Actuation apparatus for power tool

a technology of actuation apparatus and power tool, which is applied in the direction of electrical apparatus, portable percussive tools, construction, etc., can solve the problems of high manufacturing cost of hammers and easy wear and tear, and achieve the effect of better grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

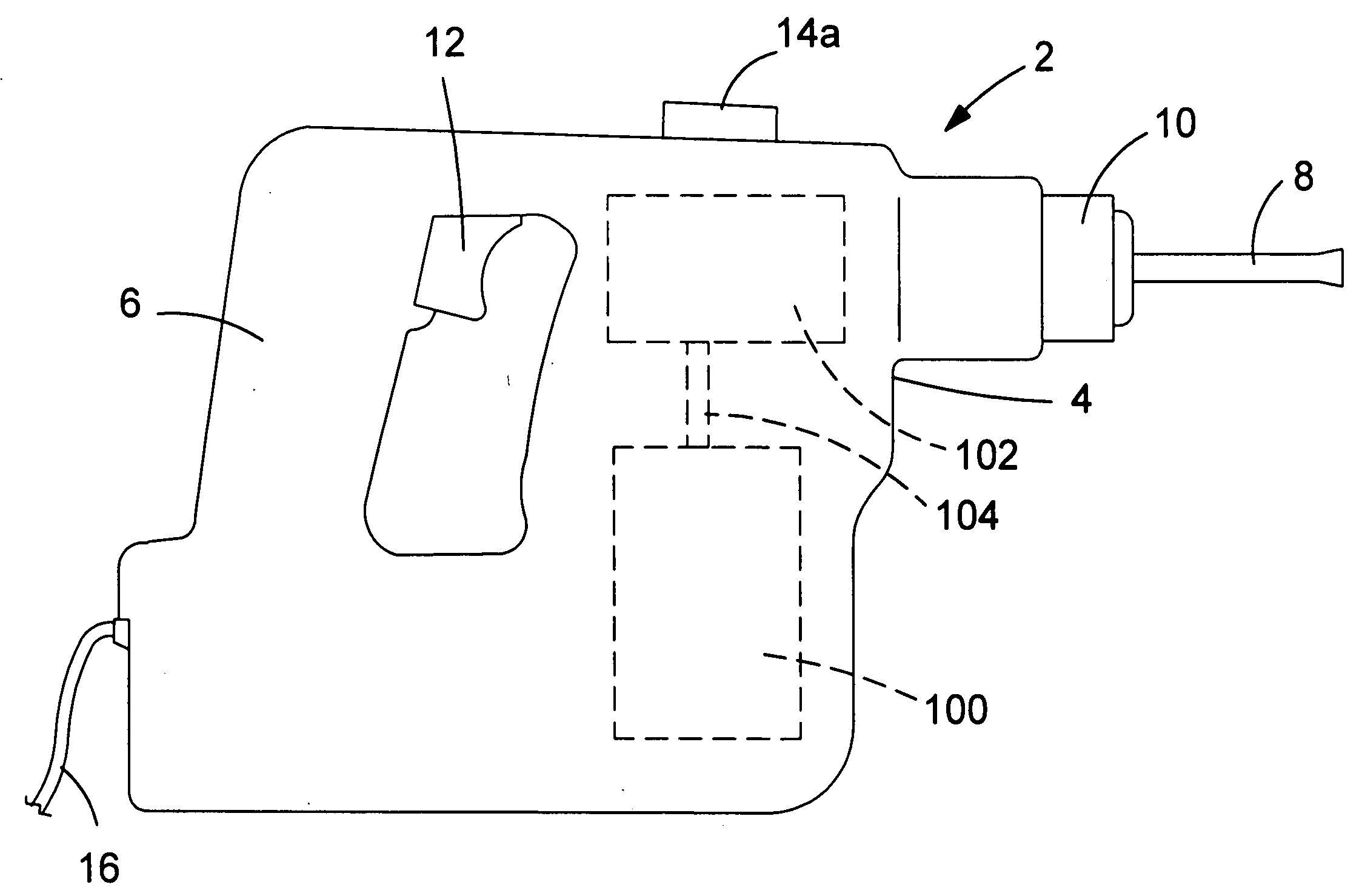

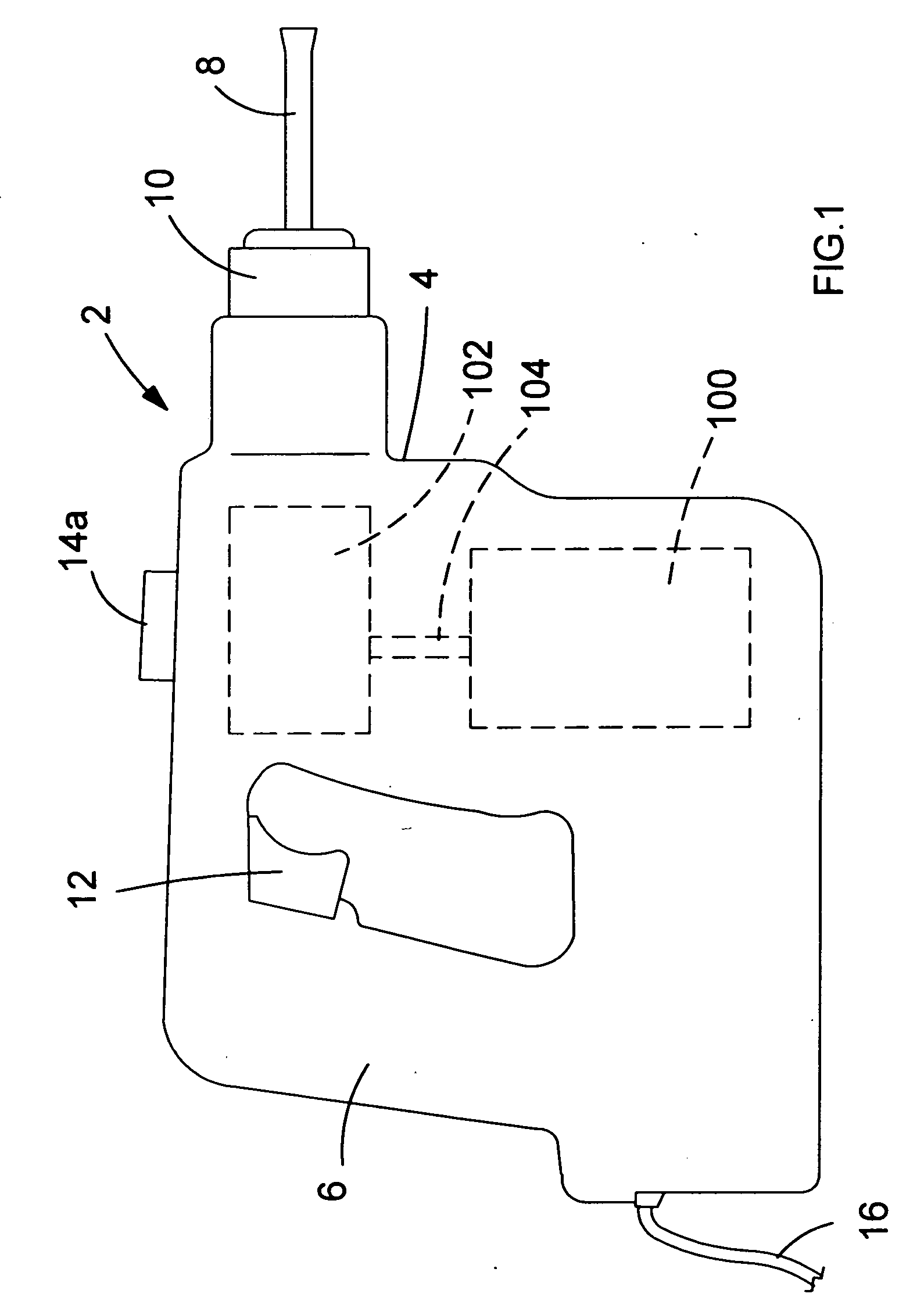

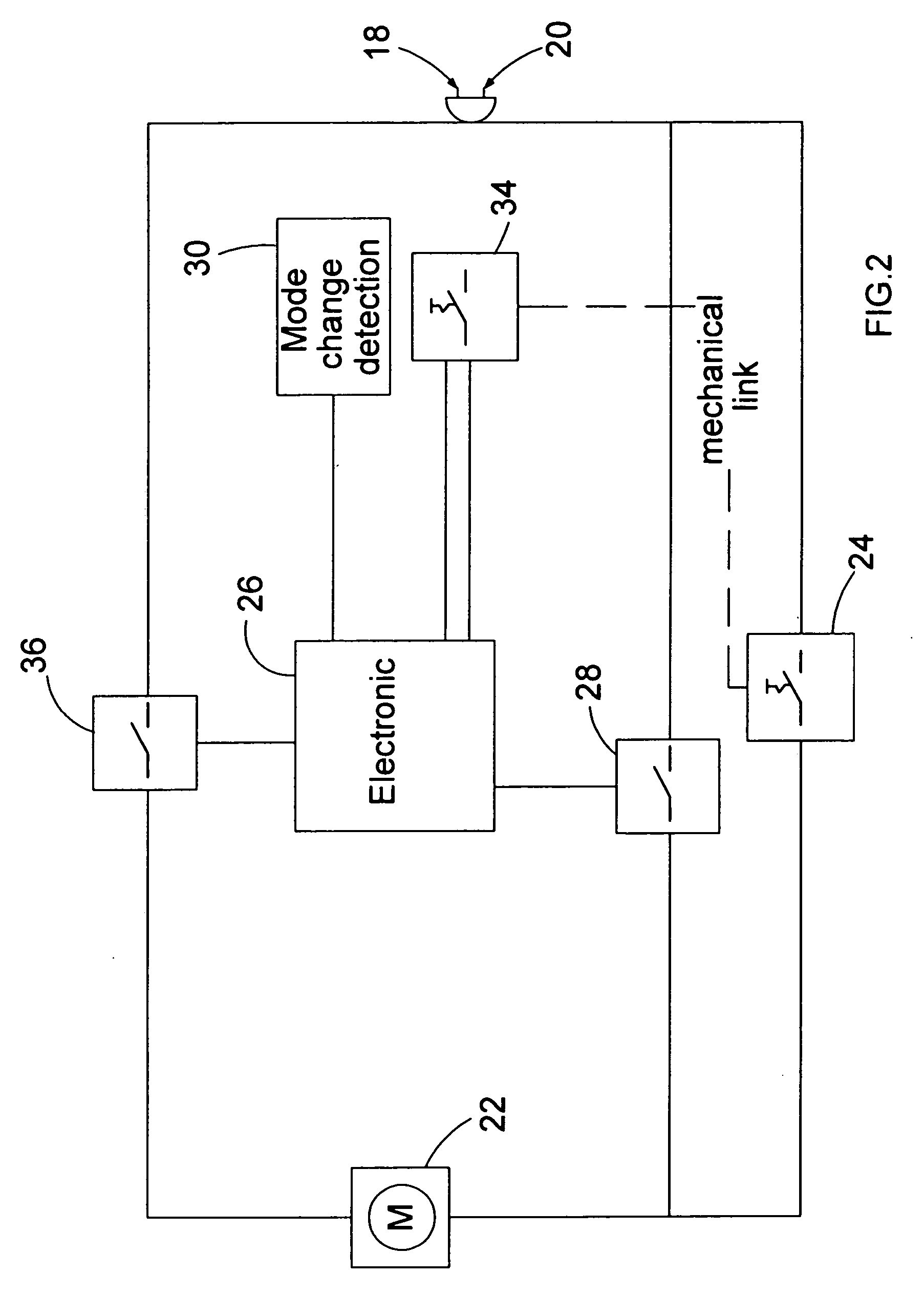

[0027] The first embodiment of the present invention will now be described with reference to FIGS. 1 and 2.

[0028] Referring to FIG. 1, a hammer drill shown generally by 2 comprises a housing 4 having a handle portion 6 for the user to grip. A motor 100 is disposed in the housing 4 which drives a drive mechanism 102 via a rotary output shaft 104, also disposed in the housing 4 and which is capable of driving a bit 8 in a drill mode, in which the bit is rotated, a hammer mode in which impacts are imparted to the bit 8, or a hammer and drill mode, in which both actions are combined. Bit 8 is held in a chuck 10 which is driveably connected to the drive mechanism 104. The operation of the drive mechanism will be familiar to persons skilled in the art and is not relevant to the understanding of the present invention, and will therefore not be described in greater detail herein.

[0029] A trigger 12 is disposed on the handle portion 6 to enable the user to activate the hammer drill 2. A mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com