Patents

Literature

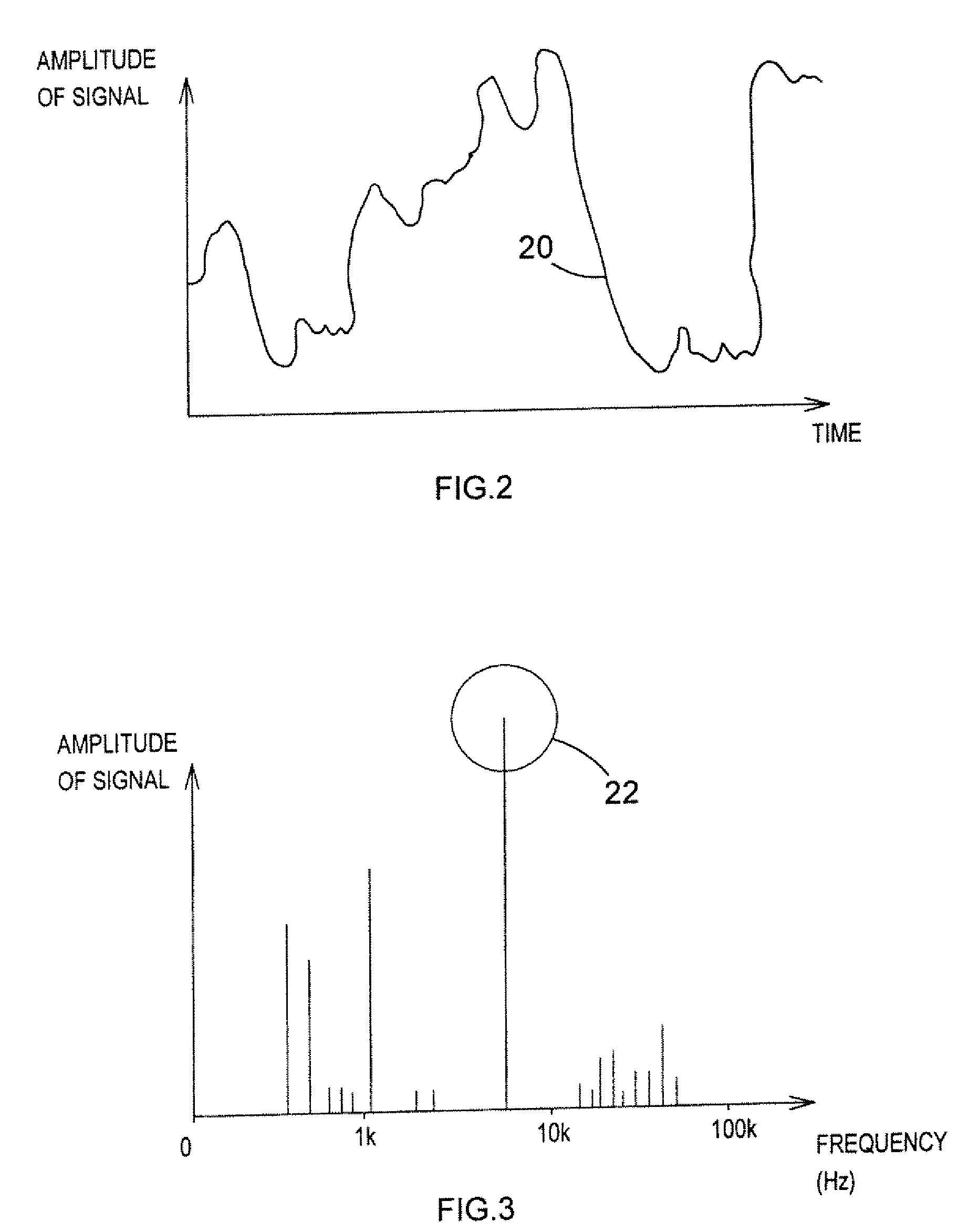

525 results about "Hammer drill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hammer drill, also known as a percussion drill or impact drill, is a power tool used chiefly for drilling in hard materials. It is a type of rotary drill with an impact mechanism that generates a hammering motion. The percussive mechanism provides a rapid succession of short hammer thrusts to pulverize the material to be bored, so as to provide quicker drilling with less effort. If a hammer drill's impact mechanism can be turned off, the tool can be used like a conventional drill to also perform tasks such as screwdriving.

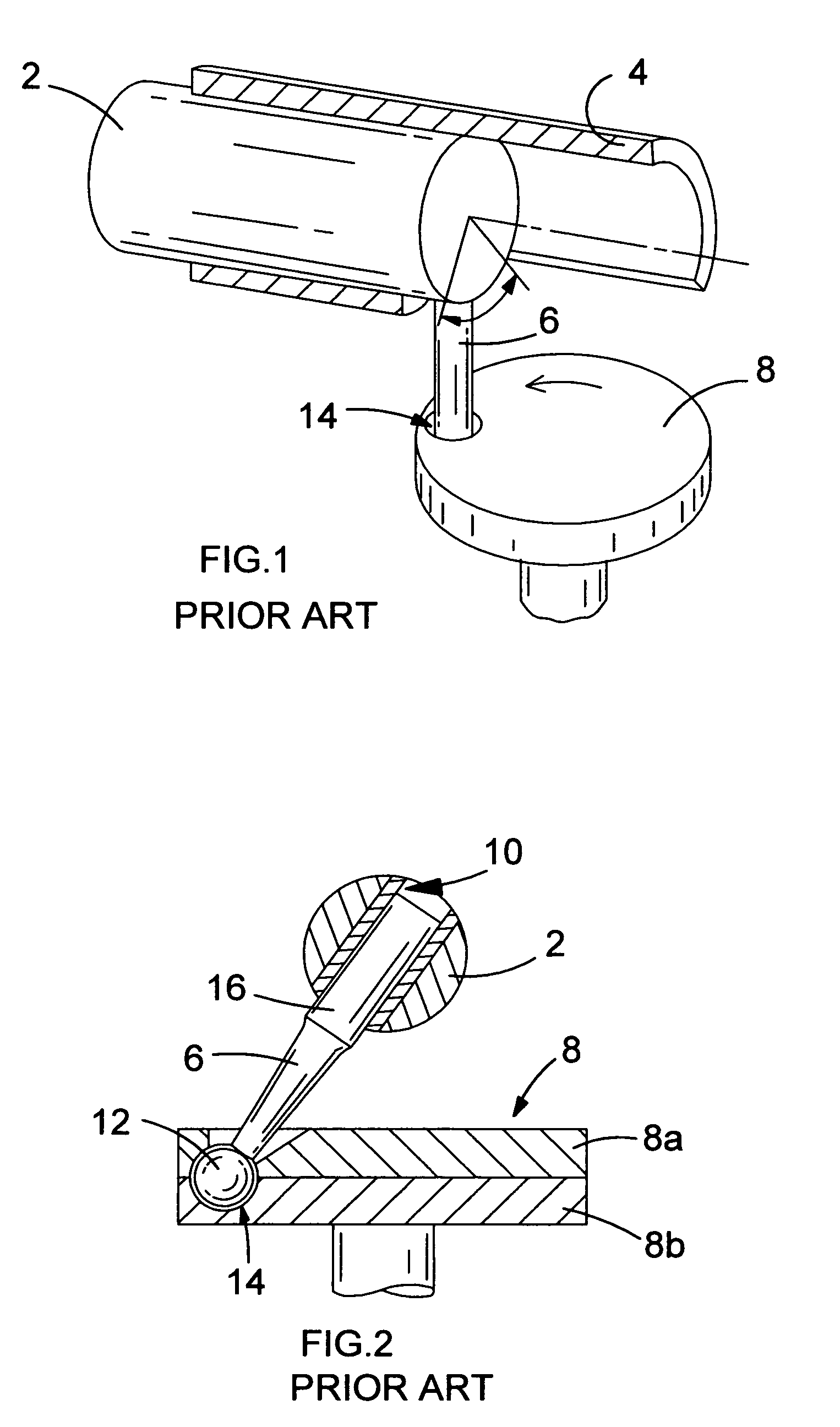

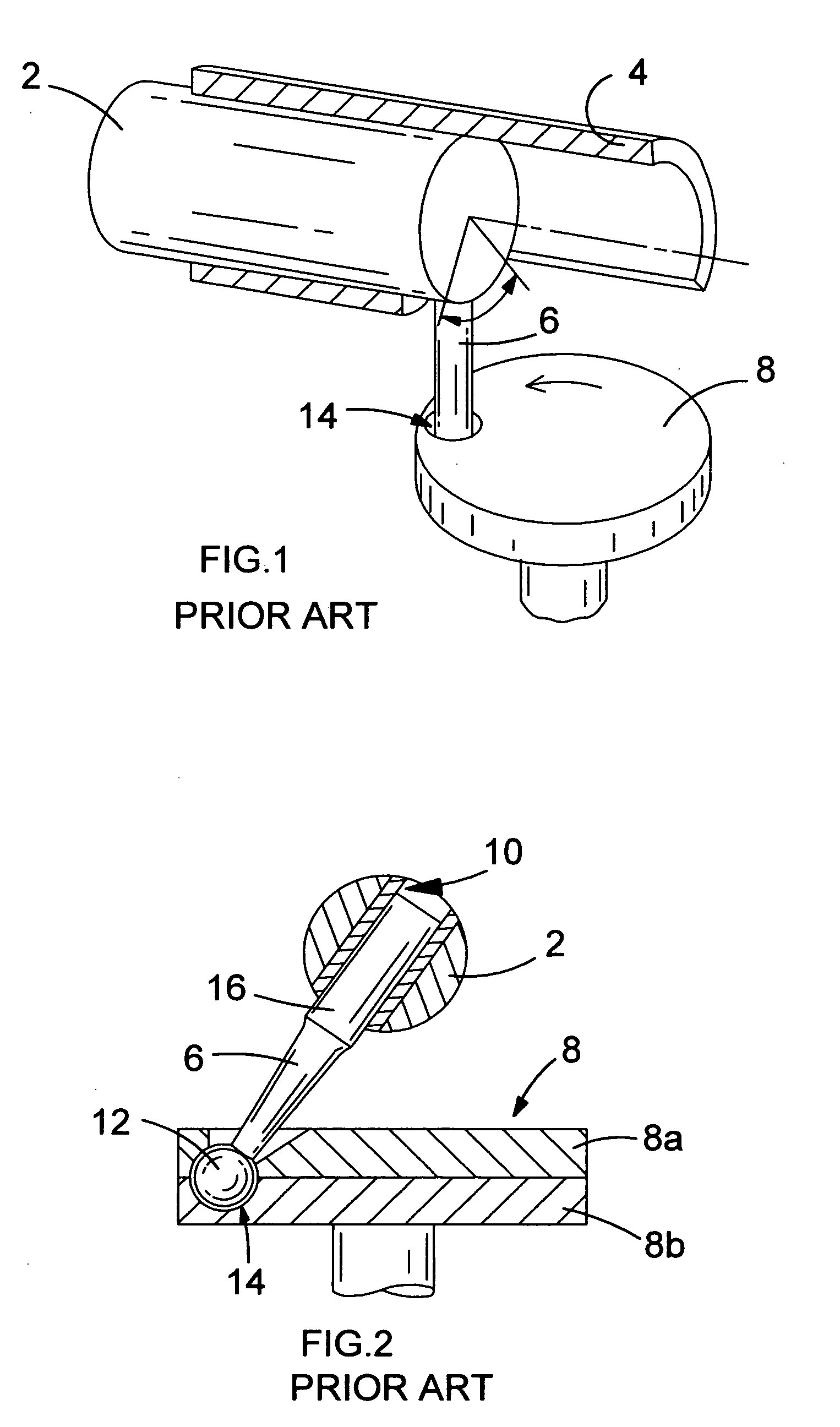

Hammer drill attachment

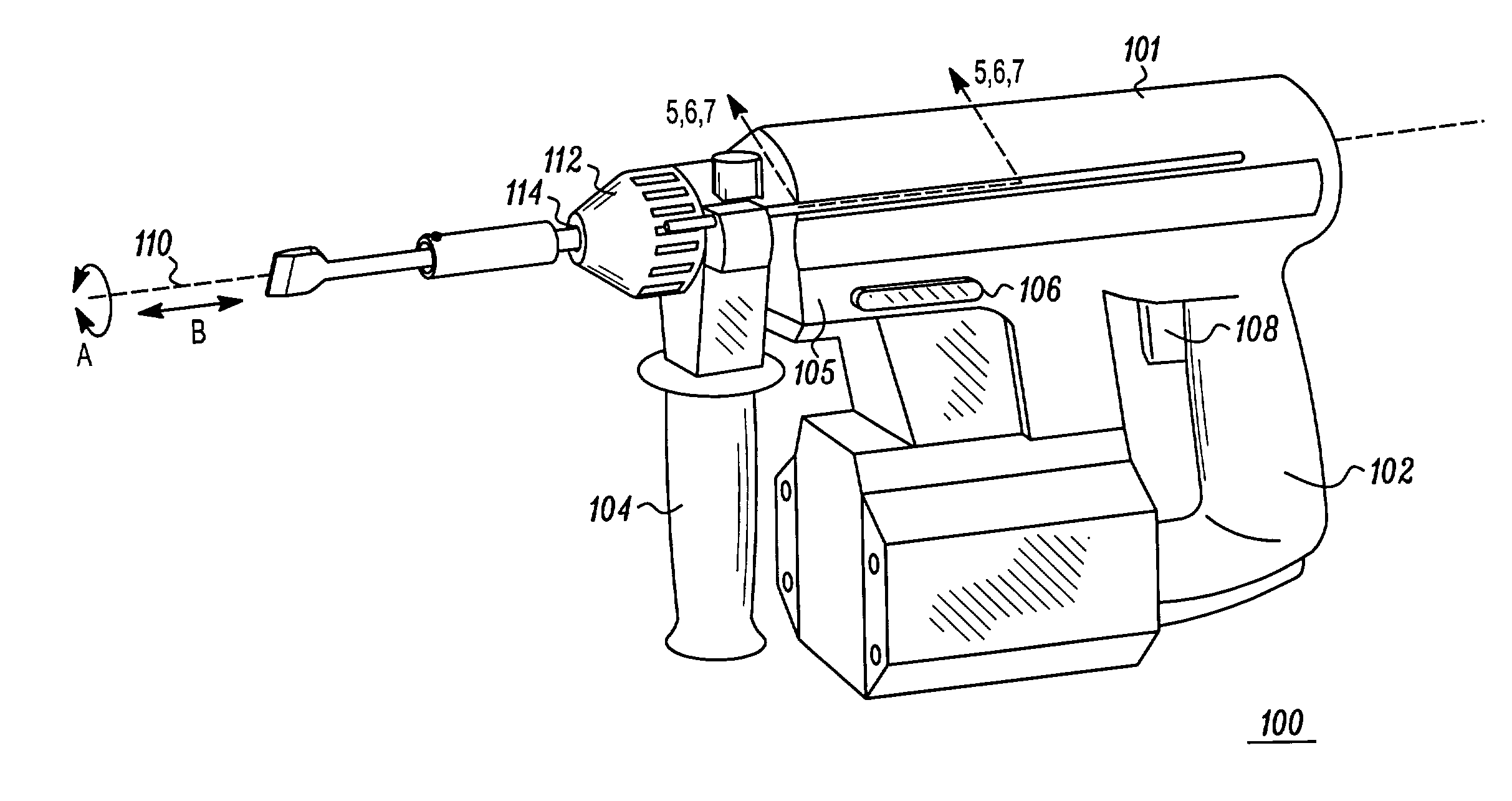

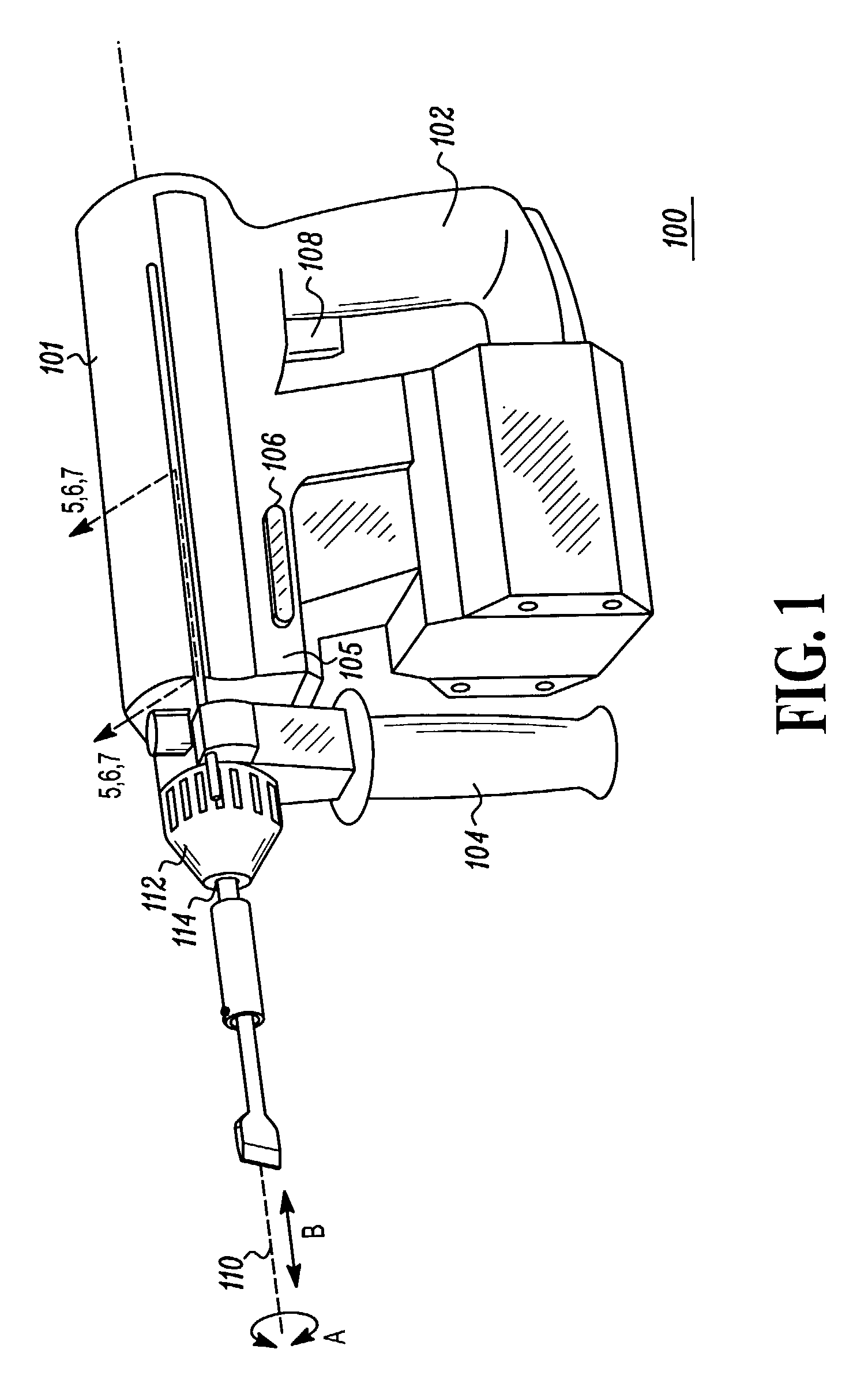

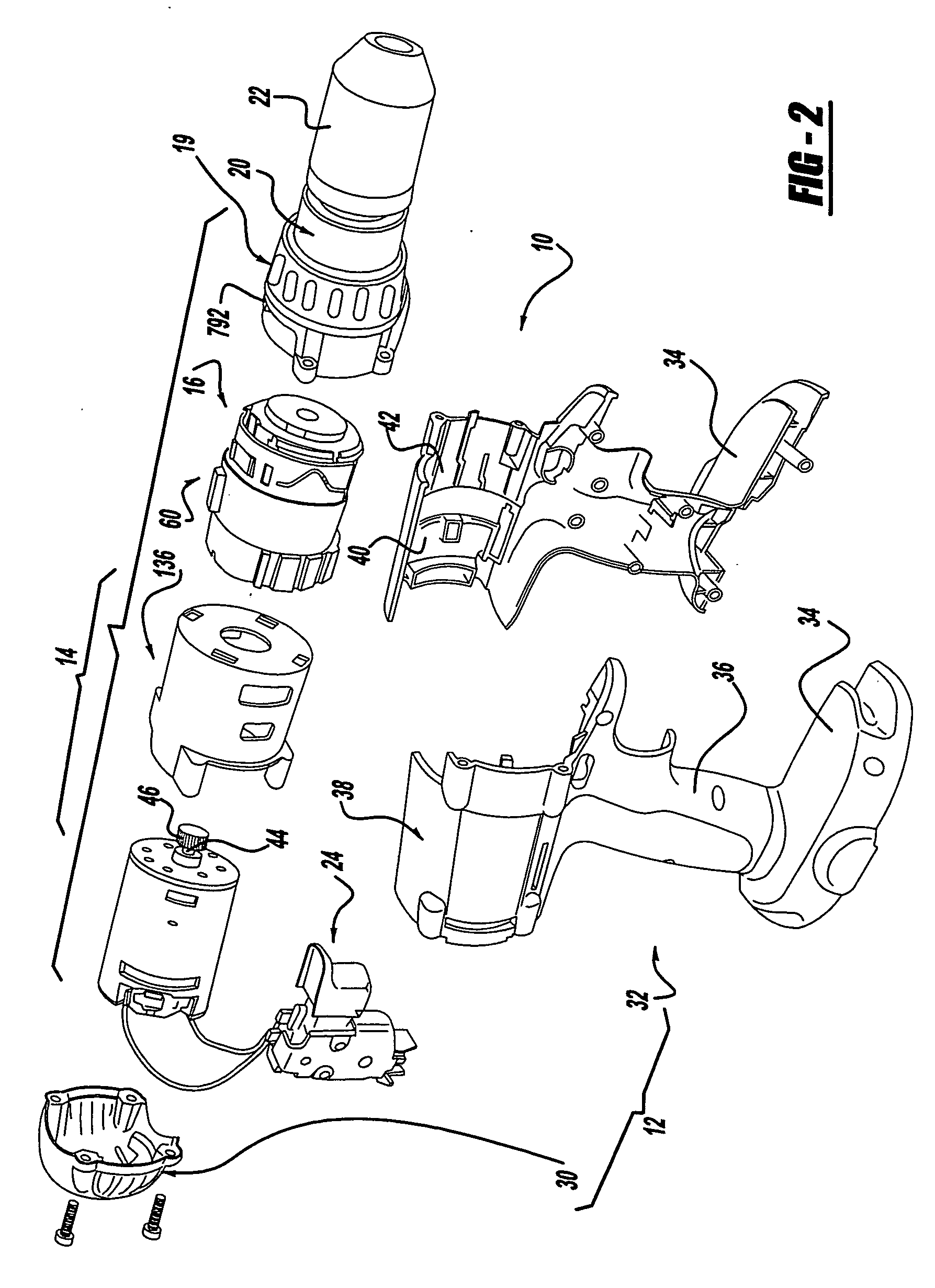

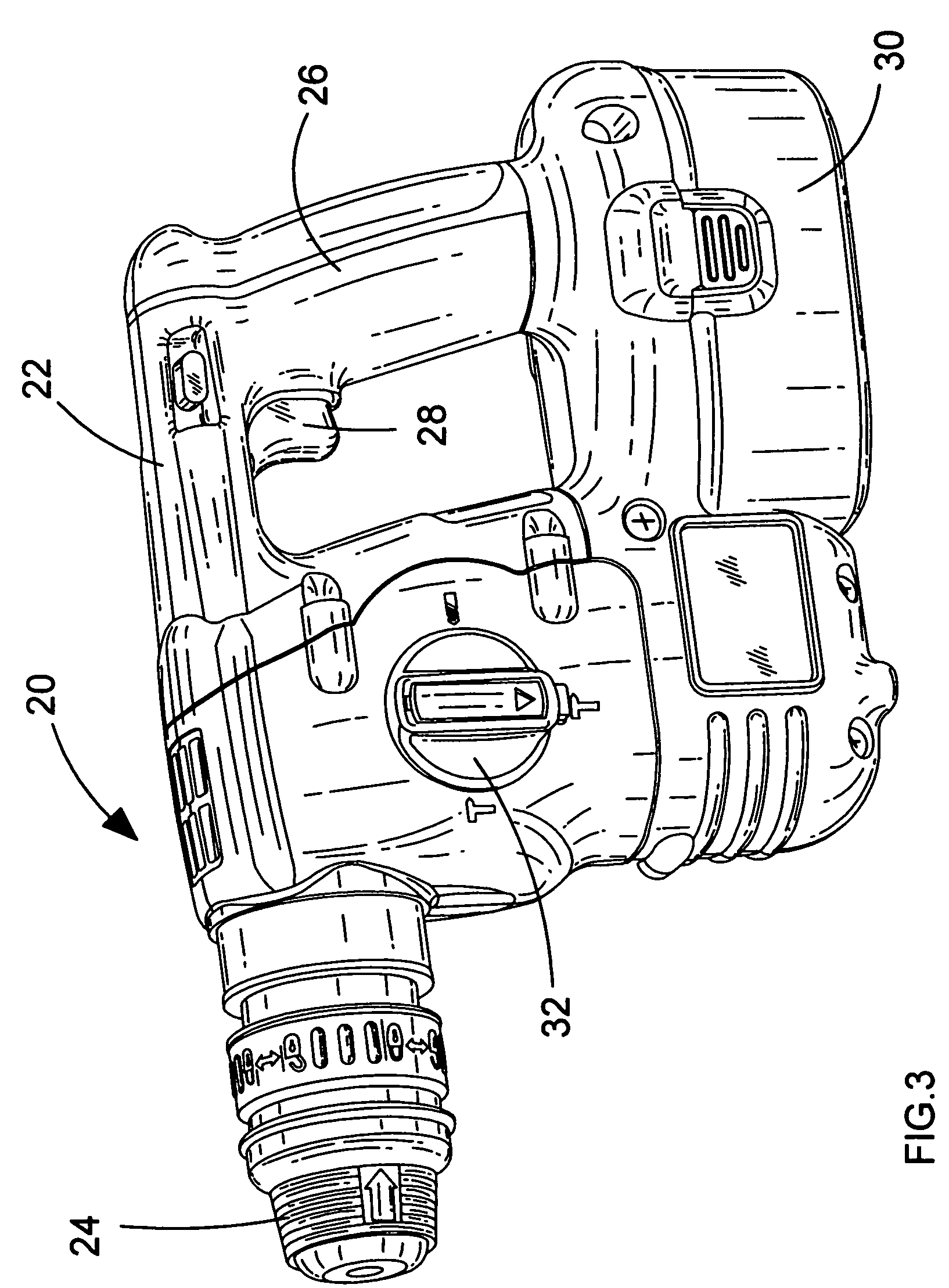

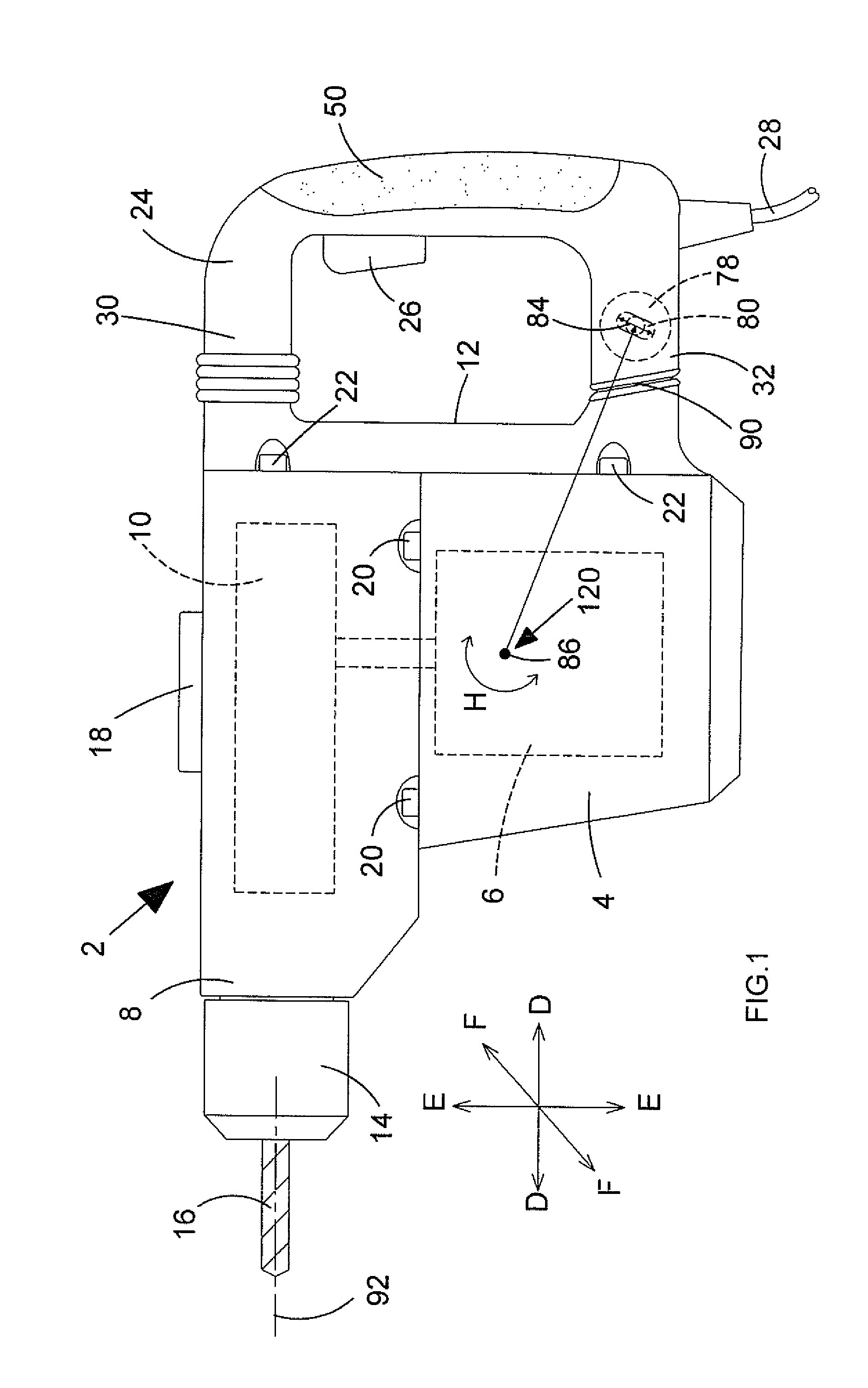

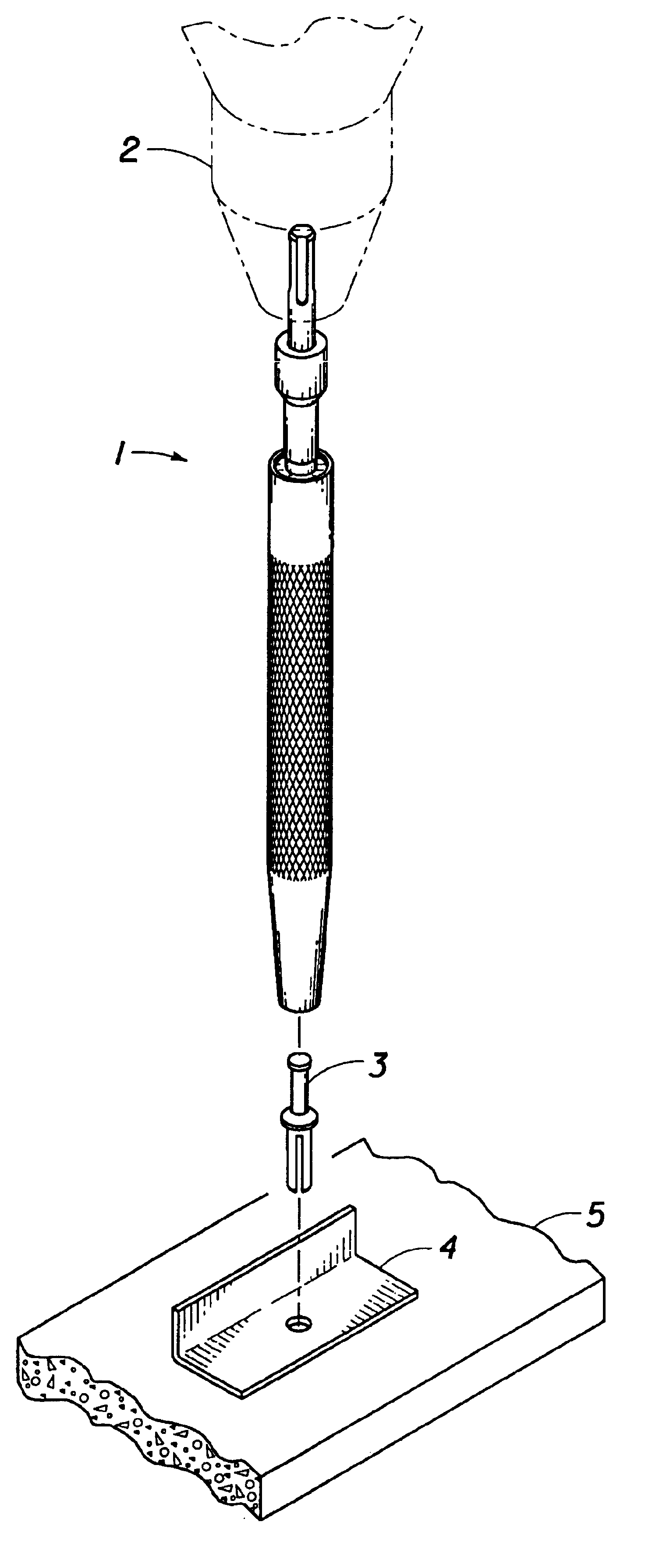

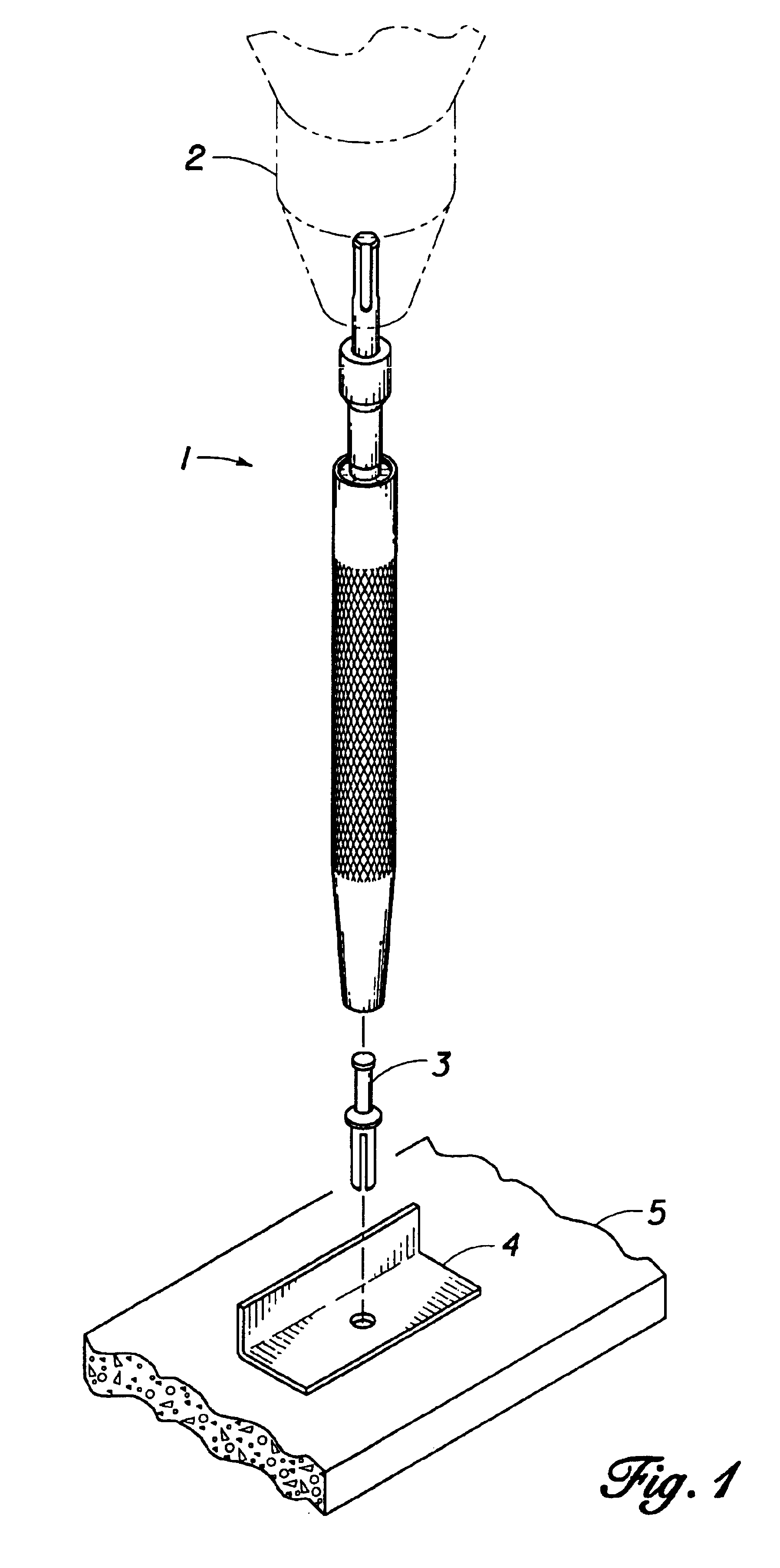

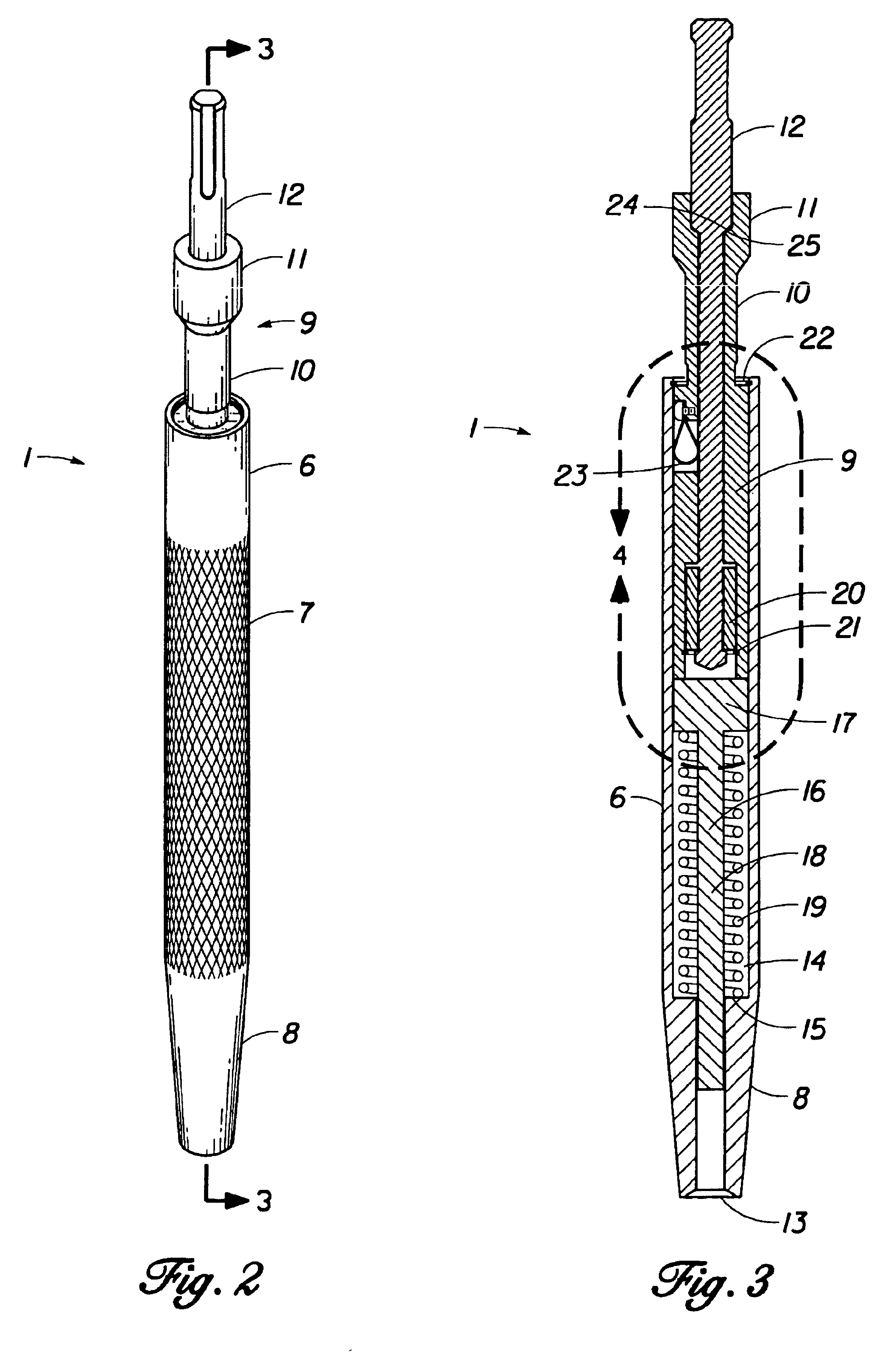

Power tools of the type under consideration include hammer drills, for example, which are electric or battery powered and includes two modes of operation: a rotation mode and a rotation-hammer mode. A manually operable selector lever enables the hammer drill to be selectively operated in one of the two modes by disengaging and engaging a hammer mechanism. In rotation-hammer mode, the drive shaft of the hammer drill rotates a tool element about a rotational axis and oscillates the tool element along a rotational axis. An attachment mountable within the chuck of a hammer drill prevents a tool element from rotating when the hammer drill is operating in rotation-hammer mode. The hammer drill attachment transfers hammer action, but not rotation, to the tool element. The hammer drill attachment enables dual function power tools to be operated in a hammer only mode to perform a function, for example, chiseling.

Owner:OROZCO JR EFREM

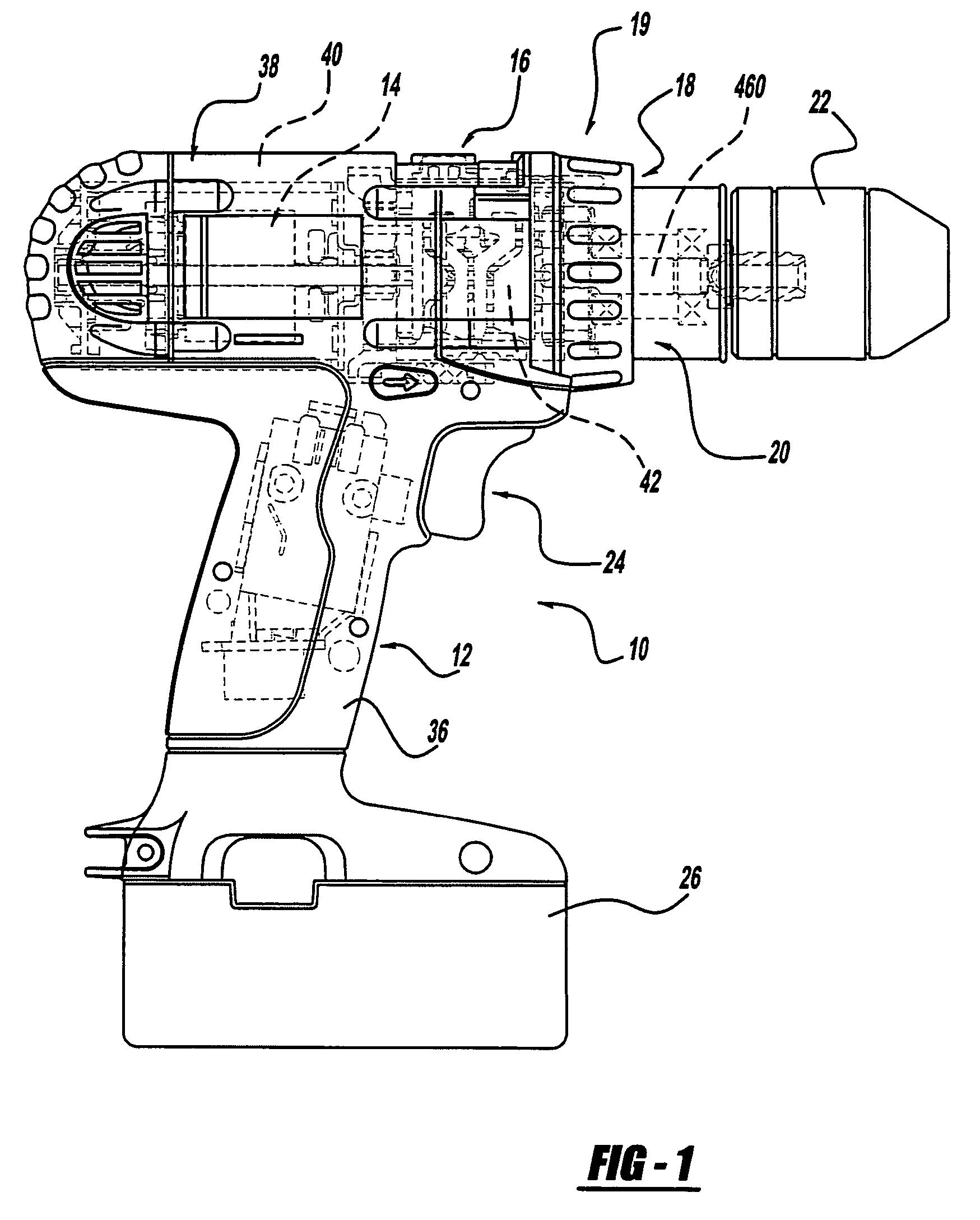

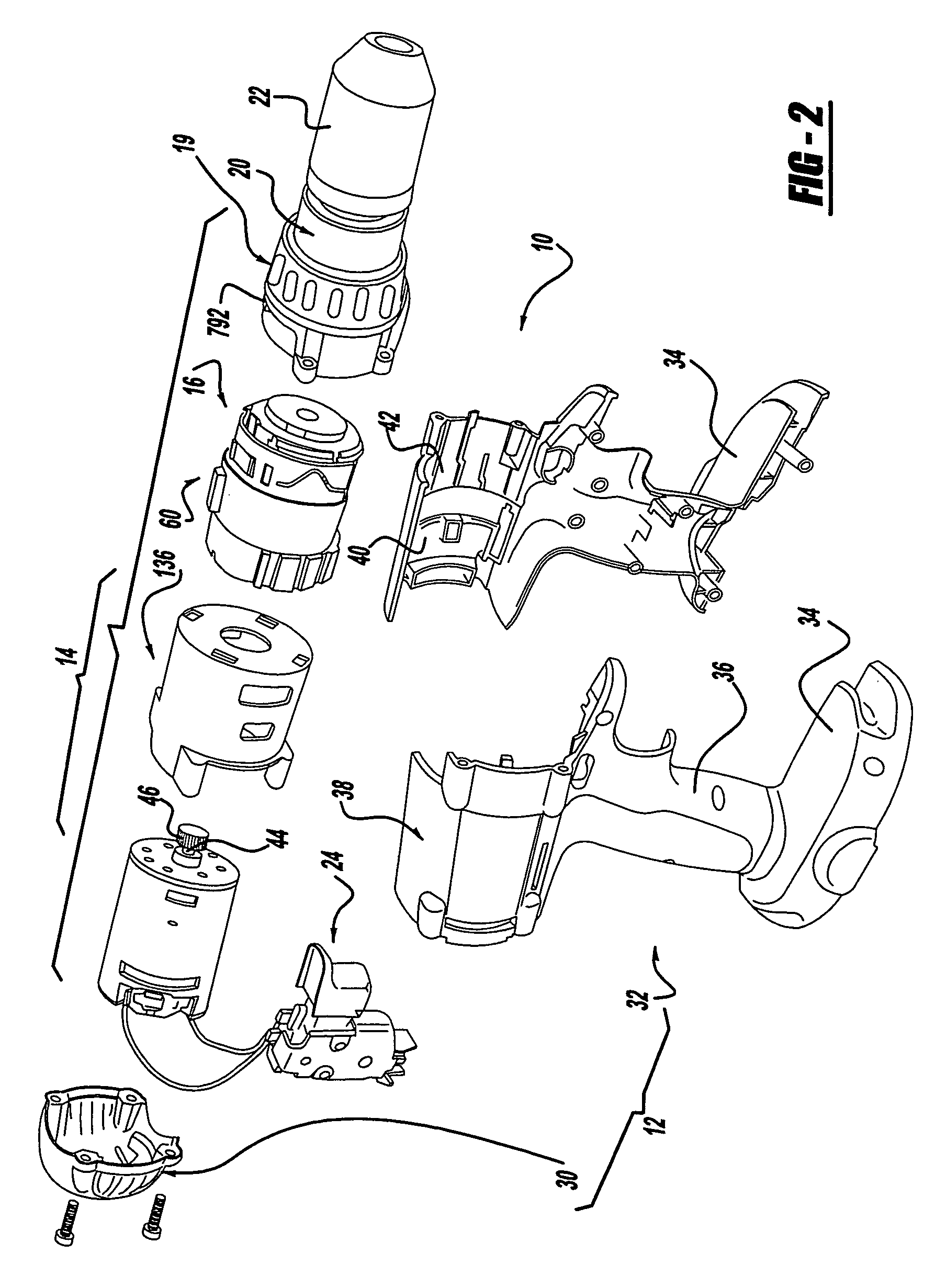

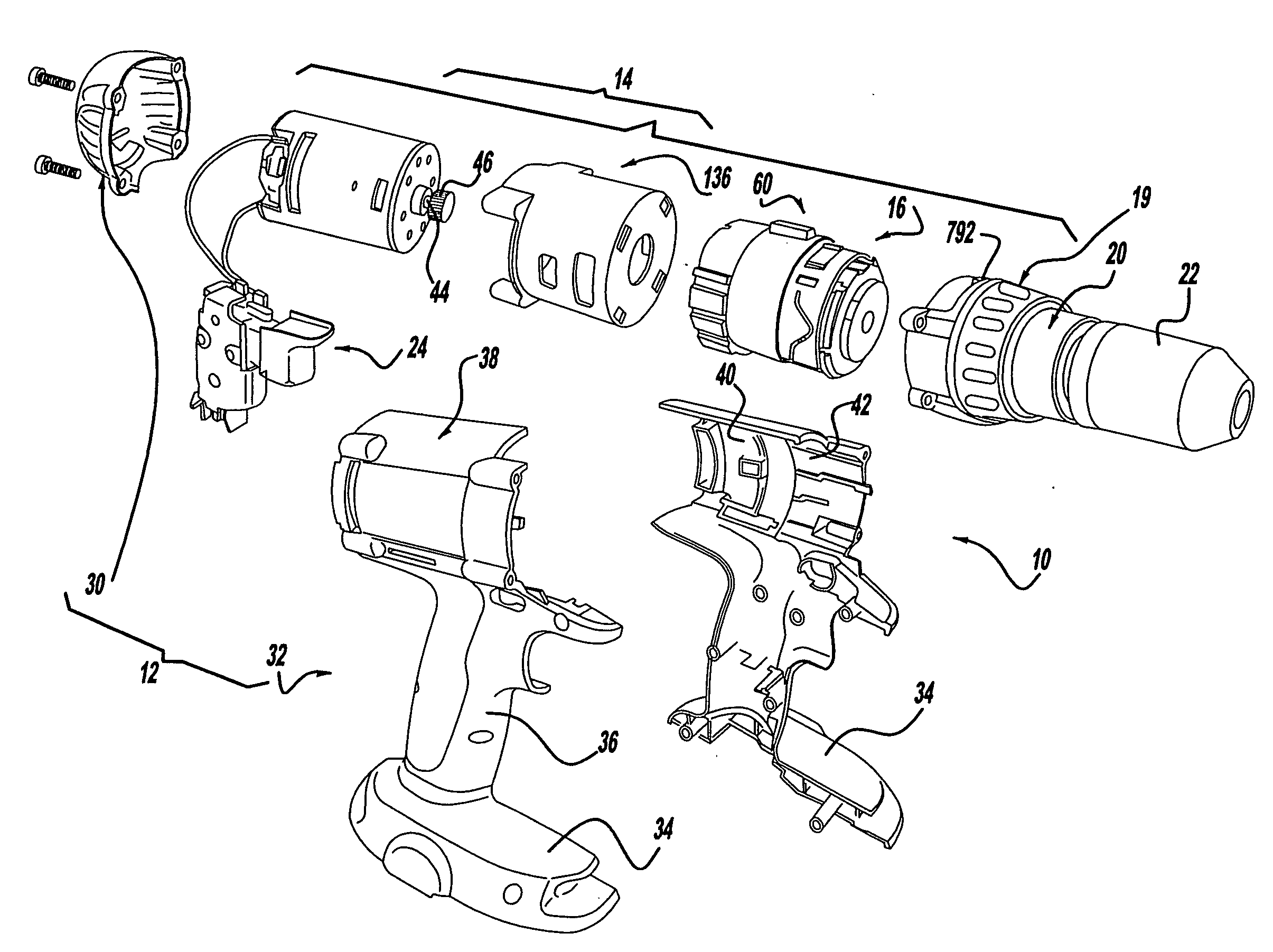

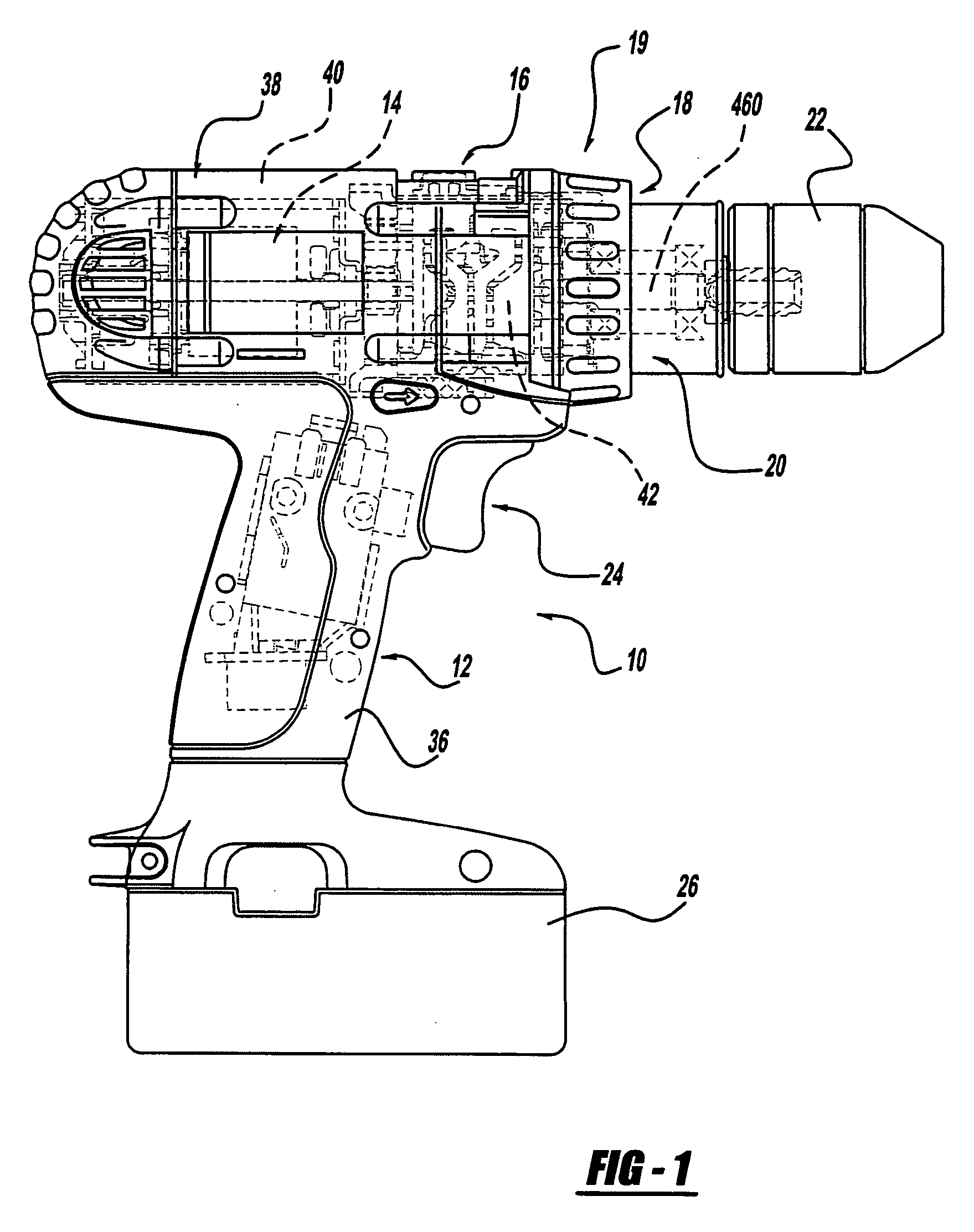

Hammer drill with a mode changeover mechanism

Owner:BLACK & DECKER INC

Hammer drill with a mode changeover mechanism

Owner:BLACK & DECKER INC

Hammer drill

InactiveUS6644418B2Reduce vibrationDrilling rodsReciprocating drilling machinesEngineeringMechanical engineering

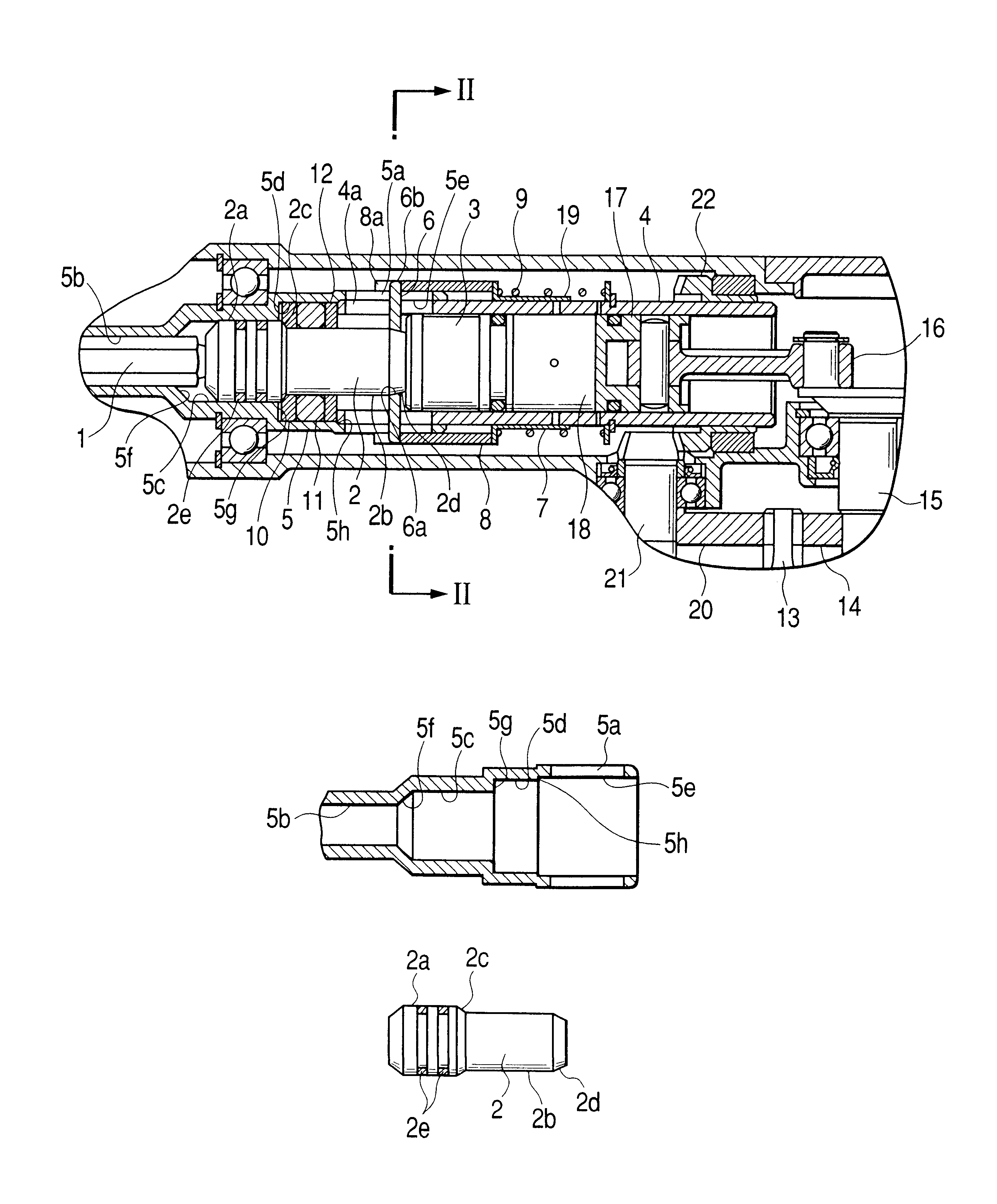

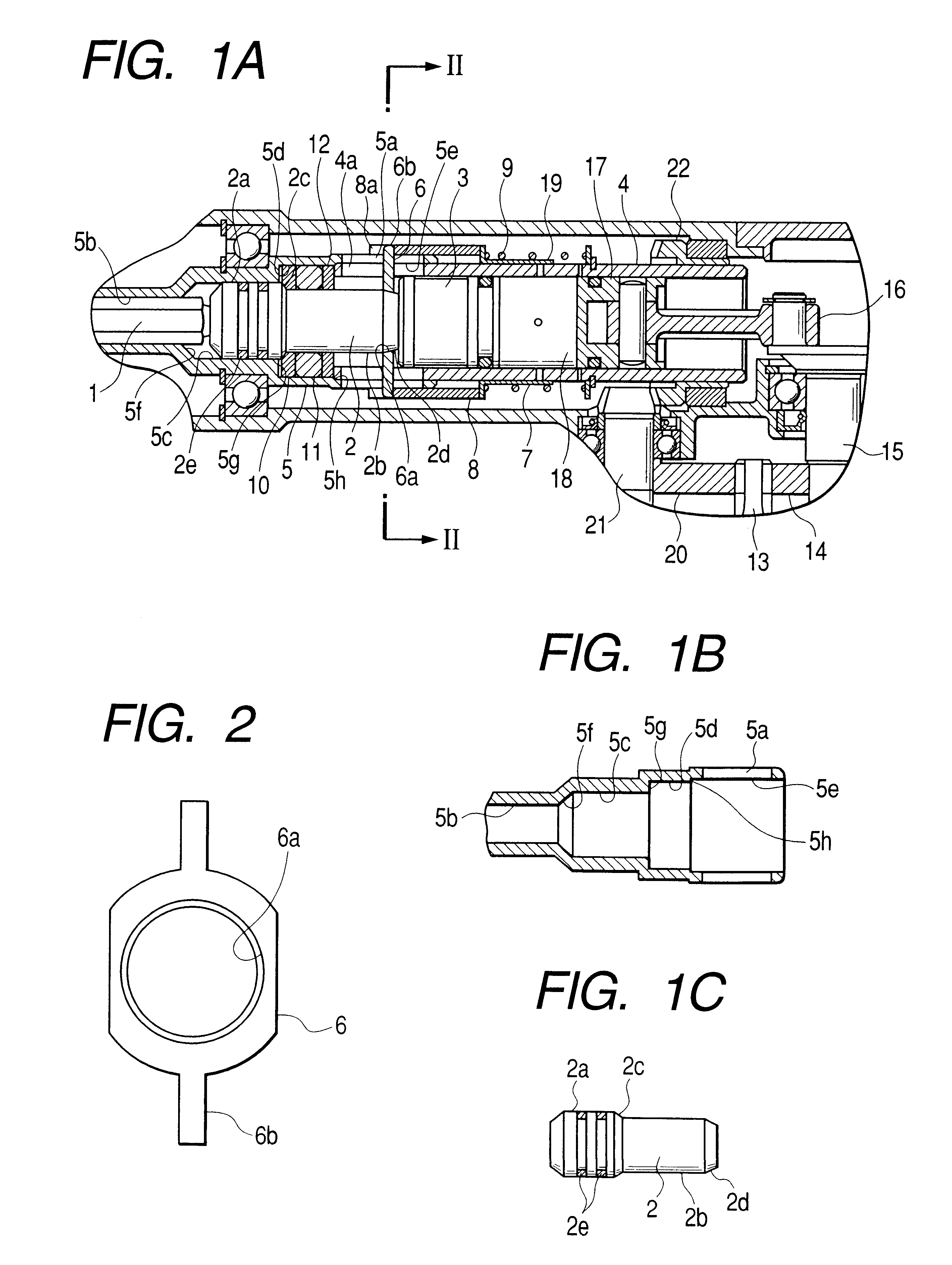

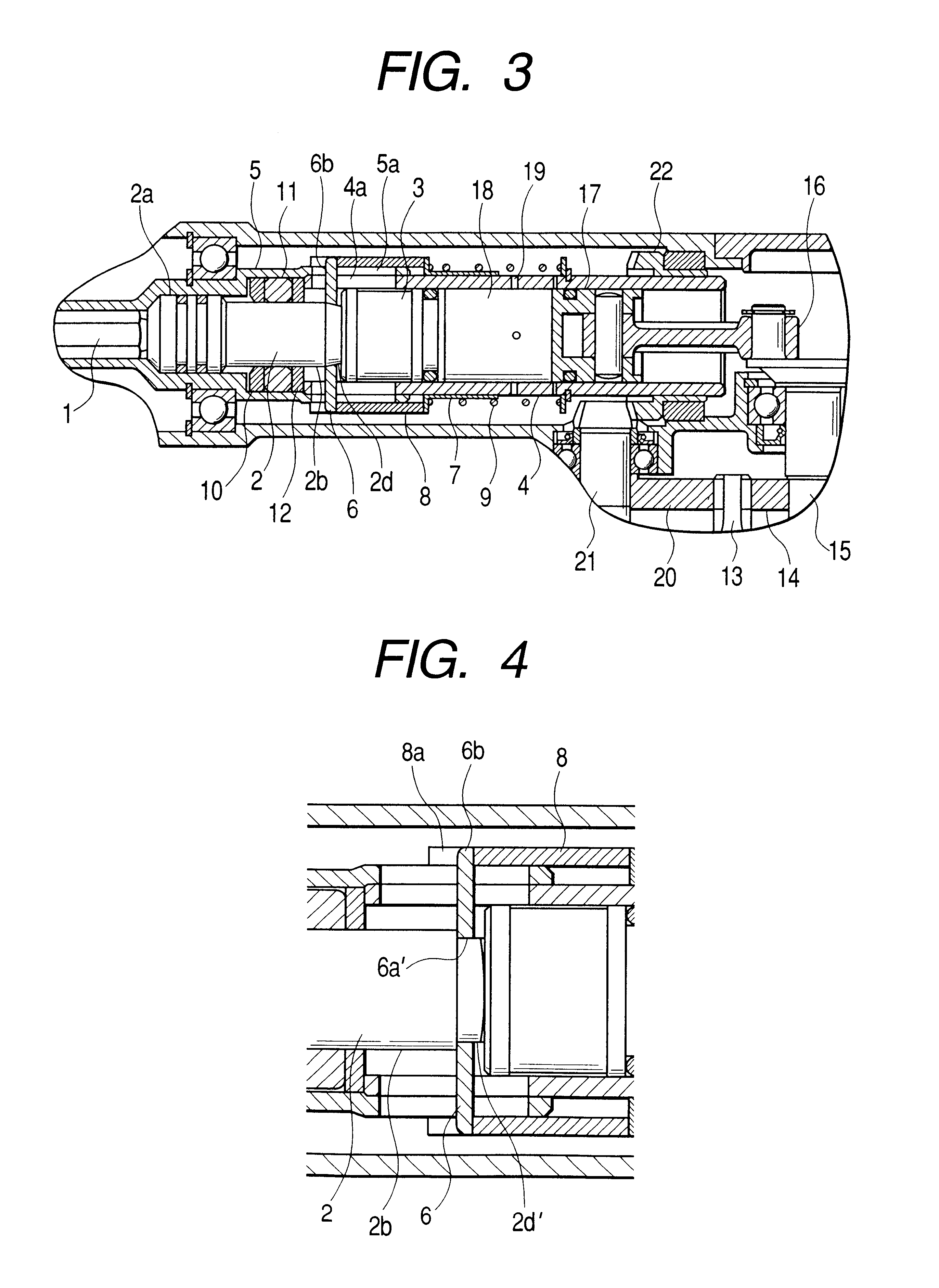

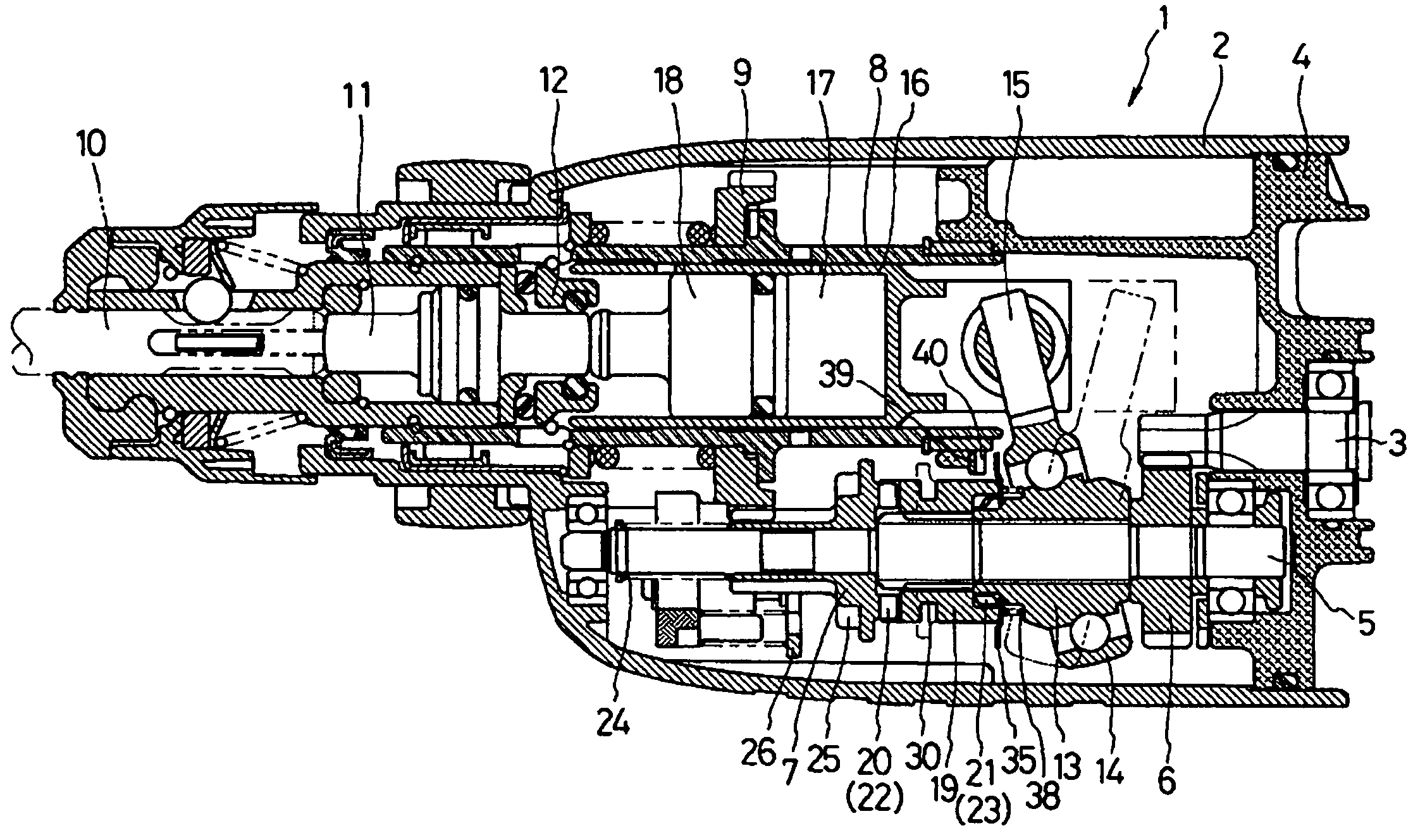

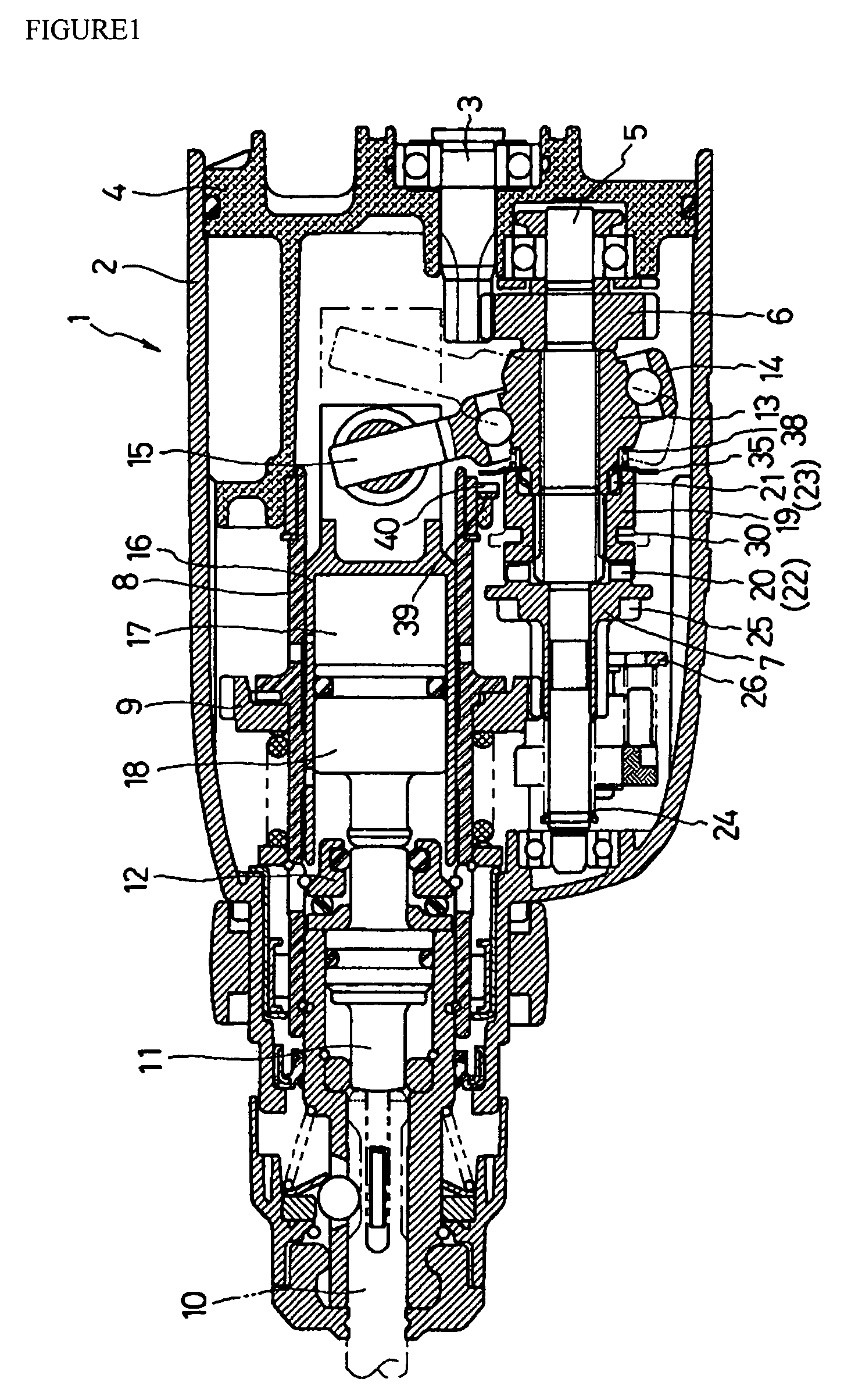

An engaging portion, formed at an axial end of an intermediate member, is engageable with a slide sleeve. A cylinder has an elongated hole with an axial length longer than a shifting distance of the intermediate member. The slide sleeve includes an annular member and a slide member. The annular member has an inner cylindrical wall engageable with the engaging portion of the intermediate member and a projection extending in a radially outward direction passing through the elongated hole beyond an outer surface of the cylinder. The slide member is coupled around the outer surface of the cylinder and is slidable in the axial direction of the cylinder. One axial end of the slide member, positioned closer to a working tool, is engaged with the projection of the annular member. The other axial end of the slide member is urged toward the working tool by an urging member.

Owner:KOKI HLDG CO LTD

Power tool housing

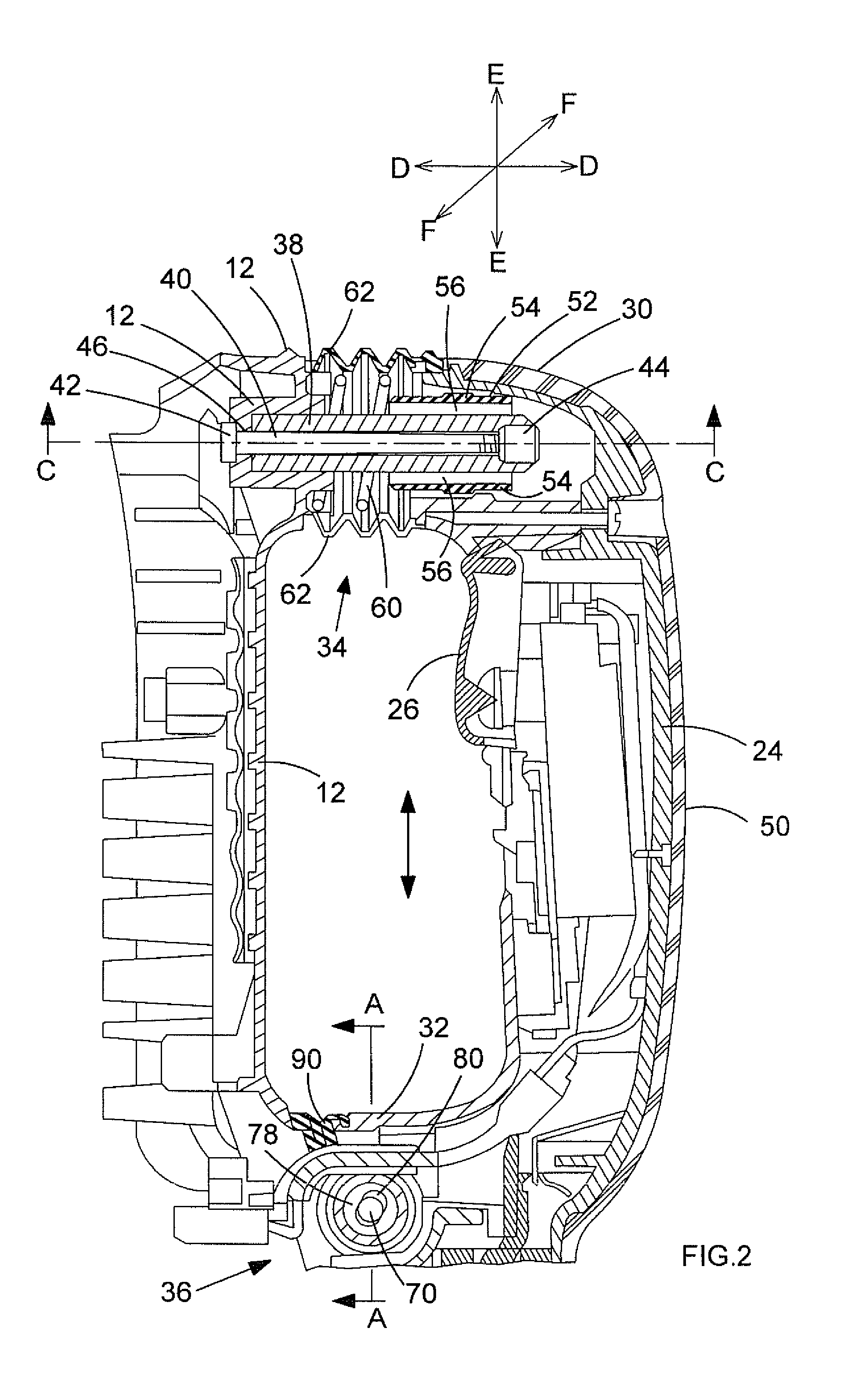

ActiveUS7331408B2Weaken energyOptimize volumeDrilling rodsReciprocating drilling machinesBall bearingReciprocating motion

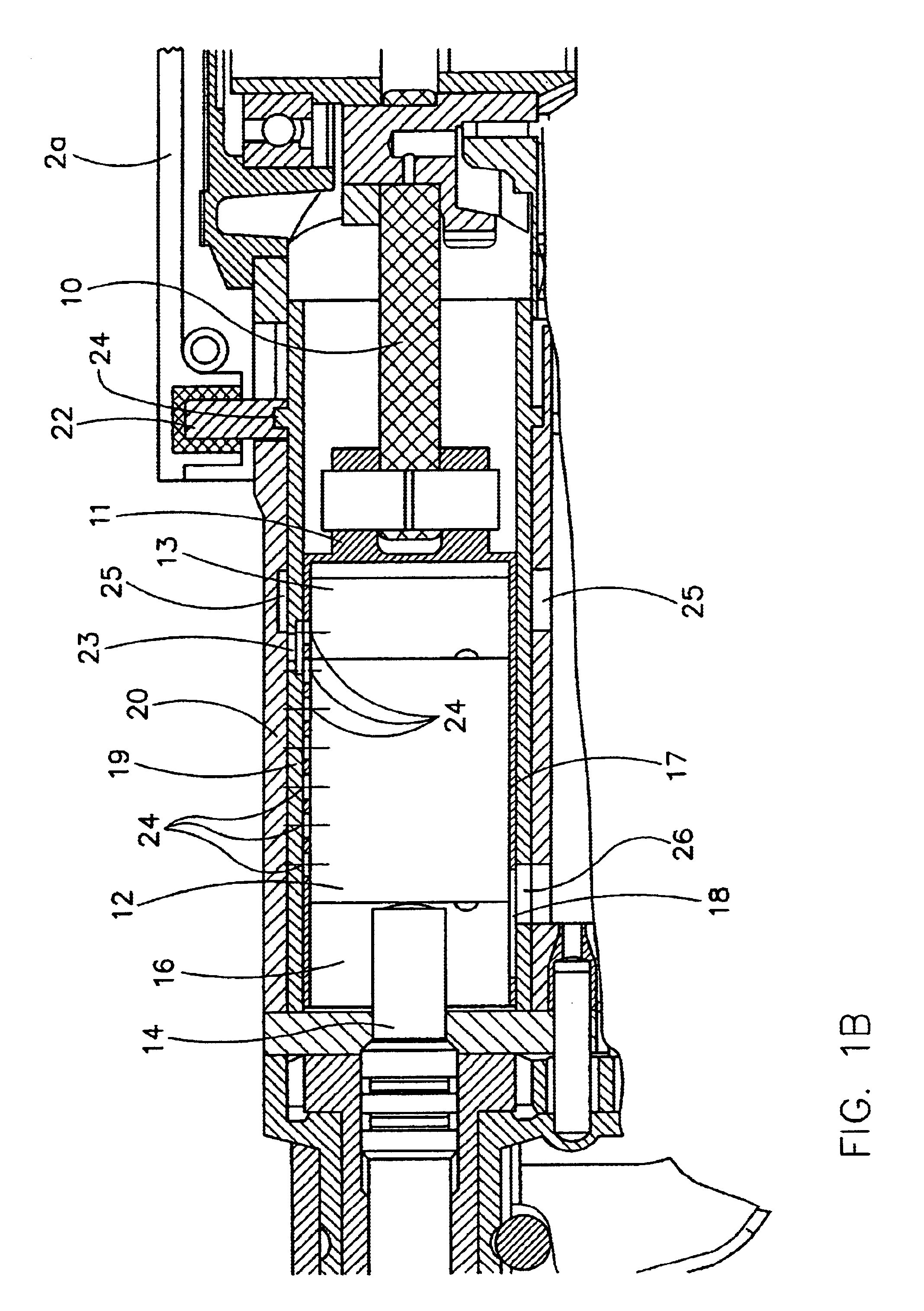

A transmission housing for a hammer drill comprises two clamshell halves and that mate to define a first transmission housing chamber and a second transmission housing chamber disposed on either side of a ball bearing race. The first and second transmission housing chambers are interconnected by channels. The rear end of a hollow piston, a cylindrical bearing, a crank pin and a crank plate are disposed in the first transmission housing chamber, and a spindle is disposed in the second transmission housing chamber. Overflow channels and allow movement of air between the first and second transmission housing chambers to reduce compression of air iduring reciprocation of the hollow piston.

Owner:BLACK & DECKER INC

Suction device for a pick power tool

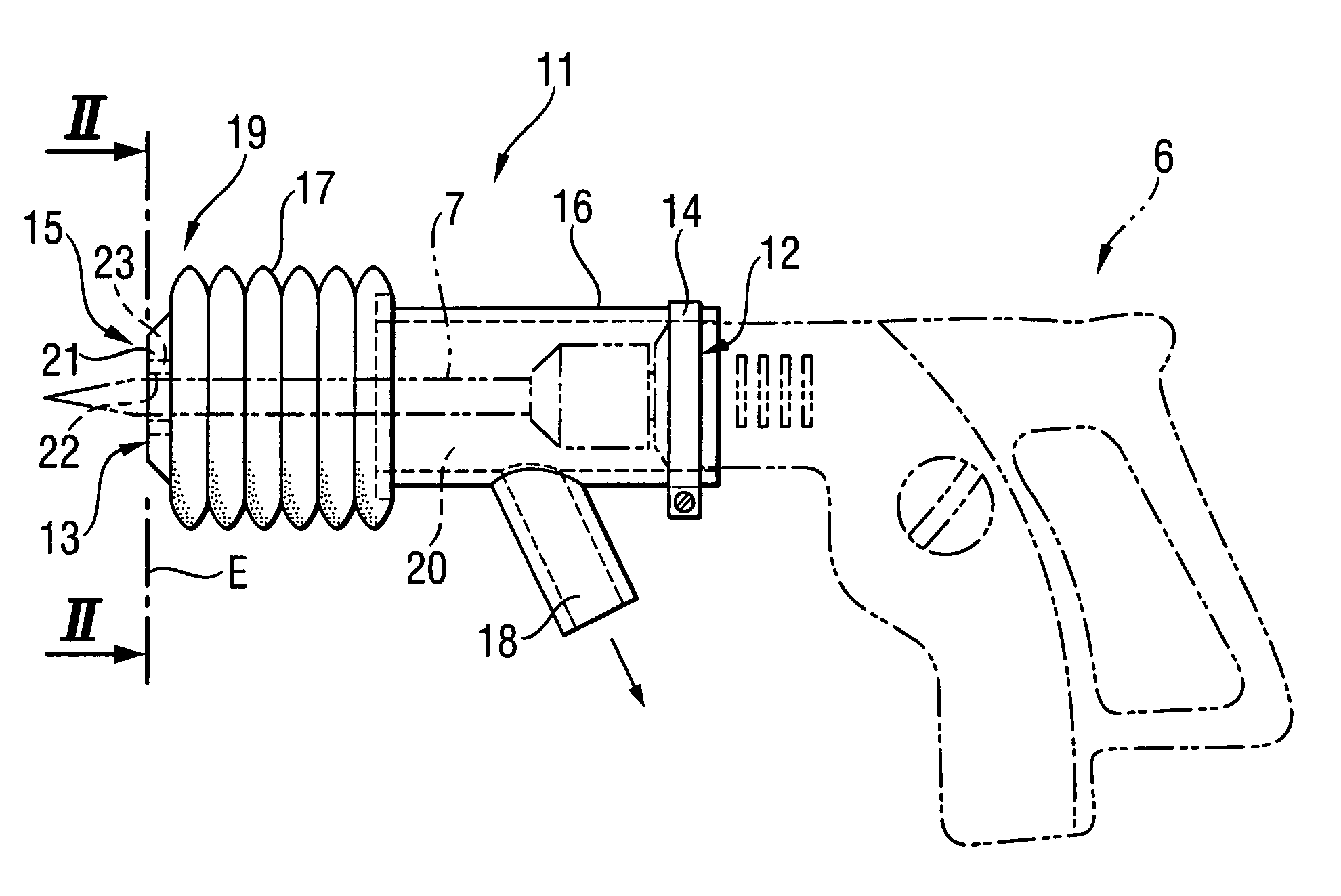

ActiveUS7740086B2Avoid cloggingGreat suctionTransportation and packagingMulti-purpose machinesClassical mechanicsPower tool

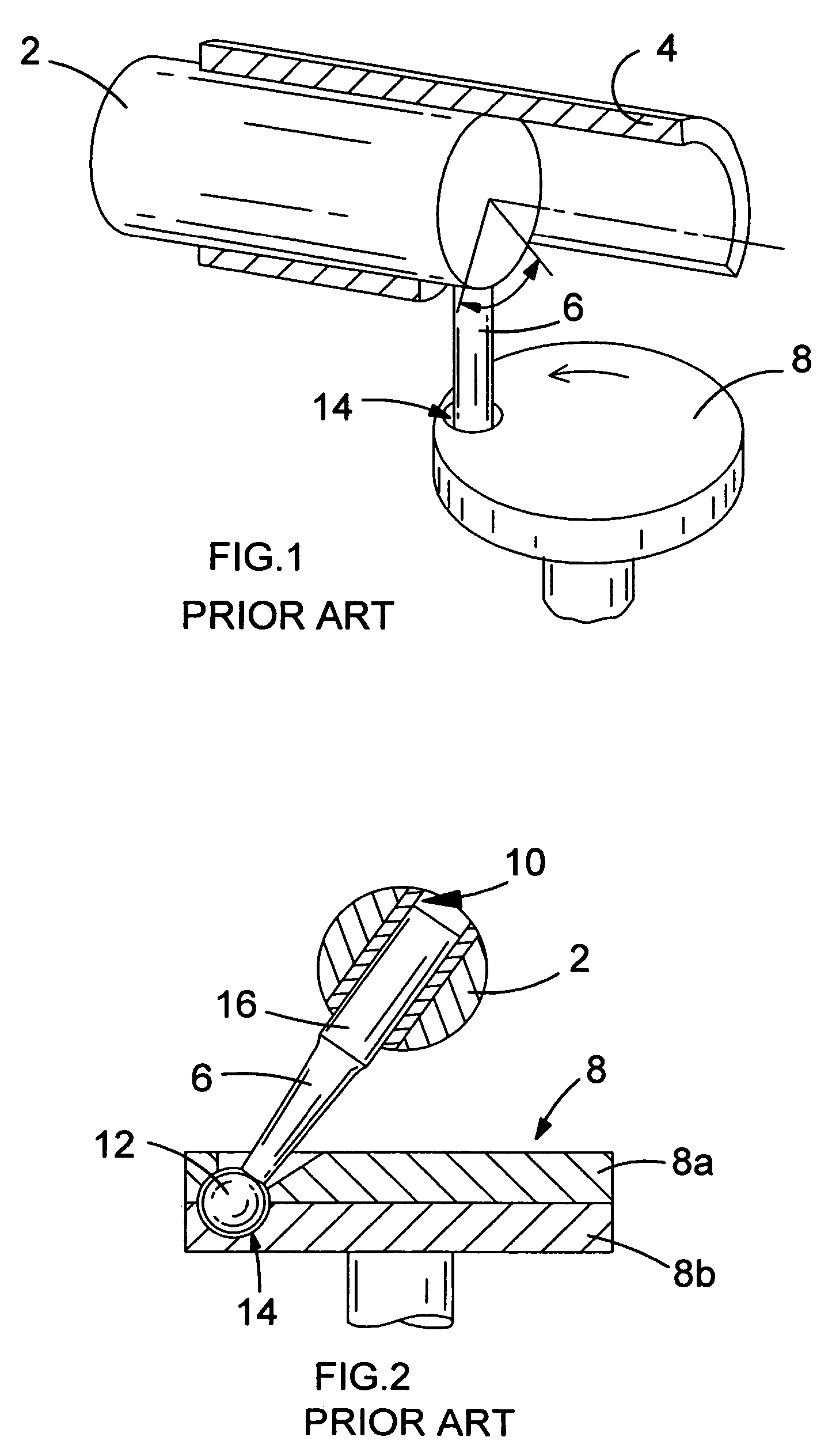

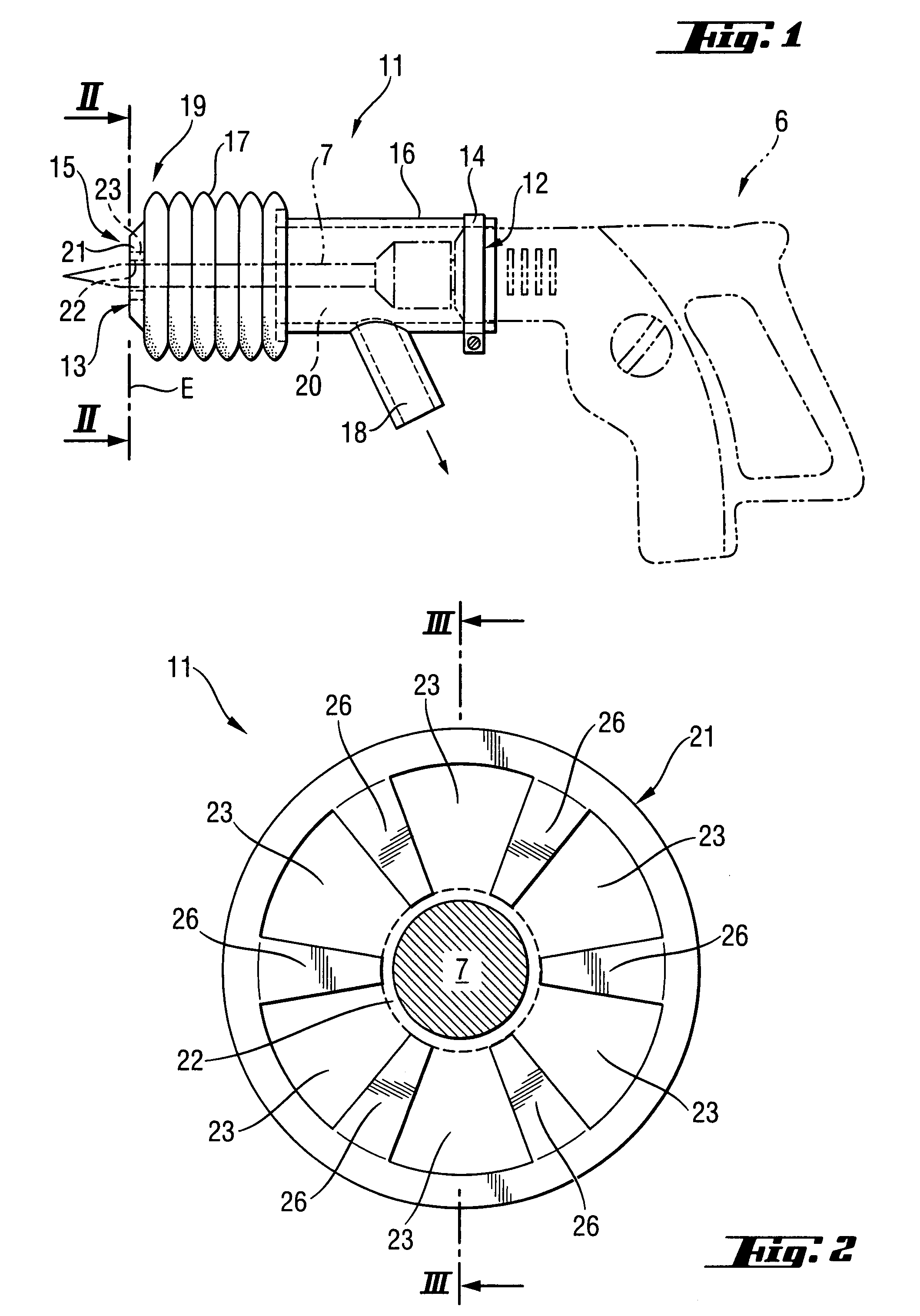

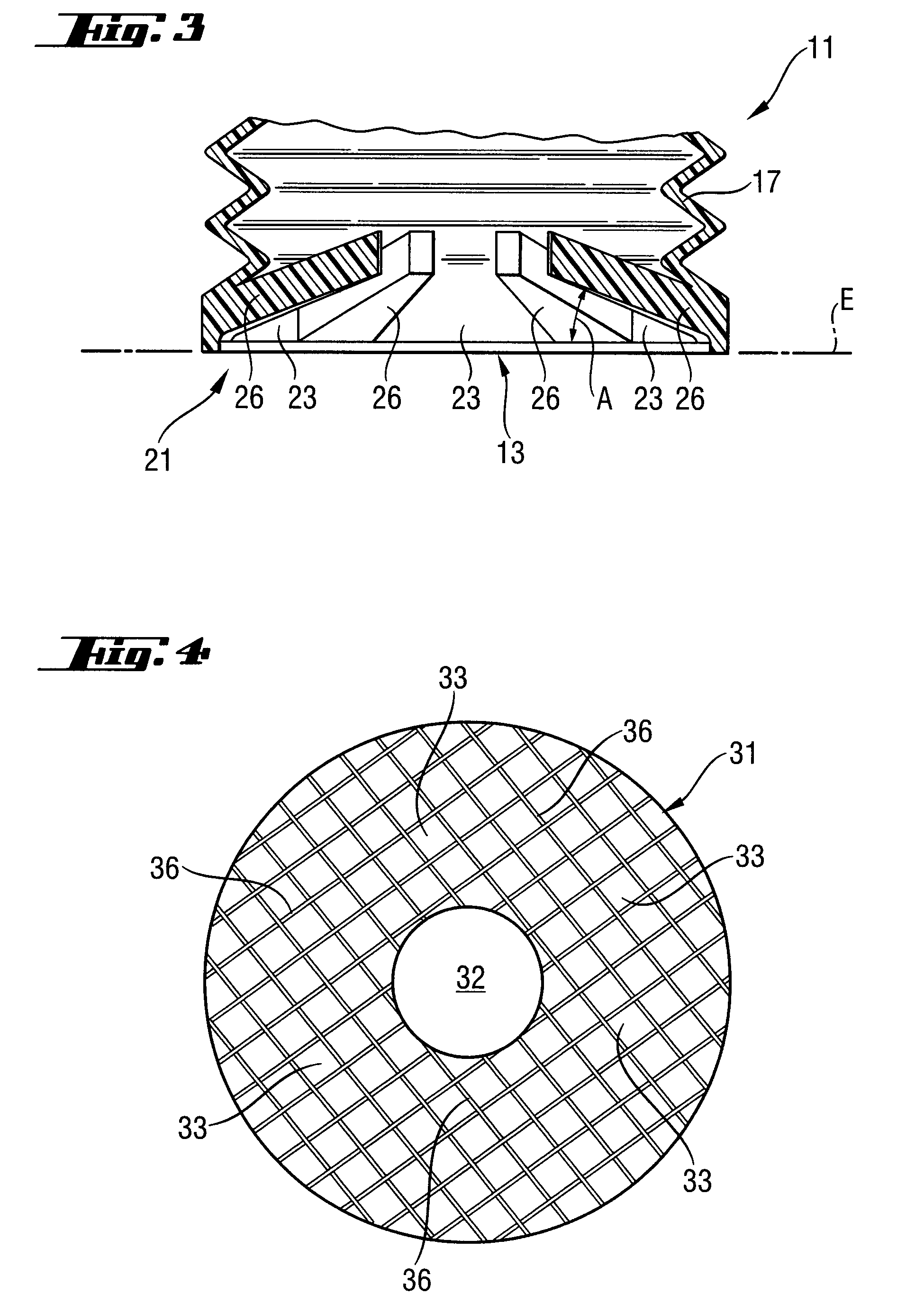

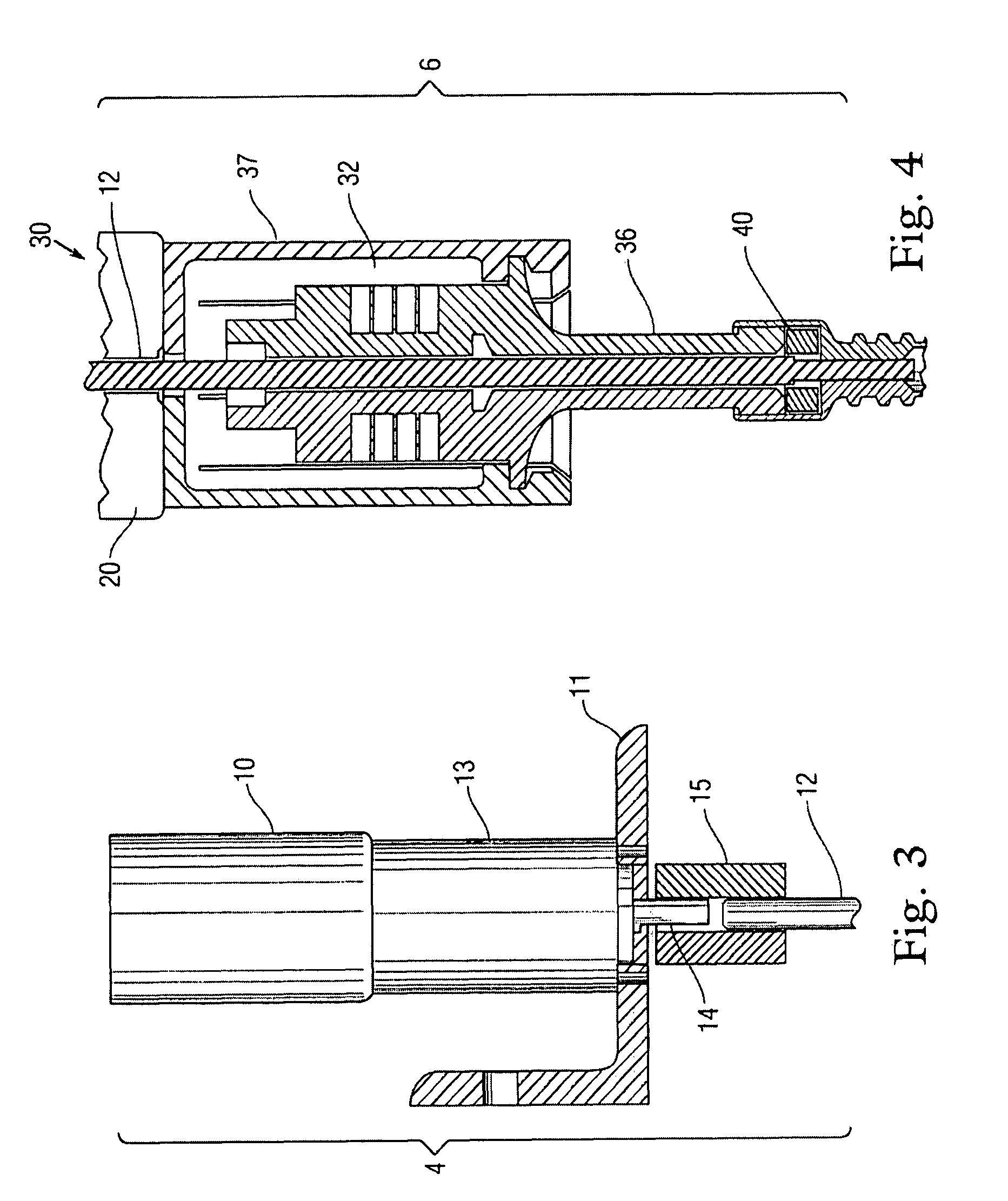

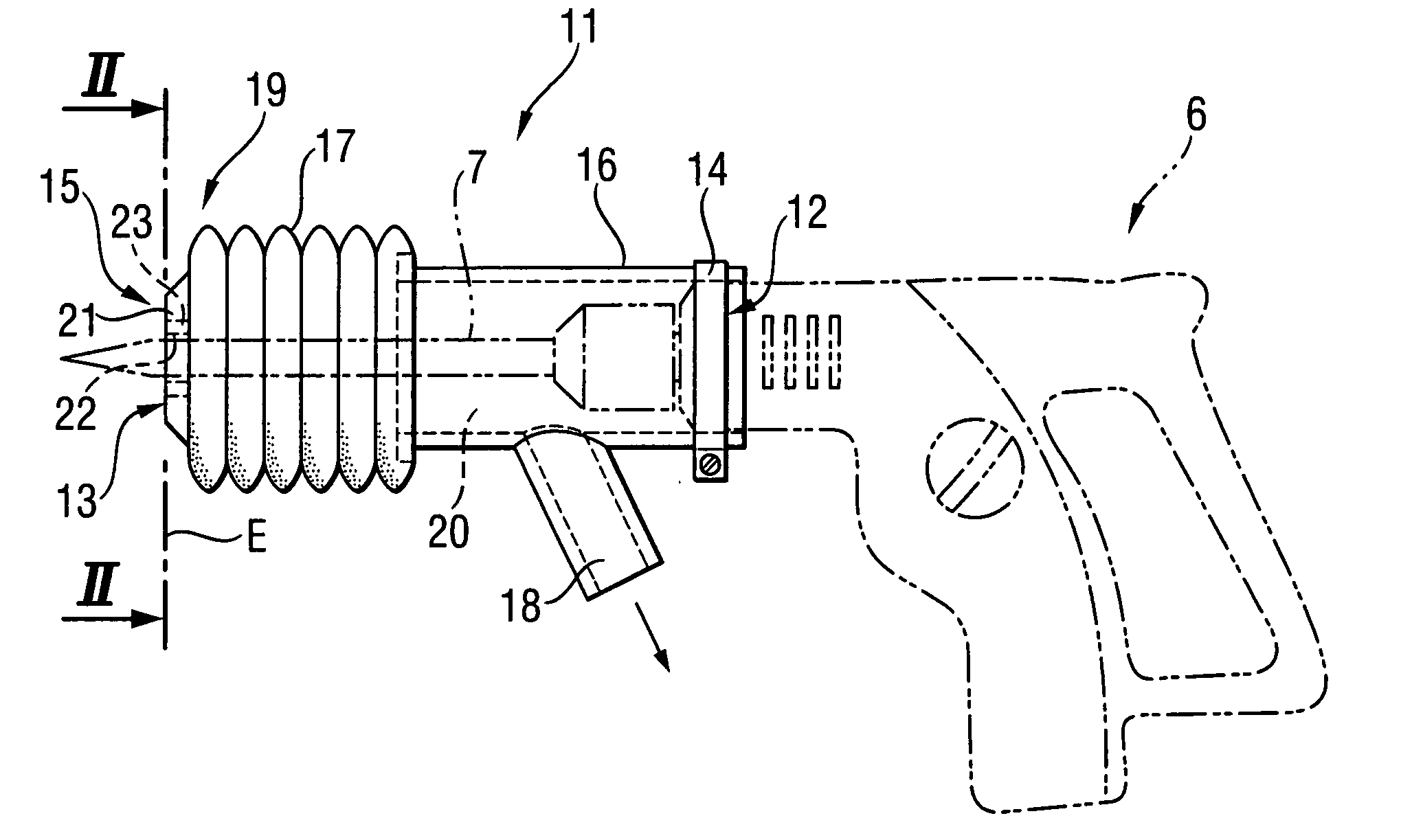

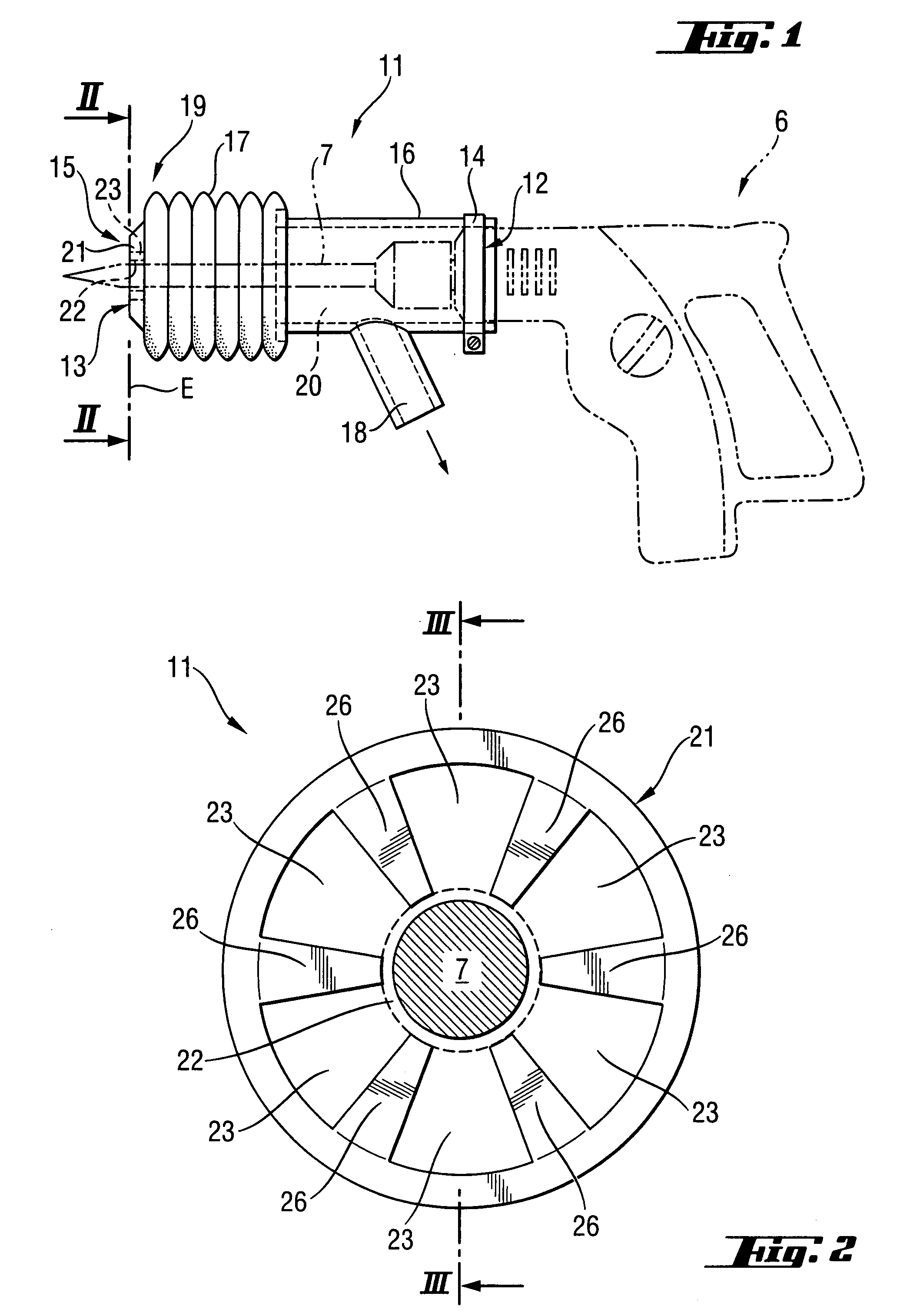

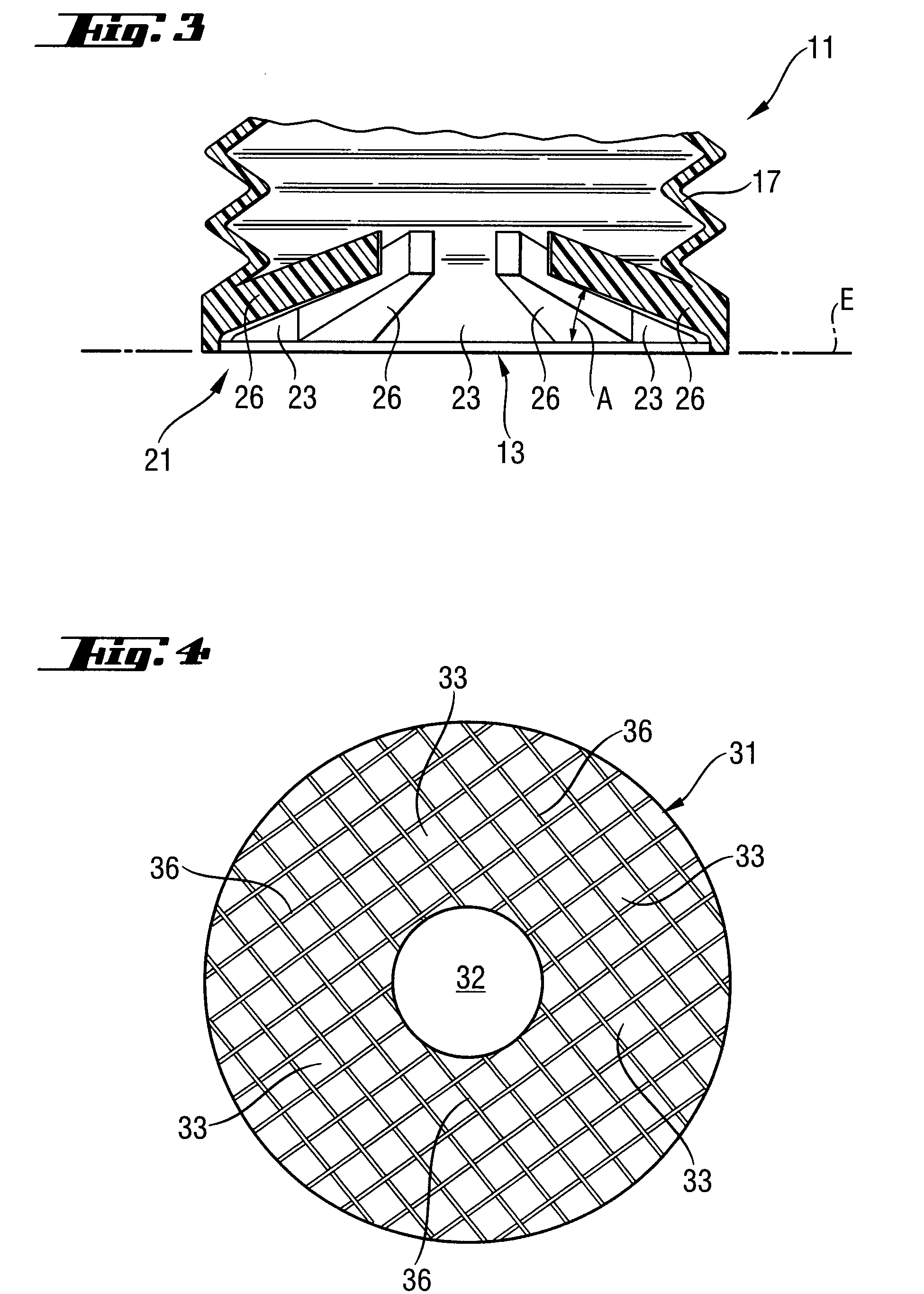

A suction device (11) for a hammer drill (6) has a first end (12) with a securing device (14) for securing the suction device (11) to the hammer drill (6) and a second end (13) opposite first end (12) and which has a contact area (15) with which the suction device (11) contacts a constructional component, the suction device (11) further having a receiving space (20) which at least partially encloses a working tool (7) of the pick power tool (6), and being provided with a connection device (18) for a vacuum source. A retaining element (21) having a through-opening (22) for the working tool (7) and a plurality of suction openings (23) is provided in an area (19) of the second end (13).

Owner:HILTI AG

Hammer drill with a mechanism for preventing inadvertent hammer blows

InactiveUS6971455B2Reliably prevents inadvertent blows to the bitImprove reliabilityReciprocating drilling machinesPortable percussive toolsCoil springEngineering

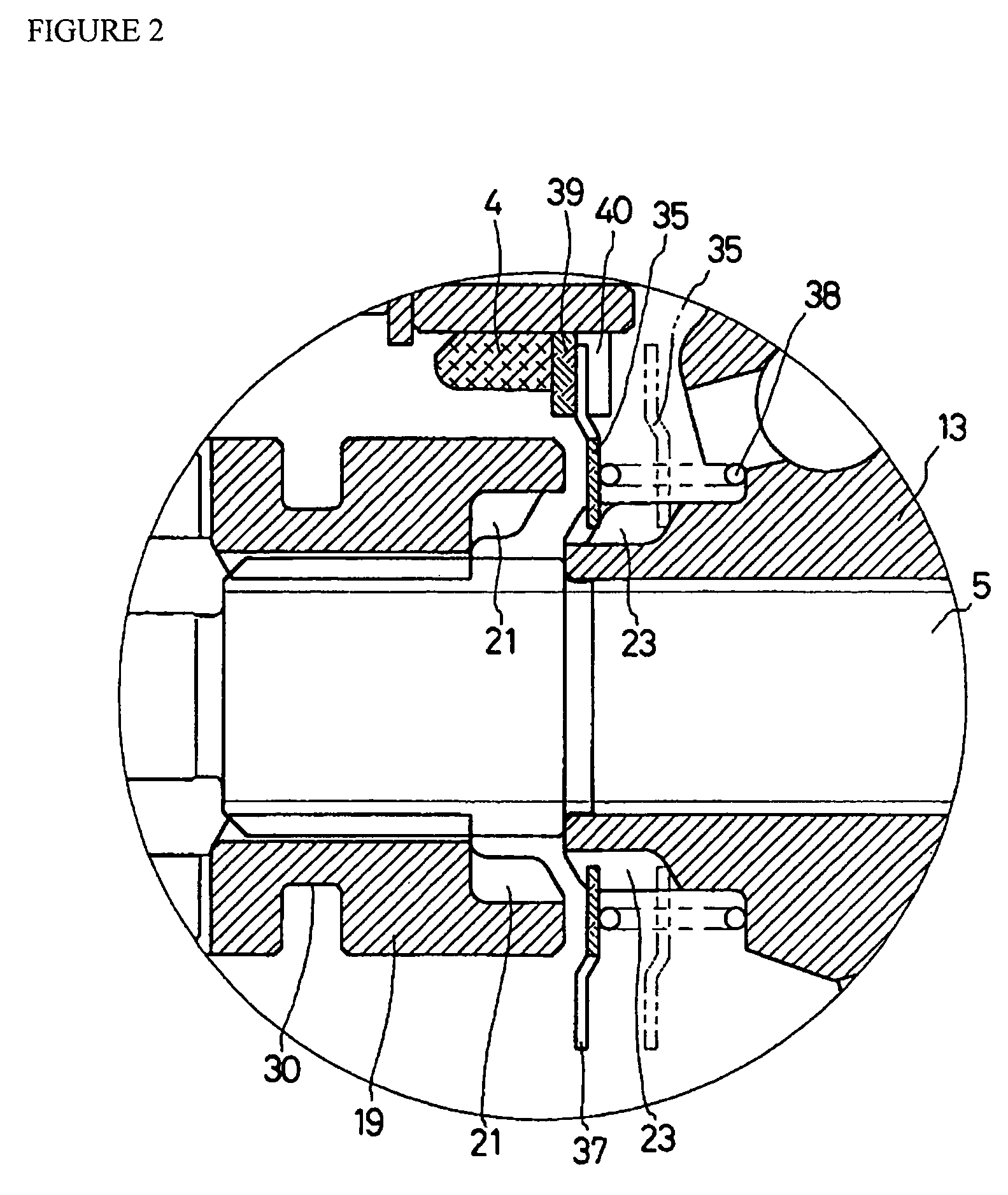

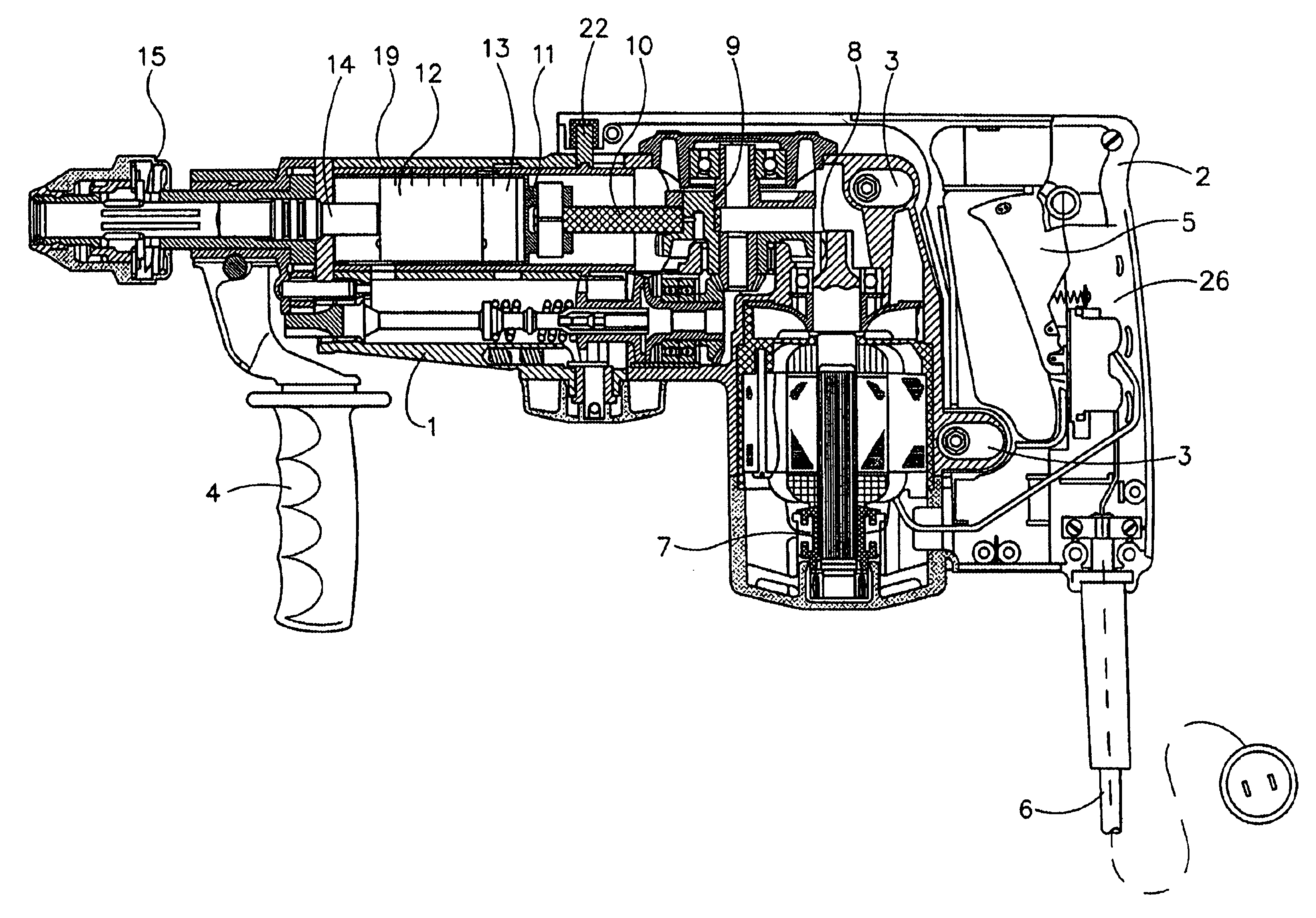

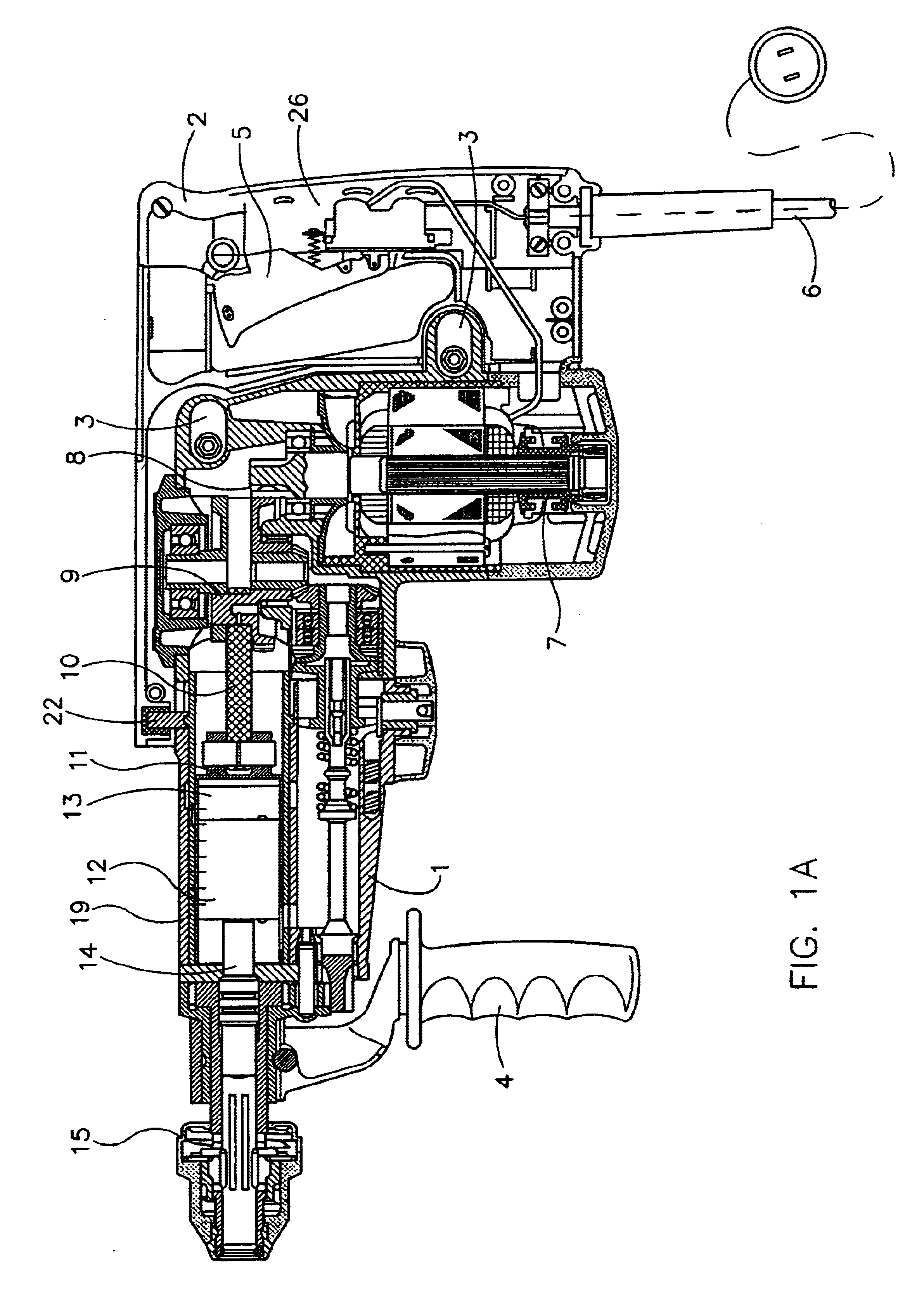

A hammer drill (1) includes a lock plate (35) forward of a boss sleeve (13) and a swash bearing (14) which cooperates with the boss sleeve to convert the rotation of an intermediate shaft (5) on which the boss sleeve is mounted. The lock plate is mounted on the boss sleeve and selectively engages claws (23) of the boss sleeve (13) in a manner that permits its integral rotation with and axial slide with respect to the boss sleeve. The lock plate is additionally biased in the forward direction by a coil spring (38) so that when a clutch (19) is shifted forward in a drill mode, the lock plate also moves forward into engagement with a stopper (39) secured to an inner housing (4), preventing inadvertent rotation of the boss sleeve.

Owner:MAKITA CORP

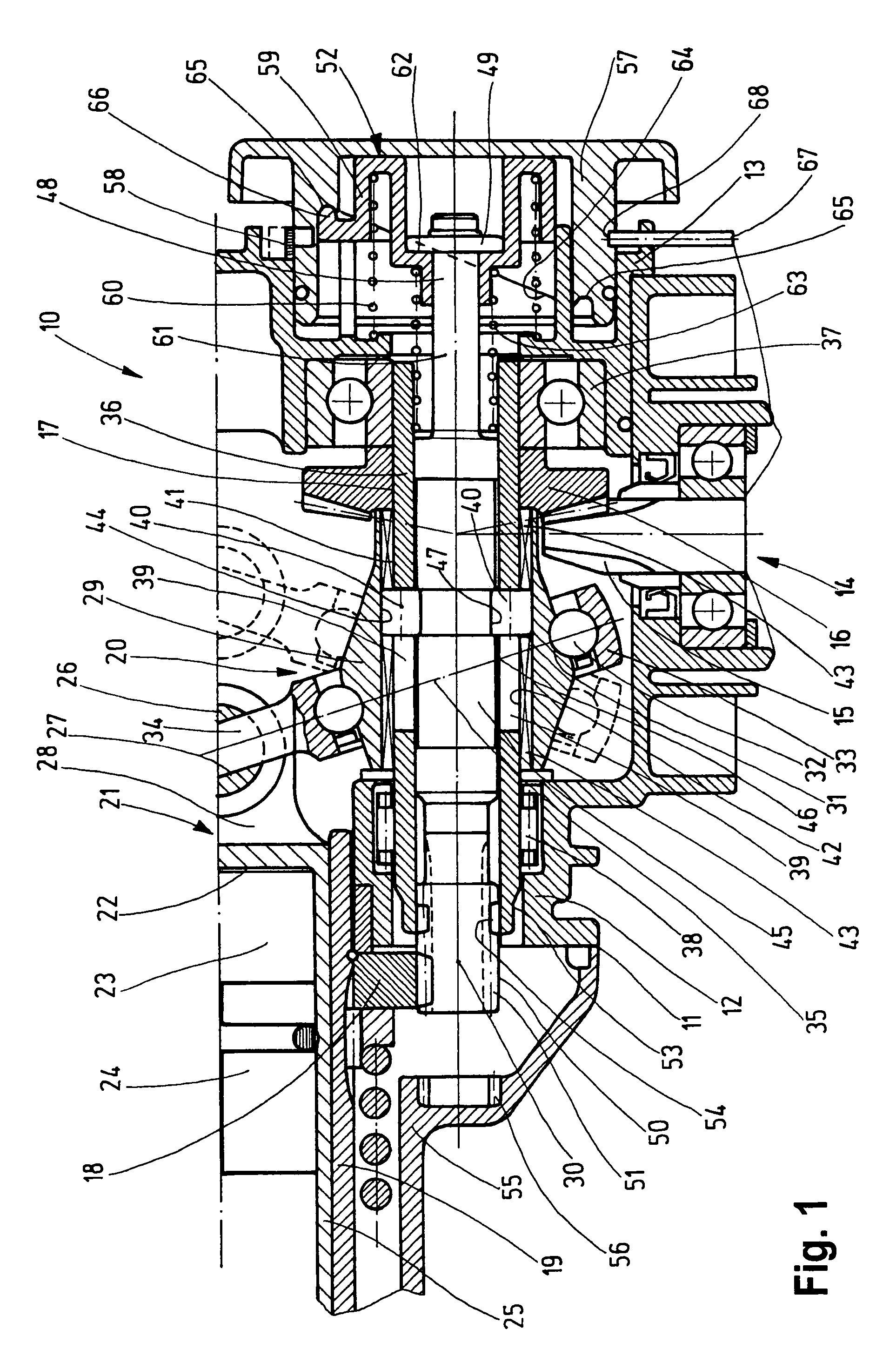

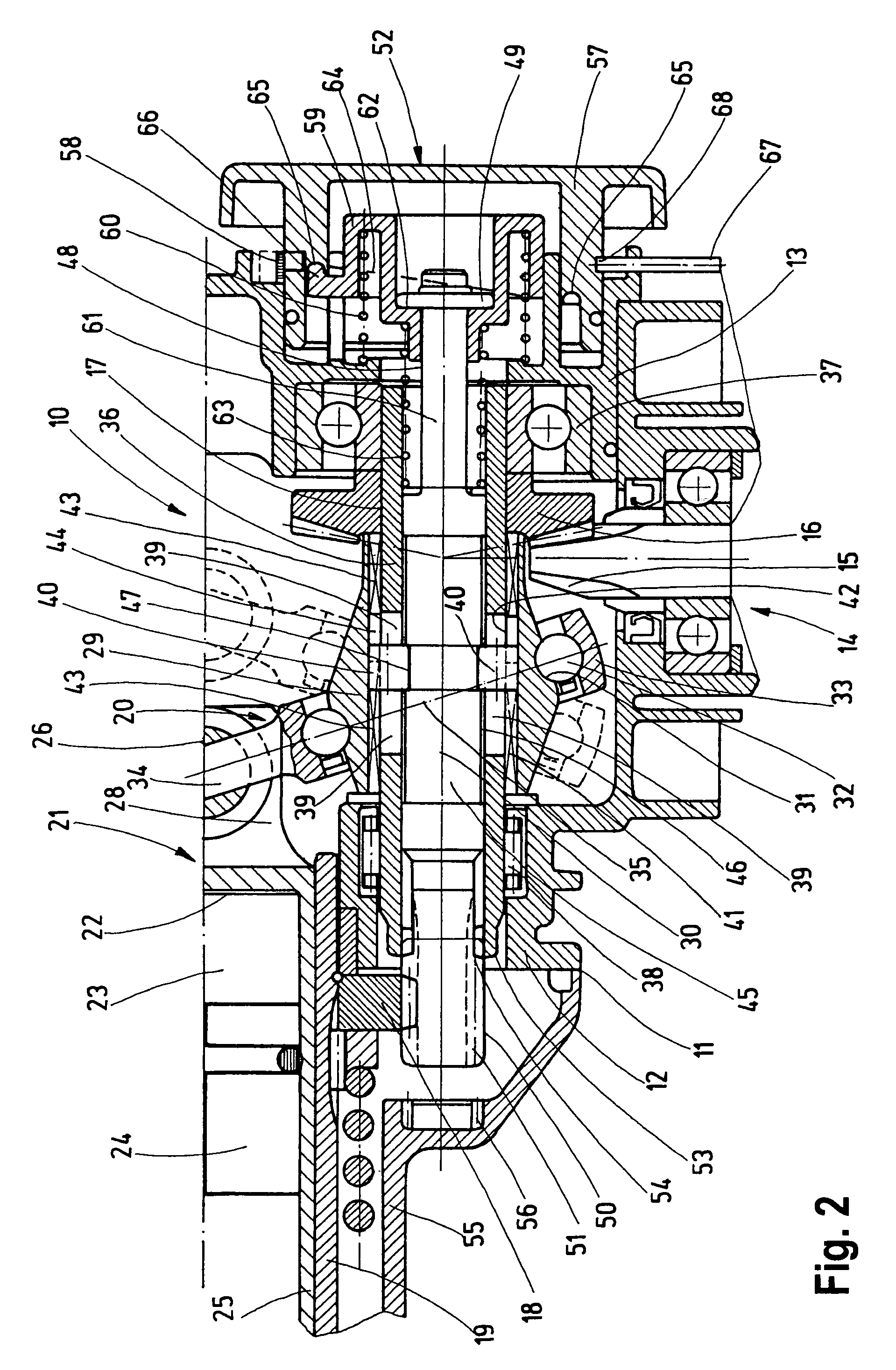

Hammer drill and /or percussion hammer with no-load operation control that depends on application pressure

InactiveUS6913088B2Reliable changeReliable acquisitionReciprocating drilling machinesPortable percussive toolsEngineeringMechanical engineering

A percussion hammer drill and / or percussion hammer that can be guided by a handgrip comprises a pneumatic spring striking mechanism with a reciprocating drive piston and with a percussion piston that can be operated by the drive piston. A cavity for accommodating a pneumatic spring is provided between the drive piston and the percussion piston. The cavity can be connected to the surrounding area via a no-load operation channel in order to achieve a no-load operation. This this end, a valve is situated inside the no-load operation channel and can be controlled according to an application force that can be applied to the handgrip by the operator.

Owner:WACKER NEUSON SE

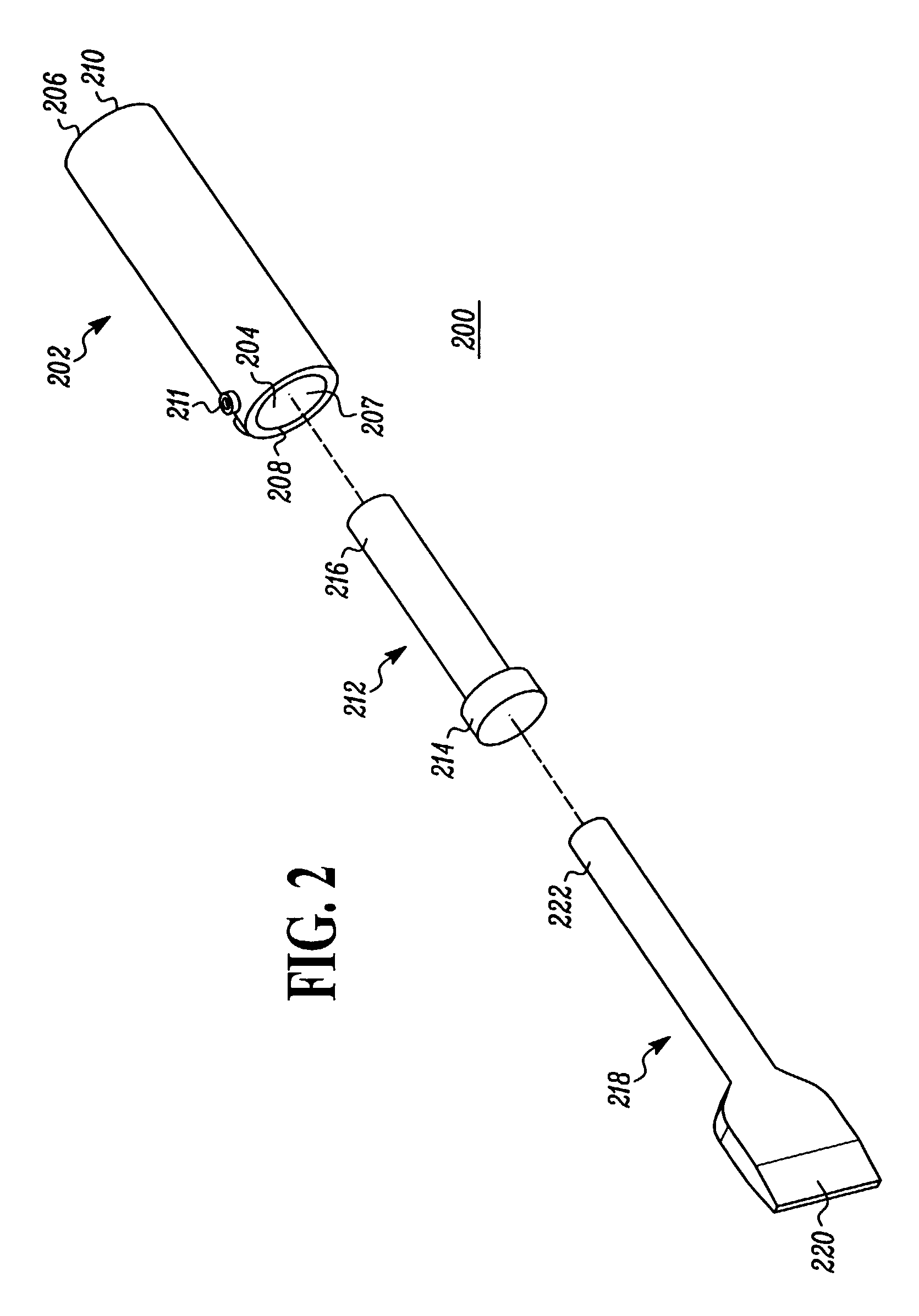

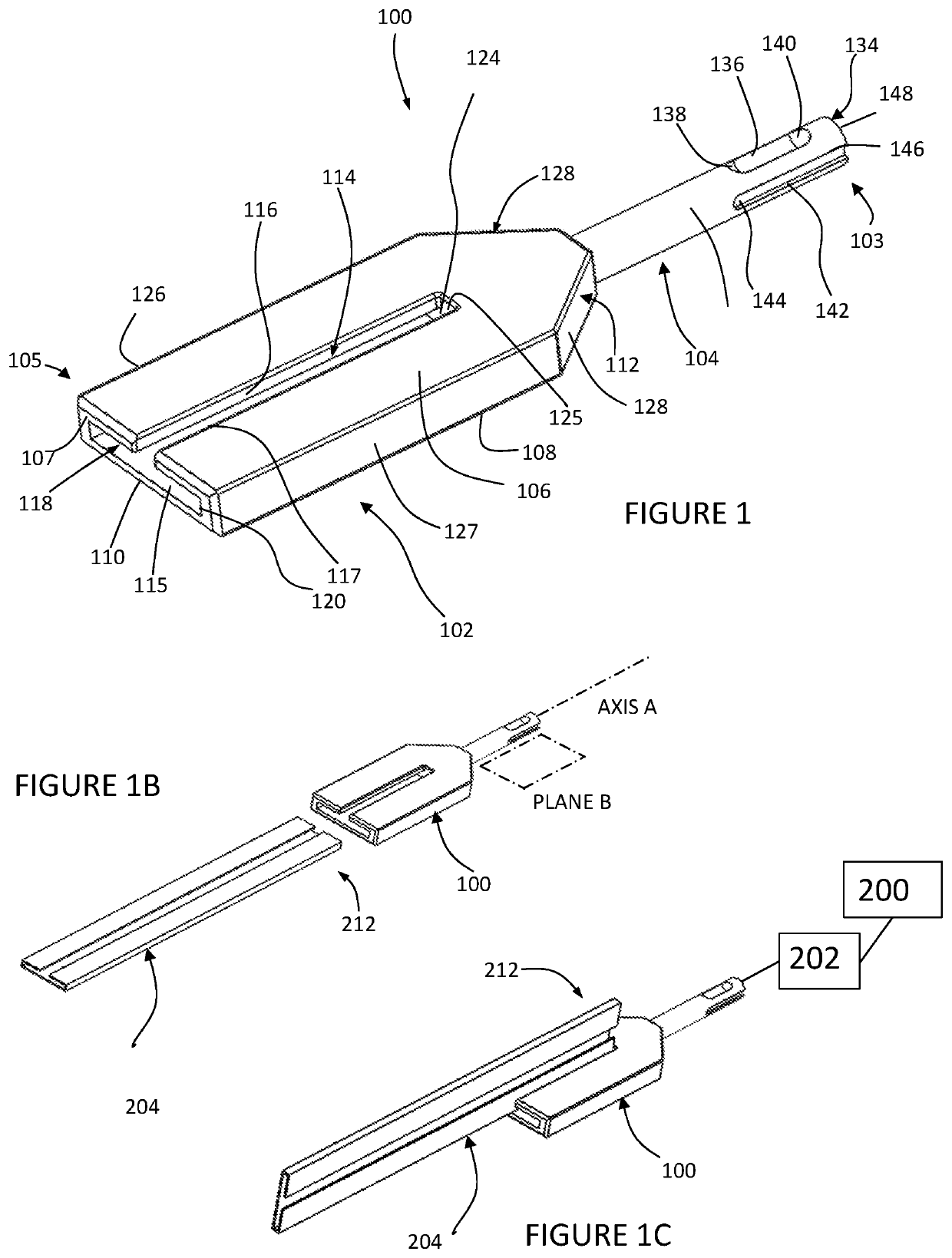

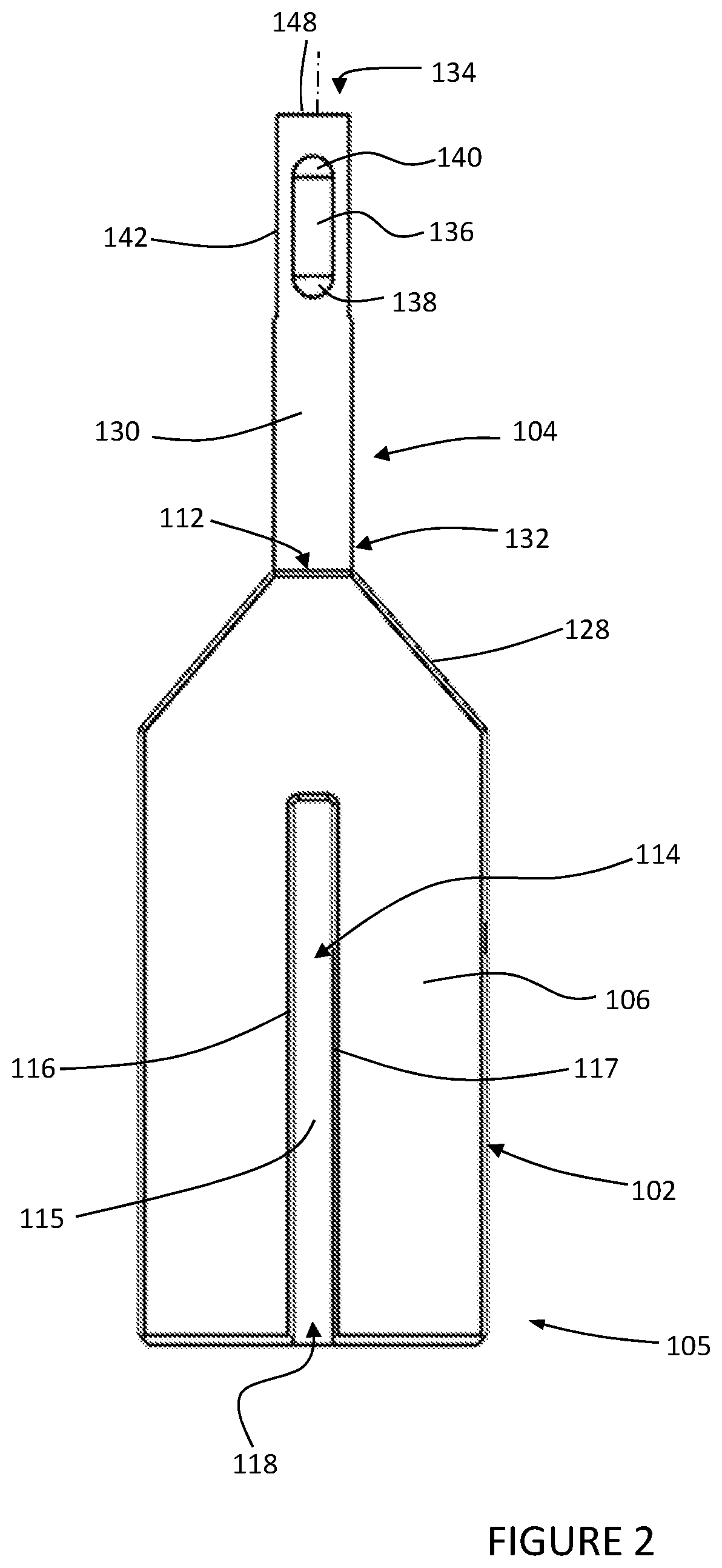

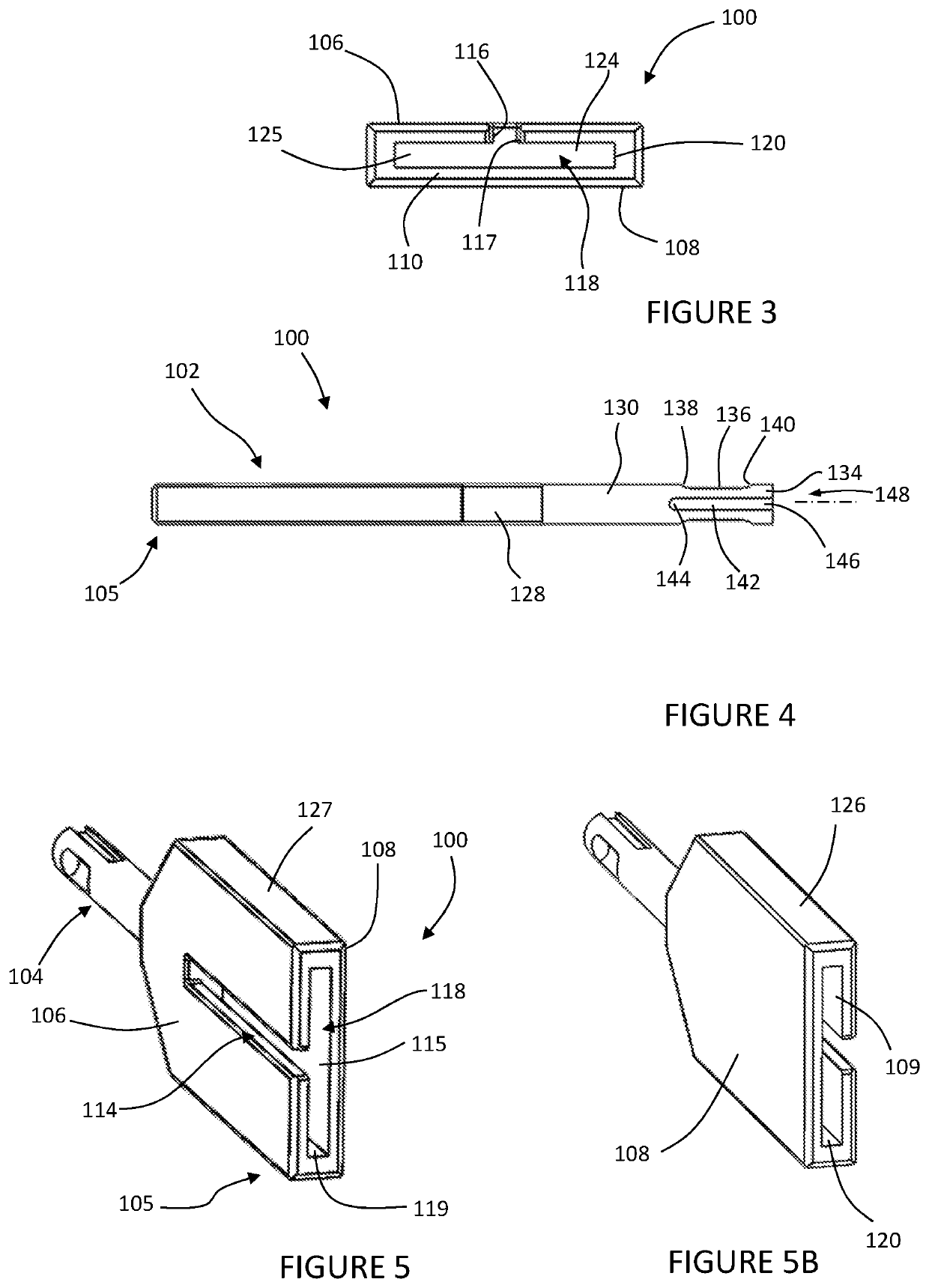

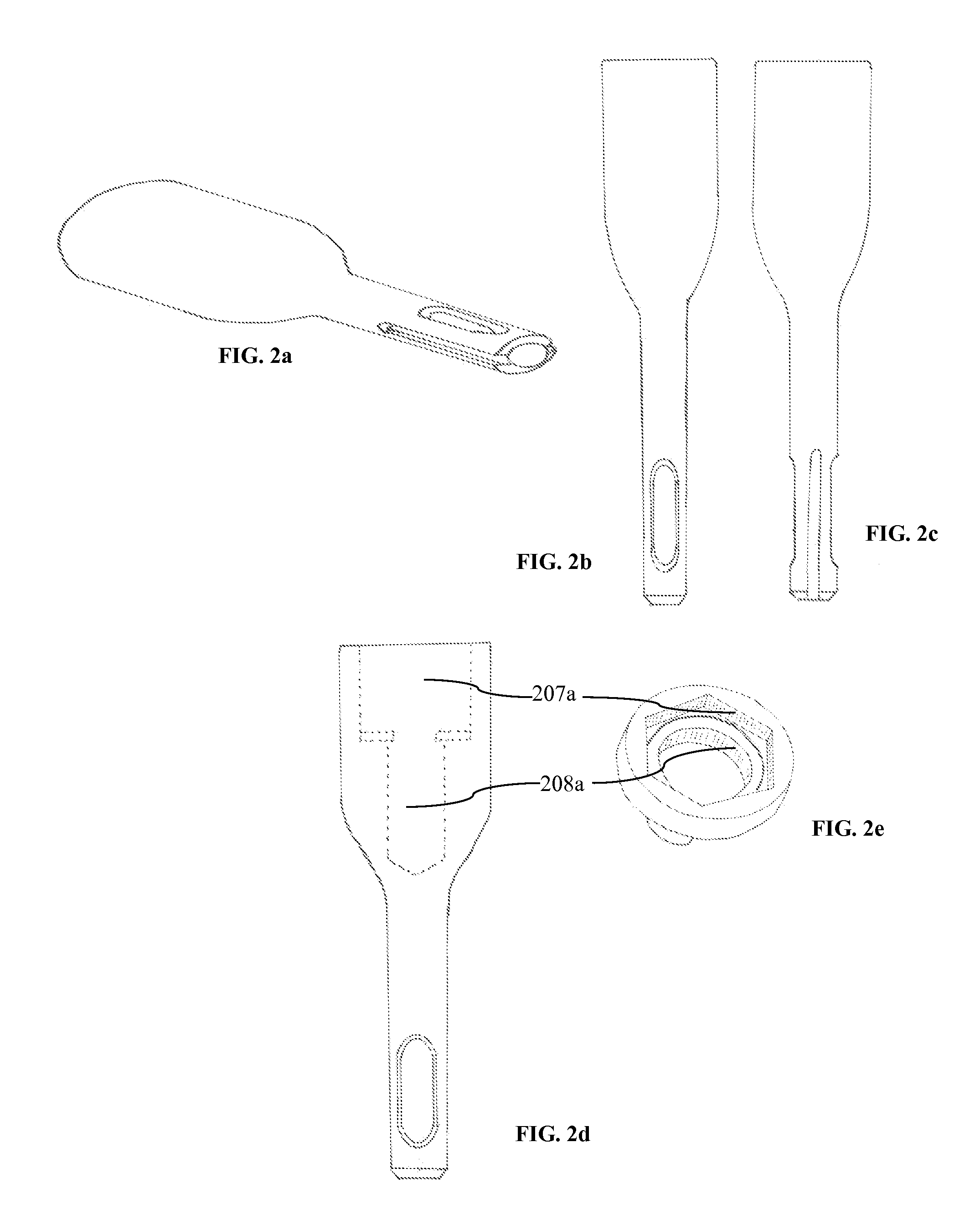

Hammer drill adaptors and methods of use

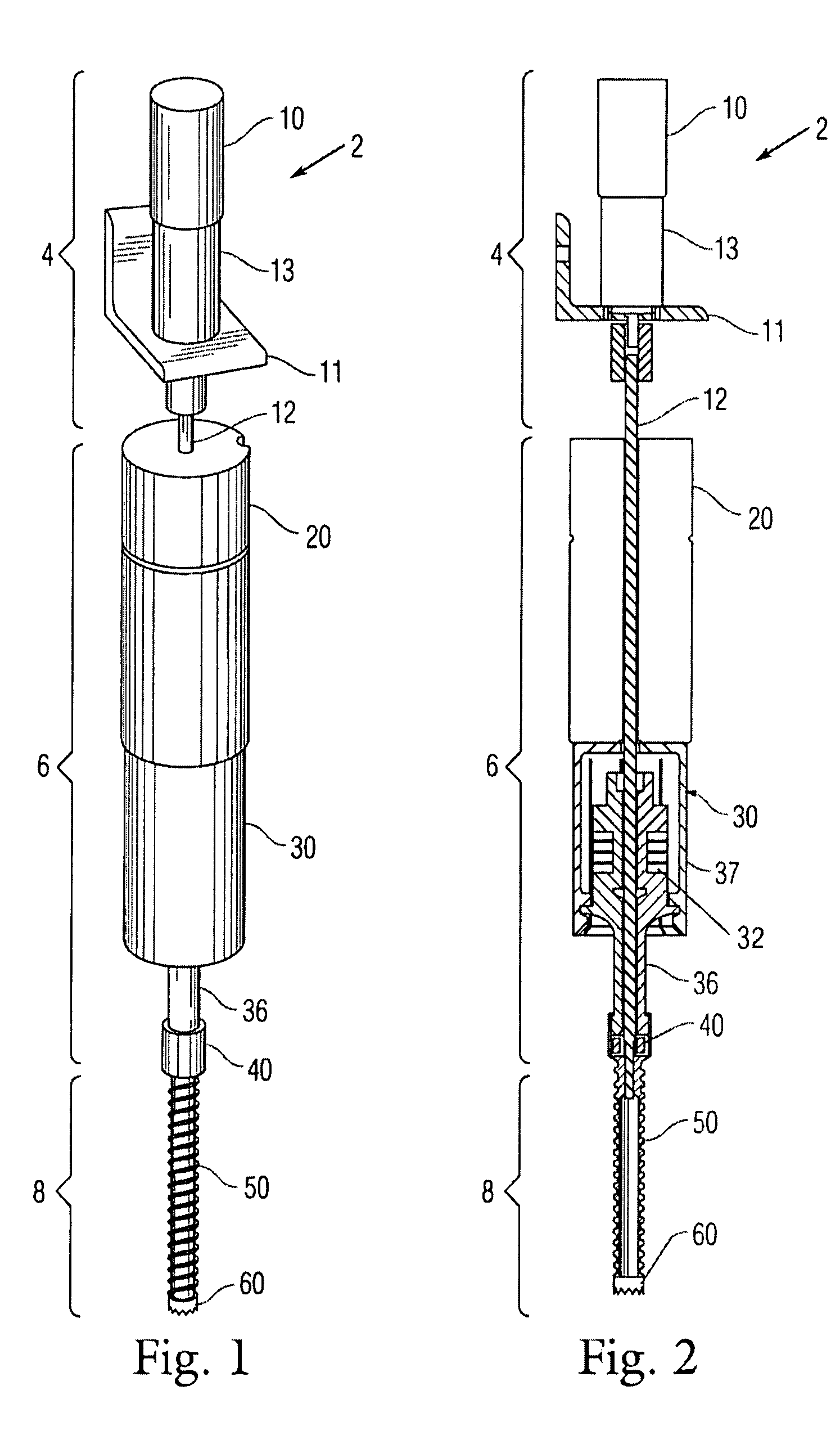

ActiveUS10589410B2Short, rapid hammer thrustBrittle materialPortable percussive toolsStructural engineeringMechanical engineering

A hammer drill adapter for driving a drive cleat to join opposed ends of a duct comprising: a first portion generally aligned in a plane; a shaft portion having an elongate axis generally parallel to said plane; the first portion fixed to the shaft portion; an entry surface at a distal end of the first portion; a capture cavity extending through the entry surface; the capture cavity defined proximally by a rear surface and by an opposed lower and upper capture surfaces; the capture cavity also laterally defined by an opposed first capture surface and a second capture surface; the capture cavity sized to house a trailing end portion of a drive cleat; and wherein the shaft portion comprises a connection portion at a proximal end of said shaft portion for fixation within a hammer drill chuck. Also disclosed are methods for use to advance a drive cleat.

Owner:AHO RONALD

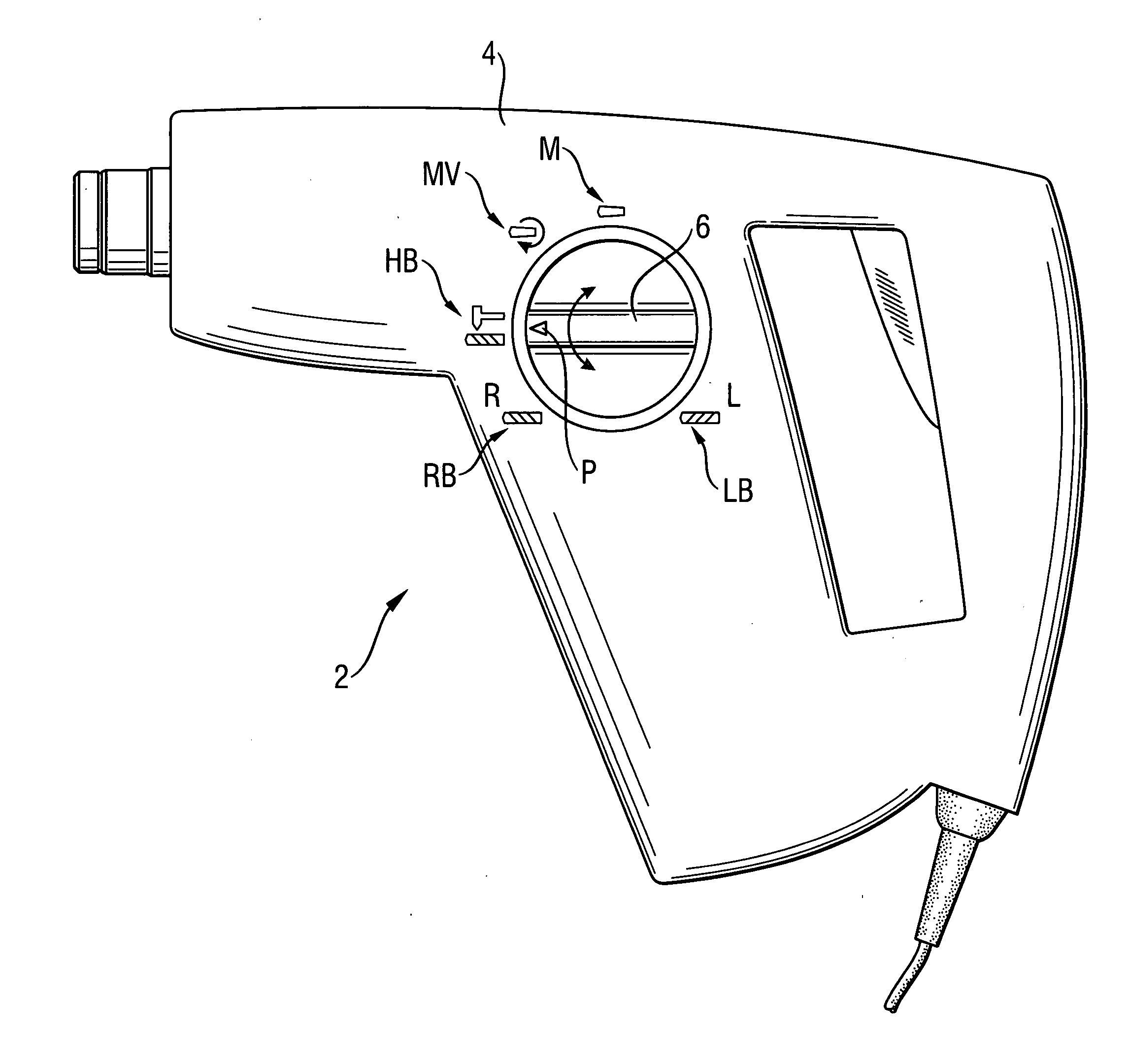

Hammer drill

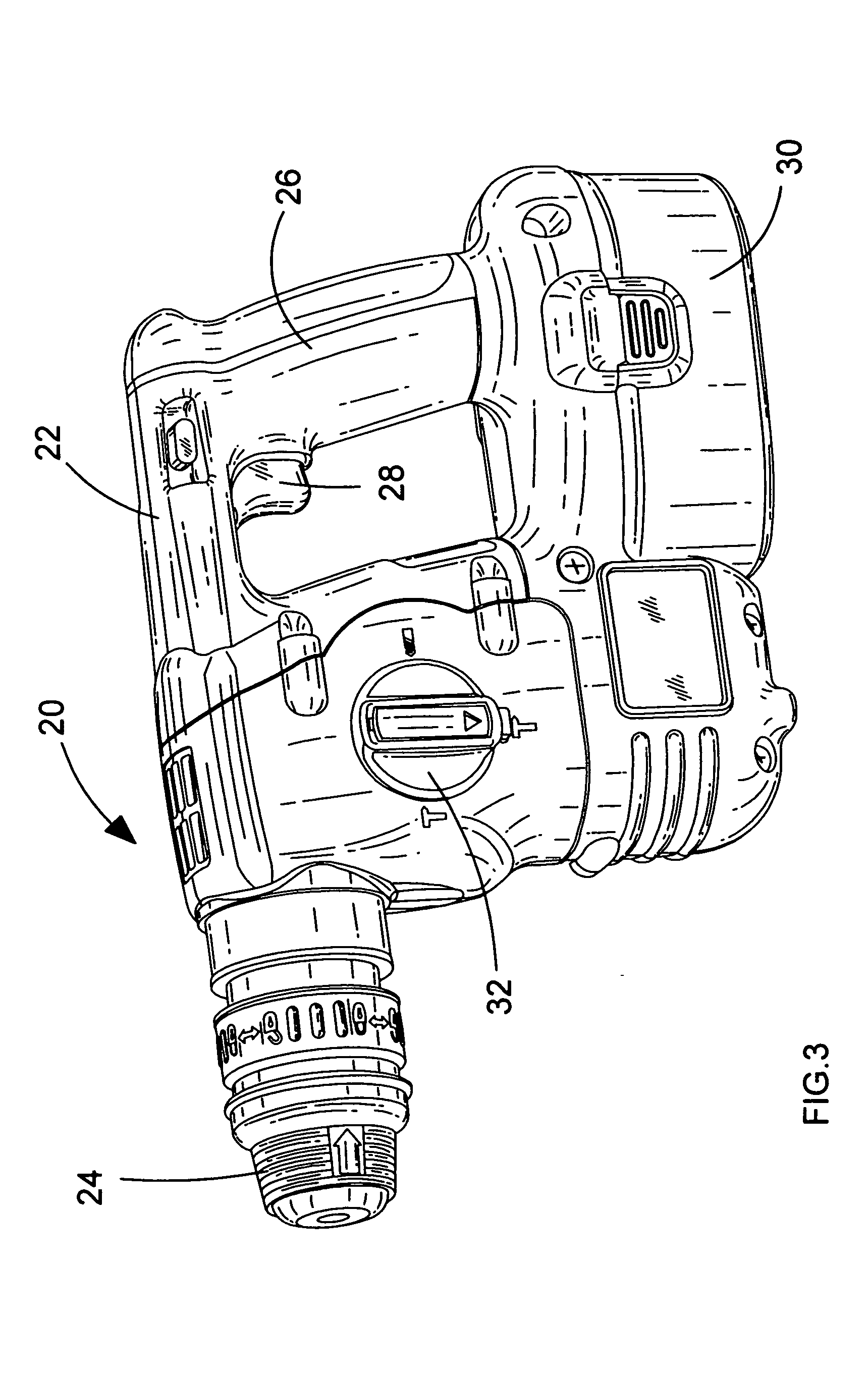

ActiveUS20050224242A1Easy constructionReduce manufacturing costStapling toolsMechanical apparatusPinionClockwise

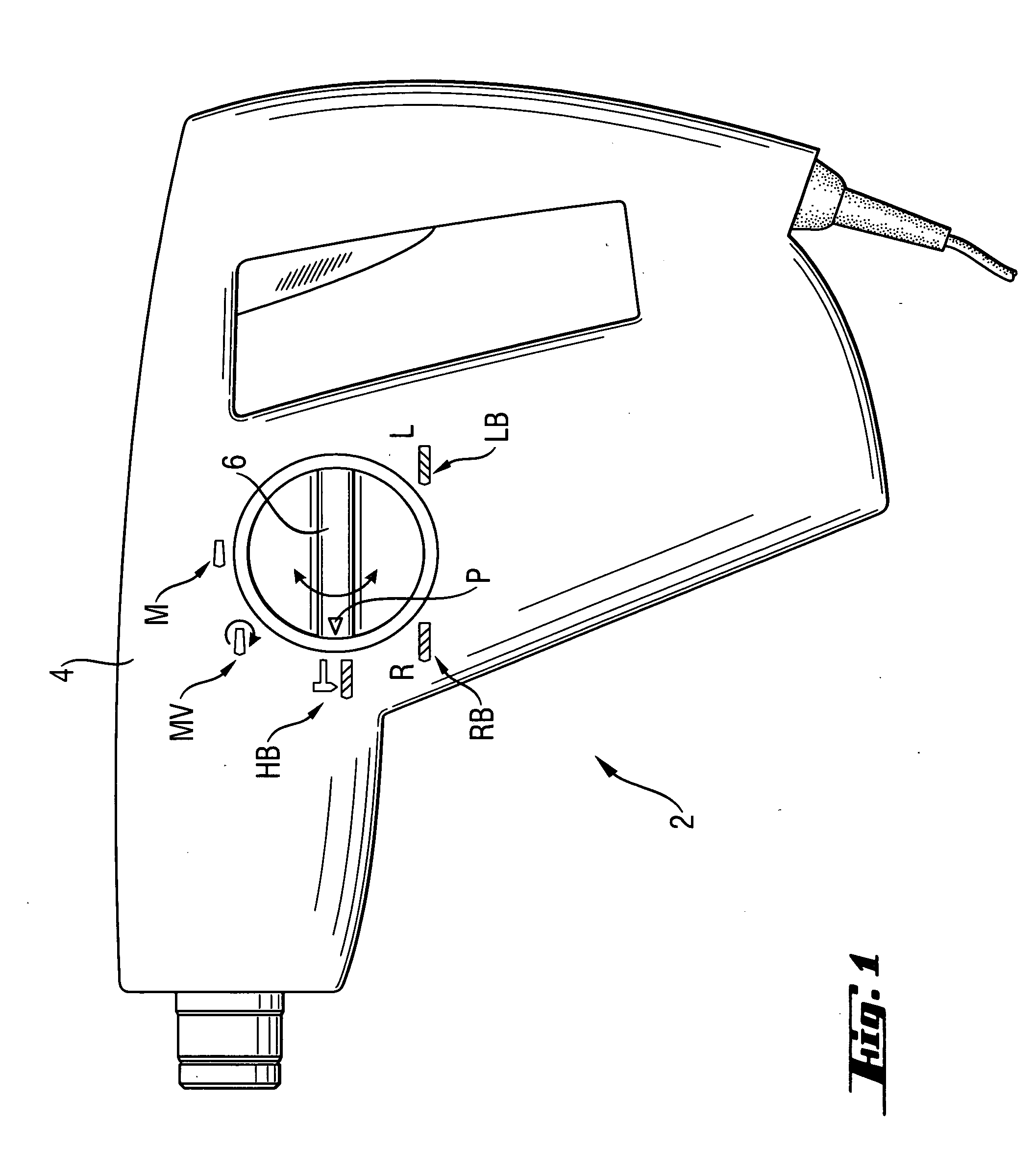

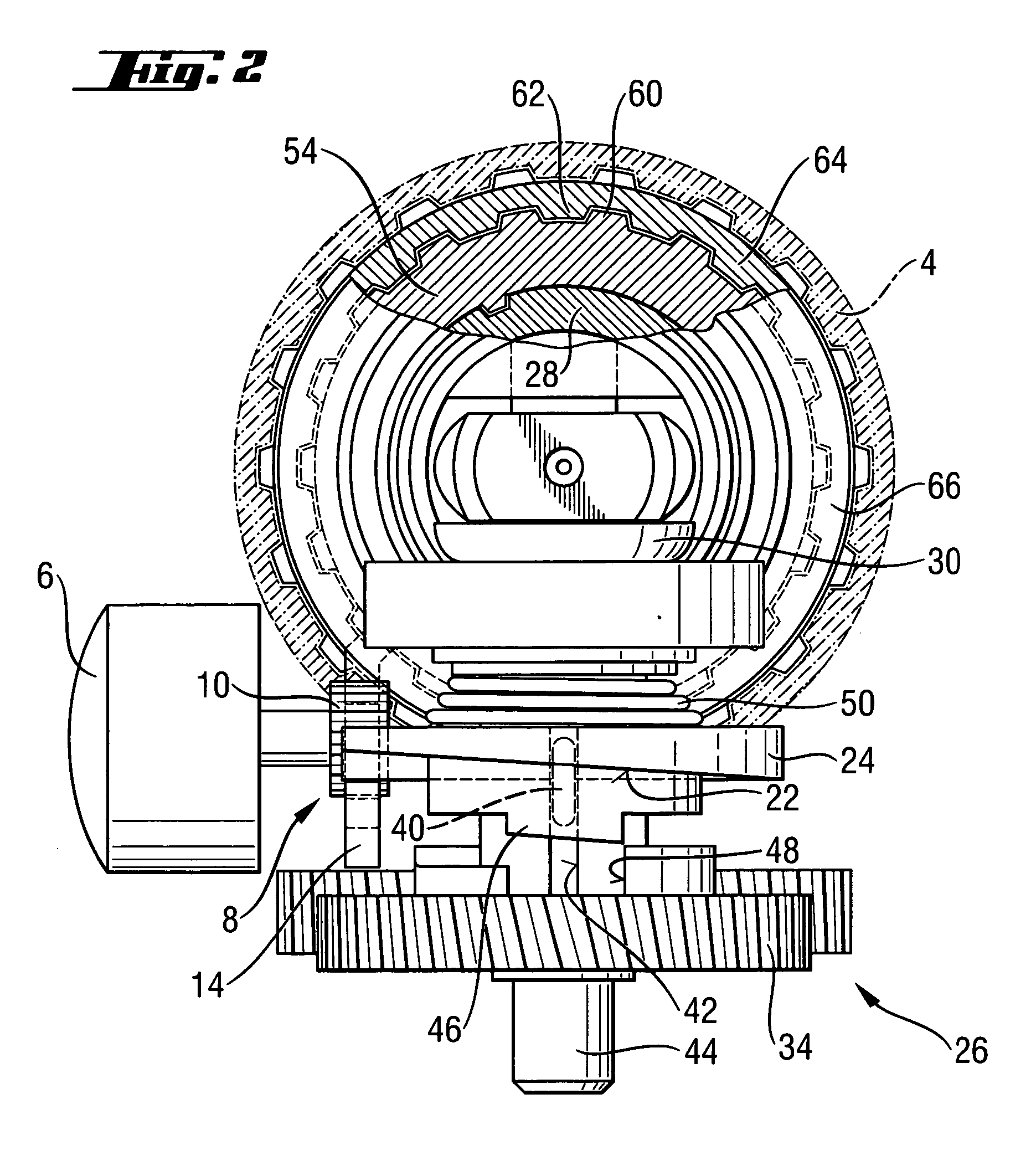

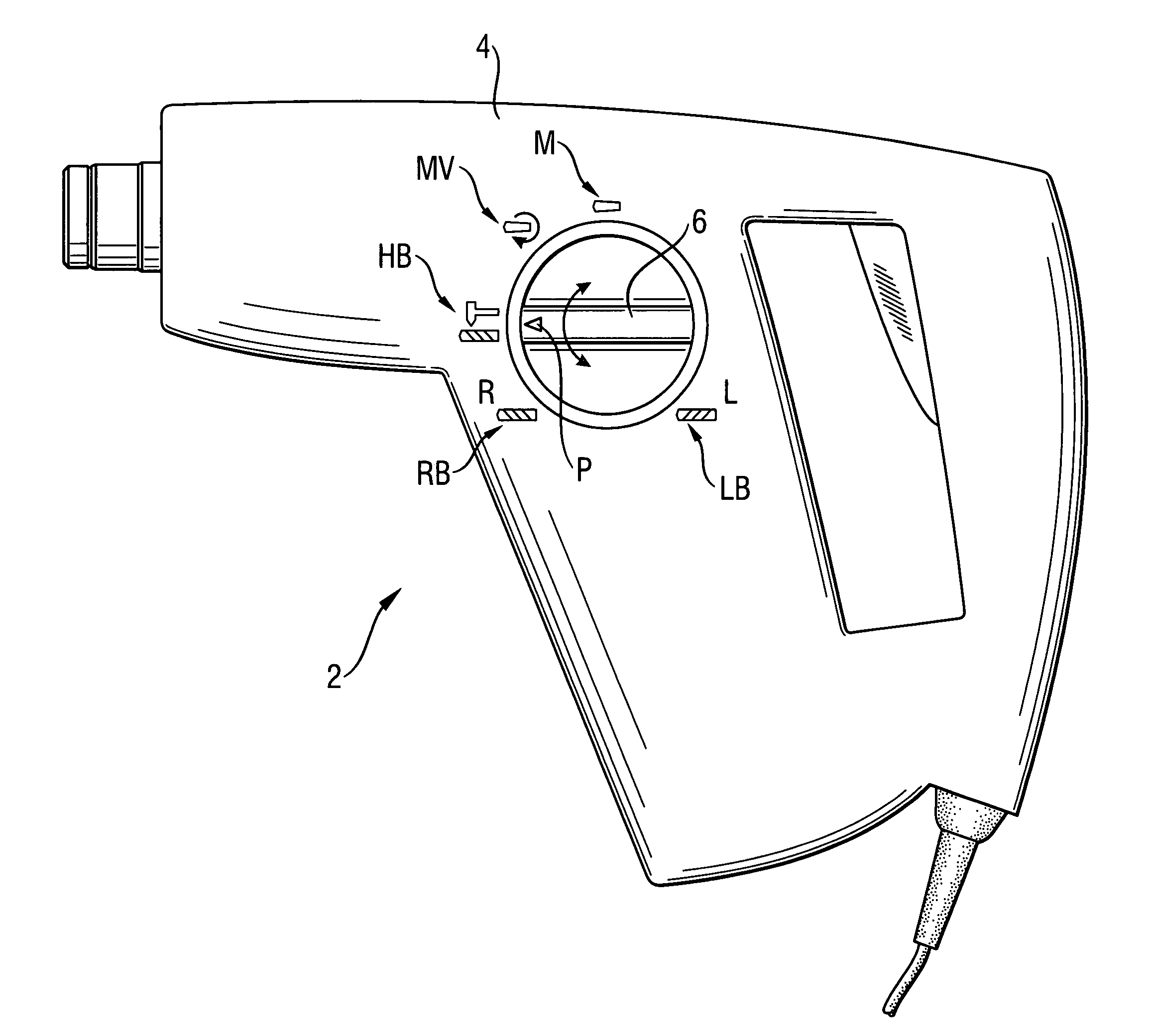

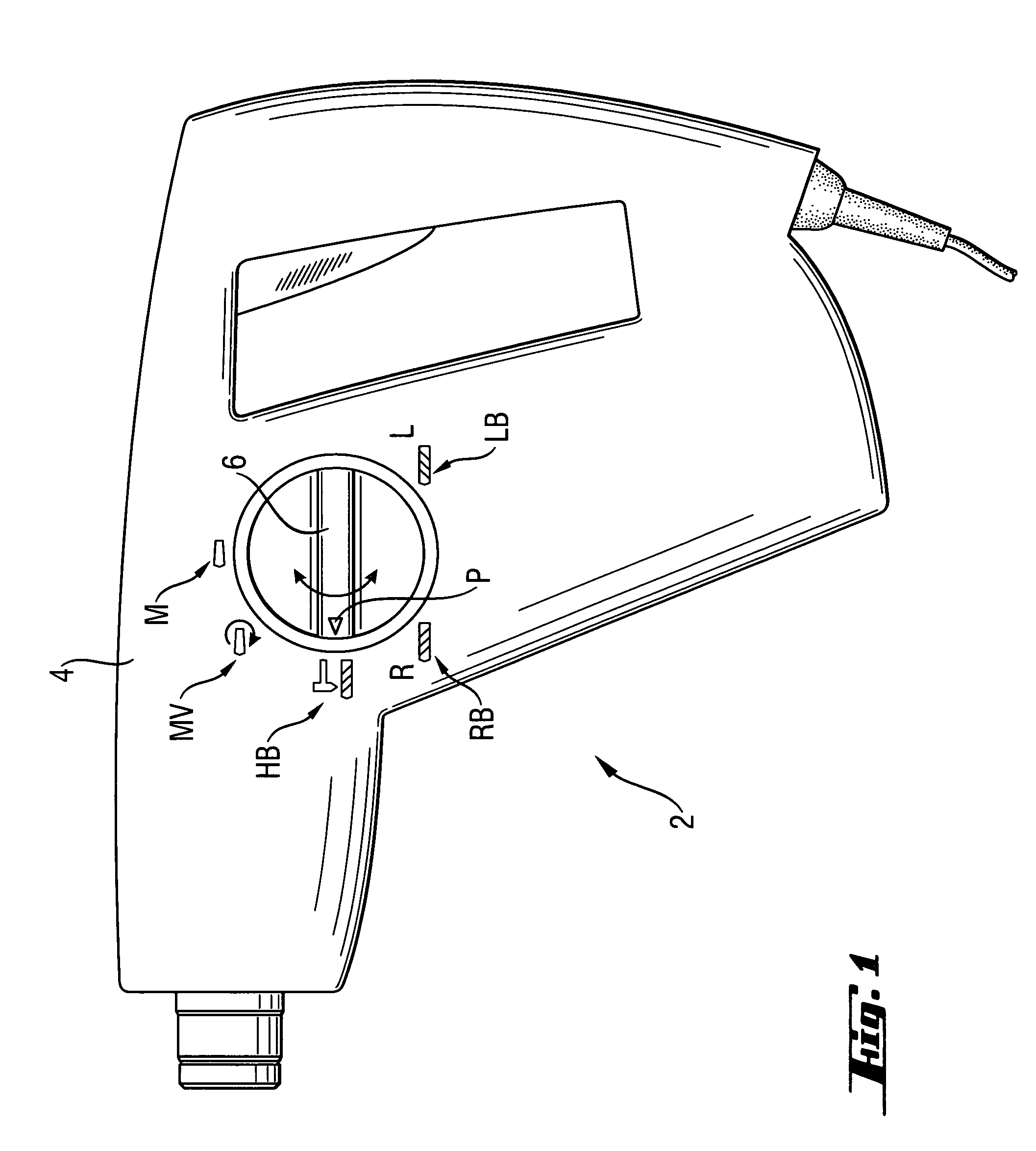

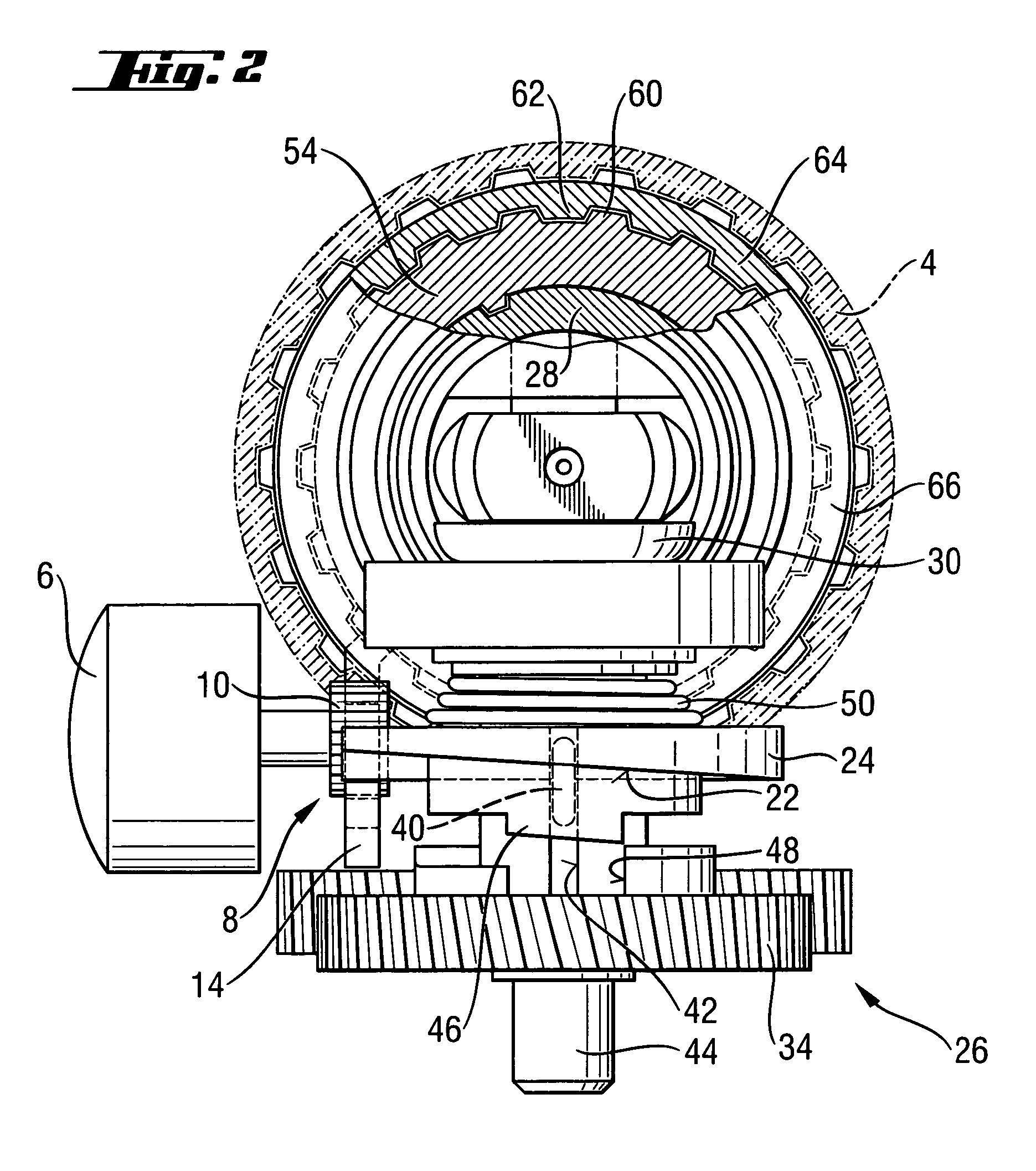

A hammer drill (2) includes a clockwise and counterclockwise driven tool spindle (28), a drive pinion (70) operatively connectable with the tool spindle (28) for transmitting a torque thereto, a separate control handle (6) for selecting one of the hammer drill functions including a pure drilling operation, a pure percussion operation, and a rotary-percussion operation), and a switching device (8) which is adjustable in accordance with a position of the control handle (6) and which is shiftable by the control handle (6) in a clockwise rotation position for effecting a pure drilling operation in a clockwise direction and in a counterclockwise rotation position for effecting a pure drilling operation in a counterclockwise direction.

Owner:HILTI AG

Hammer drill with selective lock-on

Owner:BLACK & DECKER INC

Actuation apparatus for power tool

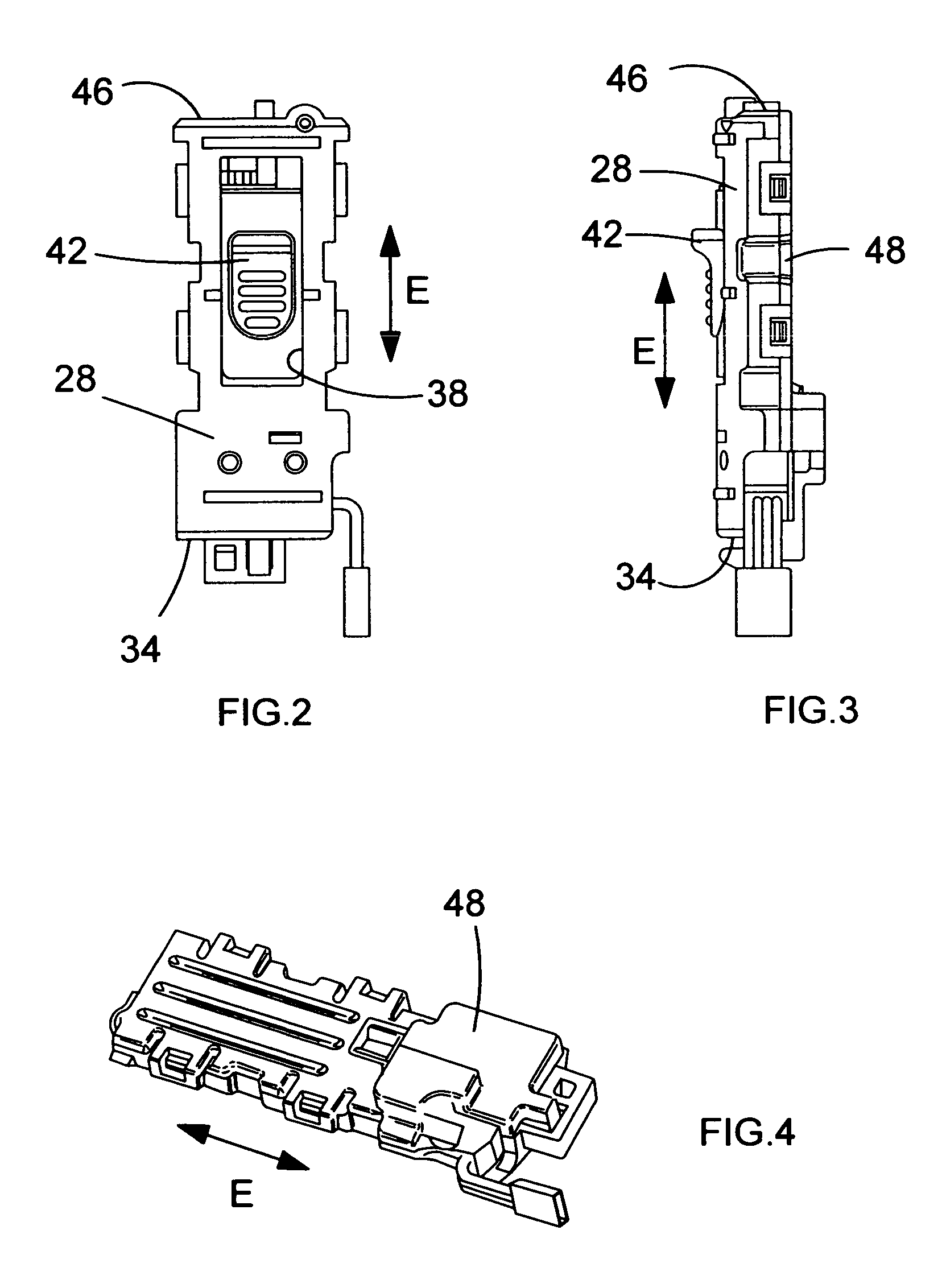

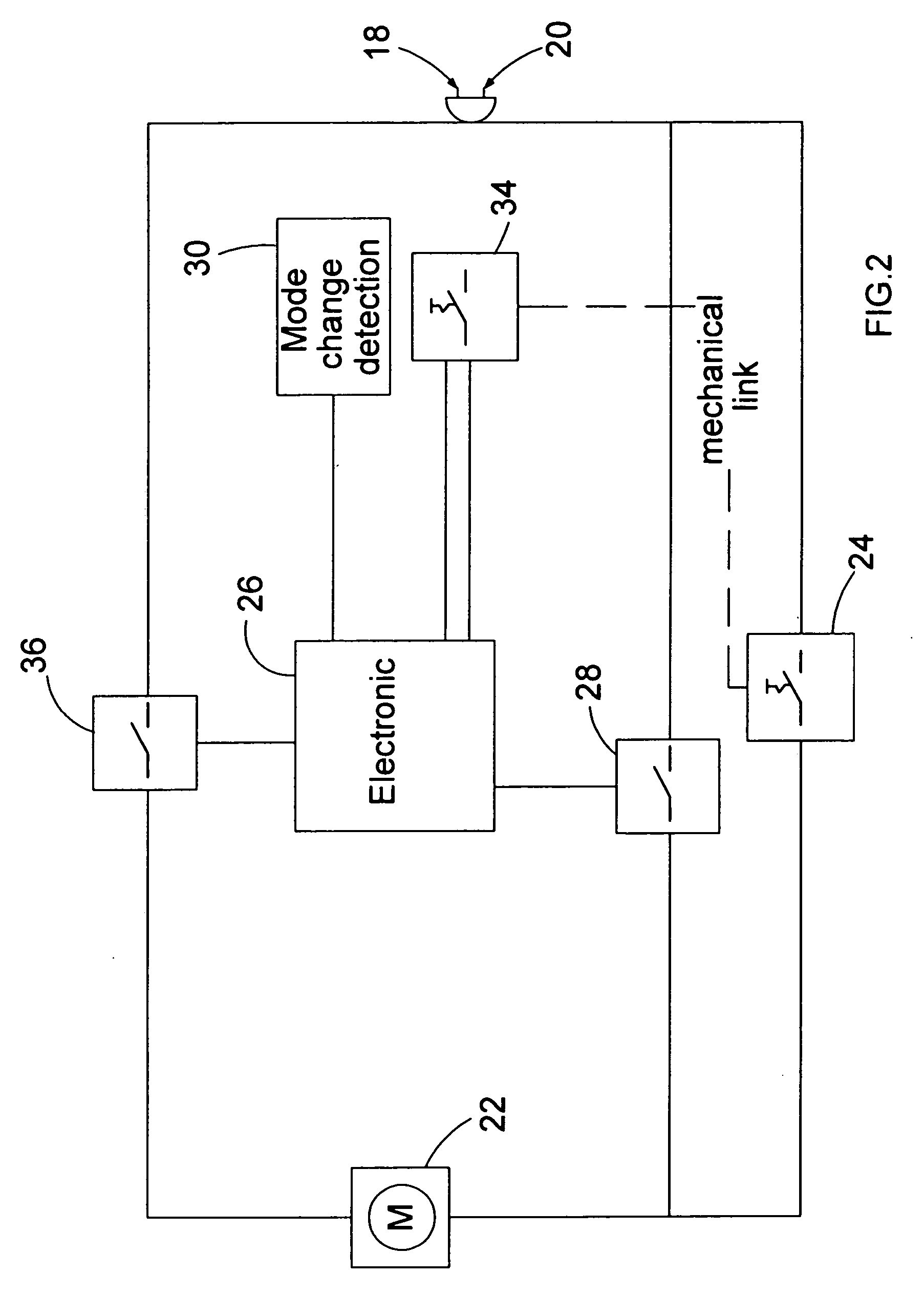

InactiveUS20060185865A1Improve gripReduced dimensionPortable percussive toolsElectric switchesElectric machineTRIAC

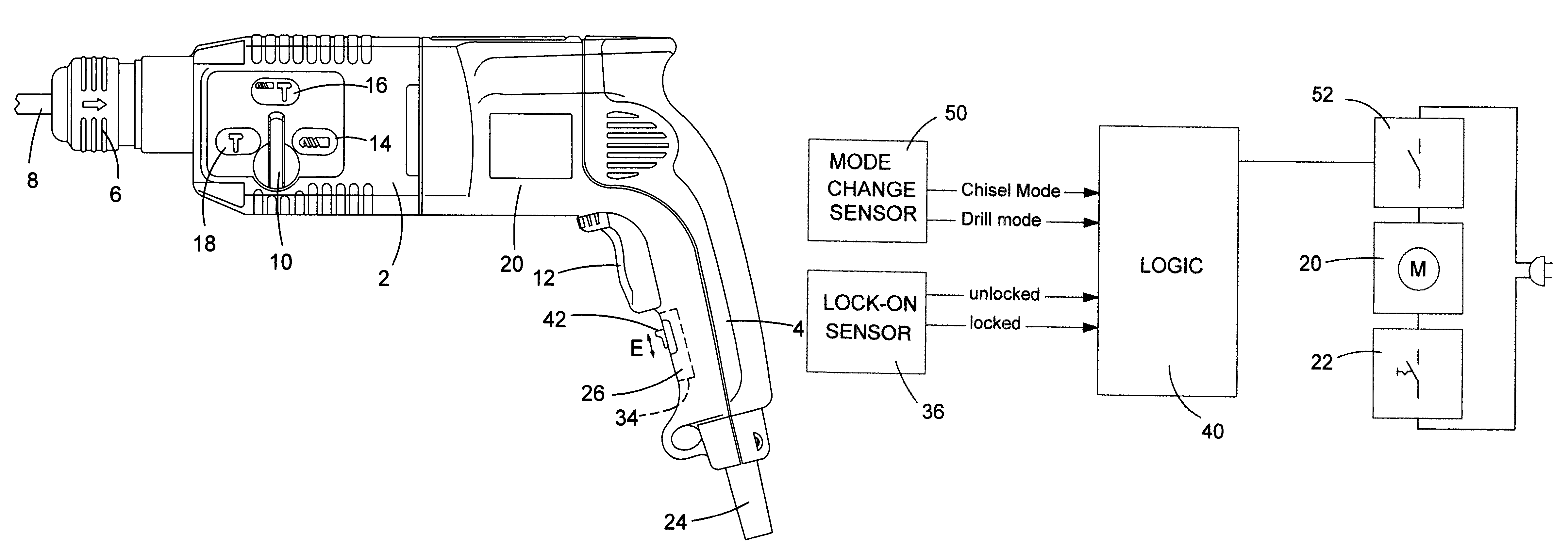

When the mode change knob of a multi-mode hammer drill is moved to the hammer only position, an electronic sensor sends a signal to a control logic circuit. When the user then depresses the trigger mechanically closing the ON / OFF switch, the control logic circuit applies a voltage either to a holding relay or to the gate of a triac which enables the relay or triac to conduct, thus providing a parallel circuit by-passing the ON / OFF switch. Consequently, when the user releases the trigger and opens the ON / OFF switch, the parallel relay or triac maintains current flow to the motor. It can be seen that in hammer only mode the user can activate the hammer drill by simply tapping the trigger to depress it and does not need to hold down trigger during use of the hammer in operation.

Owner:BLACK & DECKER INC

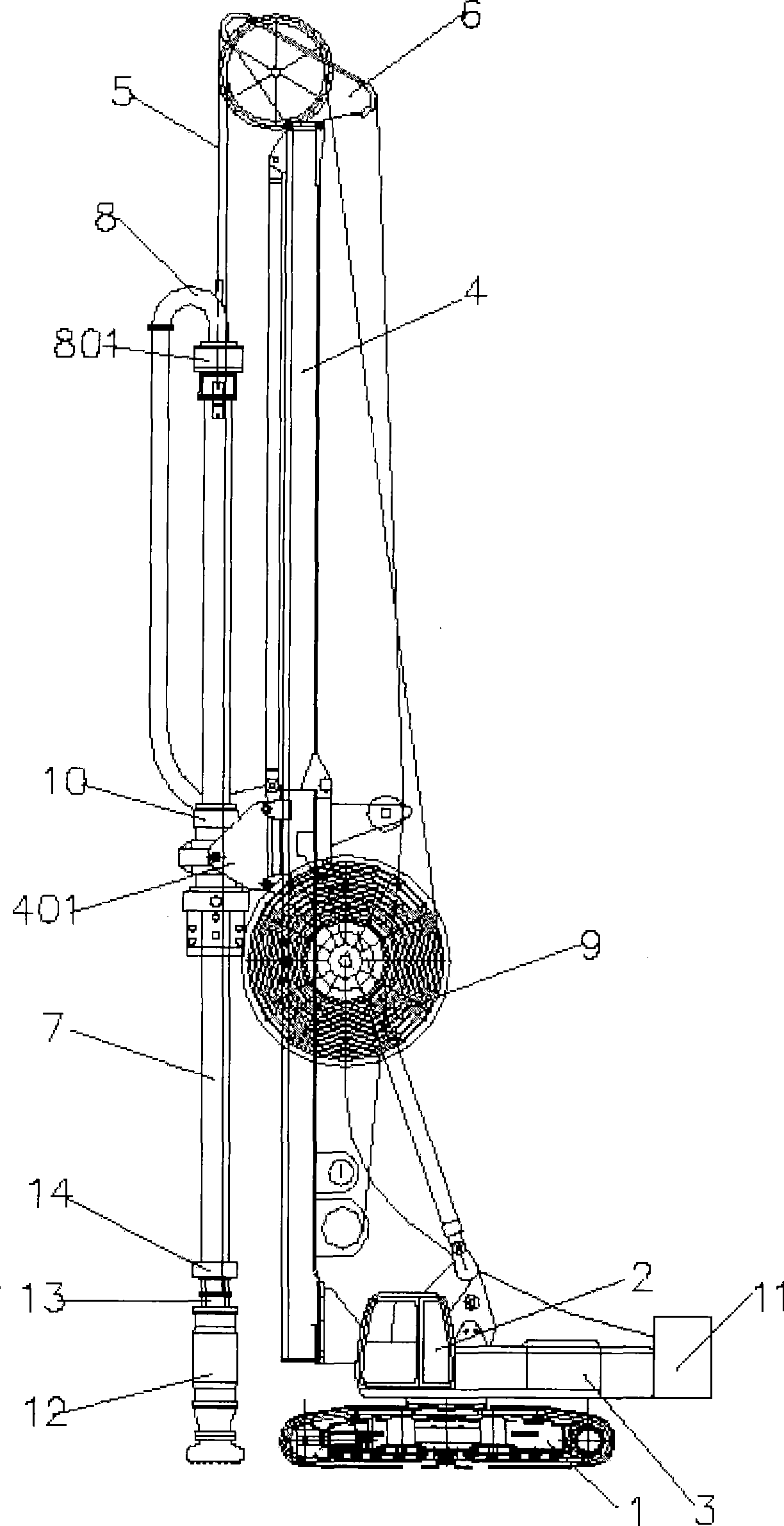

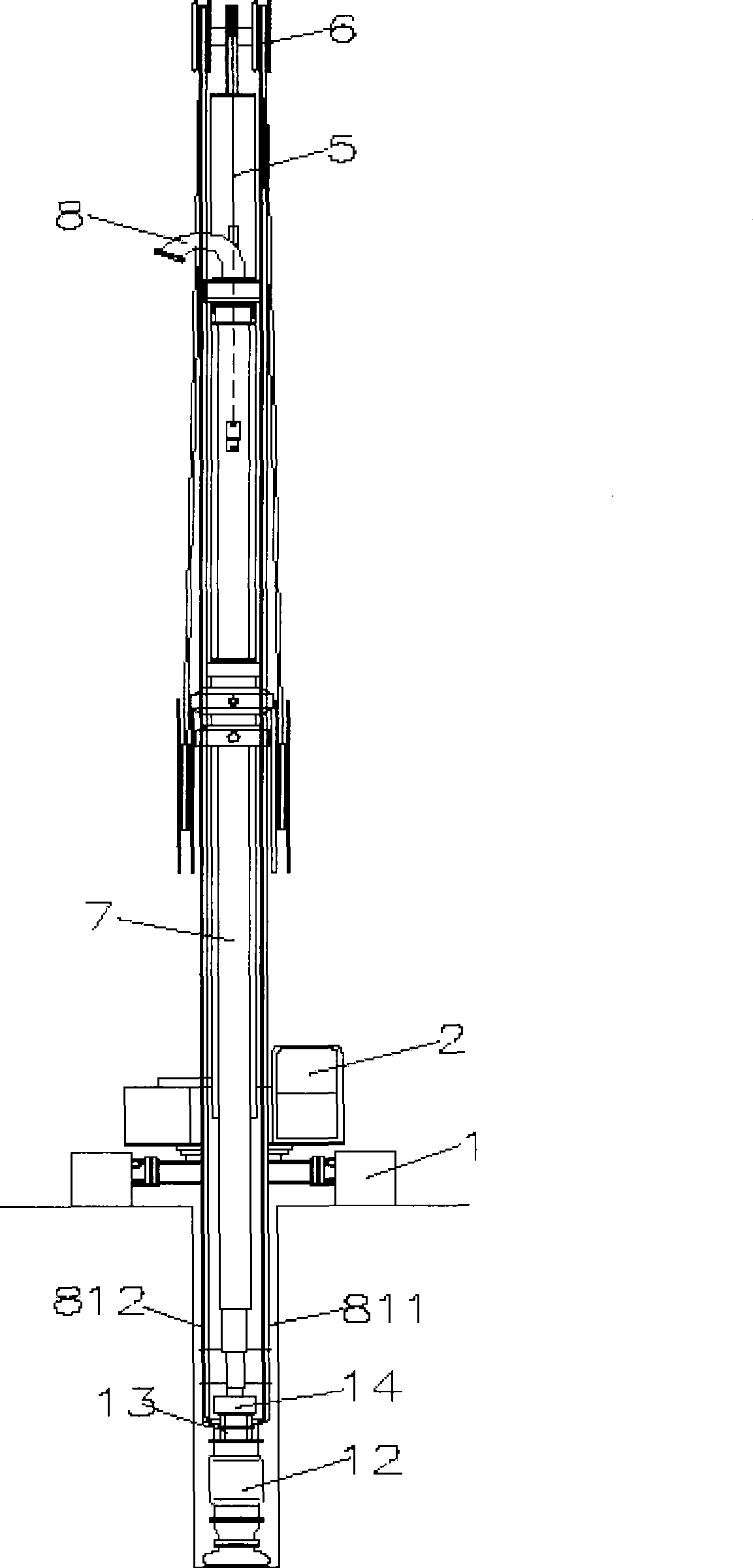

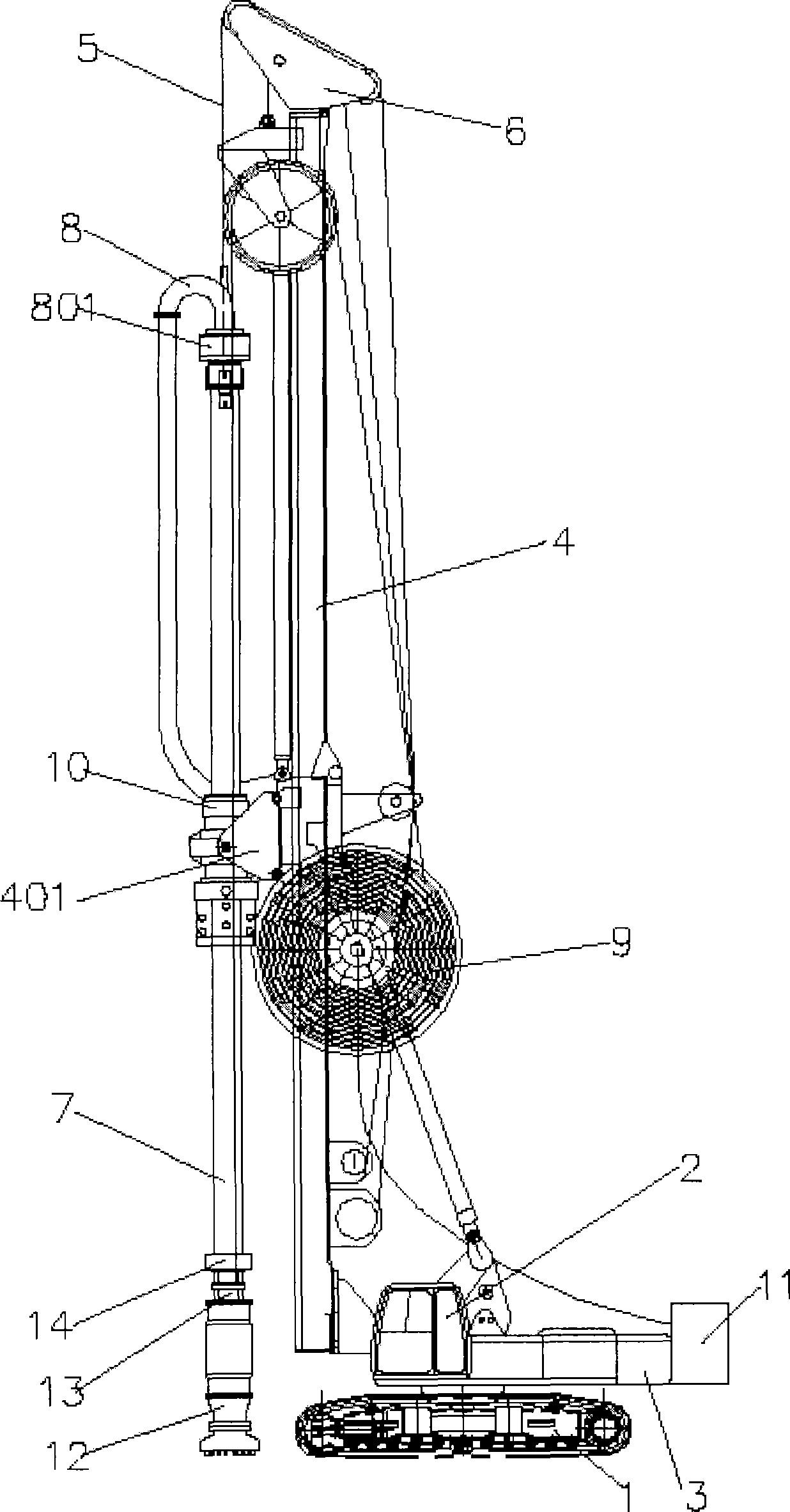

Multifunctional hammer drill

ActiveCN101435312AImprove reliabilityExtended service lifeConstructionsReciprocating drilling machinesBasementPositive pressure

The invention relates to a multifunctional percussion drill which is mainly used for drilling into basement rocks, comprising a chassis control chamber, a host machine of a drilling machine and a mast. The mast is provided with a mounting bracket, a wire rope, and an overhead travelling crane and a multilayer hollow sealed telescopic drill rod which are arranged at the top of the mast. The mast body is provided with a deslagging cock and comprises a power device of an impacting device arranged on a chassis, a plurality of pipelines and a pipeline winch fixed on the mast, wherein, the pipelines are communicated with the inner cavity of the drill rod through the winch device and can extend along with the extending of the drill rod; the mast body also comprises at least one power transmitting pipeline communicated with the power device of the impacting device, at least one pollution discharging and deslagging pipeline, one positive pressure maintaining pipeline and a power head arranged on the mast of the drill, wherein, the impacting device communicated with the power transmitting pipeline is connected at the bottom part of the drill rod at the innermost layer by transition joints, and the power head drives the drill rod to force the impacting device to swing for working. The drill can effectively improve the working efficiency, conveniently and fast transform functions, and walk.

Owner:SHANGHAI JINTAI ENG MACHINERY

Anchor driver

A wedge anchor driver comprising: a first member having a first opening configured to fit onto the nut of a wedge anchor and a second opening configured to receive a predetermined length of the outer end of the wedge anchor's bolt; and a second member associated with the first member, wherein the second member's distal end is configured to fit, and be lockable, into the chuck of a hammer drill, such that, after the wedge anchor driver is locked into the chuck of the hammer drill, a user can drive the wedge anchor into a corresponding hole with the hammer drill in hammer mode and then tighten the nut of the wedge anchor by switching the hammer drill from hammer mode to drill mode.

Owner:PRUNEAN DAVID C

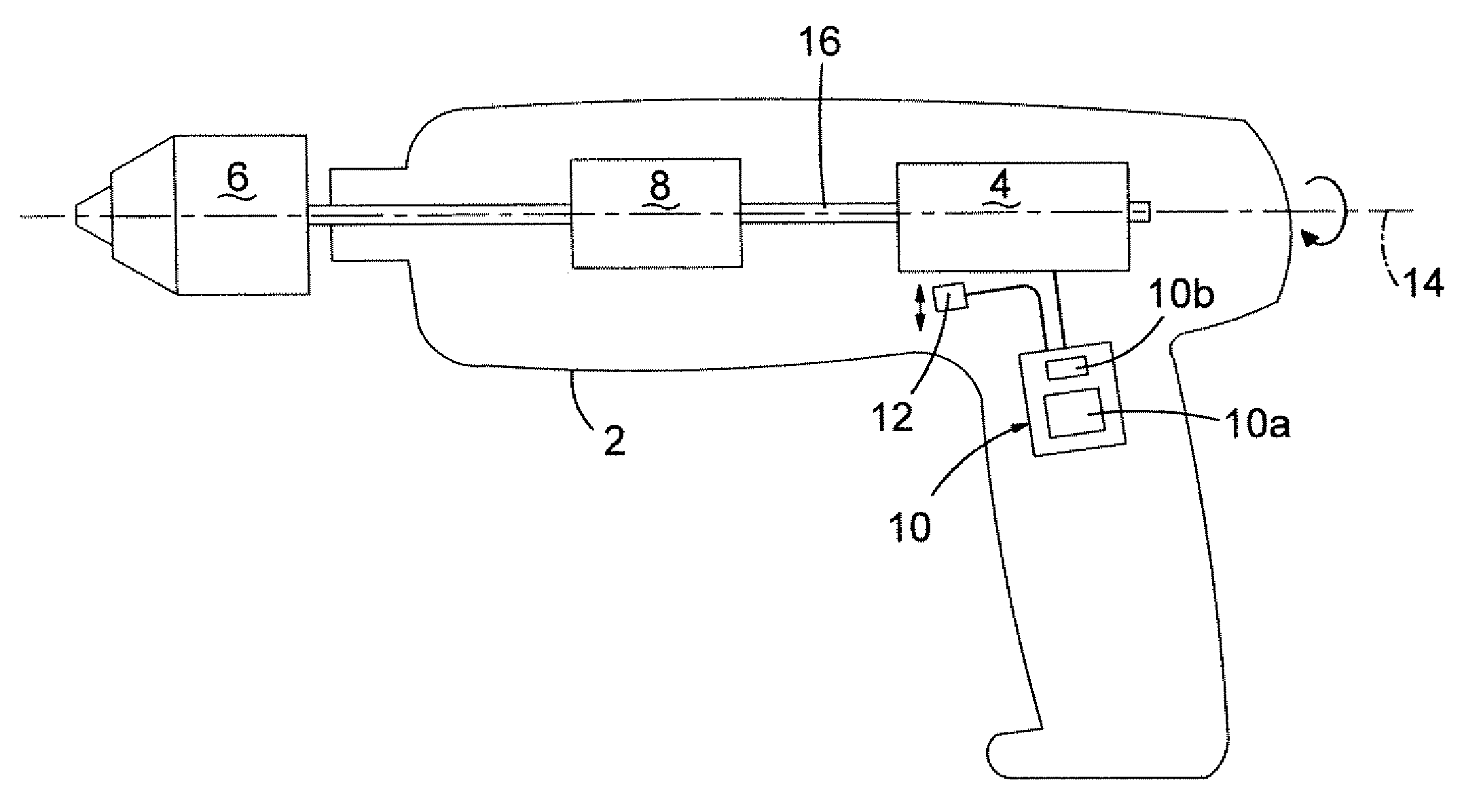

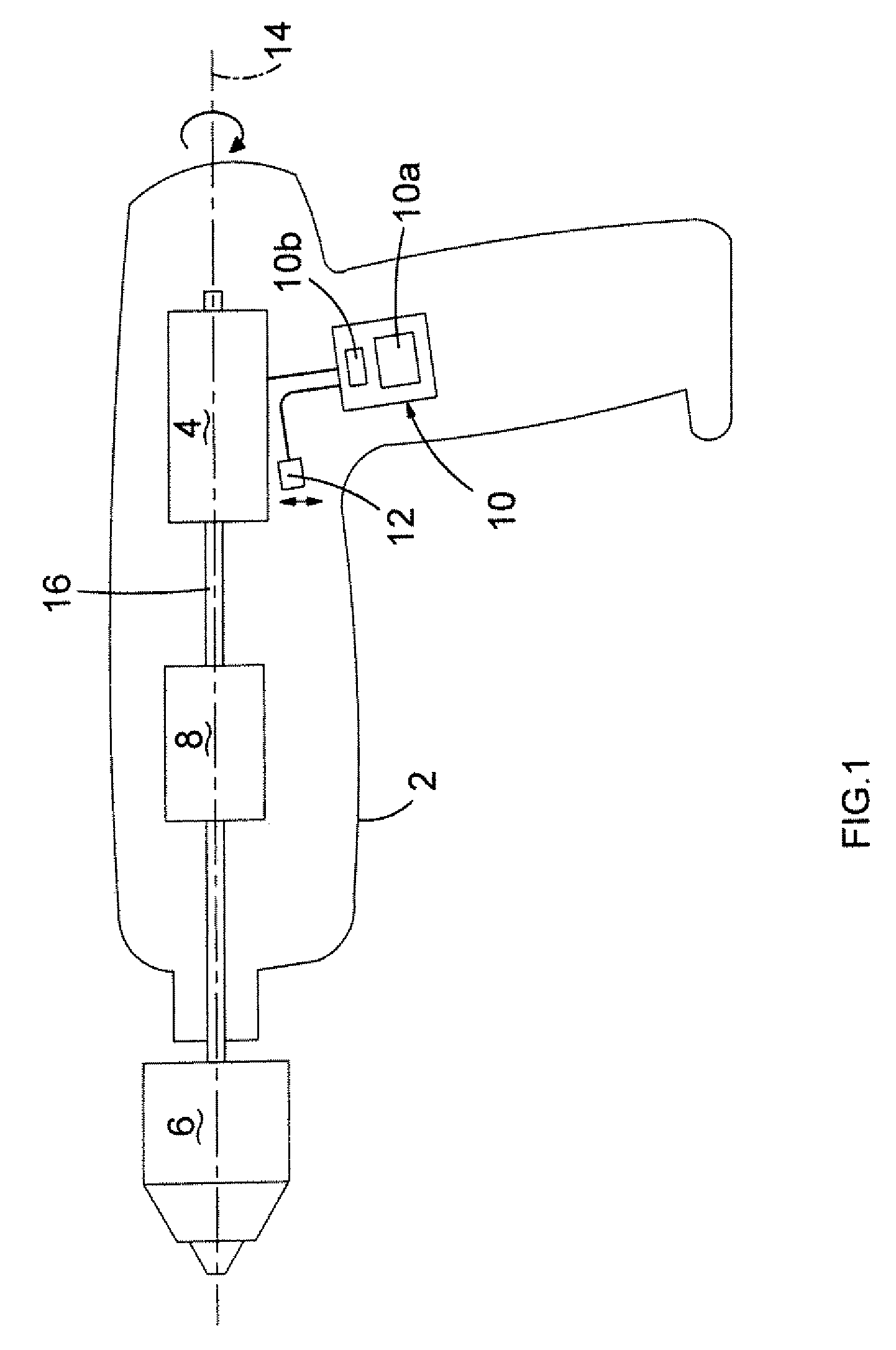

Power Tool Having Motor Speed Monitor

InactiveUS20090195204A1Avoid overall overheatingConstant motor speedVibration measurement in solidsMotor/generator/converter stoppersMotor speedTransducer

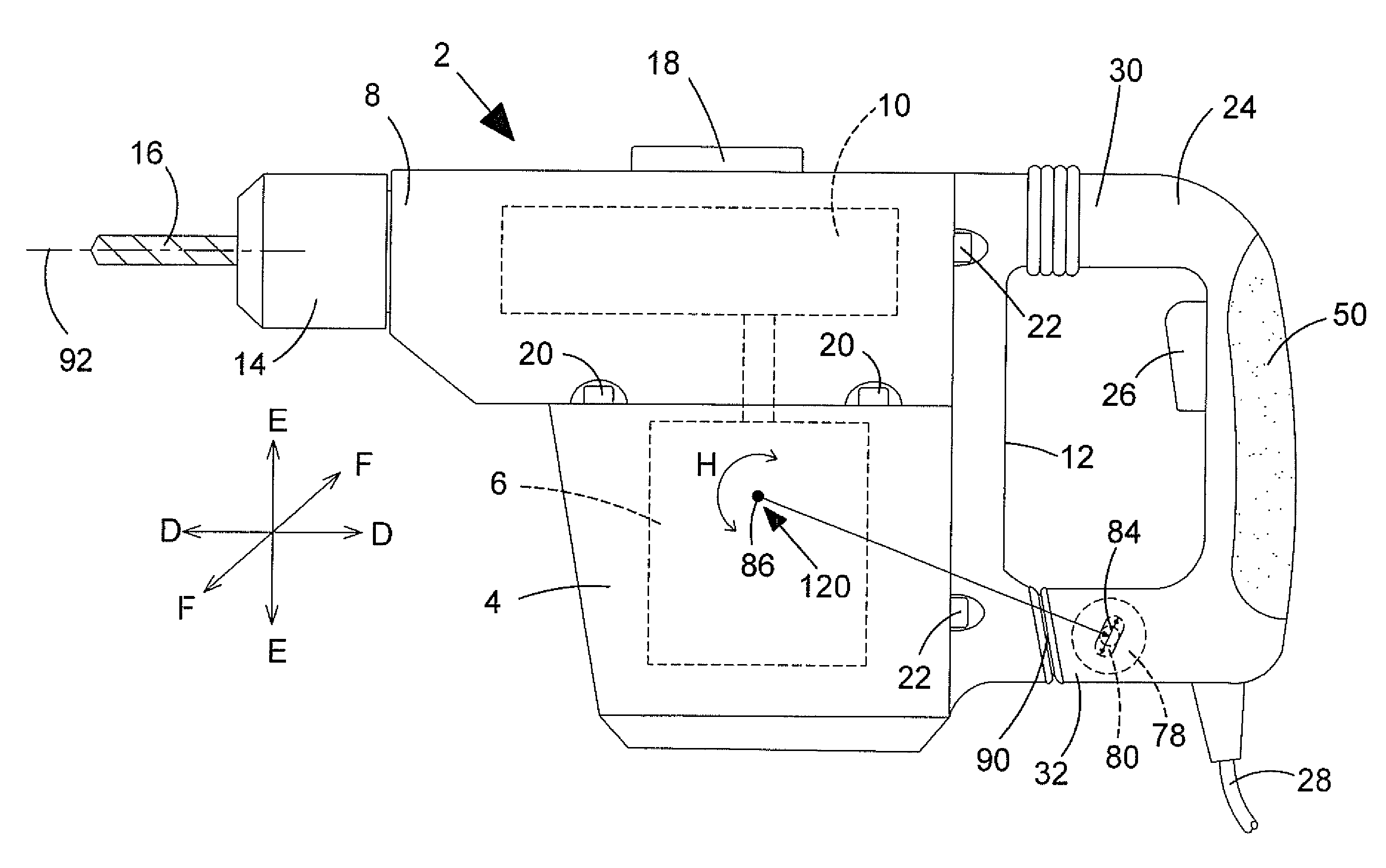

A hammer drill comprising a body (2) containing an electric motor (4) for driving an output (6) of the drill is disclosed. A vibration transducer (12) senses vibrations generated by the motor and produces a vibration signal dependent upon the sensed vibrations. An electronic module (10) includes a controller (10a) for controlling the rotational speed of the motor, and a signal processor (10b) for receiving the vibration signal from the vibration transducer, determining the rotational speed of the motor based on the vibration signal, and providing an output signal to the controller to cause the controller to control the rotational speed of the motor.

Owner:BLACK & DECKER INC

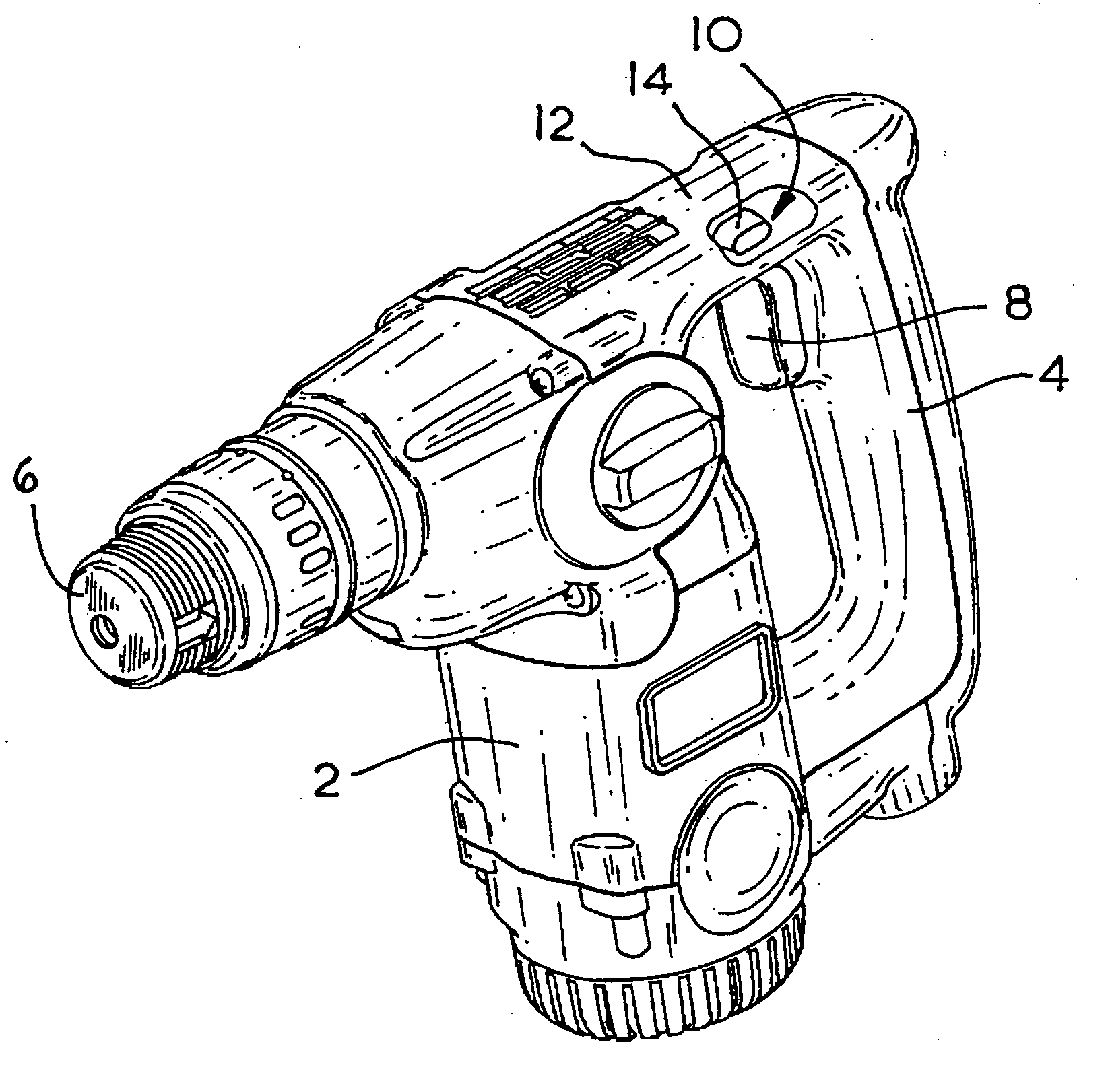

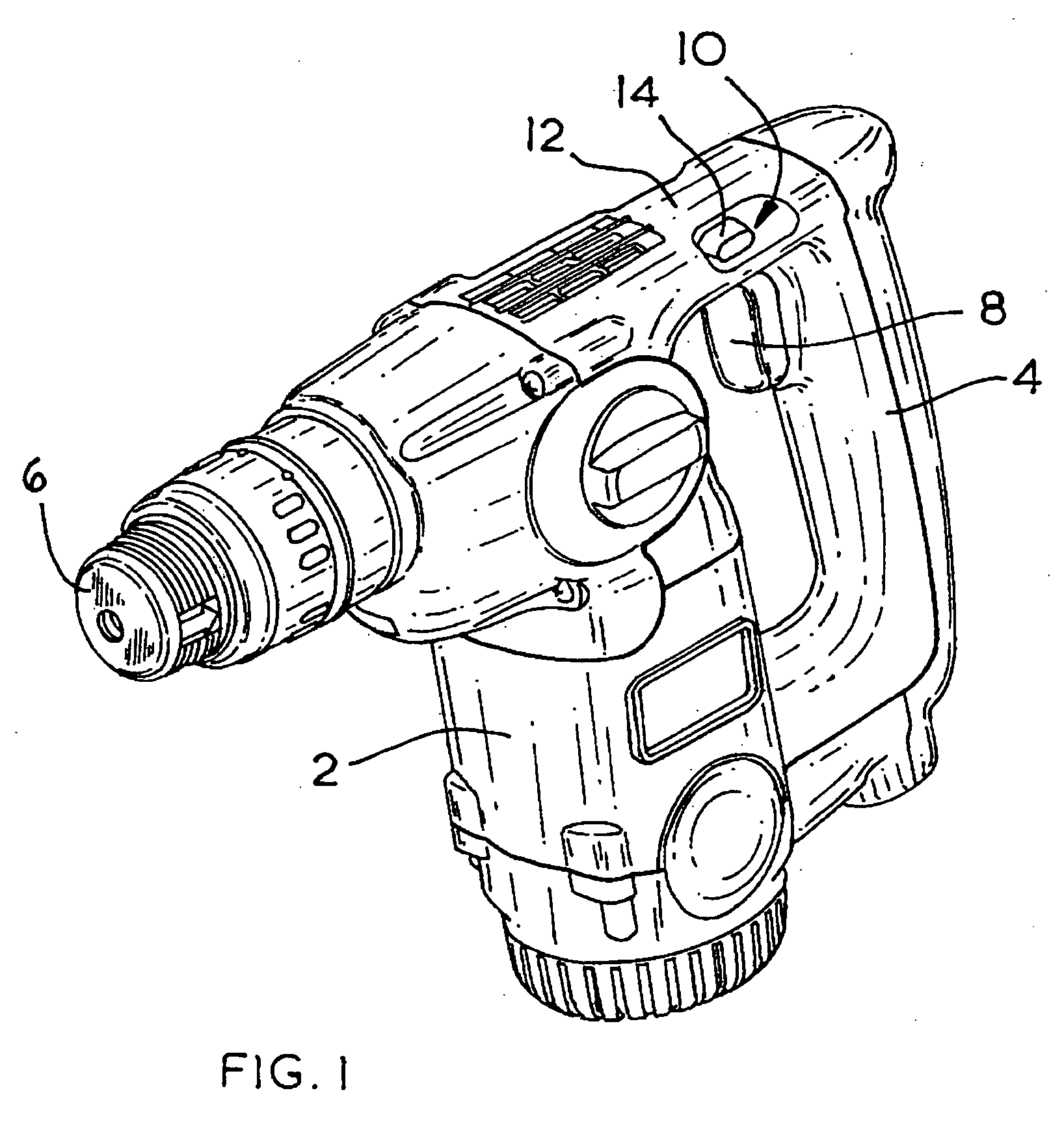

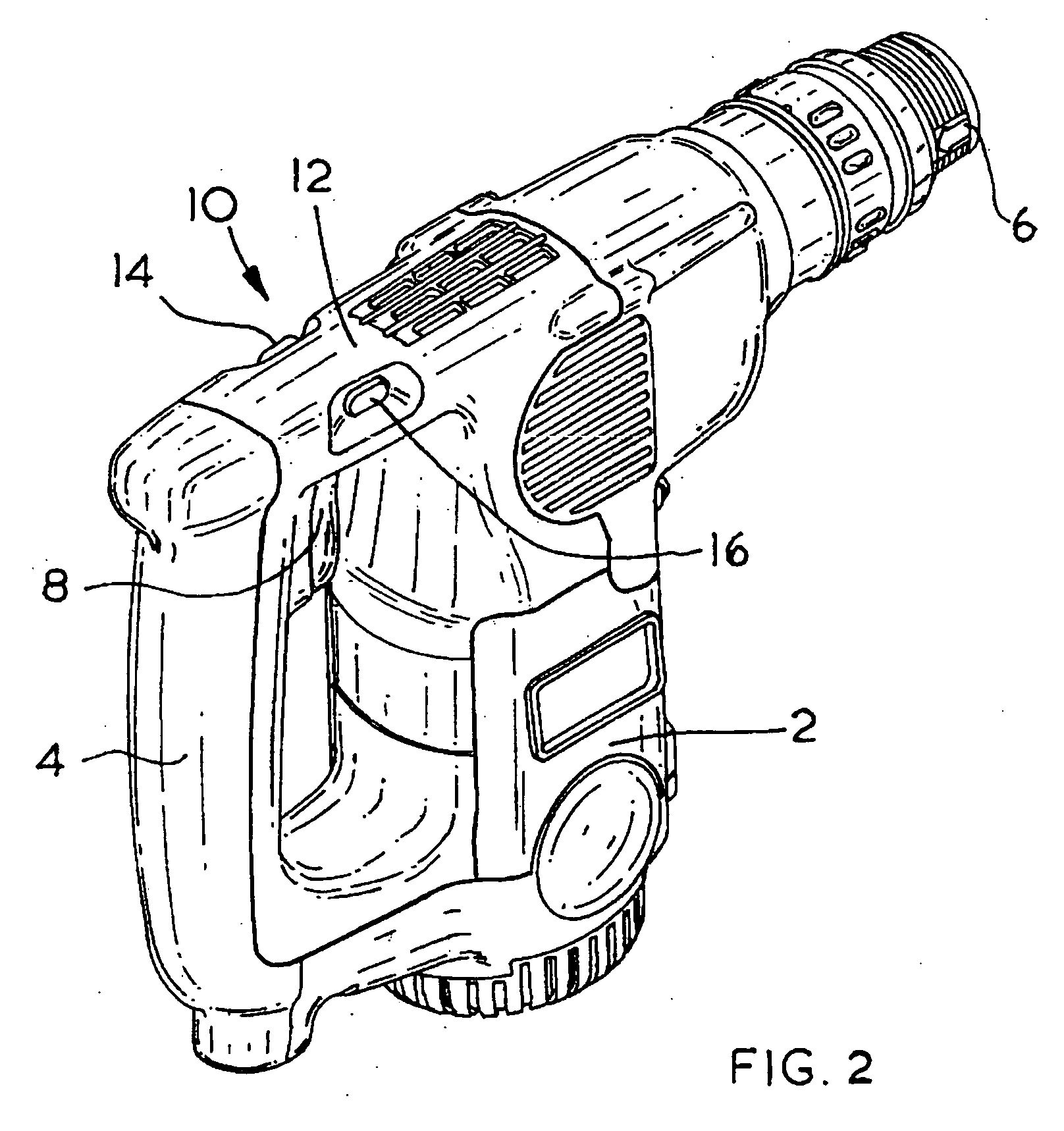

Hammer drill

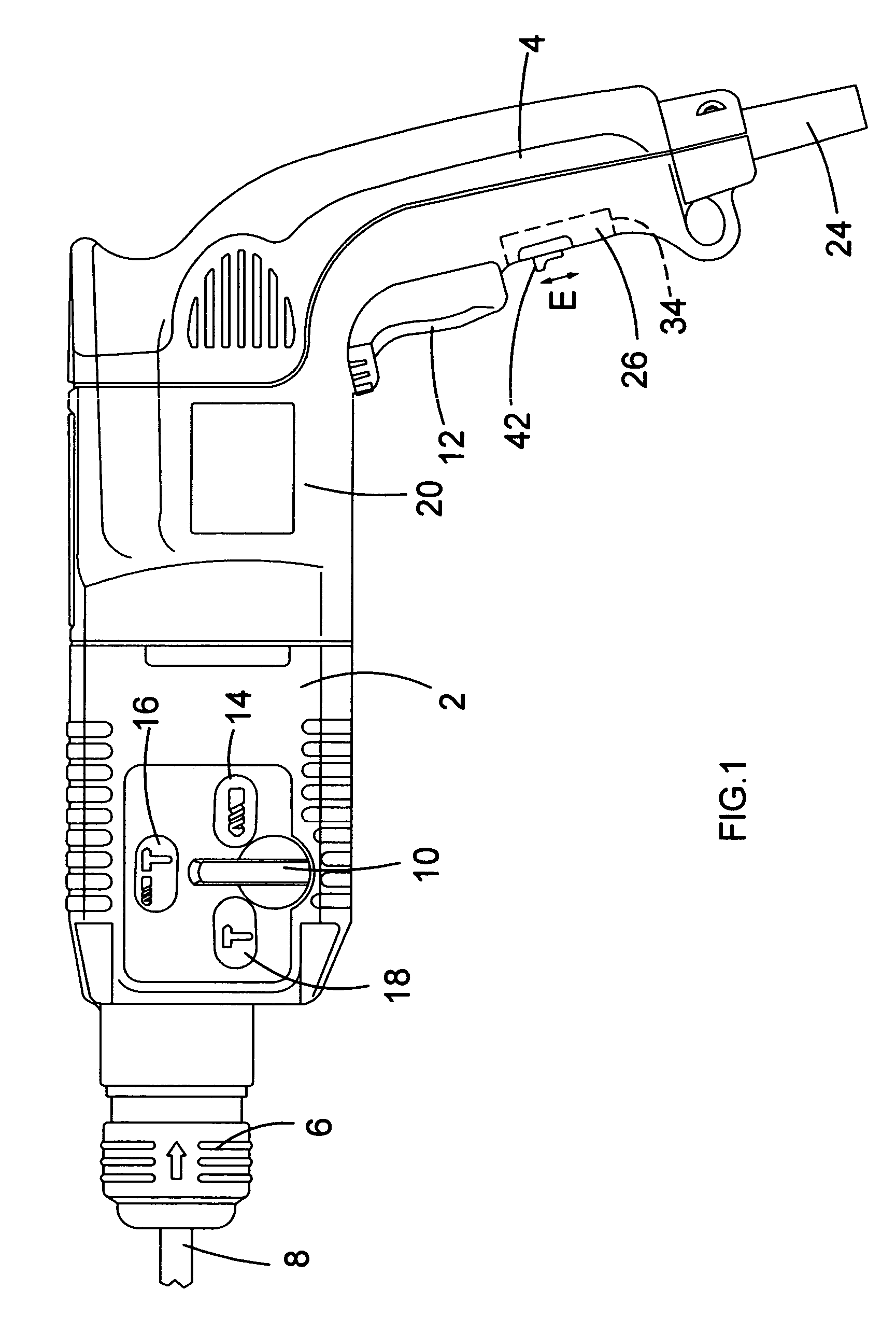

A hammer drill, in particular a chipper comprising: a body 2 having at least one support handle 4; an electric motor mounted within the body 2; an electric switch 22, capable of being switched on and off by a trigger button 8 connected to it, to activate or deactivate respectively the electric motor, wherein the trigger button 8 is moveable between two positions, a first position where the electric switch 22 is off and a second position where the electric switch 22 is on; a locking arm 38 moveably mounted on the electric switch 22 which, when the trigger button 8 is located in its second position, is moveable between two positions, a first position where it is disengaged from the trigger button 8 and a second position where it engages with the trigger button 8 and holds the trigger button 8 in its second position. When the locking arm is in its second position it causes the hammer to remain switch on even if the operator removes their fingers from the trigger button.

Owner:BLACK & DECKER INC

Hammer drill

A hammer drill (2) includes a clockwise and counterclockwise driven tool spindle (28), a drive pinion (70) operatively connectable with the tool spindle (28) for transmitting a torque thereto, a separate control handle (6) for selecting one of the hammer drill functions including a pure drilling operation, a pure percussion operation, and a rotary-percussion operation), and a switching device (8) which is adjustable in accordance with a position of the control handle (6) and which is shiftable by the control handle (6) in a clockwise rotation position for effecting a pure drilling operation in a clockwise direction and in a counterclockwise rotation position for effecting a pure drilling operation in a counterclockwise direction.

Owner:HILTI AG

Rear handle

A power tool, for example a hammer drill comprising: a housing; a handle having two ends, the first end being moveably mounted to the housing via a first mounting assembly, the second end being moveably mounted to the housing via a second mounting assembly; wherein the first mounting assembly comprises: a first part mounted on the housing and a second part mounted on the first end of the handle, one part comprising a sleeve, the other part comprising a rod mounted in an axially slideable manner in the sleeve to enable the first end of the handle to slide towards or away from the housing; and a biasing mechanism connected between the two parts which biases the first end of the handle away from the housing; wherein the second mounting assembly comprises: a third part mounted on the body and a fourth part mounted on the second end of the handle, one part comprising a support, the other part comprising a pin located in the support which is capable of being rotated in the support to enable the second end of the handle to rotate relative to the housing and to move linearly in the support to enable the second end of the handle to move linearly relative to the housing; characterized in that the support comprises a passage in which the pin is located, the pin being capable of freely moving within the passage either rotationally to enable the second end of the handle to rotate relative to the housing or linearly to enable the second end of the handle to move linearly relative to the housing.

Owner:BLACK & DECKER INC

Ultrasonic rotary-hammer drill

InactiveUS7740088B1Light weightConsume low amountDrill bitsPiezoelectric/electrostriction/magnetostriction machinesDrive shaftAcoustic wave

A mechanism for drilling or coring by a combination of sonic hammering and rotation. The drill includes a hammering section with a set of preload weights mounted atop a hammering actuator and an axial passage through the hammering section. In addition, a rotary section includes a motor coupled to a drive shaft that traverses the axial passage through the hammering section. A drill bit is coupled to the drive shaft for drilling by a combination of sonic hammering and rotation. The drill bit includes a fluted shaft leading to a distal crown cutter with teeth. The bit penetrates sampled media by repeated hammering action. In addition, the bit is rotated. As it rotates the fluted bit carries powdered cuttings helically upward along the side of the bit to the surface.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR OF THE

Suction device for a pick power tool

ActiveUS20070264091A1Solve the lack of suctionAvoid inhalationTransportation and packagingMulti-purpose machinesEngineeringPower tool

A suction device (11) for a hammer drill (6) has a first end (12) with a securing device (14) for securing the suction device (11) to the hammer drill (6) and a second end (13) opposite first end (12) and which has a contact area (15) with which the suction device (11) contacts a constructional component, the suction device (11) further having a receiving space (20) which at least partially encloses a working tool (7) of the pick power tool (6), and being provided with a connection device (18) for a vacuum source. A retaining element (21) having a through-opening (22) for the working tool (7) and a plurality of suction openings (23) is provided in an area (19) of the second end (13).

Owner:HILTI AG

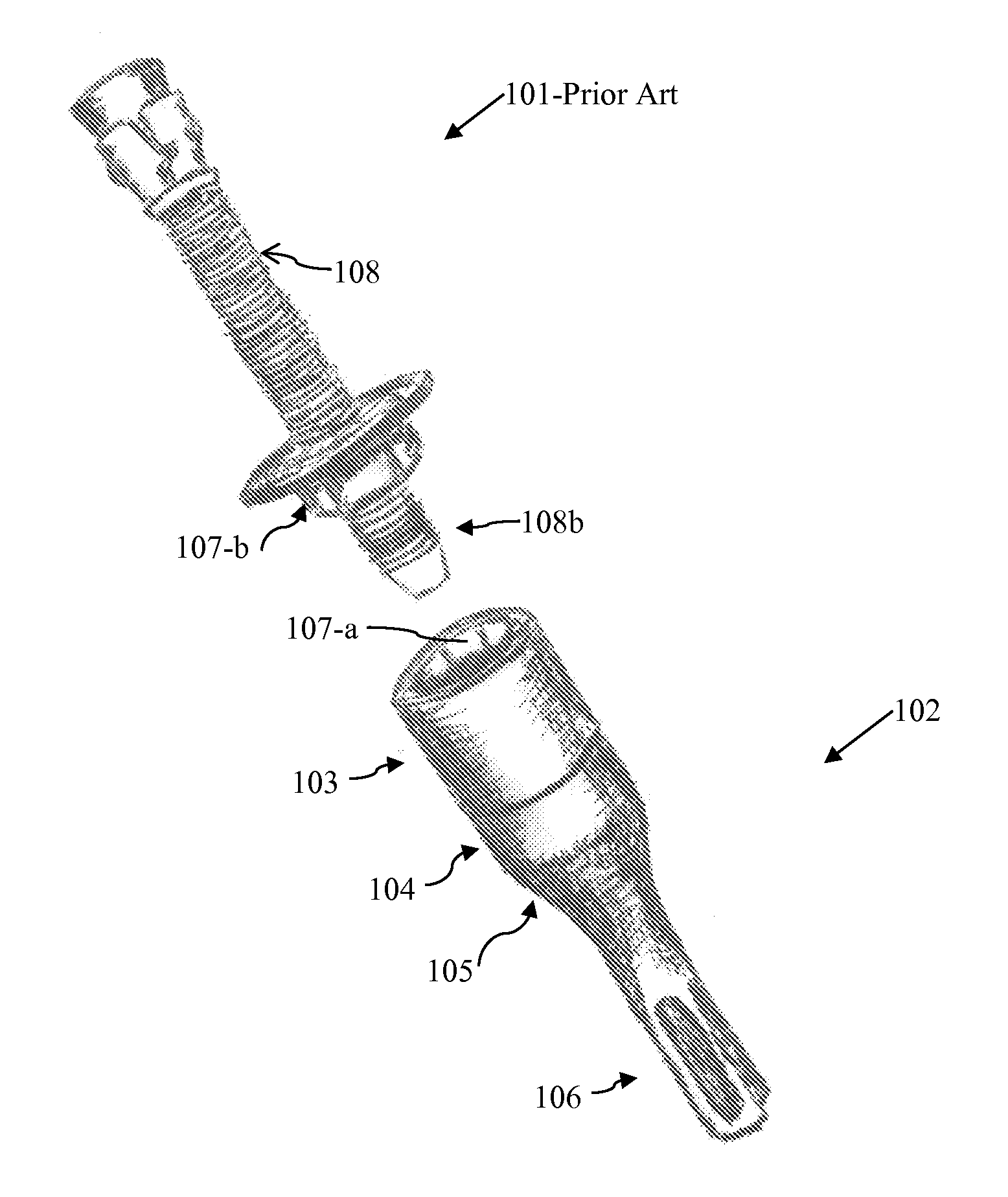

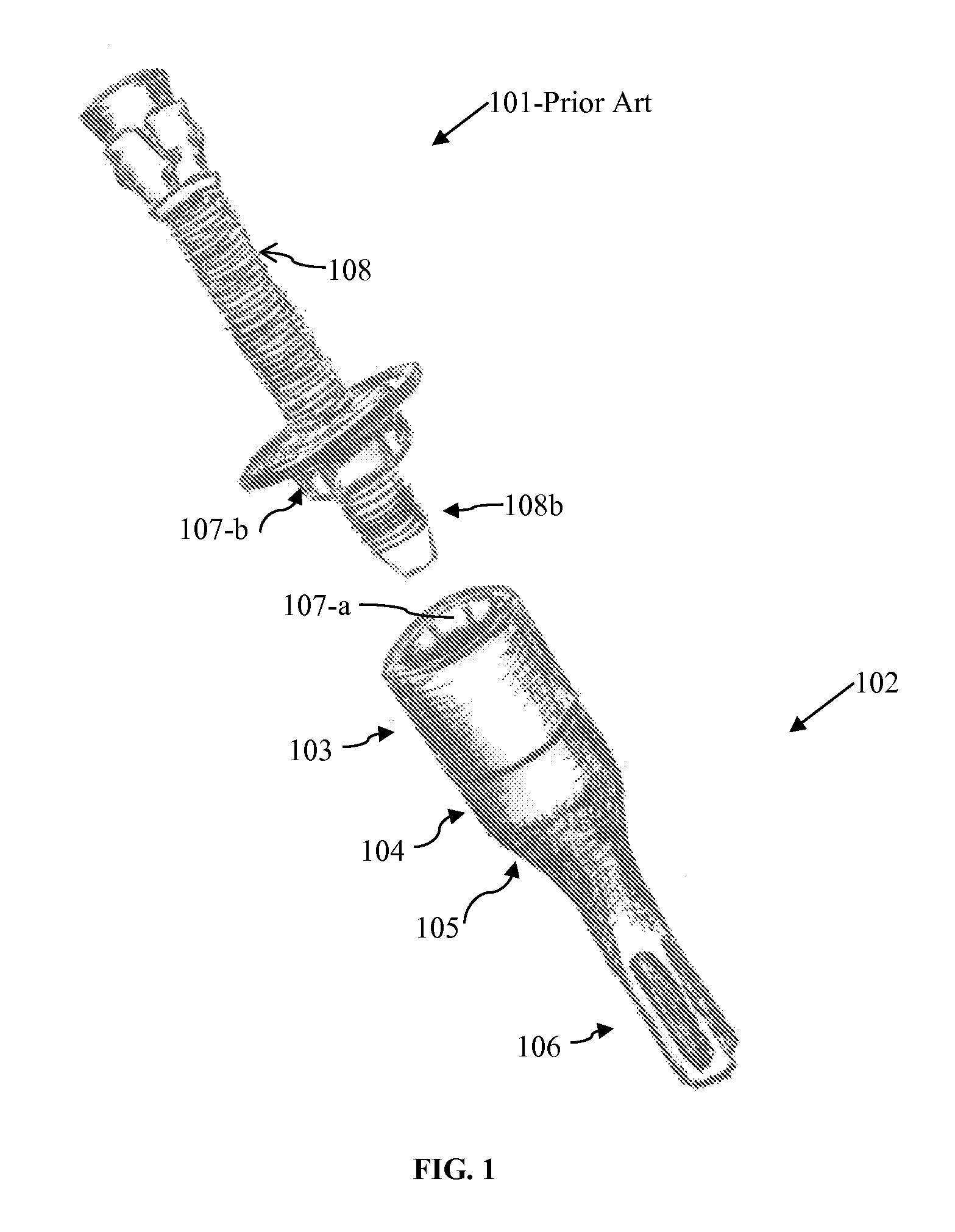

Tool for installing nail-pin anchors and anchor bolts

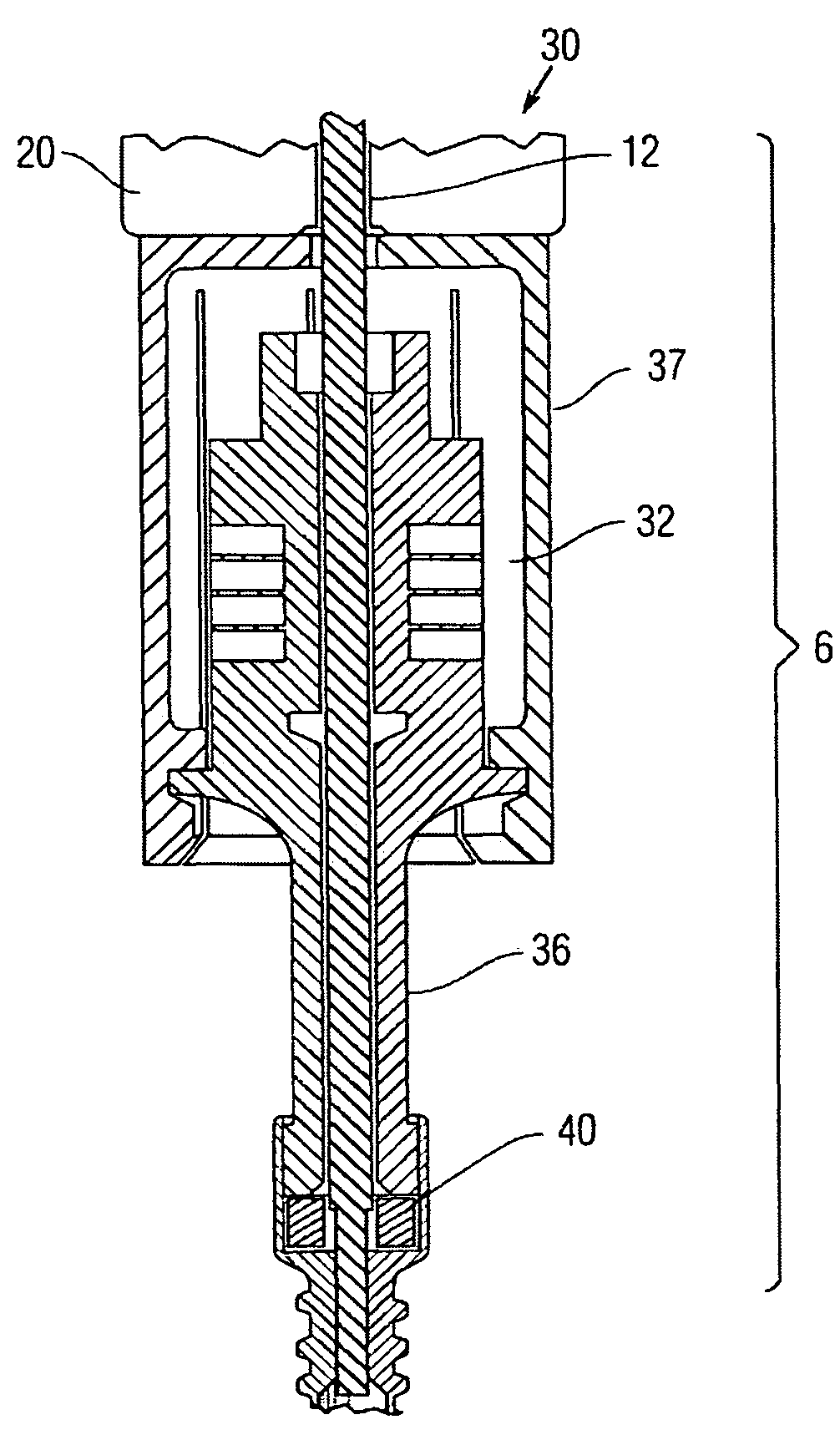

InactiveUS6915936B2Safe and comfortable to useShorten the timeStapling toolsDispensing apparatusHammer drillIt impact

A tool for driving and setting nail-pin anchors and anchor bolts into concrete, the tool using the percussive action of a rotary hammer drill. The tool comprises a body member with a spring, a driver, and a ram inserted into the body member's bore. After a hole is drilled for insertion of the anchor, the masonry drill bit of the rotary hammer drill is slid inside the bore of the ram and temporarily locked to the tool. The rotary hammer drill is activated, and the drill bit turns inside the ram without affecting the body member or the anchor. Instead, the percussive force of the rotary hammer drill transfers its impact to the ram and the driver, which impacts the nail of the nail-pin anchor, or the stem of the anchor bolt, setting it into the concrete. A keyed bearing can be installed inside a sleeve of the ram in order to protect the tip of the masonry drill bit from shearing.

Owner:MATRIX TOOL

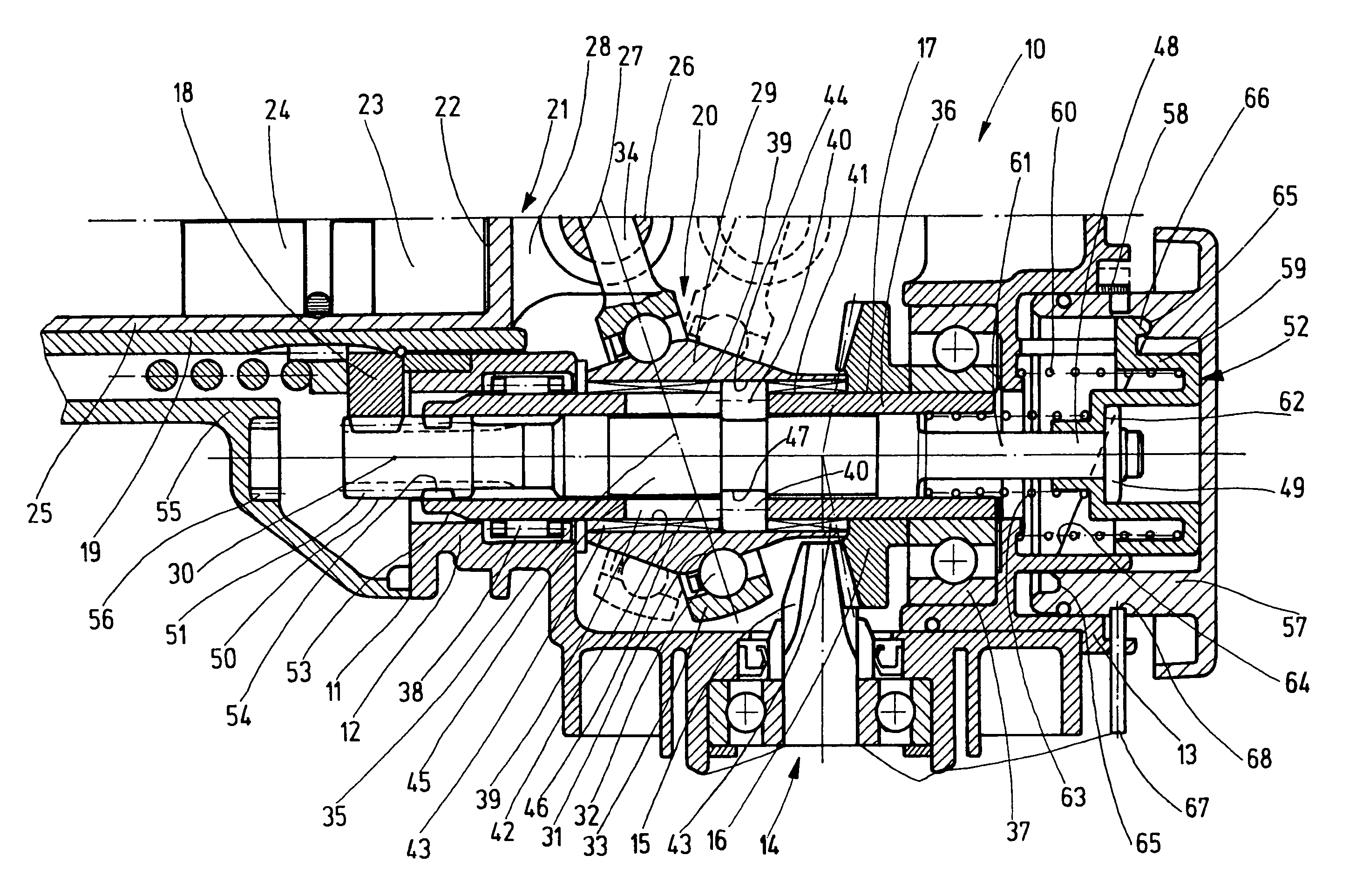

Hammer drill with wobble mechanism and hollow drive shaft

InactiveUS7287600B2Eliminate disadvantagesReduce in quantityDrilling rodsReciprocating drilling machinesDrive wheelDrive shaft

A hand power tool has a housing, a drive motor and a gear mechanism arranged in the housing. A tool receptacle accommodates a tool, and a gear wheel drives a rotary sleeve in rotation from the drive motor and the gear mechanism and thereby the tool receptacle. A hammering mechanism is located inside the rotary sleeve and drivable translationally via a wobble gear. The gear mechanism has a driving gear wheel meshing with a motor pinion and arranged on a shaft by which the wobble gear mechanism is drivable to revolve. The shaft is configured as a hollow shaft on which the driving gear wheel is retained nondisplaceably and in a manner fixed against rotation. The wobble gear mechanism is located adjacent to the driving gear wheel on the shaft rotatably and couplably to the hollow shaft.

Owner:ROBERT BOSCH GMBH

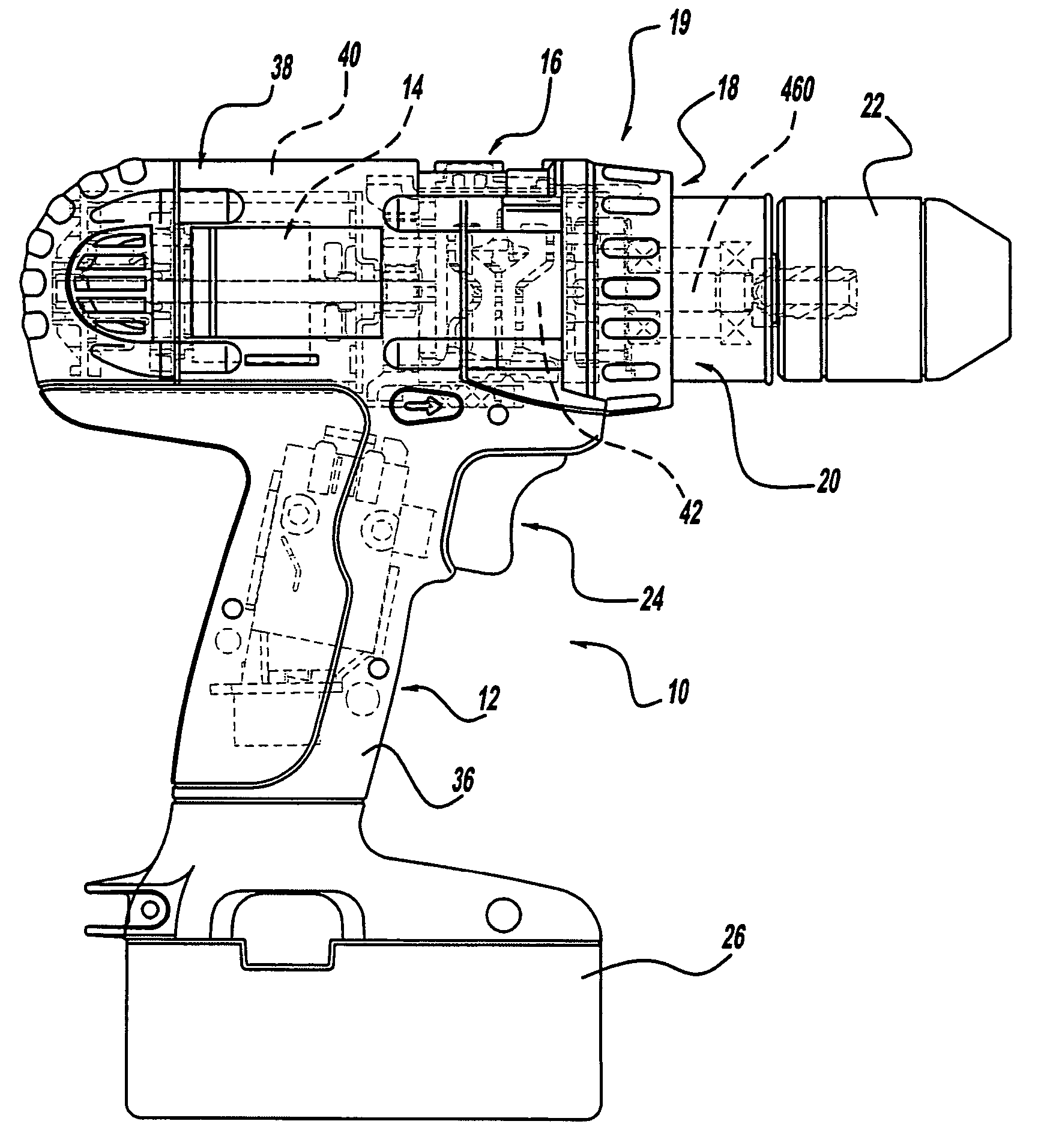

Portable power drill with gearbox

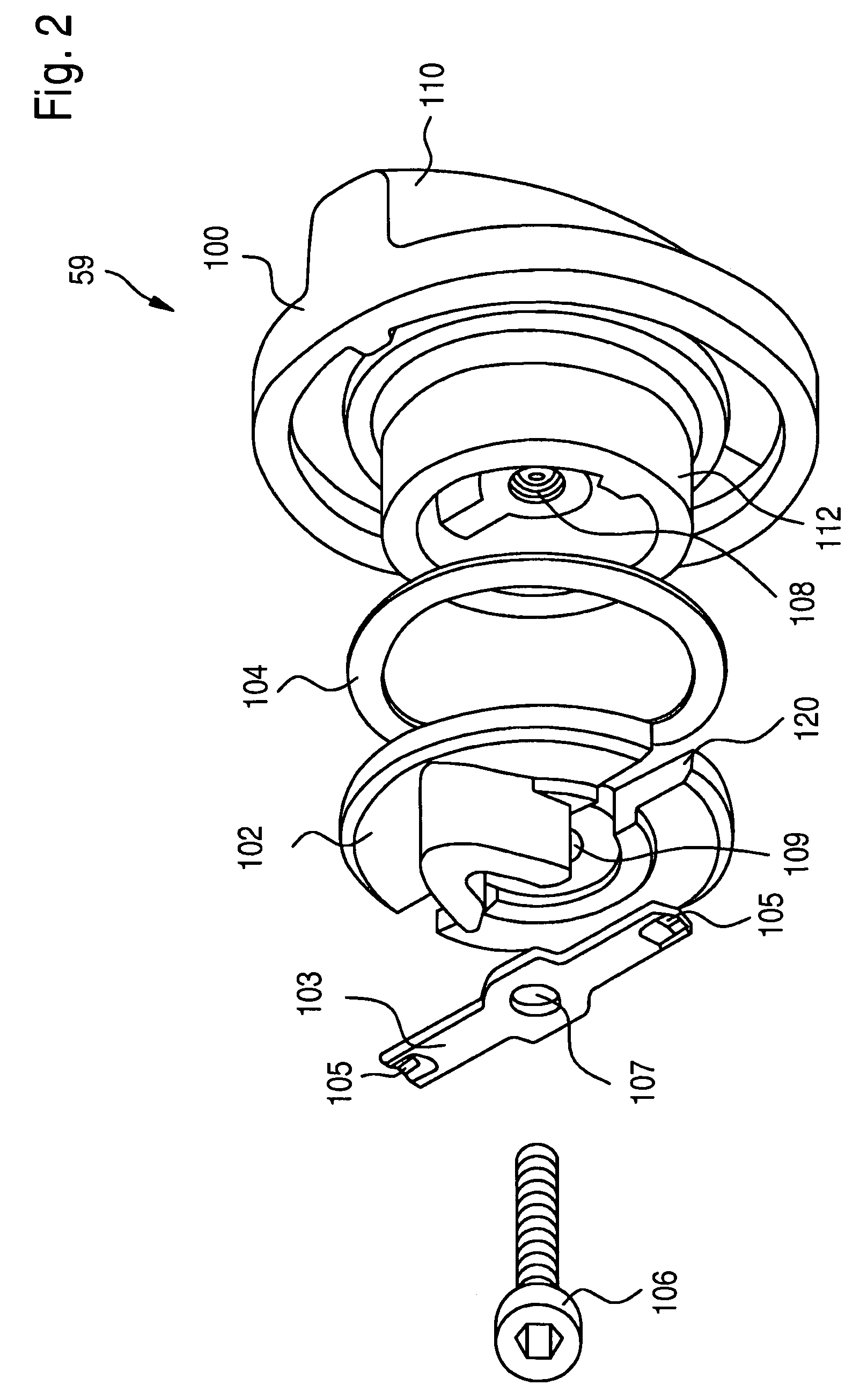

InactiveUS7708084B2Solution to short lifeReliable functionDrilling rodsReciprocating drilling machinesPortable powerEngineering

A portable power drill or hammer drill having a housing (12) which consists in particular of half shells (13, 14) and accommodates a manual gearbox (26), wherein a shift element (59) that can be rotated by hand converts its rotary movement into a shift movement, can be produced cost-effectively and can be easily operated, without lubricant escaping from the housing (12), by the shift element (59) consisting of a shell-like handle part (100) which can be joined together with a further, shell-like shift part (102) in a sealing manner from outside and inside relative to a housing shell (13).

Owner:ROBERT BOSCH GMBH

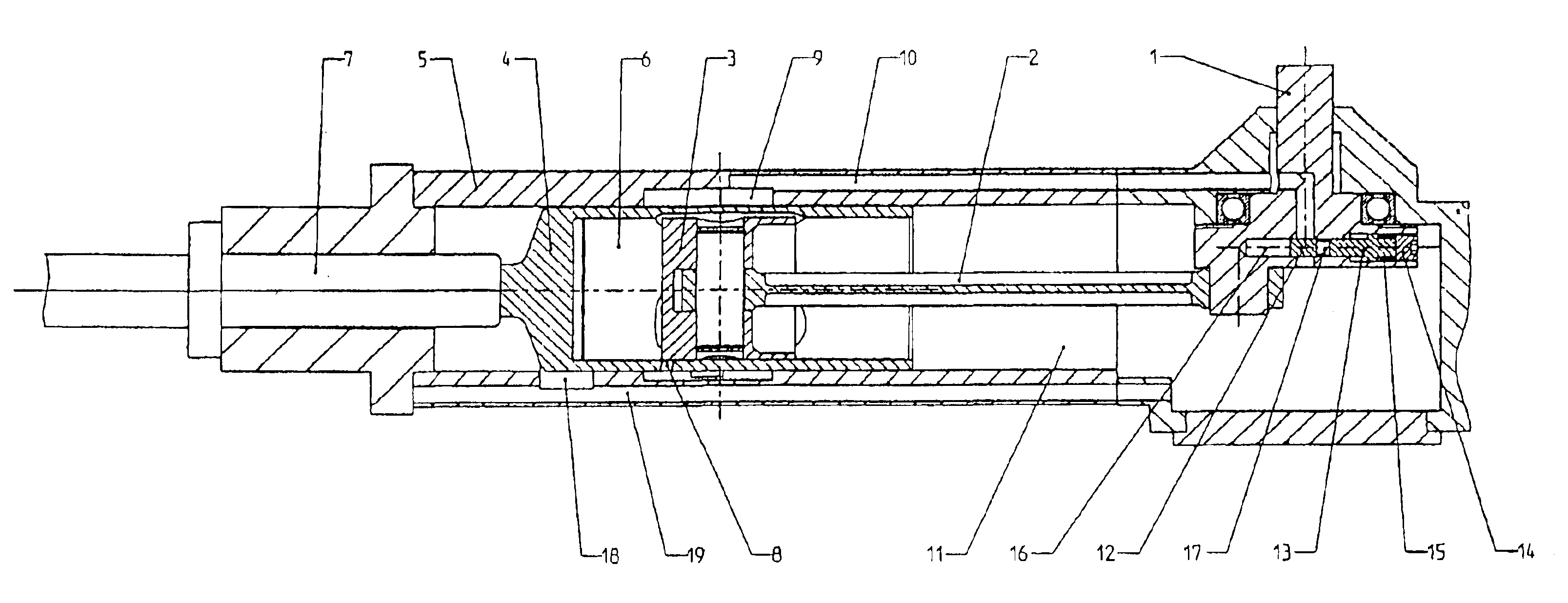

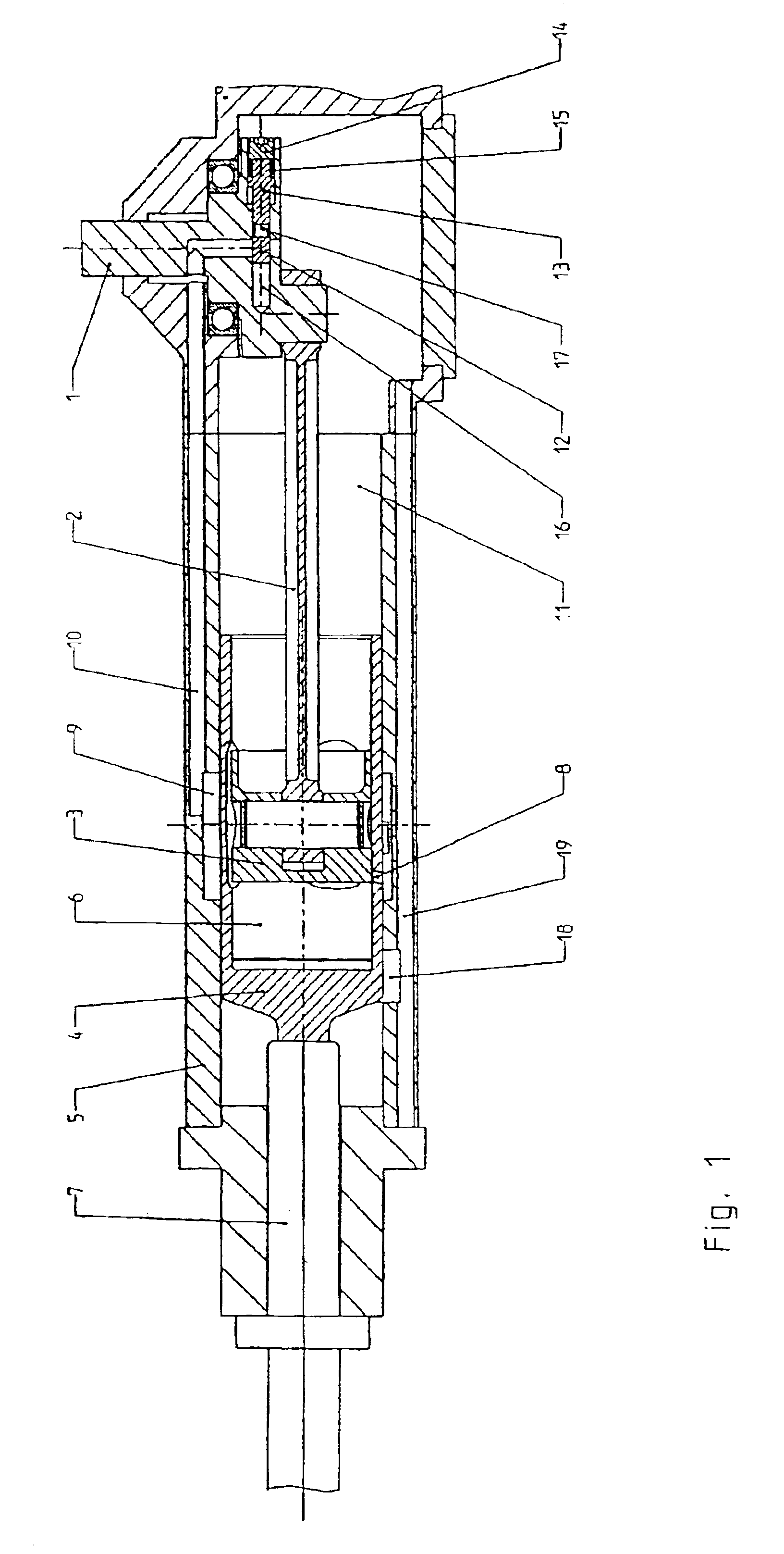

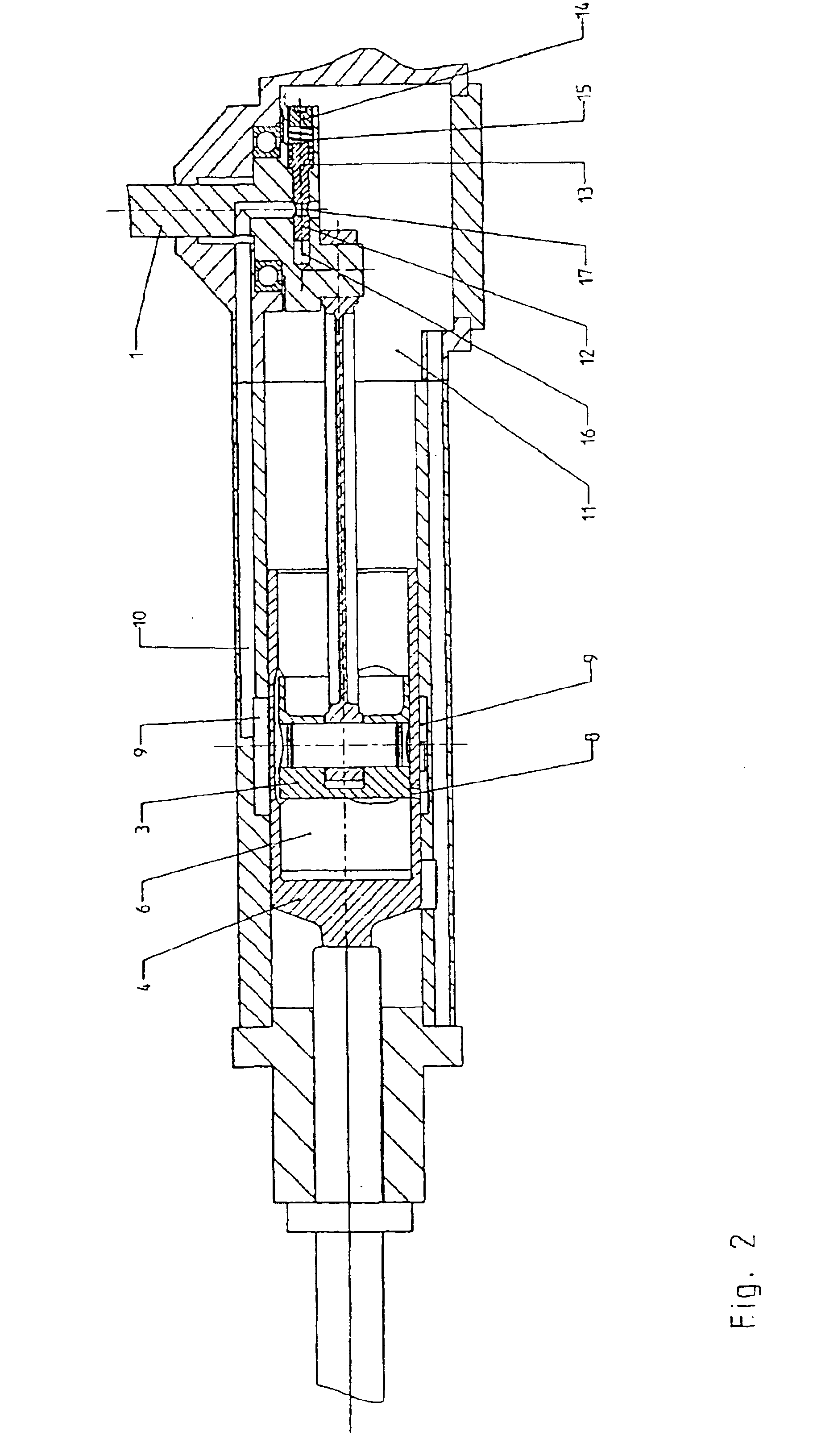

Pneumatic percussive tool with a movement frequency controlled idling position

InactiveUS6938704B2Reliable interruptionReciprocating drilling machinesConstructionsEngineeringIdle speed

The invention relates to a pneumatic percussive tool for a paving breaker and / or a hammer drill comprising a drive piston which is displaceable both backwards and forwards by a crankshaft and arranged in a percussion piston which is displaceable both backwards and forwards. A hollow chamber is connected to a compensating chamber by an idling air channel and embodied between the drive piston and the percussion piston in order to receive a pneumatic spring. A valve is arranged in the idling air channel, the opening and closing position thereof depending on the rotational speed of the crankshaft. If the rotational speed of the crankshaft falls below a predetermined value, the valve opens the connection between the hollow chamber and the compensating chamber so that a pneumatic spring can no longer be to embodied in the hollow chamber and the pneumatic percussion tool is placed in a idling position.

Owner:WACKER NEUSON SE

Power tool housing

ActiveUS8430182B2Improve damping performanceIncrease pressureReciprocating drilling machinesConstructionsEngineeringPower tool

Owner:BLACK & DECKER INC

Power tool housing

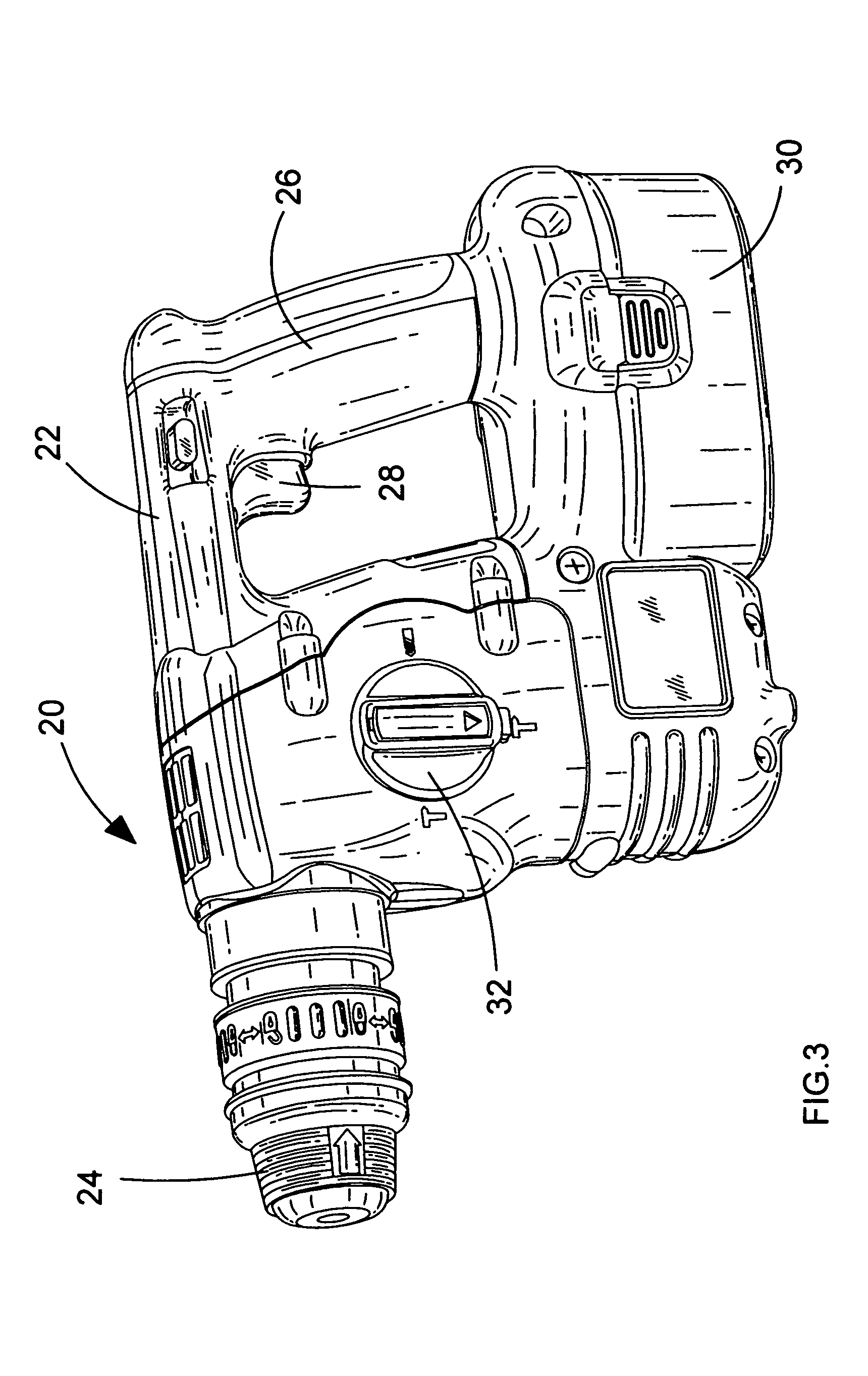

ActiveUS20060144604A1Improve damping performanceGreat pressure being appliedReciprocating drilling machinesConstructionsPower toolHammer drill

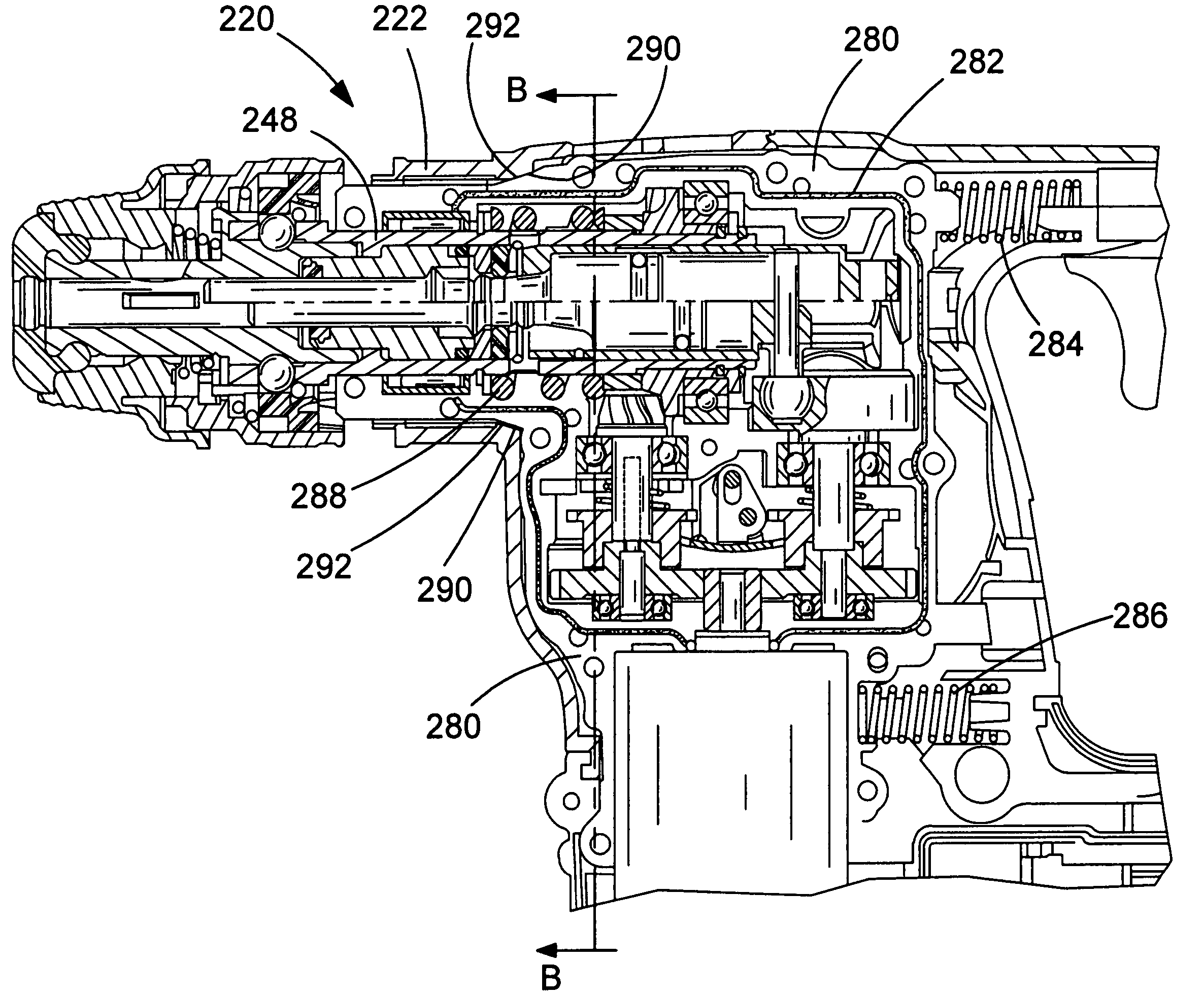

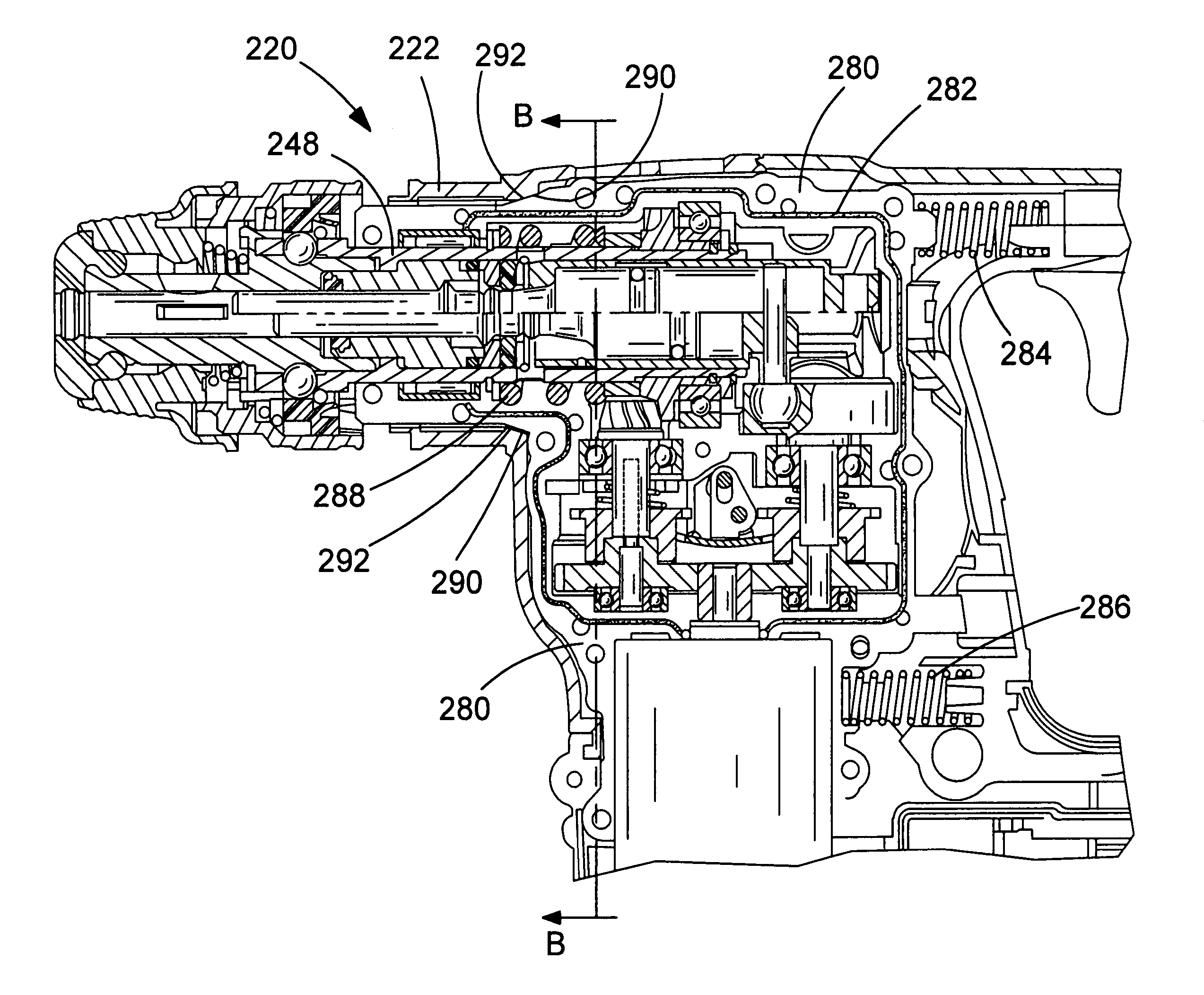

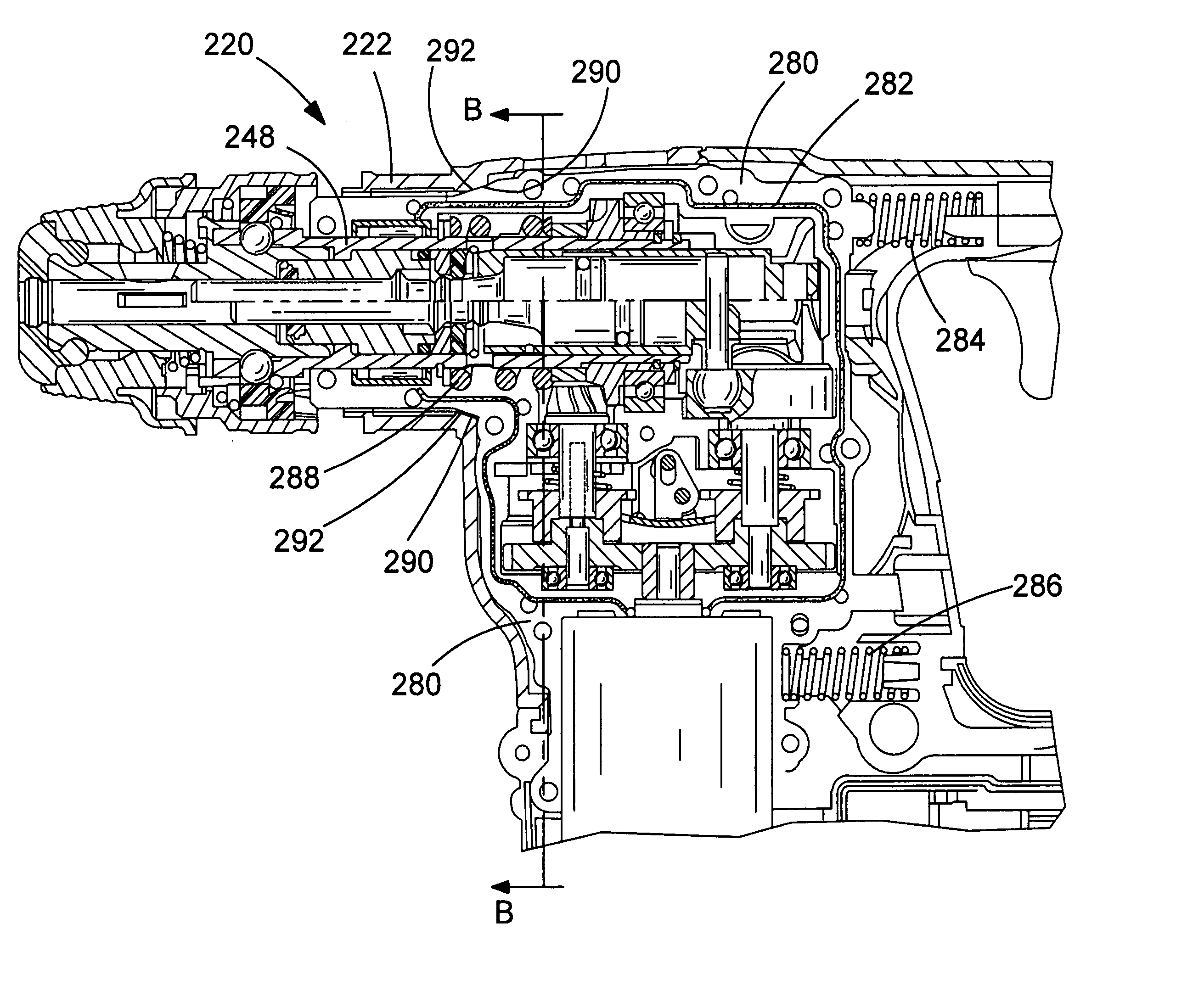

A hammer drill has a transmission housing 280 is formed from two clamshell halves of durable plastics or cast metal material. The transmission housing 280 is mounted on first and second damping springs 284 and 286 at its rearward end. The transmission housing 280 is also mounted on parallel rails (not shown) disposed within the tool housing 222 such that the transmission housing 280 can slide a small distance relative to the tool housing 222. The forward end of the transmission housing 280 has a generally part conical portion 290, which abuts a corresponding part conical portion 292 formed on the tool housing 222. The interface defined by conical portions 290 and 292 defines a stop against which the transmission housing 280 rests against the tool housing 222 in the inoperative condition of the hammer drill 220. When the hammer drill 220 is being used, a gap opens up between the conical surfaces 290 and 292 which helps to damp axial and lateral vibrations that would otherwise be transmitted from the tool bit (not shown) to the user. However, the gap is sufficiently small that the hammer drill 220 and the transmission housing 280 can still be adequately controlled by the user, and the part conical shape of the interface also assists in aligning the transmission housing 280 with the tool housing 222 in order to give a user greater control over the direction of the tool bit.

Owner:BLACK & DECKER INC

Hammer drill

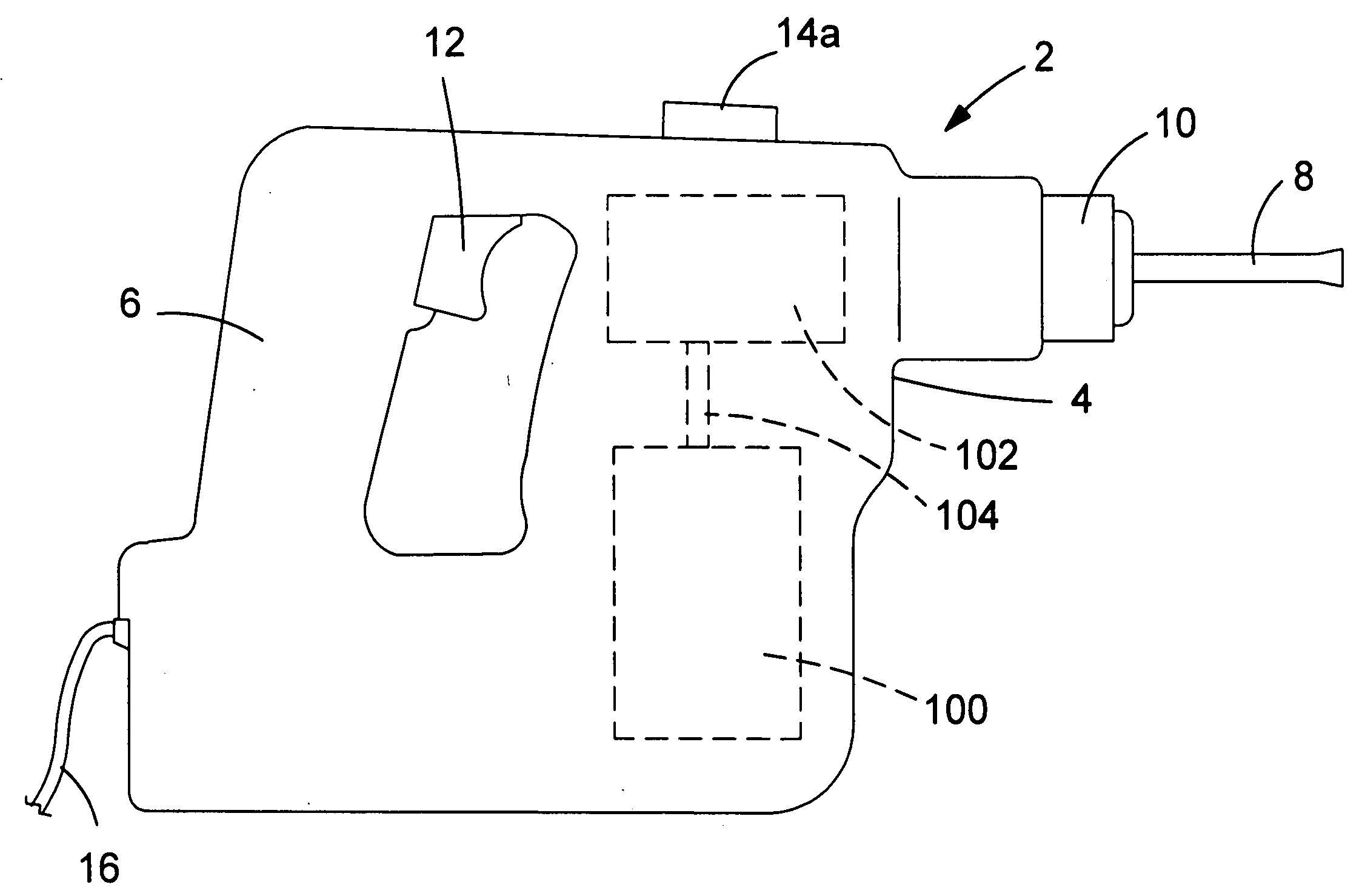

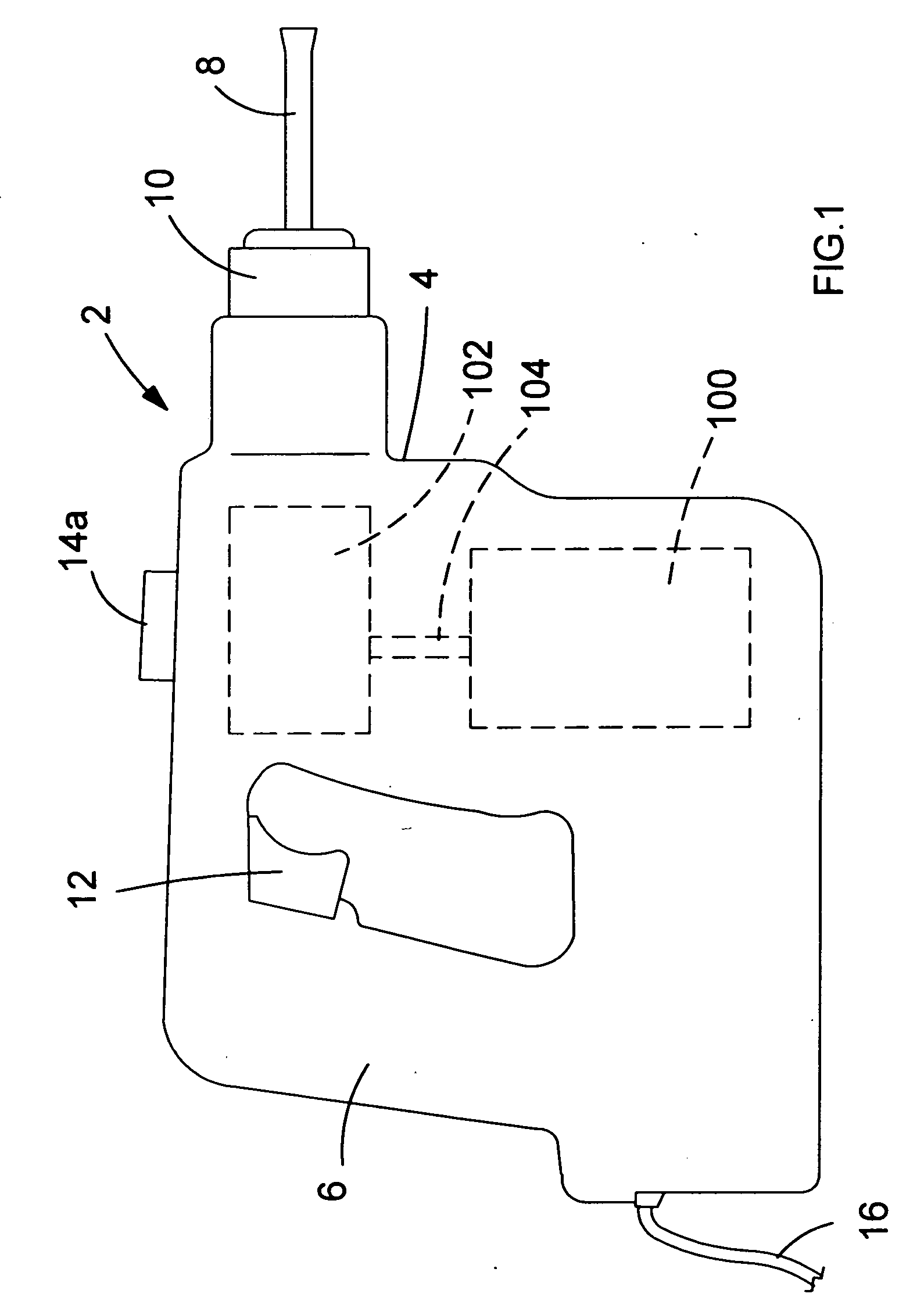

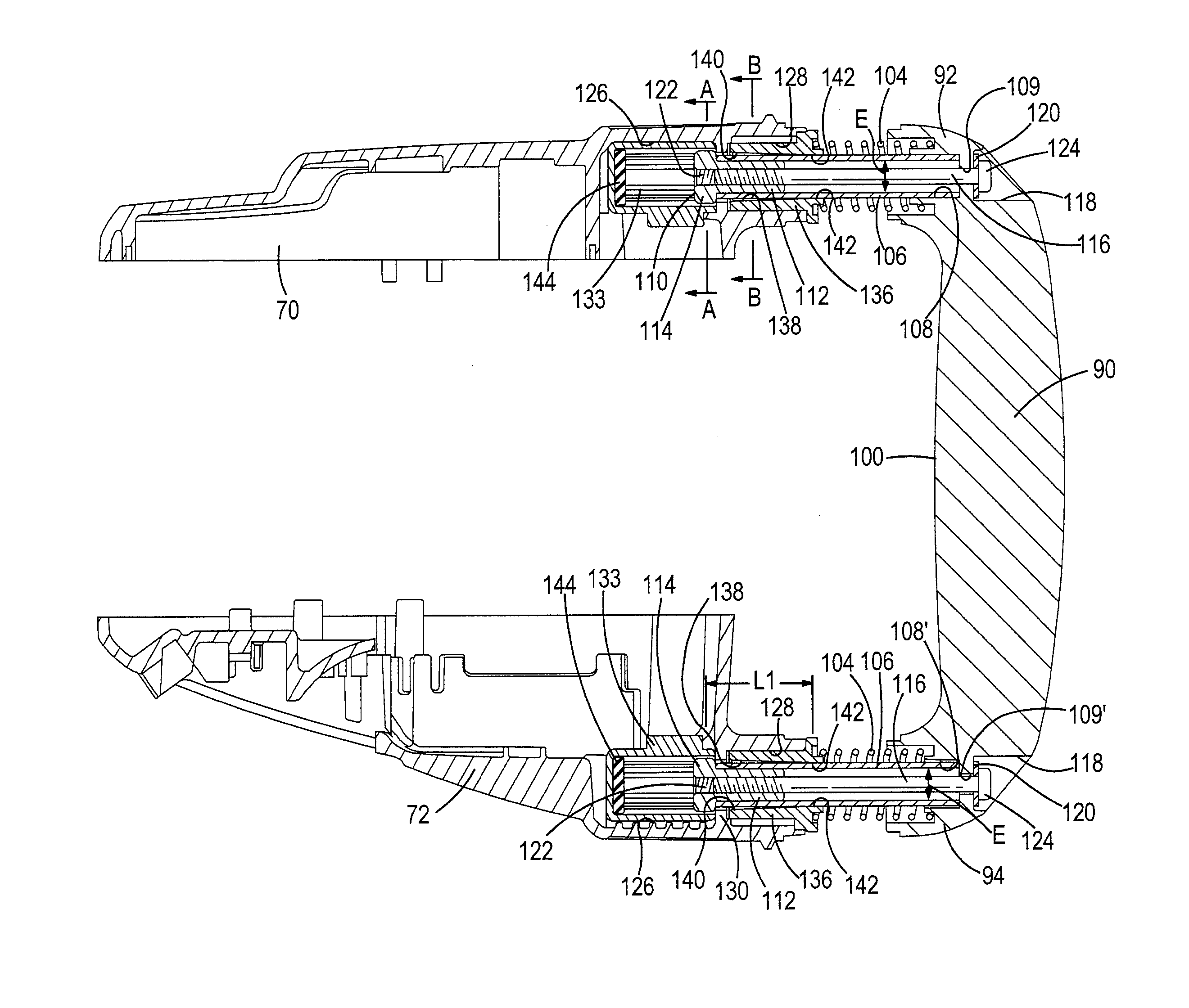

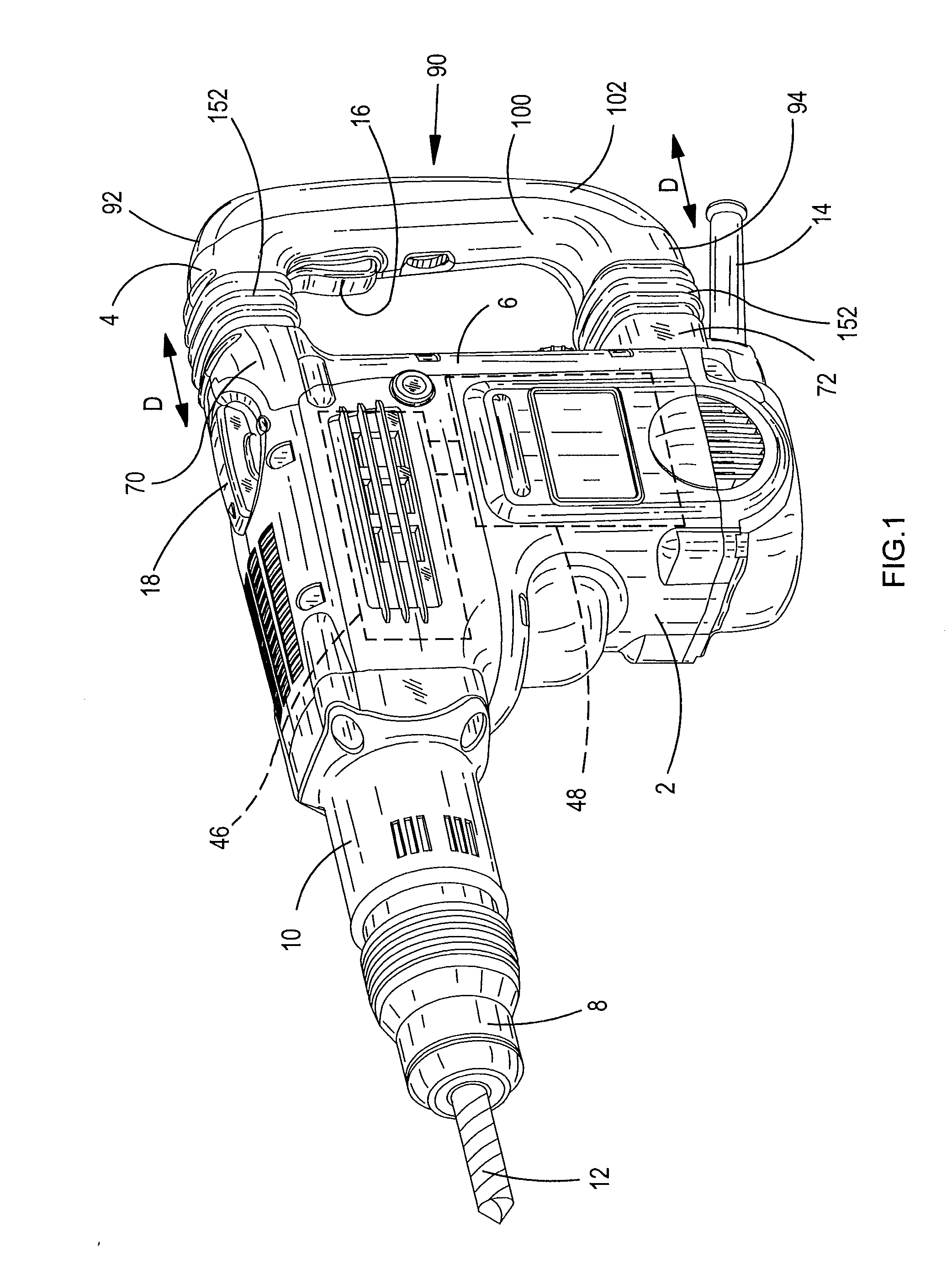

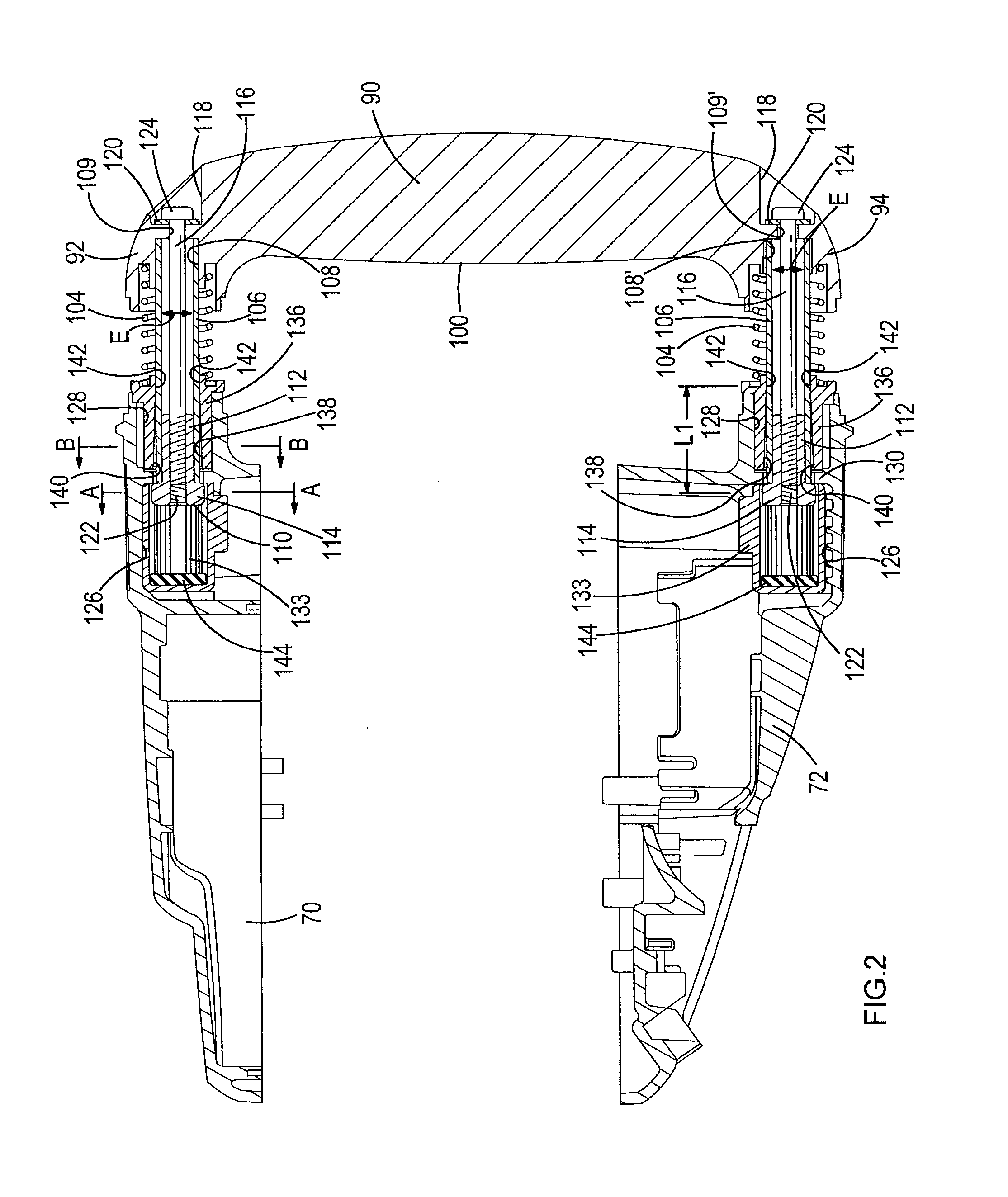

ActiveUS20110127056A1Minimize impactReduce amountPortable percussive toolsMulti-purpose toolsEngineeringMovement control

A hammer drill comprising: a body 2 in which is mounted a motor 48 and a hammer mechanism 46 which is driven by the motor 48 when the motor 48 is activated; a tool holder 8 mounted on the front of the body 2 and which is capable of holding a cutting tool 12, the hammer mechanism 46, when driven by the motor 48, capable of imparting impacts to the cutting tool 12, when held by the tool holder 8; a rear handle 4, moveably mounted on to the rear of the body 2 via at least one movement control mechanism and which is capable of moving towards or away from the body 2; a biasing mechanism 104 which biases the rear handle 4 away from the body 2; wherein each movement control mechanism comprises: a first mount; a rod 106, having a longitudinal axis 107, rigidly connected at one of it ends to the first mount; a second mount which slidingly engages with the rod 106 at two distinct points only along its length to allow the rod 106 to slide relative to the second mount in a direction parallel to the longitudinal axis 107 whilst preventing the rod 106 from moving relative to second mount in a direction perpendicular to longitudinal axis 107; wherein one mount 70, 133, 136 is attached to the body 2 and the other mount 92 is attached to the rear handle 4.

Owner:BLACK & DECKER INC

Hammer drill with camming hammer drive mechanism

A reciprocating drive mechanism for a striker in a hammer, a rotary hammer, or a power drill having a hammer action, includes a sinusoidal cam channel formed on a drive member and a cam follower, in the form of a ball bearing, attached to a driven member which, due to the interaction of the cam and cam follower, results in a reciprocating movement of the driven member. Both the drive member and driven member can be rotatingly driven by a motor, their relative speeds resulting in the reciprocating movement of the driven member. The driven member is connected to the striker either via a mechanical helical spring or an air spring.

Owner:BLACK & DECKER INC

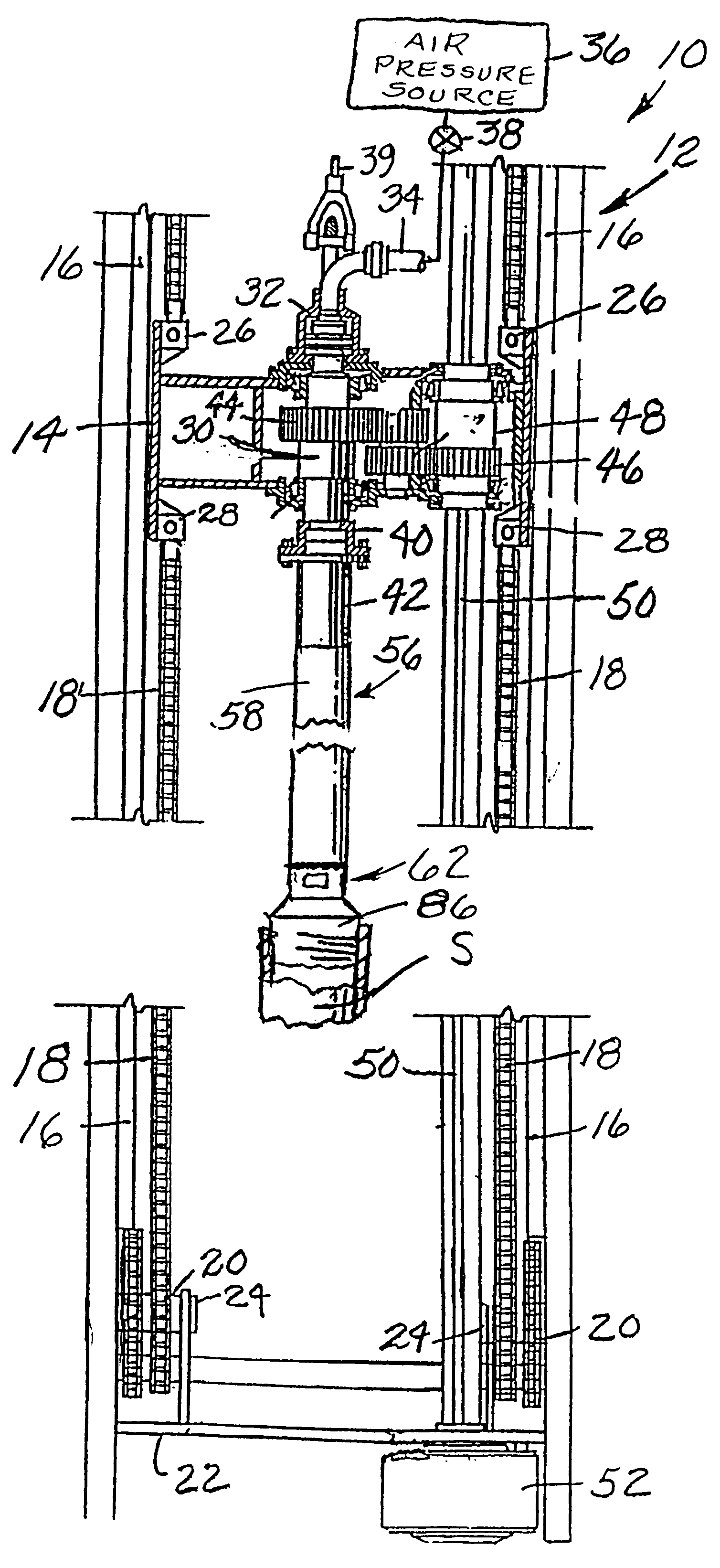

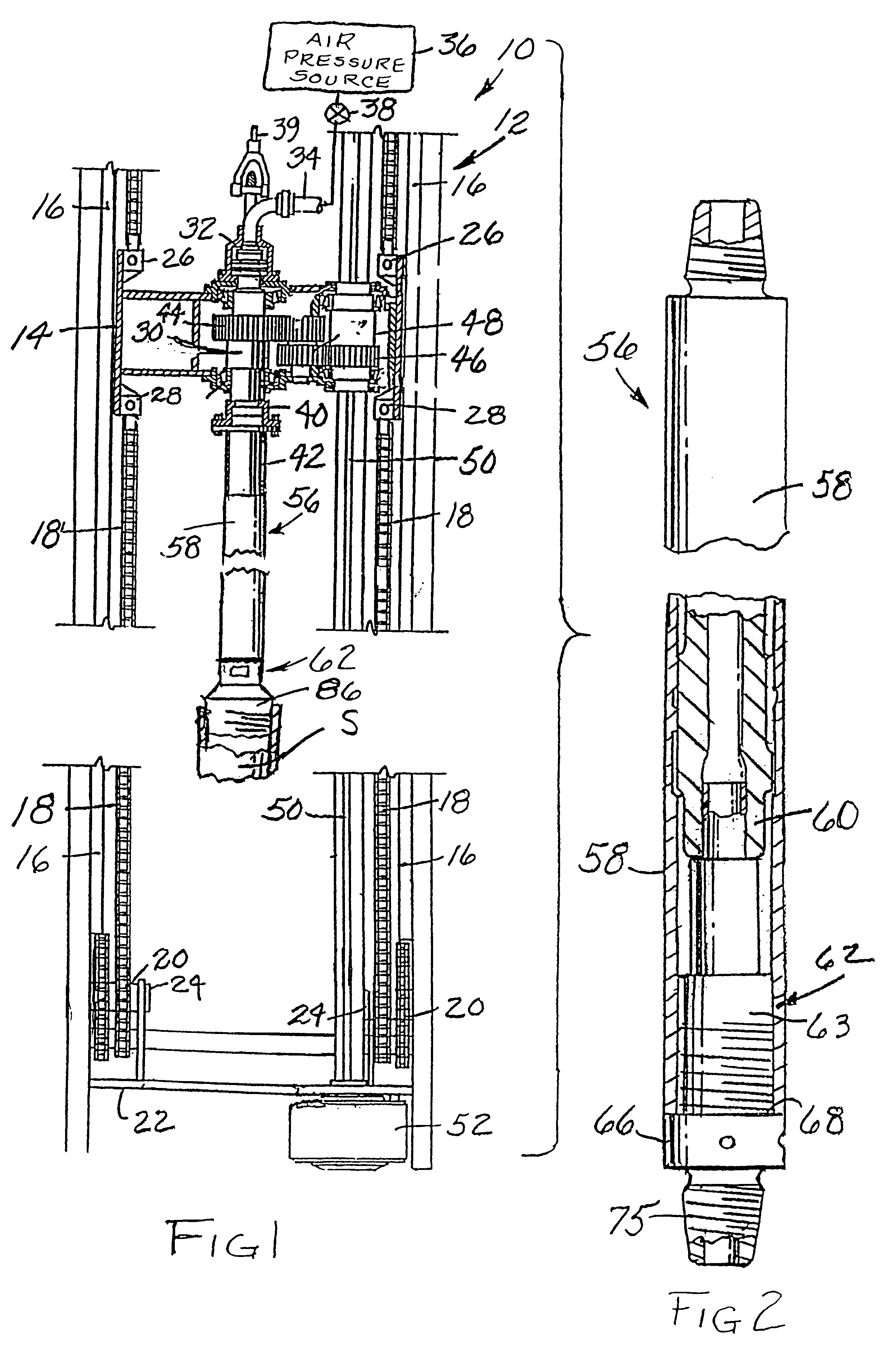

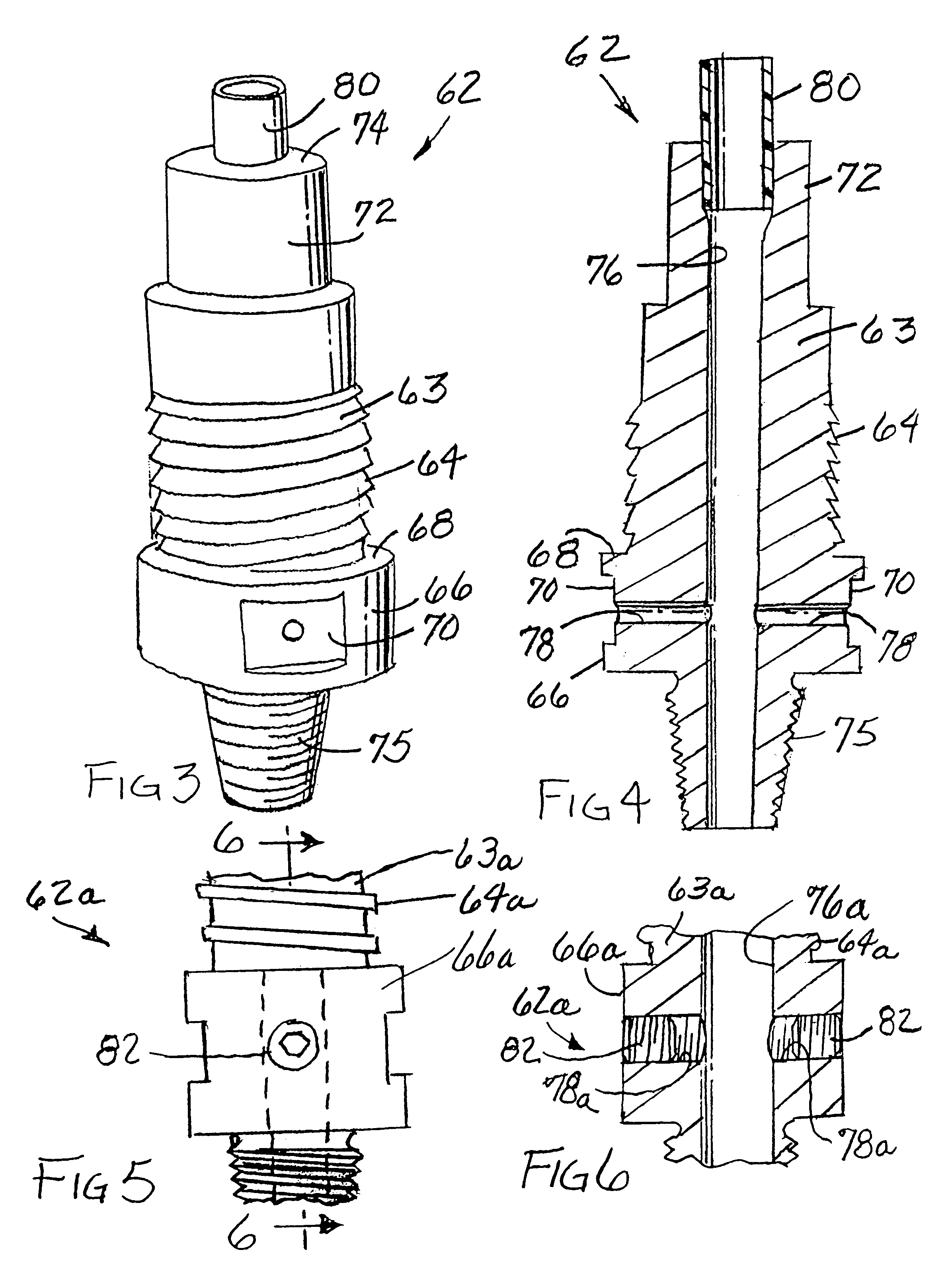

Well casing installation and removal apparatus and method

A downhole well drilling apparatus includes an above-ground mast and an axially elongated generally cylindrical pneumatic hammer drill supported by the mast and mounted in an axially vertical above-ground position. An installation and removal adapter mounted on the lower end of the pneumatic hammer drill couples the hammer drill to a pipe string and maintains a movable part of the hammer drill in an operative condition at all times thereby enabling the hammer drill to operate while rotational torque and upward directed force are simultaneously applied to the operating hammer drill by the apparatus during removal of a casing from a downhole position. Hammer operation is controlled by a manually operable air supply valve.

Owner:ALLYN JOHN F +1

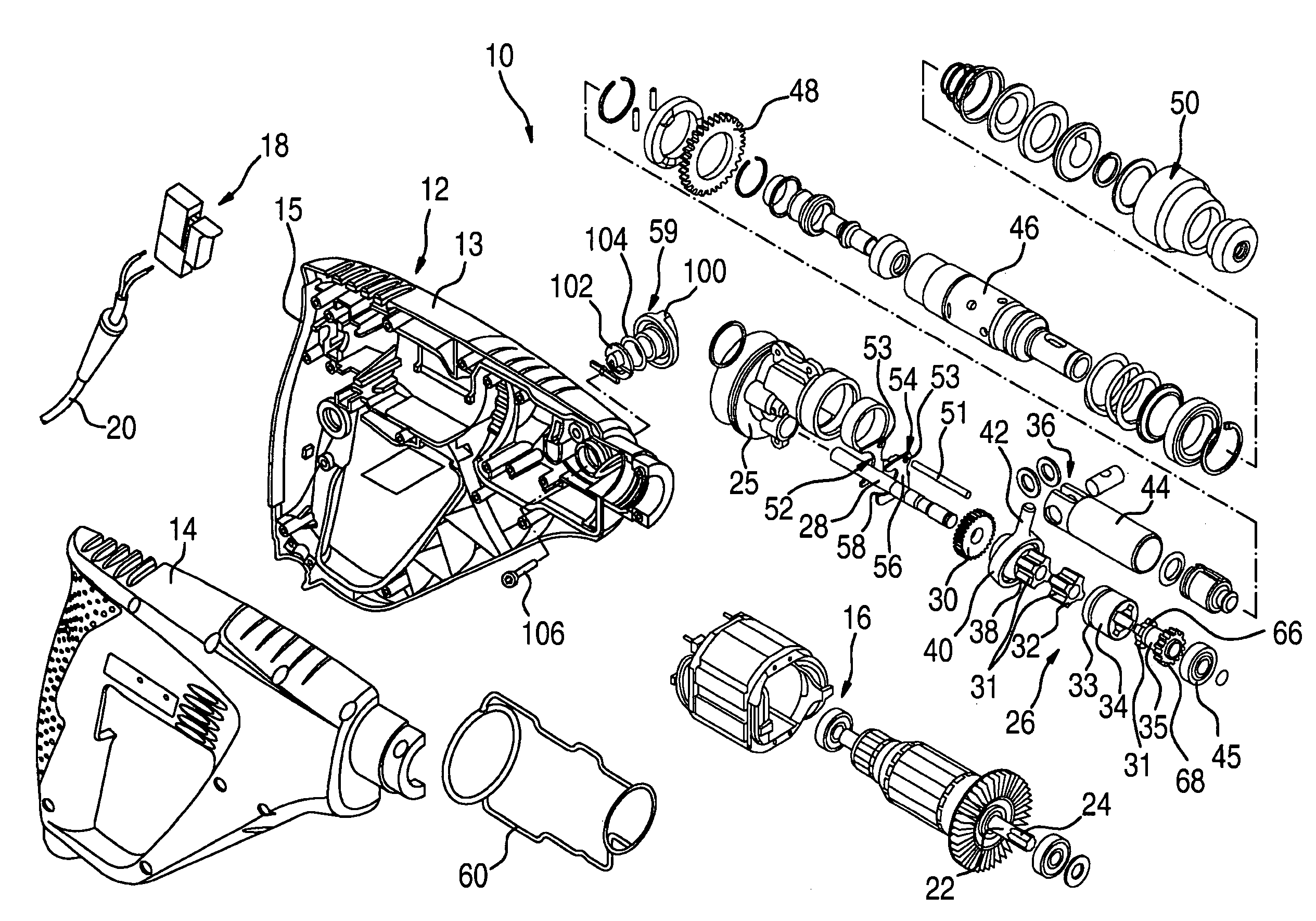

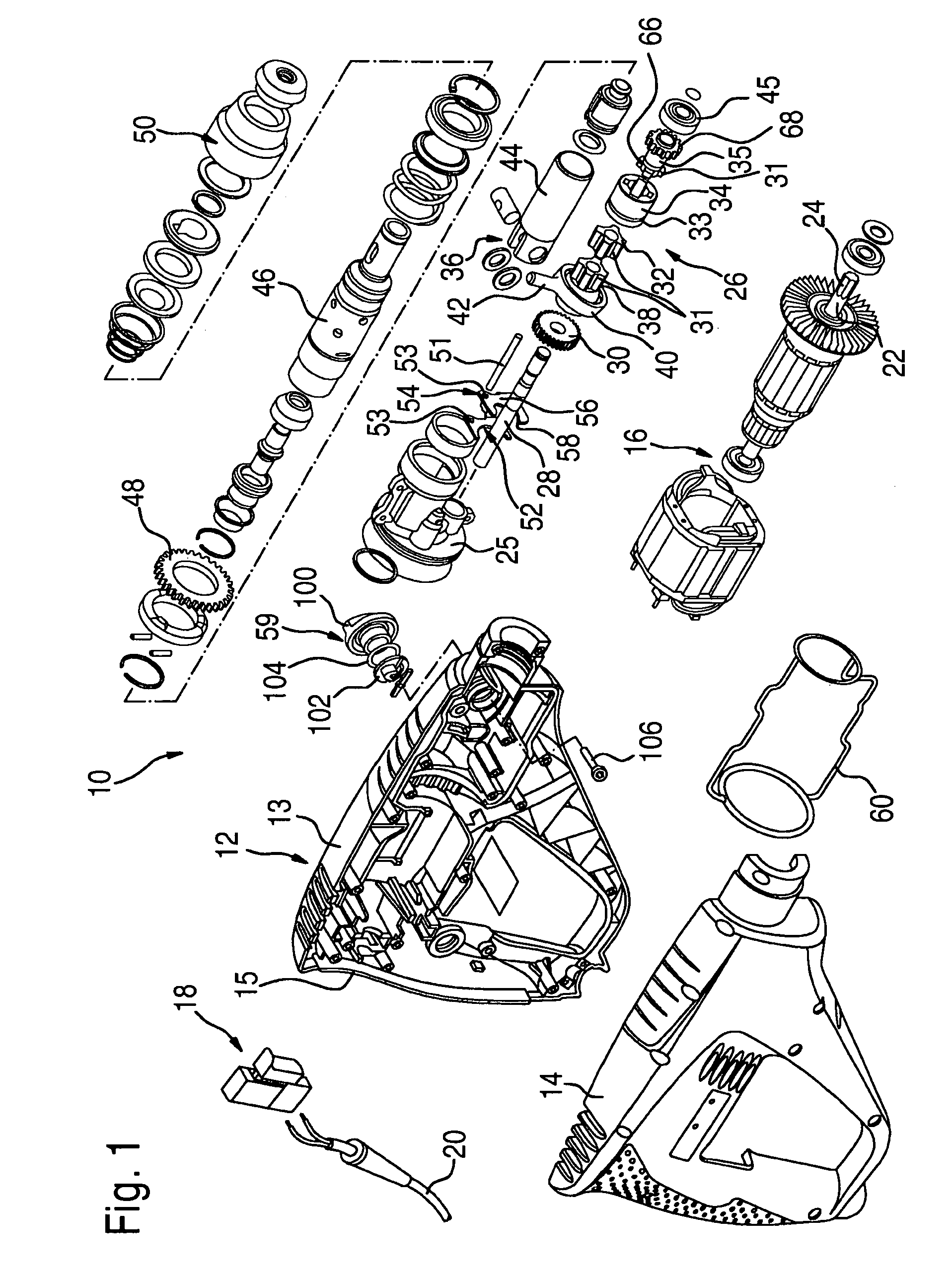

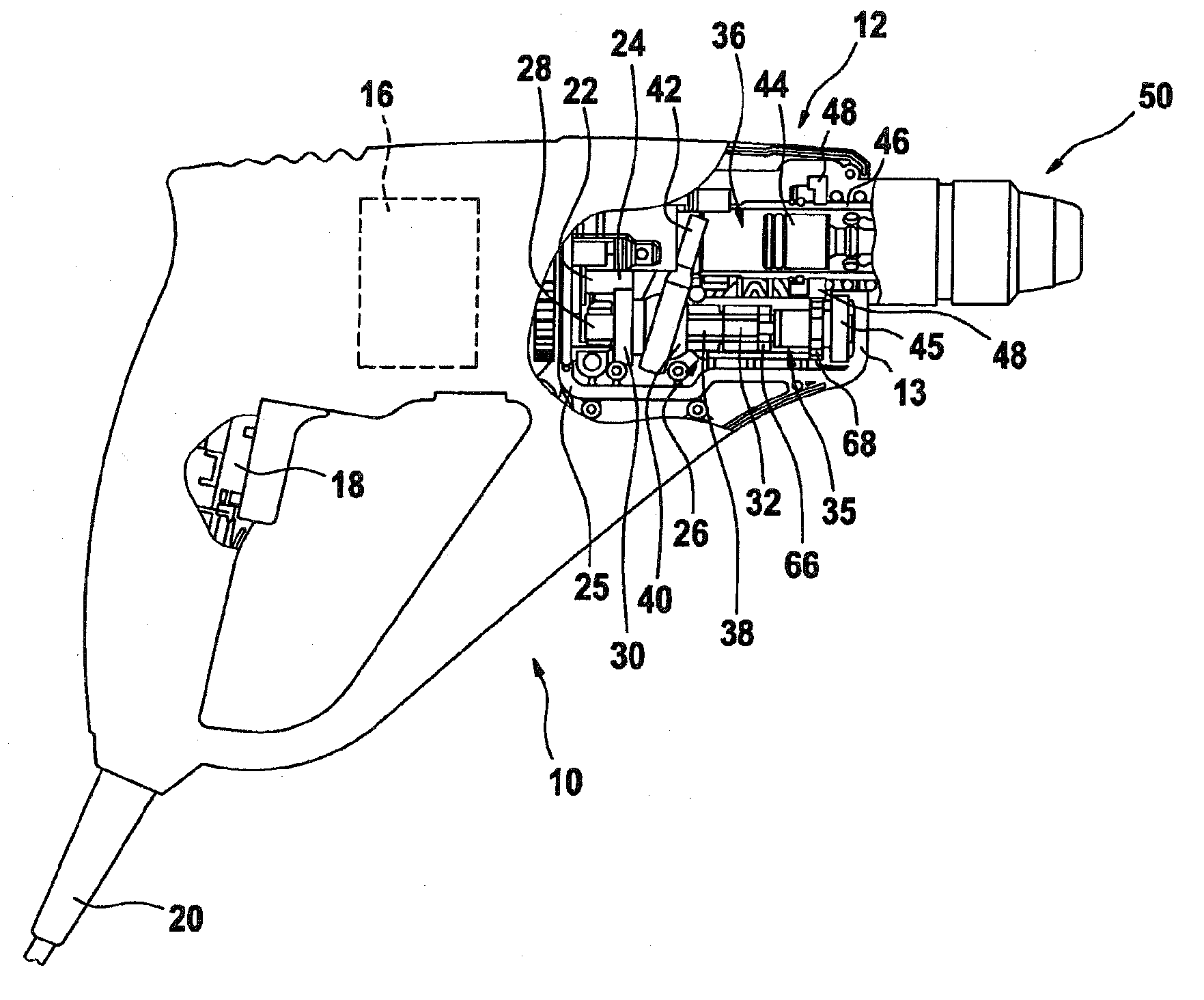

Drill Hammer With Three Modes of Operation

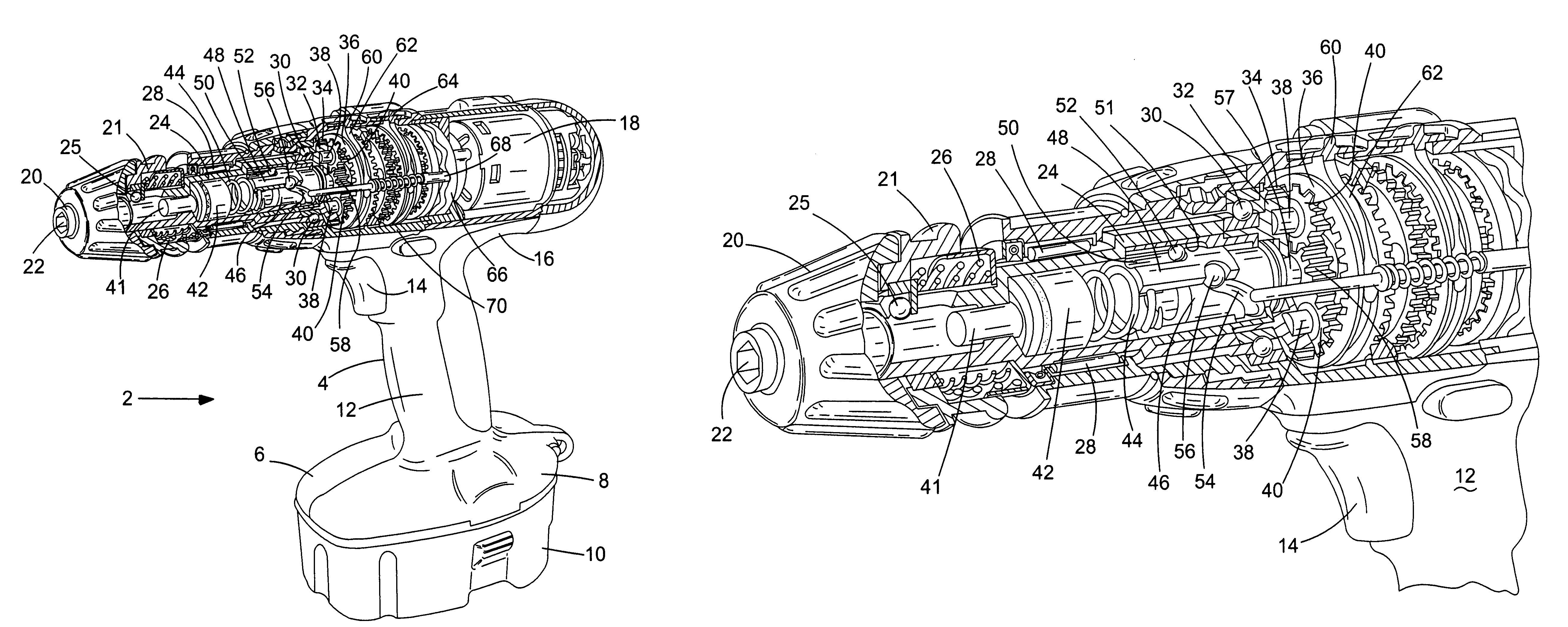

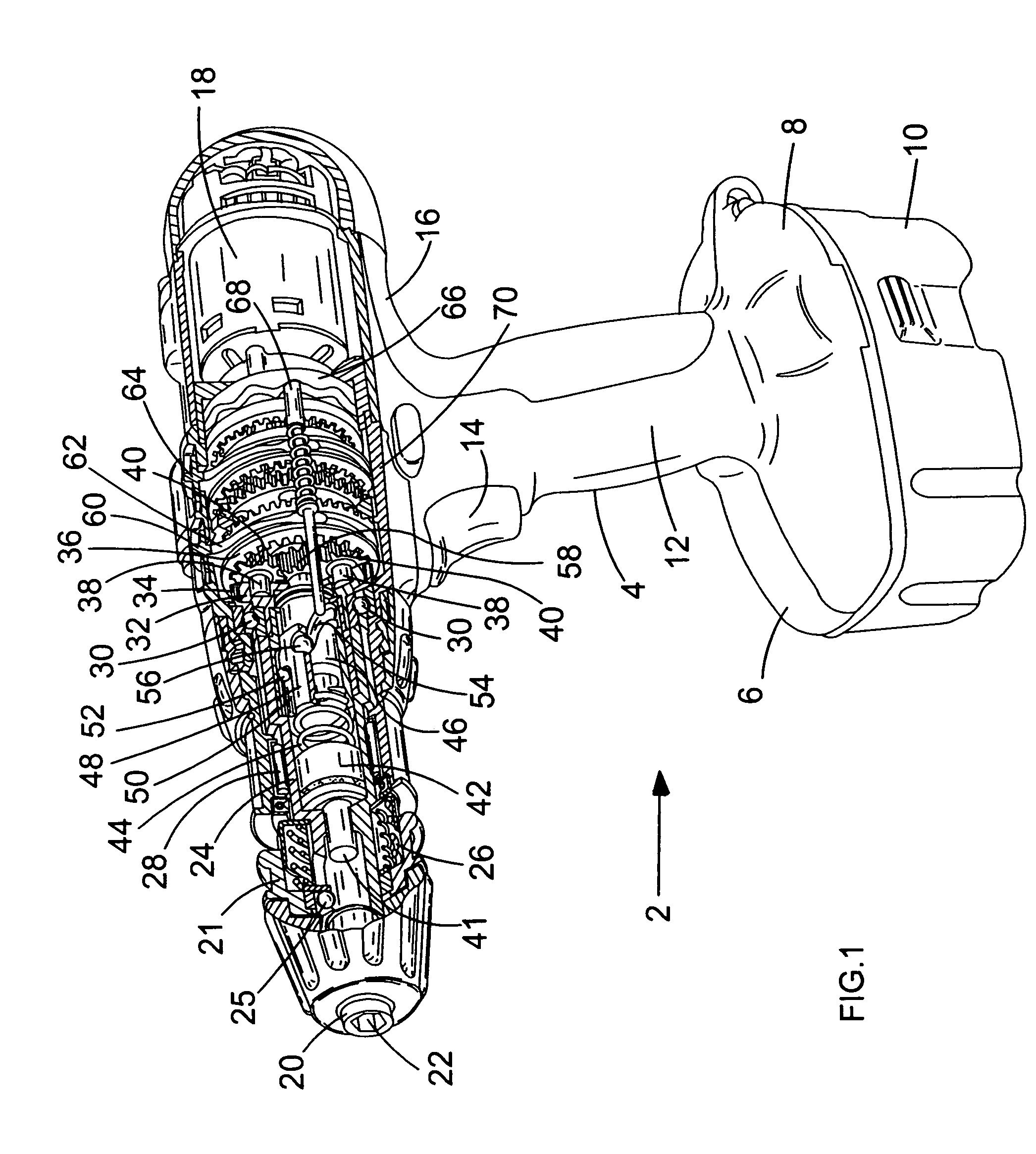

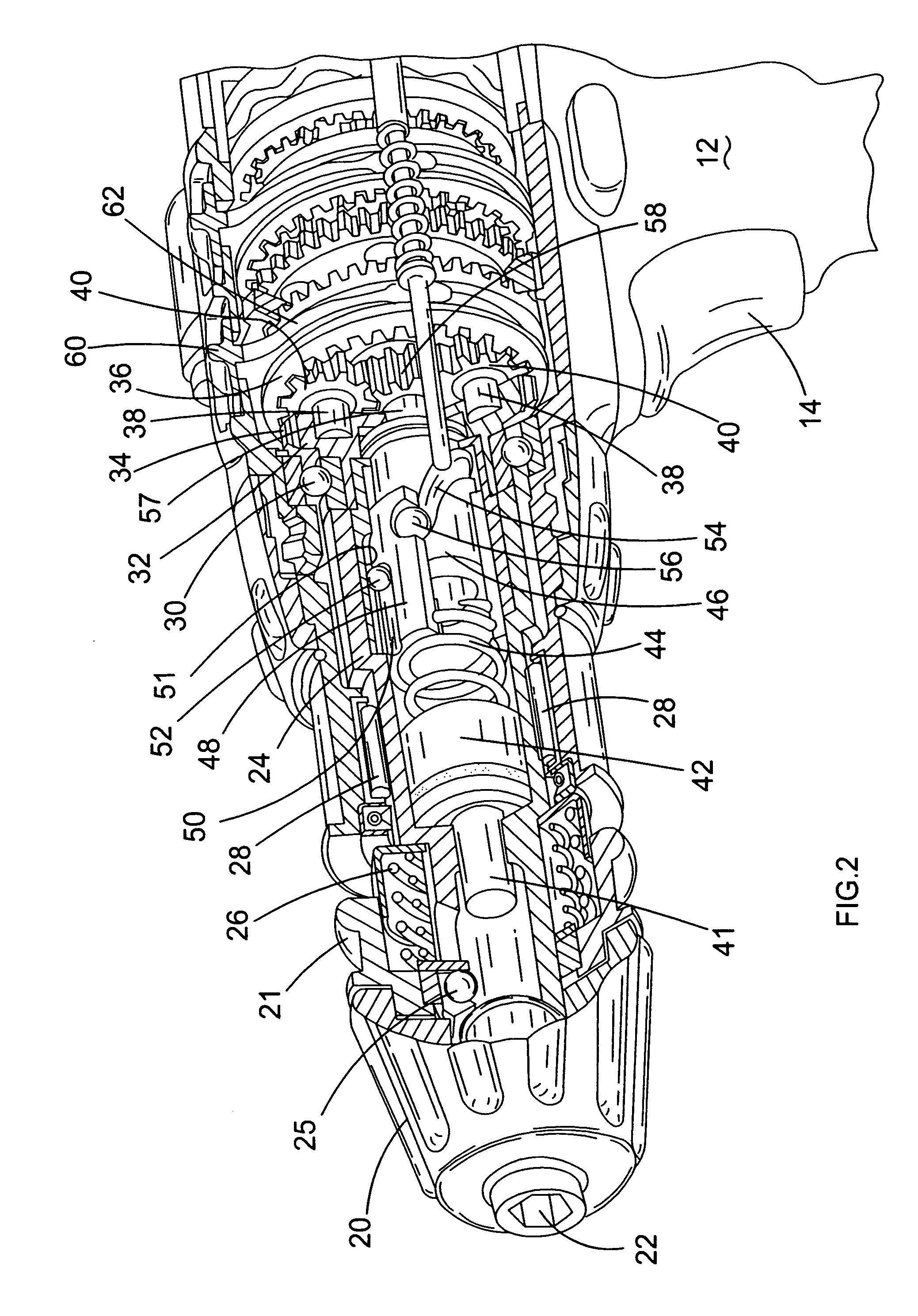

ActiveUS20080169111A1Promote conversionReduce friction lossDrilling rodsReciprocating drilling machinesGear wheelElectric machine

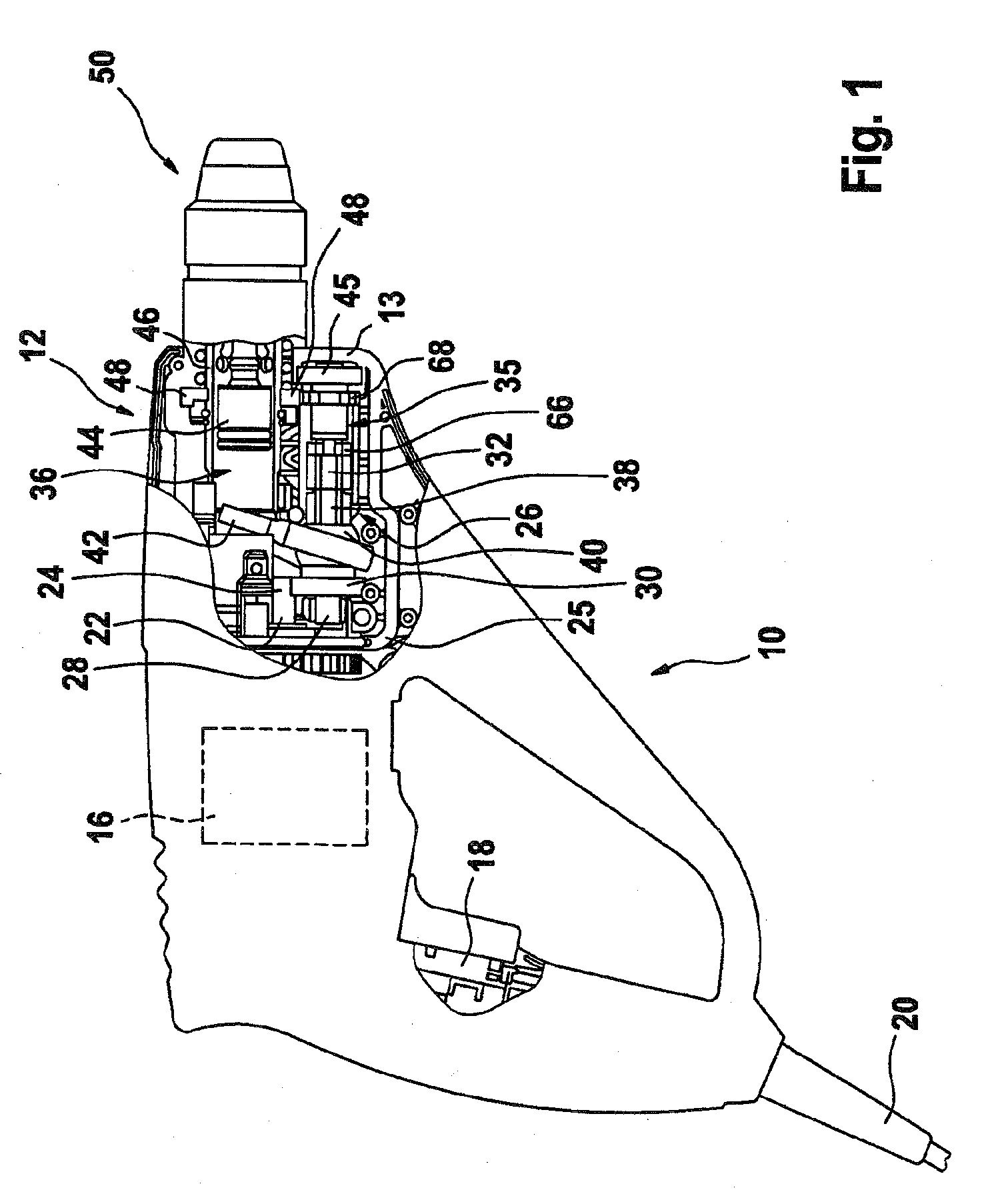

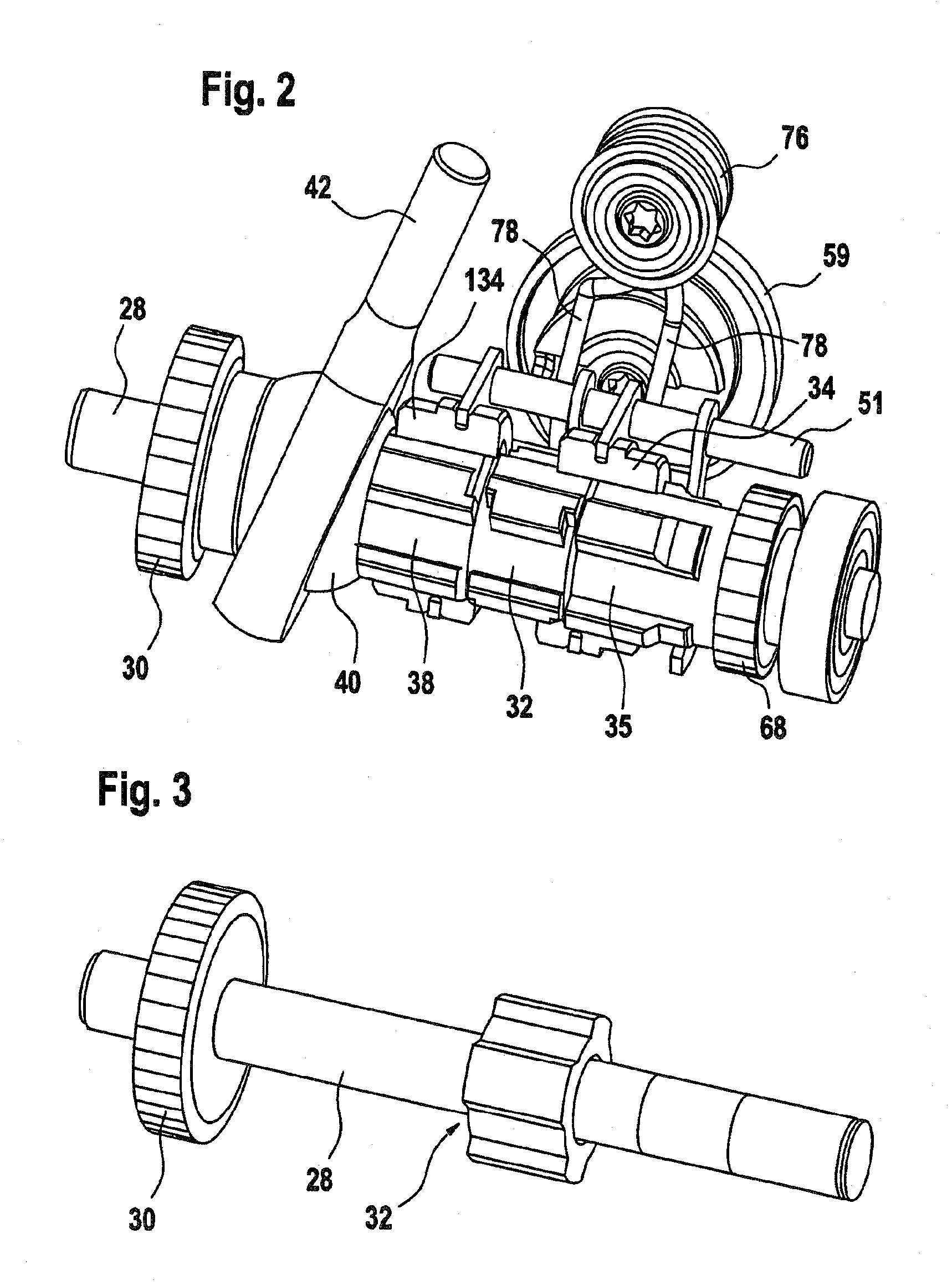

A hammer drill (10), consisting of a housing (12), accommodating the parts mentioned below and assembled in particular from half shells (13, 14), a motor (16) with an on / off switch (18) and with a motor shaft (22) with motor pinion (24), a gear unit (26) with an intermediate shaft (28), with a drive gear (30), with a splined driving shaft (32), with a shifting sleeve (34) and with an output gear (35), a percussion mechanism (36), in particular with a wobble plate (40), with a wobble gear (38) with wobble finger (42), and with a percussion element (44), an output shaft (46) with a drive gear (48), and a drill chuck (50), wherein the motor (16) meshes with the drive gear (30) of the intermediate shaft (28) via its motor pinion (24), wherein the rotary driving of the wobble plate (40) with the intermediate shaft (28) can be set or stopped via coupling or release of the shifting sleeve (34), in particular with the splined driving shaft, preferably by displacing with shifting means (52), and wherein the rotary driving of the output shaft (46) with the intermediate shaft (28) can be set or stopped via separate means, in particular independently of the shifting sleeve (34), can be produced cost-effectively and works at a high efficiency by virtue of the fact that a second shifting sleeve (134) serves to set the rotation of the output shaft (46), said shifting sleeve (134) enclosing the splined driving shaft (32) and / or the output gear (35) in a positive-locking and axially displaceable shiftable manner.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com