Patents

Literature

833results about How to "Guaranteed processing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

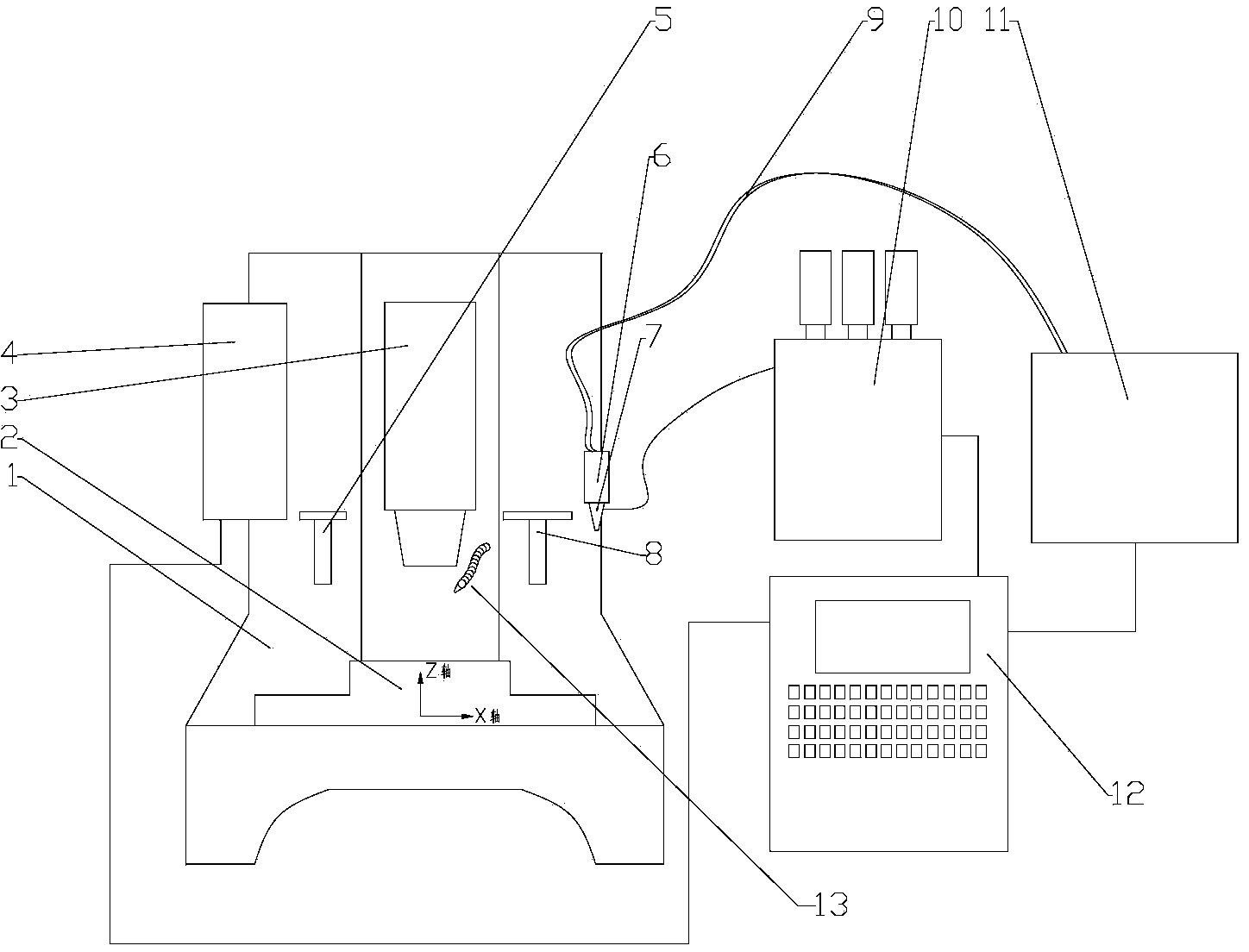

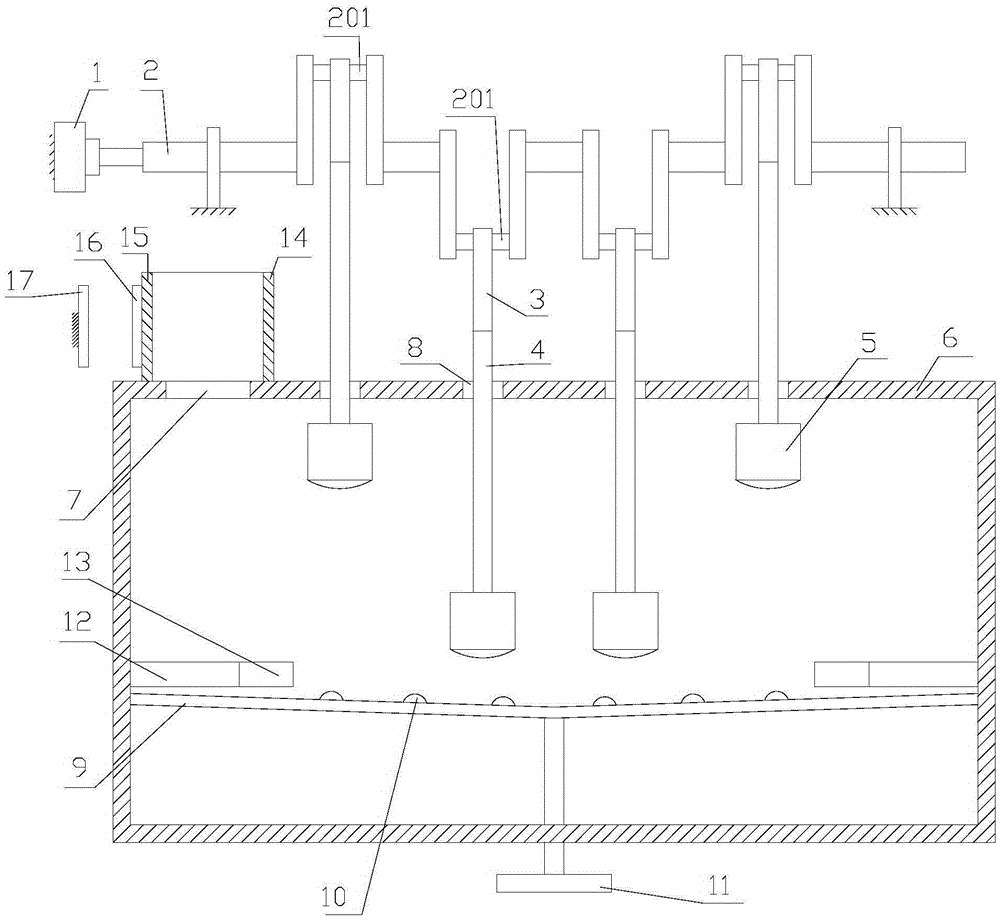

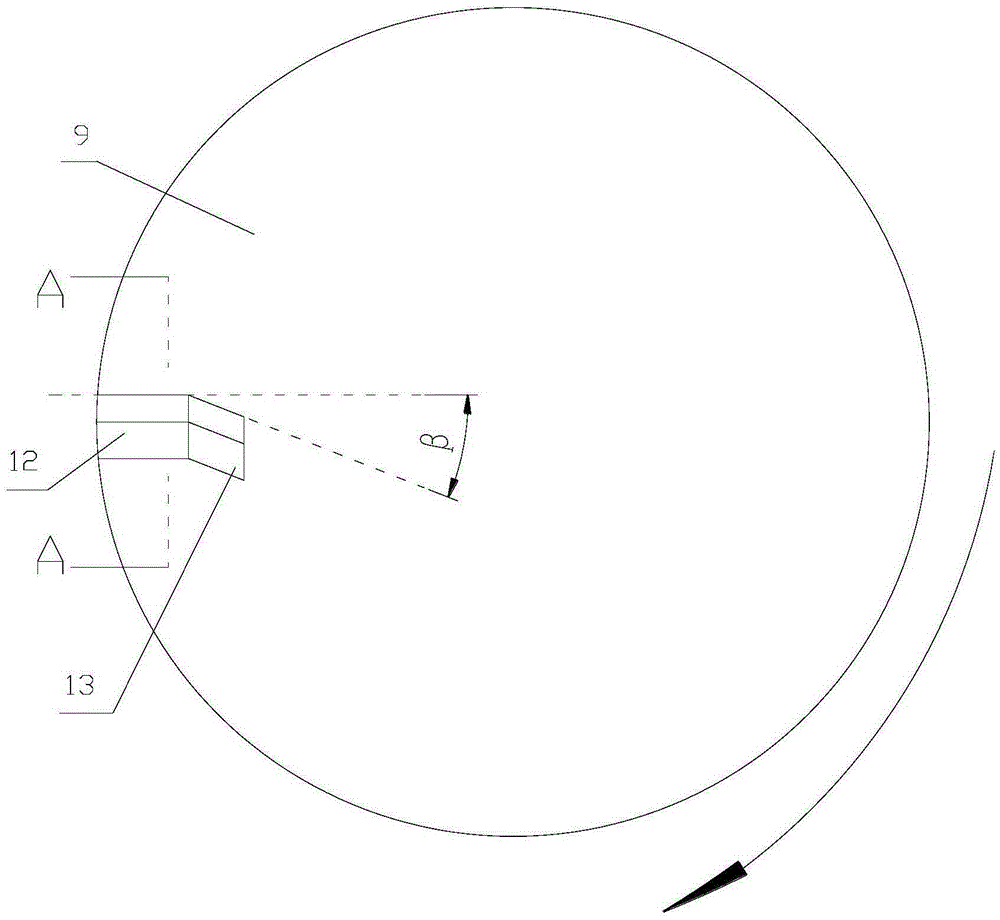

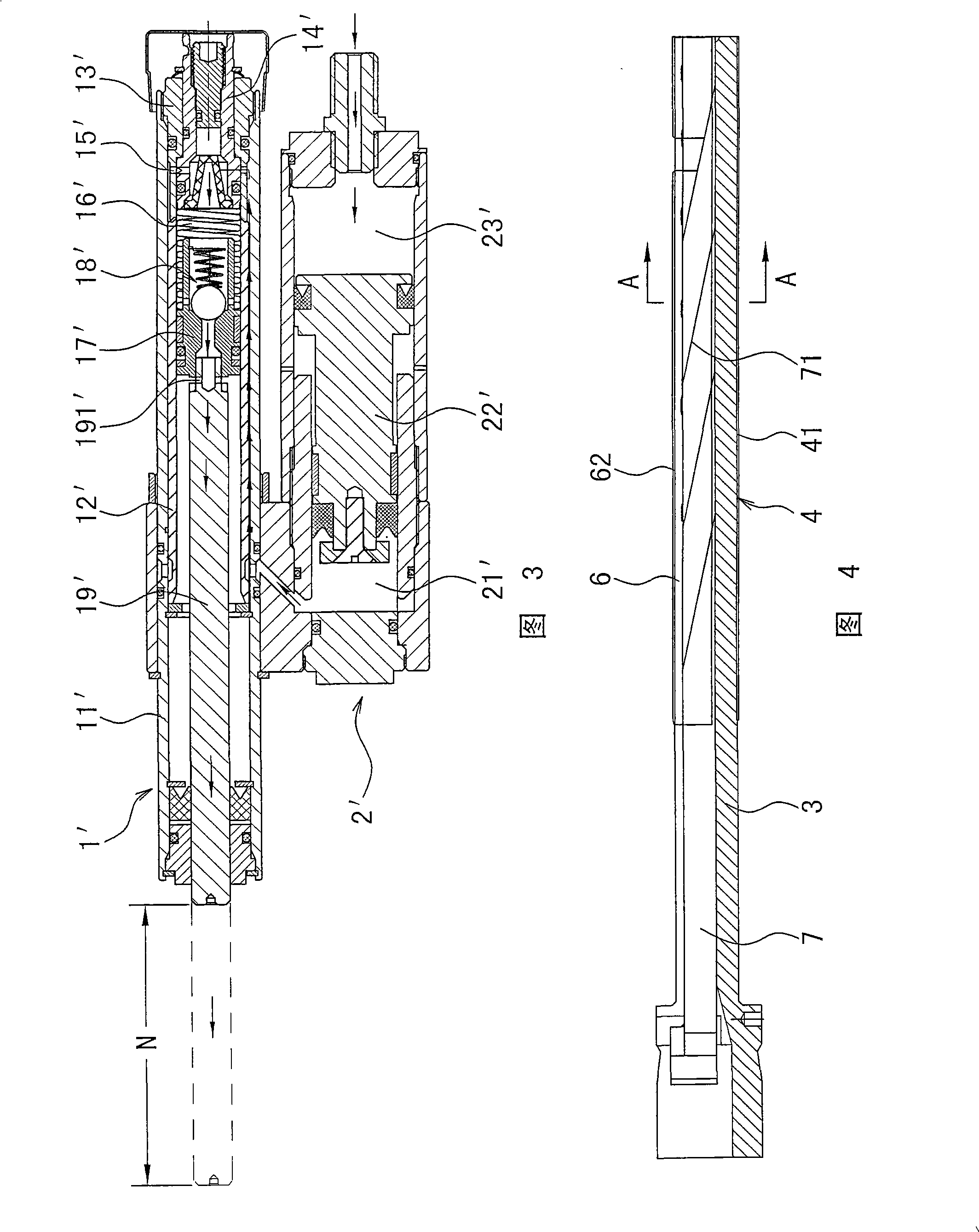

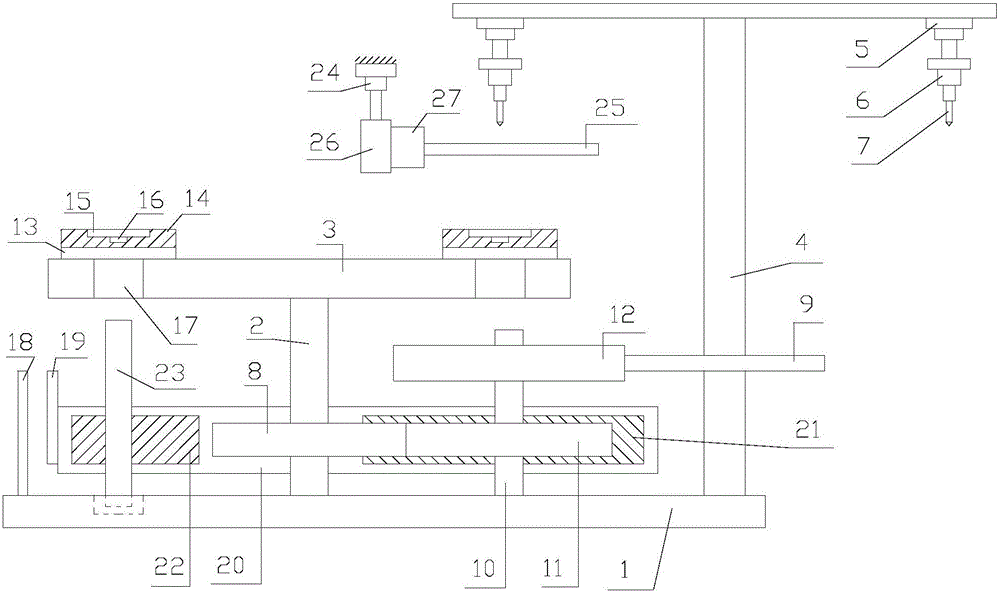

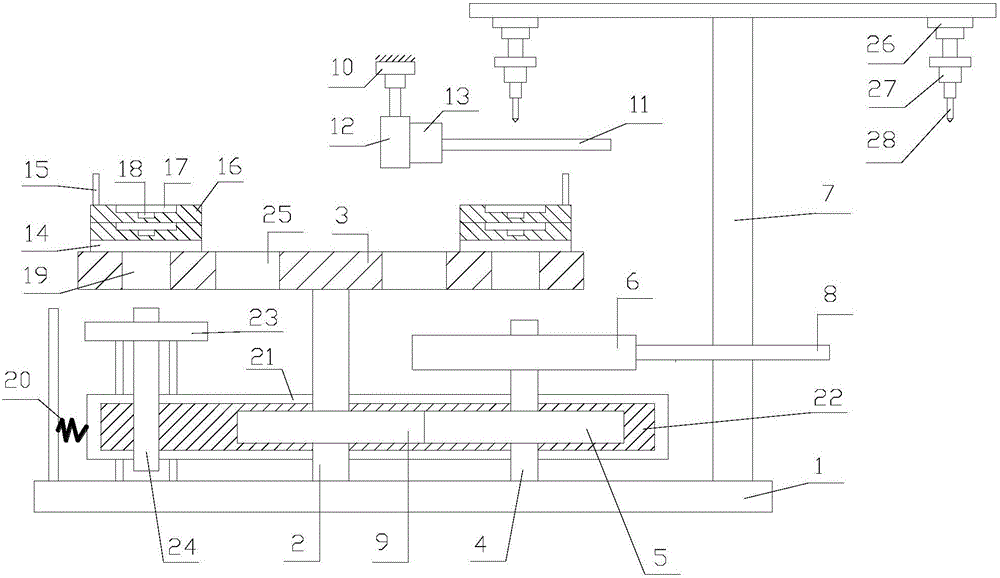

Combined additive and subtractive manufacturing machine tool

ActiveCN104384936AGuaranteed complexityGuaranteed processing effectOther manufacturing equipments/toolsUltrasonic vibrationMachining process

The invention belongs to the field of machine tool design, and relates to a combined additive and subtractive manufacturing machine tool, which comprises a body, a workbench, a main shaft, a numerical control system, a subtractive machining module and an additive manufacturing module. According to the combined additive and subtractive manufacturing machine tool, the additive manufacturing module is controlled by the numerical control system to form a basic structure of a required part on the workbench, then the subtractive machining module is controlled by the numerical control system to perform subtractive machining on the basic structure obtained by additive manufacturing, a function of applying ultrasonic vibration to a cutter and a gas cooling function are realized in a subtractive machining process, and the whole combined additive / subtractive manufacturing process is finally implemented. The combined additive and subtractive manufacturing machine tool can be used for realizing the efficient and precise combined additive and subtractive manufacturing of the component, the manufacturability of a complex part is improved, the production cycle is shortened, and the manufacturing accuracy of the complex part is ensured.

Owner:DALIAN UNIV OF TECH

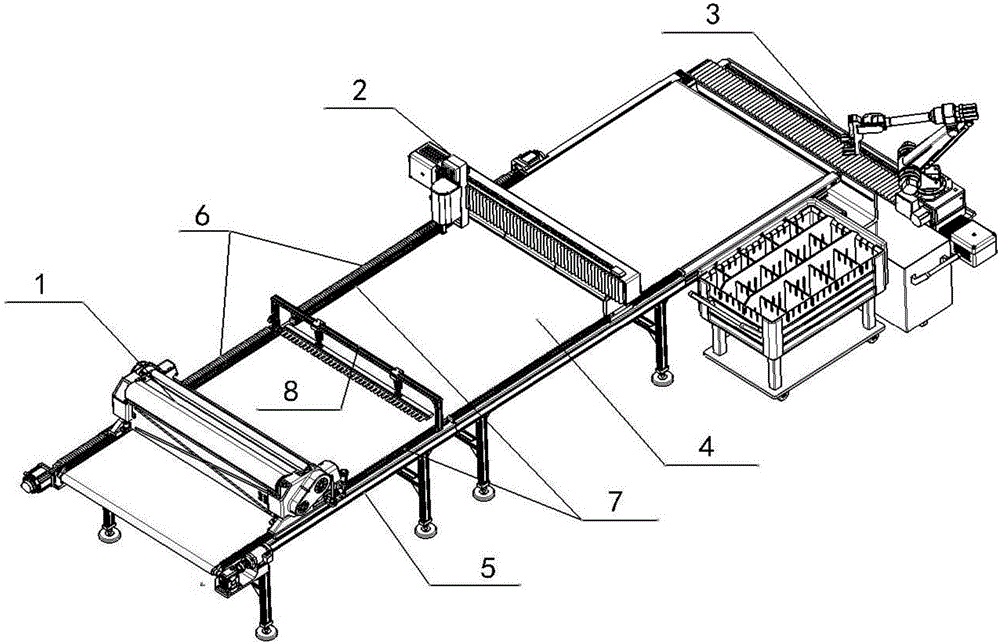

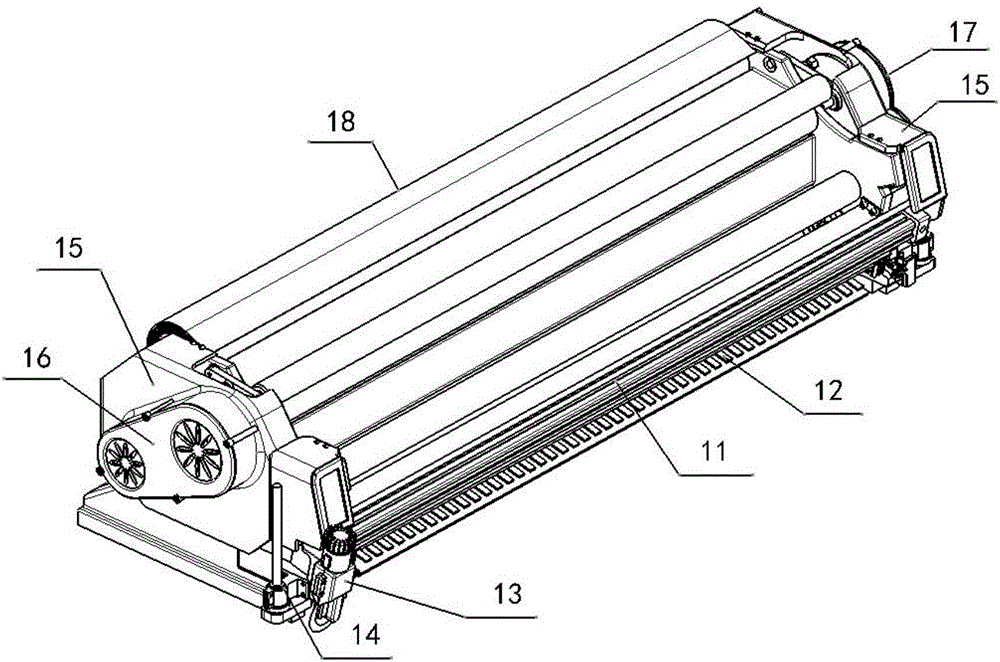

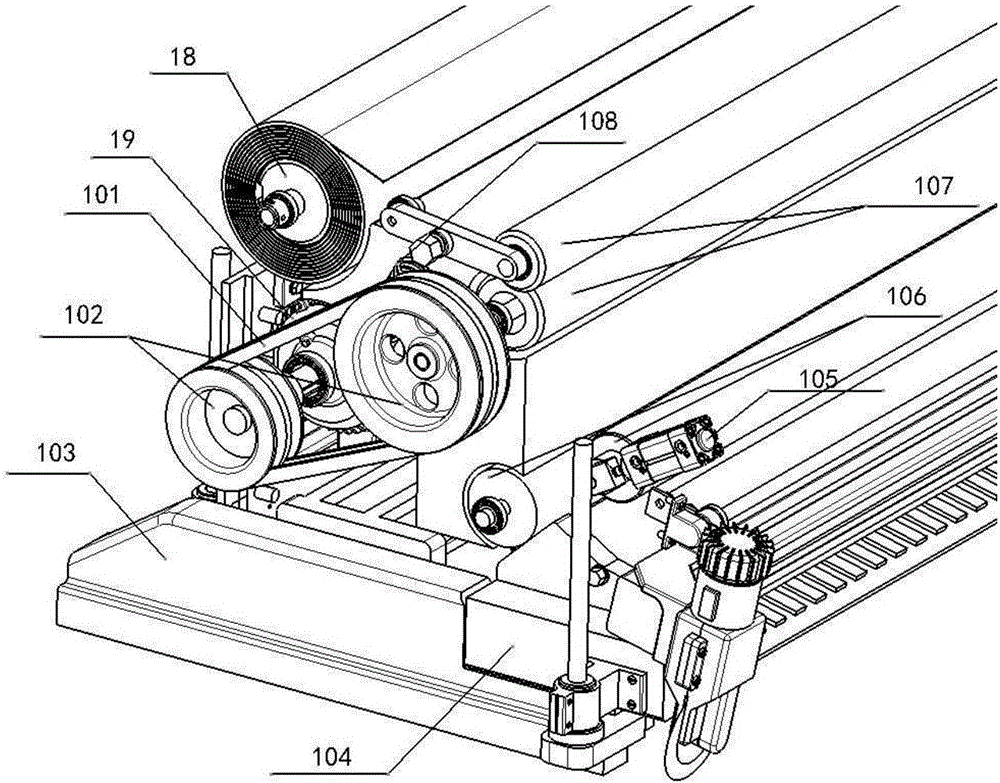

Full-automatic cloth paving and cutting integrated machine

InactiveCN106592194AImprove processing intelligenceImprove processing efficiencySevering textilesUnfolding thin materialsEngineeringMechanical engineering

The invention discloses a full-automatic cloth paving and cutting integrated machine which comprises a cutting platform, a cloth paving device, a cloth paving device walking mechanism, a cloth-spreading pressing mechanism, a cloth cutting device and a cloth cutting device walking mechanism. The full-automatic cloth paving and cutting integrated machine is characterized by further comprising a cloth settling mechanism, wherein the cloth settling mechanism comprises a mechanical arm and a cloth collecting trolley; the mechanical arm and the cloth collecting trolley are wholly arranged at the positions outside the cutting platform and close to the cutting platform; a cloth picking claw which is composed of a claw mechanism is fixedly arranged at an executing end of the mechanical arm; the cloth picking claw is used for picking the cloth which is cut by the cloth cutting device and is leaved on the cutting platform. The full-automatic cloth paving and cutting integrated machine can continuously automatically complete the cloth processing processes of spreading the cloth, cutting the cloth and picking the cloth and can obviously increase the intelligent degree of cloth processing and the processing efficiency.

Owner:CHONGQING UNIV OF TECH

Propylene homopolymer having high melt strength and preparation method thereof

The present invention provides a process for preparing high melt strength propylene polymer by direct polymerization, comprising that a propylene polymer with wide molecular weight distribution and containing “very high molecular weight fraction” can be prepared by controlling the species and ratios of the external electron donors in the Ziegler-Natta catalyst system at different reaction stages according to the requirment for different molecular weight fractions in the different propylene polymerization stage of the series operation, and said polymer has excellent mechnical properties, especially with very high melt strength. The present invention also provides a propylene homopolymer with high melt strength, comprising the following features: (1) the MFR is 0.2-10 g / 10 min at 230° C. with a load of 2.16 kg; (2) the molecular weight distribution Mw / Mn is 6-20; (3) the content of the fraction with a molecular weight higher than 5,000,000 is higher than or equal to 0.8 wt %; (4) Mz+1 / Mn is higher than or equal to 70. Said homopolymer can be used in the preparation of foam products, thermoforming products, biaxial stretching films, blown films and blow-molded products.

Owner:CHINA PETROCHEMICAL CORP +1

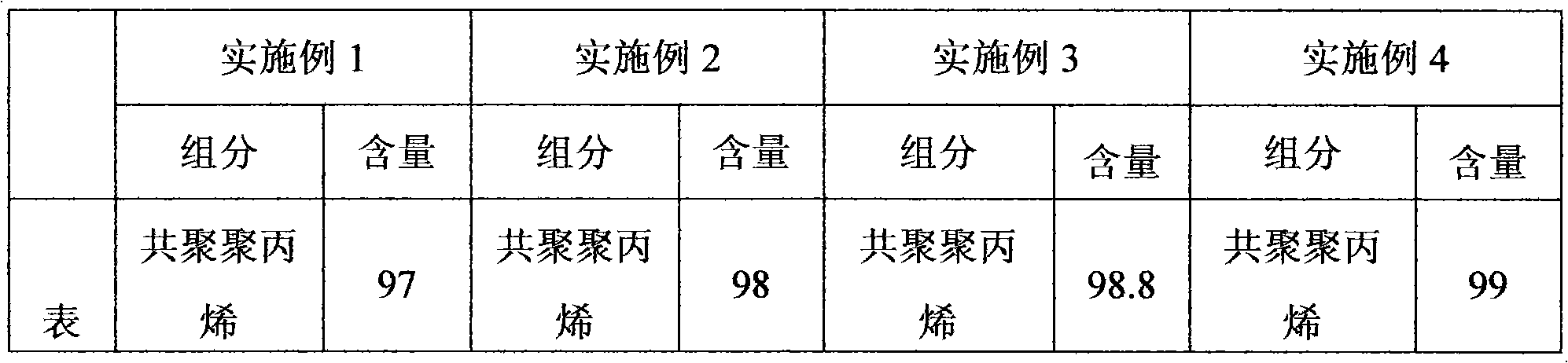

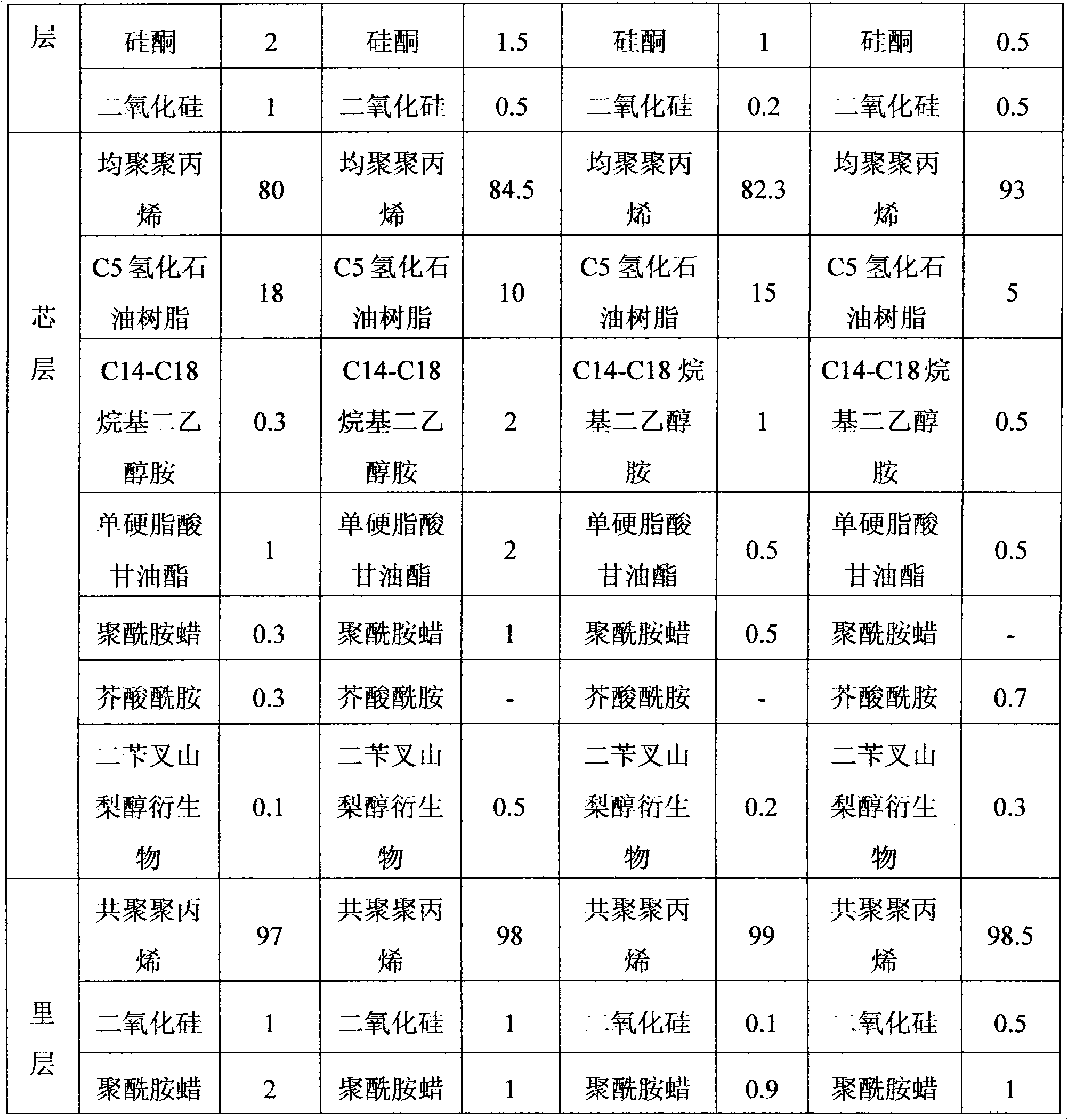

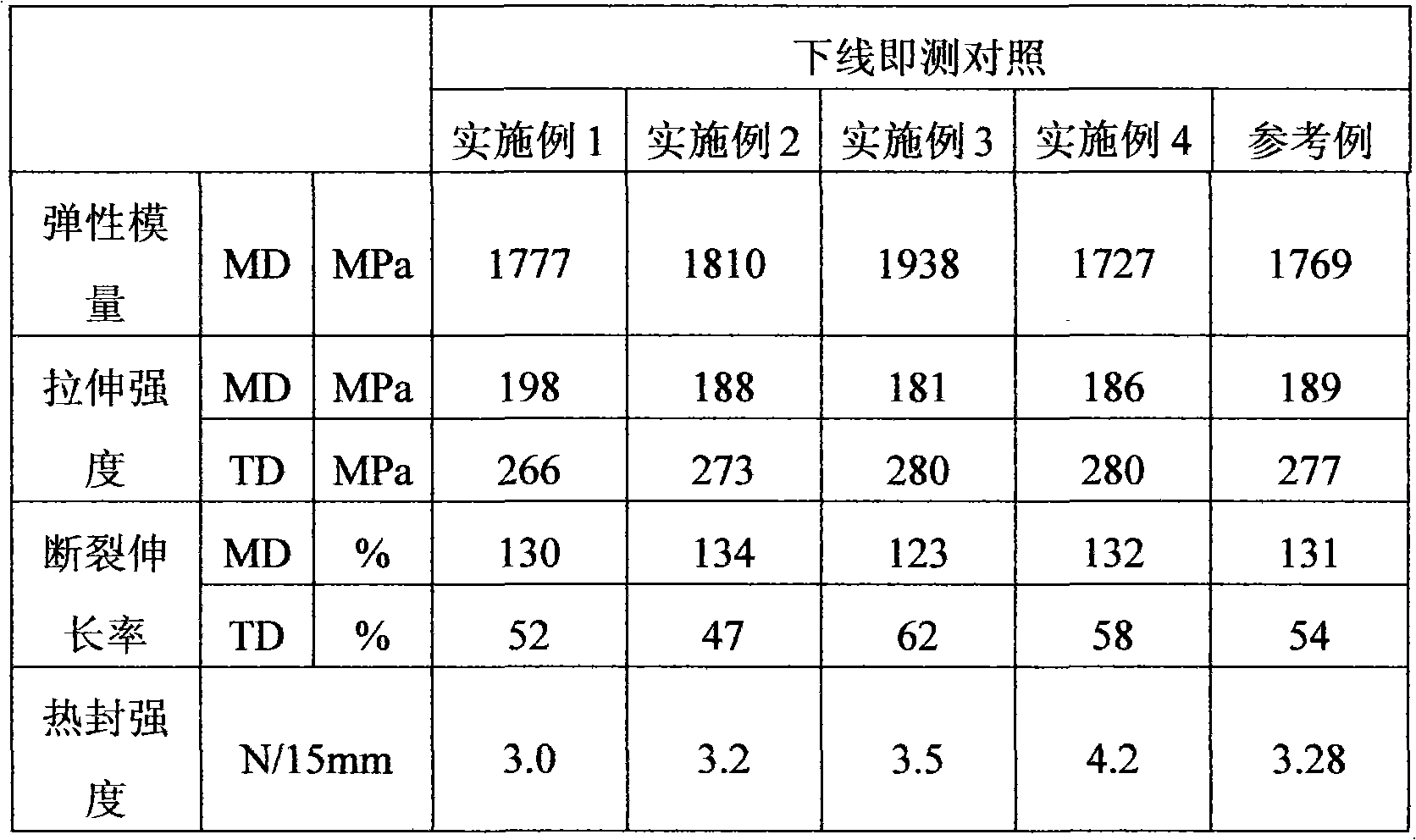

Thermal shrinkage biaxially oriented film

InactiveCN102059836ACrystallization perfectHigh heat shrinkageSynthetic resin layered productsTime changesAcrylic resin

The invention discloses a thermal shrinkage biaxially oriented film which is composed of a surface layer, a sandwich layer and an inner layer, wherein the thickness of the surface layer is 0.5-1.5 micrometers, the thickness of the sandwich layer is 19-22 micrometers, the thickness of the inner layer is 0.5-1.5 micrometers, and the total thickness of the three layers is 20-23 micrometers. The surface layer comprises the following components in percentage by weight: 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The sandwich layer comprises 80-93% of acrylic resin homopolymer, 0.3-3% of anti-static agent, 0.1-0.5% of crystal regulator, 1-2% of surfactant, 5-18% of stiffening agent and 0.5-1% of lubricant. The inner layer comprises 97-99% of acrylic resin copolymer, 0.5-2% of lubricant and 0.1-1% of antiblocking agent. The film has a stable thermal shrinkage factor which slightly changes as the storage time changes.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

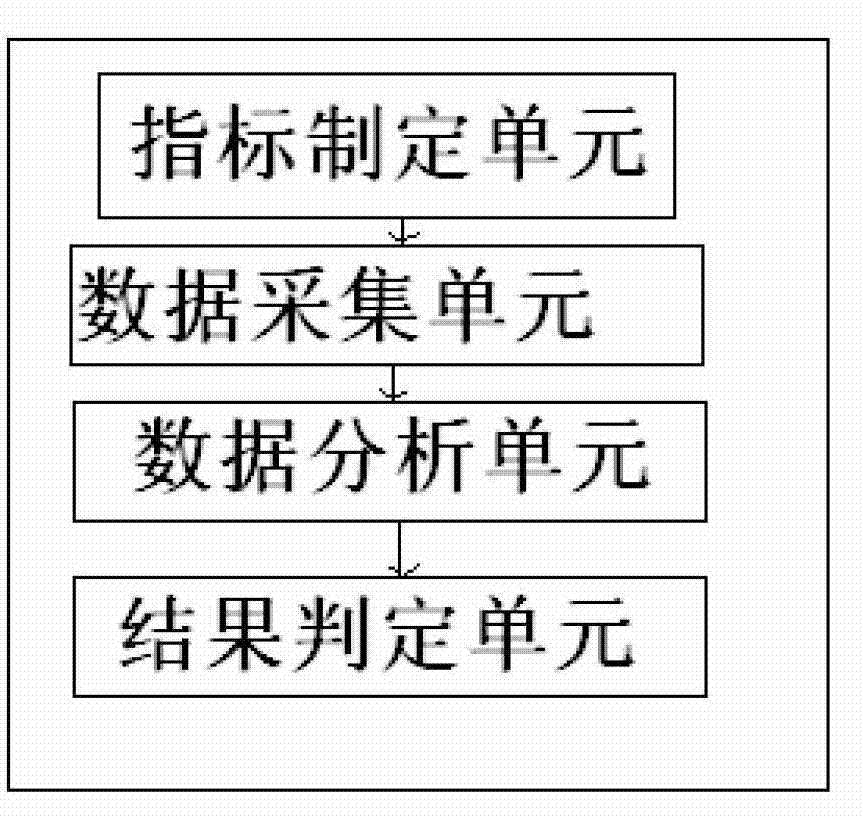

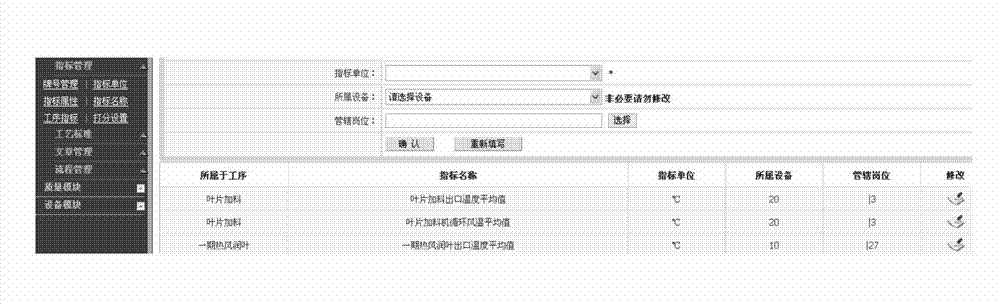

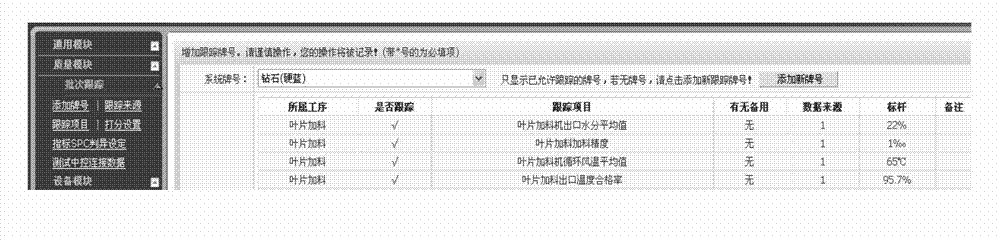

Quality monitoring system and method of tobacco primary process

ActiveCN102885392AGuaranteed processing effectEasy to operateTobacco preparationAutoanalysisControl data

The invention relates to a quality monitoring system and a method of a tobacco primary process. The quality monitoring system of the tobacco primary process comprises an index formulating unit, a data collection unit, a data analysis unit and a result determination unit; the collected data is modeled and analyzed on the basis of a tobacco primary process center control data system, so that the indexes according with current tobacco requirements, device processing capacity and processing direction are obtained, and the indexes are subjected to SPC (statistical process control) tracking determination. According to the technical scheme, the technical problem that a tobacco primary process parameter in the prior art cannot objectively reflect an actual production condition is effectively avoided. The quality monitoring method and the system are capable of monitoring and automatically analyzing the tobacco primary process.

Owner:ZHANGJIAKOU CIGARETTE FACTORY

Agricultural smashing machine

ActiveCN105413791ARedistribution lawImprove crushing efficiencyGrain treatmentsPulverizerAgricultural engineering

The invention discloses an agricultural smashing machine. The agricultural smashing machine comprises a driving unit, a crankshaft, N connecting pieces, N connecting rods, N striking pieces and a box; the driving unit is connected with the crankshaft in a transmission manner to drive the crankshaft to rotate; the crankshaft is horizontally arranged and comprises N connecting shaft necks; the N connecting pieces are rotationally connected with the N connecting shaft necks respectively; and one ends of the N connecting rods are rotationally connected with the N connecting pieces. The agricultural smashing machine is good in material processing effect and high in material processing efficiency.

Owner:全椒县汊河农机服务专业合作社

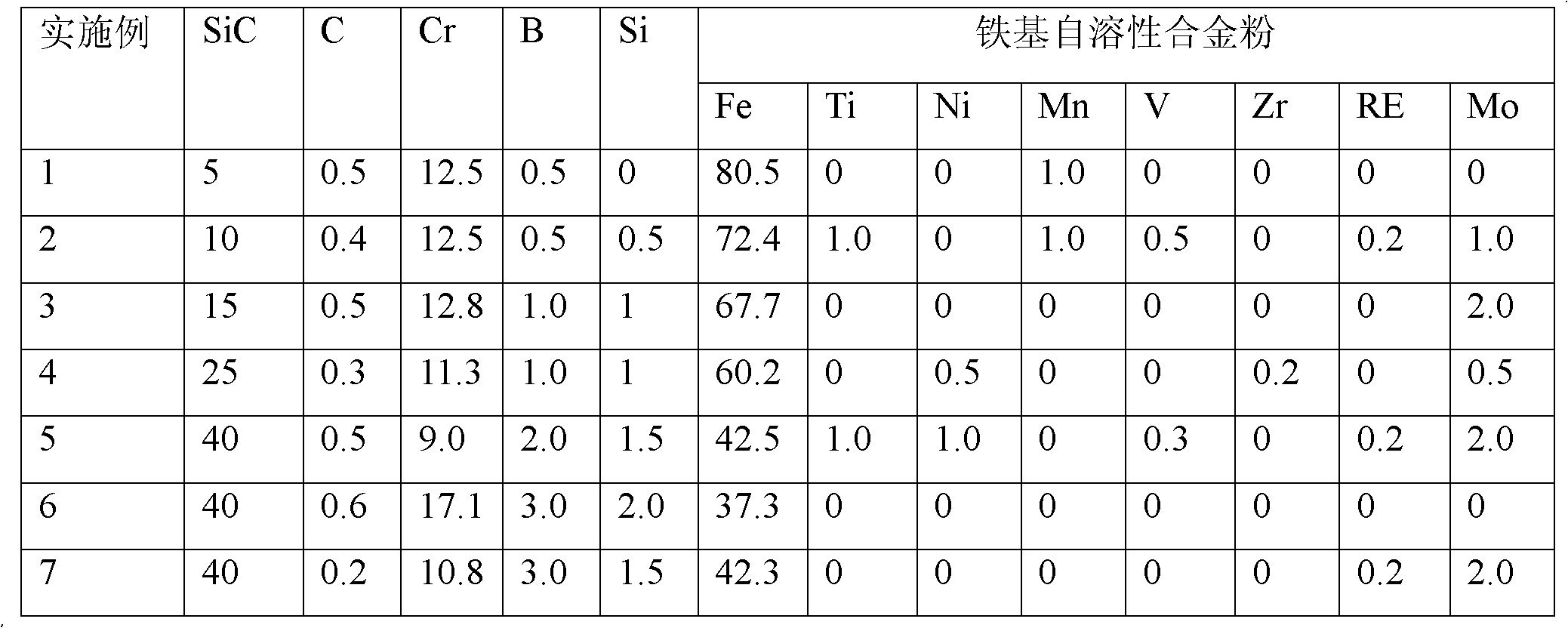

Composite material coated with SiC-Fe based alloy layer and preparation method of composite material

InactiveCN102218857ALow costGood value for moneyMolten spray coatingMetal layered productsHardnessPrice ratio

The invention discloses a composite material coated with a SiC-Fe based alloy layer and a preparation method of the composite material. The composite material coated with the SiC-Fe based alloy layer is formed by coating the SiC-Fe based alloy layer on the surface of a steel base material, wherein the steel base material is carbon steel or alloy steel of which the carbon content is 0.2 to 0.7 weight percent, and the raw material of a SiC-Fe composite material layer is SiC powder and iron-based autolytic alloy powder. The preparation method of the composite material comprises the following steps of: mixing the iron-based autolytic alloy powder with the SiC powder; and spraying the mixture on the surface of the steel base material. The composite material coated with the SiC-Fe based alloy layer has excellent performances of high hardness, good wearing resistance, low brittleness, capability of being subjected to heat treatment and machining, low cost, high performance price ratio and the like, and can obviously improve the surface property of the steel base material.

Owner:HEFEI JINSIDA TECH

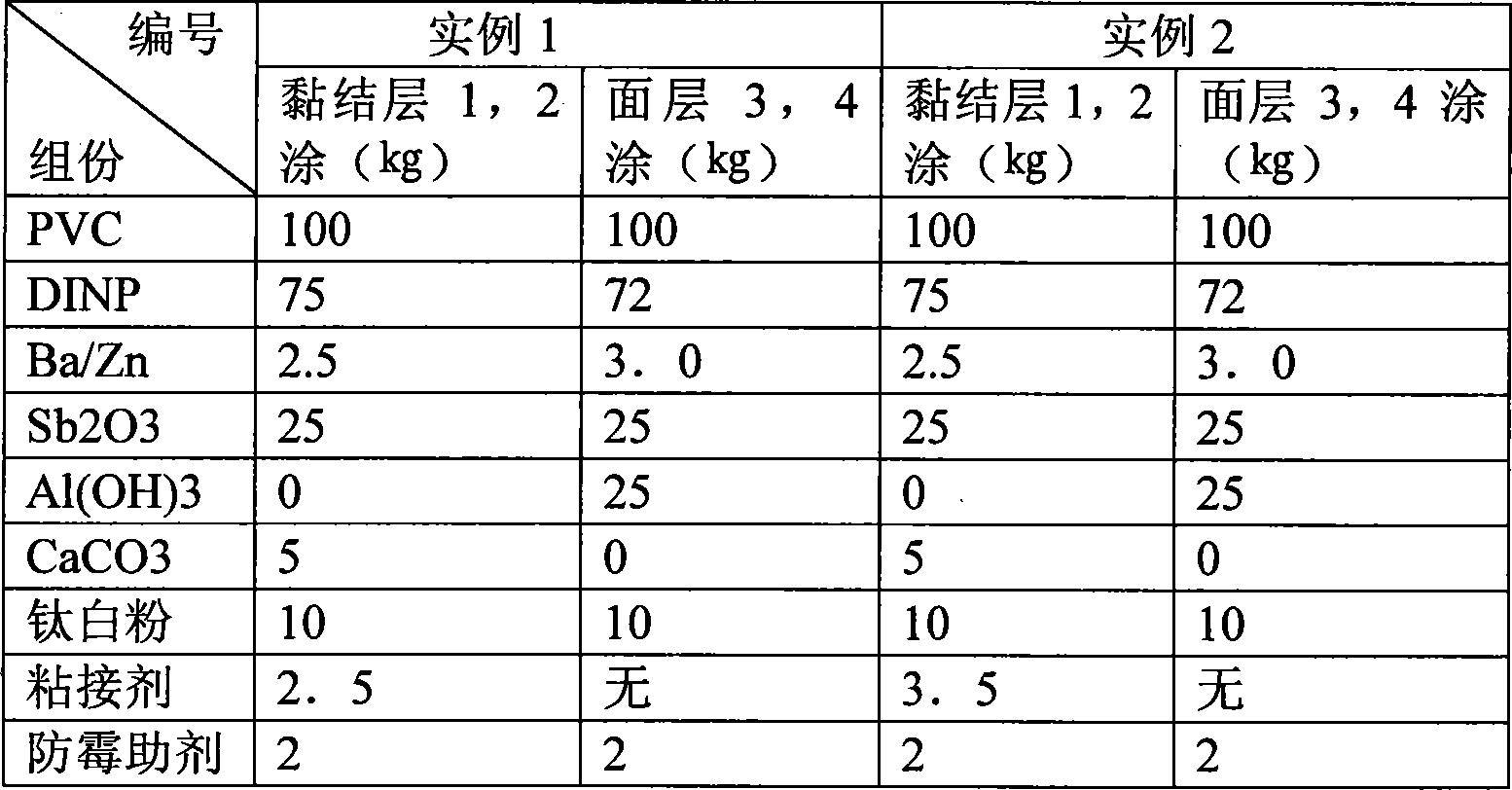

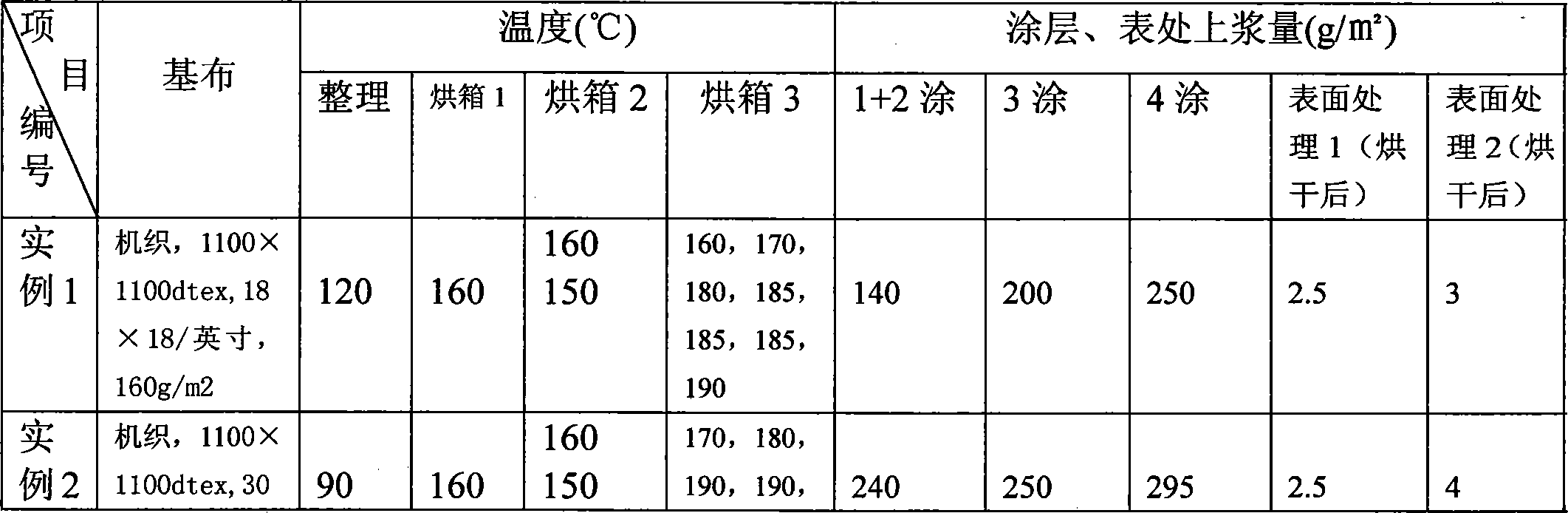

High-performance self-clean type building structural membrane material and preparation method thereof

InactiveCN101230543AReduce surface tensionGuaranteed anti-fouling, self-cleaning and weather resistanceSynthetic resin layered productsTextiles and paperPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a high performance self-cleaning building structure membrane material and a preparation method thereof. The preparation method comprises the technical steps as follows: (1) the preparation of a sizing agent for a PVC coat, (2) the PVC coat, and (3) superficial treatment. Compared with the prior art, the invention has the advantages as follows: polyvinylidene fluoride (PVDF) solution modified from acrylic ester is used as a surface treatment agent containing fluorine; wherein, the acrylic ester ensures the interconsistency between a surface treatment layer and the PVC coat, and ensures the handling characteristic of the product; and the polyvinylidene fluoride ensures the antifouling property, self cleaning and resistance to elements of the building structure membrane material; through adjusting the compoment ratio of the acrylic ester and the polyvinylidene fluoride, the comprehensive effect that the performances such as the working quality, the self cleaning, the resistance to elements, etc. of the building structure membrane material are combined is obtained.

Owner:FOSHAN GAOMING YILONG PLASTICS & RUBBER IND

Nickel-based positive active material of lithium ion secondary battery and preparation method thereof

ActiveCN103943822AIncrease gram capacityIncrease working voltageCell electrodesSecondary cellsLithiumGram

The invention discloses a nickel-based positive active material of a lithium ion secondary battery. The nickel-based positive active material is subjected to wrapping treatment and is prepared from the following components in percentage by weight: 50%-99.5 percent of nickel-based material as a matrix and 0.05-50 percent of shell material. A general formula of the lithium ion secondary battery can be expressed as [Li(p)Ni(x)Co(y)Mn(z)O2][Li(q)Ni(a)Co(b)Mn(c)O2]. A preparation method of the nickel-based positive active material comprises the steps of preparing a precursor of the positive material of the lithium ion secondary battery; and preparing the positive material of the lithium ion secondary battery. According to the invention, as the gradient variation of nickel concentration between the matrix material and the shell material is realized by virtue of wrapping, the nickel-based positive active material has good electrochemical performance of high gram volume, high working voltage, good cycle performance and the like, and the safety and the machinability of the material are also ensured. In addition, the preparation method is high in the operability, is favorable for industrial production and has high application value.

Owner:NANTONG RESHINE NEW MATERIAL

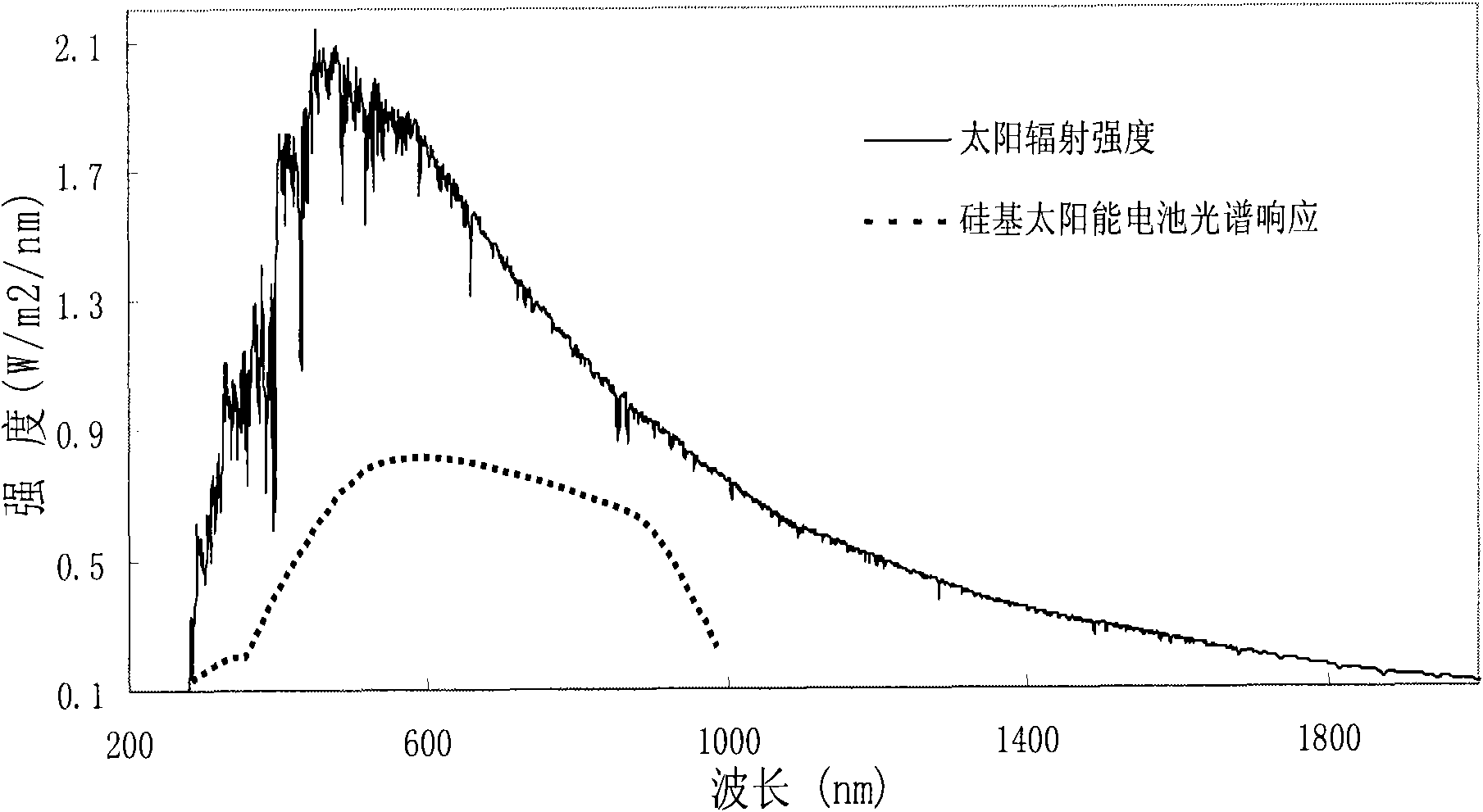

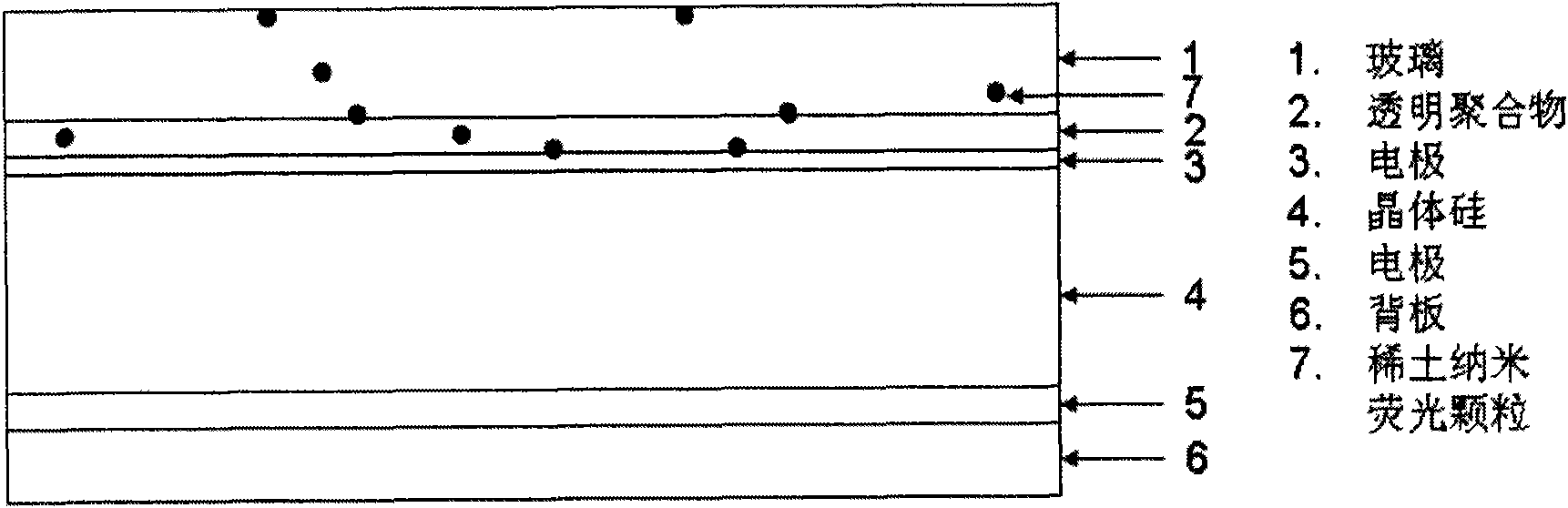

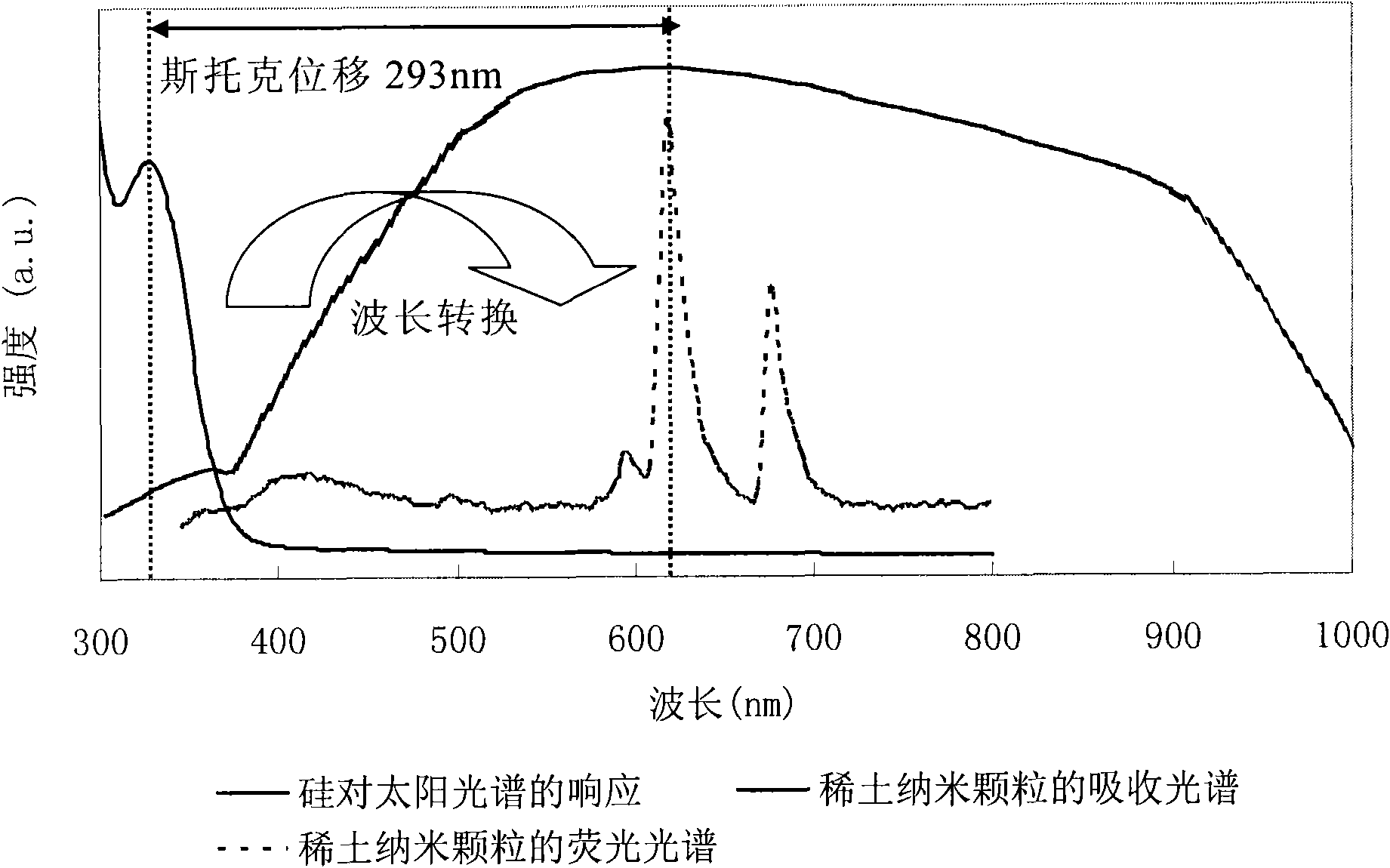

Nano fluorescent particles doping with rare-earth ions and relevant application thereof

InactiveCN101787272AHigh fluorescence efficiencyEffective absorptionTenebresent compositionsPhotovoltaic energy generationMischmetalRare earth ions

The invention provides nano fluorescent particles doping with rare-earth ions. The grain size of the nano particles is 1-200nm, and the nano particles comprise a nano particle matrix and rare-earth ions. The invention also provides a solar battery containing the nano particles.

Owner:EI DU PONT DE NEMOURS & CO

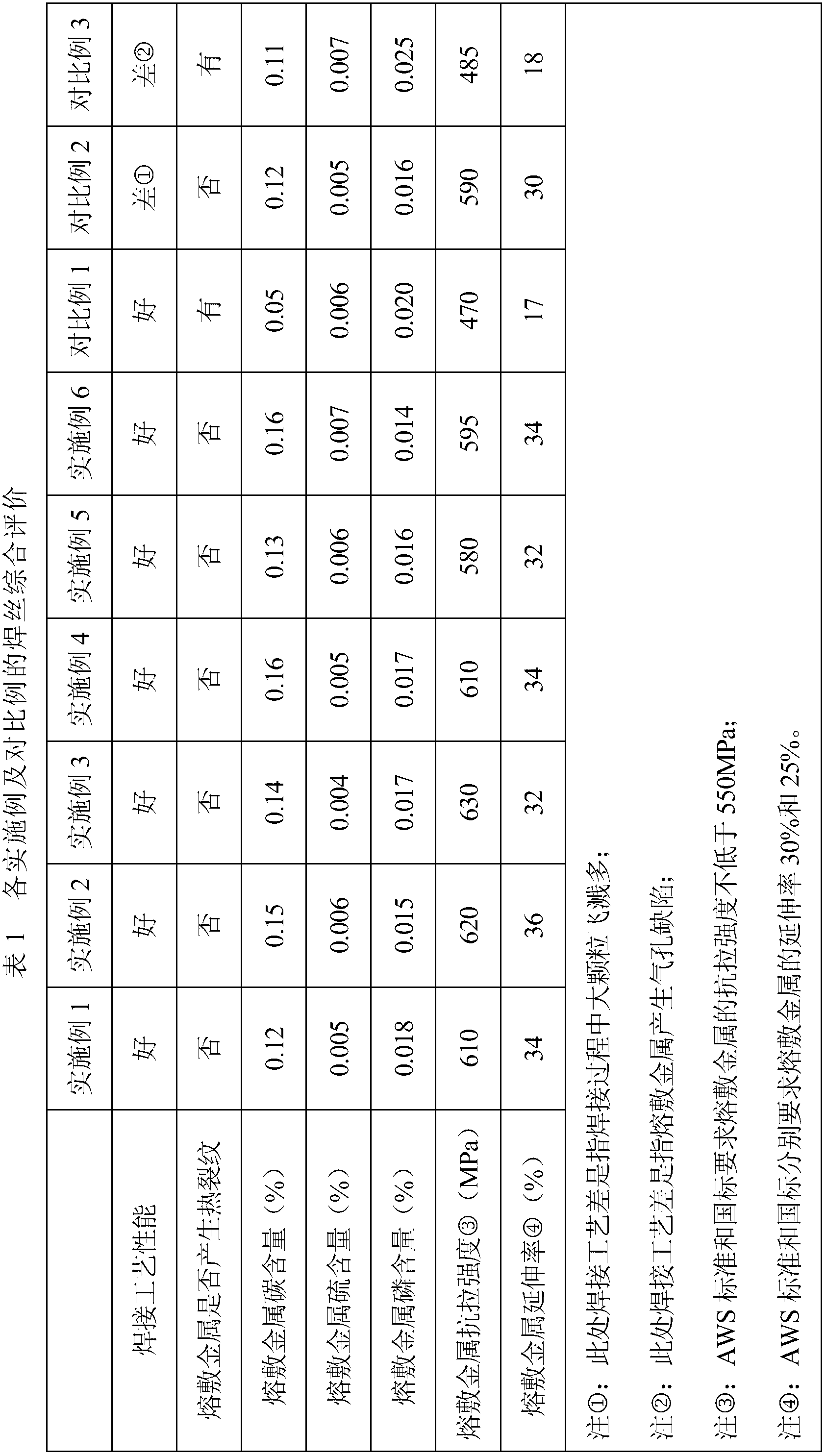

Flux-cored wire for gas-shielded welding of high-chromium-nickel all-austenitic stainless steel

InactiveCN102699579AGuaranteed processing effectIncrease widthWelding/cutting media/materialsSoldering mediaChromium nickelManganese

The invention provides a flux-cored wire for the all-position welding of an austenitic stainless steel, comprising flux powder and a stainless steel band for external use, wherein the weight of a flux core accounts for 28.0-30.0 percent of the total weight of the flux-cored wire, the flux core contains the following components accounting for the flux core in percentage by weight: 25.0%-28.0% of metallic chromium powder, 29.0%-32.0% of metallic nickel powder, 4.0%-5.0% of electrolytic metallic manganese, 2.0%-4.0% of high carbon ferro-chrome, 18.0%-20.0% of rutiles, 1.0%-2.0% of quartz, 1.0%-2.0% of zircon sands, 1.0%-3.0% of feldspars, 0.5%-1.0% of fluorspars, 0.5%-1.5% of calcium carbonate, 0.5%-1.5% of barium carbonate, and the balance of ferrous powder. The flux-cored wire has good welding process property and is suitable for the all-position gas-shielded welding of a high-chromium-nickel all-austenitic stainless steel.

Owner:CHINA JINGYE ENG +1

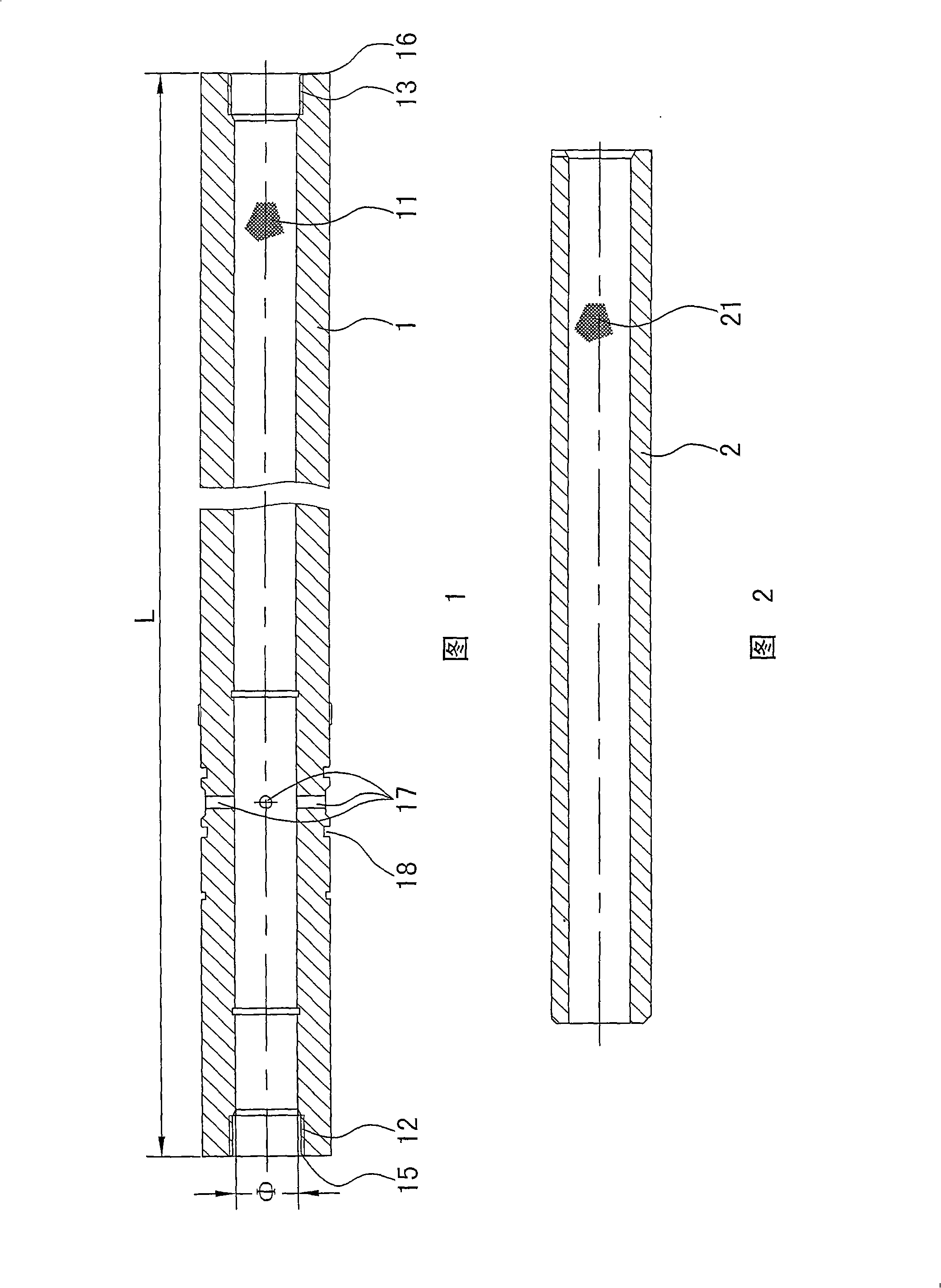

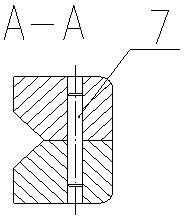

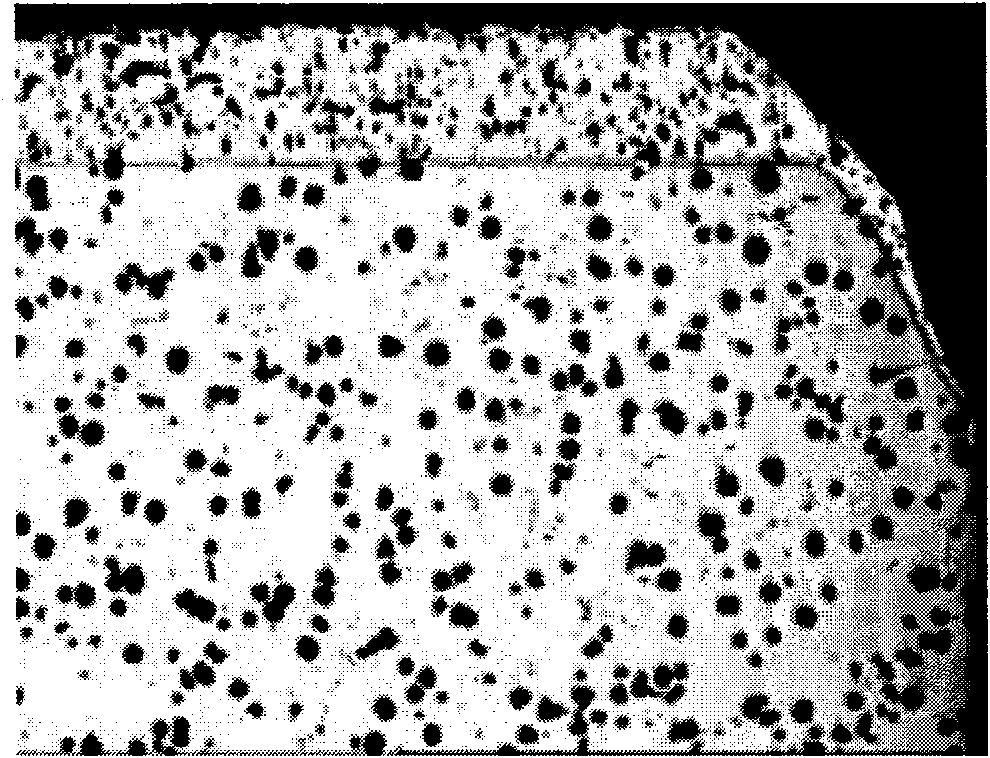

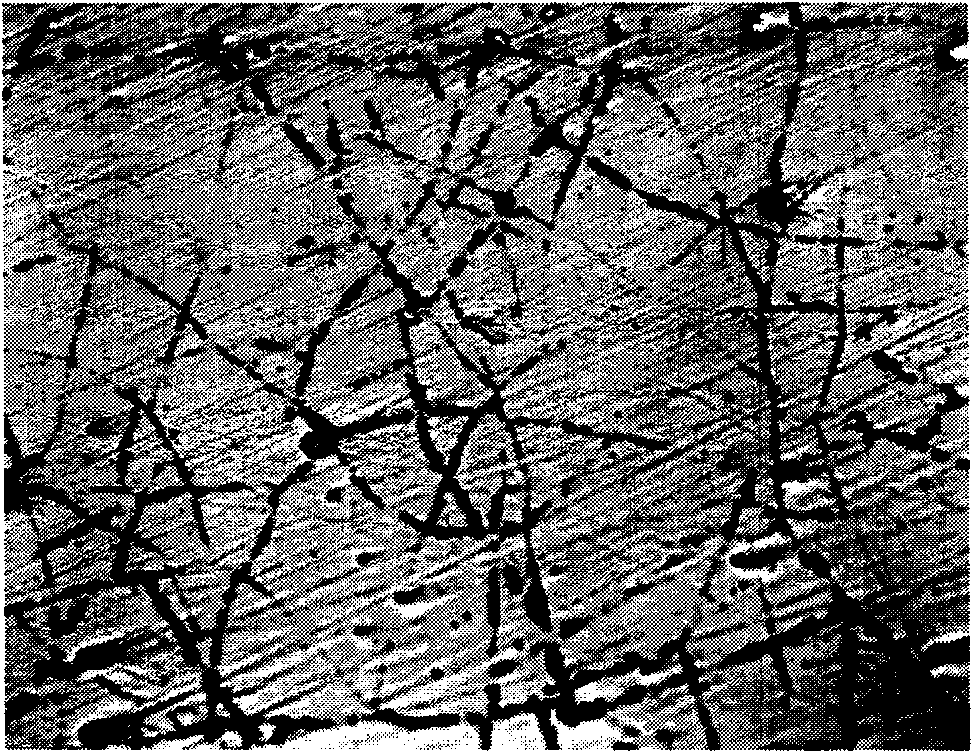

Long-stroke pneumatic hydraulic cylinder body and its processing method

InactiveCN101344169AHoning is easyGuaranteed processing effectCylindersHydraulic cylinderPulp and paper industry

The invention discloses a long-stroke pneumatic hydraulic cylinder body which includes an outer cylinder body and an inner cylinder body which are made of circular steel pipes; the middle part of the outer cylinder body has an oil through which is communicated with the hydraulic cavity of the pneumatic cylinder body; the pneumatic hydraulic cylinder body is characterized in that the inner wall surfaces of the outer cylinder body and the inner cylinder body are respectively provided with grids which can store oil and lead the outer cylinder body and the inner cylinder body to keep long-time lubrication, reduce wear and prolong service life although the grids are tiny. The processing method of the outer cylinder body is as follows: a. fetching a seamless precision steel pipe with the specification of inner hole diameter of 15<-0.07><-0.10>mm, and length of 400 mm; b. using a lathe for turning both ends flat, and heat treatment quenching and tempering stereotype; c. using honing roughing, grinding the inner hole diameter up to be 15<-0.02><-0.03>mm; d. using a mandrel for sheathing the inner hole, using an excircle grinder for grinding the excircle, requesting concentricity; e. using a CNC lathe for cutting the oil through; f. carbonation treatment: enabling the depth up to be more than 0.05 mm; and g. adopting honing finishing so as to lead the finish to be about 0.05 mm and the straightness to be 400 / 0.01 mm, and the roundness to be controlled as 0.002 mm, and lead the inner wall surface of the steel pipe to form small grids.

Owner:浙江速成精密机械有限公司

Composite solder flux-cored aluminum welding wire and preparation method thereof

ActiveCN103612026ALower the melting point of solderAlloying time is shortWelding/cutting media/materialsSoldering mediaAluminiumComposite solder

The invention discloses a composite solder flux-cored aluminum welding wire and a preparation method thereof. The composite solder flux aluminum welding wire comprises a sheath and a flux core filling the sheath. The sheath is made by rolling the alloy of Cu, Al and the like. The composite solder flux-cored aluminum welding wire and the preparation method thereof have the advantages that the sheath in the composite belt form replaces the traditional alloy sheath, good processability of the composite belt ensures processability of the composite solder flux-cored welding wire, and the problem that solder is hard to process into the flux-cored welding wire is solved.

Owner:SHANGHAI LONGSHUO WELDING MATERIAL

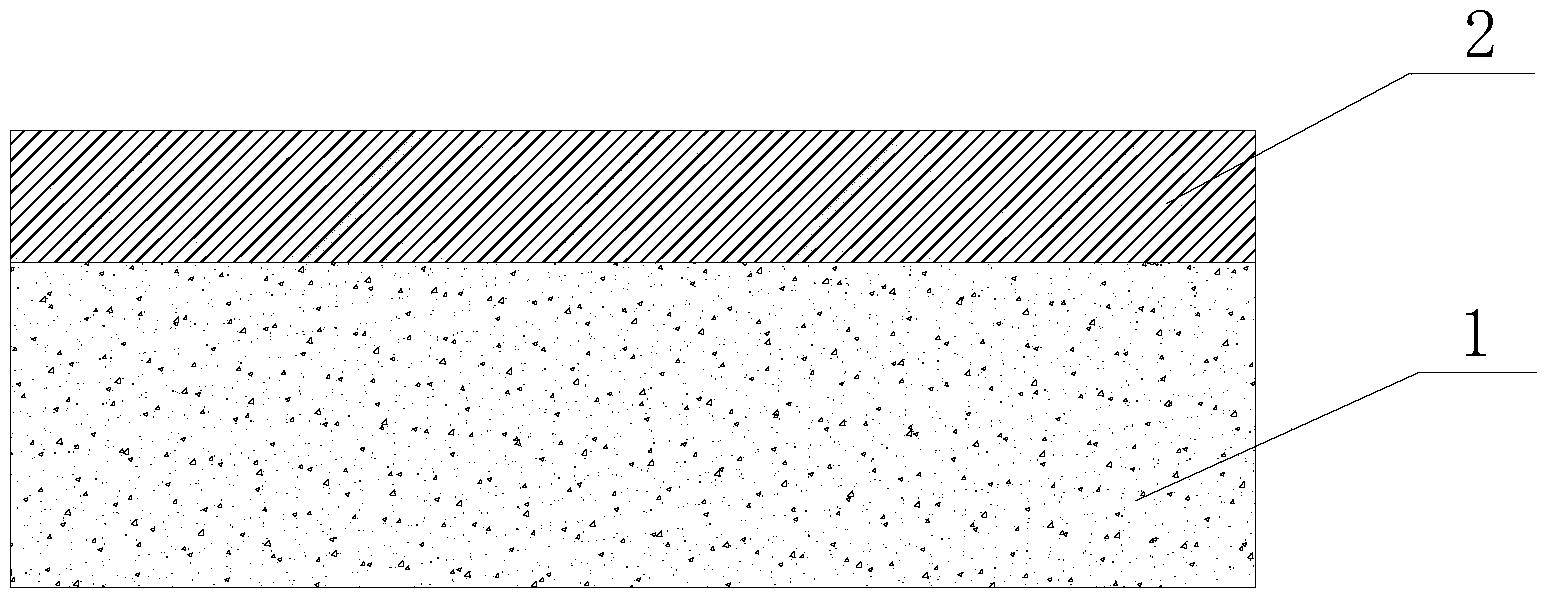

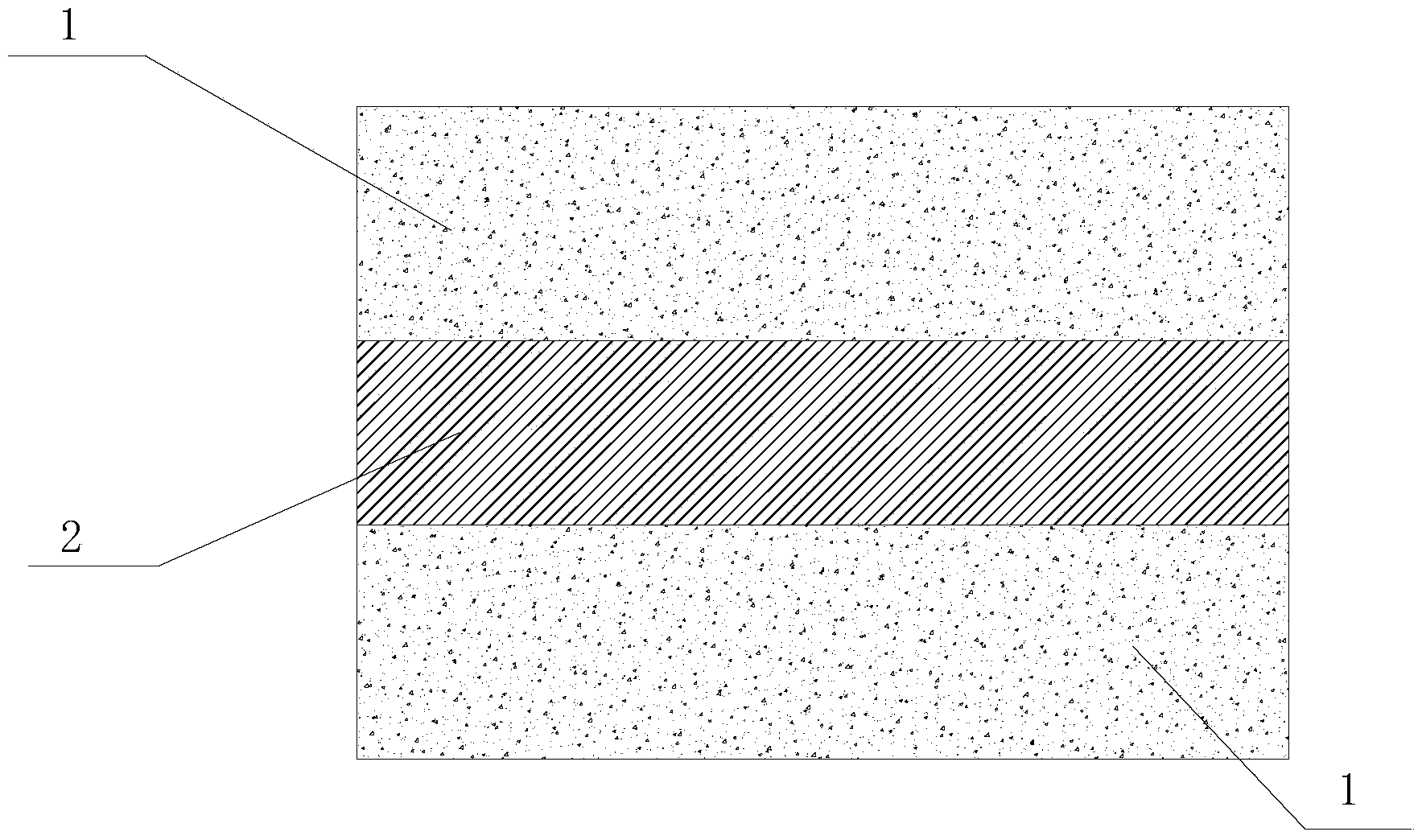

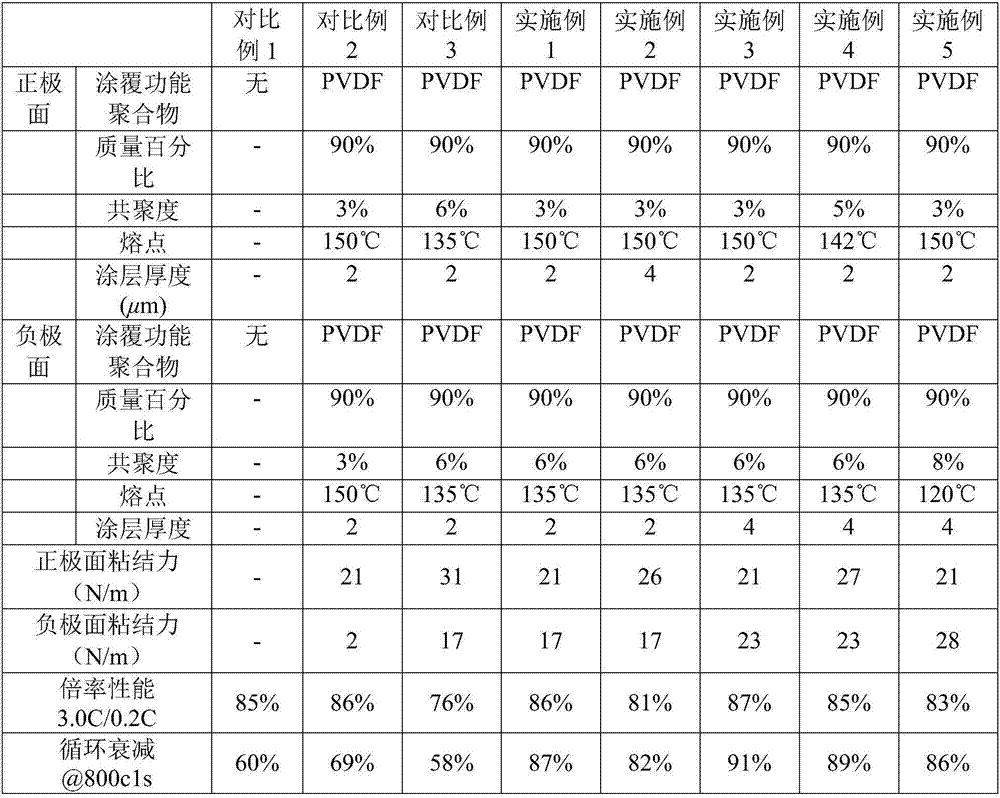

Organic functional porous isolating membrane, preparation method and lithium ion battery

ActiveCN107123767AImprove adhesionExcellent rate performanceCell seperators/membranes/diaphragms/spacersSecondary cellsSodium-ion batteryLong term cycling

The invention discloses an organic functional porous isolating membrane, a preparation method and a lithium ion battery, and aims to the solve the problem that a function of a coating layer is influenced caused by different binding effects when the surfaces of two coating layers of the same specification of an isolating membrane are laminated and glued with positive and negative plates of different physical properties of a battery. According to the main points of the technical scheme, the organic functional porous isolating membrane comprises a porous base material and organic functional coating layers attached to two surfaces of the porous base material; and each organic functional coating layer comprises organic functional polymer polyvinylidene fluoride, an aqueous polymer thickening agent, and an aqueous polymer binder. According to the different characteristics of the positive and negative electrode materials of the lithium ion battery corresponding to the two surfaces of the porous base material, the organic functional polymer polyvinylidene fluoride with different copolymerization degrees and fusing temperatures can be selected on the surfaces of the isolating membranes of the corresponding positive and negative electrodes, so that the safety performance and the long-term cycling stability of the battery can be improved.

Owner:深圳市旭然电子有限公司

Automatic processing system for drilling machine

The invention discloses an automatic processing system for a drilling machine, which comprises a base, a first rotating shaft, a turntable, a plurality of fixtures, a second rotating shaft, two processing mechanisms, a driving mechanism, a position sensor, a distance sensor, and a controller; the first rotating shaft is vertical Installed on the base, the first rotating shaft is rotatably connected with the base; the turntable is installed on the first rotating shaft; multiple fixtures are installed on the turntable, and the plurality of fixtures evenly surround the rotation center of the turntable; the second rotating shaft is installed on the base , the axis of the second rotating shaft is parallel to the axis of the first rotating shaft; the two processing mechanisms are installed on the second rotating shaft, the two processing mechanisms are symmetrical about the second rotating shaft, and the two processing mechanisms are placed above the fixture; the driving mechanism It is used to drive the turntable to rotate to drive the fixture to enter or leave the projection area of the processing mechanism on the horizontal plane; and the drive mechanism is used to drive the second rotating shaft to rotate. The invention has good processing effect and high processing precision.

Owner:芜湖中驰机床制造有限公司

Propylene homopolymer having high melt strength and preparation method thereof

ActiveUS9068030B2High molecular weightImprove mechanical propertiesZiegler–Natta catalystElectron donor

The present invention provides a process for preparing high melt strength propylene polymer by direct polymerization, comprising that a propylene polymer with wide molecular weight distribution and containing “very high molecular weight fraction” can be prepared by controlling the species and ratios of the external electron donors in the Ziegler-Natta catalyst system at different reaction stages according to the requirement for different molecular weight fractions in the different propylene polymerization stage of the series operation, and said polymer has excellent mechanical properties, especially with very high melt strength. The present invention also provides a propylene homopolymer with high melt strength, comprising the following features: (1) the MFR is 0.2-10 g / 10 min at 230° C. with a load of 2.16 kg; (2) the molecular weight distribution Mw / Mn is 6-20; (3) the content of the fraction with a molecular weight higher than 5,000,000 is higher than or equal to 0.8 wt %; (4) Mz+1 / Mn is higher than or equal to 70. Said homopolymer can be used in the preparation of foam products, thermoforming products, biaxial stretching films, blown films and blow-molded products.

Owner:CHINA PETROCHEMICAL CORP +1

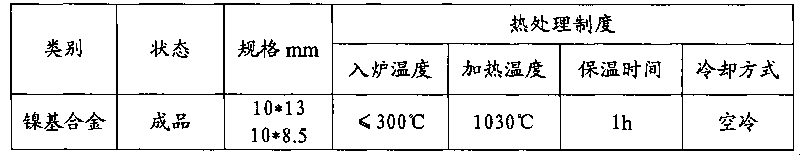

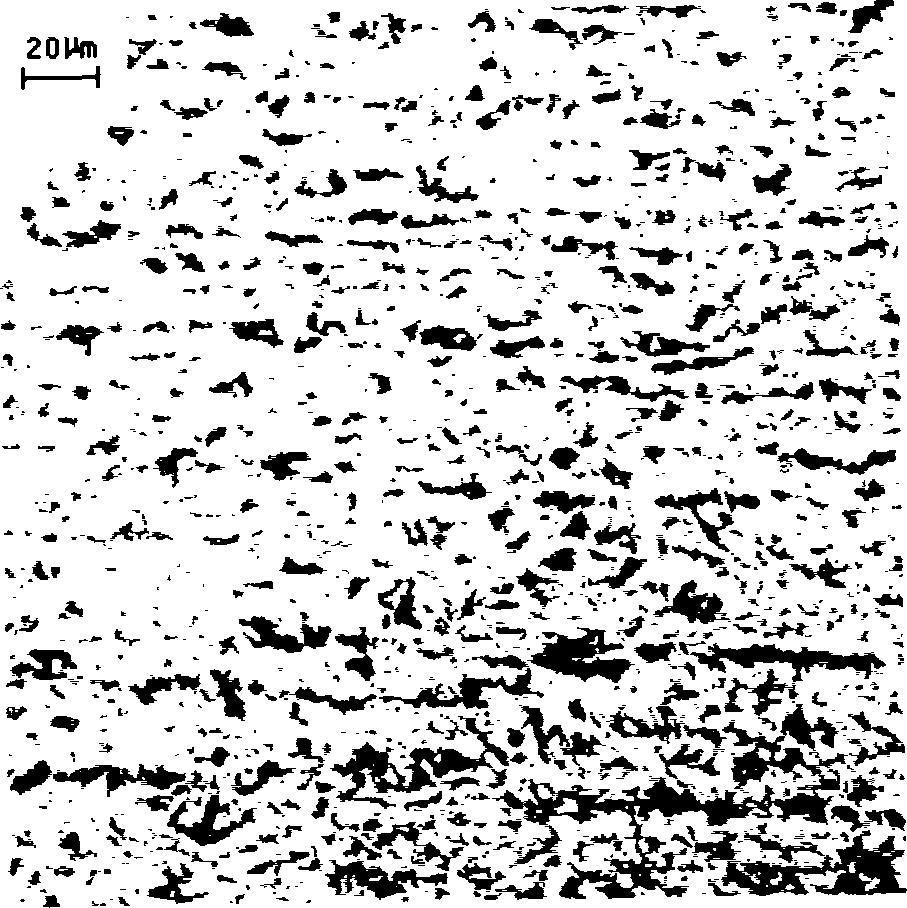

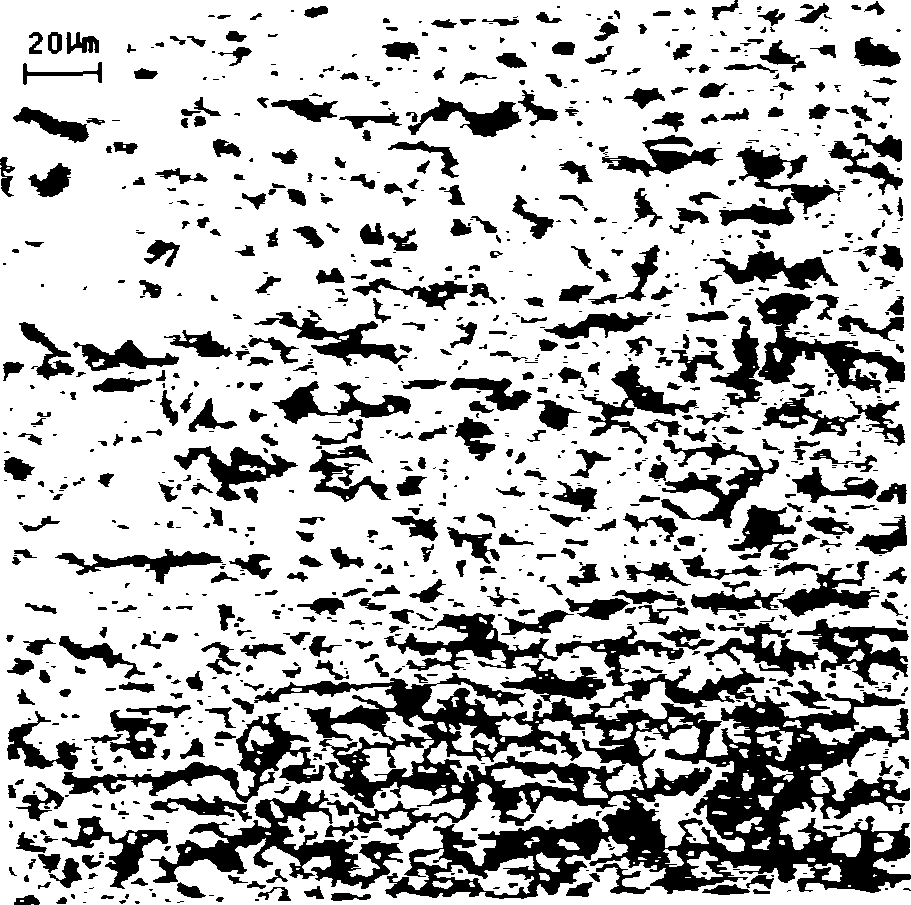

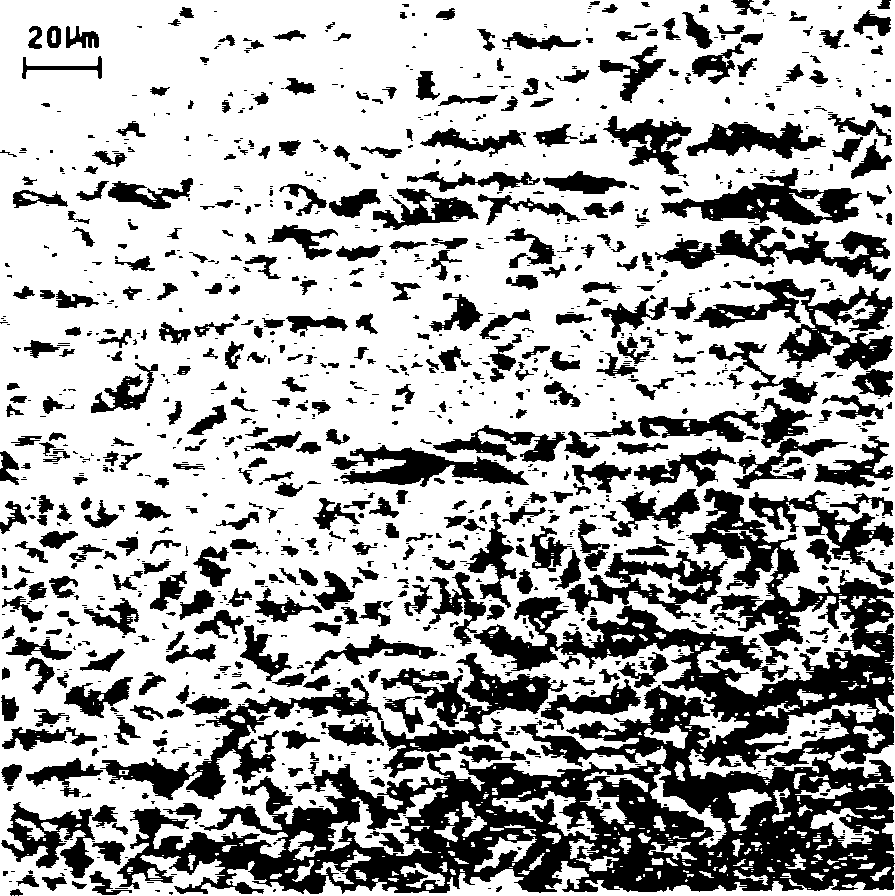

Nickel-based alloy of nuclear power steam generator

The invention relates to a nickel-based alloy of a nuclear power steam generator. The invention can maintain or increase the alloy performance while reducing the alloy cost. The specific scheme of the invention is as follows: 1. a defined amount of rare earth elements are added in steel to have purification and metamorphism functions of deoxidizing, desulfurizing, changing the shape of inclusion and the like, have microalloy function in the alloy and finally increase the oxidation resistance, high temperature strength and plasticity, fatigue life, corrosion resistance, crack resistance and the like of the steel; 2. in view of the production cost, the content of the precious element nickel is needed to be as low as the lower limit under the premise of ensuring the processability and ensuring that the alloy can form the desired metallographic structure; 3. the content of chromium element is increased properly so as to increase the high temperature oxidation resistance and corrosion resistance of alloy; 4. the content of silicon element is adjusted so as to increase the tensile strength and corrosion resistance of alloy while the plasticity of alloy is ensured; and 5. the content of carbon is controlled and titanium element is added at the same time so as to further increase the oxidation resistance and corrosion resistance of steel.

Owner:江苏龙鑫特殊钢实业总公司

Machine tool for processing workpieces

InactiveCN105710730ACooperate skillfullyConvenient and flexible processingMetal working apparatusPositioning apparatusEngineeringMachine tool

The invention discloses a machine tool for workpiece processing, which comprises a base, a rotating shaft, a wheel disc, a plurality of clamps, a rotating shaft, a first rotating wheel, a second rotating wheel, a supporting shaft, a driven gear, and M actuators . Drive mechanism, wherein, M is an integer greater than or equal to 2; the rotating shaft is installed on the base in rotation, the center line of the rotating shaft is vertically arranged, and the circumferential surface of the rotating shaft is provided with first gear teeth; the wheel disc is installed on on the rotating shaft; multiple fixtures are installed on the wheel, and the multiple fixtures are evenly distributed on the circumference centered on the center of rotation of the wheel; the rotating shaft is installed vertically on the base, and the rotating shaft is connected to the base in rotation on one side of the wheel. The invention has high processing precision and good processing effect.

Owner:芜湖中驰机床制造有限公司

Composite SiC and its making process

InactiveCN1931462AGuaranteed toughnessGuaranteed StrengthMolten spray coatingShaft and bearingsHardnessHigh wear resistance

The present invention is composite SiC guide roller and its making process, and features that the composite SiC guide roller has a steel base body and a surface composite material layer of material comprising SiC 5-40 %, C 0.2-0.6 %, Cr 0-3.0 %, Mo 0-2.0 %, Mn 0-2.0 %, other metal and non-metal elements not more than 5 %, and Fe for the rest. The composite material is coated to the surface of the steel base body with powder, wire or rod of the composite material and through hot spraying, hot spray welding or laser depositing and combined with the steel base body. The composite SiC guide roller of the present invention has high hardness, high wear resistance, low brittleness, capacity of being heat -treated, machinability, low cost, high performance / cost rate and other advantages.

Owner:HEFEI UNIV OF TECH

Method for producing J55-grade steel for petroleum casing based on electric furnace sheet billet continuous casting an rolling process

InactiveCN1884787AHigh strengthImprove toughnessDrilling rodsTemperature control deviceChemical compositionSolderability

The invention relates to a method for producing J55 steel used in oil sleeve, based on furnace sheet blank continuous casting rolling process, wherein the invention uses electric furnace to smelt, refine, continuously cast the sheet blank and, and solidifies the casting blank, to feed it to rolling heating or uniformly heating furnace, then removes scales with high-pressure water, hot rolls, laminated cools, and coils. The chemical components of steel water comprises (wt %): C in 0.15-0.22%, Si <=0.45%, Mn in 0.70-1.60%, P<=0.025%, S<=0.020%, Nb<=0.06% and Ti<=0.035%. The invention can make C content between 0.15-0.22wt percent, to produce the J55 steel as Nb and Ti alloy, with high strength, high flexibility and welding property.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

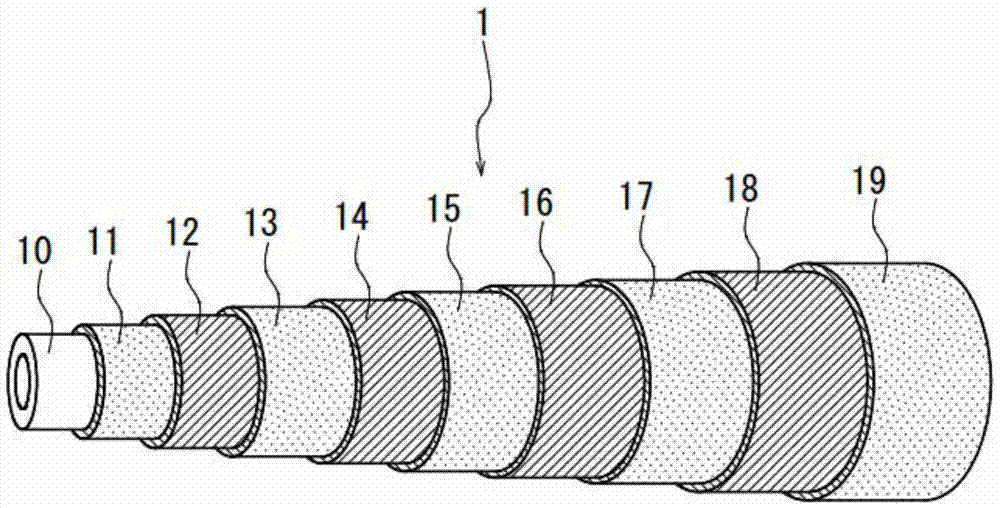

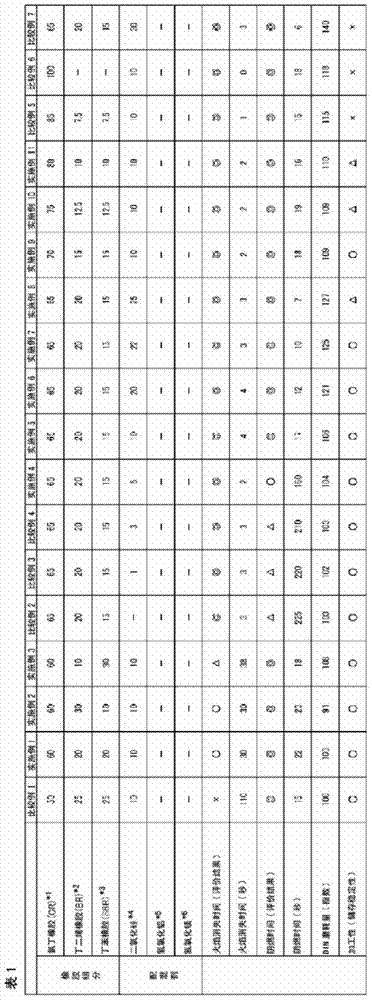

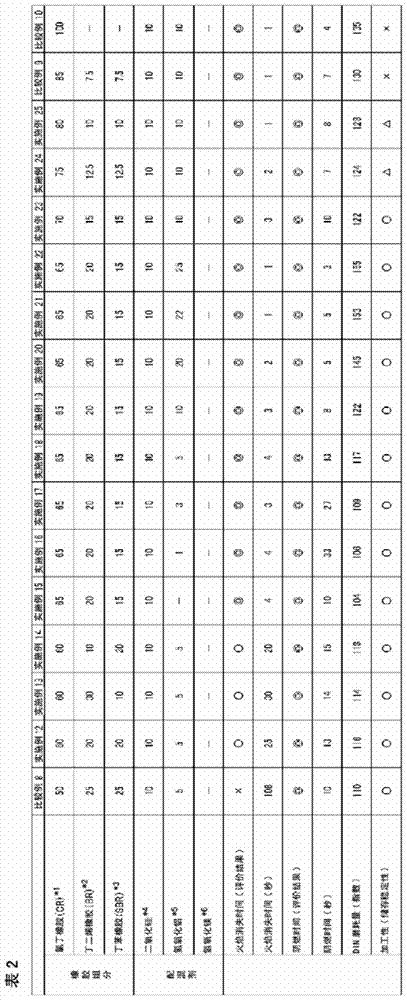

Rubber composition for hoses, and hose

ActiveCN103946300AImprove flame retardant performanceImprove wear resistanceFlexible pipesThin material handlingPolymer scienceNeoprene

Provided are: a rubber composition for hoses which is capable of improving flame retardancy and wear resistance, while ensuring processability; and a hose. This rubber composition for hoses contains, as rubber components, a chloroprene rubber, a butadiene rubber and a styrene-butadiene rubber. The chloroprene rubber is contained in an amount of 60-80 parts by mass in 100 parts by mass of the rubber components. In addition, 5-25 parts by mass of silica is blended into this rubber composition for hoses per 100 parts by mass of the rubber components.

Owner:BRIDGESTONE CORP

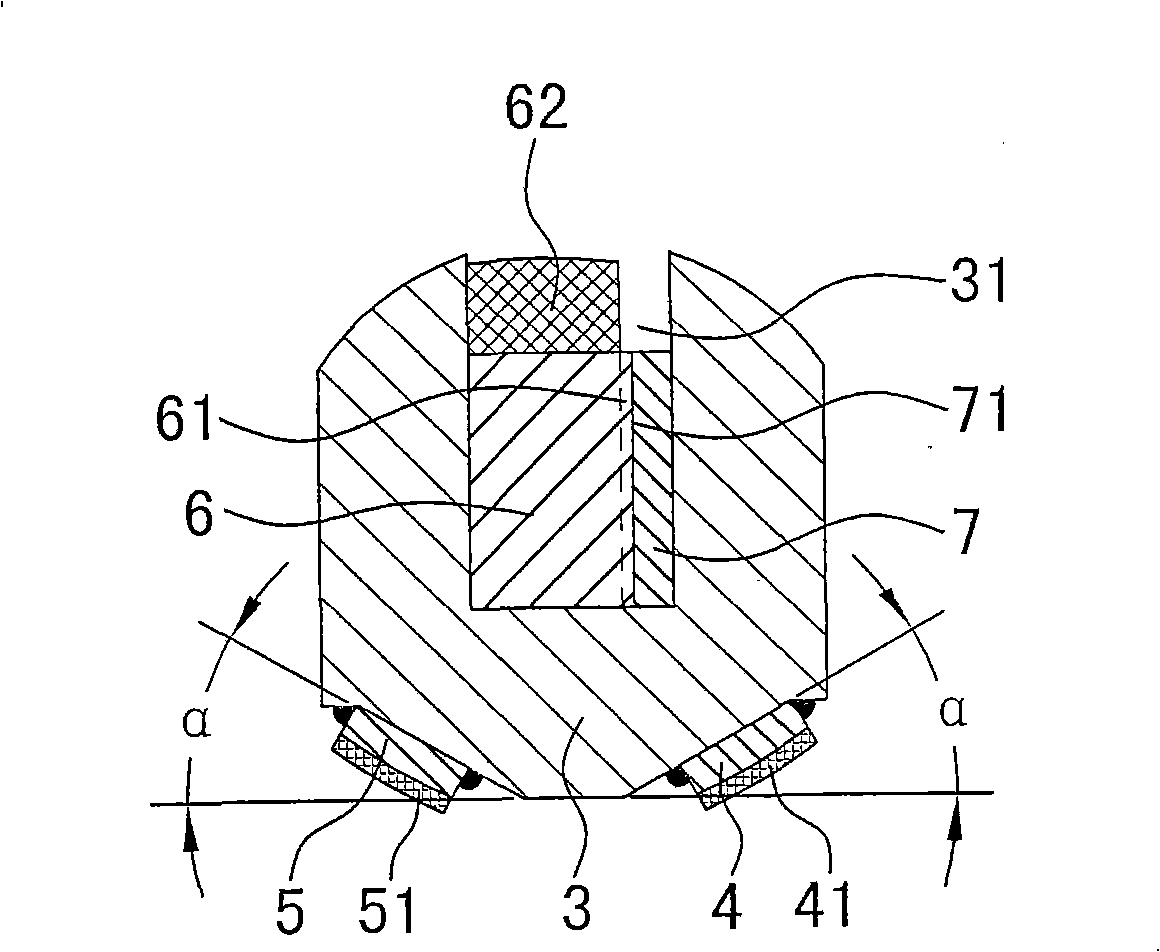

WC composite guide roller and manufacturing method thereof

InactiveCN101695713AGuaranteed toughnessGuaranteed StrengthRollsMetal rolling arrangementsFragilityPlasma coating

The invention discloses a WC composite guide roller and a manufacturing method thereof. A composite layer is arranged on the surface of matrix steel of the composite guide roller. The WC composite guide roller is characterized in that the matrix steel is carbon steel or alloy steel containing 0.2-0.7 percent by weight of carbon; the composite layer comprises the following material components in percentage by weight: 10-50 percent of WC, 0.2-0.8 percent of C, 0-3.0 percent of Cr, 0-2.0 percent of Mo, 0-2.0 percent of Mn, 0.11-0.5 percent of RE, not more than 5 percent of other metallic and non-metallic elements and the balance of Fe. The manufacturing method of the WC composite guide roller comprises the following steps of: coating composite powder on the surface of the matrix steel by using an plasma coating method and enabling the composite powder to be remelted together with the matrix steel by using an argon arc remelting method so as to form the composite layer on the surface of the matrix steel; or directly spraying the composite powder on the surface of the matrix steel and enabling the composite powder to be remelted together with the matrix steel by using the argon arc remelting method. The composite guide roller has high rigidity, good abrasion resistance, low fragility, capability of thermal treatment and mechanical machining, low cost and high cost performance.

Owner:合肥上雅电子科技有限公司

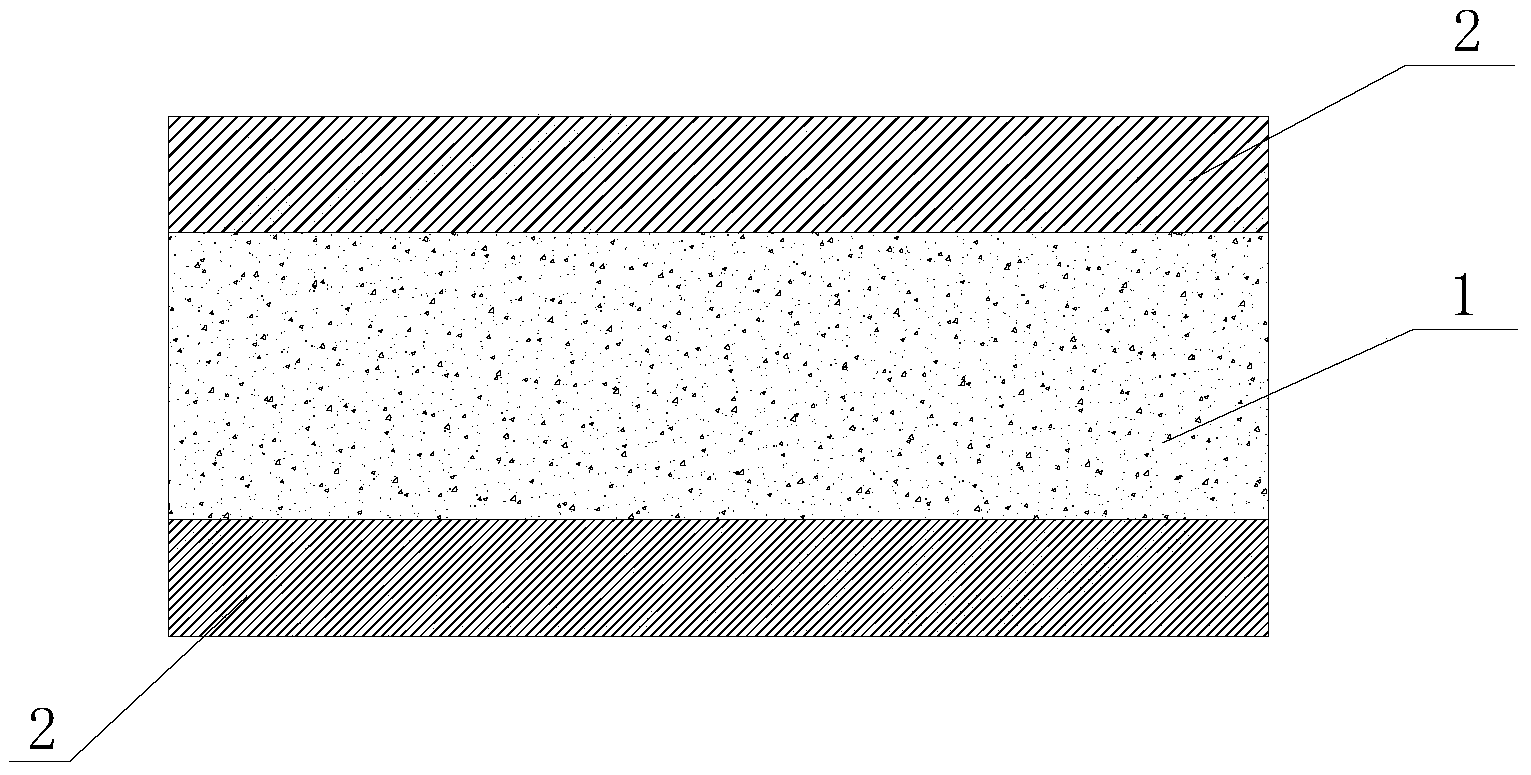

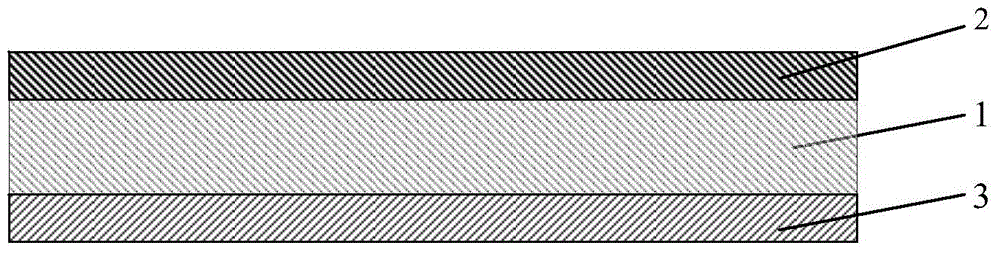

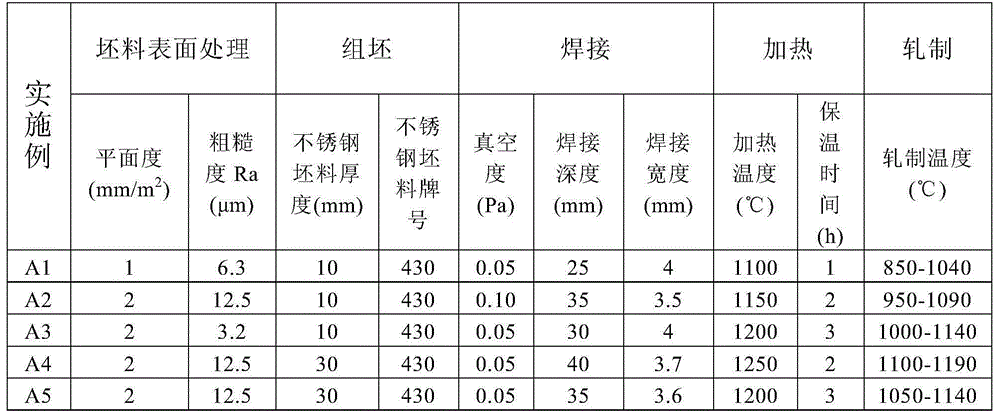

Steel plate for concrete precast element production line mould platform surface and manufacture method of steel plate

ActiveCN104786582AImprove composite effectHigh strengthAuxillary arrangementsMetal rolling arrangementsMechanical propertyAustenitic stainless steel

The invention provides a steel plate for a concrete precast element production line mould platform surface and a manufacture method of the steel plate. The steel plate for the mould platform surface comprises a carbon steel base material layer and a stainless steel composite layer(s) compounded on the upper surface or / and the lower surface of the carbon steel base material layer; the carbon steel base material layer and the stainless steel composite layer(s) are combined through the manner that atoms in the carbon steel base material layer and atoms in the stainless steel composite layer(s) mutually diffuse towards adjacent layers. The steel plate for the mould platform surface is formed by compounding ferritic stainless steel with extremely high magnetic conductivity and an ordinary carbon steel plate, and is good in corrosion resistance, excellent in wear resistance, good in machinability, high in solderability, good in forming property, excellent in both thermal conductivity and magnetic conductivity, high in mechanical strength and excellent in other comprehensive mechanical properties, the manufacture cost of the mould platform is effectively reduced and the service life of the mould platform is prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD +1

High practicality lithium nickel manganese oxide and preparation method thereof

InactiveCN104900865ASmall specific surface areaGuaranteed cycle performanceCell electrodesSecondary cellsCarbon layerMaterials processing

The invention discloses a high practicality lithium nickel manganese oxide and a preparation method thereof. The lithium nickel manganese oxide is characterized in that manganese source, lithium source, nickel source and a certain amount of grinding aid are blended by a dry grinding mode, the lithium nickel manganese oxide material with low specific surface area is prepared by using the characteristics of slow crystal nucleation rate and little nucleation of a precursor, contact area of the material and an electrolyte is increased, cycle life of the material is increased; cation disorder degree and crystal structure dislocation of the crystal can be controlled through a multi-step calcining technology for guaranteeing the multiplying power performance of the material; the obtained lithium nickel manganese oxide coats the surface of a carbon layer by using a vapour deposition method, anchoring strength of the material and a current collector is enhanced, peeling intensity of pole sheet is enhanced, material processing property is ensured, and multiplying power performance is increased. The material has the advantages of long service life and good processing property, and is the lithium nickel manganese oxide material with high practicality, the preparation method is economic and easy to operate, and is suitable for commercialization popularization.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

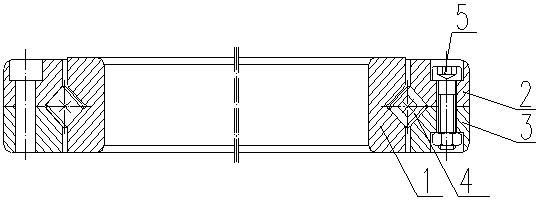

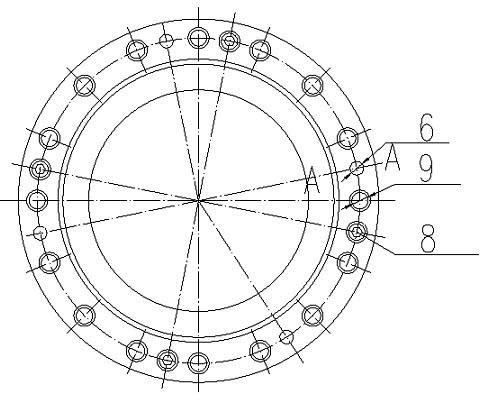

Method for machining separated type outer ring of small and medium-sized thin-wall crossed cylindrical roller turntable bearing

The invention discloses a method for machining a separated type outer ring of a small and medium-sized thin-wall crossed cylindrical roller turntable bearing. According to the method, the outer ring of the bearing is machined integrally and is lathed to form two half bodies; and the method comprises the following steps of: a, lathing, namely lathing the outer ring integrally, calculating the allowance of an end face and a roller path according to the size of the outer ring, connecting the two half outer rings partially, lathing the middles of the insides of the two half outer rings to form cutting grooves, and leaving cut-off guiding openings on outer diameters; b, drilling and performing heat treatment, namely drilling the outer ring integrally before performing the heat treatment, and performing the heat treatment integrally after drilling; c, grinding, namely in the processes of initial grinding, performing initial grinding on the outer ring integrally without cutting the outer ring off; before final grinding, performing hard lathing to cut the outer ring off along the cut-off guiding openings on the outer diameters, and marking assorted marks; and polishing a cut-off surface, and connecting the upper half outer ring and the lower half outer ring by using a connecting hole to form an integral outer ring, and performing final grinding. By the method, the problems of high deformation possibility during machining and difficulty in guaranteeing concentricity after assembly are solved.

Owner:LUOYANG PRECISION OF MACHINE EQUIP TECH CO LTD

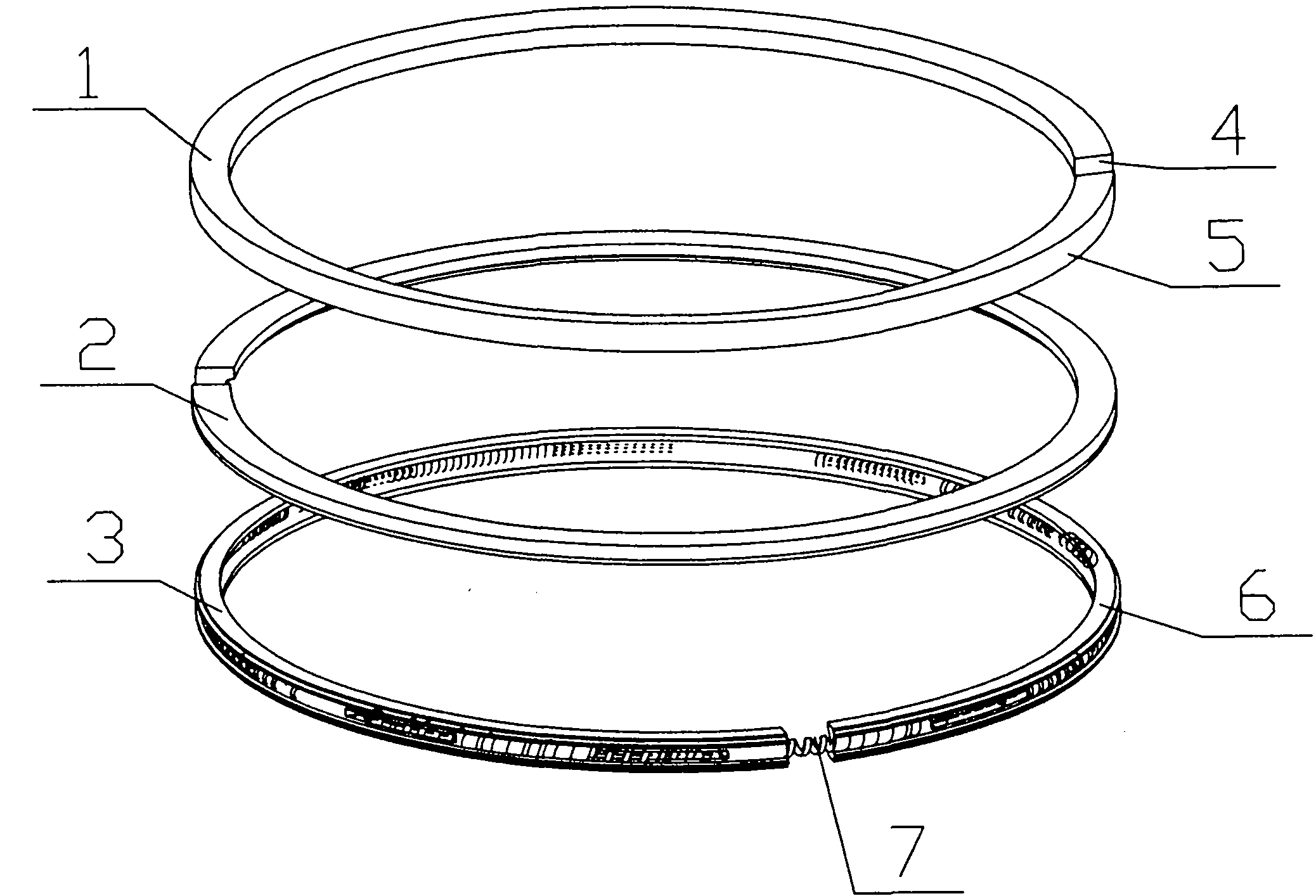

Piston ring of chrome-base ceramic composite plating layer

ActiveCN101929405AMeet high performance requirementsDoes not increase brittlenessPiston ringsMachines/enginesCeramic compositePiston ring

The invention discloses a piston ring of a chrome-base ceramic composite plating layer, comprising a first gas ring, a second gas ring, an oil ring-closure piece, wherein the first gas ring adopts a trapezoidal half-inlaid oblique barrel surface, namely that the section of the first gas ring is in a trapezoidal shape, and ceramic particles are inlaid on an outer circle-face part; the second gas ring adopts an anti-twist taper-face ring; the oil ring-closure piece is an antidromic chamfer-angle spiral spring oil ring, and the spring pitch is adjustable in the oil ring; the three rings are arranged in a piston ring groove, and openings of the first gas ring and the second gas ring are staggered. A chrome-base ceramic composite plating layer is plated on the outer circle face of the first gas ring, and the ceramic particle content reaches 5-6 percent in the chrome-base ceramic composite plating layer. In the invention, the piston ring can bear larger heat load and mechanical load; when the piston ring and a cylinder-wall oil film are in a bound state, a cylinder scuffing phenomenon can not be generated, meanwhile, because the high-hardness ceramic particles are inlaid, the wear resistance is greatly increased, and the invention can satisfy the high-performance requirement of a modern engine and has long service, low emission and high performance.

Owner:JIANGLING MOTORS

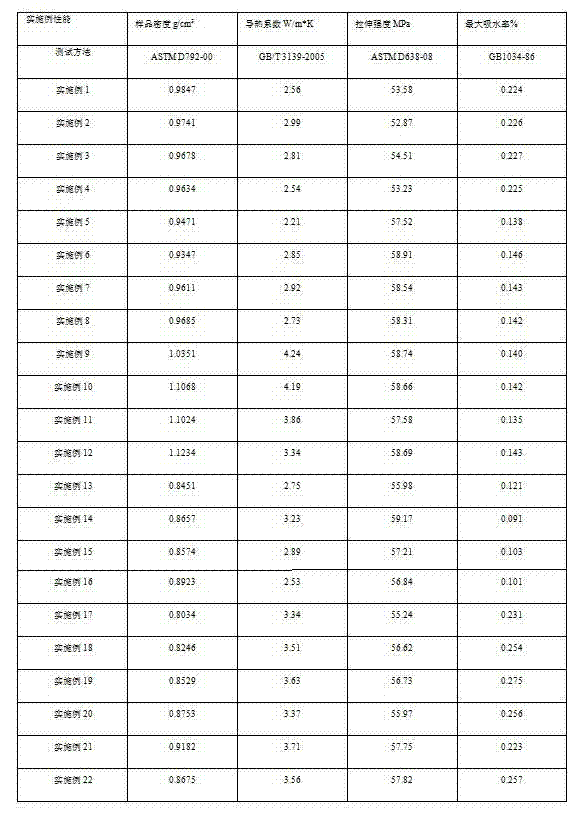

Thermosetting-resin-based heat-conductive composite material, and preparation method and application thereof

ActiveCN103756252AGuaranteed processing effectReduce dosageCooling/ventilation/heating modificationsMicrosphereHeat sink

The invention discloses a thermosetting-resin-based heat-conductive composite material, and a preparation method and application thereof. The heat-conductive composite material comprises a base body and a filling material filling the interior of the base body, wherein the base body employs thermosetting resin, and the filling material is modified hollow glass microspheres, and the surface of the hollow glass microspheres is subjected to modification processing by heat-conductive powder and is coated with the heat-conductive powder. The employed thermosetting resin is capable of well dispersing the heat-conductive powder, and the processing performance of the material is guaranteed; because of the reasonable matching of the hollow glass microspheres and the heat-conductive powder, the material has the advantages of being light, resistant to corrosion, good in heat conductivity, good in mechanical properties, free of pollution, low in cost, high in precision, long in service life and the like; and the material can be prepared into heat-radiation parts of electronic products, cooing fins of lamps, and other parts with relatively high heat-radiation requirements.

Owner:HUIZHOU MOREWARE INDAL

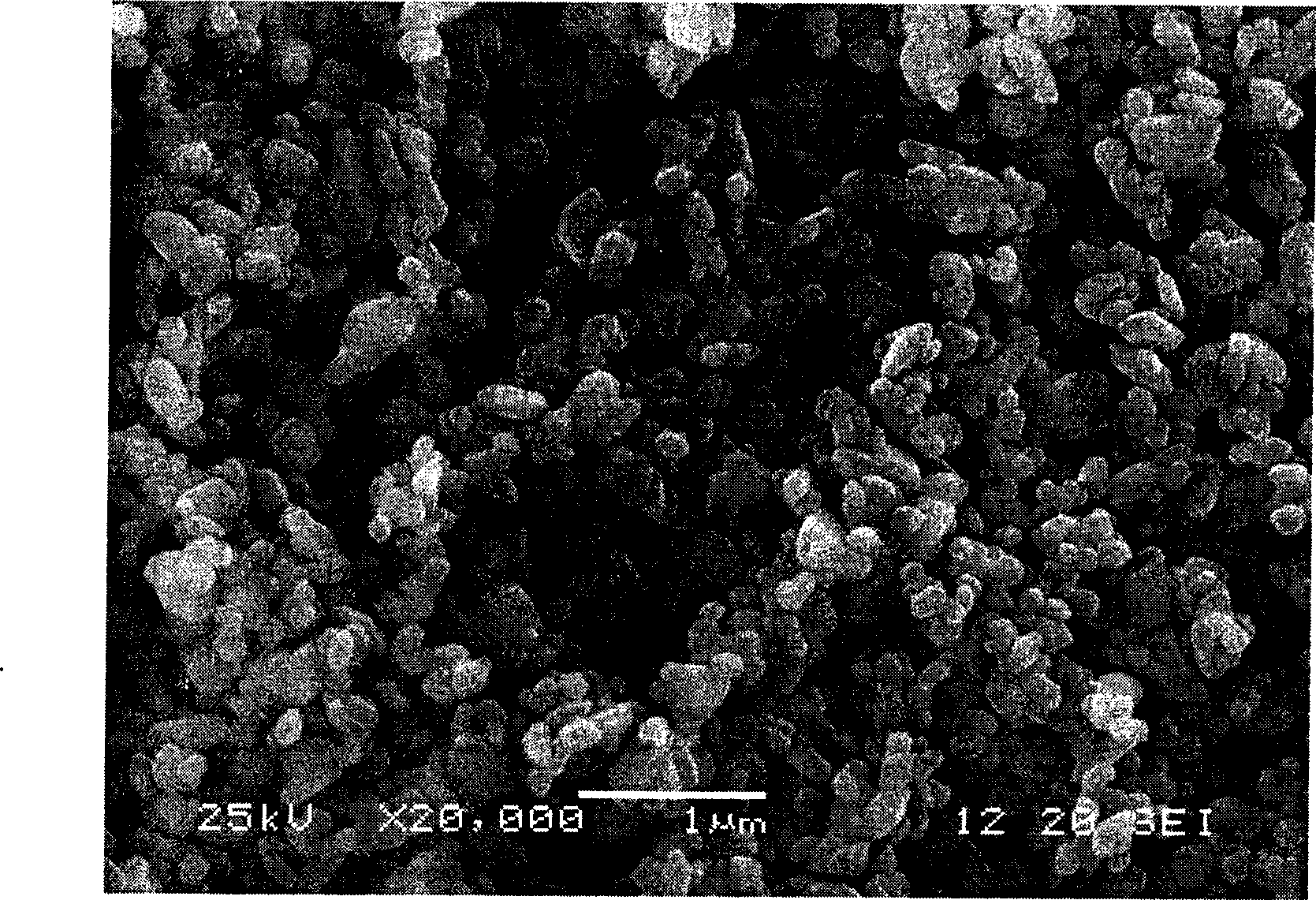

Preparation of subsphaeroidal barium sulfate by sulfuric acid process and use in copper foil substrate

ActiveCN101475200AWide range of applicationsHigh whitenessCalcium/strontium/barium sulfatesCopper foilCoal

The invention discloses a method for preparing subsphaeroidal barium sulfate by a sulfuric acid process, which aims to solve the problems that barium sulfate particles have unshaped morphology and wide particle size distribution. The method comprises the following concrete steps that: (a) coal is used to calcine barite to generate barium sulfate; (b) water is used to dissolve the barium sulfate to be prepared into 70 to 130g / L barium sulfate solution, the temperature is adjusted to be between 45 and 85 DEG C, the barium sulfate solution and excessive sulfuric acid are synchronously added into a continuous reactor to react to generate barium sulfate slurry and hydrogen sulfide, and the adding rate of the barium sulfate solution is between 500 and 7,000L / h; (c) hot air is introduced into the barium sulfate slurry to discharge the hydrogen sulfide; and (d) the barium sulfate slurry is dehydrated, washed, dried and crushed to obtain a finished product of the subsphaeroidal barium sulfate. The barium sulfate which is spheroidal or subsphaeroidal and has continuously adjusted particle size distribution can be obtained by the preparation method. At the same time, the invention also discloses application of the subsphaeroidal barium sulfate used as a packing material to copper foil substrates.

Owner:GUIZHOU REDSTAR DEVING

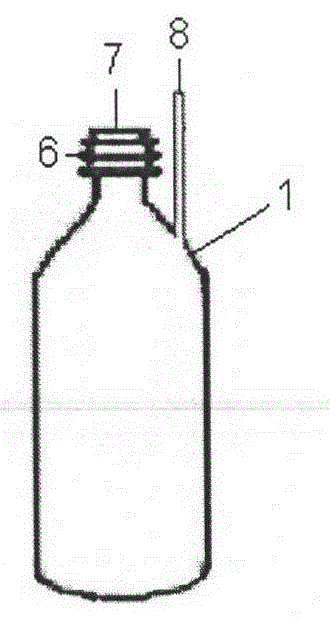

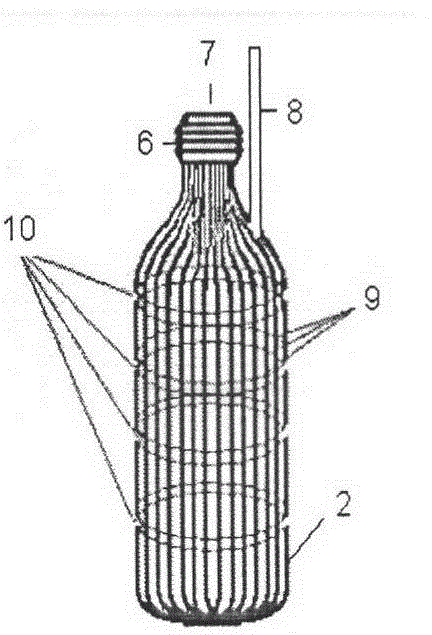

Seeping micro-irrigation container and preparation method thereof

InactiveCN102742489AAntibacterialRodent-proofWatering devicesSynthetic resin layered productsThermoplasticCapillary network

The invention relates to a seeping micro-irrigation container and a preparation method thereof. The container is made of a micro-irrigation material with a capillary water seeping function, has a three-dimensional network capillary water seeping structure of inorganic particles and thermoplastic plastics, and has a power-free self-adaptation, continuous and balanced seeping function. According to water potential of soil contacted with the container, water can seep outwards automatically through the capillary network structure inside the container or stop seeping outwards. The container further comprises a gel protective layer (11). The container has good water seeping capacity, can prevent blocking, bacteria and rats, can be used as a mini reservoir independently, can also be connected with a pipeline system, and forms a power-free self-adaptation, continuous and balanced seeping micro-irrigation system.

Owner:深圳市金麦田网络技术有限公司

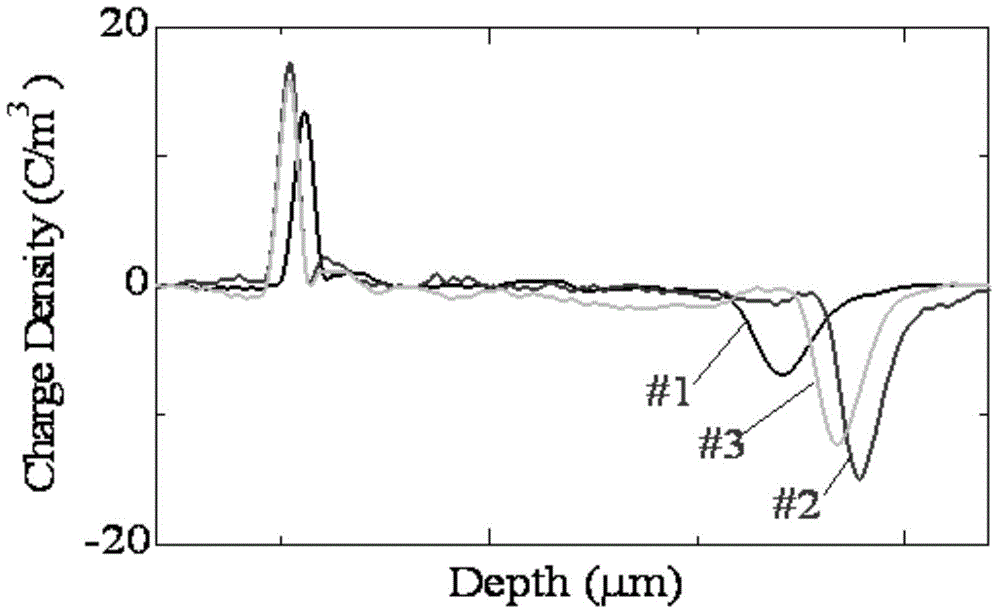

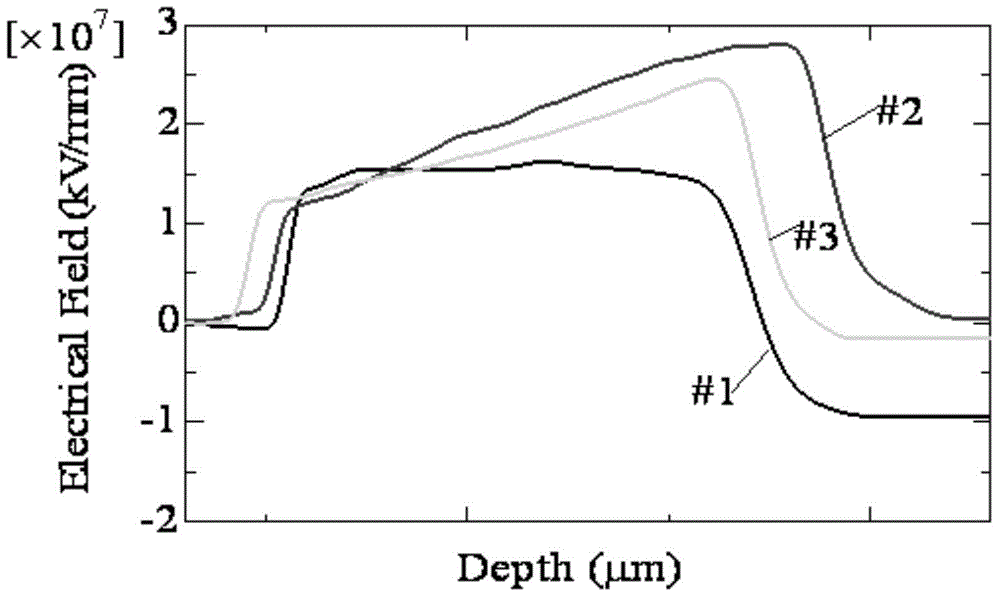

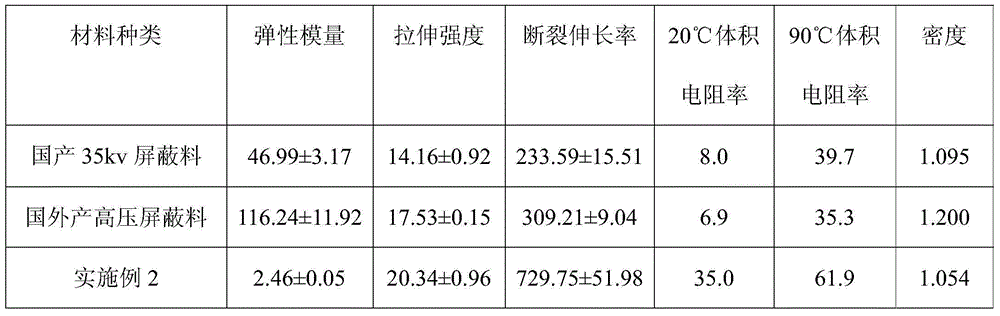

Semi-conductive shield material used for high-voltage direct-current cable and preparation method thereof

The invention discloses a semi-conductive shield material used for a high-voltage direct-current cable and a preparation method thereof. With ethylene-ethyl acrylate polymers or ethylene-butyl acrylate polymers being matrix resin, superconducting carbon black is added into the matrix resin to serve as conducting filler, antioxidant, lubricating agents and dispersing agents are added, after mixing, granulating, cooling and drying are performed, cross-linking agents are added into granules for adsorption and permeation, and finally the granule-shaped semi-conductive shield material used for the high-voltage direct-current cable is obtained through air drying. The finished product shield material is particularly suitable for producing the high-voltage direct-current cable, can completely meet the requirements for performance of direct-current shield materials used for high-voltage direct current and has good space charge control performance.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com