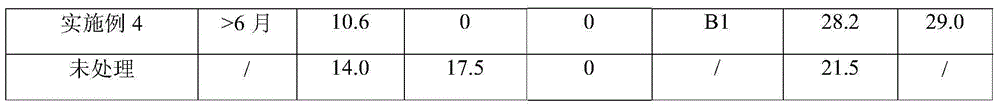

Patents

Literature

55results about How to "Convenient and flexible processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

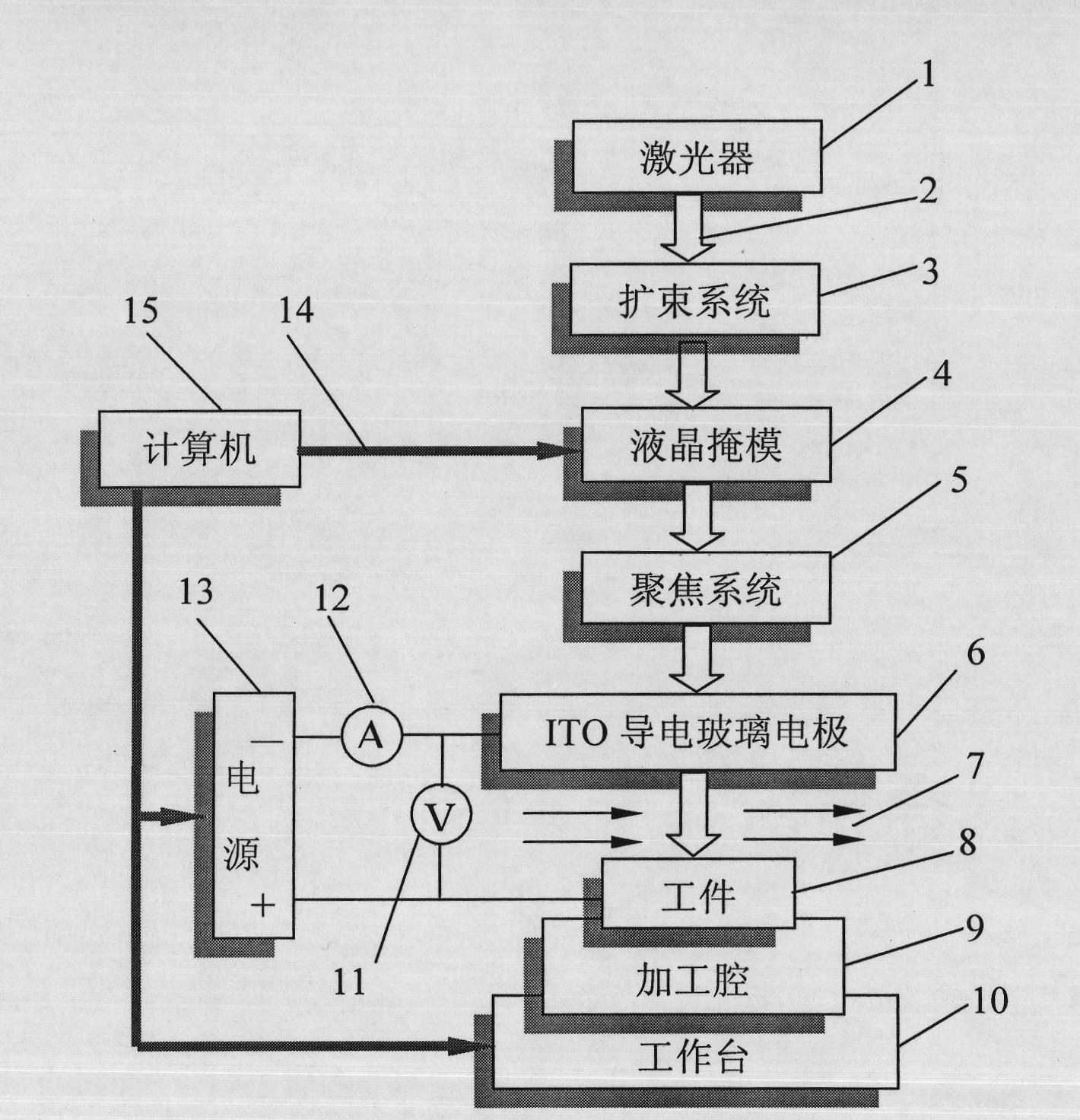

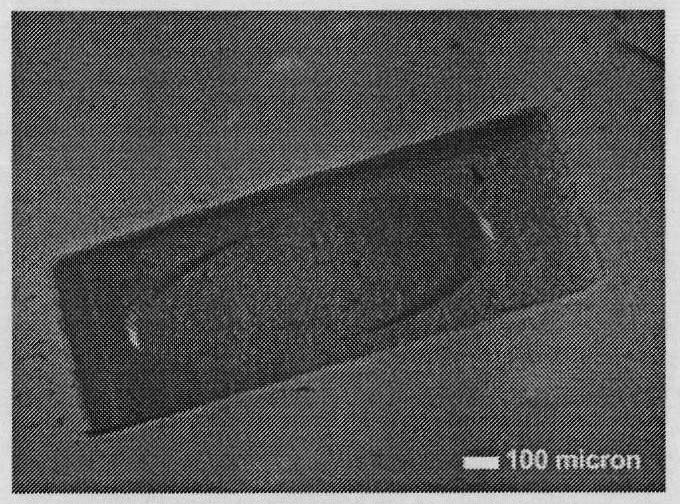

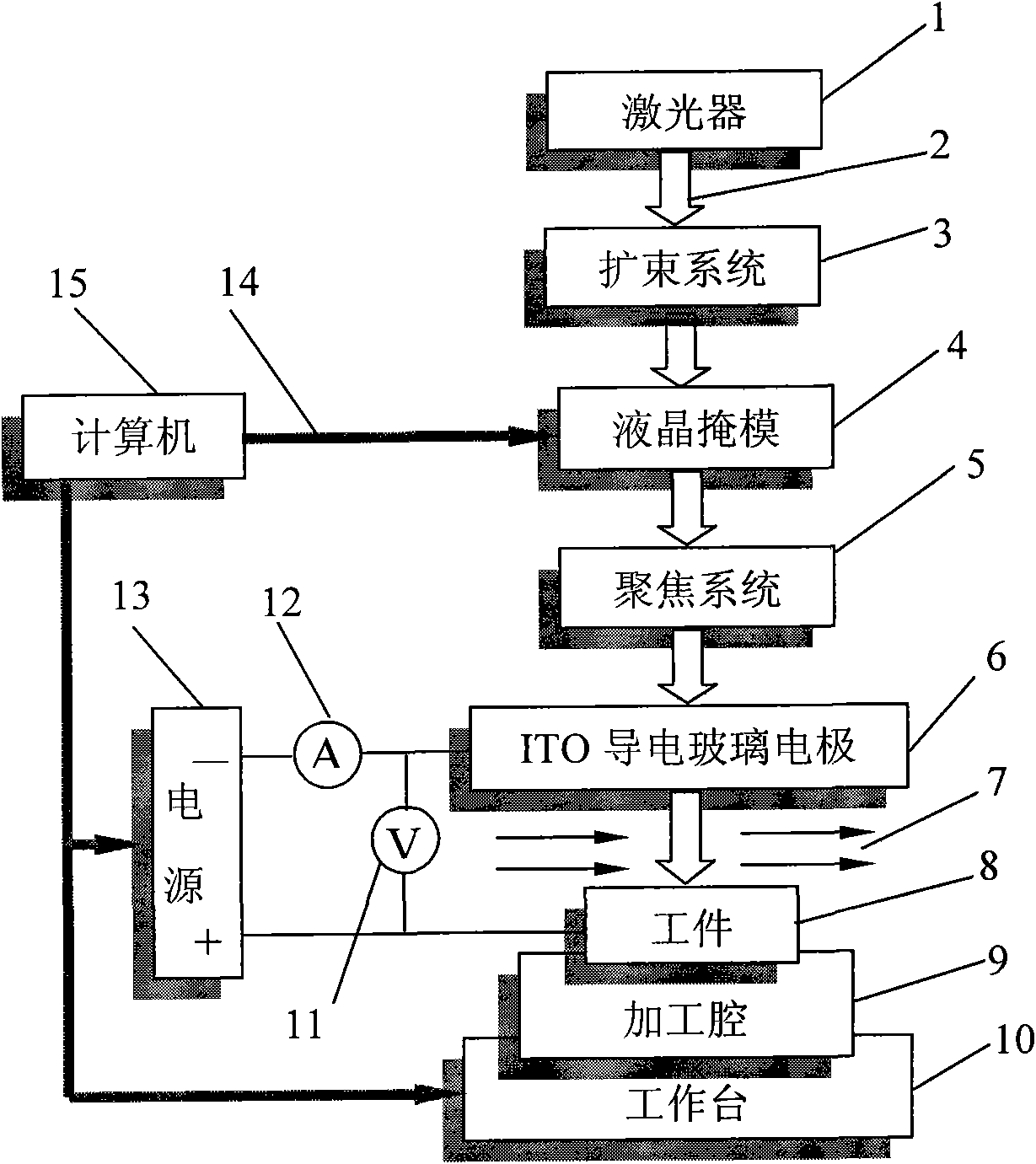

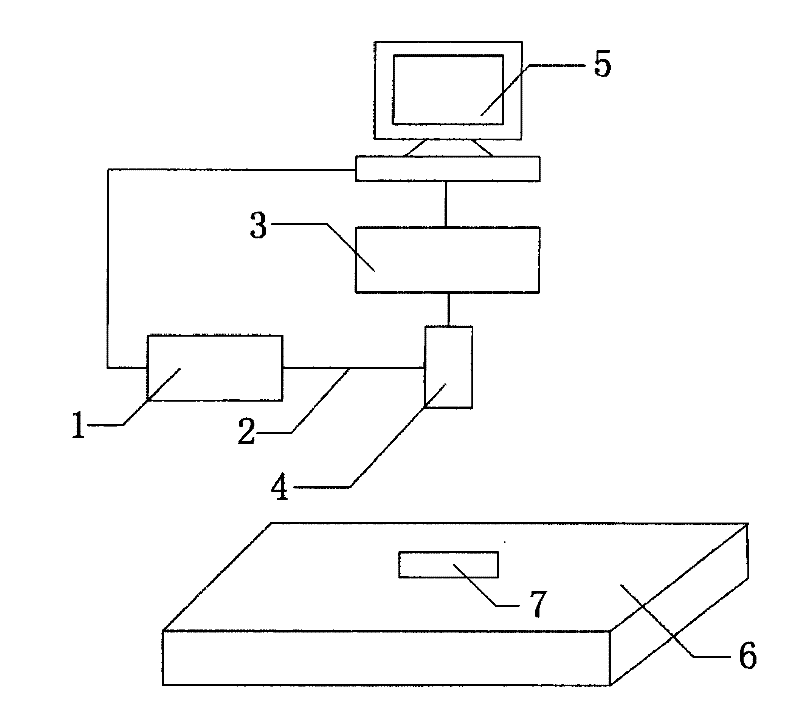

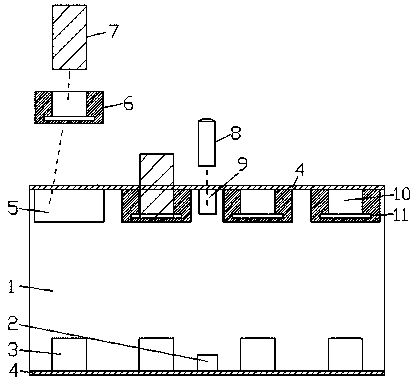

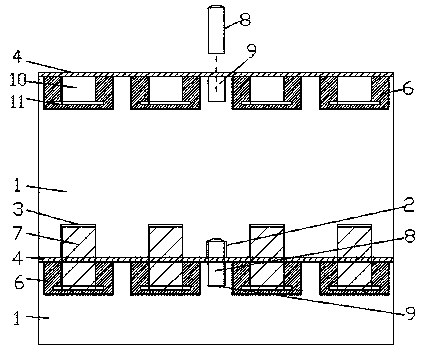

Photoelectrochemical three-dimensional processing method and device of laser bubble cavitation

InactiveCN101856753ALarge amount of erosionErosion is smallMachining electrodesElectrical-based machining electrodesElectrochemical responseManufacturing technology

The invention relates to a photoelectrochemical three-dimensional processing method and device of laser bubble cavitation, belonging to the non traditional combined machining field of the manufacturing technology. The method utilizes laser beam to irradiate the surface of workpieces in the solution and generate bubbles, as the bubble cavitation caused by bubble-collapsing combines with the electrochemical reaction so as to remove workpiece material under the action of photoelectrochemical reaction and realize etching and processing. In the device of the invention, a liquid crystal display of which the display of the grey level image is controlled by a computer is used as a mask plate, and when laser beam penetrates through the liquid crystal mask, an image with gray feature is generated to perform spatial modulation to the energy distribution in the laser spot. In the areas with higher laser radiation energy on the workpieces, the bubble cavitation is stronger, the speed of the photoelectrochemical reaction is higher and the etching removal rate is higher; in the areas with lower energy, the reverse happens, thus the processing of three-dimensional image can be realized. The device of the invention is applicable to the removal and processing of conductive metal material; and the display of the grey level image of the liquid crystal mask can be controlled by a computer, thus the processing efficiency of complex three-dimensional images can be increased greatly.

Owner:JIANGSU UNIV

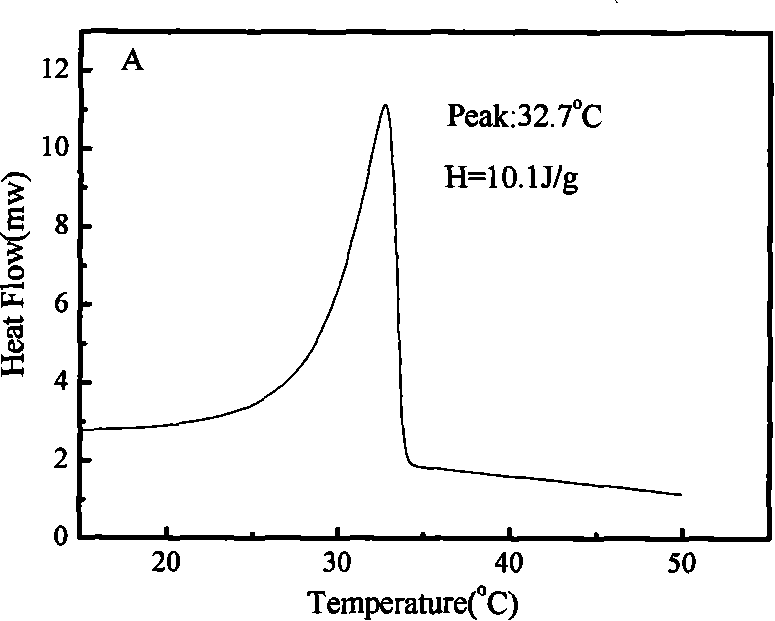

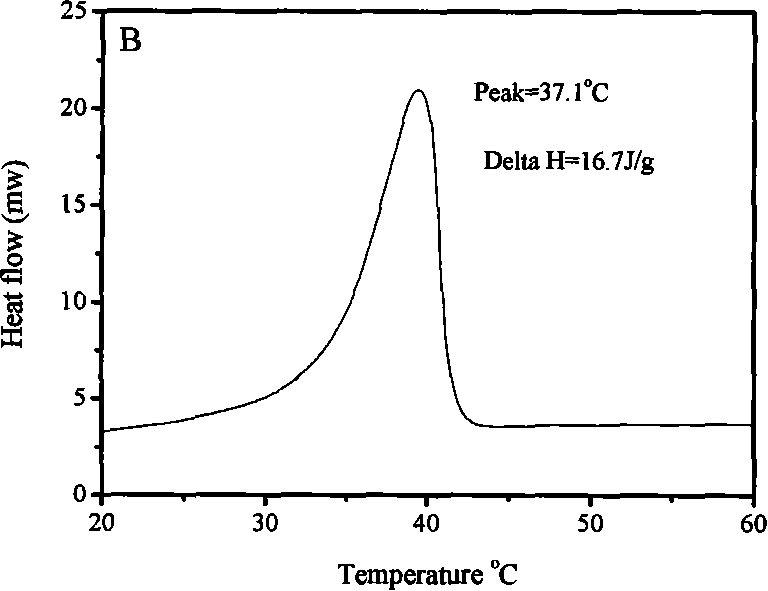

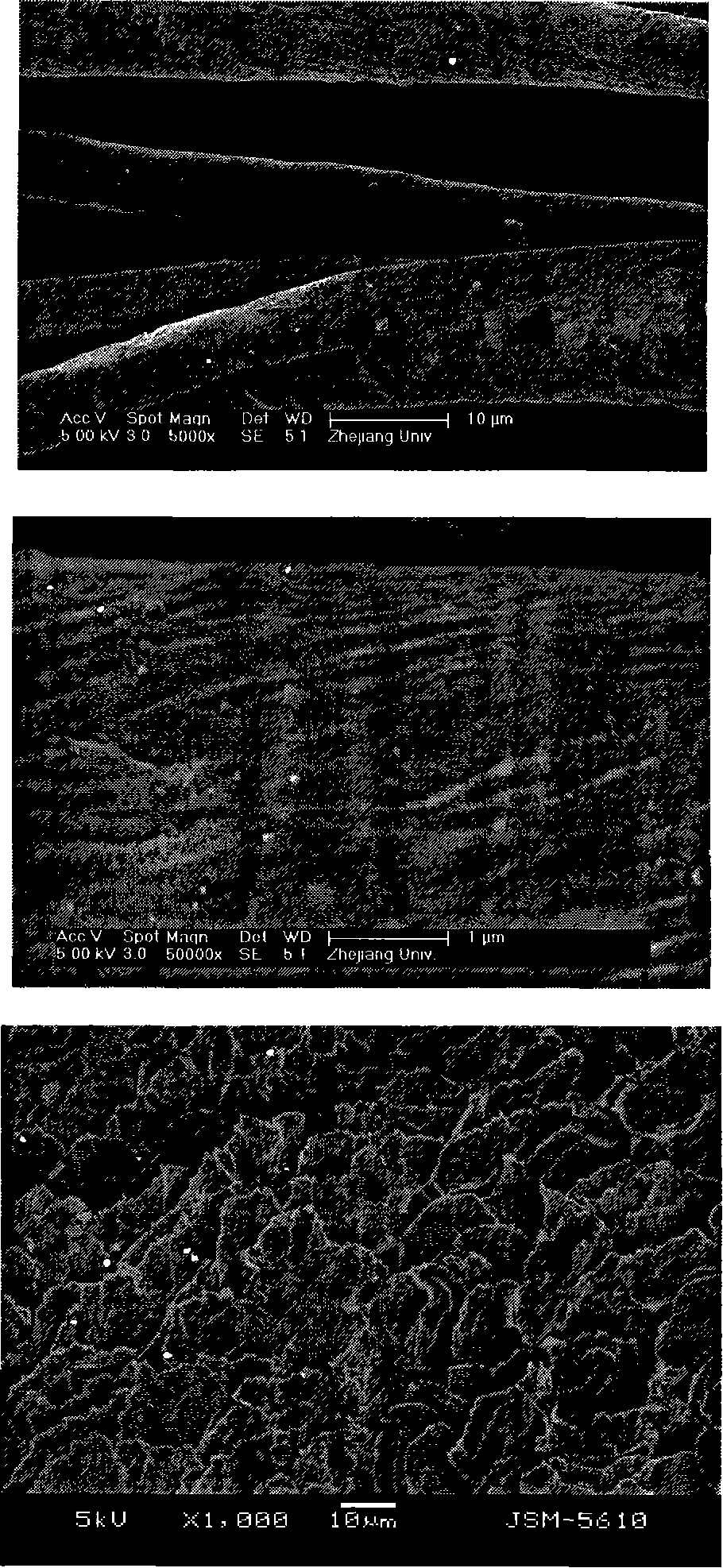

Method for manufacturing intelligent thermoregulation type functional yarn

InactiveCN101250818AMechanical properties unchangedDoes not affect breathabilityVegetal fibresYarnOperability

The invention discloses a method for preparing an intelligent temperature regulating functional yarn, which has the following steps of charging cementing agent and thickening agent into phase-change microcapsule dispersion to intimately mix and obtain phase-change microcapsule functional finishing agent with viscosity, wherein the content of the cementing agent and the thickening agent are respectively 0.5-5% by weight of the finishing agent, the phase-change microcapsule functional finishing agent is finished on the yarn via a double-nip-double-dip or a sizing process, and then obtaining textiles via weave technology. The selected capsule is water dispersion with good surroundings, wherein the capsule size is about 100nm which is only one-tenth or one-percent of the yarn fineness, thereby being capable of greatly improving dosages of the capsules in the yarns, at the same time holding constant raw mechanical property of the yarn, furthermore, the method has the advantages of convenient and flexible processing, good operability and being basically not influence on hand feeling and breathability of fabrics due to adopting the double dip double nip or the slashing process, and the performance test indicates that the finished textile has obvious heat storage and temperature regulating effects.

Owner:ZHEJIANG SCI-TECH UNIV +2

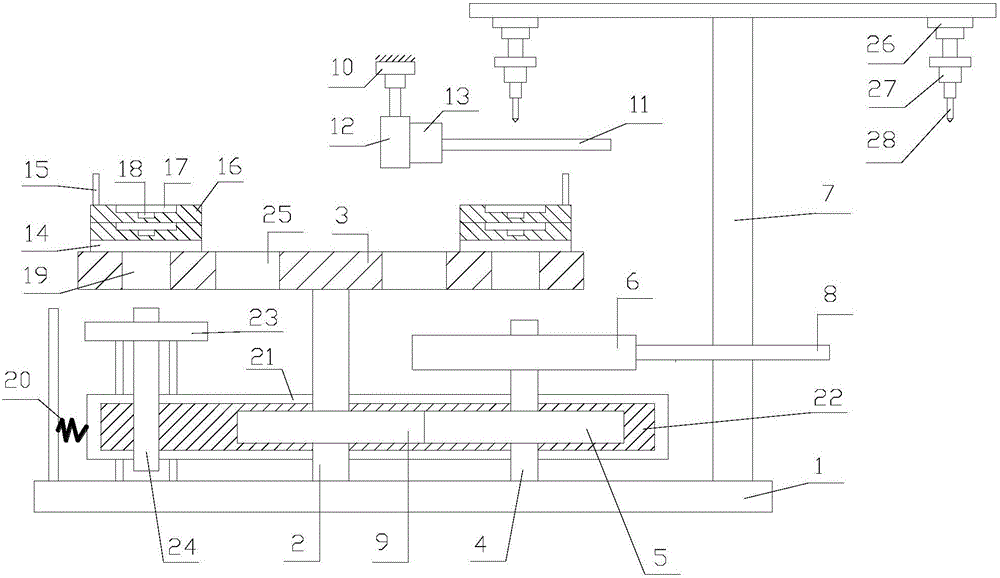

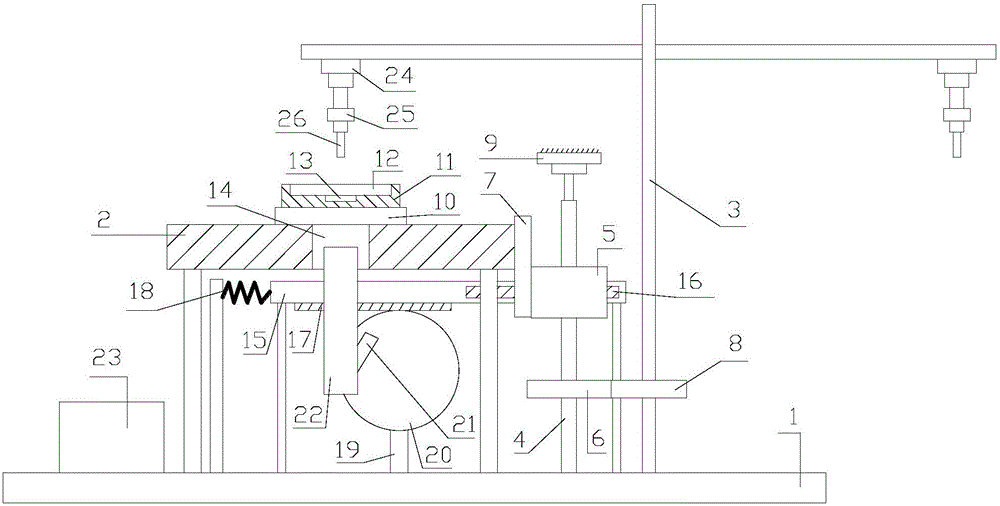

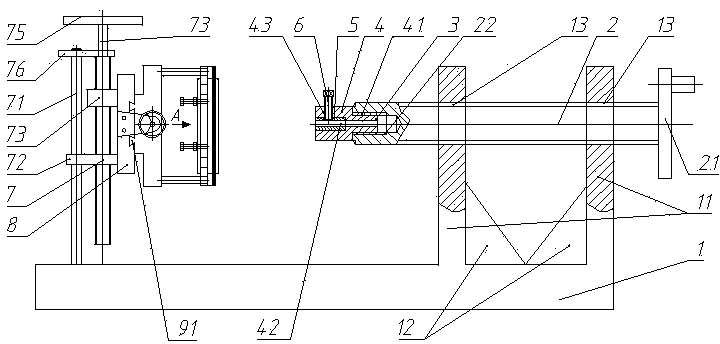

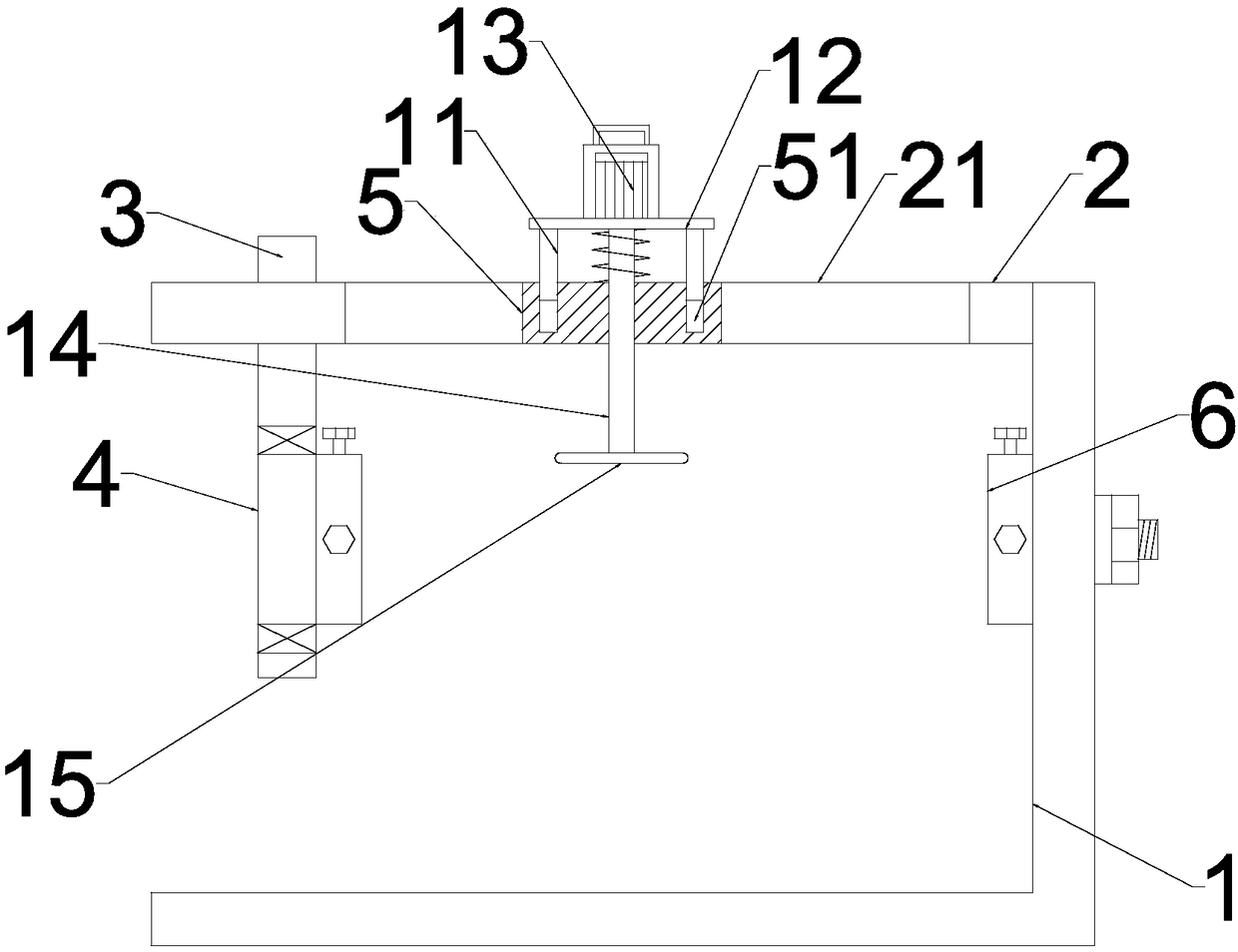

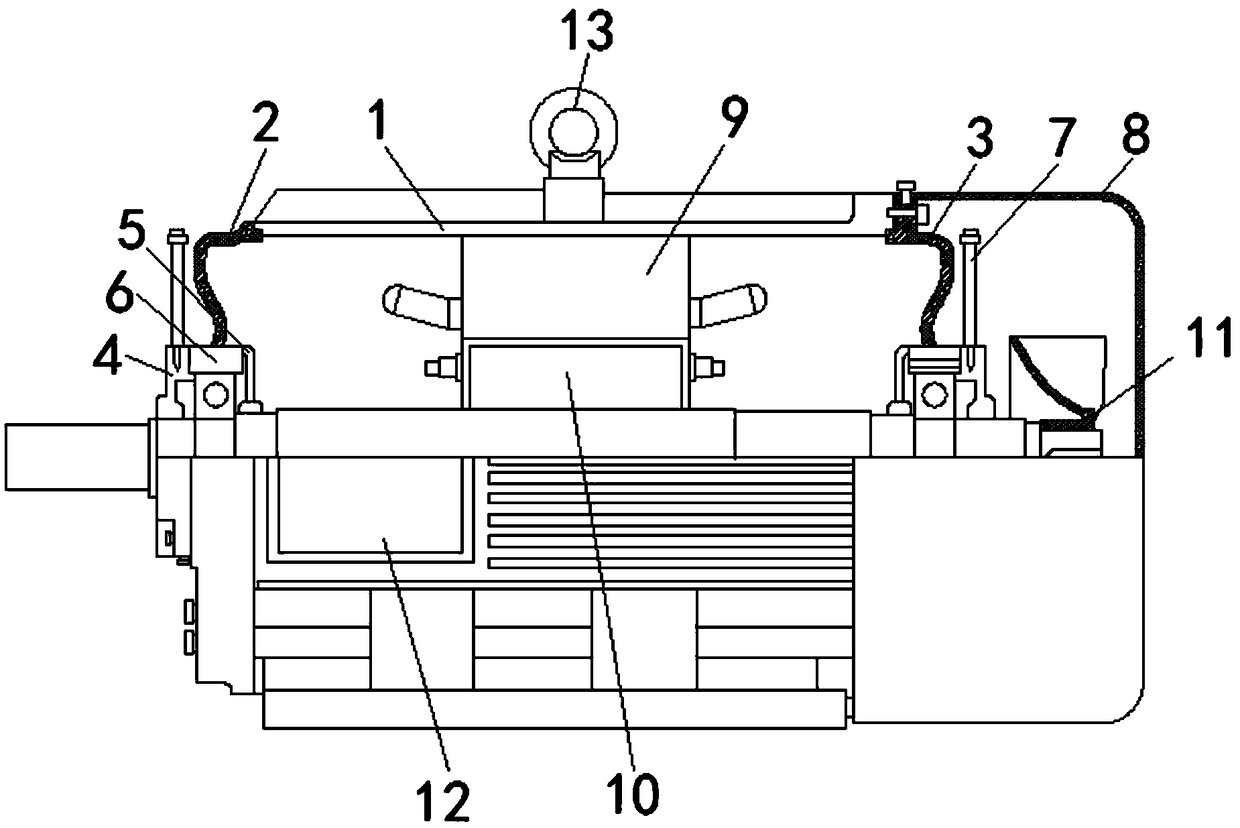

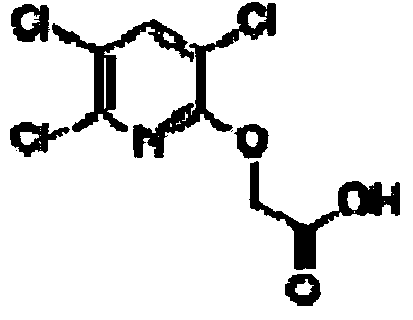

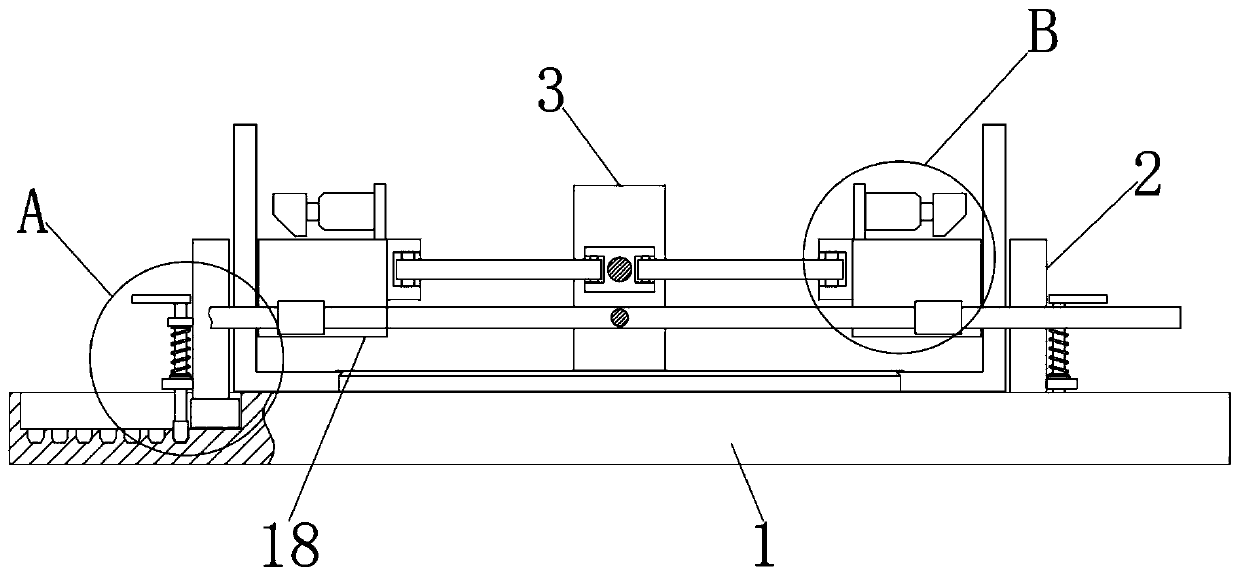

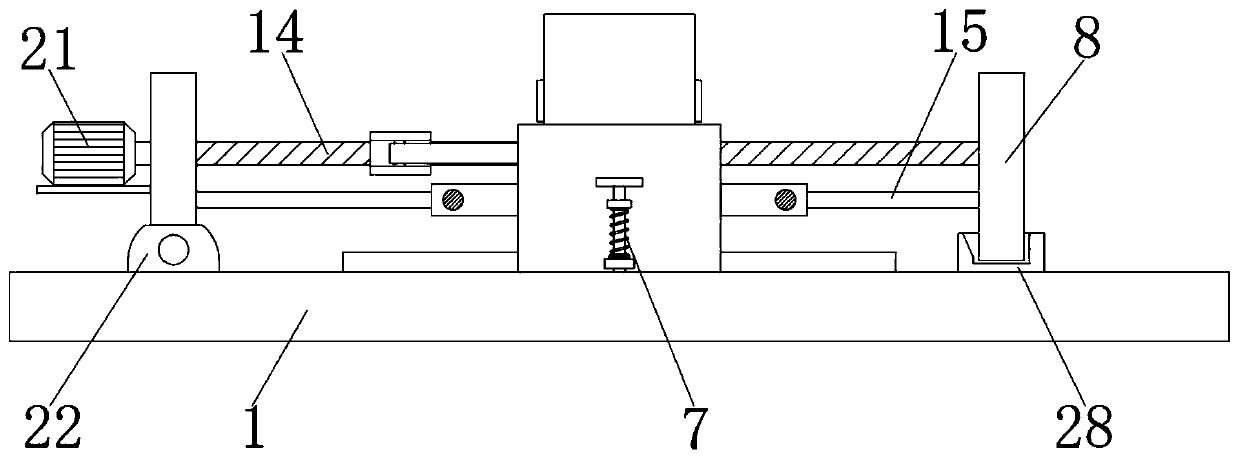

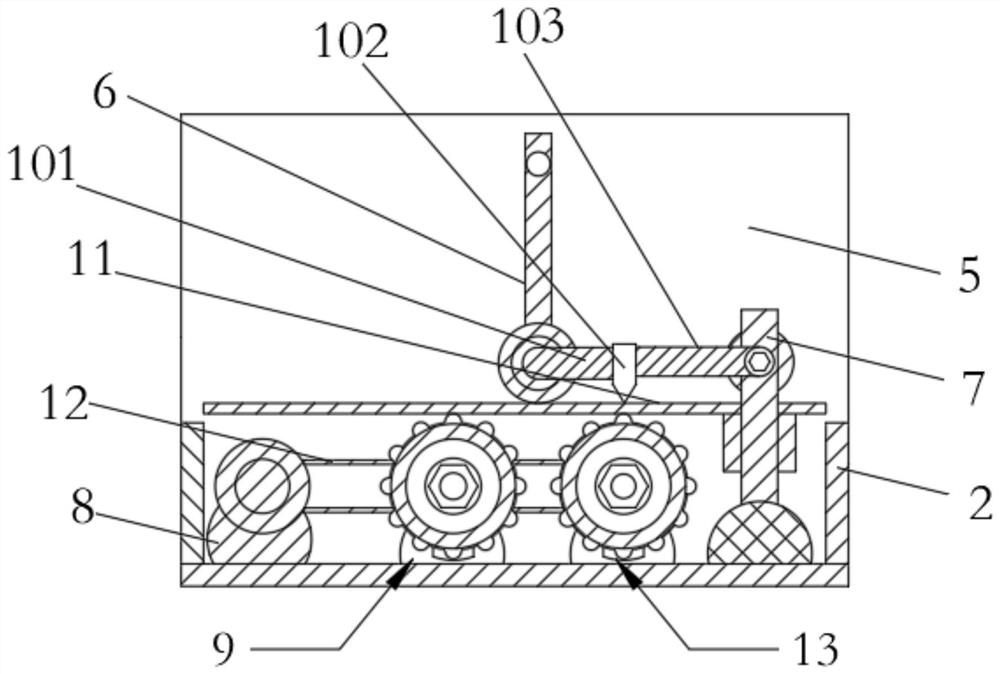

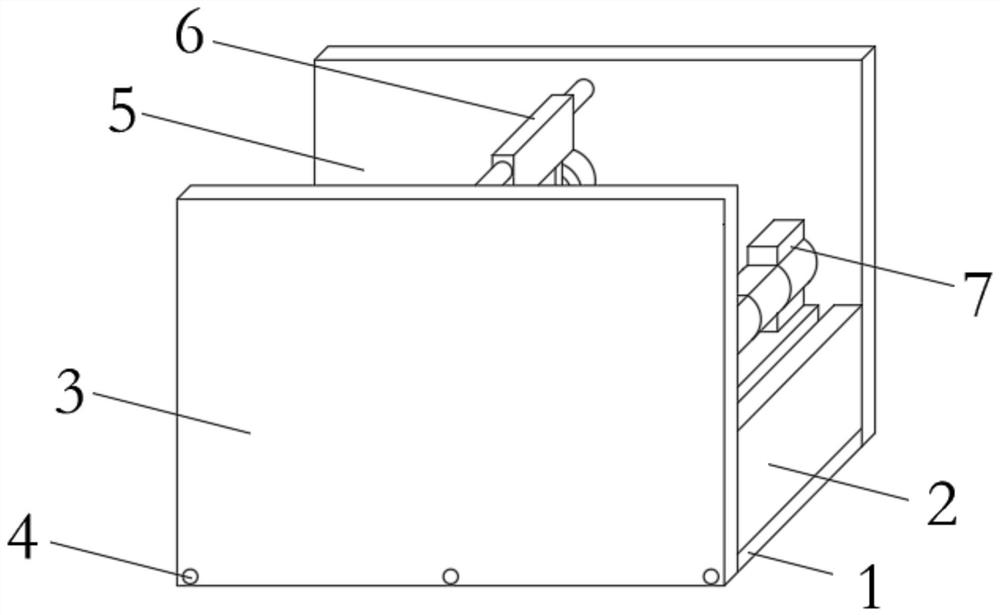

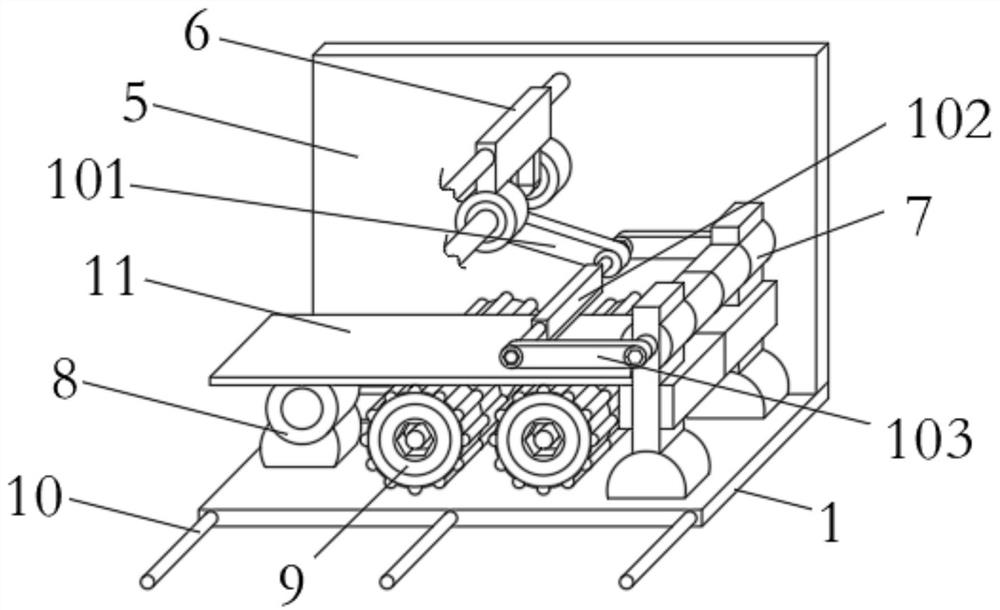

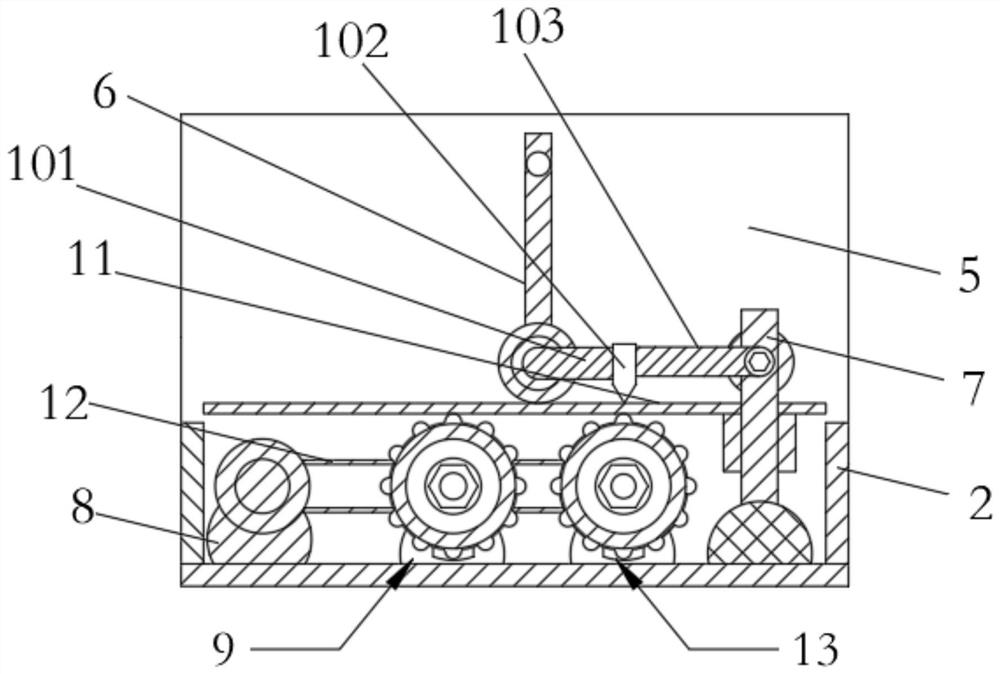

Machine tool for processing workpieces

InactiveCN105710730ACooperate skillfullyConvenient and flexible processingMetal working apparatusPositioning apparatusEngineeringMachine tool

The invention discloses a machine tool for workpiece processing, which comprises a base, a rotating shaft, a wheel disc, a plurality of clamps, a rotating shaft, a first rotating wheel, a second rotating wheel, a supporting shaft, a driven gear, and M actuators . Drive mechanism, wherein, M is an integer greater than or equal to 2; the rotating shaft is installed on the base in rotation, the center line of the rotating shaft is vertically arranged, and the circumferential surface of the rotating shaft is provided with first gear teeth; the wheel disc is installed on on the rotating shaft; multiple fixtures are installed on the wheel, and the multiple fixtures are evenly distributed on the circumference centered on the center of rotation of the wheel; the rotating shaft is installed vertically on the base, and the rotating shaft is connected to the base in rotation on one side of the wheel. The invention has high processing precision and good processing effect.

Owner:芜湖中驰机床制造有限公司

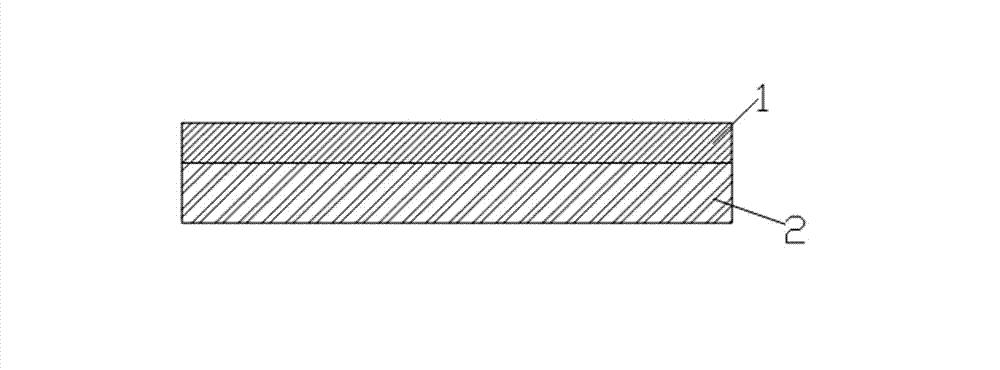

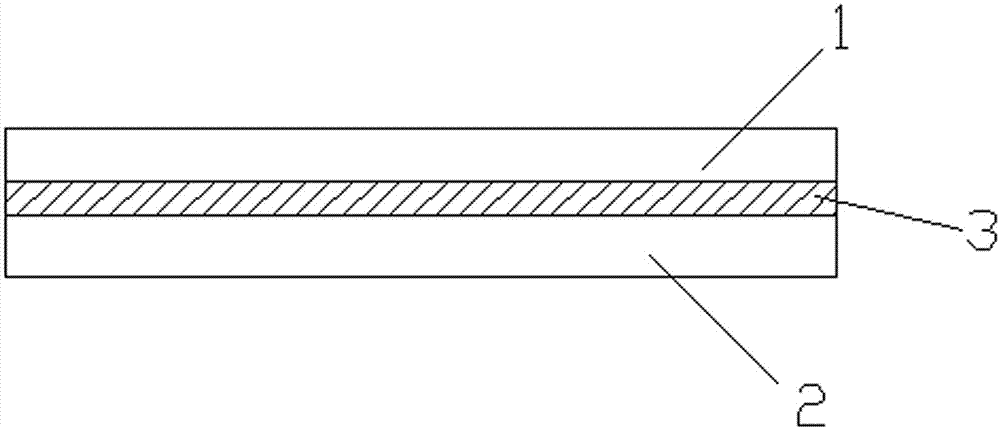

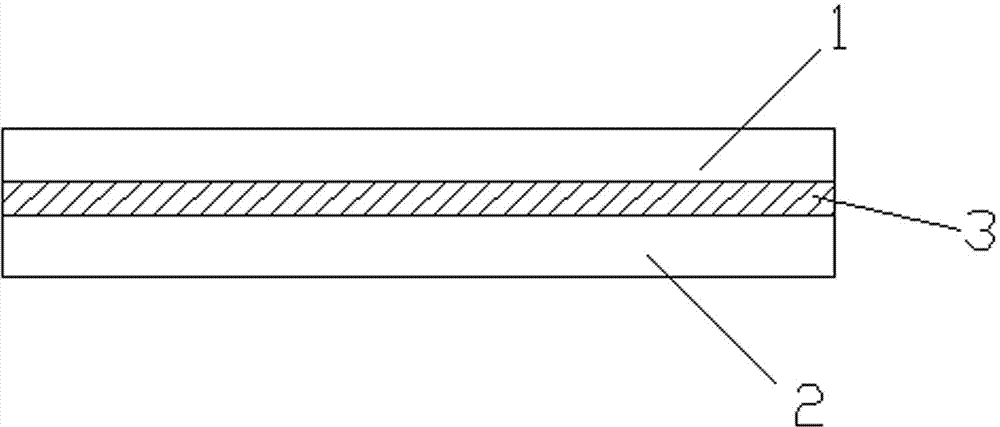

Hot-melt-adhesive laminated TPU (thermoplastic polyurethane) foamed film

InactiveCN103571364AExtended service lifeGood physical propertiesFilm/foil adhesivesHeat resistanceHeat stability

The invention belongs to the technical field of a foamed product, in particular to TPU (thermoplastic polyurethane) hot-melt-adhesive laminated TPU foamed film. The TPU hot-melt-adhesive laminated TPU foamed film comprises a TPU hot-melt-adhesive laminated TPU foamed film layer and also comprises a TPU hot-melt-adhesive layer which is arranged on the surface of the TPU hot-melt-adhesive laminated TPU foamed film layer. Compared with the prior art, the invention has the advantage that the hot-melt-adhesive layer is compounded on the surface of the TPU hot-melt-adhesive laminated TPU foamed film layer to obtain the TPU hot-melt-adhesive laminated TPU foamed film which has good physical performance and can completely substitute a soft PVC (polyvinyl chloride) foamed plastic film in the automobile industry field. The TPU hot-melt-adhesive laminated TPU foamed film not only has good adhesive property, but also is environment-friendly and can be greatly recycled, and no substance which is harmful to the health and the environment is produced when the TPU hot-melt-adhesive laminated TPU foamed film is burned under a possible situation. In addition, the TPU hot-melt-adhesive layer is strong in adhesive force and wide in applicable temperature range, has good heat resistance, cold resistance, acid resistance, alkali resistance, corrosion resistance and heat stability, has good stationarity, is slip-resisting, high in adhesive strength and has excellent temperature-resistant property, so that a product of the TPU hot-melt-adhesive laminated TPU foamed film has the advantage of long service life when being applied to the fields such as clothing manufacturing, shoemaking, building materials, automobile industry and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

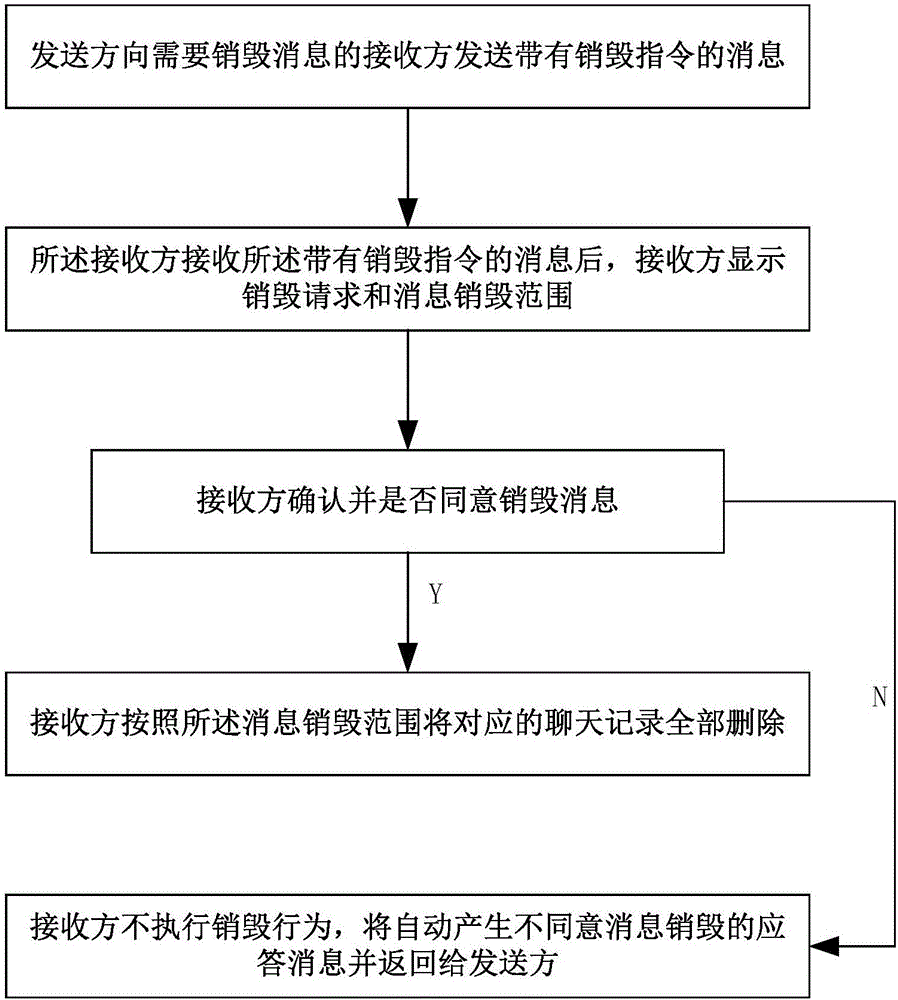

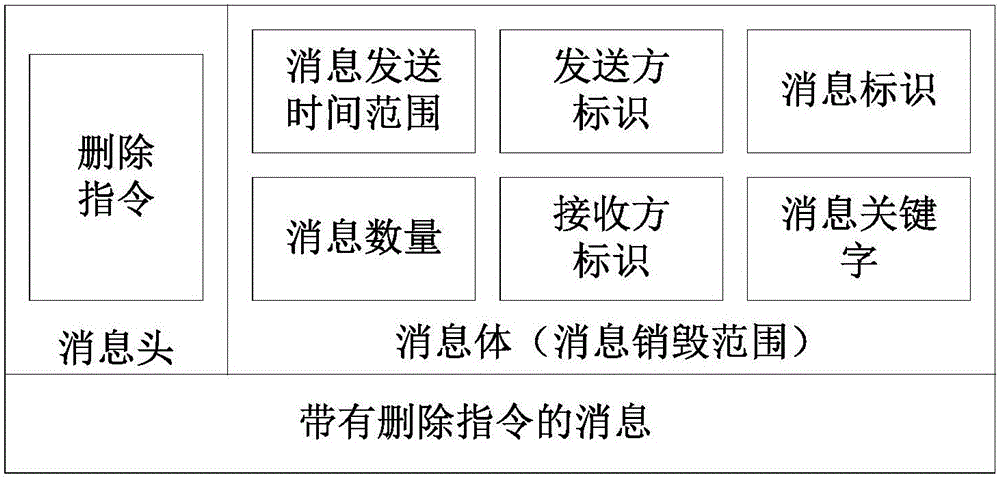

Remote destroying method for instant messages

InactiveCN105763432AFlexible and convenient processingConvenient and flexible processingData switching networksComputer hardwareInstant messaging

The invention discloses a remote destroying method for instant messages. The method comprises the steps that firstly, a sender sends a message with a deleting instruction to a receiver of the message needing to be destroyed; then, after receiving the message with the deleting instruction, the receiver displays a destroying request and the message destroying range; furthermore, after confirming and agreeing to destroy the message, the receiver deletes all corresponding chatting records according to the message destroying range, and if the receiver does not agree to destroy the message, the next step is executed; finally, the receiver does not execute the destroying behavior, automatically generates a response message that the receiver does not agree to destroy the message and returns the response message to the sender. According to the method, a user can withdraw or destroy the sent instant messages in real time and even can withdraw and destroy all the messages within a certain range according to a certain attribute or character of the messages, and a more flexible and convenient and faster processing mode is provided for the user.

Owner:BEIJING VRV SOFTWARE CO LTD

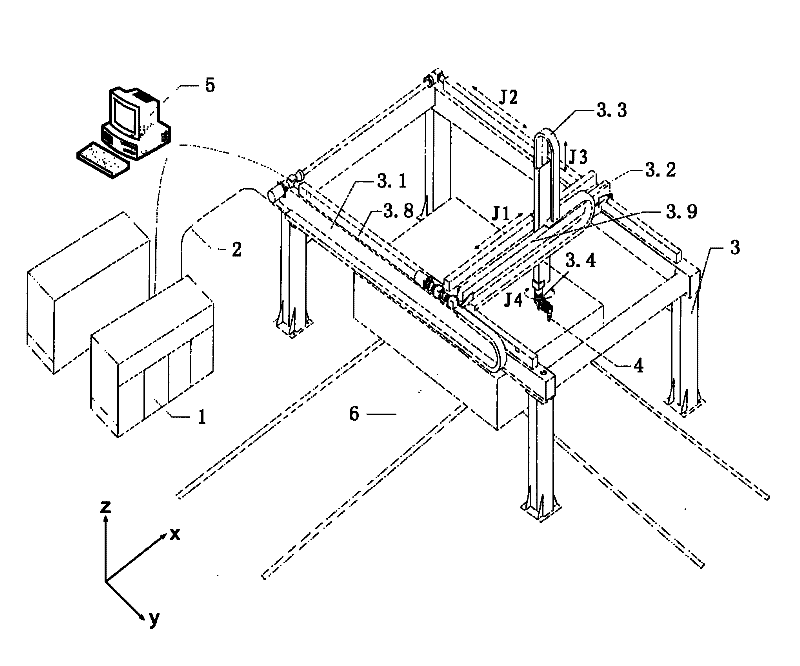

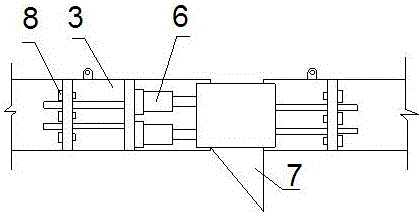

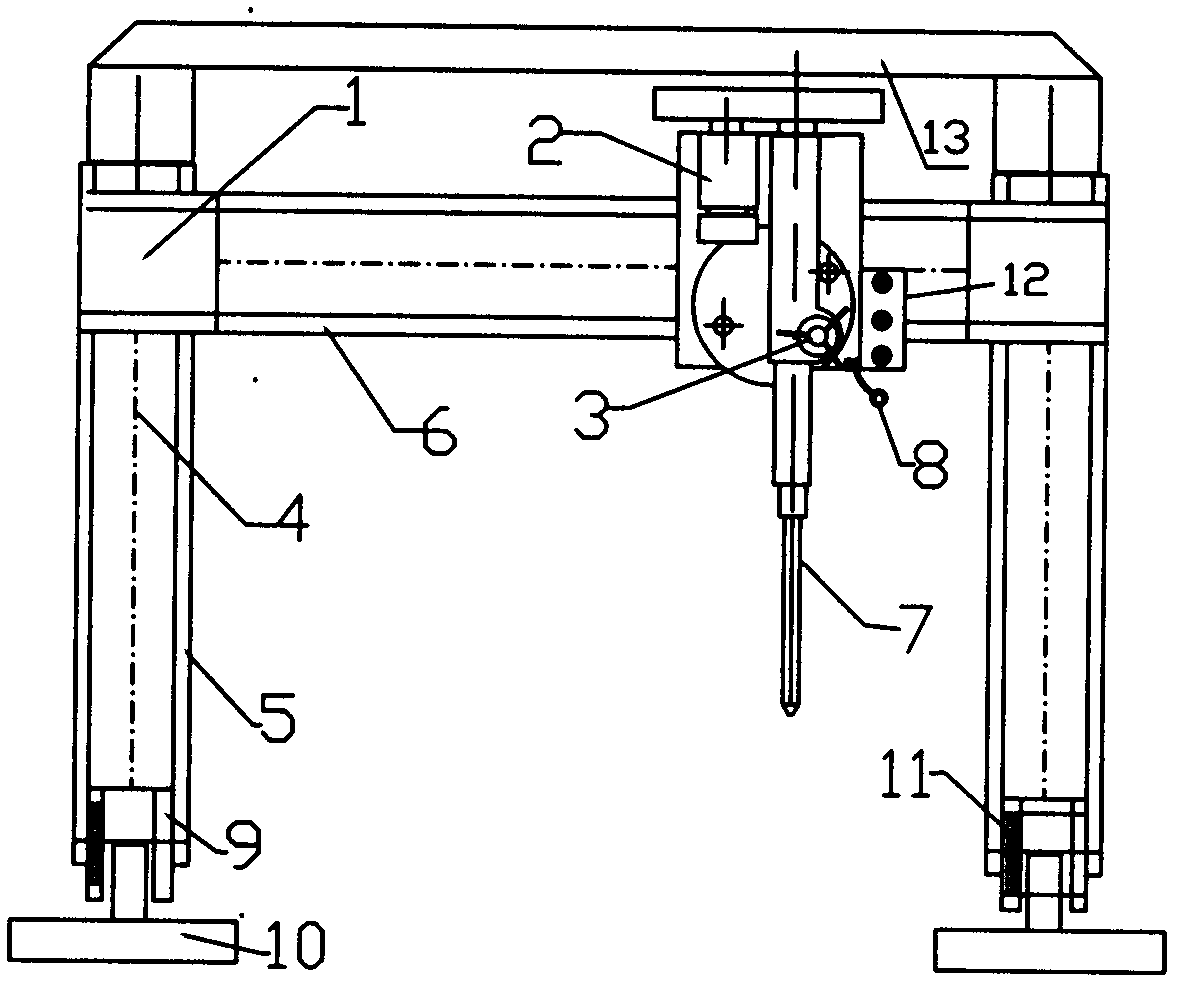

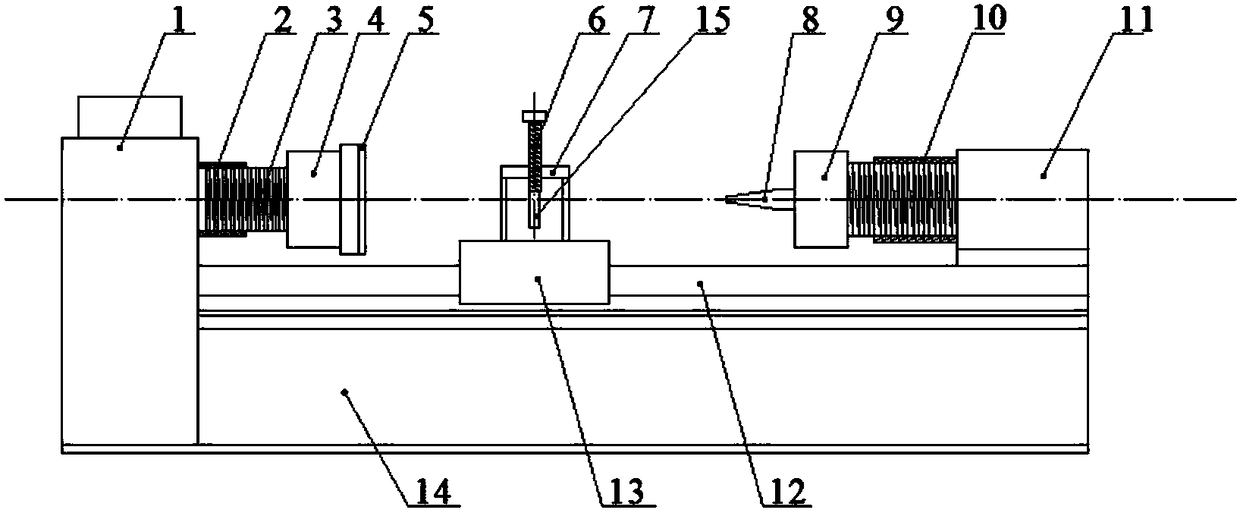

Multi-functional laser processing manufacturing system

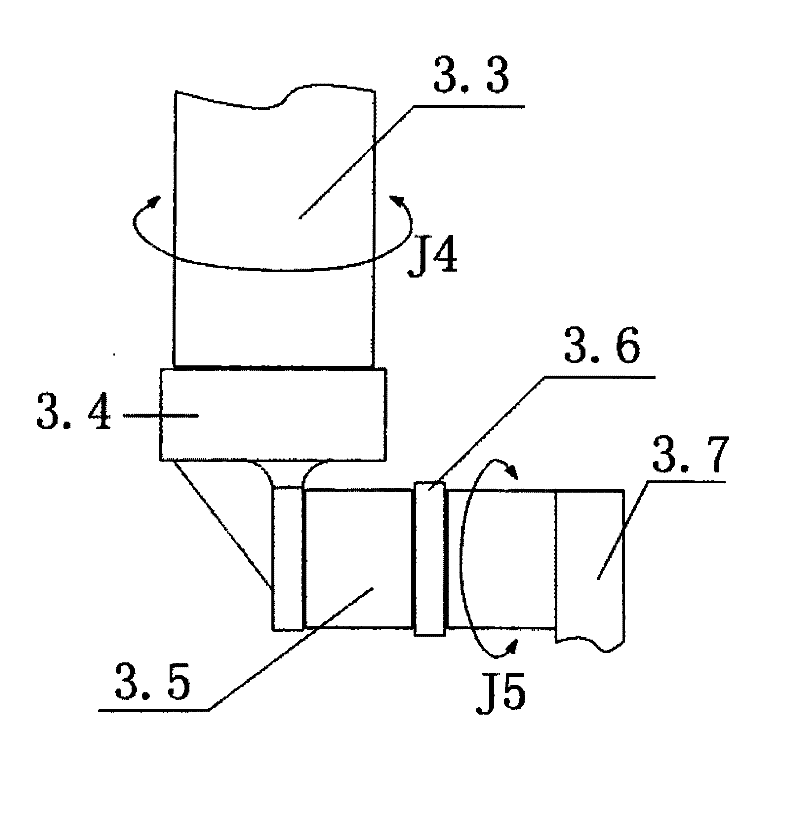

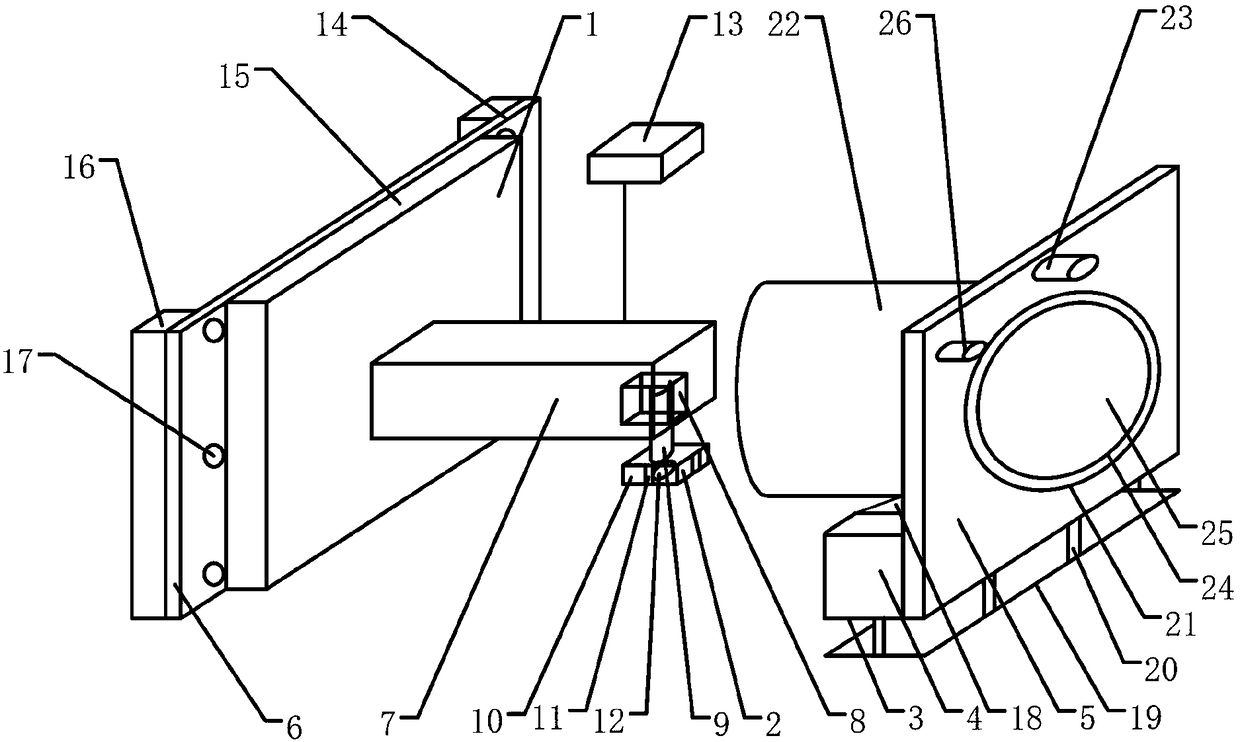

InactiveCN102451953AImprovement of processing and manufacturing process typesOperational securityProgramme-controlled manipulatorLaser beam welding apparatusEngineeringControllability

The invention discloses a multi-functional laser processing manufacturing system, which comprises a laser, an optical fiber, a laser processing head, a work platform, a multi-movement-parameter robot and a control device, wherein the multi-movement-parameter robot is used for bearing the laser processing head and a workpiece, and is provided with a motor; the control device is used for controlling the laser and the robot, and comprises a computer, a laser control unit and a robot control unit; the robot is used for controlling five movement parameters, including transverse displacement, longitudinal displacement, vertical displacement, horizontal rotation joint rotation and vertical rotation joint rotation of the laser processing head; and the computer is connected with the laser and the multi-movement parameter robot. The multi-functional laser processing manufacturing system has the advantages of capability of solving the problem that the laser processing head moves along a small-curvature track difficultly in the prior art, multi-movement-parameter controllability, expandability and suitability for laser processing of large-sized and complex curved workpieces in a plurality of environments.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

System used for automatically machining workpiece

InactiveCN105773313AEasy to collectContinuous operationMetal working apparatusEngineeringMechanical engineering

Owner:芜湖中驰机床制造有限公司

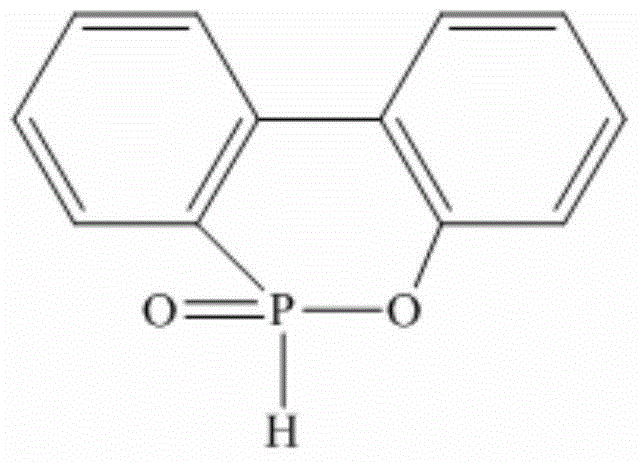

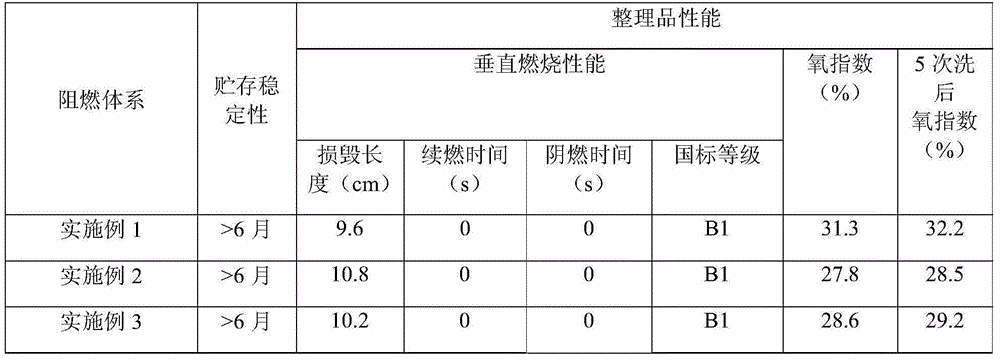

Phosphorus-containing flame retardant system polyester after-treatment and preparation and application thereof

Owner:DONGHUA UNIV

Water-stop PC steel pipe pile and inner pre-stressed section steel support combined supporting construction method

The invention discloses a water-stop PC steel pipe pile and inner pre-stressed section steel support combined supporting construction method. The method is characterized by comprising the following steps: 1) processing of steel pipe piles; 2) preparation before construction; 3) stacking and lifting of materials; 4) placement of a pile hammer; 5) verticality adjustment; 6) insertion and driving of the steel pipe piles and I steel for connection; 7) earth excavation and arrangement of a top beam and an inner support; 8) foundation construction and foundation pit backfilling; and 9) removal of the steel pipe piles. The method has the following beneficial effects: the method has a good water-stop effect and is simple and convenient in construction; after construction is over, the steel pipe piles and the I steel can be recycled so that the cost is saved; and meanwhile, the whole construction process is free of noise and mud, energy is saved, the environment is protected, and the problems of noise and mud produced by a traditional cast-in-place pile can be solved.

Owner:HANGZHOU TIANHE CONSTR GRP +1

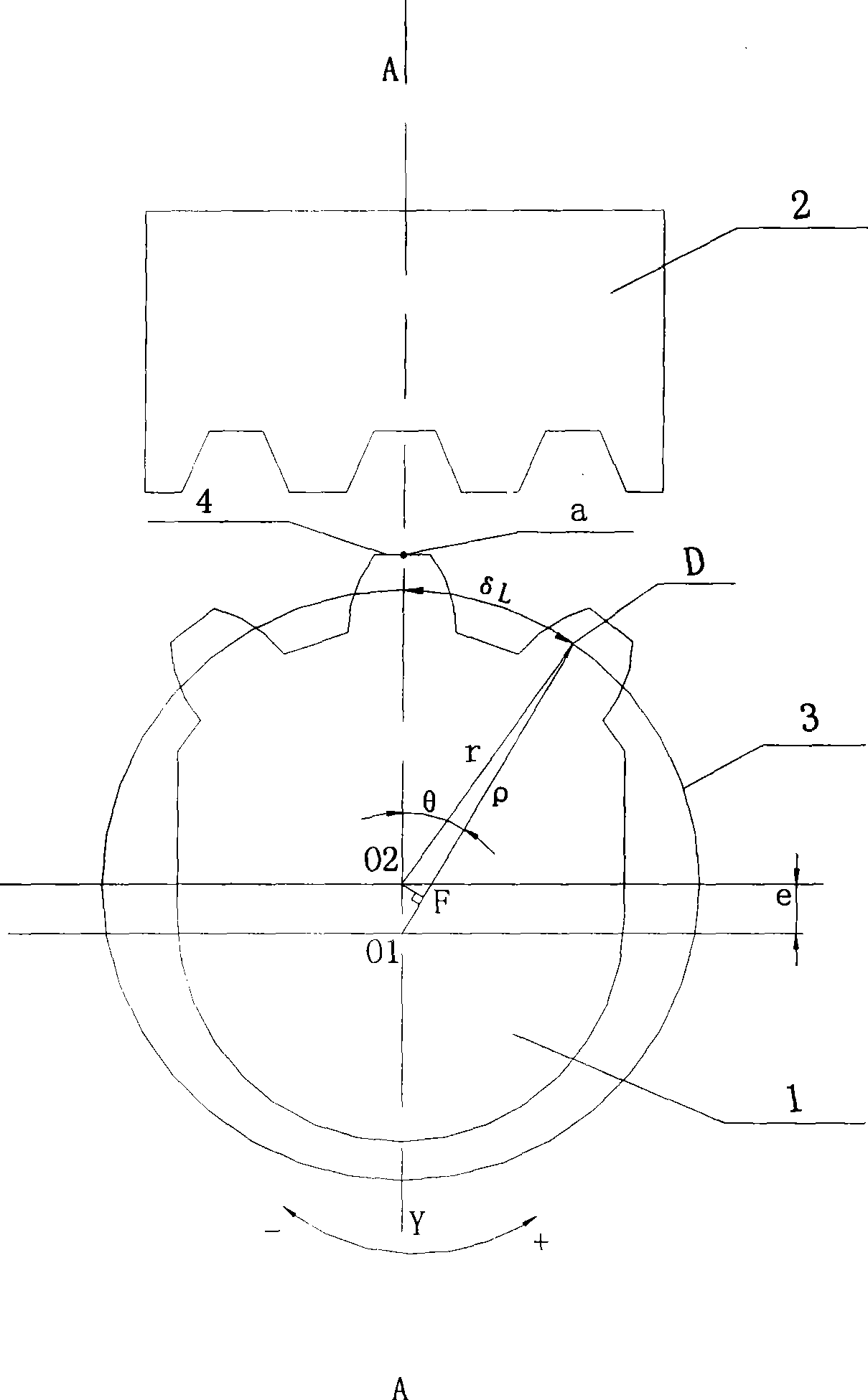

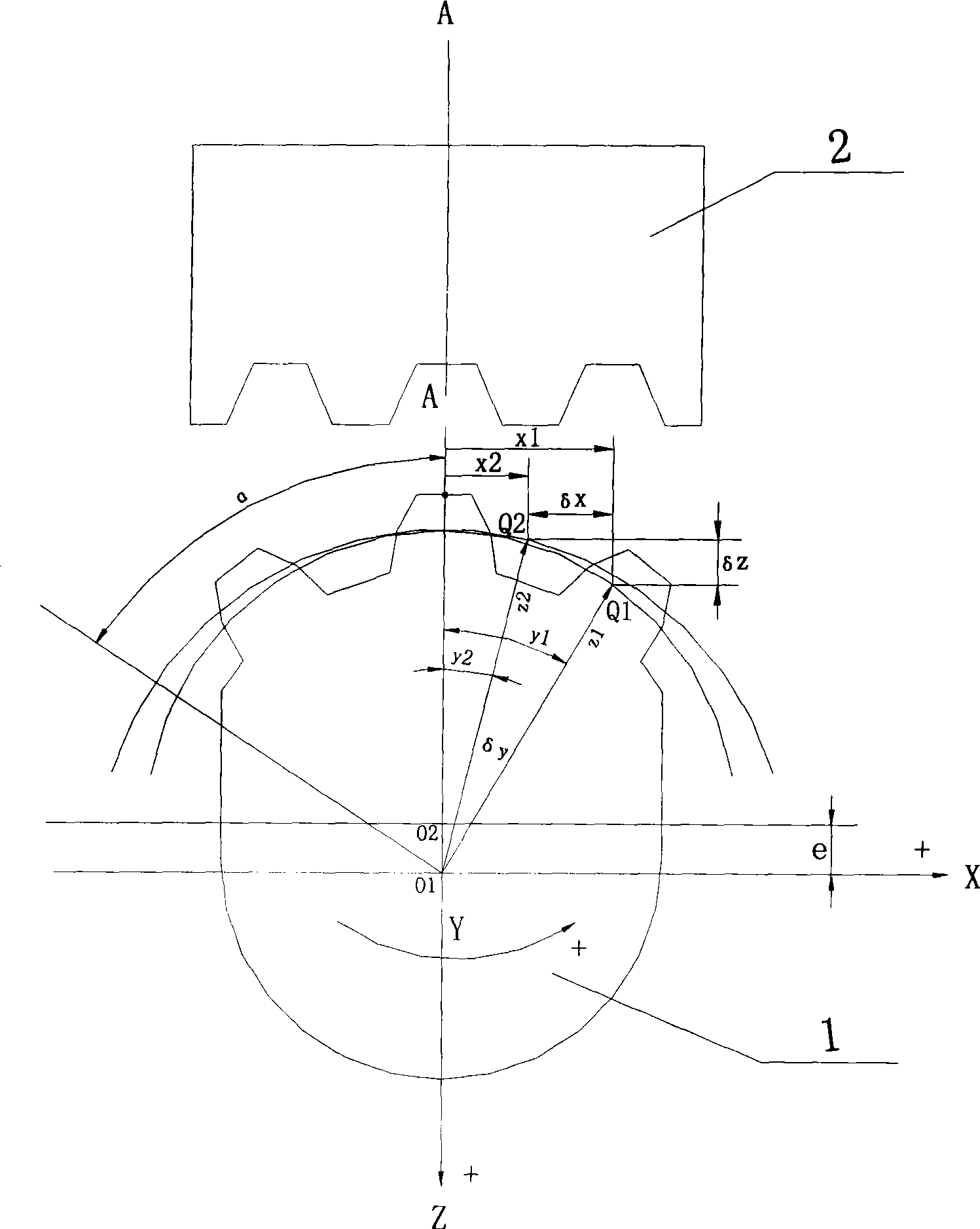

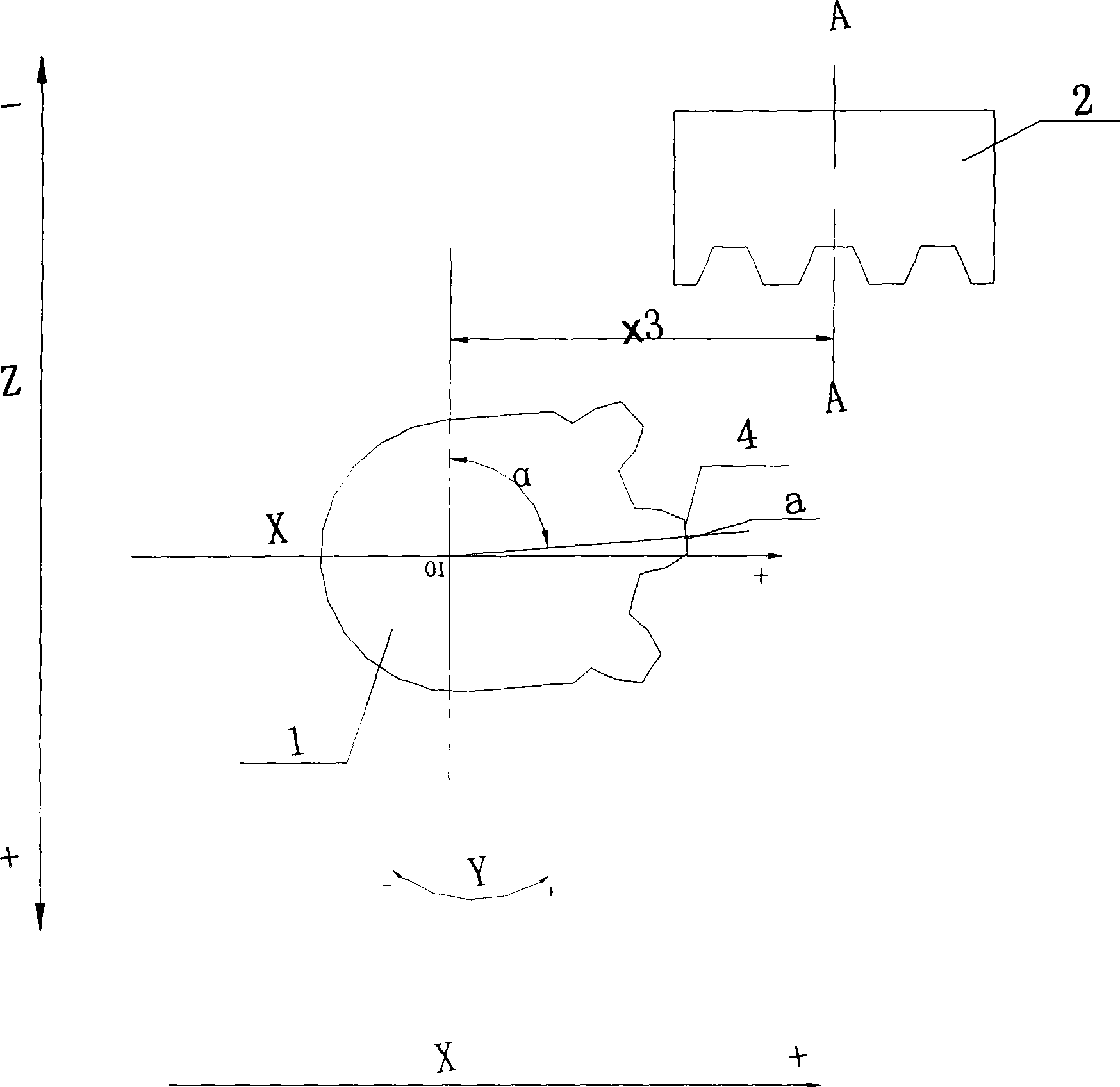

Computing formula for processing rocker shaft eccentric toothed sector of numerical control gear shaping machine and processing method

ActiveCN101412129AHigh precisionConvenient and flexible processingGear teethEngineeringCooling fluid

The invention discloses a computing formula for a numerical control gear sector gear slotting machine to process an eccentric gear sector of a rock arm shaft, and a method for processing the same. The computing formula comprises a computing formula of the hobbing radial radius rho of the eccentric gear sector of the rock arm shaft, a computing formula of the corresponding arc length of the revolution angle of the eccentric gear sector of the rock arm shaft and a computing formula for processing the contour curve of a reference circle of the eccentric gear sector of the rock arm shaft. The processing method comprises the following steps: 1) starting a program; 2) computing the initial position of the eccentric gear sector of the rock arm shaft; 3) starting auxiliary actions; 4) starting to cut the position; 5) inputting the cutting parameter into a numerical control register; 6) computing the displacement at three coordinate axes by a numerical control system; 7) cutting the contour line of the eccentric gear sector through the linkage of the three coordinate axes; 8) extending the Z axis to a retracting position; 9) extending the Y axis and the X axis to the retracting position; 10) stopping a cooling fluid and stopping a slotting cutter; and 11) ending the program. The computing formula and the method have the advantages that a parameterized programming can finish the computation and processing of the contour curve of the whole workpiece, and the parameter can be input into the numerical system in a short time to achieve the requirement of processing an eccentric distance gear sector.

Owner:通用技术集团天津第一机床有限公司

Wet-type PU (polyurethane) thin film attached with TPU (thermoplastic polyurethane) thin film

ActiveCN103568387AAvoid direct contactImprove environmental performanceSynthetic resin layered productsEnvironmental resistanceThermoplastic polyurethane

The invention belongs to the technical field of thin film products and in particular relates to a wet-type PU (polyurethane) thin film attached with a TPU (thermoplastic polyurethane) thin film. The wet-type PU (polyurethane) thin film attached with the TPU (thermoplastic polyurethane) thin film comprises a wet-type PU thin film layer, a TPU thin film layer and a hot melt adhesive layer arranged between the PU thin film layer and the TPU thin film layer. Compared with the prior art, the wet-type PU thin film attached with the TPU thin film has the advantages that a wet-type PU thin film is compounded with the TPU thin film, TPU can insulate toxic materials, like DMF (dimethyl formamide), contained in the wet-type PU thin film, and a user can not directly contact the wet-type PU thin film, so that environmental protection performance of the wet-type PU thin film can be greatly improved, and harm of the wet-type PU thin film to a human body is reduced; meanwhile, characteristics of TPU can be fully displayed, so that the wet-type PU thin film attached with the TPU thin film has good elasticity, toughness, abrasion resistance, cold resistance and the like, crack and fracture can be hardly produced, and cost for manufacturing products of bags, building materials, shoe materials and the like can be greatly reduced.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Manual drilling machine for drilling holes in thin plate

InactiveCN103978245AConvenient and flexible processingImprove drilling qualityPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a manual drilling machine for drilling holes in a thin plate. The manual drilling machine comprises a base, drilling screw rods, a drill bit clamping device, an adjusting device and a fixing device. Two parallel supporting plates are fixedly arranged at one end of the base, and two parallel guiding columns are fixedly arranged at the other end of the base. The supporting plates are provided with threaded holes I, the drilling screw rods penetrate through the threaded holes I in the two supporting plates to form a threaded pair, a hand wheel I is arranged at one end of each drilling screw rod, a threaded hole II is formed in the other end of each drilling screw rod, and the drilling screw rods are connected with the drill bit clamping device. The manual drilling machine is simple in structure, convenient to operate, safe and reliable, and capable of effectively solving the technical problem that an existing device can not be used for economically drilling holes in a single thin plate type part.

Owner:赵夫超

Material-increasing manufacturing method for easy-to-segregate high-elasticity Cu-Ni-Sn alloy

InactiveCN108330321AIncrease profitUniform compositionAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyAlloy

The invention belongs to the technical field of preparation of easy-to-segregate high-elasticity Cu-Ni-Sn alloy materials, and particularly relates to a material-increasing manufacturing method for aneasy-to-segregate high-elasticity Cu-Ni-Sn alloy. According to the material-increasing manufacturing method for the easy-to-segregate high-elasticity Cu-Ni-Sn alloy, dried Cu-Ni-Sn alloy powder prepared through gas atomization is subjected to material-increasing manufacturing by adopting a material-increasing manufacturing technology and reasonably setting technological parameters so as to obtaina sample material with the homogeneous microstructure, fine crystal grains and the high strength. By adopting the technical scheme, the material-increasing manufacturing method has the advantages that the process is simple and reliable, the alloy composition is controllable, the material-increasing manufacturing method is suitable for production of parts with the complex shapes, high-temperatureand long-time solid solution treatment is not required, the processing cost is low, operation is flexible, and the adaptability is high.

Owner:UNIV OF SCI & TECH BEIJING

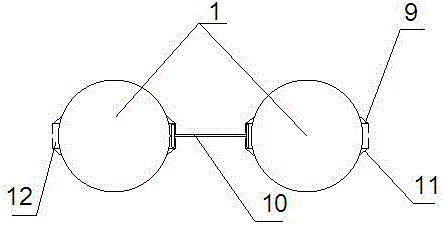

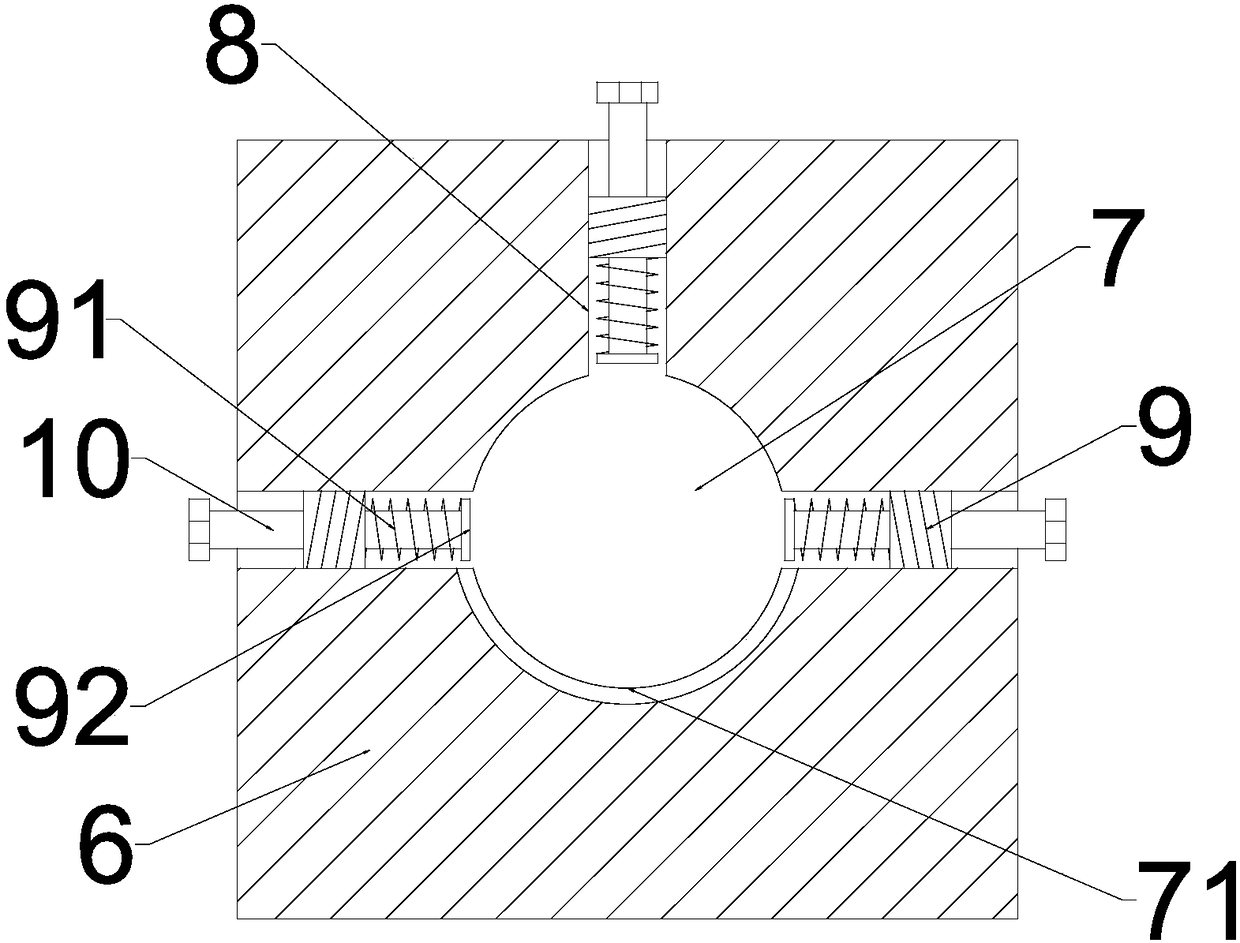

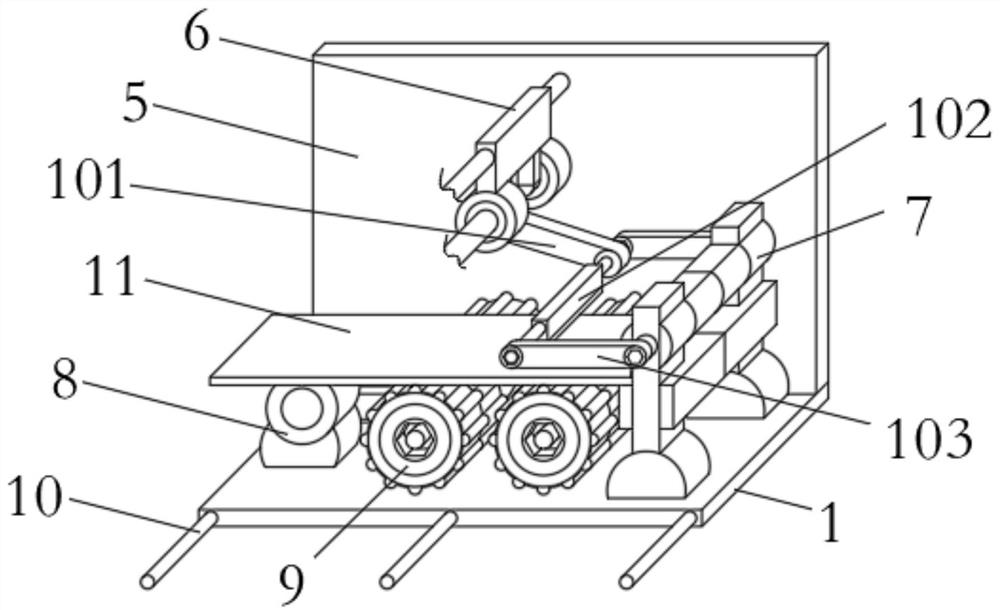

Rotary surface grinding platform for pipe

InactiveCN108177034AEasy to fixGuaranteed stabilityRevolution surface grinding machinesGrinding work supportsEngineeringGrinding wheel

The invention discloses a rotary surface grinding platform for a pipe. The rotary surface grinding platform for the pipe comprises a placement underframe, a horizontal placement rod, fixing clamping plates, a motor, a rotating shaft and a grinding wheel; the horizontal placement rod is arranged at the upper end of the placement underframe; a through sliding groove is formed in the middle of the horizontal placement rod; a sliding vertical plate is arranged on the periphery of the horizontal placement rod; a rotary placement plate is arranged at the lower part of the sliding vertical plate; a sliding placement plate is arranged in the through sliding groove; a placement blind hole, a limiting rod, a movable plate, the motor, the rotating shaft and the grinding wheel are arranged on the sliding placement plate; a fixing clamping plate is arranged on each of the rotary placement plate and the placement underframe; and a pipeline through hole, a rubber cushion layer, a threaded hole, a threaded block, an anti-skid gasket and a rotating regulating rod are arranged in each of the fixing clamping plates. The rotary surface grinding platform for the pipe can horizontally clamp a pipeline and control the pipe to rotate to regulate a machining position to match a grinding device which moves horizontally, so that the surface of the pipe can be ground safely and conveniently.

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

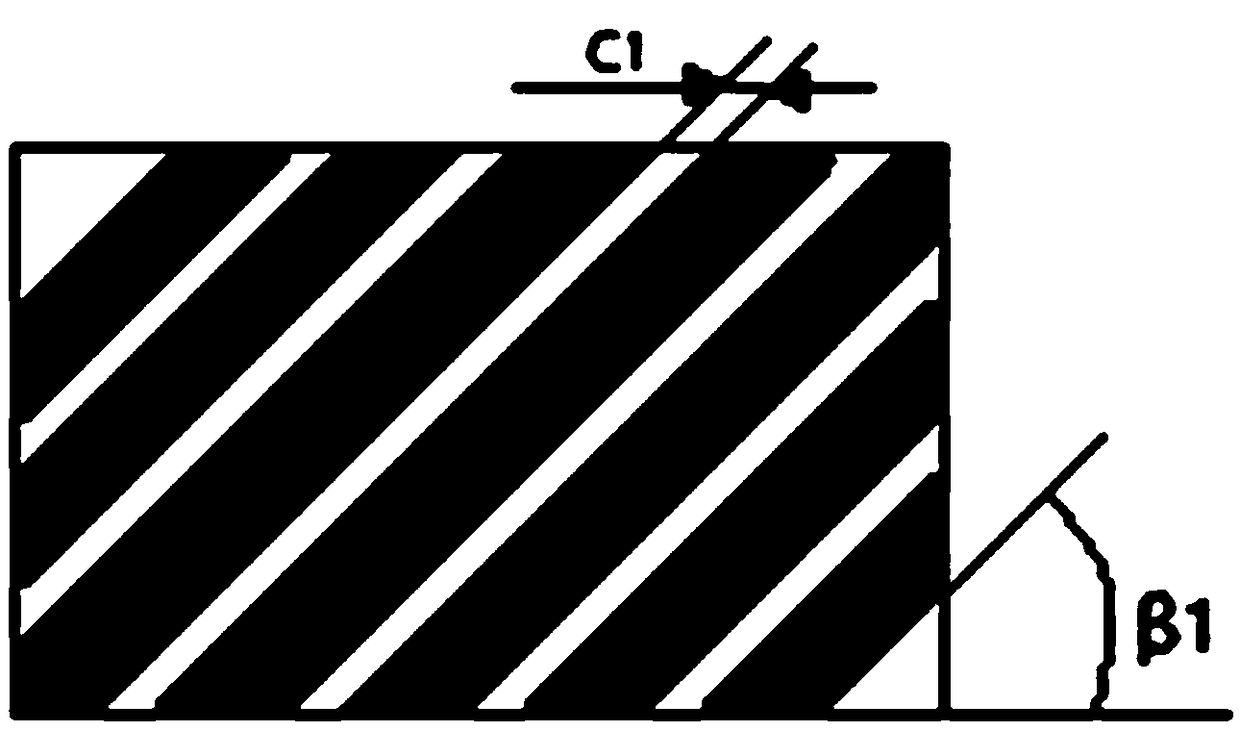

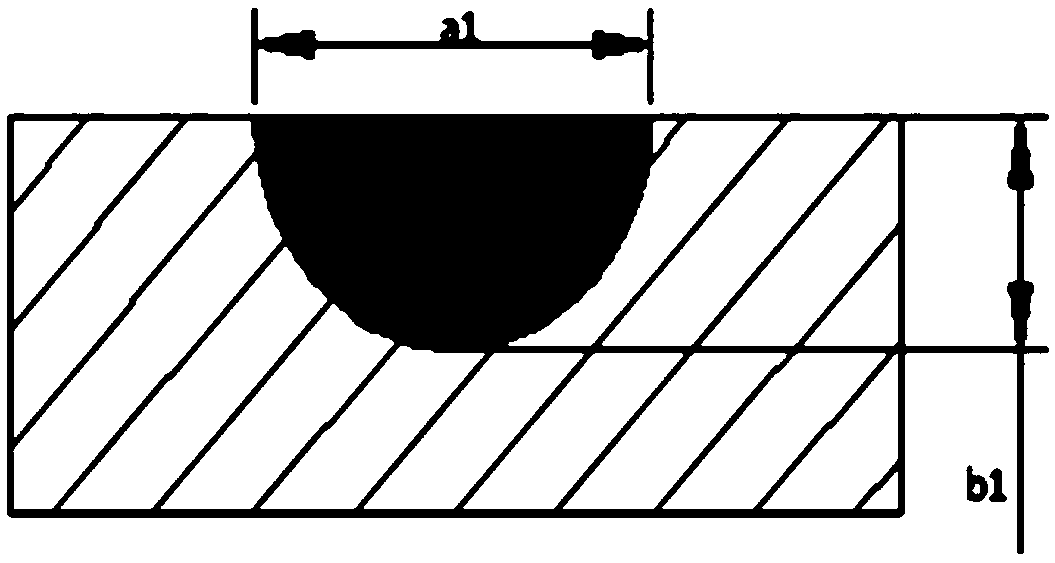

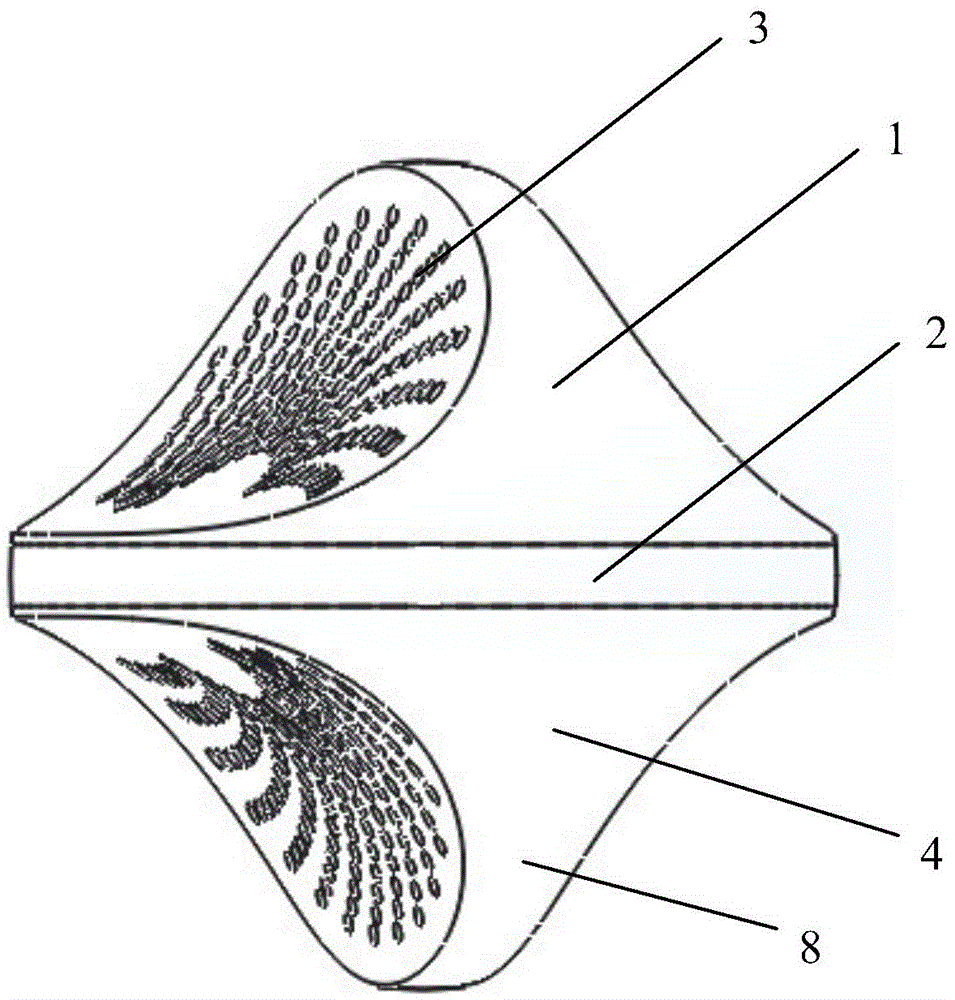

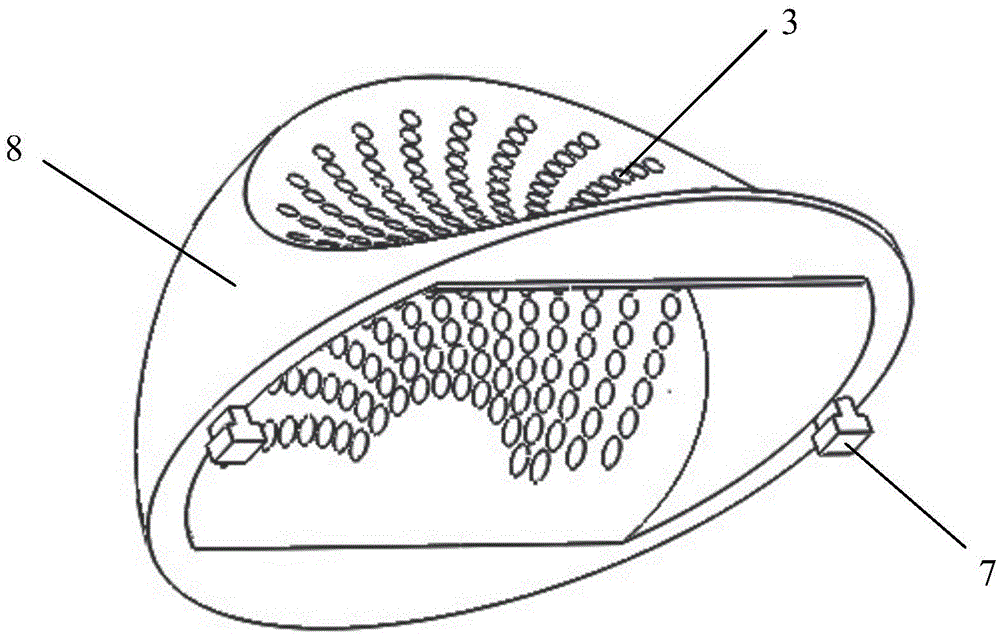

Large crankshaft mold with coupling bionic surface

ActiveCN109158522AHigh hardnessImprove wear resistanceForging/hammering/pressing machinesEngine componentsHardnessUltimate tensile strength

The invention relates to a large crankshaft mold with a coupling bionic surface. Referring to the abrasion condition of a scrapped mold and according to differences of the stress size, the damage modeand the abrasion morphology, the working surface of the mold is divided into three zones; a convex part in a mold cavity is a zone A, a concave part of the mold cavity is a zone B, and a contact surface of an upper mold and a lower mold after being closed is a zone C; the zone A is used for preparing a dense-arranged heavy stripe unit body model to retard the abrasion effectively; the zone B is used for preparing a sparse-arranged thin stripe unit body model to hinder the development of fatigue cracks effectively, and to retard the abrasion; and the zone C is used for preparing a uniformly-arranged latticed unit body model so as to enhance the strength of an arc transition joint of the mold, and to retard the abrasion effectively. According to the large crankshaft mold with the coupling bionic surface, the hardness, wear resistance and the thermal-crack-development-resistance performance of the working surface of the mold can be remarkably improved.

Owner:JILIN UNIV

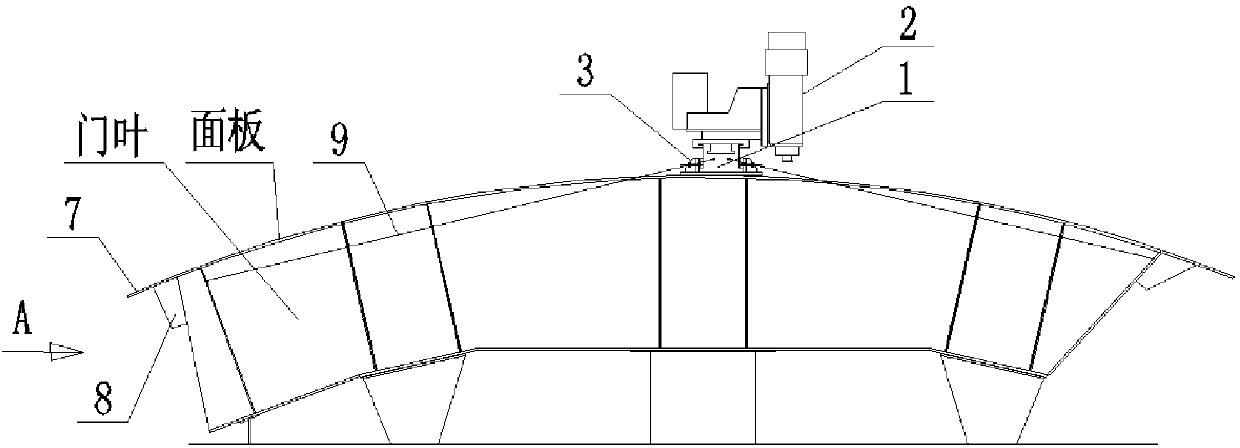

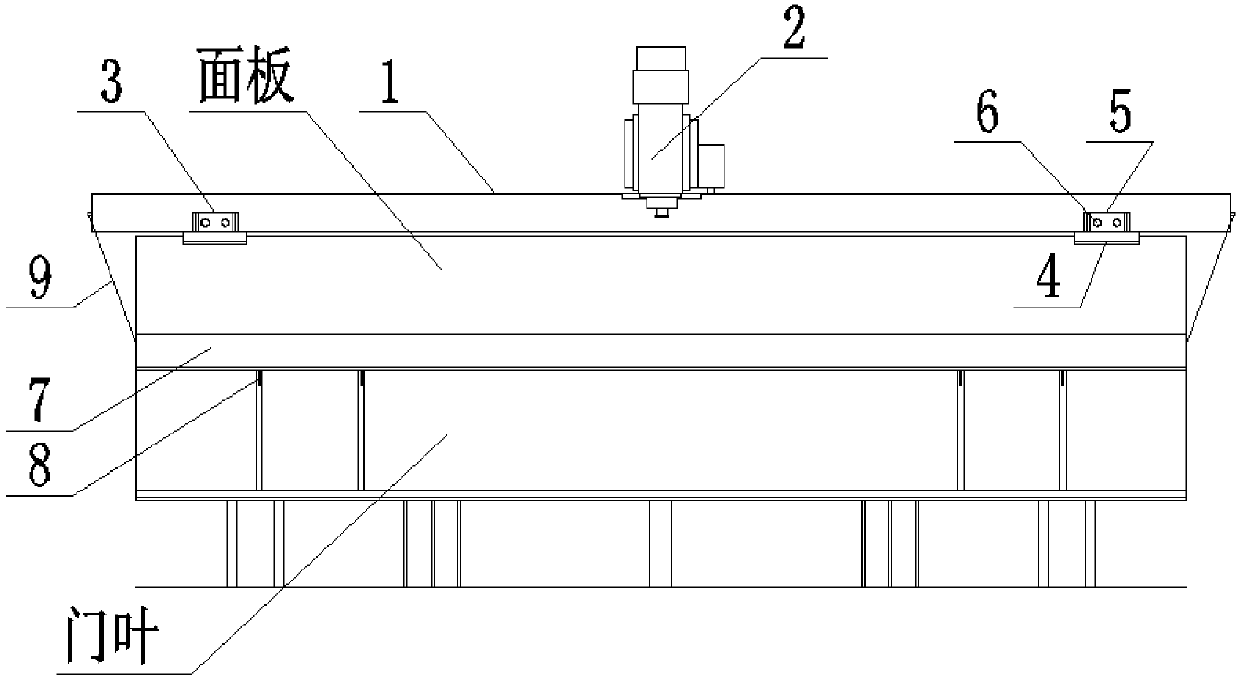

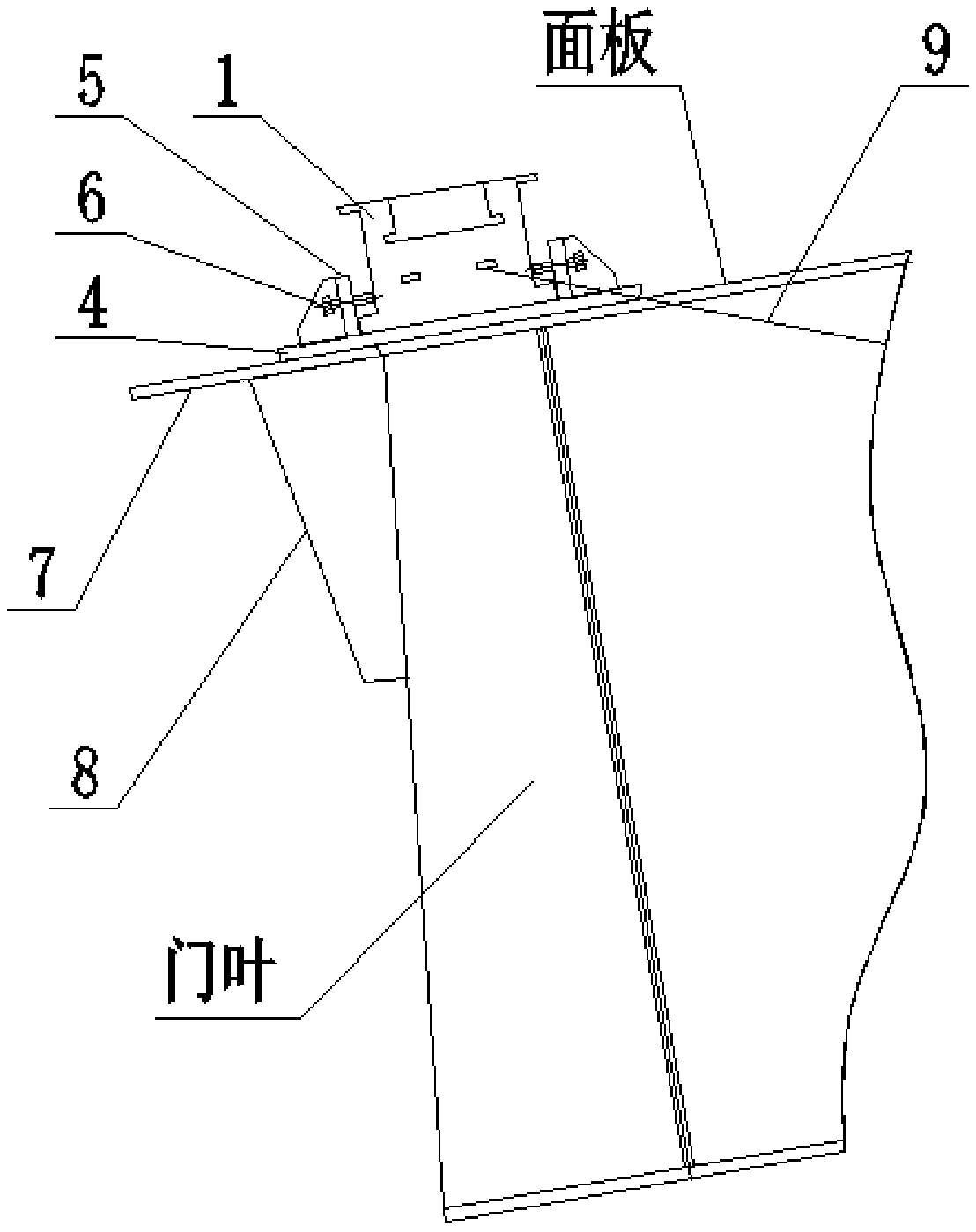

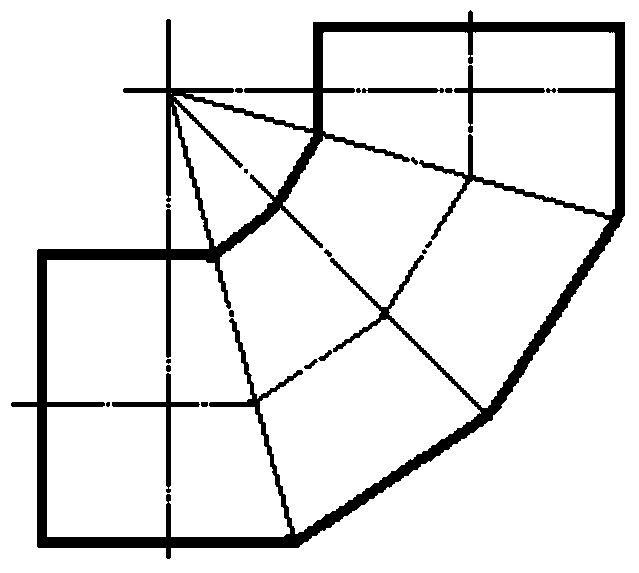

Radial gateleaf horizontal machining method and special tool

PendingCN107685235AShorten production timeEasy to operateOther manufacturing equipments/toolsMachiningIndustrial engineering

The invention discloses anradial gate leaf horizontal machining method and a special tool. The special tool comprises a machining rail, a mill front and a rail gasket assembly, the mill front is arranged on the machining rail and can reciprocate relative to the machined rail, and the rail gasket assembly is arranged below the machining rail. The machining method comprises the steps of 1, installing a panel extending component; 2, erecting the tool; 3, fixing the tool and 4, machining the panel. The machining method can solve the technical problem that a tool machined on an existing radial gateleaf is complex in structure, large in cost investment and complicated in processing step, the cost can be saved, the processing steps can be simplified, and the gate leaf manufacturing time is shortened, so that a gate leaf panel is more flexibly and more conveniently machined; in the aspects of structural design, installation and machining of the tool itself, the structural design is reasonableand simple, manufacturing is facilitated, the cost is low, and the gate leaf is easy and convenient to machine and operate.

Owner:SINOHYDRO ENG BUREAU 4 XIANGYUN MACHINERY ENERGY EQUIP CO LTD

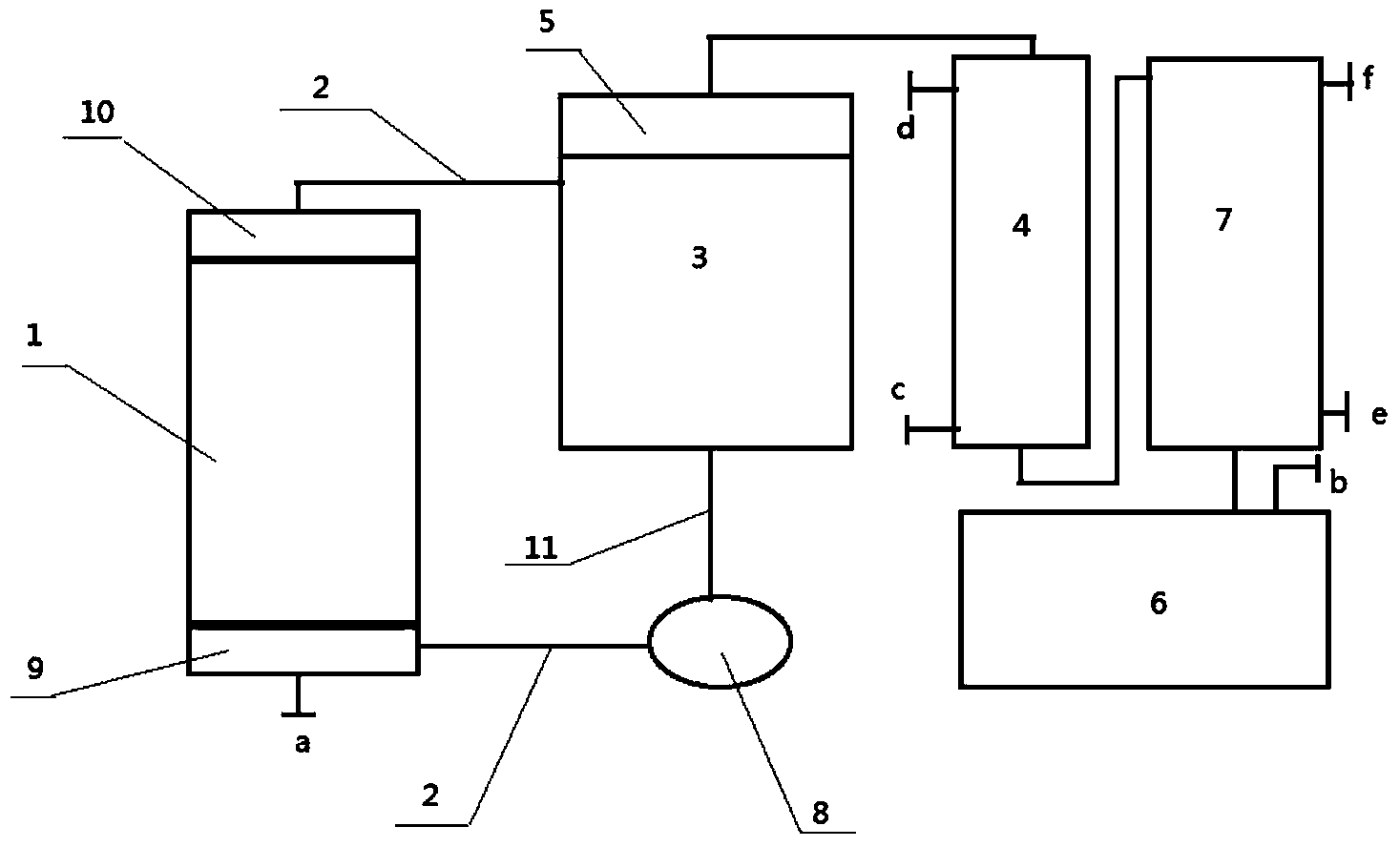

Online tons-level traditional Chinese medicine anti-wall-hanging evaporation and concentration device and operating method thereof

The invention provides an online tons-level traditional Chinese medicine anti-wall-hanging evaporation and concentration device and an operating method thereof. A gas-liquid-solid three-phase natural circulation fluidized bed evaporation and concentration device in an industrial production scale in which the heating area of a heater is 18.9 m<2> and the evaporative power is 1100-1400 kg / h is determined. The inventions and innovations of a screen type discharging device, a 90-degree multi-section short-radius elbow connecting pipe and a demister on the upper part of a separation chamber are designed. At present, the production operation result of the industrial scale device of about 100-ton extracting solutions of Menopause Ease and other over ten traditional Chinese medicines proves that compared with a traditional two-phase flow evaporation concentrator with the heating area of 18 m<2> in a factory and an operating method thereof, the device and the method under approximate operation conditions have the advantages that the total heat transfer coefficient and evaporation intensity are improved, a wall hanging phenomenon of the two-phase flow evaporation concentrator is avoided, the wall hanging phenomenon existing in a traditional Chinese medicine extracting solution evaporation concentrator is eliminated, and high-efficiency continuous and stable operation is realized.

Owner:TIANJIN UNIV

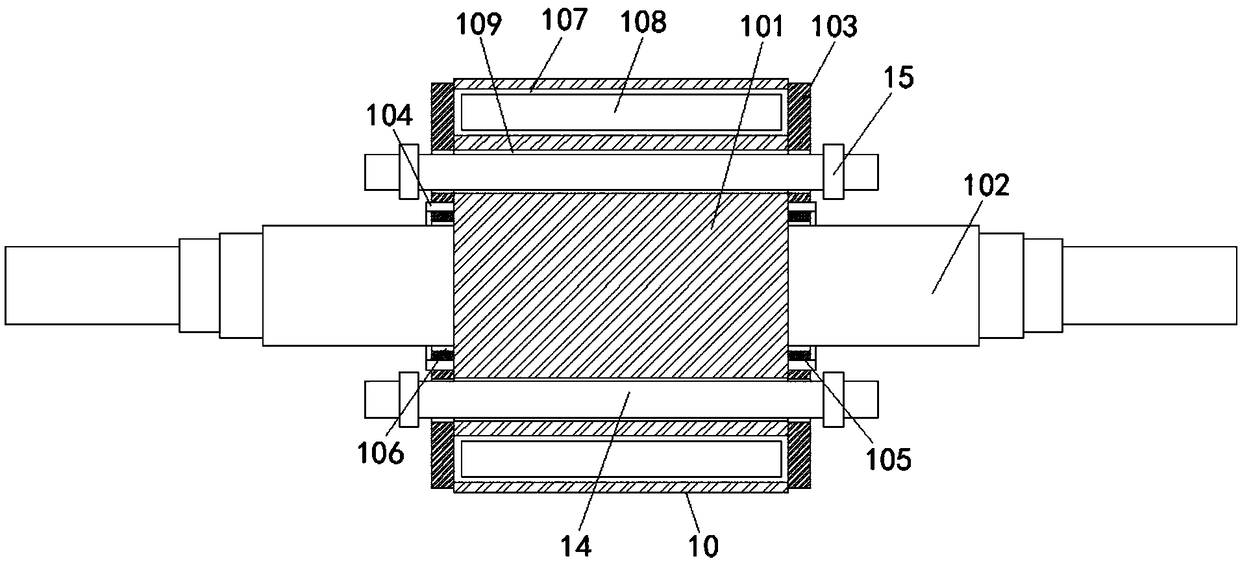

Rotor ironless permanent magnet synchronous motor

InactiveCN108832790ASave resourcesRotor material is lightMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsStatorMagnet

The invention relates to the technical field of motors, and discloses a rotor ironless permanent magnet synchronous motor, which comprises a motor outer shell, wherein a front end cover is fixedly mounted on the left side of the motor outer shell, a rear end cover is fixedly mounted on the right side of the motor outer shell, the left side of the front end cover and the right side of the rear endcover are each fixedly provided with a bearing outer cover, the left side of the front end cover and the left side of the rear end cover are each fixedly provided with a bearing inner cover, bearingsare fixedly mounted in the interior of the front end cover and the interior of the rear end cover, oil inlet pipes are fixedly mounted in the interior of the two bearing outer covers, a wind cover isfixedly mounted on the right side of the rear end cover, a stator is are fixedly mounted on the inner surface of the motor outer shell, and the inner surface of the stator is movably connected with arotor. The rotor ironless permanent magnet synchronous motor adopts a polymer material to replace silicon steel sheets and other ferrous magnetic conductive materials, realizes ironless permanent magnetization, has no iron loss and high magnet usage rate, and reduces the magnet usage amount.

Owner:武汉麦迪嘉机电科技有限公司

Continuous pre-baked anode carbon block with split type independent carbon bowl and ultra-long filling block structure

ActiveCN110029363ASimple structureHigh green block forming rateElectrical resistance and conductanceContinuous use

The invention discloses a continuous pre-baked anode carbon block with a split type independent carbon bowl and ultra-long filling block structure. The continuous pre-baked anode carbon block comprises a carbon block body, wherein carbon bowl assembly connecting pits are formed in the carbon block body, carbon bowl assemblies are arranged in the carbon bowl assembly connecting pits, carbon bowls are arranged on the carbon bowl assemblies, mechanical steel claw connecting ring grooves are formed in the positions, at the bottoms of the carbon bowls, of the charcoal bowl assemblies, and ultra-long carbon bowl filling blocks are movably arranged in the parts, on the carbon bowl assemblies, of the carbon bowls. The continuous pre-baked anode carbon block cooperates with casting-mechanical steelclaws so that the continuous use of a pre-baked anode can be realized, the time for connecting a new anode carbon block is short, the labor intensity is low, the use is convenient, the filling rate of the continuous pre-baked anode carbon block is improved, the connection strength of the carbon block is improved, the whole resistance of the anode carbon block is reduced, the service life of the single carbon block is prolonged, the production cost is low, moreover, manufacturing, roasting, transportation and use of the carbon block body, the split type independent carbon bowls, and the ultra-long filling blocks are all simple, and the characteristics of being high in manufacturing finished product rate, low in expense is low, low in cost and the like are achieved.

Owner:贵州铝城铝业原材料研究发展有限公司

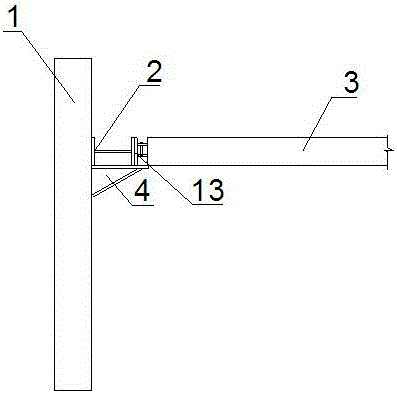

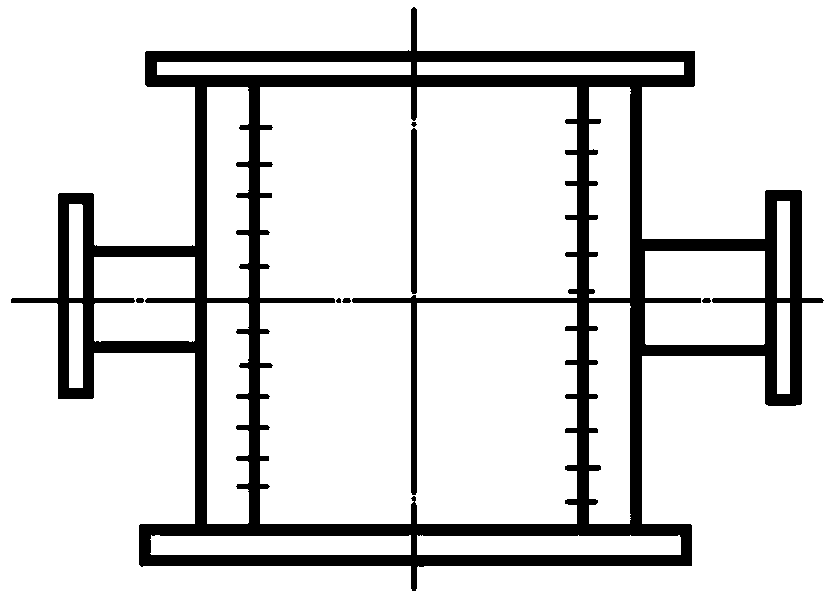

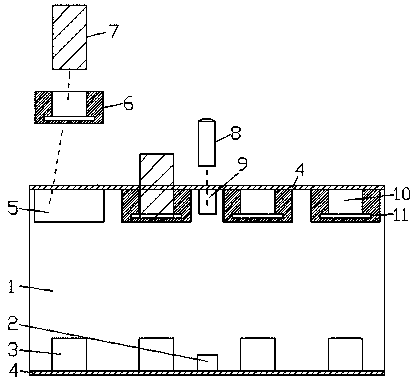

Special equipment for drilling and reaming large scale equipment dowel hole

InactiveCN103170843AConvenient and flexible processingExpand the scope of processingOther manufacturing equipments/toolsPortal frameMachining

The invention relates to special equipment for drilling and reaming a large scale equipment dowel hole. The special equipment is composed of a portal frame, a main shaft box, a drilling device, lead screws, rotating wheels, guide rails and a control device. Supports on two sides are connected with a top beam, a transverse beam is arranged in the middle, a rotating wheel is arranged on the lower side of each support, two guide rails are arranged on the lower sides of the rotating wheels, and therefore the portal frame capable of moving forwards and backwards and braking is formed. The lead screws are arranged in the two supports and the transverse beam, the supports and the transverse beam are connected through guide rail armature iron pressing plates, the transverse beam can move vertically on the portal frame formed by the supports, the main shaft box is installed on the transverse beam, the drilling device is installed in the main shaft box, the main shaft box and the drilling device can move horizontally on a guide rail of the transverse beam, and tightening blocks are installed in the main shaft box and the drilling device. Processing of the dowel hole of large scale equipment is convenient, locating is accurate, stable, high in power and high in efficiency in the process of machining, holes which cannot be machined via a drilling machine can be machined by the special equipment, and machining range of hole drilling and reaming is enlarged.

Owner:SHANDONG UNIV OF SCI & TECH

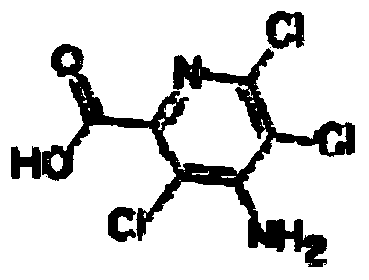

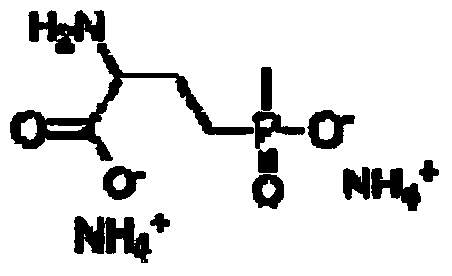

Mixed herbicide containing glufosinate ammonium

ActiveCN104365659AImprove herbicidal activityReduced resistance generation rateBiocideAnimal repellantsPicloramAmmonium glufosinate

The invention discloses a mixed herbicide containing glufosinate ammonium, picloram and triklopir. Glufosinate ammonium, picloram and triklopir are effective components; a mass ratio of glufosinate ammonium to picloram to triklopir is (5-50) to (5-50) to (10-20). The mixed herbicide can be used for weeding woodlands or non-cultivated lands, especially has remarkable effect in application of prevention and removal of undershrub, gramineous weeds and broadleaf weeds planted in woodlands or non-cultivated lands. Compared with a single preparation, the herbicide is capable of improving weed resistance under the condition that the herbicide effect is improved, and is wide in herbicide spectrum and long in preserving effect period.

Owner:NANJING HUAZHOU PHARMA +1

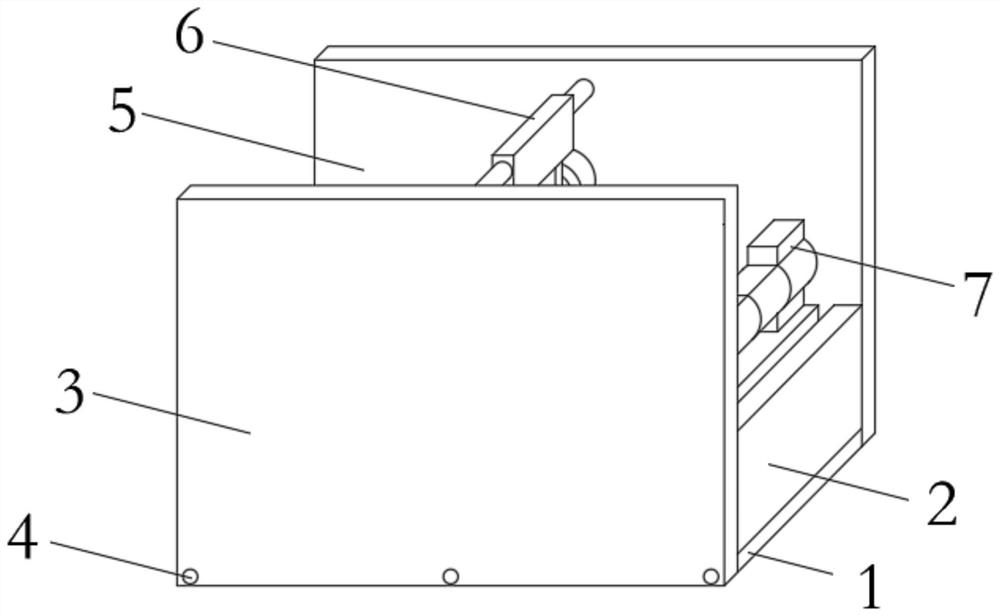

Hardware pin bending mechanism and bending method

ActiveCN110918824AConvenient and flexible processingImprove usabilityComputer hardwareMechanical engineering

The invention discloses a hardware pin bending mechanism and bending method. The hardware pin bending mechanism comprises a machining platform. Positioning assemblies used for hardware positioning arefixed to the machining platform. A bending device for bending the hardware pins is mounted on the machining platform. Hardware is positioned through the positioning assemblies on the machining platform; the bending device is used for bending the pins of the hardware; and in the bending process, by adjusting the distance between the two positioning assemblies and adjusting the bending device, thehardware with the pins at different distances can be positioned and bent, machining is more flexible and convenient, and usability is high.

Owner:深圳市鑫立方科技有限公司

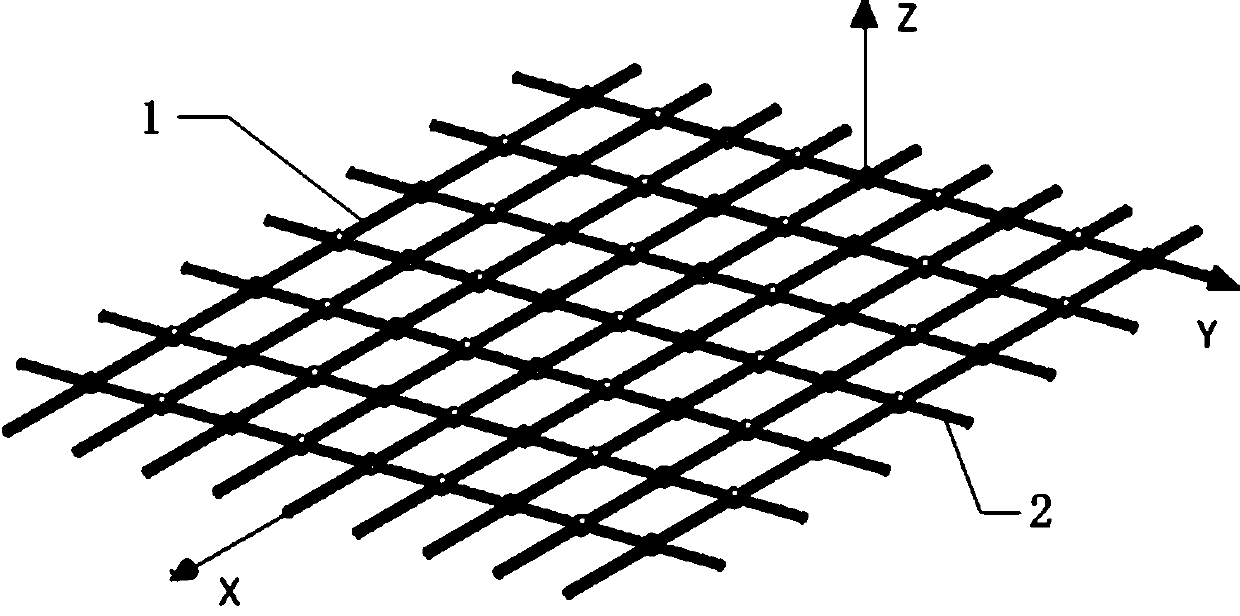

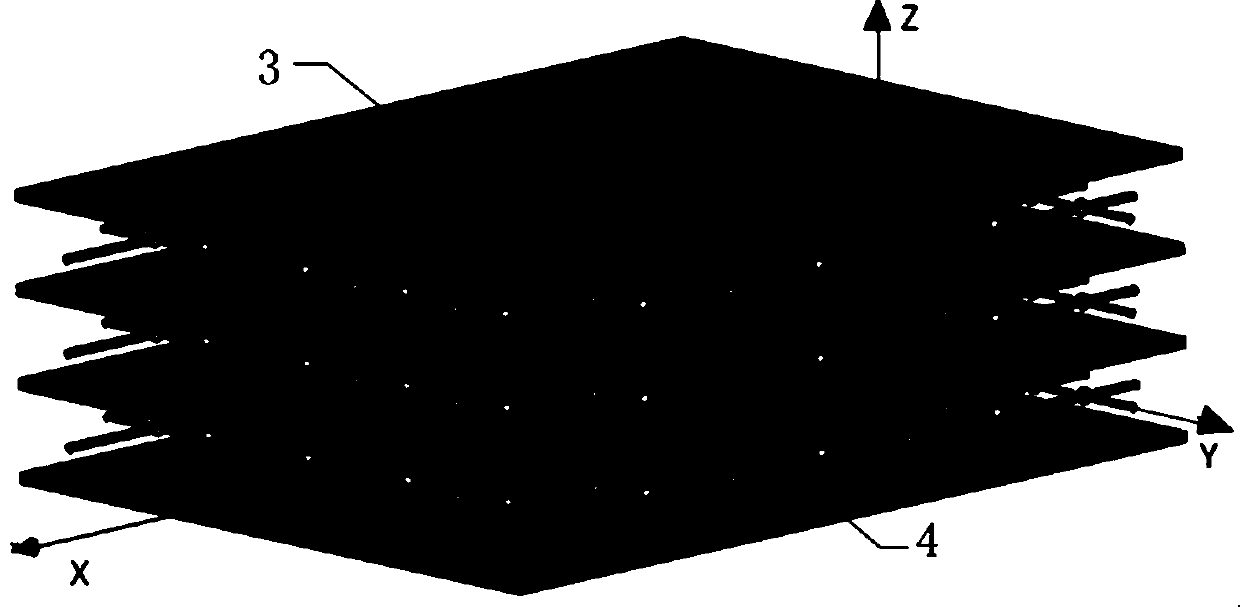

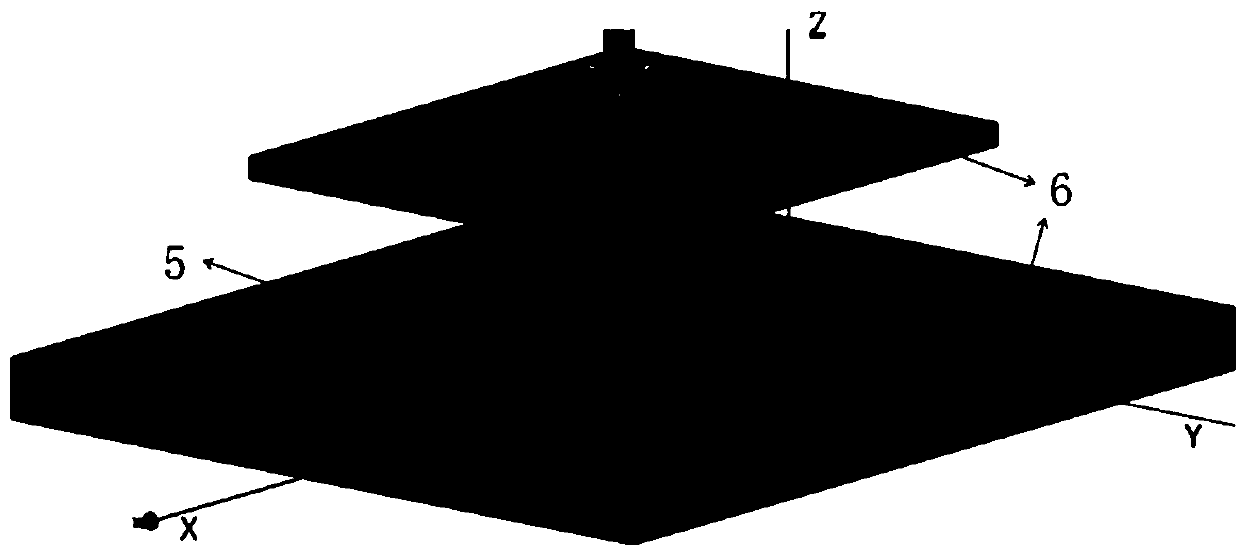

Preparation methods of anisotropic conductive silk screen, block and diaphragm, and product

ActiveCN109979646ASimple methodIncrease elasticityConductive layers on insulating-supportsBraidIntegrated circuitHigher Power

The invention discloses preparation methods of an anisotropic conductive silk screen, a block and a diaphragm, and a product. The anisotropic electric conduction silk screen is obtained by carrying out net knitting on a conductive wire and an insulating fiber. The anisotropic conductive block is obtained by superposing the silk screen and an insulating medium, and conducting pressing and heating.The anisotropic conductive diaphragm is obtained by carrying out interface slicing on the anisotropic conductive silk screen, carrying out polishing and plating treatment on the end of the conductivewire and carrying out adhesion removal treatment on the surface of the diaphragm. The conductive silk screen manufactured through simple technology is convenient for large-scale manufacturing. The manufactured conductive diaphragm can complete approximately non-damage, high-frequency, high-power and high-efficiency microwave integrated circuit testing. The intermediate products for preparing the diaphragm can be independently used, and convenience is provided for the preparation of subsequent products.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

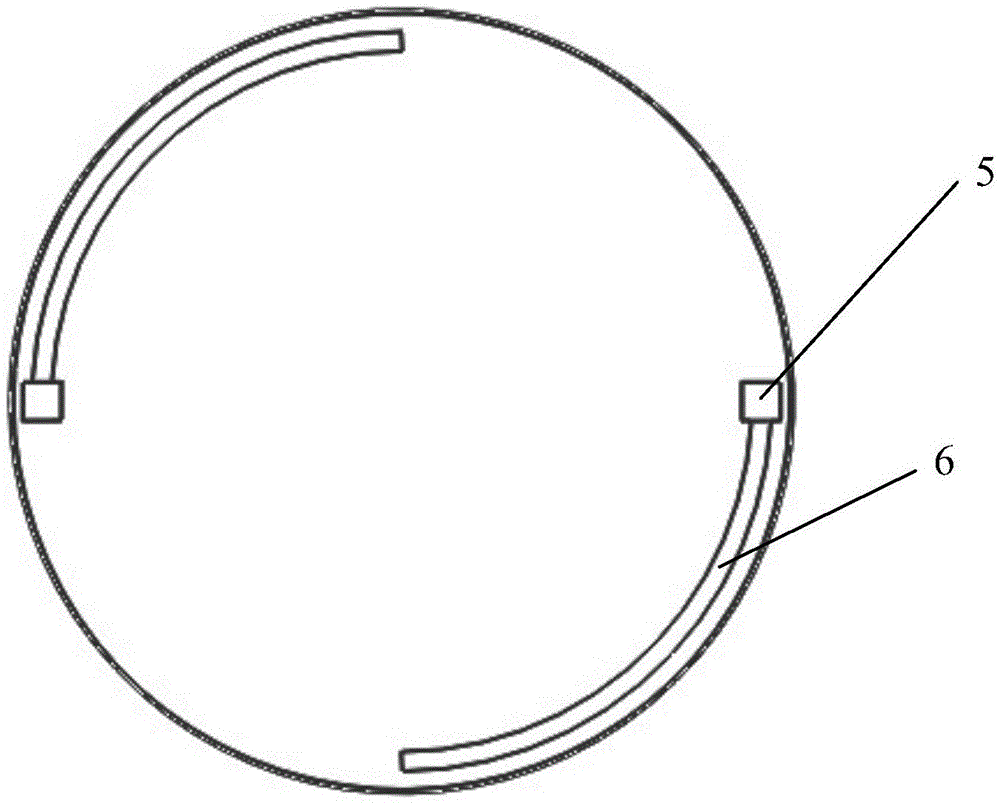

Detachable turning plate type gathered draining device with double-layer filter screen

InactiveCN105544669ACompact structureThe principle of hair collection is ingeniousDomestic plumbingEngineeringMechanical engineering

The invention discloses a detachable turning plate type gathered draining device with a double-layer filter screen, and belongs to the technical field of daily necessities. On one hand, the device can collect and clean hairs in a tub and a wash basin thoroughly; on the other hand, the device can realize flexible switch between a totally-closed ponding mode and a collected drainage mode. The detachable turning plate type gathered draining device comprises a snap ring, an intermediate separating plate and a filter screen, wherein the filter screen comprises an upper layer filter screen and a lower layer filter screen; sliding blocks are respectively arranged at the bottom of the upper layer filter screen and the top of the lower layer filter screen; sliding chutes are respectively formed in the upper bottom surface and the lower bottom surface of the intermediate separating plate; sliding block pressing inlets are formed in the sliding chutes; the sliding block of the upper layer filter screen is arranged in the sliding chute on the upper bottom surface of the intermediate separating plate through the sliding block pressing inlet; the sliding block of the lower layer filter screen is arranged in the sliding chute on the lower bottom surface of the intermediate separating plate through the sliding block pressing inlet; the upper layer filter screen and the lower layer filter screen both comprise intermediate beams; filter holes are formed in the filter screen at the both sides of the intermediate beams; the intermediate beams, the intermediate separating plate and the snap ring work together to form the turning plate type structure.

Owner:NORTHEASTERN UNIV LIAONING

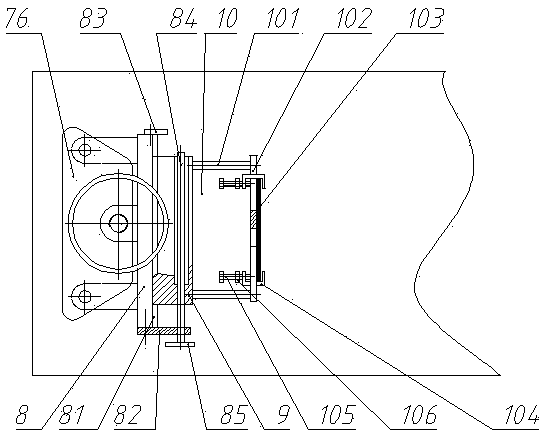

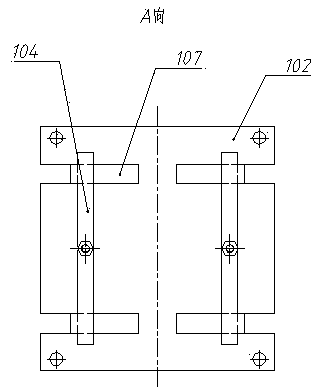

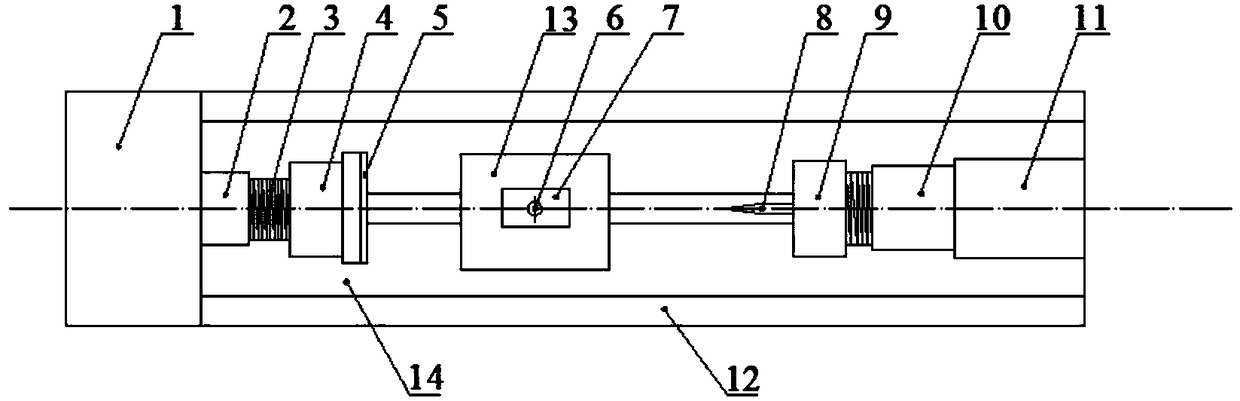

Multi-purpose core rod machining feeding device

PendingCN108176861AAchieve diversificationImprove machining accuracyTurning machinesEngineeringTailstock

The invention relates to a multi-purpose core rod machining feeding device which comprises a main case, a body and a tailstock, wherein the case is arranged on one side of the body; the tailstock is correspondingly arranged on the other side of the body; and sliding rails are arranged on the body and between the case and the tailstock. The multi-purpose core rod machining feeding device disclosedby the invention is scientific and reasonable in design and simple in structure. A connecting piece and a detachable supporting sleeve are detachably mounted on the main case and the tailstock of thetraditional core rod turning equipment, so that the adjustable core rod feeding device is applicable to machining of core rods of different specifications, the cost is effectively saved, the core rodmachining production efficiency is increased, and diversified requirements of core rod machining are met.

Owner:天津滨海龙泰科技发展有限公司

Hot melt adhesive attached with dry-type PU (polyurethane) on wet-type PU

InactiveCN103568448AAvoid direct contactBeautiful and environmentally friendlySynthetic resin layered productsLaminationThermoplastic polyurethaneHydrolysis

The invention belongs to the technical field of TPU (thermoplastic polyurethane) products and in particular relates to a TPU holt melt adhesive attached with dry-type PU (polyurethane) on wet-type PU. The TPU holt melt adhesive attached with the dry-type PU on the wet-type PU comprises a dry-type PU thin film layer and a wet-type PU thin film layer, and a TPU hot melt adhesive layer is arranged on the back of the wet-type PU thin film layer. Compared with the prior art, the TPU holt melt adhesive attached with the dry-type PU on the wet-type PU has the advantages that the dry-type PU thin film layer is compounded with the wet-type PU thin film layer by virtue of a first TPU hot melt adhesive layer, and a second TPU hot melt adhesive layer is arranged on the back of the wet-type PU thin film layer, so that the TPU holt melt adhesive attached with the dry-type PU on the wet-type PU has good hydrolysis resistance, abrasion resistance, toughness and elasticity and high thickness, also has the characteristics of soft handfeel, fullness and lightness and is beautiful in appearance. The TPU holt melt adhesive attached with the dry-type PU on the wet-type PU needs to be pasted on a knitted fabric base by virtue of the second TPU hot melt adhesive layer only when being used, can be applied to the fields of furniture, building materials, bags and the like, is simple and convenient and has good applicability.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

A production and processing system for pvc boards

ActiveCN111823291BRealize local scraping functionAvoid shakingRollersMetal working apparatusHydraulic press

The invention discloses a production and processing system of a PVC plate. The production and processing system comprises a bottom plate; a rear baffle is arranged at the position, close to the rightside, of the surface of the upper end of the bottom plate; a left surrounding plate is installed on the surface of the front end of the bottom plate, and inserting holes are evenly formed in the positions, close to the lower side, of the surface of the front end of the left surrounding plate; and a right surrounding plate is installed on the surface of the rear end of the bottom plate, a top mounting plate body is installed in the middle position between the left surrounding plate and the right surrounding plate, and a hydraulic machine is installed at the part, close to the right side, between the left surrounding plate and the right surrounding plate. According to the production and processing system of the PVC plate, PVC plates with different thicknesses can be conveyed in a limited mode, the PVC plates are prevented from shaking, meanwhile, common processing treatment of the equipment on the plates with different models is facilitated, the local thinning function on the plates canbe achieved, the transverse distance between all components is changed, and thus the transverse conveying area of a second transmission structure is enlarged; and the phenomenon of local thread loosening in the processing process of the production system is prevented, the overall transverse operation space of the equipment is enlarged, and convenience is provided for the equipment for processing wide and large plates.

Owner:YANGZHOU FUMING NEW MATERIAL CO LTD

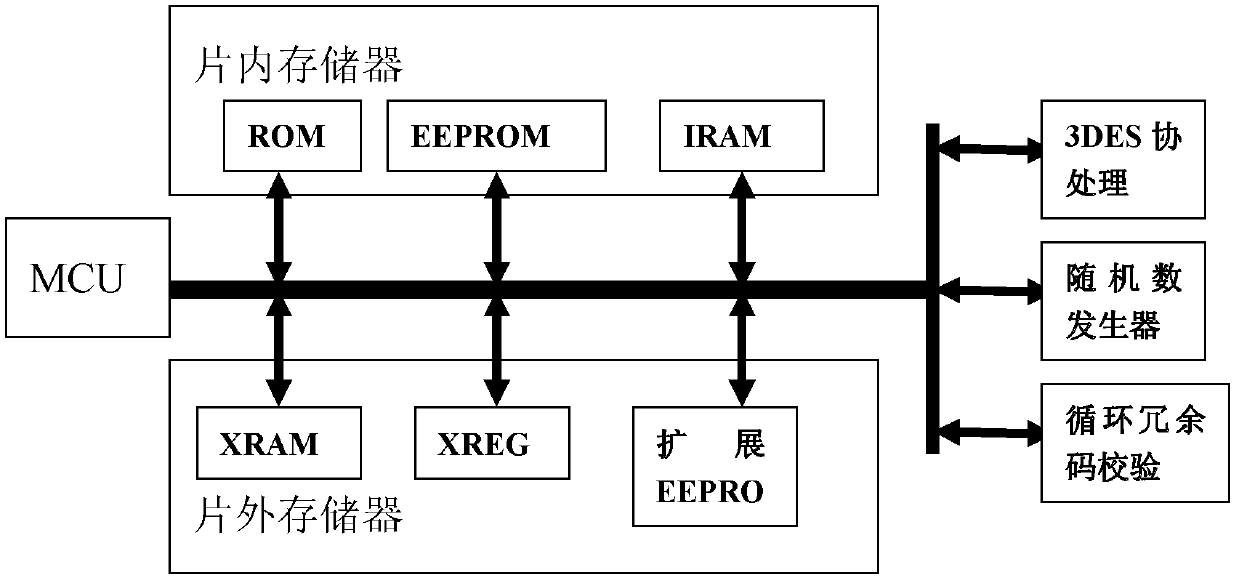

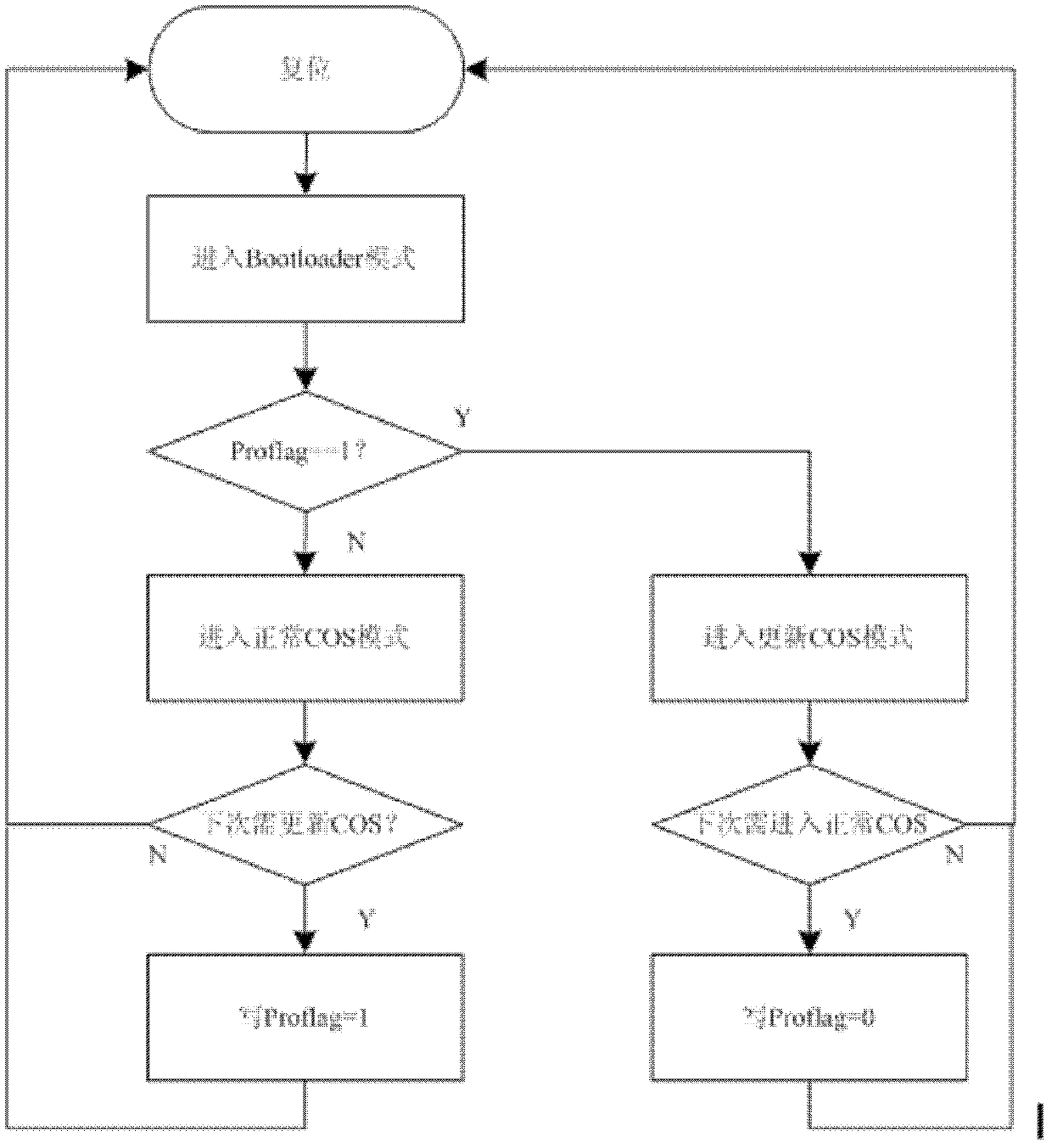

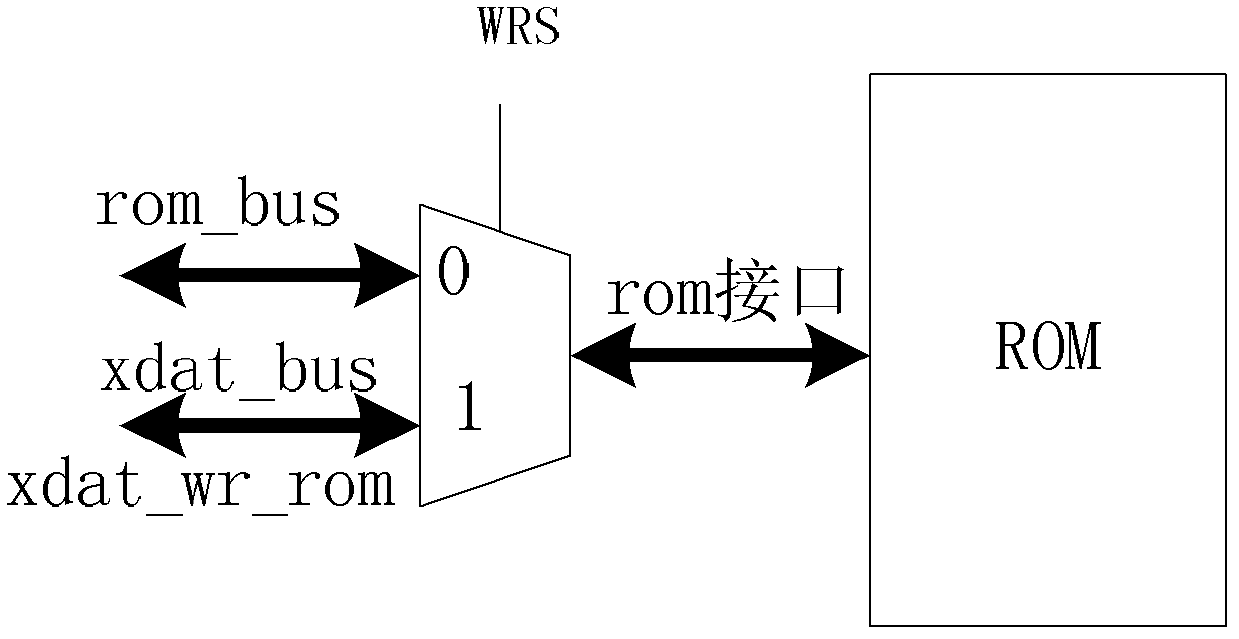

Soft mask card based on high-capacity EEPROM

InactiveCN102567772AEasy to modifySimple, convenient and perfectRecord carriers used with machinesCommunication interfaceNormal mode

The invention discloses a soft mask card based on a high-capacity EEPROM, which comprises a memory unit, a data address bus and an MCU unit. The memory unit comprises an on-chip memory and an off-chip memory; the on-chip memory comprises an ROM unit for storing a Bootloader program, an EEPROM unit for storing a COS program, and an IRAM unit for storing intermediate data; the off-chip memory comprises an XRAM unit served as an off-chip data memory of an MCU, an expansion EEPROM unit served as a nonvolatile data memory of the MCU, and an XREG unit served as a communication interface of the MCU and peripheral equipment and used for an expansion 3DES co-processor, a random number generator and the like; the EEPROM unit comprises an EEPROM-C unit for storing the COS program and an EEPROM-D unit provided with a Proflag sign and judging whether to enter the COS program or to update the COS program; the address of the ROM unit is connected with a rom_addr when the ROM unit is in a normal mode, and the ROM unit adopts an rom_bus to read program storage space; the address of the ROM unit is connected with an xdat_addr when the ROM unit is in a programming mode, and the ROM unit adopts an xdat_wr_rom of an xdat_bus to write the program storage space; and the two modes are selected through a WRS of an SPC_FNC register.

Owner:广州中大数码科技有限公司

Production and processing system of PVC plate

ActiveCN111823291ARealize local scraping functionAvoid shakingRollersMetal working apparatusEngineeringHydraulic press

The invention discloses a production and processing system of a PVC plate. The production and processing system comprises a bottom plate; a rear baffle is arranged at the position, close to the rightside, of the surface of the upper end of the bottom plate; a left surrounding plate is installed on the surface of the front end of the bottom plate, and inserting holes are evenly formed in the positions, close to the lower side, of the surface of the front end of the left surrounding plate; and a right surrounding plate is installed on the surface of the rear end of the bottom plate, a top mounting plate body is installed in the middle position between the left surrounding plate and the right surrounding plate, and a hydraulic machine is installed at the part, close to the right side, between the left surrounding plate and the right surrounding plate. According to the production and processing system of the PVC plate, PVC plates with different thicknesses can be conveyed in a limited mode, the PVC plates are prevented from shaking, meanwhile, common processing treatment of the equipment on the plates with different models is facilitated, the local thinning function on the plates canbe achieved, the transverse distance between all components is changed, and thus the transverse conveying area of a second transmission structure is enlarged; and the phenomenon of local thread loosening in the processing process of the production system is prevented, the overall transverse operation space of the equipment is enlarged, and convenience is provided for the equipment for processing wide and large plates.

Owner:YANGZHOU FUMING NEW MATERIAL CO LTD

Milling part for machining uniform grooves

InactiveCN108161092AEasy to processFlexible and convenient processingMilling equipment detailsArchitectural engineering

The invention discloses a milling part for machining uniform grooves. The milling part includes a milling part body, a motor, a cutter and a fixing device; the milling part body is movably connected to a main shaft of a horizontal milling machine; the motor is arranged inside the milling part body; the cutter is movably connected with the milling part body and is driven by the motor to rotate; thefixing device is movably connected to a workbench of the horizontal milling machine and is arranged opposite to the milling part body; the fixing device includes a fixing base, a fixing groove and afixing plate; the fixing groove is formed in the surface of the fixing base and is close to the end, away from the milling part body, of the fixing base; the bottom edge of the fixing plate is connected to the edge of the end, away from the milling part body, of the fixing base. The milling part for machining the uniform grooves can be used after being mounted on the horizontal milling machine; the milling part is convenient and flexible to use, high in production efficiency, small in size, exquisite in appearance and more suitable for machining small-space inner grooves.

Owner:河北博萨机械制造集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com