Patents

Literature

30901results about "Bulkheads/piles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

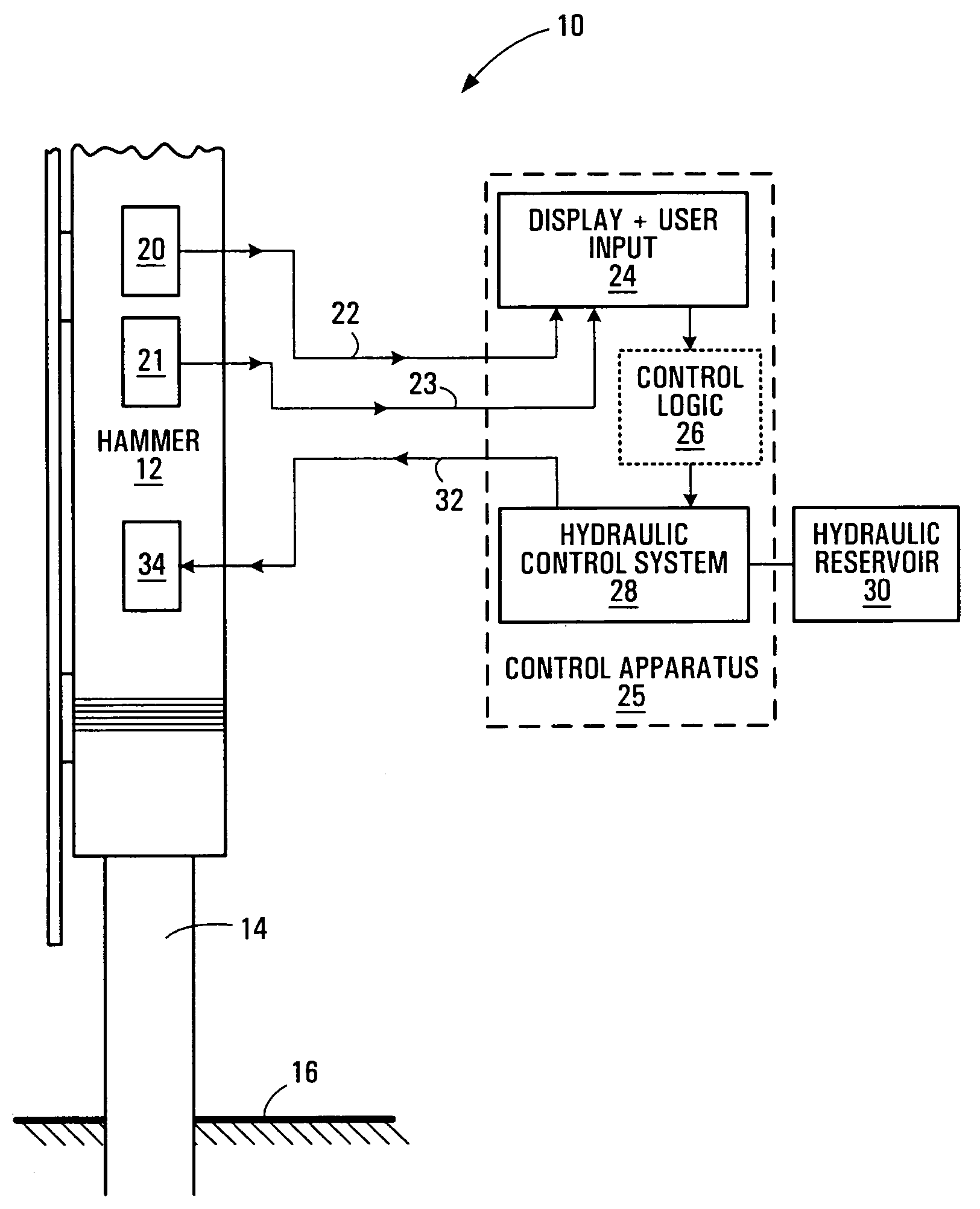

Impact tool

According to one embodiment, an impact tool includes: a motor; and a hammer that is connected to the motor and that has a striking-side surface; and an anvil that is journalled to be rotatable with respect to the hammer, that has a struck-side surface and that provides a striking power to a tip tool, wherein the motor is drivable in: a first driving mode in which the motor is continuously driven in a normal rotation; a second driving mode in which the motor is intermittently driven only in the normal rotation; and a third driving mode in which the motor is intermittently driven in the normal rotation and in a reverse rotation.

Owner:KOKI HLDG CO LTD

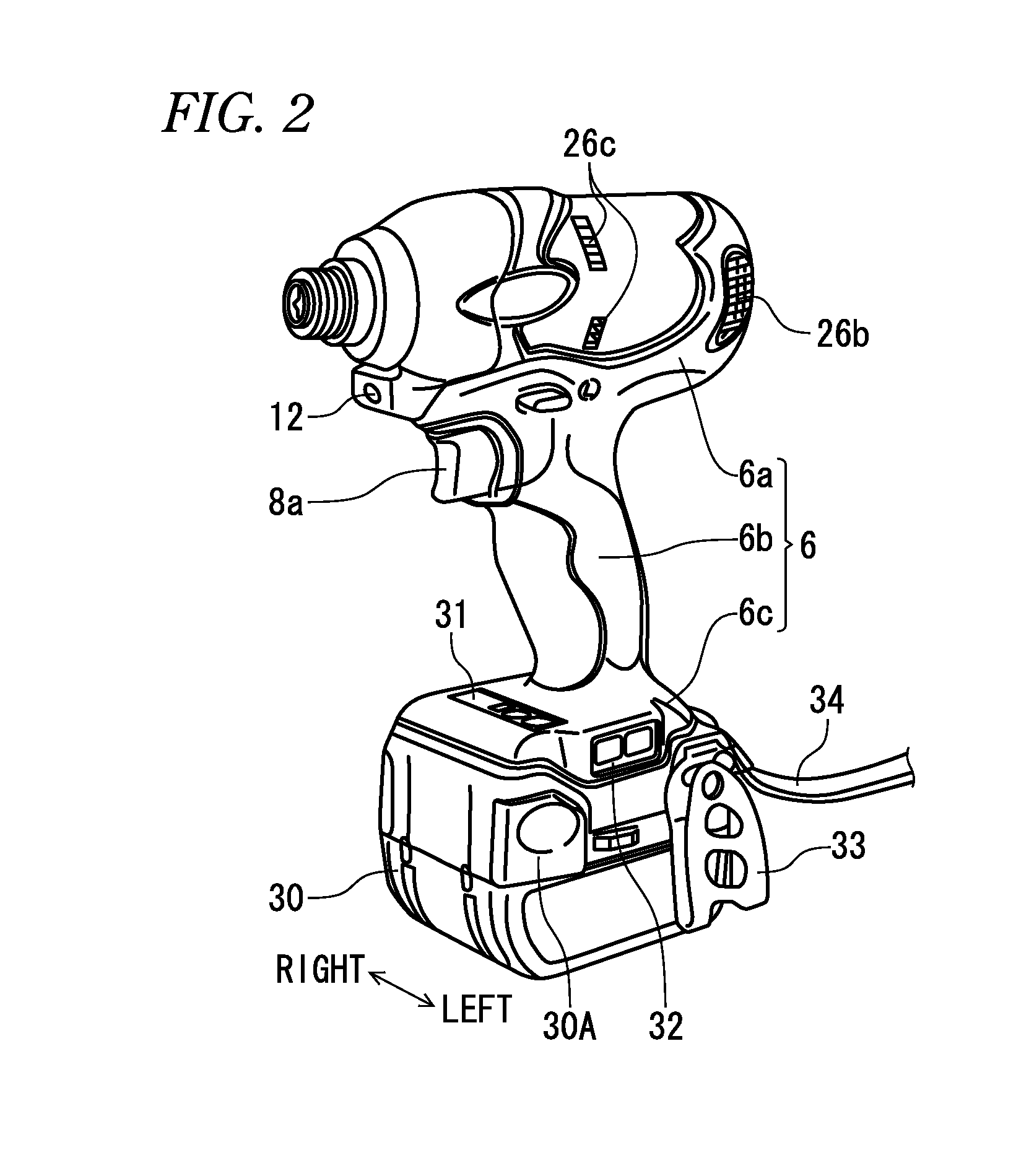

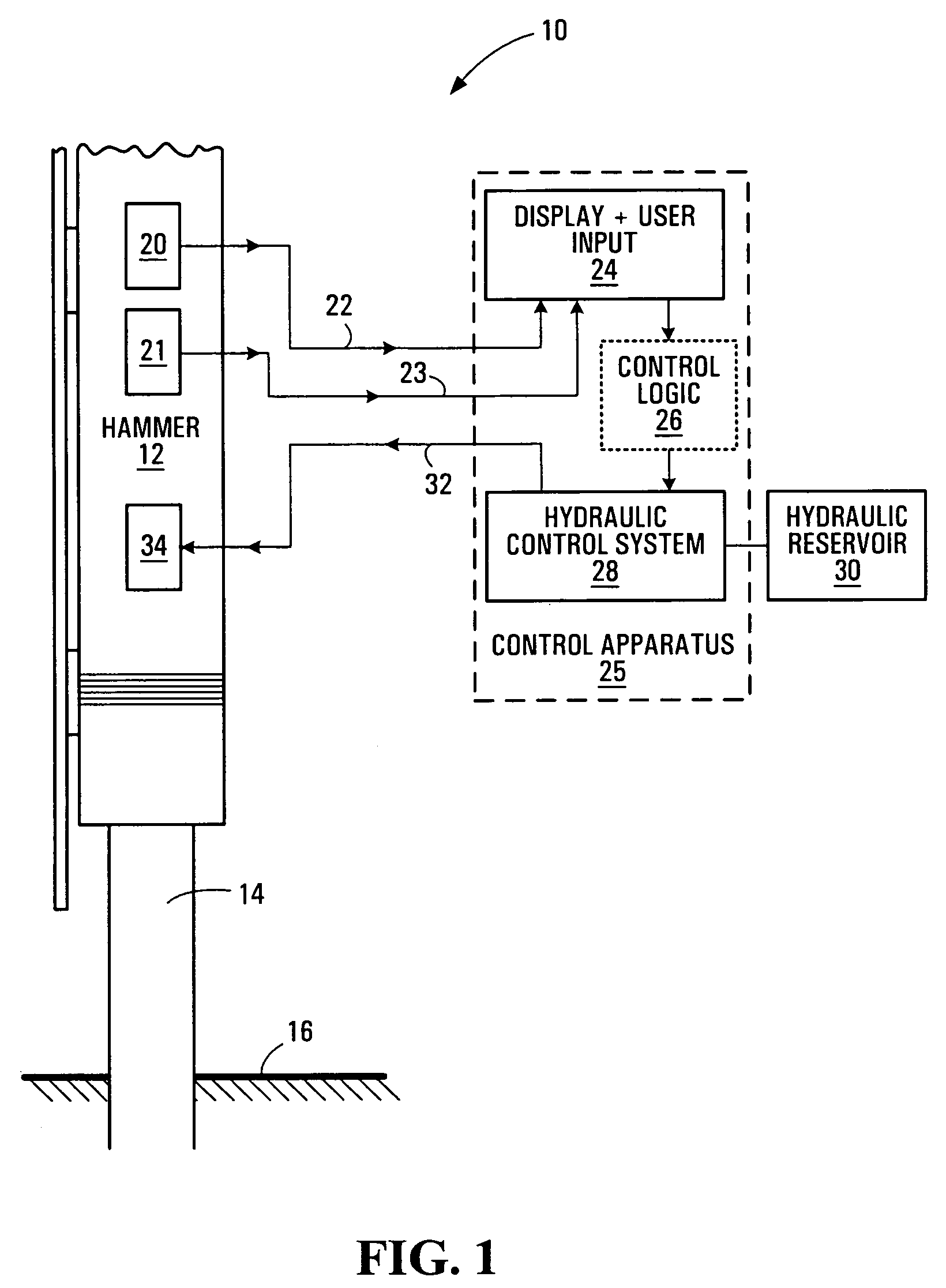

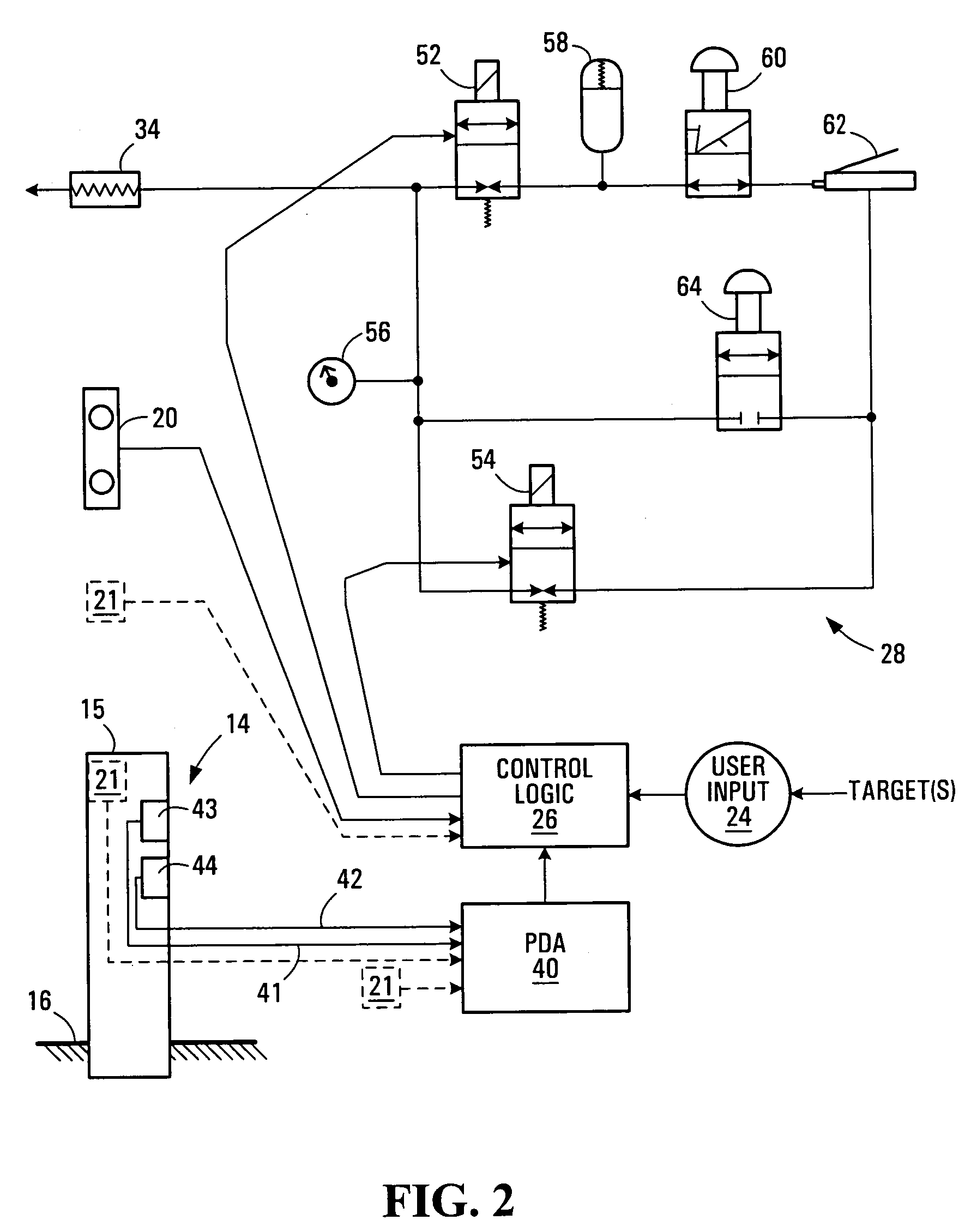

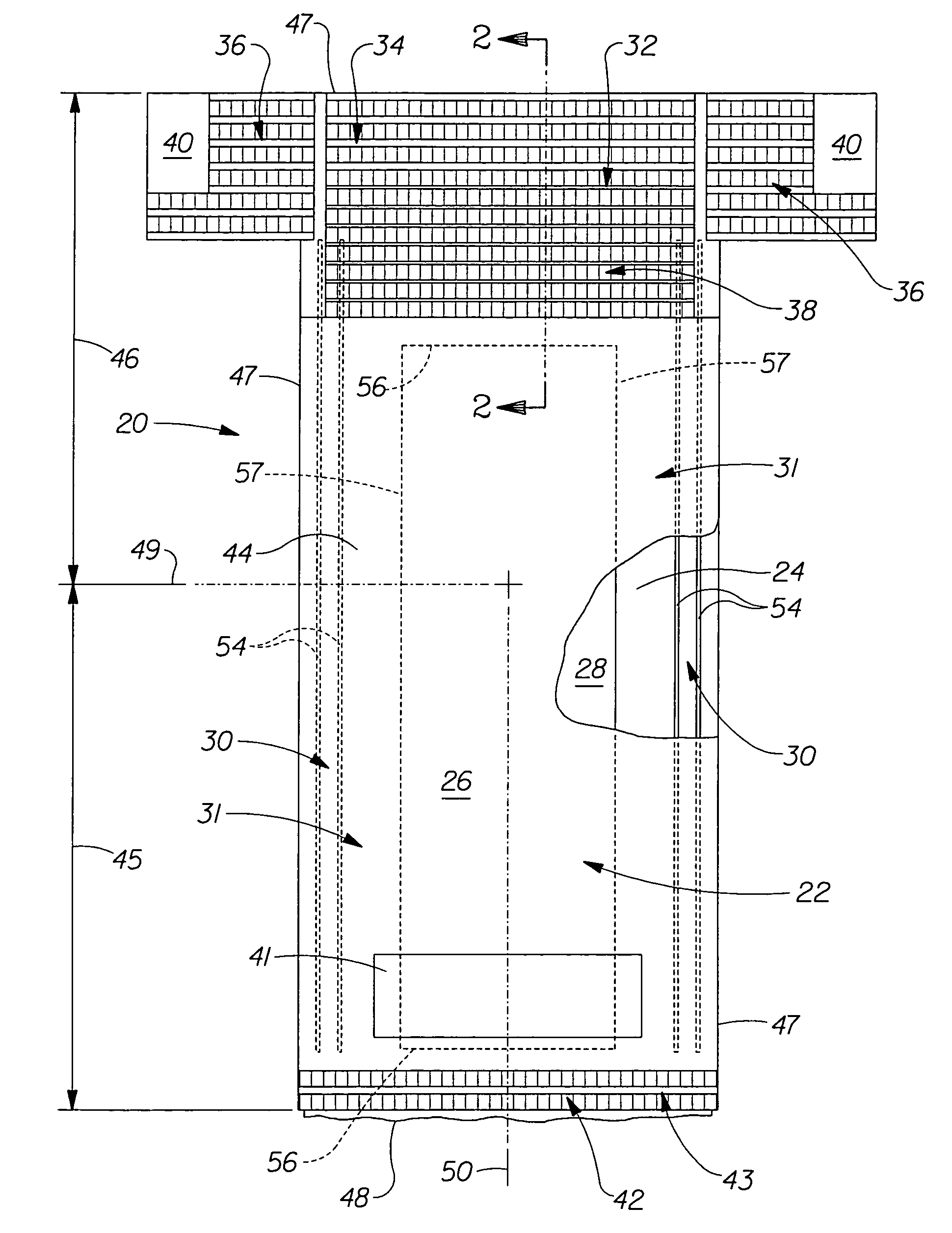

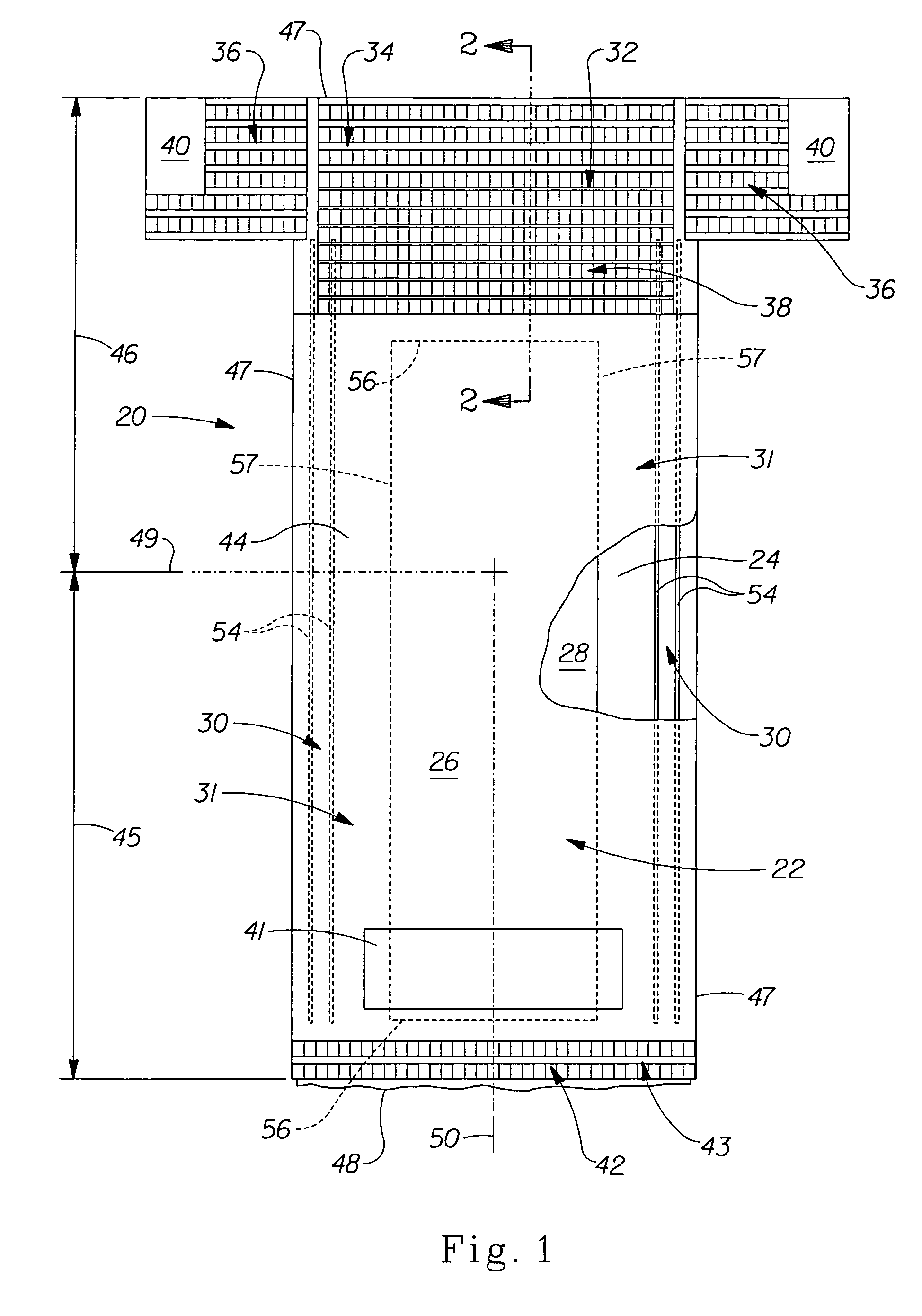

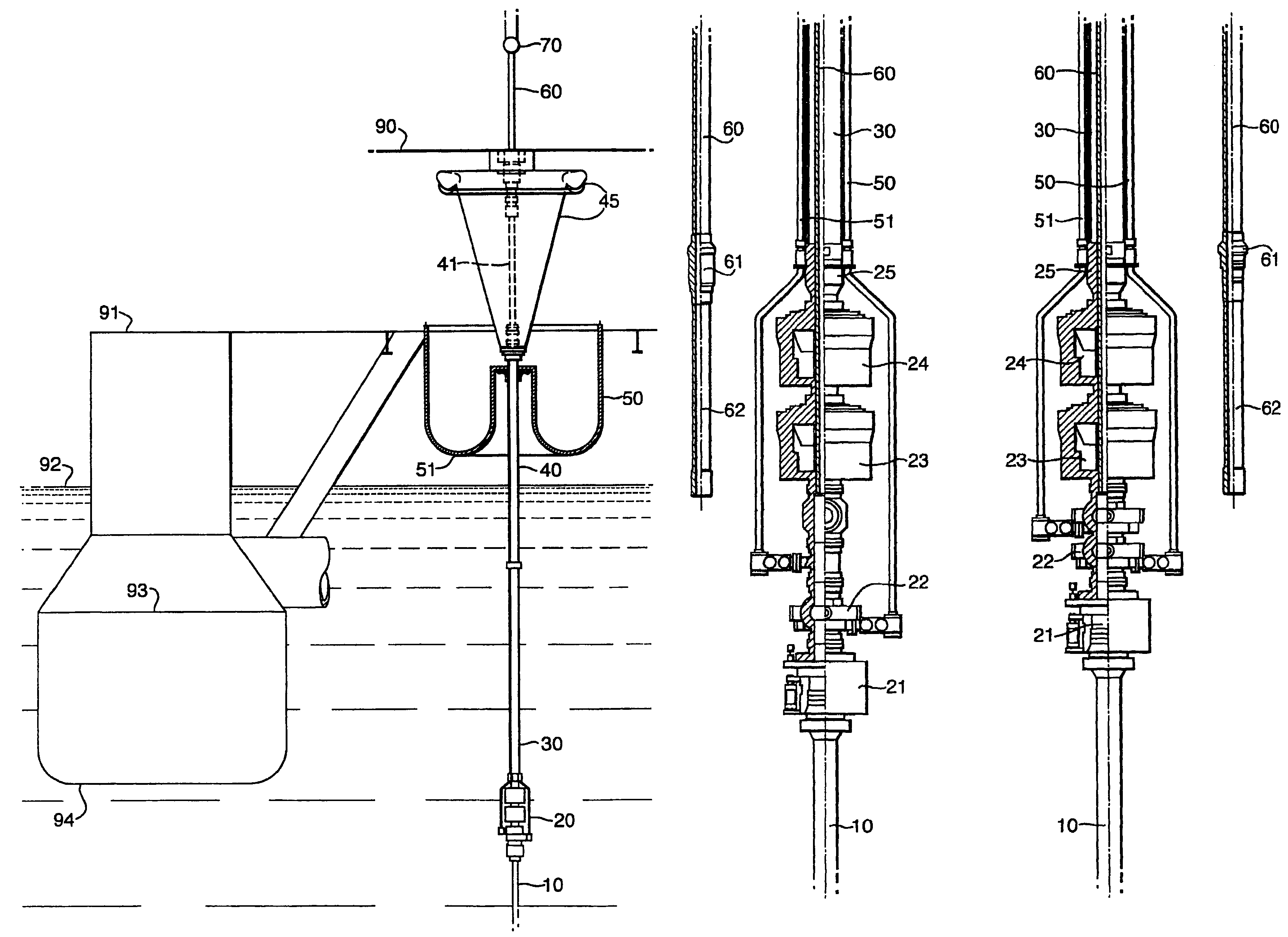

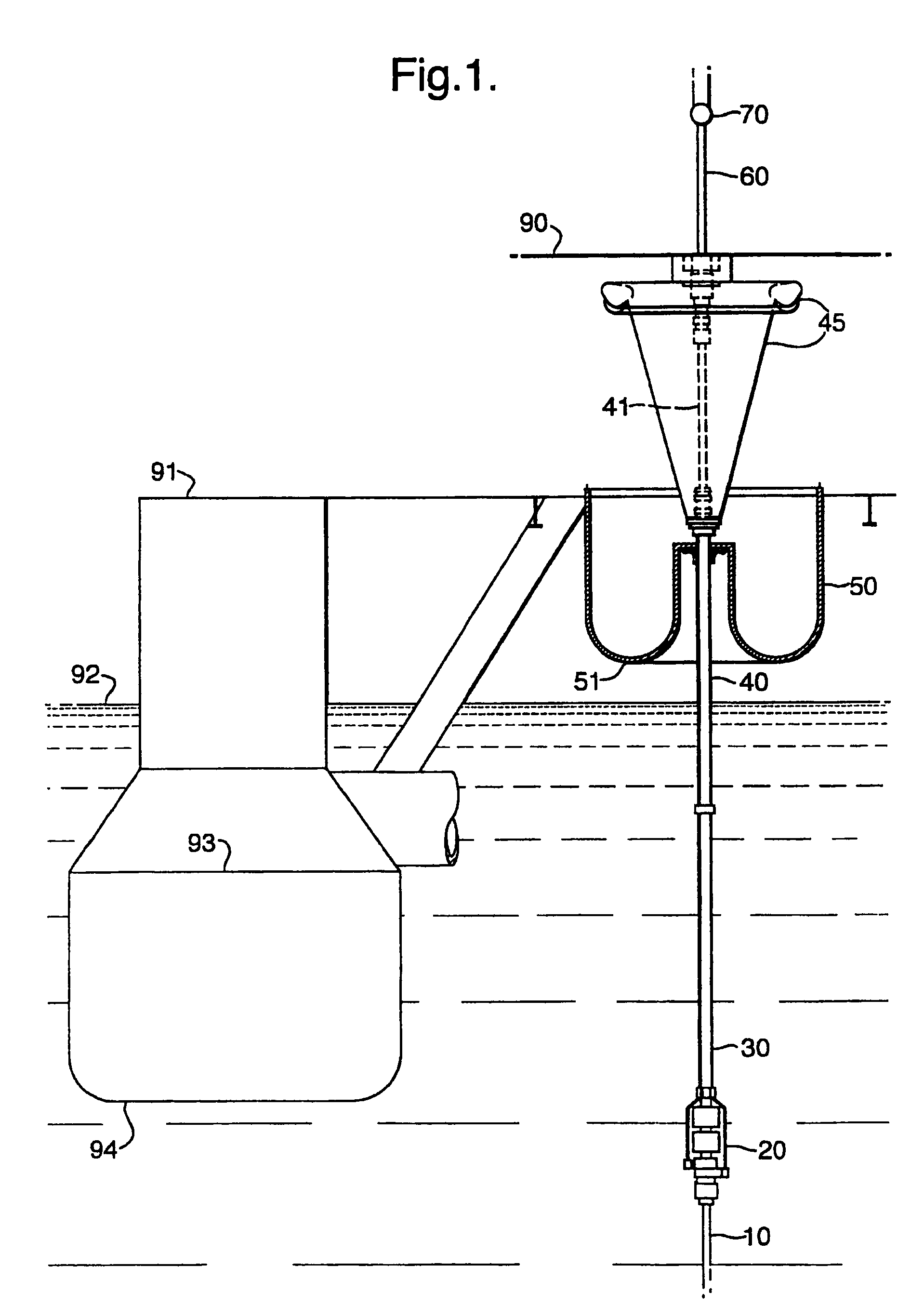

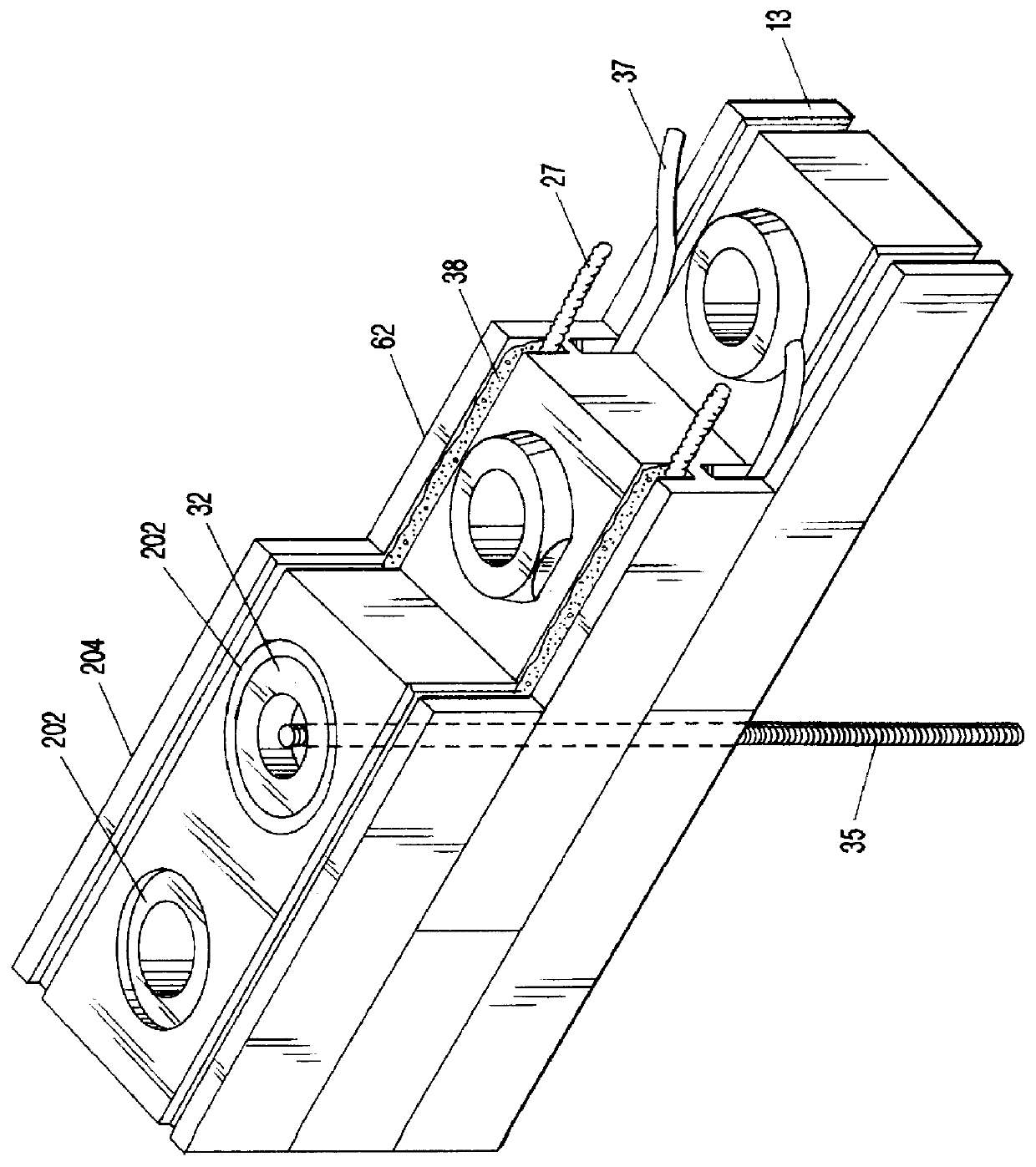

Pile driving control apparatus and pile driving system

ActiveUS7404449B2Reduce impact speedReciprocating drilling machinesDerricks/mastsVibration controlControl system

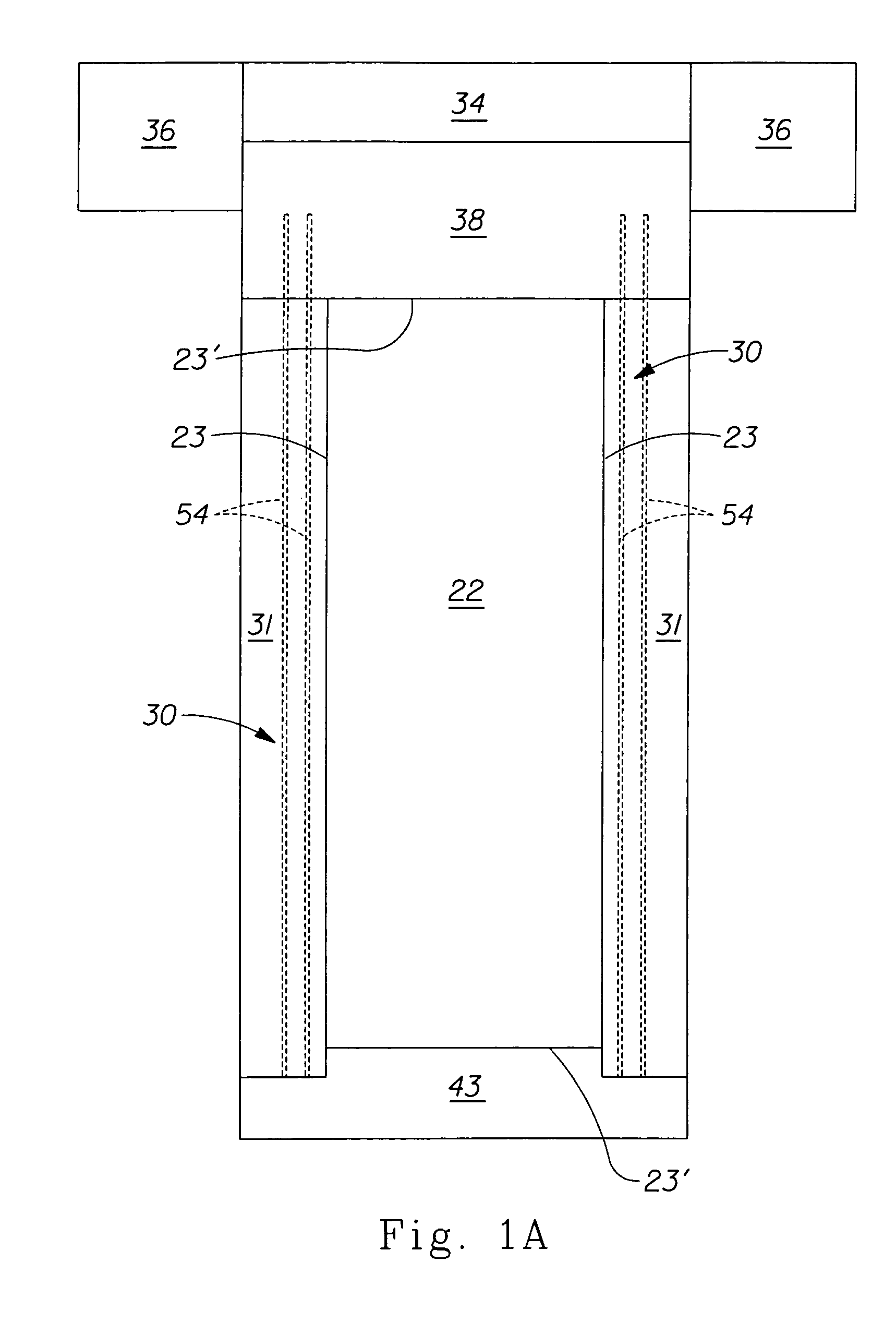

A pile driving control apparatus for a pile driving system includes a hydraulic control system that controls a throttle of a pile driving hammer, and thereby controls an impact velocity of the hammer with a pile. A controller provides a control signal to the hydraulic control system. Based on the control signal, the hydraulic control system controls an impact velocity of the hammer during a subsequent hammer stroke. The controller may determine one or more control parameters such as sound pressure at a sound control location during a hammer stroke, vibration at a vibration control location during a hammer stroke, an impact force imparted to the pile during a hammer stroke, and / or actual pile capacity of the pile, and provide to the hydraulic control system a control signal based on the determined control parameter(s).

Owner:BERMINGHAM FOUND SOLUTIONS LTD

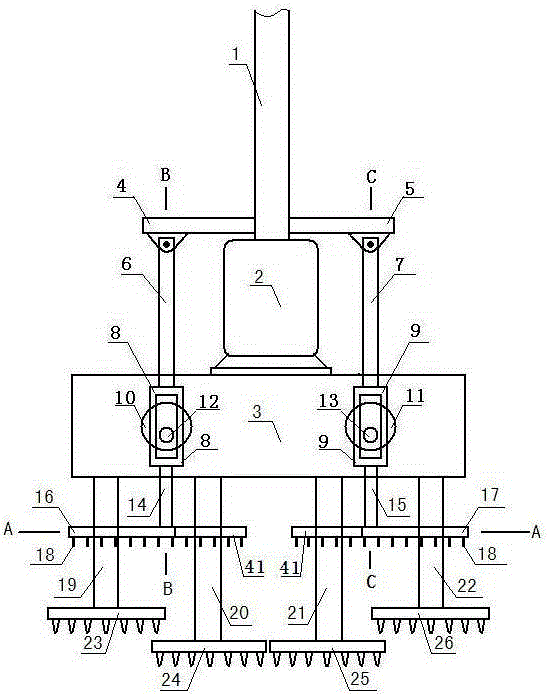

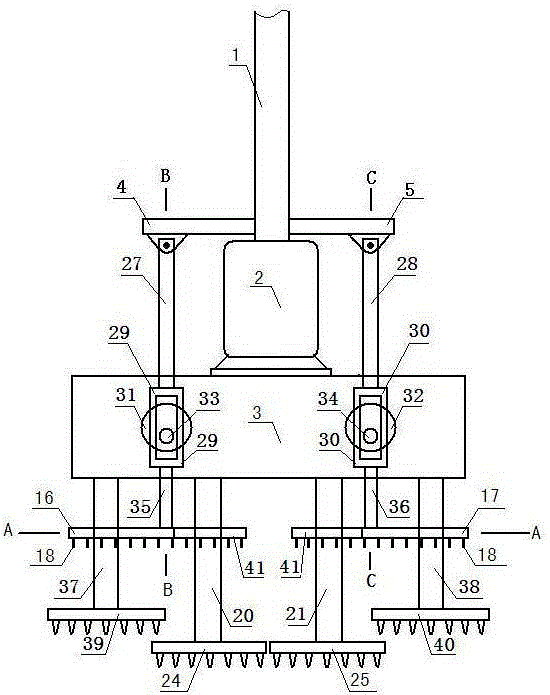

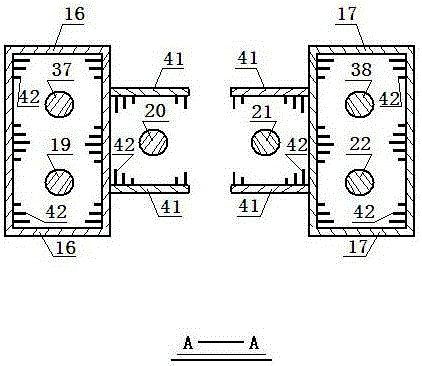

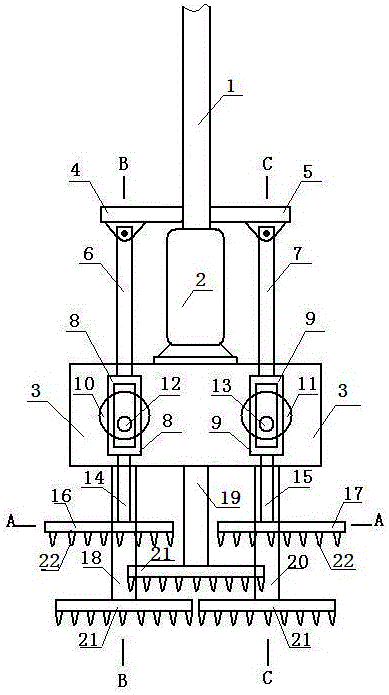

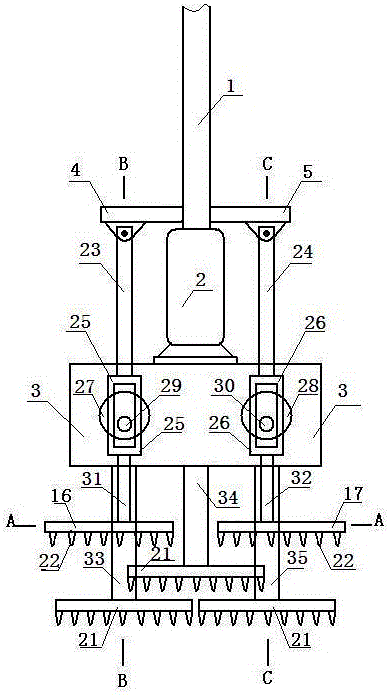

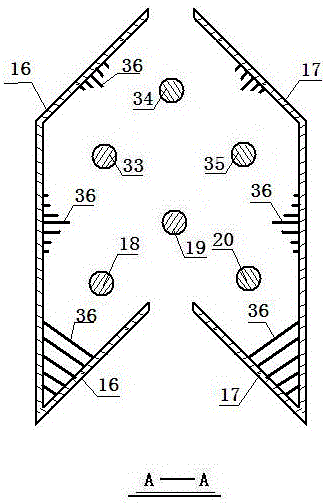

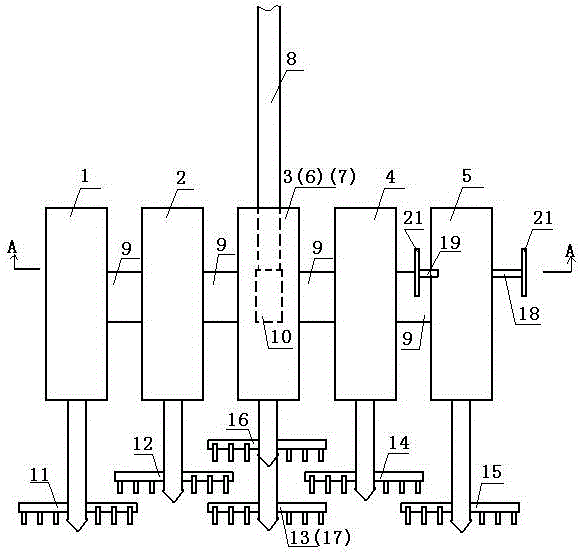

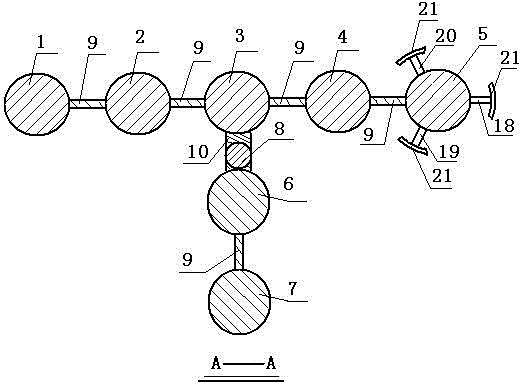

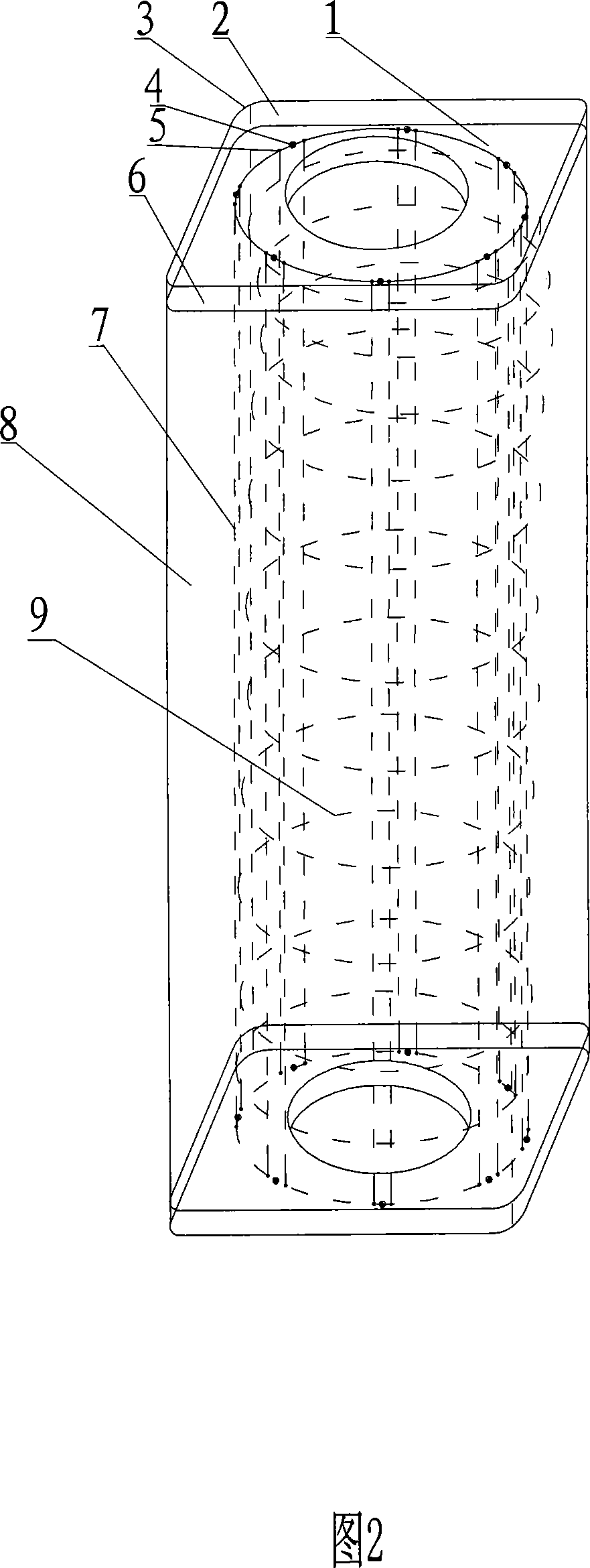

H-shaped mixing pile equipment

Disclosed is H-shaped mixing pile equipment. Mixing arms are fixed to the front portion and the rear portion of the right portion of a first large square frame respectively, a plurality of second tool teeth are arranged in the direction, facing a second mixing shaft, of the two mixing arms respectively, and the lower portions of the two mixing arms are each provided with a plurality of first tool teeth. Mixing arms are fixed to the front portion and the rear portion of the left portion of a second large square frame respectively, a plurality of second tool teeth are arranged in the direction, facing a third mixing shaft, of the two mixing arms respectively, and the lower portions of the two mixing arms are each provided with a plurality of first tool teeth. A plurality of second tool teeth are arranged in a frame body of the first large square frame, and a plurality of first tool teeth are arranged on the lower portion of the frame body of the first large square frame. A plurality of second tool teeth are arranged in a frame body of the second large square frame, and a plurality of first tool teeth are arranged on the lower portion of the frame body of the second large square frame.

Owner:朱艳菊

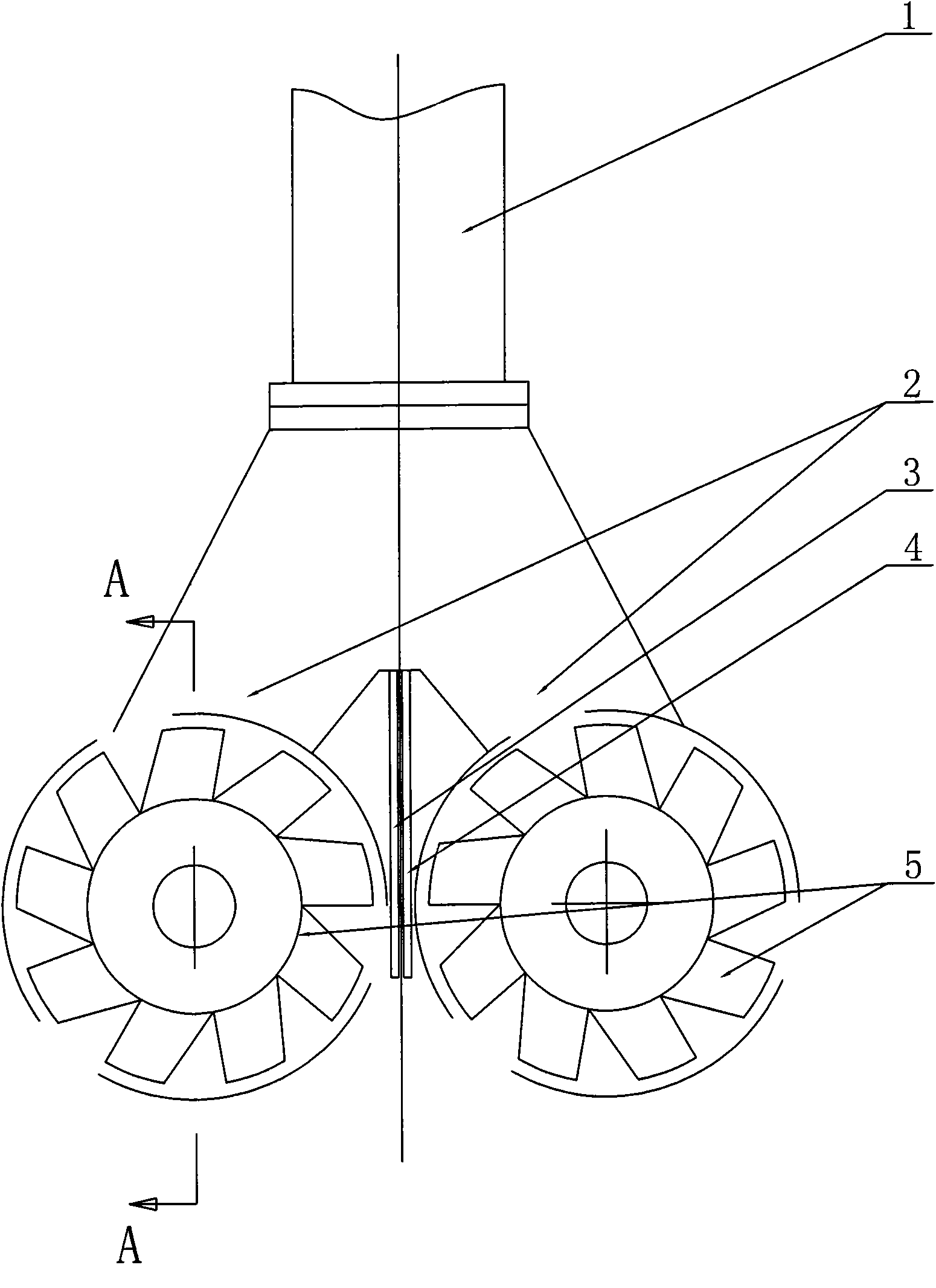

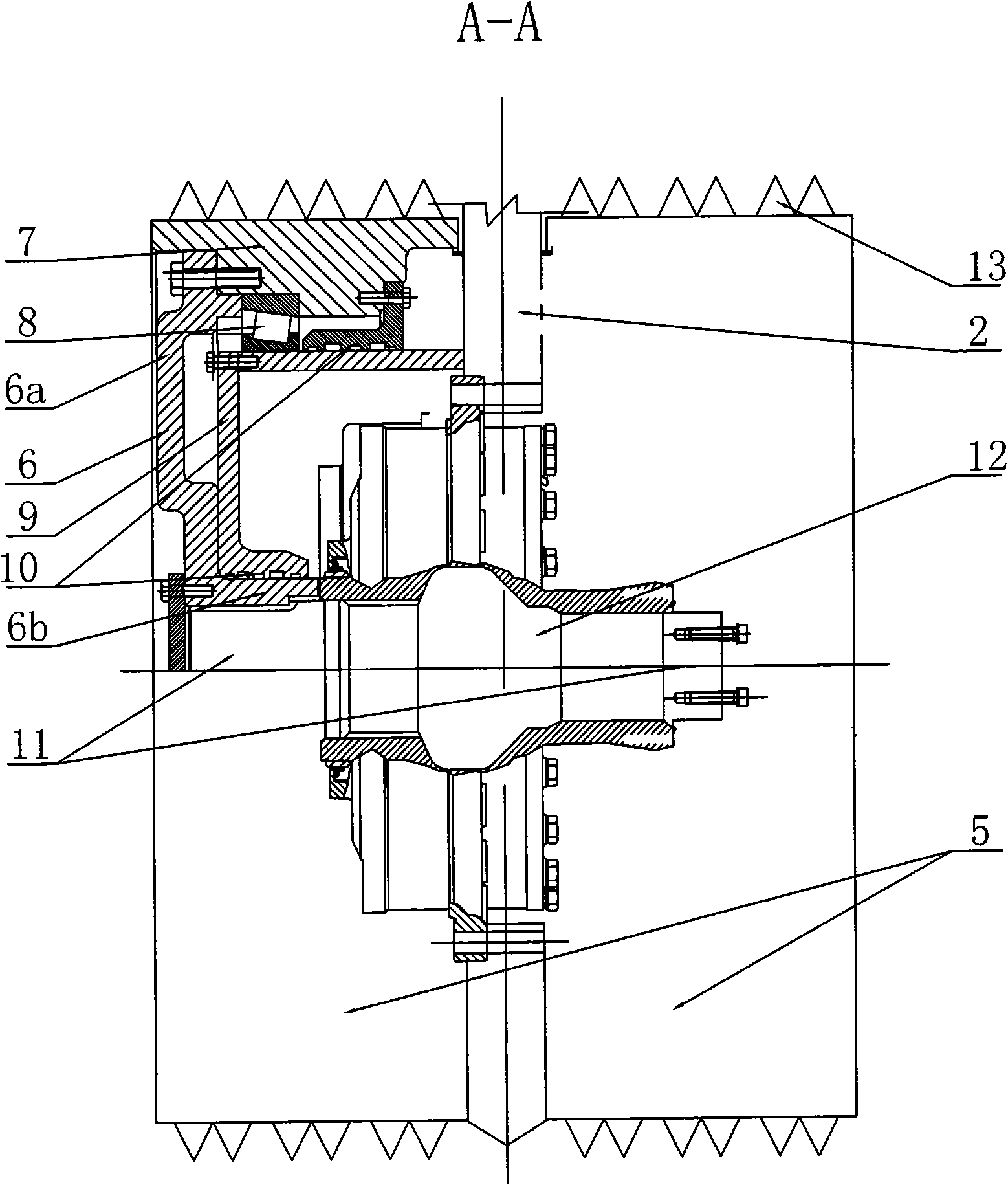

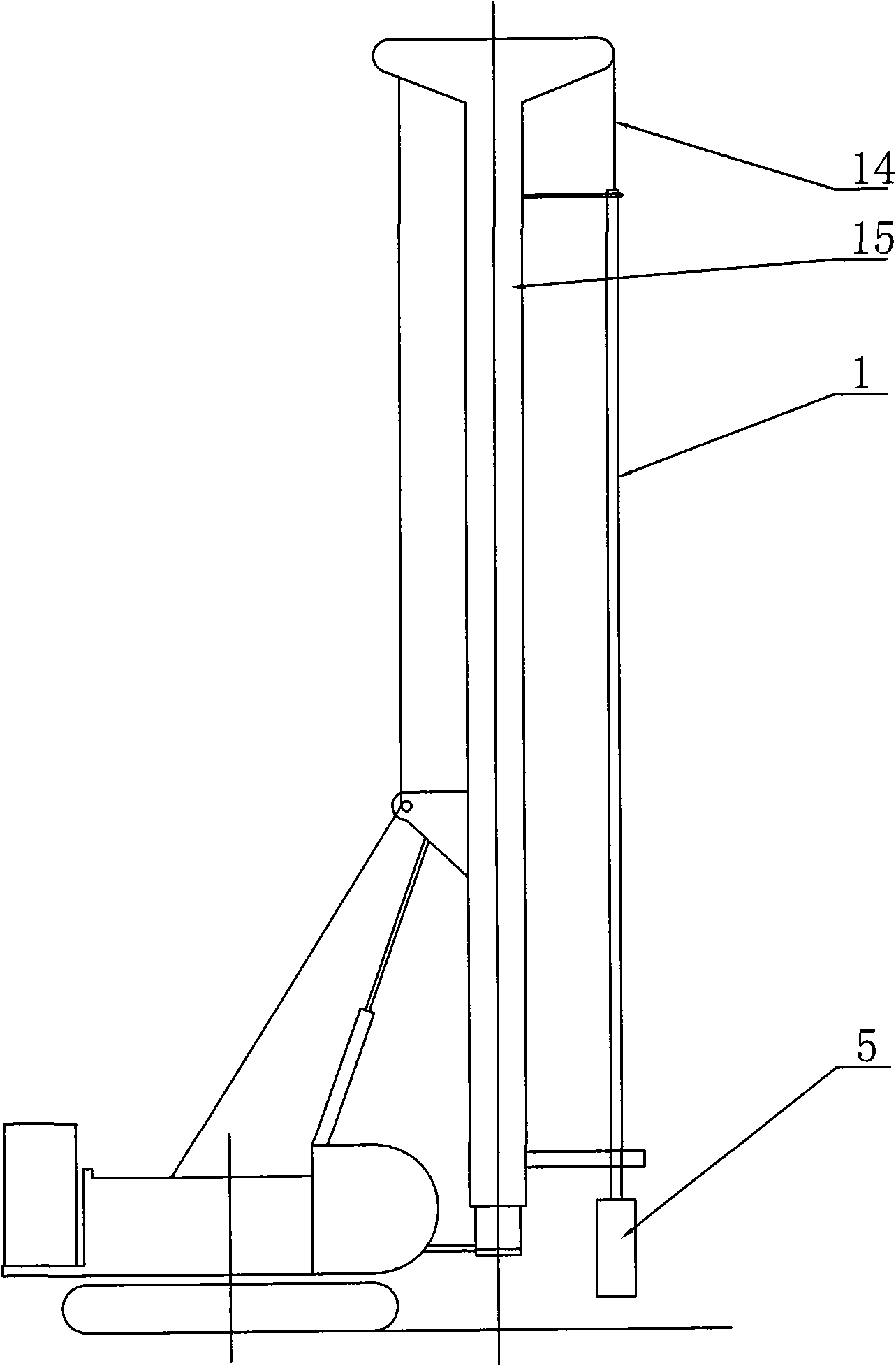

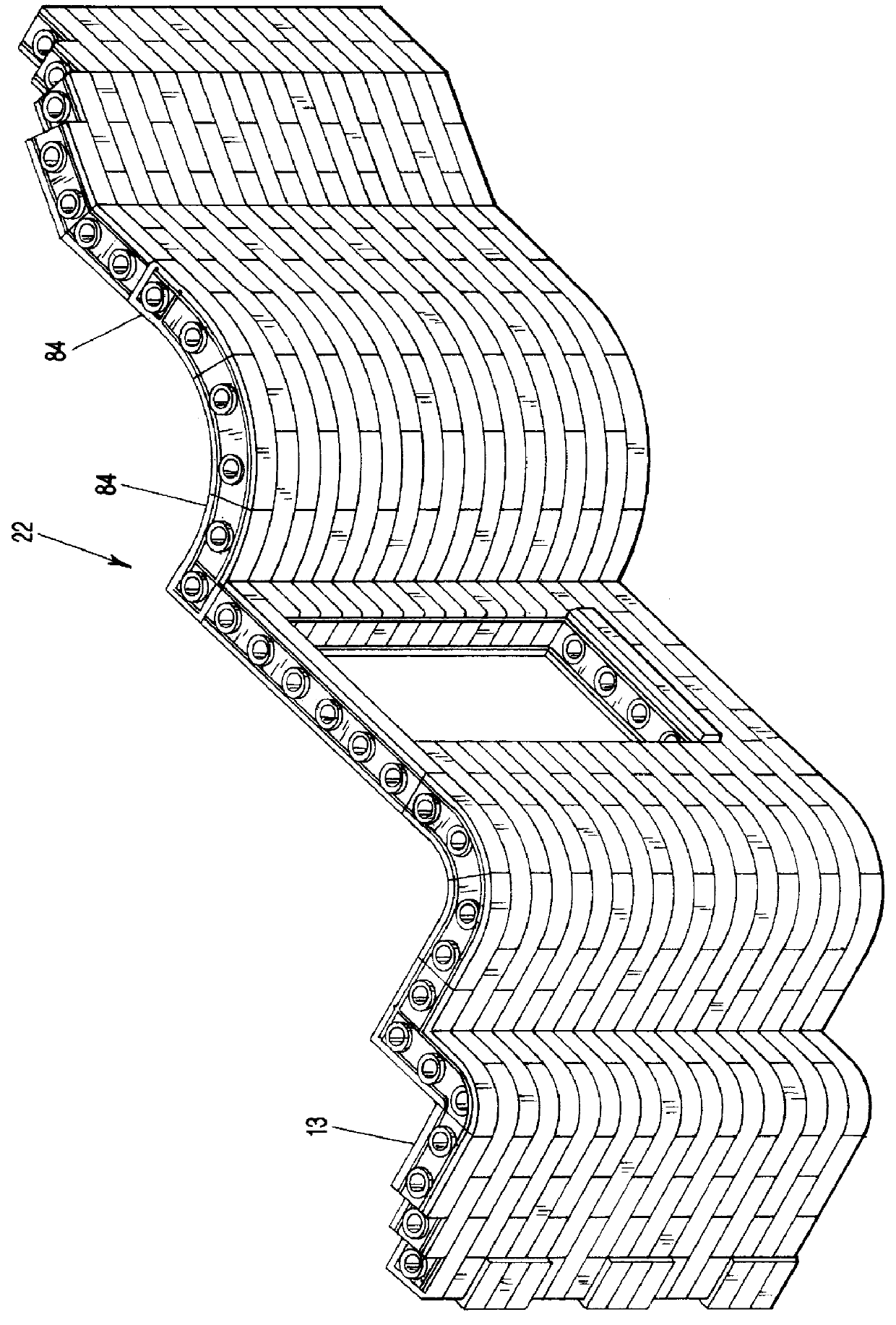

Hydraulic pressure milling deep-mixing underground-wall machine

ActiveCN101619572AEven by forceWork reliablySoil-shifting machines/dredgersBulkheads/pilesSlurryEngineering

The invention discloses a hydraulic pressure milling deep-mixing underground-wall machine in the field of construction machinery, comprising a guide rod; an air conveying pipeline and a slurry conveying pipeline are arranged in the guide rod, two fixing plates are symmetrically arranged at the lower end of the guide rod left and right, at least one group of sealing milling and digging mechanism is arranged on each fixing plate, the sealing milling and digging mechanism comprises a hydraulic pressure motor fixed on the fixing plate, the output shaft end of the hydraulic pressure motor is provided with a sealing cover board, the sealing cover board comprises an axial section sheathed on the output shaft of the hydraulic pressure motor and a radial disc which is radially extended outwards, a rotating body is arranged at the periphery of the radial disc, a plurality of digging mixing teeth are circularly distributed at the periphery of the rotating body; an inner cover shell is sheathed outside the axial section, a bearing is arranged between the outer circumference of the inner cover shell and the inner circumference of the rotating body, the outer ring of the inner cover shell is fixed with the fixing plate, and the inner cover shell, the axial section and the rotating body are connected in a motive sealing way. The machine can cut soil layers and rock, the structure is simple, the sealing is good, can be used for constructing deep underground wall.

Owner:孙刚

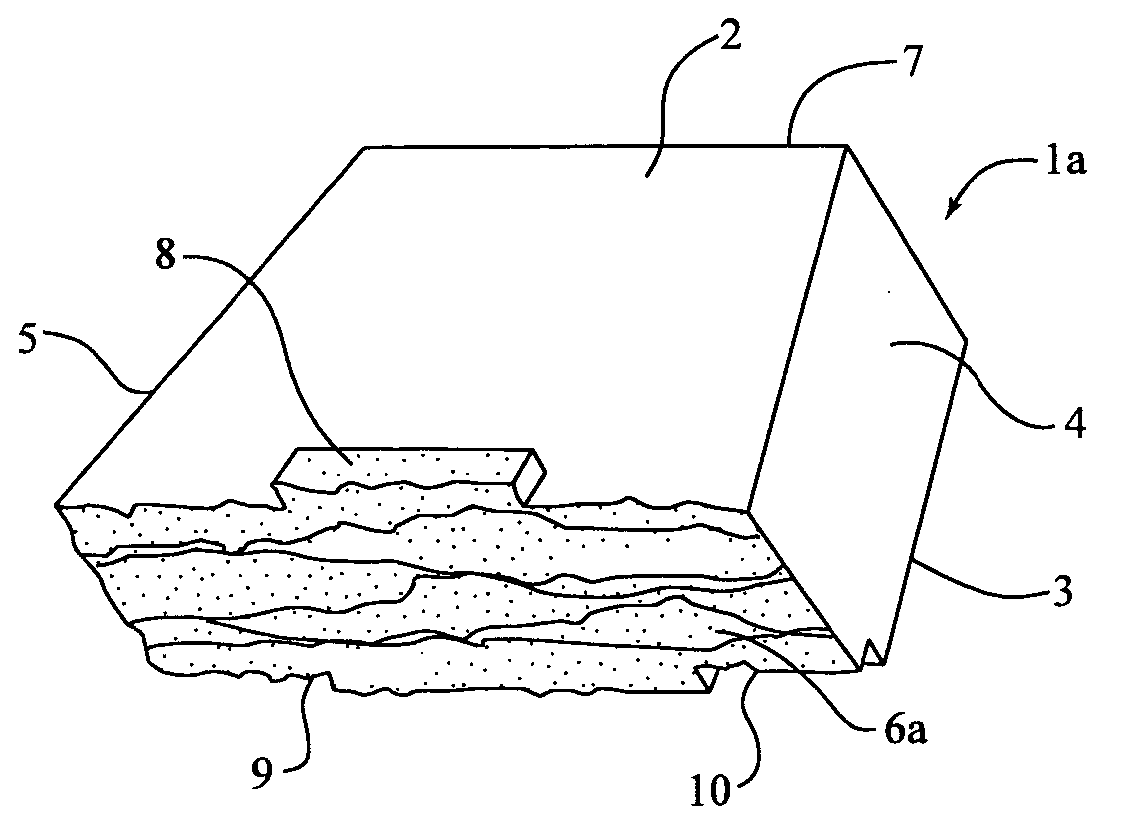

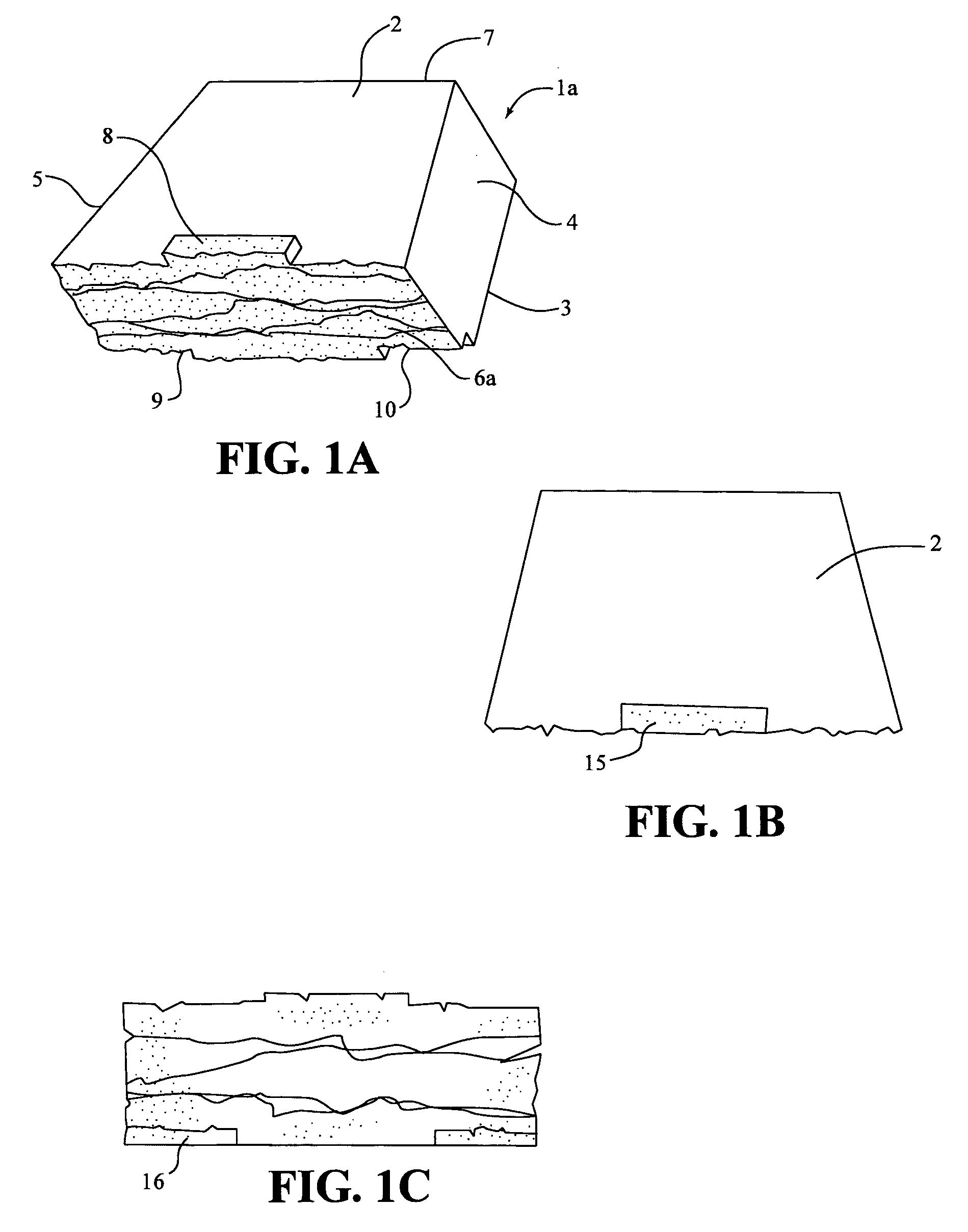

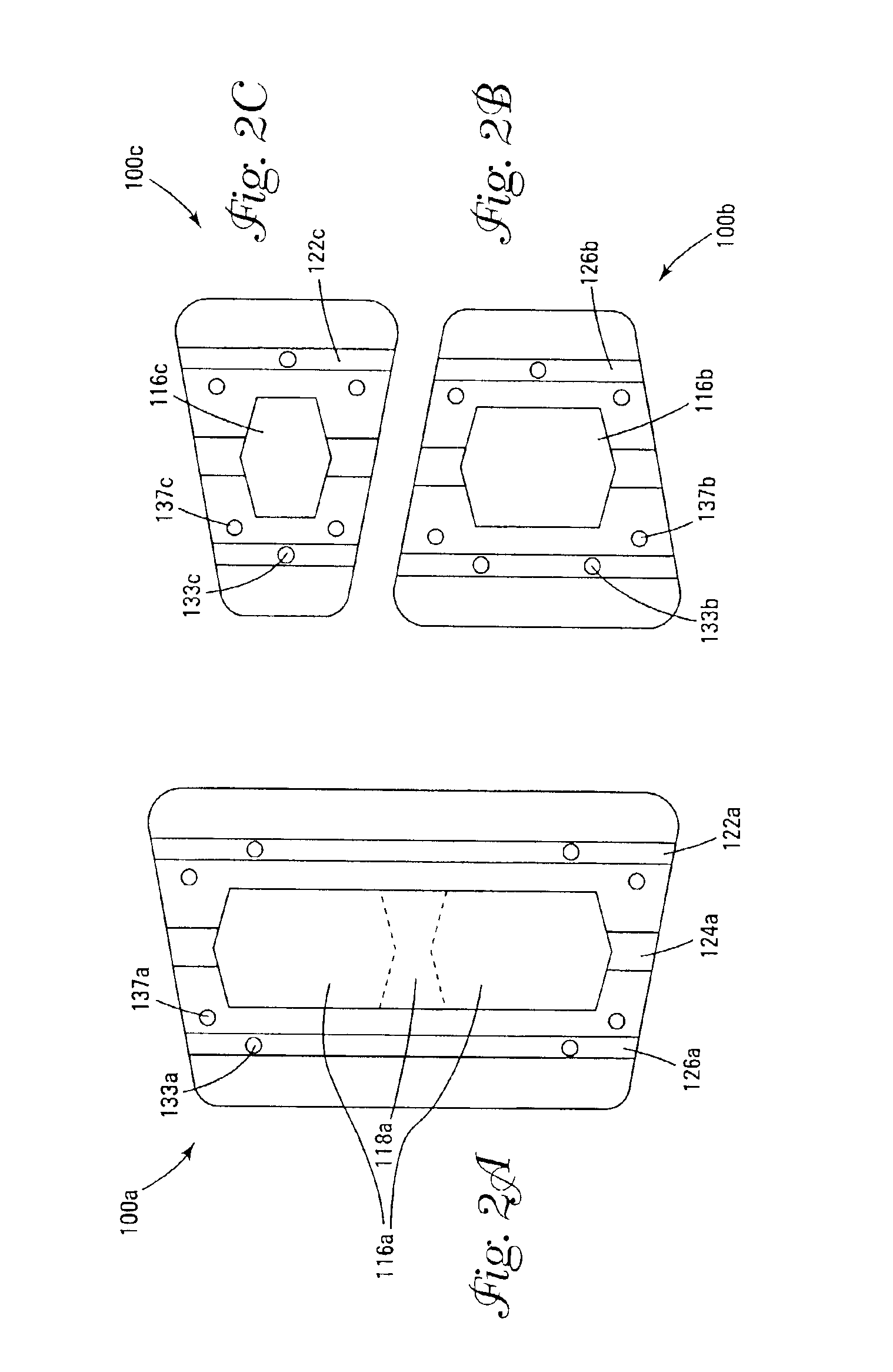

Retaining wall block with face connection

Single and multiple retaining wall blocks and block systems are disclosed. The blocks are provided with a face connection system which includes at least one front lip extending from a top surface of the block and a bottom channel formed into a front face and bottom surface of the block. The front lips have a length which is less than the width of the blocks.

Owner:CONTECH TECH

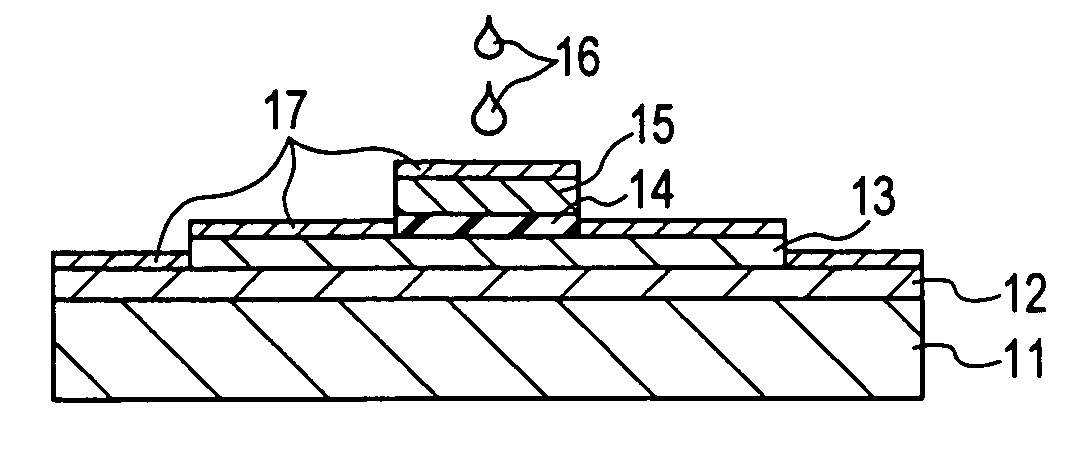

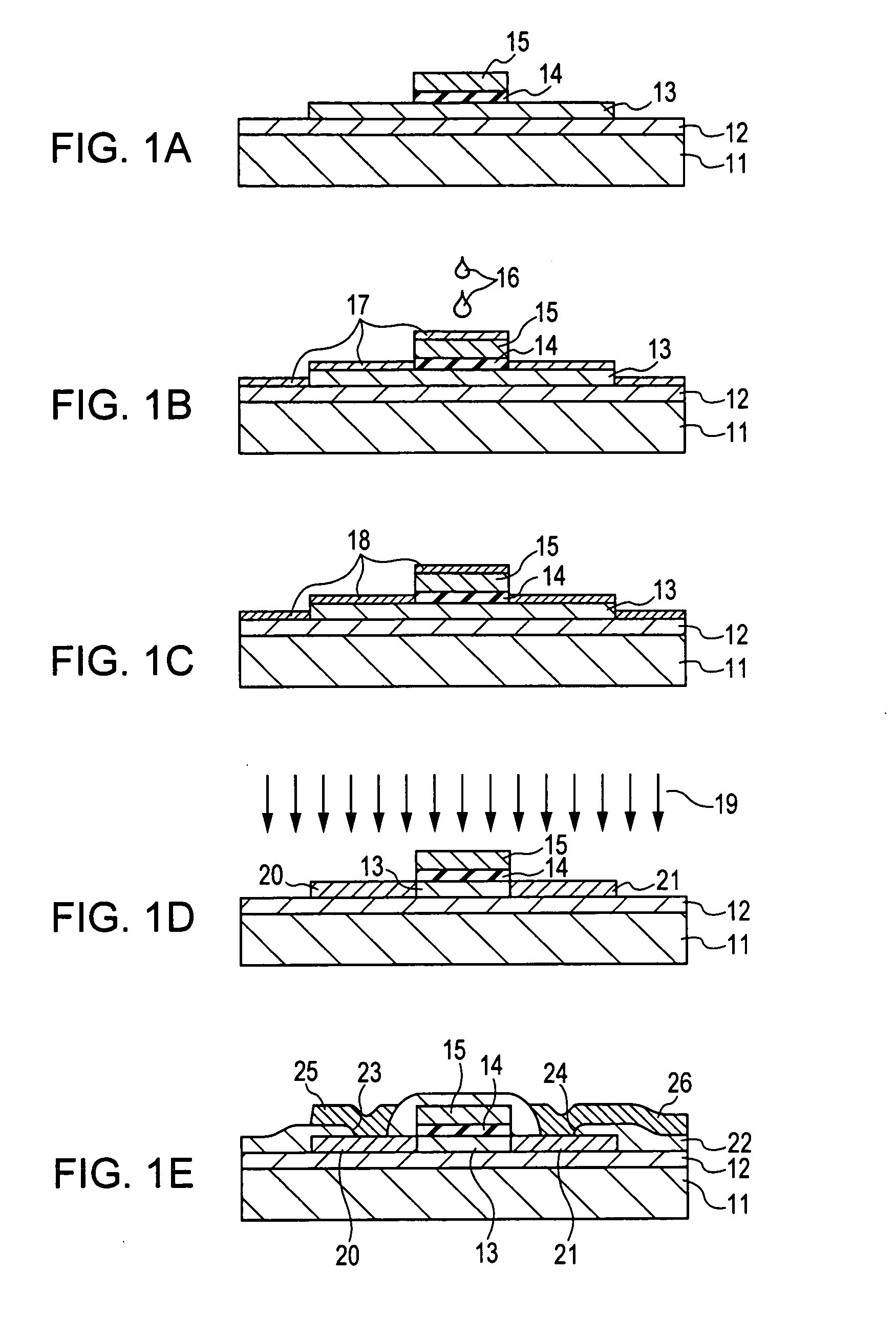

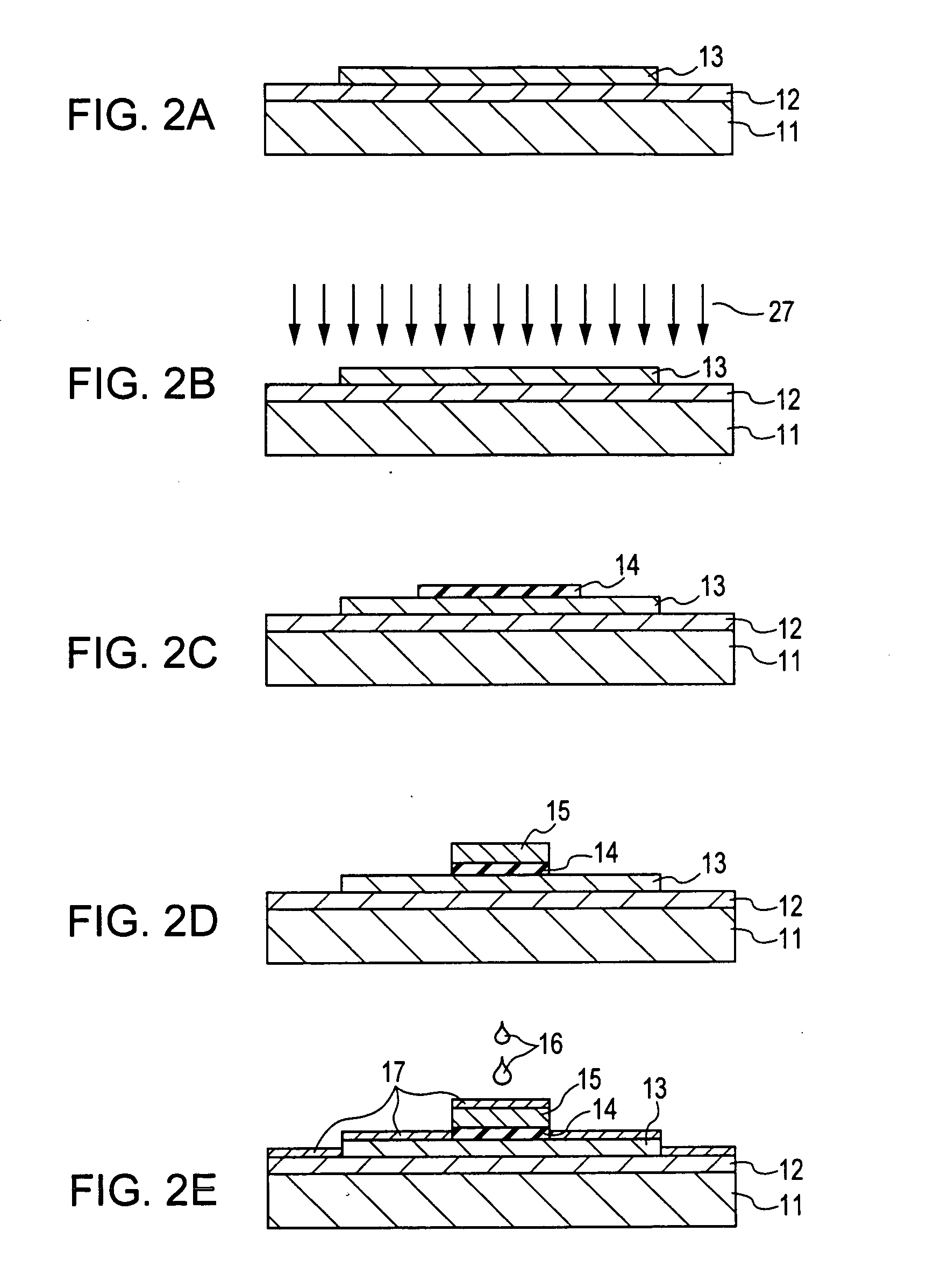

Method for doping impurities, methods for producing semiconductor device and applied electronic apparatus

InactiveUS20050181566A1Low level of contaminationReduce usageTransistorSolid-state devicesDevice materialImpurity ions

A solution containing impurity ions is applied onto the surface of a silicon film to form a solution layer, followed by drying into a compound layer containing the impurities. Heat treatment is performed by irradiation with an energy beam so as to diffuse the impurity atoms in the compound layer toward the silicon film into a source region and a drain region. Subsequently, the compound layer is removed.

Owner:SONY CORP

Structural elastic-like nonwoven web

Owner:PROCTER & GAMBLE CO

Information equipment remote operating system

InactiveUS20050235214A1More convenience of userImprove user convenienceTelemetry/telecontrol selection arrangementsDigital computer detailsComputer hardwareInformation processing

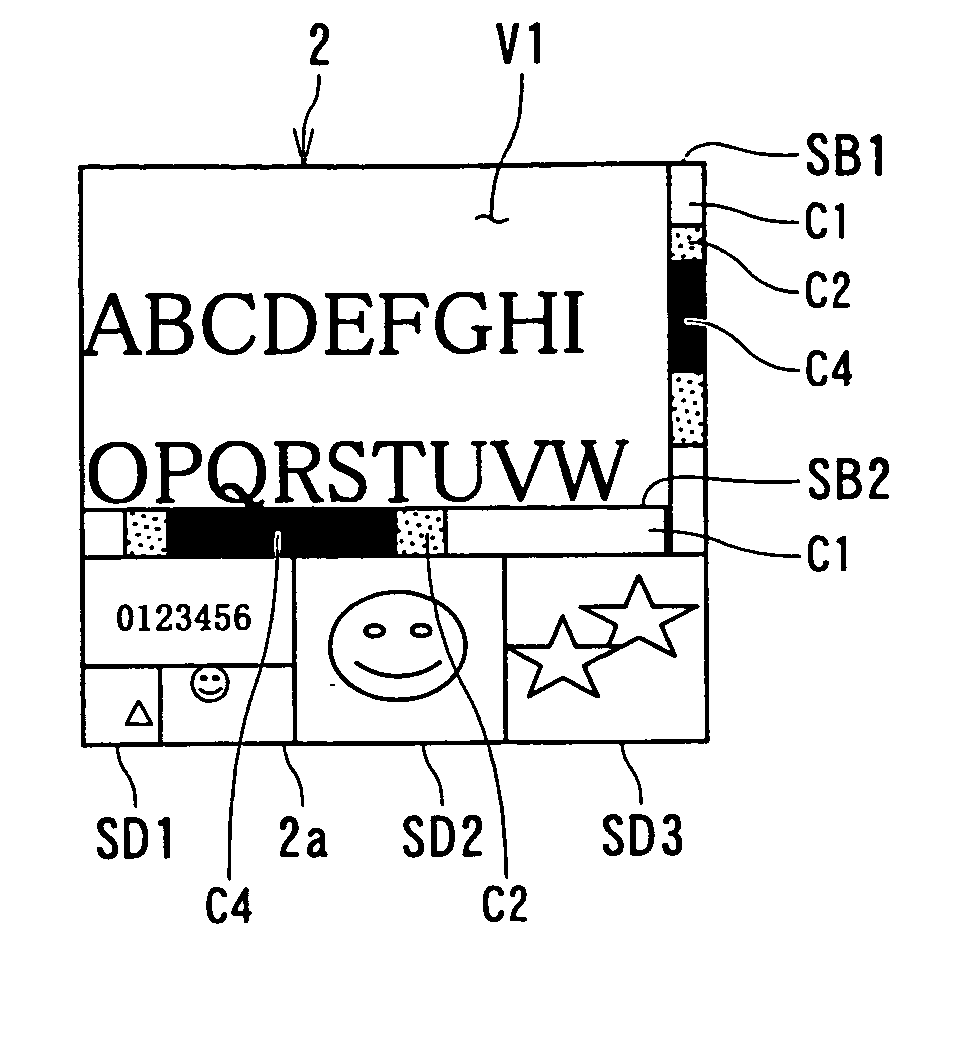

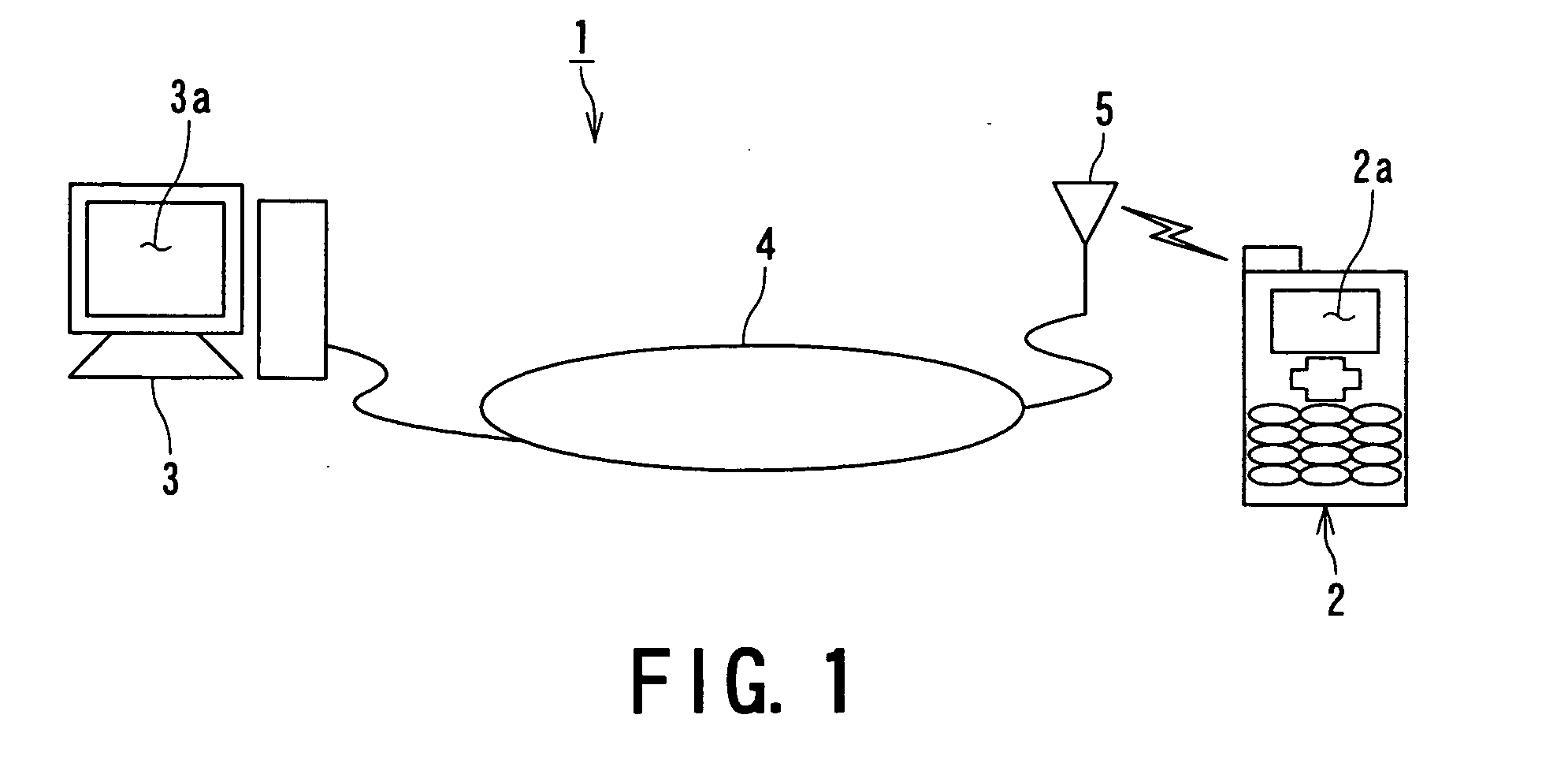

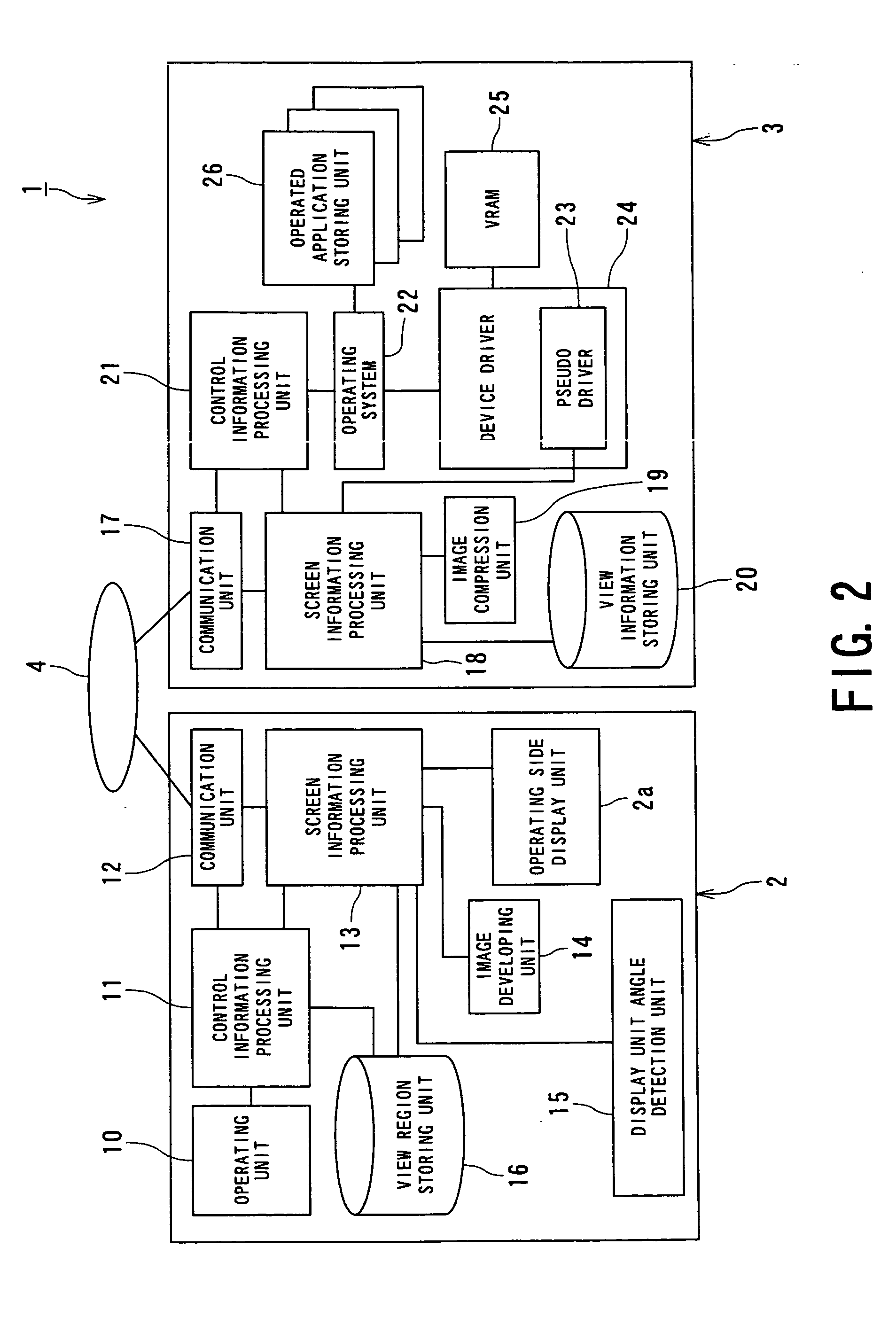

An information equipment remote operating system includes an operated-side information equipment and an operating-side information equipment. The operated-side information equipment includes a view region storing unit for storing view information regarding a view region correlated with an window, a screen information processing unit for generating an image to be displayed on an operating-side display unit as an initial state based on the view information, a communication unit, and a control information processing unit for operating an application. The operating-side information equipment includes a communication unit, a view region storing unit for storing the view information, a screen information processing unit for displaying images on multiple display regions in high to low display priority order, and a control information processing unit for transmitting application operating information to the operated-side information equipment.

Owner:KK TOSHIBA

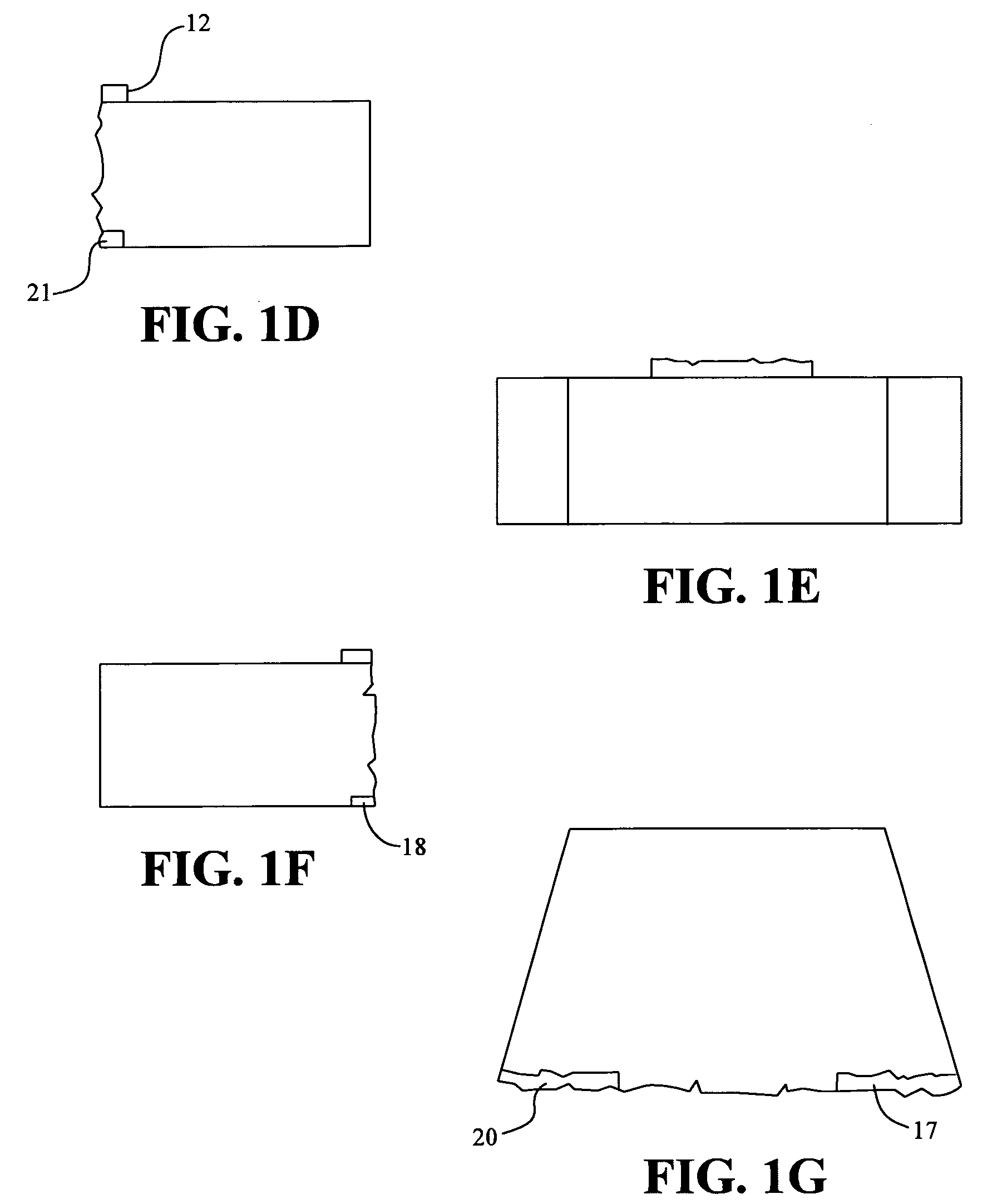

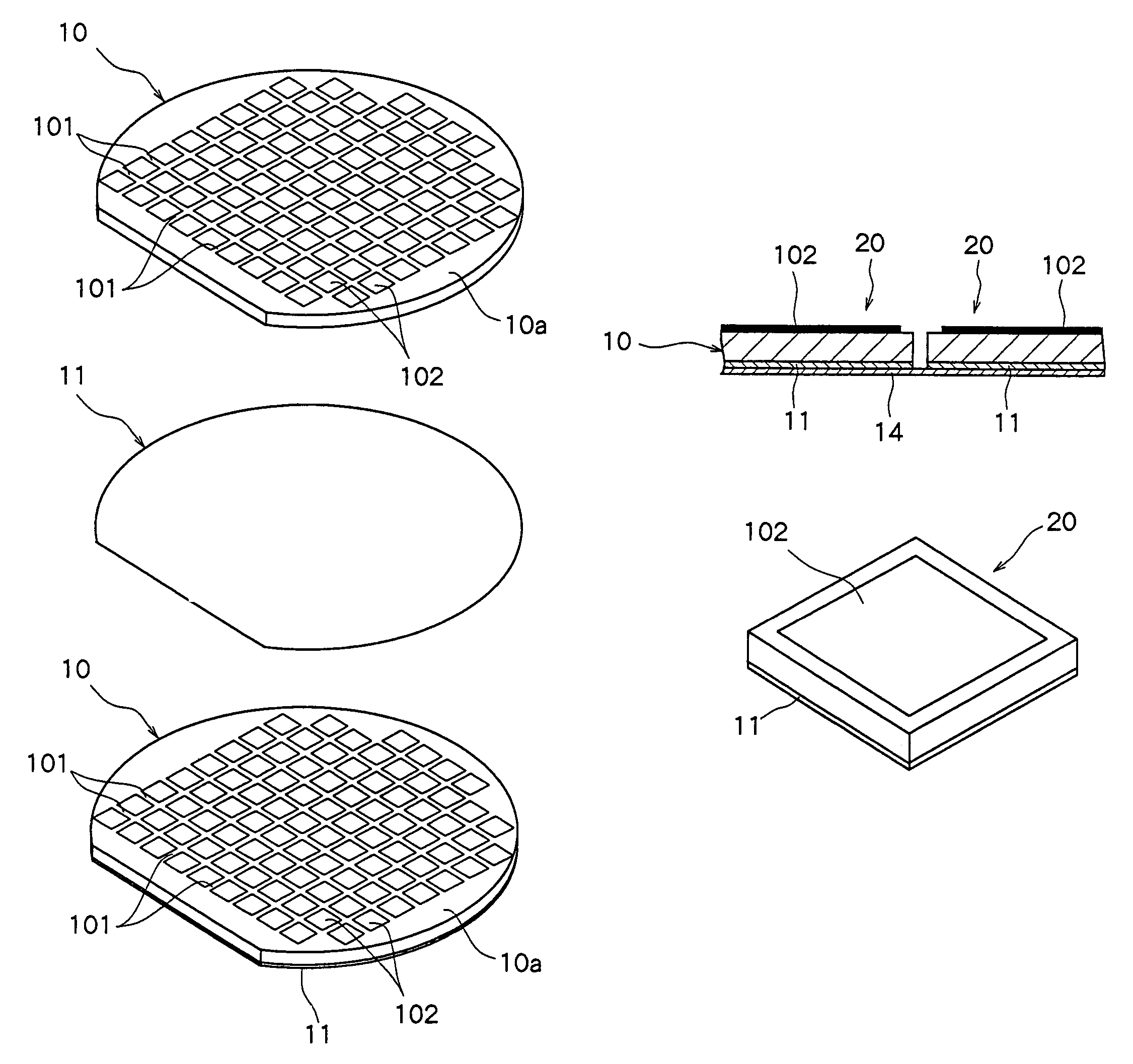

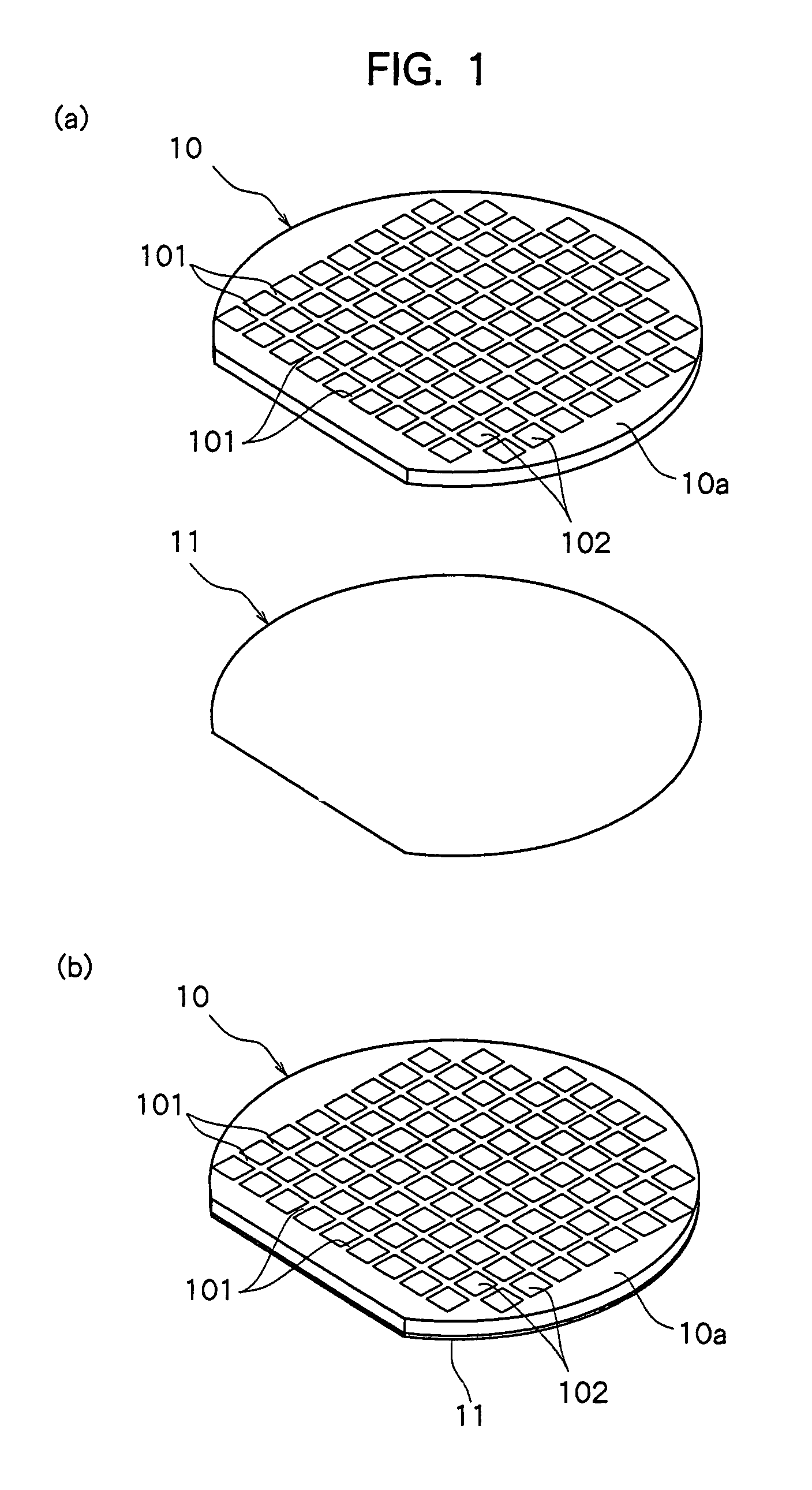

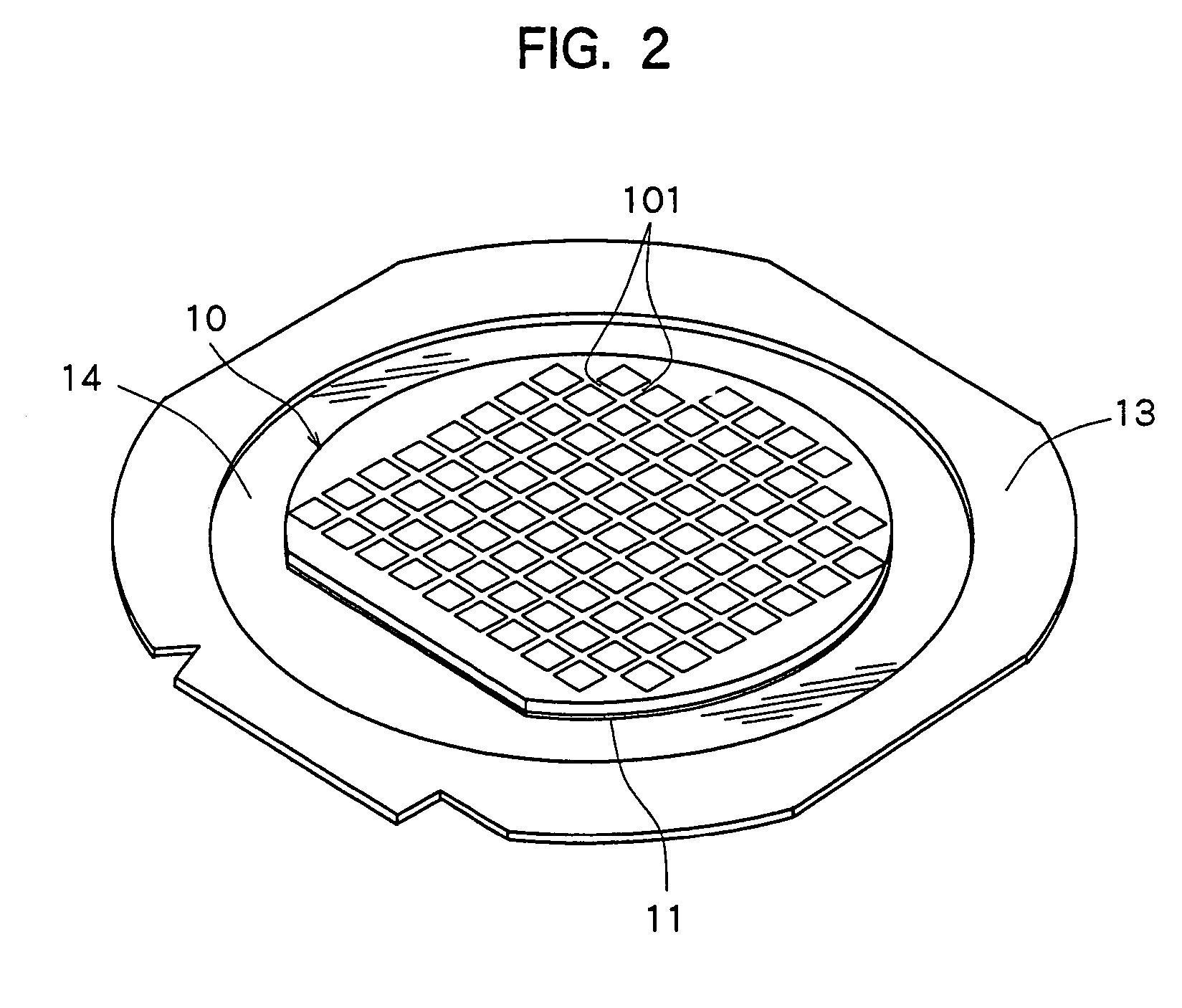

Method of dividing a semiconductor wafer

ActiveUS7129150B2Solid-state devicesSemiconductor/solid-state device manufacturingAdhesive beltSemiconductor chip

A method of dividing a semiconductor wafer comprising:a bonding film adhering step of adhering a bonding film for die bonding to the back surface of the semiconductor wafer;a protective adhesive tape affixing step of affixing an extensible protective adhesive tape to the bonding film side of the semiconductor wafer having the bonding film on the back surface;a dividing step of dividing the semiconductor wafer affixed to the protective adhesive tape into individual semiconductor chips by applying a laser beam along the streets;a bonding film breaking step of breaking the bonding film for every semiconductor chip by extending the protective adhesive tape so as to give tensile force to the bonding film; anda semiconductor chip removing step of removing the semiconductor chips having the broken bonding film from the protective adhesive tape.

Owner:DISCO CORP

Settable fluids and methods for use in subterranean formations

The present invention relates to subterranean operations, and more particularly, to settable fluids comprising vitrified shale and hydrated lime and methods of using such settable fluids in subterranean applications. In an exemplary embodiment, the settable fluids of the present invention may be used as a displacement fluid. In another exemplary embodiment, the settable fluids of the present invention may be used as a drilling fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

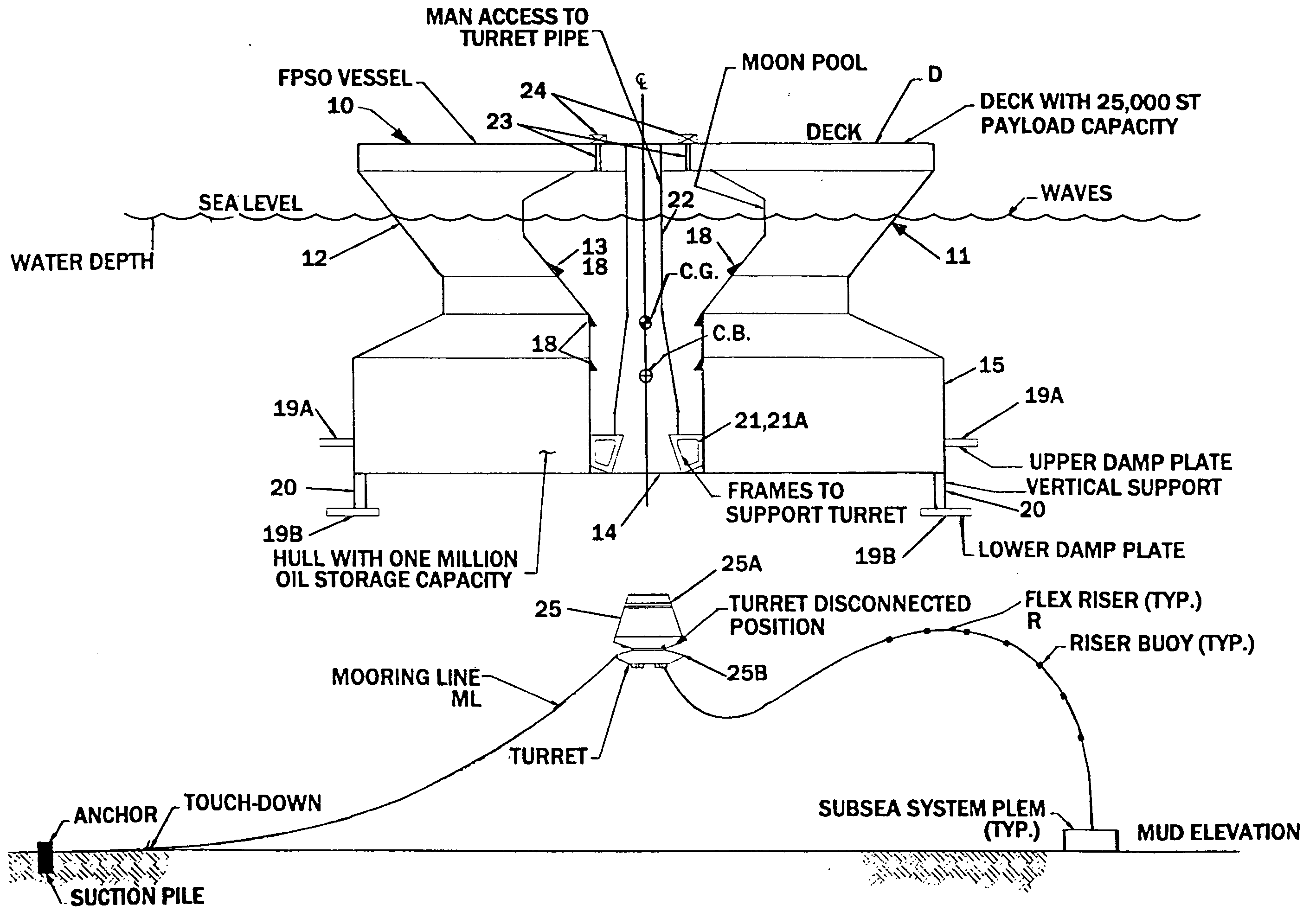

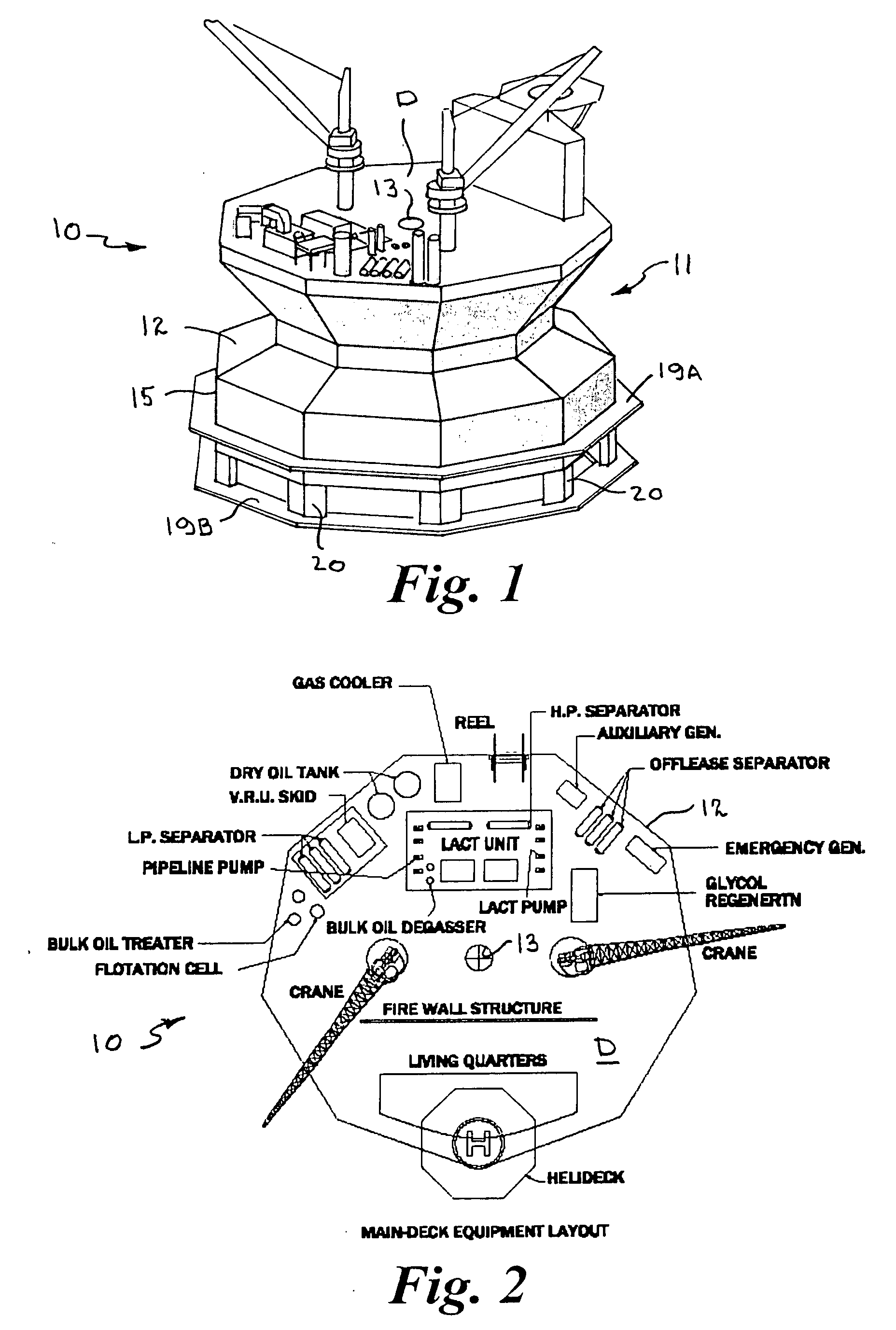

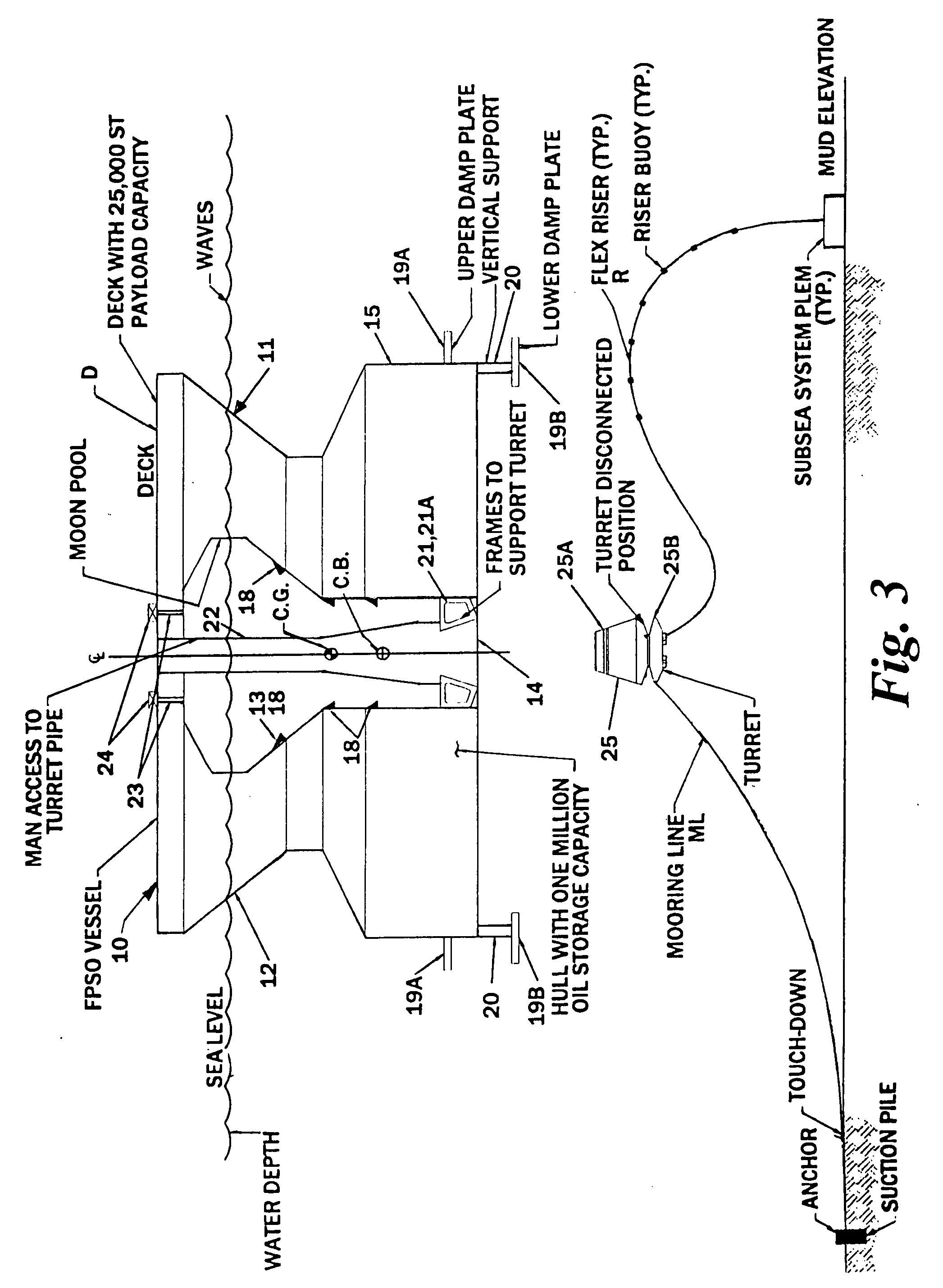

Offshore floating production, storage, and off-loading vessel for use in ice-covered and clear water applications

InactiveUS20090126616A1Reduces dynamic amplificationReduce resonanceProtective foundationMovement controllersResonanceBuoy

An offshore floating production, storage, and off-loading vessel has a monolithic non ship-shaped hull of polygonal configuration surrounding a central double tapered conical moon pool and contains water ballast and oil storage compartments. The exterior side walls of the hull have flat surfaces and sharp corners to cut ice sheets, resist and break ice, and move ice pressure ridges away from the structure. An adjustable water ballast system induces heave, roll, pitch and surge motions of the vessel to dynamically position and maneuver the vessel to accomplish ice cutting, breaking and moving operations. The moon pool shape and other devices on the vessel provide added virtual mass capable of increasing the natural period of the roll and heave modes, reducing dynamic amplification and resonance due to waves and vessel motion, and facilitate maneuvering the vessel. The vessel may be moored by a disconnectable turret buoy received in a support frame at the bottom of the moon pool and to which flexible well risers and mooring lines are connected.

Owner:SRINIVASAN NAGAN

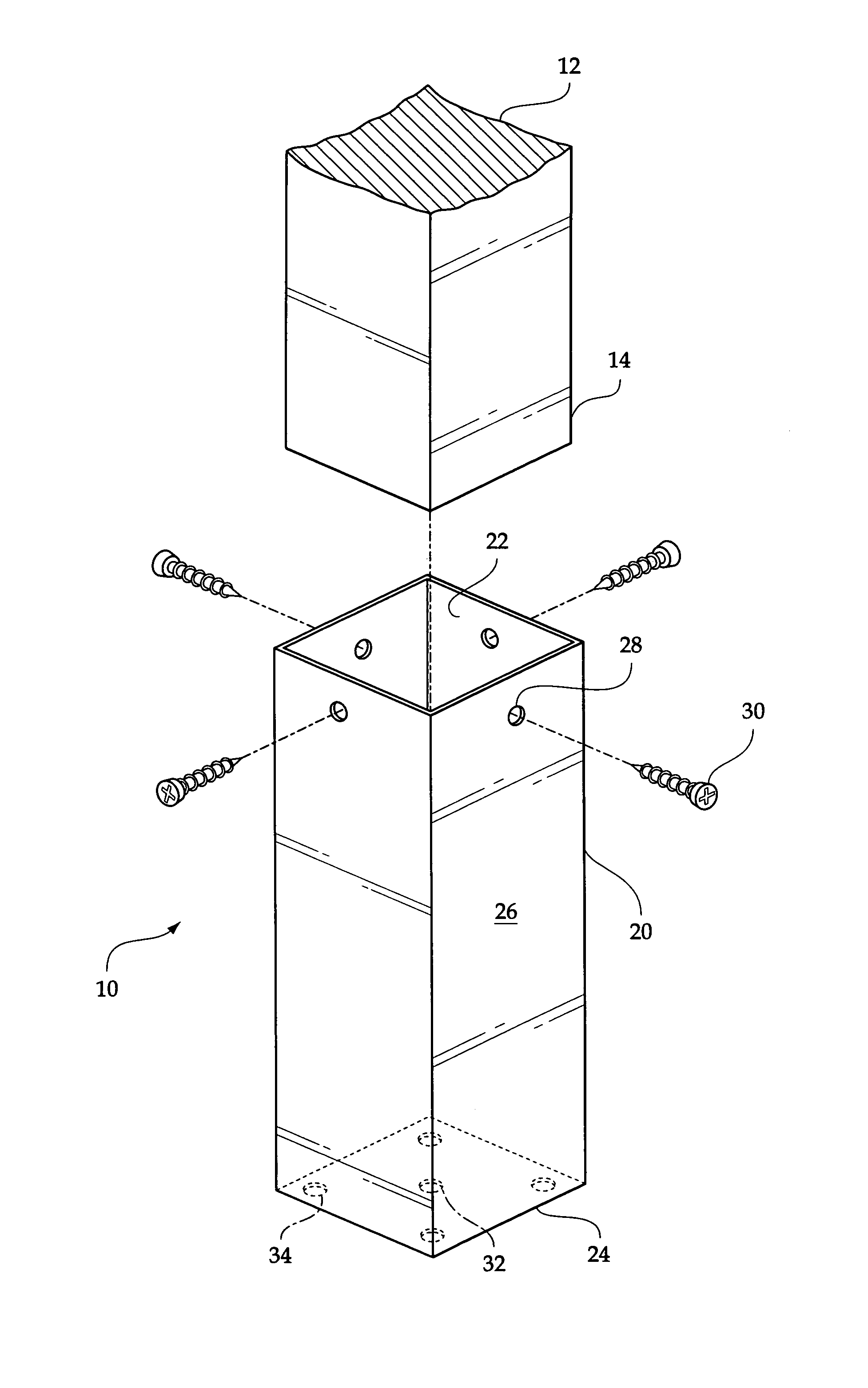

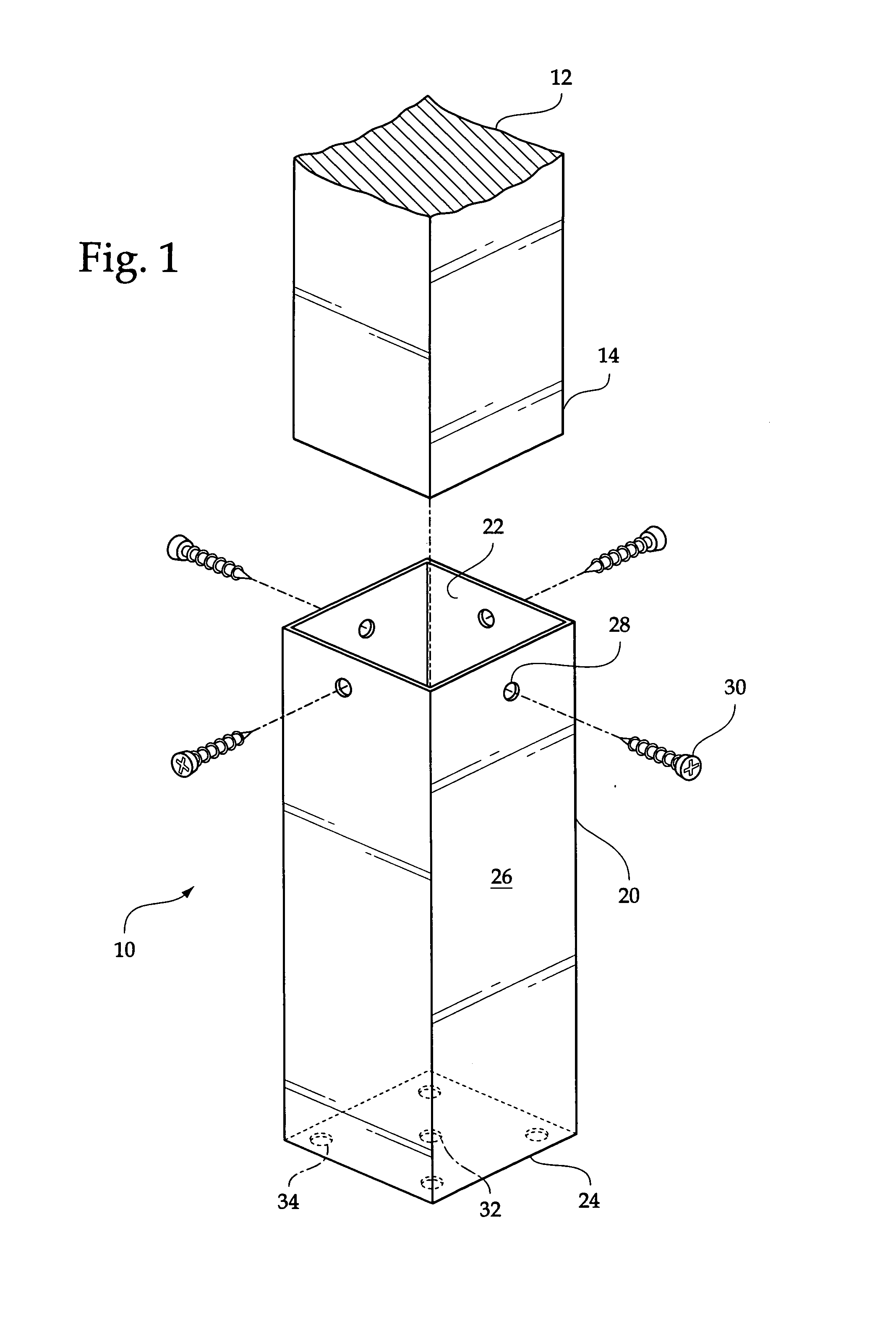

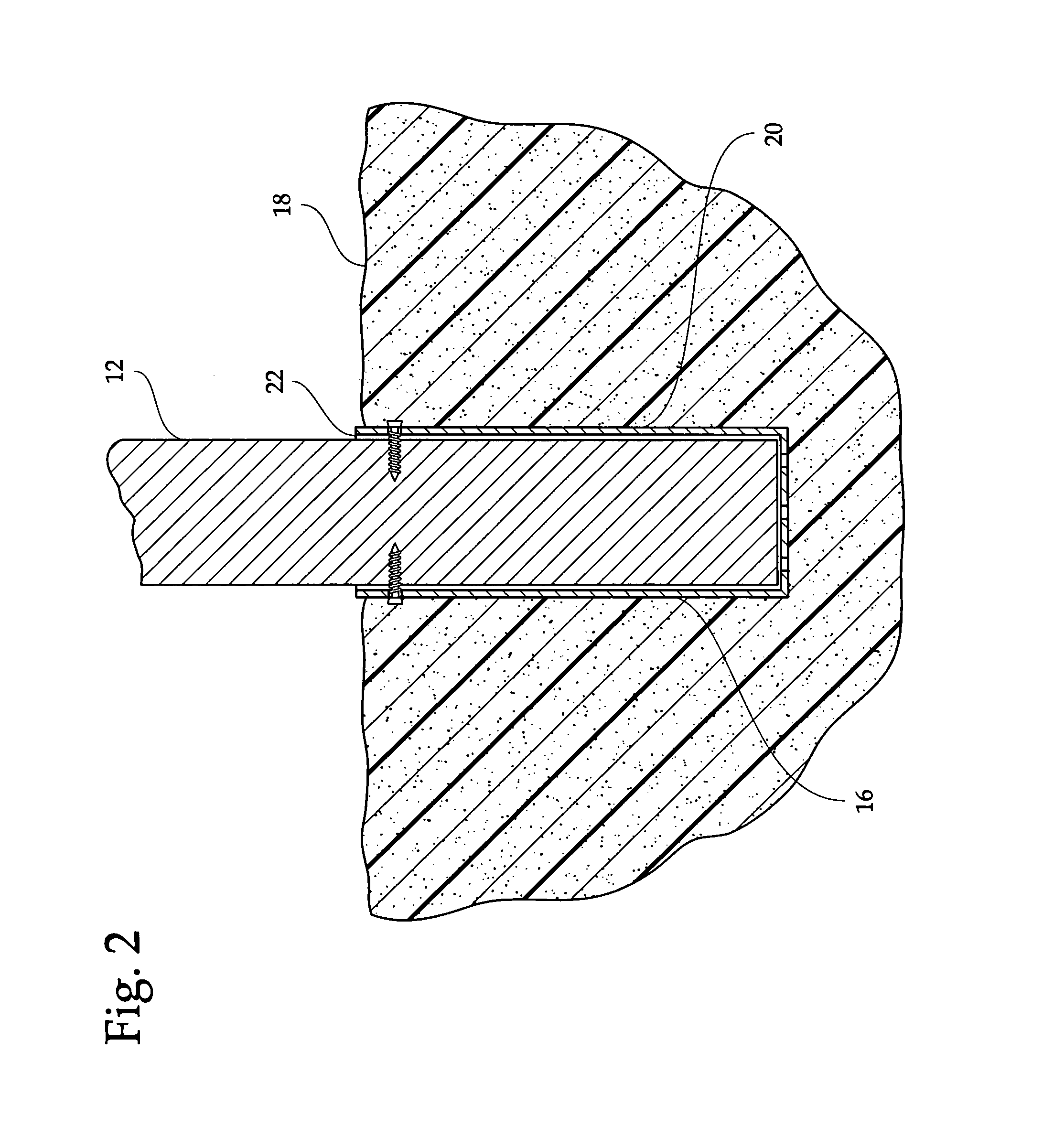

Wooden post protective sleeve

InactiveUS6886296B1Easy and efficient to manufactureDurable and reliable constructionLoad-supporting elementsStands/trestlesEngineering

A wooden post protective sleeve including a collar having an open upper end, a closed lower end, and a surrounding side wall. The open upper end is dimensioned for receiving the lower end of the wooden post therein. The surrounding side wall has a plurality of apertures therethrough downwardly of the open upper end. The apertures are dimensioned for receiving wood screws therethrough for engaging the lower end of the wooden post. The closed lower end has a plurality of drainage apertures therethrough. The drainage apertures include a central aperture and four peripheral apertures. The collar is fabricated of plastic.

Owner:JOHN MICHAEL +1

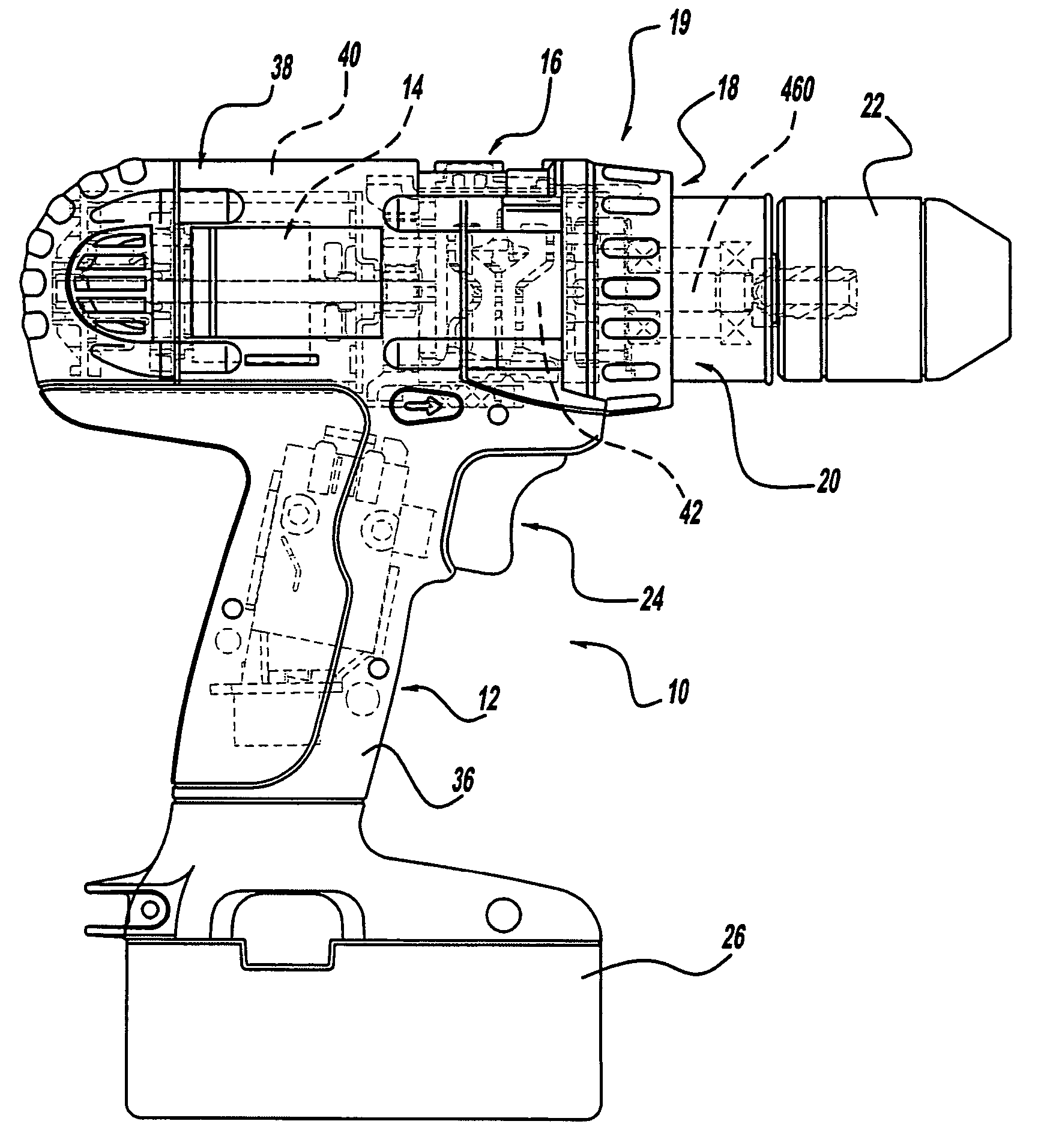

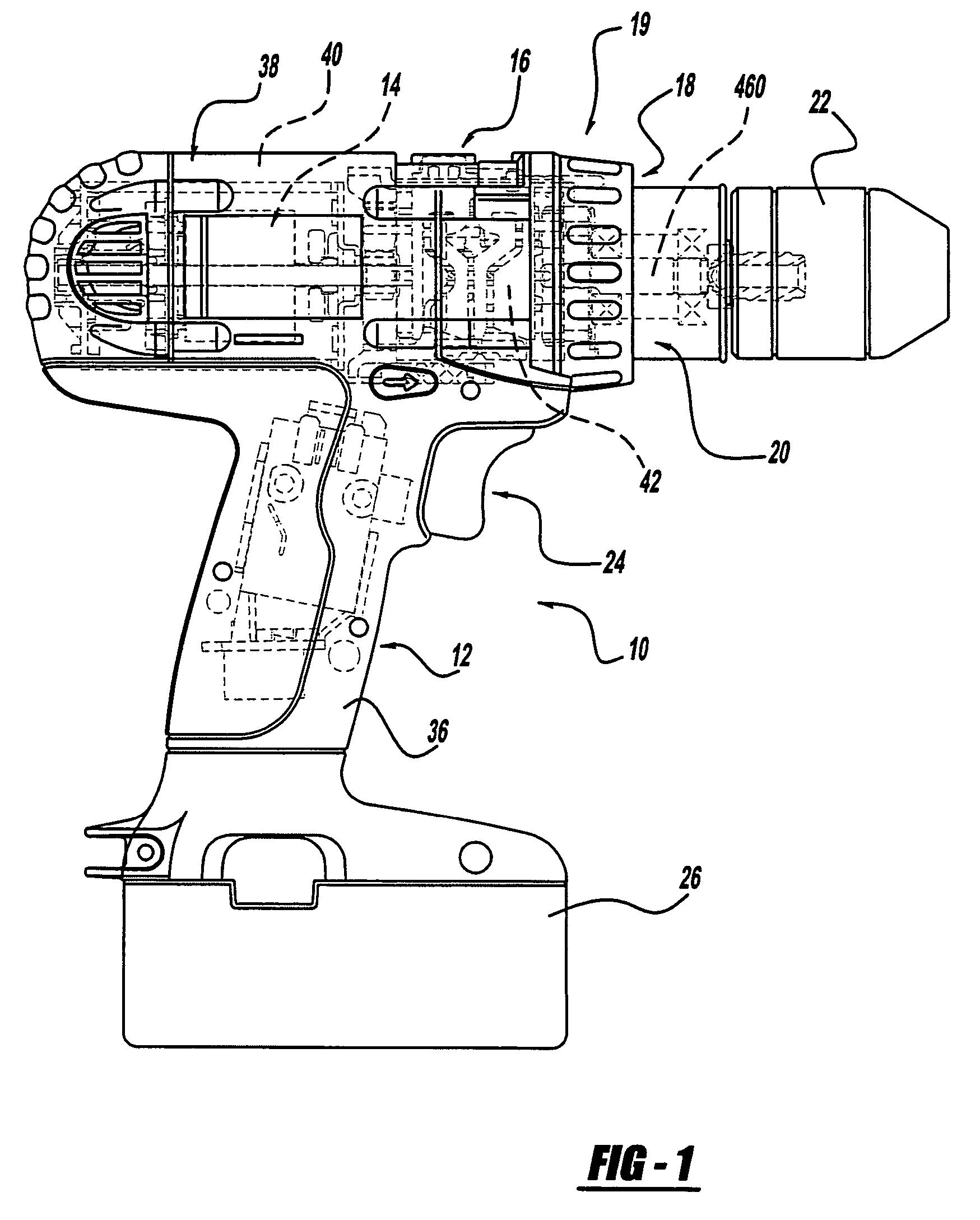

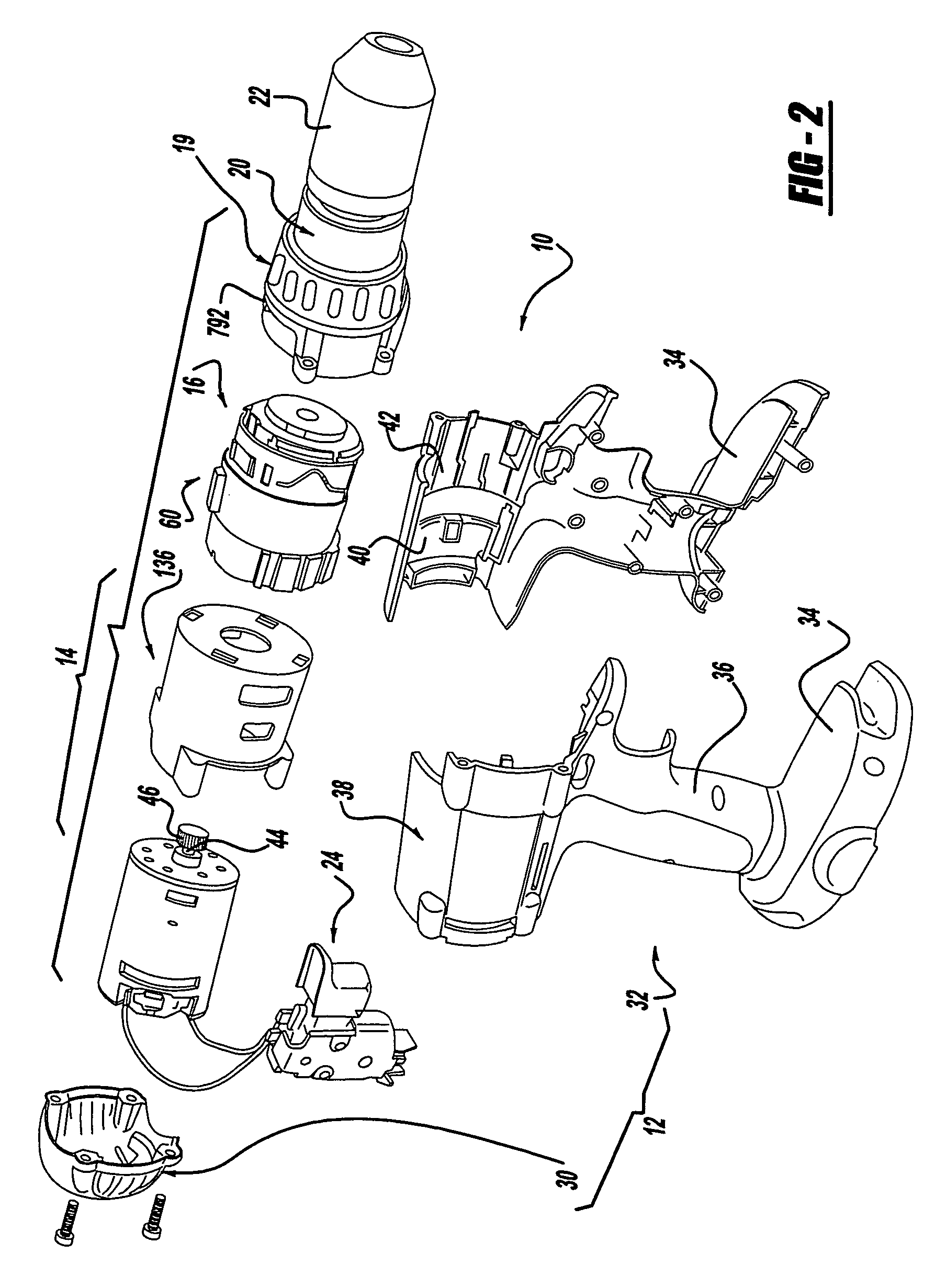

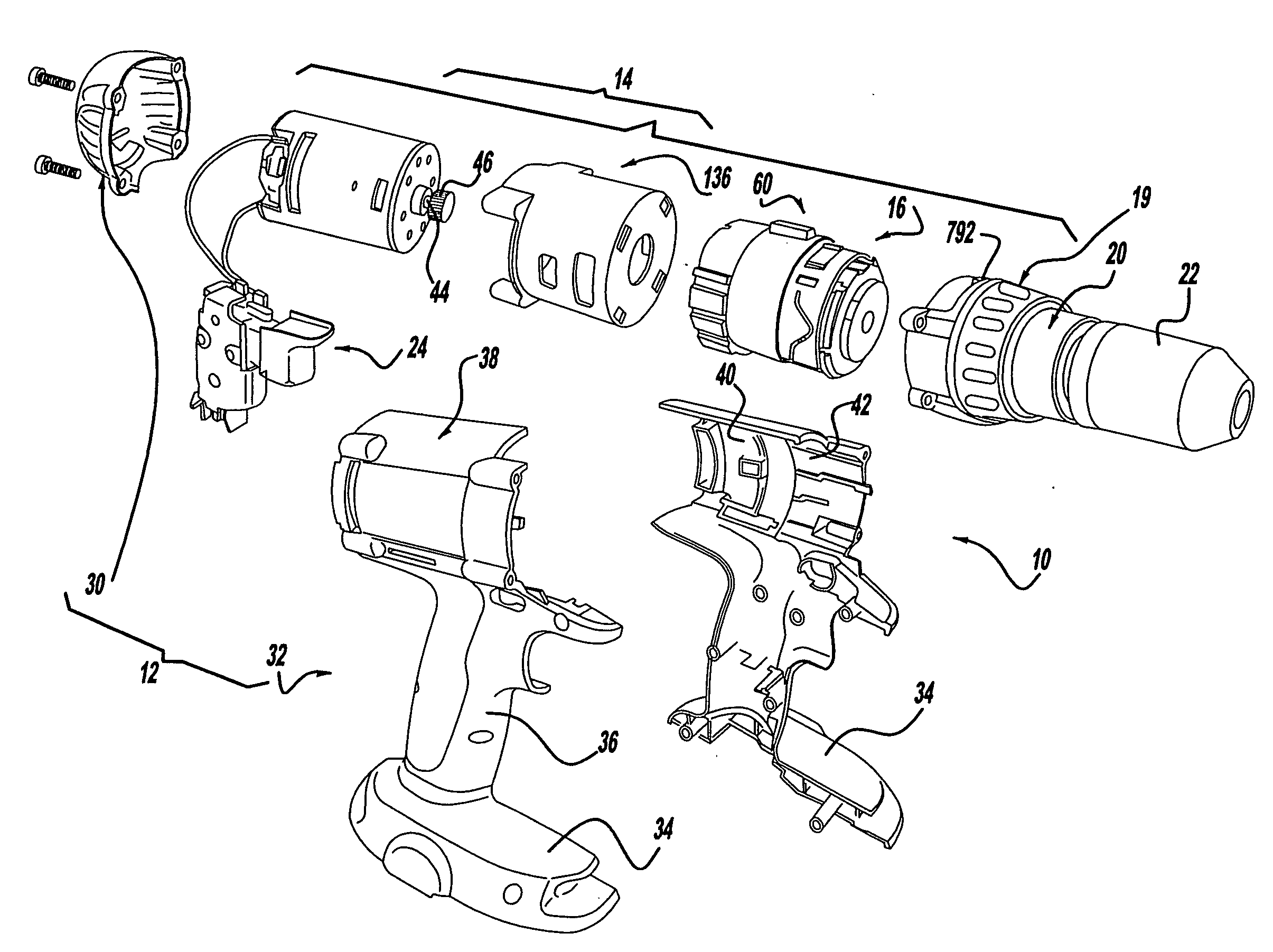

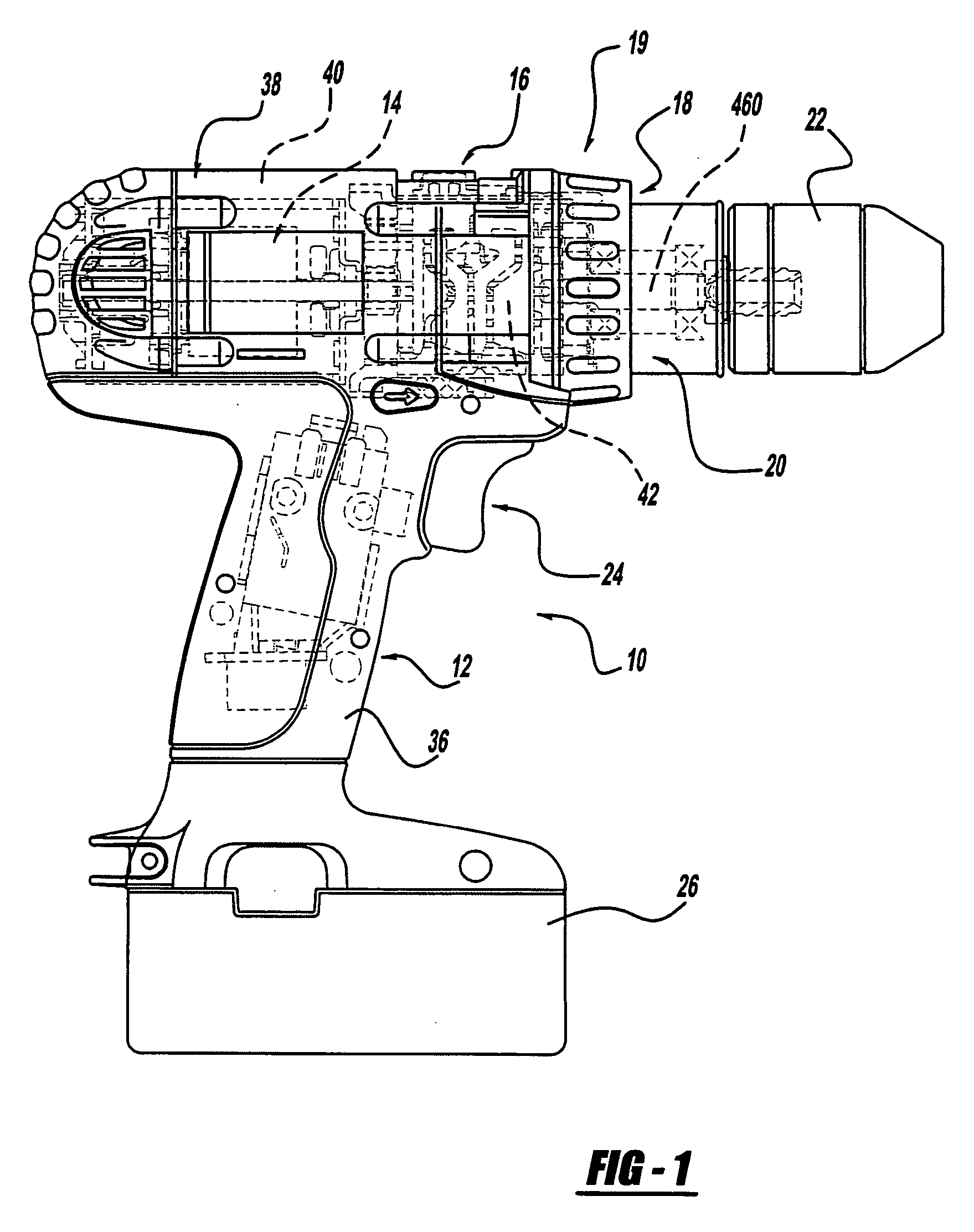

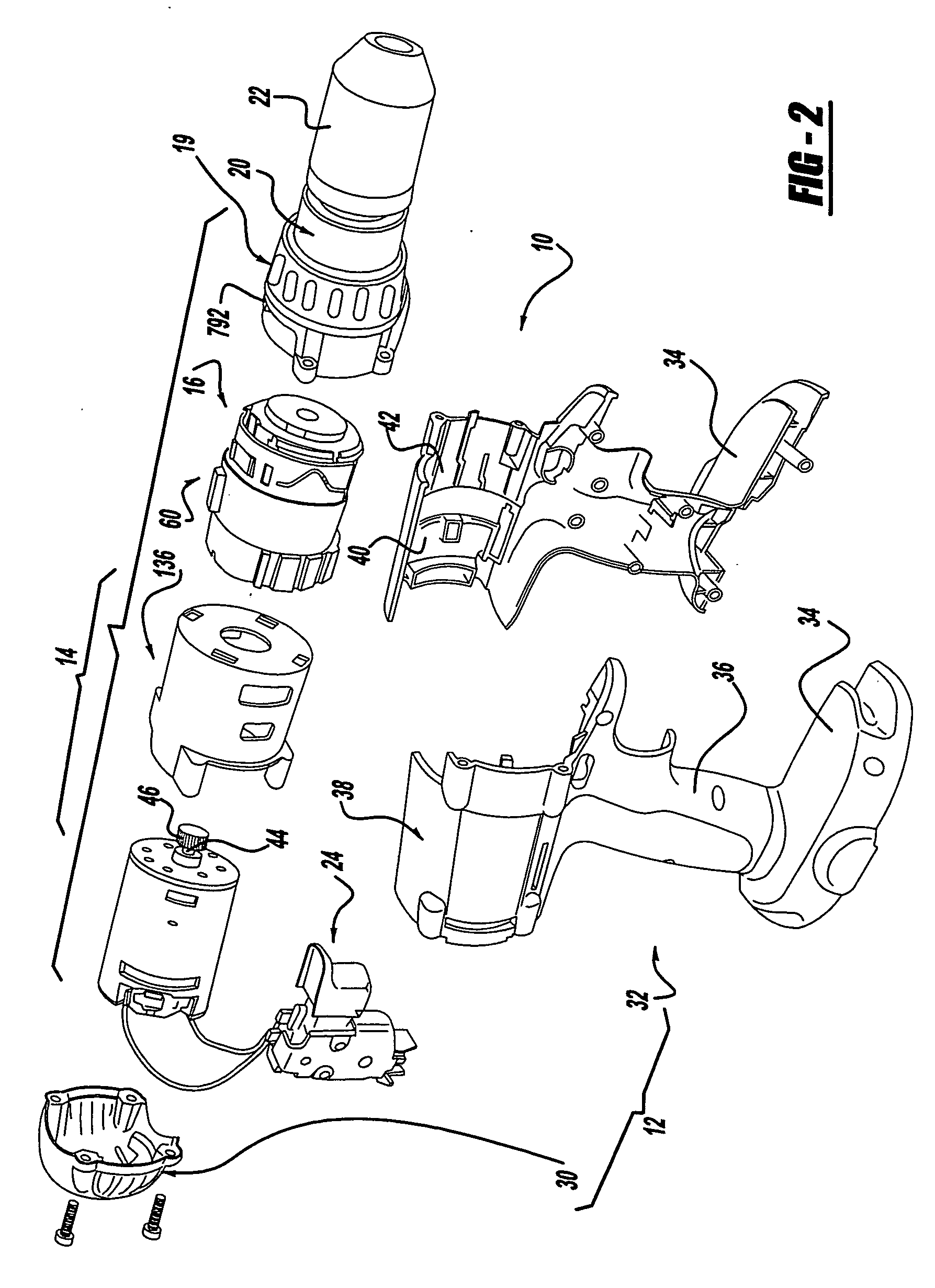

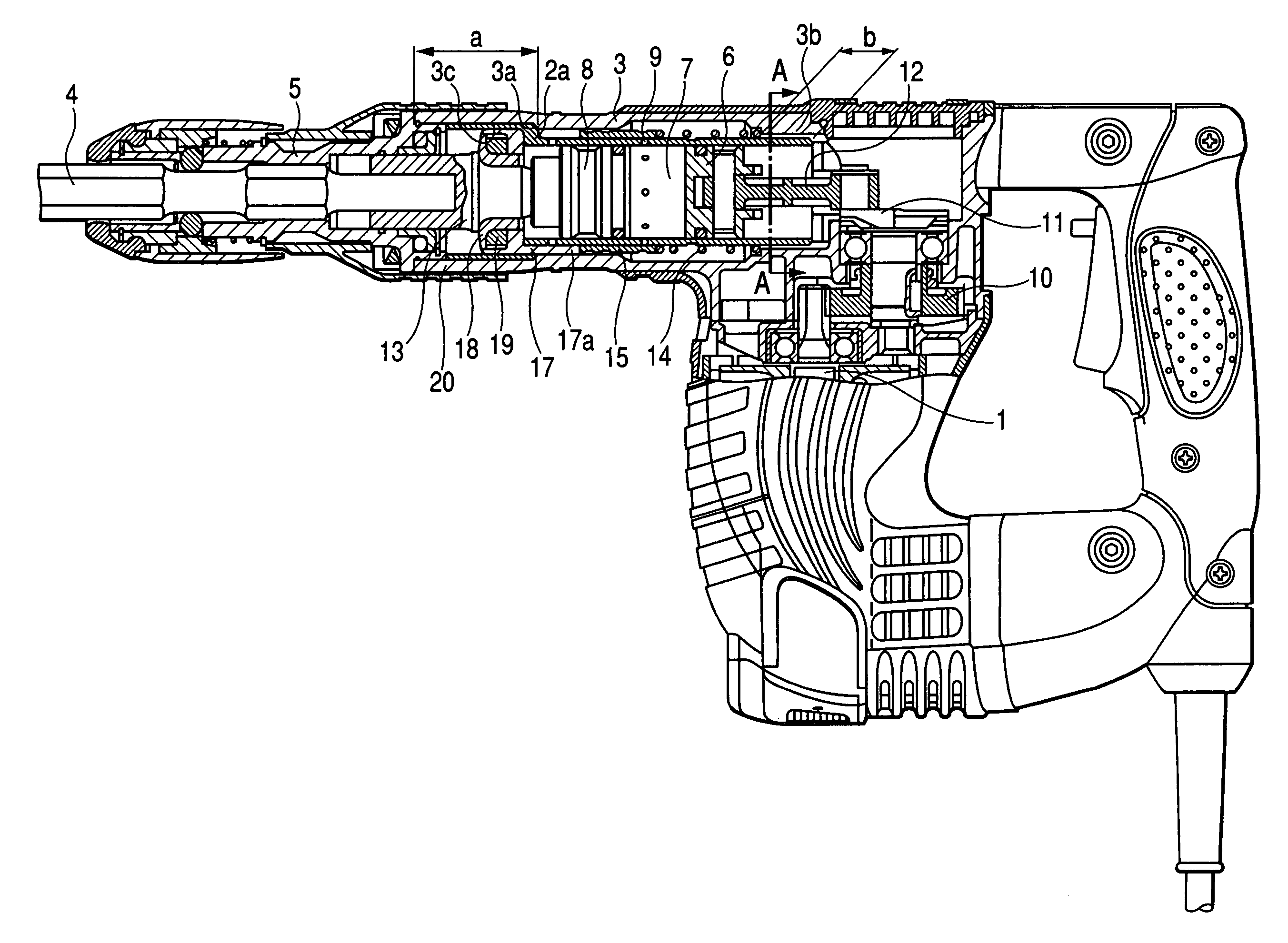

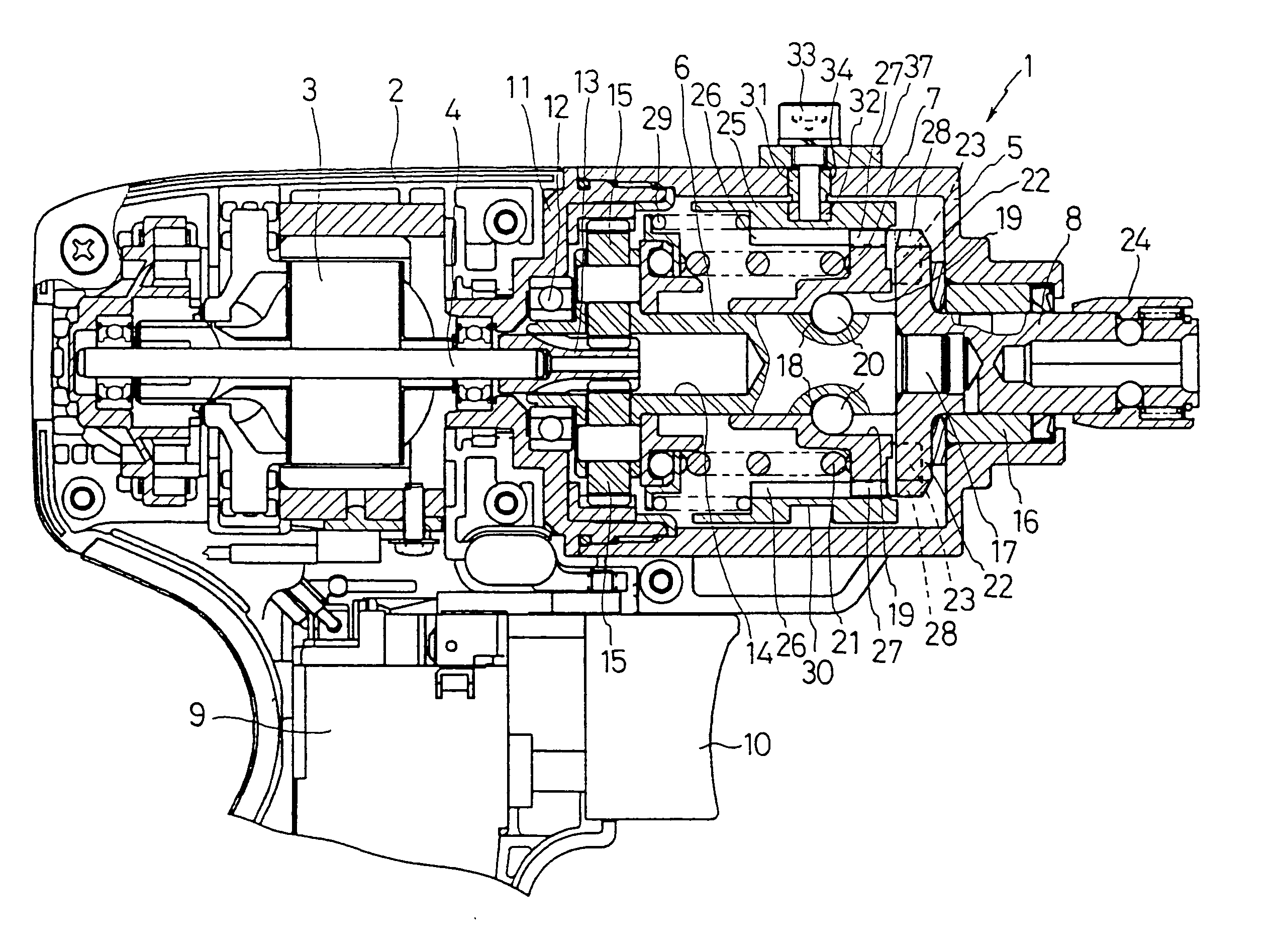

Hammer drill with a mode changeover mechanism

Owner:BLACK & DECKER INC

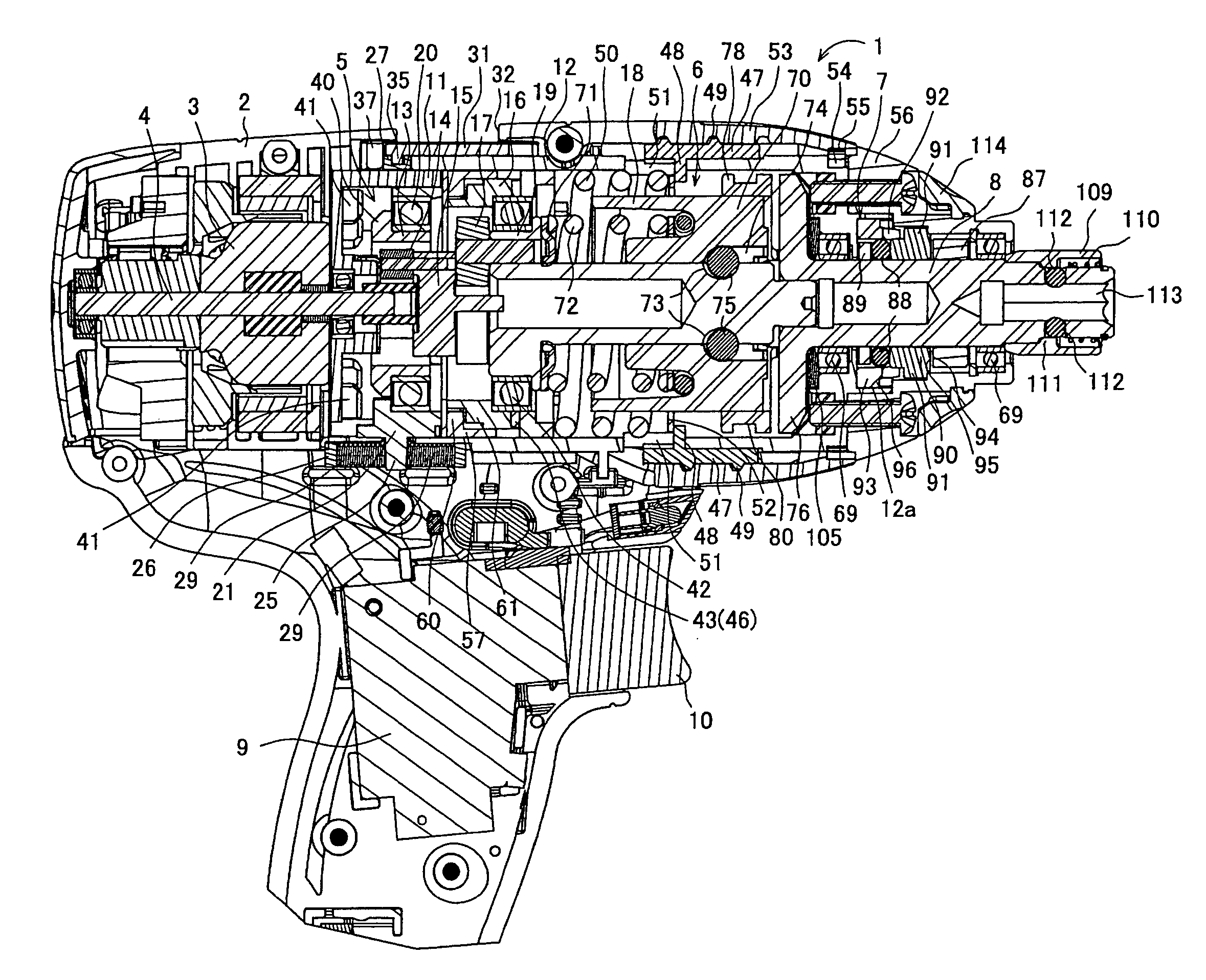

Hammer drill with a mode changeover mechanism

Owner:BLACK & DECKER INC

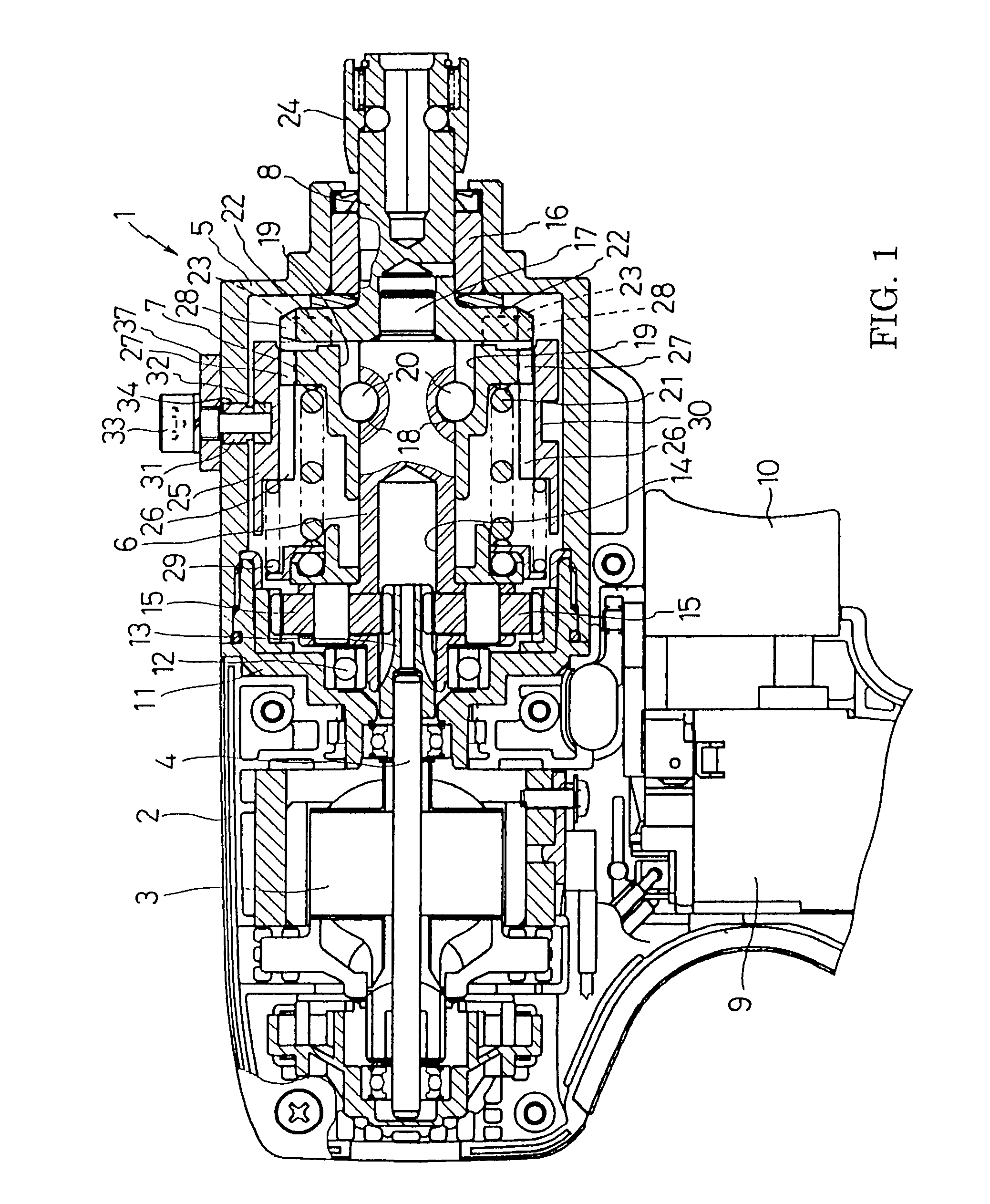

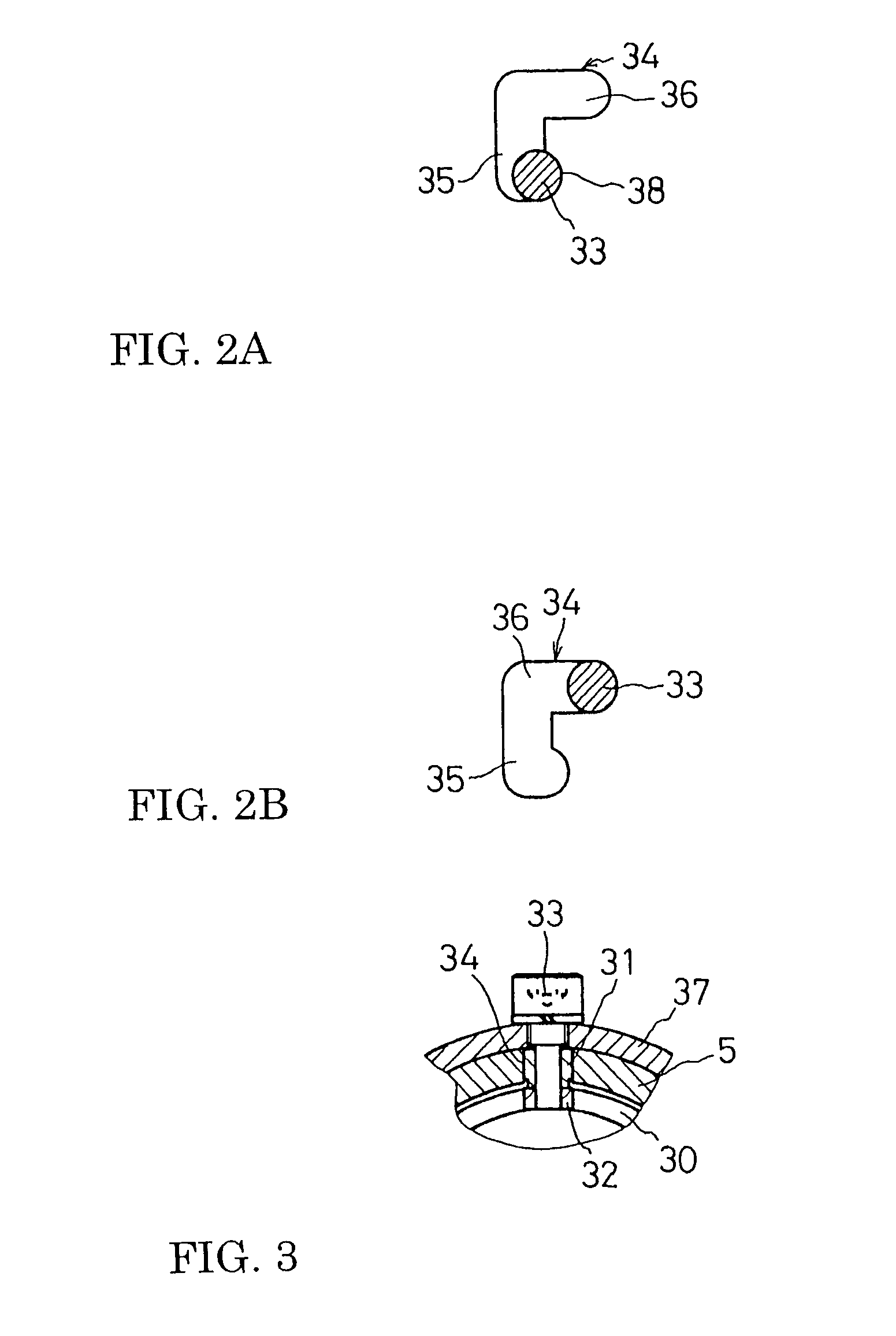

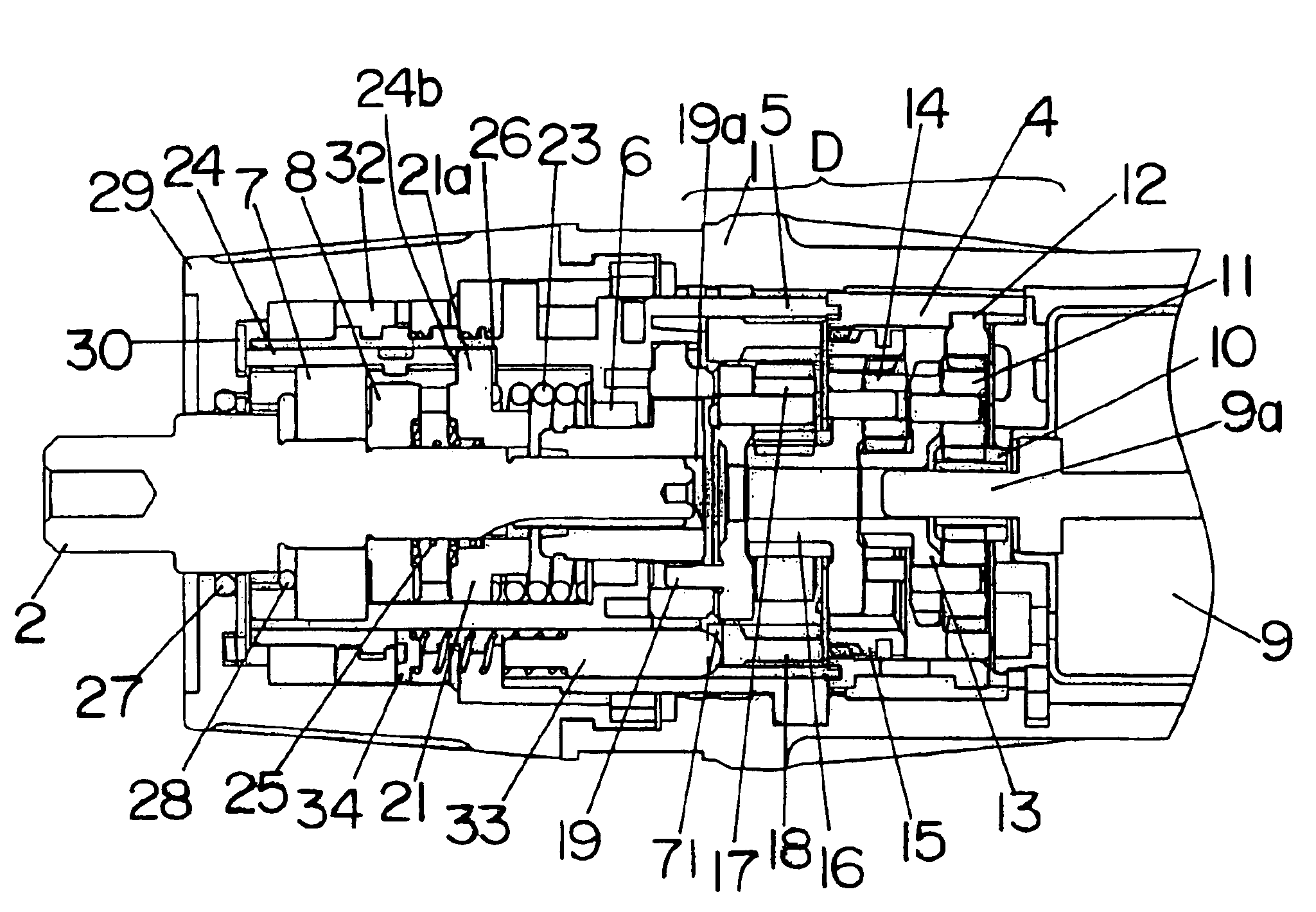

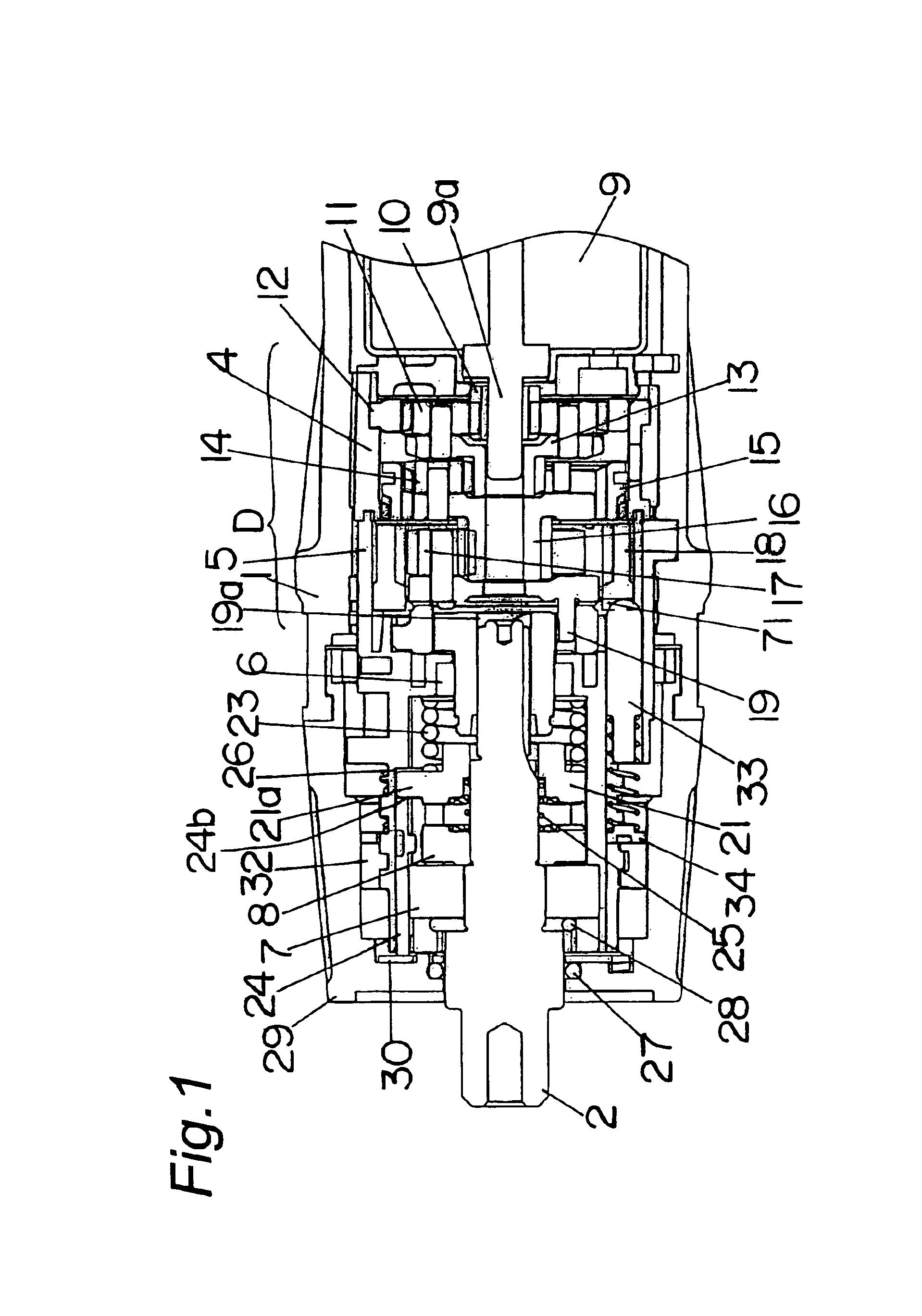

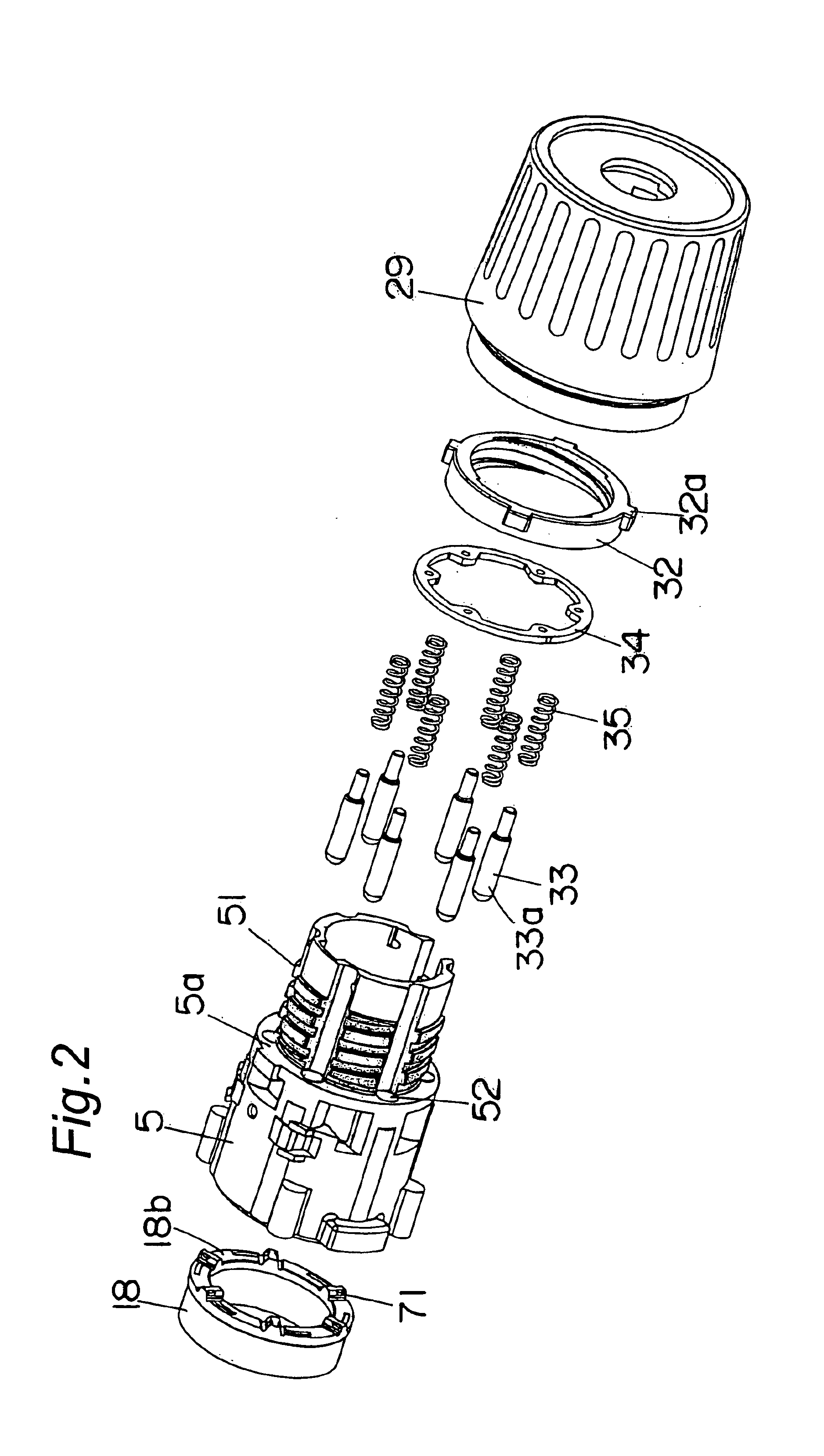

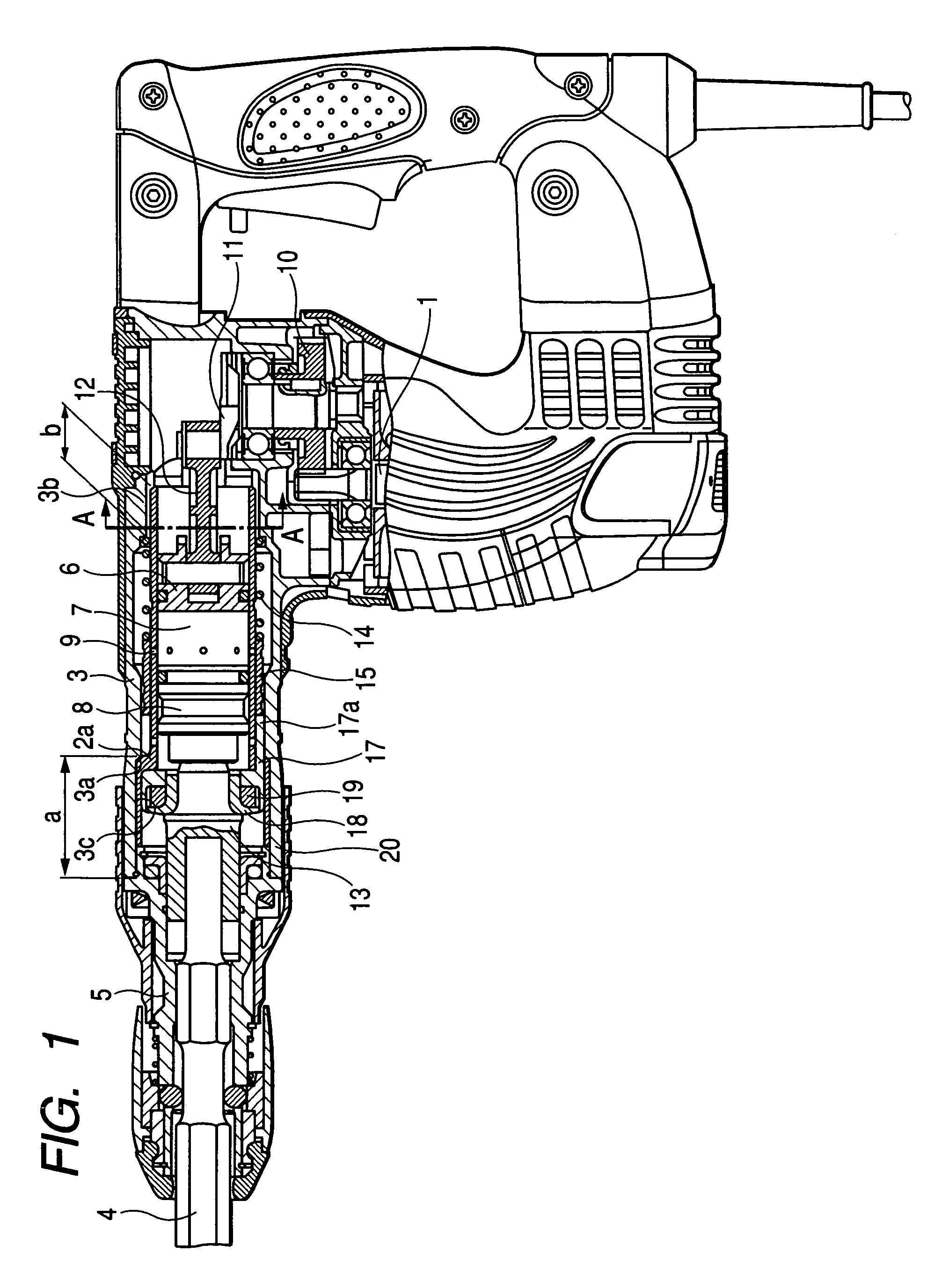

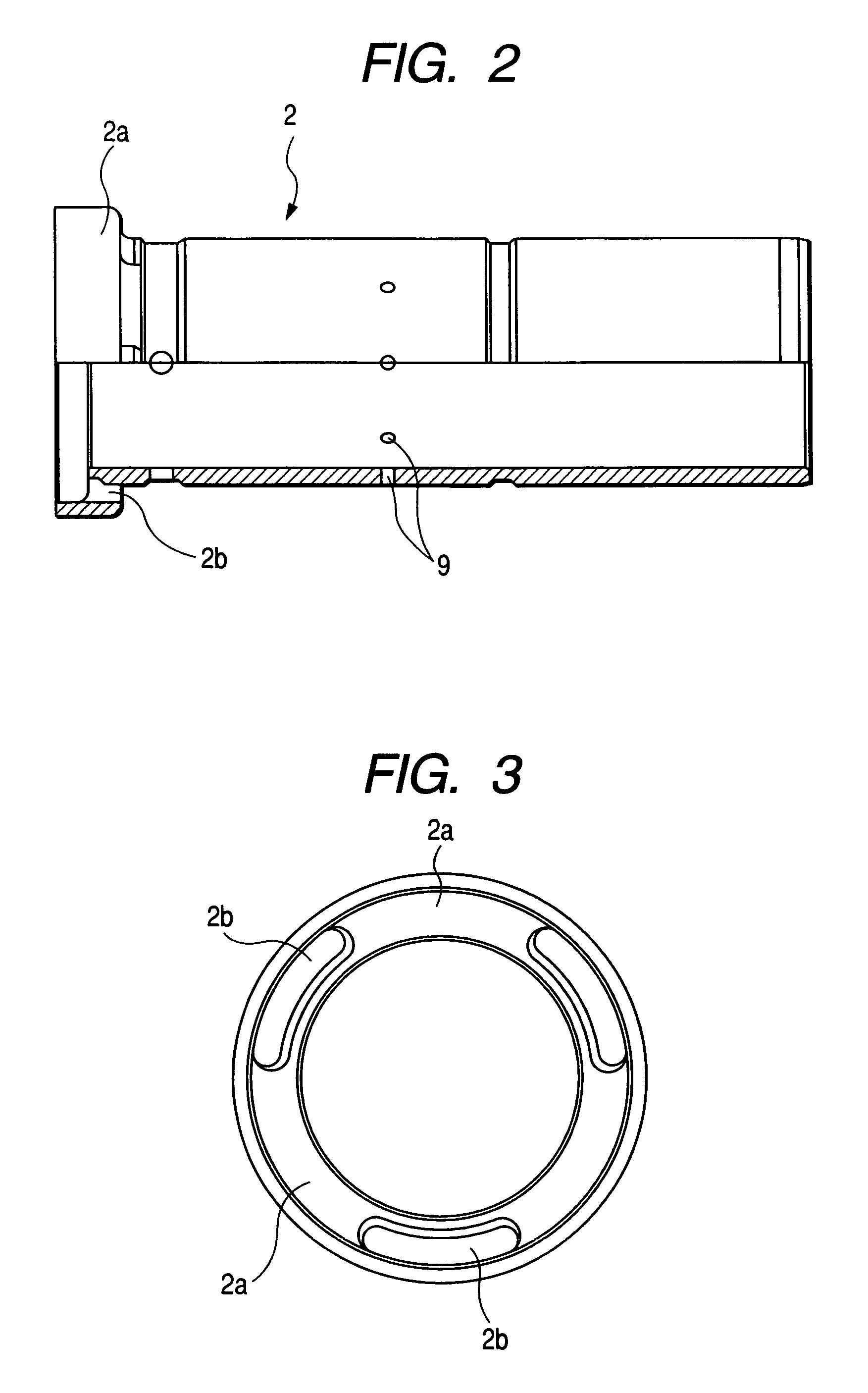

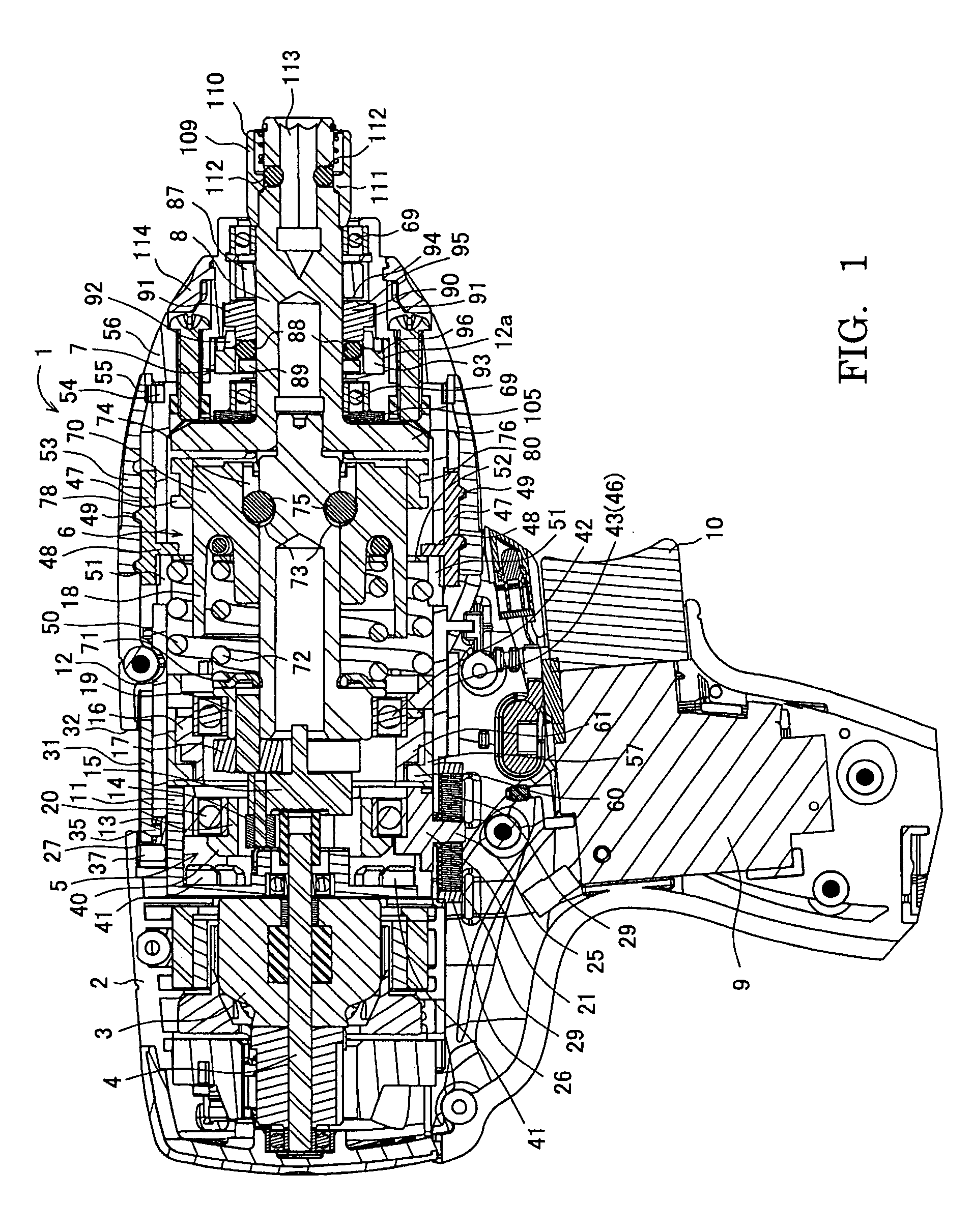

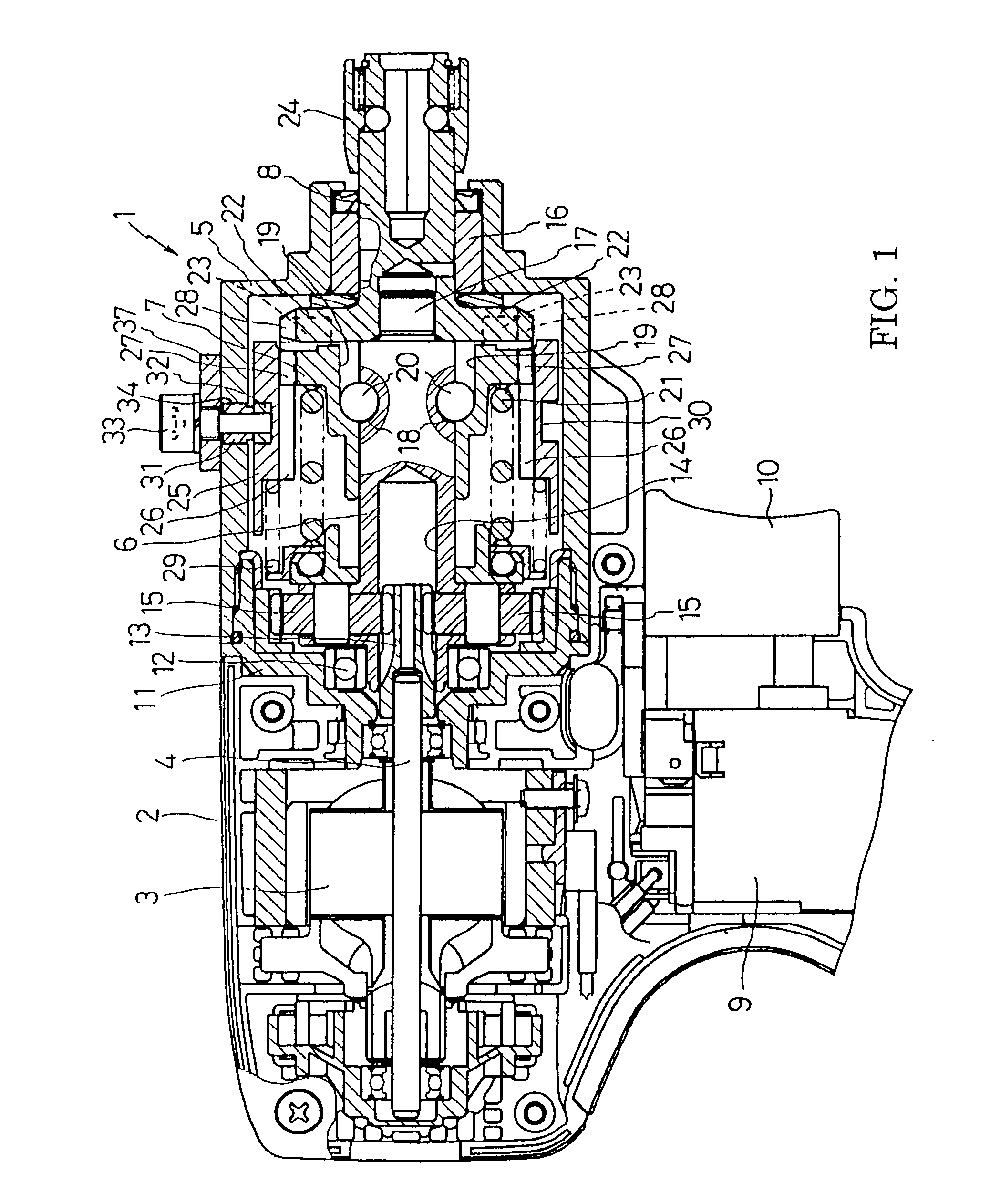

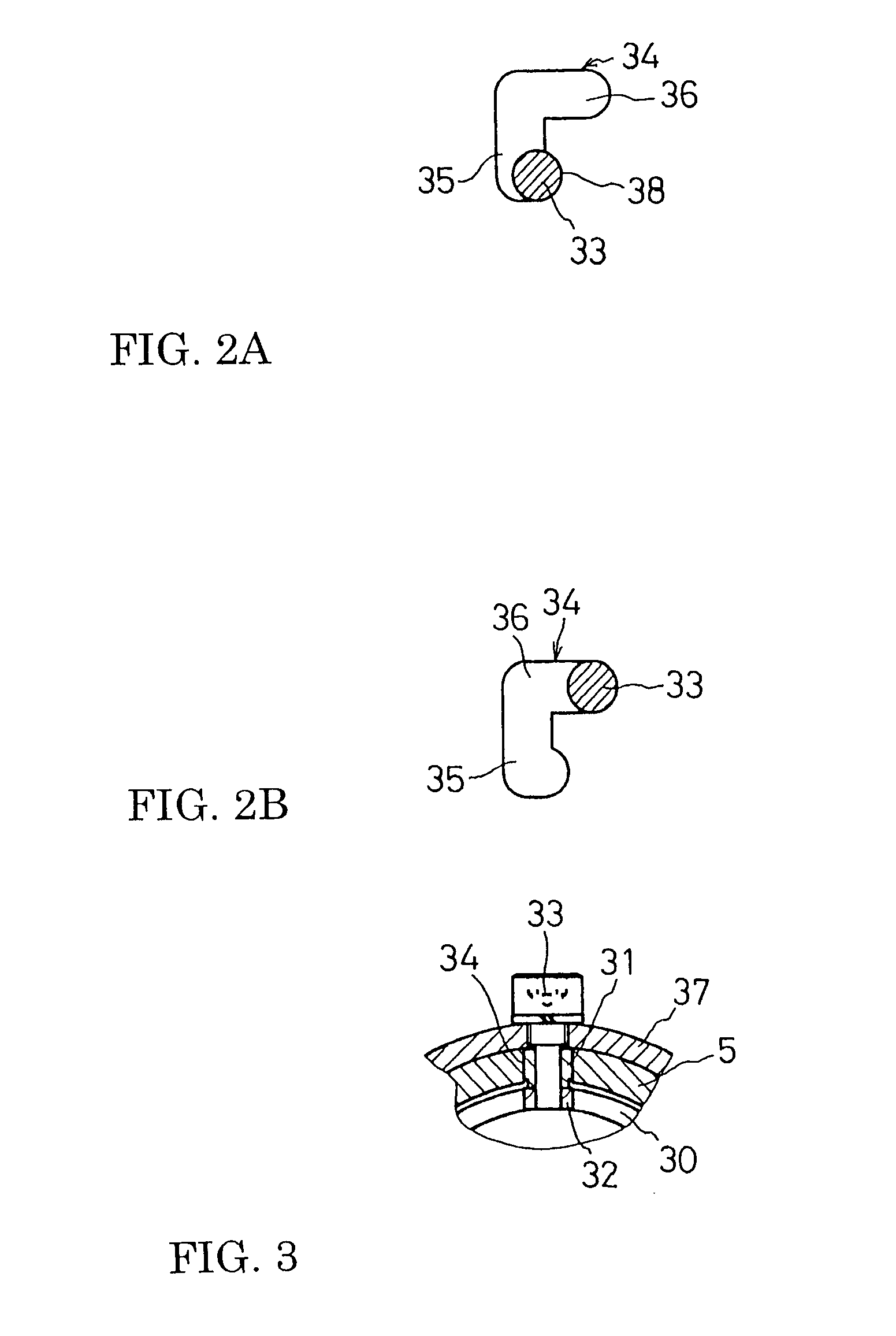

Impact driver having an external mechanism which operation mode can be selectively switched between impact and drill modes

ActiveUS7124839B2Simple structureImprove usabilityReciprocating drilling machinesPortable percussive toolsOperation modeEngineering

An impact driver in which a drill mode can be selected without fail is provided. In a hammer case, a connecting sleeve is provided so as to be slidable back and forth. At the backward position, the connecting sleeve engages with only a first engaging tooth provided on the outer circumference of the hammer for rotating integrally. At the forward position, it engages with both the first engaging tooth of the hammer and a second engaging tooth of an anvil for rotating integrally with both of them, and thus a drill mode is obtained. Further, an operating bolt is provided in the hammer case to be inserted into a concave groove of the connecting sleeve through a guide groove formed in the hammer case. The operating bolt slides the connecting sleeve to the forward or backward position by its movement in the guide groove.

Owner:MAKITA CORP

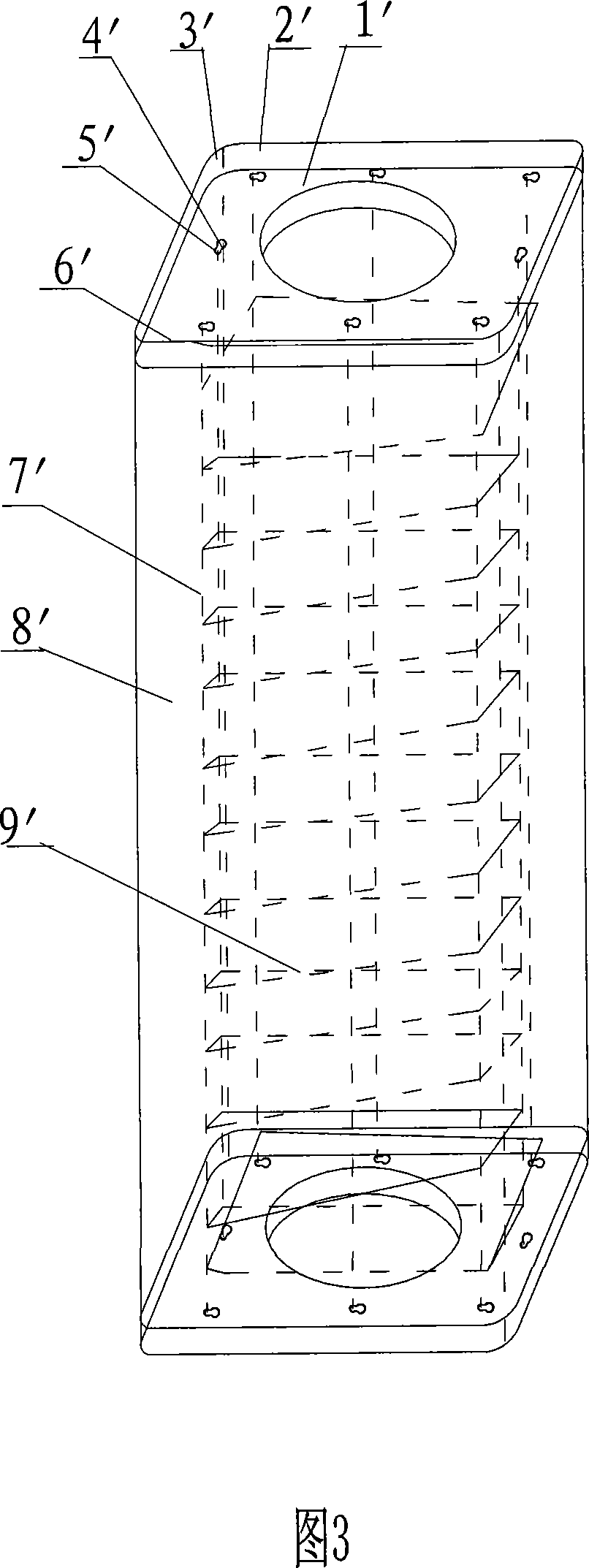

Socket pile molding device

Disclosed is a socket pile molding device. A left half socket frame and a right half socket frame are opposite to form a fish-spindle frame; the front end of the fish-spindle frame is in a concave-fold line shape, and the rear end of the fish-spindle frame is in a convex-fold line shape; and the concave-fold line at the front end and the convex-fold line at the rear end are matched; multiple first stirring teeth are arranged at the lower end of the left half socket frame, and multiple second stirring teeth are arranged inside the left half socket frame; and multiple first stirring teeth are arranged at the lower end of the right half socket frame, and multiple second stirring teeth are arranged inside the right half socket frame.

Owner:靖江汇恒新材料有限公司

Electrically operated vibrating drill/driver

A vibrating drill / driver includes a motor for driving a spindle about the longitudinal axis thereof, a switching handle supported for rotation about a longitudinal axis thereof, a clutch mechanism for varying a working torque in dependence on rotation of the switching handle, a switching ring having a recess and capable of rotating together with the switching handle, and a switching plate having a tip for engagement in the recess. A vibrating cam mechanism is provided to be operable to undergo a slidable engagement to provide a vibration for the spindle in an axial direction thereof when the tip of the switching plate is engaged in the recess of the switching ring. With the above-described construction, the rotation of the switching handle in one direction causes the vibrating drill / driver to be set in one of a clutch mode, a vibrating mode, and a drilling mode in this order.

Owner:MATSUSHITA ELECTRIC WORKS LTD

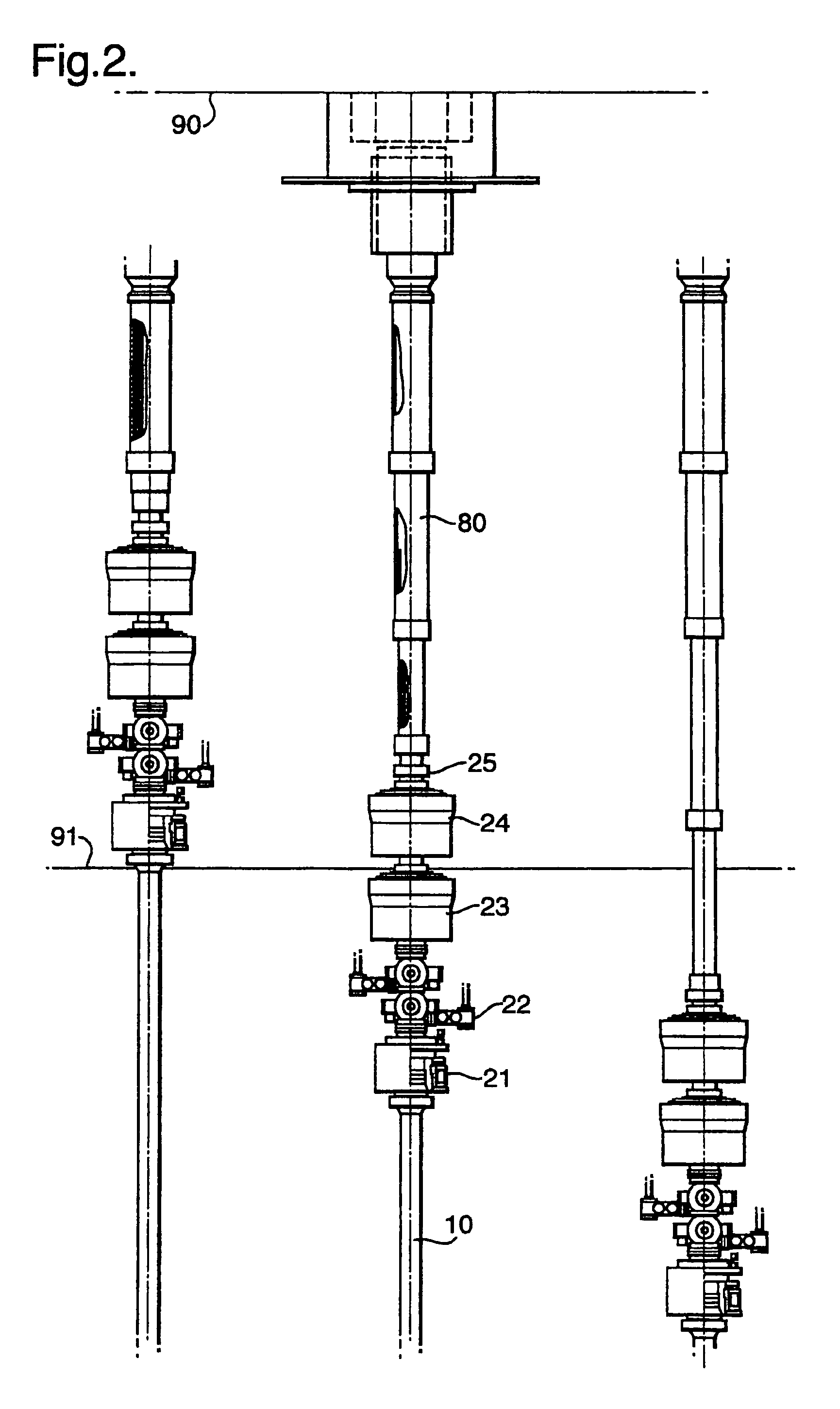

High pressure system

An arrangement and method for integrating a high pressure riser sleeve from the upper end of a high pressure drilling and workover riser terminated by an upper BOP close to sea level in one end and by a sub-sea blowout preventer BOP or a low riser package LRP close to the seabed in the lower end. The high pressure riser sleeve being installed, connected and integrated to the high pressure drilling and workover riser and extending up to and above the drill floor, inside a low pressure drilling riser slip joint which is connected to the drilling and workover riser. This relates to offshore drilling and well activities preformed from a floating drilling or workover rig or vessel. Operations can be switched from drilling with jointed drillpipe in a conventional manner, into performing underbalanced wireline and / or coiled tubing activities with full well pressure, much more effectively than with prior art.

Owner:ENHANCED DRILLING

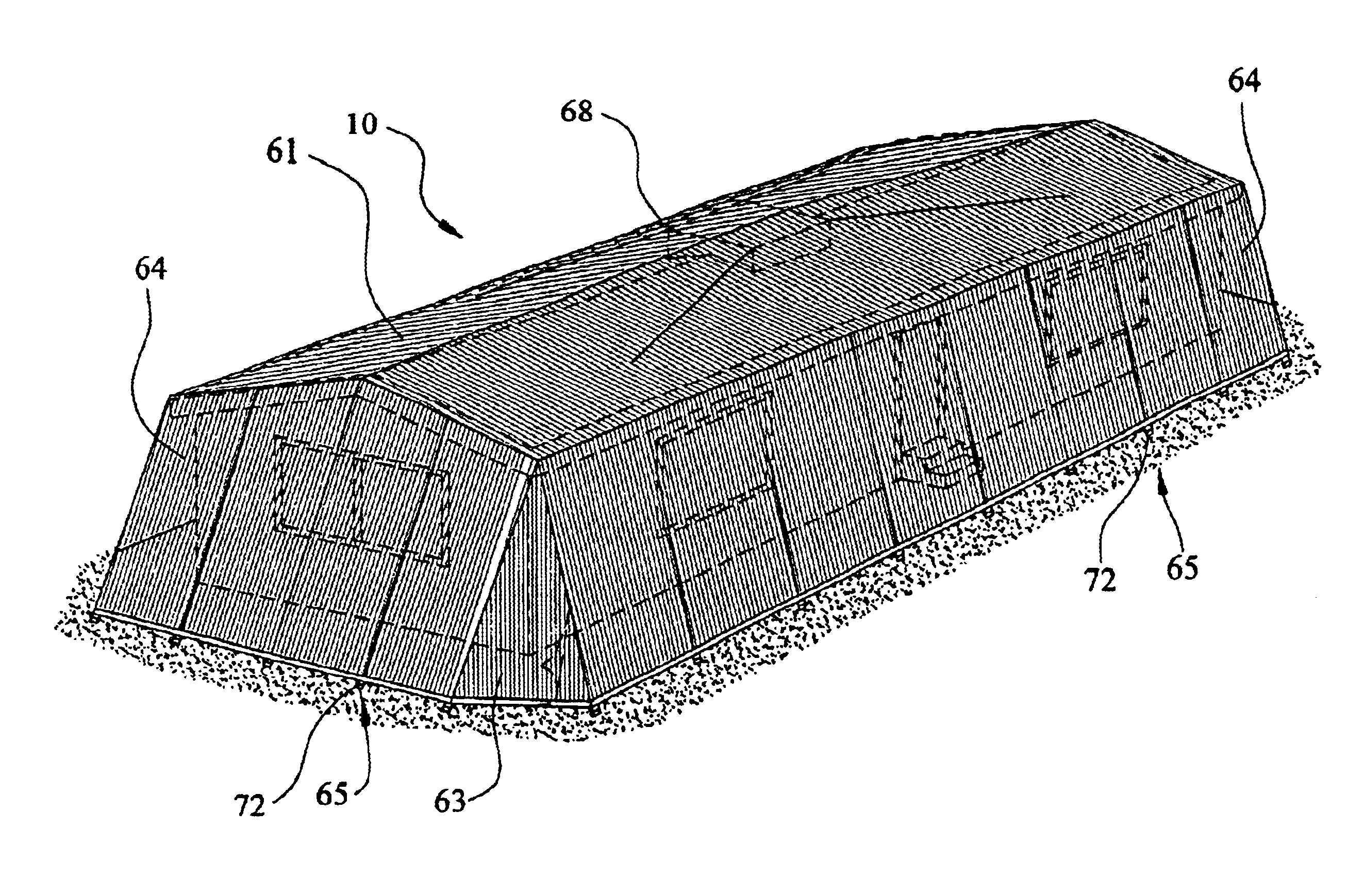

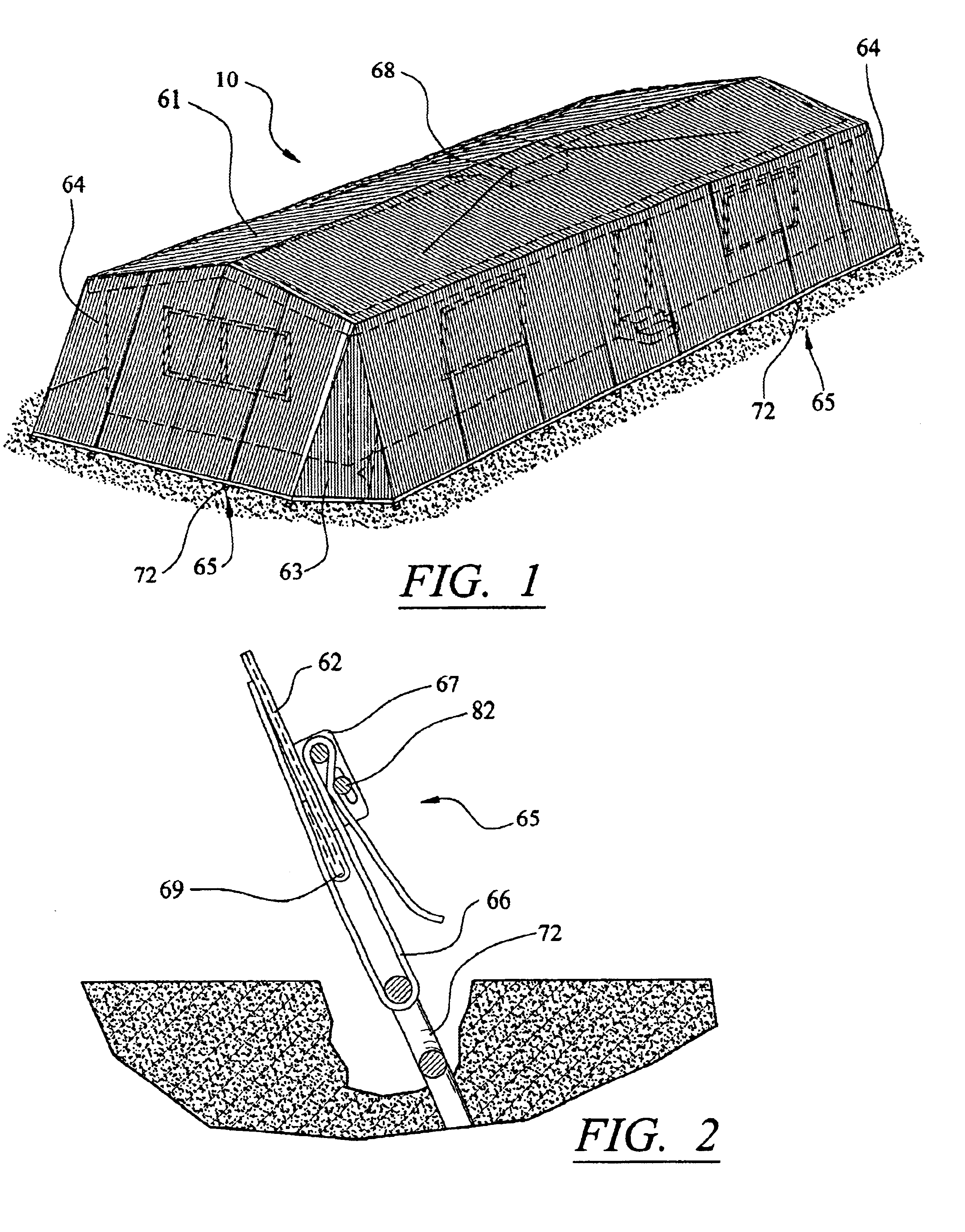

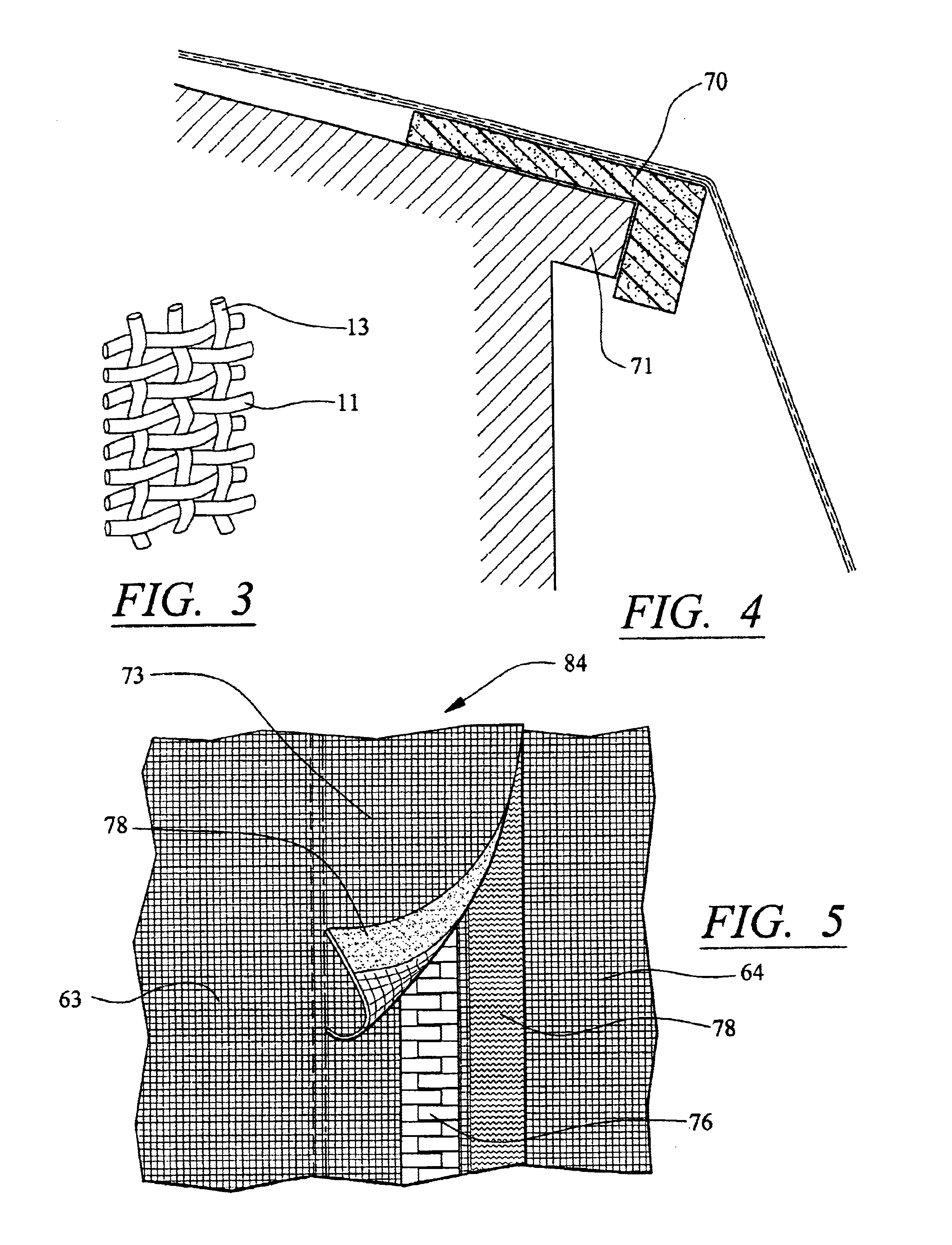

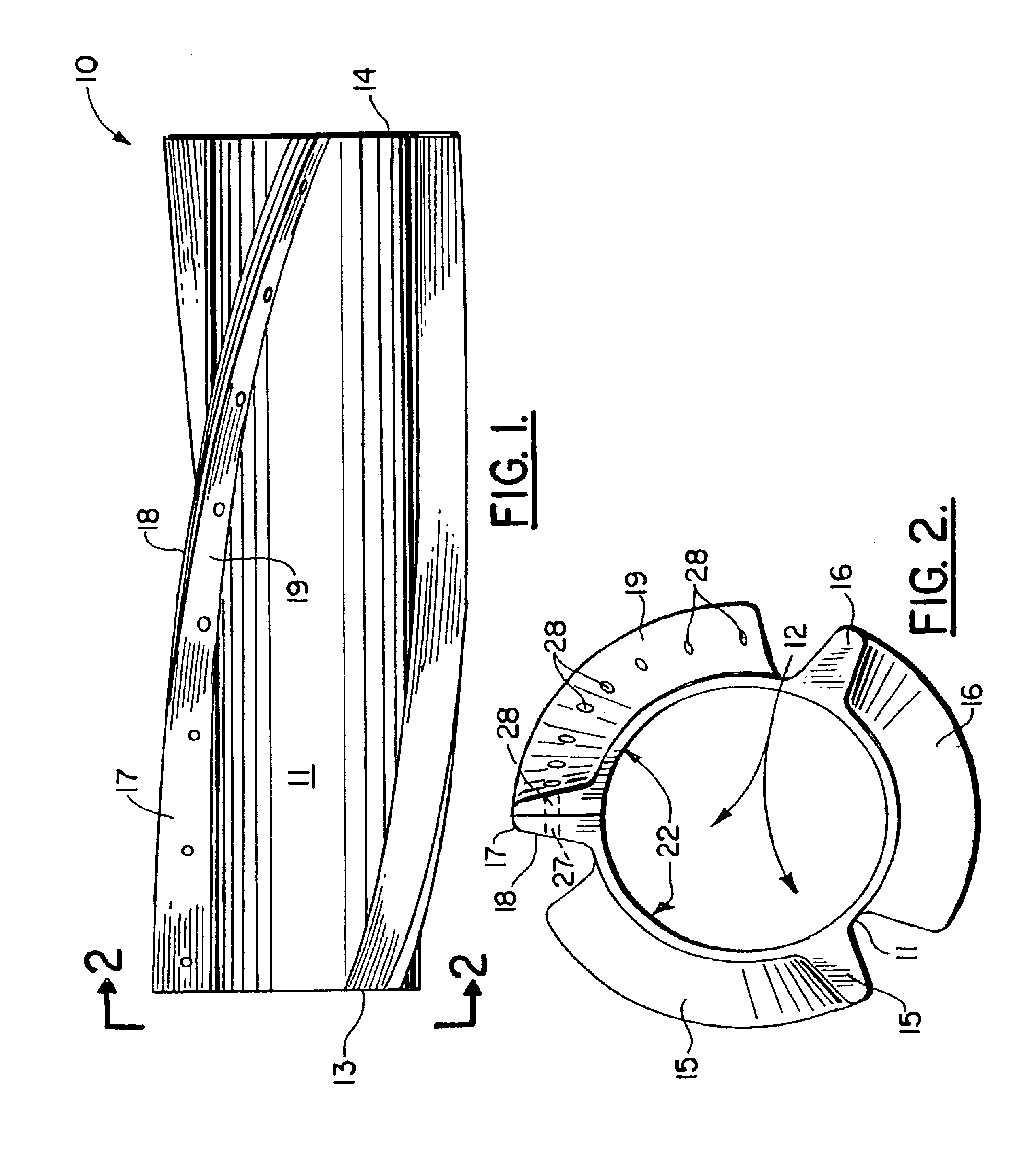

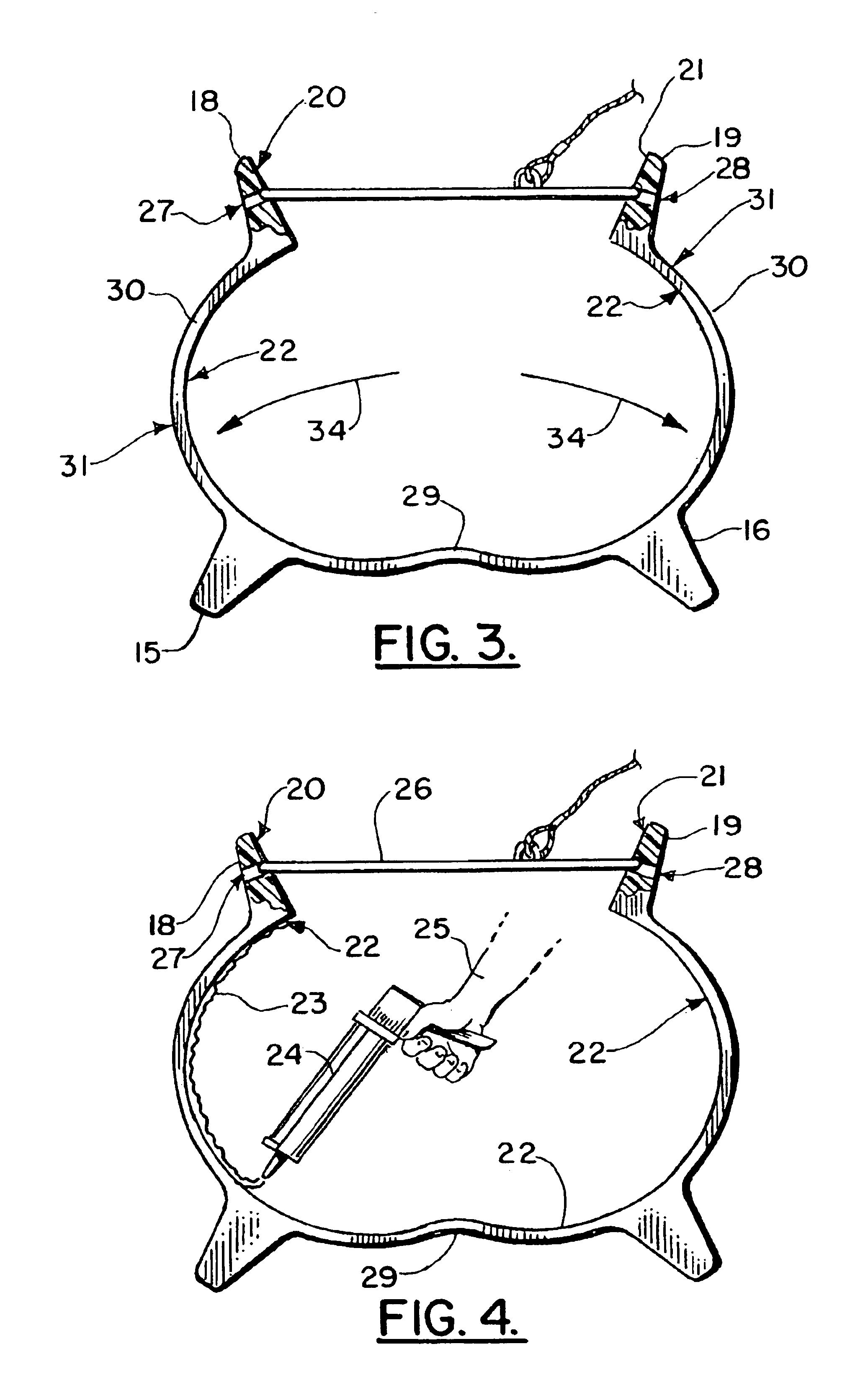

Flexible wind abatement system

A device for protection of property against high winds comprising a flexible material of predetermined strength and stretch characteristics, and in the form of a panel or several panels, utilized to protect the side of a structure including its windows and doors from the strong winds and debris impacts occurring during a hurricane. The device is anchored in a manner to space it out from the area being protected according to formula provided, and can safely dissipate substantial impacting energy. The preferred embodiment attaches to an overhanging eave and the ground below protecting in addition to the windows and doors, plantings, outdoor furniture, decorative shutters, downspouts, and such as are enclosed behind the barrier. Several methods of storage and deployment of said curtain are described including rolling, sliding, and converting to awning. The barrier has the added feature of acting as a tie down in certain applications.

Owner:ARMOR SCREEN

Striking tool

ActiveUS6938705B2Improve performanceEasy to integrateReciprocating drilling machinesPortable percussive toolsMechanical engineering

A projected portion provided at a cylinder and projected in a radius direction is formed at an end face thereof on a side of a tool holding portion, and a holding portion on one side of holding portions for holding an outer periphery of the cylinder by at least two portions remote from each other in an axial direction to position in the radius direction of the cylinder is configured by a guide face having an inner diameter of a dimension substantially the same as an outer diameter of the projected portion and extended over to a contact face brought into contact with the projected portion from an end face of a cylinder case on a side of the tool holding portion.

Owner:KOKI HLDG CO LTD

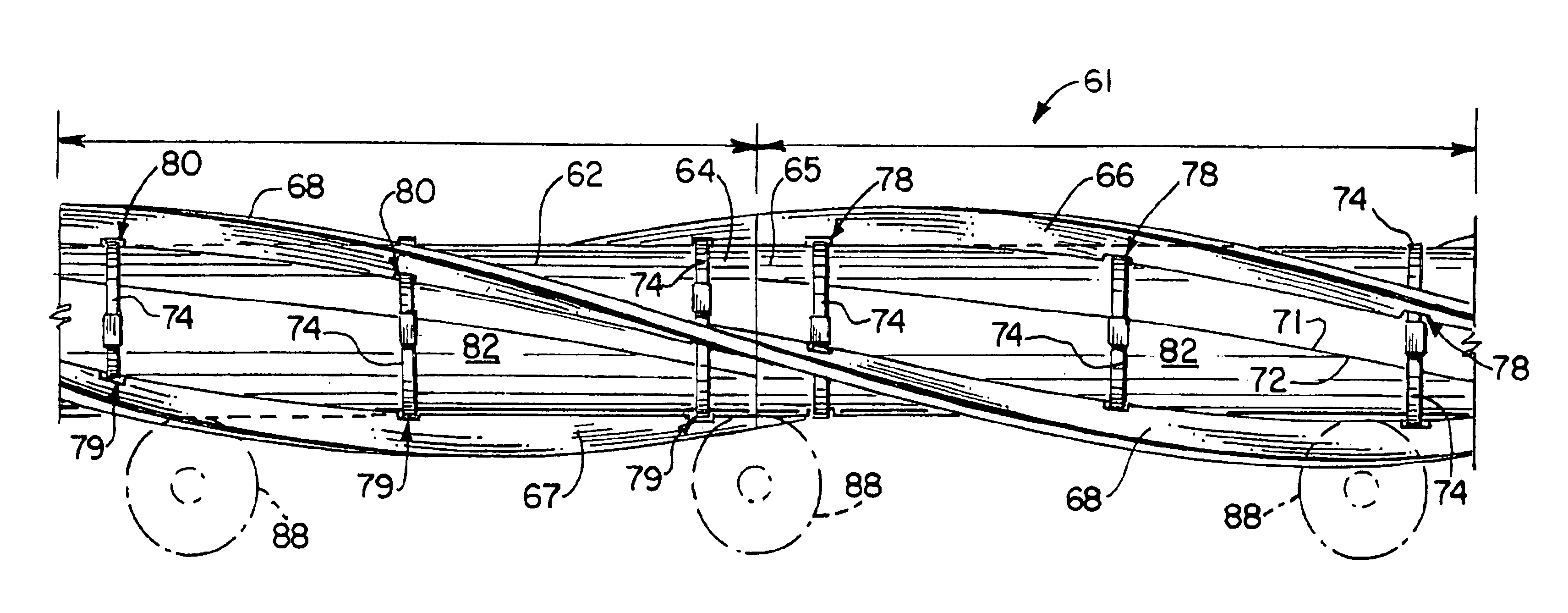

Vortex induced vibration suppression device and method

InactiveUS6896447B1Easy to installEasy constructionPipe laying and repairDrilling rodsVertical tubeHelical blade

A vortex induced vibration suppressor and method is disclosed. The apparatus includes a body that is a flexible member of a polymeric (e.g., polyurethane) construction. A plurality of helical vanes on the body extend longitudinally along and helically about the body. Each vane has one or more openings extending transversely there through. A longitudinal slot enables the body to be spread apart for placing the body upon a riser, pipe or pipeline. Tensile members that encircle the body and pass through the vane openings enable the body to be secured to the pipe, pipeline or riser.

Owner:TAQUINO WELDON

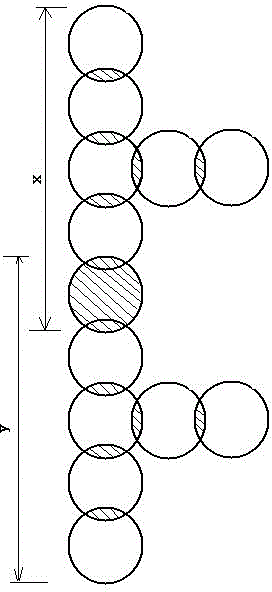

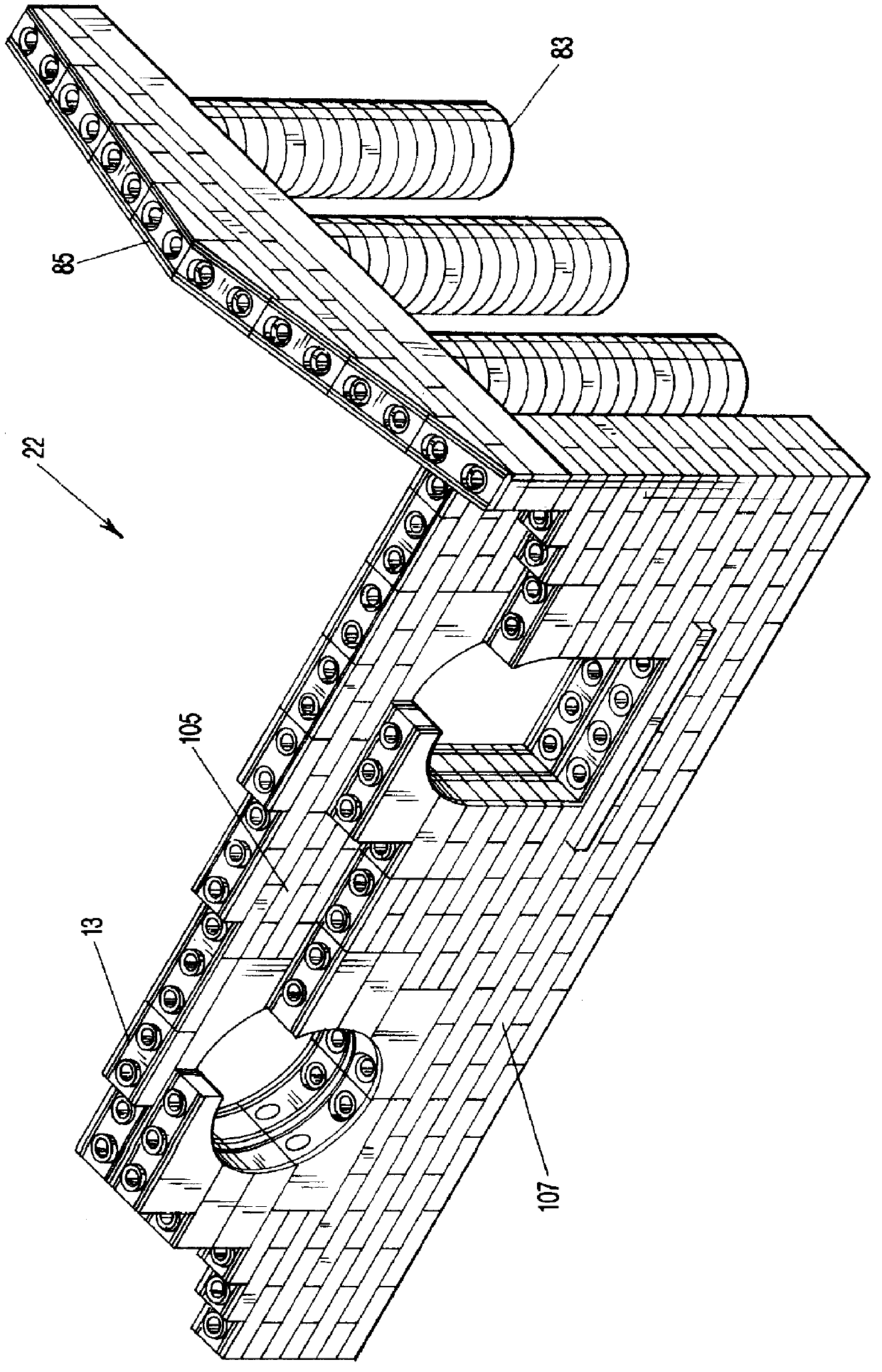

T-shaped stirring drilling machine

ActiveCN104612141AStrong bending resistanceImprove anti-seepage effectBulkheads/pilesGravity centerEngineering

The invention discloses a T-shaped stirring drilling machine. A motor A, a motor B, a motor C, a motor D, a motor E, a motor F and a motor G form a T-shaped structure; the motor A and the motor B, the motor B and the motor C, the motor C and the motor D, the motor D and the motor E, as well as the motor F and the motor G are fixedly connected through a connection rod A; the motor C is fixedly connected with the motor F through a connection rod B; the lower end of a drilling rod is fixed at the gravity center position of the T-shaped structure and is fixed on the connection rod B; a connection rod C is fixed on the right of the motor E; an arc-shaped plate is fixed at the right end of the connection rod C; the position, which leftwards rotates by 120 degrees by taking the center of the motor E as a circle center, of the connection rod C is fixed on a connection rod E; an arc-shaped plate is fixed at the outer end of the connection rod E; the position, which rightwards rotates by 120 degrees by taking the center of the motor E as the circle center, of the connection rod C is fixed on a connection rod D, and an arc-shaped plate is also fixed at the outer end of the connection rod D.

Owner:南通重矿金属新材料有限公司

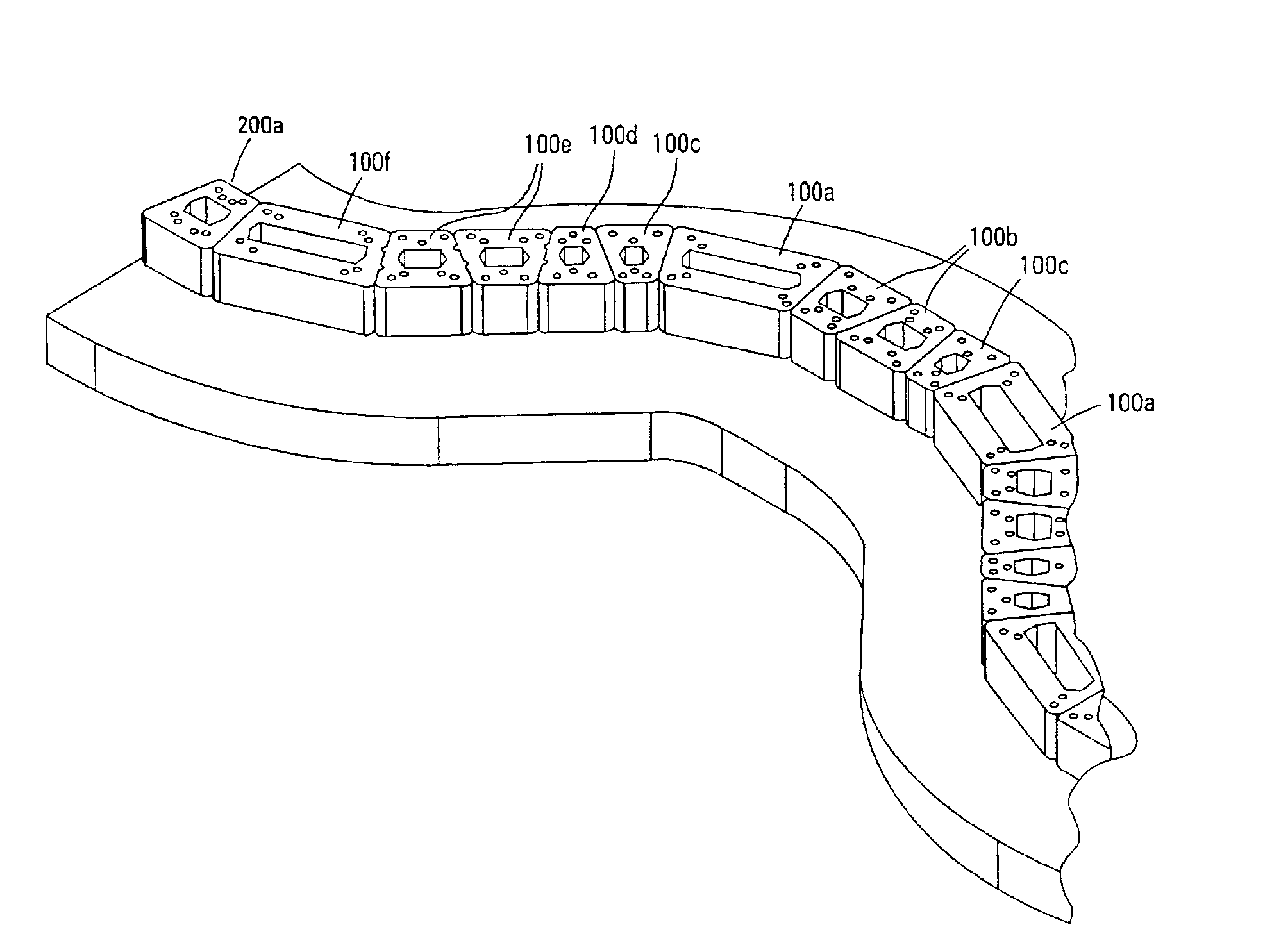

Modular building materials

Building materials of modules of at least one mortise and tenon and either a curvilinear side face or joinder of the modules at angles other than zero and ninety degrees. Lateral ends of the modules are flush with lateral ends of adjacent modules. Preferably, the modules are: (1) of a low density aggregate cementitious mix; and / or (2) have a hollow space extending from the mortise to the tenon and include a structural support member passing through the hollow space and a compression retainer securing the structural support member to the modules; and / or (3) have grooves circumscribing the modules and which are proximate corresponding grooves on modules placed on top or below. The modules are preferably sealed to one another with sealant placed in the grooves.

Owner:SIMMONS SCOTT +1

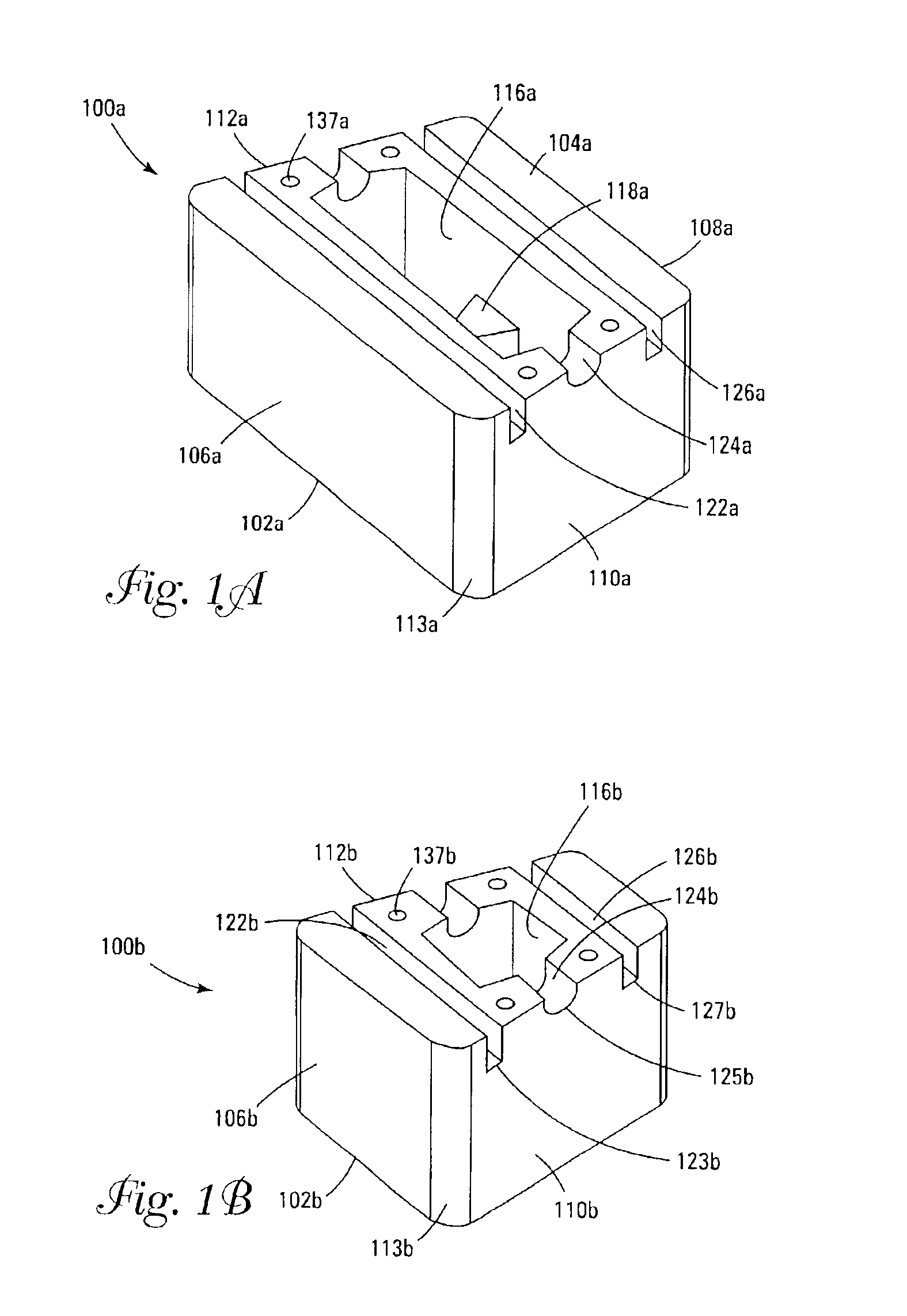

Multi-channel retaining wall block and system

A retaining wall block system having multiple sizes and shapes of blocks with differently dimensioned, interchangeable front and back faces. The blocks are used to construct an irregularly textured wall having a weathered, natural appearance. Multiple channels in the lower face of the block are used to engage pins in pin-receiving apertures to form an attachment system. A side connection system is particularly useful for stabilizing free-standing walls. Horizontal reinforcing members are also used in the channels and vertical reinforcing members are used in cores of adjacent blocks for reinforcing a wall. Reinforcing geosynthetic materials can also be firmly held in a wall by means of the pins or by connectors adapted to fit in the block channels.

Owner:KEYSTONE RETAINING WALL SYST

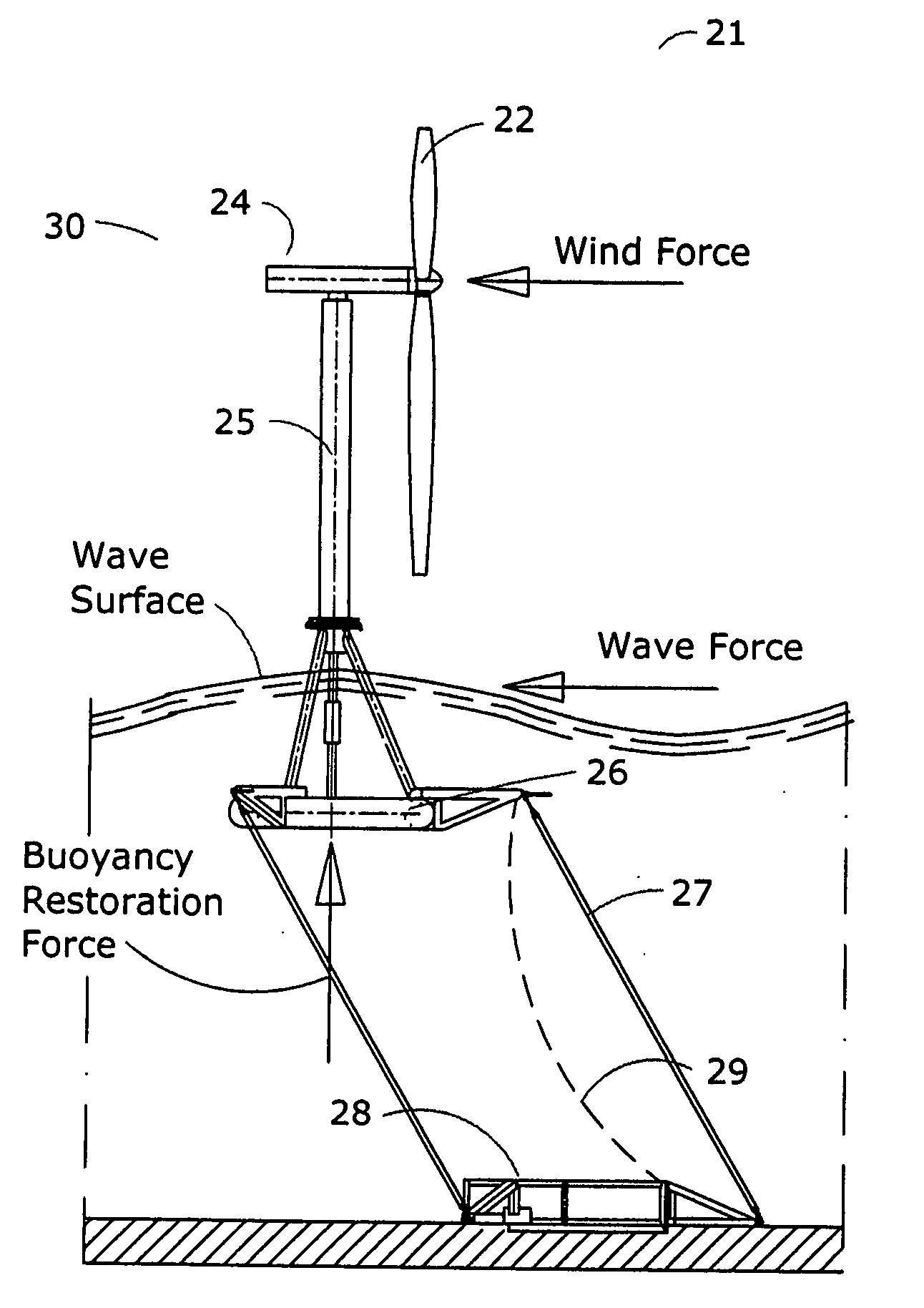

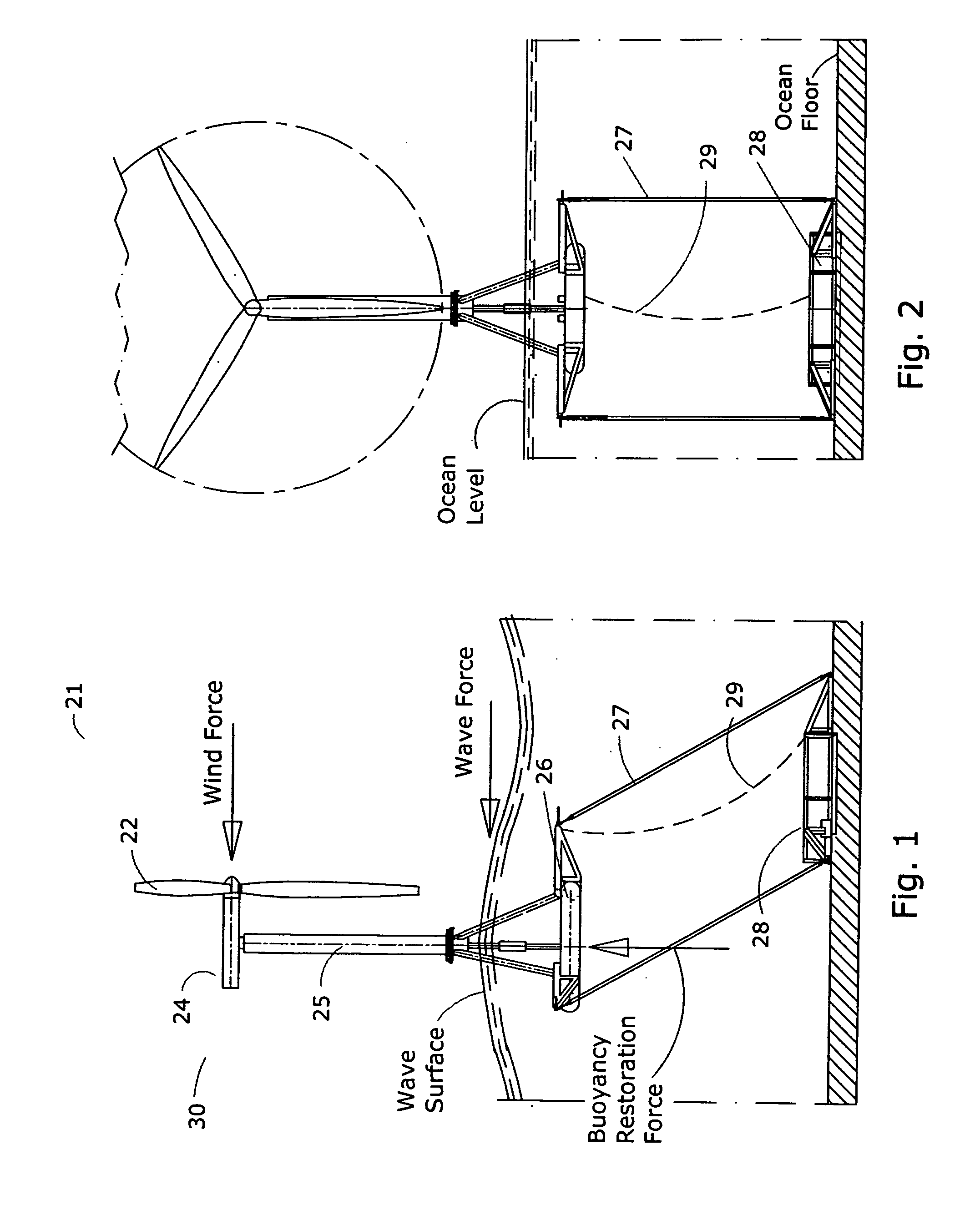

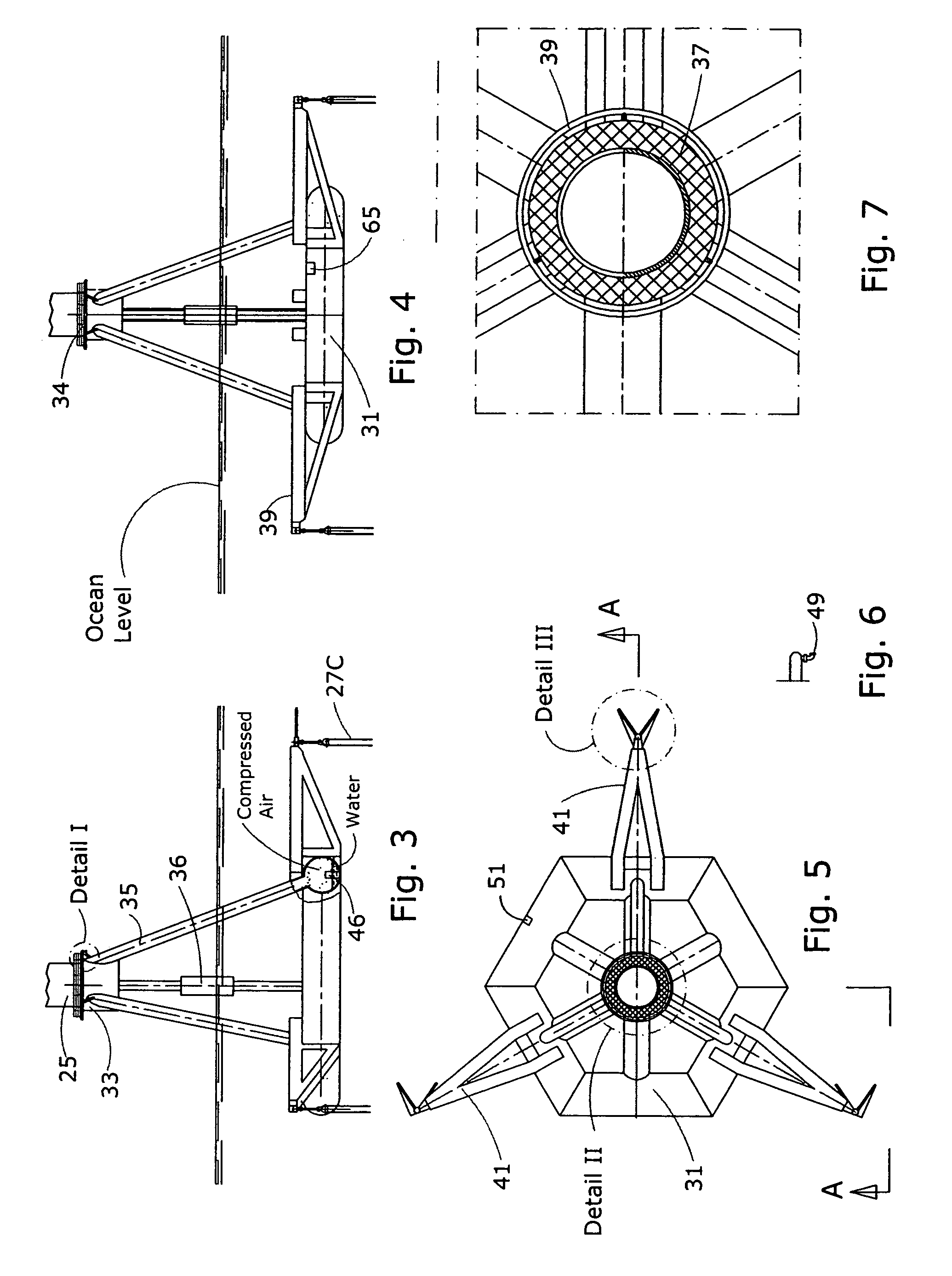

Assembly, transportation and installation of deepwater windpower plant

InactiveUS20080240864A1Reduce installationShorten assembly timeWind motor assemblyWind motor supports/mountsOcean bottomBuoy

A deepwater windpower plant (DWP) has a tension leg-type floating platform with an evacuable base for adjusting its buoyancy for installation at ocean depths ranging from 40 meters up to 1.5 kilometers and more. The DWP has a typical offshore wind turbine assembled close to shore which is then towed to a desired installation site on the ocean, and held in place by a gravity anchoring base (GAB), to which an evacuable portion or space of the DWP platform is anchored. The GAB has upwardly extending mooring tethers and a power cable which are brought to the ocean surface by attached buoys. The GAB is sunk to the ocean floor at the installation site under controlled conditions so that the GAB lands flat on the ocean floor. As the GAB sinks to the ocean floor, the mooring tethers and power cable are pulled to the surface by their respective buoys. The GAB is loaded with heavy ballast material that can be dropped from barges on the ocean surface into the upwardly open GAB below the barges.

Owner:DEEPWATER WIND

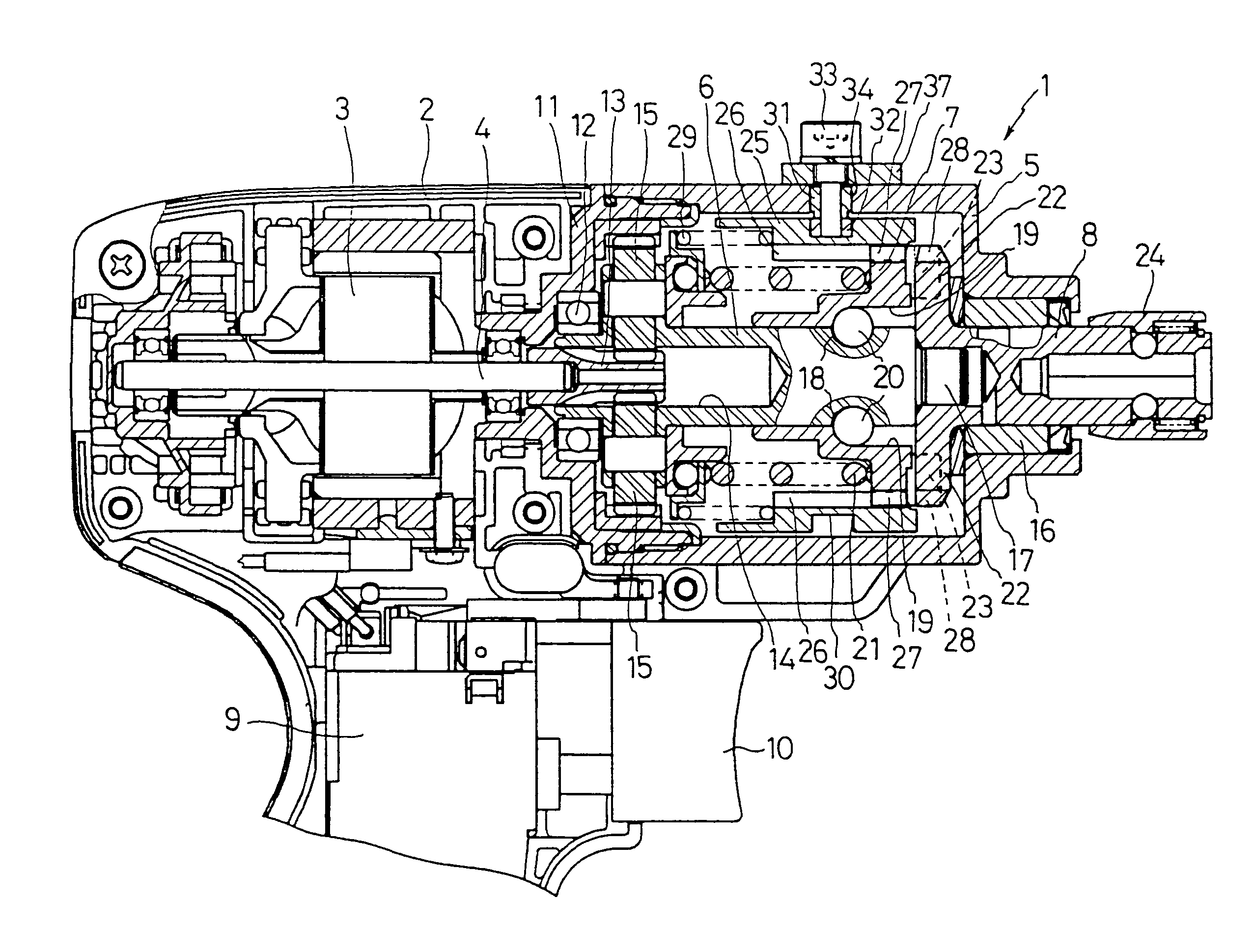

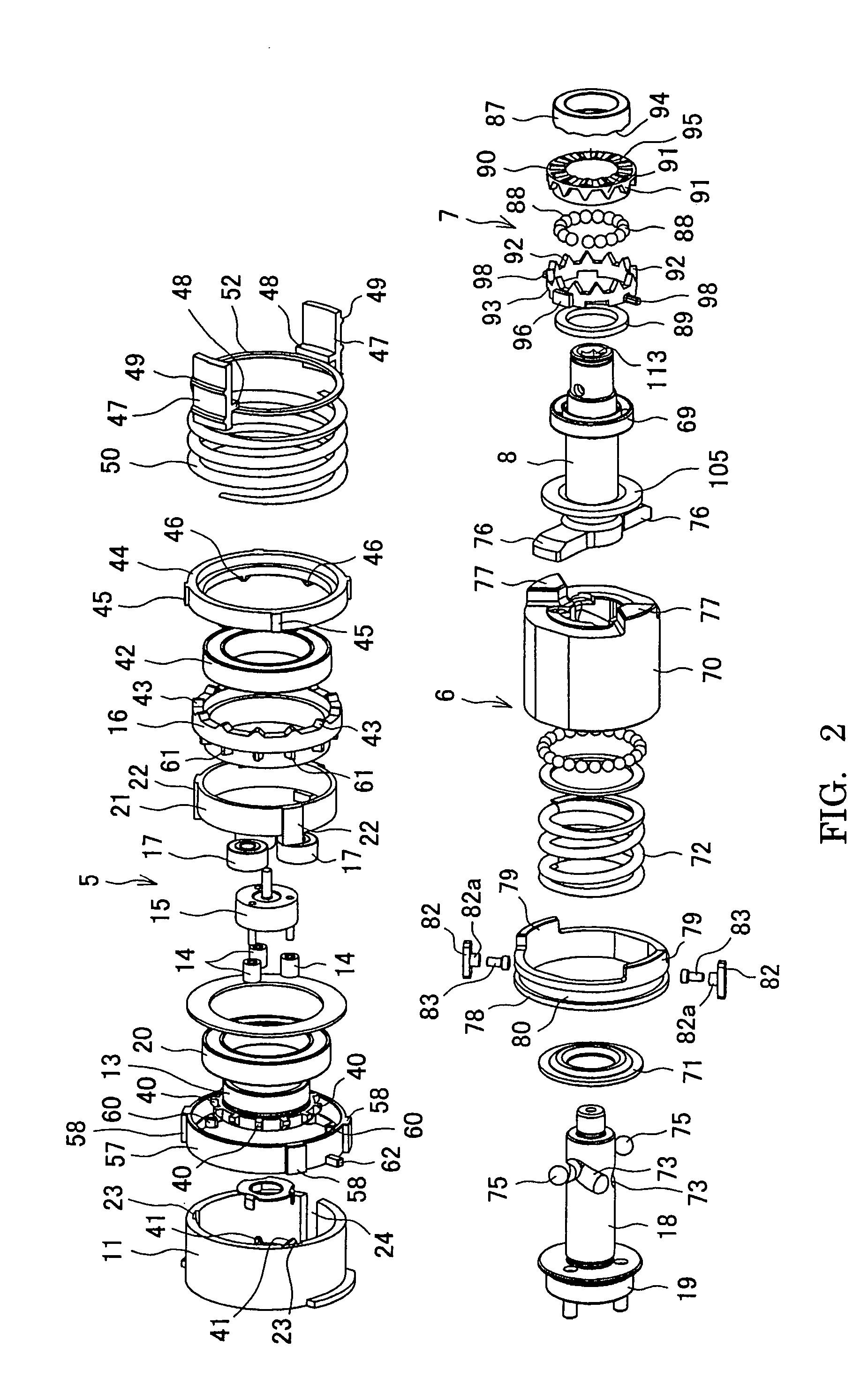

Electric power tool

InactiveUS7308948B2Easy to operateImprove reliabilityDrilling rodsWrenchesElectric power systemOperability

An electric power tool is provided which prevents malfunction with excellent operability even when one operation mode among various modes is selectable. In a gear case of a housing, there are provided a clutch switching groove which engages with a connecting projection of a clutch switching lever, a slit which guides a guide body having a stepped pin which penetrates an impact switching groove to engage with an auxiliary ring, and a percussion switching groove which engages with a connecting projection of a percussion switching lever. In addition, a switching case is externally provided, so that combination of sliding positions of each switching member can be changed. As the switching case can be operated by a switching button, any of all operation modes, which are, a drill mode, an impact mode, a percussion drill mode, and a clutch mode can be selected with the switching button only.

Owner:MAKITA CORP

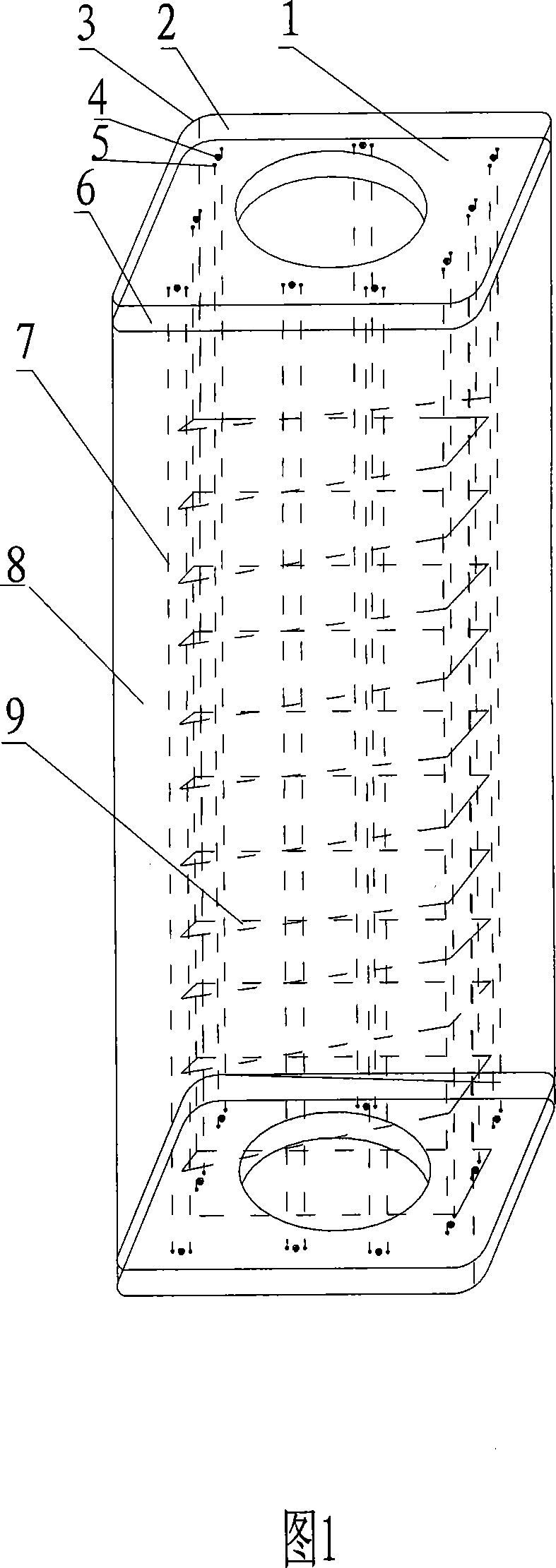

Prestress high intensity concrete square pile and its production method and moulding die

InactiveCN101054800AHigh pile rateIncrease profitCeramic shaping apparatusBulkheads/pilesHigh strength concretePre stress

The invention belongs to the architecture field, which relates to an improvement with the foundation pile shape and the structure and the manufacturing method of the foundation pile and the foundation pile shaper in the architecture field, in particular the invention is a prestressing force high strength concrete square pile and the manufacturing method thereof and the shaping device. In the invention a square terminal plate is disposed on the two ends of the square pile, and the four sides of the terminal plate is provided with a groove, while the center is equipped with a circular hole, and between the circular hole and the four sides, a strain hole and a threading hole are arranged symmetrically; a stirrp of a reinforcement cage in a twist is welded on the principal reinforcement continuously, wherein the principal reinforcement is the steel strand or the steel bar; the concrete square pile and the four-side corners of the terminal plate are in a stress elimination arc, and the pile core is a columnar mid level outlet having the same diameter with the terminal plate central circular hole. The manufacturing method is characterized in that, the principal reinforcement has the fix ed length and blanking, and the stirrp of the reinforcement cage is welded in the seam welder with the high degree of mechanisation; the principal reinforcement is stretched in a group of a whole pile fixed value, wherein the stretching performance is good and the balance is consistent; the disposable high pressure has short shaping time, low energy consumption, high product grade; the die design meets with the shaping requirement of the shape, which is convenient to use.

Owner:SHANGHAI ZHONGJI PILE IND

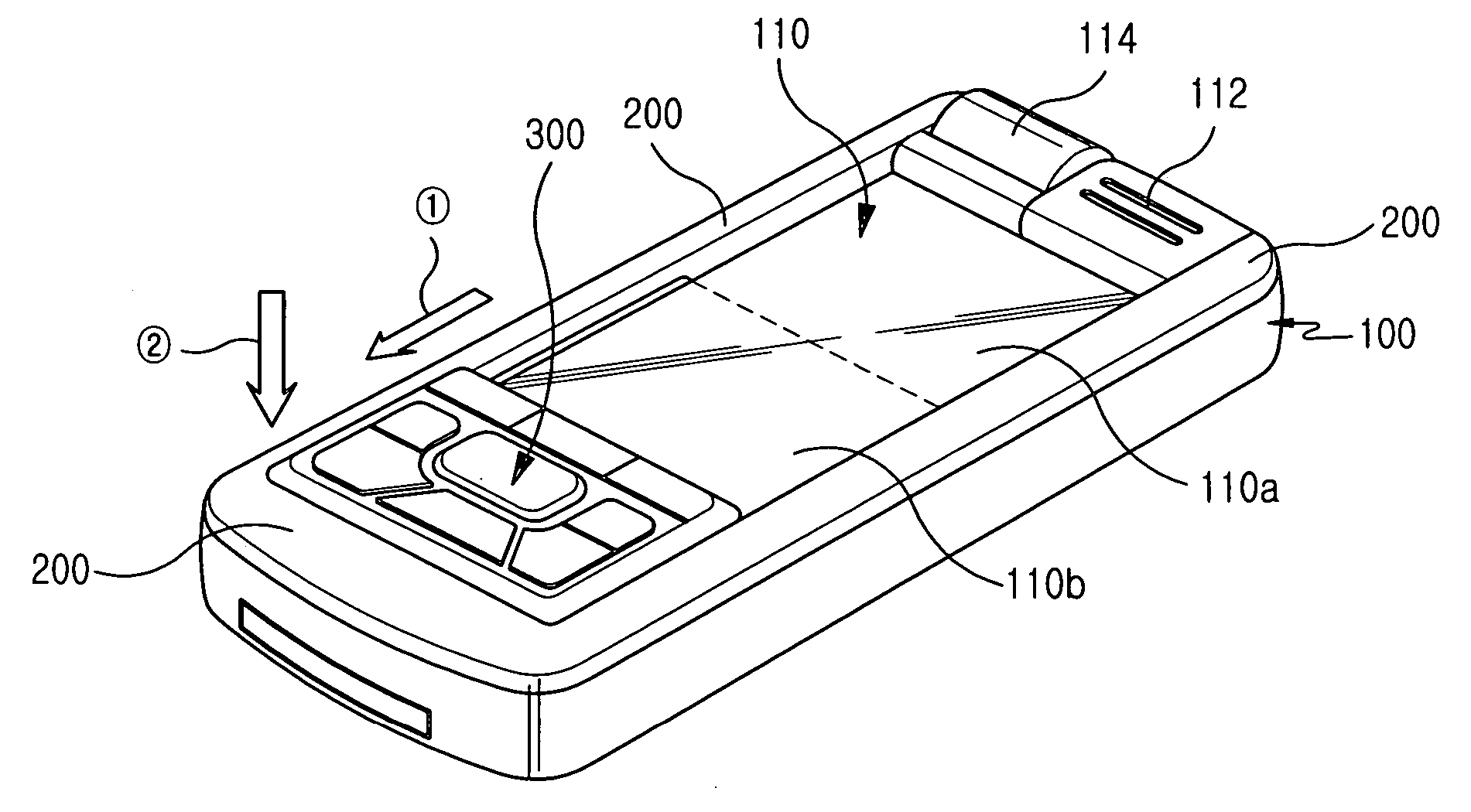

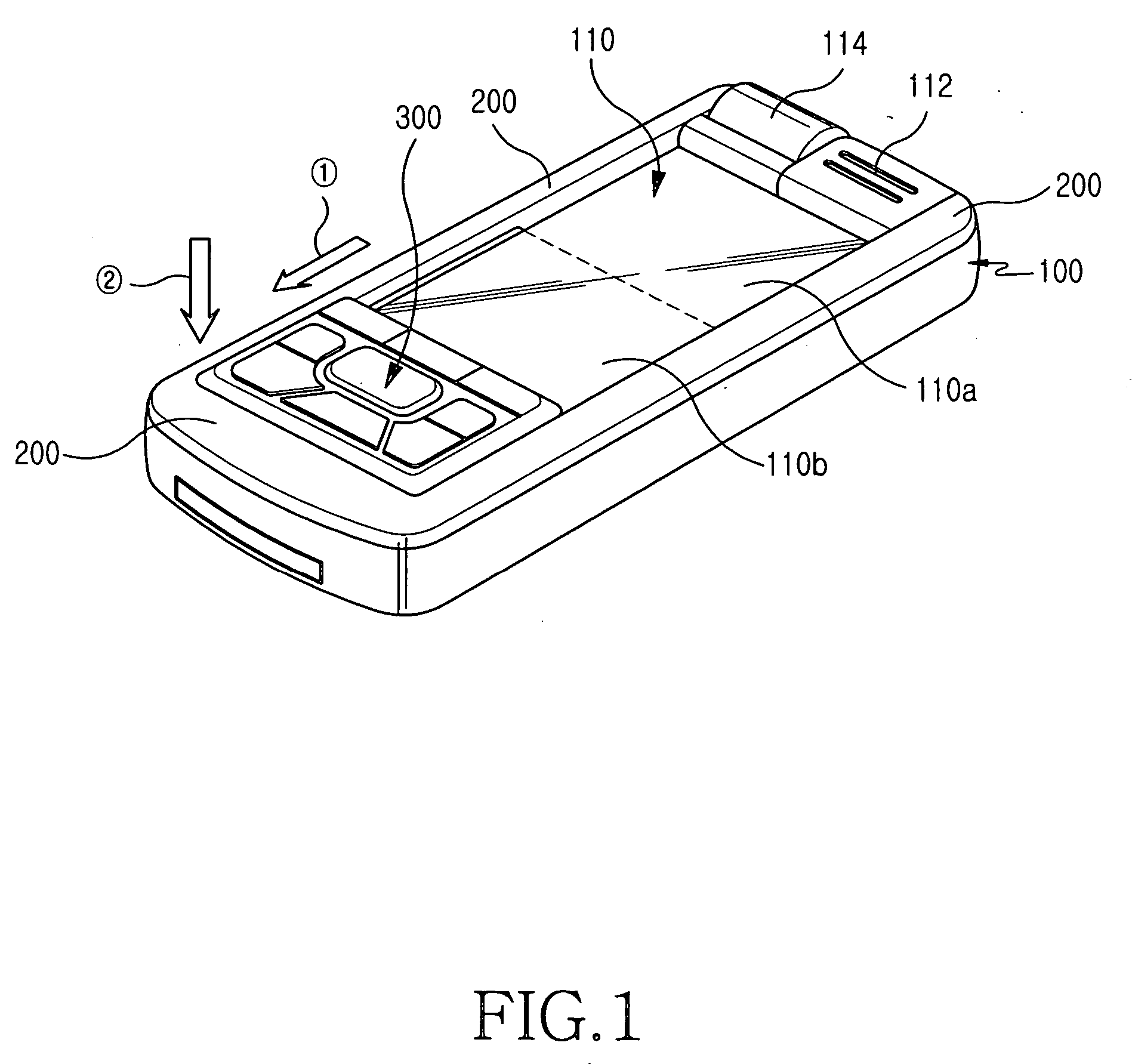

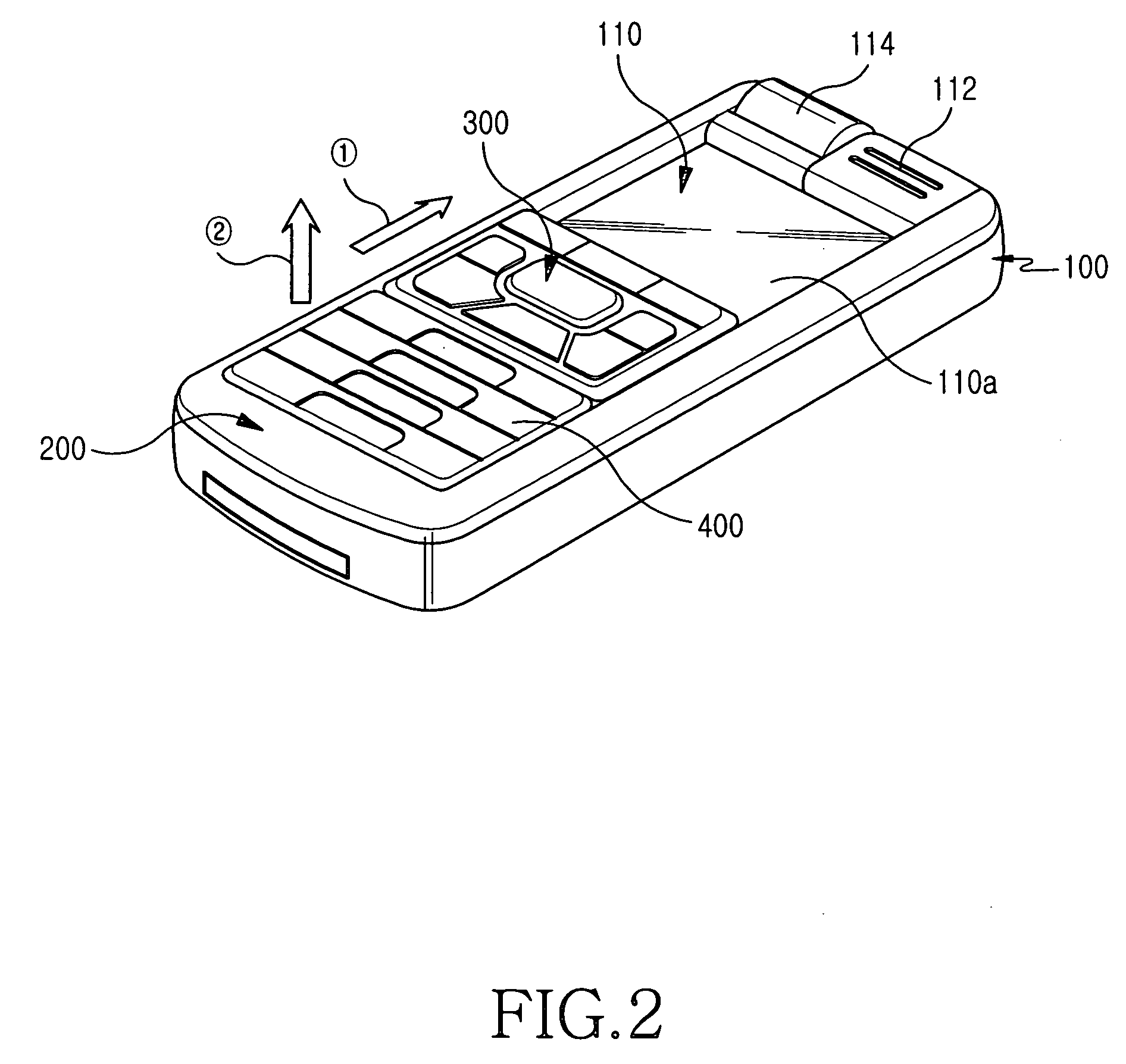

Portable communication device with sliding and pop-up type keypads

InactiveUS20050245297A1Maintaining numberConvenient ArrangementDevices with multiple keyboard unitsTransmissionEngineeringMechanical engineering

A portable slim communication device with a sliding pop-up type keypad, including a body housing having a display unit disposed at the upper surface thereof, an upper frame attached to the body housing along the upper edge of the body housing, a first keypad accommodated in the upper frame while being in parallel with the display unit for performing a sliding movement on the display unit to expose or cover a predetermined region of the display unit, a second keypad movable upward or downward in a pop-up fashion according to a sliding movement of the first keypad while being in parallel with the upper surface of the display unit in the upper frame, and a key frame to guide the pop-up movement of the second keypad while accommodating the second keypad.

Owner:SAMSUNG ELECTRONICS CO LTD

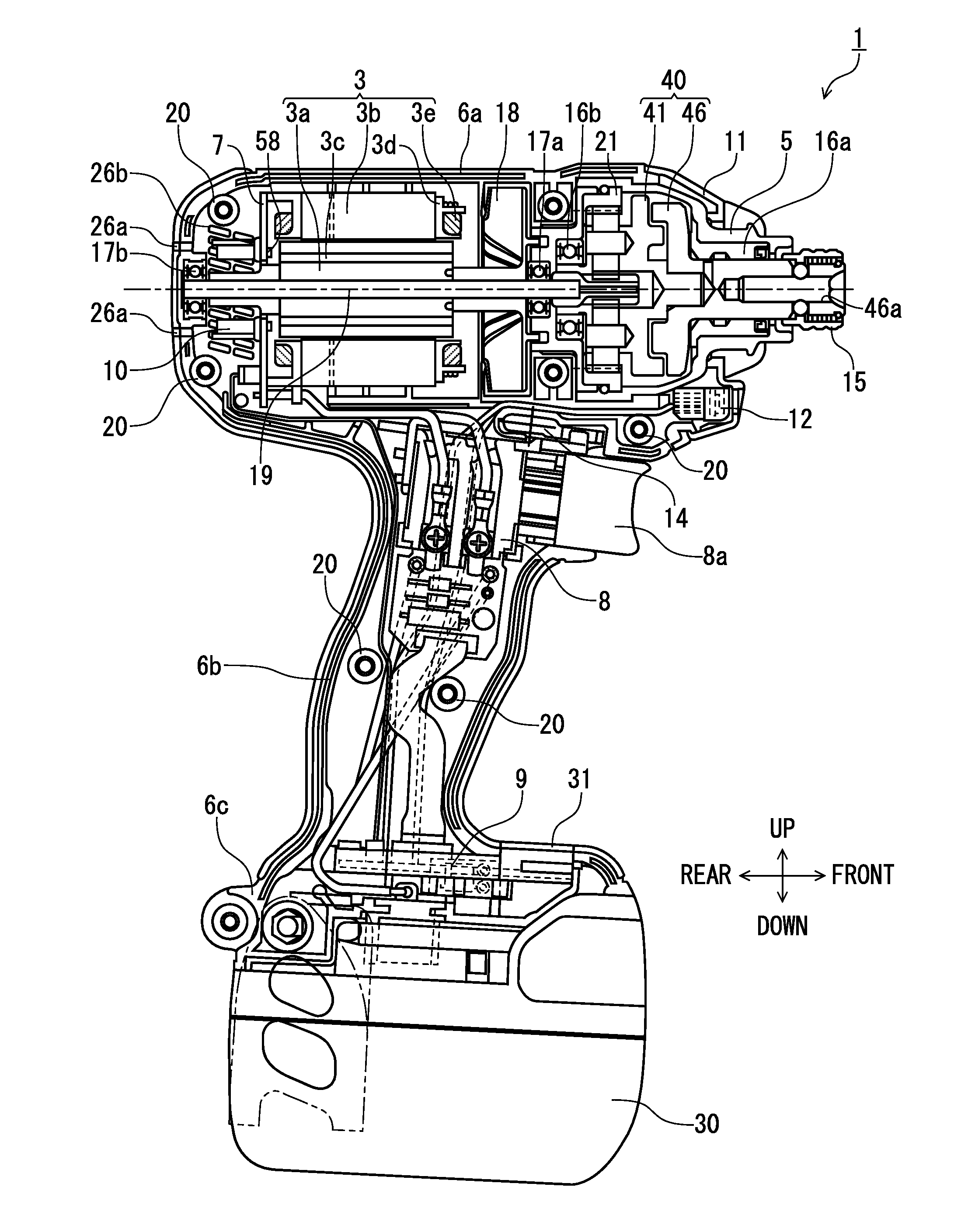

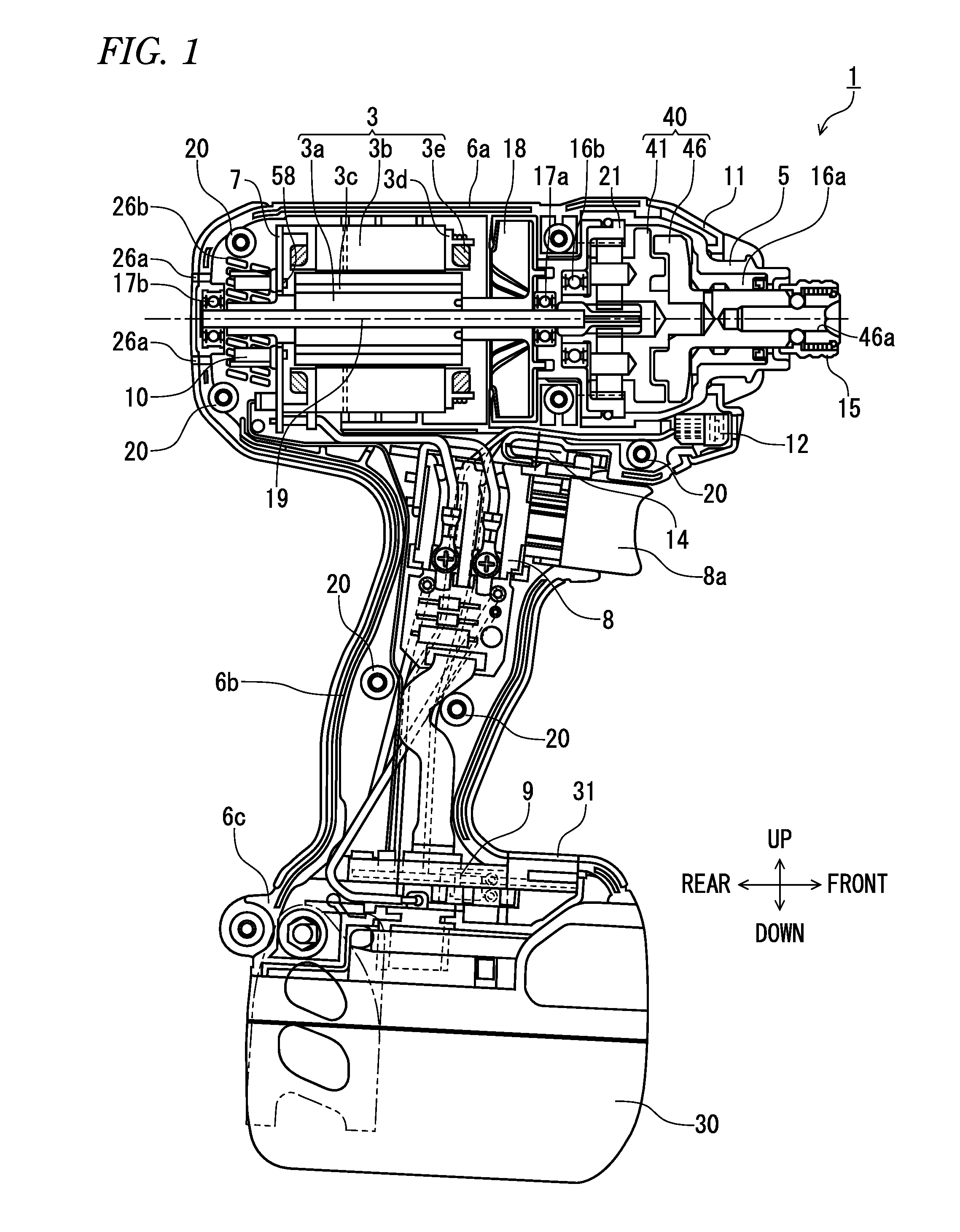

Impact driver

ActiveUS20050199404A1Simple structureImprove usabilityReciprocating drilling machinesPortable percussive toolsEngineeringMechanical engineering

An impact driver in which a drill mode can be selected without fail is provided. In a hammer case, a connecting sleeve is provided so as to be slidable back and forth. At the backward position, the connecting sleeve engages with only a first engaging tooth provided on the outer circumference of the hammer for rotating integrally. At the forward position, it engages with both the first engaging tooth of the hammer and a second engaging tooth of an anvil for rotating integrally with both of them, and thus a drill mode is obtained. Further, an operating bolt is provided in the hammer case to be inserted into a concave groove of the connecting sleeve through a guide groove formed in the hammer case. The operating bolt slides the connecting sleeve to the forward or backward position by its movement in the guide groove.

Owner:MAKITA CORP

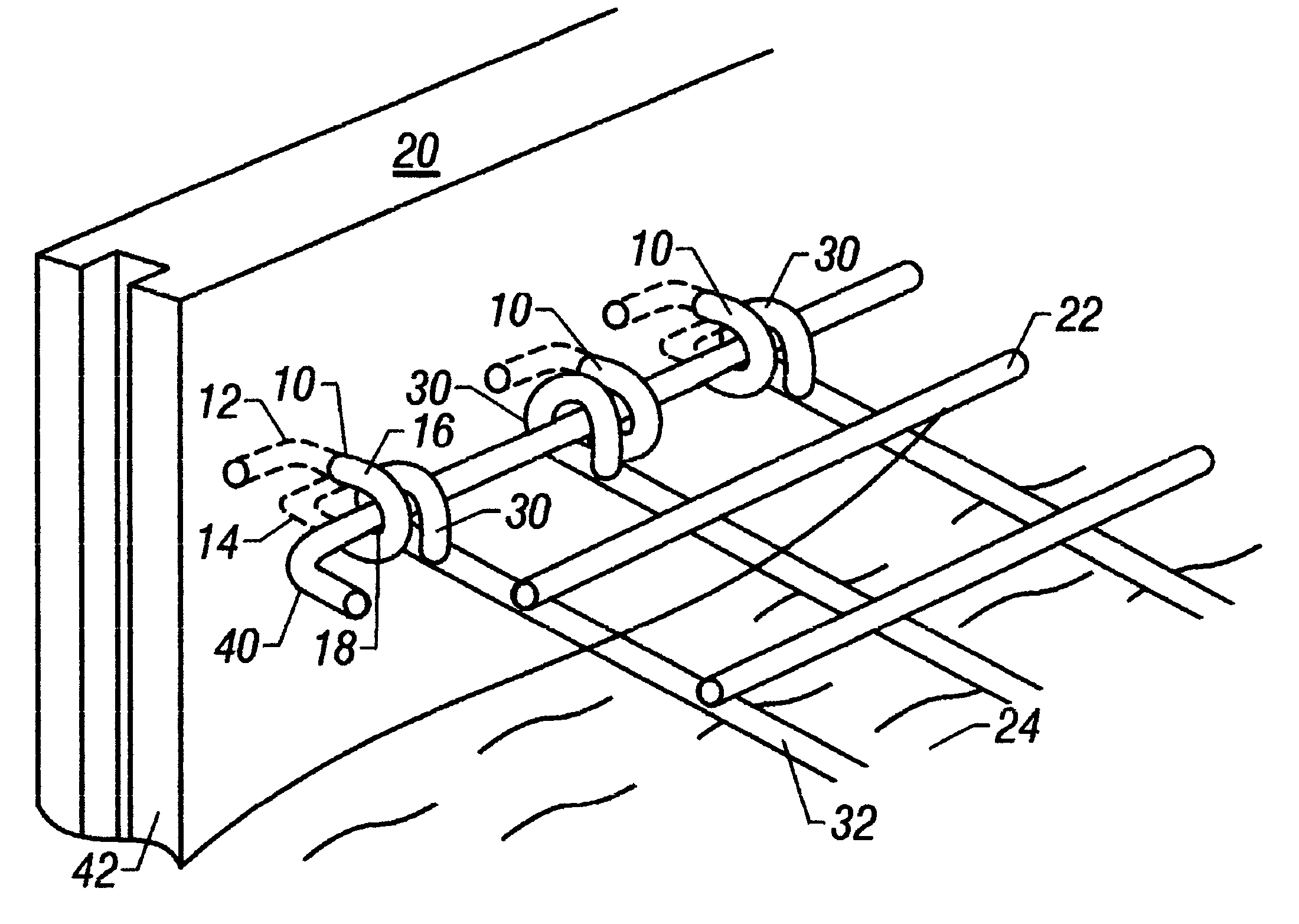

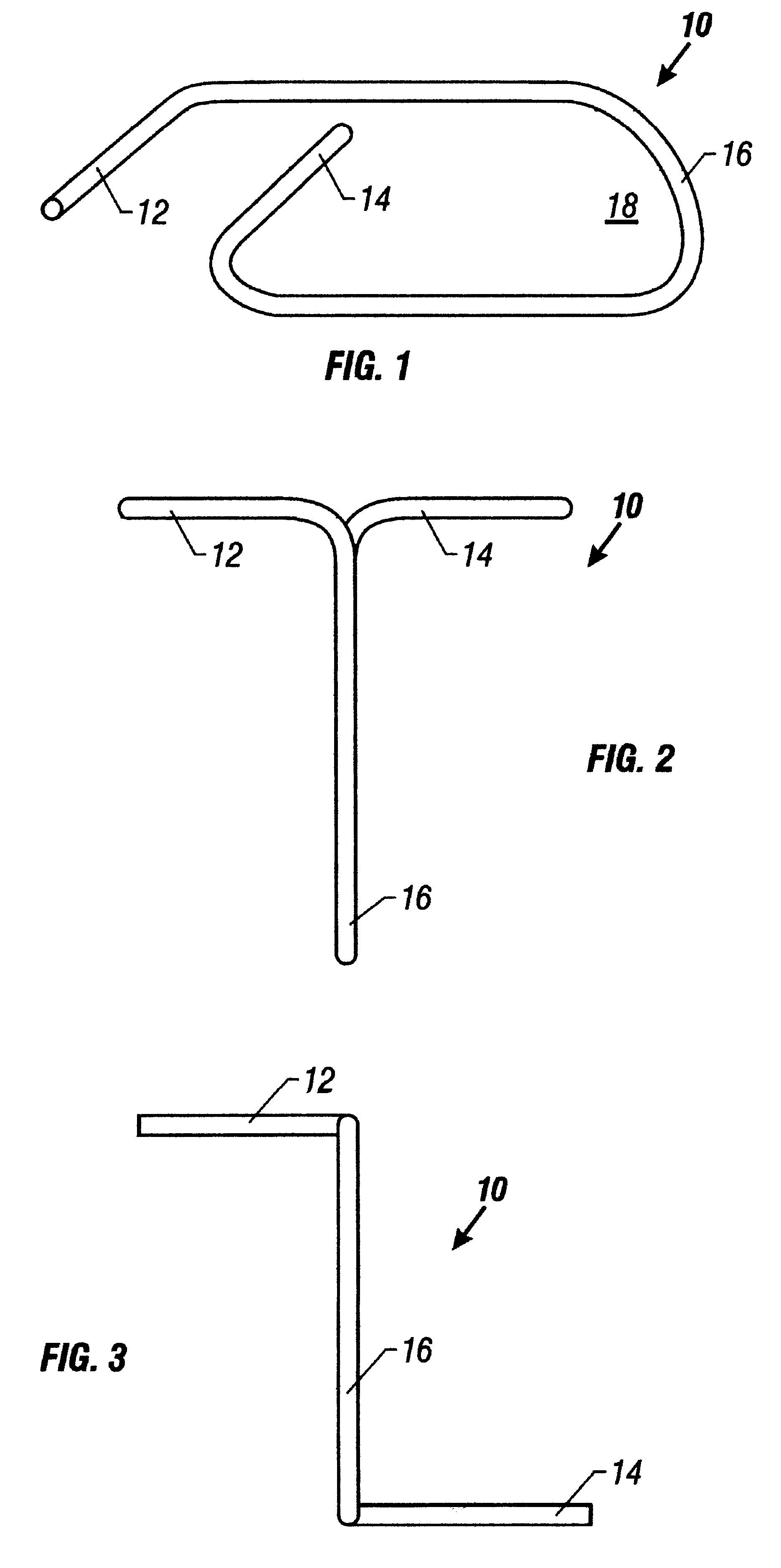

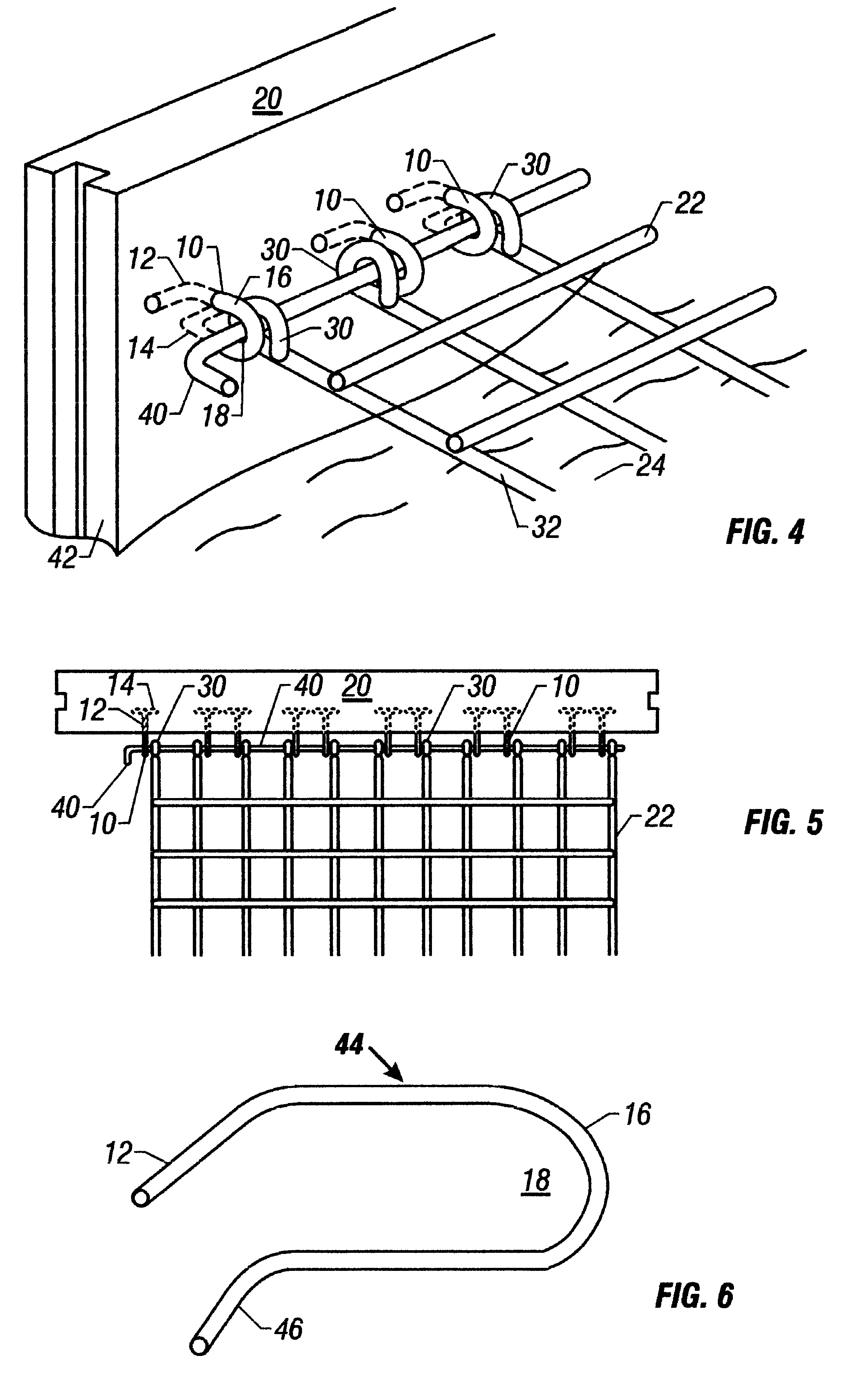

Mechanical interlocking means for retaining wall

An improved method and system for attaching a welded wire grid-work panel to a plurality of face panels of a retaining wall. The method first begins by providing a plurality of stackable face panels, each face panel having a plurality of anchor links fixed within a back portion of the face panels. Each of the anchor links forms a vertical loop extending outwardly generally perpendicular to the back portion of the face panels. Additionally, each anchor link includes two legs extending laterally from each anchor link within the face panel. Next, a first tier of the face panels is disposed at the bottom of the embankment being erected. Soil is then back-filled behind the first tier of panels to a level of the anchor links disposed within the first tier of face panels. A welded wire grid-work panel, which extends perpendicularly from the back portion of the face panels into a soil embankment, is positioned so that a plurality of wire loops at the edge of the grid-work panel aligns with the vertical loops. A connector rod is extended through the vertical loops of the anchor links and the wire loops of the grid-work panel. Next, additional soil is back-filled behind the first tier of face panels and over the anchor links, vertical loops, wire loops, and grid-work panel to a level at a top edge of the first tier of face panels. The method is repeated until the desired height of the embankment is attained.

Owner:SCR STI LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com