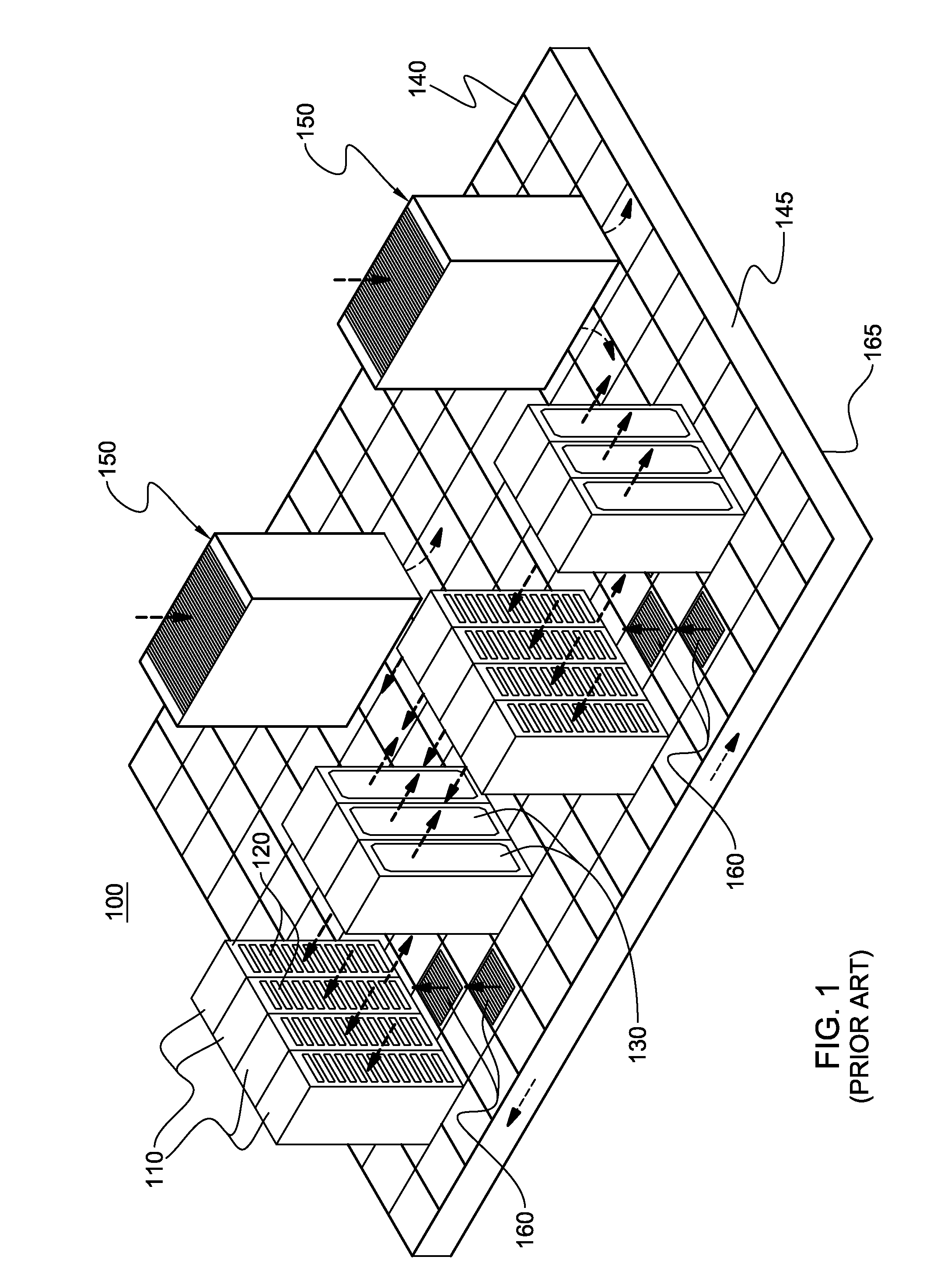

Patents

Literature

2231 results about "Stress relief" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

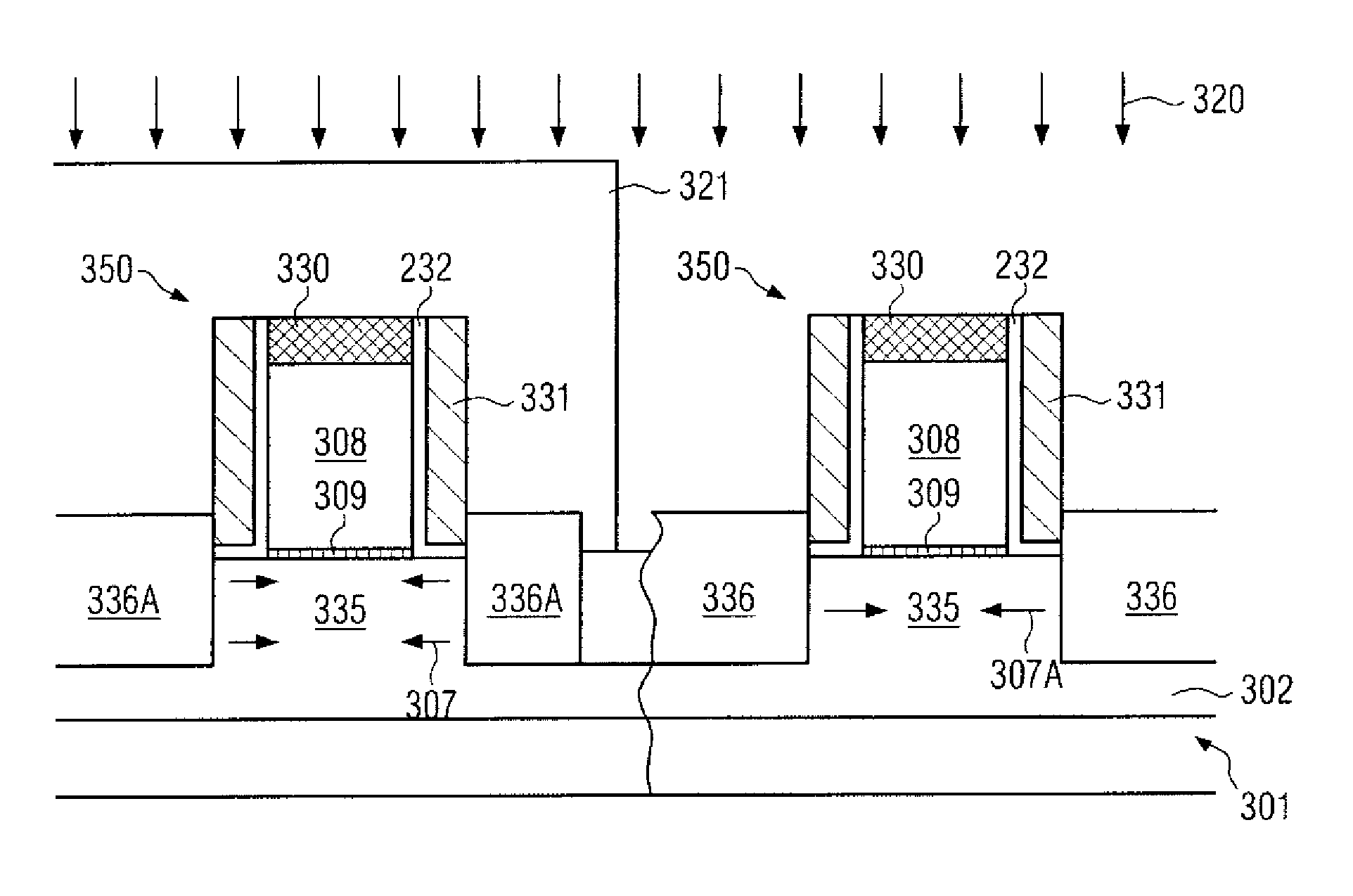

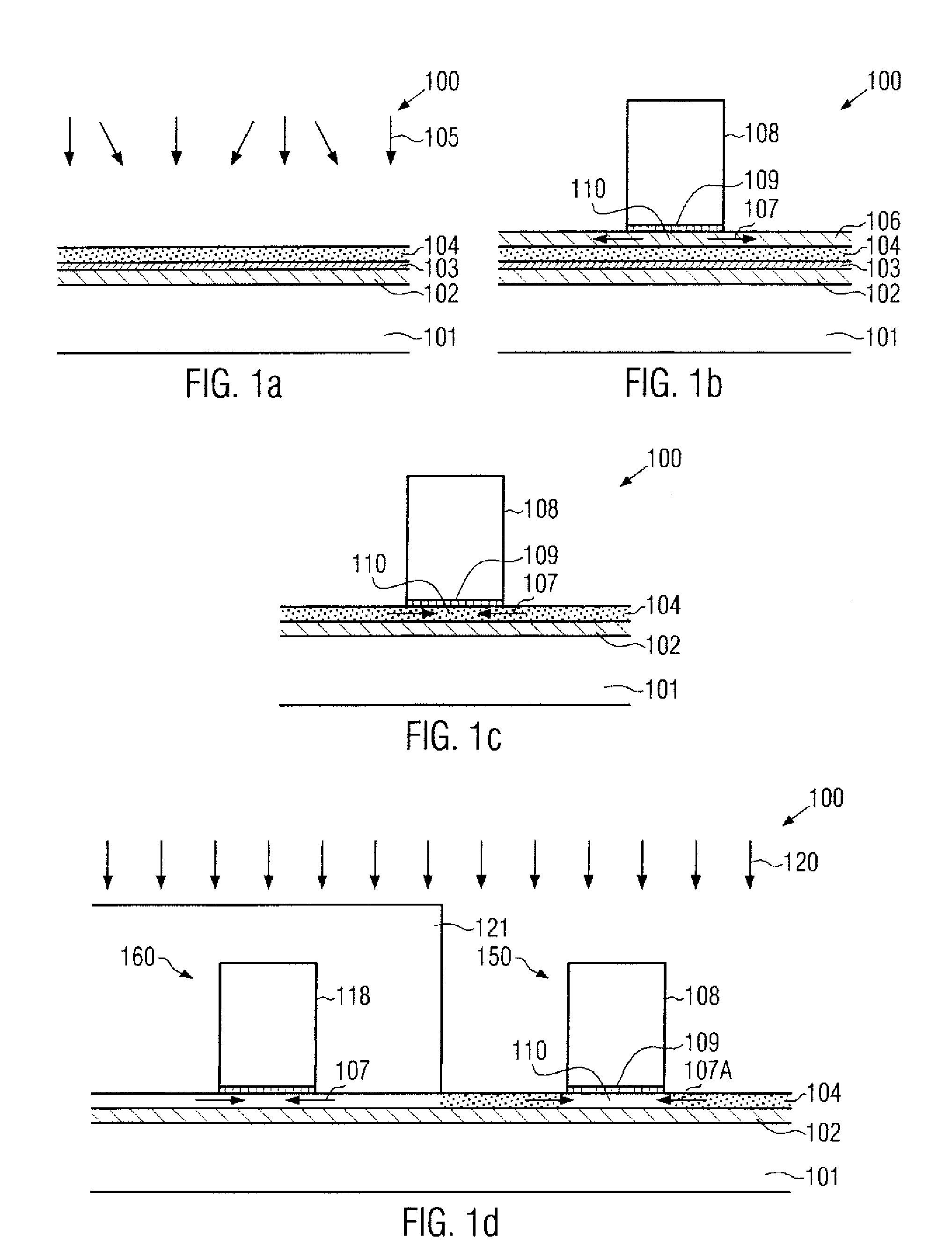

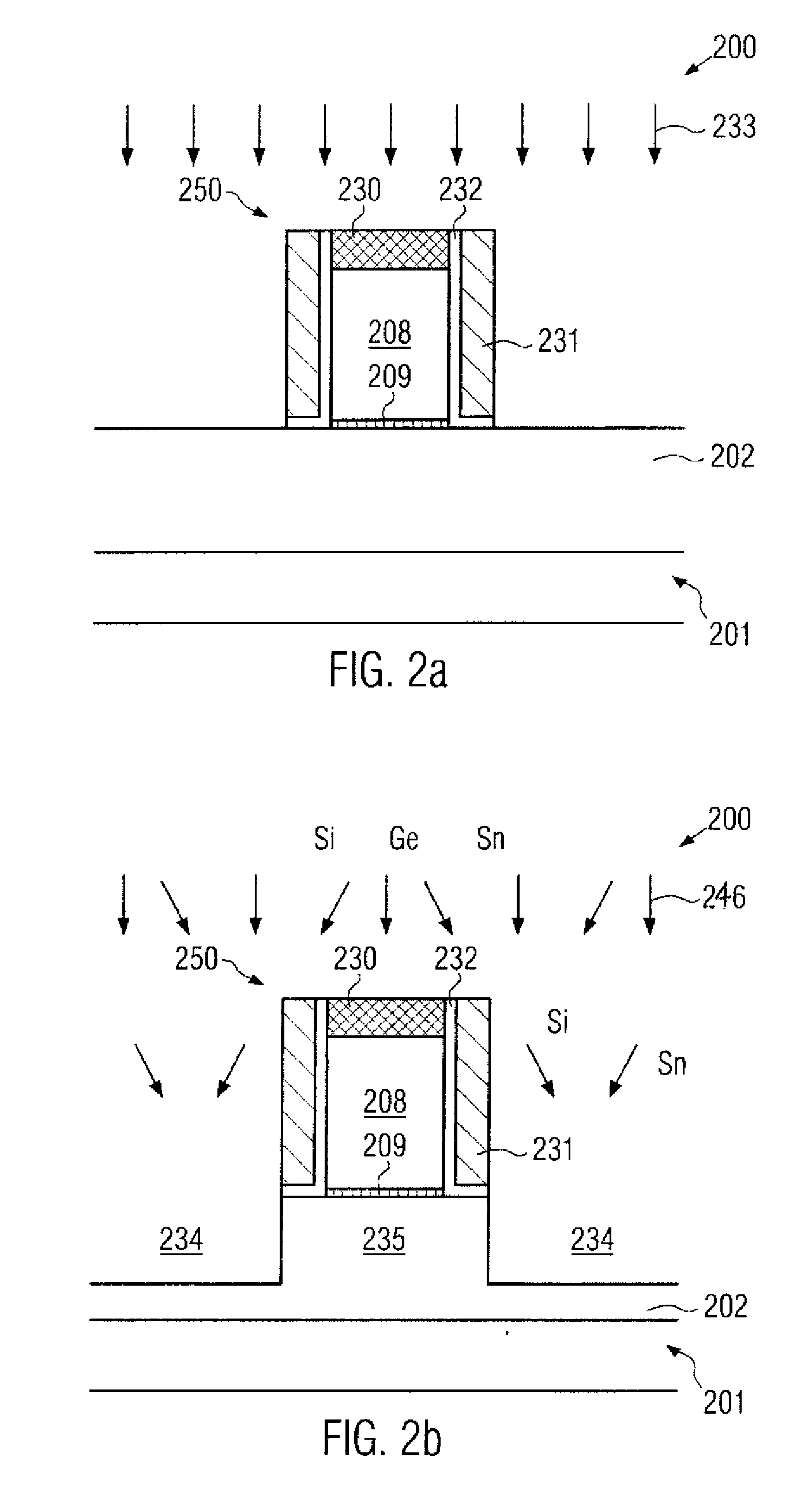

Technique for strain engineering in si-based transistors by using embedded semiconductor layers including atoms with high covalent radius

By incorporating an atomic species of increased covalent radius, which may at least partially substitute germanium, a highly efficient strain mechanism may be provided, in which the risk of stress relief due to germanium conglomeration and lattice defects may be reduced. The atomic species of increased radius, such as tin, may be readily incorporated by epitaxial growth techniques on the basis of tin hydride.

Owner:GLOBALFOUNDRIES INC

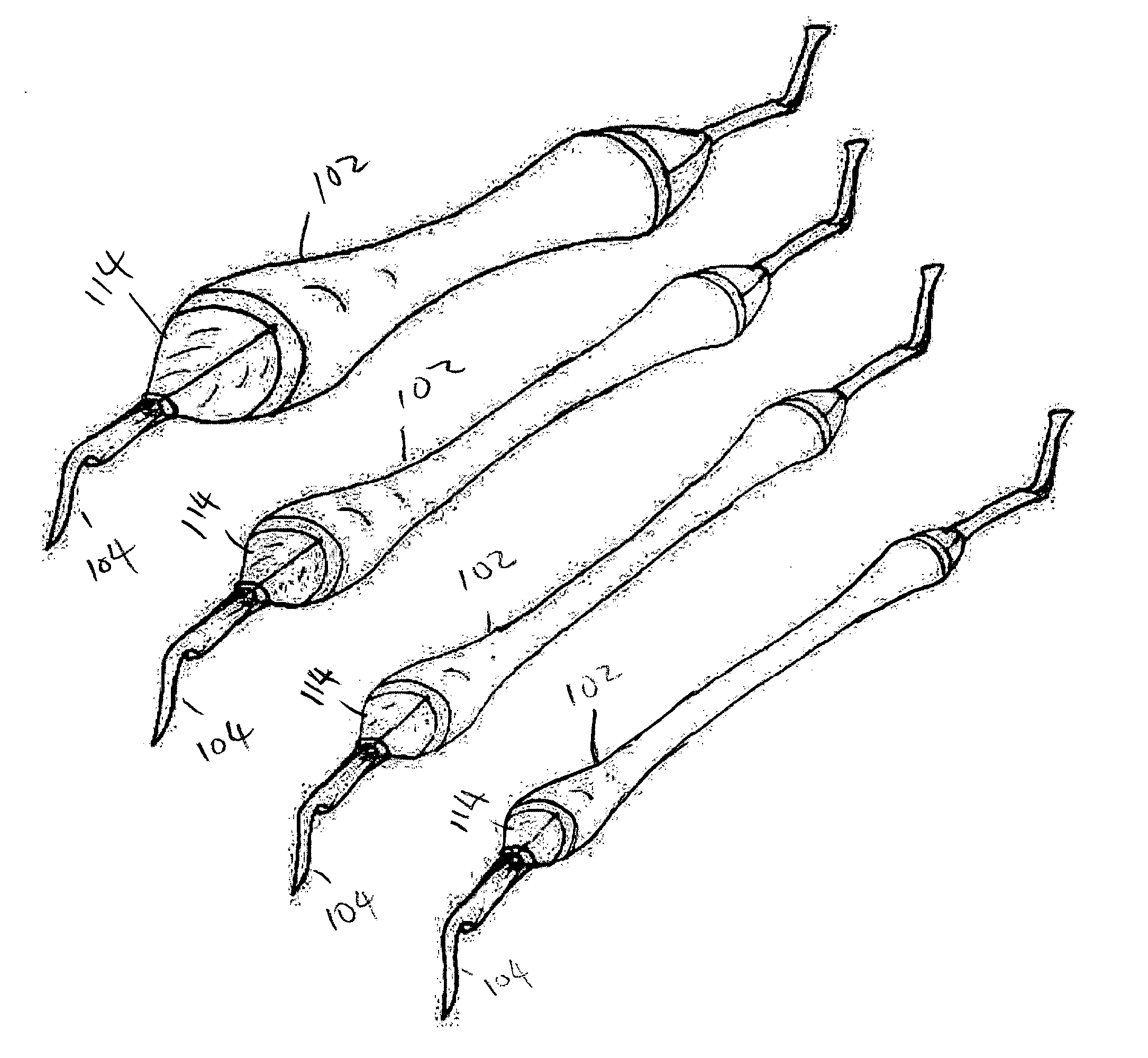

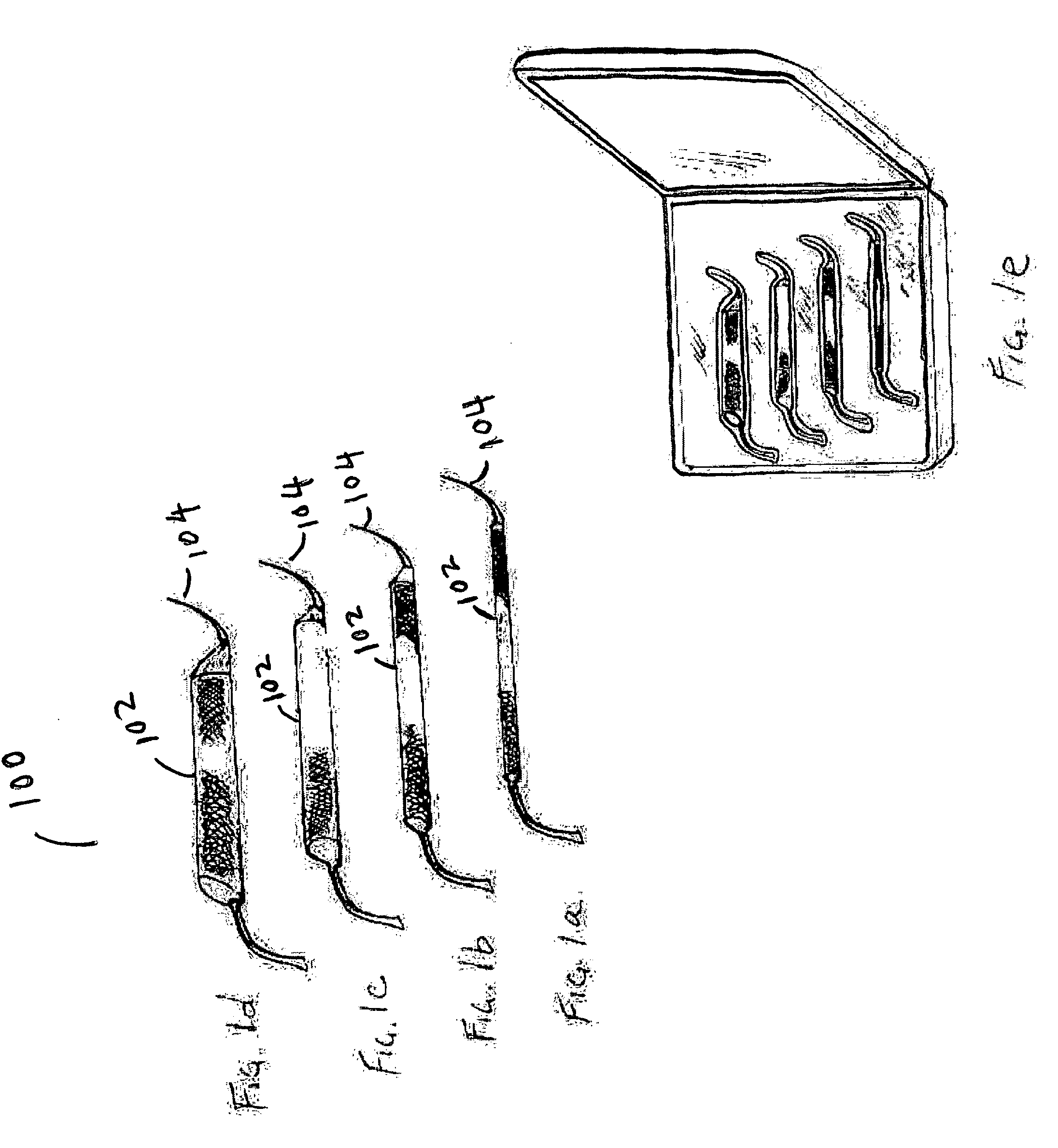

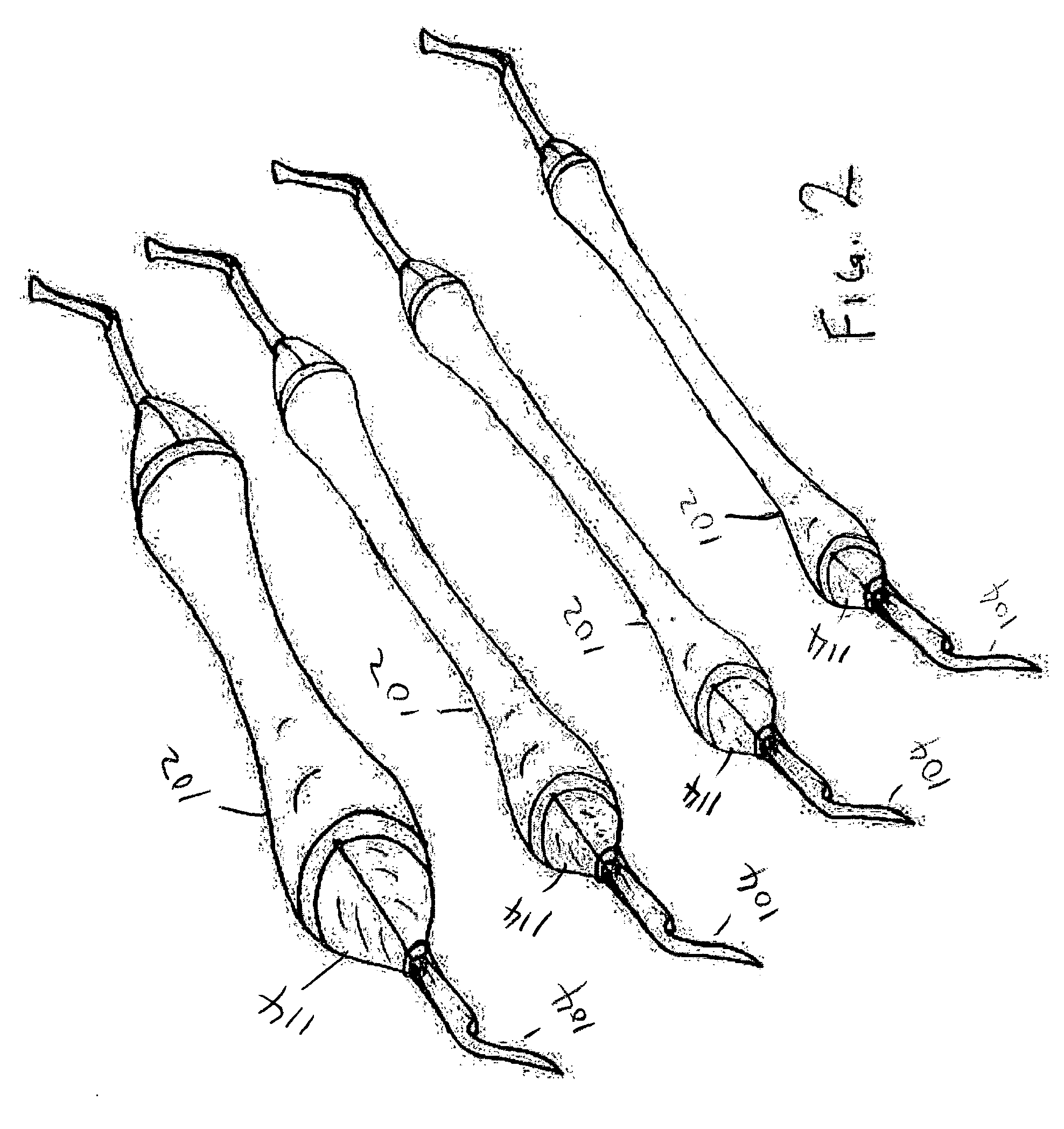

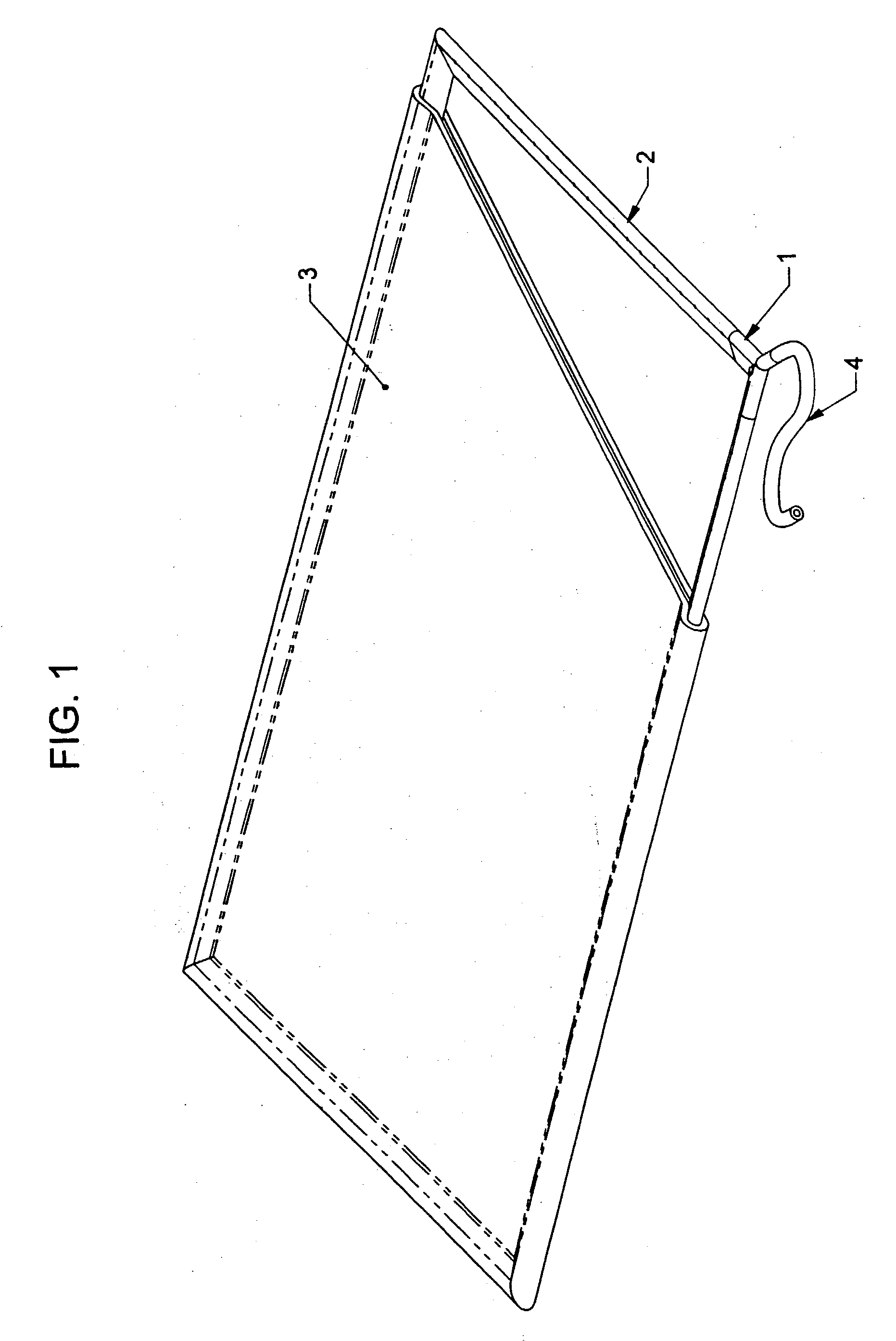

Dental instruments with stress relief

InactiveUS20060063130A1Prevent rotationRelieve pressureDental toolsTeeth cappingDental instrumentsStress relief

The present invention relates to a unique solution for relieving repetitive stress to dental professionals during the course of a day and is directed to sets of identical instruments, having handles made with varying diameters for grasping, designed to be used interchangeably throughout the day, thus cutting down on the repetitive grasping action through the change of grasp. Therefore, even if a dental professional uses the same type of instrument throughout the day, the hands, wrists and elbows can experience varying rather than repetitive action because the positioning of the hands, wrists and elbows are interchanging throughout the day. The dental instrument may also be ergonomically designed. Additionally, the instrument may also have a vibratory module. Further, a rotator may also be implemented.

Owner:DISCUS DENTAL LLC

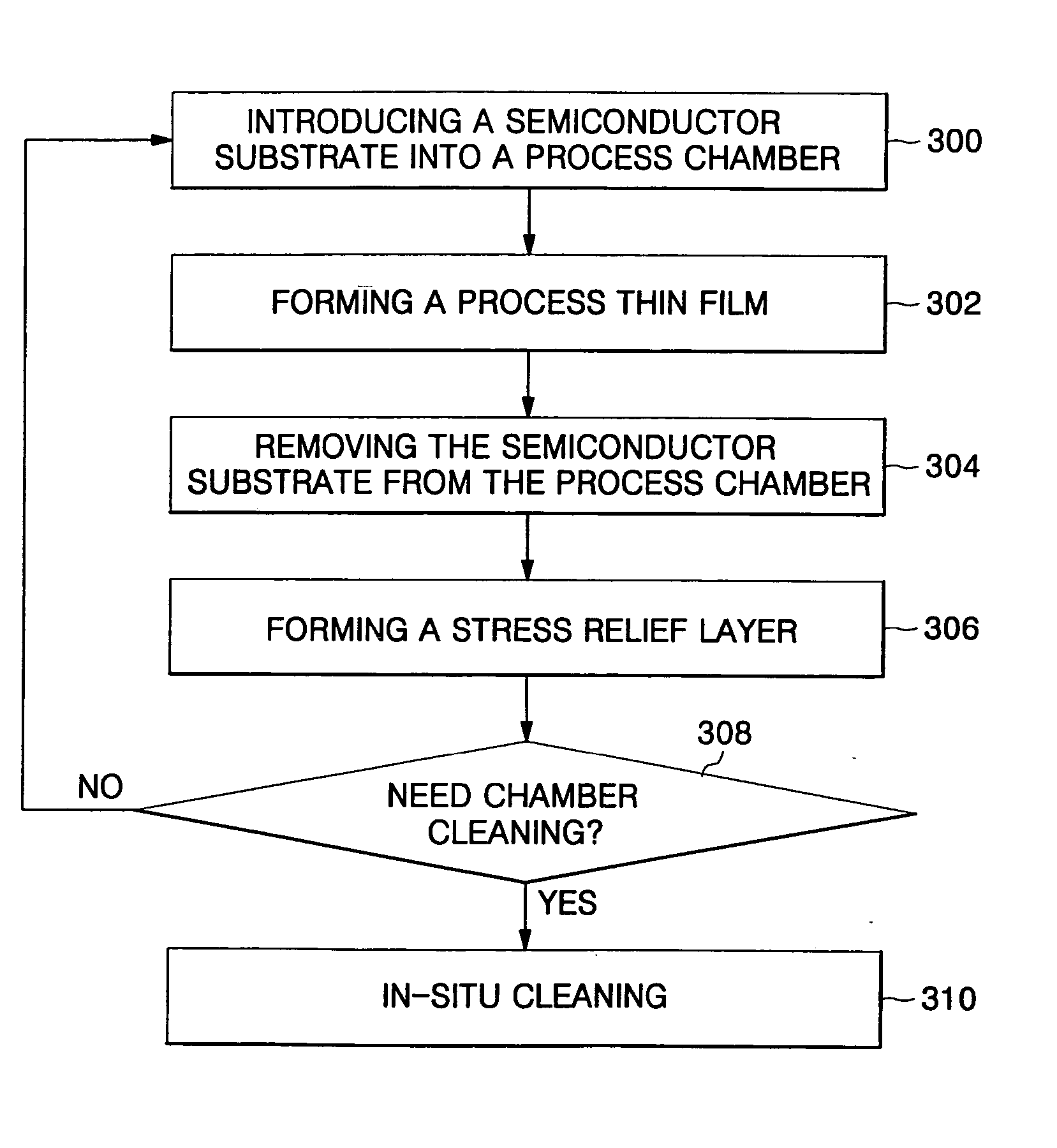

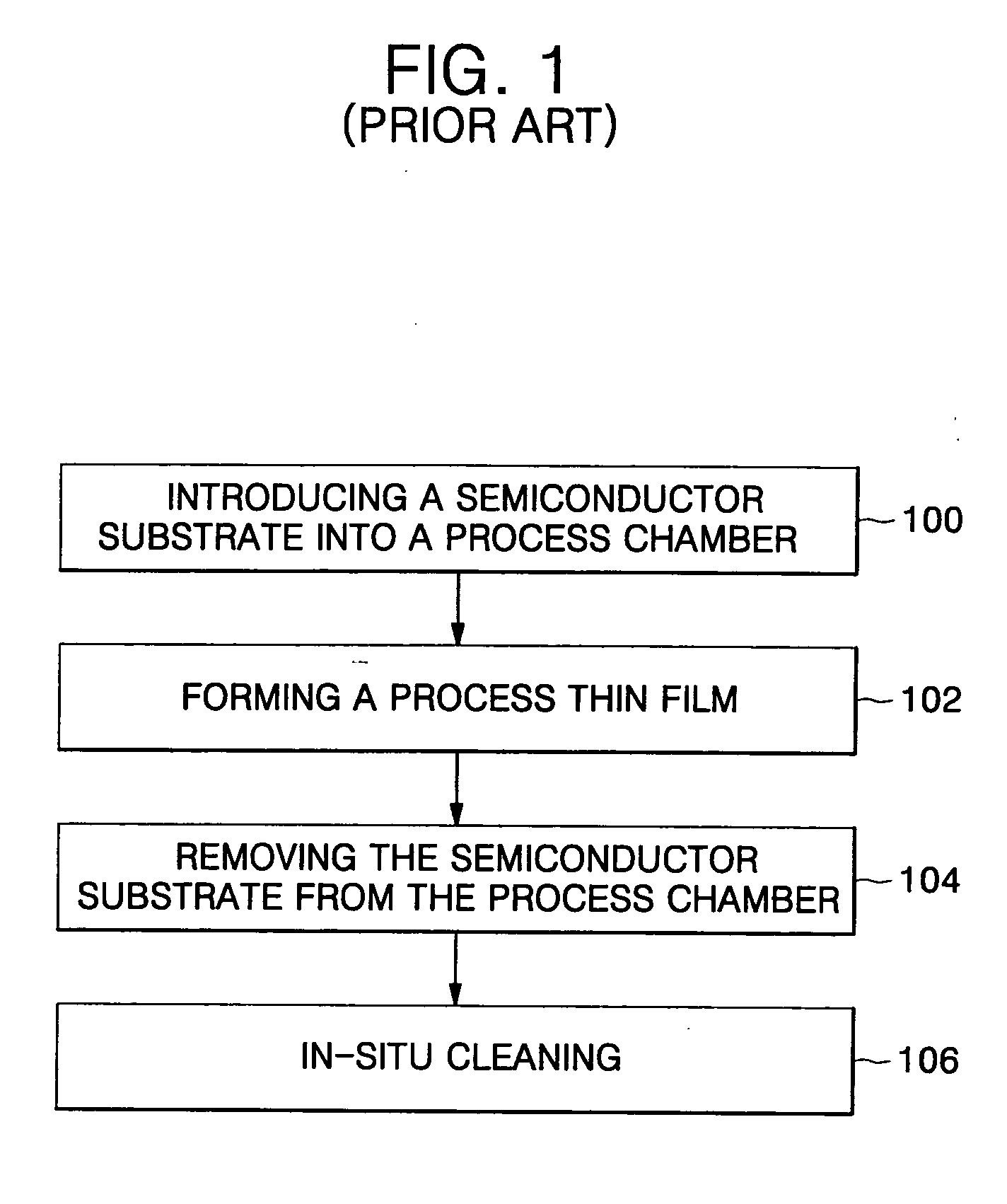

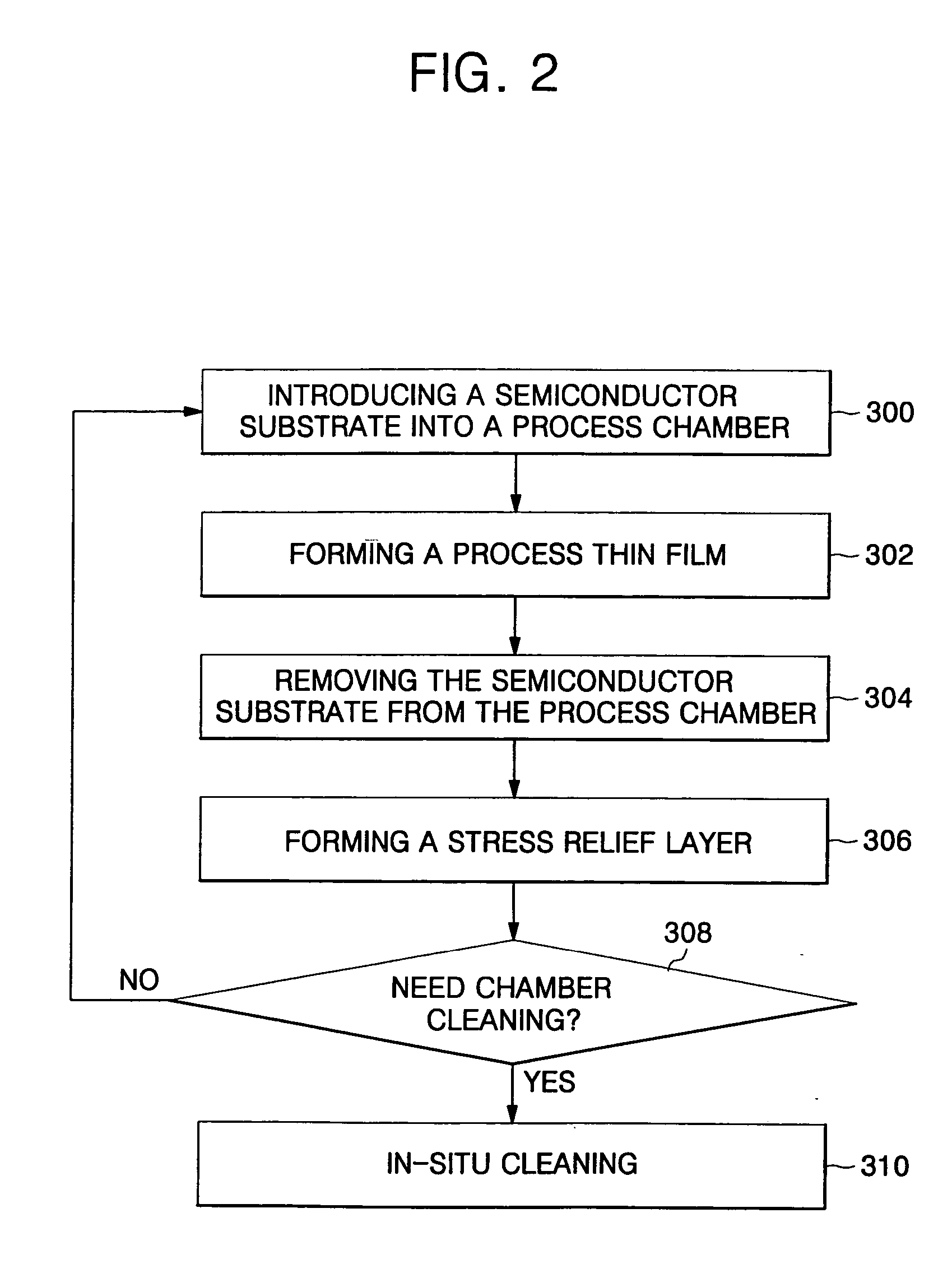

Method of forming thin film for improved productivity

ActiveUS20050130427A1Extended maintenance periodReduce processing timeElectrostatic cleaningSemiconductor/solid-state device manufacturingProduction rateStress relief

There is provided a method of forming a thin film for providing improved fabrication productivity. The method includes introducing a semiconductor substrate into a process chamber. A process thin film is formed on the semiconductor substrate, in which a chamber coating layer is formed on inner walls of the process chamber while the process thin film is formed. The semiconductor substrate is removed from the process chamber. A stress relief layer is formed on the chamber coating layer. After all of the above operations are repeatedly performed at least one time, an in-situ cleaning is performed on the chamber coating layer and the stress relief layer, which are alternately formed in stack on the inner walls of the process chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

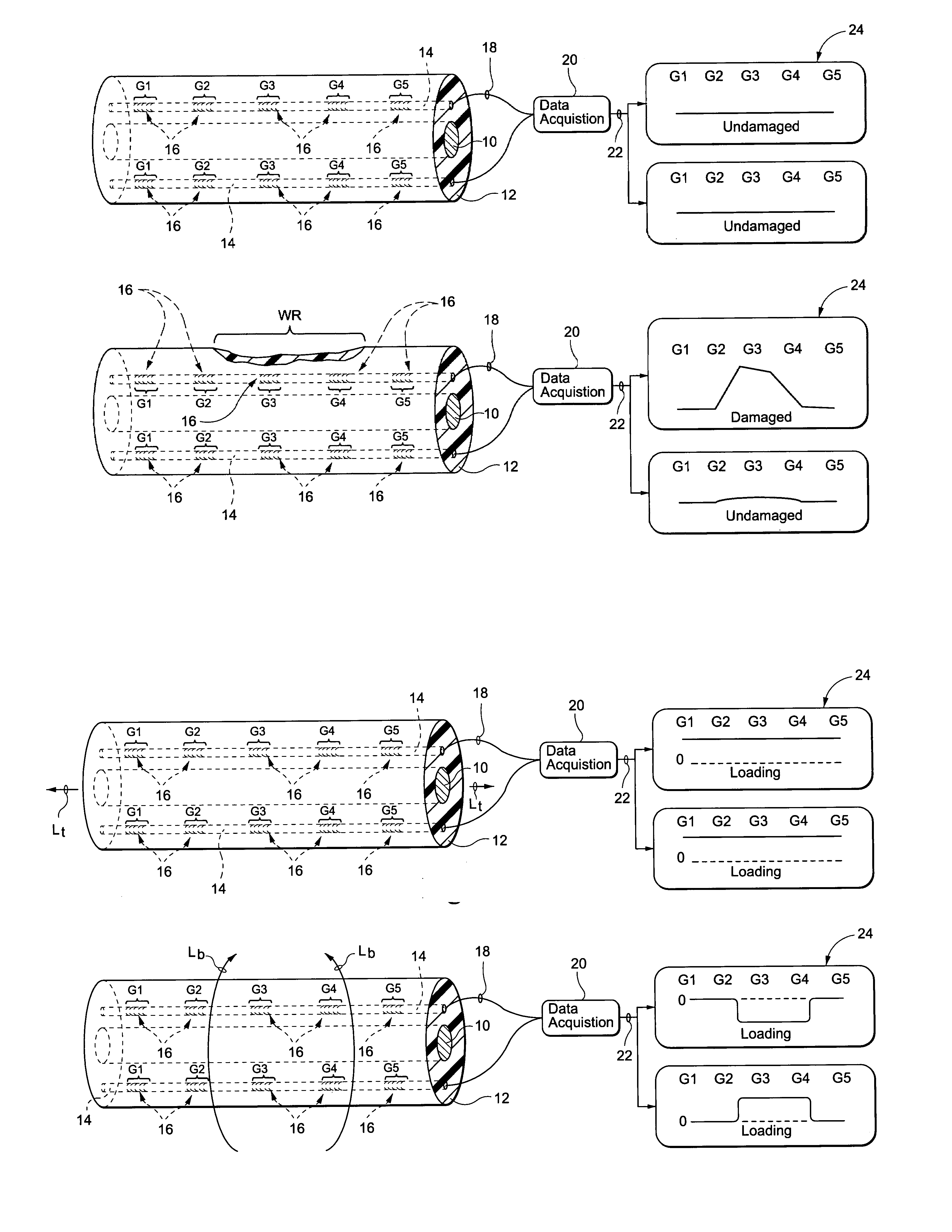

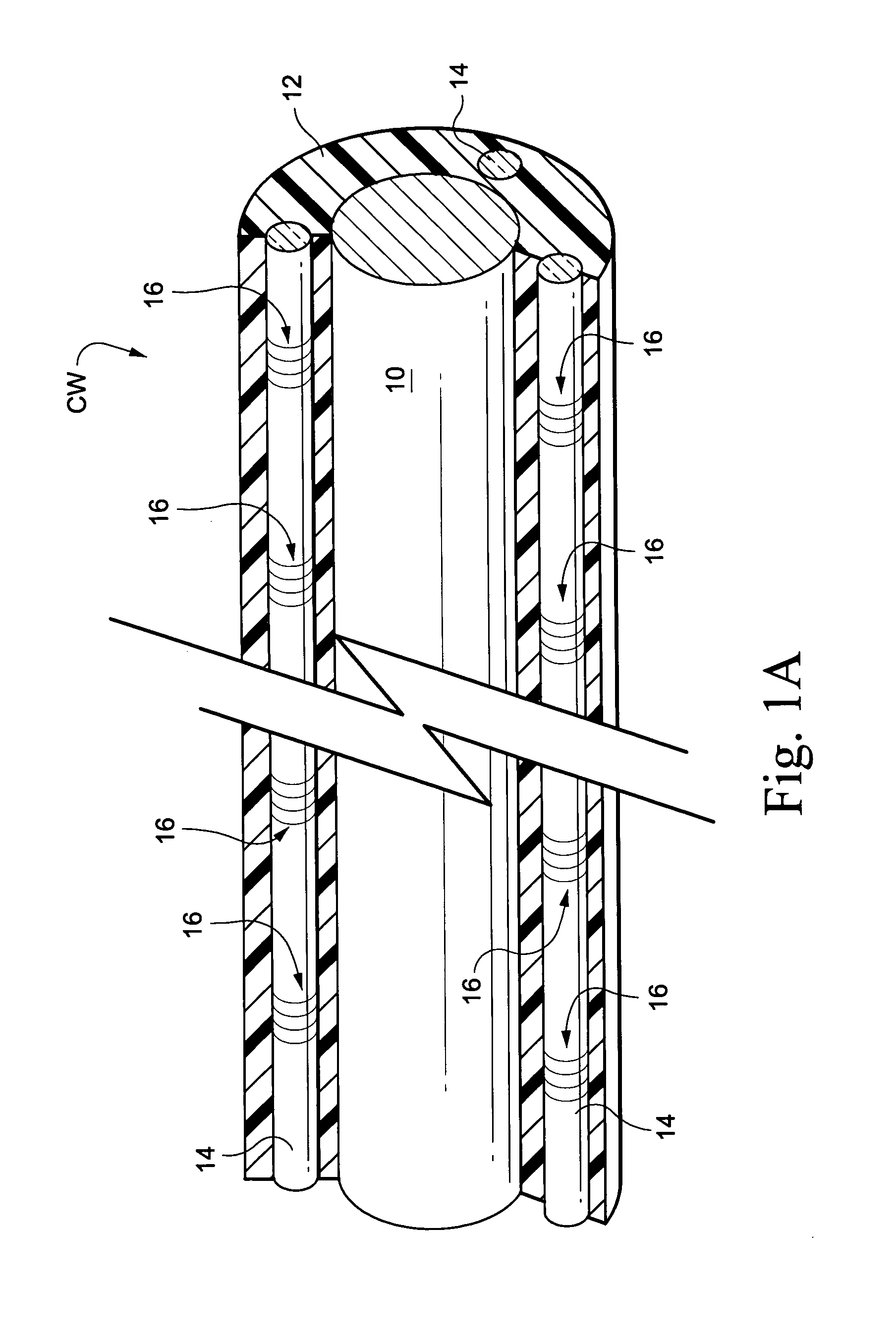

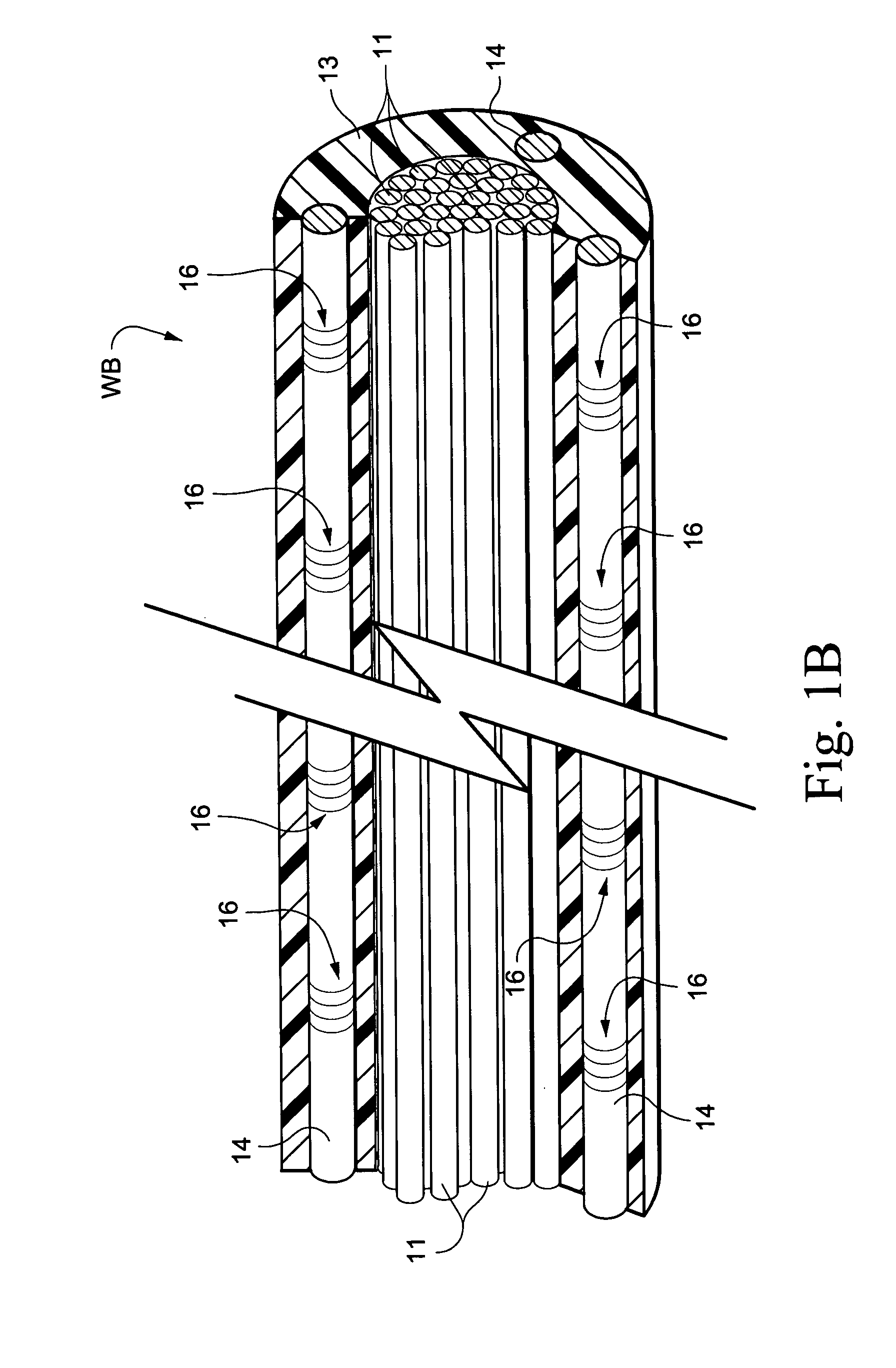

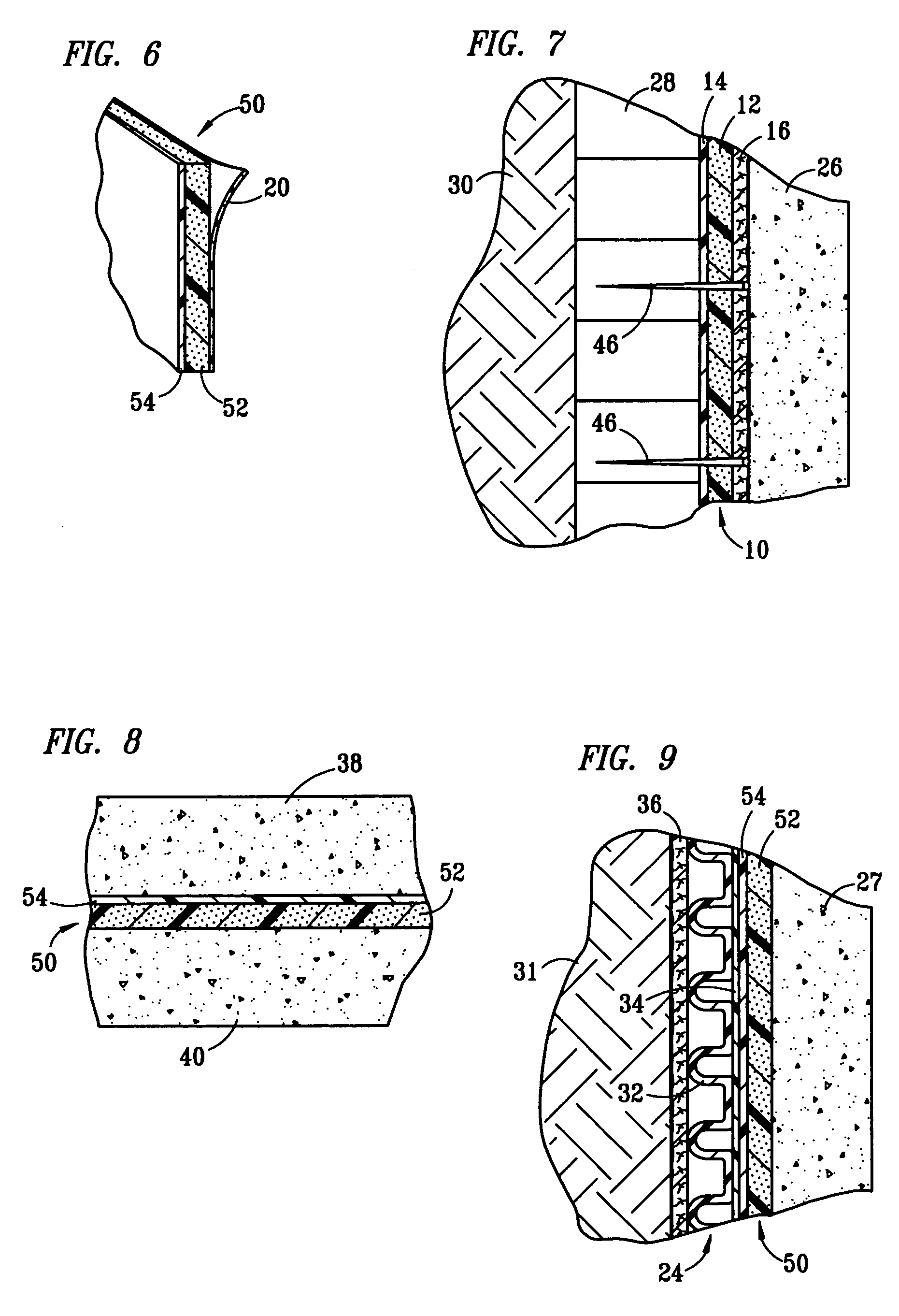

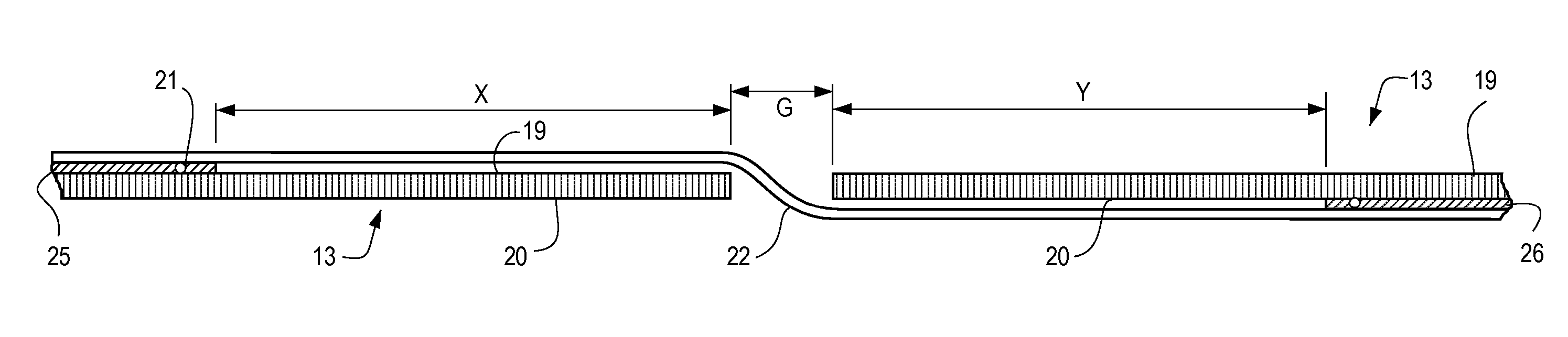

Composite structures, such as coated wiring assemblies, having integral fiber optic-based condition detectors and systems which employ the same

InactiveUS7154081B1Weakening rangeReducing compressive strainControlRadiation pyrometryElectrical conductorGrating

Integral fiber optic-based condition sensors detect conditions of a composite structure, e.g., a coated wire assembly so as to detect damage or conditions that may damage the same. Preferably, at least one optical fiber sensor having a plurality of Bragg gratings written into the fiber at spaced-apart locations along its axial length is integrated into the electrical insulator coating of a wire, wire bundle or wiring harness. The fiber optic sensor may thus be employed to measure the environmental loads on the electrical wiring including stresses from bending, axial loading, pinch points, high temperature excursions and chemical damage. The system is capable of detecting and locating transient conditions that might cause damage to a wiring system or permanent changes in state associated with damage events. The residual stress in the electrical insulator coating of a wire, wire bundle, or wiring harness are used to monitor the evolution of damage by wear or chaffing processes. Detected stress relief on one or more Bragg gratings will thus be indicative of damage to the insulator coating on the conductor. As such, the magnitude of such stress relief may be detected and used as an alert that the wire insulation is damaged to an unsafe extent.

Owner:LUNA INNOVATIONS

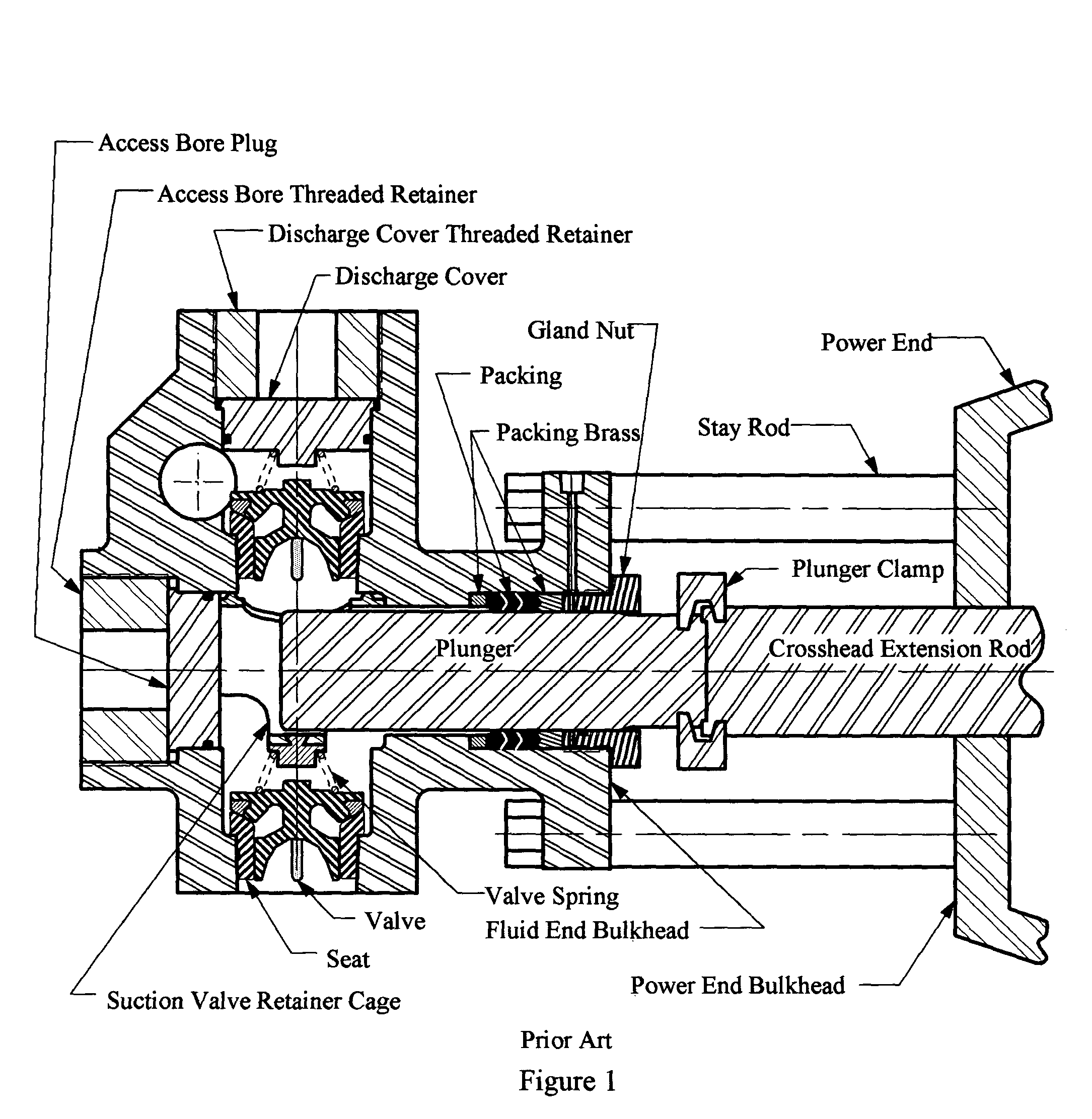

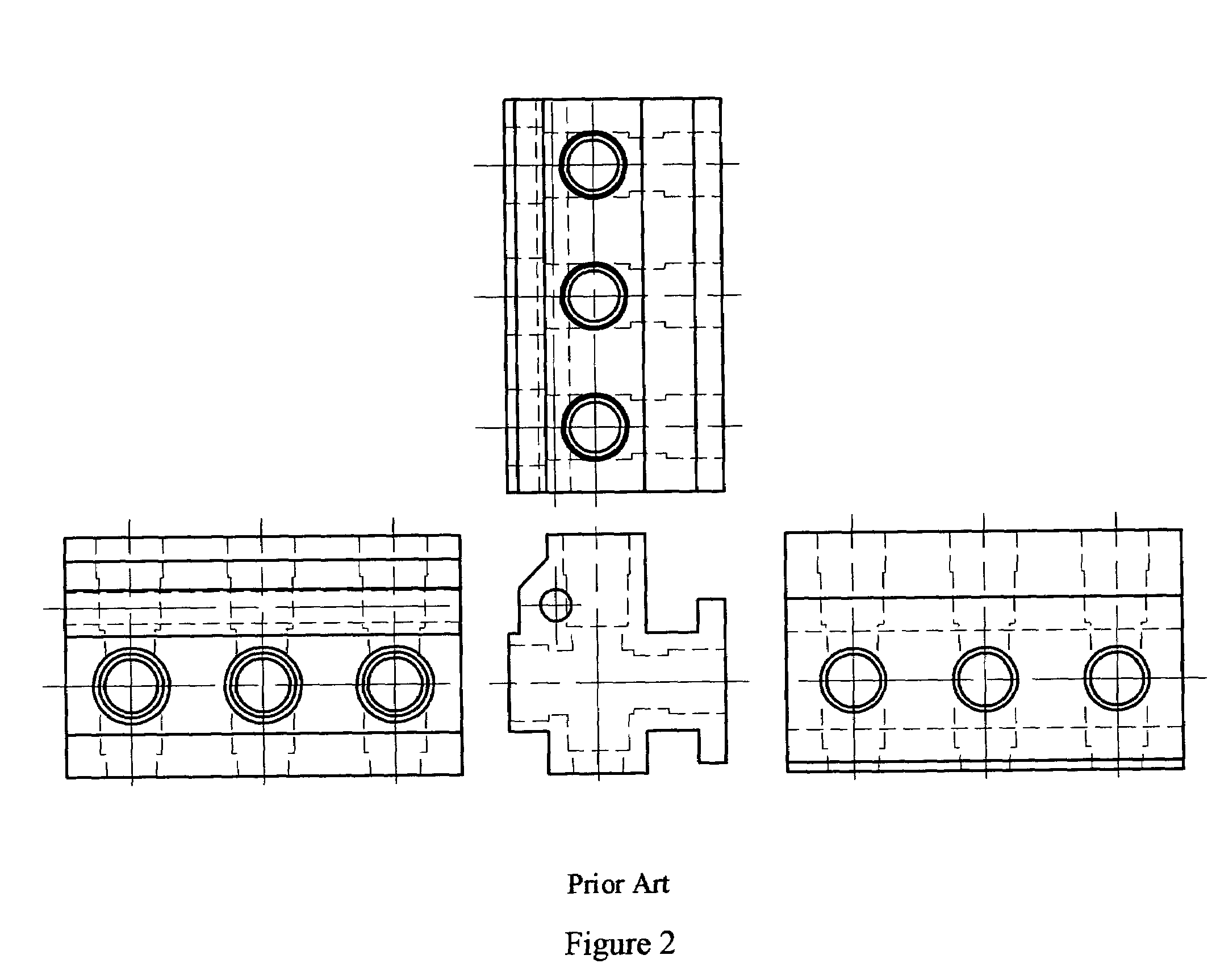

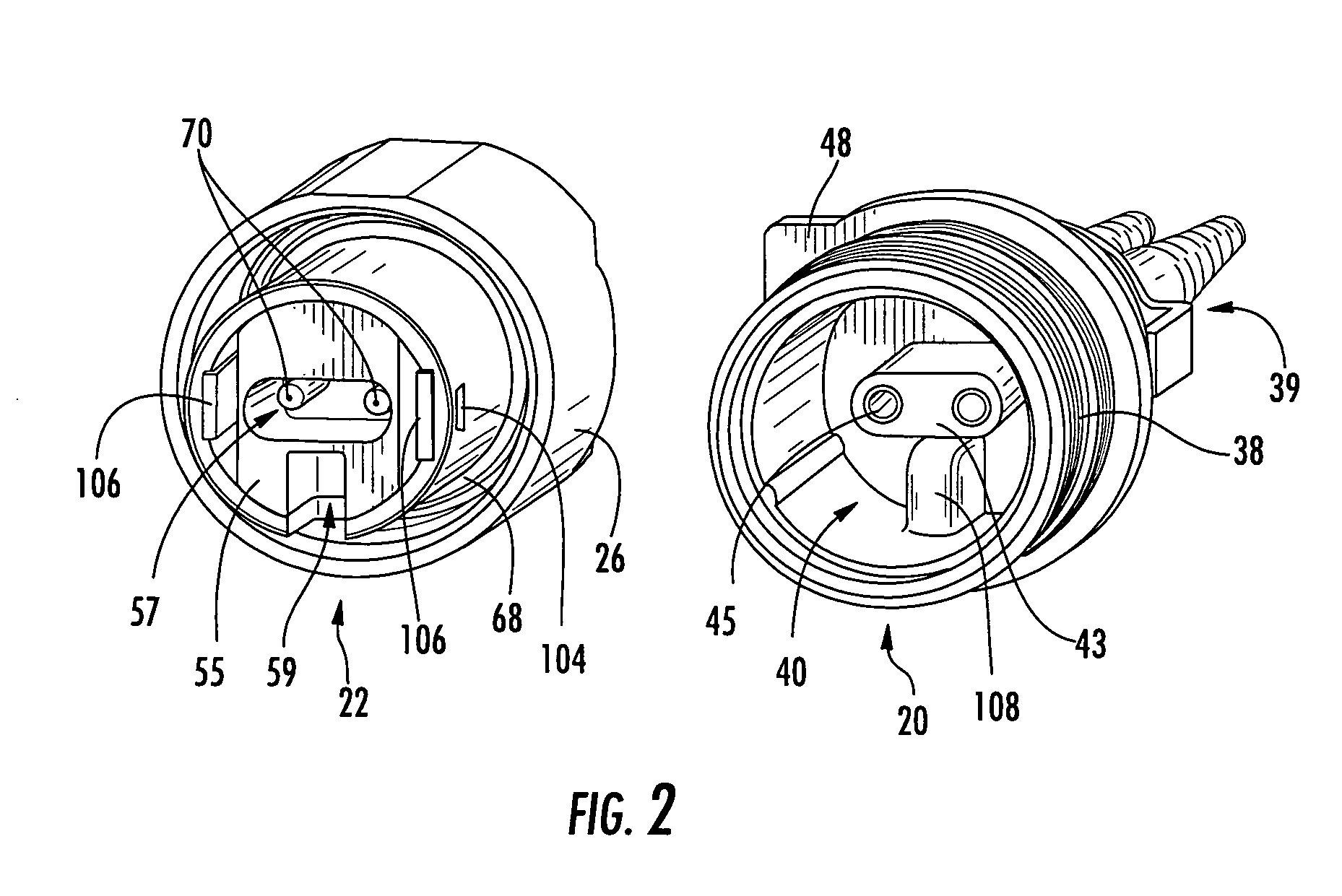

Valve guide and spring retainer assemblies

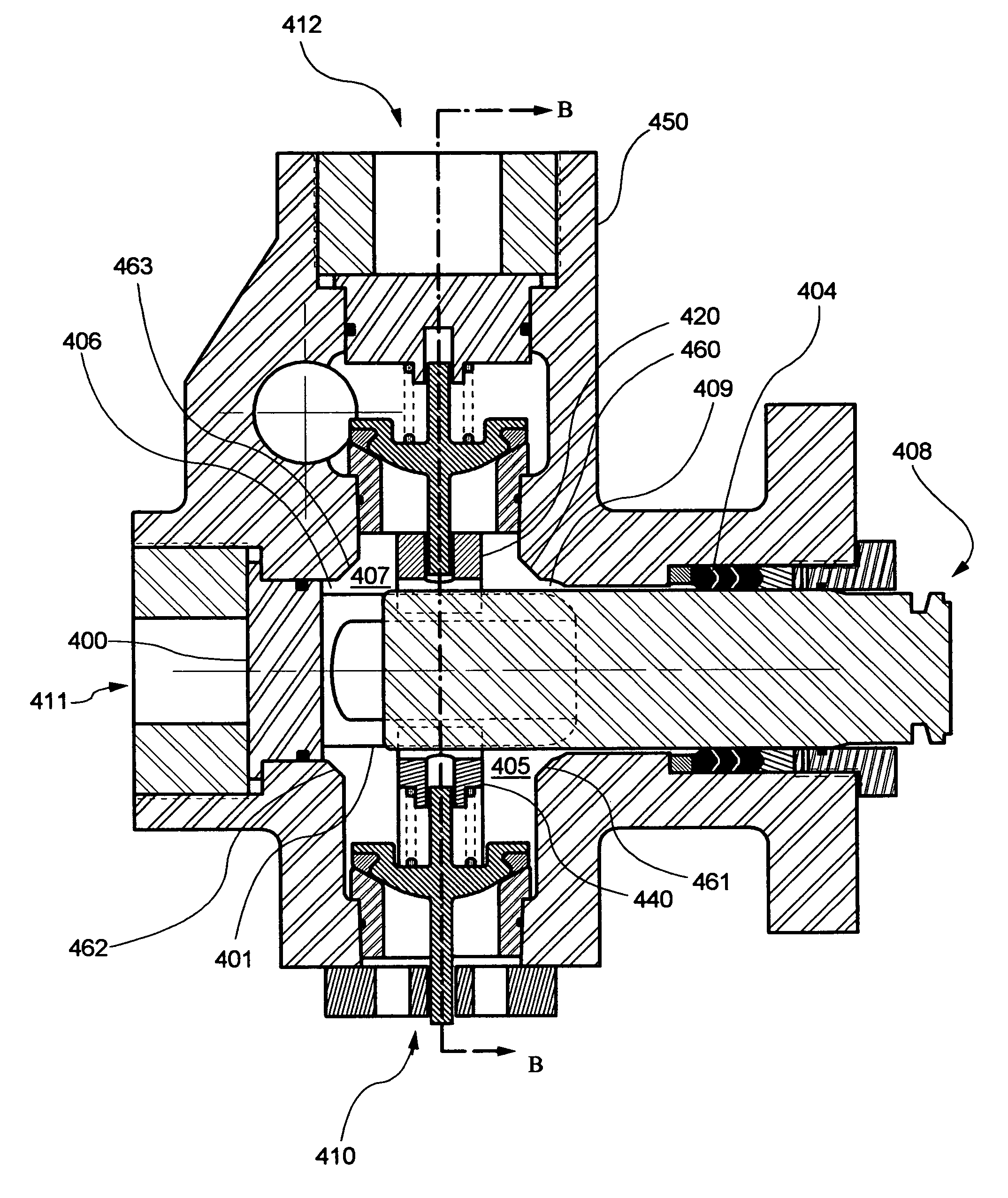

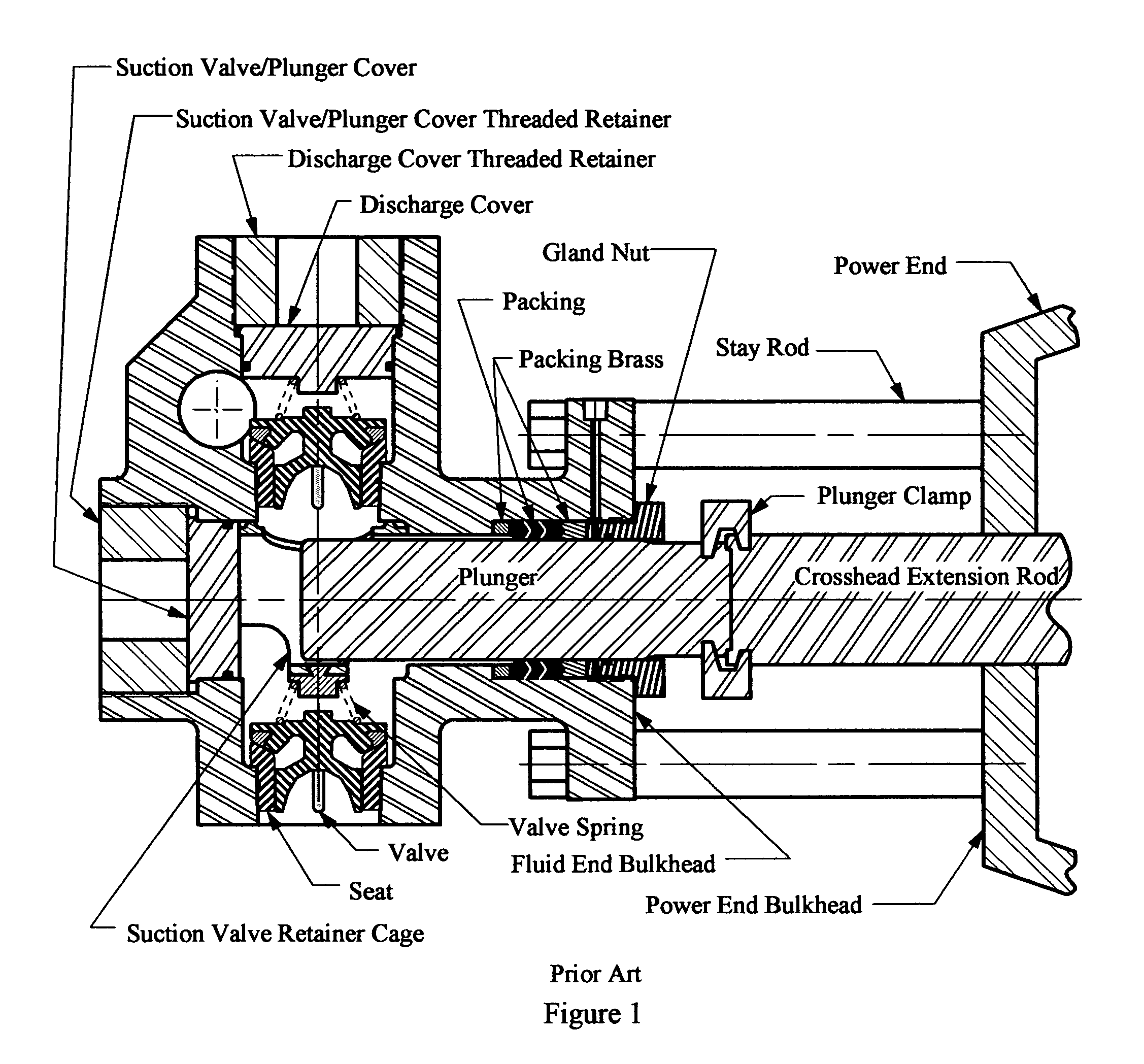

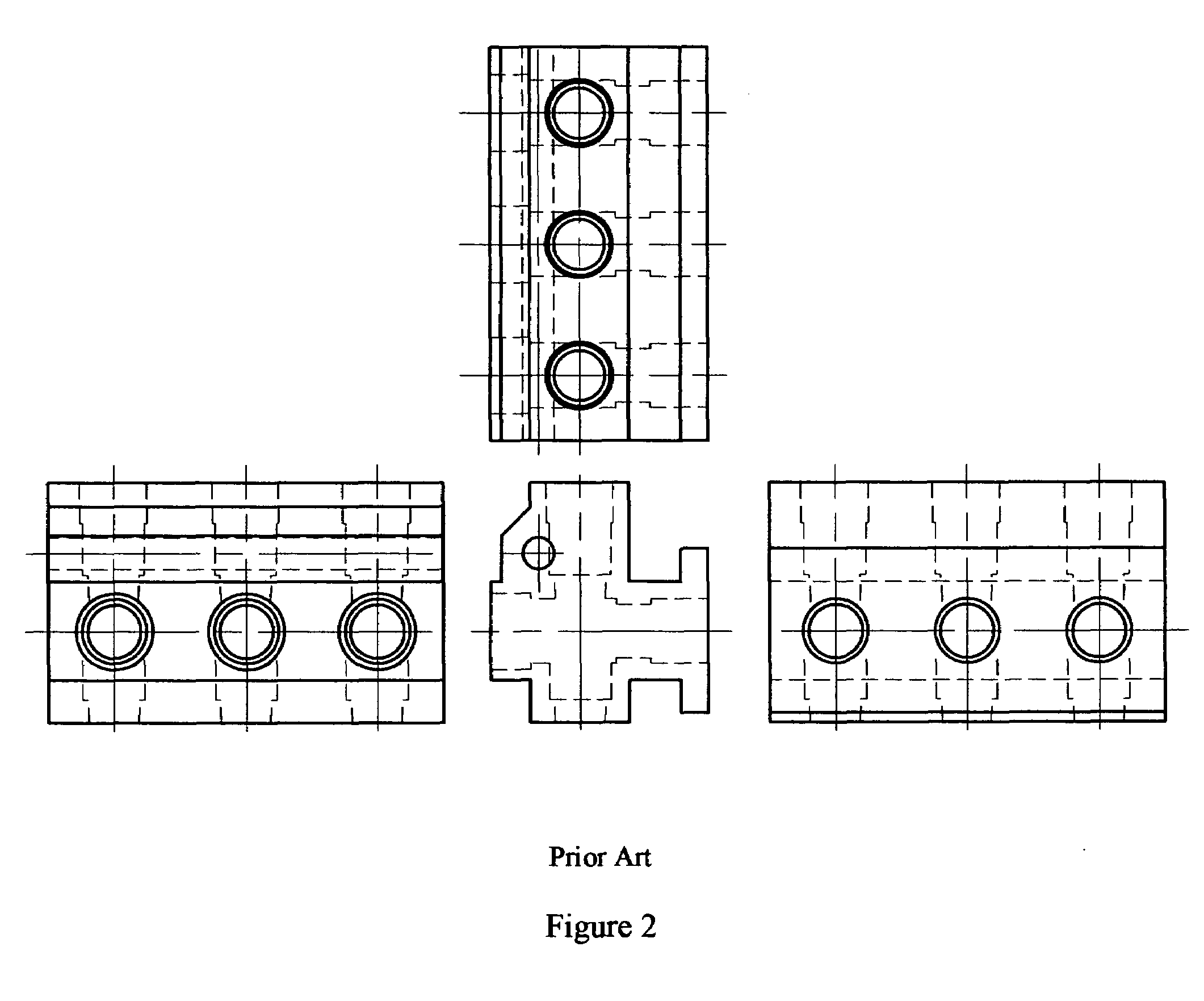

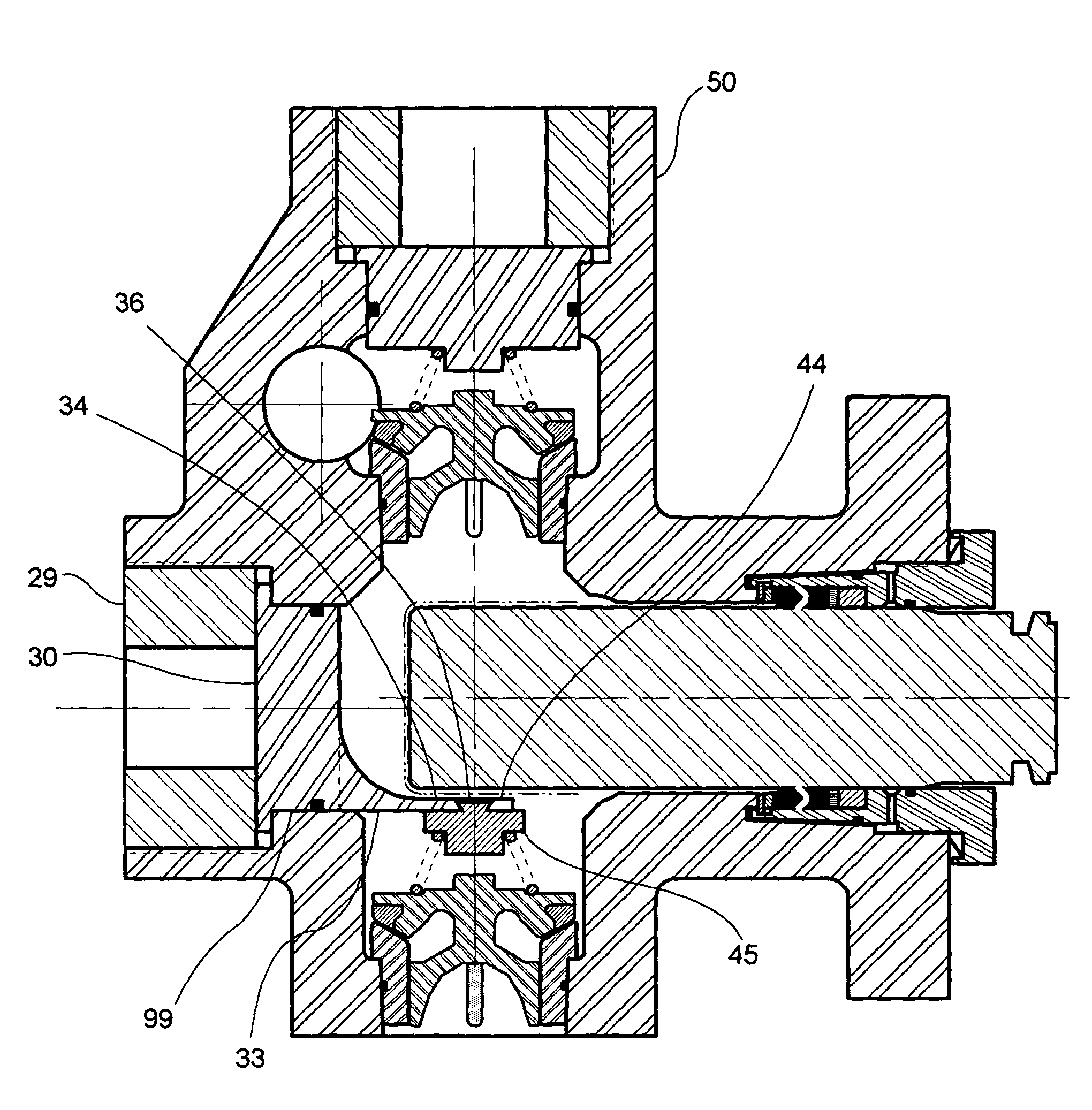

InactiveUS6910871B1Improve volumetric efficiencyEasy to insertPositive displacement pump componentsCheck valvesStress reliefEngineering

Valve guide and spring retainer assemblies are described for use in plunger pump housings that incorporate structural features for stress-relief. These pump housing structural features accommodate correspondingly-shaped valve guides and / or spring retainers that are internally fixed in place using one or more non-threaded spacers. Plunger pumps so constructed are relatively resistant to fatigue failure because of stress reductions, and they may incorporate a variety of valve styles, including top and lower stem-guided valves and crow-foot-guided valves, in easily-maintained configurations. Besides securing valve guides and / or spring retainers, non-threaded spacers may be shaped and dimensioned to aid in further reducing stress and to improve volumetric efficiency of the pumps in which they are used.

Owner:ALTIS INVESTMENTS LLC

Plunger pump housing and access bore plug

ActiveUS7186097B1Positive displacement pump componentsPositive-displacement liquid enginesStress reliefEngineering

Suction valve spring retainers mounted using an access bore plug are described for use in plunger pump housings having an offset access bore and incorporating structural features for stress-relief. These pump housing structural features accommodate access bore plugs that secure suction valve spring retainers that are internally located substantially centrally over the suction bore transition area of the plunger pump housing. Access bore plugs are secured in place on the pump housing using one or more threaded retainers. Plunger pumps so constructed are relatively resistant to fatigue failure because of stress-reducing structural features, and they may incorporate a variety of valve styles, including top and lower stem-guided valves and crow-foot-guided valves, in easily-maintained configurations. Suction valve spring retainers mounted in plunger pump housings may also incorporate a suction valve top stem guide. Further, certain structural features of access bore plugs may be dimensioned to aid in improving volumetric efficiency of the pumps in which they are used.

Owner:HARRIS CORP

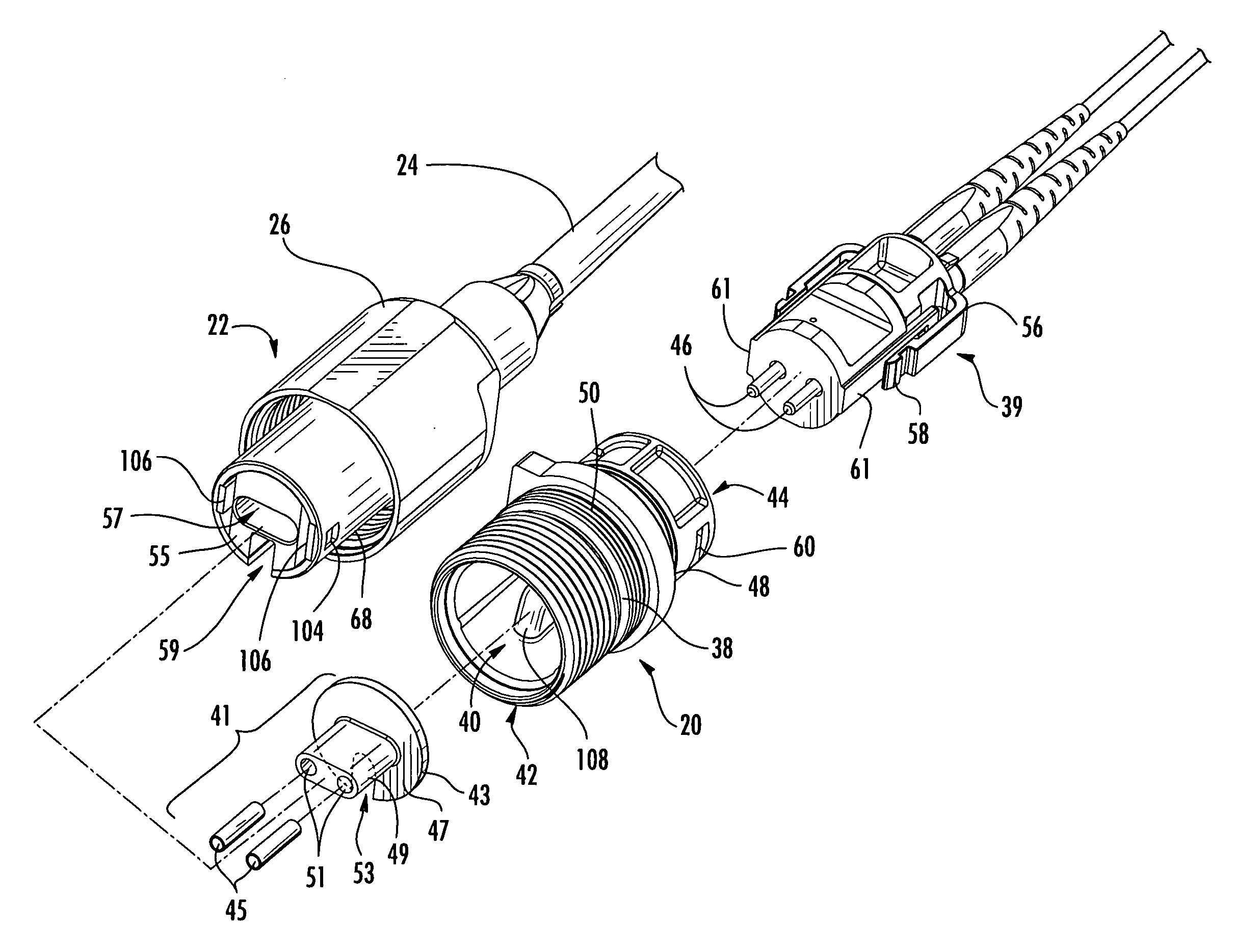

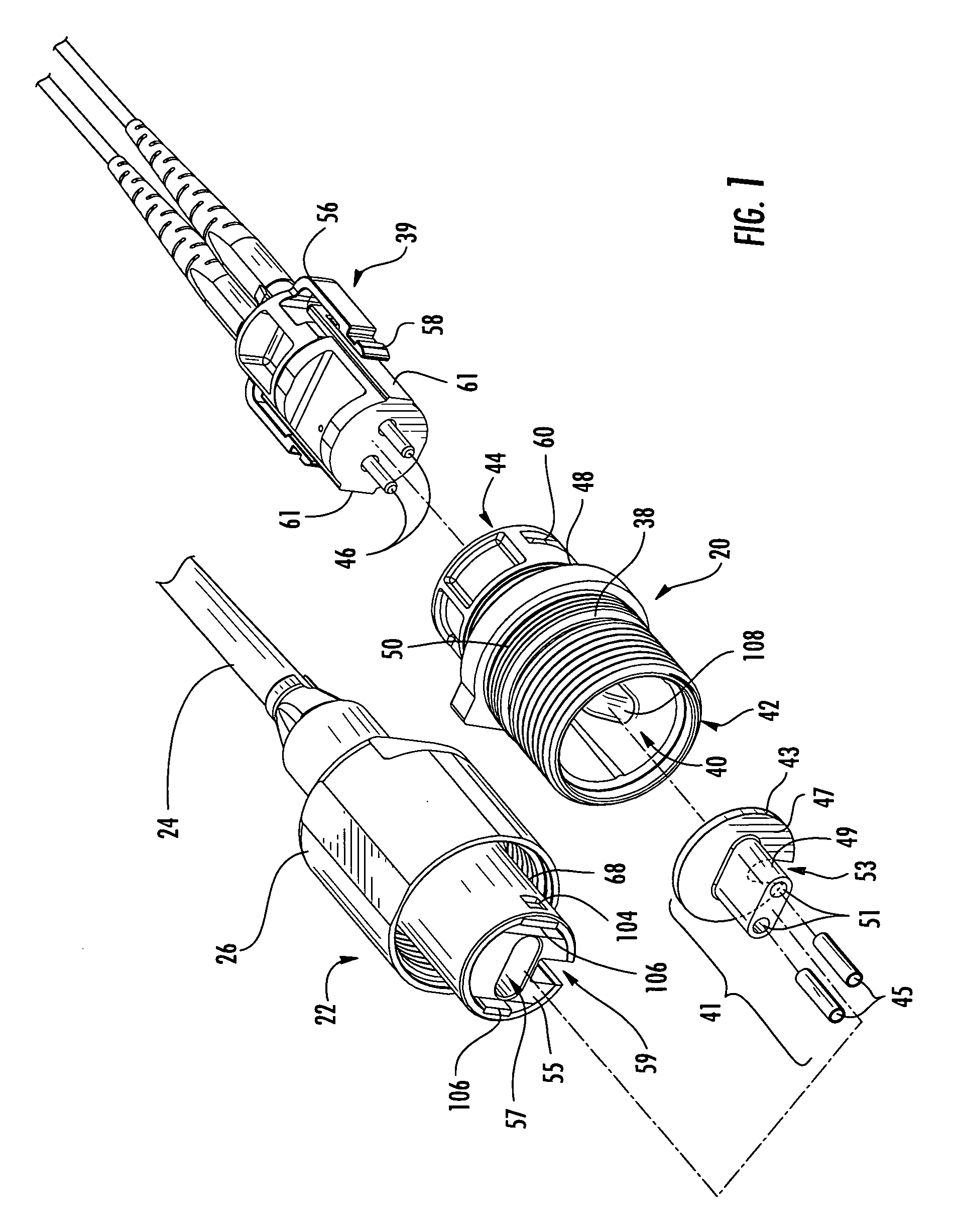

Fiber optic receptacle and plug assembly including alignment sleeve insert

A fiber optic receptacle and plug assembly includes a fiber optic receptacle adapted to be mounted within a connector port of a network connection terminal and a fiber optic plug mounted upon an end of a fiber optic cable, wherein the fiber optic receptacle and the fiber optic plug comprise complimentary alignment and keying features that allow the fiber optic receptacle to receive only a fiber optic plug of like ferrule configuration. The fiber optic receptacle includes an alignment sleeve insert operable for receiving and optically connecting at least one receptacle ferrule and at least one opposing plug ferrule. The receptacle is suitable for use in enclosures requiring a minimal receptacle penetration depth, wherein the fiber optic receptacle comprises a shoulder that is secured against an inner wall of the enclosure to provide strain relief against cable-pulling forces of up to about 600 lbs.

Owner:CORNING OPTICAL COMM LLC

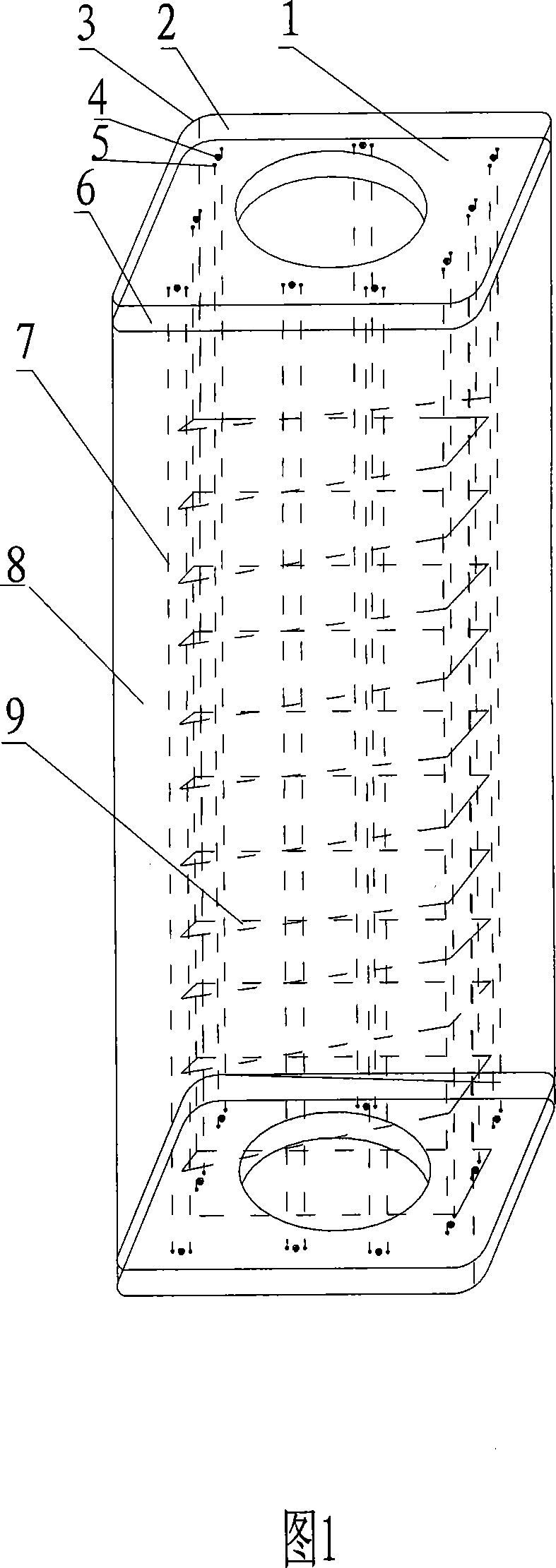

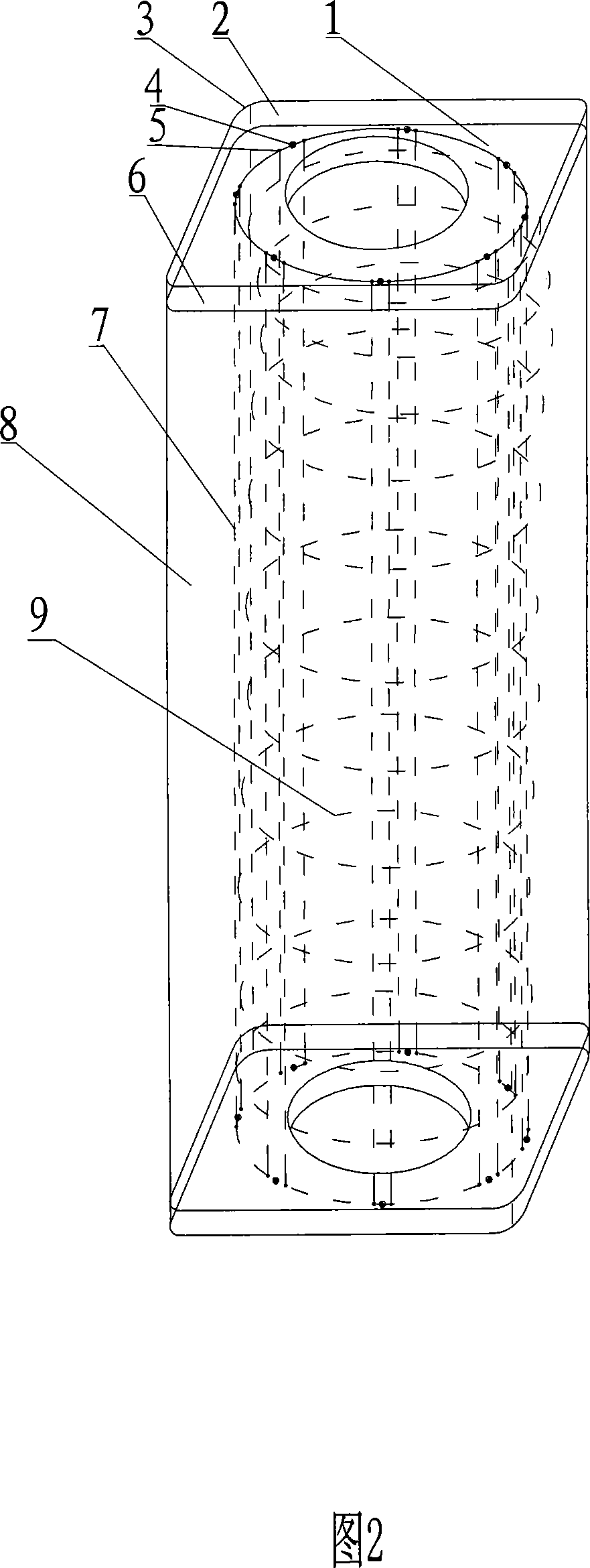

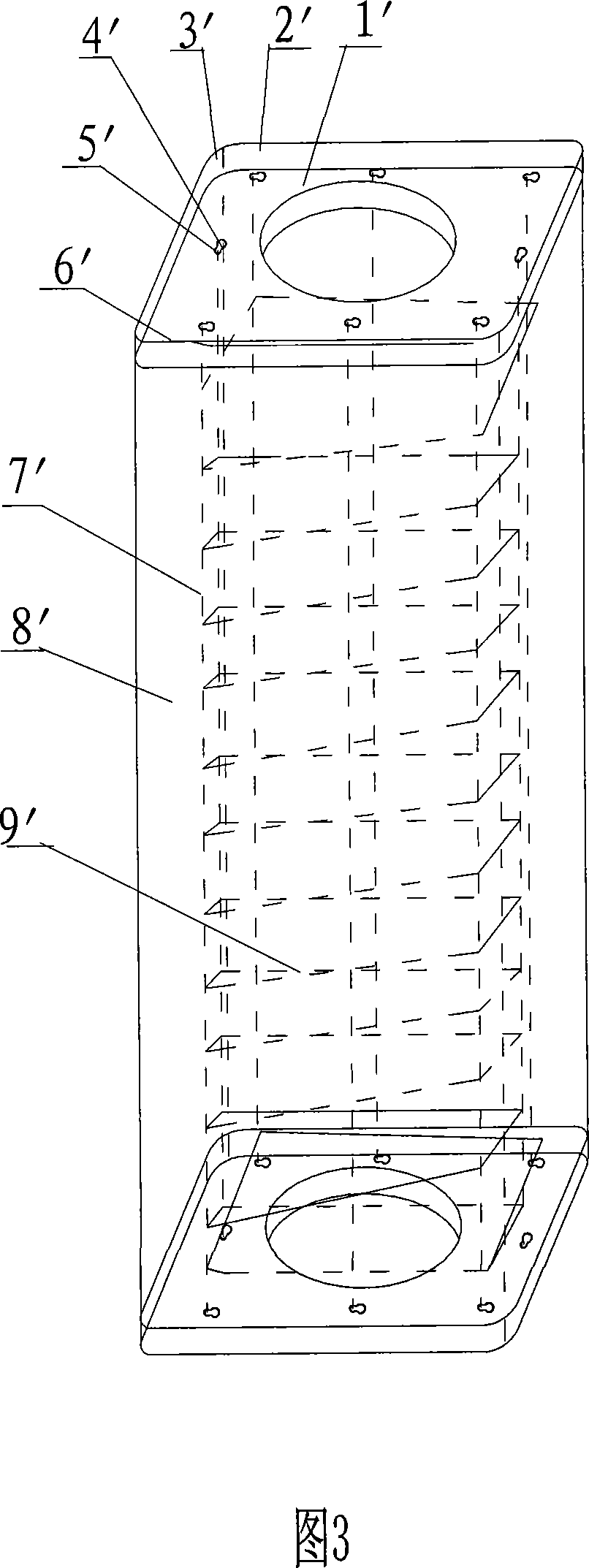

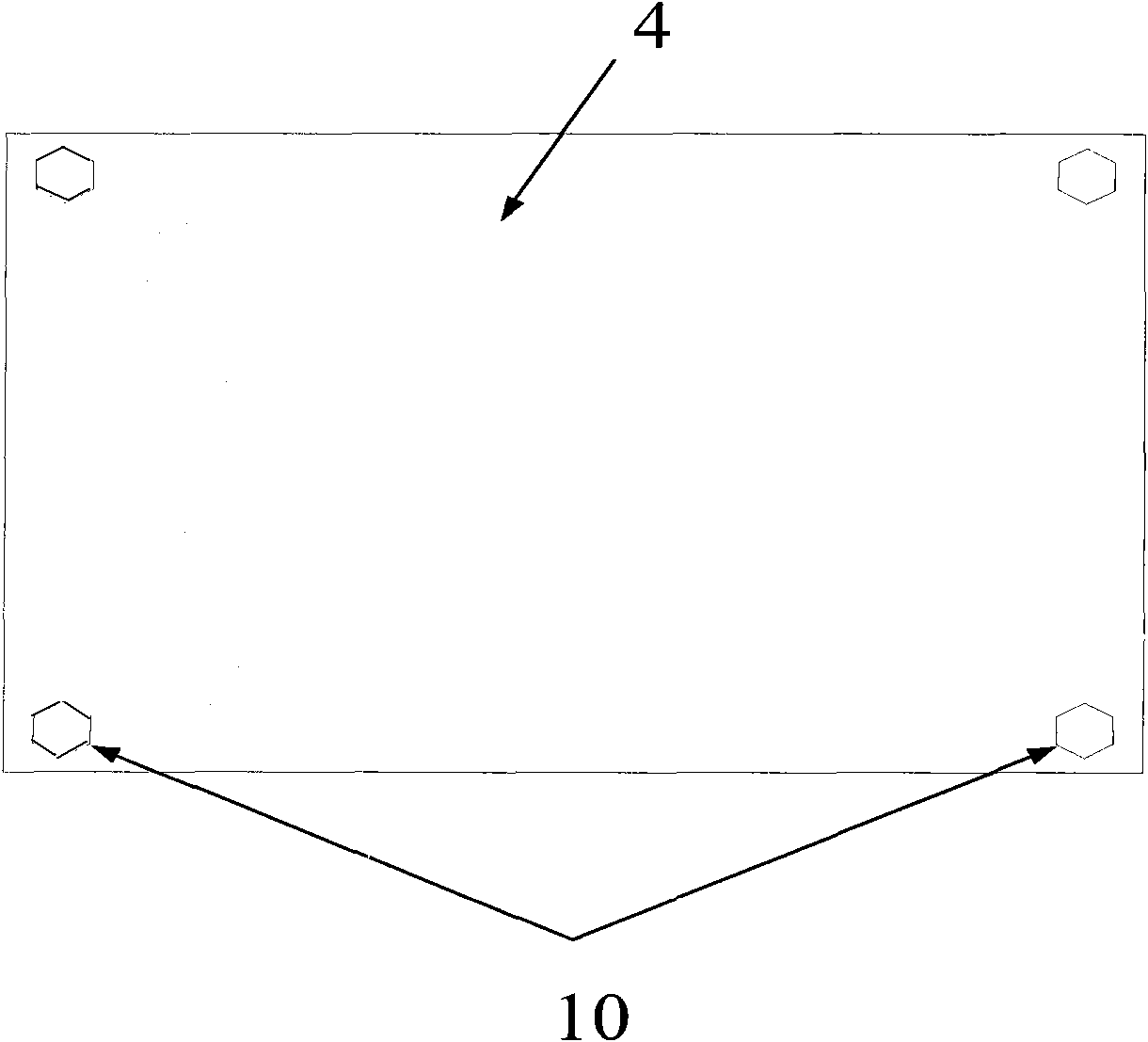

Prestress high intensity concrete square pile and its production method and moulding die

InactiveCN101054800AHigh pile rateIncrease profitCeramic shaping apparatusBulkheads/pilesHigh strength concretePre stress

The invention belongs to the architecture field, which relates to an improvement with the foundation pile shape and the structure and the manufacturing method of the foundation pile and the foundation pile shaper in the architecture field, in particular the invention is a prestressing force high strength concrete square pile and the manufacturing method thereof and the shaping device. In the invention a square terminal plate is disposed on the two ends of the square pile, and the four sides of the terminal plate is provided with a groove, while the center is equipped with a circular hole, and between the circular hole and the four sides, a strain hole and a threading hole are arranged symmetrically; a stirrp of a reinforcement cage in a twist is welded on the principal reinforcement continuously, wherein the principal reinforcement is the steel strand or the steel bar; the concrete square pile and the four-side corners of the terminal plate are in a stress elimination arc, and the pile core is a columnar mid level outlet having the same diameter with the terminal plate central circular hole. The manufacturing method is characterized in that, the principal reinforcement has the fix ed length and blanking, and the stirrp of the reinforcement cage is welded in the seam welder with the high degree of mechanisation; the principal reinforcement is stretched in a group of a whole pile fixed value, wherein the stretching performance is good and the balance is consistent; the disposable high pressure has short shaping time, low energy consumption, high product grade; the die design meets with the shaping requirement of the shape, which is convenient to use.

Owner:SHANGHAI ZHONGJI PILE IND

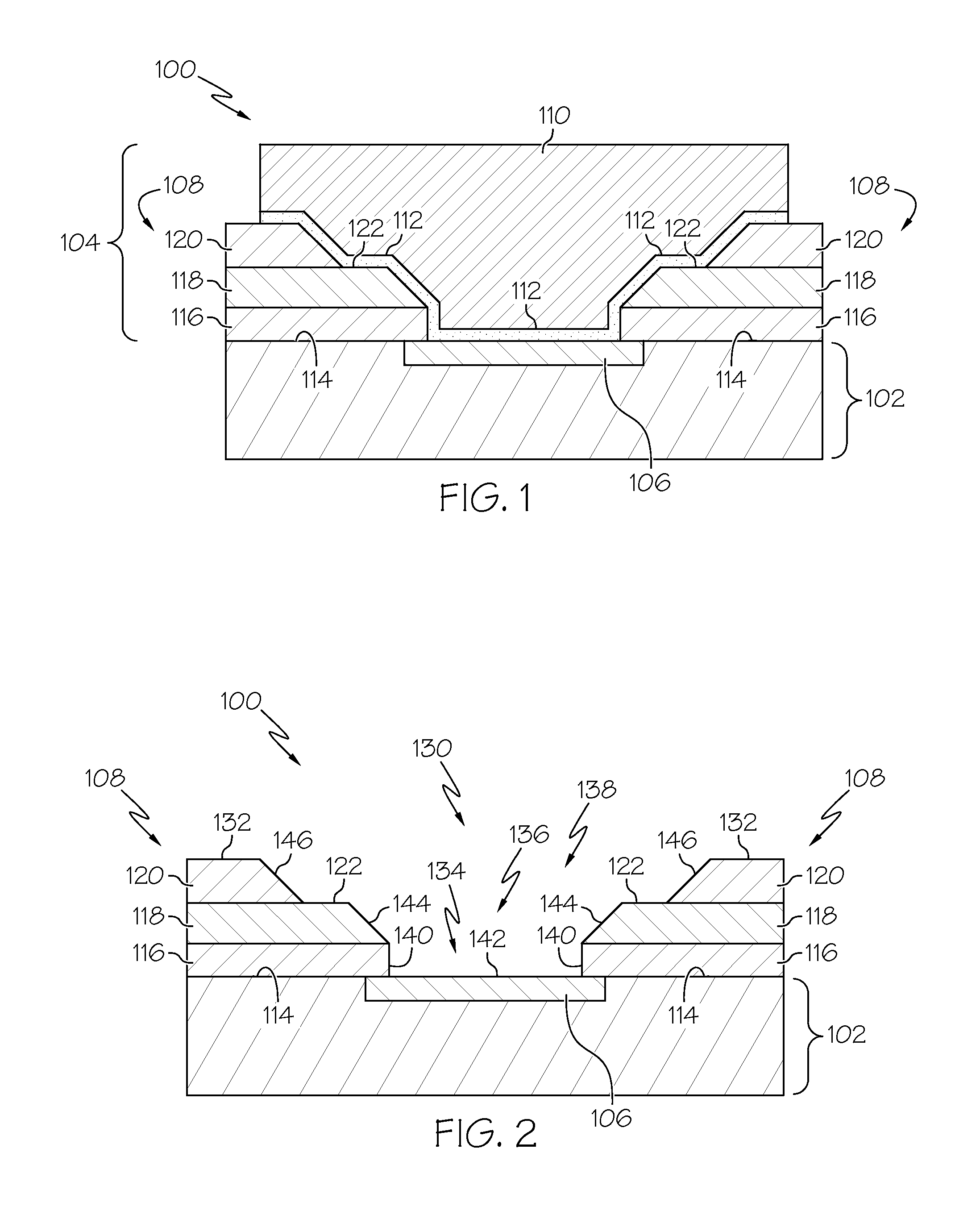

Multilayered through via

InactiveUS20100130002A1Semiconductor/solid-state device detailsSolid-state devicesTitanium nitrideStress relief

A method for forming a through substrate via (TSV) comprises forming an opening within a substrate. An adhesion layer of titanium is formed within the via opening, a nucleation layer of titanium nitride is formed over the adhesion layer, and a tungsten layer is deposited over the nucleation layer, the tungsten layer having a thickness less than or equal to a critical film thickness sufficient to provide for film integrity and adhesion stability. A stress relief layer of titanium nitride is formed over the tungsten layer and a subsequent tungsten layer is deposited over the stress relief layer. The subsequent tungsten layer has a thickness less than or equal to the critical film thickness. The method further includes planarizing to expose the interlevel dielectric layer and a top of the TSV and backgrinding a bottom surface of the substrate sufficient to expose a bottom portion of the TSV.

Owner:NXP USA INC

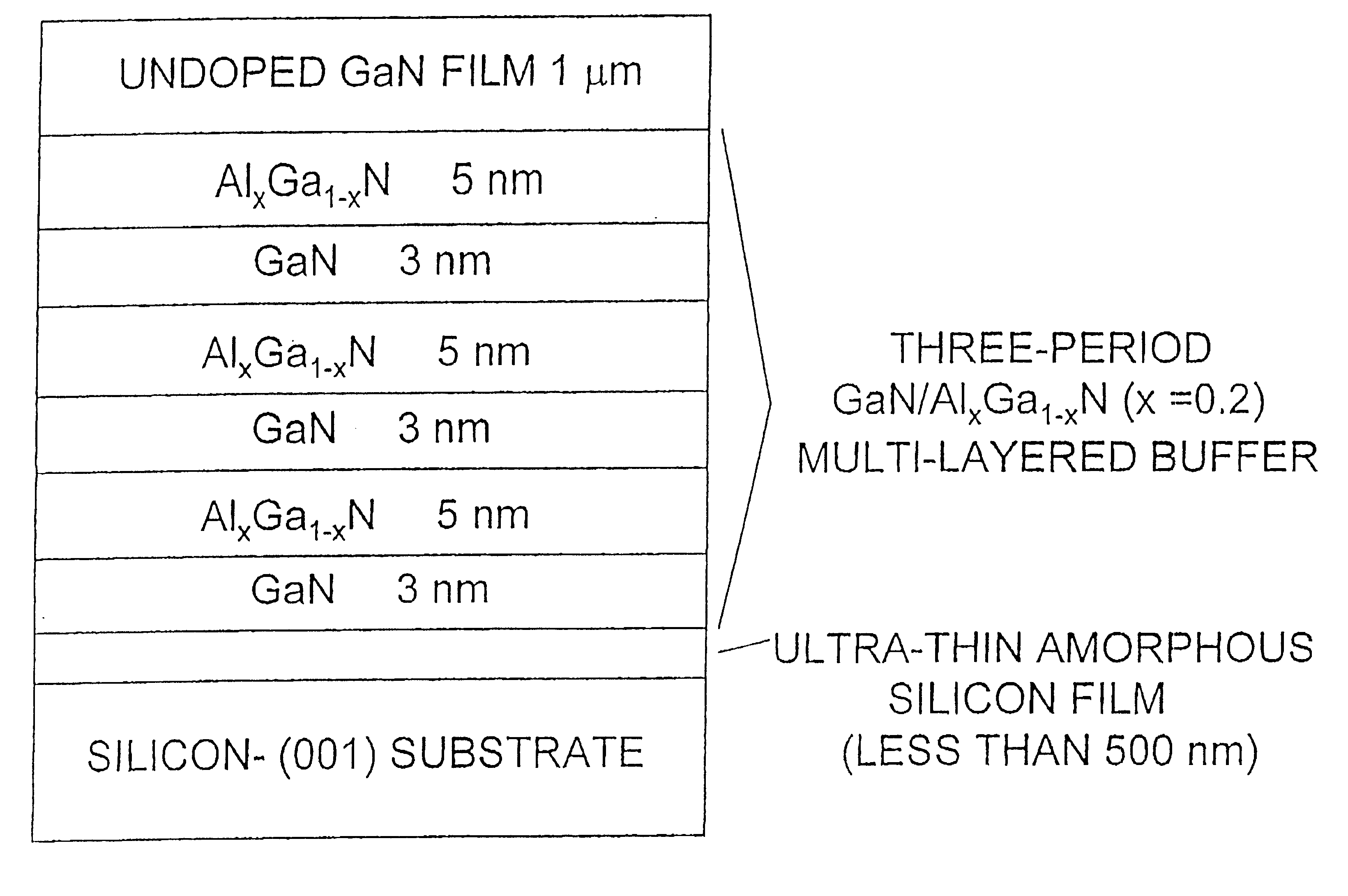

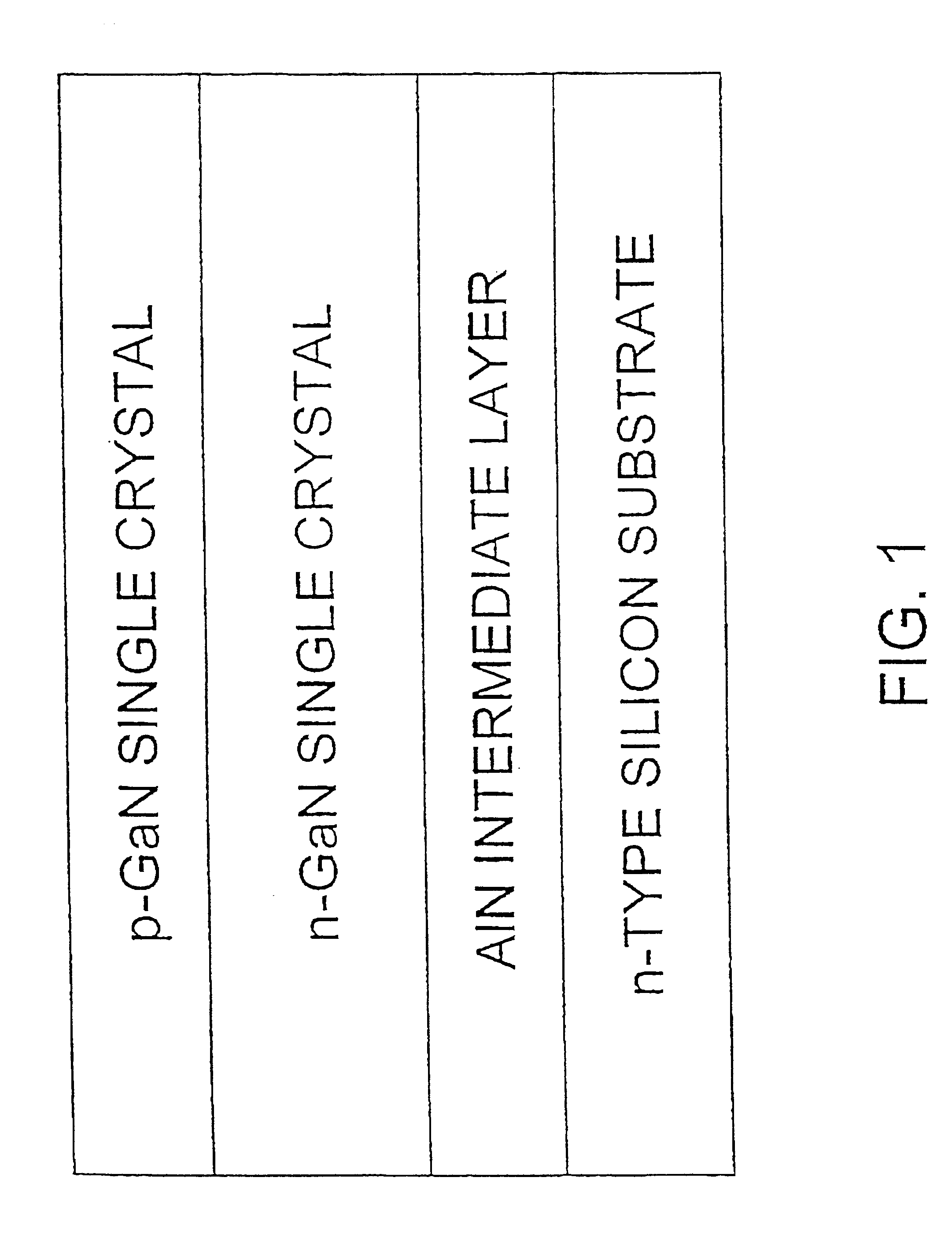

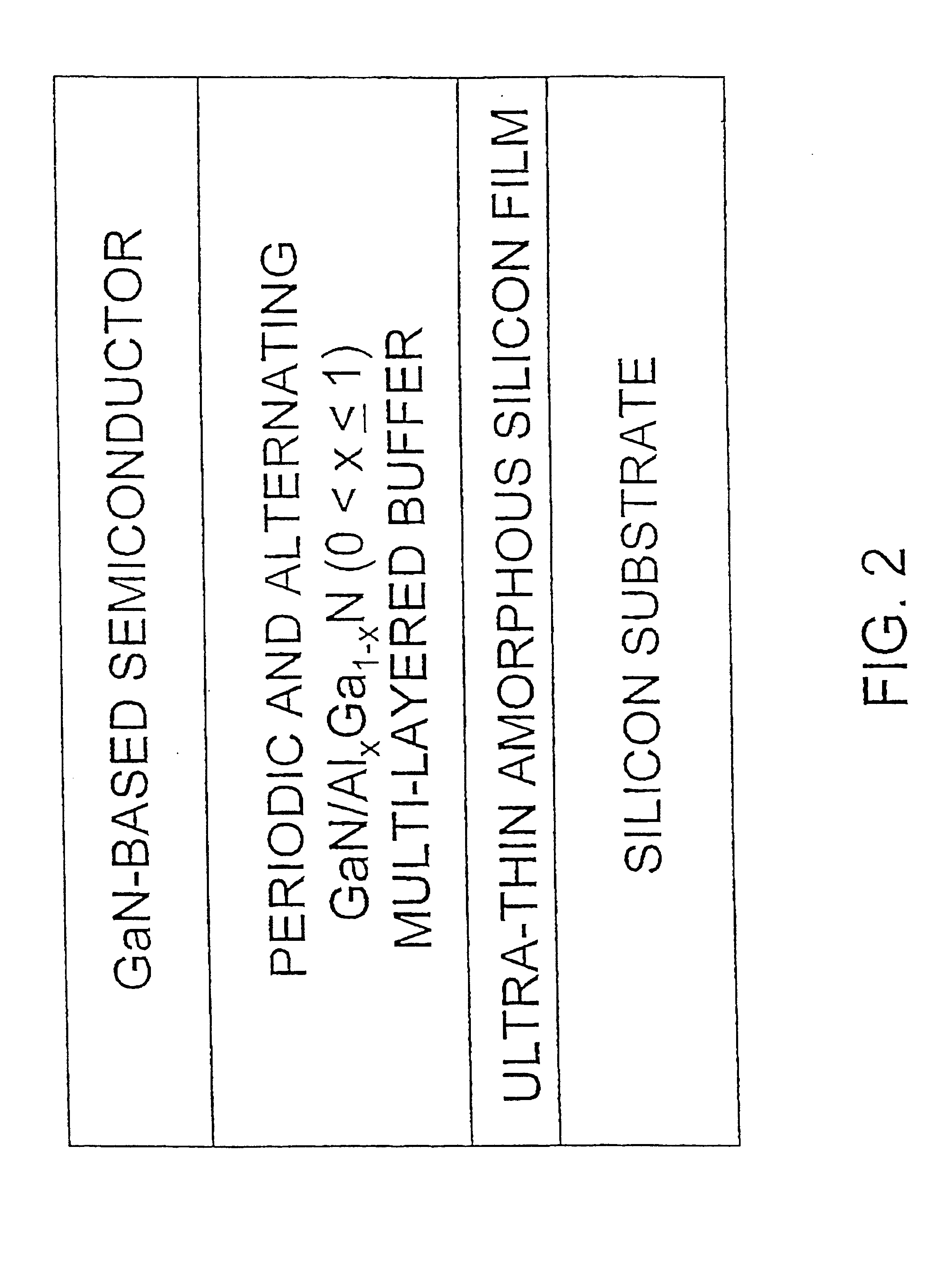

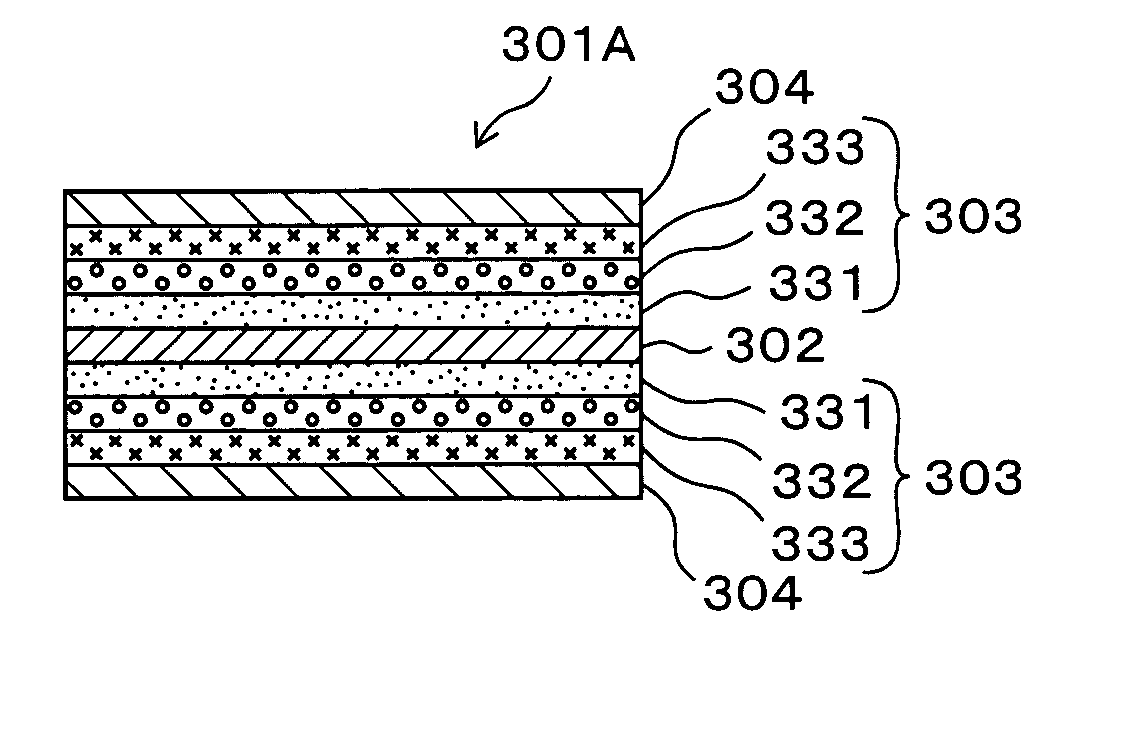

Method of fabricating group-III nitride-based semiconductor device

InactiveUS6524932B1Semiconductor/solid-state device manufacturingSemiconductor devicesInter layerLattice mismatch

Disclosed are a group-III nitride-based semiconductor device that is grown over the surface of a composite intermediate layers consisting of a thin amorphous silicon film or any stress-relief film or a combination of them and at least one multi-layered buffer on silicon substrate, and a method of fabricating the same device. The intermediate layers that suppress the occurrence of crystal defects and propagation of misfit dislocations induced by the lattice mismatch between the epitaxial layer and substrate, ca n be grown on a part or the entirety of the surface of a silicon (001) or (111) substrate which can be single crystal or coated with a thin amorphous silicon film. Then at least one layer or multiple layers of high quality group-III nitride-based semiconductors are grown over the composite intermediate layers.

Owner:NAT UNIV OF SINGAPORE

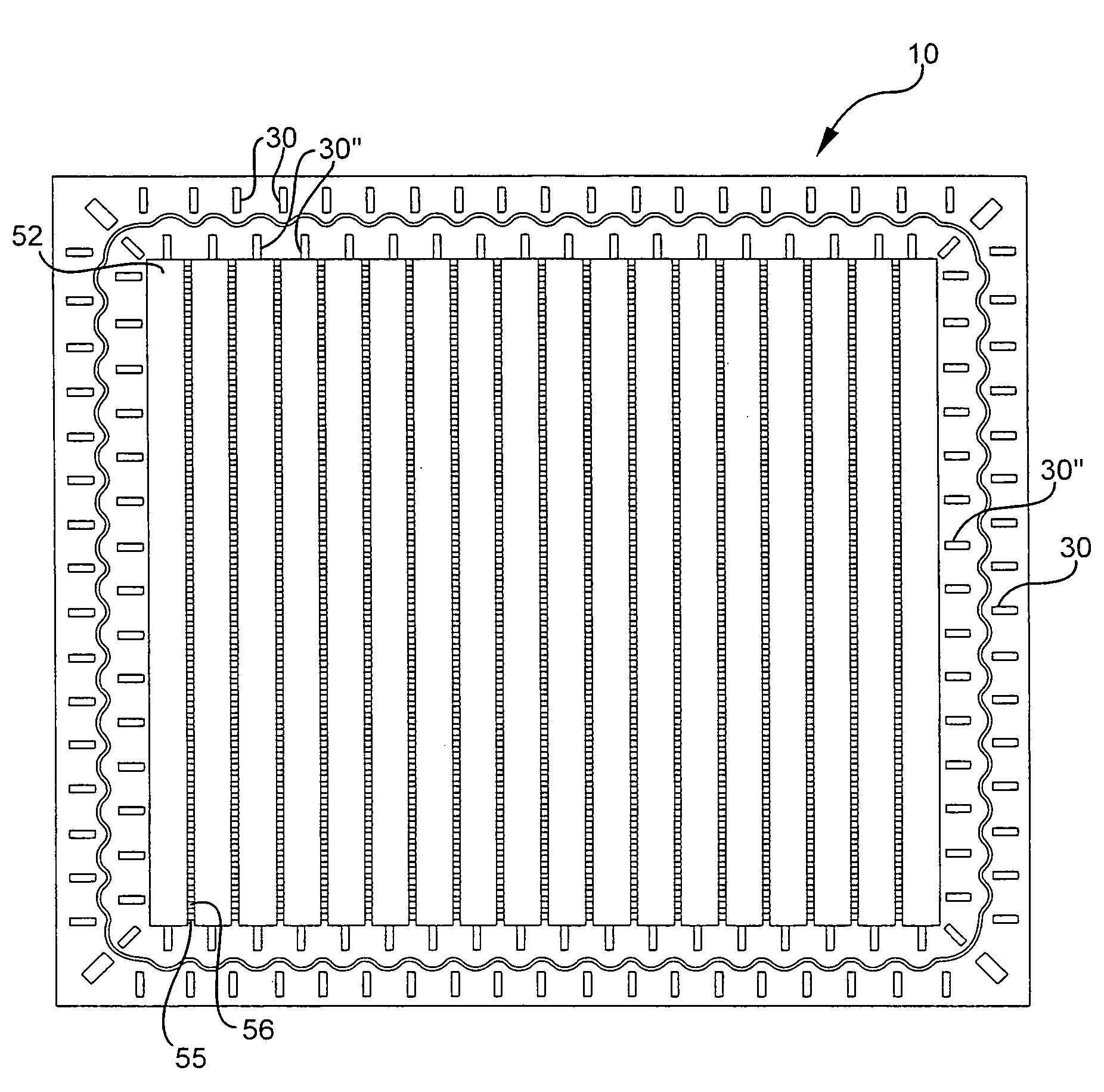

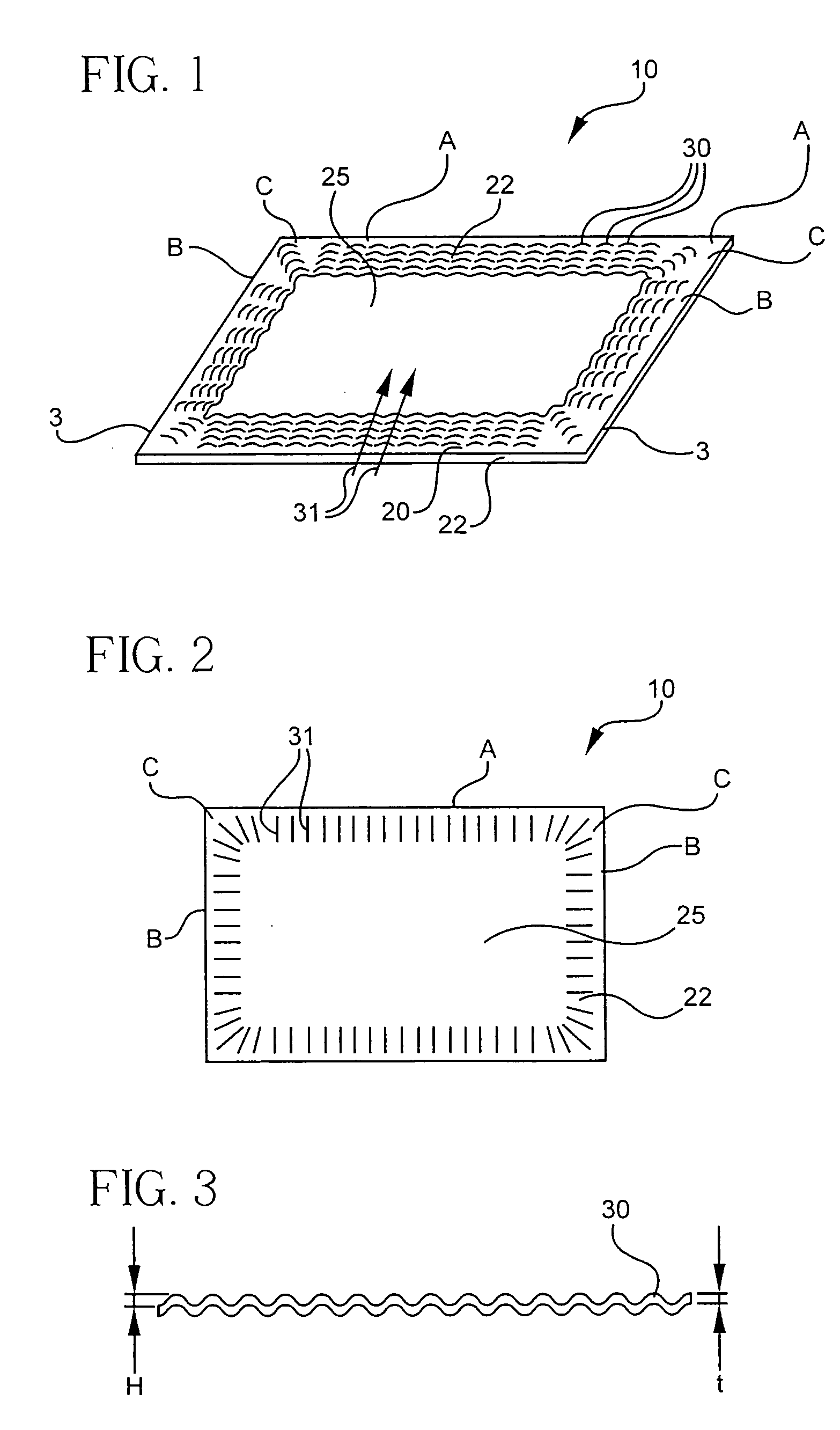

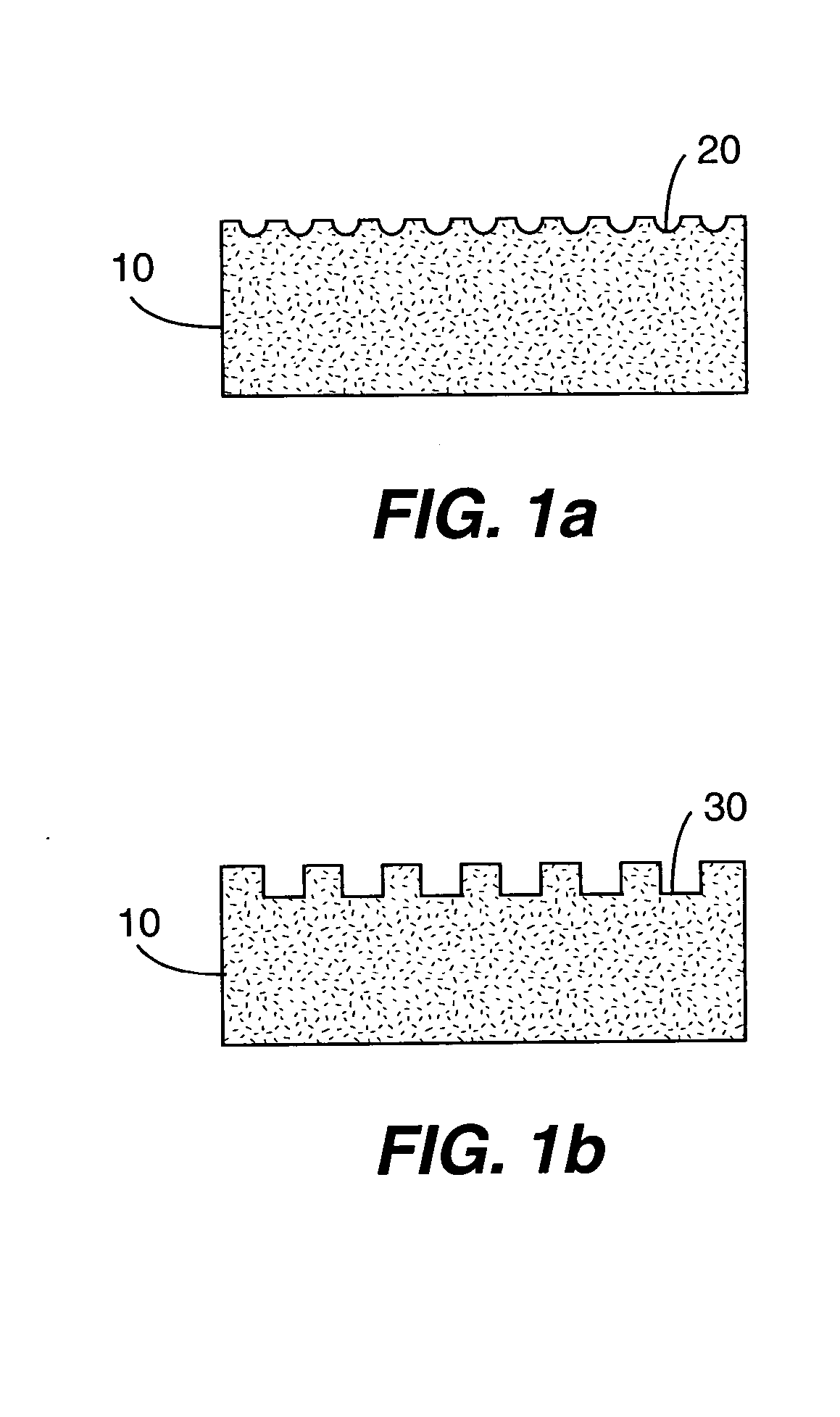

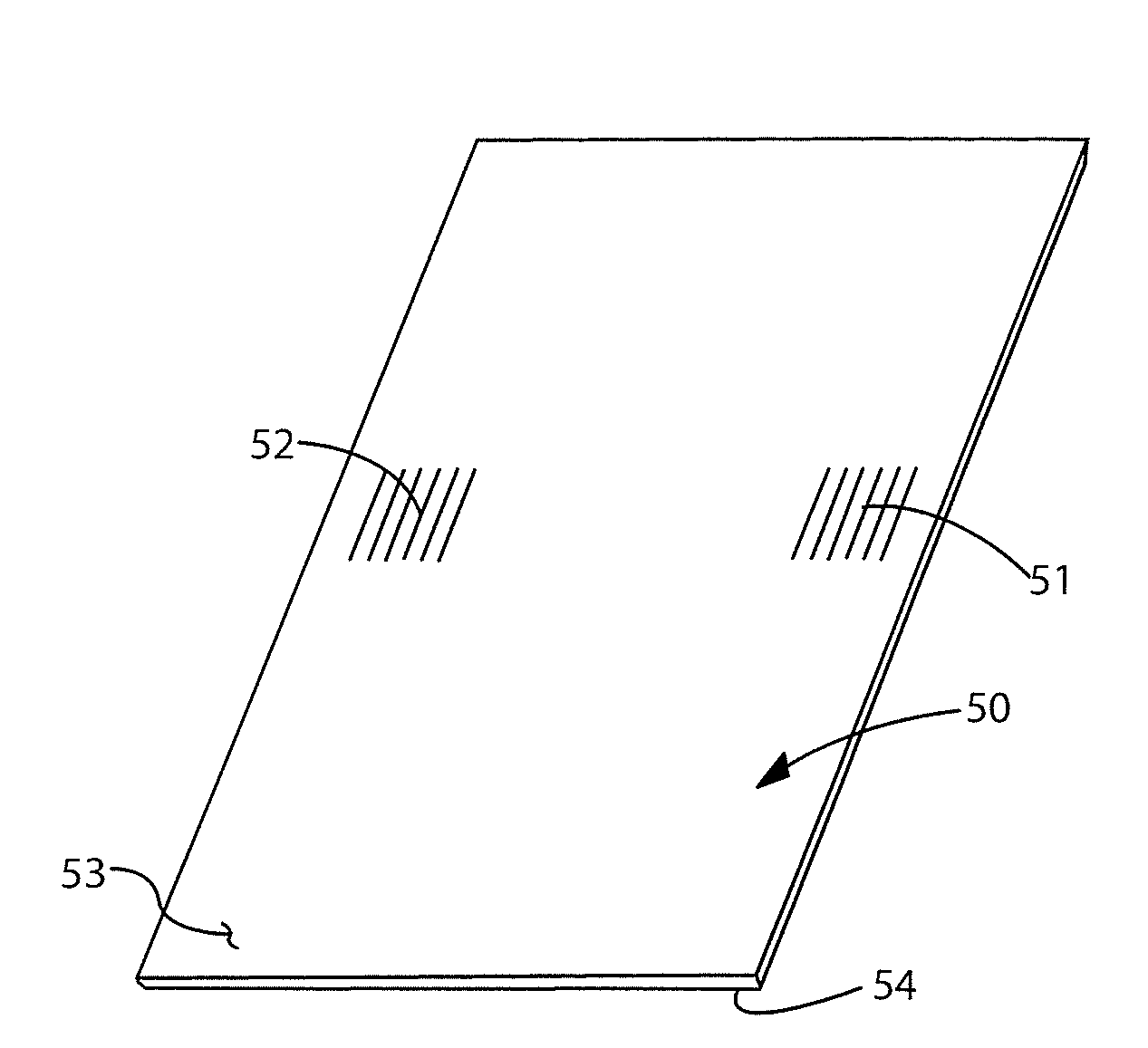

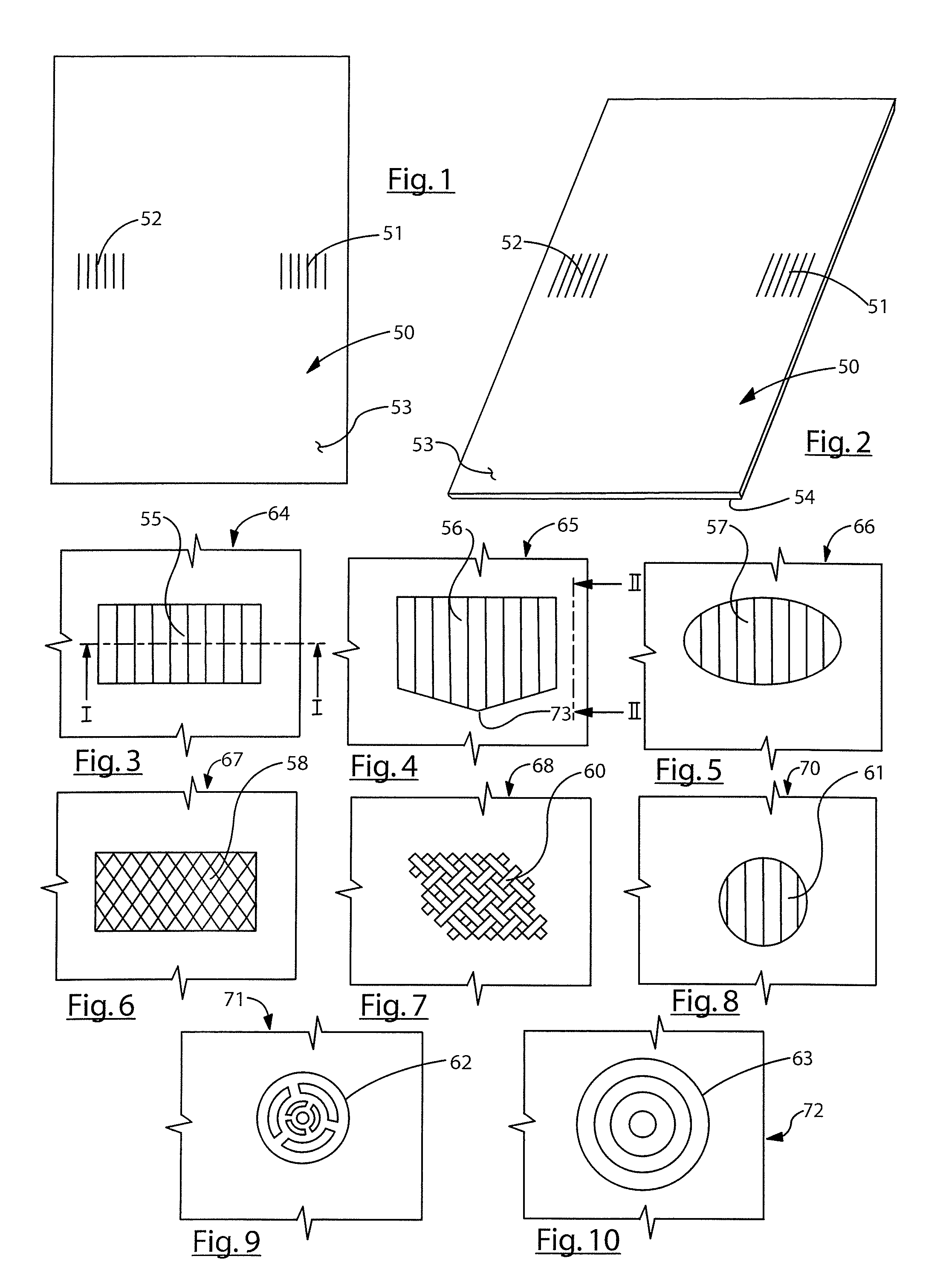

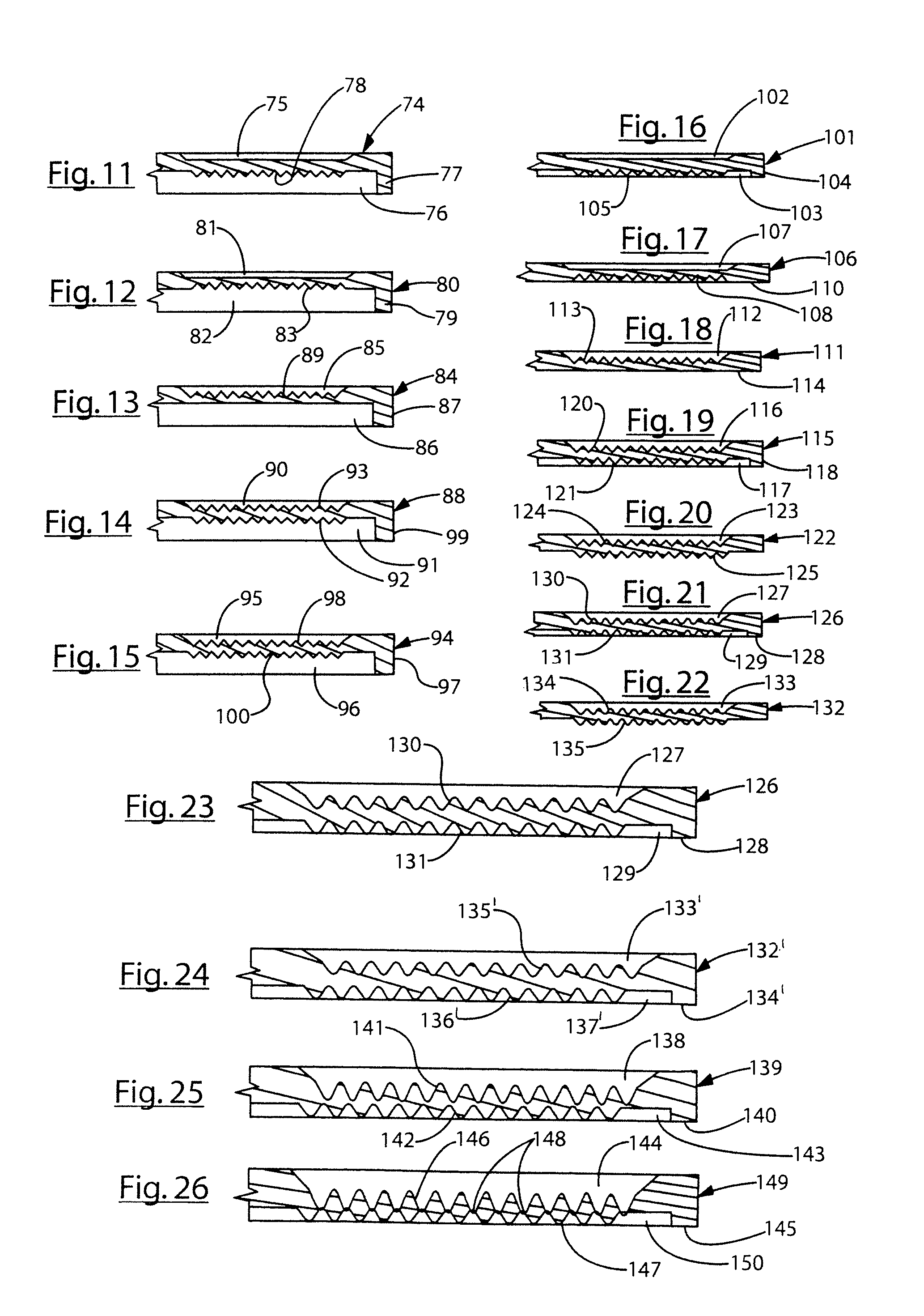

Electrolyte sheet with a corrugation pattern

ActiveUS20060003213A1Increased multi-axial strain toleranceImproving and maintaining structural strengthFuel cells groupingFinal product manufactureEngineeringStress relief

An electrolyte sheet comprises a substantially non-porous body and has at least one stress-relief area on at least a portion of the electrolyte sheet. The stress-relief area has a surface with a plurality of folds. The plurality of folds are arranged around and directed longitudinally toward a common central area.

Owner:CORNING INC

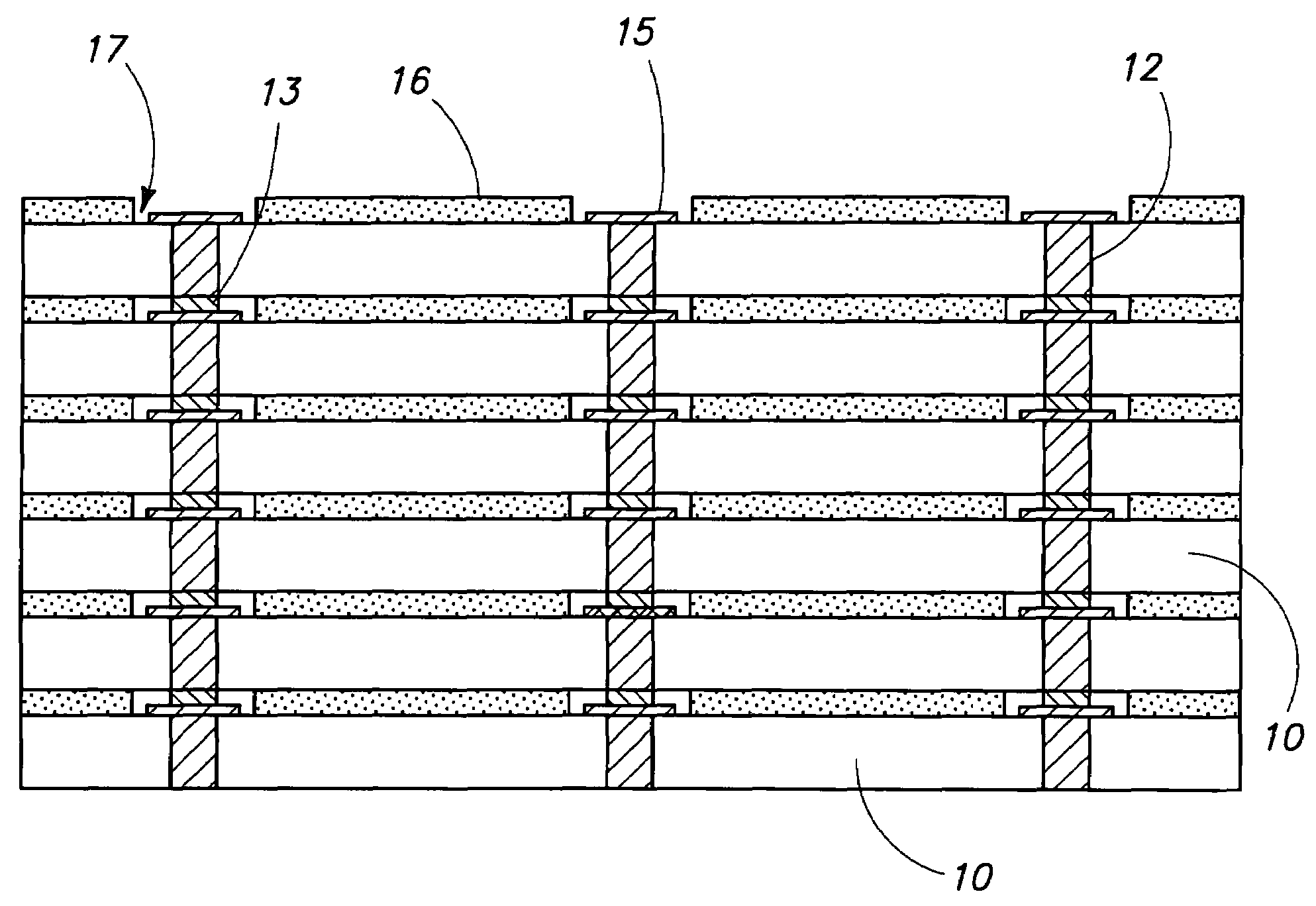

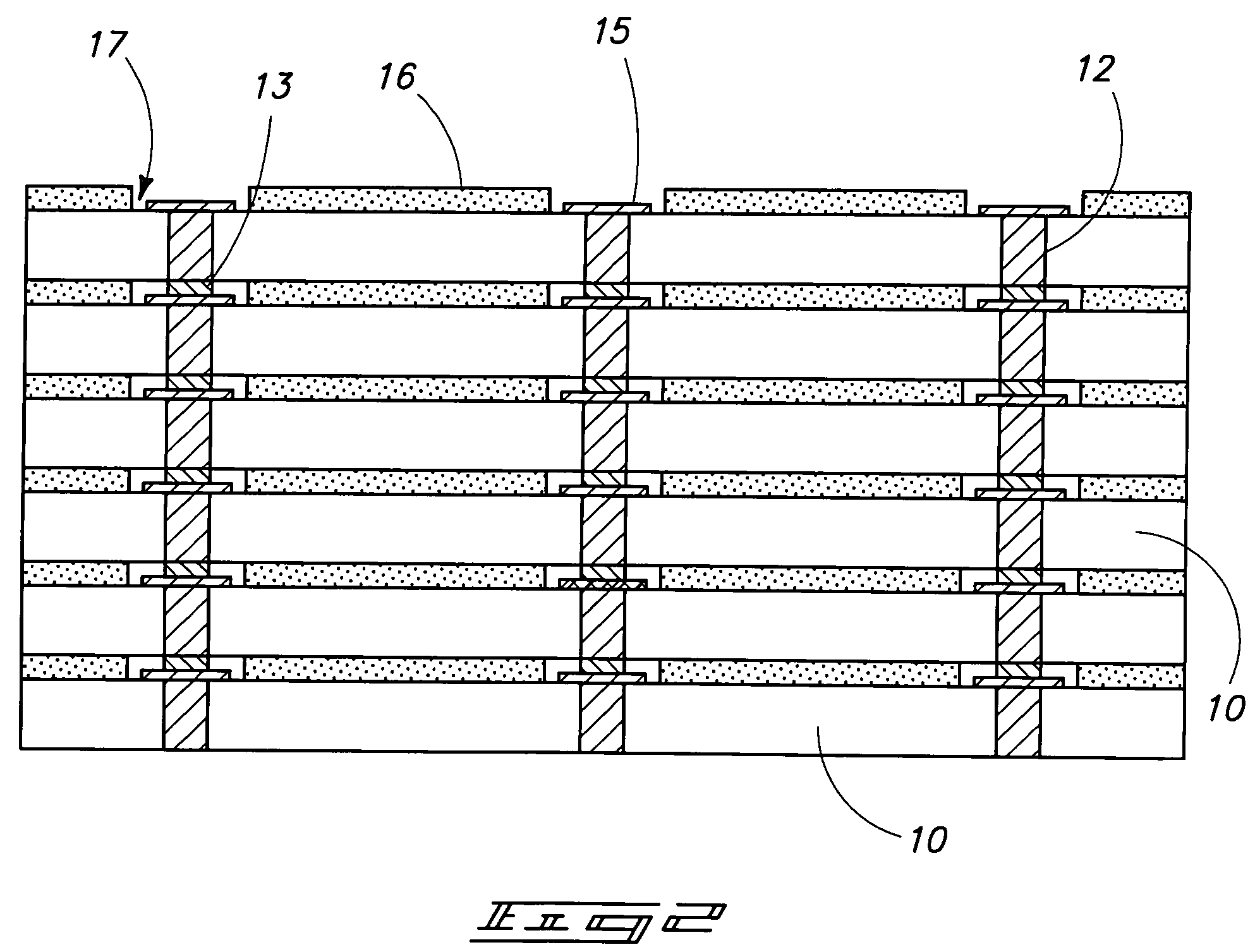

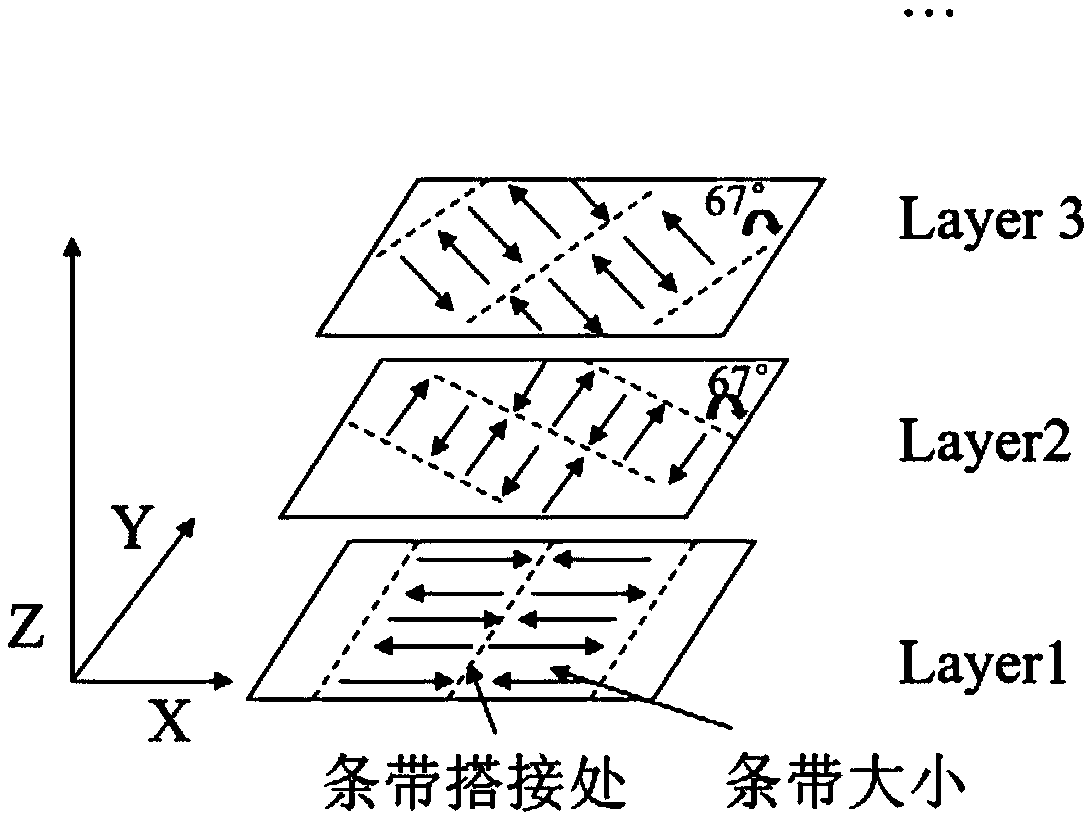

Bonding method for through-silicon-via based 3D wafer stacking

ActiveUS7683459B2Semiconductor/solid-state device detailsSolid-state devicesOutgassingWafer stacking

There is described a hybrid bonding method for through-silicon-via based wafer stacking. Patterned adhesive layers are provided to join together adjacent wafers in the stack, while solder bonding is used to electrically connect the vias. The adhesive layers are patterned to enable outgassing and to provide stress relief.

Owner:HONG KONG APPLIED SCI & TECH RES INST

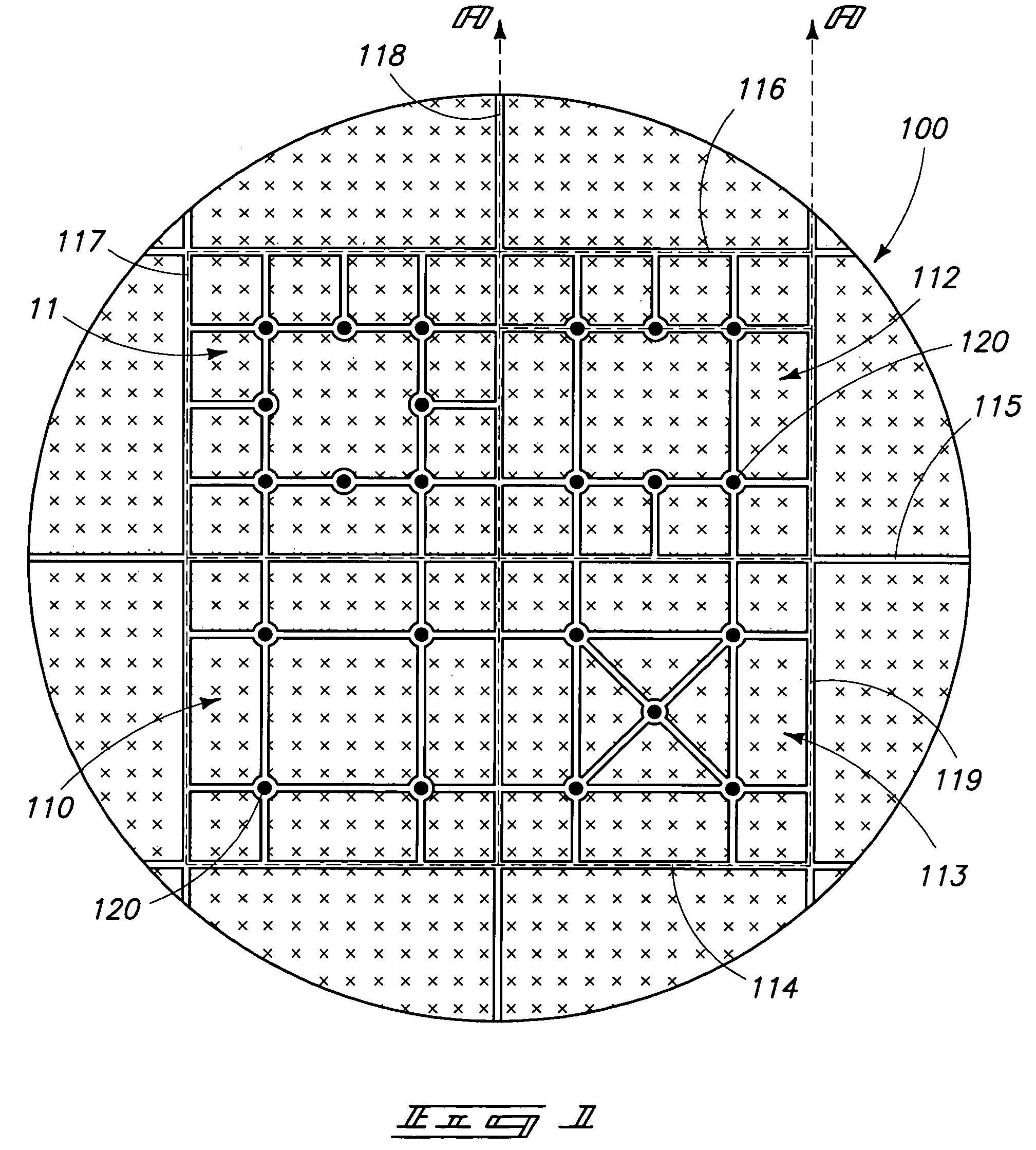

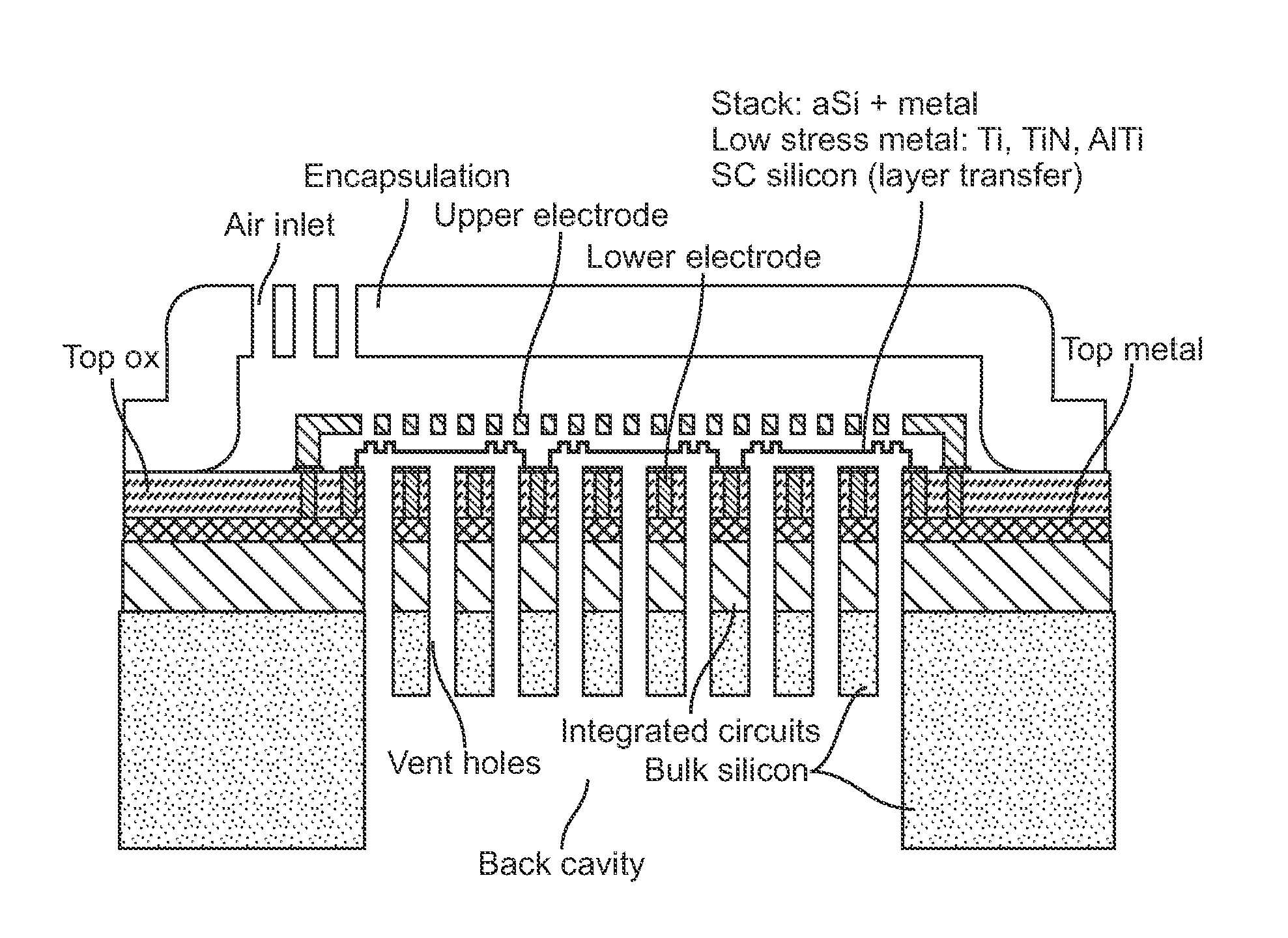

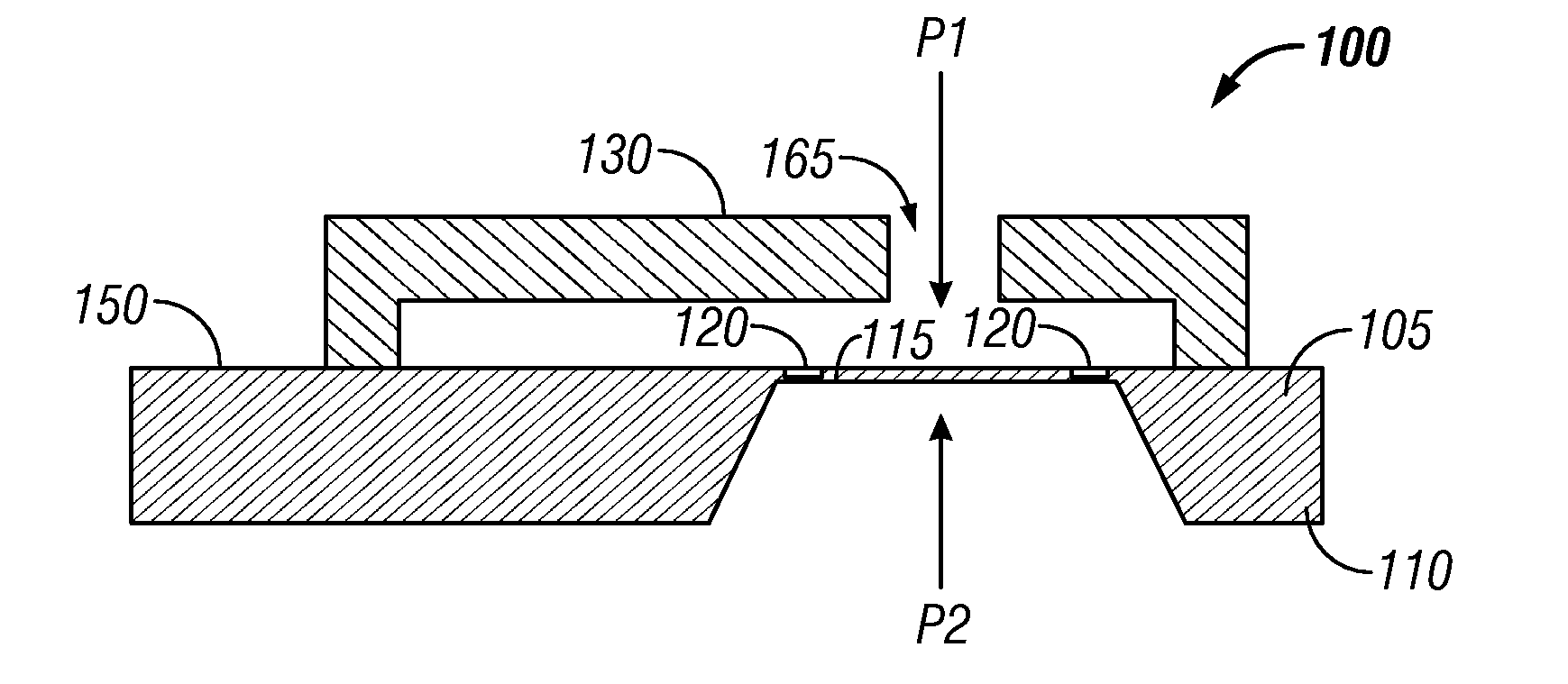

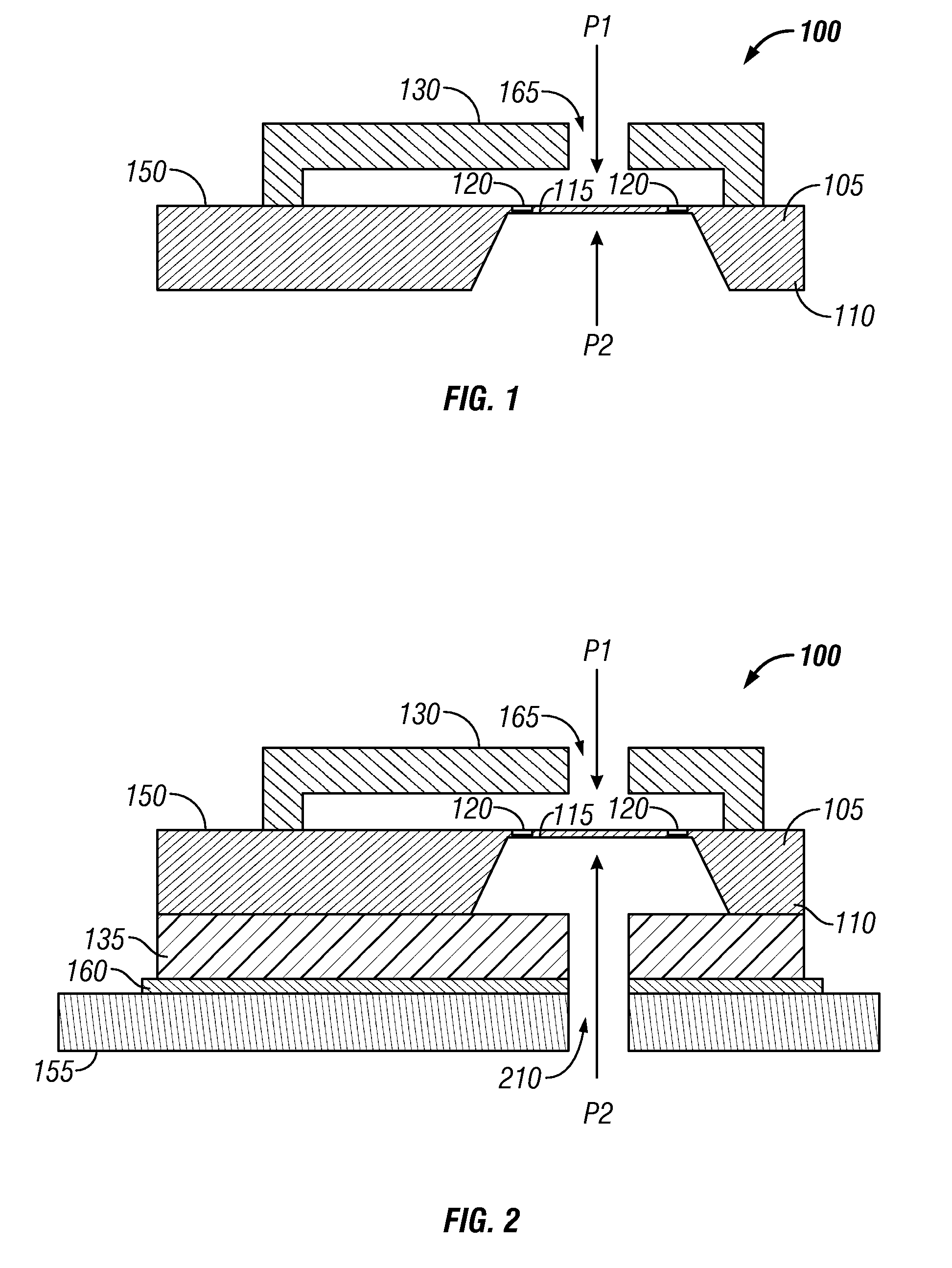

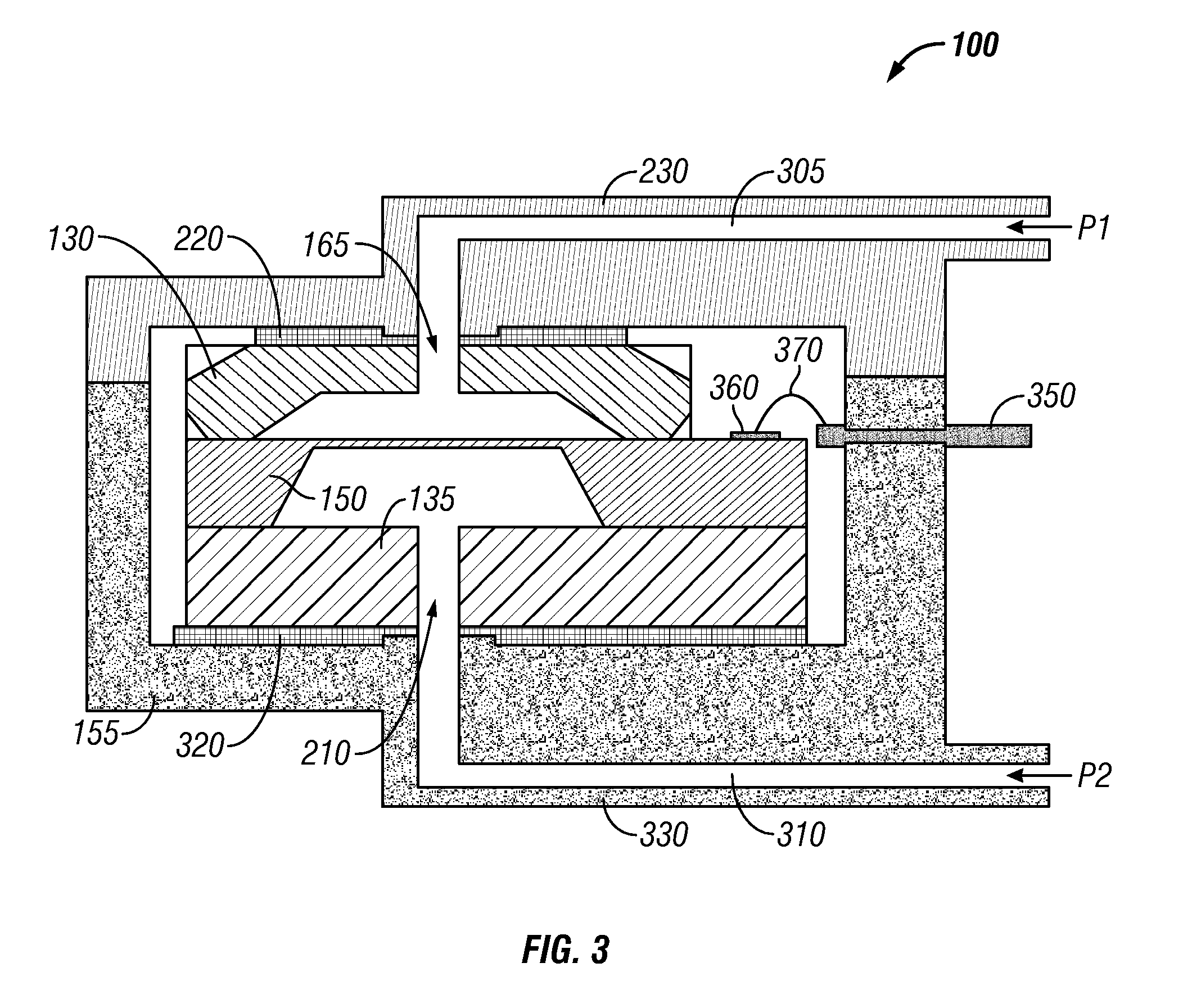

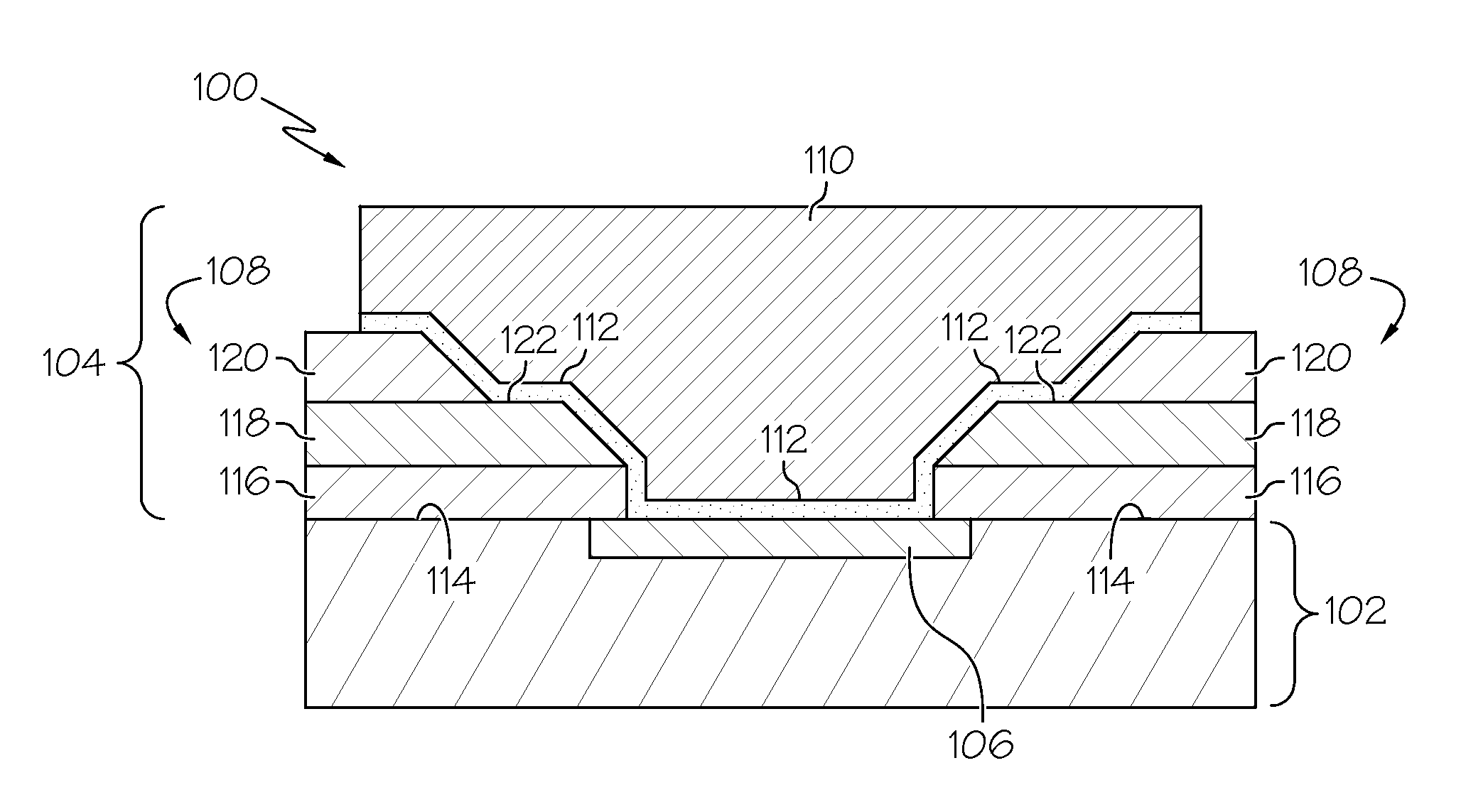

Method and structure of monolithically integrated pressure sensor using IC foundry-compatible processes

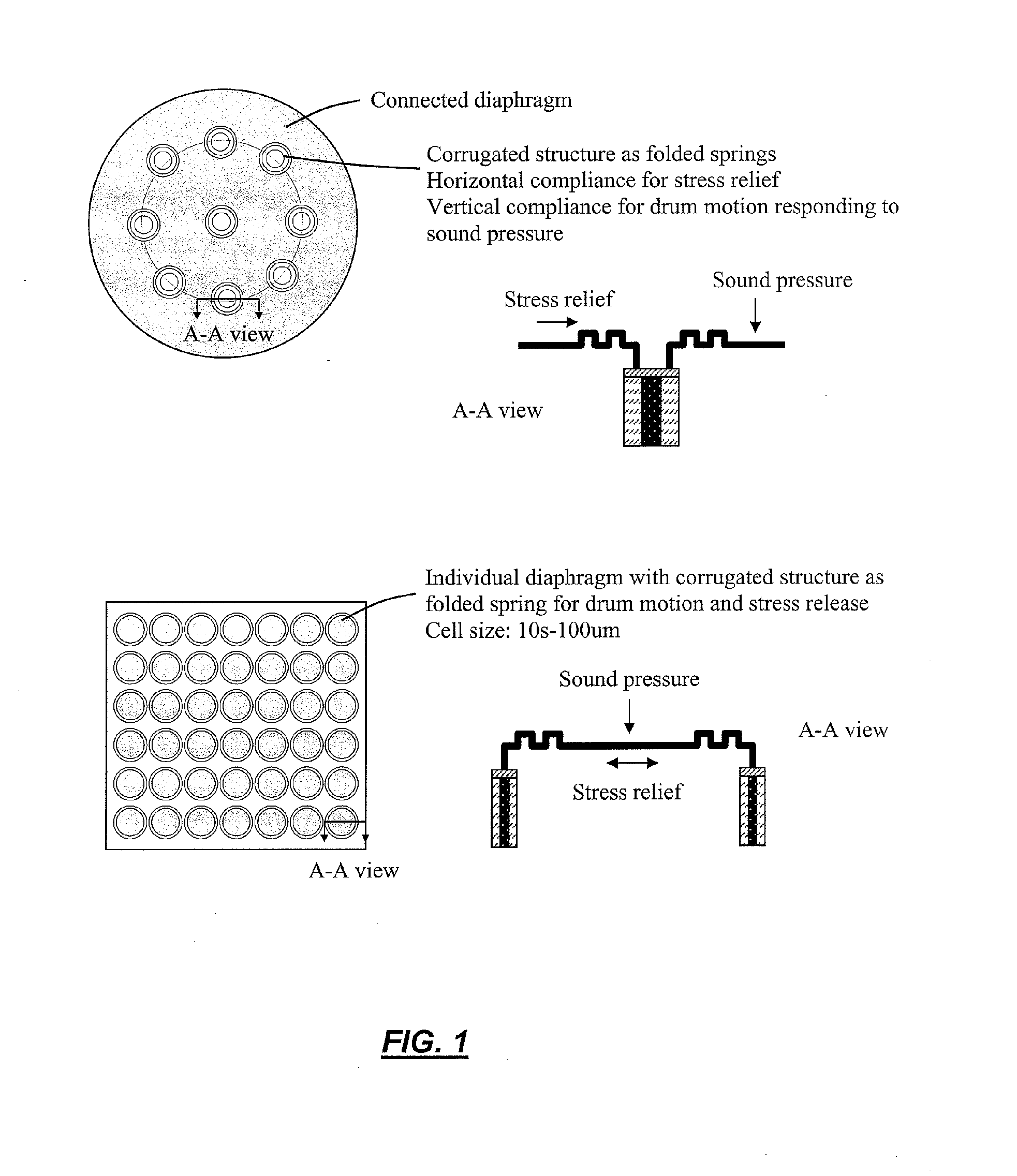

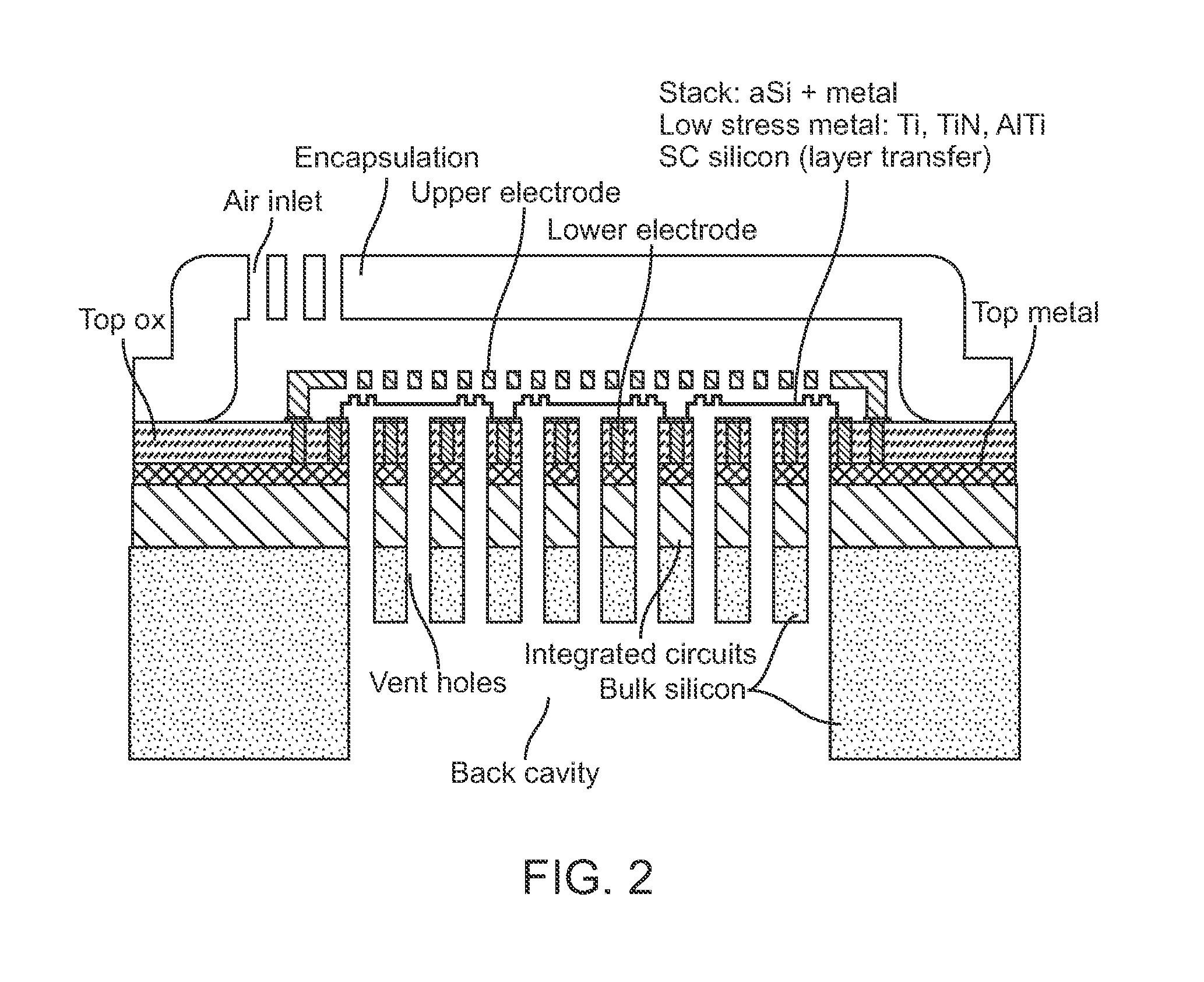

ActiveUS20100171153A1Improve performanceSmall sizeFluid pressure measurement by electric/magnetic elementsSemiconductor/solid-state device manufacturingCMOSFoundry

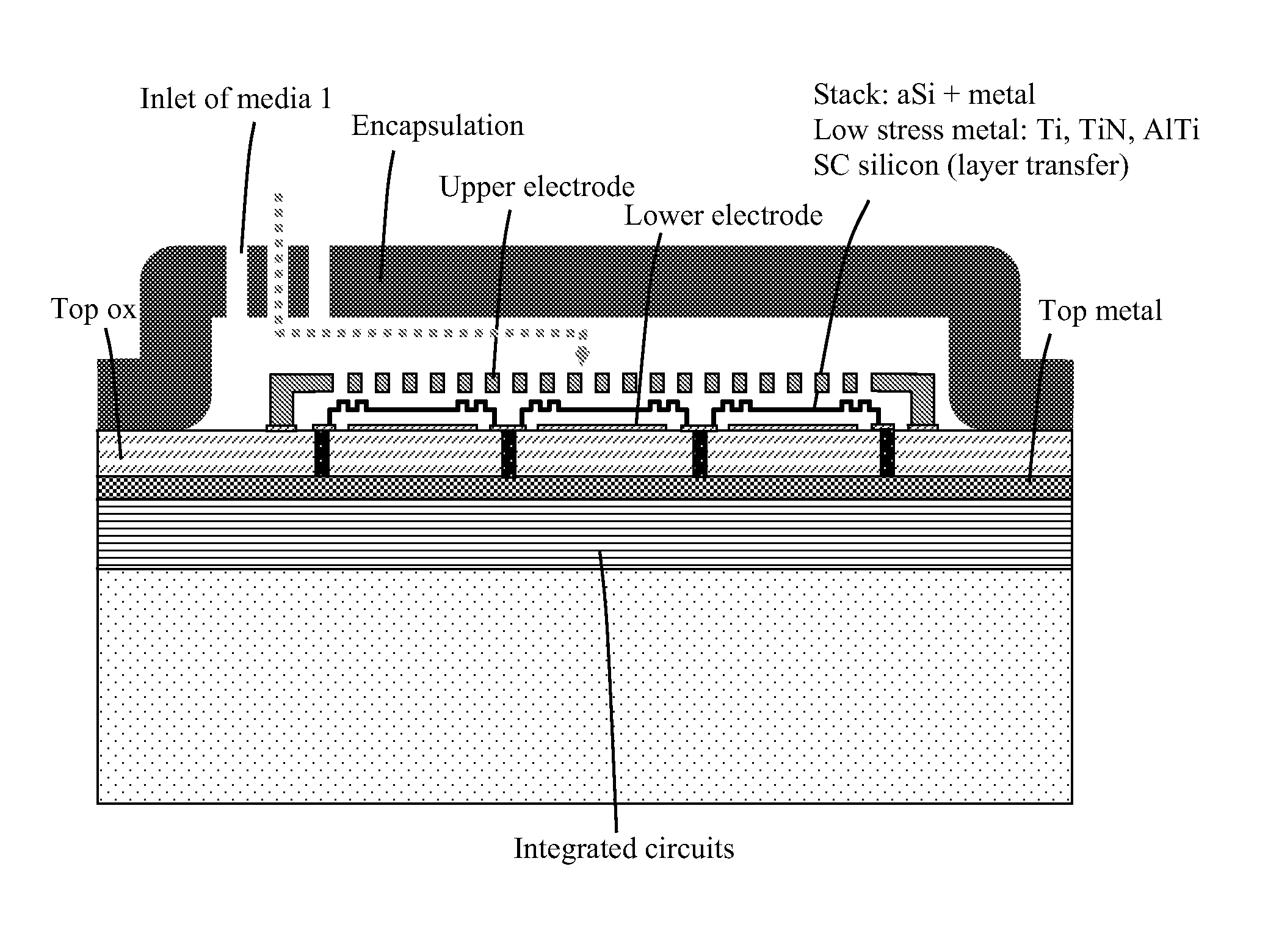

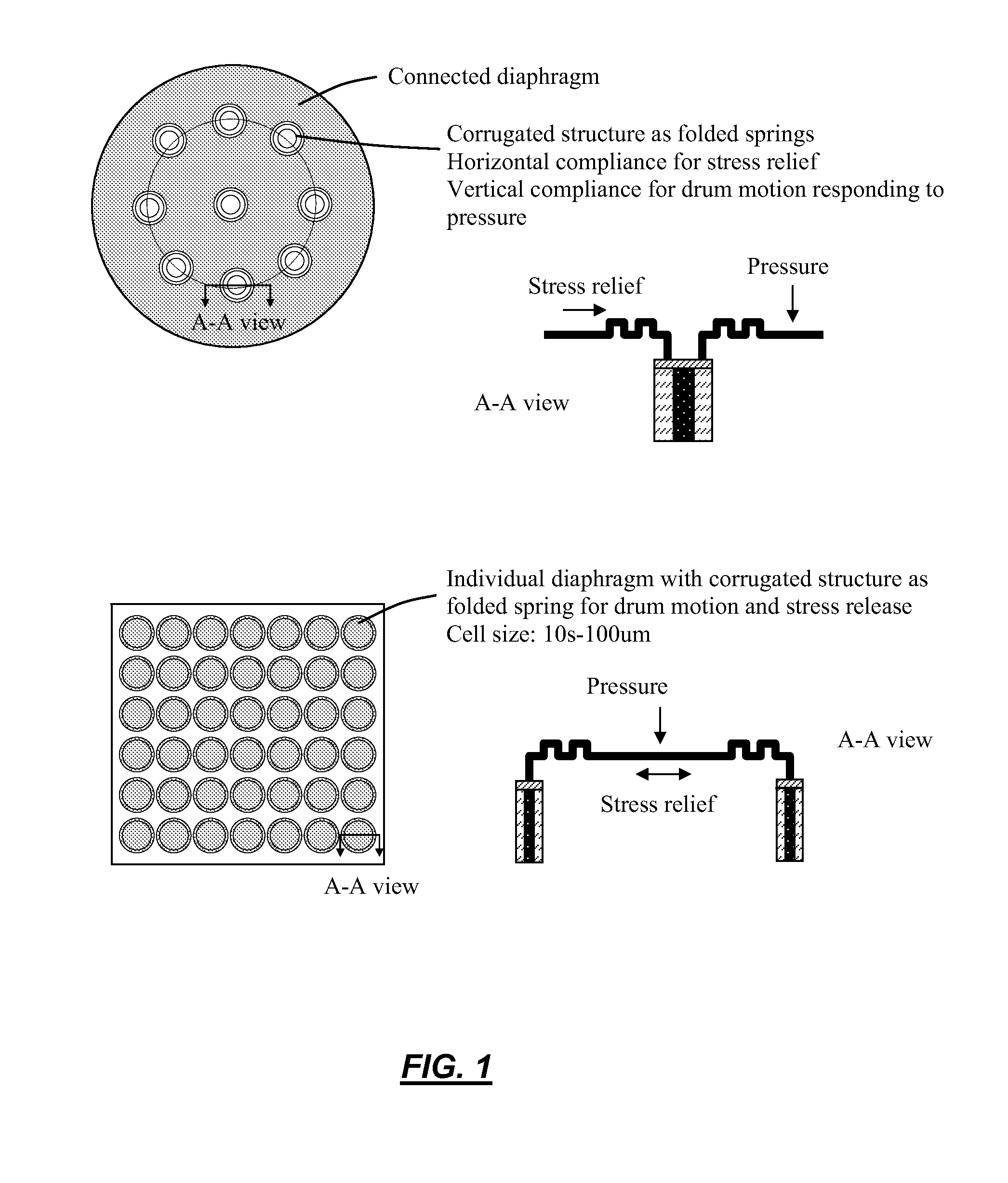

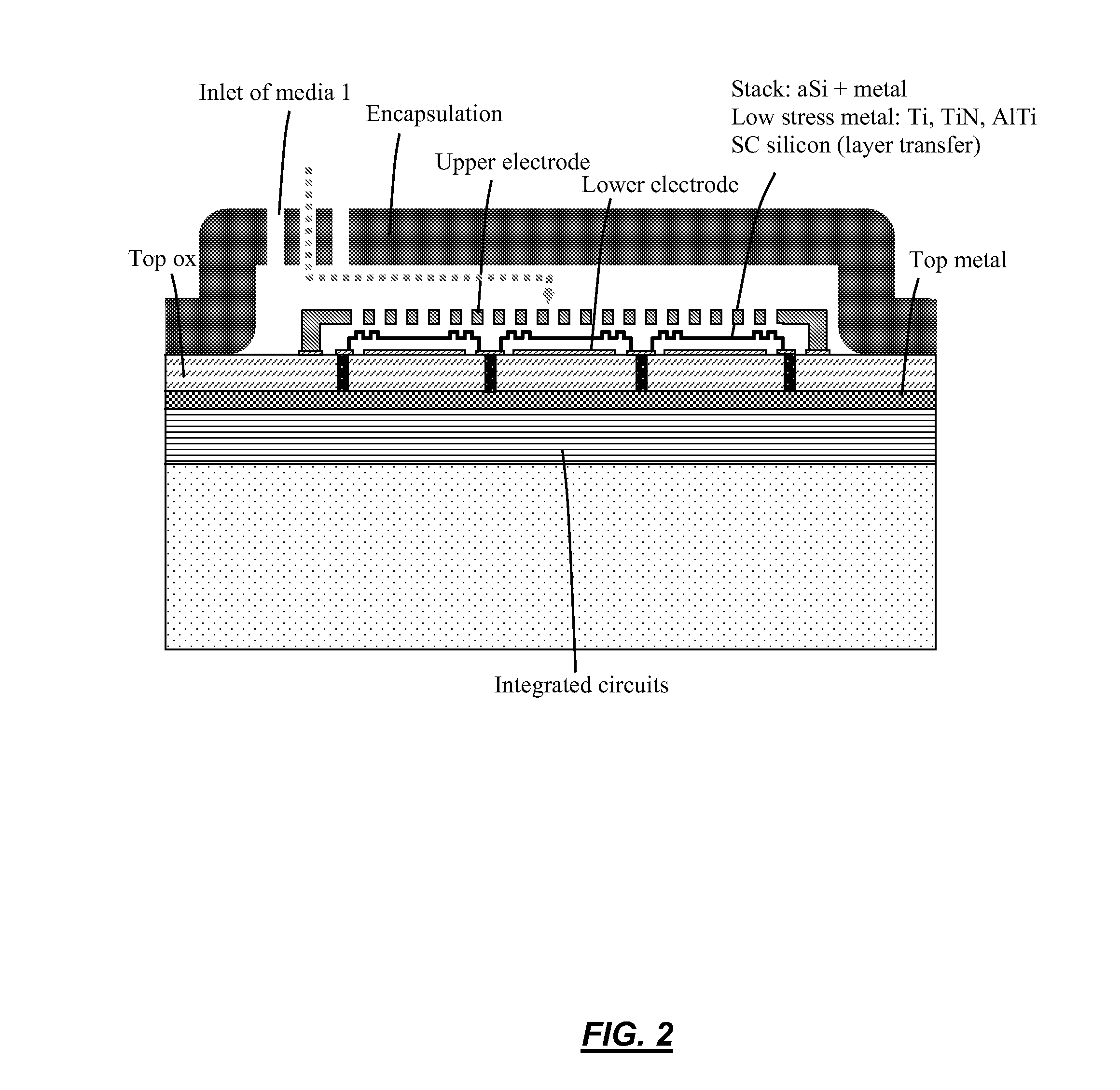

A monolithically integrated MEMS pressure sensor and CMOS substrate using IC-Foundry compatible processes. The CMOS substrate is completed first using standard IC processes. A diaphragm is then added on top of the CMOS. In one embodiment, the diaphragm is made of deposited thin films with stress relief corrugated structure. In another embodiment, the diaphragm is made of a single crystal silicon material that is layer transferred to the CMOS substrate. In an embodiment, the integrated pressure sensor is encapsulated by a thick insulating layer at the wafer level. The monolithically integrated pressure sensor that adopts IC foundry-compatible processes yields the highest performance, smallest form factor, and lowest cost.

Owner:MOVELLA INC

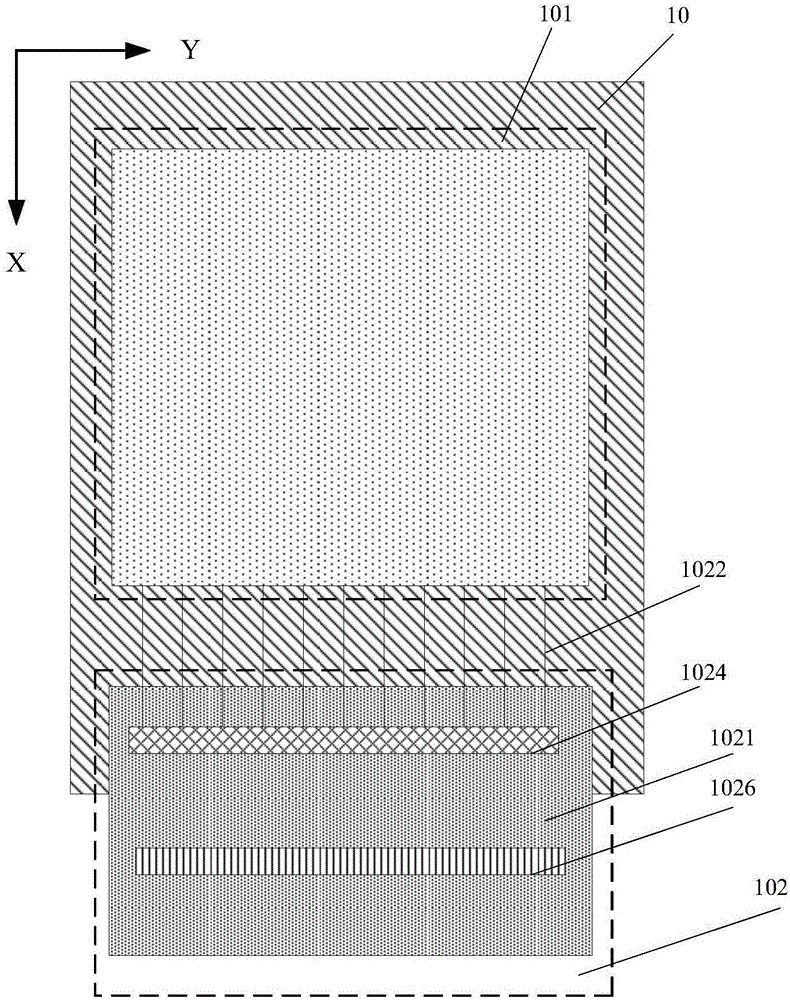

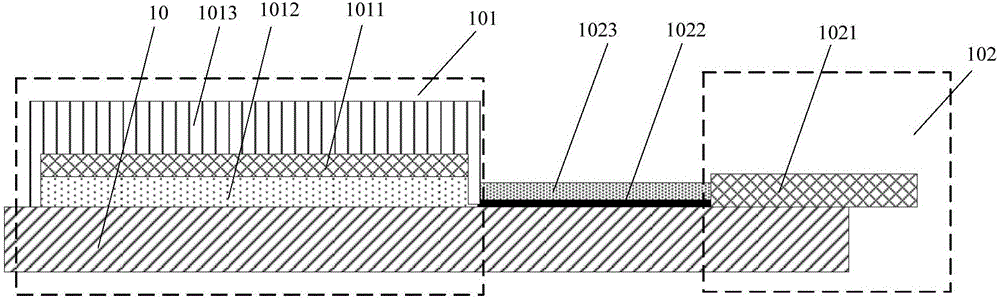

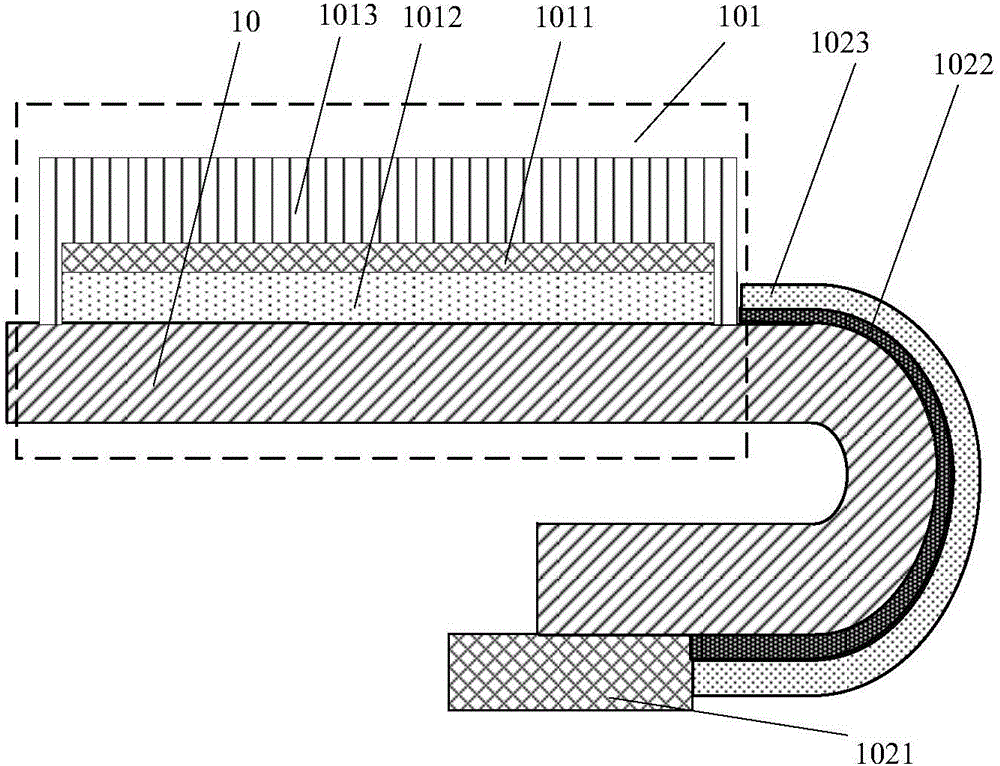

Flexible display panel and device

ActiveCN106252380AAffect the display effectEffective protectionSolid-state devicesSemiconductor devicesOrganic filmOrganic light emitting device

The invention discloses a touch control display panel. The touch control display panel is provided with a first region and a second region and is characterized in that the touch control display panel comprises a flexible substrate, an organic light emitting device layer, a driving circuit layer, a flexible circuit board and a metal line; the organic light emitting device layer is arranged on the first region and is provided with multiple organic light emitting display pixels; the driving circuit layer is formed between the flexible substrate and the organic light emitting device layer and is provided with a driving circuit used for providing driving signals for the organic light emitting display pixels; the flexible circuit board is arranged on the second region and formed on the flexible substrate; the metal line is connected between the flexible circuit board and the driving circuit; and a part of the metal line is arranged in a bending region between the first region and the second region; and the flexible display panel also comprises an organic film layer covering the metal line on the bending region. By arranging the organic film layer on the metal line, the metal line can be protected while stress relief is provided when the metal line is bent.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

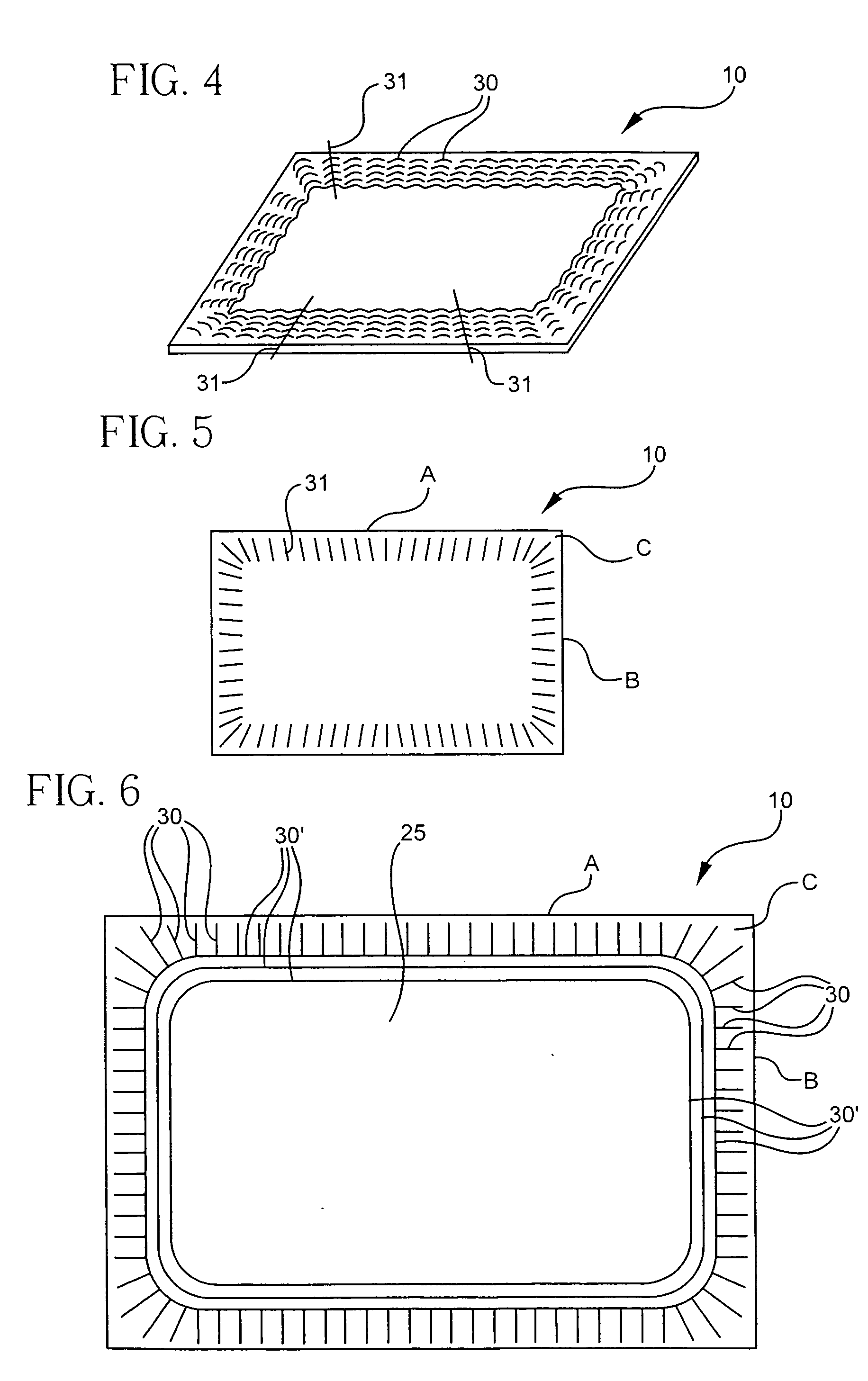

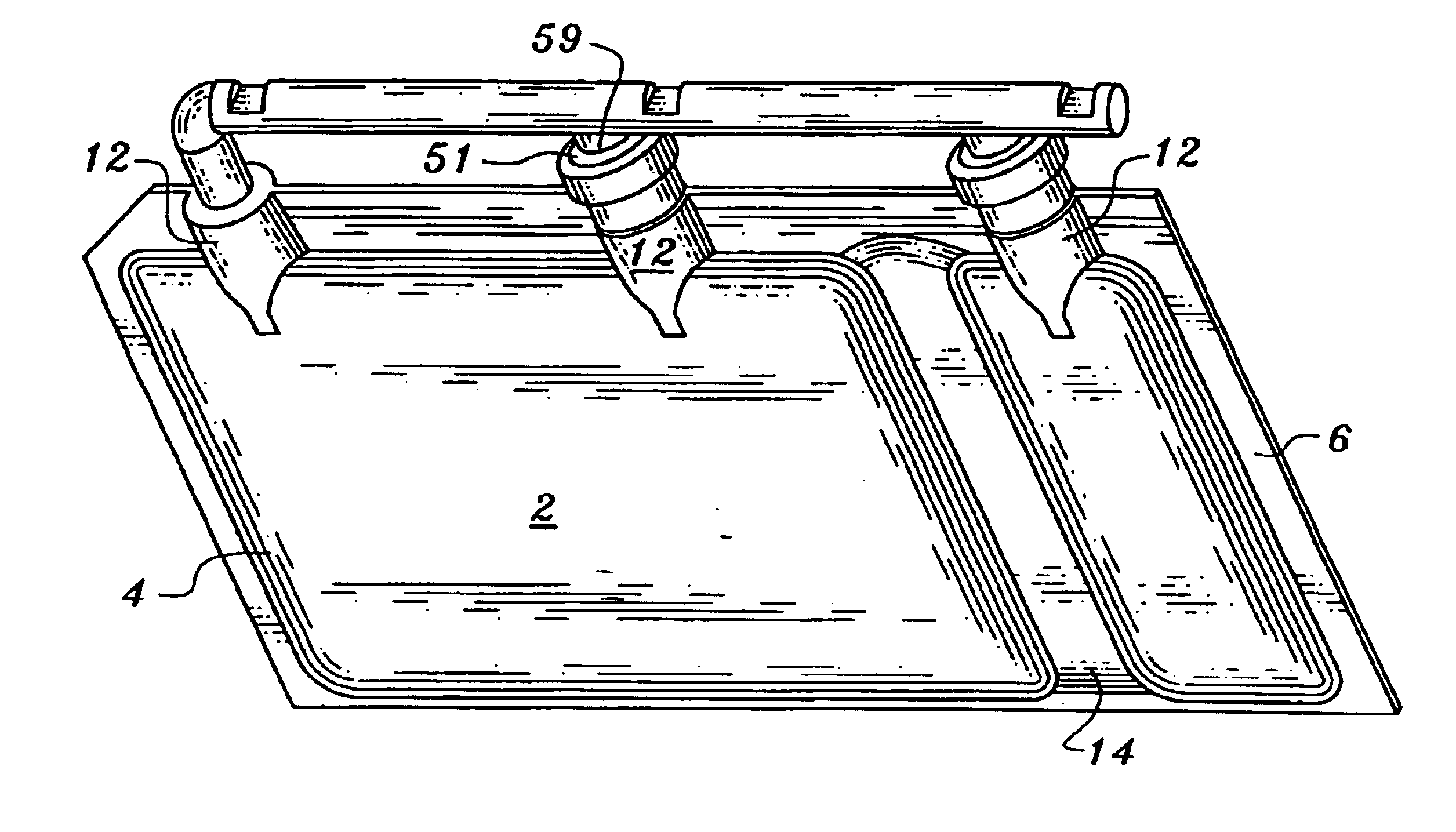

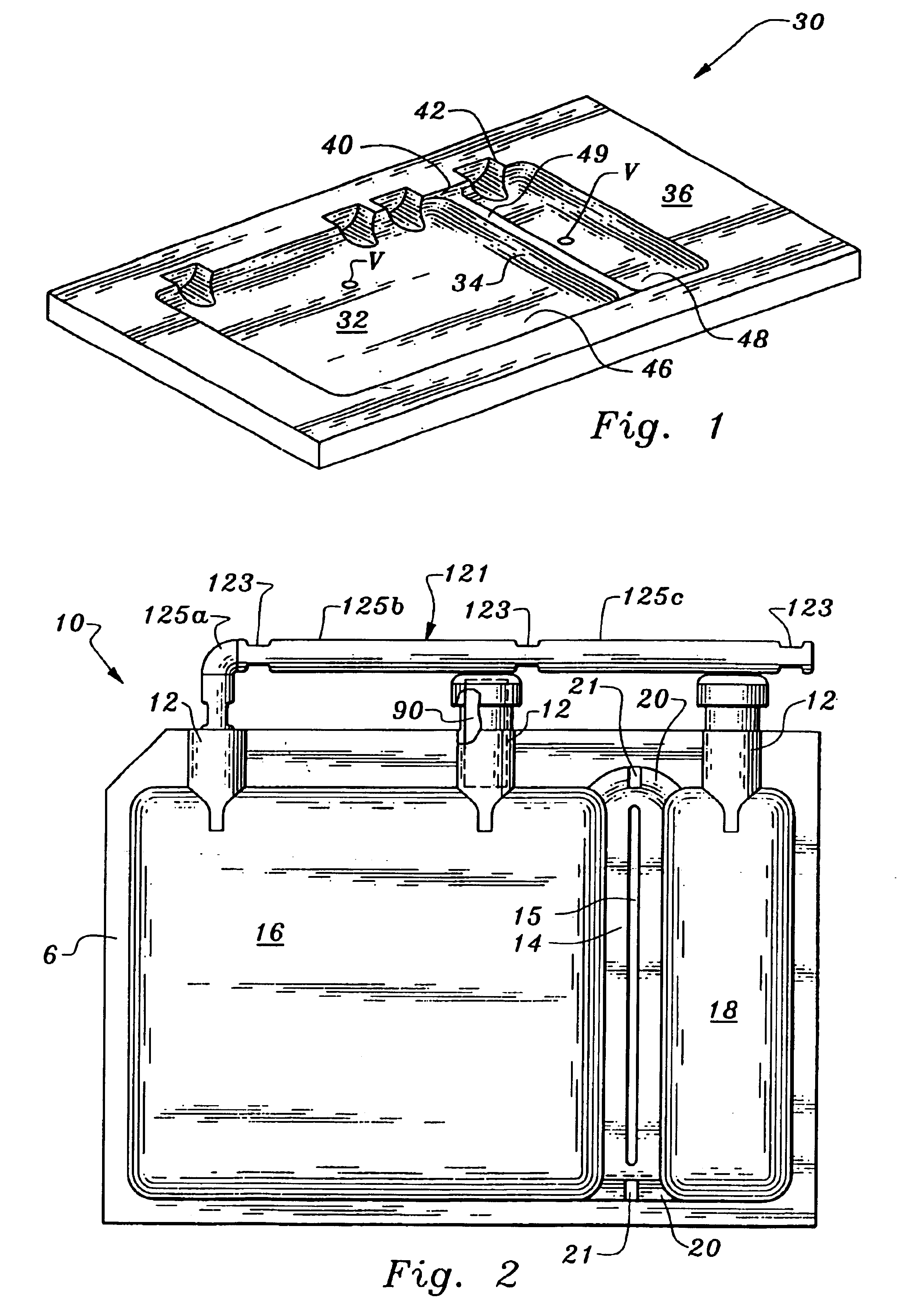

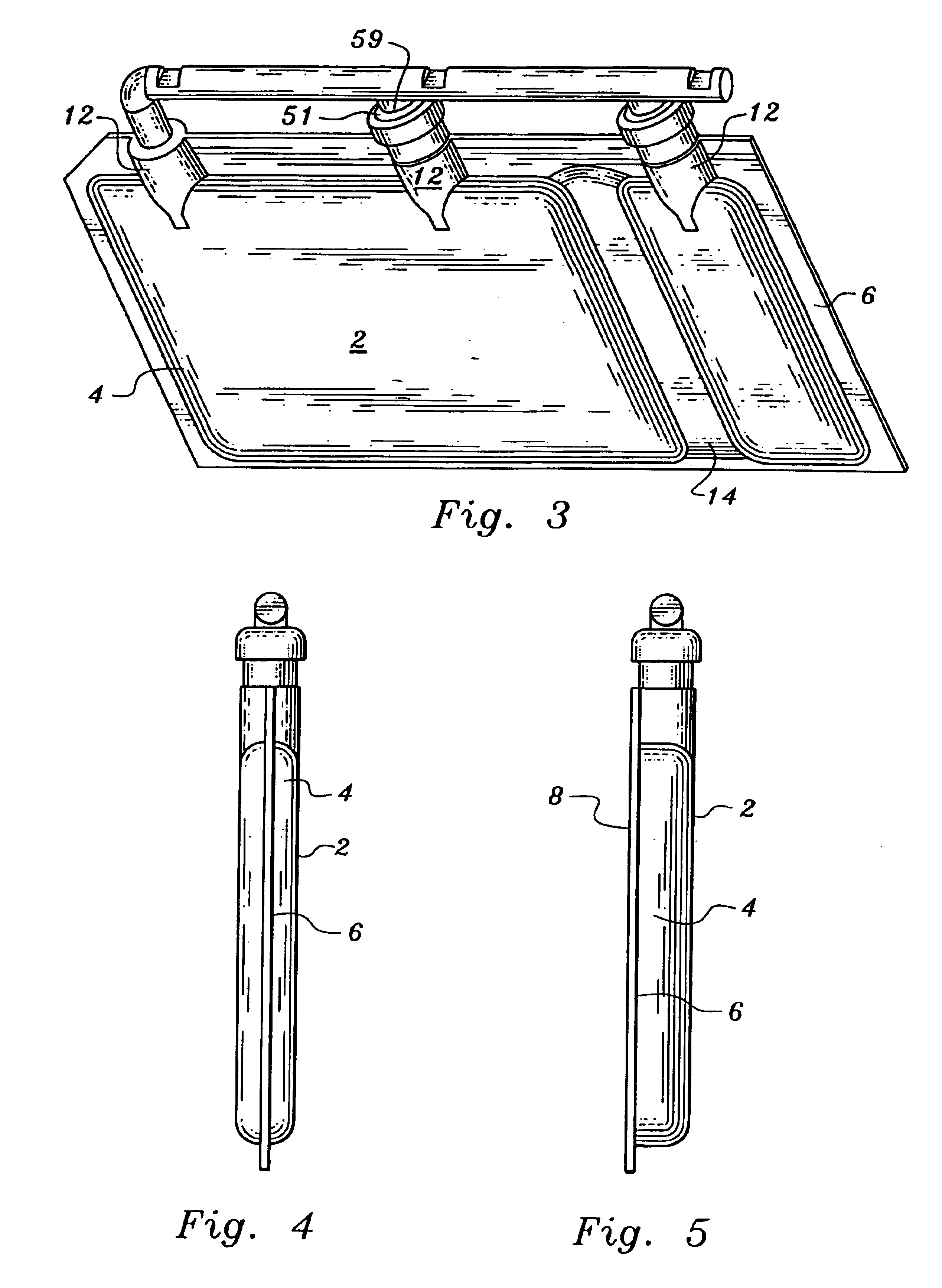

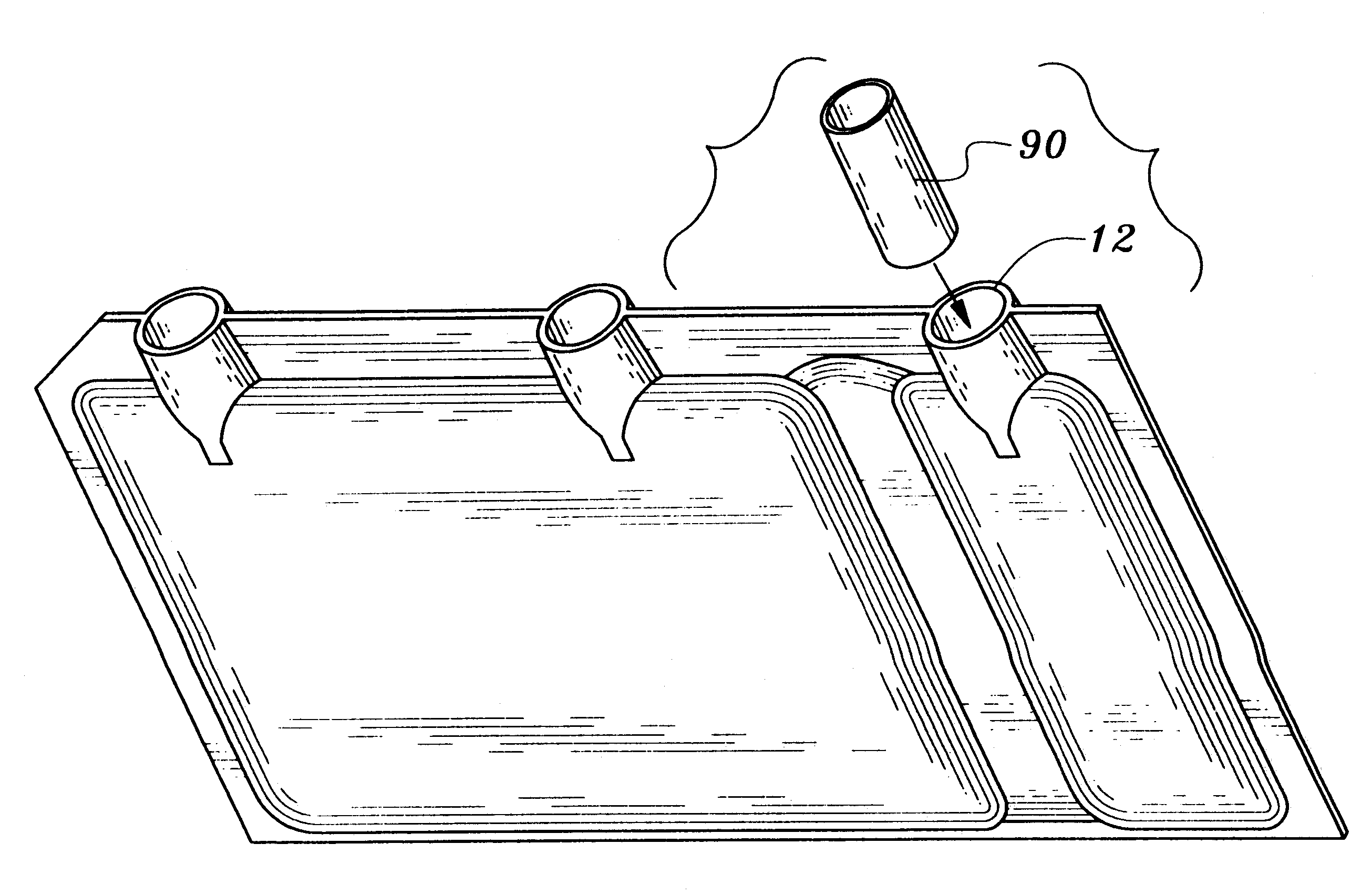

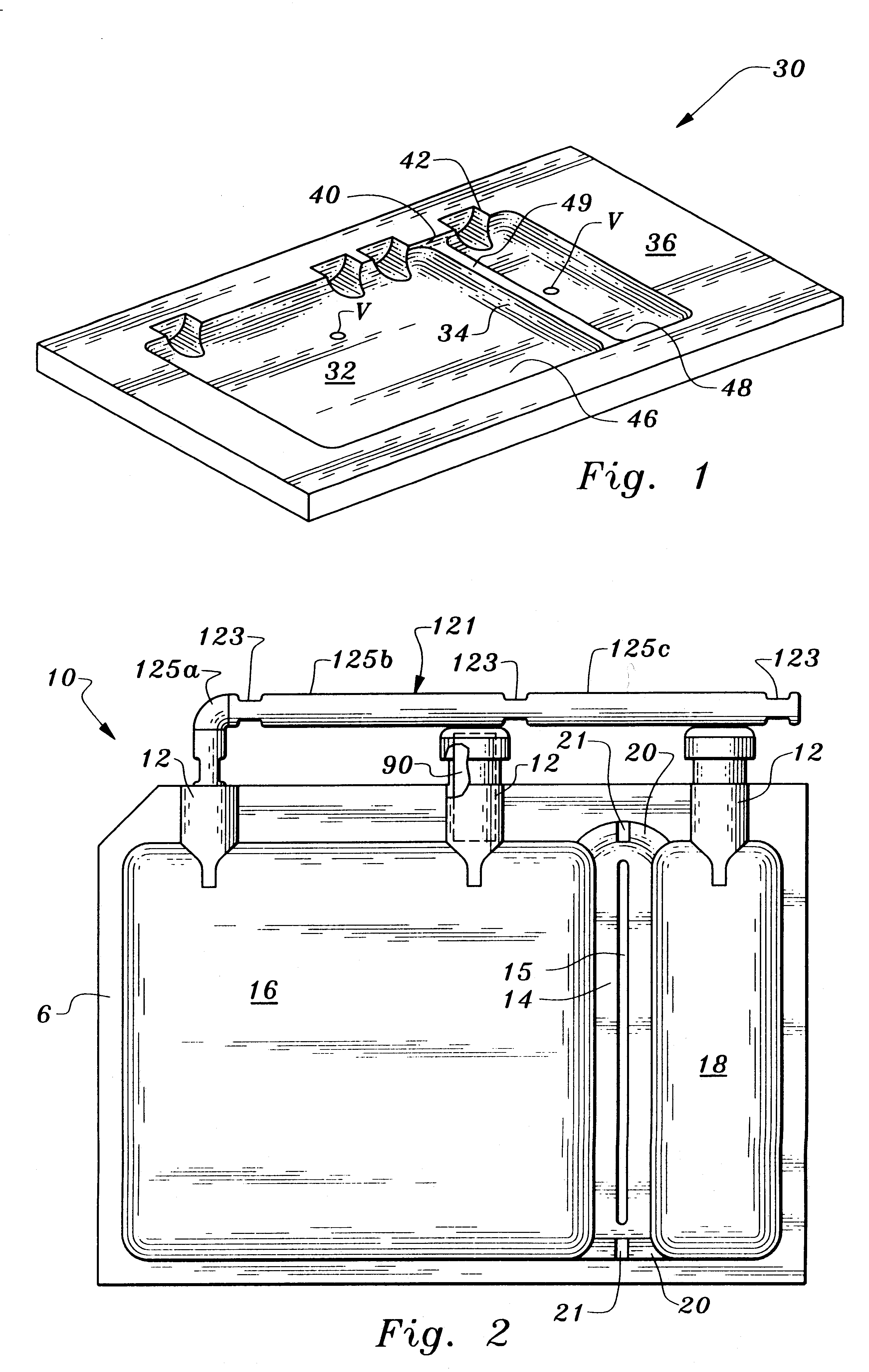

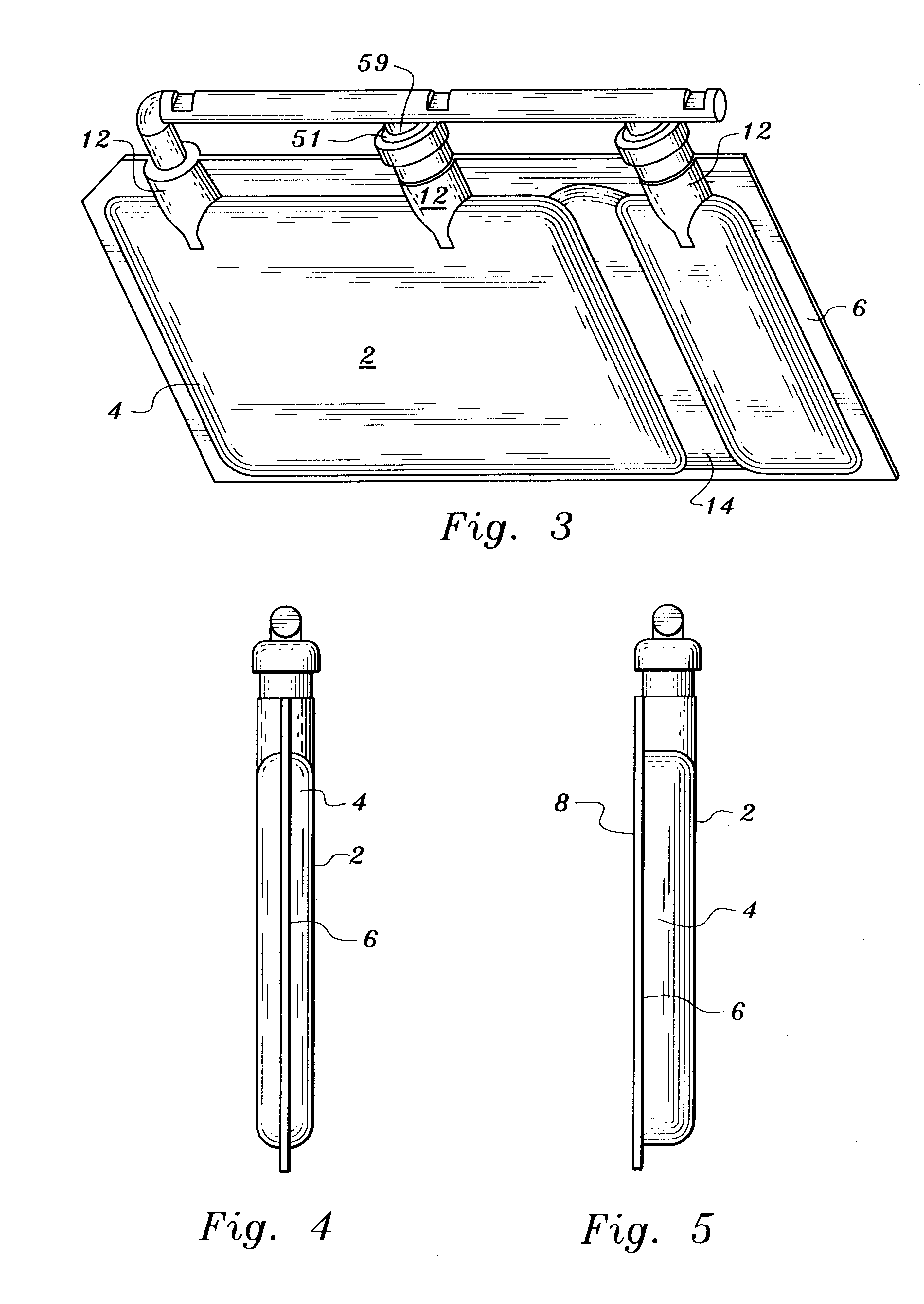

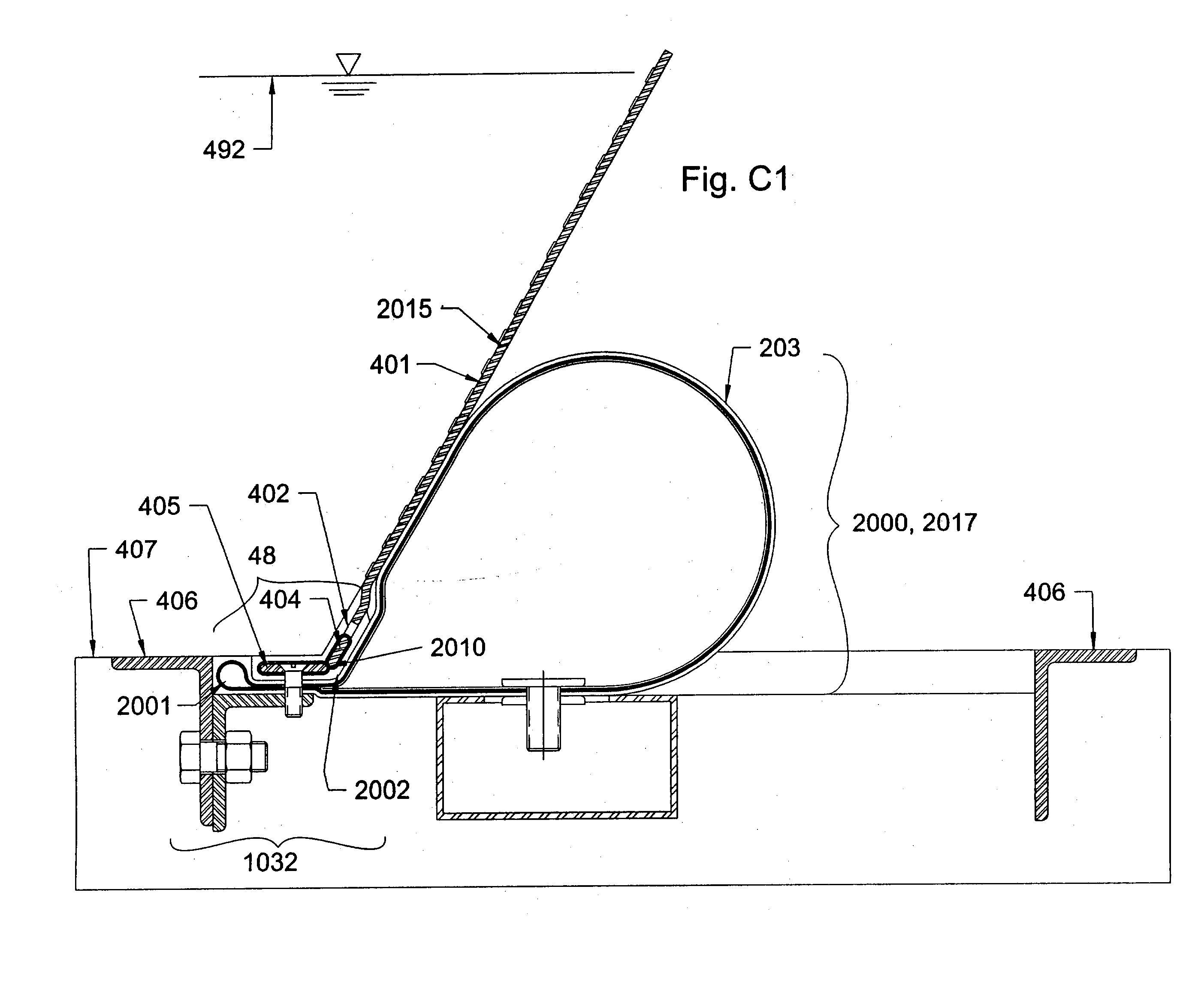

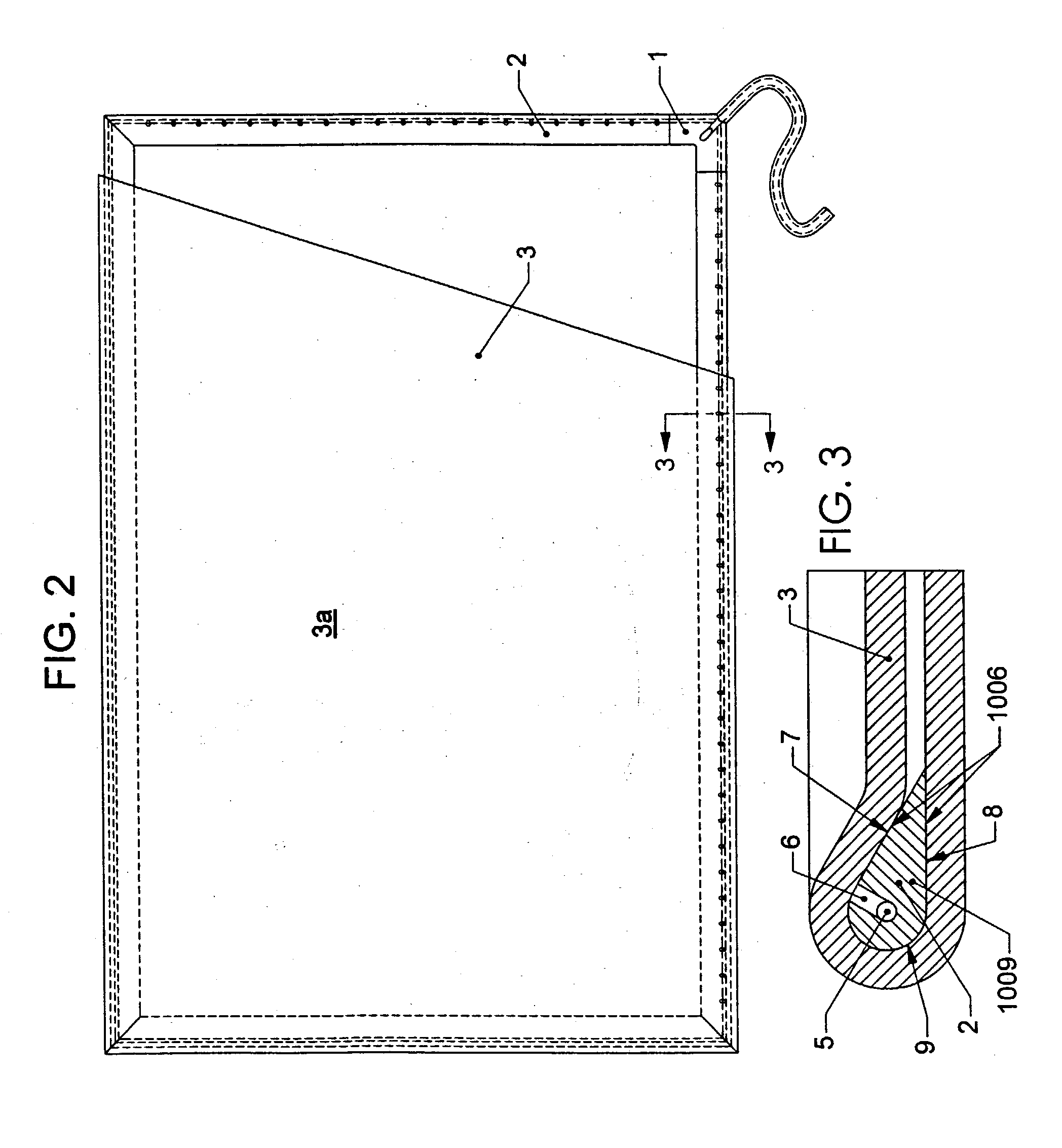

Freezing and thawing bag, mold, apparatus and method

InactiveUS6808675B1High strengthImprove integrityBioreactor/fermenter combinationsBiological substance pretreatmentsStress relievingFreeze and thaw

A bag, method of manufacture and process are disclosed for the cryopreservation of thermolabile substances. The bag is characterized as having substantially uniform thickness throughout its length and height. The bag features a radiused peripheral edge wall for stress relief and to provide the constant cross-section. A peripheral flashing circumscribes the radiused edge wall and provides a suitable purchase area for sealing so that the thus formed bag is less susceptible to fracture particularly when exposed to cryogenic temperatures. The uniform thickness of the bag promulgates uniform heat transfer to and from the contents of the bag in relation to any surrounding medium at a different temperature. The bag affords more space for efficient storage and reduces heat invasion into the contents of the bag when a plurality of bags are placed with their larger planar surfaces in contact with each other.

Owner:CESCA THERAPEUTICS

Production method for sintered metal-ceramic layered compact and production method for thermal stress relief pad

InactiveUS20050002818A1Reduce in quantityEfficient executionThermoelectric device manufacture/treatmentTransportation and packagingMicrowaveStress relief

The present invention provides a production method for a sintered metal-ceramic layered compact, comprising steps of: filling and layering a metal powder and a ceramic powder, or filling and layering a metal powder, a mixed powder of a metal powder and a ceramic powder, and a ceramic powder; forming a green compact of the layered powders by compacting the layered powders; and sintering a layer including the metal of the green compact at a temperature of lower than a melting point of the metal by heating by irradiation of microwaves in a non-oxidizing atmosphere.

Owner:HITACHI POWDERED METALS COMPANY

Freezing and thawing bag, mold, apparatus and method

InactiveUS6232115B1High strengthImprove integrityBioreactor/fermenter combinationsBiological substance pretreatmentsStress relievingFreeze and thaw

A bag, method of manufacture and process are disclosed for the cryopreservation of thermolabile substances. The bag is characterized as having substantially uniform thickness throughout its length and height. The bag features a radiused peripheral edge wall for stress relief and to provide the constant cross-section. A peripheral flashing circumscribes the radiused edge wall and provides a suitable purchase area for sealing so that the thus formed bag is less susceptible to fracture particularly when exposed to cryogenic temperatures. The uniform thickness of the bag promulgates uniform heat transfer to and from the contents of the bag in relation to any surrounding medium at a different temperature. The bag affords more space for efficient storage and reduces heat invasion into the contents of the bag when a plurality of bags are placed, with their larger planar surfaces, in contact with each other.

Owner:NEW YORK BLOOD CENT

Method and structure of monolithetically integrated micromachined microphone using IC foundry-compatiable processes

A monolithically integrated MEMS and CMOS substrates provided by an IC-foundry compatible process. The CMOS substrate is completed first using standard IC processes. A diaphragm with stress relief corrugated structure is then fabricated on top of the CMOS. Air vent holes are then etched in the CMOS substrate. Finally, the microphone device is encapsulated by a thick insulating layer at the wafer level. The monolithically integrated microphone that adopts IC foundry-compatible processes yields the highest performance, smallest form factor, and lowest cost. Using this architecture and fabrication flow, it is feasible and cost-effective to make an array of Silicon microphones for noise cancellation, beam forming, better directionality and fidelity.

Owner:MOVELLA INC

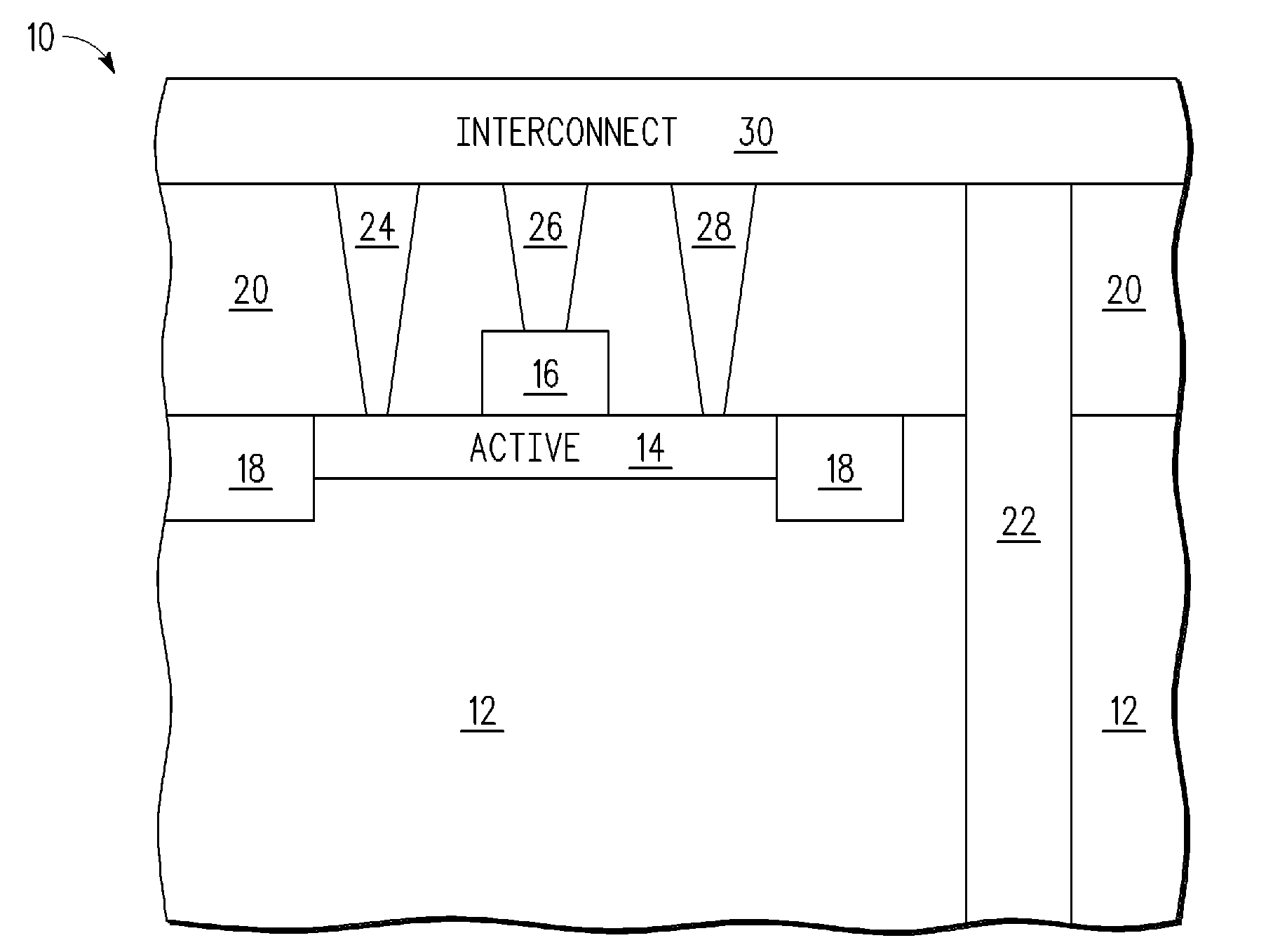

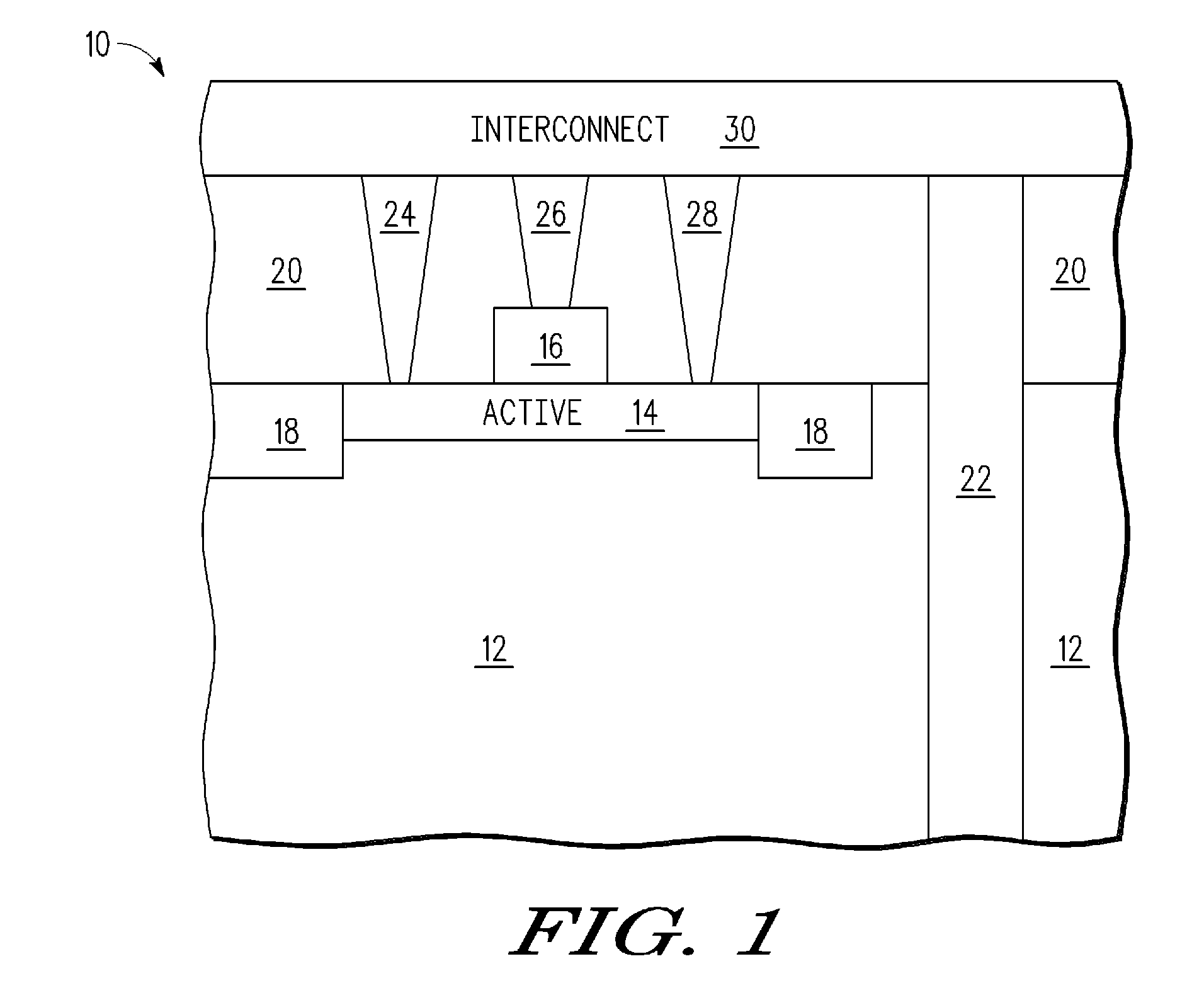

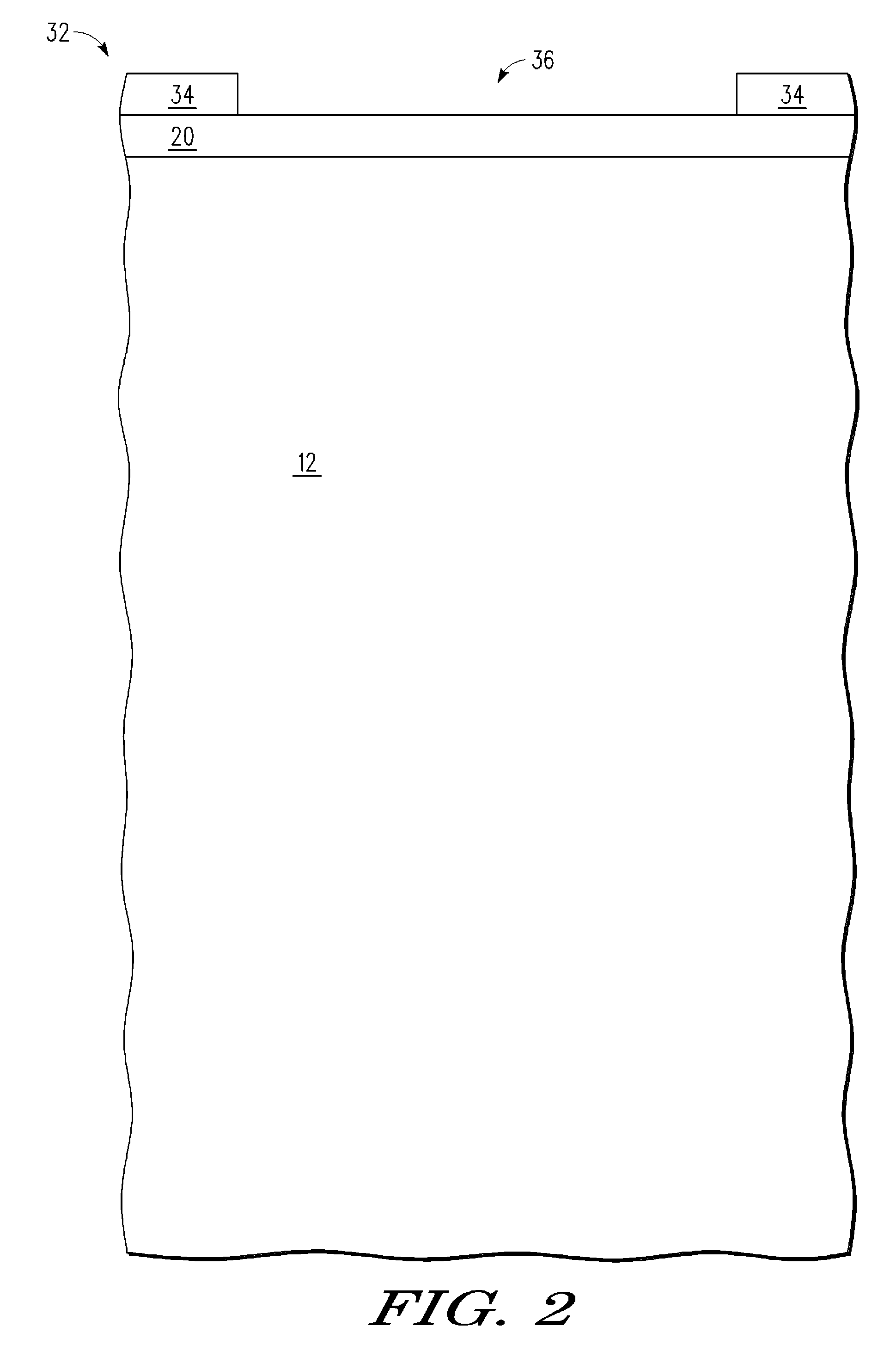

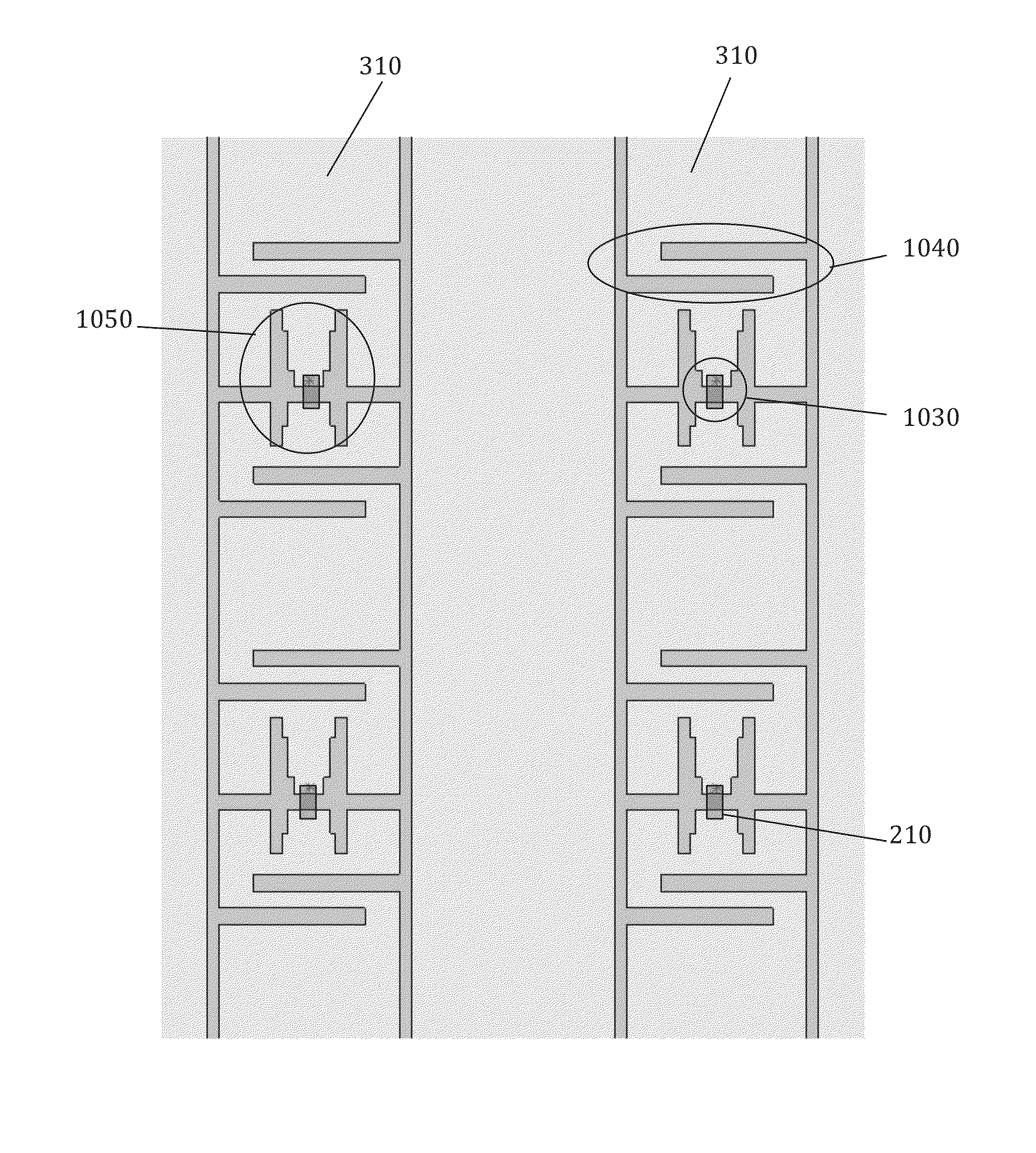

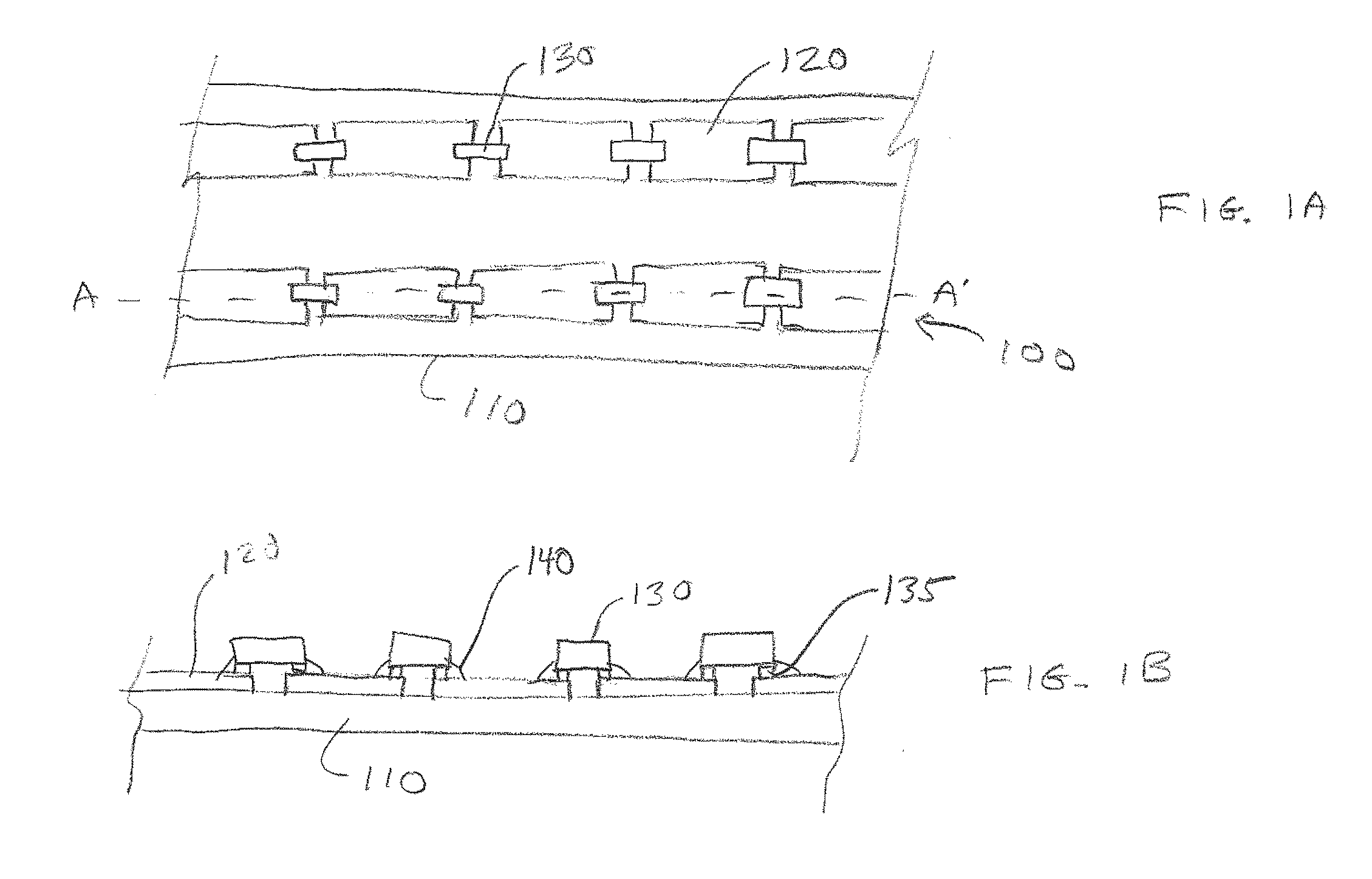

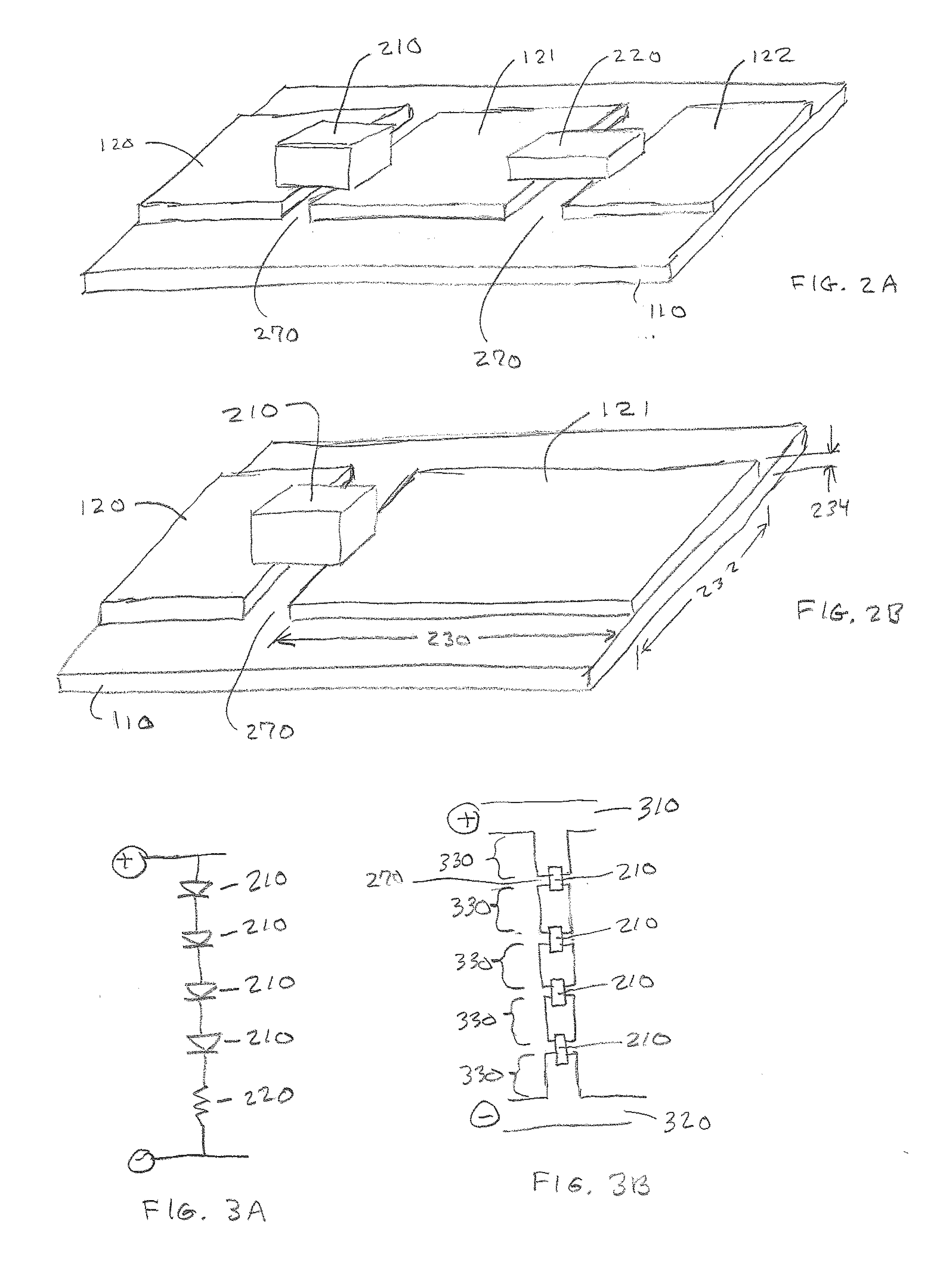

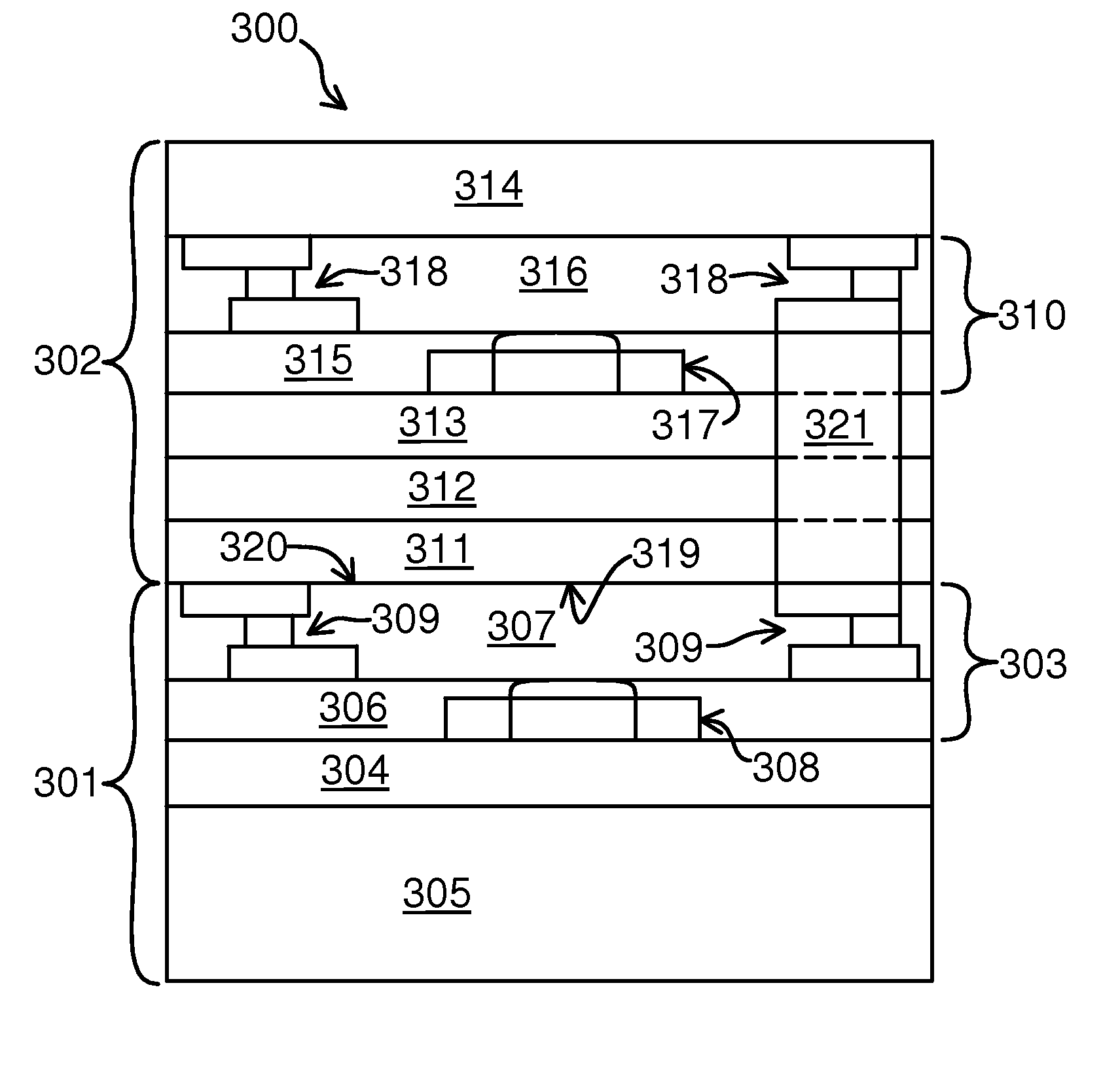

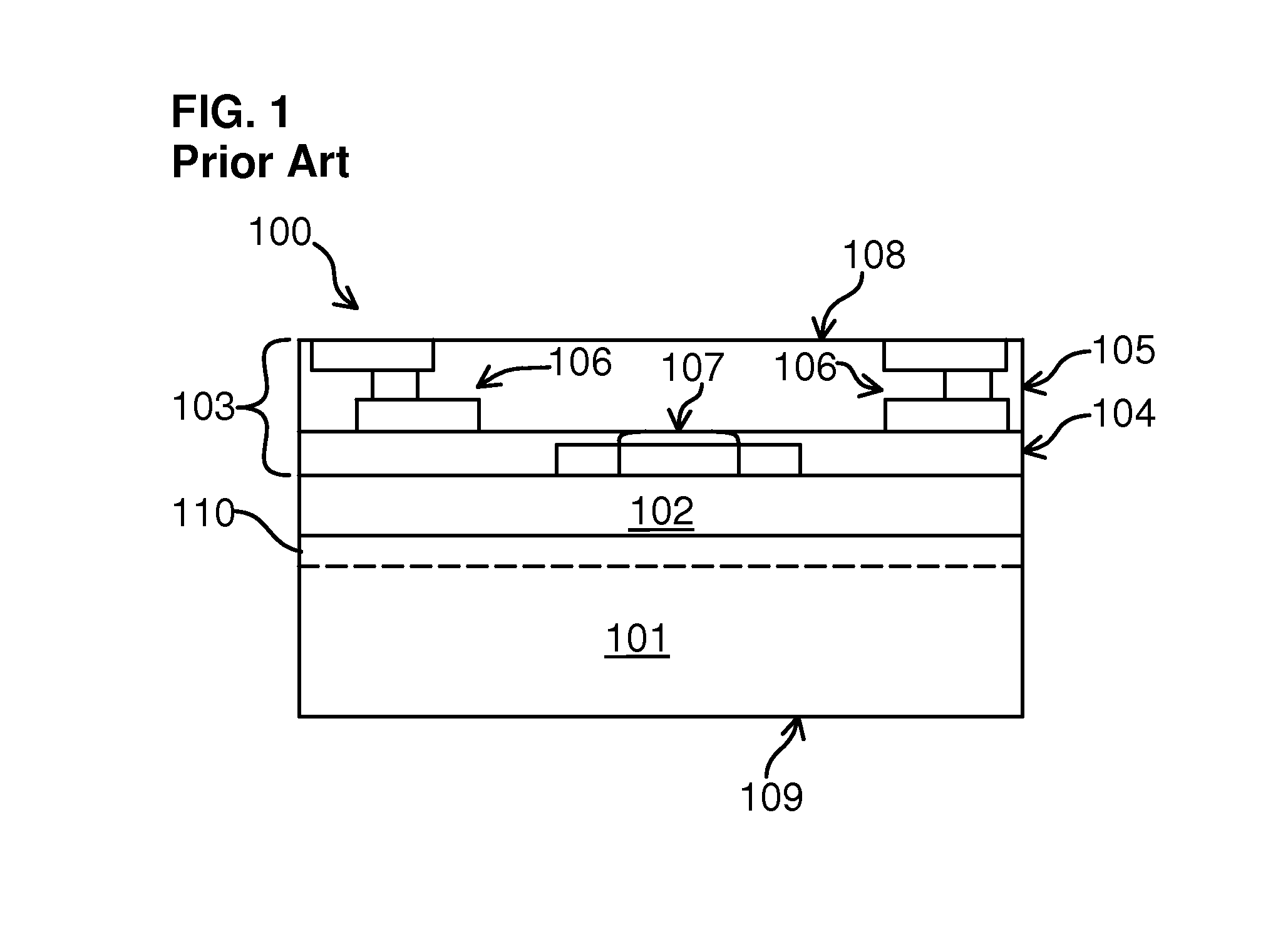

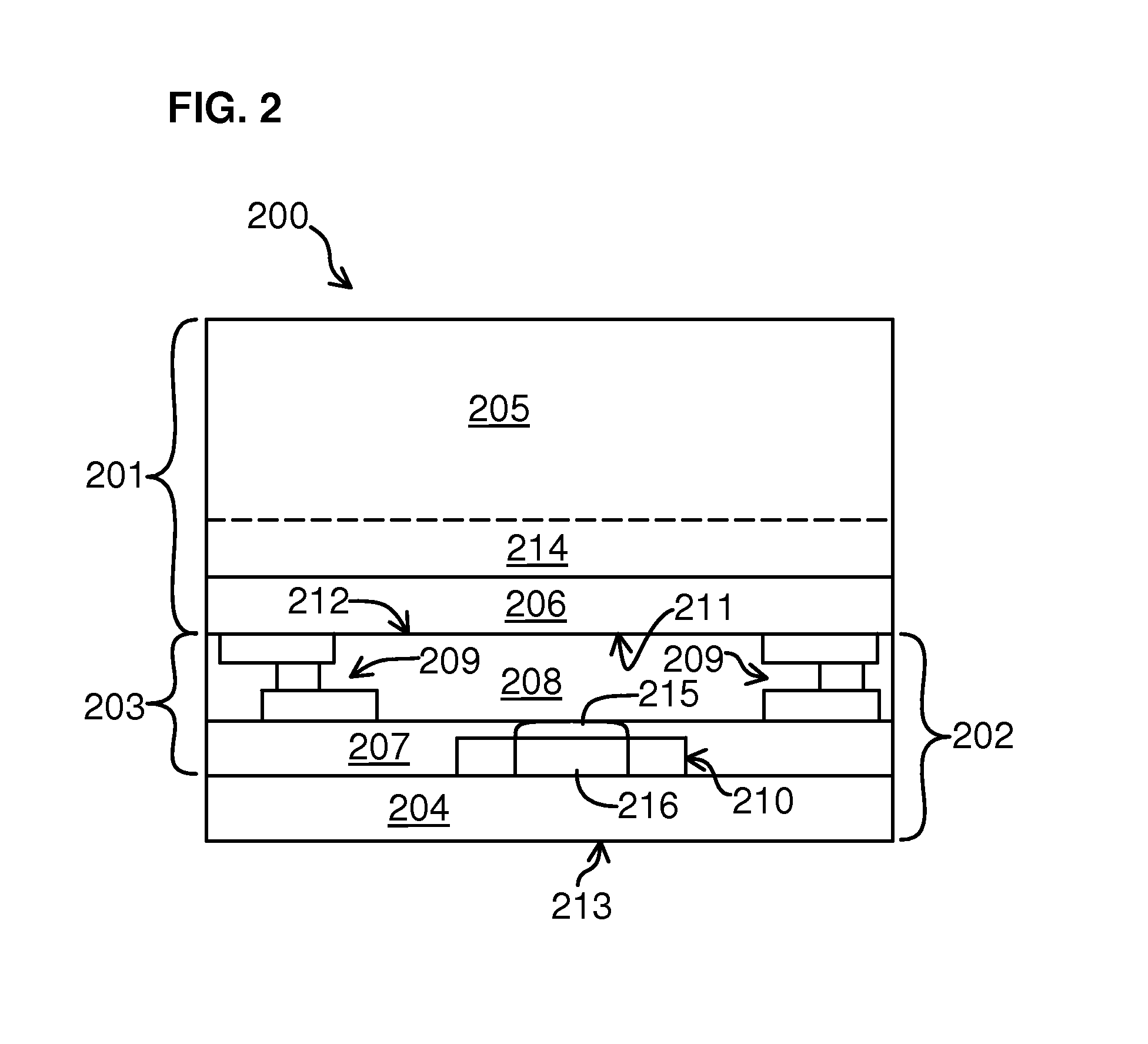

Stress relief for array-based electronic devices

InactiveUS20140264407A1Relieve pressureReduce componentsSolid-state devicesSemiconductor devicesStress reliefElectronic component

In accordance with certain embodiments, an electric device includes a flexible substrate having first and second conductive traces on a first surface thereof and separated by a gap therebetween, an electronic component spanning the gap, and a stiffener configured to substantially prevent flexing of the substrate proximate the gap during flexing of the substrate.

Owner:COOLEDGE LIGHTING

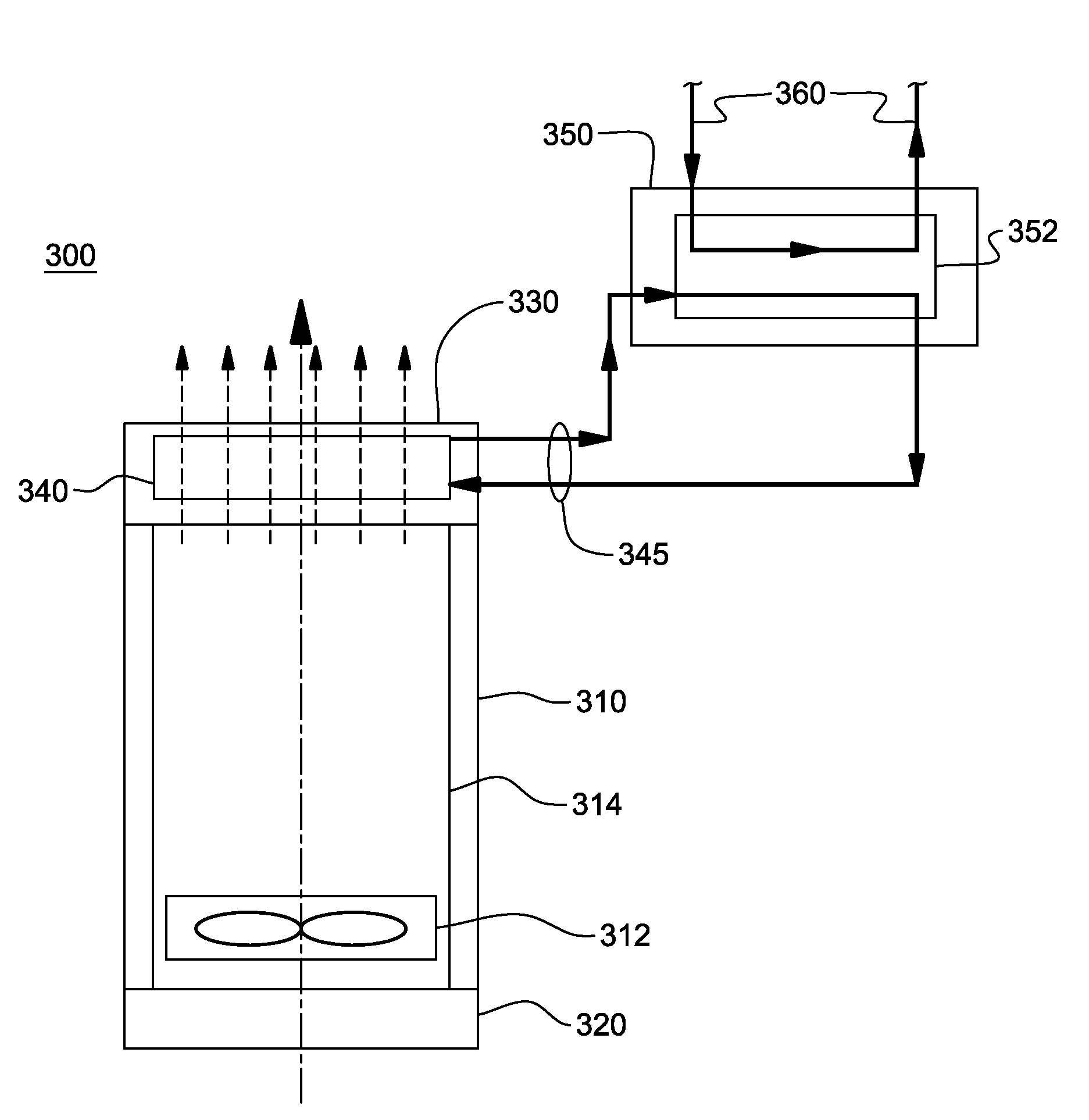

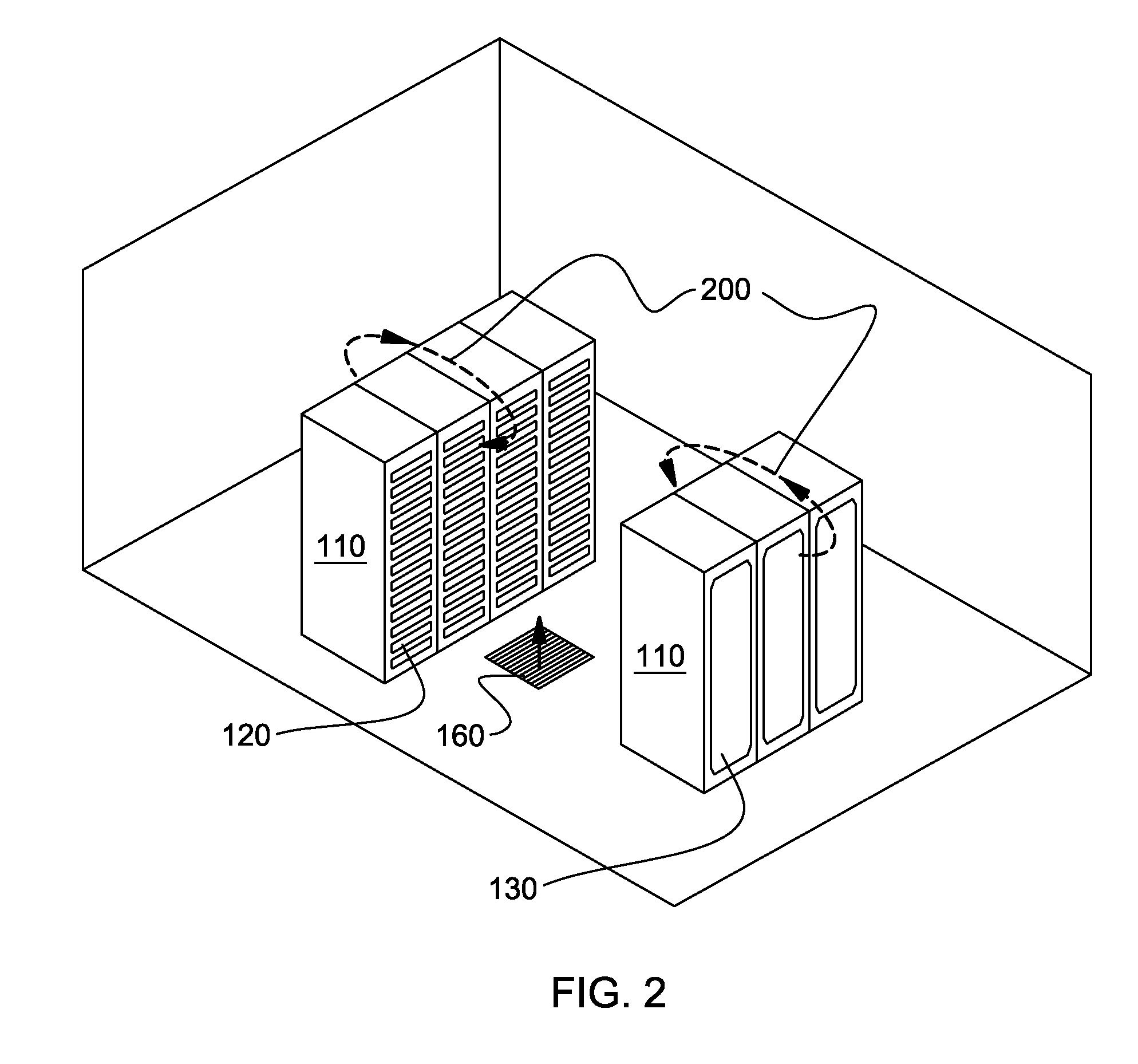

Stress relieved hose routing to liquid-cooled electronics rack door

InactiveUS20110051372A1Relieve pressureEasy accessShow cabinetsDigital data processing detailsCouplingStress relief

A cooling apparatus and method are provided which include an air-to-liquid heat exchanger and system coolant inlet and outlet plenums mounted to an electronics rack door along an edge of the door remote from the edge hingedly mounted to the rack. The plenums are in fluid communication with the heat exchanger and respectively include an inlet and outlet. Coolant supply and return hoses are disposed above the electronics rack and couple the inlet plenum to a coolant supply header and the outlet plenum to a coolant return header. The hoses are sufficiently long and flexible to open or close the door. A stress relief structure is attached to the top of the door and clamps the supply and return hoses in fixed relation to relieve stress on connect couplings at the ends of the hoses to the plenum inlet and outlet during opening or closing of the door.

Owner:IBM CORP

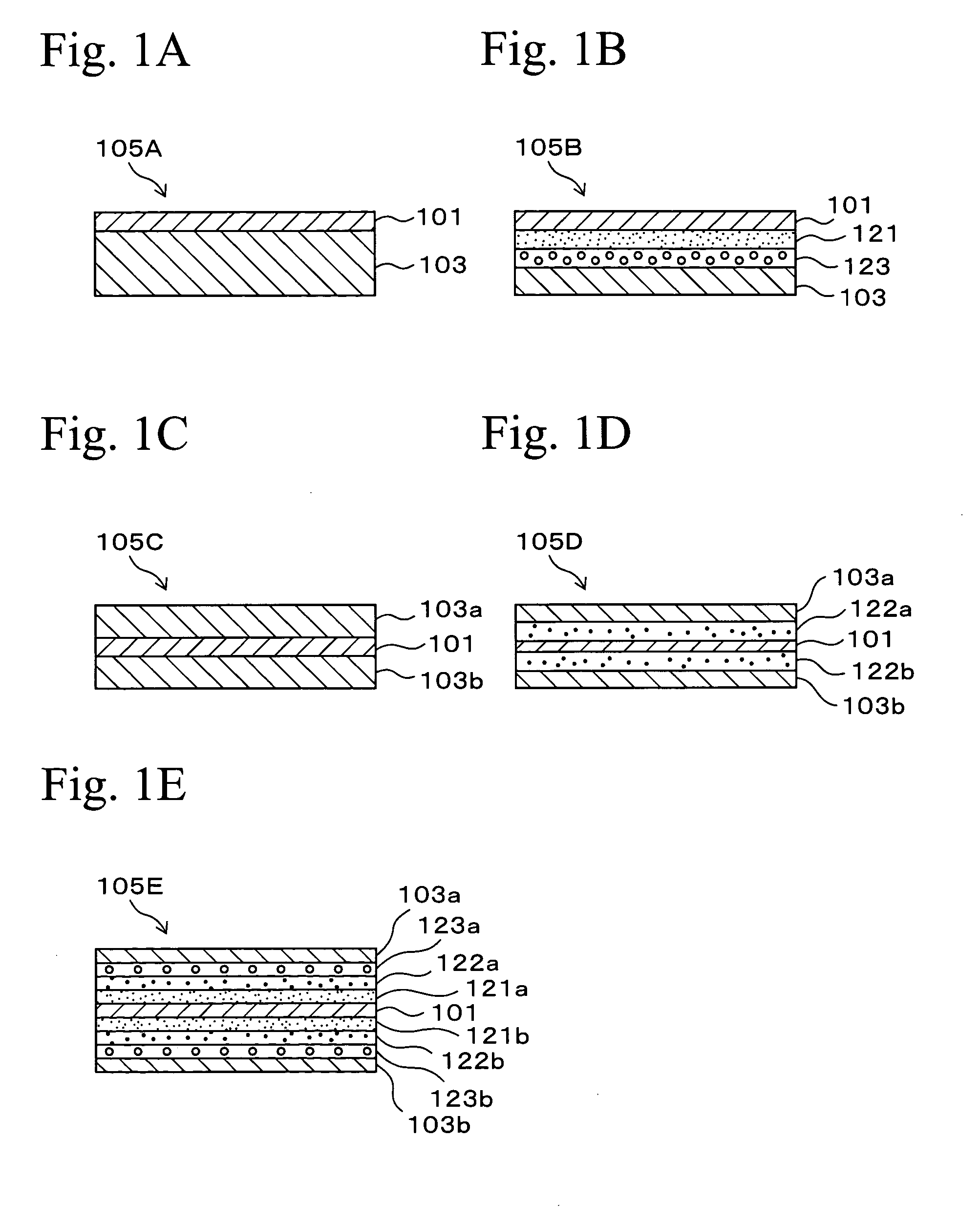

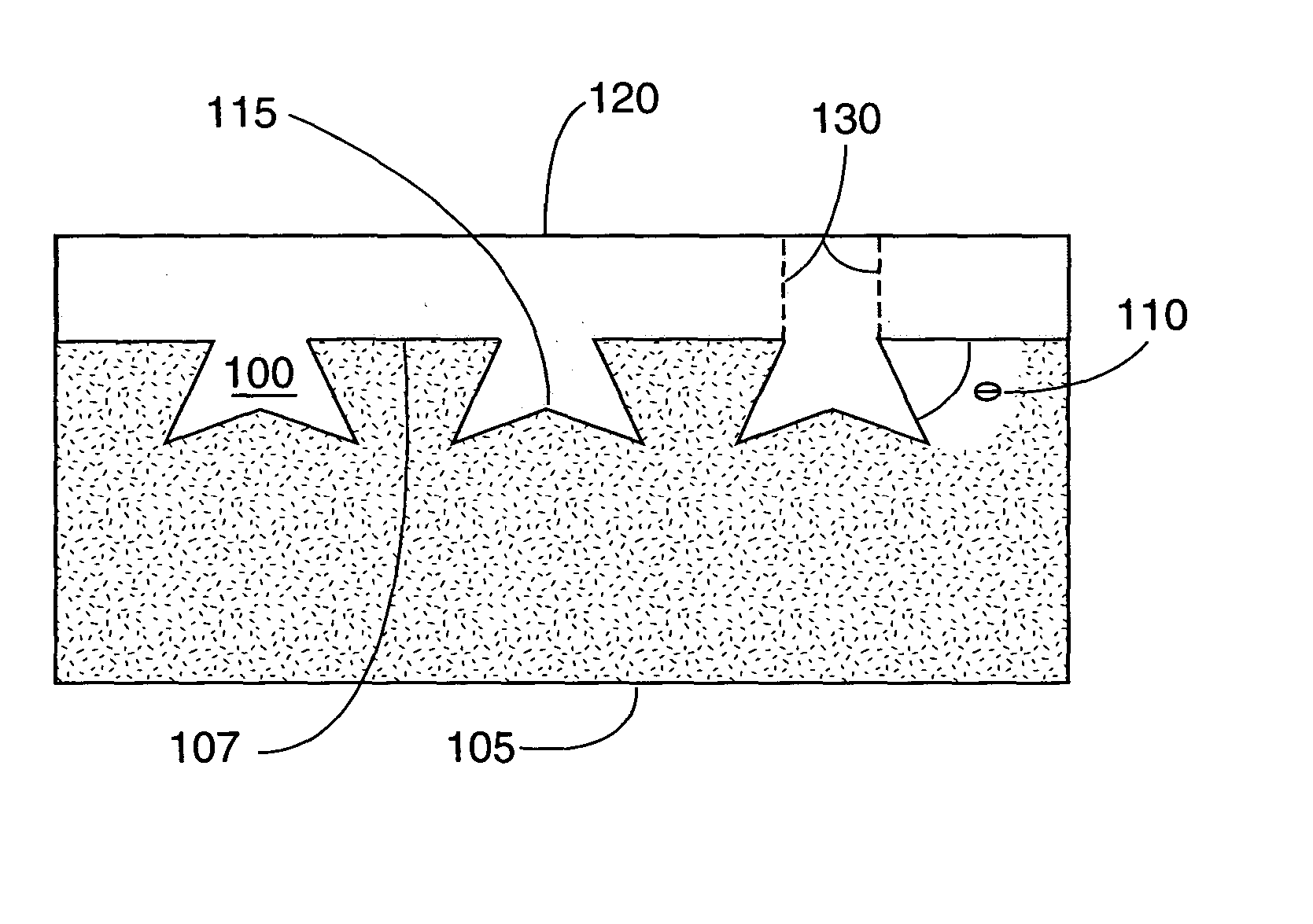

Trap Rich Layer Formation Techniques for Semiconductor Devices

ActiveUS20130084689A1Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor packageStress relief

A trap rich layer for an integrated circuit chip is formed by chemical etching and / or laser texturing of a surface of a semiconductor layer. In some embodiments, a trap rich layer is formed by a technique selected from the group of techniques consisting of laser texturing, chemical etch, irradiation, nanocavity formation, porous Si-etch, semi-insulating polysilicon, thermal stress relief and mechanical texturing. Additionally, combinations of two or more of these techniques may be used to form a trap rich layer.

Owner:QUALCOMM INC

Method for removing cracks of Rene104 nickel-based superalloy during laser additive manufacturing

ActiveCN108941560AEliminate cracksInhibition of large size cracksAdditive manufacturing apparatusTransportation and packagingRoom temperatureStress relief

Owner:CENT SOUTH UNIV

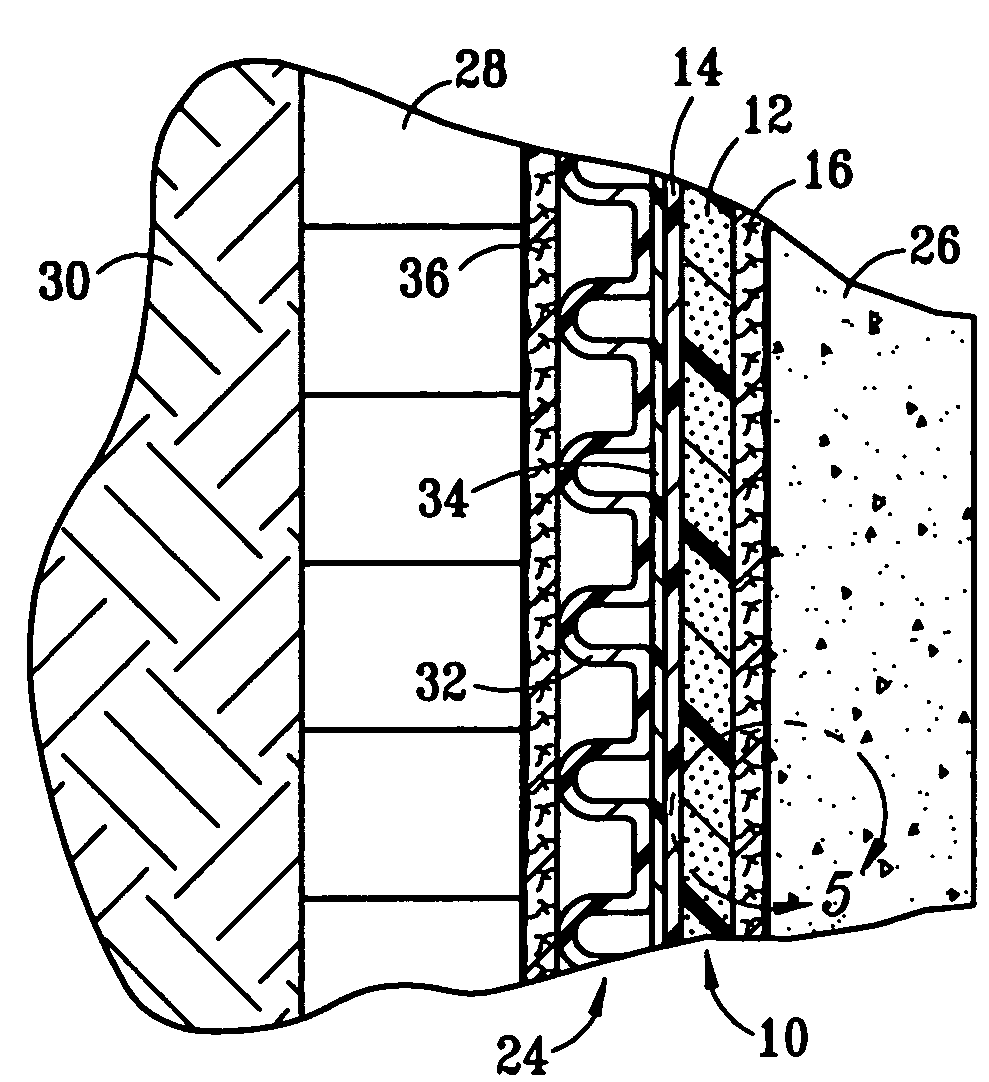

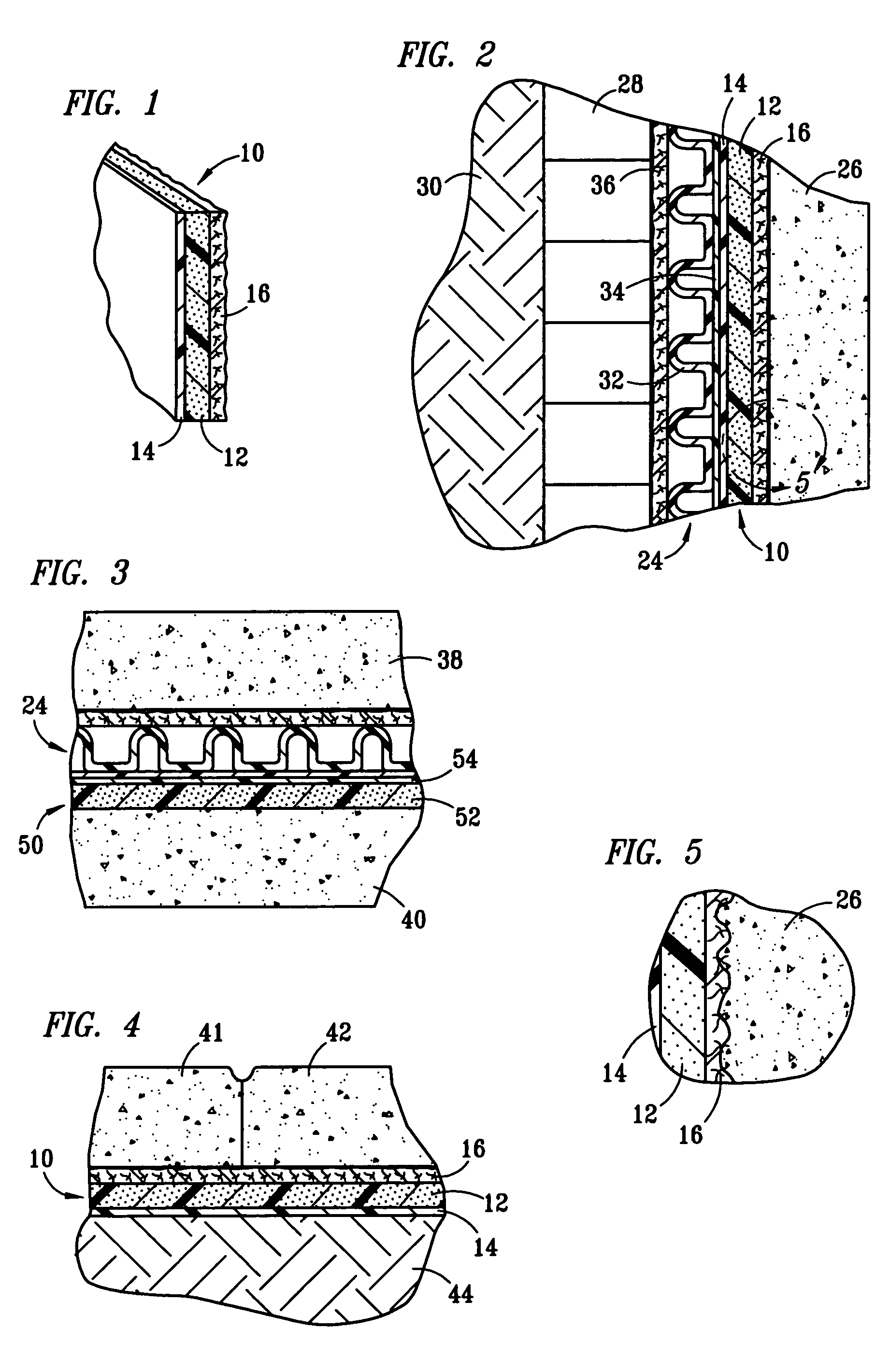

Stress-relieving barrier membrane for concrete slabs and foundation walls

ActiveUS7488523B1Relieve pressureReduce crack formationPaving reinforcementsIn situ pavingsStress relievingToxic material

A composite membrane comprising a layer of rubberized asphalt having a heavy duty plastic film layer continuously bonded to one side and, optionally, a layer of nonwoven geotextile continuously bonded to the other side. The membrane can be used in vertical or horizontal applications, and is particularly useful for its stress-relief properties that resist crack formation and propagation in concrete walls and slabs in addition to serving as a barrier to moisture, toxic substances and insects. An appropriate composite membrane of the invention can be advantageously utilized in positive side, blindside, underslab or split slab applications. The thickness of the composite membrane preferably ranges from about 30 mils to about 150 mils.

Owner:POLYGUARD PRODS

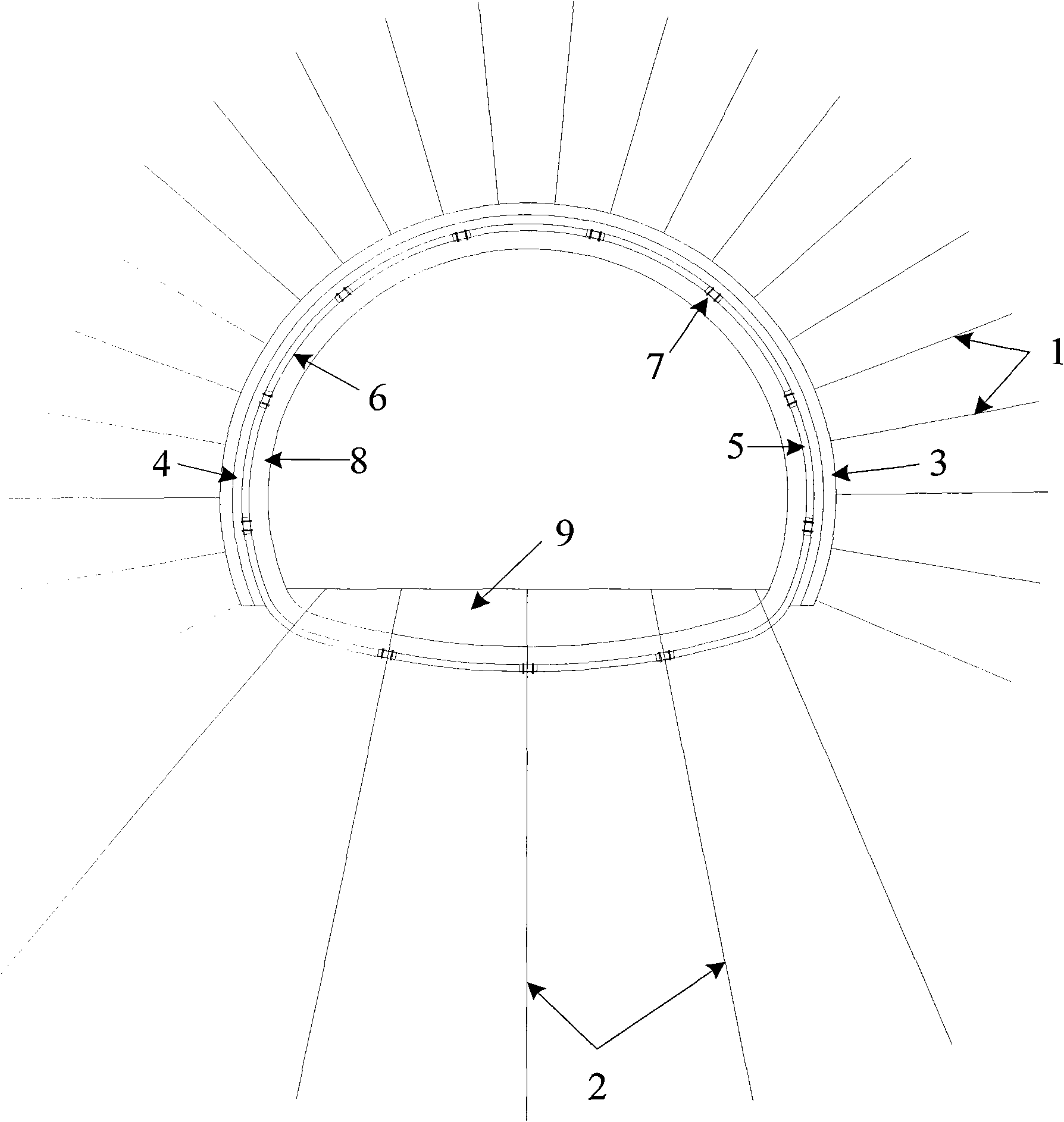

High ground stress soft rock stress-relief construction method

InactiveCN101644160AMature technologyGood effectUnderground chambersTunnel liningShotcretePolystyrene

The invention discloses a high ground stress soft rock stress-relief construction method which comprises the following steps: A. anchor shotcreting constructing, tagging the anchor shotcreting constructing with heading, and eliminating dangerous rock; B. cystosepiment hanging, carrying out hanging construction on polystyrene cystosepiment; C. inverted arch excavating and U shape steel spanning, lining tunnel to a ring, and carrying out re-spraying with shotcrete on clearance of steel racks; D. inverted arch backfilling, carrying out construction of a waterproof barrier layer after completing spanning of the U shape steel so as to conserve concrete; E. waterproof barrier layer constructing, carrying out waterproof barrier layer constructing when the convergence rate of tunnel is stabilized;F. secondary lining constructing, carrying out secondary lining constructing when the waterproof barrier layer constructing is completed; and G. prestress anchor line constructing, determining a holesite of an anchor line and the drilling direction through field lofting, and clearing the location of the hole site. The construction method has obvious effect for controlling large deformation of the soft rock with the high ground stress, is simple and convenient, and has the advantages of simple operation, obvious effect and relatively low cost.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Design of wet/wet differential pressure sensor based on microelectronic packaging process

ActiveUS20100122583A1Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEffective solutionStress relieving

Method and system for a wet / wet differential pressure sensor based on microelectronic packaging process. A top cap with a hole can be attached to a topside of a MEMS-configured pressure sense die with a pressure sensing diaphragm in order to allow sensed media to come in contact with the topside of the pressure sensing diaphragm. An optional constraint with a hole for stress relief can be attached to a backside of the pressure sense die. Adhesive and / or elastomeric seals and / or solder can be utilized to seal the pressure sense die allowing sensed media to come in contact with both sides of the pressure sensing diaphragm without coming into contact with wirebonds and other metallized surfaces. The MEMS-configured pressure sense die can also be bonded to a substrate with standard die attach materials. Such microelectronic packaging processes yield a high performance and cost effective solution thereby providing wet-wet pressure sensing capability.

Owner:HONEYWELL INT INC

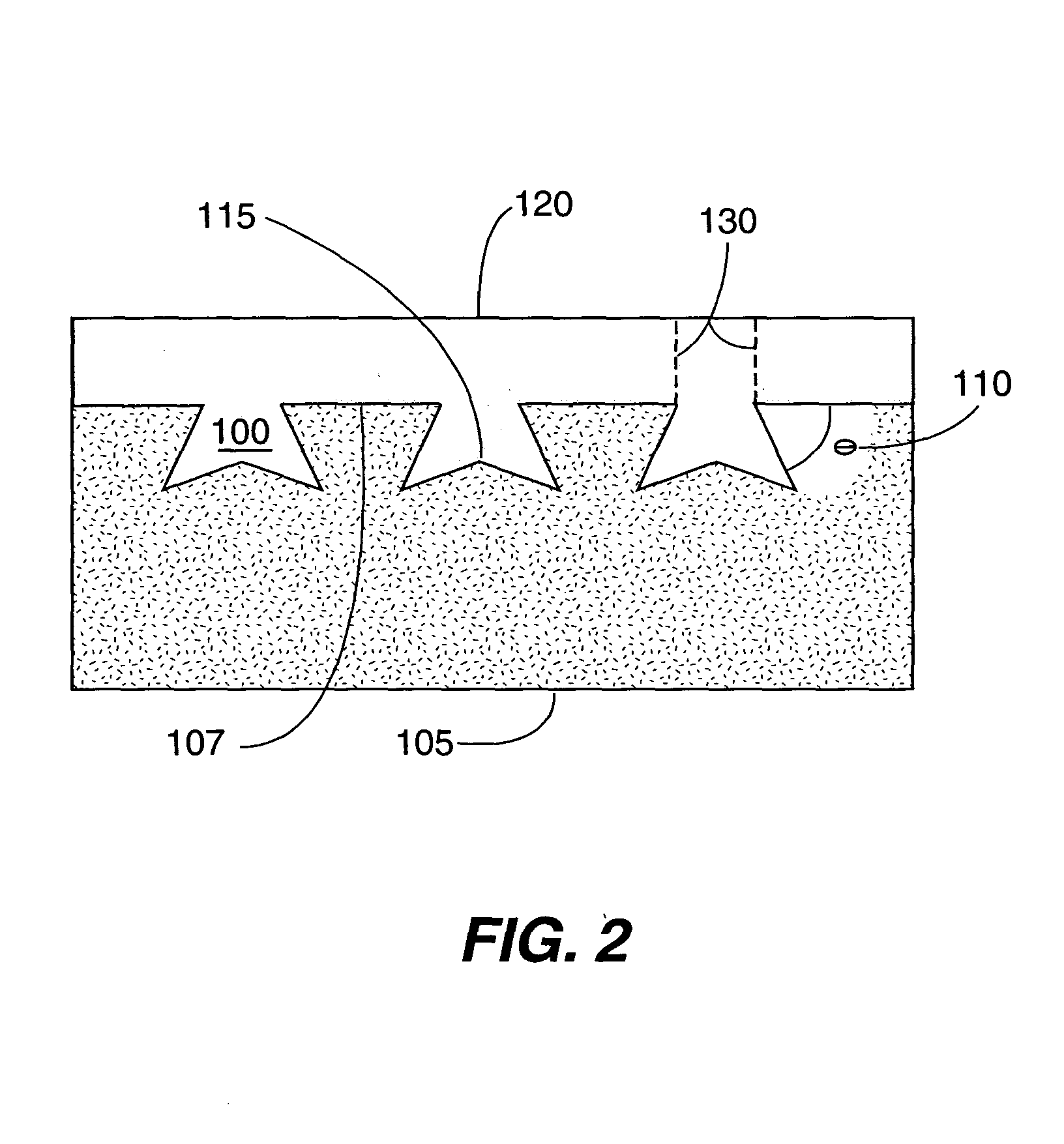

Spray shadowing for stress relief and mechanical locking in thick protective coatings

An article with a surface that includes undercut grooves depending beneath the surface to a bottom portion, where the grooves have an upper width on the surface and a lower width on the bottom portion connected by side walls, and where at least one of said side walls connects the upper width to the lower width to form an undercut angle with the surface of less than 90°. The article is covered with a coating that contains weak paths for stress relief. The coating fills the undercut grooves and ranges above the surface with a thickness from about 0.1 to 50 mm.

Owner:RGT UNIV OF CALIFORNIA +1

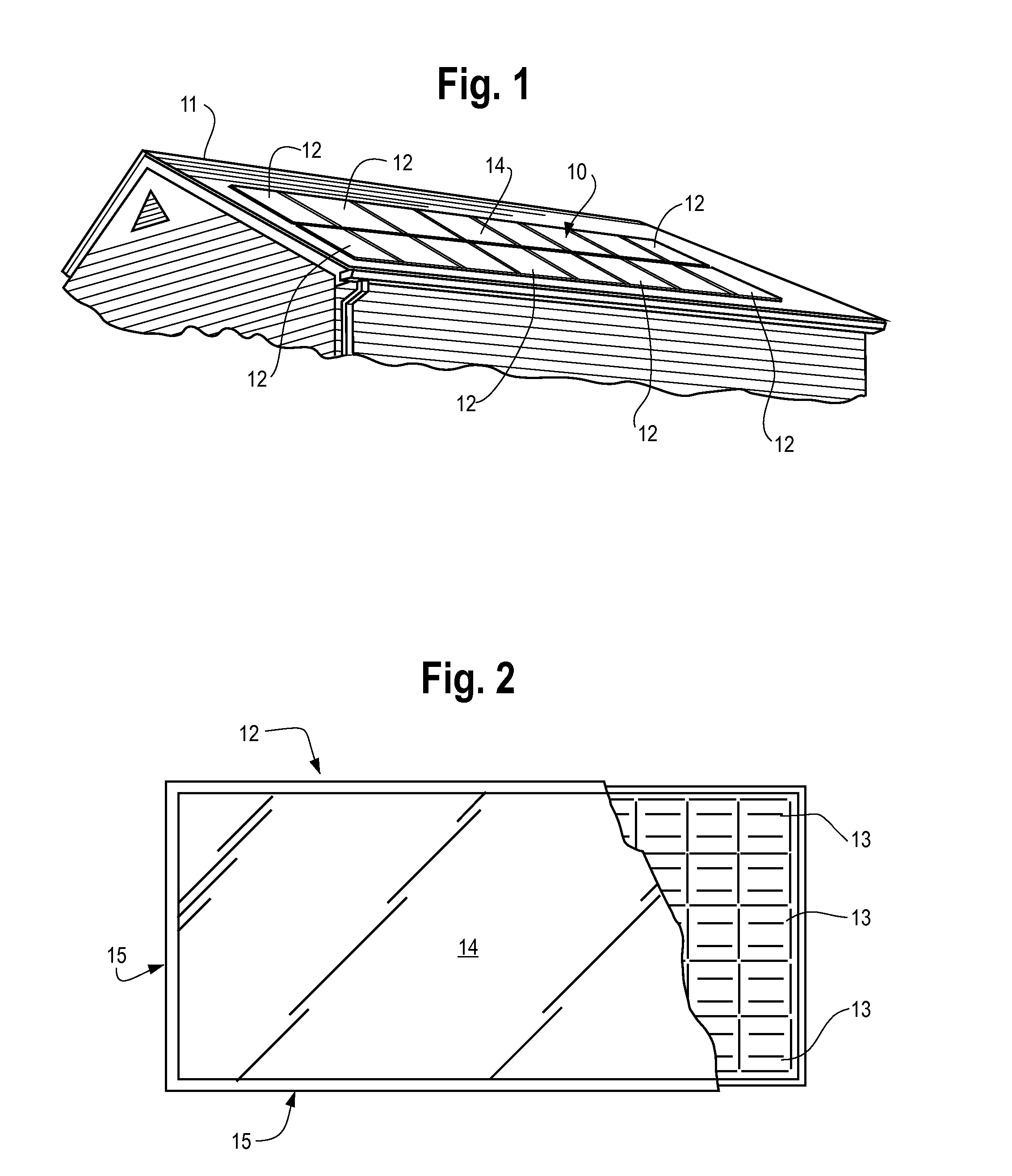

Synthetic Shingle or Tile With Stress Relief Nail Zones

ActiveUS20100077689A1Relieve stressRoof covering using tiles/slatesLayered productsRelative motionStress relief

A relatively rigid roofing shingle or tile is provided, having relatively flexible stress relief nail zones, that may comprise variations in thickness relative to the remainder of the shingle or tile, or variations in materials, such as will allow for relative movement of the shingles or tiles due to temperature variations resulting in expansion or contraction, or due to other forces, such that the movement will be between the shingles or the tiles and the nails or other fasteners that are used to secure the shingles or tiles to a roof or other surface, and is preferably within the elastic limits of the fastening zones of the shingles or tiles.

Owner:CERTAINTEED CORP

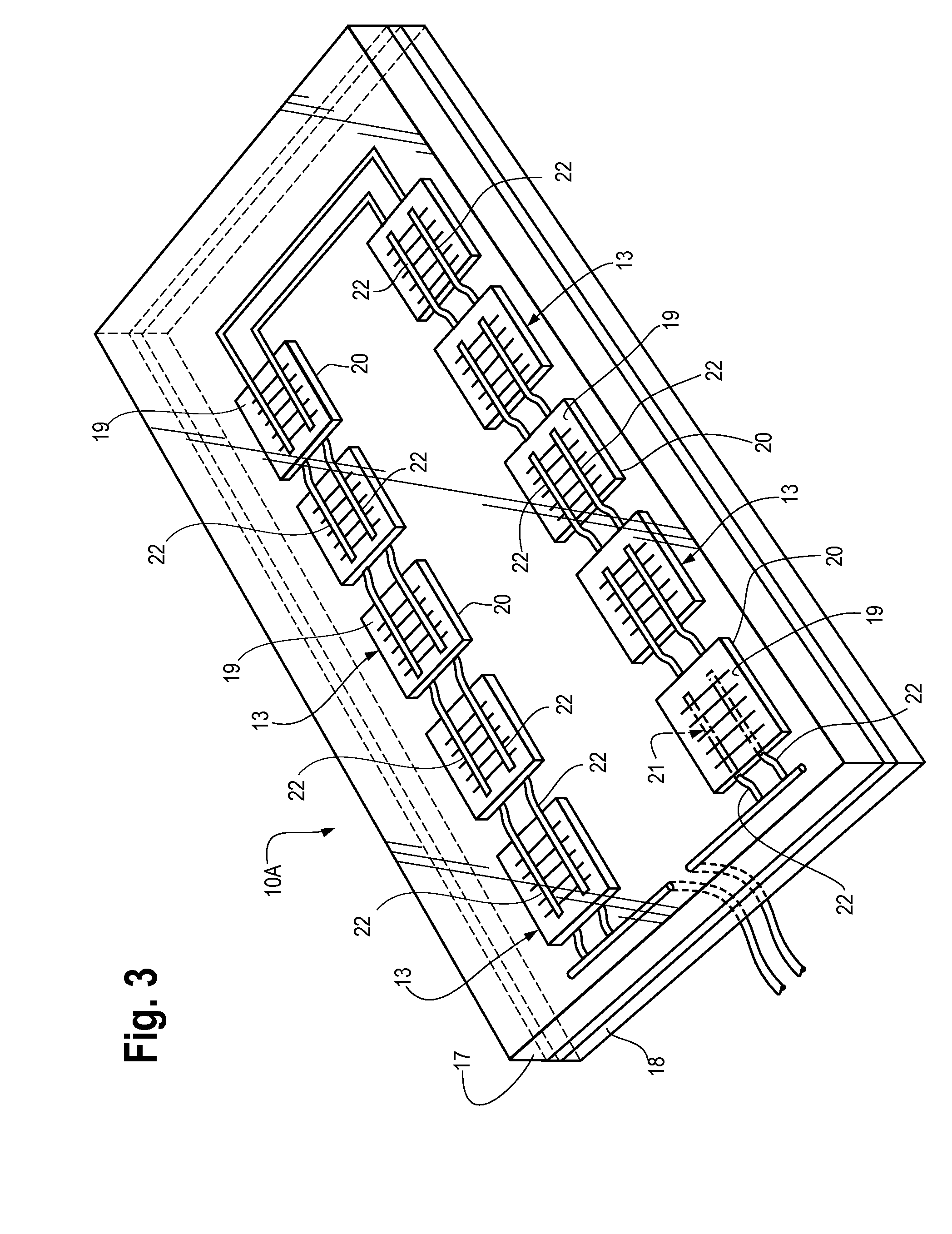

Means and Method for Electrically Connecting Photovoltaic Cells in a Solar Module

InactiveUS20070144578A1Alleviate stress failurePhotovoltaic supportsPhotovoltaic energy generationConductive materialsStress failure

A connector and method for electrically connecting adjacent solar cells together in a solar module. The terminals of the cells are connected with individual lengths of an electrically conductive material such as an electrically conductive metal ribbon. A substantial portion of the mid section of the ribbons remain unsoldered to thereby provide a stress relief zone in the ribbon between the cells to alleviate stress failures in the ribbons.

Owner:BP CORP NORTH AMERICA INC

Conductive connection structure with stress reduction arrangement for a semiconductor device, and related fabrication method

InactiveUS20120049343A1Well formedSemiconductor/solid-state device detailsSolid-state devicesContact padDevice material

A semiconductor device disclosed herein includes a conductive connection structure having a stepped profile that serves as a stress relief feature. The conductive connection structure includes a stress buffer arrangement for a contact pad. The stress buffer arrangement has a stepped via that terminates at the contact pad, and the stepped via has a plurality of inwardly sloped and concentric sections in a stacked orientation. The connection structure also includes underbump metallization overlying at least a portion of the contact pad and lining the stepped via, and a conductive connection element coupled to the underbump metallization. The conductive connection element fills the lined recess.

Owner:GLOBALFOUNDRIES INC +1

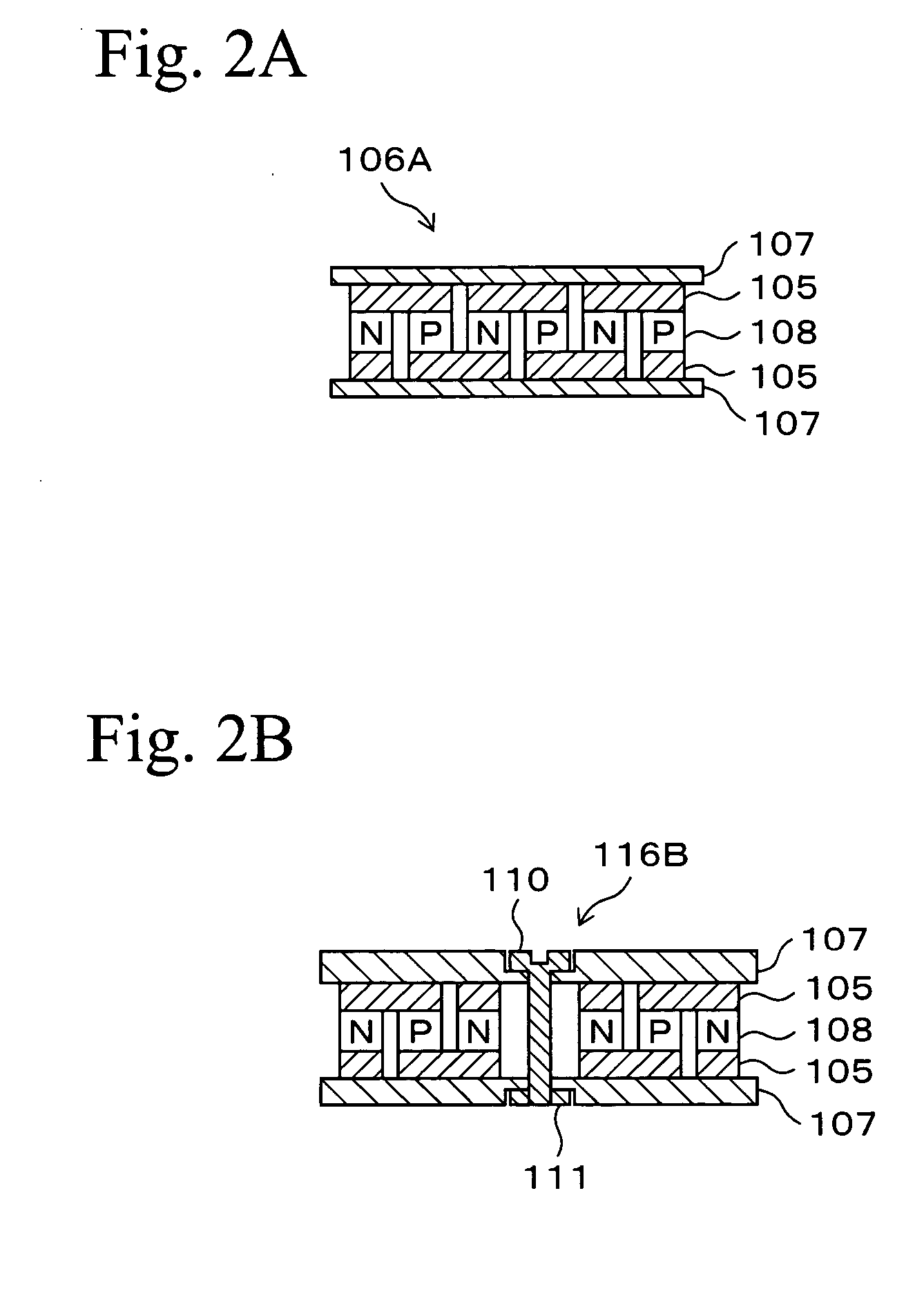

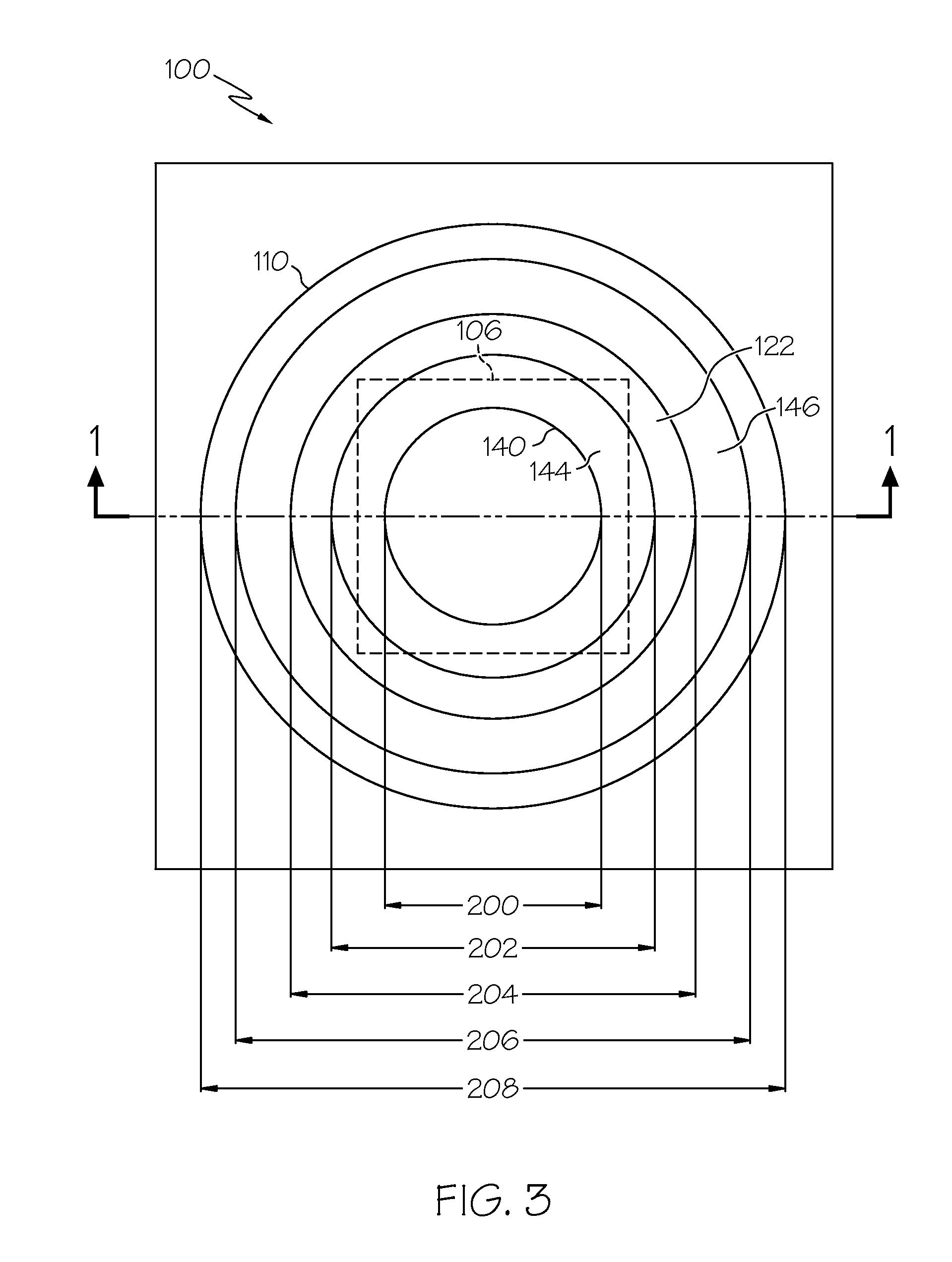

Water control gate and actuator therefore

ActiveUS20030143027A1Easy to transportEasy to installBarrages/weirsButtress damsManufacturing technologyStress relief

The invention relates to improved water control gates and related inflatable actuators, and associated sealing, manufacture and operation apparatus and methods. Advancements in technologies related to air fitting design, inflated bladder stress relief, inflatable bladder strength enhancement, water gate related slide friction mitigation, abutment and other impounded water seals, gate panel fabrication, traffic accommodating water impoundment structures, and water gate panel system operation efficiency, as well as nappe aeration, hinges, and bladder manufacture technology are some of the advancements disclosed herein.

Owner:HENRY K OBERMEYER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com