Patents

Literature

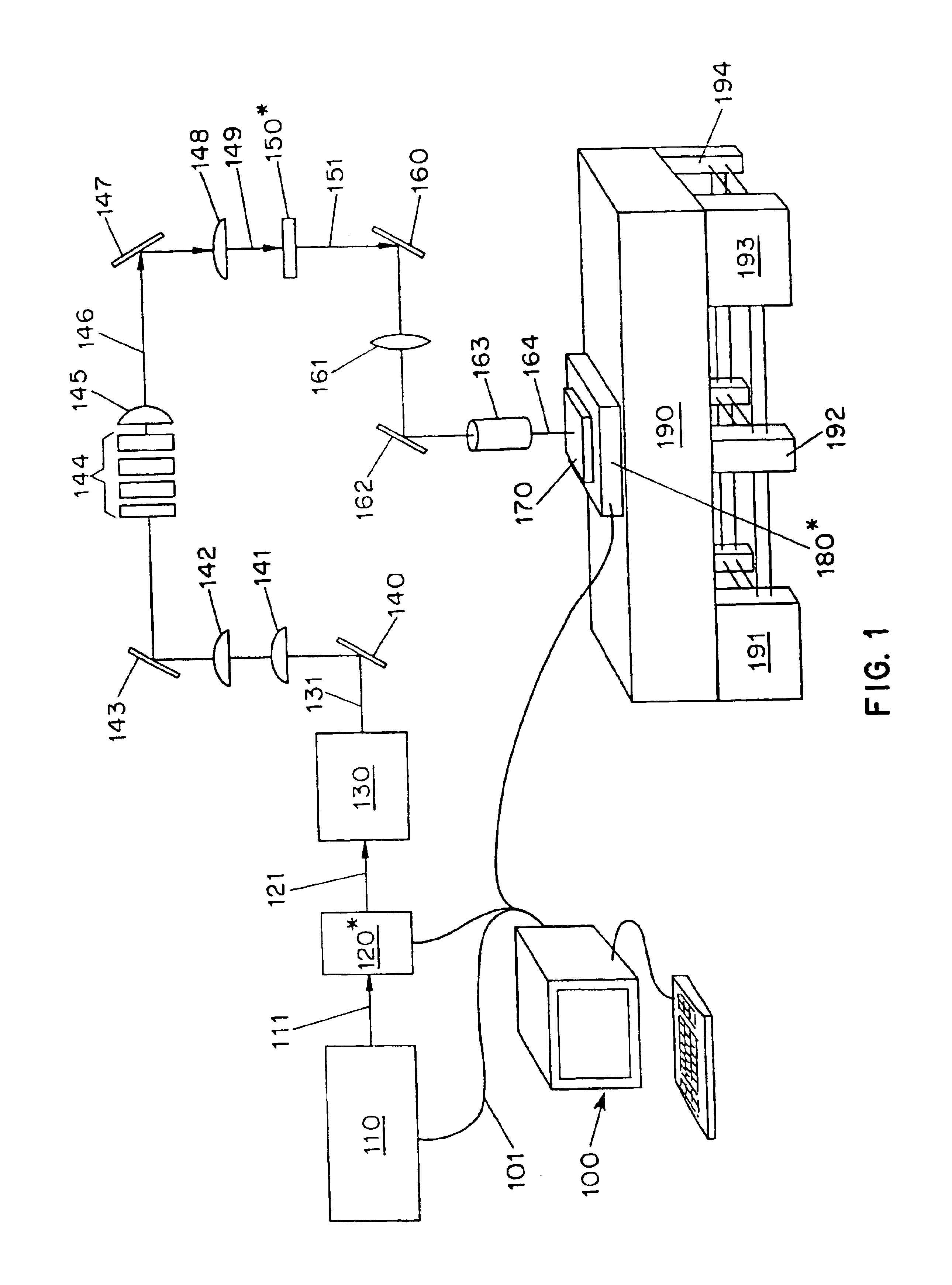

32671 results about "Machining process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machining is manufacturing process that involves removing materials using cutting tools for getting rid of the unwanted materials from some workpiece and converting it into the shape you desire.

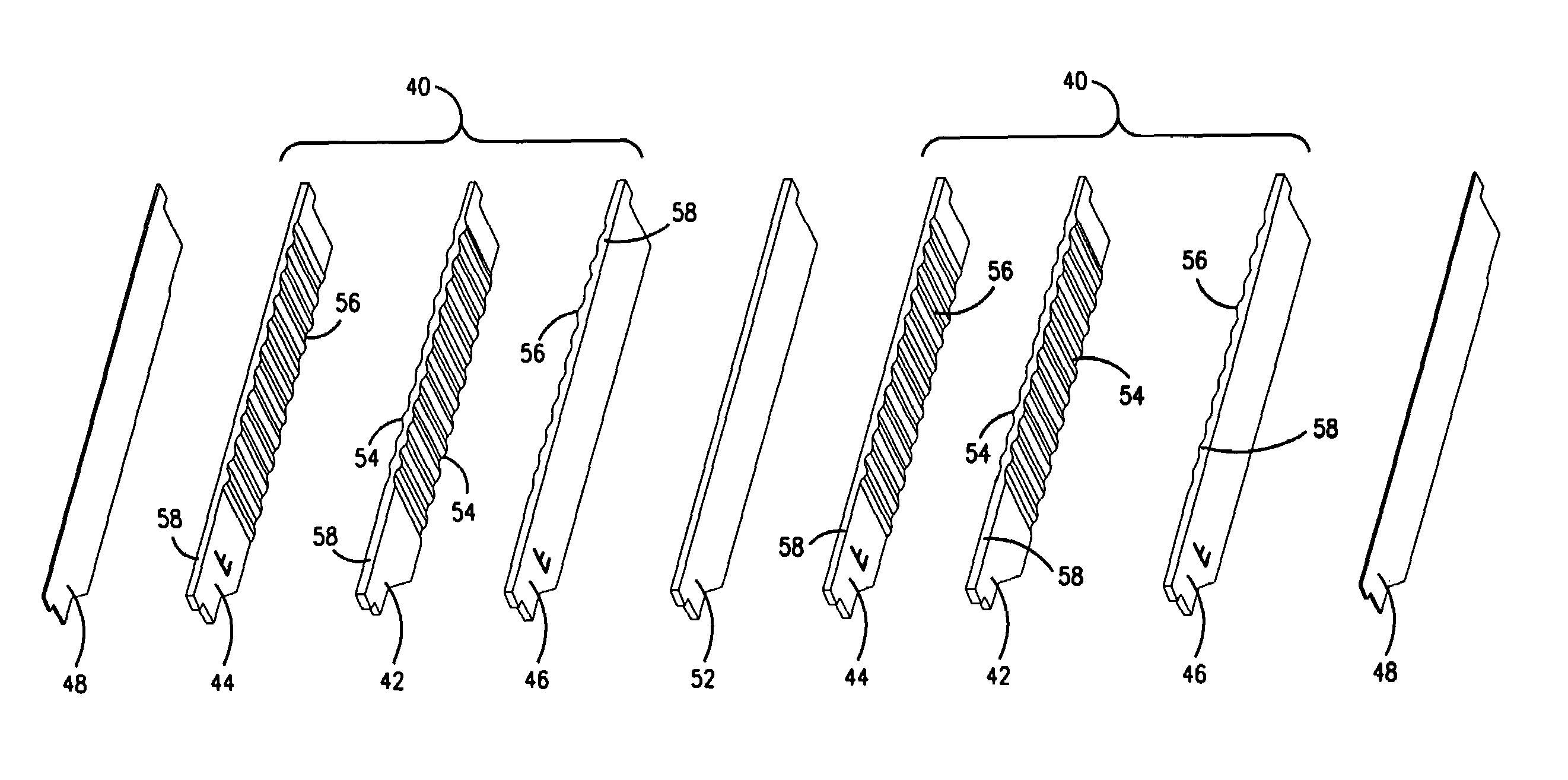

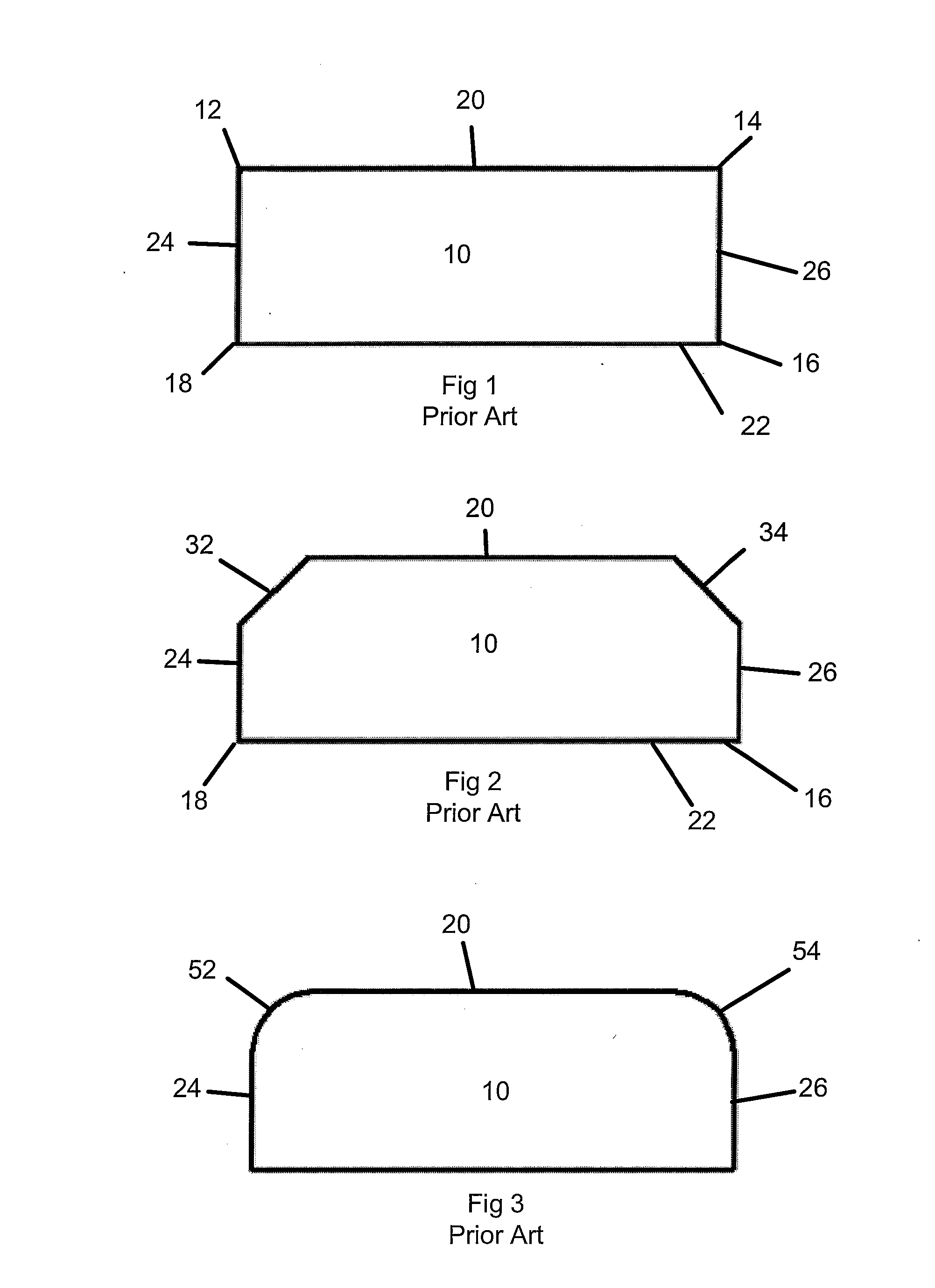

Metal-forming die and method for manufacturing same

InactiveUS7086267B2Good flexibilityIncrease flexibilitySuture equipmentsShaping toolsMetal formingEngineering

A metal-forming die according to the present invention includes die blades with convoluted opposed side surfaces that correspond to variable-width features on the working surface of the die. The convoluted side surfaces and variable-width working surface features permit the impression left by one die blade to fill space taken from an impression made by a laterally adjacent die blade. Such a die permits formation of working surface shapes not possible with flat-sided die components. The die is manufactured in discrete longitudinally extending components, or blades. Dividing the working surface of the die into longitudinally extending portions, each carried by a die blade allows conventional machining processes to be employed in forming the working surface on each die blade. An additional machining process cuts complementary shapes on the sides of the die blades. The die blades and their corresponding working surfaces interfit, or nest together.

Owner:FR W DWORAK

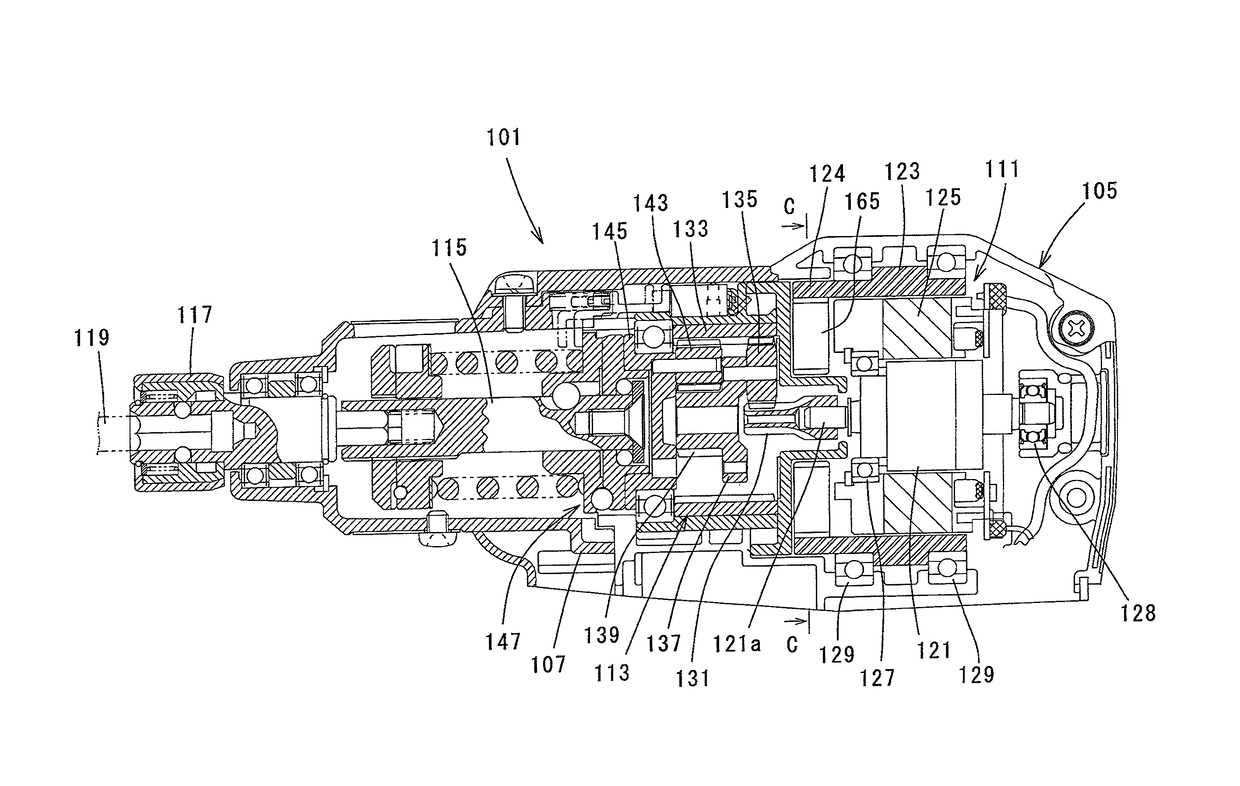

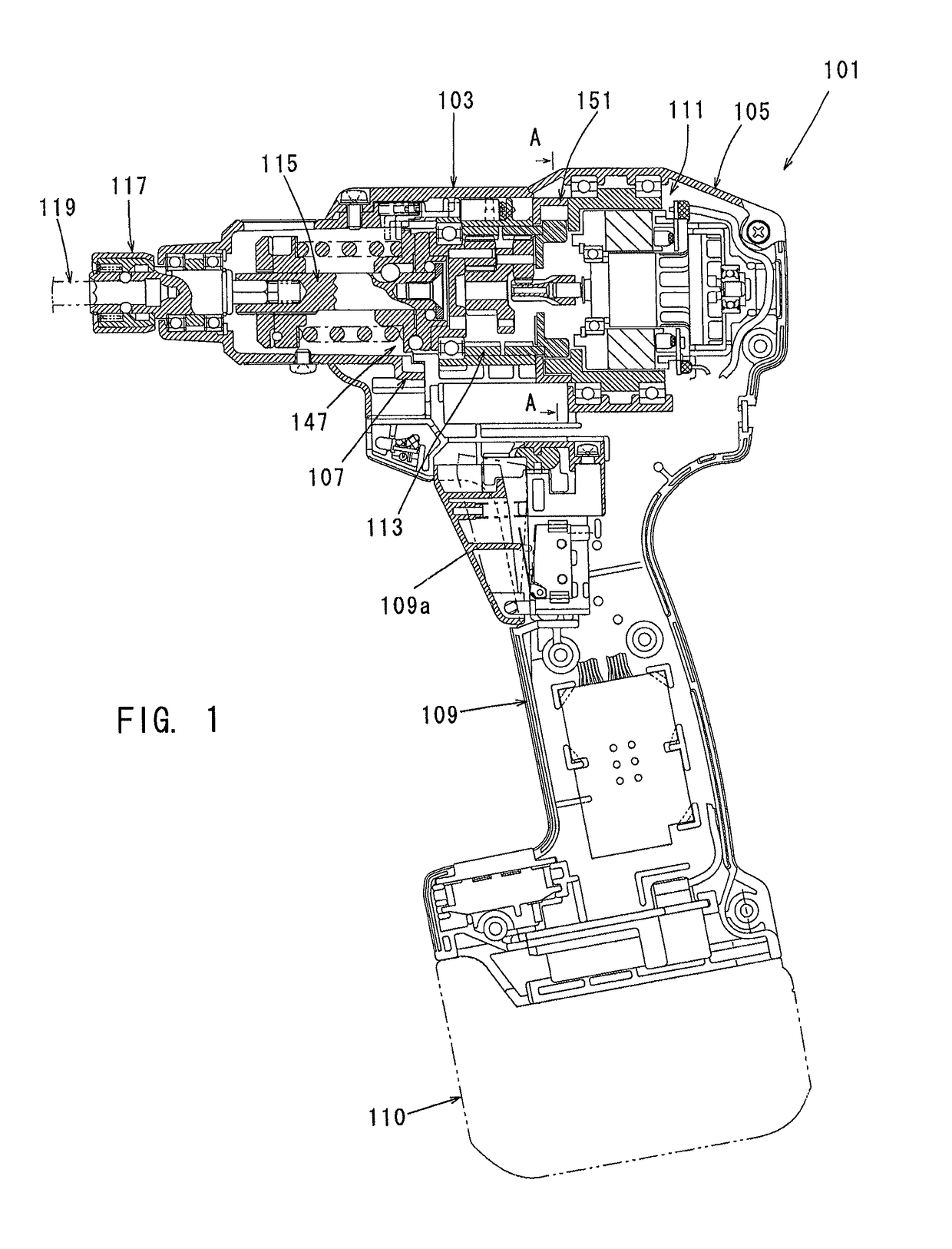

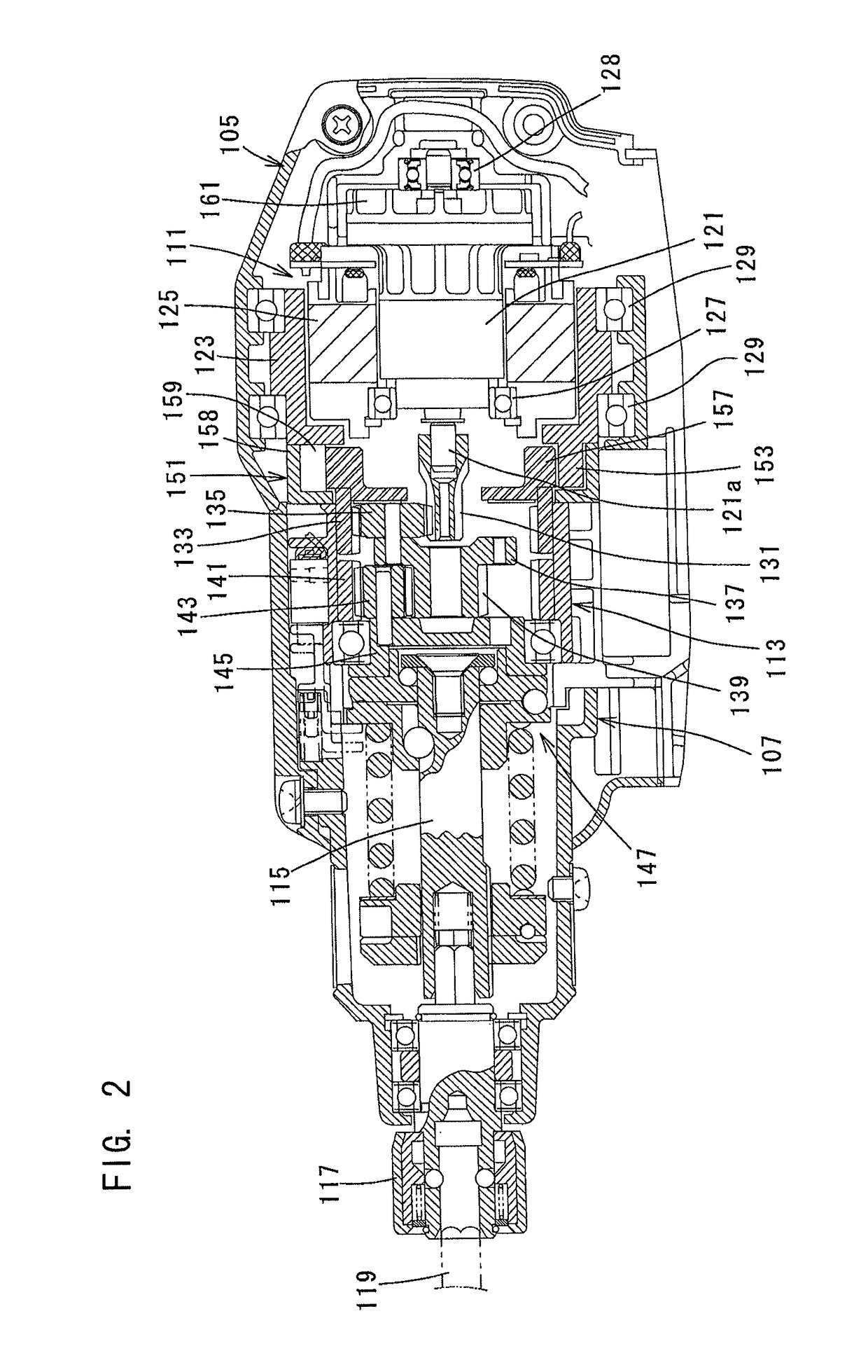

Power tool

InactiveUS9731410B2Simplify device configurationEasy to understandDrilling rodsConstructionsHand heldEngineering

Owner:MAKITA CORP

Process for improving viscosity of attapulgite clay

InactiveCN1317067CImprove processing technologyPhysical/chemical process catalystsOther chemical processesPolymer scienceMachining process

The invention discloses a jprocess for improving viscosity of attapulgite clay which comprises the steps of modification treatment, batching, agitating, milling and detect. The process can be applied into the real processing procedure of Attapulgite clay, and can increase the viscosity of the end product by over 35%.

Owner:许庆华

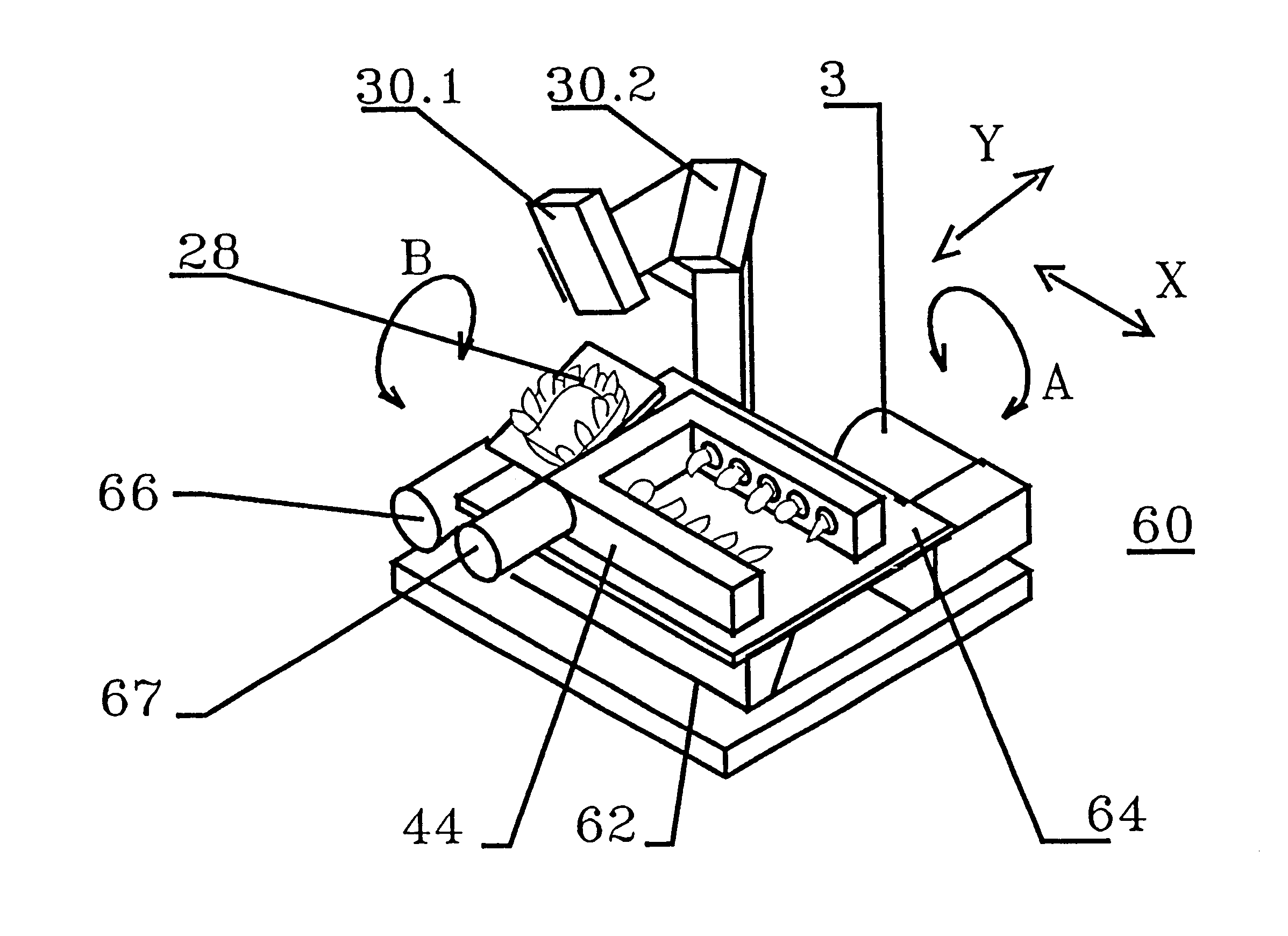

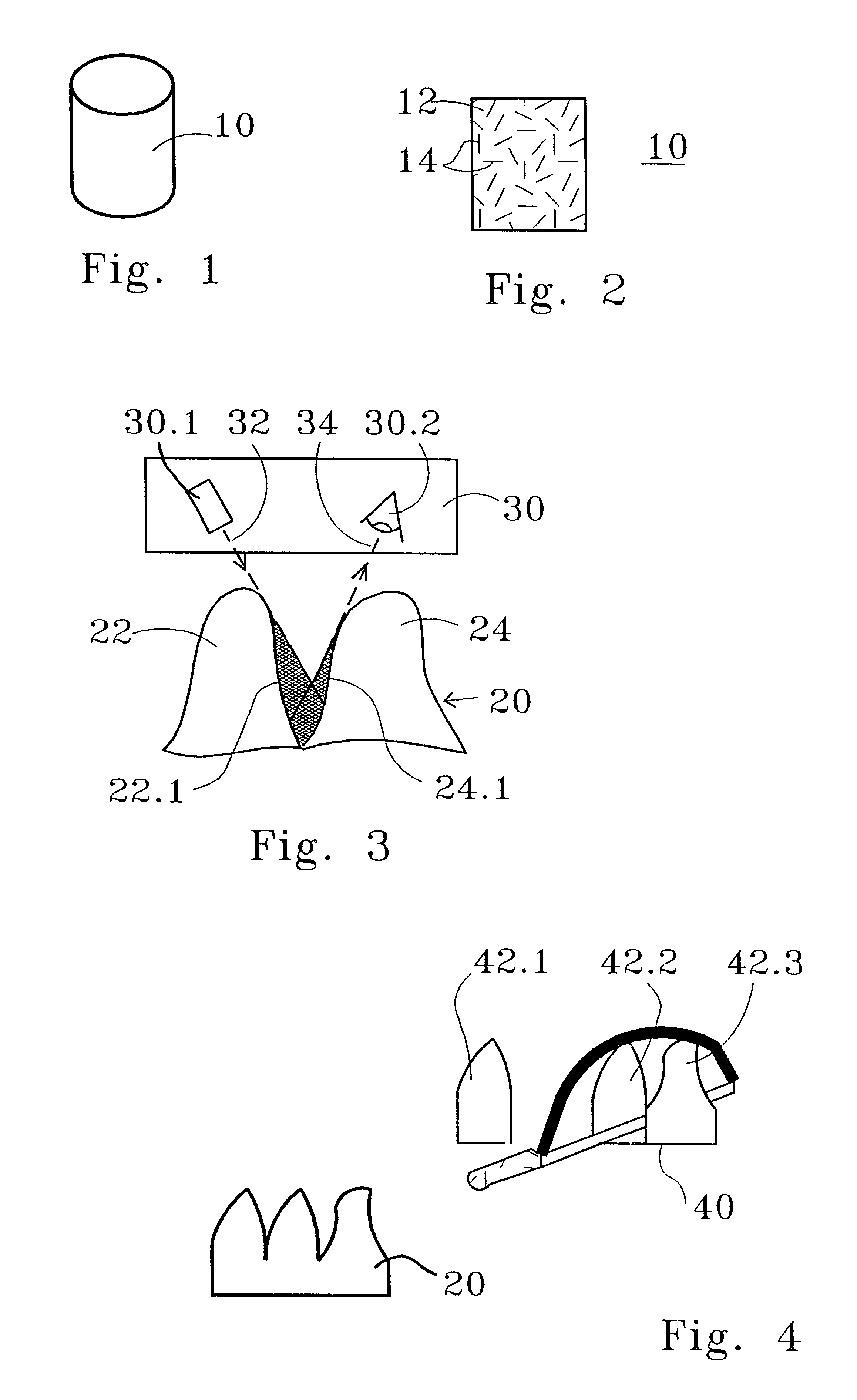

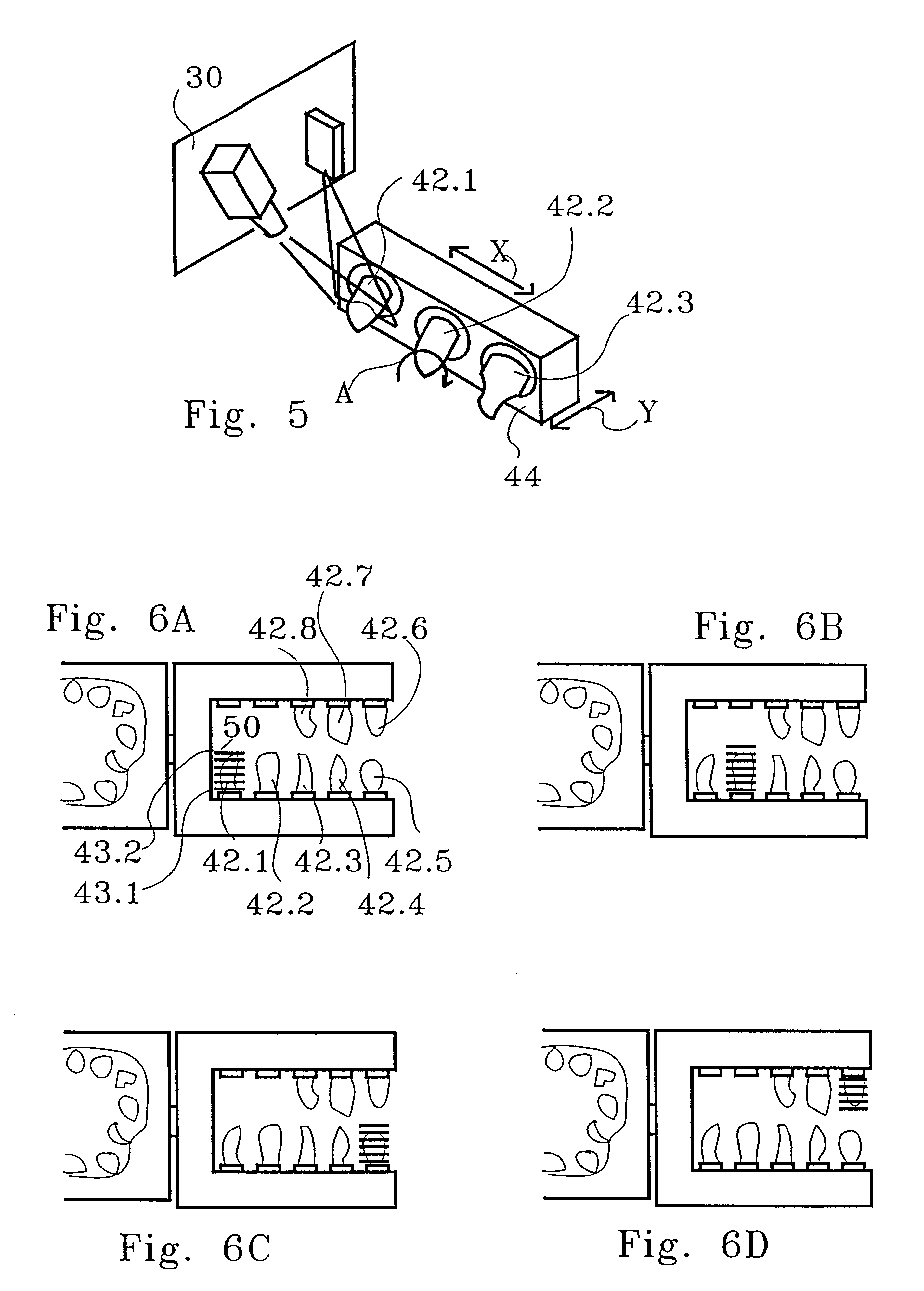

Material for a dental prosthesis, method and device for determining the shape of a remaining tooth area to be provided with a dental prosthesis, method and arrangement for producing a dental prosthesis and use of the arrangement

InactiveUS6287121B1Improve accuracySuitable for processingImpression capsTooth crownsDigital dataGlass fiber

Material for a dental prosthesis consisting of fiber glass reinforced plastic. The material is used to produce a blank by means of a special injection-molding process, which can be worked by means of a machining process. A method and a device for determining the shape of a duplicate of a remaining tooth area to be provided with a dental prosthesis. The shape of the duplicate is determined, as is the shape of duplicate sections into which the duplicate has been divided, the determined data are stored and combined. A method and arrangement for producing a dental prosthesis. The shape of a duplicate (42) of a remaining tooth area to be provided with the dental prosthesis is determined by means of a shape determination device (110), the determined data are stored in the form of digital data (DD), and the dental prosthesis (143) is produced in a production machine (114), which is controlled by means of production data (FD). The shape determination device (110) and the production machine (114) are coupled by means of an EDP installation (118), which contains a memory unit for storing the digital data (DD) and performs the calculation of the production data (FD).

Owner:STRAUMANN HLDG AG +2

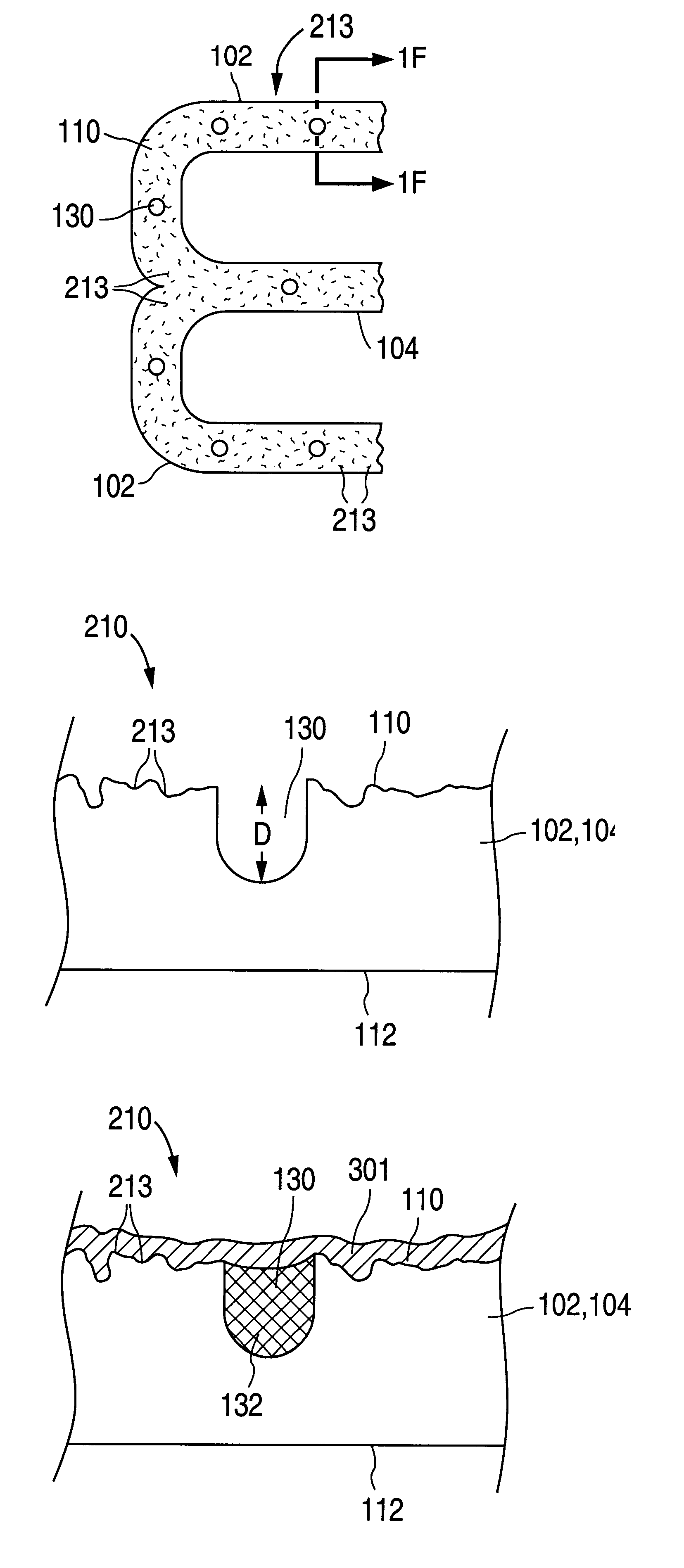

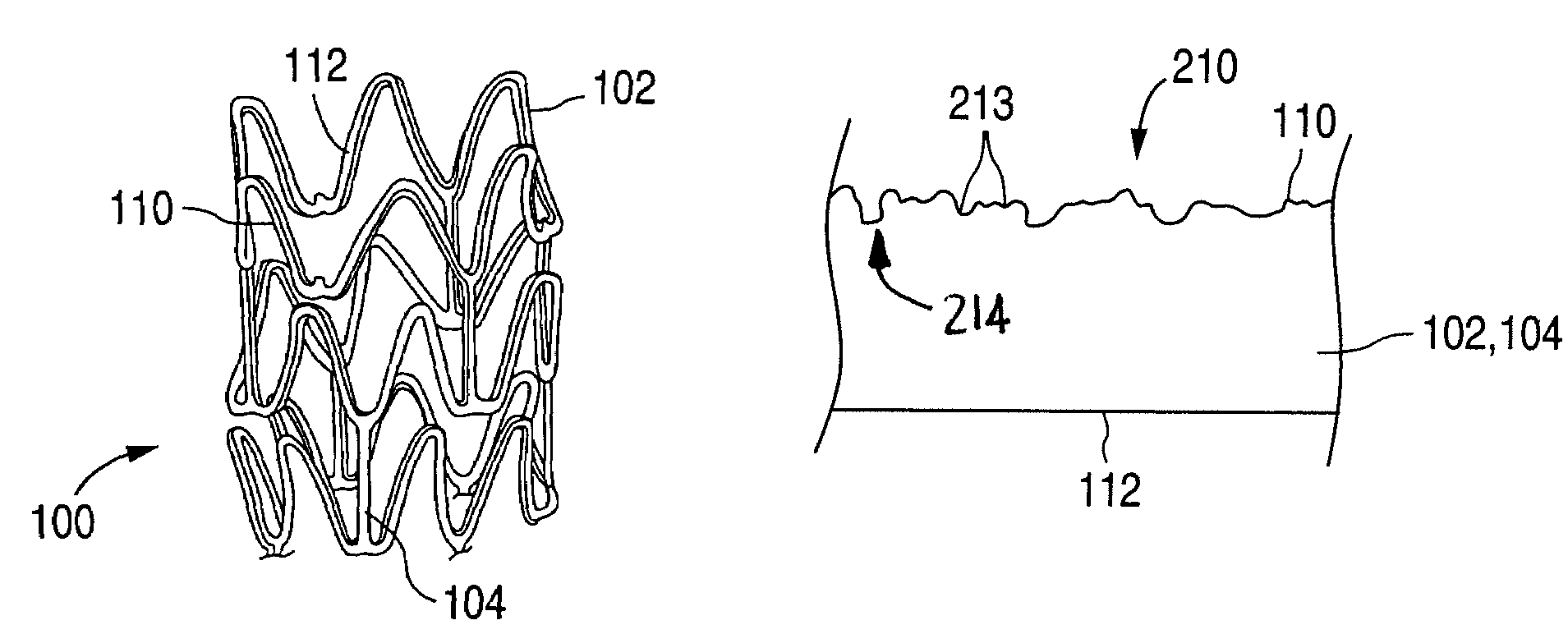

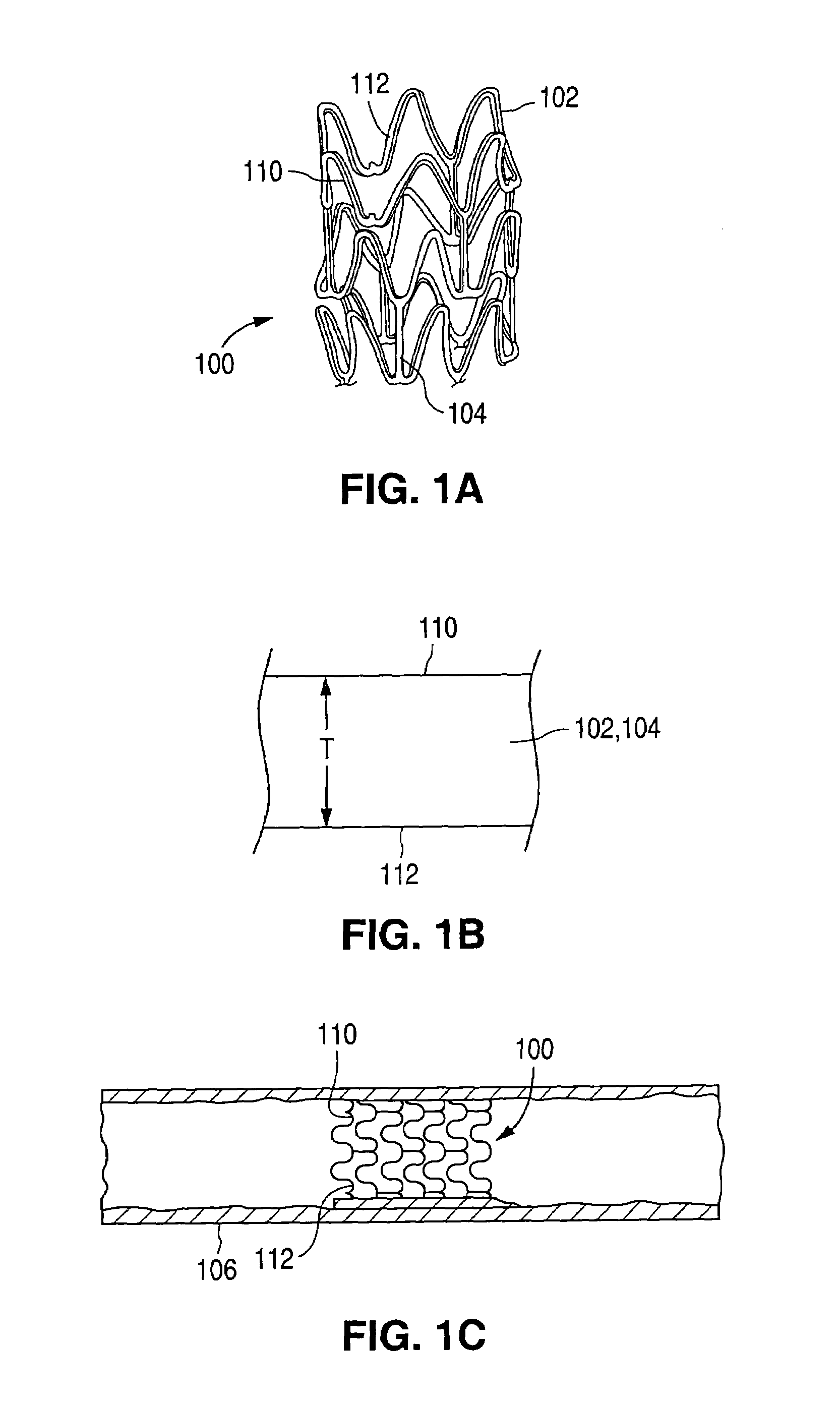

Method for creating a textured surface on an implantable medical device

InactiveUS6913617B1Great amount of therapeuticEasy to keepBlood vesselsElectricityElectric discharge

A method for forming an implantable medical device, such as a stent, is provided, in which electric discharges are applied to a metal surface of the implantable medical device. The electric discharges pit the surface. The pitted surface improves retention of a coating on the device and increases the amount of coating that can be carried by the device. An electric discharge machining process is described for applying electric discharges to the surface of the implantable medical device or portion thereof.

Owner:ABBOTT CARDIOVASCULAR

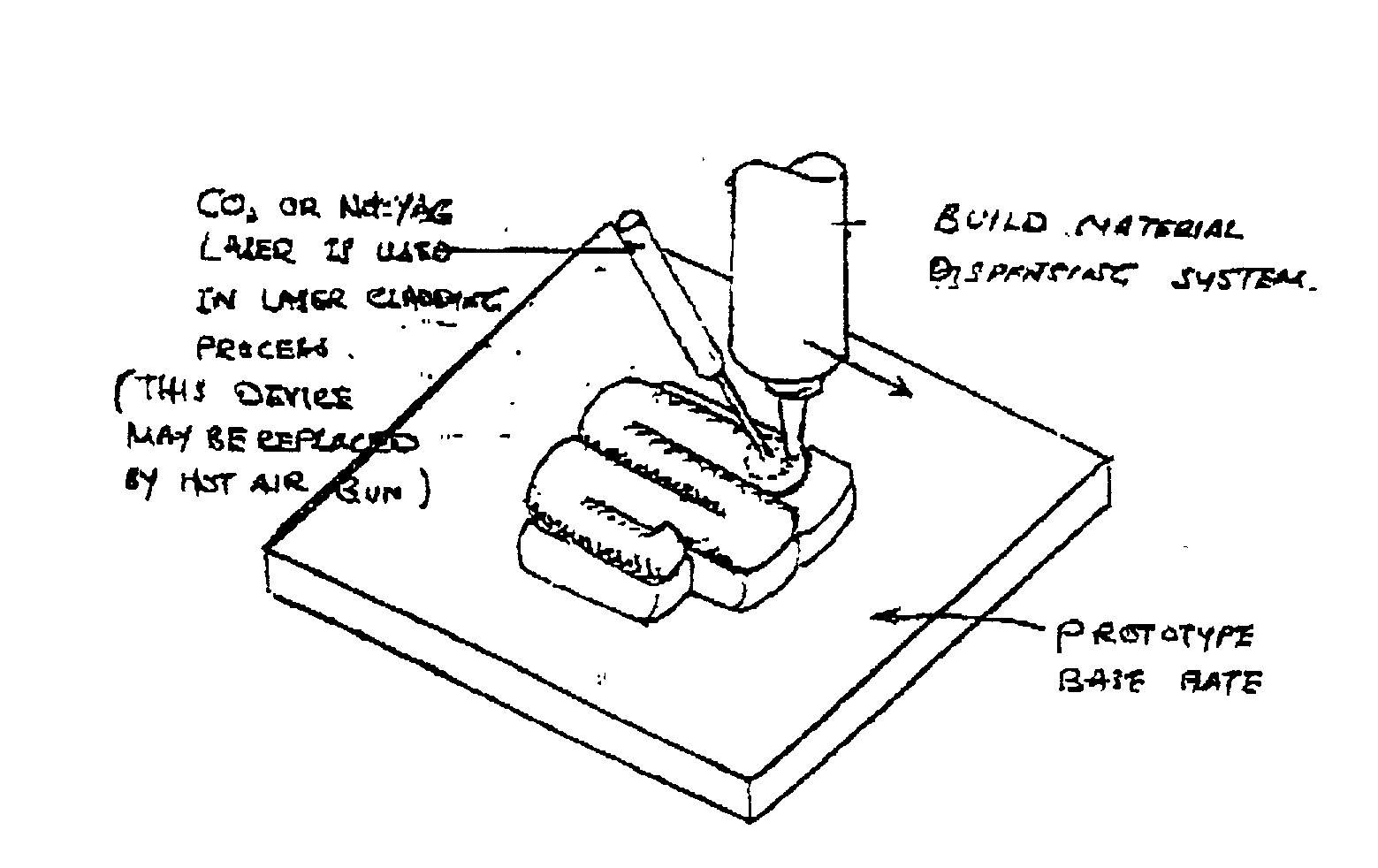

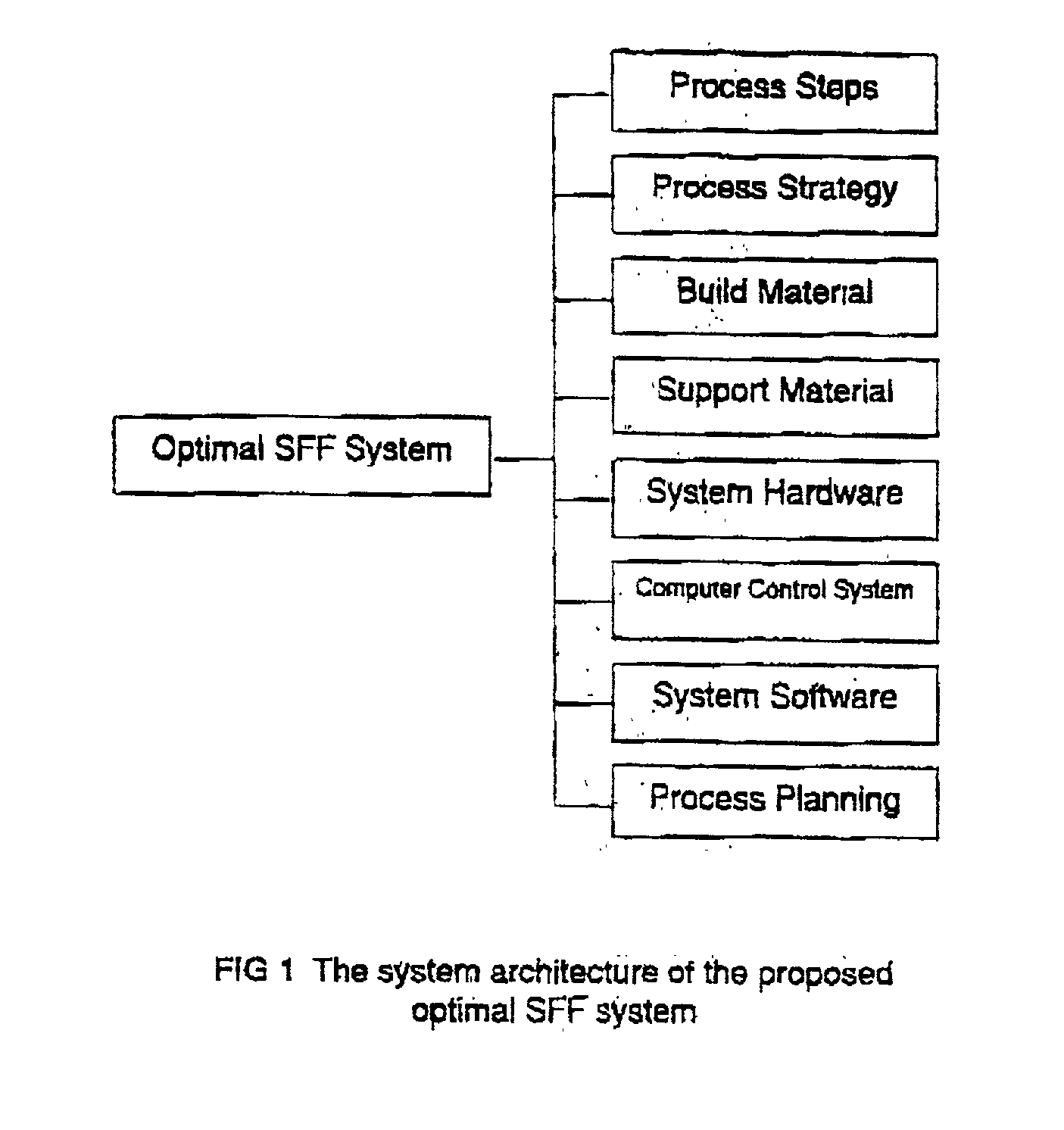

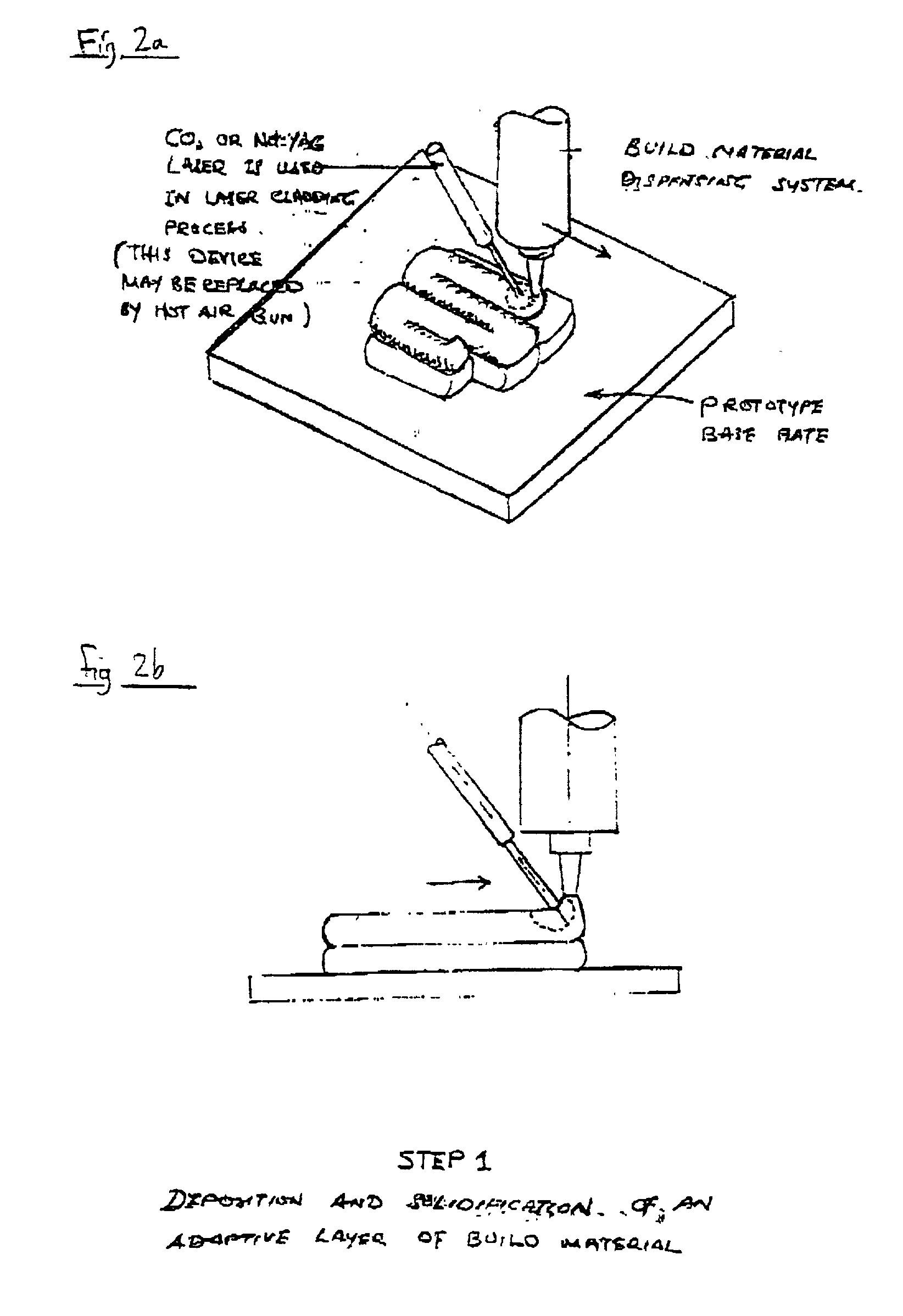

Method and apparatus for producing a prototype

InactiveUS20020129485A1Force is smallMaximize productivityProgramme controlAdditive manufacturing apparatusMachining processEngineering

An apparatus for producing a prototype, the apparatus comprising a headstock having a plurality of machining apparatuses for carrying out respective manufacturing processes on a prototype. Also disclosed is a method of producing a prototype, comprising the steps of: forming a layer of the prototype; performing a machining process on the layer to remove a part of the layer, and subsequently forming a successive layer of the prototype on the layer of the prototype.

Owner:MILLING SYST & CONCEPTS PTE

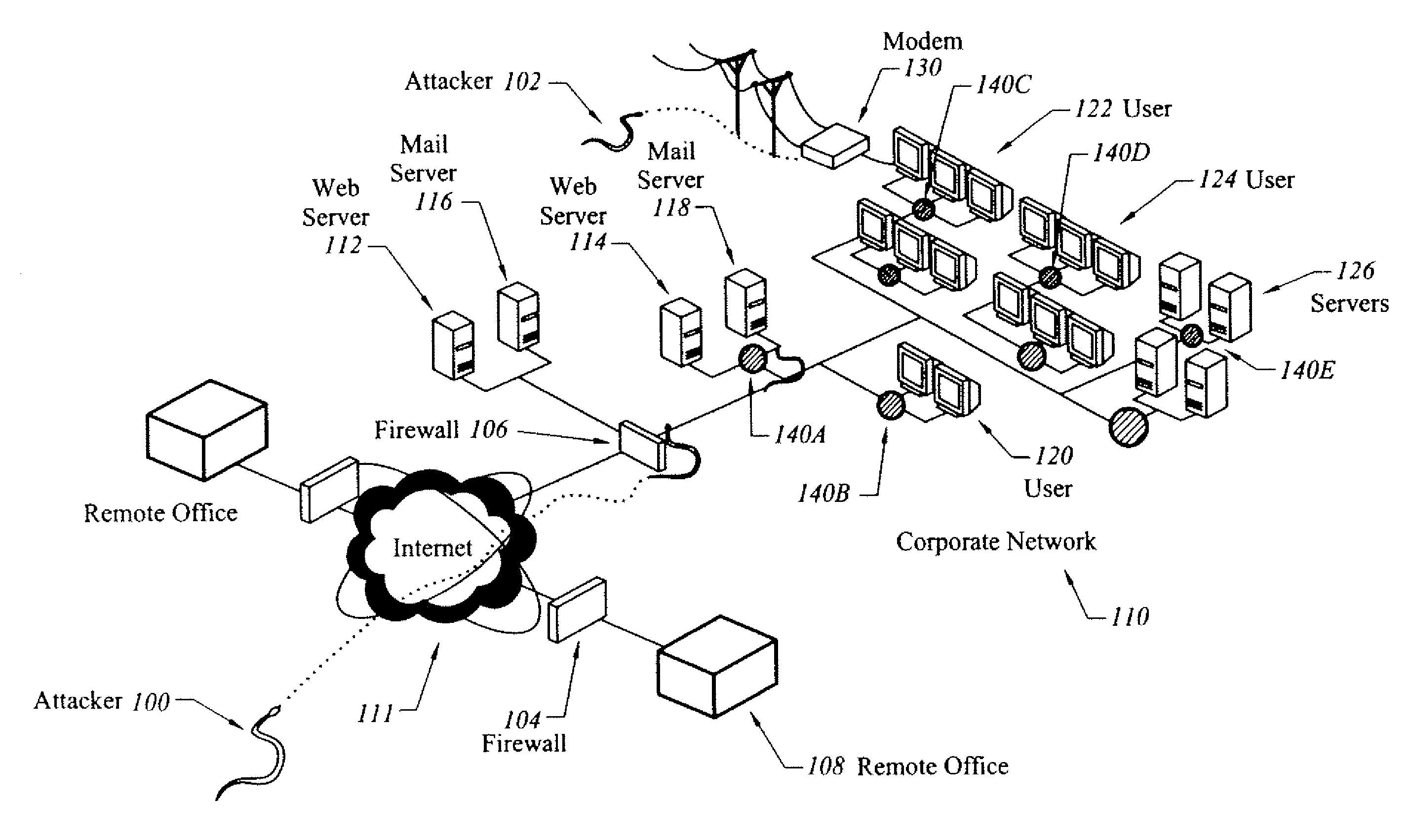

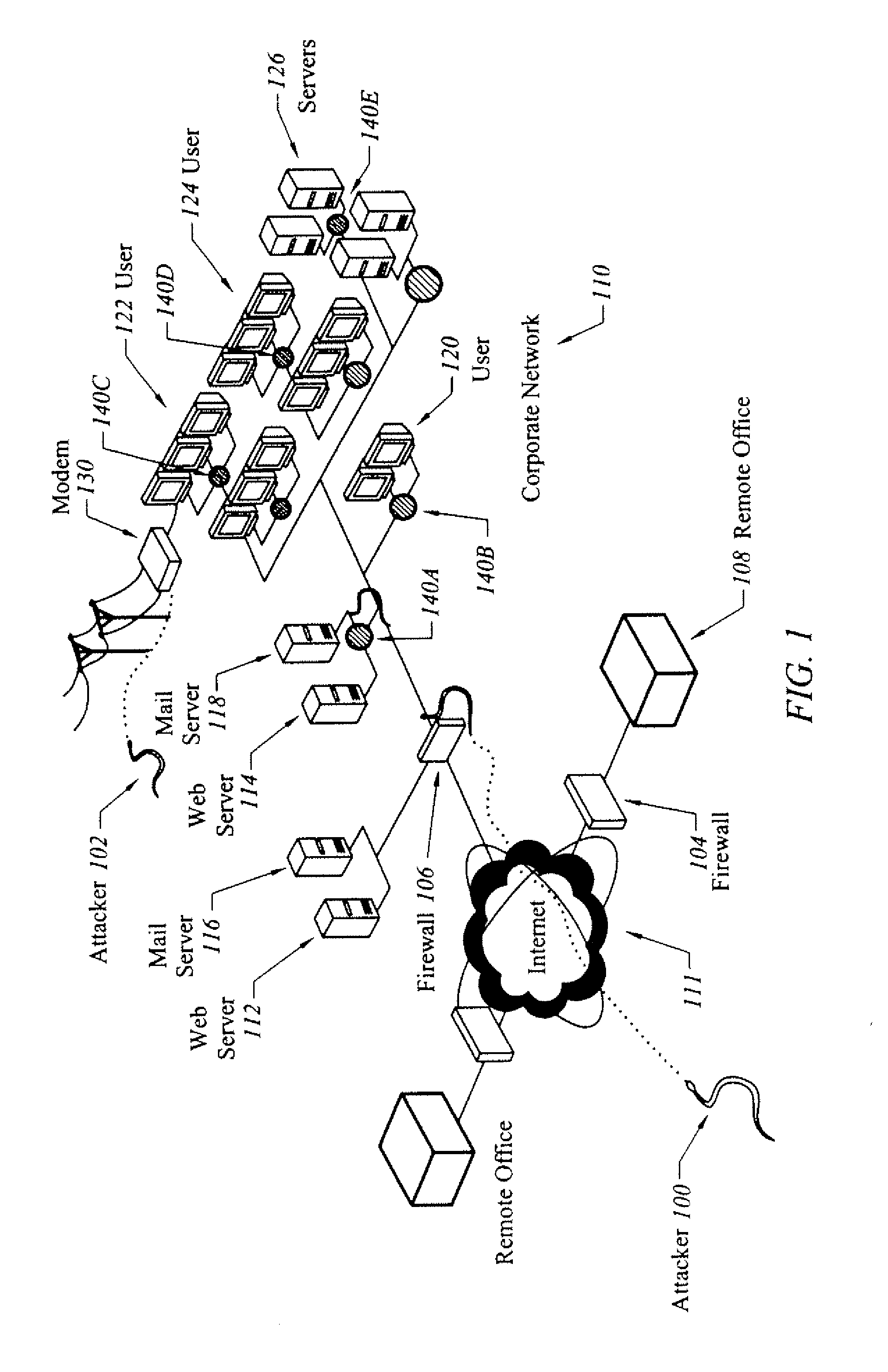

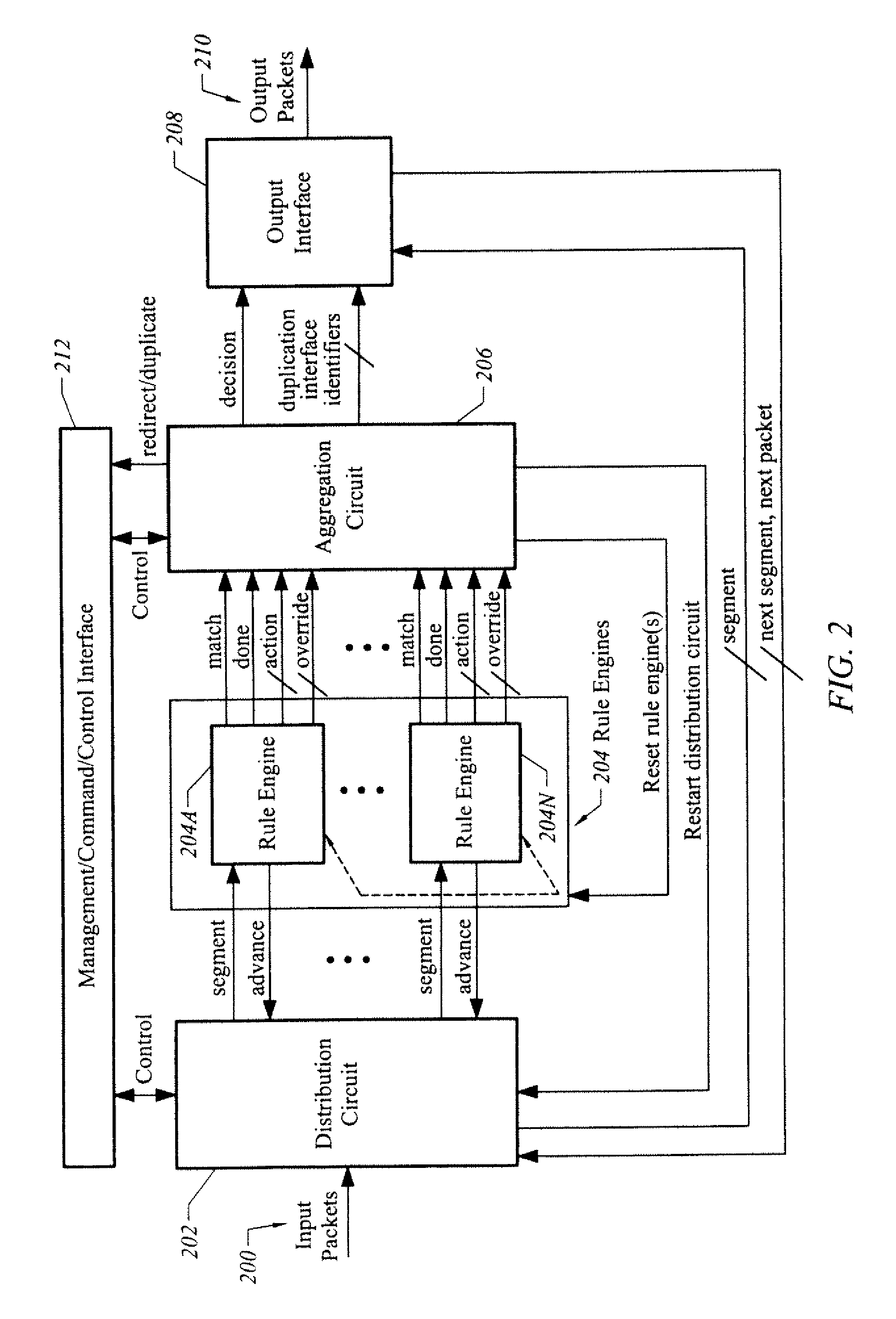

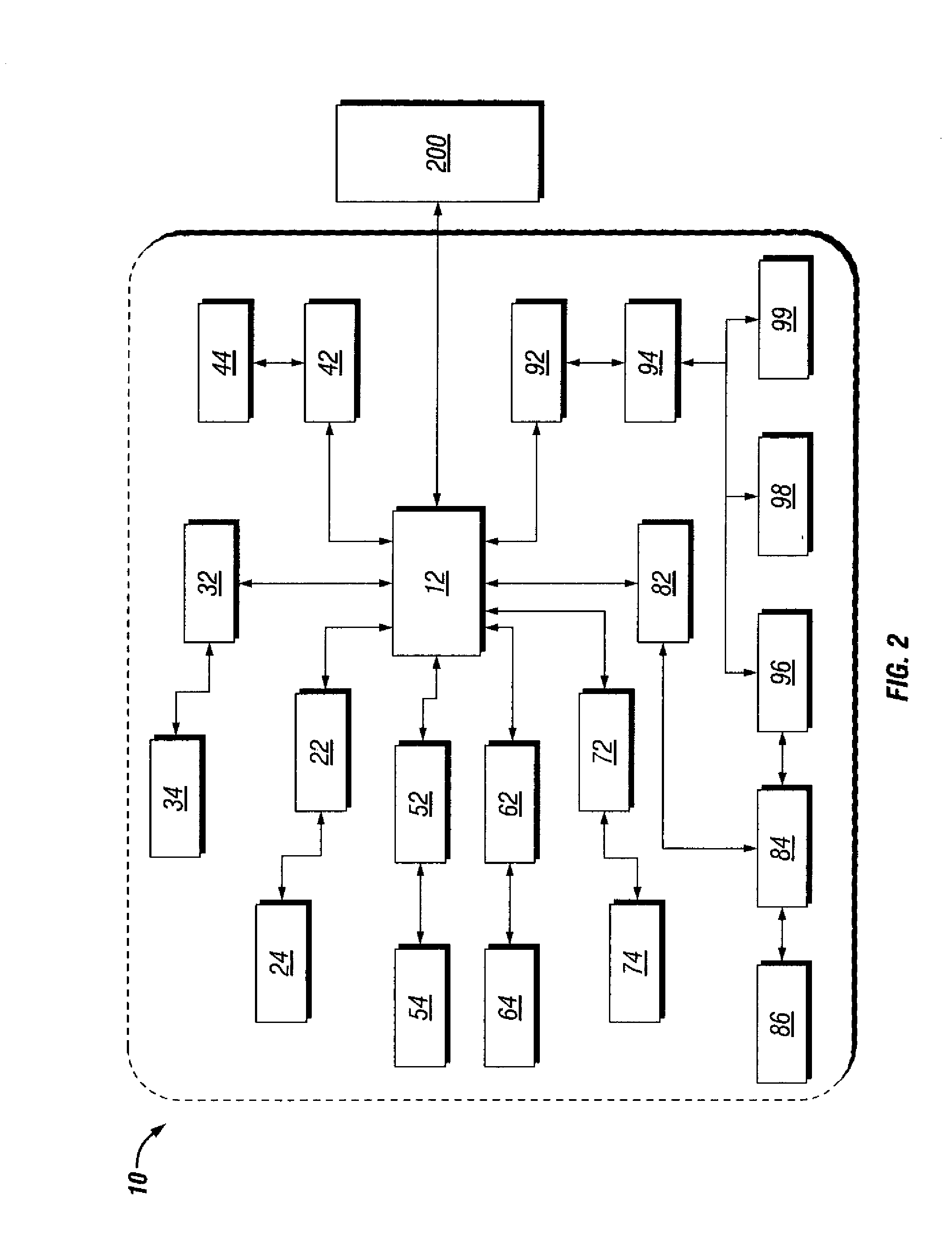

Apparatus and method for associating categorization information with network traffic to facilitate application level processing

ActiveUS20100011434A1Facilitate application level processingLow costError preventionFrequency-division multiplex detailsTraffic capacityHash function

An apparatus is described that associates categorization information with network traffic to facilitate application level processing through processing of network traffic in accordance with provisioned rules and policies. The apparatus includes a plurality of microcode controlled state machines, wherein at least one microcode state machine processes at least one input data field using a hash function to generate a hash identifier. This embodiment further includes a distribution circuit that routes input data to the plurality of microcode controlled state machines, such that at least one individual microcode controlled state machine applies a rule to the input data to produce the at least one input data field, and to produce modification instructions based on the hash identifier. This embodiment further includes a first circuit that appends the hash identifier to the input data to produce modified input data based on the modification instructions, and that routes the modified input data in accordance with an output routing strategy. Advantageously, the apparatus provides an architectural framework well suited to a low cost, high speed, robust implementation of flexible, advanced network security and monitoring features and network traffic analysis.

Owner:CPACKET NETWORKS

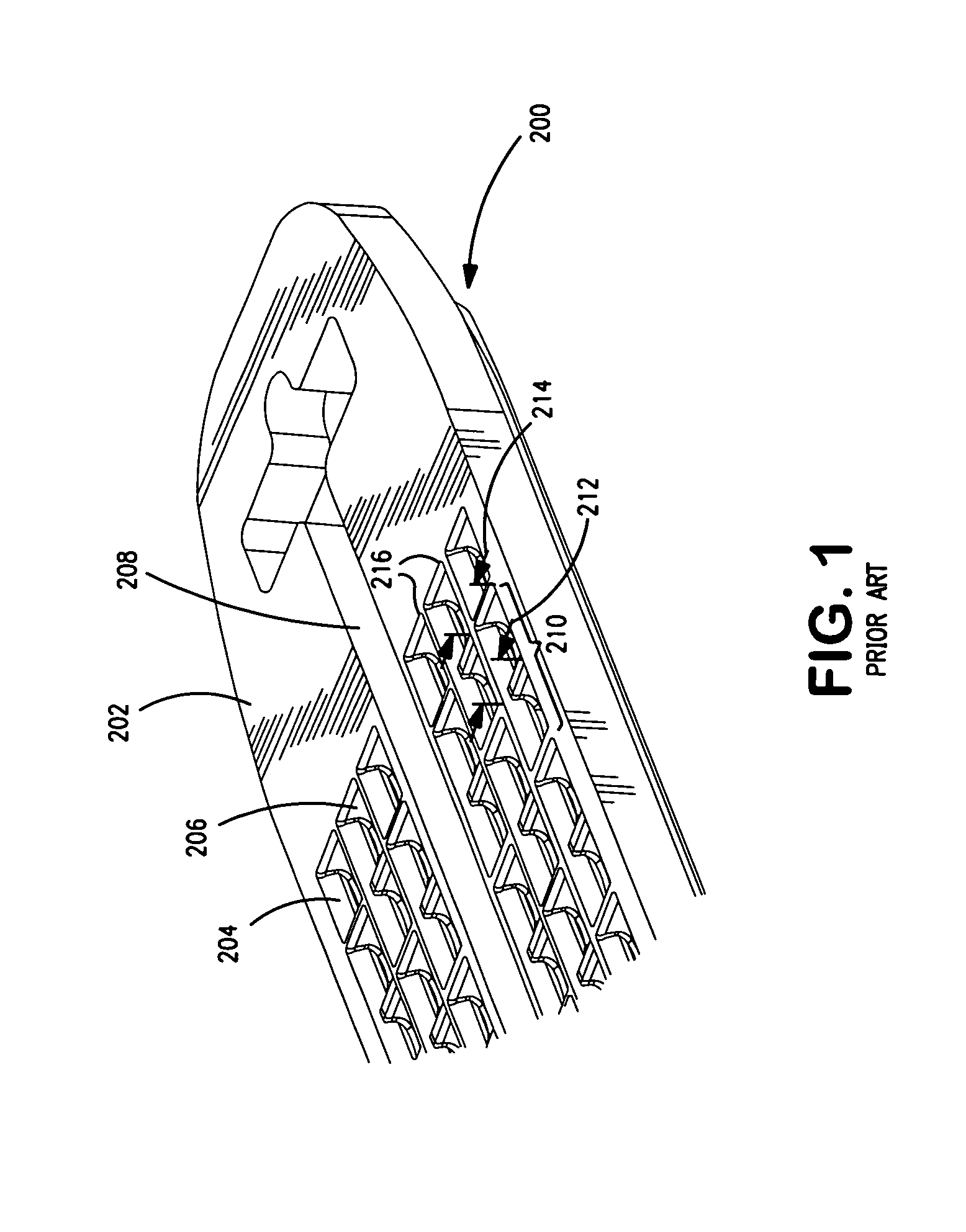

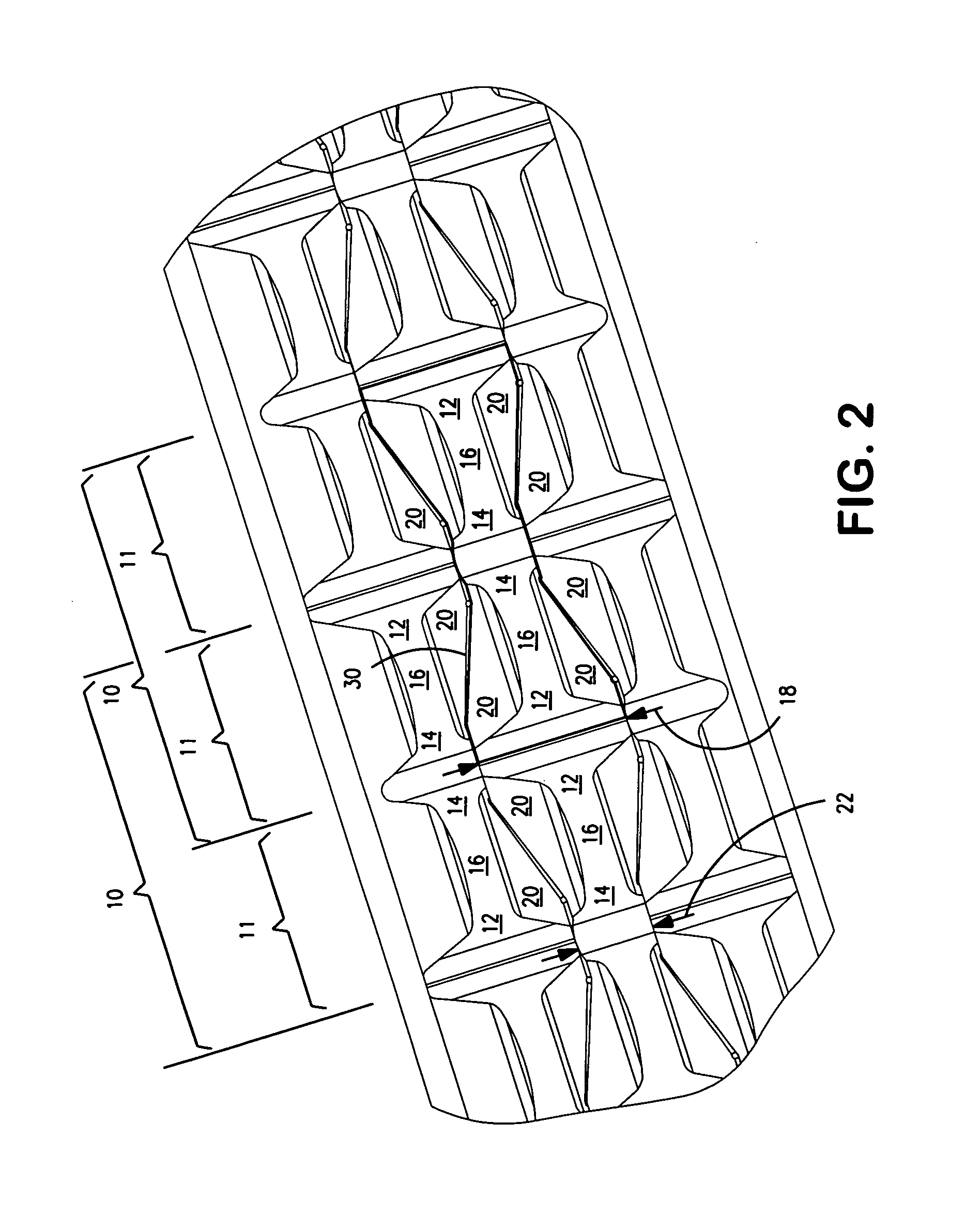

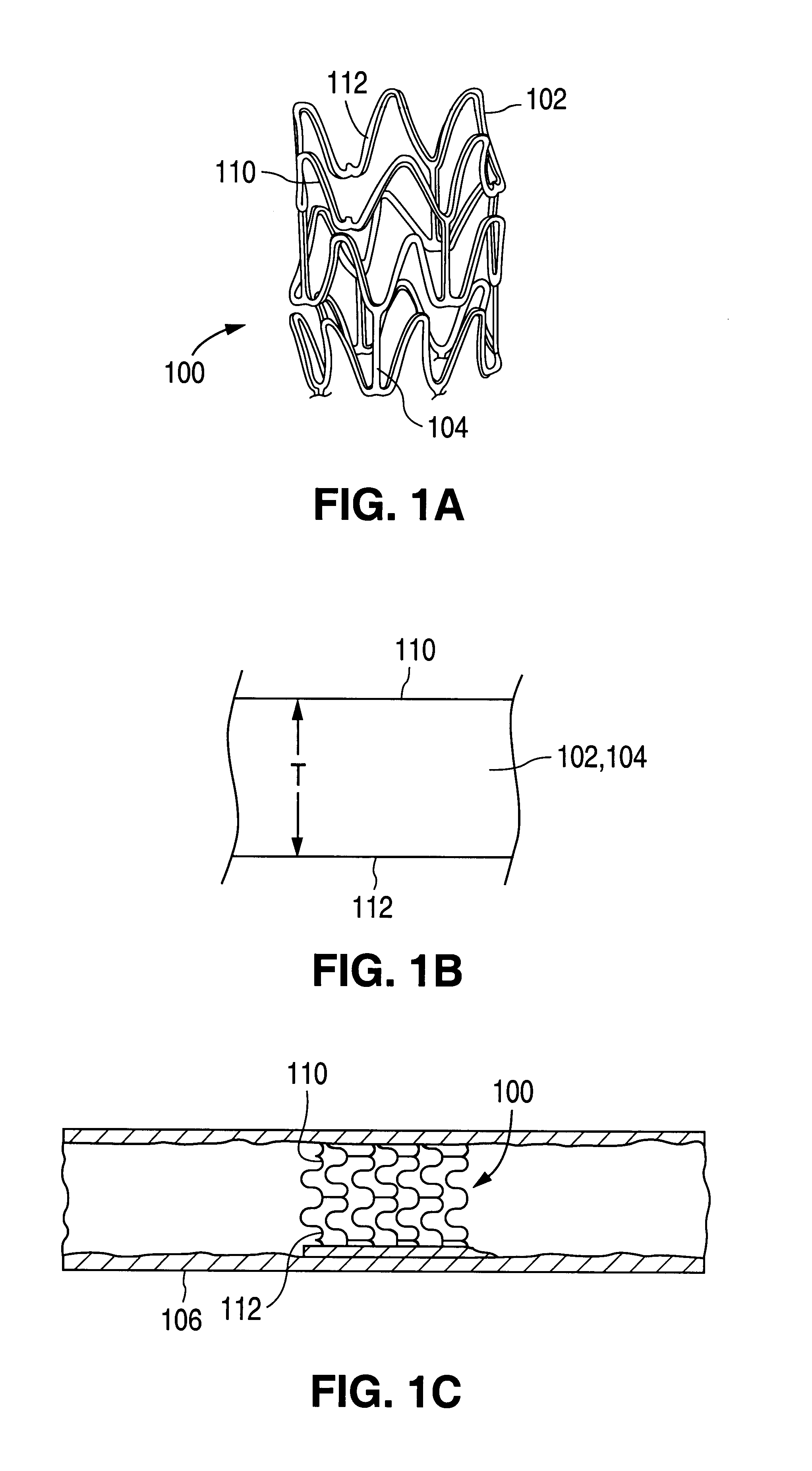

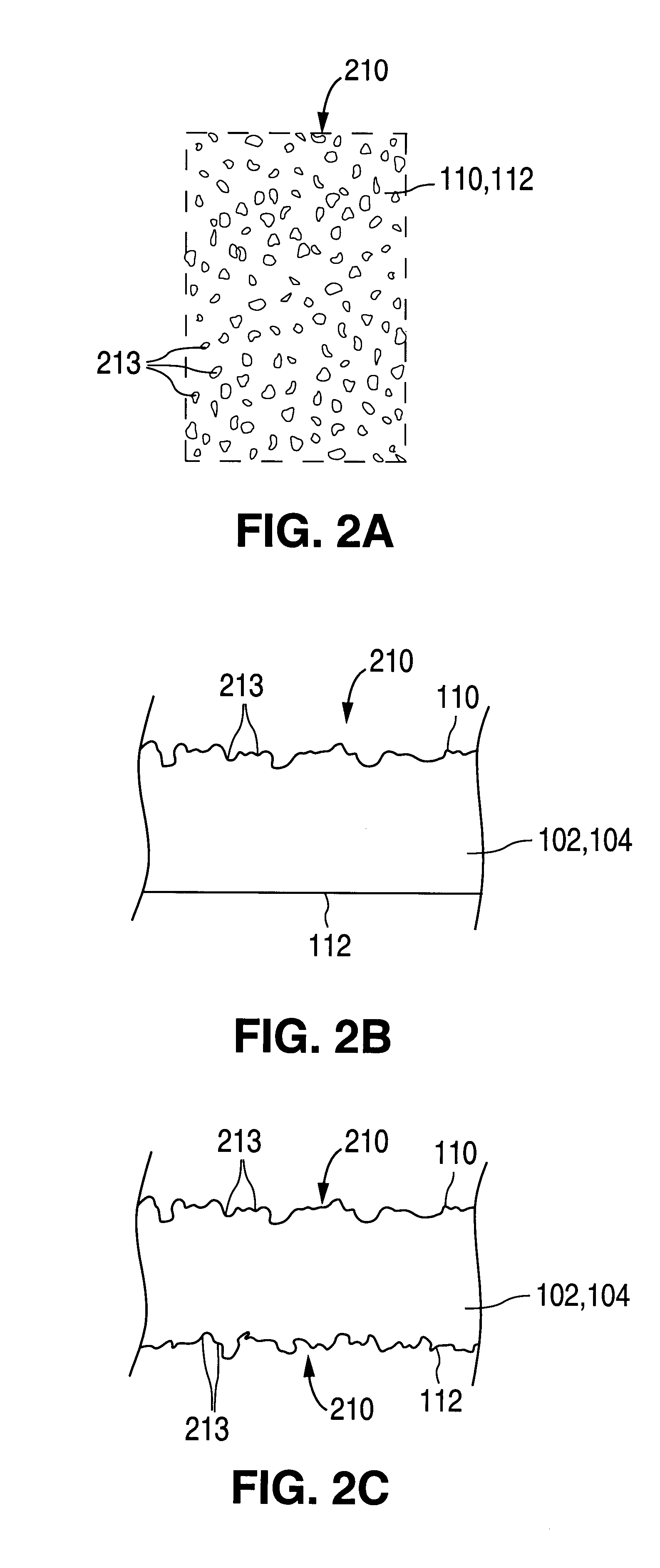

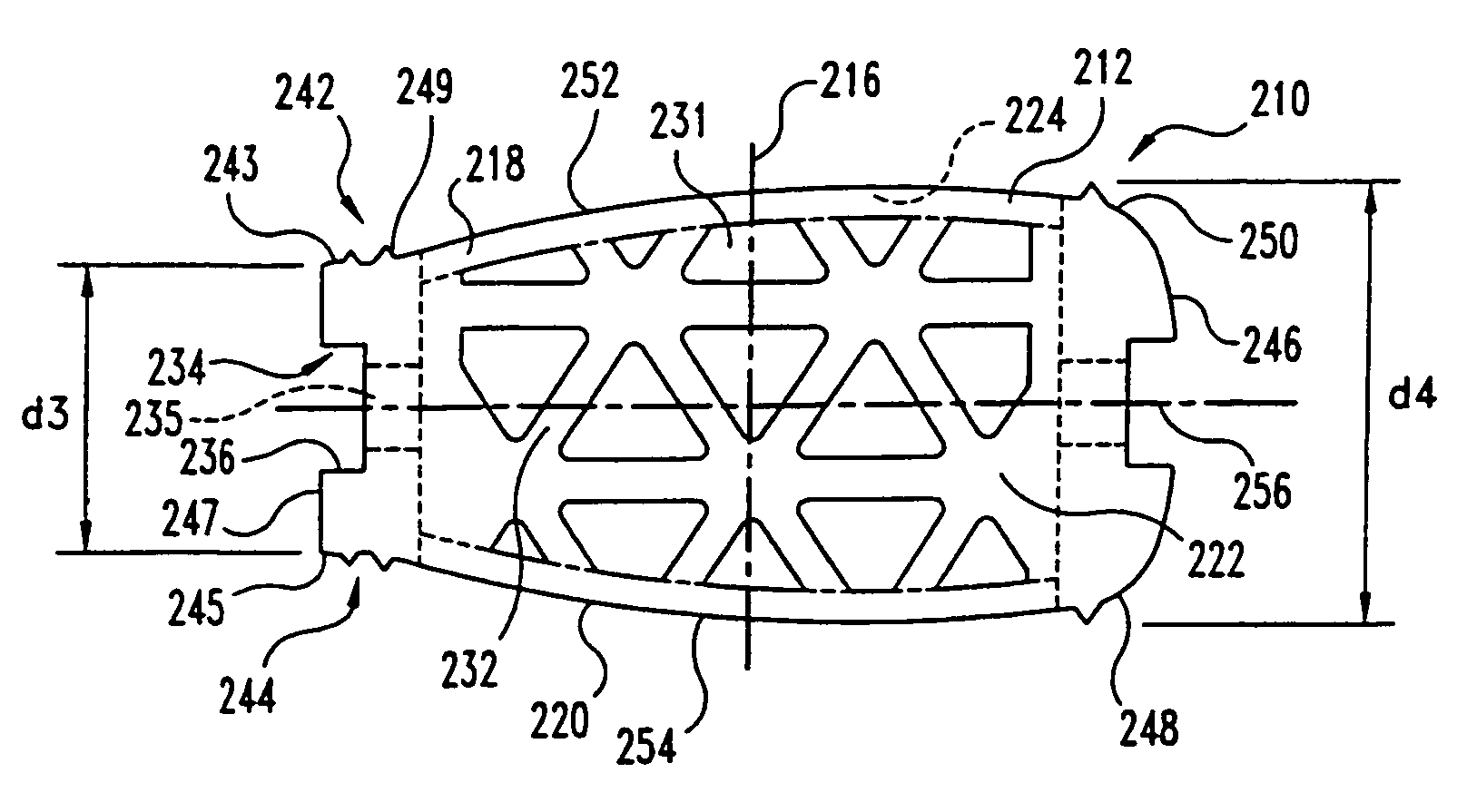

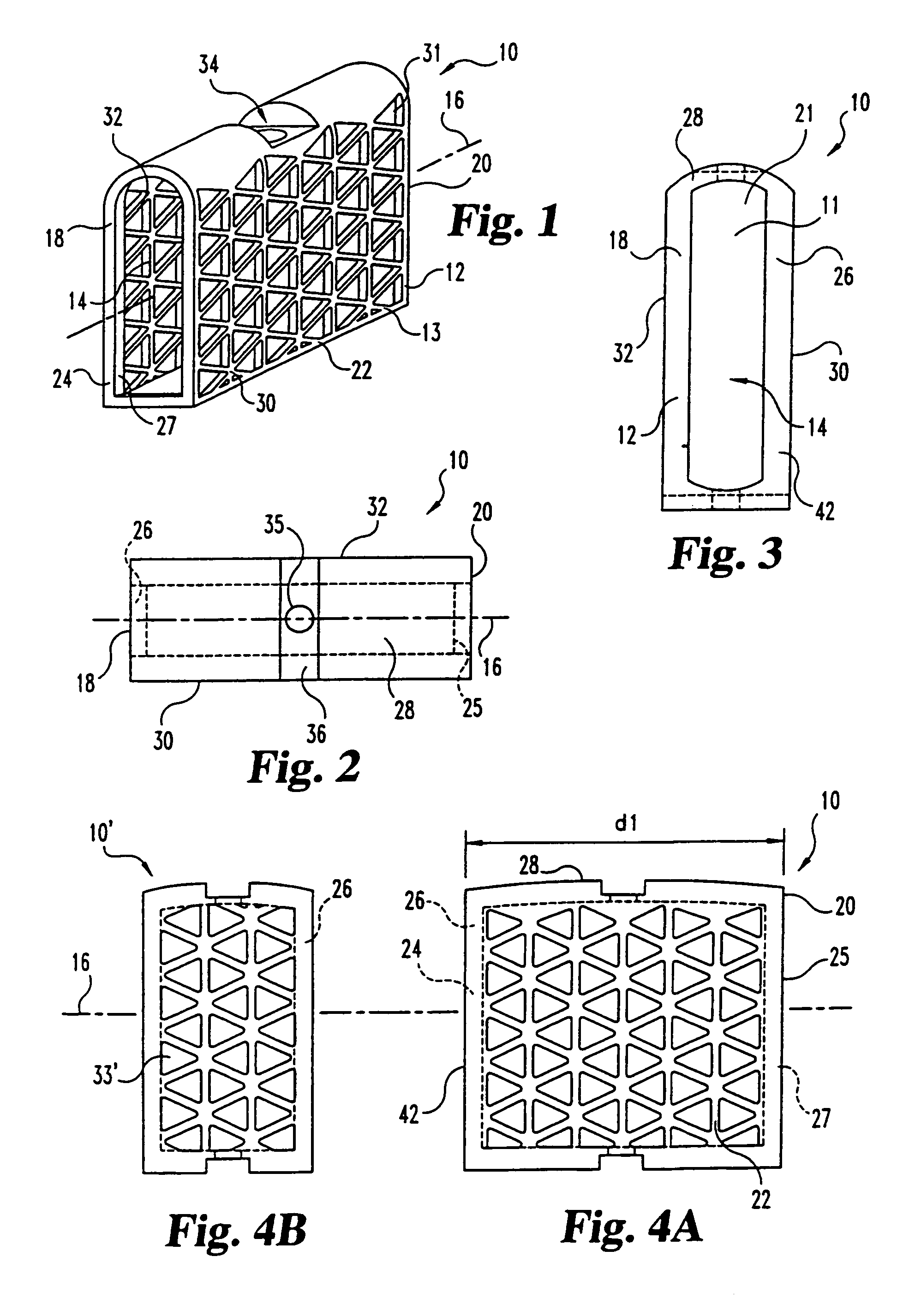

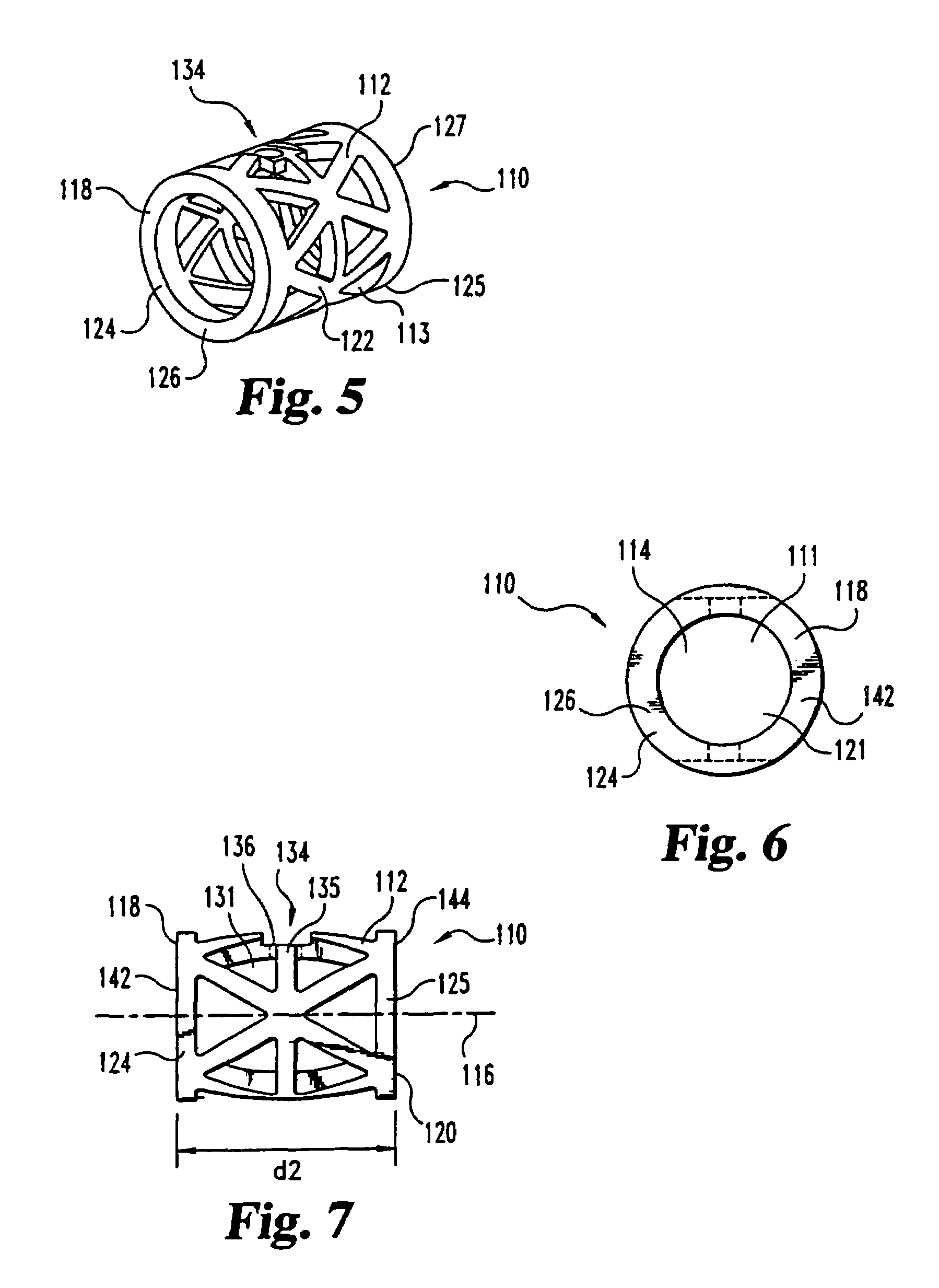

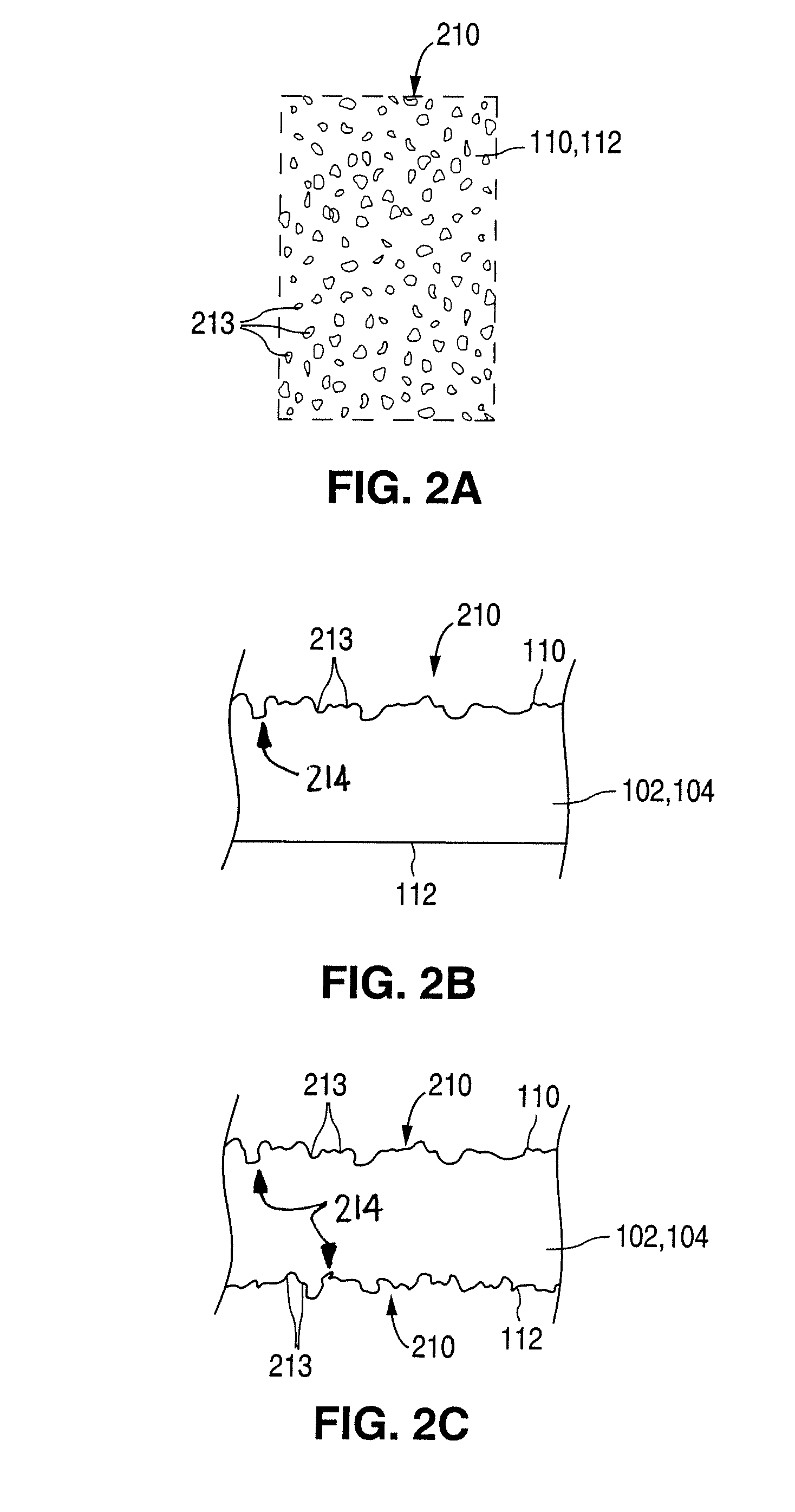

Impacted orthopedic bone support implant

InactiveUS7537616B1Promote bone growthProvide supportBone implantJoint implantsDiseaseBone structure

This invention relates to a porous bone implant (10, 110, and 210), a method of manufacturing the implant and a method of orthopedic treatment. The mesh implant can be manufactured using extrusion techniques and a variety of cutting and machining processes to provide the implant with the desired structural features and in the required dimensions to be matingly received within the bone defect or cavity. The implant can be used to strengthen bone structures and support bone tissue adjacent to a defect of cavity. Thus, the implant can be used to provide improved treatment of patients having bone defects or diseases with decreased postoperative pain and a shorter recovery time.

Owner:SDGI HLDG

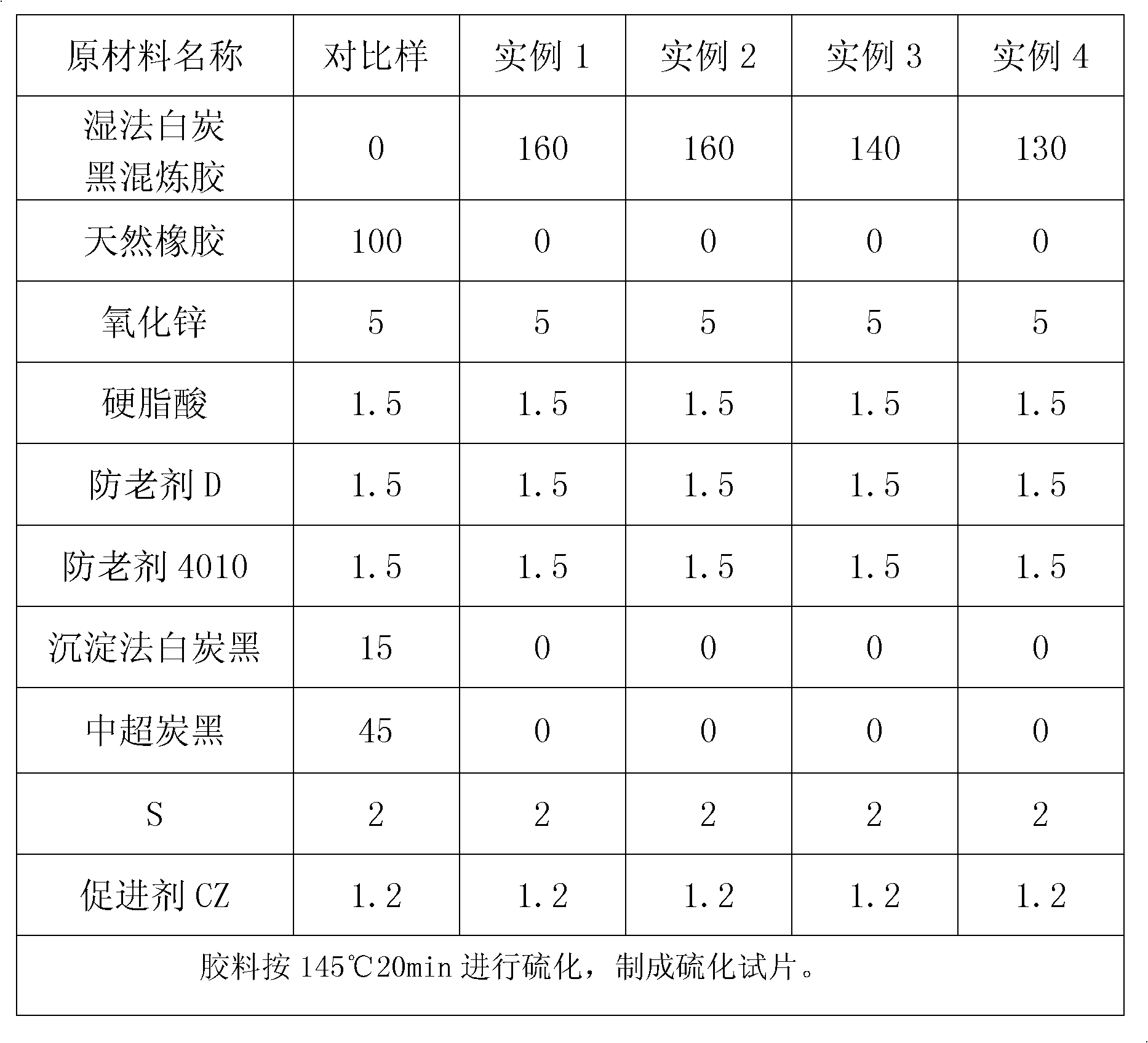

Preparation method of wet process mixed natural rubber material

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

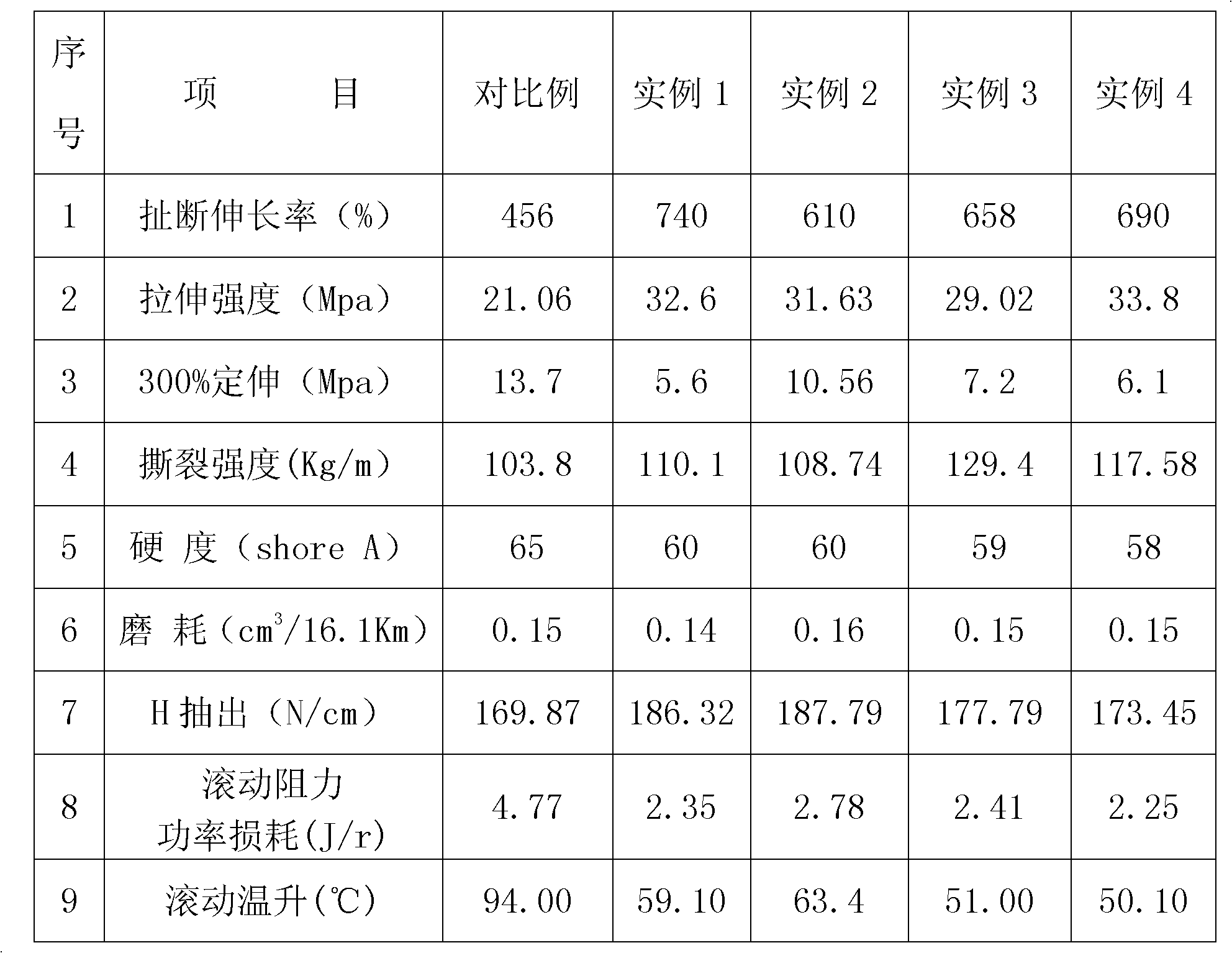

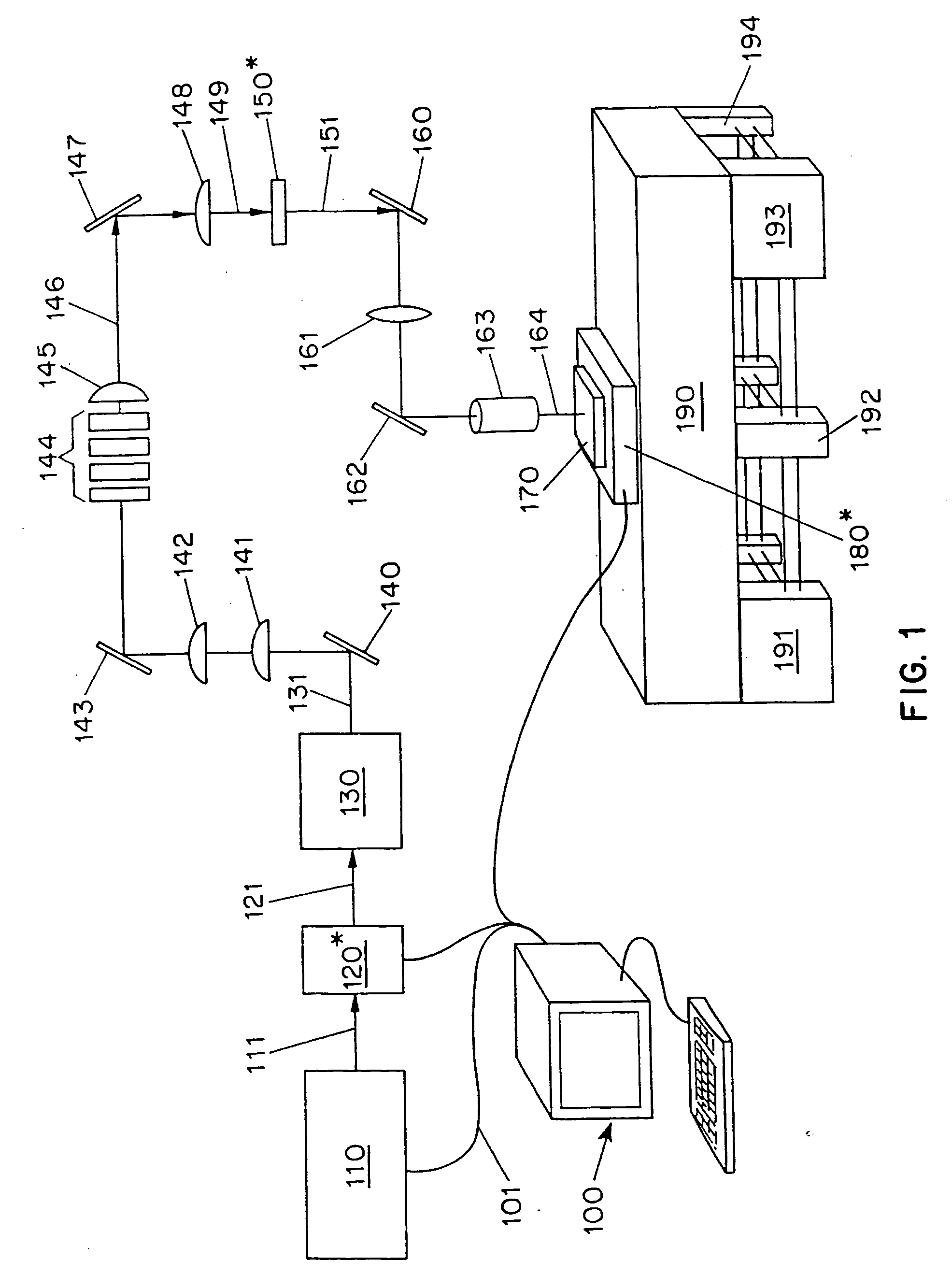

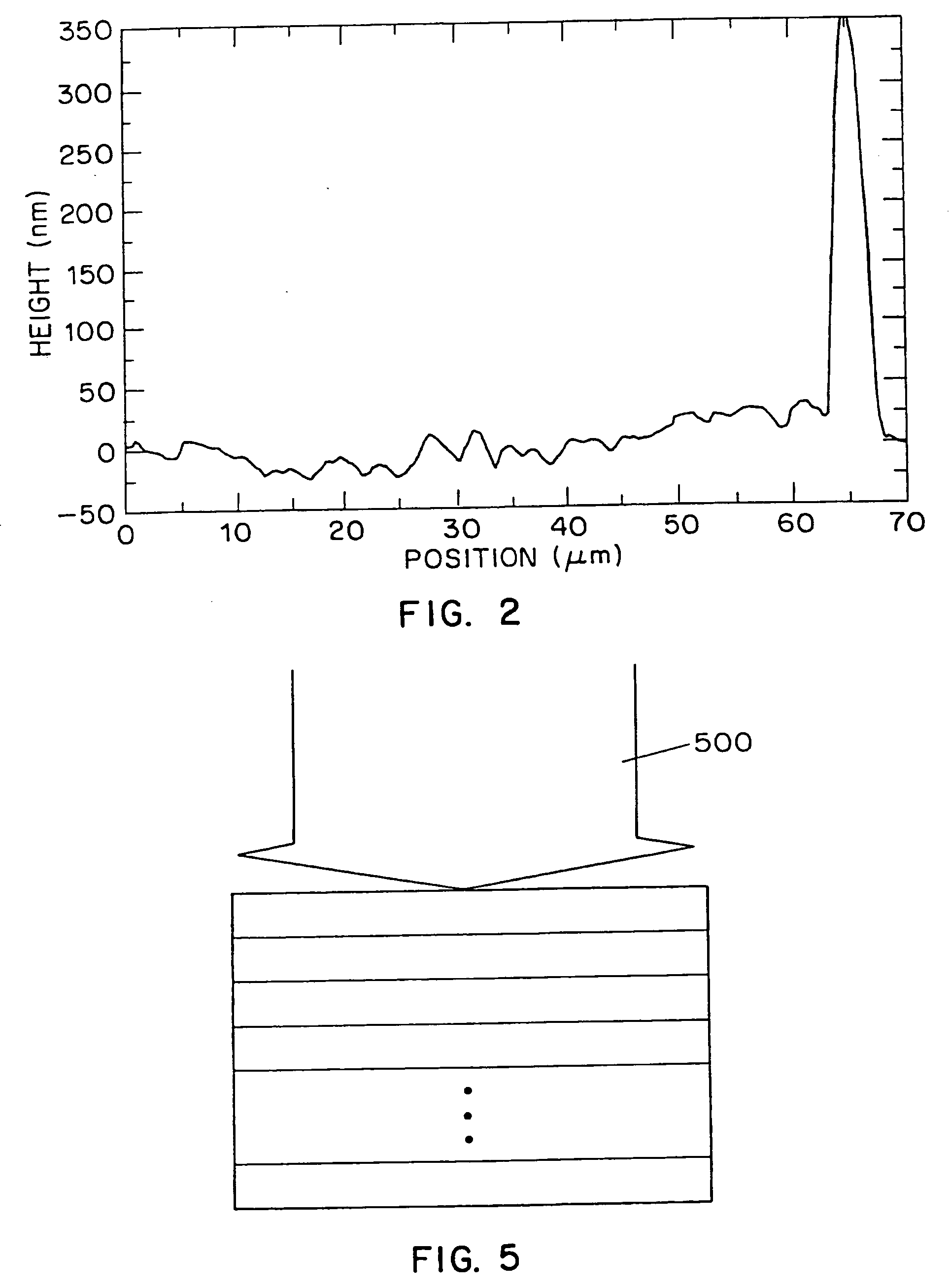

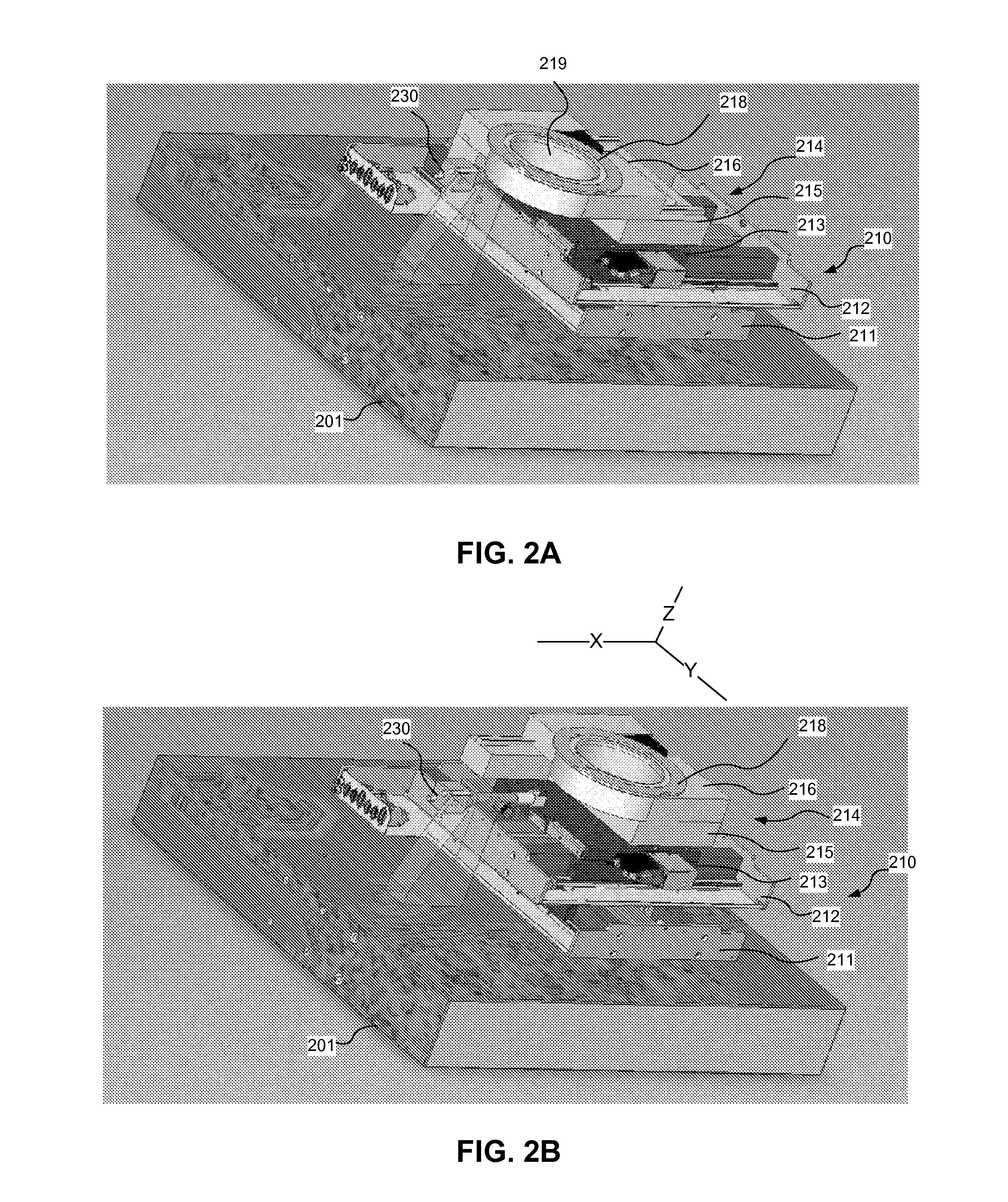

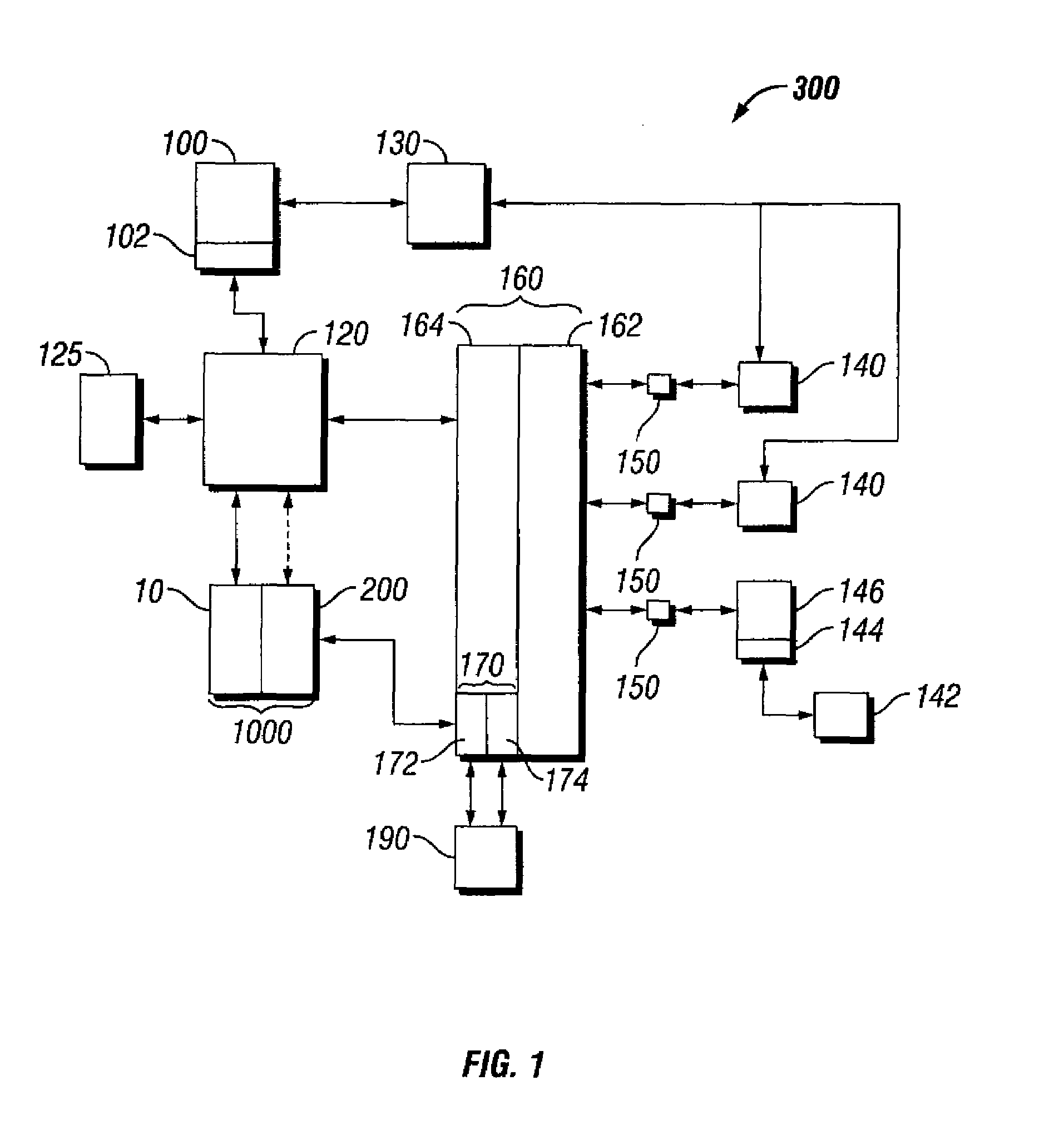

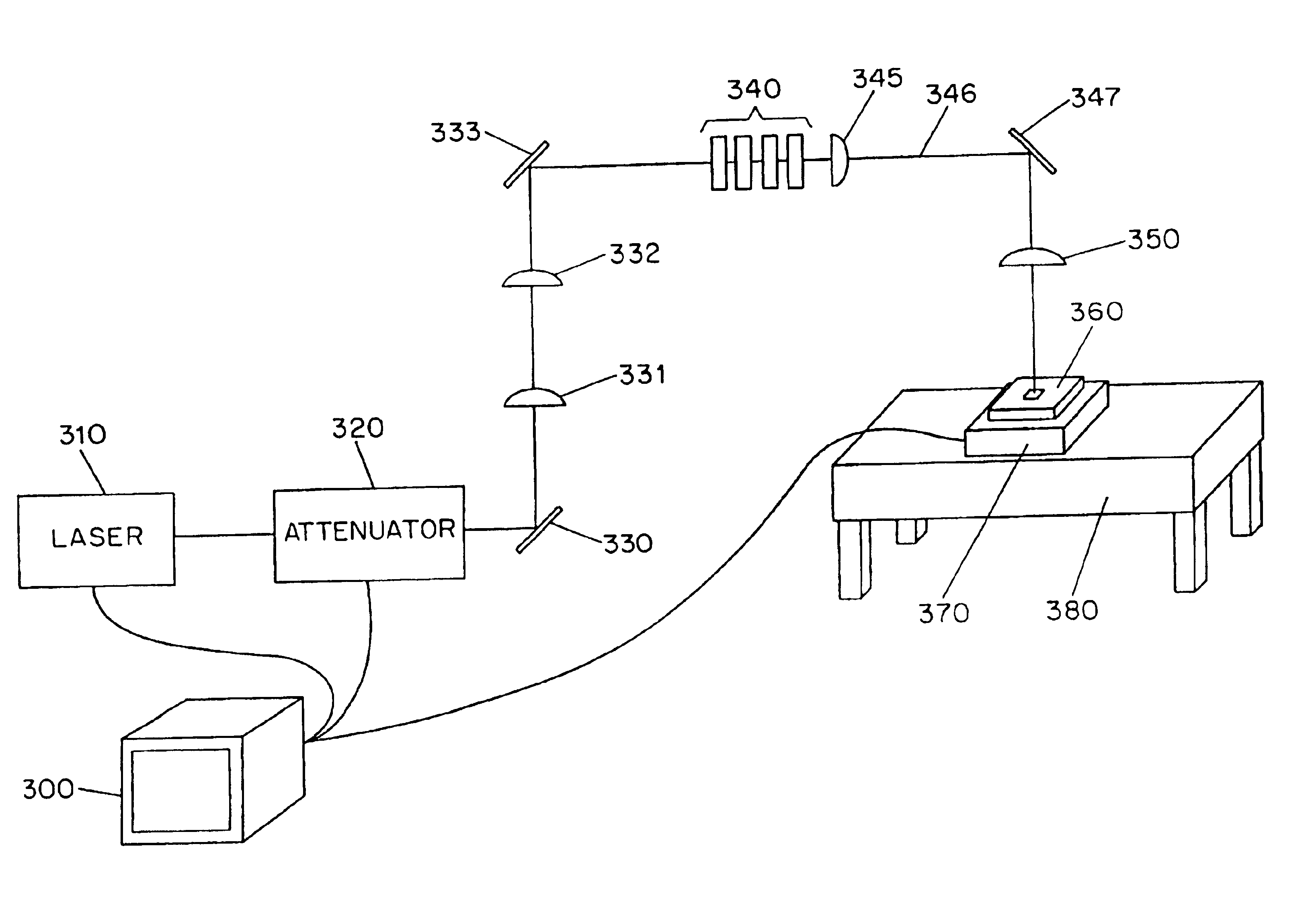

Surface planarization of thin silicon films during and after processing by the sequential lateral solidification method

InactiveUS20050032249A1Reduce surface roughnessAvoid insufficient thicknessSemiconductor/solid-state device manufacturingMetal working apparatusSurface roughnessLight beam

Systems and methods for reducing a surface roughness of a polycrystalline or single crystal thin film produced by the sequential lateral solidification process are disclosed. In one arrangement, the system includes an excimer laser (110) for generating a plurality of excimer laser pulses of a predetermined fluence, an energy density modulator (120) for controllably modulating the fluence of the excimer laser pulses such that the fluence is below that which is required to completely melt the thin film, a beam homoginizer (144) for homoginizing modulated laser pulses in a predetermined plane, a sample stage (170) for receiving homoginized laser pulses to effect melting of portions of the polycrystalline or single crystal thin film corresponding to the laser pulses, translating means for controllably translating a relative position of the sample stage (170) with respect to the laser pulses, and a computer (110) for coordinating the excimer pulse generation and fluence modulation with the relative positions of the sample stage (170) to thereby process the polycrystalline or single crystal thin film by sequential translation of the sample stage (170) relative to the laser pulses.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

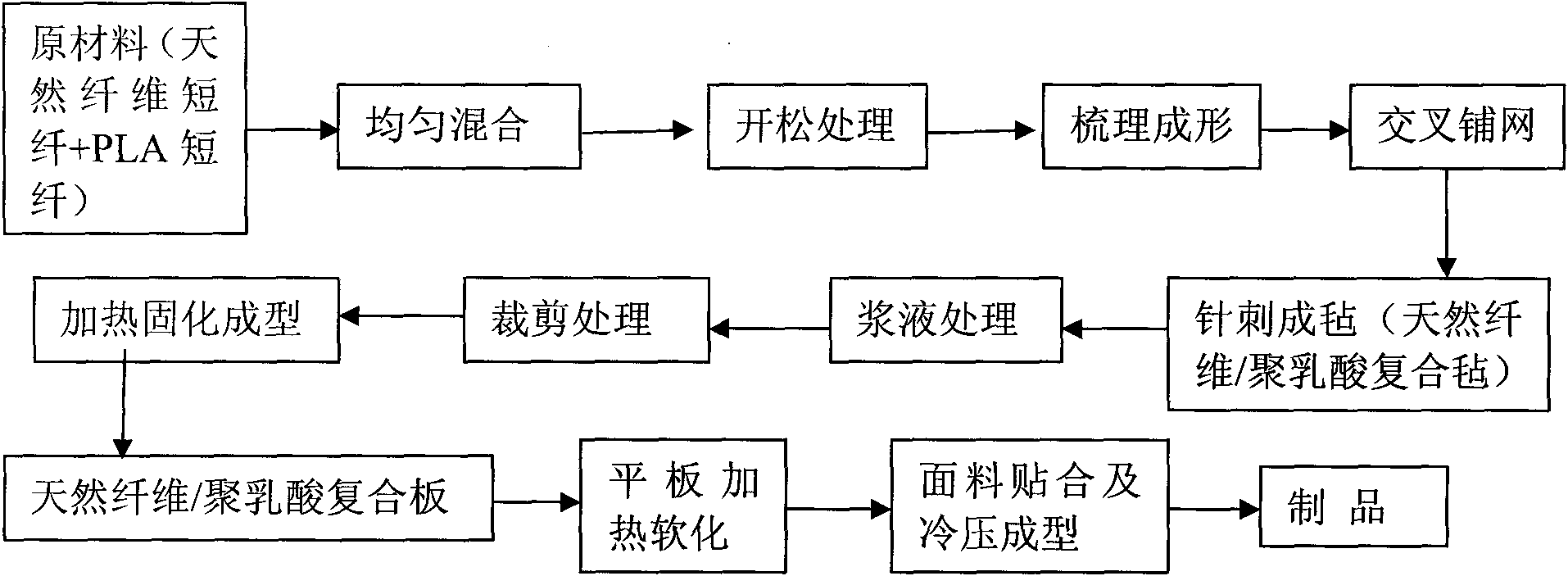

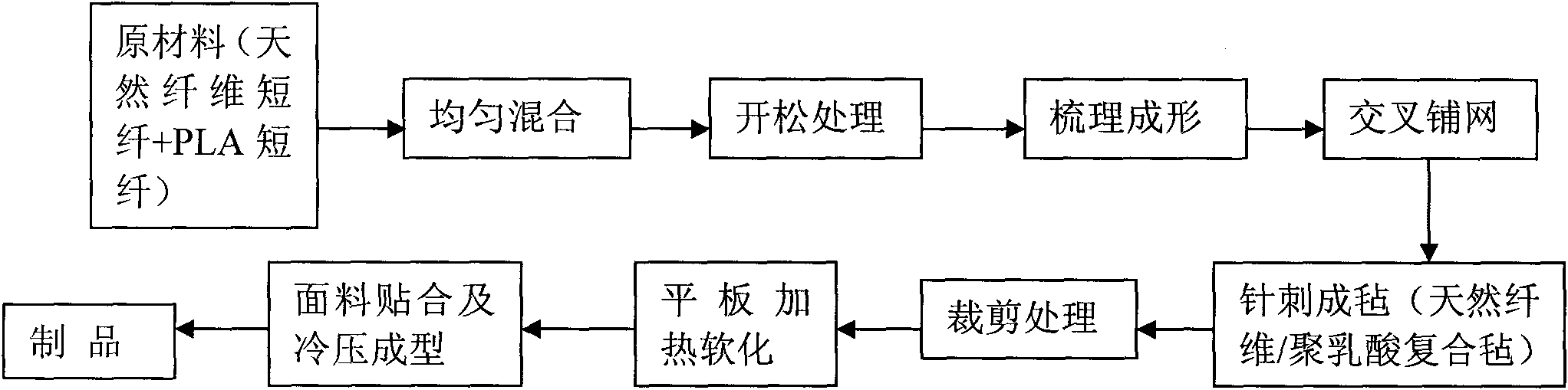

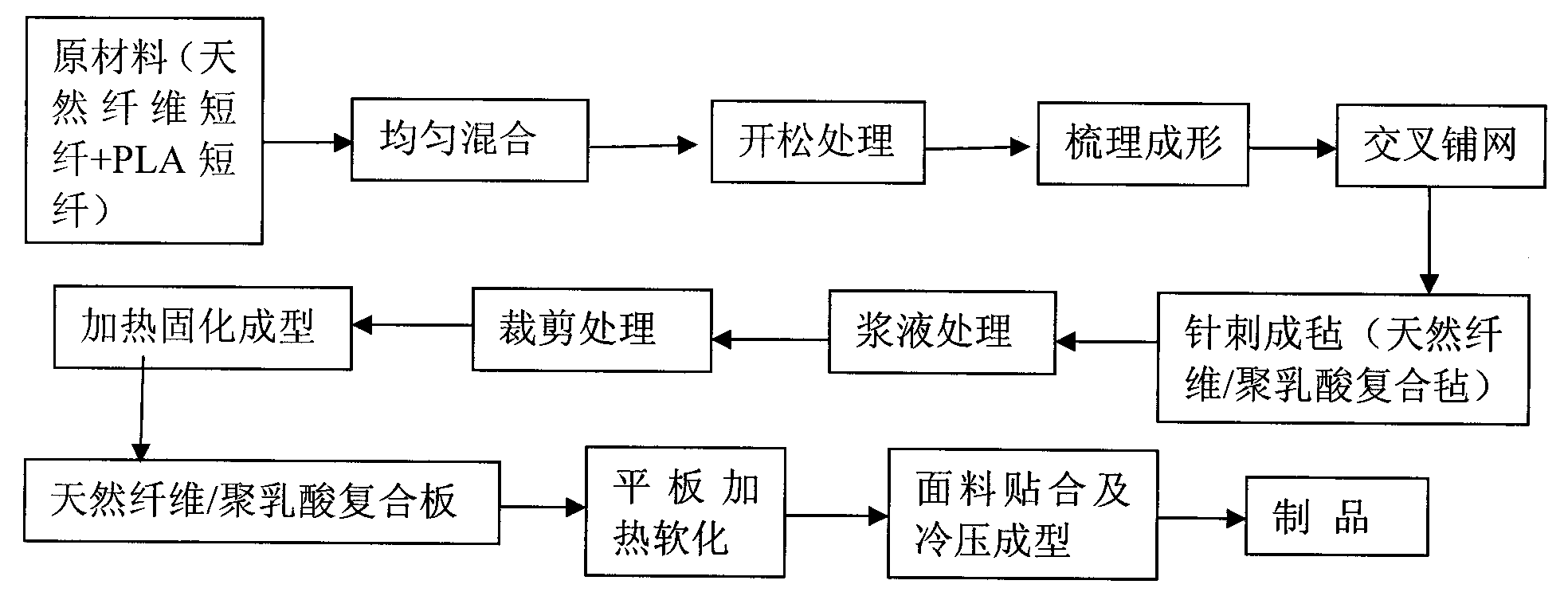

Composite material for automobile interior part and production method thereof

ActiveCN101812773ANo pollution in the processReduce lossVehicle componentsNon-woven fabricsMetallurgySlurry

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

Heat conductive insulation material and preparation method thereof

InactiveCN101899209AExcellent formabilityImprove insulation performanceLiquid crystal compositionsPlastic/resin/waxes insulatorsFiberMetallurgy

The invention discloses a heat conductive insulation material and a preparation method thereof. The heat conductive insulation material comprises the following components in percentage by weight: 15 to 50 percent of plastic substrate, 15 to 45 percent of heat conductive insulation filler A, 5 to 15 percent of heat conductive filler B, 10 to 30 percent of mineral fiber C, 0 to 2 percent of coupling agent and 0 to 2 percent of lubricant. The heat conductive insulation material has the advantages of perfect forming processing performance, high heat conductivity, higher uniformity and a small amount of gas content during processing; heat conductive fillers with different length-diameter ratios are combined, fillers with a large length-diameter ratio are arranged in melt flowing direction, and fillers with a small length-diameter ratio fill gaps left when the fillers with the large length-diameter ratio are arranged, so that the number of interfaces among filler components is greatly reduced, a conduction network is formed more easily, and heat conductivity is remarkably increased; moreover, the mineral fiber is added during the second machining process, so that the loss of material performance can be compensated due to the addition of high-powder fillers, and performance is better.

Owner:KINGFA SCI & TECH CO LTD +1

Method and system for creating a textured surface on an implantable medical device

InactiveUS7537610B2Convenient amountEasy to keepPharmaceutical containersPretreated surfacesElectricityElectric discharge

A method for forming an implantable medical device, such as a stent, is provided, in which electric discharges are applied to a metal surface of the implantable medical device. The electric discharges pit the surface. The pitted surface improves retention of a coating on the device and increases the amount of coating that can be carried by the device. An electric discharge machining process is described for applying electric discharges to the surface of the implantable medical device or portion thereof.

Owner:ABBOTT CARDIOVASCULAR

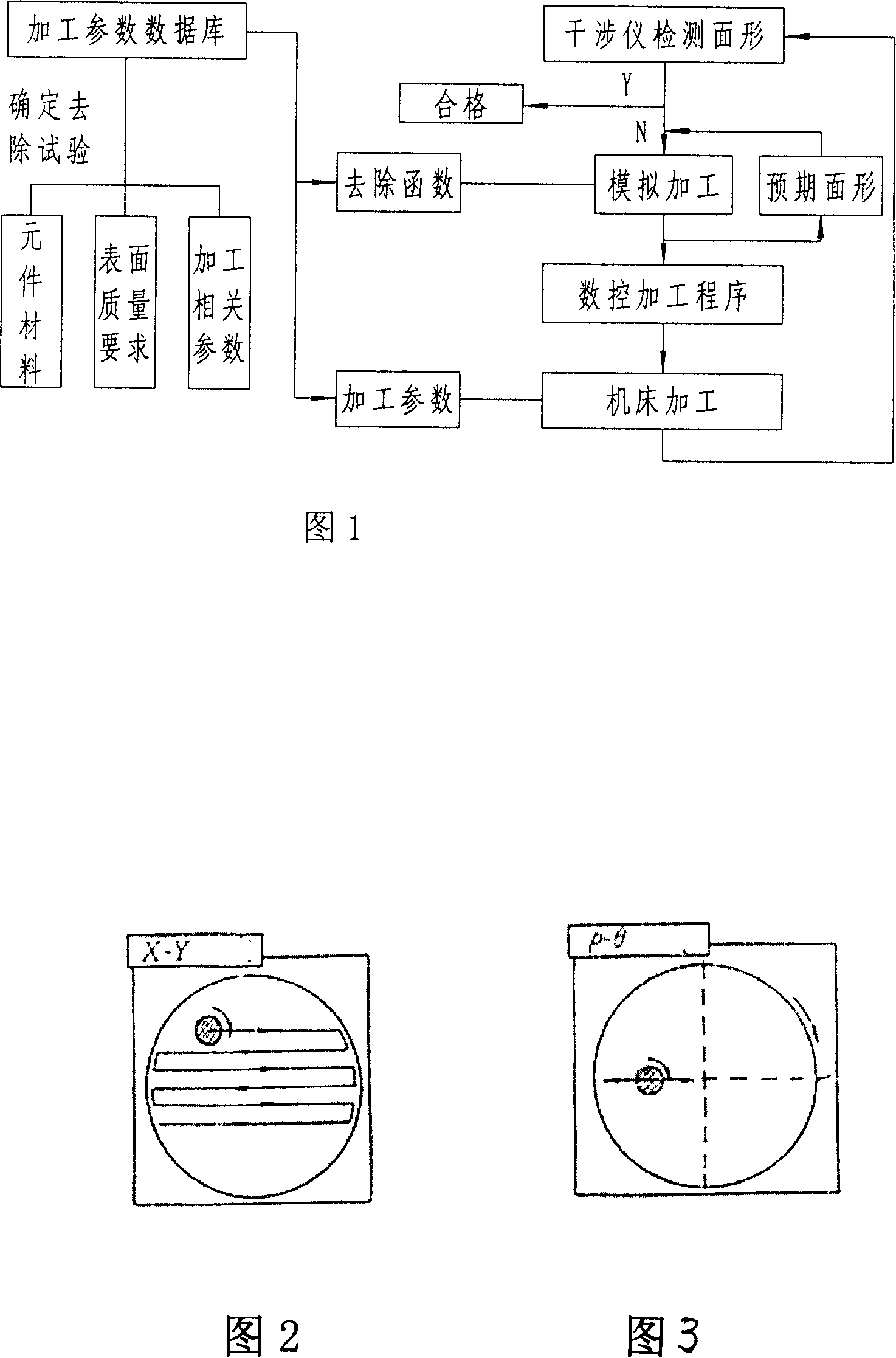

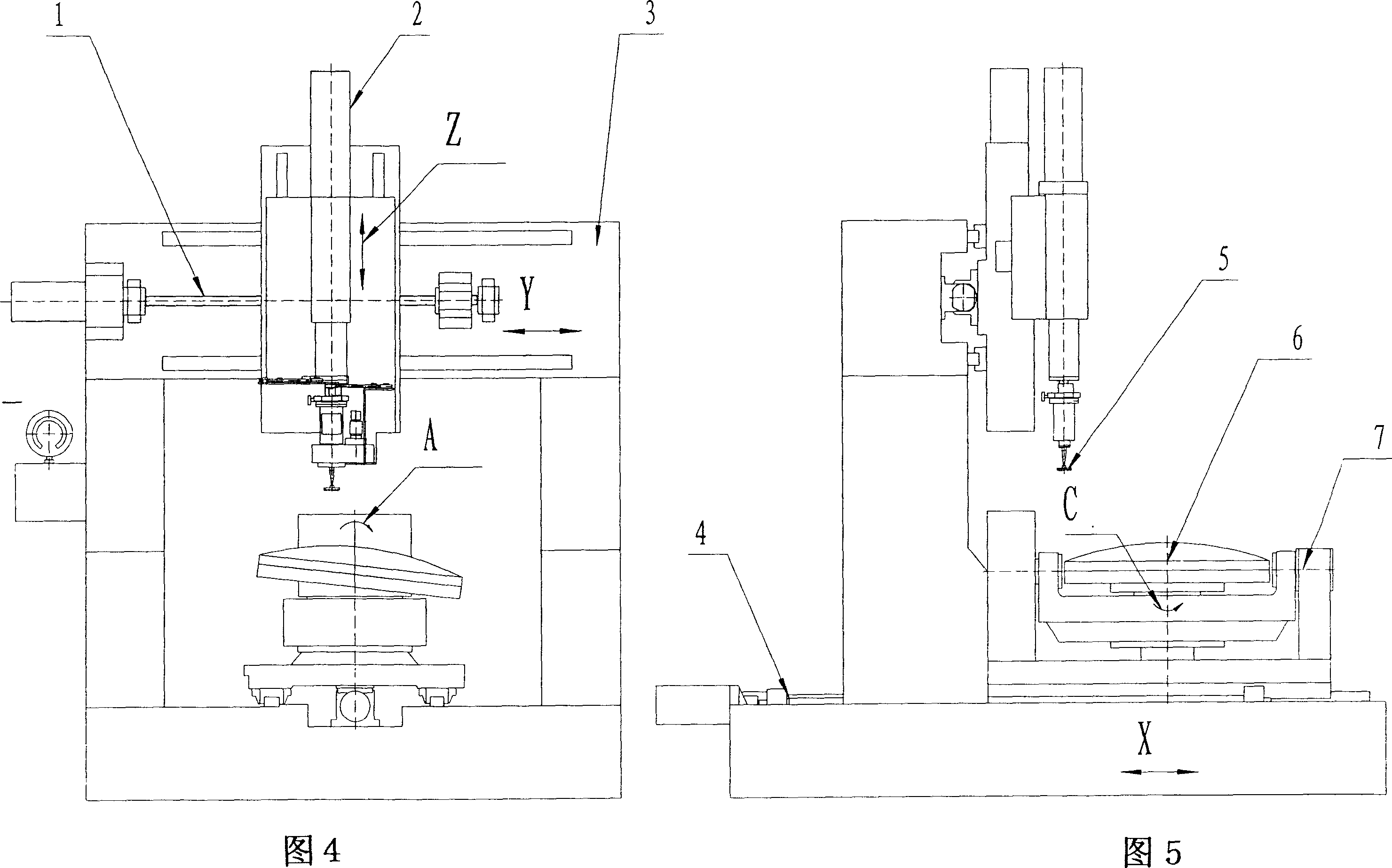

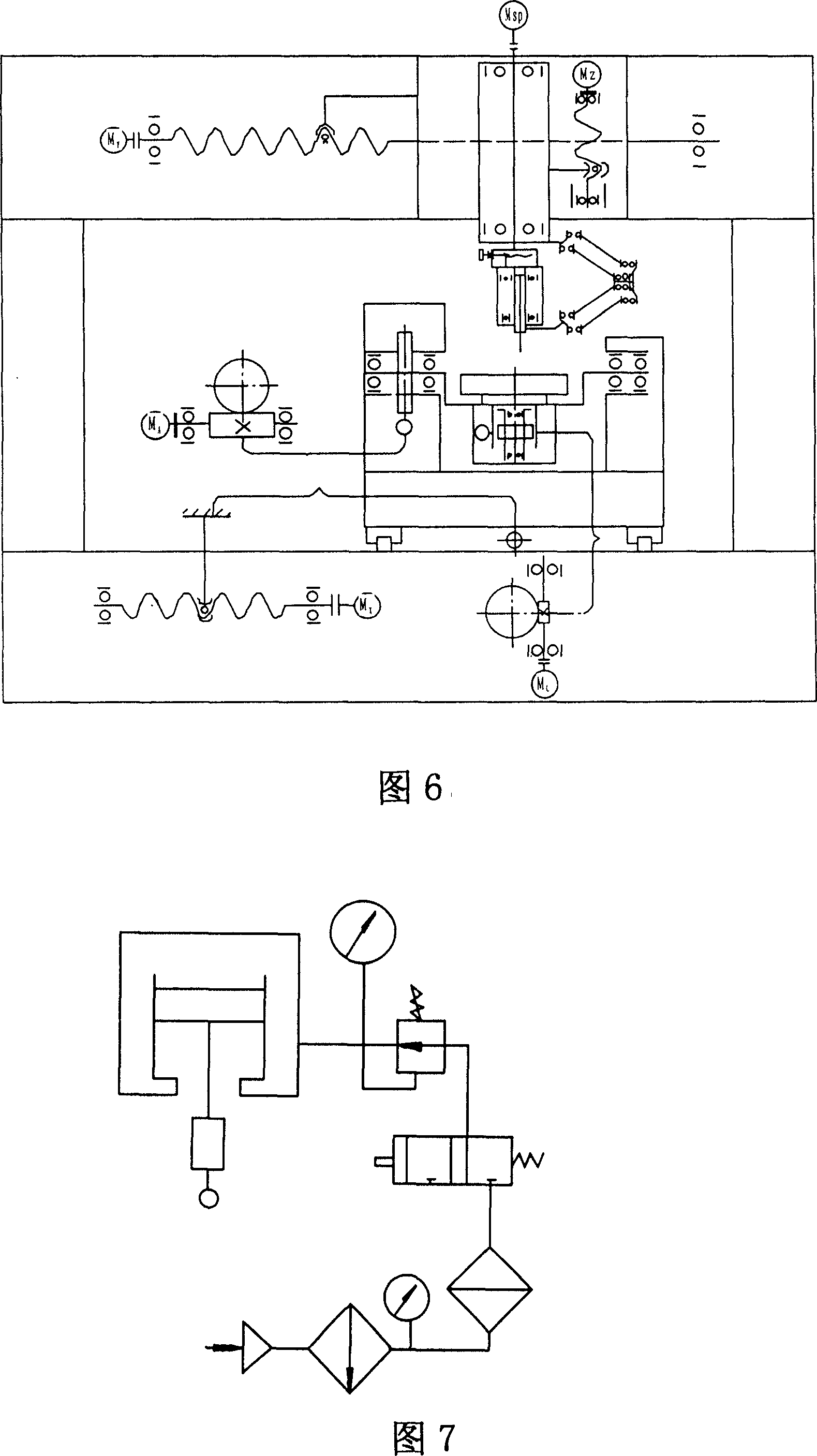

Efficient numerically controlled polishing process and apparatus for great aperture aspherical optical elements

InactiveCN101088705AReduce dependenceImprove efficiencyOptical surface grinding machinesOptical surfaceMachining process

The efficient numerically controlled polishing process and apparatus for great aperture aspherical optical elements belongs to the field of precise optical machine technology. The polishing process includes: constituting polishing process model based on the profile data obtained through measurement with interferometer or other instrument, determining the machining path, speed, pressure and other parameters of the element under the control of computer to perform simulating machining, verifying the technological parameters based on the simulating machining results and determining the ultimate technological parameters, creating NC program and machining. The present invention has high machining efficiency and high machining precision.

Owner:CHANGCHUN EQUIP TECH RES INST

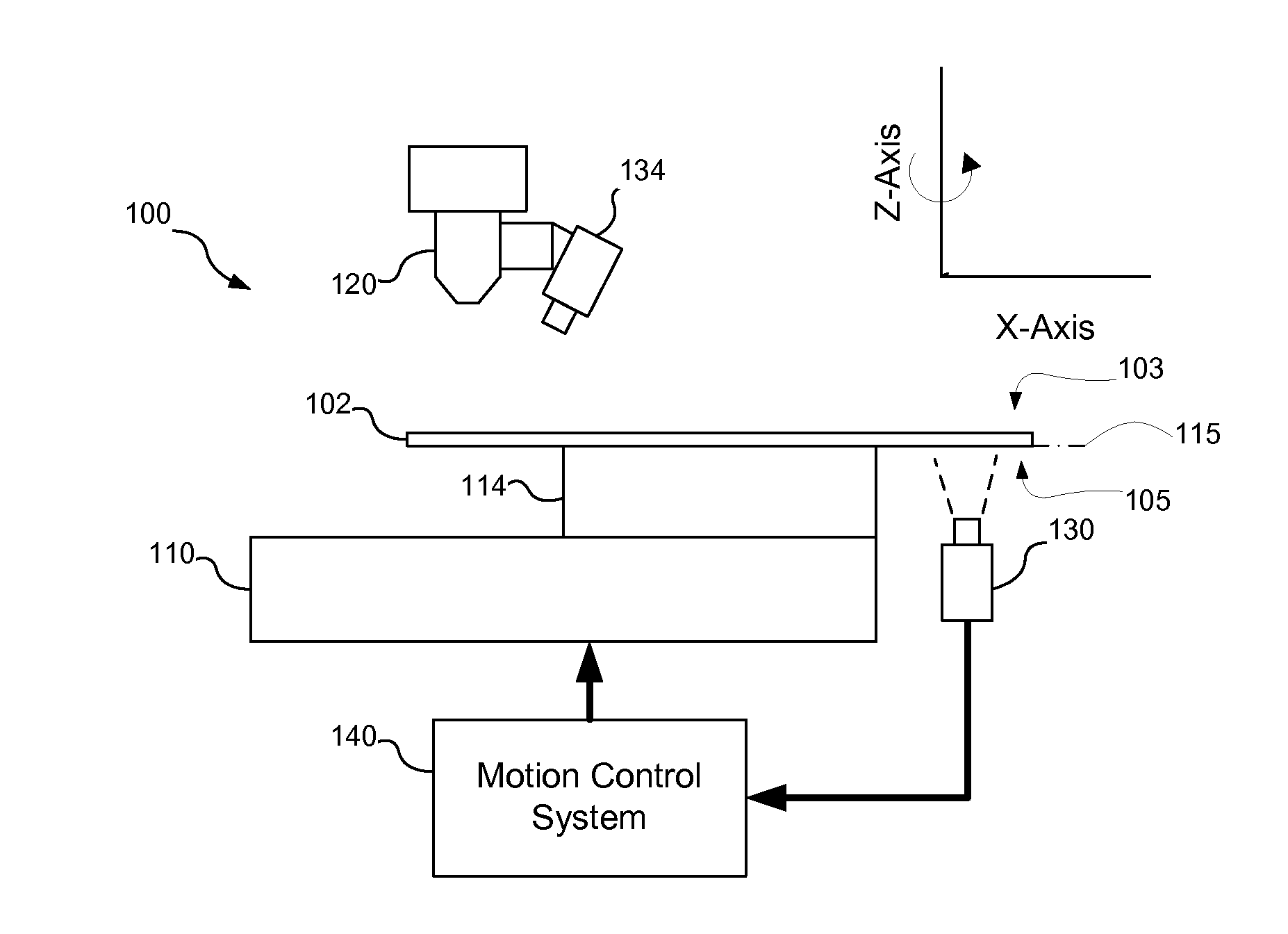

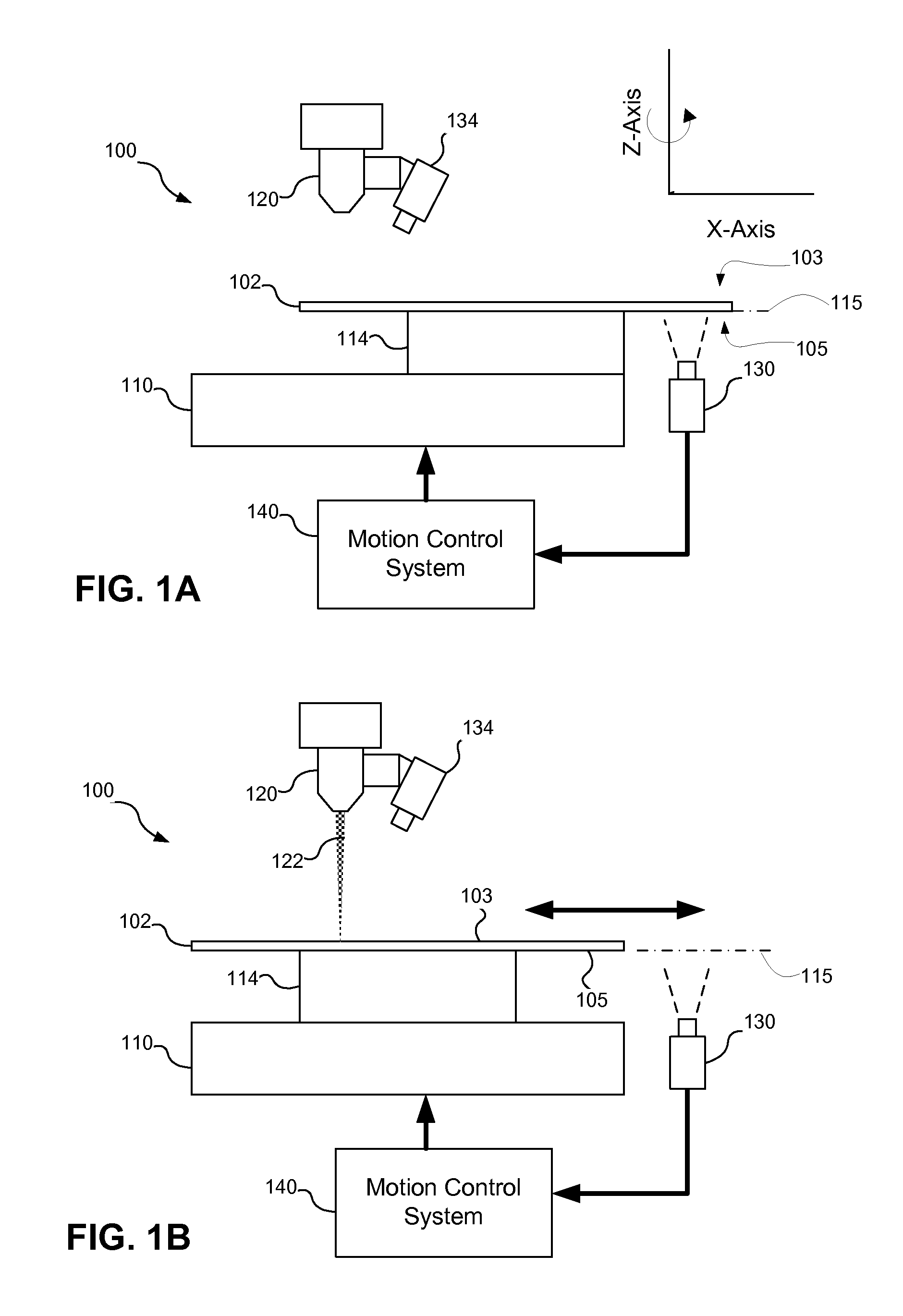

Laser machining and scribing systems and methods

InactiveUS20110132885A1Welding/soldering/cutting articlesMetal working apparatusAir bearingLight beam

A laser machining system may include an opposite side camera to provide workpiece alignment from an opposite side of the system (i.e., the side opposite the laser machining process). The opposite side camera may be used with an air bearing positioning stage, and a portion of the stage and / or the opposite side camera may be moved to allow the opposite side camera to image a feature on the workpiece to be aligned. The opposite side alignment may be used with back side scribing and / or dual side scribing of a workpiece with alignment from one or both sides of the workpiece. Laser machining systems and methods may also be used to provide quasi-stealth scribing and multi-beam scribing.

Owner:IPG PHOTONICS CORP

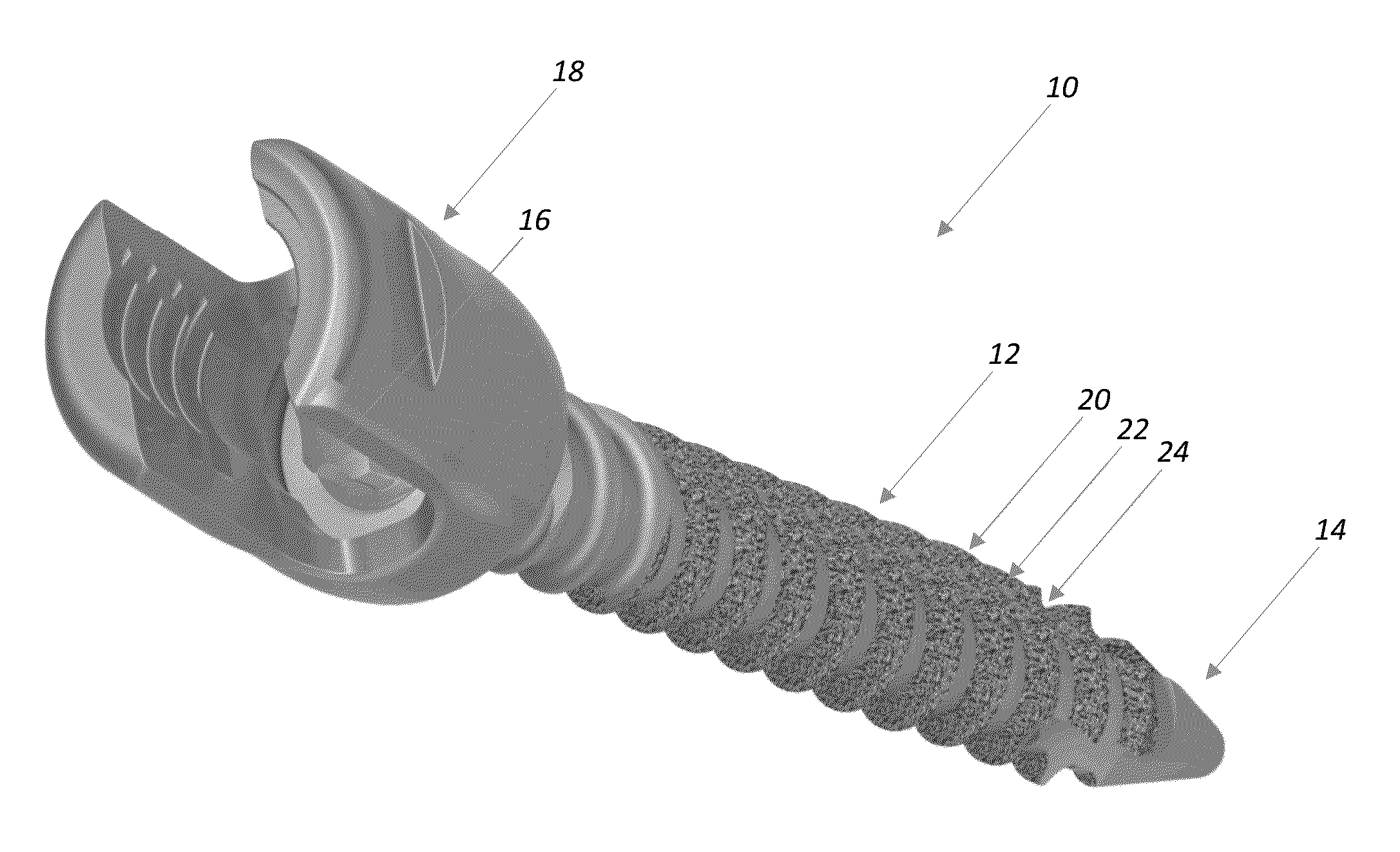

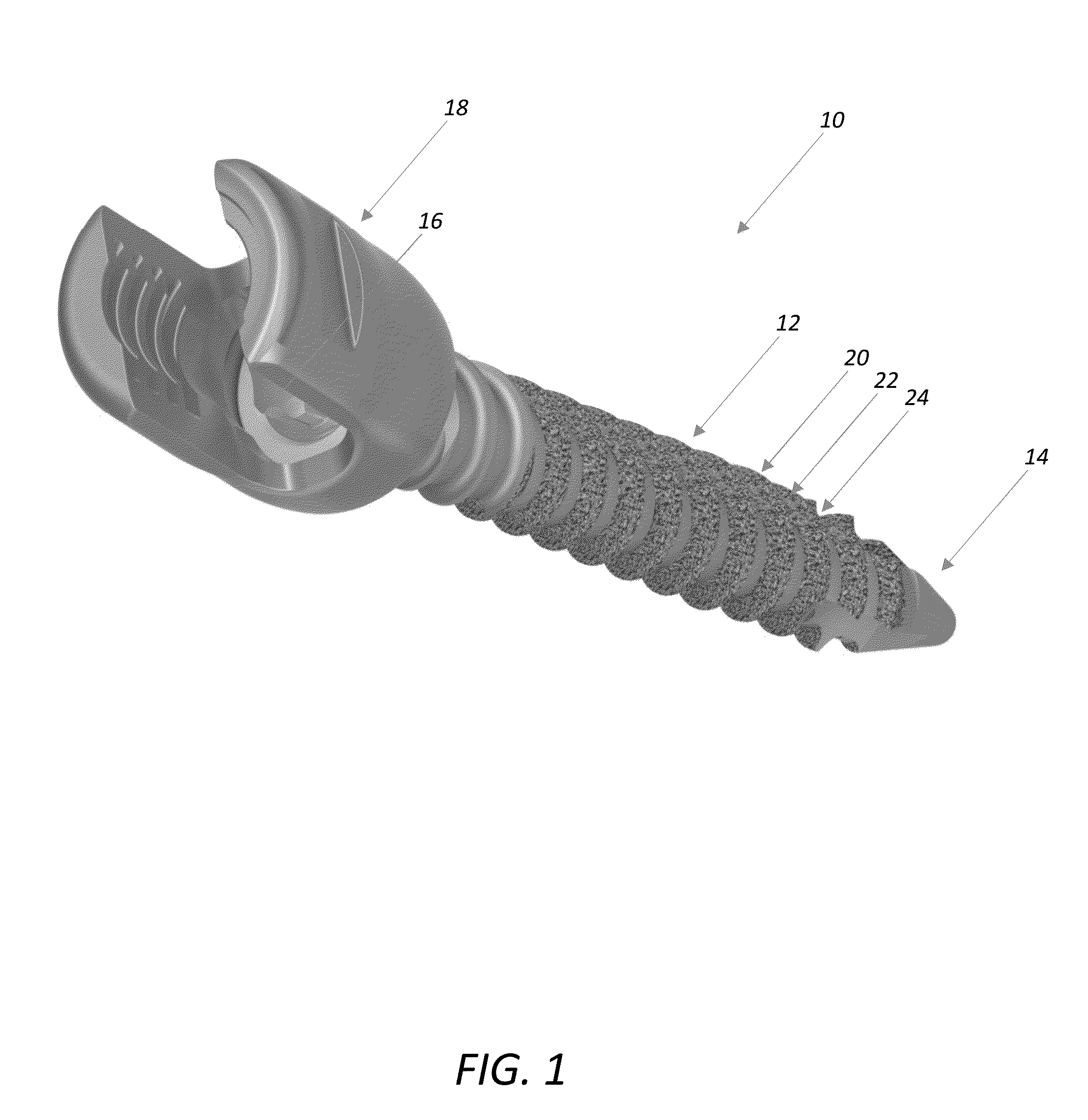

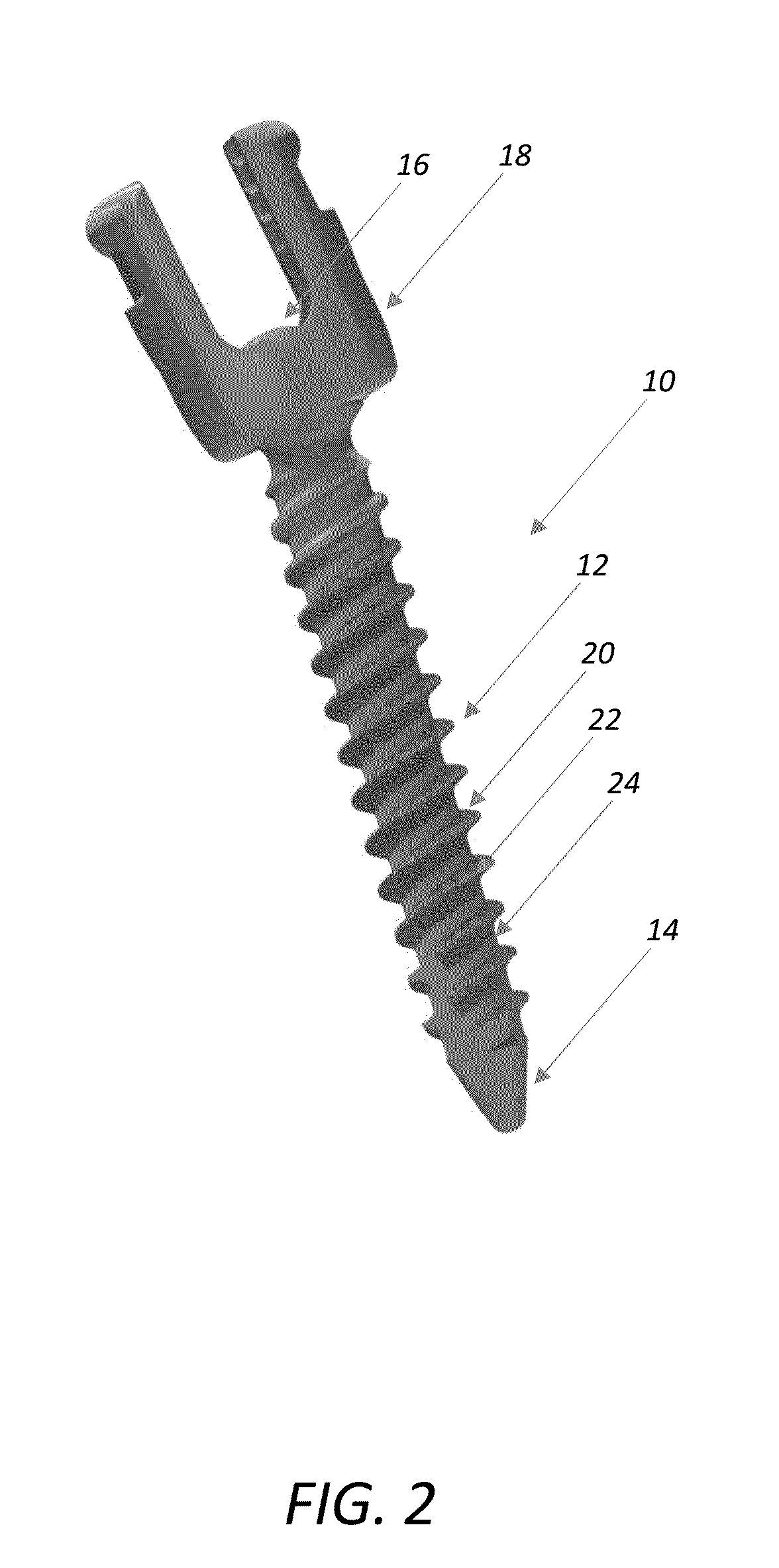

Bone screw incorporating a porous surface formed by an additive manufacturing process

ActiveUS20160157908A1Enhancing bony fixationEnhancing ingrowthSuture equipmentsAdditive manufacturing apparatusMachining processIliac screw

The present invention provides a bone screw or bone anchor, such as a threaded pedicle screw or the like, incorporating a porous surface for enhancing bony fixation, ingrowth, and purchase when implanted in bone. Preferably, this porous surface covers at least a portion of the threads of the bone screw or bone anchor. The porous surface is formed by a conventional or novel additive manufacturing process, such as three-dimensional (3D) printing or the like, optionally as well as a prior and / or subsequent machining process. The porous surface may include novel needle-like protrusions and / or lattice structures, and / or any other protruding / depressed features, whether regular or irregular.

Owner:KYOCERA MEDICAL TECH INC

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

Integrated security framework and privacy database scheme

ActiveUS7263717B1Data processing applicationsDigital data processing detailsIp addressSecurity framework

A system and method for bridging requests for access to resources between requestors in a distributed network and an authenticator servicing the distributed network is provided. The bridging mechanism has security features including a naming service for machine authentication and machine process rules to authorize what process machines can perform. The security proxy bridge intercepts an access request, and checks the IP address for machine authentication as well as the machine process rules and if both verifications are successful, the bridge then forwards the request for access to the authenticator. The security proxy framework utilizes a data structure that provides a method for storing selected security information stored as data records supporting an authentication and authorization system for users to access resources on multiple components of a distributed network supporting multiple business units of an enterprise. Primary authentication information stored herein includes general user information, security, and contact information.

Owner:T MOBILE INNOVATIONS LLC

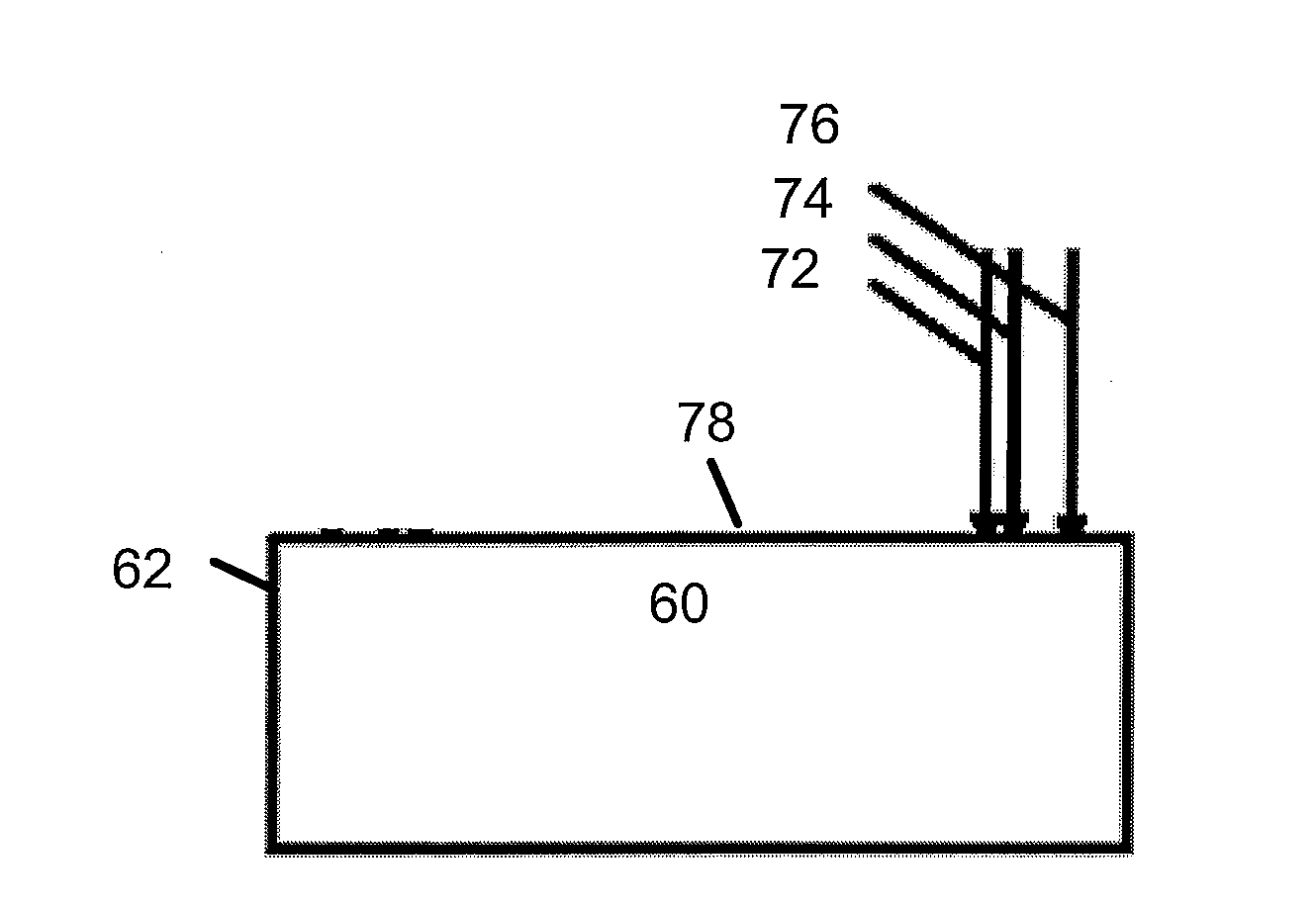

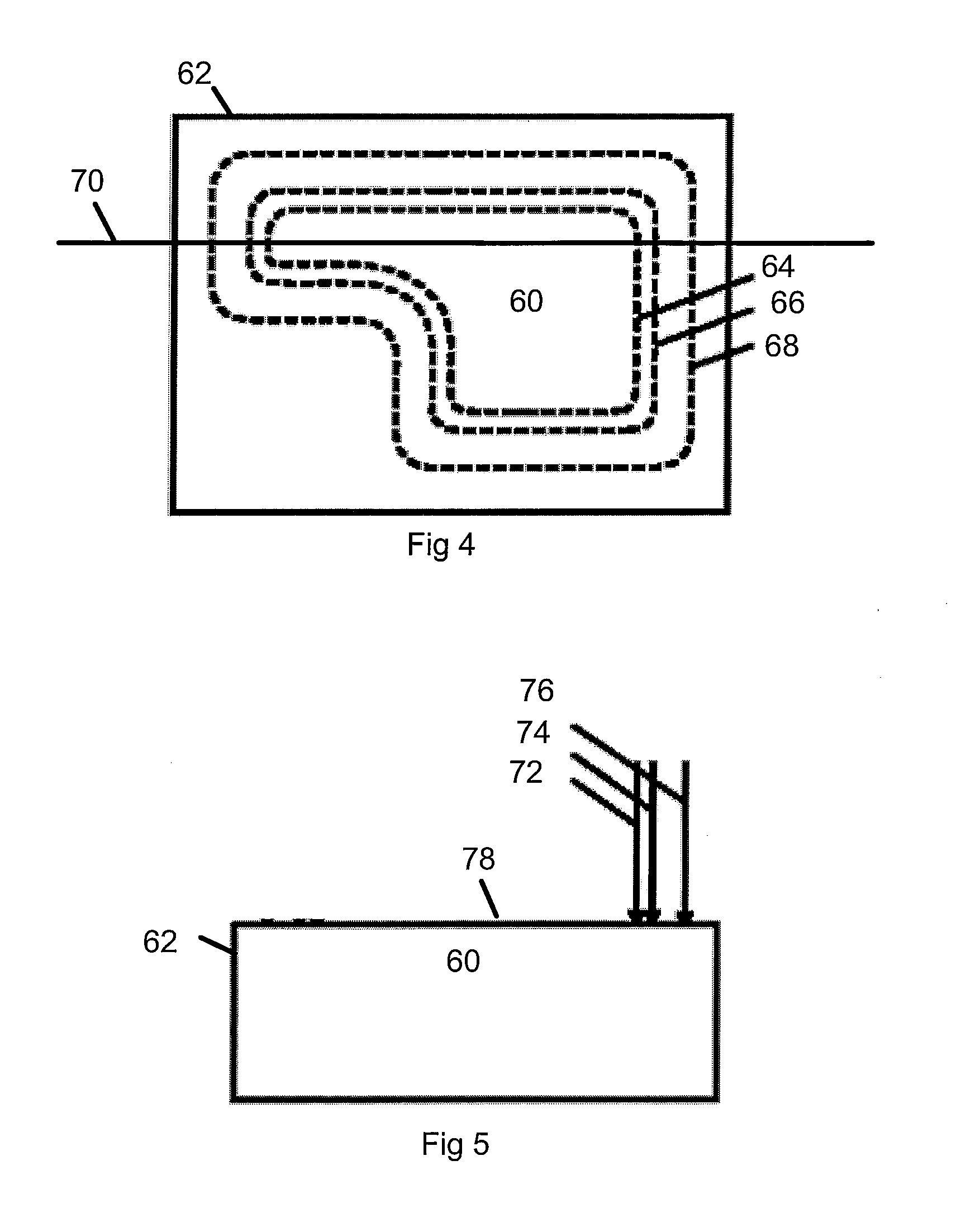

Method for laser processing glass with a chamfered edge

InactiveUS20100147813A1Easy to controlControl shapeGlass severing apparatusWelding/soldering/cutting articlesLaser processingEngineering

A laser machining process is described for laser machining glass or glass-like materials. This process machines articles or features in articles with chamfered edges in one manufacturing operation. Chamfered edges are desirable in glass and glass-like materials because they resist fracturing or chipping and eliminate sharp edges. Producing articles or features in articles in one manufacturing operation is desirable because it can save time and expense by eliminating the need to transfer the article to a separate machine for chamfering after laser machining. Alternatively, it can permit use of less expensive equipment because the same laser used for machining can be used to form the chamfer instead of having a separate process perform the chamfering. Producing chamfers with laser machining results in high quality chamfers without the need for a separate polishing or finishing step.

Owner:ELECTRO SCI IND INC

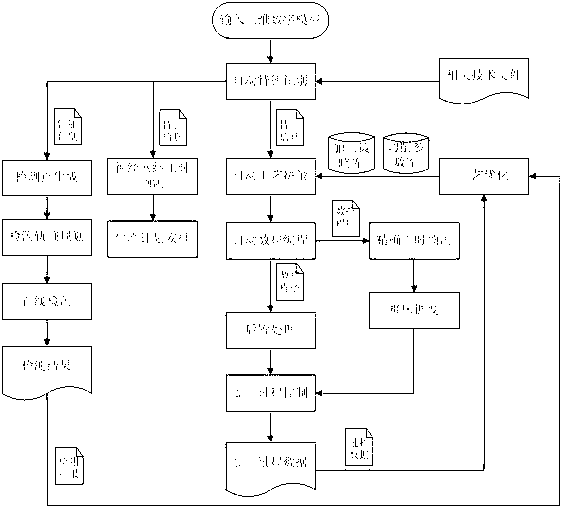

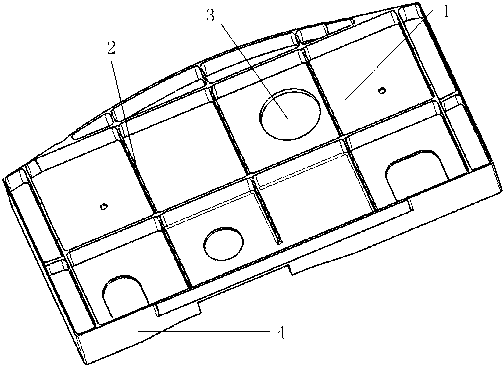

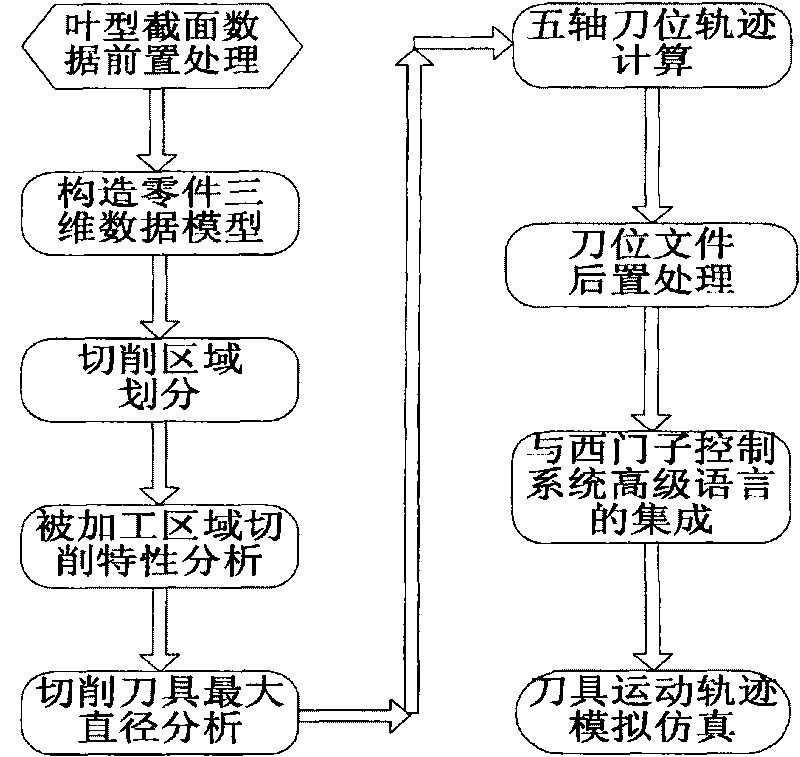

Feature-based numerical-control method for processing and manufacturing complicated parts

ActiveCN103235556AAchieve integrationAchieve deliveryProgramme controlComputer controlNumerical controlClosed loop

Disclosed is a feature-based numerical-control method for processing and manufacturing complicated parts. The feature-based numerical-control method includes expressing features on the basis of a body and an object-oriented process; expressing geometrical and technological information of a part in an integral manufacturing procedure on the basis of the features; utilizing the features as carriers of manufacturing knowledge and experience to implement effective integration and closed-loop control for information of manufacturing stages of designing, processing, detecting and the like; and carrying out automatic technological decision, automatic numerical-control programming, post-processing, control for a processing procedure, online detection, technology optimization and working hour prediction on the basis of automatic feature identification and the features. The feature-based numerical-control method has the advantages that information links are effectively connected with one another in the processing procedure, the manufacturing procedure is automatic and intelligent, dependence on manual experience is reduced in the manufacturing procedure, production management for the manufacturing procedure is facilitated, the manufacturing efficiency is improved, and the production cost is reduced.

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

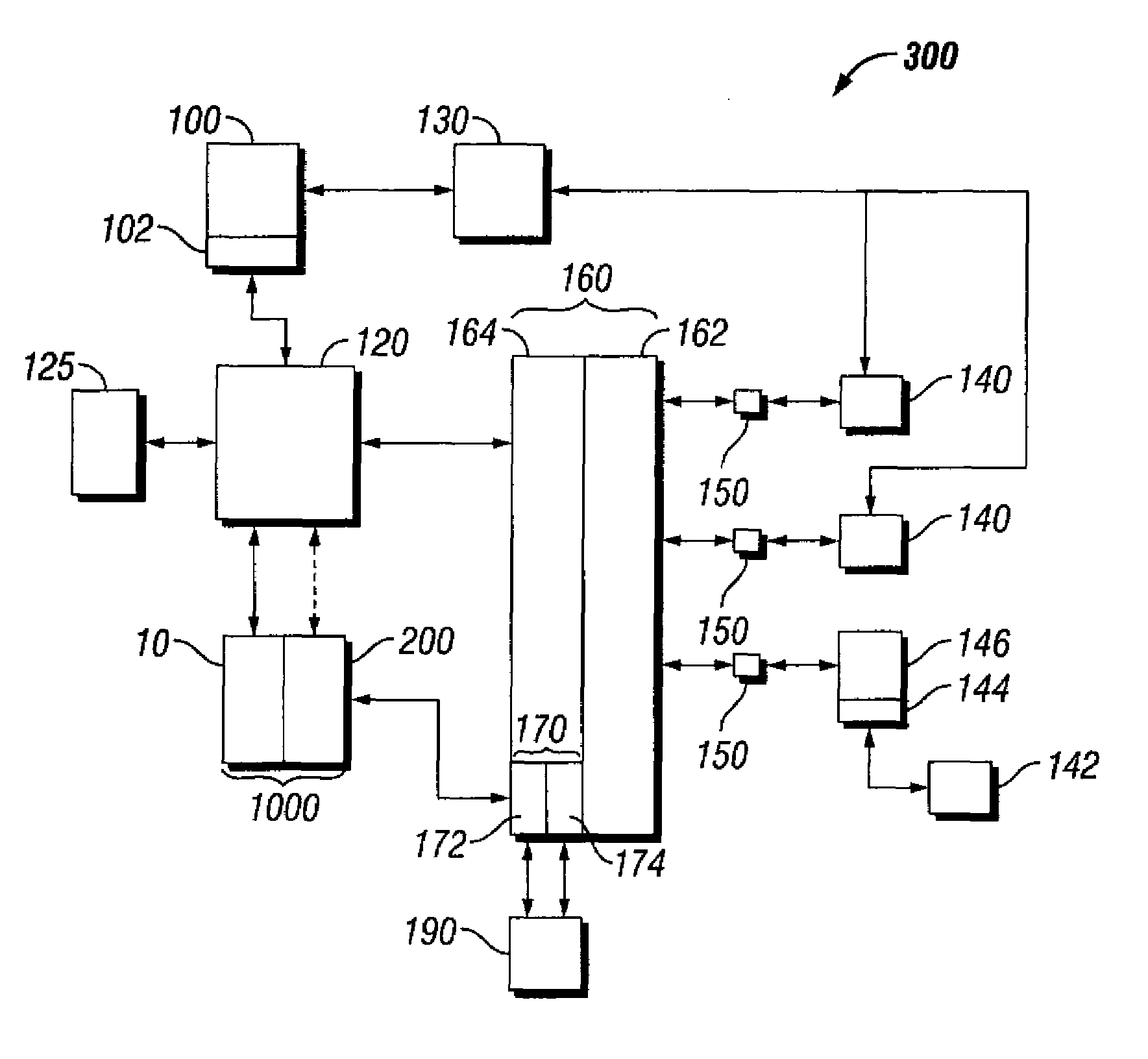

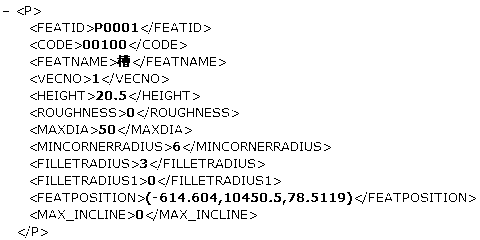

Surface planarization of thin silicon films during and after processing by the sequential lateral solidification method

InactiveUS6830993B1Reduce surface roughnessAvoid insufficient thicknessSemiconductor/solid-state device manufacturingFrom frozen solutionsLight beamSurface roughness

Systems and methods for reducing a surface roughness of a polycrystalline or single crystal thin film produced by the sequential lateral solidification process are disclosed. In one arrangement, the system includes an excimer laser (110) for generating a plurality of excimer laser pulses of a predetermined fluence, an energy density modulator (120) for controllably modulating the fluence of the excimer laser pulses such that the fluence is below that which is required to completely melt the thin film, a beam homoginizer (144) for homoginizing modulated laser pulses in a predetermined plane, a sample stage (170) for receiving homoginized laser pulses to effect melting of portions of the polycrystalline or single crystal thin film corresponding to the laser pulses, translating means for controllably translating a relative position of the sample stage (170) with respect to the laser pulses, and a computer (110) for coordinating the excimer pulse generation and fluence modulation with the relative positions of the sample stage (170) to thereby process the polycrystalline or single crystal thin film by sequential translation of the sample stage (170) relative to the laser pulses.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

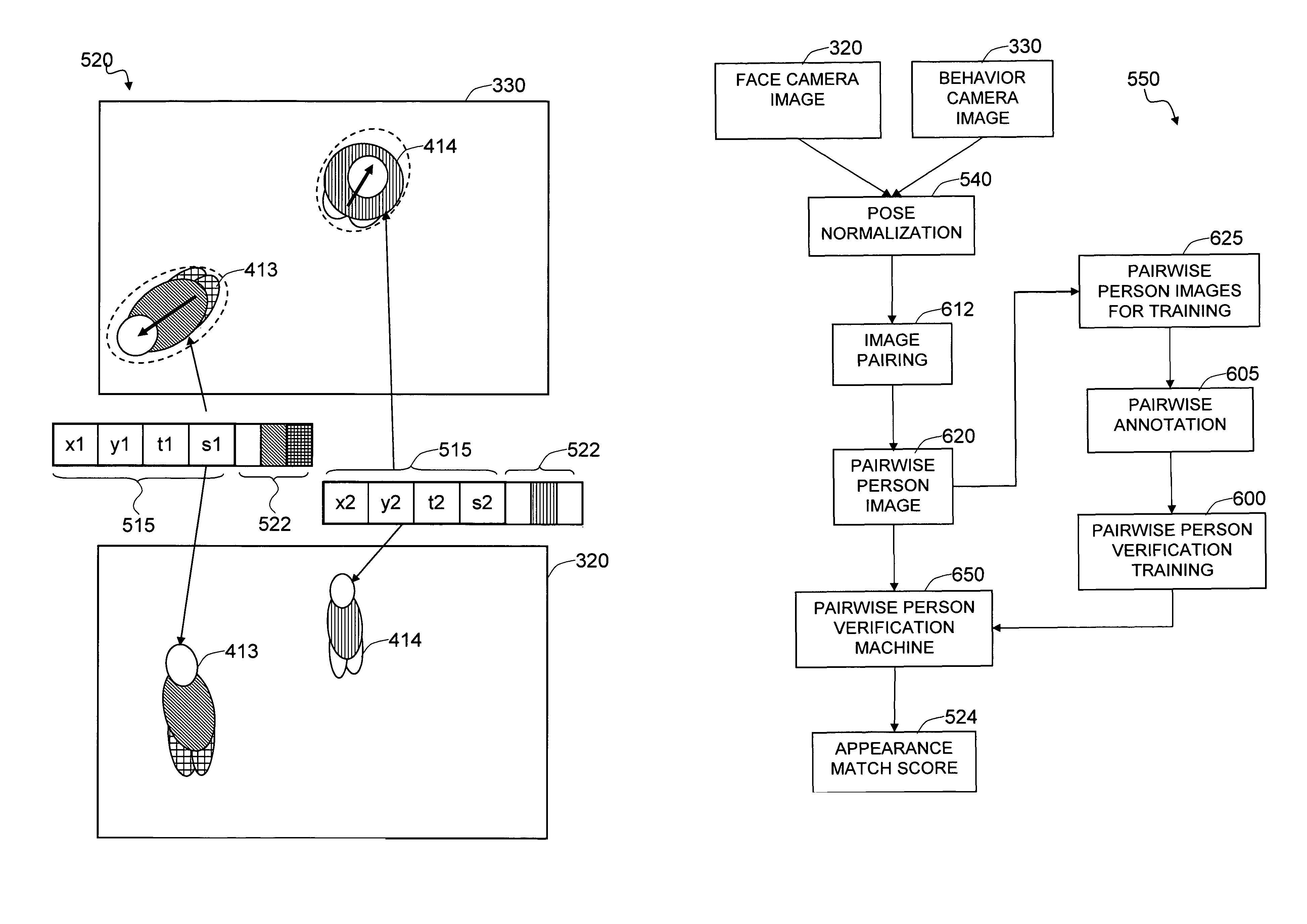

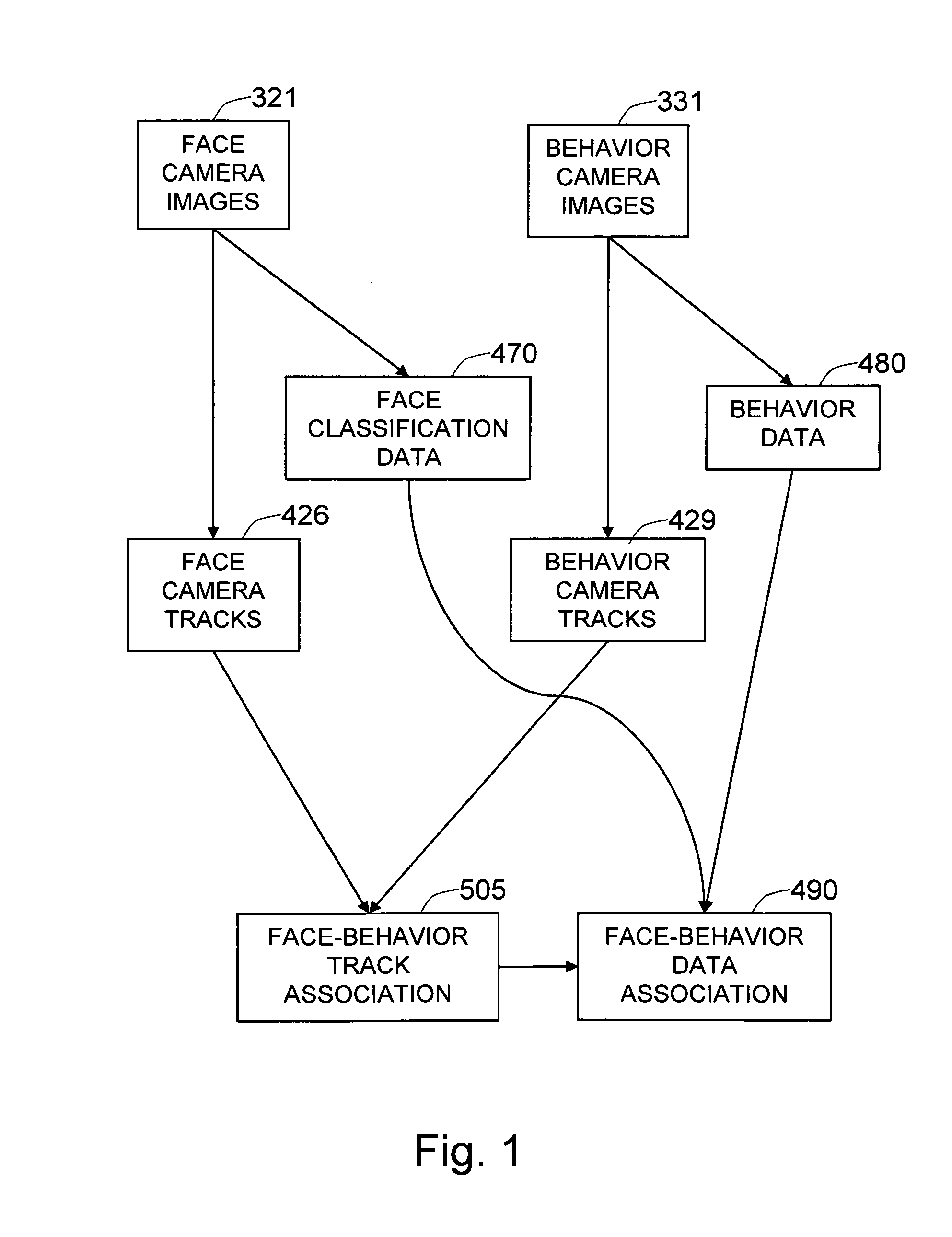

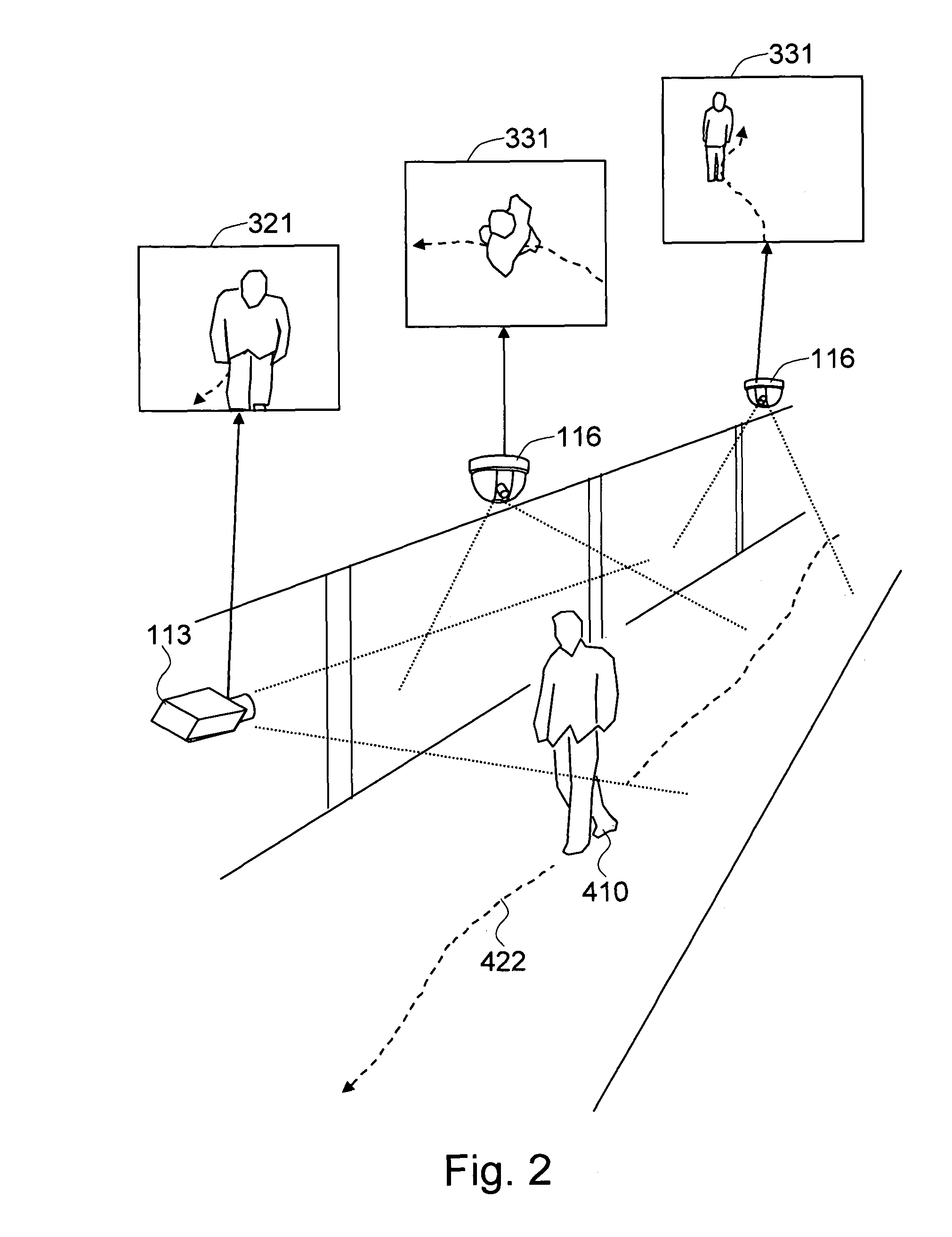

Method and system for finding correspondence between face camera views and behavior camera views

The present invention is a method and system to provide correspondences between a face camera track and a behavior camera track, for the purpose of making correspondence between the data obtained from each track. First, multiple learning machines are trained so that each of the machines processes pairwise person images from a specific pose region, and estimates the likelihood of two person images belonging to the same person based on image appearances. Then, the system acquires a person image associated with a behavior camera track, determines the pose of the person image based on its floor position, and corrects the pose of the person image. The system also acquires person images from face camera images associated with a face camera track, and combines the images with corrected person images from the previous step to form pairwise person images. The pairwise person image is fed to the trained pose-dependent pairwise person verification machines according to the pose of the person images, to compute the appearance match scores between the pair of person images. Finally, the combination of the appearance match scores and the spatiotemporal match scores of the pair of person images determines whether or not the person images belong to the same person.

Owner:VIDEOMINING CORP

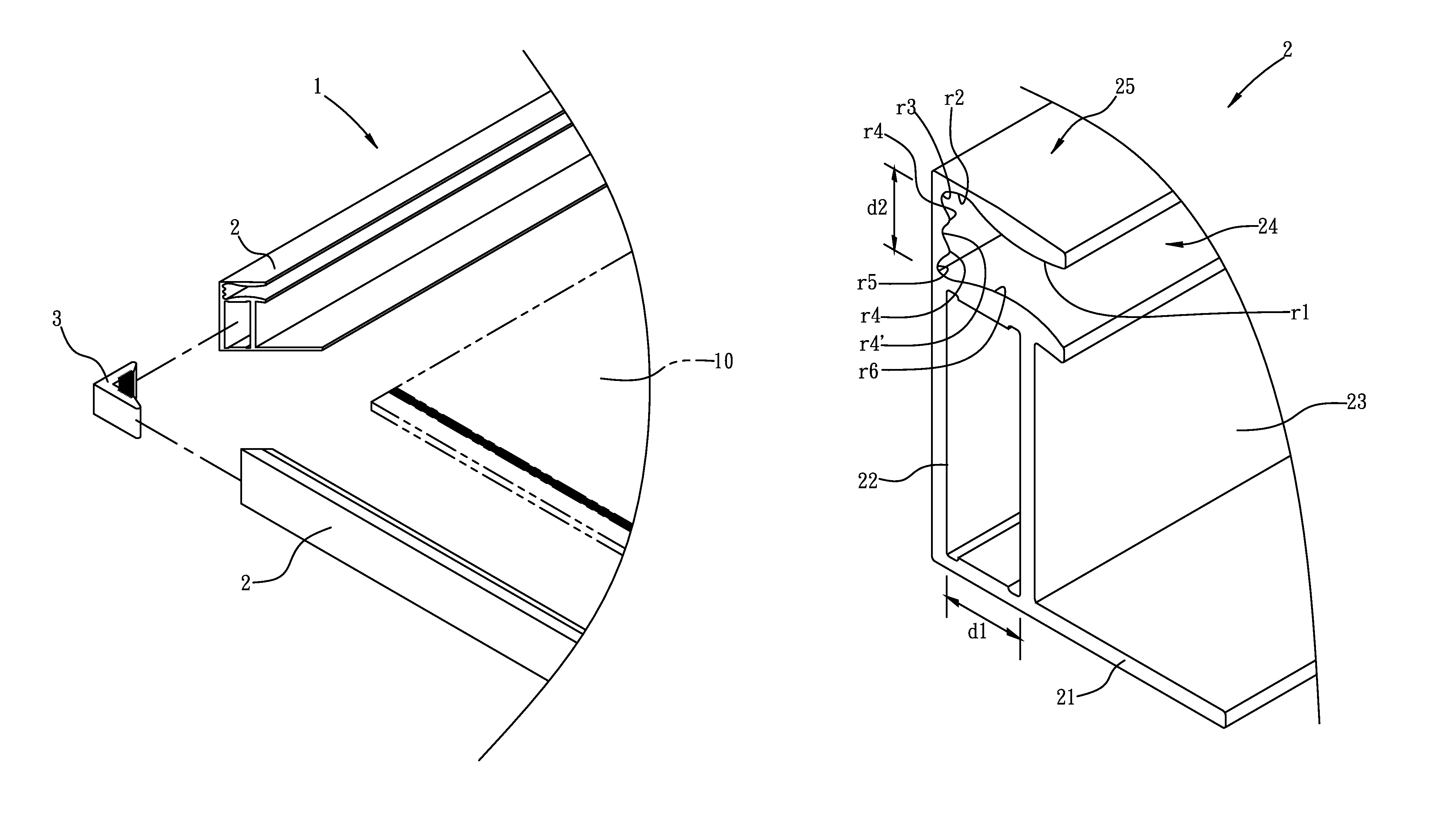

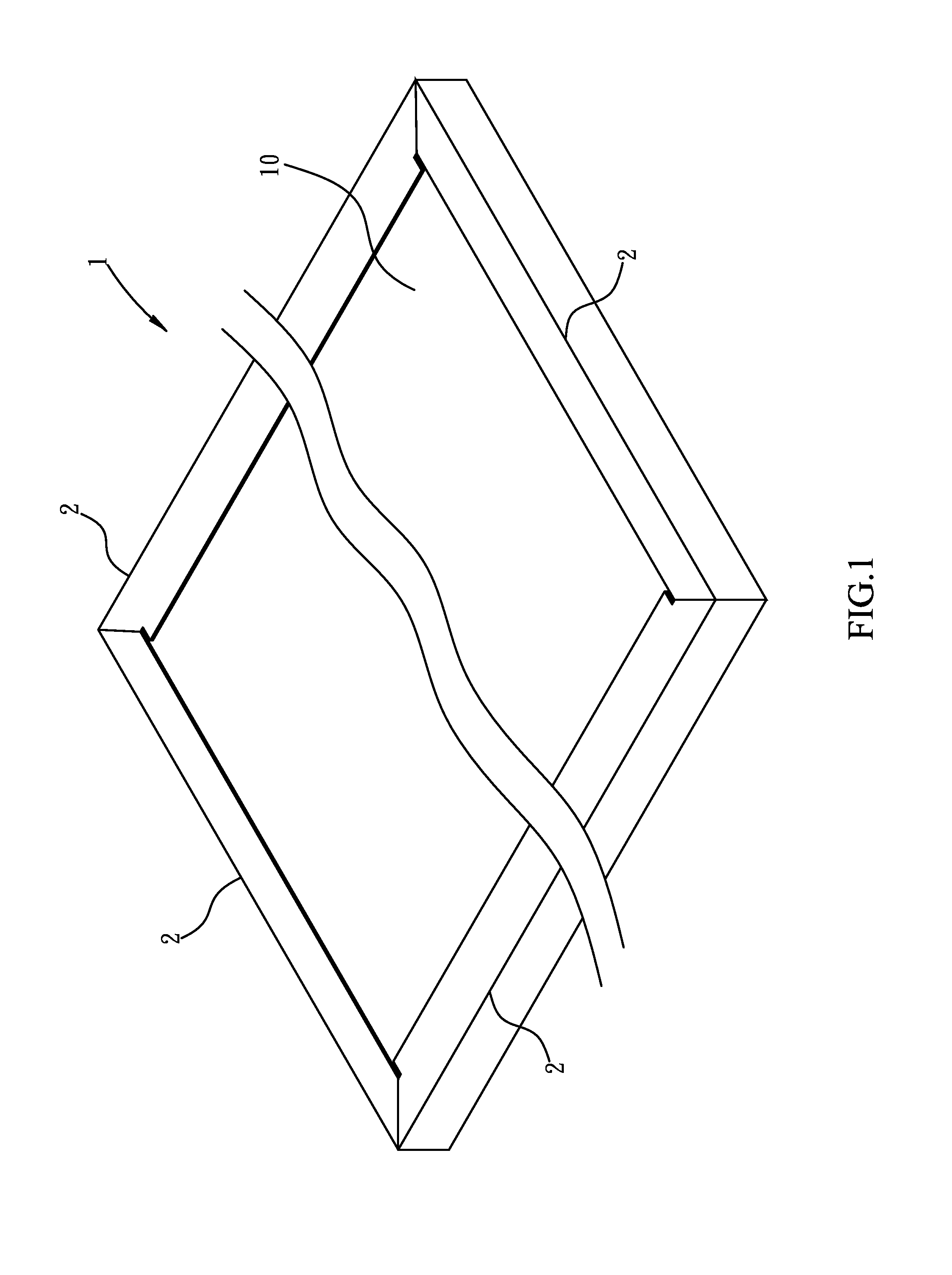

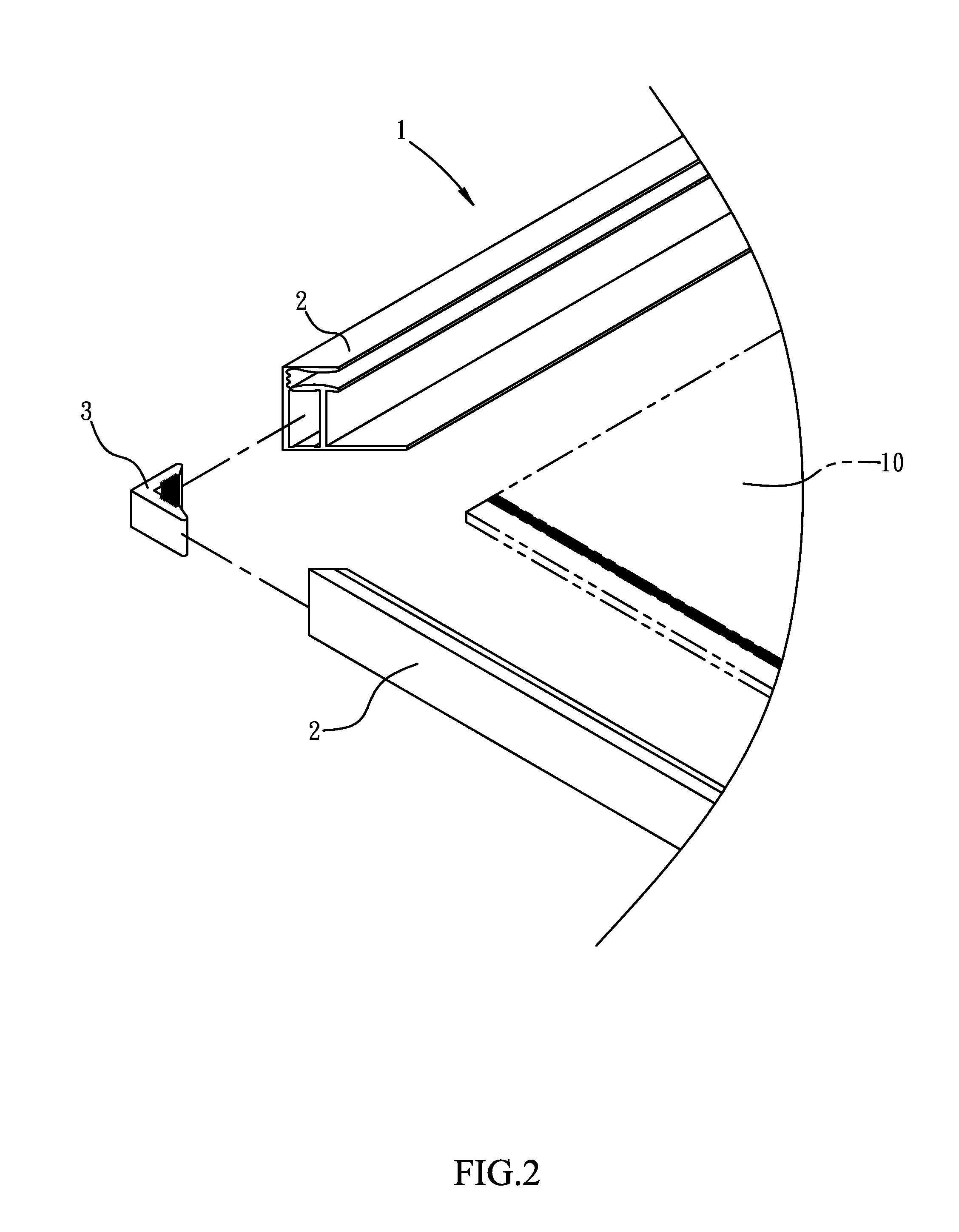

Frame structure for solar cell module

InactiveUS8505224B2Avoid damageShorten production timePhotovoltaic supportsRoof covering using slabs/sheetsFilling materialsSolar cell

A frame structure for solar cell module, in which each of the four sidebars that constructs the frame structure is comprised of a bottom, a first vertical wall, a second vertical wall, a first horizontal wall and a second horizontal wall. Substantially, the present invention provides a a frame structure constructed using parts of different curvatures, that is capable of preventing any filling material from overflowing on the front side of a solar cell element during the integration of the solar cell element and the front structure, without having the so-constructed solar cell module to be processed by an additional machining process for processing the overflowed filling material after the integration, and thus not only the sidebars of the frame structure can be prevented from being broken by the stress resulting from the machining process, but also the manufacturing time required for the consequent solar cell module can be reduced.

Owner:ETERBRIGHT SOLAR CORP

Combined additive and subtractive manufacturing machine tool

ActiveCN104384936AGuaranteed complexityGuaranteed processing effectOther manufacturing equipments/toolsUltrasonic vibrationMachining process

The invention belongs to the field of machine tool design, and relates to a combined additive and subtractive manufacturing machine tool, which comprises a body, a workbench, a main shaft, a numerical control system, a subtractive machining module and an additive manufacturing module. According to the combined additive and subtractive manufacturing machine tool, the additive manufacturing module is controlled by the numerical control system to form a basic structure of a required part on the workbench, then the subtractive machining module is controlled by the numerical control system to perform subtractive machining on the basic structure obtained by additive manufacturing, a function of applying ultrasonic vibration to a cutter and a gas cooling function are realized in a subtractive machining process, and the whole combined additive / subtractive manufacturing process is finally implemented. The combined additive and subtractive manufacturing machine tool can be used for realizing the efficient and precise combined additive and subtractive manufacturing of the component, the manufacturability of a complex part is improved, the production cycle is shortened, and the manufacturing accuracy of the complex part is ensured.

Owner:DALIAN UNIV OF TECH

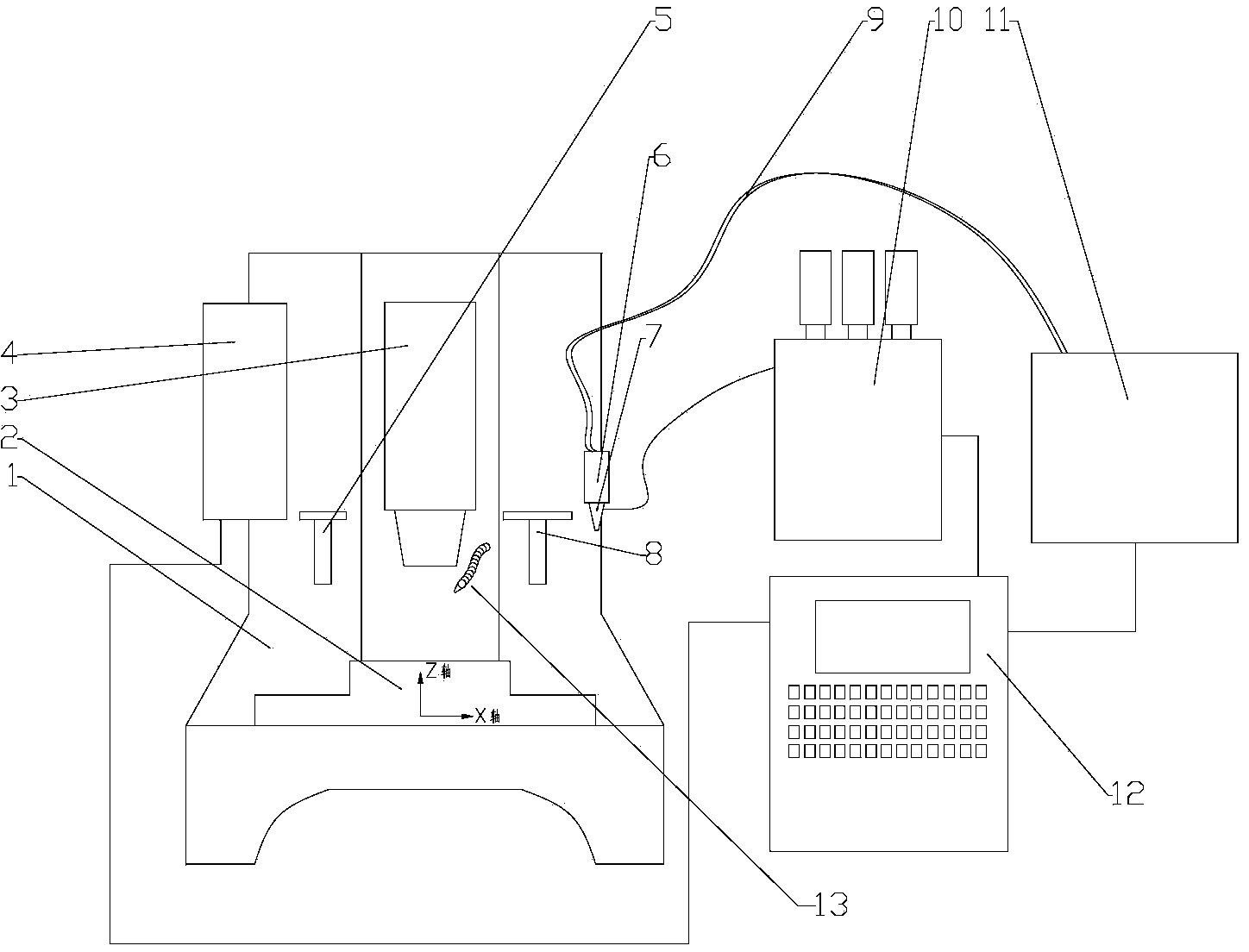

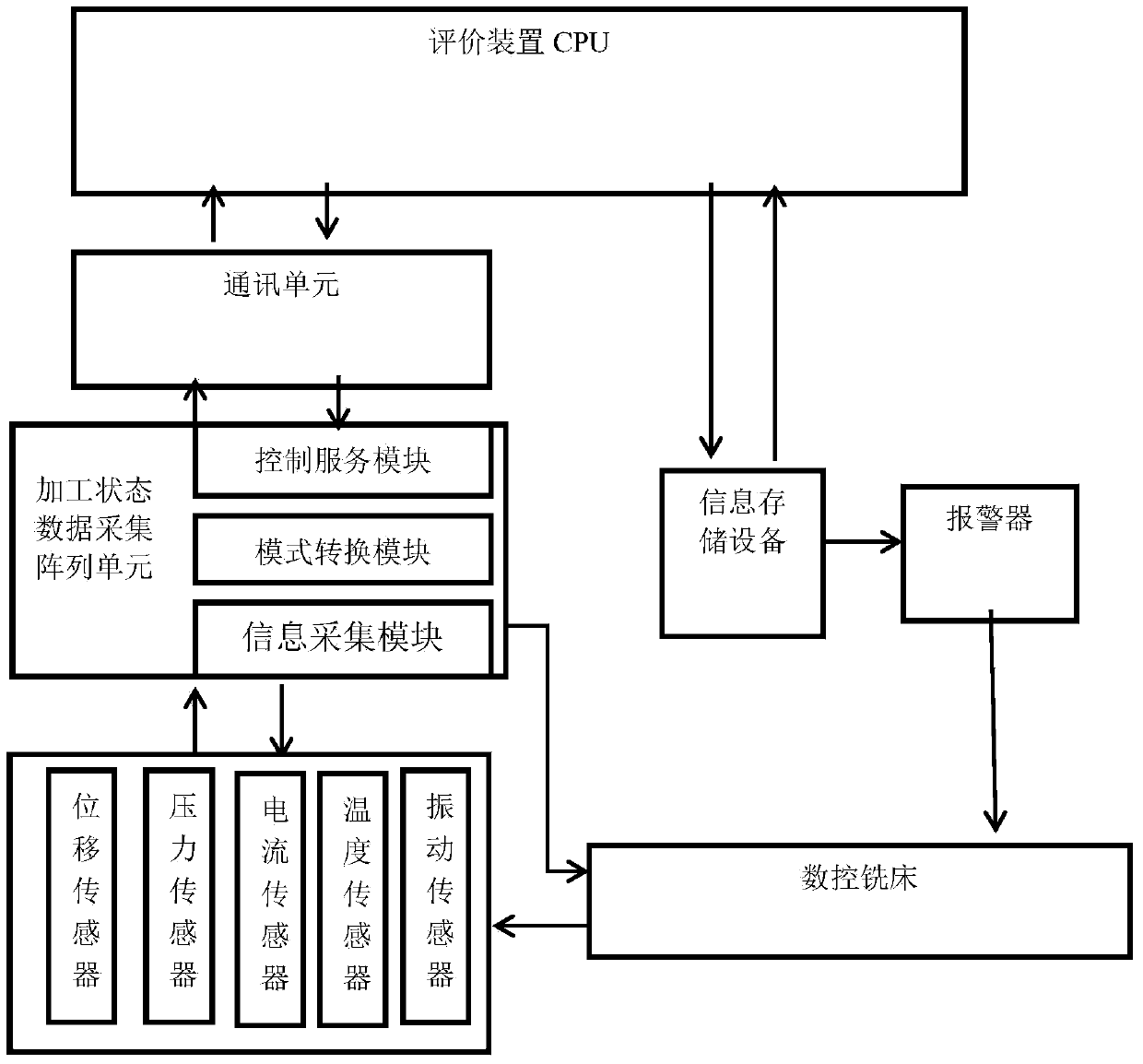

Evaluation device of state information of machining process of numerical control milling machine

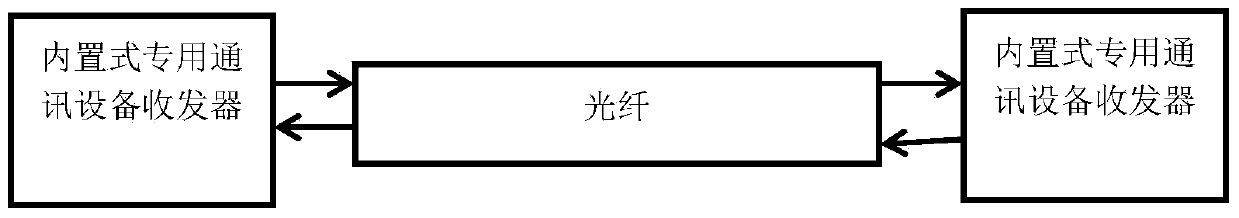

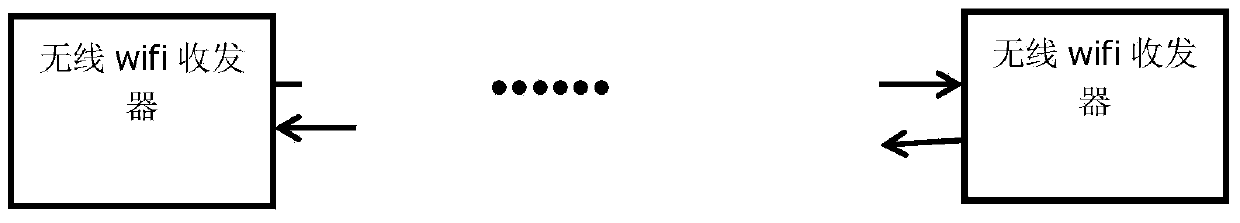

InactiveCN103760820AImprove processing qualityImprove efficiencyProgramme controlComputer controlMaterial defectCommunication unit

The invention discloses an evaluation device of state information of the machining process of a numerical control milling machine. A machining state data collecting array device, an information storage device, a numerical control system and the like on a machine tool are connected into a semi-closed-loop control circuit through the evaluation device MCU. A machining state data collecting array collects state data of main shaft currents, feed currents, vibration, machining temperatures and the like in the machining process of the numerical control machine tool and can intelligently identify abnormal states of abrasion and breakage of a cutter, material defects of workpiece blank and the like. A communication unit can achieve real-time connection between the machining state information collecting array and the evaluation device MCU. The evaluation device MCU checks and analyzes collected machining state parameters according to a certain algorithm, generates a check report and guides the information storage device to update the optimal parameter record. Meanwhile, the evaluation device has the prejudgment function, submits alarming when meeting with problems which cannot be dealt with and meanwhile analyzes corresponding error reasons and provides proper solutions. According to the evaluation device of the state information of the machining process of the numerical control milling machine, the machining parameters of the milling machine and the state information of the machining process are checked.

Owner:HUAZHONG UNIV OF SCI & TECH

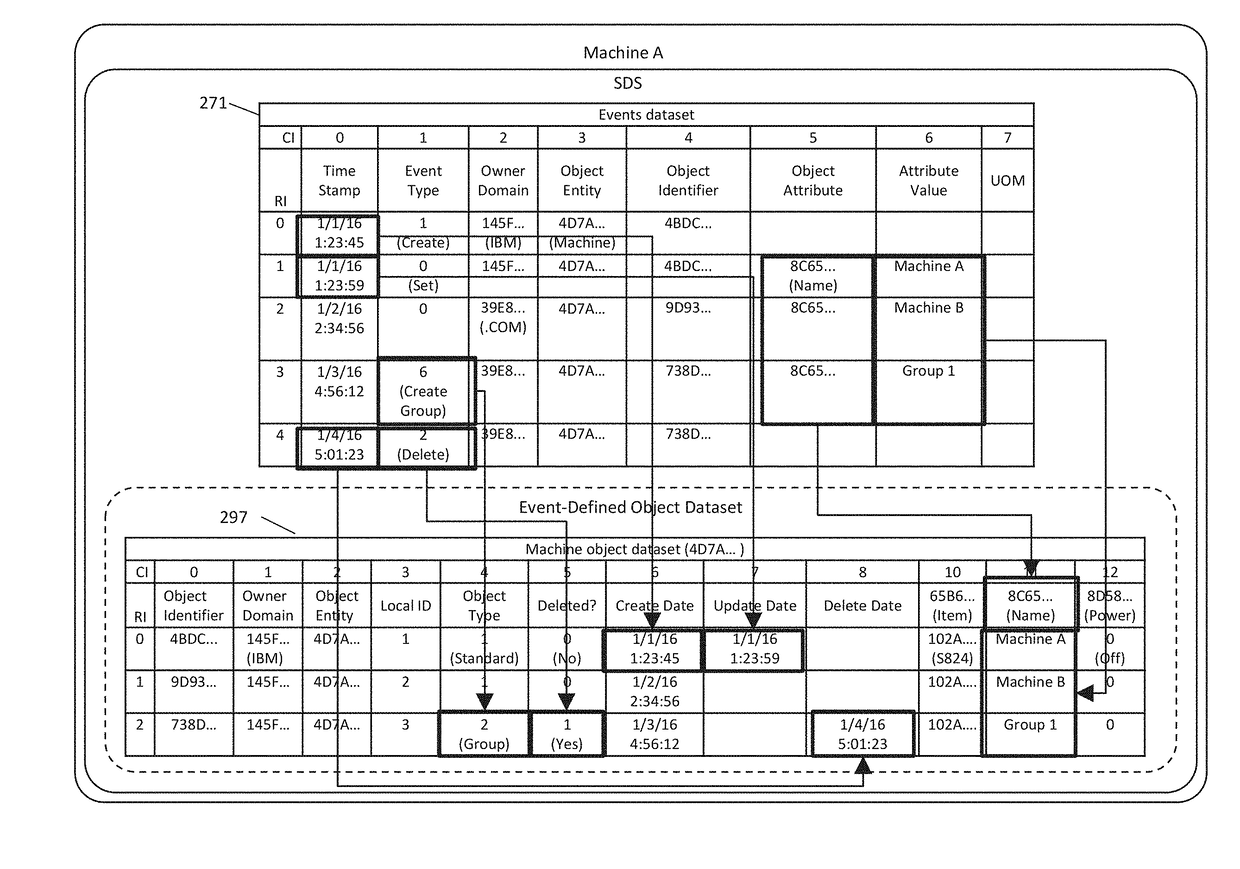

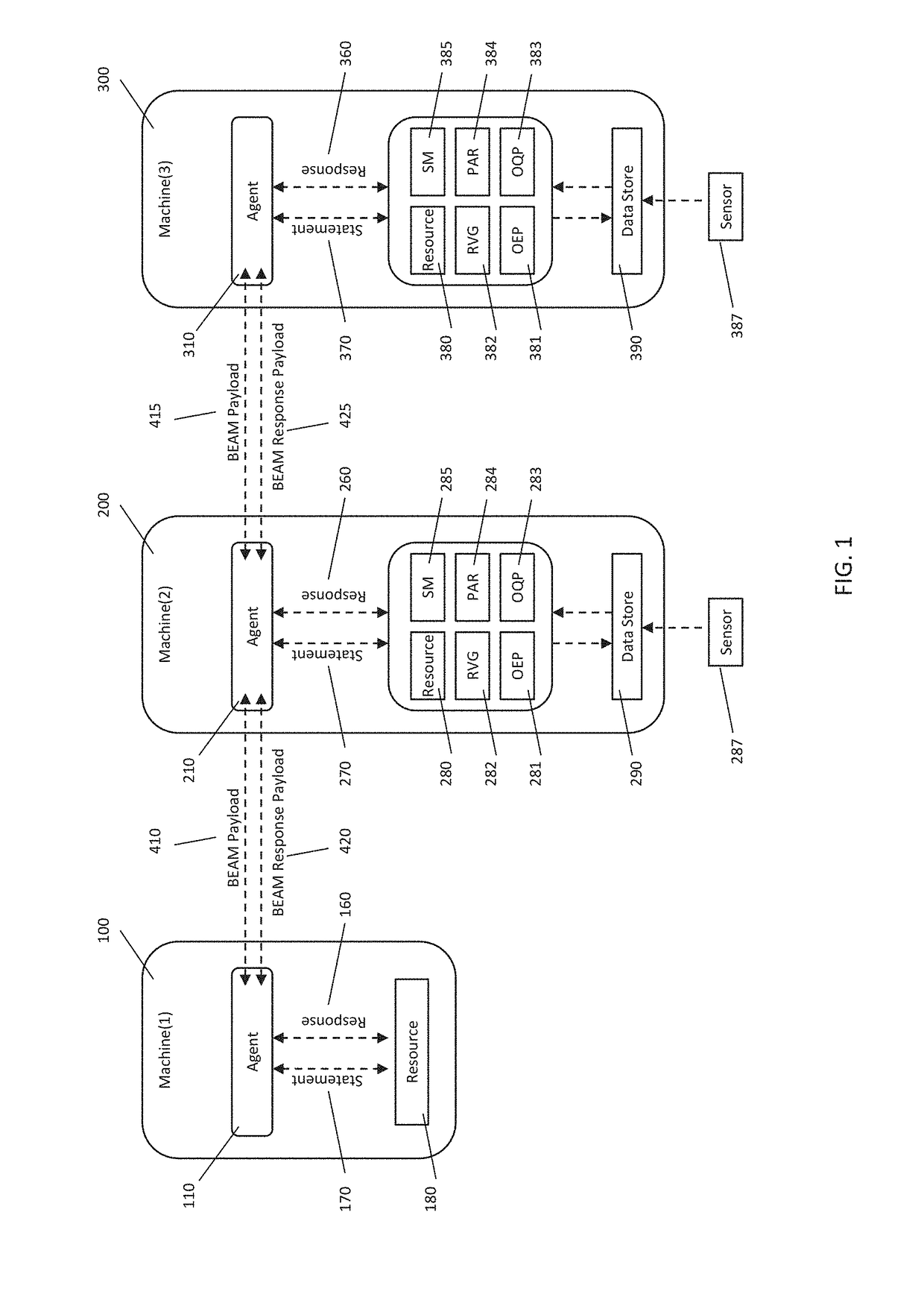

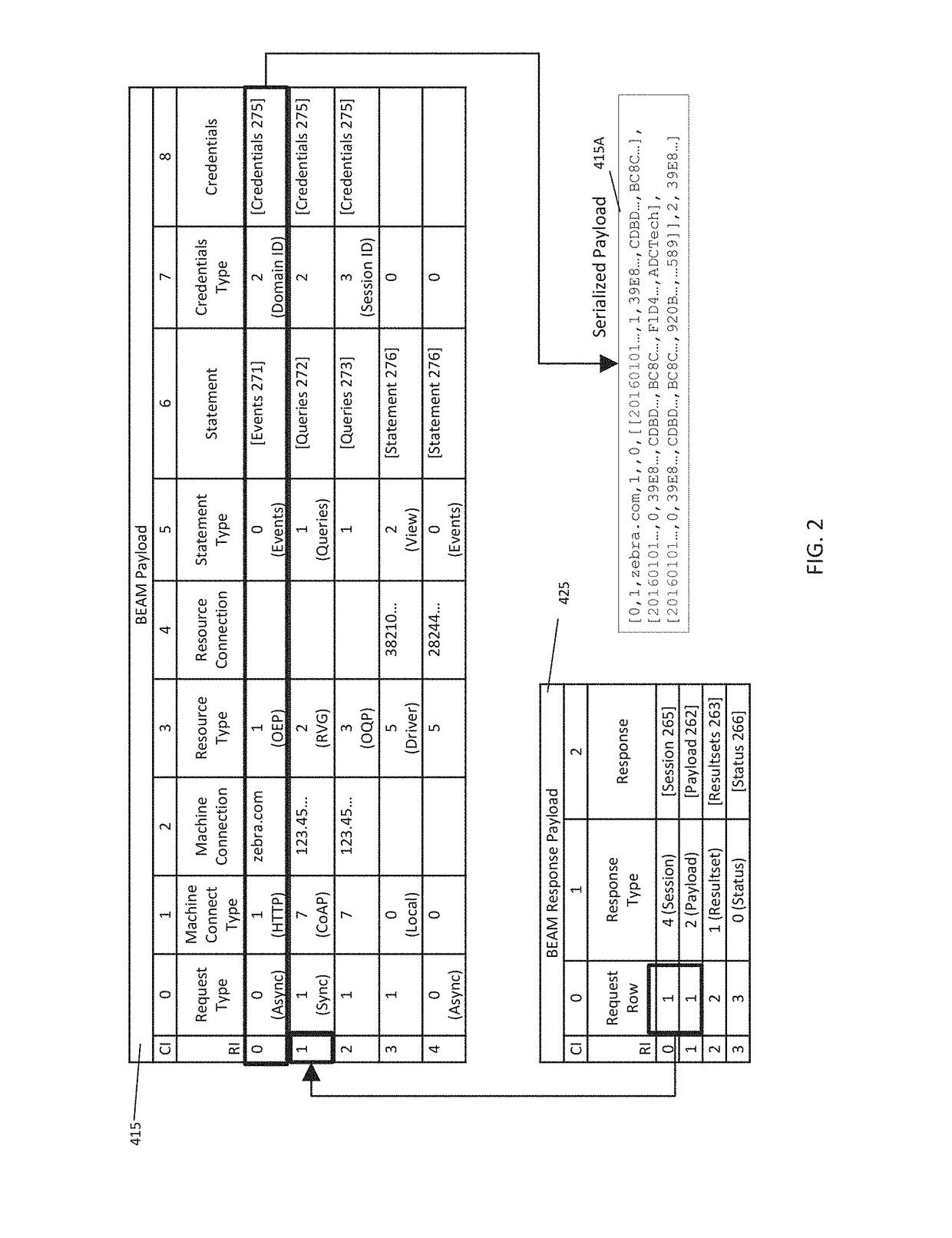

Common Data Service Providing Semantic Interoperability for IOT-Centric Commerce

Unified management, automation and interoperability of business and machine processes utilizing components of a common data service on any machine and / or across difference machines. In an embodiment, a first agent on a first machine accesses a first message payload which may represent a two-dimensional structure. Each request in the message payload comprises one of a plurality of request types, an identification of a machine, a statement, an identification of a resource to process the statement, and authentication credentials. Each row in the message payload is processed according to the elements in the row. When the identified machine is the first machine, the resource identified in the row is invoked to execute the statement. When the identified machine is not the first machine, the row is sent within a second message payload to the agent of the identified machine for processing.

Owner:MIGLIORI DOUGLAS T

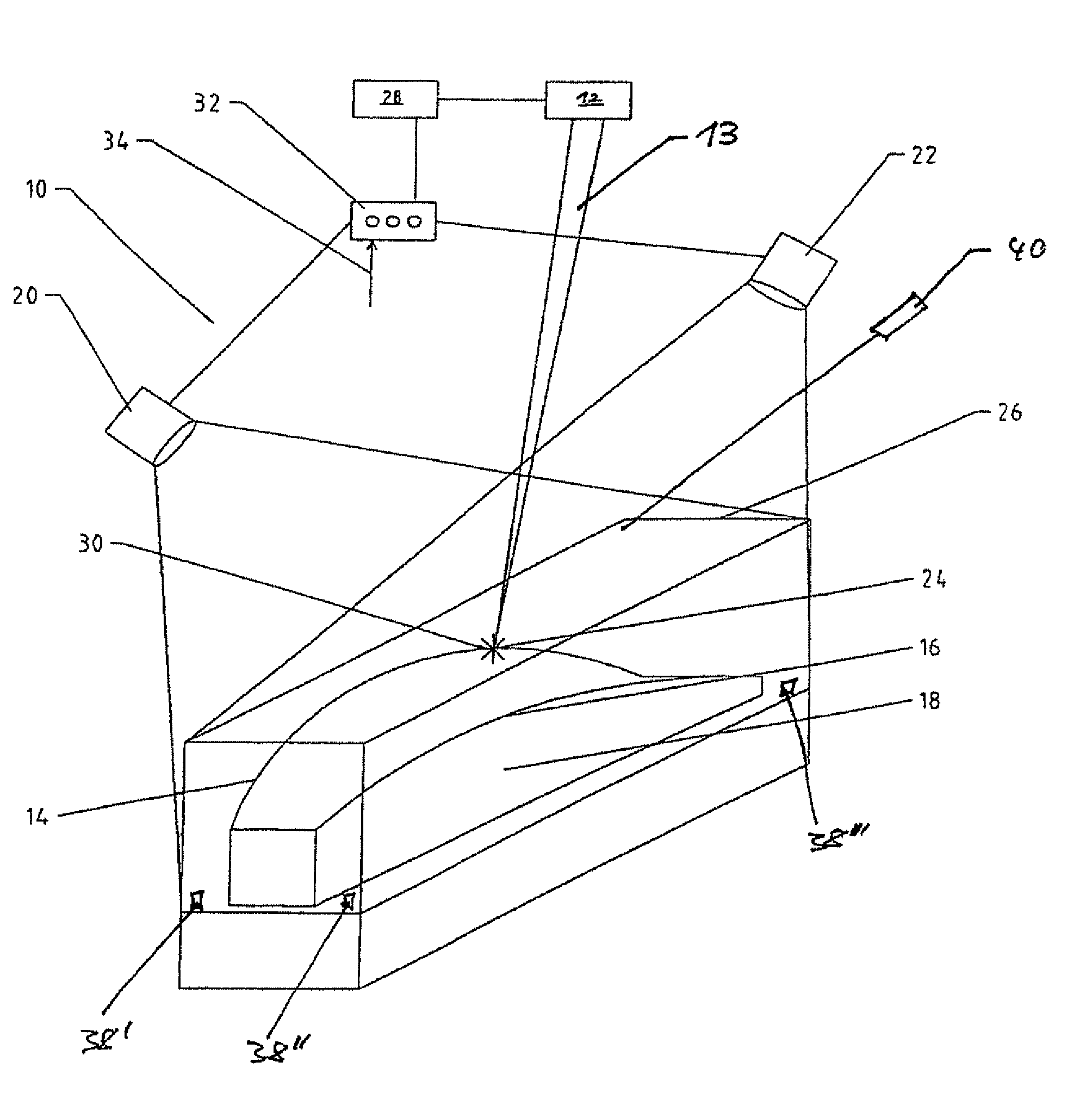

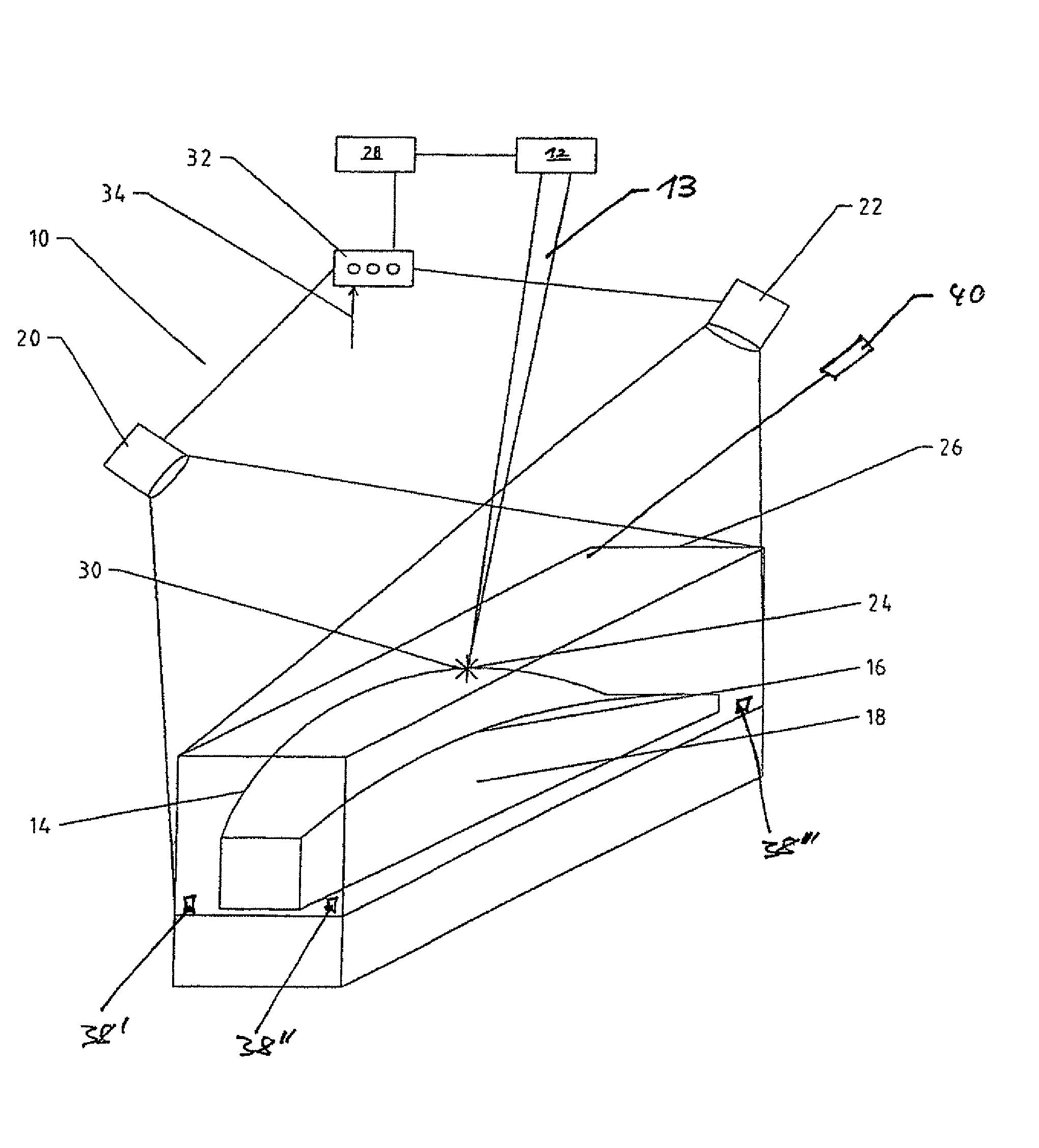

Monitoring device for a laser machining device

InactiveUS8094036B2Easy to detectEasy to adjustColor television detailsClosed circuit television systemsEngineeringMachining process

A monitoring device (10) for a laser machining device (12) that has one or more laser beams (13) that are displaced along a predetermined adjustable trajectory (14, 16) along a workpiece (18) includes one or more sensors (20, 22) which monitor(s) the processing signal (24) of the machining process in a three-dimensional section (26). The one or more sensors (20, 22) activate an alarm device or interrupter (28) for the one or more laser beams (13) of the laser machining device (12) if the one or more process signals (24) in the section (26) exceed a predetermined threshold value or fall short of it, the one or more sensors (20, 22) being independent of the laser machining device (12).

Owner:FFT PRODIONSSYST

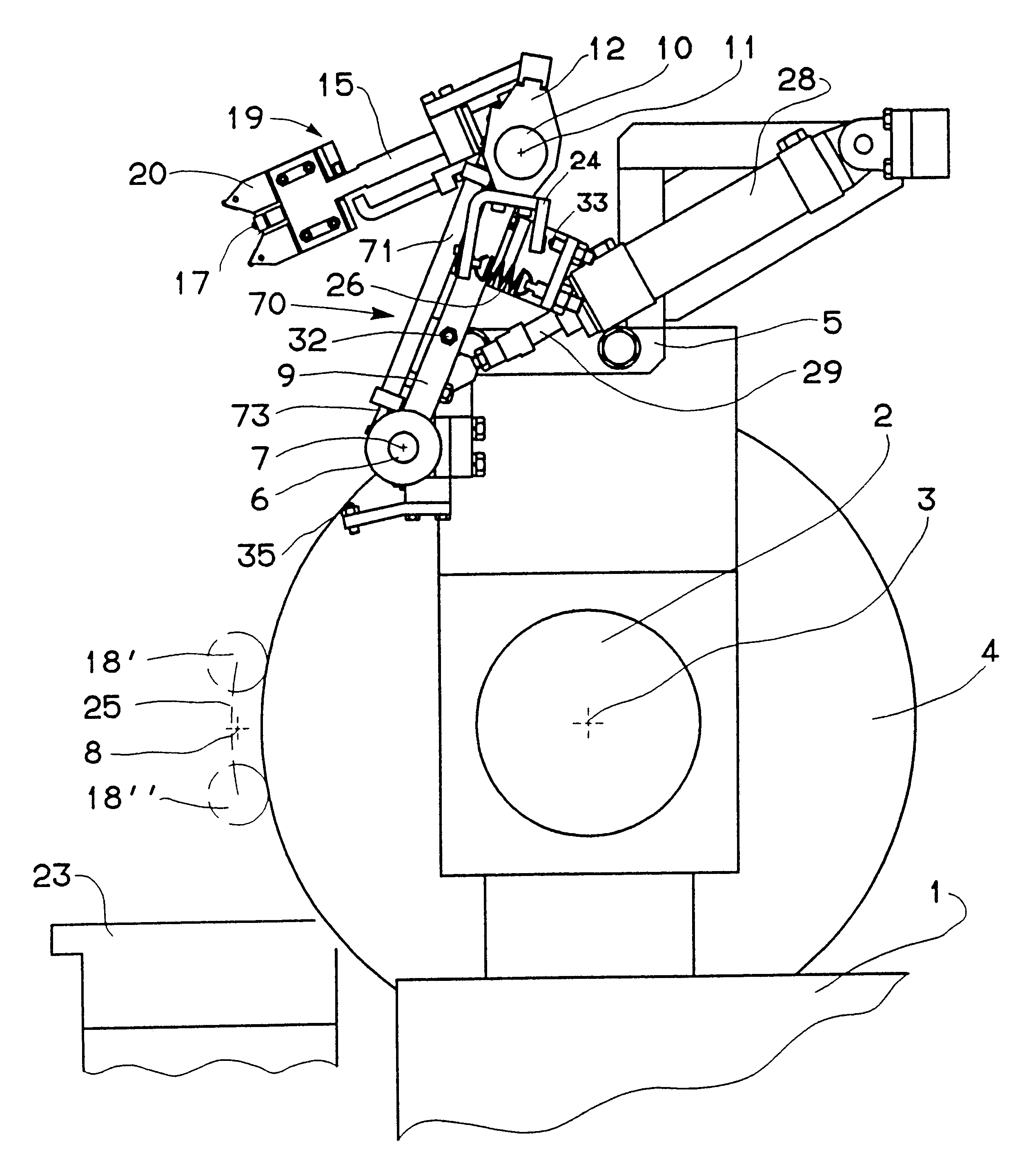

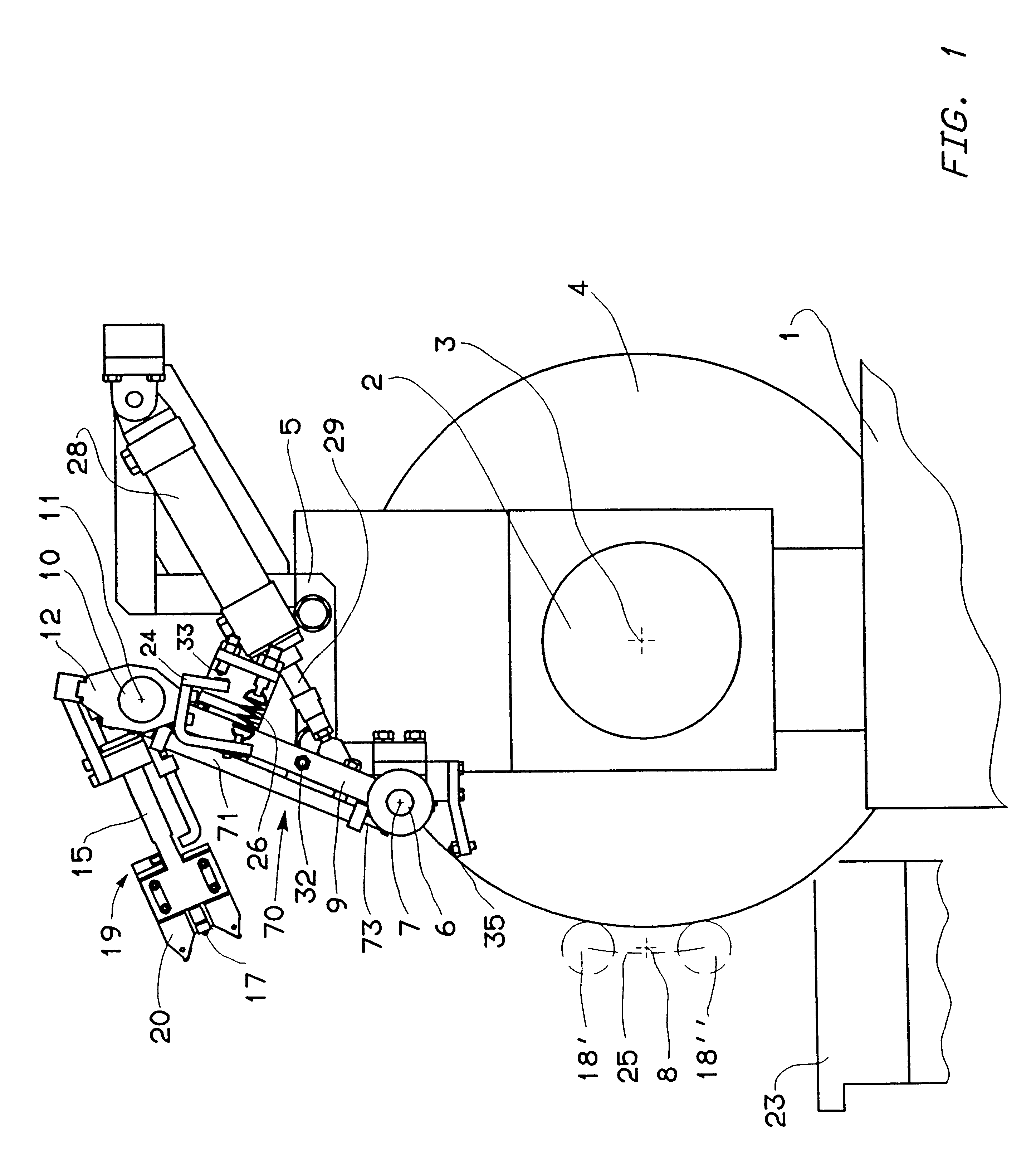

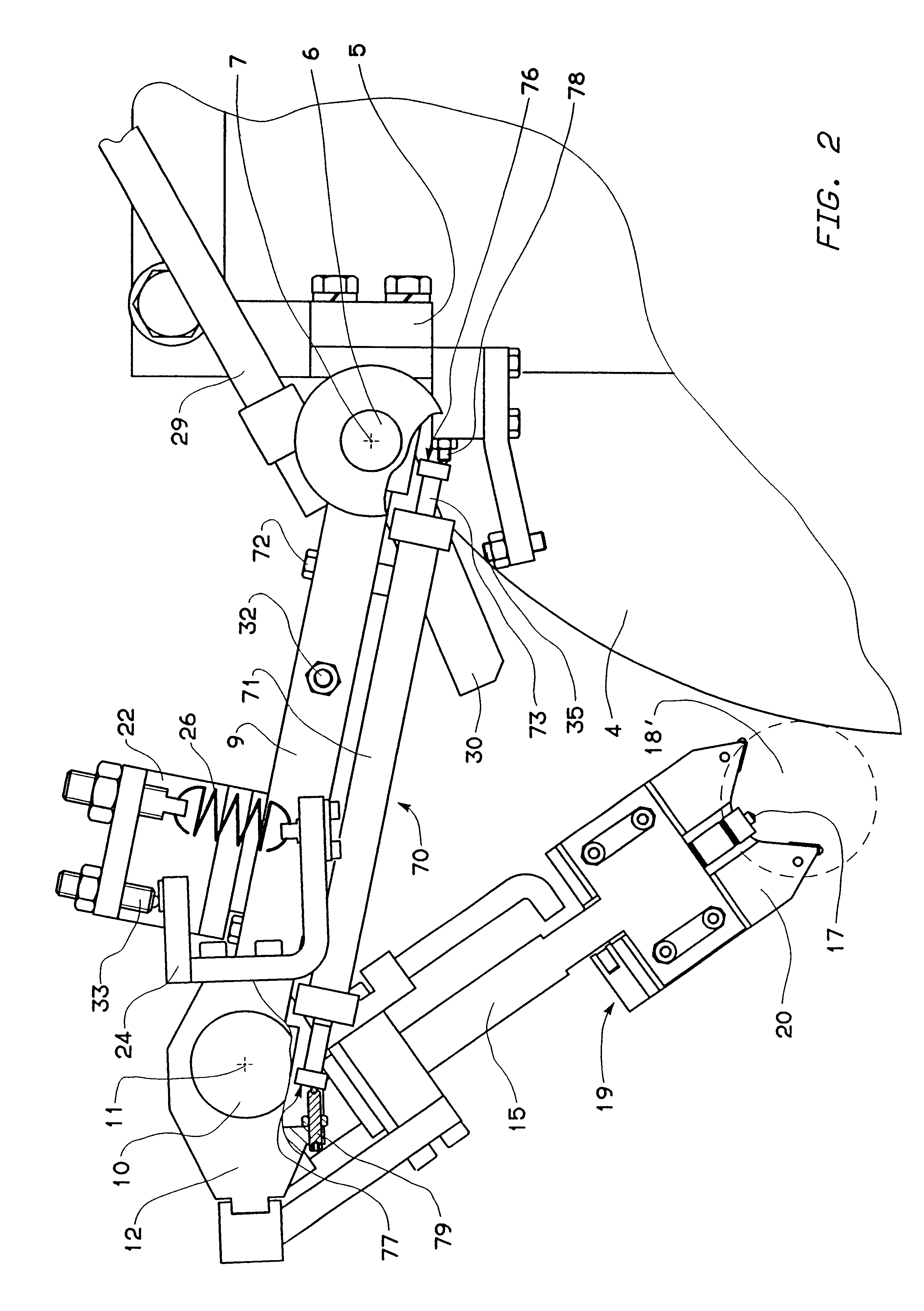

Apparatus for the in-process dimensional checking of orbitally rotating crankpins

InactiveUS6643943B2Revolution surface grinding machinesMechanical diameter measurementsReference deviceCrankpin

An apparatus for checking the diameter of crankpins of a crankshaft in the course of the machining in a grinding machine includes a Vee-shaped reference device, a measuring device associated with the reference device and including a feeler axially movable along the bisecting line of the Vee-shaped reference device, and a support device with a first arm rotating with respect to a support arranged on the grinding-wheel slide and a second arm rotating with respect to the first and carrying the Vee-shaped reference device.A guiding mechanism includes a limiting device, with mutually abutting surfaces and coupled to the support device, that guides the displacement of the reference device along a trajectory substantially parallel to the profile of the grinding wheel, allows the engagement of the reference device on a crankpin to be checked while the latter is orbitally moving, and does not interfere with the displacements of the support device caused by the orbital motion of the crankpin in the checking condition.

Owner:MARPOSS SPA

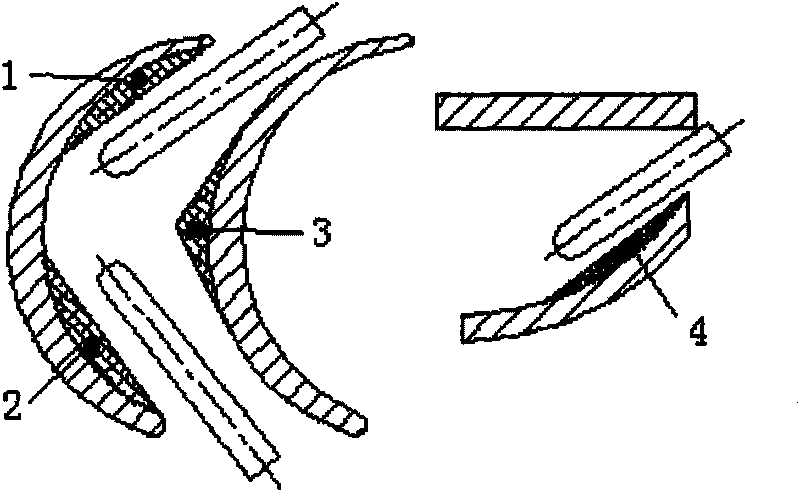

Numerically controlled drilling and milling processing method for runner of blisk of engine

InactiveCN101733618AImprove processing efficiencyShorten the manufacturing cyclePositioning apparatusNumerical controlAngular degreesEngineering

The invention provides a numerically controlled drilling and milling processing method for a runner of a blisk of an engine. The main technical flow before drilling and milling the runner comprises the following steps: lathing each surface of a blank, performing nondestructive testing, lathing inner and outer cavities of the blisk, finely milling a needed periphery and an axial benchmark, drilling and boring an angular datum hole, drilling and milling the runner and inspecting. A part and a fixture are in peripheral seam allowance fit to limit a radial degree of freedom of the part; an end face gland and a central pull bar axially limit an axial degree of freedom of the part; and a precise positioning pin angularly limits an angular degree of freedom of the part. The method has the advantages that: by applying the drilling and milling processing method to a part machining process of the blisk of the engine having the material removing rate of over 90 percent, the method improves the processing efficiency, shortens the manufacturing period of the product, and provides a new technical means for removing a large amount of remainder materials of the blisk; and the processing of a high-temperature alloy, a titanium alloy and other difficult-to-process materials shows that the material is more difficult to process, the removing rate is bigger and the effect is more obvious.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

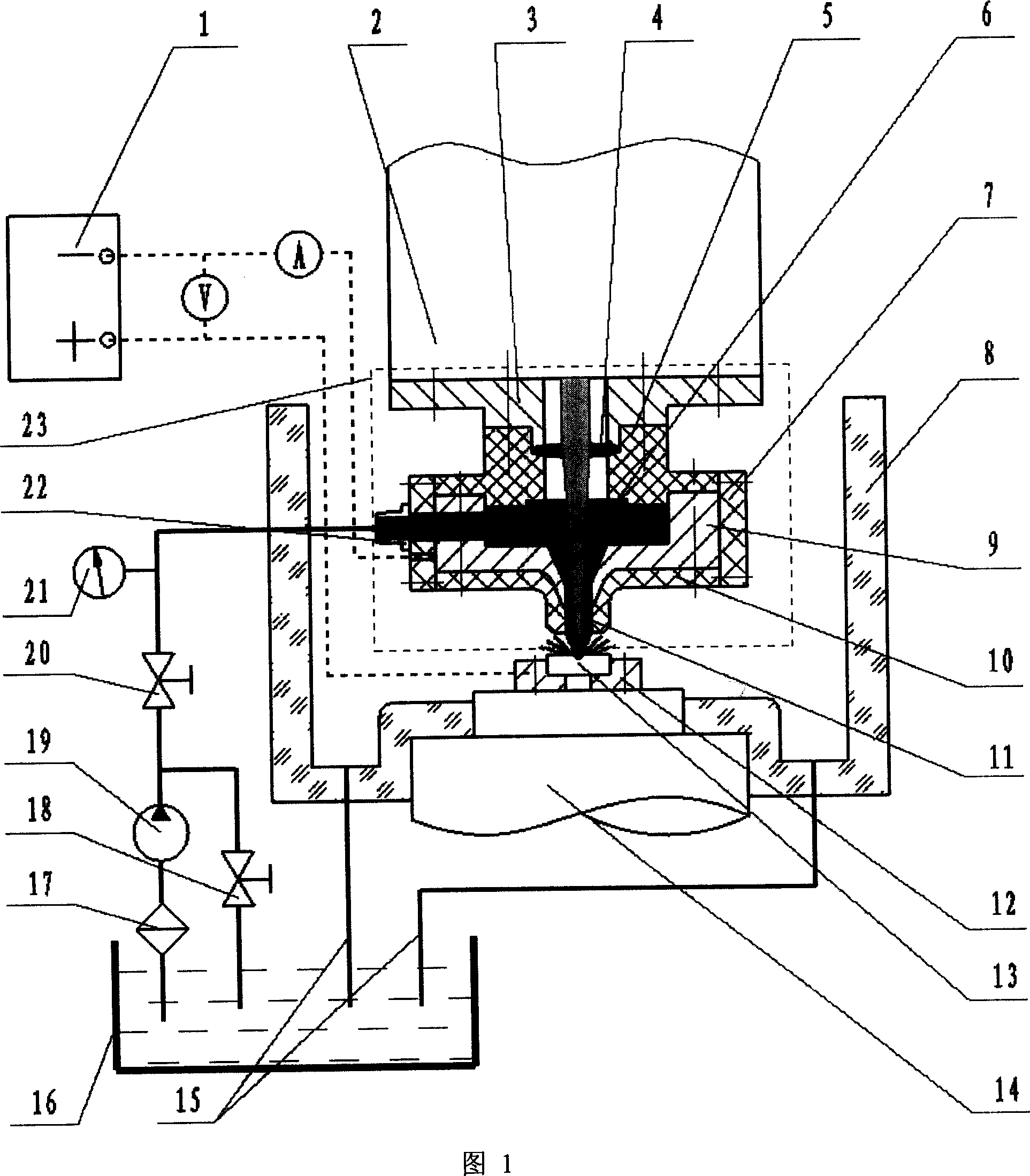

Spraying liquid bunch electrolysis-laser composite processing method and apparatus thereof

InactiveCN1919514ASolve processing problemsEfficient removalLaser beam welding apparatusElectrolysisLaser processing

The invention discloses a spraying liquid beam electrolytic-laser compound manufacturing method and device, which comprises the following steps: utilizing layer generating device to produce laser beam on the working piece, manufacturing hole, seam and groove, generating high-speed spraying liquid removing material with the same shaft of laser beam through spraying liquid beam device. The device contains layer, working piece assembling chuck, power and spraying liquid beam device, wherein the spraying liquid beam device concludes assembling seat of spraying device, insulating switching seat, cathode, focal lens, protective lens, insulating sleeve and sprayer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com