Patents

Literature

3517results about "Investigating material hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

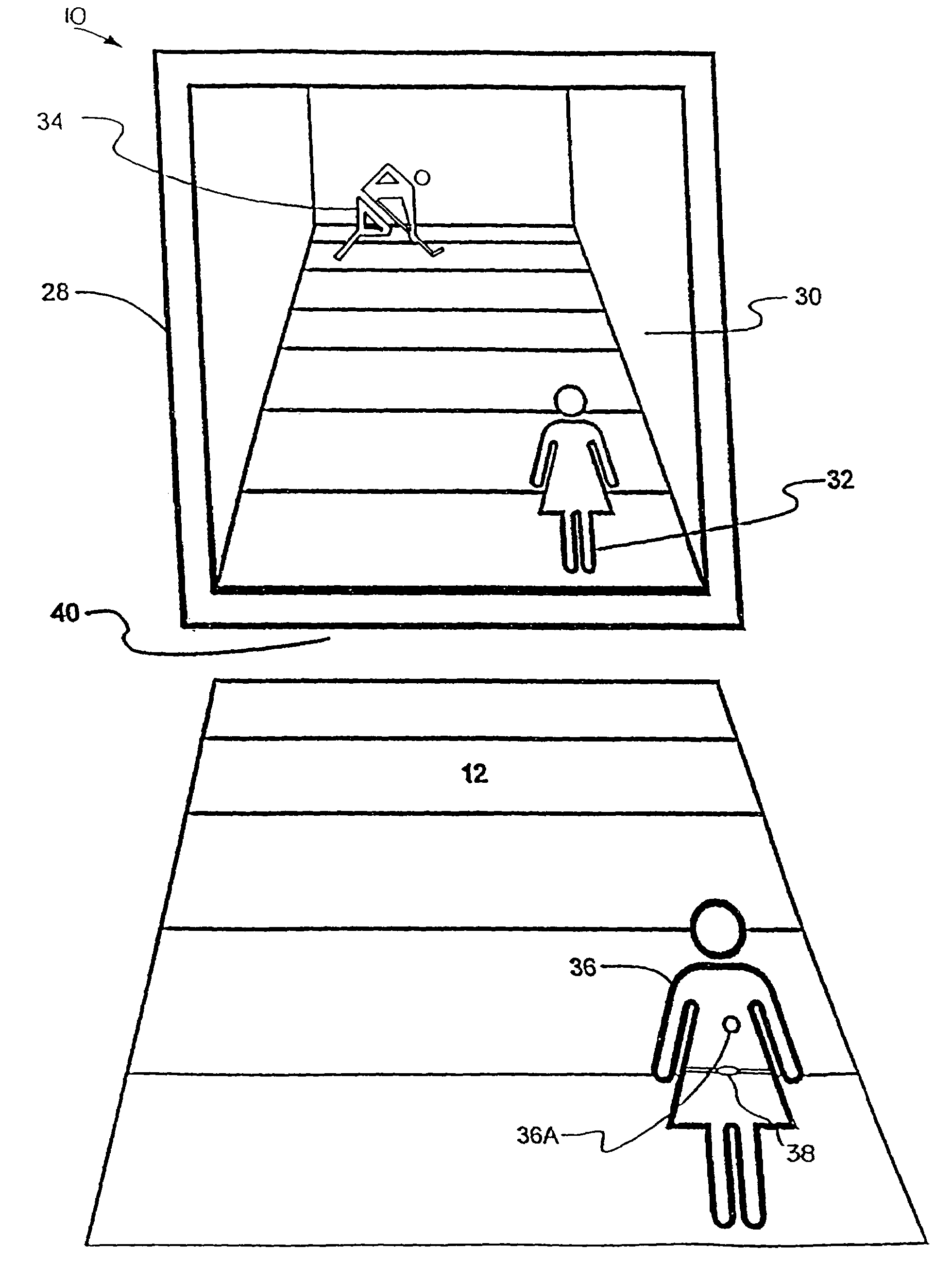

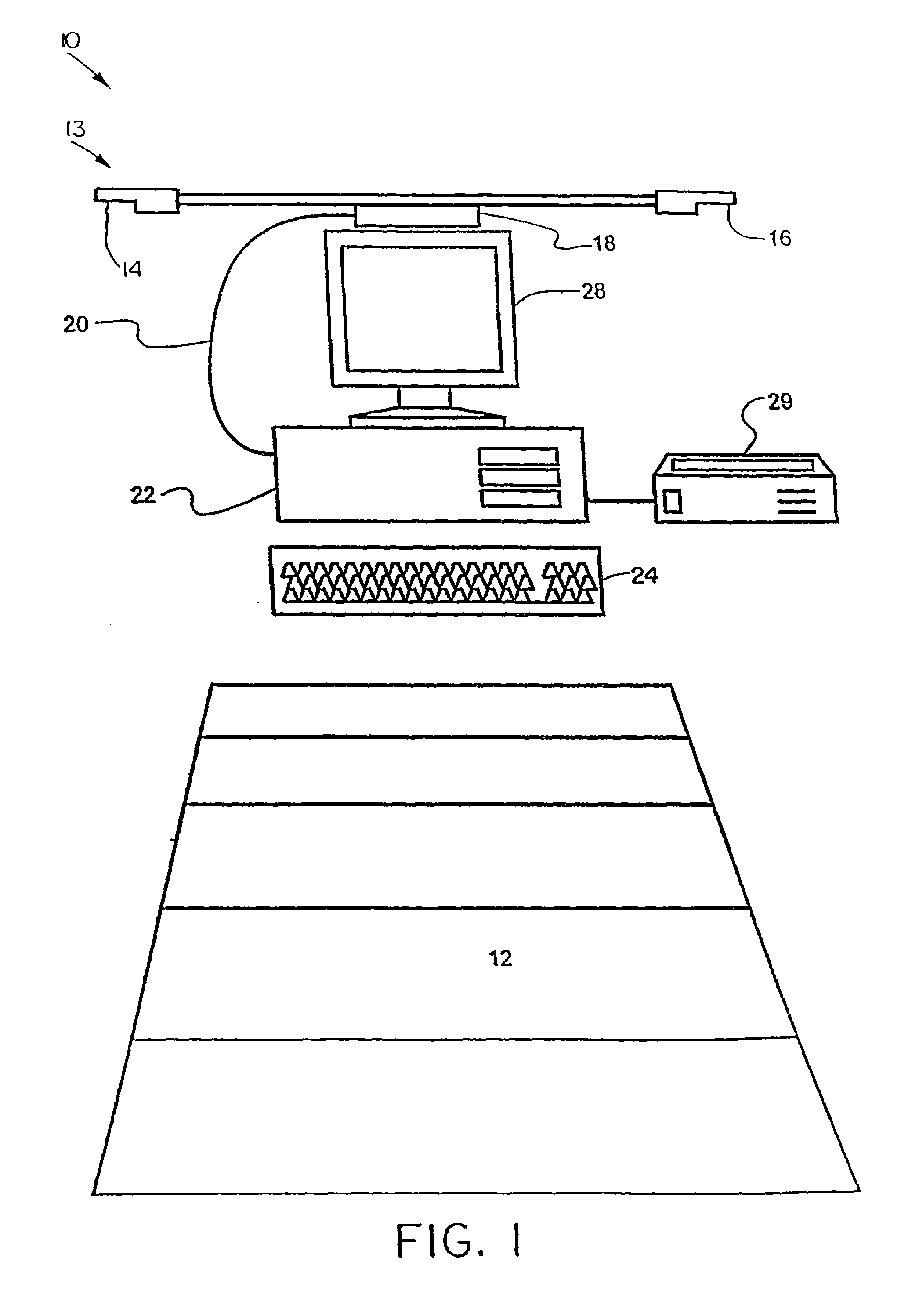

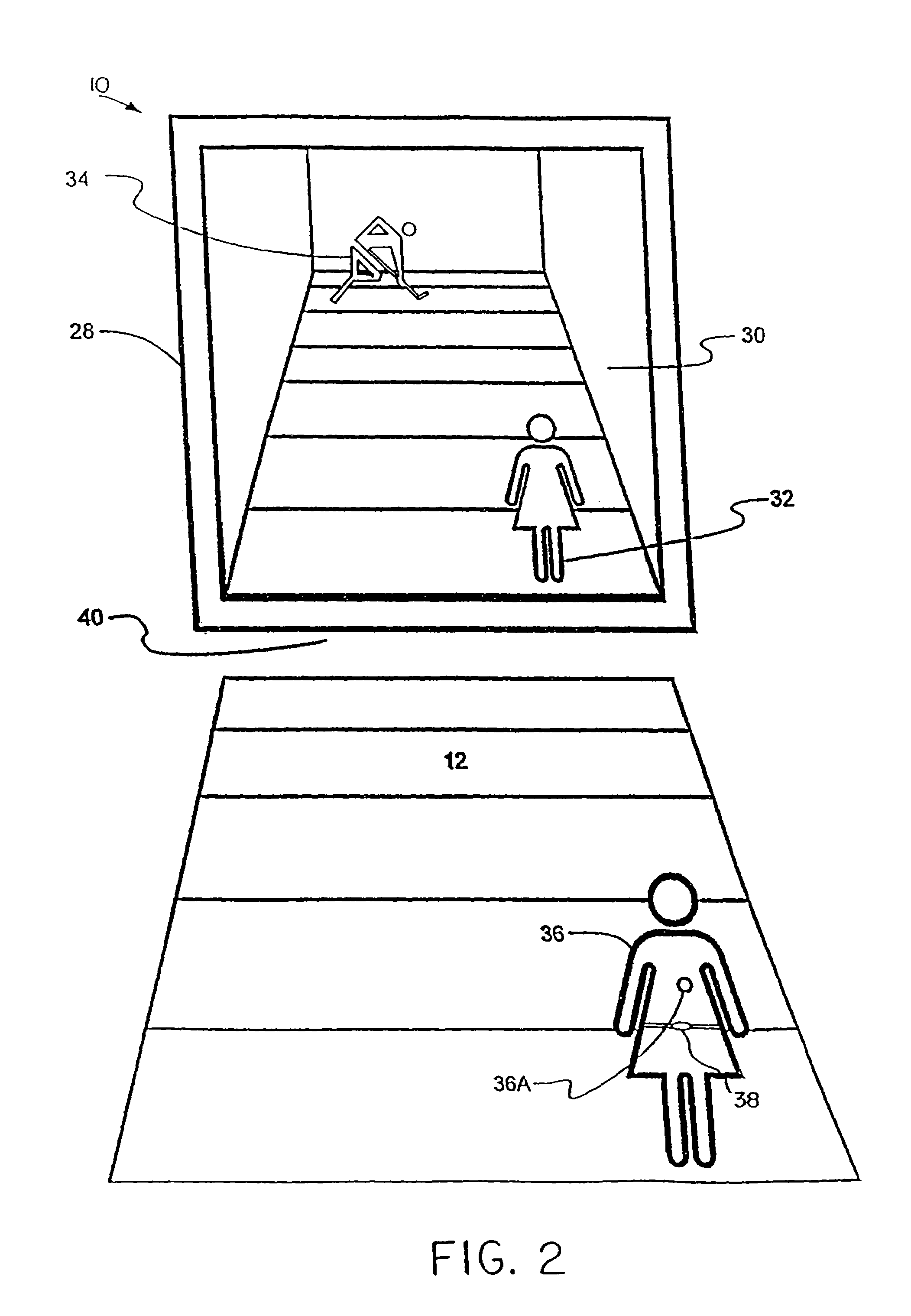

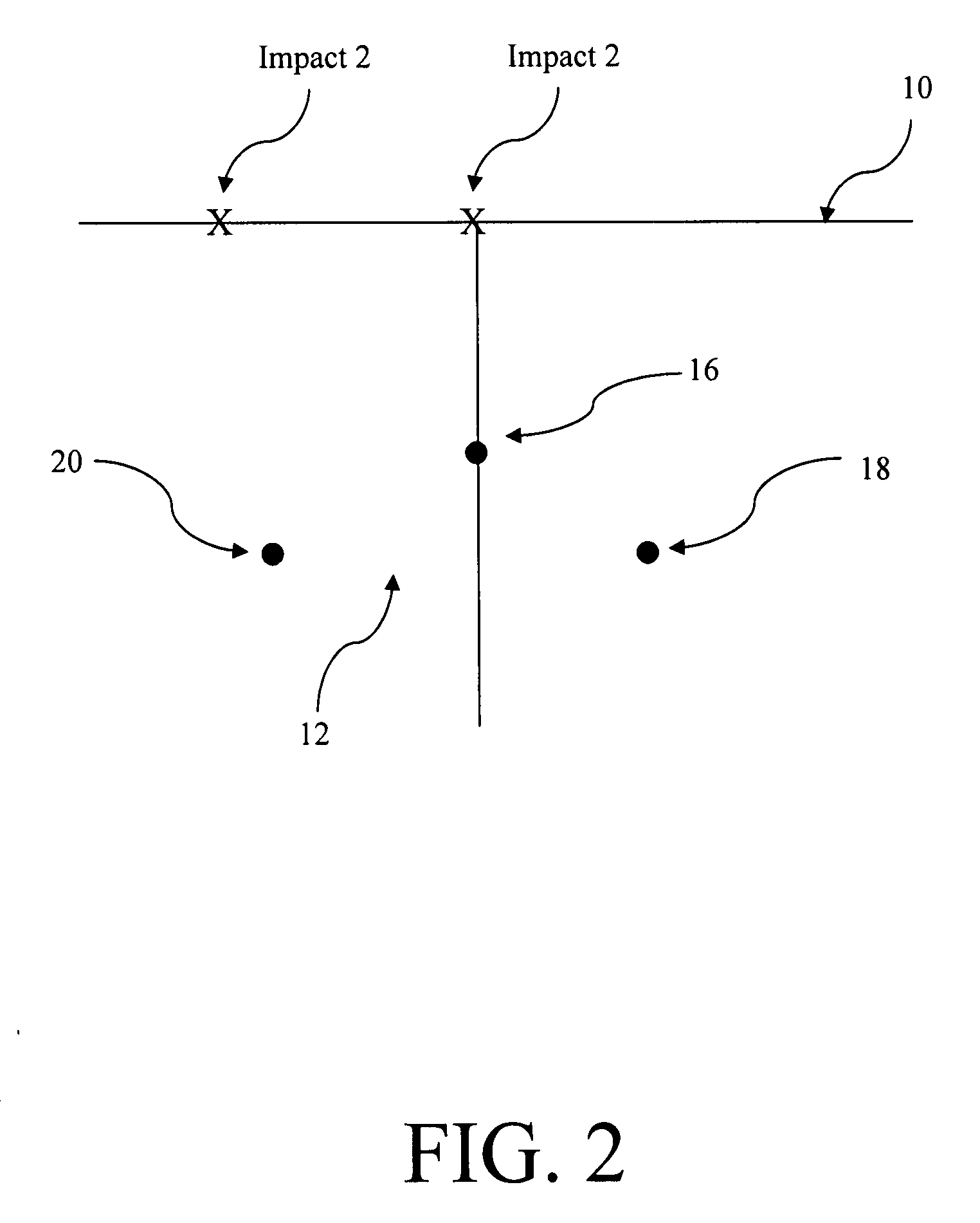

System and method for tracking and assessing movement skills in multidimensional space

Accurate simulation of sport to quantify and train performance constructs by employing sensing electronics for determining, in essentially real time, the player's three dimensional positional changes in three or more degrees of freedom (three dimensions); and computer controlled sport specific cuing that evokes or prompts sport specific responses from the player that are measured to provide meaningful indicia of performance. The sport specific cuing is characterized as a virtual opponent that is responsive to, and interactive with, the player in real time. The virtual opponent continually delivers and / or responds to stimuli to create realistic movement challenges for the player.

Owner:IMPULSE TECH

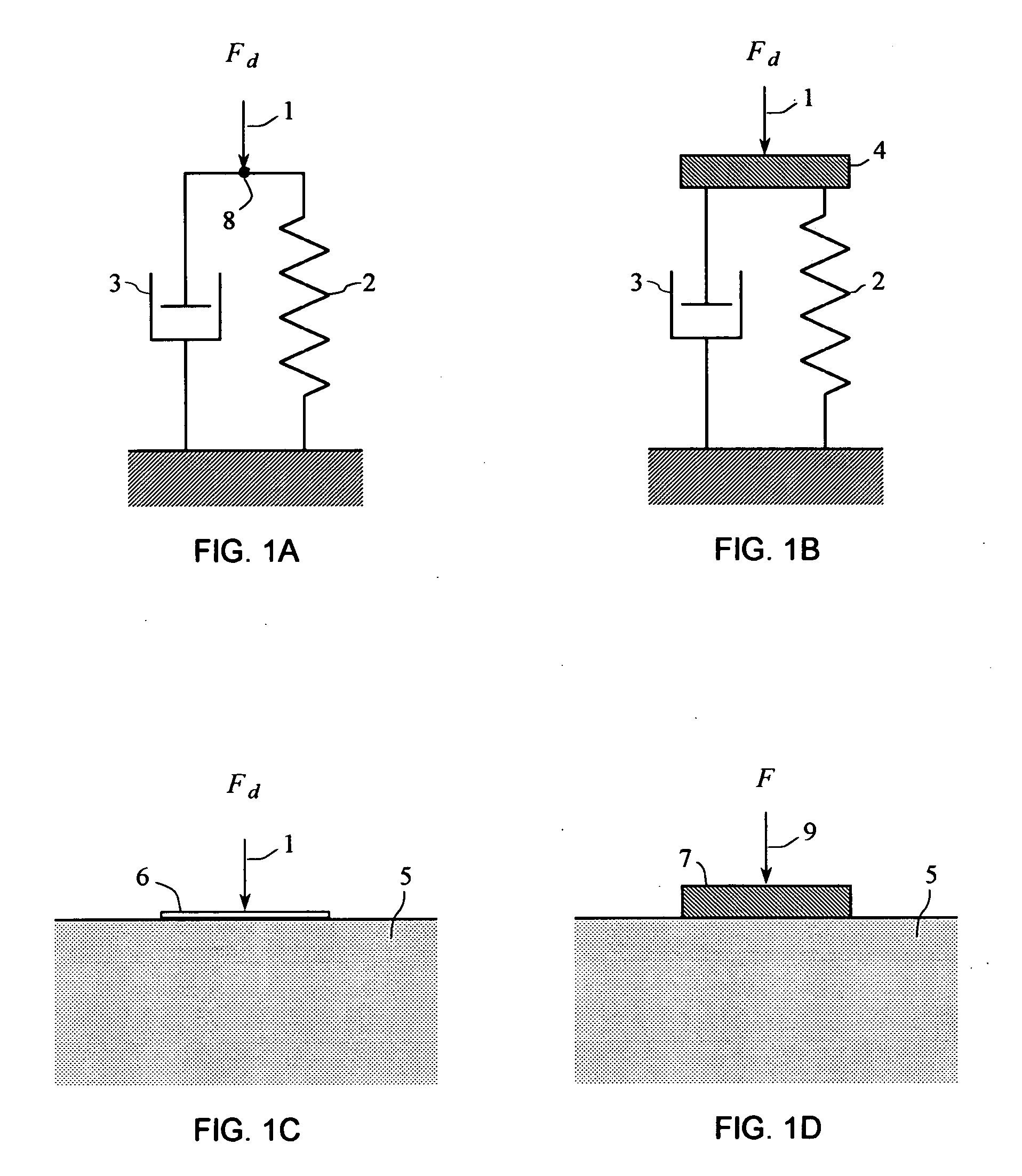

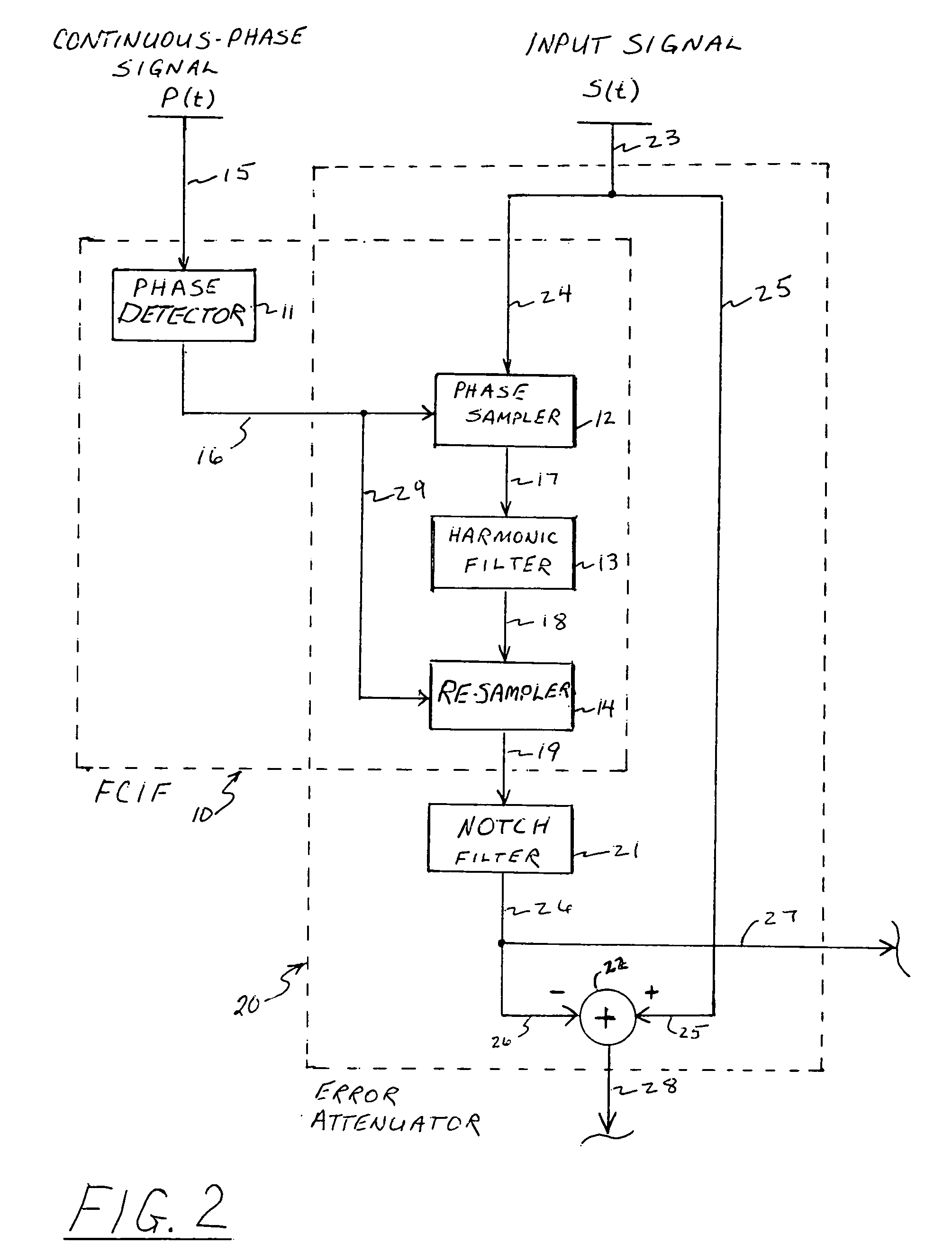

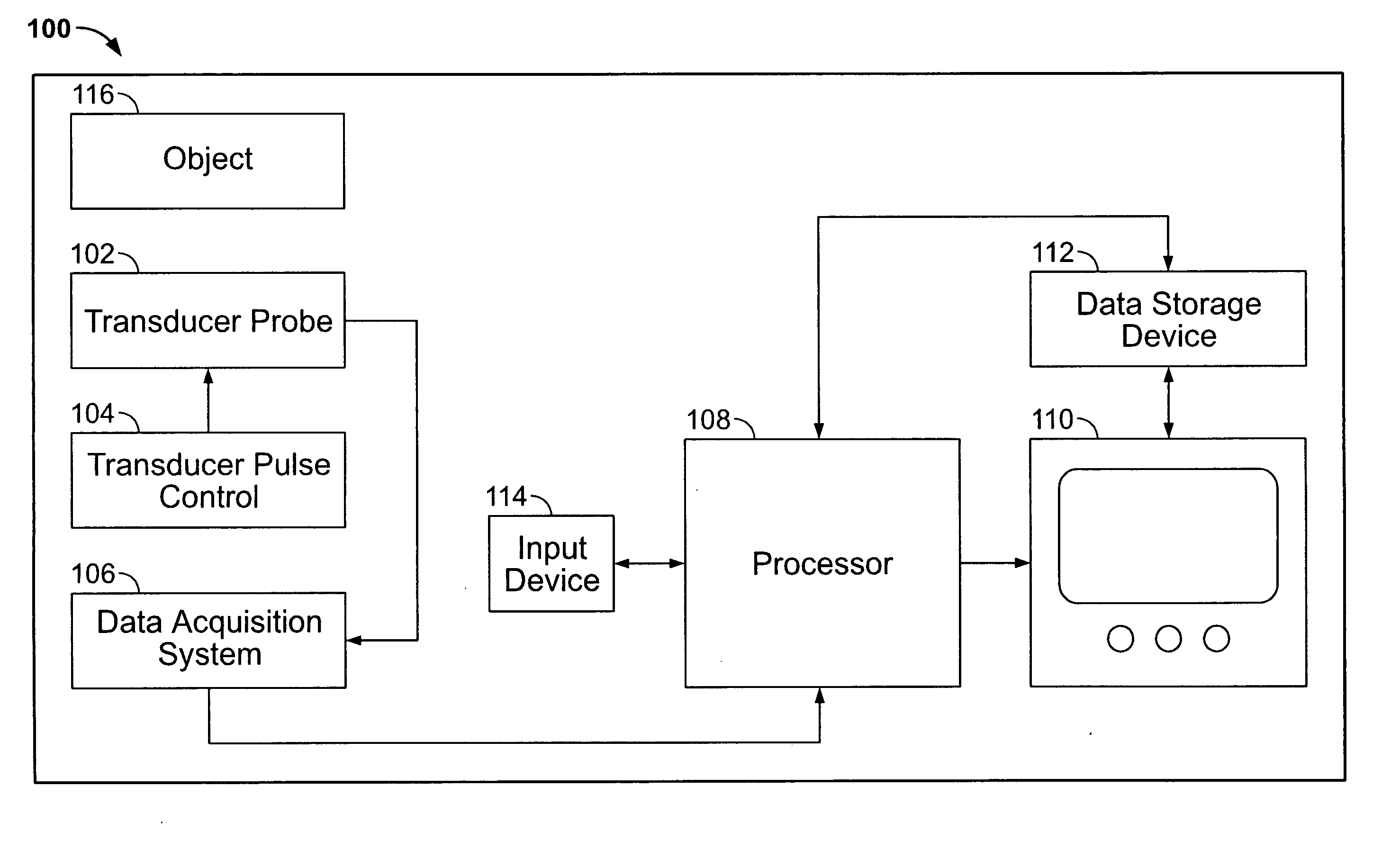

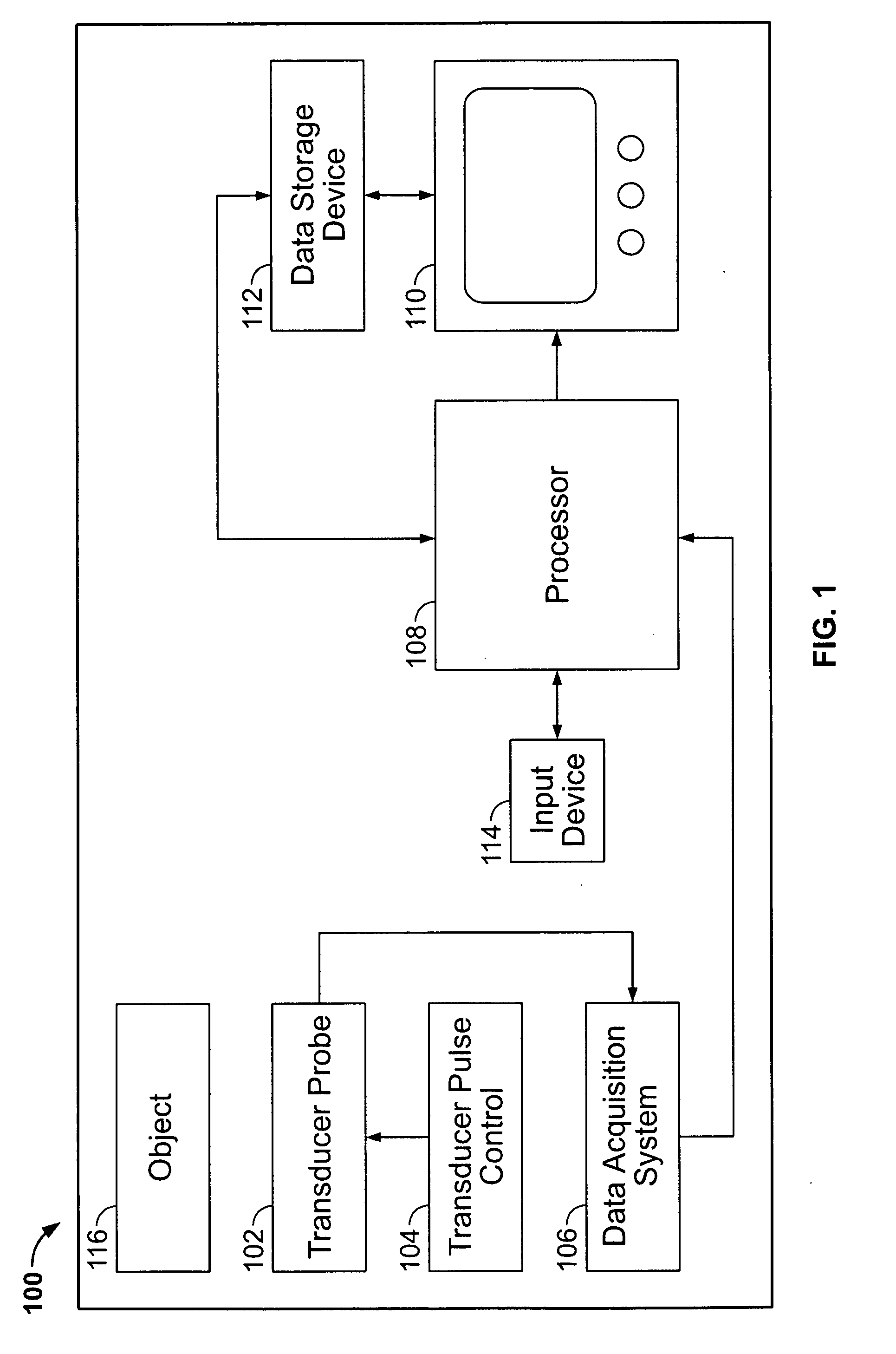

Systems and methods to determine elastic properties of materials

InactiveUS20050267695A1Elastic properties can be determinedInherent in massVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesTime domainHarmonic

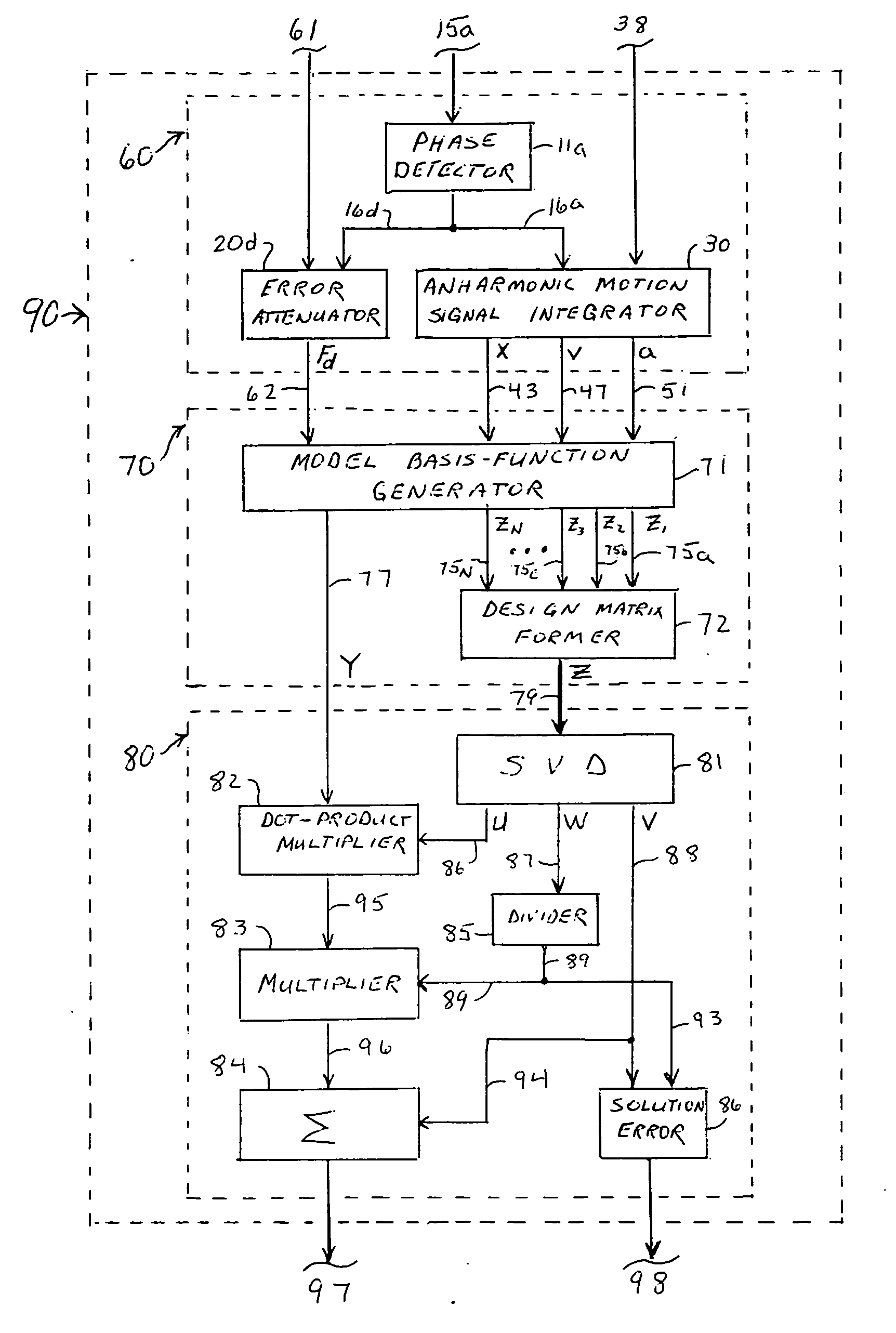

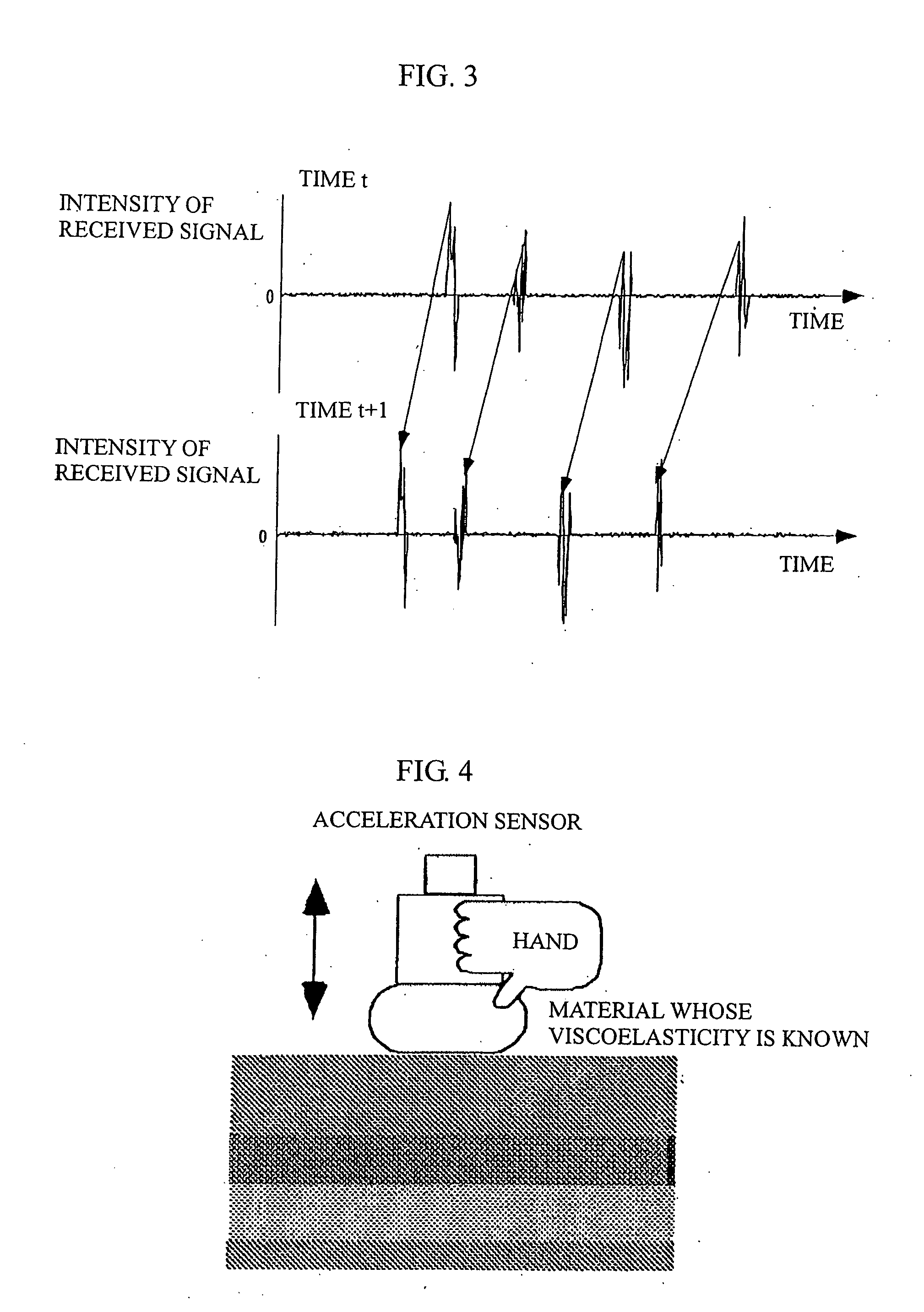

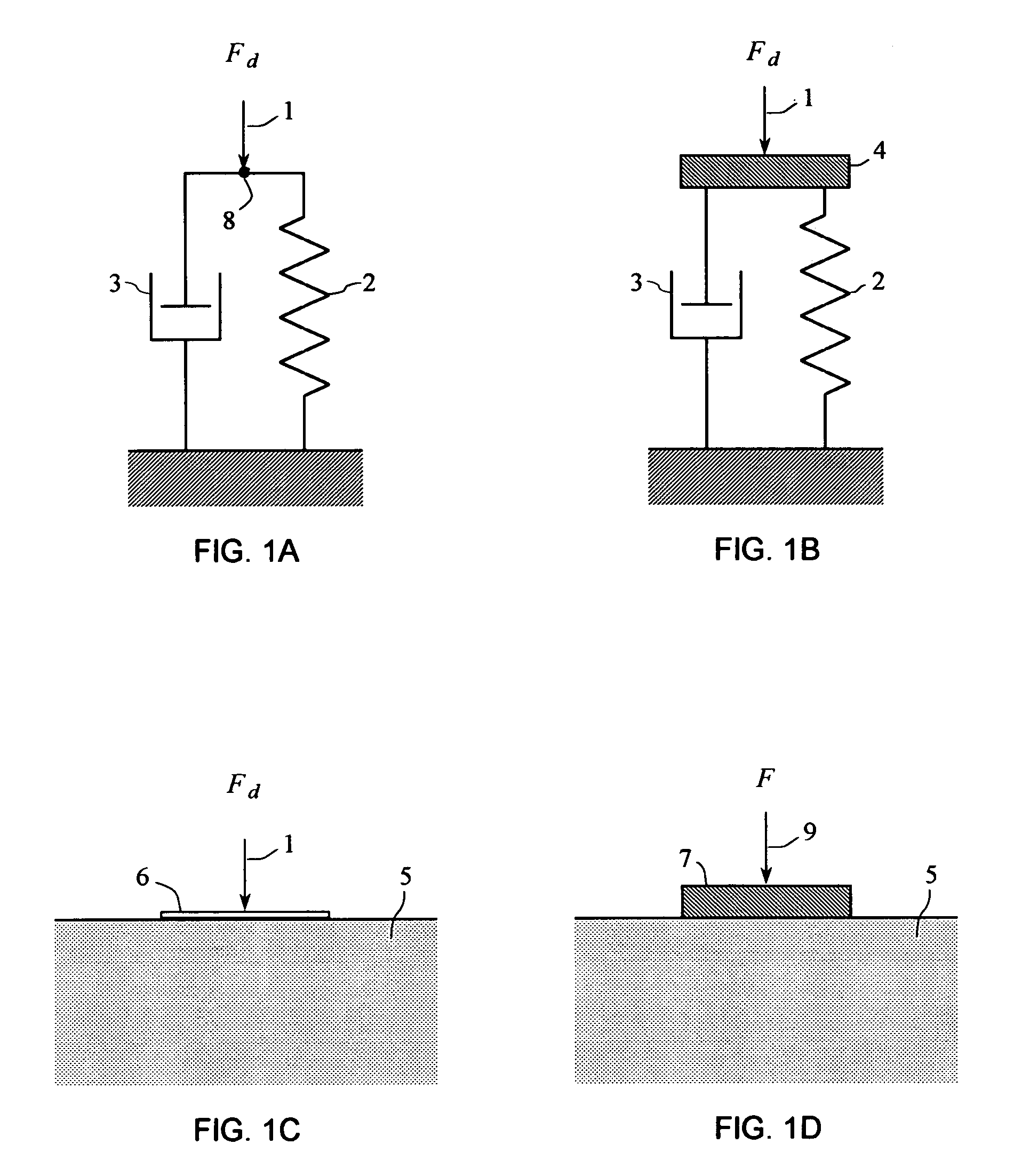

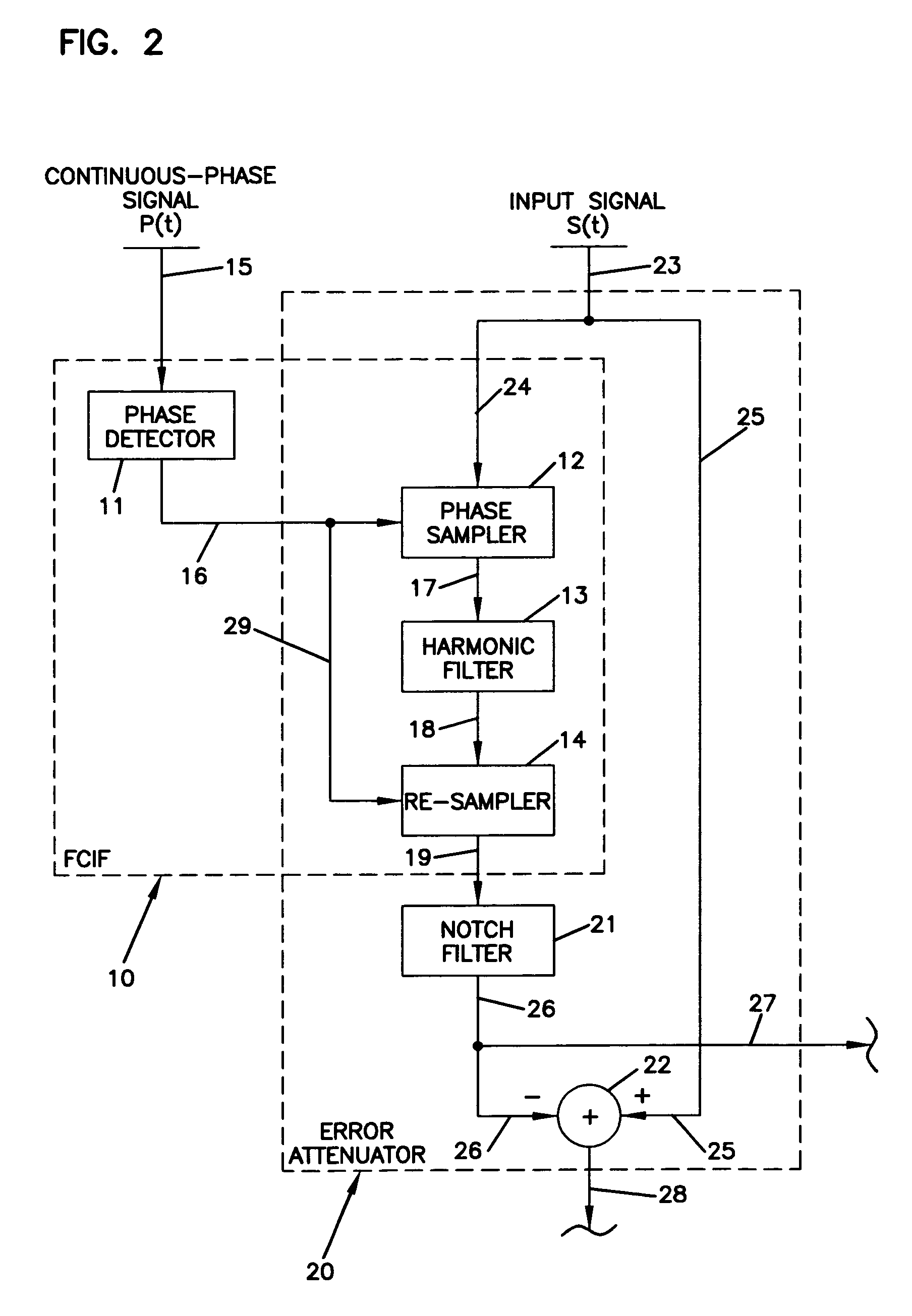

The present invention provides systems and methods to use a measured driving-point response of a nonlinear material to determine one or more elastic properties of the material. The present invention takes advantage of the full information represented by the transient component, the steady-state component, the anharmonic components, and the nonlinear response components of a measured driving-point response of a real nonlinear material, without limitation in the use of large-amplitude forces. The elastic properties are determined by forming and solving a time-domain system of linear equations representing a differential equation model of the driving-point motions of the material. Based on a single, short duration, large-amplitude driving point measurement, both linear and nonlinear properties can be determined; both large-amplitude and near-zero amplitude properties can be determined; and elastic-wave speed and elastic moduli and their variation with depth can be determined. The present invention also provides a system and a method to filter an input signal to either attenuate or preserve each of one or more selected harmonic components that are harmonics of a phase reference signal.

Owner:GERMAN PETER THOMAS

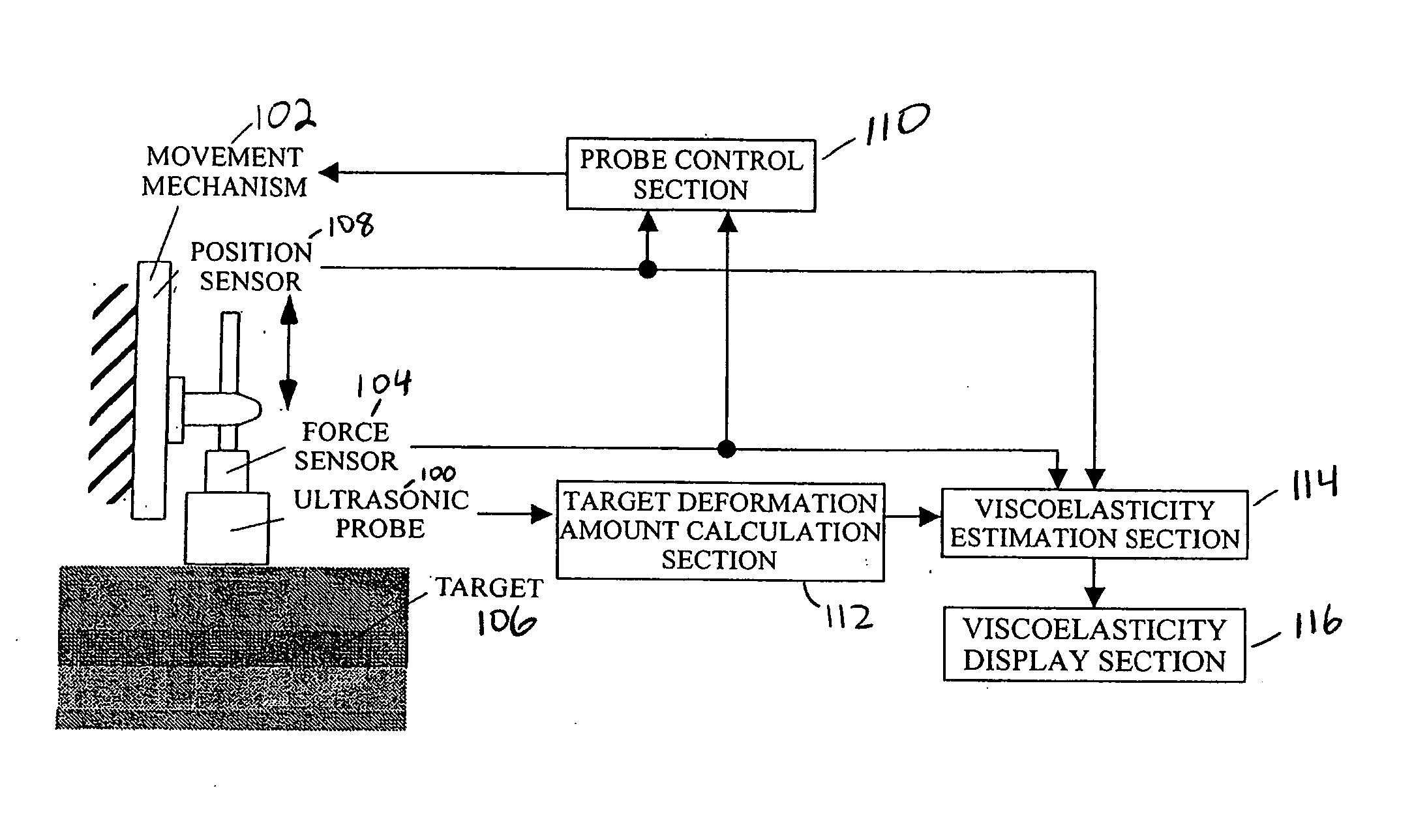

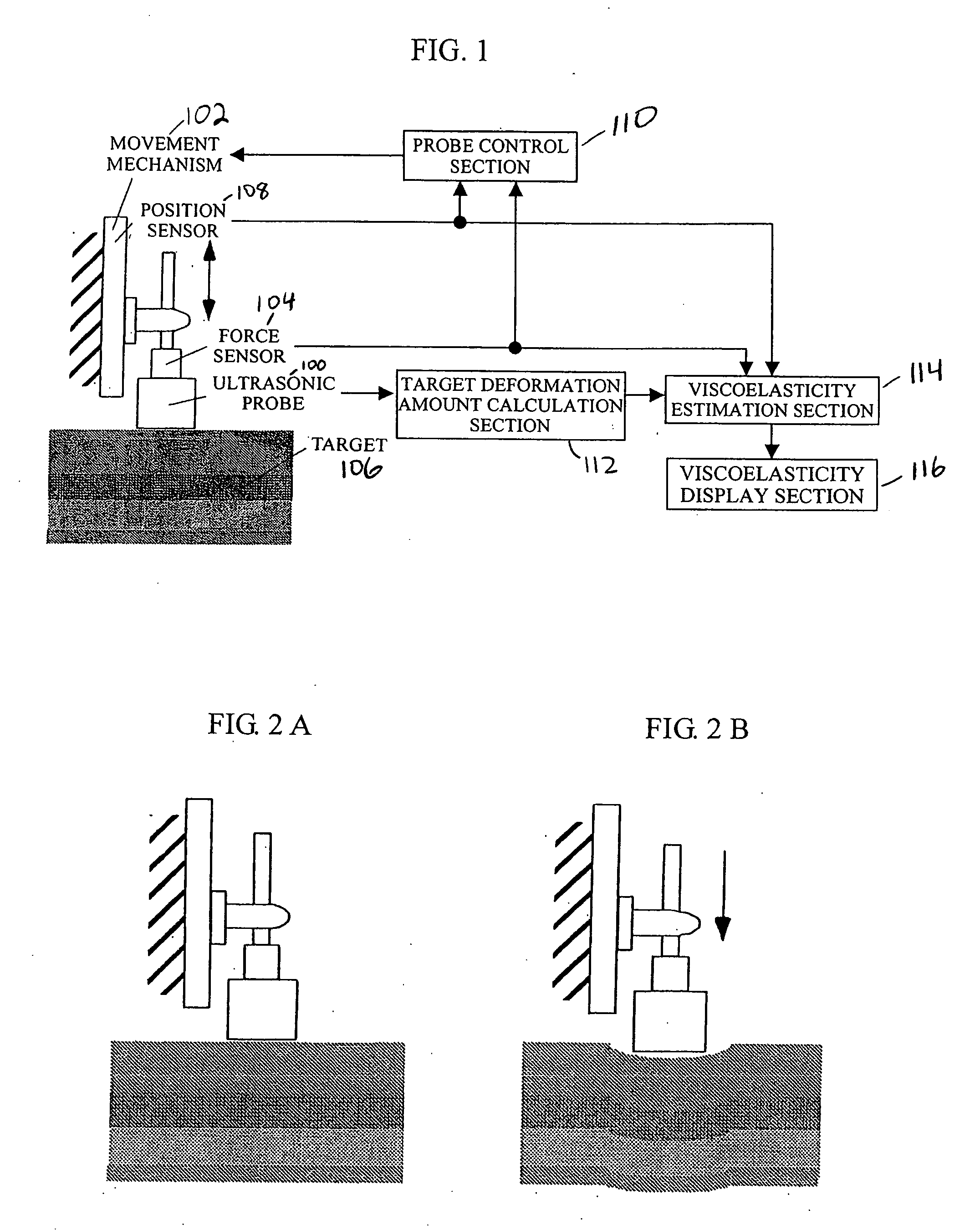

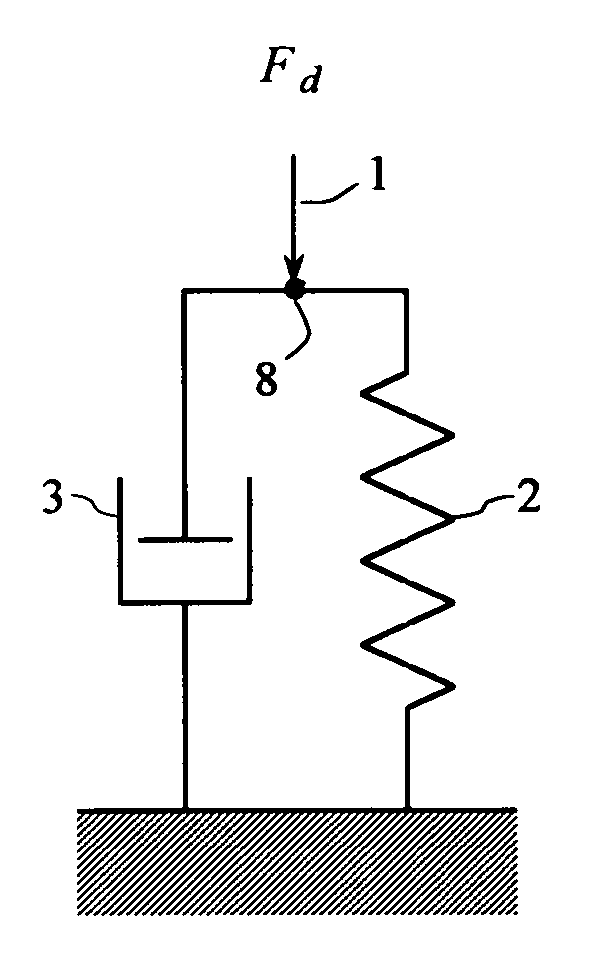

Apparatus and program for estimating viscoelasticity of soft tissue using ultrasound

InactiveUS20050085728A1Reduce harmAnalysing solids using sonic/ultrasonic/infrasonic wavesDiagnostic probe attachmentSonificationViscoelasticity

The present invention allows even soft tissue such as body tissue having a hierarchic structure of skin, fat, muscle and bone, etc., to be estimated and allows estimation only through a short-time pressing operation to thereby reduce damages to the soft tissue. The present invention is constructed of an ultrasonic probe for transmitting / receiving an ultrasonic signal, a target deformation amount calculation section for calculating an amount of deformation of a target shape from a time variation of data received from the ultrasonic probe, a movement mechanism for moving the ultrasonic probe, a probe control section for controlling the probe, a position sensor for measuring the position of the probe, a force sensor for measuring a force applied to the probe section, a viscoelasticity estimation section for estimating viscoelasticity of the target based on values obtained from the position sensor, force sensor, target deformation amount calculation section and a viscoelasticity display section for presenting the estimated viscoelasticity to the user.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Systems and methods to determine elastic properties of materials

InactiveUS7107159B2Elastic propertyInherent ambiguityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesTime domainHarmonic

The present invention provides systems and methods to used a measured driving-point response of a nonlinear material to determined one or more elastic properties of the material. The present invention takes advantage of the full information represented by the transient component, the steady-state component, the anharmonic components, and the nonlinear response components of a measured driving-point response of a real nonlinear material, without limitation in the use of large-amplitude forces. The elastic properties are determined by forming and solving a time-domain system of linear equations representing a differential equation model of the driving-point motions of the material. Based on a single, short duration, large-amplitude driving point measurement, both linear and nonlinear properties can be determined; both large-amplitude and near-zero amplitude properties can be determined; and elastic-wave speed and elastic moduli and their variation with depth can be determined.

Owner:GERMAN PETER THOMAS

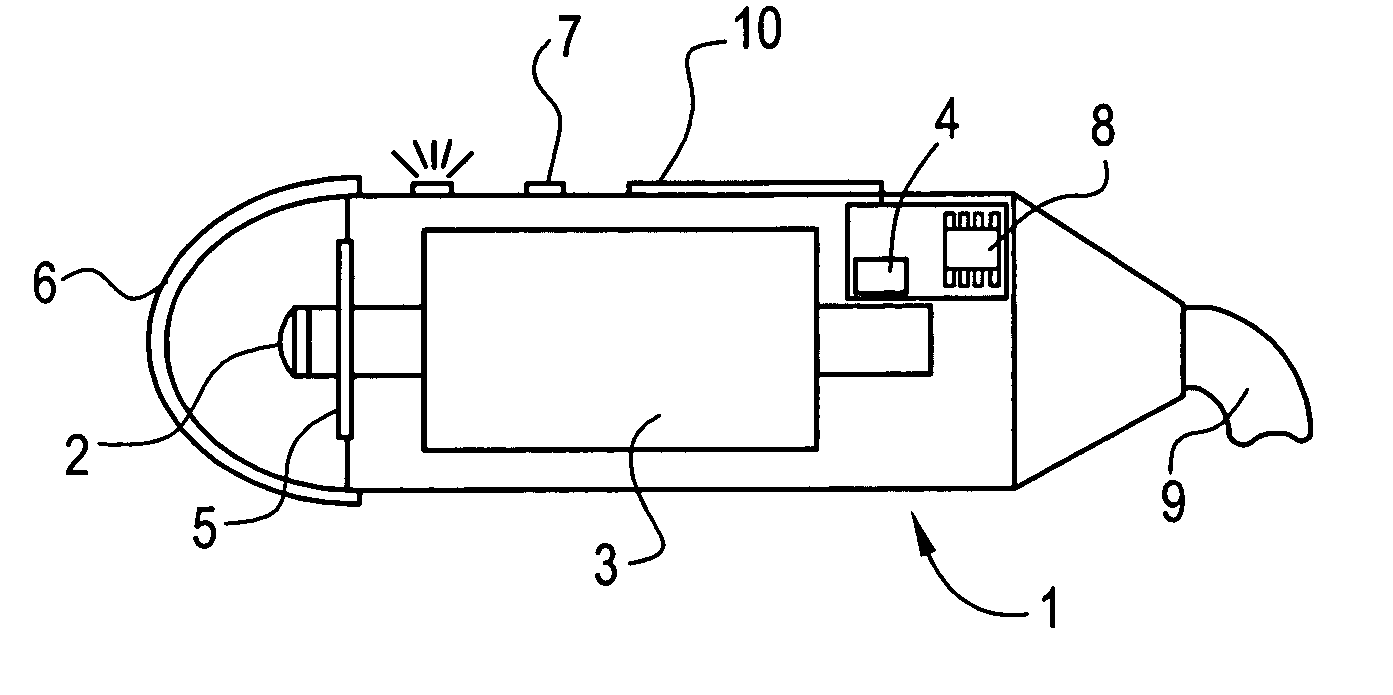

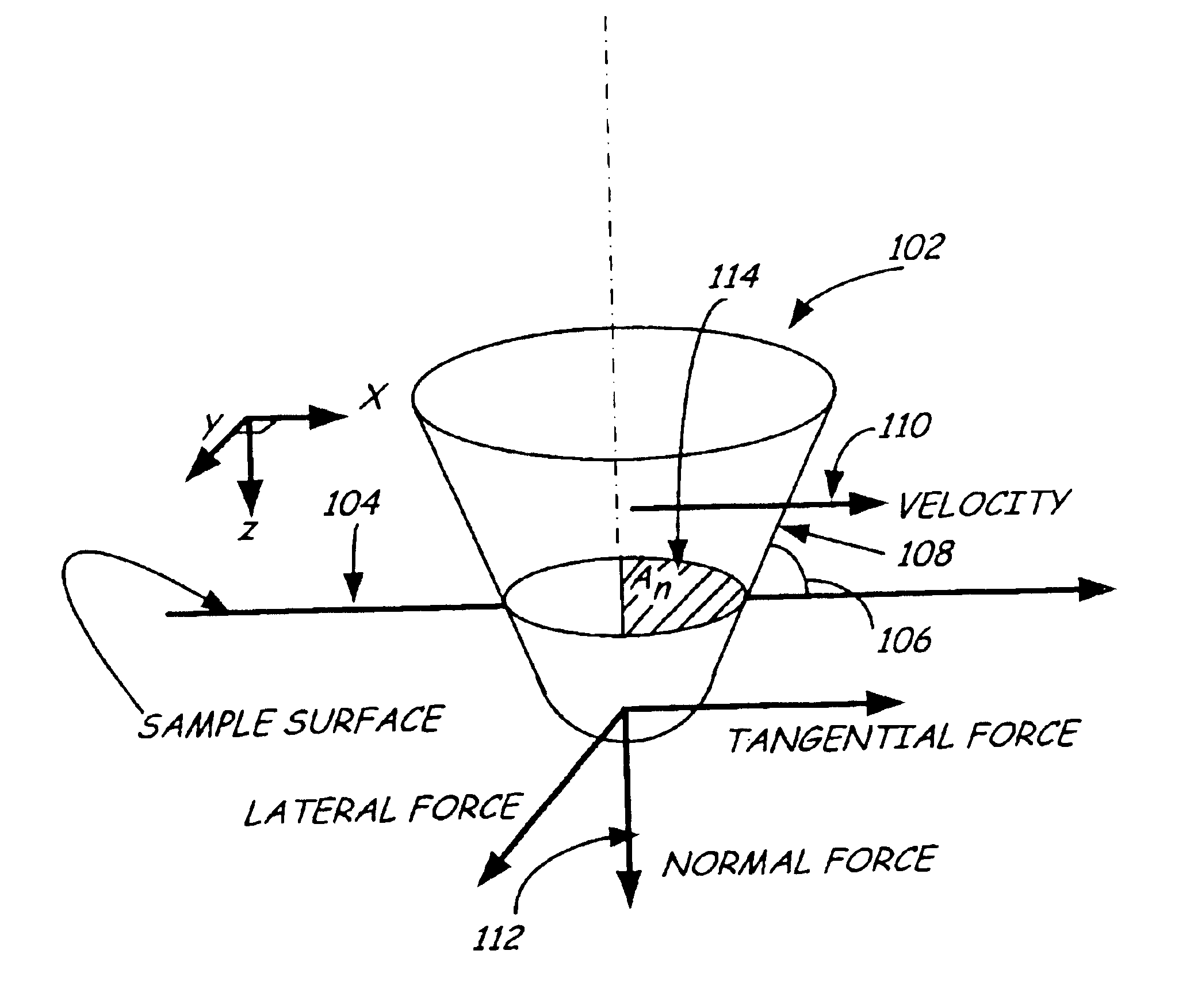

Nonlinear System Identification Techniques and Devices for Discovering Dynamic and Static Tissue Properties

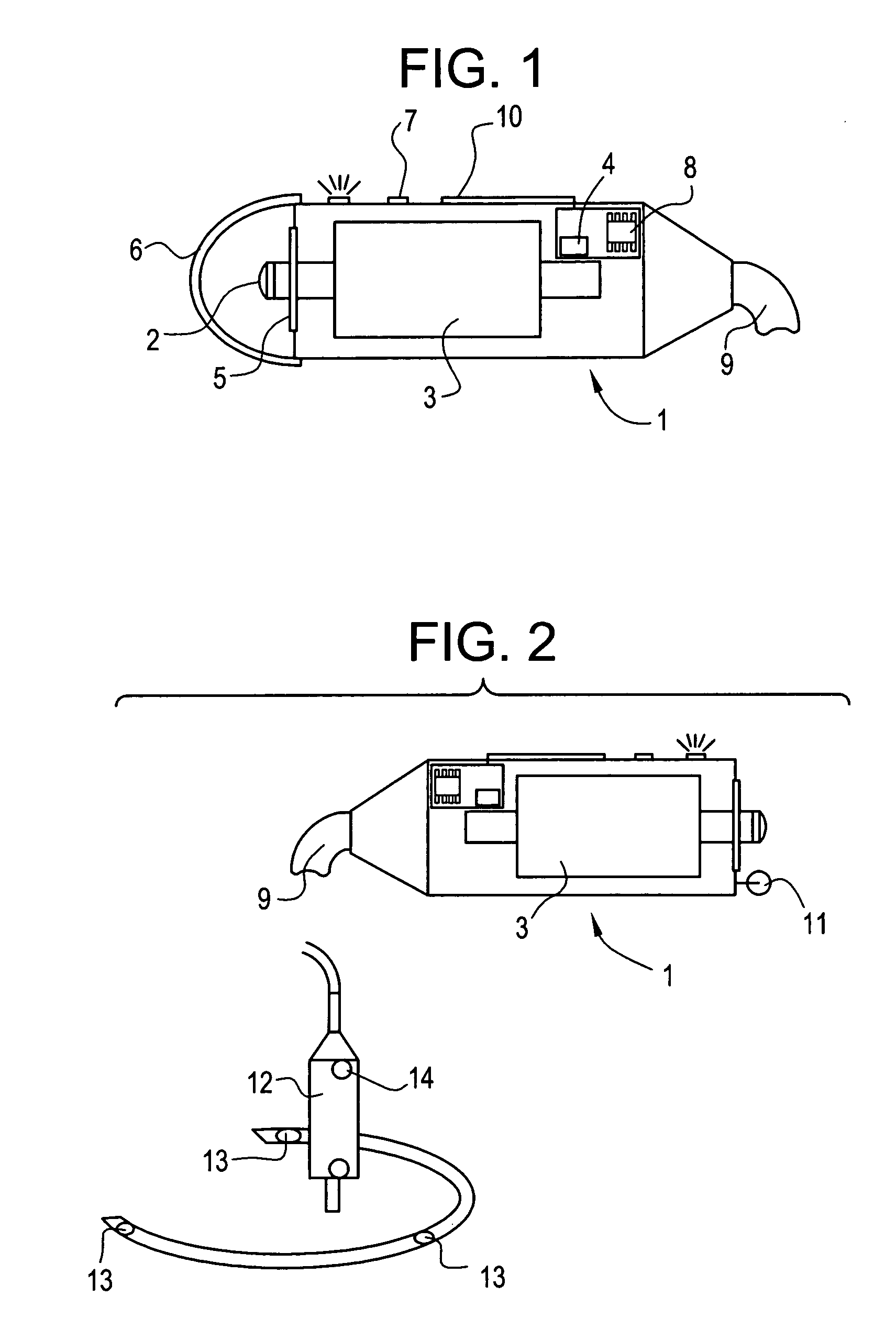

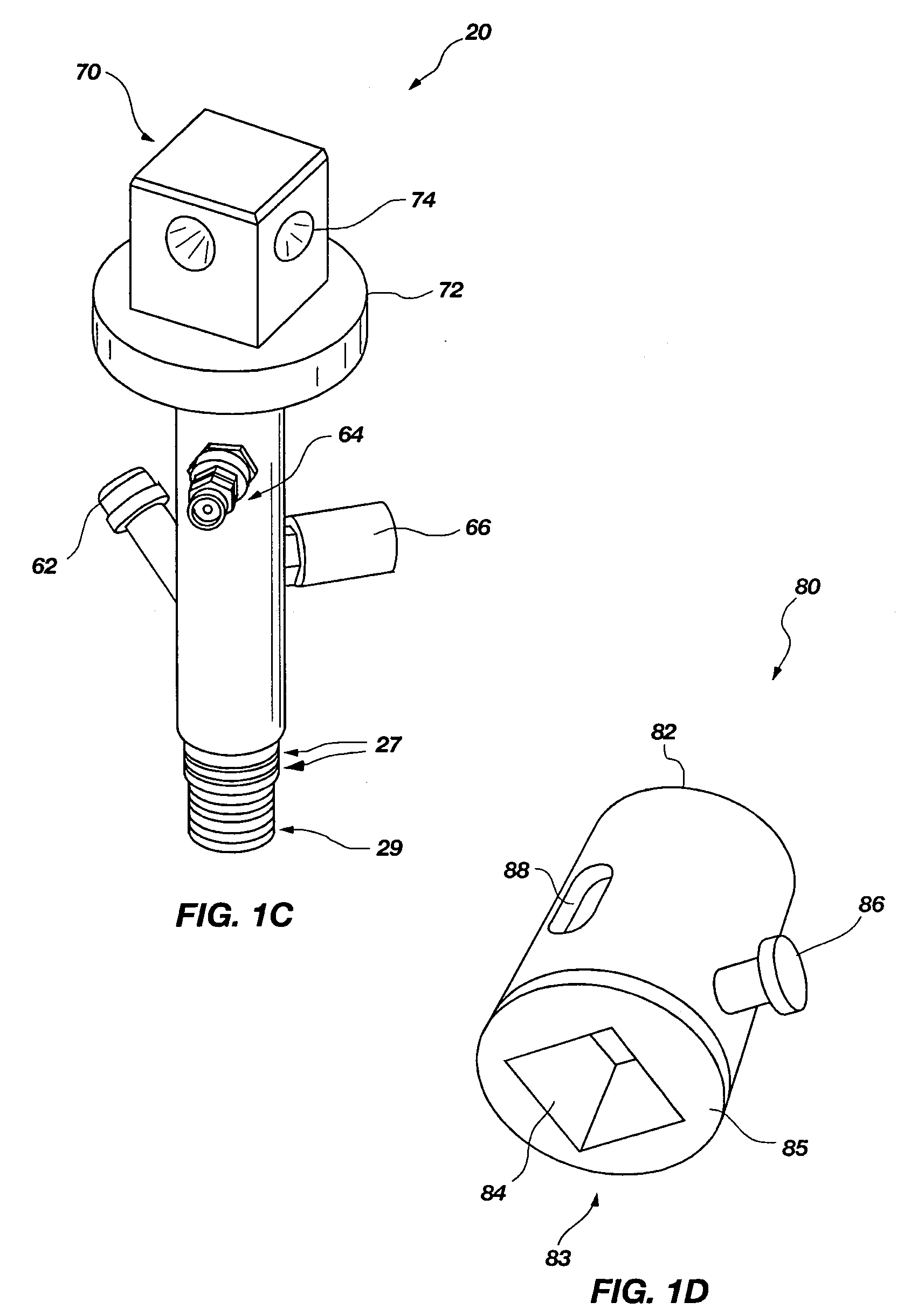

ActiveUS20110054354A1Quickly mechanical propertyLow costDiagnostics using suctionDiagnostics using pressureAccelerometerEngineering

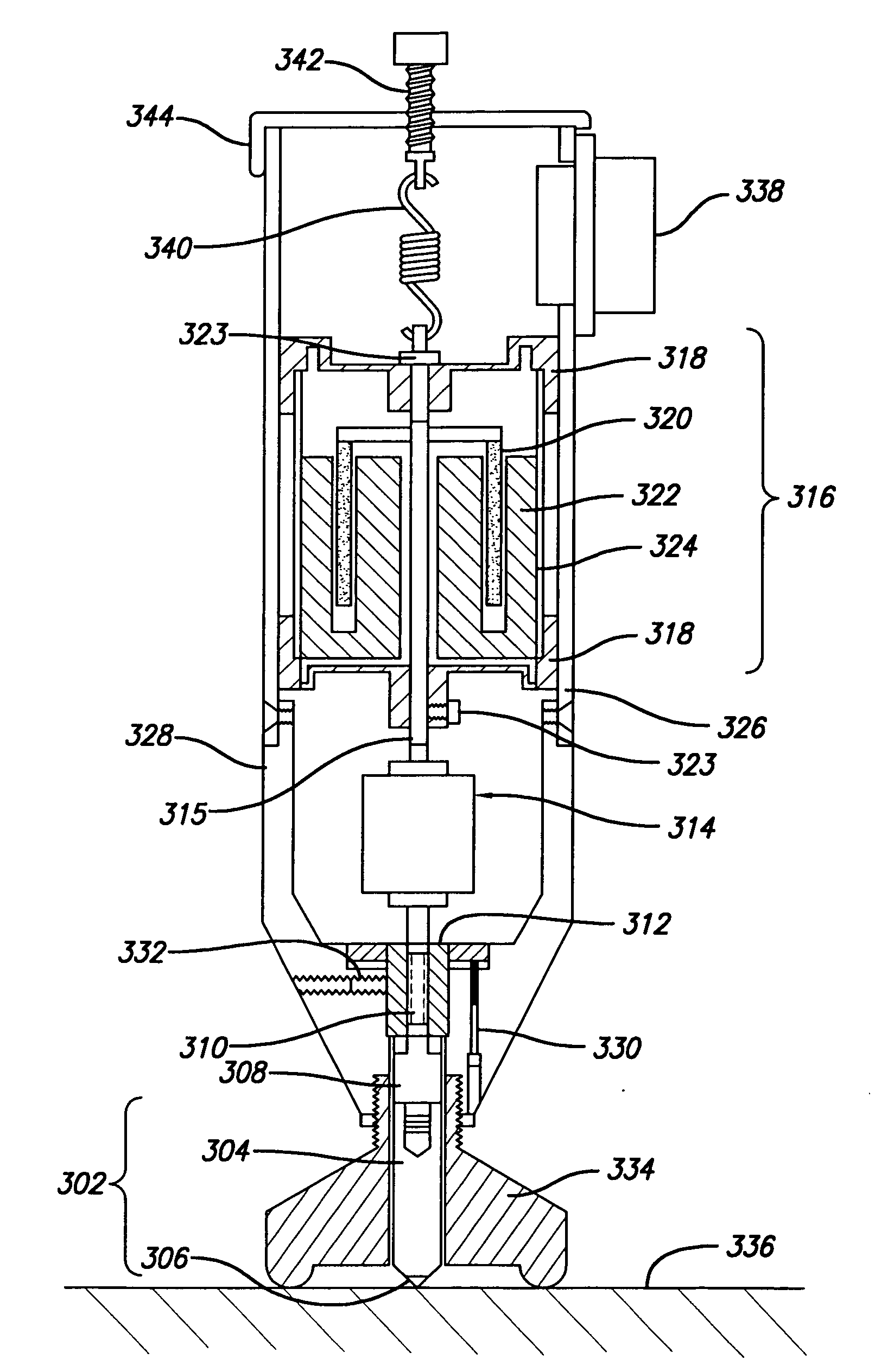

A device for measuring a mechanical property of a tissue includes a probe configured to perturb the tissue with movement relative to a surface of the tissue, an actuator coupled to the probe to move the probe, a detector configured to measure a response of the tissue to the perturbation, and a controller coupled to the actuator and the detector. The controller drives the actuator using a stochastic sequence and determines the mechanical property of the tissue using the measured response received from the detector. The probe can be coupled to the tissue surface. The device can include a reference surface configured to contact the tissue surface. The probe may include a set of interchangeable heads, the set including a head for lateral movement of the probe and a head for perpendicular movement of the probe. The perturbation can include extension of the tissue with the probe or sliding the probe across the tissue surface and may also include indentation of the tissue with the probe. In some embodiments, the actuator includes a Lorentz force linear actuator. The mechanical property may be determined using non-linear stochastic system identification. The mechanical property may be indicative of, for example, tissue compliance and tissue elasticity. The device can further include a handle for manual application of the probe to the surface of the tissue and may include an accelerometer detecting an orientation of the probe. The device can be used to test skin tissue of an animal, plant tissue, such as fruit and vegetables, or any other biological tissue.

Owner:MASSACHUSETTS INST OF TECH

Device and method for measuring the elasticity of a human or animal organ

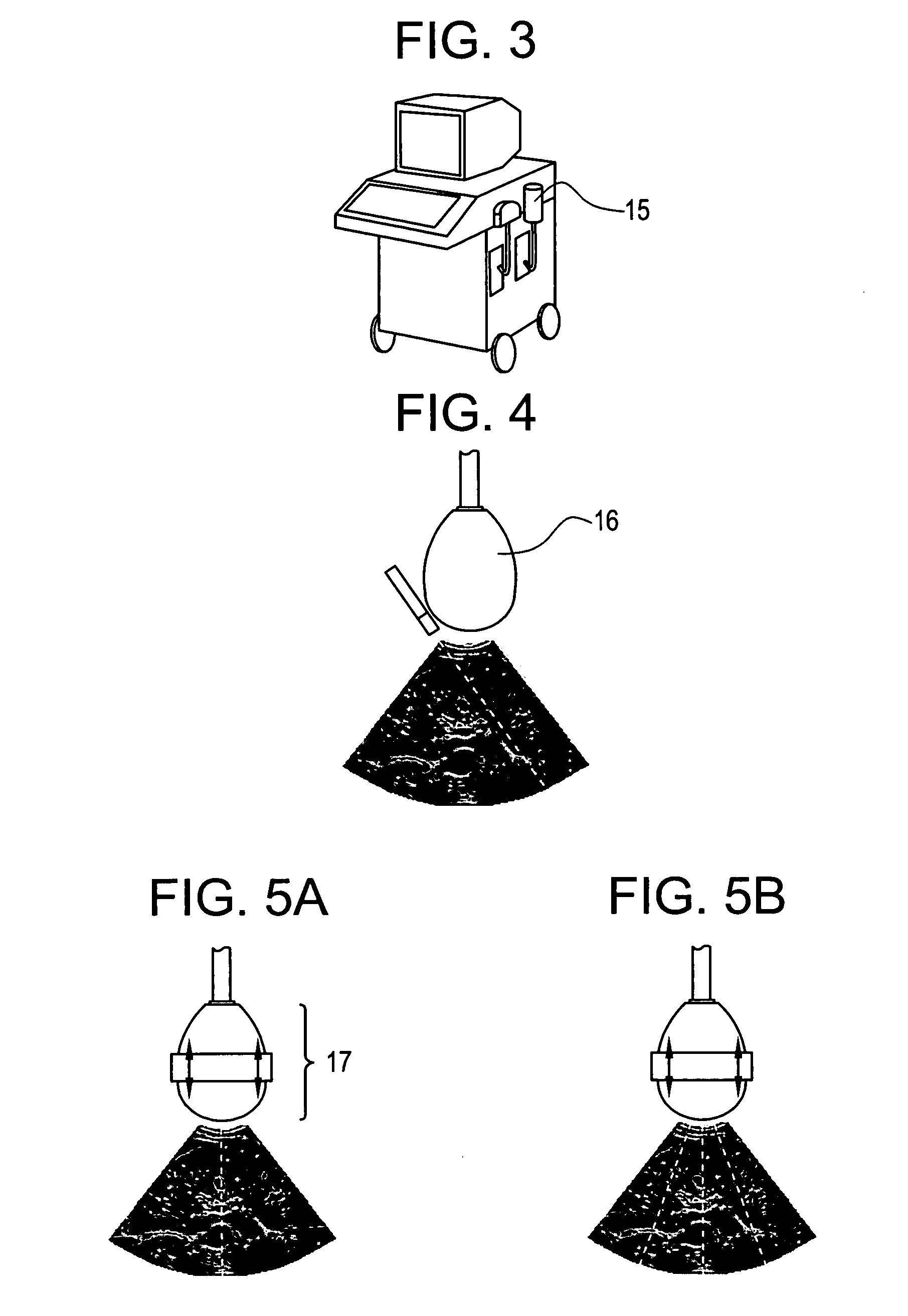

ActiveUS20050203398A1Material analysis using sonic/ultrasonic/infrasonic wavesDiagnostics using vibrationsUltrasonic sensorAnimal Organs

A device for measuring elasticity of a human or animal organ or viscoelastic media having an ultrasonic signal after ultrasonic illumination including at least one sensor including an ultrasonic transducer, at least one position sensor, an actuator to trigger the device connected by wire link to an electric power source, and a controlled electrodynamic actuator attached to the ultrasonic transducer that generates a transitory low-frequency impulse having a frequency range between about 1 Hz and about 5000 Hz.

Owner:ECHOSENS SA

Golf club head comprising a piezoelectric sensor

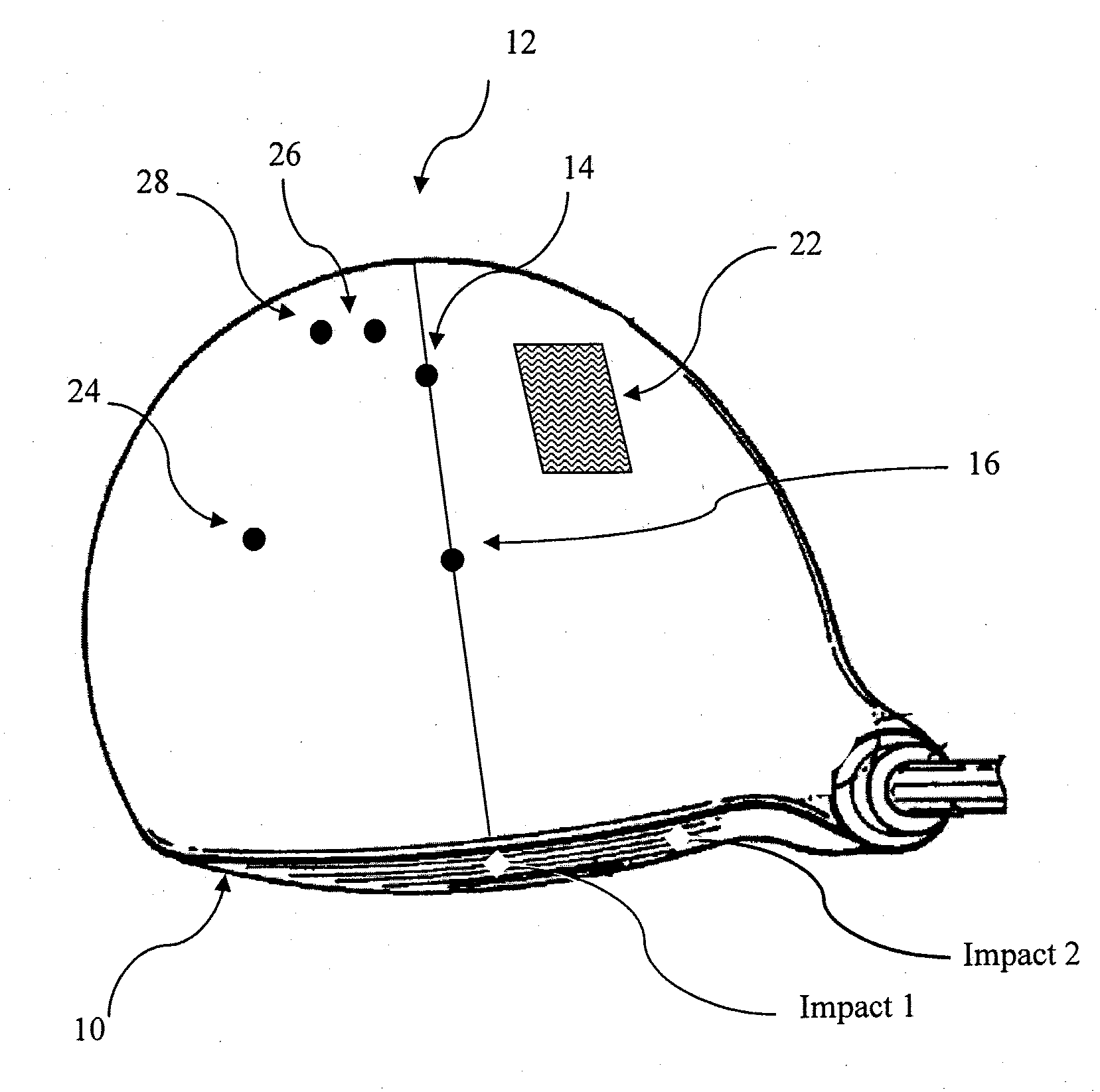

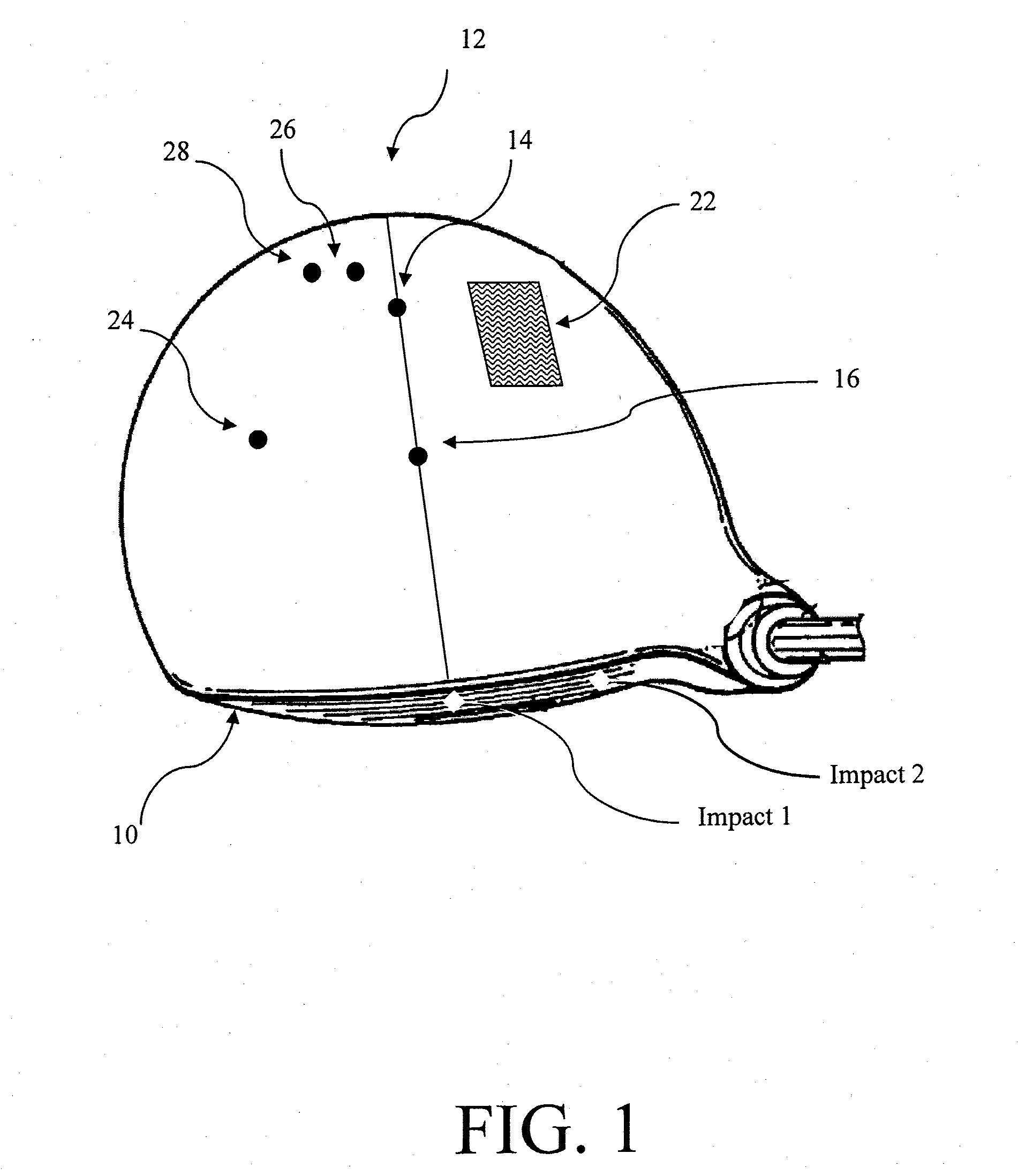

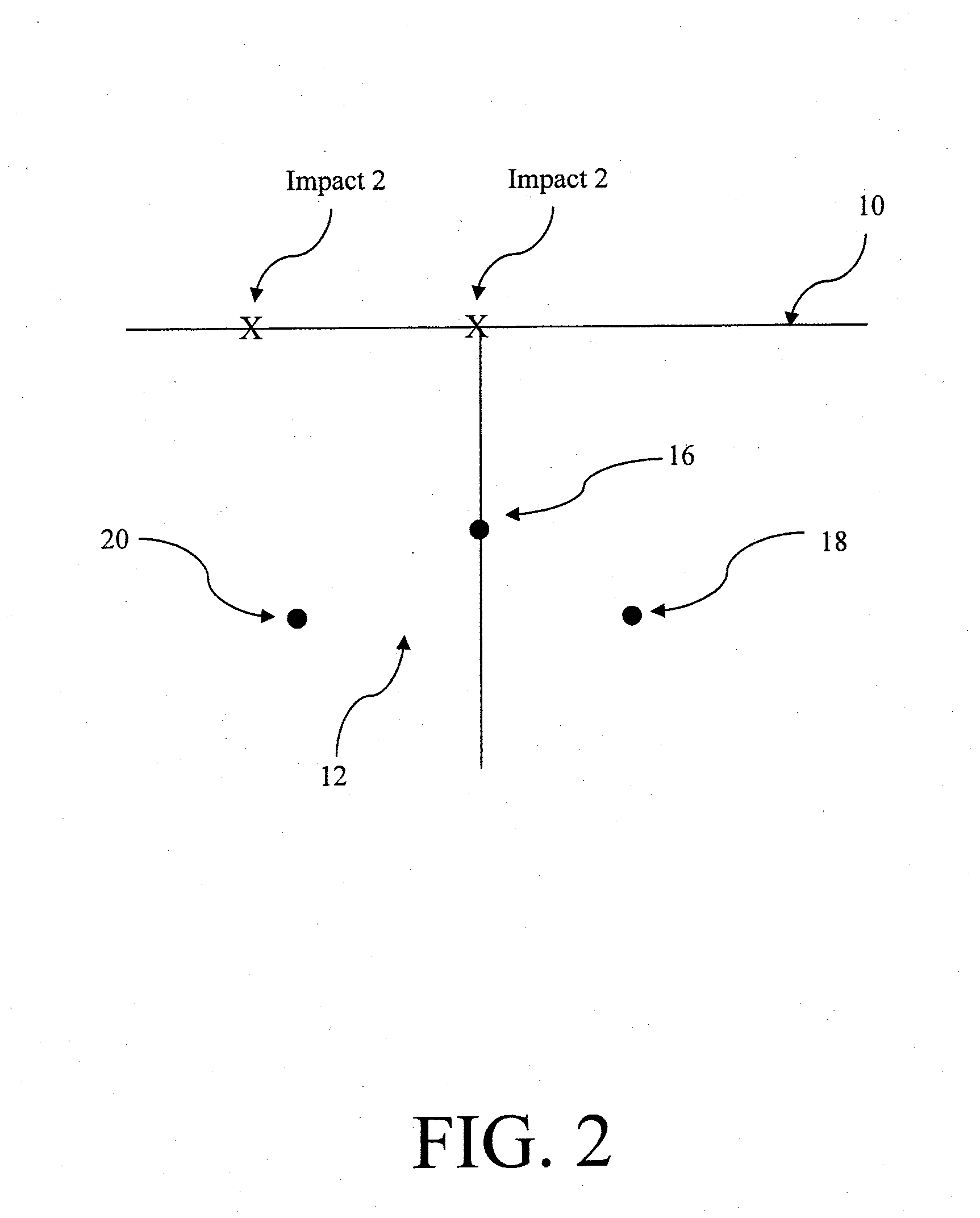

ActiveUS20090120197A1Avoid componentsVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf BallHead impact

An apparatus and method for determining the kinematic characteristics of a golf club head are disclosed. The apparatus includes at least one piezoelectric component selectively positioned within or upon a club head. The piezoelectric component is preferably positioned to the rear of the center of gravity, and near the midpoint of the face of the club head. During a golf club swing, the piezoelectric component determines the acceleration and deceleration of the golf club head. When the club head impacts an object such as a golf ball, the piezoelectric component is also operable to determine the velocity of the club head. It may also be desirable for the piezoelectric component to determine the magnitude of vibration during impact. In this manner, the piezoelectric component may function determine the efficiency of a golf club swing.

Owner:ACUSHNET CO

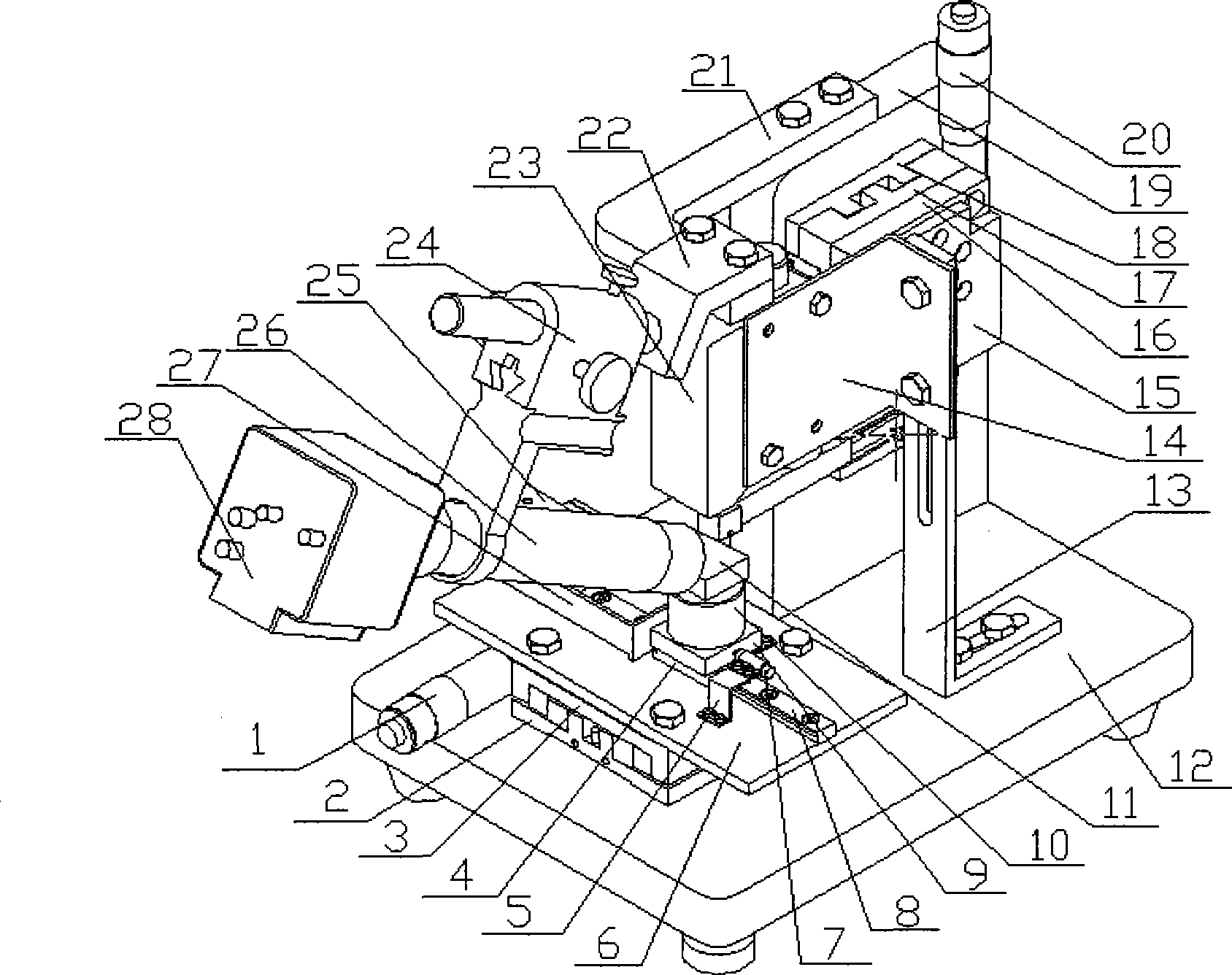

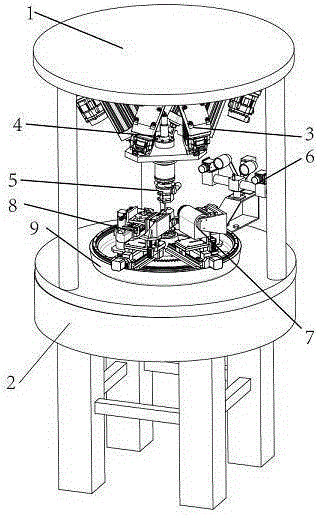

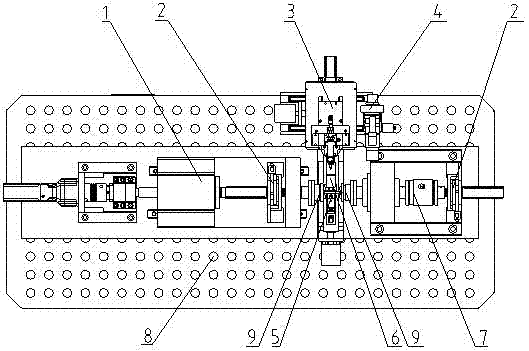

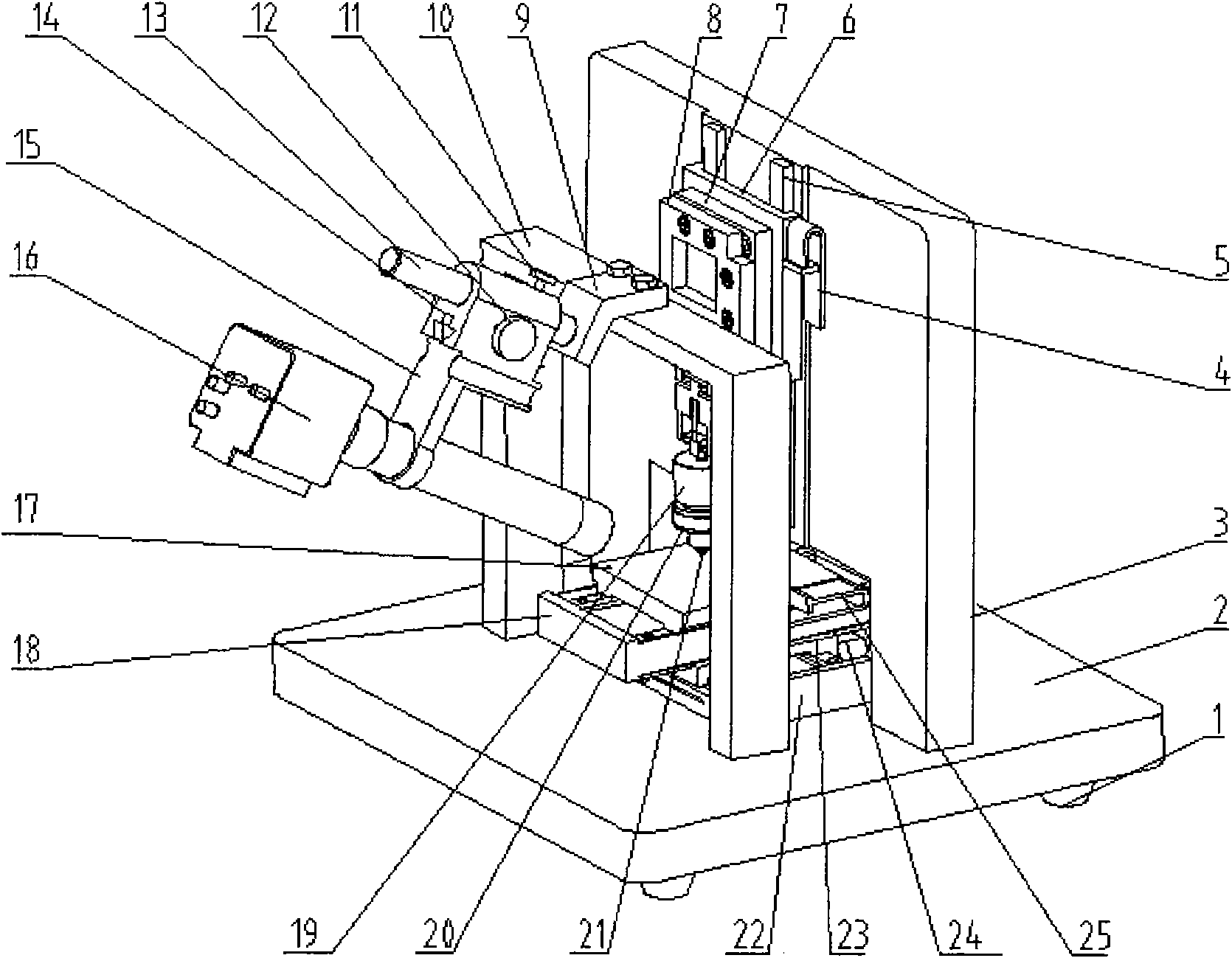

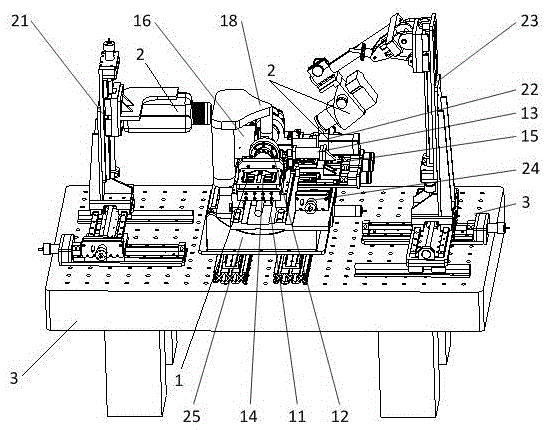

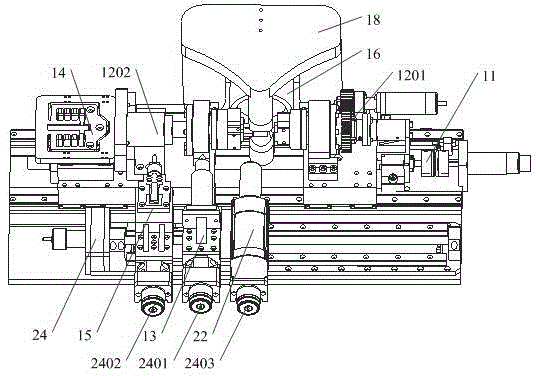

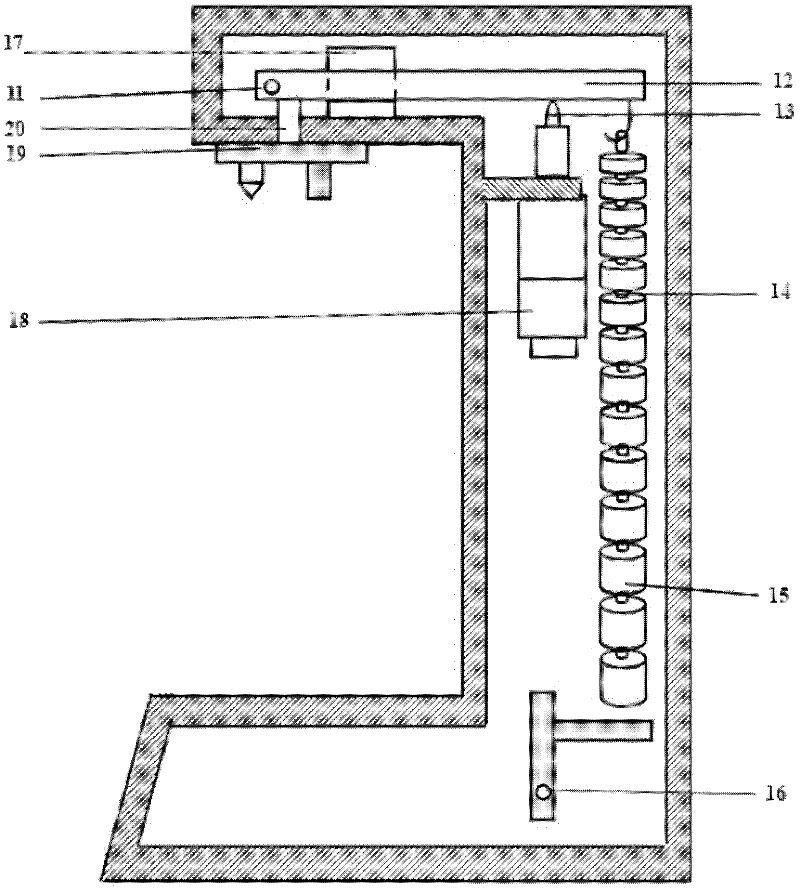

Super-precision trans-scale in-situ nanometer indentation marking test system

ActiveCN101520389AThe test method is accurateAccurate and effective research and testing methodsUsing optical meansInvestigating material hardnessHead pressingImage resolution

The invention relates to a super-precision trans-scale in-situ nanometer indentation marking test system which integrates driving, loading, detecting and micro-nanometer dynamic performance tests, super-precision marking processing and in-situ observation into a whole. The system mainly comprises an objective table, a regulation mechanism, a detection unit, a precise pressed-into driving unit, a detection unit of load signals and displacement signals and a high-resolution digital microscopic imaging system, wherein the objective table is precisely positioned along the directions of the X axis and the Y axis; the regulation mechanism and the precise pressed-into driving unit are in the direction of the Z axis and are assembled on a base; the high-resolution digital microscopic imaging system is used for observing the deforming and damaging conditions of the material in the storing and testing process; the objective table as well as the regulation mechanism and the precise pressed-into driving unit in the direction of the Z axis are assembled on a base; the high-resolution digital microscopic imaging system is arranged on the objective table; a precise dynamic sensor detecting the pressure of a diamond tool head pressed into a material and a sensor I detecting the precise displacement of the objective table in the directions of the X axis and the Y axis are arranged on the objective table; and a sensor II used for detecting the precise displacement of a diamond tool head in the direction of the Z axis of pressed-into depth is arranged on the base by a support I.

Owner:JILIN UNIV

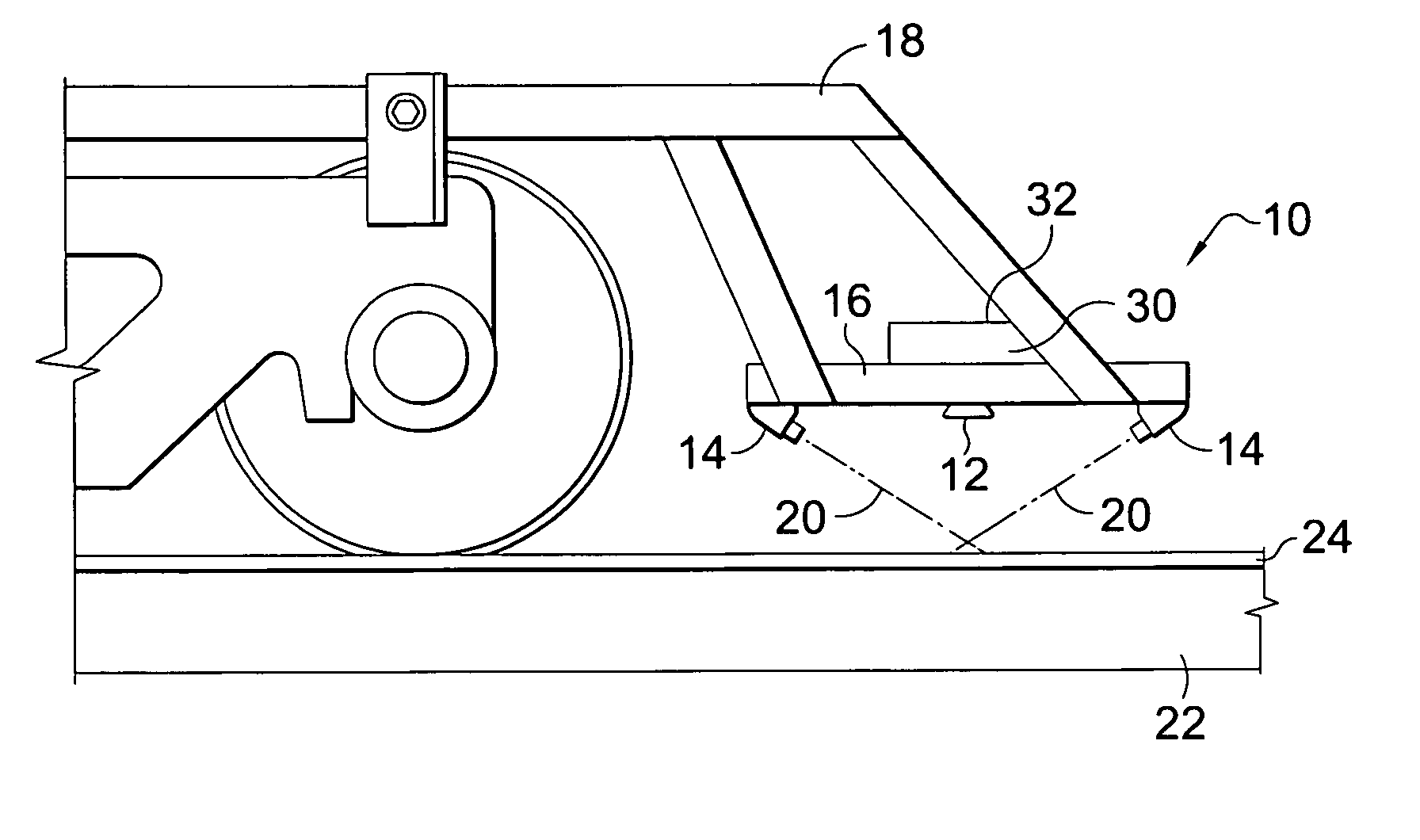

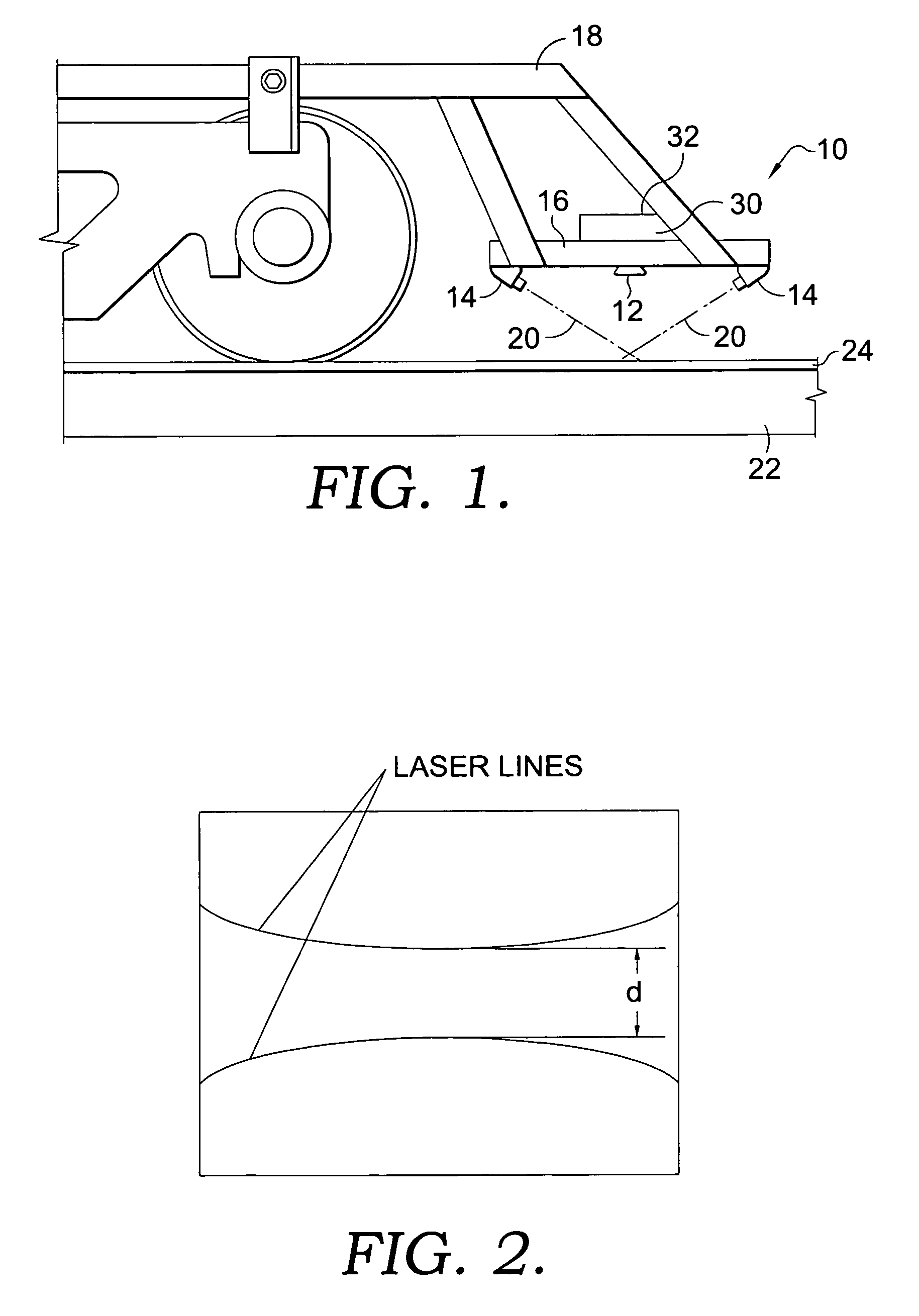

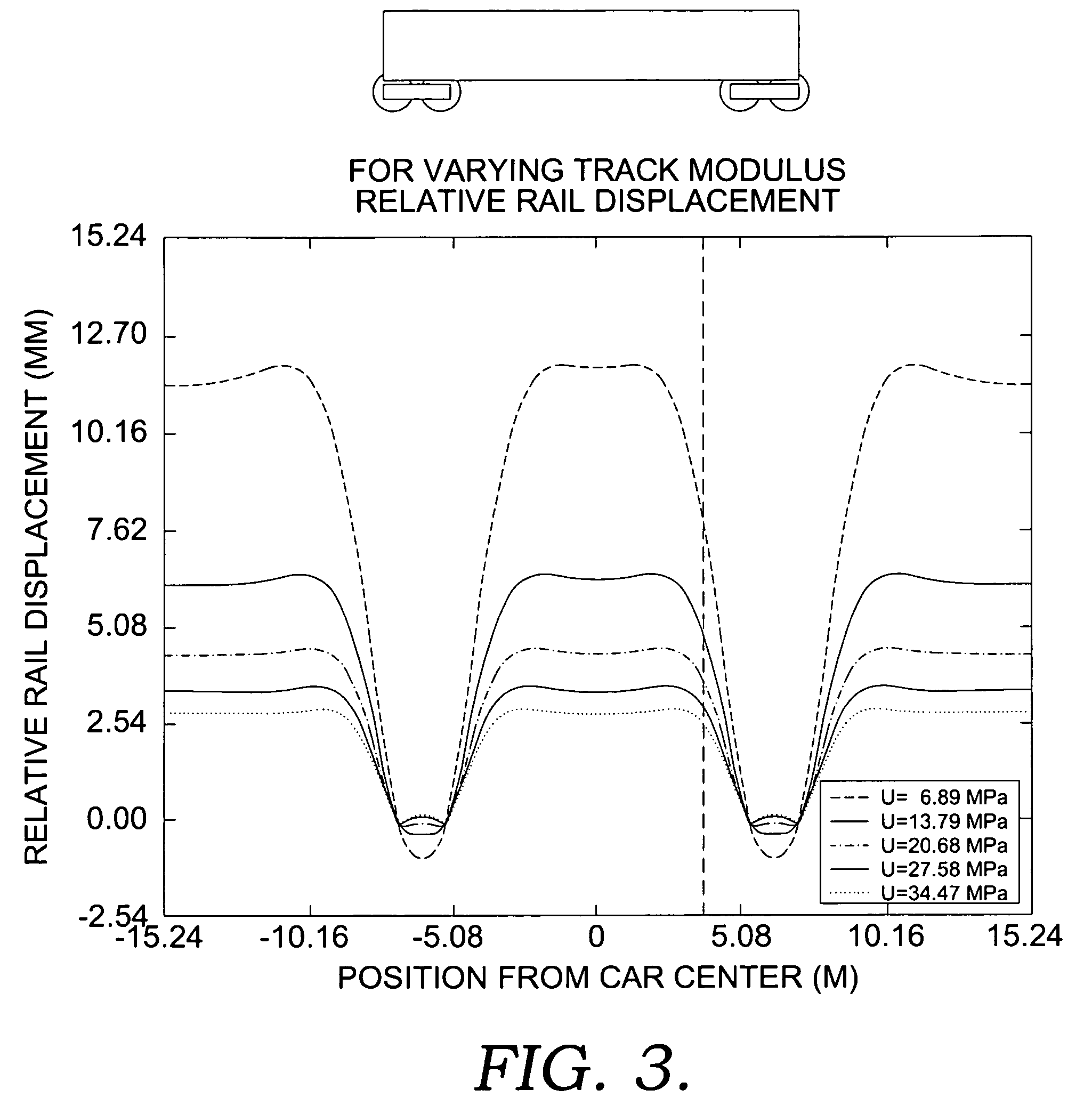

Method and apparatus for noncontact relative rail displacement, track modulus and stiffness measurement by a moving rail vehicle

Owner:BOARD OF RGT UNIV OF NEBRASKA

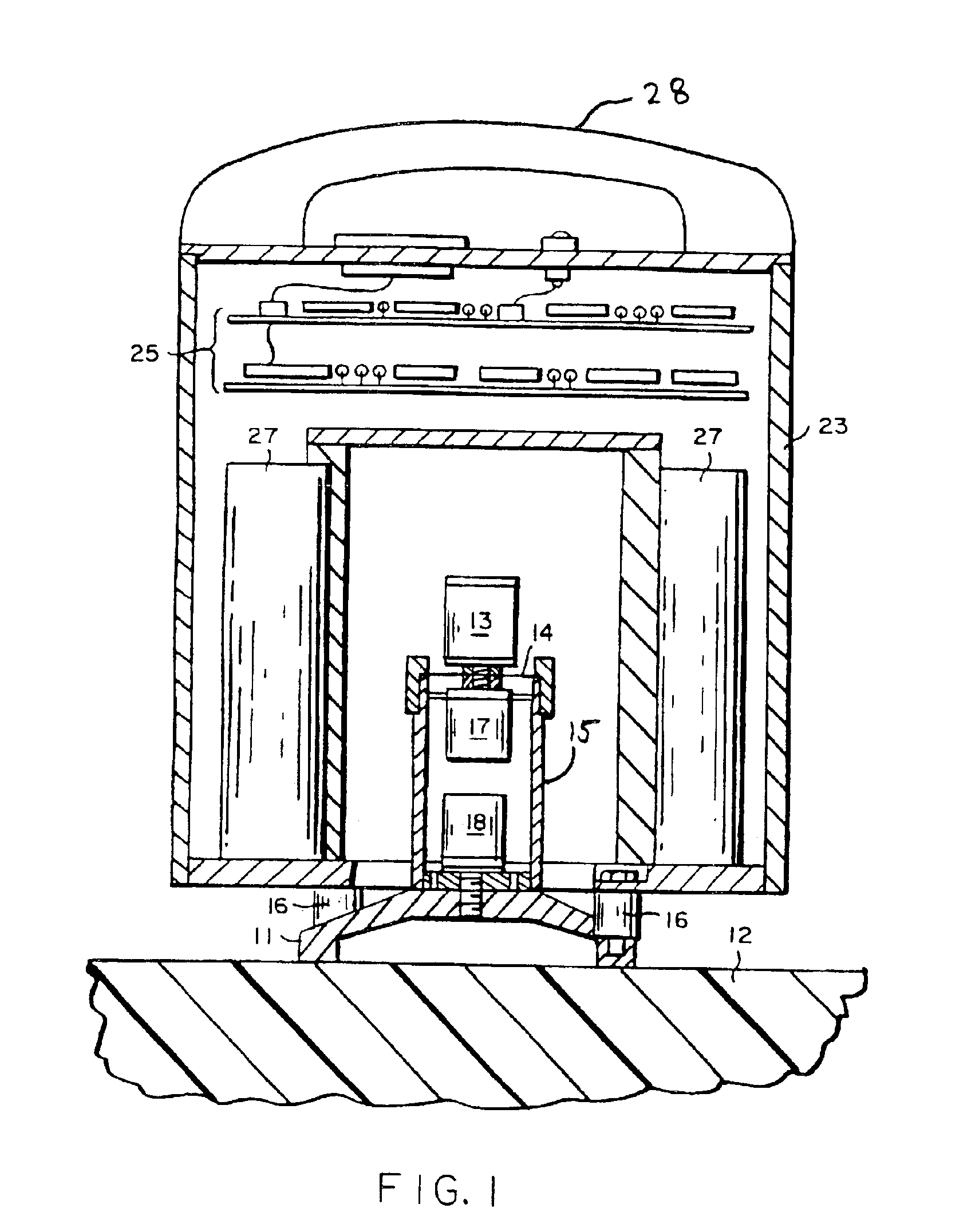

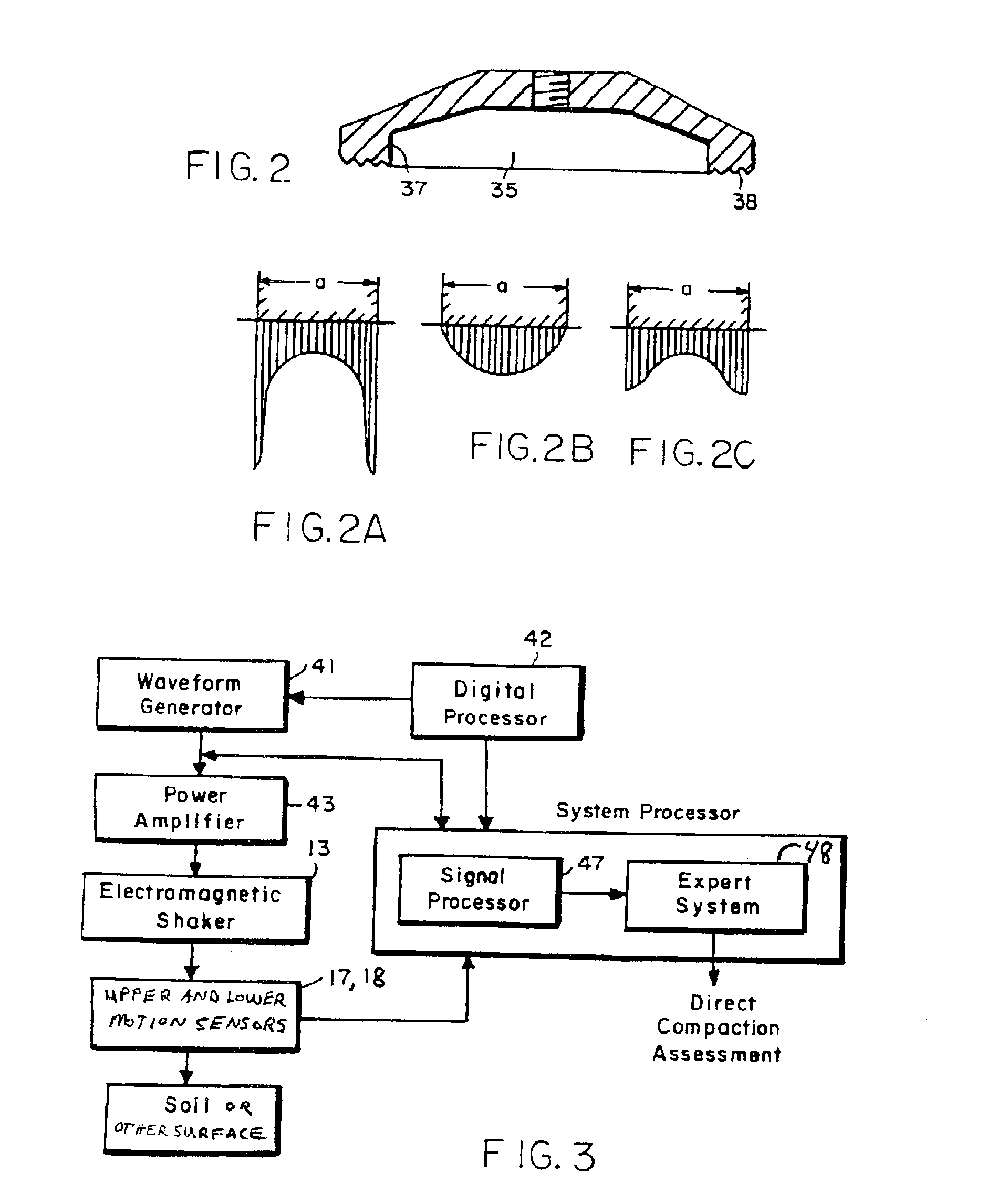

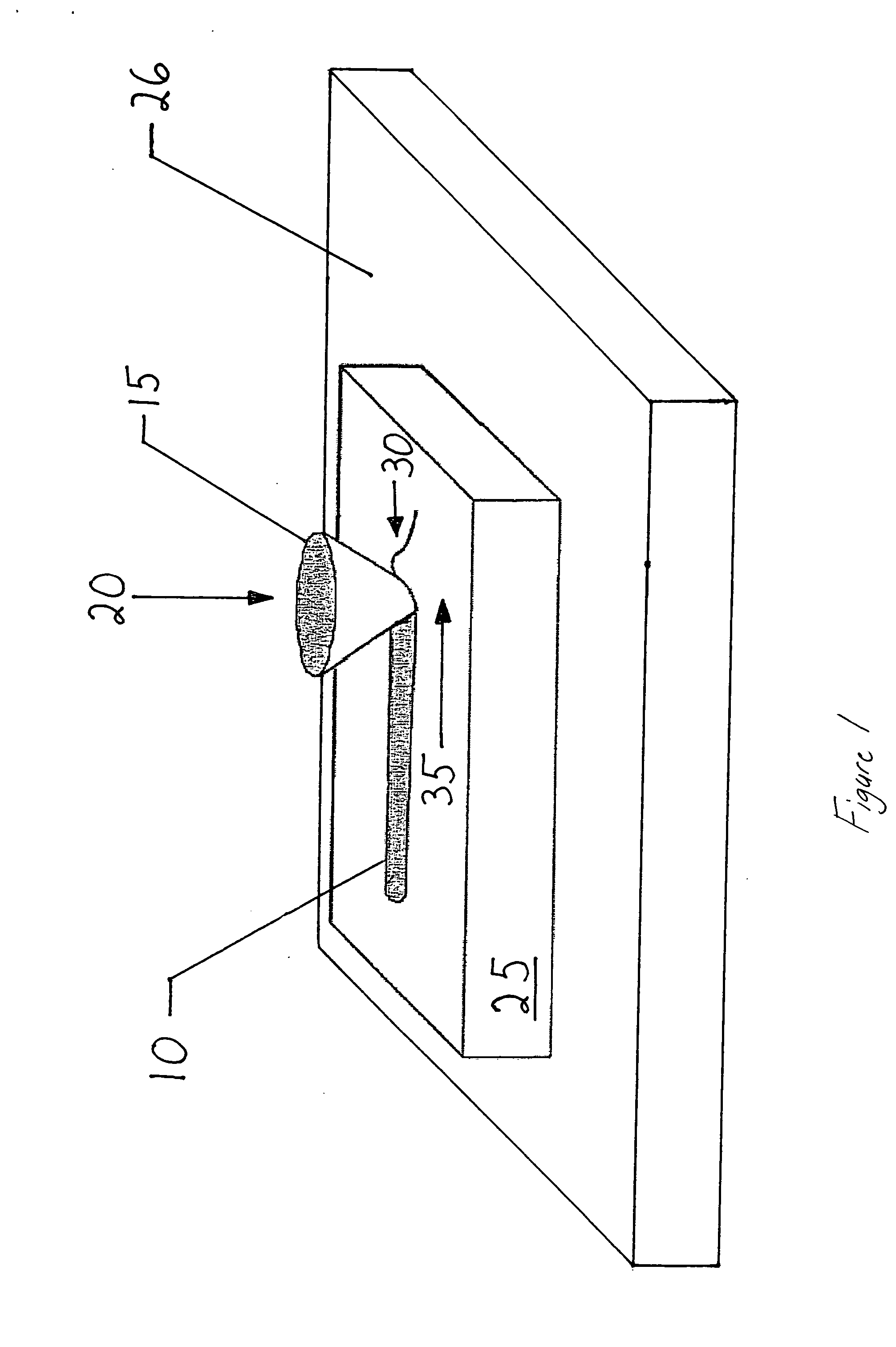

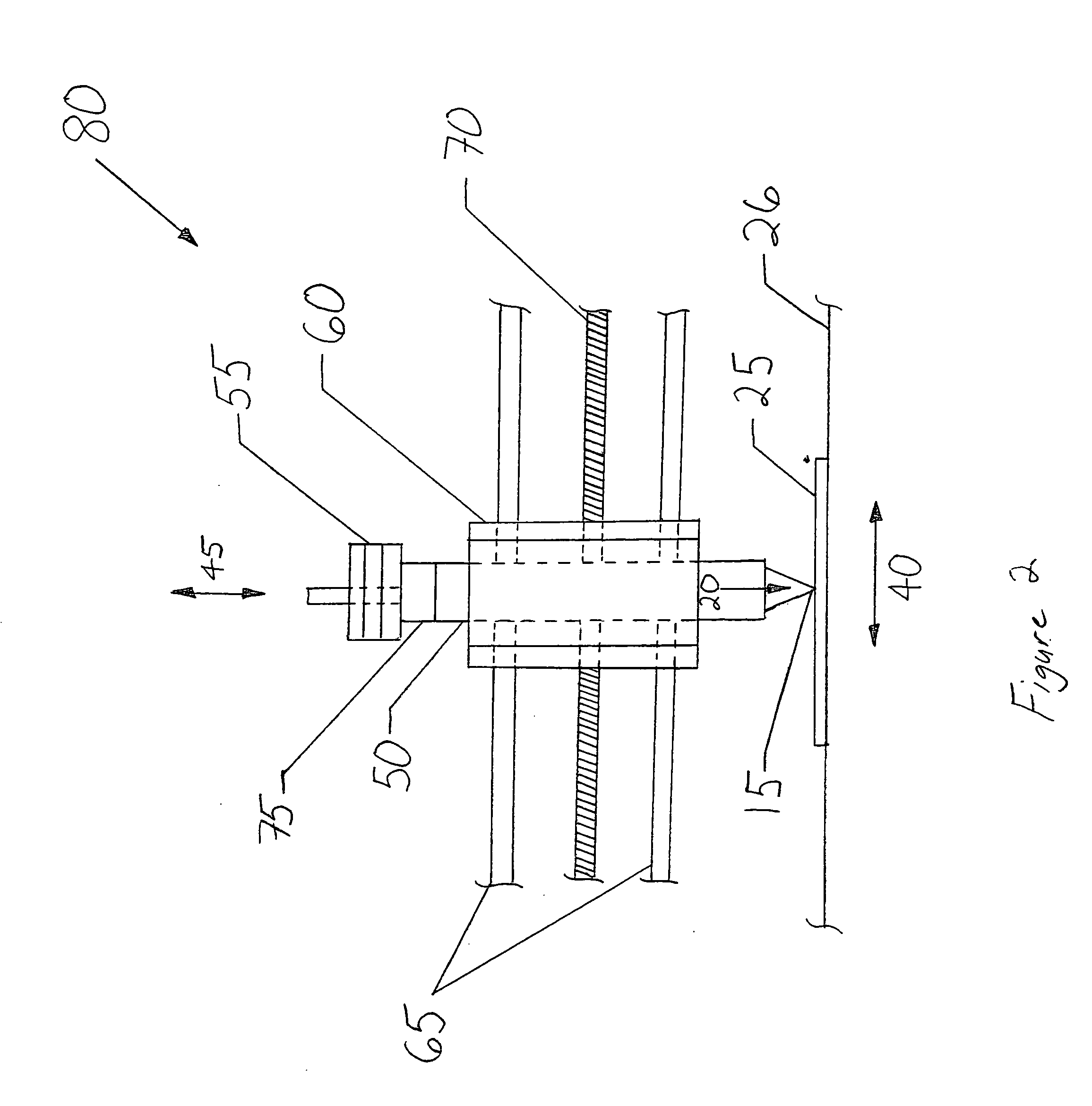

Soil compaction measurement

InactiveUS6912903B2Material analysis using sonic/ultrasonic/infrasonic wavesForce measurementClassical mechanicsTransducer

An apparatus and method are provided for the in-situ measurement of the stiffness of a layer of soil or other surface of interest. The apparatus includes a contact foot for engaging the surface and a drive transducer coupled to the contact foot for applying a vibratory force to the contact foot in response to a drive signal. A motion sensor is coupled to the contact foot and in a preferred embodiment an additional sensor measures the force applied to the contact foot and hence to the surface. These sensors generate corresponding output signals. The output signals are used to generate a measurement signal that is representative of the surface stiffness.

Owner:RAYTHEON BBN TECH CORP

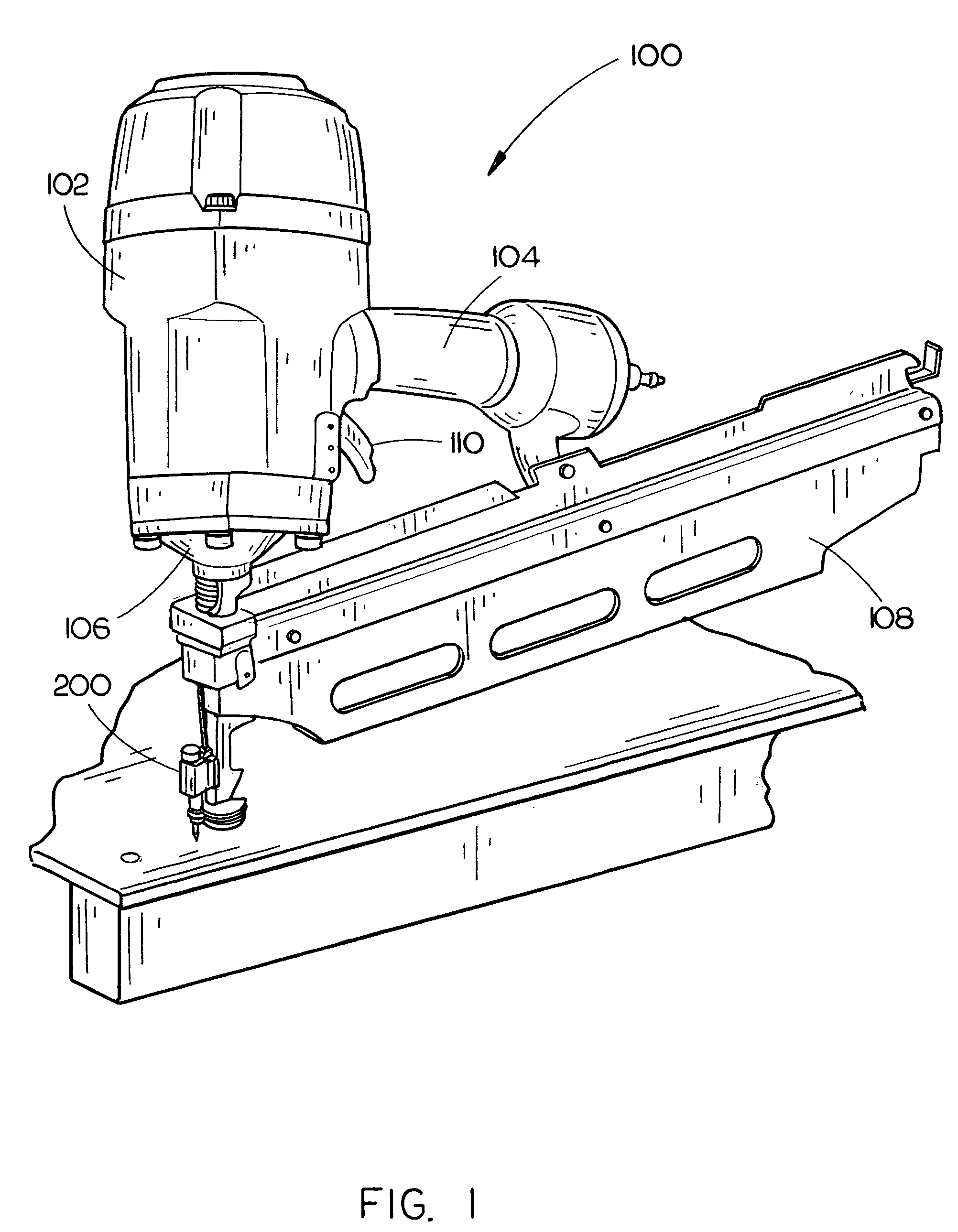

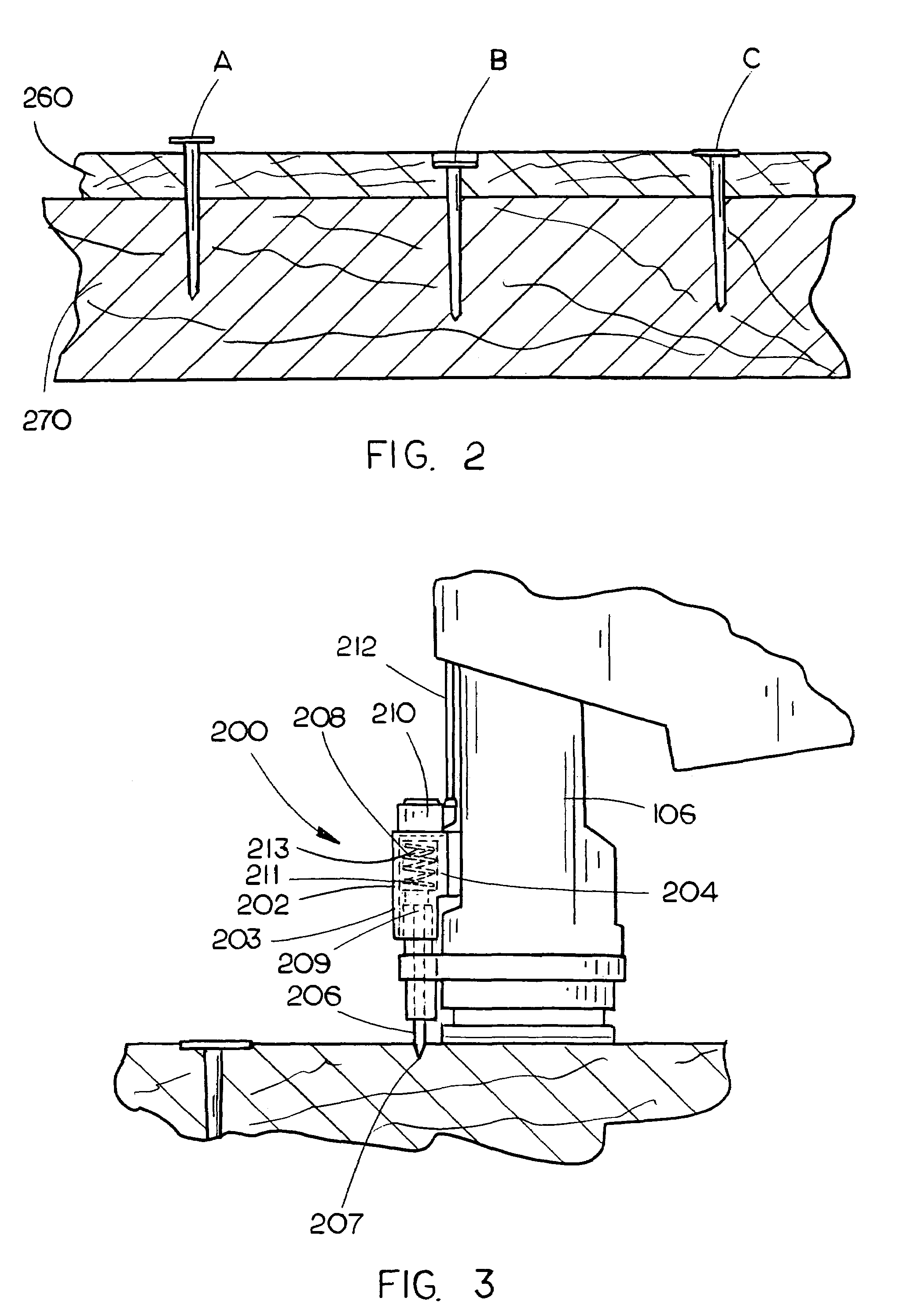

Gauge for use with power tools

InactiveUS7243440B2Improve efficiencyEasy to operateStapling toolsDrilling/boring measurement devicesEngineeringPower tool

Owner:BLACK & DECKER INC

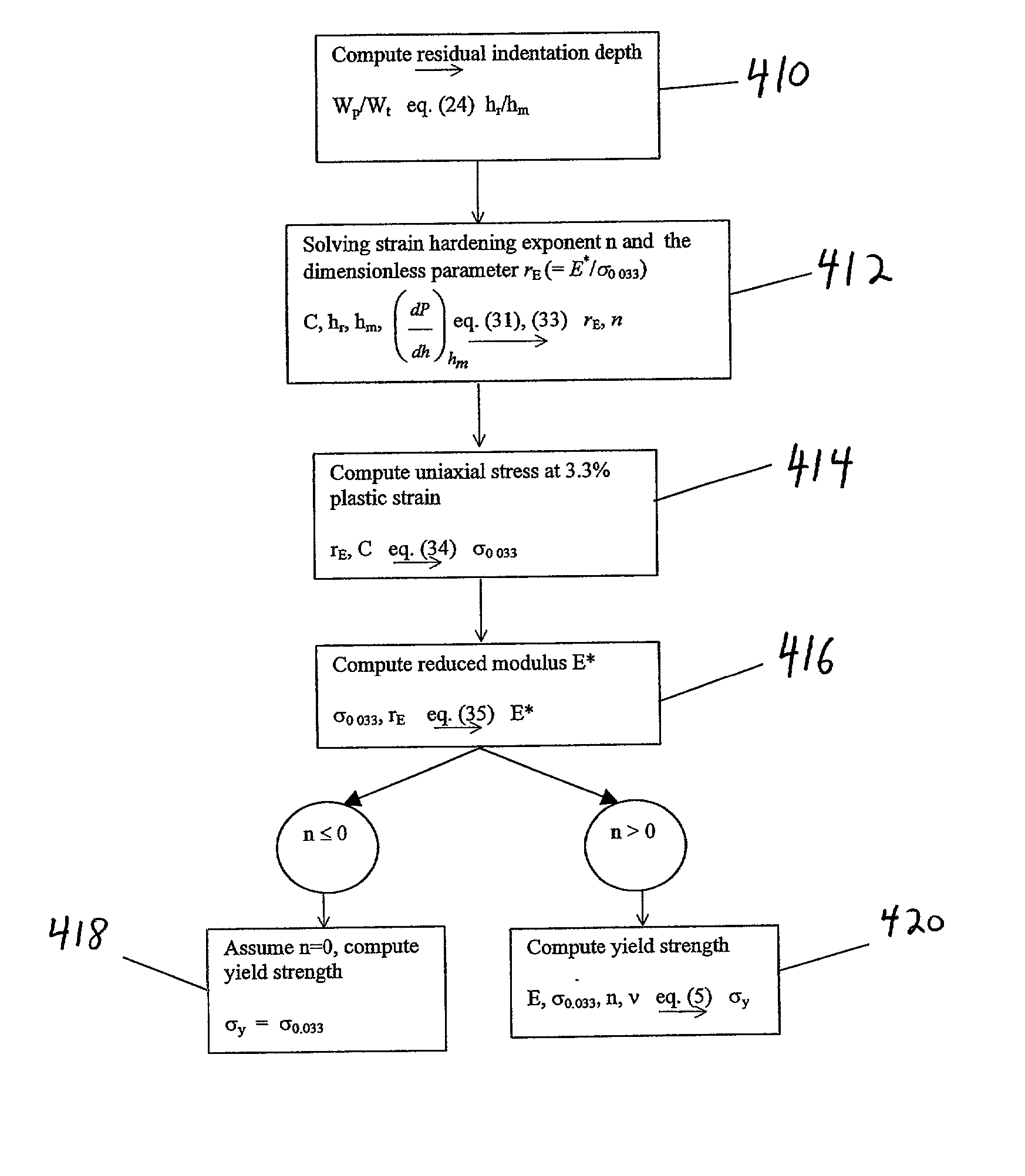

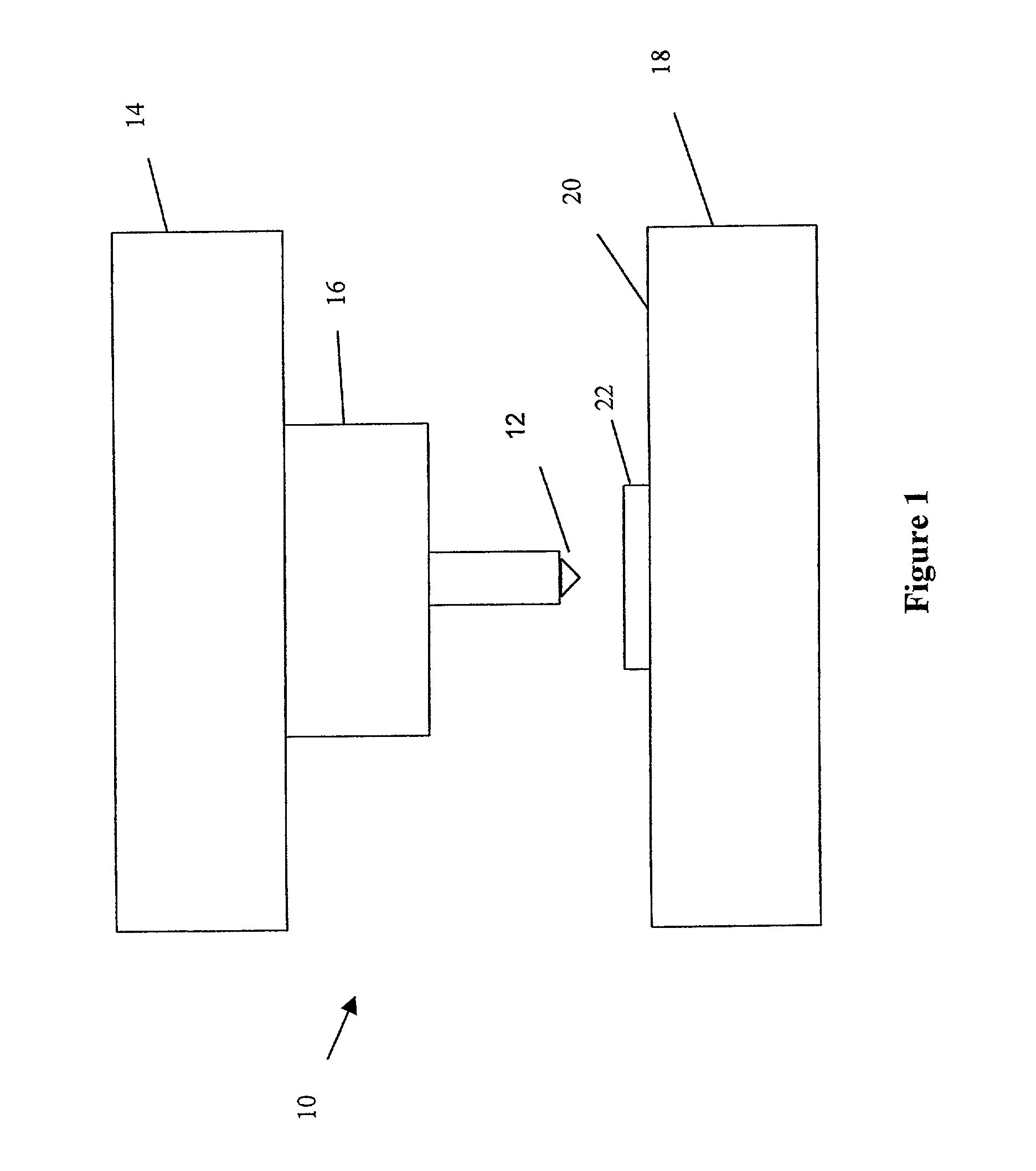

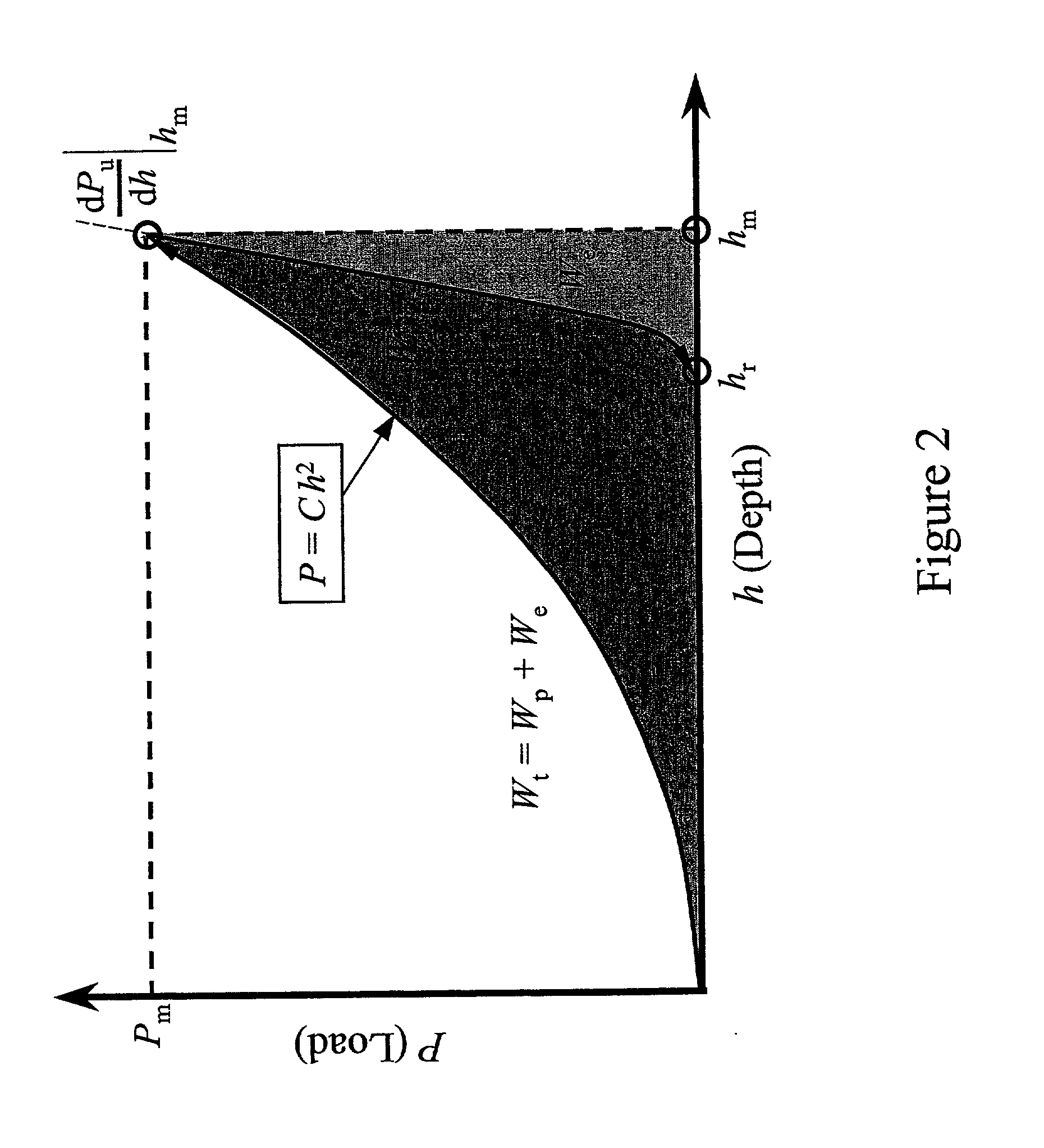

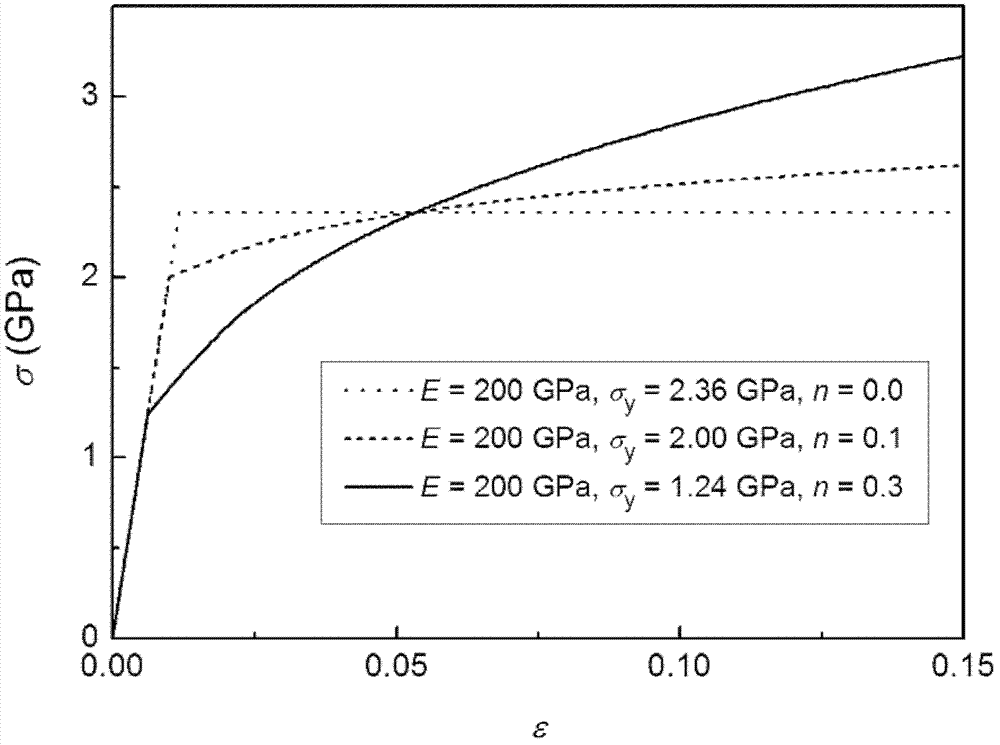

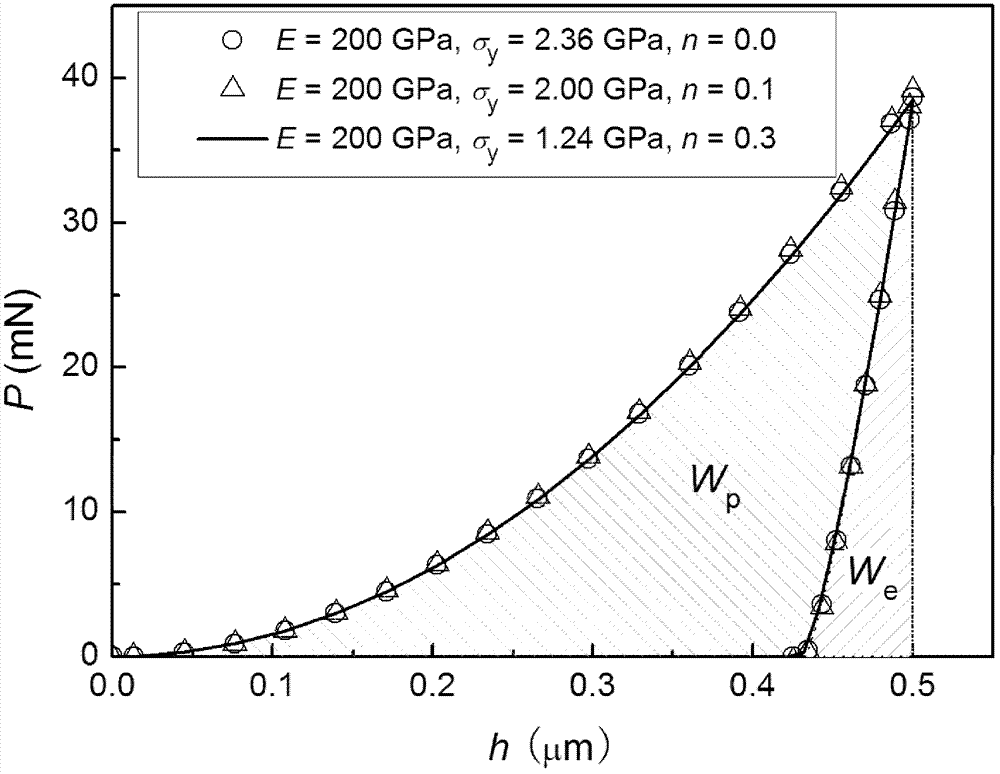

Systems and methods for estimation and analysis of mechanical property data associated with indentation testing

Systems and methods are disclosed that can provide estimates of elasto-plastic properties of material samples using data from instrumented indentation tests. Alternatively, or in addition, estimated load-depth curves can be constructed by certain methods and systems provided based on known mechanical properties. Some disclosed systems and methods use large deformation theory for at least part of the analysis and / or determinations and / or may account for strains of at least 5% in the area of contact between the indenter and the material sample, which can result in more accurate estimates of mechanical properties and / or deformation behavior.

Owner:MASSACHUSETTS INST OF TECH

Material in-situ detection device and method under multi-load multi-physical field coupling service conditions

ActiveCN105223076ANovel structureCompact layoutMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesPhysical fieldScientific instrument

The invention relates to a material in-situ detection device and method under multi-load multi-physical-field coupling service conditions, and belongs to the field of precise scientific instruments. The material in-situ detection device is composed of a precise six-degrees-of-freedom composite load loading module, a precise torsion module, a precise indentation module, a clamp module and a control module which work together to complete a composite-load multi-physical-field coupling experiment, a digital speckle strain measurement and infrared thermal imaging module and a microscope observation module are integrated, and in-situ observation and quantitative characterization are carried out on material deformation behaviors and damage mechanism phenomena in a composite-load multi-physical-field loading process. The device and the method have the advantages that the composite-load loading can be realized, and a novel loading method such as 'cantilever type pure bending, cantilever type tensile / compression-torsion, and cantilever type bending-torsion' is carried out. Silicon nitride ceramic heating sheets, Peltier tiles and current loading are used for achieving simulation of cold / hot-electricity and other multiple physical fields, and an improvement innovative experimental testing method is provided for material micromechanical property tests close to the serving conditions.

Owner:JILIN UNIV

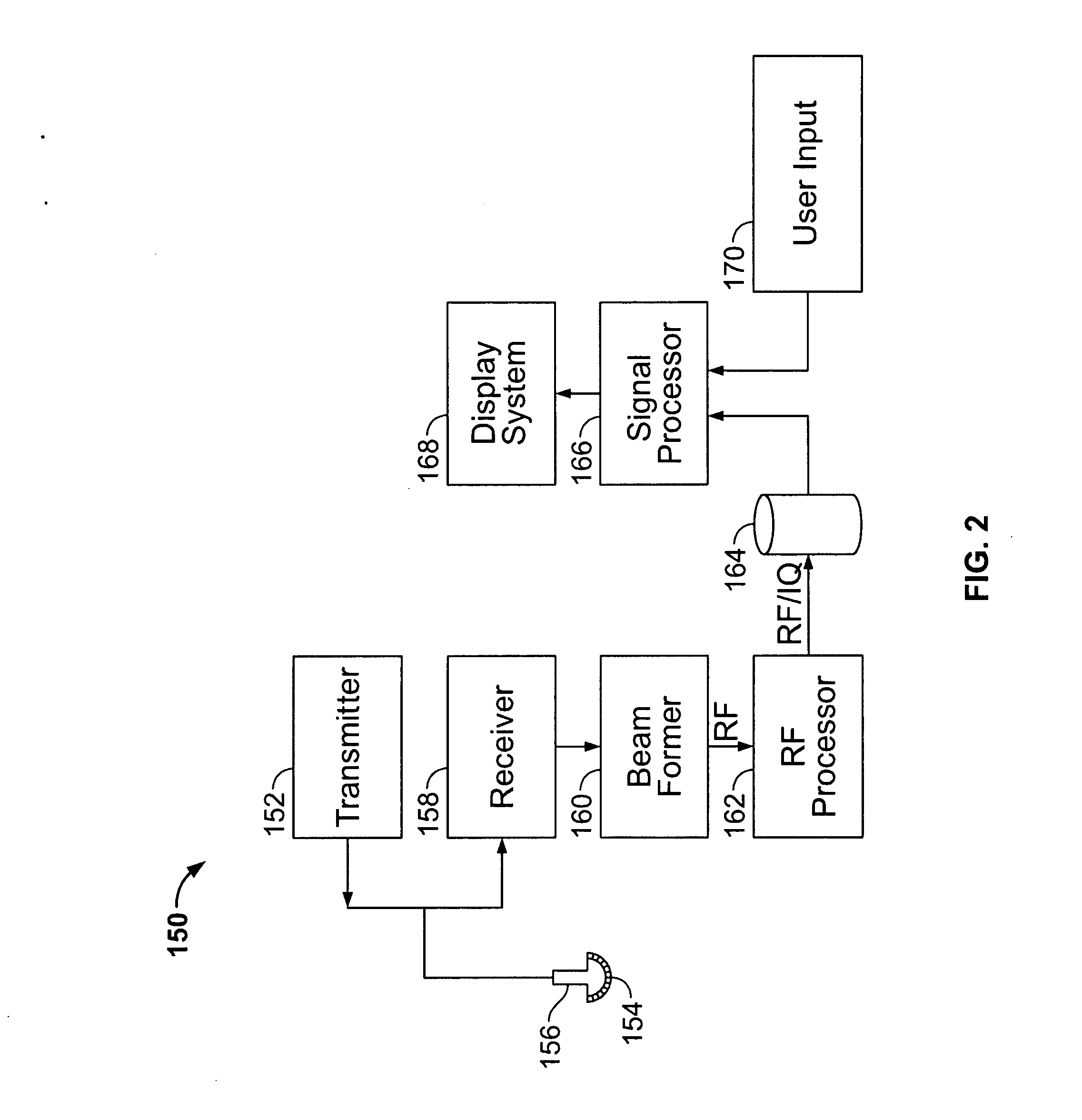

Method and system for determining contact along a surface of an ultrasound probe

ActiveUS20070010742A1Ultrasonic/sonic/infrasonic diagnosticsVibration measurement in solidsObject basedUltrasound probe

A method and system for determining contact along a surface of an ultrasound probe are provided. The method includes frequency analyzing ultrasound signals received by the ultrasound probe and displaying indicators of acoustic contact of the ultrasound probe with an object based on the frequency analysis.

Owner:GENERAL ELECTRIC CO

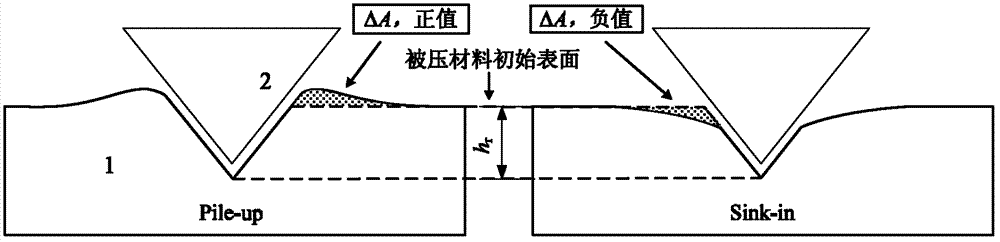

Process for characterizing elastoplasticity of metal material through indentation method

The invention discloses a process for characterizing the elastoplasticity of a metal material by introducing an extra residual area through an indentation method, belonging to the field of researches on the mechanical properties of a material. Experiment devices required by the method mainly comprise an indentor, and an atomic force microscope or a three-dimensional optical imaging system. The method mainly comprises the following steps: indenting a material to be tested through the indentor to obtain an indention load displacement curve, extracting relevant parameters from the indention load displacement curve, substituting the extracted parameters to an established model, and calculating to obtain the elastoplasticity of the material. The method mainly has the following advantages: different materials having similar indention curves can be successfully separated, and the obtained solution is only; and the solution obtained through back-stepping has a high precision. So the only high-precision elastoplasticity of the indented material can be obtained through back-stepping by utilizing the theoretic model in the invention.

Owner:XIANGTAN UNIV

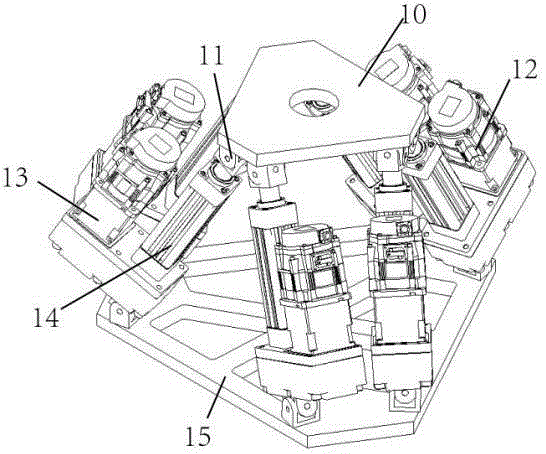

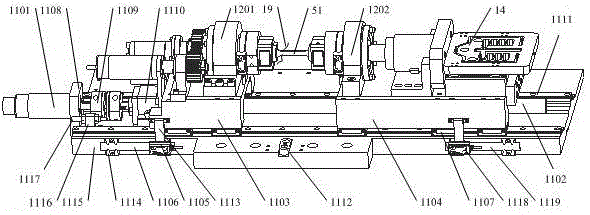

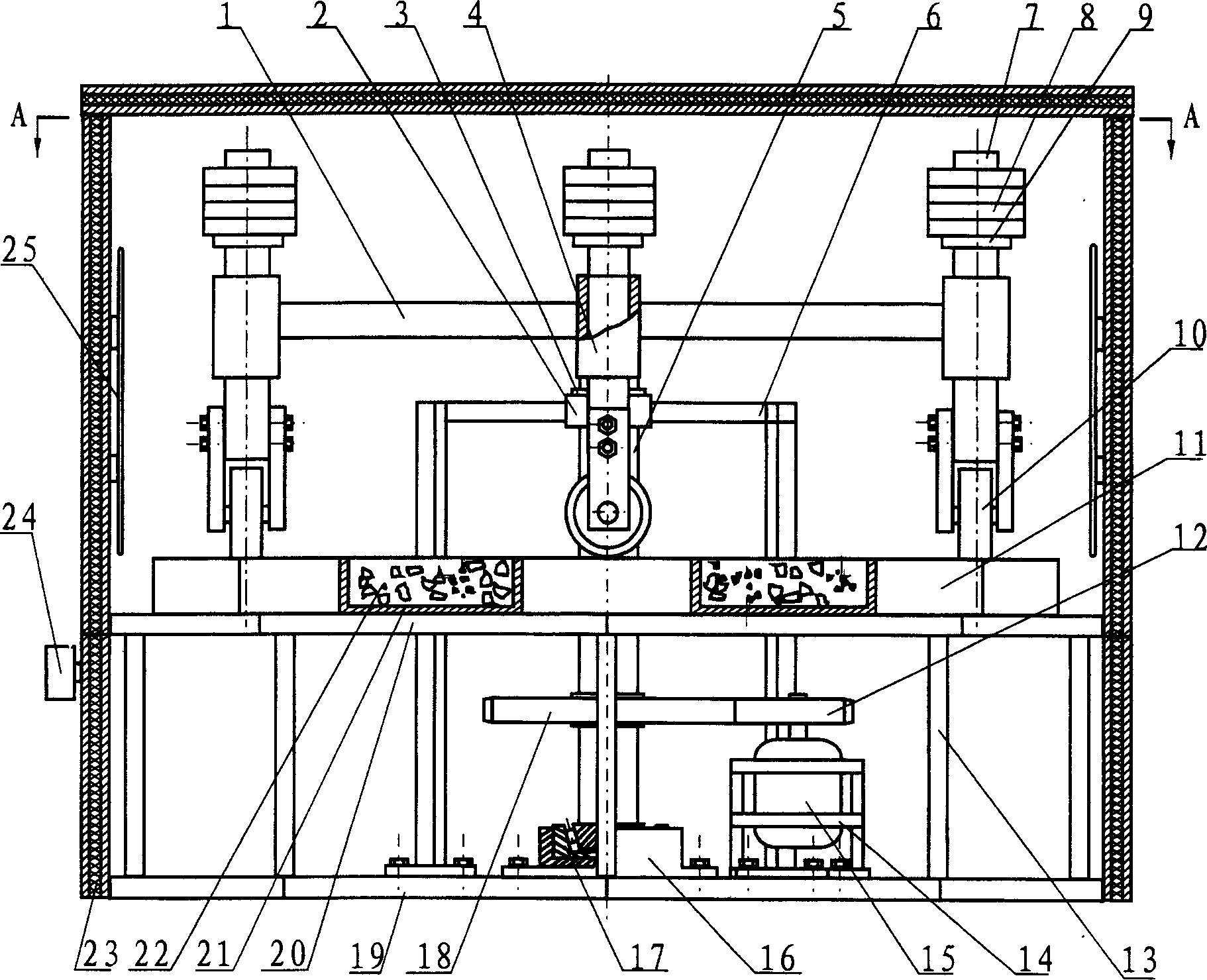

In-situ testing machine for microcosmic performance of multi-load and multi-physical-field coupling material

ActiveCN103499483AEfficient combinationSimulate micromechanical propertiesMaterial strength using tensile/compressive forcesInvestigating material hardnessMicro imagingPhysical field

The invention relates to an in-situ testing machine for the microcosmic performance for a multi-load and multi-physical-field coupling material, belonging to the technical field of material mechanics property testing. The in-situ testing machine comprises a micro / nanometer-precision driving / transmission module, a 'mechanical-electric-thermal-magnetic' loading module and a control module, is integrated with a high-field-depth 3D (three dimensional) micro-imaging lens, a Raman spectrometer and a visual in-situ monitoring module and is capable of dynamically monitoring deformational behaviors, damage mechanisms and performance evolvement rules of the material in a loading process. The in-situ testing machine has the advantages that the whole structure is compact, and the space layout is saved; the loads of four manners including 'stretching / compression-torsion-bending-indentation' can be singly loaded, two or more loads can be combined to be loaded as well, and externally-applied physical fields such as heat, electricity, magnetism and the like can be combined to maximally simulate the real working conditions of components of the material, and effective measures and methods are provided for testing the micromechanical performance of the material under a service-approximating condition.

Owner:JILIN UNIV

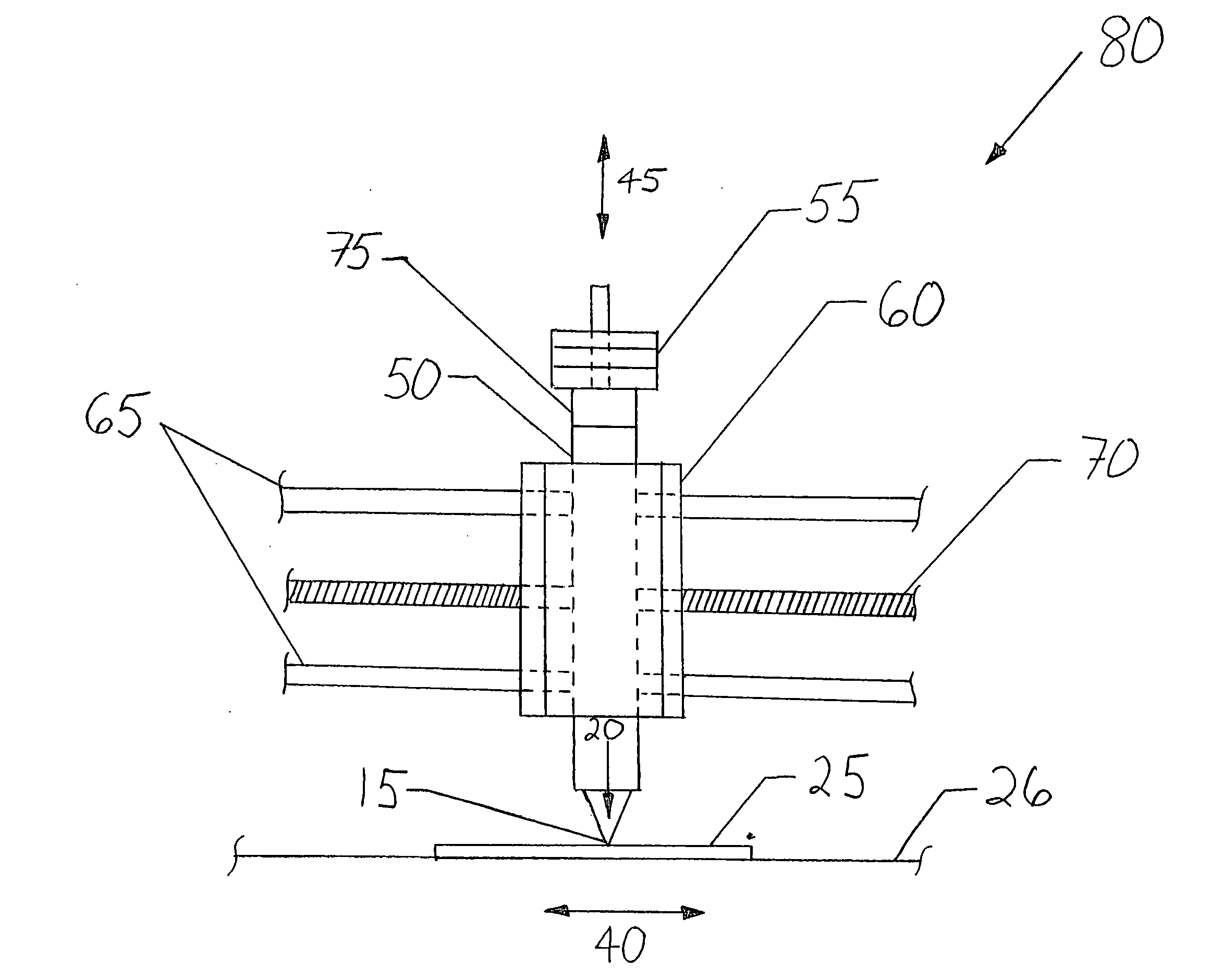

Scratch testing device

ActiveUS20060150710A1Using mechanical meansInvestigating material hardnessEngineeringEmbedded system

A device and method for scratch and / or mar testing the surface of a material specimen. In an embodiment, the scratch testing device comprises a scratching member. In addition, the scratch testing device comprises a carriage operable to move the scratching member. Further, the scratch testing device comprises a load mechanism, wherein the load mechanism applies a load to the scratching member.

Owner:MOYSE ALLAN H +1

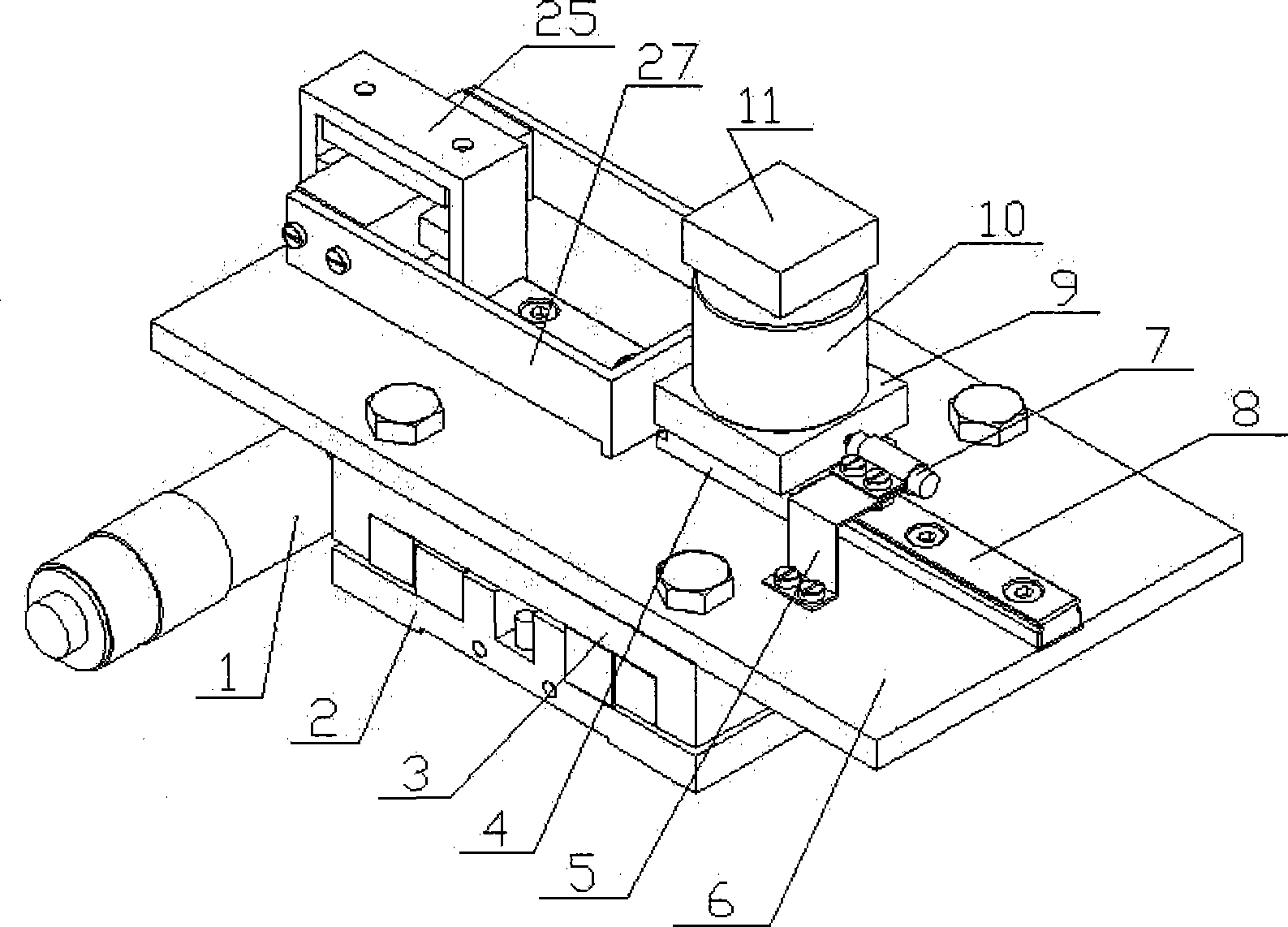

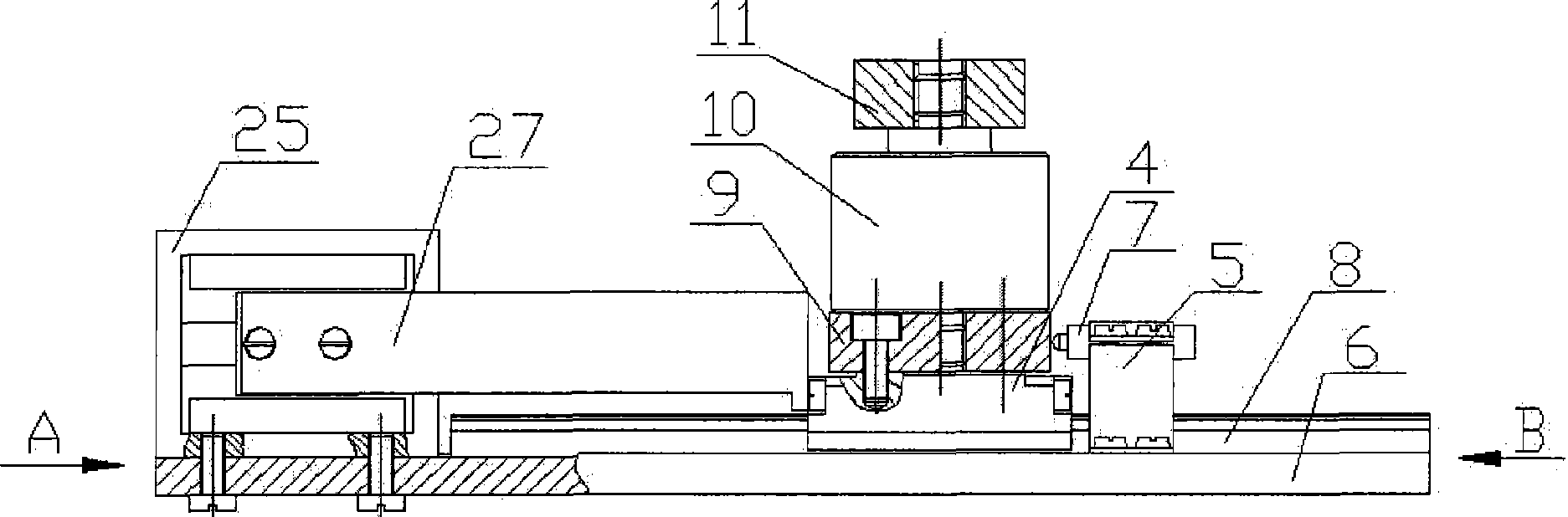

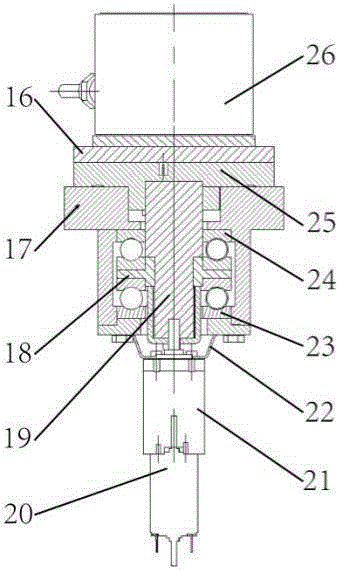

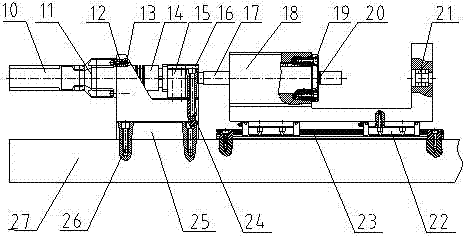

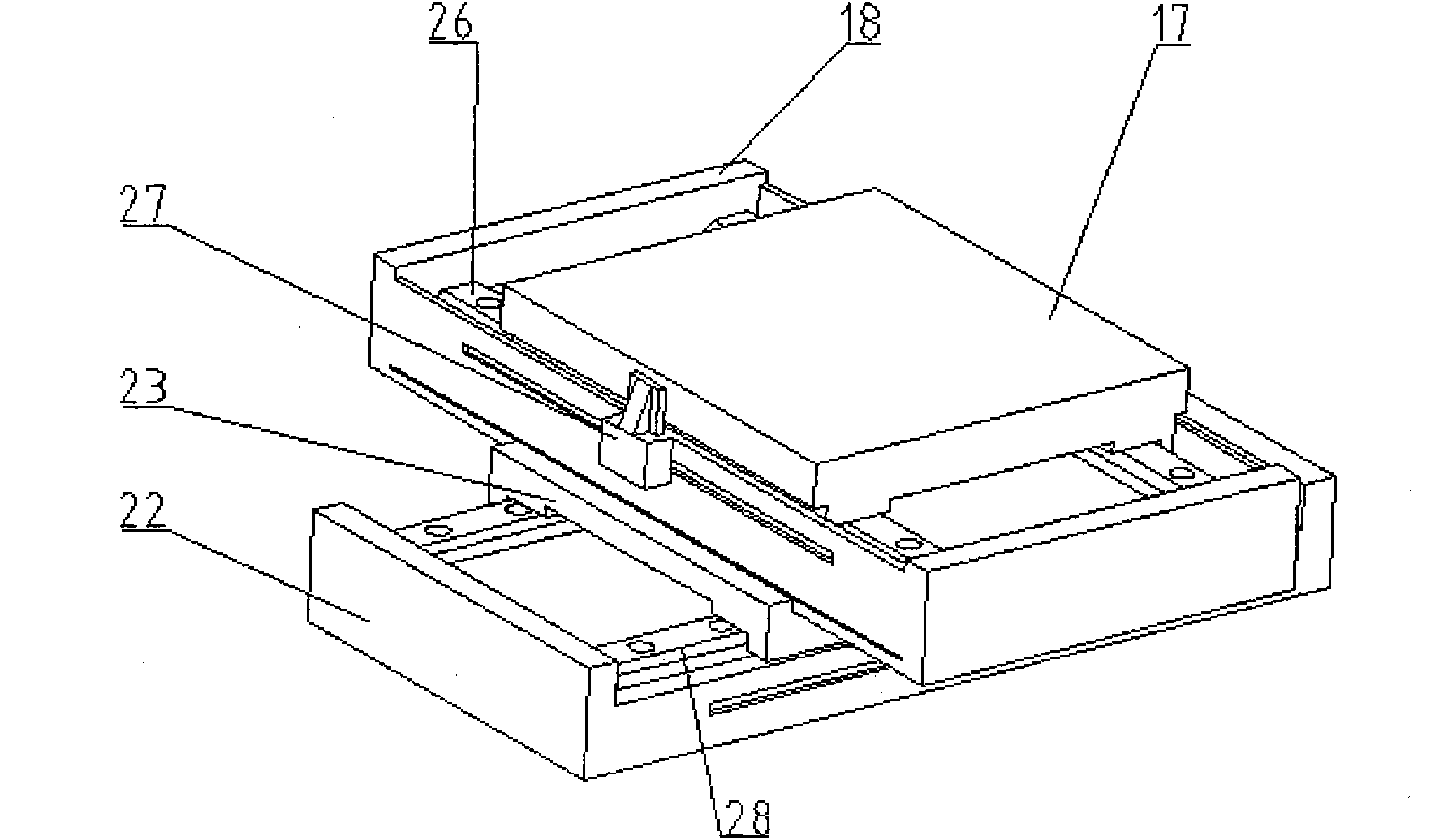

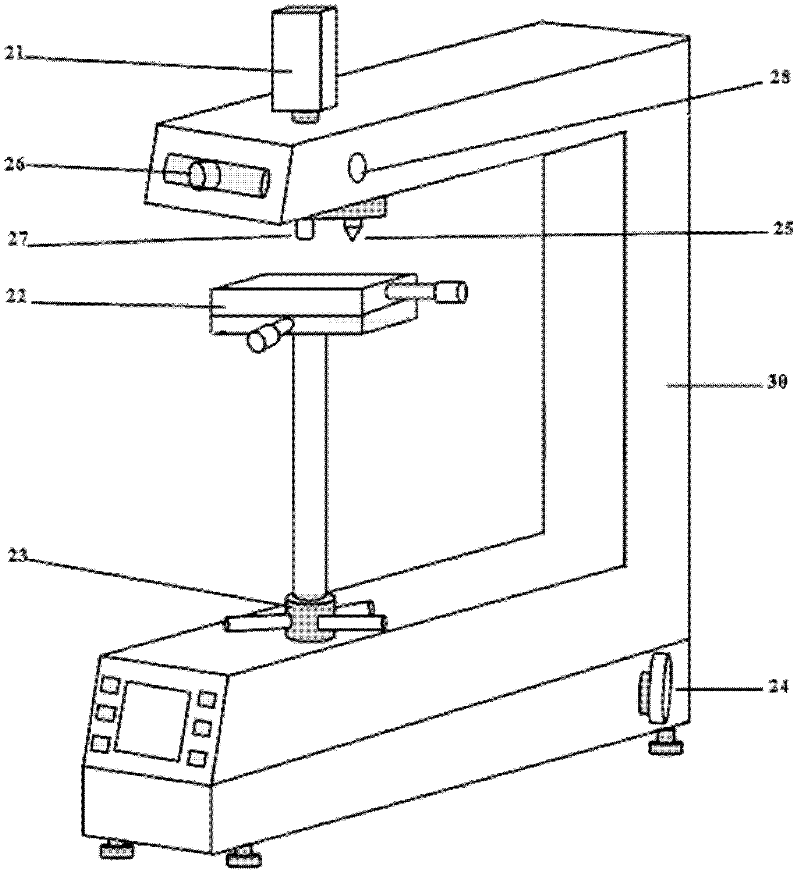

Micron-nano scale in-situ nano indentation and scratching test system

InactiveCN101876609AThe test method is accuratePrecision equipmentUsing optical meansInvestigating material hardnessImage resolutionEngineering

The invention relates to a micron-nano scale in-situ nano indentation and scratching test system which integrates driving, precise loading and signal detection, micron-nano scale mechanics performance testing, ultraprecise scratching processing and high resolution in-situ observing as one. The system is mainly composed of a precise positioning platform at X-axis and Y-axis directions, a precise linear positioning platform at Z-axis direction, a precise indentation driving unit, a load signal and displacement signal detection unit and a high resolution digital microscopic imaging system for observing and storing material deformation and damage conditions in the test process. The precise positioning platform at the X-axis and Y-axis directions is assembled on a base, the precise linear positioning platform at the Z-axis direction is assembled on a side plate, the precise indentation driving unit, a precise mechanical sensor for detecting the indentation material pressure of a diamond tool head and a precise displacement sensor for detecting the indentation depth of the diamond tool head to along the Z-axis direction are assembled on the precise linear positioning platform at the Z-axis direction, and the high resolution digital microscopic imaging system is assembled on a beam.

Owner:赵宏伟

Methods and instruments for materials testing

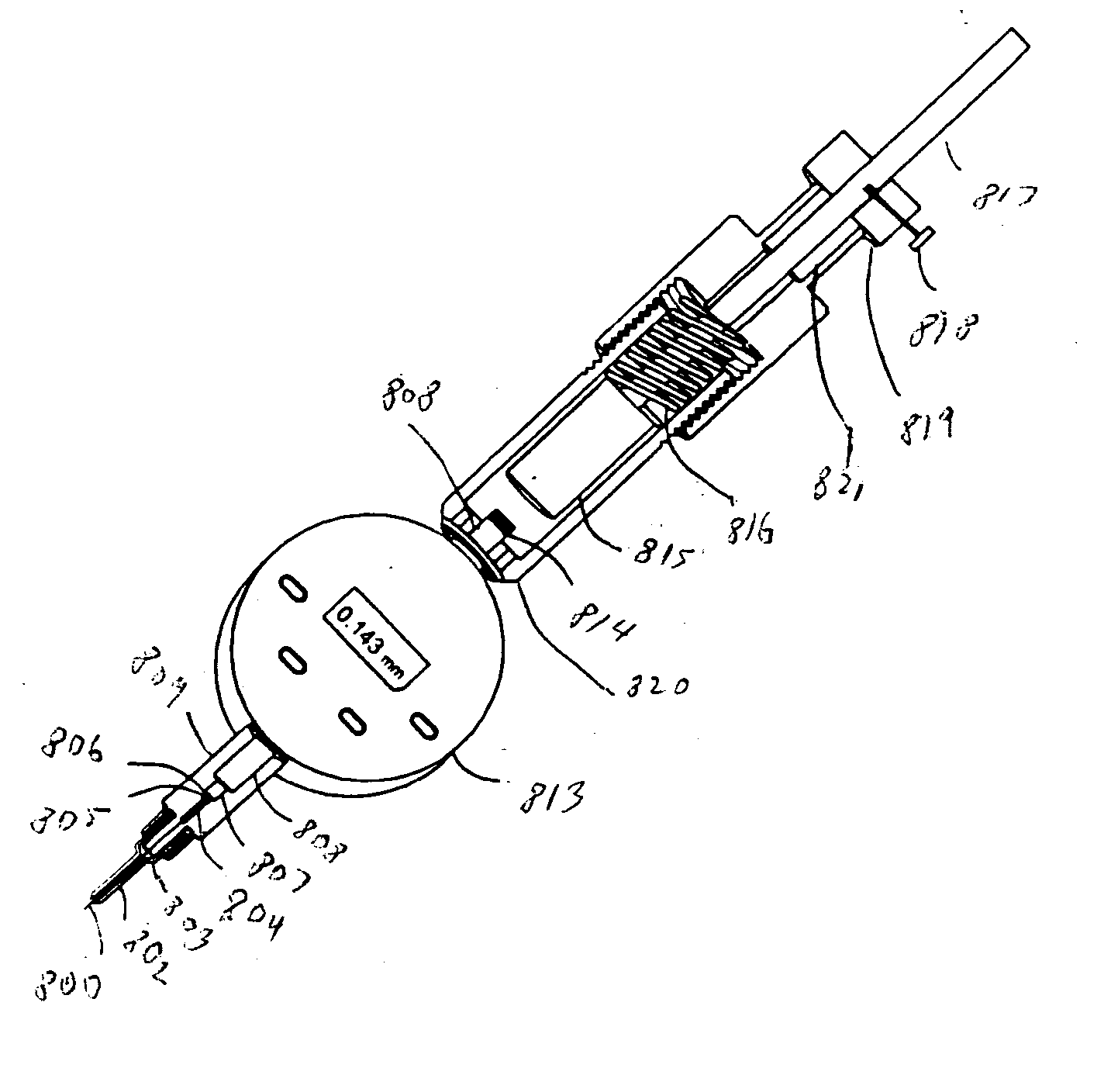

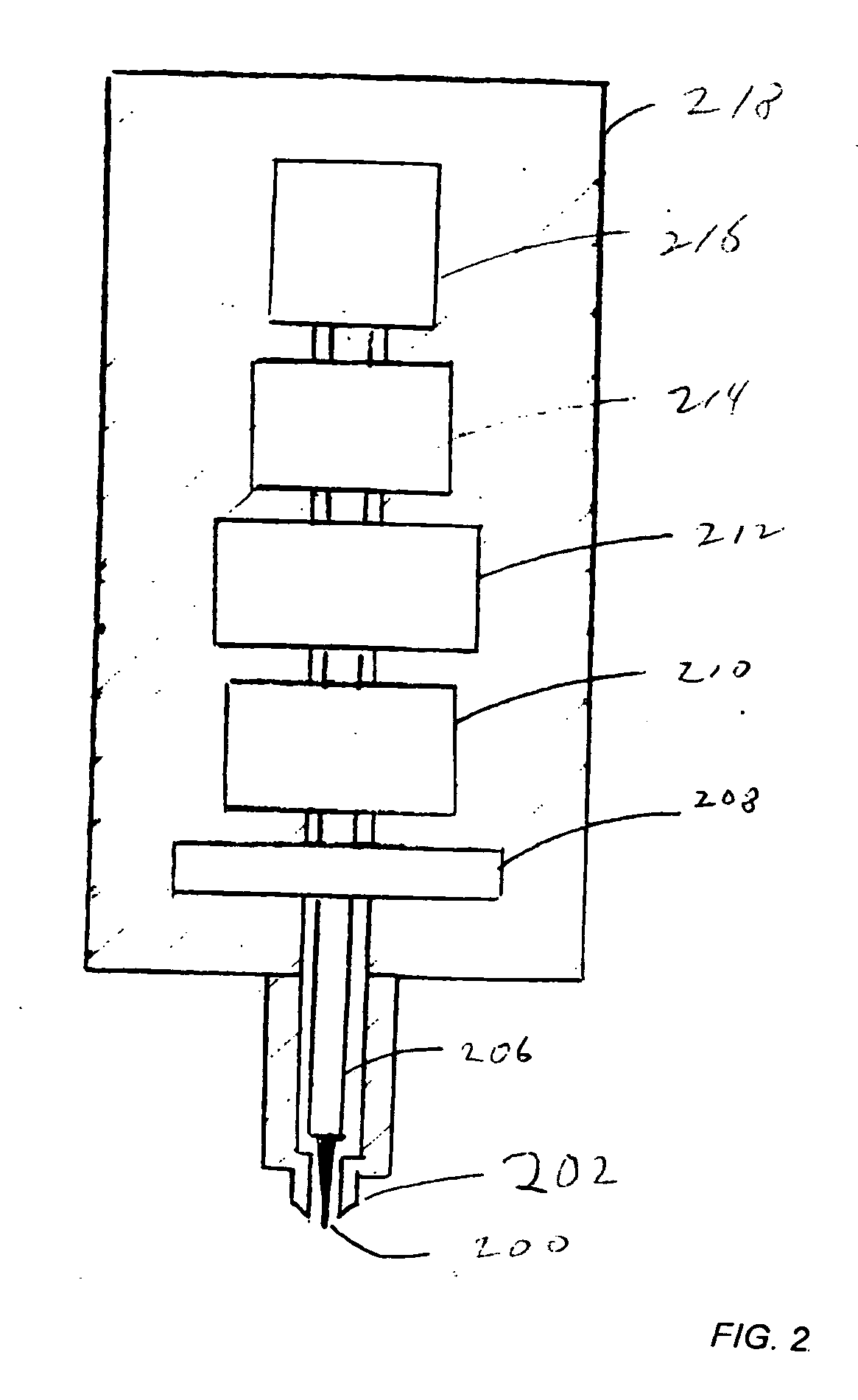

ActiveUS20090056427A1Improve abilitiesIncreases ease and speedDiagnostics using pressureSurgeryMaterials testingHand held

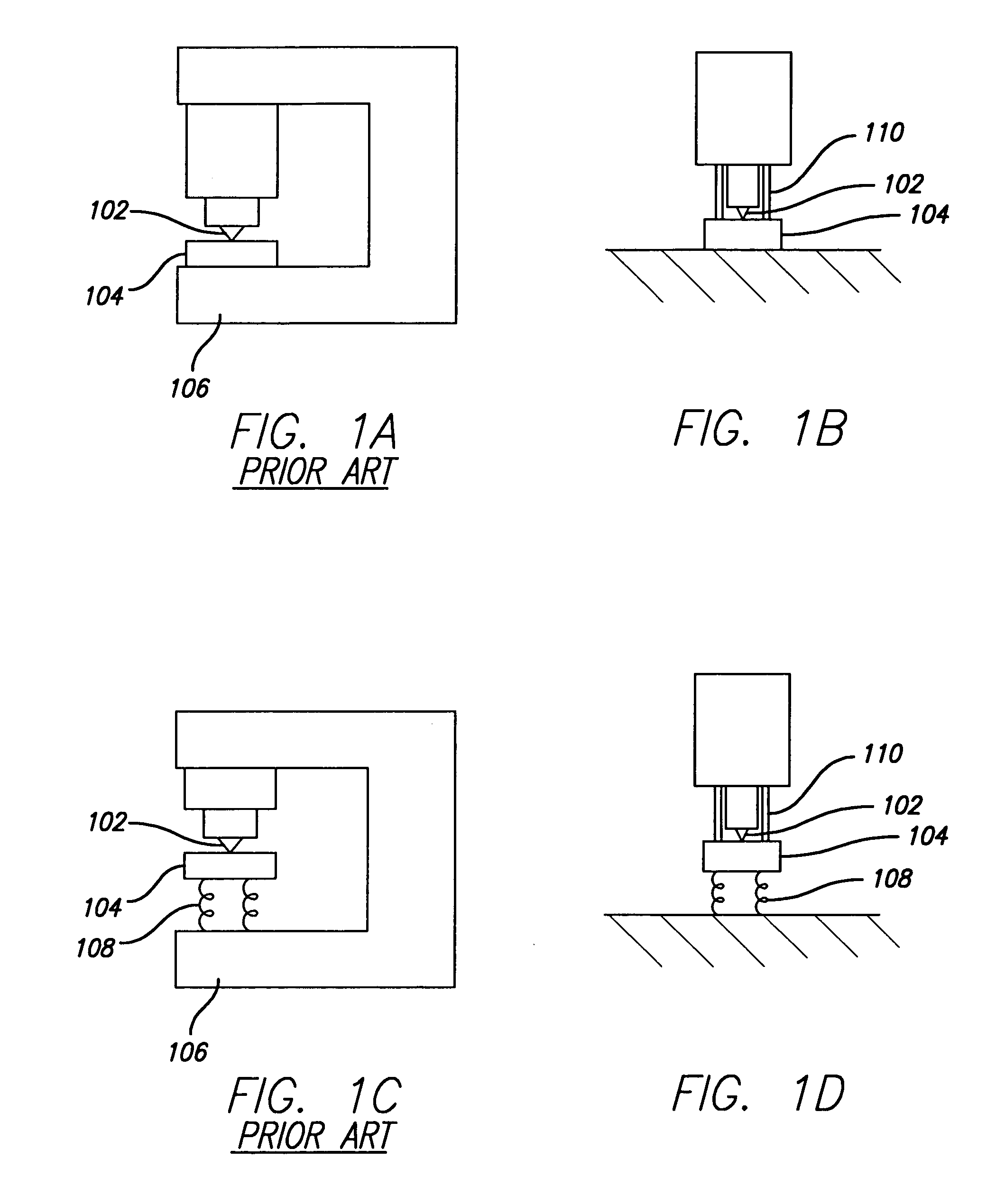

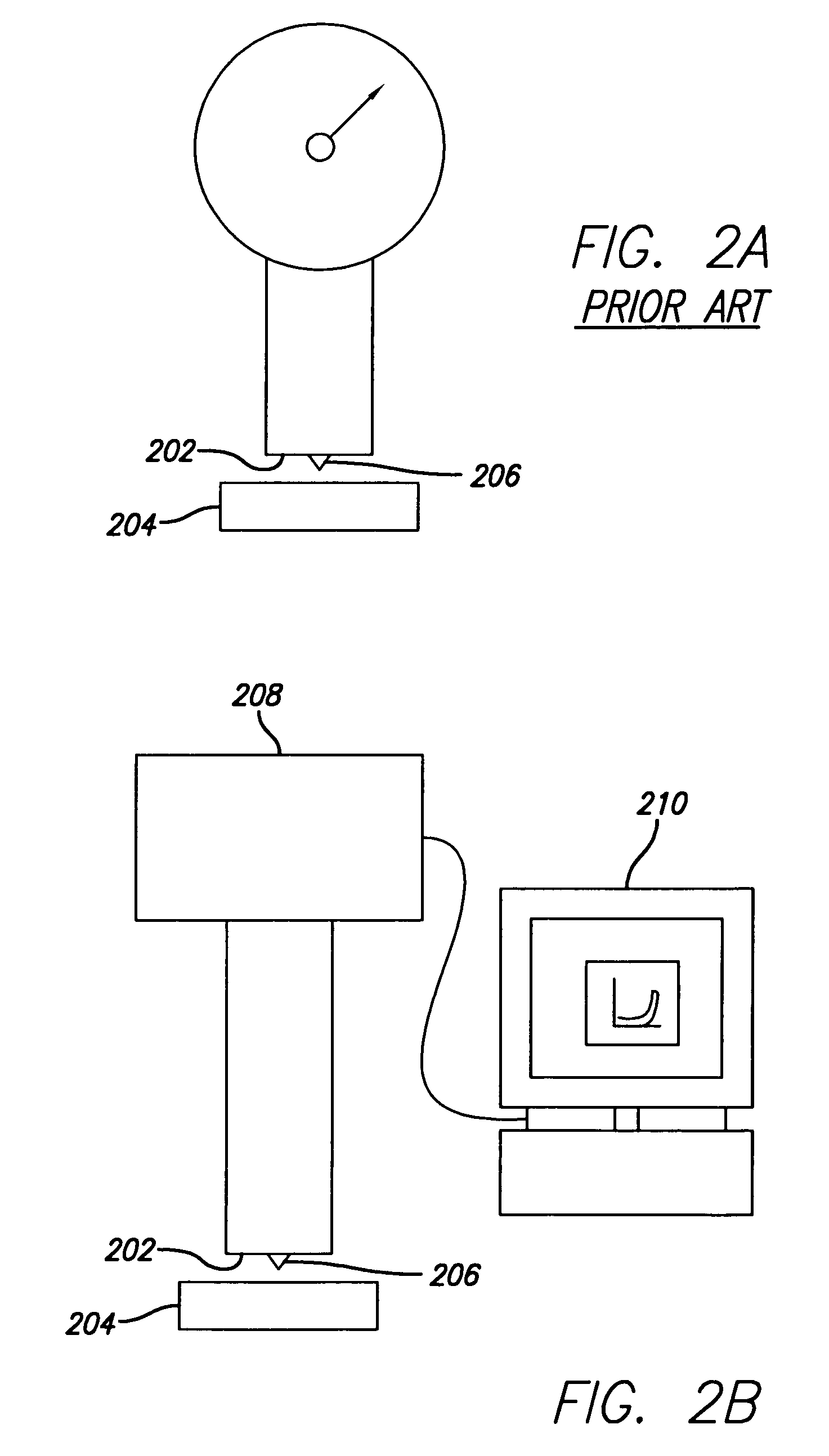

Methods and instruments for characterizing a material, such as the properties of bone in a living human subject, using a test probe constructed for insertion into the material and a reference probe aligned with the test probe in a housing. The housing is hand held or placed so that the reference probe contacts the surface of the material under pressure applied either by hand or by the weight of the housing. The test probe is inserted into the material to indent the material while maintaining the reference probe substantially under the hand pressure or weight of the housing allowing evaluation of a property of the material related to indentation of the material by the probe. Force can be generated by a voice coil in a magnet structure to the end of which the test probe is connected and supported in the magnet structure by a flexure, opposing flexures, a linear translation stage, or a linear bearing. Optionally, a measurement unit containing the test probe and reference probe is connected to a base unit with a wireless connection, allowing in the field material testing.

Owner:RGT UNIV OF CALIFORNIA

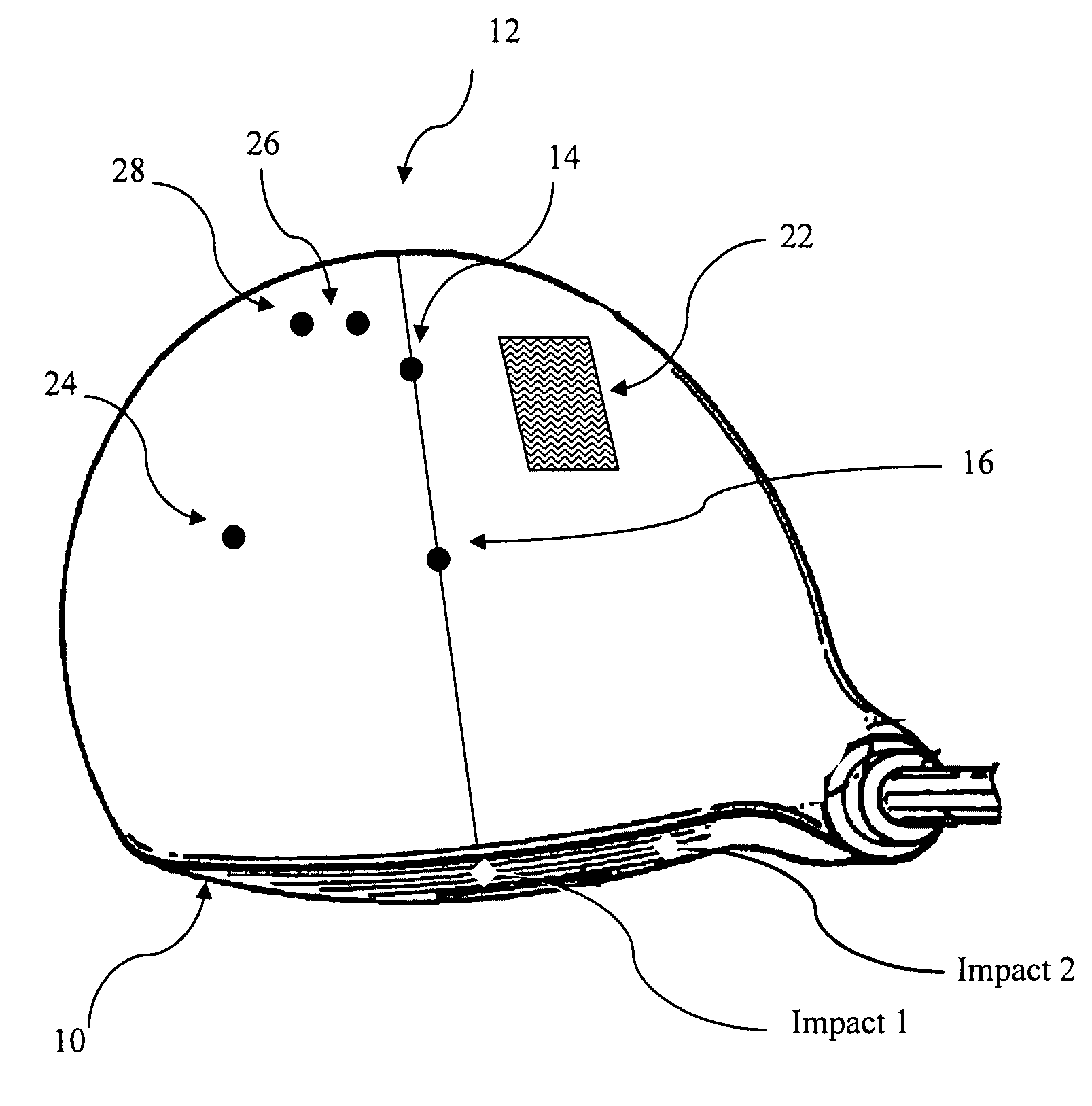

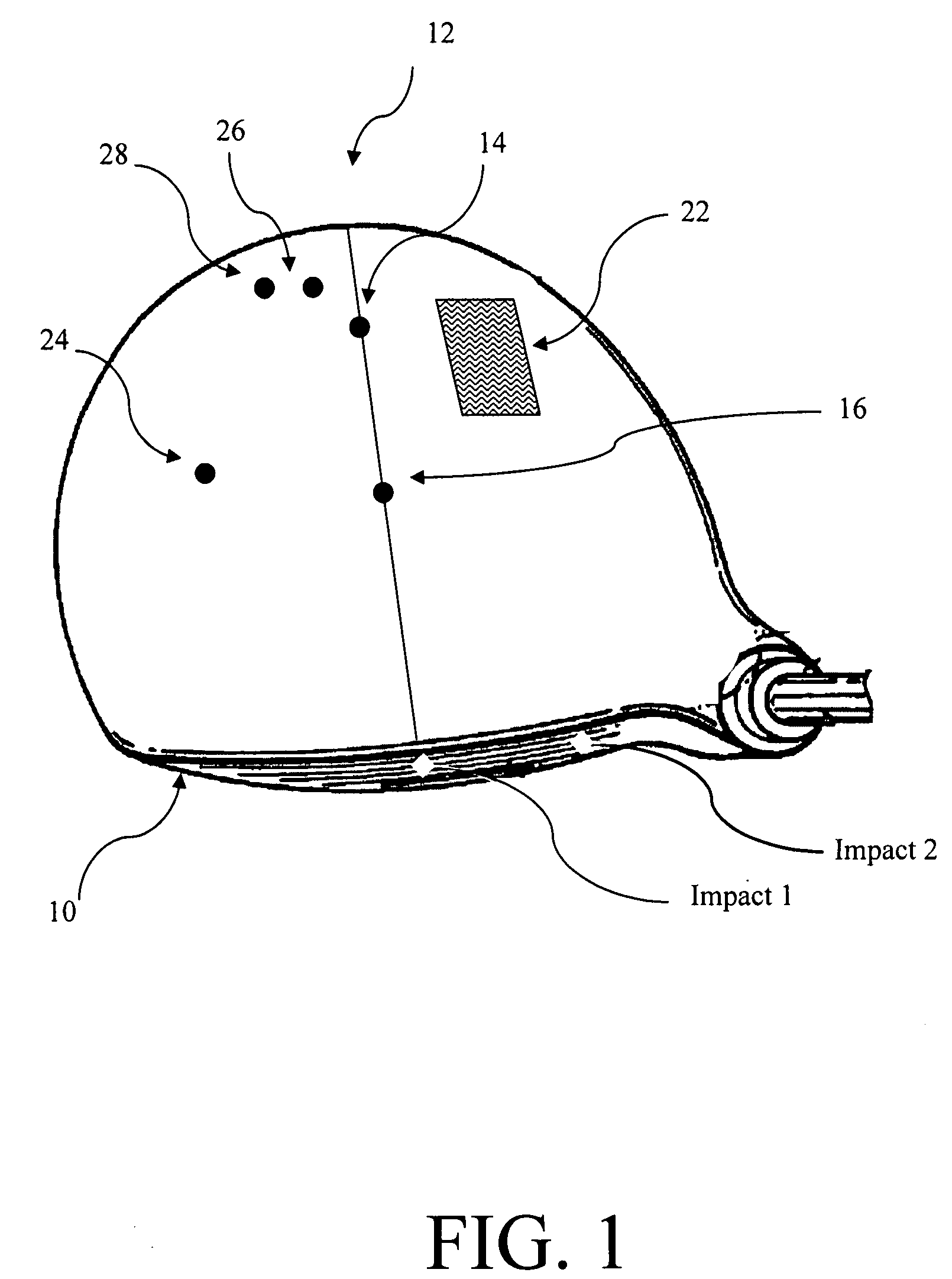

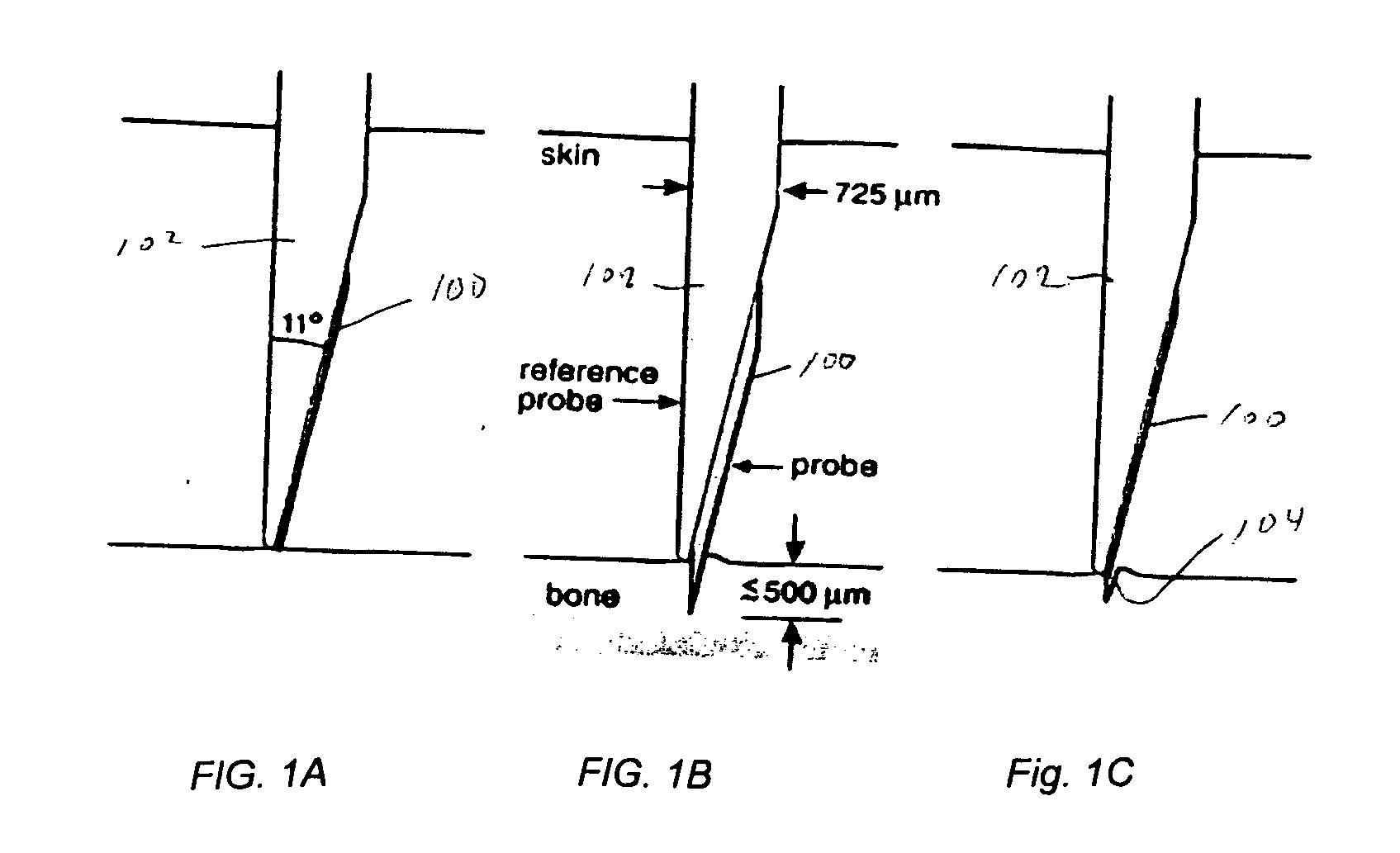

Methods and instruments for assessing bone fracture risk

ActiveUS20070276292A1Quick and inexpensive testRisk of fracturePerson identificationSensorsHealth riskFracture risk

Methods and instruments for assessing bone, for example fracture risk, in a subject in which a test probe is inserted through the skin of the subject so that the test probe contacts the subject's bone and the resistance of the test bone to microscopic fracture by the test probe is determined. Macroscopic bone fracture risk is assessed by measuring the resistance of the bone to microscopic fractures caused by the test probe. The microscopic fractures are so small that they pose negligible health risks. The instrument may also be useful in characterizing other materials, especially if it is necessary to penetrate a layer to get to the material to be characterized.

Owner:RGT UNIV OF CALIFORNIA

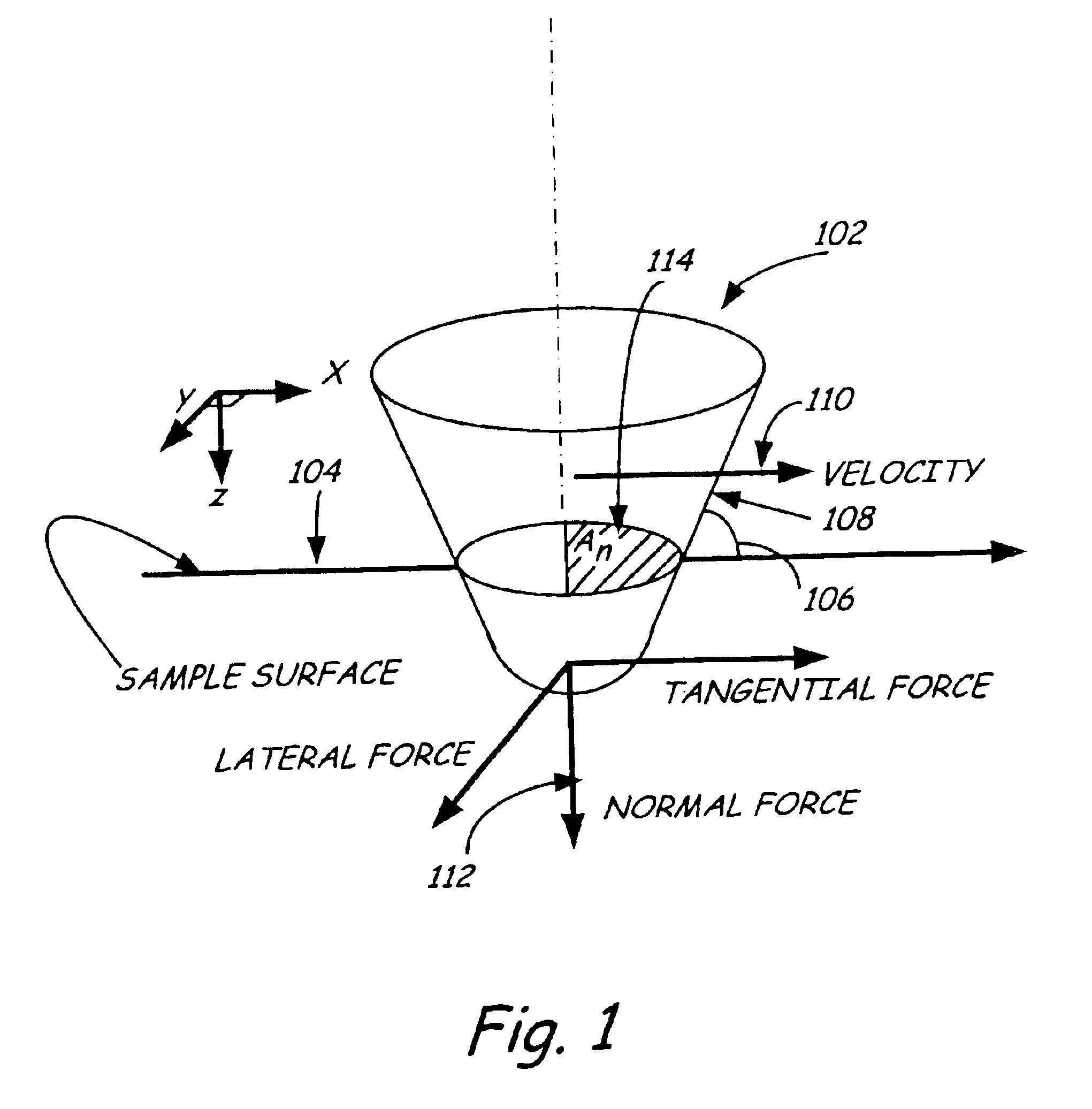

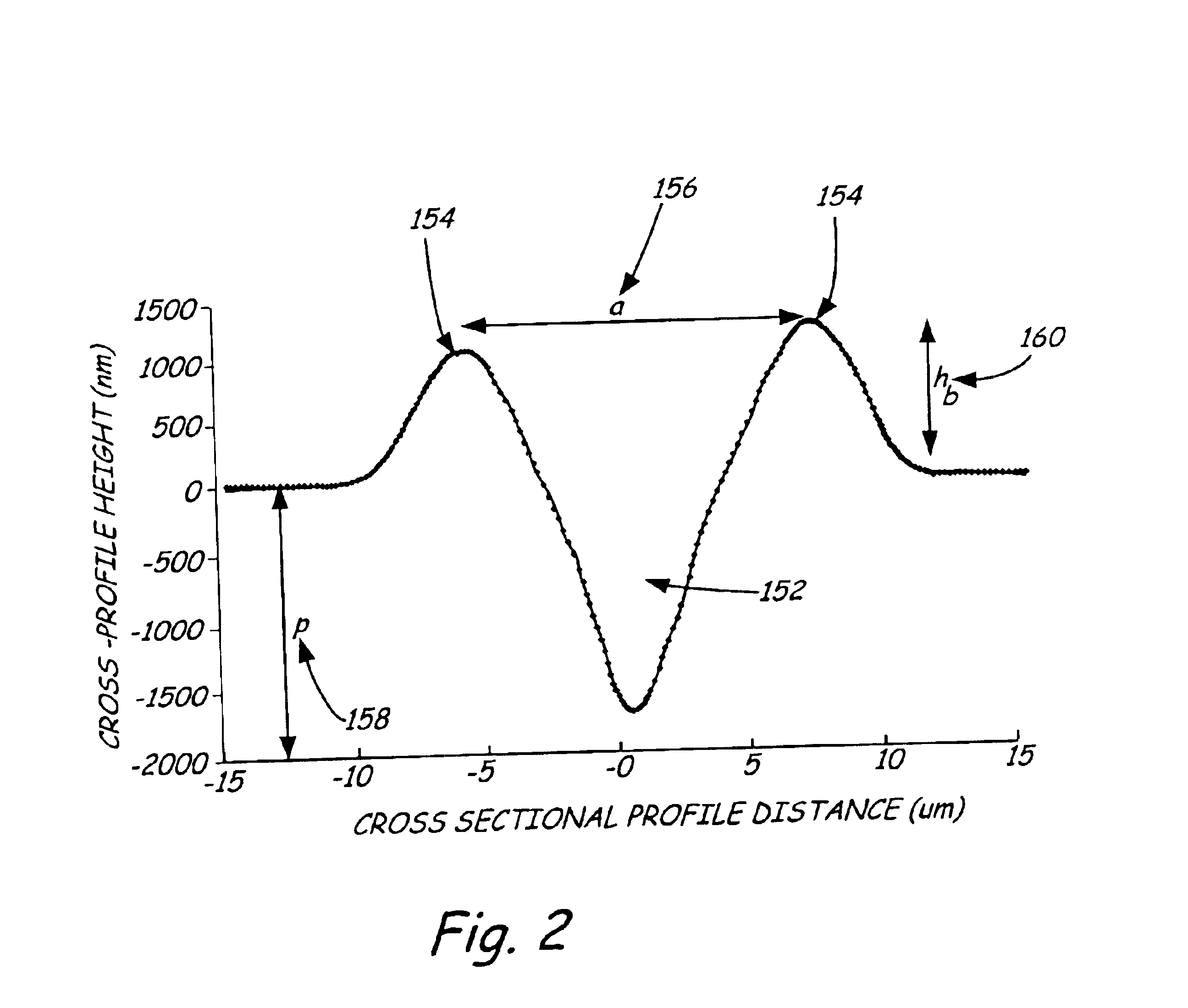

Characteristic strain and fracture resistance for scratch independently of indenter geometry

InactiveUS6945097B2Analysing solids using sonic/ultrasonic/infrasonic wavesForce measurementScratch testEnvironmental geology

The invention involves an apparatus and method for calculating characteristics of materials, such as equivalent strain, using an indenter where the method used is independent of indenter geometry. The method includes performing a scratch test to calculate the strain for each of a plurality of indenter shapes, such as a theoretical sphere and cone, using known equations. The strain of a composite indenter, such as a cone with a rounded tip, can then be determined taking into account contributions from each of the plurality of theoretical shapes.

Owner:KEYSIGHT TECH

Combined load mode mechanical-electrical and thermal-magnetic coupling material performance in-situ test instrument and method

ActiveCN105628487ARich physical performance parametersRich performance parametersMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesCouplingPhysical field

The invention relates to a combined load mode mechanical-electrical and thermal-magnetic coupling material performance in-situ test instrument and method, and belongs to the field of precise scientific instruments. The test instrument comprises three parts: namely a combined load-multi-physical field loading test platform, an in-situ monitoring platform and a vibration-isolating base, wherein the vibration-isolating base is mainly used for supporting the combined load-multi-physical field loading test platform and the in-situ monitoring platform, and provides a positioning service for installation of the platforms and effective vibration isolating treatment for various precise driving loading elements, detecting elements and in-situ monitoring elements; the in-situ monitoring platform realizes real-time dynamic and in-situ monitoring on micro deformation, injury mechanism, microstructure changes and property evolution of a material sample under the combined load condition by precisely adjusting the position and posture of various monitoring modules. The combined load mode mechanical-electrical and thermal-magnetic coupling material performance in-situ test instrument has the following advantages: the structure is miniaturized and lightened in weight, and the instrument body can be placed in an optionally equipped vacuum cavity, so that testing environments like low pressure, vacuum and inert gases can be provided for the material sample to be tested, and the practicability is high.

Owner:JILIN UNIV

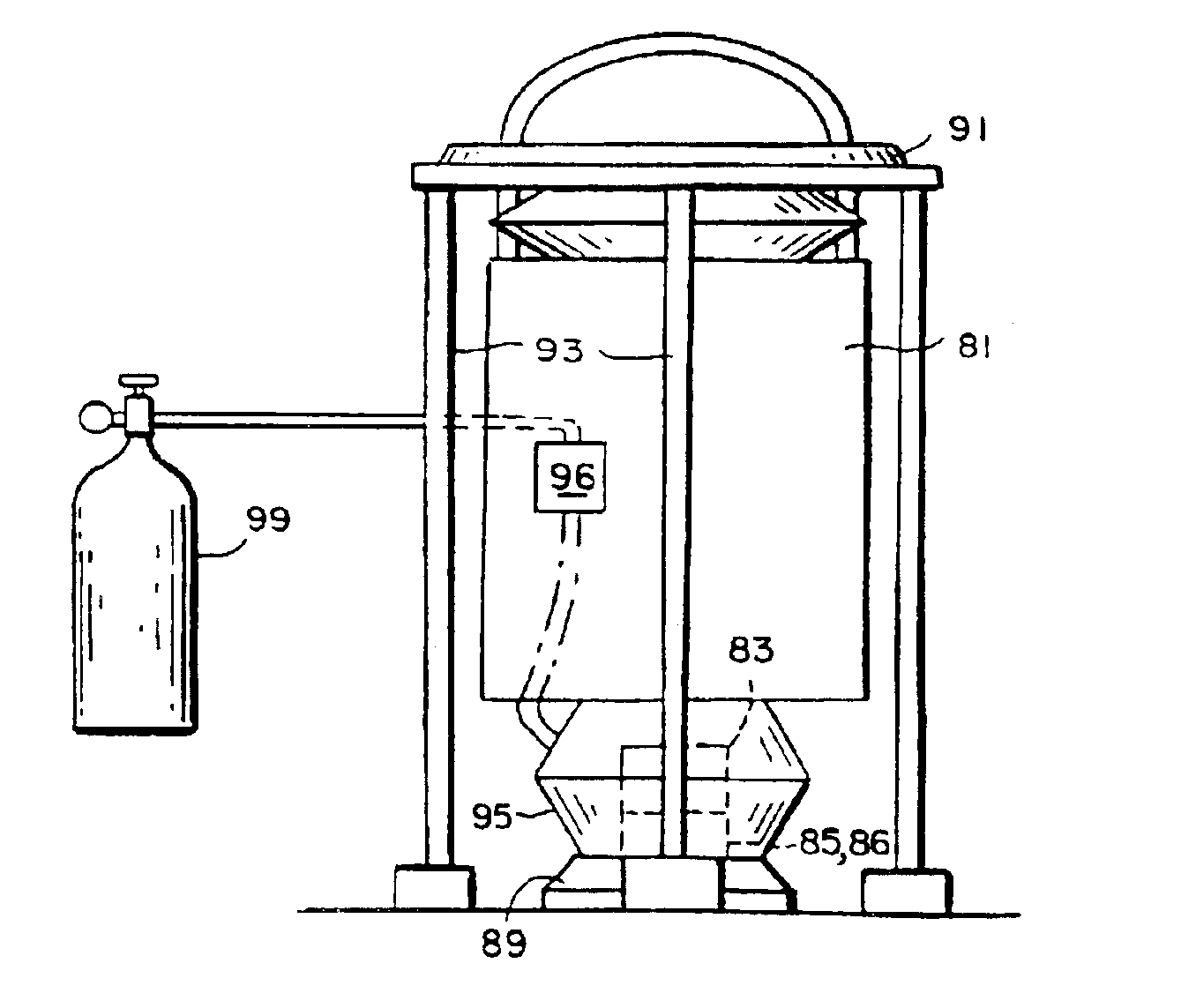

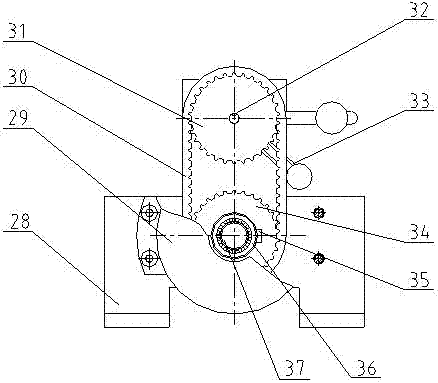

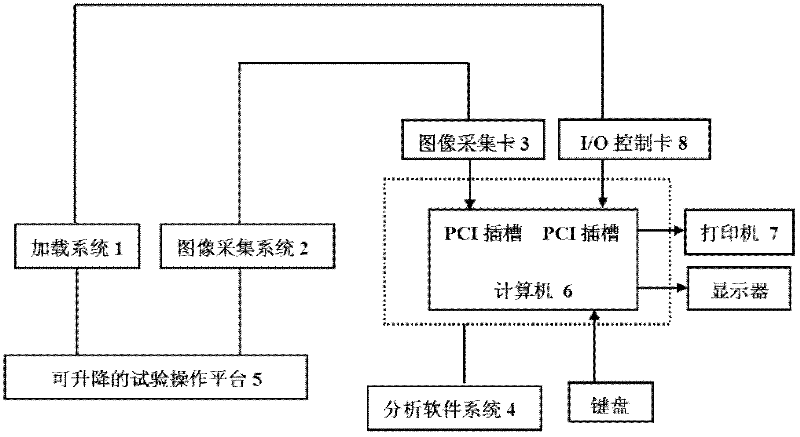

Device for testing hardness, fracture toughness and residual stress of brittle material with indentation method

ActiveCN102393341AAutomate analysisLower acquisition costsInvestigating material hardnessElectric machineryFilm material

The invention discloses a device for testing the hardness, fracture toughness and residual stress of a brittle material with an indentation method, belonging to the technical field of material property representation. The device comprises a frame and an image acquiring system, wherein the frame is provided with an eye lens, a height-adjustable testing operation platform and an adjusting rotating wheel; a loading system is arranged in the frame, and comprises a fixing support base, a lever, a mandrel, a hanging rod, a middle main shaft and a second motor; and a first motor and the second motor of the loading system are connected with a computer through an I / O (Input / Output) control card. In the invention, the conventional digital image low-load Vickers hardness meter is improved, so that the micro-hardness of a material can be directly tested, and the fracture toughness and residual stress of an interface system of the brittle material and a brittle coating film material can be directly tested; and the device can be widely applied to departments such as industrial enterprises, universities, academies and the like for rapidly detecting relevant indexes.

Owner:XIANGTAN UNIV

Golf club head comprising a piezoelectric sensor

ActiveUS20090165530A1Gymnastic exercisingForce measurement using piezo-electric devicesGolf BallHead impact

An apparatus and method for determining the kinematic characteristics of a golf club head are disclosed. The apparatus includes at least one piezoelectric component selectively positioned within or upon a club head. The piezoelectric component is preferably positioned to the rear of the center of gravity, and near the midpoint of the face of the club head. During a golf club swing, the piezoelectric component determines the acceleration and deceleration of the golf club head. When the club head impacts an object such as a golf ball, the piezoelectric component is also operable to determine the velocity of the club head. It may also be desirable for the piezoelectric component to determine the magnitude of vibration during impact. In this manner, the piezoelectric component may function determine the efficiency of a golf club swing.

Owner:ACUSHNET CO

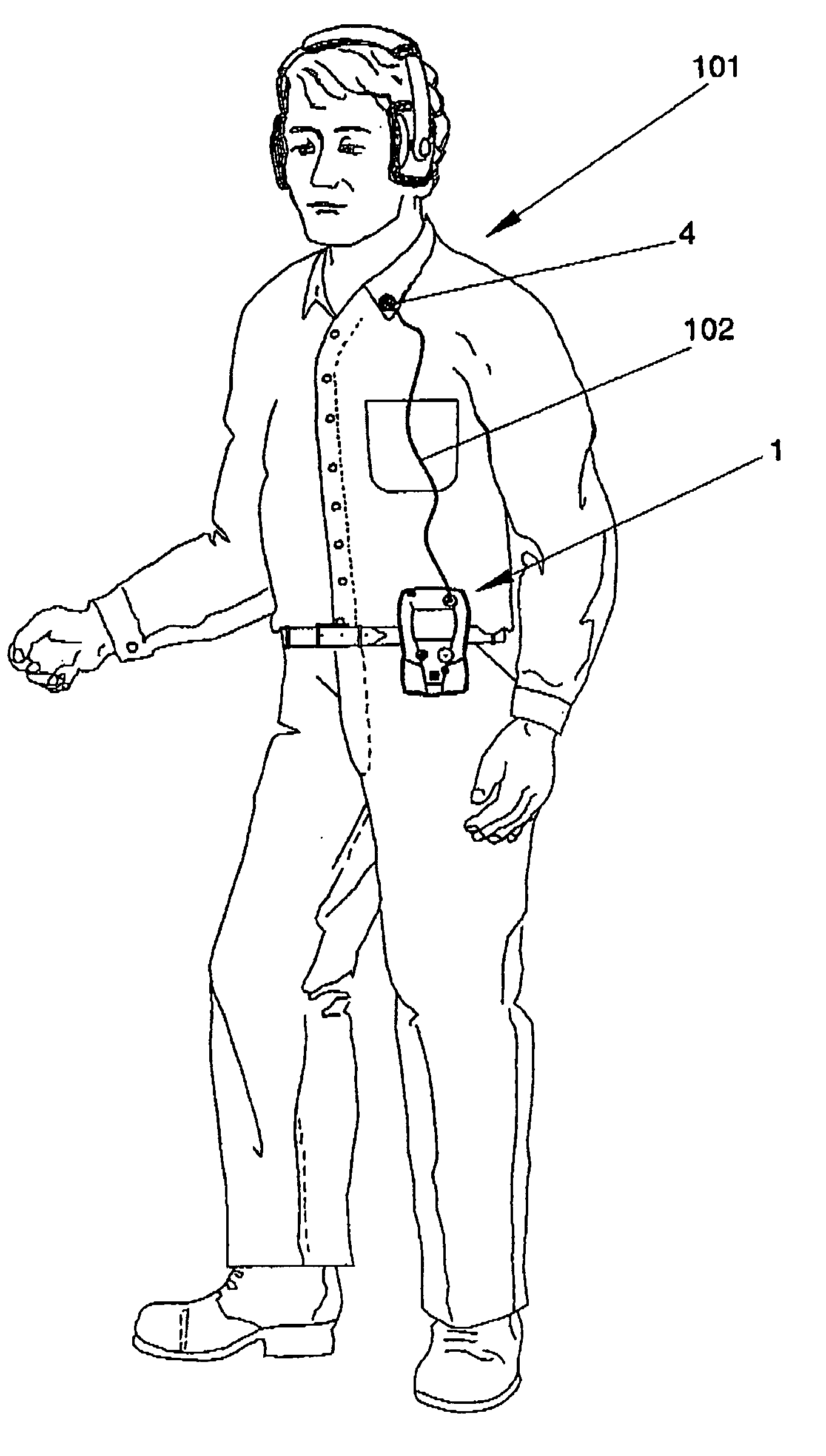

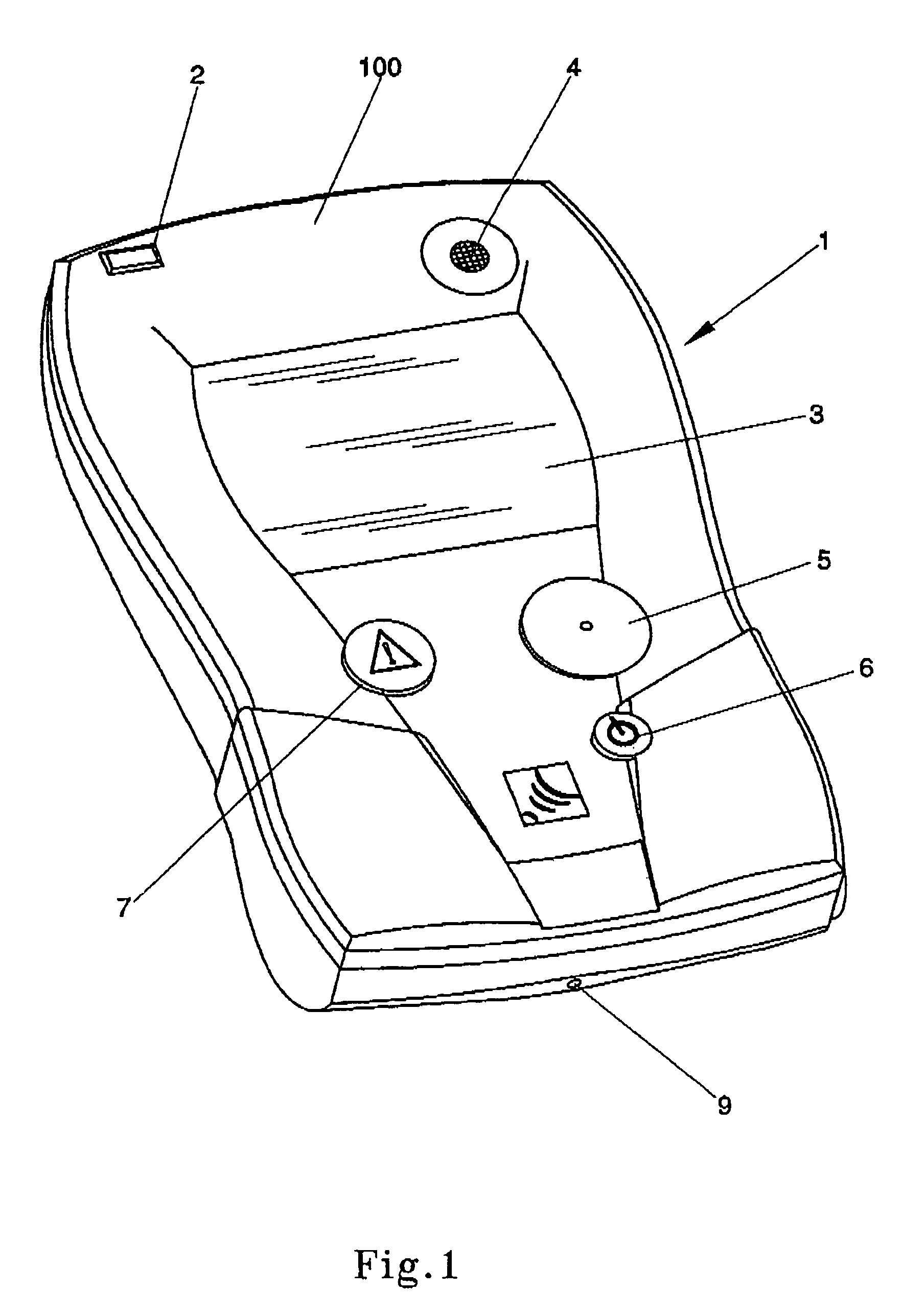

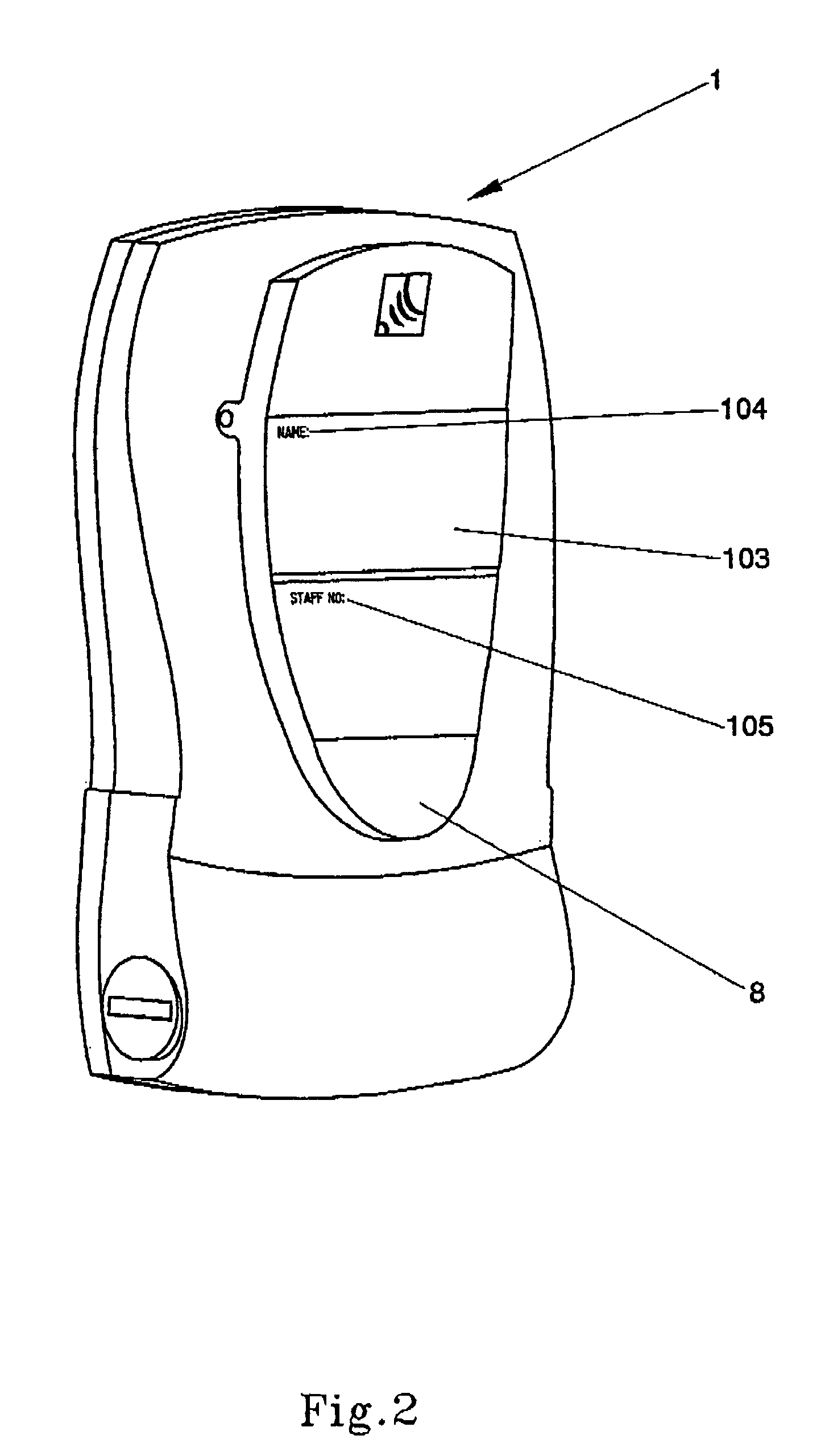

Personal noise monitoring apparatus and method

InactiveUS7151835B2Large doseVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesNoise monitoringCredit card

The present invention relates to a method, system and device for monitoring noise received by individuals operating in noisy environments.The device comprises a substantially credit card size housing and can be worn as a “badge”. The device includes a monitoring means for monitoring sound, and a display for displaying various noise parameter values, including a percentage value of cumulative noise dose received by the device. The device includes an input key which enables a user to select one of a plurality types of hearing protection equipment, so the user can indicate to the device the hearing protection equipment they are wearing. This enables the device to monitor compliance. The device also includes an input key enabling the user to acknowledge when an unallowable noise dose level has been reached.

Owner:SOUNDSAFETY

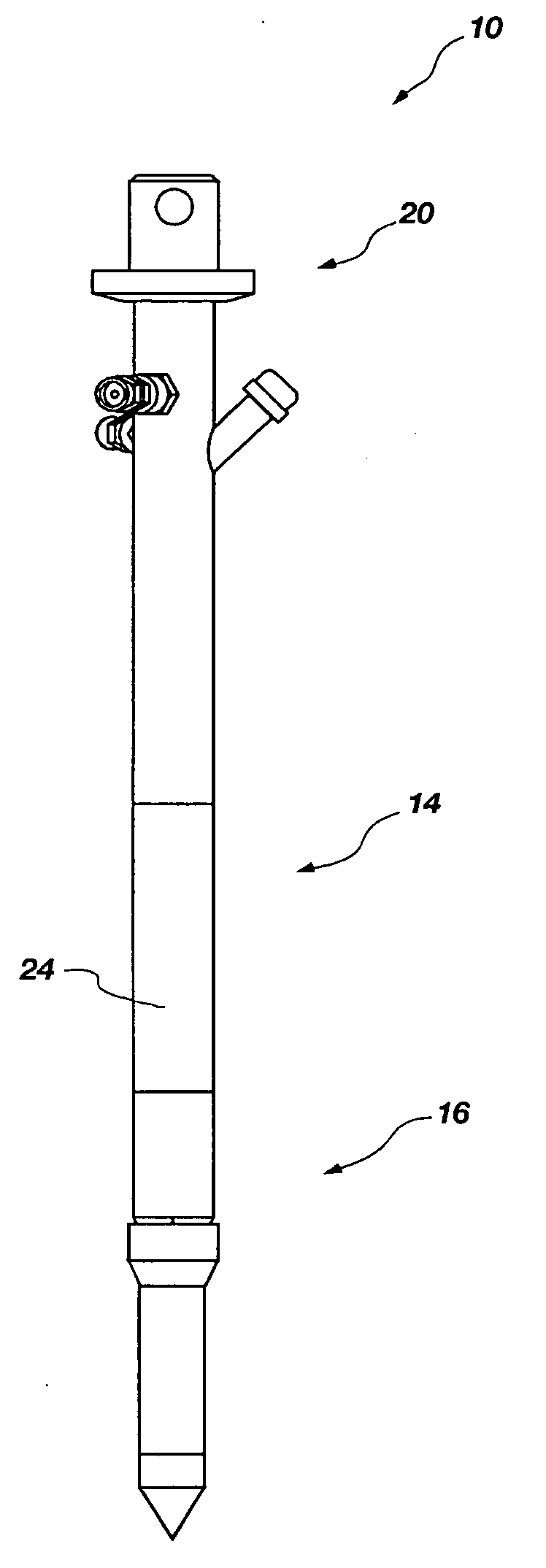

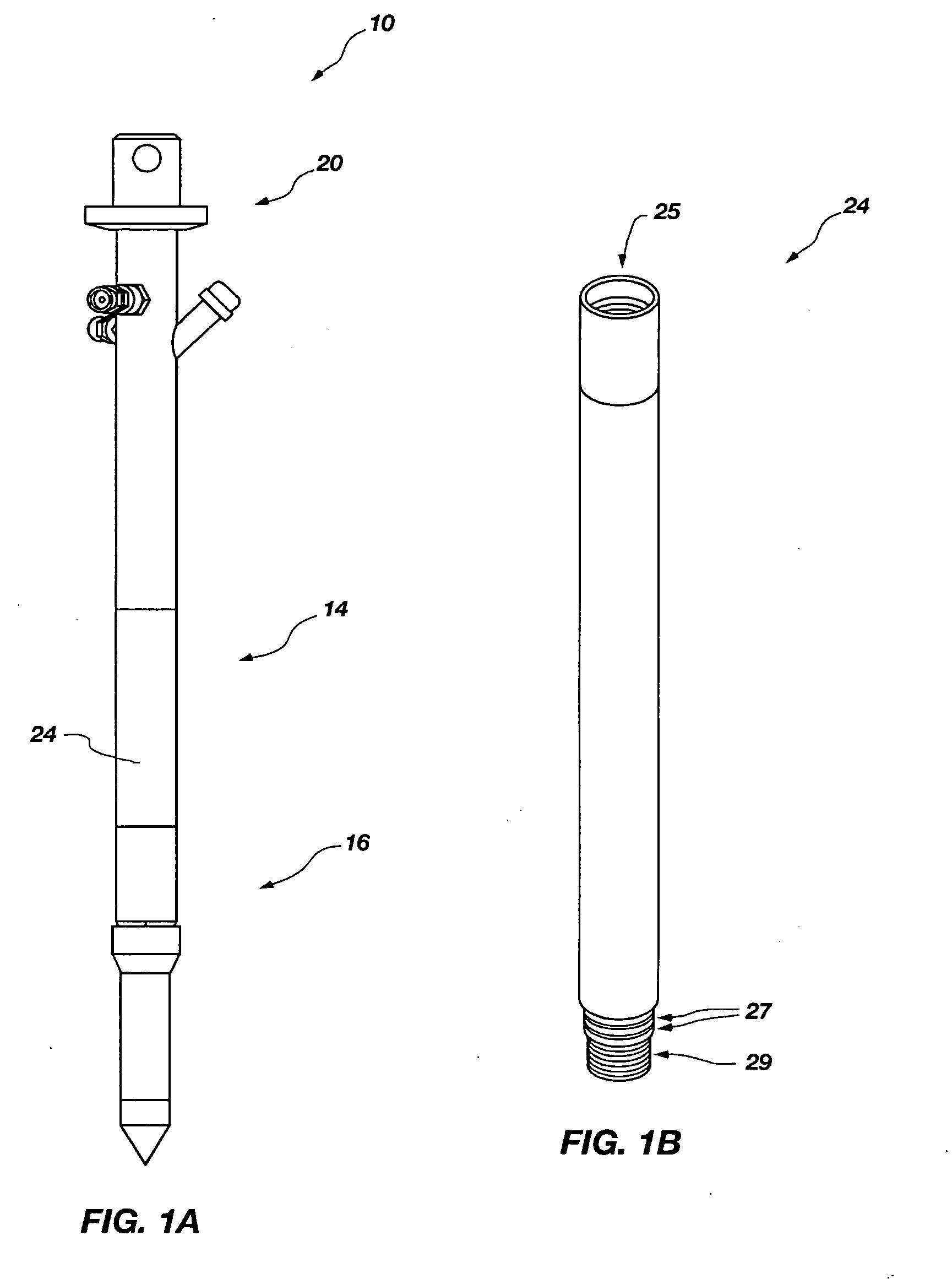

Apparatuses for interaction with a subterranean formation, and methods of use thereof

An access casing assembly structured for placement at least partially within a subterranean formation by forcing the access casing assembly thereinto, comprising a plurality of casing sections operably coupled to form a central elongated cavity for providing access to the subterranean region is disclosed. Further, a tip portion of the access casing assembly may include a porous filter through which liquid or gas may communicate with the central elongated cavity. Also, a receiving member or at least one engagement hub may form a portion of the central elongated cavity and may include an engagement feature configured for selectively and lockingly engaging a locking structure of a device to be positioned within the access casing assembly. Methods of use are disclosed. A tensiometer is disclosed including a chamber structured for allowing at least partially filling with a fluid subsequent to contact therewith.

Owner:BATTELLE ENERGY ALLIANCE LLC

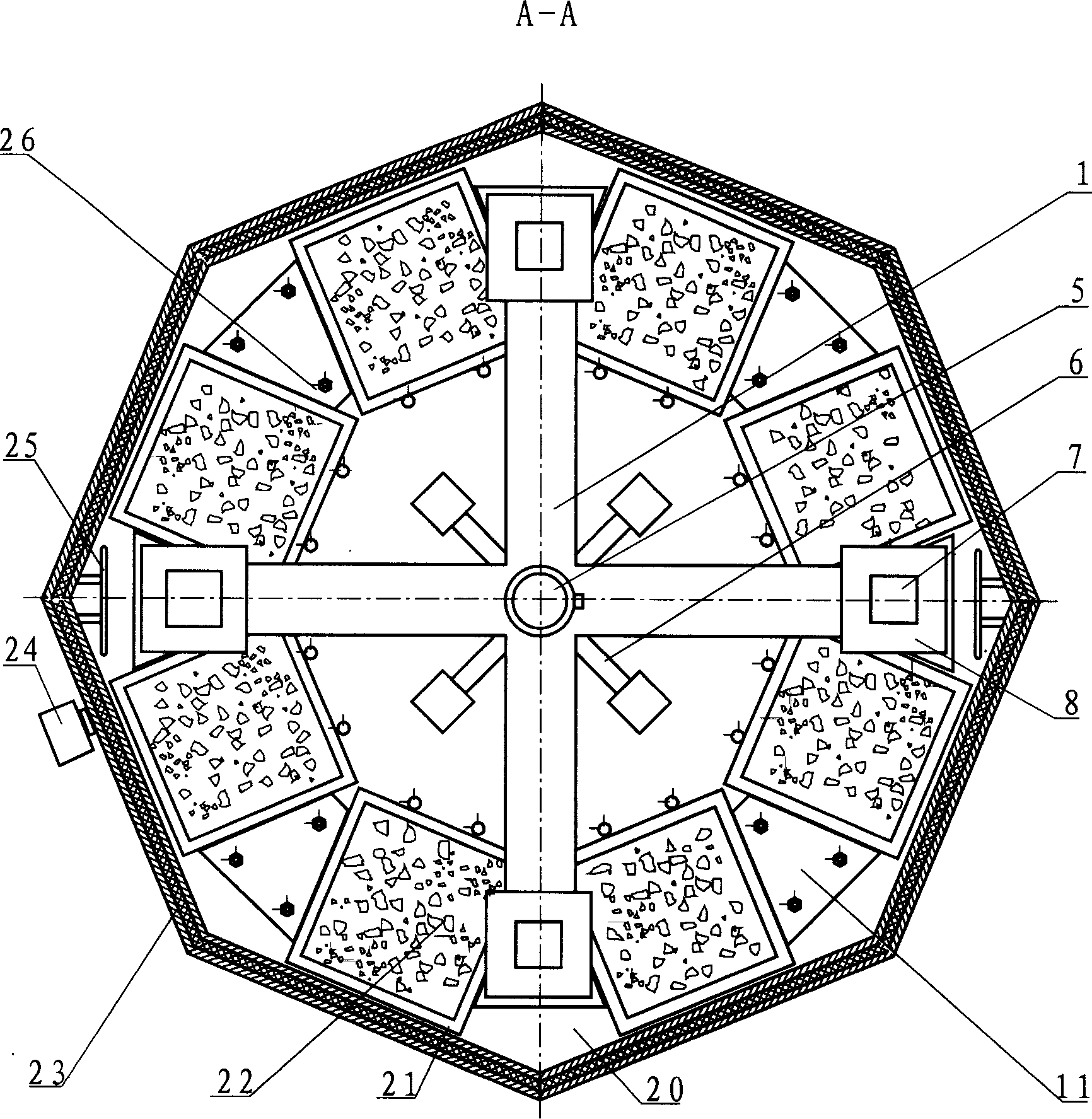

Indoor rotary wheel rutting test machine for asphalt mixture

InactiveCN1789961AShorten test timeShort test timeMaterial testing goodsInvestigating material hardnessDrive shaftTar

The invention discloses a tracking tester of indoor rotary tar hybrid material, which is characterized by the following: the rotary rack with rotary shaft is set on the floor of experimental table and in the environmental box; the top of rotary table pillar connects the experimental table panel; the speed adjustment motor contains electric rack, bearing support seat and heating pipe, which connects the rotary shaft through driving structure; the bottom of driving shaft is set on the bearing support seat; the rotary bearing is set between the rotary shaft and bearing support seat; the rotary bridge is set on the rotary shaft; the bearing sleeve and bearing are set between the rotary bridge and rotary shaft; rubber tyre column slide cylinder within at least one rubber tyre column is set on the rotary bridge; the weight block holder is set on the rubber tyre column to load the weight block and the rubber tyre is set on the bottom; the limitation column and at least two steel molds are set on the experimental table panel to assemble test piece of tar hybrid material with pad board among steel molds; the temperature controller is set on the exterior of environmental box. The invention shortens the test time and improves the efficiency, which can be used in the tracking-proof experiment of tar hybrid material pavement.

Owner:CHANGAN UNIV

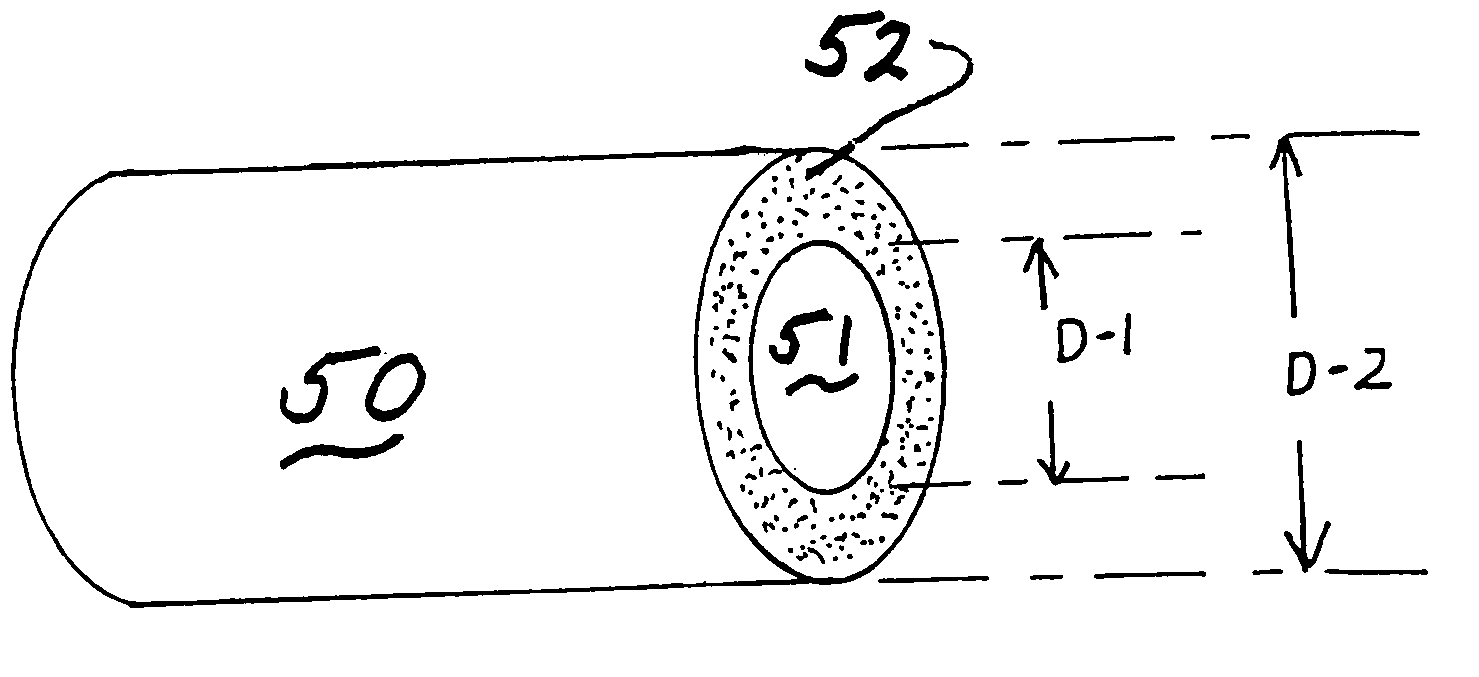

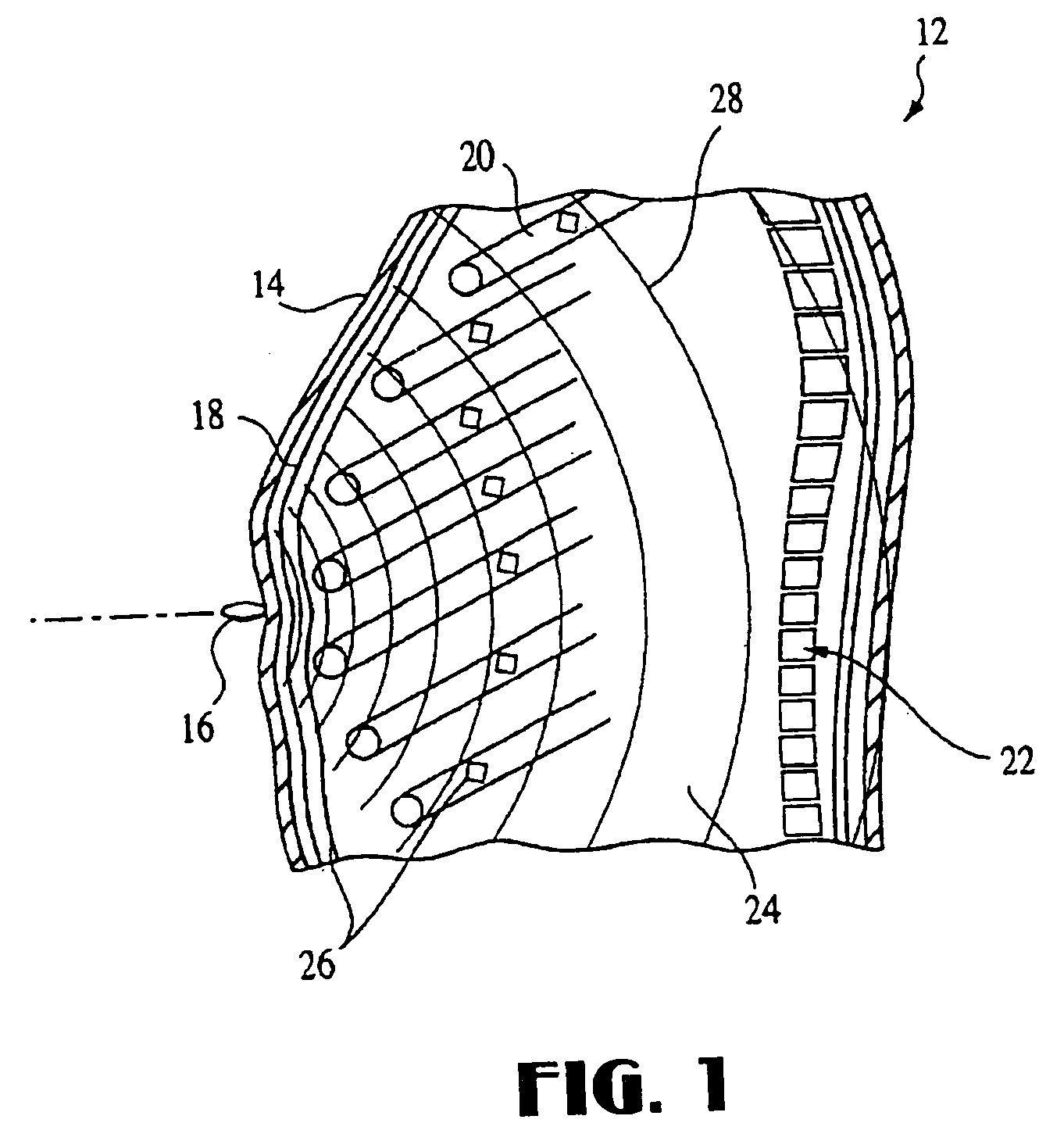

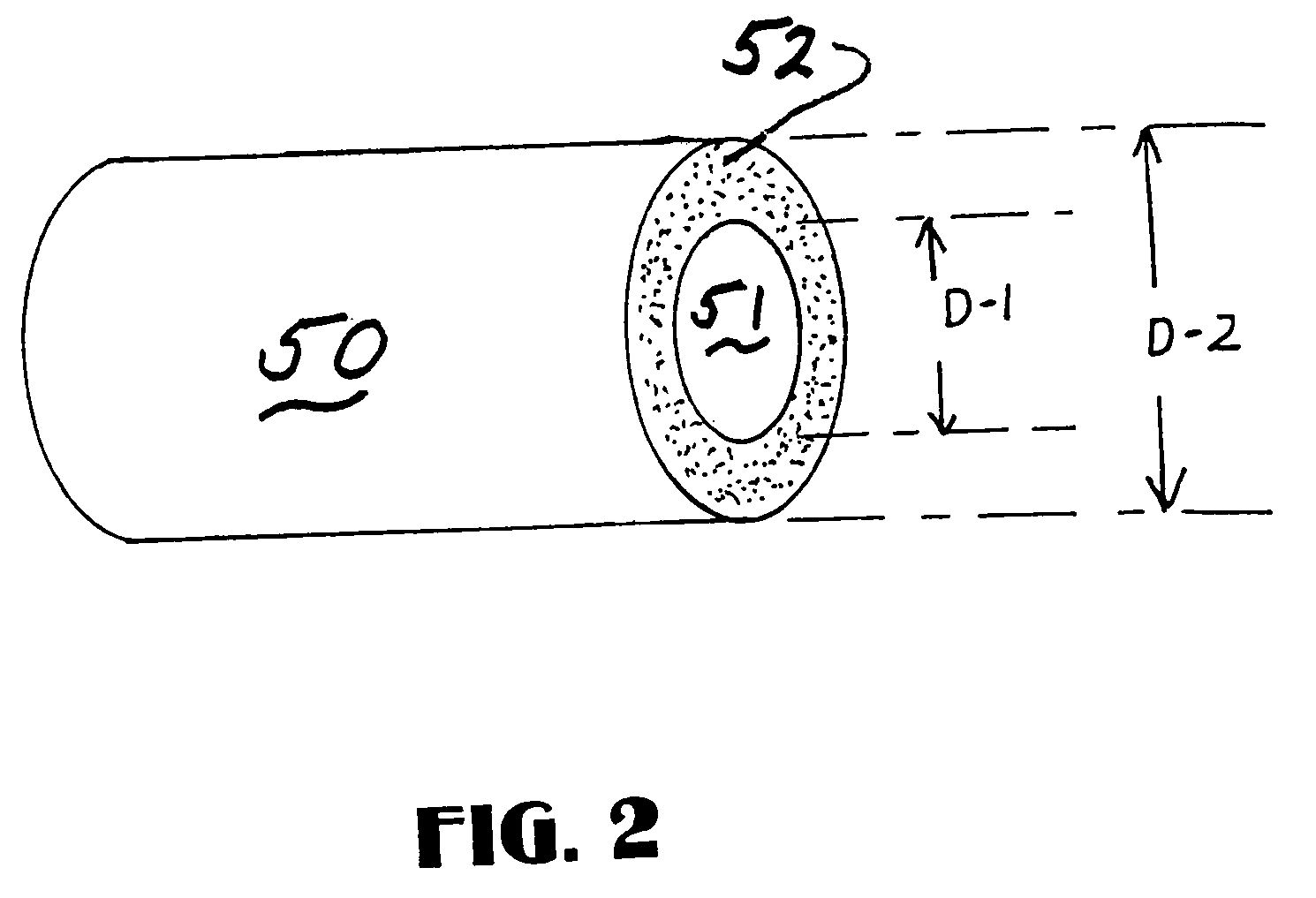

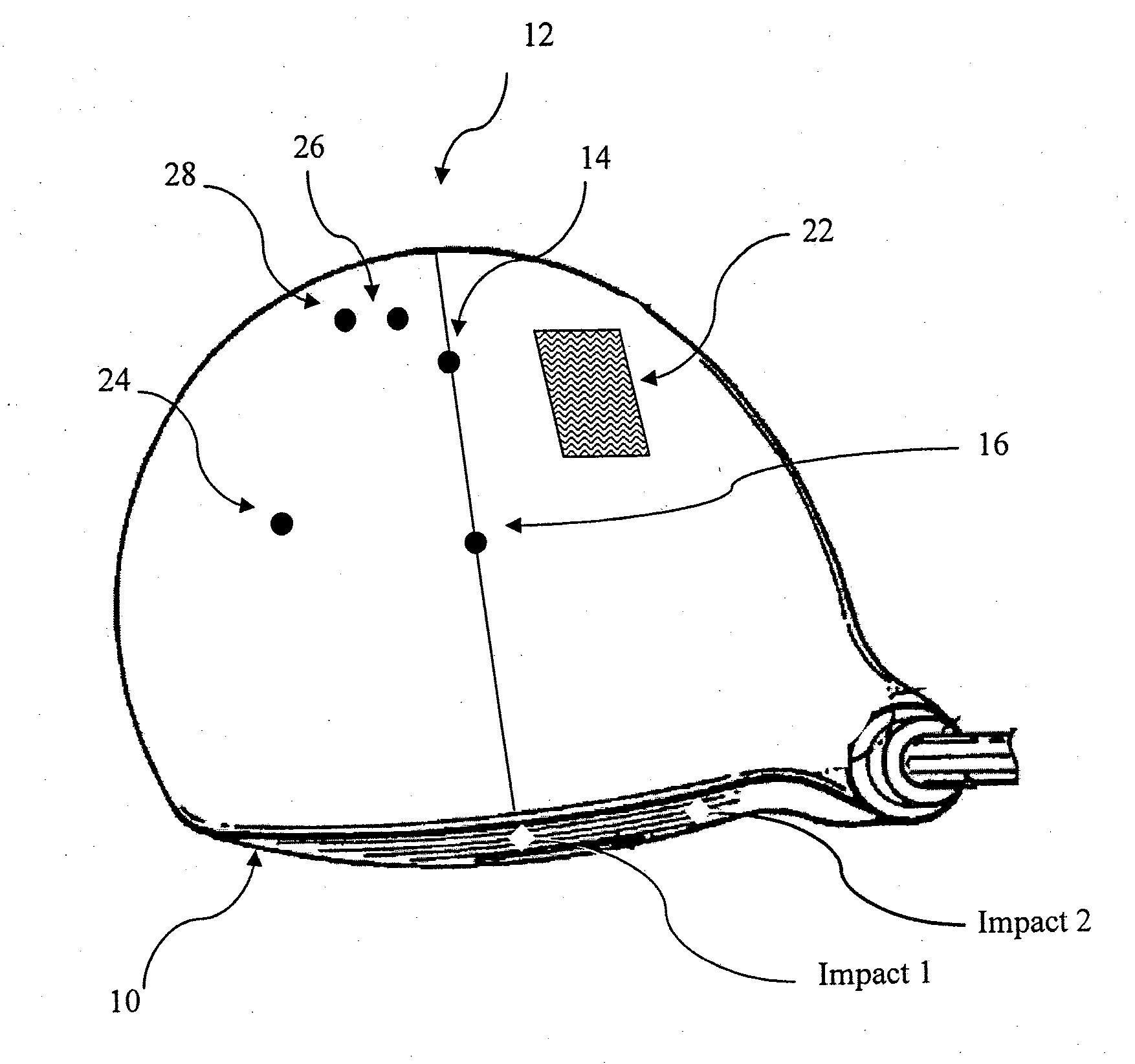

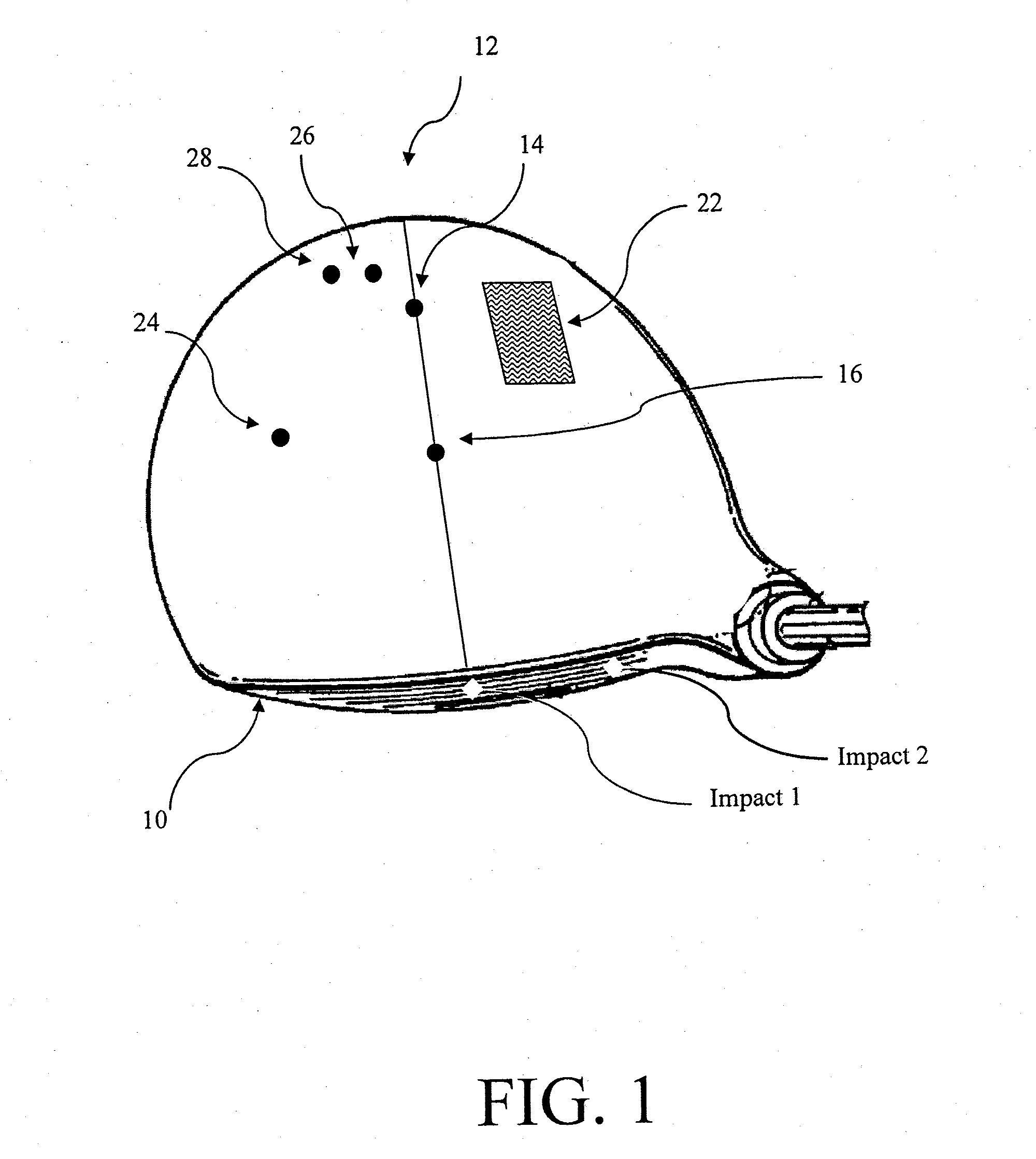

Synthetic cortical bone for ballistic testing

A bone substitute for use in impact testing of a structure simulating the human body which includes a member fabricated from epoxy resin and having a lengthwise dimension, and a fiberglass sheath embedded in an outer circumferential portion of the member, the sheath having glass fibers oriented along the length of the member.

Owner:ROBERTS JACK C +3

Golf club head comprising a piezoelectric sensor

ActiveUS20090165531A1Gymnastic exercisingForce measurement using piezo-electric devicesEngineeringGolf Ball

An apparatus and method for determining the kinematic characteristics of a golf club head are disclosed. The apparatus includes at least one piezoelectric component selectively positioned within or upon a club head. The piezoelectric component is preferably positioned to the rear of the center of gravity, and near the midpoint of the face of the club head. During a golf club swing, the piezoelectric component determines the acceleration and deceleration of the golf club head. When the club head impacts an object such as a golf ball, the piezoelectric component is also operable to determine the velocity of the club head. It may also be desirable for the piezoelectric component to determine the magnitude of vibration during impact. In this manner, the piezoelectric component may function determine the efficiency of a golf club swing.

Owner:ACUSHNET CO

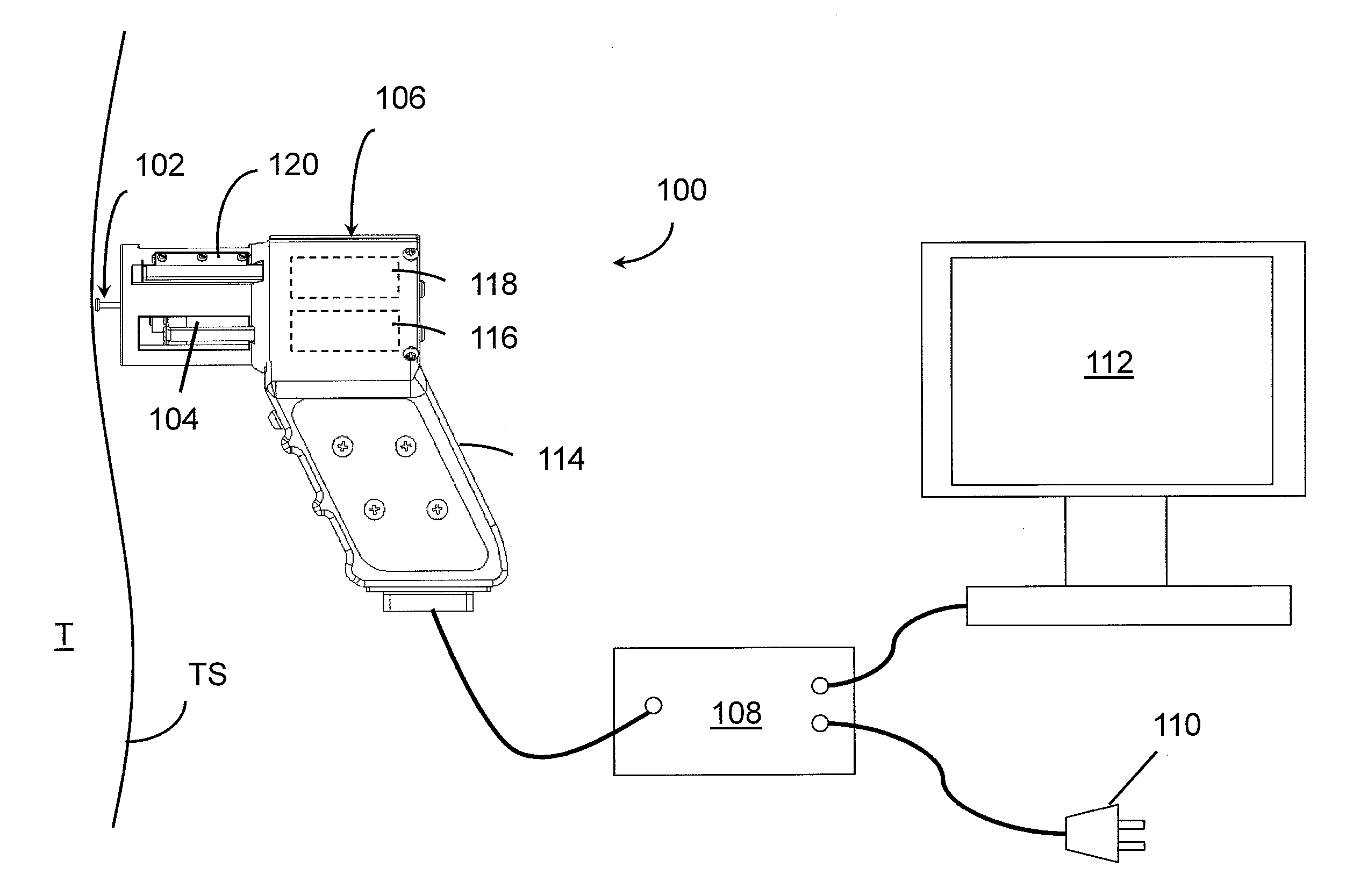

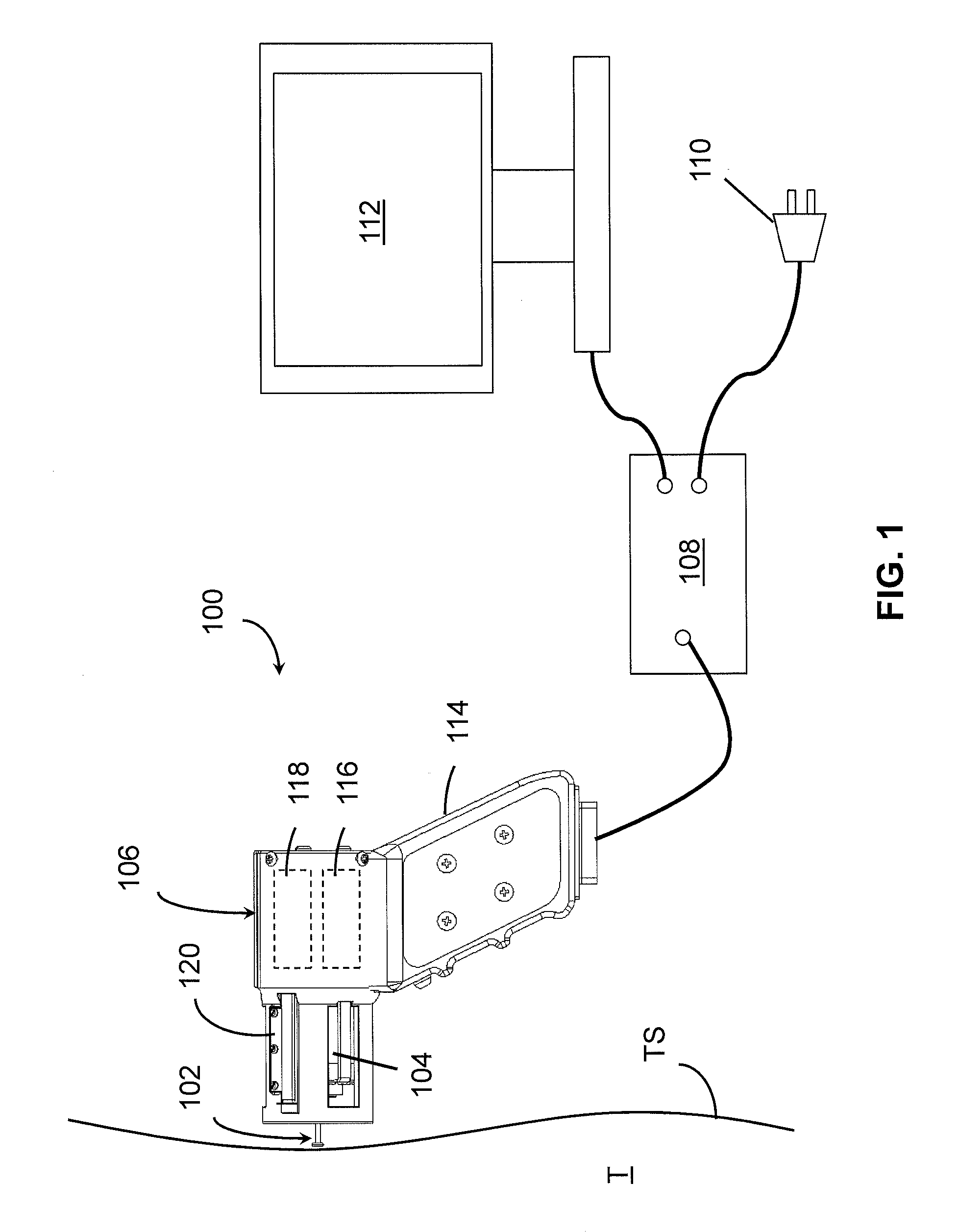

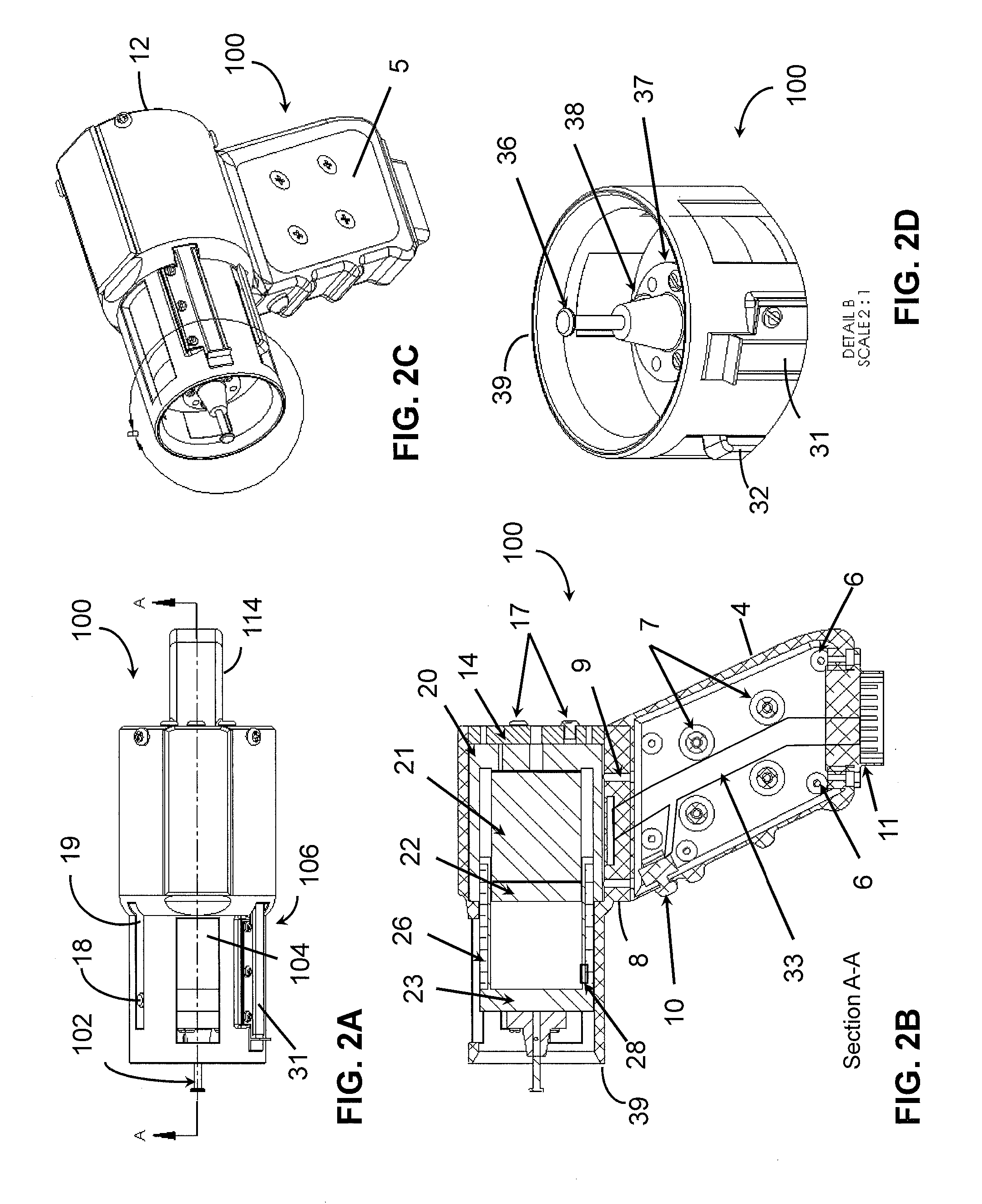

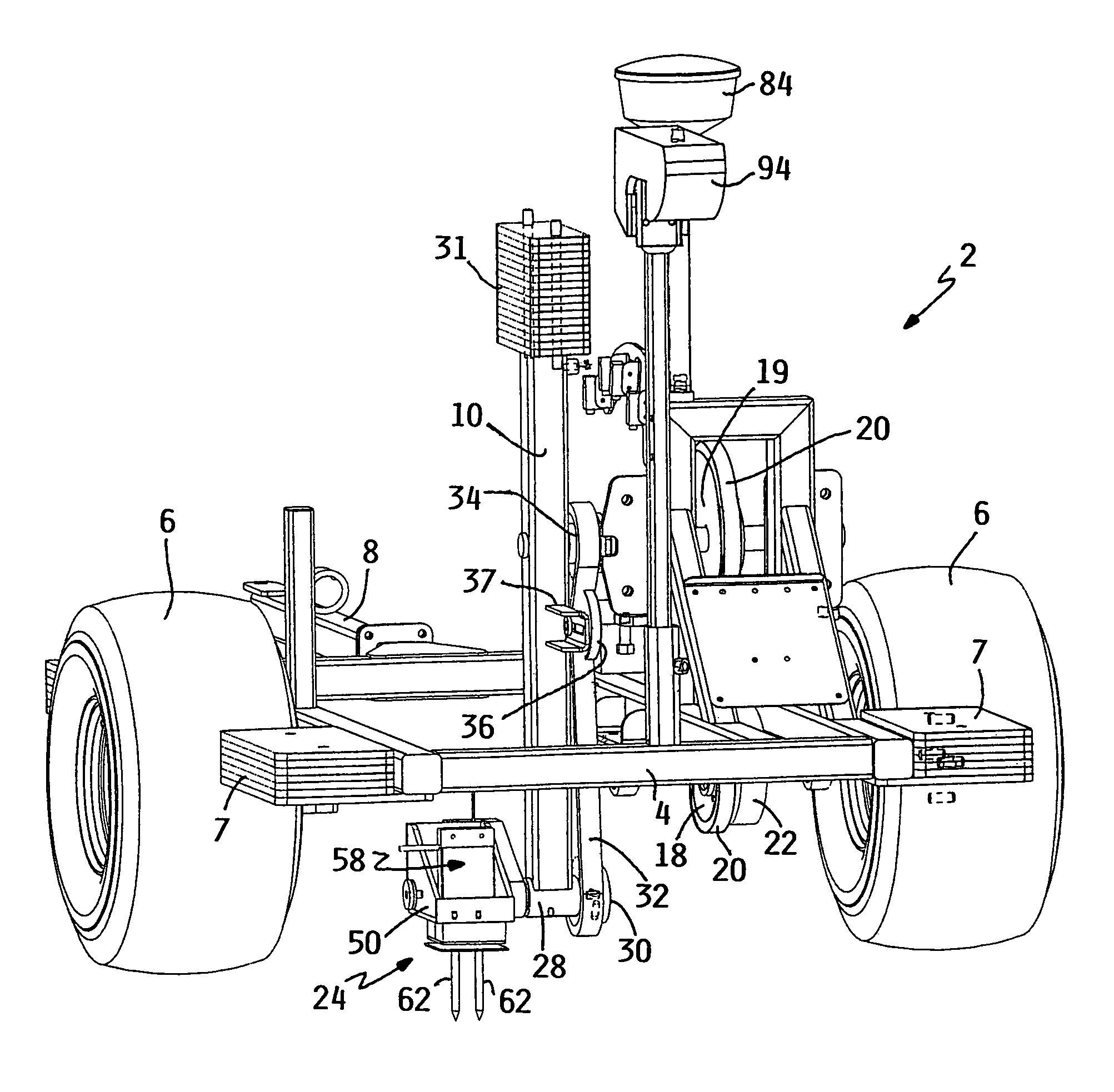

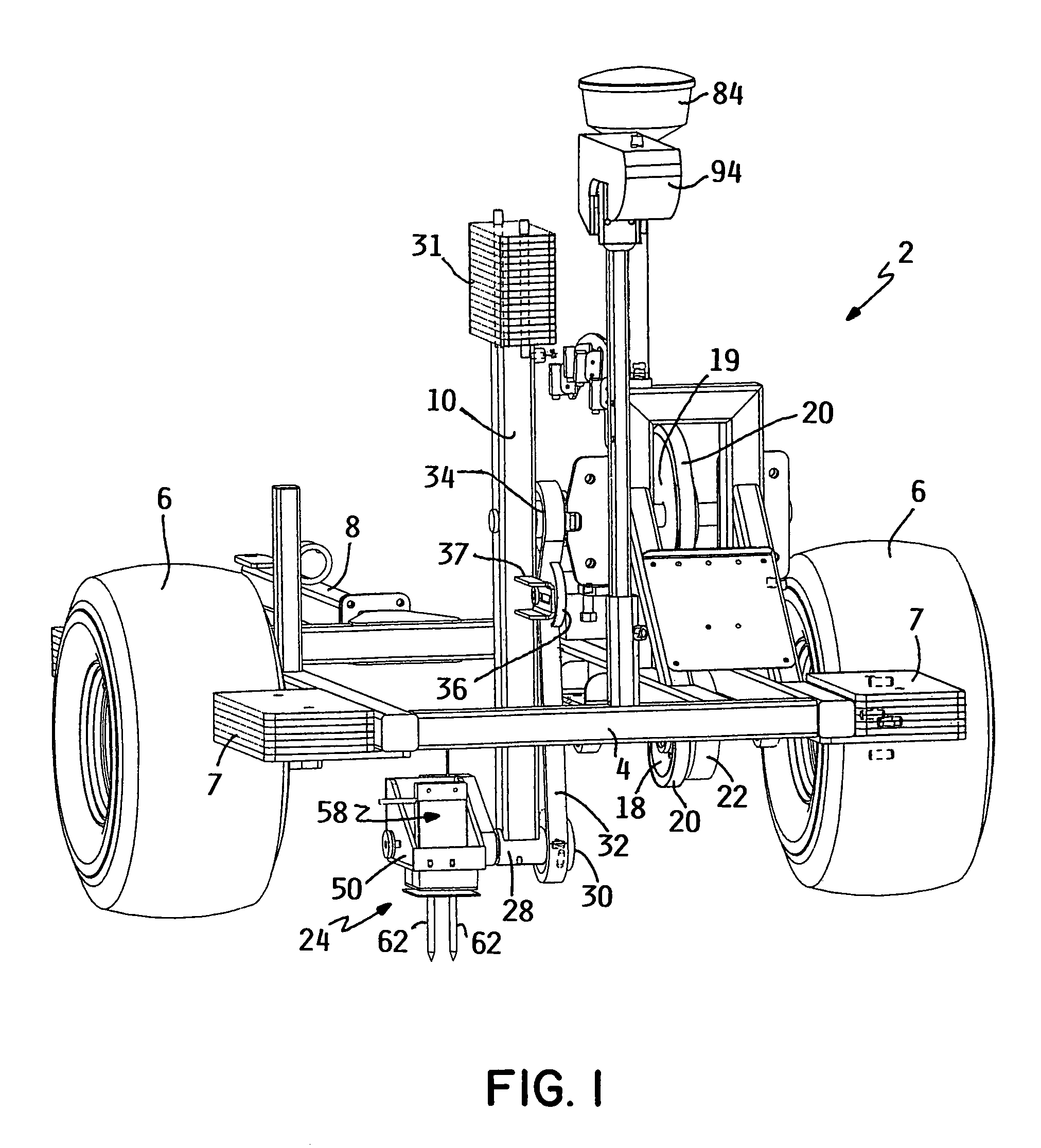

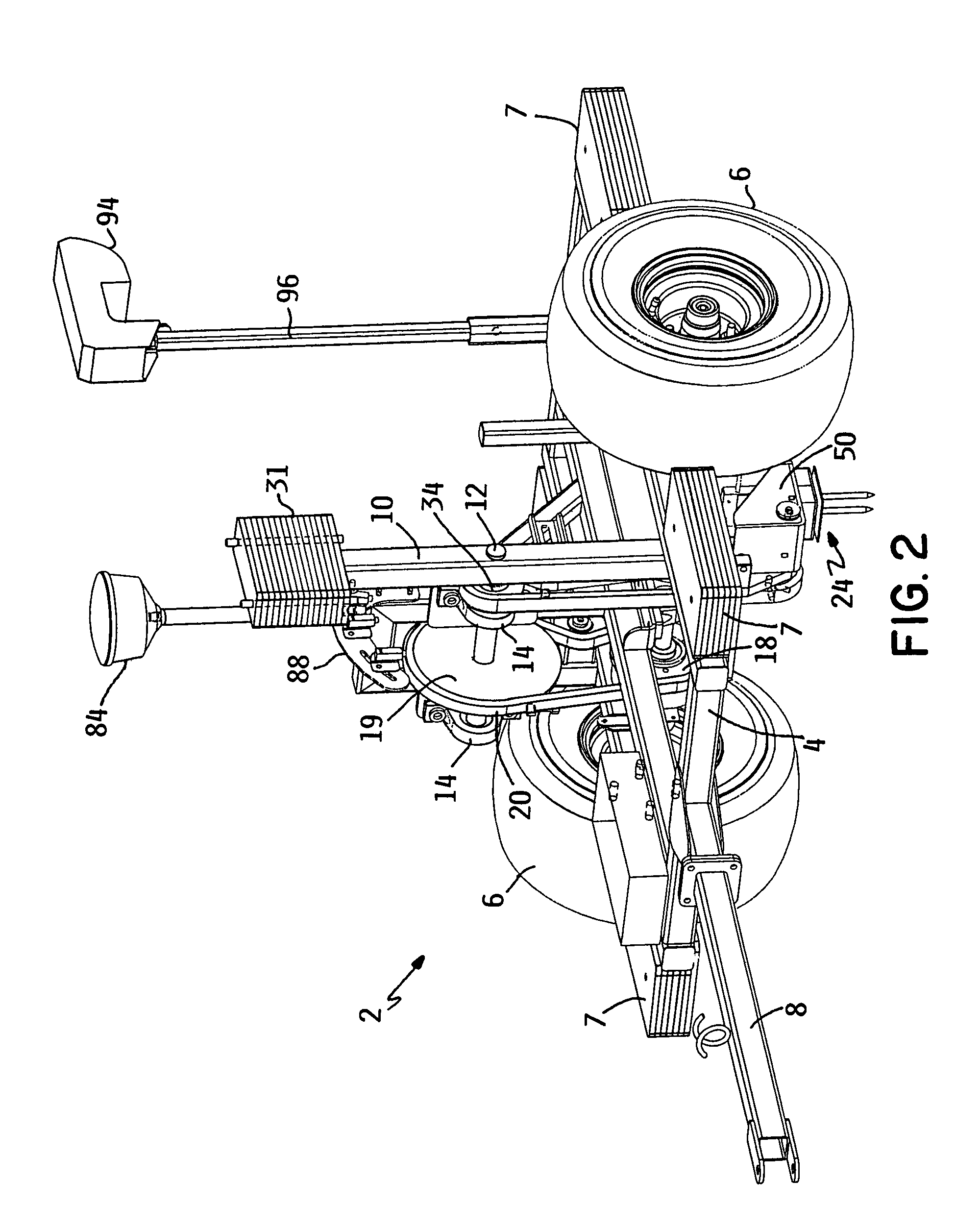

Mobile turf instrument apparatus having driven, periodically insertable, ground penetrating probe assembly

ActiveUS7628059B1In situ soil foundationInvestigating material hardnessMeasurement deviceSoil moisture sensor

A mobile turf instrument apparatus has a wheeled frame that may be propelled over the ground by a motive device, such as by a separate vehicle or by its own engine and drive train. A driven arm is carried on the frame and revolves in circles to periodically insert the probe(s) of a probe assembly into the ground during motion of the frame. The drive to the arm is momentarily disengaged when the probe(s) of the probe assembly are inserted into the ground. The probe assembly comprises two parts that rock relative to one another. Two soil measurement devices are connected to the probe assembly. A soil moisture sensor is coupled to the probe assembly for measuring soil moisture when the probe(s) are inserted into the ground. A load cell is responsive to the amount of rocking of the two parts of the probe assembly to measure soil compaction.

Owner:TORO CO THE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com