Electrolytic machining method for thin-wall machine case of aero-engine

A technology of aero-engine and processing method, which is applied in the direction of electric processing equipment, electrochemical processing equipment, metal processing equipment, etc., can solve the problems of long processing cycle, difficult control of flow field, high requirements for power supply equipment, etc., and achieve one-time processing and molding , to solve the effect of unstable flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation process of the present invention will be described in detail below with reference to the accompanying drawings.

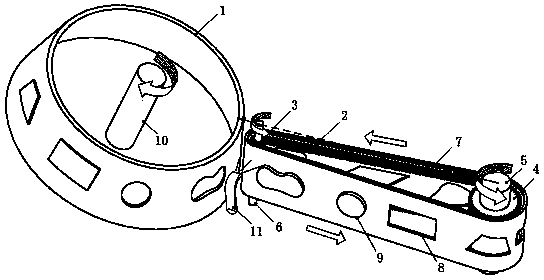

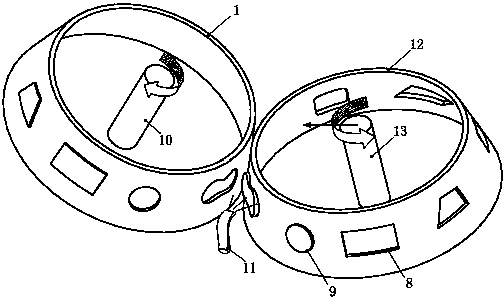

[0018] like figure 1 As shown in the figure, the electrolytic machining method of aero-engine thin-walled casing by using a flexible strip-shaped cathode assembly mainly includes a workpiece anode 1, a flexible thin-walled strip-shaped cathode 2, a first shaft 5 for realizing electrode rotation and feeding, a driving wheel 4. The driven wheel 3 , the second shaft 6 , the synchronous belt 7 , the third shaft 10 , and the liquid supply nozzle 11 . The tool cathode 2 used is a flexible ring-shaped belt structure. During the processing, the first shaft 5 drives the driving wheel 4 to rotate at a constant speed, and the synchronous belt 7 drives the driven wheel 3 and the second shaft 6 to rotate synchronously, so as to realize the flexible thin wall. The uniform circumferential motion of the strip cathode 2; at the same time, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com