Pouring concrete separating crack structure and construction method thereof

A construction method and separation joint technology, which is applied in the field of separation joints, can solve problems such as difficulty in leveling the concrete surface, easy leakage, irregular cracks in angular concrete, etc., and achieve the effect of eliminating cracks and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

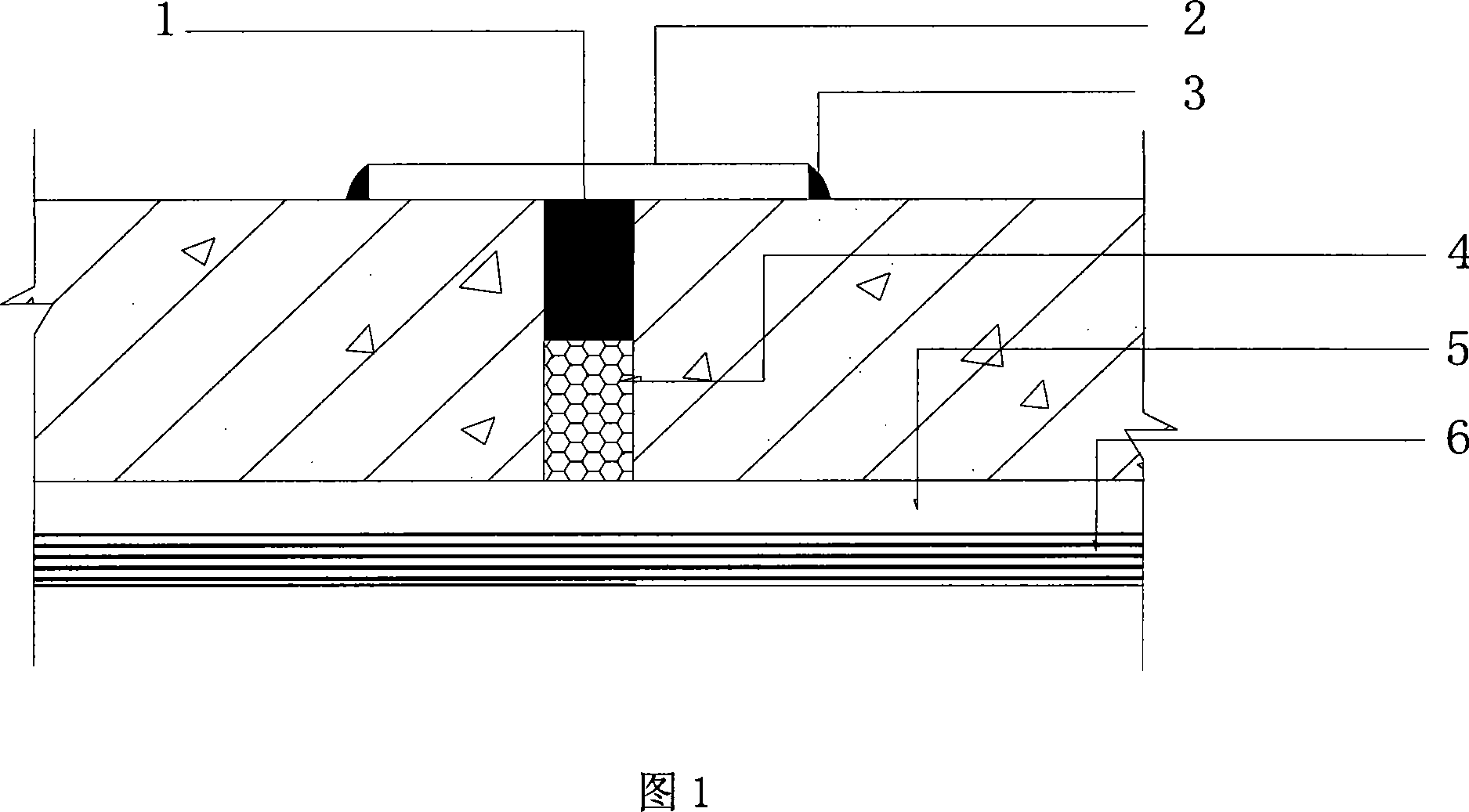

[0014] Example 1: A large number of engineering practices have proved that the best implementation method for fine stone concrete ground is: use a width of 10mm to 20mm, a thickness equal to half the thickness of the ground, generally 30mm, and a bulk density of not less than 18kg / m 3 The polystyrene board 4 is used as the lower part of the separation joint; the upper part of the slat and the gap between the poured concrete on both sides are elastic asphalt sand 1, which is covered with a waterproof membrane 2, and the two sides of the waterproof membrane 2 are provided with sealing materials 3. The sealing material 3 is common asphalt.

[0015] The construction method of the separation joint structure is as follows: firstly, when constructing the fine stone concrete ground, the line is stretched according to the position of the predetermined separation joint, and then the plain cement mortar mixed with 3%-5% waterproof powder is used to inlay the 10mm-20mm wide aggregate Benz...

Embodiment 2

[0016] Embodiment 2: It has been proved by a large number of engineering practices that the best implementation method for rigid roofs is as follows: first set an isolation layer 5 on the roof waterproof layer 6, and use a 40mm wide fine stone on the isolation layer 5 with a thickness equal to that of the rigid layer. Half of the concrete thickness, generally 30mm, and the bulk density is not less than 18kg / m 3 The polystyrene board 4 is used as the lower part of the separation joint; the upper part of the slat and the gap between the poured concrete on both sides are elastic asphalt sand 1, which is covered with a waterproof membrane 2, and the two sides of the waterproof membrane 2 are provided with sealing materials 3. The sealing material 3 is common asphalt.

[0017] The construction method of the separation joint structure for rigid roofs is as follows: firstly stretch the thread on the fine stone concrete rigid roof according to the preset position of the separation joi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com