Patents

Literature

113results about How to "Mechanical properties unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass fiber-reinforced nylon 6-polypropylene alloy material

The invention relates to glass fiber reinforcing nylon 6-polypropylene alloy material. The invention is characterized in that the invention adopts nylon 6 and polypropylene as the matrix resin, and under the condition that the addition level of plasticizer is not changed, the invention can achieve and is preferable to the mechanical property of the unilateral enforced nylon 6 material without polypropylene added, in particular to the impact property. The matrix resin, the plasticizer as well as the antioxidant are evenly mixed and then enter into a double screw extruder, simultaneously glass fiber is added from the special glass fiber opening of the double screw extruder, and the matrix resin, the plasticizer, the antioxidant and the glass fiber are cooled, dried and palletized to be produced into finished products after being mixed together and extruded. The invention has the advantages that the plasticizer can be self made, the cost of the alloy material is low, the invention has good impact property, and the other mechanical properties are kept unchanged basically.

Owner:SHANGHAI KINGFA SCI & TECH +1

Method for manufacturing intelligent thermoregulation type functional yarn

InactiveCN101250818AMechanical properties unchangedDoes not affect breathabilityVegetal fibresYarnOperability

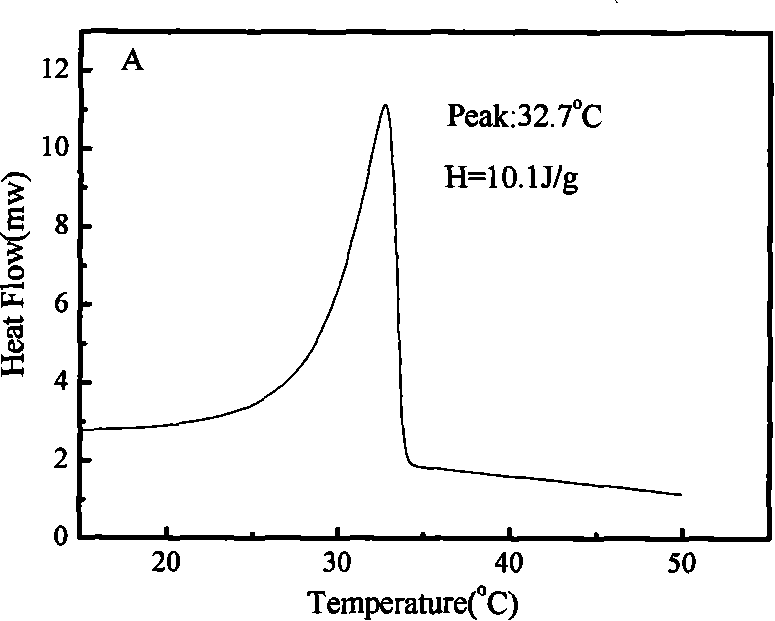

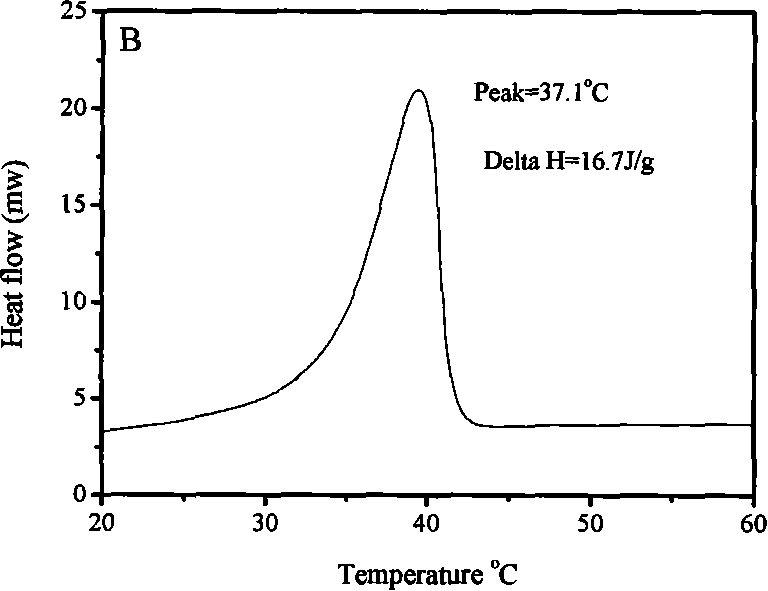

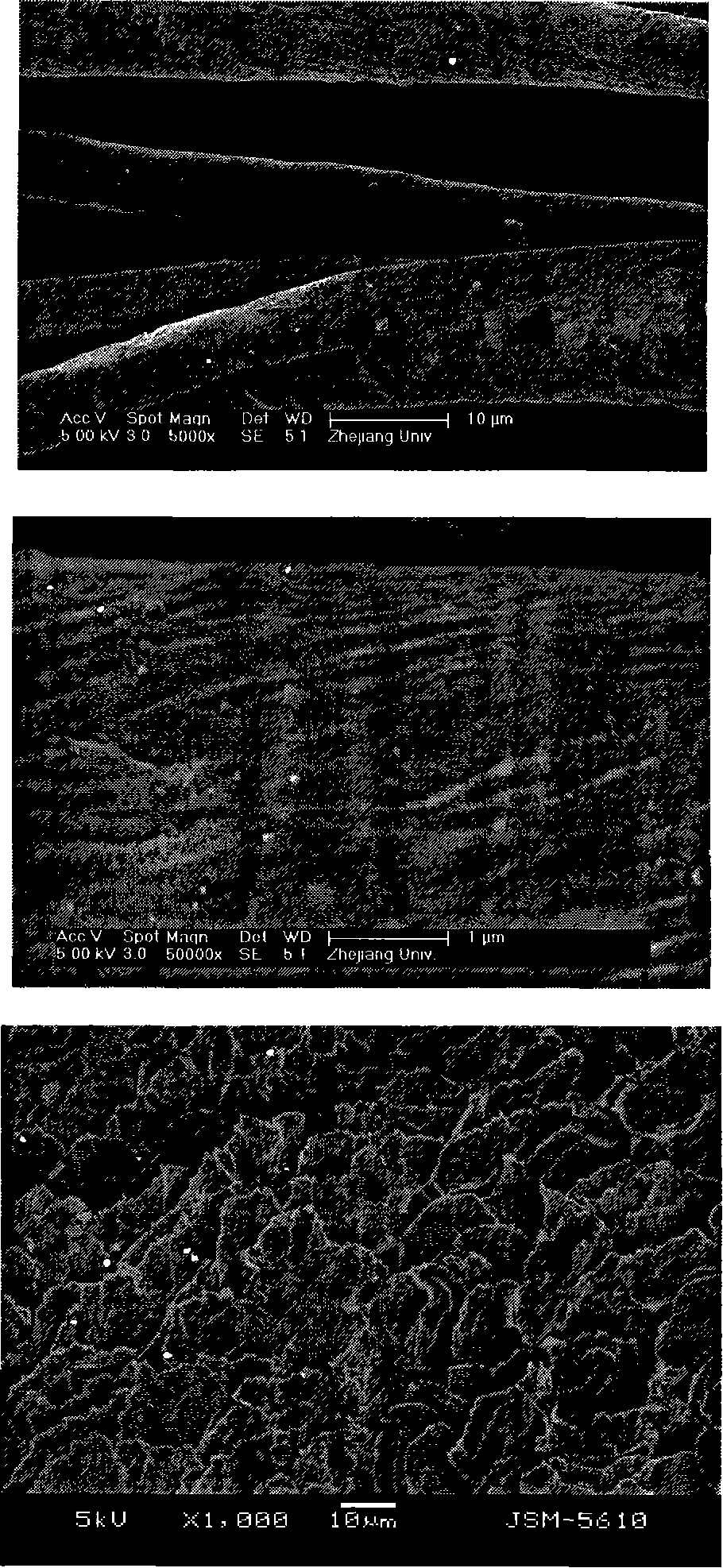

The invention discloses a method for preparing an intelligent temperature regulating functional yarn, which has the following steps of charging cementing agent and thickening agent into phase-change microcapsule dispersion to intimately mix and obtain phase-change microcapsule functional finishing agent with viscosity, wherein the content of the cementing agent and the thickening agent are respectively 0.5-5% by weight of the finishing agent, the phase-change microcapsule functional finishing agent is finished on the yarn via a double-nip-double-dip or a sizing process, and then obtaining textiles via weave technology. The selected capsule is water dispersion with good surroundings, wherein the capsule size is about 100nm which is only one-tenth or one-percent of the yarn fineness, thereby being capable of greatly improving dosages of the capsules in the yarns, at the same time holding constant raw mechanical property of the yarn, furthermore, the method has the advantages of convenient and flexible processing, good operability and being basically not influence on hand feeling and breathability of fabrics due to adopting the double dip double nip or the slashing process, and the performance test indicates that the finished textile has obvious heat storage and temperature regulating effects.

Owner:ZHEJIANG SCI-TECH UNIV +2

Epoxy modified polyurethane cryogenic adhesive

InactiveCN101298548AWater resistantWith low temperature resistancePolyureas/polyurethane adhesivesEpoxy resin adhesivesSolid componentEpoxy

The invention discloses an epoxy modified polyurethane ultra-low temperature resistant adhesive. The components and the mass percentage of the adhesive are: 30-50 percent of polyurethane modified prepolymer, 5-15 percent of epoxy resin, 10-20 percent of solvent, 1-15 percent of chain extender, and 30-50 percent of filler. First, uniformly blend all the liquid components, and then add solid components to uniformly blend, and pack after grinding on a grinding mill. The epoxy modified polyurethane ultra-low temperature resistant adhesive of the invention has the nature of ultra-low temperature resistance, the mechanical property of which can remain stabilized even being used for a long term at 200 DEG C below zero, and has the advantages of high bond strength and shear strength as well as good cohesiveness and corrosion resistance.

Owner:广东海拓创新精密设备科技有限公司

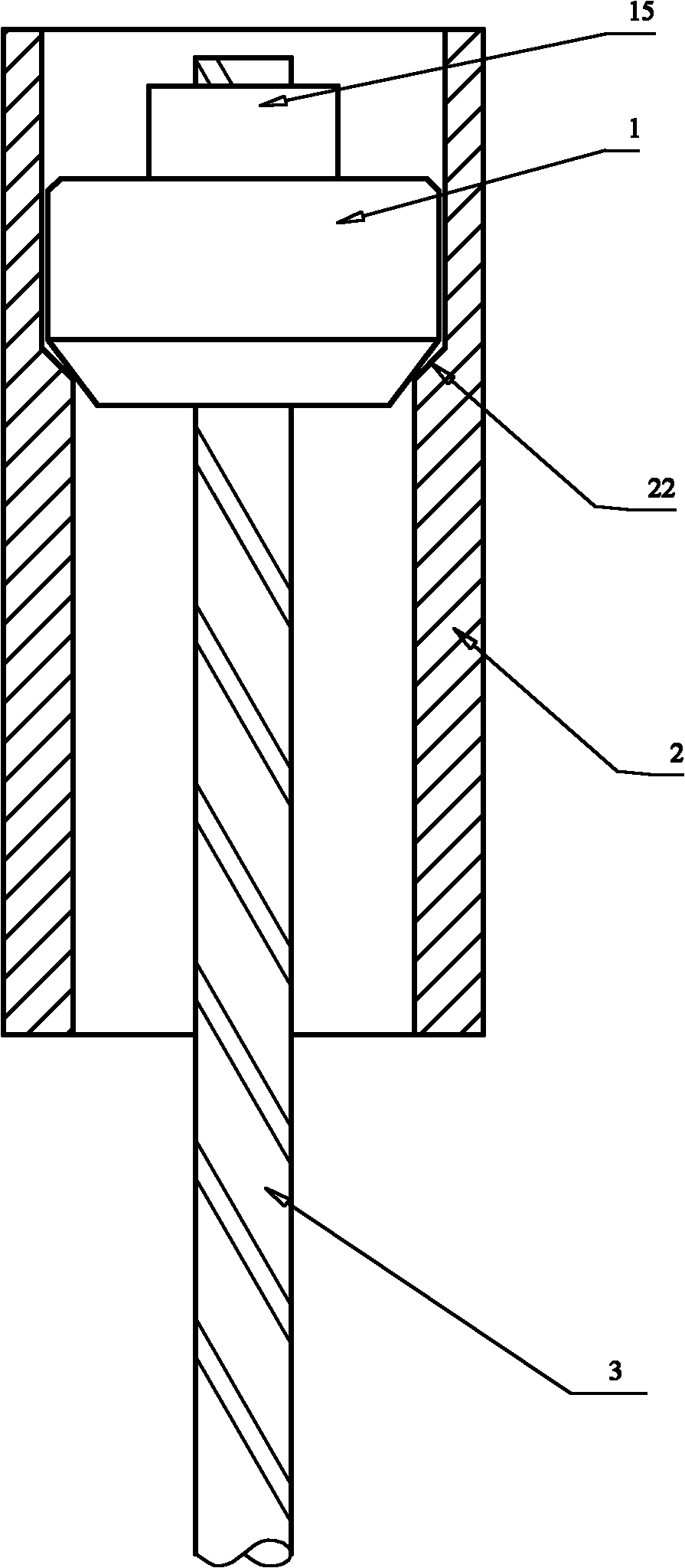

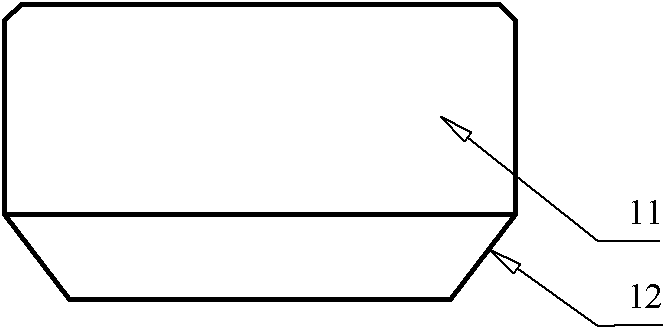

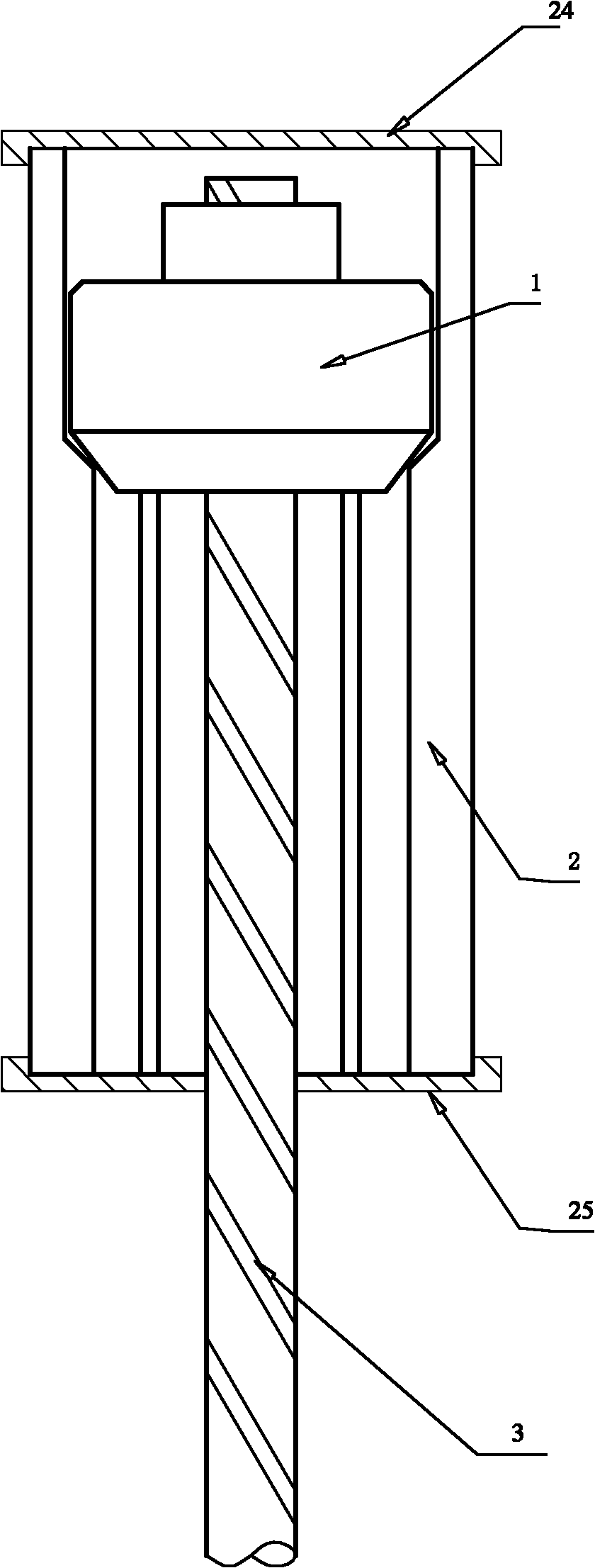

Pressure-yielding anchor device

ActiveCN102182182AMechanical properties unchangedDoes not affect the space outside the holeBridge structural detailsBulkheads/pilesEngineeringYield pressure

The invention discloses a pressure-yielding anchor device, which comprises an extrusion head, a pressure-yielding sleeve and anchor bars, wherein the extrusion head is a cylinder with the conical surface at the lower part and movably connected with the anchor bars into a whole; and the extrusion head is arranged in the pressure-yielding sleeve, the raised surface matched with the conical surface at the lower part of the extrusion head is arranged on the inner wall of the pressure-yielding sleeve, the pressure-yielding sleeve is a steel pipe with a raised edge on the inner wall preferably, andthe raised surface matched with the conical surface of the extrusion head is arranged at the end part of the raised edge. By adopting the pressure-yielding anchor device, the purposes of yielding pressure, dissipating energy and controlling deformation can be realized during anchoring, and the pressure-yielding anchor device is applicable to the anchor bars made of any material. The pressure-yielding anchor device is convenient to manufacture, reliable in effects and applicable to different engineering needs.

Owner:杭州图强工程材料有限公司

Resource-saving Q345 low-alloy series steel plate and production method thereof

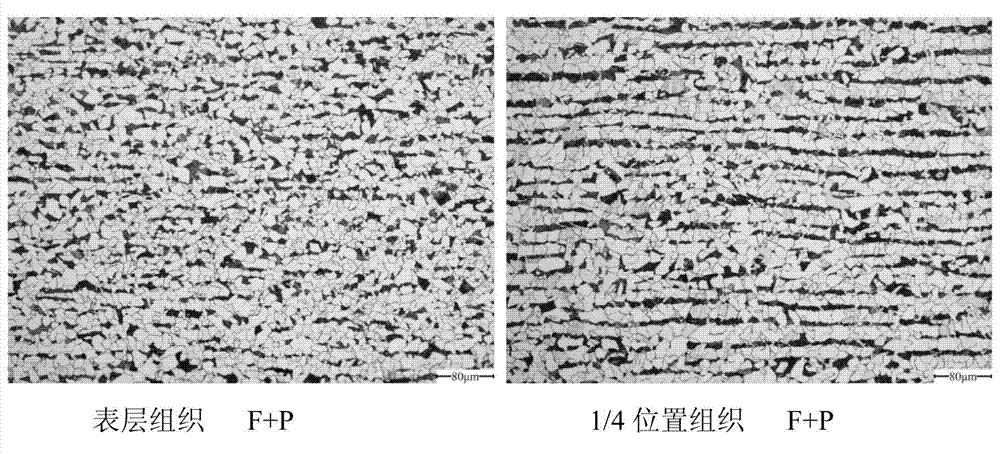

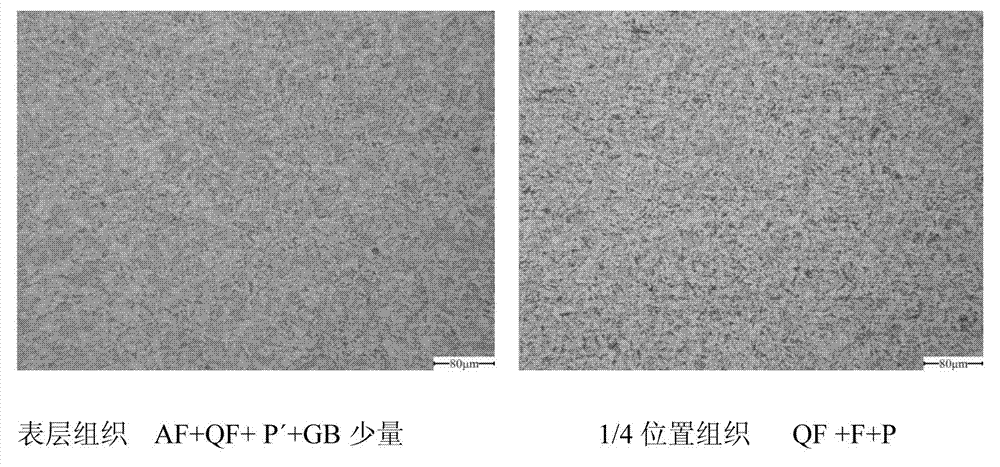

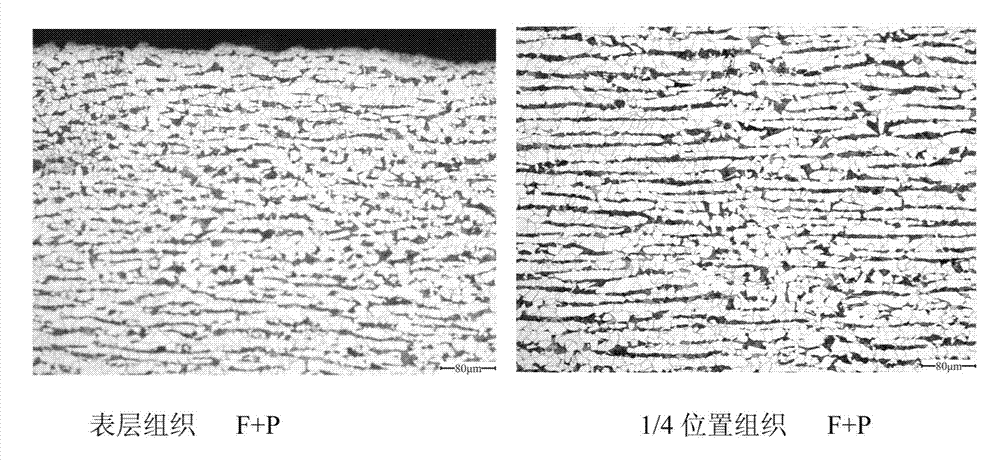

InactiveCN103045939AImprove performanceGuaranteed final performanceHeat treatment process controlAlloyPearlite

The invention discloses a resource-saving Q345 low-alloy series steel plate and a production method thereof. The steel plate comprises the following chemical components in percent by weight: 0.15 to 0.18 percent of C, 0.15 to 0.50 percent of Si, 1.10 to 1.25 percent of Mn, not more than 0.030 percent of P, not more than 0.035 percent of S, 0 to 0.045 percent of Alt, not more than 0.44 percent of carbon equivalent, and the balance of Fe and inevitable impurities. The production process of the steel plate comprises 150 t converter, LF external refining, slab continuous casting, slab heating, steckel mill controlled rolling, controlled cooling, thermal straightening, cooling, shearing and mark warehousing. The resource-saving Q345 low-alloy series steel plate, produced by the production method, has the yield strength of 360 to 420 MPa, the tensile strength of 500 to 550 MPa, and the elongation of 24 to 32%, and acicular ferrite with the thickness of 3 to 6 mm, polygonal ferrite, degenerate perlite and a small amount of granular bainite are arranged on the surface layer of the steel plate.

Owner:ANYANG IRON & STEEL

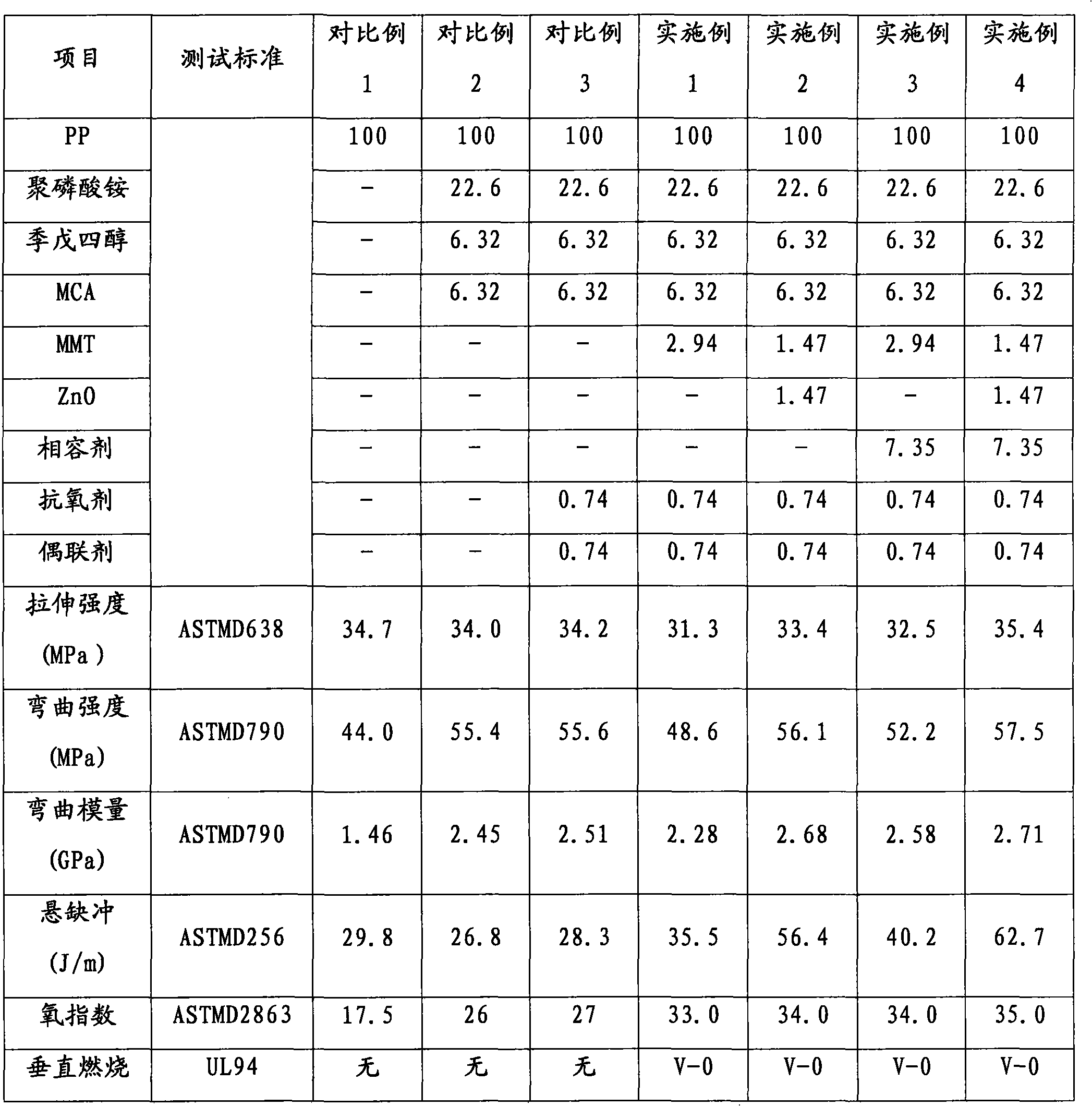

Expanded carbon flame-proof polypropelene composition and preparation method thereof

ActiveCN101293984AThe preparation method is simple and reliableGood flame retardant performanceAmmonium polyphosphateChemistry

The invention relates to an expansive char-forming flame-retardant polypropylene composition and a production method thereof. The composition comprises the following components: 100 weight parts of polypropylene, 10-30 weight parts of ammonium polyphosphate, 2.8-8.3 weight parts of pentaerythritol, 2.8-8.3 weight parts of melamine cyanurate and 0.5-5 weight parts of montmorillonite. The total additional amount of ammonium polyphosphate, pentaerythritol and melamine cyanurate is at least 31 weight parts. The production method comprises the following steps: proportioning all components (including polypropylene, ammonium polyphosphate, pentaerythritol, melamine cyanurate and montmorillonite) at the given ratios, melting, mixing, extruding and granulating. The composition has better flame retardation, good processability and mechanical property. The production method is simple and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sericite modified ultraviolet resistant polymer master batch and composite material

The invention discloses a sericite-modified UV-resistant polymer master batch and a composite material thereof. The composite material of polyolefine and master batch has parallel orientation of sericite with high diameter-thickness ratio in plastics. The ultraviolet absorption rate of the material is more than or equal to 90%. The sericite-modified UV-resistant polymer master batch is composed of surfactant-modified sericite and polymers, wherein the polymers account for 5-30% of the total weight of sericite and polymers, and the surfactant accounts for 3-8% of the total weight of sericite and polymers.

Owner:NANJING UNIV OF TECH

Low-density wood plastic board and preparation method thereof

InactiveCN102875874AReduce material consumptionReduce manufacturing costFlat articlesMaleic anhydrideAzodicarbonamide

The invention discloses a low-density wood plastic board and a preparation method thereof and belongs to the technical field of decorative materials. The technical scheme is that: the low-density wood plastic board is prepared from the following raw materials in part by weight: 35 to 60 parts of plastic particles, 20 to 60 parts of wood meal, 0.3 to 1 part of azodicarbonamide (AC) foaming agent, 1 to 5 parts of maleic anhydride grafted coupling agent, 0.15 to 0.5 part of nucleating agent and 0.15 to 0.6 part of antioxidant; and the low-density wood plastic board is processed by the process steps of material weighing, material mixing, extrusion and calendaring. Compared with the prior art, the invention has the advantages that the low-density wood plastic board can be recycled and is renewable; and the overall weight of the low-density wood plastic board is reduced by the microfoaming process, so that the energy is saved, the cost is reduced, and the economic benefit of enterprises is improved.

Owner:山东只楚民营科技园股份有限公司

Low temperature resistant LNG thermal insulation material and preparation method thereof

The invention discloses a low temperature resistant LNG heat insulating material and a preparation method thereof. The material is prepared as follows: a component A consists of 60 to 97 percent of mixed polyhydric alcohols, 0.1 to 2 percent of a catalyzer, 0.5 to 10 percent of a foam homogenizer, 2 to 15 percent of a foaming agent, 2 to 15 percent of a fire retardant and 0.1 to 5 percent of a chain extendor; the component A reacts with a component B in isocyanate series to prepare and get the low temperature resistant LNG heat insulating material. The material can be used for long term at low temperature above 220 DEG C below zero, which has excellent cold insulativity and mechanical properties. The material can be adaptable to the quick change of temperature above 300 DEG C, and has high fire resistance and small coefficient of heat conductivity, which can effectively prevent the thermal loss of ultra-low temperature fluid and is a pollution-free energy-saving thermal insulative cold insulating material with high performance.

Owner:JIANGSU UNIV OF SCI & TECH

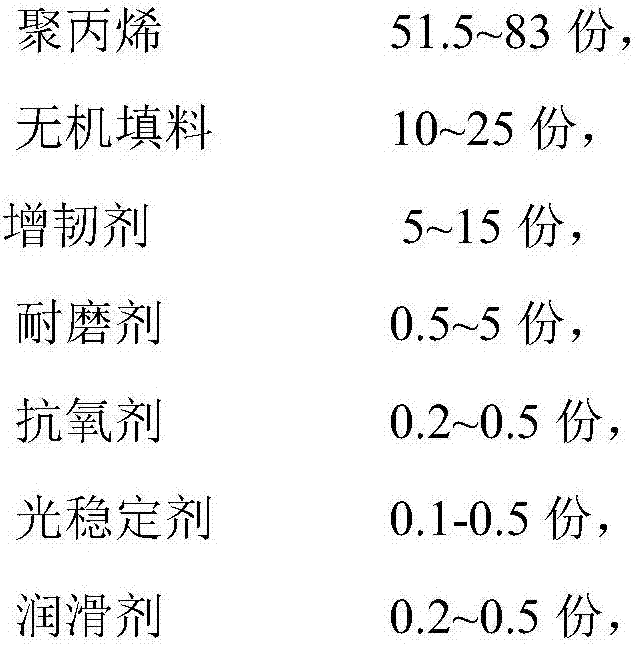

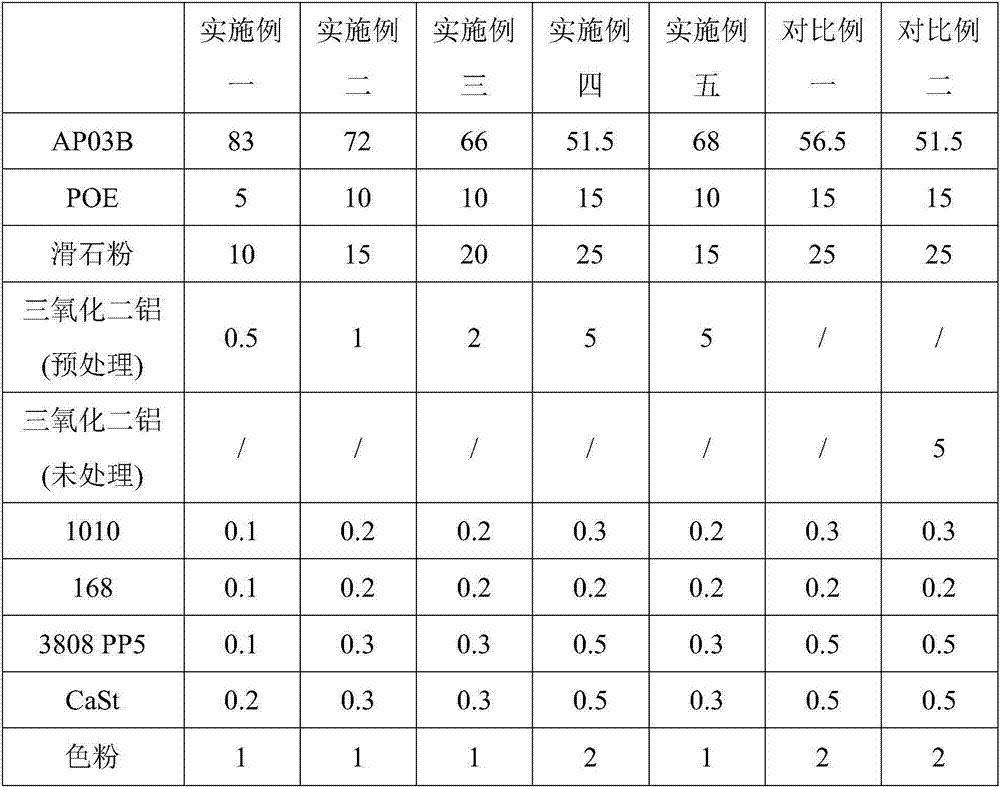

High-wear-resistant polypropylene composite material used for automobile interior trim and preparation method of polypropylene composite material

The invention provides a high-wear-resistant polypropylene composite material used for automobile interior trim and a preparation method of the polypropylene composite material. The polypropylene composite material is made from, by weight, inorganic filling materials, polypropylene, a toughening agent, a wear-resisting agent, an anti-oxidant, a lubricant, a light stabilizer and toner. The preparation method comprises pre-treating a wear-resisting agent, putting the raw materials in a high-speed mixer according to a certain ratio for uniform mixing, putting the obtained mixture in a double screw extruder, and performing melt extrusion and granulation to obtain the high-performance polypropylene composite material. Based on a basic formula of a polypropylene composite material, proper alumina is taken as the wear-resisting agent, and subjected to pre-treatment. The prepared polypropylene composite material is good in wear resistance and low in smell, and has mechanical properties meet index requirement. The preparation method is simple, and is low in cost and wide in application range.

Owner:ORINKO NEW MATERIAL CO LTD

Method for preparing nylon in lightweight

This invention discloses a process for preparing a lightweight nylon, wherein a lightweight or hollow inorganic material, after surface treatment with the silane coupling agent, is mixed withªŠ-hexanolactam and then cast to prepare a lightweight nylon-6. The density of the lightweight nylon is much lower while its mechanical properties are reserved. Besides, the product appears white and bright, and can be widely used in the decoration area as a heat-resisting material. This invention provides a simple process for preparing a lightweight nylon with reduced production cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Nano particle modified binder, preparation method and using method

ActiveCN105419720AWide heat resistanceImprove heat resistanceNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentGas phaseHeat resistance

The invention relates to a nano particle modified binder which comprises a binder main body and nanofiller, wherein the binder main body comprises 45-55 wt% of organic silicon resin, 25-35 wt% of glass powder and 15-20 wt% of boron carbide powder; and the nanofiller comprises 5-10 wt% of nanometer aluminum powder, 5-10 wt% of nanometer silica powder and 1-2 wt% of alumina whisker. A method for preparing the nano particle modified binder comprises the steps of respectively preparing the binder main body and the nanofiller and then evenly dispersing and adding the nanofiller in the binder main body. A method for using the binder comprises the steps of evenly bonding the to-be-glued surface of an object with the binder, bonding the object, and achieving object bonding after heat treatment and chemical vapor deposition. The binder accord to the preparation method and the using method not only is extensive in use range, but also has good heat resistance and keeps physical and chemical properties basically unchanged in high temperature environment for a long time.

Owner:BEIHANG UNIV

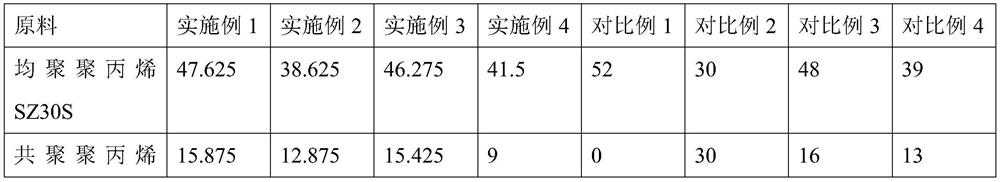

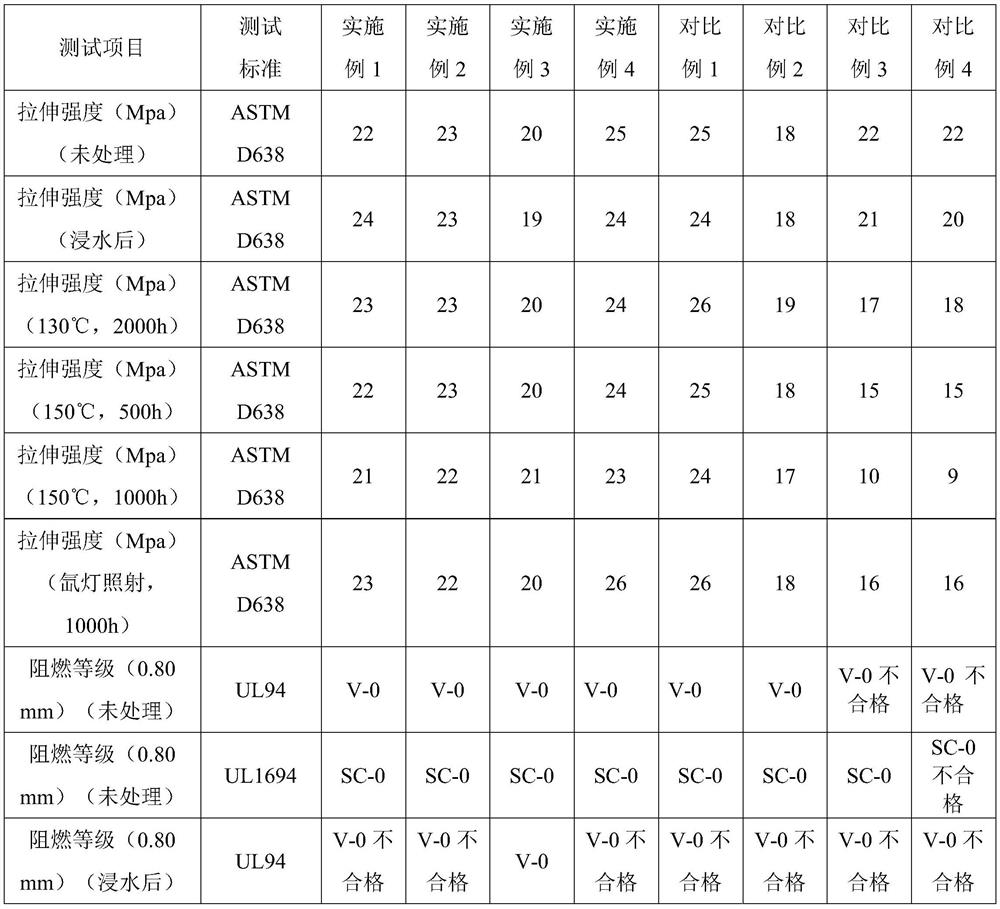

Soaking-resistant weather-resistant halogen-free flame-retardant polypropylene material, preparation method and application thereof

The invention provides a soaking-resistant weather-resistant halogen-free flame-retardant polypropylene material, a preparation method and application thereof. The halogen-free flame-retardant polypropylene material is prepared from the following raw materials by mass: 55-75 parts of polypropylene resin, 30-38 parts of a halogen-free flame retardant, 0-6 parts of filler, 0-10 parts of glass fibermaster batch, 0.5-0.8 part of a lubricant, 0.5-1.2 parts of an antioxidant and 0.5-1 part of a light stabilizer; wherein the halogen-free flame retardant comprises piperazine pyrophosphate and melamine polyphosphate. The halogen-free flame-retardant polypropylene material has high flame retardancy, does not fail in flame retardancy after being soaked in water at 70DEG C for 7 days, has mechanicalproperties maintained up to 90% or more, and has the flame retardancy maintained after being exposed to irradiation by a xenon lamp for 1000h, and the mechanical properties are maintained up to 90% ormore, and passes through the 2.0mm thickness UL94-5VA test. Also the preparation method is simple and easy to control, and the soaking-resistant weather-resistant halogen-free flame-retardant polypropylene material can be used for electric appliance parts with a fireproof grade of UL94-5VA.

Owner:GUANGDONG JUSHI CHEM CO LTD

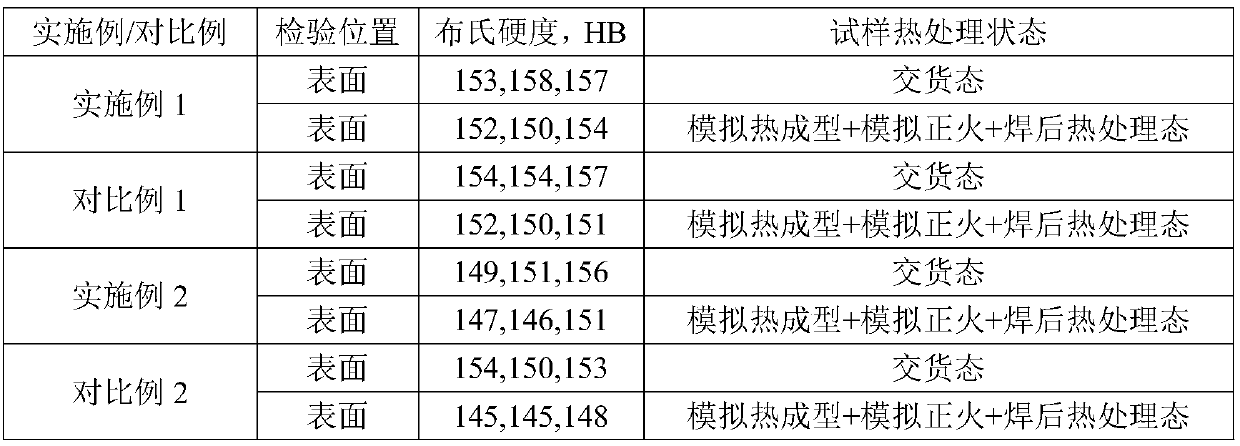

Carbon steel plate for seal head of middle and low temperature pressure vessel and manufacture method thereof

InactiveCN110184529AMeet the needs of developmentLow carbon equivalentTemperature control deviceChemical compositionPetrochemical

The invention relates to a carbon steel plate for a seal head of a middle and low temperature pressure vessel. The carbon steel plate for the seal head of the middle and low temperature pressure vessel contains chemical components by weight percentage: 0.14-0.18% of C, 0.25-0.45% of Si, 1.10-1.30% of Mn, P<=0.010%, S<=0.003%, 0.02-0.05% of Al, 0.010-0.050% of Nb, 0.010-0.030% of Ti, 0.15-0.35% ofNi, 0.10-0.30% of Cu, and the balance Fe and unavoidable impurity elements, wherein the weight percentage ratio of Ni and Cu is not less than 1, carbon equivalent Ceq is not bigger than 0.43%, and thecomputational formula of the carbon equivalent is as following: Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. A delivery state of the carbon steel plate is a normalizing rolling state, and the product is good in internal quality, and low in carbon equivalent and surface Brinell hardness. After simulated thermal forming, simulated normalization and simulated post-welding heat treatment are sequentially performed on a rough specimen, the rough specimen still has excellent mechanical performance, and can completely meet development needs of petrochemical industry.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

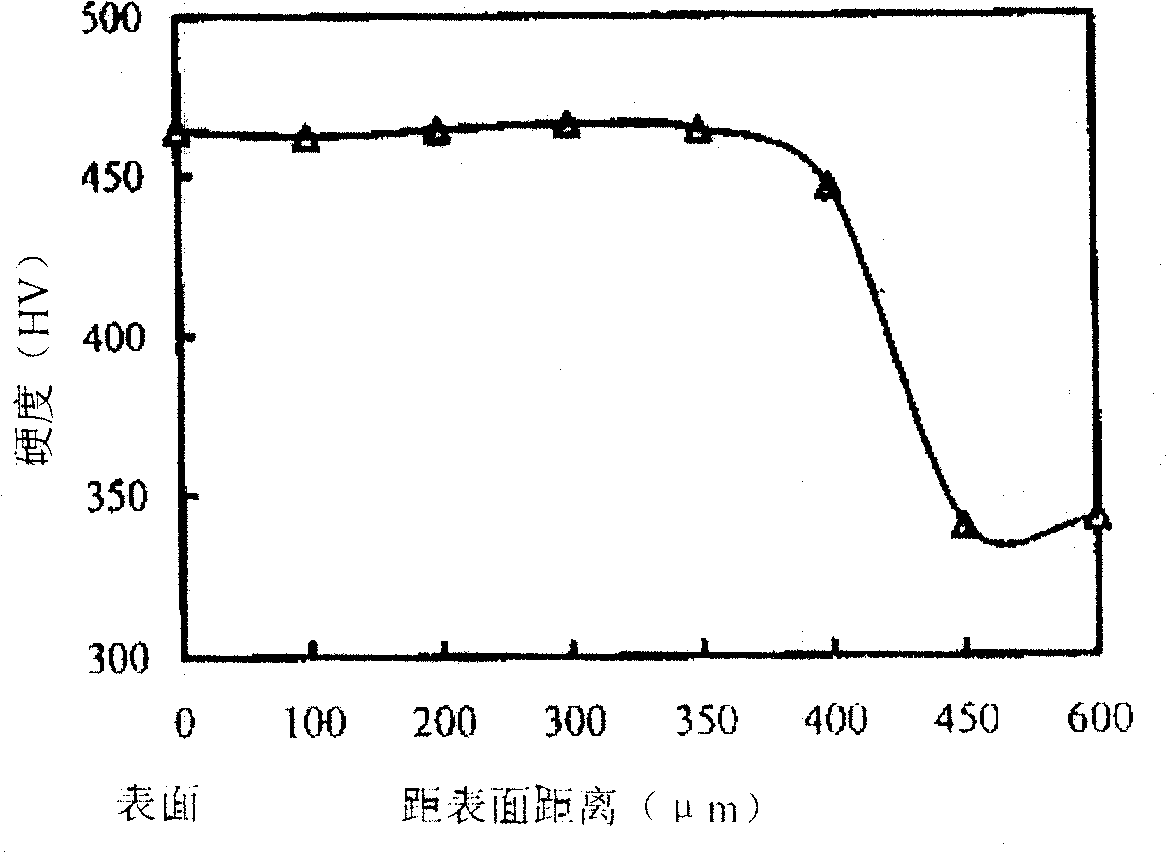

Surface treatment method for improvement of wear-resistance of titanium or titanium alloy

InactiveCN1804102AMechanical properties unchangedHigh bonding strengthSolid state diffusion coatingCleaning using liquidsWater vaporTube furnace

The surface treatment method comprises: putting the cleaned and dried Ti or Ti alloy into thermal treatment furnace or tube furnace, leading oxygen; or putting itno quartz tube furnace, leading water vapor; heating to 500-800Deg with constant speed as 5-20Deg / s, holding for 20-60min; cooling to room temperature together. This invention changes no the material original mechanical performance, improves its wear-resistance, reduces friction factor with low cost.

Owner:SOUTHWEST JIAOTONG UNIV

Impact-type high-temperature hardness test method

InactiveCN102226746ANo plastic deformationLittle elasticityInvestigating material hardnessFree fallingKnoop hardness test

An impact-type high-temperature hardness test method belongs to the technical field of hardness tests. The invention can solve the problems of low test precision and insufficient upper limit of test temperatures commonly seen in current hardness tests. In a current high-temperature hardness test, the temperature of a pressure head is the same as the test ambient temperature; elastic deformation or even plastic deformation of the pressure head can result in a bigger test error, which is also a main reason why the upper limit of the test temperature is limited at a lower level. The high-temperature hardness test method particularly comprises the following procedures: heating a sample to a set test temperature; allowing the part for hardness test to be in low-temperature environment through a water cooling system; when the sample reaches the set test temperature, rapidly moving a test head into the high-temperature region where the sample is located, realizing the free-falling control of the test head by an electromagnetic mechanism of the part for hardness test; allowing the pressure head to impact the upper surface of the sample in a free-falling manner and to fall again after rebound, determining the time interval between two impacts so as to obtain the high-temperature hardness value of the sample to be tested. The invention has an upper temperature limit of up to 1600 DEG C, and a test error of less than 2%.

Owner:HARBIN INST OF TECH

Heat radiation paint for LED lamp and preparation method thereof

InactiveCN103555130AExtended service lifeImprove adhesionEpoxy resin coatingsEpoxyHexamethylenetetramine

A heat radiation paint for an LED lamp is prepared by the following raw material by weight: 30-35 parts of E-12 epoxy resin, 12-15 parts of organic silicone resion, 5-7 parts of tetraethylenepentamine, 10-14 parts of aluminium nitride powder, 20-25 parts of n-butyl acetate, 4-6 parts of n butanol, 1-2 parts of triethanolamine, 1-2 parts of hexamethylenetetramine, 2-3 parts of vinyl tri(beta-methoxy ethoxy)silane, 2-4 parts of titanium dioxide, 1-2 parts of graphite, 3-5 parts of asbestos powder, 6-8 parts of o-xylene acid dibutyl, 1-2 parts of castor oil, and 3-4 parts of film forming auxiliary agent. Aluminium nitride powder is added, so as that the paint has high heat conduction rate and good heat radiation effect, can be long-term used under 200 DEG C without change of mechanical property; titanium dioxide is added, so as that the paint can shield ultraviolet ray, and is beneficial to human body health; and graphite is added, so as that the paint has advantages of good lubricity and easy construction; and the paint also has advantages of large adhesion stress, not easy shedding, aging resistance and long service life.

Owner:天长市天泰光电科技有限公司

Heat dissipation coating used for LED lights and preparation method thereof

InactiveCN103351775AImprove wear resistanceAging resistantPoint-like light sourceLighting heating/cooling arrangementsXylylenePolymer science

The invention provides a heat dissipation coating used for LED lights and a preparation method thereof. The coating is characterized by comprising the following raw materials by weight parts: 45-48 parts of aniline formaldehyde resin, 3-4 parts of a silane coupling agent KH 5503, 32-36 parts of aluminium nitride powder, 4-6 parts of beryllia, 6-8 parts of silicon carbide, 25-30 parts of xylene, 16-18 parts of ethyl acetate, 3-5 parts of aminopropyl triethoxysilane, 2-3 parts of phenol, 2-3 parts of zine stearate, 4-6 parts of aliphatic acid glyceride, 1-2 parts of butyl mercaptan tin, 3-4 parts of bi-propylene tri-amine, 4-6 parts of dibenzyl amine ether and 5-6 parts of a film forming agent. According to the invention, organic silicone resin is used to form film and solidify, and the formed film is excellent in moisture resistant, waterproof, antirust, cold resistant, ozone resistant and weather resistant performances. The coating is anti-aging, large in adhesion stress and good in heat radiation effect, can be used for a long time under 200 DEG C, and has unchangeable mechanical properties. The beryllia and the silicon carbide are added into the raw materials to increase a wear resistant performance of the coating, and the coating can be used for a long time under 200 DEG C.

Owner:TIANCHANG JINLING ELECTRONICS

Rare earth aluminium alloy aluminium ingot bundling and wrapping tape and fabrication method thereof

The invention relates to a rare-earth aluminum alloy aluminum ingot binding packaging tape and its making method, made by melting Al, Zn, Mg, Rare-earth, Ti, Zr, Cr, Mn, etc, it has cross section area 25-35 mm wide X1.0-1.5mm thick, tensile strength up to 350-400MPa, elongation up to 10-15%, adn good shock resistance, overcomes the defects in existing steel bands, does not corrode and change mechanical property for long time storage, has high strength, and can directly lift the whole bundle of aluminum ingots in a top-loading aluminum smelting furnace, improving working efficiency. It is smooth, no-burr, and unable to damage hands at the time of operation, etc.

Owner:SCI & TECH DEV DEPT OF BAOTOU LIGHT METAL RES INST

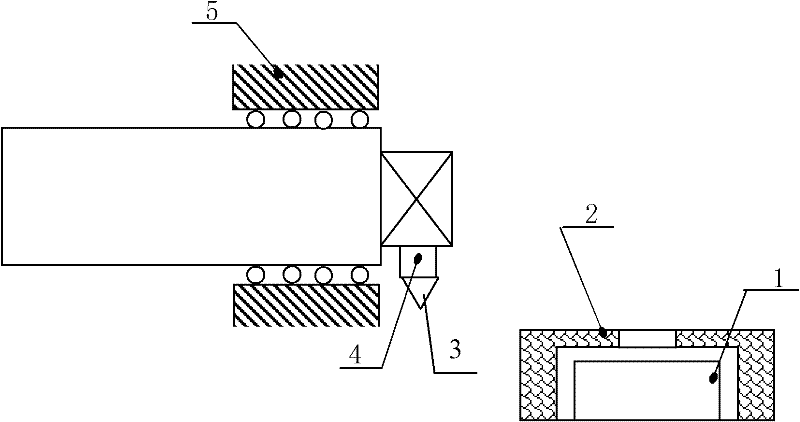

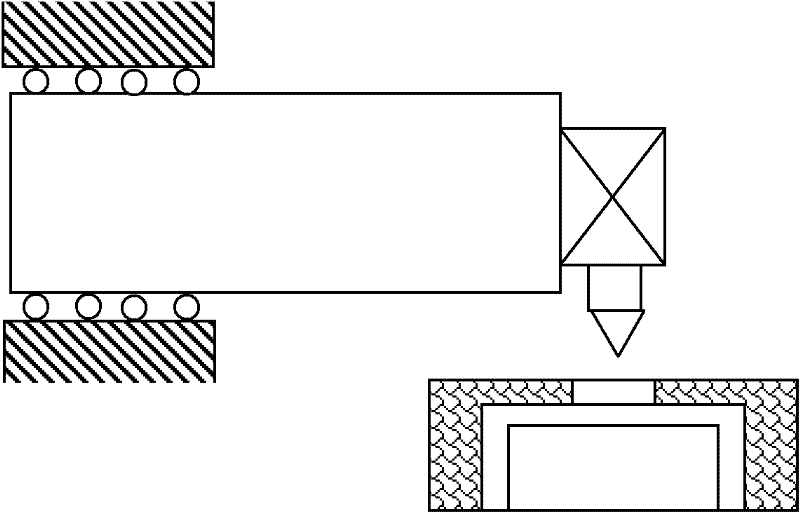

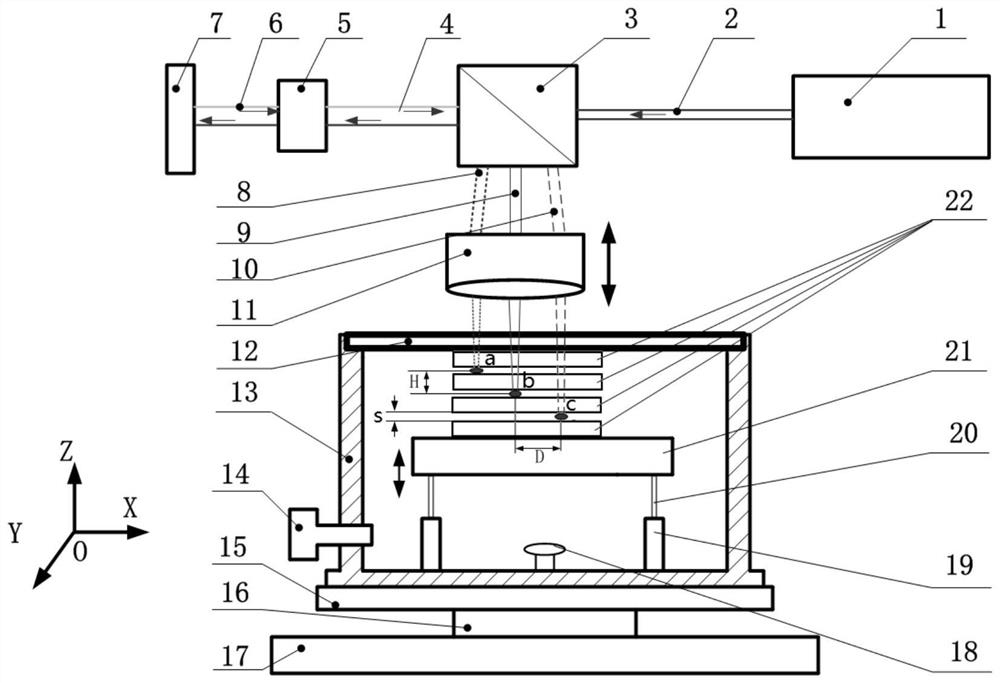

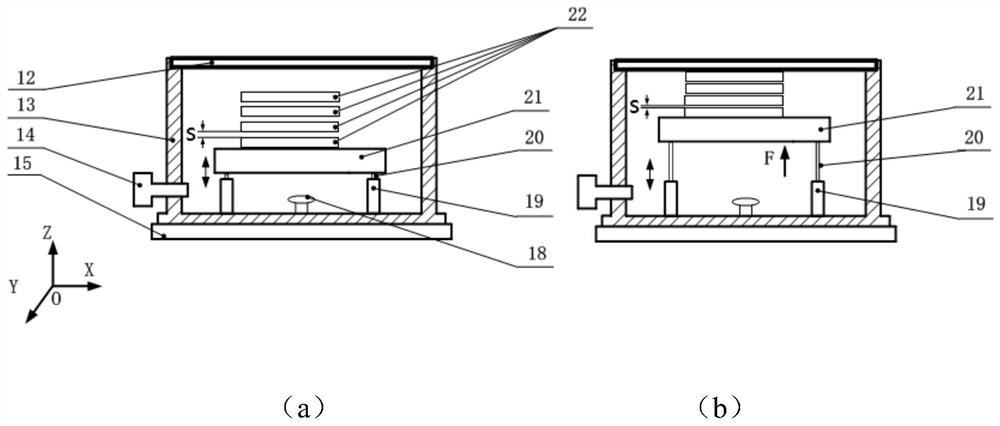

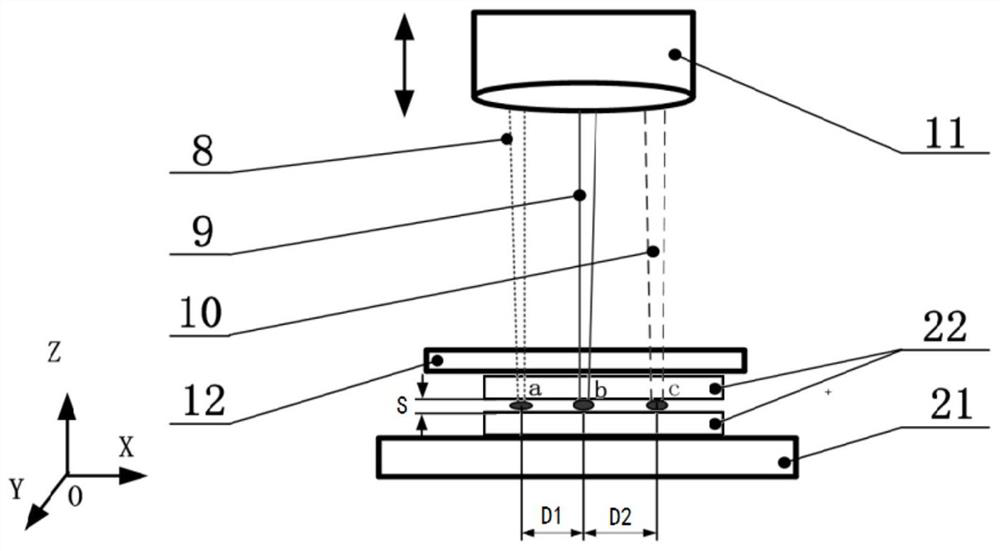

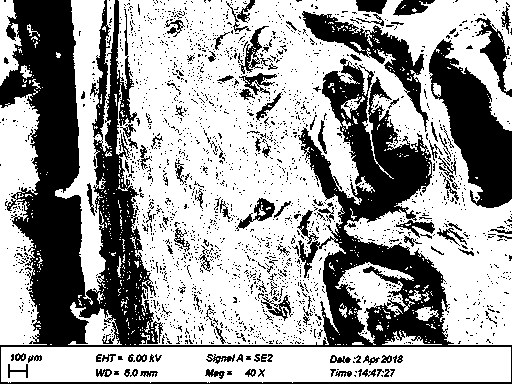

Glass material ultrafast laser precision welding system and method

ActiveCN112171055AEnhanced resistance to high and low temperature changesExtended service lifeWelding/soldering/cutting articlesLaser beam welding apparatusErbium lasersPrism

The invention relates to welding of glass materials in the technical field of laser processing, and particularly relates to a glass material ultrafast laser precision welding system and method. The glass material ultrafast laser precision welding system and the method solve the welding quality problem caused by the fact that the surfaces of glass cannot be precisely attached in the existing two-layer or multi-layer glass plate welding process, and the welding quality problem caused by stress distribution between two adjacent layers of glass is solved. The glass material ultrafast laser precision welding system comprises a clamping and preprocessing module, an optical module, a planar motion module and a vertical motion mechanism; the optical module comprises an ultrafast laser and a lightbeam modulation unit composed of a polarization splitting prism, a Faraday rotator, a reflection type light beam modulator and a telecentric micro-focusing lens; and the laser beams are precisely regulated and controlled through the light beam modulation unit, and integrated control over the welding strength and interlayer stress distribution of the double-layer or multi-layer glass plate is achieved. Meanwhile, and the invention further provides a welding method based on the glass material ultrafast laser precision welding system.

Owner:西安中科光凝科技有限公司

Fluororesin heat dissipation coating and preparation method thereof

InactiveCN103351738AGood high and low temperature resistanceExcellent dielectric propertiesCoatingsXylyleneAl powder

The invention provides a fluororesin heat dissipation coating and a preparation method thereof. The coating is characterized by comprising the following raw materials by weight parts: 30-35 parts of polytetrafluoroethylene, 12-15 parts of polyvinylidene fluoride, 2-3 parts of nonylphenol polyoxyethylene ether, 120-125 parts of xylene, 30-35 parts of ethyl acetate, 2-3 parts of cyanuric acid zinc, 3-4 parts of zinc oxide, 5-8 parts of alum powder, 12-14 parts of nano calcium carbonate powder, 8-10 parts of diatomite powder, 1-2 parts of an antioxidant OD, 2-3 parts of a silane coupling agent KH 550, 1-2 parts of urotropine, 10-12 parts of aluminium nitride powder and 4-5 parts of a film forming agent. According to the invention, the fluororesin is used as a base material; the coating is excellent in high and low temperature resistance, dielectric property, chemical stability, weatherability, incombustibility and inviscosity.

Owner:TIANCHANG CHICHENG ELECTRIC TECH

Method for preserving bone tissue materials

InactiveCN110402918AKeep Inorganic Matter IntactSimple structureDead animal preservationRinger's solutionOrganic component

The invention discloses a method for preserving bone tissue materials. The method for preserving the bone tissue materials comprises the steps that (1) the bone tissue materials are cleaned; (2) the bone tissue materials are placed into a povidone iodine preservation solution with mass concentration of 0.01%-0.5%, the mixture is stored in refrigeration equipment, and the storage temperature is lower than 0 DEG C; and (3) the bone tissue materials stored in a refrigerated mode and the immersion liquid are transferred to the refrigeration, and the mixture is taken out after thawing, the mixtureis soaked by 0.9% physiological saline, a ringer's solution or phosphate buffer and then cleaned, and the mixture can be used as a bone graft tissue. The preservation solution uses sodium bicarbonateor the phosphate buffer as a pH adjuster such that a pH value of the preservation solution is between 5.8 and 8.0. According to a cryopreservation bag, the side edge of a part of the bag body is openthe bag body is connected with a flow guiding hose, and the outer end of the hose is closed. According to the method for preserving the bone tissue materials, the integrity of a bone tissue structureis maintained, and the mechanical properties are kept unchanged; and organic components and inorganic components of the bone tissue materials are not lost, so that the suffering and economic burden ofthe patient are alleviated.

Owner:庄明华

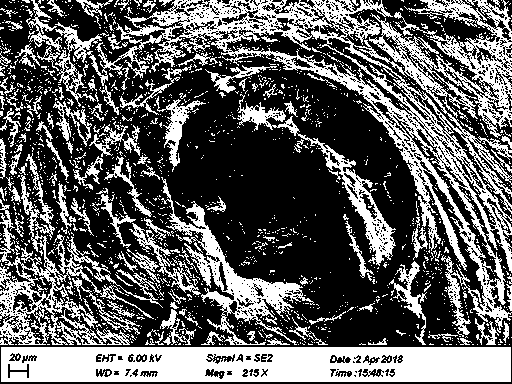

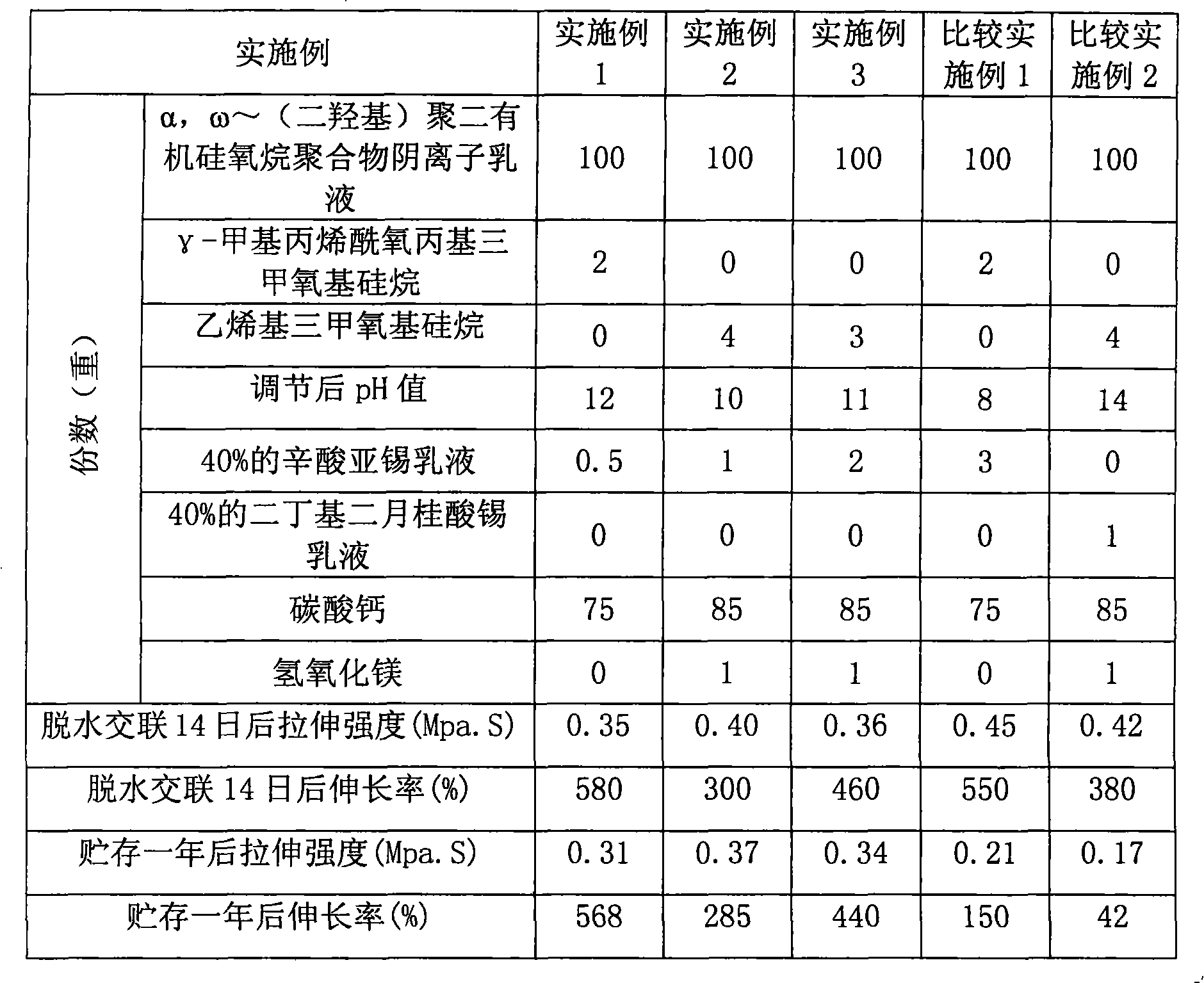

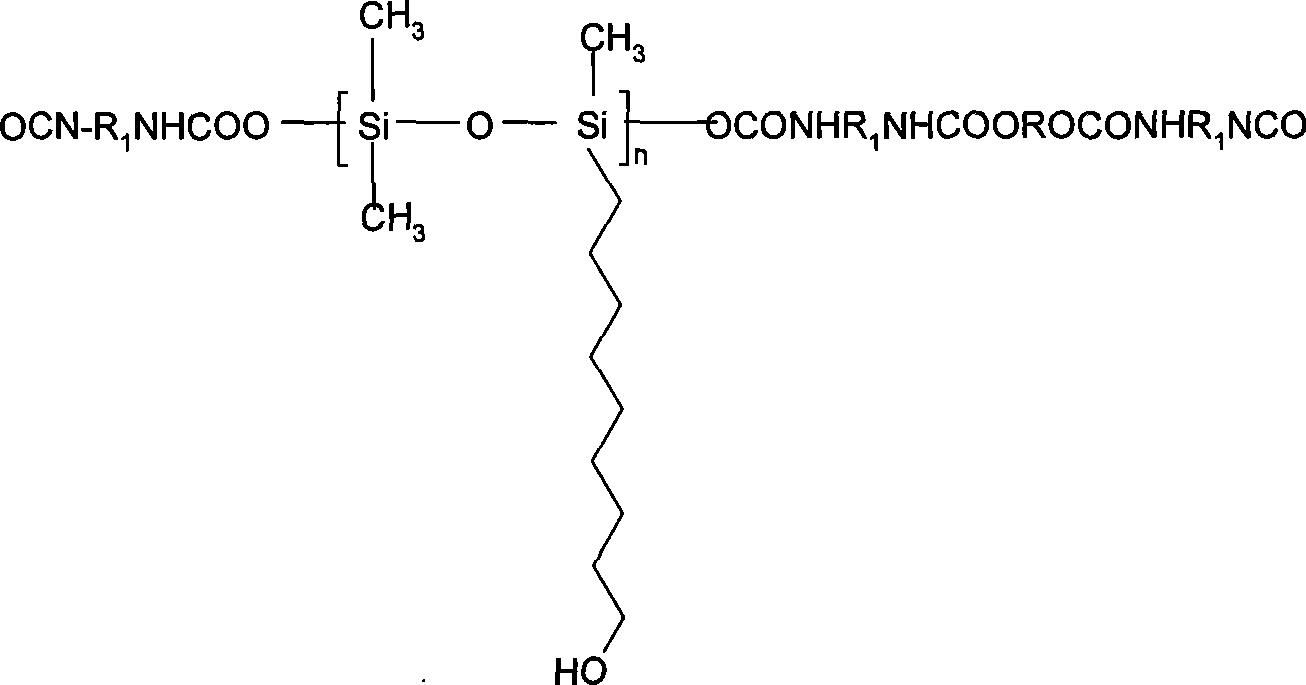

Method for preparing high storage stability room temperature dehydration sulfureted organic silicon coat

ActiveCN101260278AGood storage stabilityMechanical properties unchangedAntifouling/underwater paintsOther chemical processesCross-linkEmulsion

The invention discloses a preparation method for high storage stability room temperature dehydration curing silicone coating and is characterized in that the method comprises the following steps (the raw materials are expressed according to the weight proportion): alpha, omega-(dihydroxy)polydiorganosiloxane polymer anion emulsion 100 portions, silicone cross-linking agent 1-5 portions, and catalyst stannous octoate emulsion 0.1-5 portions are added into a stirrer to evenly mix and then cured for 1 to 4 days at room temperature, alkali is used to adjust the pH value of the compound to 10 to 14, and the compound, inorganic filler 50-100 portions, thickening agent 0.1-1 portion and defoaming agent 0.1-1 portion are added into a planetary stirring machine to evenly stir so as to obtain the high storage stability room temperature dehydration curing silicone coating.

Owner:CHENGDU GUIBAO NEW MATERIAL

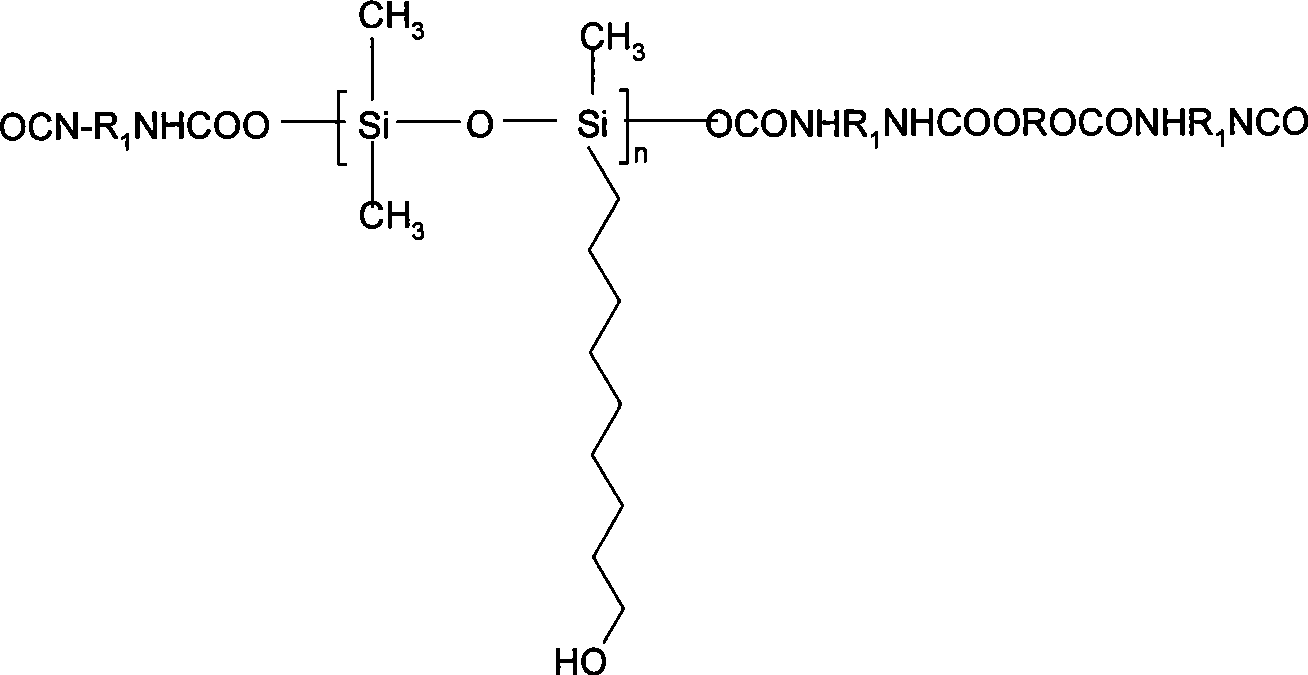

Binder used between urethane foam and glass fiber reinforced plastic of LNG ships

InactiveCN101531879AWater resistantWith low temperature resistancePolyureas/polyurethane adhesivesEpoxyGlass fiber

The invention discloses a binder used between urethane foam and glass fiber reinforced plastic of LNG ships, which comprises the following compositions by mass percentage: 30 to 50 percent of organosilicone polyurethane modified prepolymer, 5 to 15 percent of epoxide resin, 10 to 20 percent of solvent, 1 to 15 percent of chain extender, 1 to 10 percent of vermiculite, 10 to 18 percent of SiO2, 10 to 20 percent of CaCO3 and 2 to 10 percent of CaCl2. The liquid compositions are uniformly mixed firstly, and then added with the solid compositions for uniform stirring, and the mixture is ground on a grinding machine and then packaged. The binder used between the urethane foam and the glass fiber reinforced plastic of the LNG ships has large binding power between the urethane foam and the glass fiber reinforced plastic, and properties of ultralow temperature resistance and water resistance, and can be used at 200 DEG C below zero for a long time and keep the mechanical property to achieve the aim of fully protecting heat insulating materials.

Owner:JIANGSU UNIV OF SCI & TECH +1

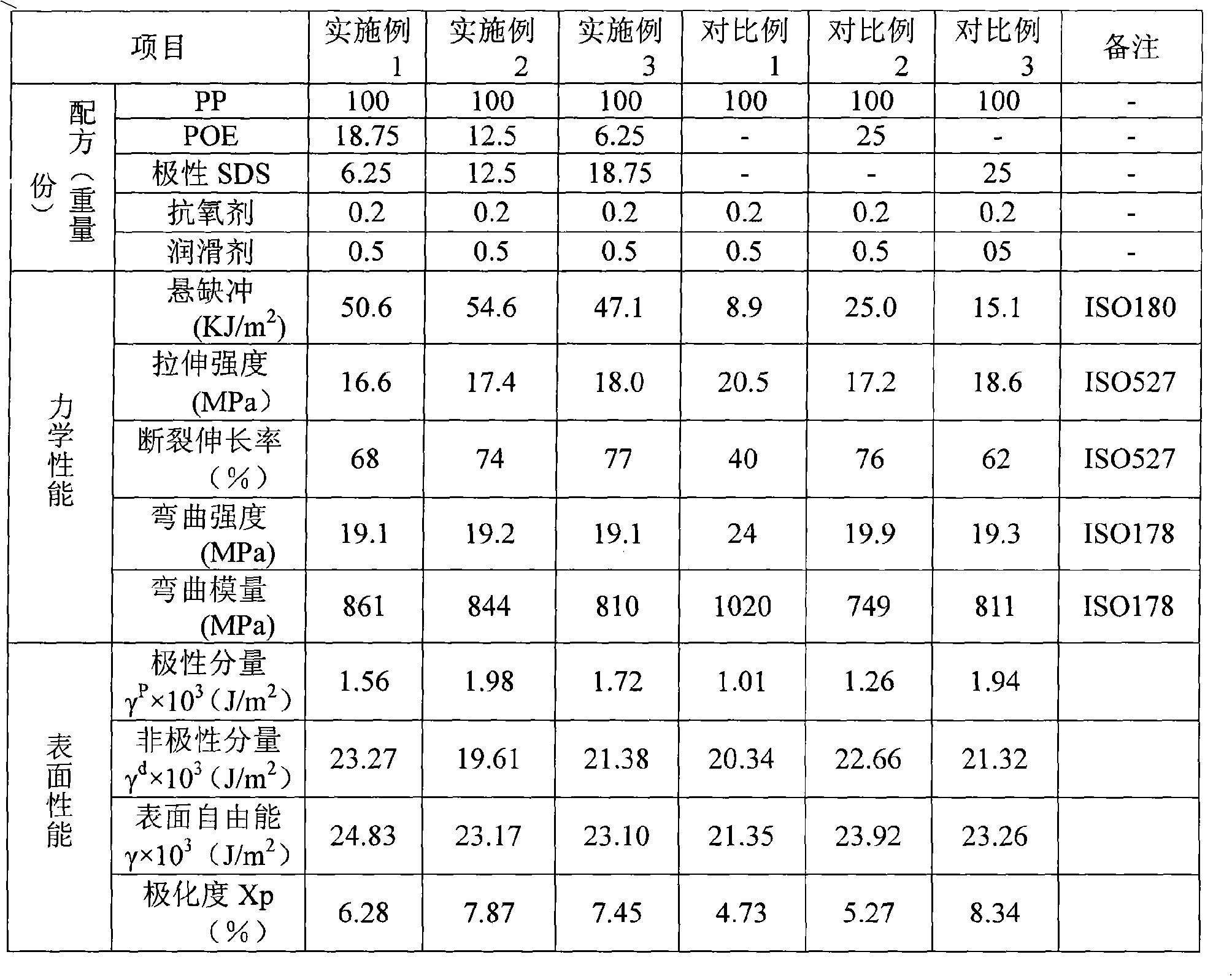

Sprayable and toughened polypropylene composition and preparation method thereof

The invention provides a sprayable and toughened polypropylene composition, which contains the following blended components: 100 weight parts of acrylic resin, 5 to 30 weight parts of thermoplastic polyolefin elastomer, and 5 to 30 weight parts of thermoplastic elastomer graft, wherein the thermoplastic polyolefin elastomer is an ethylene-octene copolymer; and the thermoplastic elastomer graft isa styrene-butadiene-styrene block copolymer or a graft of a styrene-pentadiene-styrene block copolymer and a polar monomer, and the polar monomer is at least one of 2-vinylpyridine, 4-vinylpyridine orisomers thereof. The sprayable polypropylene composition is prepared by melt blending of the components. The polypropylene composition has good toughness and sprayable performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

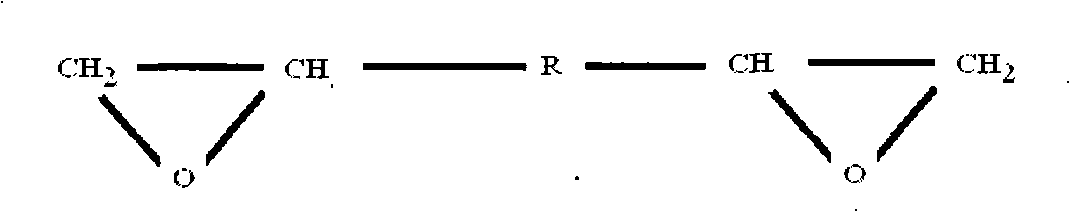

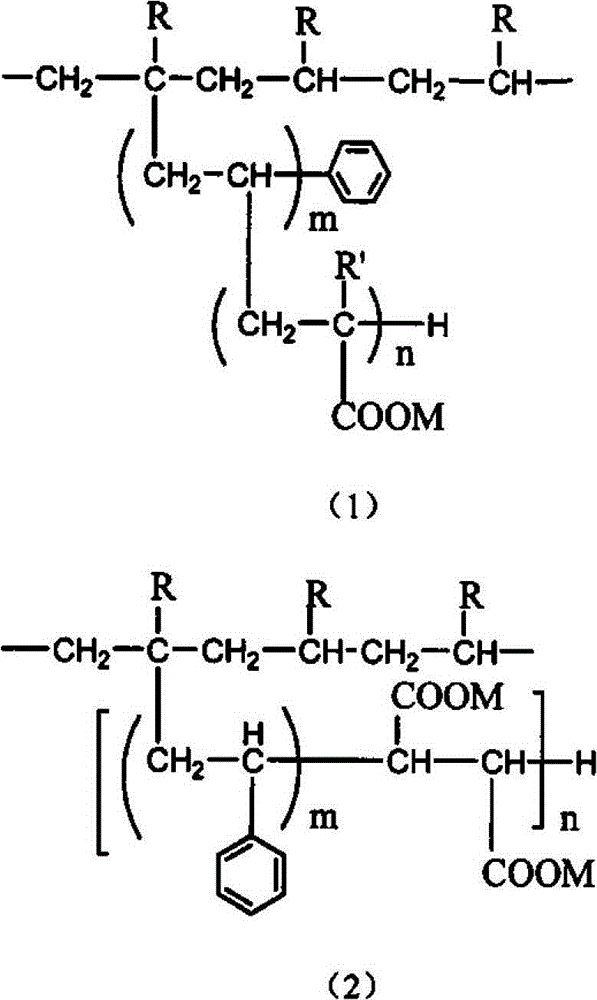

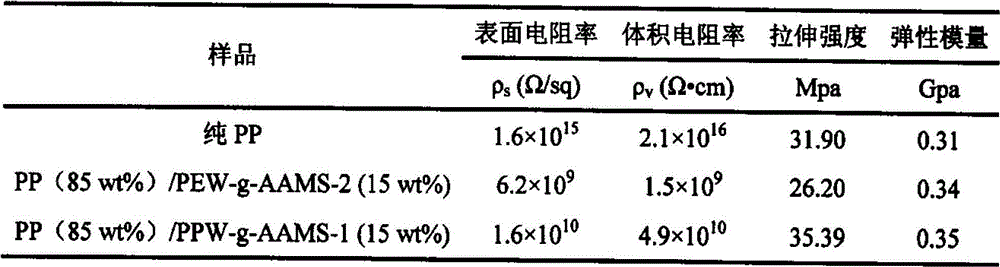

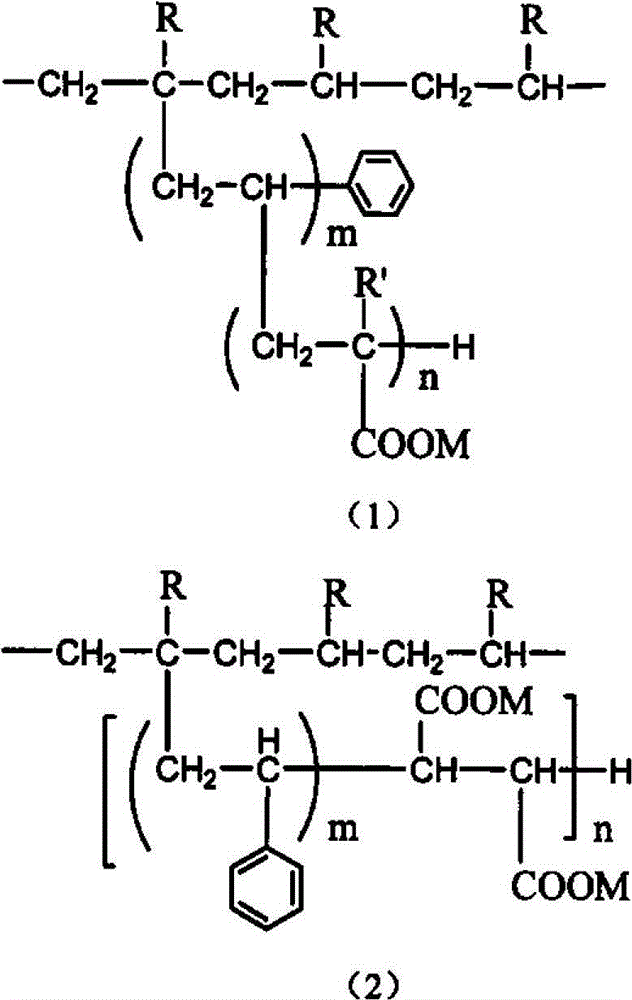

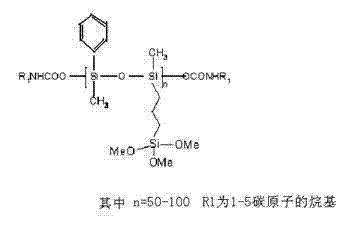

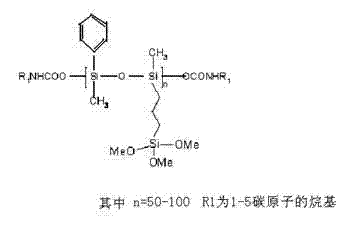

Permanent polyolefin antistatic agent and preparation method thereof

The invention relates to a permanent polyolefin antistatic agent which has a chemical structural formula shown in (1) or (2), wherein R represents H or CH3, R' represents H, CH3 or CH3COOM, M represents H or Na or K or Li, n is an integer of 1-30, and m is an integer of 1-30. According to the invention, the antistatic agent is prepared by adopting a solution grafting method or an emulsion grafting method. The prepared antistatic agent has a good heat resistance and thermal resistance and an excellent antistatic property, has a good compatibility with polyolefins, and the volume resistance of polyolefins can be reduced by 3-6 orders of magnitude.

Owner:EAST CHINA UNIV OF SCI & TECH

Heat-dissipation paint for light-emitting diode (LED) lamp

InactiveCN101942270BImprove adhesionImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsSolid componentPhysical chemistry

The invention discloses heat-dissipation paint for an LED lamp, which is characterized by comprising the following components in percentage by mass: 30 to 50 percent of organosilicon polyurethane prepolymer, 10 to 20 percent of mixed solvent, 1 to 5 percent of silane coupling agent KH560, 8 to 15 percent of beryllium oxide, 15 to 50 percent of aluminium nitride and 1 to 5 percent of oleinic acid.A preparation method comprises the following steps of: firstly, uniformly blending the liquid components; secondly, adding solid components and uniformly stirring; and finally, grinding on a grinder and then packaging. The heat-dissipation paint for the LED lamp in the invention has the advantages of temperature resistance, aging resistance, high adhesion and good heat-dissipation effect.

Owner:JIANGSU UNIV OF SCI & TECH

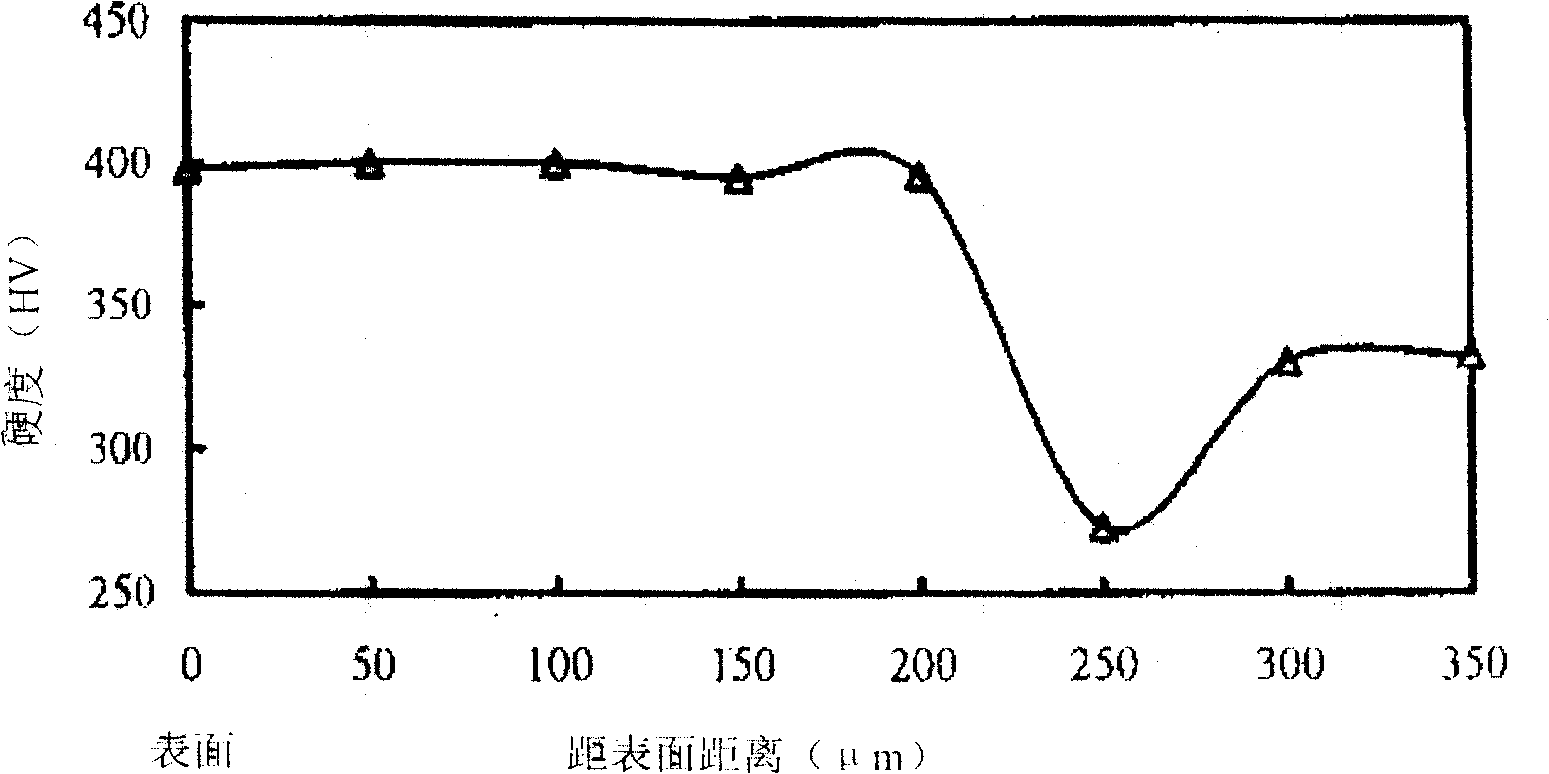

Hardening technology for precipitation hardening stainless steel laser surface

InactiveCN100443597CHigh hardnessMechanical properties unchangedHeat treatment process controlShielding gasCase hardening

In the invention, a specific wave-length laser is used for scanning radiation on the surface of the precipitation hardening stainless steel within a certain condition, so, making the surface of said steel to smelt. Low temperature shield gas is used for being cover onto the scanned area, for speeding-up the cooling. After that, the steel is subjected to heat treatment, so the hardness of the surface in a certain thickness is harder than that of the main body of the steel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

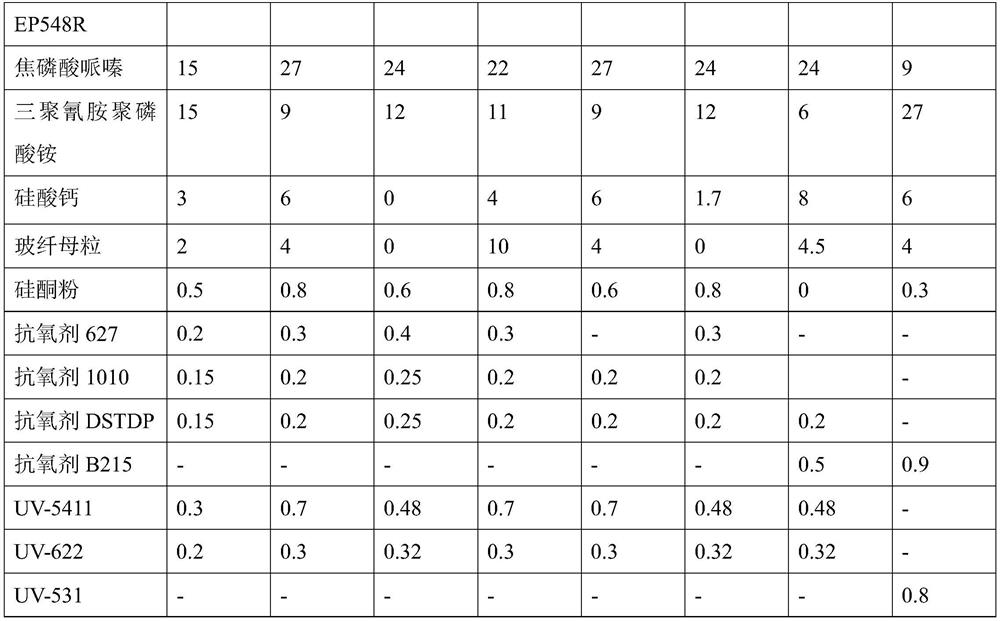

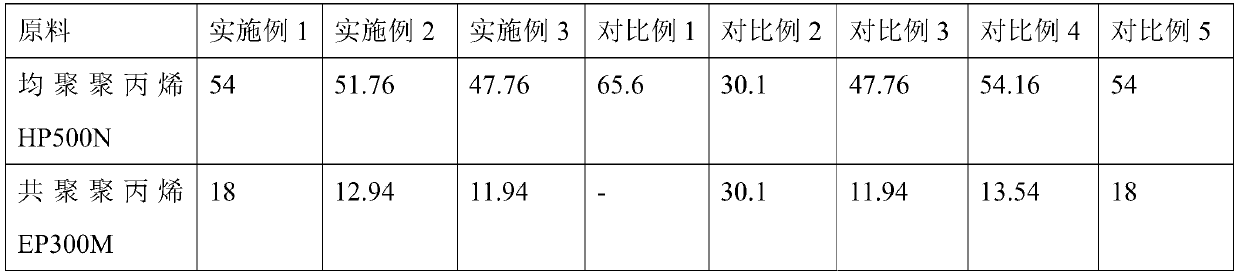

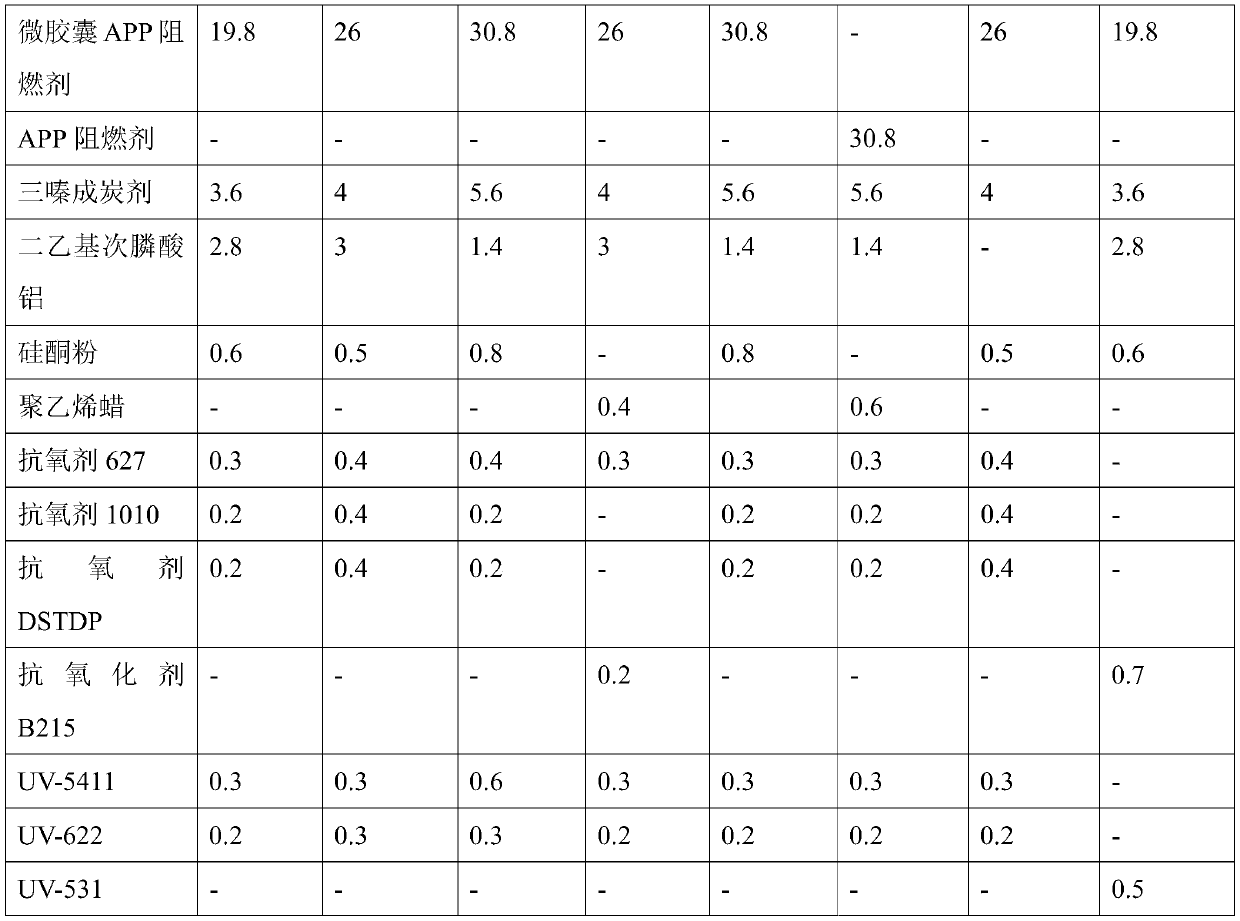

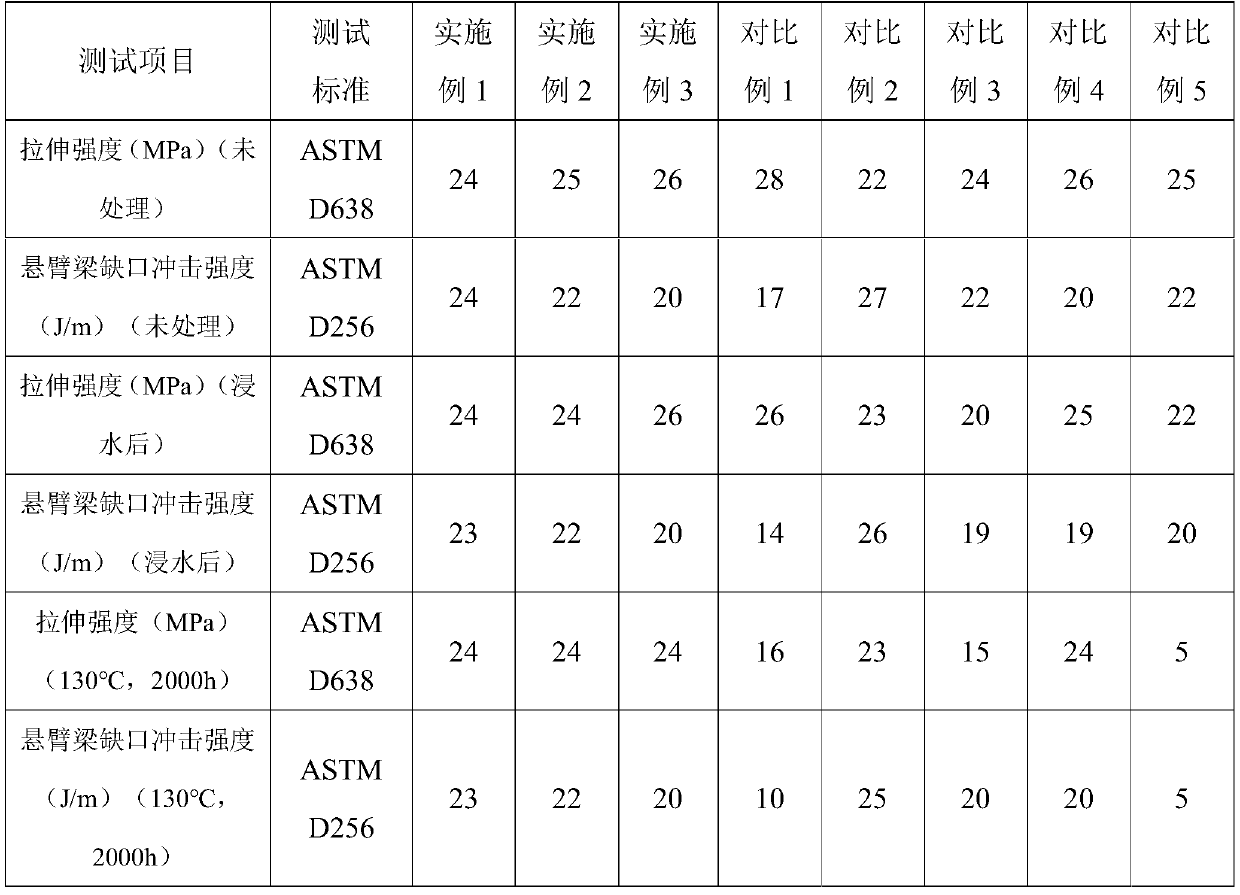

Weather-resistant halogen-free flame-retardant polypropylene material as well as preparation method and application thereof

PendingCN111548559AImprove flame retardant performanceImprove water resistancePolymer sciencePolypropylene

The invention provides a weather-resistant halogen-free flame-retardant polypropylene material as well as a preparation method and application thereof. The weather-resistant halogen-free flame-retardant polypropylene material is prepared from the following raw materials in parts by mass: 55-75 parts of polypropylene resin, 20-38 parts of halogen-free flame retardant, 1-3 parts of a flame-retardantsynergist, 0.5-0.8 part of a lubricant, 0.5-1.2 parts of an antioxidant and 0.3-1 part of a light stabilizer; wherein the halogen-free flame retardant comprises microcapsule ammonium polyphosphate and a charring agent. The weather-resistant halogen-free combustion-supporting polypropylene material has a high flame retardant performance (UL94 V-0 and UL1694 SC-0 with a thickness of 0.75 mm), and after being soaked in water at 70 DEG C for 7 days, at least 90% of mechanical properties are still maintained. After the material is irradiated by a xenon lamp for 1000 hours, at least 90% of mechanical properties are maintained. In addition, the preparation method is simple and easy to control. The material is applied to a soft core of decorative lighting.

Owner:GUANGDONG JUSHI CHEM CO LTD

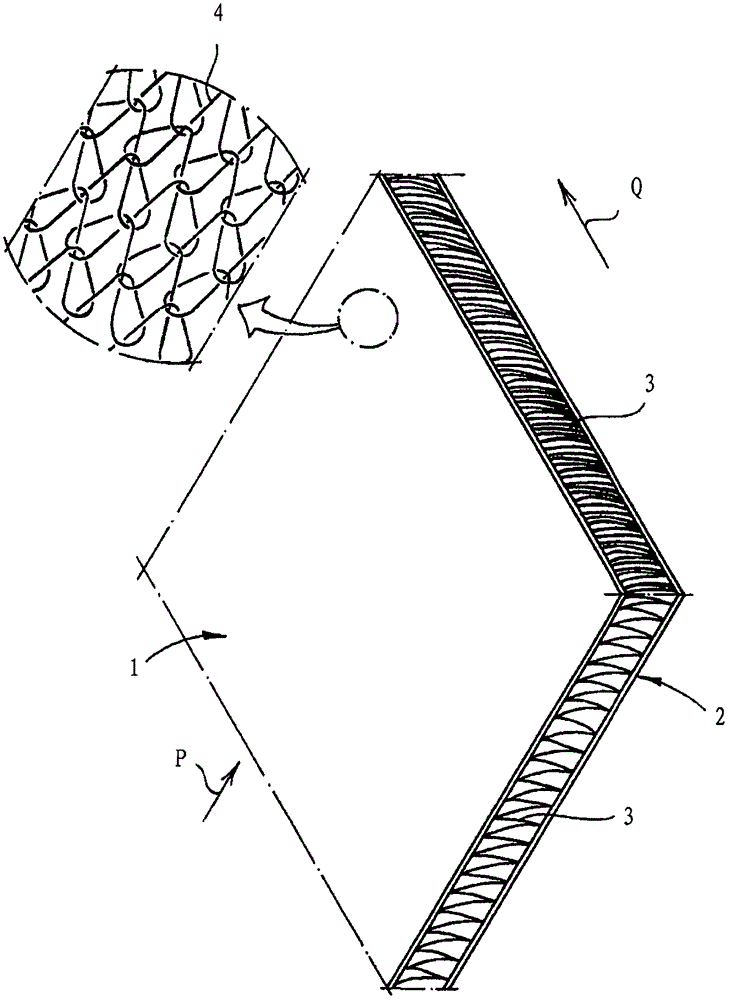

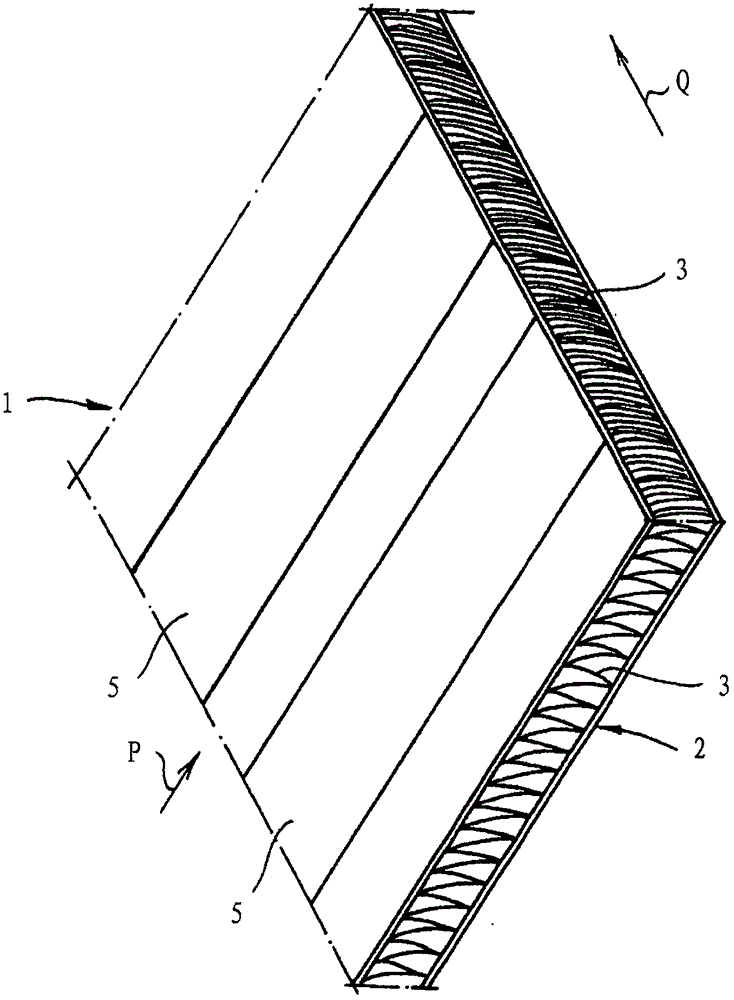

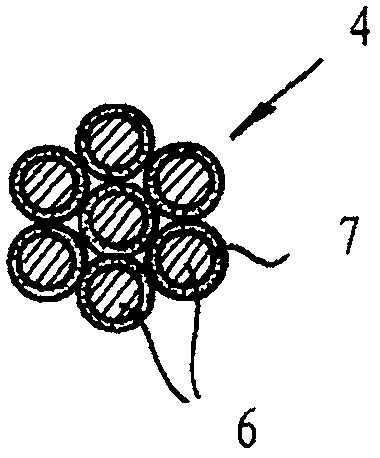

Spacer fabric, spacer fabric section and heatable cladding element

InactiveCN106498619AStress reliefImprove machinabilityDomestic stoves or rangesOrnamental textile articlesYarnConductive coating

The invention relates to a spacer fabric, a spacer fabric section and a heatable cladding element. The spacer fabric includes a face-shaped first fabric layer (1) having a transmission yarn (4), a face-shape fabric layer (2) and a spacer yarn (3) which is connected to the fabric layers (1, 2). The conduction yarn (4) has a conductive coating (7). A conduction stripe (5) which extends comprehensively in the first fabric layer (1) or along a production direction has adjacent conduction yarns which are in direct electrical connection. The conduction yarn (4) forms a coil with an inlay in at least two coil columns in the first fabric layer (1), and in a conductive synthesized material yarn (4), the content of the conductive coating (7) is less than 50 weight %. The invention also relates to a spacer fabric section composed of the spacer fabric and a heatable cladding element which has the spacer fabric section and a covering layer.

Owner:MULLER TEXTIL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com