Patents

Literature

83 results about "Torque multiplier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A torque multiplier is a tool used to provide a mechanical advantage in applying torque to turn bolts, nuts or other items designed to be actuated by application of torque, such as the actuation of valves, particularly where there are relatively high torque requirements.

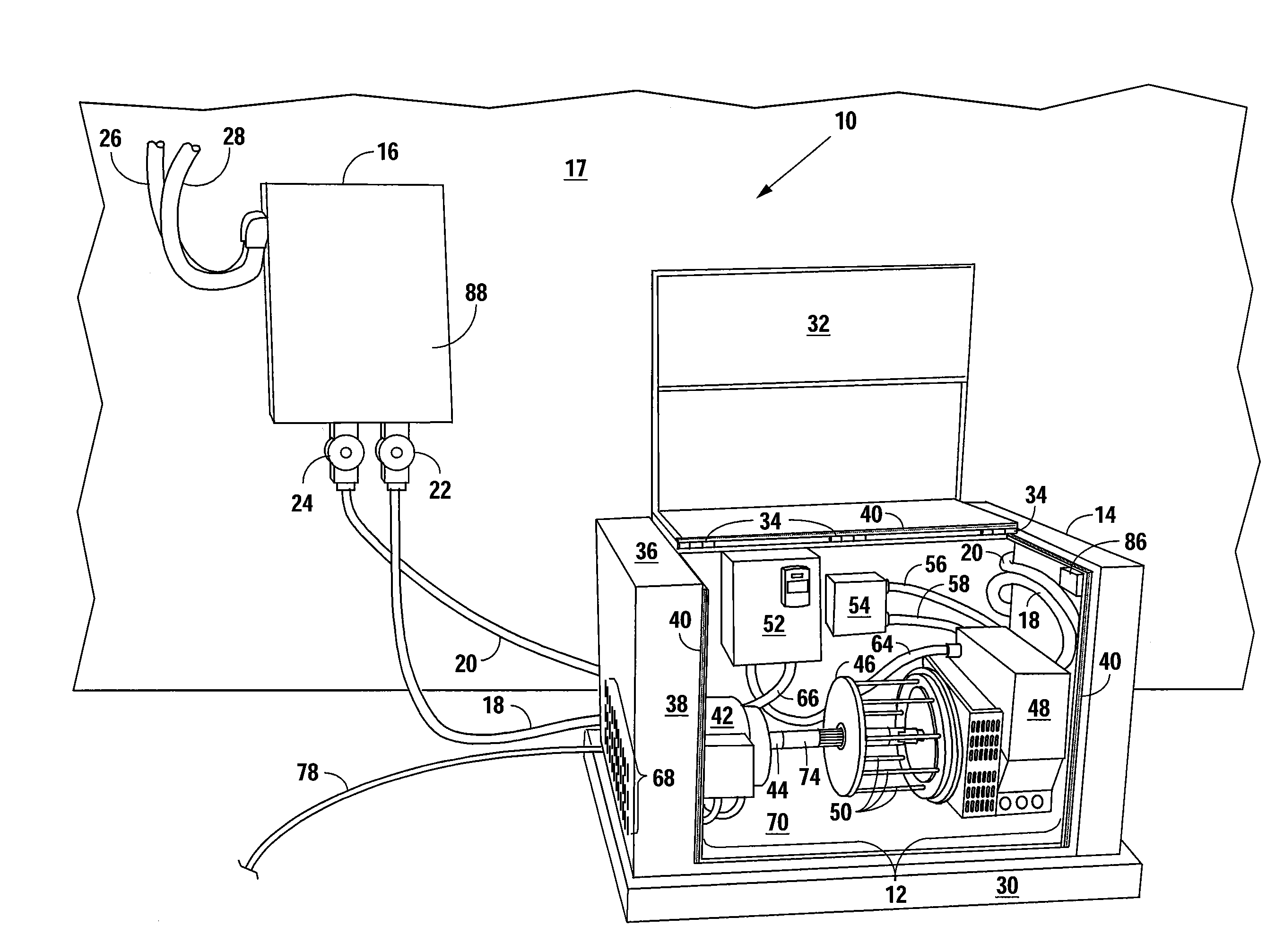

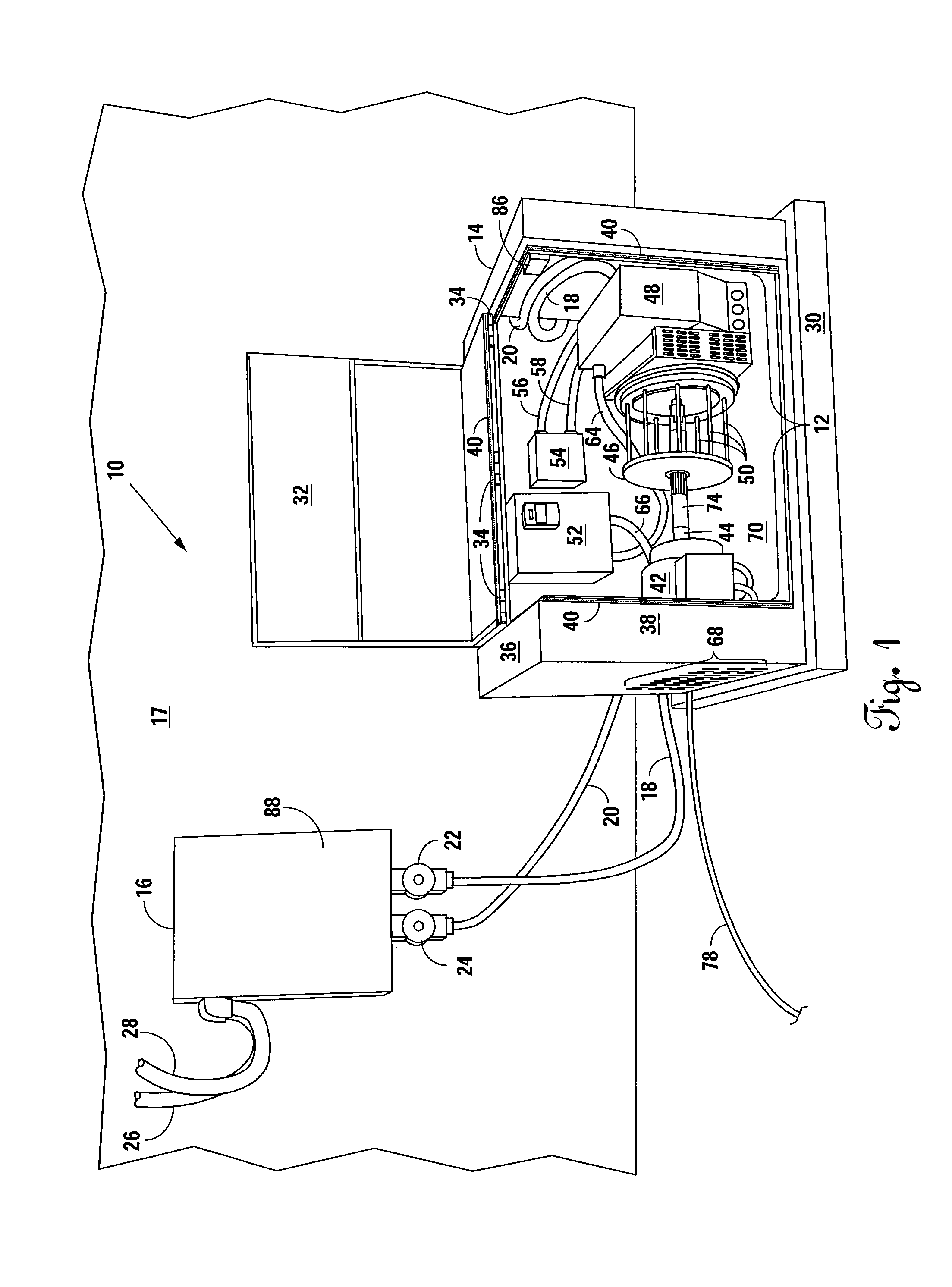

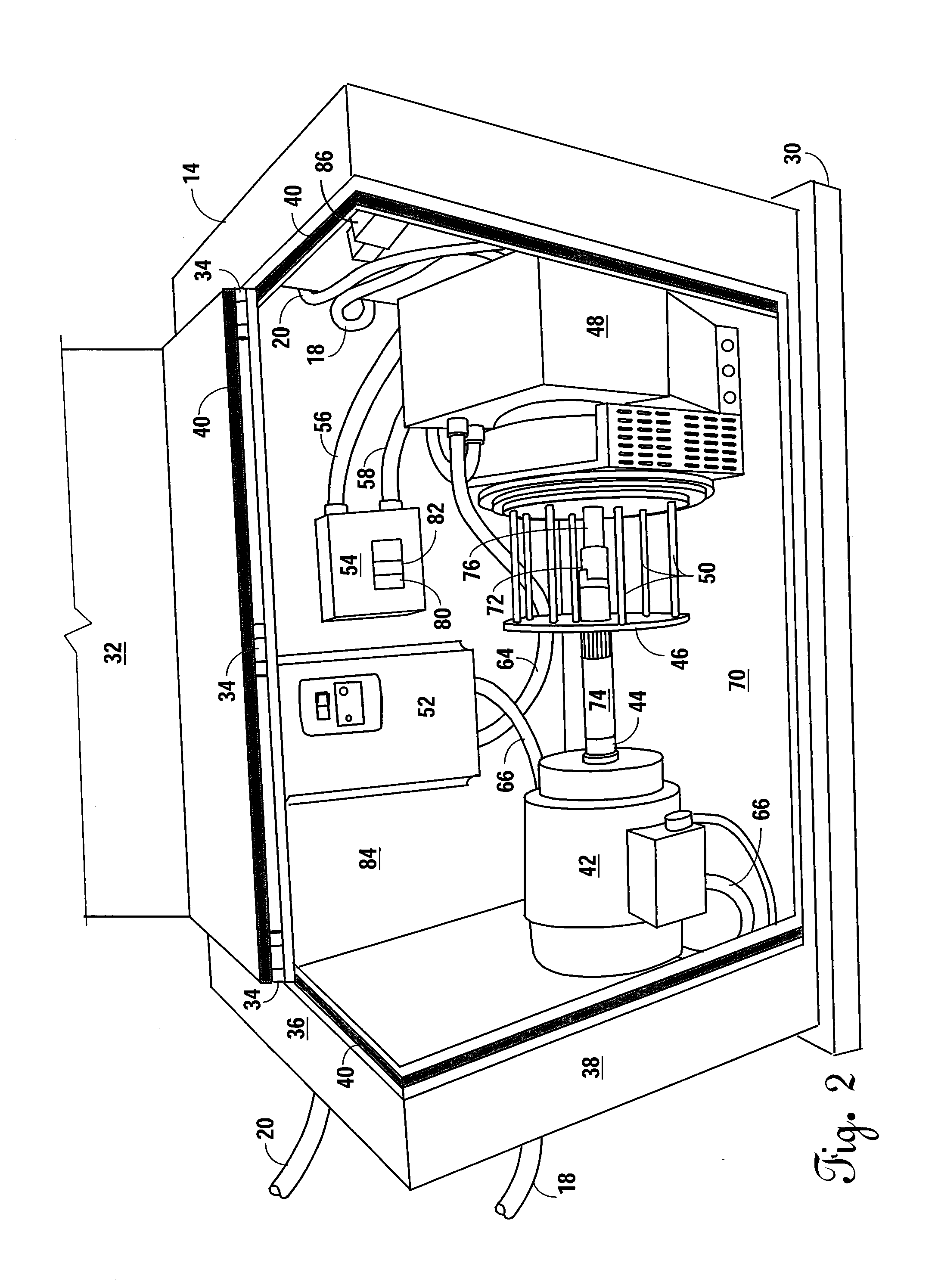

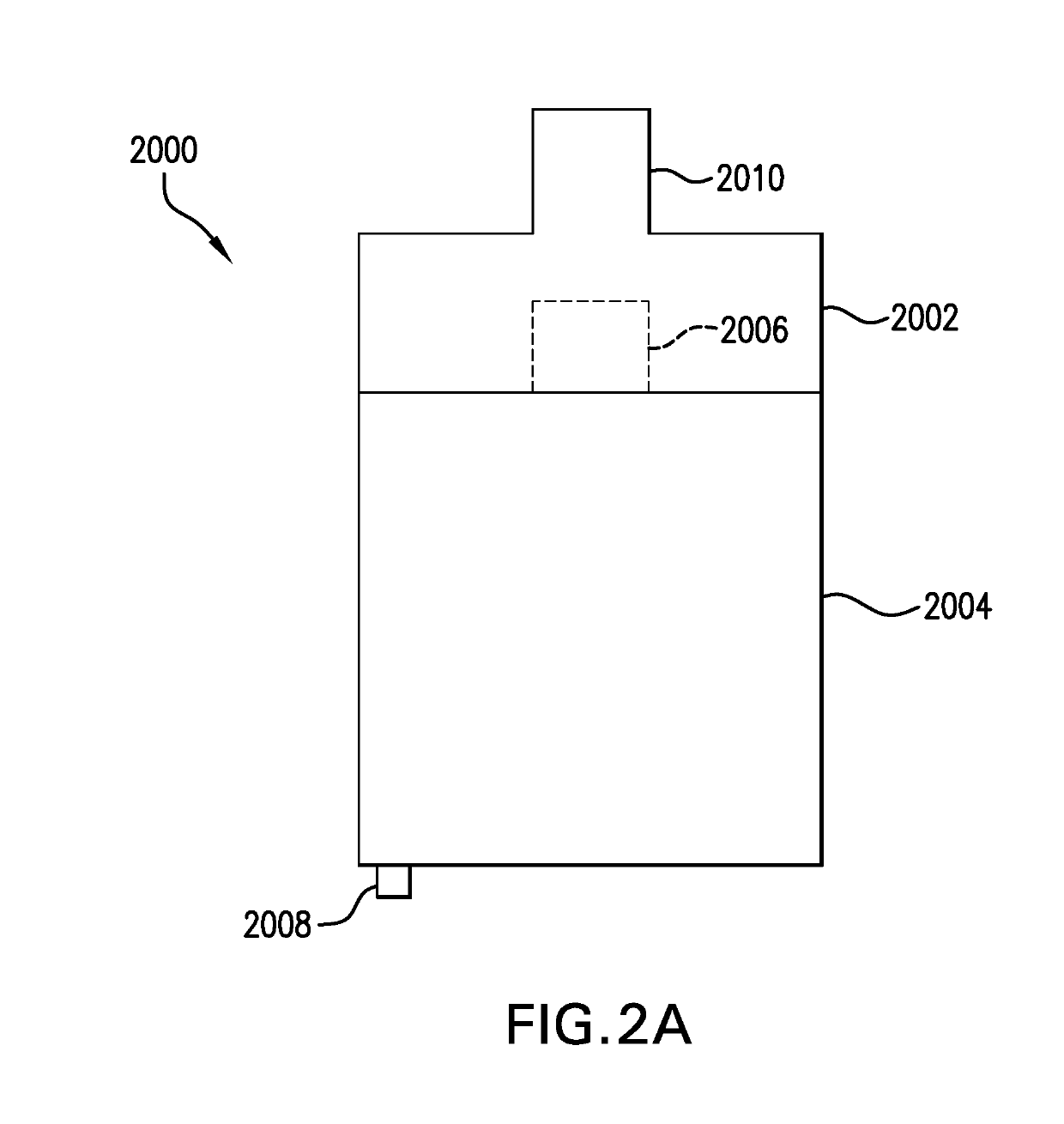

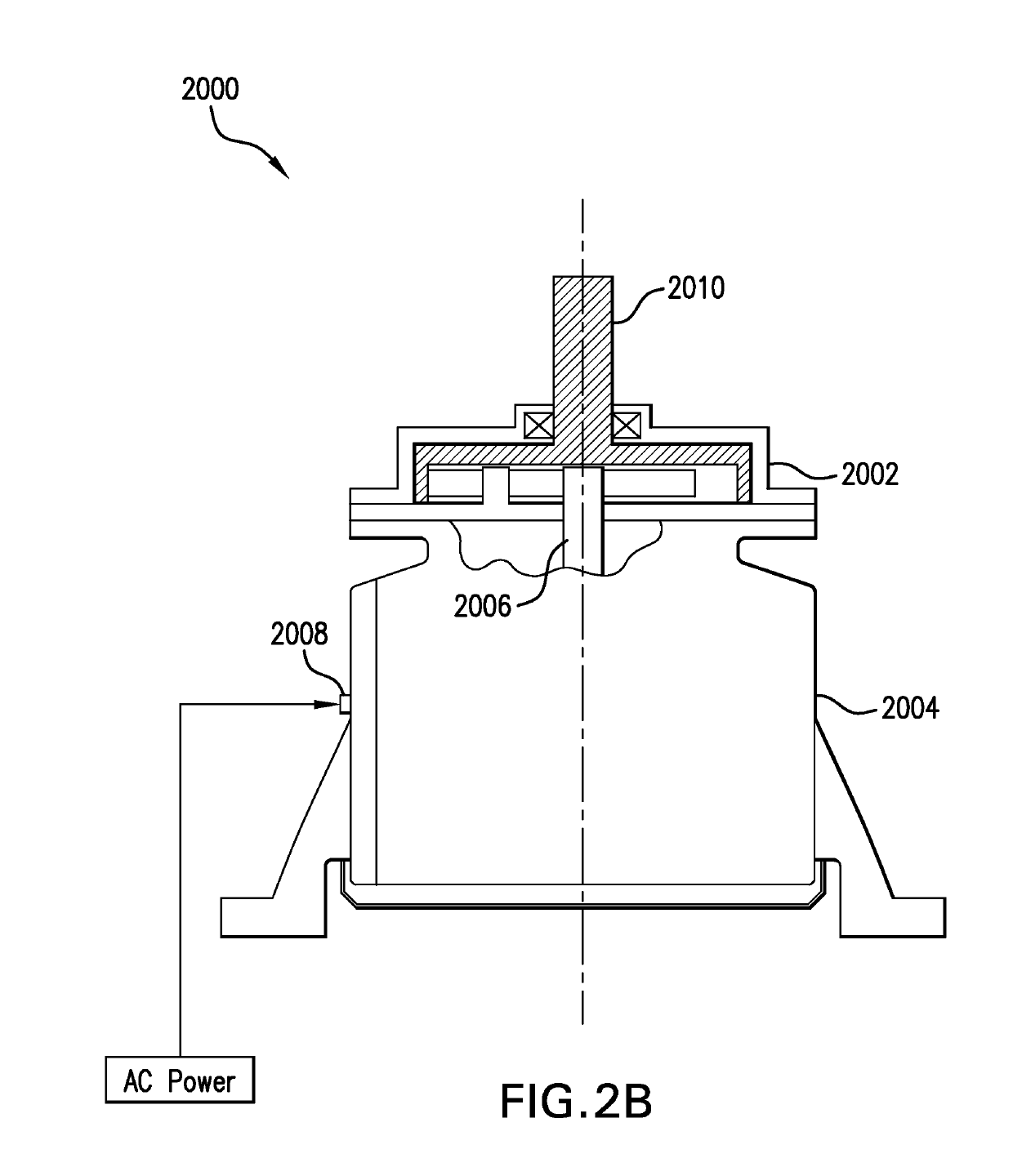

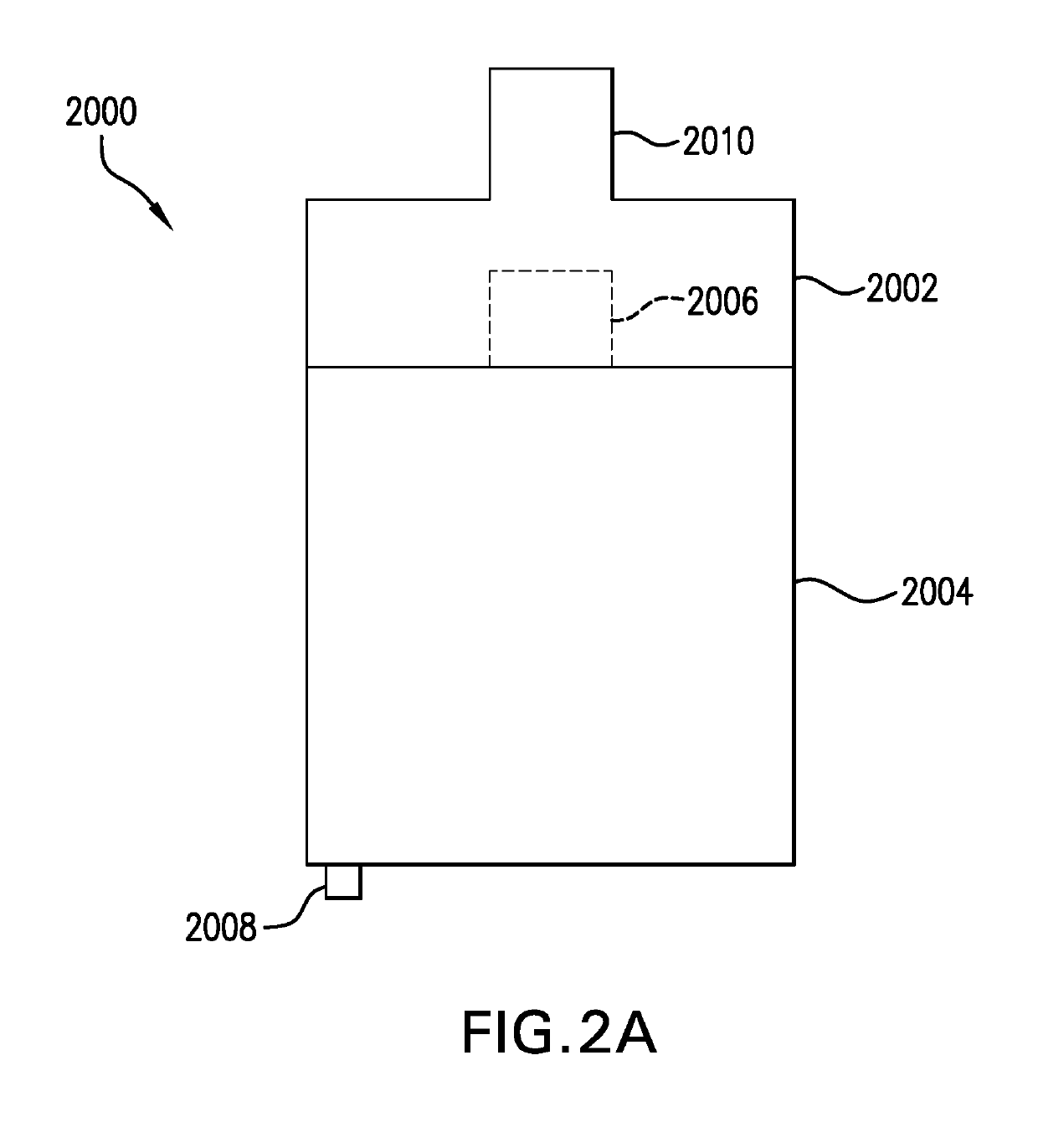

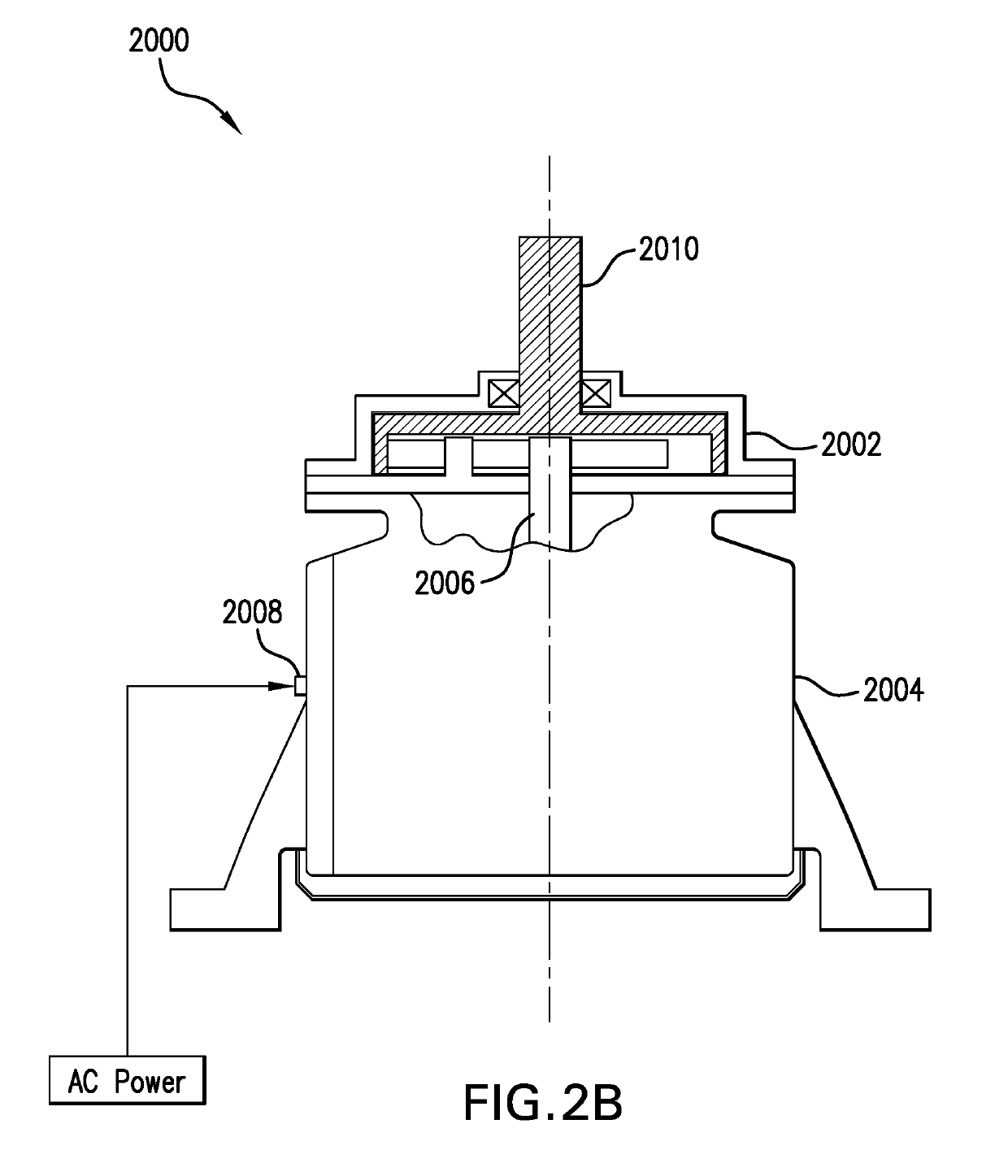

Direct-Drive System For Cooling System Fans, Exhaust Blowers And Pumps

ActiveUS20160069624A1Eliminate the problemPump componentsSemiconductor/solid-state device detailsCooling towerControl system

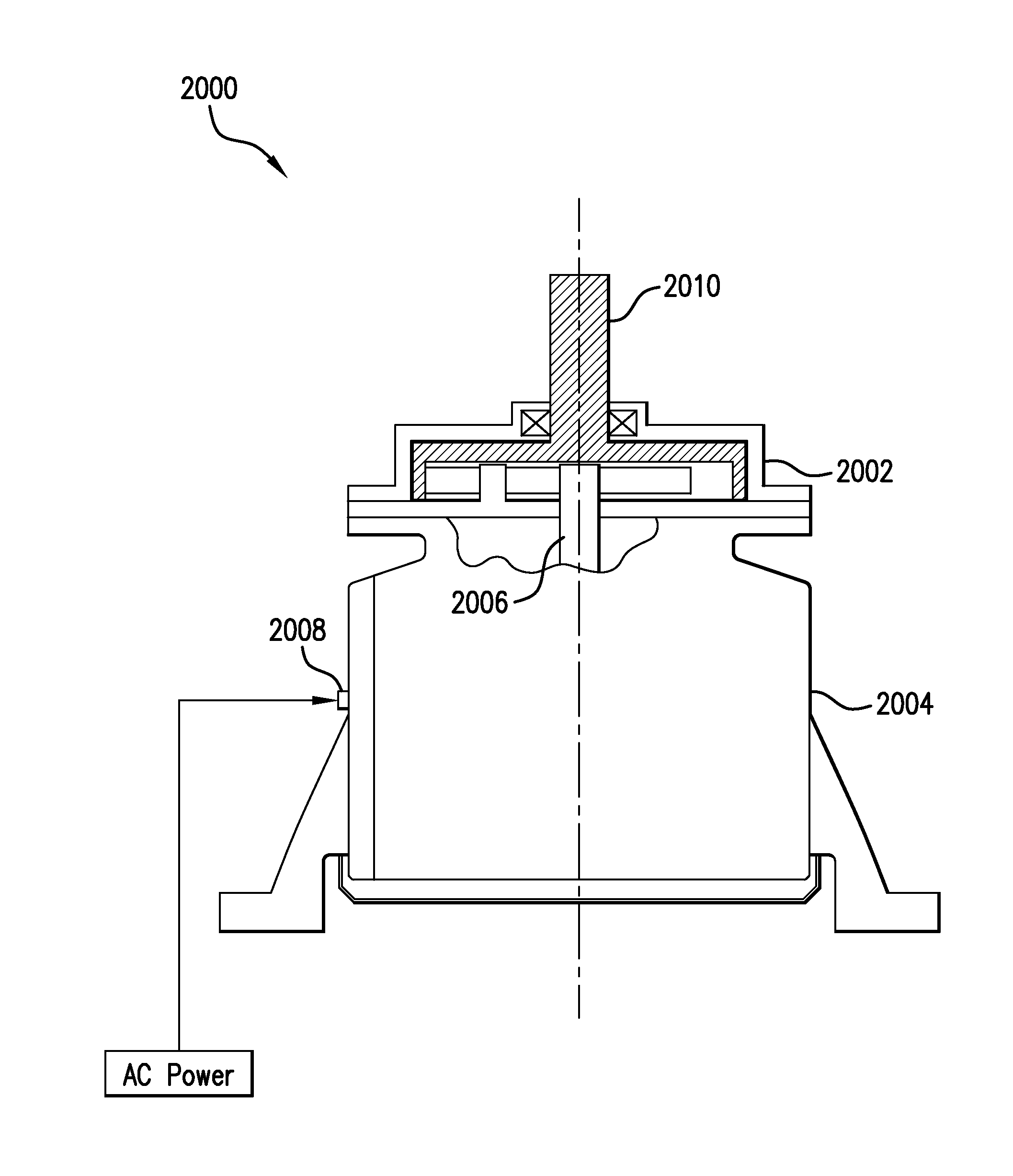

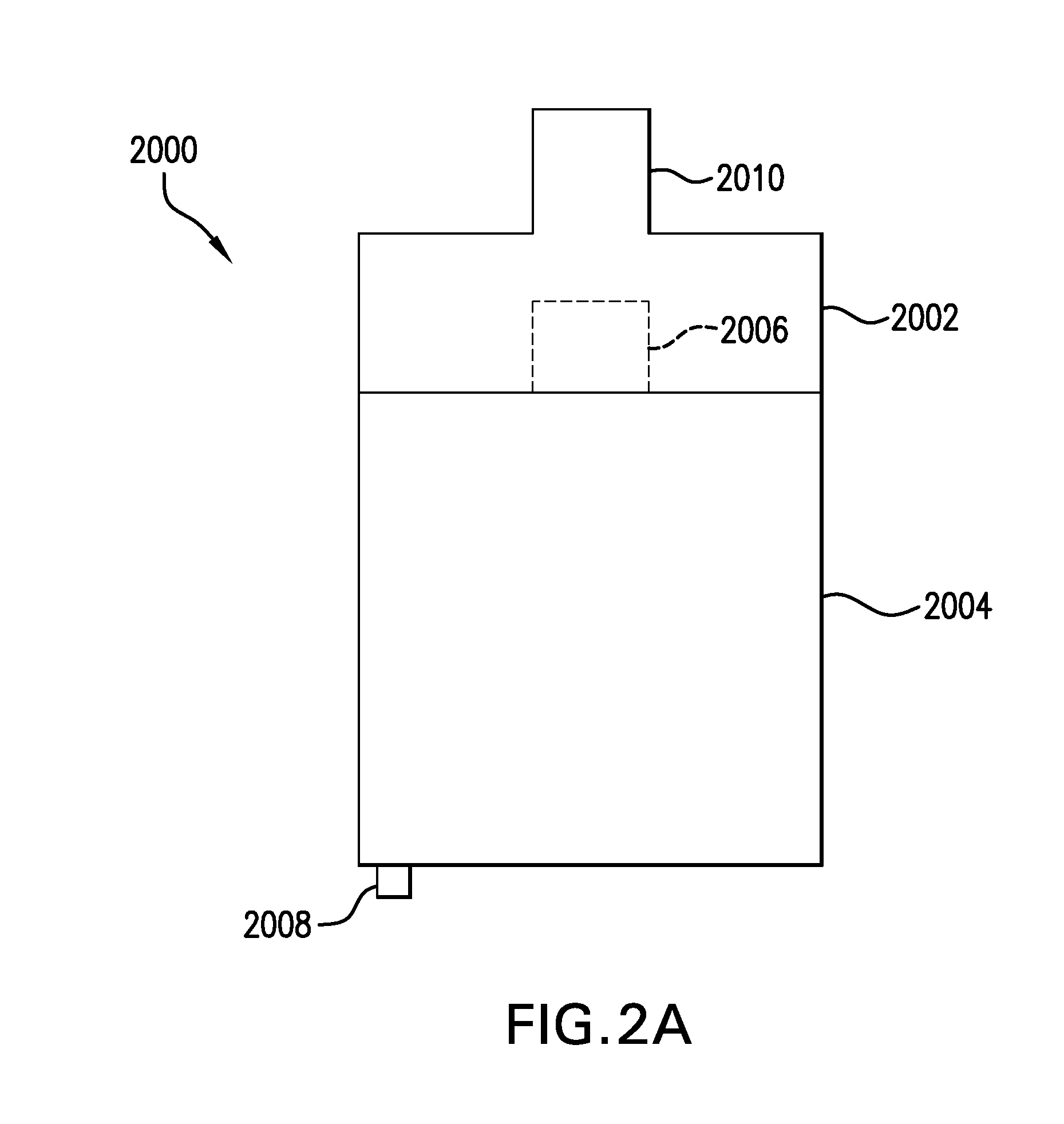

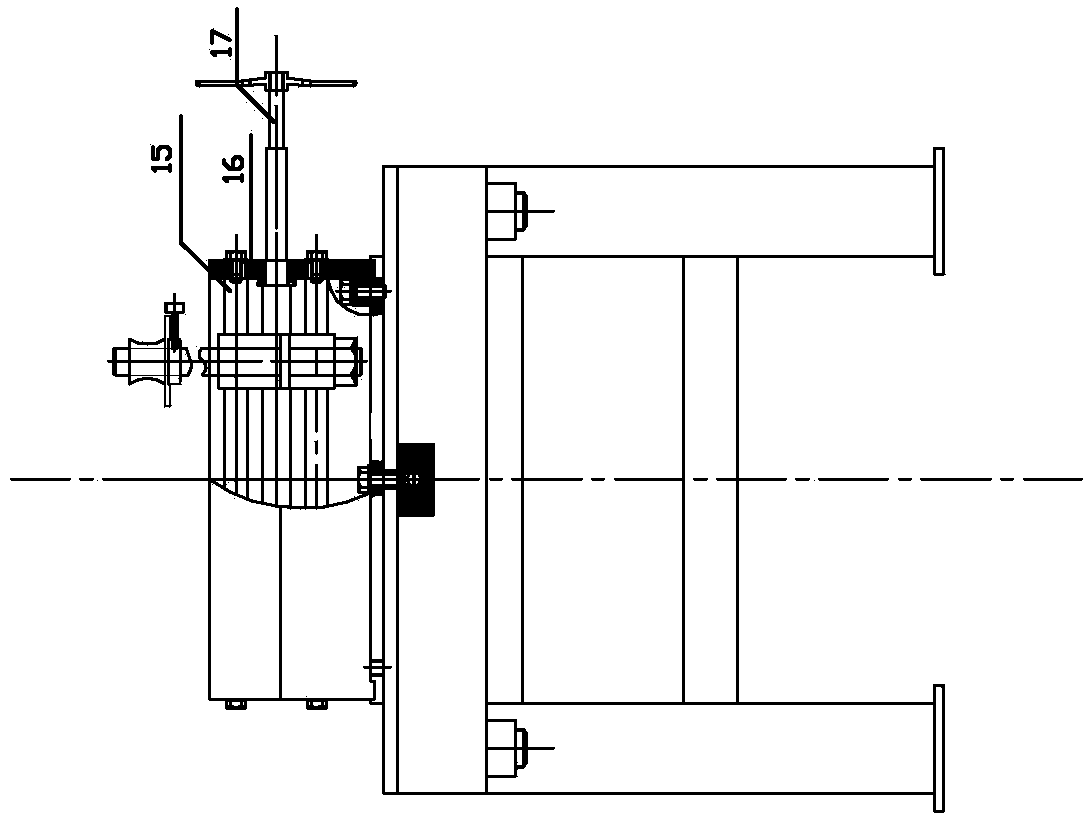

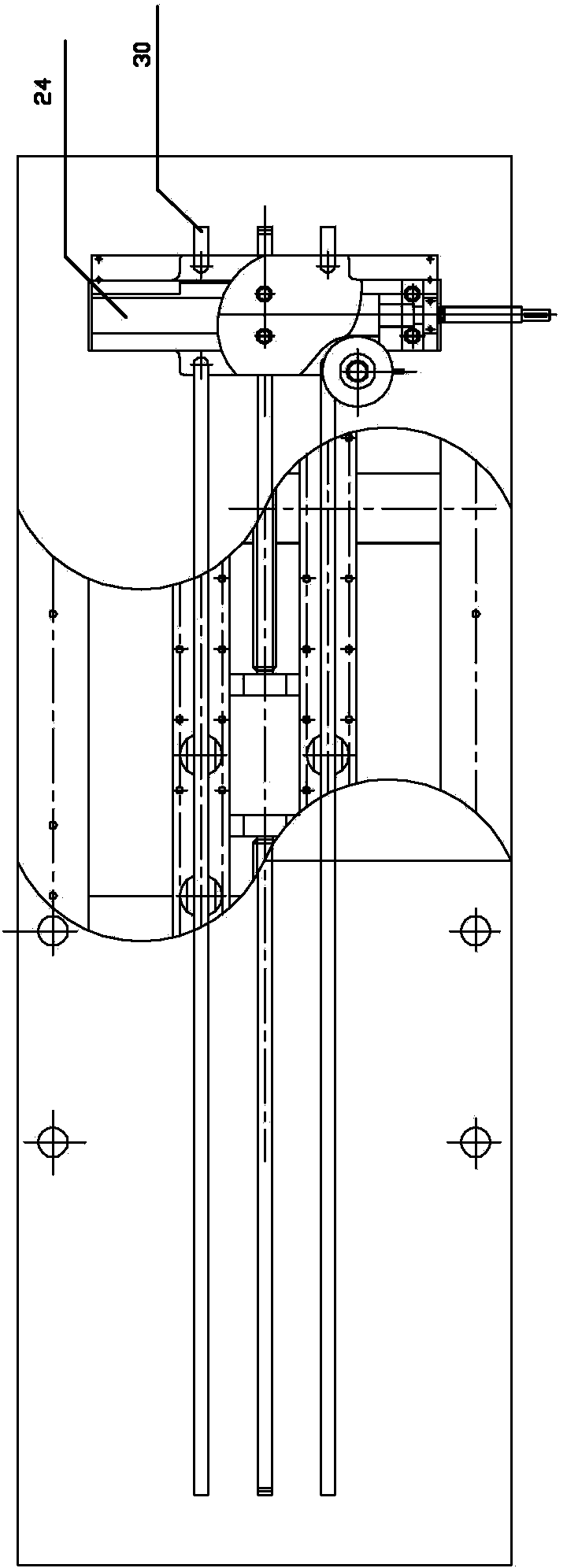

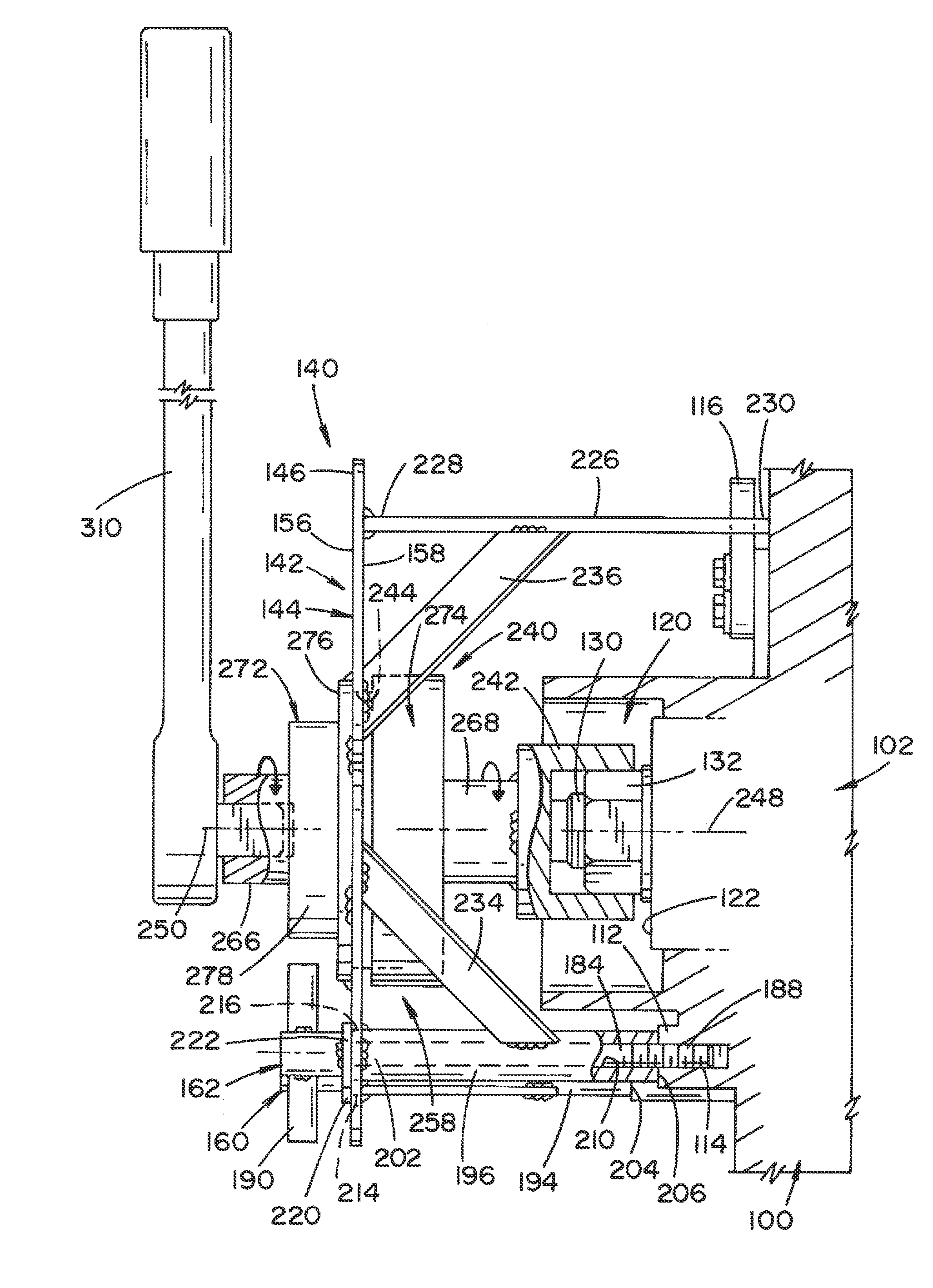

The present invention is directed to a load bearing direct-drive system and a variable process control system for efficiently managing the operation of fans in a cooling system such as a wet-cooling tower, air-cooled heat exchanger (ACHE), HVAC system, blowers and centrifugal blowers, mechanical towers or chiller systems. In one embodiment, the load bearing direct-drive system comprises a load bearing torque multiplier device having an output rotatable shaft connected to a fan, and a load bearing motor comprising a rotatable shaft that drives the load bearing torque multiplier device.

Owner:PRIME DATUM

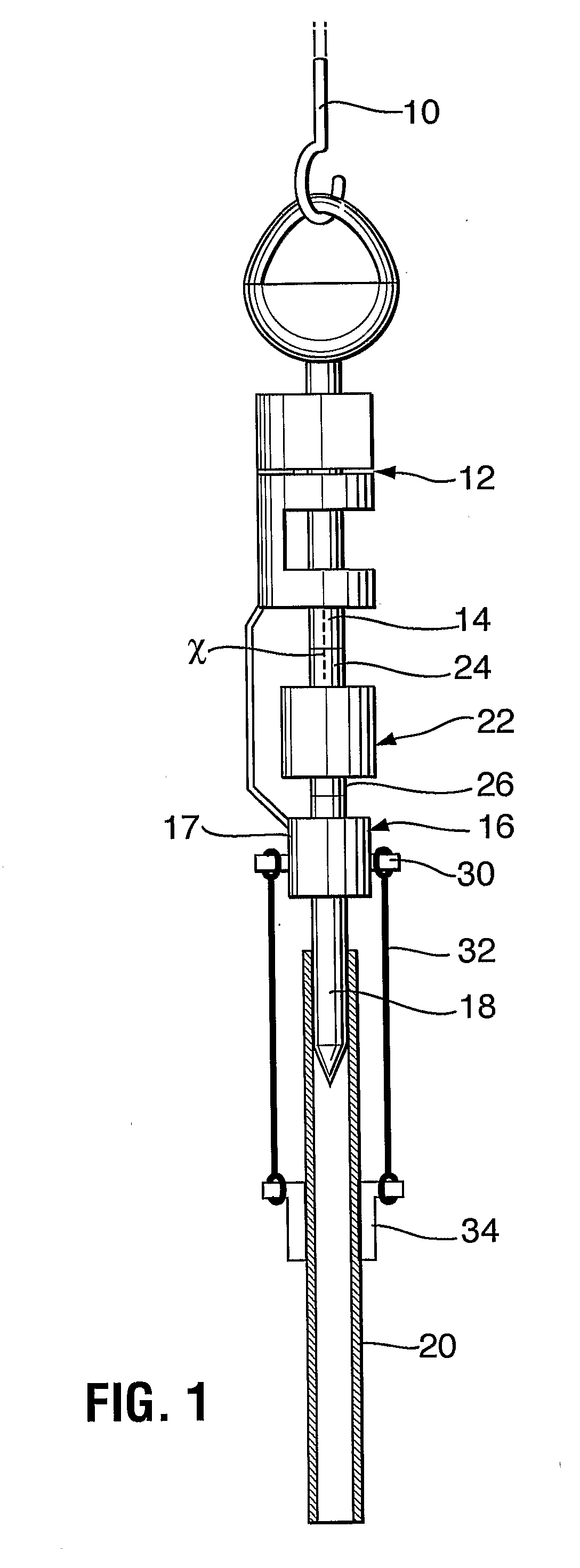

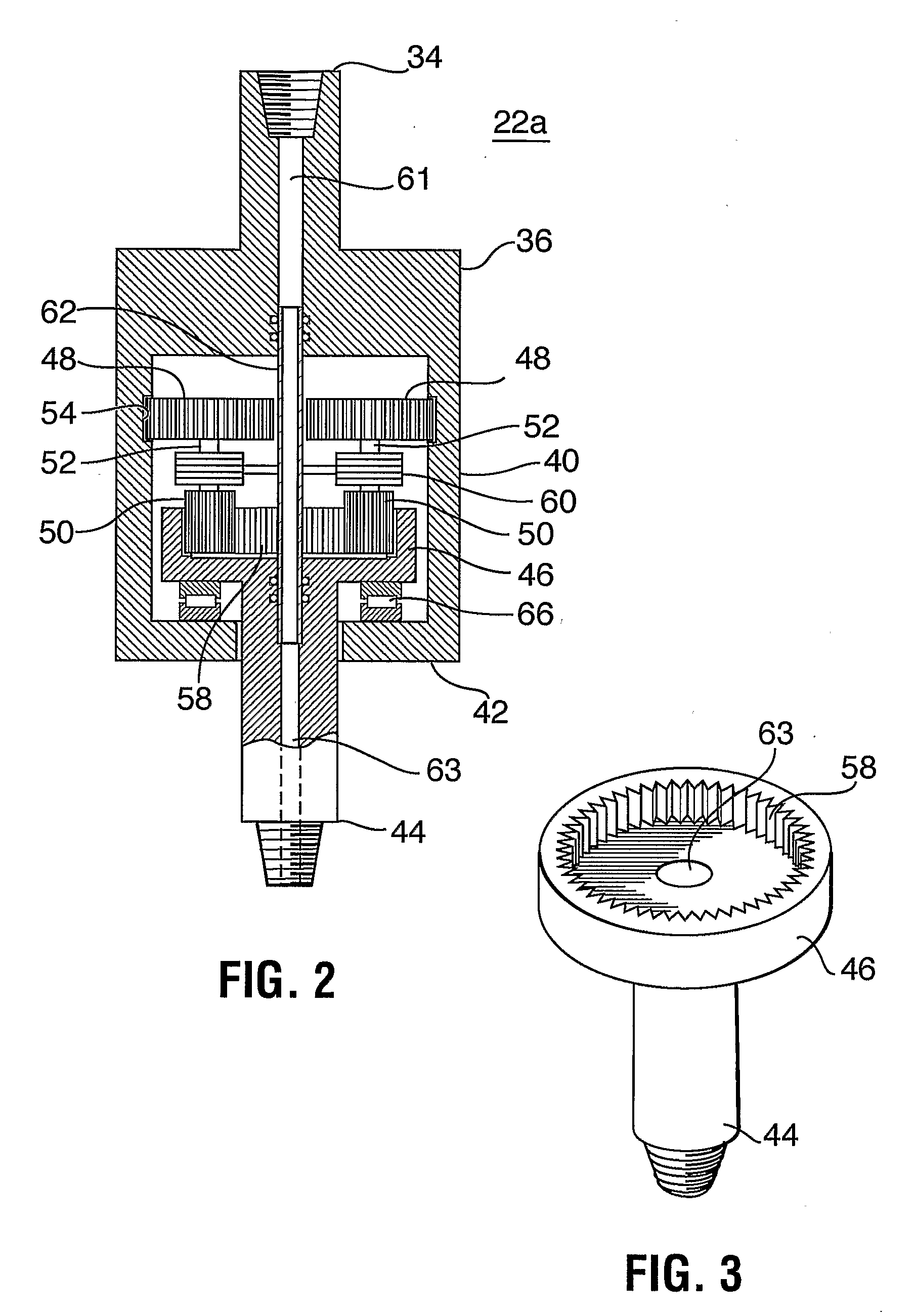

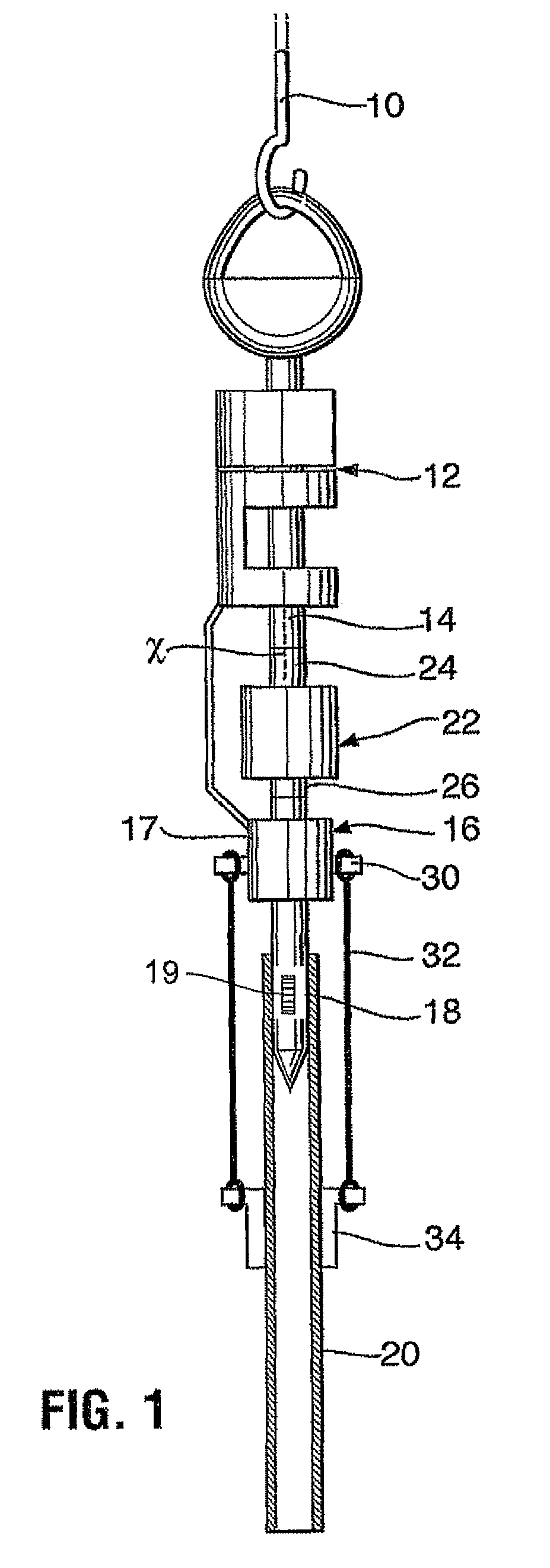

Wellbore Tubular Handling Torque Multiplier

A tubular handling torque multiplier includes a torque input end for connection to the quill of a top drive, a torque output end for connection at least indirectly to a well tubular joint to be driven to rotate, gears for adjusting the torque output from the torque output end from that torque input at the torque input end, an axial support between the torque input end and the torque output end to allow axial stress to be communicated from the torque output end to the torque input end and a fluid circulating path open between the torque input end and the torque output end.

Owner:NABORS DRILLING TECH USA INC

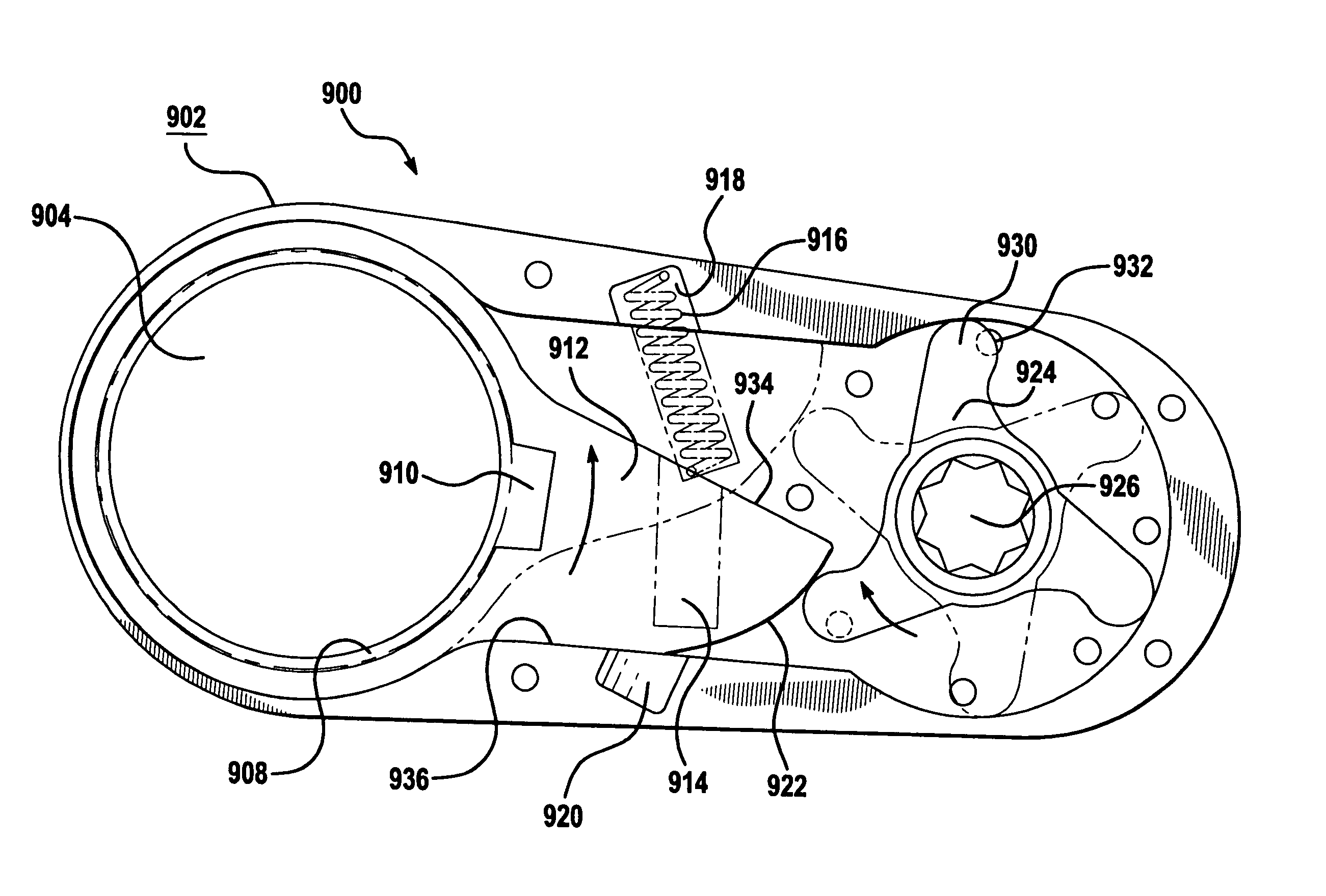

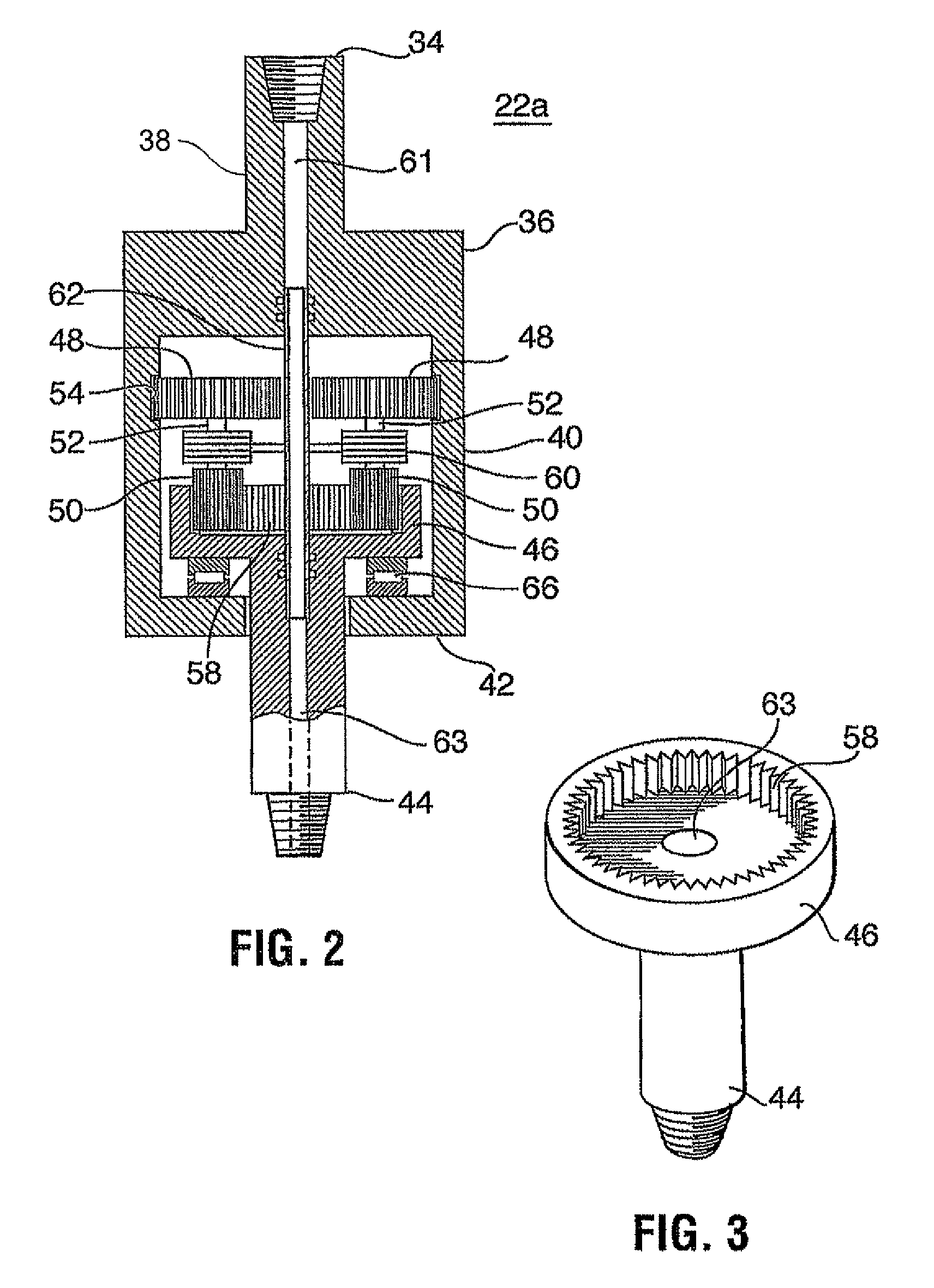

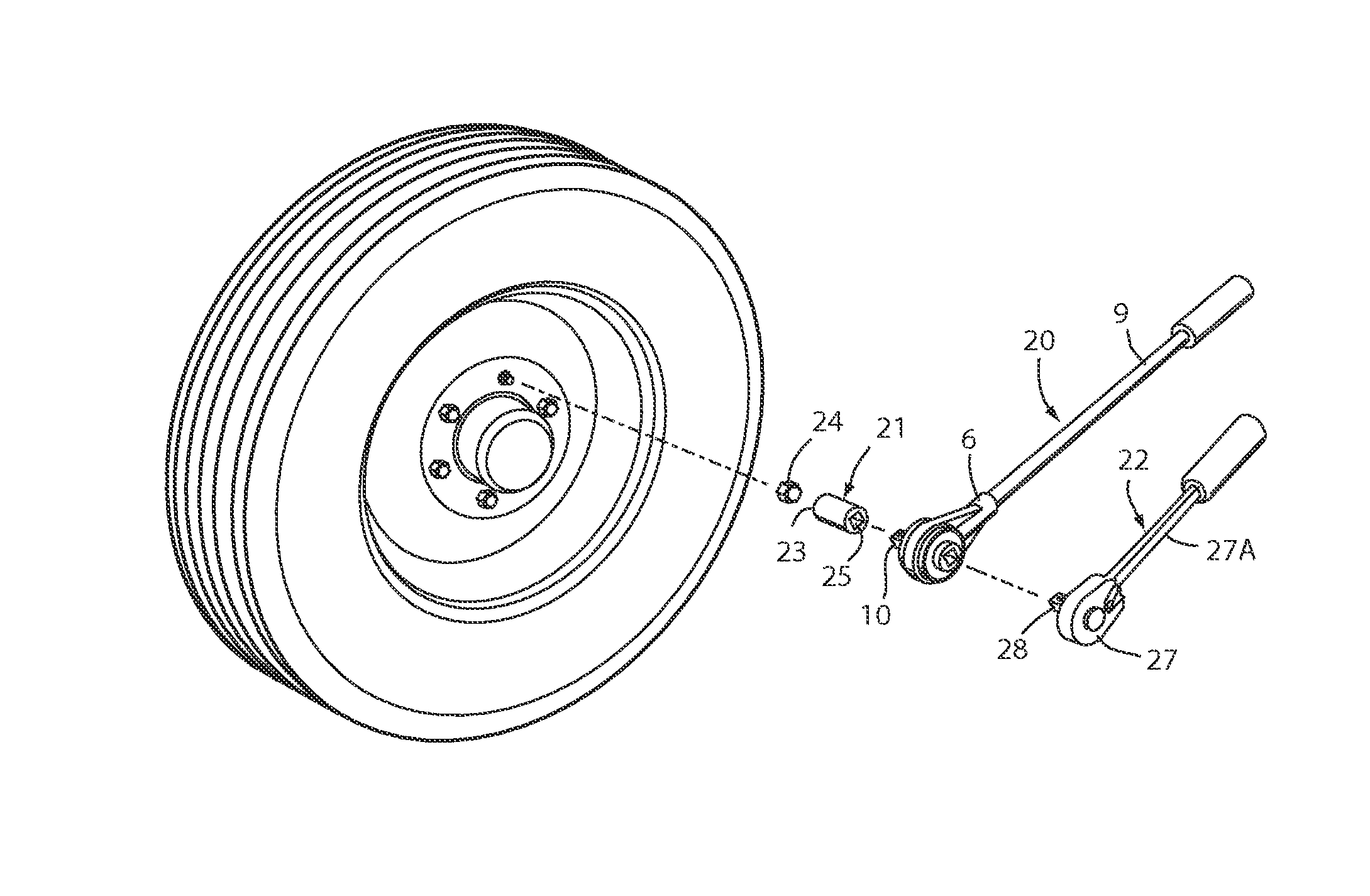

Constant rotation rotary torque multiplier

A wrench with torque augmenting means consisting of an output socket wrench which utilizes a ratchet arrangement and which includes an input cog that is adapted to receive an external drive tool. The input cog constantly rotates under the influence of the external drive tool and a camming surface formed on the arm of the input cog coacts with a cam follower surface on the drive plate of the output to move the drive plate. A spring within the housing of the apparatus connected to the drive plate will cause the drive plate to return to its initial position where the action of the camming surface of the rotating cog arm from the input cog can then repeat its function. Rotary movement of the output in one direction is accomplished during the oscillation of the drive plate by means of the ratchet positioned within the drive plate.

Owner:NORWOLF TOOL WORKS

Constant rotation rotary torque multiplier

A wrench with torque augmenting means consisting of an output socket wrench which utilizes a ratchet arrangement and which includes an input cog that is adapted to receive an external drive tool. The input cog constantly rotates under the influence of the external drive tool and a camming surface formed on the arm of the input cog coacts with a cam follower surface on the drive plate of the output to move the drive plate. A spring within the housing of the apparatus connected to the drive plate will cause the drive plate to return to its initial position where the action of the camming surface of the rotating cog arm from the input cog can then repeat its function. Rotary movement of the output in one direction is accomplished during the oscillation of the drive plate by means of the ratchet positioned within the drive plate.

Owner:NORWOLF TOOL WORKS

System for Generating and Recovering Energy

InactiveUS20150048703A1Minimize dependenciesReduce environmental pollutionMechanical apparatusData processing applicationsPaymentAlternator

A system for generating and recovering energy comprising an electric generator integrated with a consumer's utility provider's network to generate electrical energy. Electrical power is transmitted from an electric power grid to a control box at a location requiring energy (e.g., home or business) via a bidirectional meter which measures power delivered by and to the power grid. The control box powers an AC driver which feeds a load to and controls the speed of a motor. A torque multiplier multiplies a first torque output from the motor to produce a second torque output which is fed to an alternator. The power generated by the electric generator is transmitted to a remote location for consumption. In one embodiment, exported energy is returned to the utility provider in exchange for credit against the consumer's account or for payment. In an alternative embodiment, the present invention functions as an independent power plant.

Owner:HIGH VOLTAGE LLC

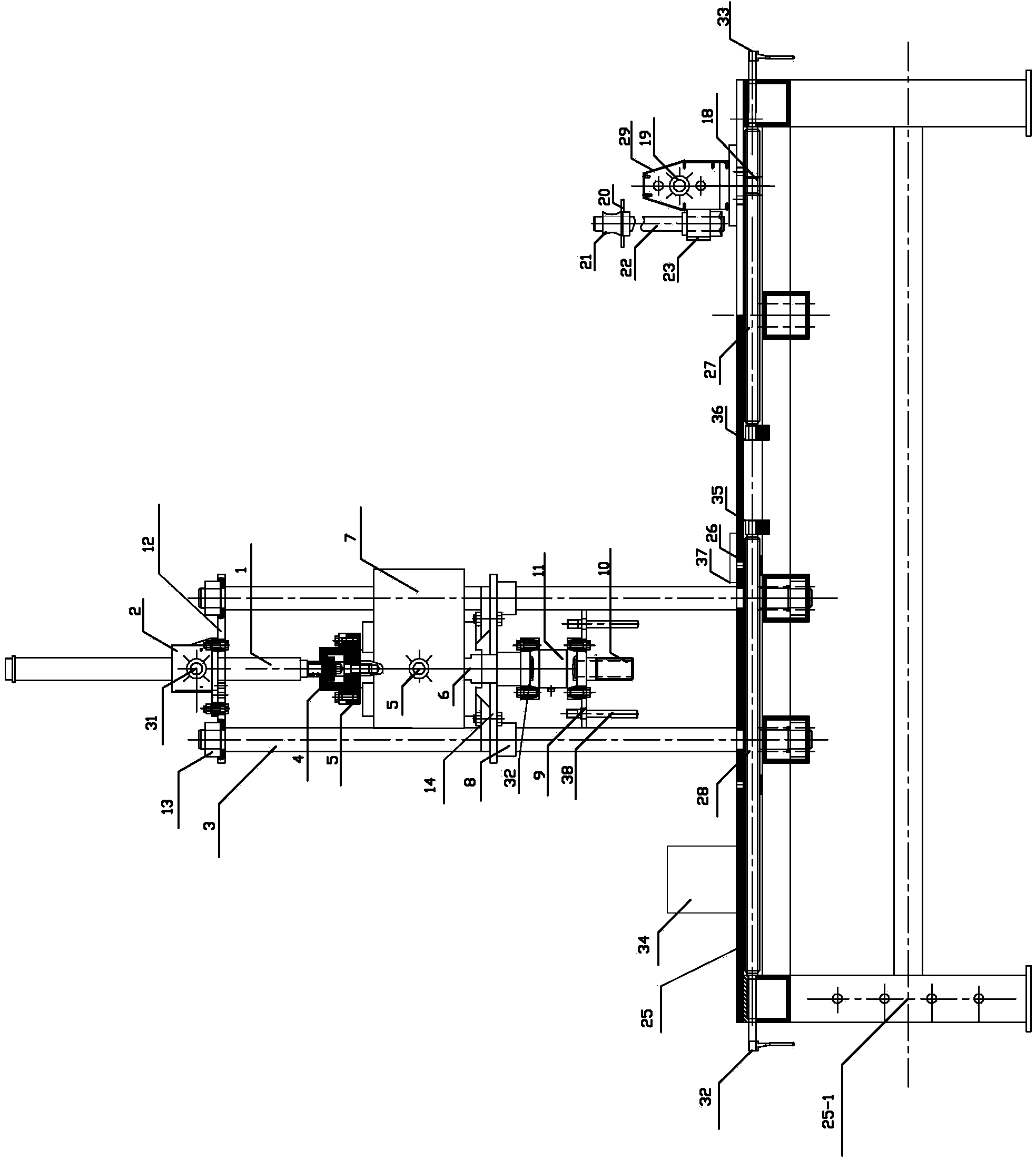

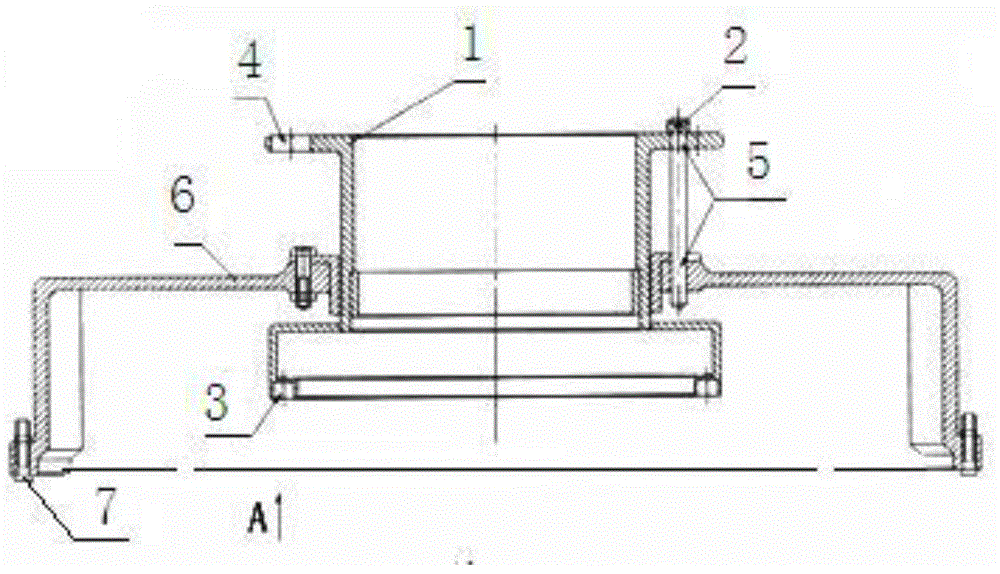

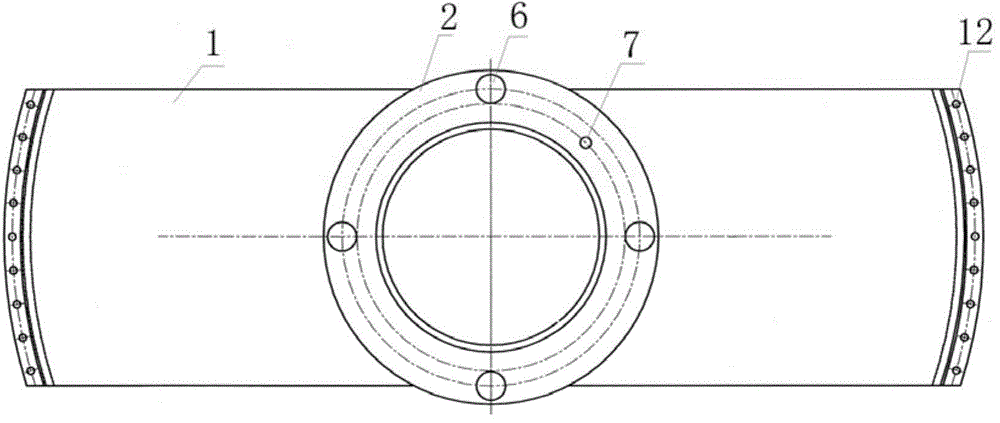

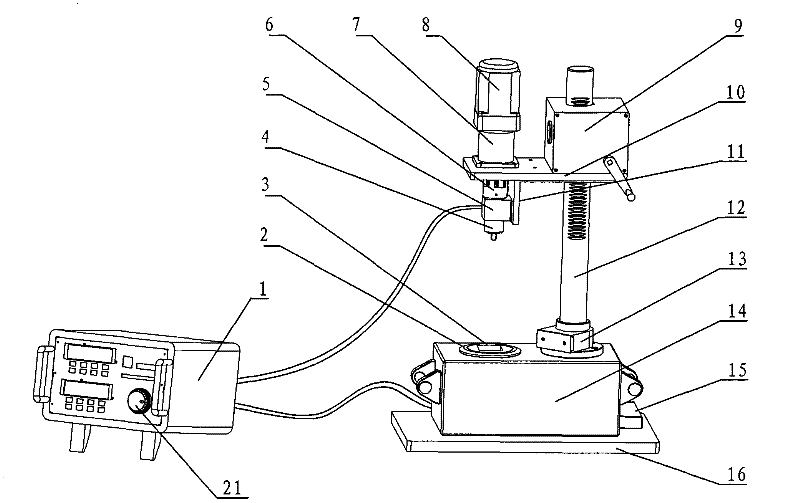

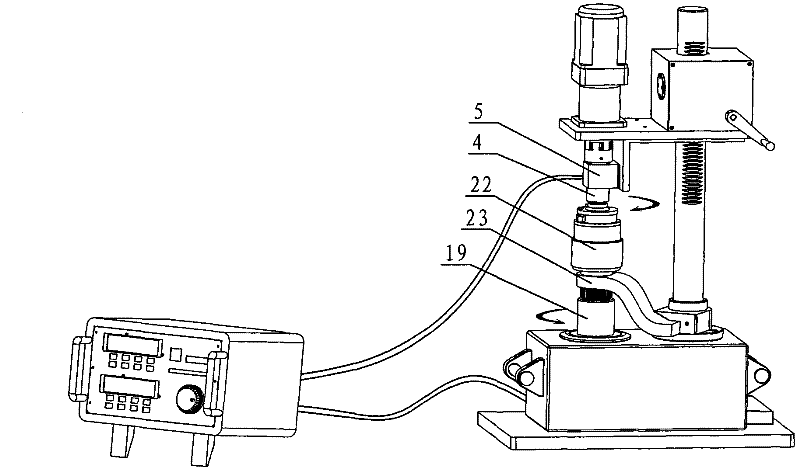

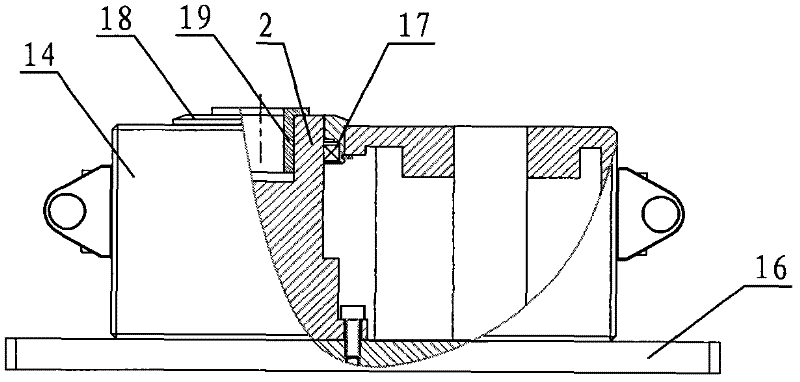

Multifunctional calibrating and loading device for torque multiplier

InactiveCN103471768ALarge torque applied load rangeHigh bending and torsional rigidityForce/torque/work measurement apparatus calibration/testingProduction lineMeasurement device

The invention provides a multifunctional calibrating and loading device for a torque multiplier and relates to the testing and calibrating techniques of the torque multiplier. The multifunctional calibrating and loading device is used for solving the problems that a torque loading device is small in measurement range and low in measurement accuracy, has few functions and cannot calibrate torque measurement devices of different structures in the background art. The calibrating and loading device comprises a pure torque loading subsystem, a lifting mechanism subsystem, a screw rod loading subsystem, a non-coaxial multiplier loading-mounting-regulating subsystem and a loading platform system. The multifunctional calibrating and loading device can utilize multiple torque loading manners including a coaxial torque loading manner, a non-coaxial torque loading manner, a double-moment arm torque loading manner or the like and is an important constituent part of a torque multiplier calibrating device; the loading position and manner of the loading device can be regulated according to the size and loading manner of the torque multiplier, and the torque loading problems caused when various torque devices of an assembling production line of an engine are calibrated can be solved by utilizing one set of loading device, so that the practicality of the multifunctional calibrating and loading device is greatly improved, and the cost is saved.

Owner:HARBIN INST OF TECH

Torque tool

The invention relates to an external connecting tool for an ROV and aims to provide a torque tool. The torque tool comprises a torque driving unit, an insertion opening unit and a locking bolt unit. According to the torque tool, a method that a torque multiplier is used for torque transmission and amplification is provided, the output torque is increased, the operation time is shortened, the size of a product is reduced, and the transmission efficiency of the product is improved; the design that a telescopic sleeve insertion opening is used is provided, self-adaptive butt joint of a plurality of stages of ports can be achieved without manual replacement of the insertion opening, and the usability of the product is improved; and a sliding block is used for converting axial movement into radial movement, so that the contact area is enlarged, the movement precision is improved, and the stress reliability and accuracy are guaranteed when a locking bolt finger moves.

Owner:HANGZHOU YUKONG MECHANICAL & ELECTRICAL ENG

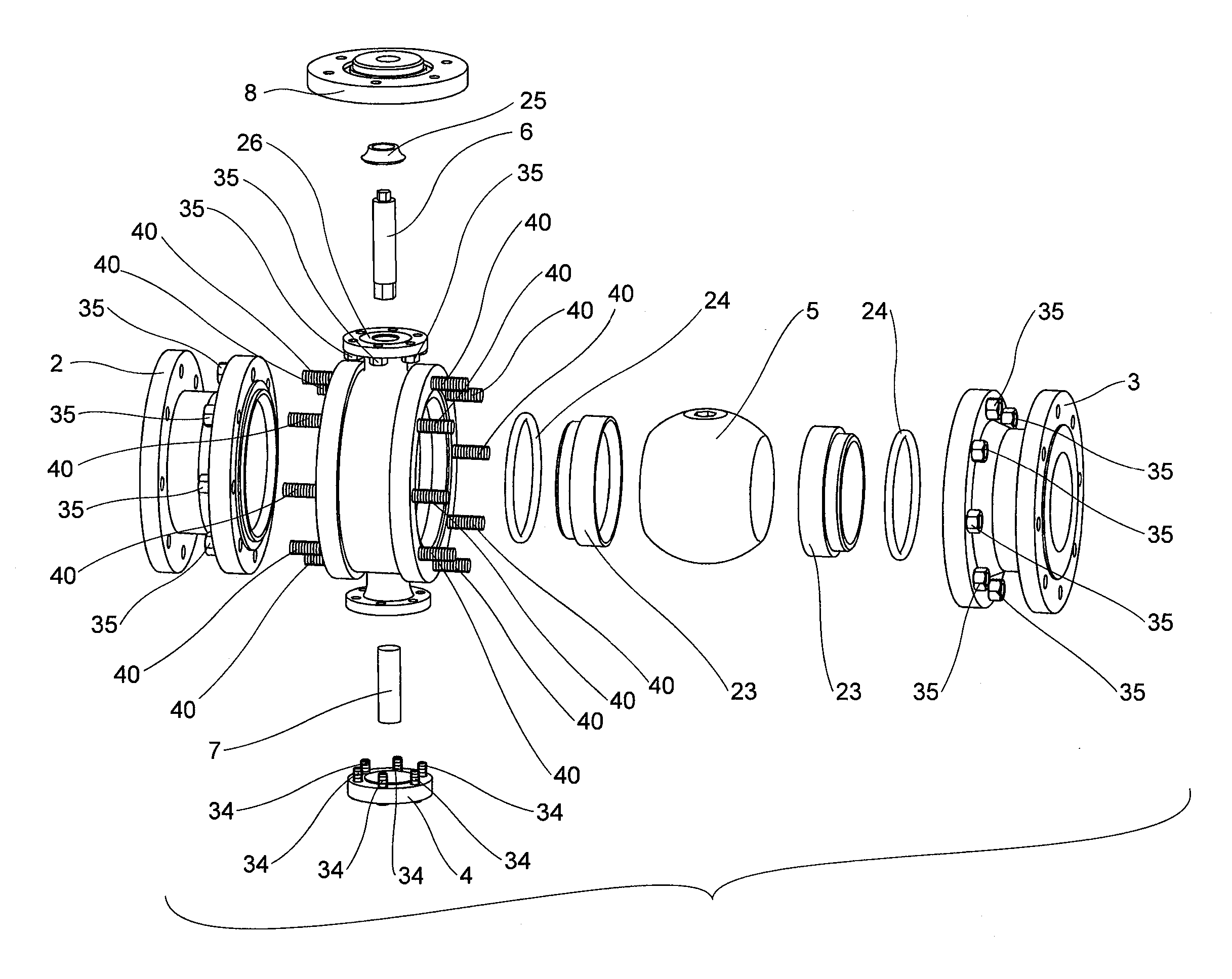

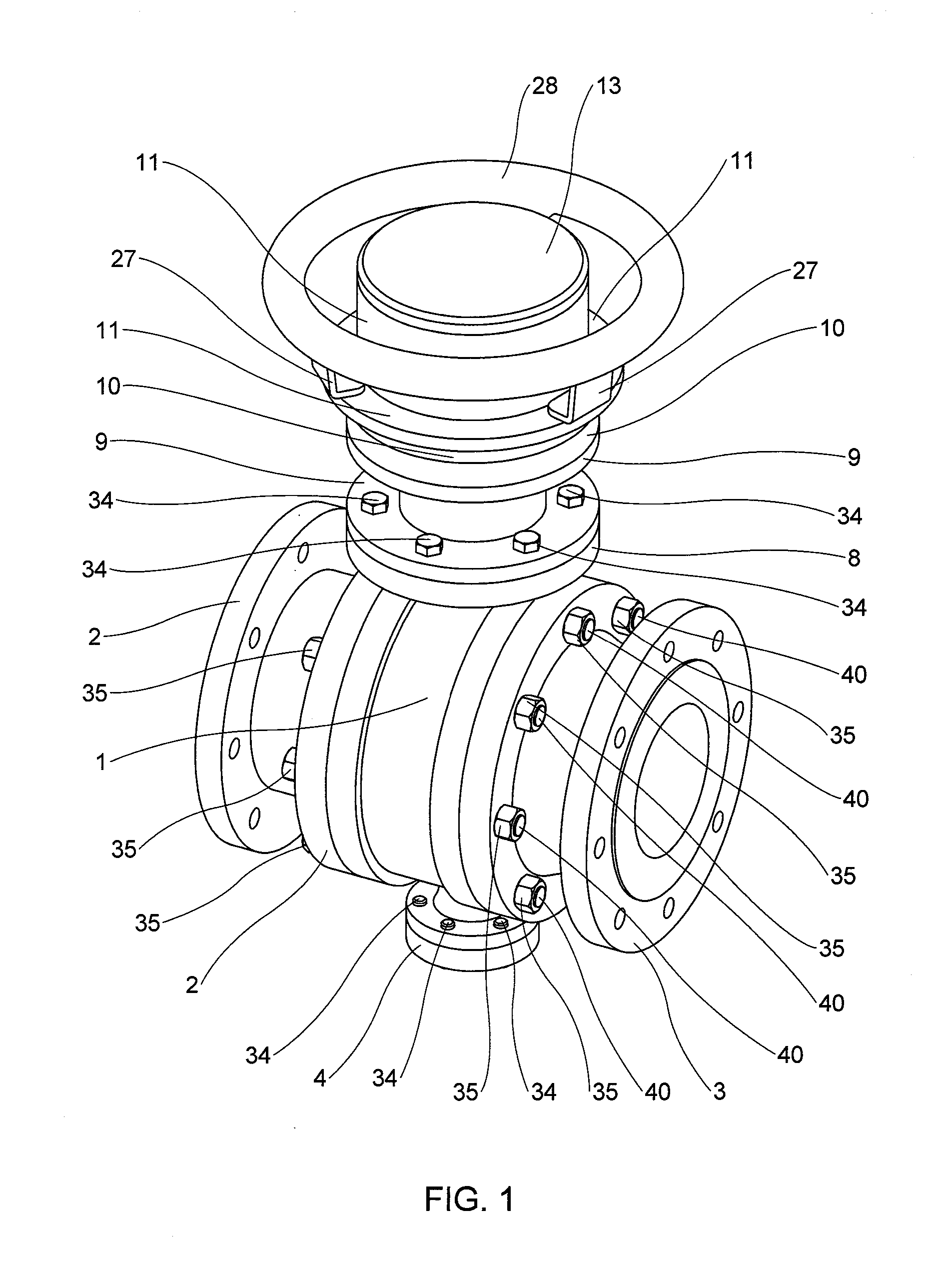

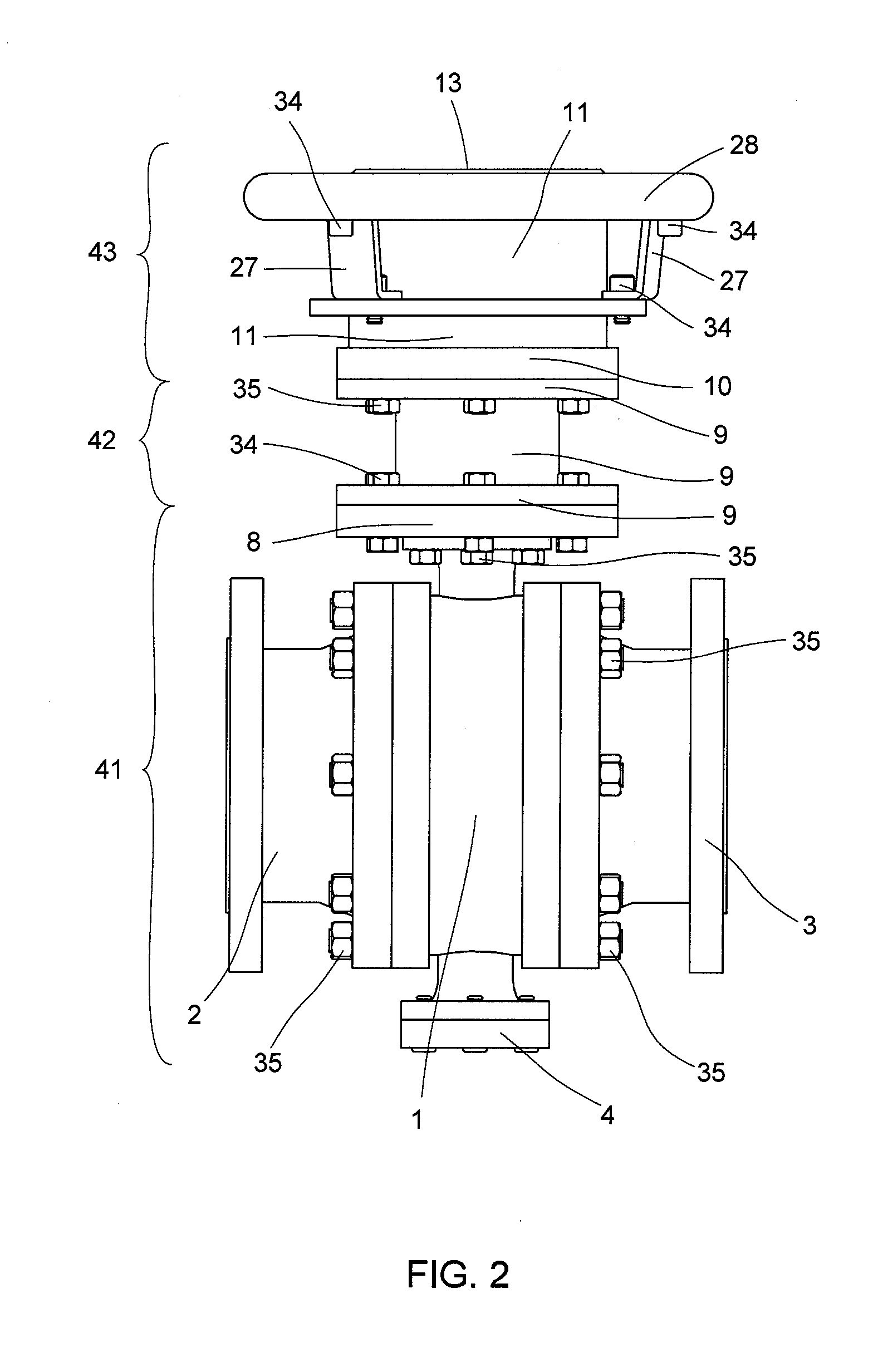

Rotary valve adapter assembly with planetary gear system

A rotary valve adapter assembly comprising an adapter plate configured to attach to a rotary valve body, a torque multiplier assembly comprising one or more planetary gear subassemblies, each of which comprises a sun gear, a ring gear, and a plurality of planetary gears, a magnetic actuator assembly comprising two sets of magnetically coupled magnets, and a shaft. The magnetic actuator assembly interfaces with the torque multiplier assembly such that when the magnets of the magnetic actuator assembly rotate, they cause the sun gear of a first planetary gear subassembly to rotate and the planetary gears to walk on the ring gear. When the carrier of the first planetary gear subassembly rotates, it causes the sun gear of a second planetary gear subassembly to rotate. When the carrier of the second planetary gear subassembly rotates, the shaft also rotates, thereby causing the valve to open and close.

Owner:BIG HORN VALVE INC

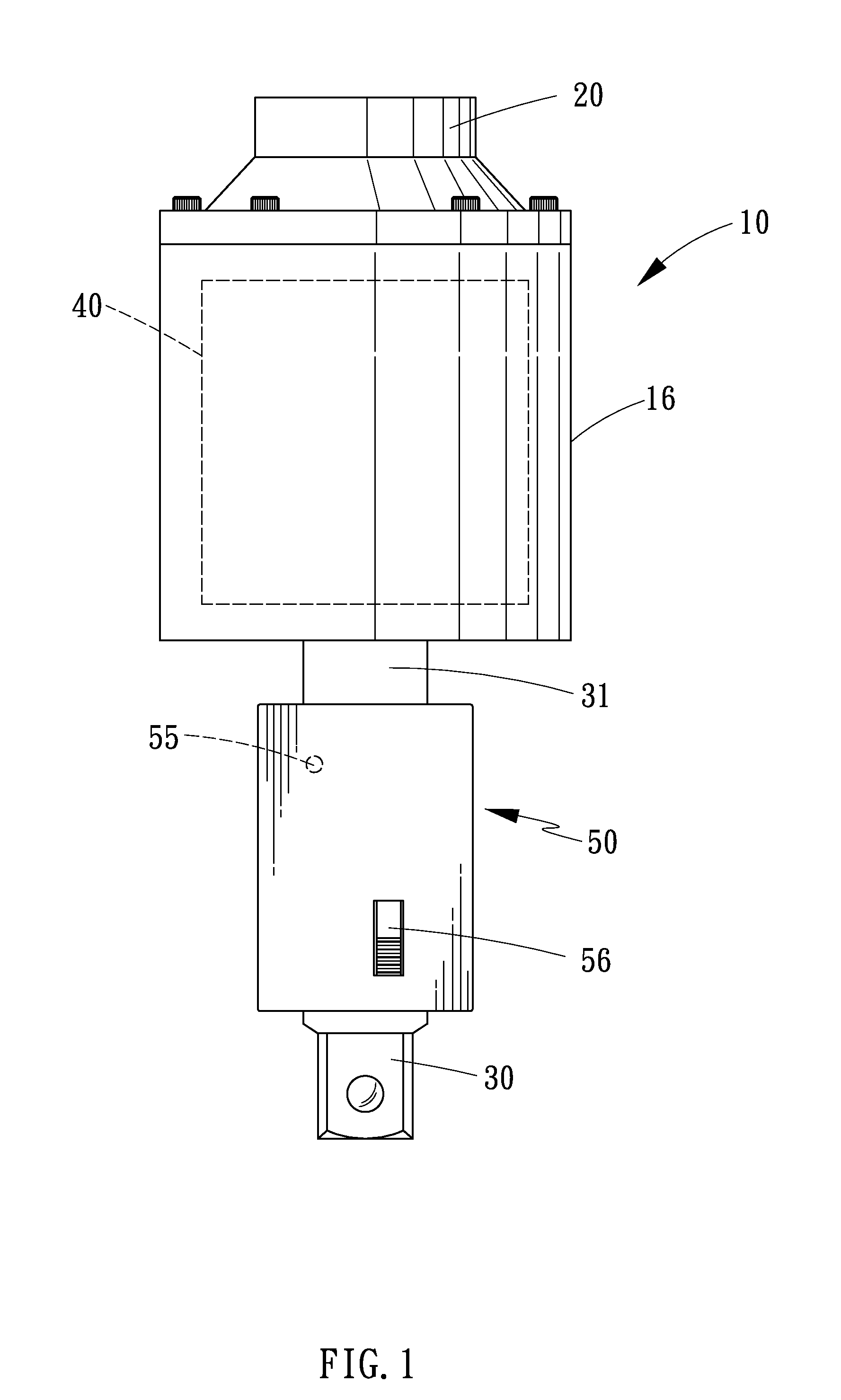

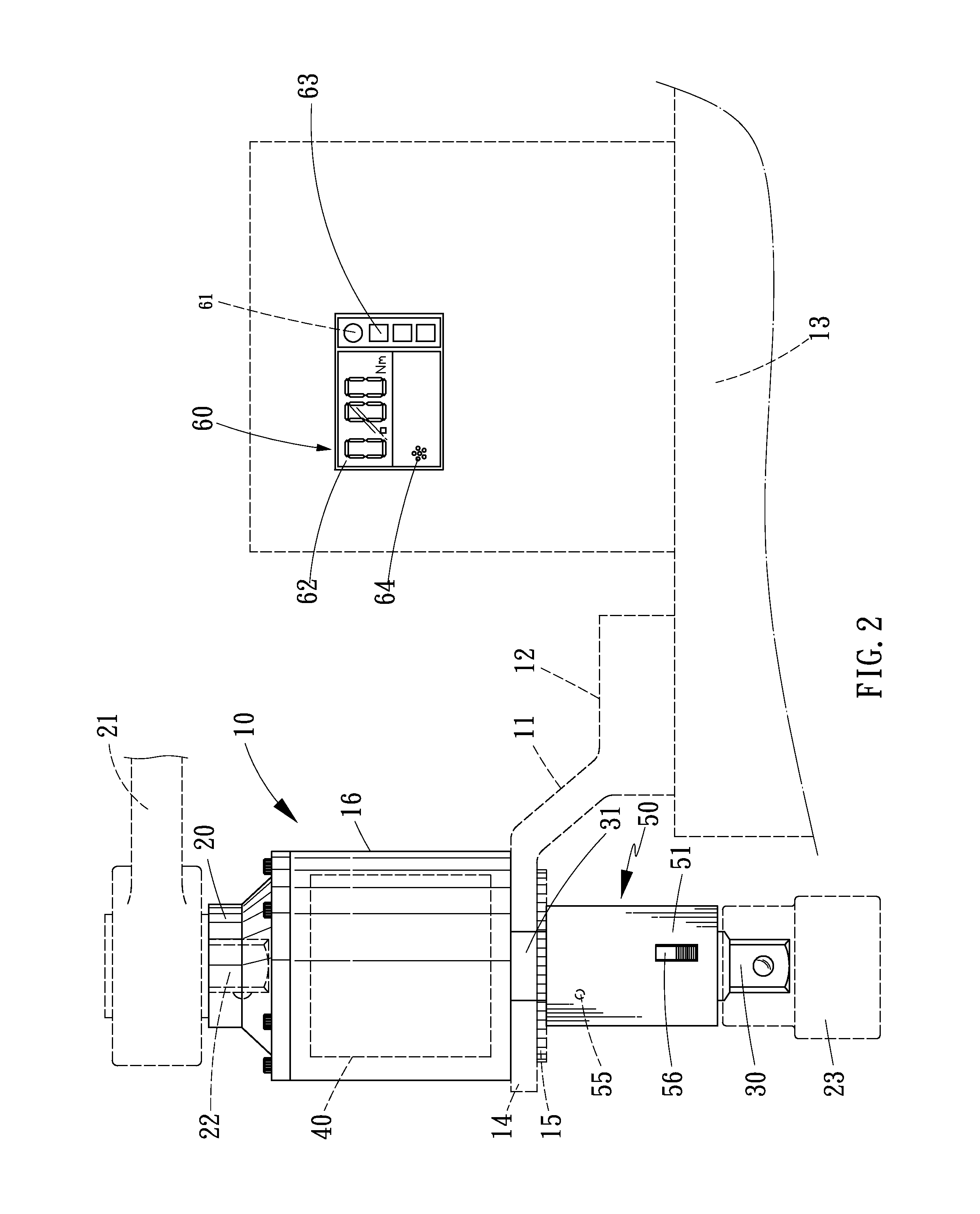

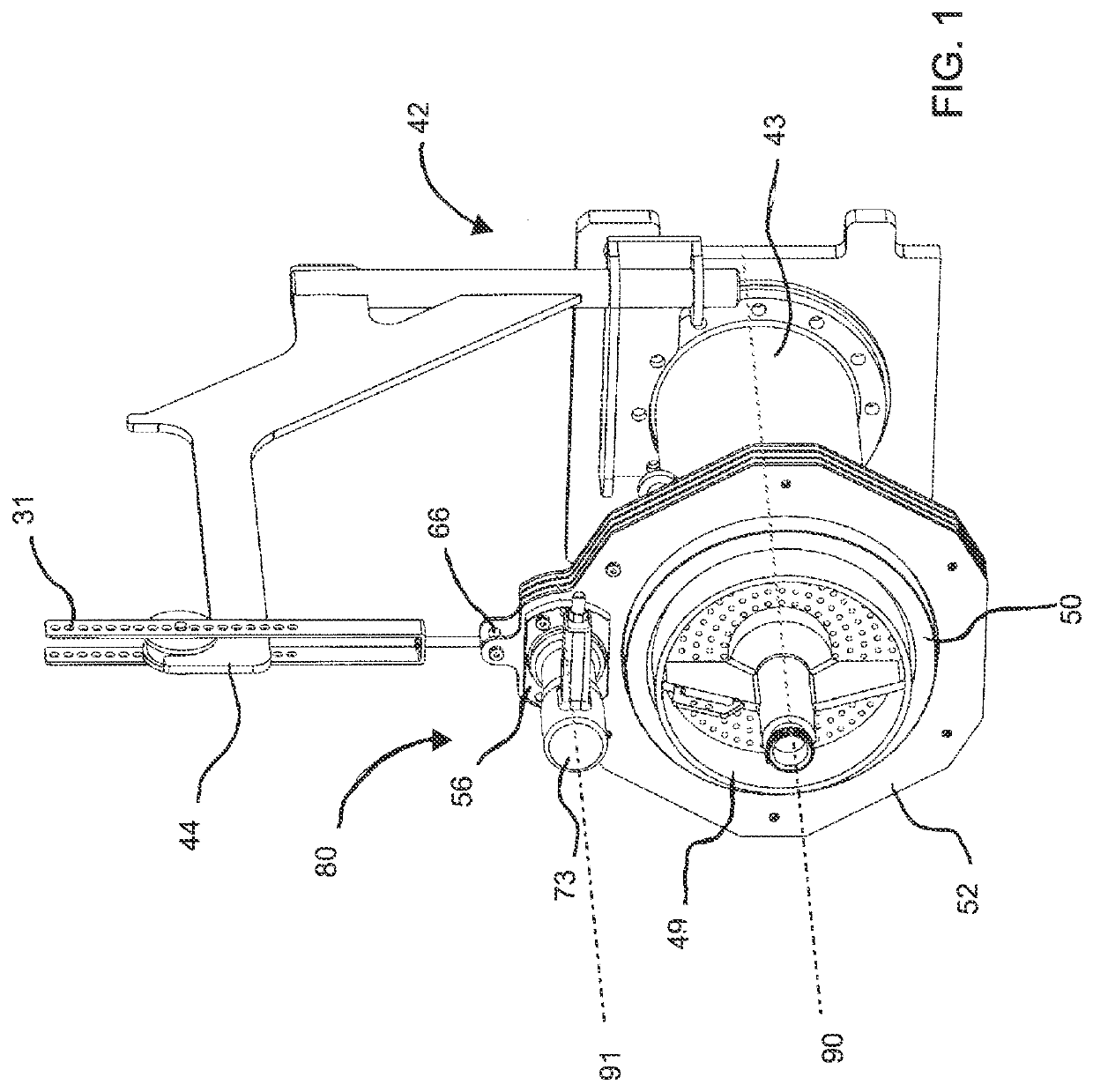

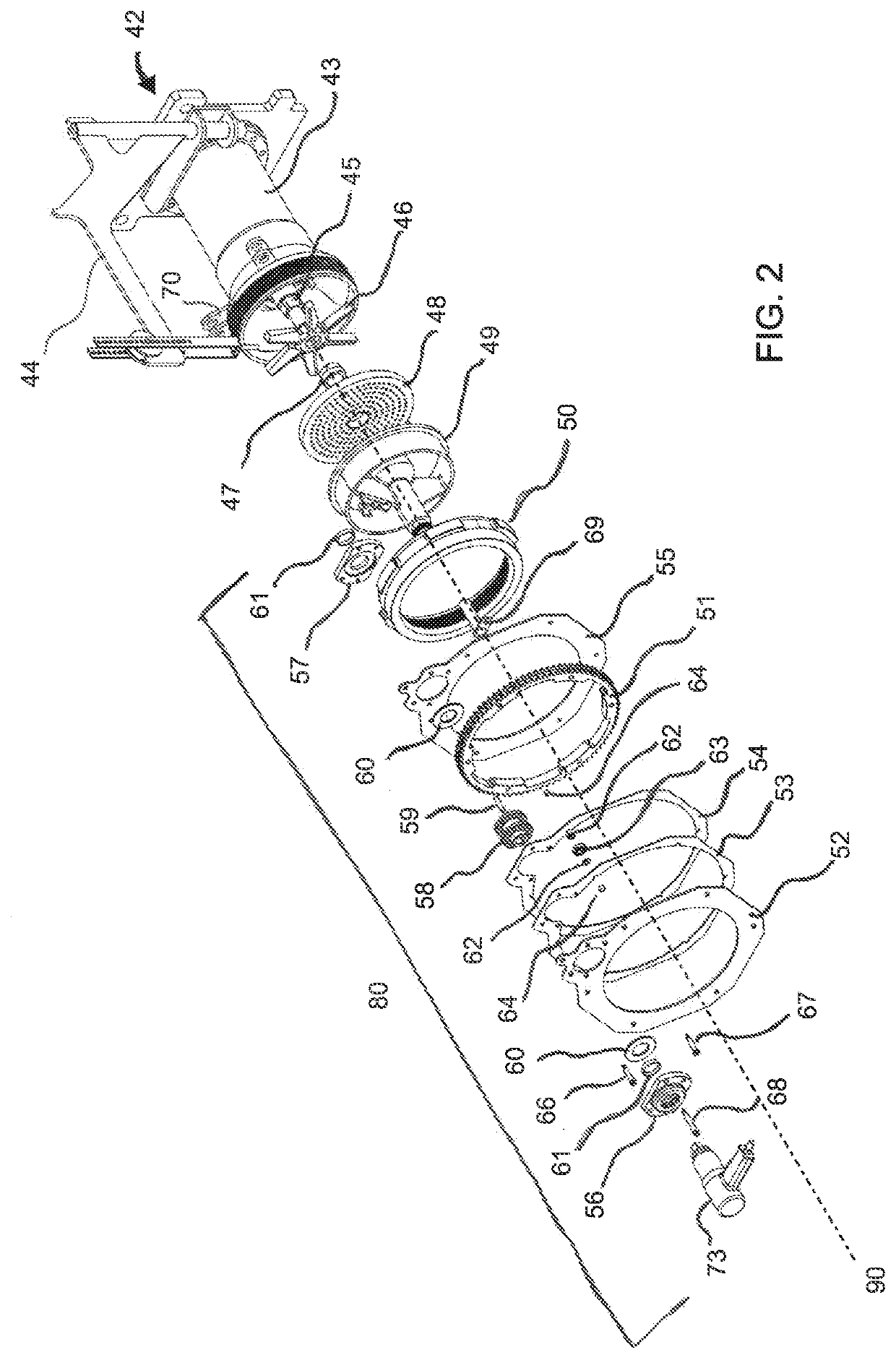

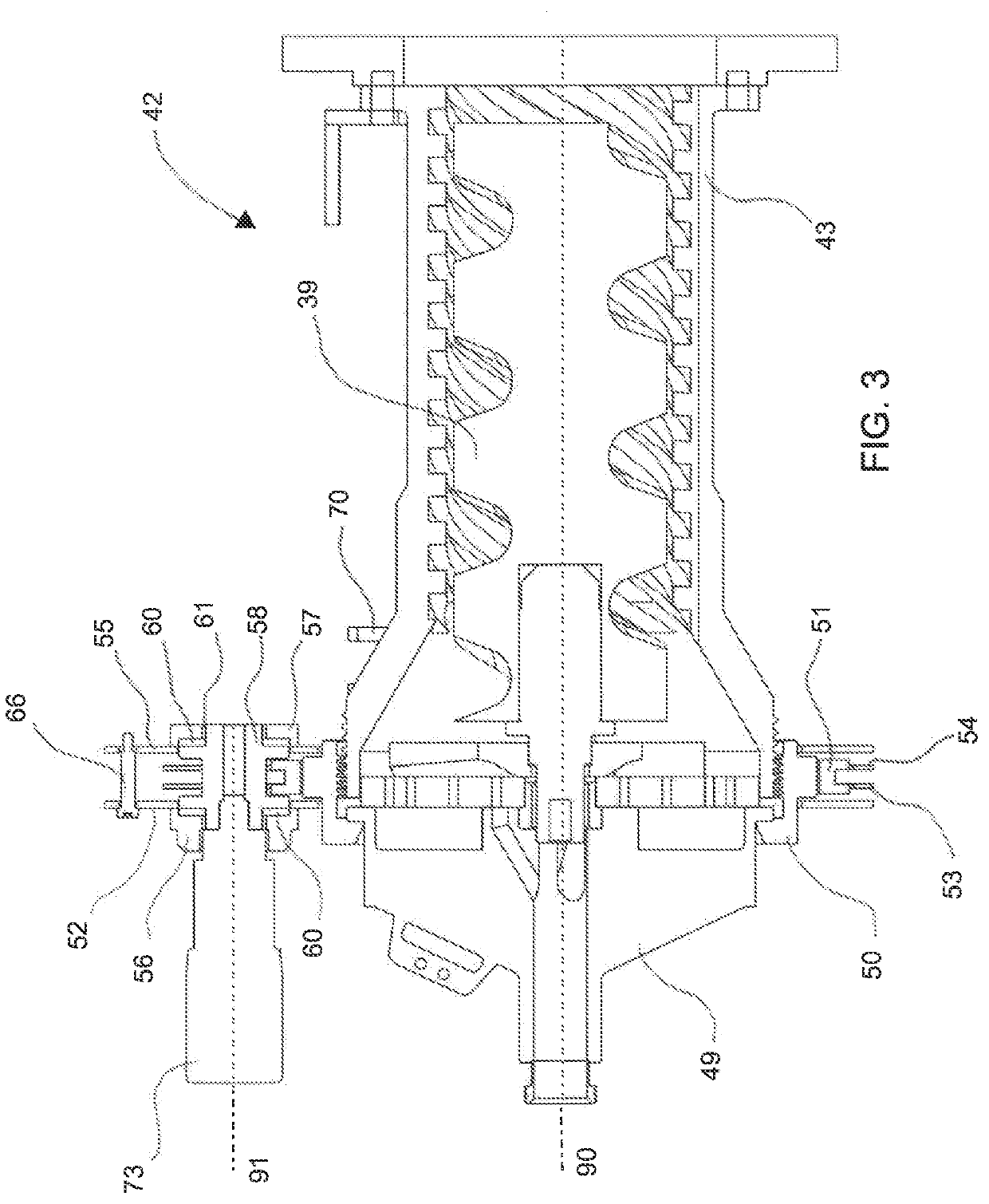

Direct-drive system for cooling system fans, exhaust blowers and pumps

The present invention is directed to a load bearing direct-drive system and a variable process control system for efficiently managing the operation of fans in a cooling system such as a wet-cooling tower, air-cooled heat exchanger (ACHE), HVAC system, blowers and centrifugal blowers, mechanical towers or chiller systems. In one embodiment, the load bearing direct-drive system comprises a load bearing torque multiplier device having an output rotatable shaft connected to a fan, and a load bearing motor comprising a rotatable shaft that drives the load bearing torque multiplier device.

Owner:PRIME DATUM

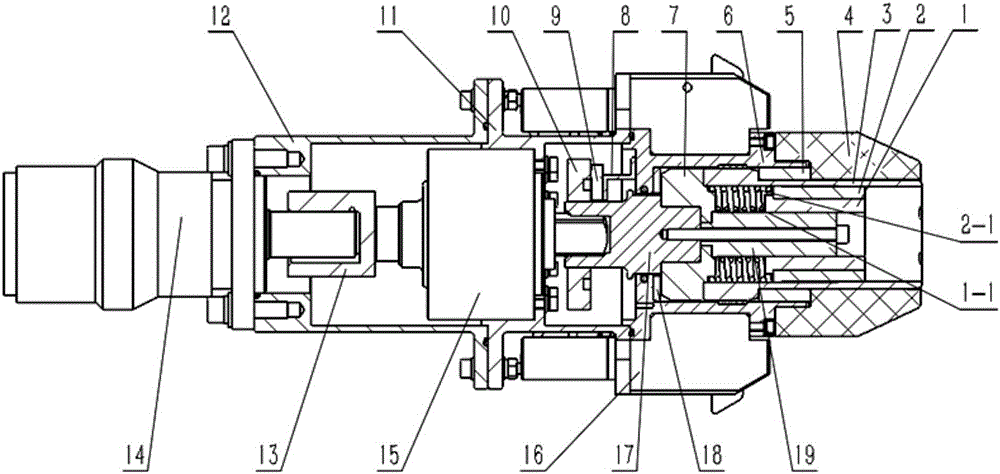

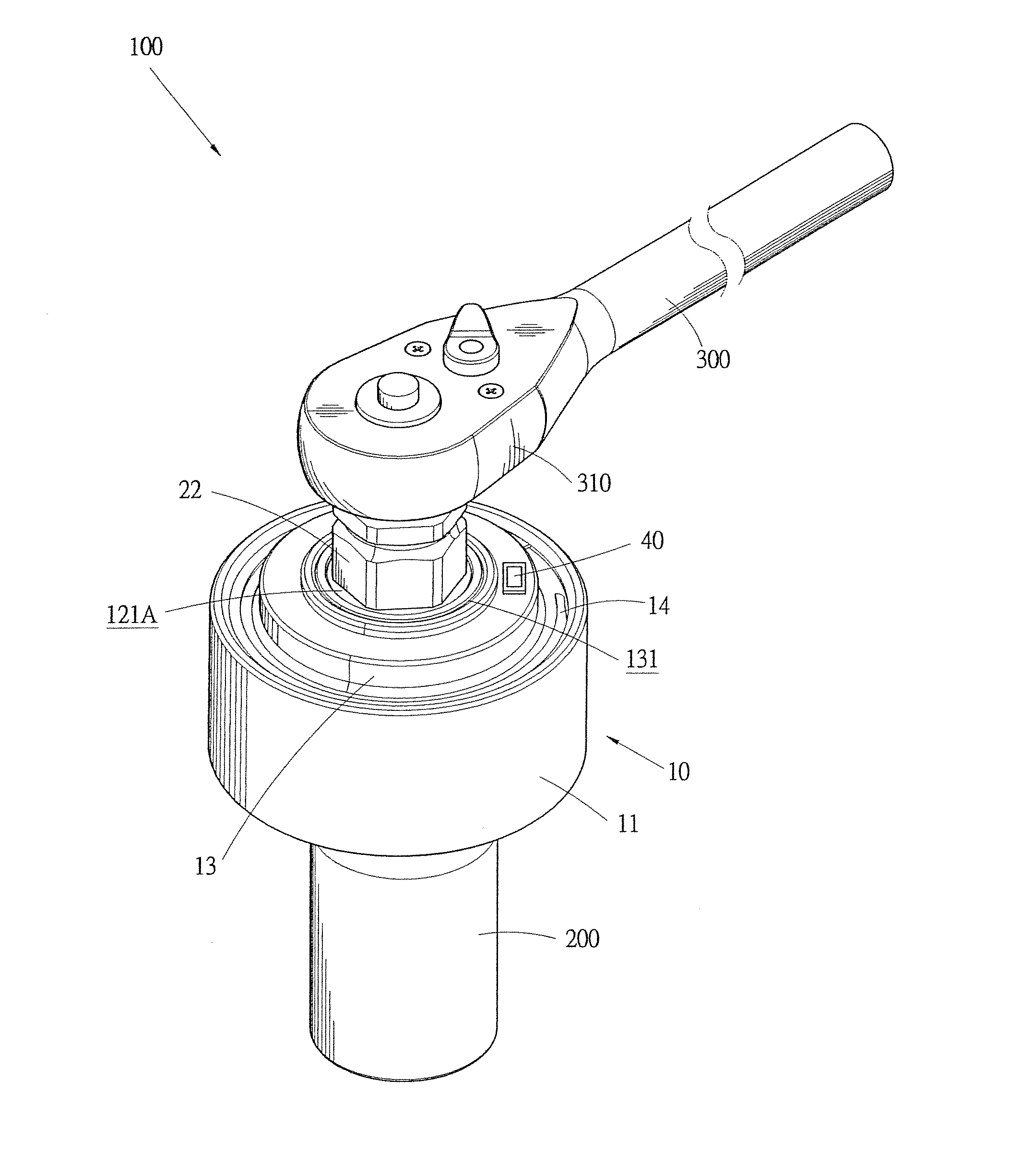

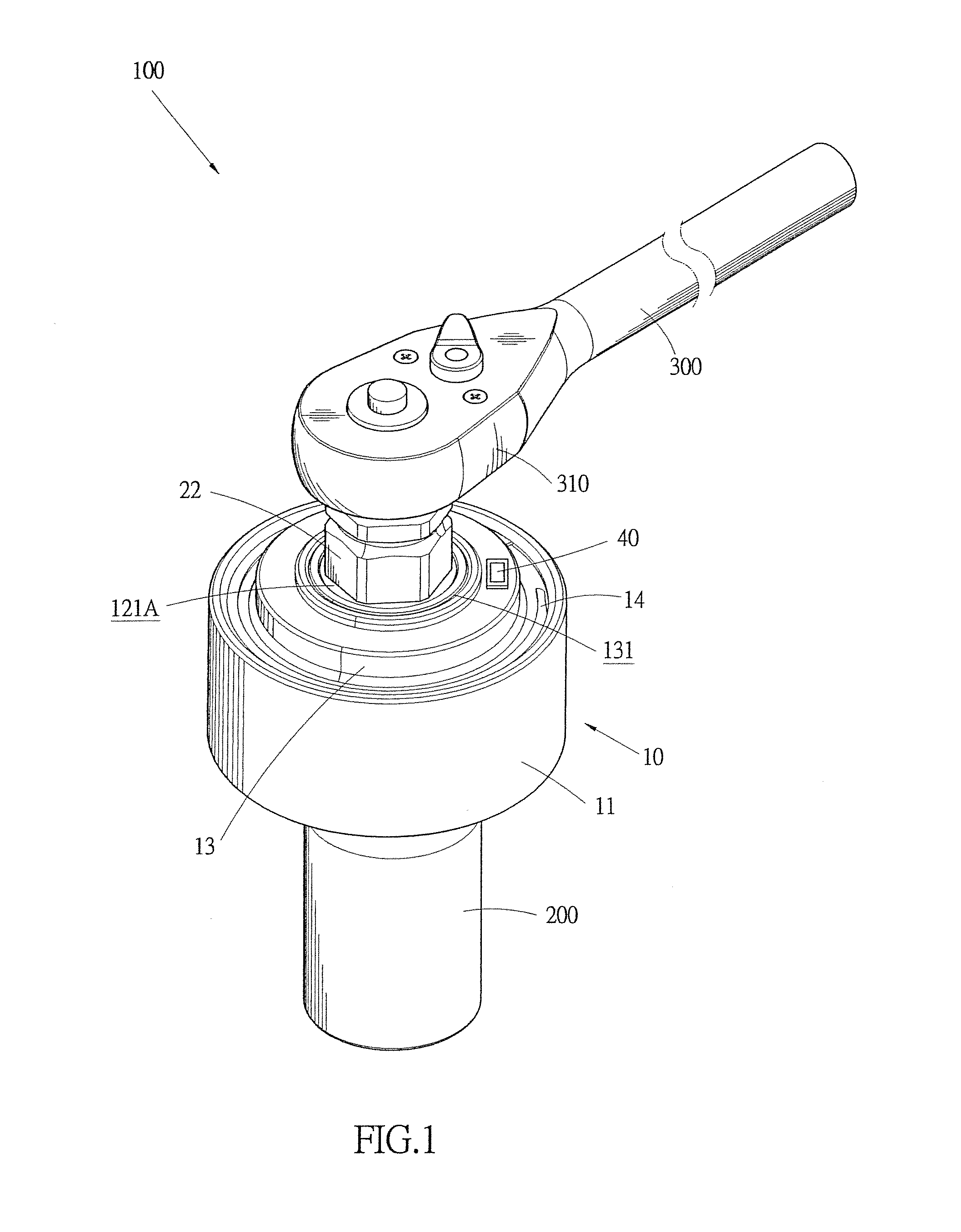

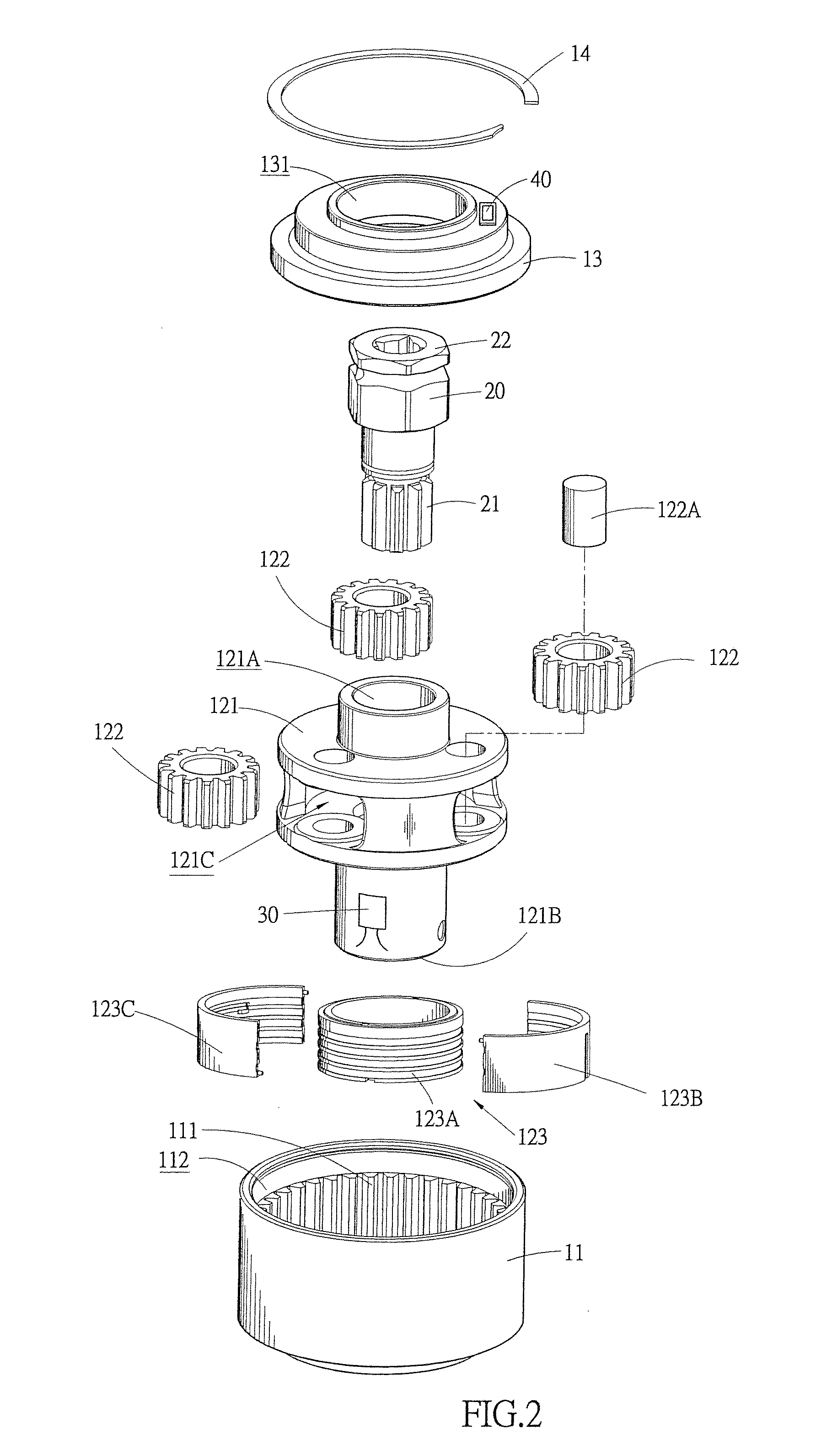

Torque multiplier

ActiveUS8584554B2Ensure qualityAccurate detectionTailstocks/centresSpannersInformation transmissionPneumatic tool

A torque multiplier includes a main body, a torque input shaft, at least one torque sensor, an angle sensor, and an information transmission circuit. The main body contains therein at least one gear train. The gear train has upper and lower ends respectively forming a torque input port and a torque output shaft. The torque output shaft is coupleable with a tool piece, such as a socket. The torque input shaft has an end fit into the torque input port and an opposite end coupleable with a torque device, such as a hand tool, an electrical tool, or a pneumatic tool. The torque device applies a torque input to the torque input shaft that in turn rotates the gear train to provide a multiplied torque output to the torque output shaft. The torque sensor is mounted to a surface of the torque output shaft of the gear train of the main body to detect the torque value of the torque output shaft and provide a torque value signal. At least one angle sensor mounted to the main body detects a horizontal angle of the main body and the torque output shaft and provides an angle value signal. The information transmission circuit is arranged inside the main body to transmit, in a wired or wireless fashion, the torque value signal and the angle value signal to at least one electronic device for storage, display or use.

Owner:LEGEND LIFESTYLE PRODS CORP

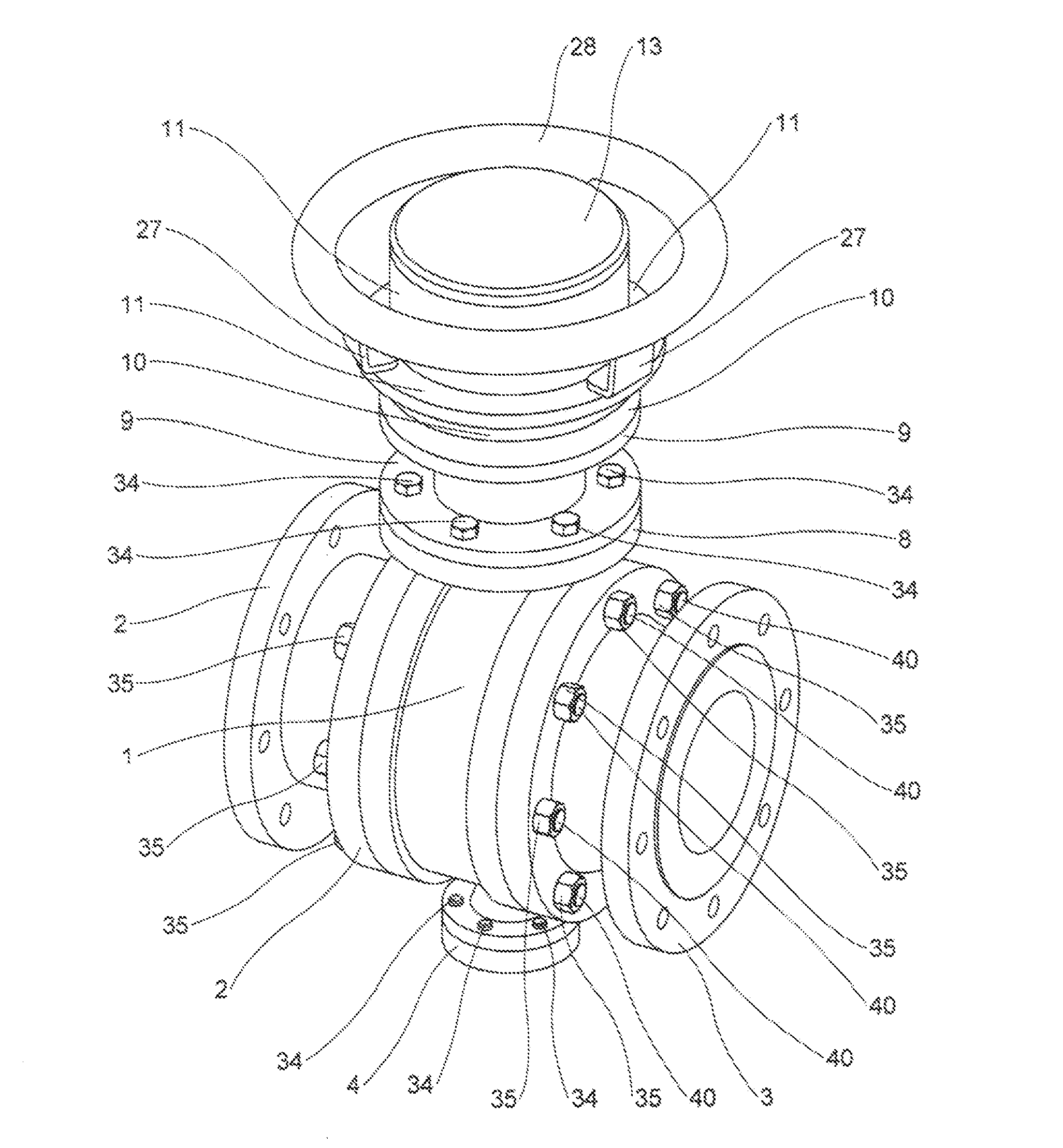

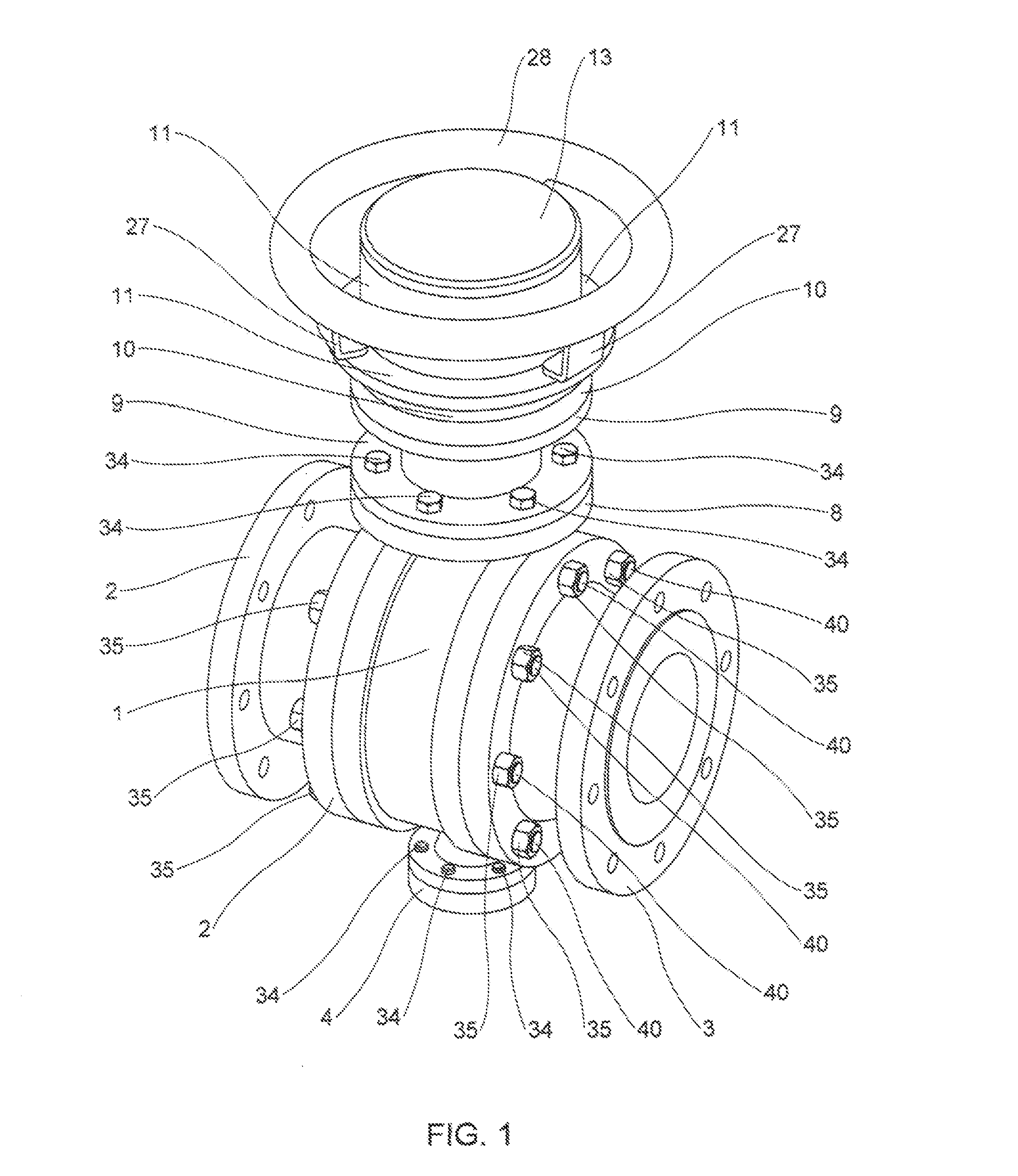

Rotary valve adapter assembly with planetary gear system

A rotary valve adapter assembly comprising an adapter plate configured to attach to a rotary valve body, a torque multiplier assembly comprising one or more planetary gear subassemblies, each of which comprises a sun gear, ring gear, and a plurality of planetary gears, a magnetic actuator assembly comprising two sets of magnetically coupled magnets, and a shaft. The magnetic actuator assembly interfaces with the torque multiplier assembly such that when the magnets of the magnetic actuator assembly rotate, they cause the sun gear of a first planetary gear subassembly to rotate and the planetary gears to walk on the ring gear. The shaft interfaces with the carrier of one of the planetary gear subassemblies such that when the carrier rotates, the shaft also rotates, thereby causing the valve to open and close. The assembly further comprises a pressure equalization system comprising a piston and piston spring or spring washer stack.

Owner:BIG HORN VALVE INC

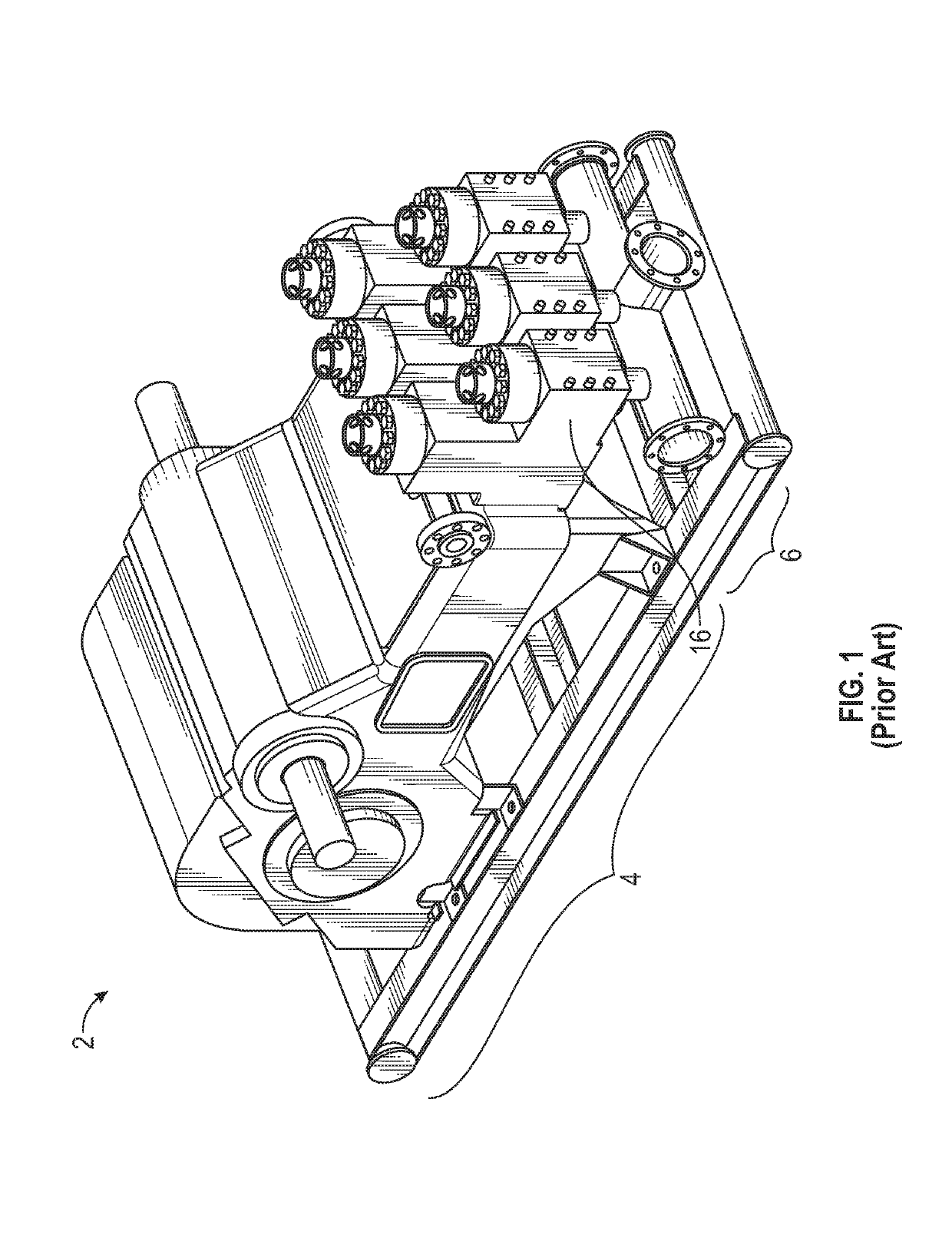

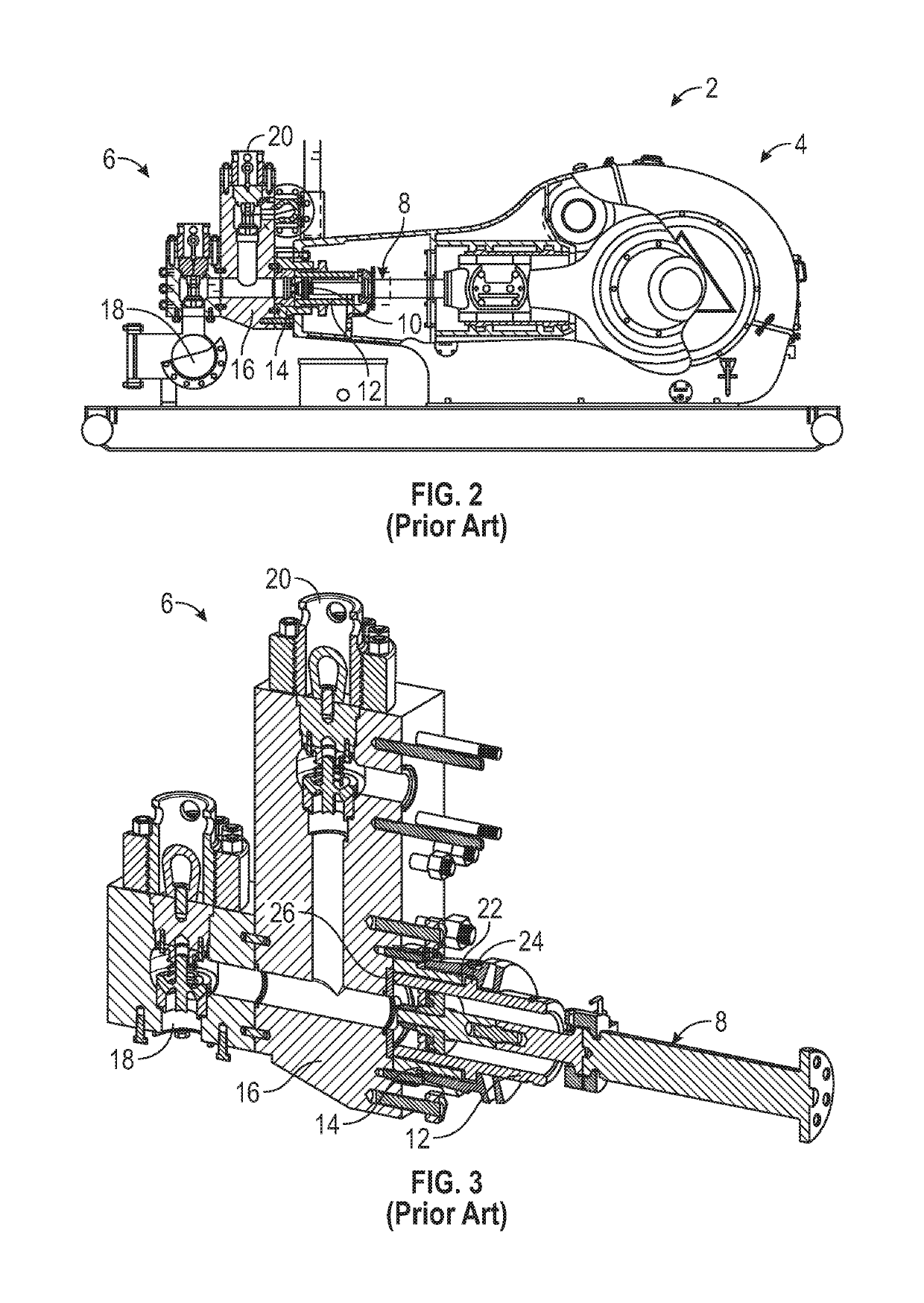

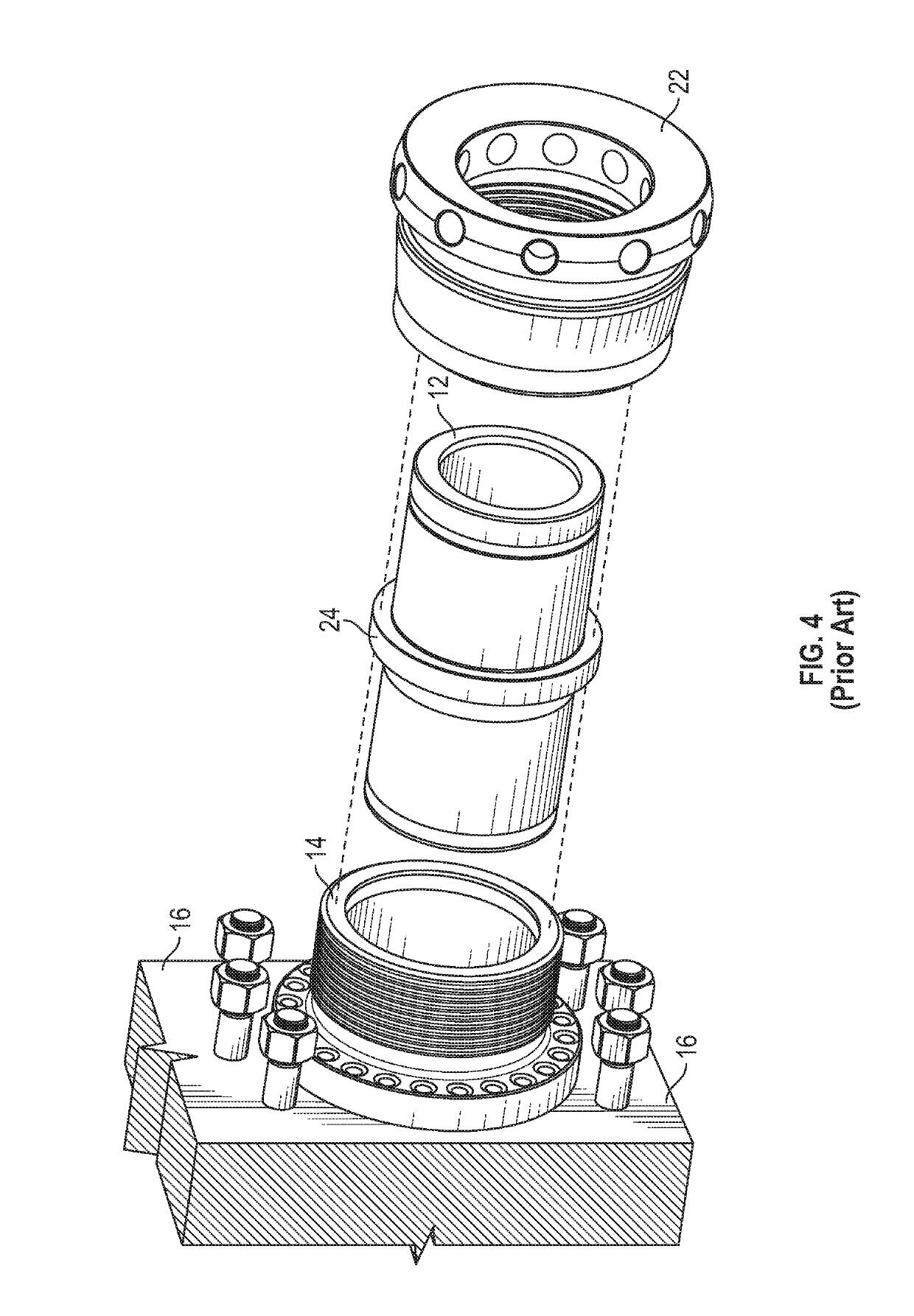

Cylinder liner retainer system with torque multiplier and method

ActiveUS10436193B1Quick releasePositive displacement pump componentsCylindersEngineeringMechanical engineering

The present invention provides a cylinder liner retainer system with a torque multiplier and associated method to quickly release an existing cylinder liner and reinsert a new cylinder liner as a replacement.

Owner:PREMIUM OILFIELD TECH LLC

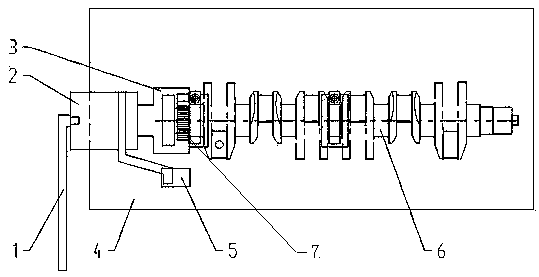

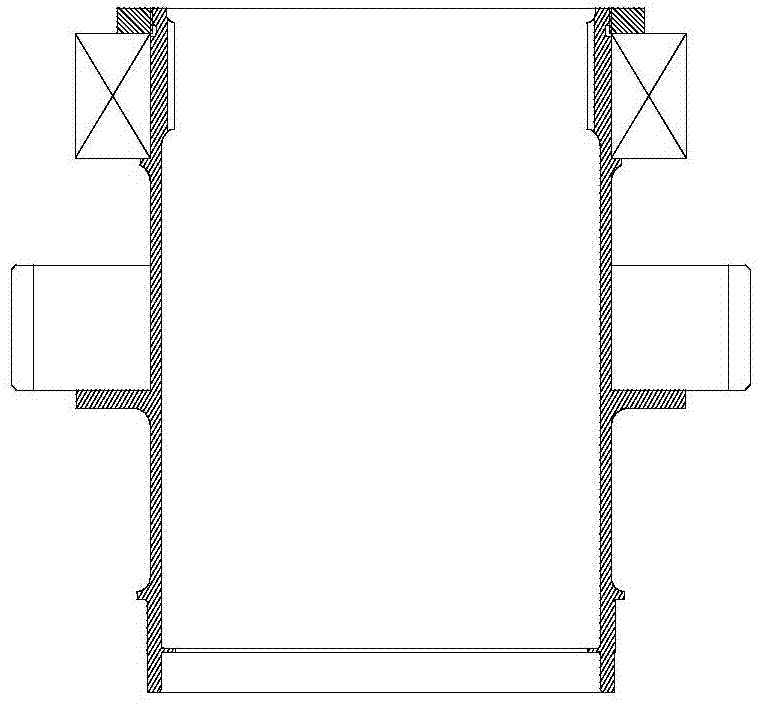

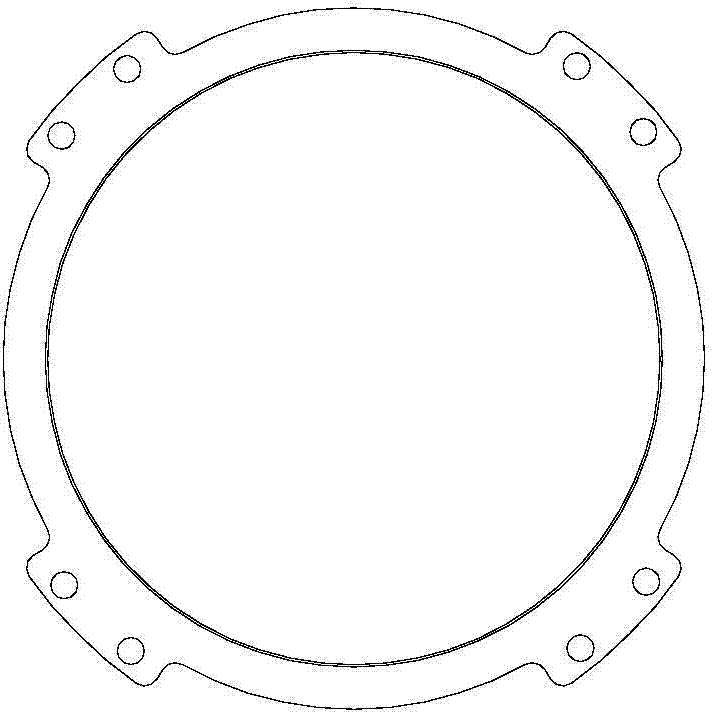

Detection device for rotation torque of hot assembly gear

InactiveCN104374513AImplement testSimple structureMeasurement of torque/twisting force while tighteningControl theoryCrankshaft

The invention relates to a detection device for the rotation torque of a hot assembly gear. The detection device comprises a torque wrench, a torsion multiplier, a torsion sleeve and a workpiece to be detected. The workpiece to be detected is composed of a crankshaft and a gear, and is installed on a crankshaft assembly table. The torsion sleeve is fixed to the gear at the rear end of the crankshaft through an internal gear. The torsion multiplier is installed on the torsion sleeve. The torque wrench is installed on the torsion multiplier. Force is applied to the torque wrench with set torque, the torsion sleeve drives the gear to rotate, and therefore the torque of the hot assembly gear in the rotation process is detected. The detection device is simple and reasonable in structure and convenient to use and operate, and can accurately detect the actual numerical value of the rotation torque of the hot assembly gear.

Owner:TIANRUN IND TECH CO LTD

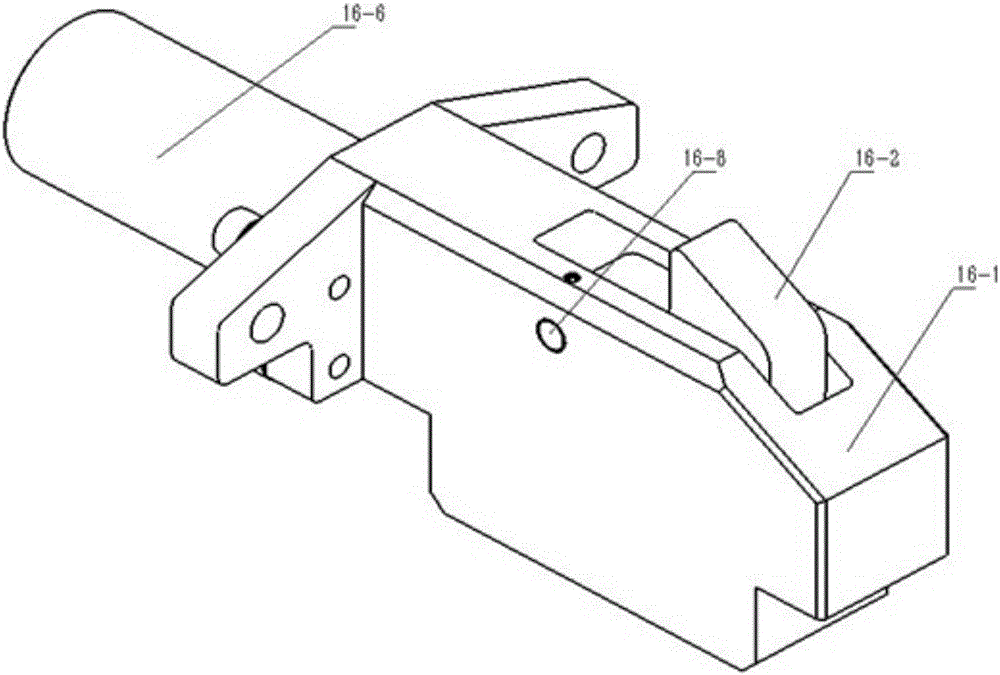

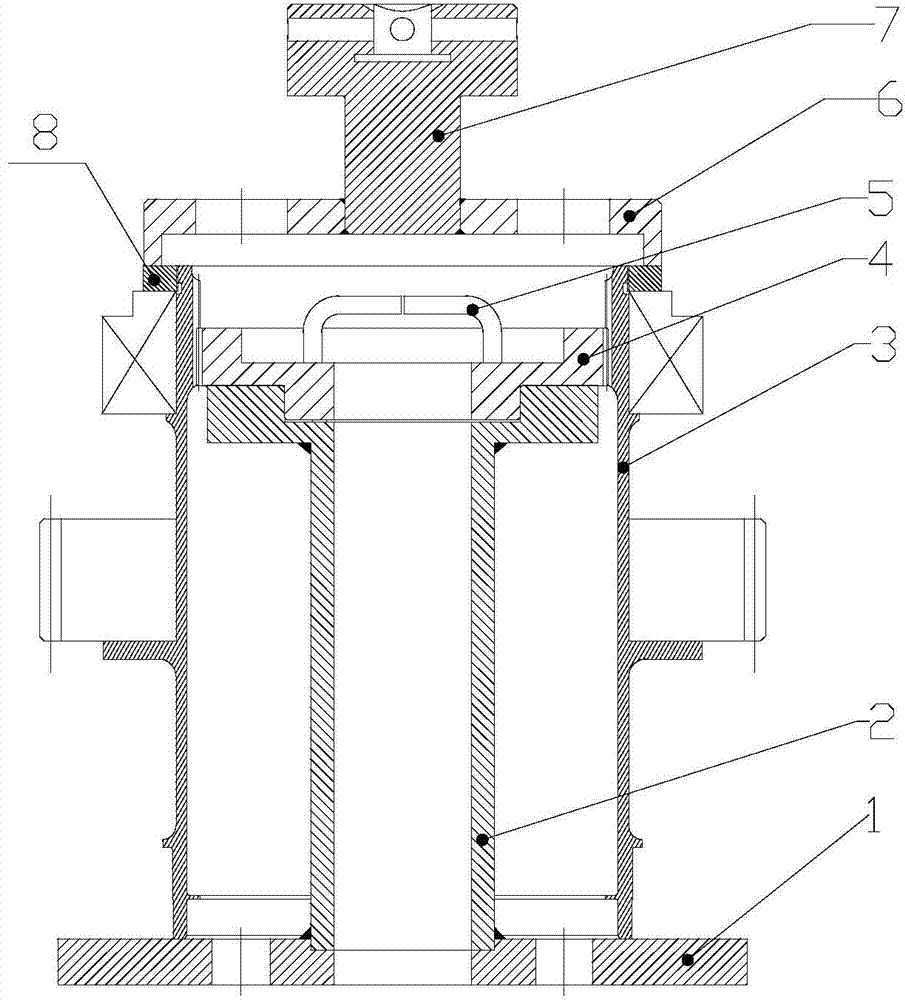

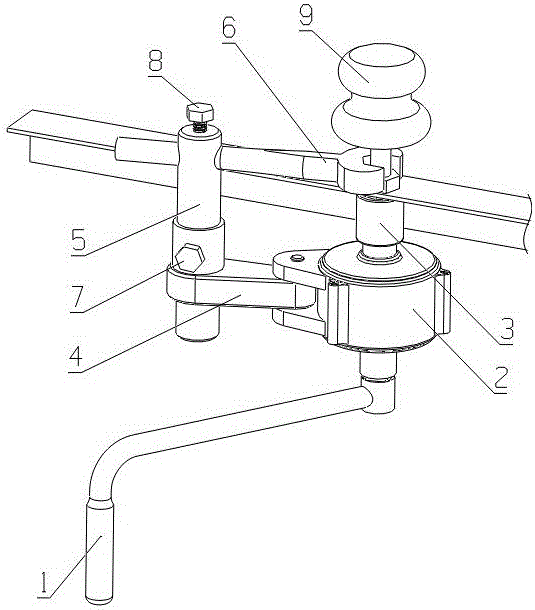

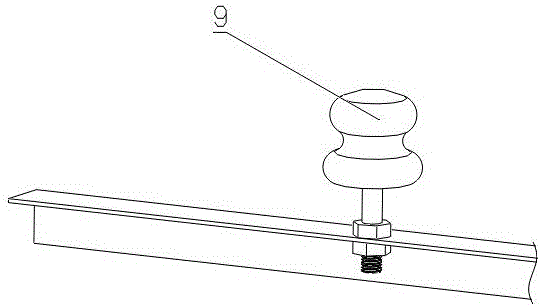

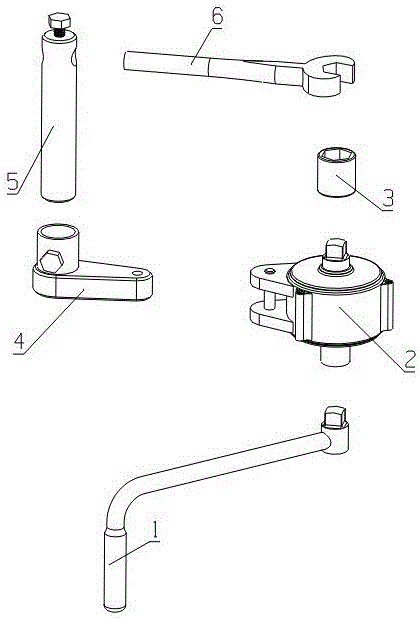

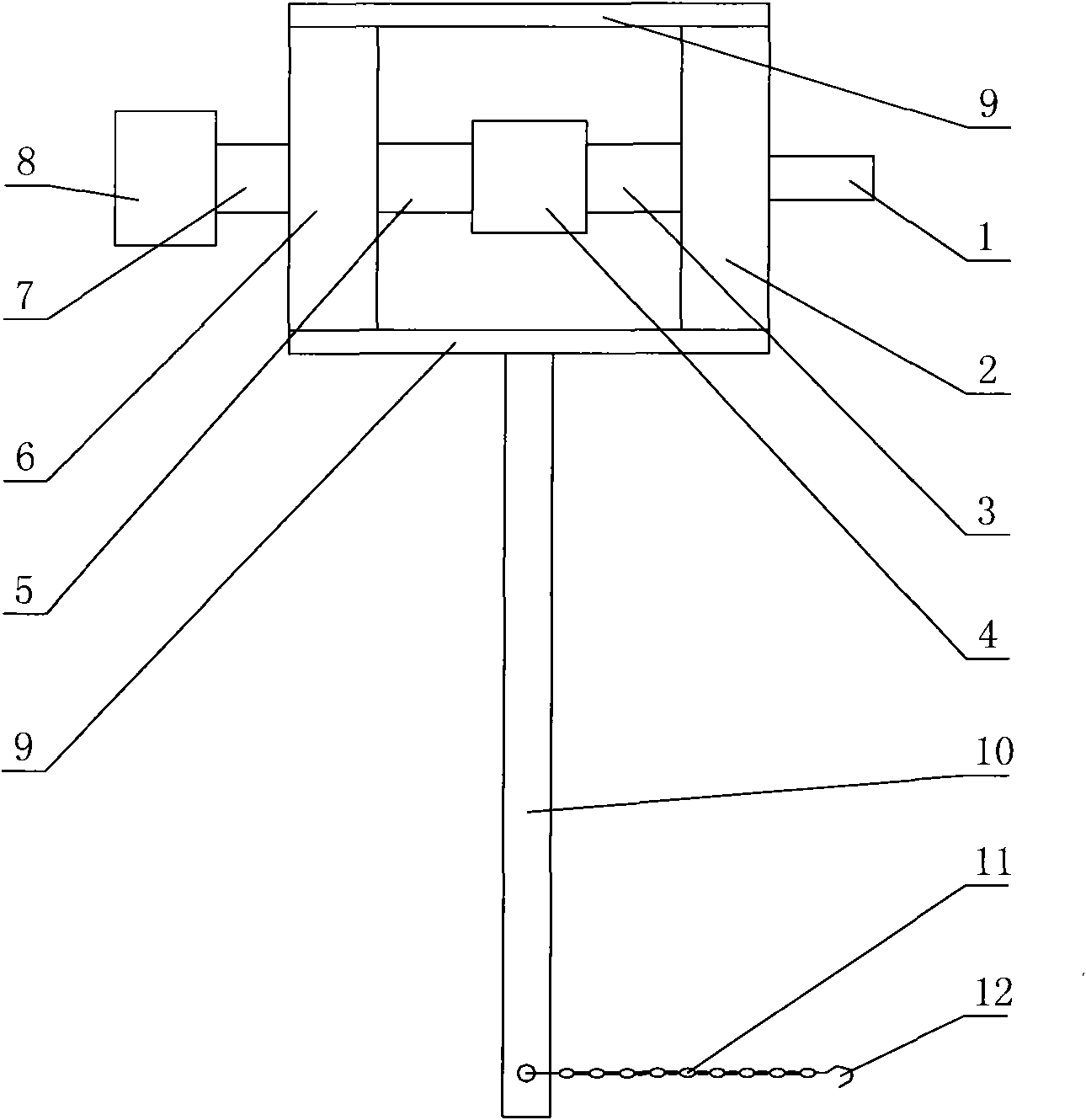

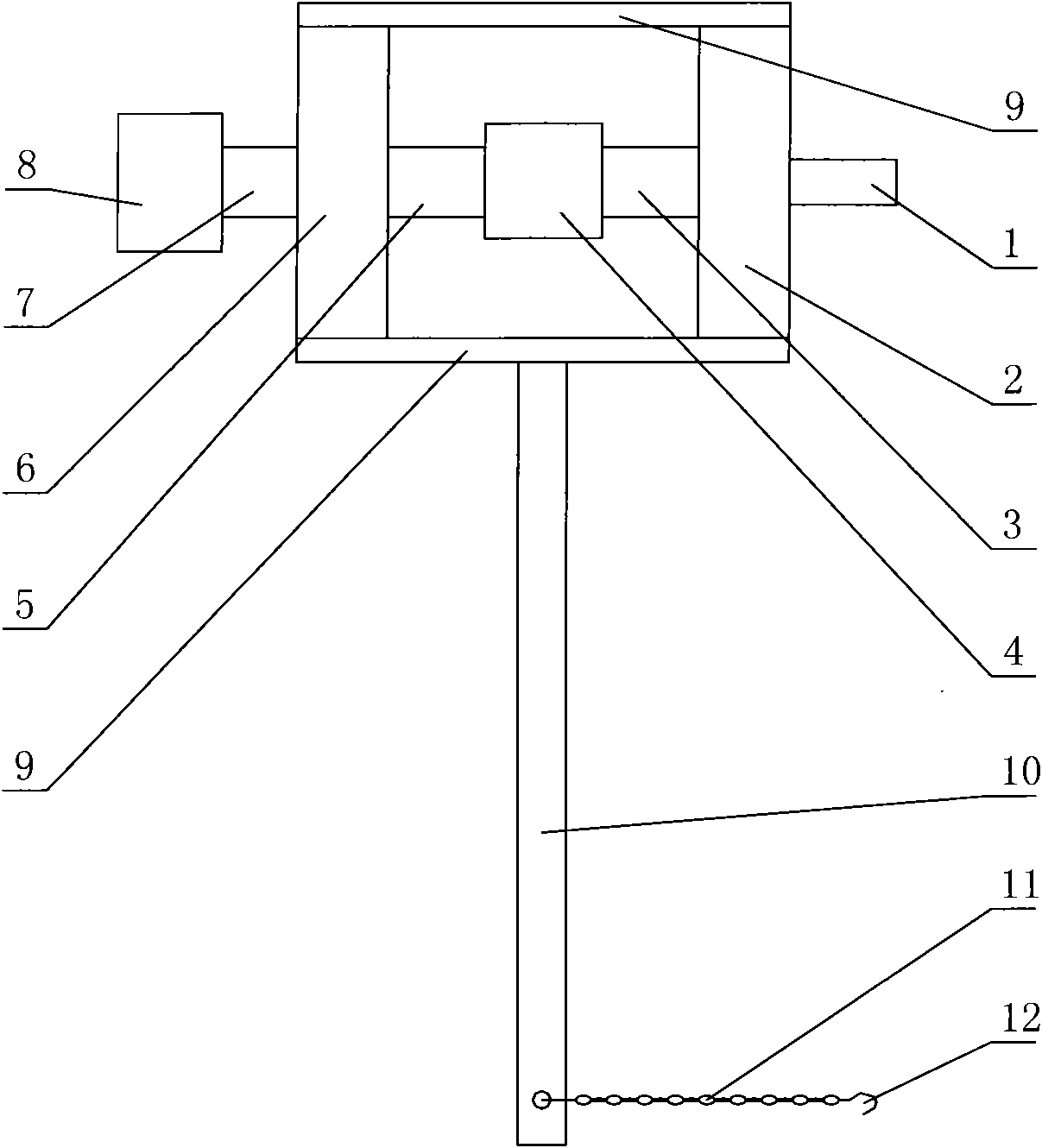

Assembling and disassembling tool for gear shaft round nut

ActiveCN103878743AEven by forceAvoid scratchesMetal-working hand toolsEngineeringMechanical engineering

The invention relates to an assembling and disassembling tool for a gear shaft round nut. The assembling and disassembling tool comprises a brake clamp and an assembling and disassembling clamp. A positioning shaft 4 of the brake clamp is fixedly installed at one end of a stand column 2 and is provided with an external spline matched with an internal spline of a gear shaft 3. The other end of the stand column 2 is installed on a base 1, and the stand column 2 can extend to the interior of the gear shaft 3 from the bottom. The external spline on the positioning shaft 4 is meshed with the internal spline of the gear shaft 3. A spanner 6 of the assembling and disassembling clamp is matched with the external outline of the round nut 8 and fixedly connected with the round nut 8. A torque multiplier is fixedly installed on a connecting rod 7. The assembling and disassembling tool for the gear shaft round nut is simple in principle, convenient to operate and reliable in use, the round nut can be safely and conveniently locked and disassembled, the round nut is not damaged, and the use reliability of the round nut is ensured.

Owner:HARBIN DONGAN ENGINE GRP

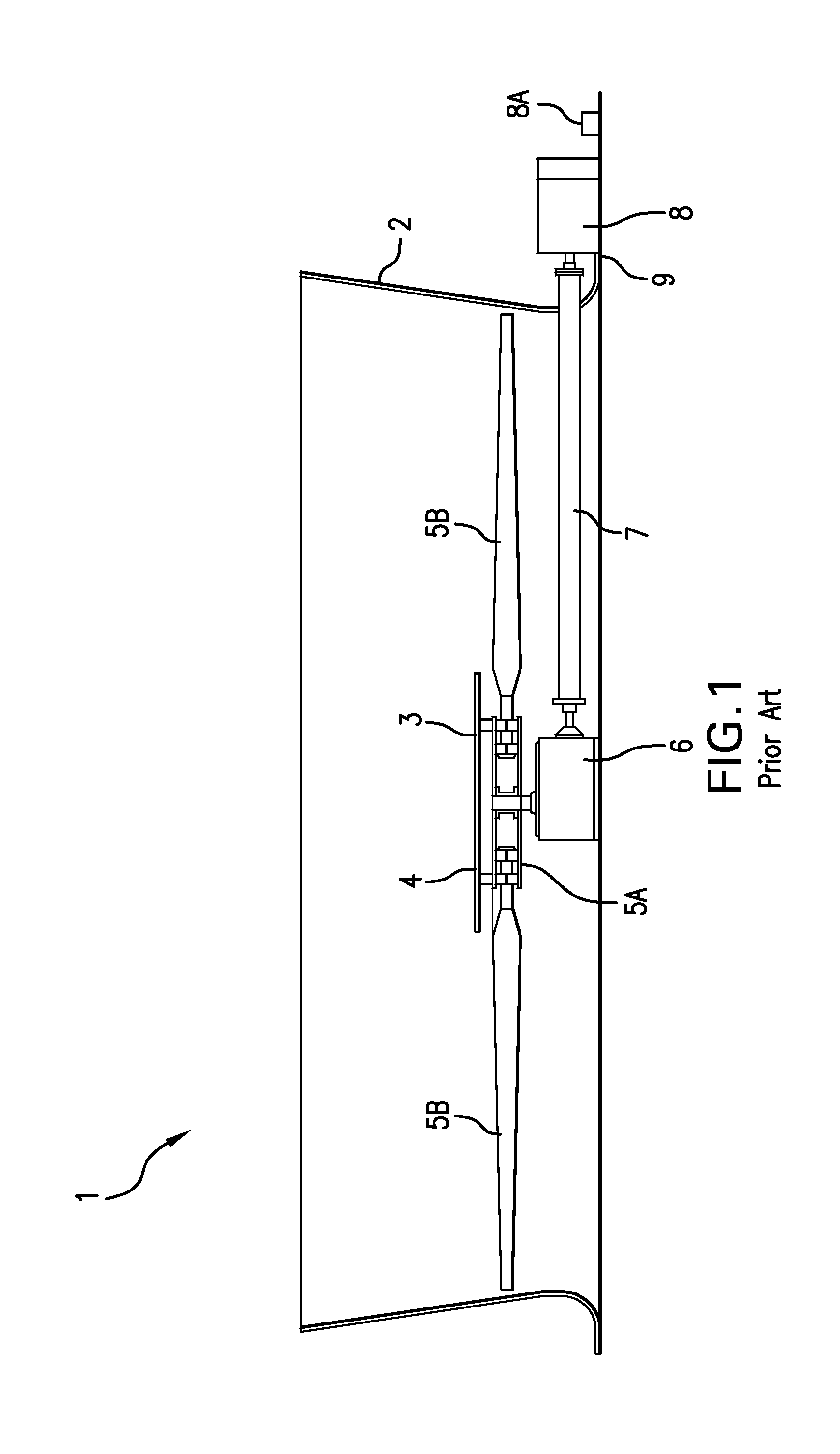

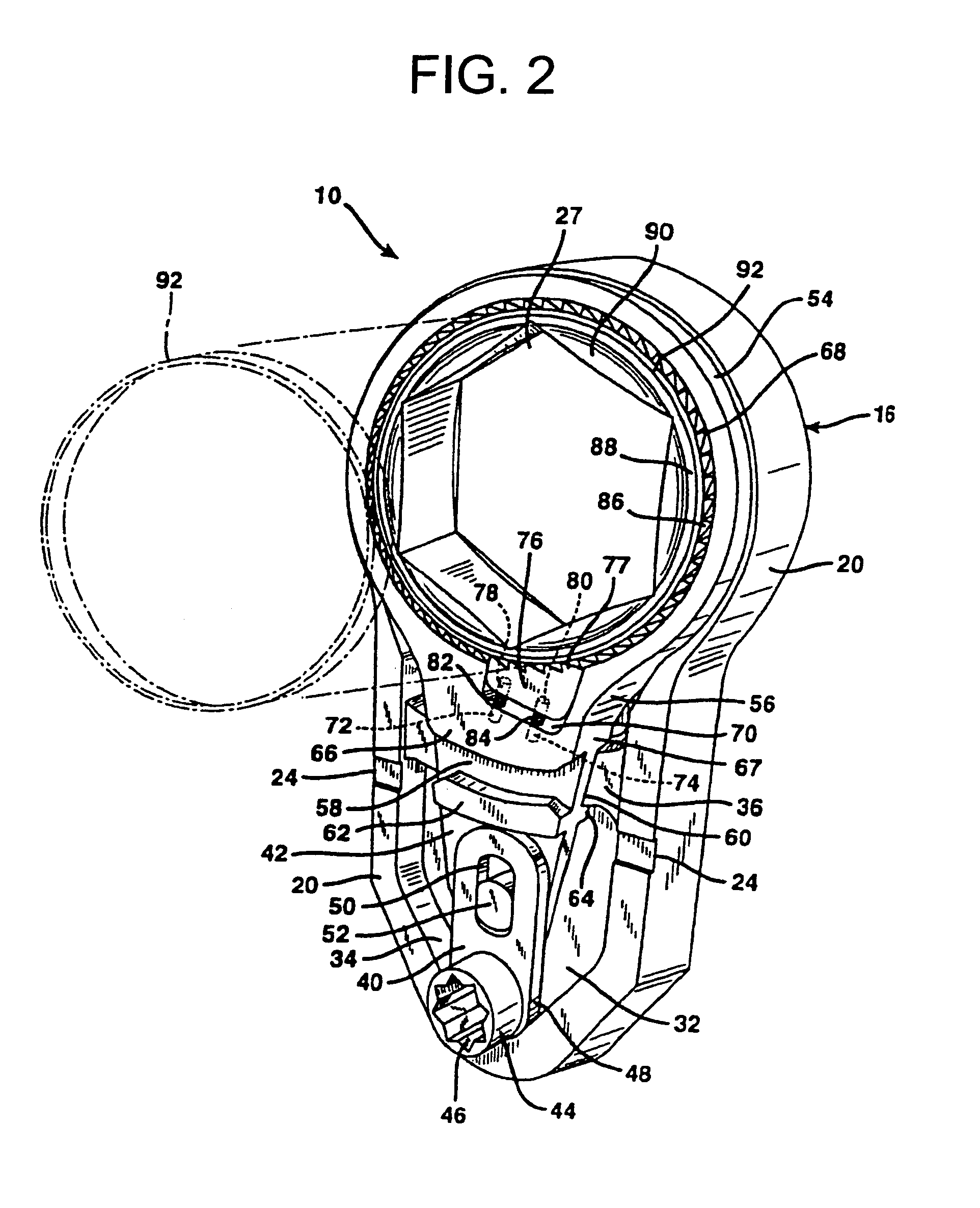

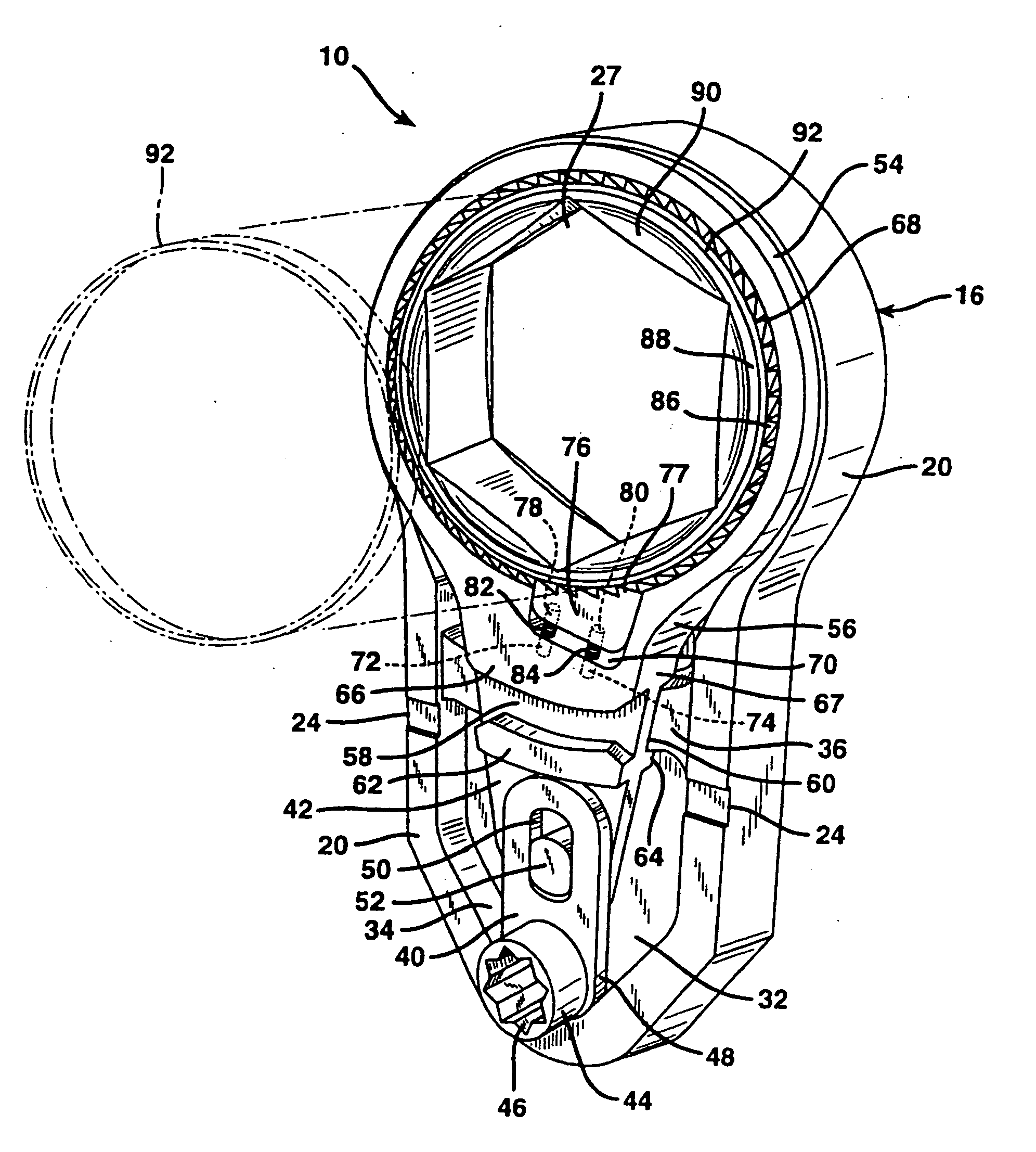

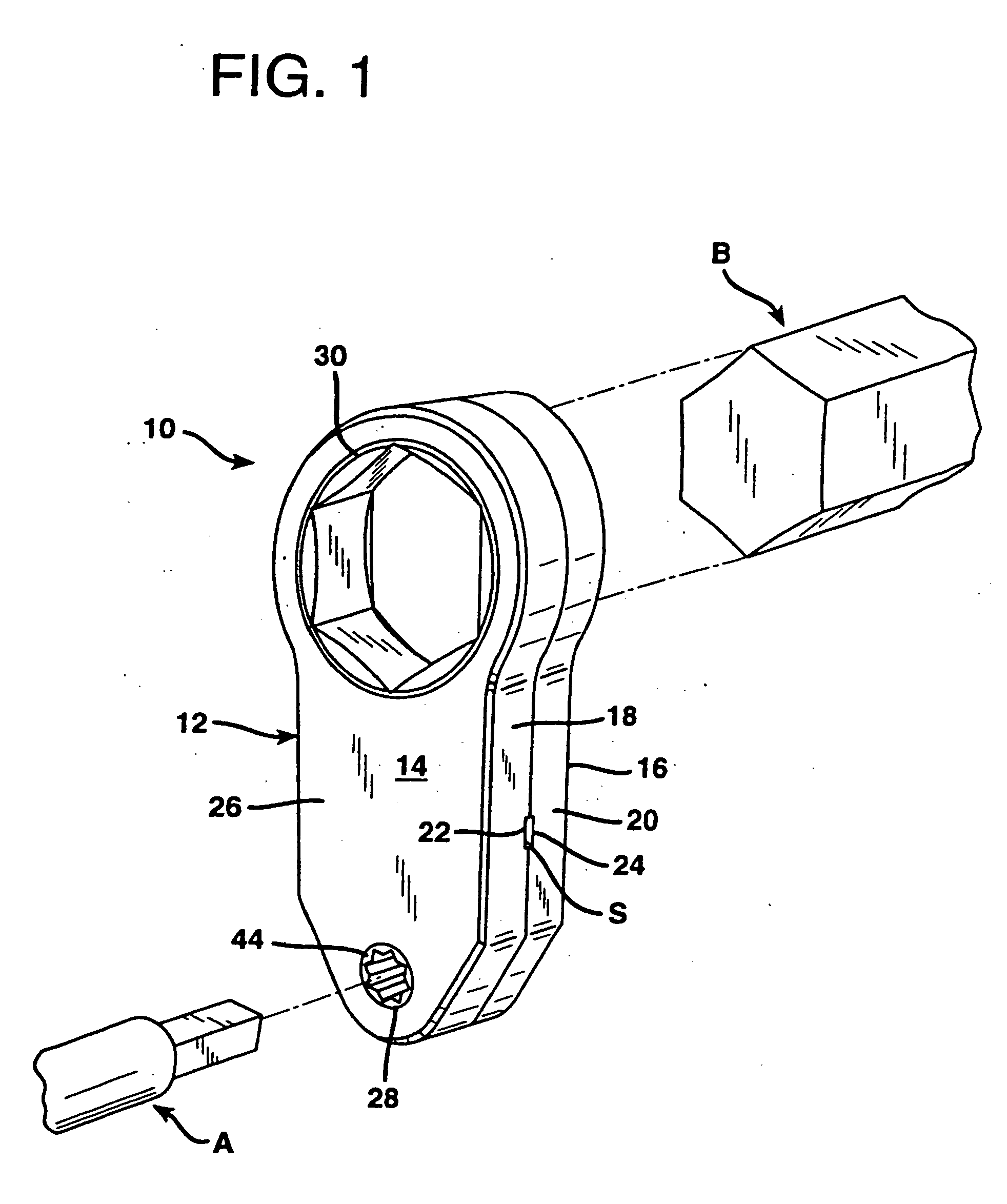

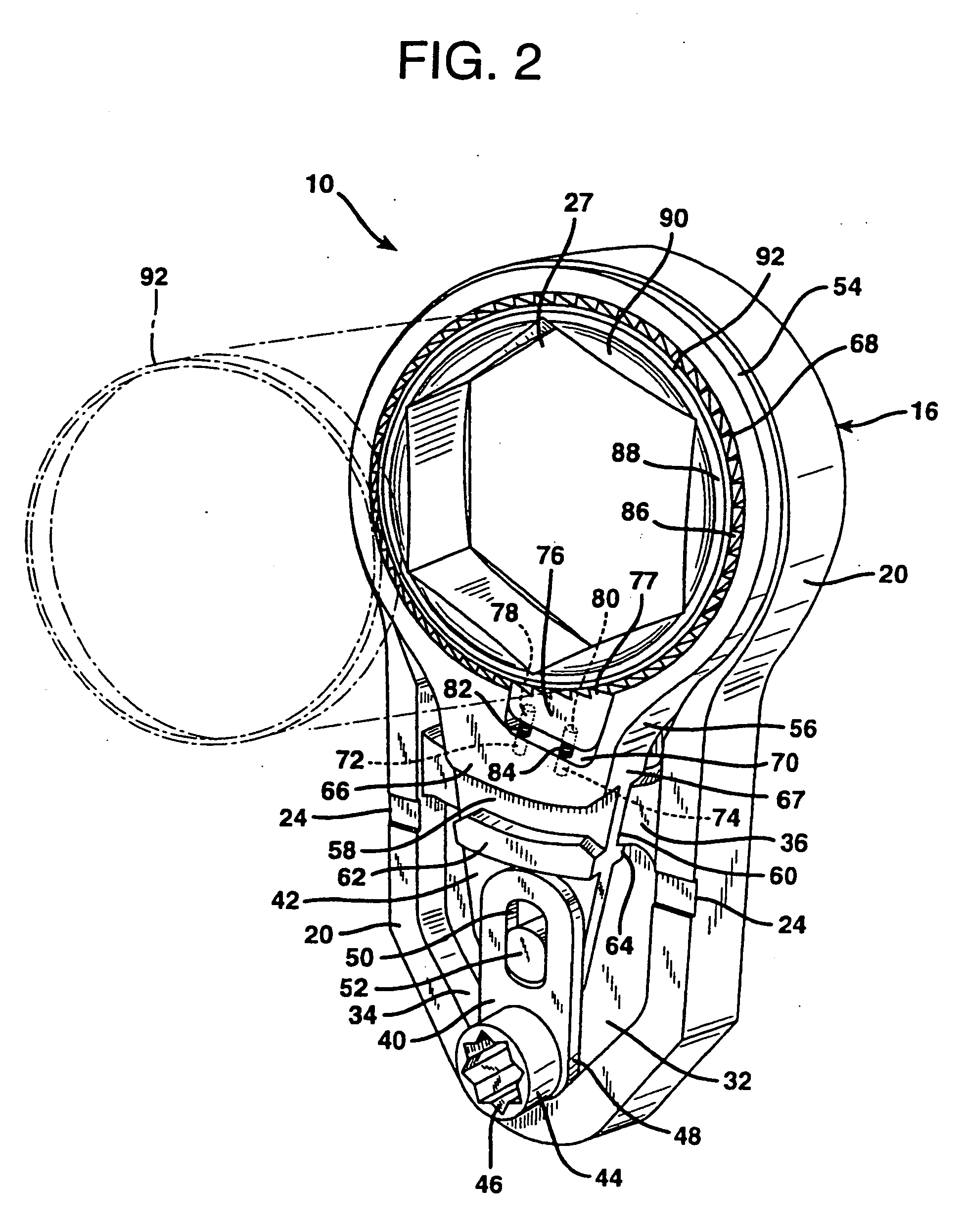

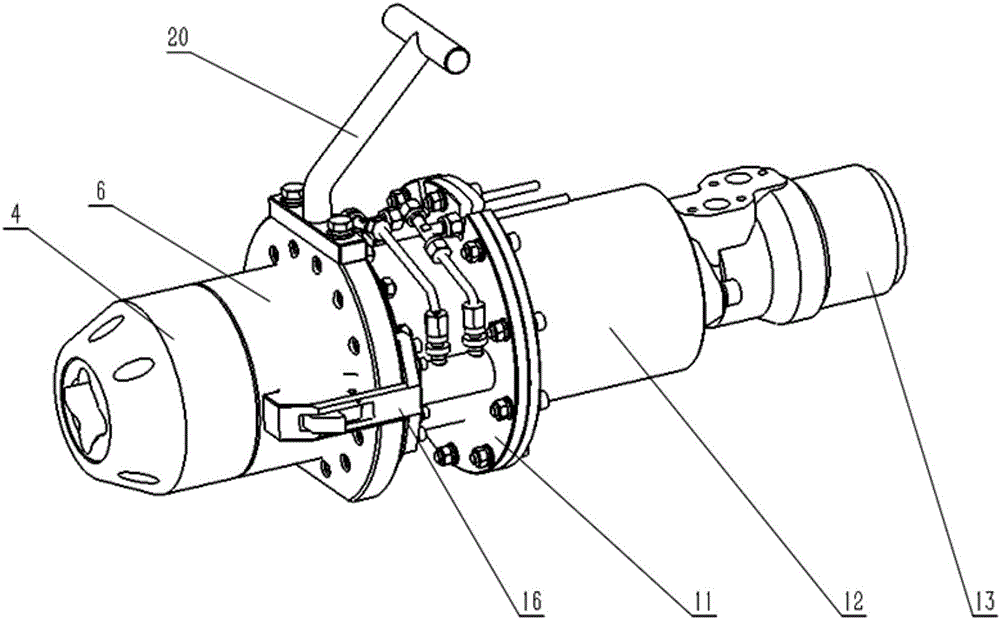

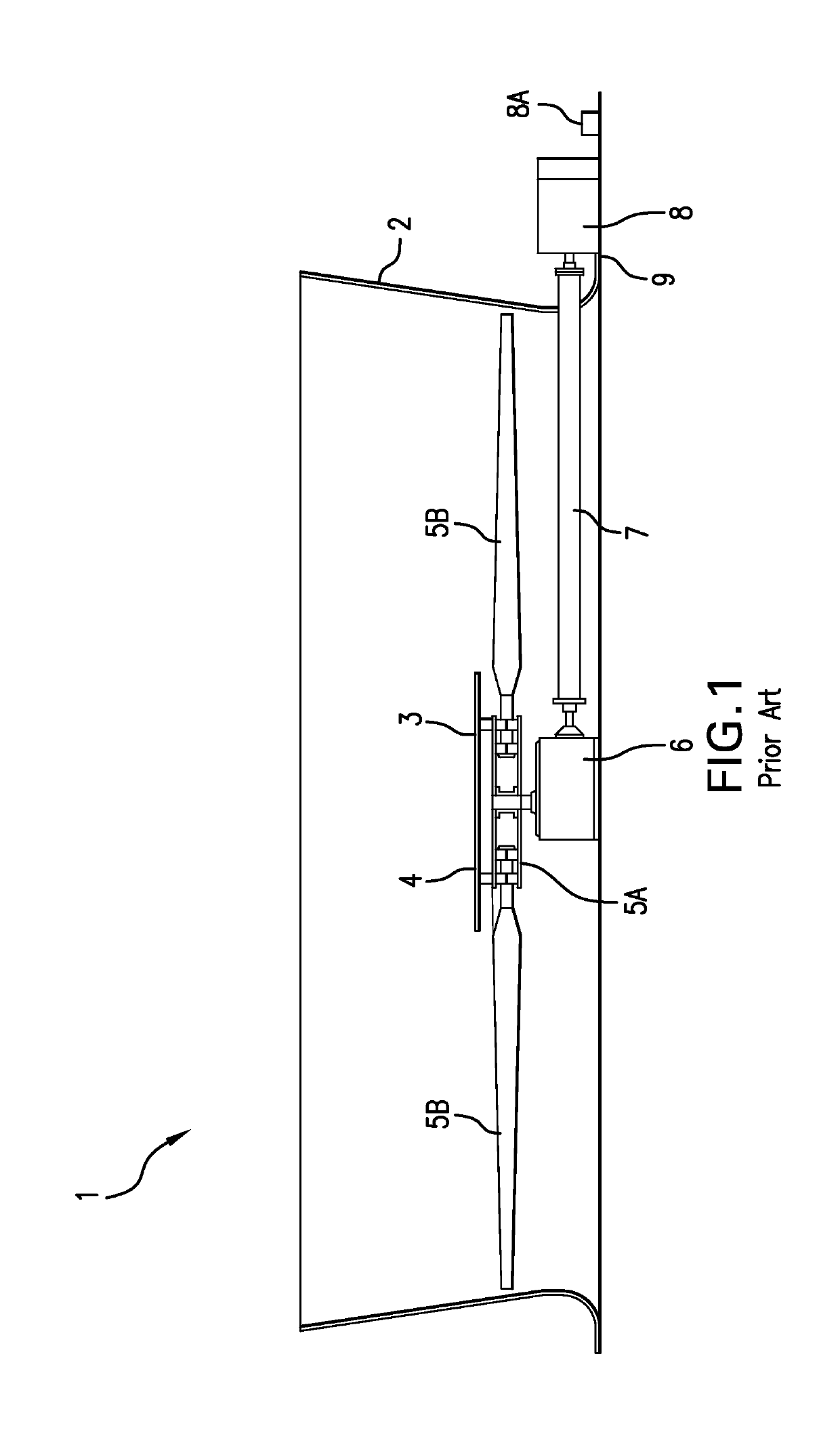

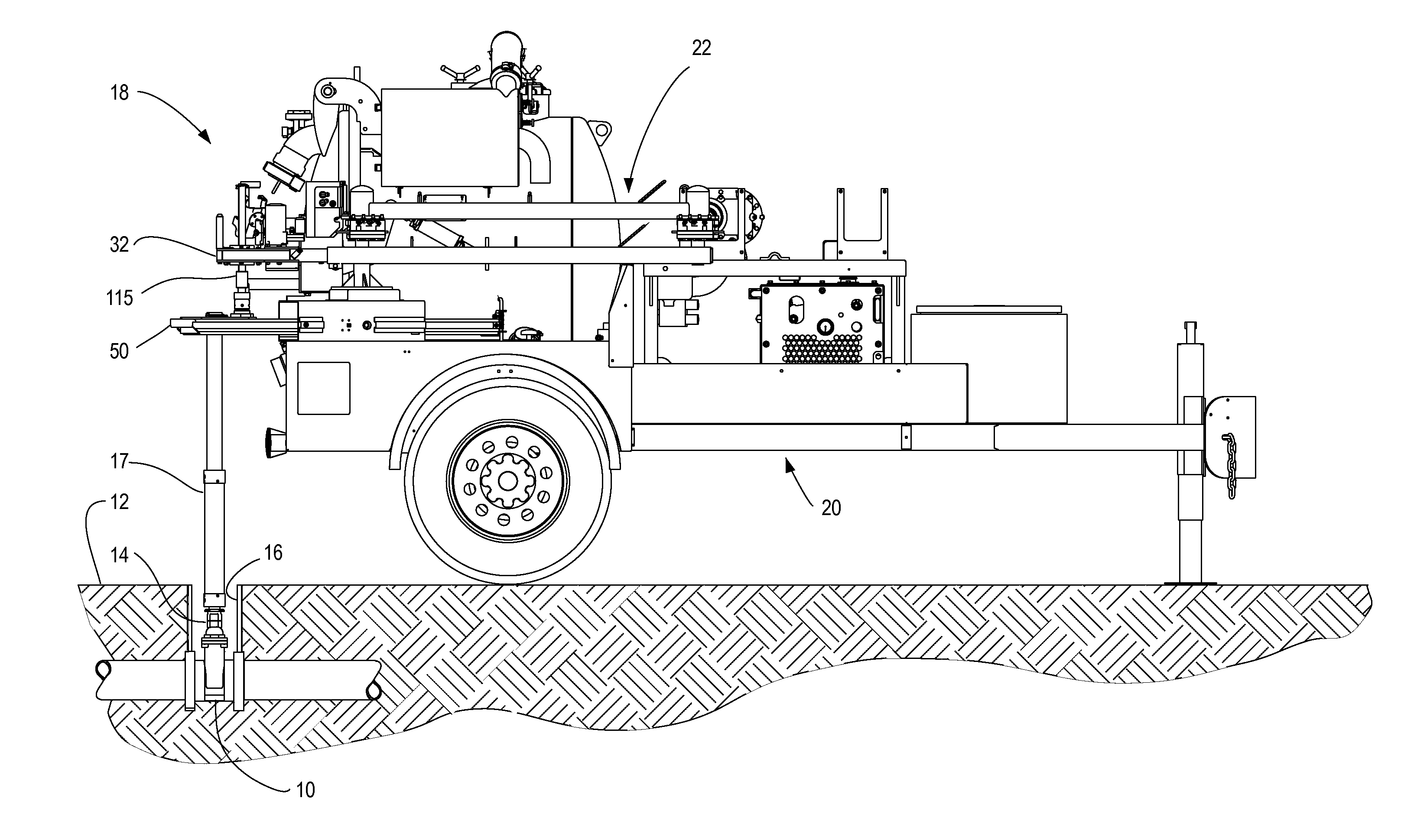

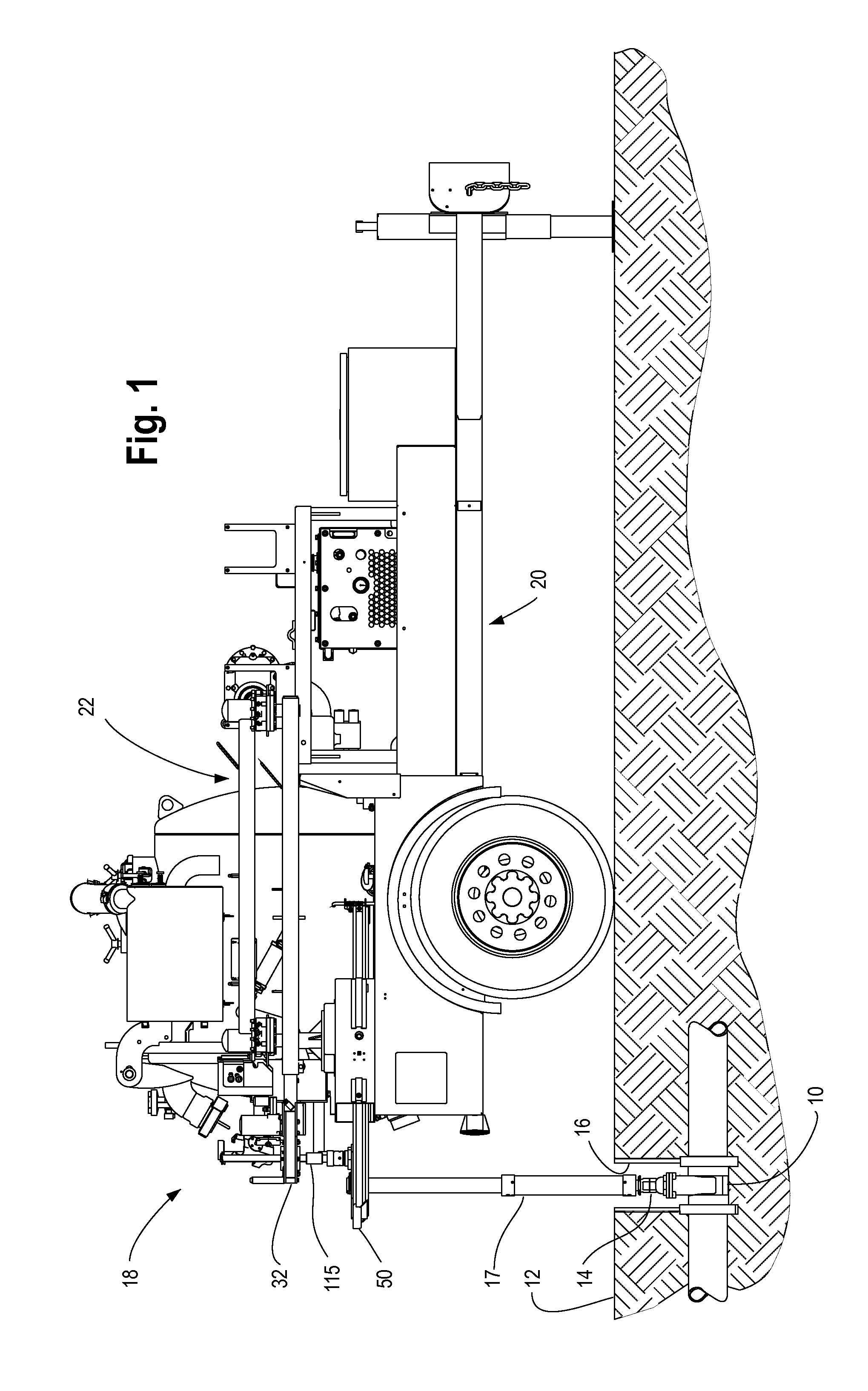

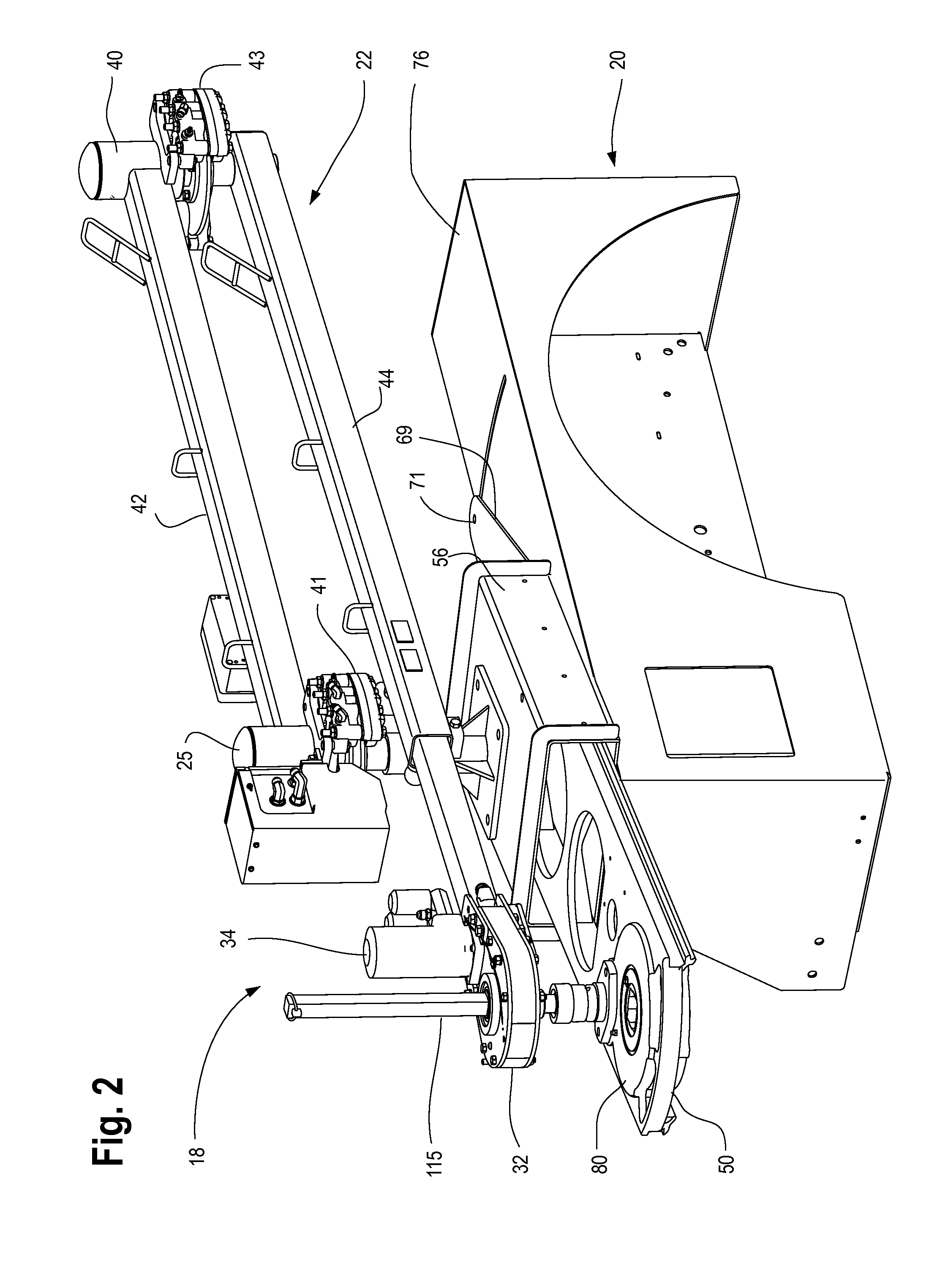

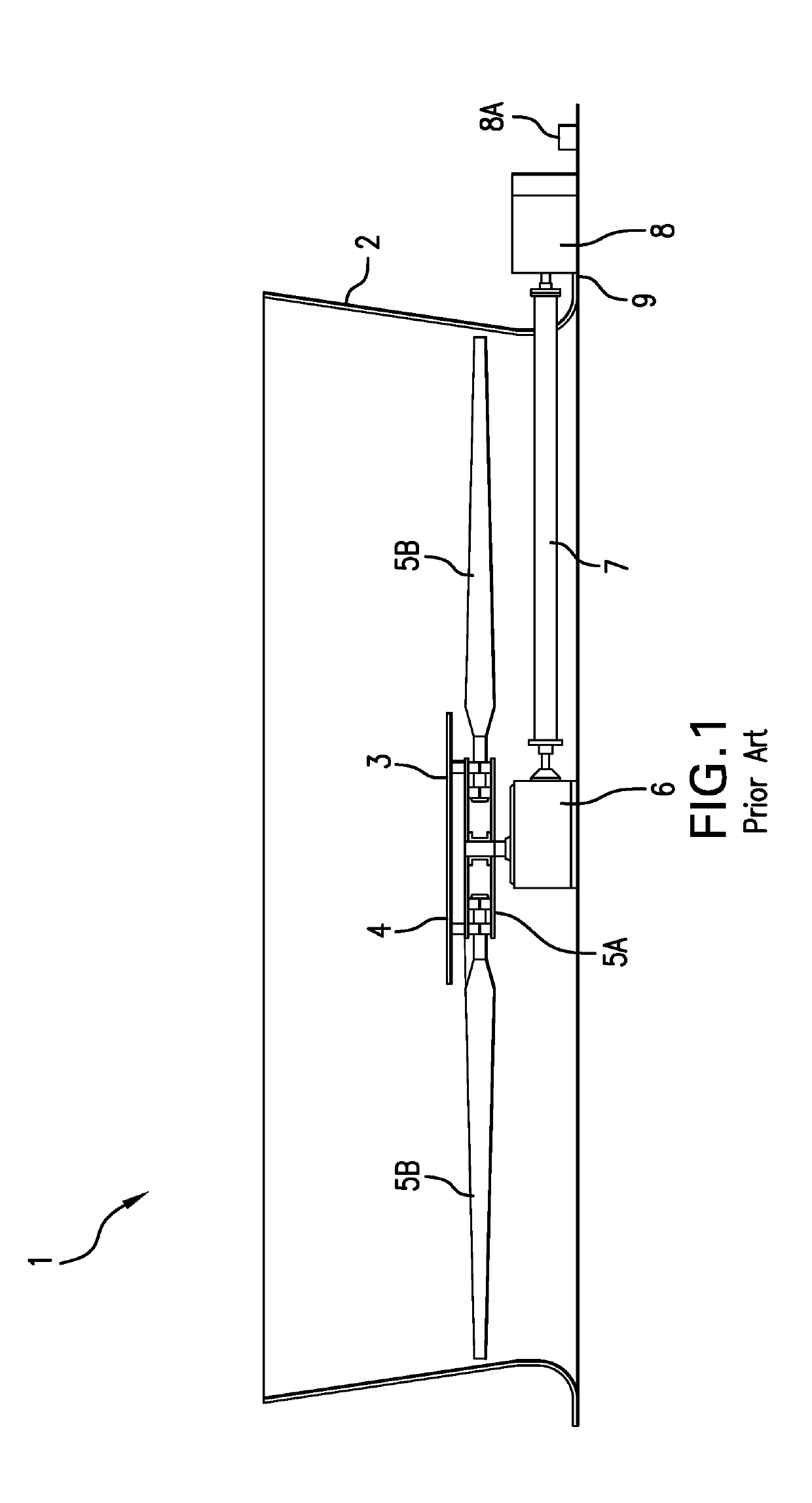

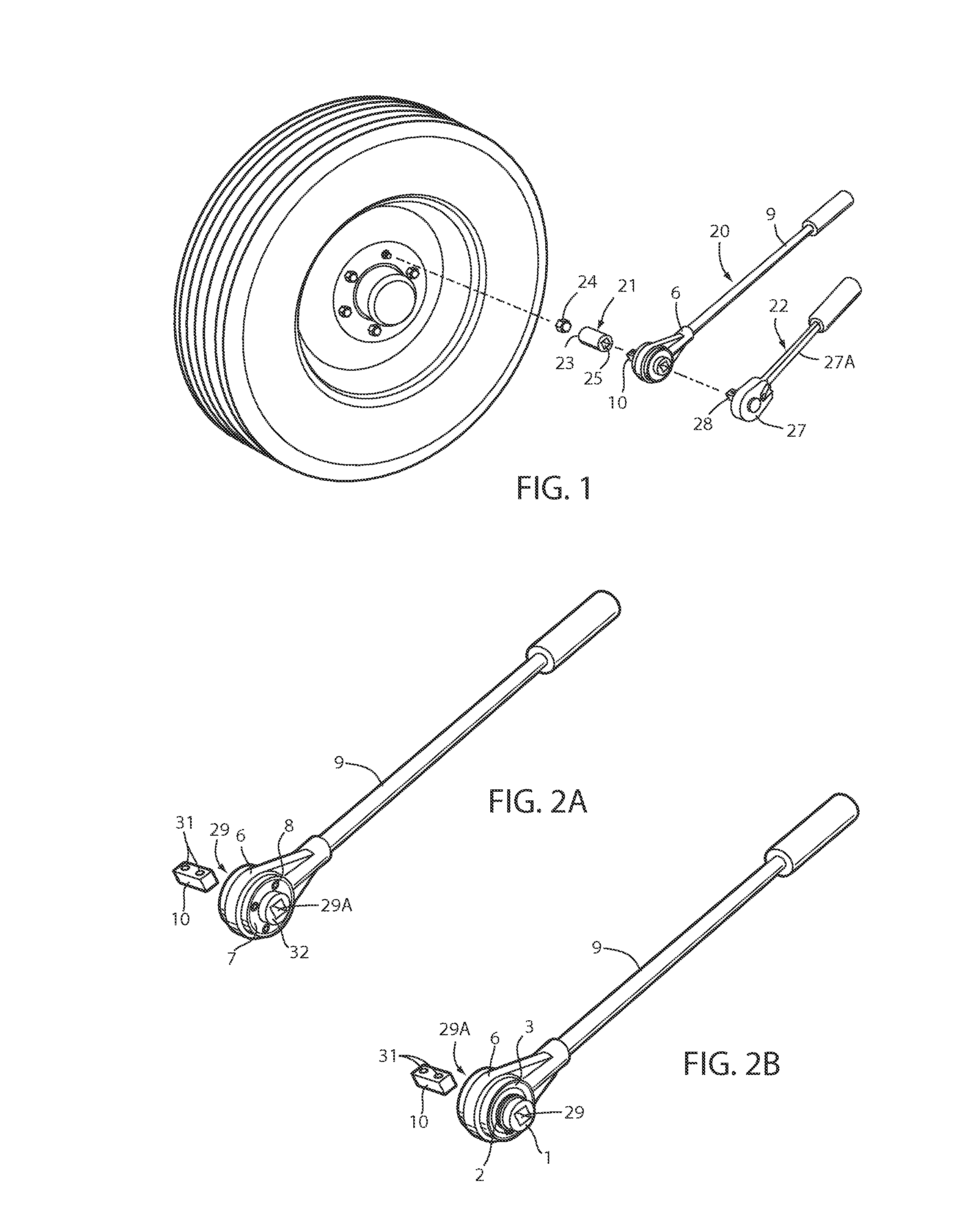

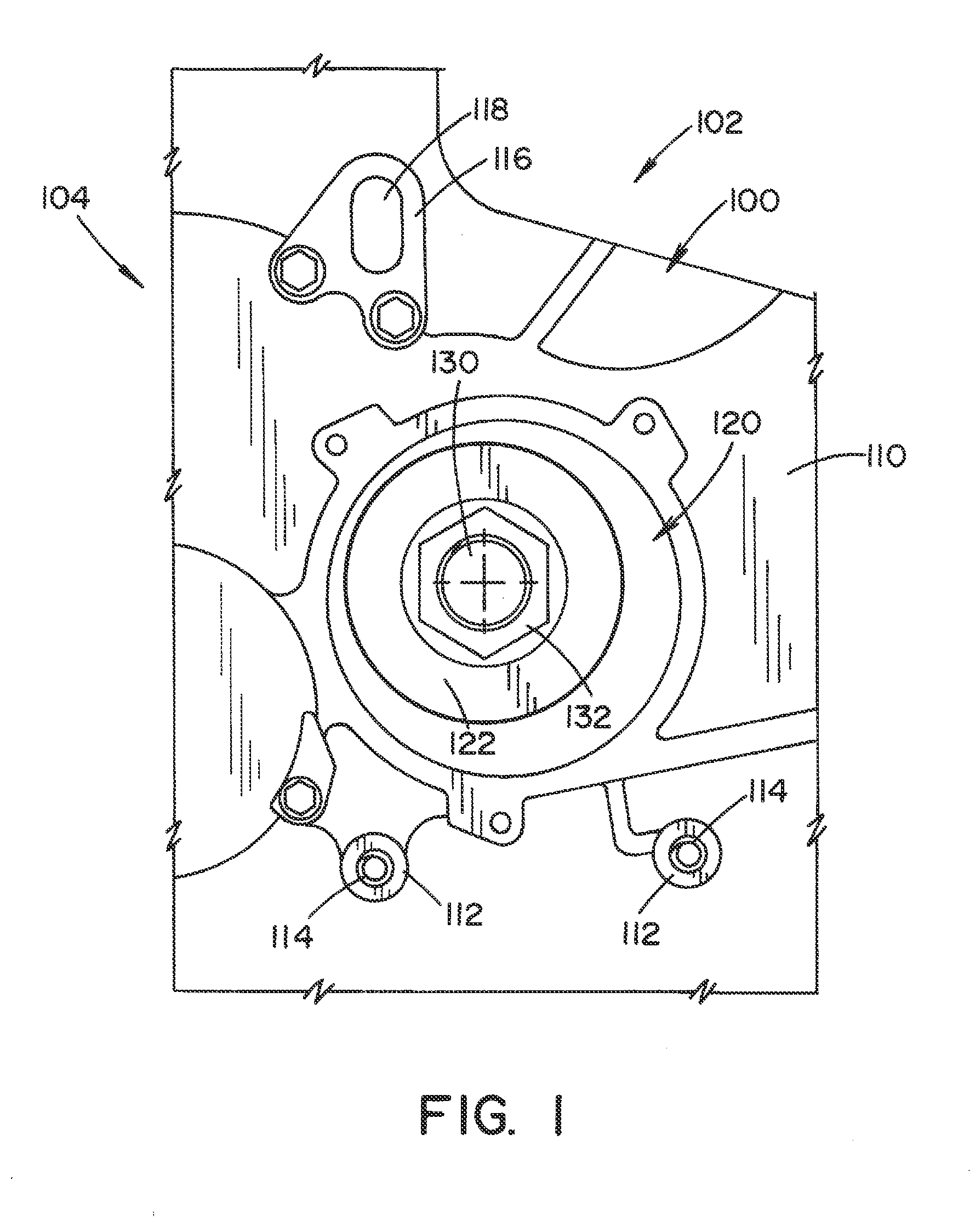

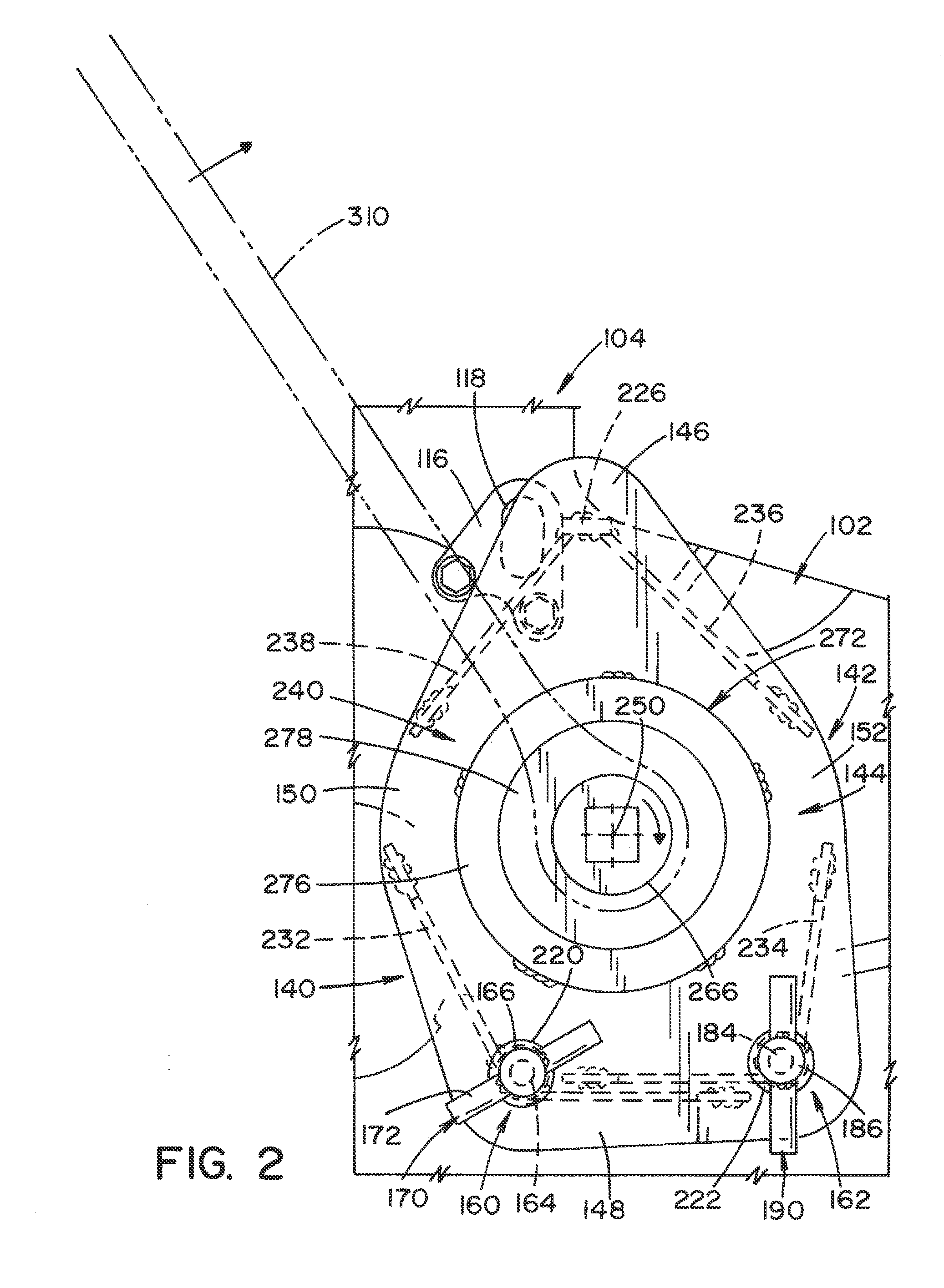

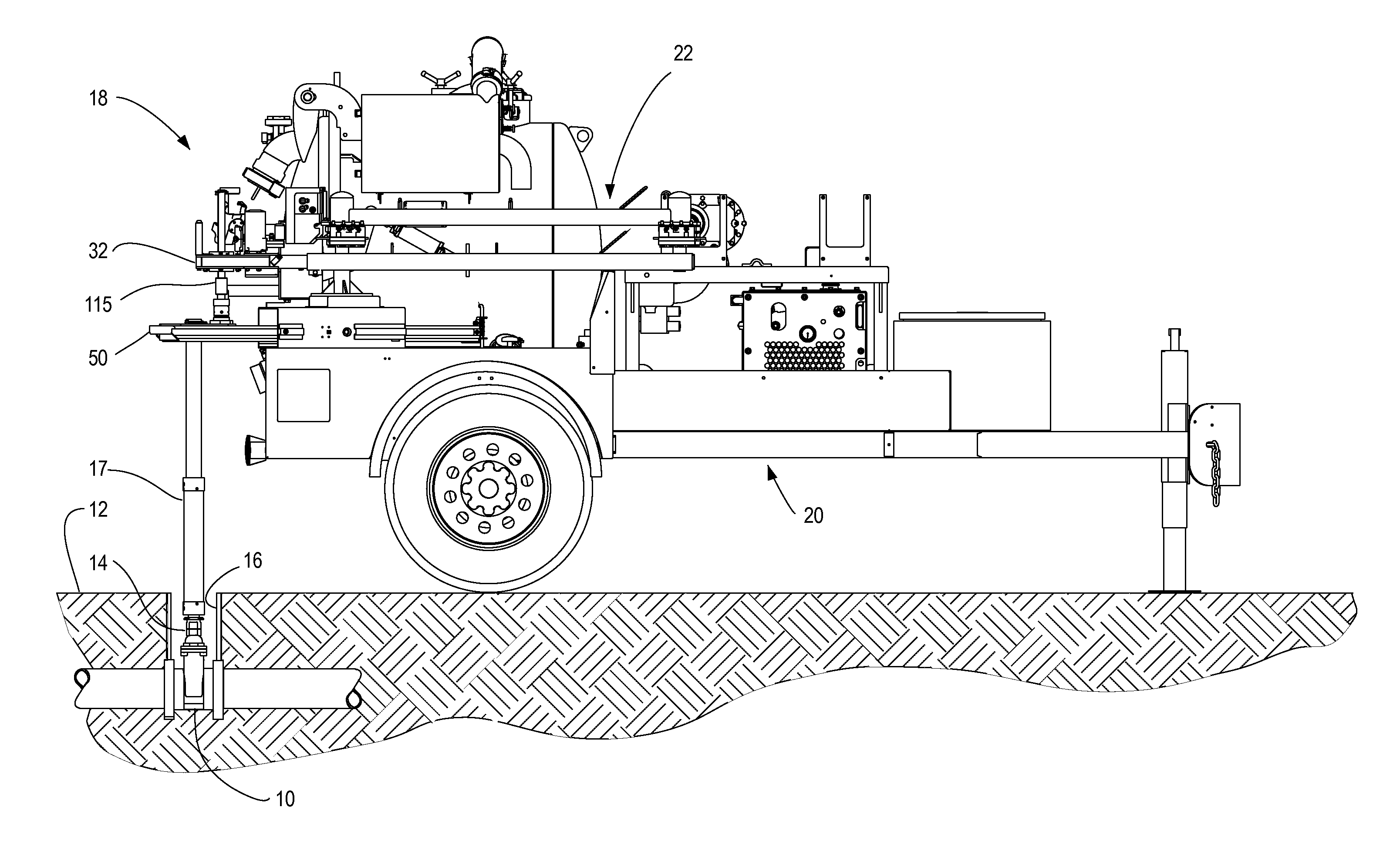

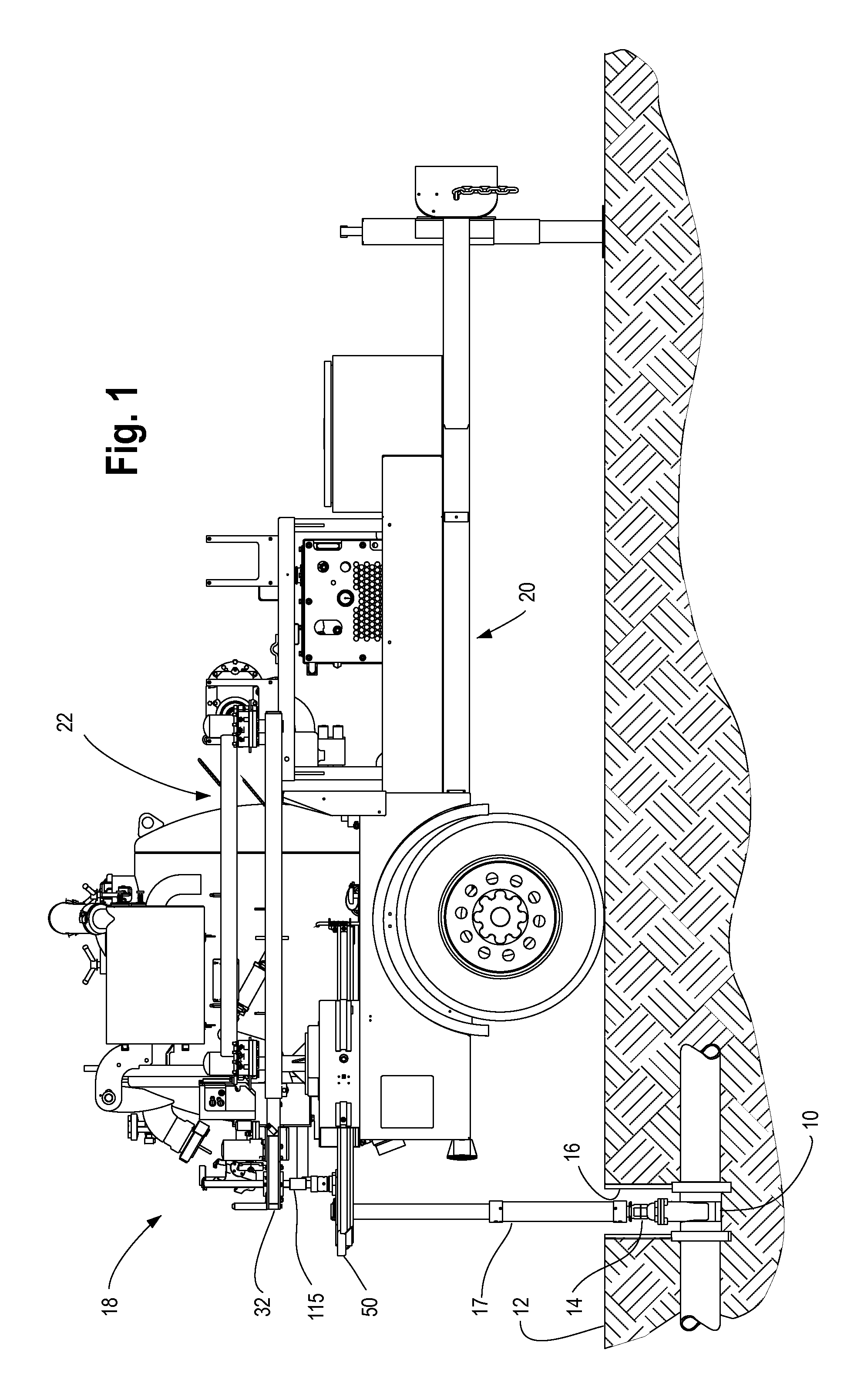

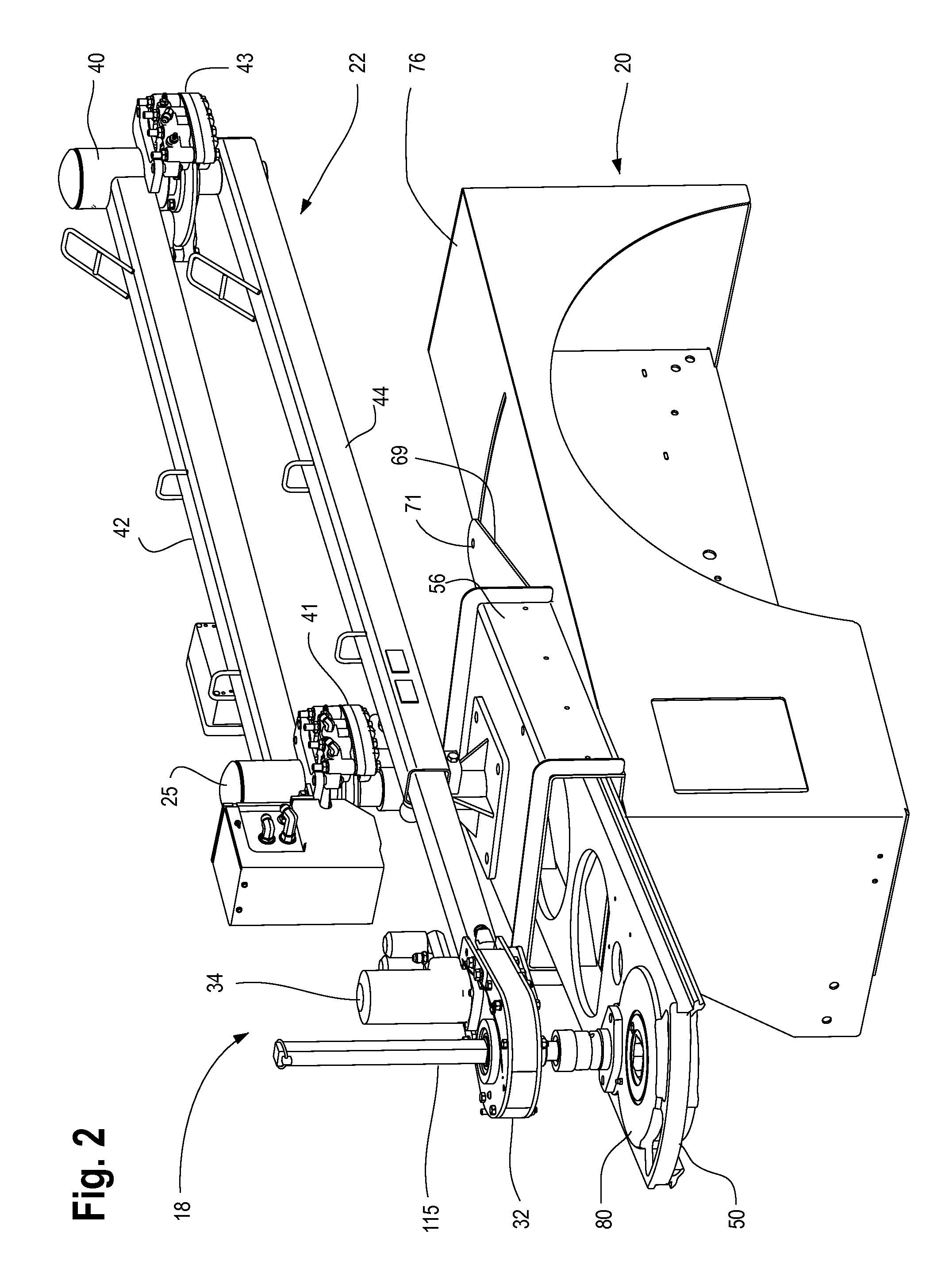

Torque Multiplier for Valve Turning Machine

ActiveUS20120138830A1Light weightLimit output torqueOperating means/releasing devices for valvesThin material handlingEngineeringControl theory

A vehicle with devices thereon for exercising the valves of a municipal water system includes a first arm with a valve turning machine at its outer end. A second arm is also attached to the vehicle, the second arm having a torque multiplier head having an input end and an output. A connector connects the valve turning machine to the input and the output of the torque multiplier applies increased torque to the stem of a valve.

Owner:ILLINOIS TOOL WORKS INC

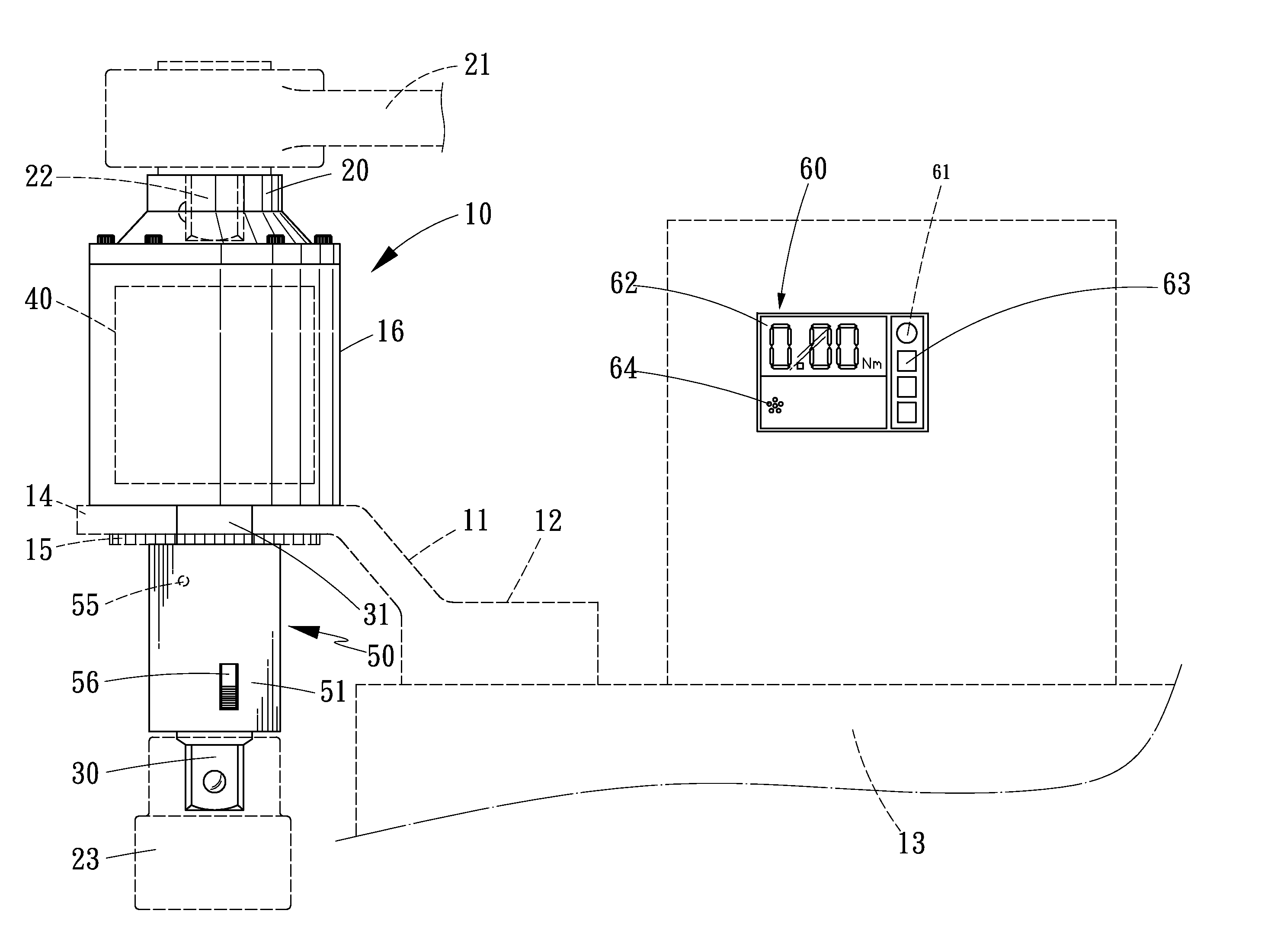

Torque Multiplier

A torque multiplier includes an input element, an output element, a multiplying unit, a measurement unit and a display. The input element is used for connection to a tool operable for exerting torque. The output element is used for connection to an object to be driven by the tool. The multiplying unit is used for connecting the input element to the output element and turning a lower value of torque at the input element to a higher value of torque at the output element. The measurement unit is used for measuring the higher value of torque and accordingly sending a wireless signal. The display is used for receiving the wireless signal and accordingly showing the higher value of torque.

Owner:MIKAWA KK

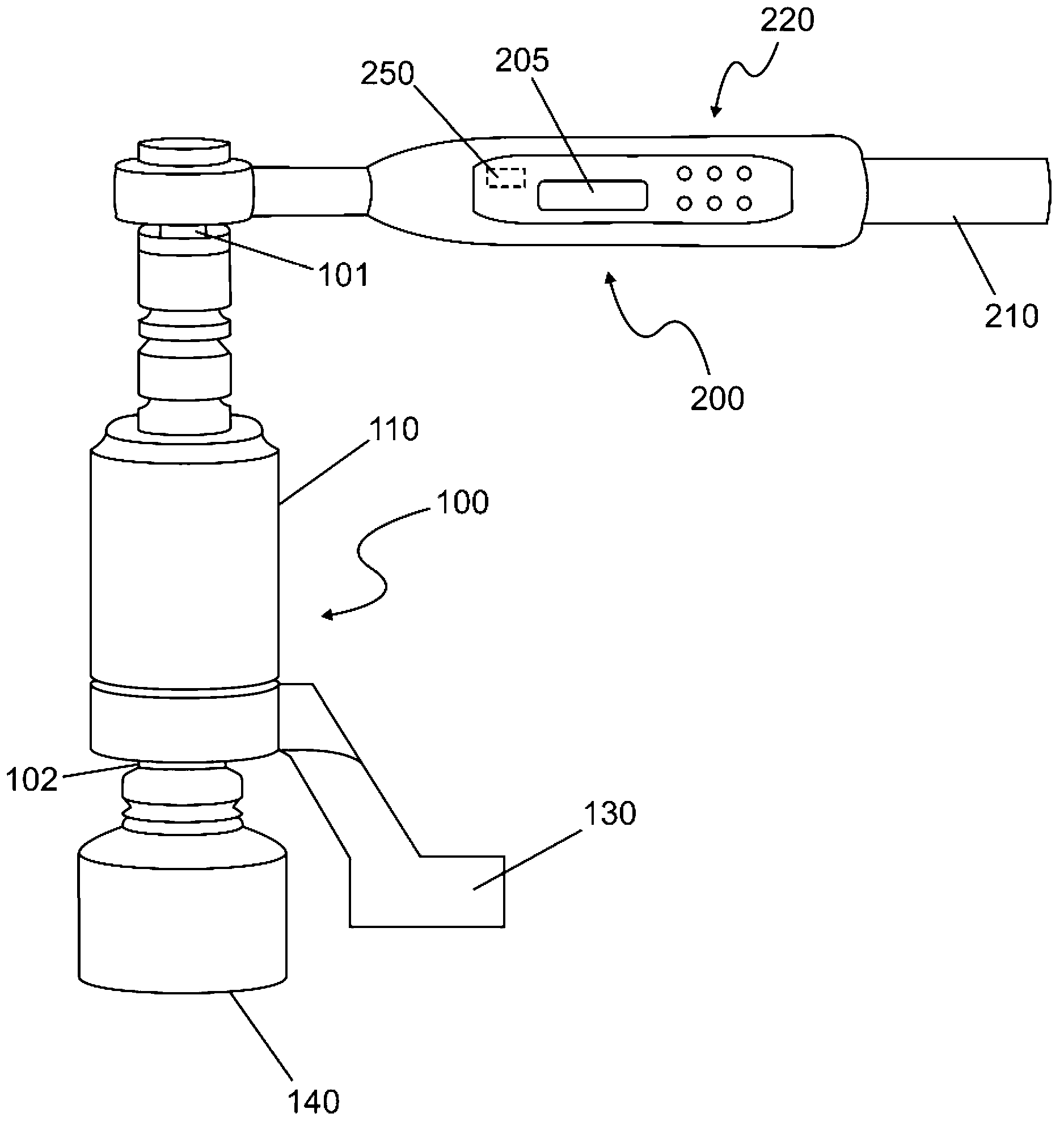

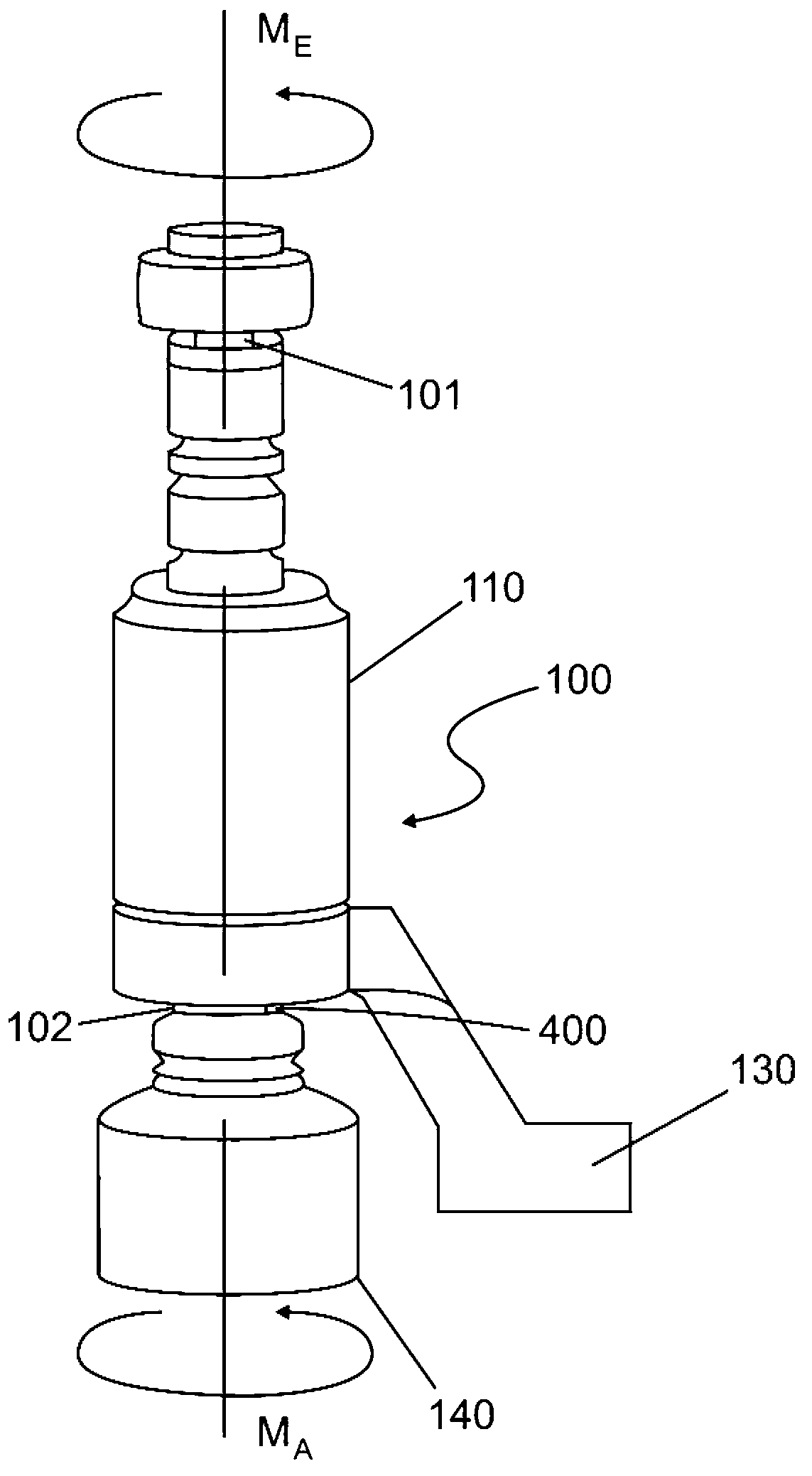

Device for producing precise tightening torque for screw connections

The invention relates to a device for producing precise tightening torque for screw connections characterised by the combination of a torque multiplier (100) and a torque wrench (200) which is adapted to said torque multiplier and calibrated therewith. The invention also relates to a method for calibrating said type of device.

Owner:罗素麦特拧紧技术公司

Direct-Drive System For Cooling System Fans, Exhaust Blowers And Pumps

The present invention is directed to a load bearing direct-drive system and a variable process control system for efficiently managing the operation of fans in a cooling system such as a wet-cooling tower, air-cooled heat exchanger (ACHE), HVAC system, blowers and centrifugal blowers, mechanical towers or chiller systems. In one embodiment, the load bearing direct-drive system comprises a load bearing torque multiplier device having an output rotatable shaft connected to a fan, and a load bearing motor comprising a rotatable shaft that drives the load bearing torque multiplier device.

Owner:PRIME DATUM

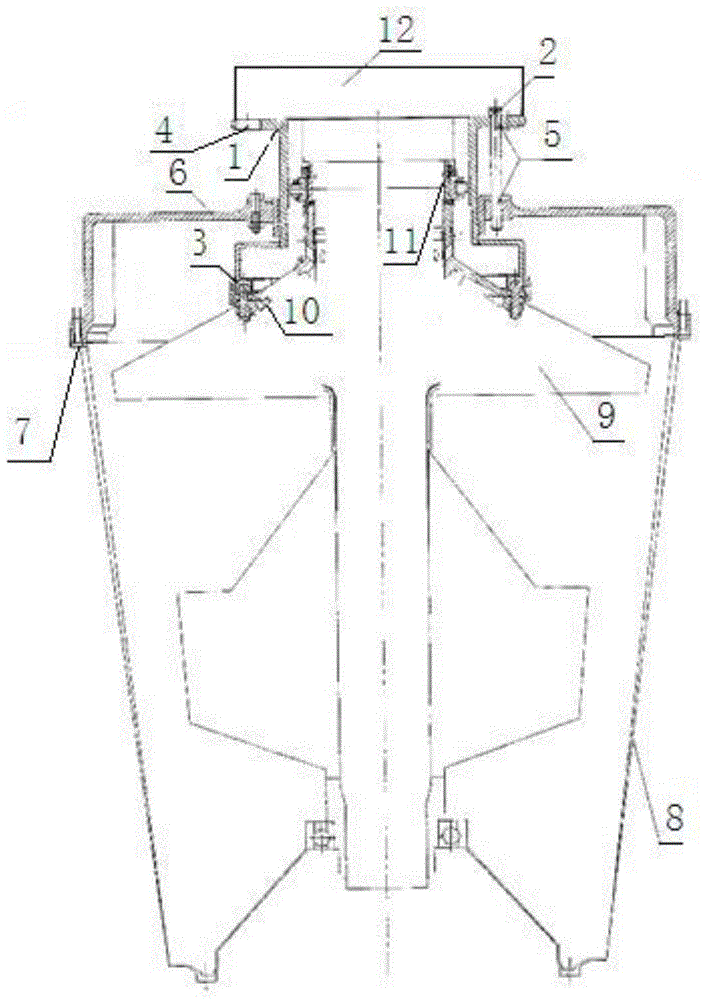

Stop device of engine rotor and stator tightened part and use method of stop device of engine rotor and stator tightened part

ActiveCN104440779AGuarantee the problem of tightening with high torque limitReduce labor intensityMetal working apparatusMetal-working hand toolsStops deviceEngineering

The invention relates to a stop device of an engine rotor and stator tightened part and a use method of the stop device of the engine rotor and stator tightened part. According to the technical scheme, the device comprises a technological stator case, a rotor stop sleeve and stop pins. The rotor stop sleeve is installed in the middle of the technological stator case, and the rotor stop sleeve and the technological stator case can rotate relatively. The technological stator case is used for being connected with an engine stator case. The rotor stop sleeve is provided with an upper installation side and a lower installation side, the upper installation side is provided with first holes, the lower installation side is provided with second holes, the upper installation side is further provided with first pin holes, and the second holes and bolts on an engine rotor are installed in a matched mode to achieve connection between the rotor stop sleeve and the engine rotor; the technological stator case is provided with second pin holes, and the stop pins can be inserted into the first pin holes and the second pin holes for connecting the engine rotor with a stator together to implement stop; the first holes are used for being provided with torque multipliers and tightening a tool. By means of the technical scheme, the stop device is easy to manufacture and easy and convenient to assemble, the assembling period is shortened, and the working efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

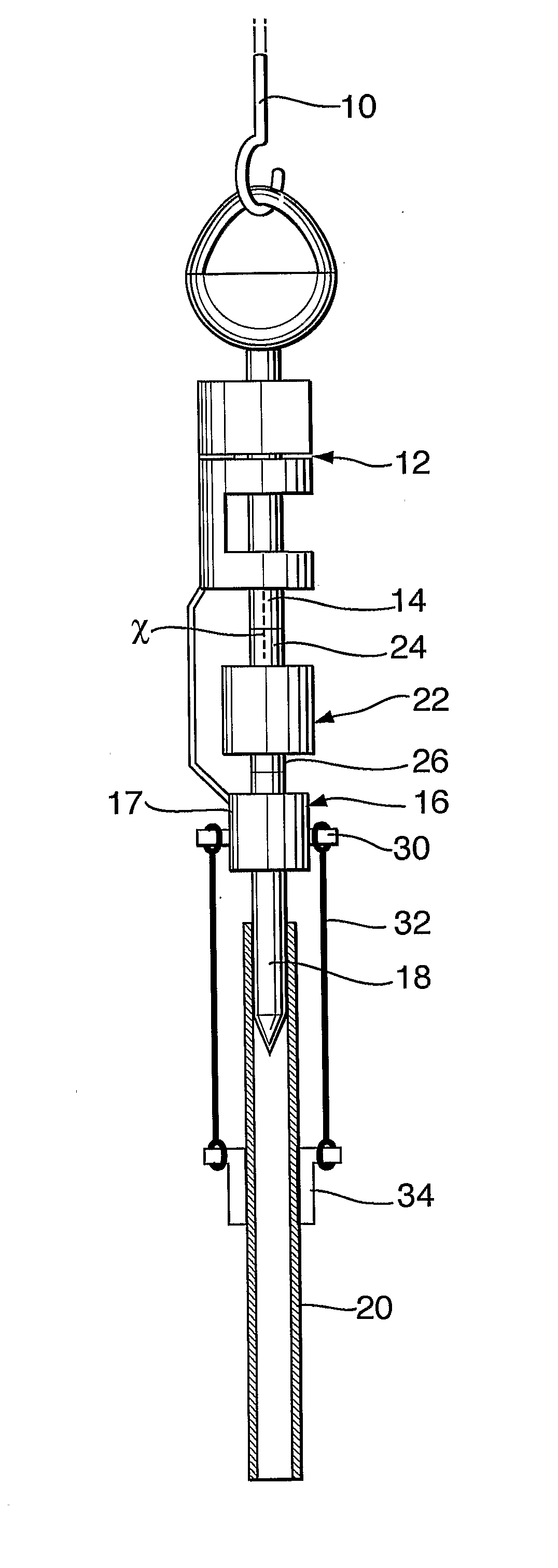

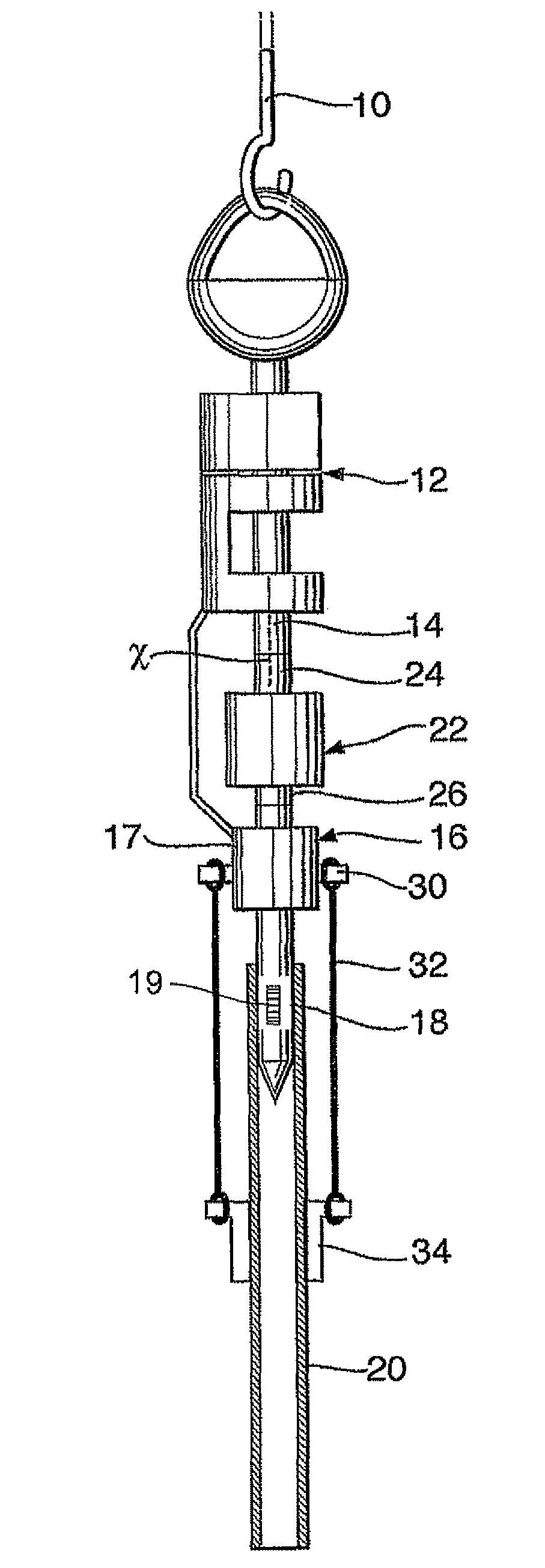

Wellbore tubular handling torque multiplier

A tubular handling torque multiplier includes a torque input end for connection to the quill of a top drive, a torque output end for connection at least indirectly to a well tubular joint to be driven to rotate, gears for adjusting the torque output from the torque output end from that torque input at the torque input end, an axial support between the torque input end and the torque output end to allow axial stress to be communicated from the torque output end to the torque input end and a fluid circulating path open between the torque input end and the torque output end.

Owner:NABORS DRILLING TECH USA INC

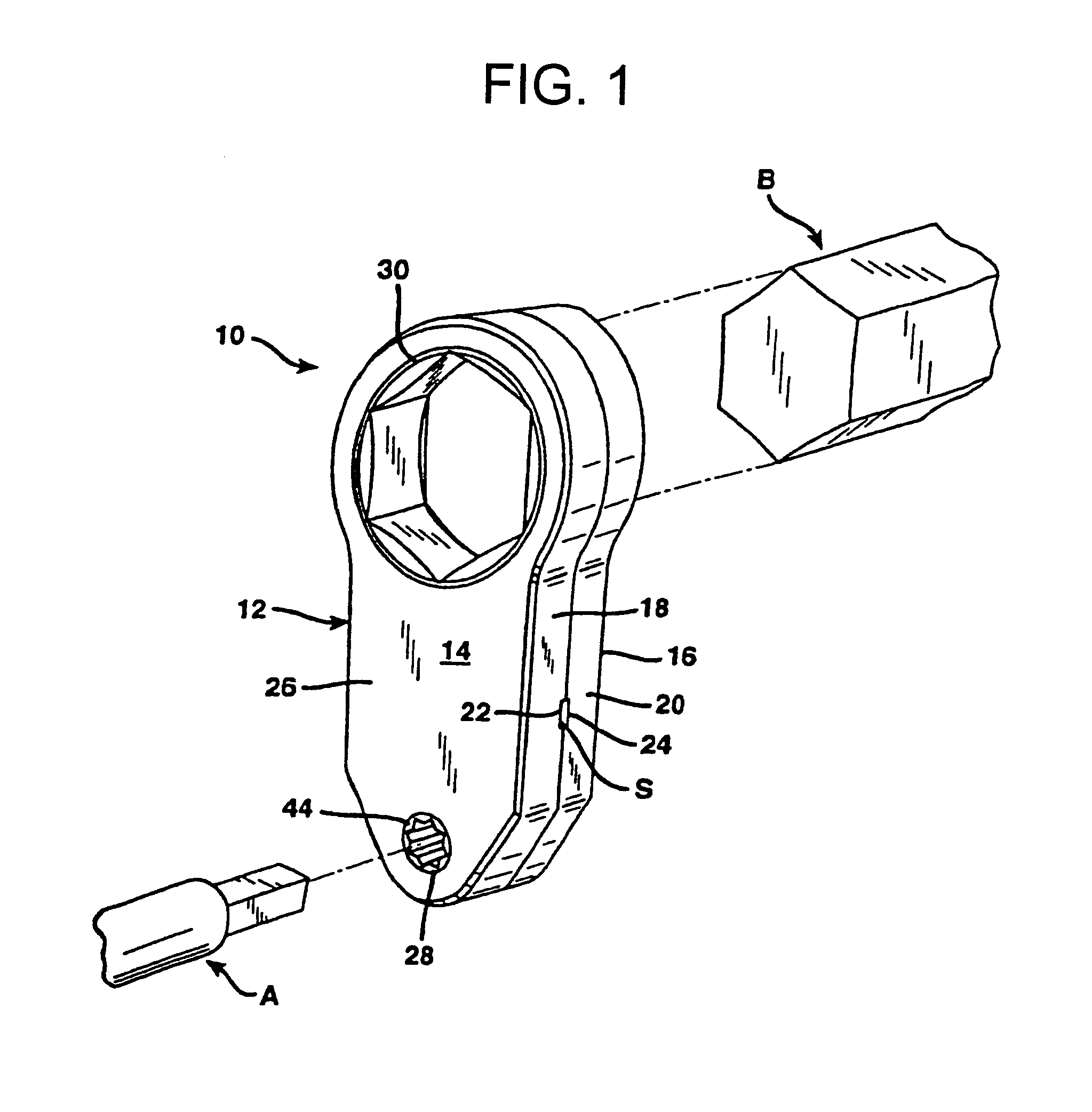

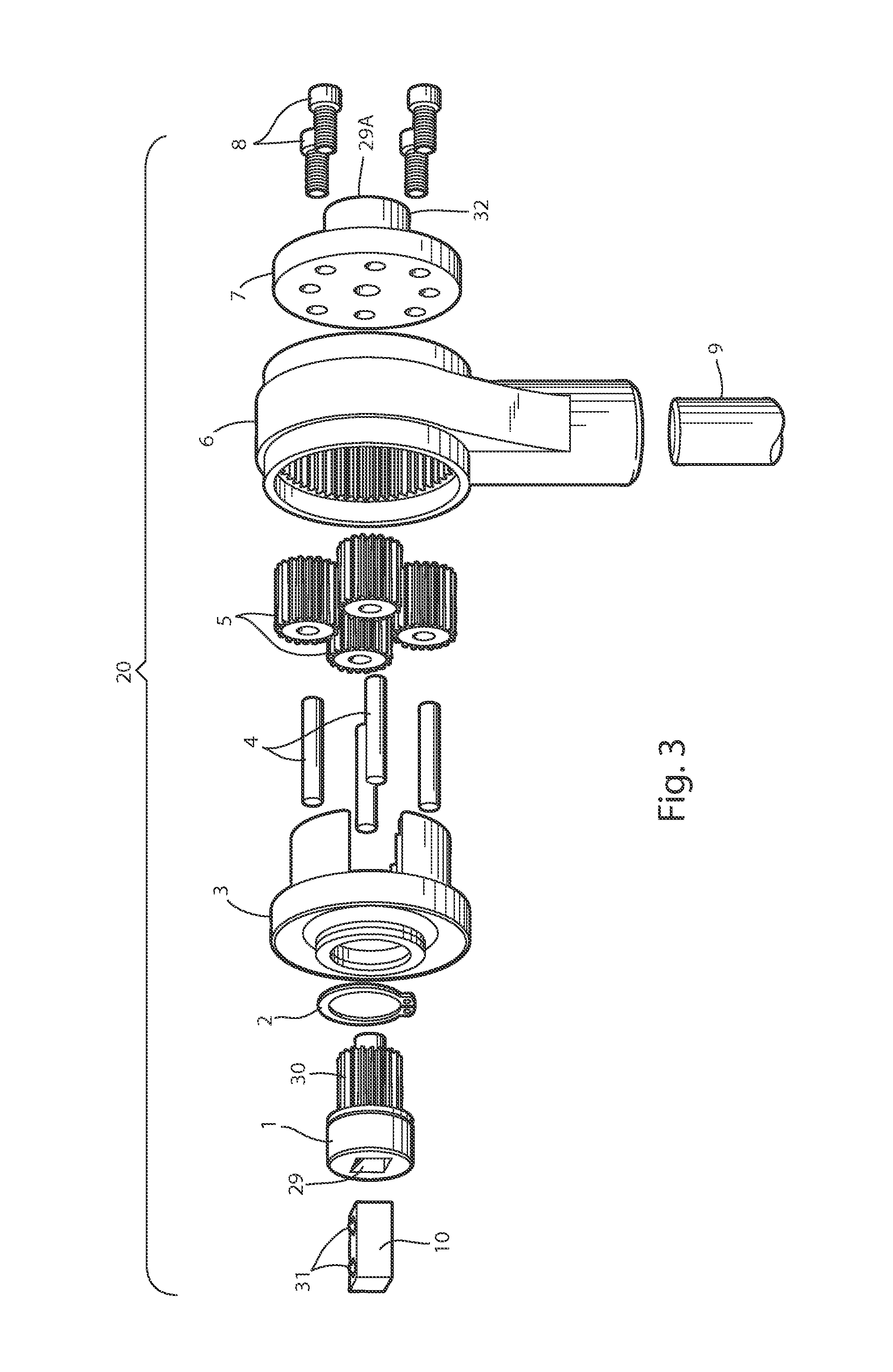

Torque multiplier and method of use

A torque multiplier apparatus includes an input pinion, a geared torque multiplier mechanism, and an input retainer. The input pinion and the input retainer include first and second identical connectors so that a detent stud can be positioned in either one of the first and second connectors, allowing the torque multiplier to be used for increased torque (and reduced speed) or for increased speed (and lesser torque). A related method includes engaging the driving tool with the first connector and the socket with the second connector to provide an increased torque on a socket to break loose a fastener, and flipping the torque multiplier so that the driving tool engages the second connector and the socket engages the first connector to provide an increased speed of torsional rotation to more quickly remove the fastener from the shaft. The detent stud is torsionally shearable, thus preventing over-stressing and damaging the tool.

Owner:CULLISON ROBERT F

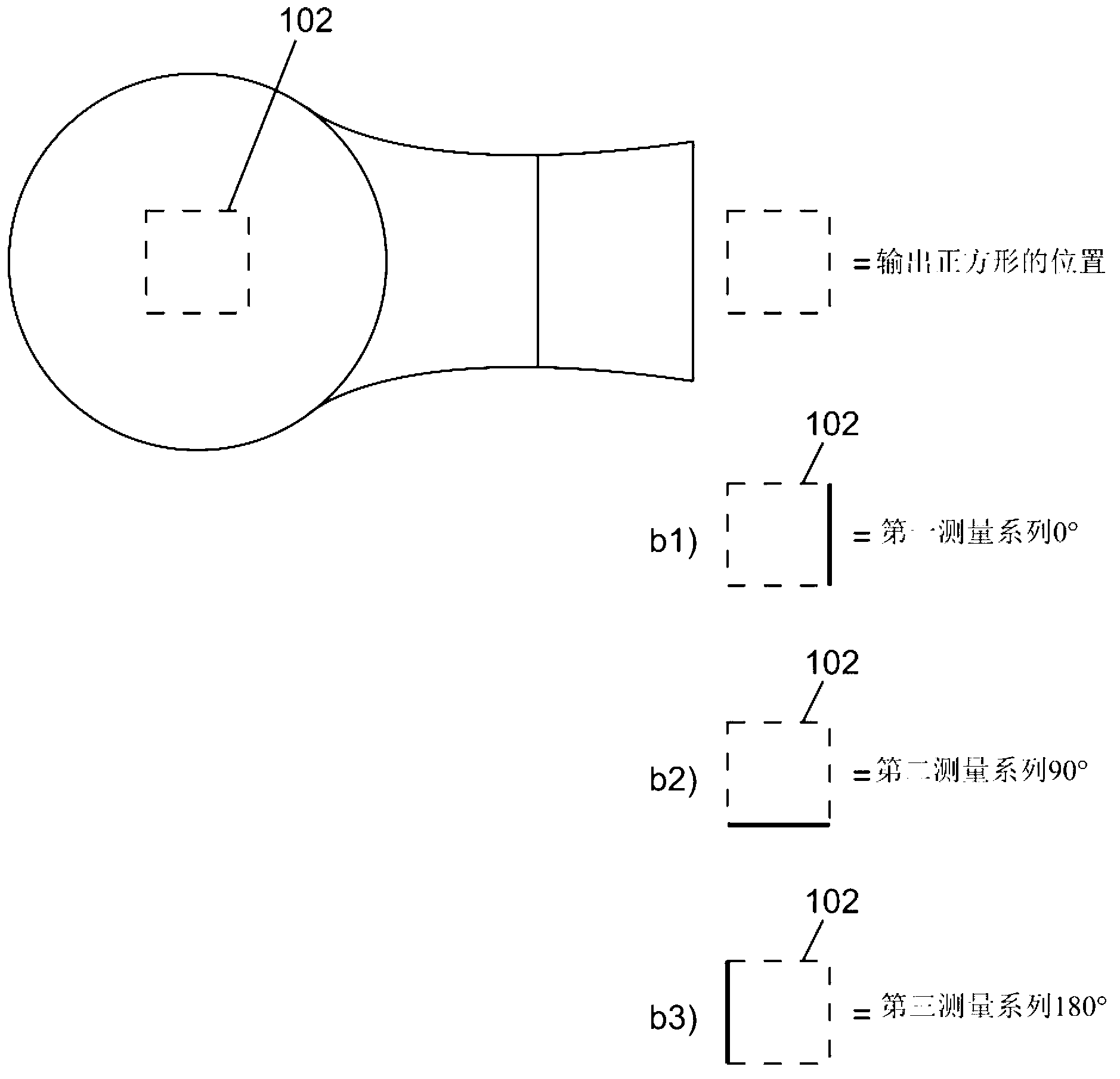

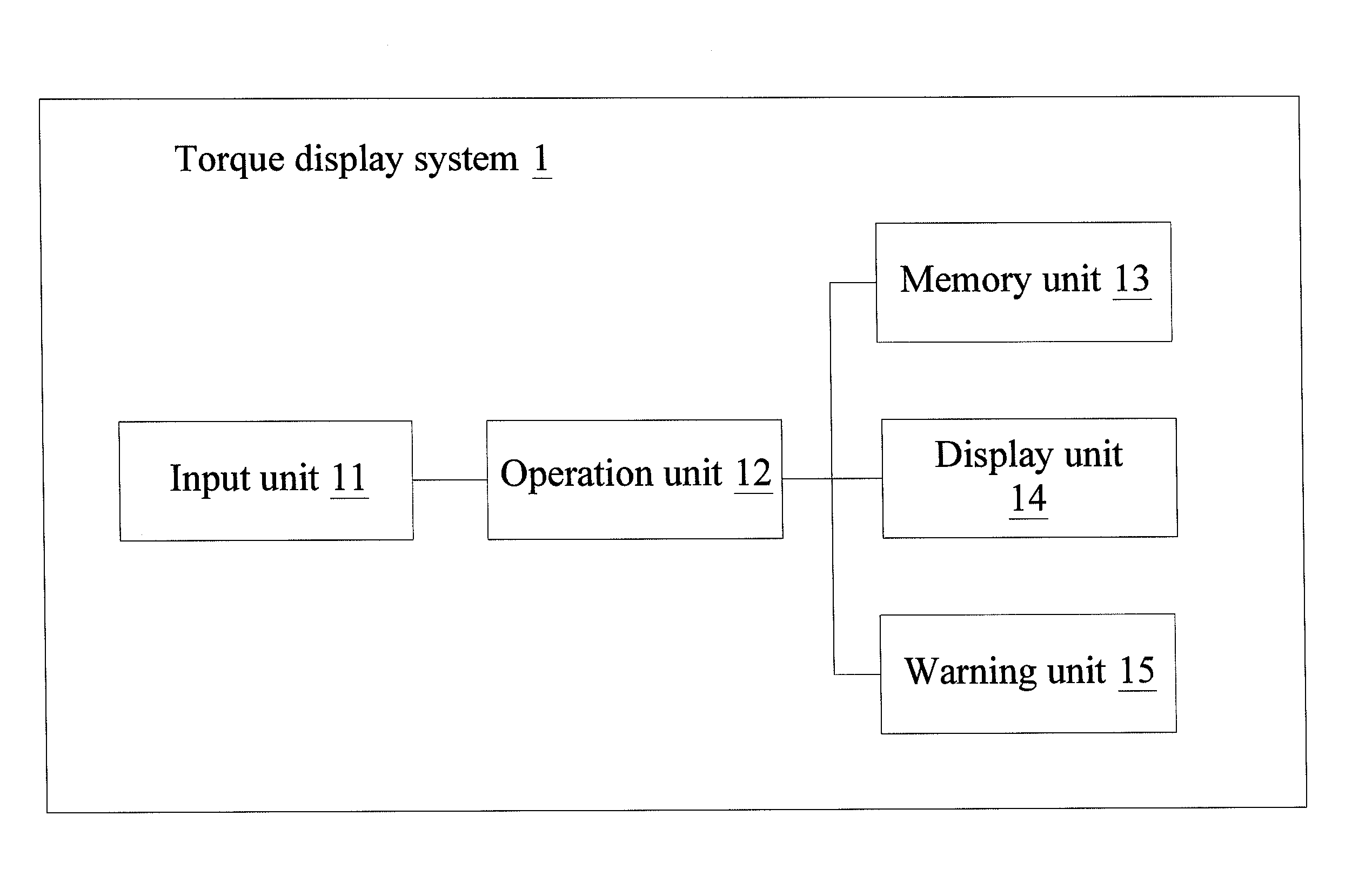

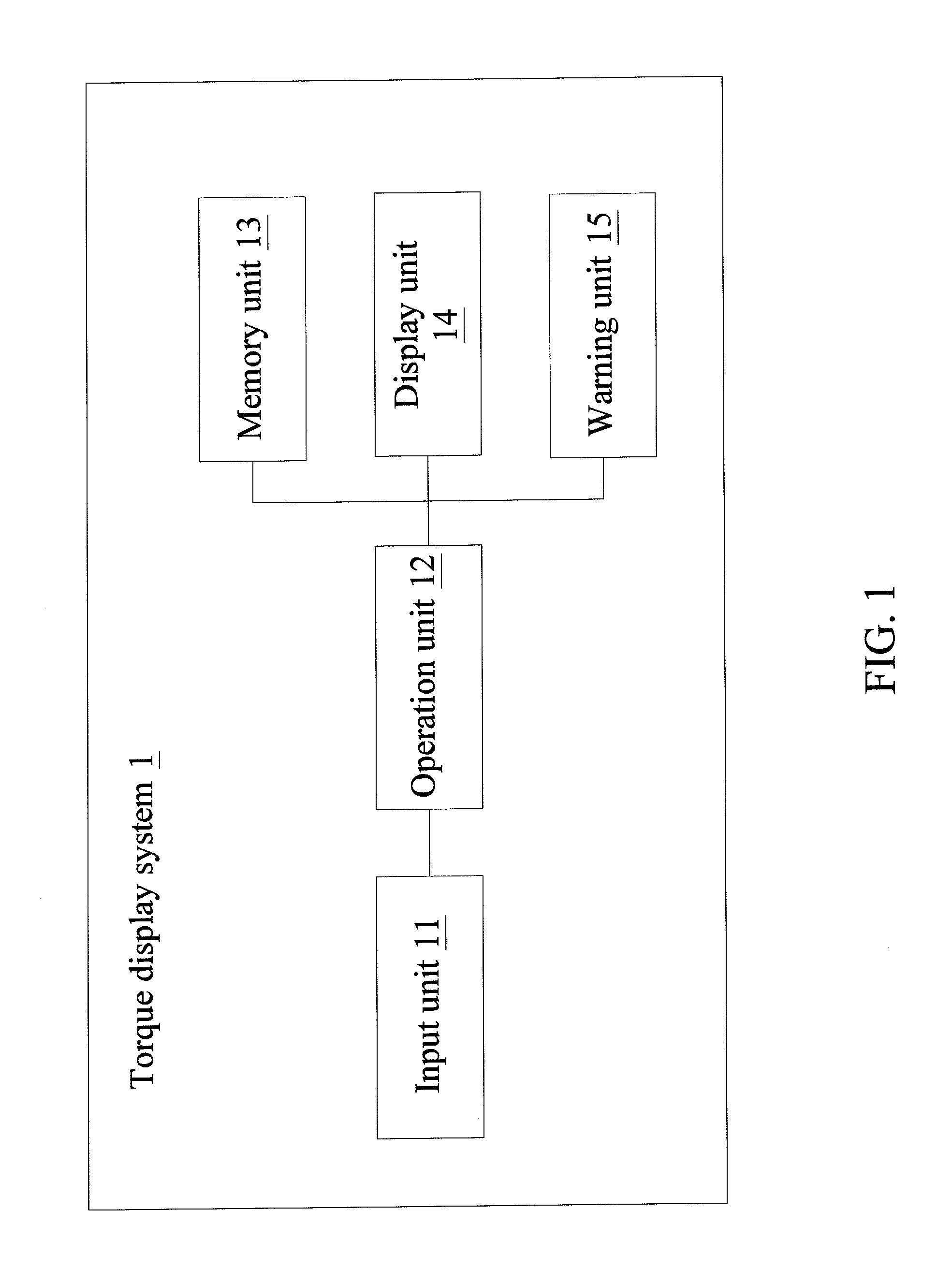

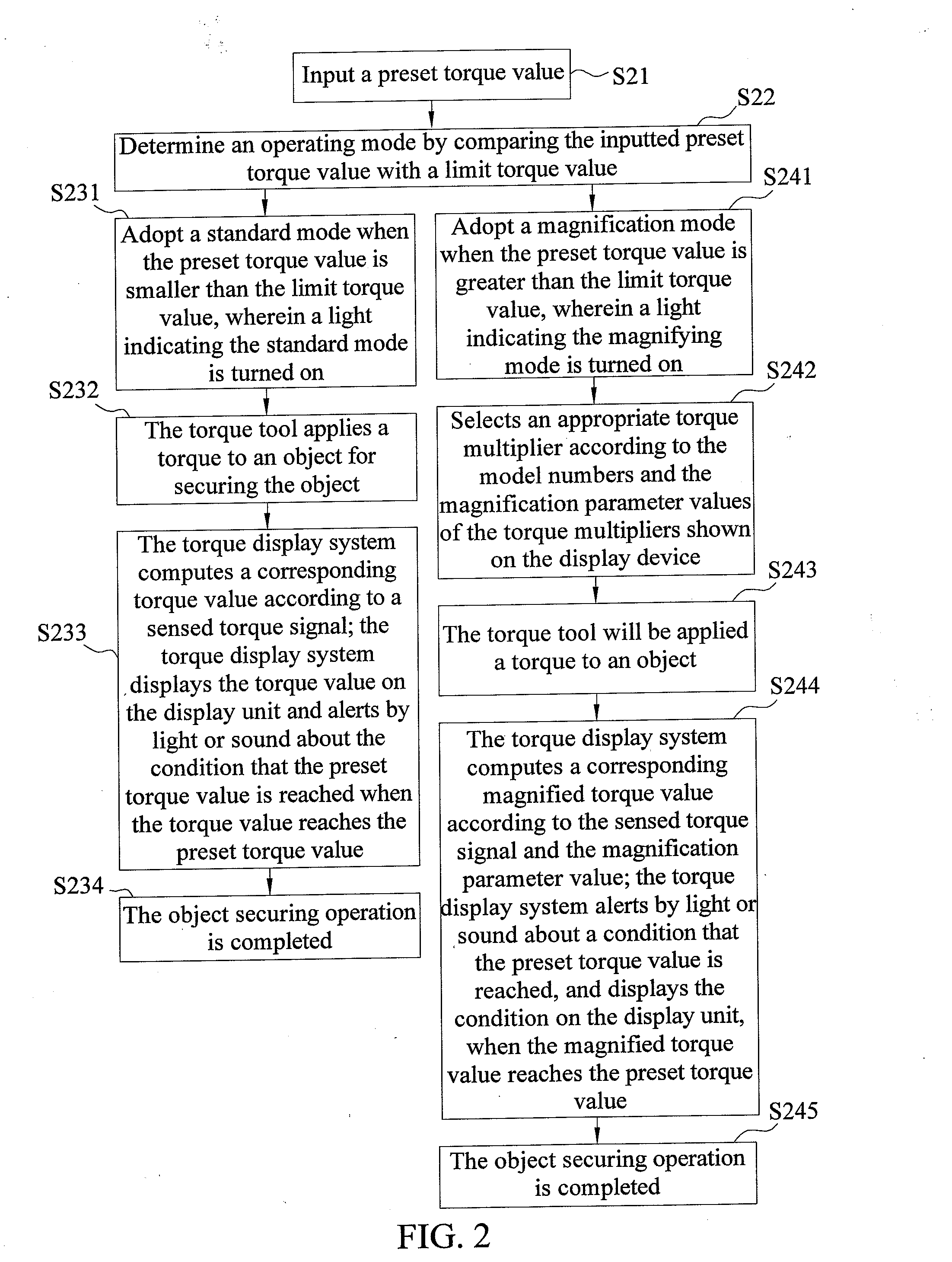

Torque display system and method thereof

InactiveUS20120253703A1Accurate torque valueExtended service lifeMeasurement of torque/twisting force while tighteningData visualisationMagnificationControl theory

The present invention discloses a torque display system and a method thereof. This system comprises an input unit, an operation unit, a memory unit, a display unit and a warning unit. The input unit is used to receive a torque signal sensed by the torque tool with or without a torque multiplier and receive a magnification parameter value inputted by the user according to the torque multiplier selected. The operation unit is used to compute a magnified torque value according to the torque signal and magnification parameter value. The display unit is used to display the preset torque value, the magnified torque value and the magnification parameter value inputted. The warning unit is used to alert the user that the preset torque value is reached and the computation of the magnified torque value is completed. The memory unit is used to save magnification parameter values of several torque multipliers.

Owner:CHINA PNEUMATIC CORP

Verification instrument of torque multiplier

InactiveCN102359845AEasy to plug inQuick plugForce/torque/work measurement apparatus calibration/testingCouplingControl theory

The invention discloses a verification instrument of a torque multiplier. The verification instrument mainly comprises: a pedestal; a torque output sensor, which is installed on the pedestal; a guide pillar, which is fixed on the pedestal; an elevating mechanism, which is cooperatedly installed on the guide pillar; a torque input assembly, which is fixedly installed on the elevating mechanism through a horizontal support plate; and a numerically controlled digital display instrument, which is additionally arranged. The torque input assembly is composed of a stepping motor, a decelerator, a shaft coupling, a torque input sensor and an input terminal conversion adaptor, wherein the stepping motor, the decelerator, the shaft coupling, the torque input sensor and the input terminal conversion adaptor are successively in shaft connection from top to bottom. The two sensors are corresponded upwards and downwards and central axises of the two sensors are superposed; besides, the two sensors are respectively connected with the numerically controlled digital display instrument through leads. And a central position at an upper end surface of the torque input sensor is provided with a polygonal blind hole that is plugged with an output terminal conversion adaptor; and the stepping motor is controlled by the numerically controlled digital display instrument. According to the invention, the instrument can be used conveniently; detected torque multipliers with various specifications and types can be localized on the verification instrument through an output terminal conversion adaptor, so that detection can be carried out; moreover, the instrument has advantages of good versatility and accurate measuring data.

Owner:AVIC SHAANXI DONGFANG AVIATION INSTR

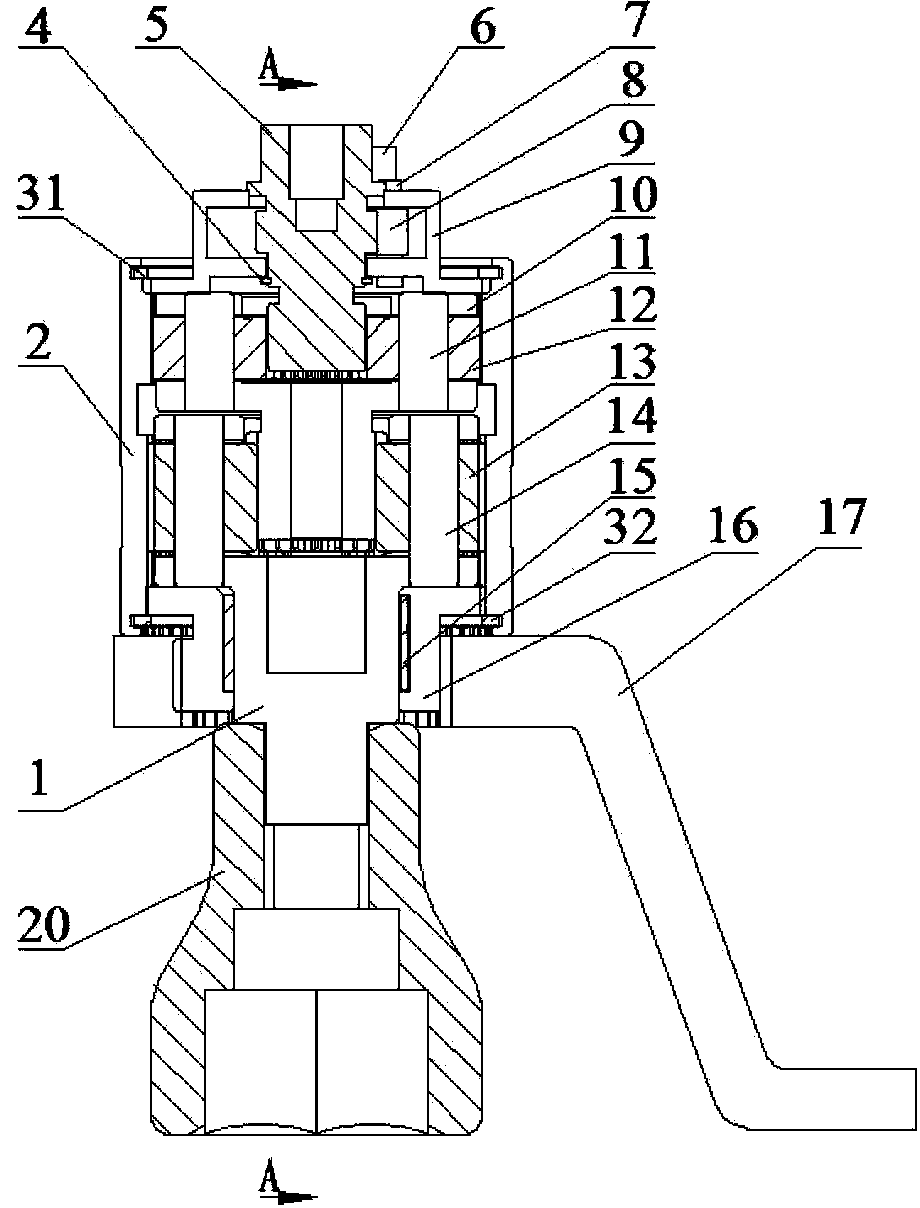

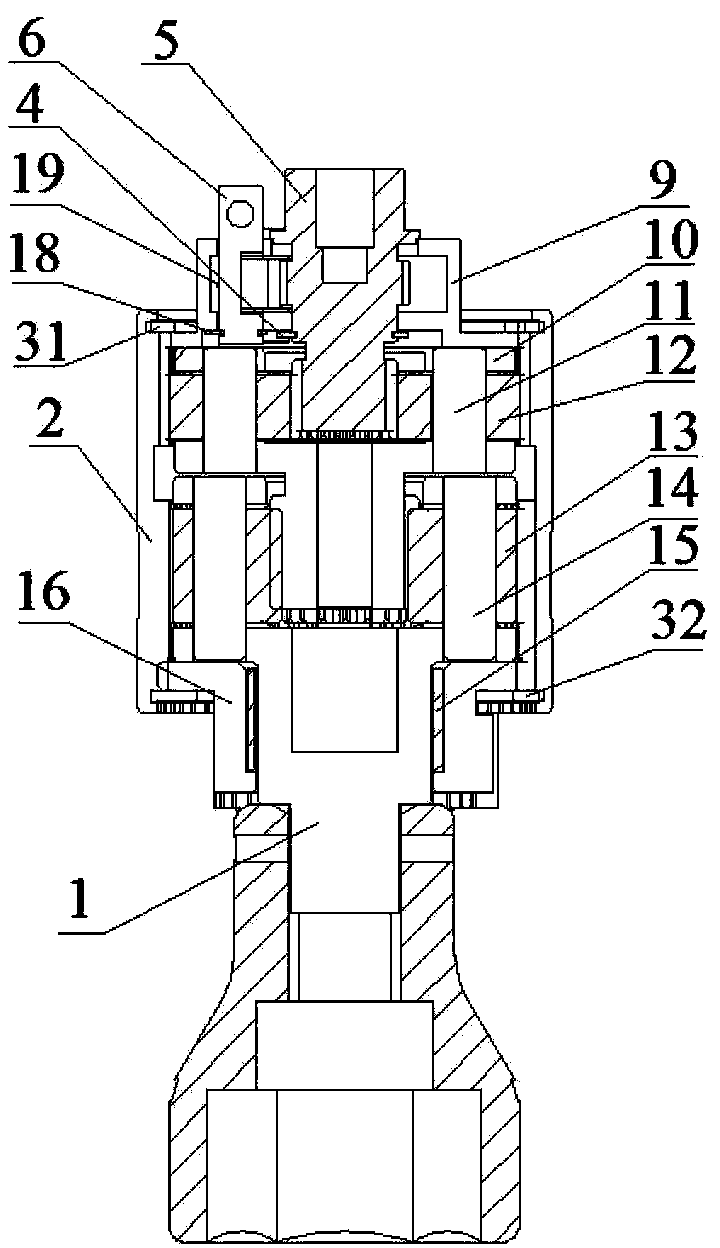

Torque multiplier for a vehicle transmission flange nut

A torque multiplier for applying a predetermined torque to a transmission flange nut of a vehicle engine includes a support member for mounting the torque multiplier directly to a transmission case of a vehicle engine. A gear train is secured to the body. A socket is operably connected to the gear train. The socket engages a transmission flange nut.

Owner:HONDA MOTOR CO LTD

Torque multiplier

The invention discloses a torque multiplier and belongs to the technical field of wrenches. The torque multiplier comprises an input transmission shaft, a mounting cover is arranged outside the input transmission shaft, a ratchet and a shaft snap spring, the ratchet is fixed through a limit pin, and one side of the transmission input shaft is provided with a reversing lever; the tail gear of the input transmission shaft is engaged with a first planet gear, which is fixed onto a first-stage planet carrier through a first-stage planet pin, and the tail gear of the first-stage planet carrier is engaged with a last-stage planet gear, which is fixed onto a last-stage planet carrier through a last-stage planet pin; a gear ring is arranged on the outer ring of the last-stage planet carrier, and rolling pins are arranged between the last-stage planet carrier and the gear ring; an external reducer gearbox is arranged under the mounting cover and above the last-stage planet carrier, the first-stage planet carrier and the gear ring, an inner snap spring is arranged between the mounting cover and the reducer gearbox, and another inner snap spring is arranged between the gear ring and the reducer gearbox. The torque multiplier can be used in cooperation with a manual torque wrench, thereby simplifying highly-difficult operations, achieving high-torque assembly of bolts and nuts and obtaining a high security coefficient.

Owner:江苏金立电子机械科技有限公司

Anti-following torque multiplying wrench

ActiveCN105965443ASolve the technical problems of follow-upEasy to operateFastener toolsMetal-working hand toolsControl theoryWrench

The invention discloses an anti-following torque multiplying wrench, and belongs to the field of tools. The anti-following torque multiplying wrench comprises a torque multiplier and an anti-following mechanism mounted on the torque multiplier. A rocker is mounted on an input shaft of the torque multiplier, and a nut socket, which is an inner hexagonal socket or an outer hexagonal sleeve or a quincuncial socket, is mounted on an output shaft of the torque multiplier. A pair of lateral lugs is disposed on a sidewall of the torque multiplier. The anti-following torque multiplying wrench, which is hinged to the torque multiplier by means of the side lugs, comprises a connecting handle having one end hinged to the side lugs of the torque multiplier and the other end on which a limiting beam in a vertical direction is fixedly mounted. An anti-fooling wrench is fixedly mounted on a top end of the limiting beam. The anti-following torque multiplying wrench solves the problem of following that is common in the use of a bolt and a nut, and has the outstanding advantages of integrated structure convenient in use, large torque and the like.

Owner:STATE GRID CORP OF CHINA +2

Torque multiplier for valve turning machine

Owner:ILLINOIS TOOL WORKS INC

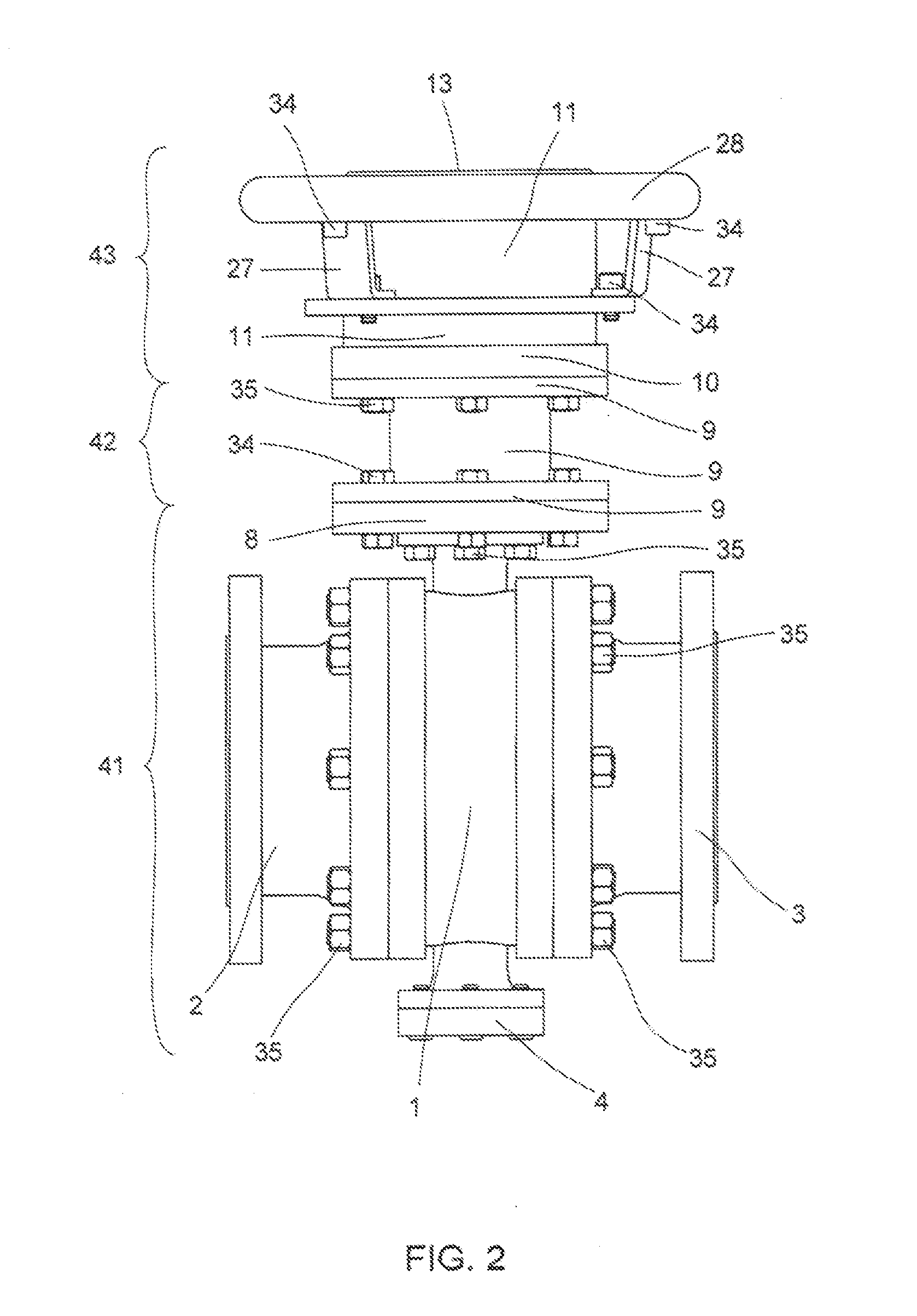

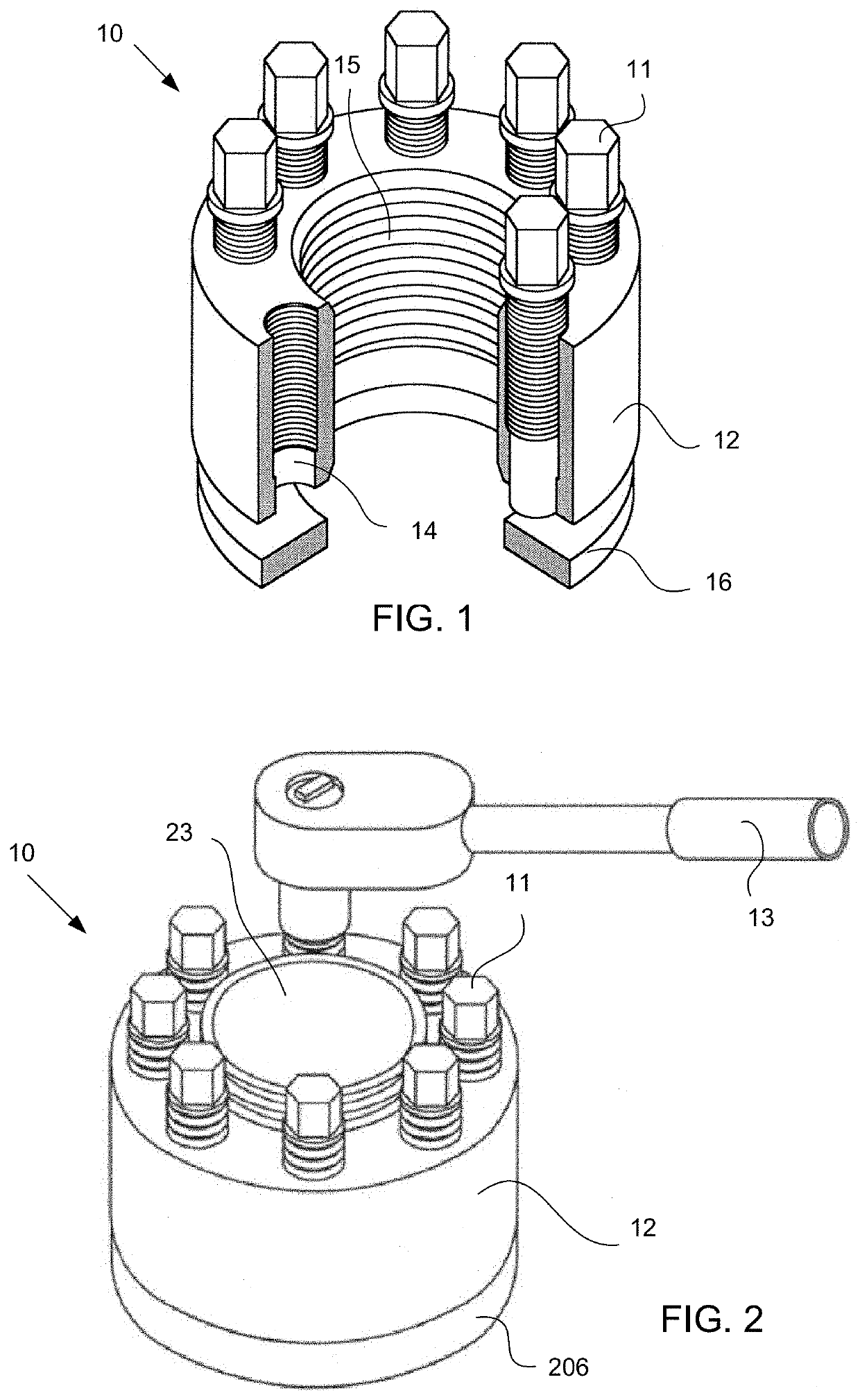

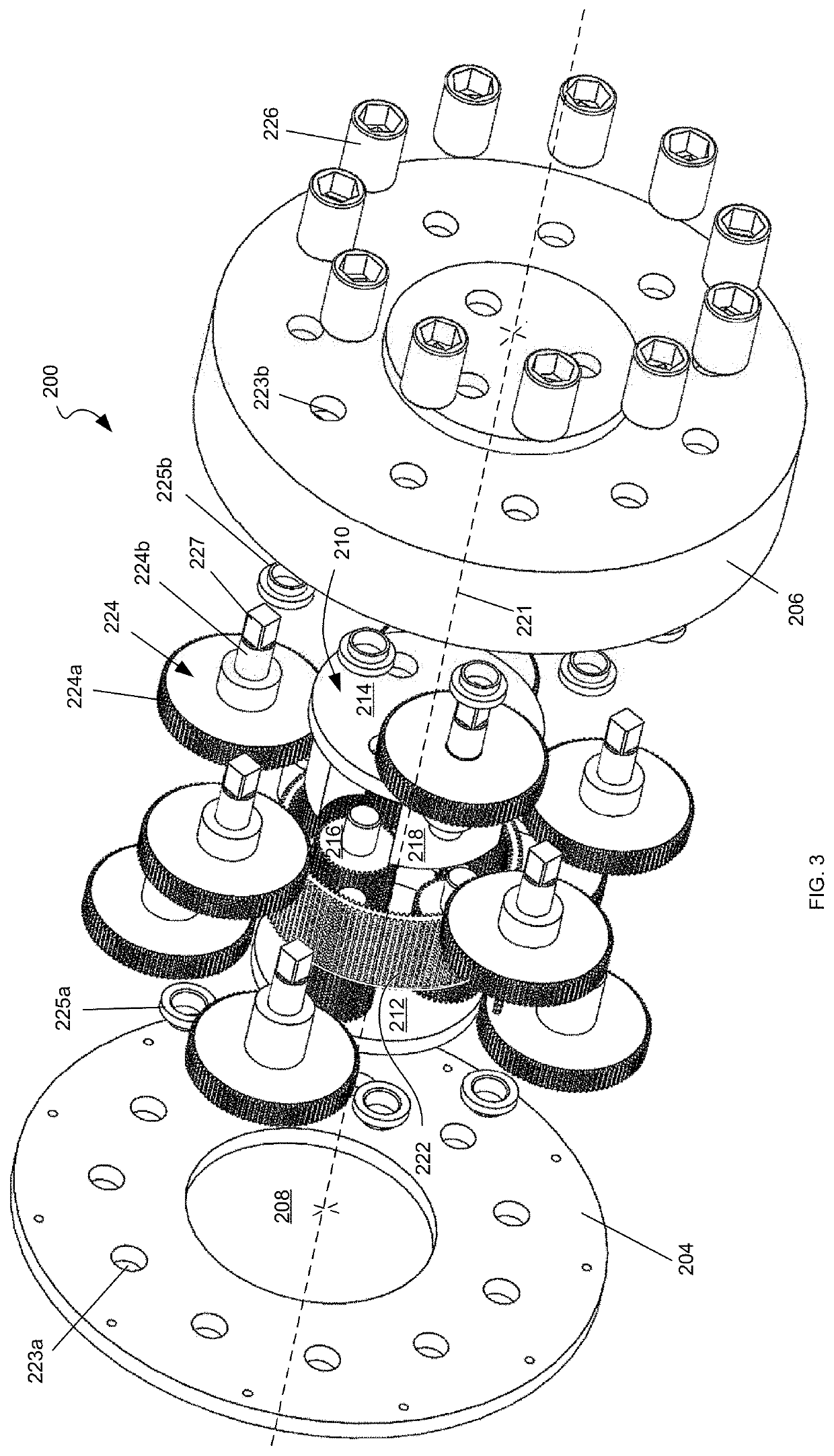

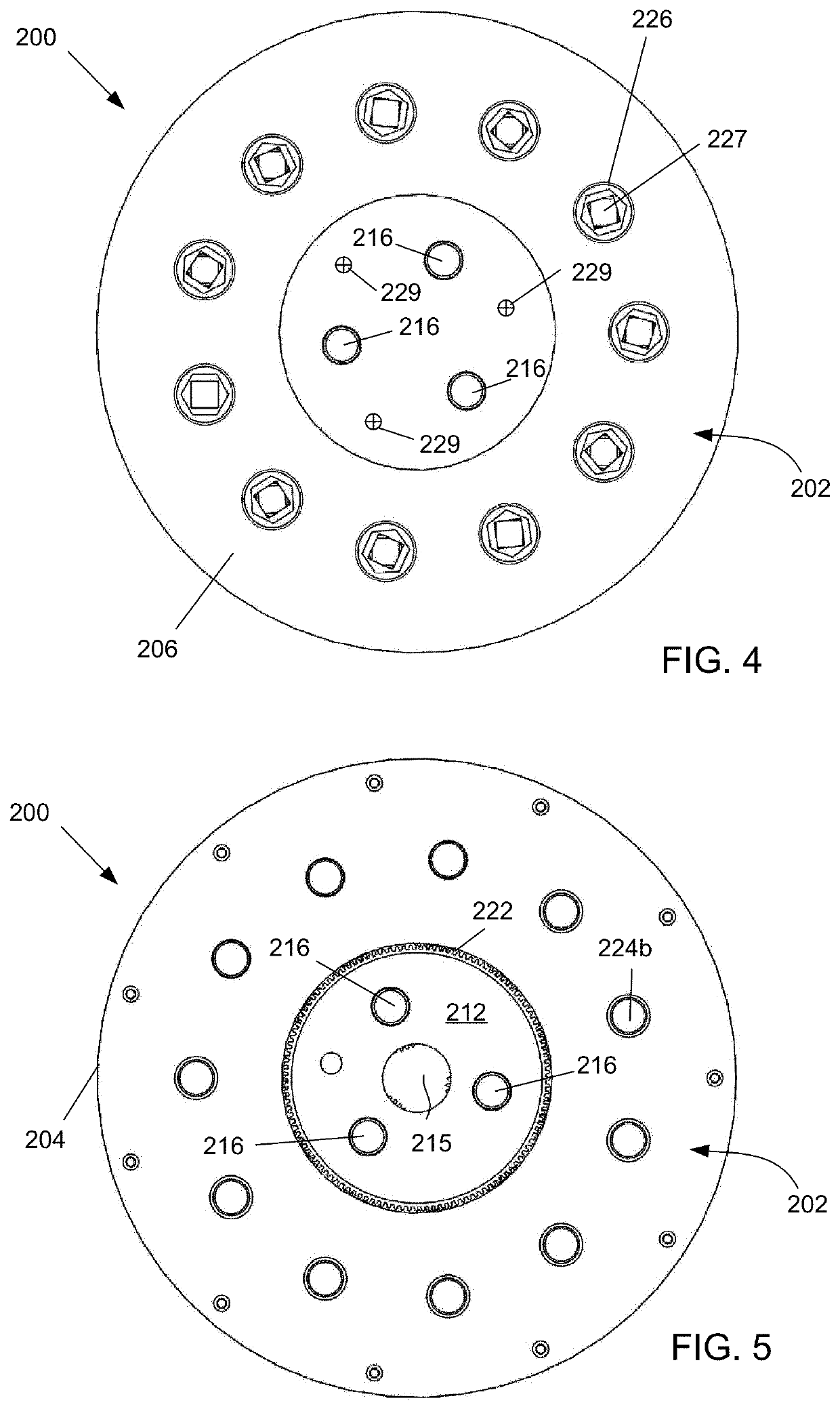

Apparatus for simultaneously applying torque to a plurality of jackbolts of a multi jackbolt tensioner

ActiveUS20200338699A1Decrease in angular separationLoad modified fastenersWheel mounting apparatusGear wheelClassical mechanics

A tensioning apparatus is provided that is arranged to simultaneously tension a plurality of jackbolts of a multi jackbolt tensioner (MJT). The tensioning apparatus has a housing that is arranged for receiving a drive gear from a drive unit. The tensioning apparatus includes one or more planetary gears that are retained within the housing and which mesh with the drive gear in use. A ring gear encircles the one or more planetary gears and meshes with them. A plurality of spindle gears is retained in the housing. Each of the spindle gears has a spindle for coupling to a respective one of the jackbolts. The spindle gears are located around the ring gear and mesh with teeth on an outside of the ring gear. In use the drive gear rotates the one or more planetary gears to thereby rotate the spindle gears via the ring gear to thereby tension the jackbolts. The tensioning apparatus may be made compact by overlapping gear disks of the spindle gears and acts as a torque multiplier between the planetary gears and the spindle gears.

Owner:SUPERBOLT INC

Mounting ring installation system for a meat grinding system

A mounting ring installation system including a torque multiplier introduced to a grinder head to aid in the installation and removal of the mounting ring which holds the grinding plate system securely into the grinder head. The torque multiplying device can have multiple sources of input power including human power or a mechanical source and can be installed on a variety of grinder types and sizes.

Owner:LEWIN JESSE JAMES

Torque-adjustable multiplier

The invention discloses a torque-adjustable multiplier. The torque-adjustable multiplier is provided with a reverse torque limit rod and also provided with two monomer torque multipliers, namely an active monomer multiplier and a driven monomer multiplier respectively, wherein the output shaft of the active monomer multiplier and the driven monomer multiplier are coaxially connected with each other in series through a shaft-shaft type torque-adjustable limiter; and the inner gear rings of the active monomer multiplier and the driven monomer multiplier are fixedly connected with more than one connecting plate respectively, wherein one connecting plate is fixedly connected with the reverse torque limit rod. The range of the ratio of the torque input to the torque output of the multiplier of the invention is greater than a conventional monomer multiplier, wherein the ratio can be adjusted freely according to design requirements; and the multiplier has the characteristics of prolonged service life, convenient use, safety and rapidness.

Owner:SHANXI GAOHE ENERGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com