Prestress high intensity concrete square pile and its production method and moulding die

A high-strength concrete, prestressed technology, applied in manufacturing tools, ceramic forming machines, sheet pile walls, etc., can solve the problem that it is not suitable for making extra-large centrifugal concrete square piles, the centrifugal force cannot overcome it, and weakens the axial bearing capacity of the pile body. problems such as force, to achieve the effect of light weight, high pile utilization rate and high pile rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

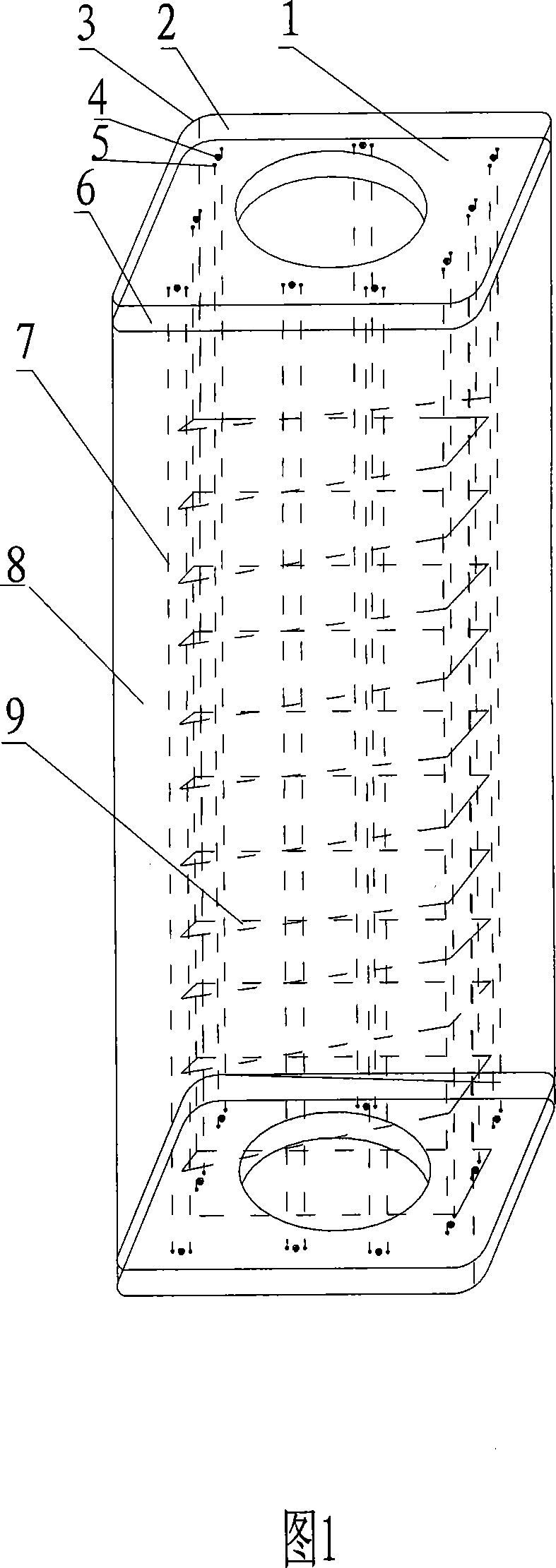

[0053] Embodiment 1 product as shown in Figure 1:

[0054] A kind of prestressed high-strength concrete square pile of present embodiment comprises, reinforcing cage, concrete; The two ends of square pile are provided with the metal end plate 1 (Fig. 5) that is connected with reinforcing cage, and two square end plates four sides establish welding groove 2 , the center is a round hole, and the tension hole 4 and the threading hole 5 on both sides of the tension hole are symmetrically arranged between the round hole and the four sides. The threading hole and the tension hole arranged symmetrically are symmetrical to the holes on the two opposite sides, and each tension hole 4. A threading hole 5 is respectively arranged equidistantly on both sides. The stirrup 9 of the reinforcement cage is welded on the main reinforcement continuously in a spiral shape; the shape of the concrete square pile and the end plate 1 is square, and the corners of its four sides are arc-shaped for str...

Embodiment 2

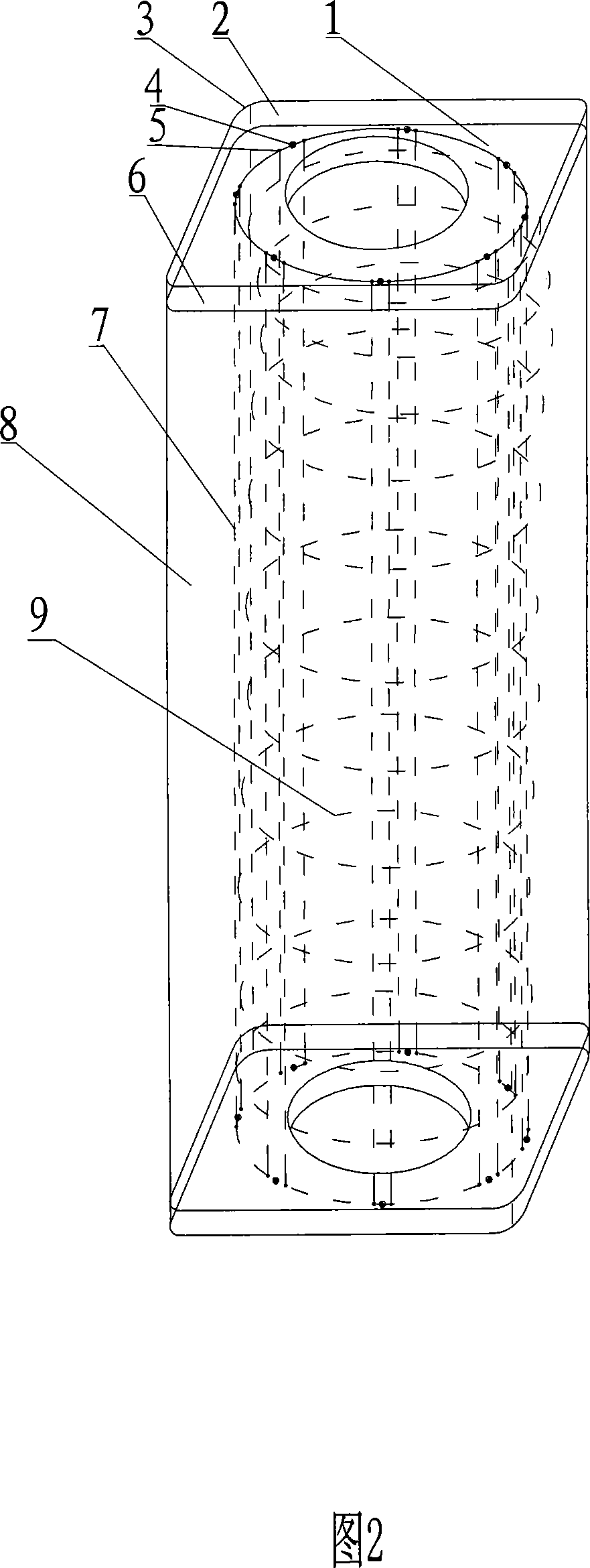

[0069] Embodiment 2 product as shown in Figure 2:

[0070] A kind of prestressed high-strength concrete square pile of present embodiment comprises, reinforcing cage, concrete; The two ends of square pile are provided with the metal end plate 1 (Fig. 6) that is connected with reinforcing cage, and two square end plates four sides establish welding groove 2 , the center is a round hole, and the tension hole 4 and the threading hole 5 on both sides of the tension hole are symmetrically arranged between the round hole and the four sides. The threading hole and the tension hole arranged symmetrically are symmetrical to the holes on the two opposite sides, and each tension hole 4. A threading hole 5 is respectively arranged equidistantly on both sides. The stirrup 9 of the reinforcement cage is welded on the main reinforcement continuously in a spiral shape; the shape of the concrete square pile and the end plate 1 is square, and the corners of its four sides are arc-shaped for str...

Embodiment 3

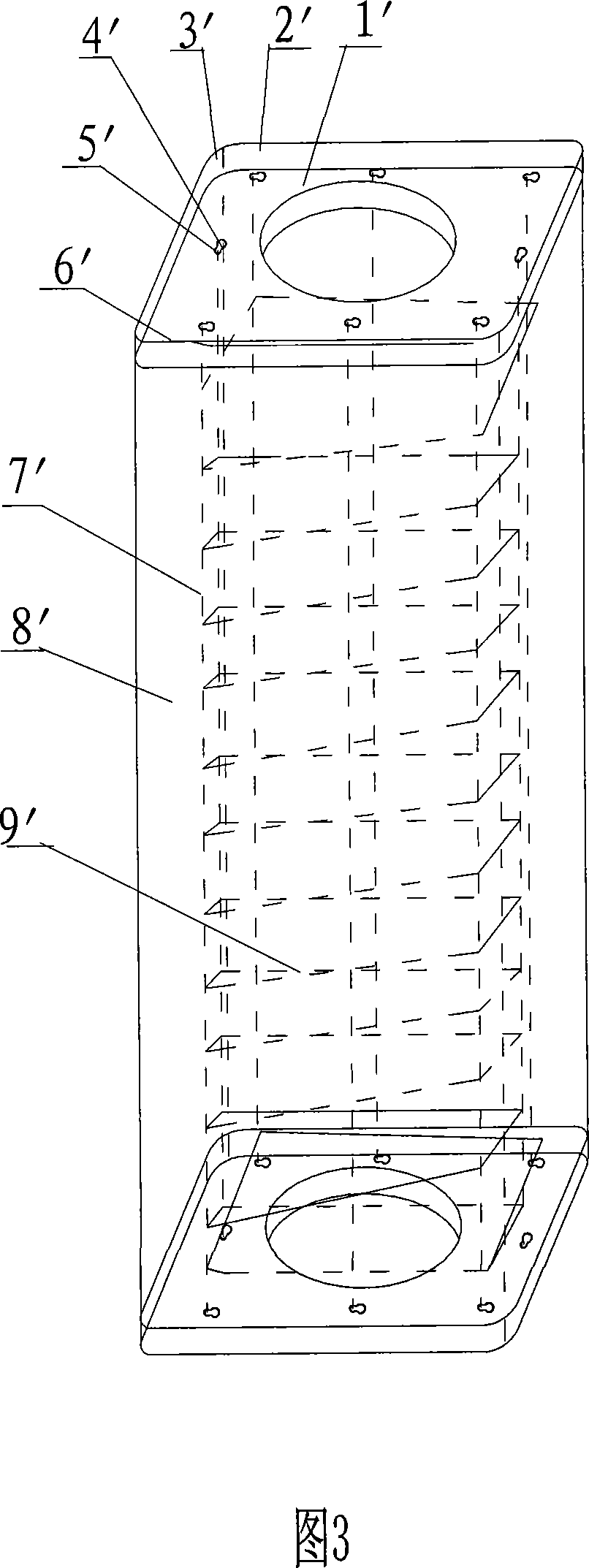

[0086] Embodiment 3 is to make a large-scale concrete square pile (the side length of the square pile is more than 450MM) and the label should be checked

[0087] The product of embodiment 3 is as shown in Figure 3: a kind of prestressed high-strength concrete square pile, comprises, reinforcement cage, concrete; It is characterized in that, the two ends of square pile are provided with the metal end plate 1 ' that is connected with reinforcement cage, two The four sides of the square end plate are provided with welding grooves 2', and the center is a round hole. There are threading holes 5' and tension holes 4' symmetrically between the round hole and the four sides. The symmetrical threading holes and tension holes are on the two opposite sides. The holes are symmetrical, and each tension hole 4' is connected to the threading hole 5' respectively.

[0088] The stirrup 9' of the reinforcement cage is welded to the main reinforcement 7' continuously in a spiral shape; the shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com