Patents

Literature

3228 results about "Convex structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

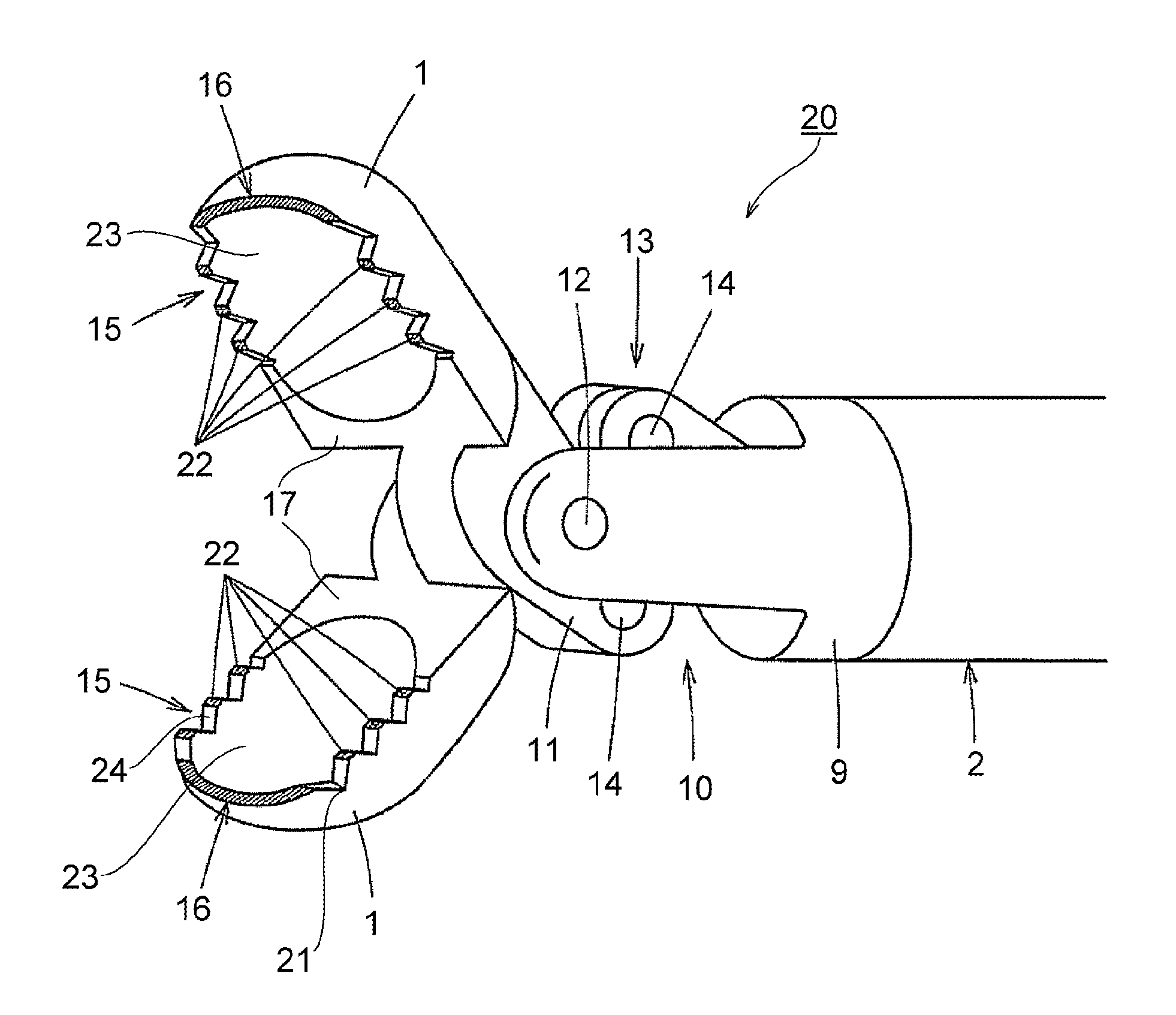

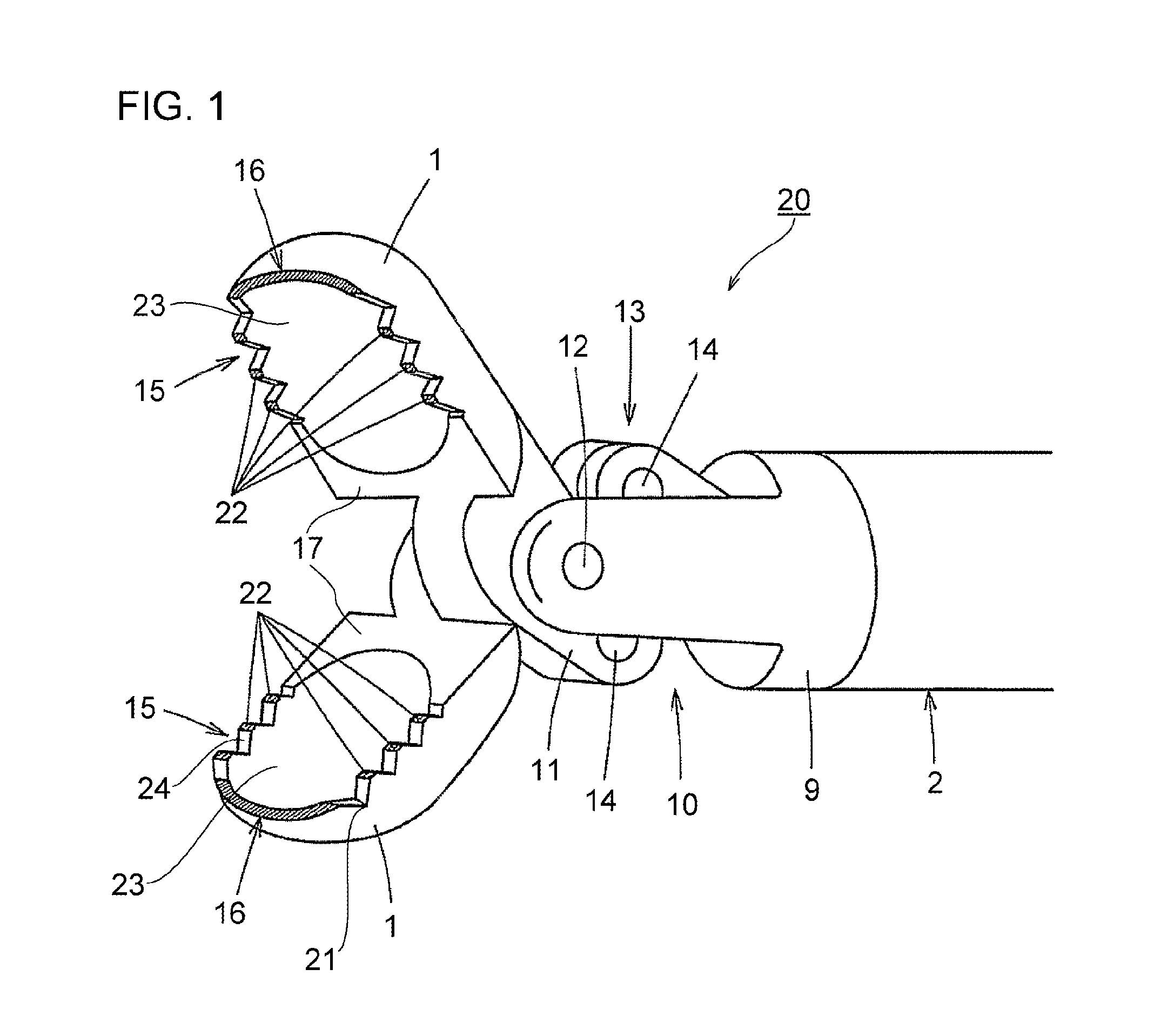

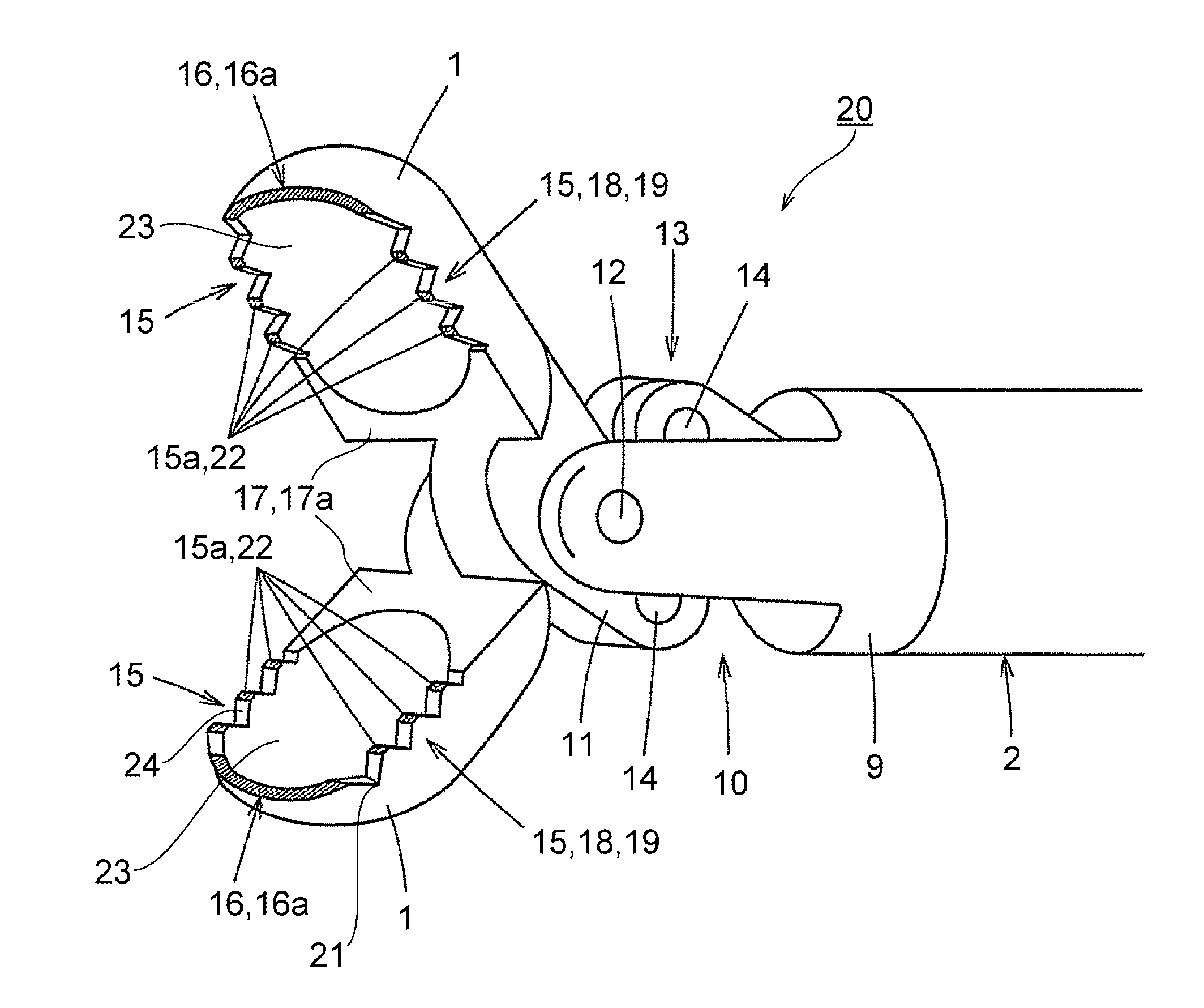

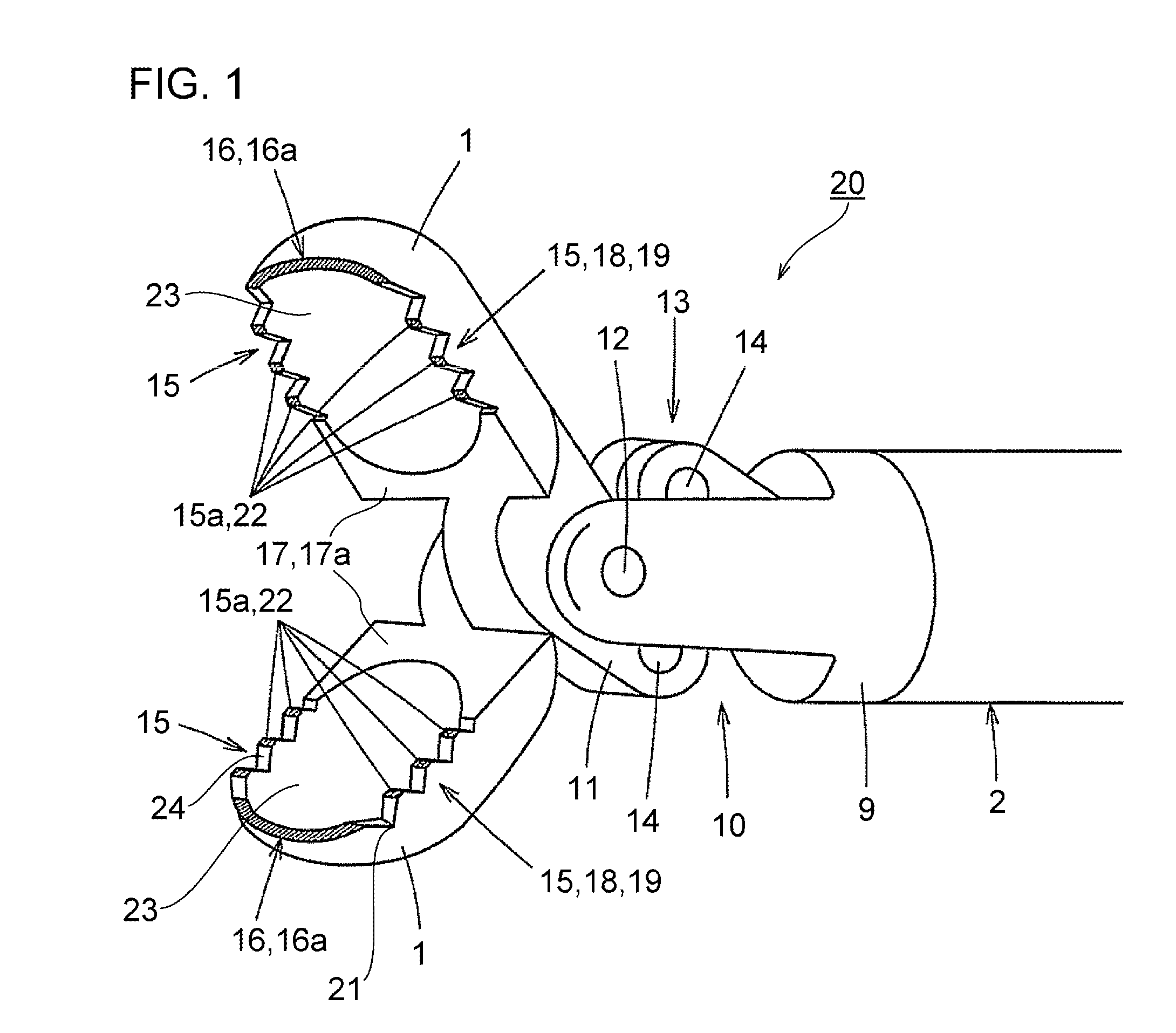

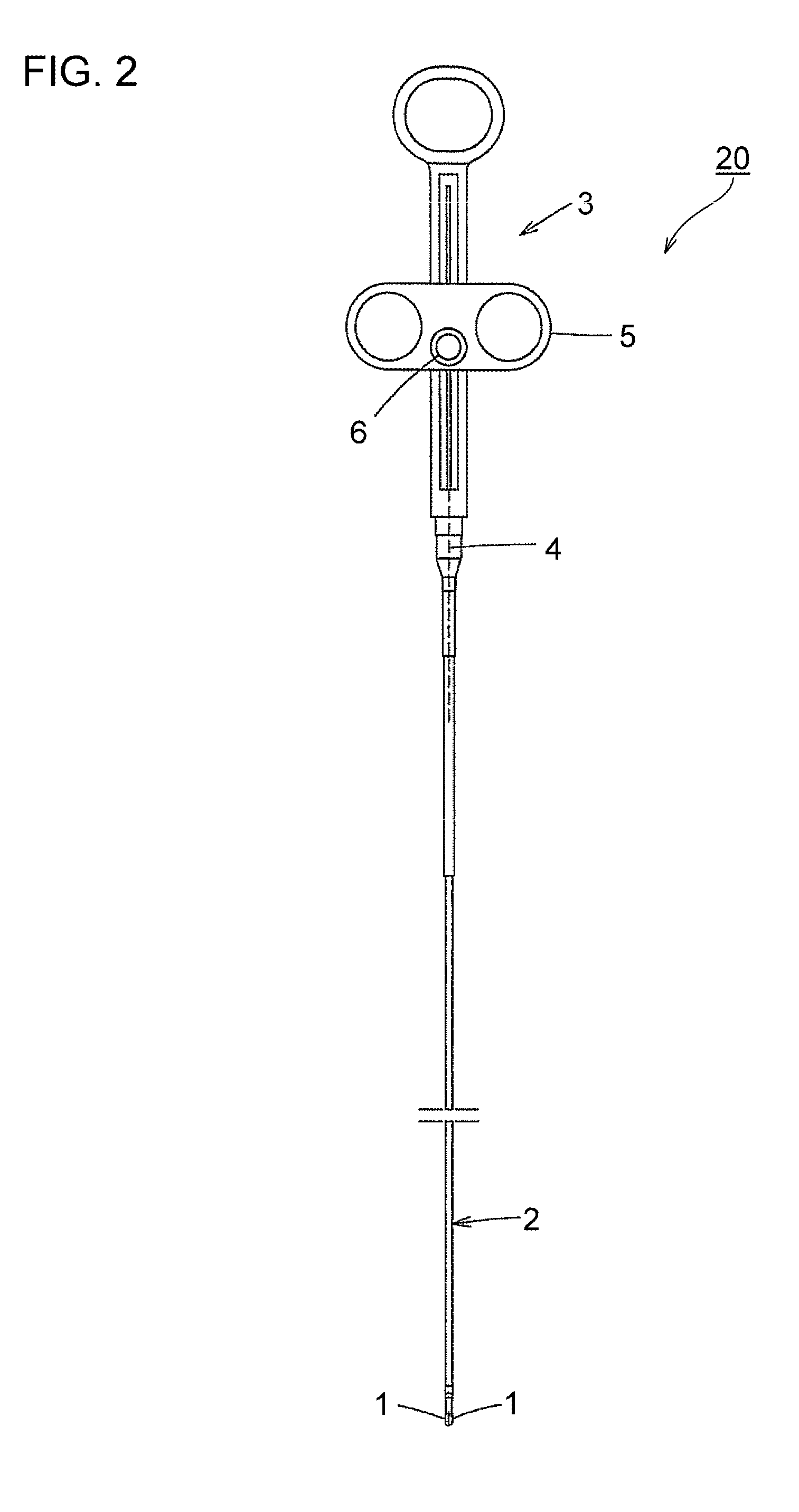

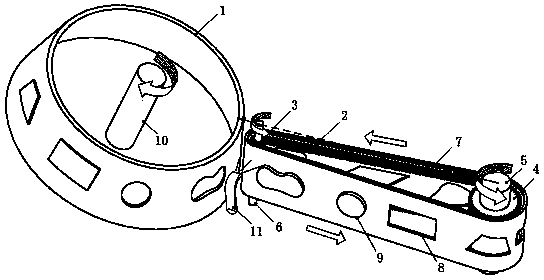

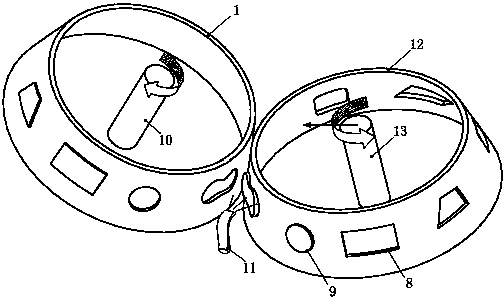

Endoscopic high-frequency hemostatic forceps

ActiveUS9186204B2Reduce areaFixed securitySurgical instruments for heatingSurgical forcepsConvex structureEngineering

A hemostatic forceps (20) includes a pair of forceps elements (forceps cups (1)) constituted of a conductive metal and configured to serve as high-frequency electrodes and configured to be able to change into a state where front portions of the pair of forceps cups (1) are open, and a state where the pair of forceps cups (1) are close. A sawtooth portion (15) having a plurality of concavo-convex structures which constitute a sawtooth-shape is provided on at least one of respective closing-side surfaces (17) of the pair of forceps cups (1). The sawtooth portion (15) is provided with an electrically insulative coating over its bottom portion (21), but not on a top portion (22) thereof, and hence the top portion (22) is conductive.

Owner:KANEKA CORP +1

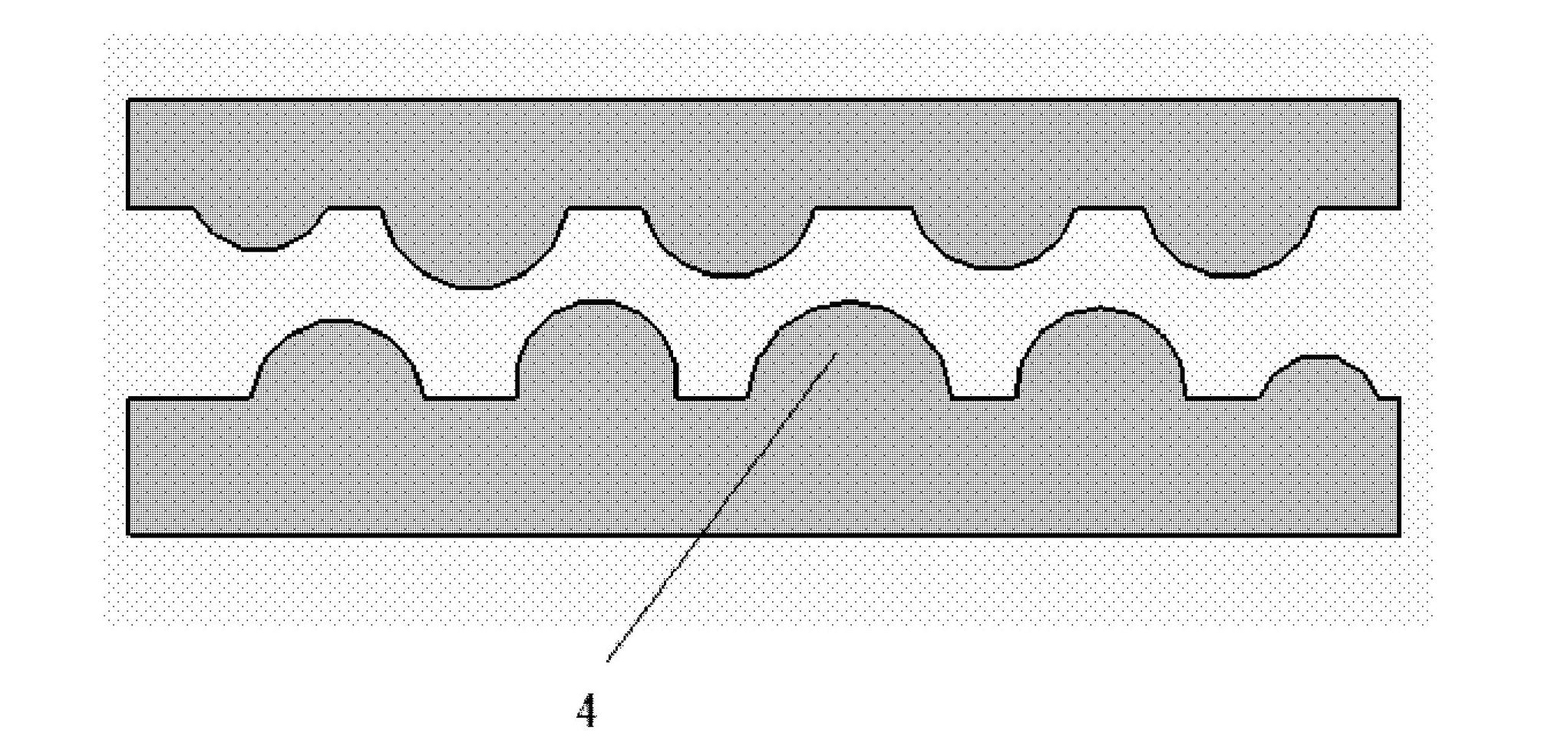

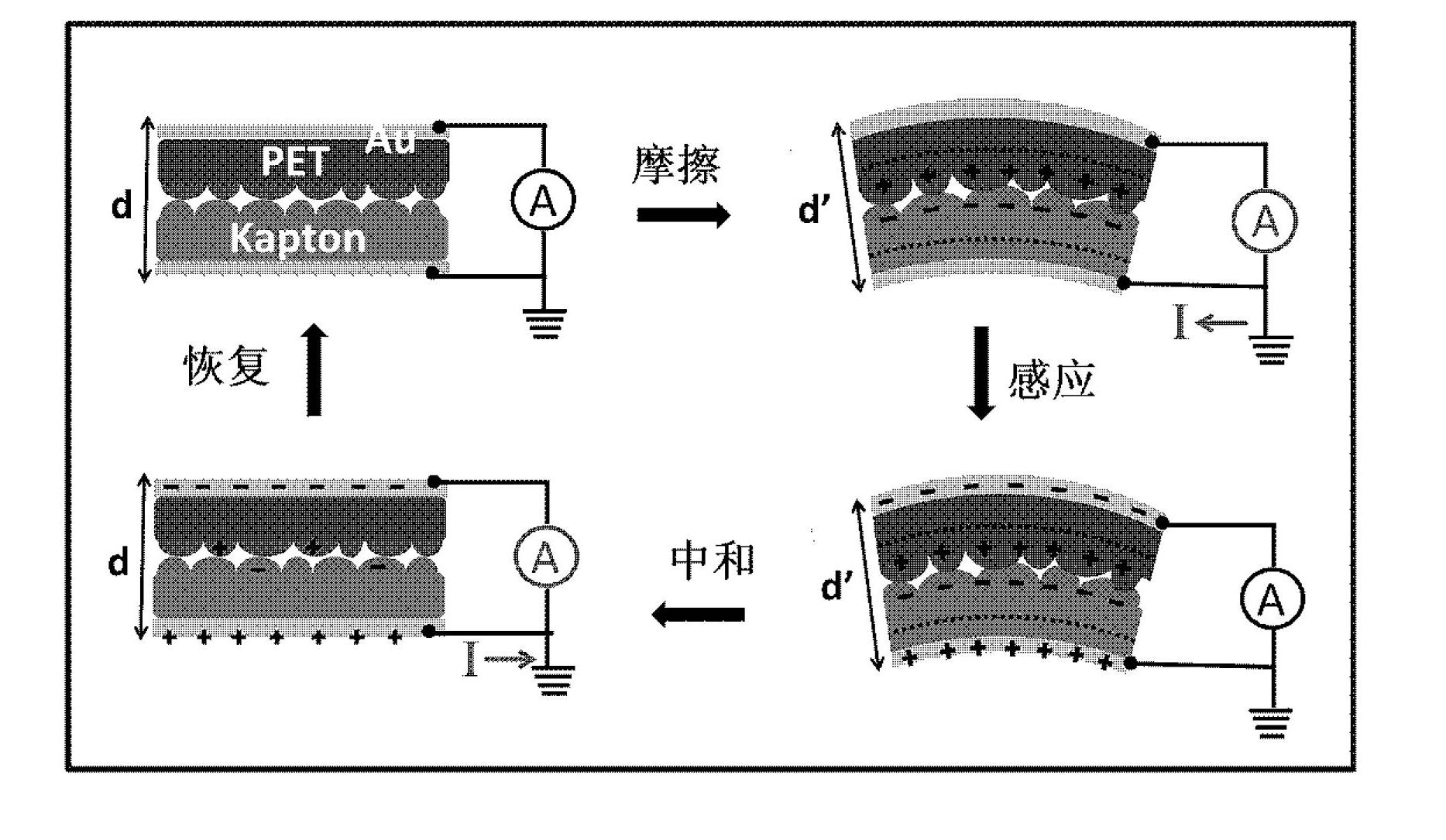

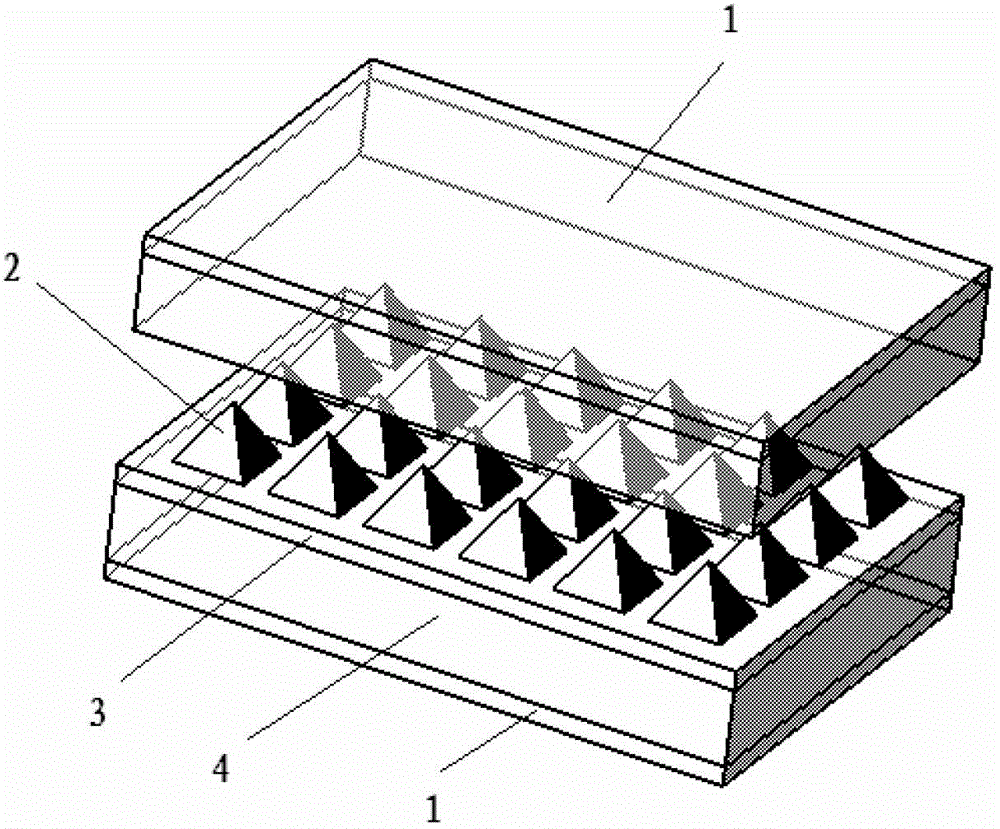

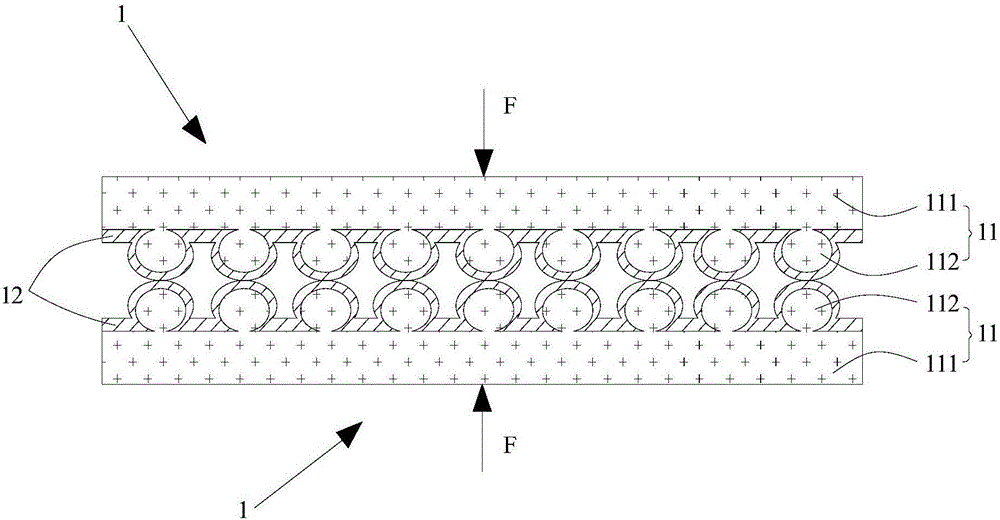

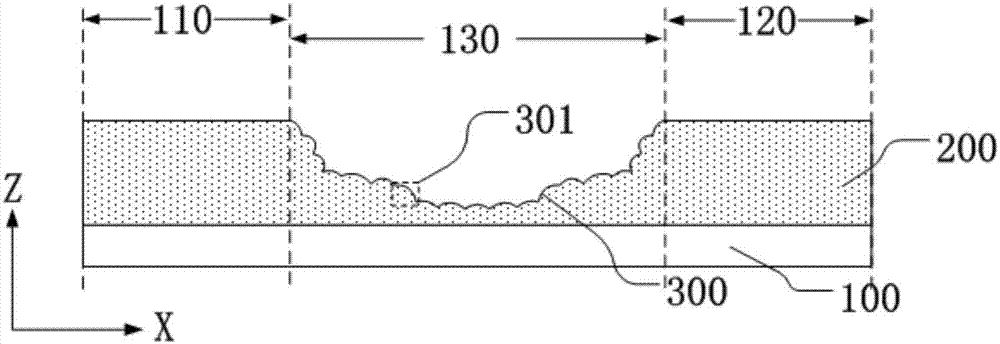

Friction generator

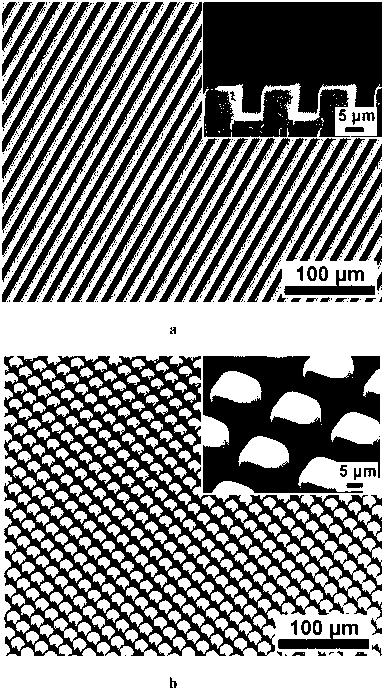

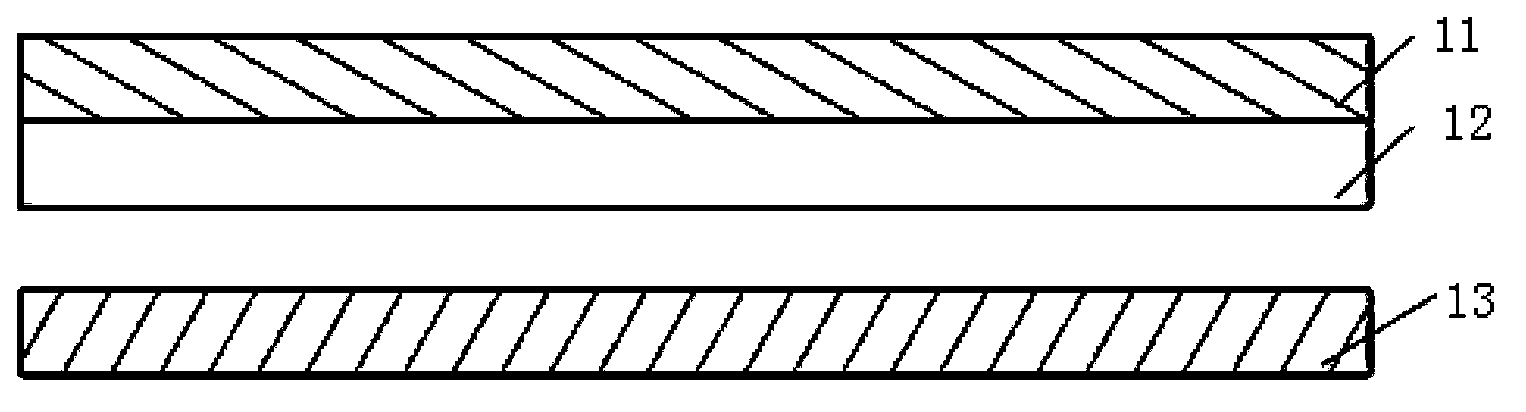

ActiveCN102684546AExtended service lifeLow costFriction generatorsMetal layered productsConvex structureMicro nano

The invention provides a friction generator. The friction generator comprises two electrodes; the electrode comprises a macromolecular polymer insulating layer; a micro-nano concave-convex structure is arranged on one side surface of the macromolecular polymer insulating layer, and a metal film is arranged on the other side surface; the surface of the electrode micro-nano concave-convex structure of one insulating layer is directly attached to the surface of the electrode micro-nano concave-convex structure of the other insulating layer, and the two are fixedly connected through the outer edge; and the metal film is an electrode for outputting voltage and current of the friction generator. The invention provides a novel and effective method for obtaining energy by use of the friction effect. The friction generator generates electric energy by use of the potential change of the internal electrification by friction and the inductive effect of the metal pole plates on the two sides; and the method is simple and efficient and the cost is low.

Owner:NAZHIYUAN TECH TANGSHAN LLC

Friction generator

ActiveCN102710166AExtended service lifeLow costFriction generatorsMetal layered productsMicro nanoConvex structure

The invention provides a friction generator, which comprises a first electrode, a second electrode and an intermediate film, wherein the first electrode comprises a first macromoleclar polymer insulation layer of which one side surface is provided with a conductive film; the second electrode comprises a second macromoleclar polymer insulation layer of which one side surface is provided with a conductive film; the intermediate film is fixed on the other side surface of the second macromoleclar polymer insulation layer; the non-fixed surface of the intermediate film is provided with a micro-nano concave-convex structure; the surface of the micro-nano concave-convex structure of the intermediate film on the second electrode and the surface without the conductive film of the first electrode are oppositely fit and are mutually fixedly connected; and the conductive film of the first macromoleclar polymer insulation layer and the conductive film of the second macromoleclar polymer insulation layer are both the voltage and current output electrodes of the friction generator. The invention provides an innovated and effective method by the friction action, and electricity energy is generated by the variation of internal friction electrification electric potential and the induction effect of metal pole plates on two sides. The method is simple and efficient and has low cost.

Owner:NEWNAGY TANGSHAN

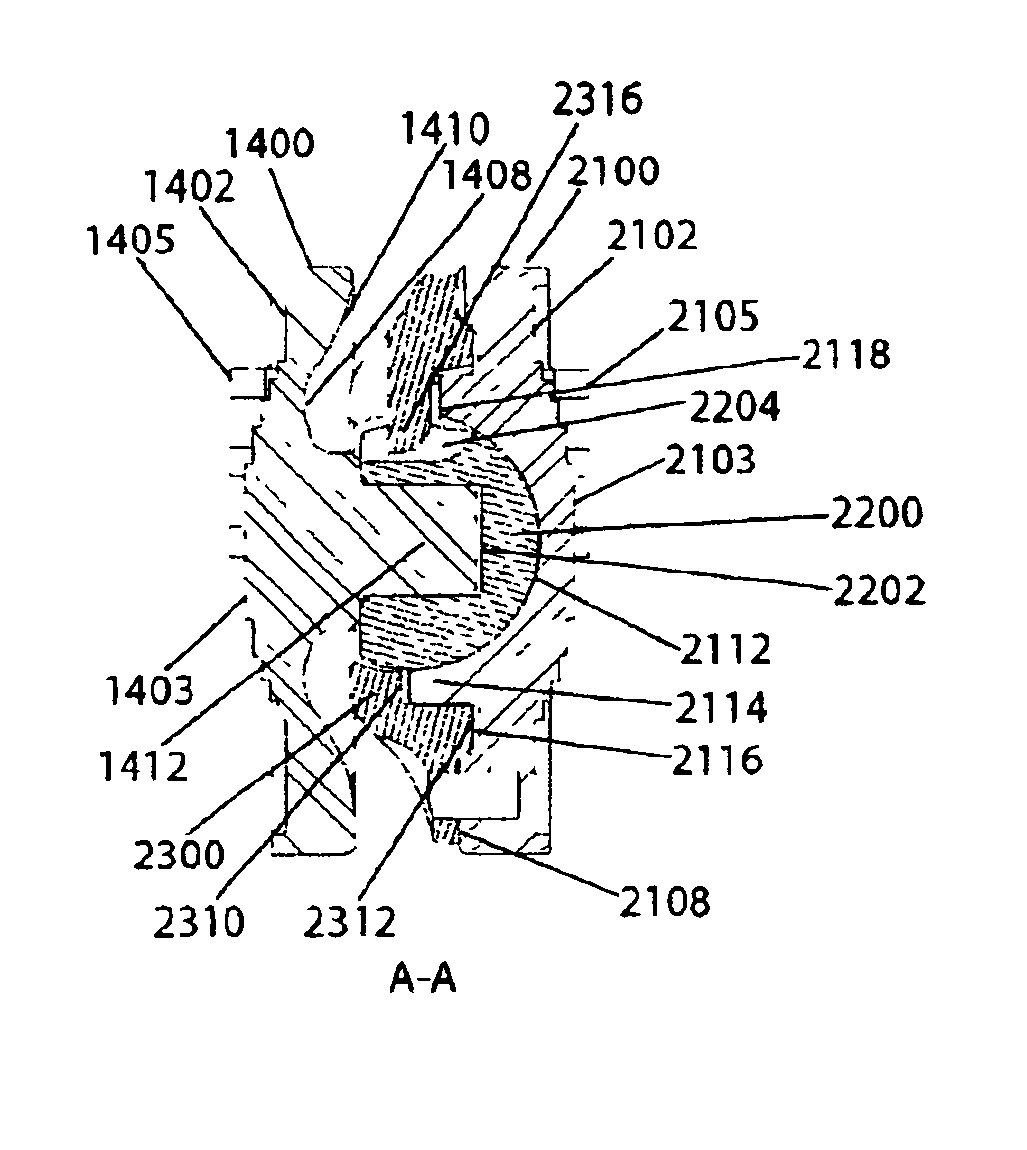

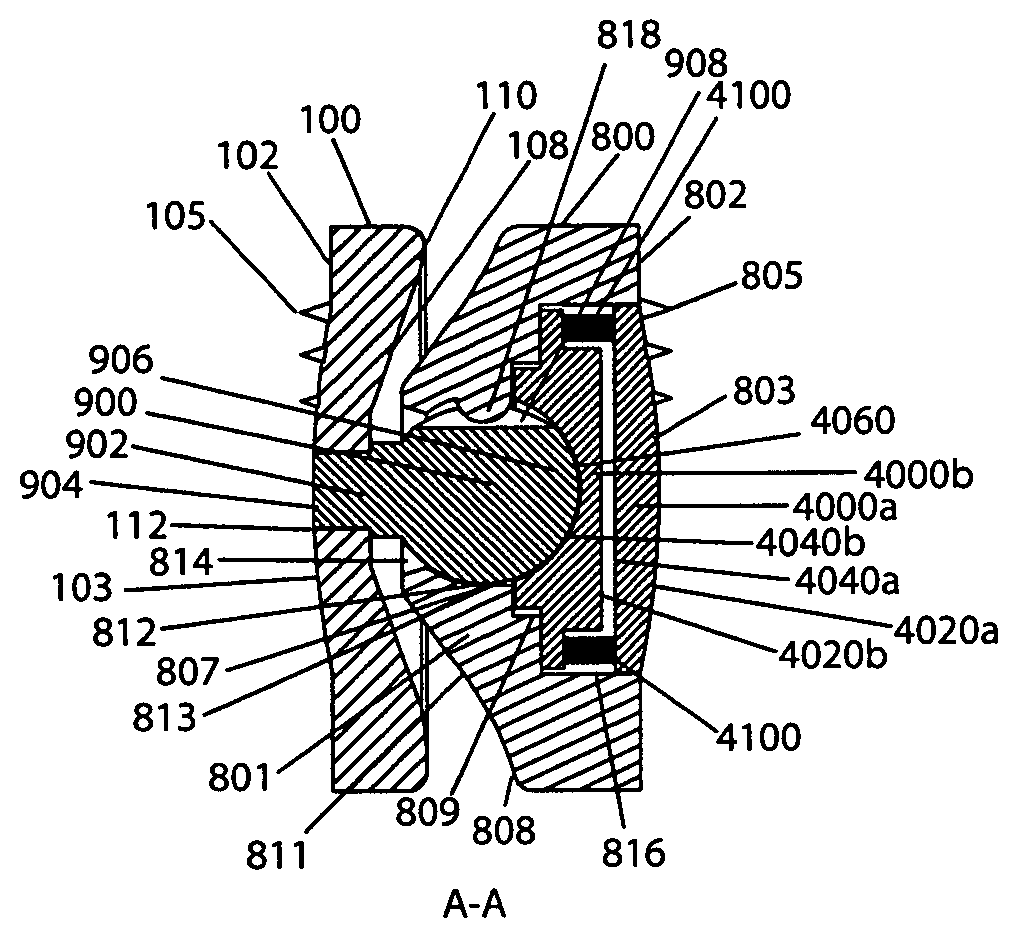

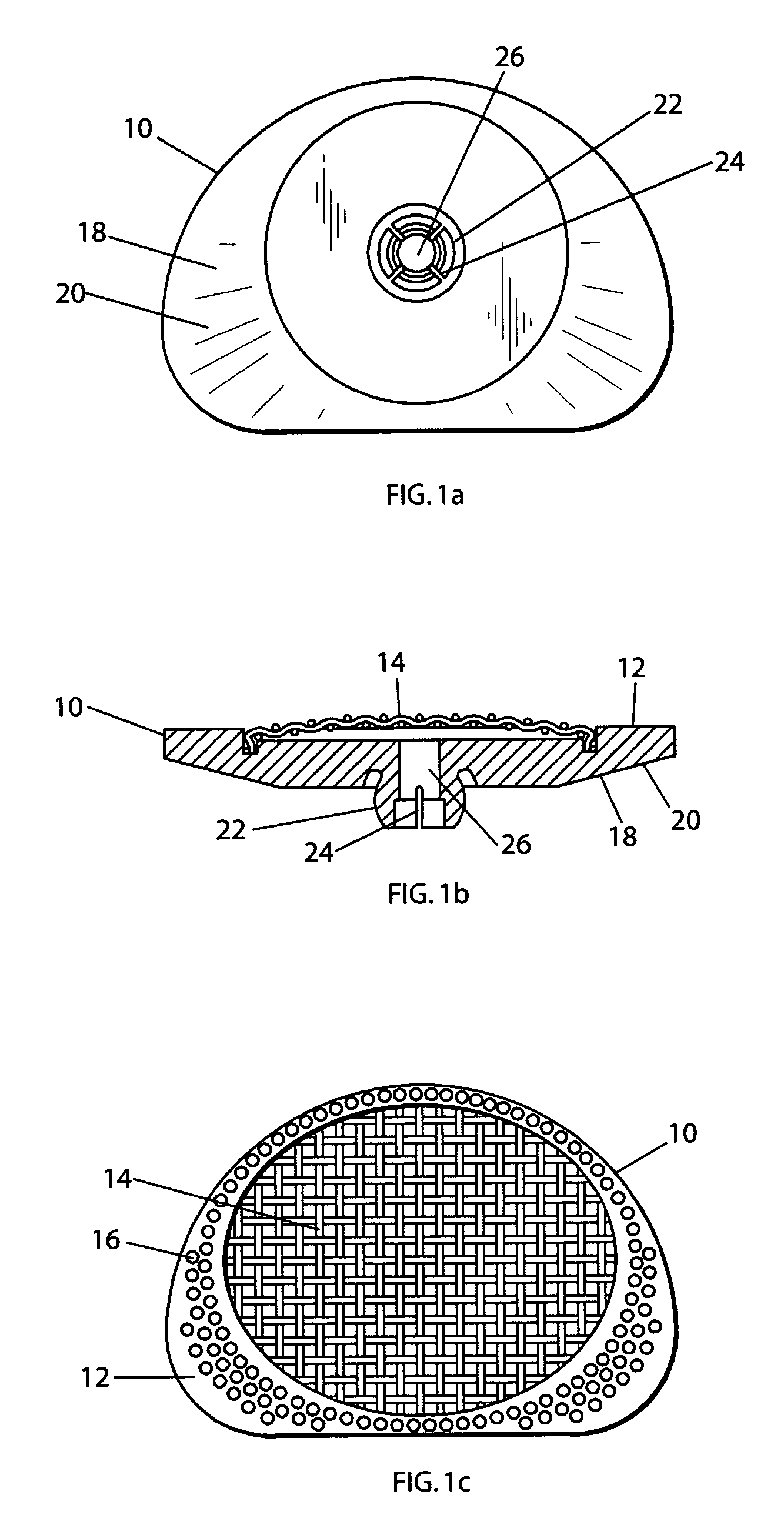

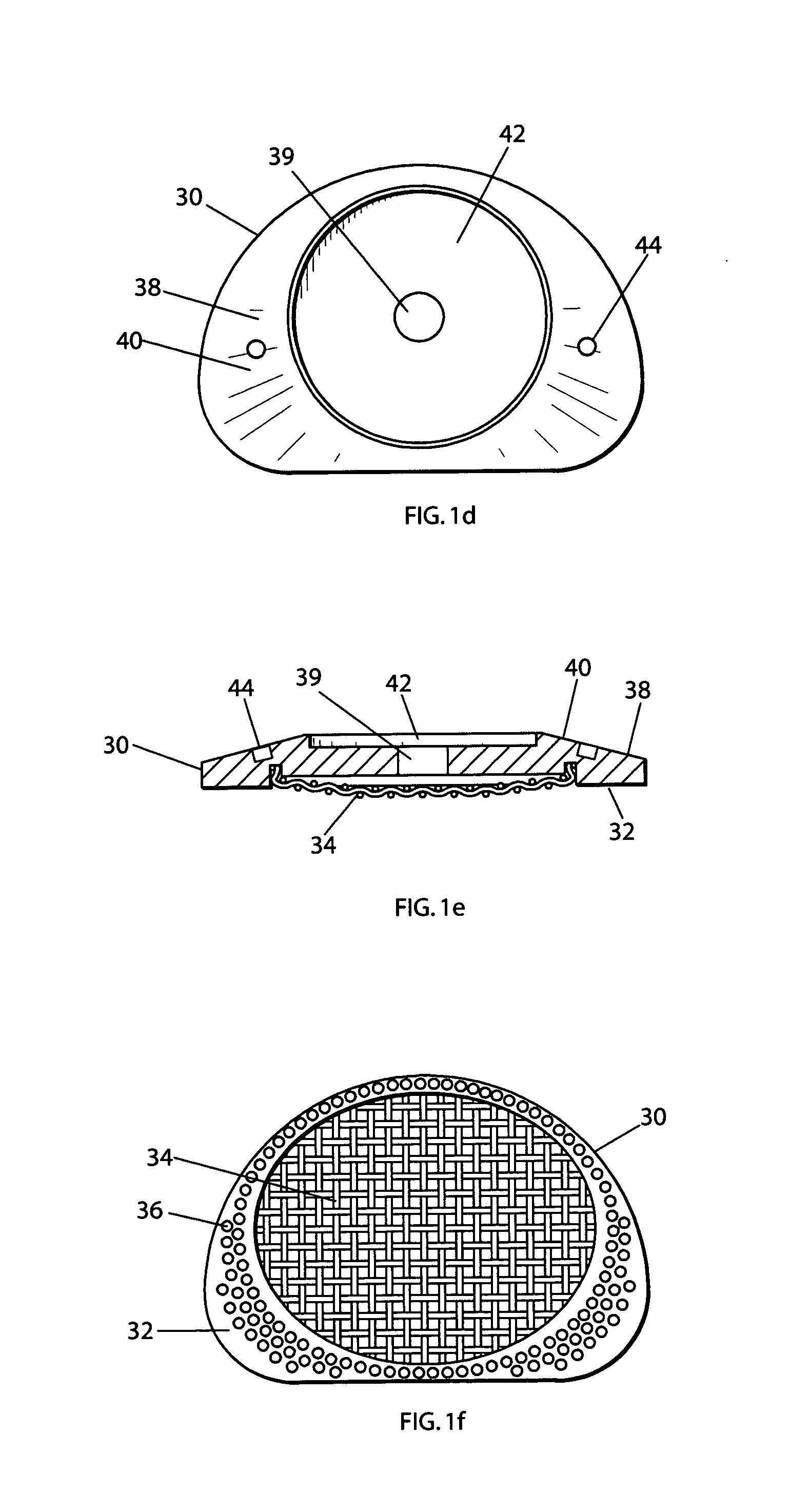

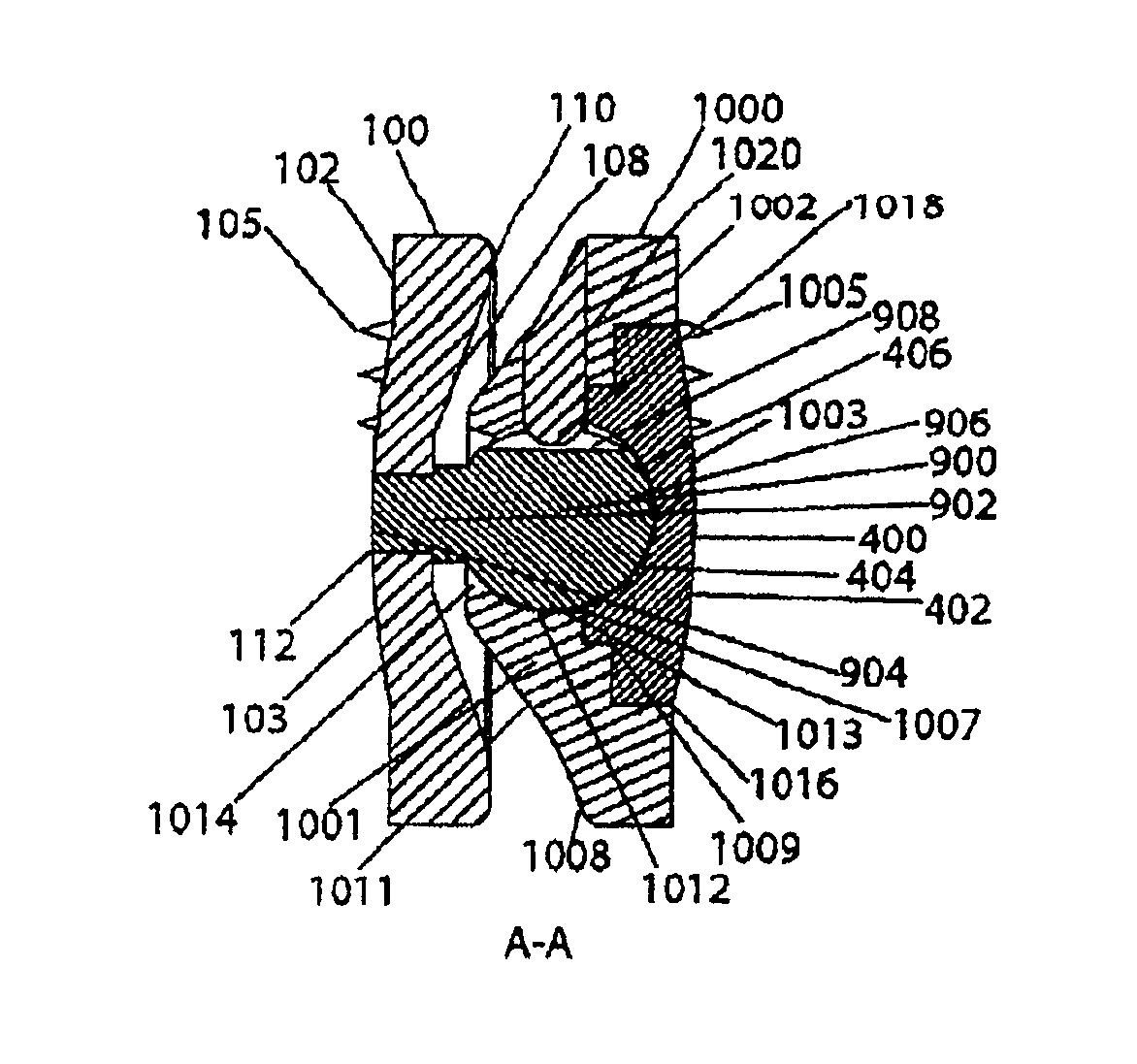

Artificial intervertebral disc

InactiveUS6989032B2Inhibition of translationAvoid separationJoint implantsSpinal implantsConvex structureVertebral bone

An artificial disc having a pair of opposing baseplates, for seating against opposing vertebral bone surfaces, separated by a ball and socket joint that includes a ball compression locked to a post extending from one of the baseplates. The ball is captured within a curvate socket formed in a peak of a convex structure attached to the other of the baseplates. The socket is formed by opposing curvate surfaces, one on the convex structure and one on the other of the baseplates. While the ball angulates freely in the socket, the rotation of the ball in the socket has a limited range due to interference between a protrusion on the convex structure that extends into the socket and a curvate recess on the ball. The ball and socket joint therefore permits the baseplates to rotate relative to one another through a limited range and also angulate relative to one another.

Owner:HOWMEDICA OSTEONICS CORP

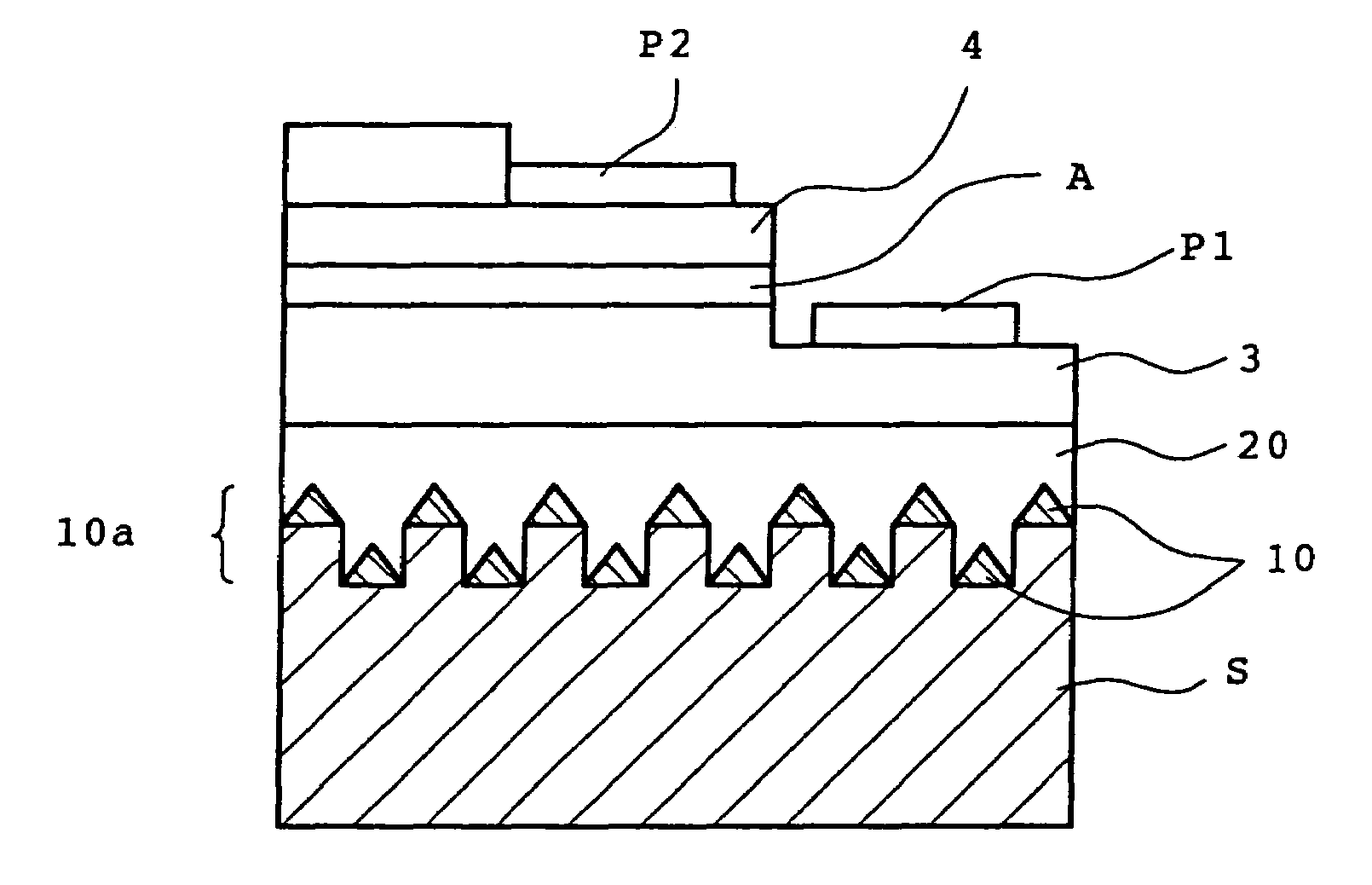

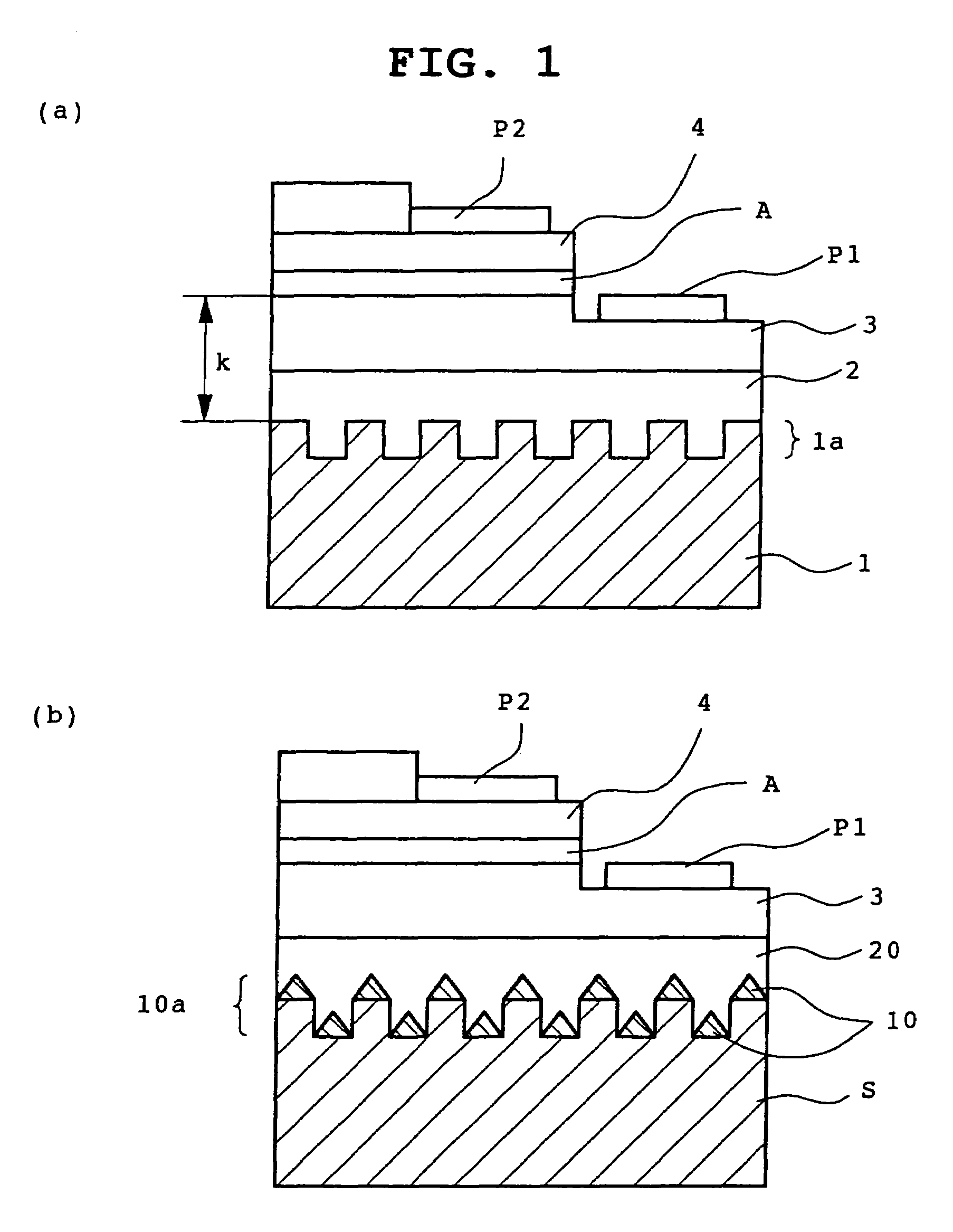

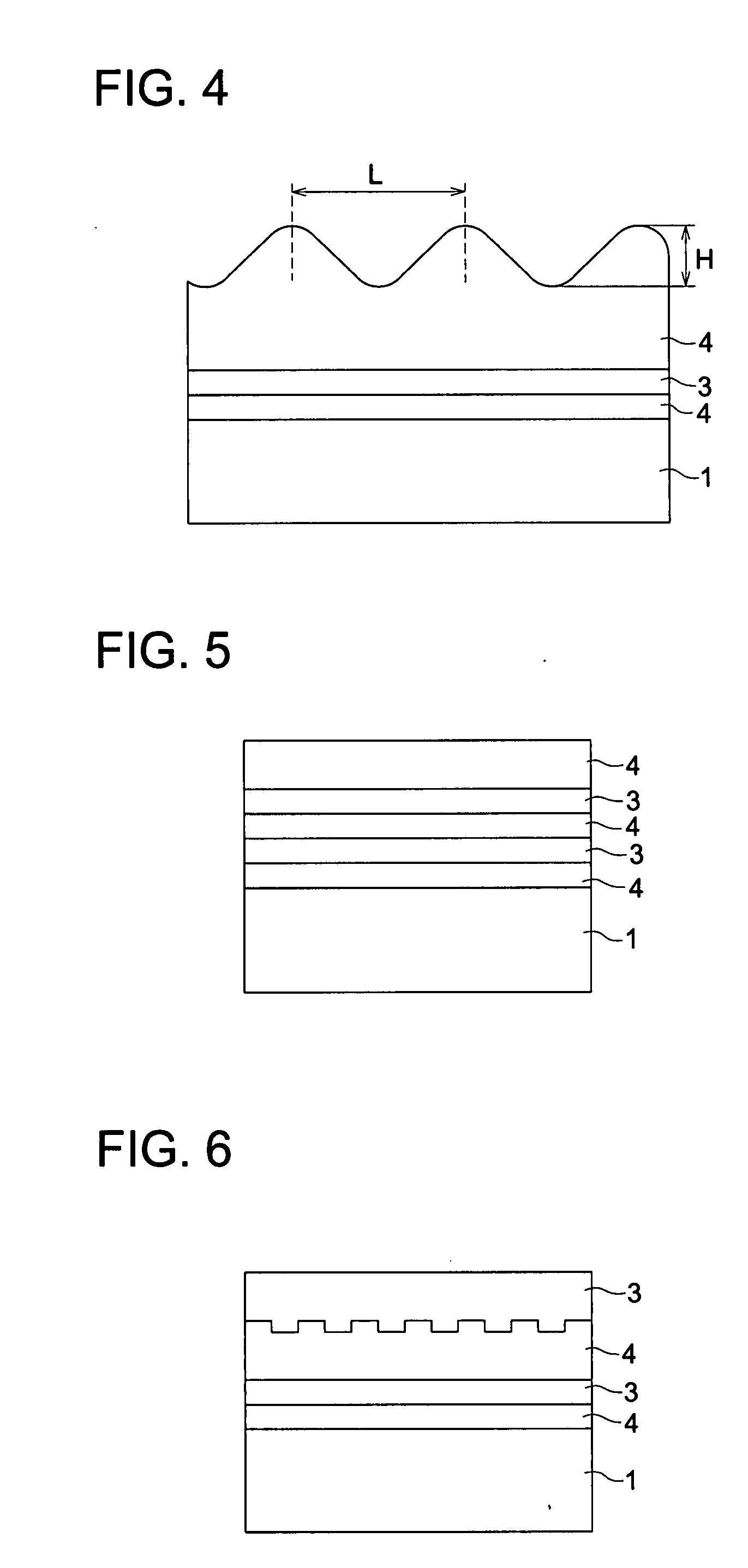

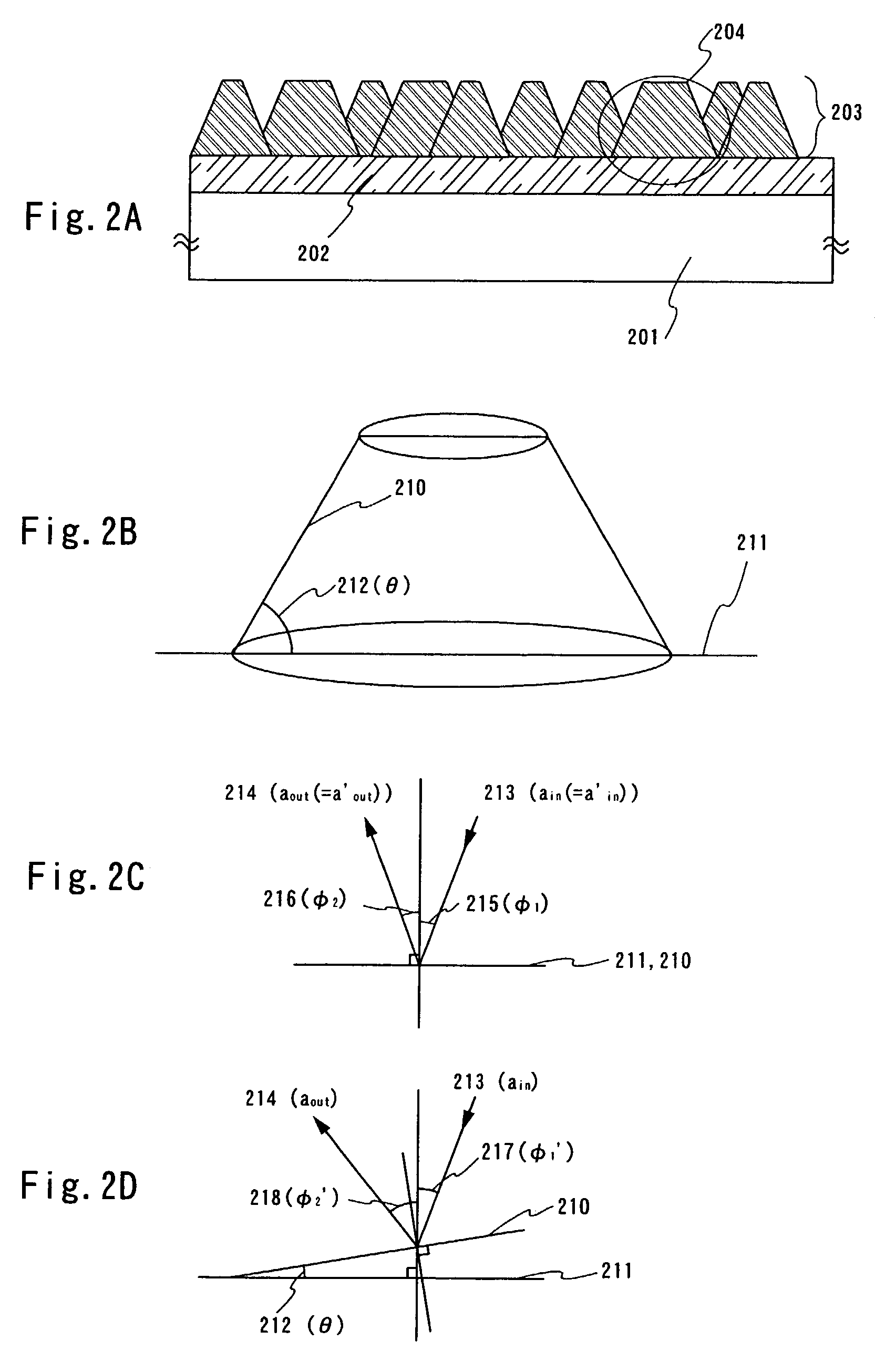

GaN group semiconductor light-emitting element with concave and convex structures on the substrate and a production method thereof

InactiveUS7053420B2Semiconductor/solid-state device manufacturingSemiconductor devicesConvex structureSurface layer

Concaves and convexes 1a are formed by processing the surface layer of a first layer 1, and second layer 2 having a different refractive index from the first layer is grown while burying the concaves and convexes (or first crystal 10 is grown as concaves and convexes on crystal layer S to be the base of the growth, and second crystal 20 is grown, which has a different refractive index from the first crystal). After forming these concavo-convex refractive index interfaces 1a (10a), an element structure, wherein semiconductor crystal layers containing a light-emitting layer A are laminated, is formed. As a result, the light in the lateral direction, which is generated in the light-emitting layer changes its direction by an influence of the concavo-convex refractive index interface and heads toward the outside. Particularly, when an ultraviolet light is to be emitted using InGaN as a material of a light-emitting layer, a quantum well structure is employed and all the layers between the quantum well structure and the low temperature buffer layer are formed of a GaN crystal, removing AlGaN. The quantum well structure preferably consists of a well layer made of InGaN and a barrier layer made of GaN, and the thickness of the barrier layer is preferably 6 nm–30 nm.

Owner:TOYODA GOSEI CO LTD

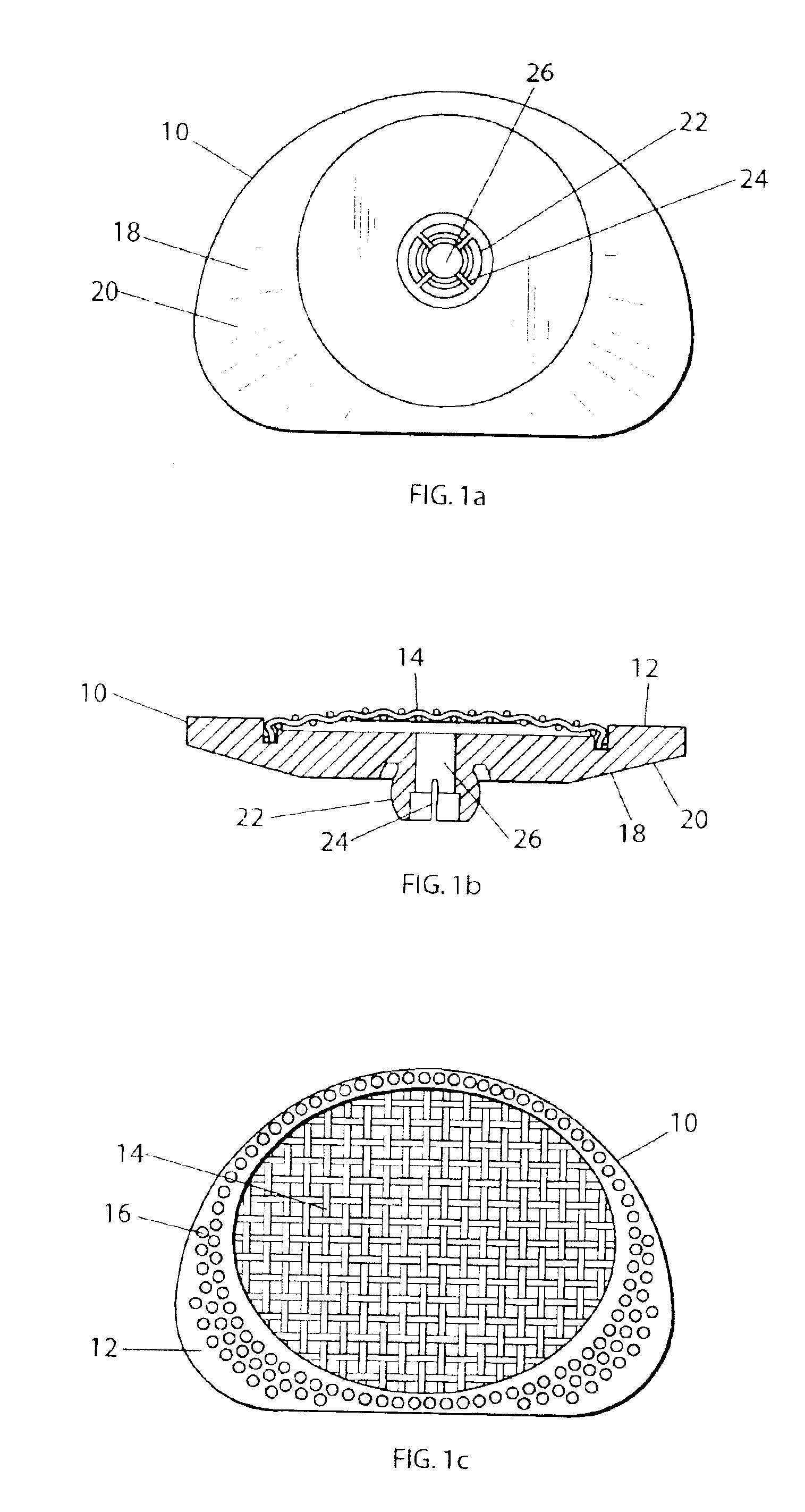

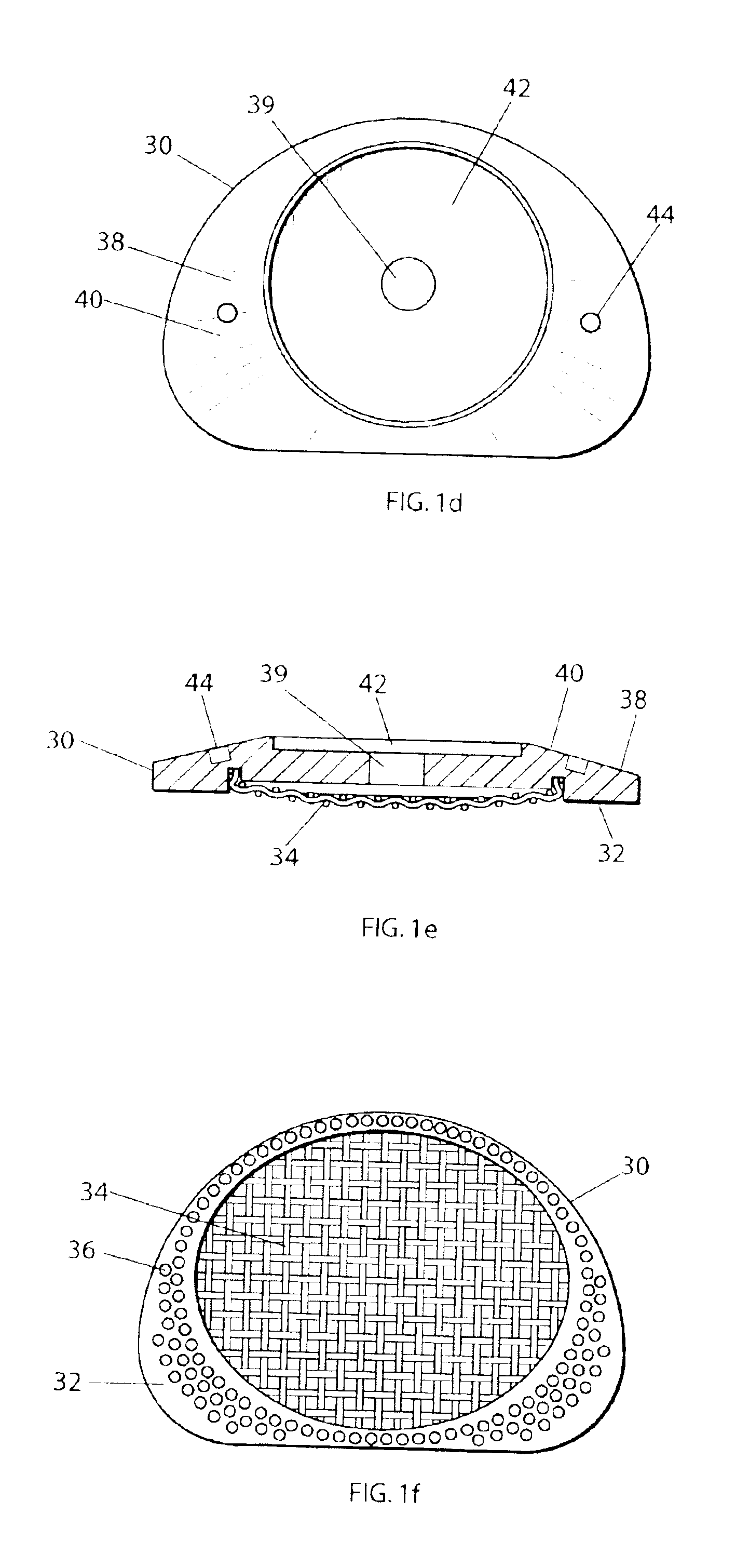

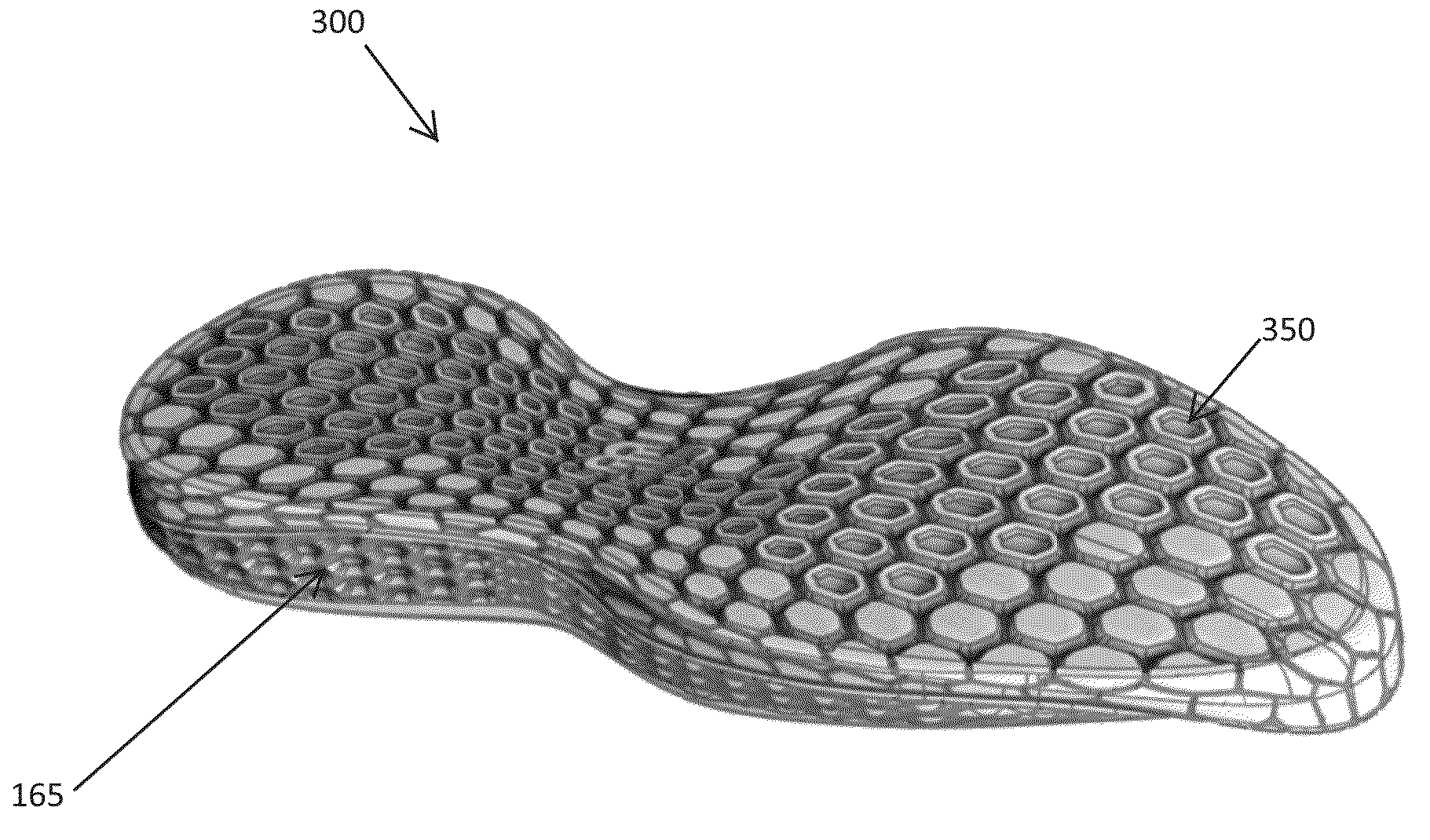

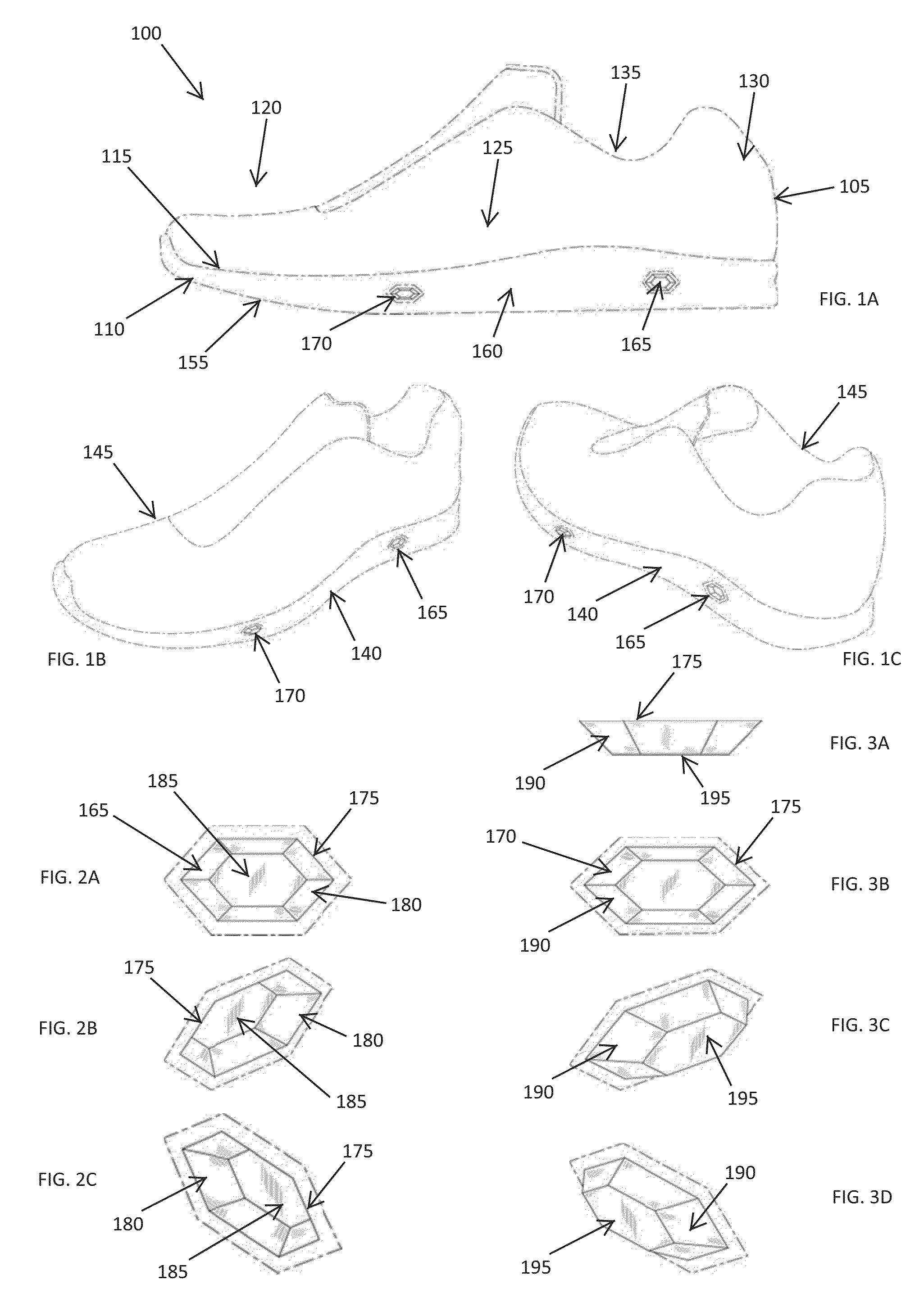

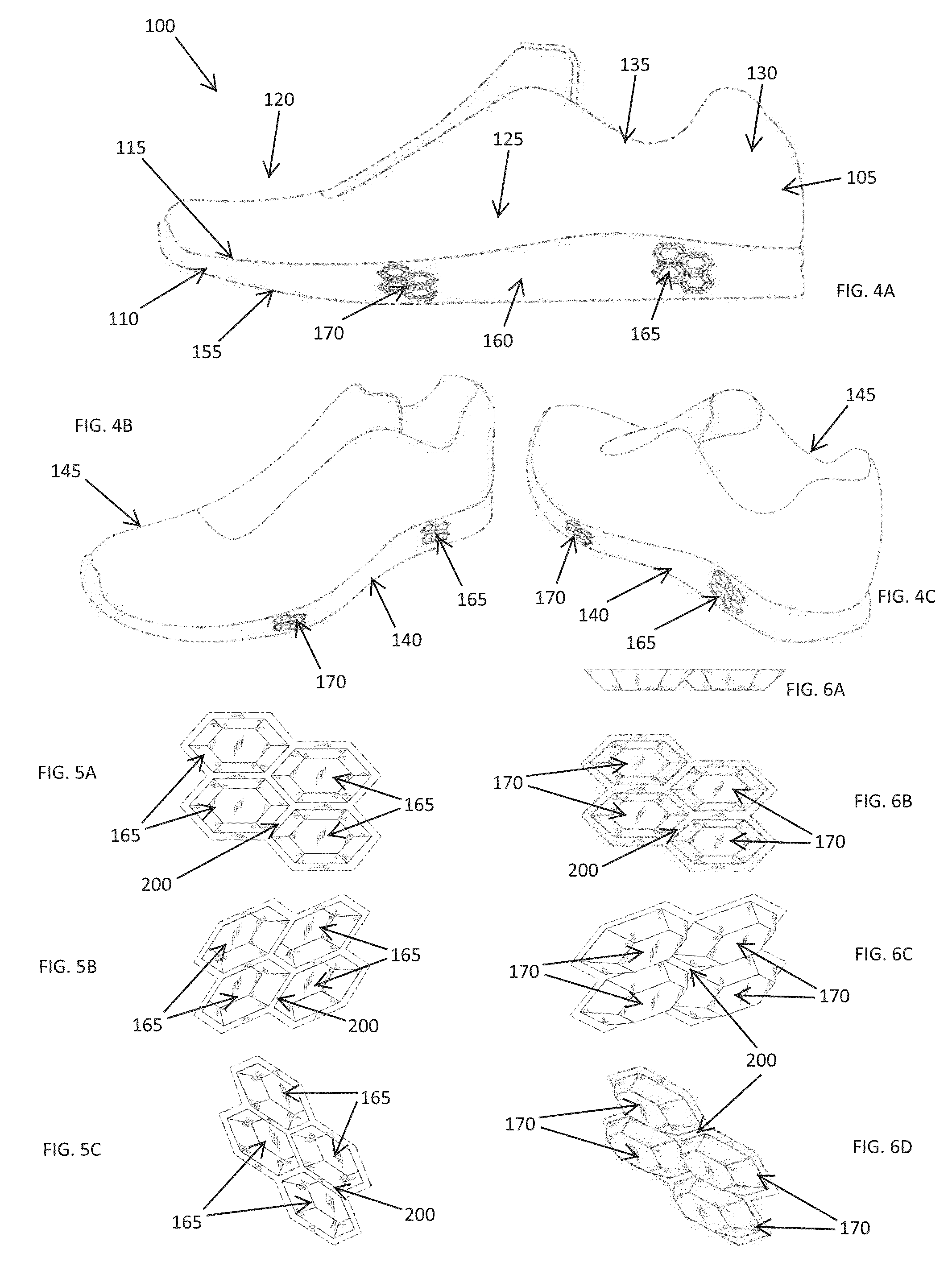

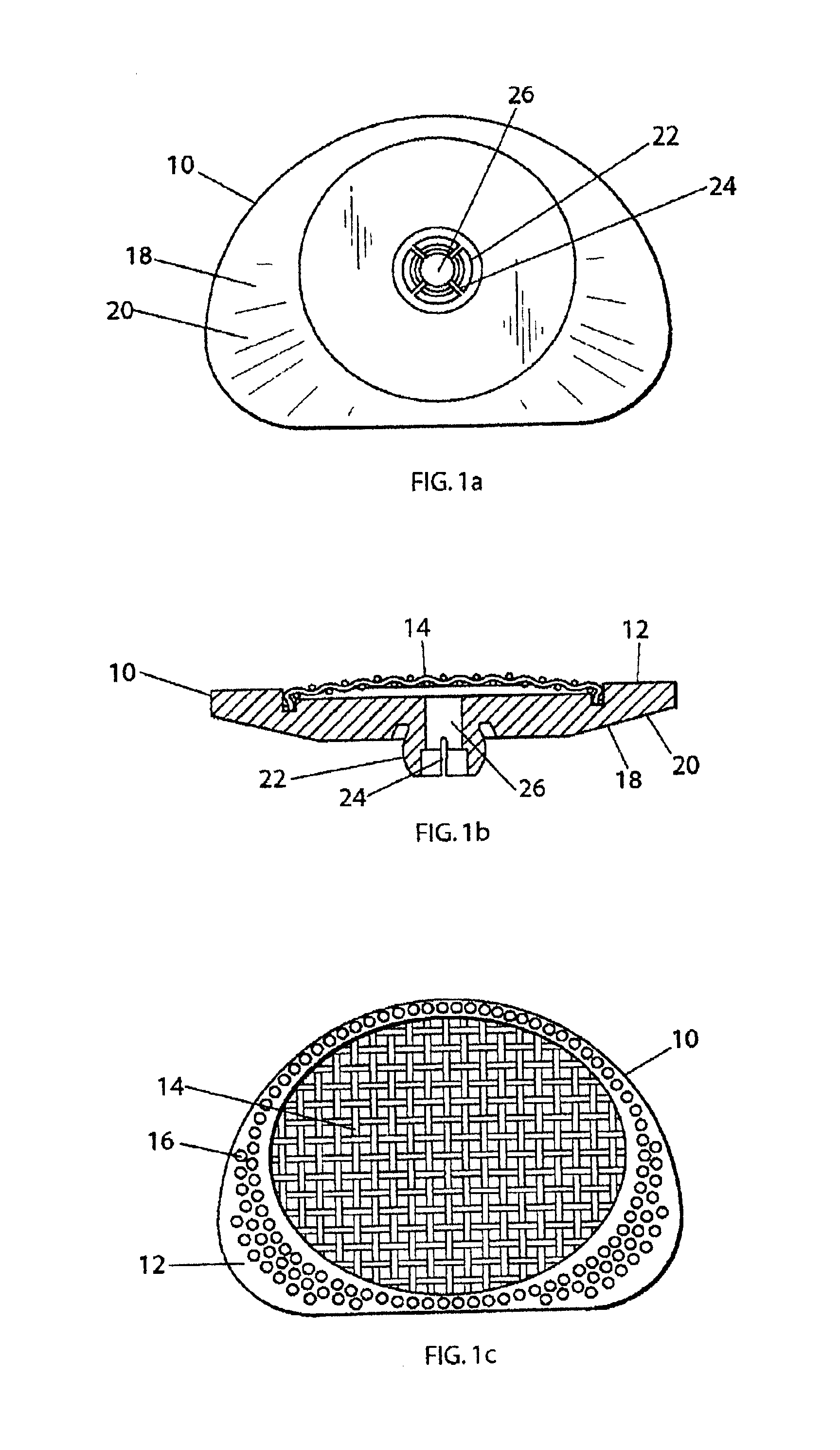

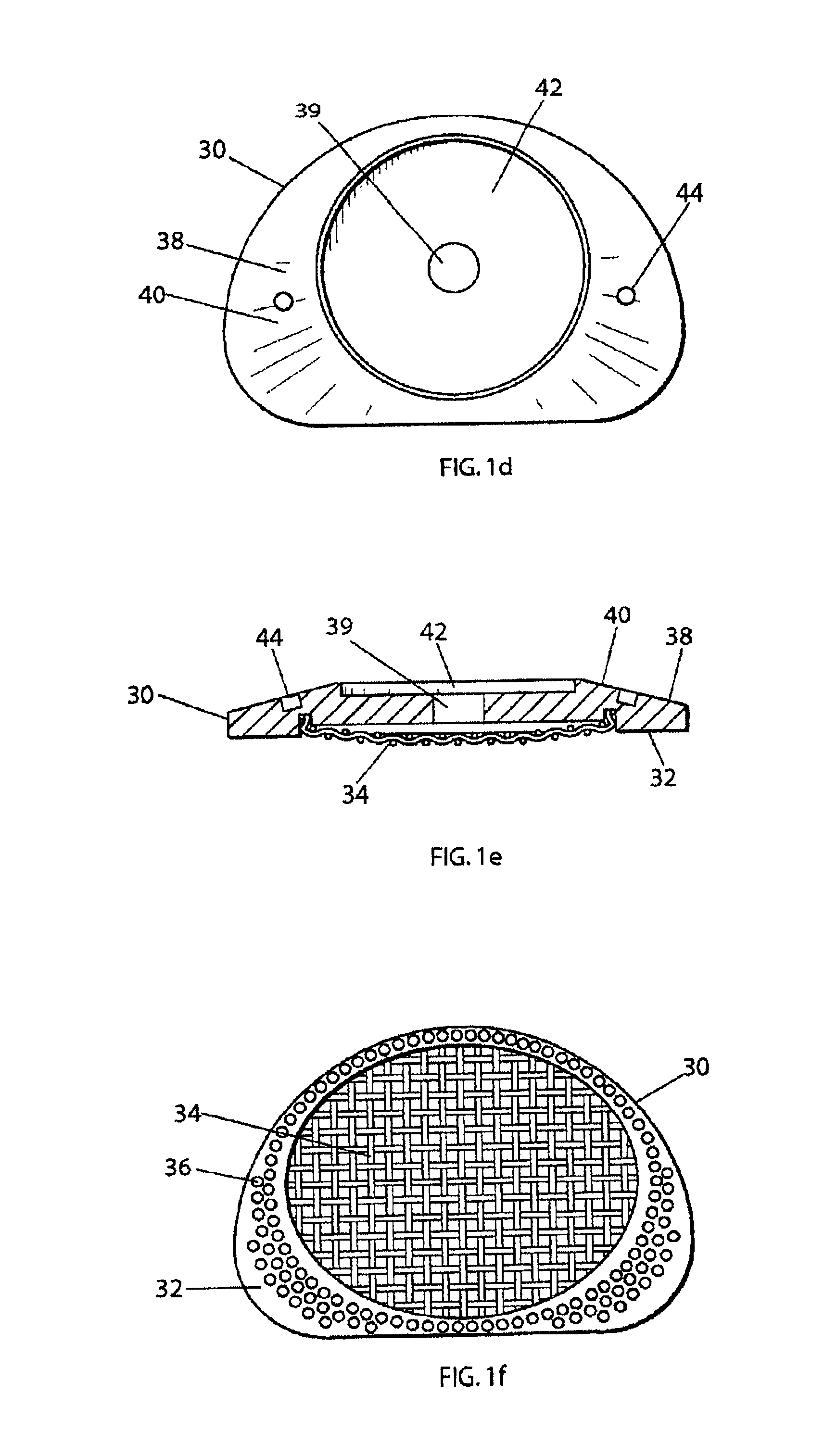

Sole for Footwear, and Systems and Methods for Designing and Manufacturing Same

ActiveUS20150223560A1Improved performance characteristicsFoot measurement devicesAdditive manufacturing apparatusConvex structureEngineering

The invention relates to articles of footwear, and portions thereof, including convex and / or concave elements thereon, and related systems and methods for designing and manufacturing same. An example article of footwear including a midsole having a medial side, a lateral side, a forefoot region, a midfoot region, and a heel region, the midsole including a sidewall, wherein the sidewall includes a first wall portion having a plurality of convex structures extending out from the sidewall and a second wall portion having a plurality of concave structures extending into the sidewall.

Owner:NEW BALANCE ATHLETICS

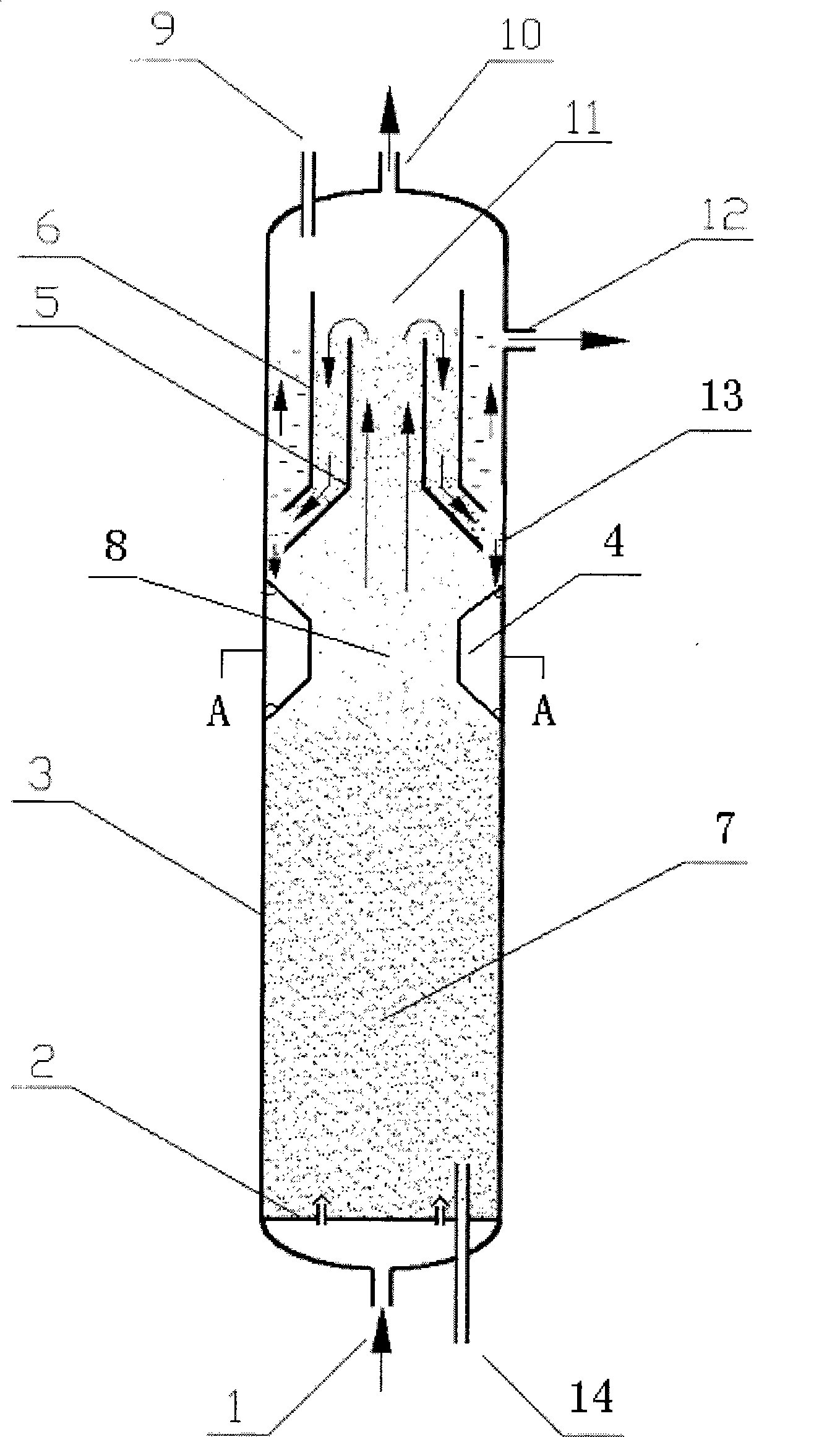

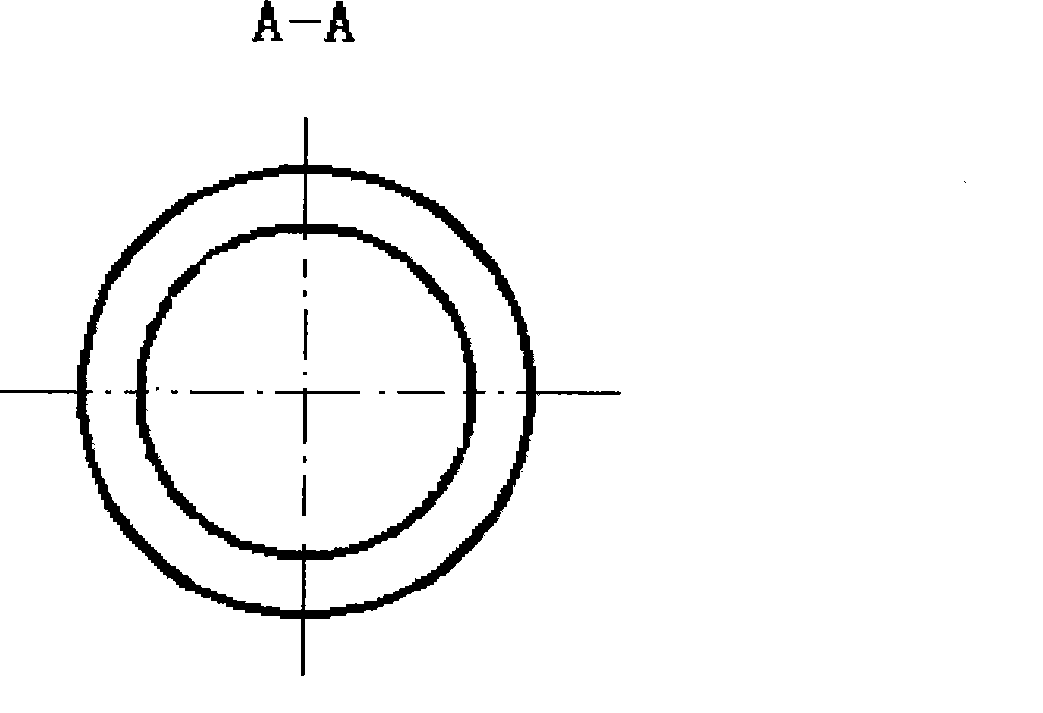

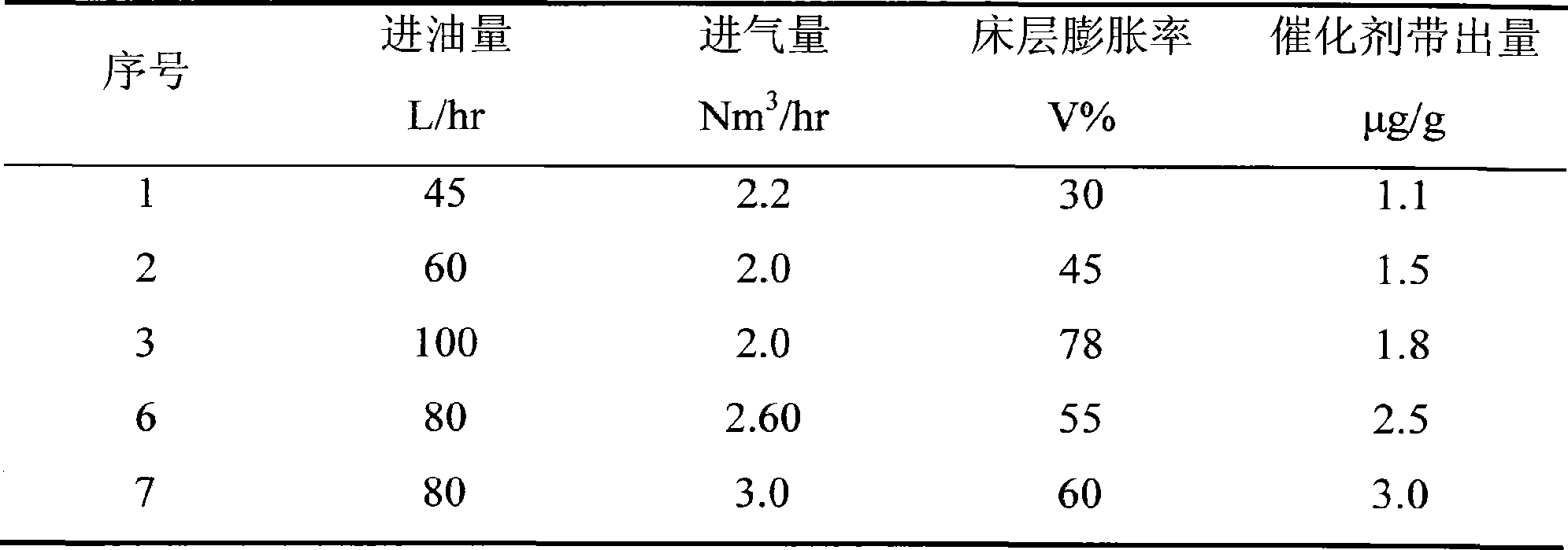

Novel bubbling bed reactor

ActiveCN101376092AGreat operating flexibilityEfficient separationHydrocarbon oils refiningChemical/physical processesConvex structureChemical reaction

The invention discloses a new fluidized bed hydrogenation reactor. The fluidized bed hydrogenation reactor of the invention comprises a cylinder-shaped reactor shell perpendicular to the ground, a three-phase separator arranged at the upper part in the reactor shell and a guiding structure arranged at the middle upper part of the reactor. The guiding structure is an annular convex structure arranged on the inner wall of the reactor and has the lengthwise section of a trapezoid or an arc along the axle of the reactor. The combination of the guiding structure and the three-phase separator increases the operating flexibility of the three-phase separator, and ensures the high-efficiency separation on the three-phase separator, thereby greatly reducing the carrying amount of catalyst. The fluidized bed hydrogenation reactor of the invention can be applied to the chemical reactions between different liquids or gases and solid grains under the condition of contacting, and is characterized by large catalyst inventory, high reactor utility ratio, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

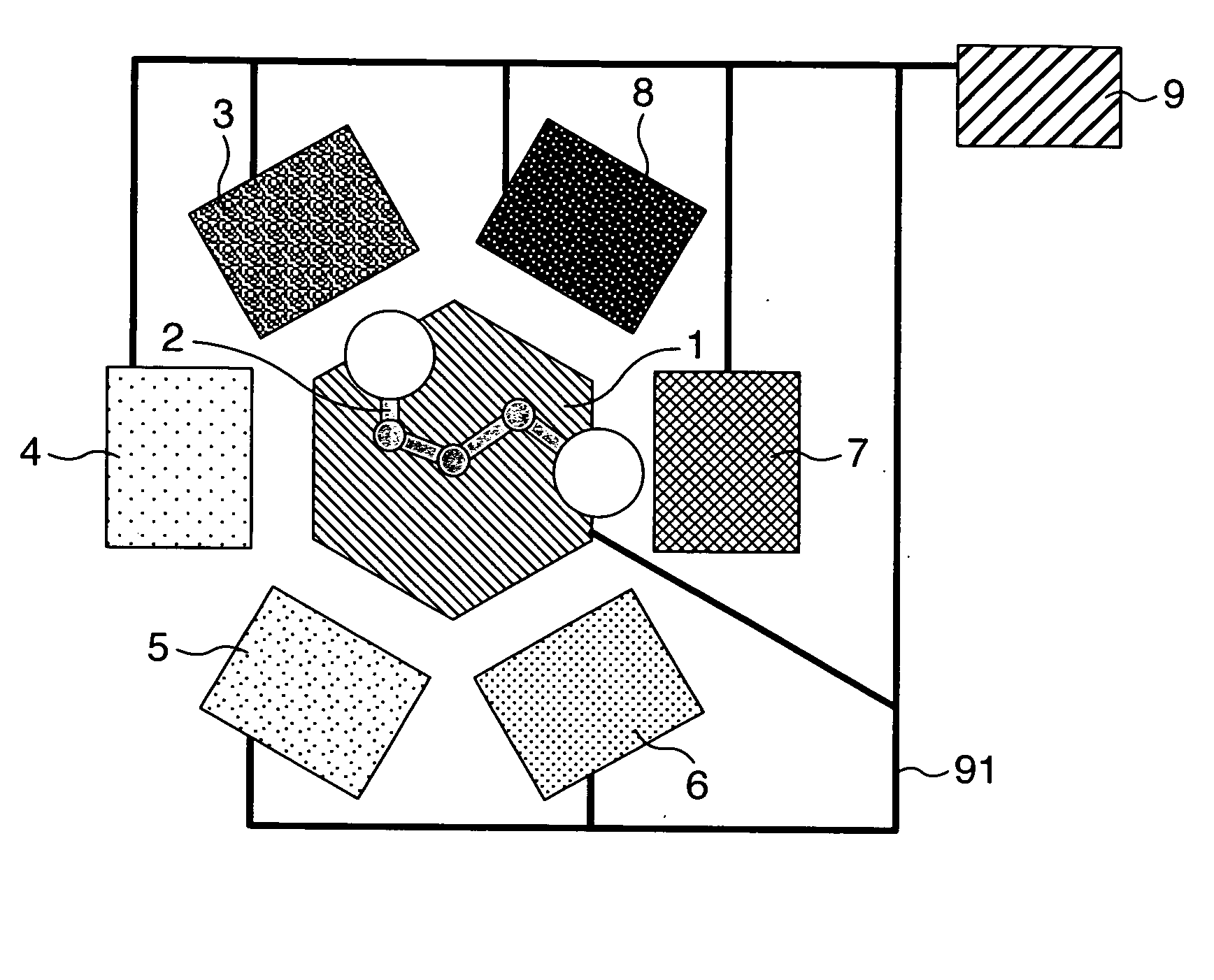

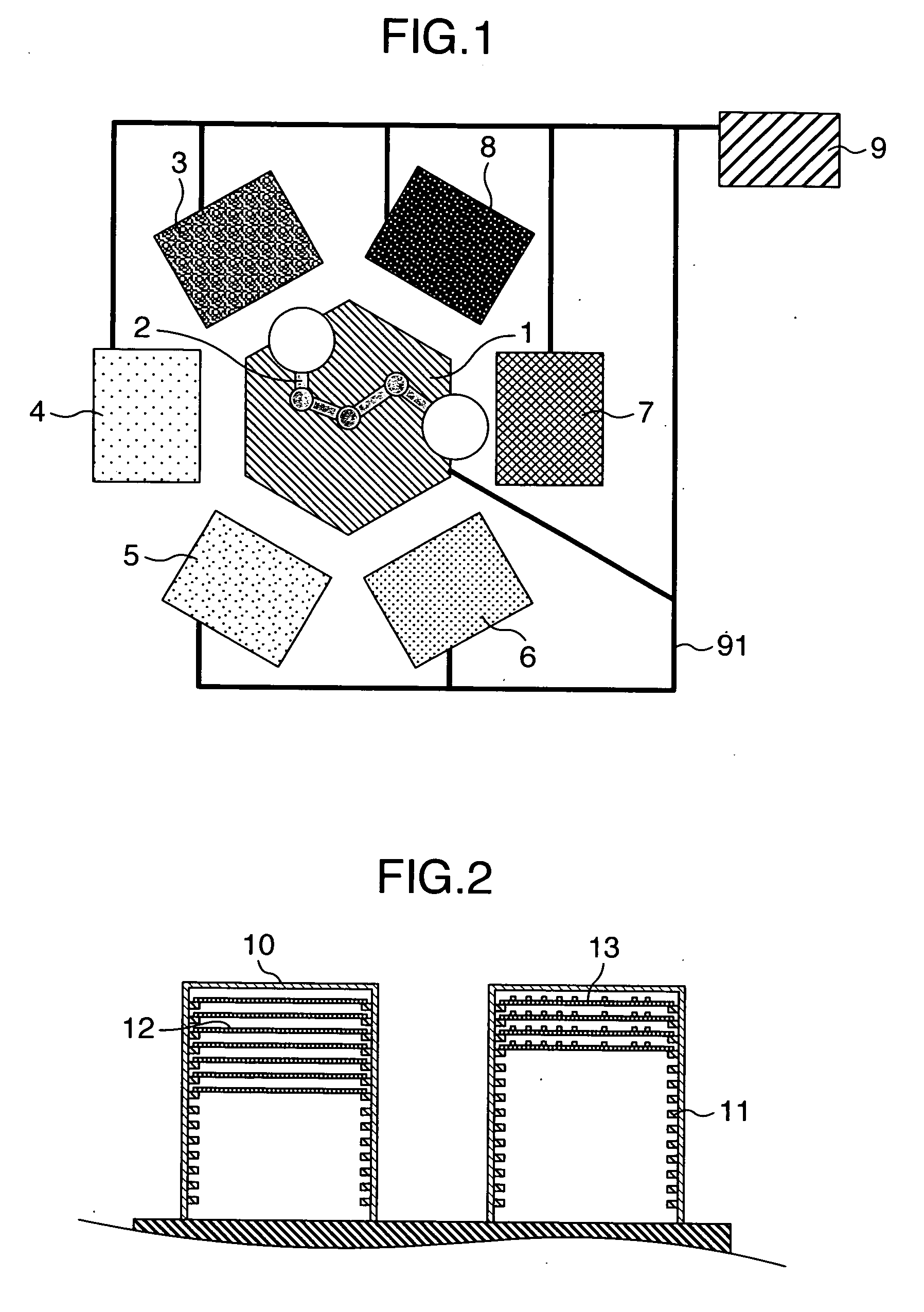

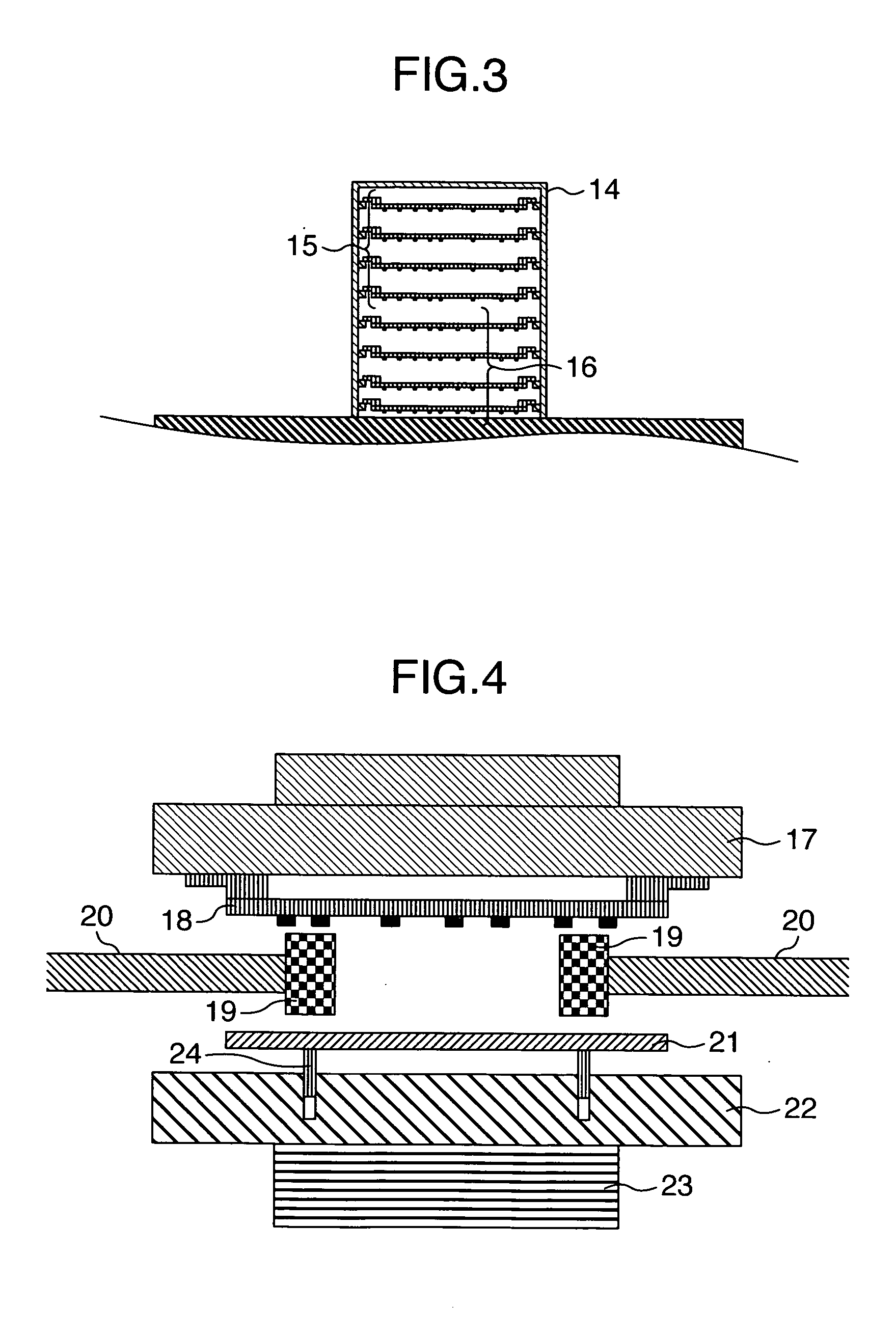

Imprinting machine and imprinting method

InactiveUS20050116370A1Rapid change of pressureIncreased substrate speedNanoinformaticsPhotomechanical apparatusConvex structureNanometer size

An object of the invention is to execute an imprinting process at a higher speed and a higher accuracy, in an imprinting apparatus. In an imprinting apparatus for contacting and pressurizing a mold having a micro concavo-convex structure formed on a surface thereof to a substrate surface in order to form a micro and nanometer size structure on a substrate, a step of pressurizing the mold and the substrate and a step of peeling the mold from the substrate are constituted by independent units, the mold and the substrate are moved in a closely attached state at a time of moving from the pressurizing step to the peeling step, and preferably at least two sets of molds and substrates are processed by the different steps simultaneously or a temporarily overlapped manner.

Owner:HITACHI PLANT TECH LTD

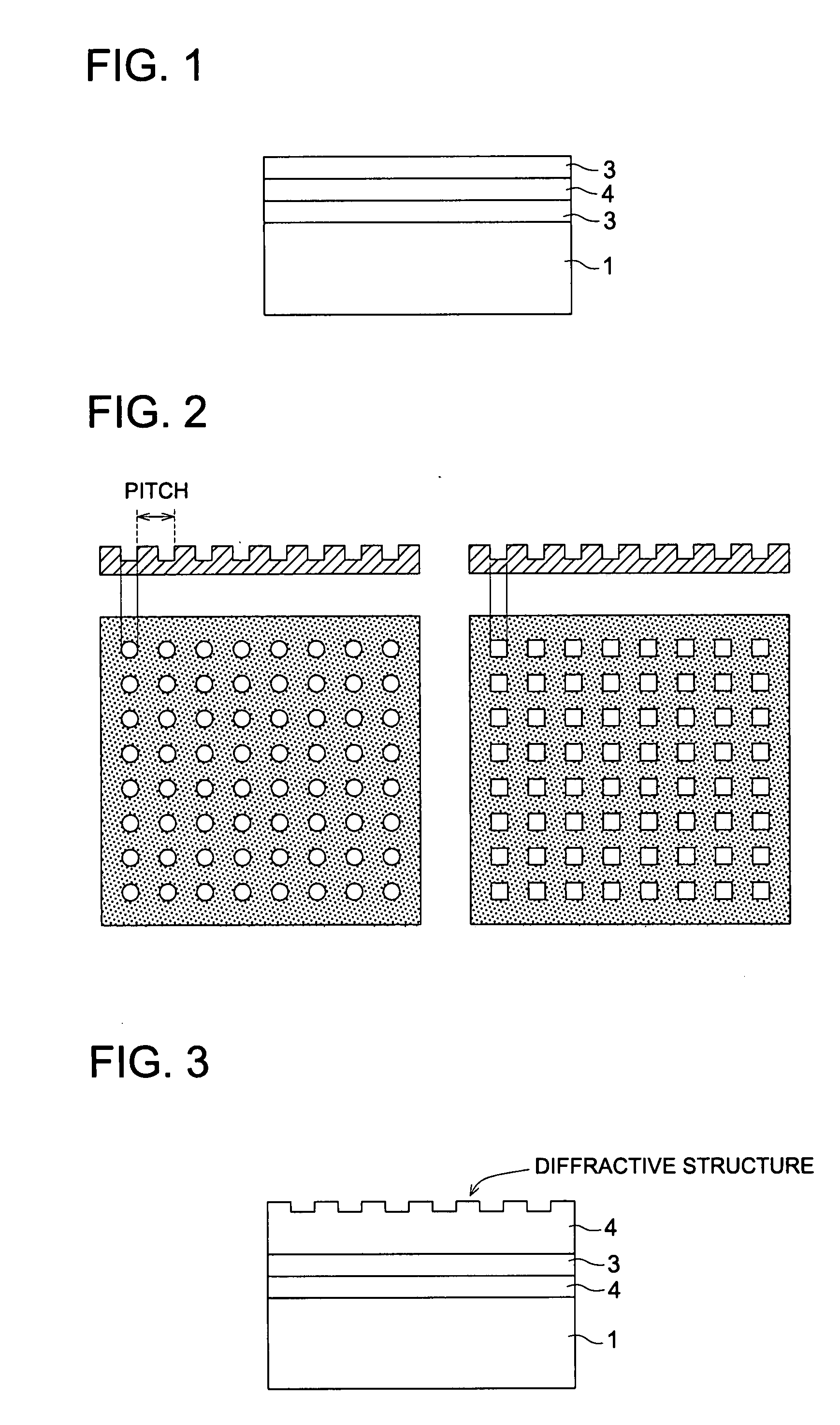

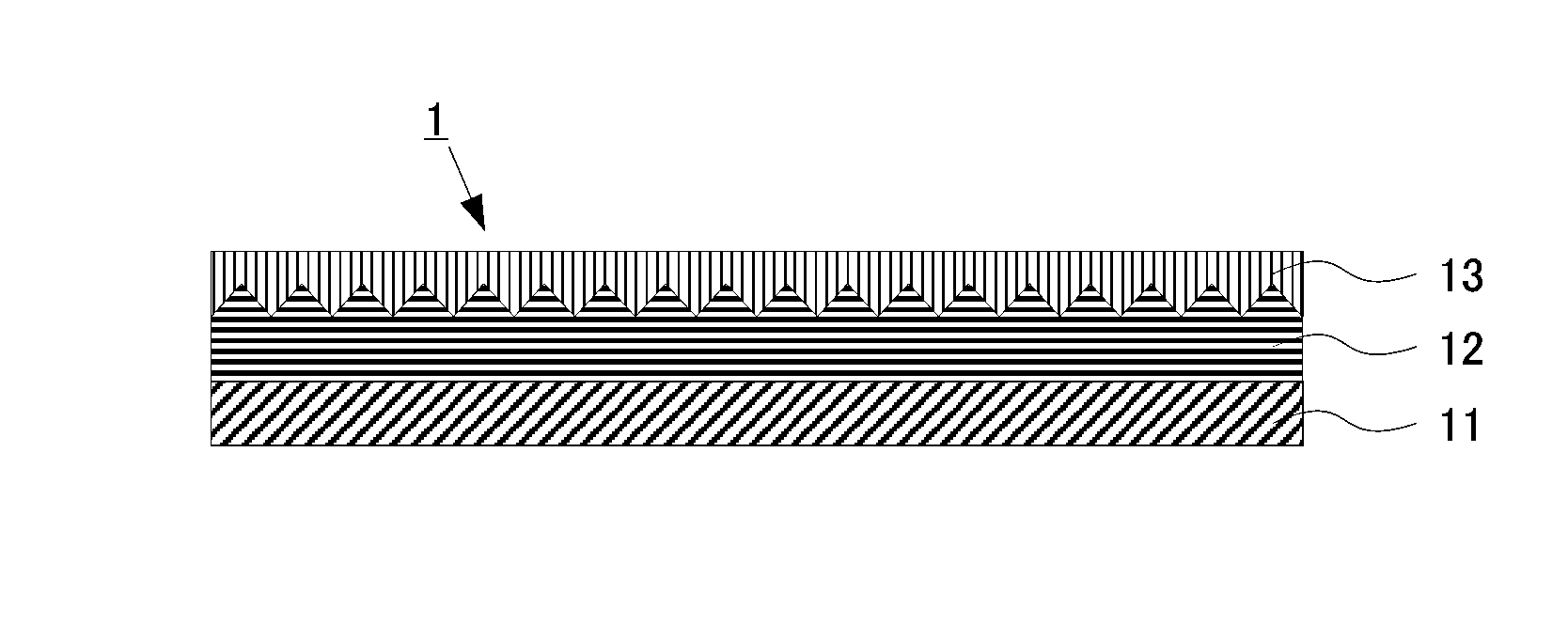

Optical diffusing layer, optical diffusing sheet, and optical element

InactiveUS6861121B2Maintain anti-glare propertyGlare is suppressedLiquid crystal compositionsTelevision system detailsConvex structureSurface roughness

An optical diffusing layer comprising a resin coated layer having a surface fine concavo-convex structure, wherein an average of peak-to-peak distance (Sm), an average of center line surface roughness (Ra), and an average of ten-point surface roughness (Rz) on the surface with fine concavo-convex structure satisfy specified equations, is capable of maintaining antiglare property and screen glare simultaneously controlled, when applied to an LCD in which high definition is required.

Owner:NITTO DENKO CORP

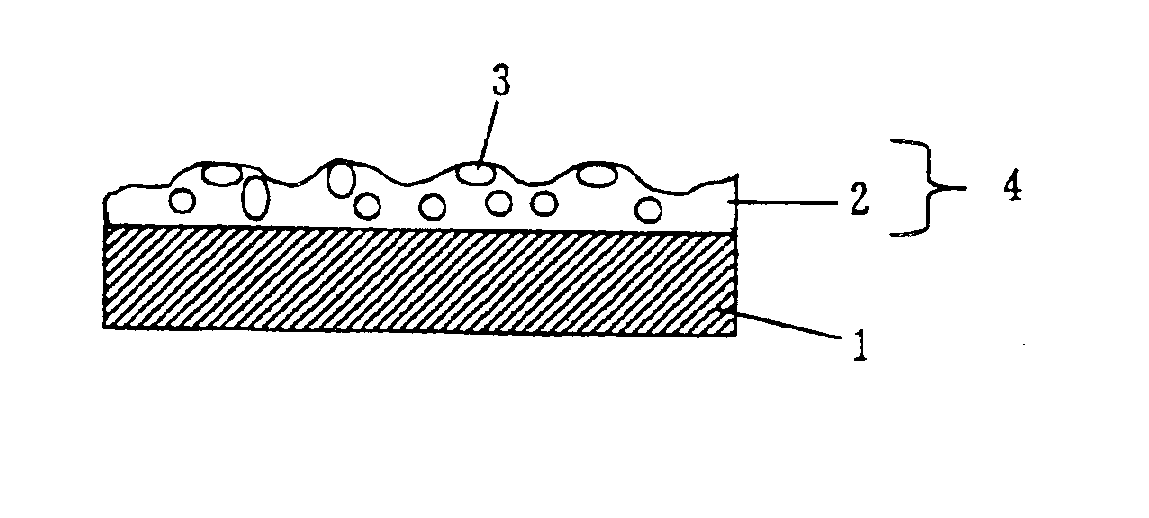

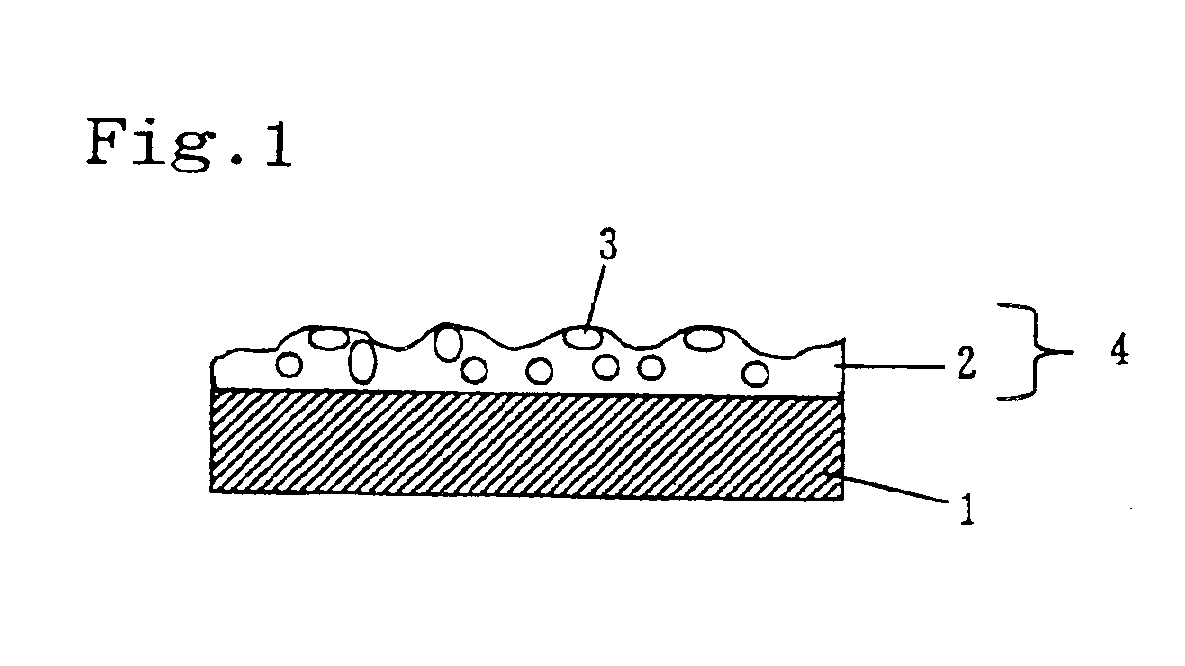

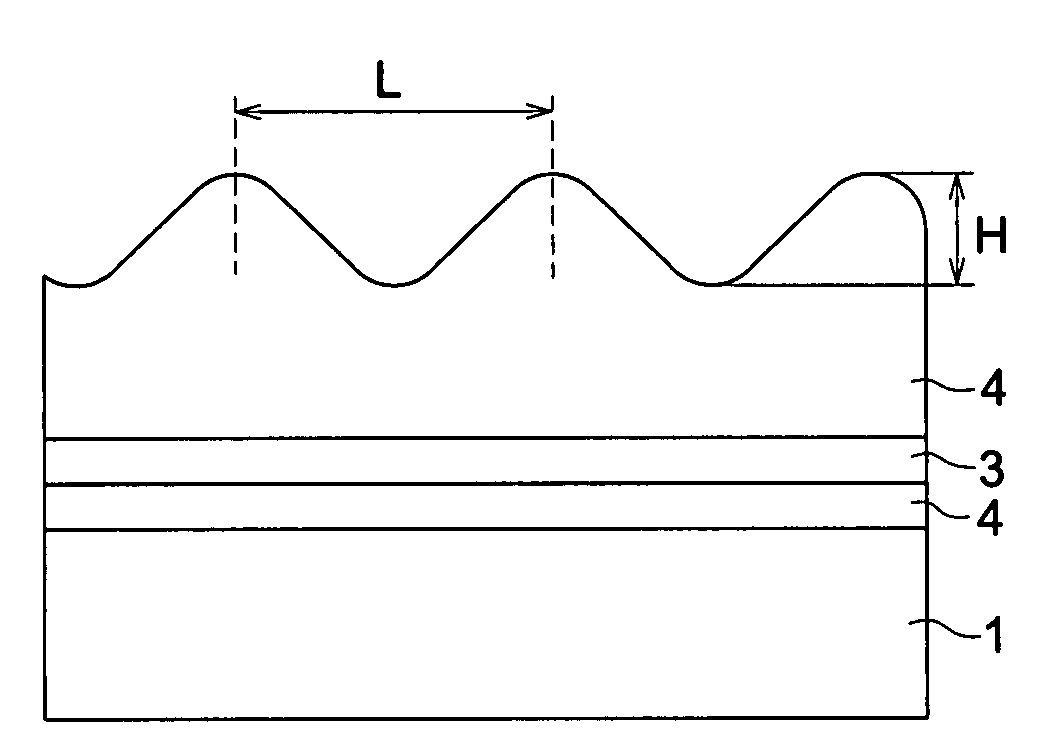

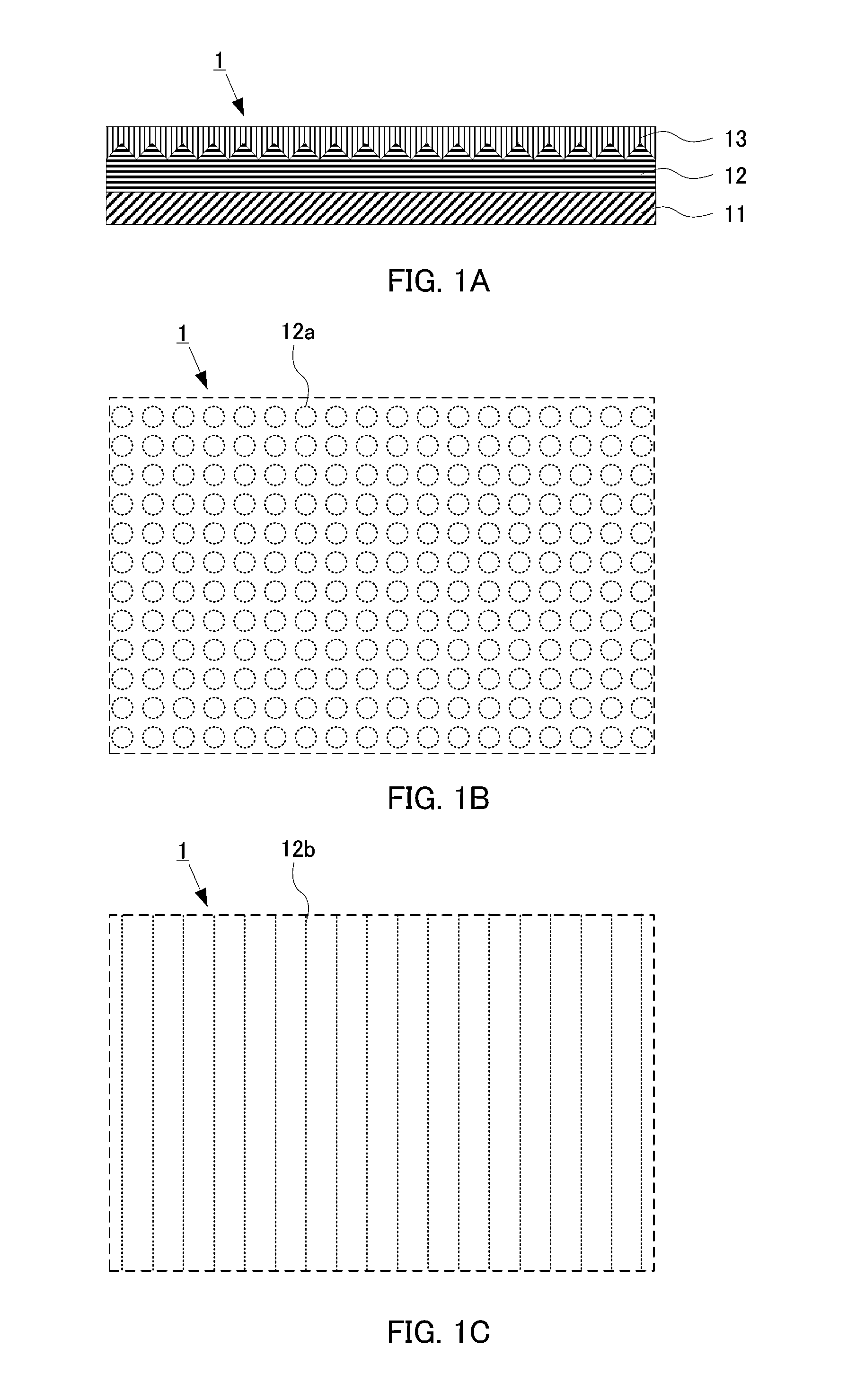

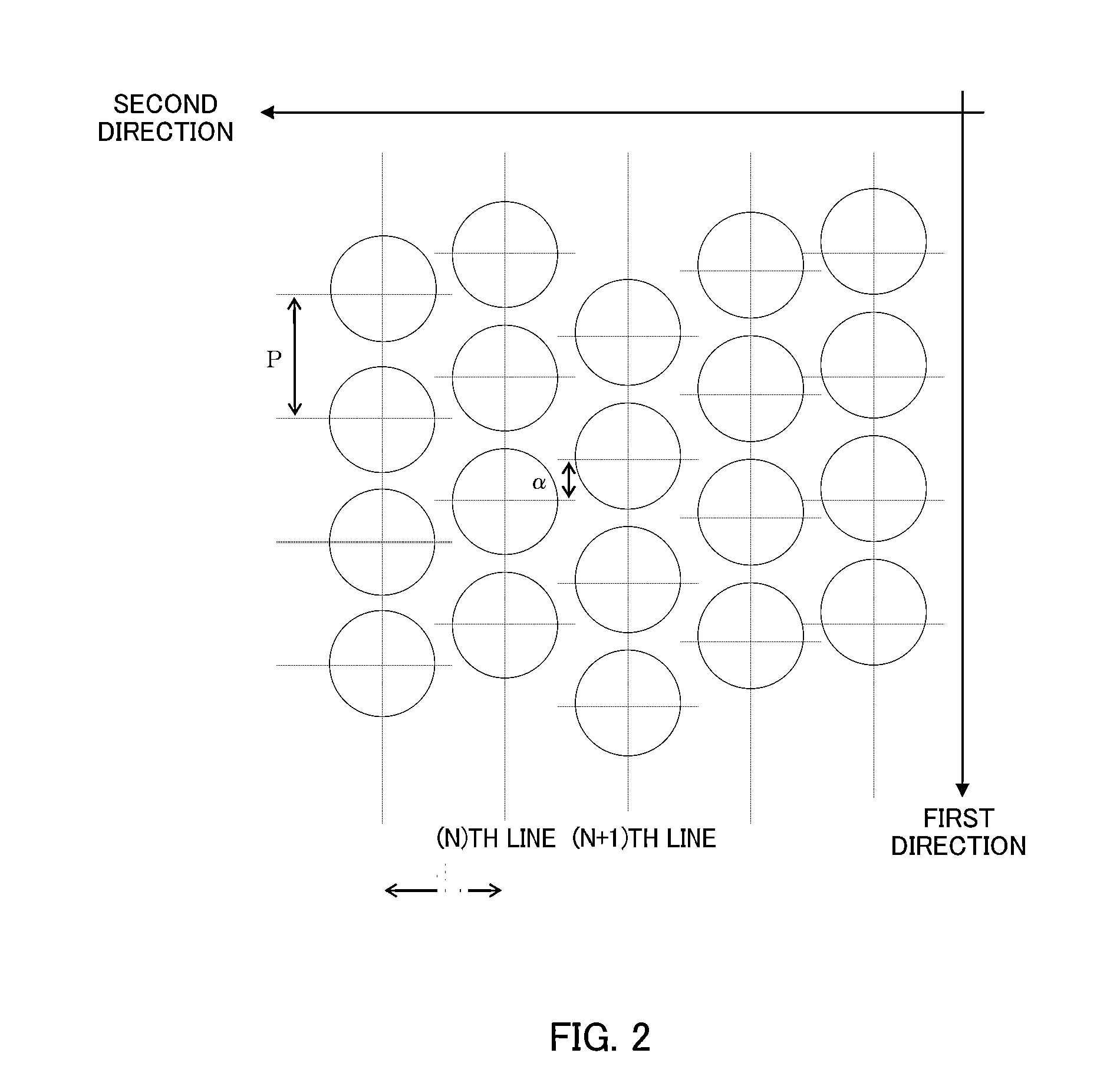

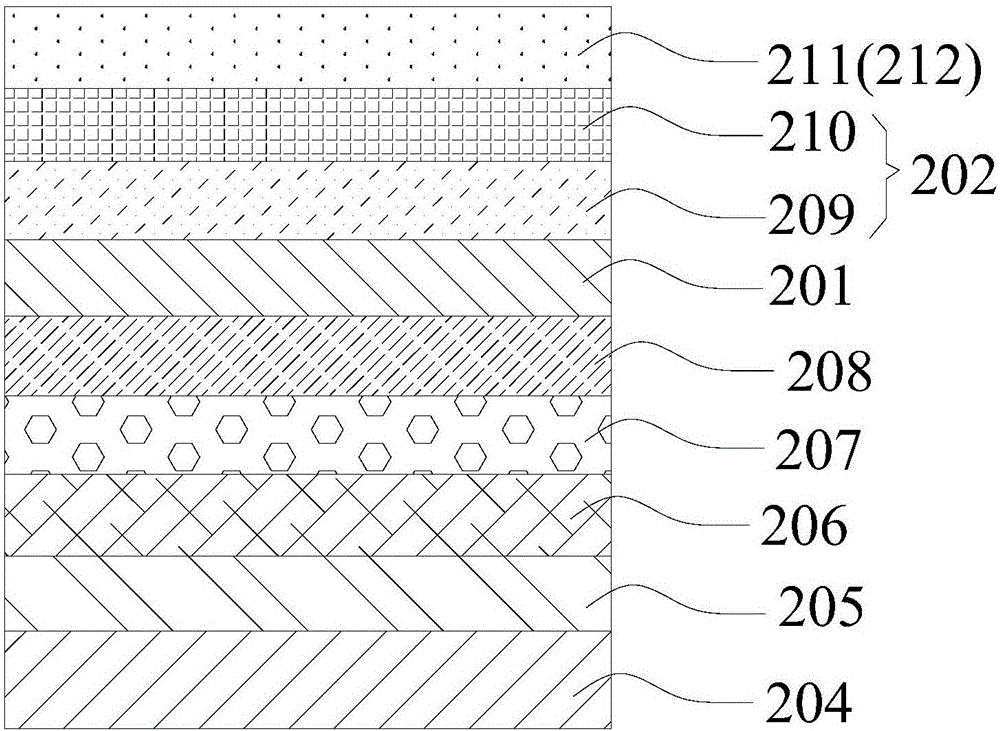

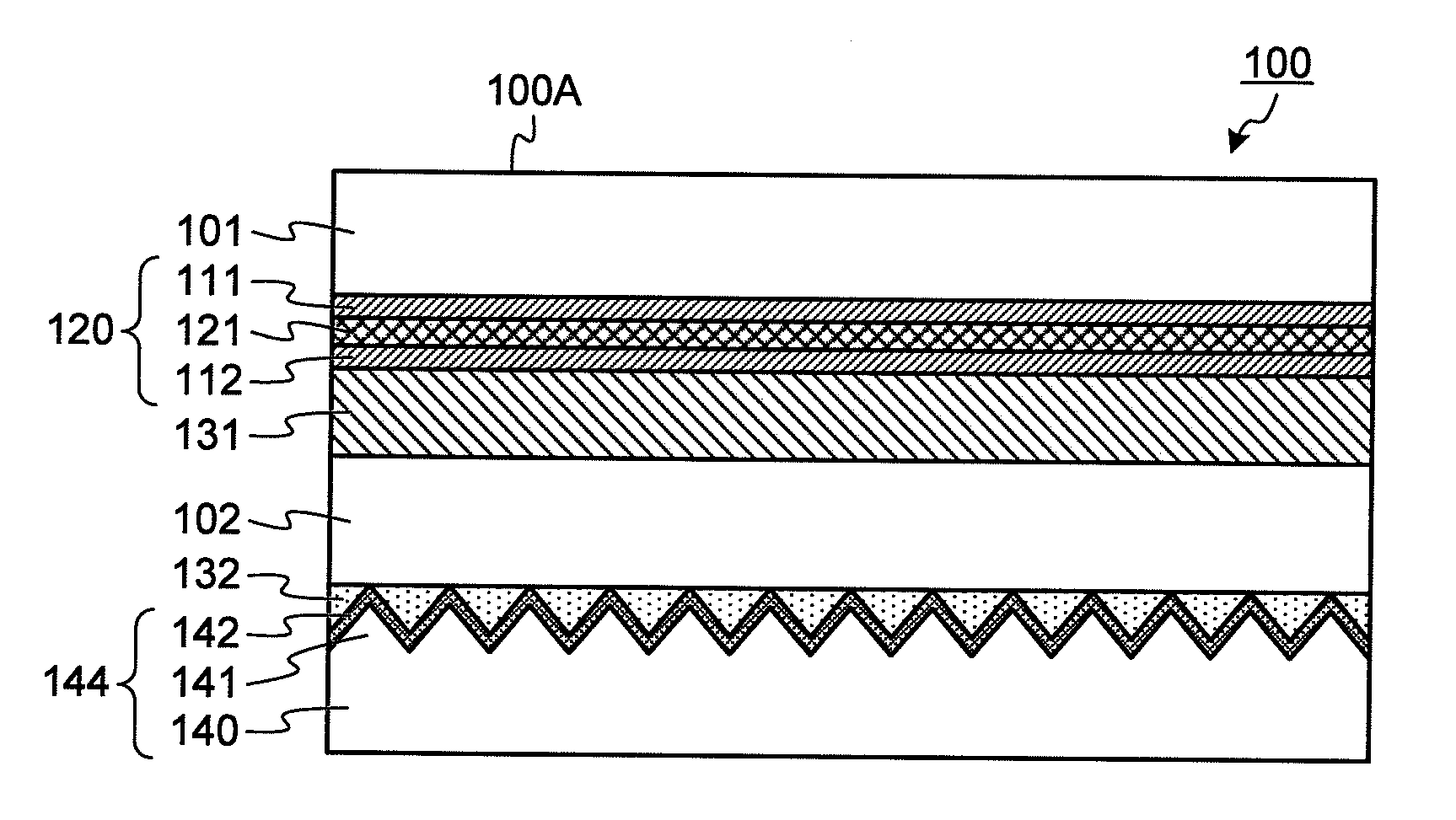

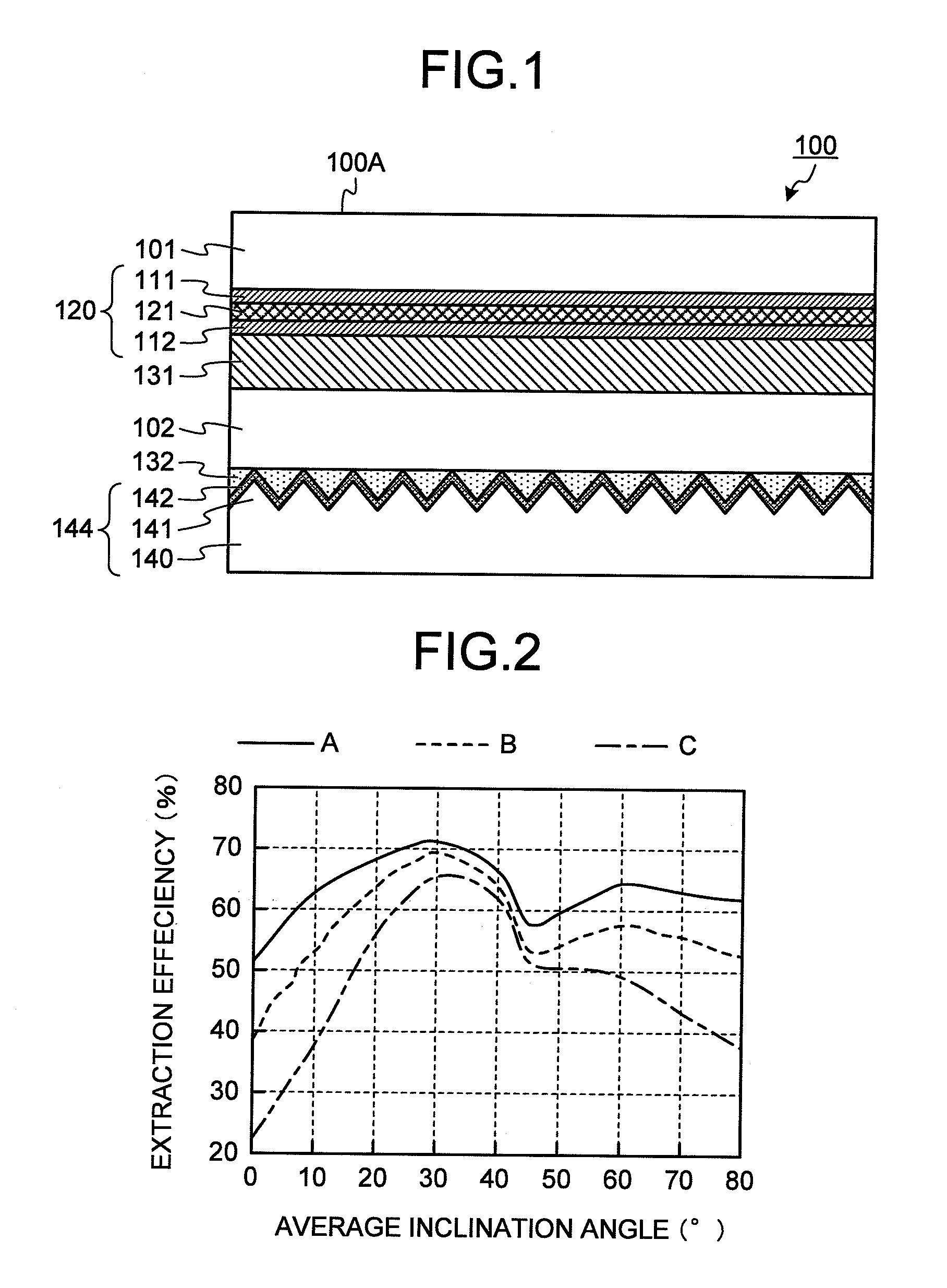

Resin Film Substrate for Organic Electroluminescence and Organic Electroluminescence Device

InactiveUS20080176041A1Low costExcellent gas barrier performanceSynthetic resin layered productsSolid-state devicesConvex structureOrganic electroluminescence

Disclosed is a low-cost resin film substrate for organic electroluminescence which comprises a gas barrier layer having high gas barrier properties while being improved in light taking-out efficiency. Also disclosed is an organic electroluminescence device using such a resin film substrate. Specifically disclosed is a resin film substrate for organic electroluminescence comprising at least one gas barrier layer on a resin film. This resin Film substrate is characterized in that the surface of the outermost layer on the side having the gas barrier layer has a concavo-convex structure for diffracting of diffusing light.

Owner:KONICA MINOLTA INC

Endoscopic high-frequency hemostatic forceps

ActiveUS20120101501A1Satisfy safety performance requirementsQuicker and saferSurgical instrument detailsSurgical forcepsConvex structureEngineering

A hemostatic forceps (20) includes a pair of forceps elements (forceps cups (1)) constituted of a conductive metal and configured to serve as high-frequency electrodes and configured to be able to change into a state where front portions of the pair of forceps cups (1) are open, and a state where the pair of forceps cups (1) are close. A sawtooth portion (15) having a plurality of concavo-convex structures which constitute a sawtooth-shape is provided on at least one of respective closing-side surfaces (17) of the pair of forceps cups (1). The sawtooth portion (15) is provided with an electrically insulative coating over its bottom portion (21), but not on a top portion (22) thereof, and hence the top portion (22) is conductive.

Owner:KANEKA CORP +1

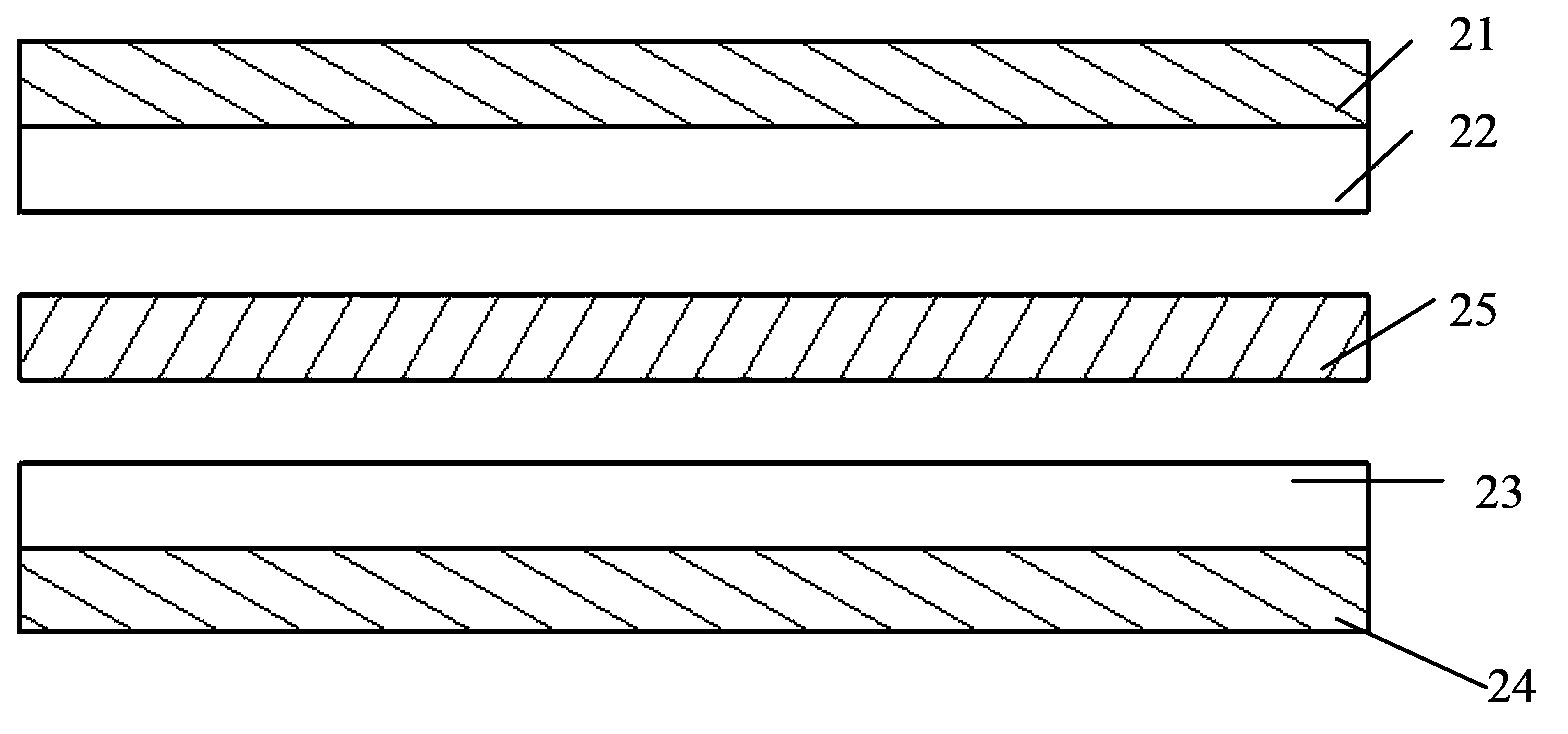

Self-powered pressure sensor

ActiveCN102749158AHigh sensitivityPromote generationForce measurement using piezo-electric devicesConvex structurePolymer

The invention provides a self-powered pressure sensor which comprises a first induction electrode, a second induction electrode and an intermediate film. The first induction electrode comprises a first macromolecular polymer insulating layer, wherein a conductive film is arranged on the surface of one side of the first macromolecular polymer insulating layer. The second induction electrode comprises a second macromolecular polymer insulating layer, wherein a conductive film is arranged on the surface of one side of the second macromolecular polymer insulating layer, and the intermediate film is fixed on the surface of the other side of the second macromolecular polymer insulating layer. The non-fixed surface of the intermediate film is provided with a micro / nano concave-convex structure. The surface of the micro / nano concave-convex structure of the intermediate film on the second induction electrode is just oppositely attached to and fixedly connected with the surface of the first induction electrode not provided with the conductive film, and the conductive film on the first induction electrode and the conductive film on the second induction electrode are both induction signal output poles. The self-powered pressure sensor is ingeniously made by utilizing a principle of electrification by friction and has the advantages of being high in sensitivity, easy to prepare, low in cost, good in stability in use and quick in response speed and the like.

Owner:NAZHIYUAN TECH TANGSHAN LLC

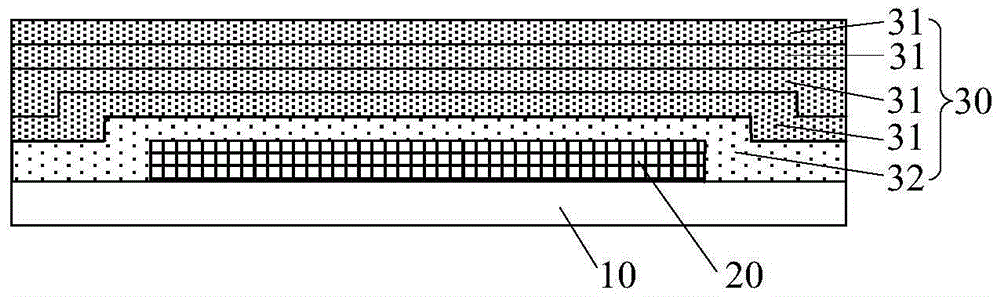

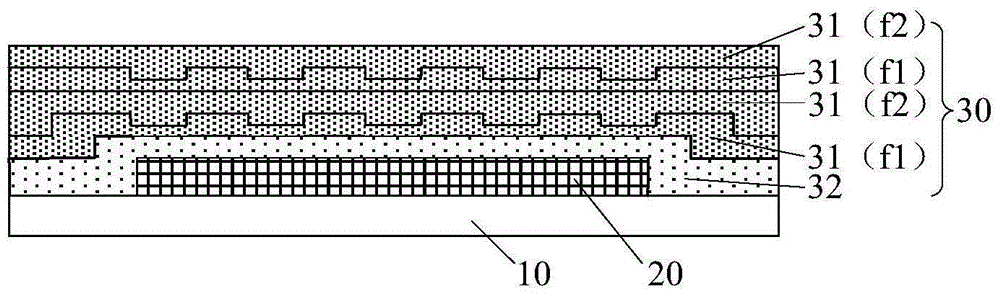

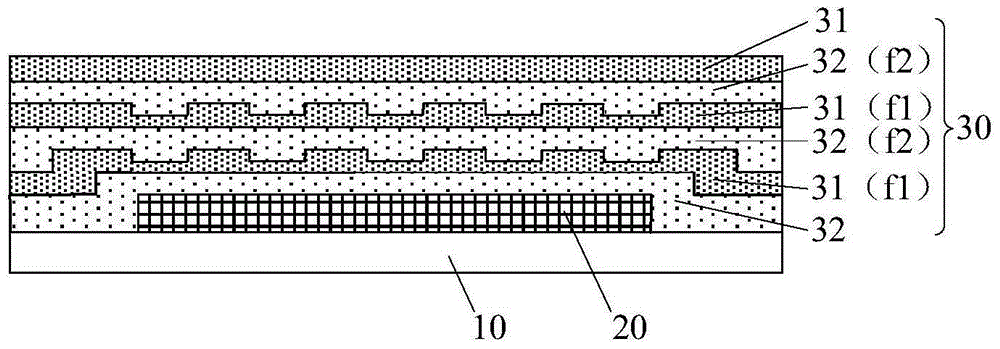

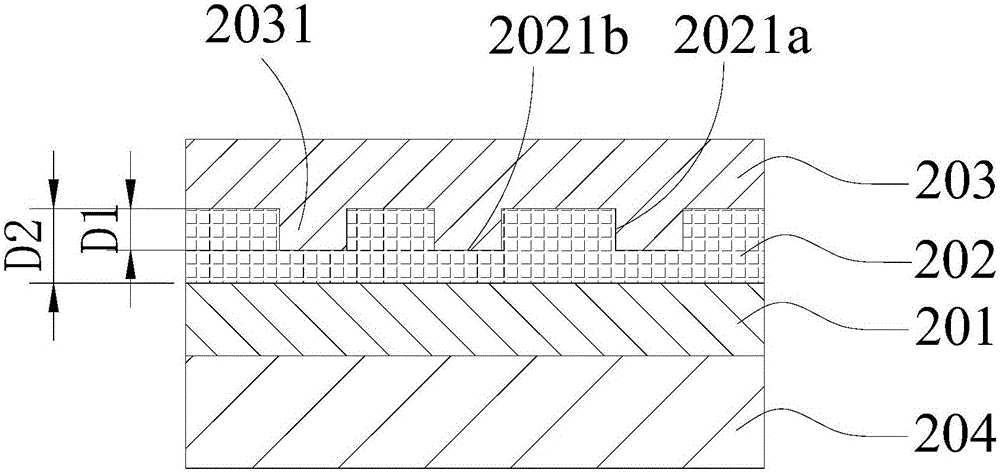

Flexible displayer and production method thereof

ActiveCN105206763AImprove antioxidant capacityImprove flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingConvex structureDisplay device

The invention provides a flexible displayer and a production method thereof, and relates to the technical field of displayers. A packaging structure of the flexible displayer can meet not only the requirement of oxidation resistance, but also the requirement of flexibility. The flexible displayer comprises the packaging structure; the packaging structure comprises a plurality of overlapped packaging films; the packaging films comprise a plurality of inorganic films; matched concave-convex structures are formed in two contact surfaces of at least one pair of adjacent packaging films; at least one of two adjacent packaging films is an inorganic film. The flexible displayer is used for picture displaying.

Owner:BOE TECH GRP CO LTD +1

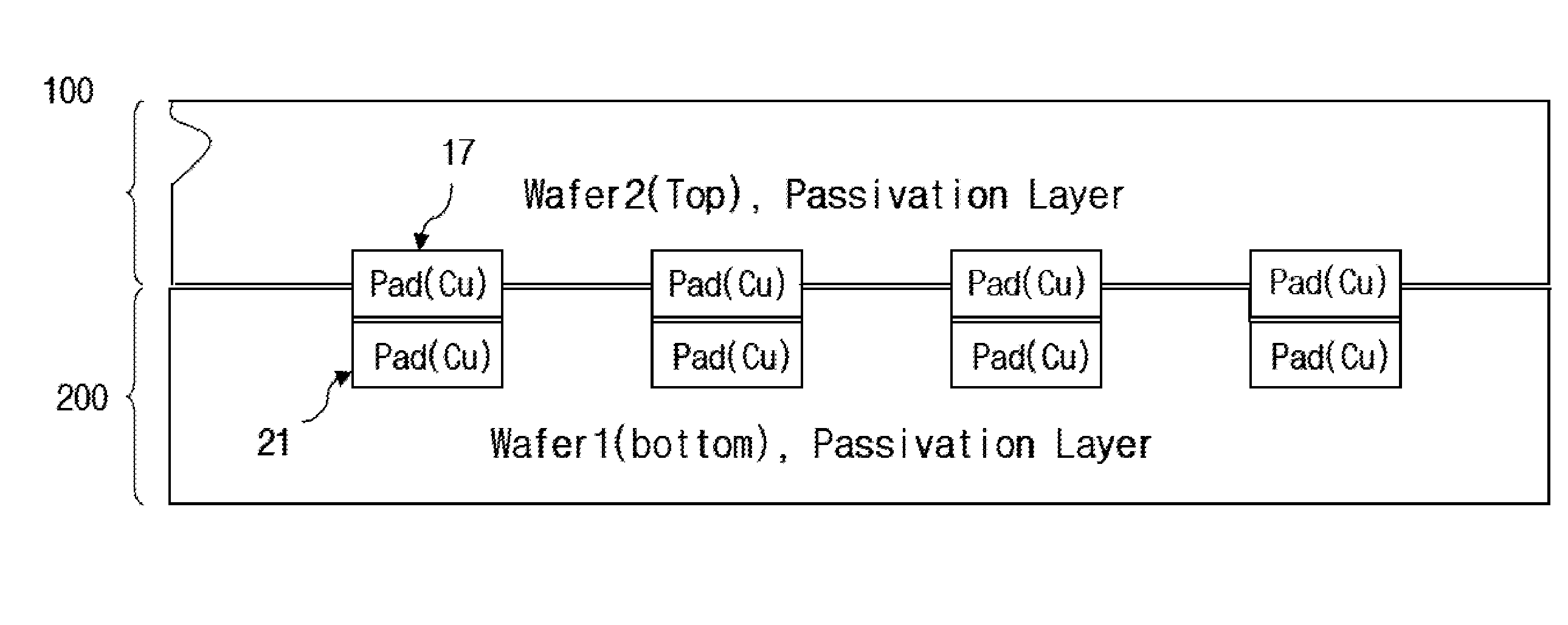

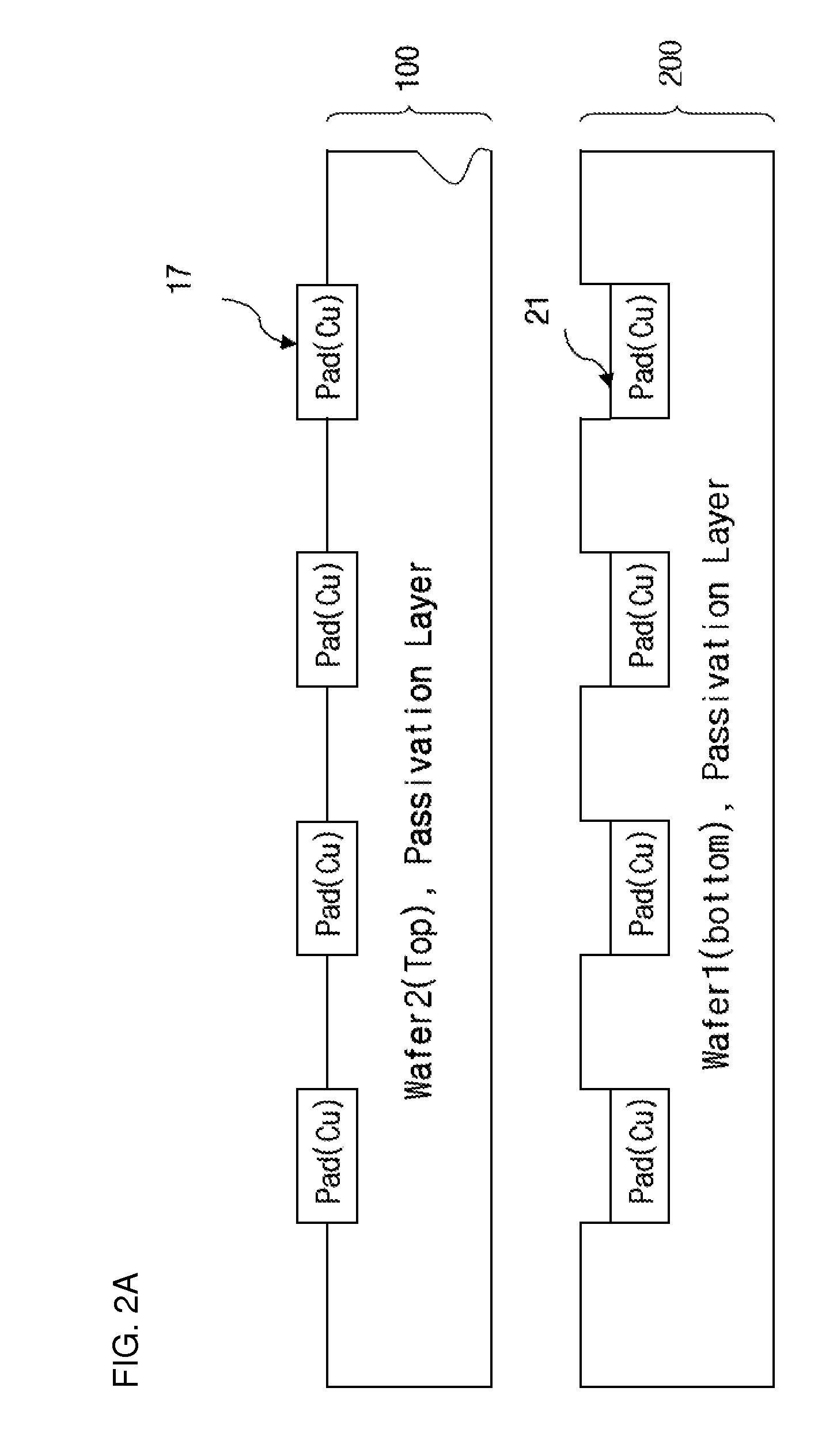

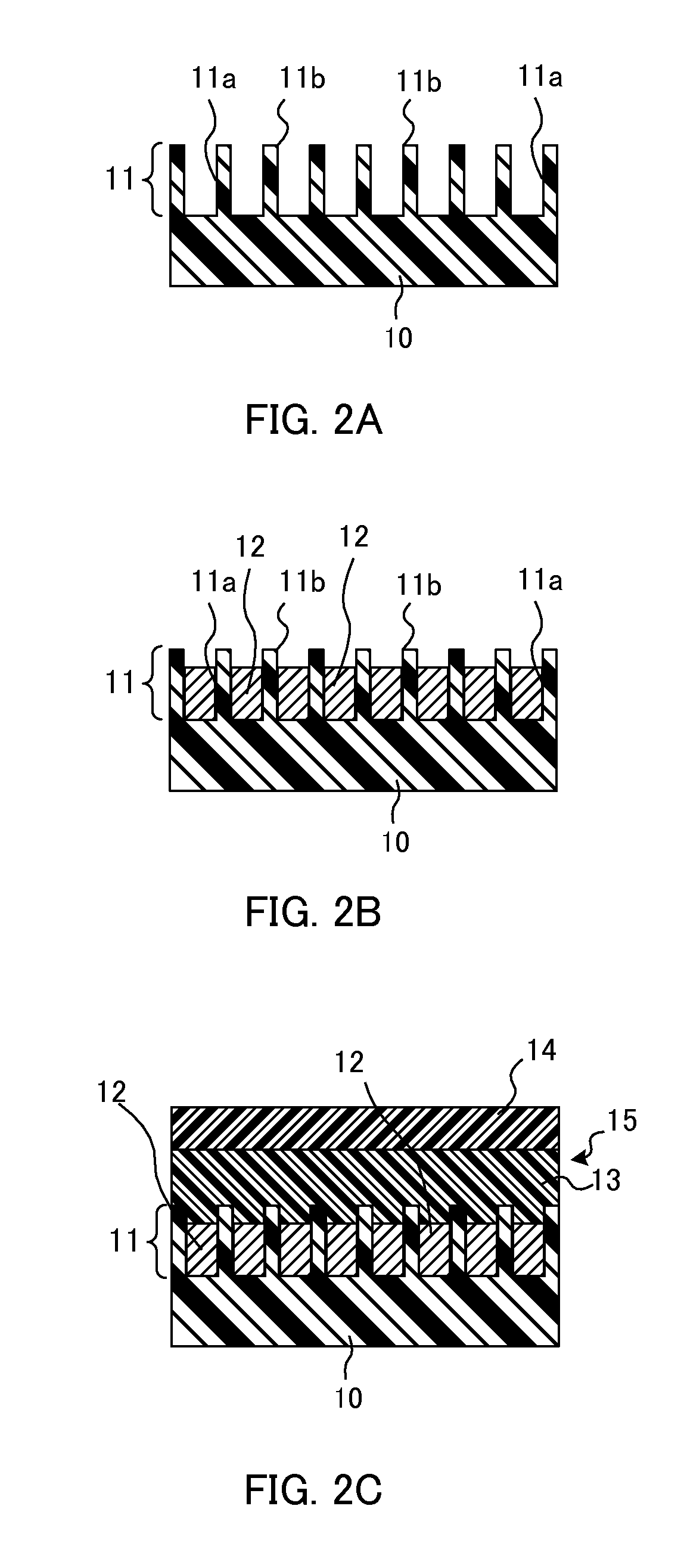

Unit pixel of image sensor having three-dimensional structure and method for manufacturing the same

ActiveUS20100258890A1Easily and precisely implementedEliminate needSemiconductor/solid-state device detailsSolid-state devicesConvex structurePhotodiode

A unit pixel of an image sensor having a three-dimensional structure includes a first chip and a second chip which are stacked, one of the first chip and the second chip having a photodiode, and the other of the first chip and the second chip having a circuit for receiving information from the photodiode and outputting received information. The first chip includes a first pad which is projectedly disposed on an upper surface of the first chip in such a way as to define a concavo-convex structure, and the second chip includes a second pad which is depressedly disposed on an upper surface of the second chip in such a way as to define a concavo-convex structure corresponding to the concavo-convex structure of the first chip. The first chip and the second chip are mated with each other through bonding of the first pad and the second pad.

Owner:SK HYNIX INC

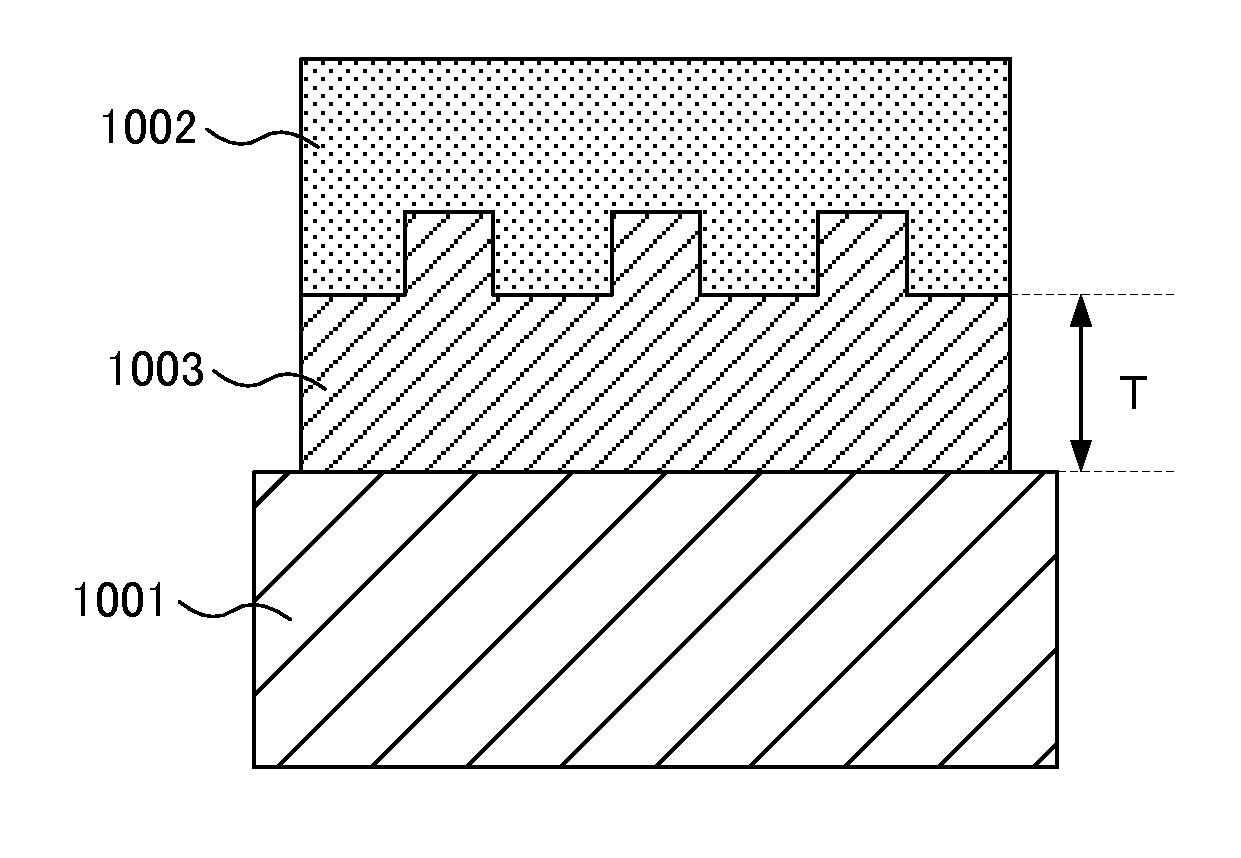

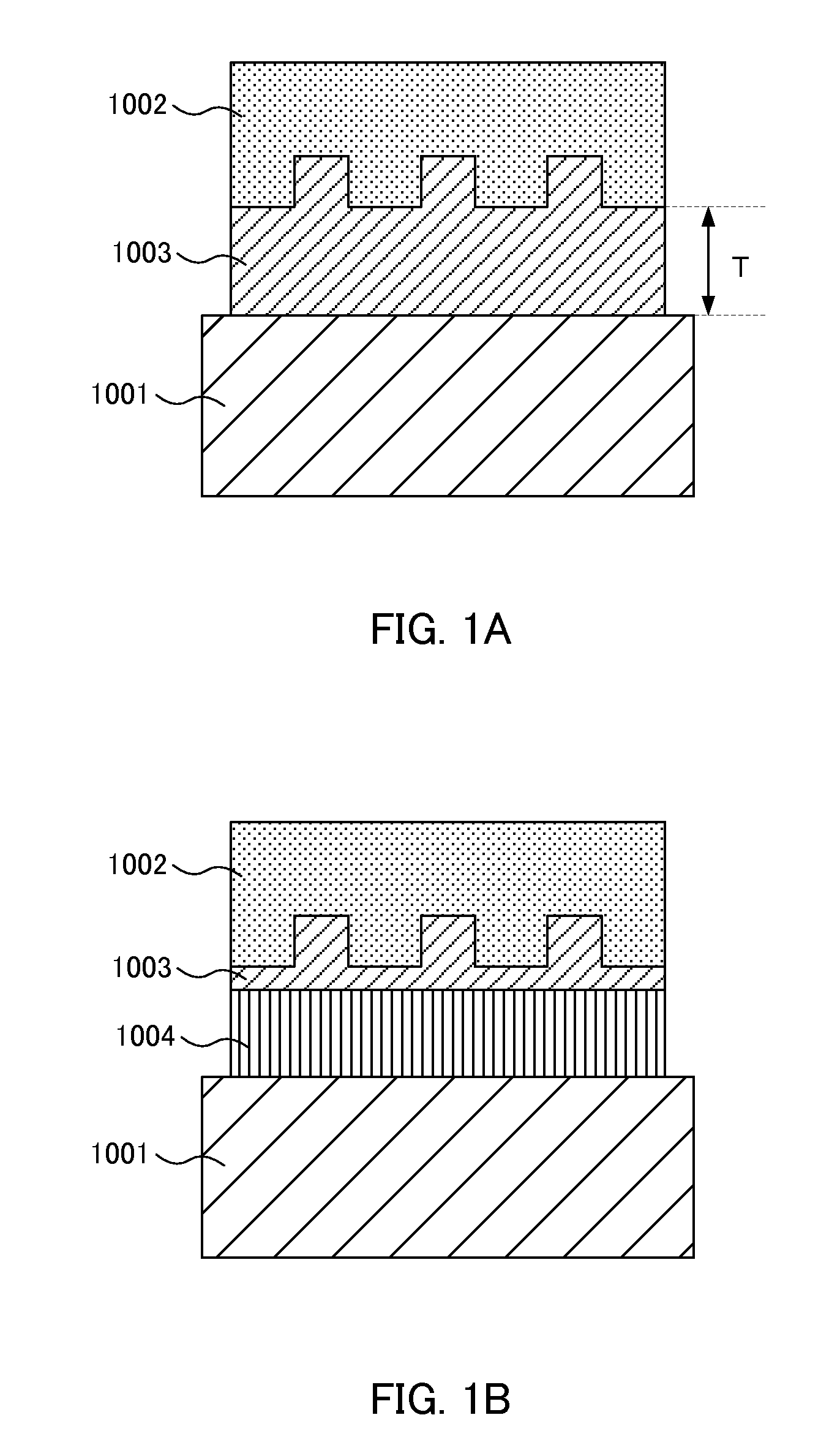

Layered product for fine pattern formation and method of manufacturing layered product for fine pattern formation

ActiveUS20140151733A1High aspect ratioWell formedConfectioneryNanoinformaticsConvex structureMaterials science

Disclosed is a layered product for fine pattern formation and a method of manufacturing the layered product for fine pattern formation, capable of easily forming a fine pattern having a thin or no remaining film in order to form a fine pattern having a high aspect ratio on a processing object. The layered product for fine pattern formation (1) of the present invention used to form a fine pattern (220) in a processing object (200) using a first mask layer (103) includes: a mold (101) having a concavo-convex structure (101a) on a surface; and a second mask layer (102) provided on the concavo-convex structure (101a), wherein in the second mask layer (102), a distance (lcc) and a height (h) of the concavo-convex structure (101a) satisfy Formula (1) 0<lcc<1.0 h, and a distance (lcv) and the height (h) satisfy Formula (2) 0≦lcv≦0.05 h.

Owner:ASAHI KASEI E-MATERIALS CORPORATION

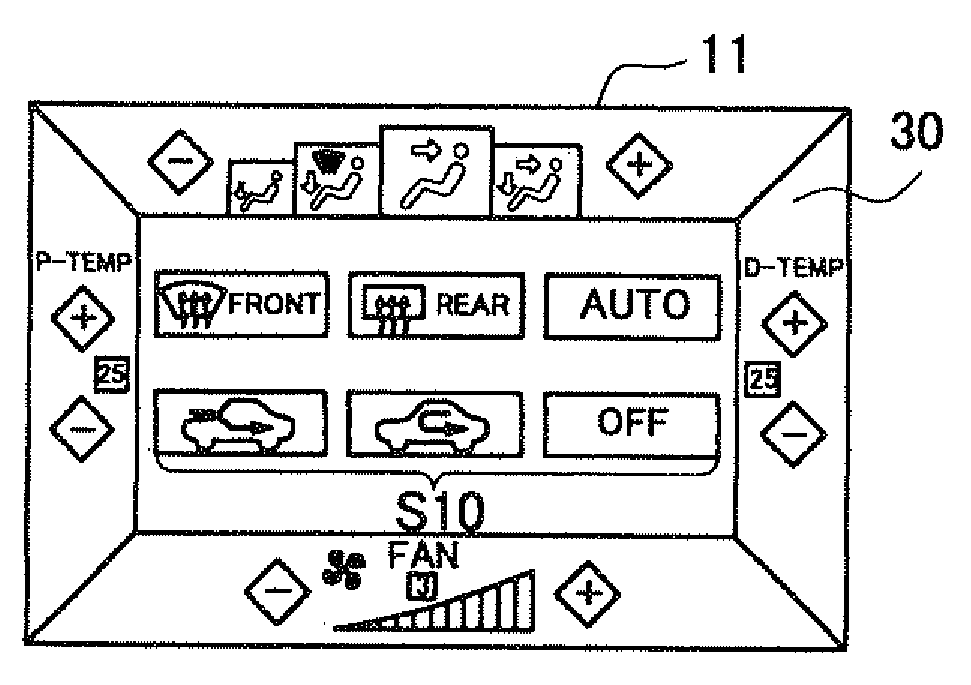

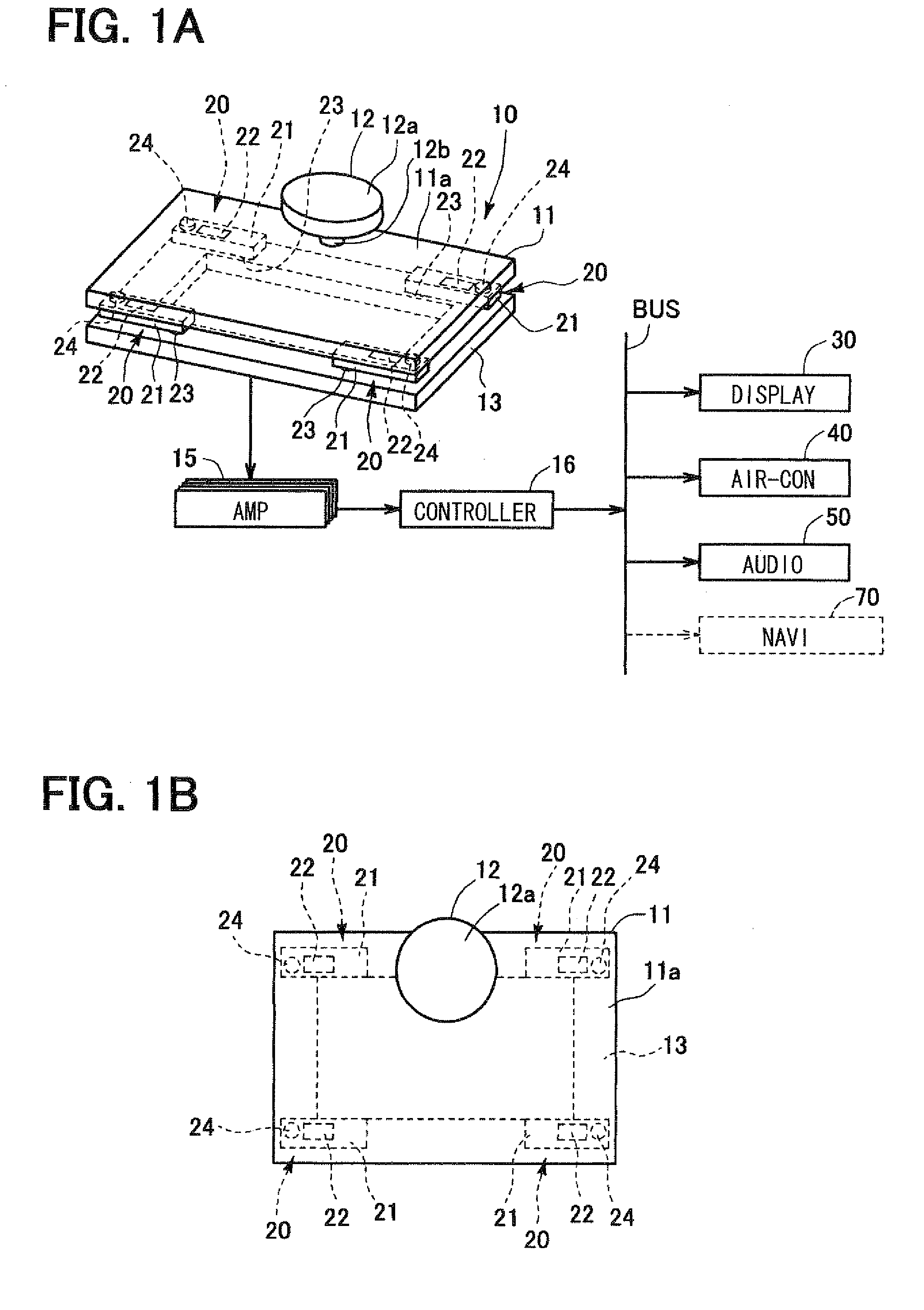

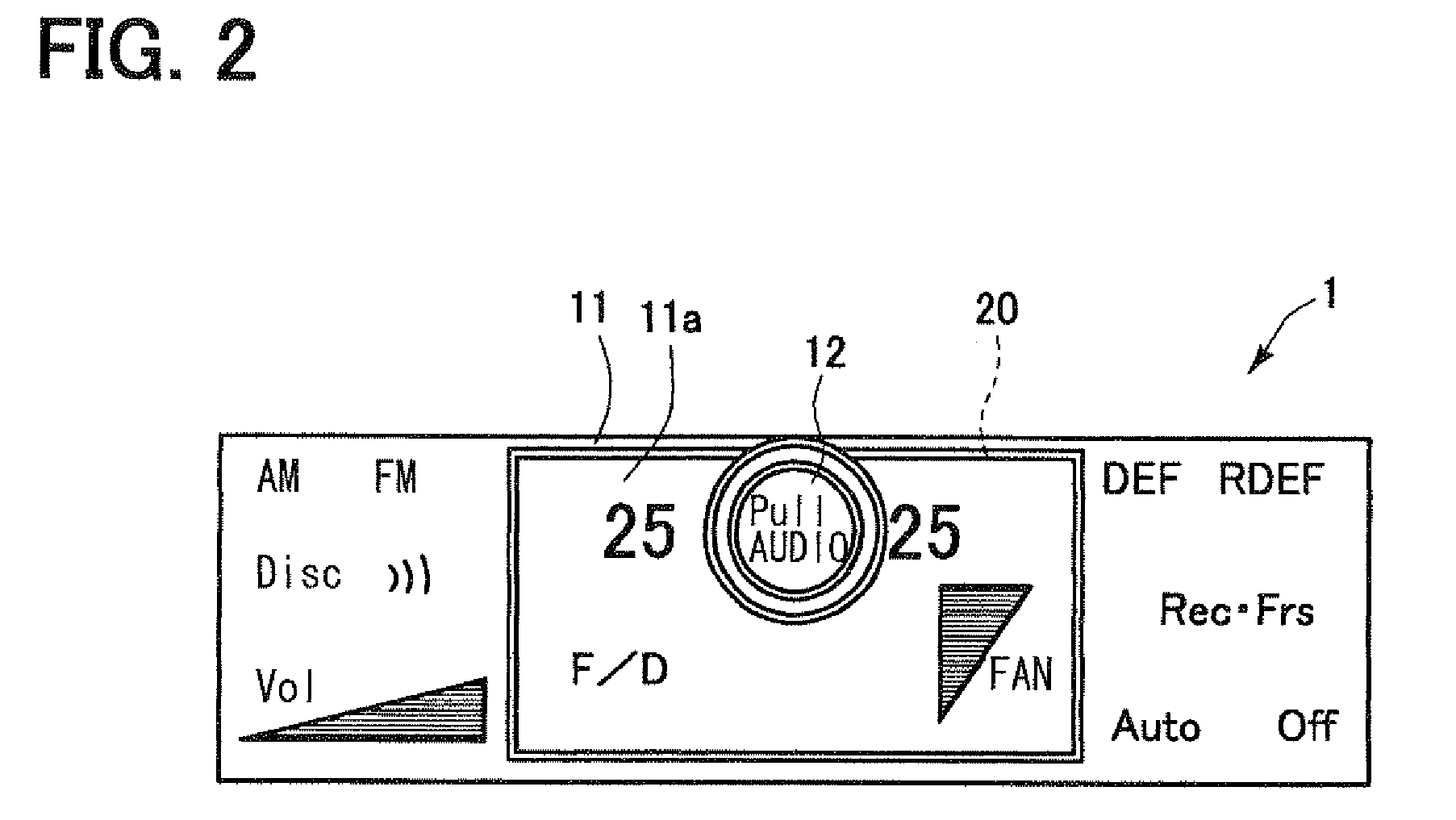

Manipulation input apparatus

InactiveUS20100045624A1Easy to operateIncreasing manipulation modeInstruments for road network navigationDashboard fitting arrangementsConvex structureStrain gauge

Owner:DENSO CORP

Fine-structure layered product, preparation method of the fine-structure layered product and manufacturing method of a fine-structure product

InactiveUS20130319522A1Increase resistanceImprove stabilitySynthetic resin layered productsSemiconductor/solid-state device manufacturingConvex structureWeather resistance

To provide a fine-structure layered product, and a preparation method of a fine-structure layered product using the fine-structure layered product for enabling a fine concavo-convex structure excellent in environmental resistance, weather resistance and long-term stability to be formed with a large area and high productivity, and provide a manufacturing method of a fine-structure product for enabling a large area to be made with high productivity, a fine-structure layered product of the invention is provided with a substrate, a resin layer that is formed on one main surface of the substrate and that has a fine concavo-convex structure on its surface, and an inorganic layer that is provided on the fine concavo-convex structure of the resin layer and that contains a sol-gel material having a fine concavo-convex structure in a shape associated with the fine concavo-convex structure of the resin layer, where a fluorine element concentration (Es) in a region on the inorganic layer side of the resin layer is higher than an average fluorine concentration (Eb) in the resin layer.

Owner:ASAHI KASEI KK

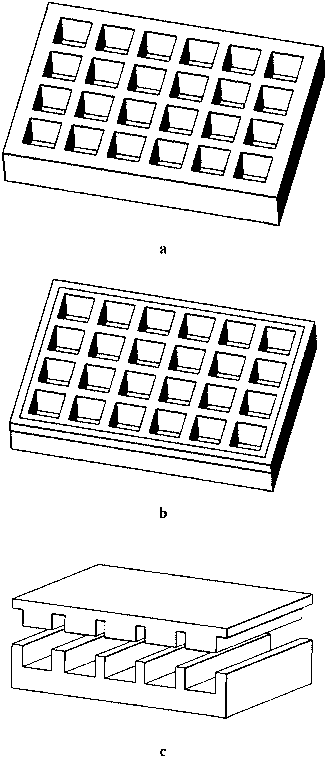

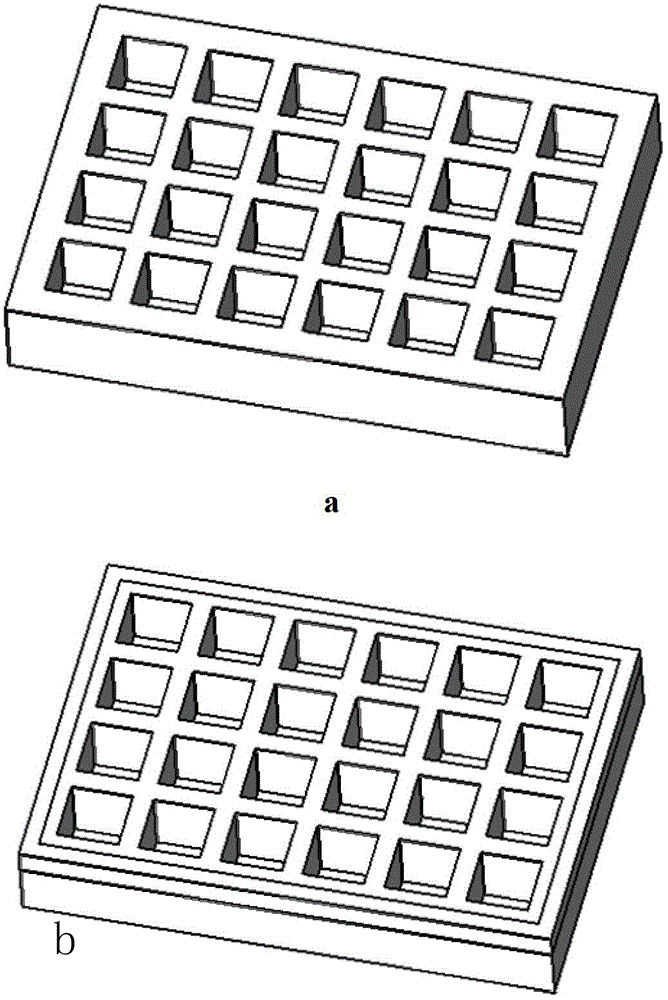

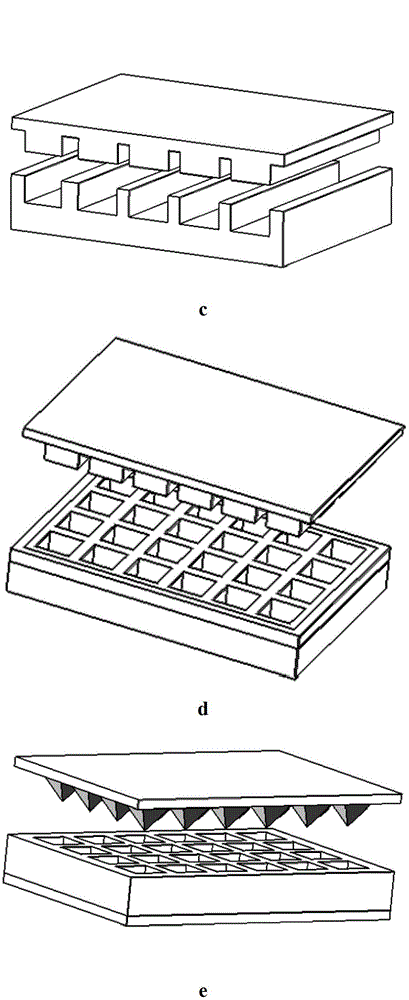

Flexible pressure sensor and manufacturing method thereof

ActiveCN106370327AEasy to transformHigh sensitivityForce measurement using piezo-resistive materialsConvex structureElectrical resistance and conductance

The invention discloses a flexible pressure sensor, which comprises two oppositely-arranged electrode structures, wherein each electrode structure comprises a flexible substrate and a conductive layer arranged on the flexible substrate; the conductive layers of the two electrode structures are connected in a mutually-facing abut joint mode; the flexible substrate comprises a substrate body and multiple convex structures arranged on the substrate body; and the conductive layer covers the surface, with the multiple convex structures, of the flexible substrate. According to the flexible pressure sensor disclosed by the invention, by using the characteristic that the inner multiple convex structures formed by a flexible material are likely to deform under a pressure effect, resistance changes, adjustment and control caused by contact area changes when the two conductive layers in the opposite electrode structures make contact can be realized, and thus, pressure sensing is realized. The invention also discloses a method of manufacturing the above flexible pressure sensor. Compared with an MEMS processing process generally adopted by the flexible pressure sensor in the prior art, the manufacturing method of the invention is simple and convenient, and the cost is lower.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

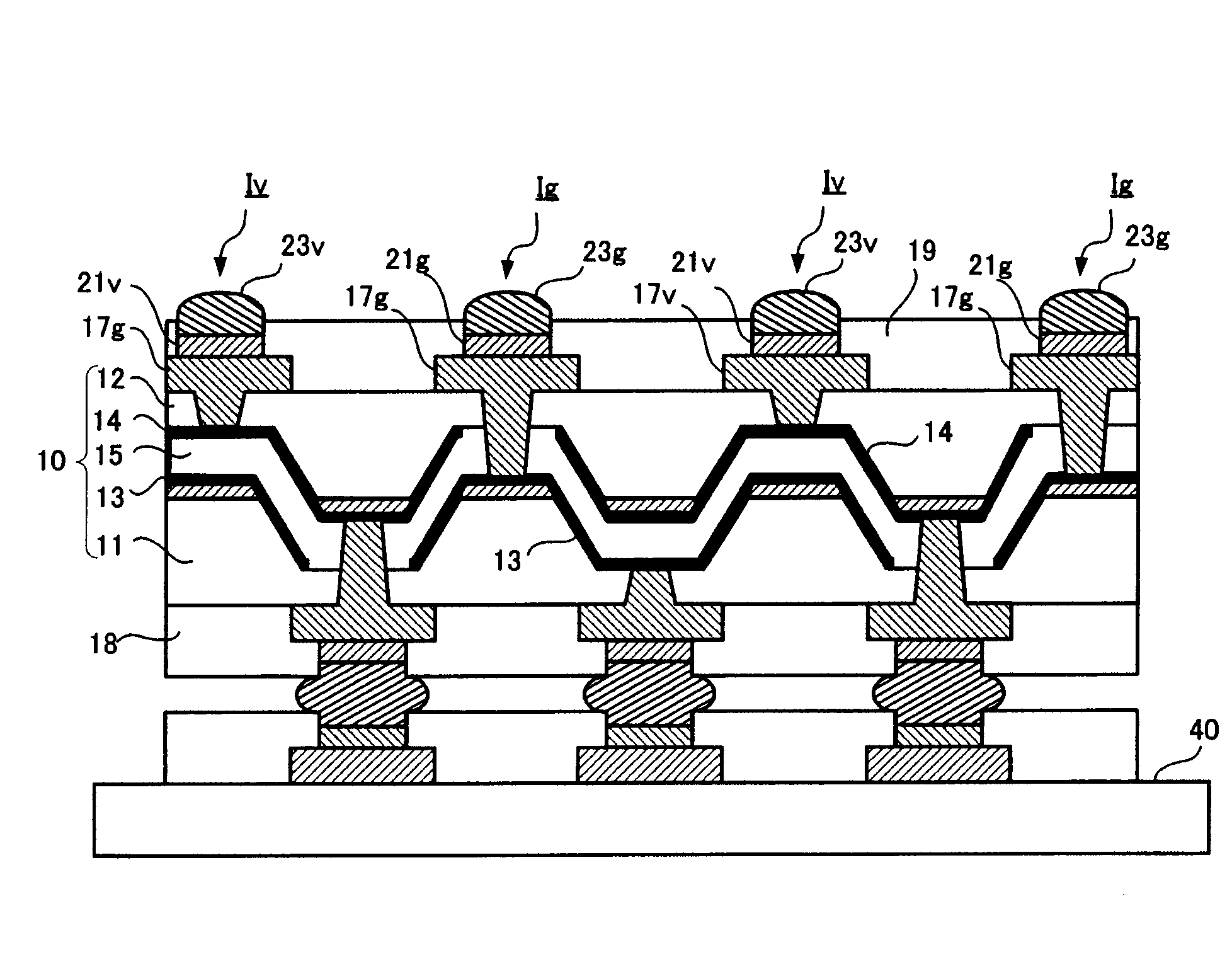

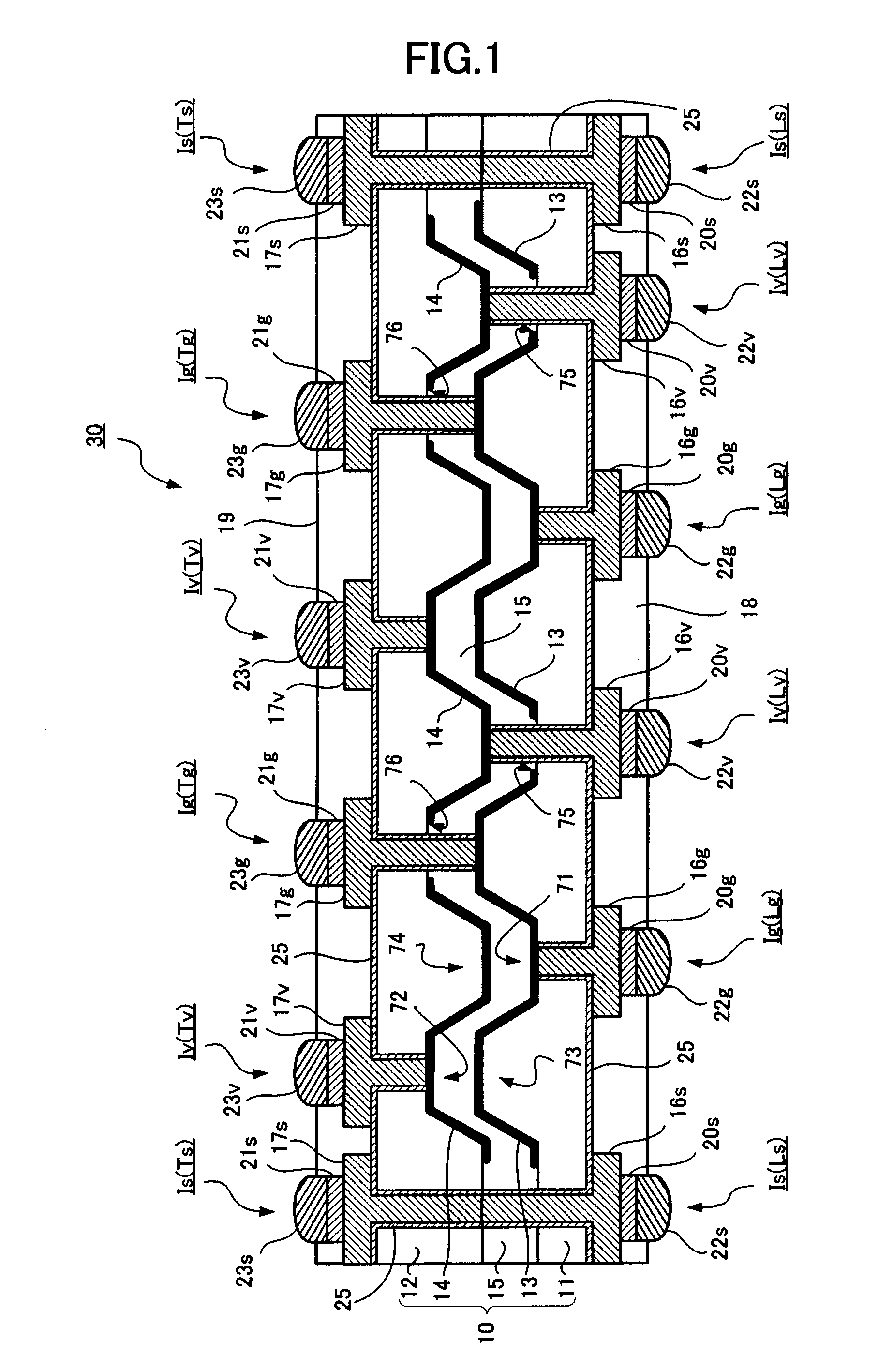

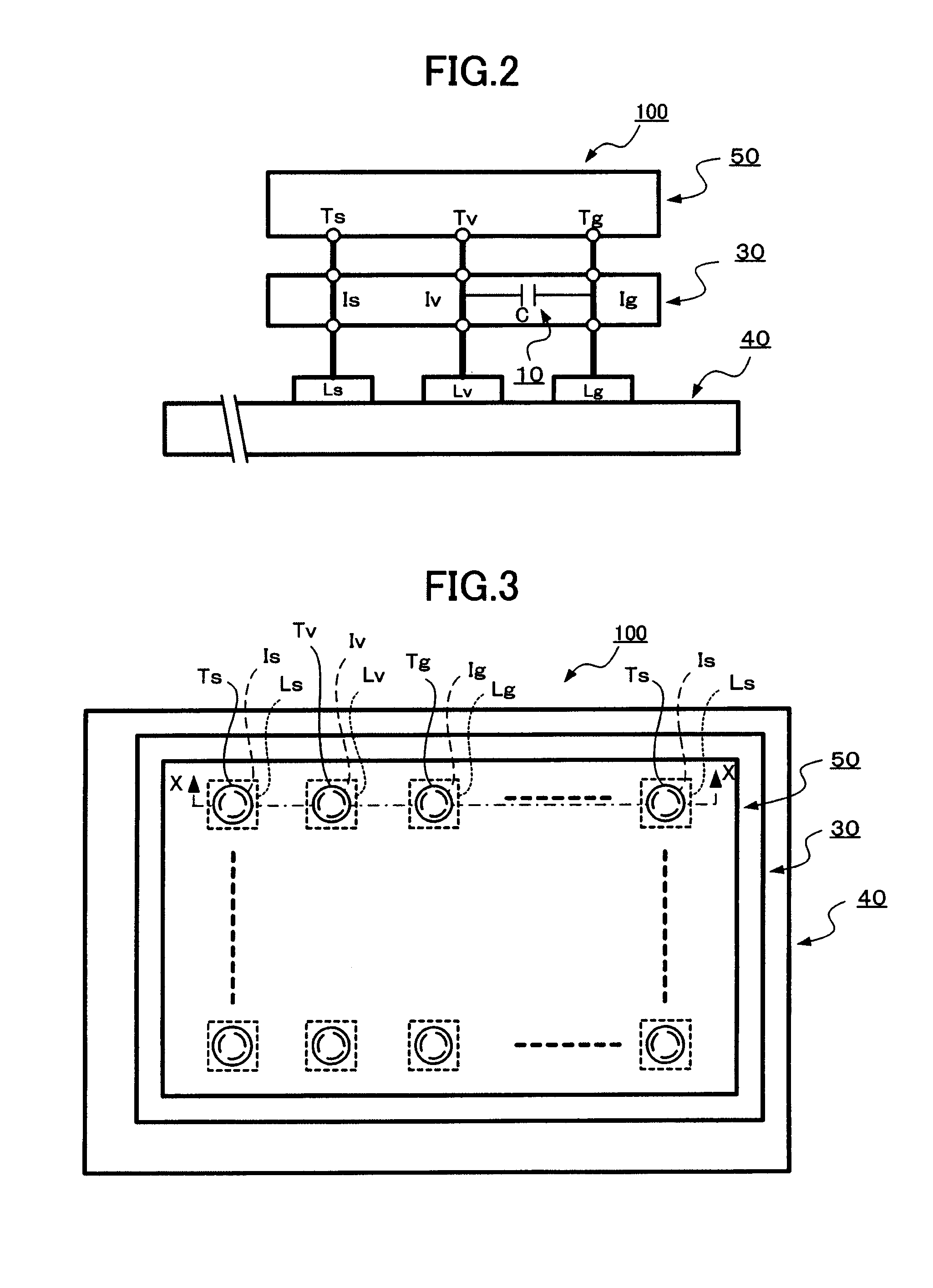

Interposer, a method for manufacturing the same and an electronic circuit package

ActiveUS20080247116A1Little degradation of electrical characteristicAvoid absorptionAnti-noise capacitorsFixed capacitor electrodesConvex structureInterposer

An interposer including: a substrate including a first layer and second layer, wherein the first layer and second layer are positioned parallel to each other; electrodes each having a concave-convex structure formed on each facing surface of the first layer and second layer of the substrate; a dielectric layer sandwiched between the electrodes which are formed on each facing surface of the first layer and second layer of the substrate; a first conductive part which vertically passes through the first layer of the substrate from a first outer surface of the substrate and is electrically connected to an electrode formed on a surface of the second layer of the substrate that faces the first layer of the substrate; and a second conductive part which vertically passes through the second layer of the substrate from a second outer surface of the substrate and is electrically connected to an electrode formed on a surface of the first layer of the substrate that faces the second layer of the substrate.

Owner:IBIDEN CO LTD

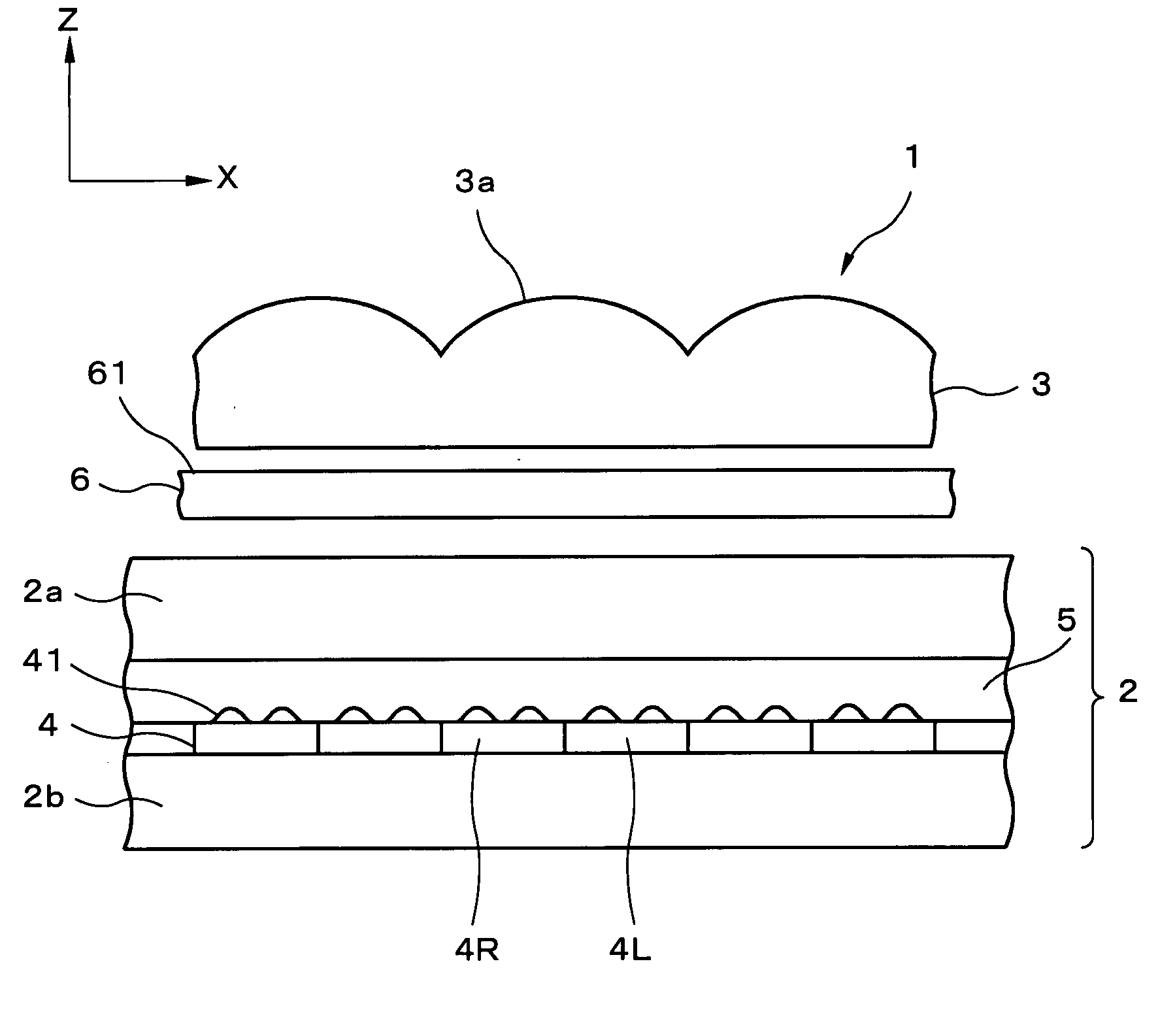

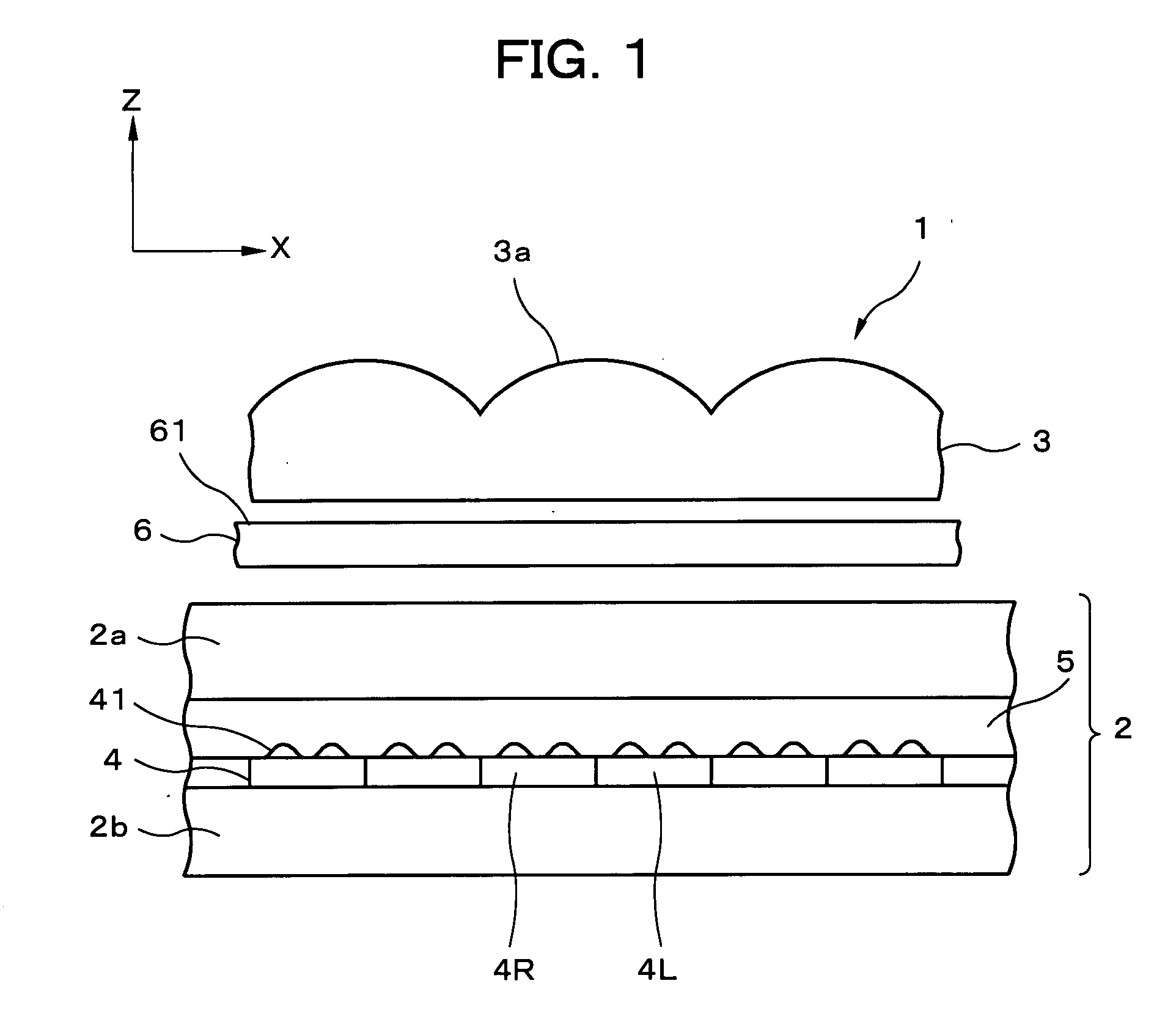

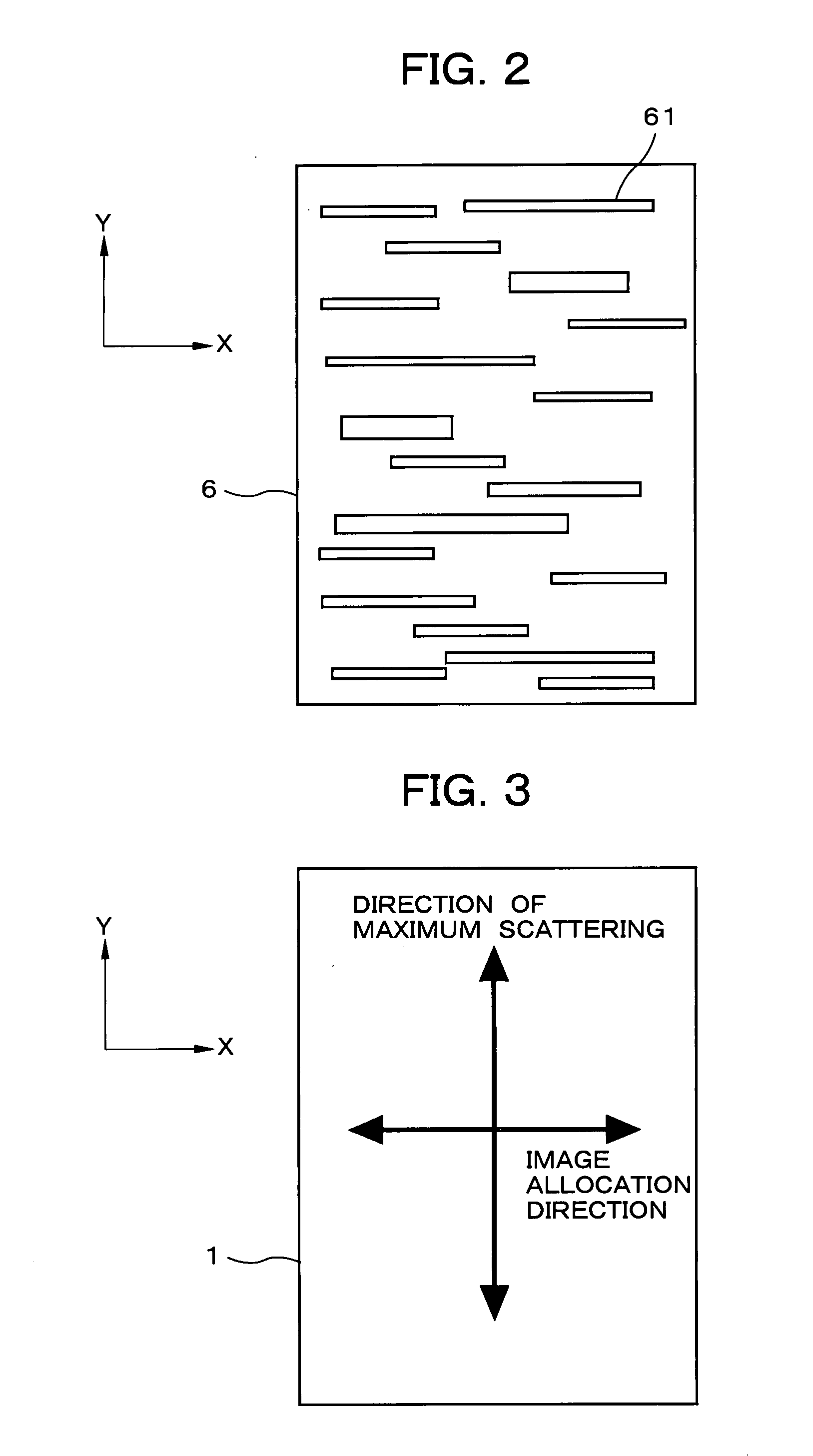

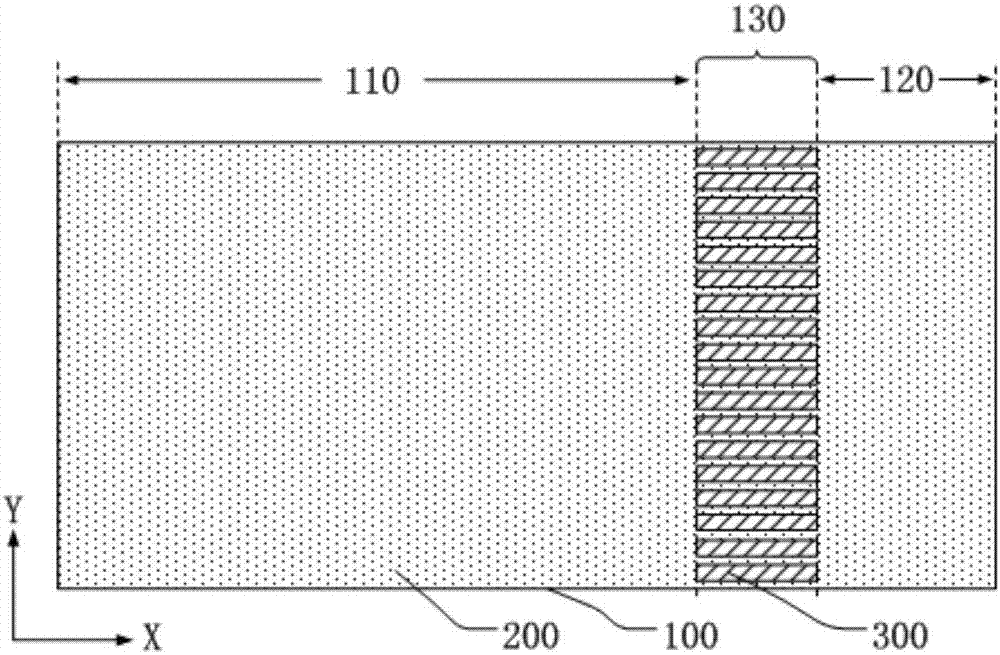

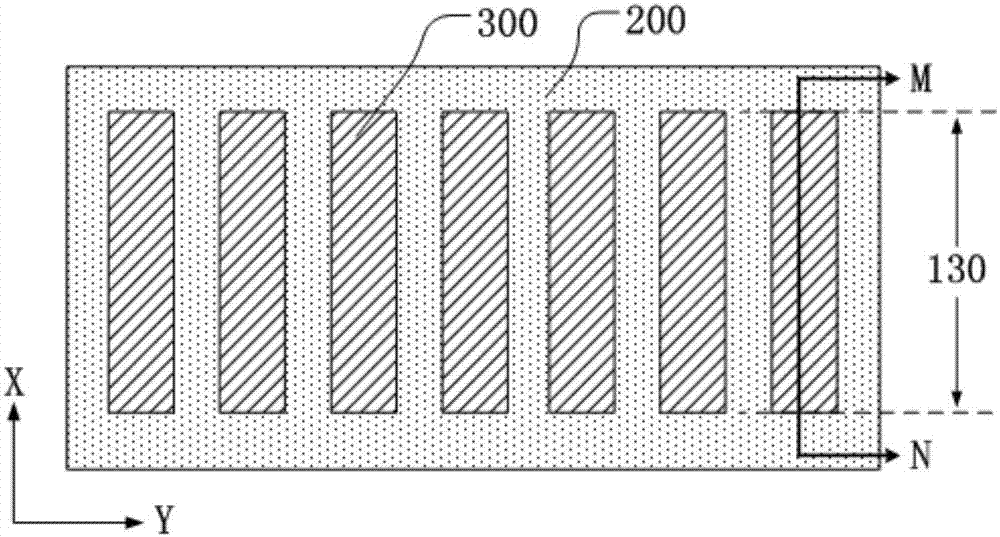

Display device, terminal device, display panel, and optical member

ActiveUS20080094700A1Quality improvementImprove image qualityOptical light guidesSteroscopic systemsConvex structureLiquid-crystal display

A reflective liquid crystal display panel is a display panel for three-dimensional display in which pixel pairs as display elements composed of one left-eye pixel L and one right-eye pixel R each are provided in a matrix. The lenticular lens is an optical member for image separation that is provided to separate the light from the left and right pixels, and numerous lenticular lenses form a lens array that is arranged in one dimension. An anisotropic scattering sheet as an anisotropic scattering element is provided between the lenticular lens and the reflective liquid crystal display panel. According to this configuration, a reduction in the quality of the reflective display can be minimized, and improved image quality can be achieved without changing the concavo-convex structure of the reflecting panel and the lens shape of the lenticular lens in display device that is capable of displaying different images to a plurality of viewpoints.

Owner:NEC LCD TECH CORP

Axially compressible artificial intervertebral disc having limited rotation using a captured ball and socket joint with a solid ball and compression locking post

InactiveUS7160327B2Inhibition of translationAvoid separationSurgeryJoint implantsConvex structureSolder ball

An artificial disc having a pair of opposing baseplates, for seating against opposing vertebral bone surfaces, separated by a ball and socket joint that includes a ball compression locked to a post extending from one of the baseplates. The ball is captured within a curvate socket formed in a peak of a convex structure attached to the other of the baseplates. The socket is formed by opposing curvate surfaces, one on the convex structure and one on the other of the baseplates. While the ball angulates freely in the socket, the rotation of the ball in the socket has a limited range due to interference between a protrusion on the convex structure that extends into the socket and a curvate recess on the ball. The ball and socket joint therefore permits the baseplates to rotate relative to one another through a limited range and also angulate relative to one another.

Owner:HOWMEDICA OSTEONICS CORP

Electrolytic machining method for thin-wall machine case of aero-engine

ActiveCN104384643AFix stability issuesSolve the costElectrical-based machining electrodesElectrochemical machining apparatusConvex structureAviation

The invention provides an electrolytic machining method for a thin-wall machine case of an aero-engine, belonging to the technical field of electrolytic machining. The electrolytic machining method mainly aims at the machining of a surface concave-convex structure of a complicated thin-wall rotary body part in the aviation field, and is characterized in that a tool cathode is of a thin-wall strip-shaped structure or a rigid rotary body structure; window or lug boss structures with different shapes are distributed on the surface of the cathode. In a machining process, a workpiece anode automatically rotates and the tool cathode is fed to the anode in a peripheral movement process. In the whole machining process, electrodes do not need to be replaced, and the surface concave-convex structure of the thin-wall rotary body part is machined and molded once through rolling sleeve electrolytic action of a cathode window.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

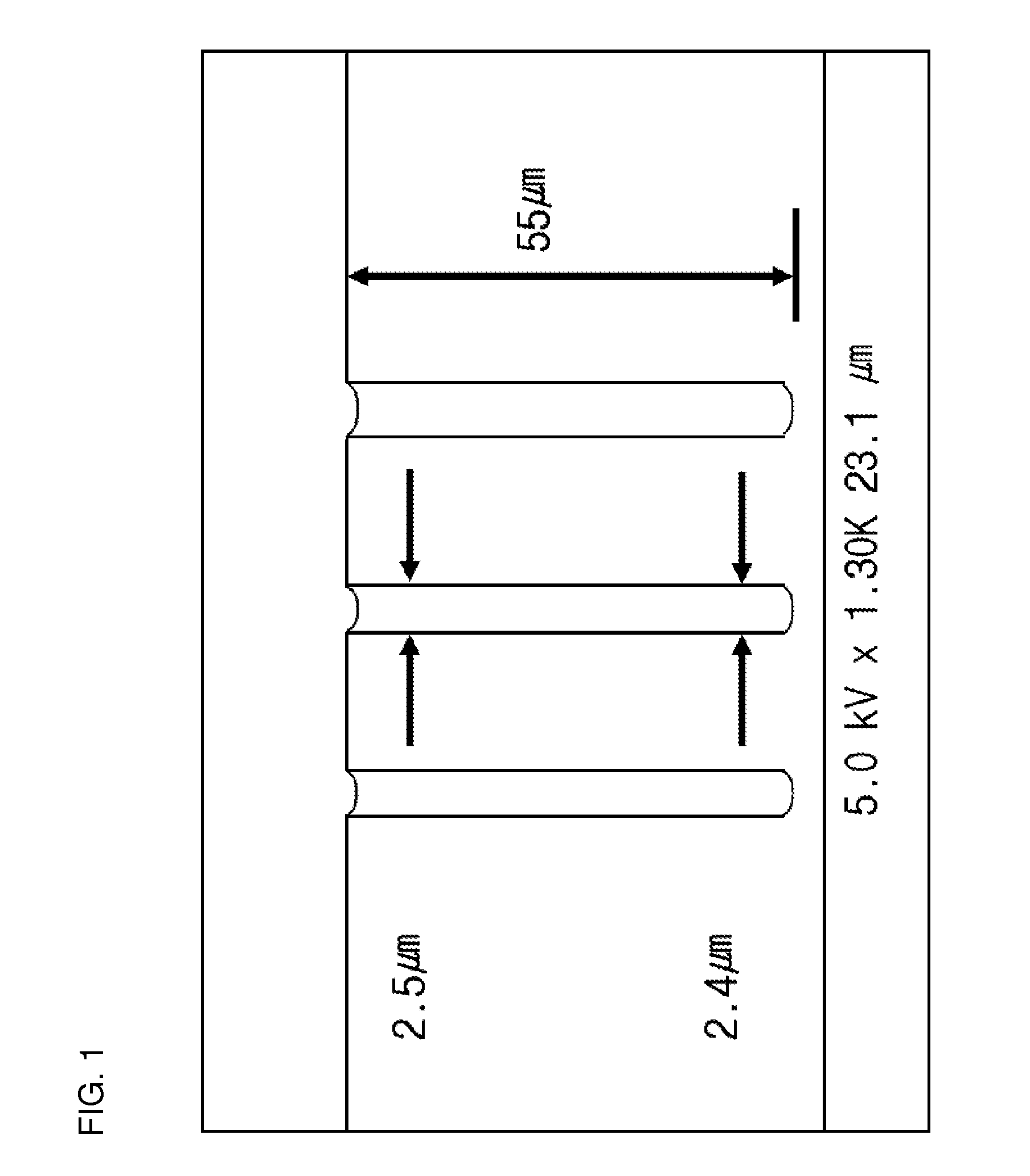

Semiconductor light emitting device and method for manufacturing the same

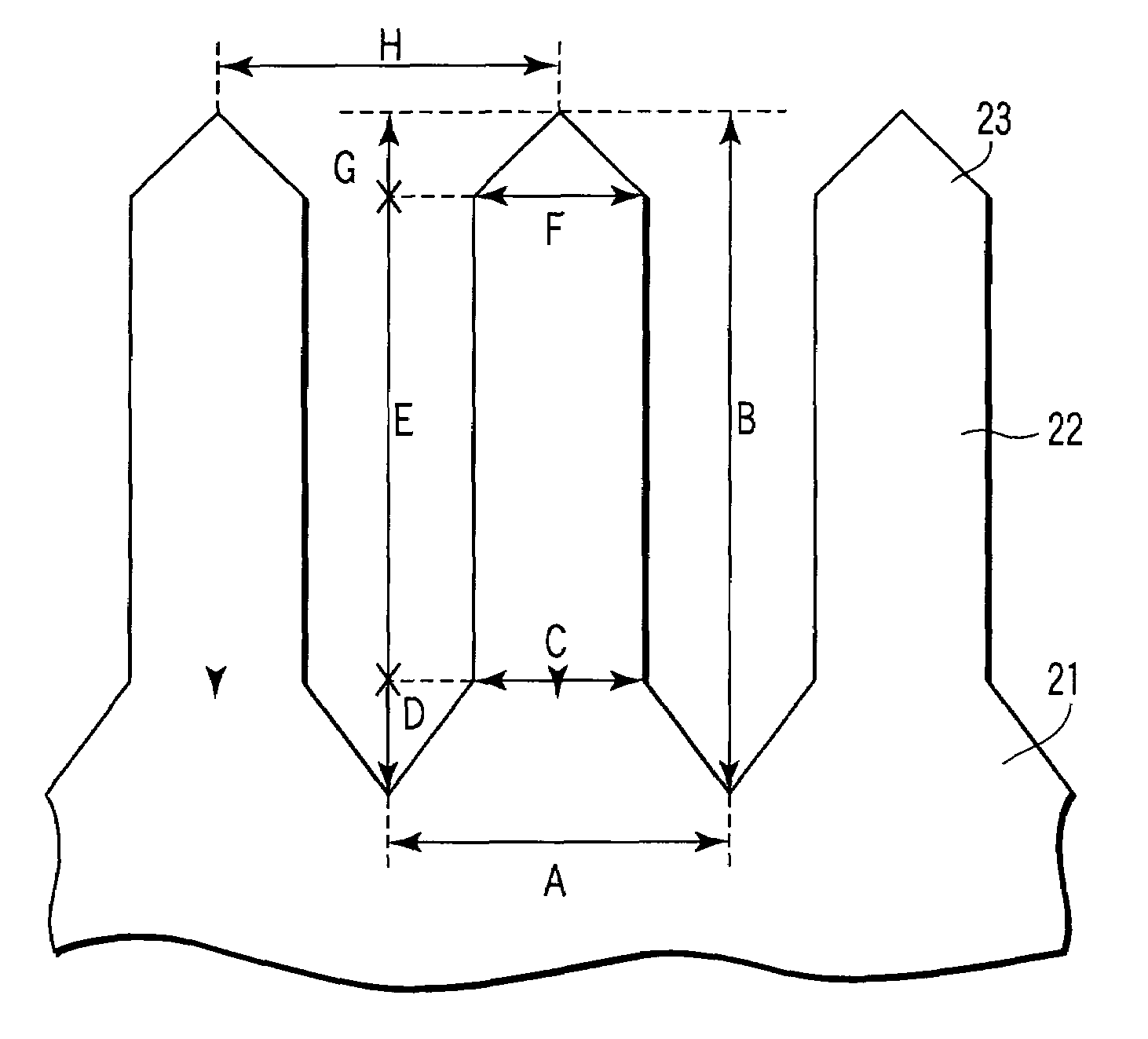

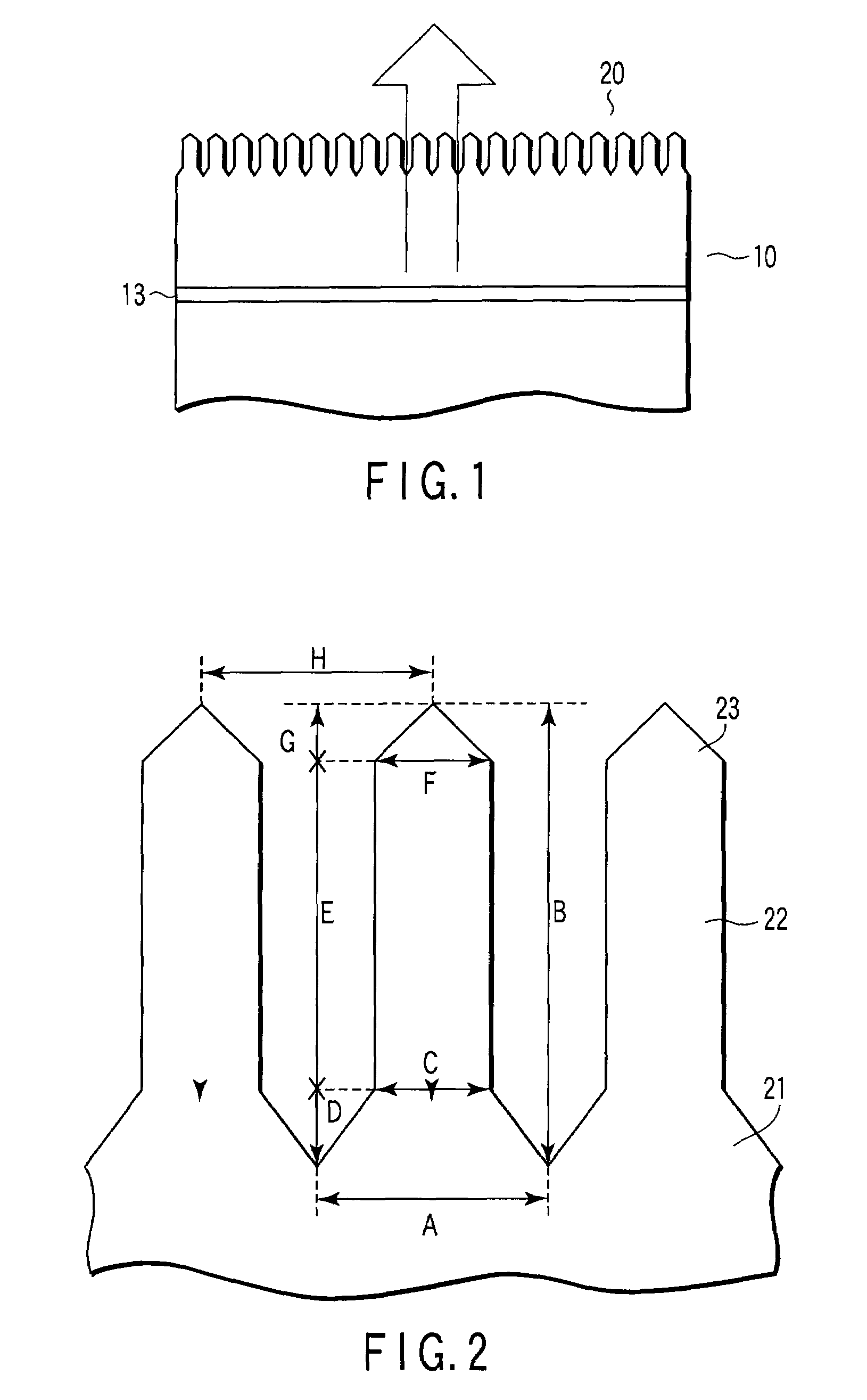

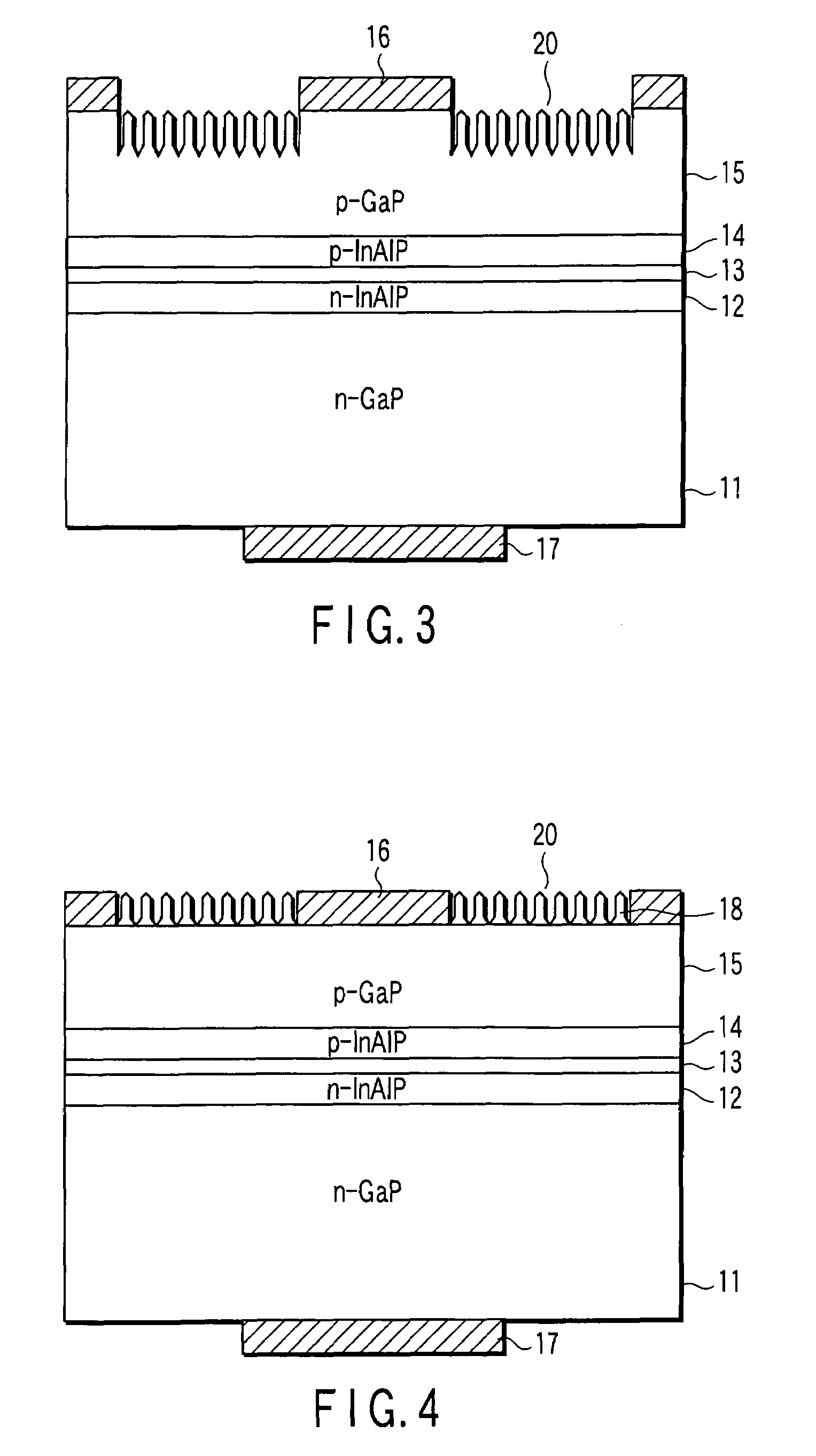

In a semiconductor light emitting device, a semiconductor light emitting element has a light extracted surface on which a plurality of convex structures is formed. The convex structures each have a conical mesa portion constituting a refractive index gradient structure, a cylindrical portion constituting a diffraction grating structure, and a conical portion constituting a refractive index gradient structure. The mesa portion, cylindrical portion, and conical portion are arranged in this order from the light extracted surface. The period between the convex structures is longer than 1 / (the refractive index of an external medium+the refractive index of the convex structures) of an emission wavelength and equal to or shorter than the emission wavelength. The circle-equivalent average diameter of the cylindrical portion is ⅓ to 9 / 10 of that of the bottom of the mesa portion.

Owner:KK TOSHIBA

Flexible display panel, display device and forming method of flexible display panel

ActiveCN107527556AImprove reliabilityGood for stress reliefIdentification meansConvex structureDisplay device

The invention relates to the technical field of display, in particular to a flexible display panel, a display device and a forming method of the flexible display panel. The flexible display panel comprises a flexible substrate, the flexible substrate is provided with a display area and a non-display area, and the non-display area is provided with a bending part; the bending part comprises a signal transmission line layer, a first covering layer and a second covering layer, the signal transmission line layer and the first covering layer are arranged in a laminated mode, and one or more grooves are formed in at least the side, away from the signal transmission line layer, of the first covering layer; the second covering layer covers the side, away from the signal transmission line layer, of the first covering layer, and the grooves are filled with the second covering layer. According to the flexible display panel, two adjacent boundary layers form a concave-convex structure, accordingly, the contact area between the first covering layer and the second covering layer is increased, the attachment force between the first covering layer and the second covering layer is improved, and accordingly the reliability of the display panel is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

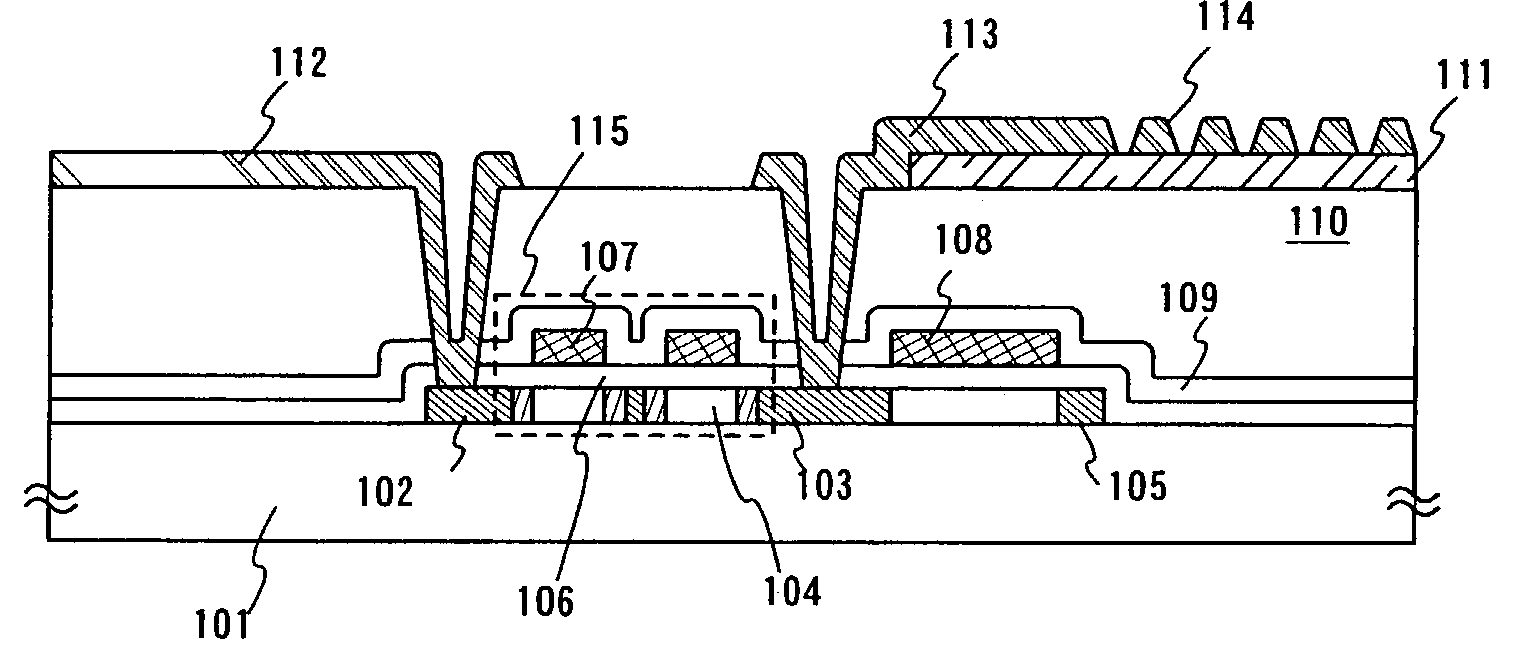

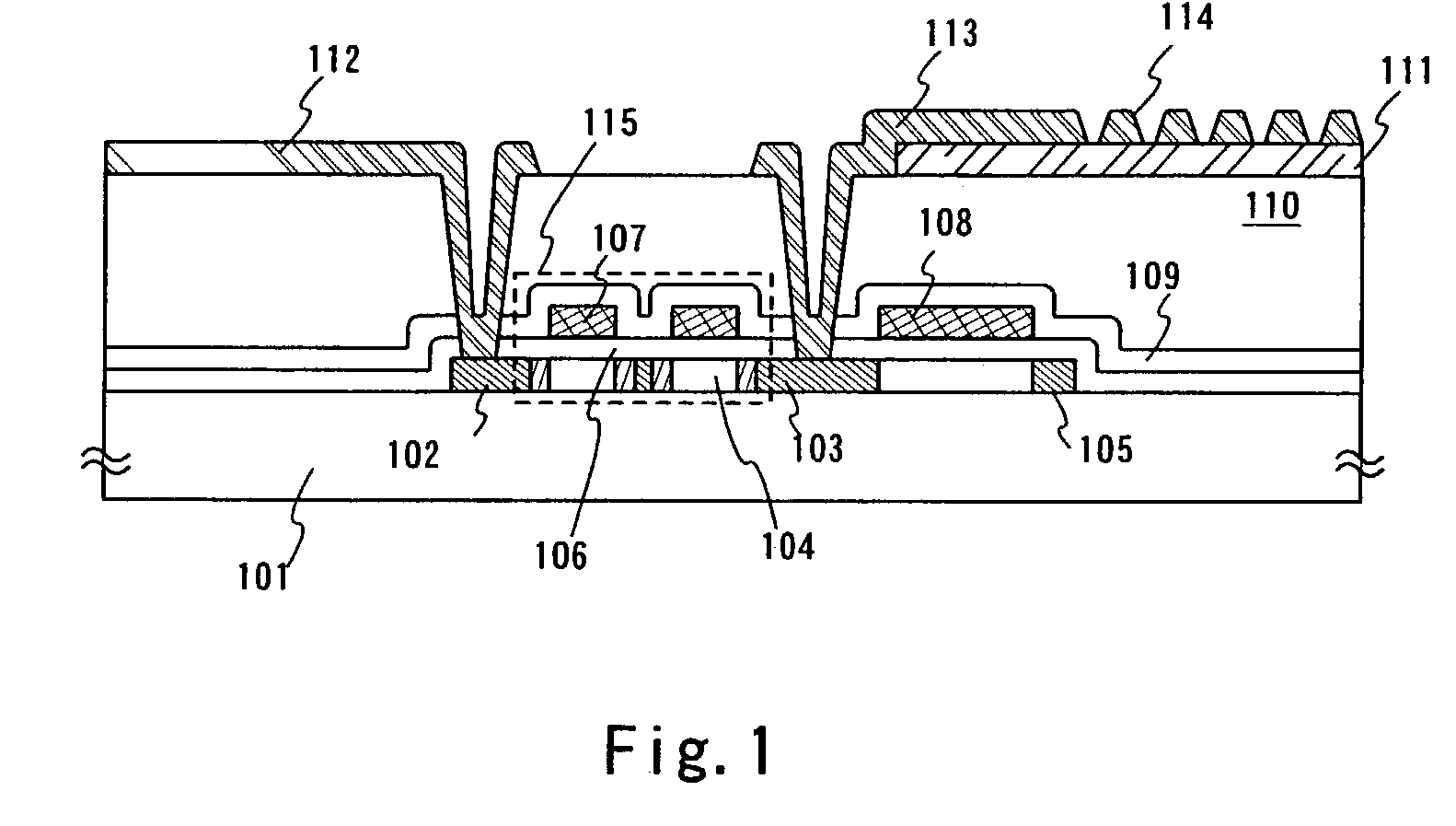

Liquid crystal display device

InactiveUS7053969B2Low costImprove productivityTransistorSolid-state devicesVisibilityConvex structure

It is an object to provide a display having high visibility and a transflective type liquid crystal display device having a reflection electrode having a concavo-convex structure formed without especially increasing the process. During manufacturing a transflective liquid crystal display device, a reflection electrode of a plurality of irregularly arranged island-like patterns and a transparent electrode of a transparent conductive film are layered in forming an electrode having transparent and reflection electrodes thereby having a concavo-convex form to enhance the scattering ability of light and hence the visibility of display. Furthermore, because the plurality of irregularly arranged island-like patterns can be formed simultaneous with an interconnection, a concavo-convex structure can be formed during the manufacturing process without especially increasing the patterning process only for forming a concavo-convex structure. It is accordingly possible to greatly reduce cost and improve productivity.

Owner:SEMICON ENERGY LAB CO LTD

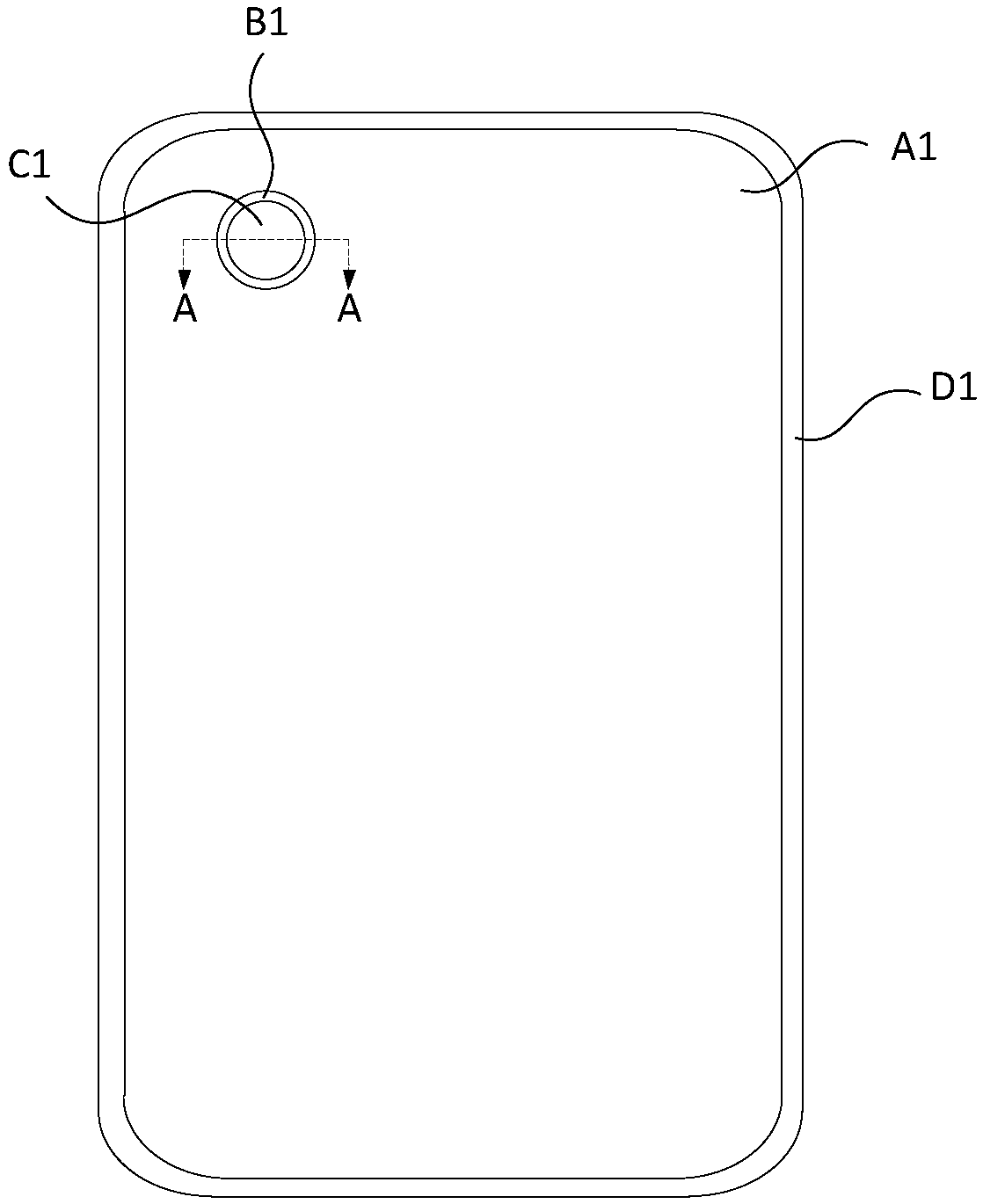

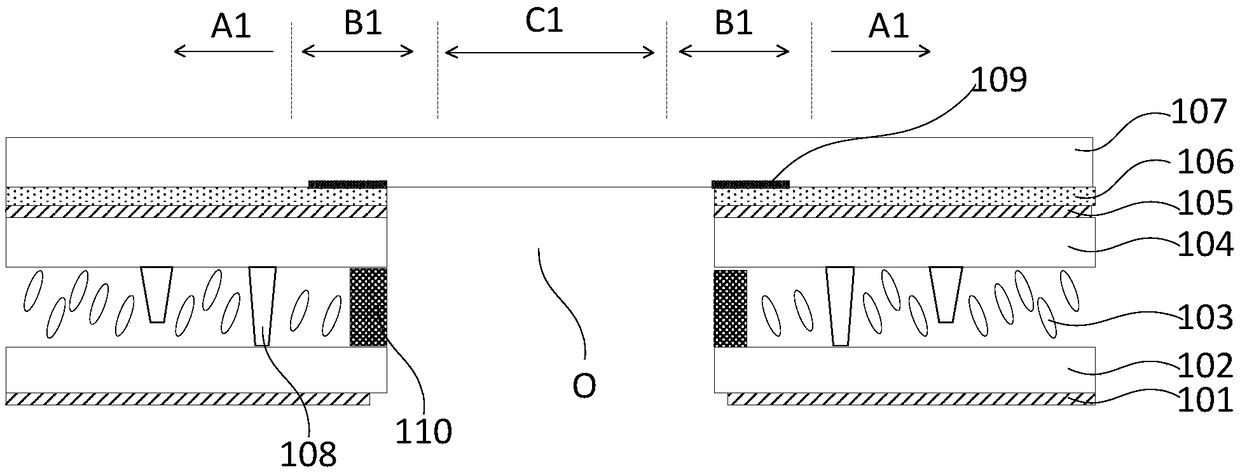

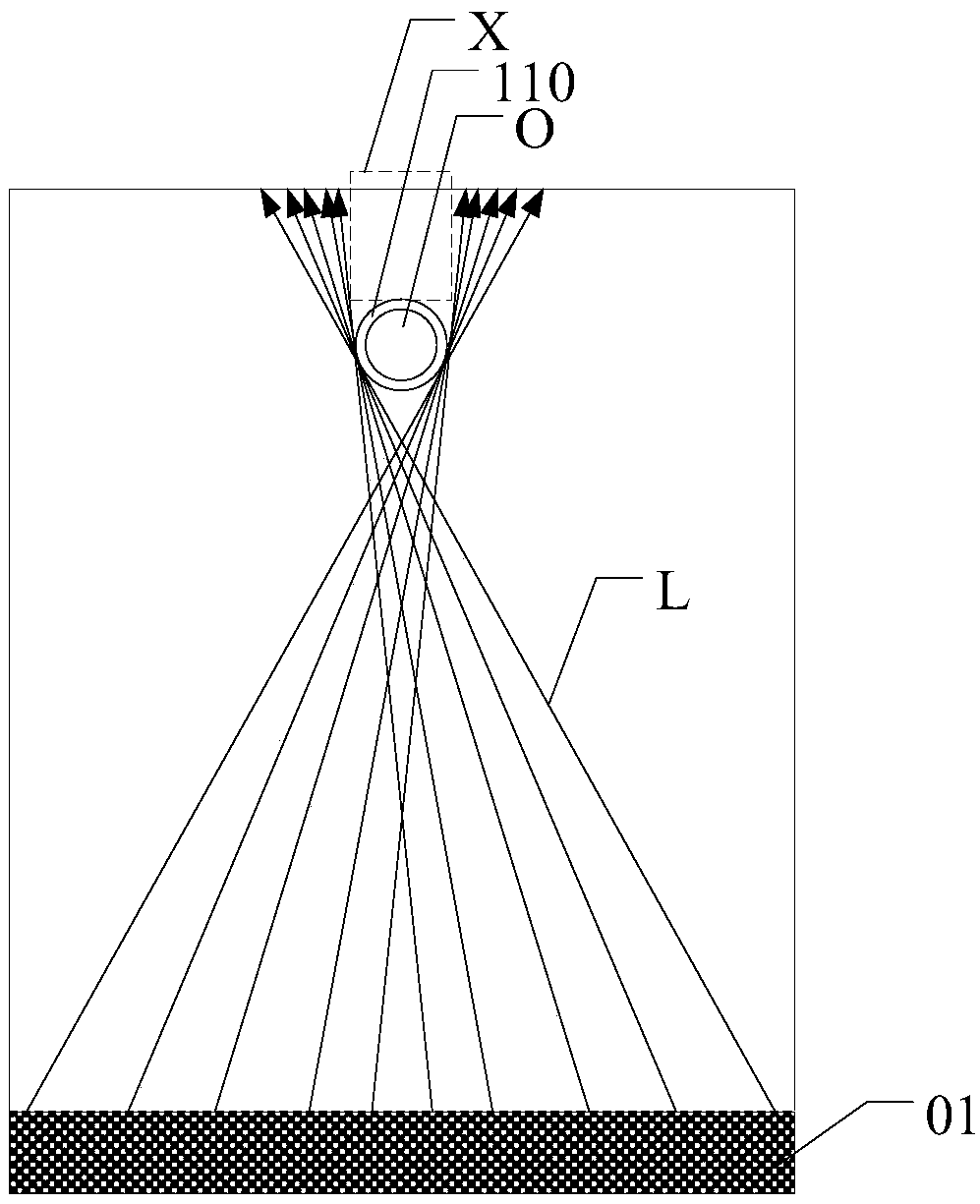

Display panel and display device

The invention discloses a display panel and a display device, which are used for solving the technical problem that the display panel in the prior art has a low screen-to-body ratio due to boring. Wherein the display panel includes: a light transmitting area, a display area, and a first non-display area. The display area surrounds the light transmitting area, and the first non-display area surrounds the display area. The display panel includes a first substrate and a second substrate disposed opposite to each other; a first support portion and a first liquid crystal layer are disposed betweenthe first substrate and the second substrate in the display area; a plurality of color filter film blocks are disposed on one side of the second substrate adjacent to the first substrate; a black matrix is disposed between each of the color filter film blocks; in the light transmitting area, at least one convex structure is disposed on the side of the second substrate adjacent to the first substrate.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

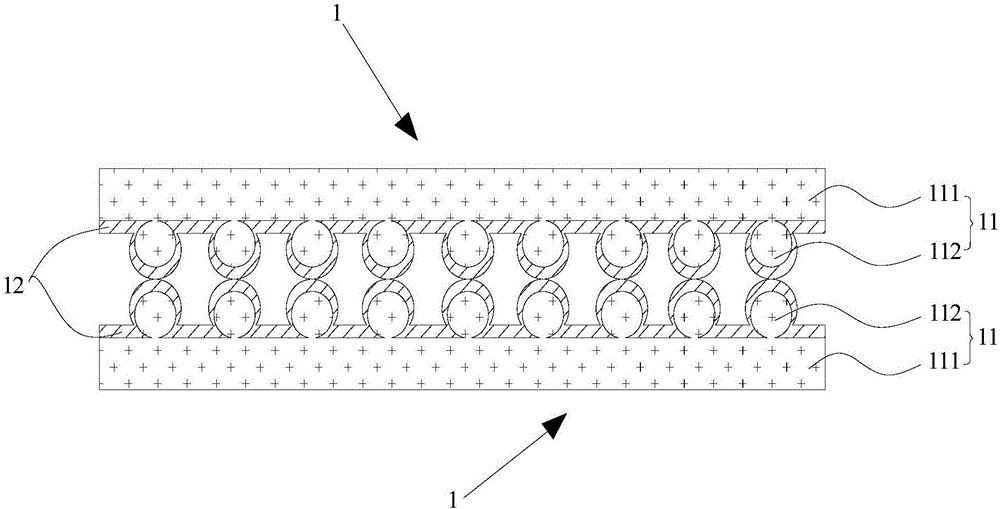

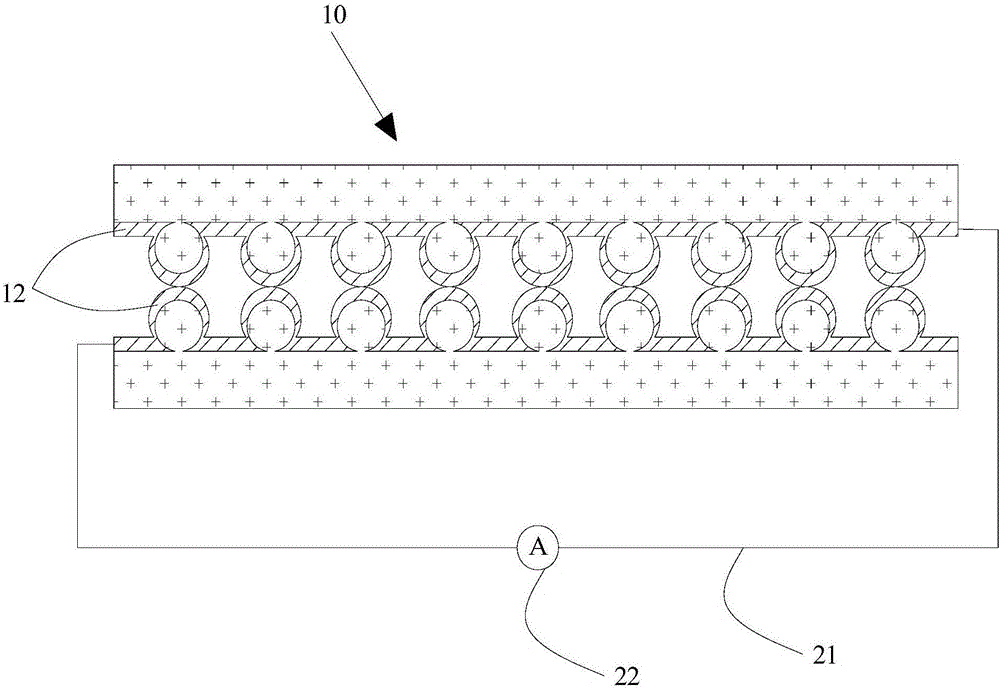

Multilayer high power nano friction generator

The invention discloses a nano friction generator which comprises an electrode, a polymer insulating layer and a friction electrode, wherein the electrode, the polymer insulating layer and the friction electrode are sequentially overlapped. A micro nano concave convex structure is arranged on at least one surface in two surfaces, which are oppositely arranged, of the polymer insulating layer and the friction electrode. The electrode and the friction electrode are voltage and current output electrodes of the friction generator. According to the invention, the friction of a conductive (metal) film and polymer is used; and metal is easy to lose electrons, thus the friction electrode and the polymer insulating layer form an induction electric field.

Owner:NEWNAGY TANGSHAN

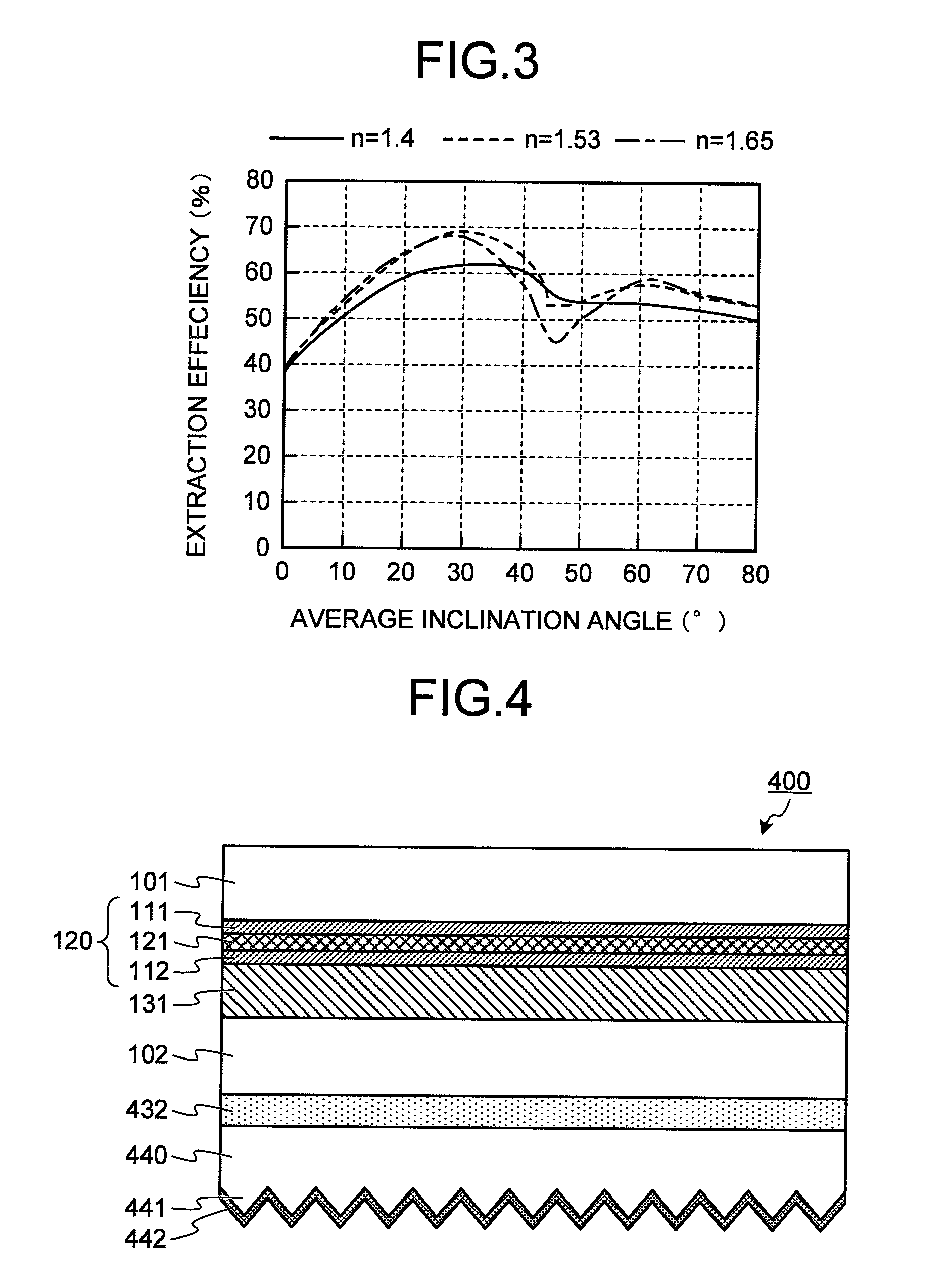

Organic electroluminescent light source

InactiveUS20110050082A1Improve extraction efficiencyIncreased durabilityDischarge tube luminescnet screensLamp detailsConvex structureOptoelectronics

An organic electroluminescent light source device includes, in the following order from a light-emitting surface side, a first transparent electrode layer, a luminescent layer, a second transparent electrode layer, and a reflecting layer, wherein the reflecting layer includes a concavo-convex structure with an average inclination angle of 12 to 45°. An organic electroluminescent light source device includes, in the following order, a first transparent electrode layer, a luminescent layer, a second transparent electrode layer, a diffusing layer, and a reflecting-scattering layer, wherein the diffusing layer has a concavo-convex surface including a concavo-convex structure with an average inclination angle of 17 to 45°.

Owner:ZEON CORP

Substrate and preparation method thereof, display panel, and display device

ActiveCN107424520AIncrease the extension areaAvoid breakingSolid-state devicesPhotovoltaic energy generationConvex structureDisplay device

A substrate and a preparation method thereof, a display panel, and a display device are provided. The substrate comprises: a base plate that includes a bent area; an insulating layer arranged on the base plate, wherein the insulating layer at the bent area is provided with at least one trench, and the surface of each trench includes at least one concave-convex structure. The concave-convex structures of the substrate can provide enlarged extension area of the surface of the trenches during bending, so that breakage is avoided during bending of members on the trenches, and product yield is increased.

Owner:BOE TECH GRP CO LTD +1

Artificial intervertebral disc

InactiveUS7118599B2Inhibition of translationAvoid separationJoint implantsSpinal implantsConvex structureSolder ball

An artificial disc having a pair of opposing baseplates, for seating against opposing vertebral bone surfaces, separated by a ball and socket joint that includes a solid ball mounted to protrude from one of the baseplates. The ball is captured within a curvate socket formed in a peak of a convex structure integral with the other of the baseplates. The socket is formed by opposing curvate pockets, one on vex structure and one on a cap secured to the other of the baseplates. While the ball angulates in the socket, its rotation in the socket has a limited range due to interference between an interference pin's rounded head that extends into the socket and a curvate recess on the ball. The ball and socket joint therefore permits the baseplates to rotate relative to one another through a limited range and also angulate relative to one another.

Owner:HOWMEDICA OSTEONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com