Anti-following torque multiplying wrench

A torque multiplication and wrench technology, applied in hand-held tools, hand tools suitable for fasteners, manufacturing tools, etc., can solve problems such as difficulty in dismantling porcelain bottles, falling objects from high altitudes, etc., to achieve convenient operation, avoid using cutting tools, torque big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is described in further detail:

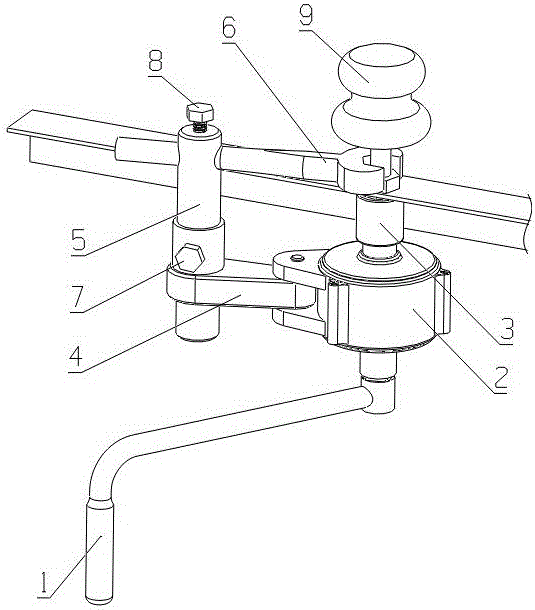

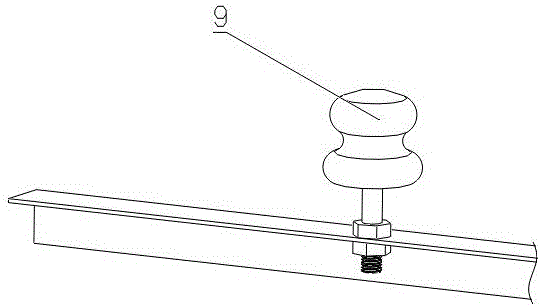

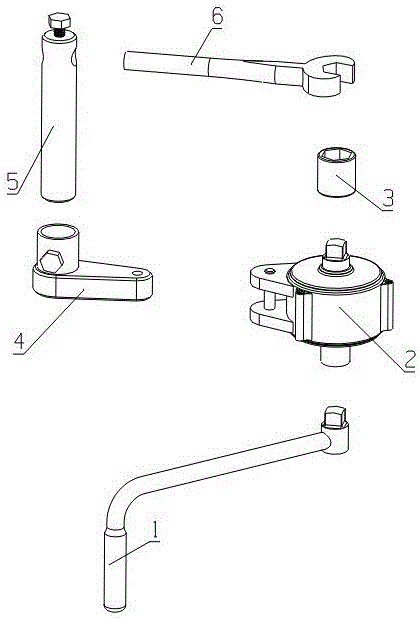

[0021] Such as figure 1 with image 3 As shown, the present invention is an anti-coil rotation torque multiplication wrench, which mainly includes a torque multiplier 2 and an anti-coil rotation mechanism installed on the torque multiplier 2 in a preferred embodiment.

[0022] The anti-heel rotation mechanism includes a connecting handle 4 installed on the torque multiplier 2, a trip beam 5 and an anti-heel rotation wrench 6. One end of the connecting handle 4 is hinged by a pair of side ears arranged on the side wall of the torque multiplier 2 and the torque multiplier 2, and a vertical trip beam 5 is installed at the other end, and an anti-following wrench is installed on the top of the trip beam 5 6.

[0023] Torque multiplier 2, also known as torque multiplier, torque amplifier, gear reducer, torque amplifier, force booster, etc., is a device that can increase torque for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com