Method for removing cracks of Rene104 nickel-based superalloy during laser additive manufacturing

A nickel-based superalloy and laser additive technology, which is applied in the direction of additive manufacturing, additive processing, and energy efficiency improvement, can solve the problems of reducing the mechanical properties of formed parts, large residual stress of formed parts, and easy cracking, etc., to achieve control The generation and superposition of residual stress, excellent mechanical properties, and the effect of eliminating internal cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

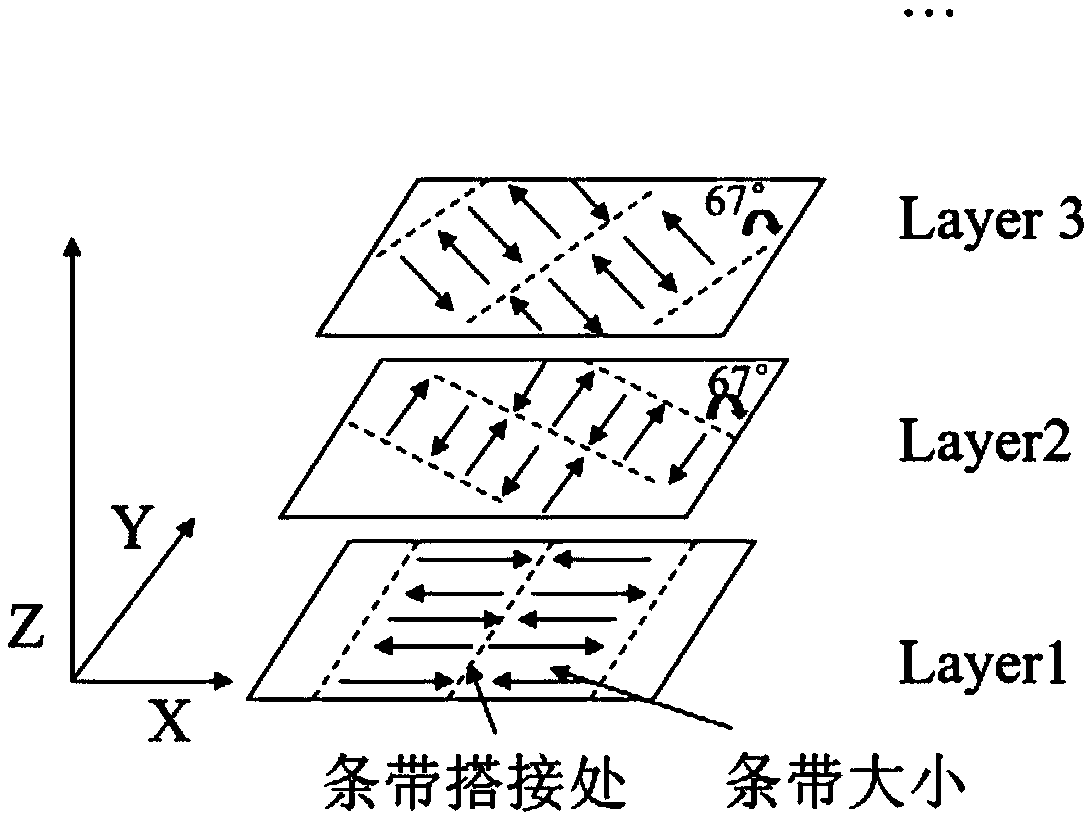

Method used

Image

Examples

Embodiment 1

[0054] Use 3D design software and 3D composition software to construct a 3D cylinder model with a diameter of 40mm and a height of 15mm, convert it into an STL file and import it into the laser selection melting construction software, and import it into the SLM printing system after the software slices itself. After the substrate is heated to 150°C, the Renè 104 nickel-based superalloy powder is added to the powder supply cylinder and powder is spread, and argon gas is introduced into the working chamber until the oxygen content is lower than 100ppm. After entering the printing program, the steps of powder spreading and laser scanning powder are repeated until the printing is completed and a cylinder is obtained. Afterwards, the printed cylinder is sequentially subjected to stress relief annealing and spark plasma sintering.

[0055] Among them, the particle size of Renè104 nickel-based superalloy powder is 15-53 μm, D10 is 17.5 μm, D50 is 29.3 μm, and D90 is 46.9 μm.

[0056...

Embodiment 2

[0064] Use 3D design software and 3D composition software to construct a 3D cylinder model with a diameter of 40mm and a height of 15mm, convert it into an STL file and import it into the laser selection melting construction software, and import it into the SLM printing system after the software slices itself. After the substrate is heated to 150°C, the Renè 104 nickel-based superalloy powder is added to the powder supply cylinder for powder spreading, and argon gas is introduced into the working chamber until the oxygen content is lower than 0.1%. Then enter the printing program, and repeat the steps of powder spreading and laser scanning powder until the printing is completed and a cylinder is obtained.

[0065] Among them, the particle size of Renè104 nickel-based superalloy powder is 15-53 μm, D10 is 17.5 μm, D50 is 29.3 μm, and D90 is 46.9 μm.

[0066] The SLM process parameters are: laser power 225W, spot diameter 0.12mm, scanning speed 600mm / s, scanning distance 0.11mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com