Patents

Literature

5229results about "Power driven tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

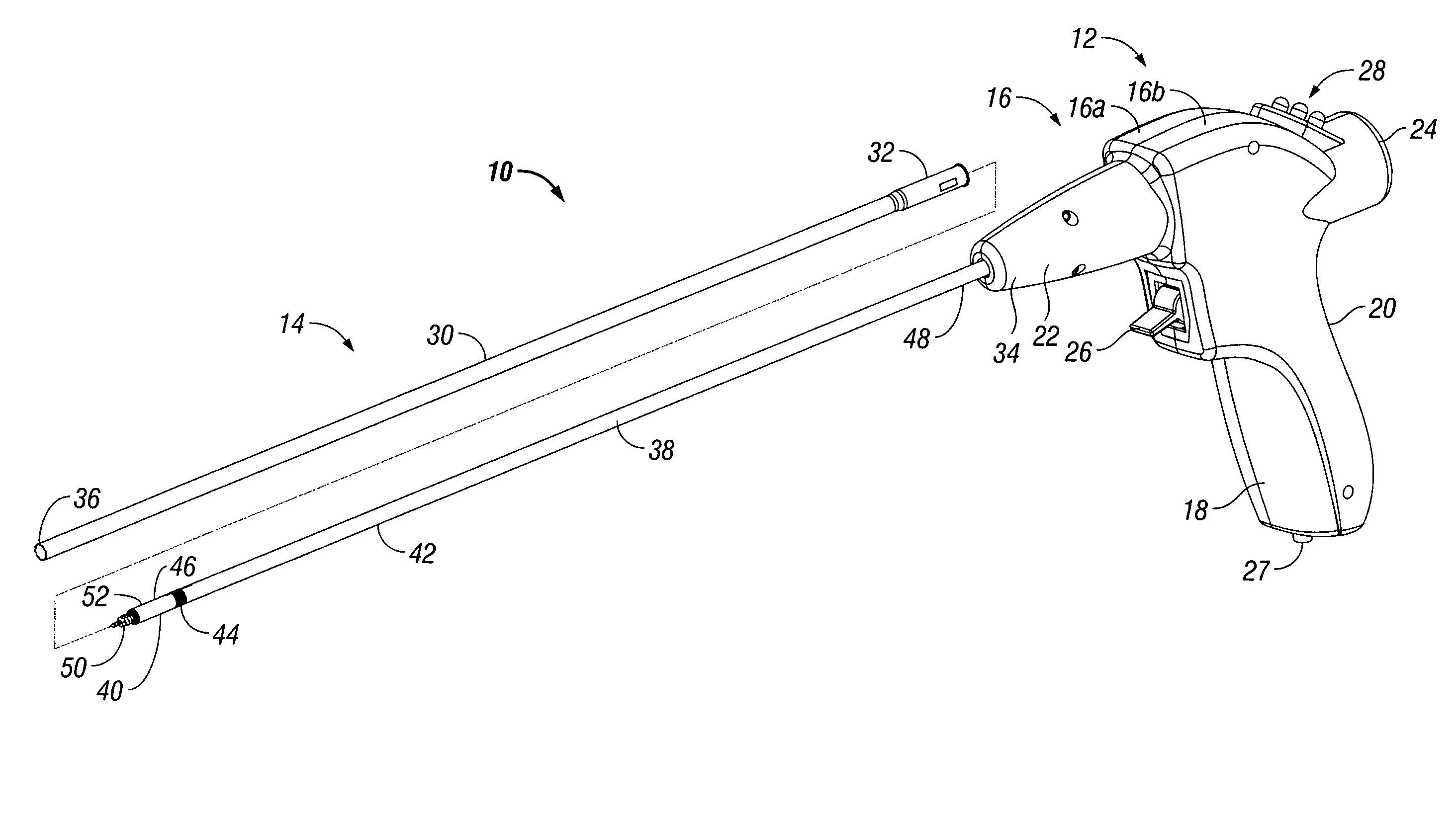

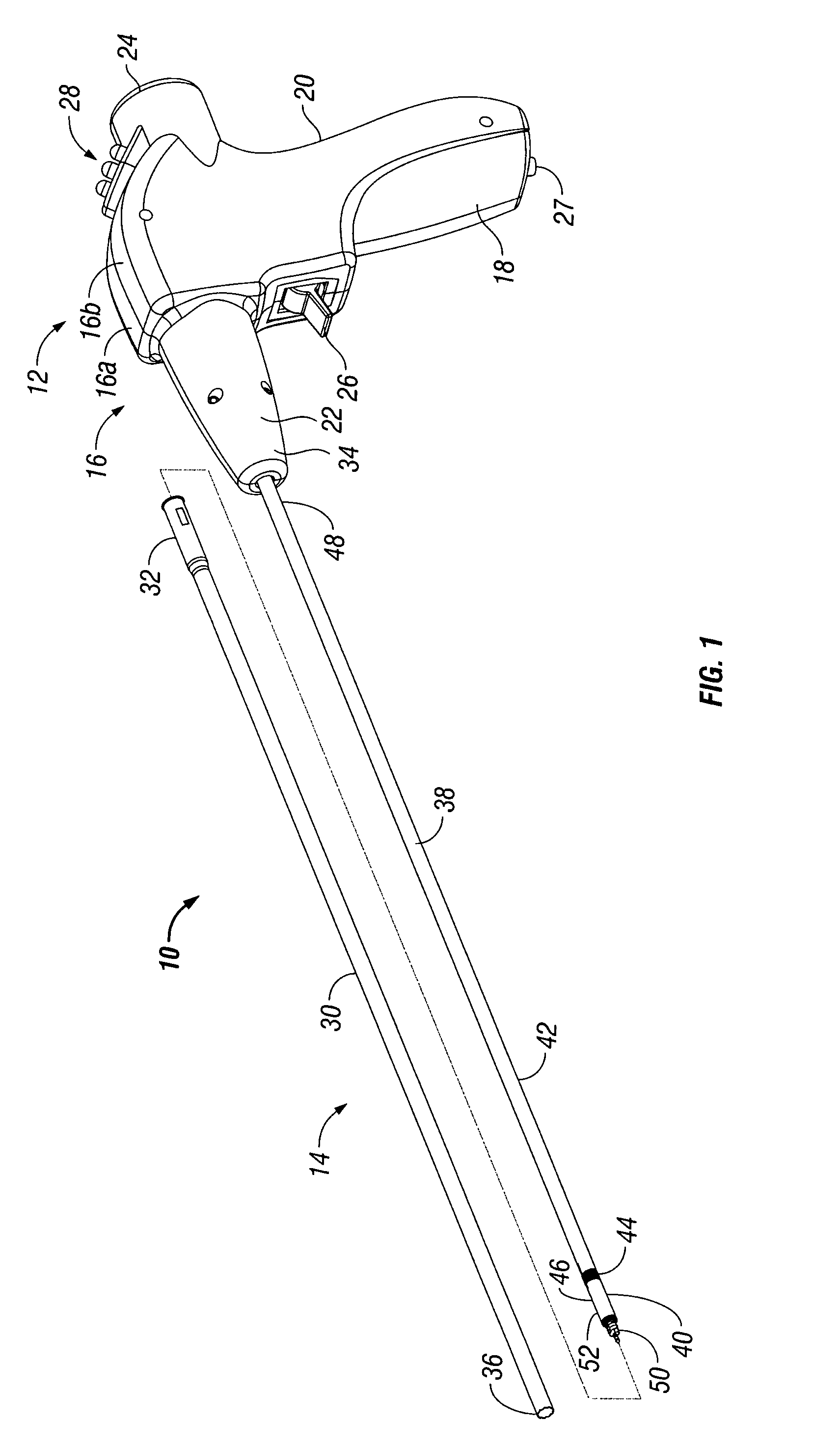

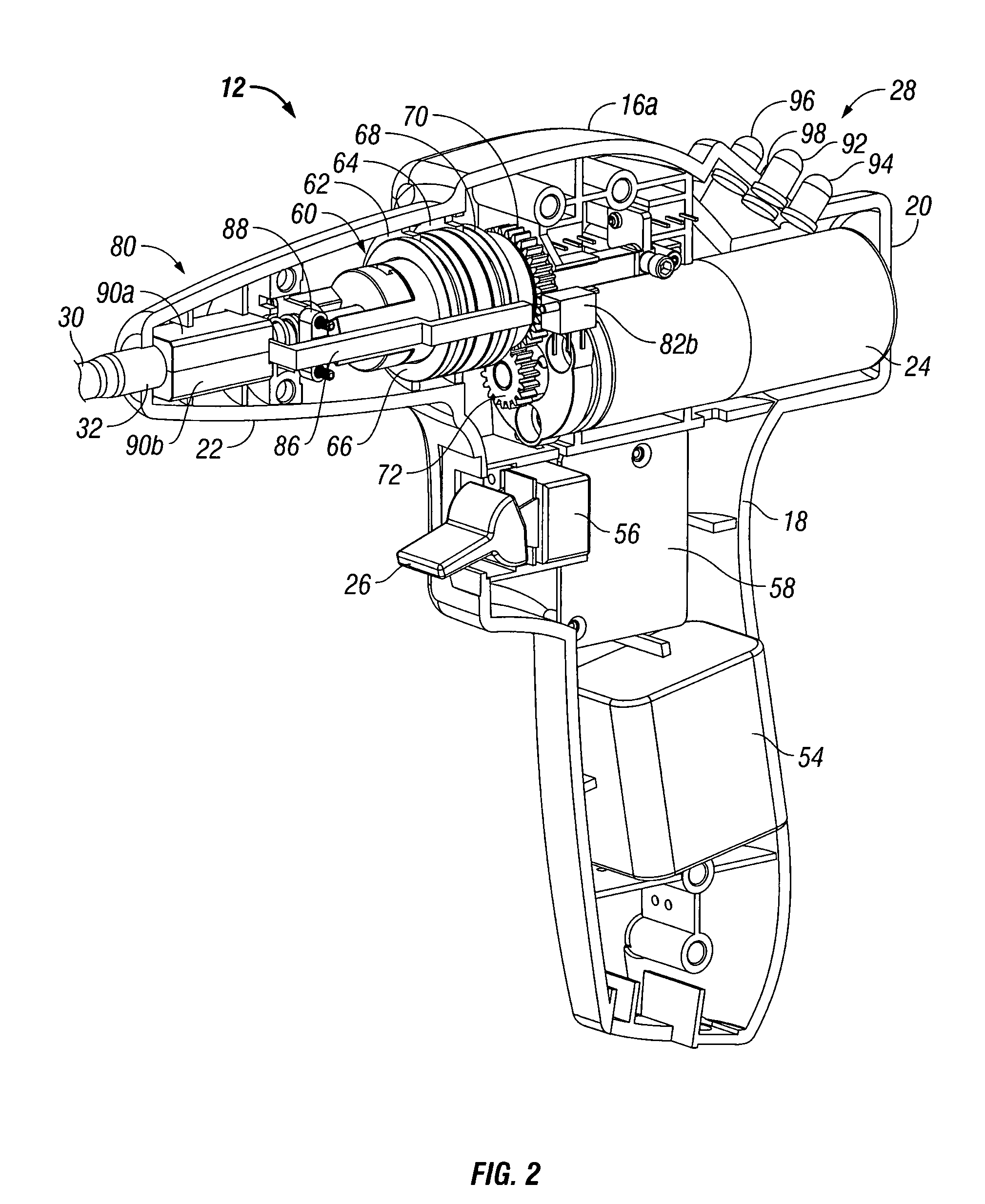

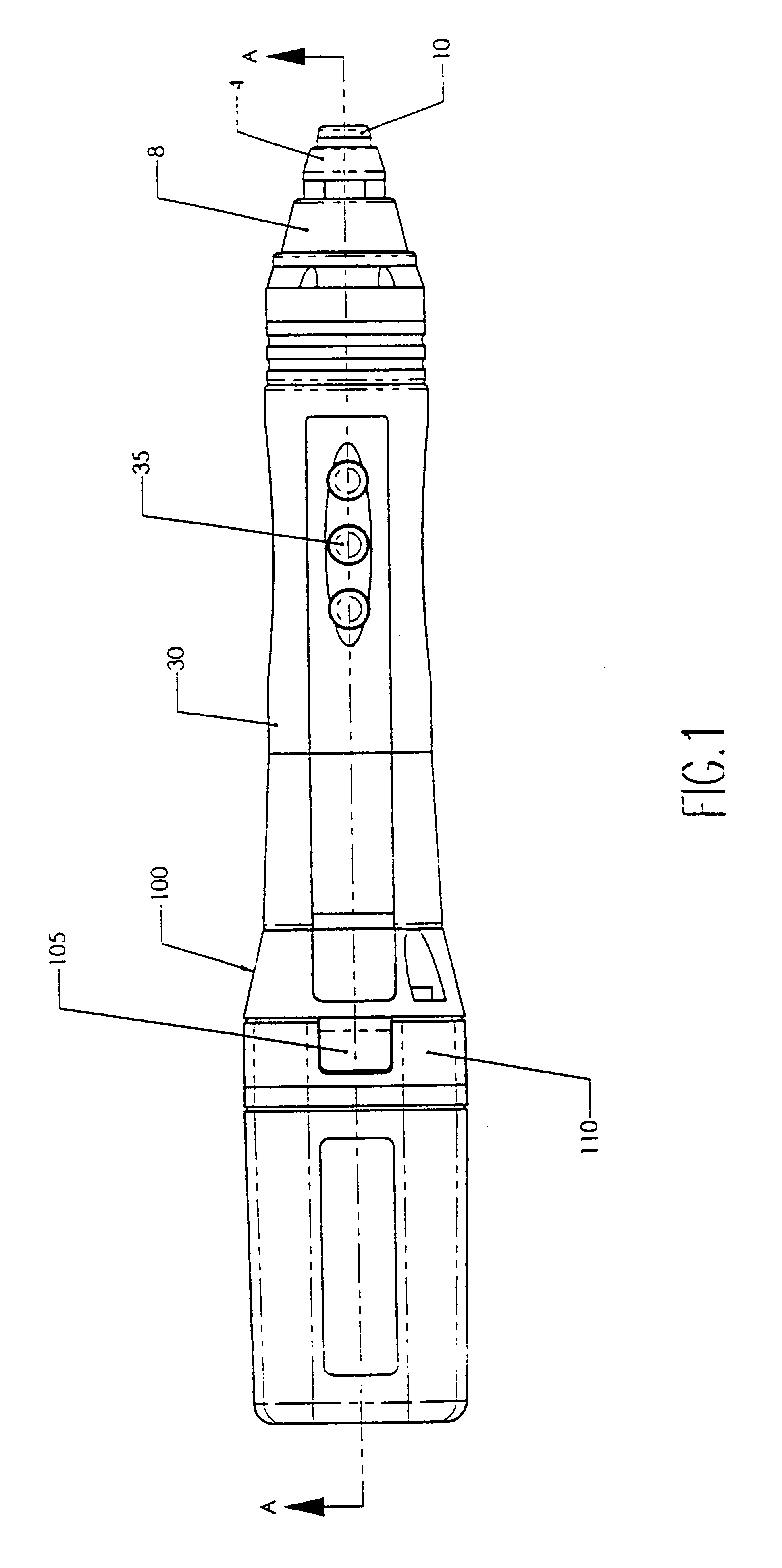

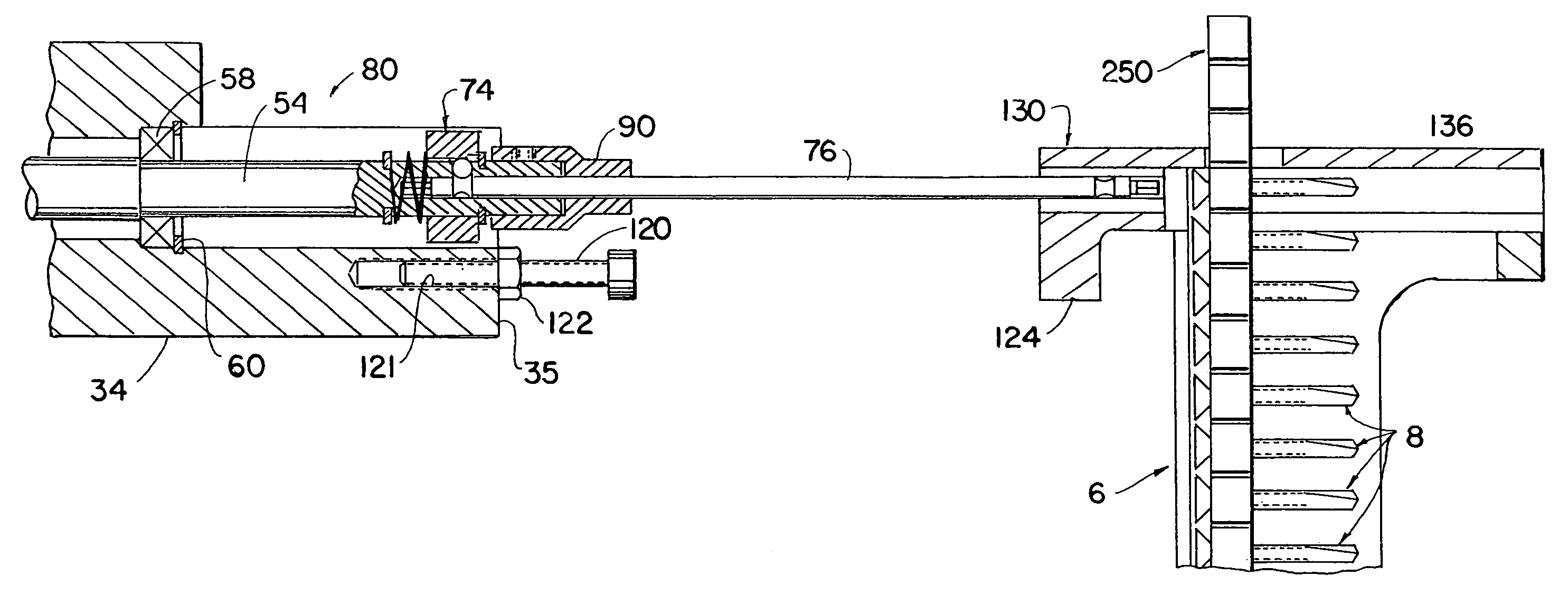

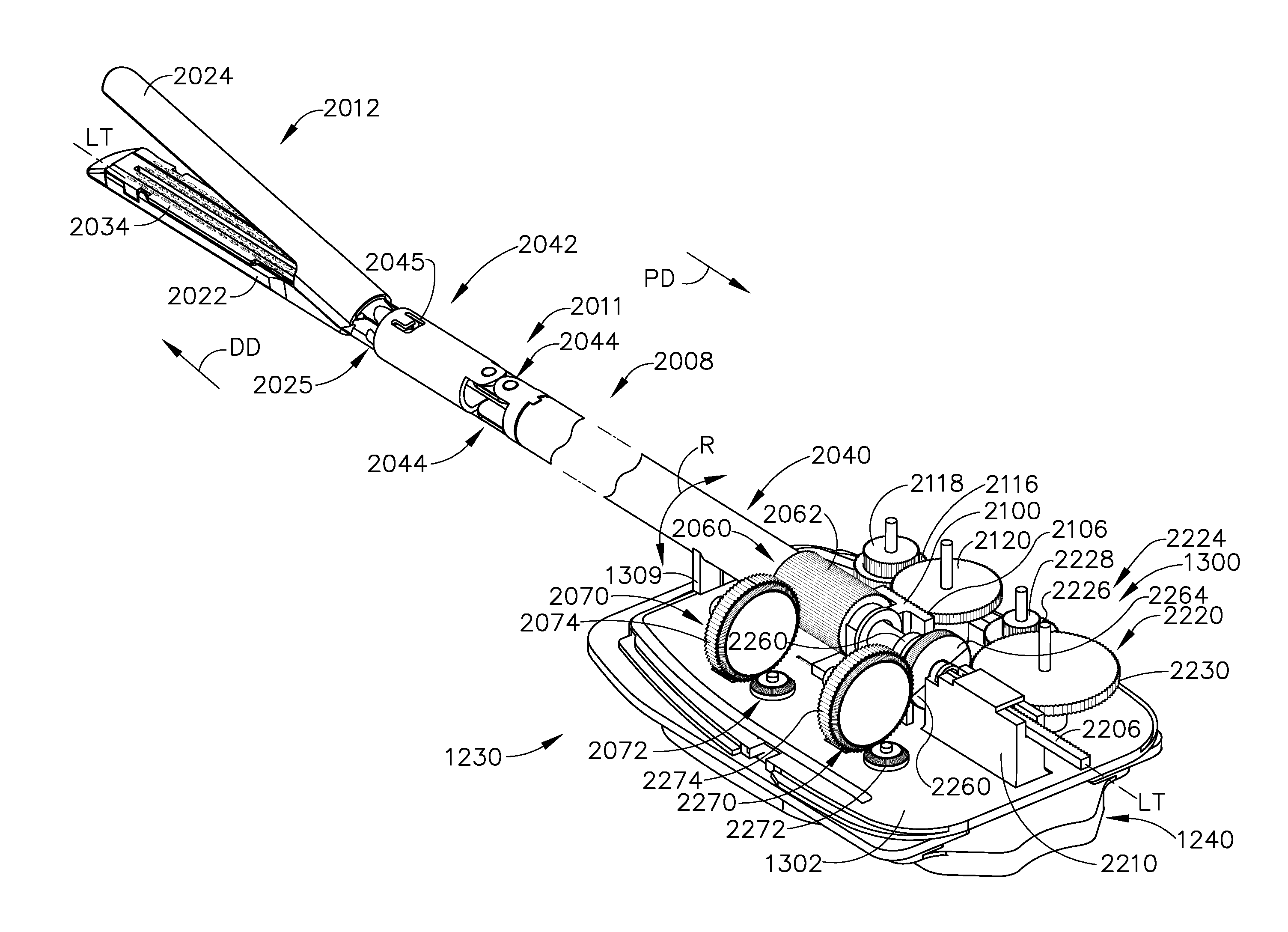

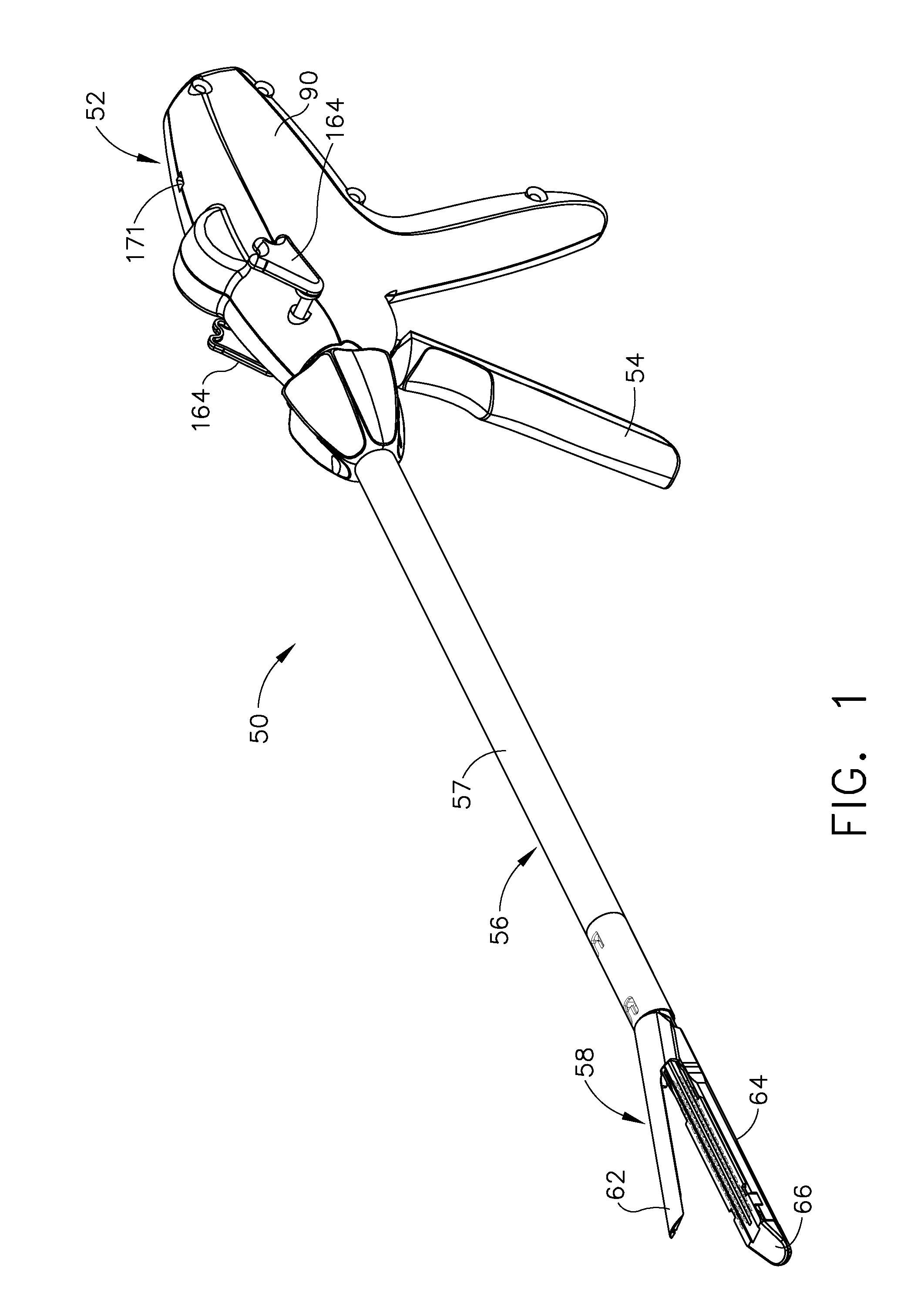

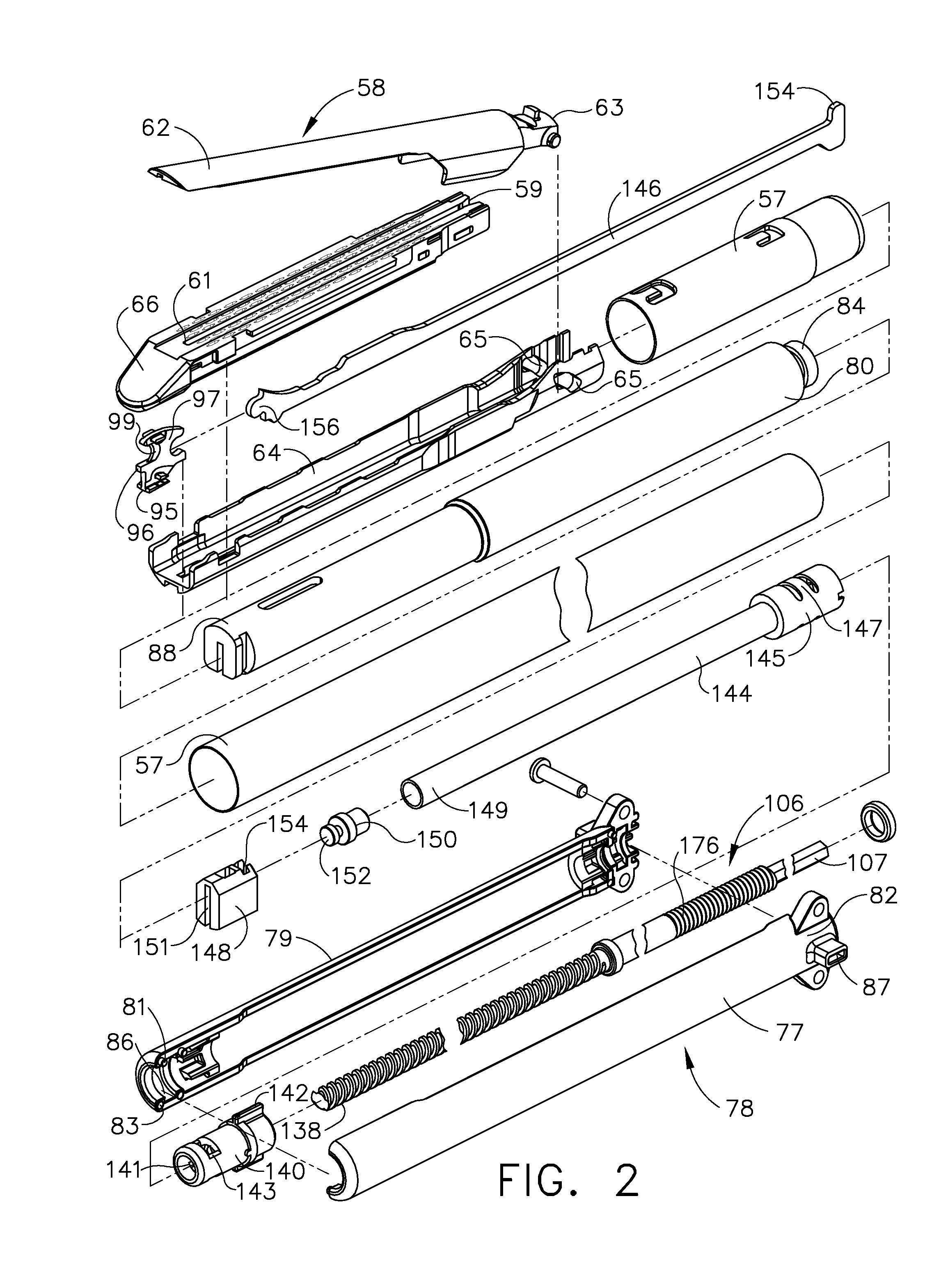

Powered tacker instrument

ActiveUS7931660B2Prevent rotationActuation can be preventedLigamentsMusclesBiomedical engineeringSurgical Fasteners

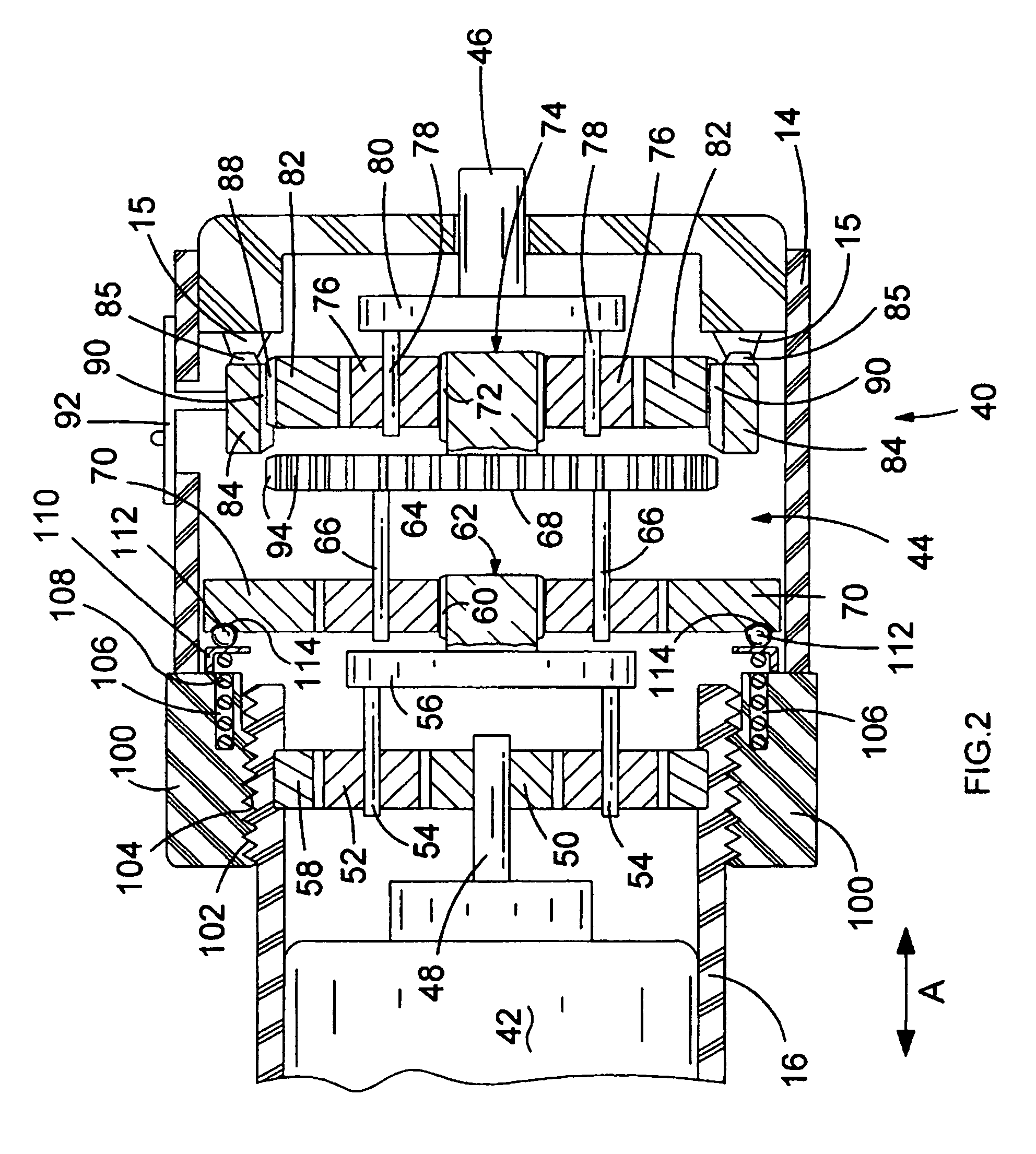

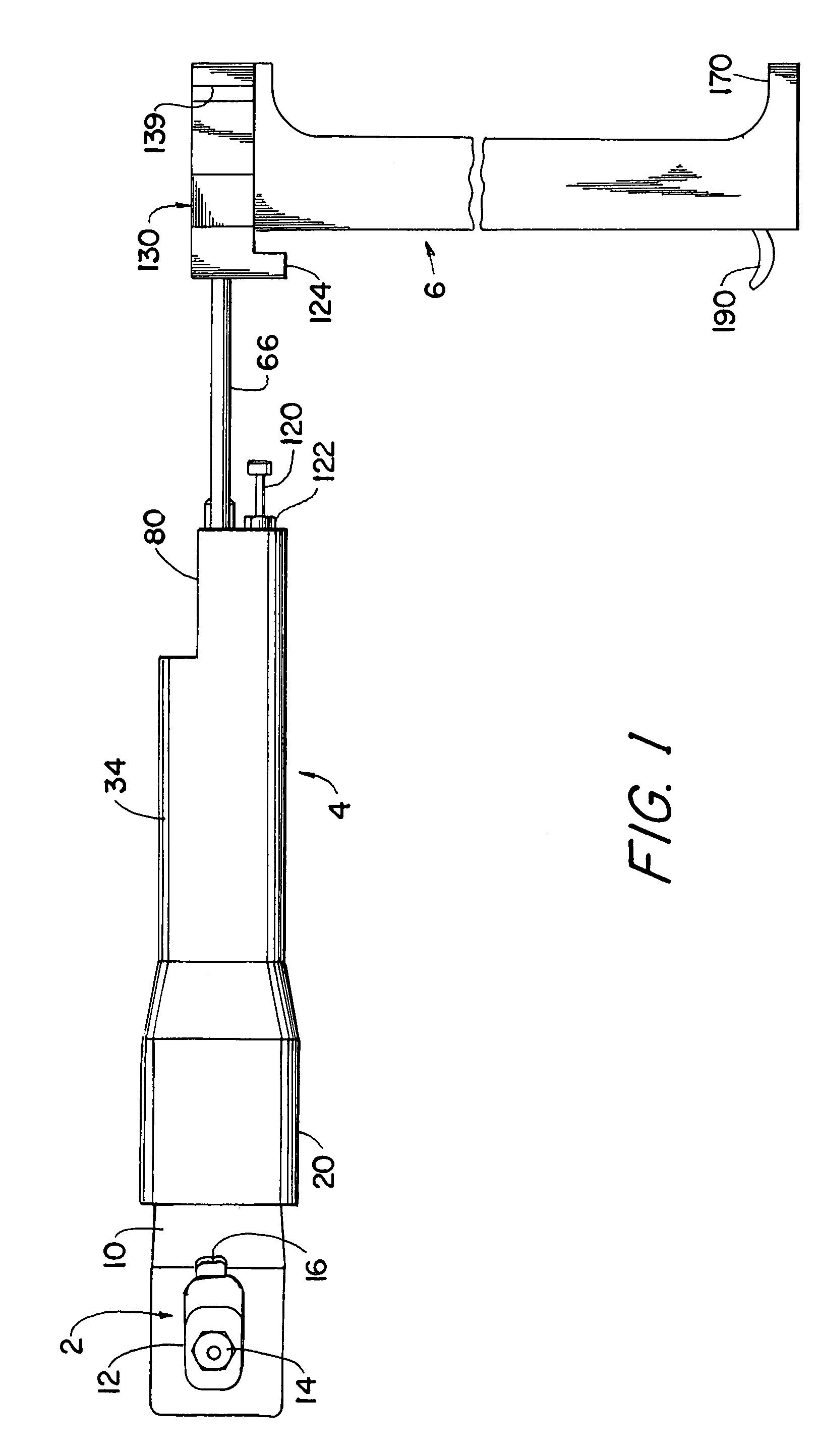

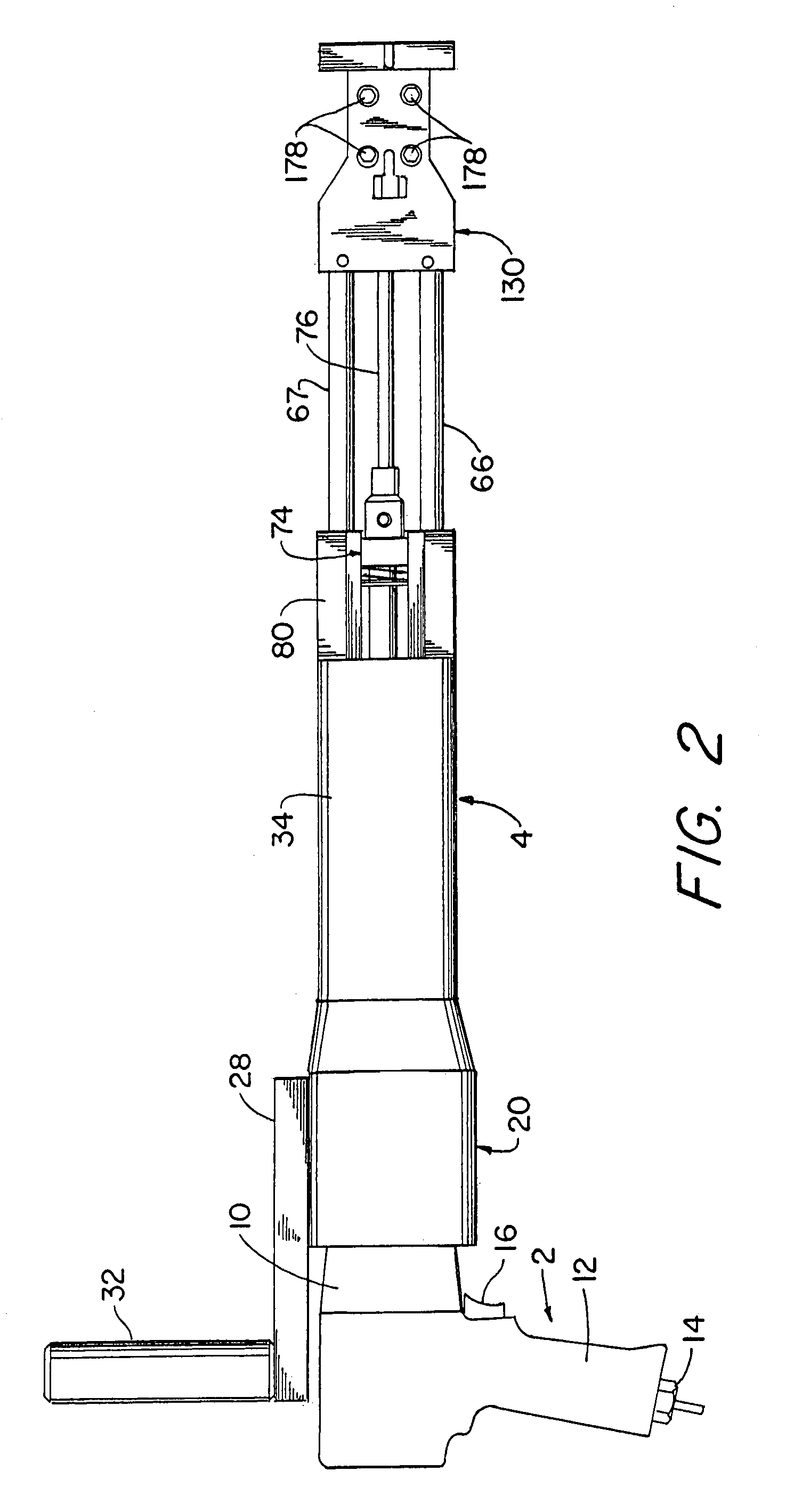

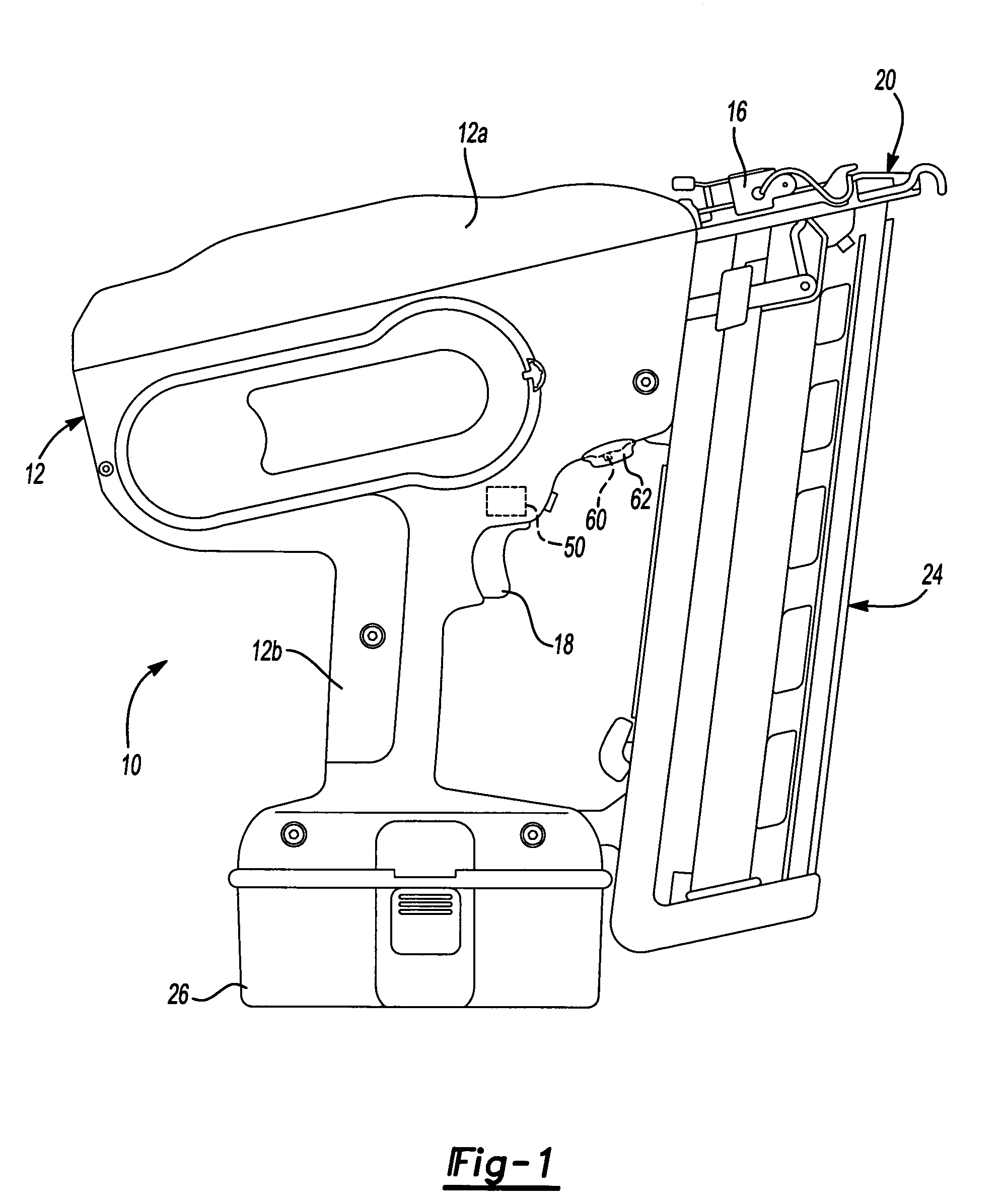

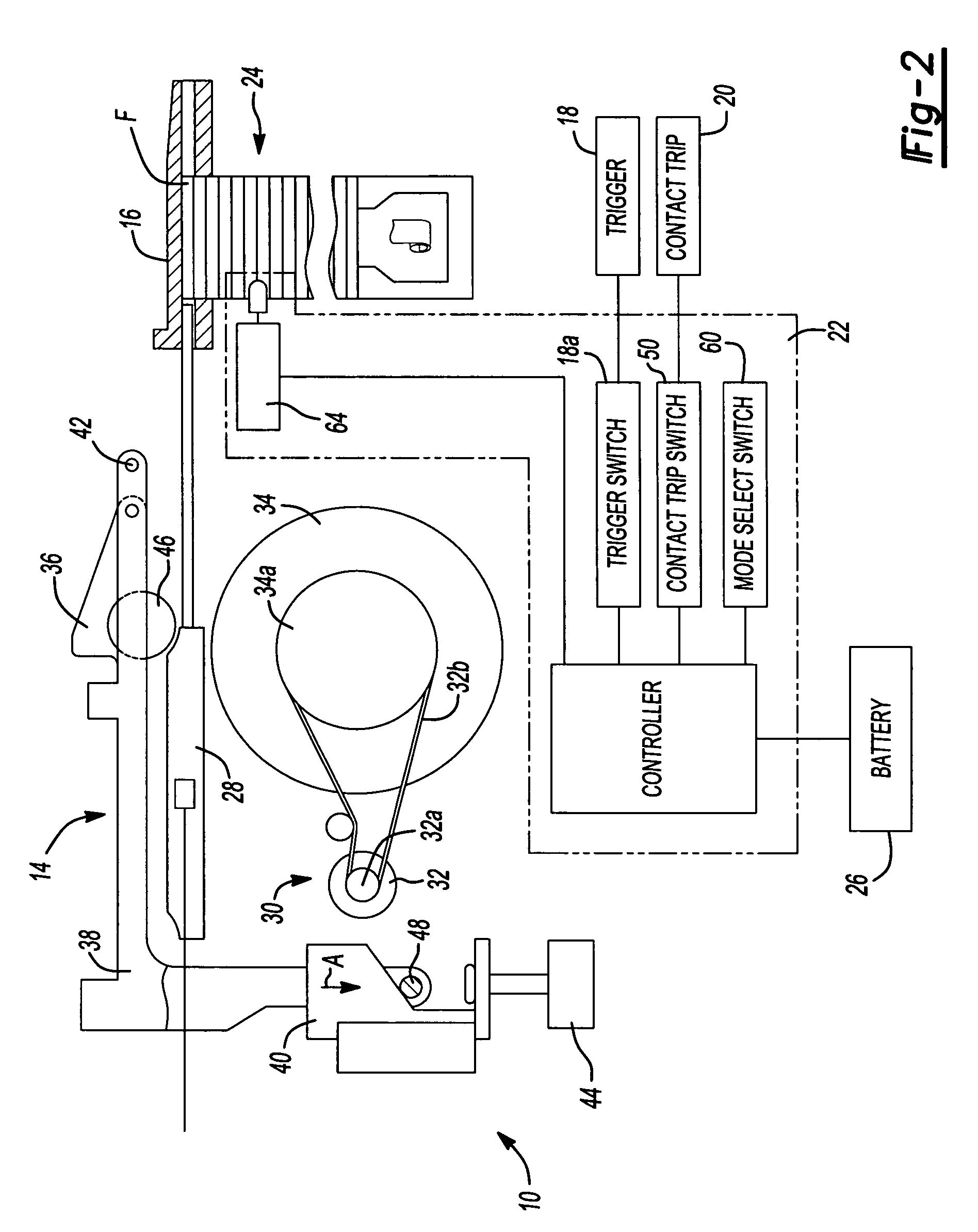

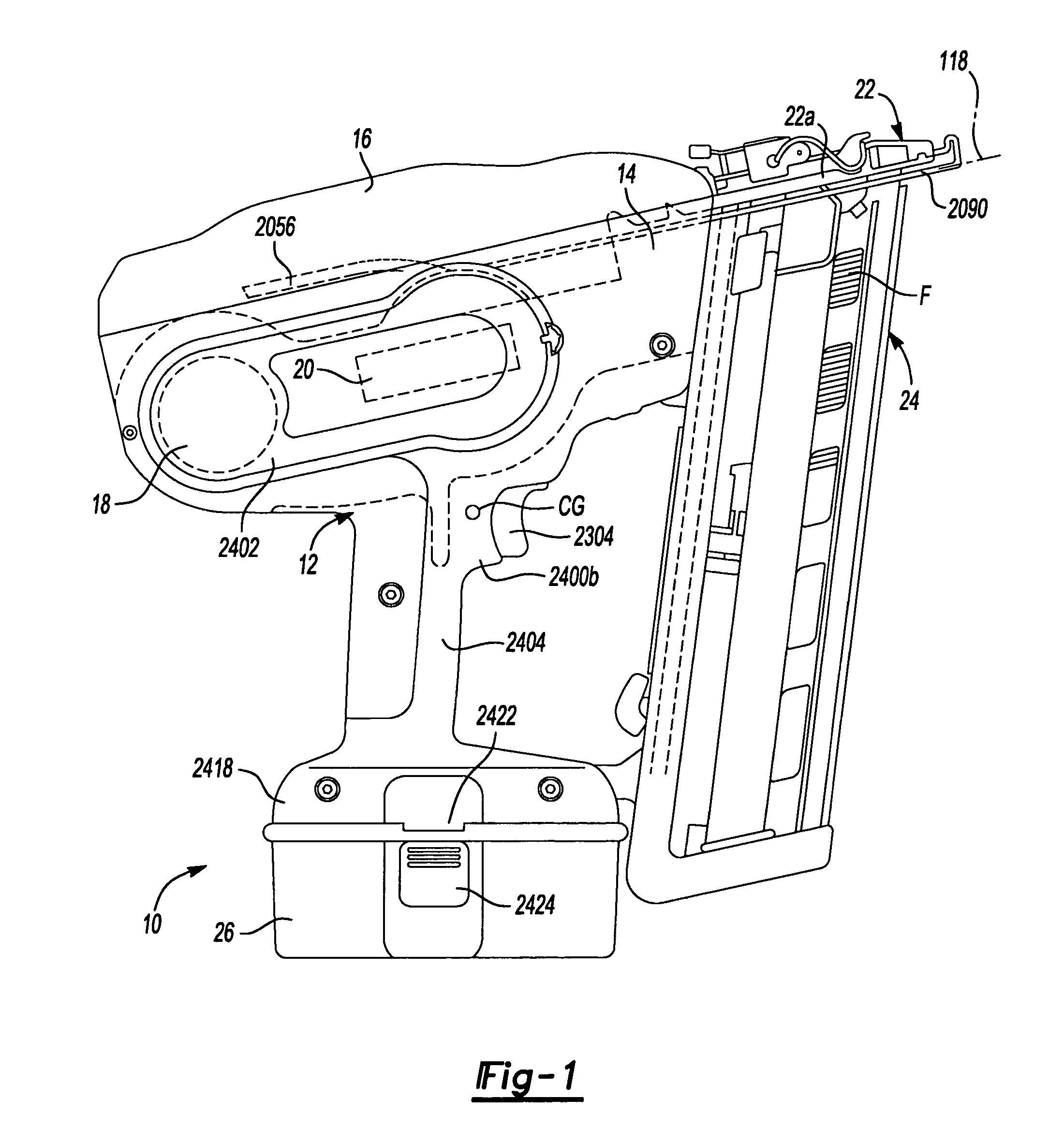

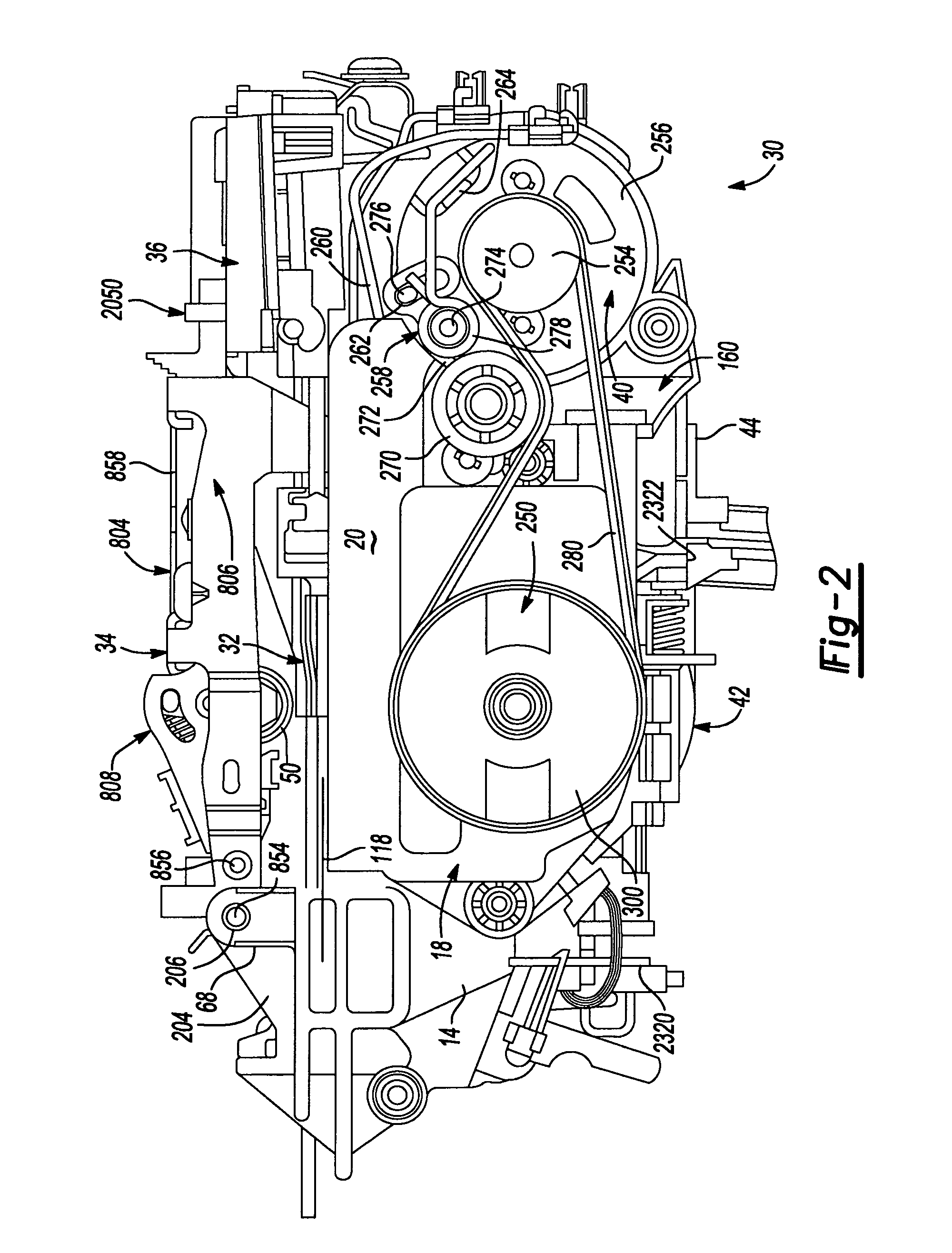

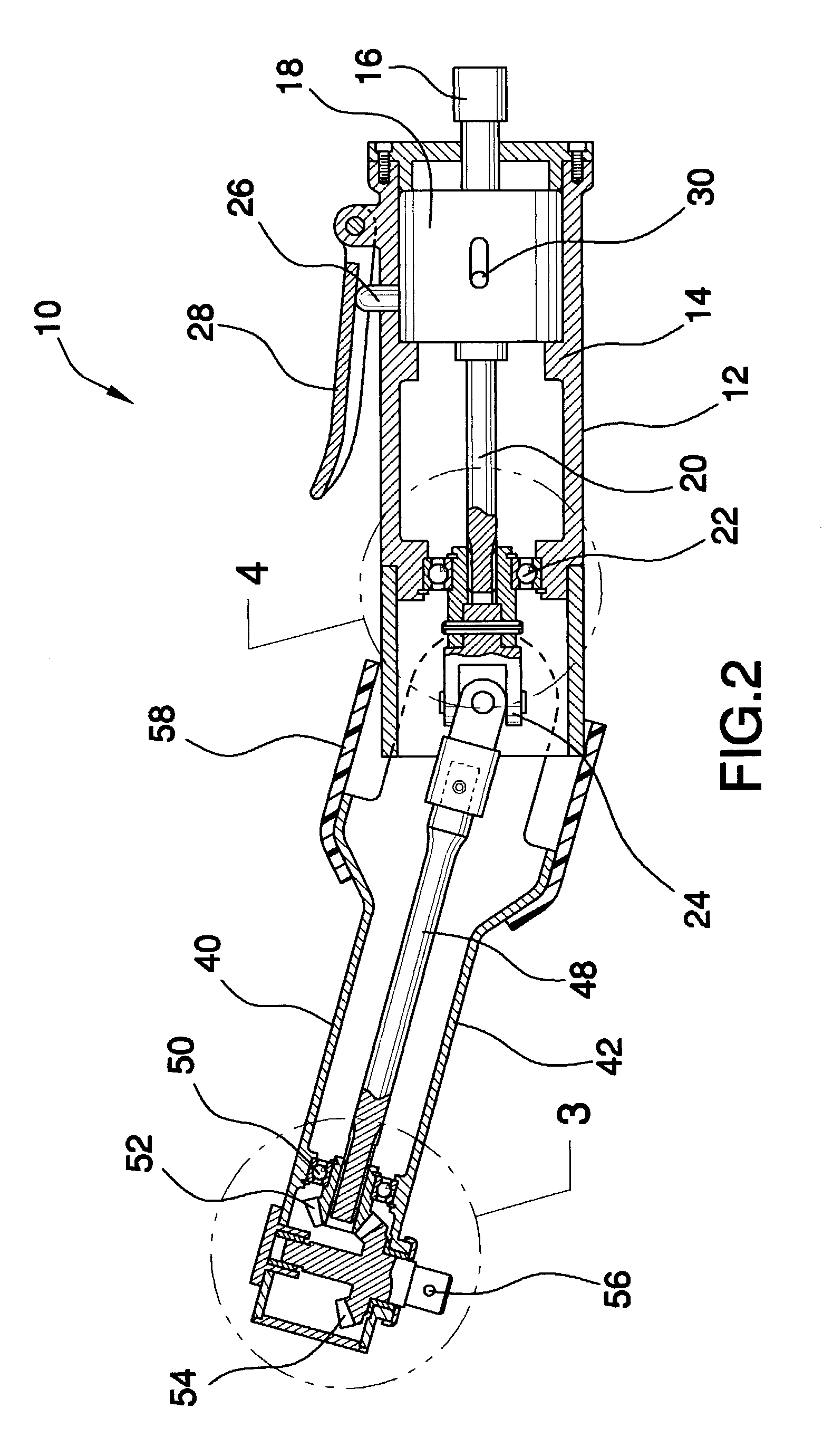

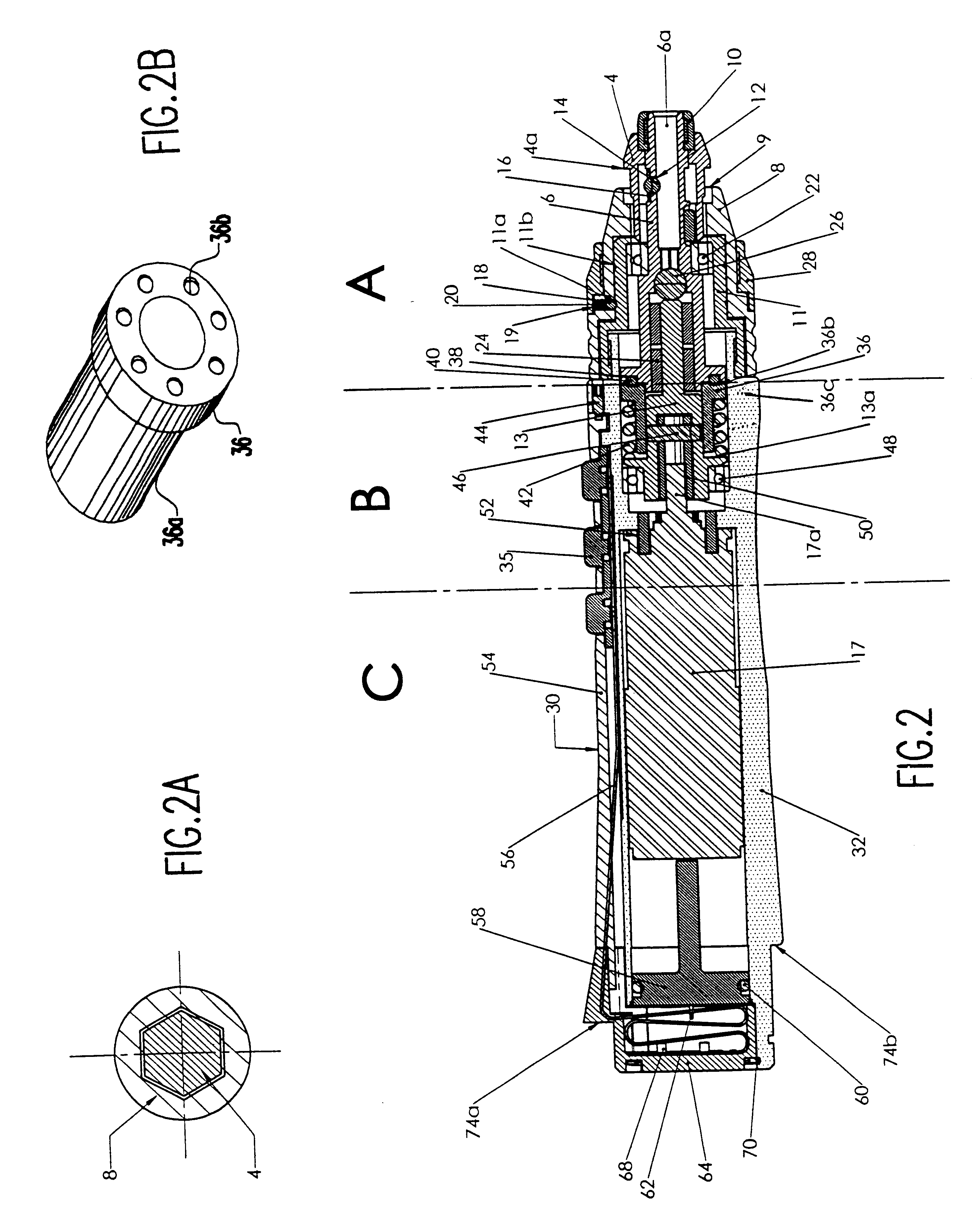

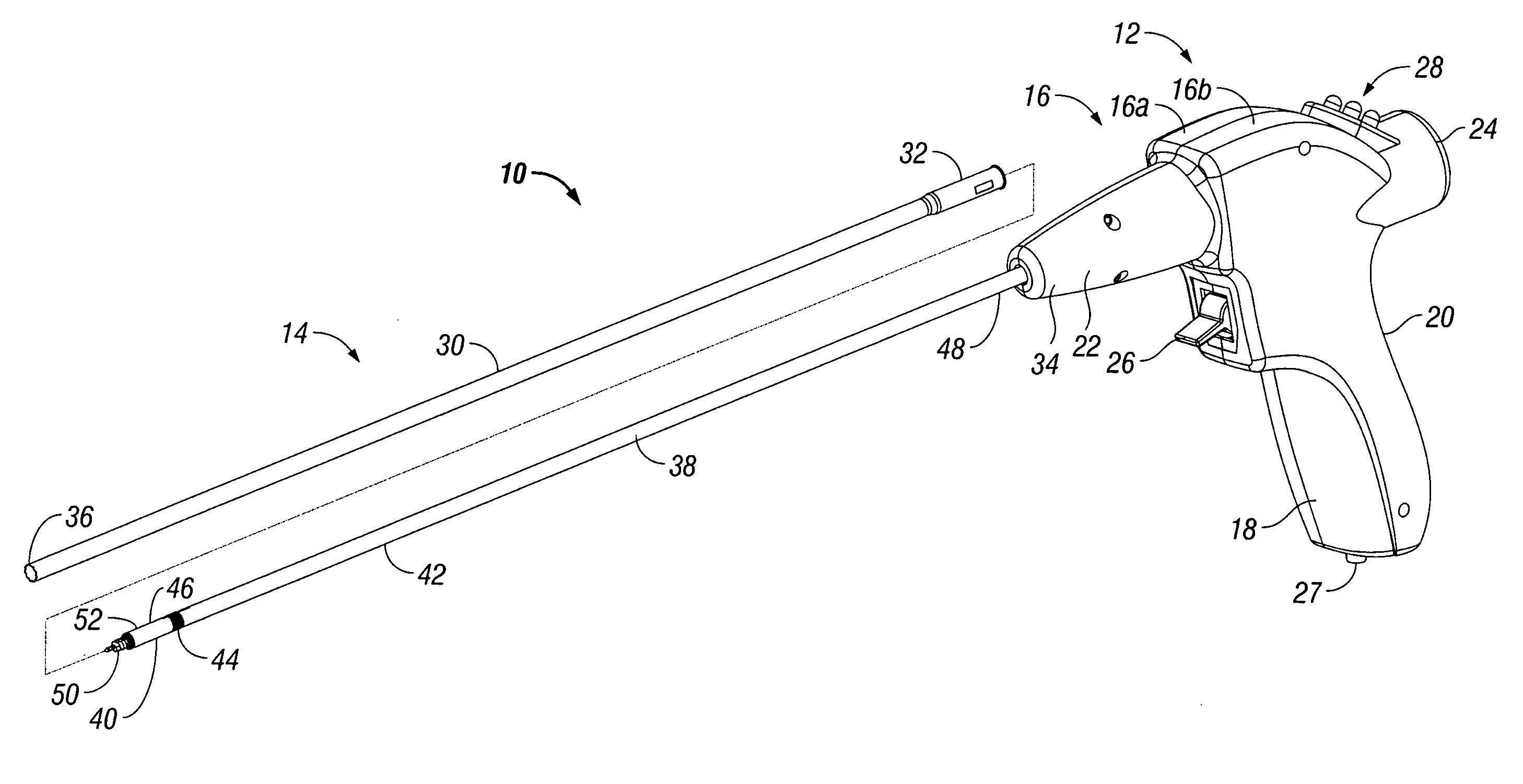

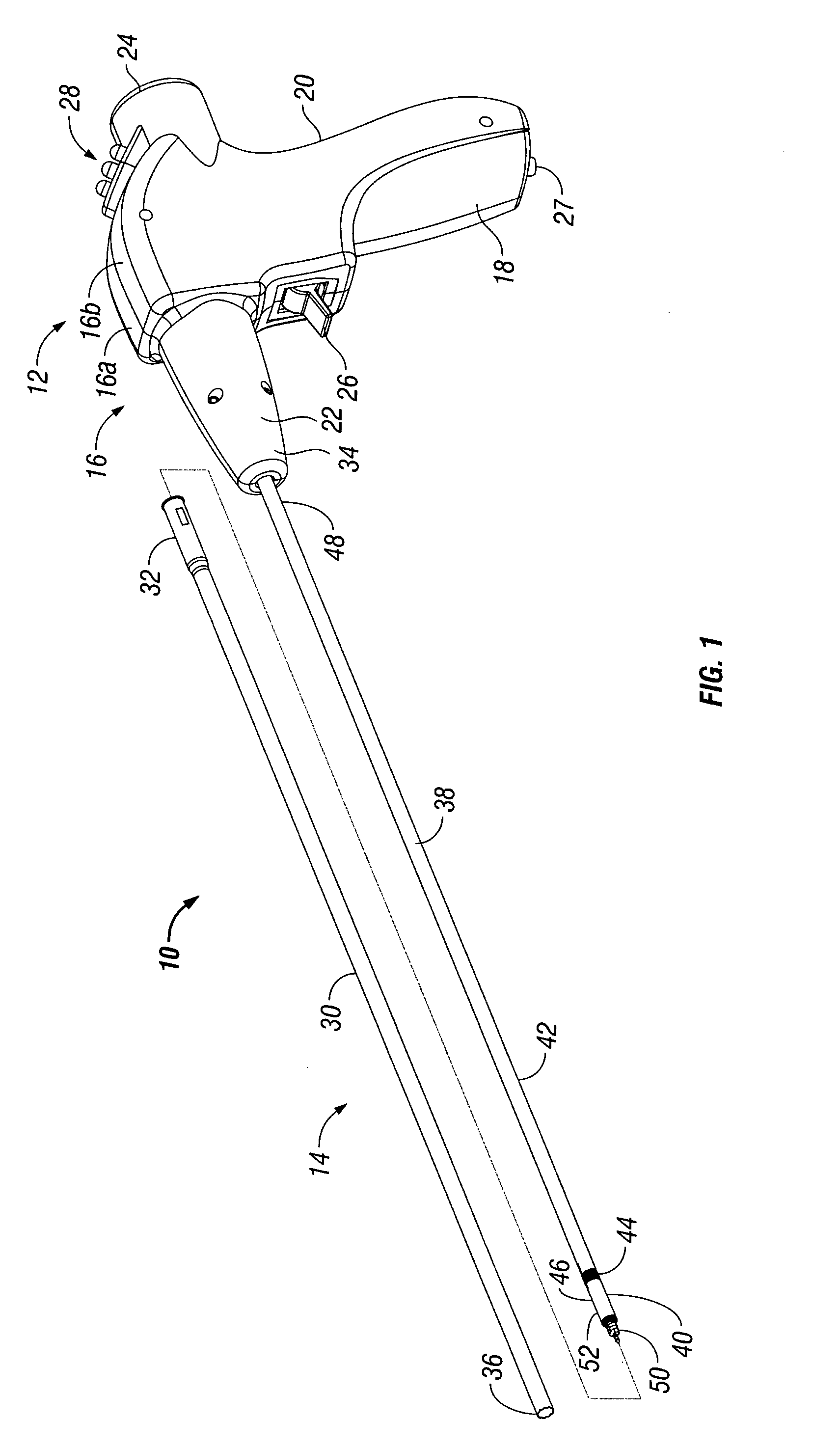

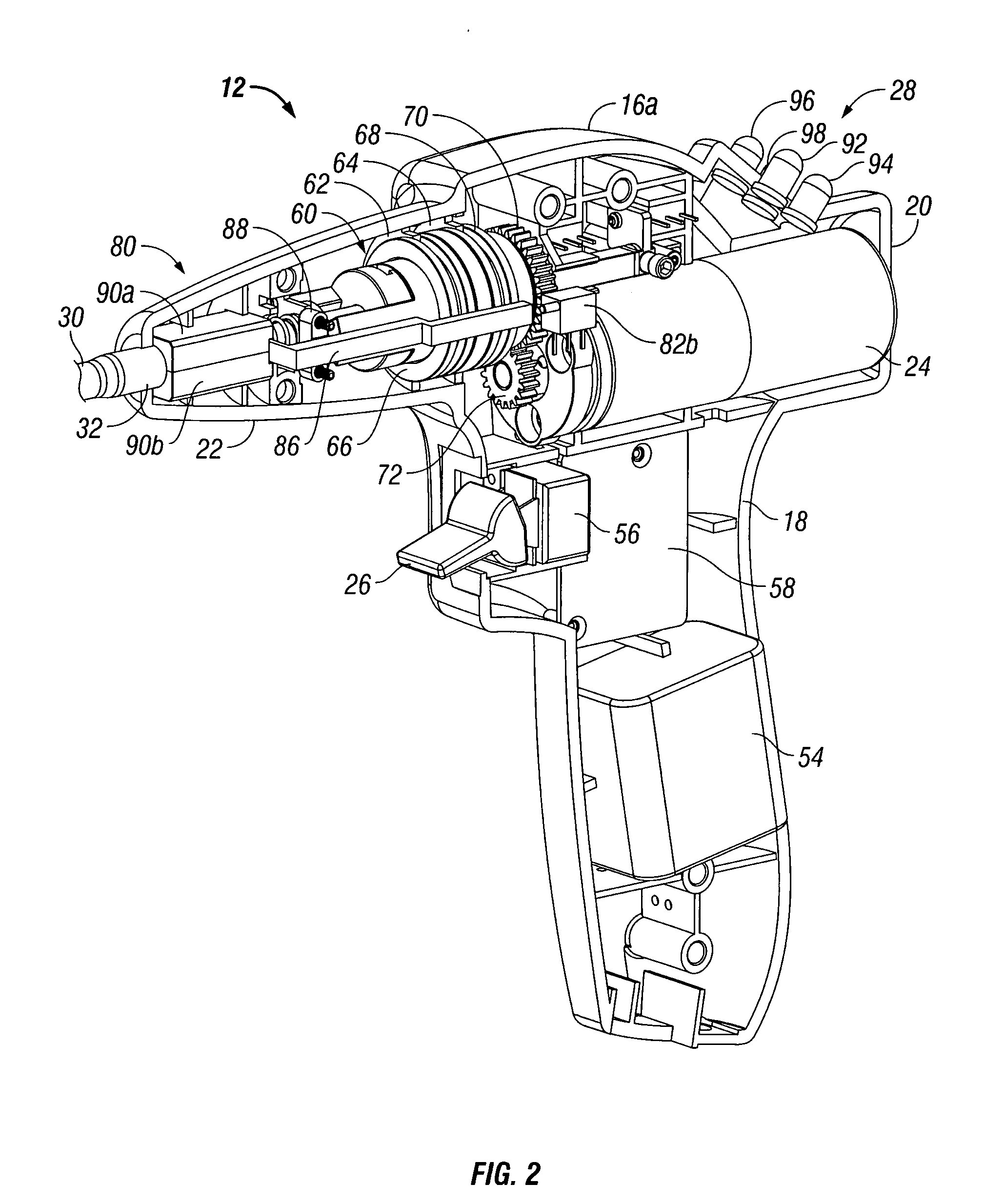

There is provided a powered tacker device for use in installing multiple surgical fasteners through a prosthetic mesh into tissue. The powered tacker device generally includes a handle assembly and a tacker assembly extending distally from the handle assembly. The handle assembly includes a motor and self-contained power assembly to rotate the surgical fasteners into tissue. The handle assembly is provided with a drive assembly which allows for rotation, as well as distal longitudinal movement, of a surgical fastener relative to the powered tacker device. The tacker assembly includes an inner tube for containing the plurality of surgical fasteners and a driver which is movable out of alignment with the inner tube so as to install a single fastener at a time into tissue.

Owner:TYCO HEALTHCARE GRP LP

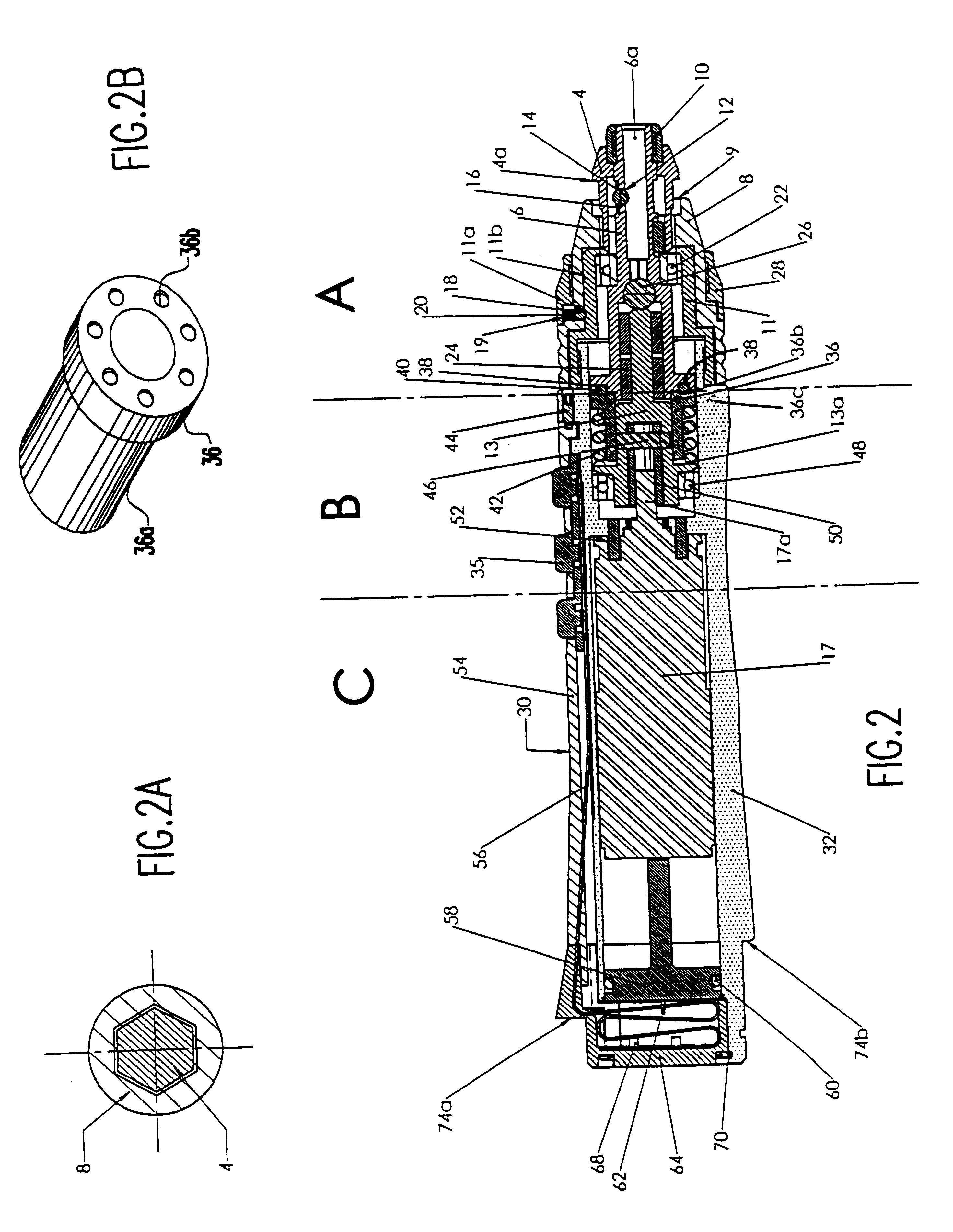

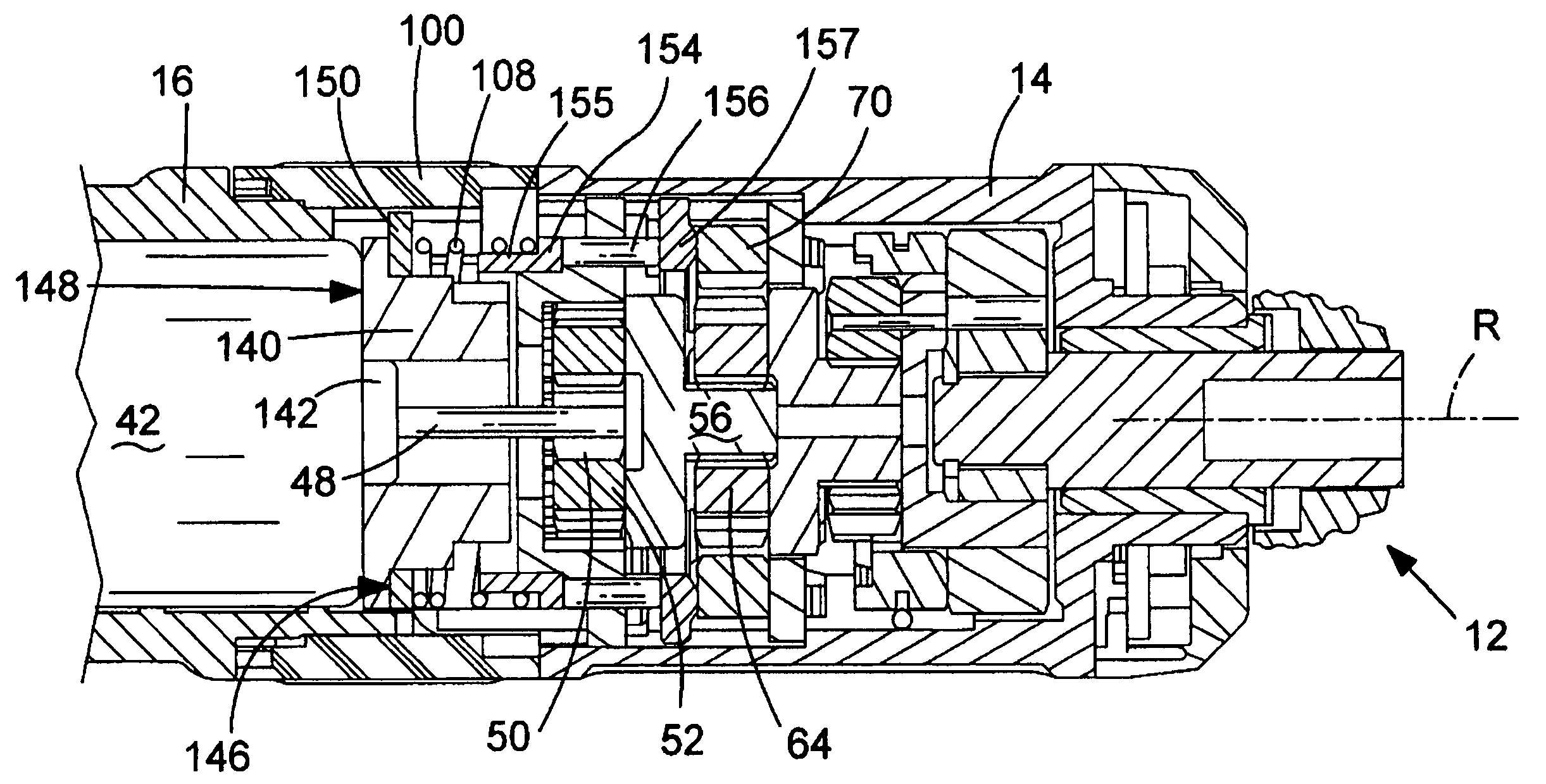

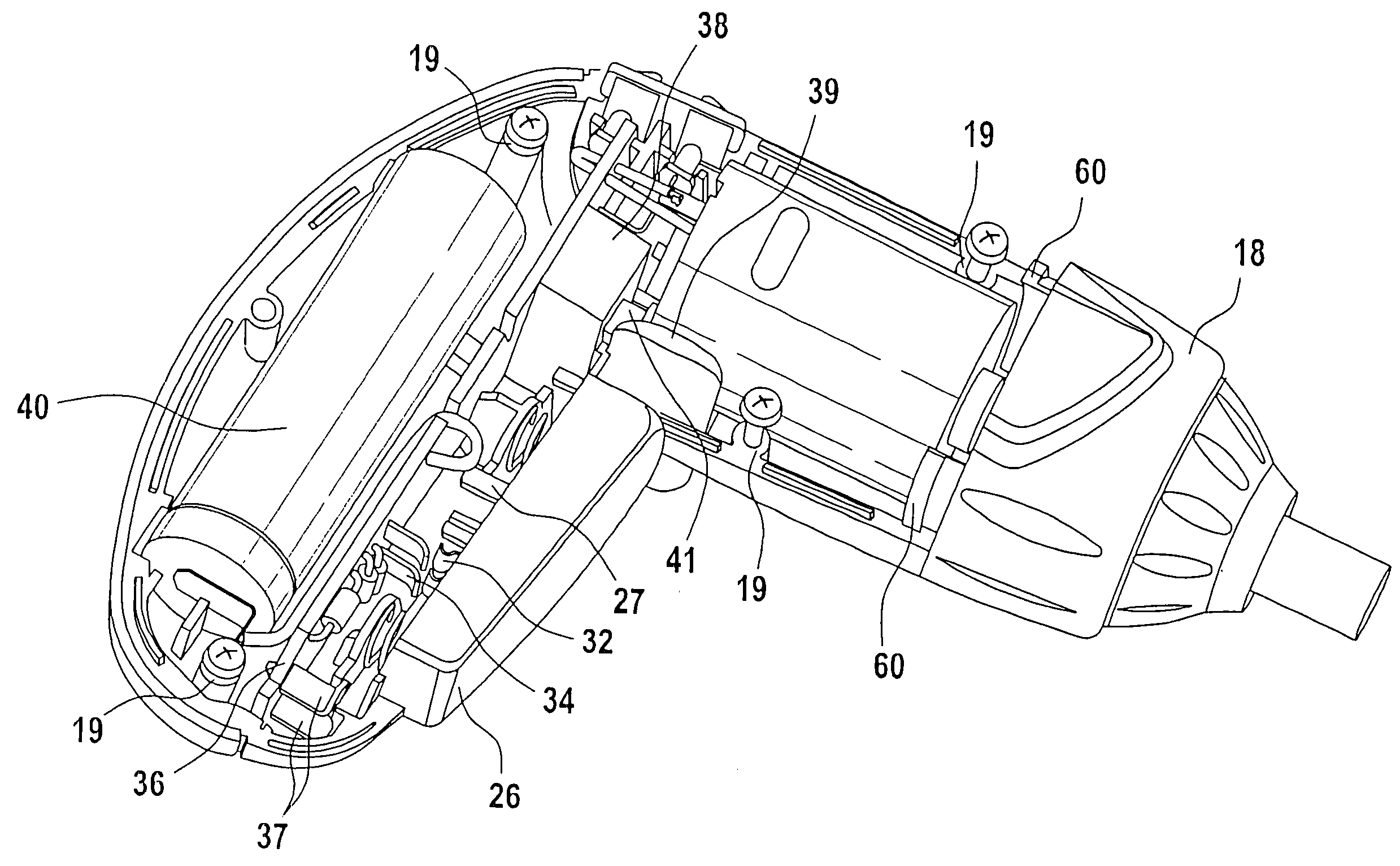

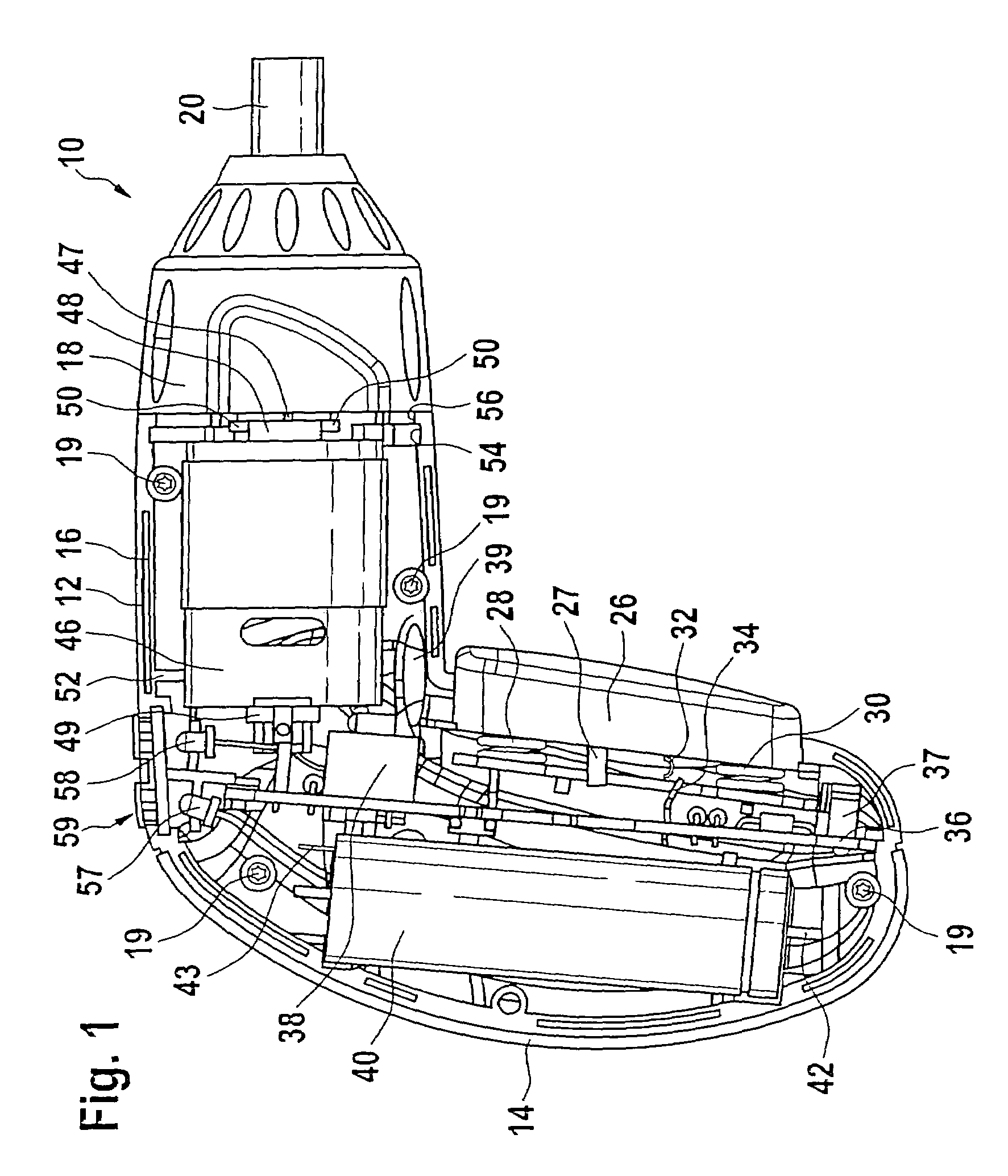

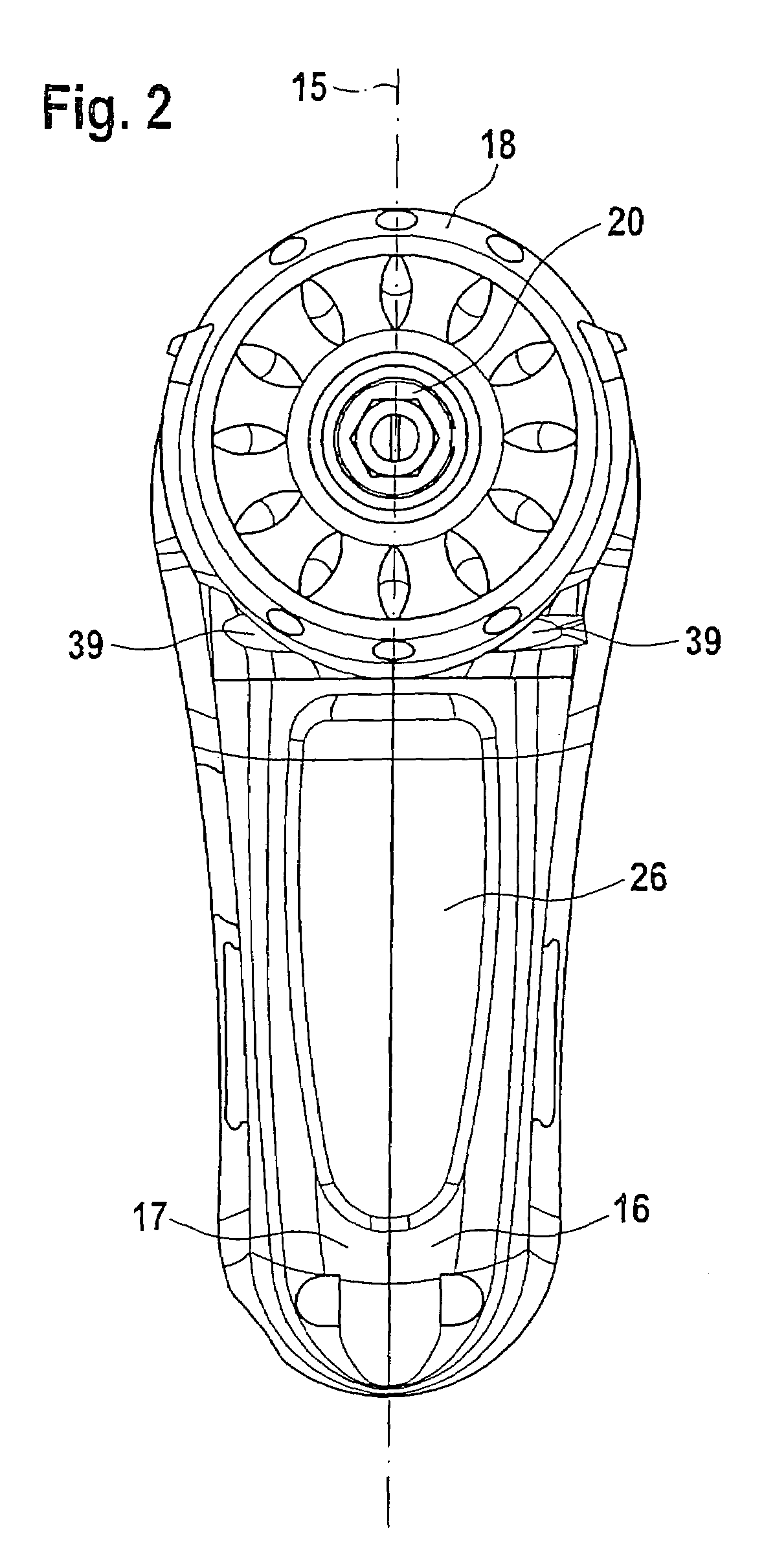

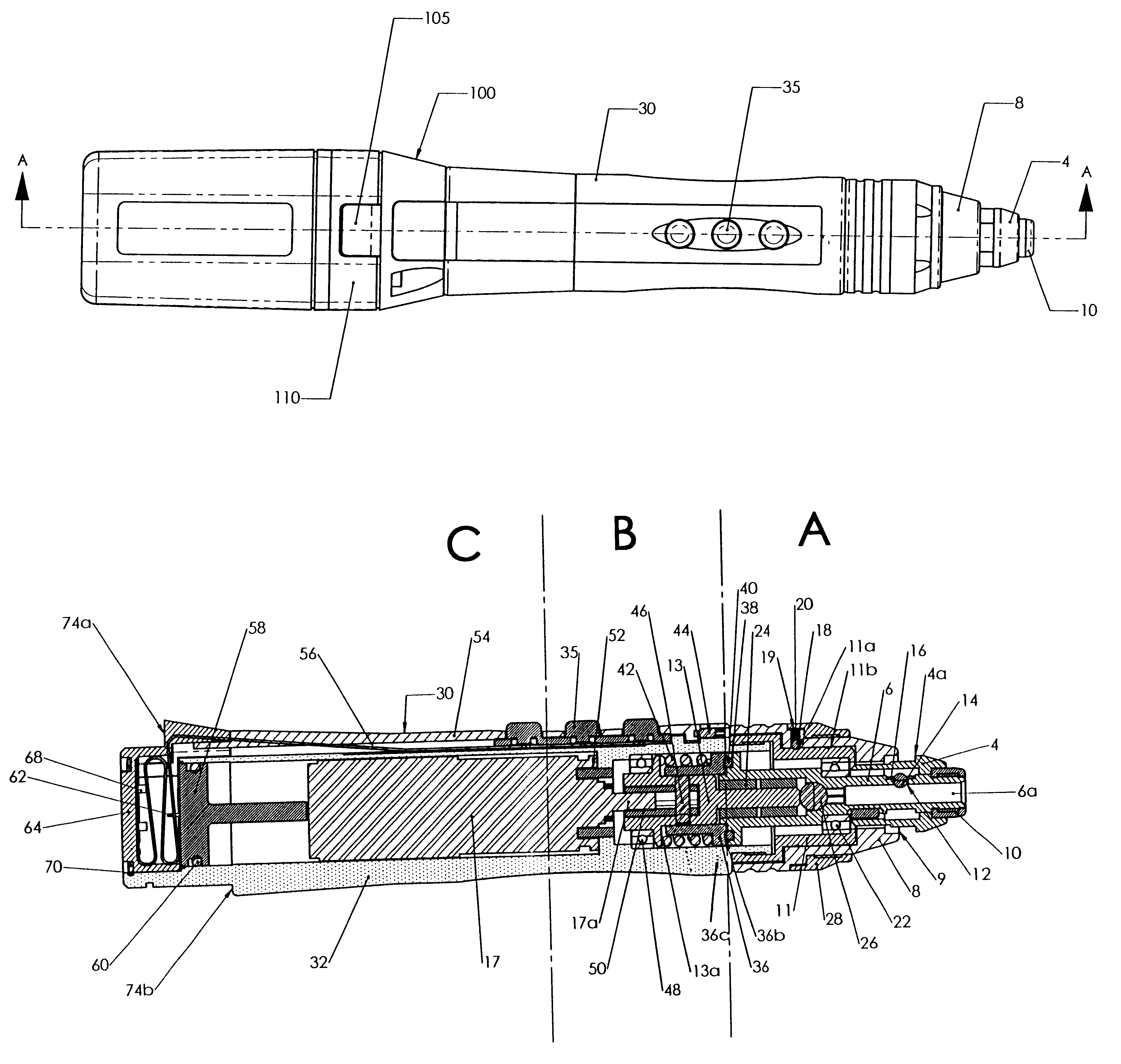

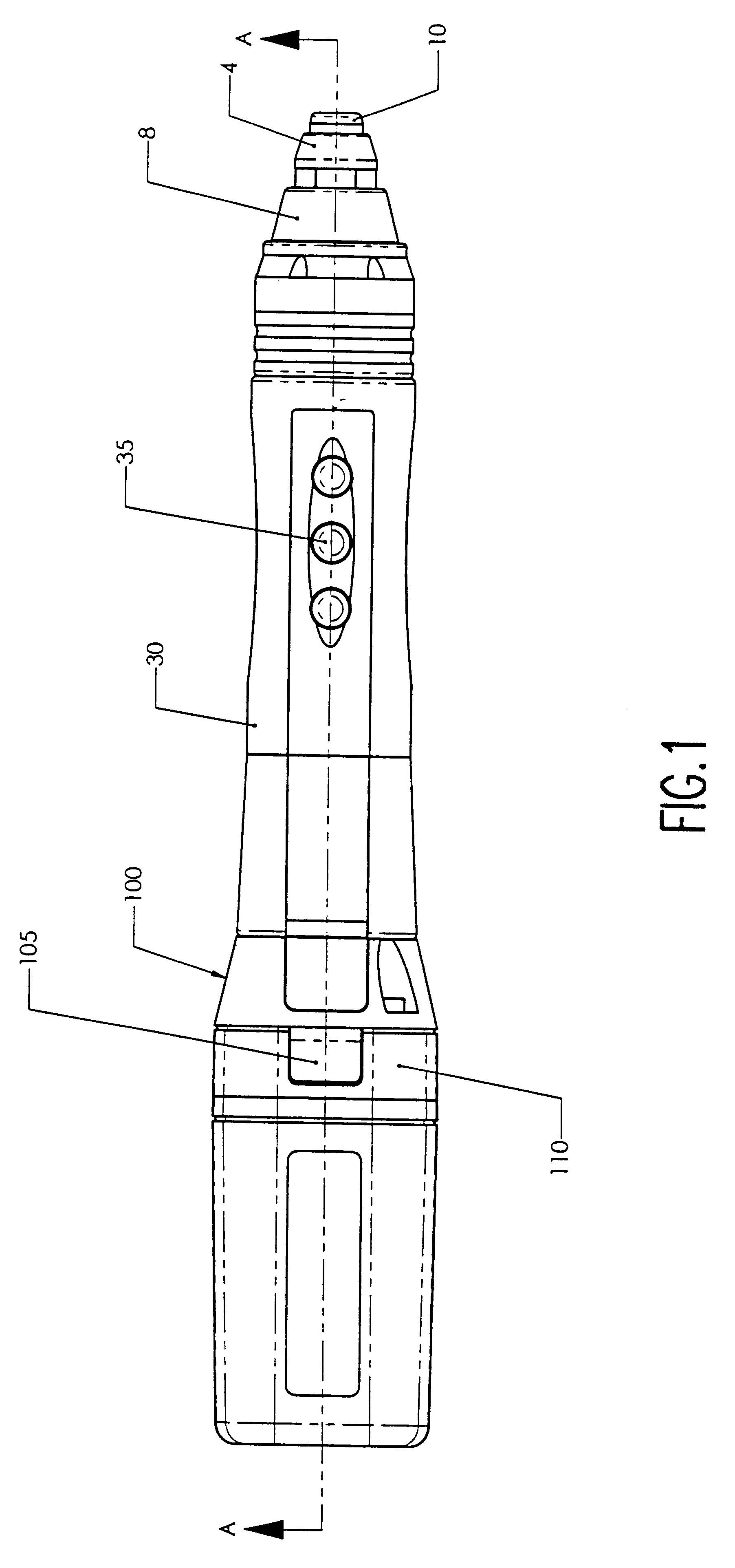

Powered surgical instrument having locking systems and a clutch mechanism

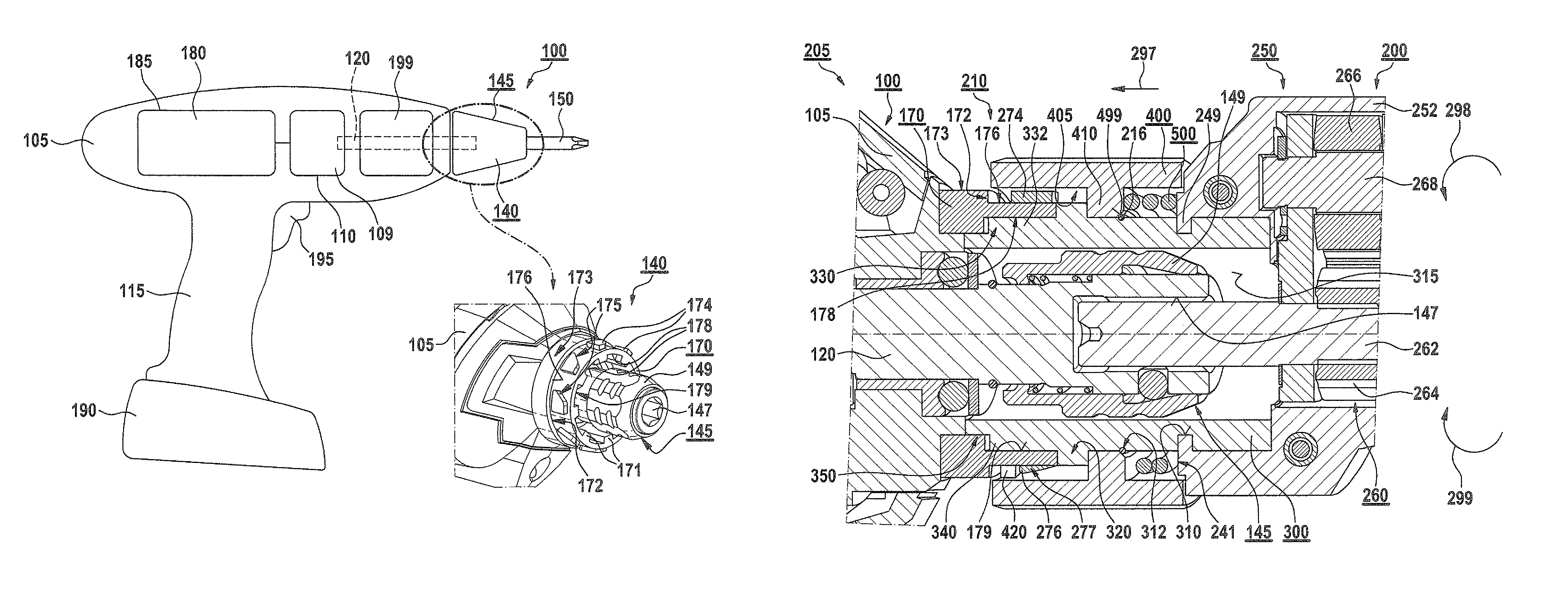

InactiveUS6220368B1Easy to mountEasy to removeDrilling rodsConstructionsLocking mechanismDrive shaft

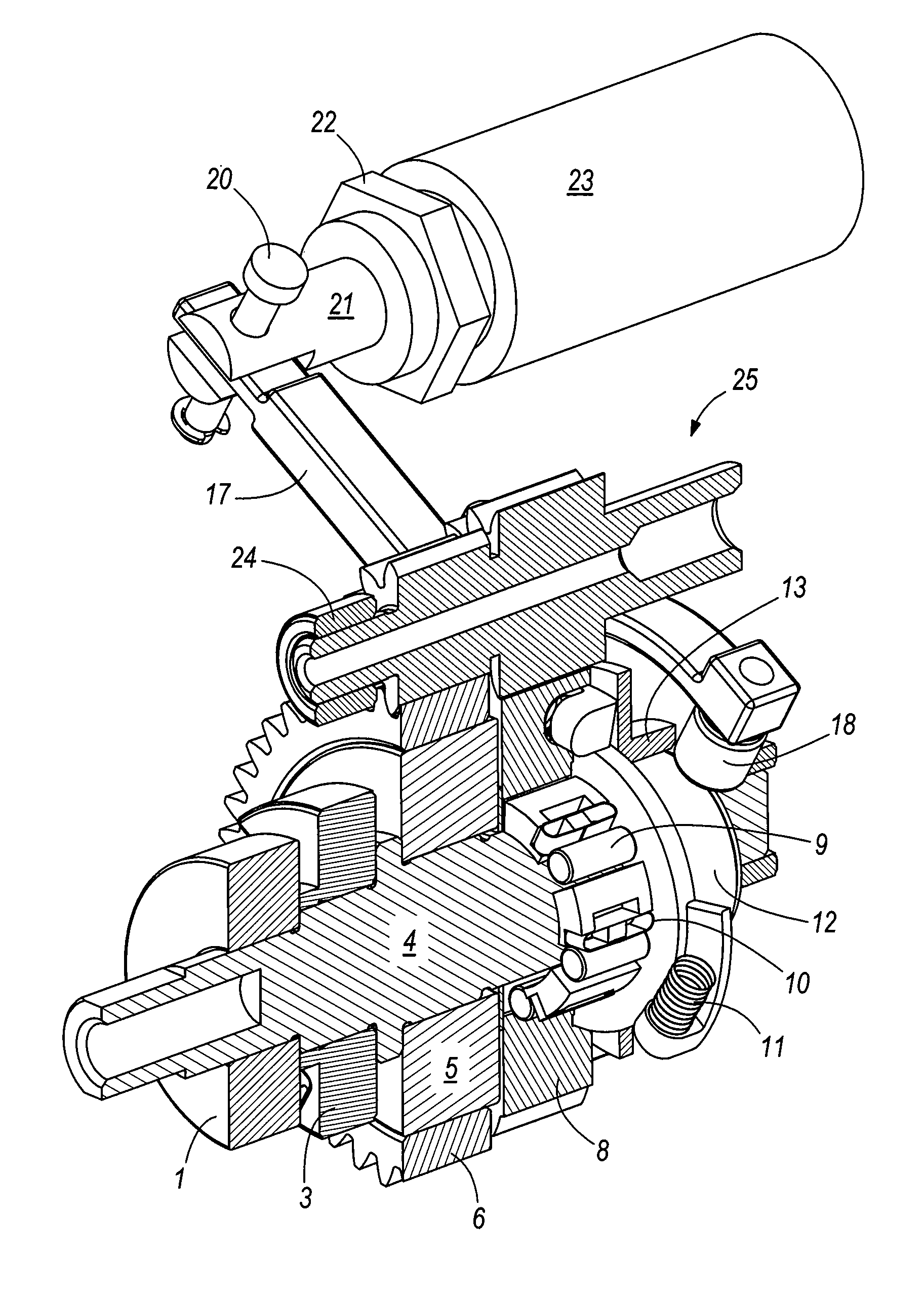

A surgical instrument having a locking mechanism for preventing an output shaft of the surgical instrument from rotating and a further locking mechanism for mounting a battery pack to a distal end of a housing of the surgical instrument. The surgical instrument further includes a clutch mechanism for limiting the torque of a drive shaft of the surgical instrument. The locking mechanism for preventing the output shaft from rotating includes a locking switch which mates with a locking cap disposed on the output shaft. The locking mechanism for mounting the battery pack to the housing includes a groove at the distal end of the housing and a retaining ring which engages the groove when the battery pack is mounted on the housing. The clutch mechanism includes a clutch plate that interfaces with both the output shaft and the drive shaft and prevents failure of the motor shaft.

Owner:MICROAIRE SURGICAL INSTR

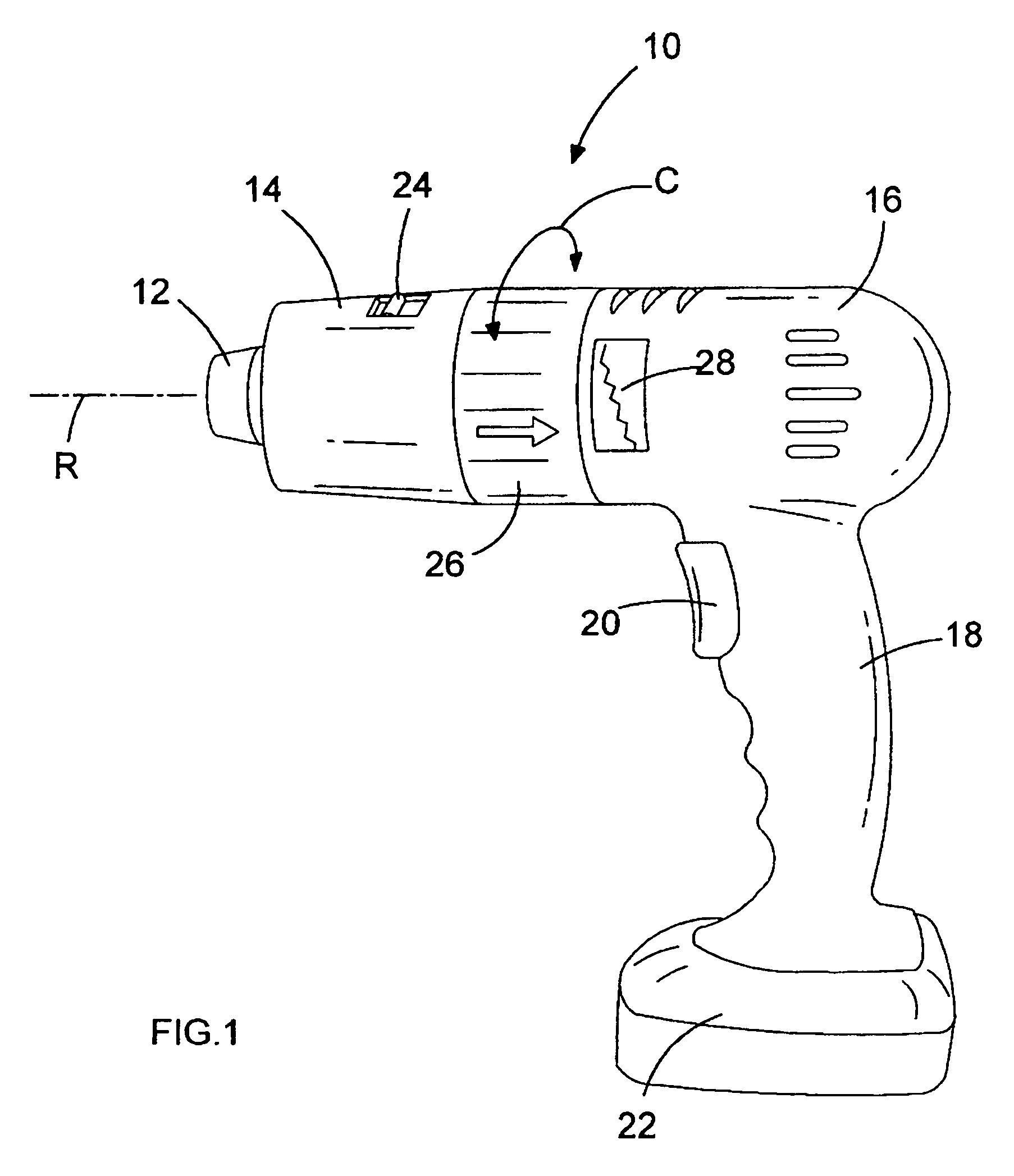

Power tool gear-train and torque overload clutch therefor

A power tool transmission is described in which an overload clutch mechanism is arranged to provide a relatively compact power tool. A torque adjustment dial is arranged between the visible portions of the motor housing and the gearbox, and the dial is coupled to a compression spring such that rotation of the dial cause the spring to be compressed or decompressed, thereby adjusting the torque at which the clutch overloads and ratchets. The compression spring is arranged at least partially between the motor and gearbox or gear train, in a space which conventional power tools do not utilized for this purpose. Thus, the dimensions of the power tool's transmission can be reduced with respect to conventional power tools. Furthermore, the space on the gearbox immediately behind a chuck can be used for another purpose other than accommodating the adjustment collar, as is the case with conventional power tools.

Owner:BLACK & DECKER INC

Tool attachment

A tool attachment for mounting on a hand-held machine tool provided with a tool holder, the tool attachment having an output shaft and a base body at whose outer circumference a locking sleeve is disposed in a manner allowing it to rotate to release at least one assigned locking element; at the outer circumference of the base body, an anti-rotation unit is formed for the twist-proof mounting of the base body on a fastening unit assigned to the hand-held machine tool; on the anti-rotation unit and at an inner circumference of the fastening unit, complementary geometrical forms are provided which are configured to mesh with each other for the releasable, twist-proof mounting of the base body on the fastening unit.

Owner:ROBERT BOSCH GMBH

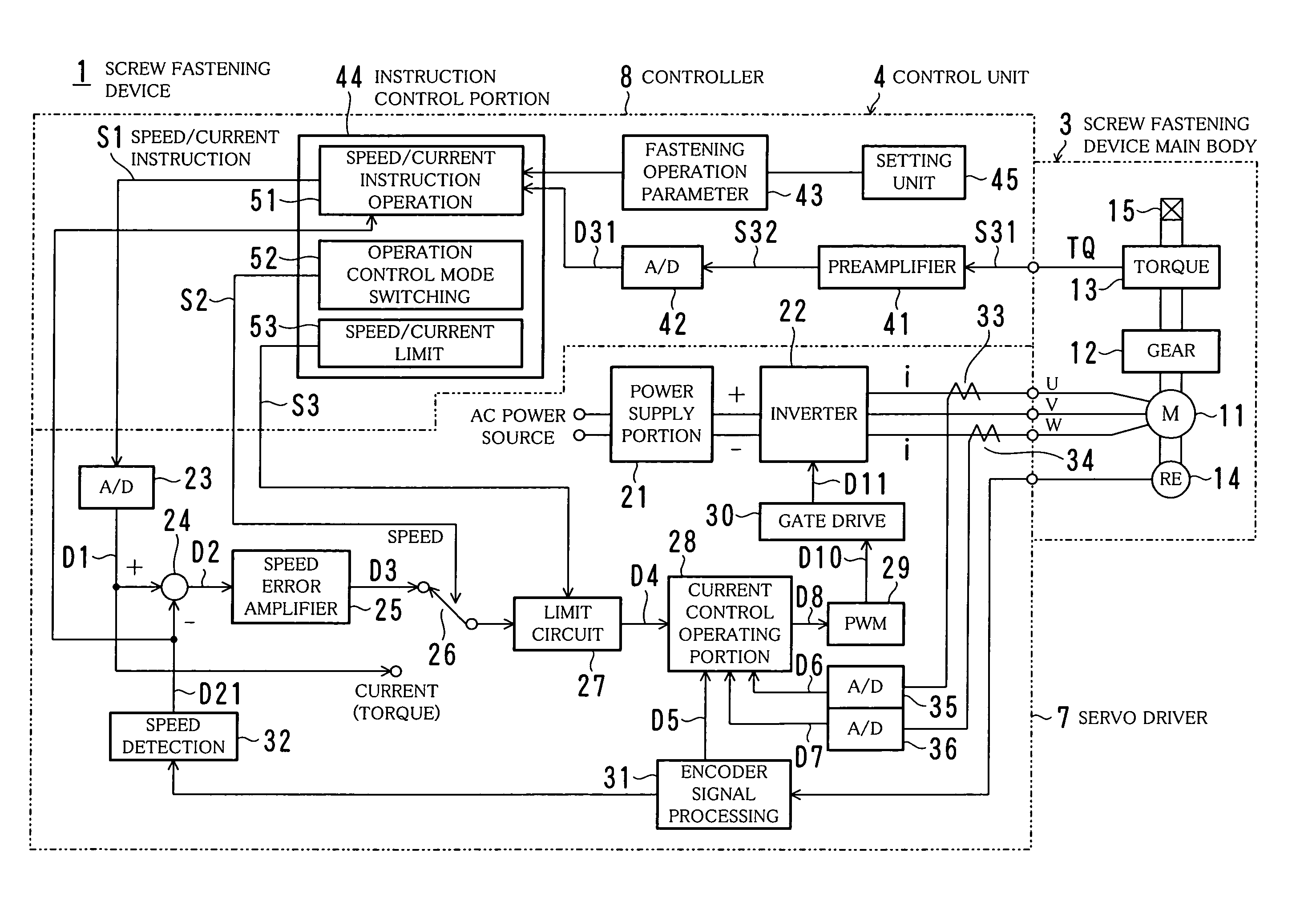

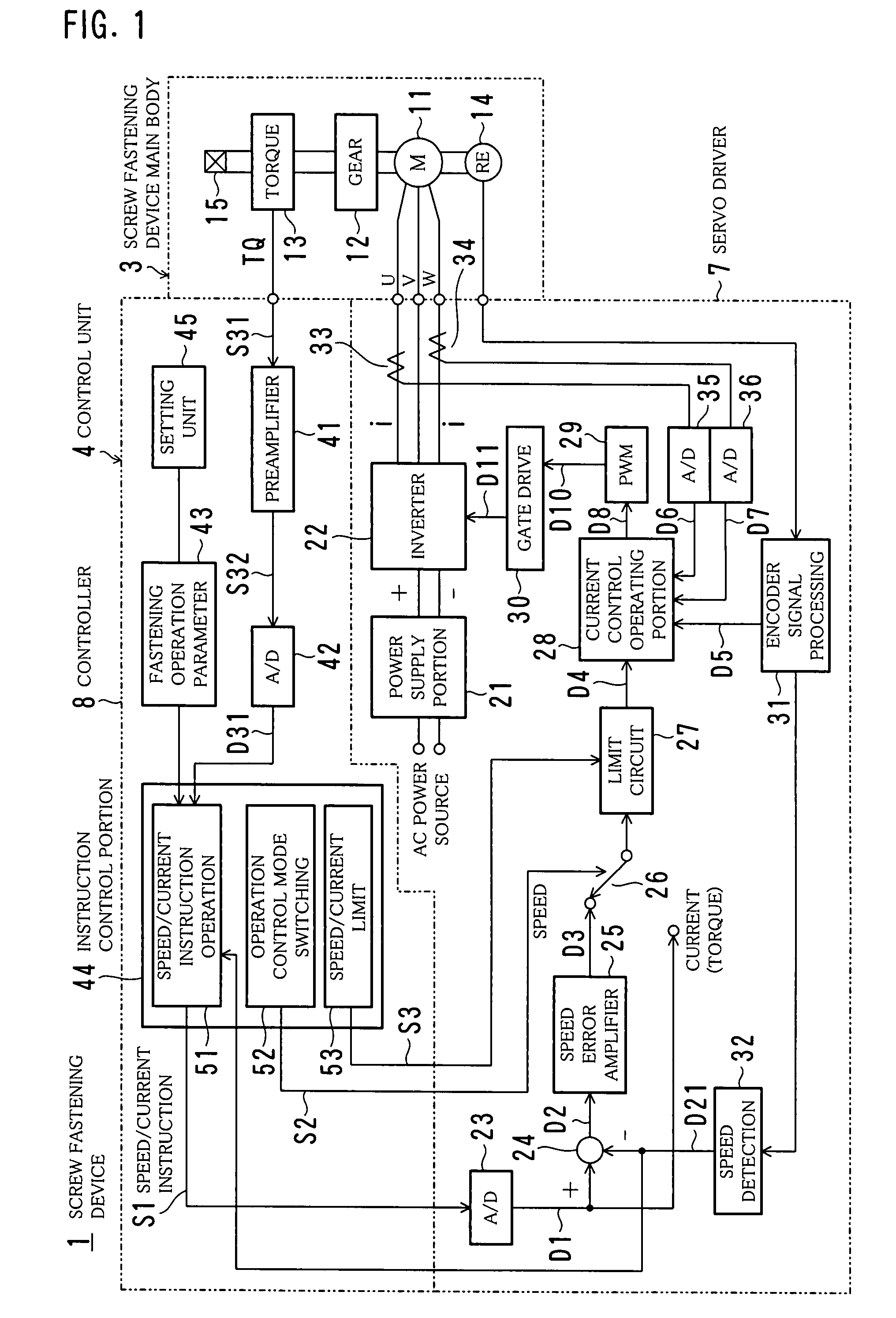

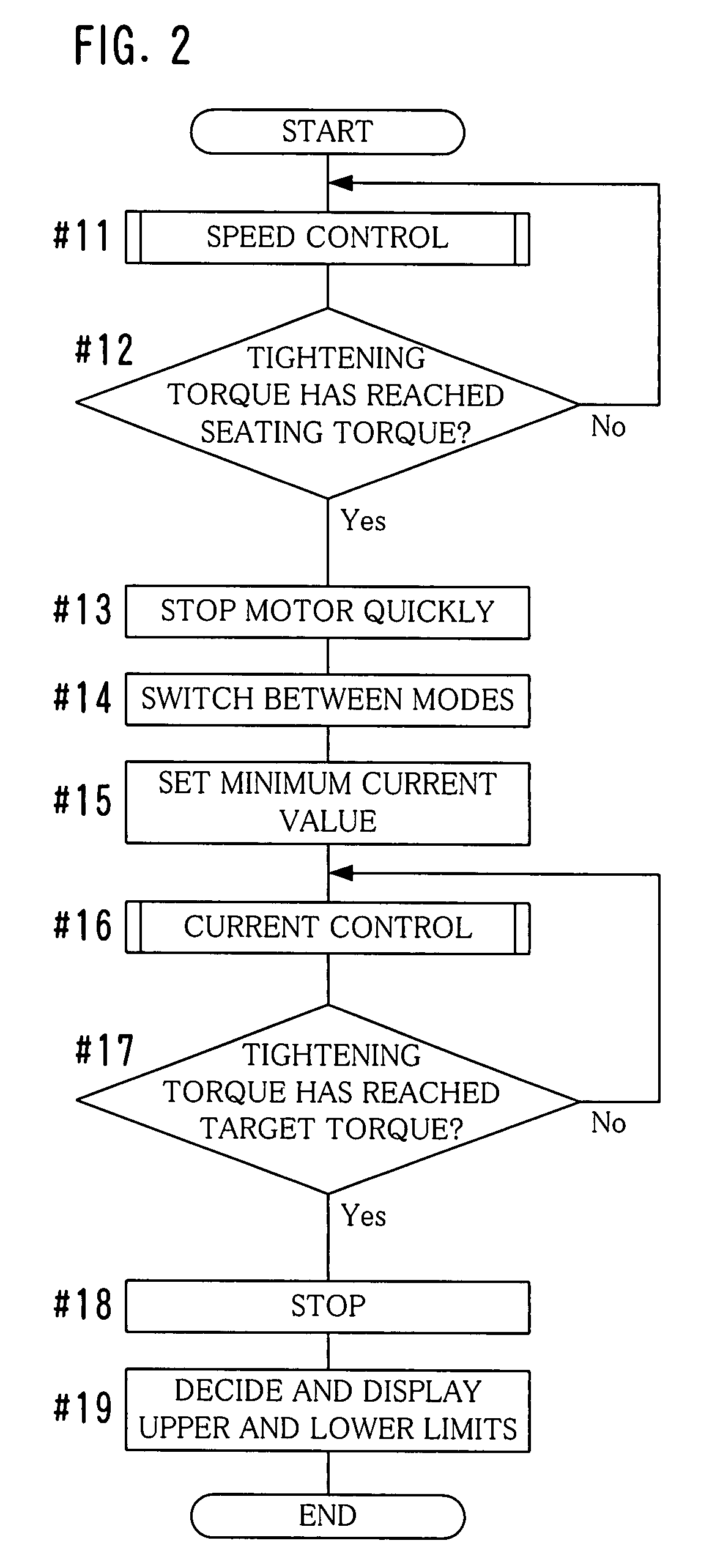

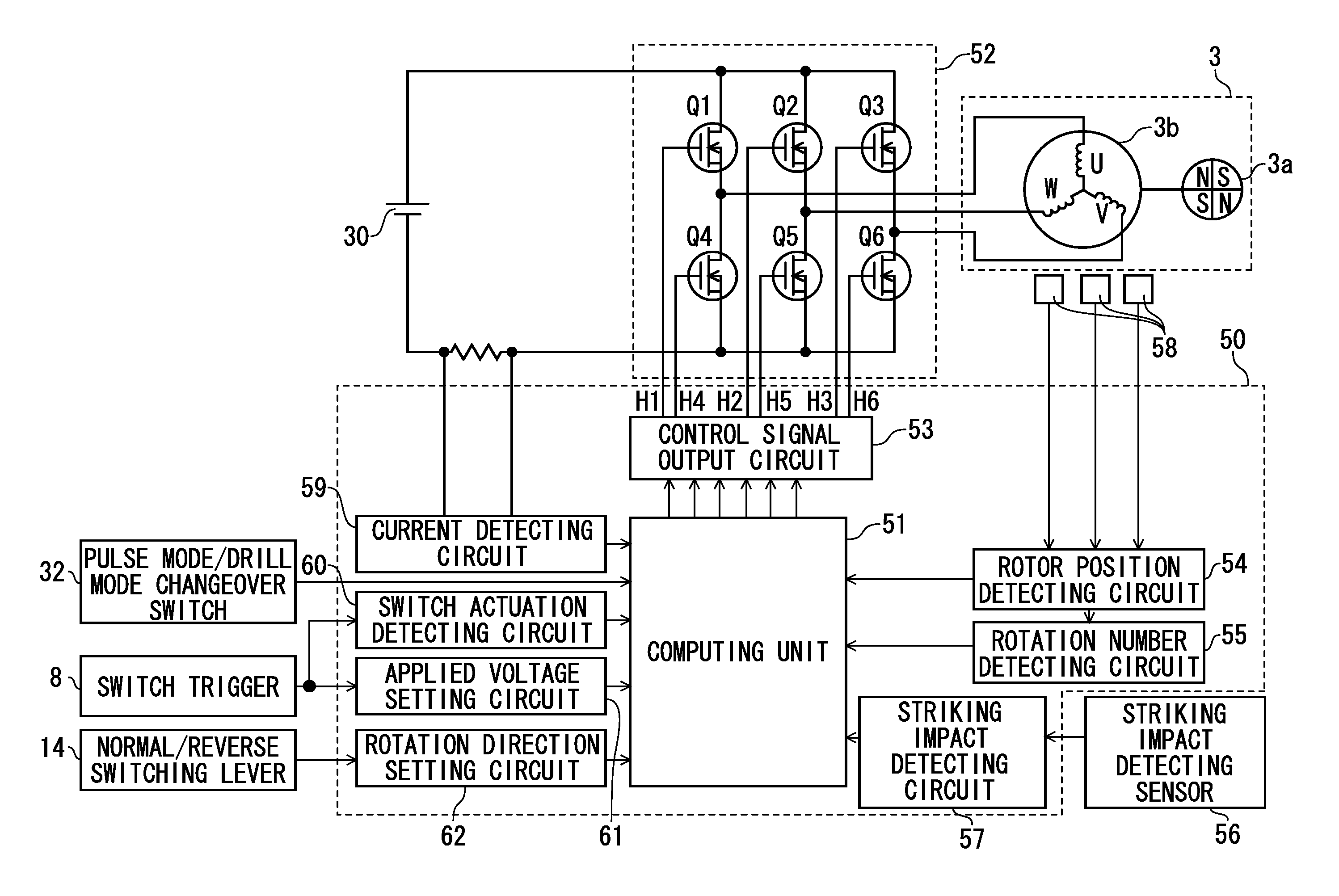

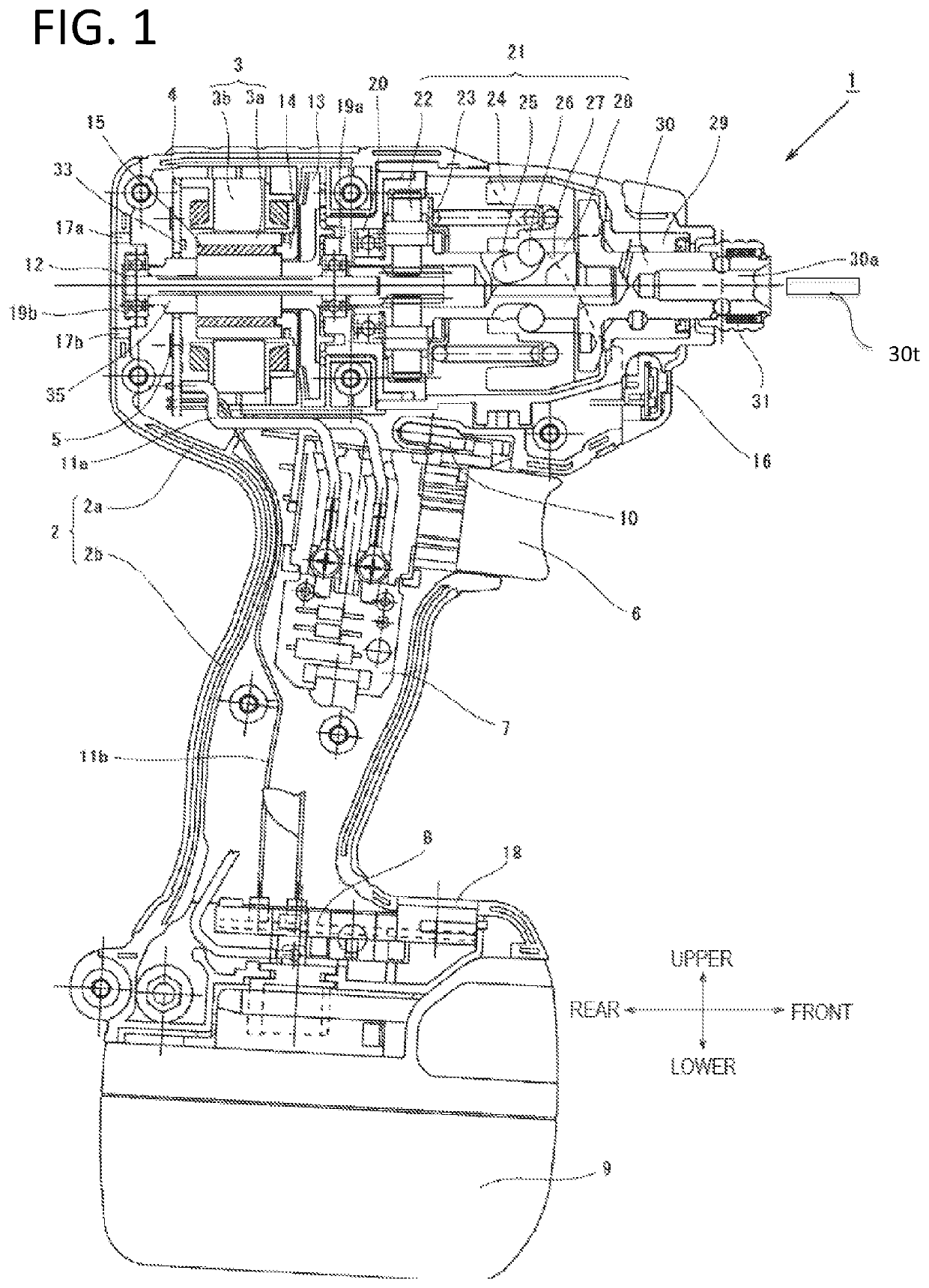

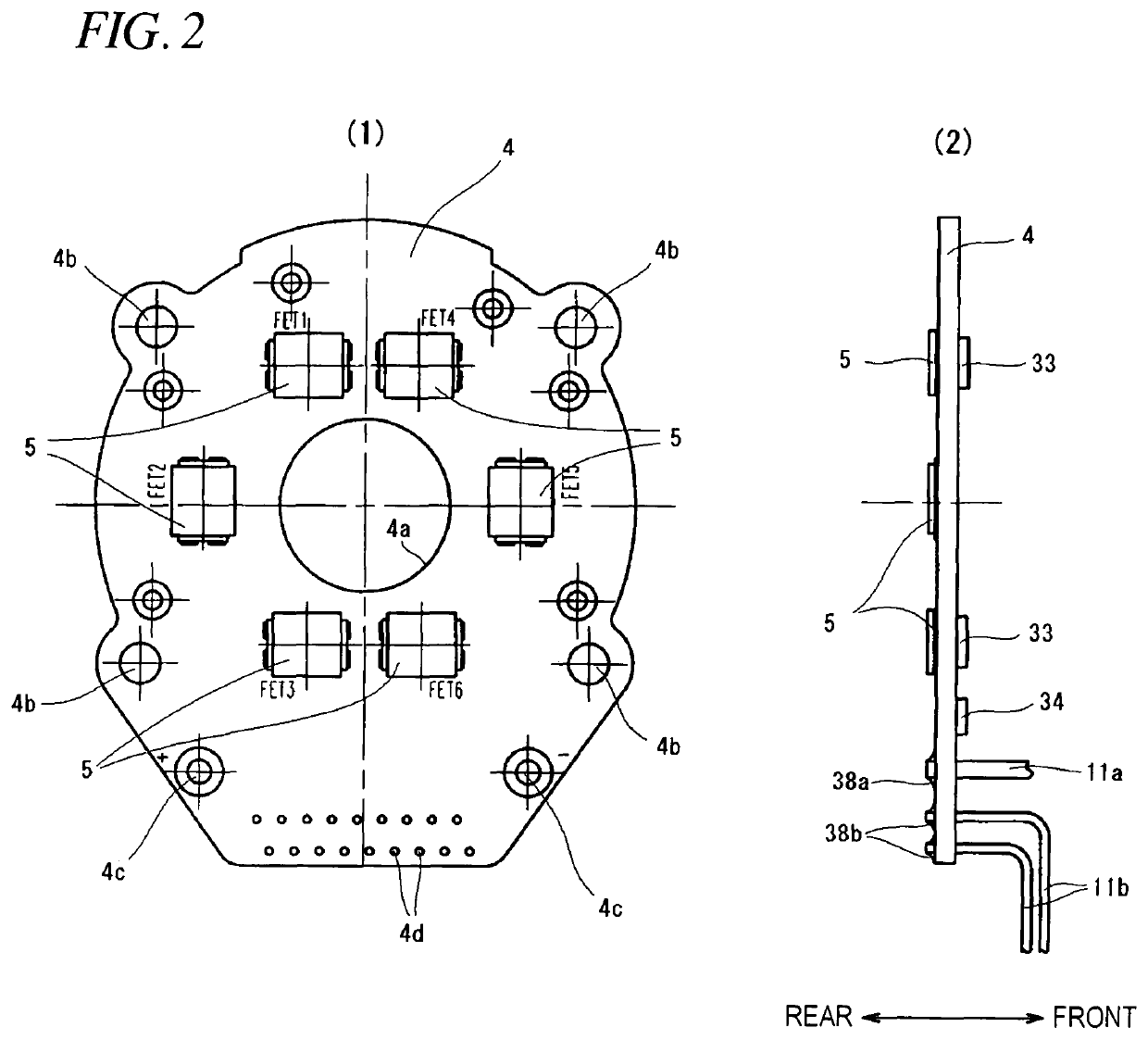

Control method and control unit for impact type screw fastening device

ActiveUS7770658B2Improve accuracyImprove fastening accuracyDrilling rodsConstructionsControl theoryElectrical current

An object is to improve accuracy of tightening torque and to shorten time necessary for fastening a screw in an impact type screw fastening device that uses an electric motor as a rotation driving source. A control method for the impact type screw fastening device that uses an electric motor as a rotation driving source includes the steps of driving the motor to rotate by supplying current to the motor intermittently so that torque exerted on a load by rotation of the motor becomes like pulses on the time axis, and controlling the current of every time of each pulse so that an increment of every time of each pulse of the torque after the torque reaches a target approach torque TQN that is a first set value becomes smaller than that before it reaches the target approach torque TQN.

Owner:ESTIC CORP

Method and apparatus for fastening together structural components

Owner:HAYTAYAN HARRY M

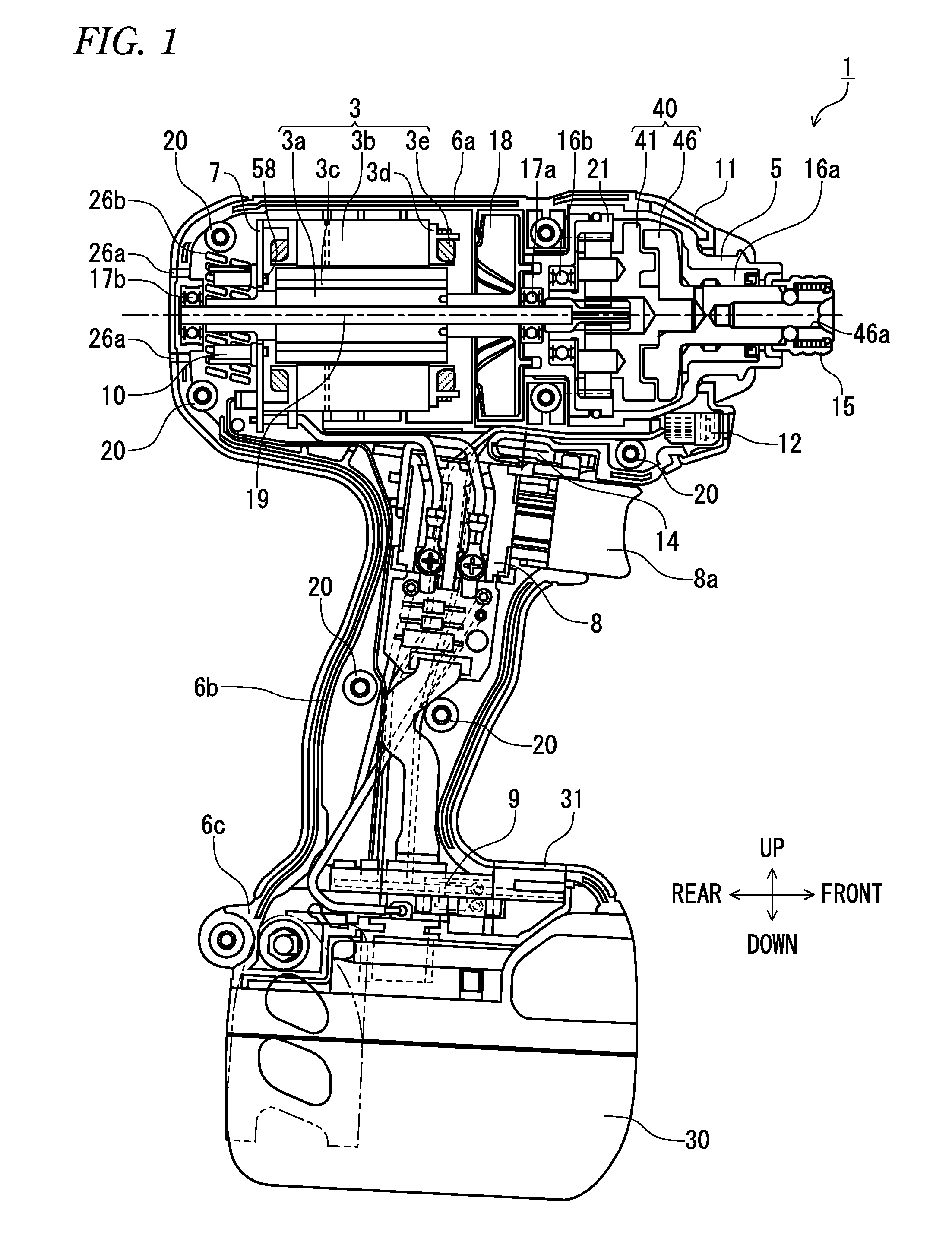

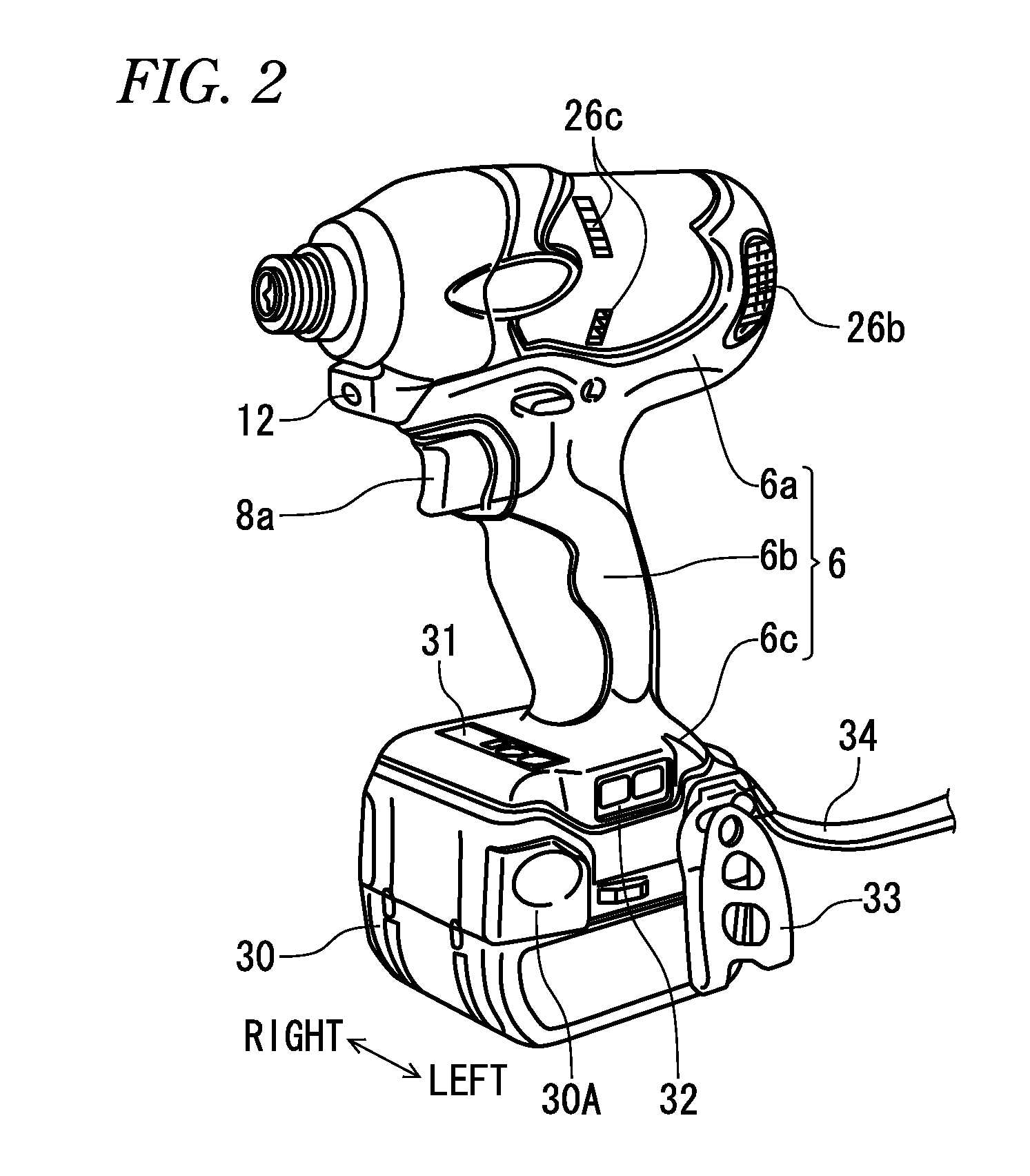

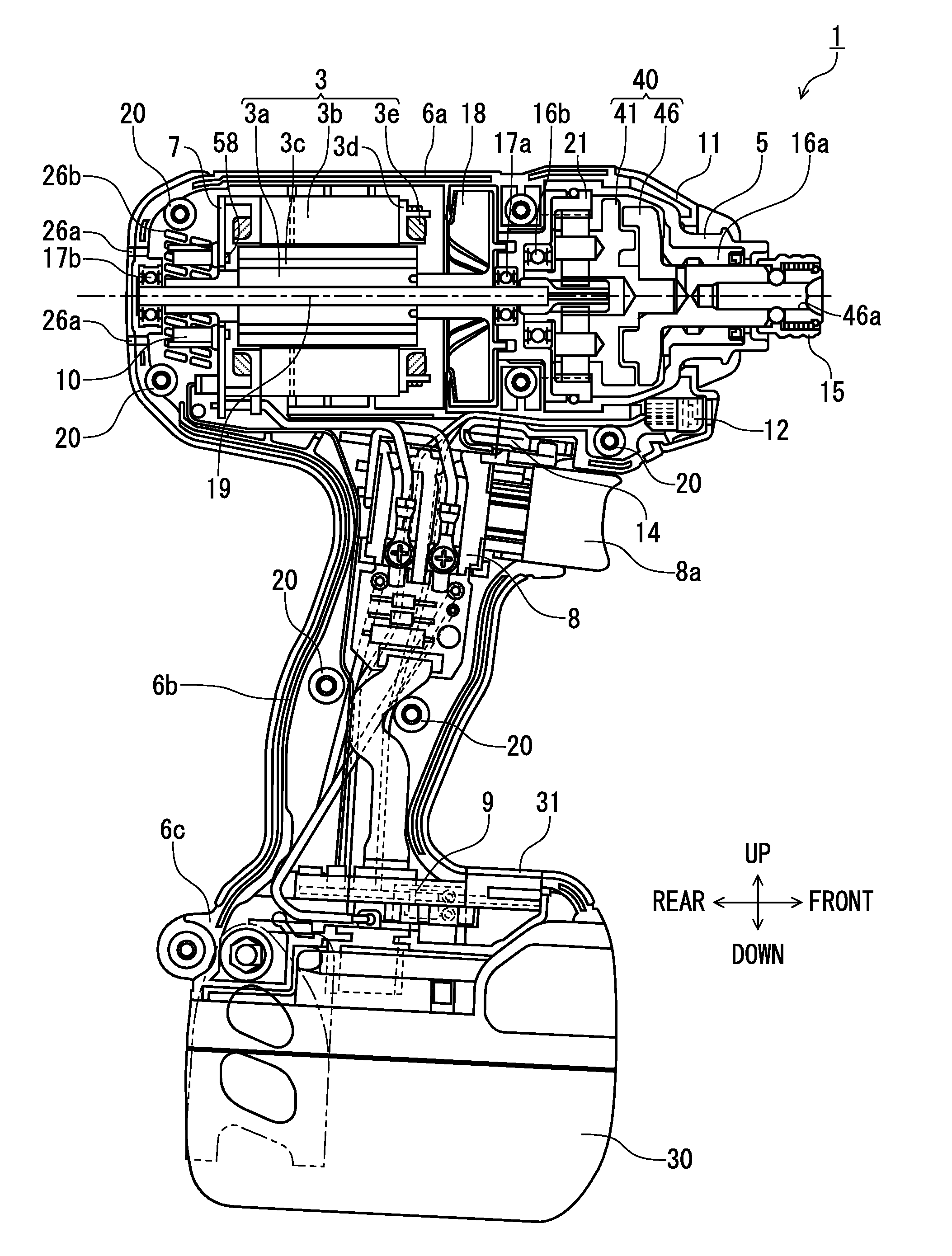

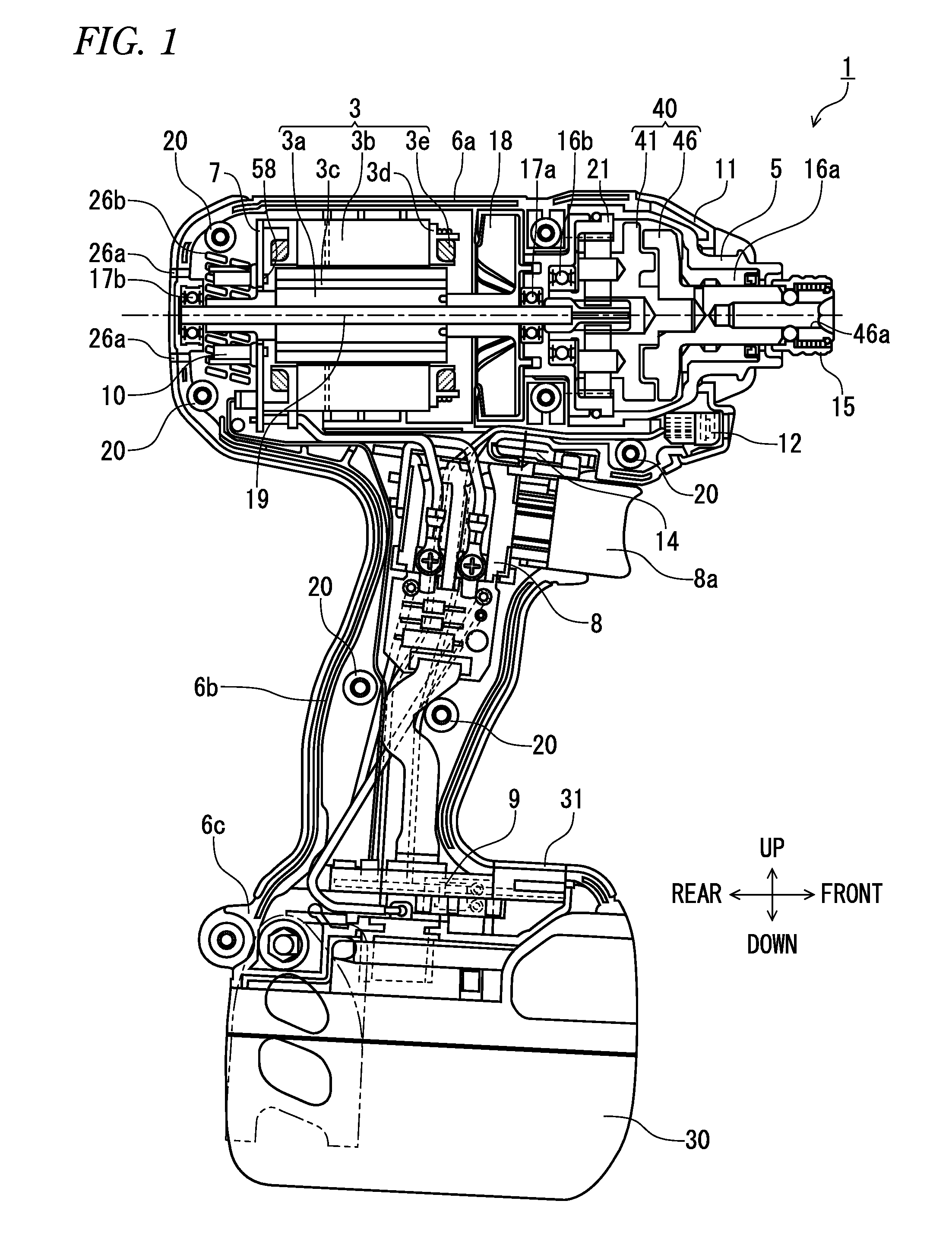

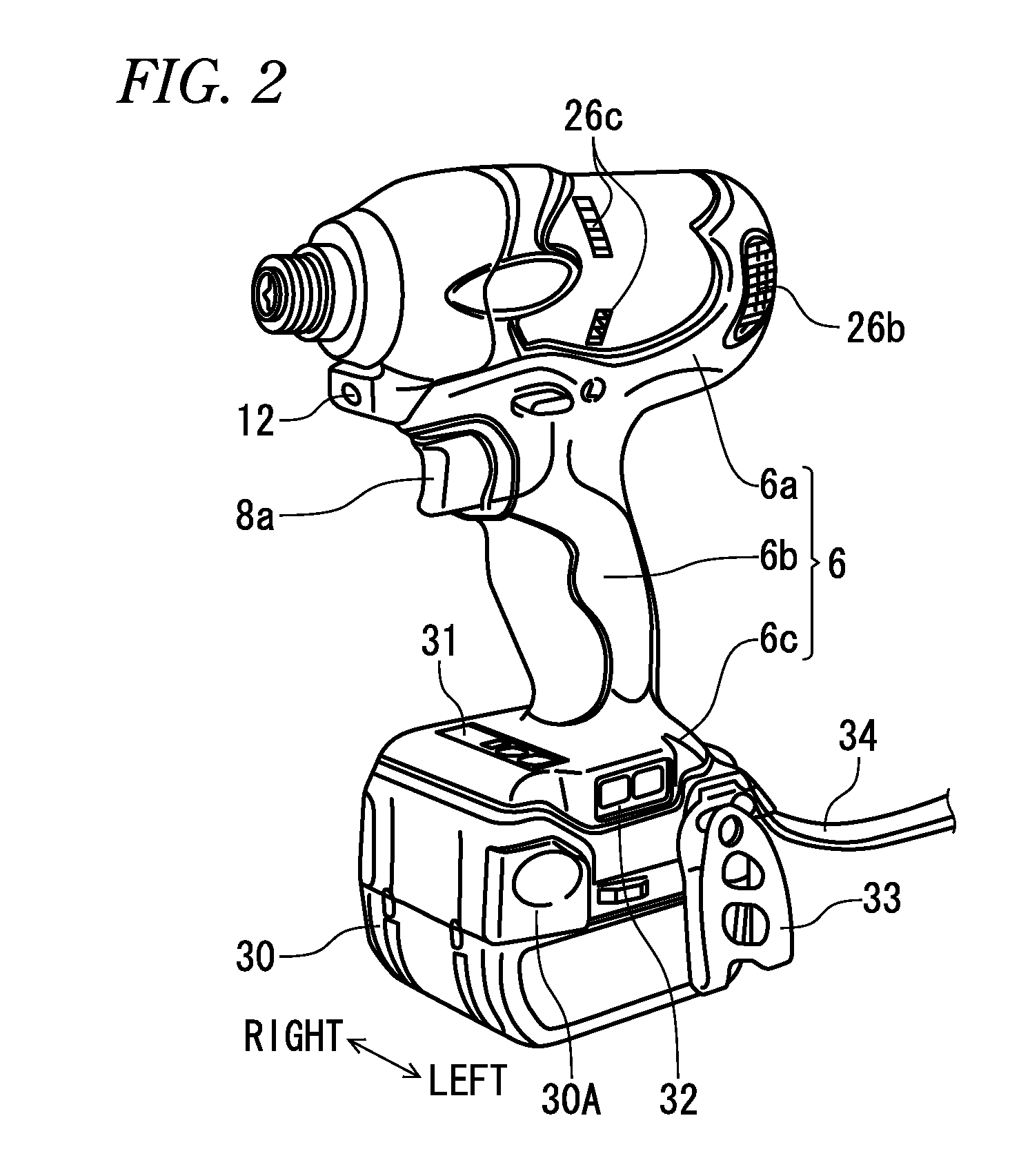

Impact tool

According to one embodiment, an impact tool includes: a motor; and a hammer that is connected to the motor and that has a striking-side surface; and an anvil that is journalled to be rotatable with respect to the hammer, that has a struck-side surface and that provides a striking power to a tip tool, wherein the motor is drivable in: a first driving mode in which the motor is continuously driven in a normal rotation; a second driving mode in which the motor is intermittently driven only in the normal rotation; and a third driving mode in which the motor is intermittently driven in the normal rotation and in a reverse rotation.

Owner:KOKI HLDG CO LTD

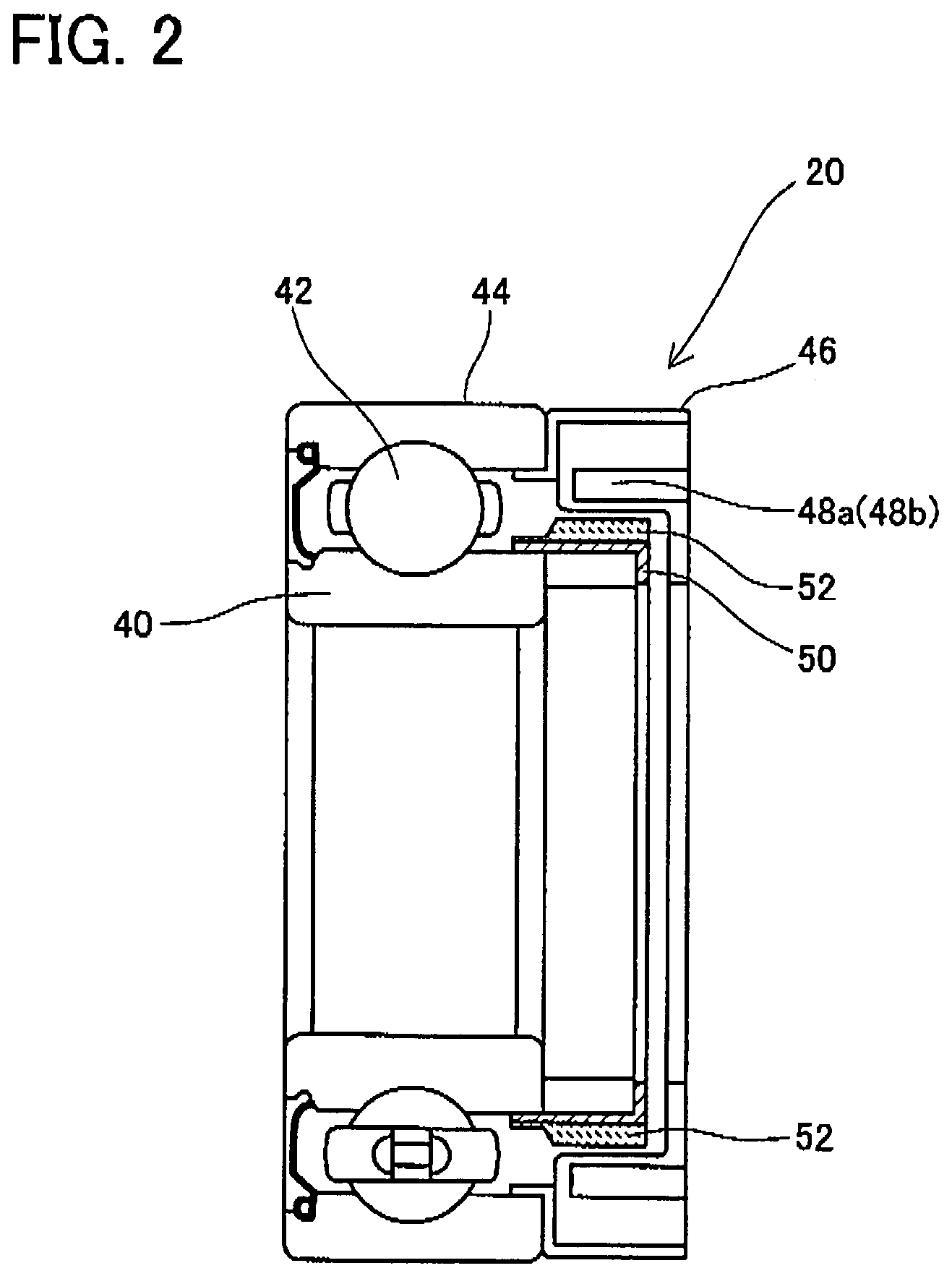

Power tools

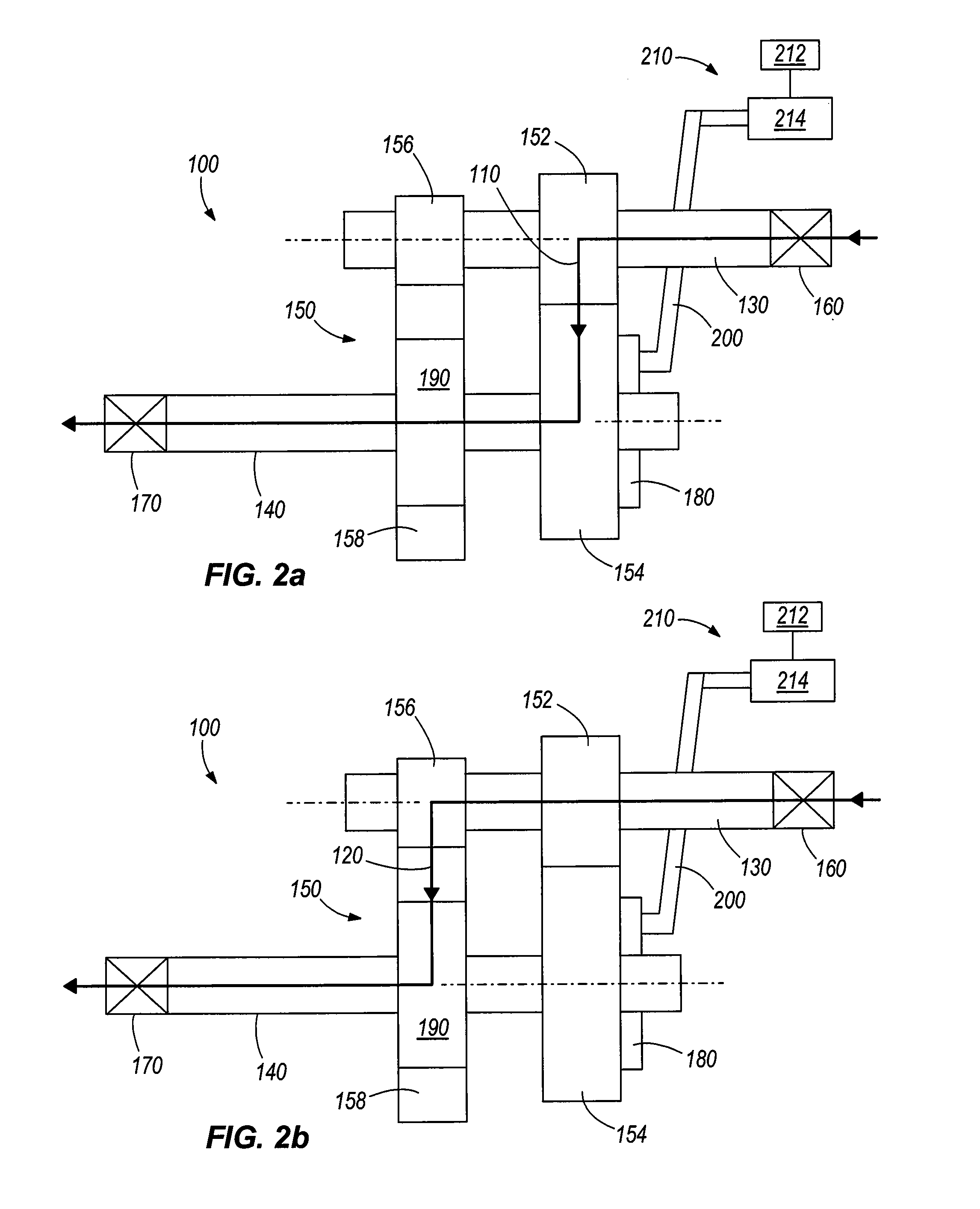

Power tool (11) may include a motor and oil pulse unit (22) that generates an elevated torque. Oil pulse unit (22) may be coupled to the motor and have output shaft (18). When load acting on output shaft (18) is less than a predetermined value, rotating torque generated by the motor is directly transmitted to output shaft (18). When the load acting on output shaft (22) exceeds the predetermined value, an elevated torque is generated by oil pulse unit (22) and applied to output shaft (18). Output shaft (18) may be connected to load shaft (12). A socket may be attached to the distal end of load shaft (12). Power tool (11) may further include detecting device (20) for detecting change in rotational angle of output shaft (18) and the direction of rotation thereof, and a control device. The detecting device (20) may output signals corresponding to a state of output shaft (18) to the control device. The control device may store the state of output shaft (18) at predetermined interval. Preferably, the control device may further determine a generating time, at which oil pulse unit (22) generates the elevated torque, based upon the state of output shaft (18).

Owner:MAKITA CORP

Impact tool

ActiveUS9314908B2Optimization mechanismConstructionsReciprocating drilling machinesEngineeringDriving mode

According to an aspect of the present invention, there is provided an impact tool including: a motor drivable in an intermittent driving mode; a hammer connected to the motor; an anvil to be struck by the hammer to thereby rotate / strike a tip tool; and a control unit that controls a rotation of the motor by switching a driving pulse supplied to the motor in accordance with a load applied onto the tip tool.

Owner:KOKI HLDG CO LTD

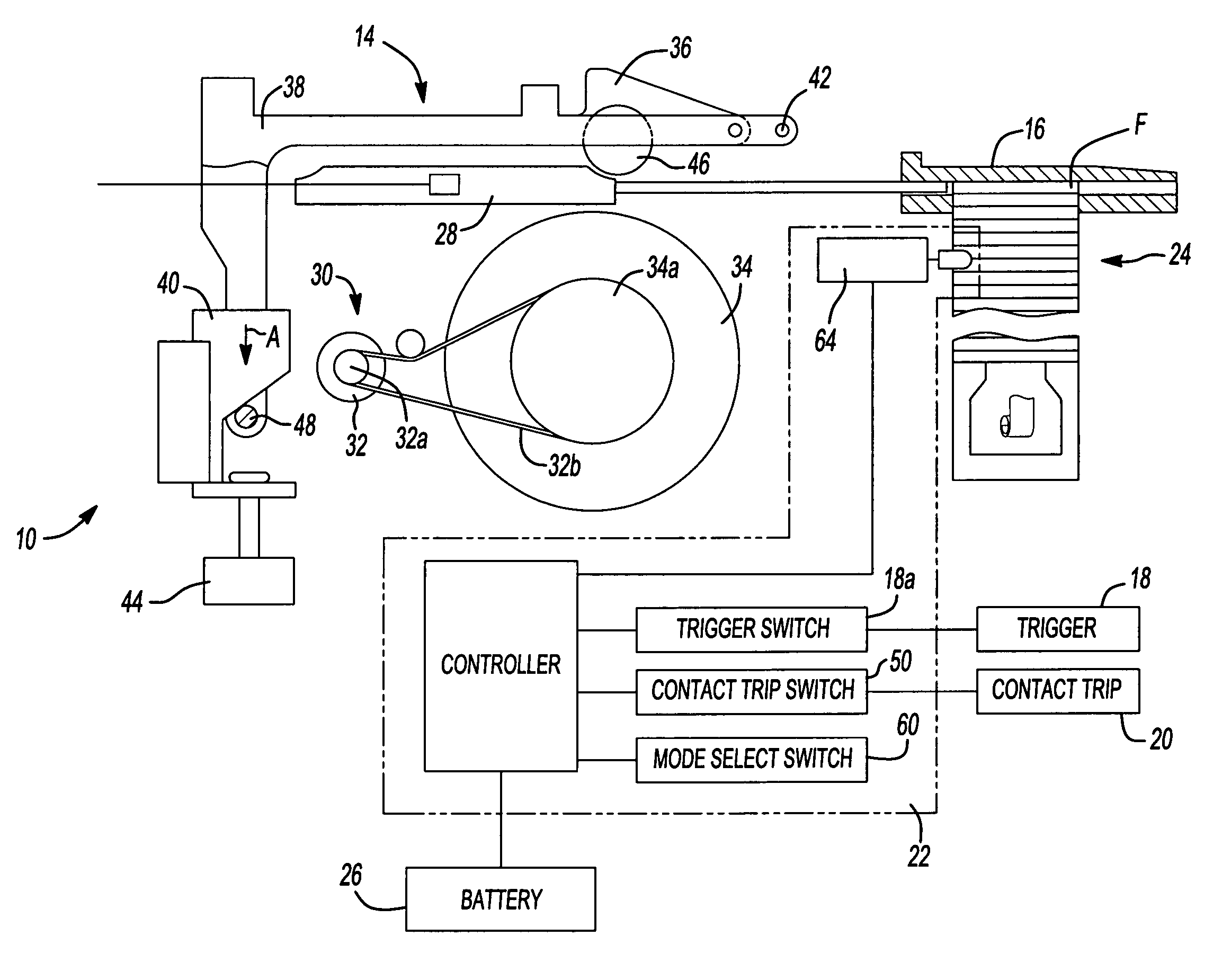

Method for controlling a power driver

A driving tool having a driver, a power source, a sensor and a controller. The power source selectively provides an input to the driver to cause the driver to translate along an axis. The sensor senses a condition in the power source that is indicative of a level of kinetic energy of an element in the power source and generates a sensor signal in response thereto. The controller is coupled to the power source and the sensor and is responsive to the sensor signal for deactivating the power source to inhibit the power source from providing the input to the driver when the level of kinetic energy of the element in the power source is below a predetermined threshold. A method for operating a driving tool is also provided.

Owner:BLACK & DECKER INC

Automatic transmission for a power tool

Owner:TECHTRONIC POWER TOOLS TECHNOLOGY LTD

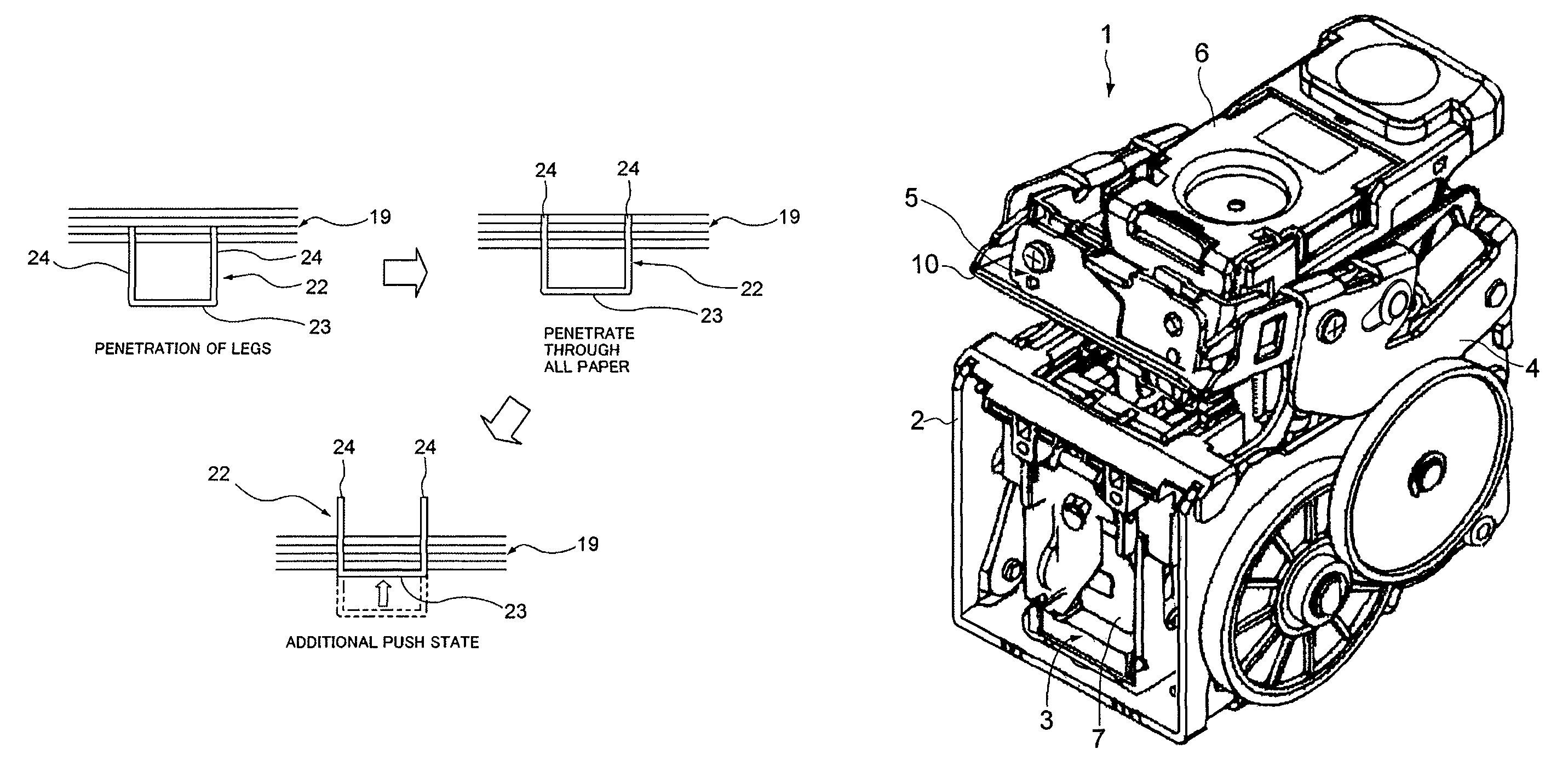

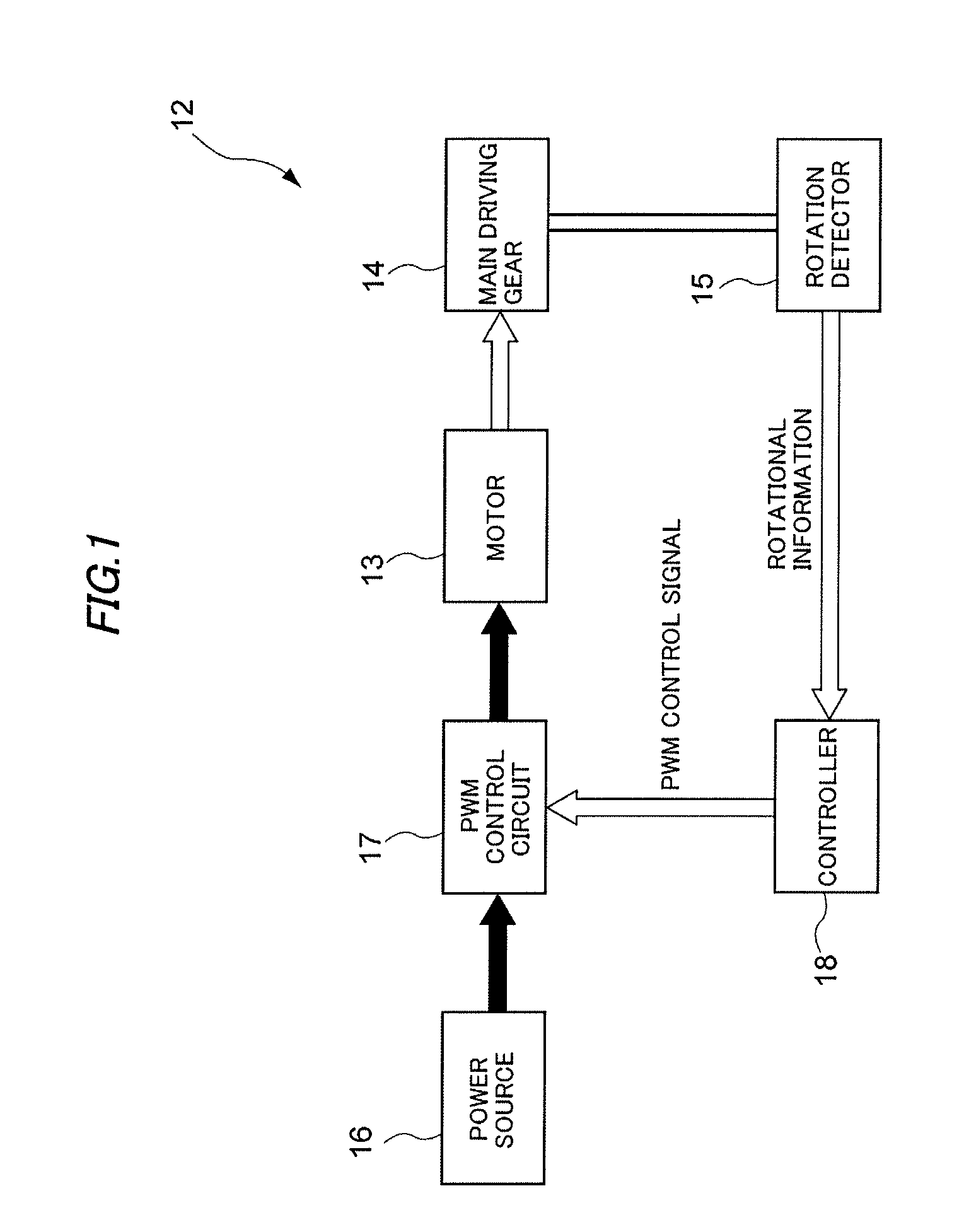

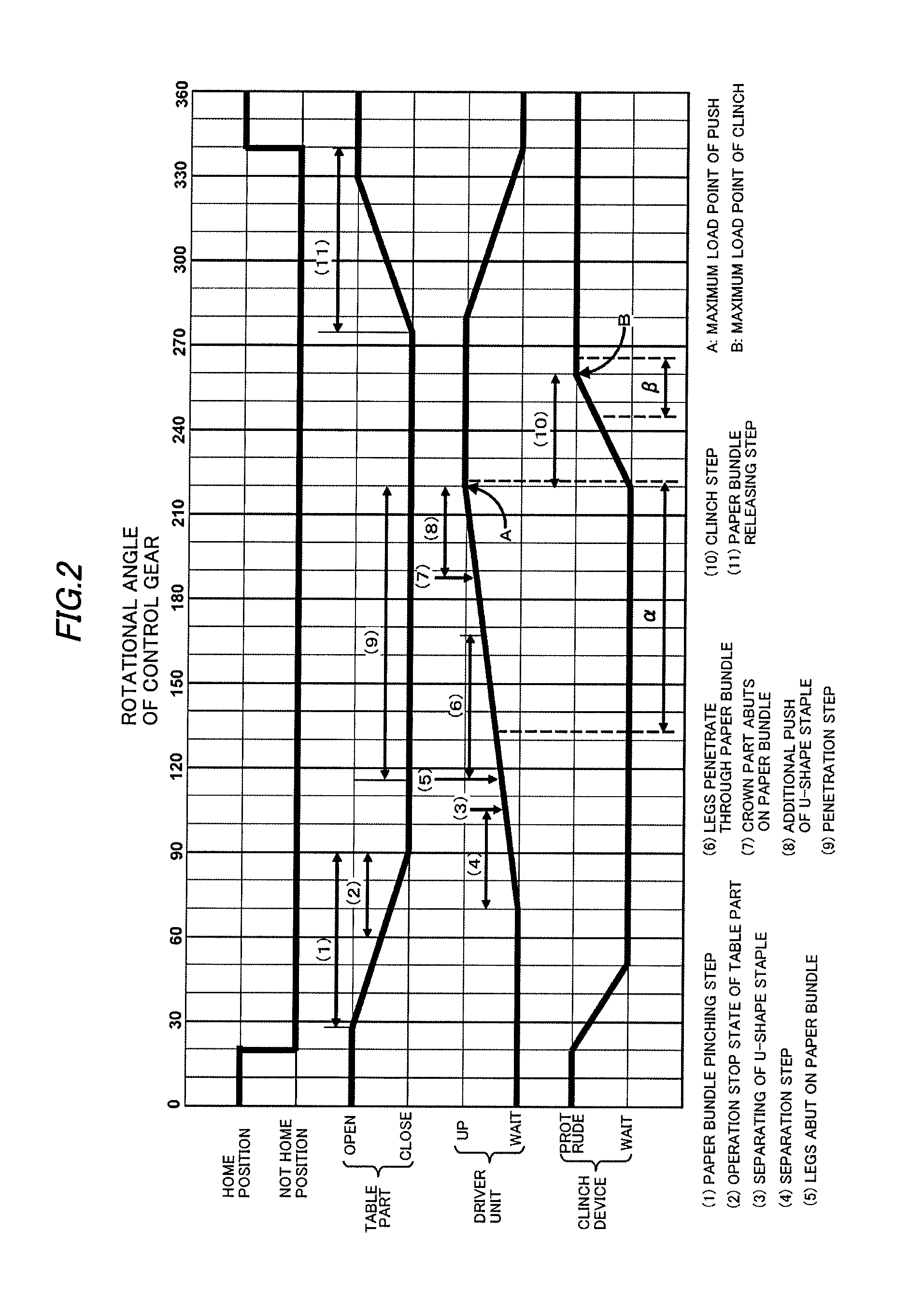

Electric stapler and operation method of electric stapler

ActiveUS8371393B2Reduce running noiseIncrease the number ofStapling toolsDispensing apparatusEngineeringElectric motor

Owner:MAX CO LTD

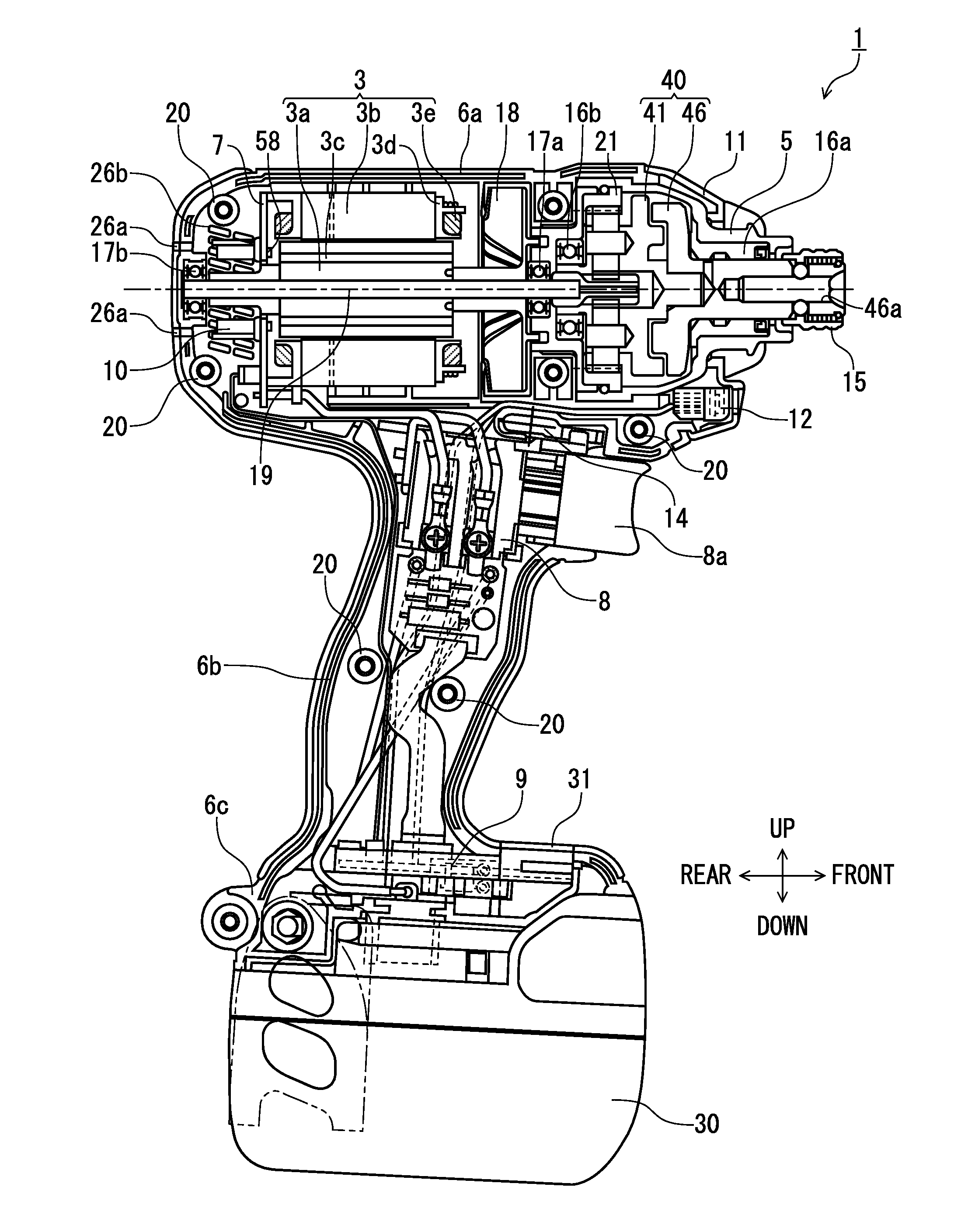

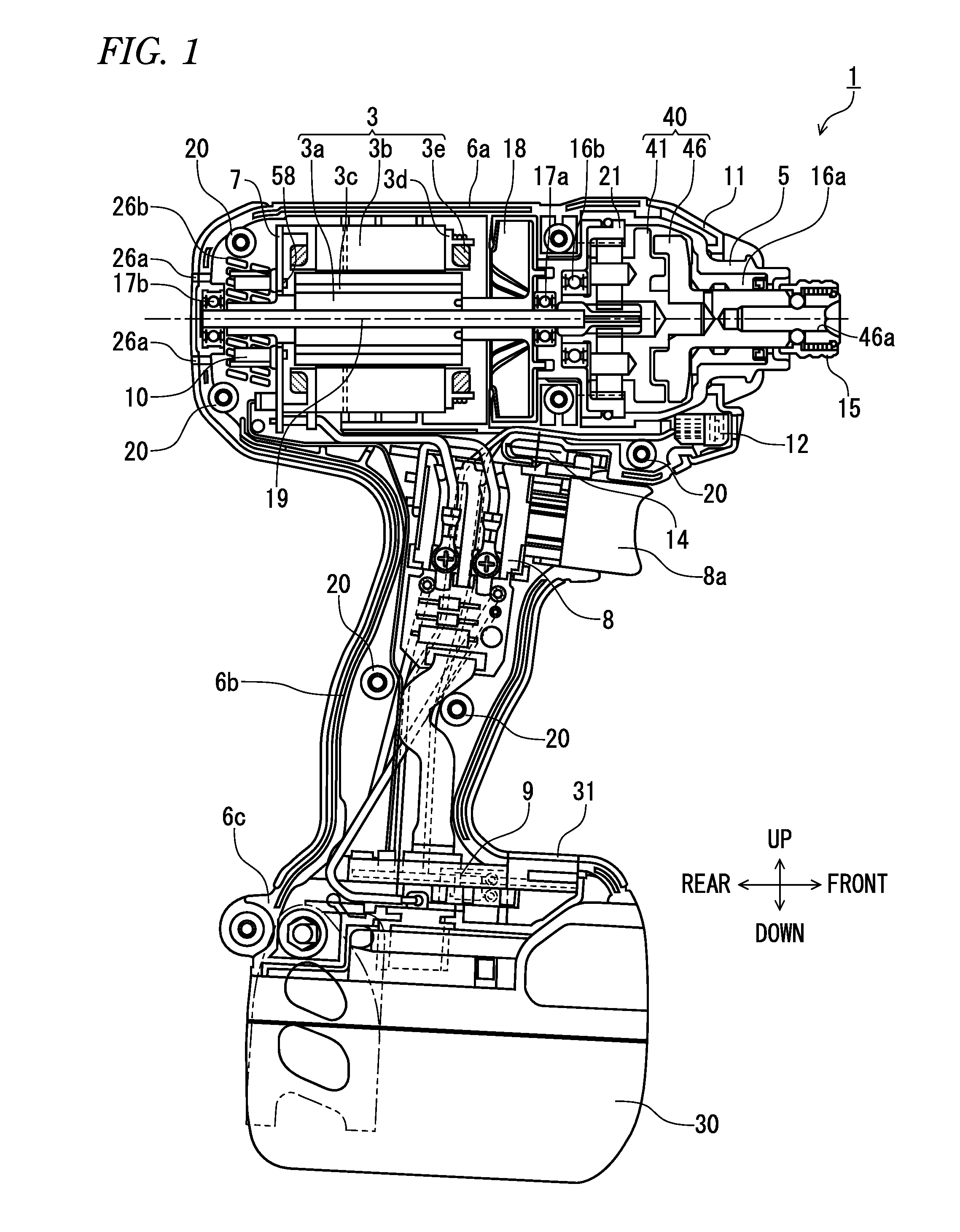

Power tool

InactiveUS9731410B2Simplify device configurationEasy to understandDrilling rodsConstructionsHand heldEngineering

Owner:MAKITA CORP

Lock-out for activation arm mechanism in a power tool

A power tool, such as a nailer, having a driver, a flywheel and an activation arm for selectively driving the driver into contact with the flywheel to transfer energy therebetween to cause the driver to translate. The power tool includes a bar that may be moved so as to resist movement of the activation arm in a direction that would bring the driver into contact with the flywheel. A method for operating a power tool is also provided.

Owner:BLACK & DECKER INC

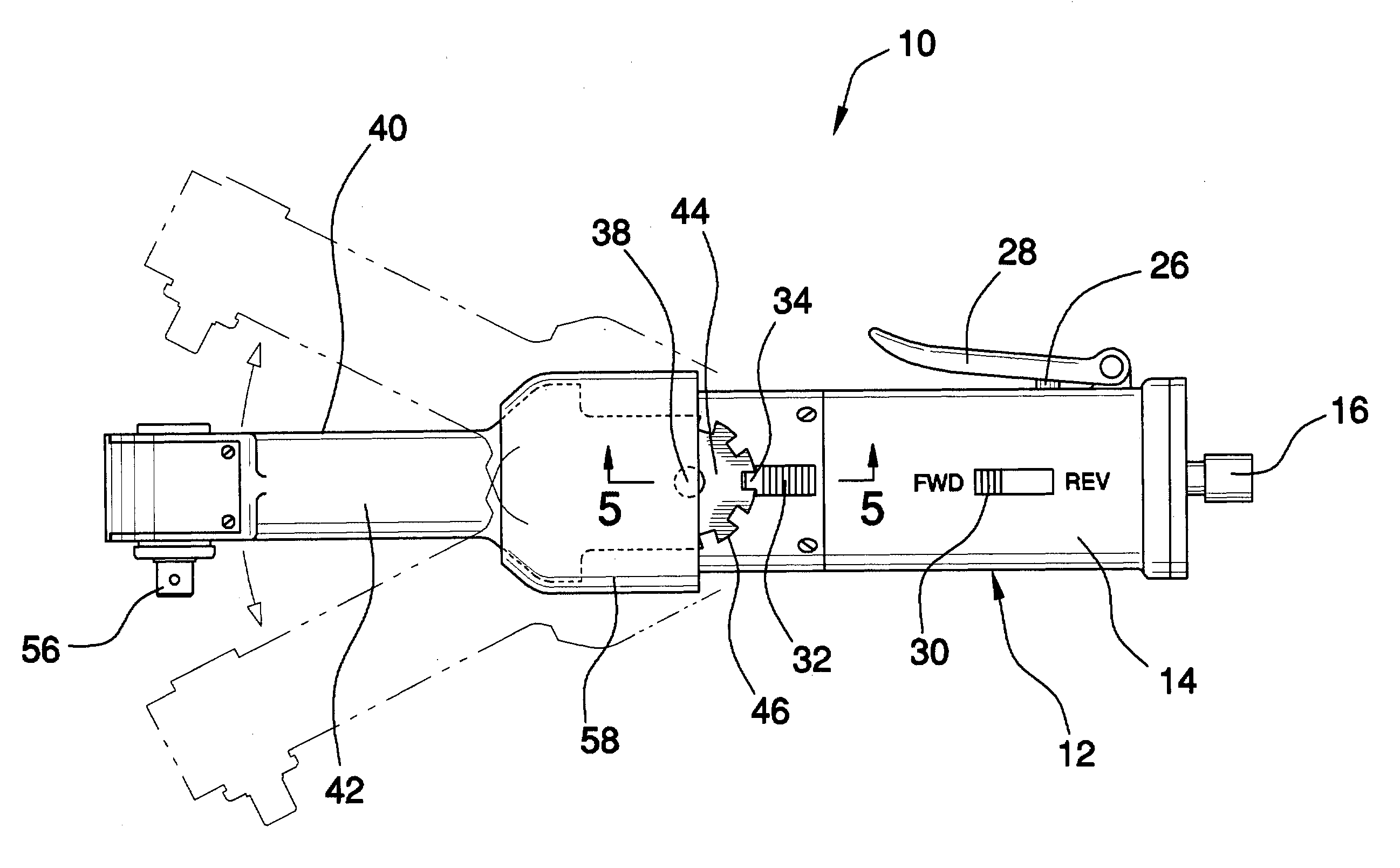

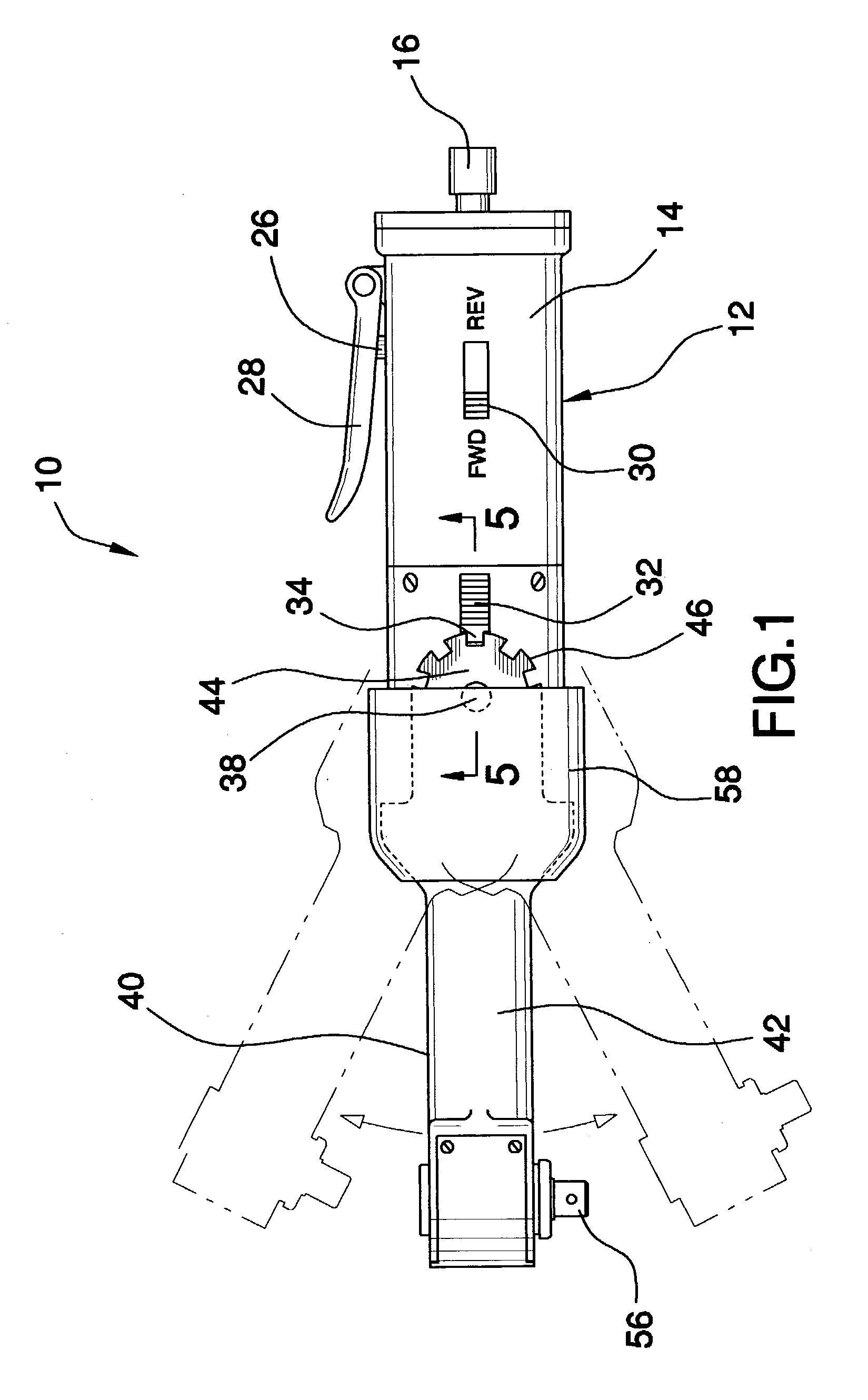

Air powered wrench device with pivotable head and method of using

InactiveUS6928902B1Easy and efficient to manufactureLower sales priceSpannersWrenchesBall bearingUniversal joint

An air powered wrench device with a pivotable head and associated method of using. The device comprises a handle pivotally attached to an arm. The handle comprises a housing, an air intake nozzle, an air driven motor, a drive shaft, a ball bearing collar, a universal joint, an on / off button, a trigger switch, a directional throw switch, a lock pin, a spring, and a pivot post. The arm is pivotally attached to the handle via the pivot post. The arm includes: an outer casing, an extension rod, a ball bearing sleeve, a first pawl gear, a second pawl gear, and a bit connector. The method of using the device comprises the steps of adjoining, affixing, aligning, allowing, enshrouding, getting, moving, obtaining, putting, rotating, shifting, squeezing, and tightening.

Owner:EYSSALLENNE LUIS P

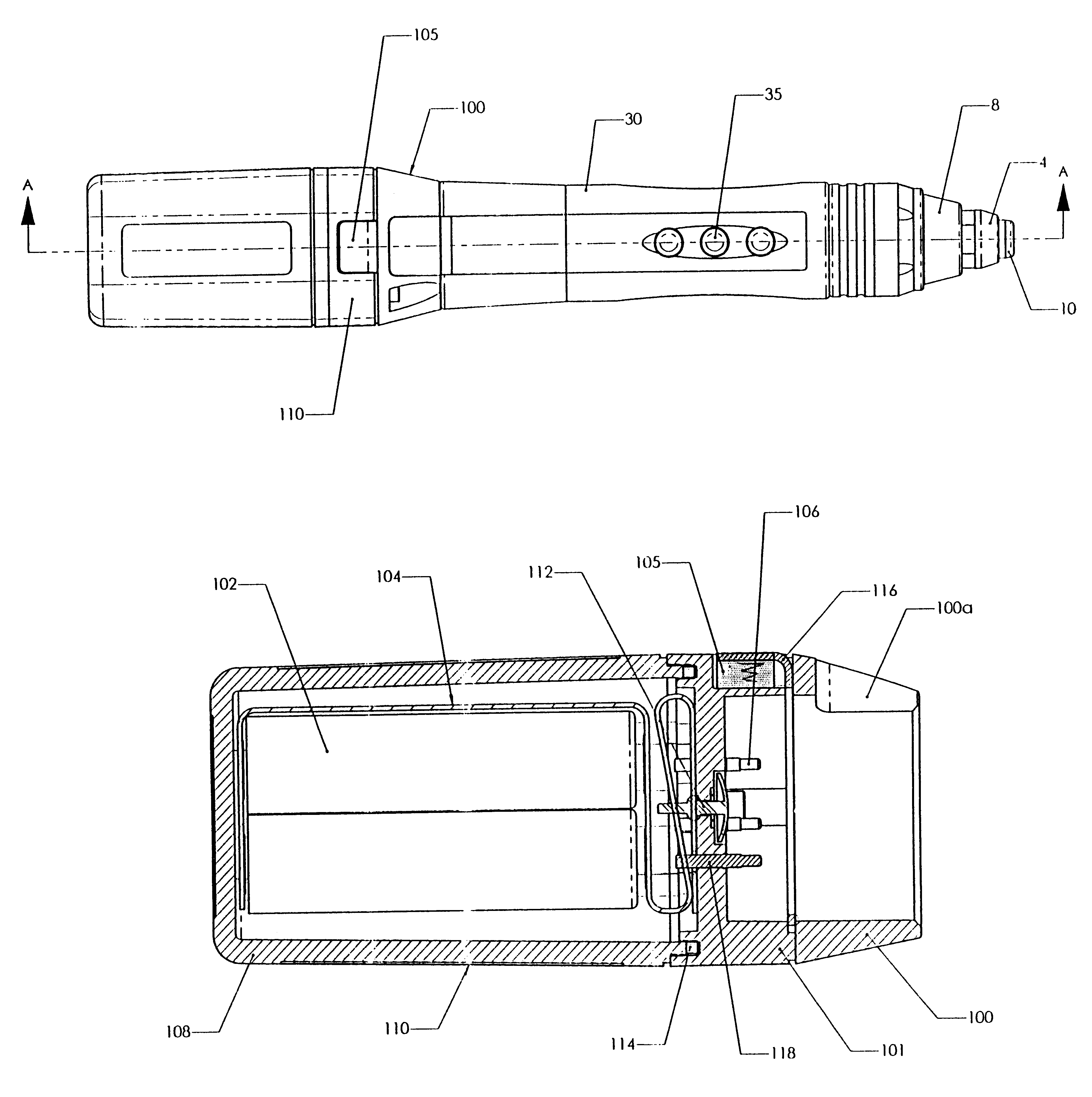

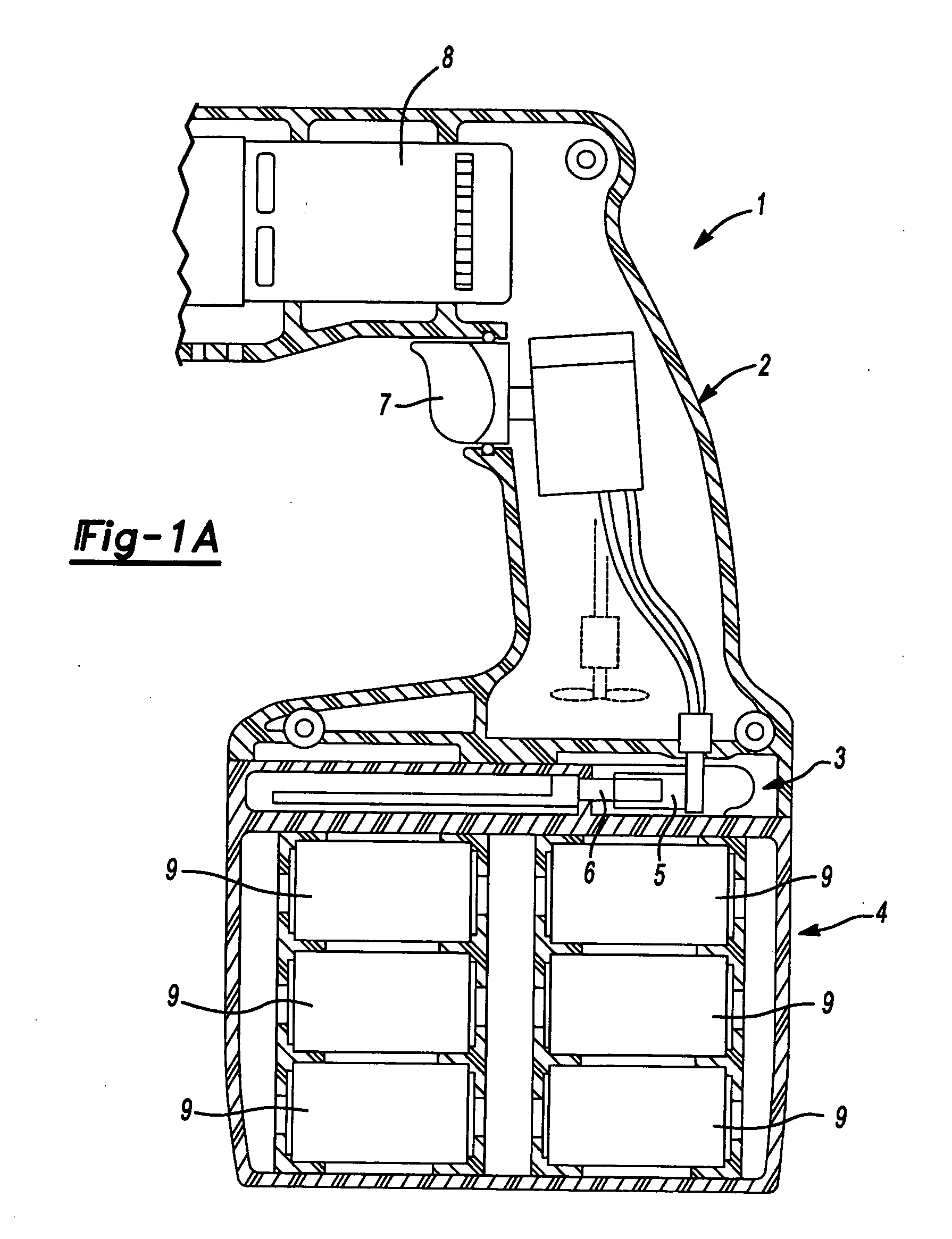

Battery powered surgical tool with guide wire

ActiveUS8974932B2Primary cell to battery groupingInternal osteosythesisElectrical batteryEngineering

A battery pack for a use with a powered surgical tool. The battery pack may include a housing with an outer wall and opposing first and second ends. The housing may include an elongated shape that extends between the first and second ends. A first member may extend across the first end of the housing and include a first aperture, and a second end member may extend across the second end of the housing and may include a second aperture. A passage may extend through the housing with a first end that aligns with the first aperture and a second end that aligns with the second aperture. The housing may be sized for a plurality of storage locations positioned between the first and second members and around the passage, and each of the storage locations may be configured to store a power cell.

Owner:WARSAW ORTHOPEDIC INC

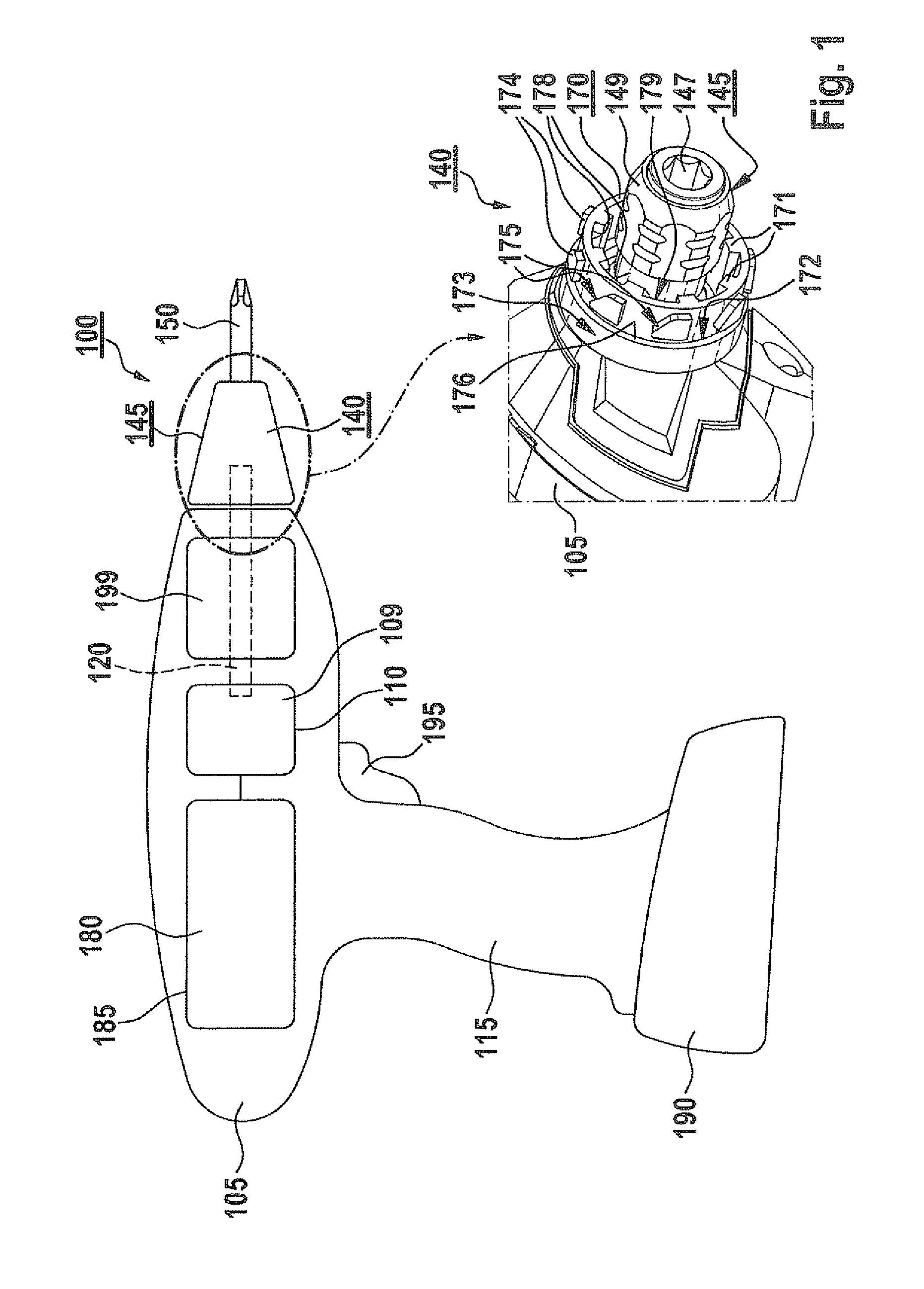

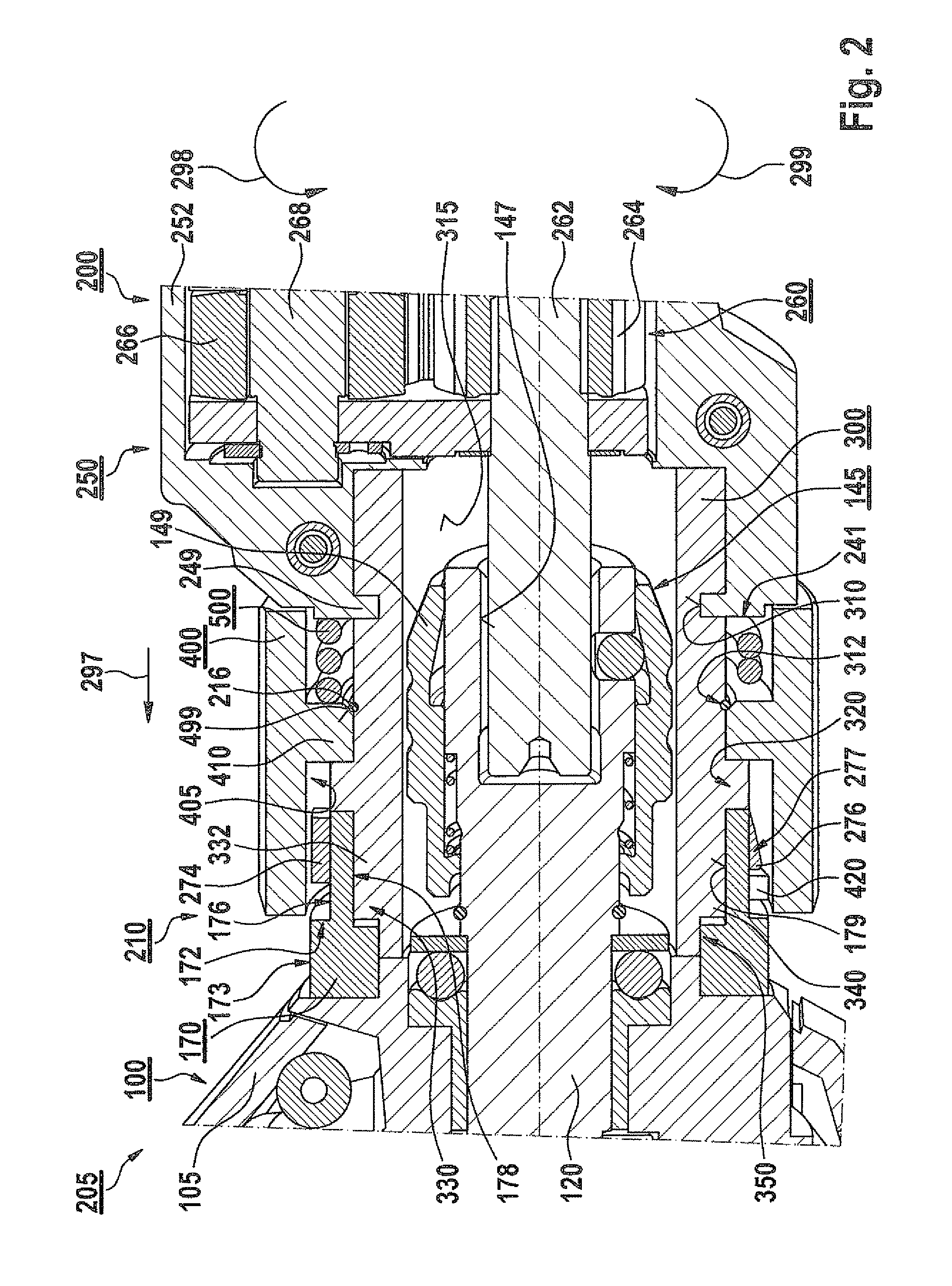

Battery-driven screwdriver

InactiveUS7134364B2Fit tightlyBatteries circuit arrangementsDrilling rodsElectrical and Electronics engineering

Owner:ROBERT BOSCH GMBH

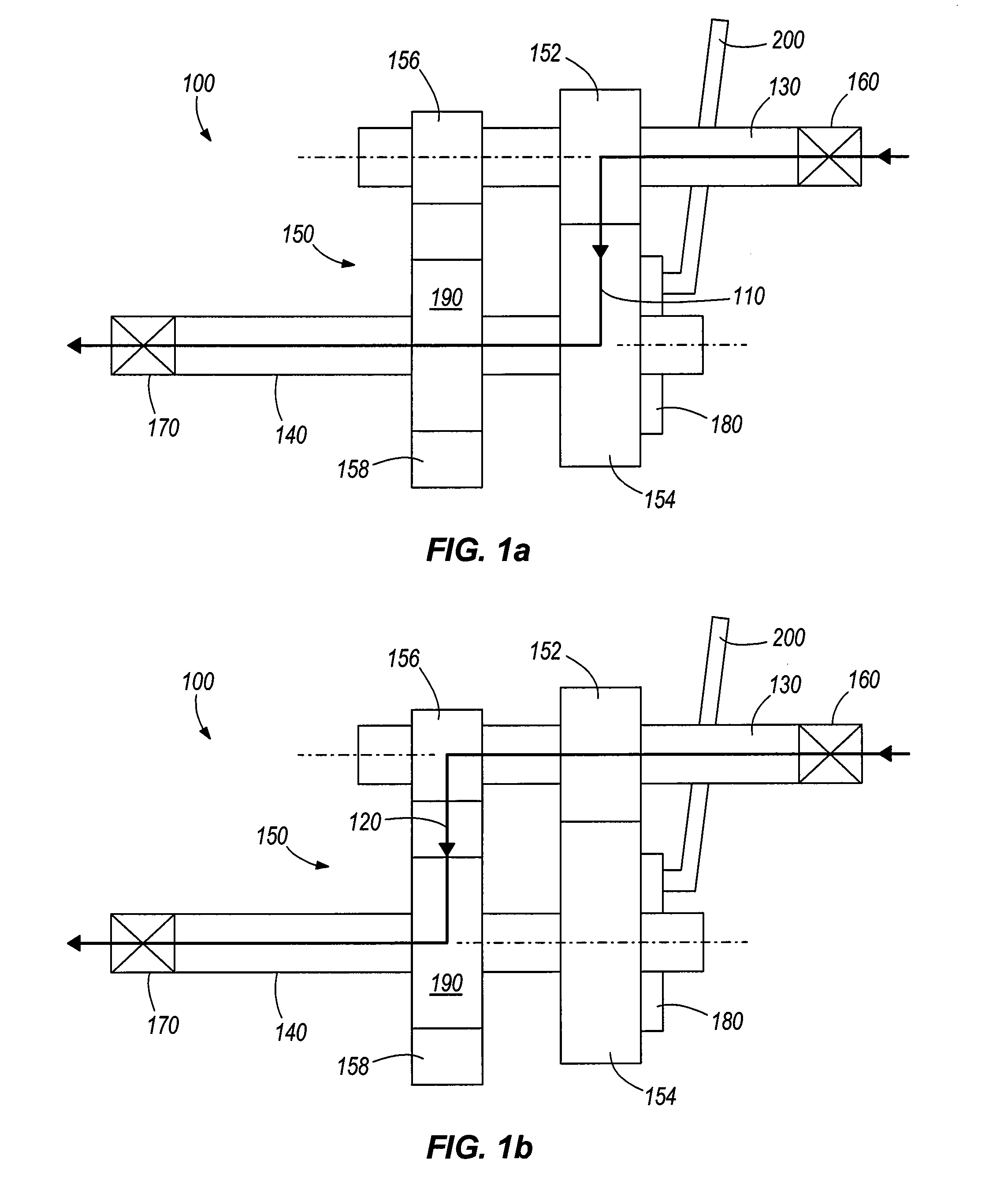

Shiftable drive interface for robotically-controlled surgical tool

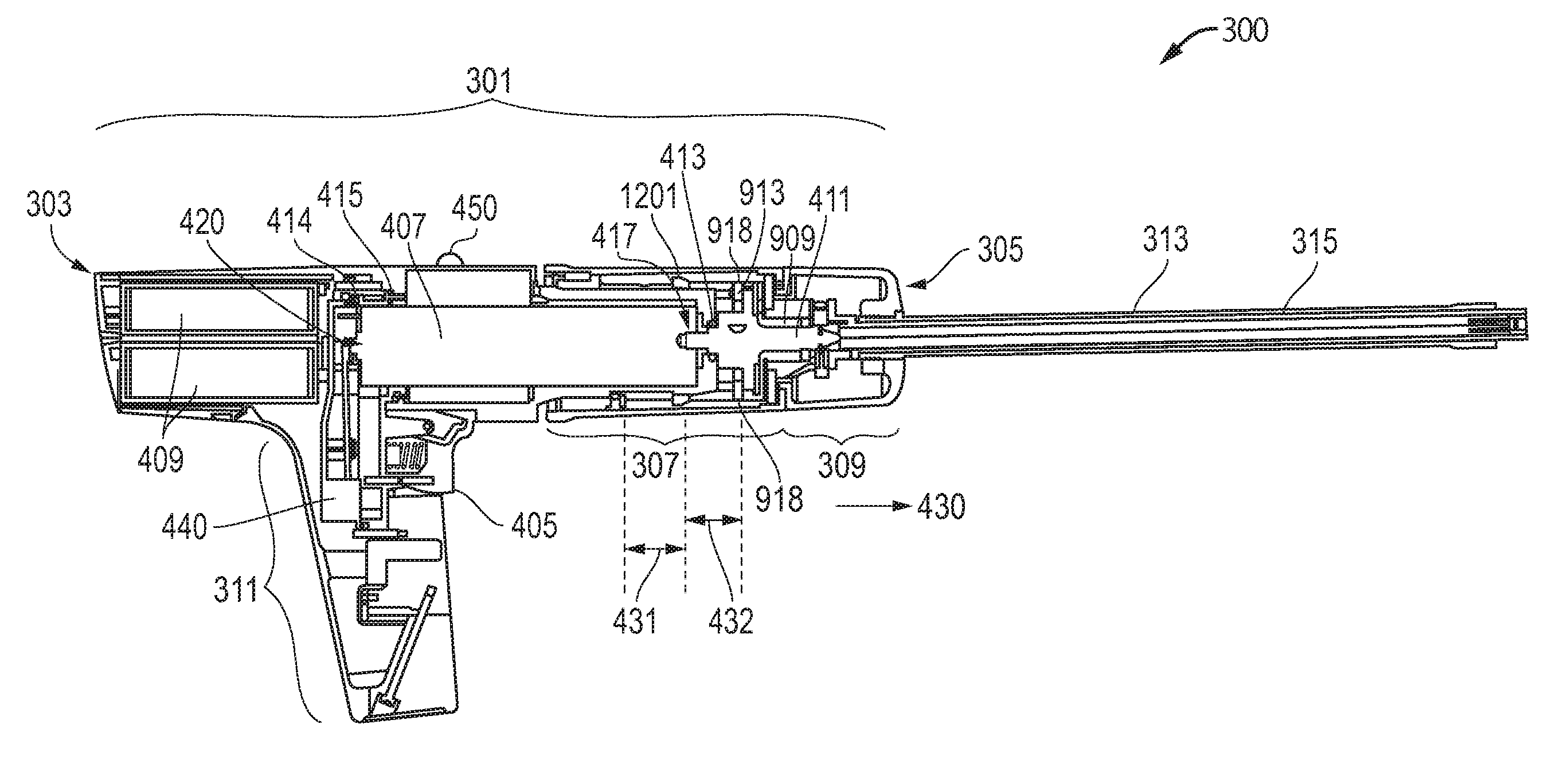

ActiveUS20120132450A1Quickly and conveniently selectSurgical furnitureDiagnosticsRobotic systemsReciprocating motion

A surgical instrument including an end effector that has a selectively reciprocatable implement movably supported therein. The implement is selectively advanceable in a distal direction upon application of a rotary actuation motion thereto and retractable in a proximal direction upon application of a rotary retraction motion thereto. An elongate shaft assembly is coupled to the end effector and is configured to transmit the rotary actuation motion and rotary retraction motion to the reciprocatable implement from a robotic system that is configured to generate the rotary actuation motion and said rotary retraction motion.

Owner:CILAG GMBH INT

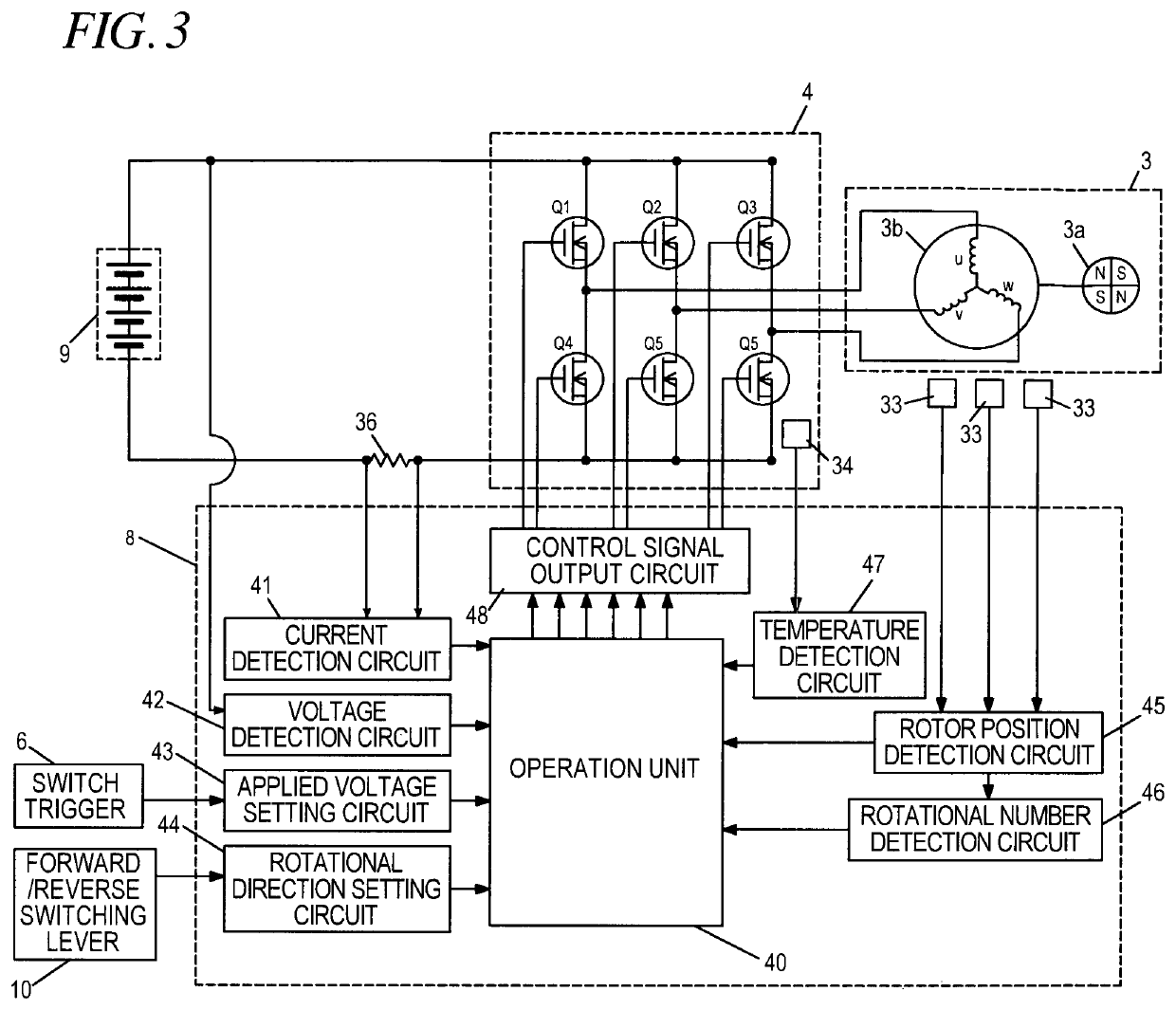

Impact tool and method of controlling impact tool

An impact tool includes: a motor; a trigger; a controller configured to control driving power supplied to the motor using a semiconductor switching element according to an operation of the trigger; a striking mechanism configured to drive a tip tool continuously or intermittently by rotation force of the motor, the striking mechanism including a hammer and an anvil. The controller drives the semiconductor switching element at a high duty ratio when the trigger is manipulated. The motor is driven so that the duty ratio is lowered before a first striking of the hammer on the anvil is performed and the first striking is performed at a low duty ratio lower than the high duty ratio.

Owner:KOKI HLDG CO LTD

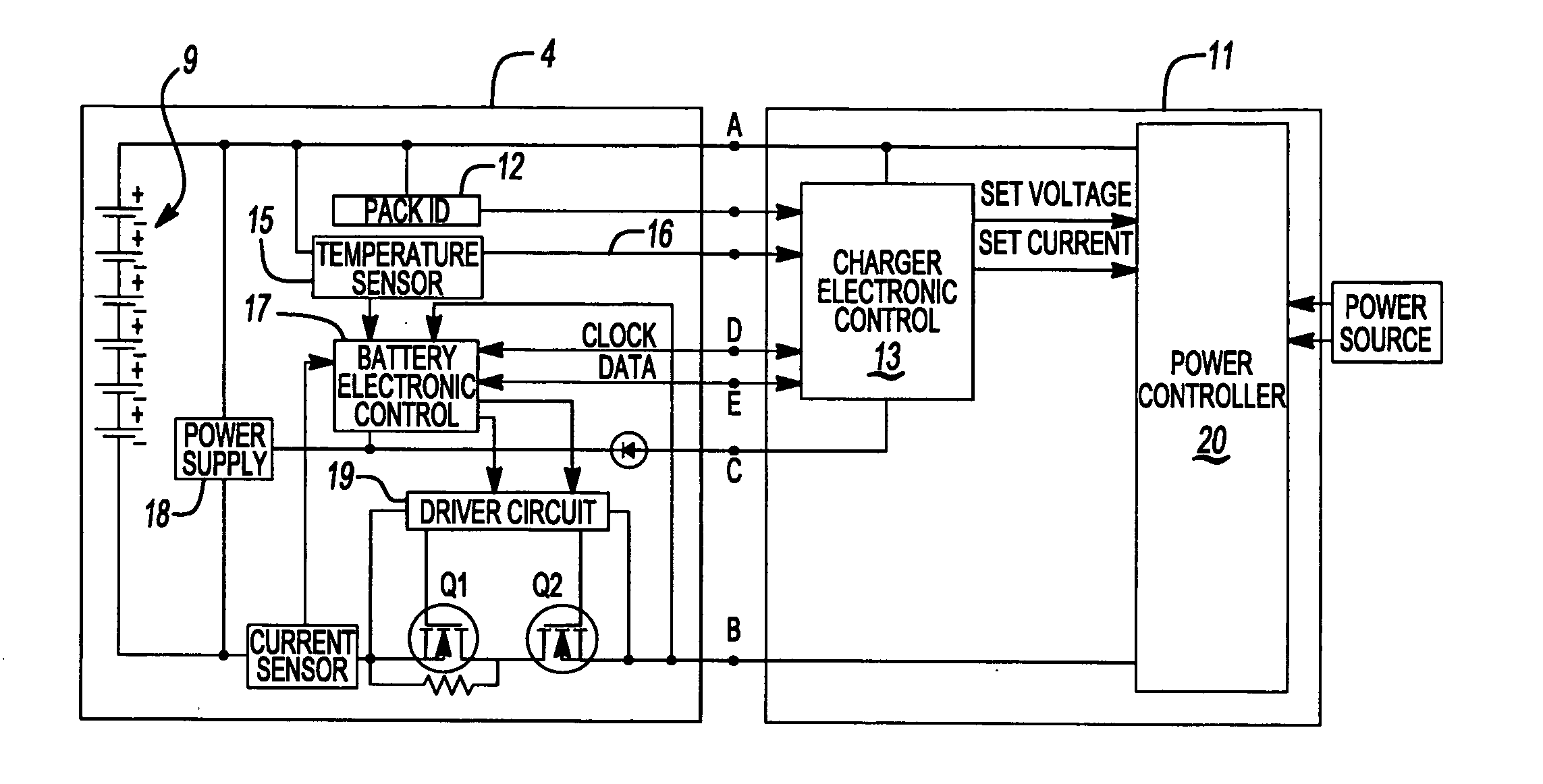

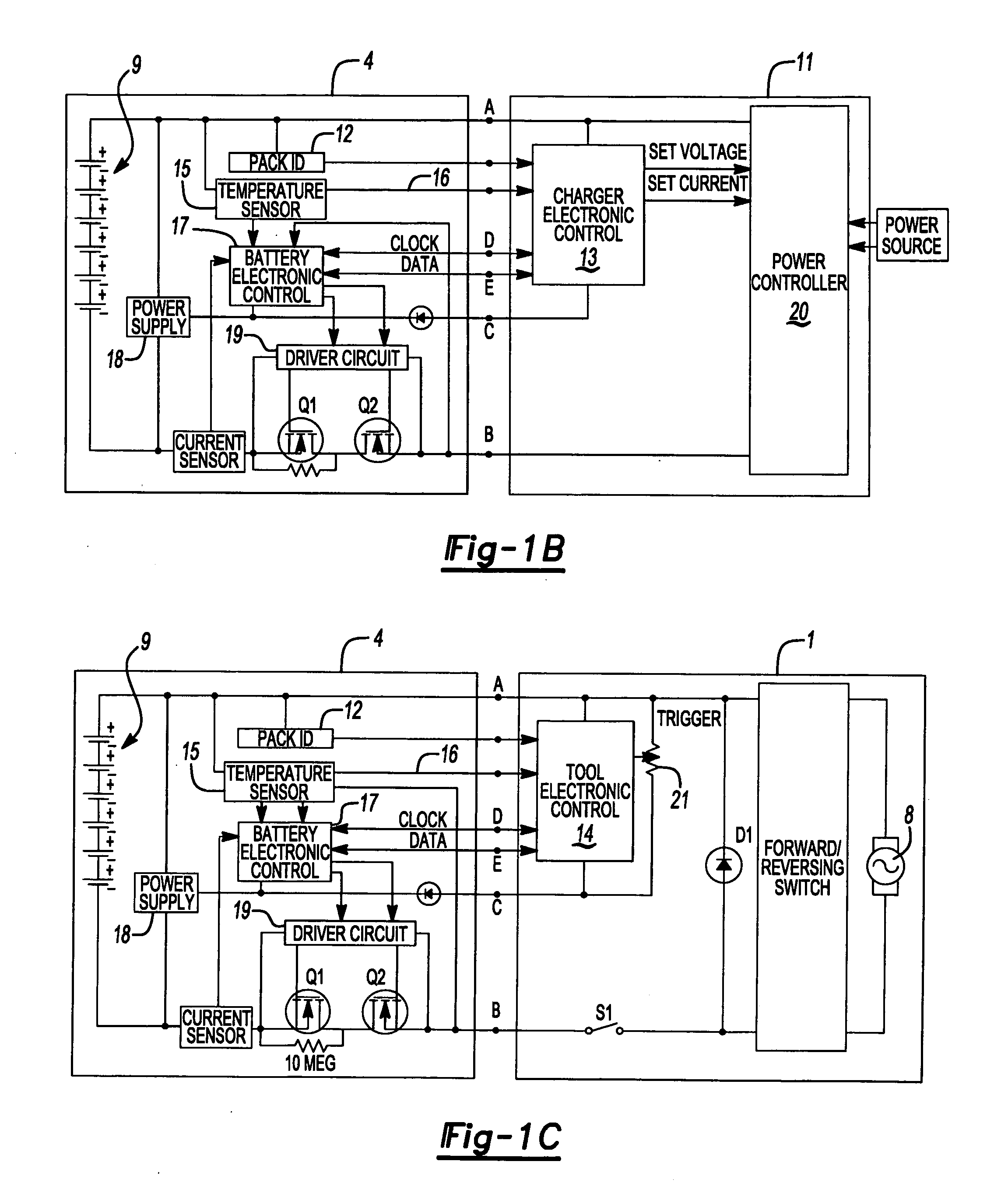

Thermal management systems for battery packs

ActiveUS20050202310A1Improve cooling effectCircuit monitoring/indicationPrimary cell maintainance/servicingElectrical batteryEngineering

A cordless power tool has a housing which includes a mechanism to couple with a removable battery pack. The battery pack includes one or more battery cells as well as a system to dissipate heat from the battery pack.

Owner:BLACK & DECKER INC

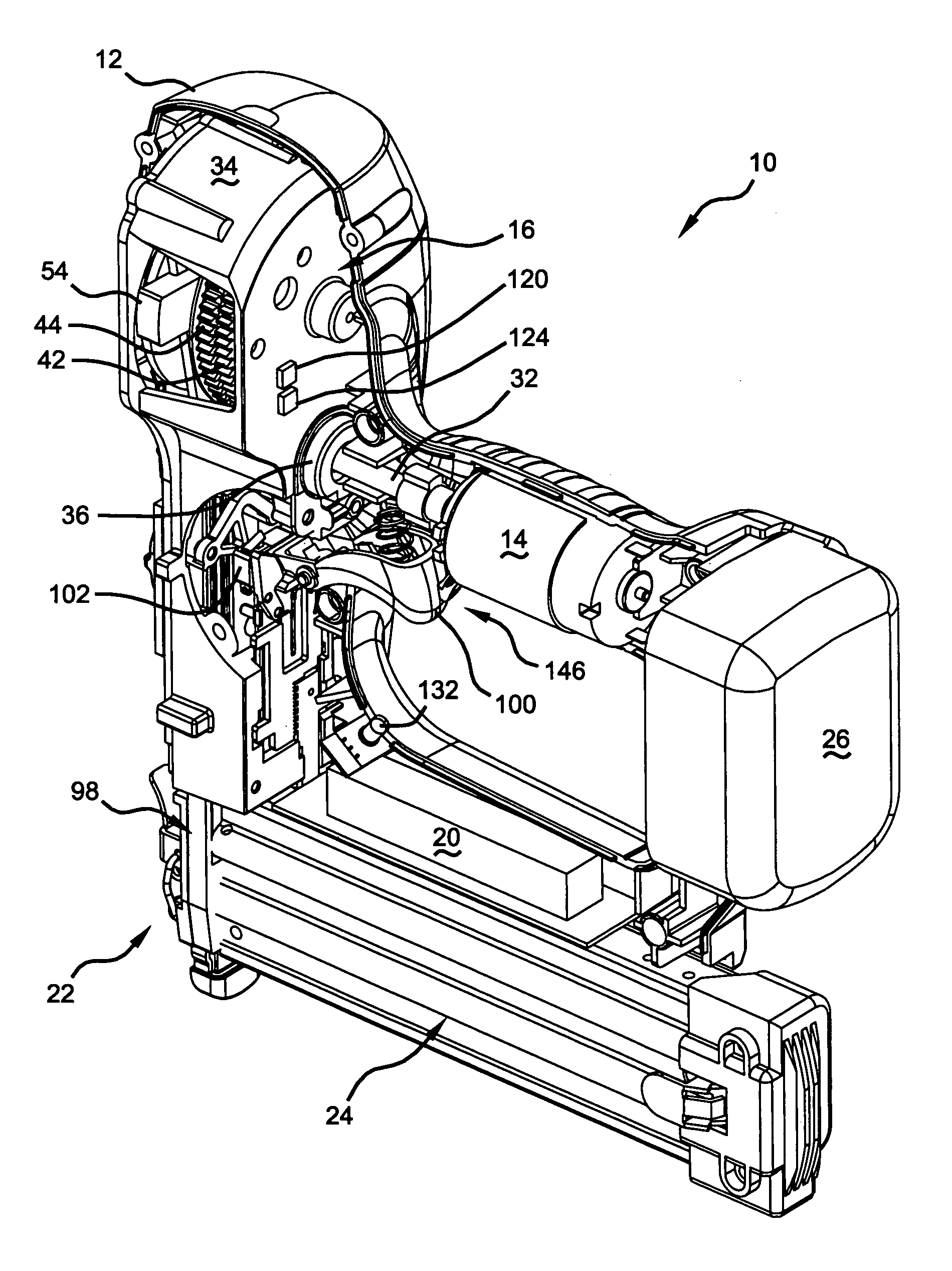

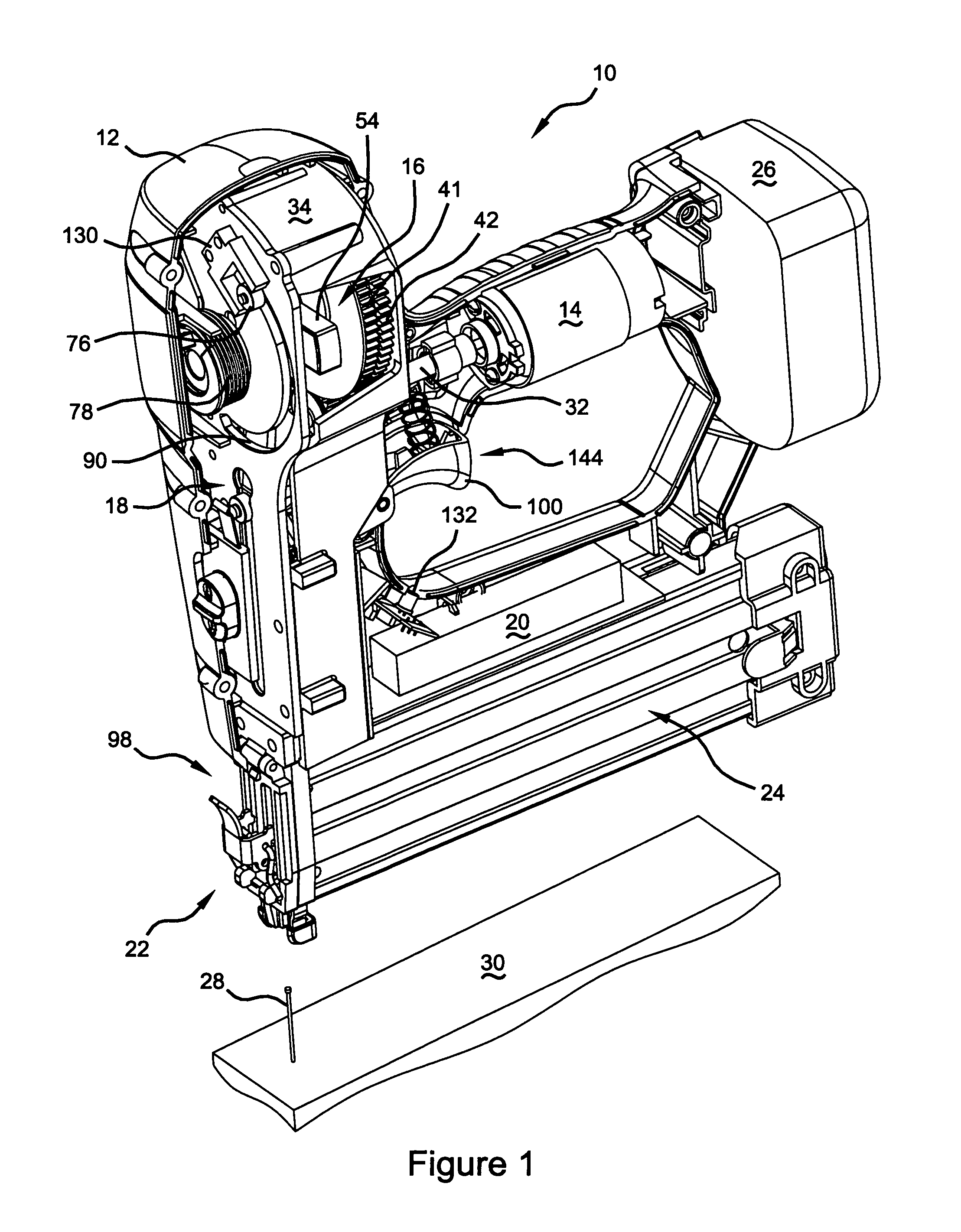

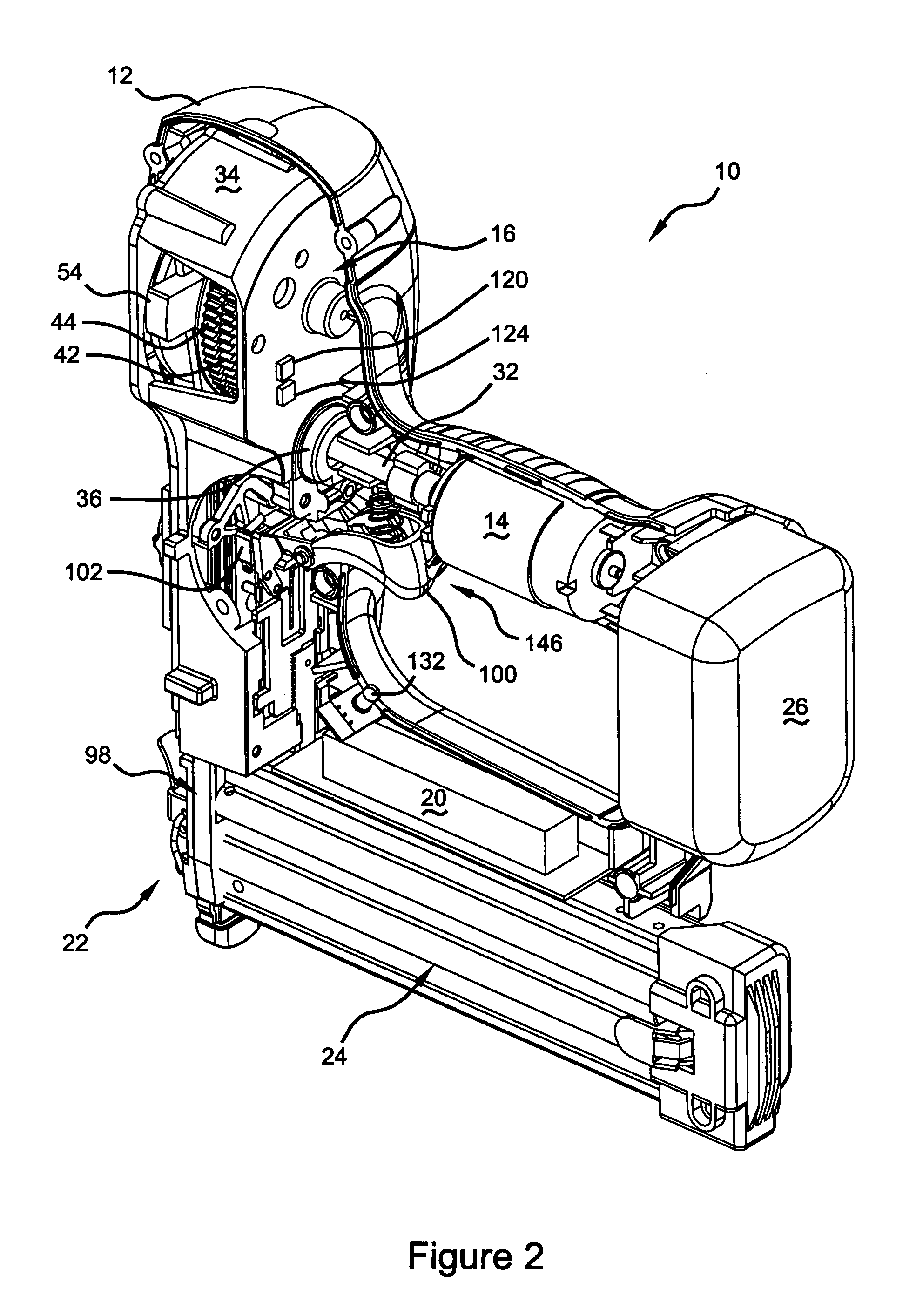

Electronic control of a cordless fastening tool

A fastening tool that drives a fastener into a work-piece. The tool includes a motor that is connected to a transmission. The transmission includes a flywheel. The tool also includes a driver mechanism that is adapted to drive the fastener into the work-piece. The flywheel is connected to the driver mechanism when the flywheel is in a flywheel firing position. The tool includes a control module that detects a flywheel position and compares the flywheel position to the flywheel firing position. The control module also adjusts the flywheel position based on the comparison. The control module ensures that the transmission has enough rotations to ensure that enough momentum can be generated to drive the fastener into the work-piece.

Owner:BLACK & DECKER INC

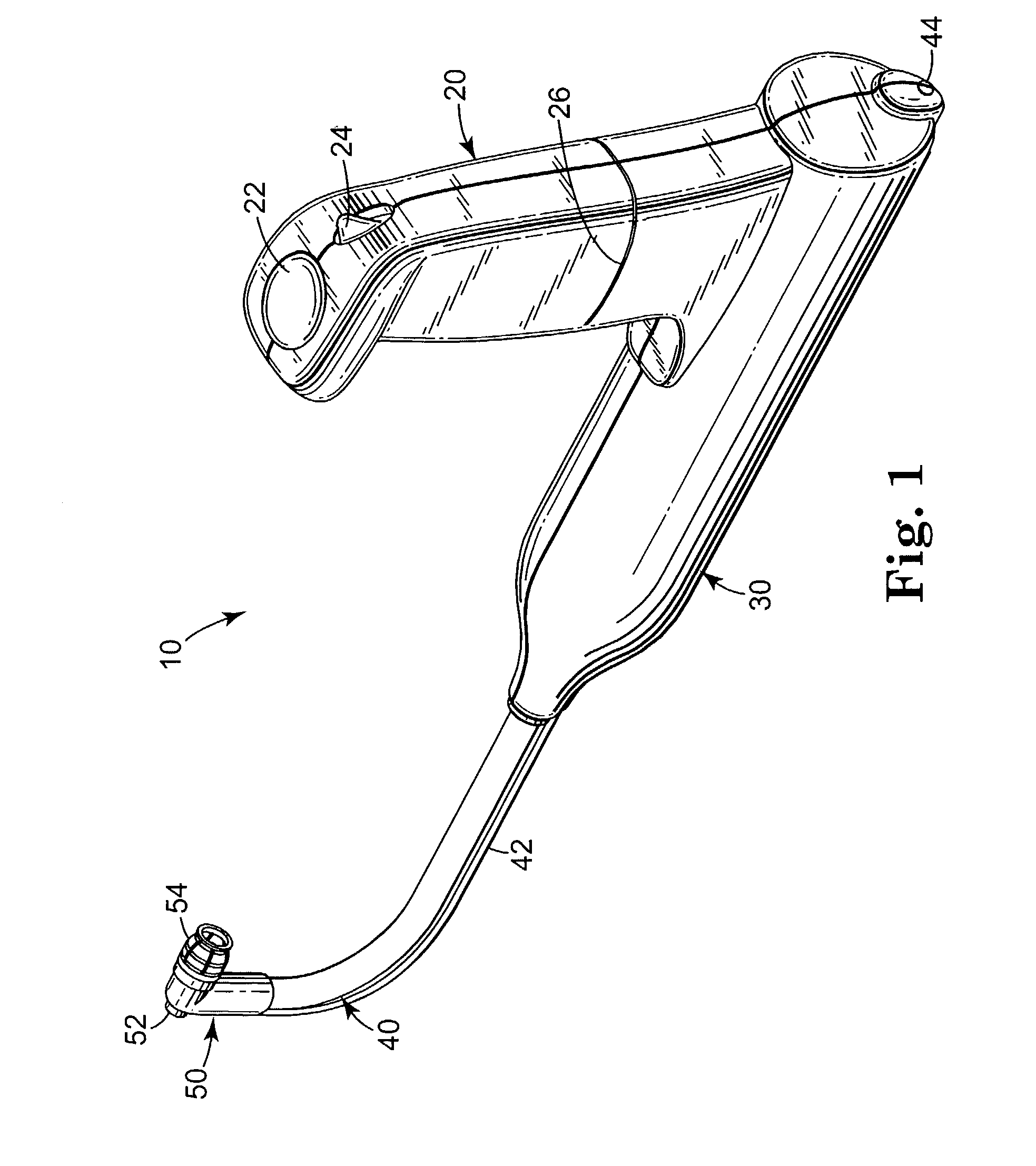

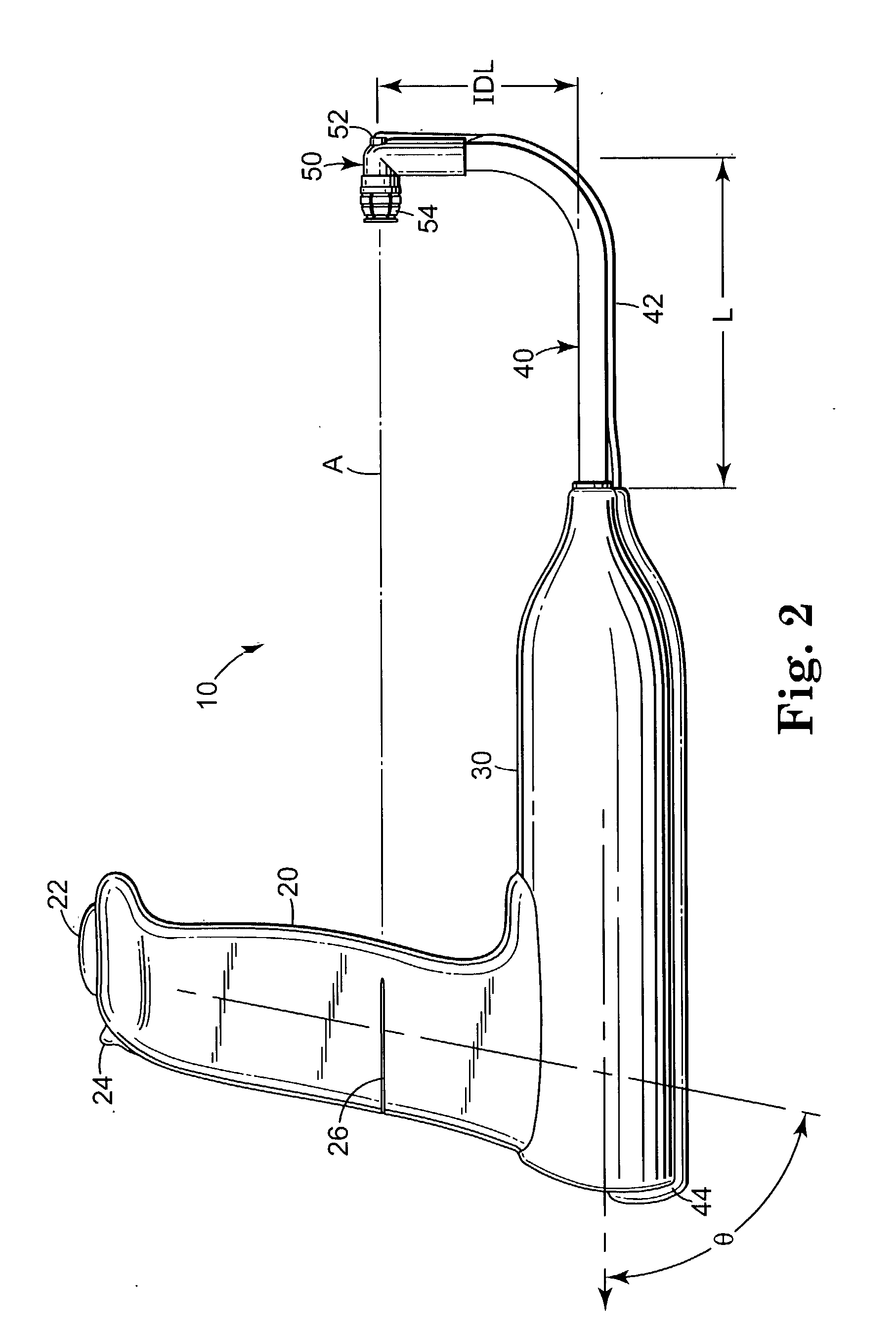

Bone anchor inserters and methods

InactiveUS20020183762A1Small sizeAvoid damageSuture equipmentsSpannersBiomedical engineeringBone Anchors

Bone anchor inserters are described. The inserters may be used in novel methods. Kits that include the novel inserters are also described.

Owner:AMS RES CORP

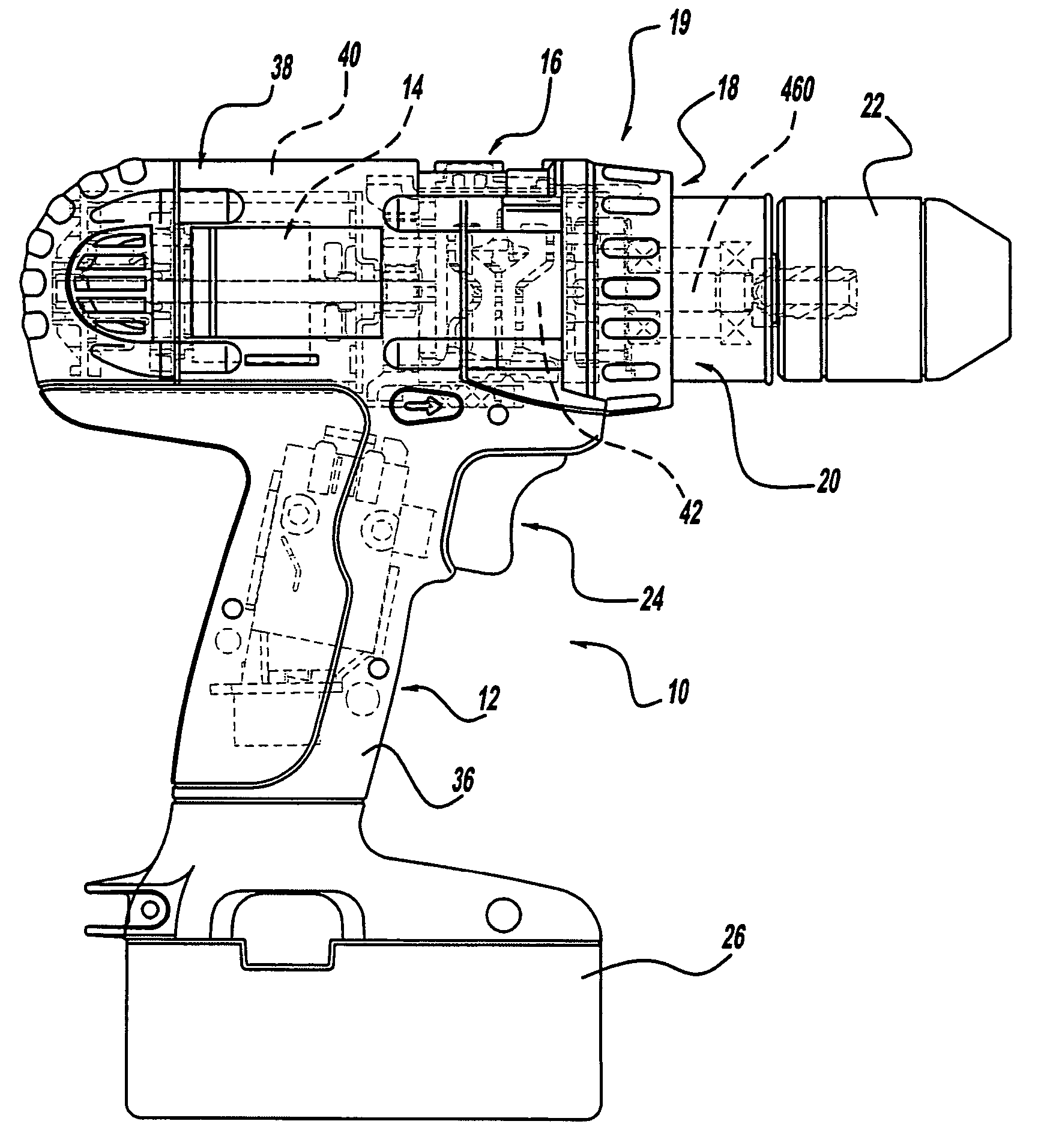

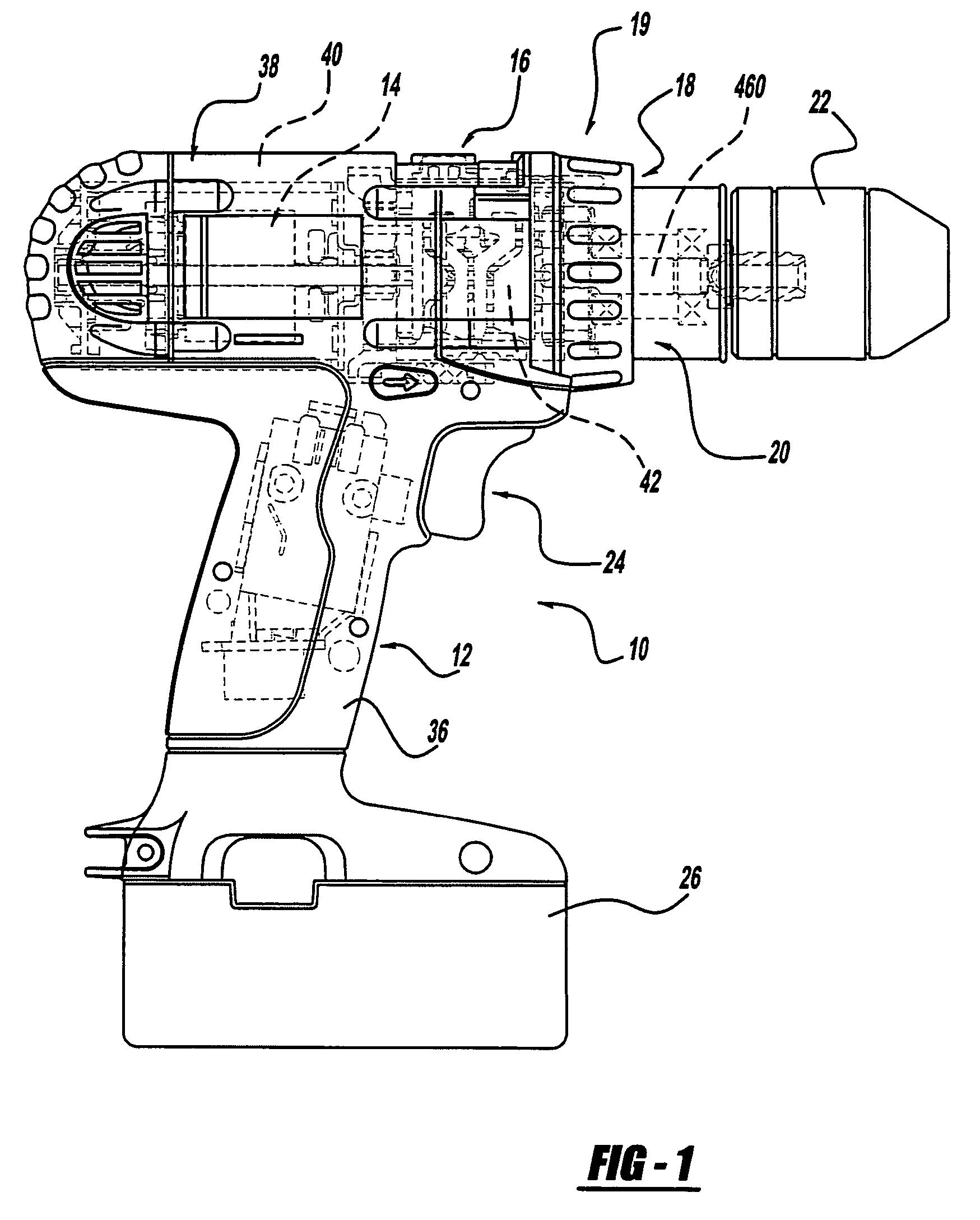

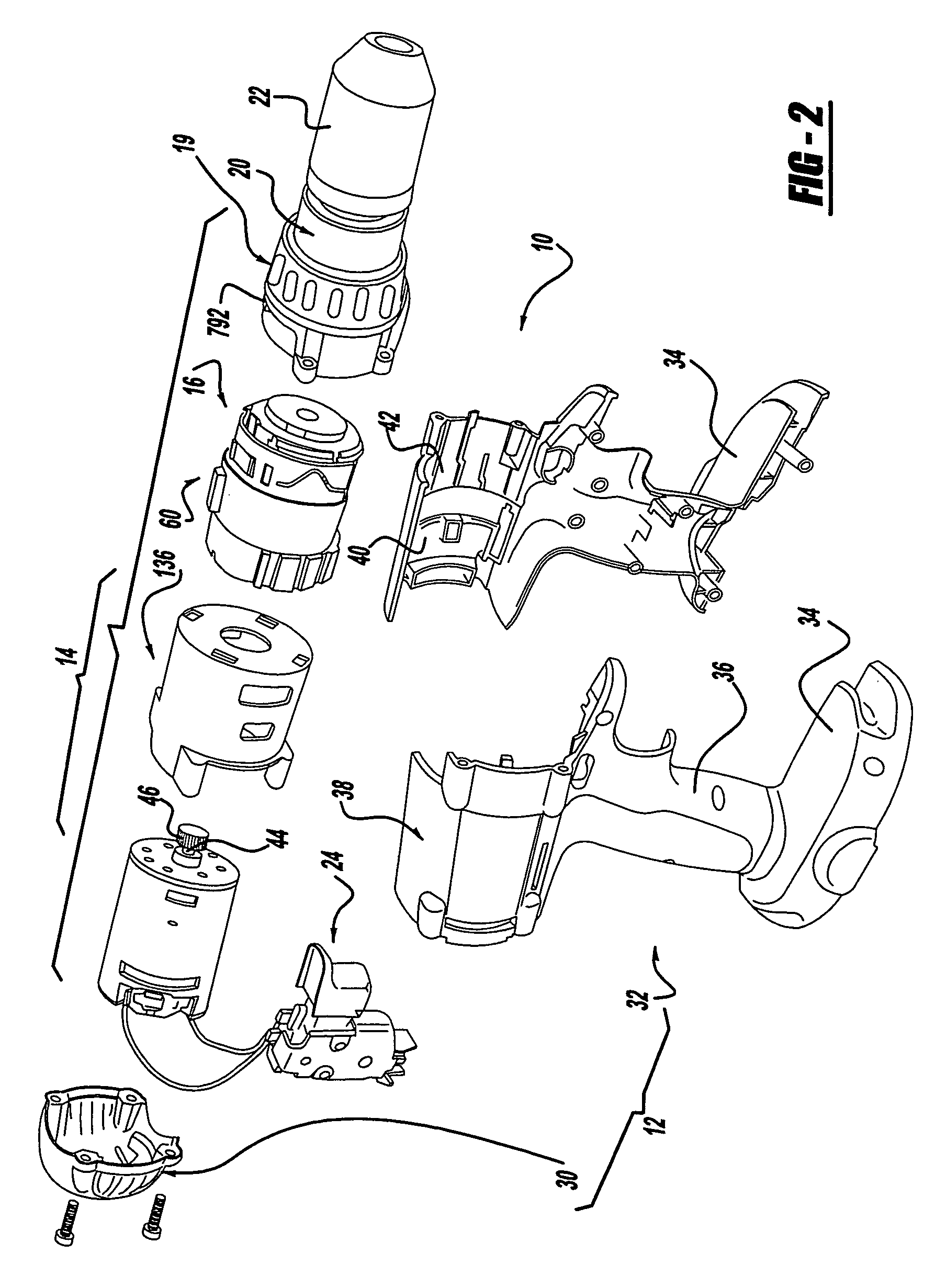

Powered surgical instrument having locking systems and a clutch mechanism

InactiveUS6257351B1Easy to mountEasy to removeDrilling rodsConstructionsLocking mechanismDrive shaft

A surgical instrument having a locking mechanism for preventing an output shaft of the surgical instrument from rotating and a further locking mechanism for mounting a battery pack to a distal end of a housing of the surgical instrument. The surgical instrument further includes a clutch mechanism for limiting the torque of a drive shaft of the surgical instrument. The locking mechanism for preventing the output shaft from rotating includes a locking switch which mates with a locking cap disposed on the output shaft. The locking mechanism for mounting the battery pack to the housing includes a groove at the distal end of the housing and a retaining ring which engages the groove when the battery pack is mounted on the housing. The clutch mechanism includes a clutch plate that interfaces with both the output shaft and the drive shaft and prevents failure of the motor shaft.

Owner:MICROAIRE SURGICAL INSTR

Impact tool

ActiveUS20120279736A1Shorten the timeIncrease production capacityReciprocating drilling machinesConstructionsEngineeringDriving mode

According to an aspect of the present invention, there is provided an impact tool including: a motor drivable in an intermittent driving mode; a hammer connected to the motor; an anvil to be struck by the hammer to thereby rotate / strike a tip tool; and a control unit that controls a rotation of the motor by switching a driving pulse supplied to the motor in accordance with a load applied onto the tip tool.

Owner:HITACHI KOKI CO LTD

Hammer drill with a mode changeover mechanism

Owner:BLACK & DECKER INC

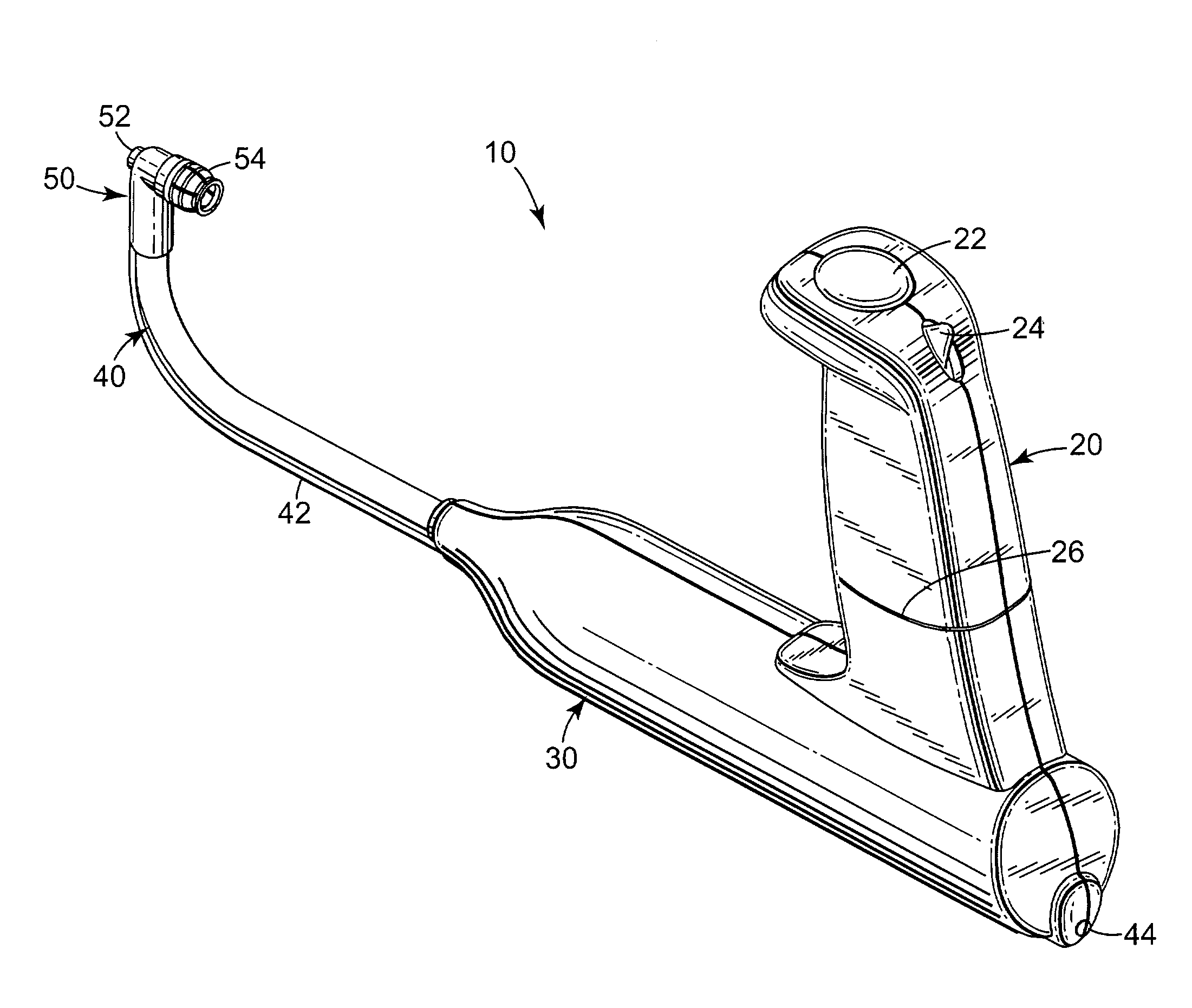

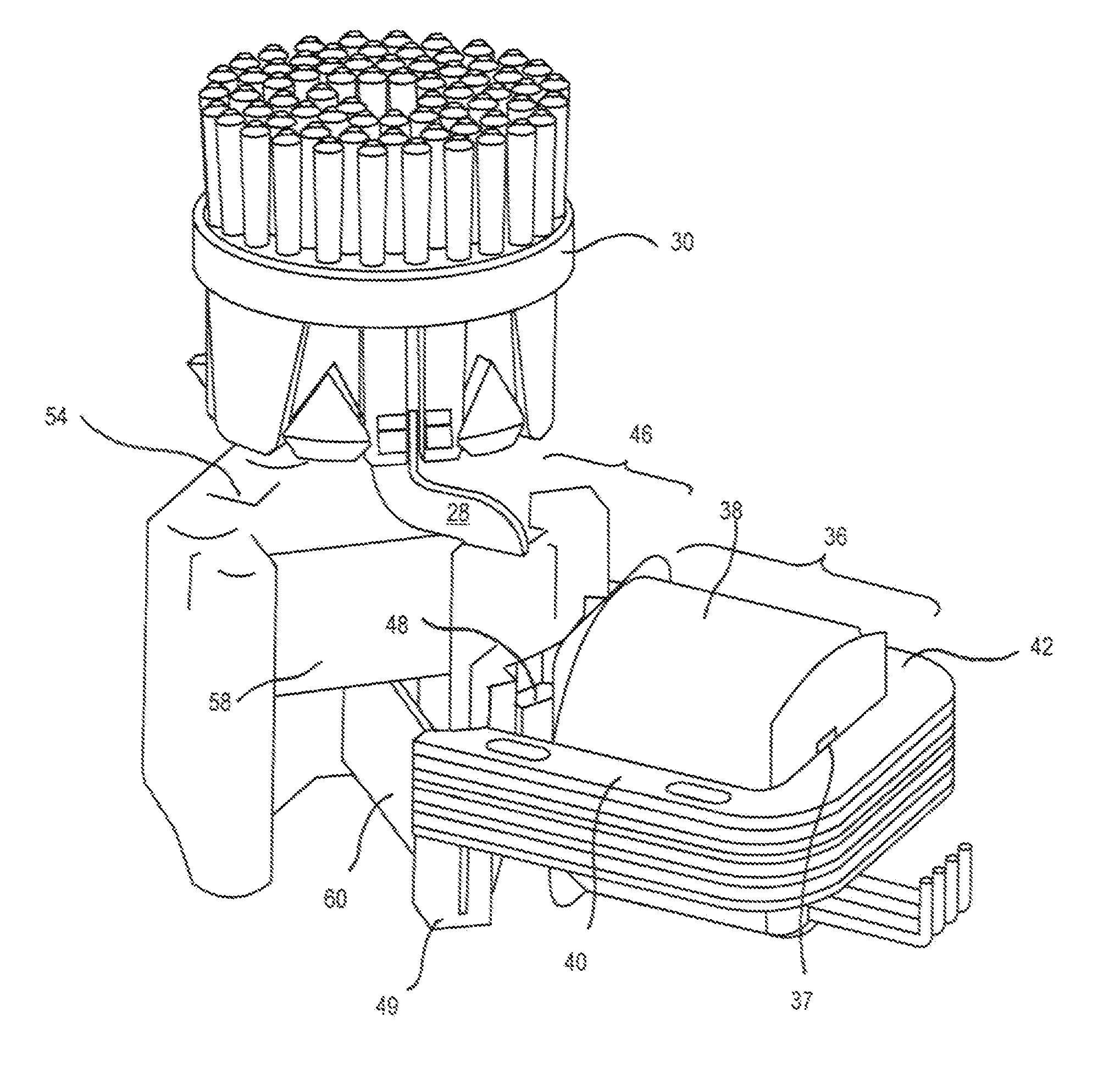

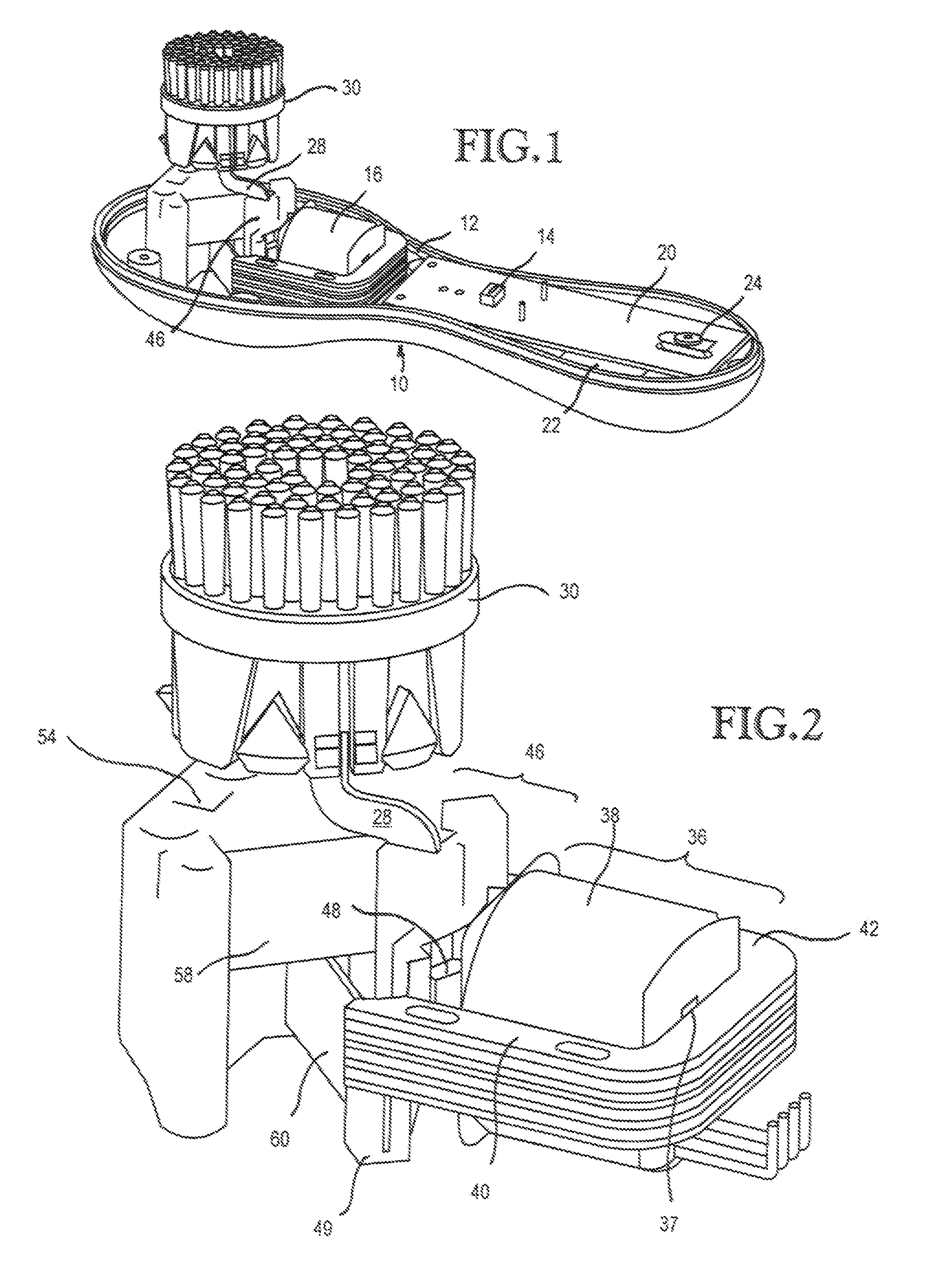

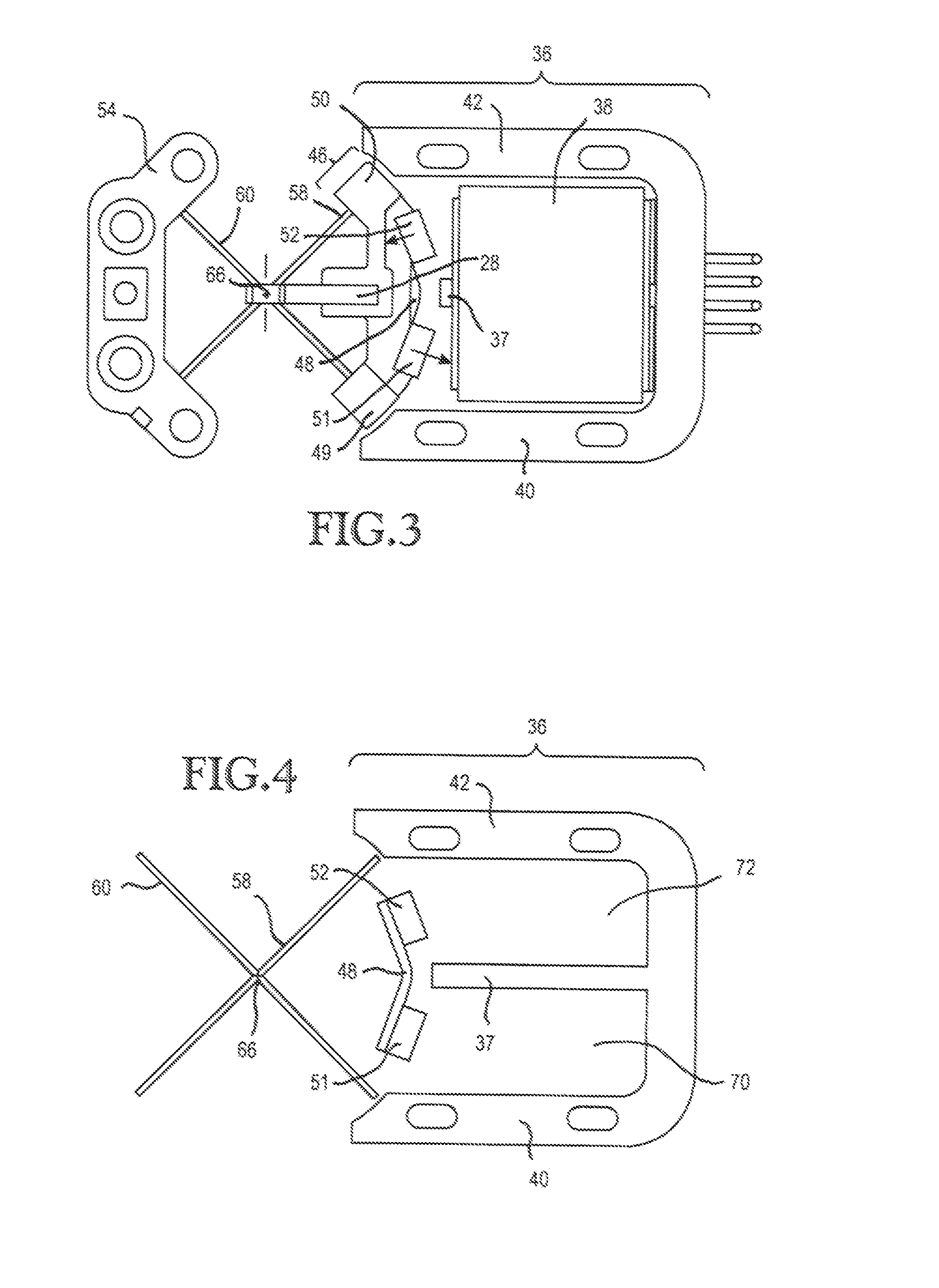

Oscillating motor for a personal care appliance

The motor includes an E-core stator assembly with a source of alternating current and an armature portion mounted to be responsive to the stator to oscillate back and forth through an arc portion of the personal care appliance and flexure elements are connected between the armature and the mounting member, the flexure elements crossing each other, wherein the crossing point defines a pivot point about which the armature rotates. A workpiece assembly, which includes a mounting arm, is configured so that a skin brush mounted on a free end of the mounting arm has an axis of rotation about the pivot point.

Owner:LOREAL SA

Powered tacker instrument

ActiveUS20080281353A1Prevent rotationActuation can be preventedStaplesLigamentsSurgical departmentBiomedical engineering

There is provided a powered tacker device for use in installing multiple surgical fasteners through a prosthetic mesh in into tissue. The powered tacker device generally includes a handle assembly and a tacker assembly extending distally from handle assembly. The handle assembly includes a motor and self-contained power assembly to rotate the surgical fasteners into tissue. The handle assembly is provided with a drive assembly which allows for rotation, as well as distal longitudinal movement, of a surgical fastener relative to the powered tacker device. The tacker assembly includes an inner tube for containing the plurality of surgical fasteners and a driver which is movable out of alignment with the inner tube so as to install a single fastener at a time into tissue.

Owner:TYCO HEALTHCARE GRP LP

Power tool control system

InactiveUS20060076385A1Quality improvementWell formedStapling toolsDrilling/boring measurement devicesUser needsGraphics

A power tool control system allows a user to operate a power tool through a graphical user interface communicatively coupled with a non-contact measurement and alignment device. The graphical user interface correlates user engageable selectors with a logically related menu of power tool setting options displayed on a display screen in a high quality and easily readable format. The non-contact measurement and alignment device uses one or more lasers to determine power tool settings and establish proper alignment based on user needs. The power tool control system further enables stud detection and visual indication of stud location.

Owner:BLACK & DECKER INC

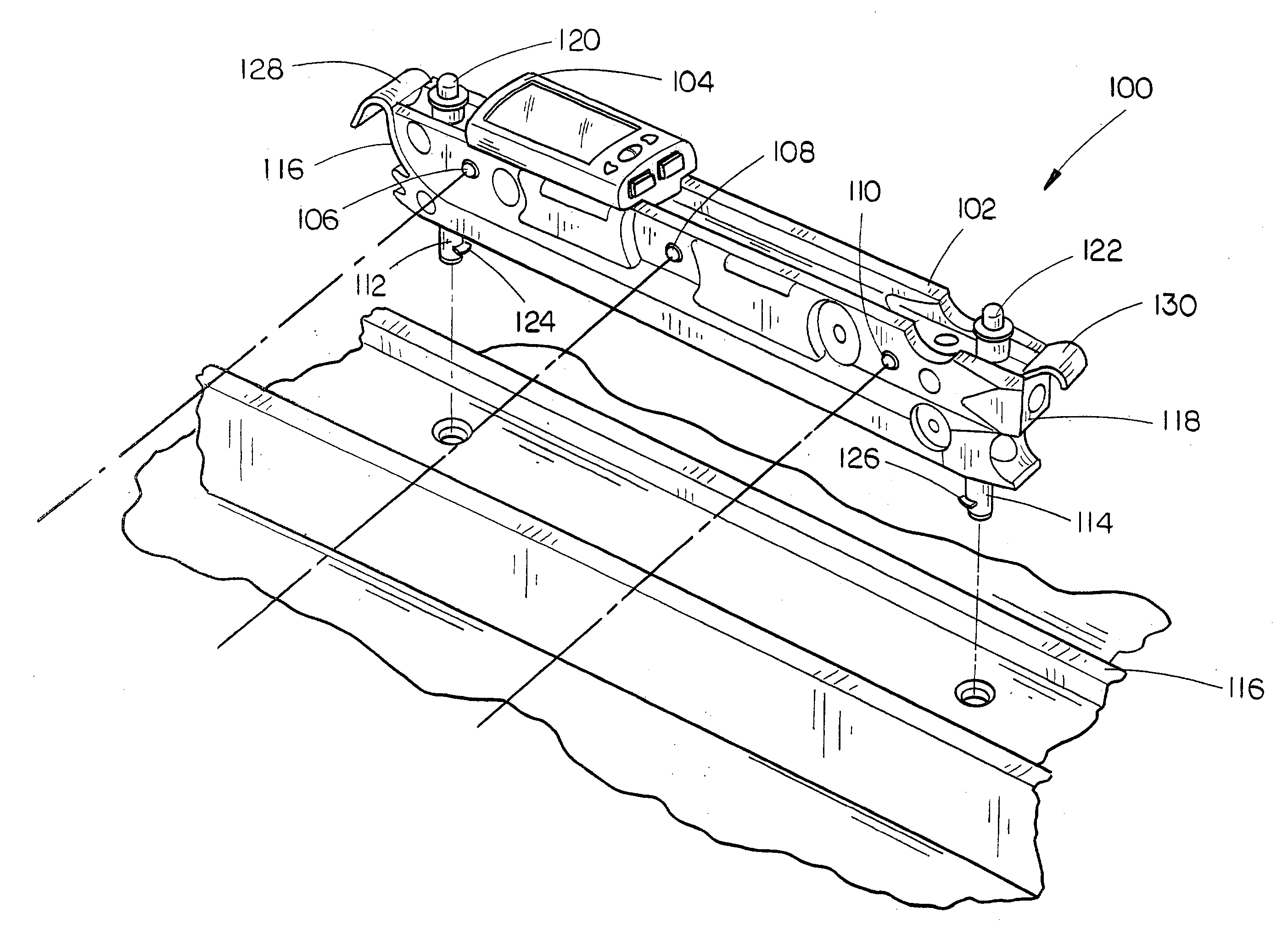

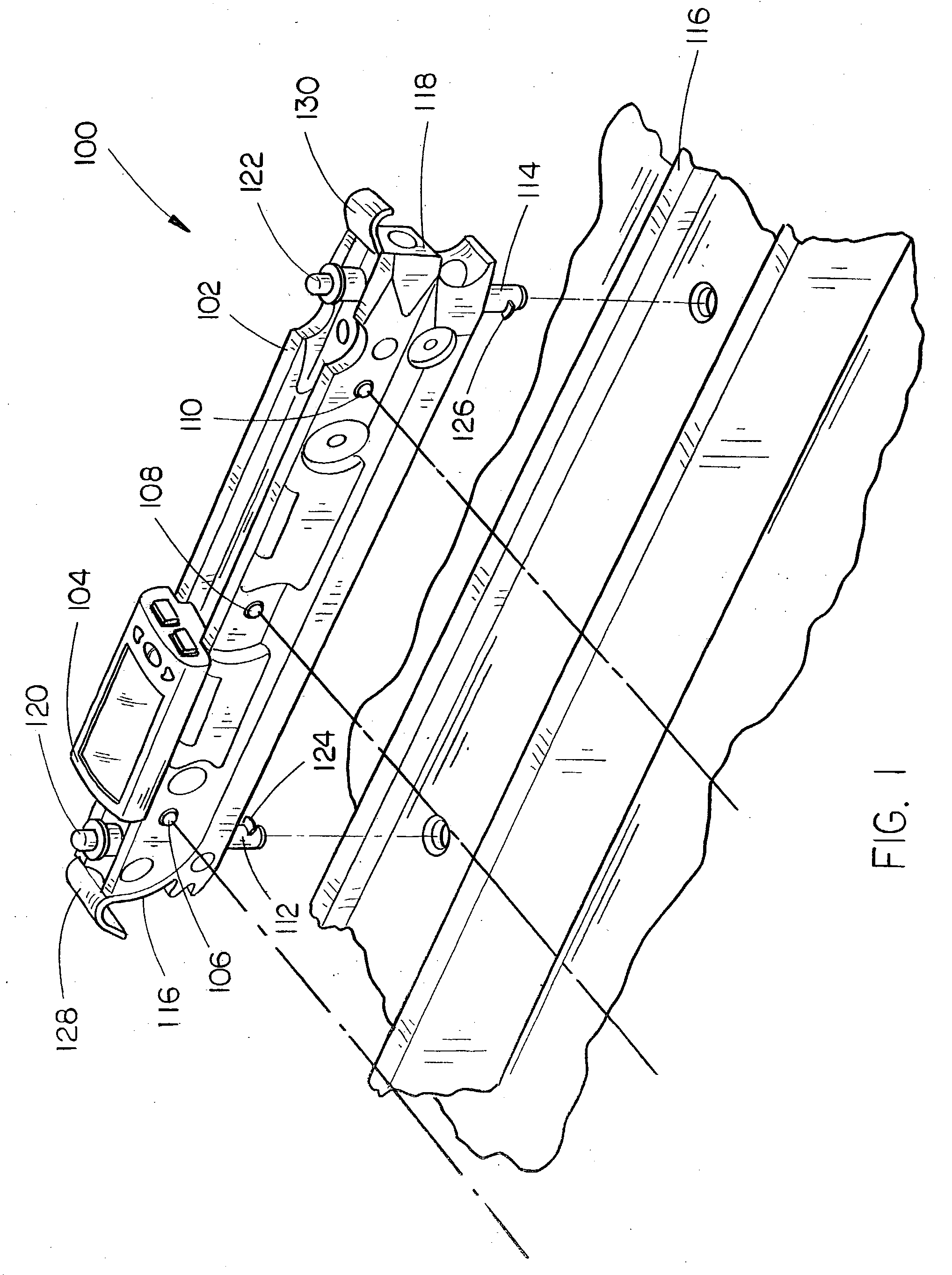

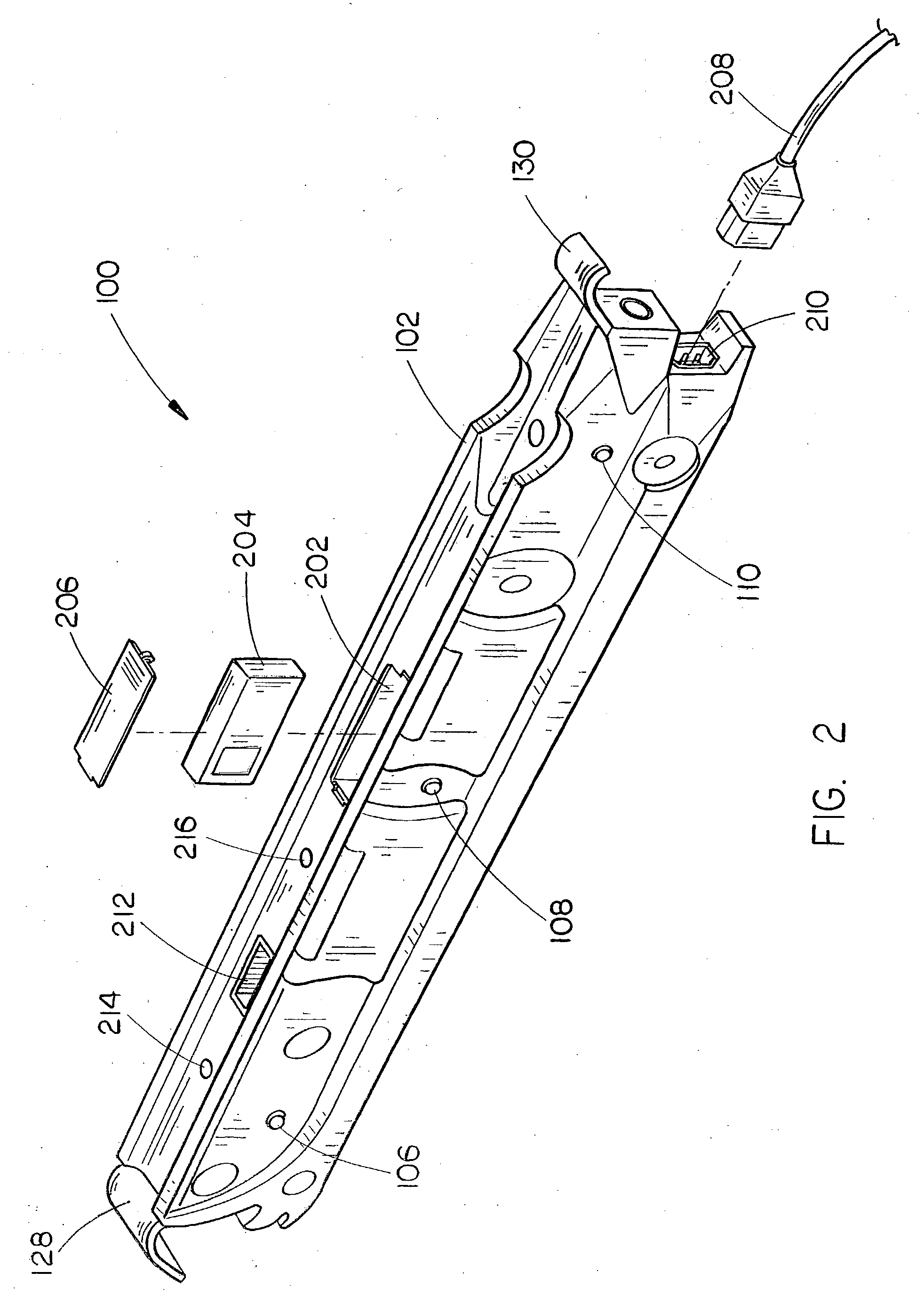

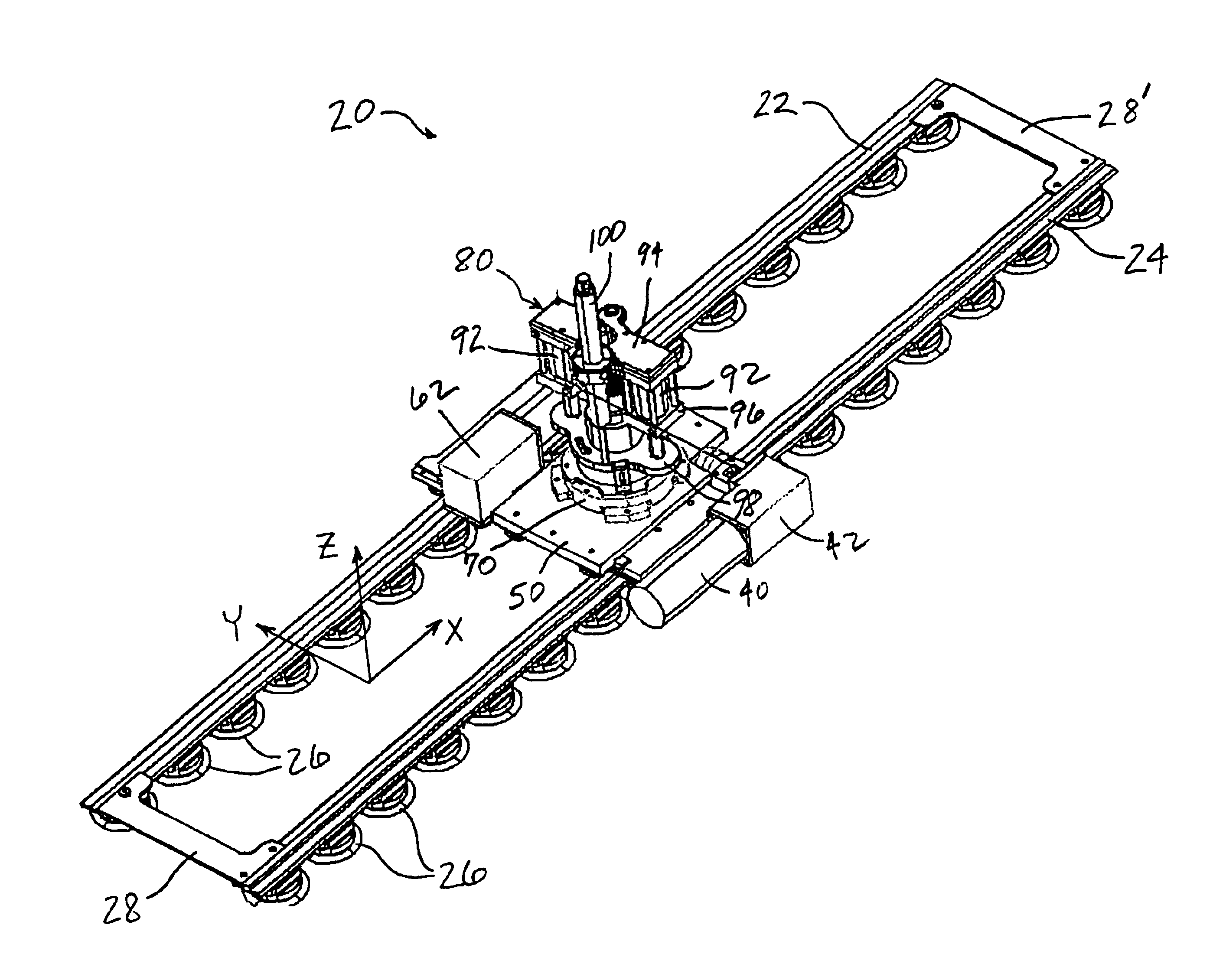

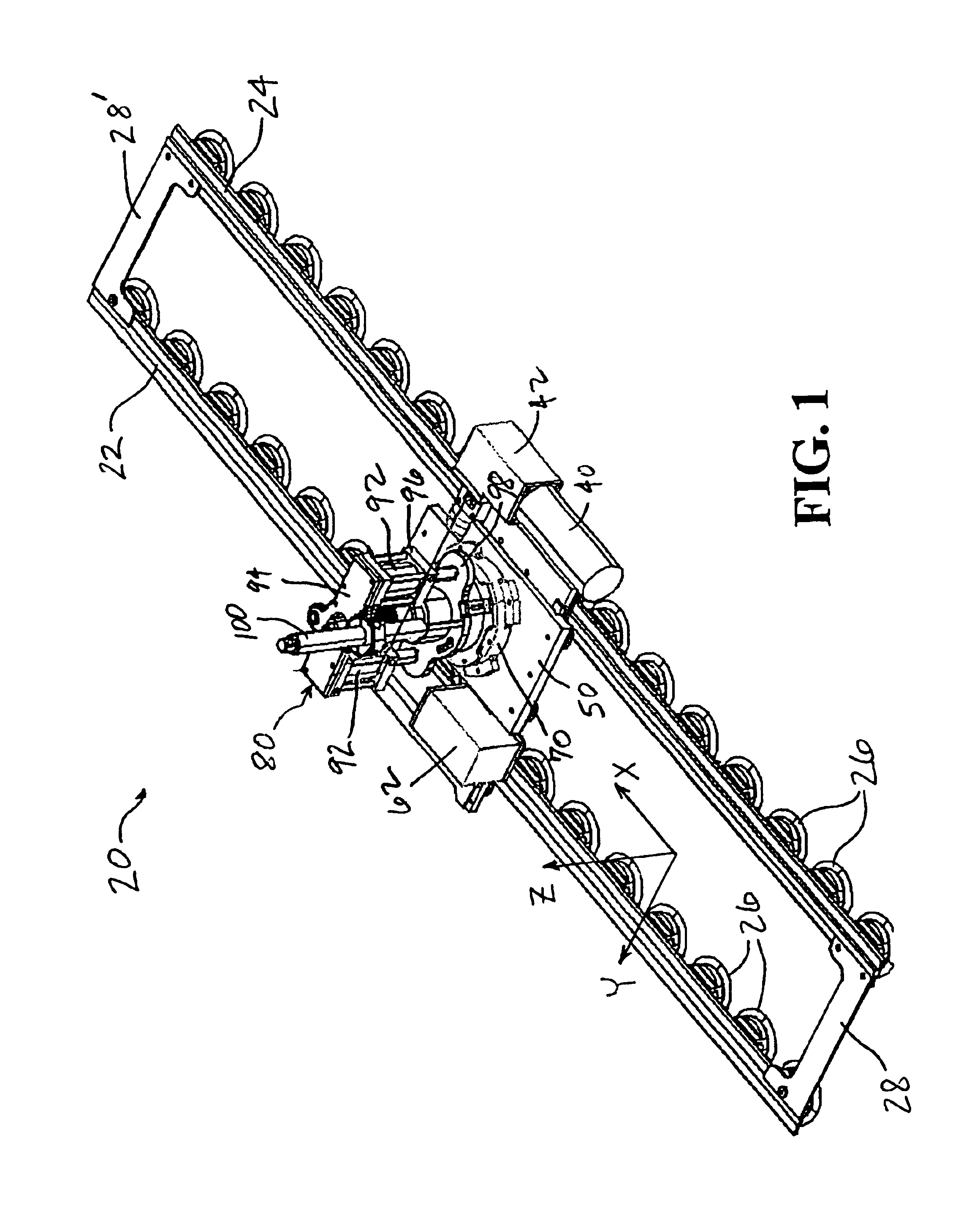

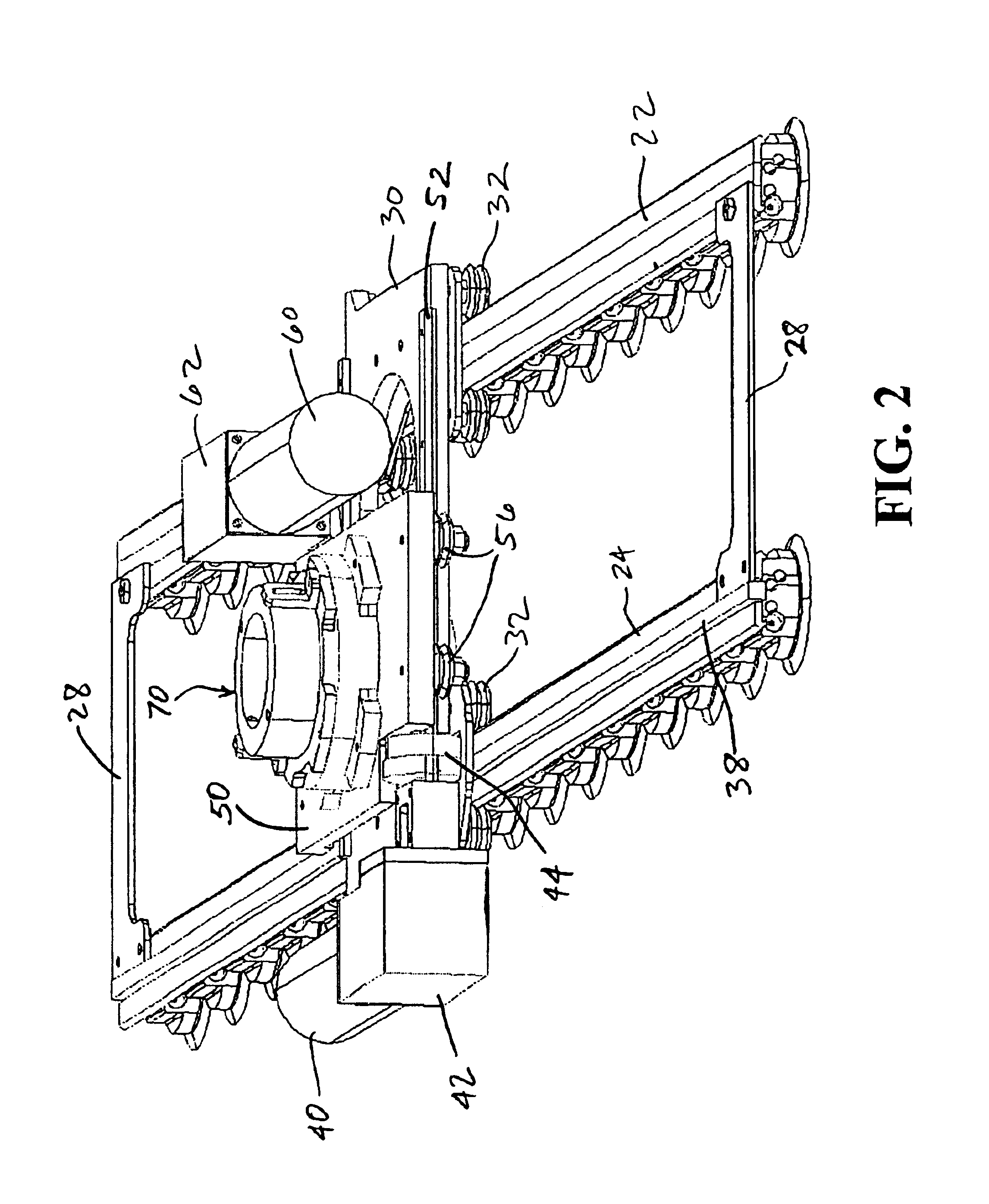

Flexible track drilling machine

InactiveUS6843328B2Prevent movementLower pre-loading forcesProgramme controlDrilling rodsEngineeringThree dimensional surface

A flexible track drilling machine employs a pair of rails that are flexible in one direction to conform to a non-flat workpiece surface and are substantially stiff in a direction parallel to the workpiece surface. The rails are attached to the workpiece by vacuum cups spaced along each rail. An X-axis carriage is slidably mounted on the rails by rollers mounted on flexible spring plates affixed to the carriage. A drill or other device to be positioned is mounted on a Y-axis carriage that is slidably connected to the X-axis carriage. The three-dimensional surface of the workpiece is mathematically transformed into a two-dimensional flat pattern, and the positioning of the carriages is controlled based on the flat pattern.

Owner:THE BOEING CO

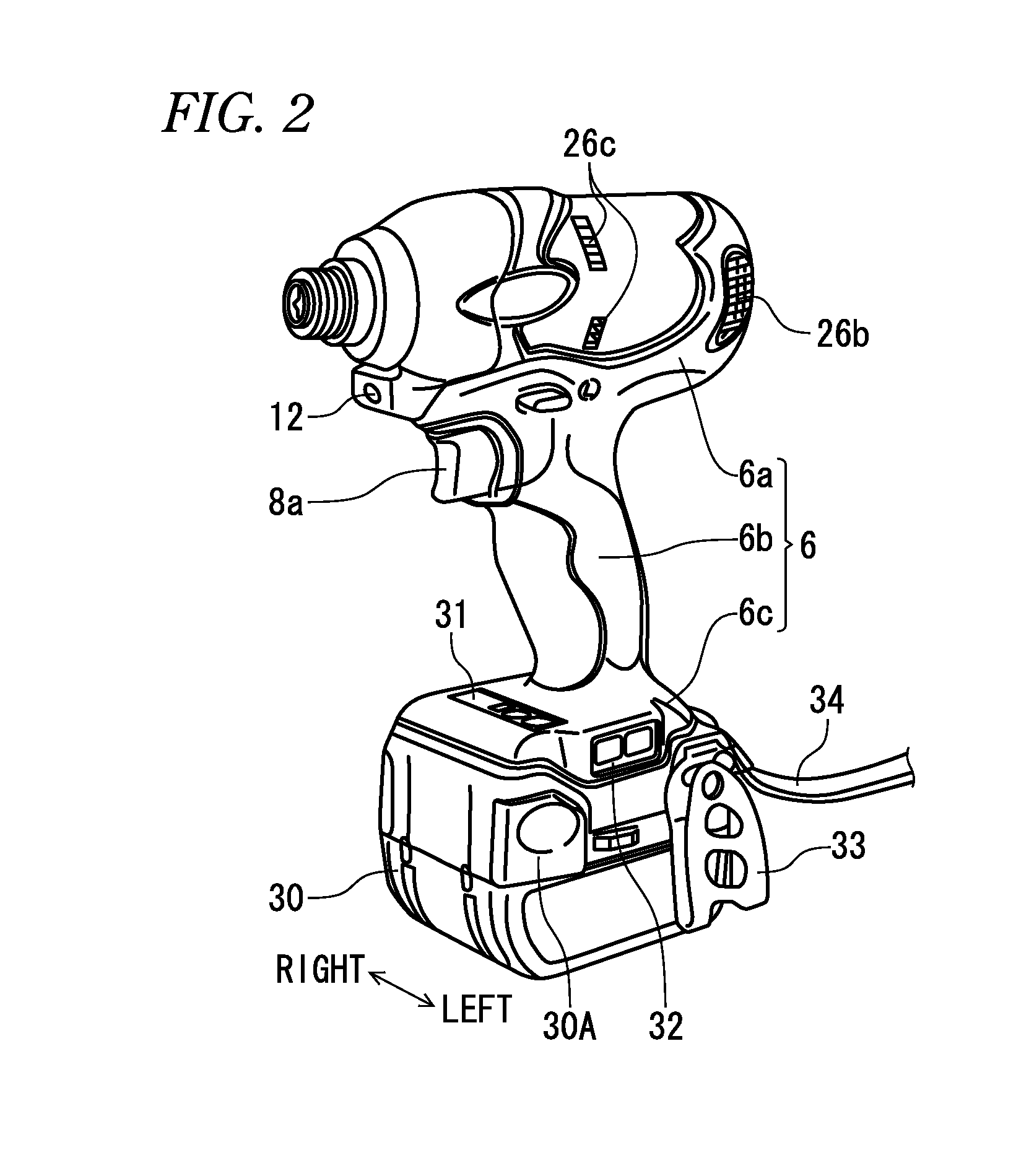

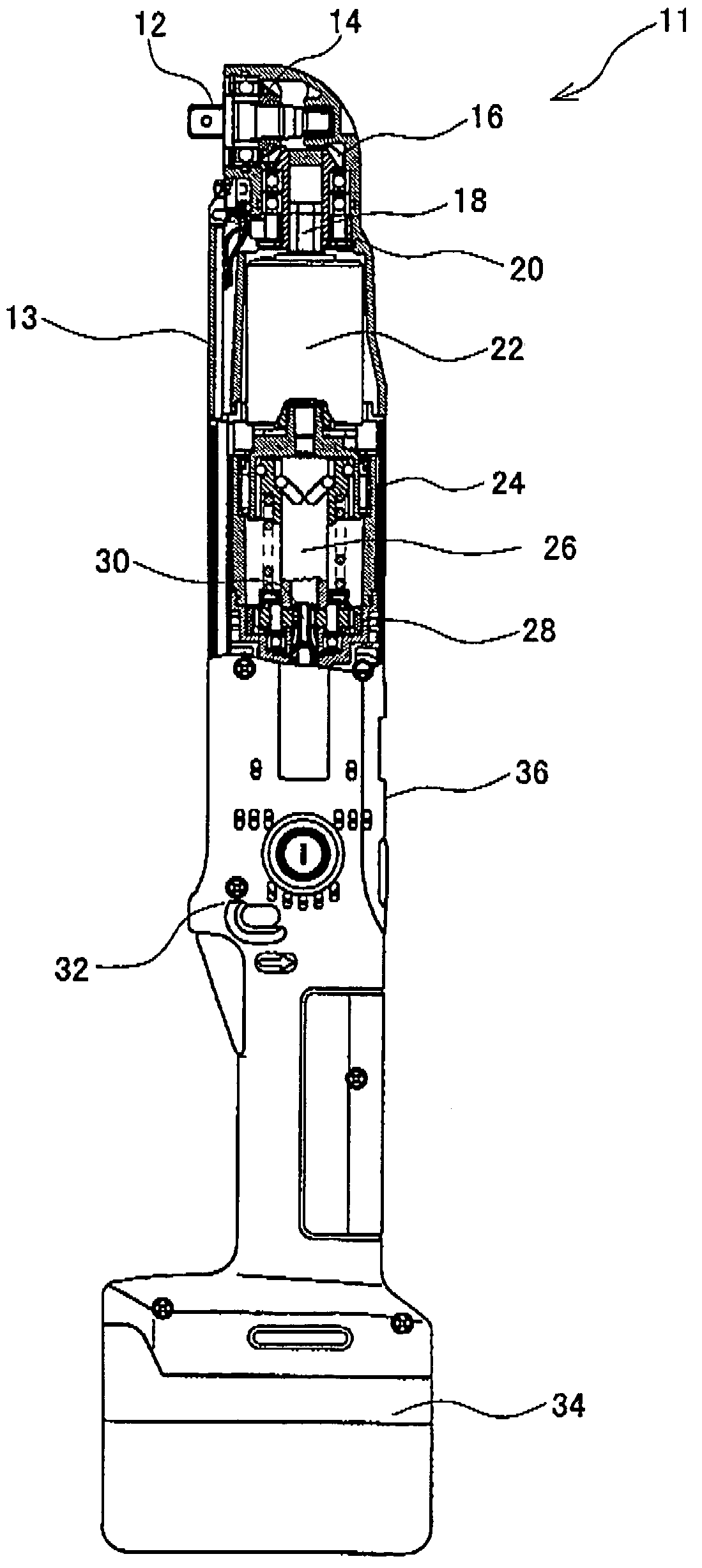

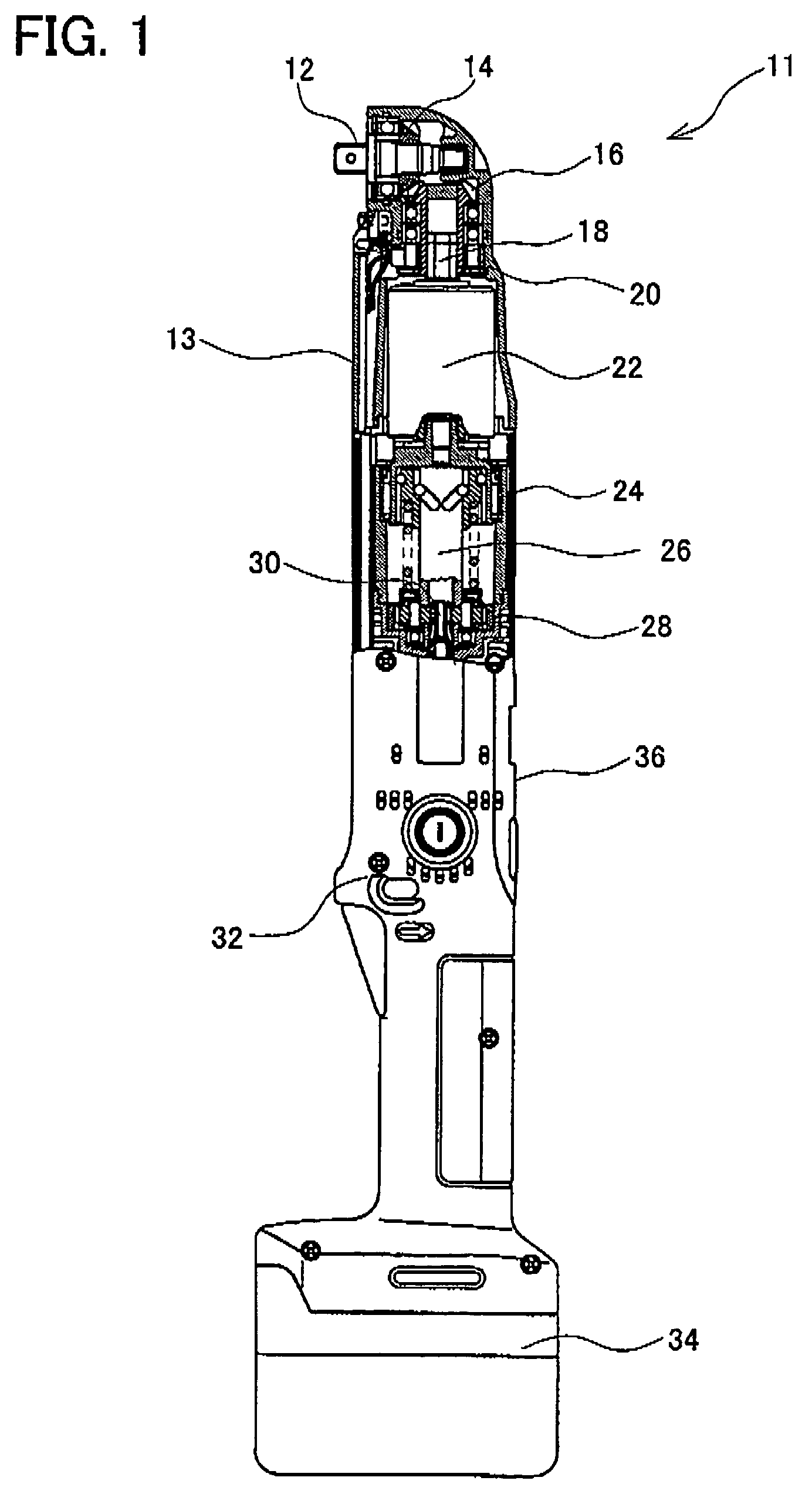

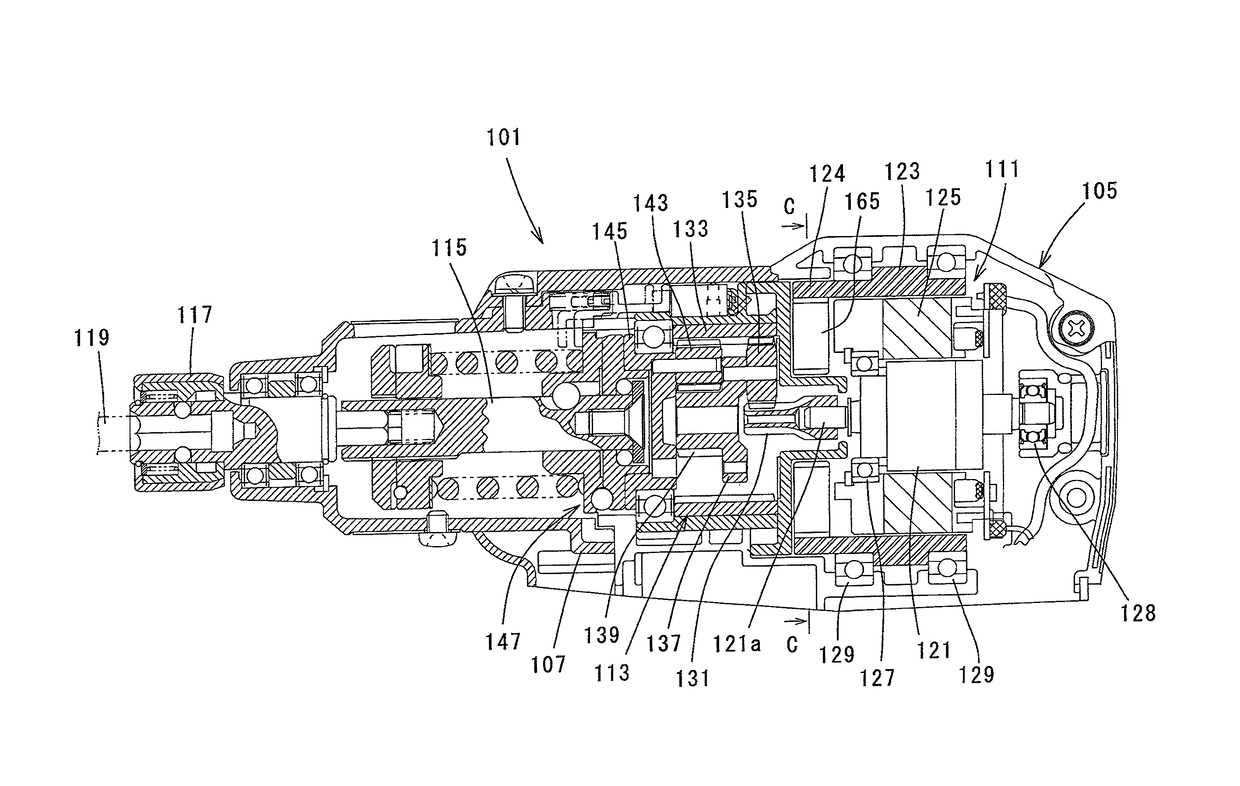

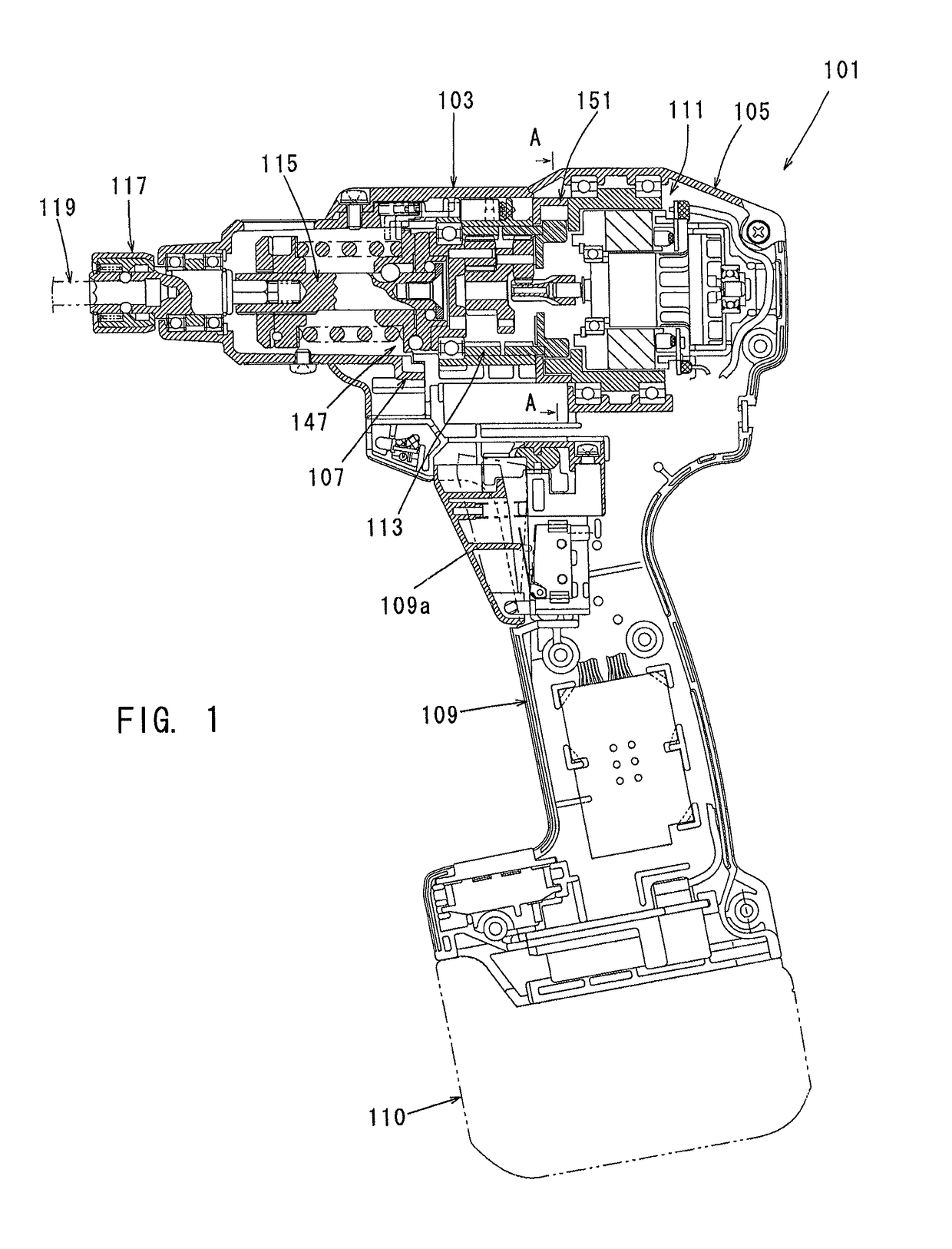

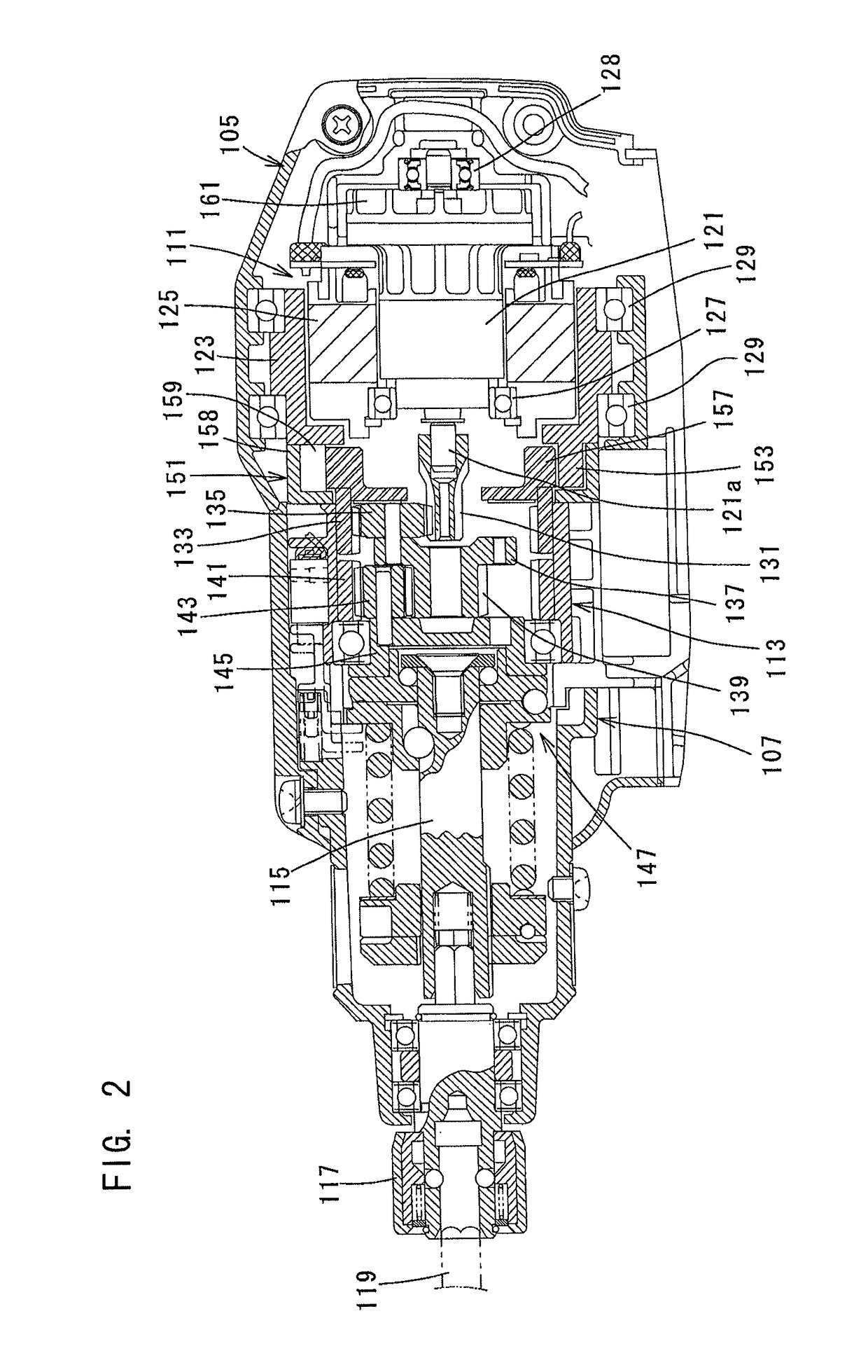

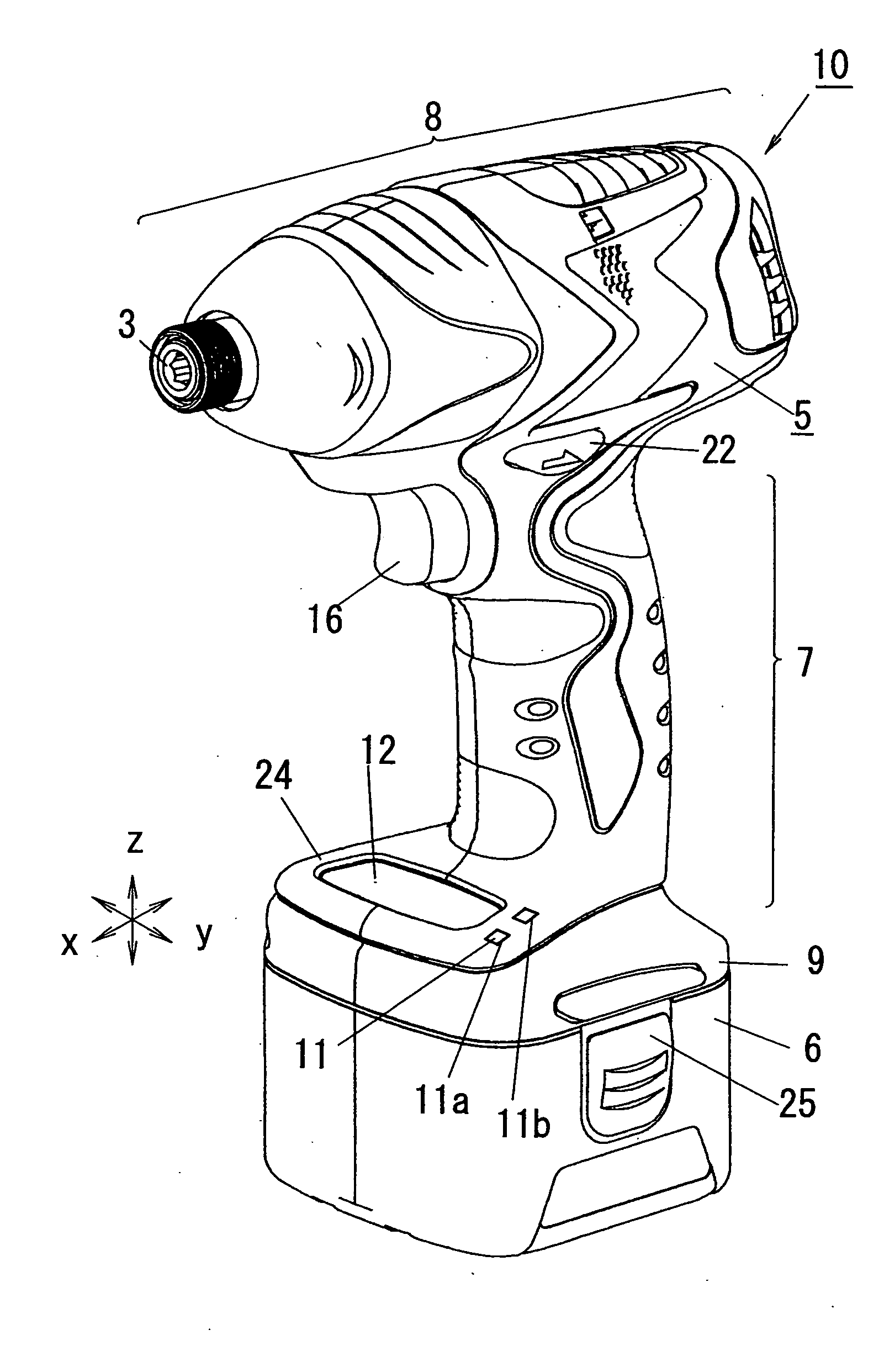

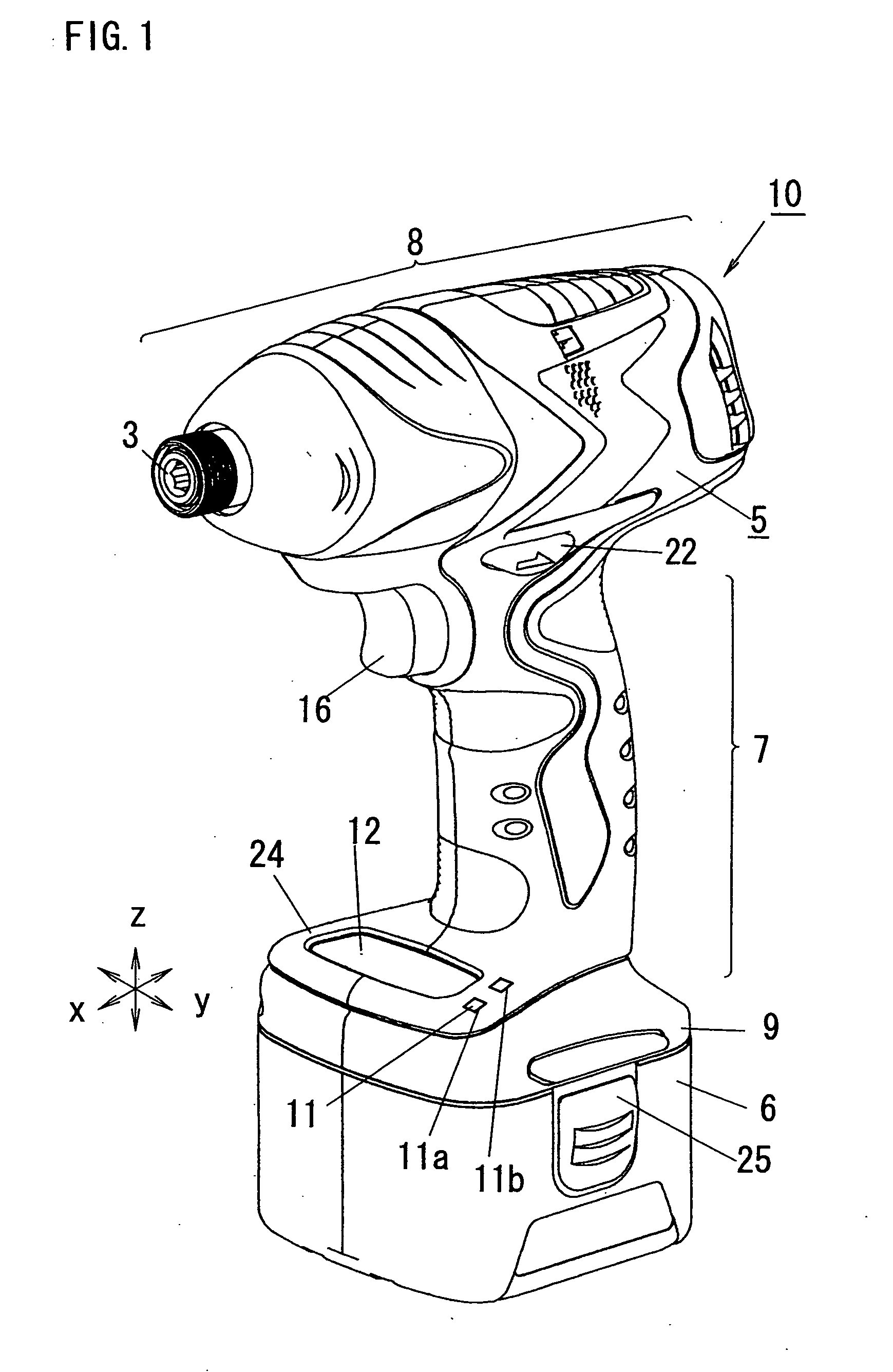

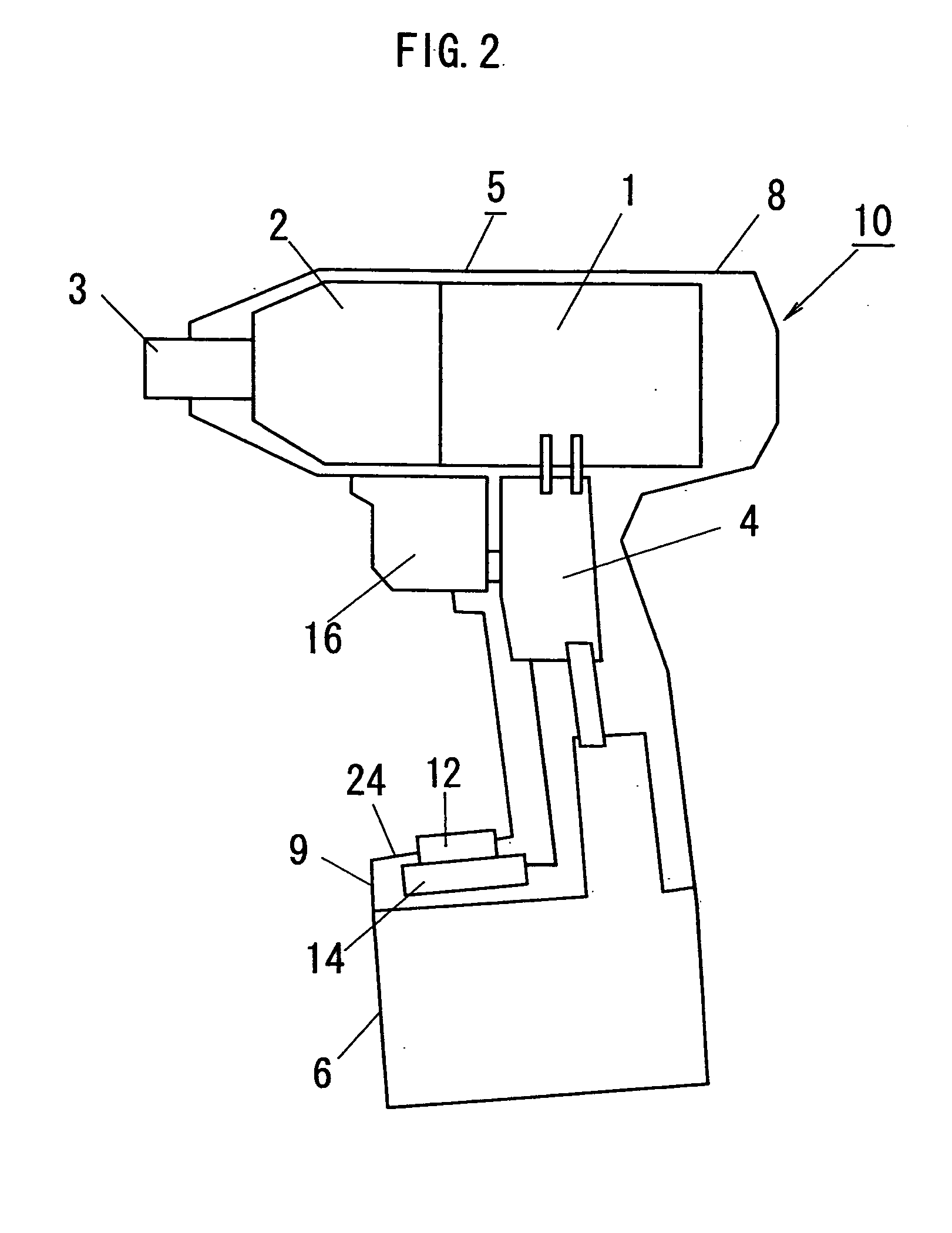

Transportable power tool

InactiveUS20050121209A1Low costEasy to useDrilling rodsConstructionsMaximum dimensionReduction drive

A transportable power tool such as an impact driver has a power unit in which a motor and a reducer-transmitter are contained, a grip and a coupler unit with which a battery pack is coupled. Maximum dimensions of the power unit and maximum dimensions of the battery pack in a direction perpendicular to both of center axes of the power unit and the grip and in a direction parallel to the center axis of the power unit are larger than those of the grip in the same directions. Operation members used for selecting an operation mode of the motor and a display device are provided at positions near to the grip from a line binding contacting portions of the power unit and the battery pack when the power unit and the battery pack are simultaneously contacted with the same plane in each state.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com