Patents

Literature

14381 results about "Wrench" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wrench or spanner is a tool used to provide grip and mechanical advantage in applying torque to turn objects—usually rotary fasteners, such as nuts and bolts—or keep them from turning. In Commonwealth English (excluding Canada), spanner is the standard term. The most common shapes are called open-ended spanner and ring spanner. The term wrench is generally used for tools that turn non-fastening devices (e.g. tap wrench and pipe wrench), or may be used for a monkey wrench - an adjustable pipe wrench.

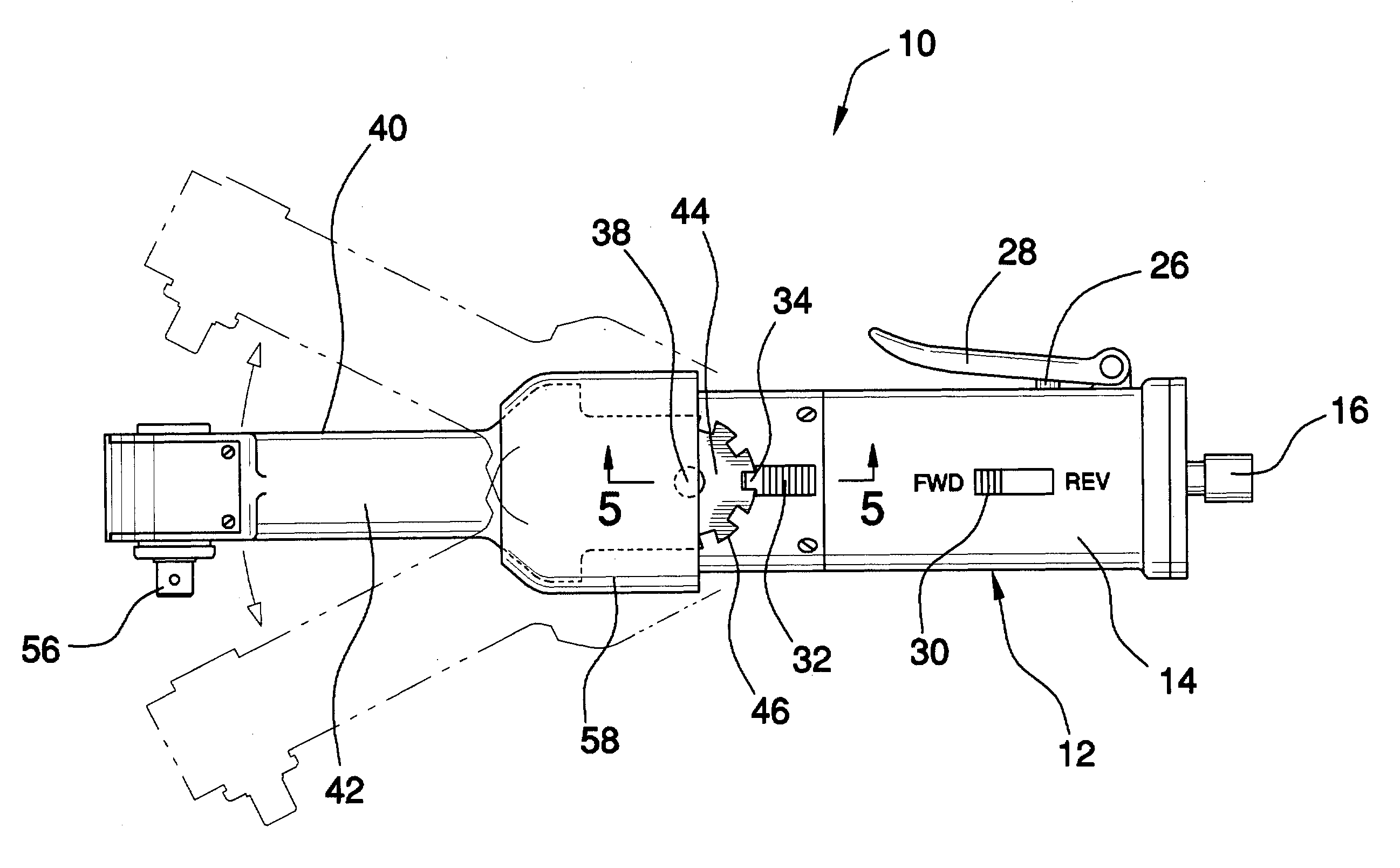

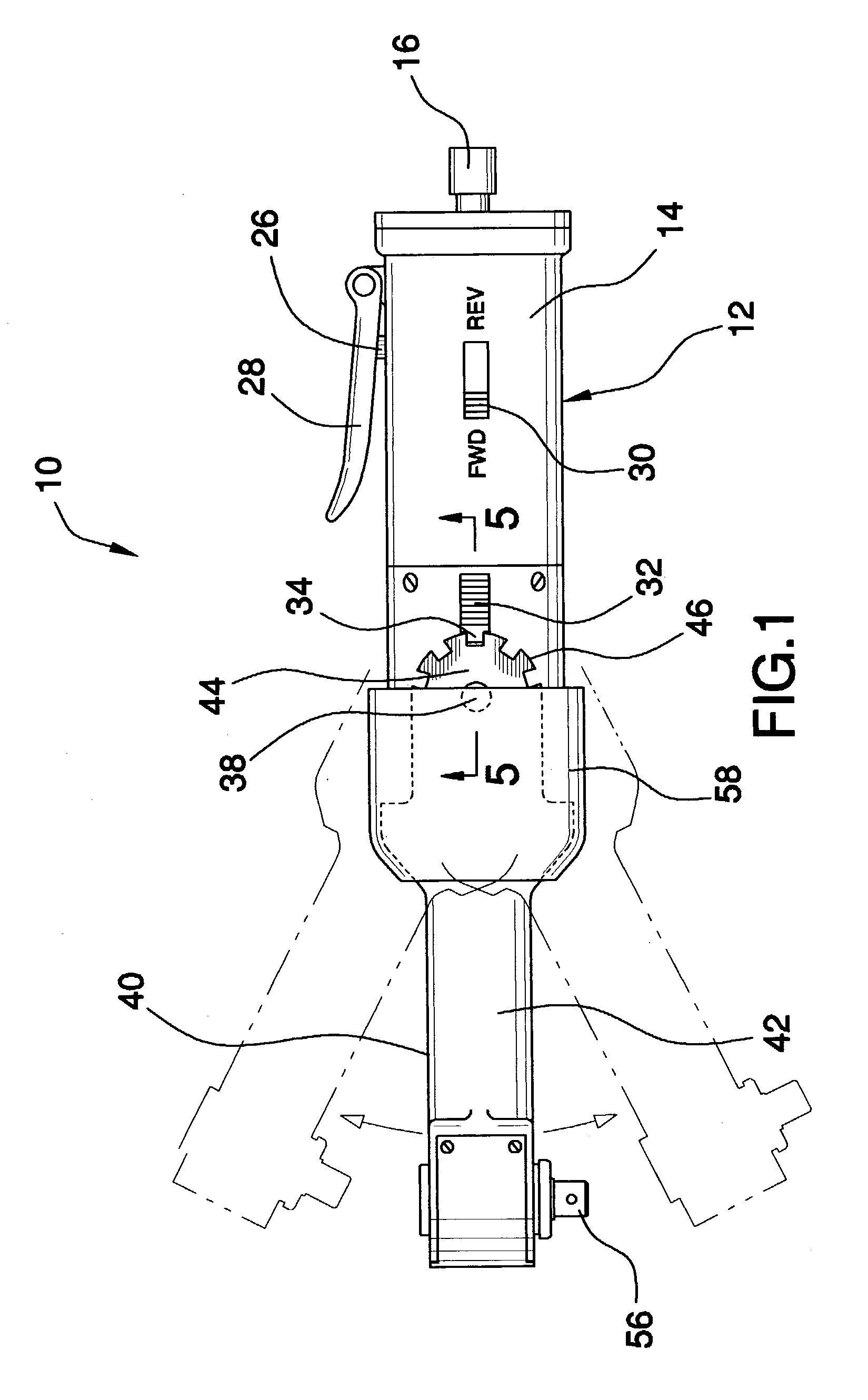

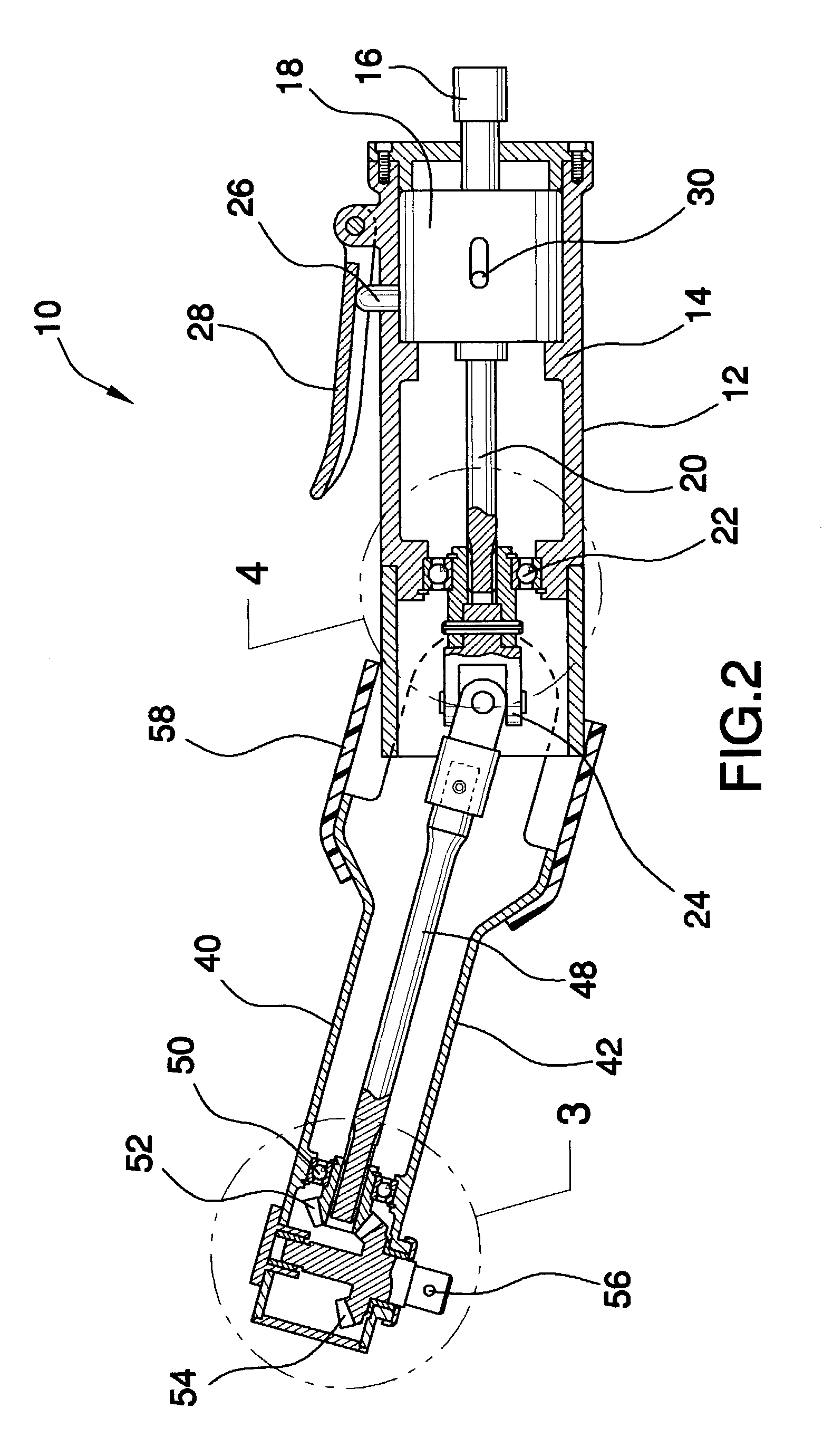

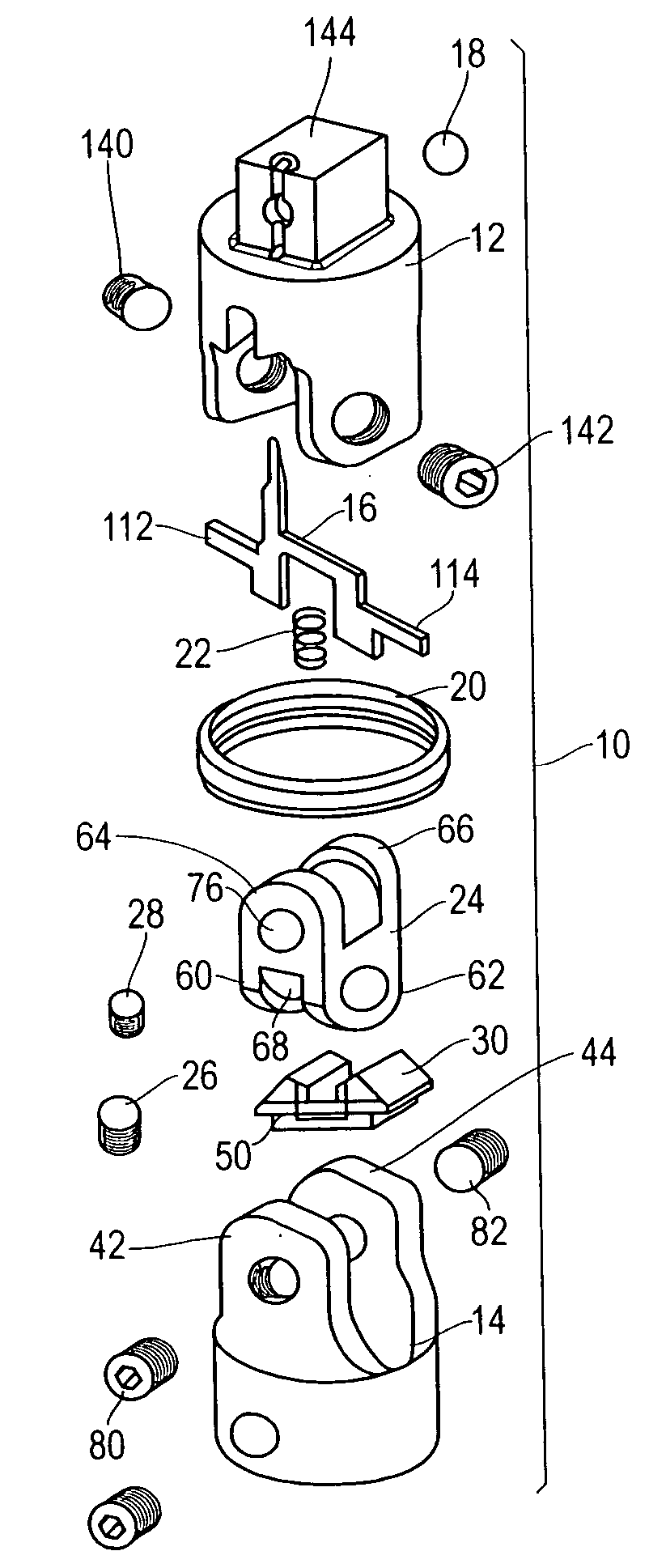

Air powered wrench device with pivotable head and method of using

InactiveUS6928902B1Easy and efficient to manufactureLower sales priceSpannersWrenchesBall bearingUniversal joint

An air powered wrench device with a pivotable head and associated method of using. The device comprises a handle pivotally attached to an arm. The handle comprises a housing, an air intake nozzle, an air driven motor, a drive shaft, a ball bearing collar, a universal joint, an on / off button, a trigger switch, a directional throw switch, a lock pin, a spring, and a pivot post. The arm is pivotally attached to the handle via the pivot post. The arm includes: an outer casing, an extension rod, a ball bearing sleeve, a first pawl gear, a second pawl gear, and a bit connector. The method of using the device comprises the steps of adjoining, affixing, aligning, allowing, enshrouding, getting, moving, obtaining, putting, rotating, shifting, squeezing, and tightening.

Owner:EYSSALLENNE LUIS P

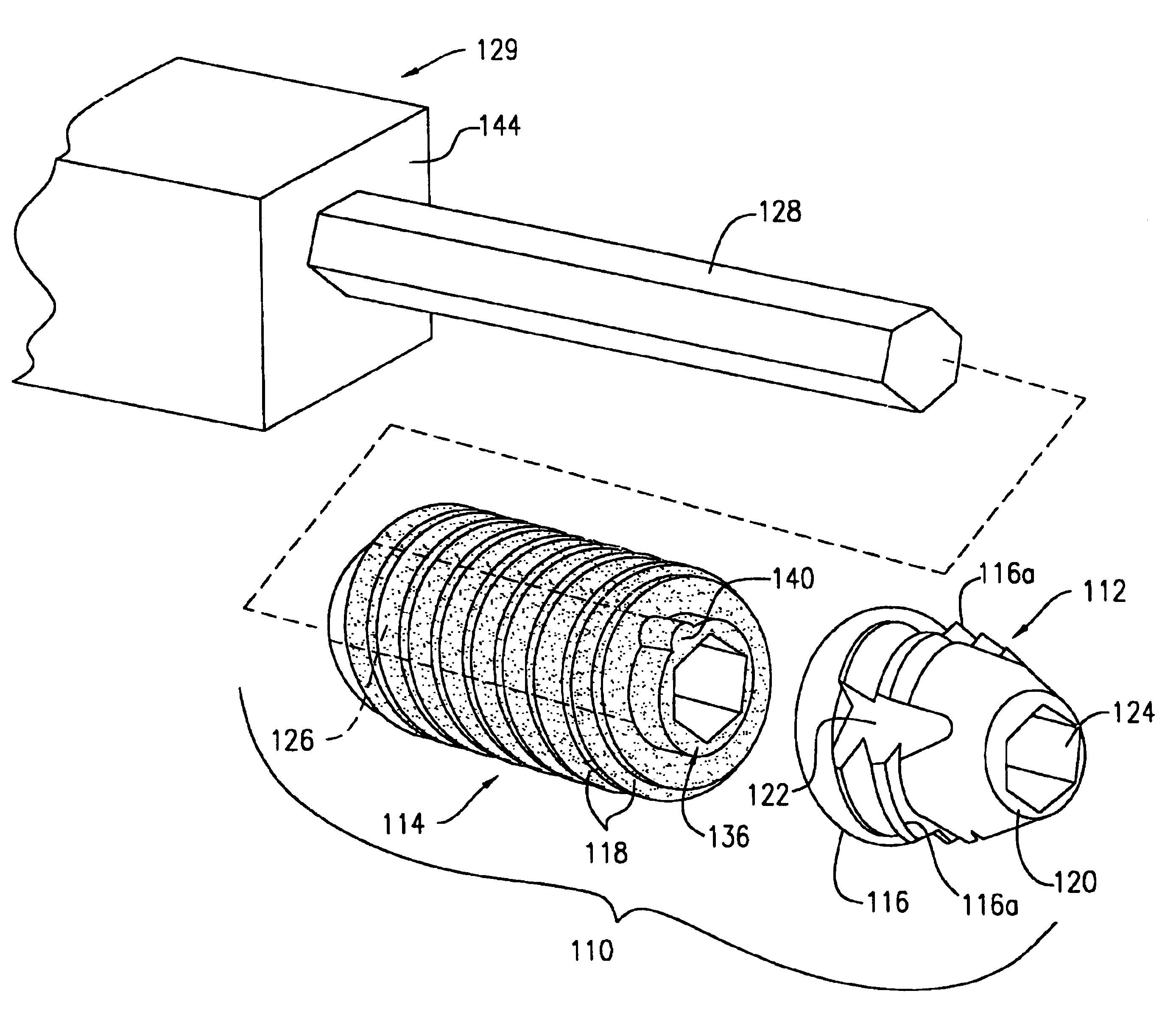

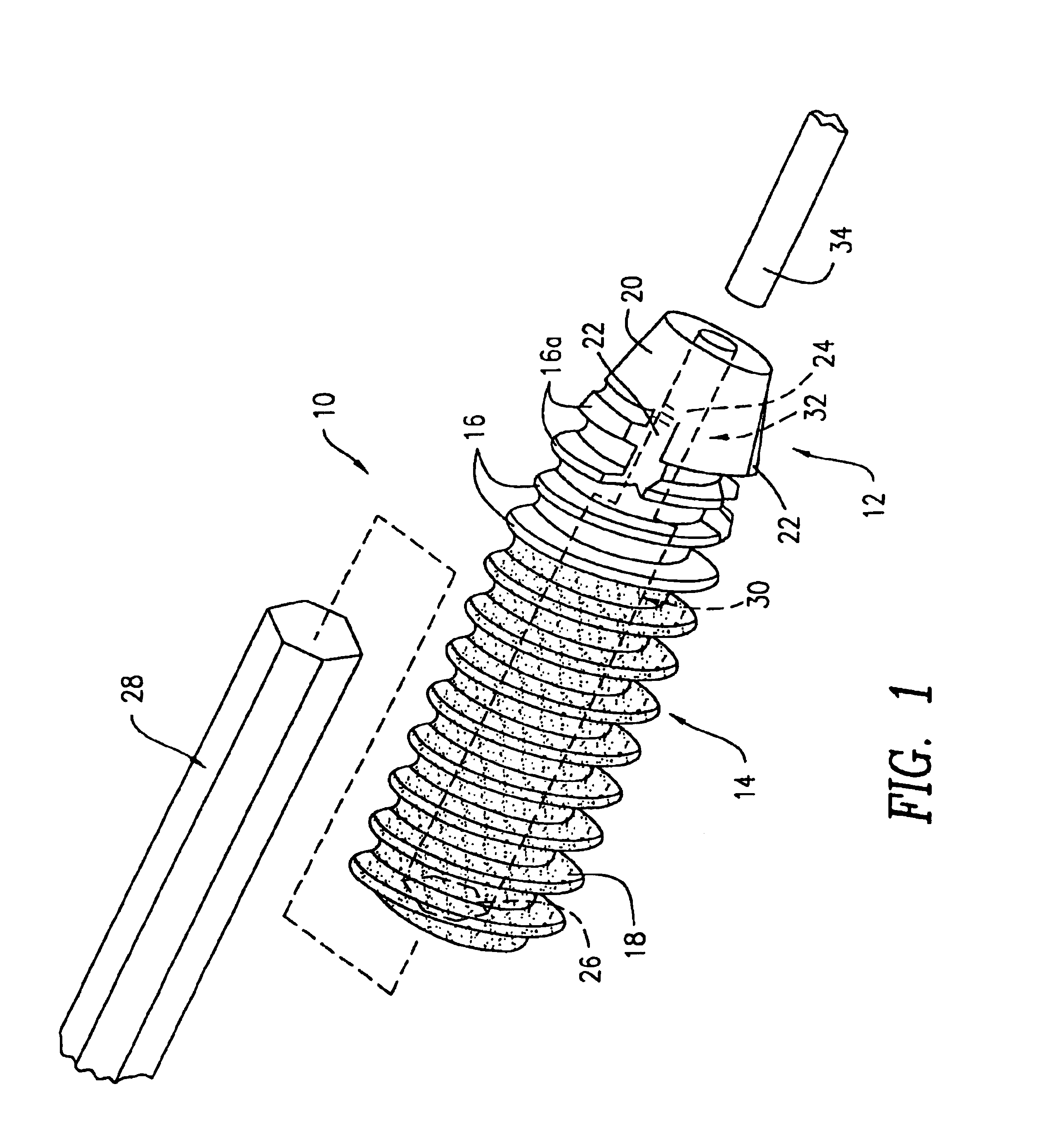

Self-tapping resorbable two-piece bone screw

An orthopedic interference screw has a hard, self-threading front section and a bioabsorbable rear section. The two sections are conjoined and threaded such that the hard front section cuts threads into the bone and the softer rear section follows the threads into the bone. Preferably, the screw has an axial bore for matingly receiving a turning tool such as a hex wrench.

Owner:ETHICON INC

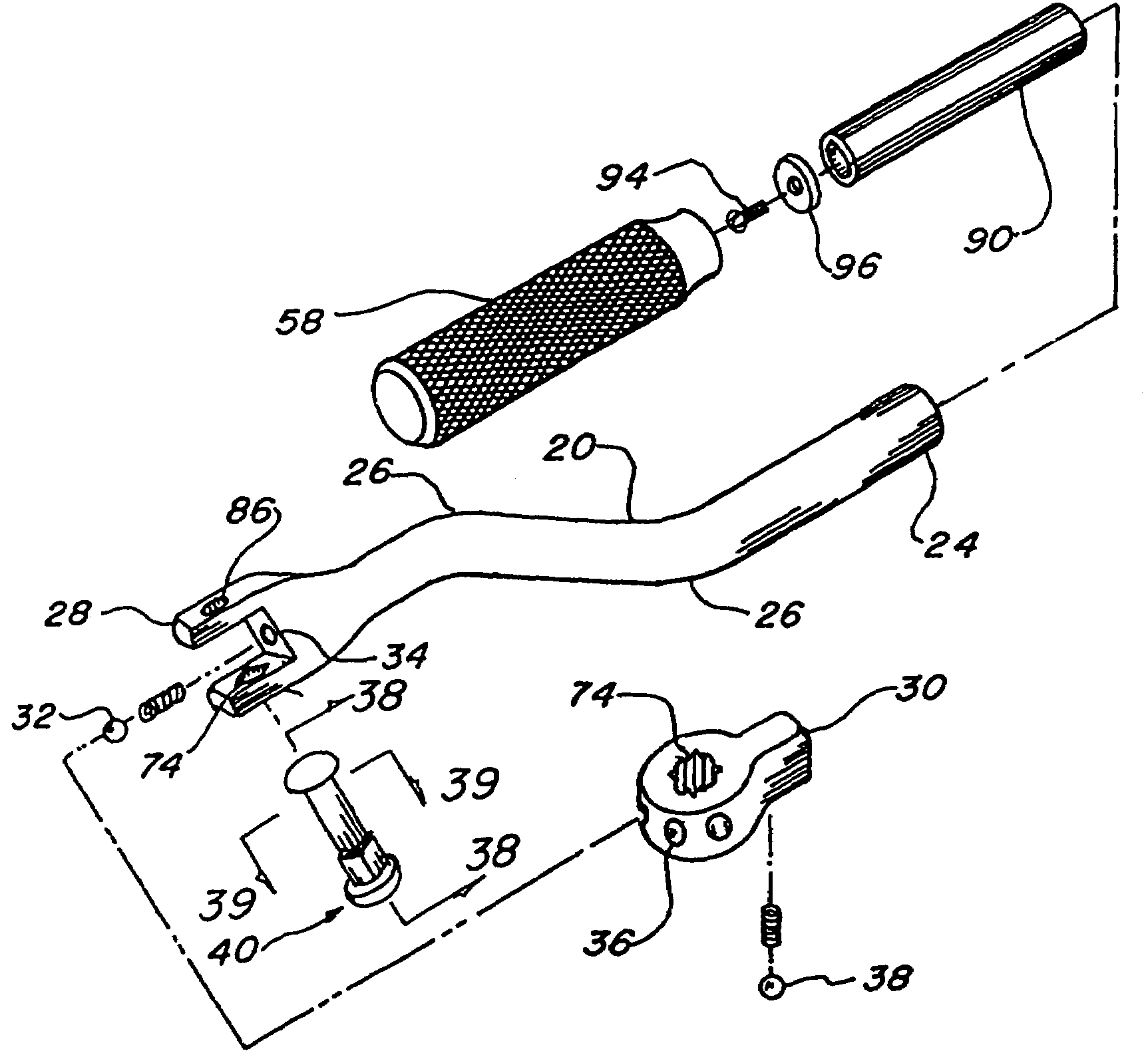

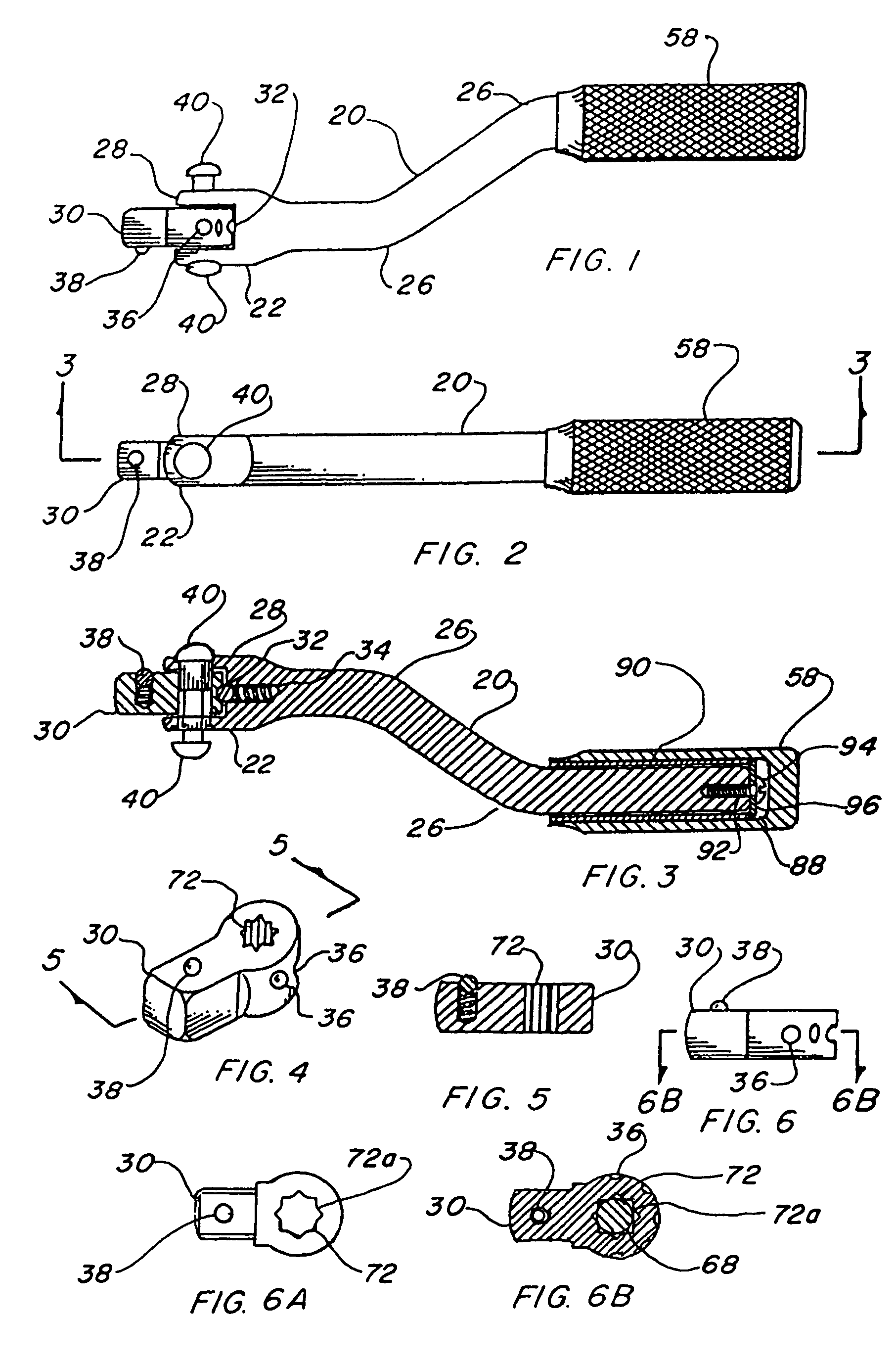

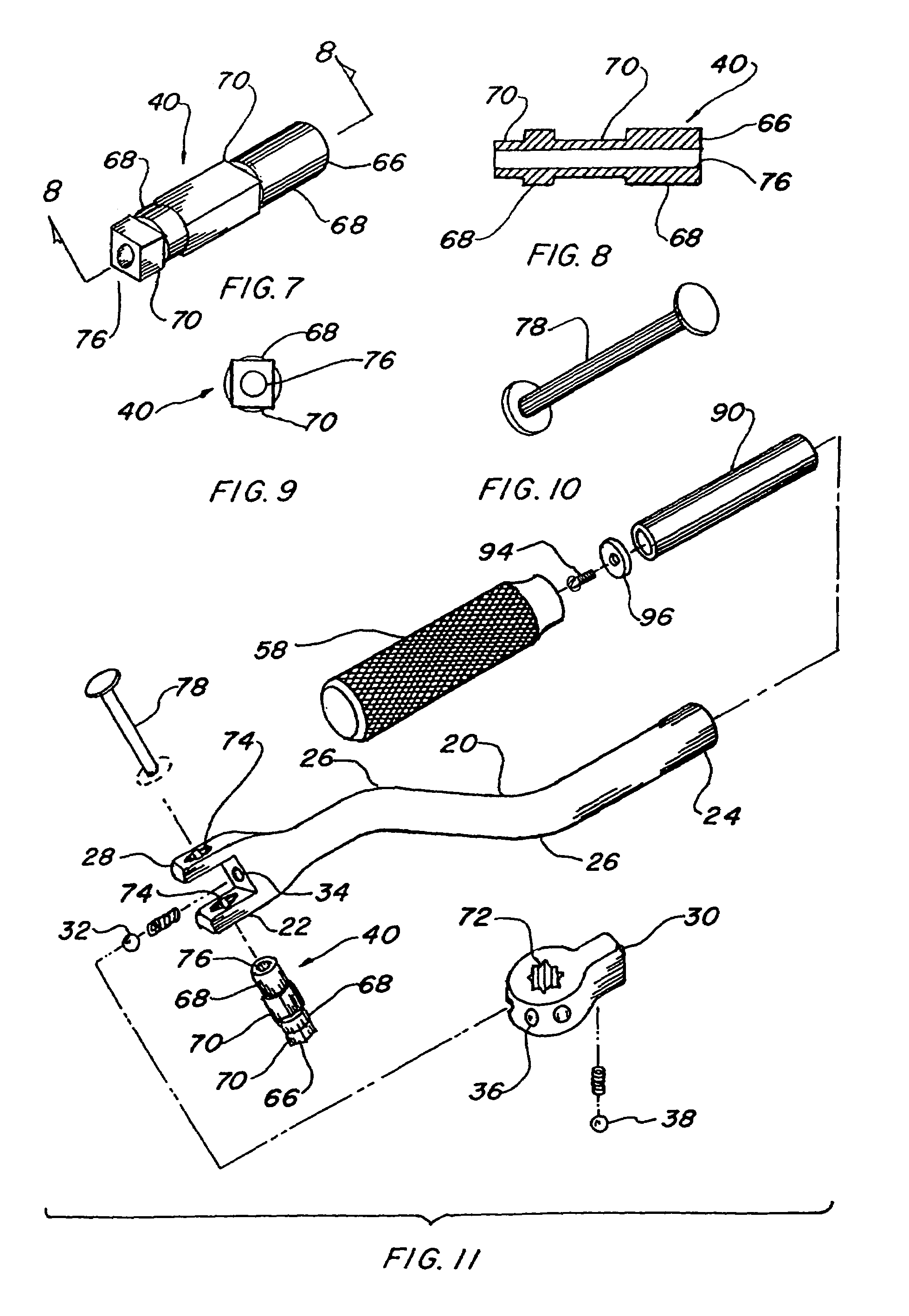

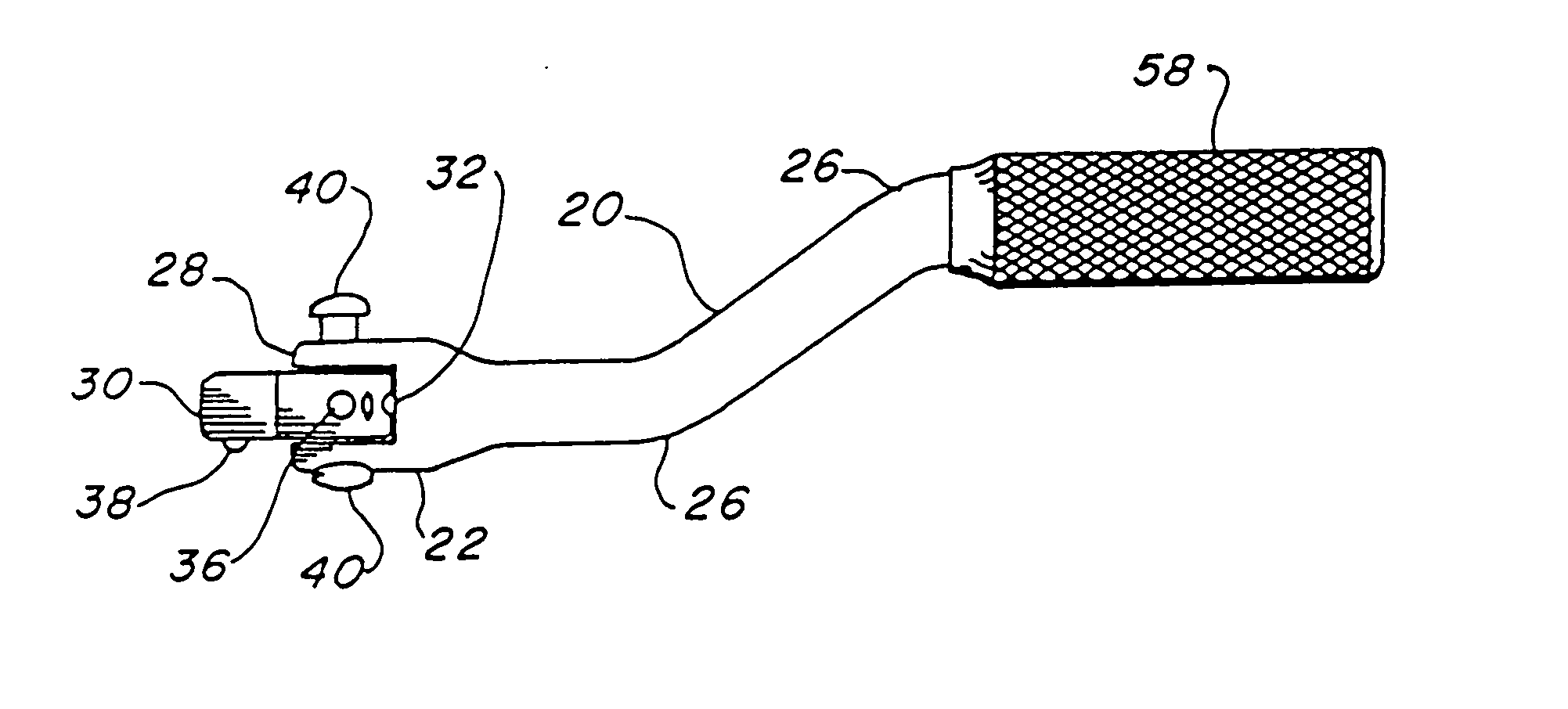

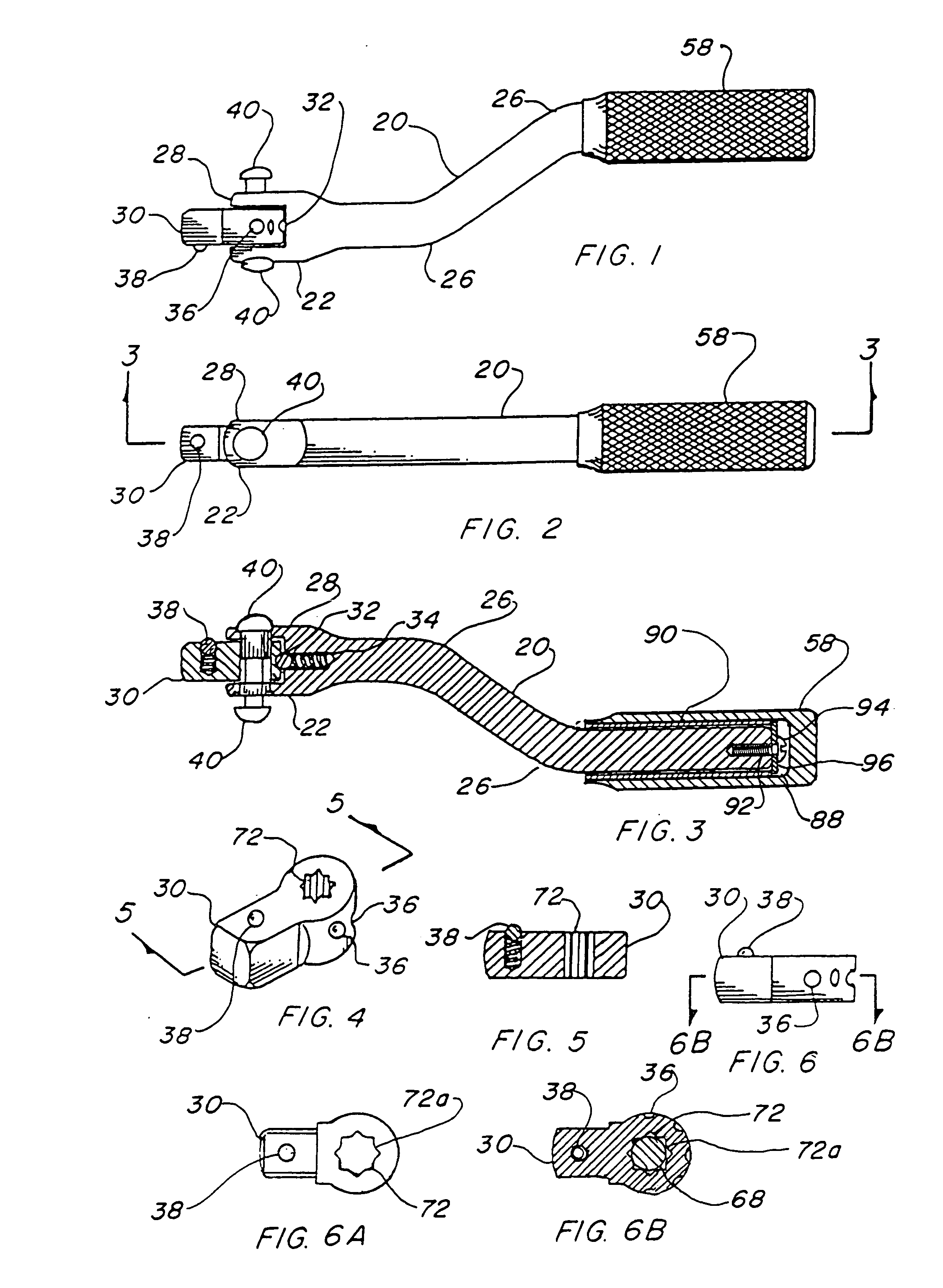

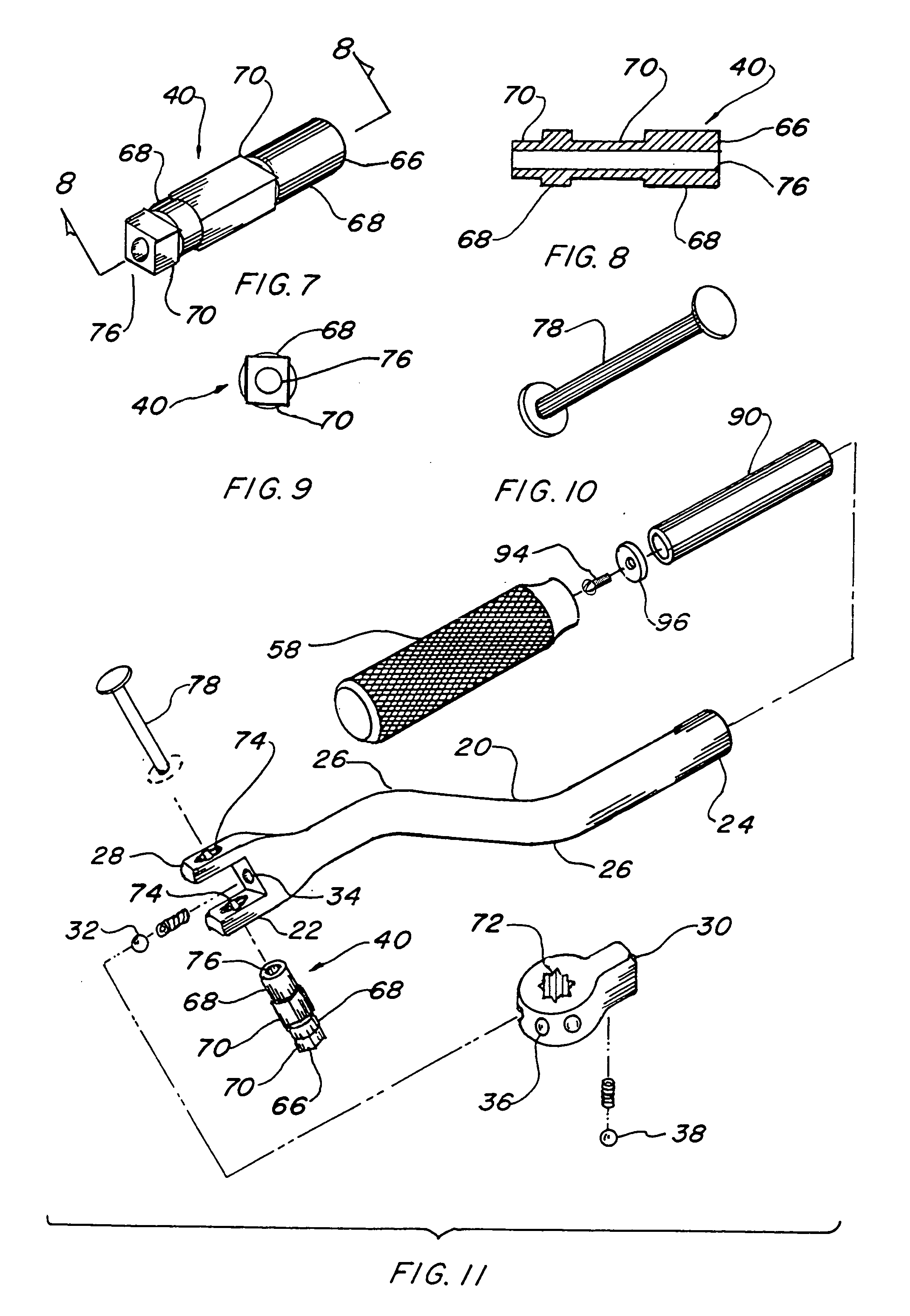

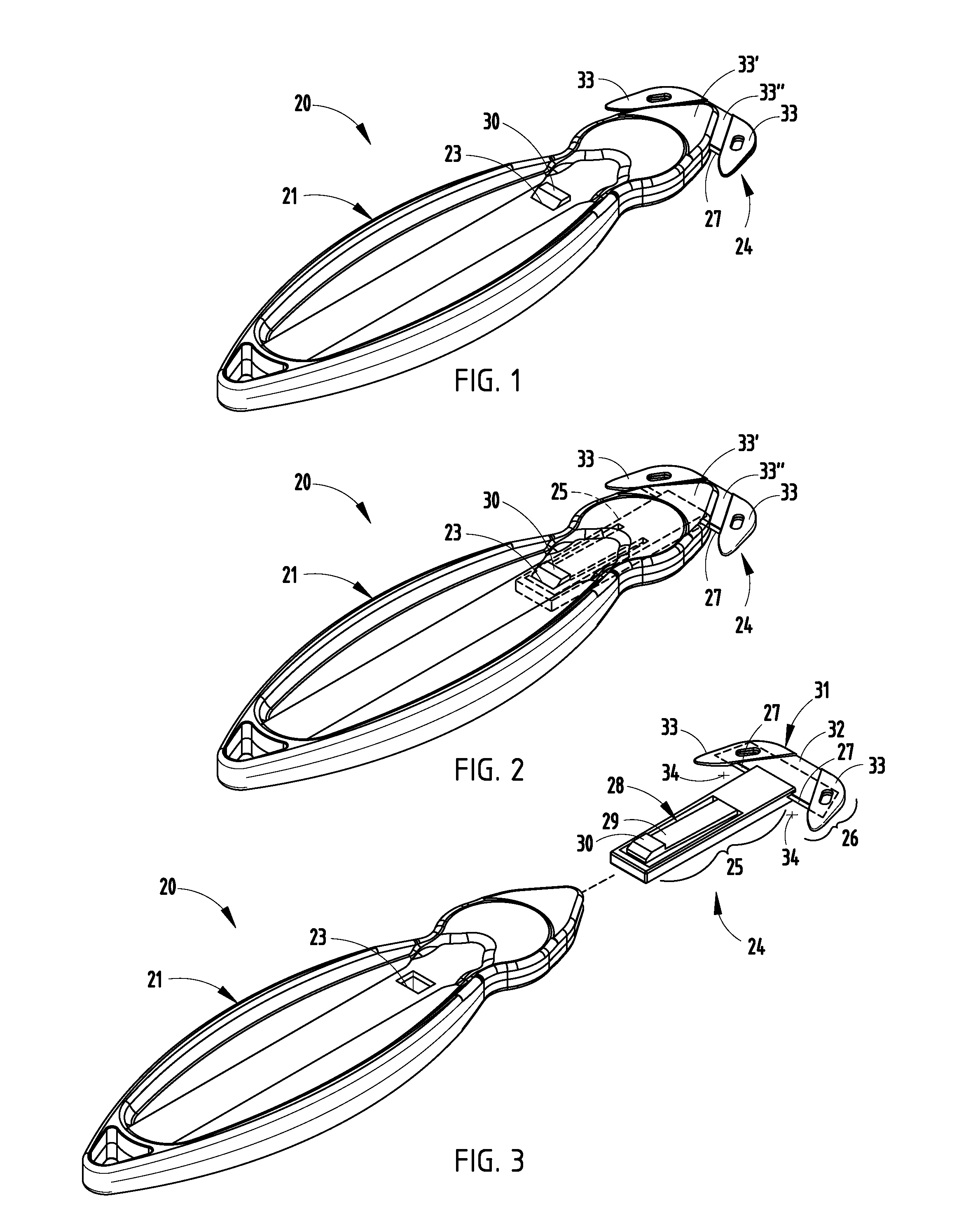

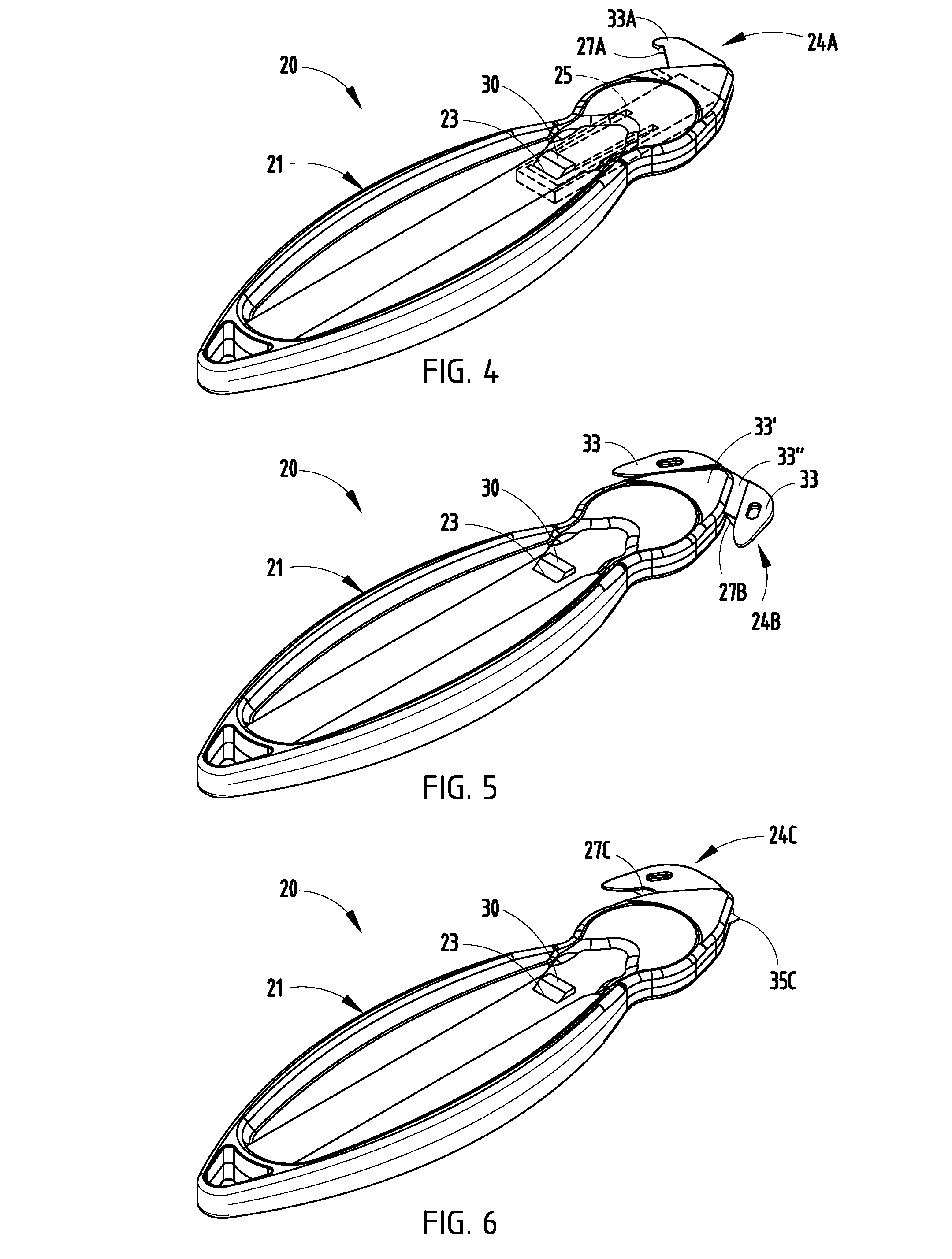

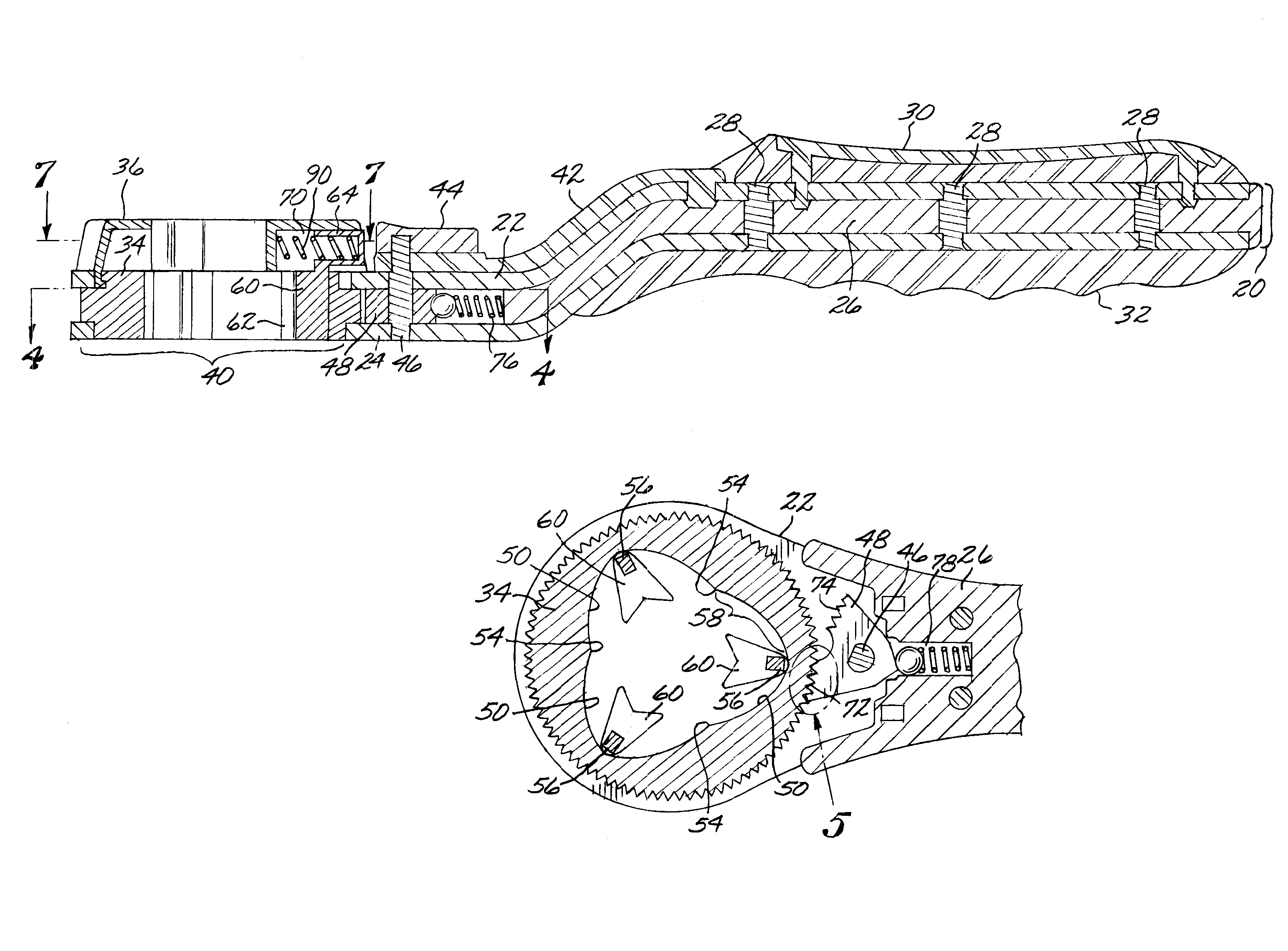

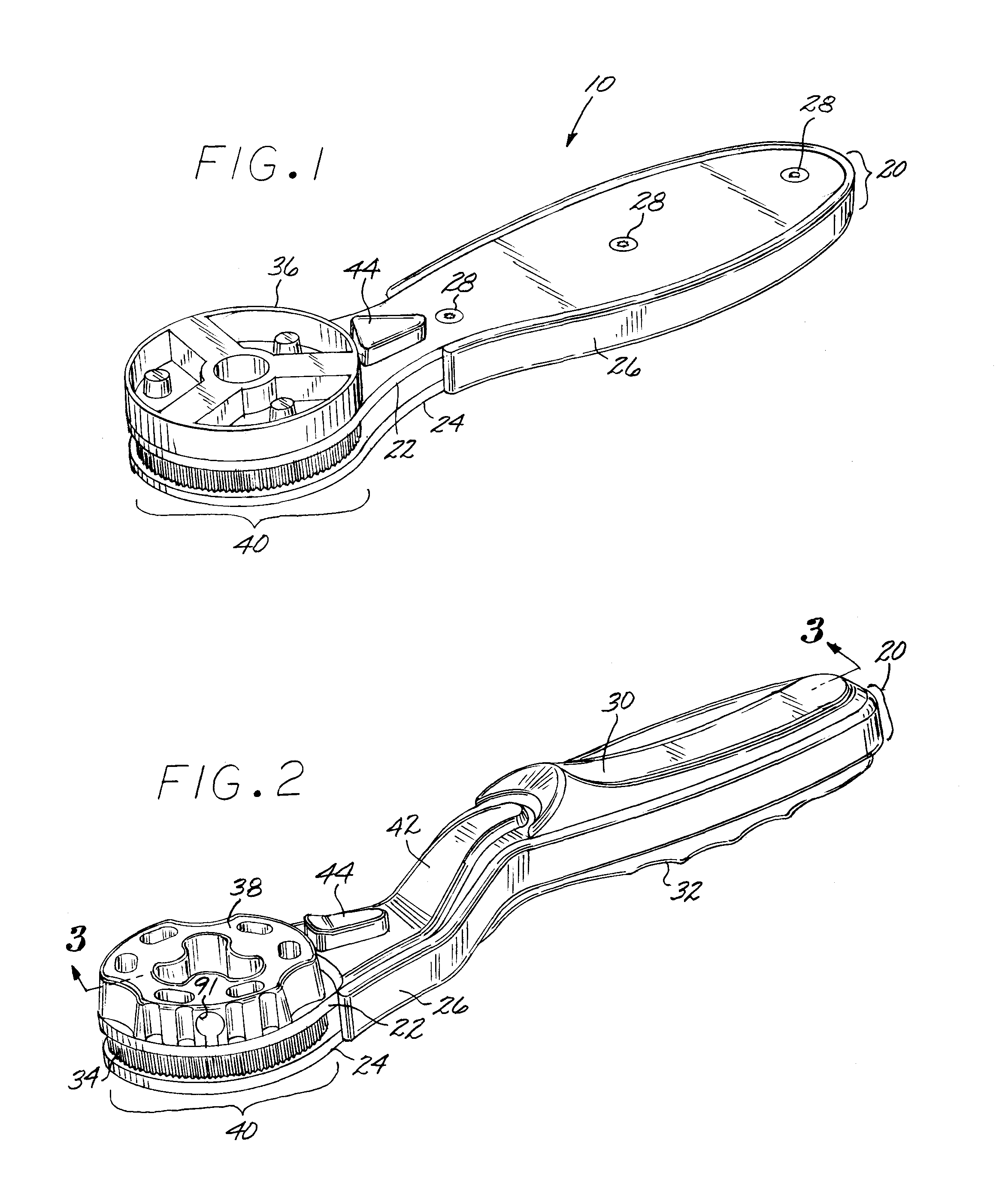

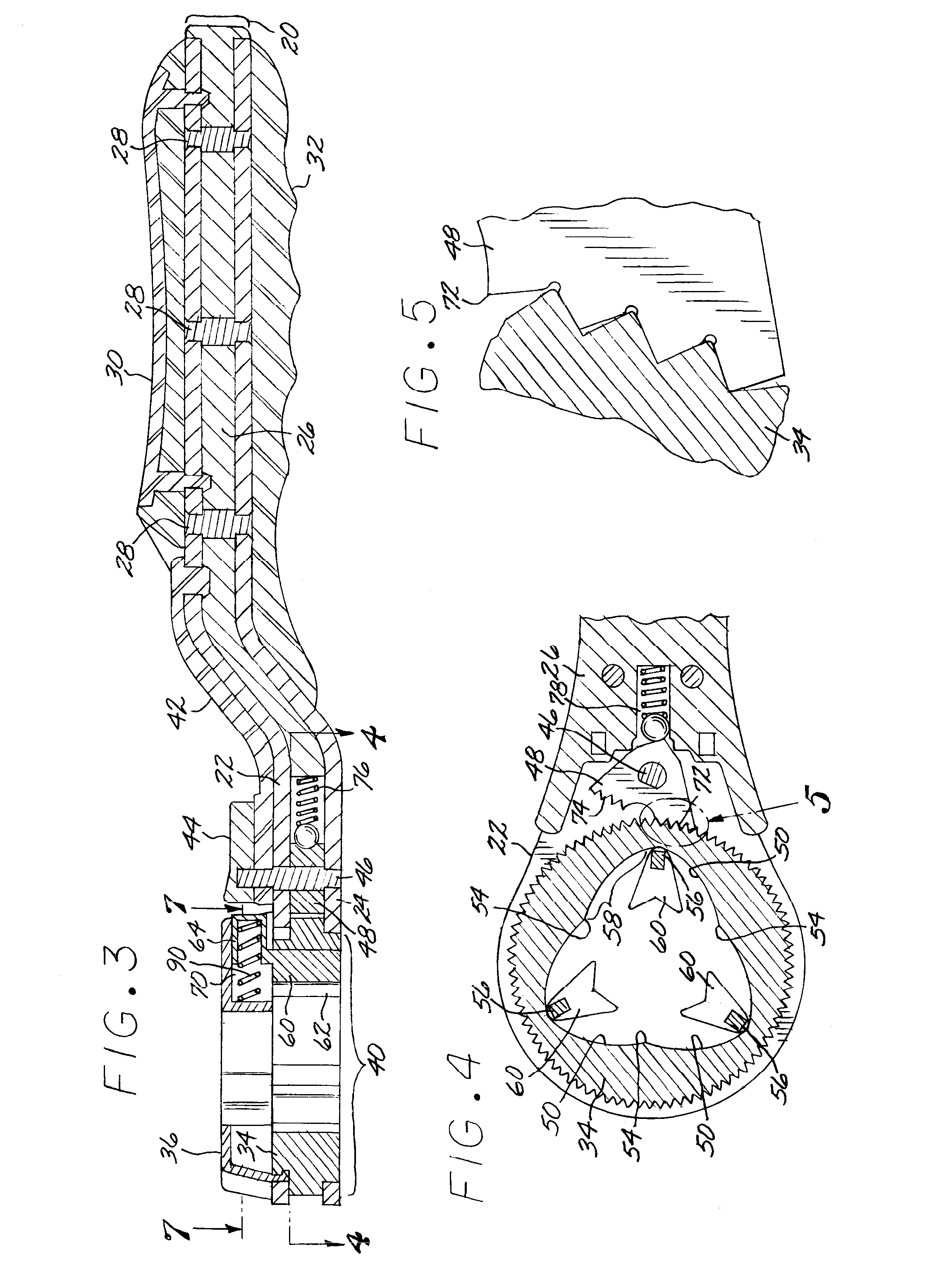

Hinged socket wrench speed handle

InactiveUS7197965B1Shorten the timeFast spinSpannersWrenchesAngular displacementStructural integrity

A hinged socket wrench speed handle having an offset shank (20) with a first end (22) and a second end (24). Attached to the first end (22) is a clevis (28) which receives a 180-degree drive head that is held by a hinge pin (40). The drive head consists of either a square drive head (30) or a ratchet drive head (31). To the second end (24) is attached a handle (58), which rotates the wrench. A second embodiment of the hinged socket wrench includes a second clevis (28) that is added to the second end (24) of the offset shank. The second clevis (28) adds further combinations of angular displacement of the handle (58). Thus increasing the value of the wrench as a tool and also its utility in difficult work areas. The wrench consists of five hinge pin (40) variations which provide additional surface interface with both the hinge pin and the handle yoke, thereby improving the structural integrity and prolonging the tool's life.

Owner:ANDERSON STEVEN P

Hinged socket wrench speed handle

InactiveUS20050120836A1Improve tool lifeShorten the timeSpannersWrenchesEngineeringAngular displacement

A hinged socket wrench having an offset shank (20) with a first end (22) and a second end (24). Attached to the first end (22) is a clevis (28) which receives a 180-degree drive head held by a hinge pin (40). The drive head consists of either a square drive head (30) or a ratchet drive head (31). To the second end is attached a rotatable handle (58), which rotates the wrench upon reciprocation of the handle (58). A second embodiment of the hinged socket wrench includes a second clevis (28) that is added to the second end (24) of the offset shank. The second clevis (28) adds further combinations of angular displacement of the handle (58). Thus, increasing the value of the wrench as a tool and also its productivenss in difficult work areas. Five configurations of the hinge pin (40) provide additional surface interface with both the hinge pin and the handle yoke improving the structural integrity and prolonging tool life.

Owner:ANDERSON STEVEN P

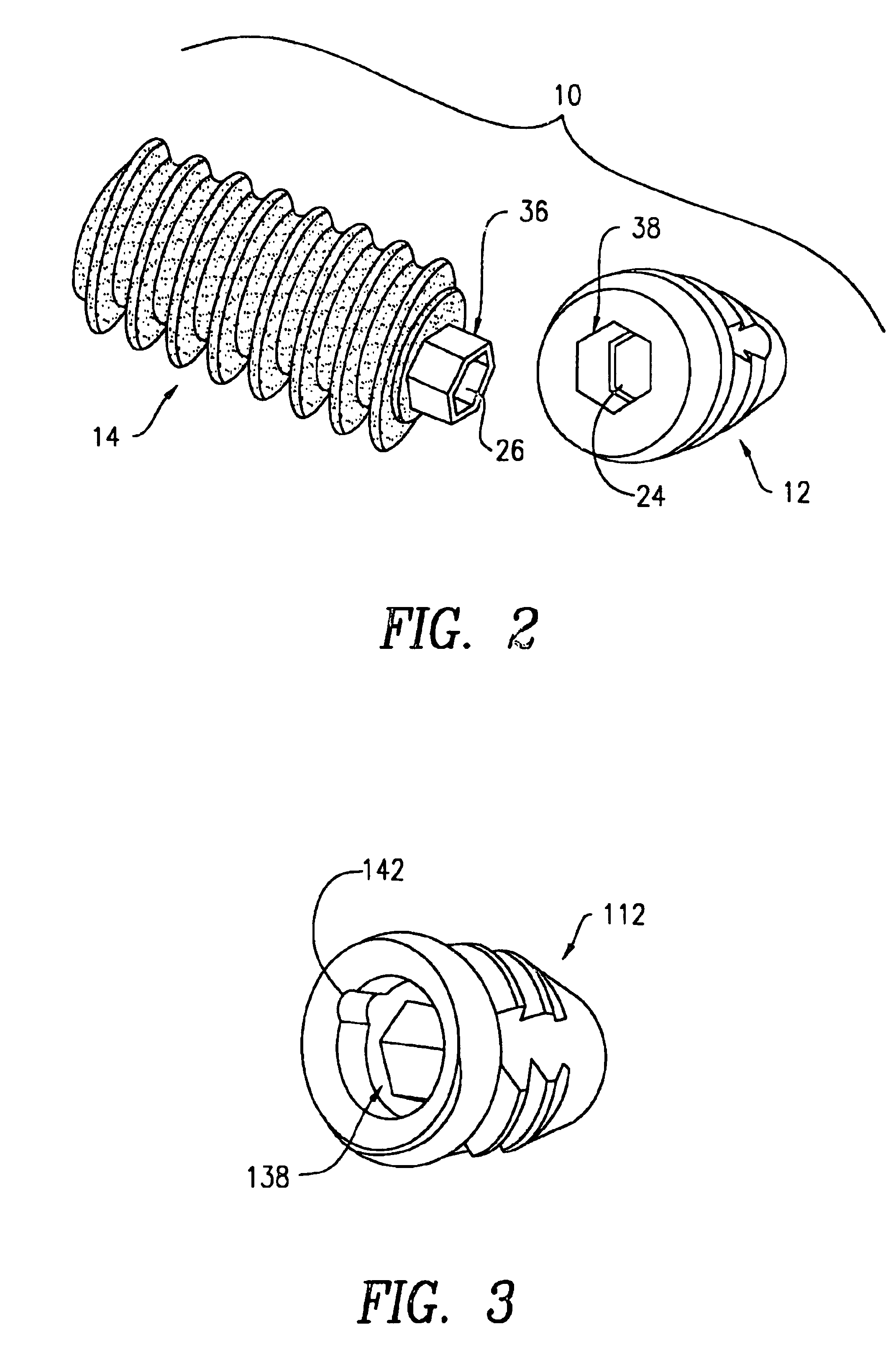

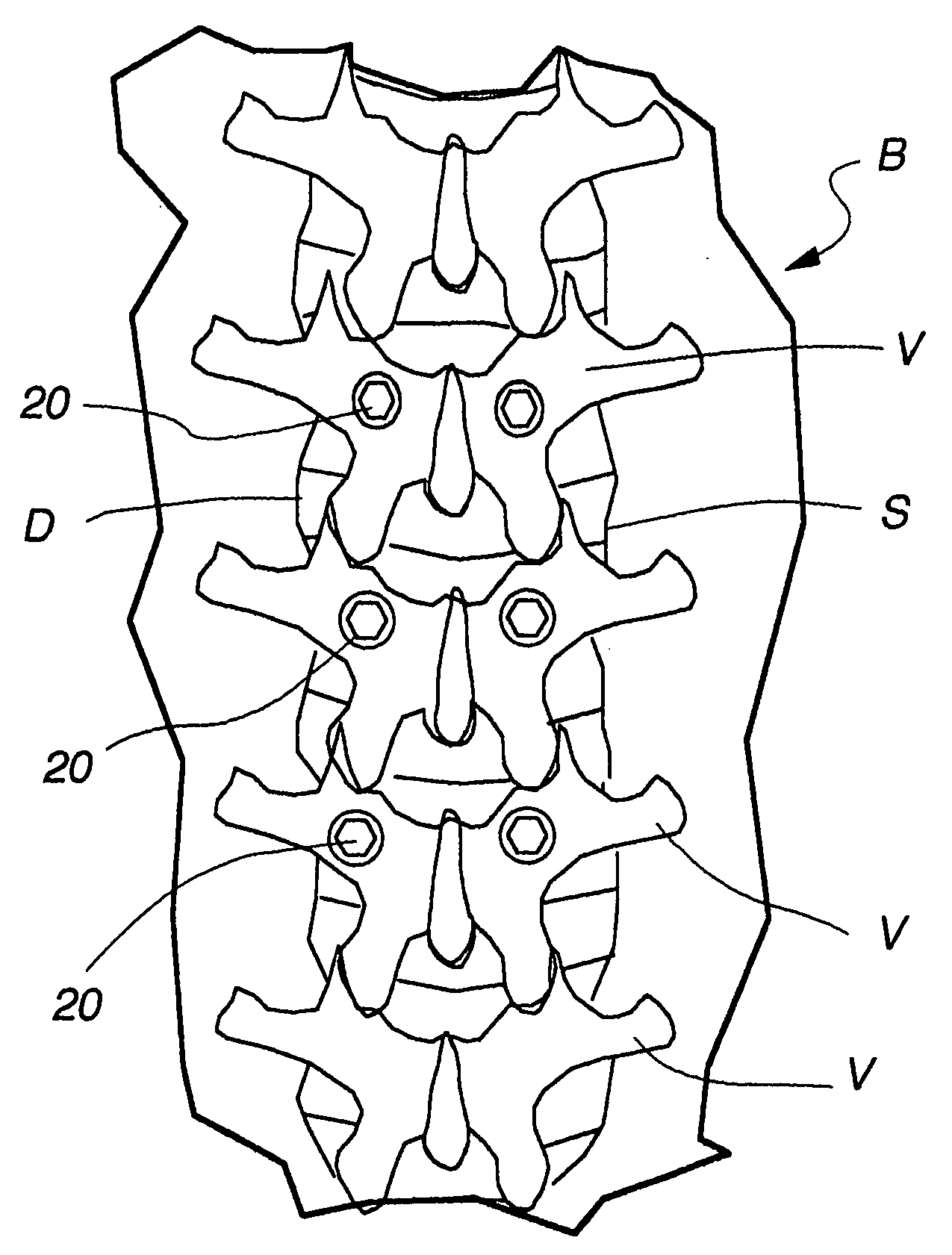

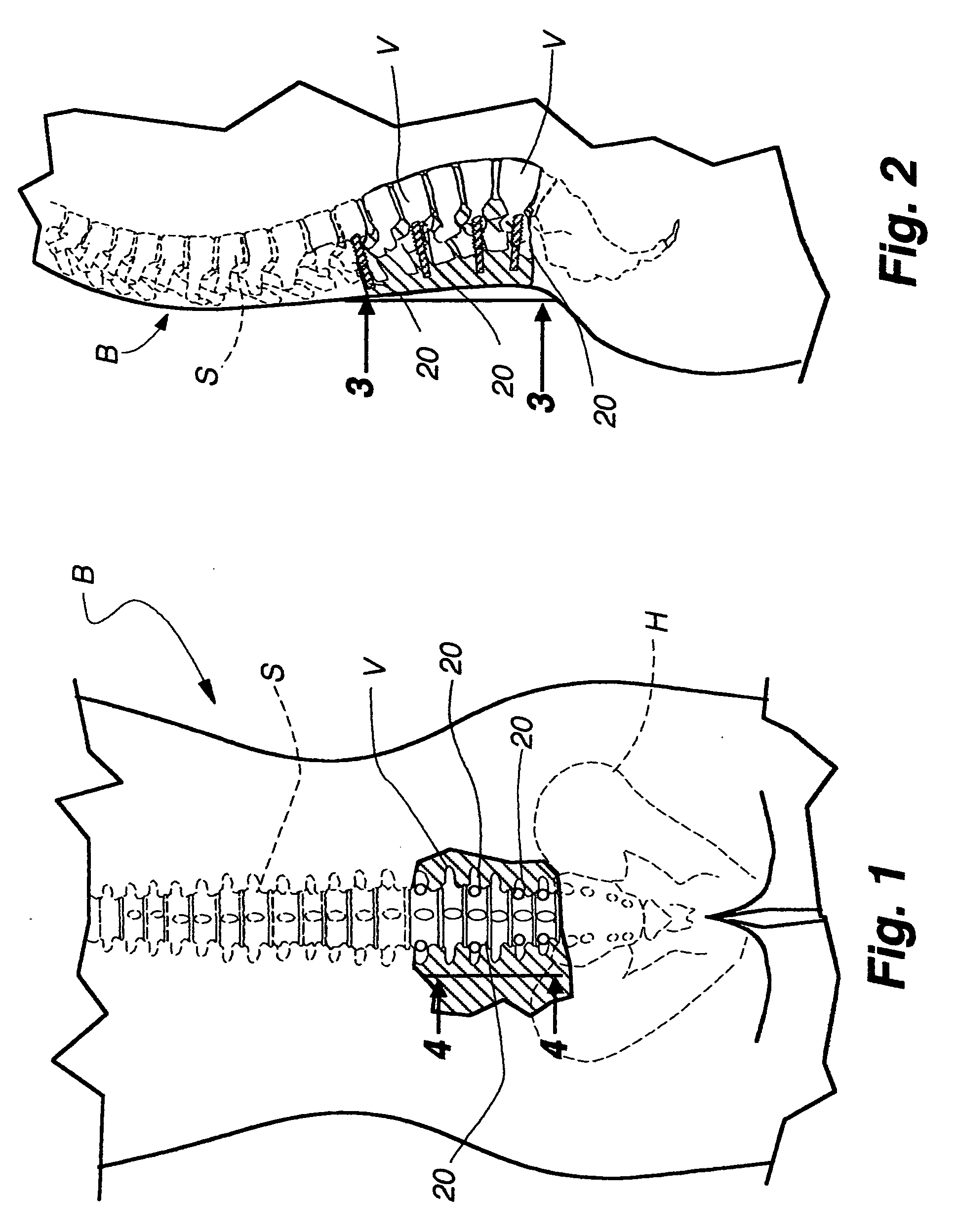

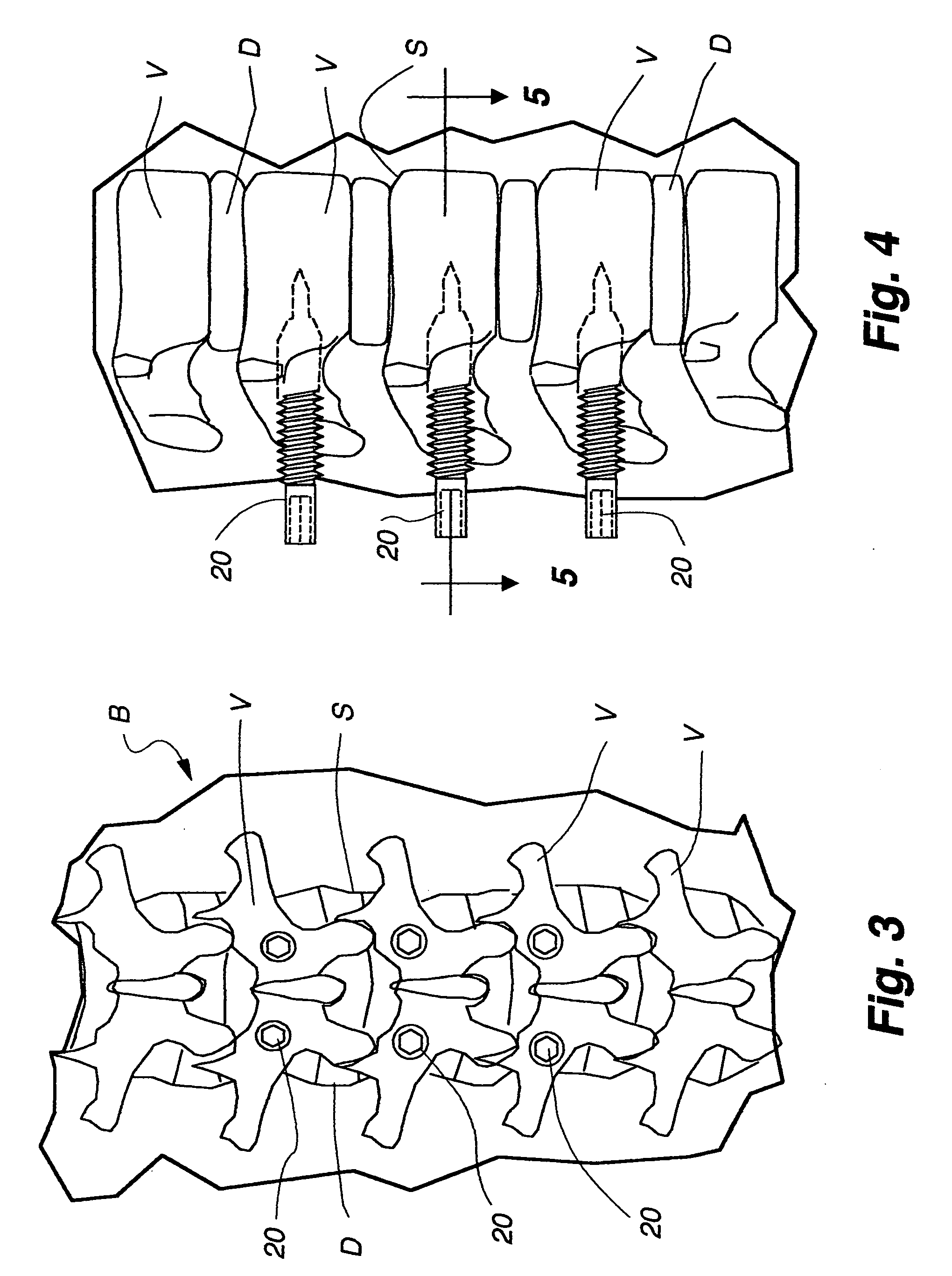

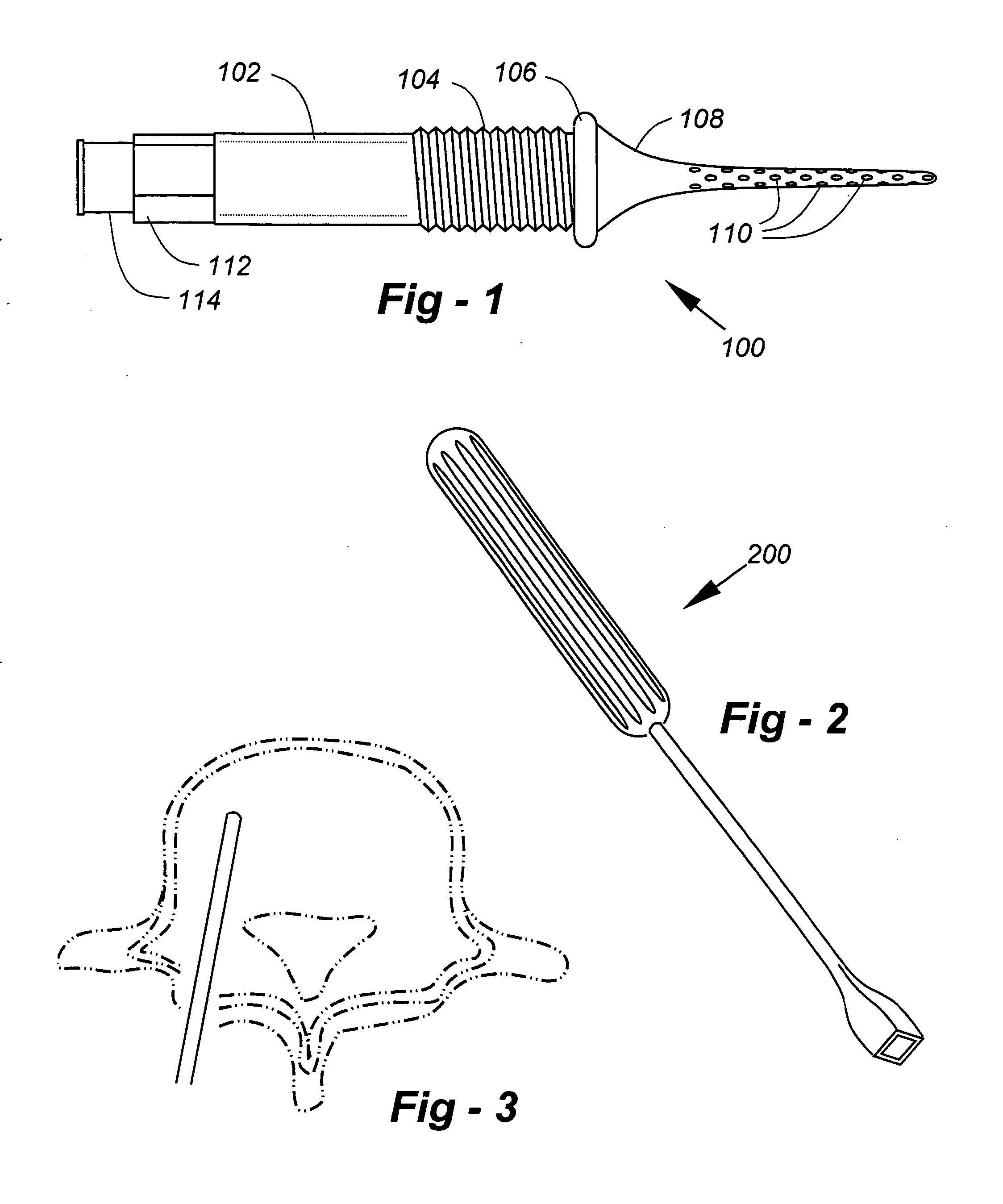

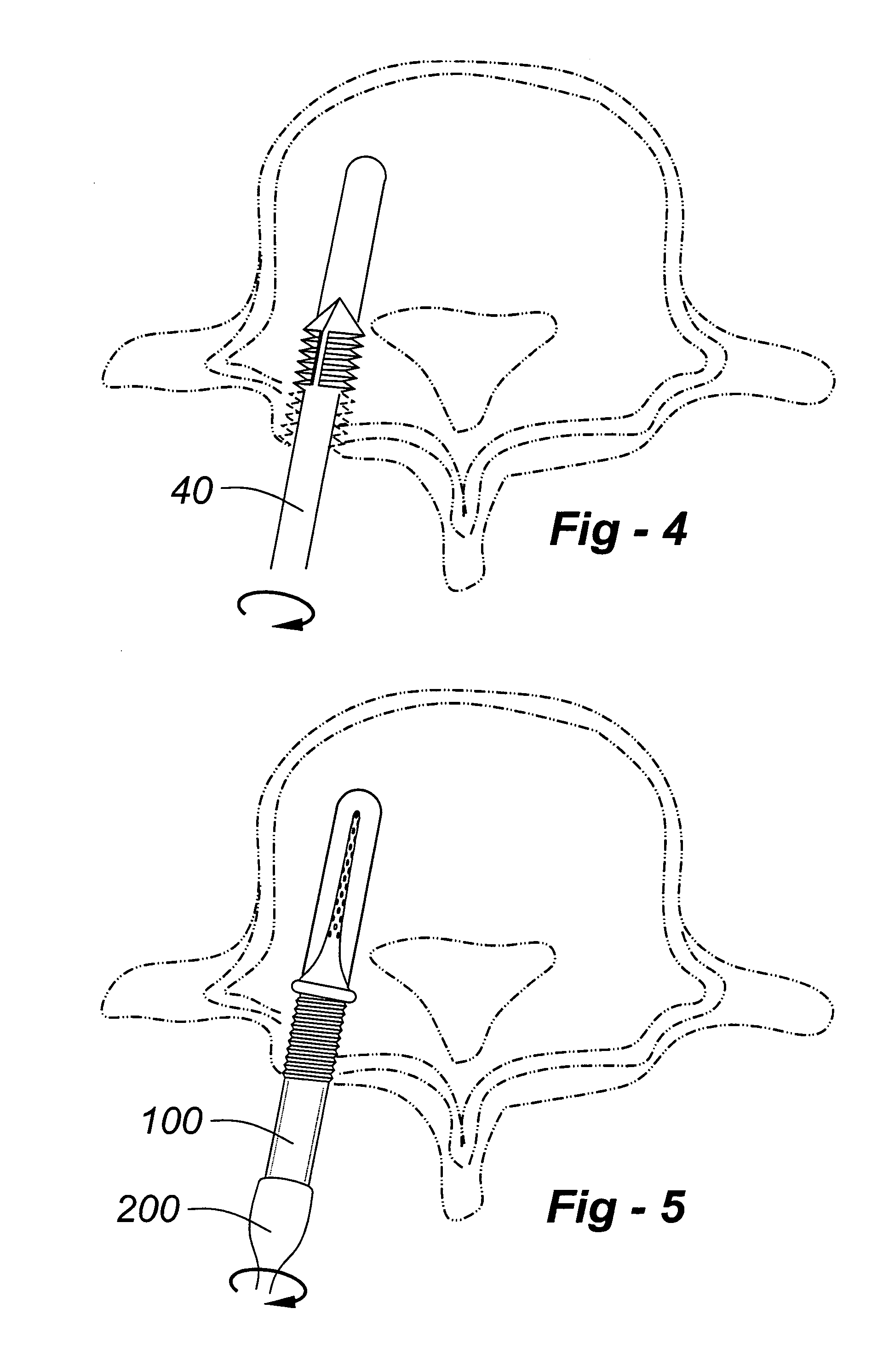

Minimally invasive pedicle screw and guide support

A minimally invasive orthopedic bone attachment system comprising a pedicle screw and guide support sleeve for insertion of the screw. The pedicle screw is a self-boring, self-tapping integral screw having a distal sharply pointed end for guiding the insertion of the screw as well as forming a borehole for the self-tapping threads of the screw. The proximal end of the screw provides a cylindrical extension which can include a recess for receiving a rotational drive tool or wrench. The length of the threads and the type of threads provided in the screw are designed for the type of orthopedic surgery that is intended. A relatively thin hollow support sleeve including an internal threaded section in the distal end is provided to match the threads and the length of the threaded portion of the pedicle screw. The proximal end of the sleeve includes a central passageway having an internal diameter that can receive the extension portion of the screw and also guide and receive a drive device for the screw. A retainer clip associated with circumferential slots spacedly indexed along the longitudinal surface of the drive device can be used to limit the depth of the screw upon insertion as well as to lock the drive device as an assembly with the screw and sleeve to form the attachment system. A small diameter passageway can be provided along the longitudinal axis of the assembly extending from the proximal end of the drive device through the screw to exit through the pointed distal end of the screw. A thin rigid rod having a point at the distal end is slidably positioned within the narrow passageway. The proximal end of the road includes a cap. A flange surface on the under portion of the cap limits the travel of the rod through the assembly. The length of the rod is determined so that it equals the length of the assembly plus an additional dimension corresponding to the anticipated installed depth of the screw. Prior to insertion of the screw, the rod is driven into the bone through the assembly. The location of the rod is ascertained by an image guidance system to determine the correct final projected location of the screw upon installation.

Owner:WONG DAVID A

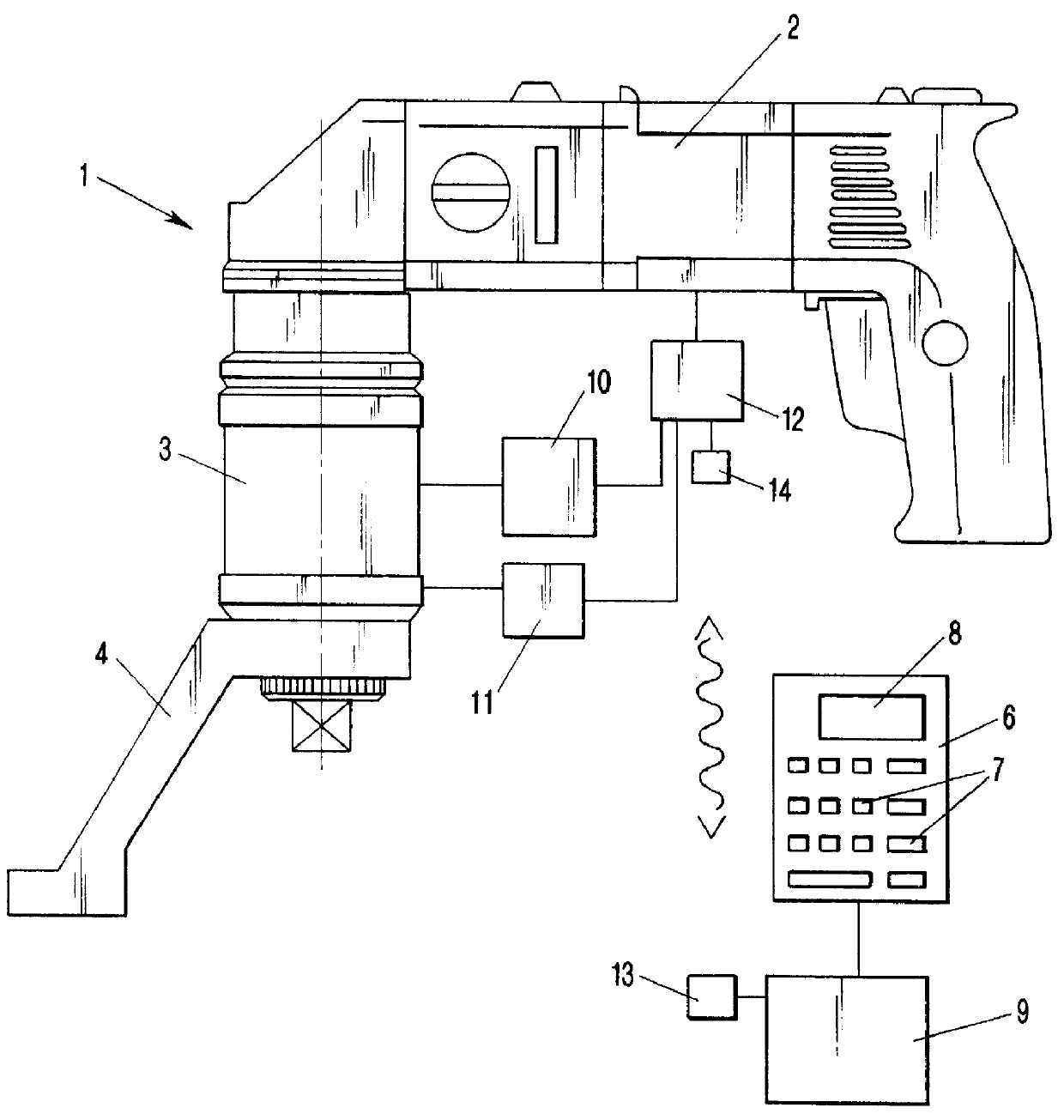

Power wrench

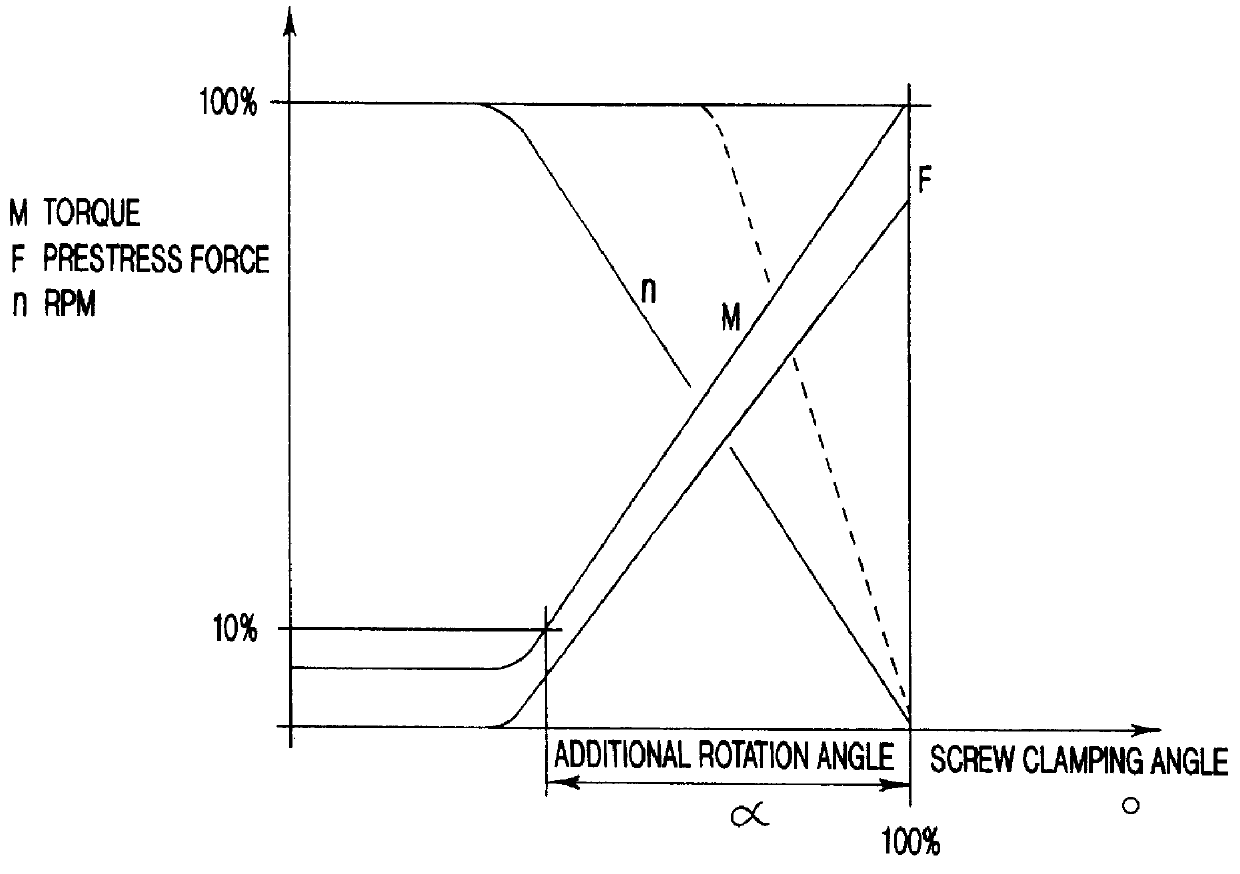

PCT No. PCT / EP97 / 05974 Sec. 371 Date Jul. 16, 1999 Sec. 102(e) Date Jul. 16, 1999 PCT Filed Oct. 29, 1997 PCT Pub. No. WO98 / 22263 PCT Pub. Date May 28, 1998A power screwdriver has a drive unit and an input circuit for inputting screw size, material quality, pitch, and clamping length of a screw. An evaluation circuit is provided for determining a nominal prestress force based on input screw size, material quality, and clamping length, for determining a nominal torque based on the nominal prestress force and the pitch, and for determining the screw clamping angle resulting from the nominal prestress force and the pitch. A sensing device for sensing the actual torque is provided, and a further sensing device for sensing the actual screw clamping angle is present. A control and switch-off device controls further rotation of the drive unit when the actual torque coincides with the nominal torque and switches off the drive unit when the actual screw clamping angle coincides with the nominal screw clamping angle. The nominal torque, based on which the additional rotation o f the drive unit is controlled until the nominal screw clamping angle is reached, is set to a value which is smaller than the torque corresponding to the nominal pretension force. An additional rotation angle of the drive unit, for reaching the nominal screw clamping angle corresponding to the nominal prestress force, is determined based on the difference between the nominal screw clamping angle and the adjusted screw clamping angle corresponding to the preset nominal torque and is used for switching off the drive unit.

Owner:HOHMANN JORG +1

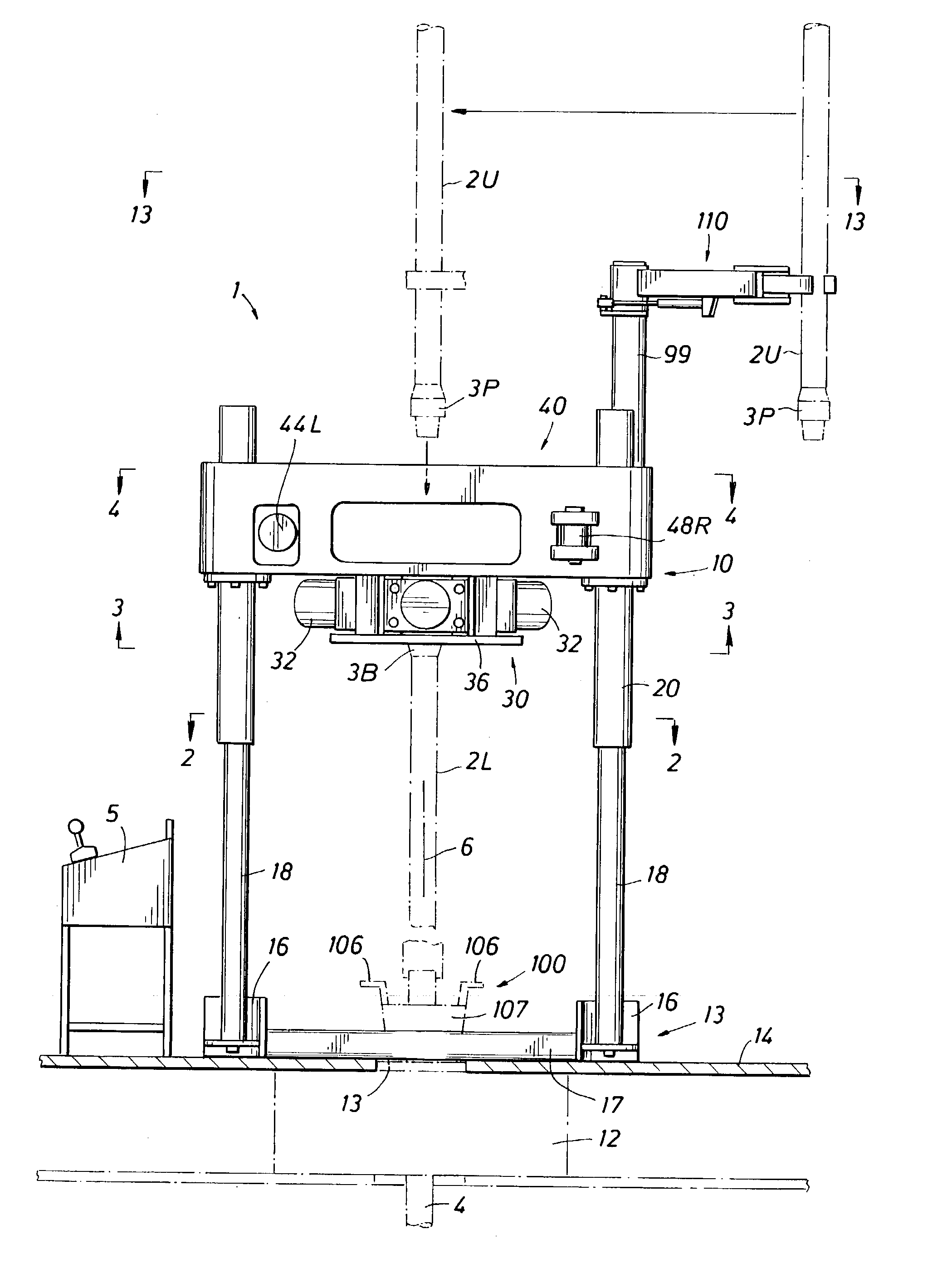

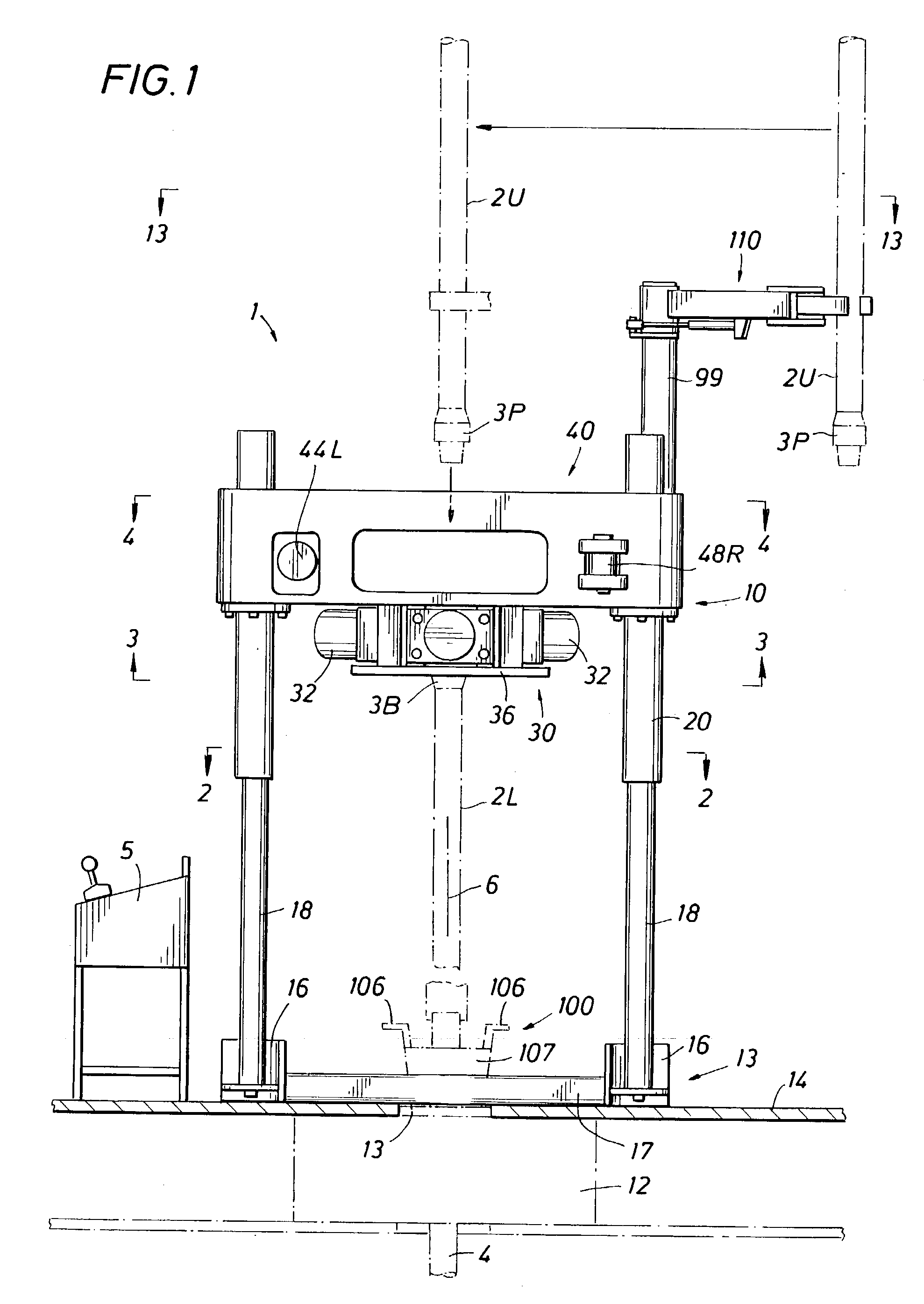

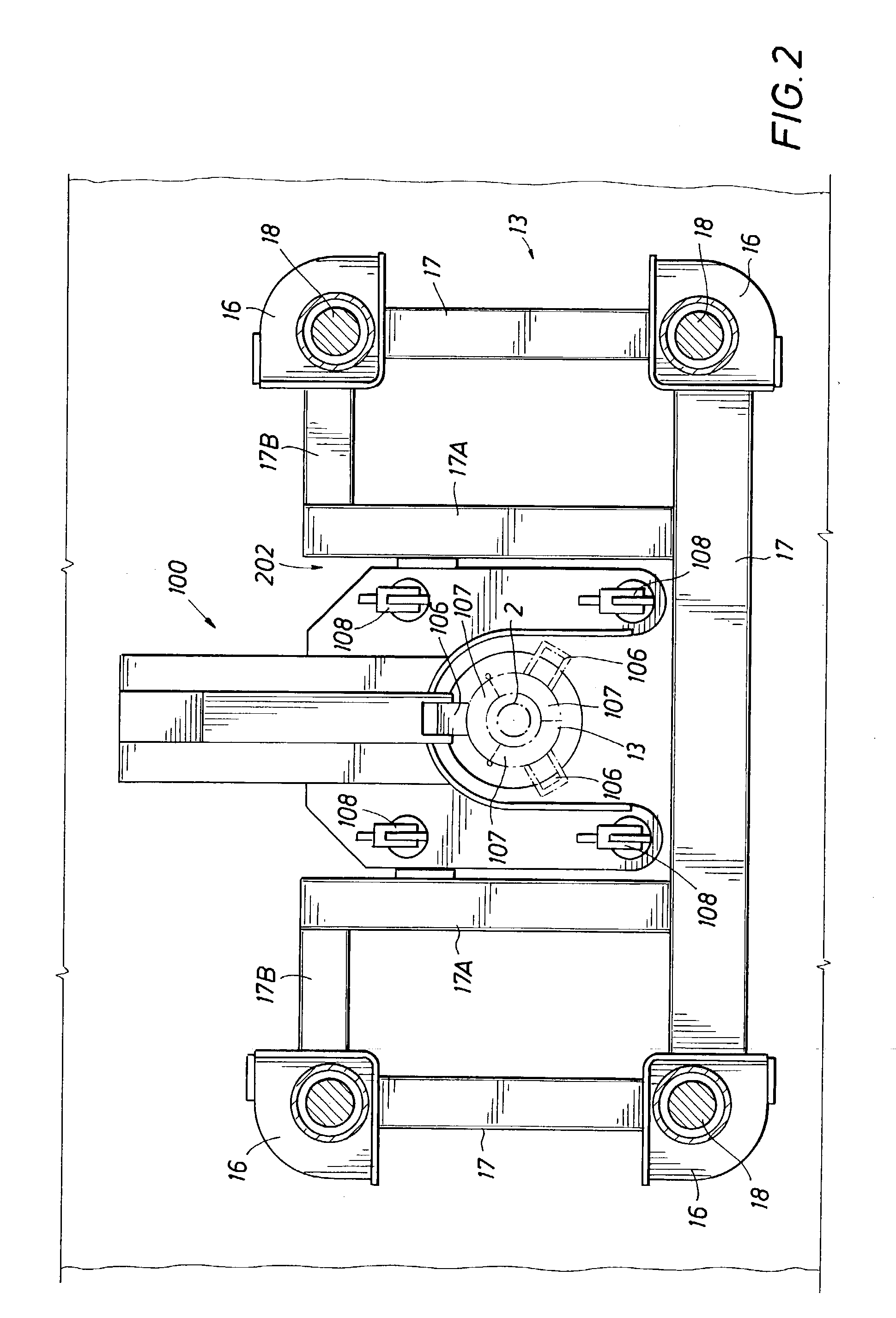

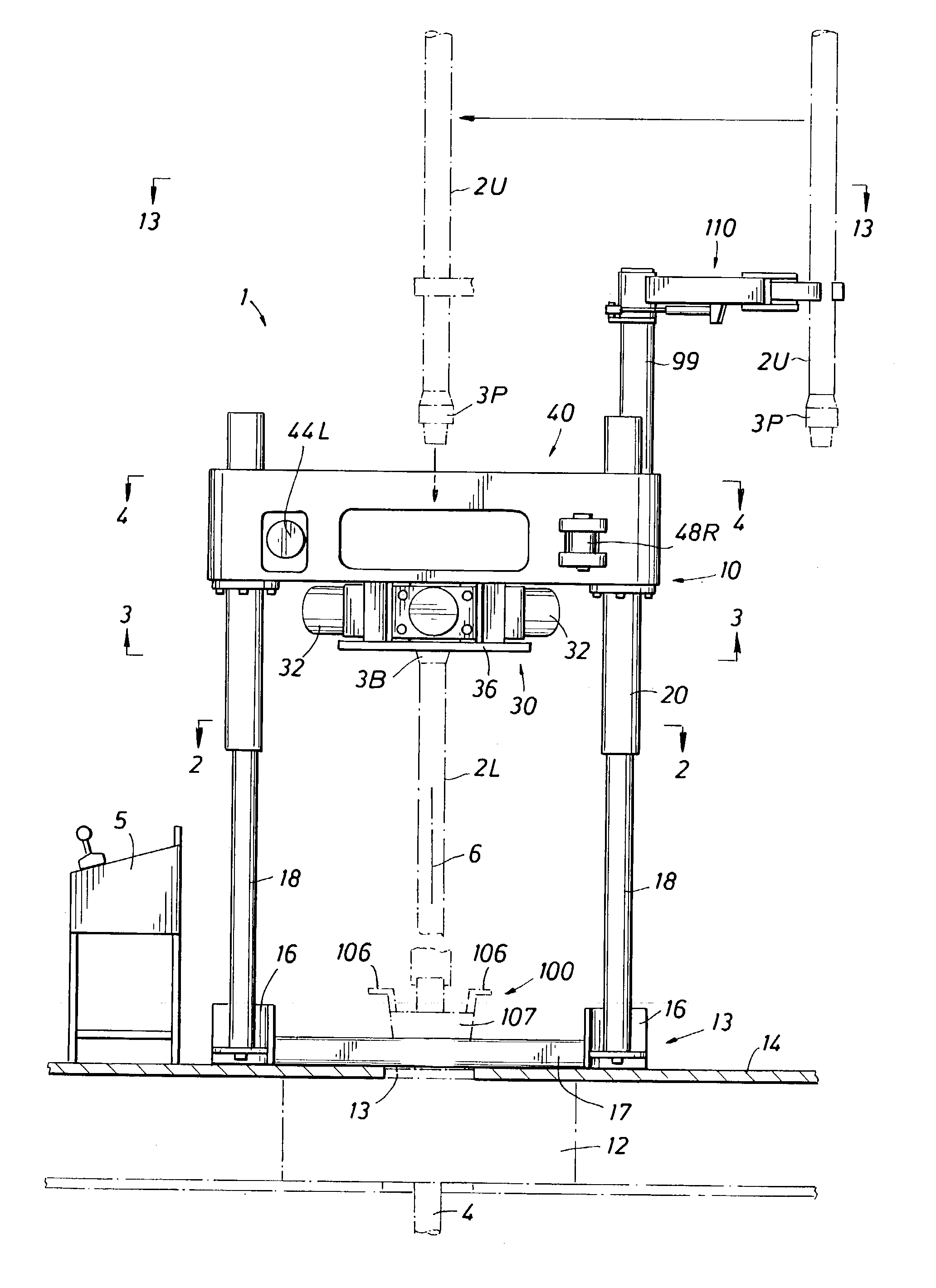

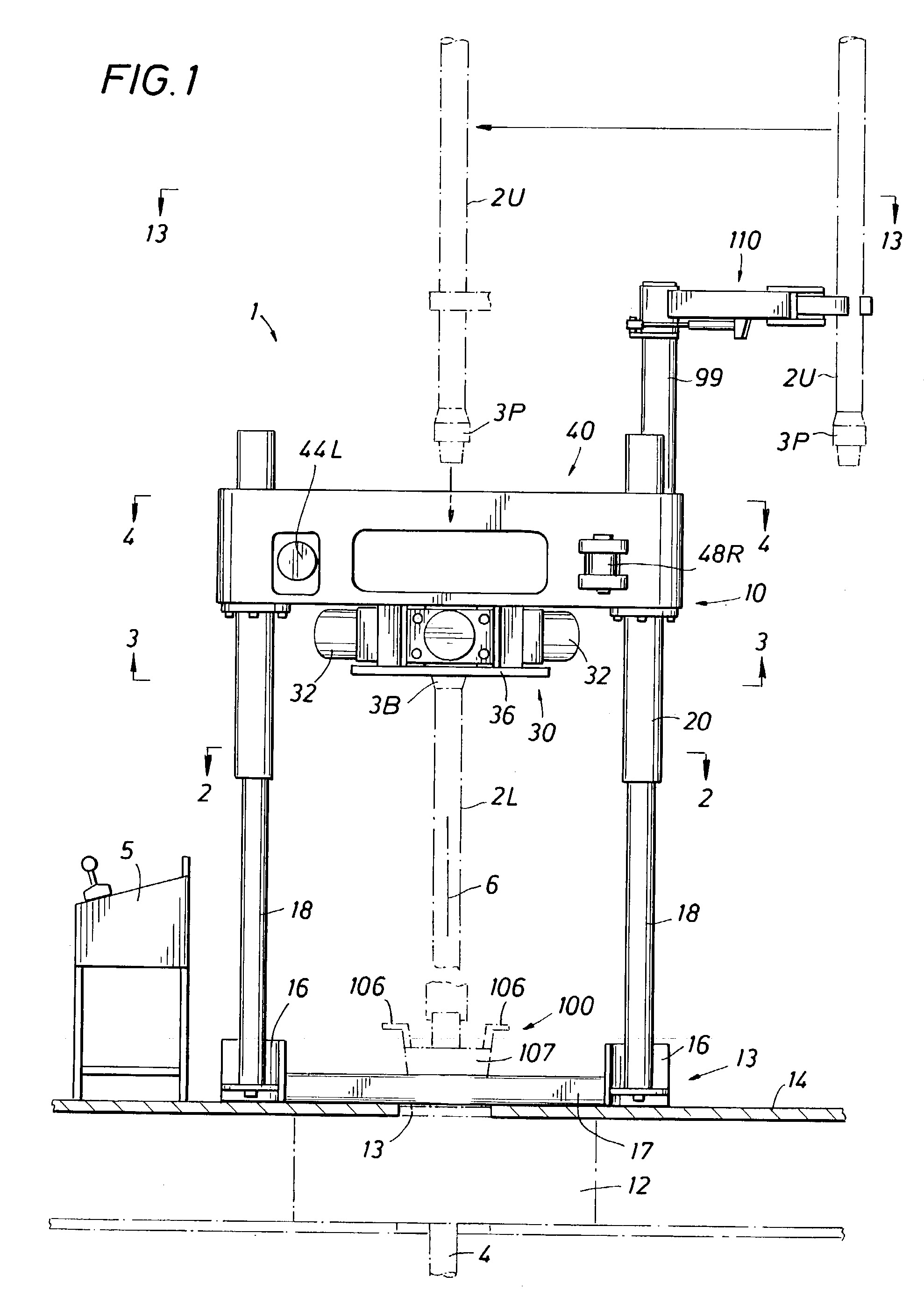

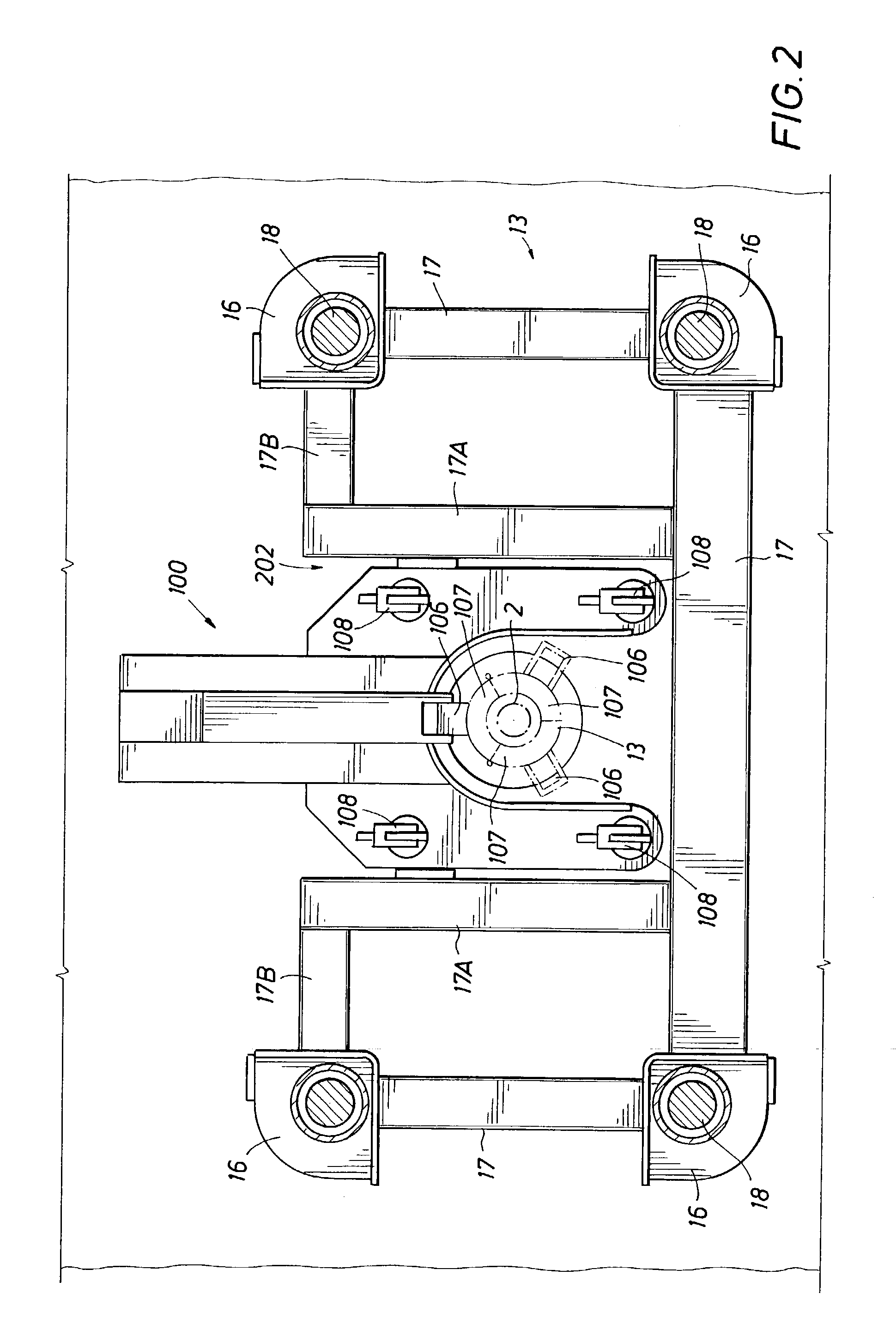

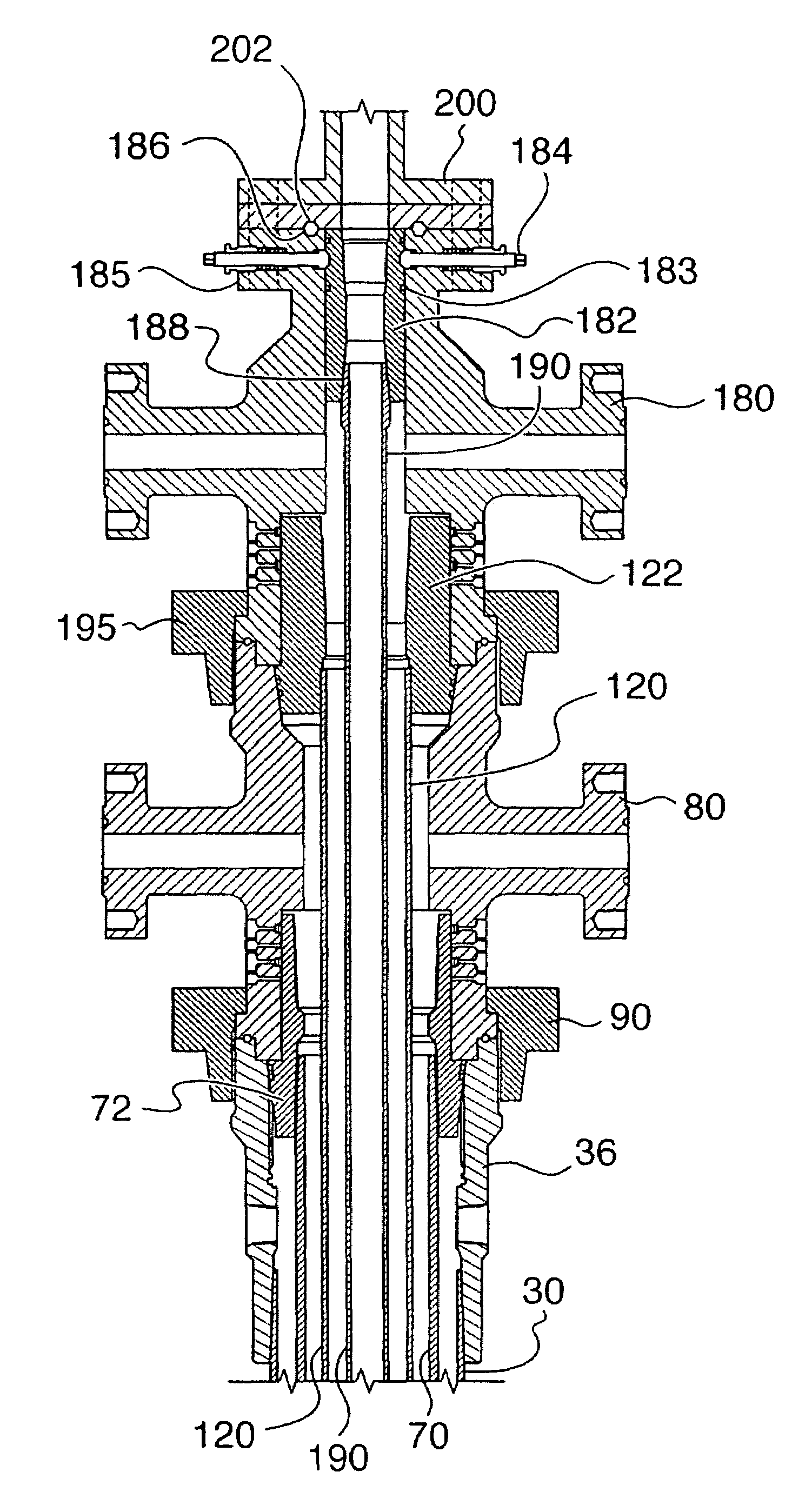

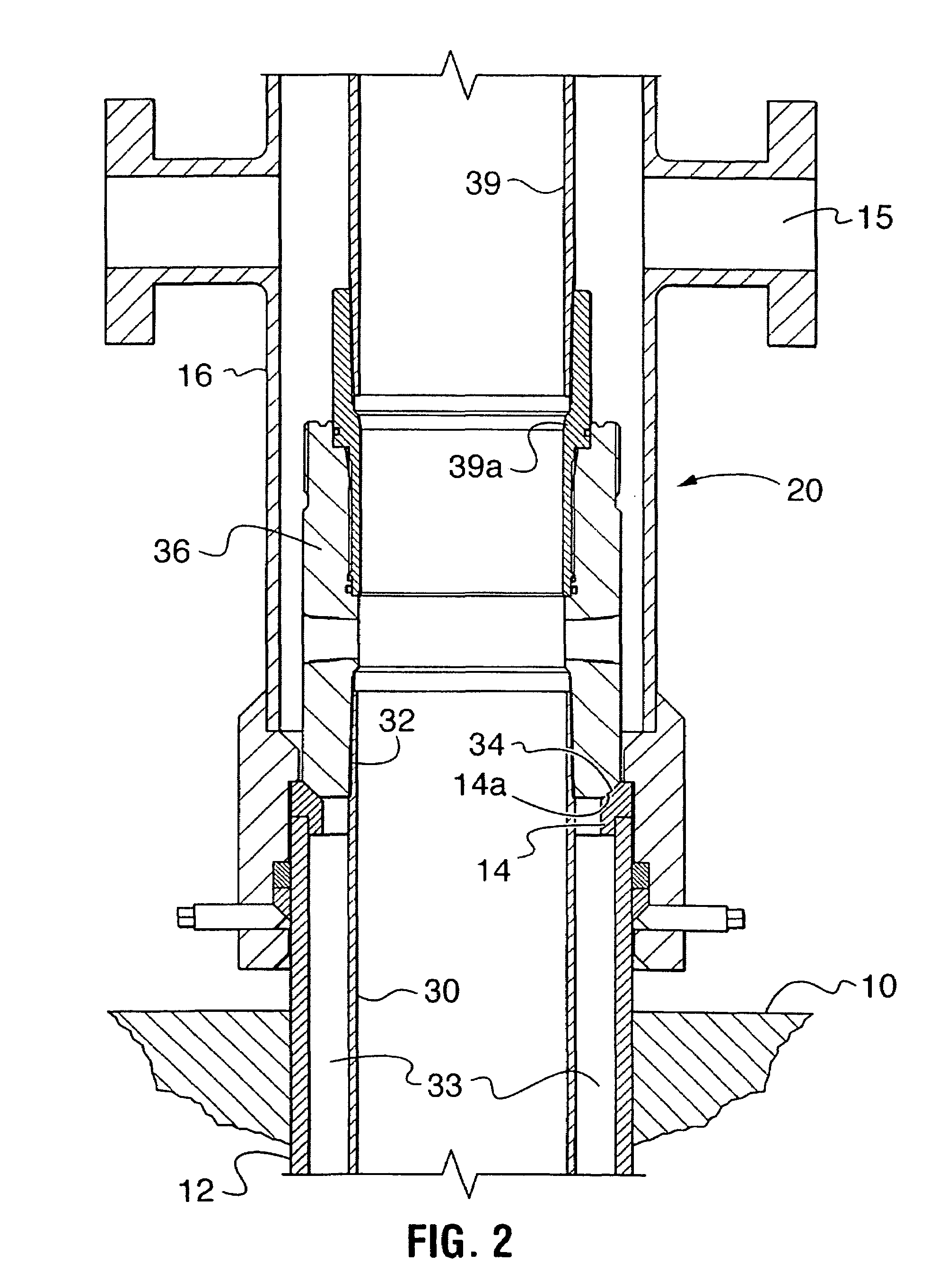

Drill pipe connecting and disconnecting apparatus

Drilling rig apparatus for connecting and disconnecting well pipe at a drilling rig. A remotely controlled power wrench assembly is mounted on a remotely controlled lifting mechanism attached to a base spaced about the well axis on the rig floor. The wrench assembly includes upper and lower wrenches carried by the lifting mechanism. The wrench assembly includes a lower wrench for gripping a lower box coupling of a drill pipe section at the well center. An upper wrench is provided for spinning an upper pin coupling into or out of threaded engagement with the lower box coupling. The upper wrench has two opposed spinner-roller pairs which translate between open and closed positions for spinning the upper pin coupling when in a closed position. The upper wrench also has two opposed jaw blocks which translate between open and closed positions for gripping the pin coupling in a closed position. The spinner roller pairs and the jaw blocks move in directions perpendicular to each other into and out of a cavity through which the well axis passes vertically. Torque cylinders are provided by which the upper wrench is torqued in a first or "torquing up" direction while the jaw blocks are gripping the pin coupling and in a second or "breaking loose" direction. A manipulator is pivotably carried on a rod supported from the wrench assembly. The manipulator includes a remotely controlled arm and hand assembly which captures a drill pipe section in its hand and transfers the drill pipe while being supported vertically by the drilling rig between the well axis and a position at the side-of the wrench assembly. The drilling rig apparatus includes a bore arranged and designed for placement on the rig floor around the well axis. A slot is provided between frame members for placement of a pneumatically remotely controlled power slip manipulator for setting and releasing slips in the rotary table for supporting the drill pipe string in the well bore during connecting and disconnecting operations of drill pipe sections.

Owner:FORUM US

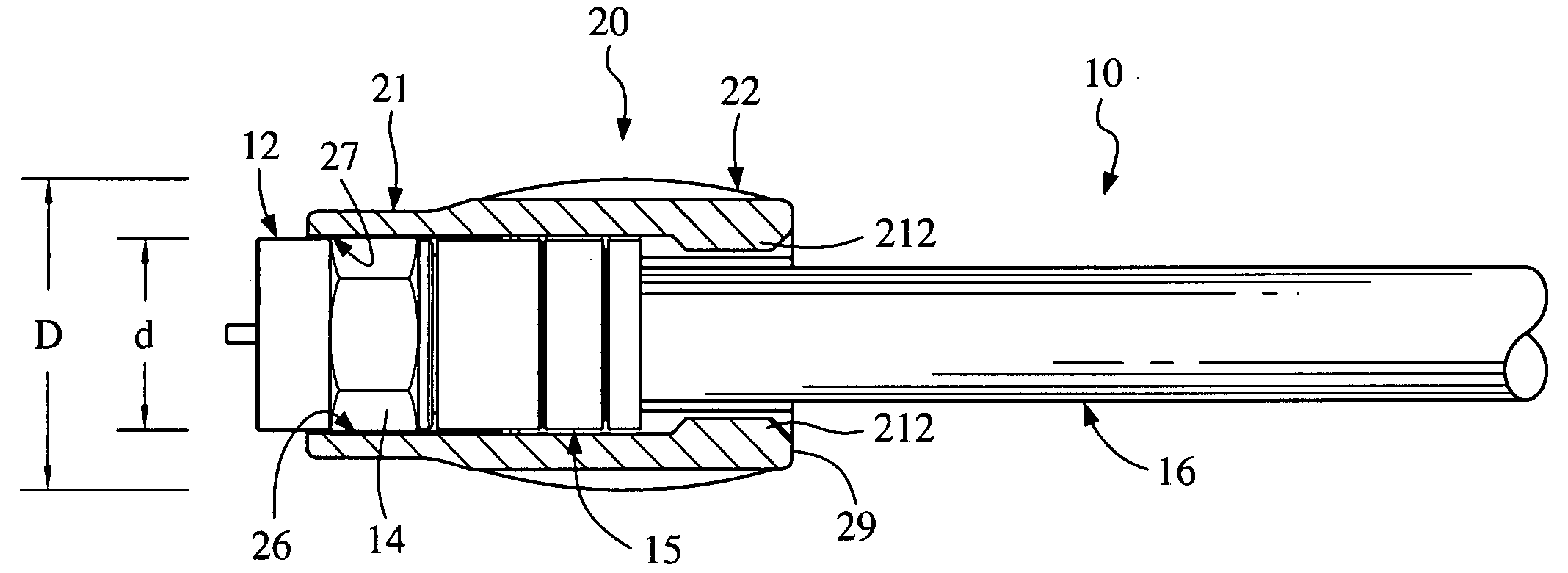

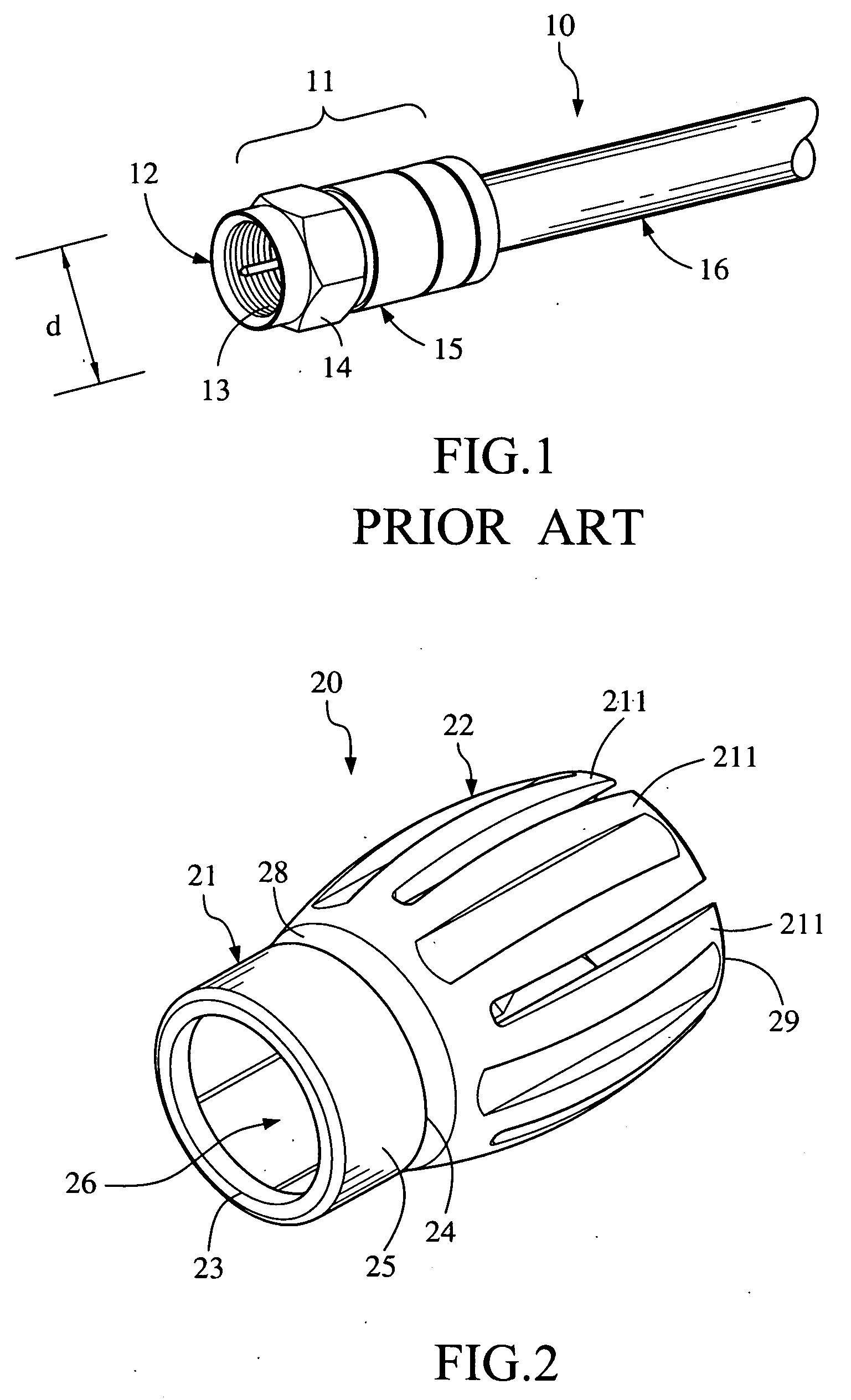

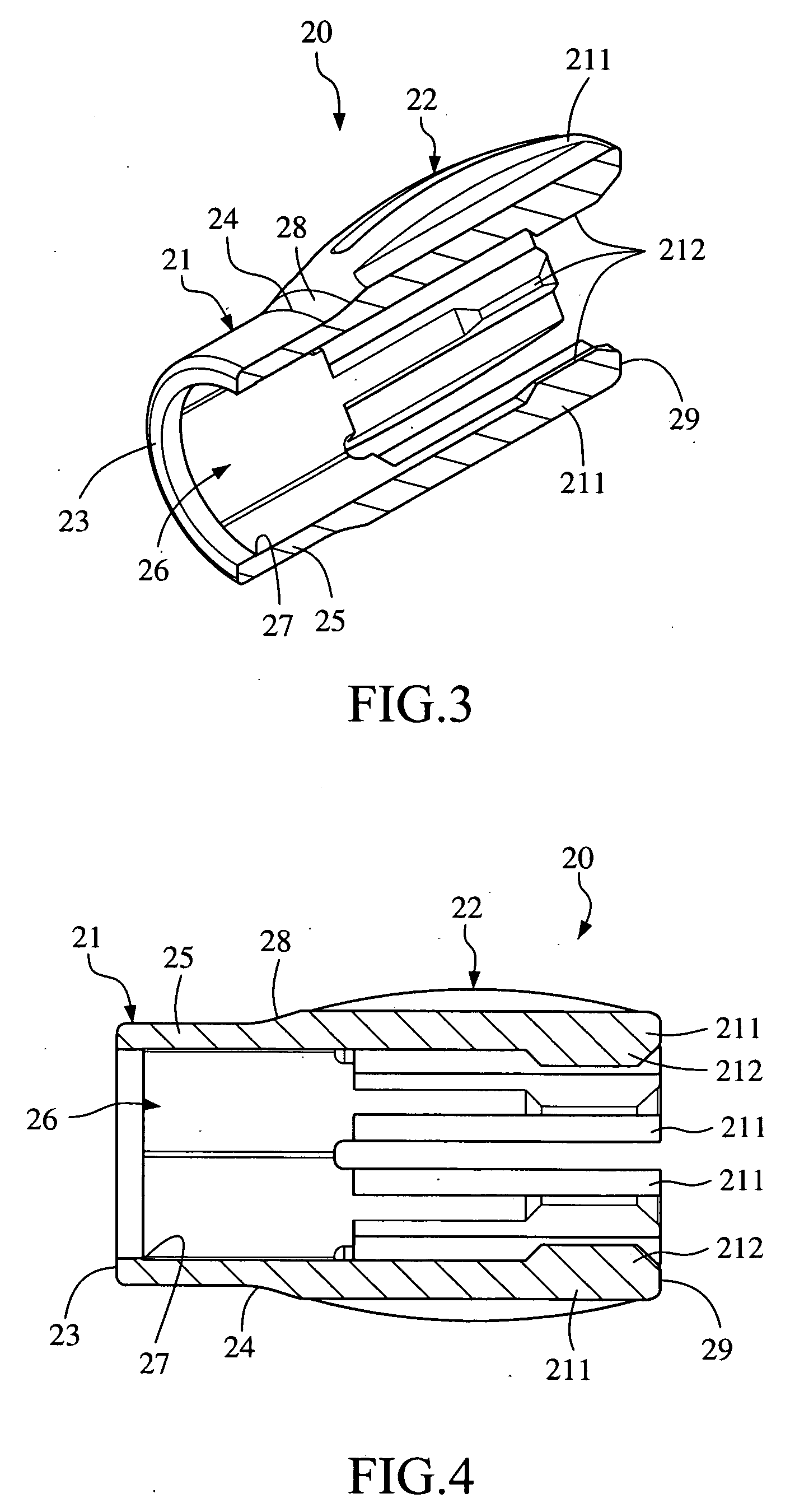

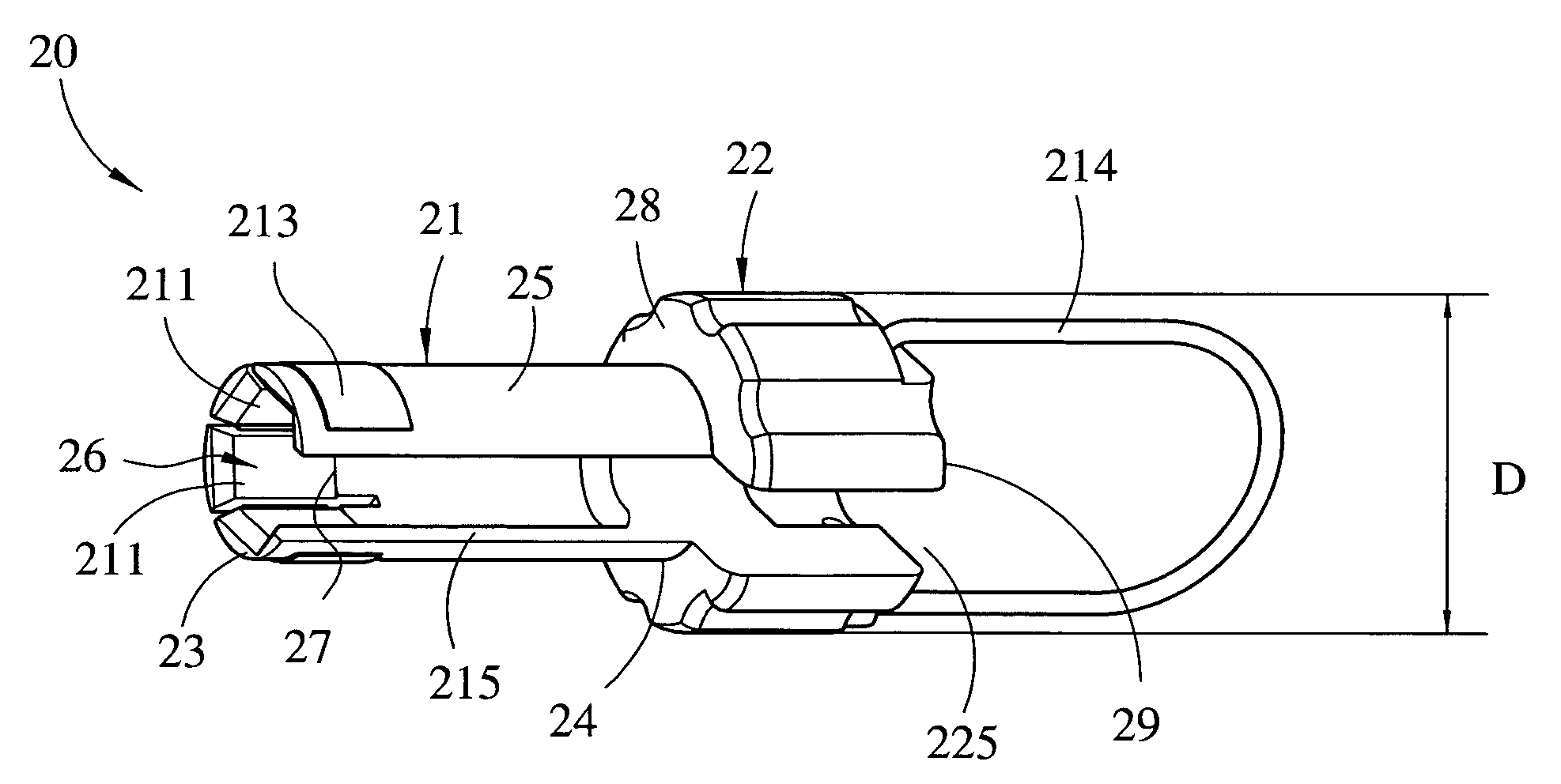

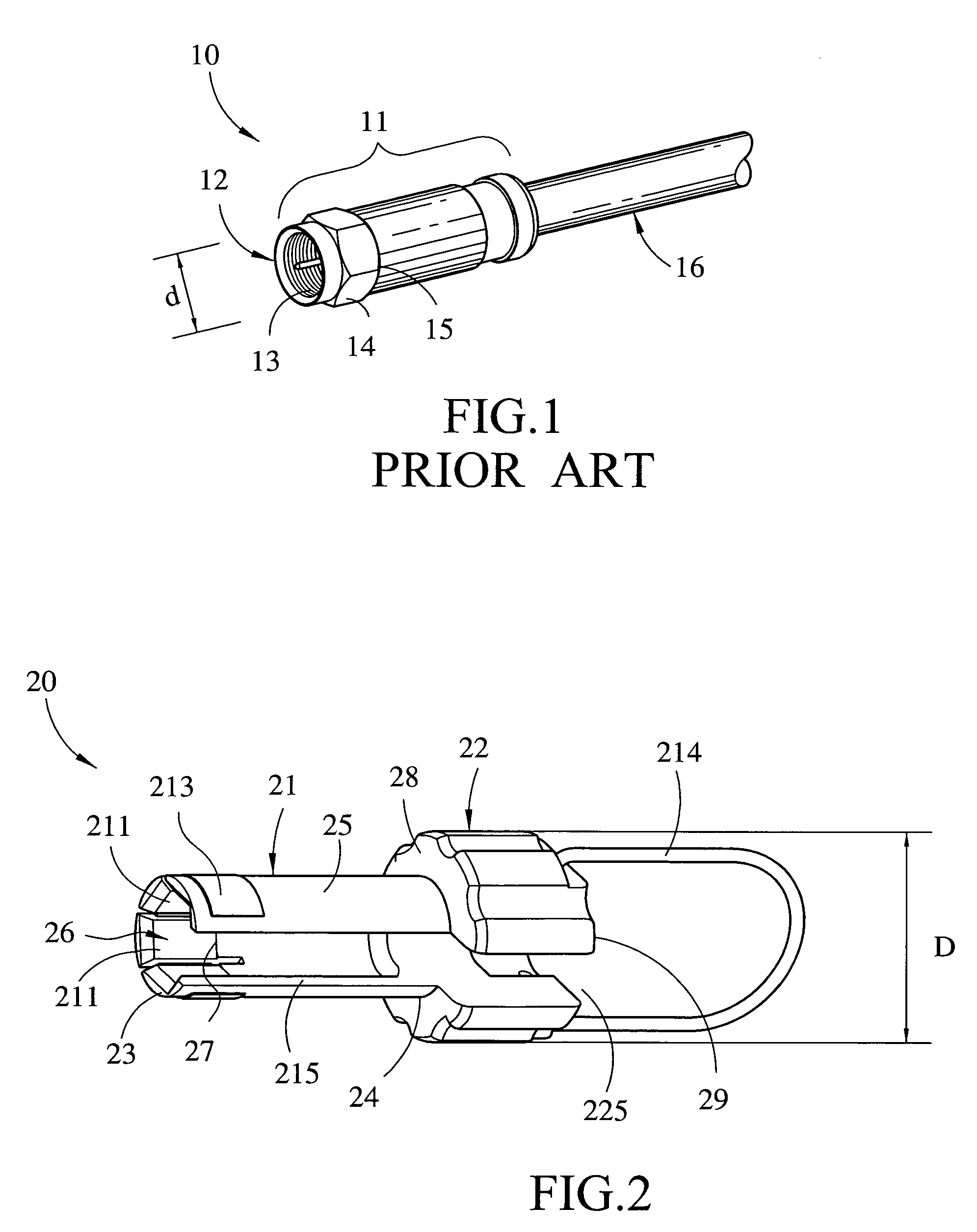

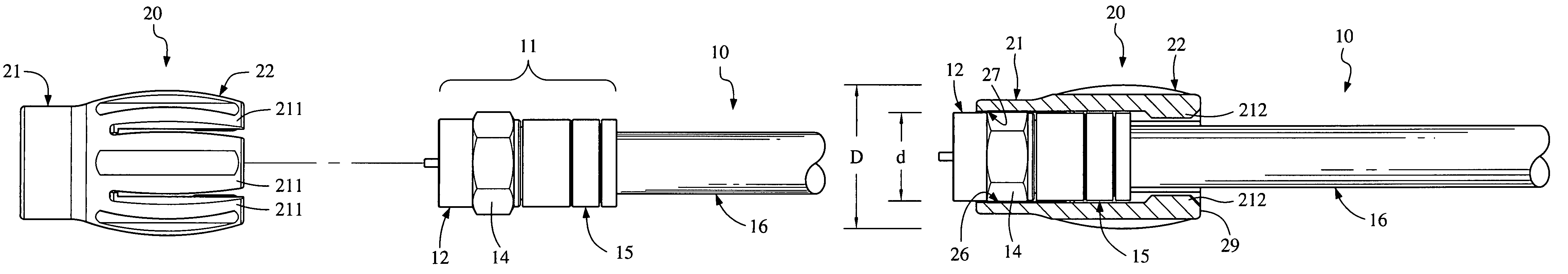

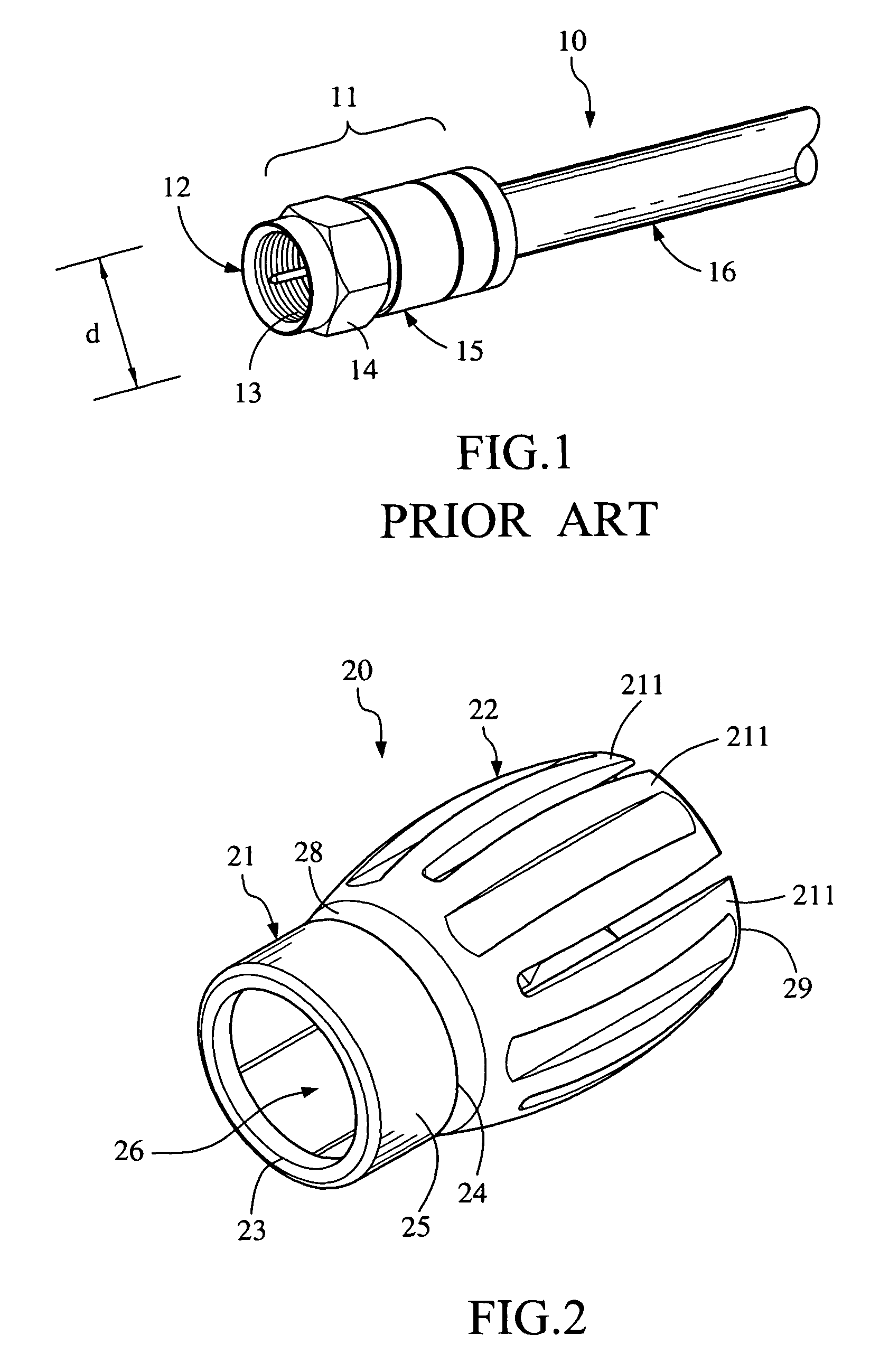

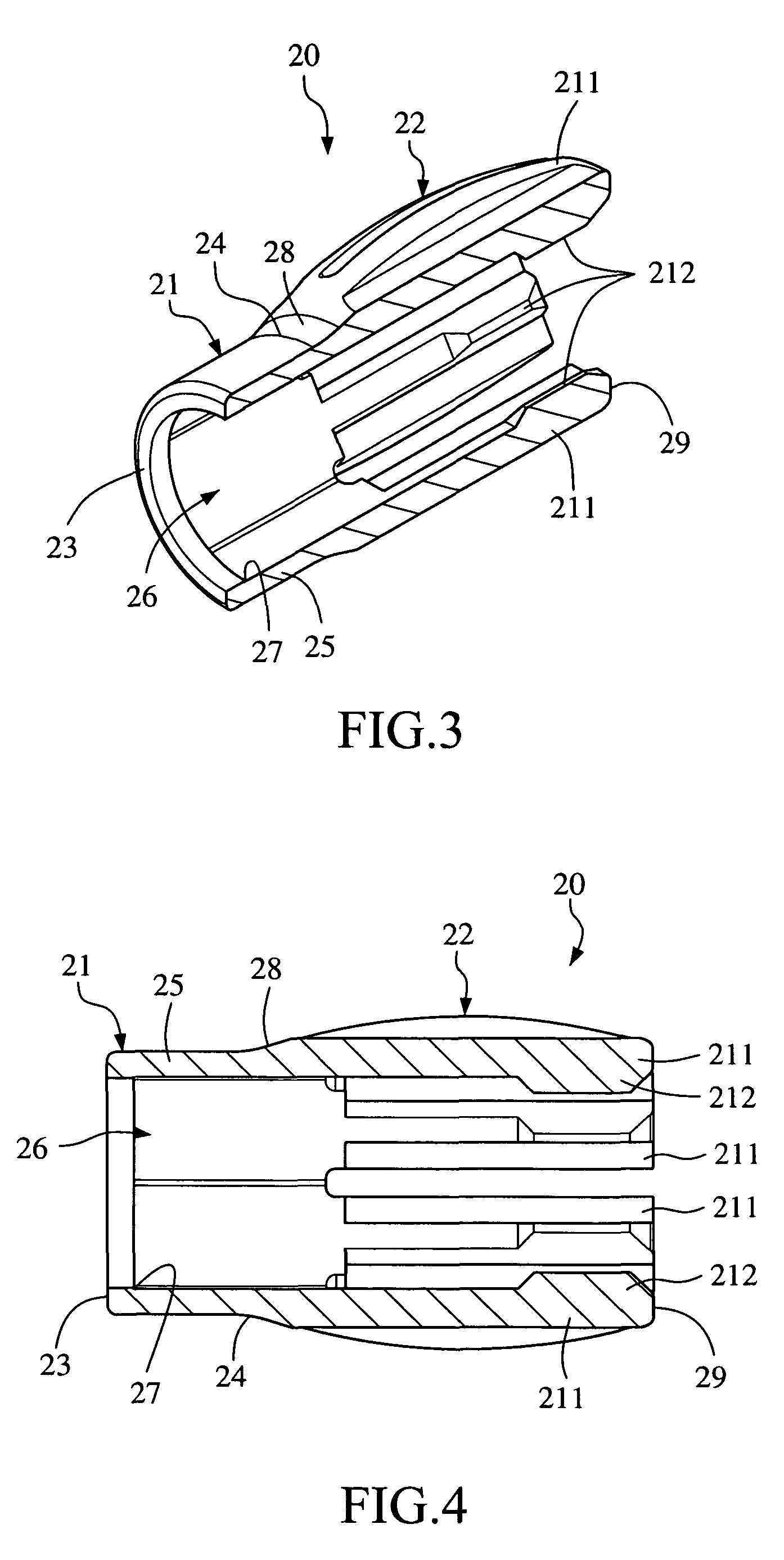

Jumper sleeve for connecting and disconnecting male f connector to and from female f connector

ActiveUS20100233902A1Firmly connectedElectrically conductive connectionsTwo pole connectionsEngineeringMechanical advantage

A jumper sleeve for connecting and disconnecting a male F connector to and from a female F connector includes a wrench portion and a grip portion. The wrench portion has a leading end, a trailing end, and a hollow main body located between the leading end and the trailing end. The main body of the wrench portion internally has a hexagonally shaped portion corresponding to a shaped outer surface of a rotatable connecting ring of the male F connector. The grip portion has a rear end and a front end connected to the trailing end of the wrench portion, and has a plurality of circumferentially spaced externally convex sections, each of which has a radially inward key formed near the rear end thereof. The jumper sleeve provides greater mechanical advantage to produce sufficient torsion force, enabling easy installation and removal of the male F connector.

Owner:PHOENIX COMM TECH INTIOAL

Drill pipe connecting and disconnecting apparatus

Drilling rig apparatus for connecting and disconnecting well pipe at a drilling rig. A remotely controlled power wrench assembly is mounted on a remotely controlled lifting mechanism attached to a base spaced about the well axis on the rig floor. The wrench assembly includes upper and lower wrenches carried by the lifting mechanism. The wrench assembly includes a lower wrench for gripping a lower box coupling of a drill pipe section at the well center. An upper wrench is provided for torquing and spinning an upper pin coupling into or out of threaded engagement with the lower box coupling. A manipulator is pivotably carried on a rod supported from the wrench assembly. The manipulator captures a drill pipe section and transfers the drill pipe section between the well axis and a position at the side of the wrench assembly. A slot is provided between frame members of the base for placement of a power slip manipulator for setting and releasing slips in the rotary table.

Owner:FORUM US

Tool operable for connecting a male F-type coaxial cable connector

ActiveUS7347129B1Coupling device engaging/disengagingCoupling device detailsCoaxial cableEngineering

A tool including a tubular wrench portion and a hollow grasping portion. The tubular wrench portion has a first end, a second end, a hollow body portion located between the first and second ends and a plurality of arc portions located at the first end. The hollow body portion has a first slot extending from the first end to the second end. The arc portions have an outer surface for installing the C-shaped fastening ring thereon to generate torsion and an inner surface formed with a shaped portion to engage with a shaped outer surface of a connector ring. The arc portions are outwardly extended by the torsion when a predetermined torsion is enough to deform the arc portions of the tubular wrench portion.

Owner:PHOENIX COMM TECH INT

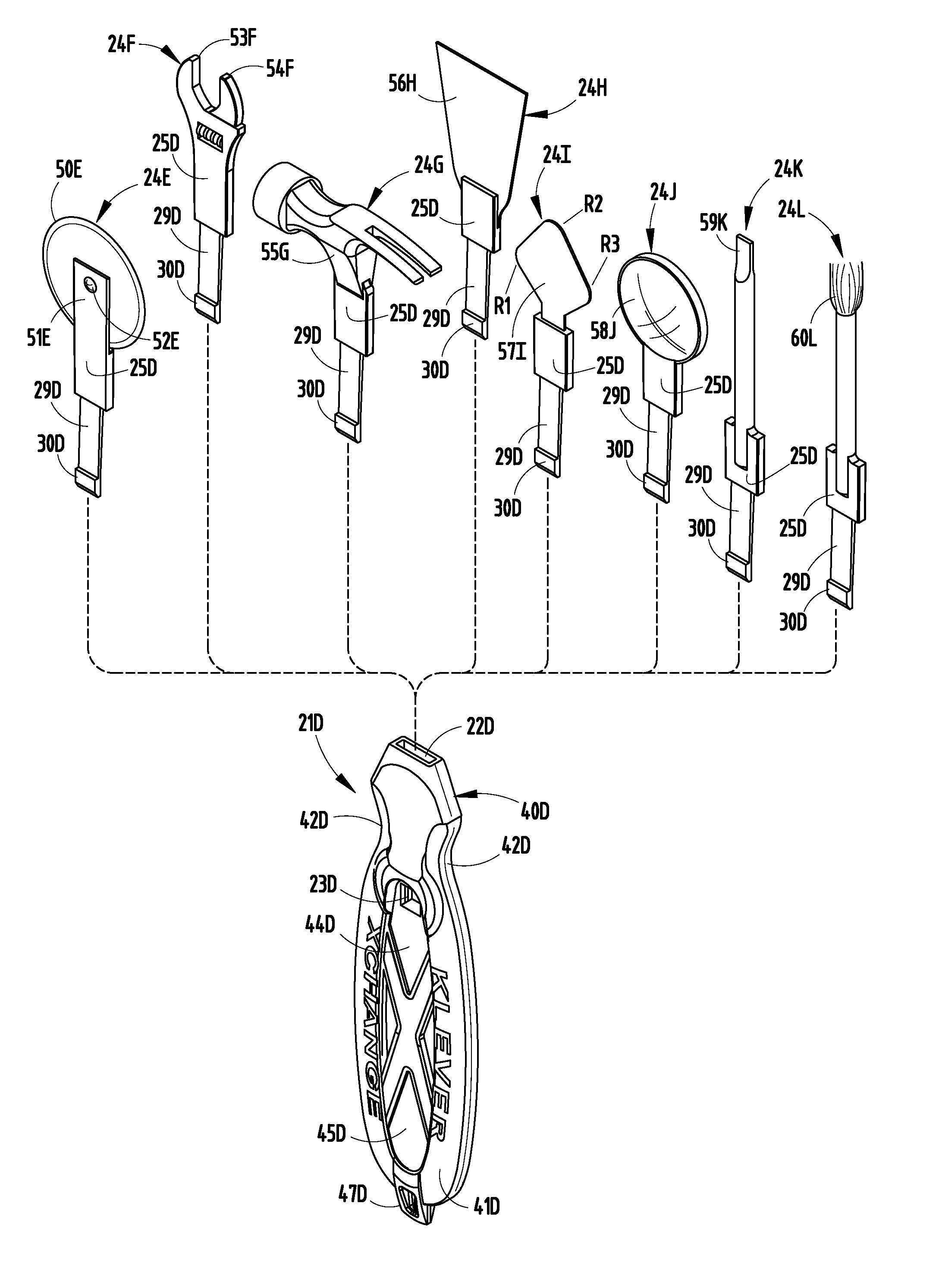

Tool with ergonomic handle and replaceable cutter head

A tool includes an elongated handle with an end recess and a side notch for latching, and a plurality of different replaceable heads. Each replaceable head includes an elongated rectangular section shaped to fit stably into the recess for providing torsional and lateral support, an operative end, and a latch releasably engaging the side notch to retain the head in the recess. The different heads can include different operative ends with structure for providing different operative functions, such as a head with oppositely-positioned partially-shielded blade tips and / or with different blade throat sizes, a head with pizza-cutting wheel, a head with hammer or wrench feature, and the like.

Owner:KLEVER KUTTER

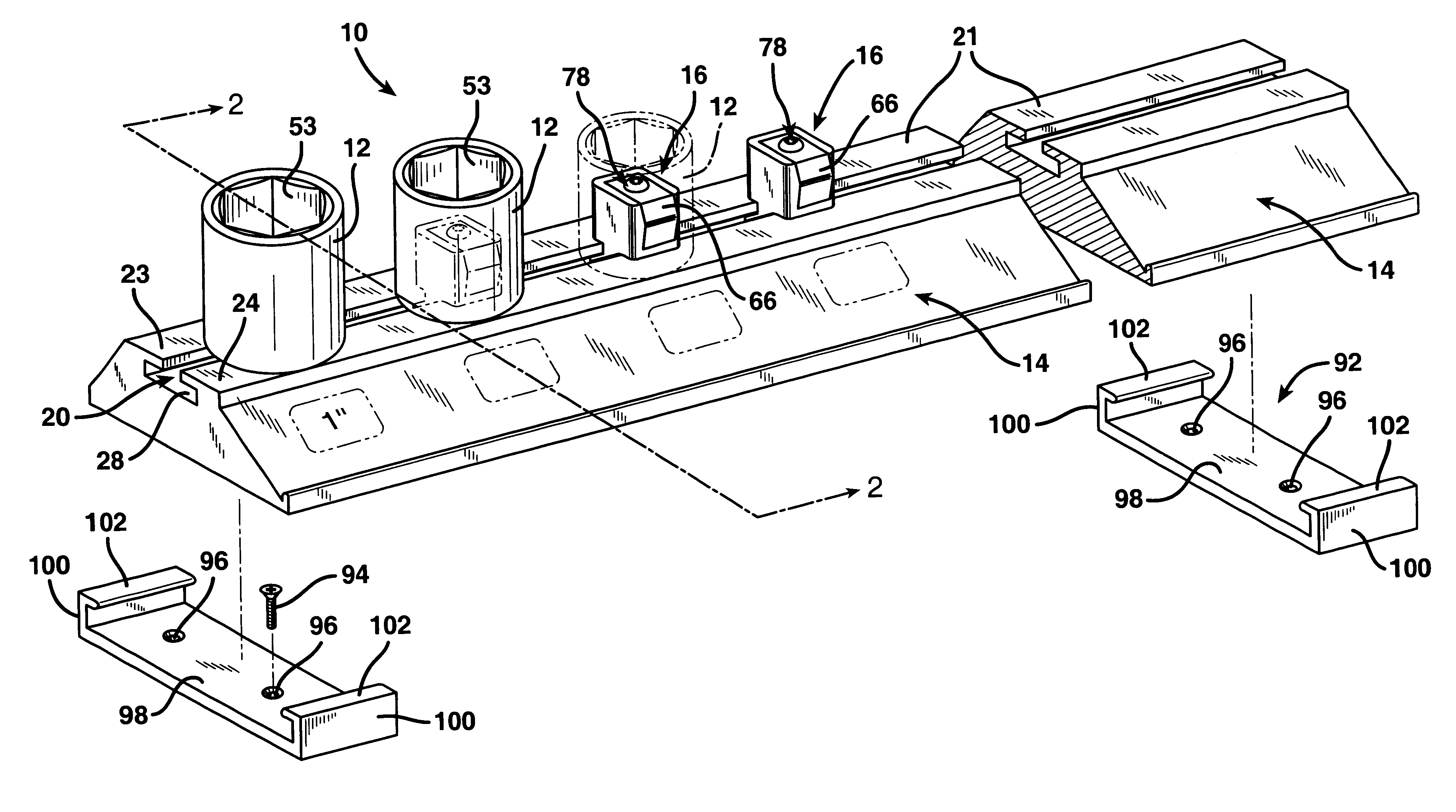

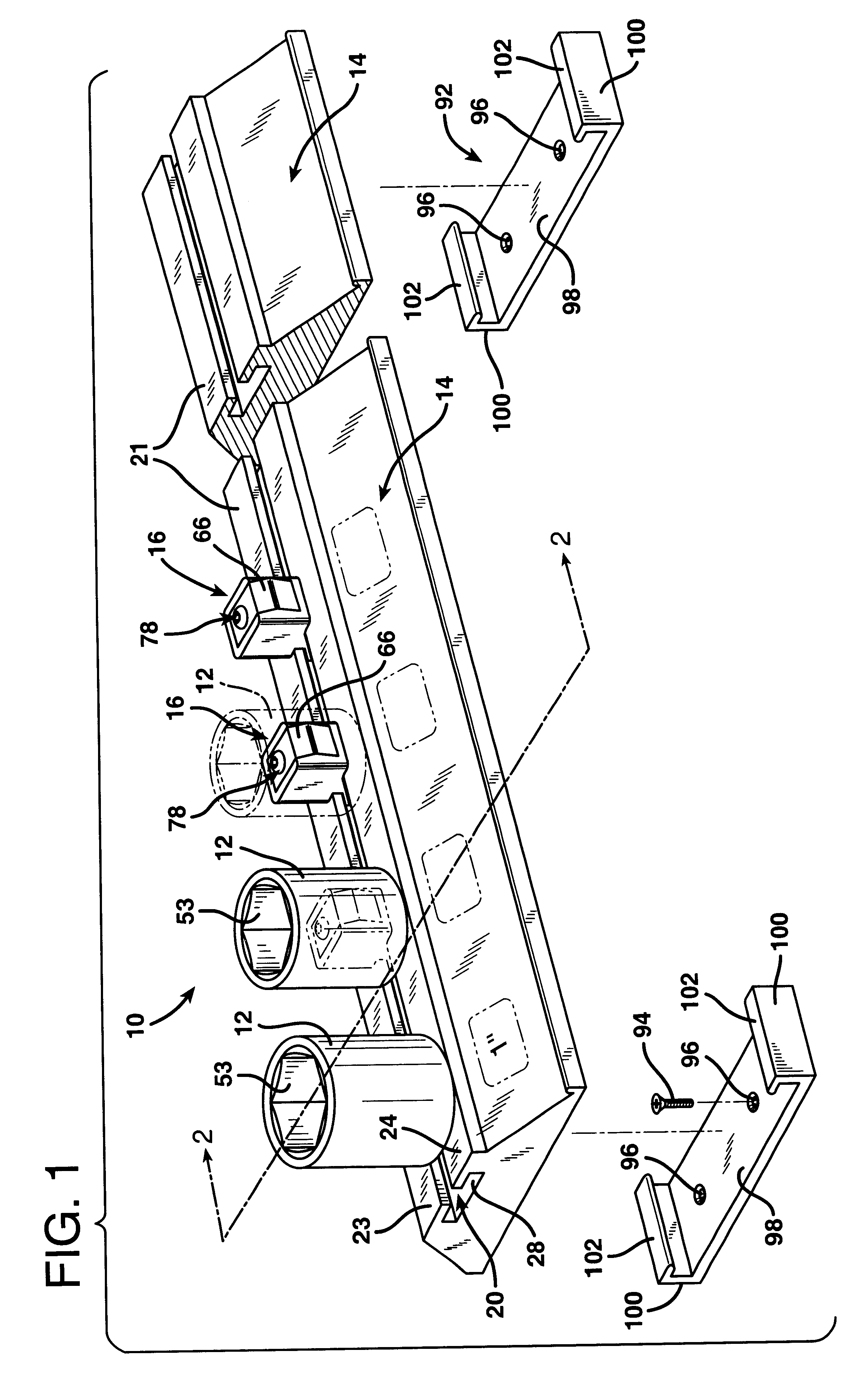

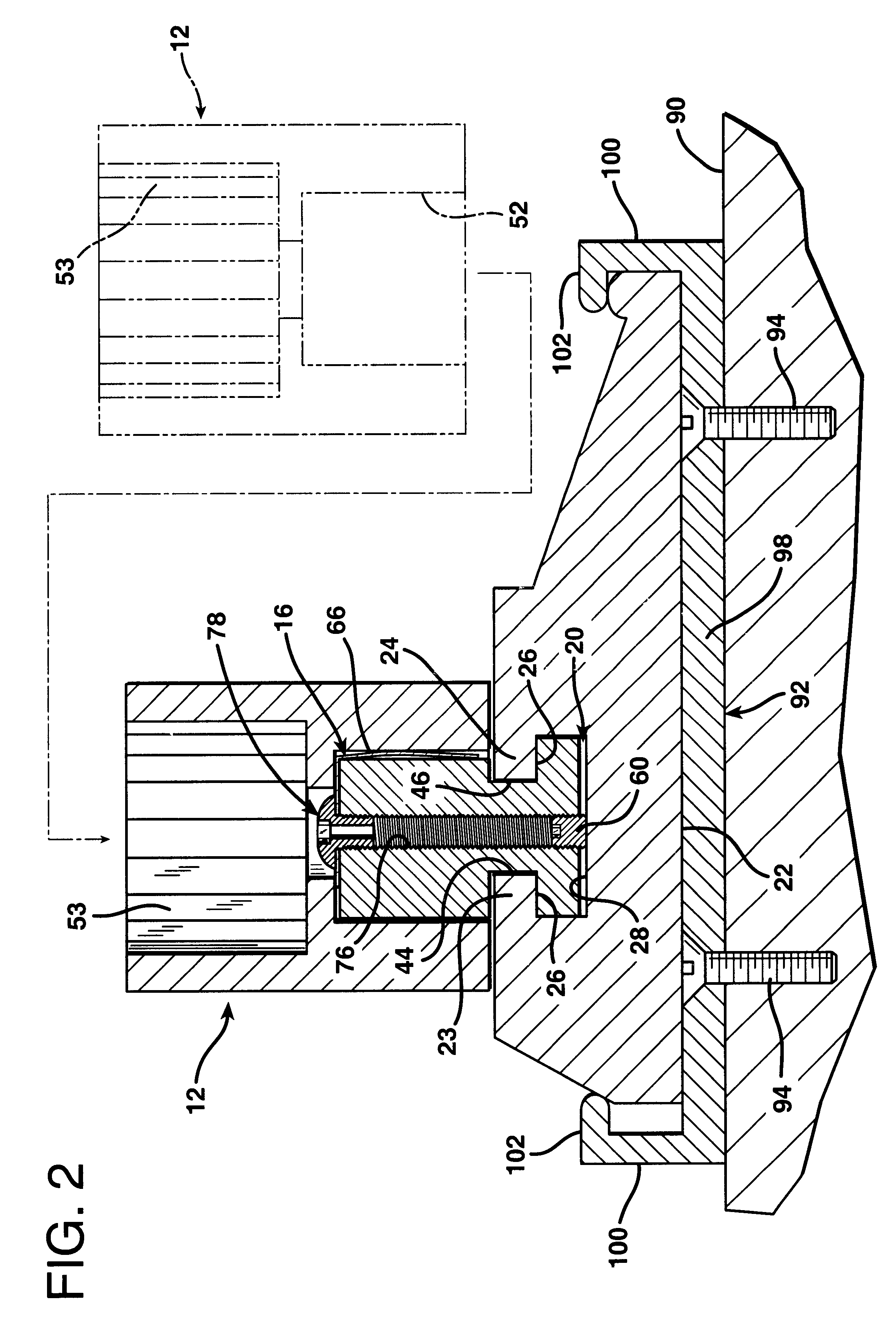

Adjustable socket rack with coaxial clamp

A wrench socket rack is formed of an elongated support defining a track with a pair of bearing surfaces overhanging the track from opposite sides. A plurality of socket pegs are provided. Each peg has a base with laterally projecting lugs that fit into the track. Each socket peg is sized to receive a wrench socket thereon. A bore with internal threads is defined from top to bottom in each of the socket pegs. A track-engaging clamp formed as a set screw that is threadably engaged in the socket peg at the bottom end of the bore. A hollow spring clamping screw is threadably engaged in the top end of the bore. The track-engaging set screw may be manipulated using a tool that is inserted through the cylindrical opening in the spring clamping screw.

Owner:RAMSEY EDWARD +1

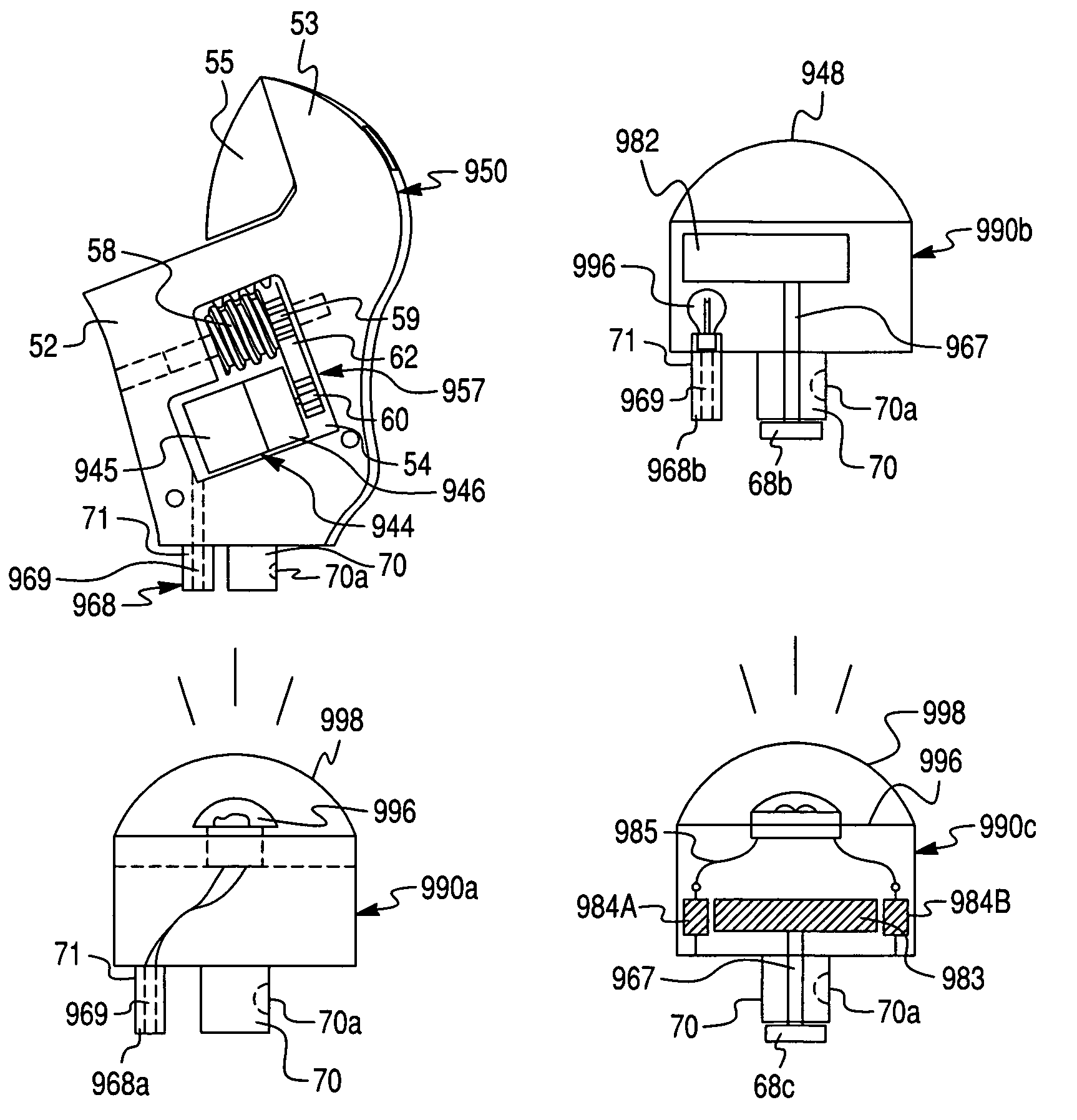

Tool monitor and assembly qualifier

InactiveUS6055484AMeasurement of torque/twisting force while tighteningForce measurementPower flowDevice Monitor

This counting apparatus is a tool monitor and assembly qualifier that verifies that the correct number of fasteners have been properly installed into an assembly. When used in conjunction with a pressure tool, proper fastener torque and count can be verified. The device monitors internal tool pressures and has the ability to "learn" the pressure characteristics of the tool during the assembly process. This assembly qualifier is a device that monitors either the pressure of an air tool, the current of an electrical tool or the torque of a mechanical wrench to determine if the tool shut off at a target torque. The qualifier also determines if some unknown means shuts off the tool.

Owner:C P ELECTRONICS

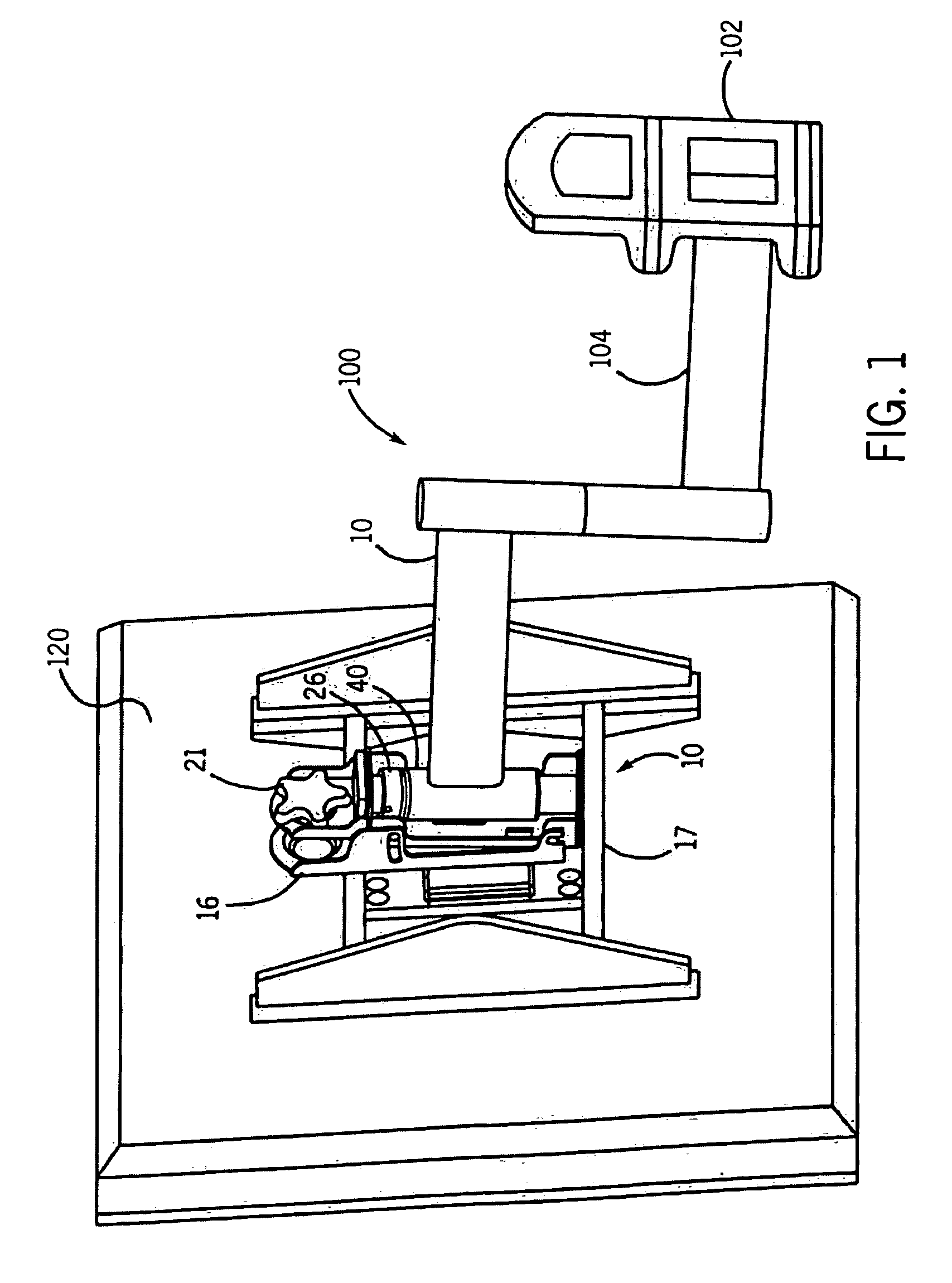

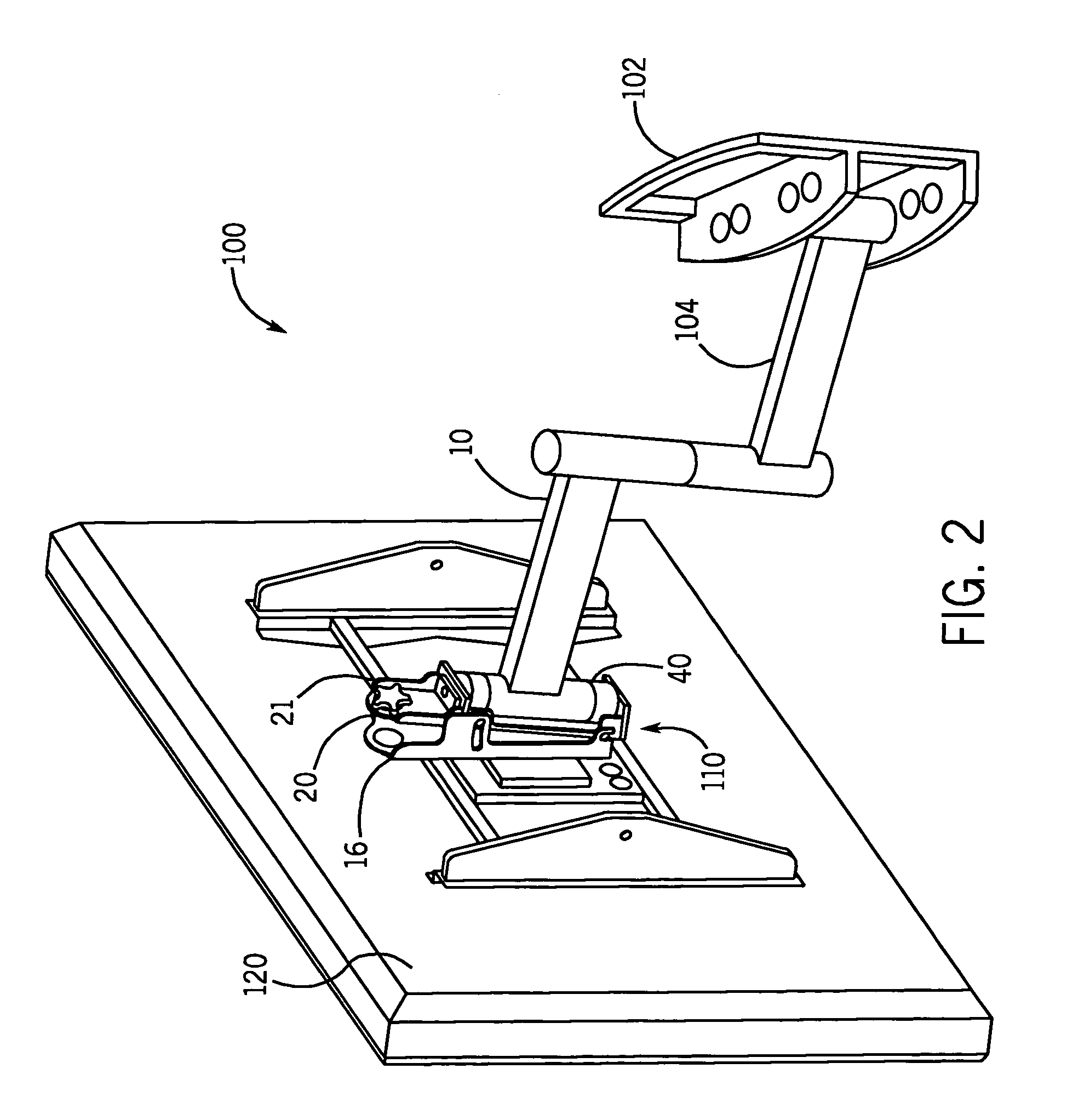

Mounting system with vertical adjustment feature

A vertical adjustment feature for a mounting system, such as a mounting system with a single articulating arm. A tool such as a hex wrench is used to rotate an adjustment bolt, which is threadedly engaged with a threaded nut. An axle is slidably received within a support arm end. Slots are positioned on the left and right sides near the top end of the primary axle. The primary axle slides up and down within the support arm end in conjunction with rotation of the adjustment bolt, enabling an associated flat panel television or other display device to move upwards or downwards relative to a wall or other support surface.

Owner:PEERLESS INDS

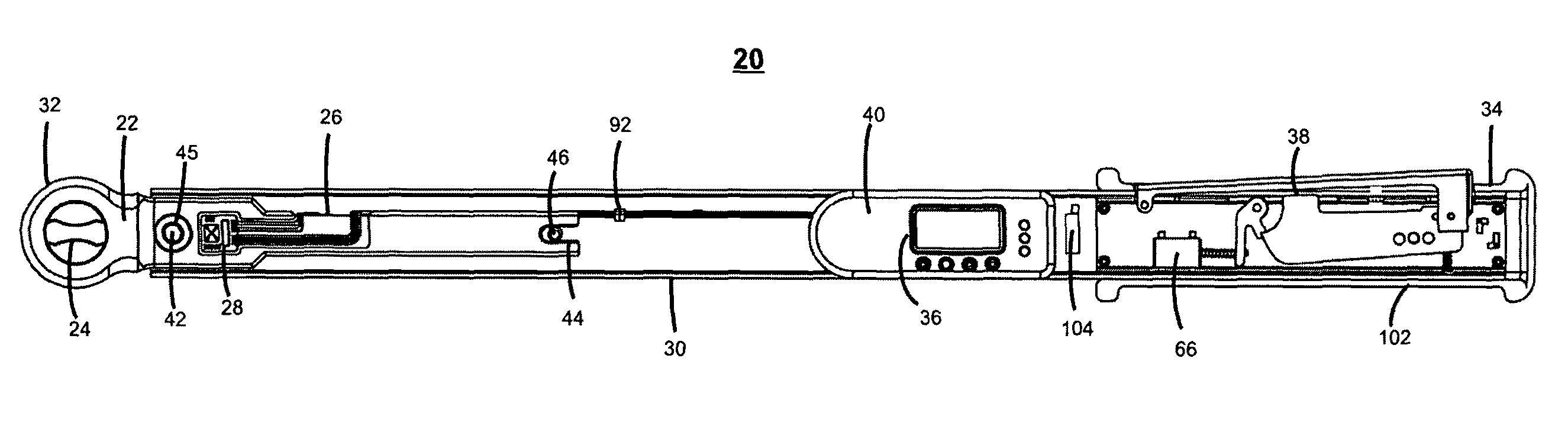

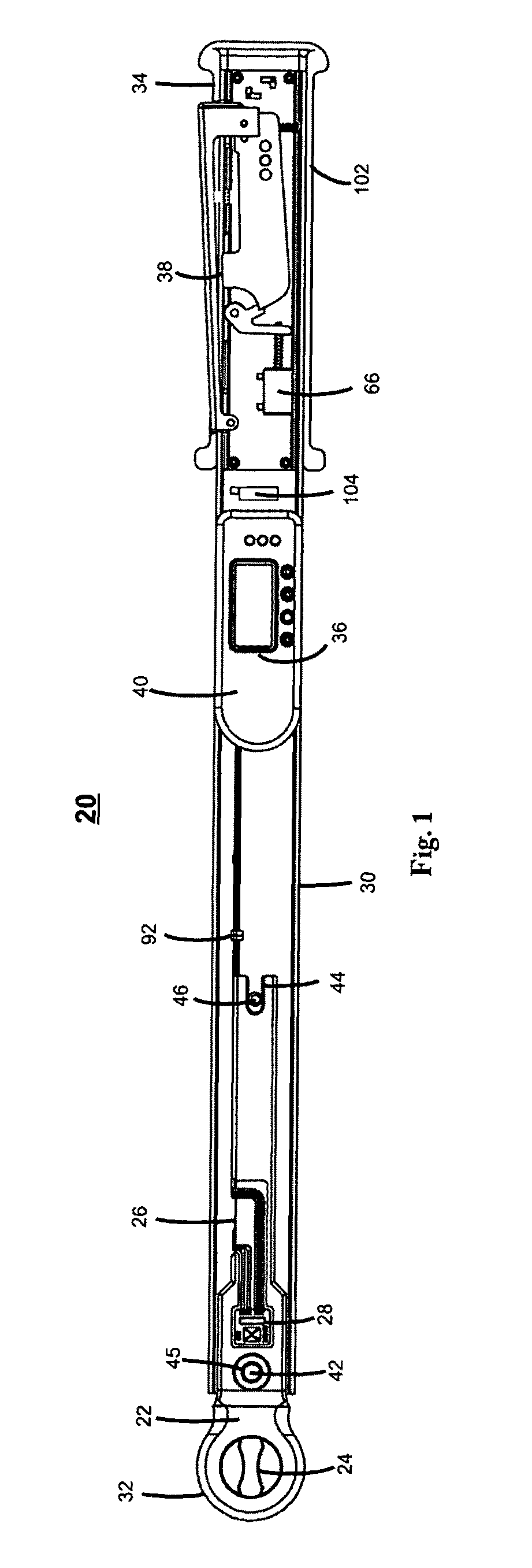

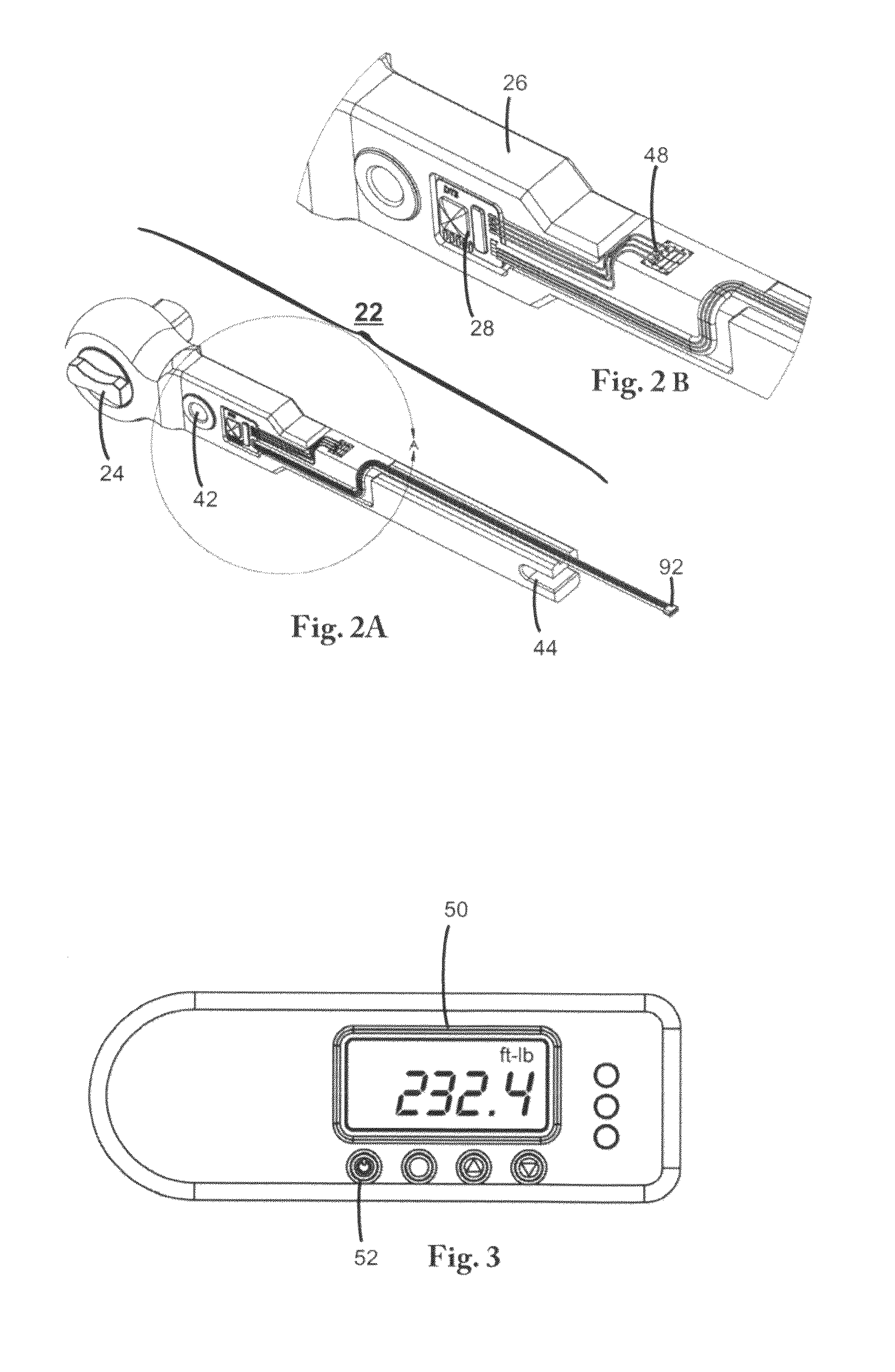

Electromechanical wrench

ActiveUS8171828B2Measurement of torque/twisting force while tighteningWork measurementRatchetEngineering

An electromechanical wrench has a housing that has a working end and a gripping end, with a driver positioned at the working end, and a handle positioned at the gripping end. The wrench further includes a click wrench emulator mechanism provided at the handle. A method of using an electromechanical wrench to secure a fastener using angular measurement without the need for establishing a zero reference point, and allowing for ratcheting, is also provided. A method of counting the number of fasteners secured by an electromechanical wrench during a wrenching job is further provided.

Owner:DIGITOOL SOLUTIONS

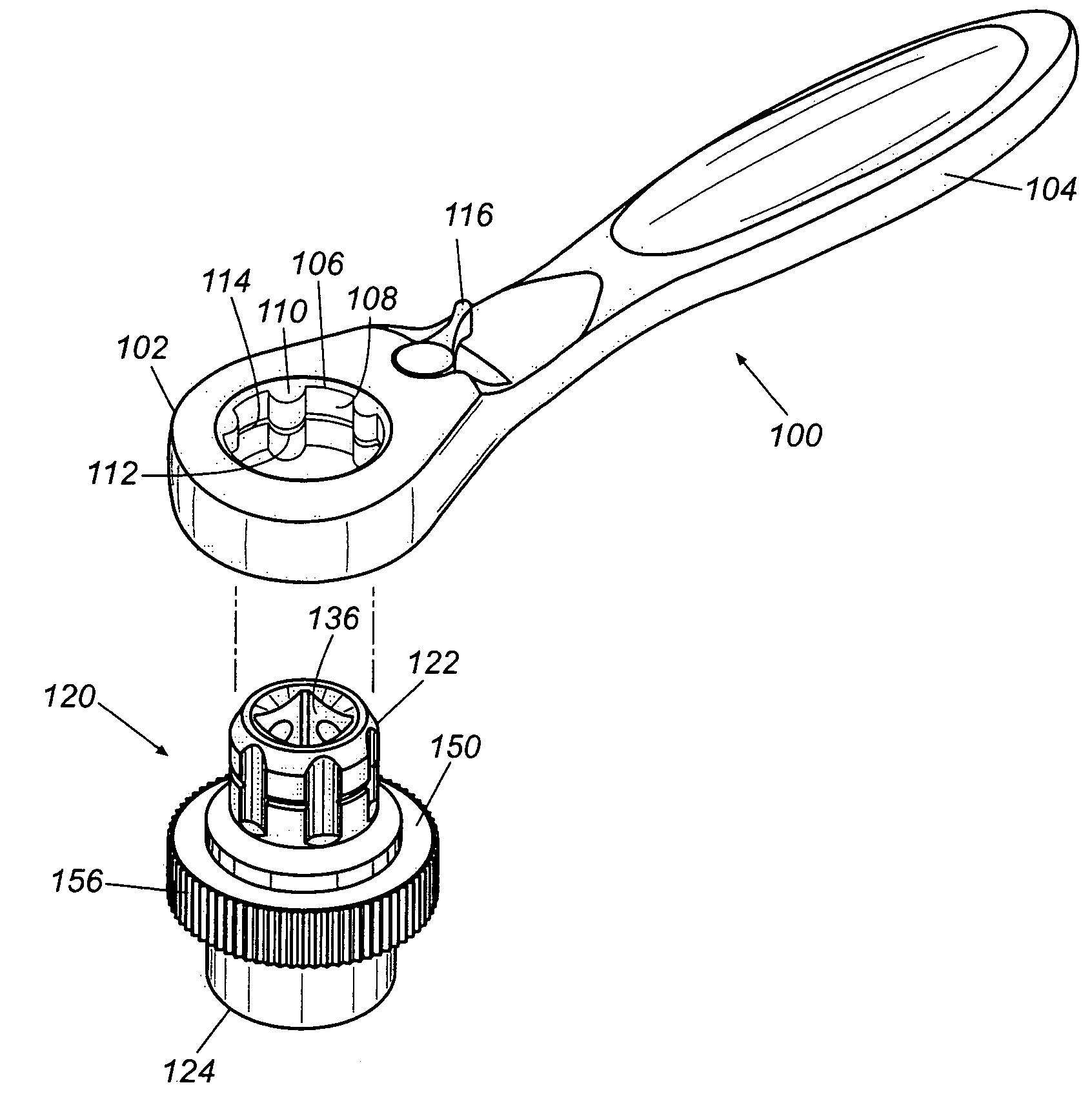

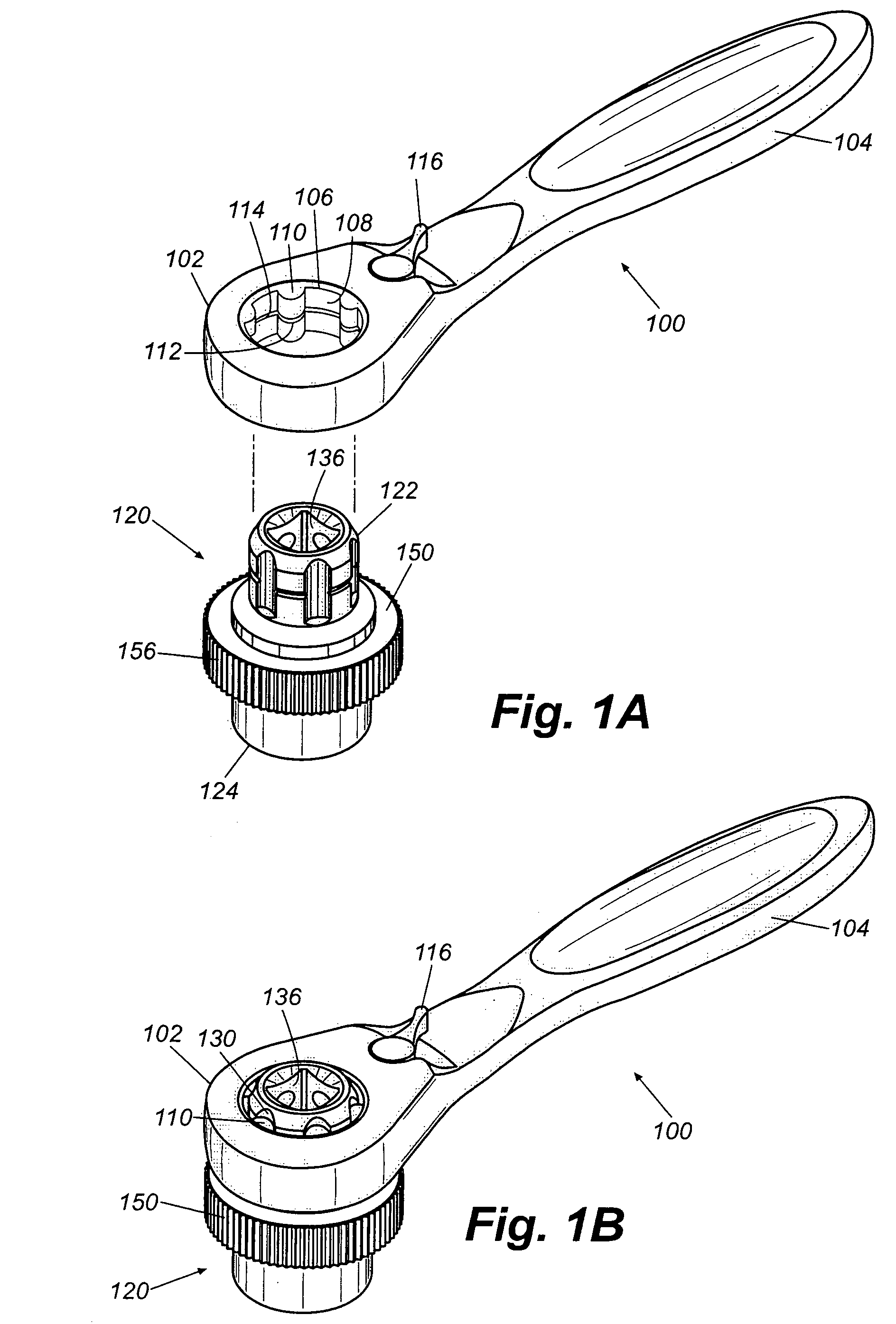

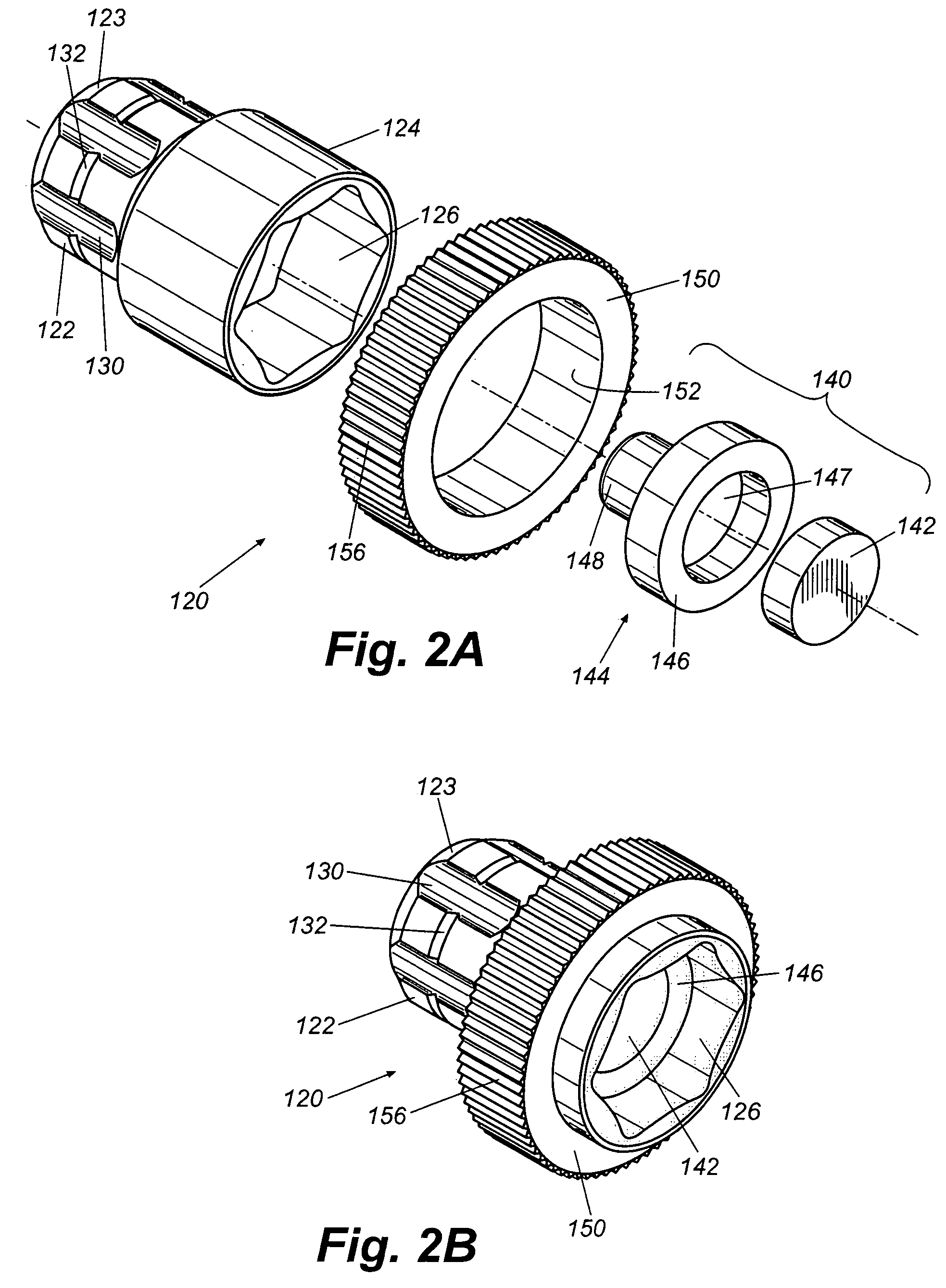

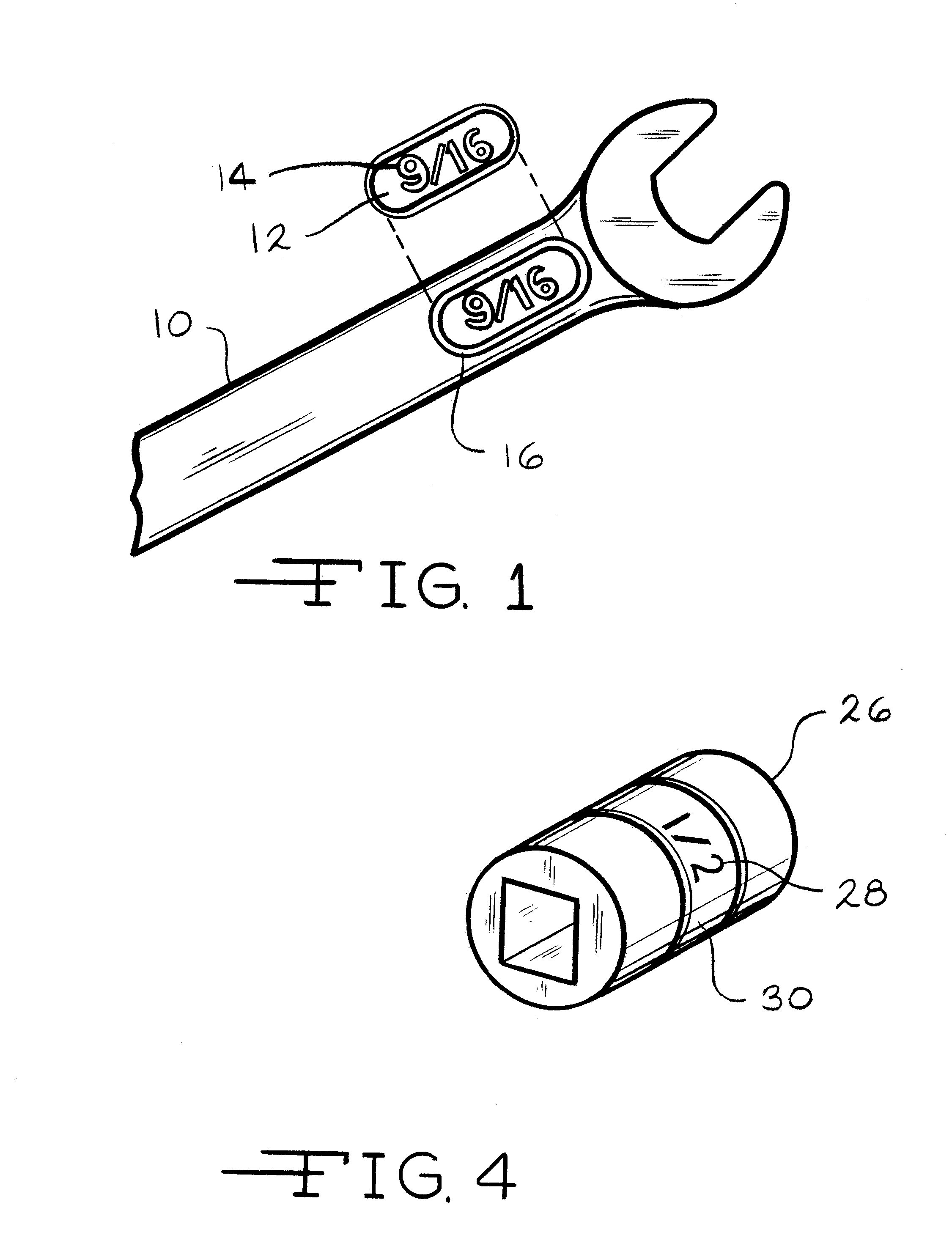

Oil drain plug socket for a wrench assembly

A ratchet wrench, the ratchet wrench having a head portion defining a substantially cylindrical inner engaging surface and a plurality of ribs extending radially inward therefrom. The socket includes a first portion defining a plurality of depressions axially aligned with the longitudinal axis in an outer surface thereof, the first portion being releasably received by the substantially cylindrical inner engaging surface, and a second portion including a cylindrical outer surface and defining a hexagonal recess therein. A grip ring includes a knurled outer surface and is disposed on the second portion outer surface. A magnetic insert is received in the hexagonal recess.

Owner:EASCO HAND TOOLS

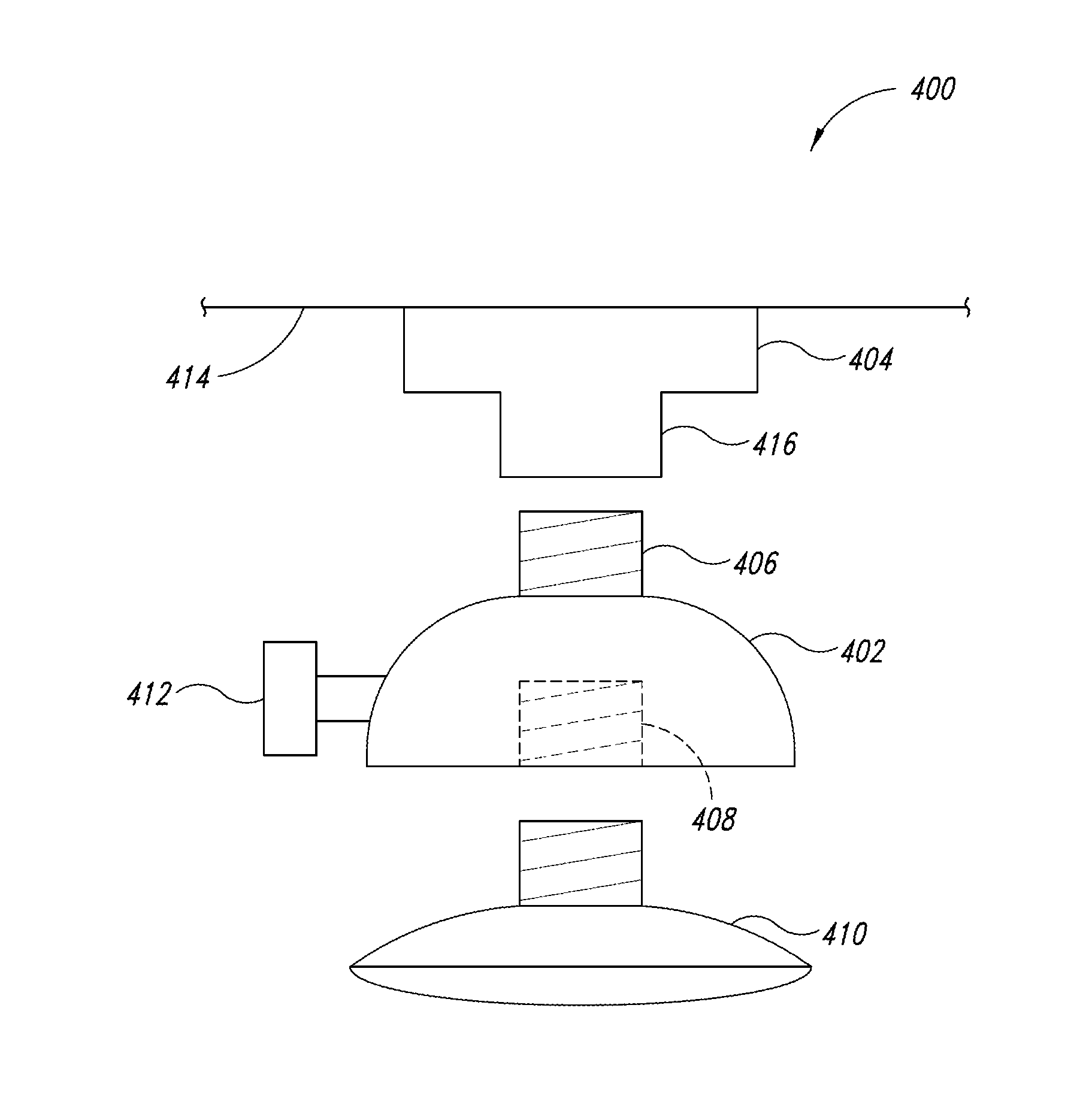

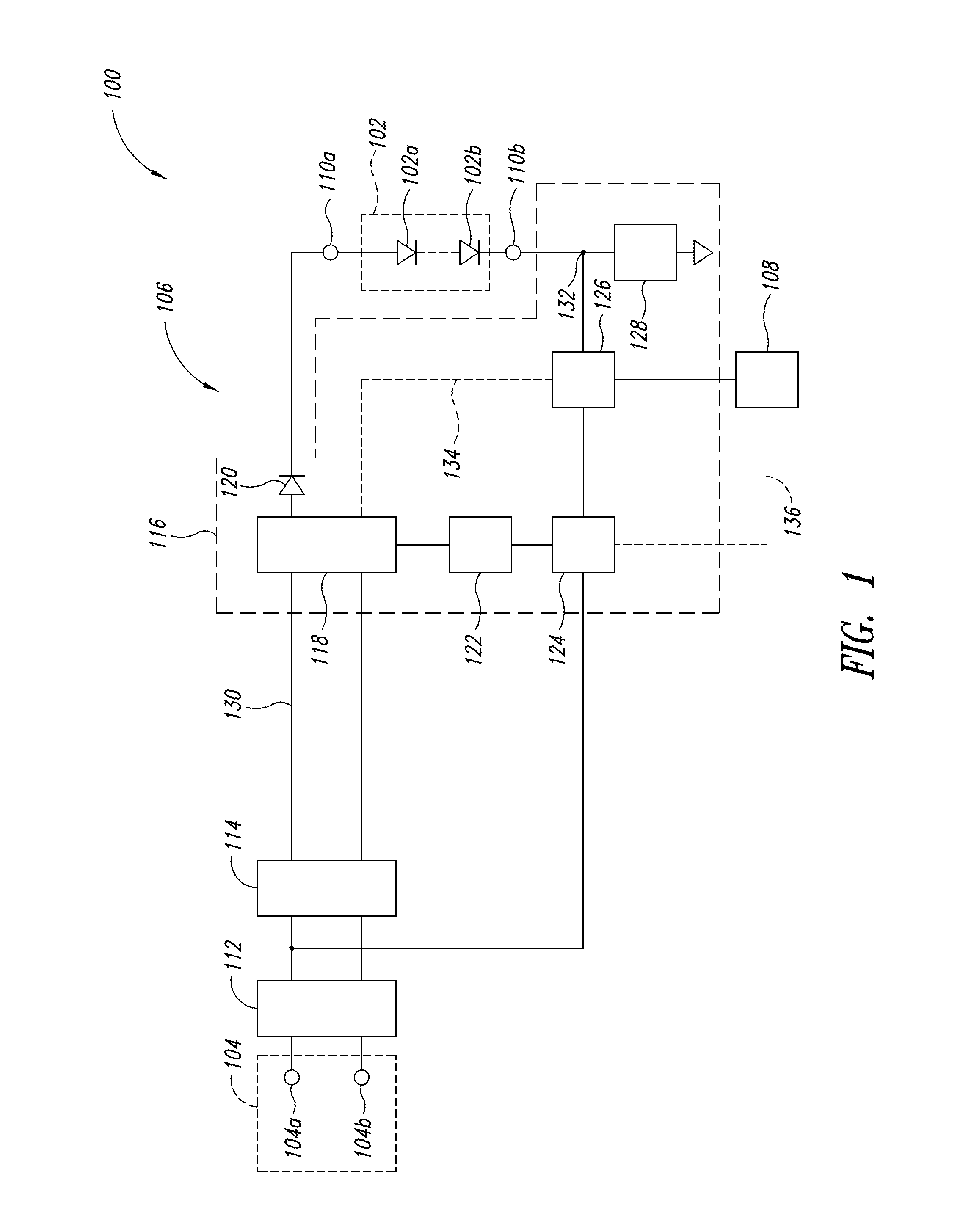

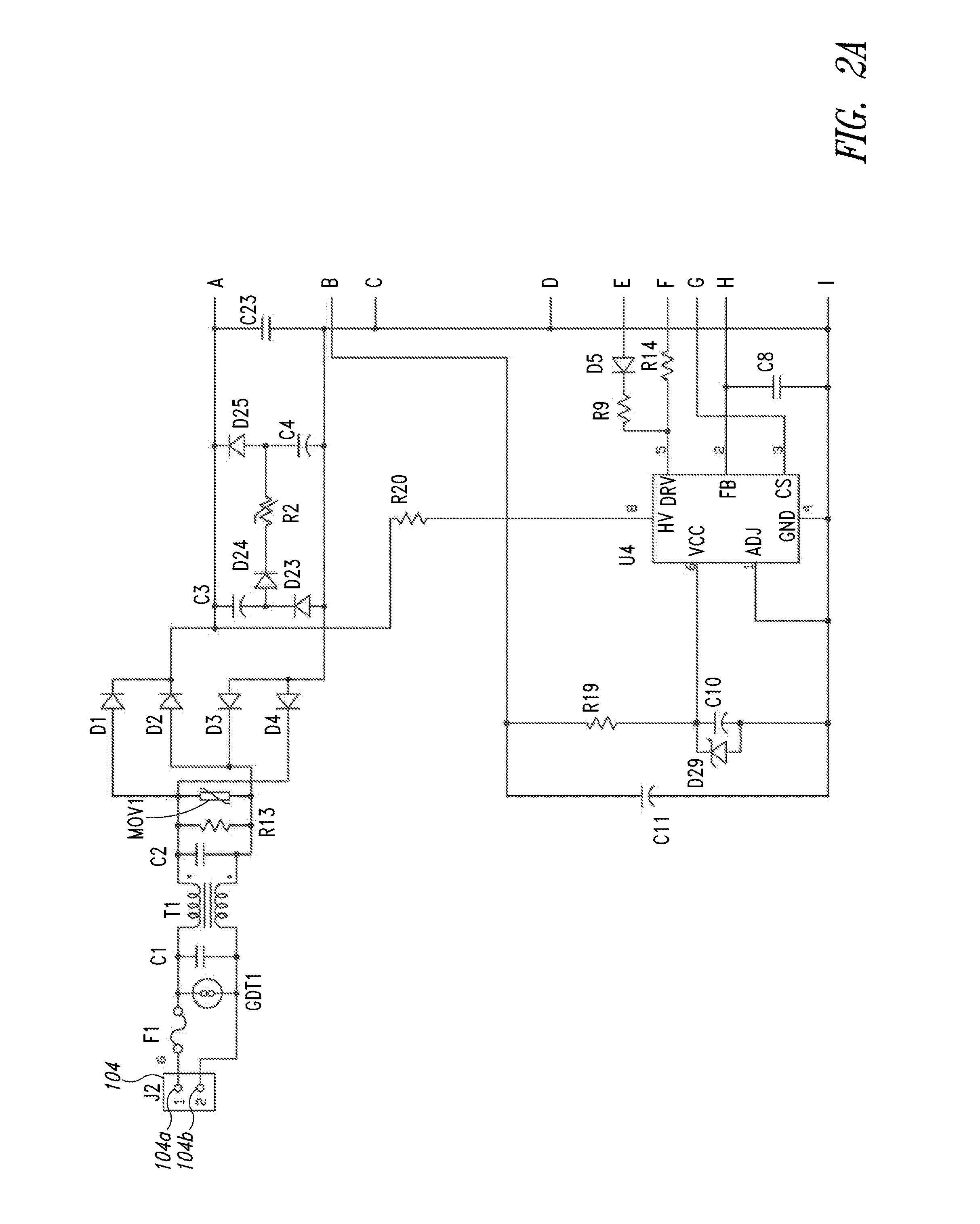

Adjustable output solid-state lighting device

ActiveUS20130163243A1Resistance may varyCoupling device connectionsPoint-like light sourceDriver circuitElectricity

A solid-state lighting device has user-engageable actuator physically manipulable by a user and accessible from an exterior of the device to adjust an amount of light output. The user-engageable actuator may take the form of a knob, slider, lever, or other manipulable surface or structure. The user-engageable actuator may extend partially or fully from a housing, or alternatively be recessed or otherwise within the housing with access provided via an aperture, slot or opening. Access may be directly by the user (e.g., finger) or via a tool (e.g., screw driver, Allen wrench, socket) manipulated by the user. The actuator may form part of an adjustment component (e.g., potentiometer, rheostat) which supplies an adjustable output to a drive circuit or electronics. The adjustment component may be electrically coupled to either a primary or secondary side of a transformer, which forms part of a power converter (e.g., flyback).

Owner:EXPRESS IMAGING SYST

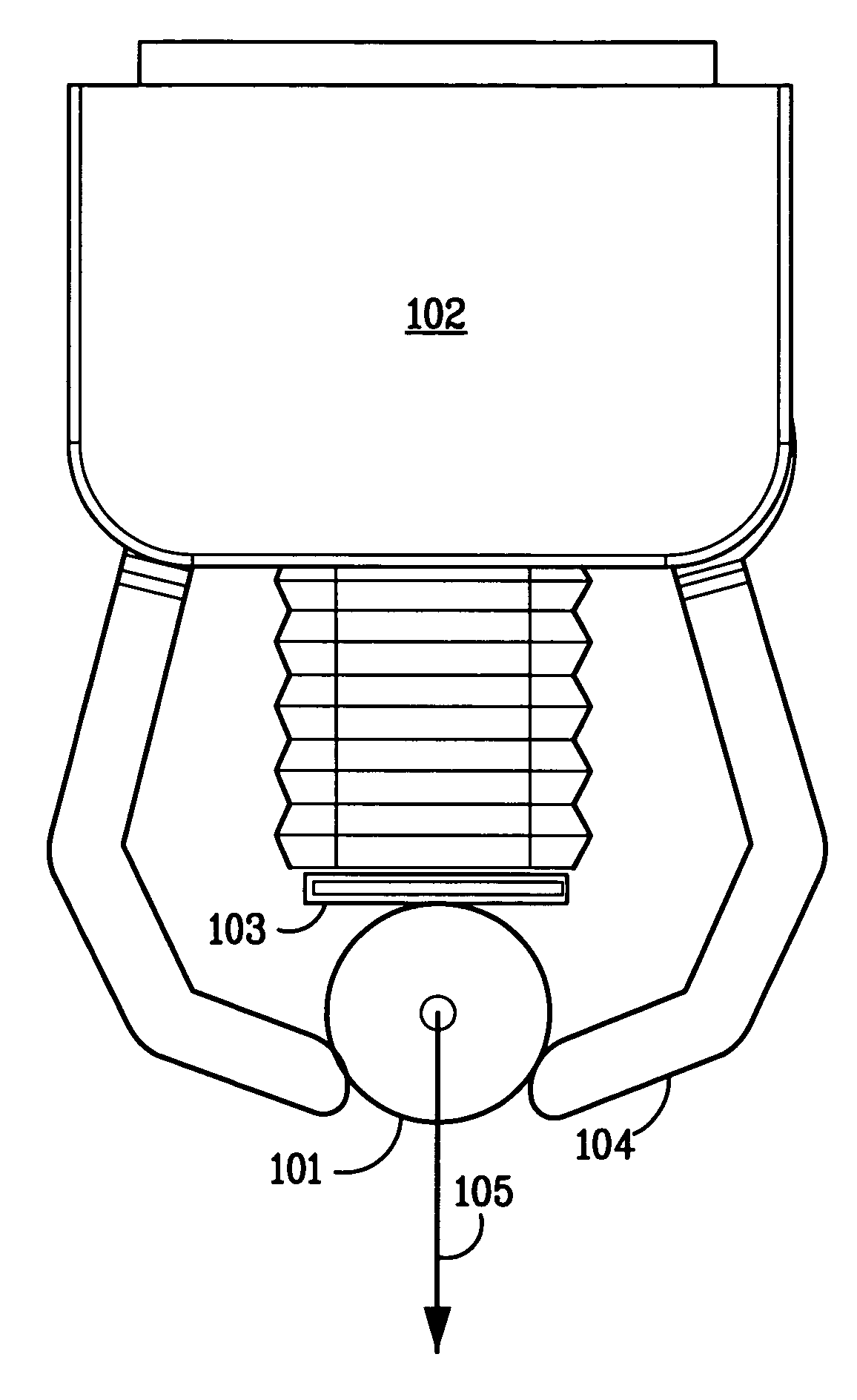

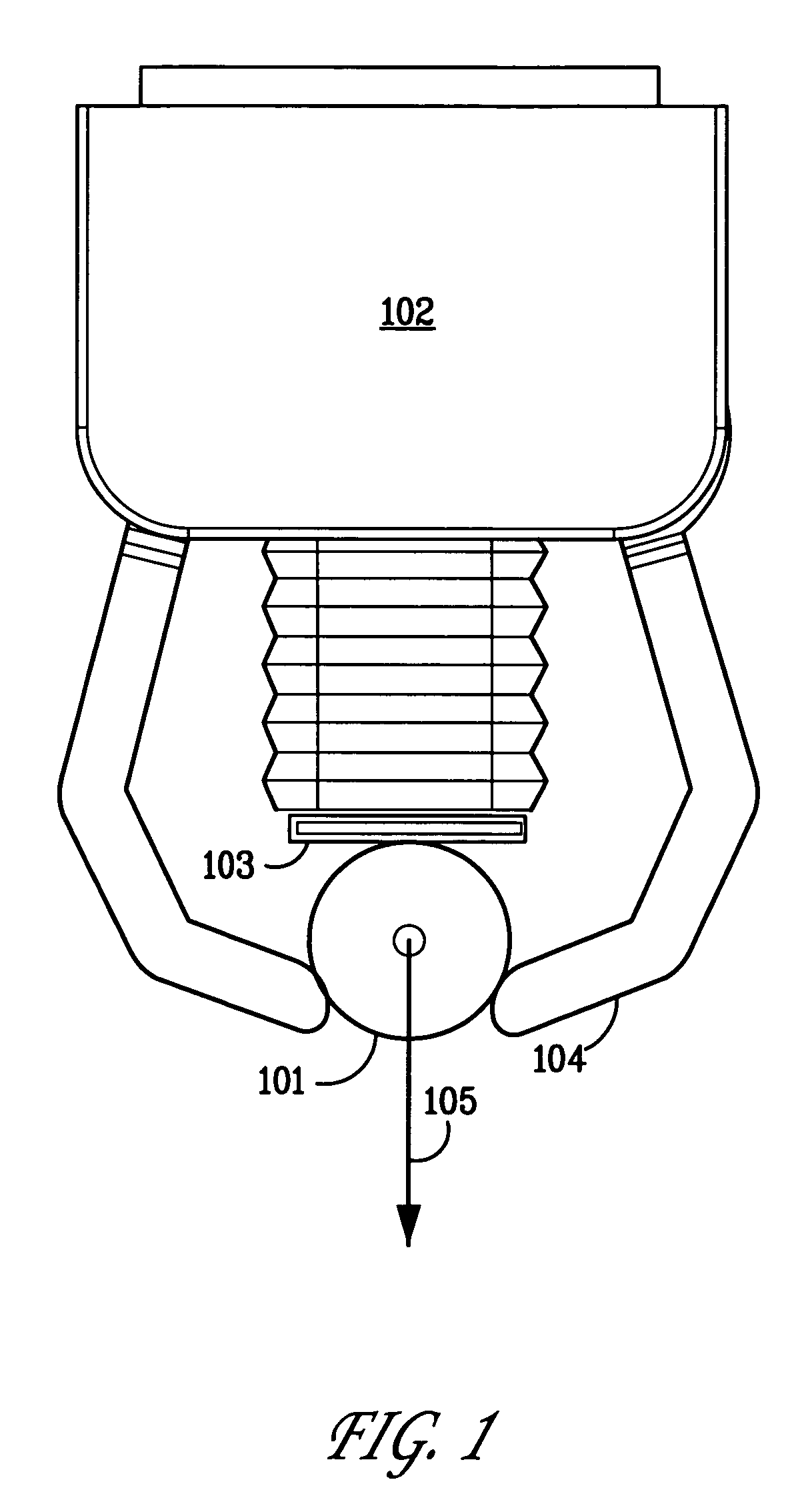

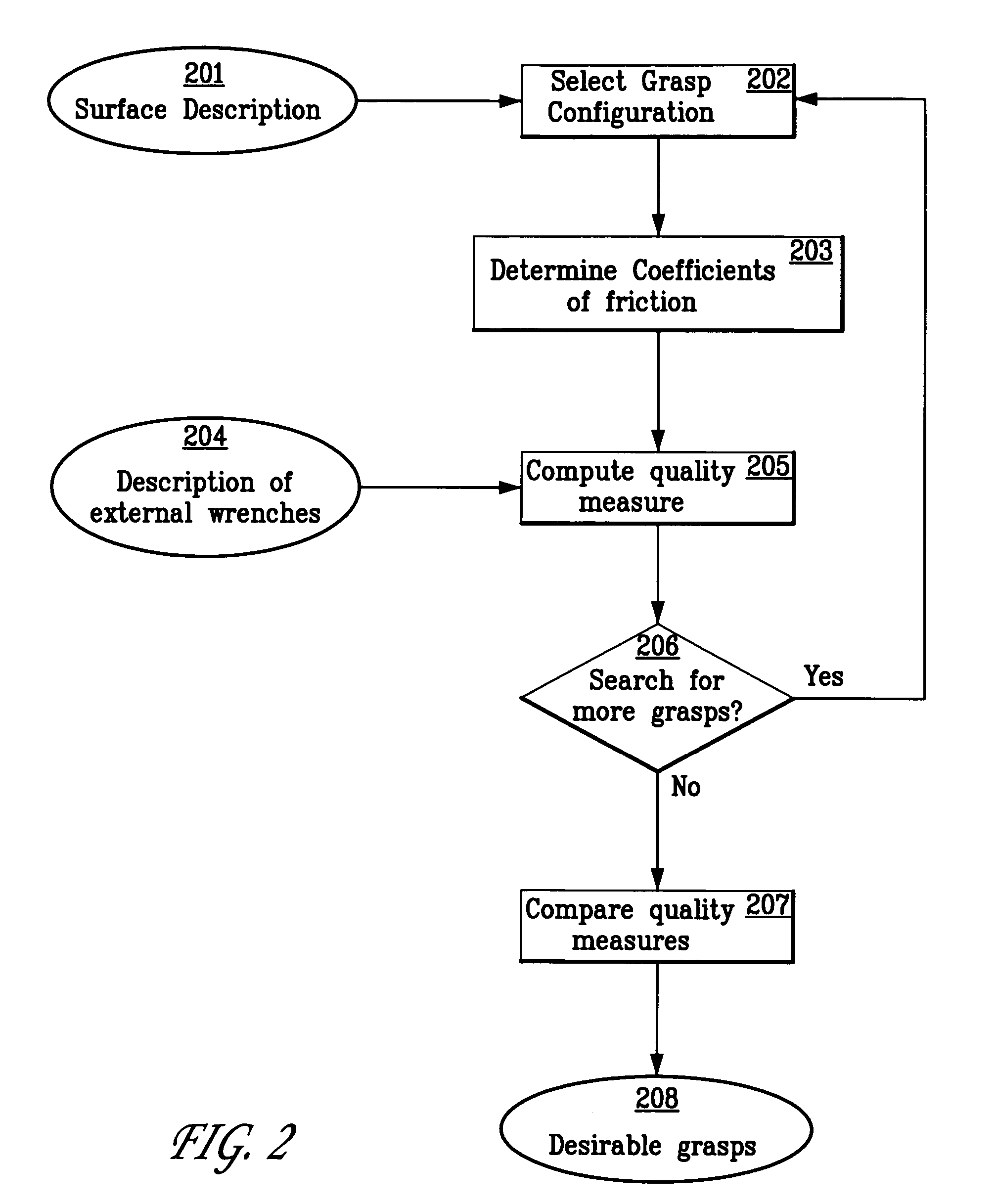

System and method for computing grasps for a robotic hand with a palm

A system and method for automatically computing desirable palm grasp configurations of an object by a robotic hand is disclosed. A description of the object's surface is obtained. A grasp configuration of a robotic hand comprising a palm and one or more fingers is selected, which specifies a hand configuration and joint variables of the hand, and a plurality of contact points on the object's surface for the palm and fingers. The coefficient of friction at each of the contact points is determined, and a description of one or more external wrenches to which may apply to the object is acquired. The ability of the robotic hand to hold the object against the external wrenches in the selected configuration is then computed. In some embodiments, a plurality of grasp configurations may be compared to determine which are the most desirable. In other embodiments, the space of hand configurations, or the smaller space of palm contact configurations, may be searched to find the most desirable grasp configurations.

Owner:STRIDER LABS

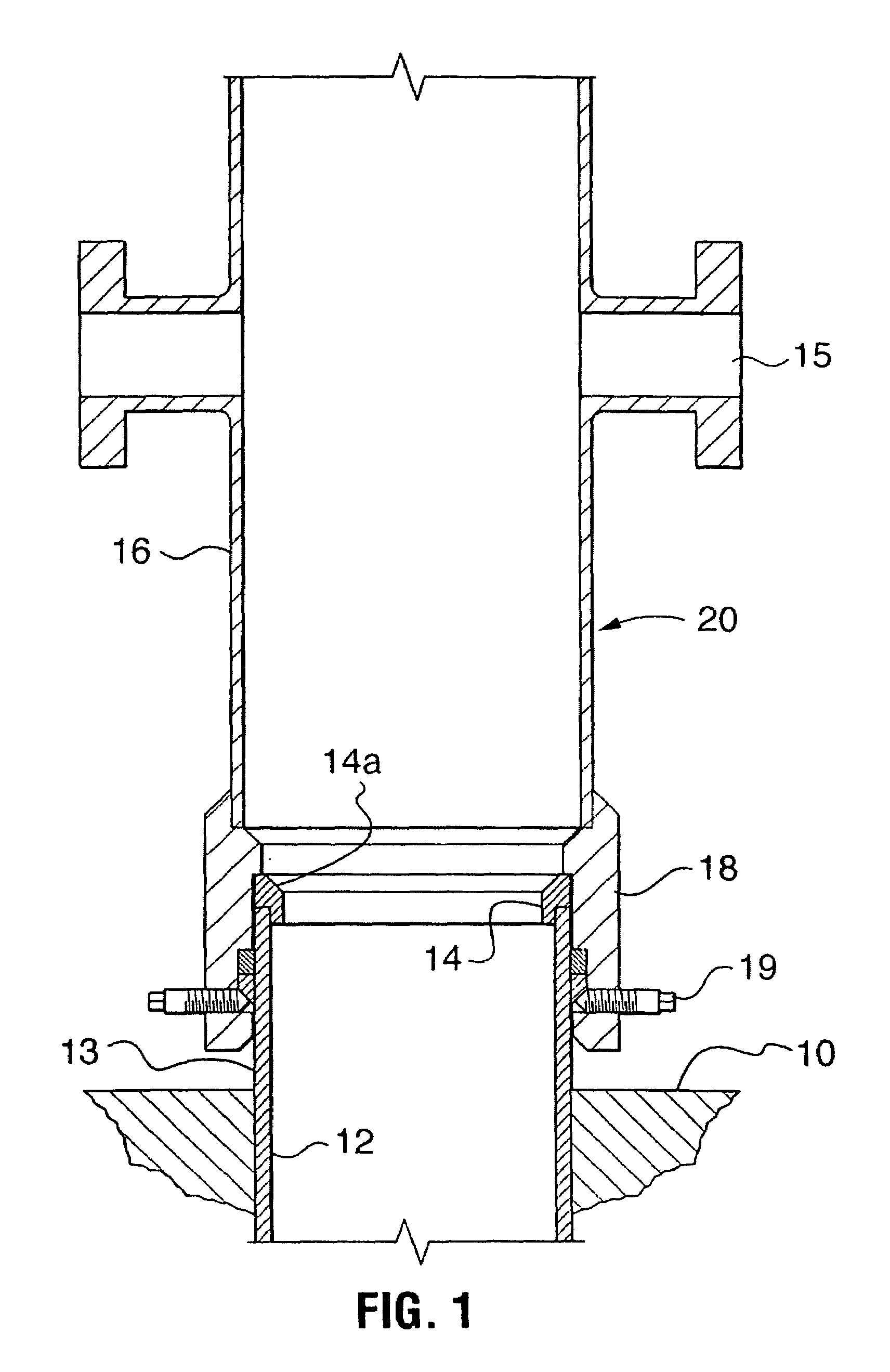

Hybrid wellhead system and method of use

ActiveUS7159663B2Easy and economical to manufacture and assembleLow costDrilling rodsFluid removalEngineeringScrew thread

A hybrid wellhead system is assembled using a plurality of threaded unions, such as spanner nuts or hammer unions, for securing respective tubular heads and a flanged connection for securing a flow control stack to a top of a tubing head spool. The tubing head spool is secured by a threaded union to an intermediate head spool. The intermediate head spool is secured by another threaded union to a wellhead. Each tubular head secures and suspends a tubular string in the well bore. The hybrid wellhead system is capable of withstanding higher fluid pressures than a conventional independent screwed wellhead, while providing a more economical alternative to a flanged, or ranged, wellhead system because it is less expensive to construct and faster to assemble.

Owner:WELLS FARGO BANK NAT ASSOC +1

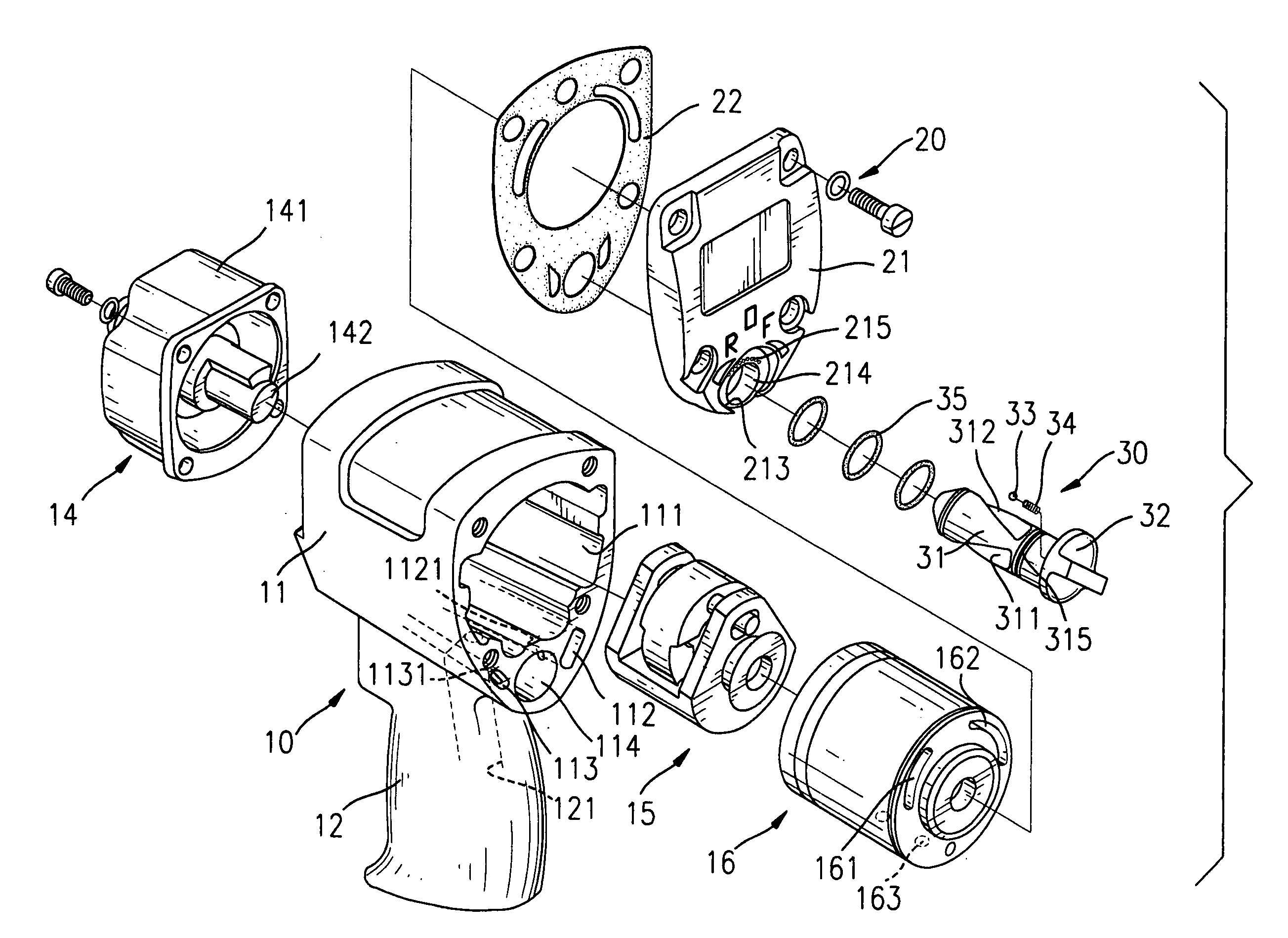

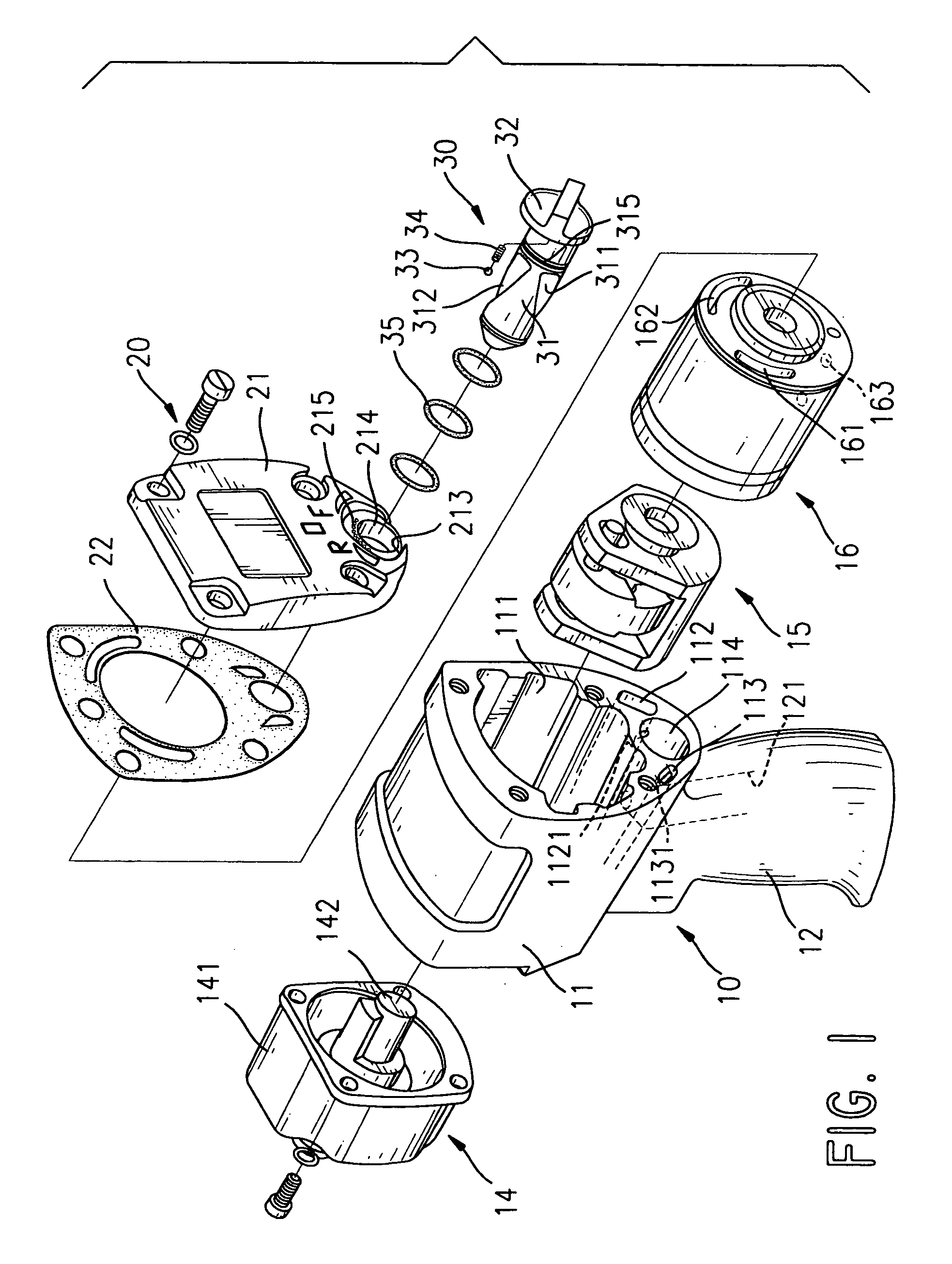

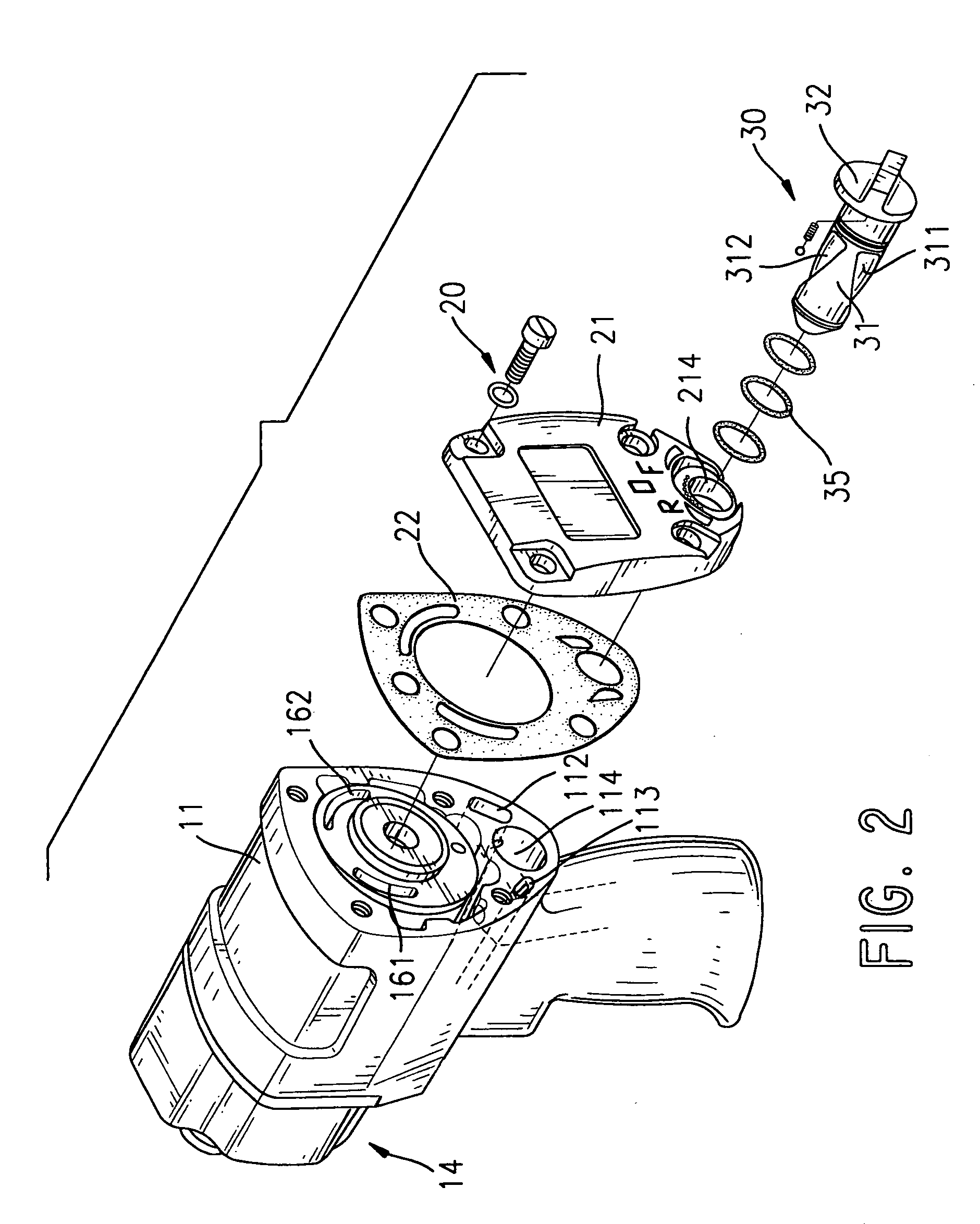

Bidirectional pneumatic impact wrench

InactiveUS6883619B1Simple structureEfficiently directsOperator-supported drilling machinesPower driven toolsControl valvesImpact wrench

A bidirectional pneumatic impact wrench has a pneumatic motor and an air control valve. The pneumatic motor has a forward air inlet and a reverse air inlet. The air control valve directs compressed air selectively into either the forward air inlet or the reverse air inlet to change the direction of rotation of the pneumatic motor and includes a rotatable shaft. The shaft has an exterior surface and a spiral forward air groove and reverse air groove that are symmetrically defined in the exterior surface to direct the compressed air efficiently. The air control valve is simple to fabricate and directs the compressed air efficiently into the pneumatic motor to improve power and efficiency of the pneumatic motor.

Owner:HUANG YUNG CHAO

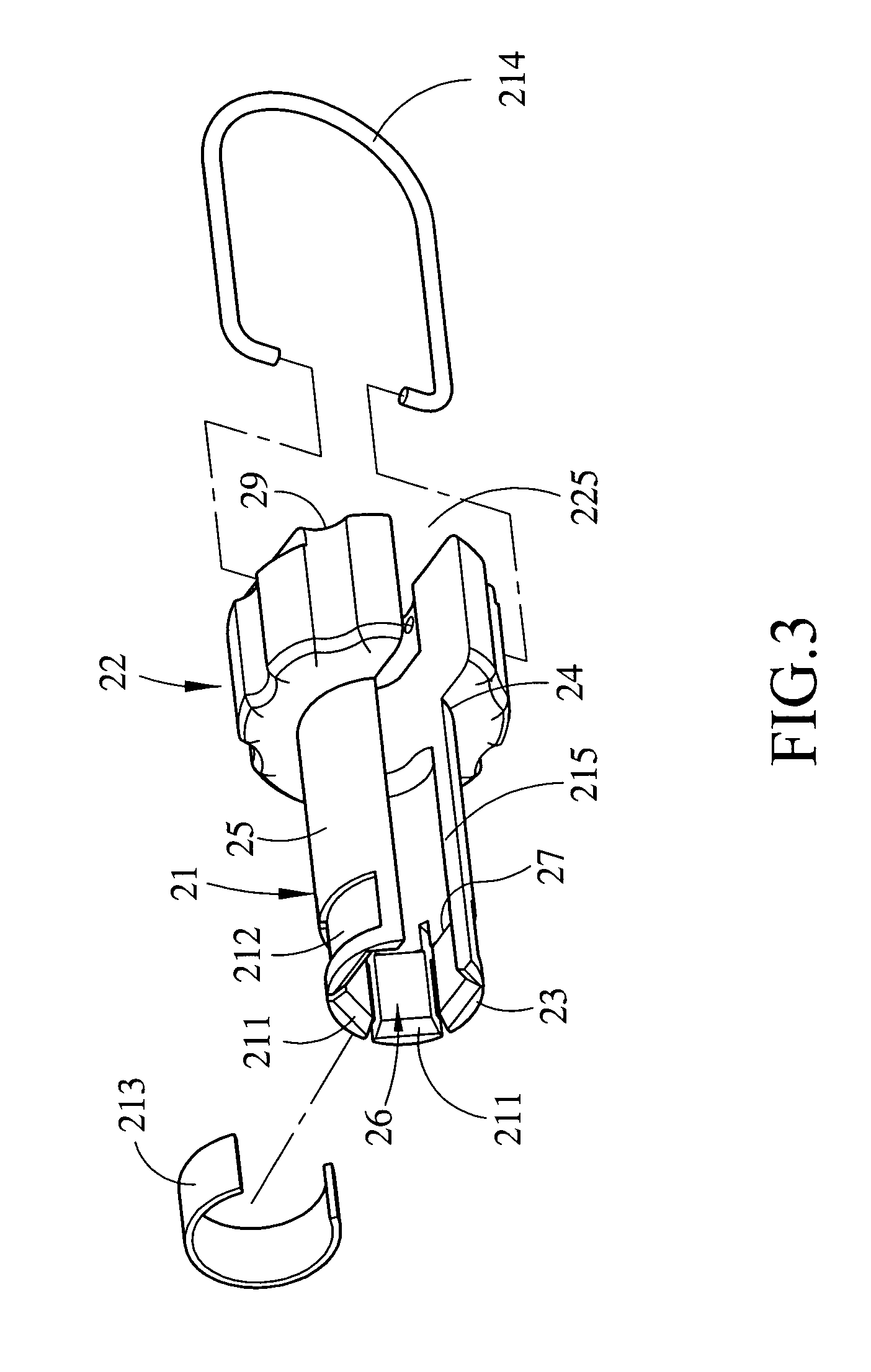

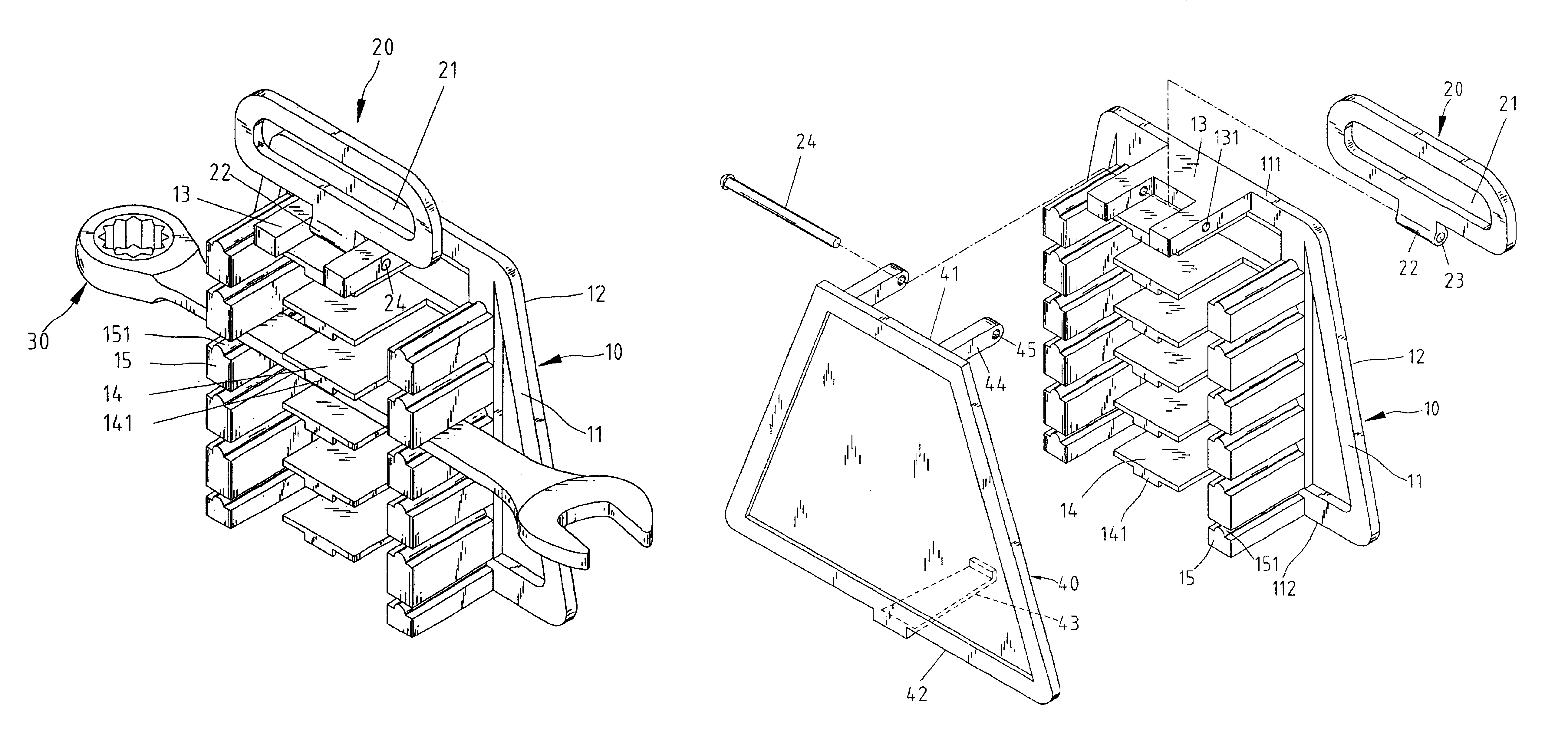

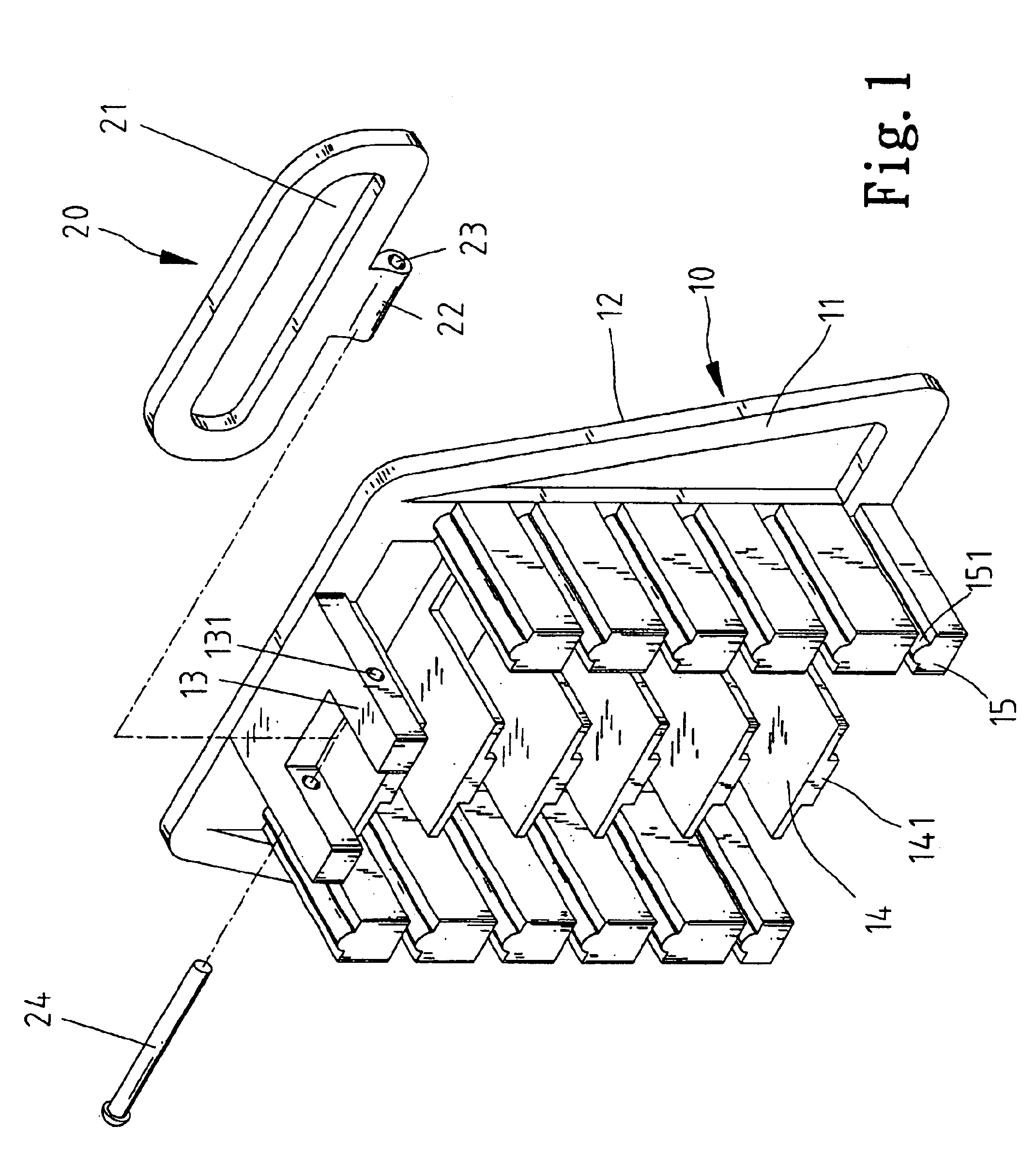

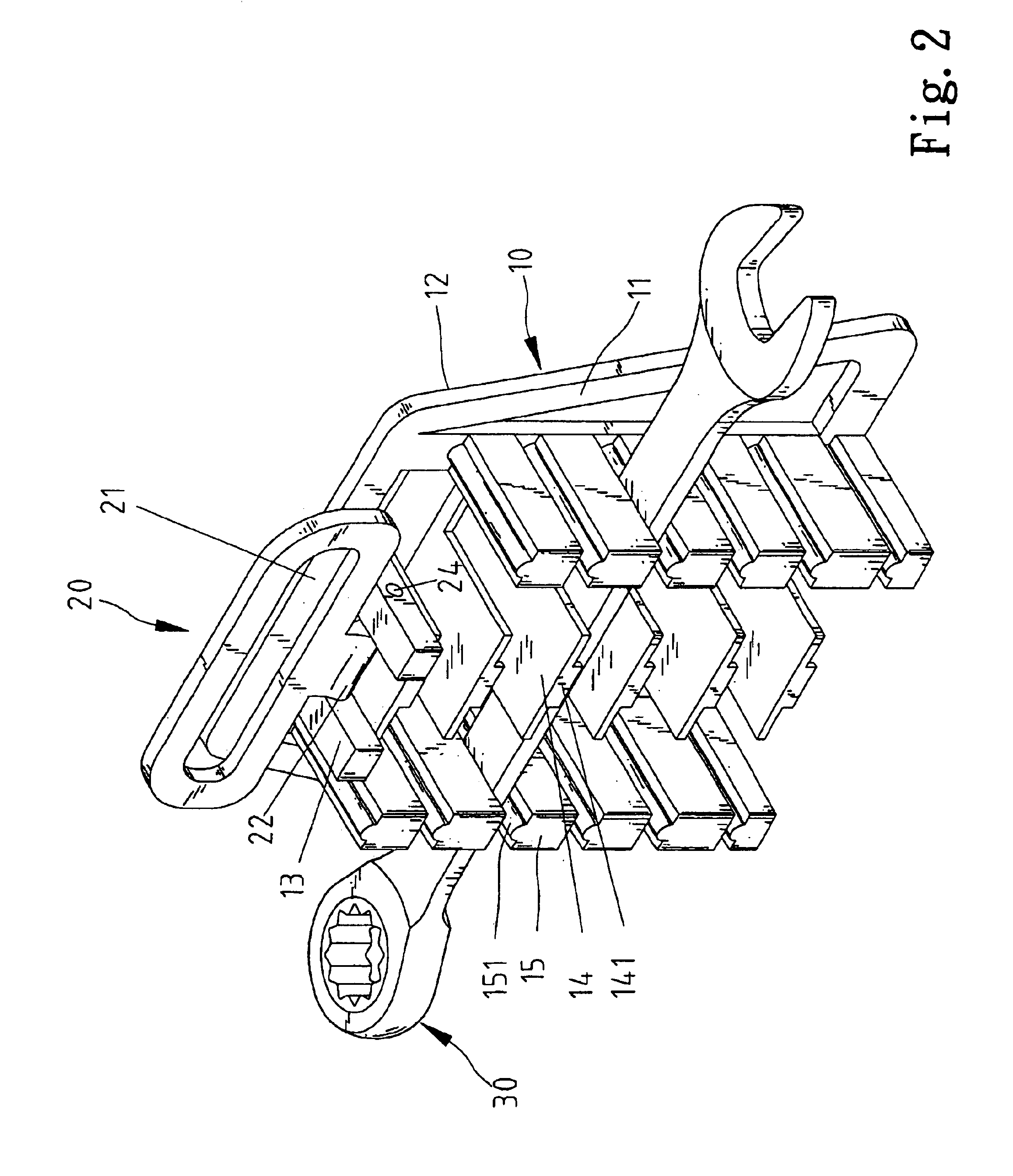

Wrench rack

A wrench rack includes a board and at least one clip formed on the board. The at least one clip includes a first jaw and two second jaws for retaining a wrench handle between the first jaw and the second jaws. The wrench rack may include a handle pivotally connected with the board. The wrench rack may include a cover pivotally connected with the board. The cover may include a hook formed thereon for hooking the board. The first jaw includes a hooking portion formed thereon. In a first aspect, each of the second jaws includes a ridge formed thereon. In a second aspect, each of the second jaws includes a hooking portion formed thereon.

Owner:LIN CLARE

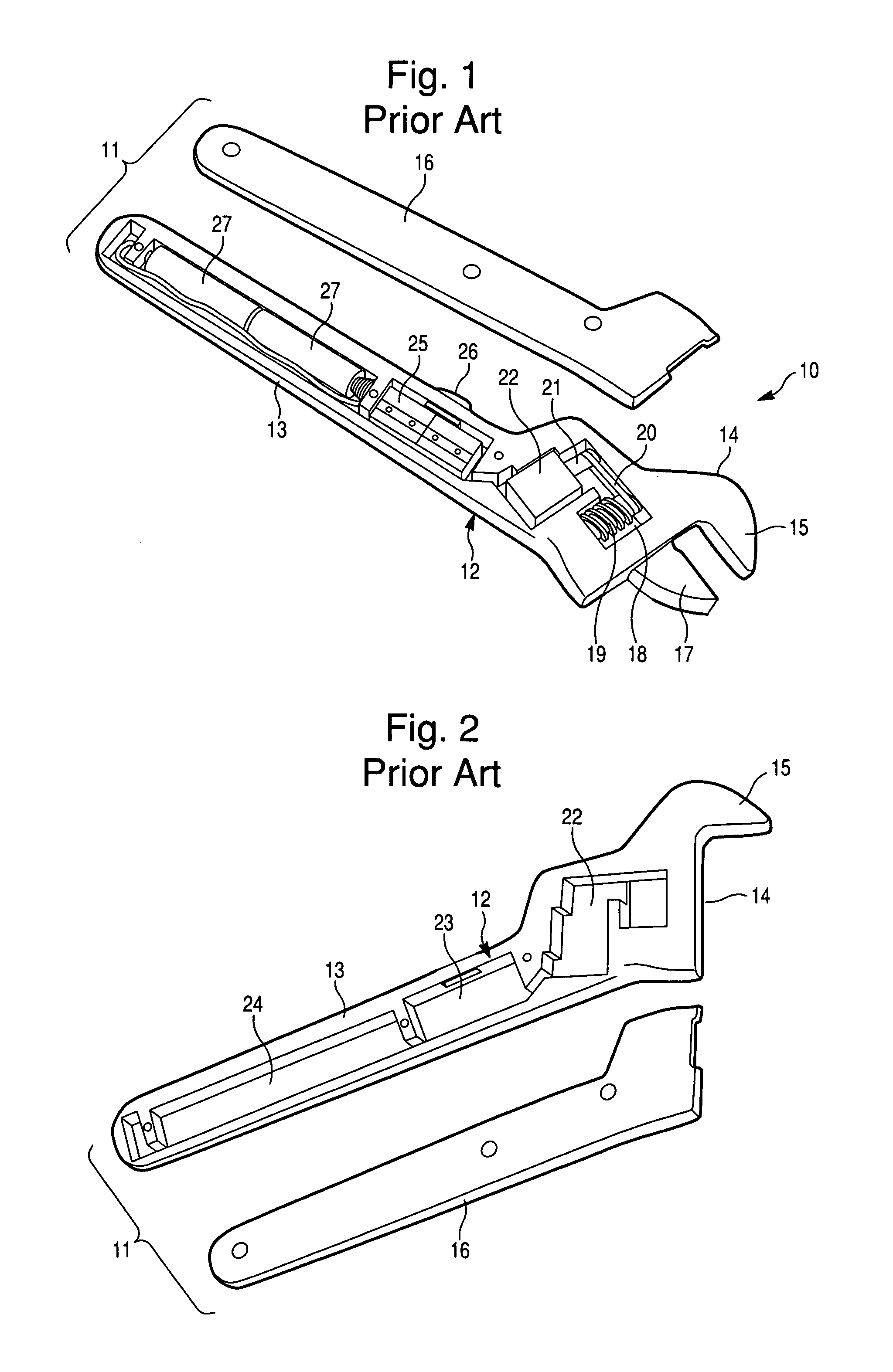

Quick adjust ratcheting wrench with cam actuated clamping

InactiveUS7478577B1Simplify structure and constructionImprove convenienceSpannersWrenchesControl orientedEngineering

The invention is a wrench with jaws adjusted by a cam mechanism and a ratchet mechanism providing a free return stroke of the handle, a simplified construction, convenience of use, durability, effectiveness, and cost and weight reduction; comprising a handle with housing, annular control and adjusting discs, a plurality of radial guide slots in the adjusting disc and cam features in the control disc, a plurality of jaws in the housing, each jaw, having a slider spring loaded, is positioned in said guide slots, and a cam follower interacting with cam features formed on the inner edge of the control disc; radial guide slots on the surface of the adjusting disc facing the control disc, each guide slot limited by the inner arch-shaped edge of the adjusting disc and open on its periphery; cam followers and profiles provide wedging to the rotation of the discs during the return stroke.

Owner:WHEELER THOMAS J

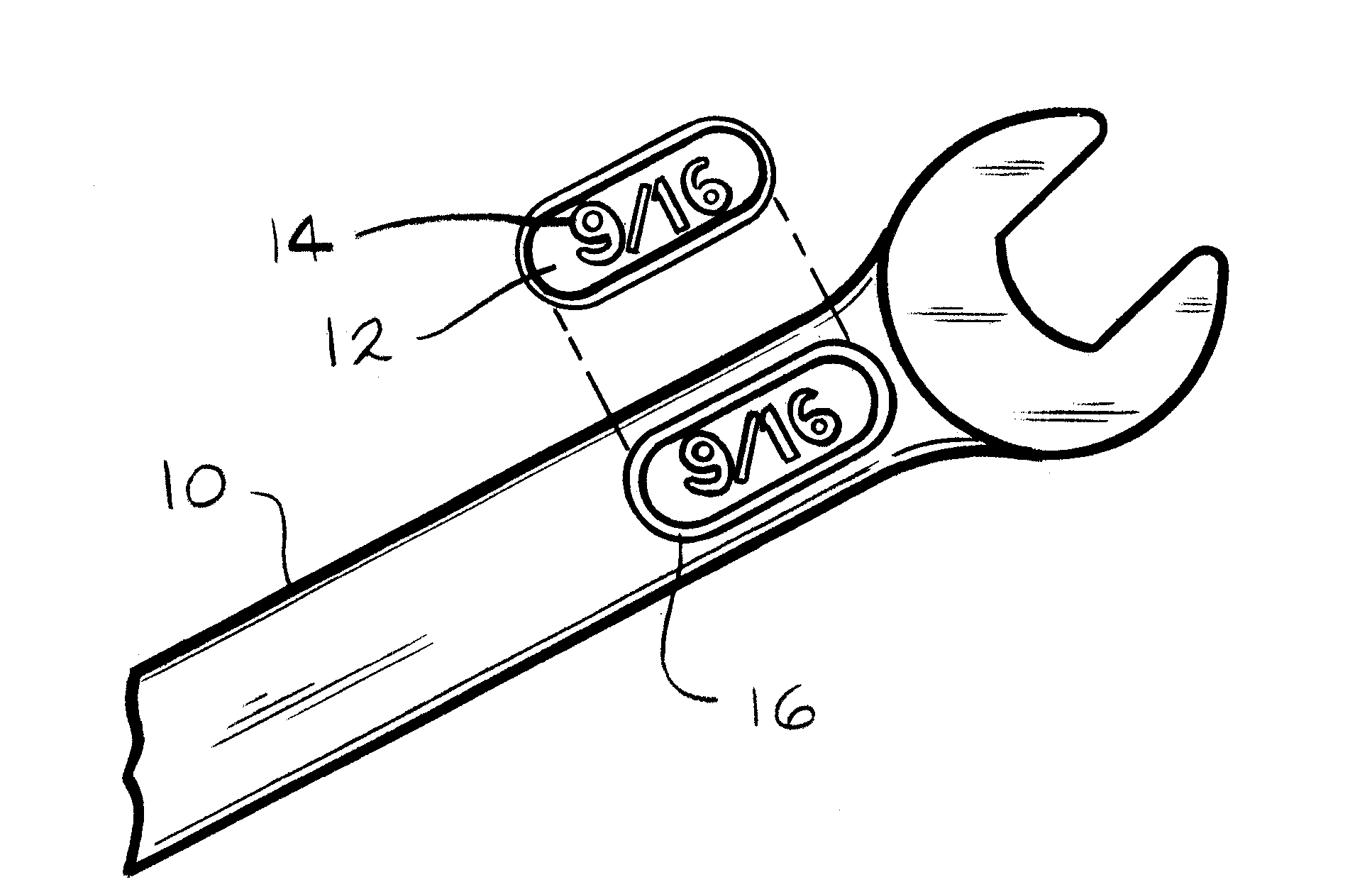

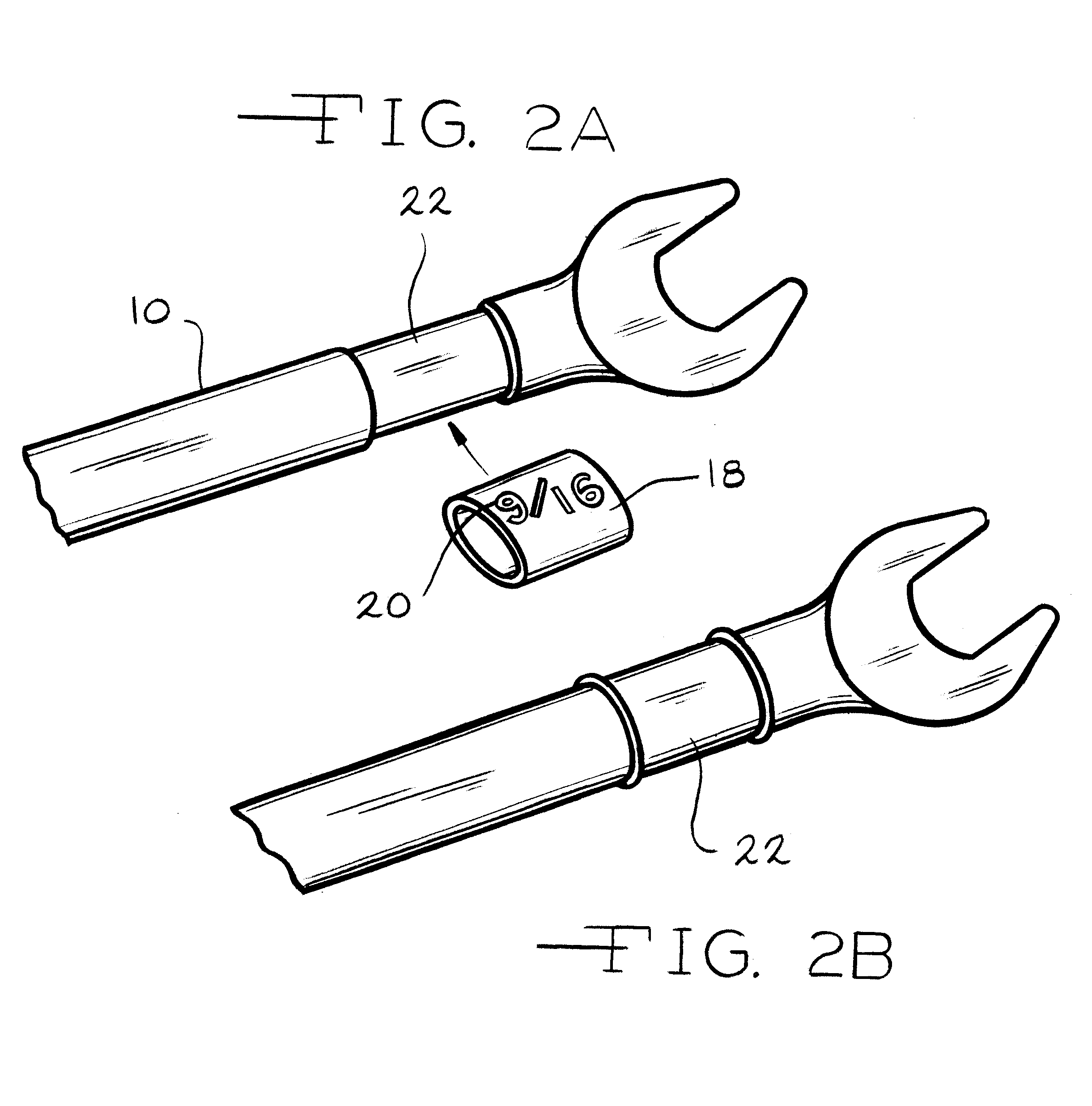

Color coded tools

The tools (wrenches) of this invention provide a one color instant identification of color coded tools. Preferably, the tools have a portion of their outer surface colored. Typically, the color impregnates the metal or plating during the manufacturing process. Another embodiment is a colored applique, band or sleeve on the outer surface of the tools. The key of this coloring is to identify the tool quickly by coloring a large area of the tool. This provides for quick identification of the tool even if the numerical designations are illegible because of small sizing or dirt obliteration. In a preferred embodiment, virtually the entire tool is colored during manufacturing. In another preferred embodiment, large raised numbers combine with the overall color scheme to make the tools quickly identifiable. Dirting the large colored surface is very unlikely as is obliterating the large raised fractional numbers.

Owner:CROSSER LARRY G

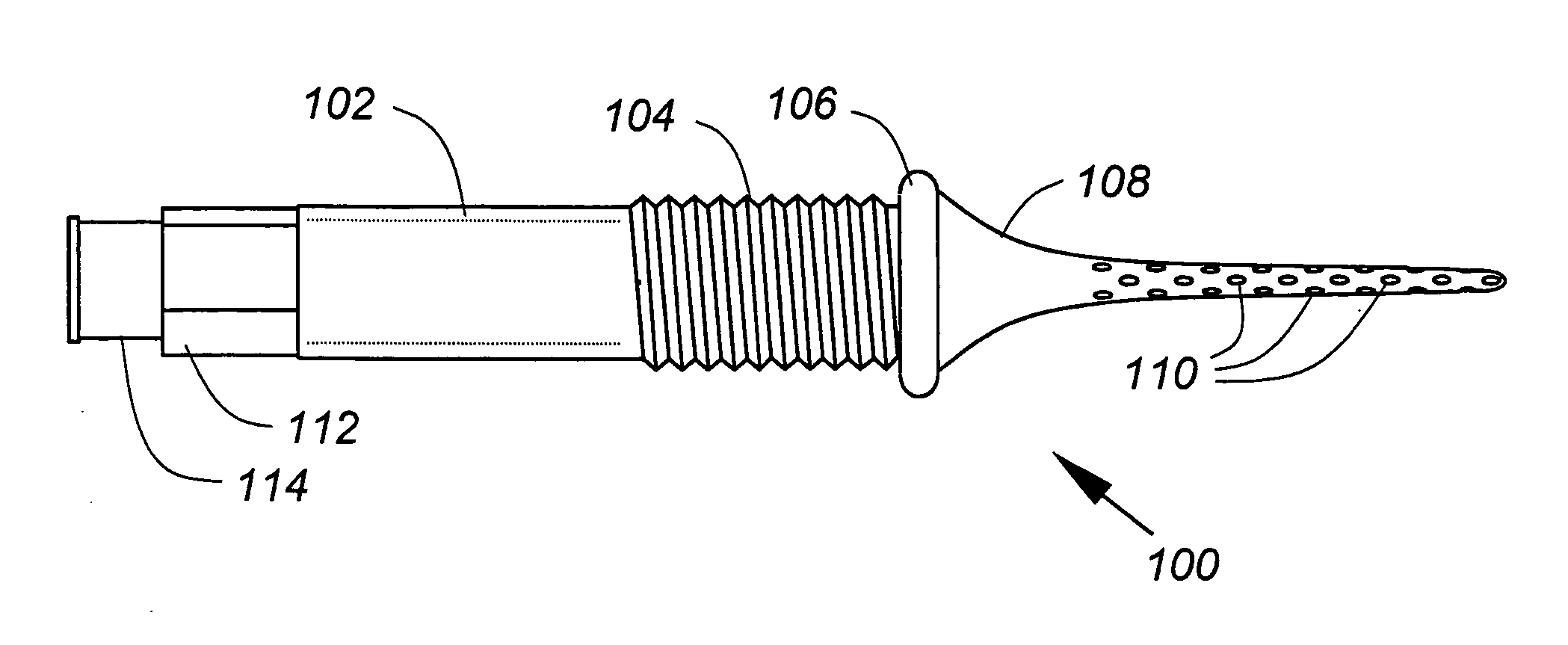

Cement/biologics inserter and method for bone-fastener fixation augmentation

An inserter and associated method improve the placement of a fastener into a bone. Although ideally suited to the placement of a pedicle screw into a vertebral body (VB), the apparatus and method are applicable to other bones and fasteners, pins, and the like. The apparatus includes cannulated body having a proximal end, a distal end, and a threaded section therebetween. The proximal end is shaped for rotational tightening by a wrench or other tool, and the distal end including a perforated nozzle so that cement and / or biologics may be injected into the bone through the cannulated body. The proximal end includes a Lur-loc or other appropriate fitting to receive a cement-filled syringe. The device is also preferably disposable using, for example, clear plastic construction. The inserter may further including a member for sealing the nozzle relative to a bone. Such a member may be composed of a silatstic or other compressible material, or may be inflatable. At least the distal end of the device is preferably provided with varying diameters for different insertion sizes.

Owner:SINTEA PLUSTEK

Golf putter with adjustable weight system

An improved golf putter incorporating a weight management system that allows for adjustment of a golf club head weighting by incorporating an adjustable weight system wherein weights may be removed and replaced quickly and easily without requiring a specialized tool is disclosed. Weights received within weight ports formed in the heel and toe portions of the putter are maintained securely affixed within the club head body by plugs adapted for snap fit engagement with the club head. Unlike other putter weight adjustment systems disclosed in the art, the present invention does not require use of a special tool, such as a wrench, to remove and replace the weights. While the preferred golf club embodiment disclosed is a putter, the present invention contemplates incorporating any of the features and / or advancements disclosed herein into any golf club. In addition, the present invention further includes novel aspects relating to overall design, including mass distribution and a rearwardly projecting portion having an upwardly sloped sole that prevents the club from snagging the turf. Furthermore a hollowed out area formed within the rearwardly projecting portion is sized and shaped to receive a correspondingly sized and shaped sensing module adapted to measure club head movement and wirelessly transmit data to a remote graphical user interface.

Owner:LUEDERS ROBERT

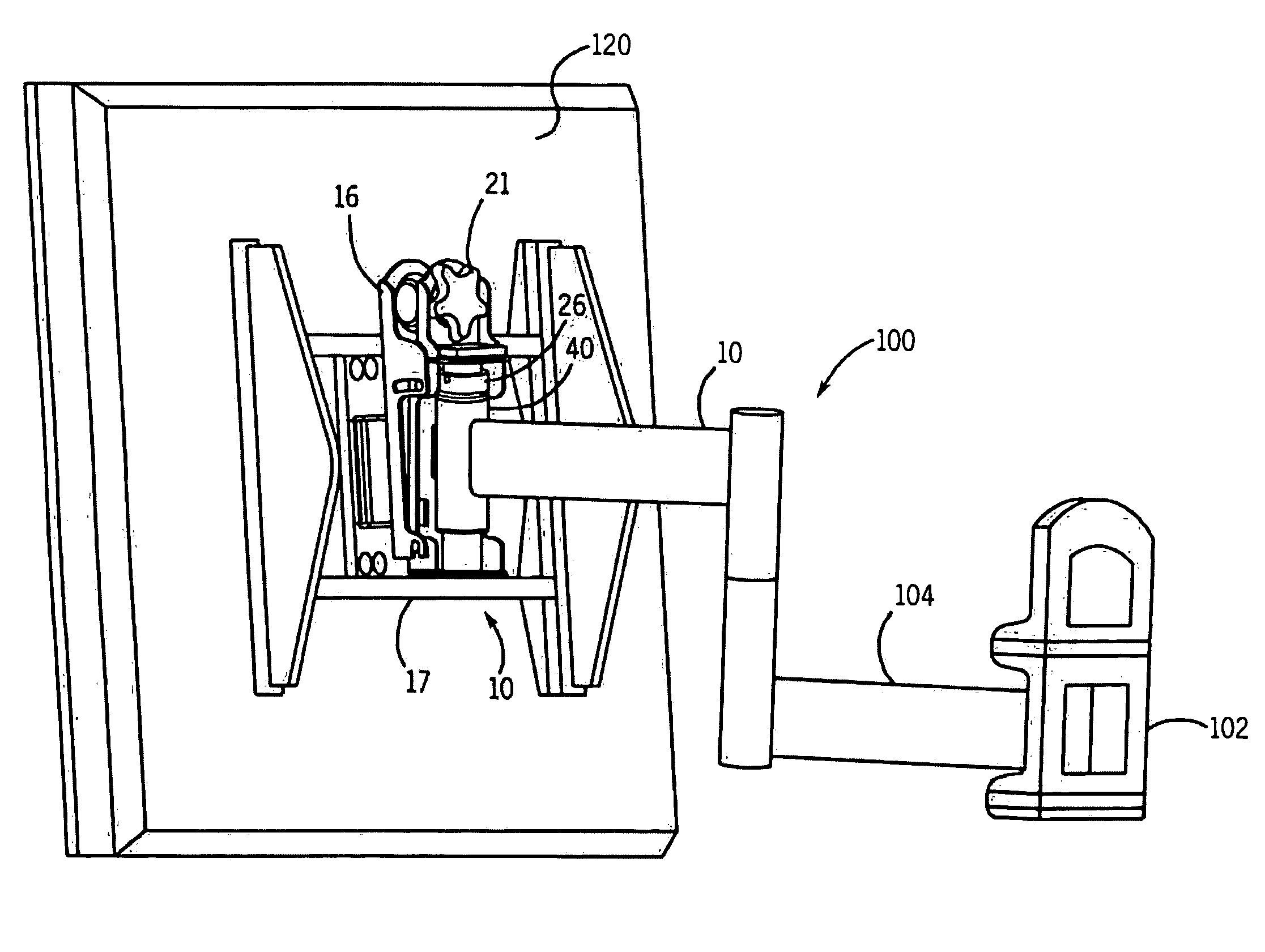

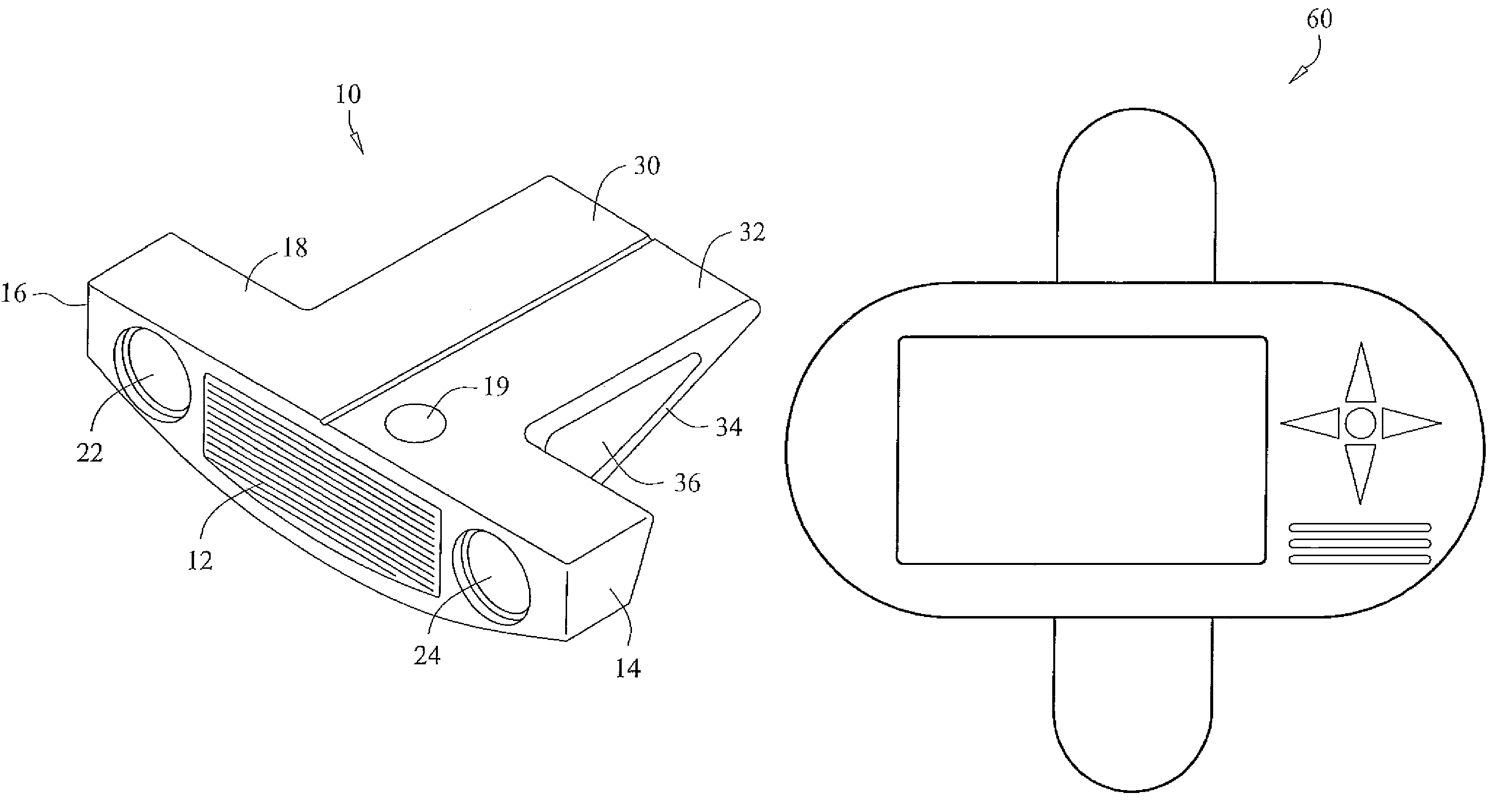

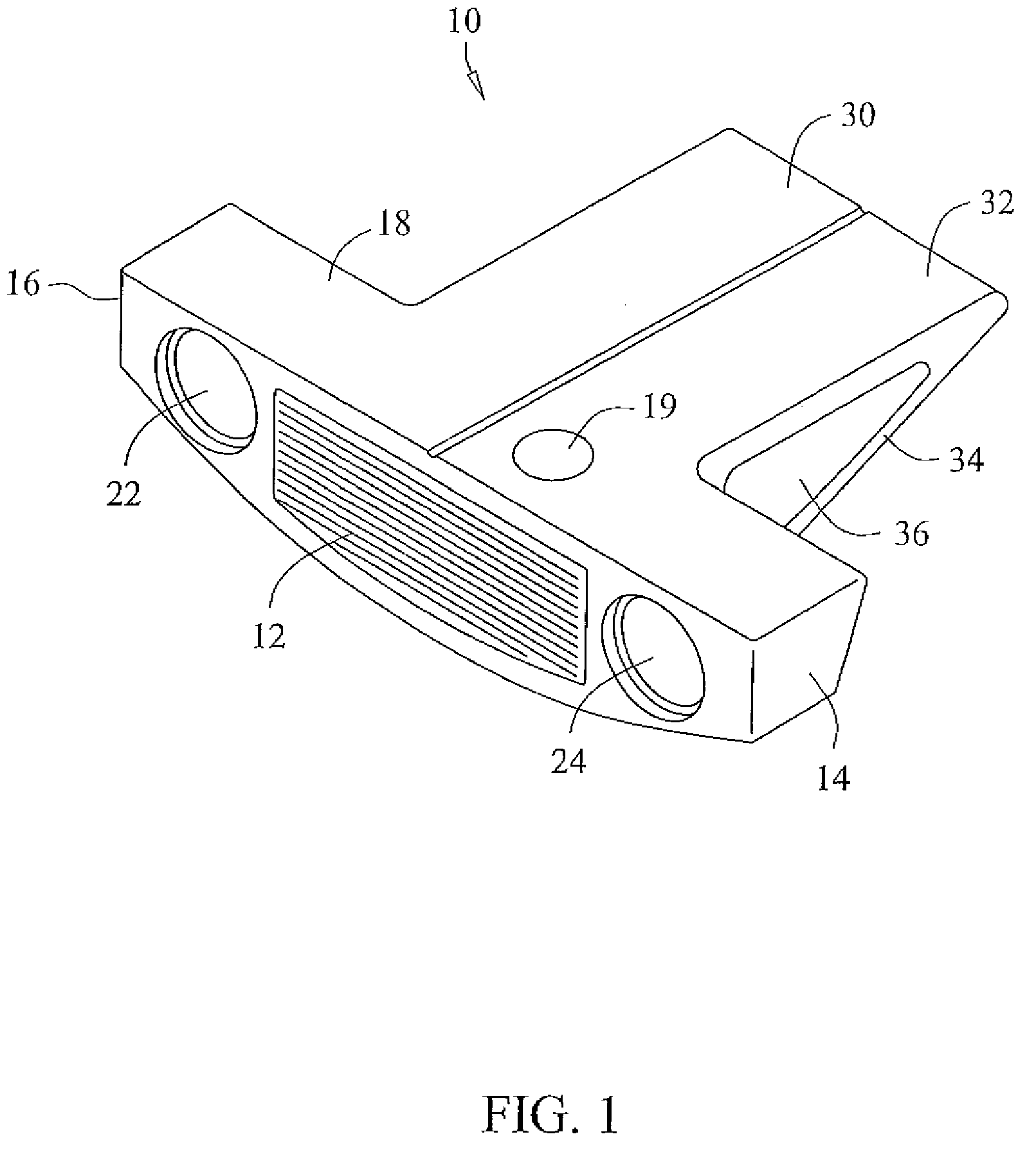

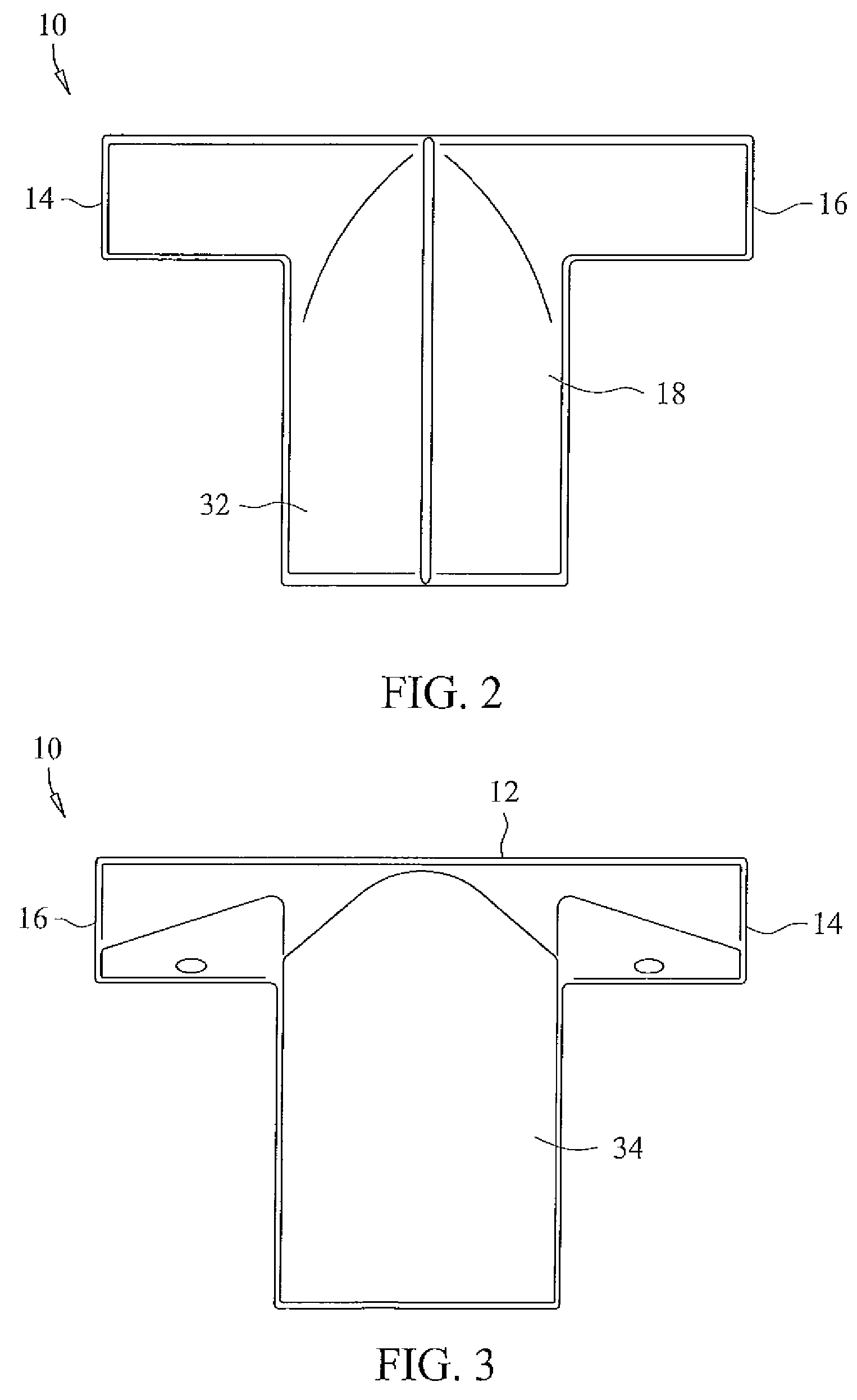

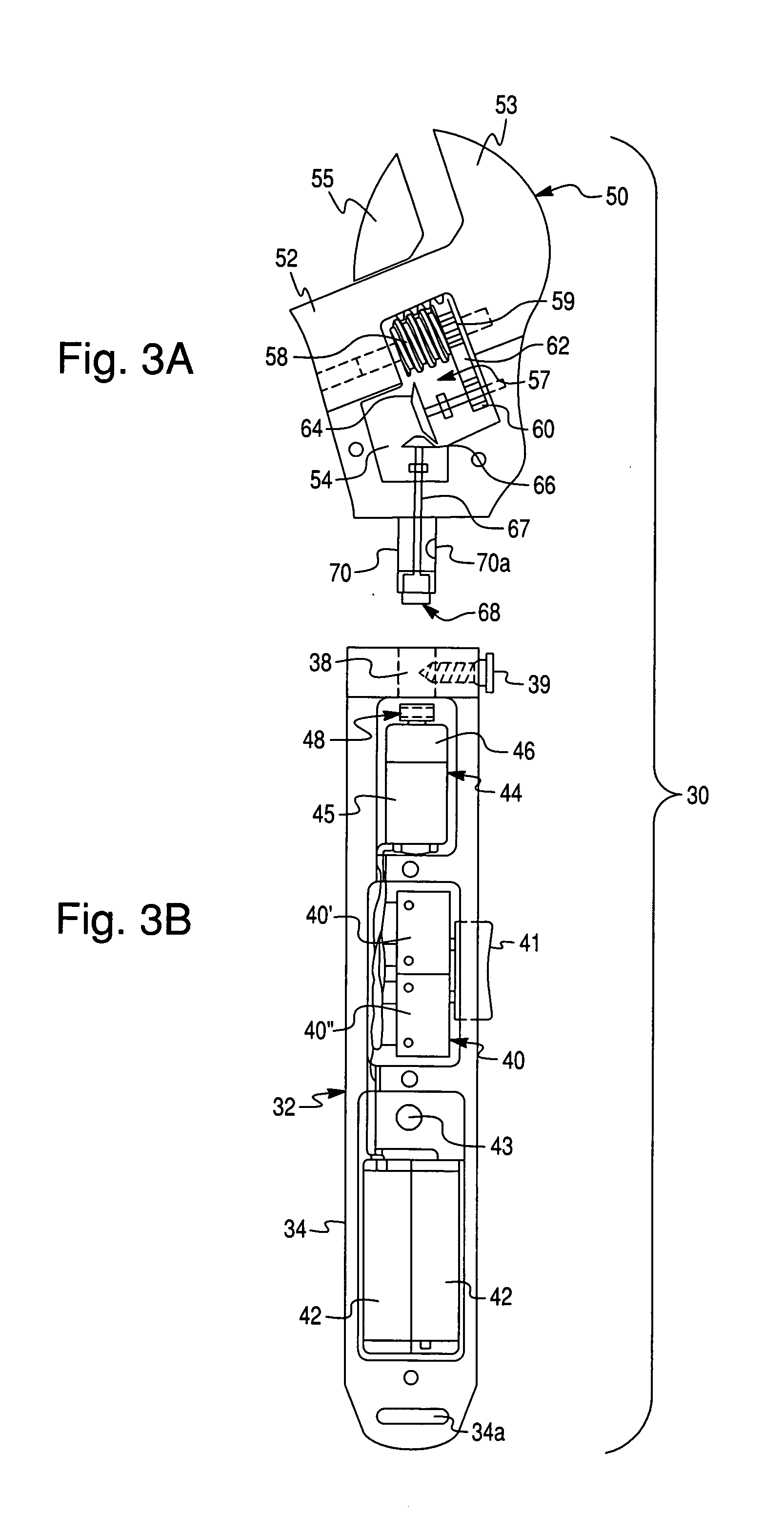

Multi-functional tool with interchangeable adjustable wrench head unit

ActiveUS7114824B2Facilitate extended reach and leverageLighting elementsSpannersReciprocating motionBiological activation

A multi-functional tool comprising an extendable power tool handle unit with an interchangeable connect feature able to receive and power various size interchangeable, adaptable adjustable wrench head units and other adaptable tool attachments. The interchangeable wrench head units are easily connected and disconnected to the power tool handle unit. Each interchangeable adjustable wrench head unit has a self-contained transmission connectible to and powered by the adaptive power handle unit. The interchangeable wrench head units comprise of a moveable jaw, a stationary jaw, and a worm gear. The worm gear is meshed with a rack of the moveable jaw and the worm gear is driven by a motor and transmission. Activation of the motor produces linear reciprocating motion of the adjustable jaw. A power source from the handle provides the power to a control switch. The switch controls the function of the adjustable wrench heads and other powered tool attachments.

Owner:PICONE PRODS

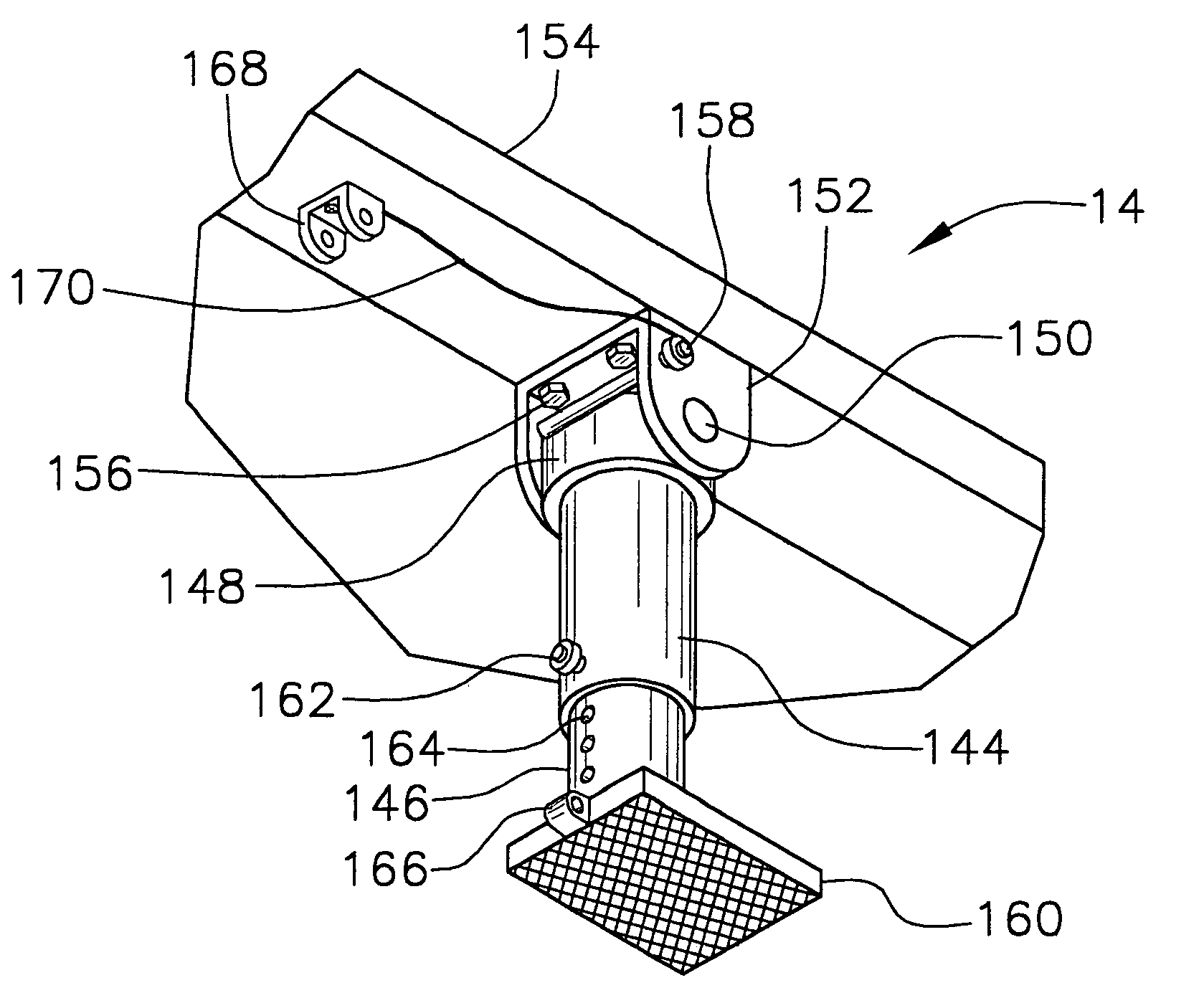

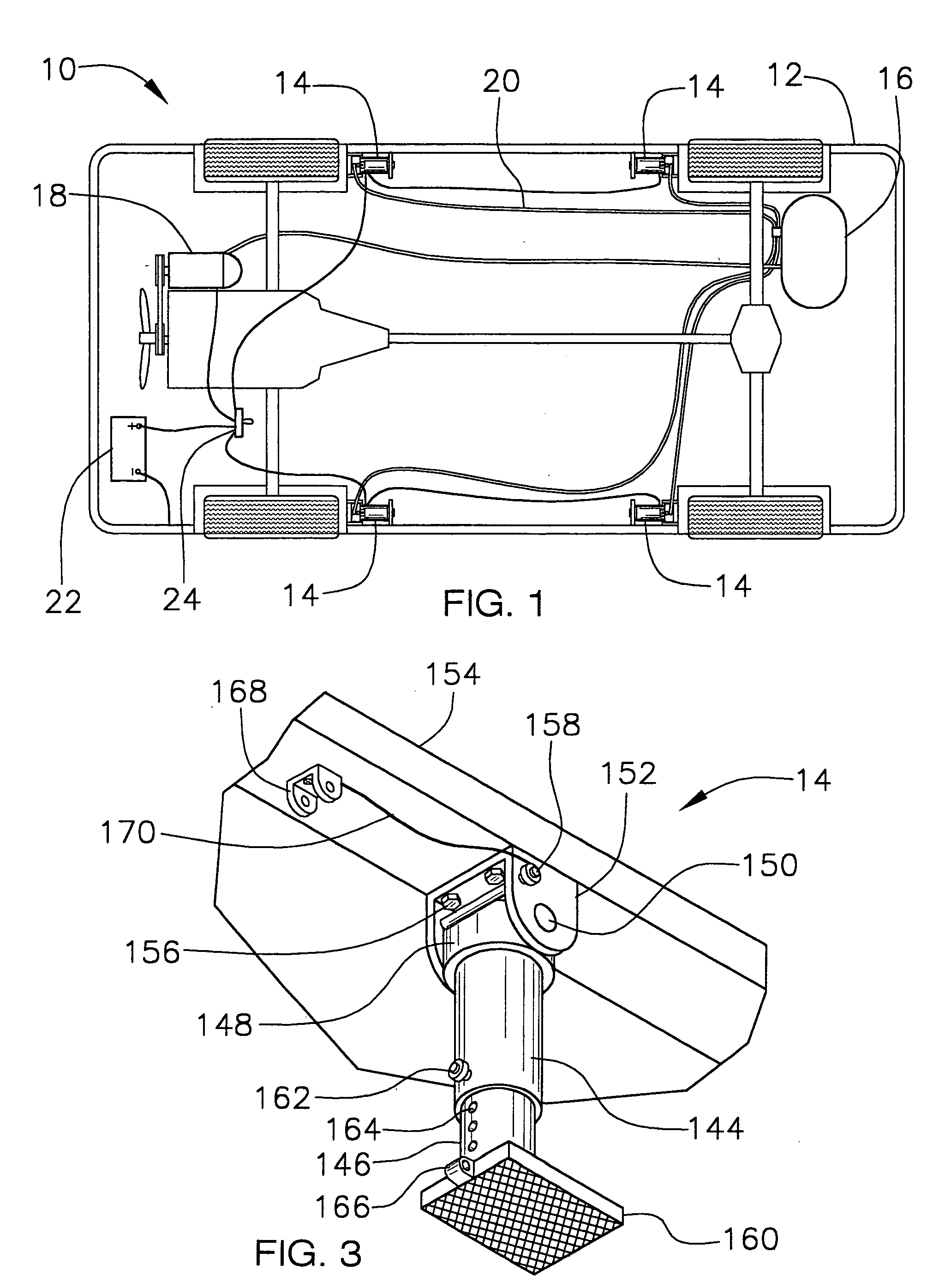

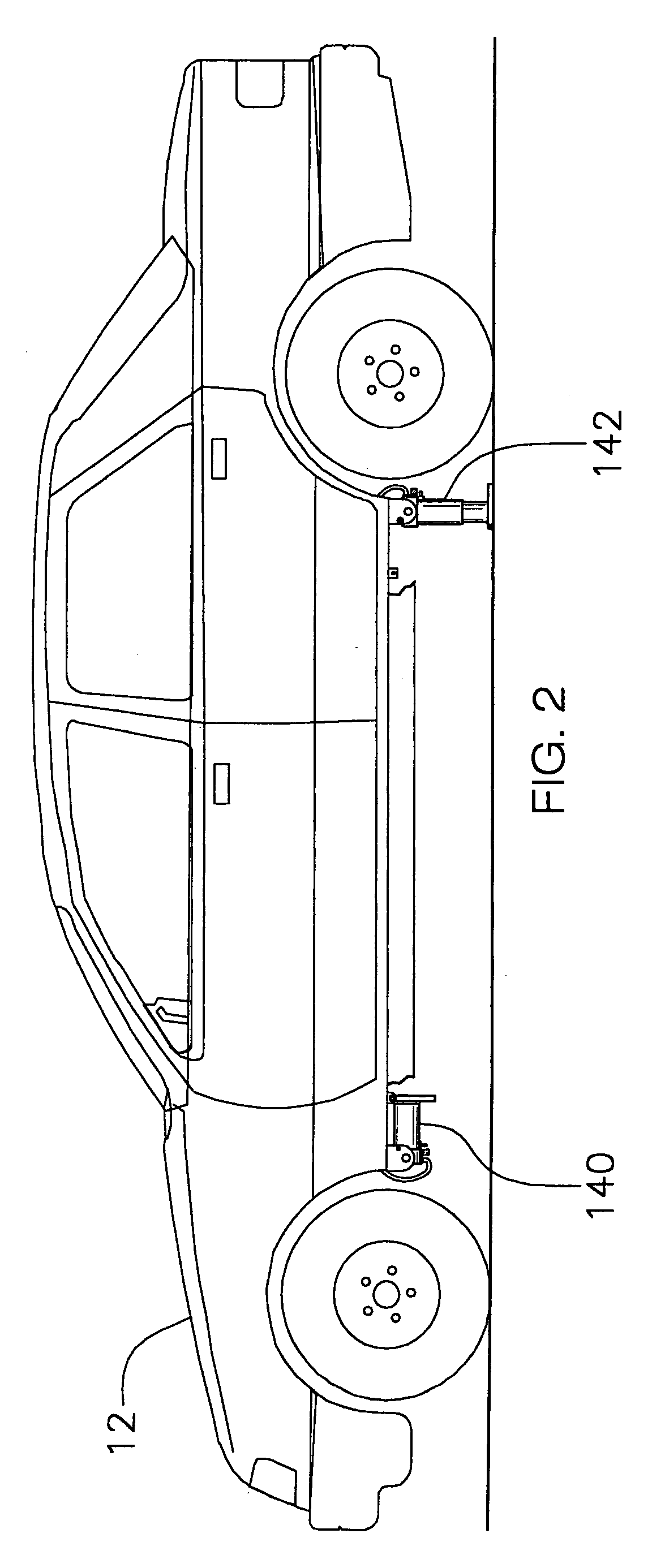

Motor vehicle pneumatic jacklift system

InactiveUS6895648B1Easy to modifyEasy and efficient to manufactureVehicle fittings for liftingVehicle cleaning apparatusSolenoid valveGas compressor

A permanently mounted pneumatic jack (jacklift) system for motor vehicles, as well as an impact wrench for removing and installing lug nuts. The system provides a quick and safe means of lifting one or more tires off the ground for replacement of a spare or rotating the tires on a motor vehicle. The present invention comprises two or more (typically four) pneumatic jacks, a system ON / OFF switch, an air compressor, a 120-psi air tank, air lines (hoses), individual jack extend / retract switches, jack position-locking pins, safety-locking pins, and impact wrench. Each jack can be locked in a horizontal stowaway or vertical operational position. The jack is cylindrical shaped with a telescopic body that can be extended or retracted as needed to raise and lower the vehicle. A solid cylindrical lift rod slides inside a cylindrical outer housing with a high-pressure seal means used to maintain pressure on the support rod. A ground support foot (plate) is mounted on the lower end of the solid cylindrical lift rod to provide sufficient traction with the ground to support the lifting process. A quick release air coupler is included on the pneumatic chamber to support the use of an air hose and impact wrench. An extend / retract toggle switch is included on each jack to control a solenoid valve to allow the air to flow into the jack. A quick release safety-locking pin is used to mechanically pin the solid cylindrical lift rod to the outer housing once the desired height is achieved to assure that the vehicle does not fall down in the event of a high-pressure air loss, thereby providing safety to the person(s) working around the vehicle. An air compressor located in the engine compartment of the vehicle is mechanically belt-driven off the engine. A high-pressure air line carries the air to a high-pressure (at least 120-psi) air tank located in the trunk or other suitable storage area on the vehicle. Separate air lines extend from the air tank to the individual jacks.

Owner:WILLETT MICHAEL J

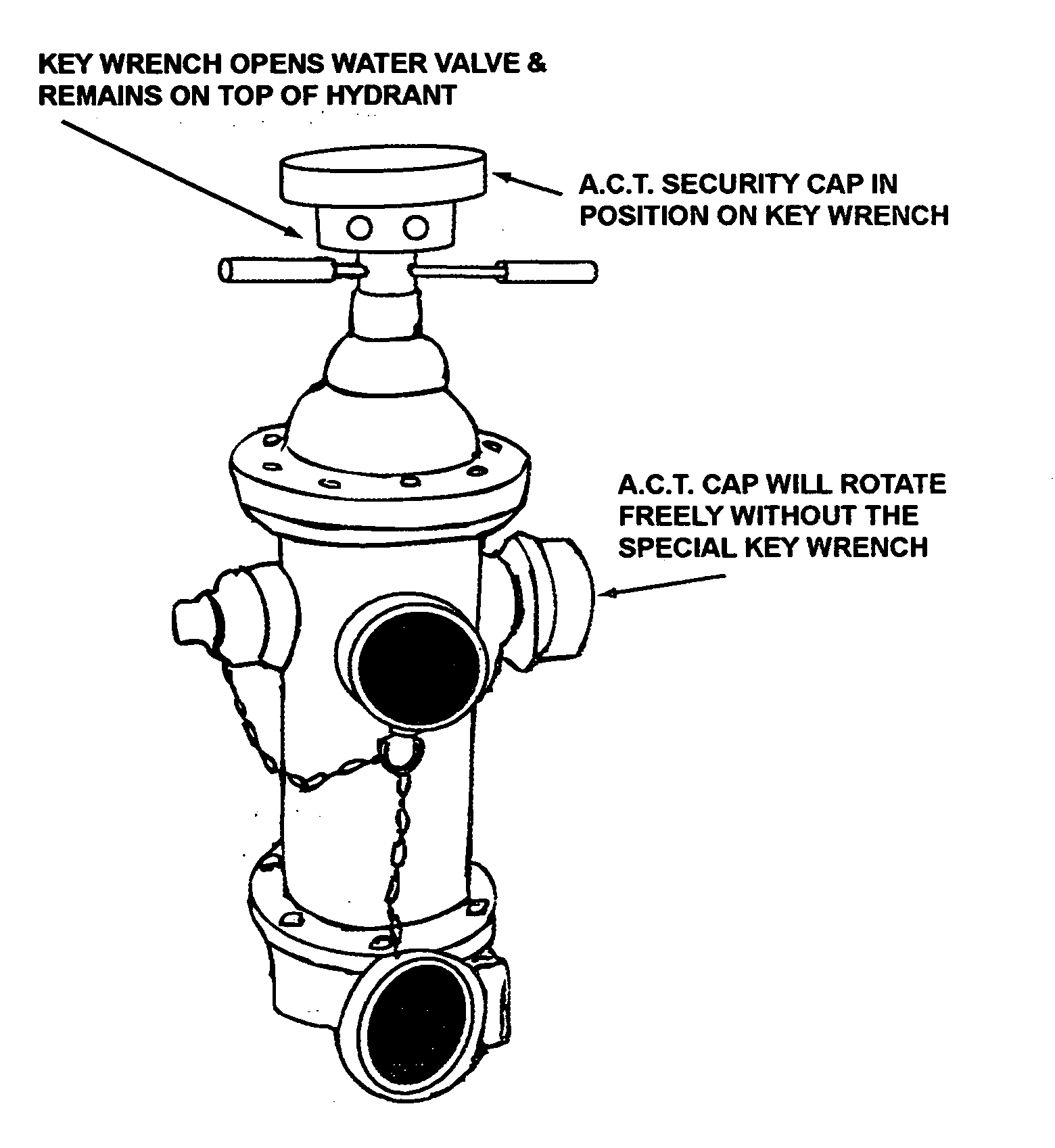

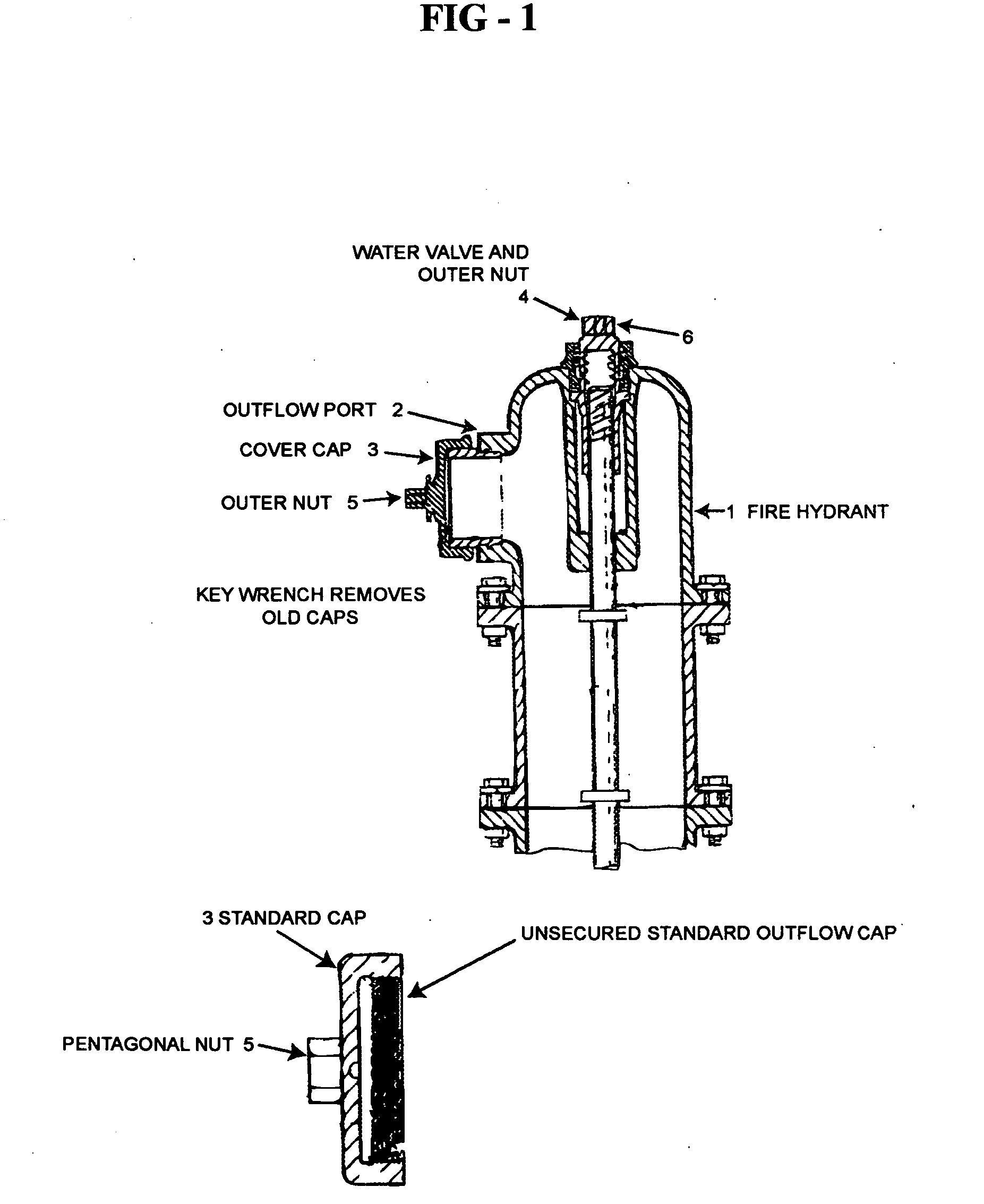

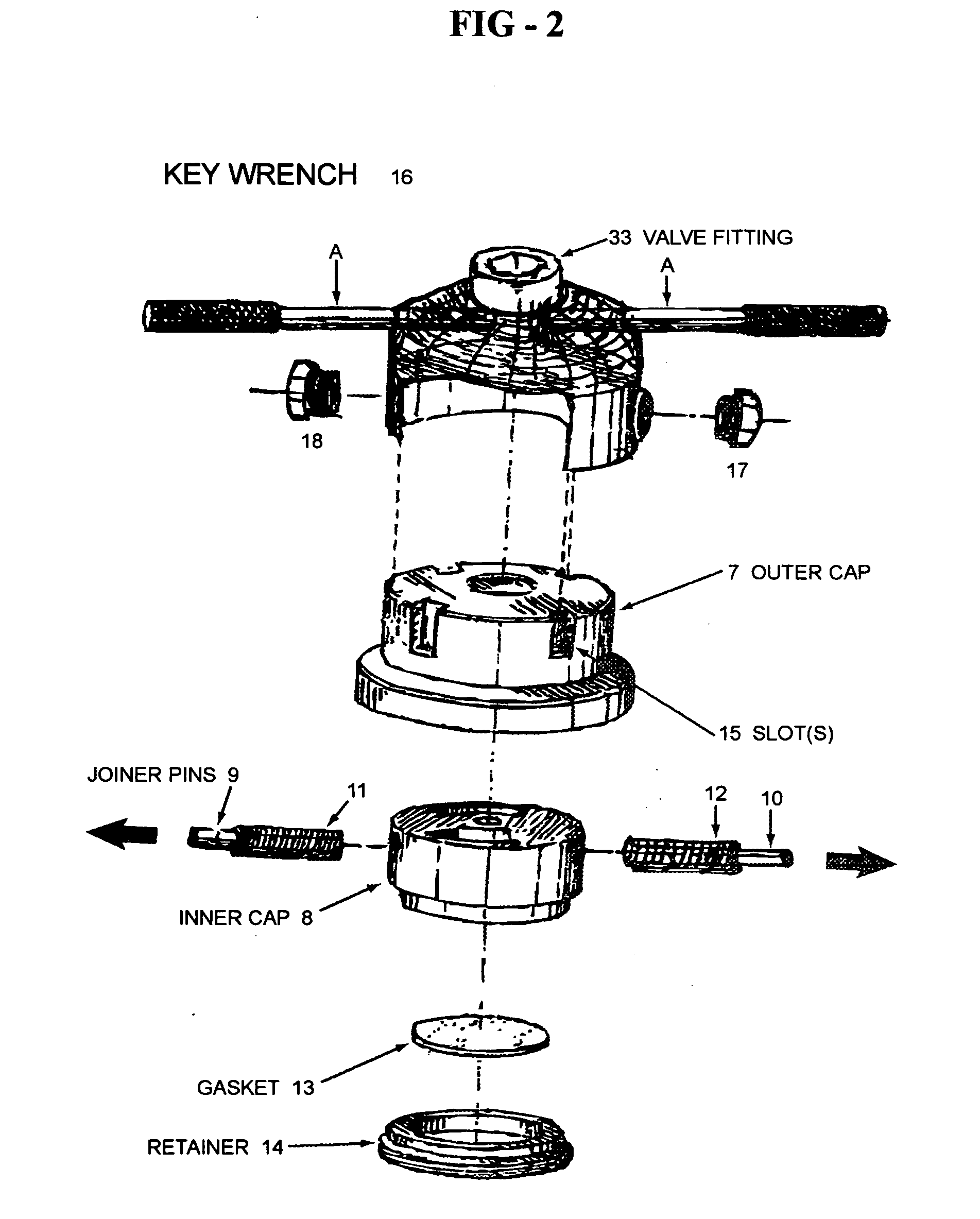

Fire hydrant security cap closure system

InactiveUS20090301571A1Avoid easy removalPrevent theftBatteries circuit arrangementsOperating means/releasing devices for valvesEngineeringFixed position

This invention provides a fire hydrant security system with an inner cap having means for attaching an outlet port of a fire hydrant in a fixed position which includes a member capable of extending from the periphery of the inner cap into a slot in the inner part of an outer cap and having means for retracting and retaining the position of the member in the inner cap, wherein said outer cap includes means for attaching the outer cap to the inner cap so that the outer cap can spin freely with respect to the inner cap, and a key wrench having means for fitting the key wrench over the outer cap and for aligning the outer cap and key wrench in a fixed position wherein the key wrench has a magnet located on the wall of the key wrench that becomes aligned with a slot on inner wall of the outer cap and wherein the rotation of the key wrench causes the magnet to align with the member and to extend the member into the slot on the inside of the outer cap thereby joining the outer cap to the inner cap.

Owner:RUHS JACK

Jumper sleeve for connecting and disconnecting male F connector to and from female F connector

ActiveUS7837501B2Electrically conductive connectionsTwo pole connectionsEngineeringMechanical advantage

A jumper sleeve for connecting and disconnecting a male F connector to and from a female F connector includes a wrench portion and a grip portion. The wrench portion has a leading end, a trailing end, and a hollow main body located between the leading end and the trailing end. The main body of the wrench portion internally has a hexagonally shaped portion corresponding to a shaped outer surface of a rotatable connecting ring of the male F connector. The grip portion has a rear end and a front end connected to the trailing end of the wrench portion, and has a plurality of circumferentially spaced externally convex sections, each of which has a radially inward key formed near the rear end thereof. The jumper sleeve provides greater mechanical advantage to produce sufficient torsion force, enabling easy installation and removal of the male F connector.

Owner:PHOENIX COMM TECH INTIOAL

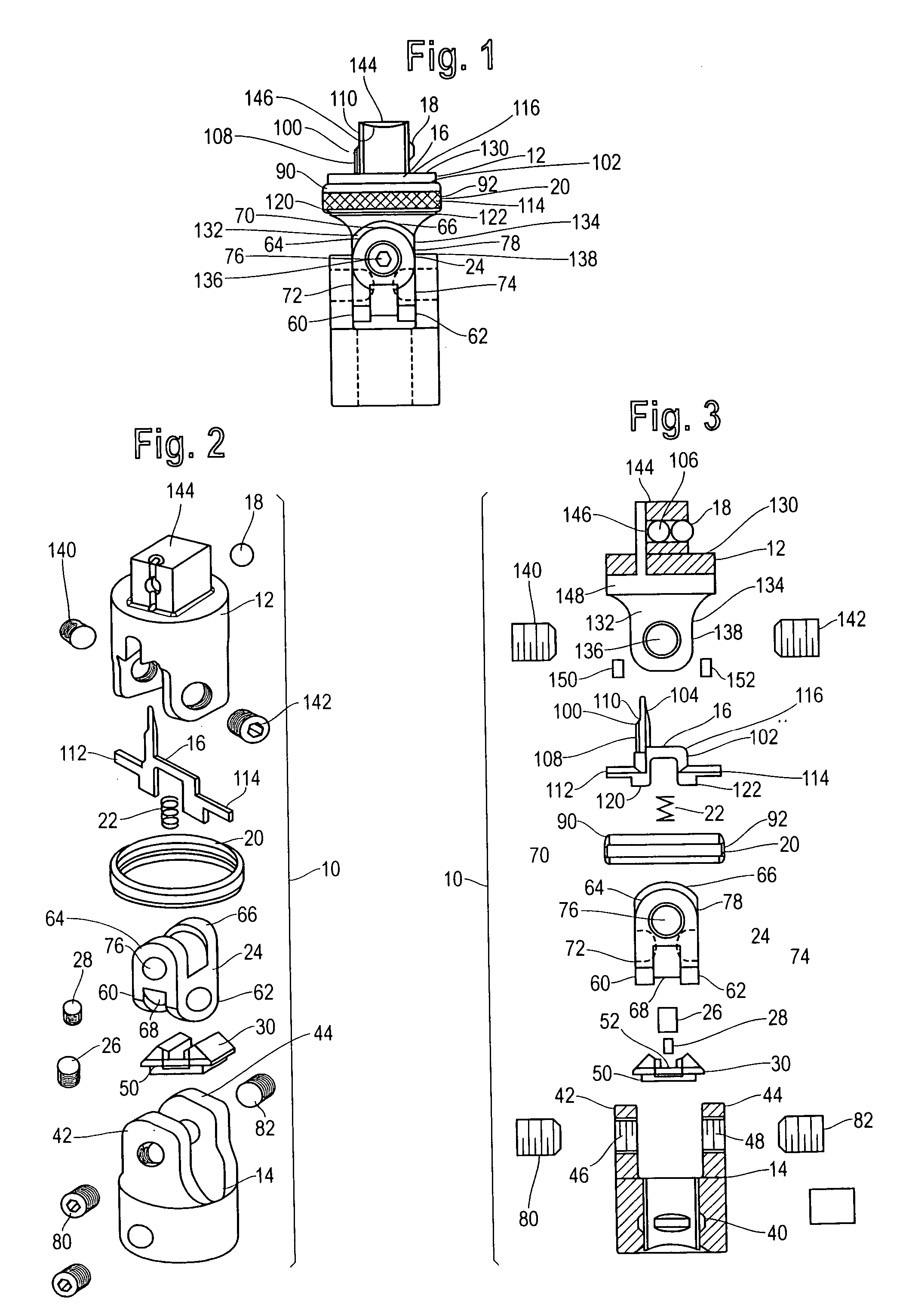

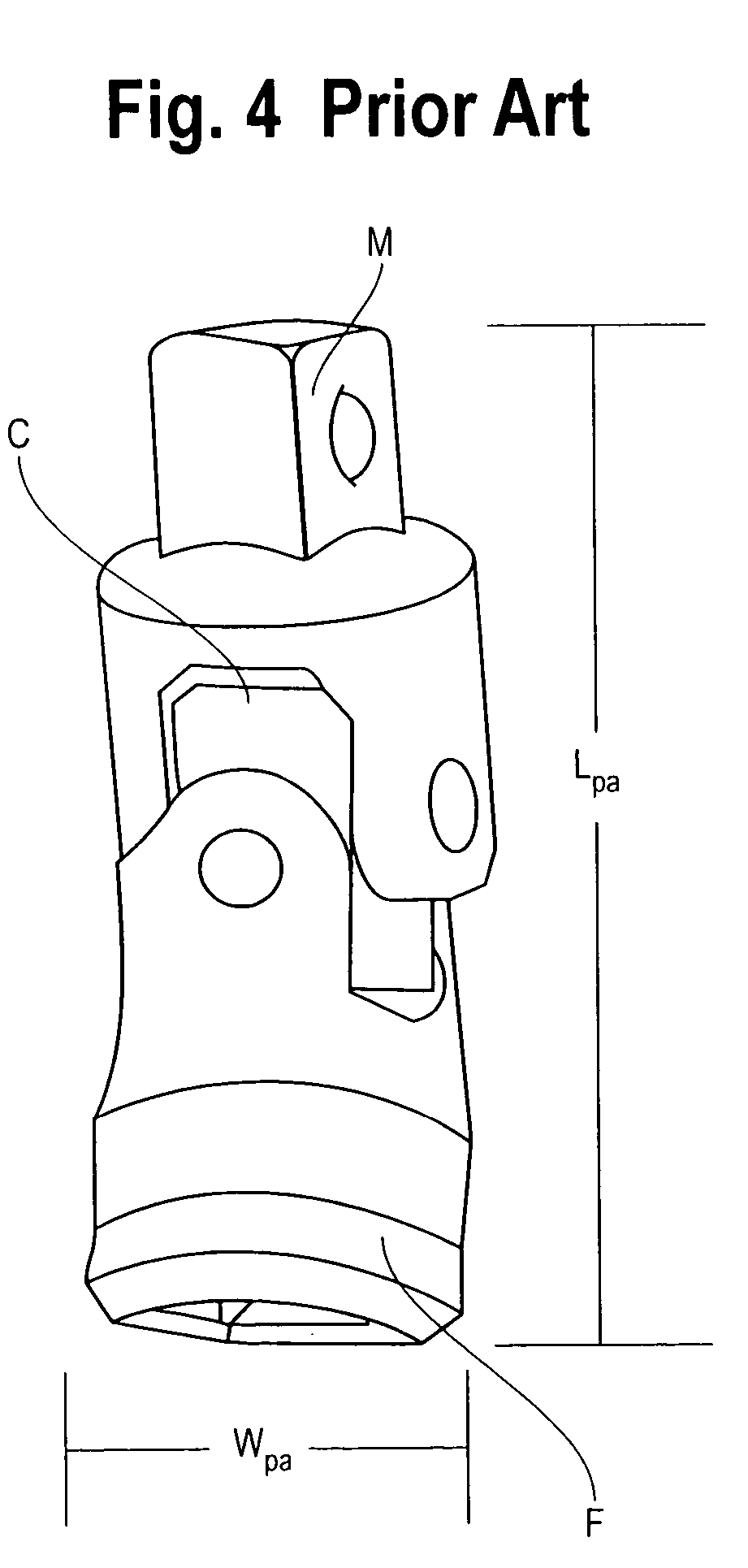

Low profile locking socket wrench universal joint

A low profile locking socket drive universal joint uses a compact locking mechanism with a control bar and a transverse actuator assembly connected to a sleeve to lock a socket to a drive stud with dual function tensioning springs, flexing clevis arms, movable spring seat and closely spaced universal coupler axes all contributing to a short, fatigue resistant universal joint that additionally supports sockets close the drive axis at rest to operator advantage and limits movement skewed to the drive axis to substantially 45°.

Owner:QUALICORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com