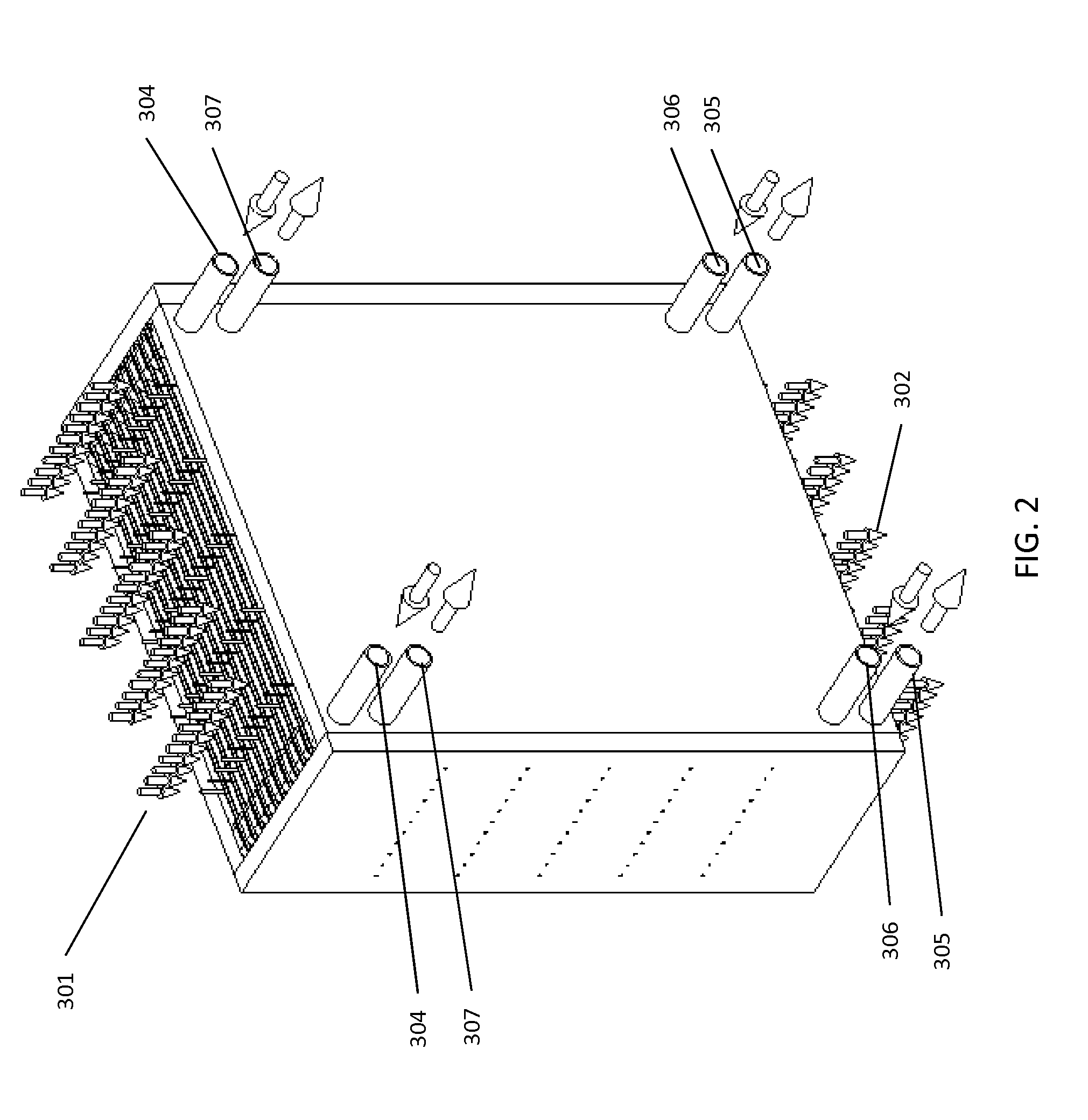

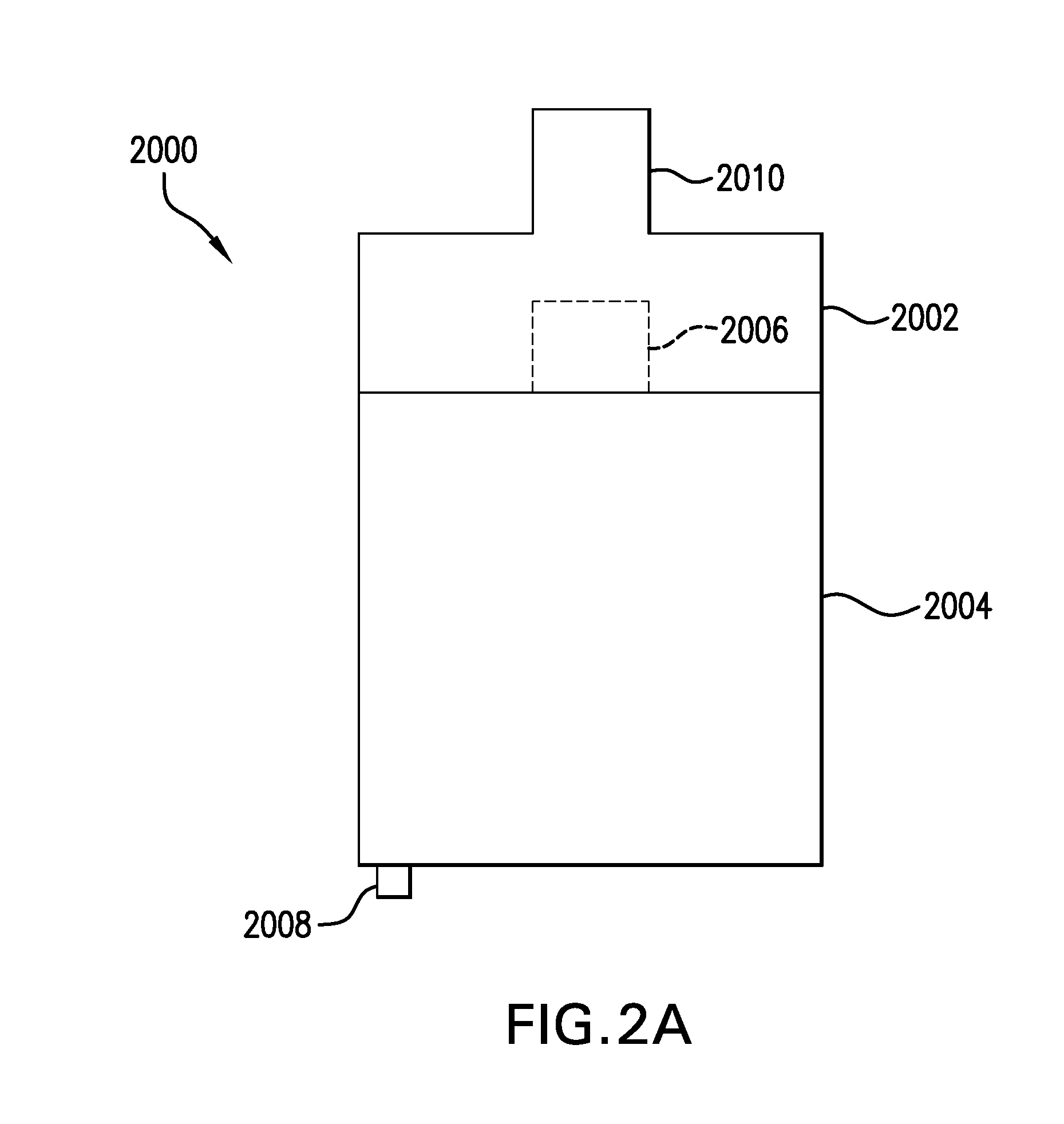

Cooling system and method utilizing thermal capacitor unit(s) for enhanced thermal energy transfer efficiency

InactiveUS20080307806A1Facilitates extracting thermal energyEfficient thermal energy transferHeat storage plantsTrickle coolersThermal energyCooling tower

A cooling system and method are provided which include a facility cooling unit, a cooling tower, and one or more thermal capacitor units. The facility cooling unit, which includes a heat dissipation coolant loop, facilitates thermal energy extraction from a facility, such as a data center, for expelling of the energy to coolant within the heat dissipation coolant loop. The cooling tower is in fluid communication with the coolant loop, and includes a liquid-to-air heat exchanger for expelling thermal energy from coolant of the heat dissipation coolant loop to the surrounding environment. The thermal capacitor unit is in fluid communication with the heat dissipation coolant loop to facilitate efficient thermal energy transfer from coolant with in the coolant loop to the surrounding environment with variation in ambient temperature about the cooling tower.

Owner:IBM CORP

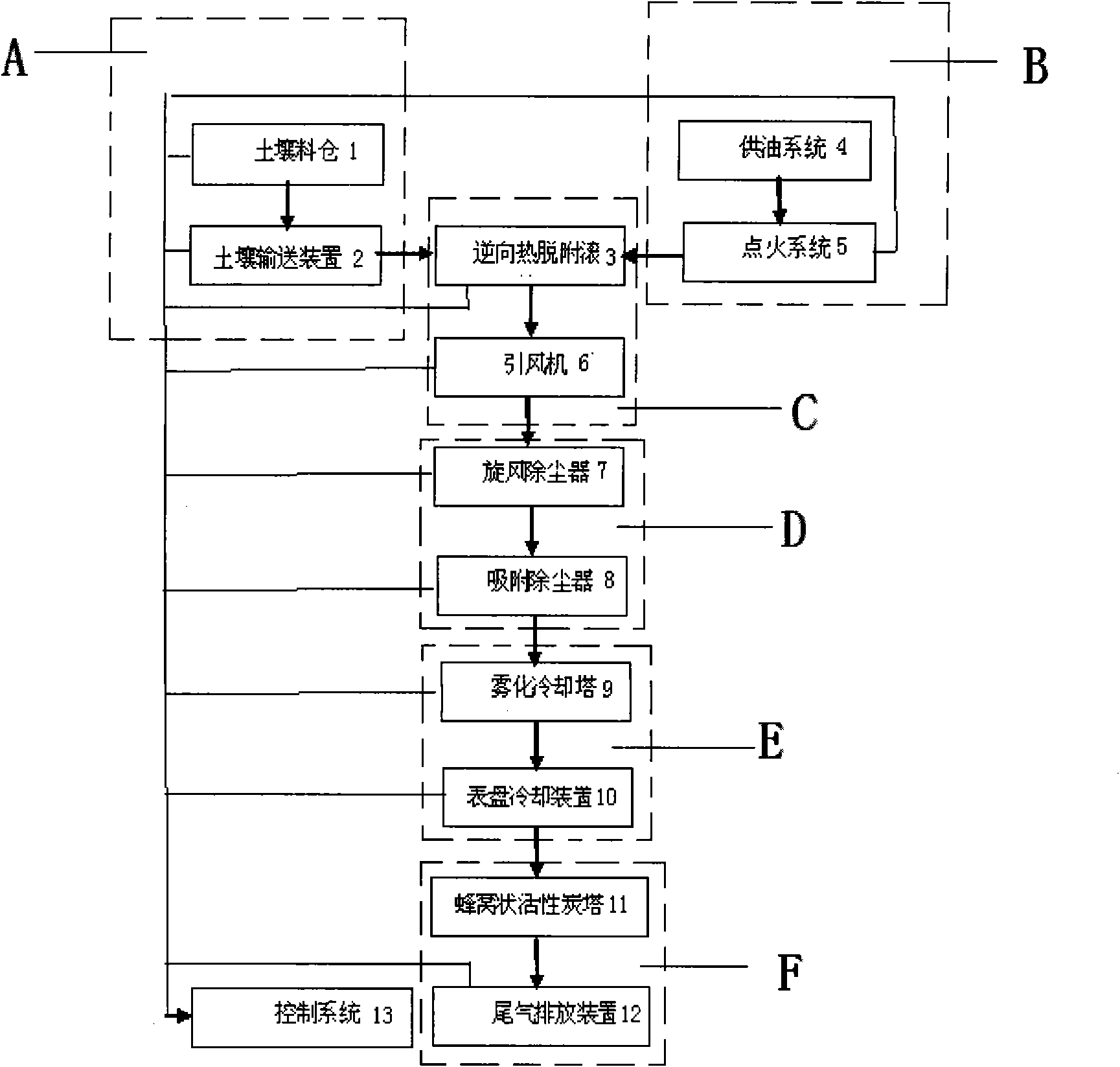

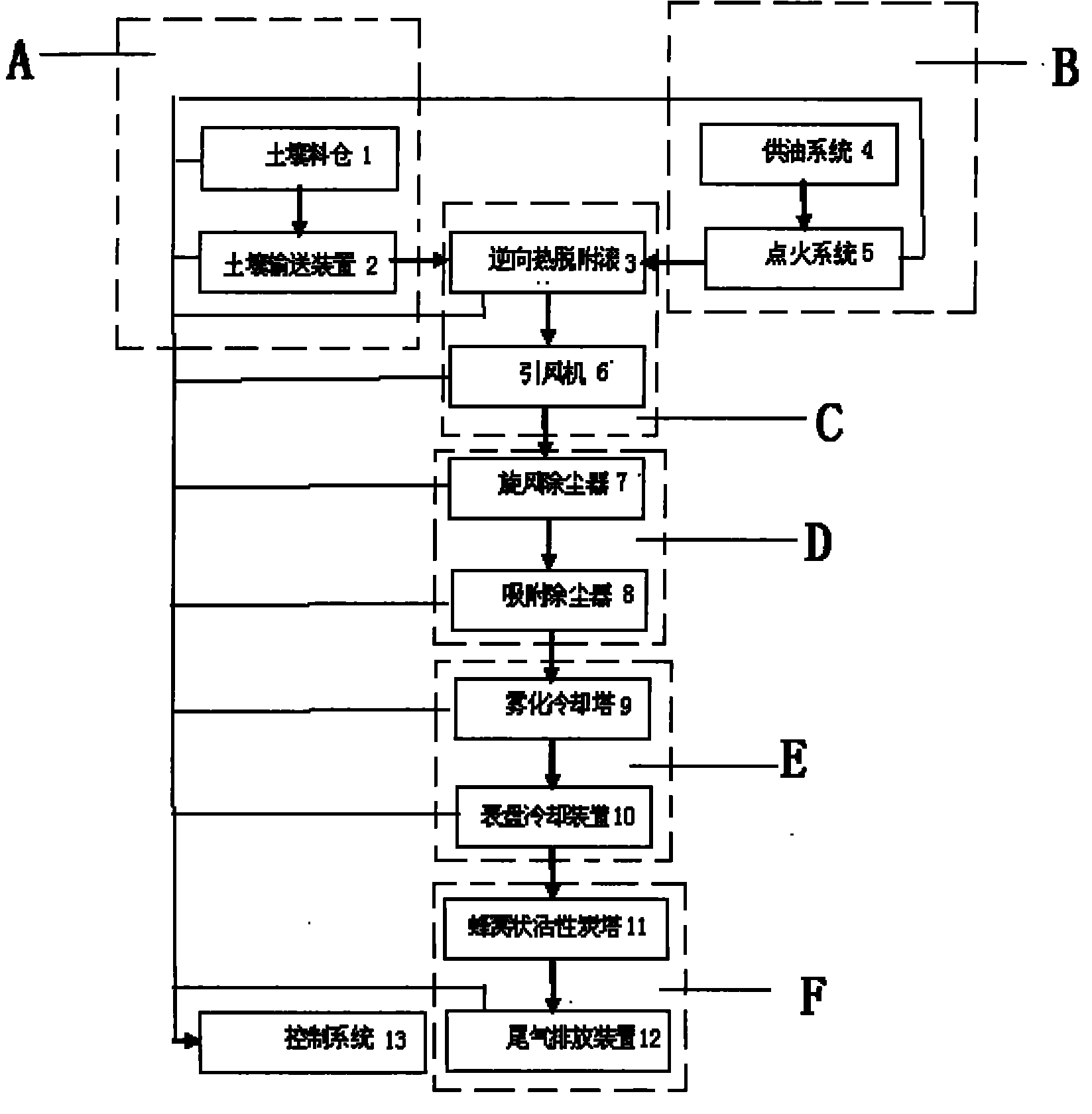

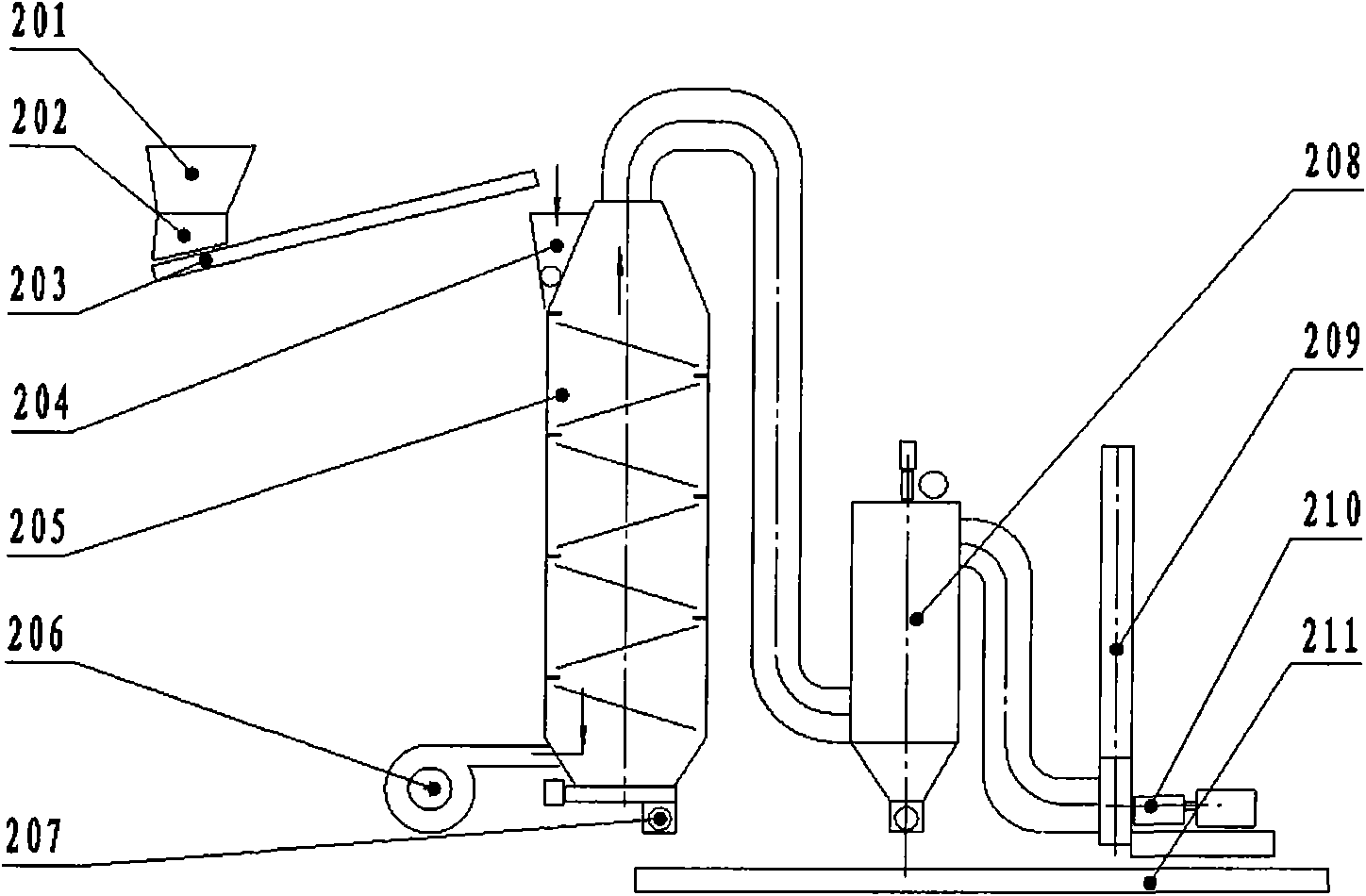

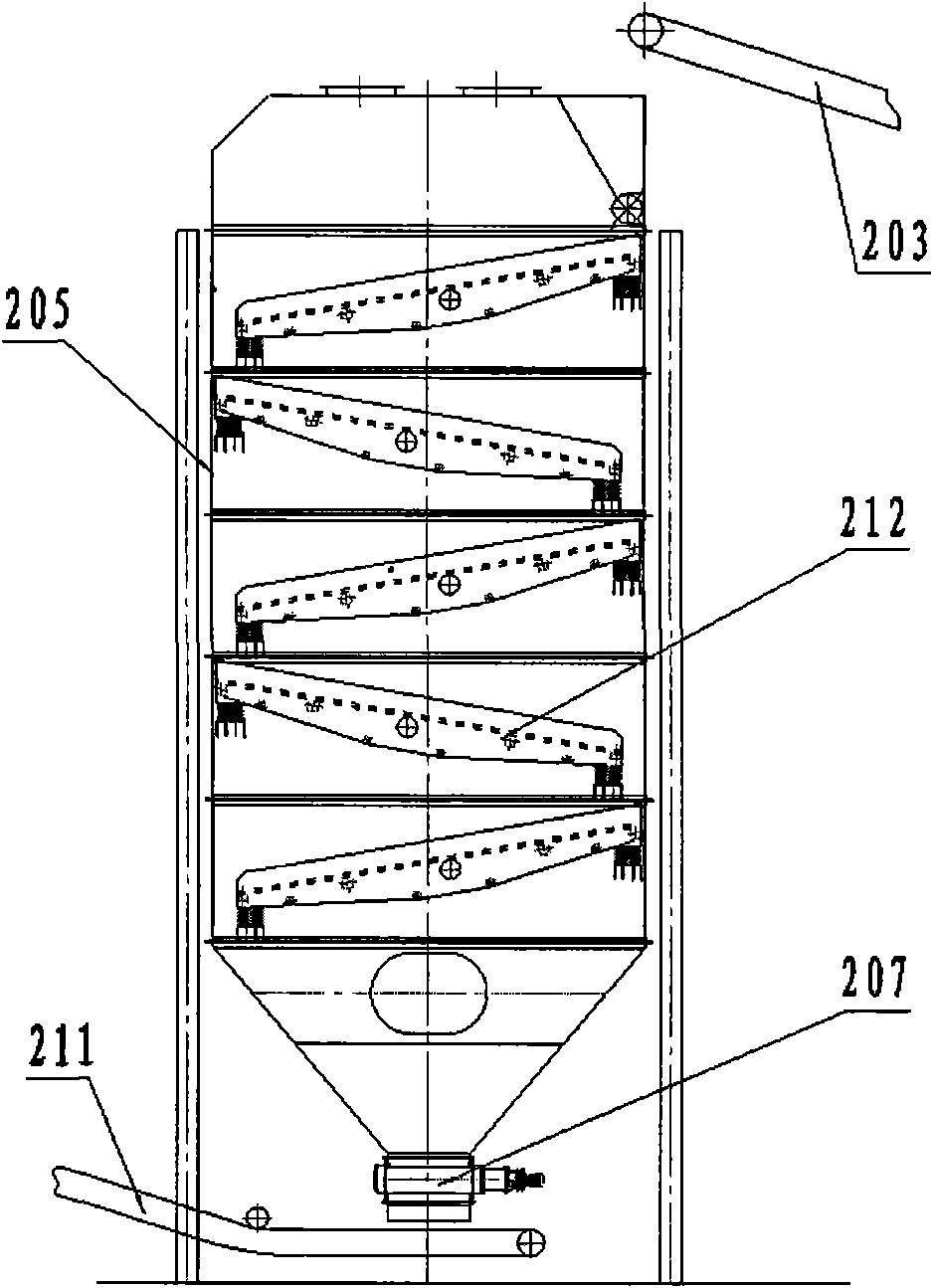

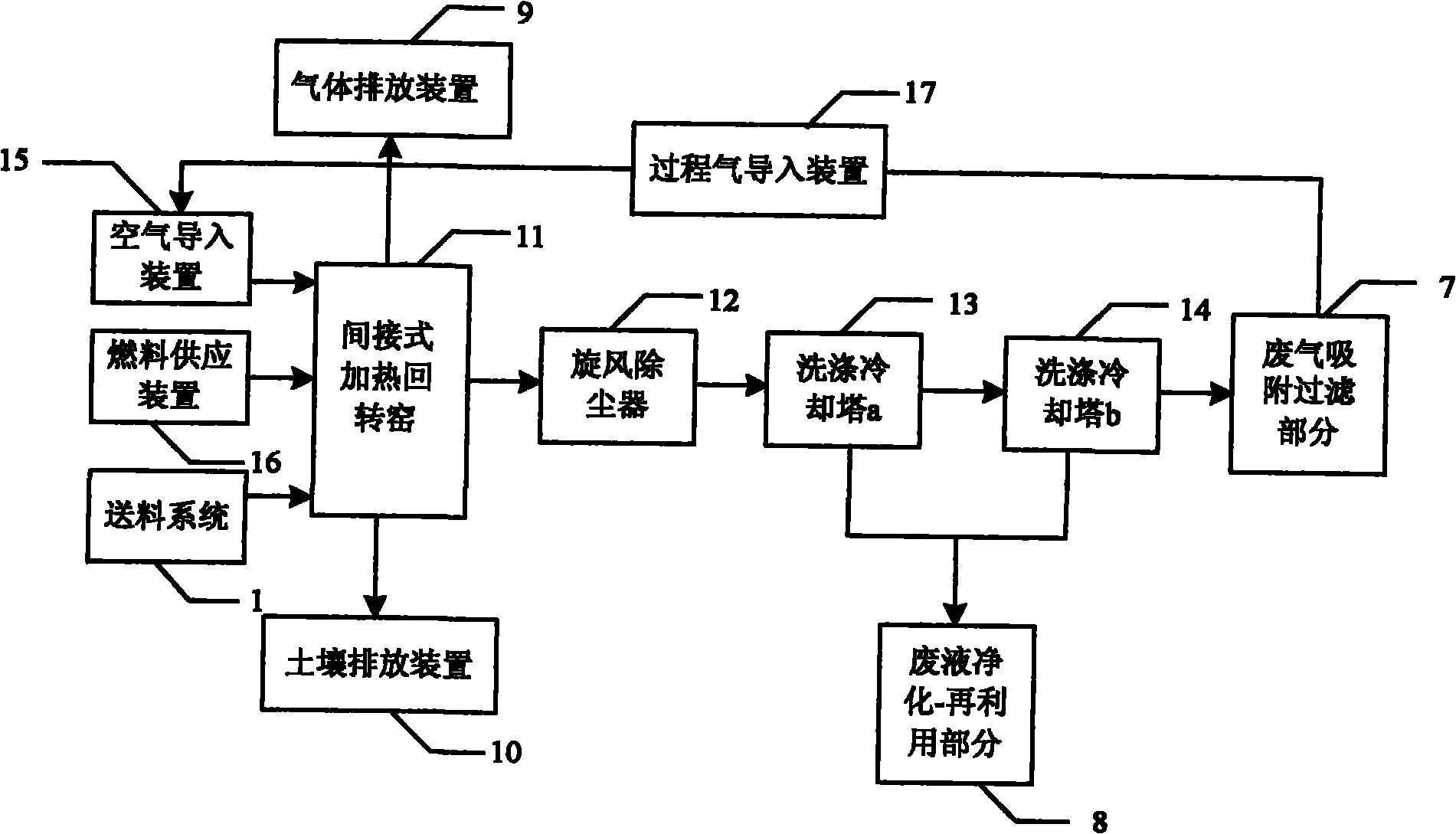

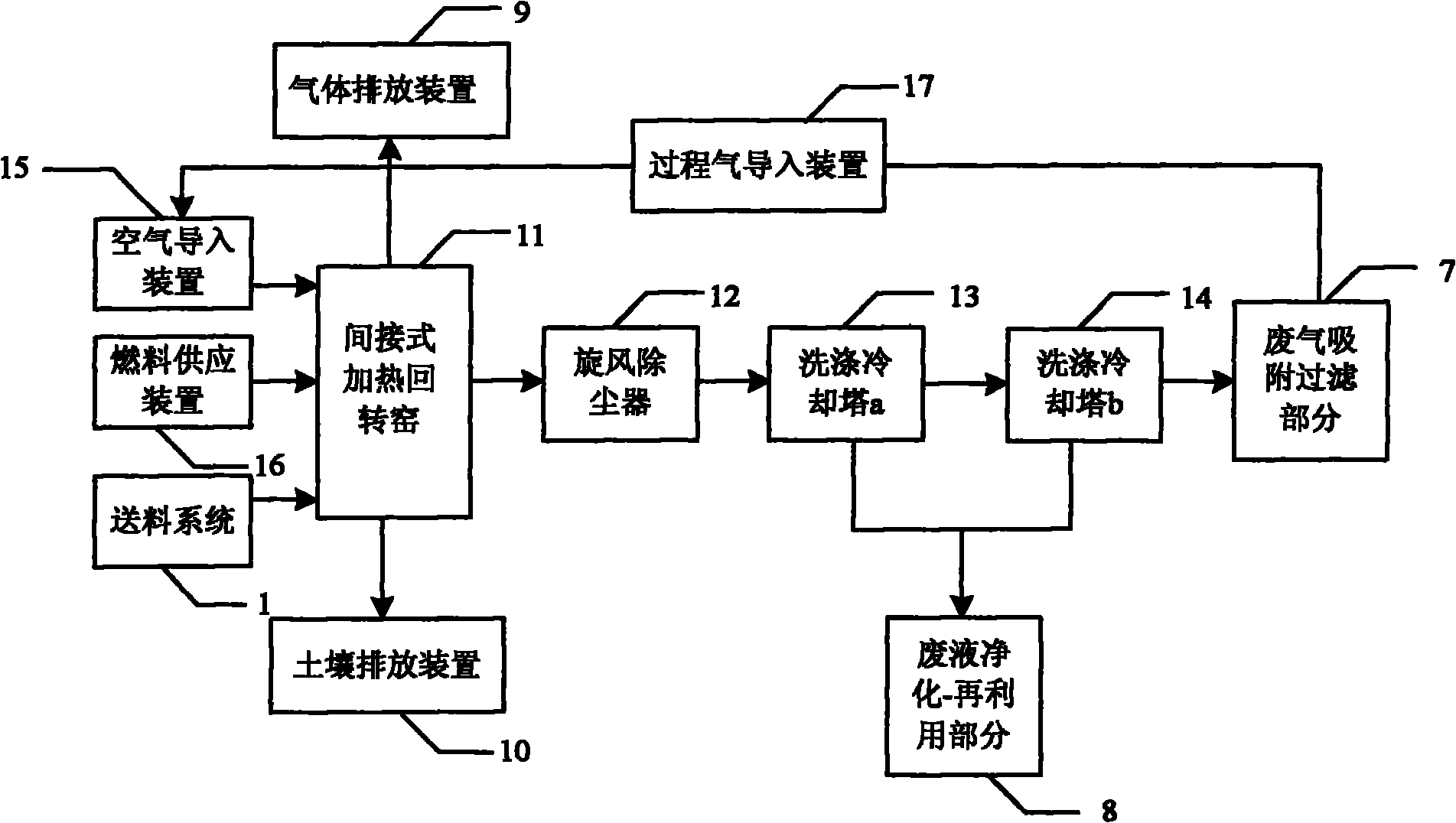

Roller-type reverse thermal desorption system for soil polluted by organic matters

ActiveCN102029287ALarge amount of processingImprove thermal desorption efficiencyContaminated soil reclamationCooling towerEngineering

The invention relates to a roller-type reverse thermal desorption system for soil polluted by organic matters. The roller-type reverse thermal desorption system comprises a soil feeding system, wherein the soil feeding system and a heat source system are connected with a reverse thermal desorption system; the reverse thermal desorption system is connected with a dust removing system, a cooling system and an active carbon adsorption system in turn; and control ends of the soil feeding system, the heat source system, the reverse thermal desorption system, the dust removing system, the cooling system and the active carbon adsorption system are connected with a control system. In the roller-type reverse thermal desorption system, hot air is fed into a reverse thermal desorption roller by an ignition system, and polluted soil is fed into the reverse thermal desorption roller by a soil transferring device, wherein the hot air contacts the soil reversely, so that organic pollutants contained in the soil are heated and volatilized; the purified soil is used as backfill soil; and the volatilized tail gas is dedusted by a cyclone dust extractor and an adsorption dust extractor after passing through an induced draft fan, and the dedusted volatilized tail gas is absorbed by a honeycomb-shaped active carbon tower after passing through an atomization cooling tower and a dial plate cooling device, and finally is discharged by a tail gas exhaust device on the basis of meeting the national standard. Materials can be fed into the roller-type reverse thermal desorption system continuously and can be heated directly; and the hot air and the polluted soil are fully mixed, and the roller-type reverse thermal desorption system has high thermal desorption efficiency.

Owner:TSINGHUA UNIV +1

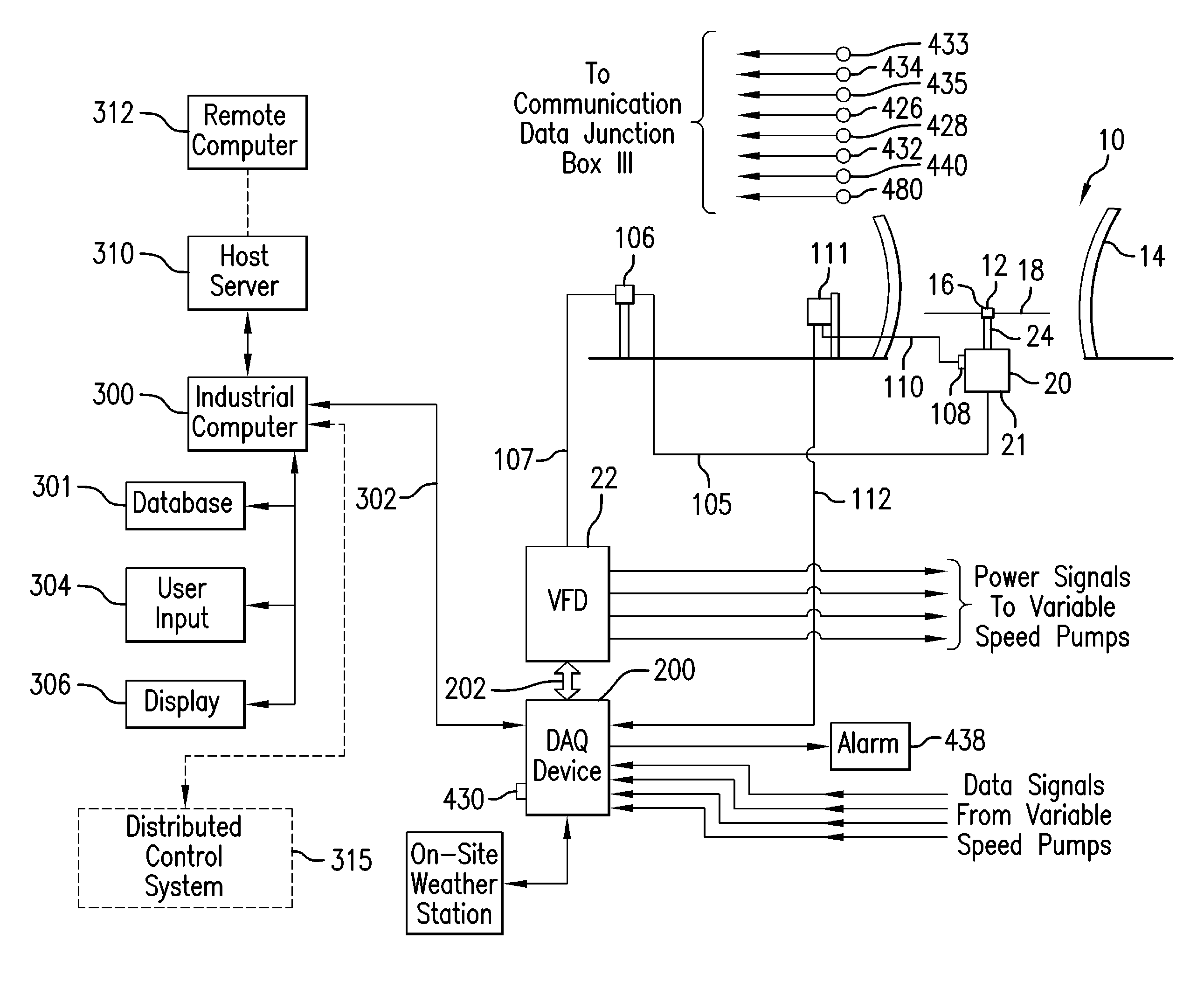

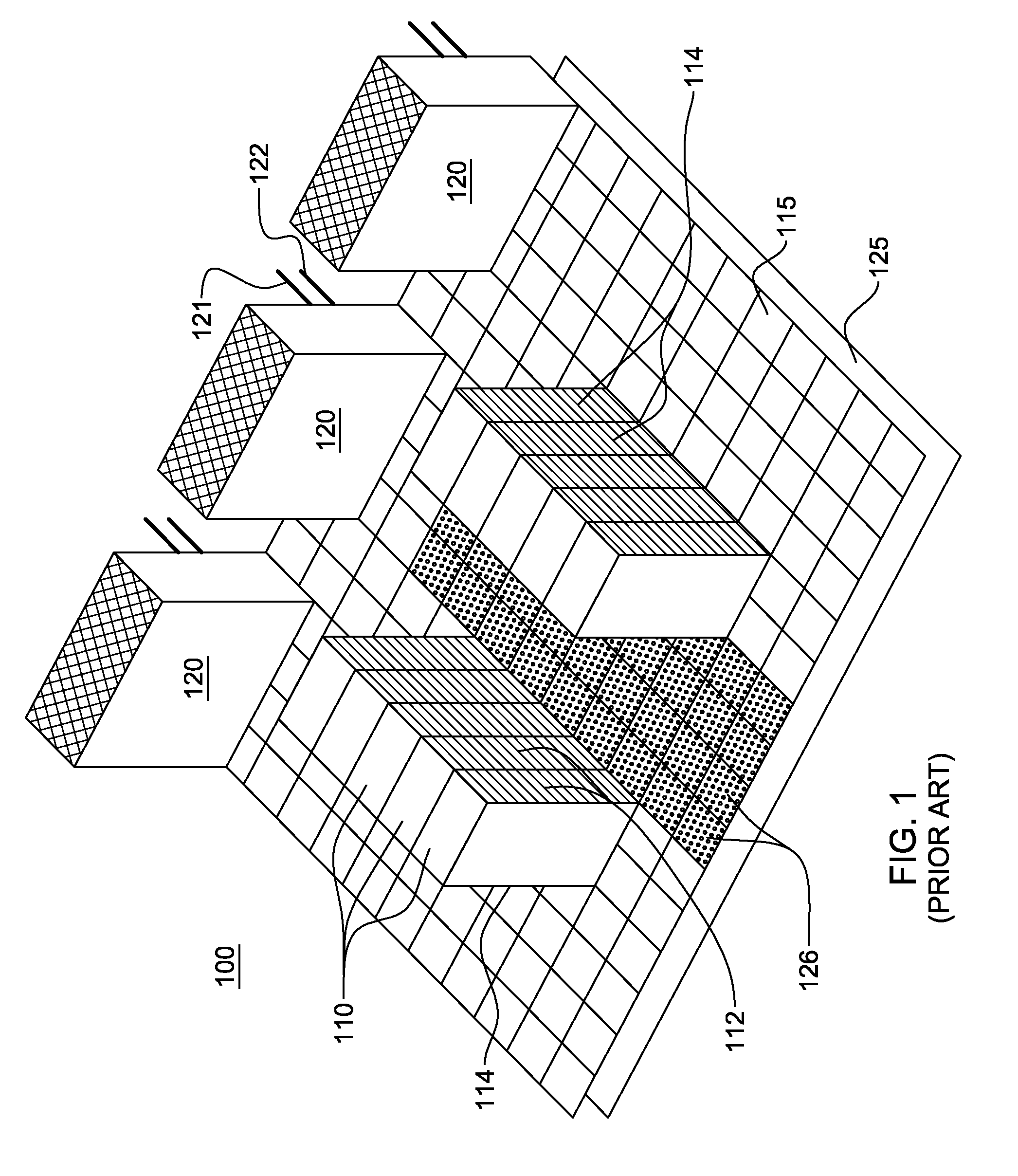

Optimized control system for cooling systems

ActiveUS7890215B2Reduce energy consumptionImprove energy efficiencySampled-variable control systemsMechanical apparatusCooling towerControl system

A cooling system for providing conditioned air to a facility includes a chiller or other cooling subsystem, a cooling tower subsystem and one or more air handling units or process cooling units. The cooling subsystem may advantageously include one or more chillers (e.g., variable speed chillers, constant speed chillers, absorption chillers, etc.) and chilled fluid pumps. The cooling tower subsystem includes one or more cooling tower units and condenser fluid pumps. In some implementations, the air handling unit has a cooling coil and a variable volume fan. In some implementations, direct expansion (DX) cooling systems comprise compressors, evaporators and air-cooled, water-cooled or evaporatively-cooled condensing systems. Such systems can be controlled to reduce energy waste, improve occupant comfort and / or improve the thermal characteristics of the process cooling unit. The cooling system further comprises a control system which is configured to evaluate a cooling load value at the air handling unit and use the cooling load value to calculate at least one operational setpoint. The operational setpoint may advantageously be selected to improve the energy efficiency of the overall cooling system.

Owner:YARDI SYST

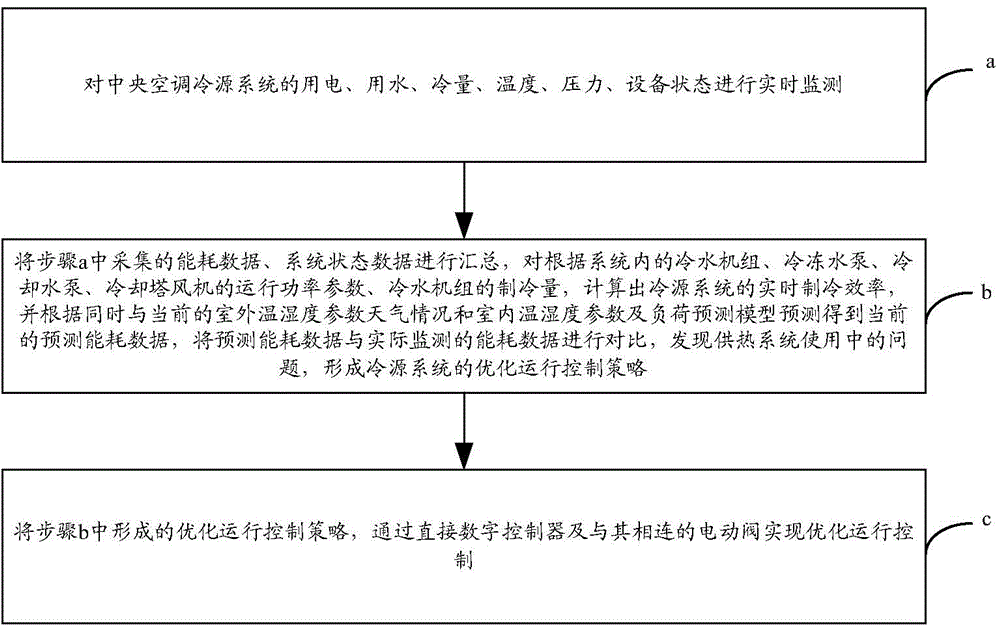

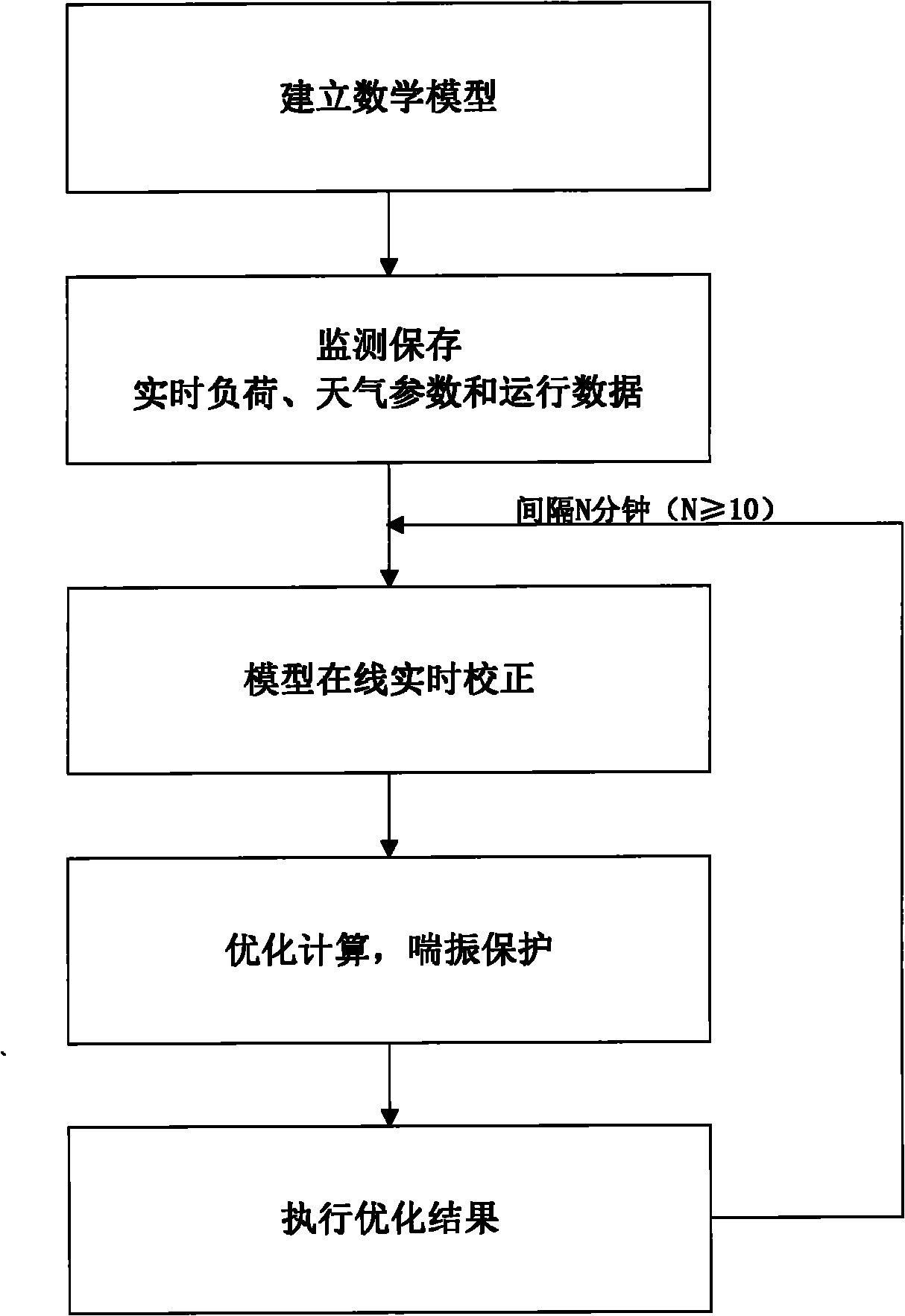

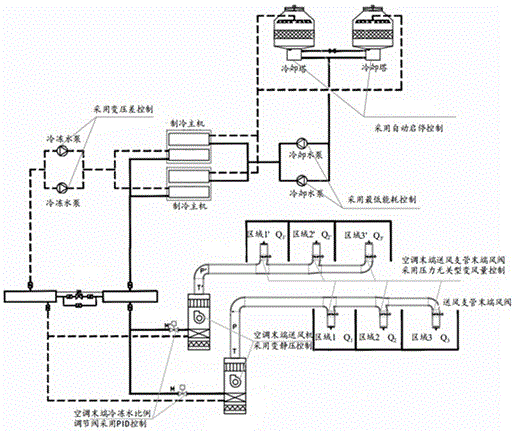

Cold source centralized digital control method based on energy consumption monitoring

ActiveCN104534617AMechanical apparatusSpace heating and ventilation safety systemsCooling towerPower parameter

The invention discloses a cold source centralized digital control method based on energy consumption monitoring. The cold source centralized digital control method based on energy consumption monitoring comprises the following steps that a, real-time monitoring is conducted on power utilization, water utilization, the cooling quantity, the temperature, the pressure and the equipment state of a cold source system of a central air conditioner; b, energy consumption data and system state data collected in the step a are summarized, real-time refrigerating efficiency of the cold source system is calculated according to operating power parameters of a water chilling unit, a chilled water pump, a cooling water pump and a cooling tower fan in the system and the refrigerating capacity of the water chilling unit, forecast energy consumption data at present are obtained through forecasting according to outdoor temperature and humidity parameters at present, indoor temperature and humidity parameters at present and a load forecast model, the forecast energy consumption data and the energy consumption data which are actually monitored are compared, problems existing in the use process of a refrigerating system are found, and an optimized operation control strategy of the cold source system is formed; c, the optimized operation control strategy formed in the step b is conducted, and optimized operation control is achieved through a direct digital controller and an electrically operated valve connected with the direct digital controller.

Owner:北京方胜有成科技股份有限公司

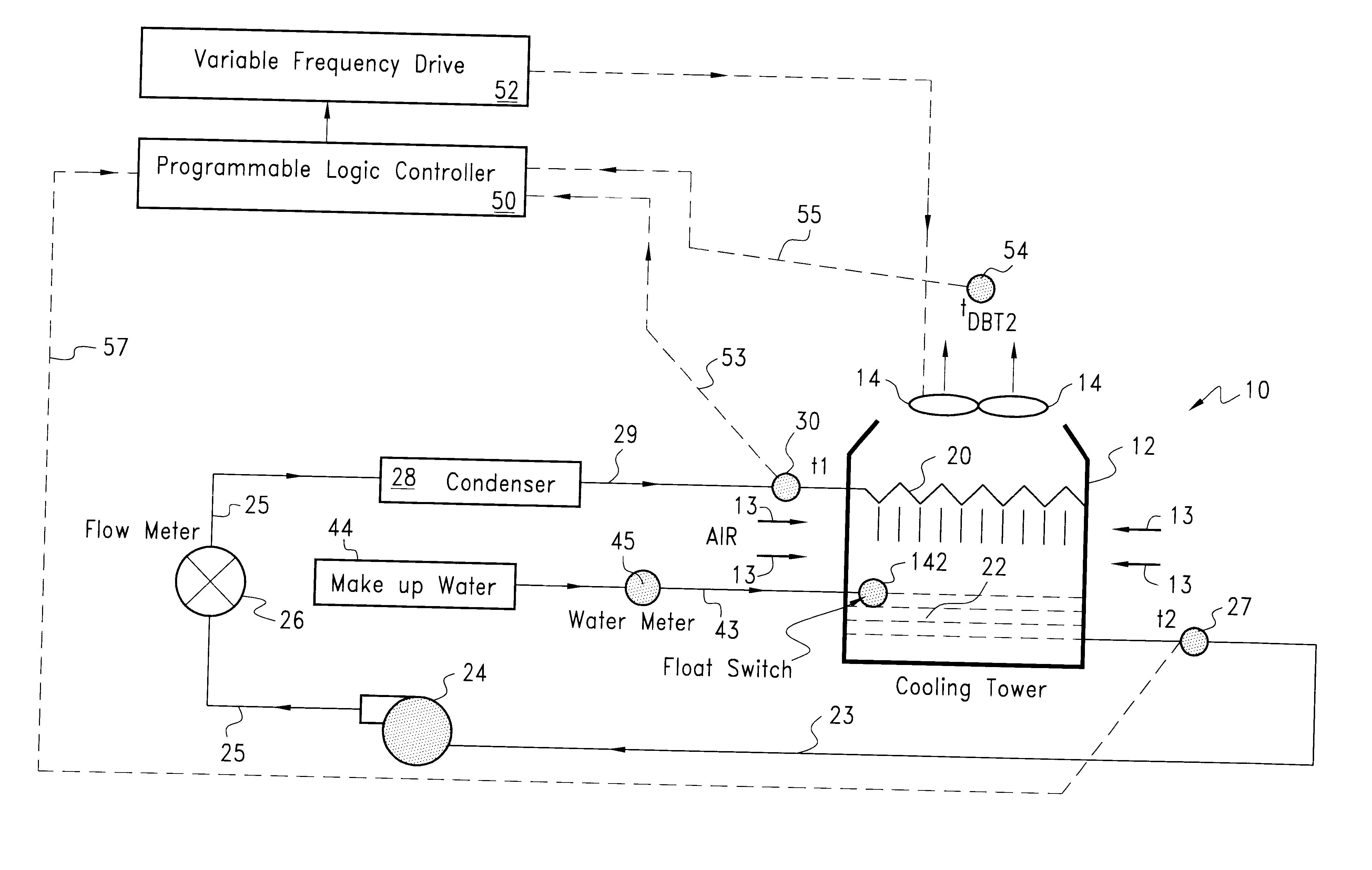

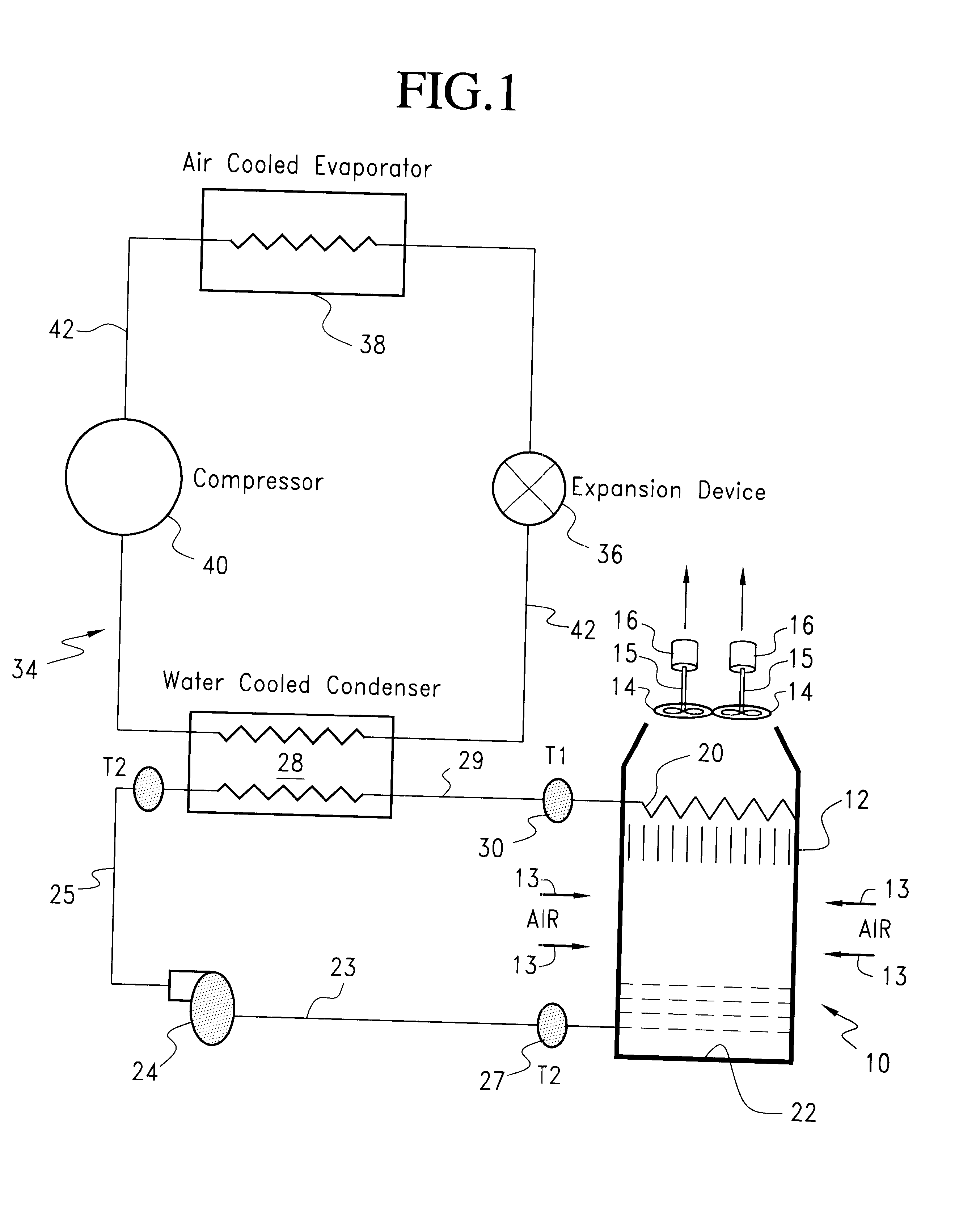

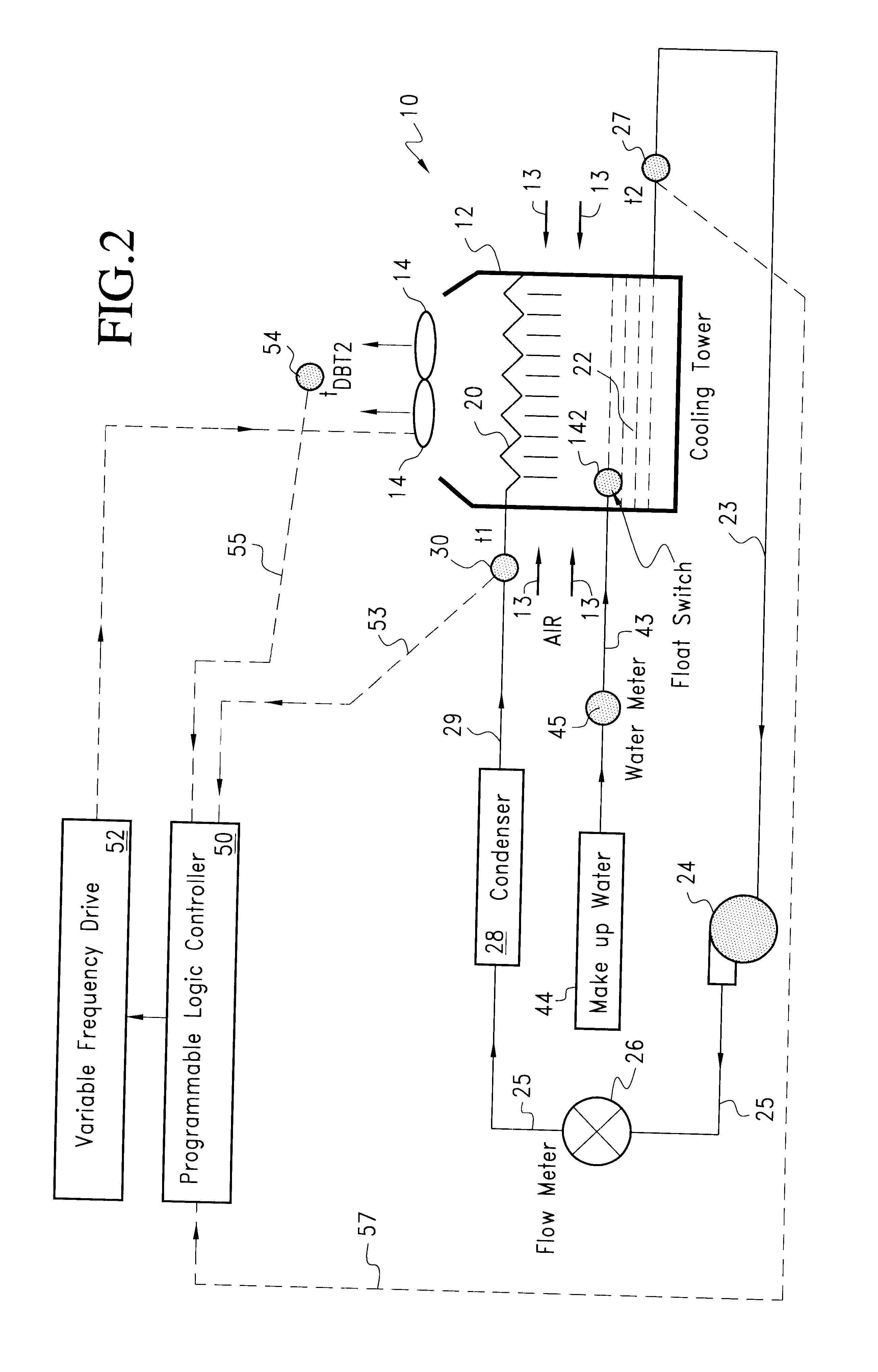

Cooling tower and method for optimizing use of water and electricity

A forced air cooling tower includes an upright casing, and elevated water distribution system disposed in an upper portion of the casing and one or more fans for drawing air through the tower. The tower also includes a catch basin for collecting the cooled air and a pump for circulating the cooled water through a condenser and back to the top of the tower and to the water distribution system. The cooling tower also includes a controller and a variable frequency device for regulating the flow of air through the tower. A first temperature sensor senses the temperature T1 of the hot process water delivered to the water distribution system and a second sensor senses the dry bulb temperature of the air leaving the tower Tdbt2. A third sensor senses the temperature of the cooled water leaving the tower. The controller such as a computer and variable frequency drive controls the speed of the fan to minimize the difference in T1 and Tdbt2. A submaster control prevents the fan speed from being further reduced when a predetermined T2 (temperature of the cooled water) is reached.

Owner:KUWAIT INST FOR SCI RES

Energy-saving optimized control system and method for refrigerator room

ActiveCN101968250ASpace heating and ventilation safety systemsLighting and heating apparatusFrequency changerRefrigerator car

The invention relates to an energy-saving optimized control system and an energy-saving optimized control method for a refrigerator room. The energy-saving optimized control system comprises an industrial control computer, a flow sensor, a temperature sensor, an outdoor temperature and humidity sensor, a three-phase active power transmitter, a water pump frequency converter and a cooling tower fan frequency converter which are connected with a programmable logic controller respectively, wherein the programmable logic controller communicates with the industrial control computer through an industrial Ethernet; and an RS485 communication interface module is connected with a water cooling unit and communicates with the industrial control computer through a ModBus protocol. A mathematical model of relationships between the energy consumption and running parameters of each equipment in the refrigerator room is established to regulate the running state of each equipment in combination with real-time refrigeration loads and weather parameters, thereby fulfilling the aim of making the lowest running energy consumption of the whole refrigerator room at the premise of meeting the refrigeration loads.

Owner:WELDTECH TECH SHANGHAI

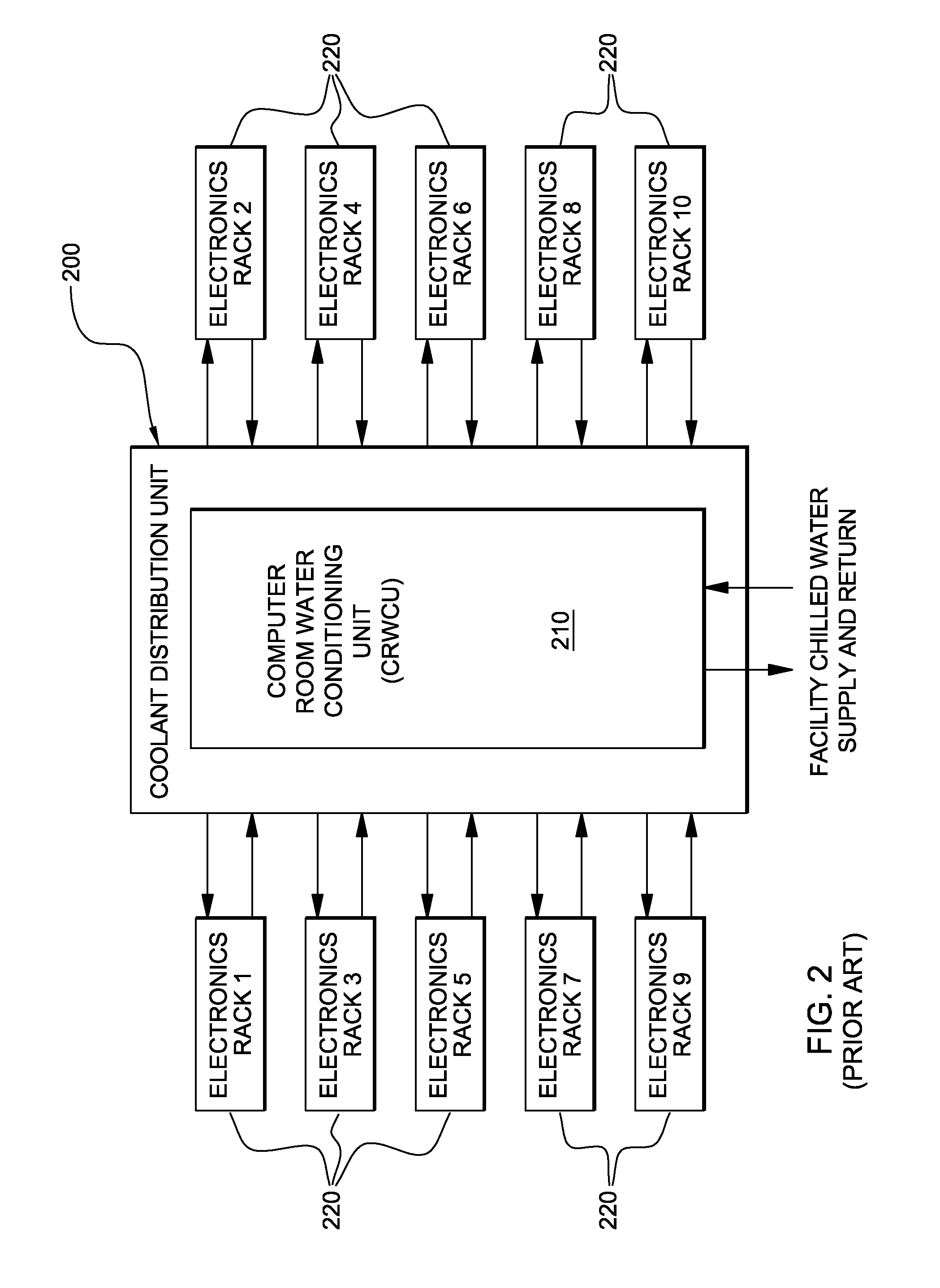

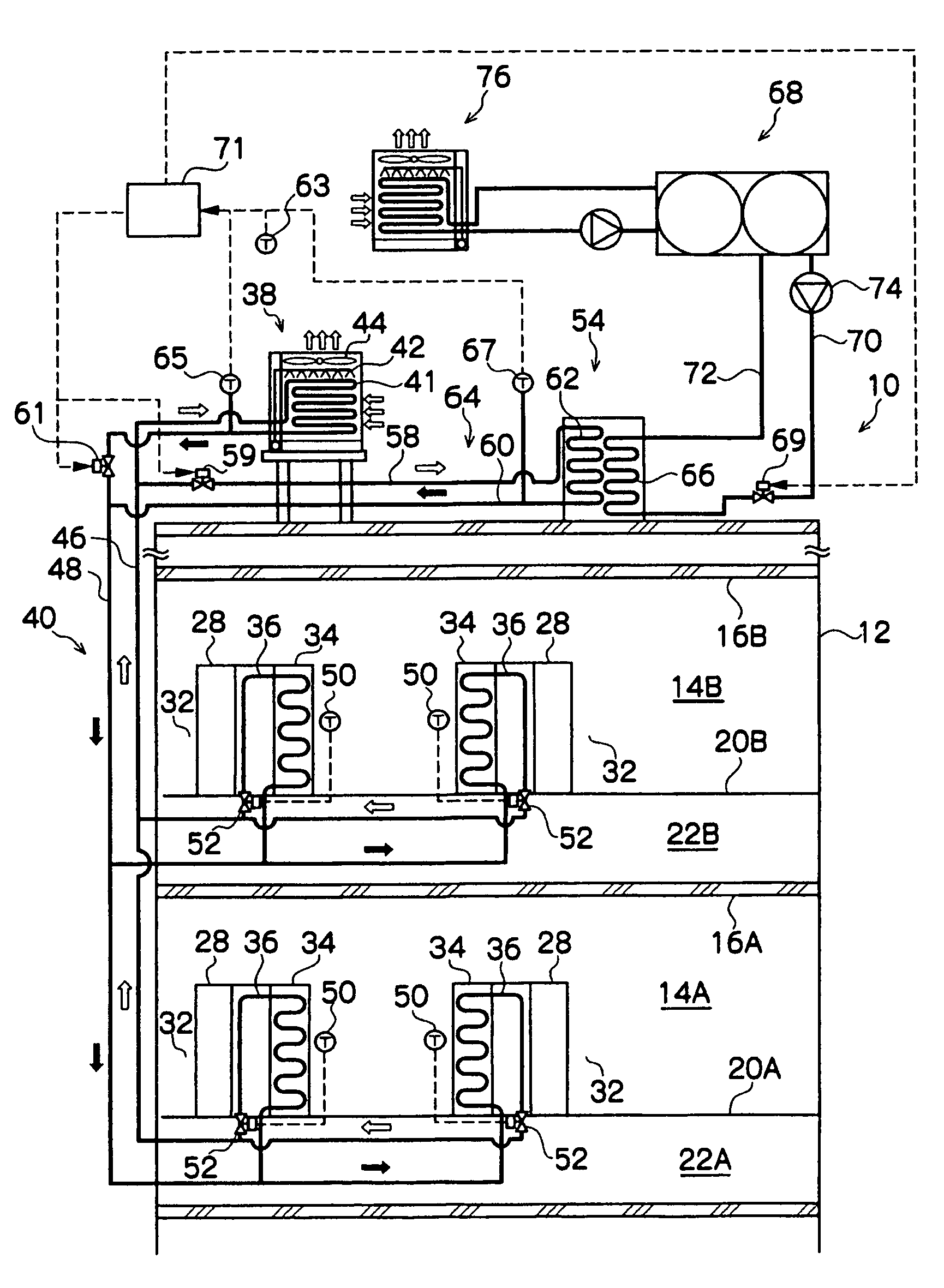

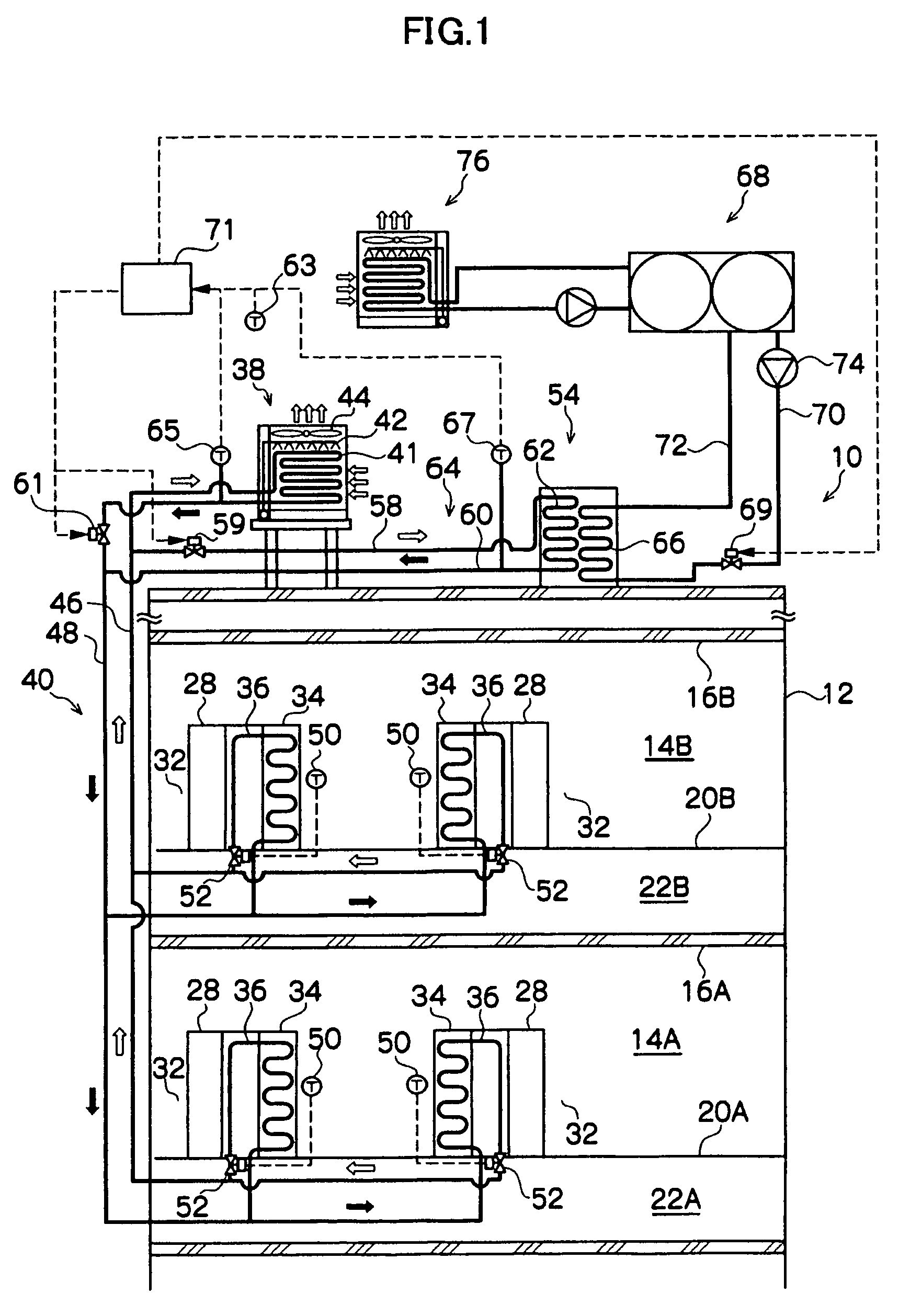

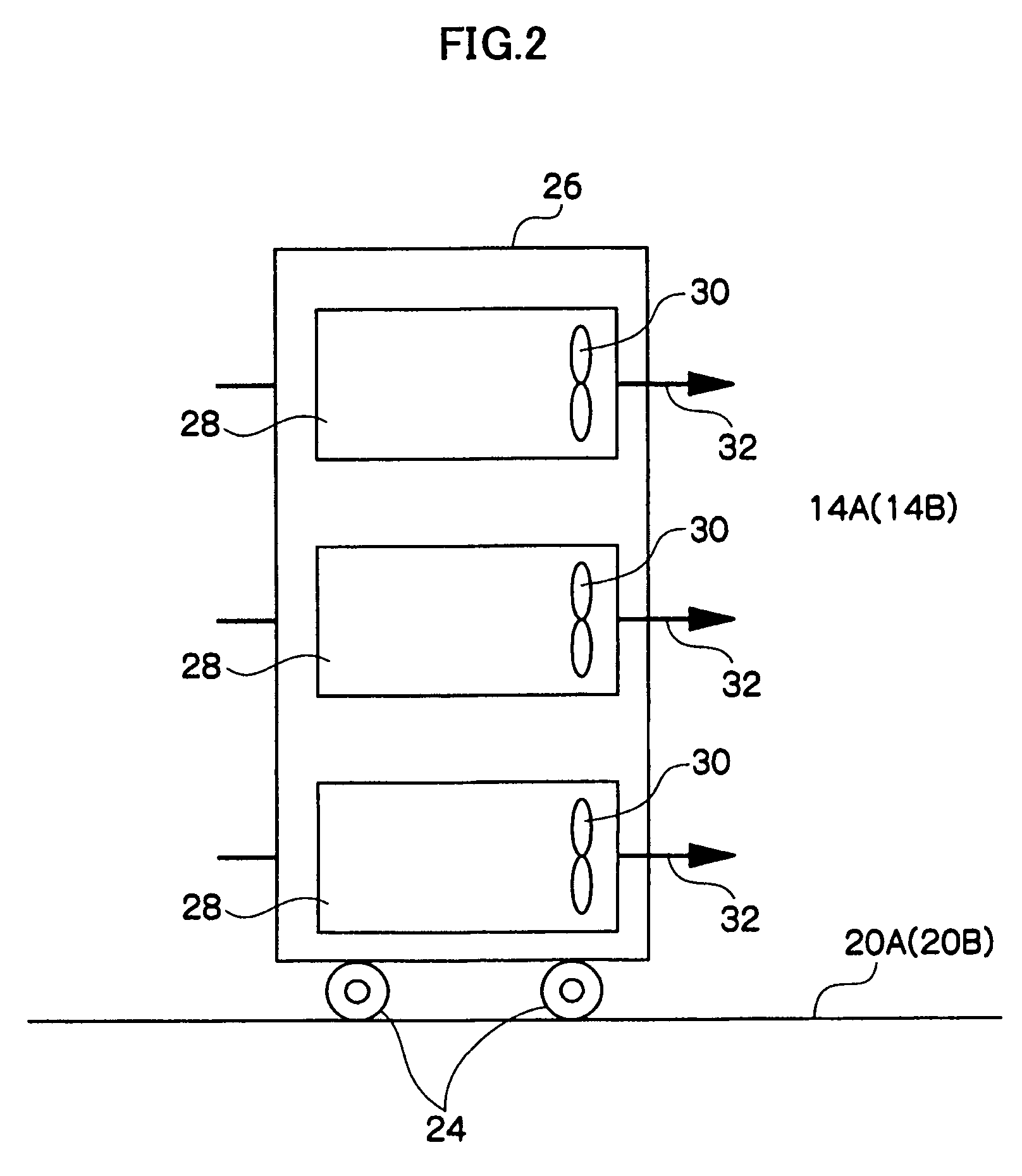

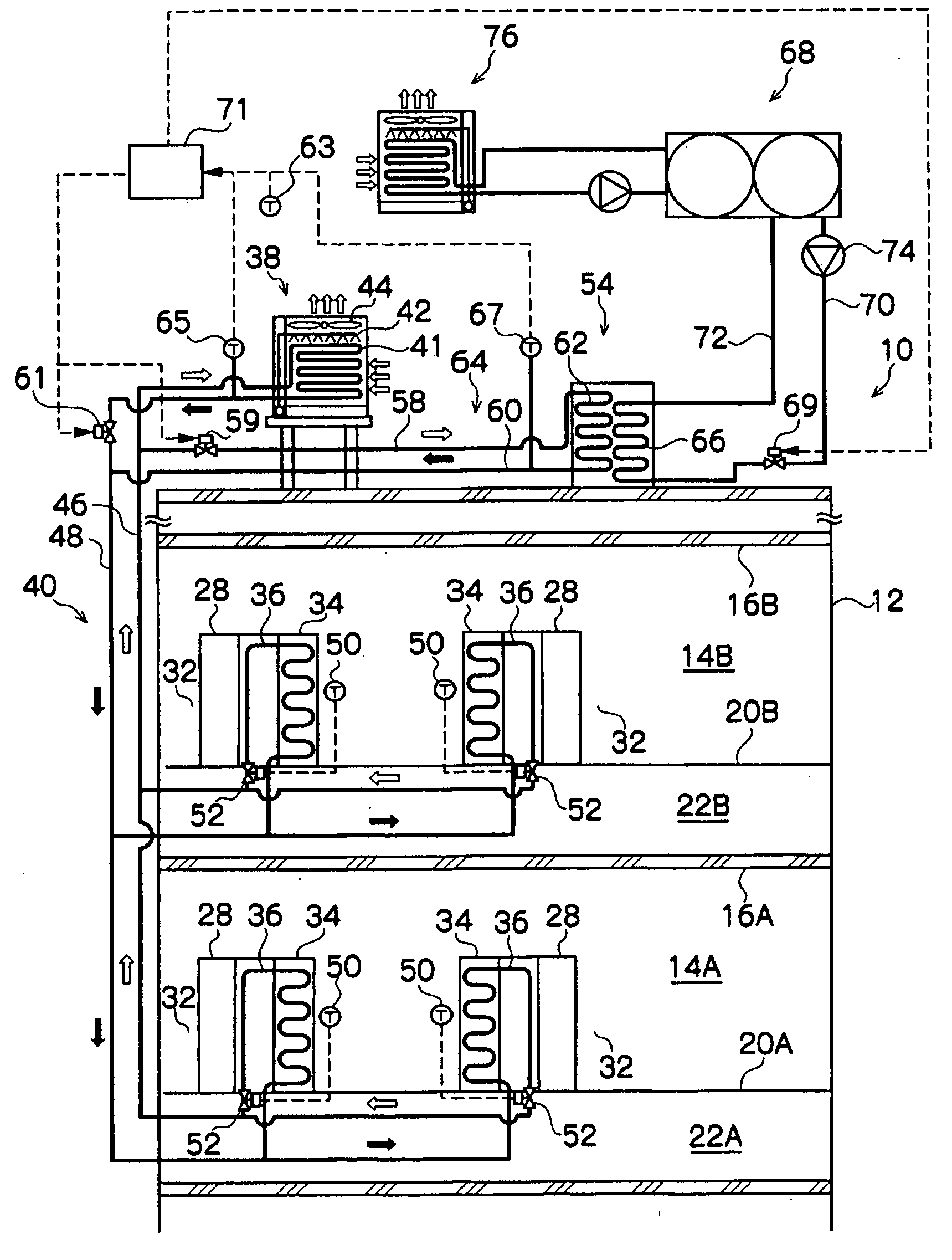

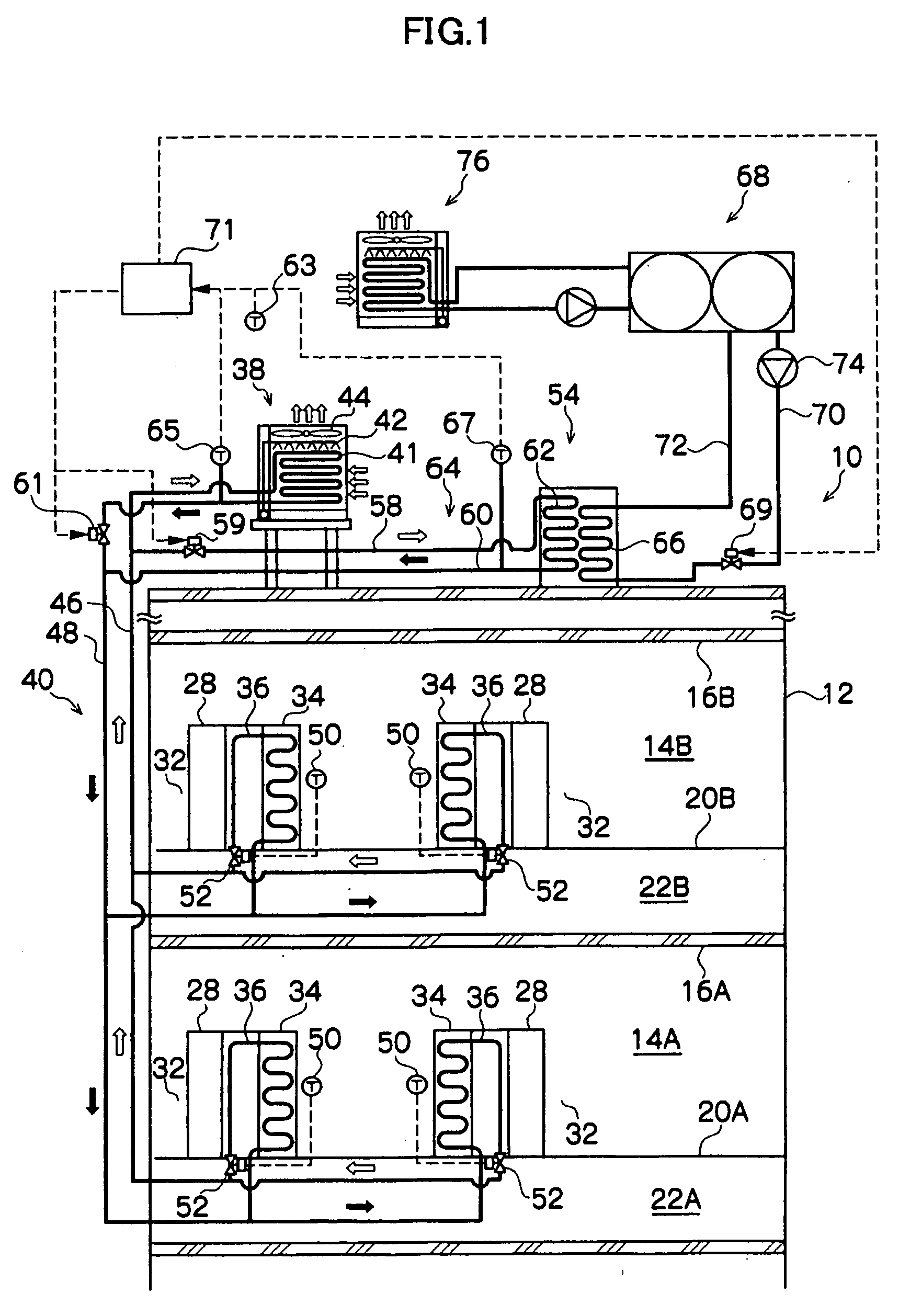

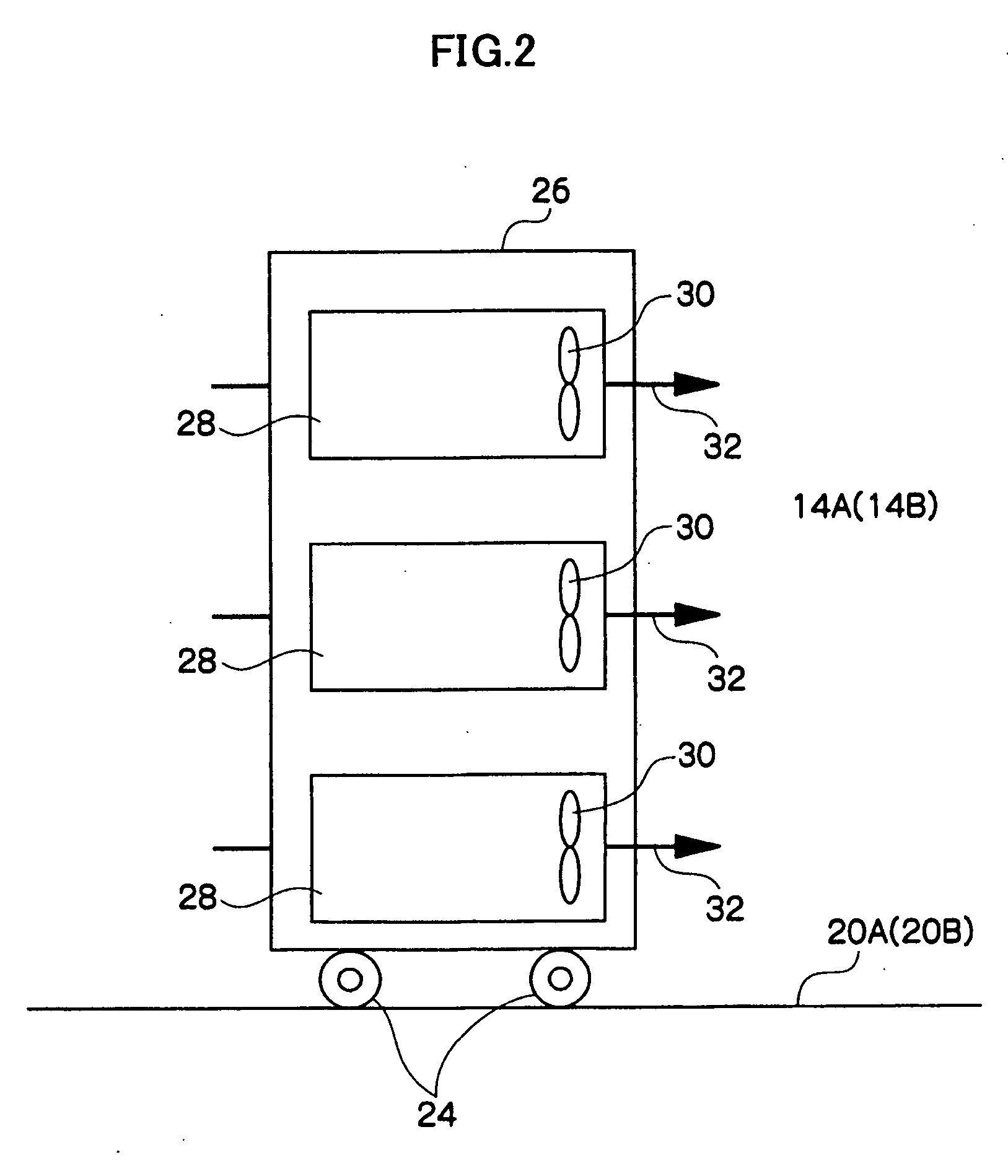

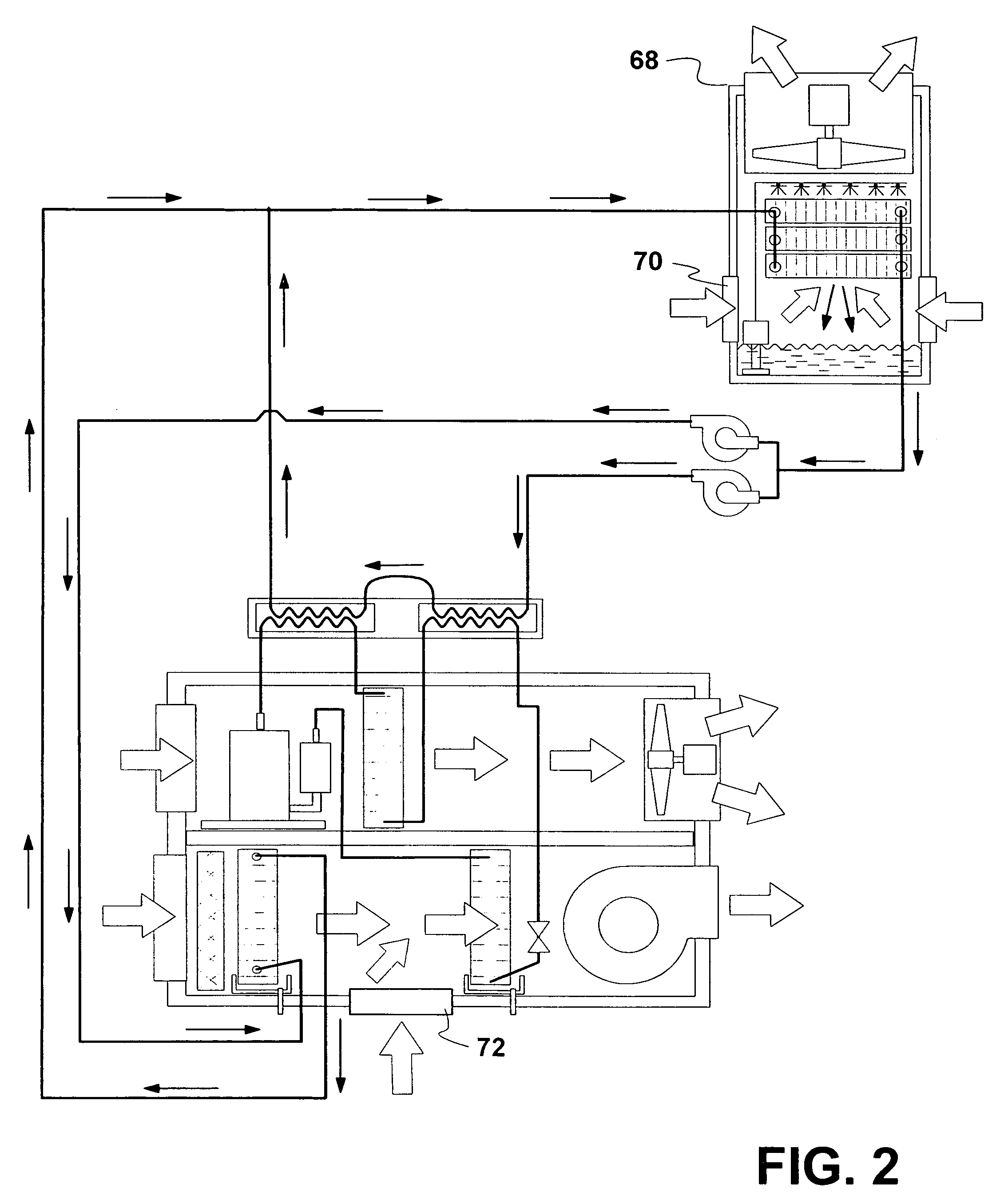

Cooling system for electronic equipment

InactiveUS7855890B2Reduce the required powerTemperatue controlDigital data processing detailsCooling towerServer room

In a cooling system for an electronic device of the present invention, server rooms in which a plurality of servers are placed, an evaporator which is provided close to each of the servers, and cools exhaust air from the server by vaporizing a refrigerant with heat generating from the server, a cooling tower which is provided at a place higher than the evaporator, cools the refrigerant by outside air and water sprinkling, and condenses the vaporized refrigerant, and a circulation line in which the refrigerant naturally circulates between the evaporator and the cooling tower. According to the cooling system, an electronic device which is required to perform a precise operation with a heat generation amount from itself being large, such as a computer and a server, can be efficiently cooled at low running cost.

Owner:HITACHI LTD

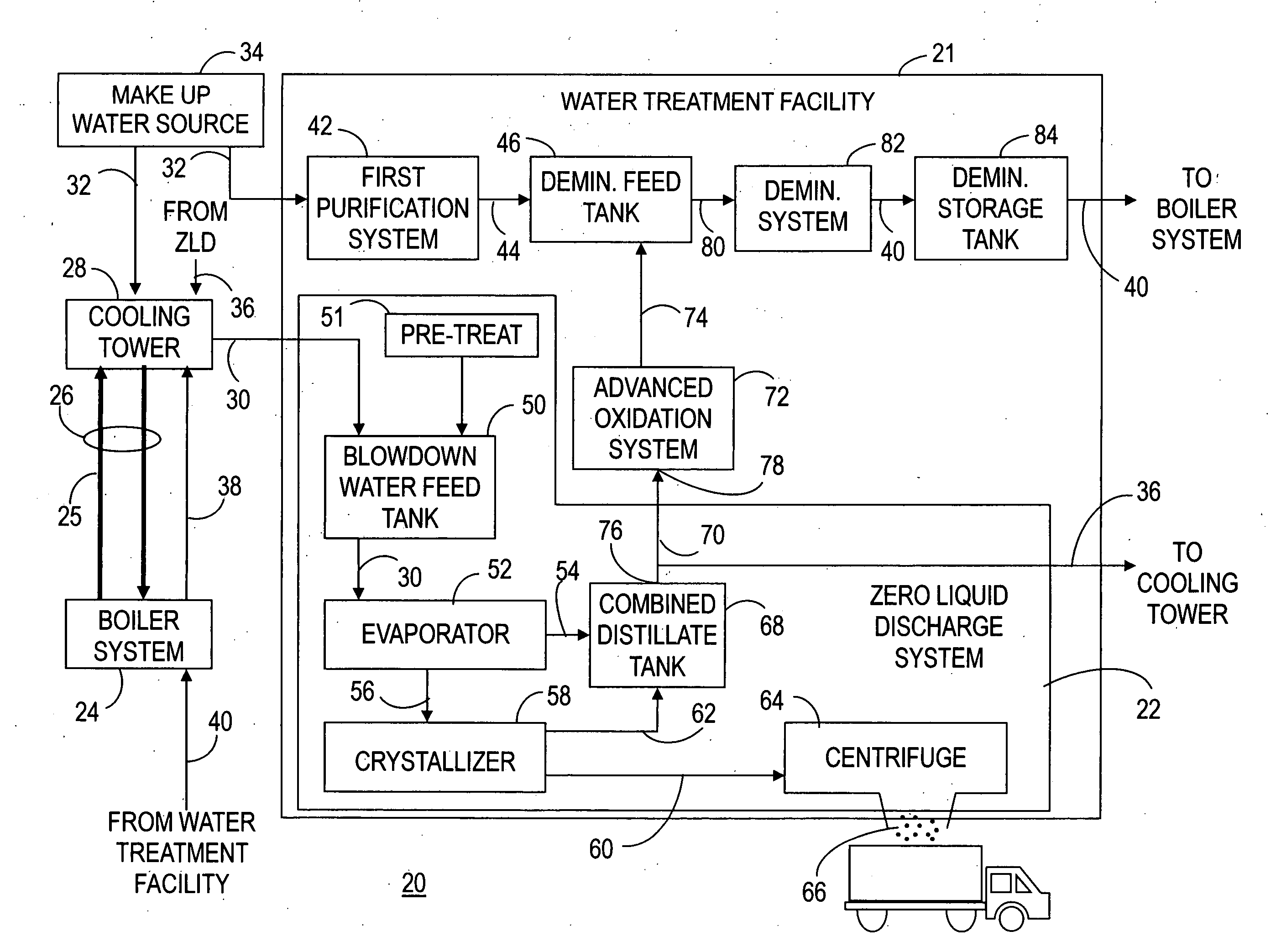

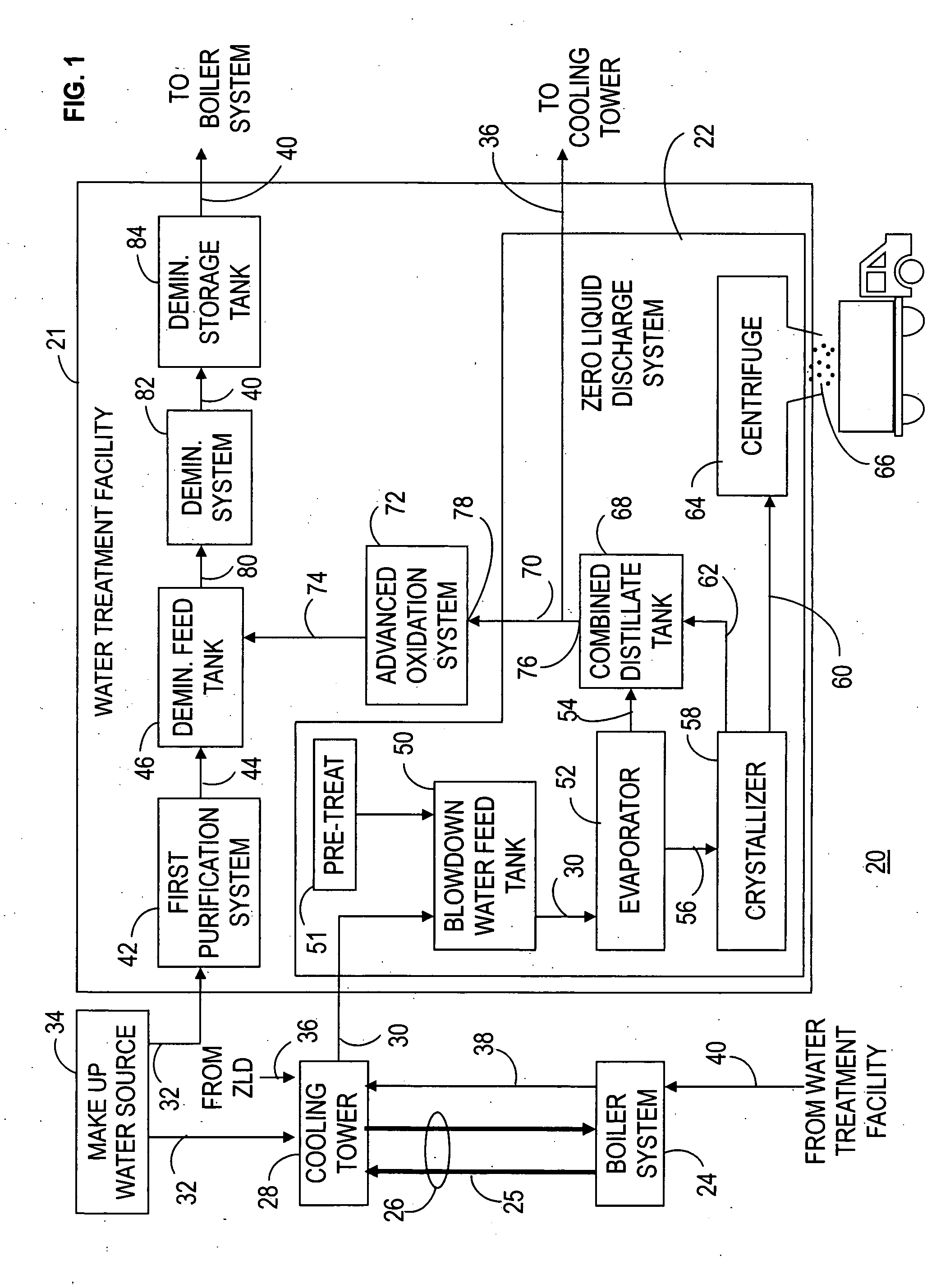

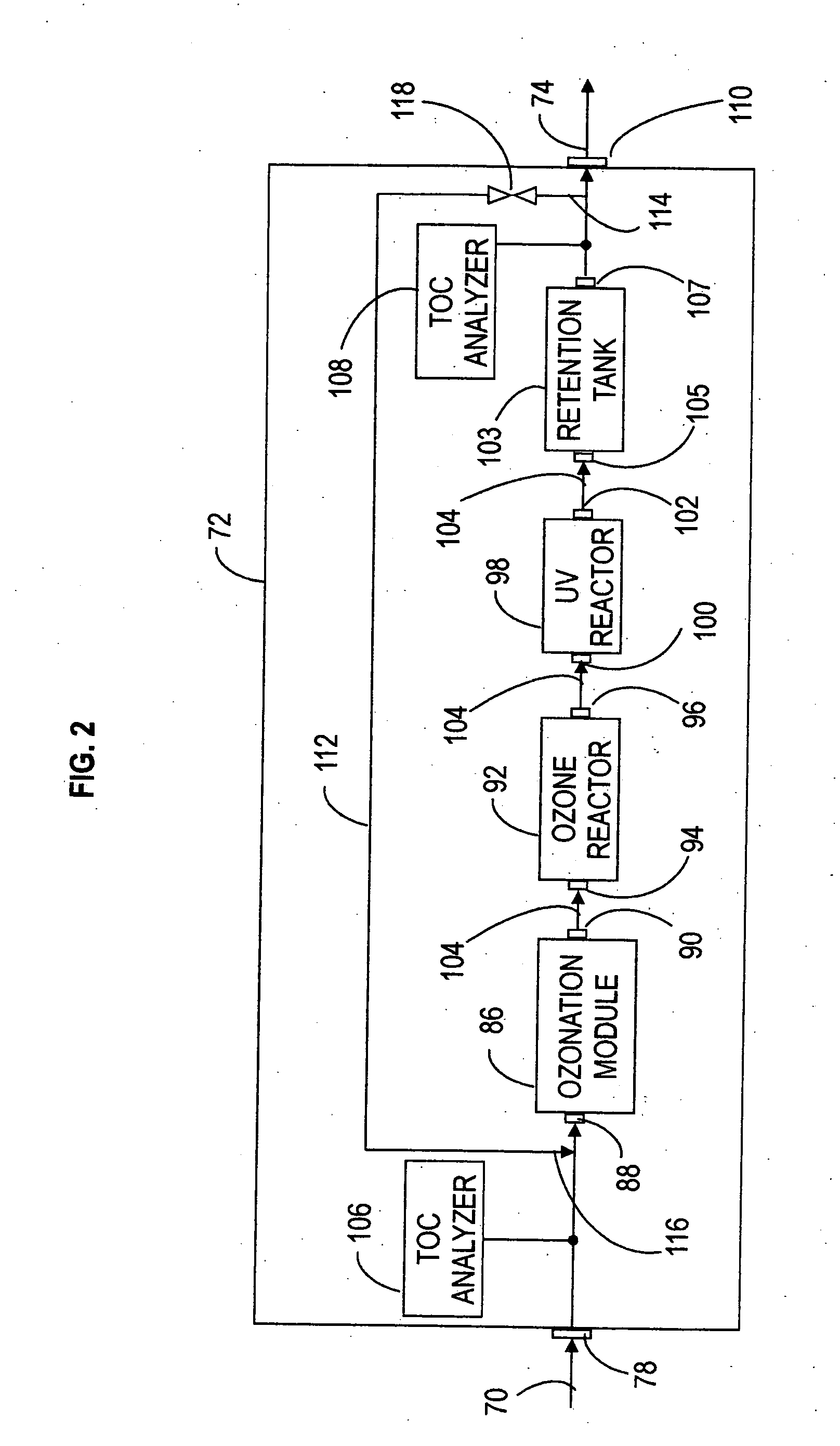

System and method of reducing organic contaminants in feed water

InactiveUS20070125719A1Reducing organic contaminantEfficient implementationWater treatment parameter controlWater/sewage treatment by irradiationHigh concentrationPower station

A zero liquid discharge (ZLD) power plant (20) includes an advanced oxidation system (72) for reducing contaminants in source water (70) to form feed water (40) for a boiler (24). The system (72) includes an ozonation module (86) for applying high concentration ozone to the source water (70) to form a mixed stream (104), an ozone reactor (92) in which the mixed stream is retained (104) under pressure, an ultraviolet reactor (98) downstream from the ozone reactor (92) for enhanced contaminant reduction, and a retention tank (103) downstream from the reactor (98). In one configuration, the source water (70) is evaporator distillate from an evaporator (52) that recycles cooling tower blowdown 30. The system (72) achieves organic contaminant reduction at total organic carbon (TOC) levels of less than three hundred parts per billion.

Owner:ARIZONA PUBLIC SERVICE

Cooling system for electronic equipment

InactiveUS20090201645A1Reduce the required powerDigital data processing detailsTemperatue controlCooling towerEngineering

In a cooling system for an electronic device of the present invention, server rooms in which a plurality of servers are placed, an evaporator which is provided close to each of the servers, and cools exhaust air from the server by vaporizing a refrigerant with heat generating from the server, a cooling tower which is provided at a place higher than the evaporator, cools the refrigerant by outside air and water sprinkling, and condenses the vaporized refrigerant, and a circulation line in which the refrigerant naturally circulates between the evaporator and the cooling tower. According to the cooling system, an electronic device which is required to perform a precise operation with a heat generation amount from itself being large, such as a computer and a server, can be efficiently cooled at low running cost.

Owner:HITACHI LTD

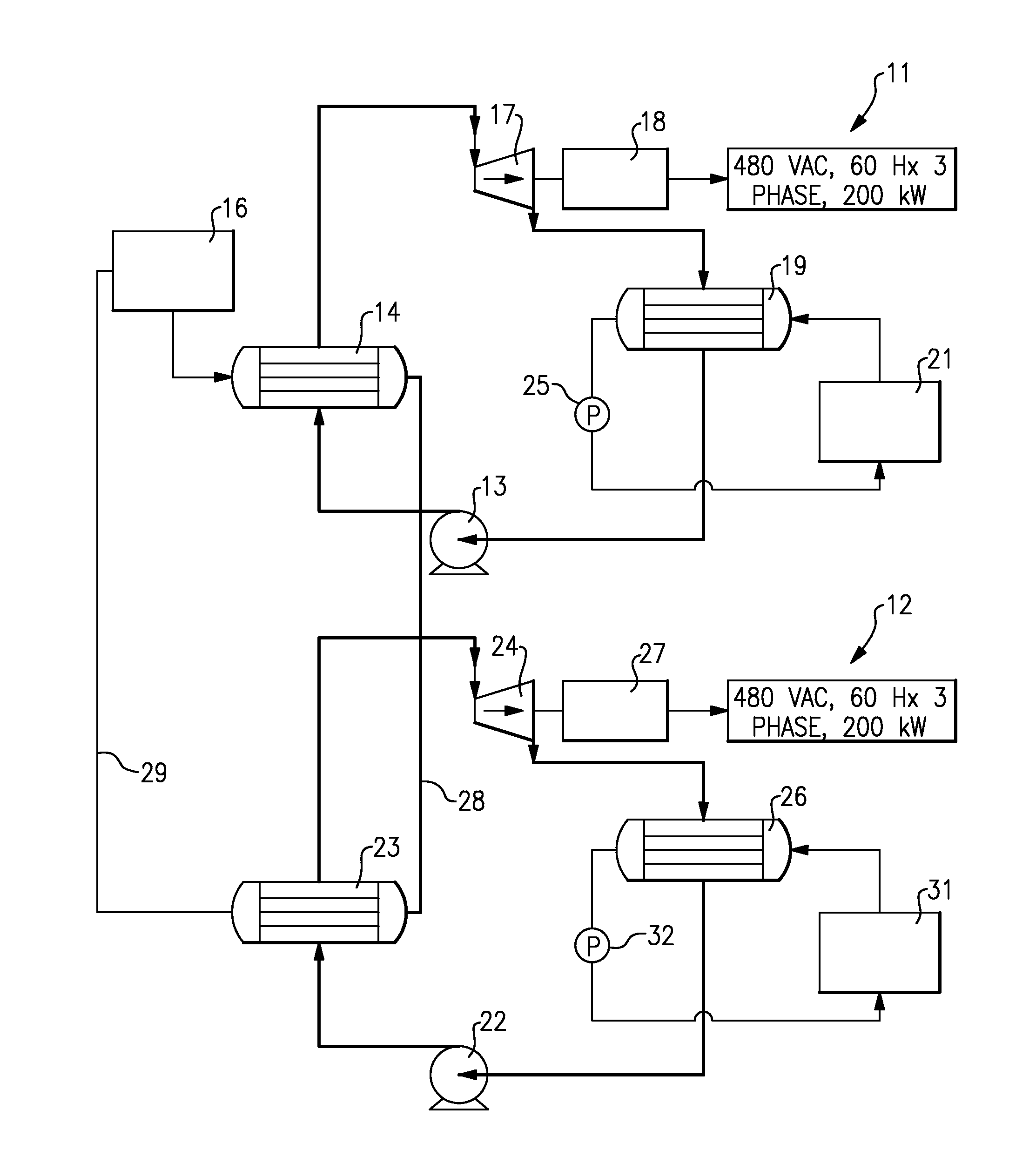

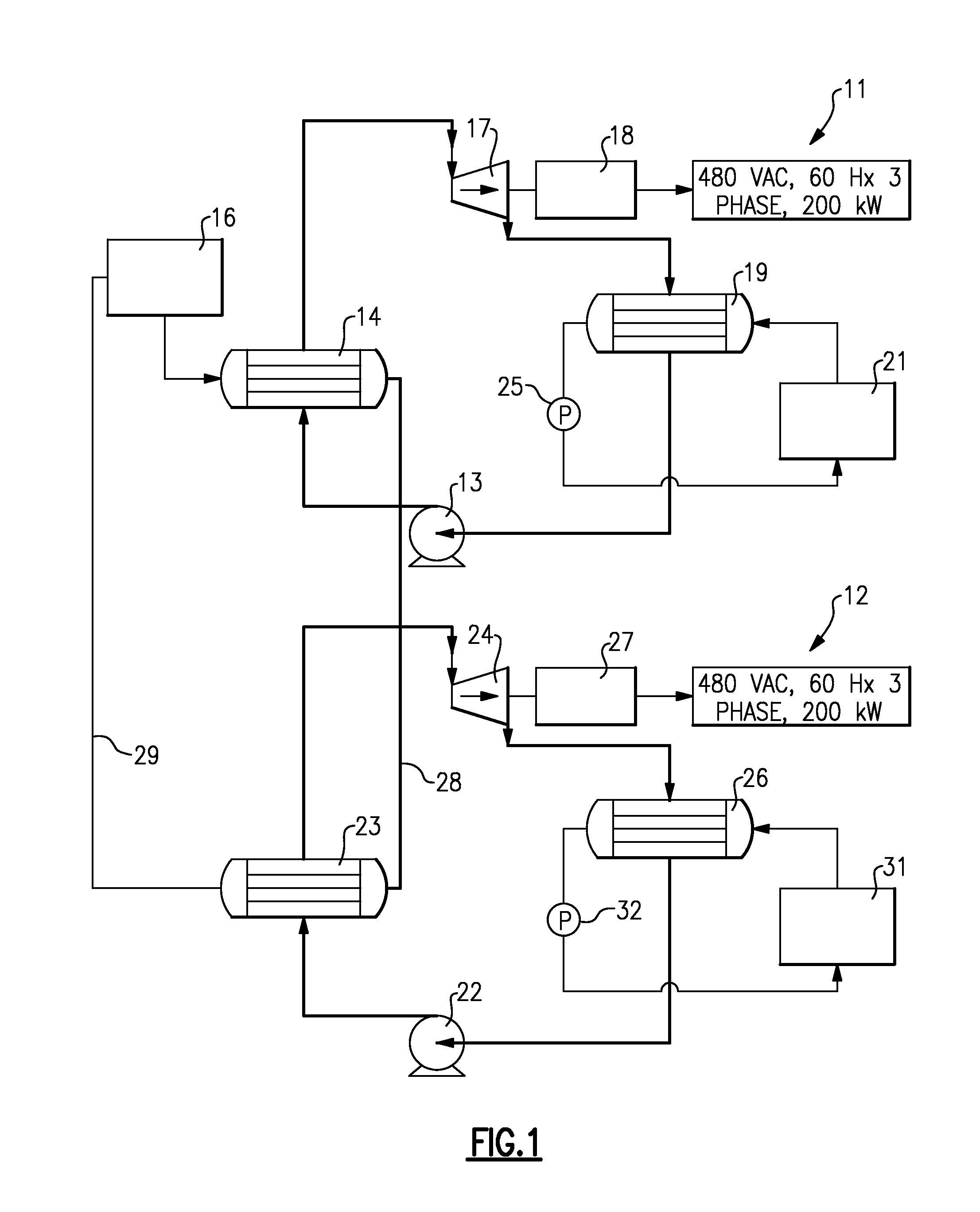

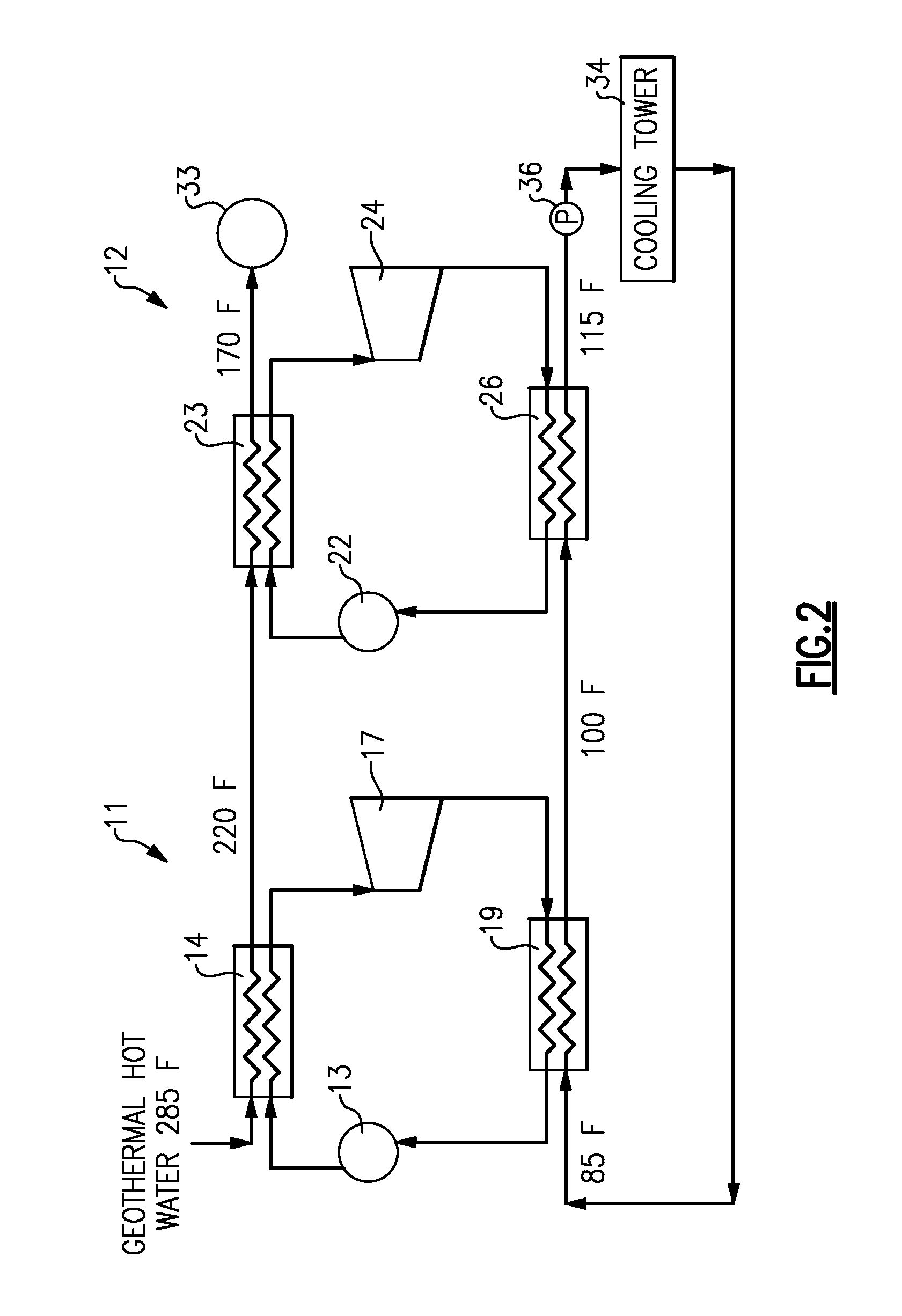

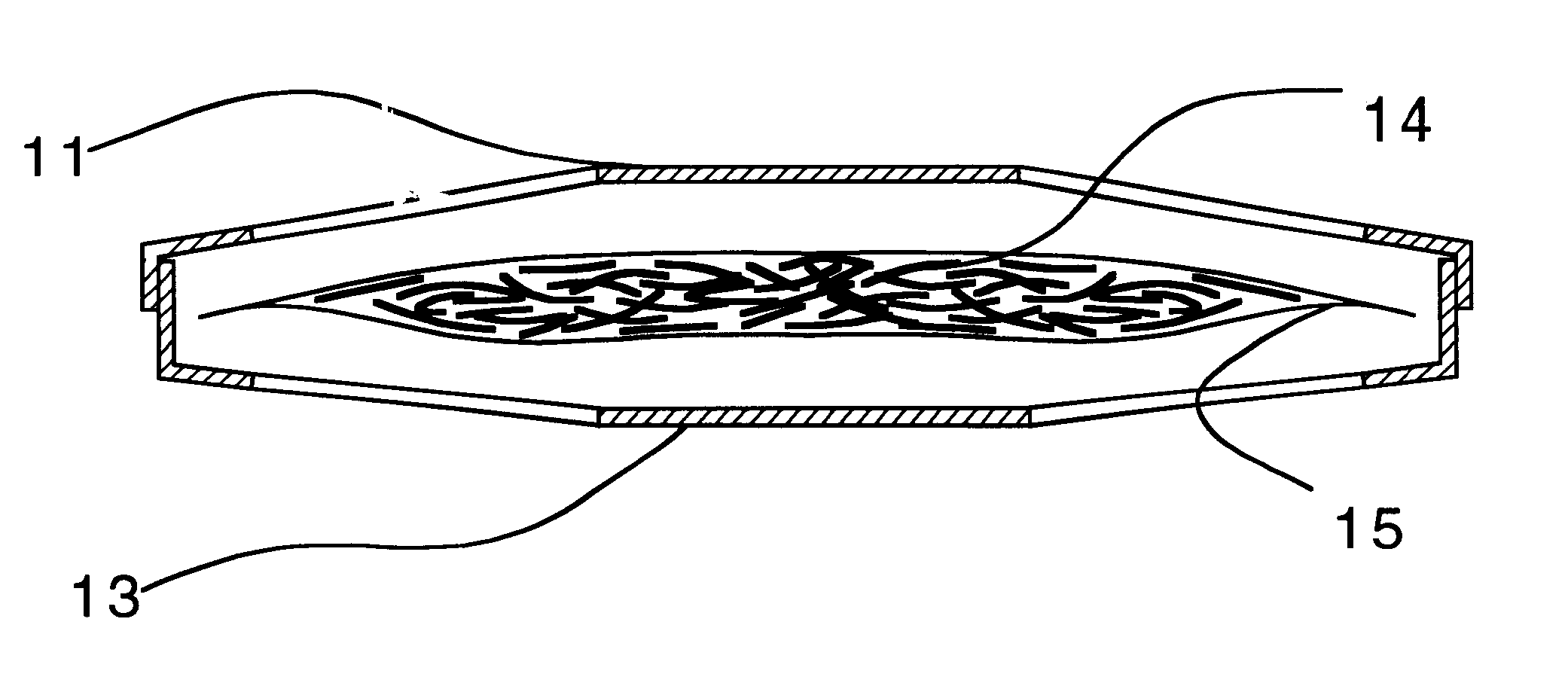

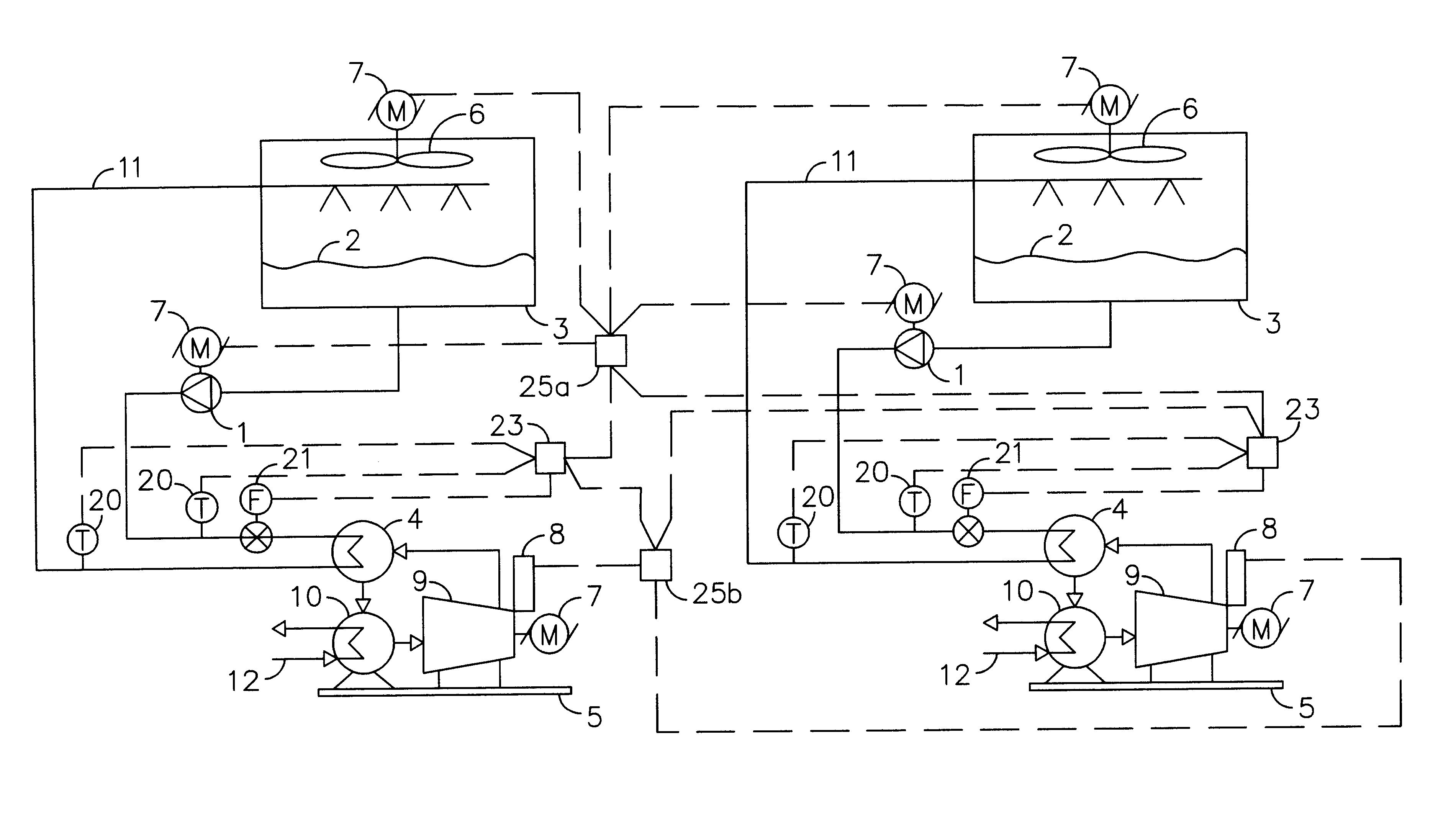

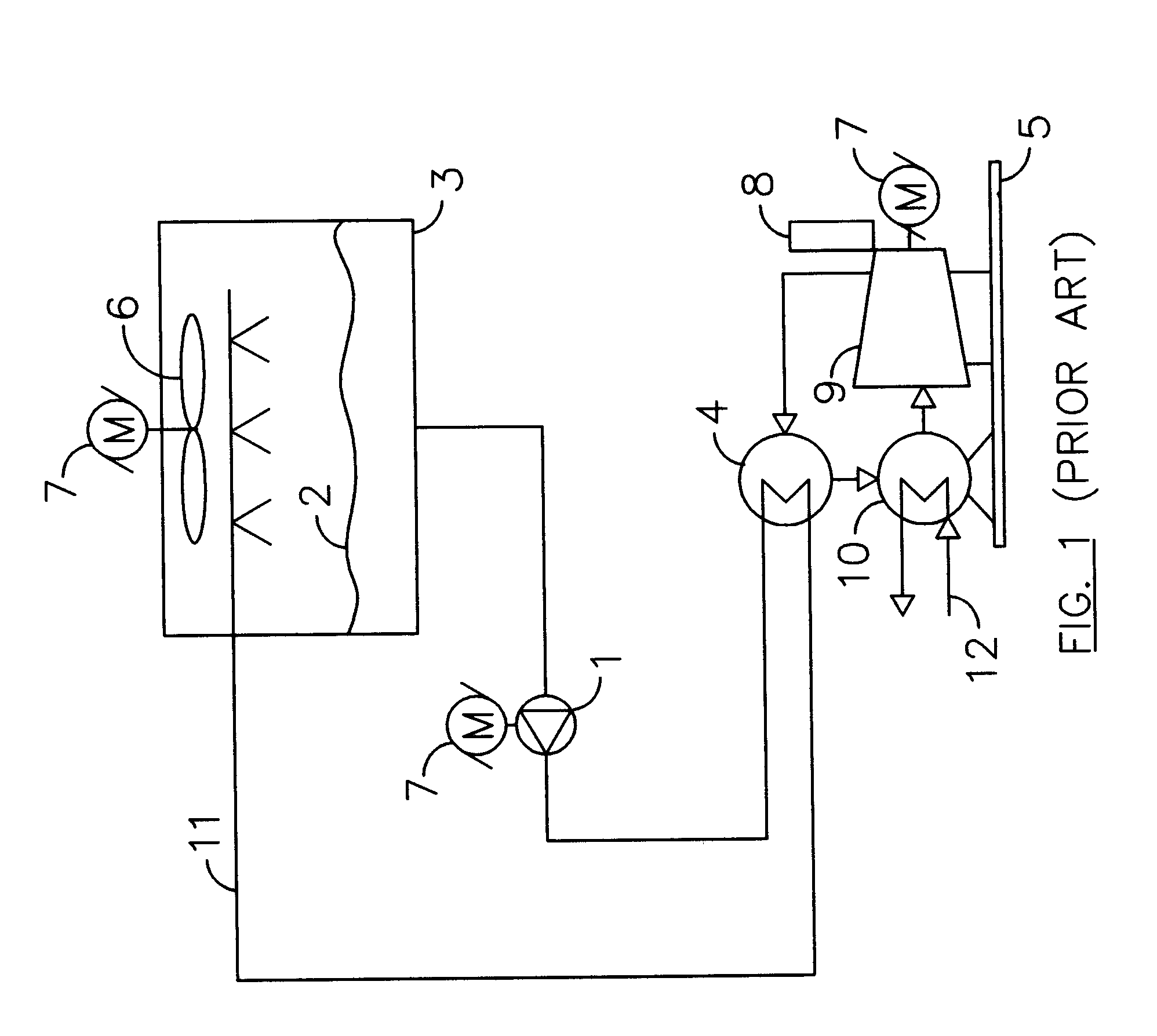

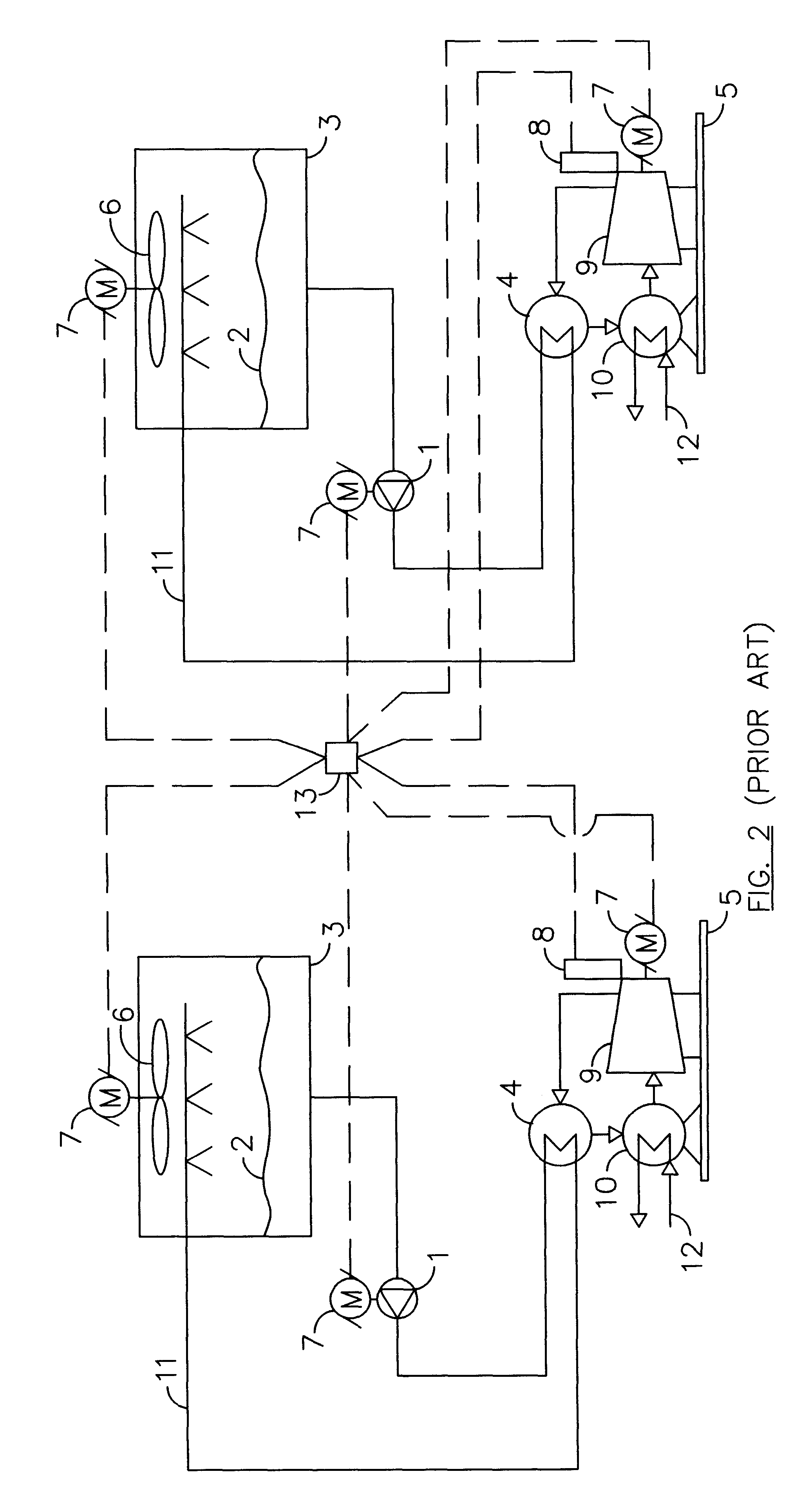

Cascaded condenser for multi-unit geothermal orc

A pair of organic rankine cycle systems are connected in series with the geothermal fluid passing first through an evaporator of the first system and then through an evaporator of the second system before returning to a sink. Similarly, the cooling tower is arranged to provide cooling water to pass first through the condenser in one system and then through the condenser of the other system, to reduce the total flow required and the size of associated cooling hardware.

Owner:UNITED TECH CORP

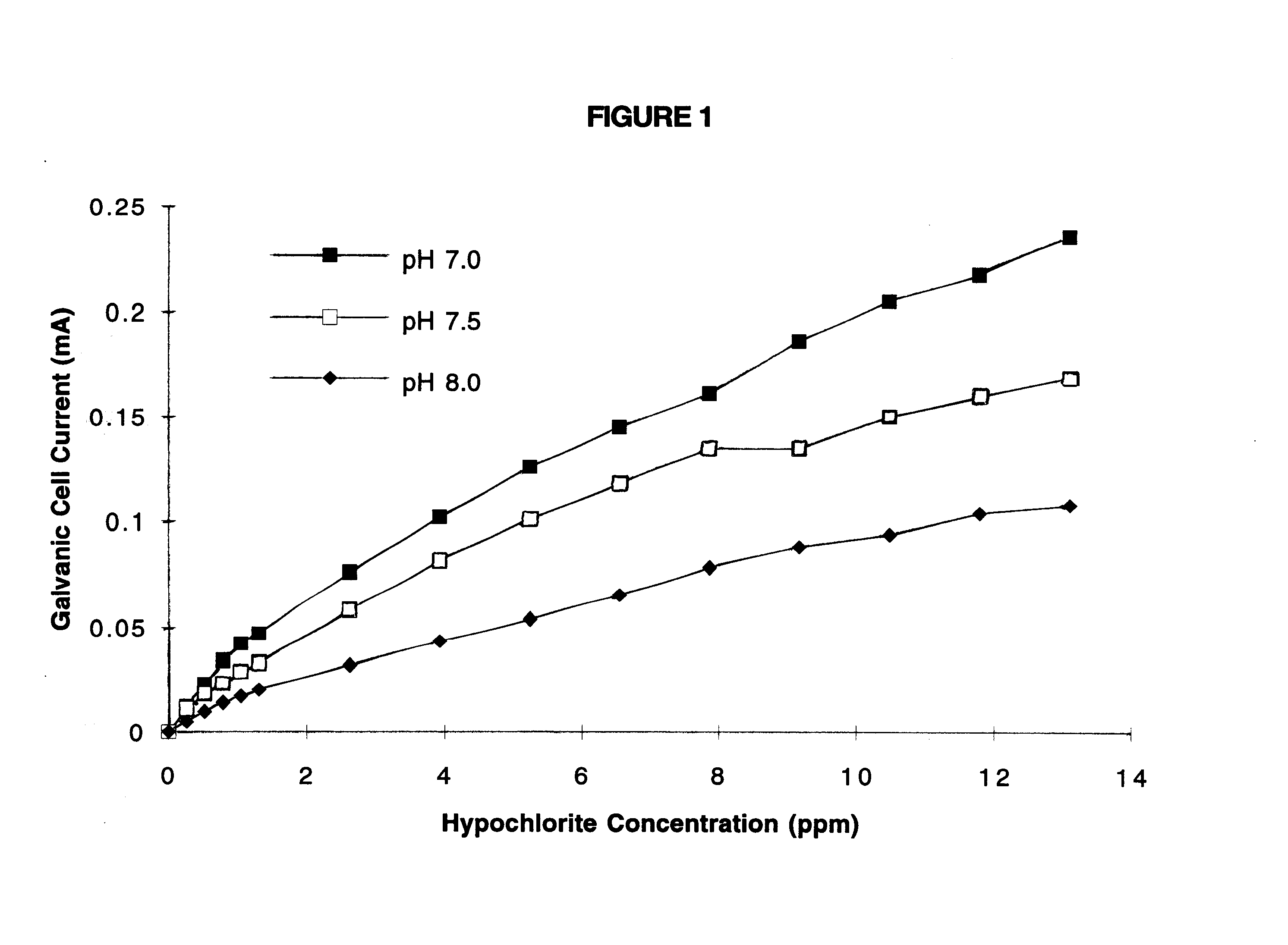

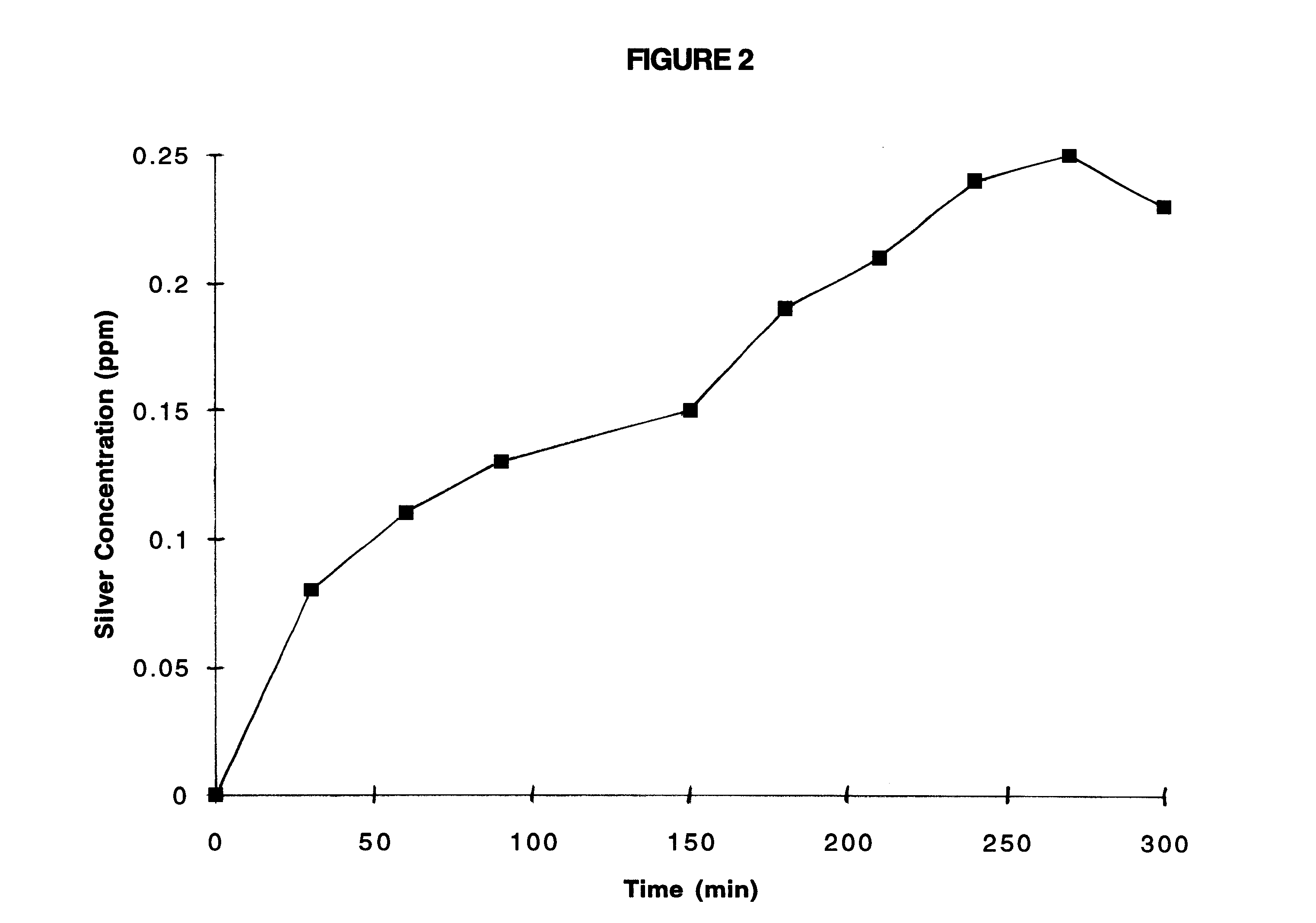

Apparatus and method for purifying water with an immersed galvanic cell

InactiveUS6287450B1Considerable energy savingReduce total usageCellsWater/sewage treatment by electrochemical methodsGramWater quality

A water purification system and method suitable for use in swimming pools, spas, hot tubs, water storage tanks, wells and water cooling towers employs a galvanic cell having a silver or copper or zinc anode electrically connected to a cathode made from a metal of still higher electrochemical potential, normally a platinum group metal and preferably palladium. A galvanic cell of some tens of square centimeters in size and some hundreds of grams in weight liberates sufficient silver or copper ions so as to treat a multi-thousand liter body of water, such as a swimming pool, for, typically under normal contamination, some months until the anode is consumed. Copper and / or silver ions liberated from the galvanic cell suppress bacterial, fungal and / or algae growth, thus, significantly reducing the amount of chlorine, bromine or other chemicals needed to maintain water quality. The invention operates on the current generated by the galvanic action between the dissimilar metals of the anode and cathode, and does not require external electrical power.

Owner:HRADIL GEORGE

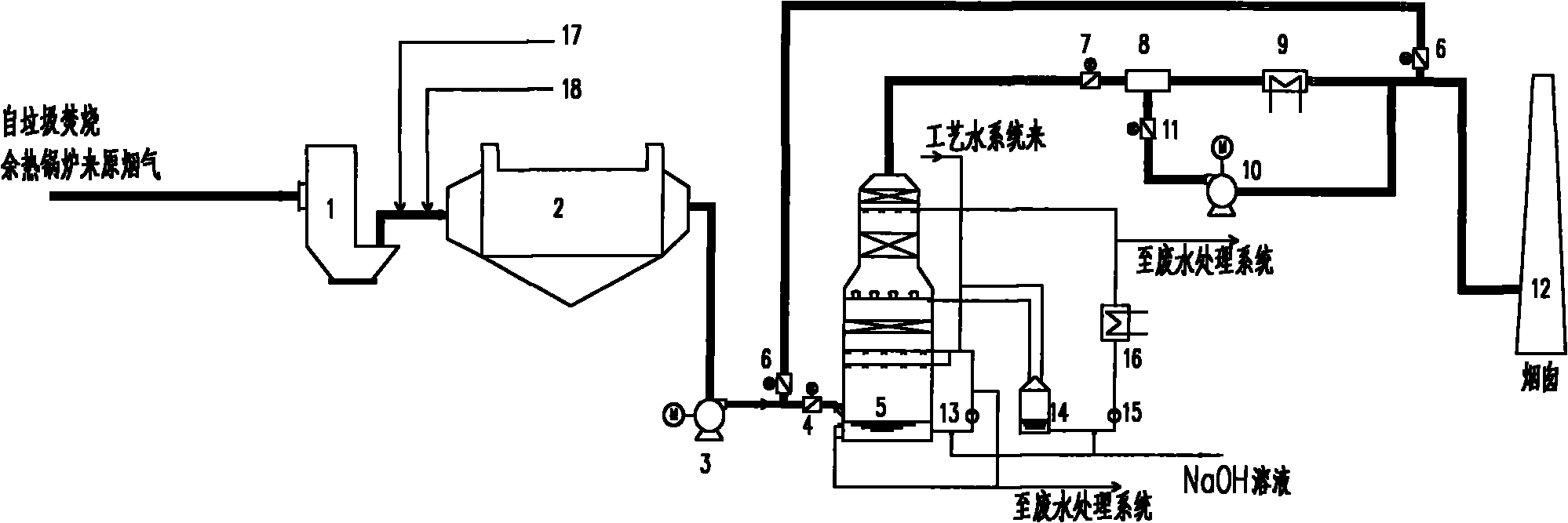

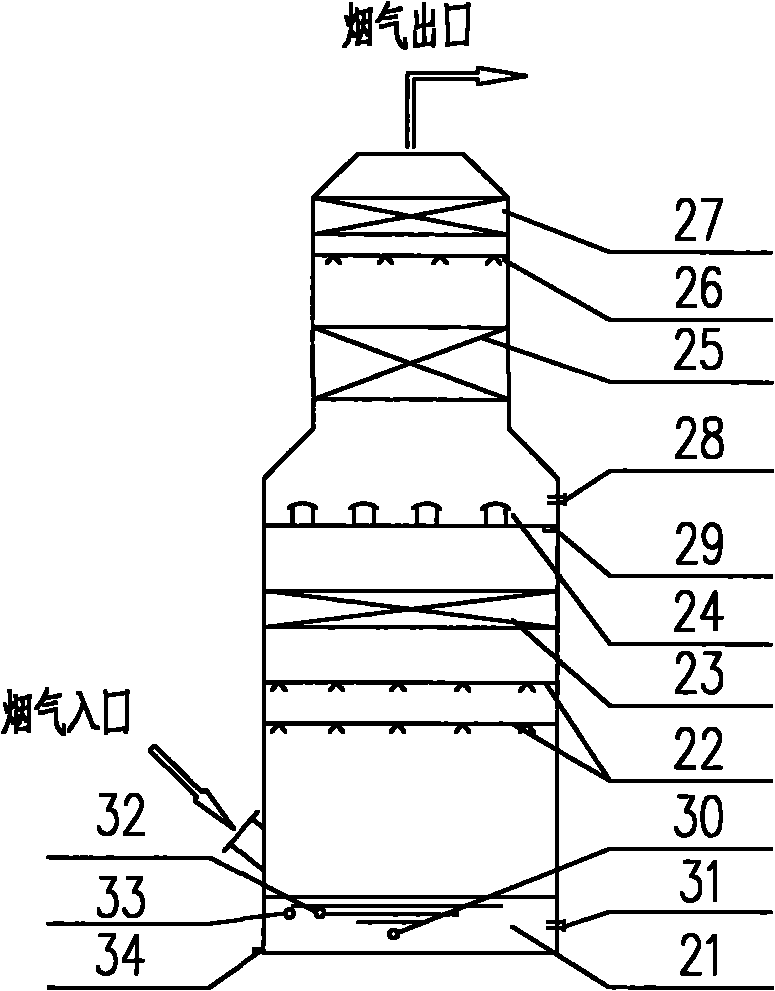

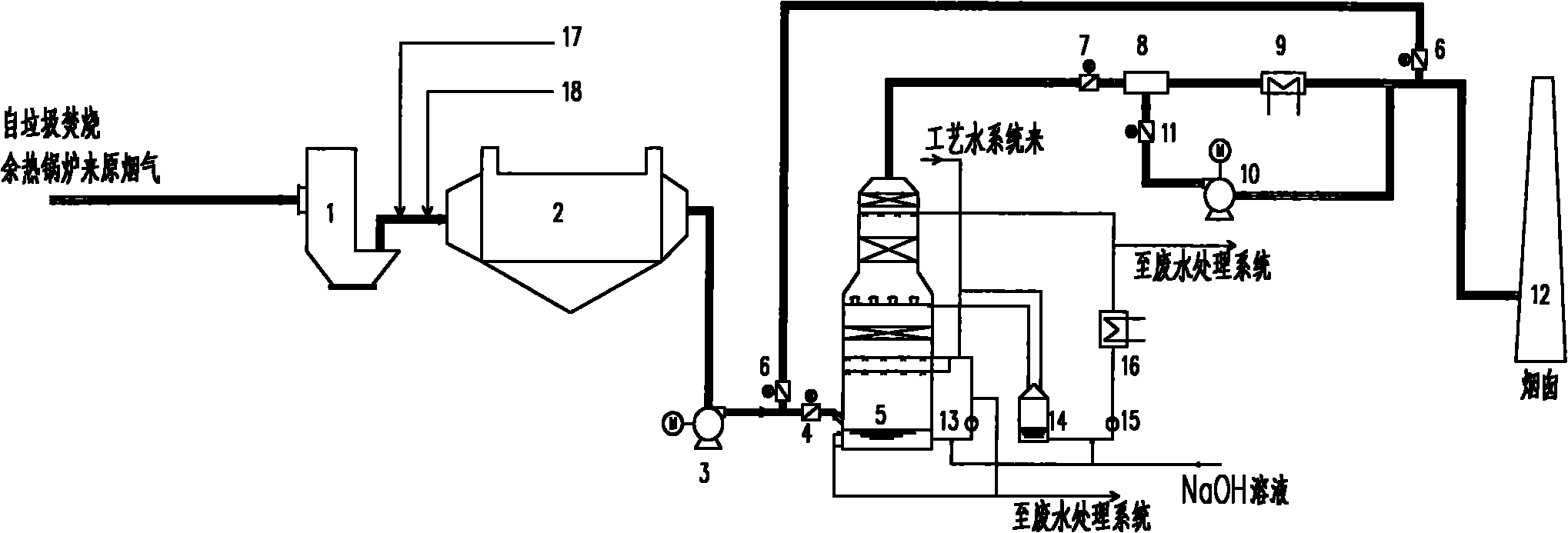

Flue-gas cleaning method and system for waste incineration

InactiveCN101829468AImprove removal efficiencyLarge load concentrationCombination devicesLighting and heating apparatusCooling towerHazardous substance

The invention discloses a flue-gas cleaning method for waste incineration, which comprises a dry process and a wet process. In the dry process, harmful substance in the flue gas is adsorbed by utilizing an adsorbent, and acid gas is neutralized by utilizing an alkaline absorbent, and in the wet process, a wet spray scrubber is utilized to purify the flu gas with higher efficiency. In addition, the invention also discloses a flue-gas cleaning system for waste incineration, which comprises a cooling tower, a bag-type dust collector, a wet washing tower and a glue-gas reheater. Flue gas from an exhaust-heat boiler enters the bag-type dust collector after being cooled by the cooling tower. Activated carbon and slaked lime powder are sprayed into the flue gas before the flue gas enters the bag-type dust collector to carry out preliminary purification on the flue gas; the purified flue gas is introduced to the wet washing tower through a draught fan for further processing; and the purified flue gas is discharged into the atomosphere by a chimney after the two-stage heating. The invention can effectively remove pollutant in flue gas and the quality of the purified flue gas can achieve the EU 2000 effluent standard.

Owner:山东三融环保工程有限公司

High efficiency heating, ventilating and air conditioning system

InactiveUS7340912B1Easy and efficient to manufactureImprove efficiencyAir treatment detailsStationary conduit assembliesCooling towerCoolant flow

A primary air flow path has a pre-cooler and an evaporator. A secondary air flow path includes portions of an air conditioner assembly including a compressor and an condenser. The air conditioner assembly also has lines connecting the compressor and the condenser the evaporator. A cooling tower has a coolant fluid input and output with a heat exchanger section. The heat exchanger section conveys coolant fluid. A pump causes cooling flow of water over the section. The coolant fluid output is adapted to feed a coolant fluid in two coolant fluid paths. The first fluid path is in heat exchanging relationship with the air conditioner assembly. The second fluid pat is coupled to the pre-cooler.

Owner:POWERCOLD TECH

Methods and systems for cooling buildings with large heat loads using desiccant chillers

ActiveUS20140150481A1Improve cooling efficiencyDispersed particle separationEfficient regulation technologiesCooling towerDesiccant

A system for providing cooling to a building includes a cooling tower for transferring waste heat from the building to the atmosphere and a liquid desiccant system for dehumidifying an air stream entering the cooling tower to increase cooling efficiency of the cooling tower. The liquid desiccant system includes a conditioner and a regenerator. The conditioner utilizes a liquid desiccant for dehumidifying the air stream entering the cooling tower. The regenerator is connected to the conditioner for receiving dilute liquid desiccant from the conditioner, concentrating the dilute liquid desiccant using waste heat from the building, and returning concentrated liquid desiccant to the conditioner.

Owner:COPELAND LP

Water treatment method and apparatus

InactiveUS6733654B1Water treatment parameter controlNature of treatment waterCooling towerWater flow

A method of operating a cooling tower comprises feeding to the cooling tower a make-up stream of water containing organic and / or biological contaminants, causing a side stream taken from the recirculating stream to pass through an electrolytic cell, removing solids precipitating by the action of the cell, and remixing the treated side stream with the main stream, before feeding them to the cooling tower.

Owner:ARGAD EYAL

Energy-saving heat supply system with function of reducing temperature of heat supply return water

InactiveCN106705185AIncrease profitReduce circulating water flowLighting and heating apparatusSteam useCooling towerTemperature difference

The invention discloses an energy-saving heat supply system with a function of reducing the temperature of heat supply return water, and belongs to the field of improvement of energy utilization efficiency. Heat exchange can be repeatedly carried out on heat sources by multistage heat exchangers, multistage absorption heat exchange units, multistage compression heat pumps and an ice making type refrigerator, accordingly, the heat supply areas can be enlarged, and the energy utilization efficiency can be improved. The energy-saving heat supply system has the advantages that the temperature of the return water of heat supply primary pipe networks can be reduced and reach 0 DEG C, the return water contains 10% of ice particles, accordingly, route heat loss of the return water of the heat supply primary pipe networks can be reduced, the temperature difference of the return water of the heat supply primary pipe networks can be increased and reaches 118 DEG C from the original 60 DEG C, the flow rate of circulating water of the heat supply primary pipe networks can be lowered, energy consumption of circulating pumps can be reduced, heat supply flow rates of a user side can be greatly increased, the delivery efficiency of the pipe networks can be improved, the heat supply scale can be expanded, waste heat of a cooling tower can be recycled, and the like.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

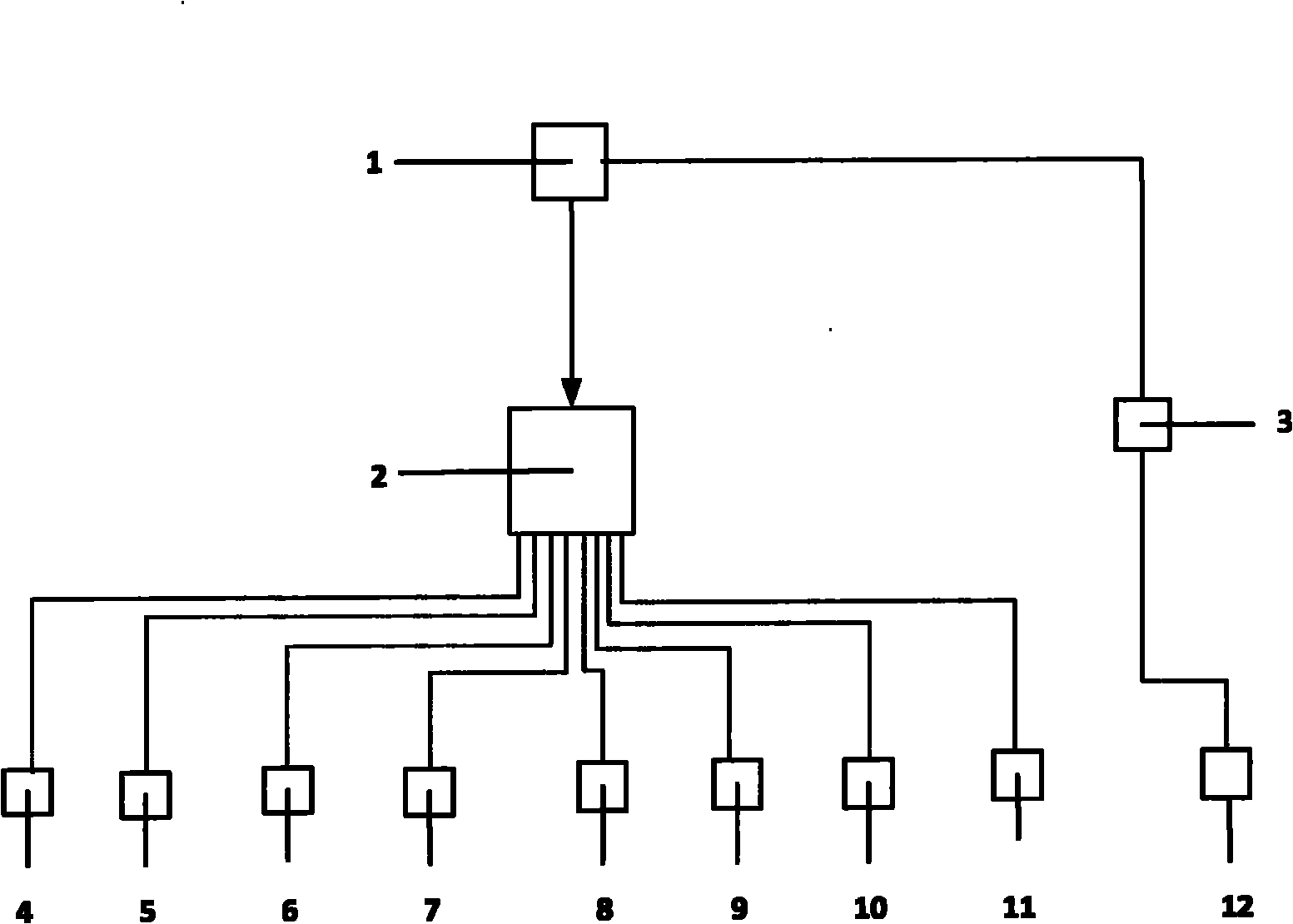

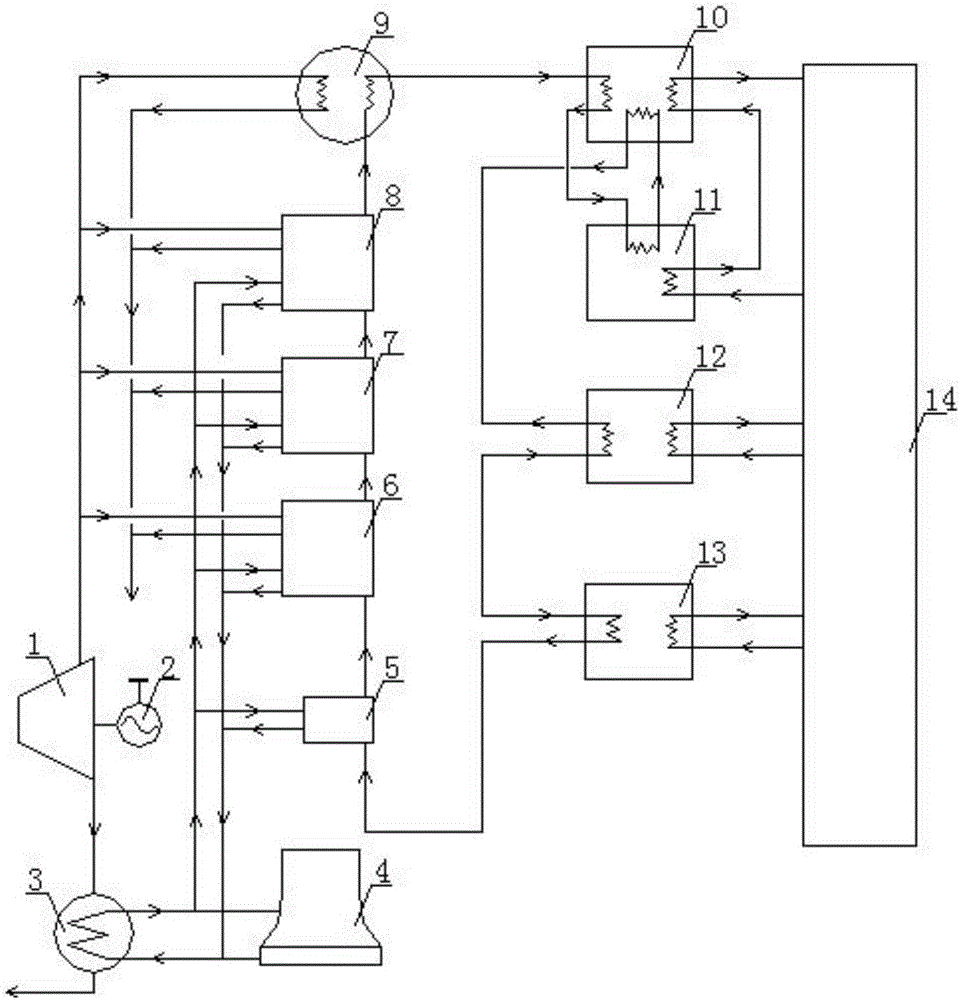

Linkage energy-saving control system and method for air conditioning system

ActiveCN105020845AZone temperature control stable without oscillationChange the air volumeSpace heating and ventilation safety systemsLighting and heating apparatusCooling towerControl system

The invention discloses a linkage energy-saving control system for an air conditioning system. An air and water linkage intelligent controller automatically adjusts an air and water linkage energy-saving control device according to working condition parameters. A cooling water pump and chilled water pump intelligent controller automatically adjusts the operation frequencies and the numbers of cooling water pumps and chilled water pumps according to the working condition parameters. A cooling tower and refrigerating host intelligent controller automatically adjusts the number of operated cooling tower draught fans and operated refrigerating hosts according to the working condition parameters. An air conditioner tail-end intelligent controller adjusts the opening degrees of air supply branch pipe tail-end air valves and chilled water proportion regulating valves and the operation frequencies of air feeders respectively through an air supply branch pipe tail-end air valve, chilled water proportion regulating valve and air feeder energy-saving controller according to the working condition parameters. The invention further discloses a linkage energy-saving control method for the air conditioning system. The linkage energy-saving control system is automatically matched with the energy-saving working condition parameters according with the current system, electric equipment and the controllers in the air conditioning system are adjusted, the air conditioning system runs at the best efficiency, and the purpose of reducing the total energy consumption of the system is achieved.

Owner:厦门立思节能科技有限公司

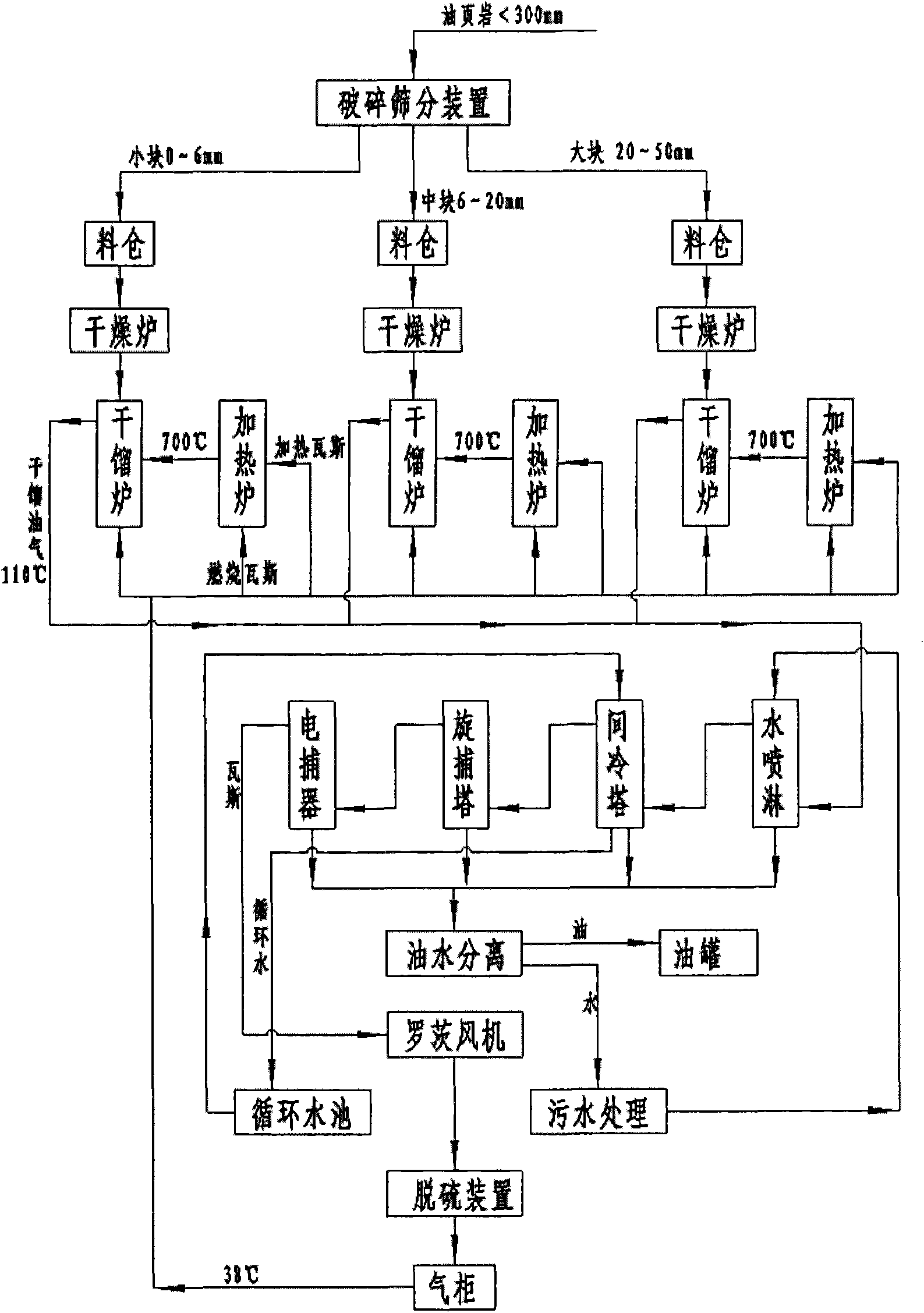

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

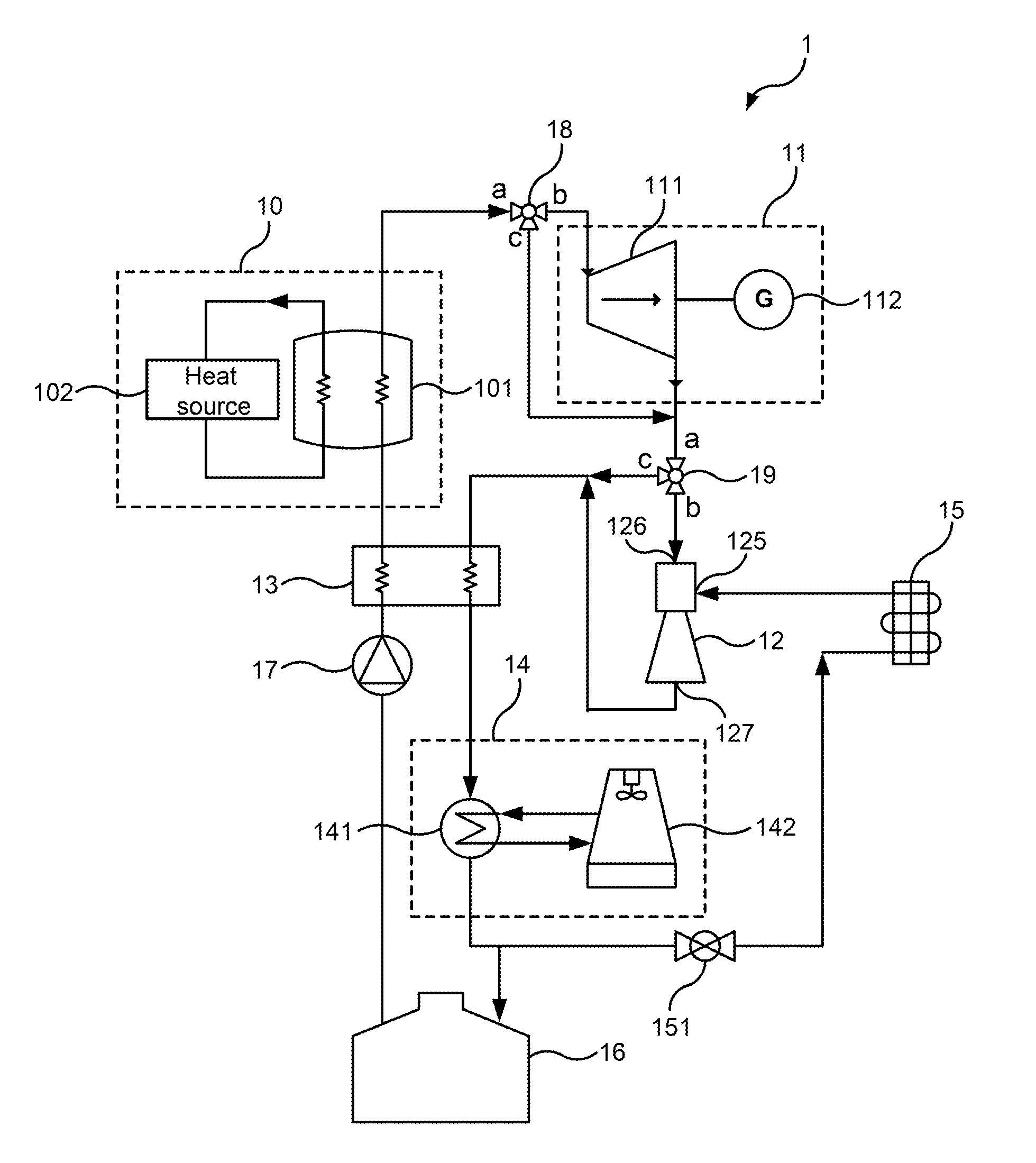

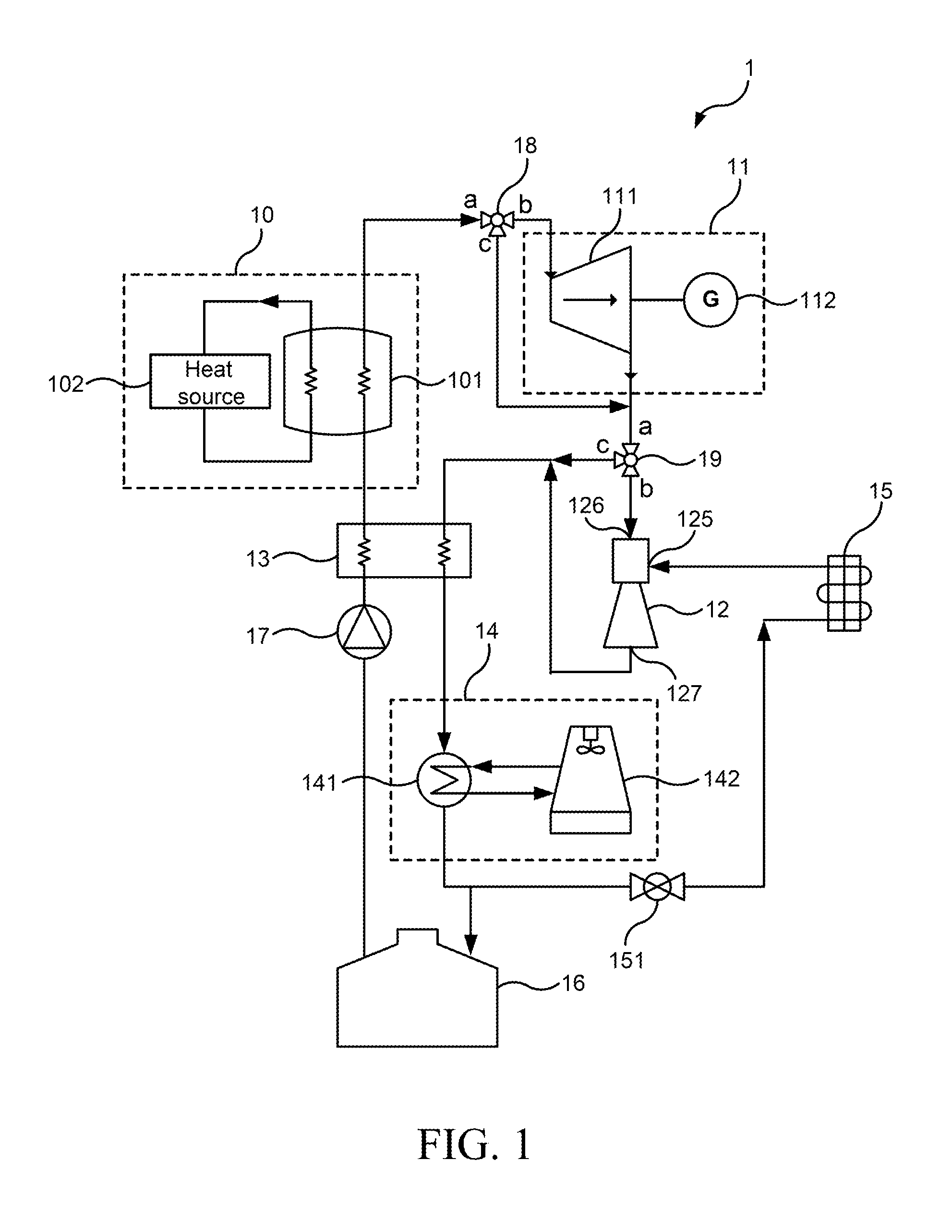

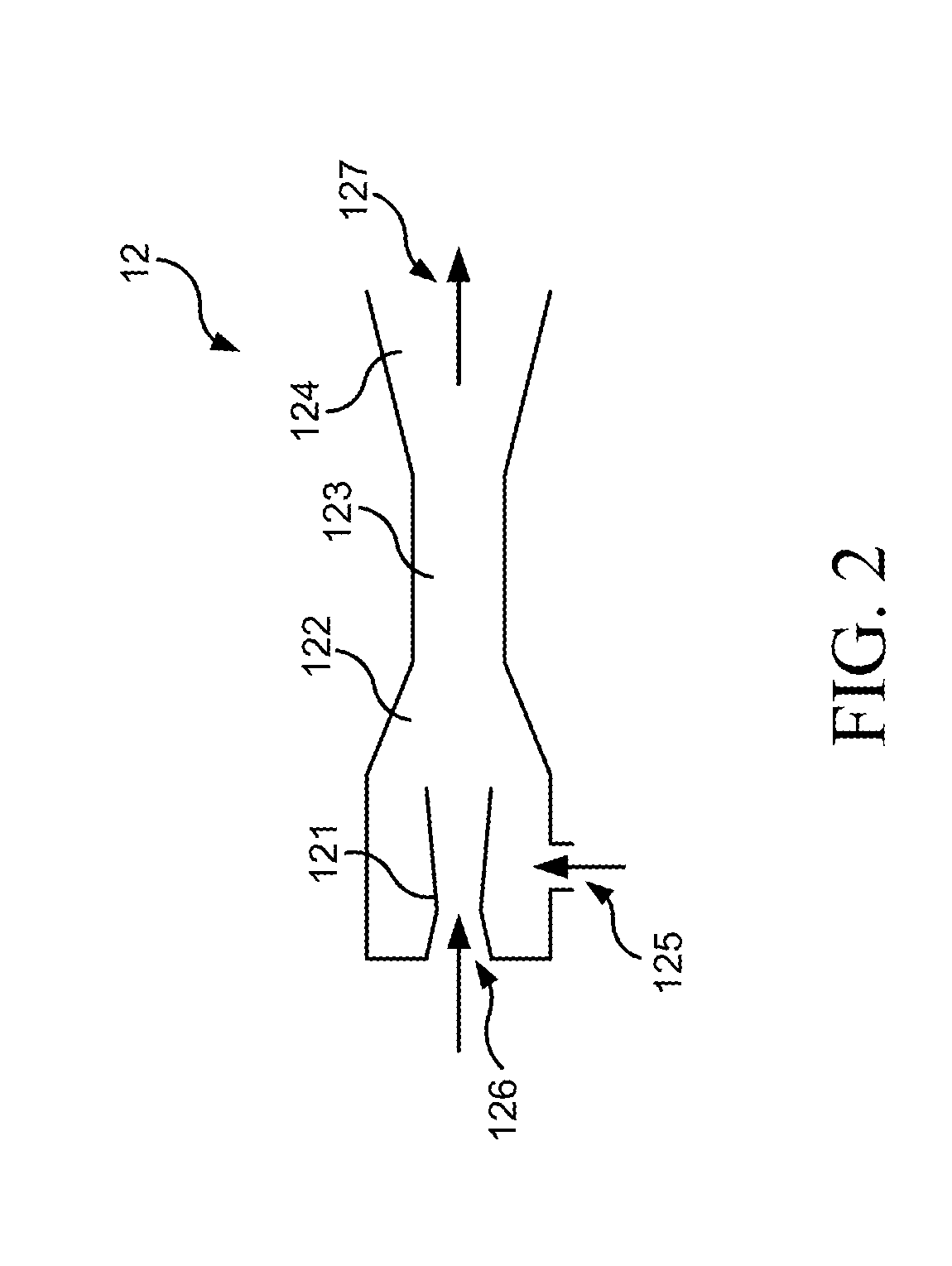

Apparatus and Method for Generating Power and Refrigeration from Low-Grade Heat

InactiveUS20120255304A1Compression machines with non-reversible cycleSteam useWorking fluidCooling tower

An apparatus and a method generate power and refrigeration from low-grade heat. The apparatus includes a heating module, a power generator module, an ejector, a heat exchanger, a condenser module, a low-temperature evaporator, a reservoir, a pressure pump and two direction controllable three-way valves. The heating module includes a heat source and a boiler. The power generator module includes an expansion turbine and a power generator. The condenser module includes a condenser and a cooling tower. The method is that the direction controllable three-way valves are operated to change the flow directions of the working fluid for executing a power generation and refrigeration mode, a power generation mode, a refrigeration mode or an idle mode.

Owner:INST NUCLEAR ENERGY RES ROCAEC

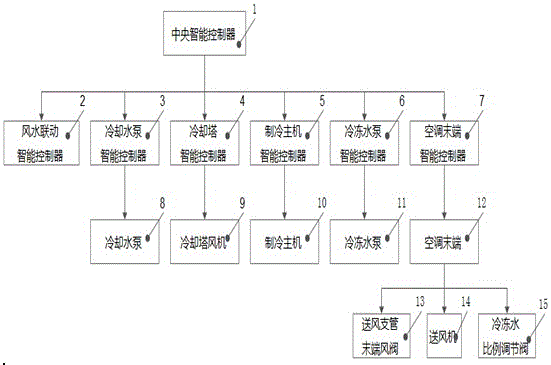

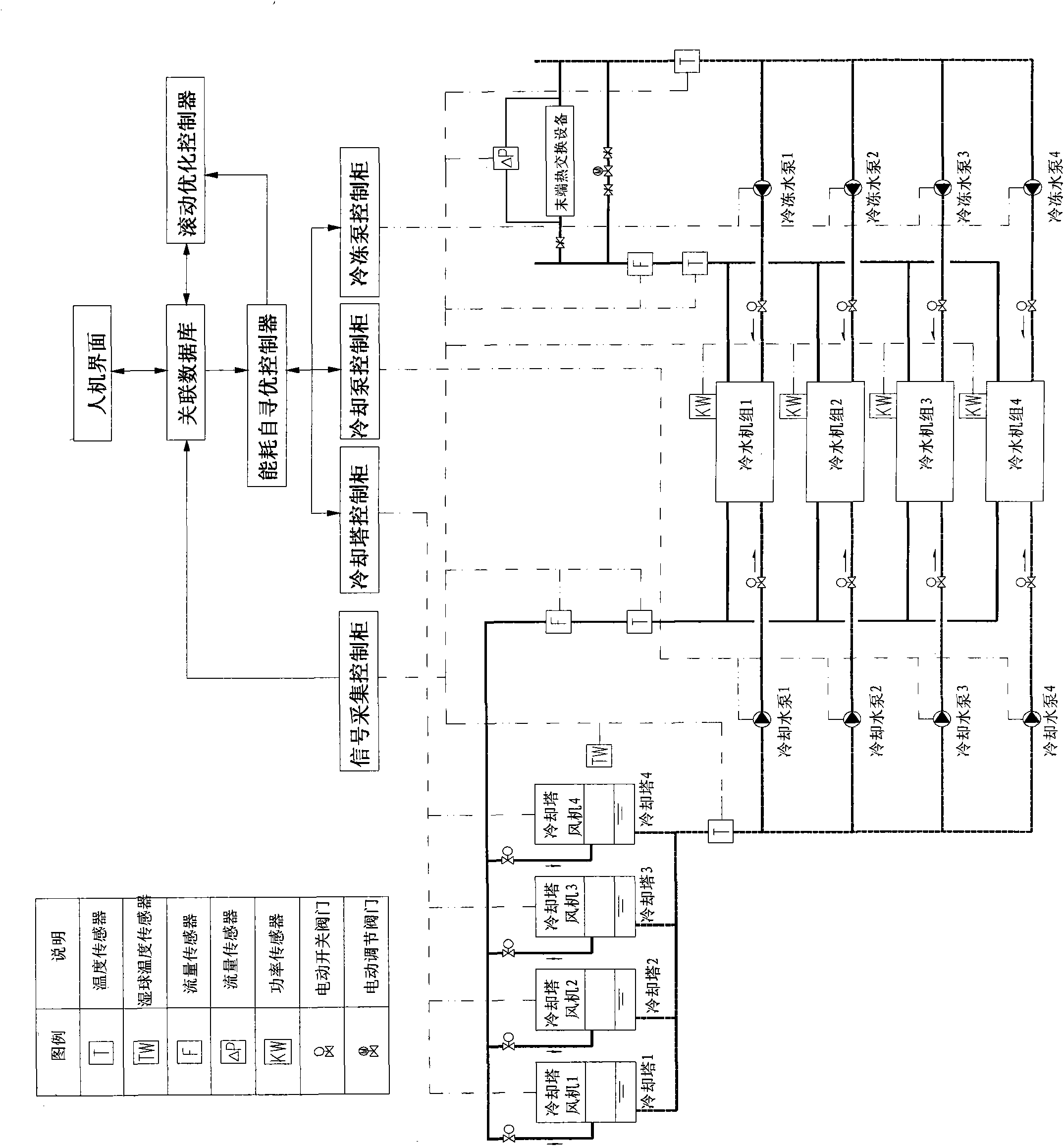

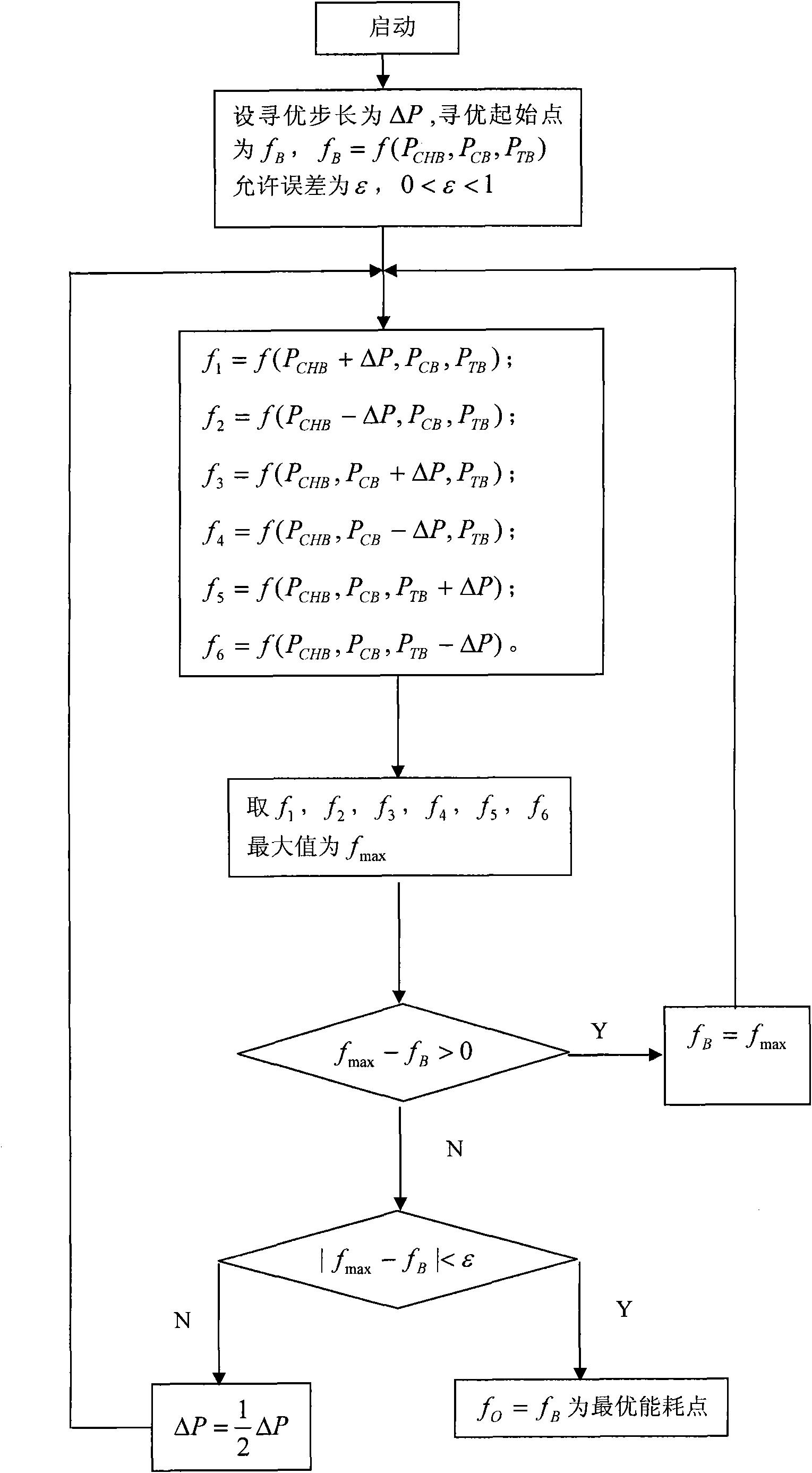

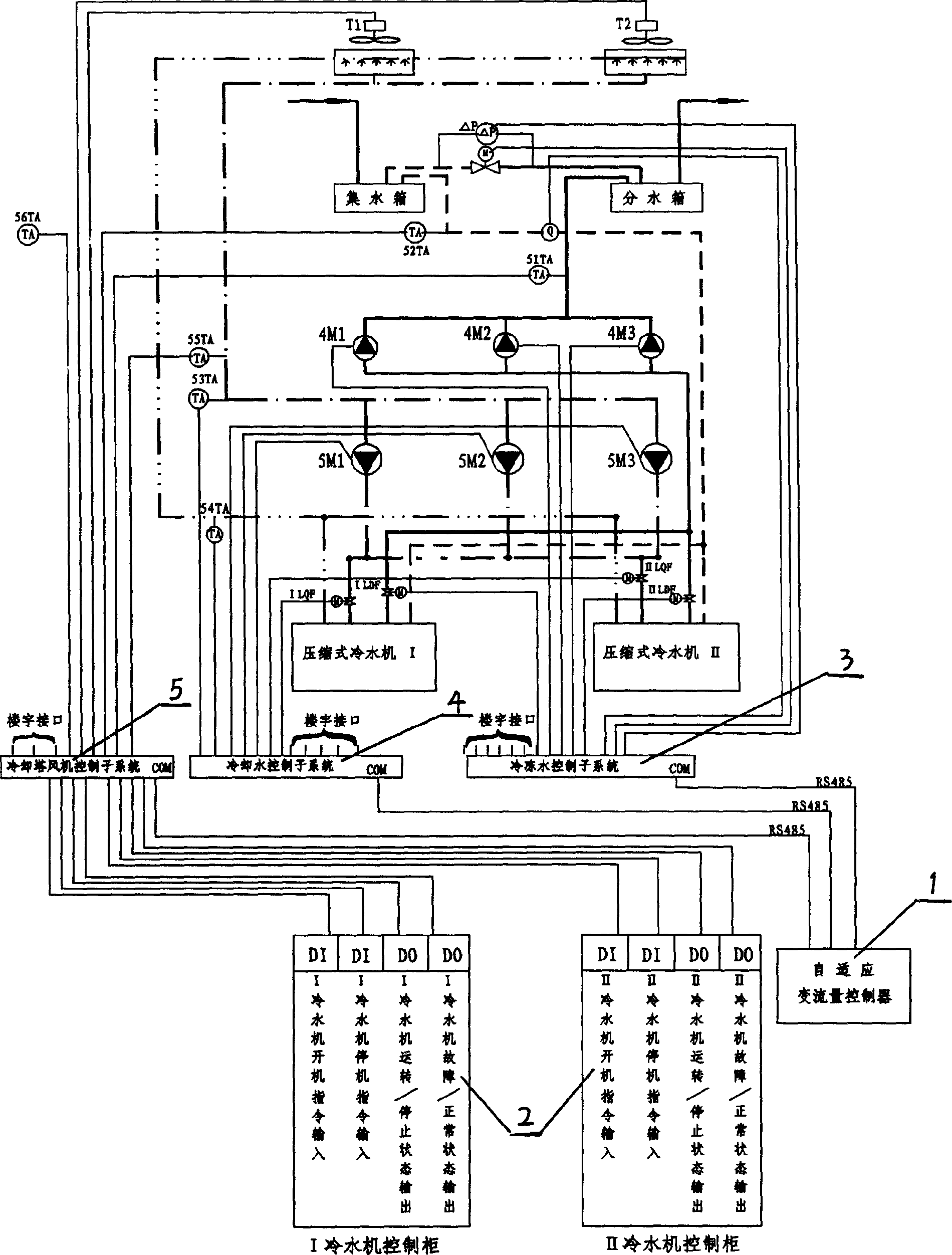

Energy-saving control system and control method of central air conditioning freezing station

ActiveCN102012077ARealize dynamic updateReduce energy consumptionSpace heating and ventilation safety systemsLighting and heating apparatusCooling towerRelational database

The invention relates to an energy-saving control system and control method of a central air conditioning freezing station. The control system is an energy conservation system with a self-learning function, and comprises a relational database, an energy consumption self-optimization controller, a rolling optimization controller, a signal acquisition control cabinet, a cooling tower control cabinet, a cooling pump control cabinet, a refrigeration pump control cabinet, and a plurality of sensors. Through relational database modeling for each main current consuming device in the central air conditioning freezing station and rolling optimization of the relational database, energy consumption associated information of each main current consuming device is obtained, and through further energy consumption self-optimization course, an optimization parameter of the operation of devices in the freezing station is obtained, thus the integral central air conditioning freezing station operates at a high-efficient and energy-saving state.

Owner:BEIJING SATELLITE MFG FACTORY +1

Combined heat and power generation energy saving device using afterheat to supply heat and energy saving method

InactiveCN101967999AIncrease small loopReduce heat transfer irreversible lossLighting and heating apparatusEnergy efficient heating/coolingCooling towerCogeneration

The invention relates to a combined heat and power generation energy saving device using afterheat to supply heat and an energy saving method. The combined heat and power generation energy saving device comprises a steam boiler, a steam extraction condensed type steam turbine, an electric generator, a condenser, a deaerator and a cooling tower, wherein the steam extraction condensed type steam turbine is connected with the condenser by an exhaust steam cylinder, and the condenser is connected with the cooling tower to form large waterway circulation; the combined heat and power generation energy saving device also comprises a backpressure turbine, a compression heat pump and a heat exchanger, wherein a steam inlet of the backpressure turbine is connected with a steam extraction hole of the steam extraction condensed type steam turbine, an exhaust steam hole is connected with a steam inlet of the heat exchanger, the compression heat pump is drawn by the backpressure turbine and is connected with the backwater end of a hot-water pipe network, the condenser and the compression heat pump are connected with the cooling tower to form small waterway circulation, the water inlet end of the heat exchanger is connected with the water outlet end of the compression heat pump, the water outlet end is connected with the water inlet end of the hot-water pipe network, and the drainage end is connected with the deaerator. The invention is capable of reducing cold source loss, increasing comprehensive heat efficiency and electrothermal proportion and reducing unit electric-generation coal consumption.

Owner:联合优发生物质能源徐州有限公司

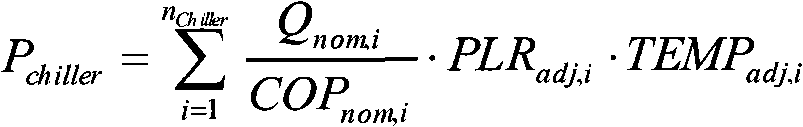

Method to optimize chiller plant operation

A chiller plant which produces chilled water for airconditioning, or an industrial process and which is comprised of chillers, cooling fluid pumps, and cooling towers with electrical motor drives uses a substantial amount of energy. A method that coordinates the operation of the cooling tower, cooling fluid pumps, and refrigeration machines so that the chiller plant operates at a higher overall efficiency thus reducing the power usage has been developed and is presented herein. The flow rate of the cooling fluid pumps are controlled to maintain a precise temperature difference across the refrigerant condenser. The cooling tower fans are controlled by comparing the cooling fluid temperature and the cooling fluid flow rate to selected design parameters. The heat rejection rate is measured for each chiller in the chiller plant and operating set points are established for each operating chiller to provide the optimum operation for best energy efficiency.

Owner:CHILLER PLANT OPTIMIZATION LLC

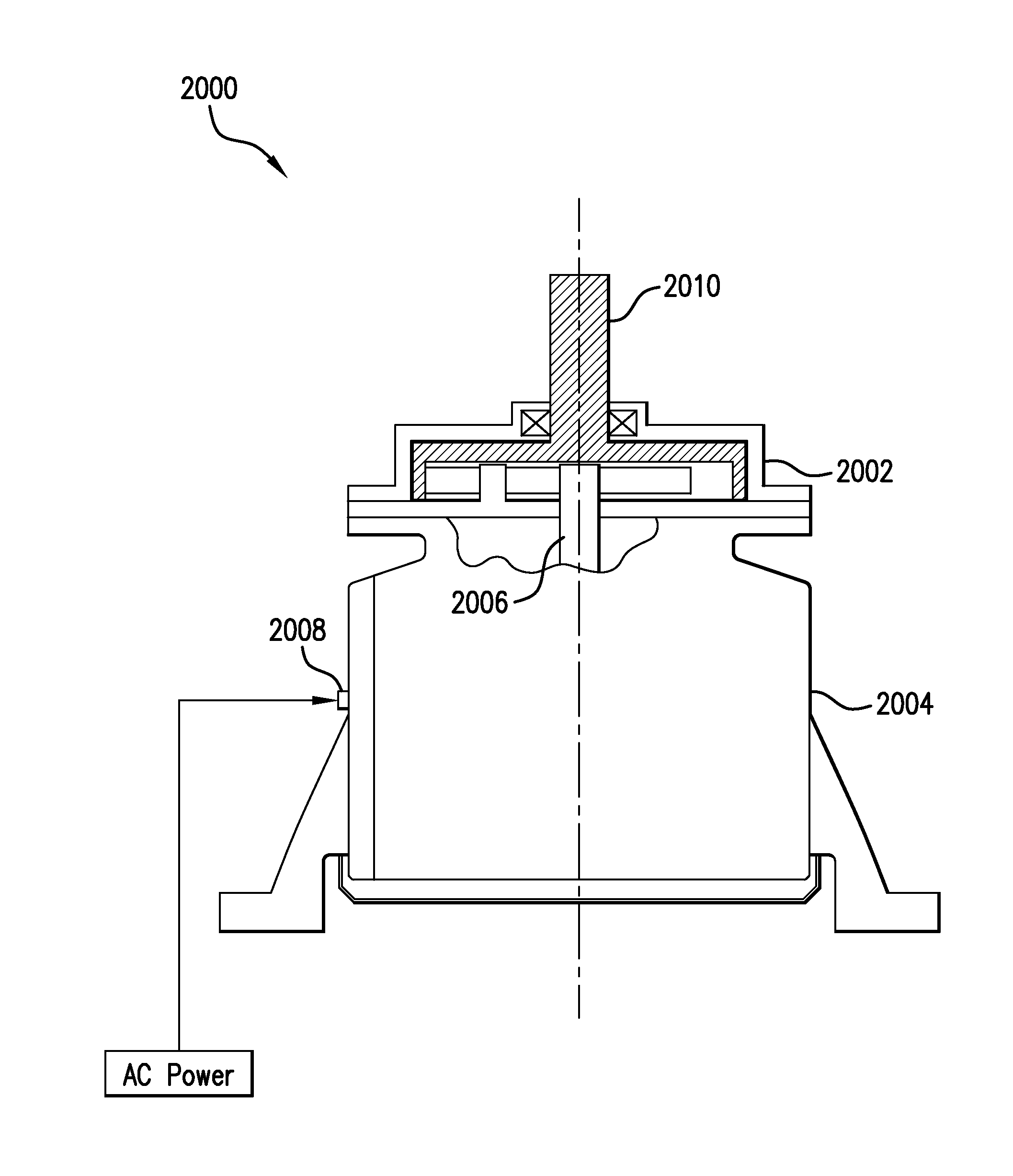

Direct-Drive System For Cooling System Fans, Exhaust Blowers And Pumps

ActiveUS20160069624A1Eliminate the problemPump componentsSemiconductor/solid-state device detailsCooling towerControl system

The present invention is directed to a load bearing direct-drive system and a variable process control system for efficiently managing the operation of fans in a cooling system such as a wet-cooling tower, air-cooled heat exchanger (ACHE), HVAC system, blowers and centrifugal blowers, mechanical towers or chiller systems. In one embodiment, the load bearing direct-drive system comprises a load bearing torque multiplier device having an output rotatable shaft connected to a fan, and a load bearing motor comprising a rotatable shaft that drives the load bearing torque multiplier device.

Owner:PRIME DATUM

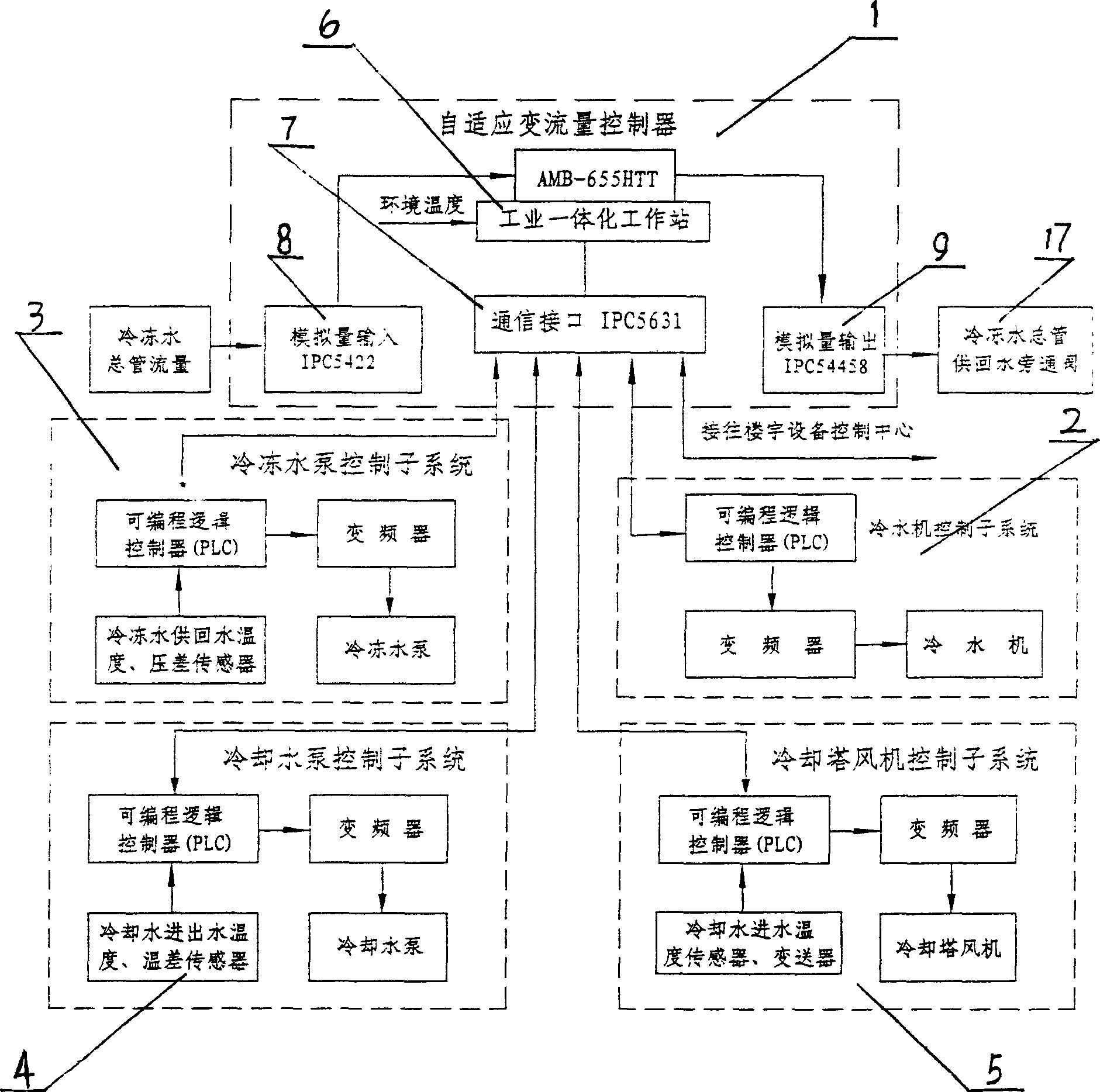

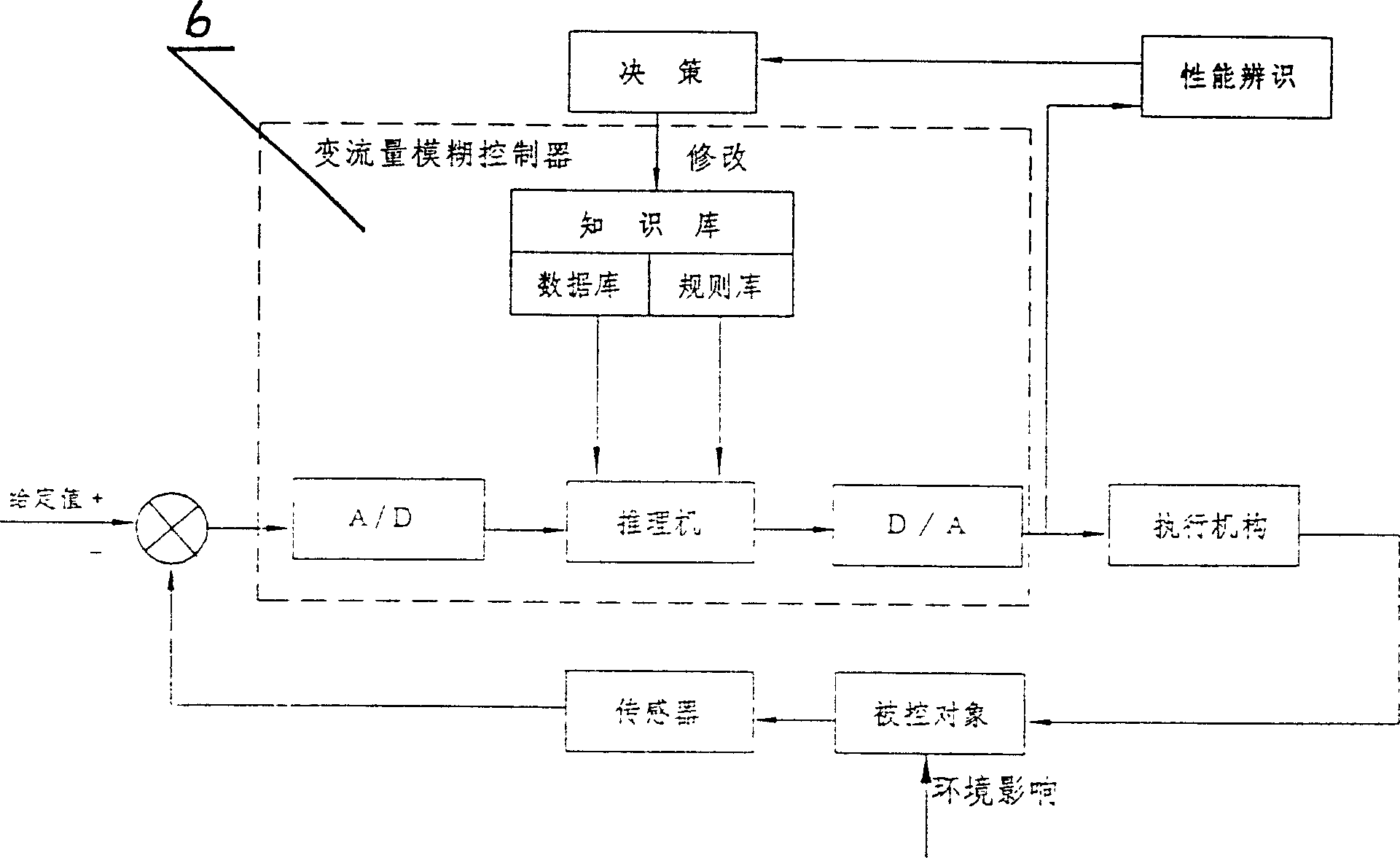

Self-adapting energy saving control device with variable flux for compression type central conditioner

InactiveCN1415915AReduce wearWith the purpose of saving energy and reducing consumptionSpace heating and ventilation safety systemsLighting and heating apparatusIce waterCooling tower

This invention discloses a compressed central air-conditioning adaptive variable flow energy saving control device composed of an adaptive variable flow controller, ice water control subsystem, frozen water control subsystem, cooling water control subsystem, cooling tower blower fan control subsystem, the adaptive variable flow controller connects with control subsystem of ice water device, frozen water pump, cooling water and blower fan of cooling tower capable of making every operational target to reach the most optimized.

Owner:贵州华城楼宇科技有限公司

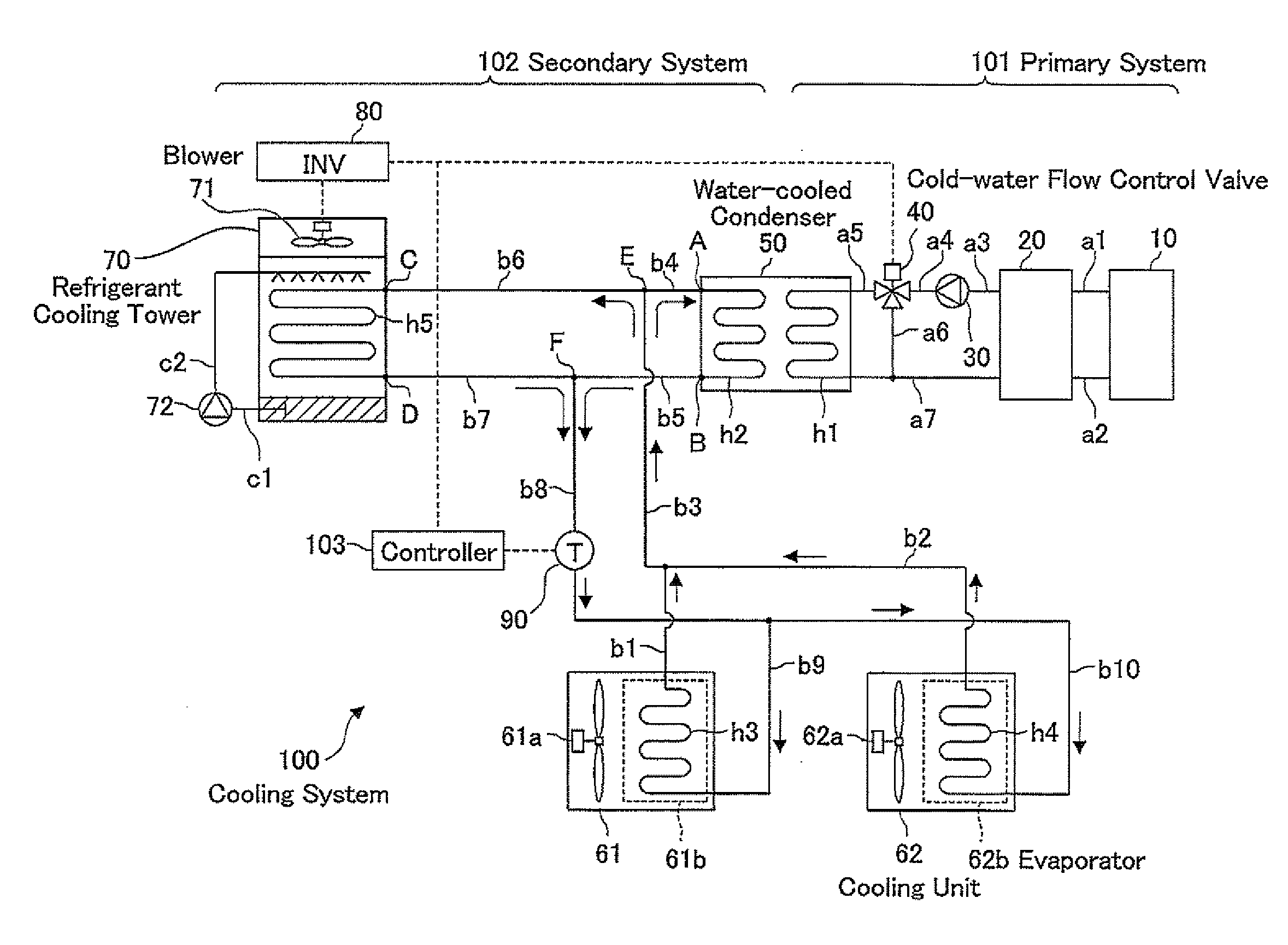

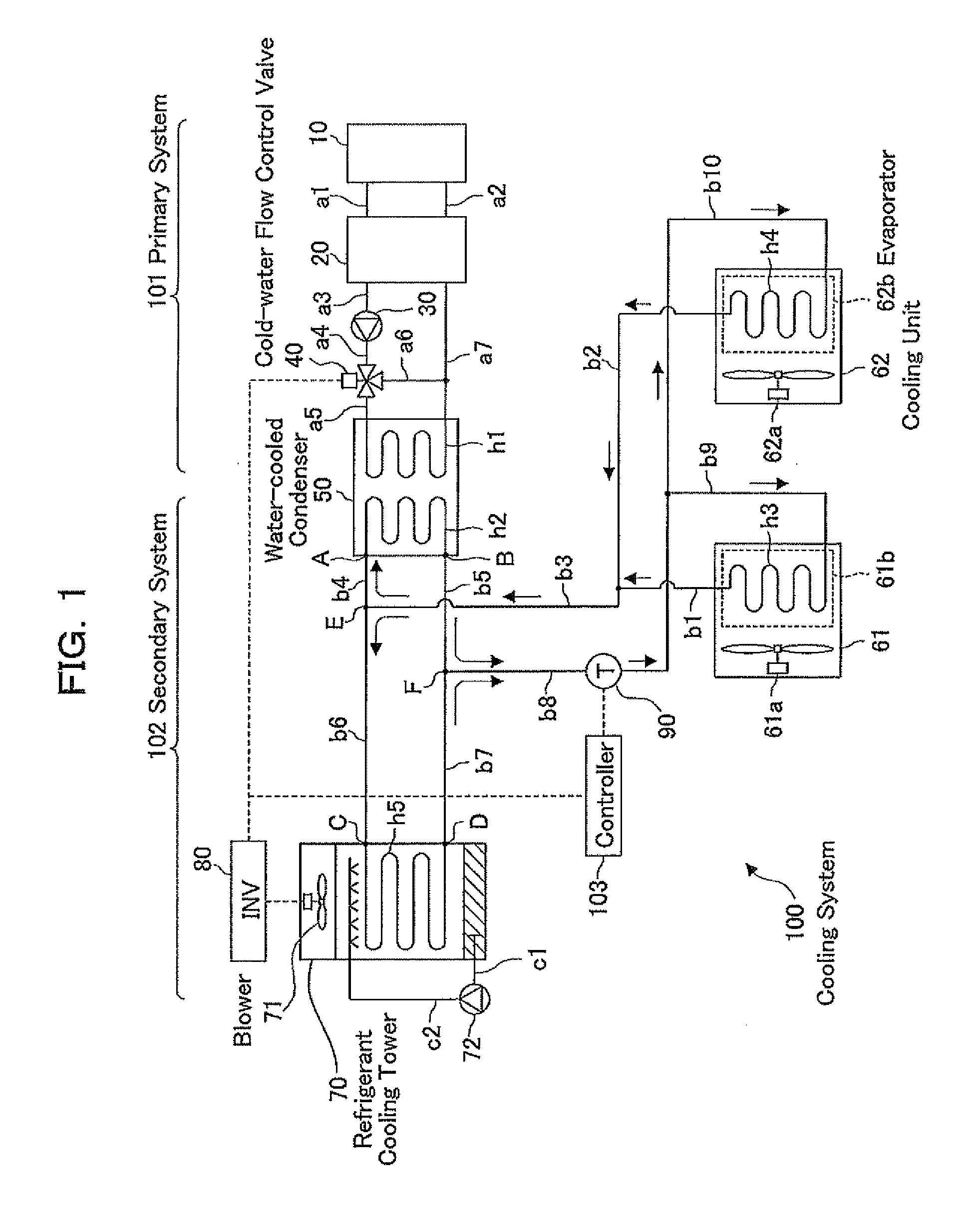

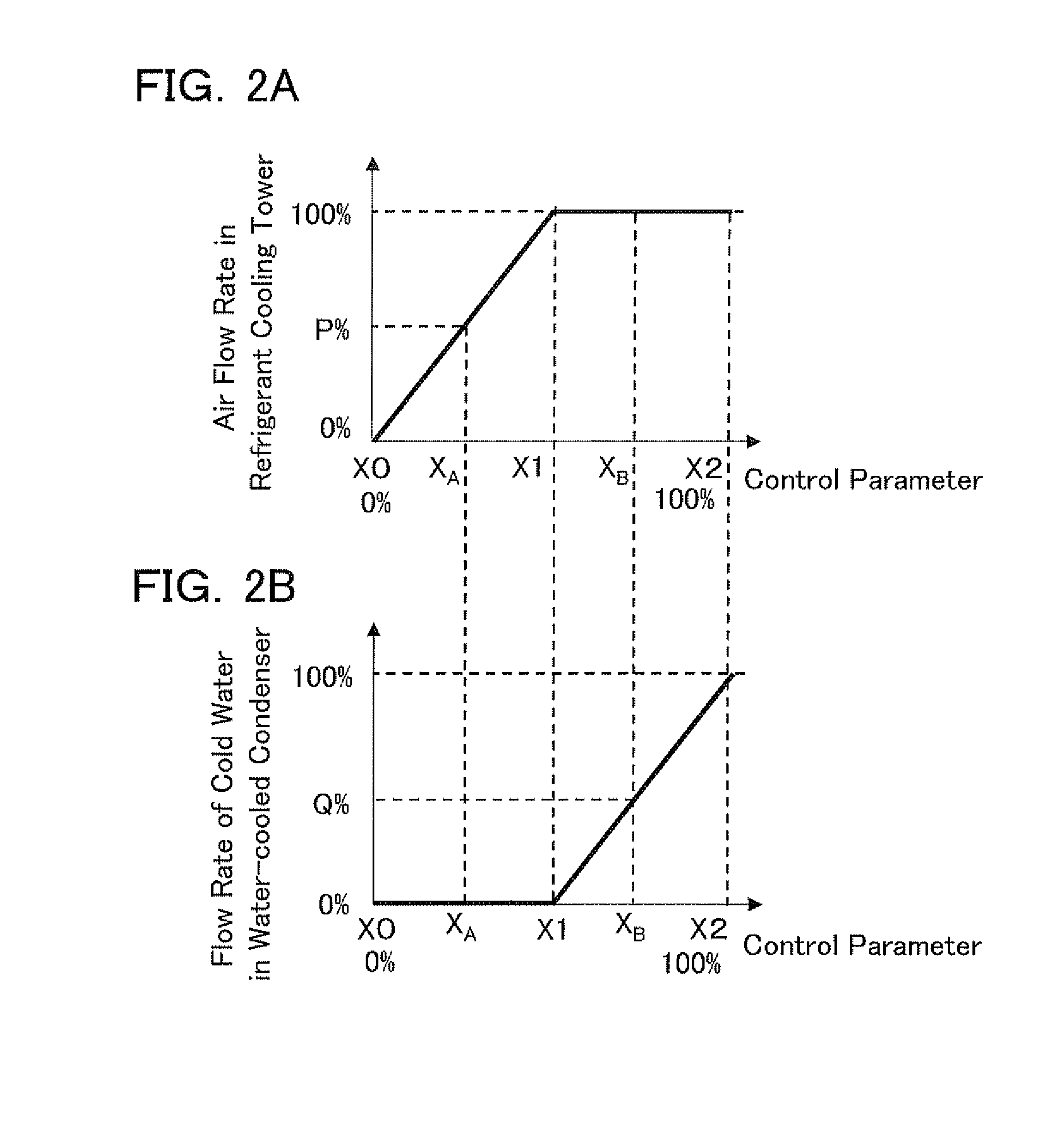

Cooling system and cooling method

InactiveUS20140000300A1Efficient air conditioningMechanical apparatusSpace heating and ventilation safety systemsCooling towerWater flow

A cooling system includes; an evaporator evaporating a refrigerant by heat exchange with room air; a water-cooled condenser being arranged above the evaporator and condensing the refrigerant by heat exchange with cold water; a cold-water flow control valve controlling the flow rate of the cold water supplied to the water-cooled condenser; a refrigerant cooling tower being arranged above the evaporator and condensing the refrigerant by heat exchange with outside air; a blower being arranged at the refrigerant cooling tower and blowing the outside air; a refrigerant-temperature detector detecting the temperature of the refrigerant condensed by the water-cooled condenser and / or the refrigerant cooling tower; and a controller changing at least one of the opening in the cold-water flow control valve and the rotational speed of a motor in the blower according to the temperature.

Owner:HITACHI LTD

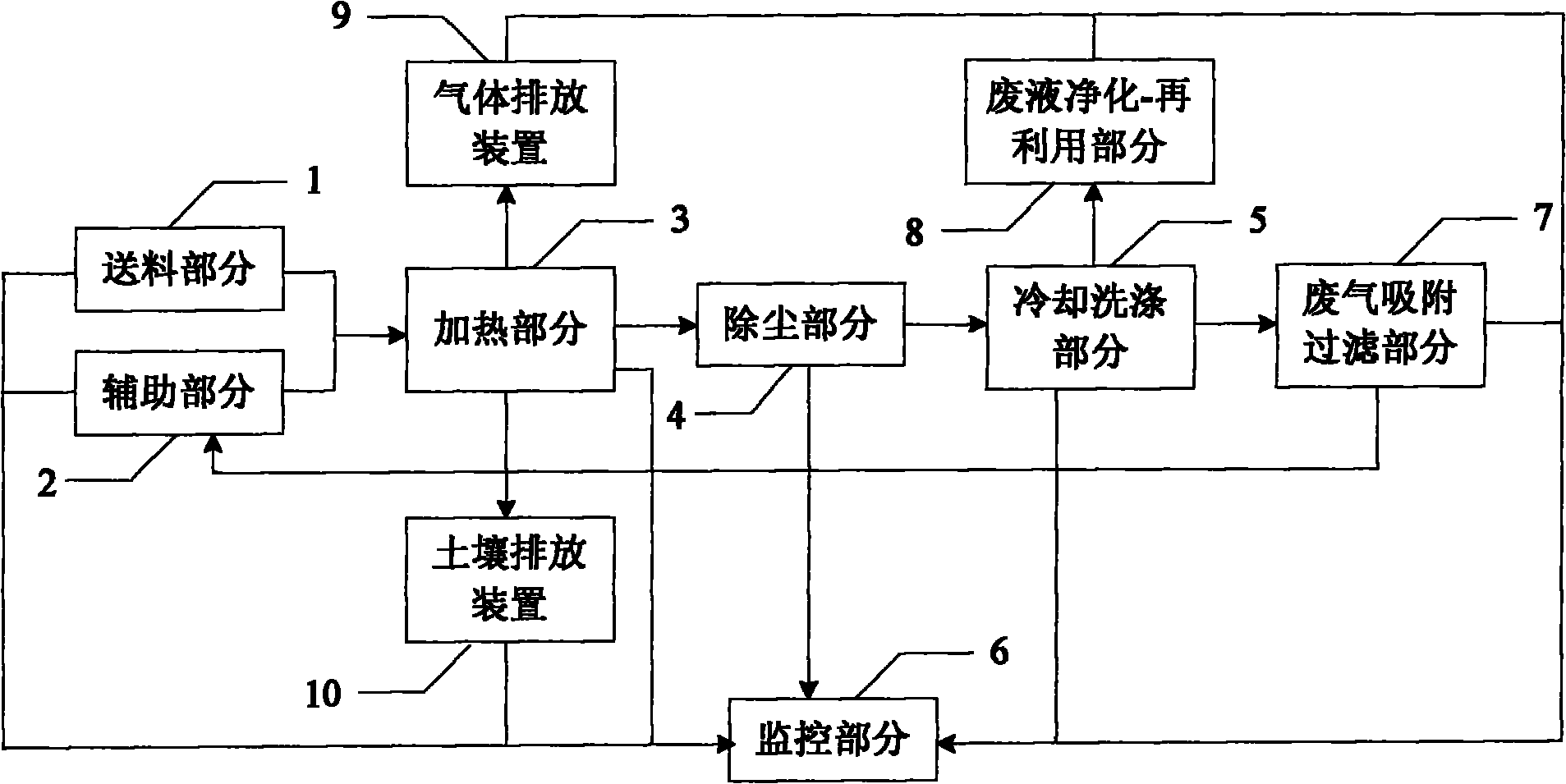

Indirect thermal desorption device

ActiveCN101780467AMaintain physical and chemical propertiesLow costCombination devicesUsing liquid separation agentLiquid wasteCooling tower

The invention relates to an indirect thermal desorption device which comprises a feeding part, an auxiliary part, a heating part, a dedusting part, a washing and cooling part, a waste liquid purifying-recycling part, a waste gas adsorbing and filtering part, a discharging part and a monitoring part, wherein the feeding part and the auxiliary part are connected with the heating part, the discharging part comprises a gas discharging device and a soil discharging device, the washing and cooling part is a washing and cooling tower, the waste liquid purifying-recycling part is connected with the washing and cooling tower, the heating part is orderly connected with the dedusting part, the washing and cooling tower and the waste gas adsorbing and filtering part, the heating part, the dedusting part, the washing and cooling tower and the waste gas adsorbing and filtering part are also respectively connected with the monitoring part, and the waste gas adsorbing and filtering part is connected with an air introducing device in the auxiliary part. The invention has the advantages of large treatment capacity, low treatment cost, soil physicochemical property maintenance and the like, can effectively separate organic matters from contaminated soil and treat the organic matters, and also can complete the processes of waste gas washing, waster gas adsorption and the like so as to reduce the energy consumption of the overall system.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com