Patents

Literature

88results about How to "The test method is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

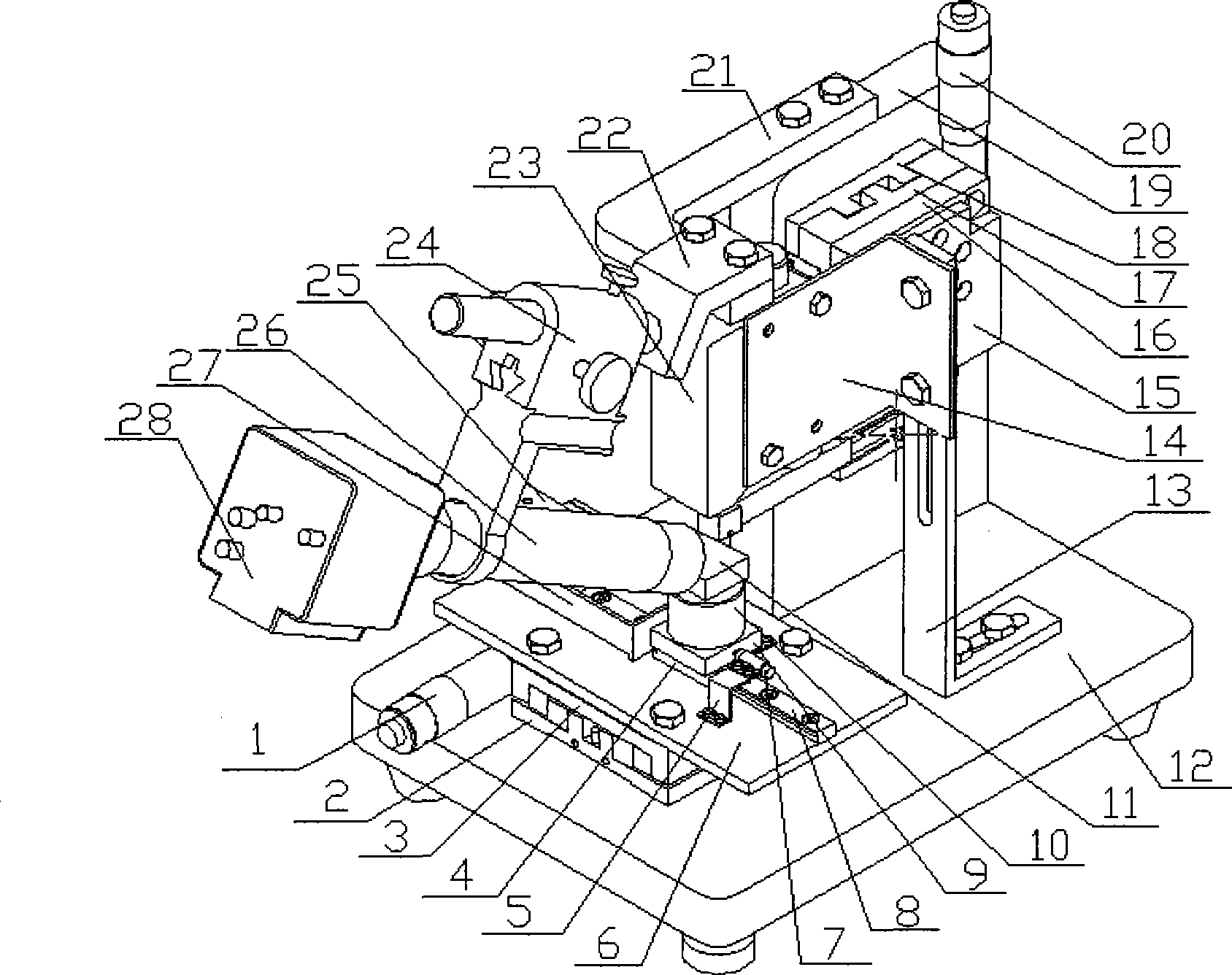

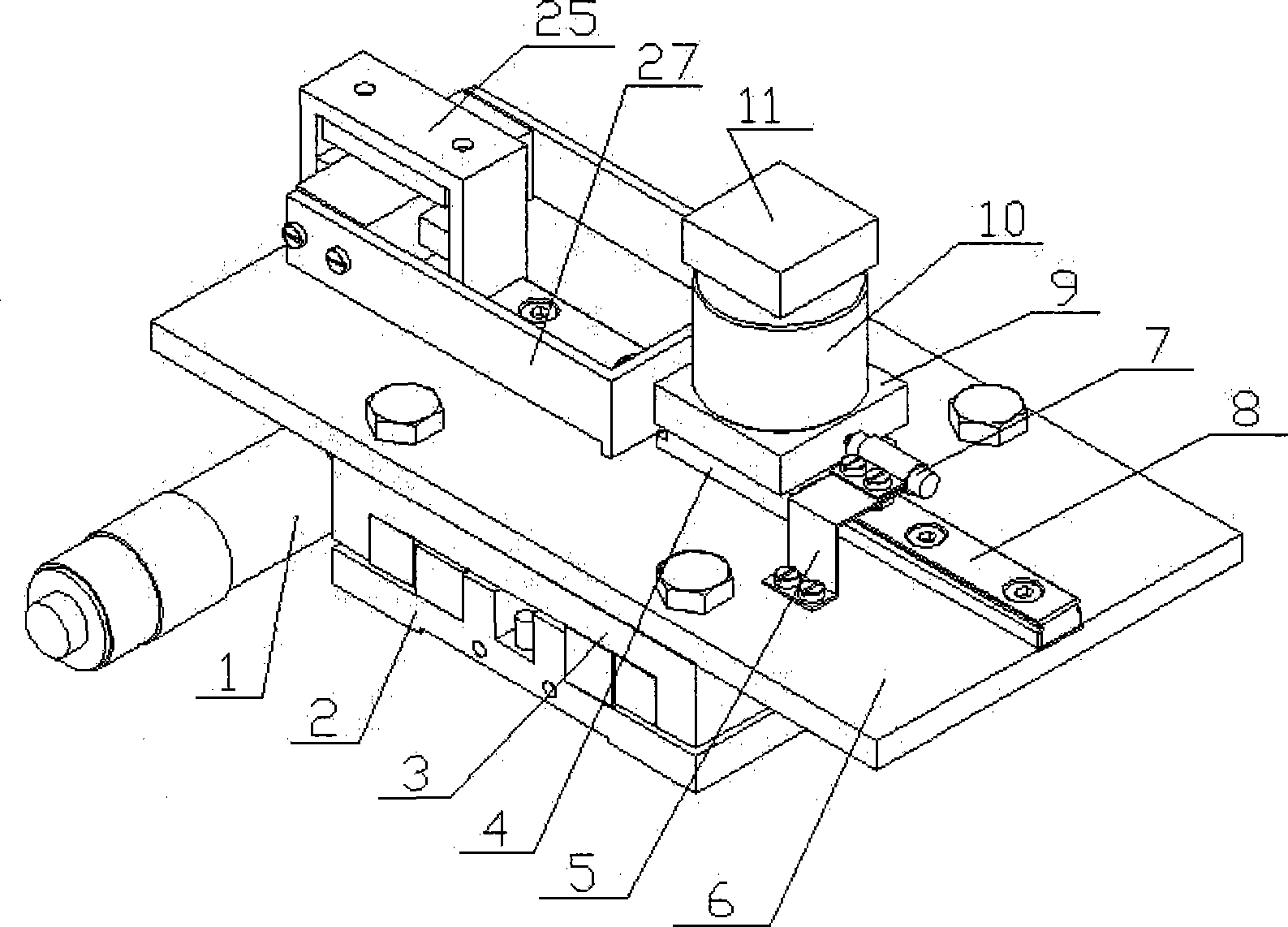

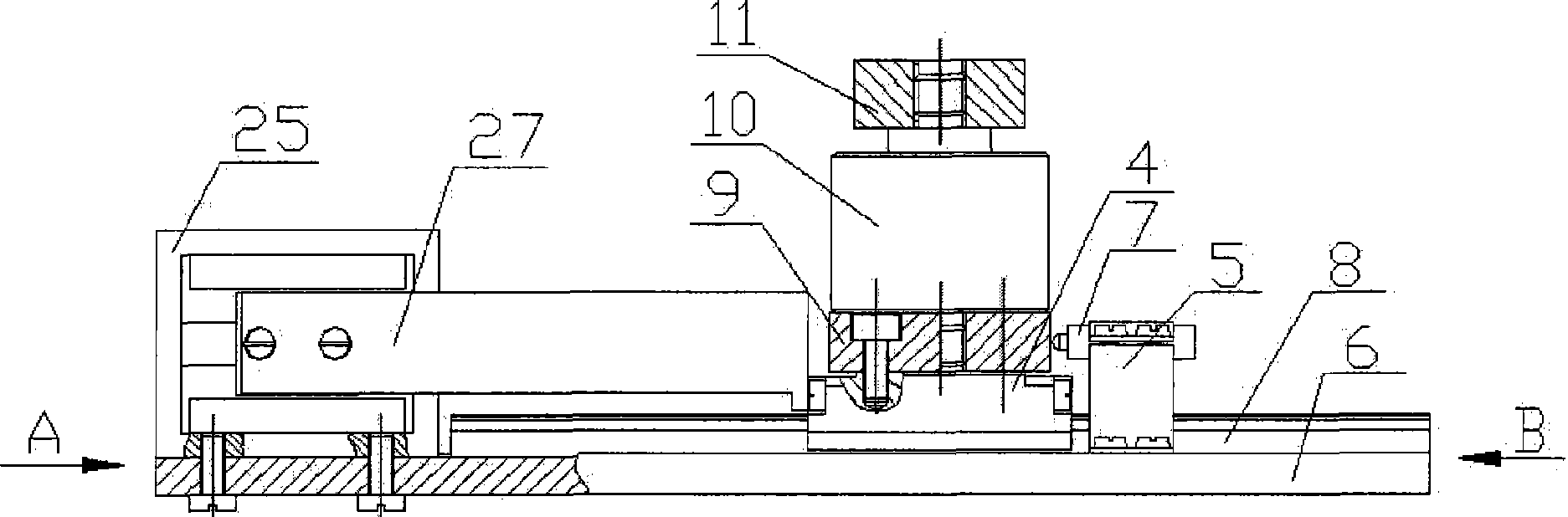

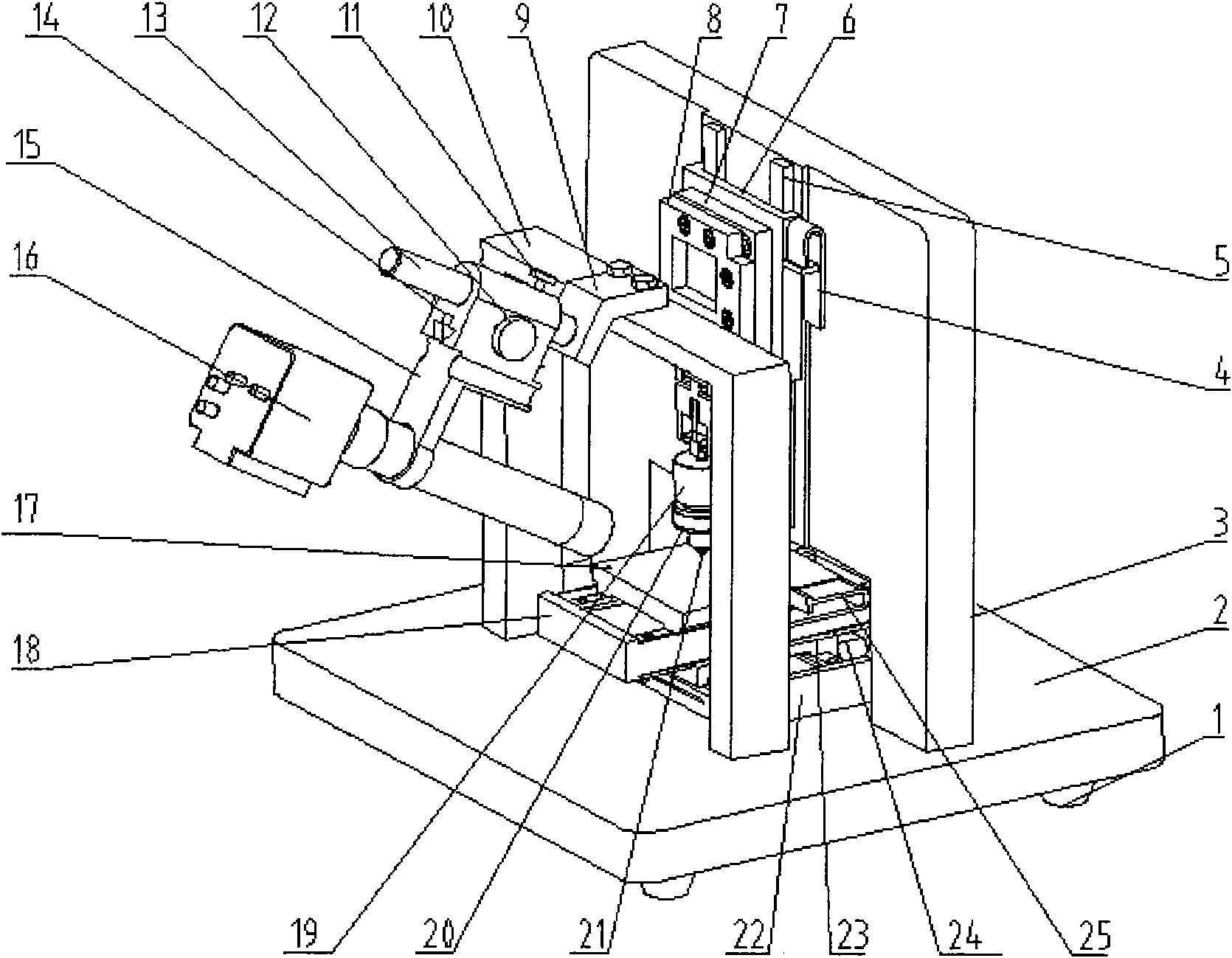

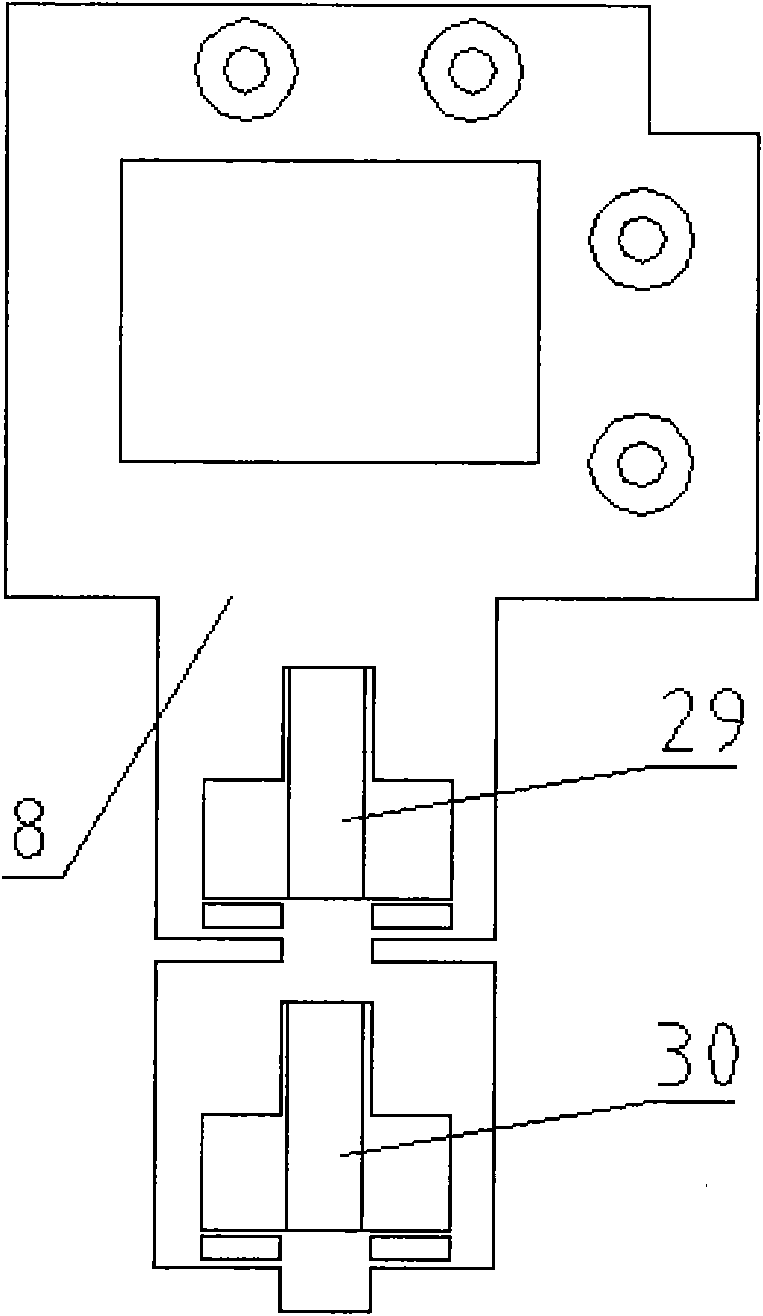

Super-precision trans-scale in-situ nanometer indentation marking test system

ActiveCN101520389AThe test method is accurateAccurate and effective research and testing methodsUsing optical meansInvestigating material hardnessHead pressingImage resolution

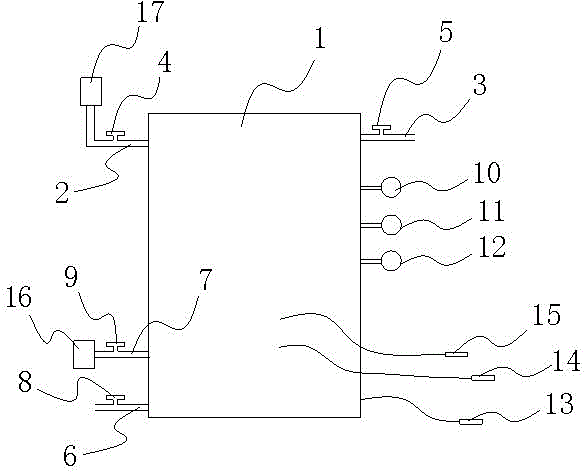

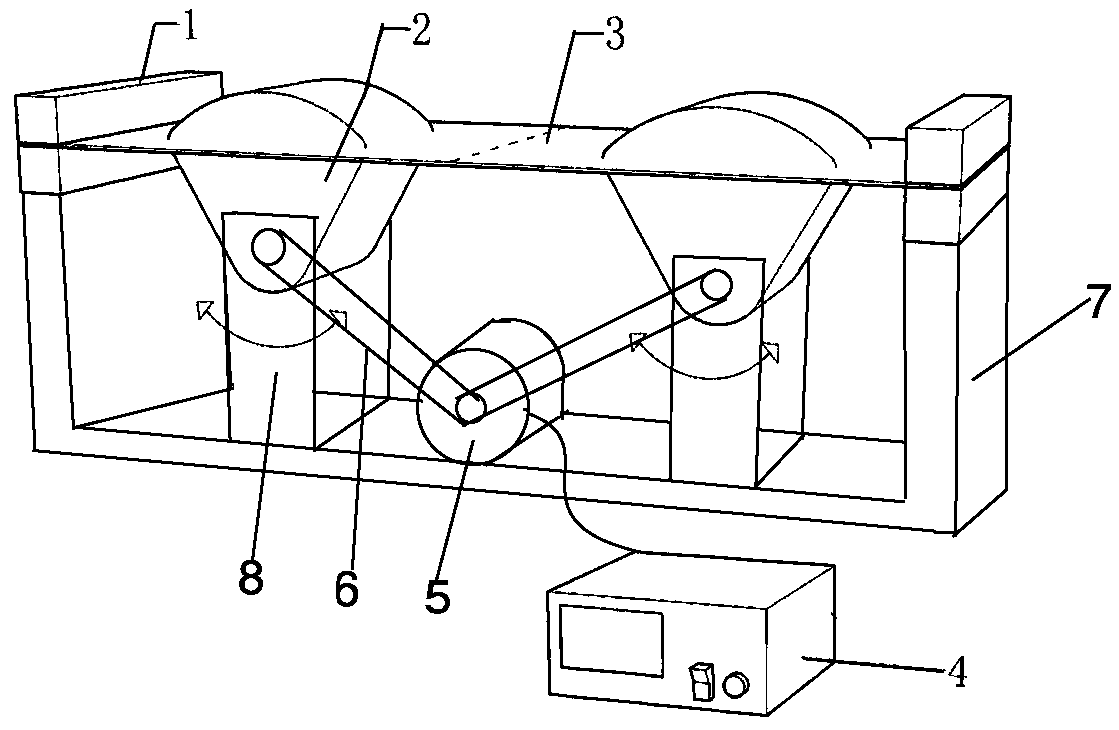

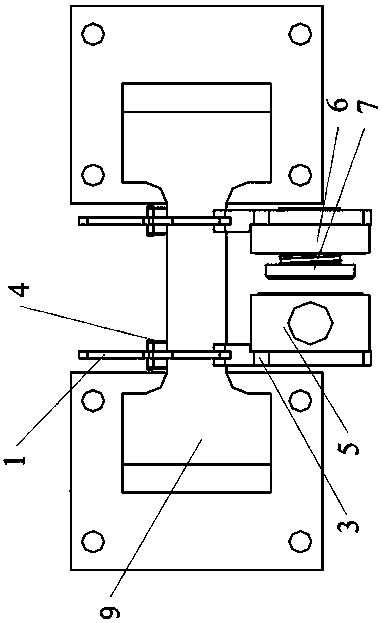

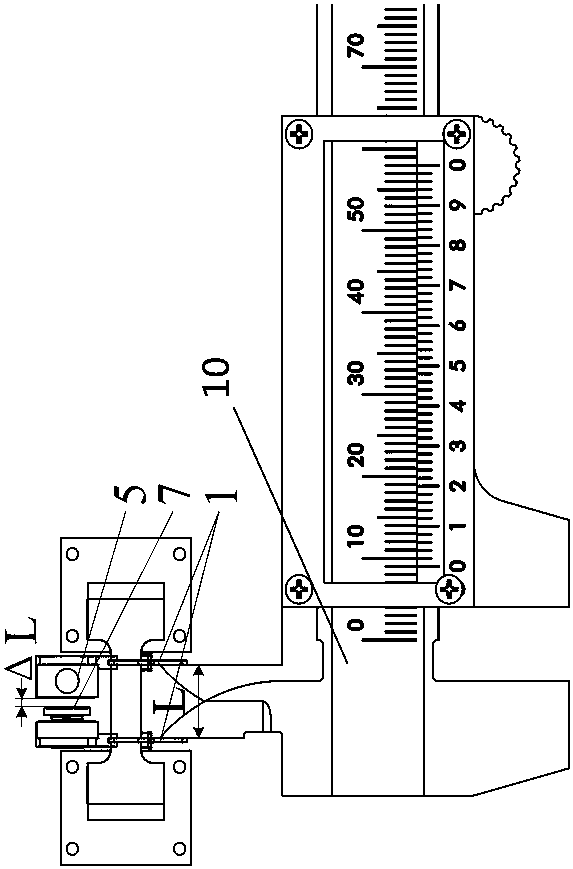

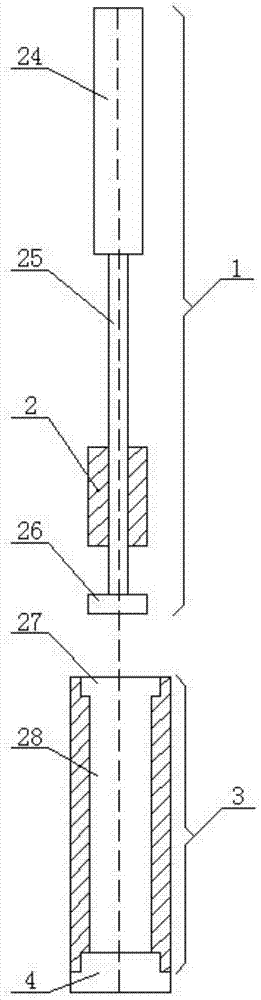

The invention relates to a super-precision trans-scale in-situ nanometer indentation marking test system which integrates driving, loading, detecting and micro-nanometer dynamic performance tests, super-precision marking processing and in-situ observation into a whole. The system mainly comprises an objective table, a regulation mechanism, a detection unit, a precise pressed-into driving unit, a detection unit of load signals and displacement signals and a high-resolution digital microscopic imaging system, wherein the objective table is precisely positioned along the directions of the X axis and the Y axis; the regulation mechanism and the precise pressed-into driving unit are in the direction of the Z axis and are assembled on a base; the high-resolution digital microscopic imaging system is used for observing the deforming and damaging conditions of the material in the storing and testing process; the objective table as well as the regulation mechanism and the precise pressed-into driving unit in the direction of the Z axis are assembled on a base; the high-resolution digital microscopic imaging system is arranged on the objective table; a precise dynamic sensor detecting the pressure of a diamond tool head pressed into a material and a sensor I detecting the precise displacement of the objective table in the directions of the X axis and the Y axis are arranged on the objective table; and a sensor II used for detecting the precise displacement of a diamond tool head in the direction of the Z axis of pressed-into depth is arranged on the base by a support I.

Owner:JILIN UNIV

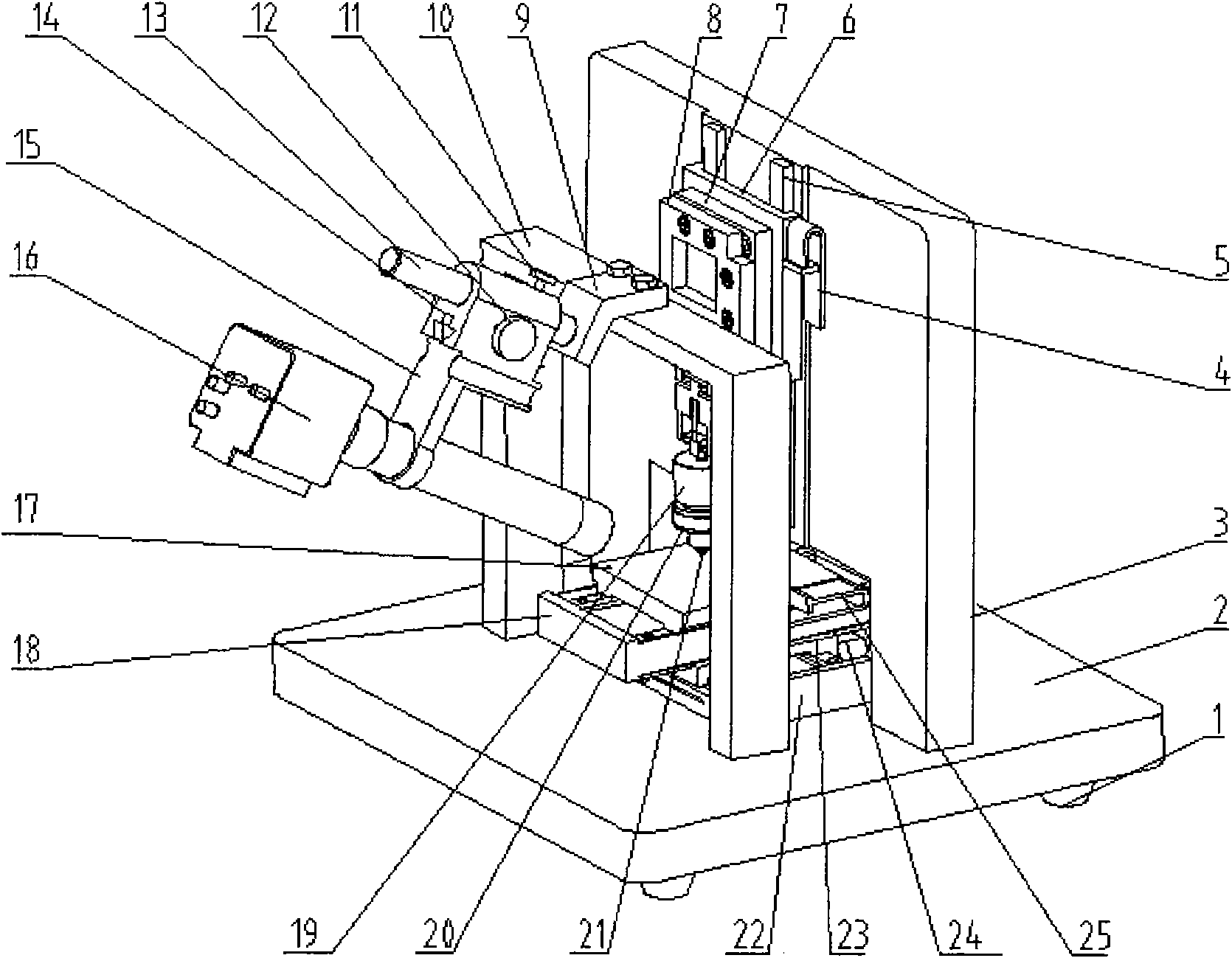

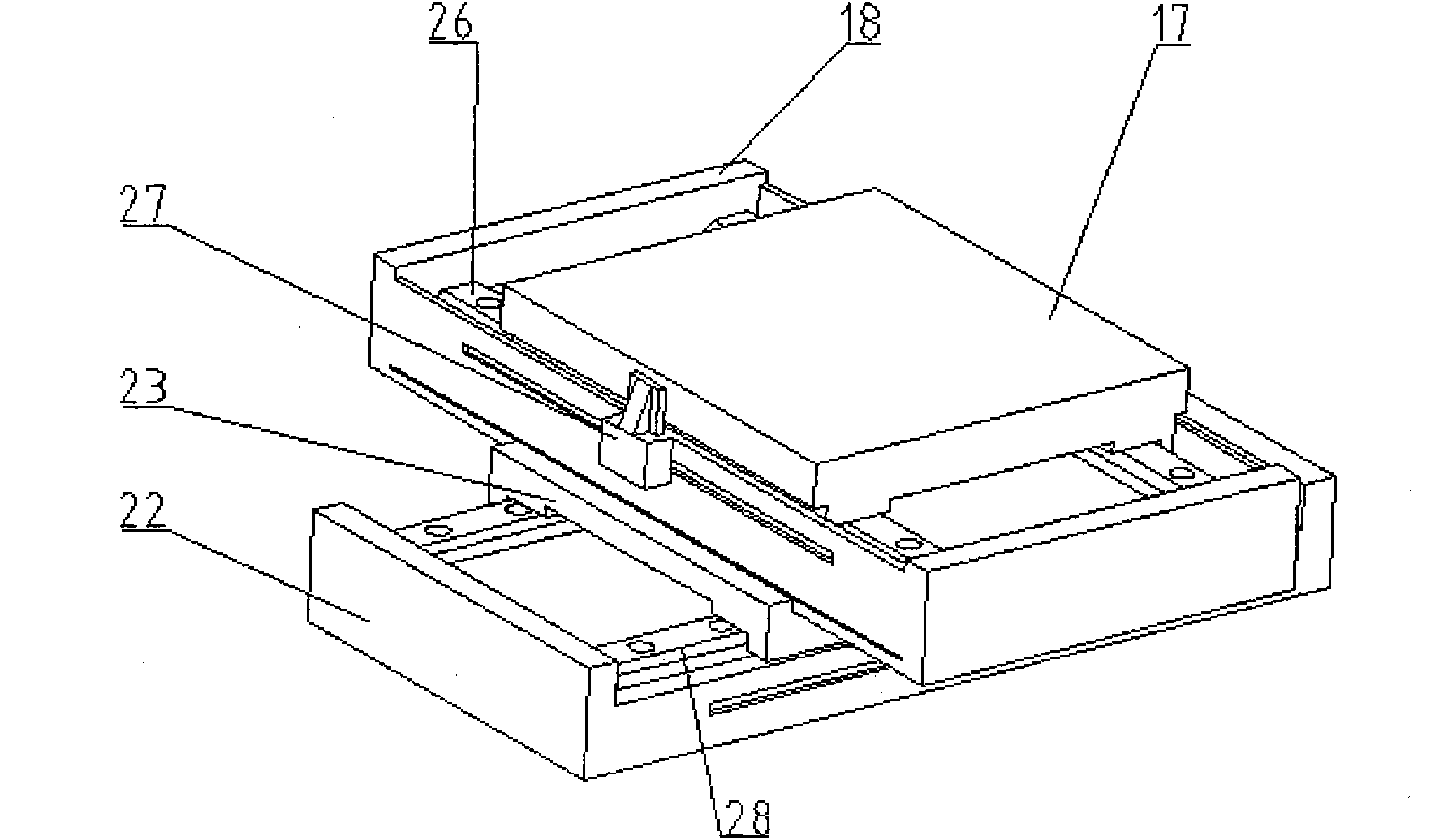

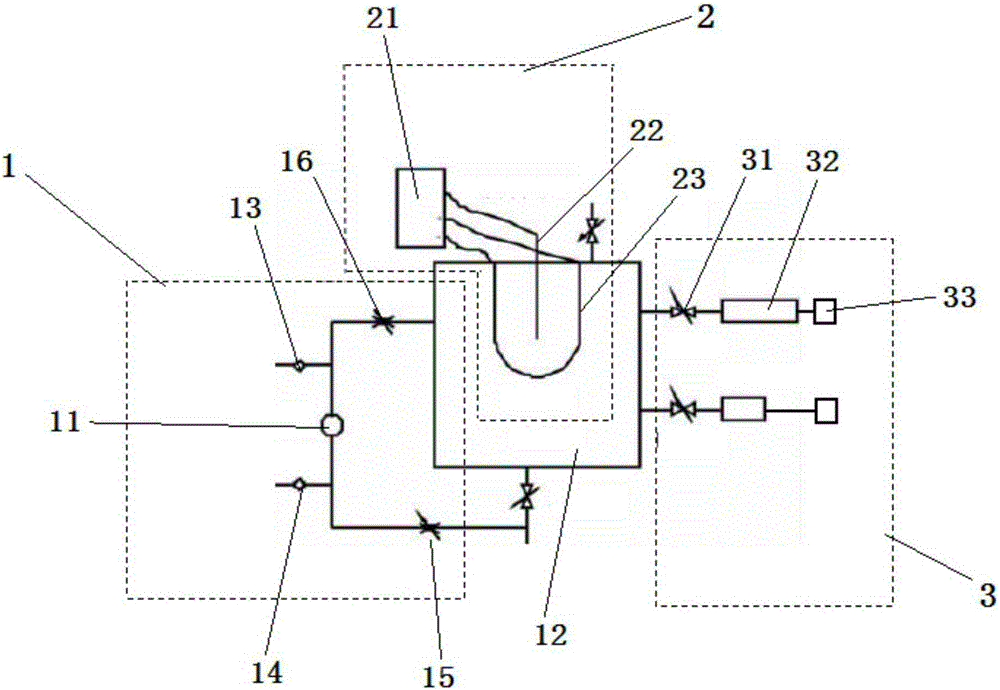

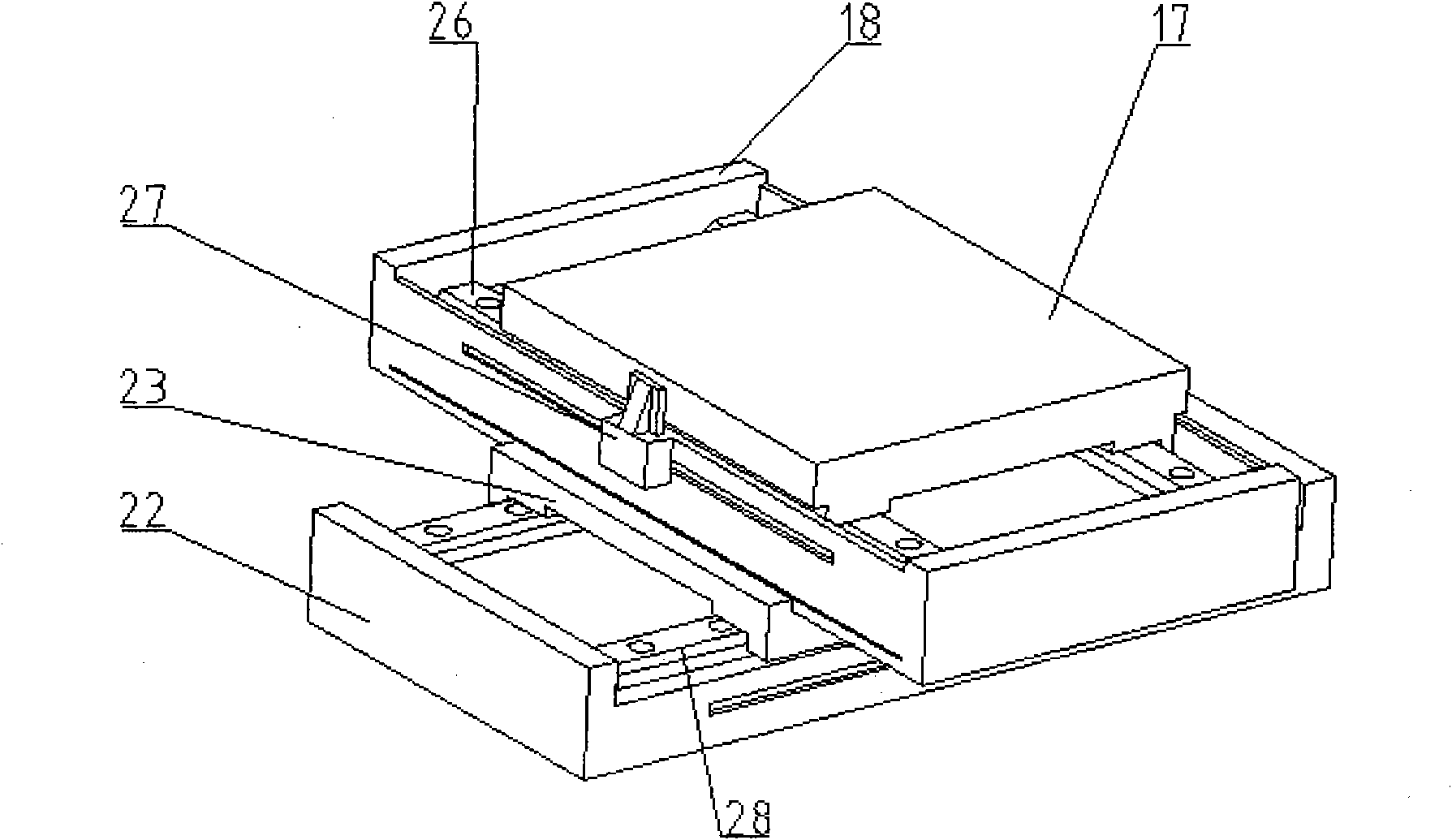

Micron-nano scale in-situ nano indentation and scratching test system

InactiveCN101876609AThe test method is accuratePrecision equipmentUsing optical meansInvestigating material hardnessImage resolutionEngineering

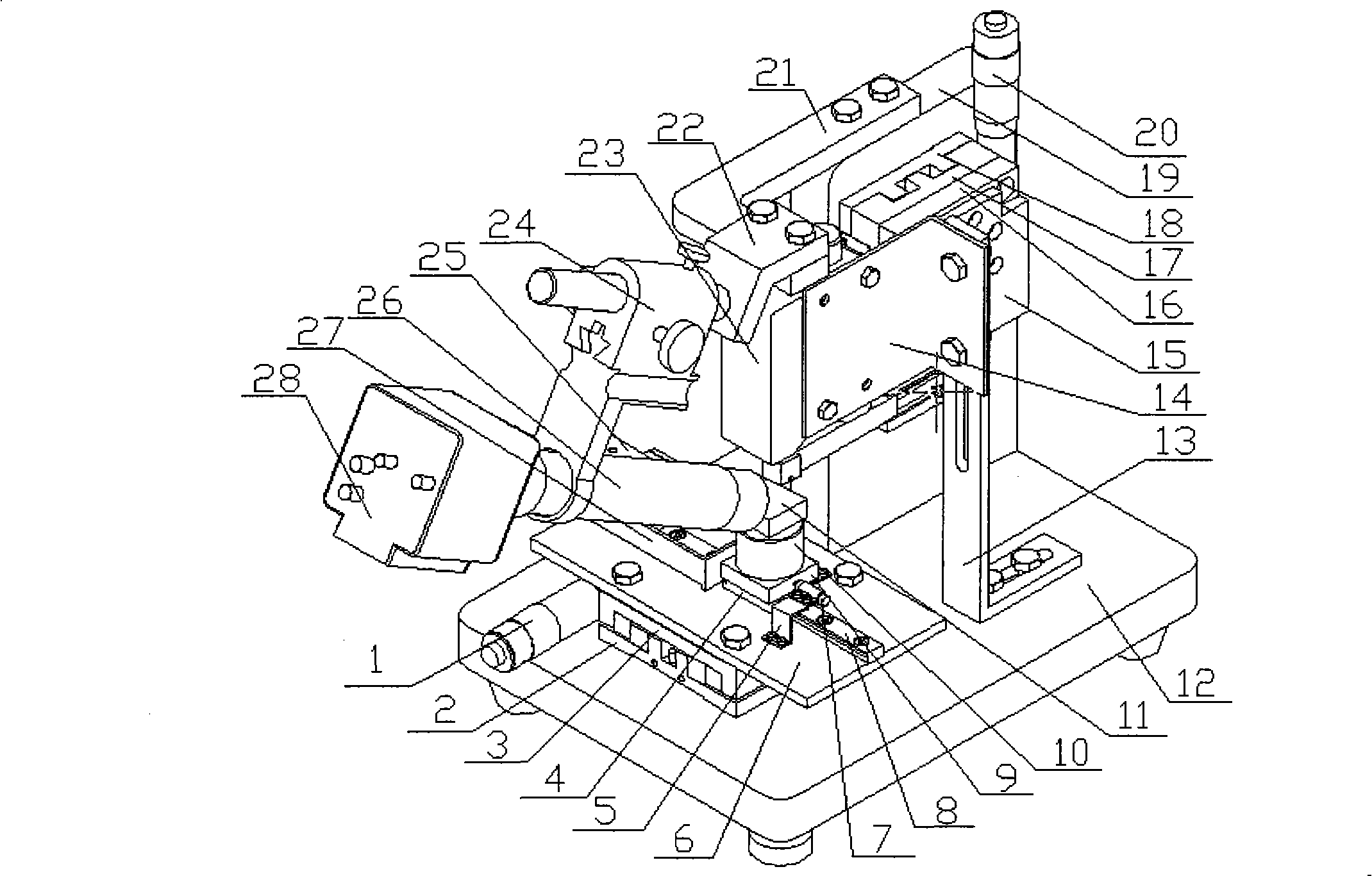

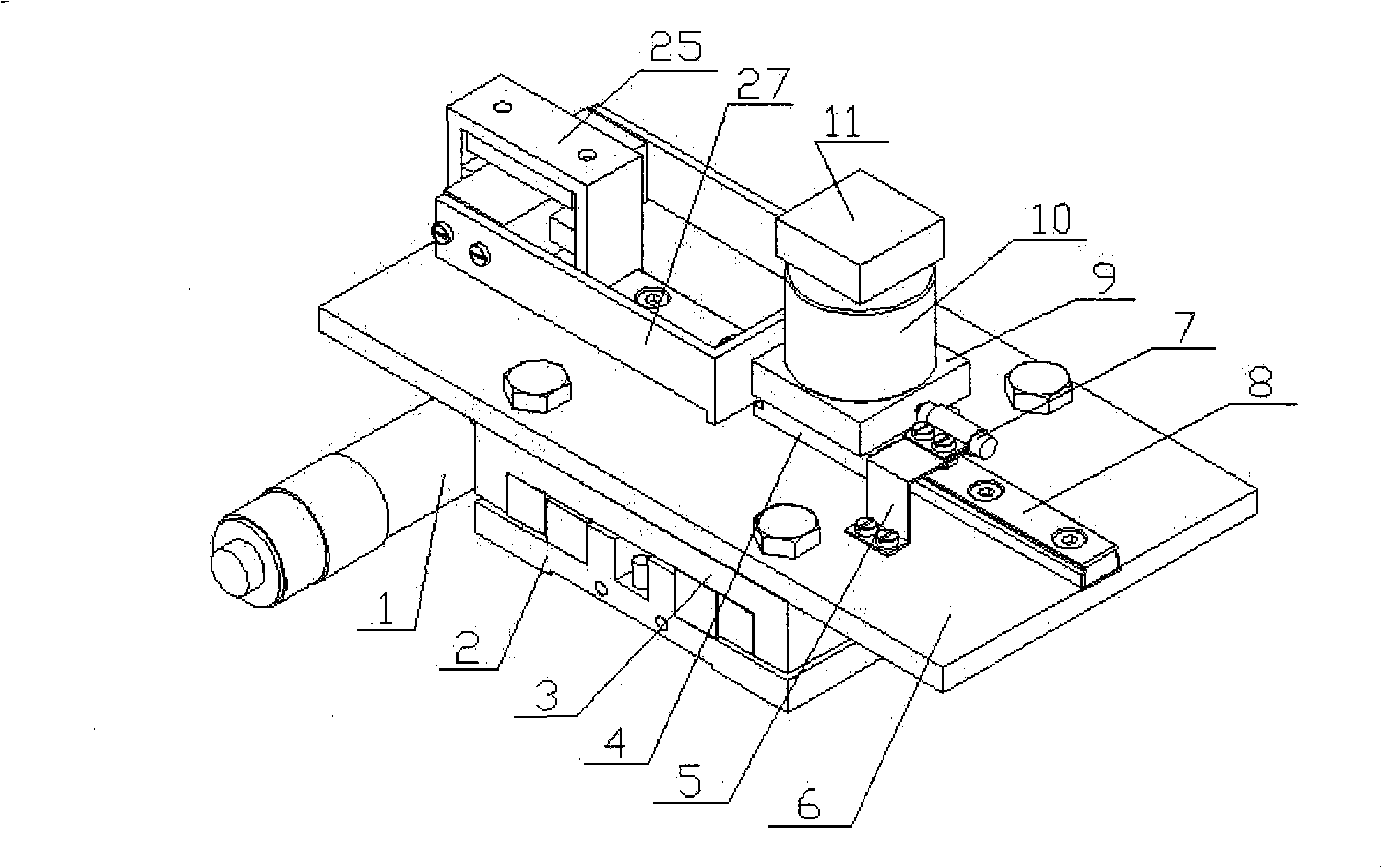

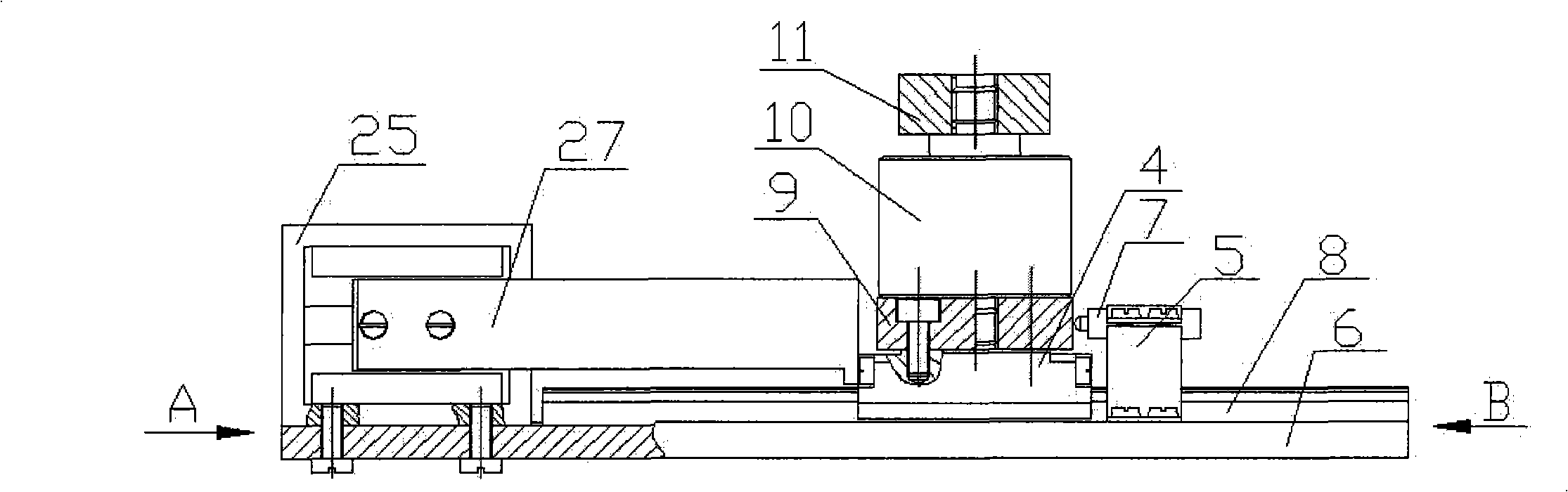

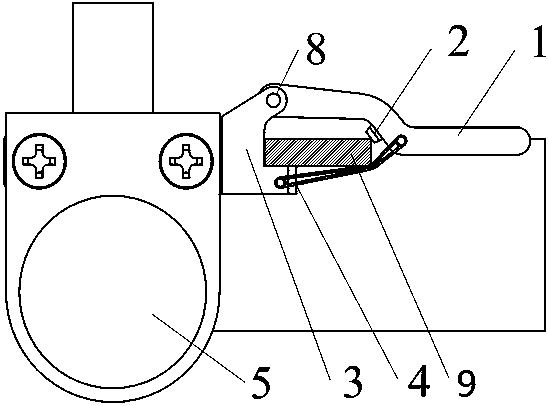

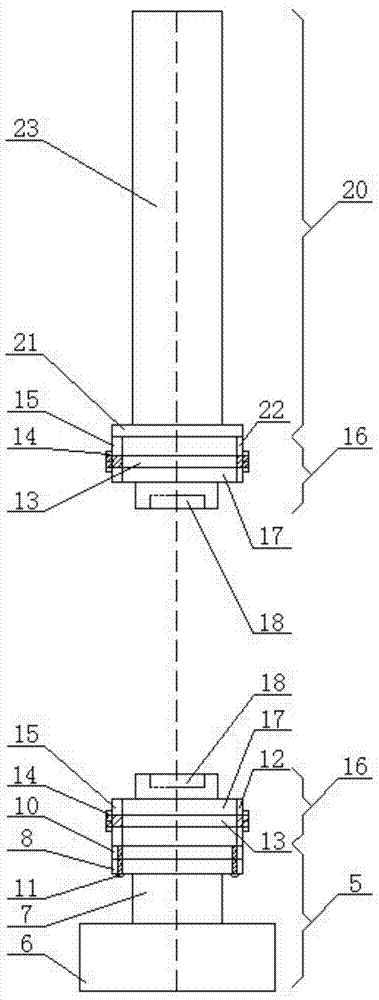

The invention relates to a micron-nano scale in-situ nano indentation and scratching test system which integrates driving, precise loading and signal detection, micron-nano scale mechanics performance testing, ultraprecise scratching processing and high resolution in-situ observing as one. The system is mainly composed of a precise positioning platform at X-axis and Y-axis directions, a precise linear positioning platform at Z-axis direction, a precise indentation driving unit, a load signal and displacement signal detection unit and a high resolution digital microscopic imaging system for observing and storing material deformation and damage conditions in the test process. The precise positioning platform at the X-axis and Y-axis directions is assembled on a base, the precise linear positioning platform at the Z-axis direction is assembled on a side plate, the precise indentation driving unit, a precise mechanical sensor for detecting the indentation material pressure of a diamond tool head and a precise displacement sensor for detecting the indentation depth of the diamond tool head to along the Z-axis direction are assembled on the precise linear positioning platform at the Z-axis direction, and the high resolution digital microscopic imaging system is assembled on a beam.

Owner:赵宏伟

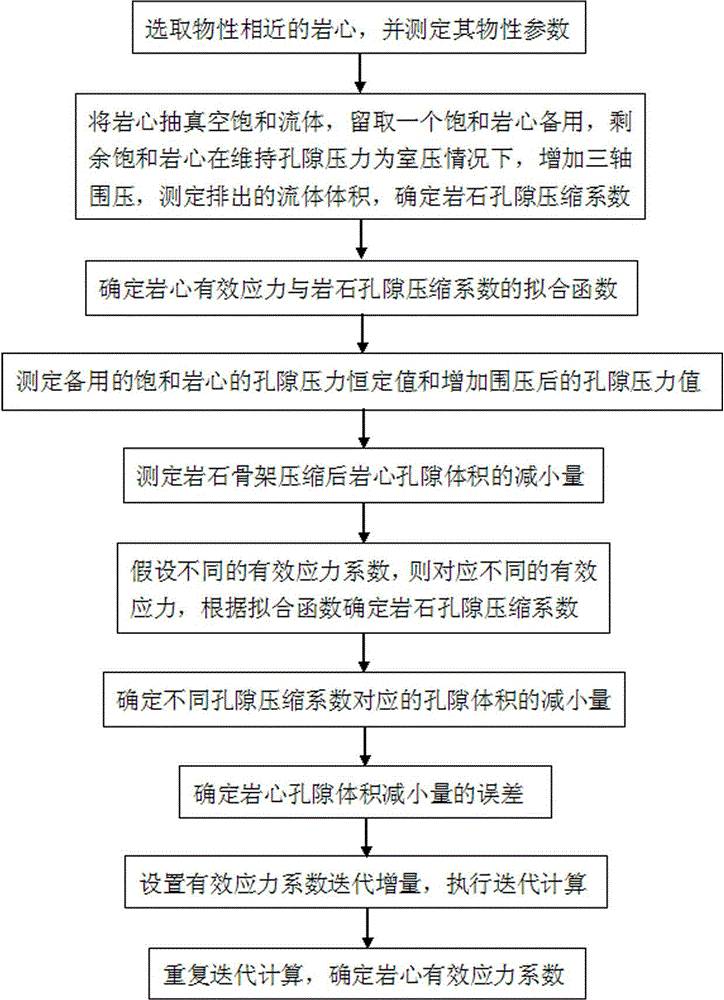

Method for determining effective rock stress coefficient based on pore compression experiment

ActiveCN104089823AThe principle of the test is clearSimple test methodMaterial strength using tensile/compressive forcesPermeability/surface area analysisPhysical propertyEffective stress

The invention discloses a method for determining an effective rock stress coefficient based on a pore compression experiment. The method comprises the following steps: selecting cores with similar physical properties in the same direction of the same rock, vacuumizing saturated fluid, gradually increasing triaxial confining pressure under the condition that the pore pressure is maintained to be room pressure, measuring the volume of fluid discharged from pores in the pressurization process, determining the rock pore compression coefficient, fitting a fitting function between the effective stress and the pore compression coefficient, measuring a pore pressure constant value of the saturated core and the pore pressure value after the confining pressure is increased, determining core pore volume reduction, and finally determining the effective rock stress coefficient value according to a calculation formula of the effective stress born by a rock matrix and the rock pore compression coefficient. The method is applied to low-permeability and ultralow-permeability reservoir stress research, the testing equipment is simple, the principle is clear, and the method is simple and accurate in measurement result.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

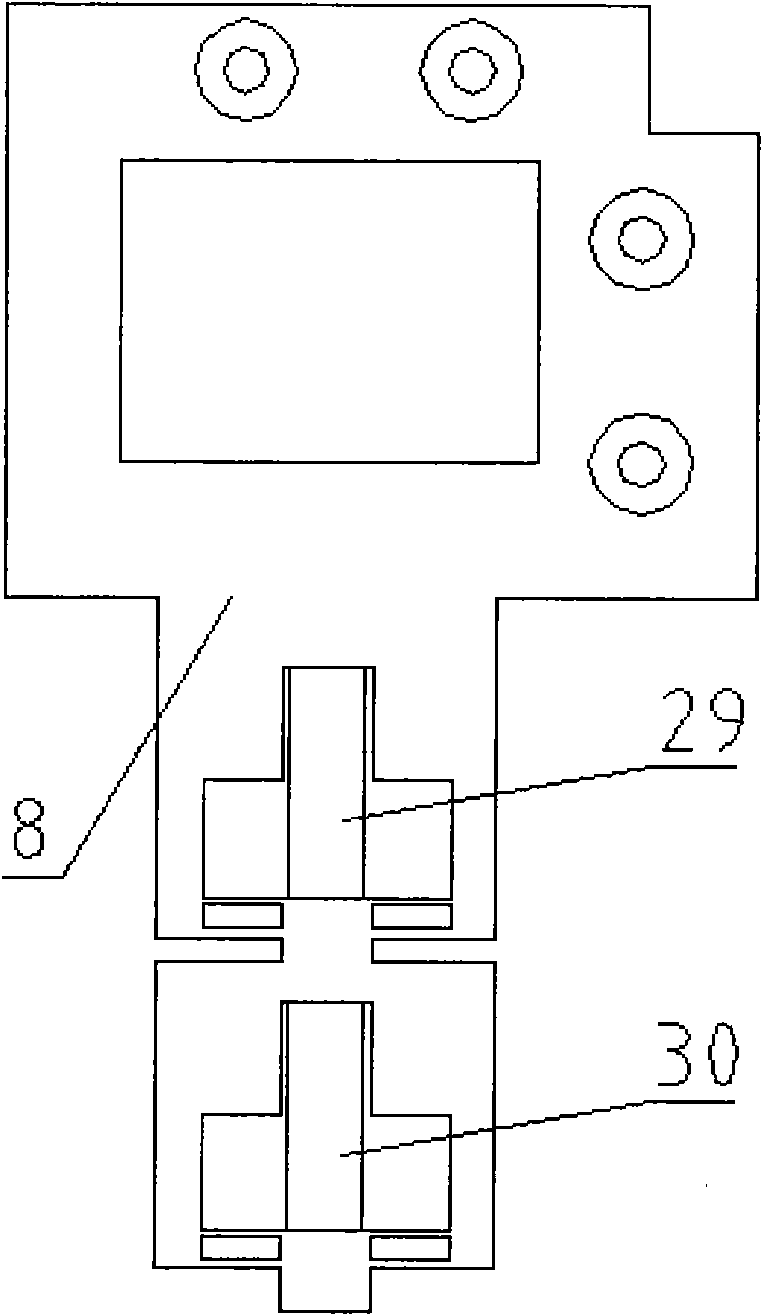

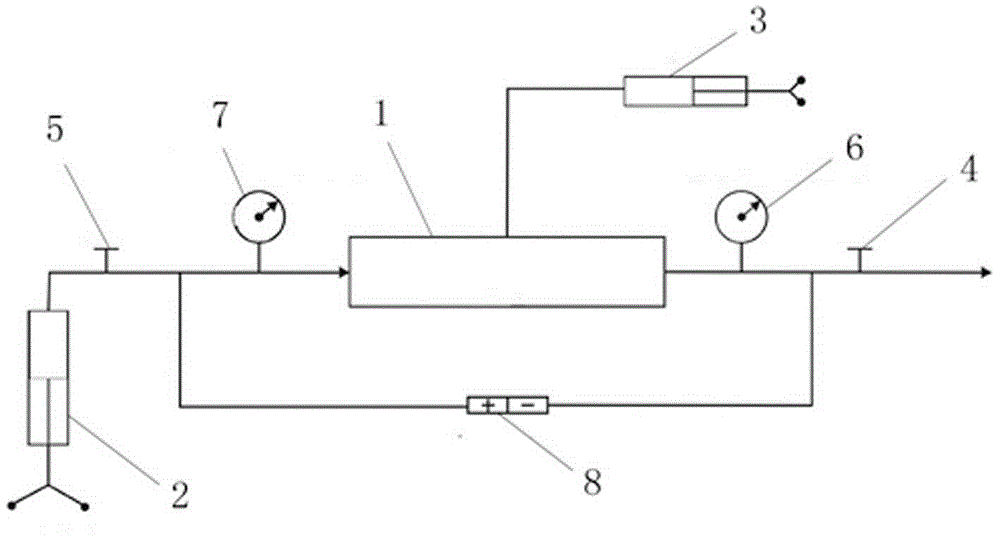

Analog device for on-line monitoring of dissolving gas in transformer oil and detection method thereof

InactiveCN106680047ADissolve evenlyRealize dynamic loopAnalysing gaseous mixturesPreparing sample for investigationTemperature controlGas detector

The invention relates to an analog device for on-line monitoring of dissolving gas in transformer oil and a detection method thereof. The analog device comprises a hydraulic circulatory system, a fuel tank temperature control system and a gas collection detection system; the hydraulic circulatory system comprises a fuel tank and an oil pump which connected through a circulation pipeline, a gas inlet port is arranged on the circulation pipeline, and a flow control valve is also provided; the fuel tank temperature control system comprises a heating pipe and a temperature sensor arranged in the fuel tank, a temperature controller respectively connected with the heating pipe and the temperature sensor; the gas collection detection system comprises at least one group of a gate valve, an air chamber and a gas detector which are connected through the pipeline in order, the gate valve is connected with the fuel tank through the pipeline, an oil gas separating membrane is arranged between the gate valve and the air chamber, and the analog device detects oil gas separating effects by changing difficult conditions to screen the optimal condition. Compared with the prior art, the analog device has the advantages of simple structure, convenient operation, and accurate simulation result.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

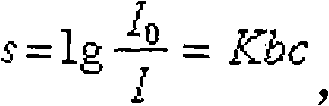

Method for detecting concentration of oil solution in producing polyacrylonitrile raw yarn in use for carbon fiber

ActiveCN101004381AConcentration is good for controllingFast test methodPhase-affecting property measurementsYarnPolymer science

A method for detecting concentration of oiling agent in production of polyacry / onitrile raw filament being used to prepare carbon fiber includes obtaining concentration and refractive power of oiling agent, optimizing linear equation, sampling, measuring refractive power and converting measured refractive power to be concentration.

Owner:WEIHAI TUOZHAN FIBER

Micro-open-type safety valve displacement test system and test method

ActiveCN106872154AGuaranteed accuracyThe test result is accurateMachine part testingWater storage tankWater flow

The invention relates to a micro-open-type safety valve displacement test system and a test method. The test system comprises a gas storage tank, a water storage tank, a test container, a sump and a weighing system used for measuring the weight of water entering the sump. The test container is communicated with a branch pipe used for mounting a tested valve. A valve opening height detector is arranged on the tested valve. The gas outlet of the gas storage tank is communicated with the water storage tank. The water outlet of the water storage tank is communicated with the test container. The water outlet of the tested valve is connected with the sump. Gas in the gas storage tank enters the water storage tank to continuously feed water in the water storage tank into the test container until water is discharged through the water outlet of the tested valve. According to the invention, for the micro-open-type safety valve, incompressible water is used as a test medium to ensure that only water flow through the tested valve; and the displacement of the tested valve can be accurately measured.

Owner:HEFEI GENERAL MACHINERY RES INST

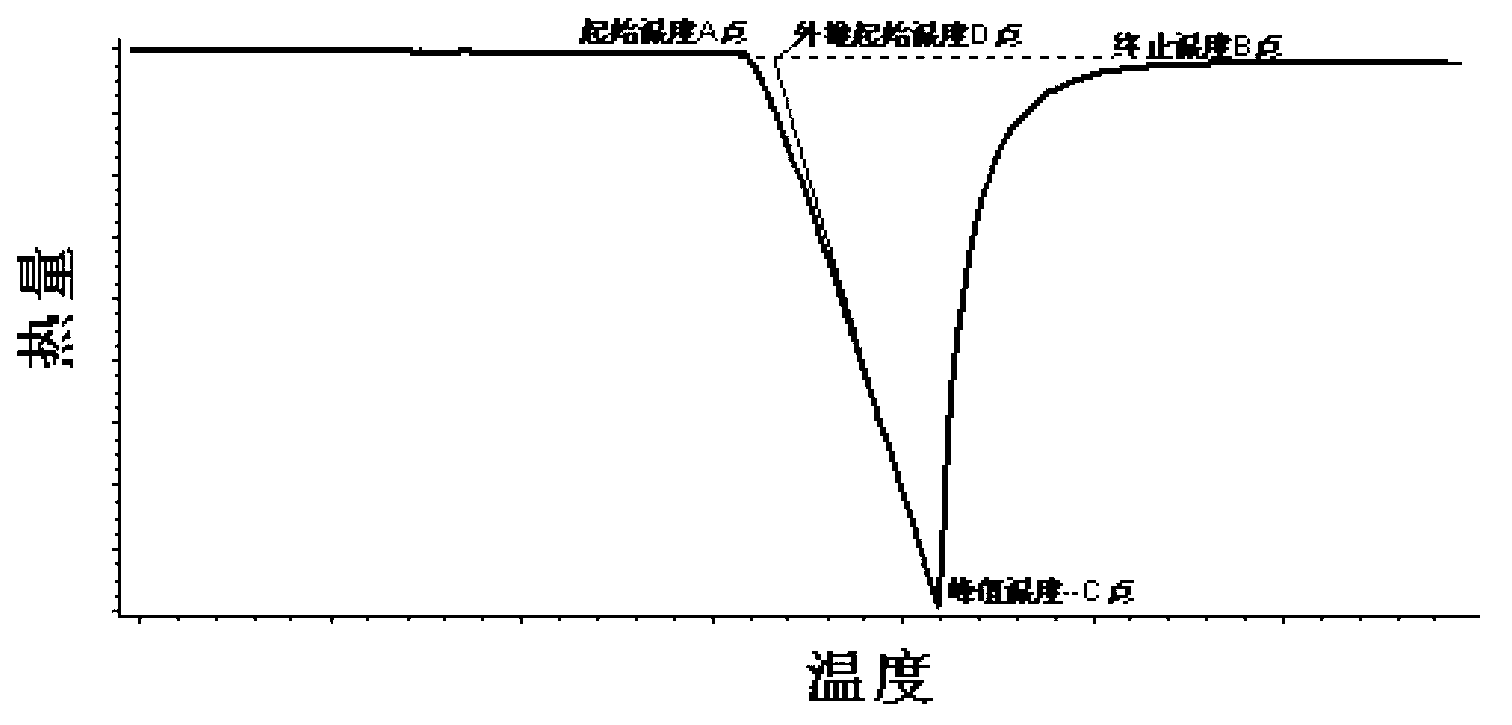

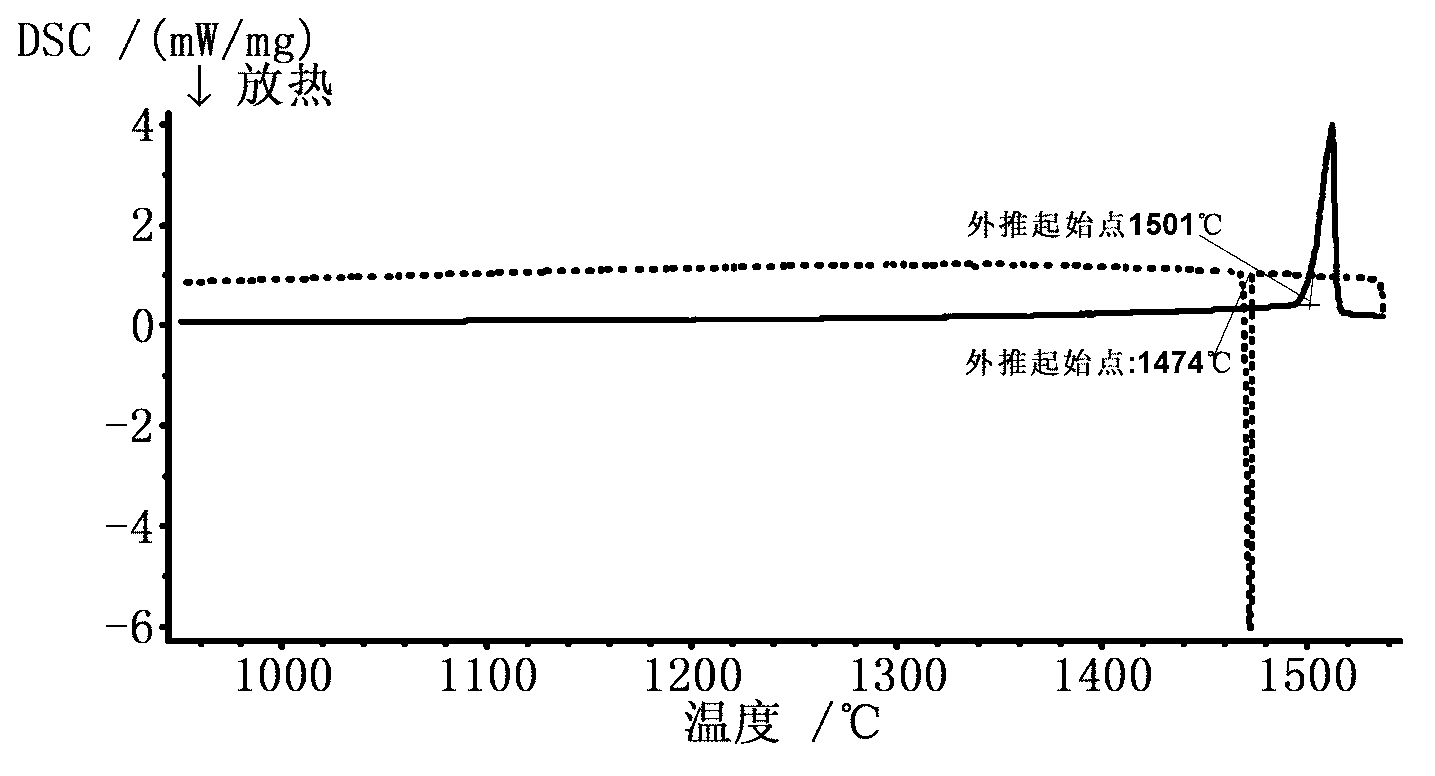

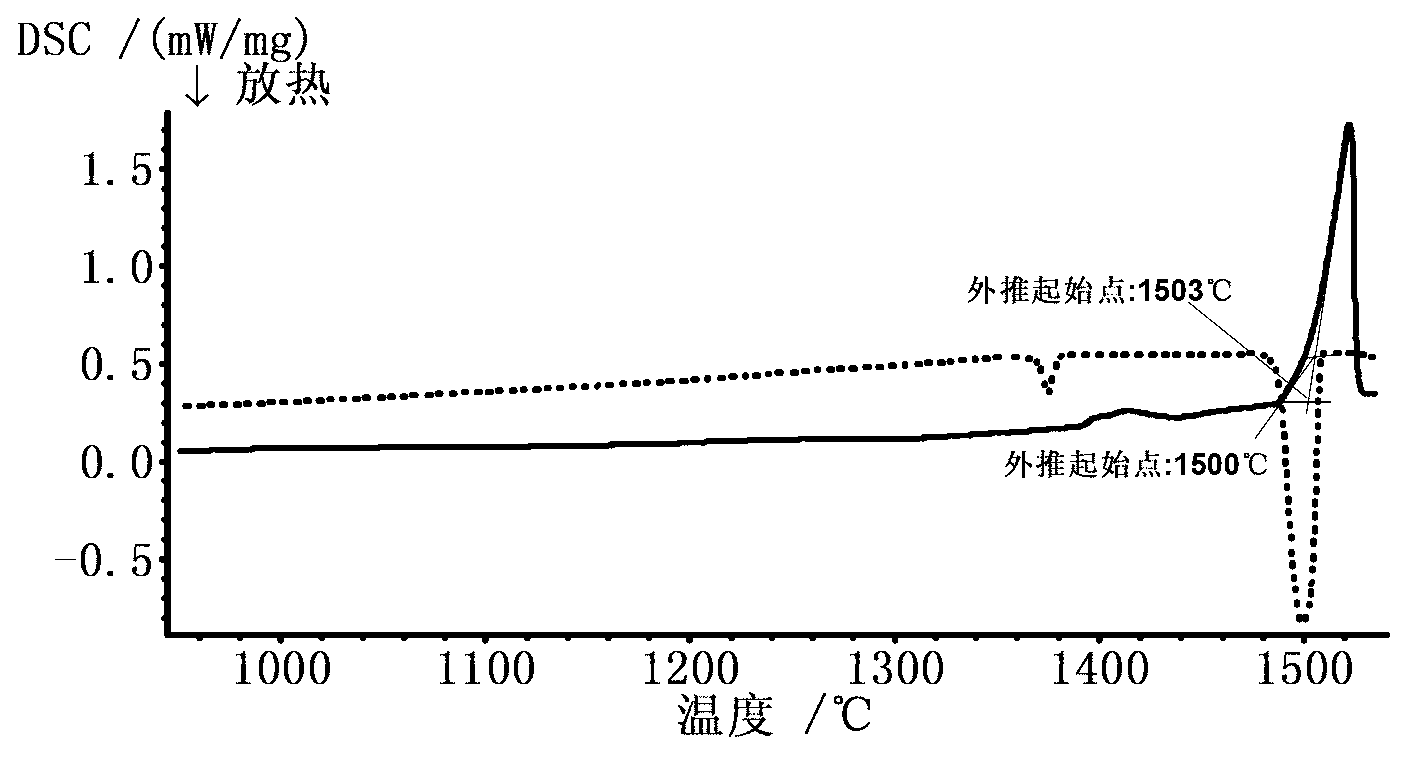

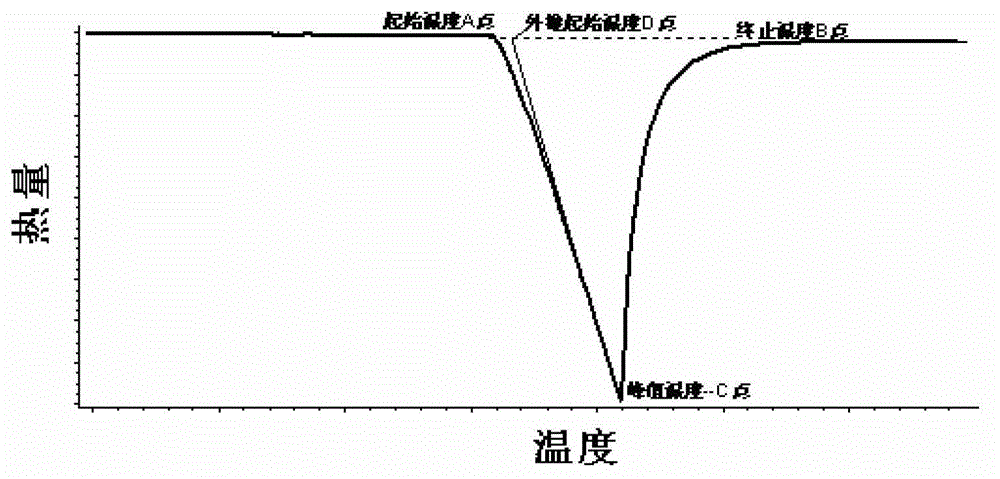

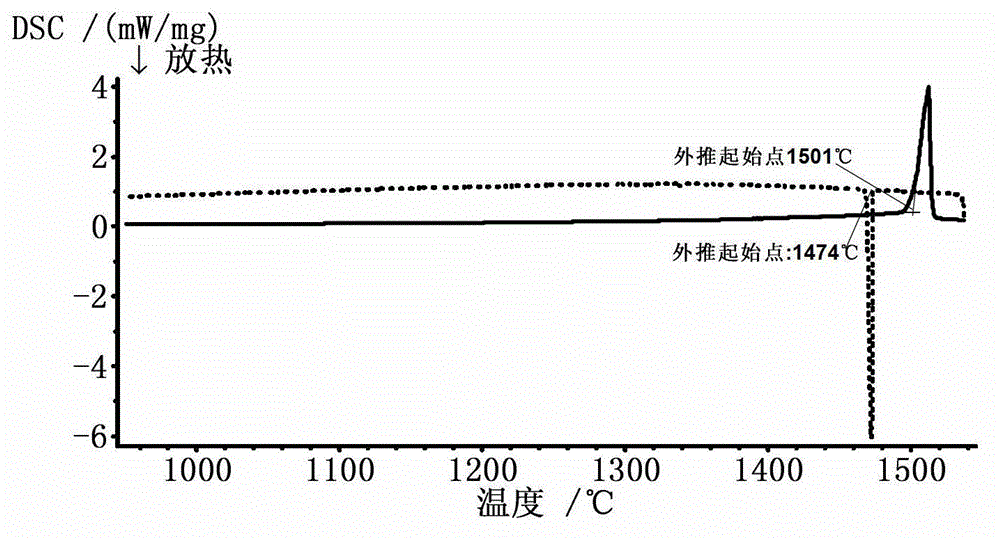

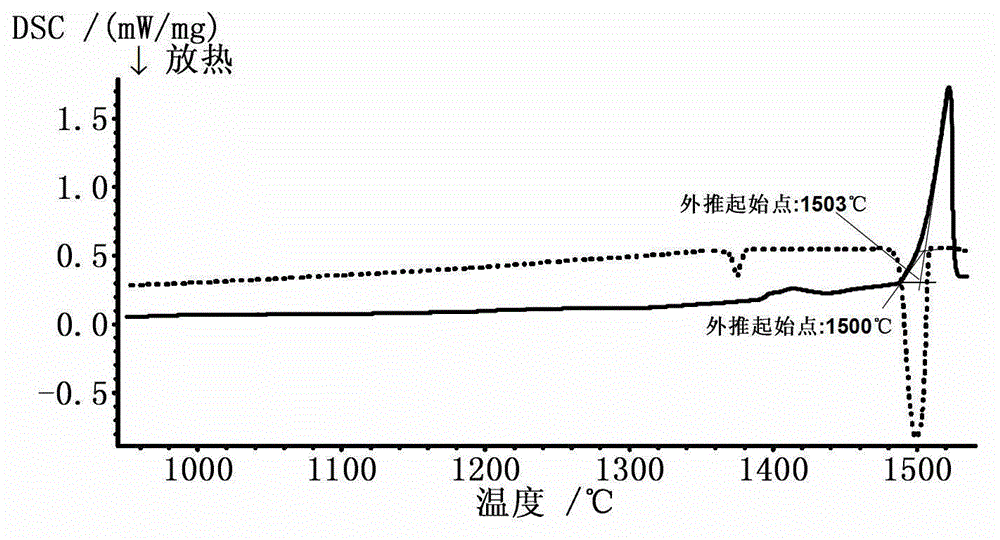

Steel solidus-liquidus temperature measurement method

ActiveCN103235001AThe test method is accurateHigh degree of automationInvestigating phase/state changeTemperature measurementMetallic materials

The invention relates to a steel solidus-liquidus temperature measurement method, and belongs to the technical field of metal material detection. The specific method comprises sample preparation, equipment calibration, experiment testing, and result analysis so as to complete the measurement. The results show that: an extrapolated onset temperature is consistent with a thermodynamic equilibrium temperature, such that a temperature corresponding to an extrapolated onset point of the first endothermic peak on a differential thermal curve during sample heating melting is judged as a liquidus temperature TL, and a temperature corresponding to an extrapolated onset point of the first exothermic peak on a differential thermal curve during sample cooling solidification is judged as a solidus temperature Ts. The measurement method has advantages of rapidness, accuracy, high automation degree, and good reproducibility.

Owner:SHOUGANG CORPORATION

Electric heating tube testing device and method

ActiveCN104535113ASimple test methodMeet the factory inspectionMeasurement devicesElectric heatingEngineering

The invention aims at providing an electric heating tube testing device and method. The electric heating tube testing device and method are used for comprehensively and reliably testing the safety performance of electric heating tubes. The electric heating tube testing device comprises a metal testing barrel with a movable barrel cover. The upper portion of the testing barrel is connected with a liquid inlet pipe and an air exhaust pipe. The liquid inlet pipe is provided with a liquid inlet valve. The air exhaust pipe is provided with an air exhaust valve. The lower portion of the testing barrel is provided with a liquid outlet pipe and an air inlet pipe. The liquid outlet pipe is provided with a liquid outlet valve. The air inlet pipe is provided with an air inlet valve. The testing barrel is connected with an air pressure gauge, a hydraulic pressure gauge and a temperature gauge through pipelines. The barrel body of the testing barrel is connected with an earth terminal through a wire. The testing barrel is provided with a testing terminal communicated with the interior and the exterior of the testing barrel. The electric heating tube testing device is applicable to testing of various electric heating tubes, the electric heating tube testing method is convenient to implement, reliable and reliable, and factory testing of the electric heating tubes can be achieved.

Owner:XINYI HUIMEI ELECTRICAL APPLIANCES +1

Method for on-line detection of coagulation bath concentration in production of polyacrylonitrile strands for carbon fibers

InactiveCN101871887AImprove timelinessFast test methodPhase-affecting property measurementsChemistryStandard curve

The invention relates to a method for the on-line detection of coagulation bath concentration in the production of polyacrylonitrile strands for carbon fibers, which comprises the following steps: 1) preparing a dimethyl sulfoxide standard solution; 2) manufacturing a standard curve equation; 3) connecting devices; 4) carrying out on-line detection; and 5) calculating the concentration. The invention solves the technical problems that the existing coagulation bath concentration detecting method is time-consuming, the detection result is inaccurate and the on-line detection can not be realized. Besides, the invention is beneficial to improving the timeliness, the dynamic nature and the accuracy of the concentration control of dimethyl sulfoxide in the coagulation bath. The detecting method is fast, accurate and visual, and is suitable for automatic production.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method for measuring content of ayfivin and its preparations by nephelometry

InactiveCN101271117AIncrease supplyPromote growthMaterial analysis by optical meansBiological testingTurbidityTest organism

The invention discloses a method for measuring bacitracin and the content of the preparation thereof by the turbidity method, and the method contains the following steps: the preparation of standard solution, the preparation of test solution, the preparation of test organism suspension, the content measurement, etc. The antibiotics-microbial test and multi-dose turbidity method of the invention are adopted for measuring the bacitracin and the content of the preparation thereof, thus the test method is accurate and effective and has low cost, and test results can truly reflect antibacterial activity of the bacitracin and the preparation thereof; the method has stronger practicality and operability in the production and the quality control of the drug and the preparation thereof.

Owner:高燕霞

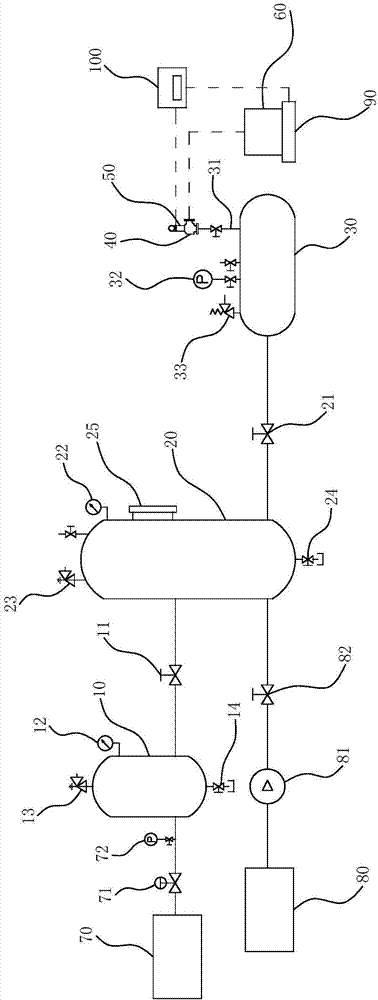

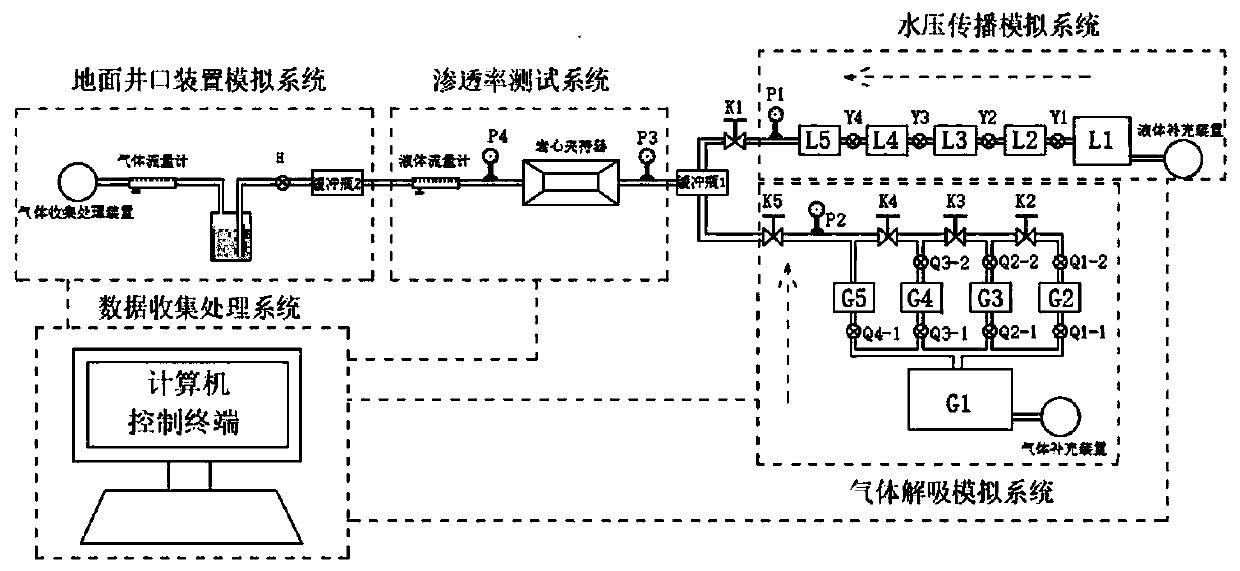

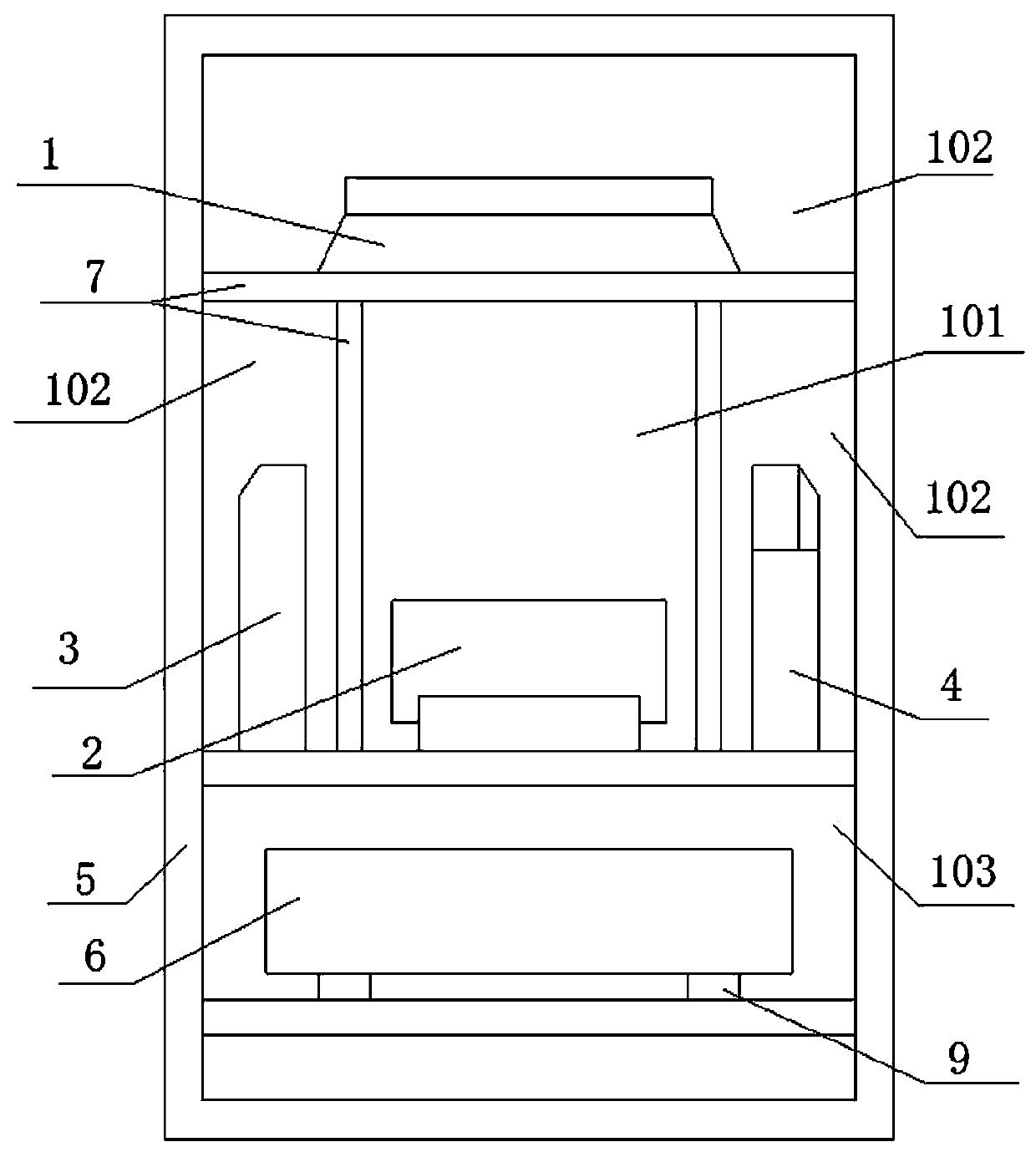

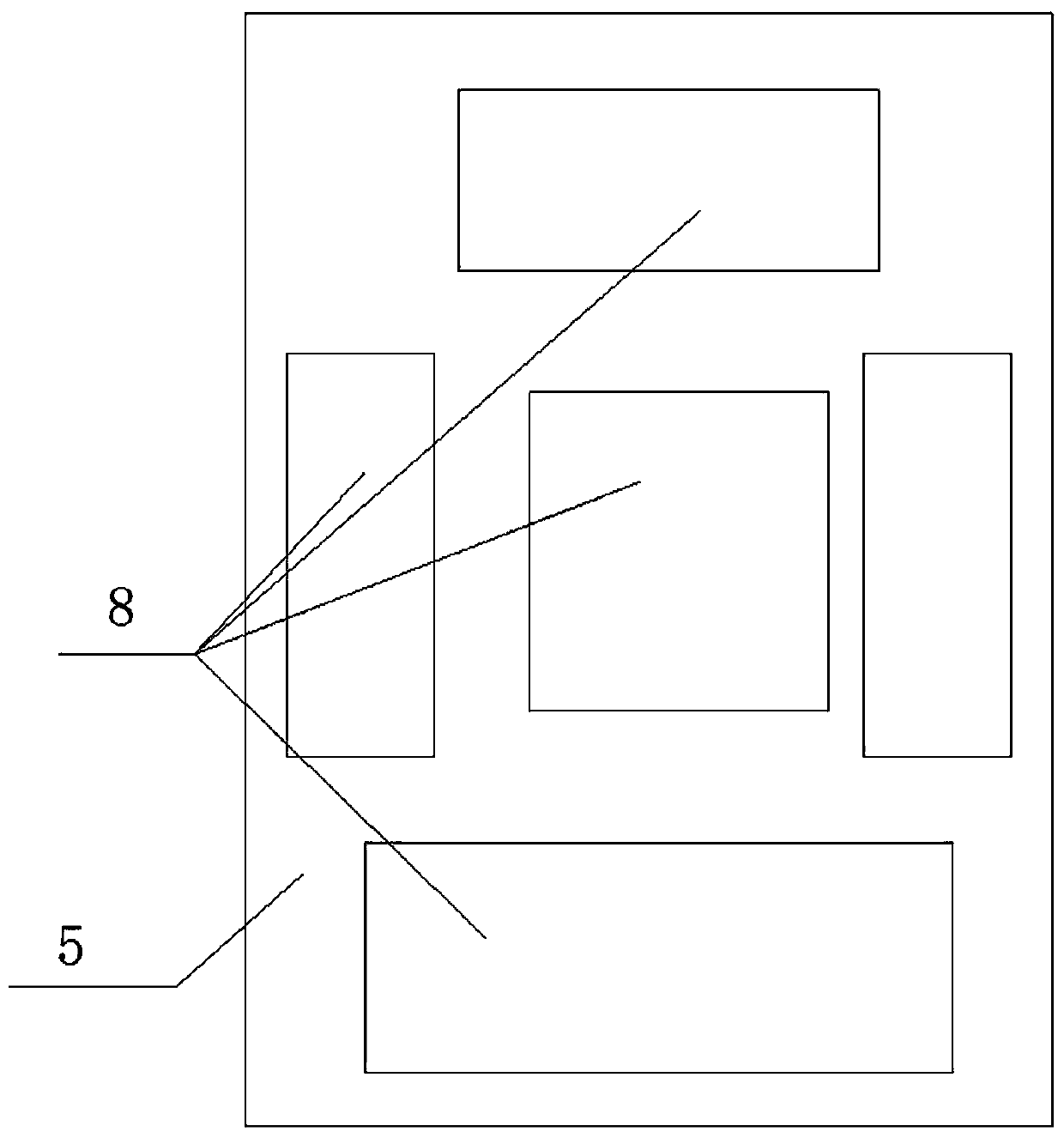

Simulation test device and method for coalbed methane production capacity change caused by discontinuous drainage

PendingCN110082280AImprove work efficiencyImprove detection accuracyPermeability/surface area analysisDesorptionDevice simulation

The invention relates to a simulation test device for the coalbed methane production capacity change caused by discontinuous drainage. The device comprises a wellhead device simulation device, a permeability test device, a water pressure propagation simulation device, a gas desorption simulation device, an experimental cabinet and a data acquisition and processing device. The internal space in theexperimental cabinet is divided into an experimental detection chamber, three experimental driving chambers and a control chamber through partition plates; the permeability test device is arranged inthe experimental detection chamber; the wellhead device simulation device, the water pressure propagation simulation device, and the gas desorption simulation device are arranged in all experimentaldriving chambers and are communicated with the permeability test device. In addition, the experimental steps include equipment assembling, initial experiment parameter setting, displacement operation,experimental detection, data analysis and experiment ending. On the one hand, the working efficiency and the detection precision of the detecting operation can be improved; and on the other hand, thetest risk is low, the test method is convenient and accurate and has the high similarity with the coalbed methane drainage gas production mechanism, and dynamic monitoring can be realized.

Owner:HENAN POLYTECHNIC UNIV

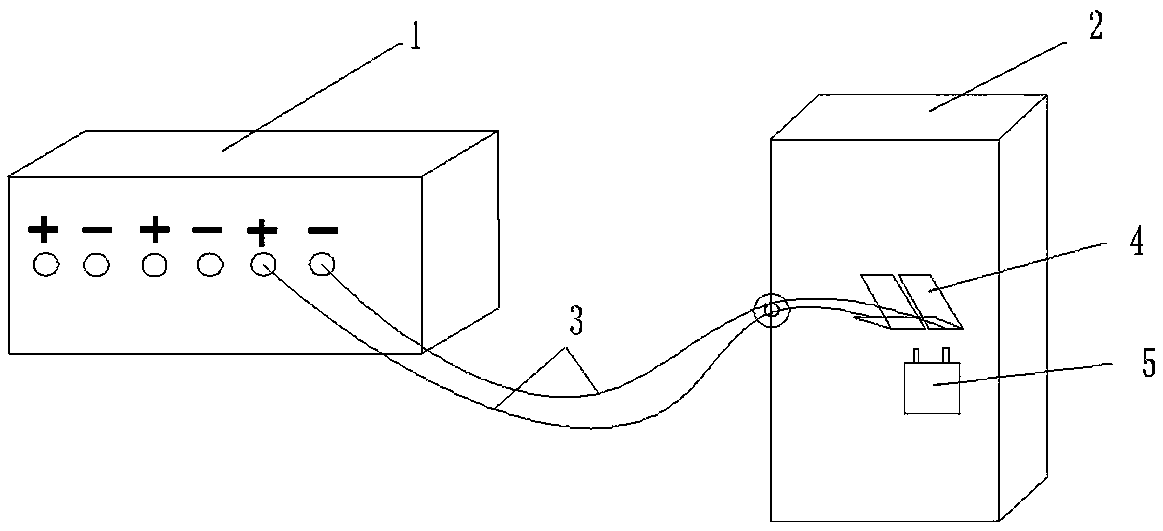

Method for quickly detecting self-discharge consistency of lithium ion battery and test device

PendingCN108196204AFast and accurate self-discharge rateThe test method is accurateElectrical testingSortingElectricityElectrical battery

The invention discloses a method for quickly detecting self-discharge consistency of a lithium ion battery and a test device. The detecting method comprises the steps that the fact that a battery corefixture arranged in a heating device is electrically connected with the positive and negative poles of a charging and discharging device is determined; the battery core fixture clamps the positive and negative poles of a battery core to be tested; the charging and discharging temperature of the heating device and the charging and discharging standby time of the charging and discharging device areset; when the heating device is kept at the charging and discharging temperature, the charging and discharging device is activated; at the charging and discharging standby time, the voltage value ofthe battery core is recorded; the voltage change value of the battery core before and after charging and discharging standby time is calculated; and battery cores with great self-discharge consistencyare sorted out and used for lithium ion battery grouping, wherein the voltage change value of the battery cores is less than or equal to a voltage calibration value. According to the invention, theself-discharge normal temperature environment of battery cores is deteriorated; the voltage change value is used as the measuring standard; in a high temperature environment, the self-discharge rateof lithium ion battery cores is accelerated; the test period is shortened; and the method is fast and accurate, and can be used to carry out real-time voltage monitoring on battery cores.

Owner:GREE ELECTRIC APPLIANCES INC

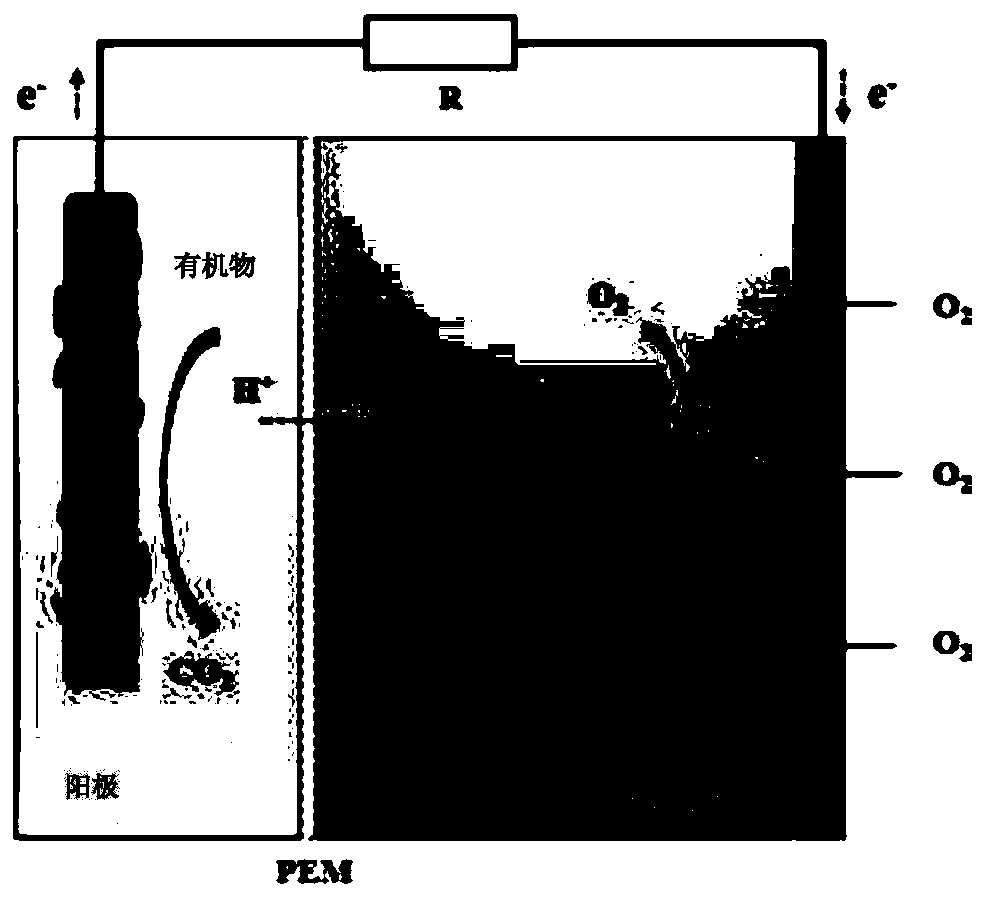

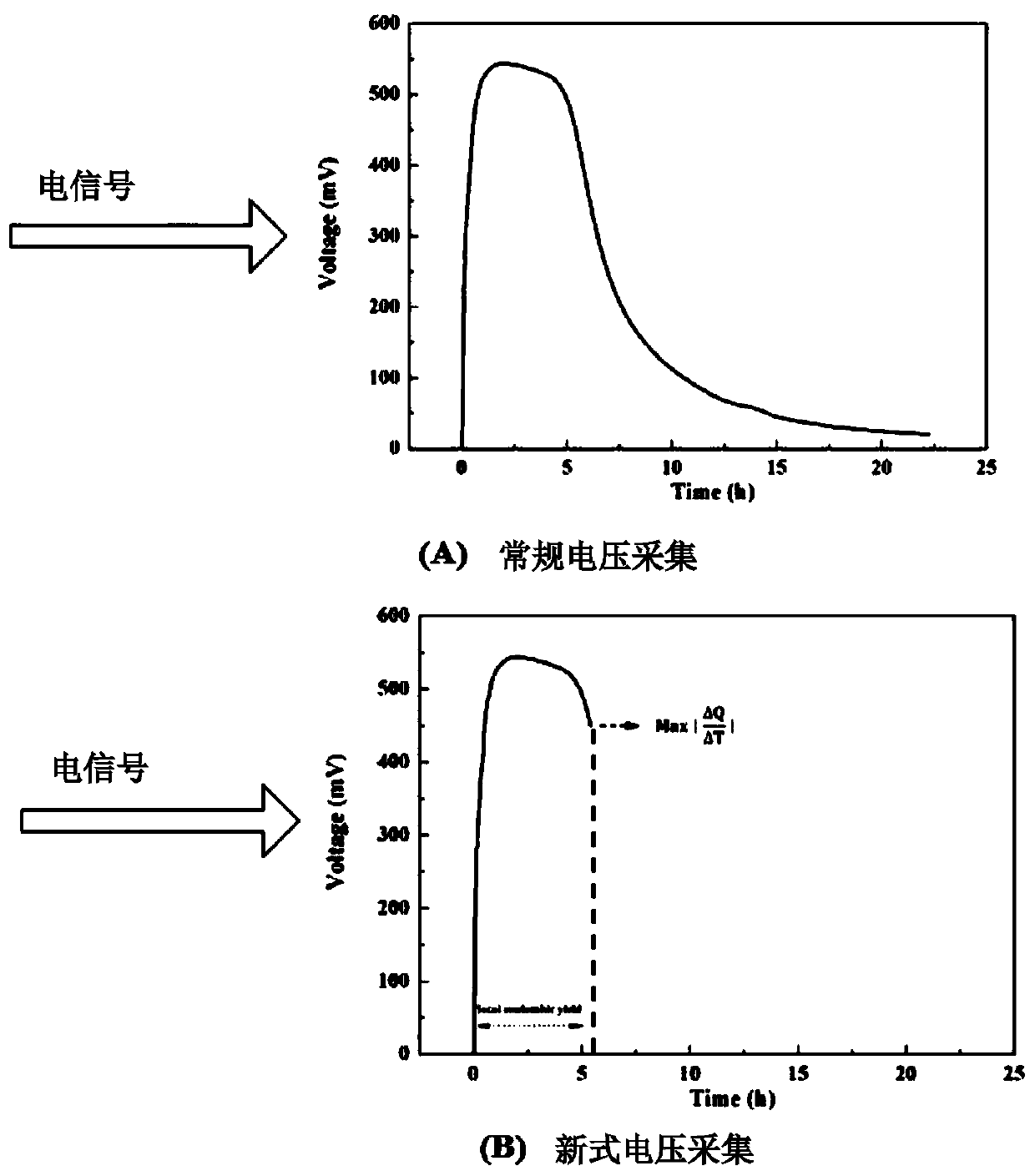

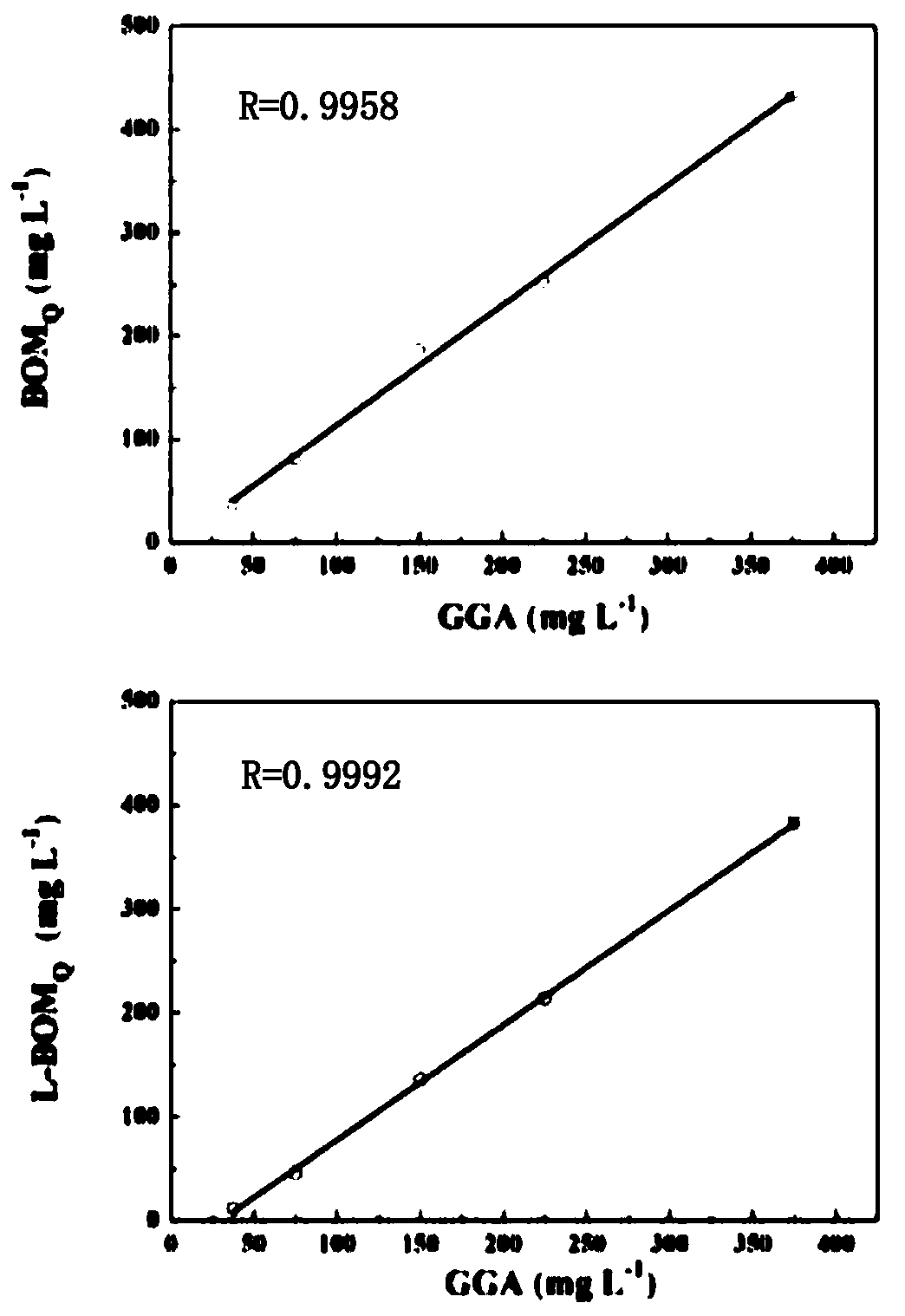

Local coulomb method for measuring biochemically degradable organic matters in water body

ActiveCN110530956AEasy to findGood linear correlationMaterial electrochemical variablesLinear correlationEngineering

The invention belongs to the technical field of water environment chemical analysis, and particularly relates to a local coulomb method for measuring biochemically degradable organic matters in a water body. According to the method, uniquely a fastest voltage reduction point is selected as a cut-off point for collecting a voltage; the cut-off point is easy to find, and the measurement time can begreatly shortened, so that the operation efficiency is improved; by means of the local coulomb method of the cut-off point selection method, the linear correlation between the value of oxygen consumption BOMQ1 in a measurement result and the concentration of a GGA standard solution for culture of electricigens is better, the more scientific, reasonable and accurate test method is provided for measuring the biochemically degradable organic matters in the water body by utilizing a microbial fuel cell, and new idea and direction are provided for scientific control of water environment pollution;and the method has great popularization values and wide application prospects.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Method for testing calcium and magnesium content in limestone-gypsum wet desulphurization absorbent

InactiveCN103454271ASimple test methodFast test methodMaterial analysis by observing effect on chemical indicatorActive componentMaterial resources

The invention provides a method for testing calcium and magnesium content in a limestone-gypsum wet desulphurization absorbent. The method comprises the following steps: (1) taking a sample and drying; (2) slowly adding an acid; (3) heating and boiling; (4) cooling and obtaining a constant volume; (5) determining calcium and magnesium; and (6) processing data, wherein the step (5) comprises a step (5.1) of determining the calcium content and a step (5.2) of determining the total content of the calcium and the magnesium. According to the method, a hydrochloric acid solution is used for dissolving limestone to realize the aim of accurately representing active components of the absorbent of an FGD (Flue Gas Desulfurization) system. The method has the advantages that (1) a testing method for representing active components of the absorbent of the FGD system is simple, rapid and accurate; manpower, material resources and financial resources are saved; operation is facilitated; (2) the method is used for testing the calcium and magnesium content in the limestone-gypsum wet desulphurization absorbent of a thermal power plant so as to really reflect the condition of the active components of the absorbent needed by the FGD system of the thermal power plant.

Owner:STATE GRID CORP OF CHINA +2

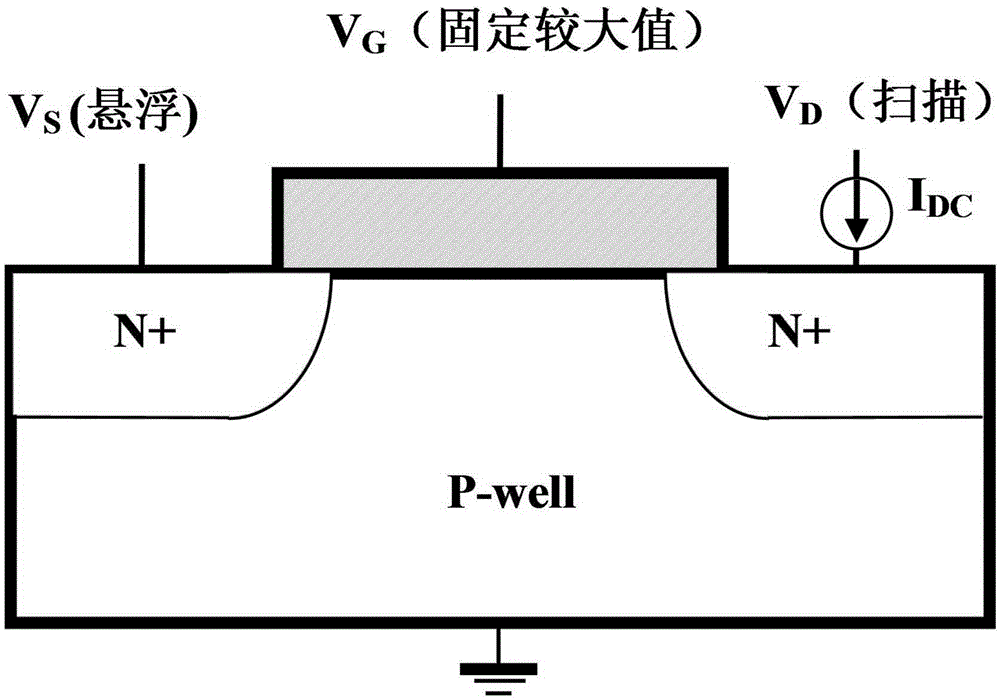

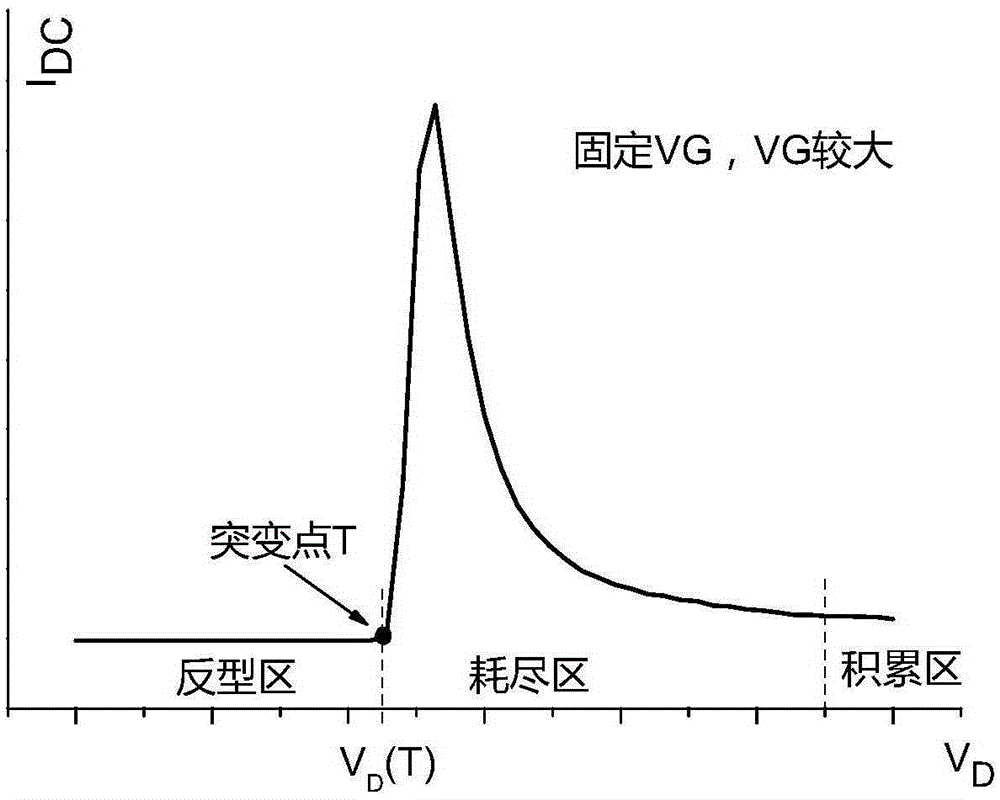

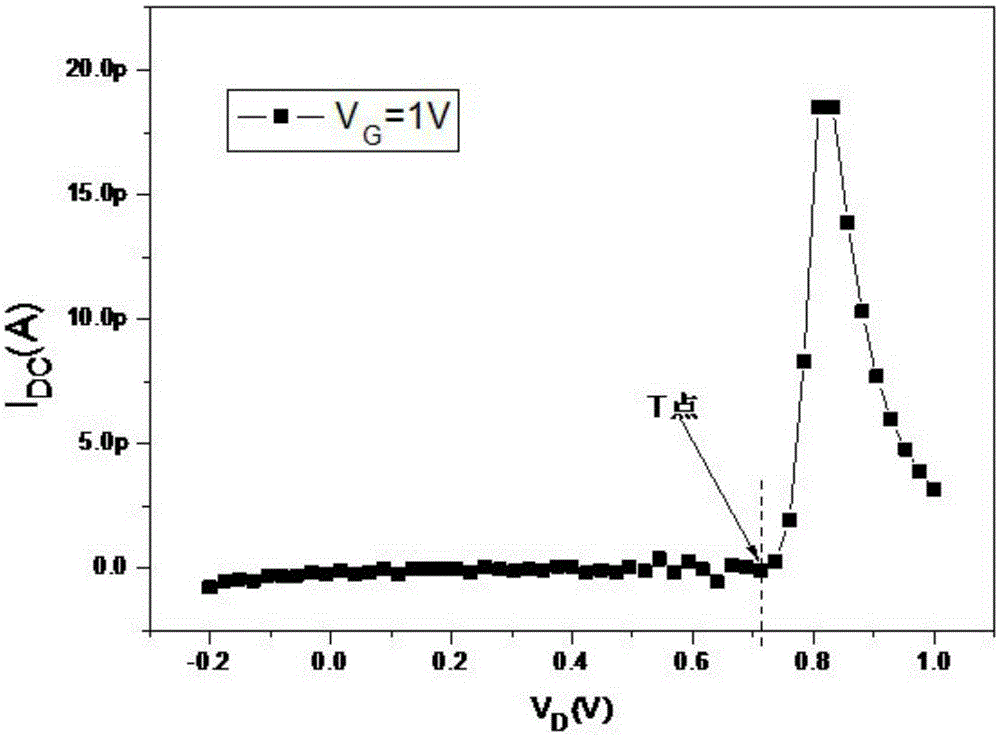

Extraction method for of threshold voltage of MOSFET on the basis of drain control generation current

The present invention discloses an extraction method for of a threshold voltage of MOSFET on the basis of a drain control generation current. The extraction method provided by the invention comprise: a channel inversion layer is located in the inversion state through adoption of fixation of large gate voltage VG, and at the same time a drain voltage VD is scanned to obtain a curve of a drain control generation current IDC; and when the drain voltage VD is increased up to allow a channel at the edge of the drain end to start the occurrence of exhaustion, the IDC curve is beginning to rapidly increase and turns up a peak, and the point of abrupt change is just a difference of a gate voltage and the drain voltage with respect to a critical point or a turning point inverting up to exhaustion, namely the threshold voltage VT. An accurate, simple and fast test method of MOSFET is provided by the invention. Because the curve presents an abrupt change, the drain voltage point with respect to the turning point inverting up to exhaustion may be easier observed, so that the man-made observation error may be avoided; the operation of obtaining a threshold voltage is simple; and the measurement is fast, and a direct current test is only needed.

Owner:XIAN UNIV OF POSTS & TELECOMM

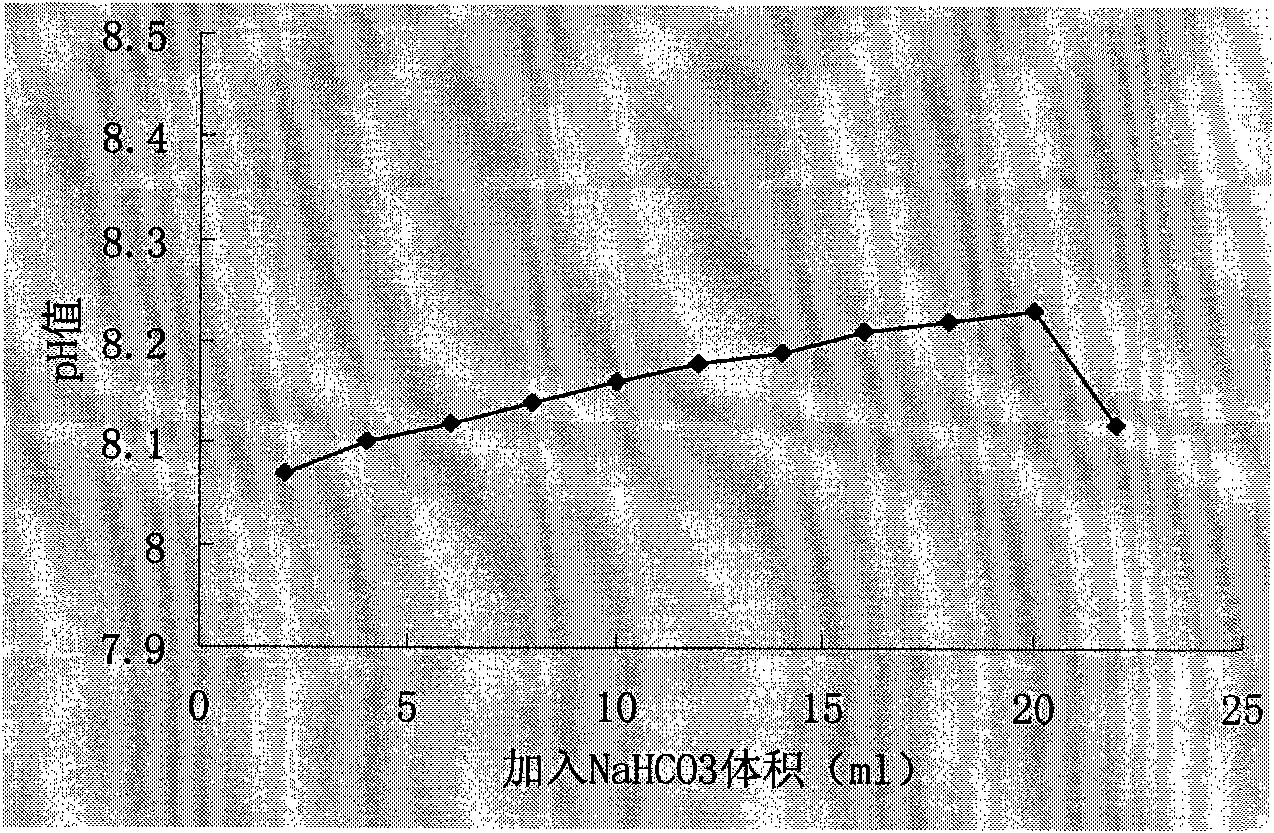

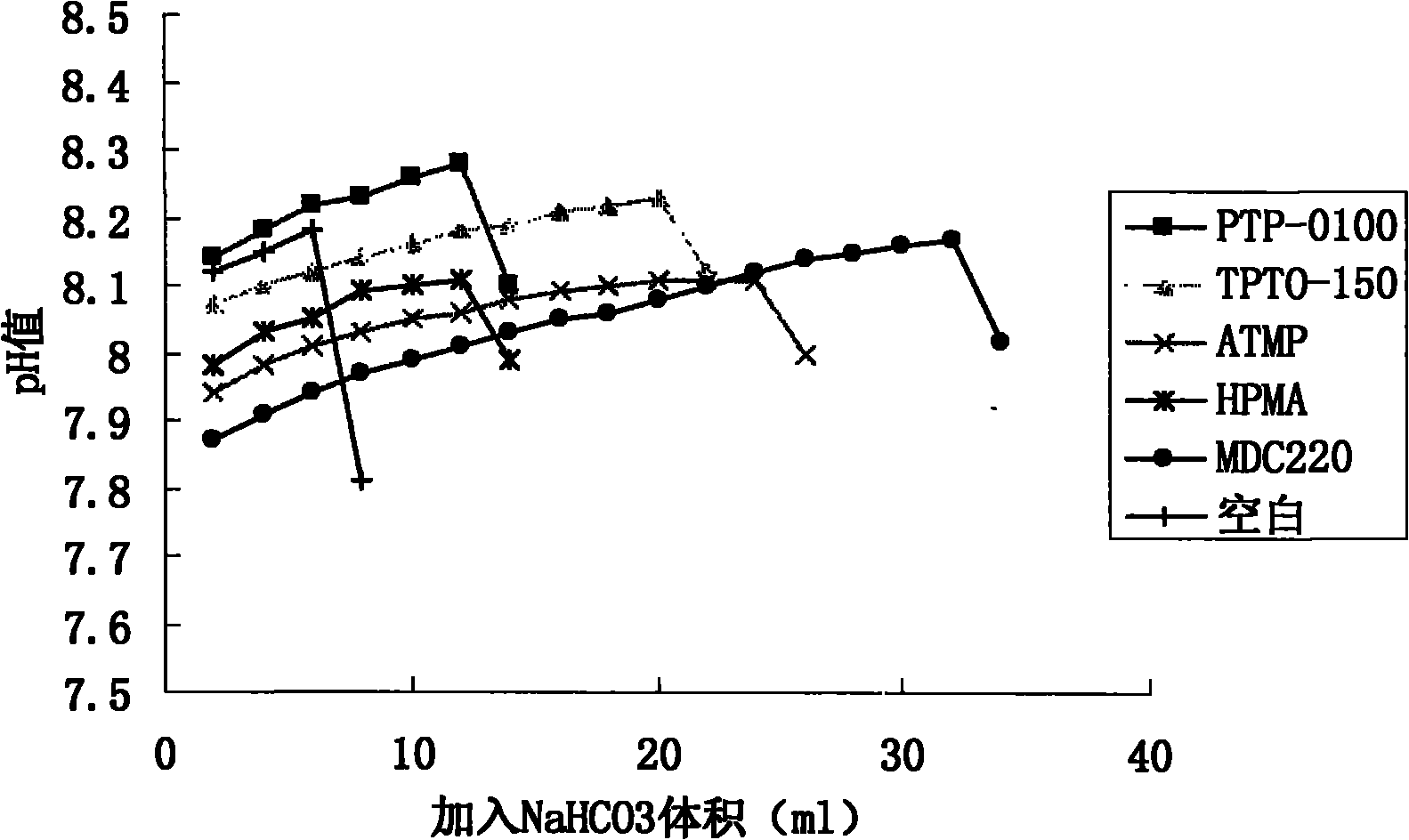

Method for rapidly evaluating performance of reverse osmosis antisludging agent by determining pH value of solution

ActiveCN101975779AHigh sensitivitySimple test methodMaterial analysis by observing effect on chemical indicatorReverse osmosisSupersaturation

The invention relates to a method for rapidly evaluating the performance of a reverse osmosis antisludging agent by determining the pH value of a solution, comprising the following steps of: (1) adding a CaCl2 solution the concentration of which is C1 and the volume of which is V1 and an antisludging agent the dosage of which is W to a container; (2) making the container airtight at constant temperature under stirring, then dropwise adding a NaHCO3 solution the concentration of which is C2 and the volume of which is V2 and marking as the first time; (3) recording the pH value of the solution after t min, simultaneously dropwise adding the NaHCO3 solution the concentration of which is C2 and the volume of which is V2 and marking as the second time; (4) repeating the step (3) until the pH value of the solution falls, wherein the adding time of the NaHCO3 solution sums to n, and recording the pH value of the solution when the NaHCO3 solution is added for the (n-1) time and the volume (n-1)V2 of the accumulatively consumed NaHCO3 solution; and (5) working out the supersaturation S of CaCO3 in the solution when the NaHCO3 solution is added for the (n-1) time, and judging the performance of the antisludging agent according to the S magnitude. The method is rapid and accurate, has simple test condition and is easy to operate.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

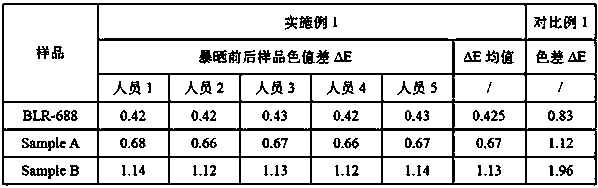

Method for rapidly testing weather resistance of titanium dioxide and application

ActiveCN110286082AGuaranteed repeatabilityGood dispersionWeather/light/corrosion resistancePreparing sample for investigationWeather resistanceTest sample

The invention belongs to the technical field of titanium dioxide performance testing, and discloses a method for rapidly testing weather resistance of titanium dioxide and application. The method comprises the following steps of (1) uniformly mixing materials for preparing a test sample wafer, wherein the material formula comprises the following components in parts by weight: 100 parts of polyvinyl chloride resins, 5-10 parts of titanium dioxide, 3-10 parts of lead salt stabilizers, 2-8 parts of chlorinated polyethylene, 1-3 parts of plasticizers, 3-20 parts of calcium carbonate, 1-3 parts of ACR-401 and 0.1-1 part of paraffin; (2) processing a mixture obtained in the step (1) into a sample wafer by adopting an extruder; (3) cutting the mixture obtained in the step (2) into a test sample wafer, and testing color values L0, a0 and b0; (4) sealing the test sample wafer in water, isolating air and carrying out sun exposure for 2-48 hours, and testing color values L1, a1 and b1; and (5) computing a color difference before and after the sun exposure, and judging the weather resistance of the titanium dioxide. According to the method, the weather resistance of the titanium dioxide can be rapidly, efficiently and accurately detected.

Owner:上海龙蟒佰利联技术服务有限公司 +1

Online testing method for oil solution concentration of polyacrylonitile production used in carbon fiber

ActiveCN101017136AImprove timelinessImprove dynamic performancePhase-affecting property measurementsCarbon fibersOnline test

This invention belongs to measurement technique and relates to one carbon fiber polyacryl-nitrile protofilament process oil agent concentration online test method, which is characterized by the following: it uses series oil agent work pool to feed materials tube or to exit pipe online reflection index meter for online test and comprises the steps as: getting oil agent concentration and reflection index or sugar degree standard curve; optimizing line equation; online testing.

Owner:WEIHAI TUOZHAN FIBER

Device and method for dynamically testing fabric quality

ActiveCN108844808AGood detection effectImprove efficiencyMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceThrough transmissionCam

Owner:江苏省纺织产品质量监督检验研究院

Super-precision trans-scale in-situ nanometer indentation marking test system

ActiveCN101520389BThe test method is accurateAccurate and effective research and testing methodsUsing optical meansInvestigating material hardnessImage resolutionEngineering

The invention relates to a super-precision trans-scale in-situ nanometer indentation marking test system which integrates driving, loading, detecting and micro-nanometer dynamic performance tests, supThe invention relates to a super-precision trans-scale in-situ nanometer indentation marking test system which integrates driving, loading, detecting and micro-nanometer dynamic performance tests, super-precision marking processing and in-situ observation into a whole. The system mainly comprises an objective table, a regulation mechanism, a detection unit, a precise pressed-into driving unit, a der-precision marking processing and in-situ observation into a whole. The system mainly comprises an objective table, a regulation mechanism, a detection unit, a precise pressed-into driving unit, a detection unit of load signals and displacement signals and a high-resolution digital microscopic imaging system, wherein the objective table is precisely positioned along the directions of the X axisetection unit of load signals and displacement signals and a high-resolution digital microscopic imaging system, wherein the objective table is precisely positioned along the directions of the X axisand the Y axis; the regulation mechanism and the precise pressed-into driving unit are in the direction of the Z axis and are assembled on a base; the high-resolution digital microscopic imaging systeand the Y axis; the regulation mechanism and the precise pressed-into driving unit are in the direction of the Z axis and are assembled on a base; the high-resolution digital microscopic imaging system is used for observing the deforming and damaging conditions of the material in the storing and testing process; the objective table as well as the regulation mechanism and the precise pressed-into dm is used for observing the deforming and damaging conditions of the material in the storing and testing process; the objective table as well as the regulation mechanism and the precise pressed-into driving unit in the direction of the Z axis are assembled on a base; the high-resolution digital microscopic imaging system is arranged on the objective table; a precise dynamic sensor detecting the prriving unit in the direction of the Z axis are assembled on a base; the high-resolution digital microscopic imaging system is arranged on the objective table; a precise dynamic sensor detecting the pressure of a diamond tool head pressed into a material and a sensor I detecting the precise displacement of the objective table in the directions of the X axis and the Y axis are arranged on the objectessure of a diamond tool head pressed into a material and a sensor I detecting the precise displacement of the objective table in the directions of the X axis and the Y axis are arranged on the objective table; and a sensor II used for detecting the precise displacement of a diamond tool head in the direction of the Z axis of pressed-into depth is arranged on the base by a support I.ive table; and a sensor II used for detecting the precise displacement of a diamond tool head in the direction of the Z axis of pressed-into depth is arranged on the base by a support I.

Owner:JILIN UNIV

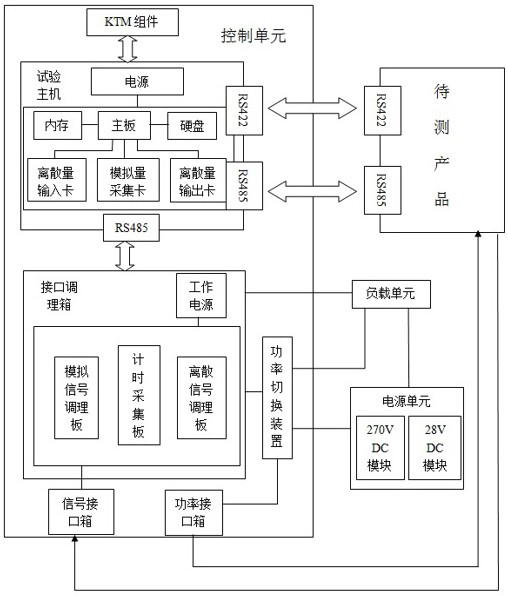

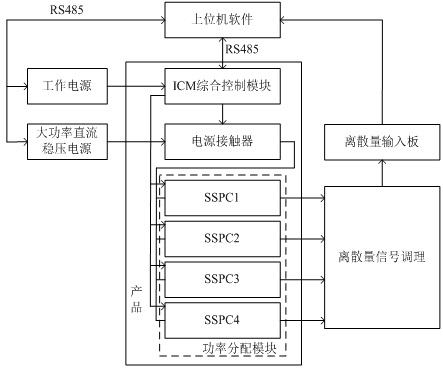

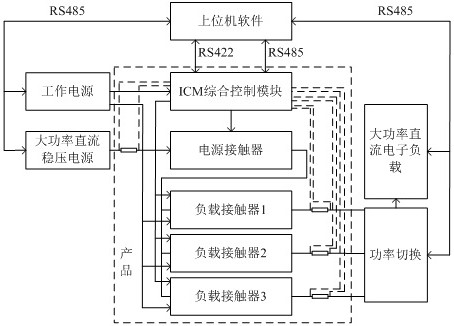

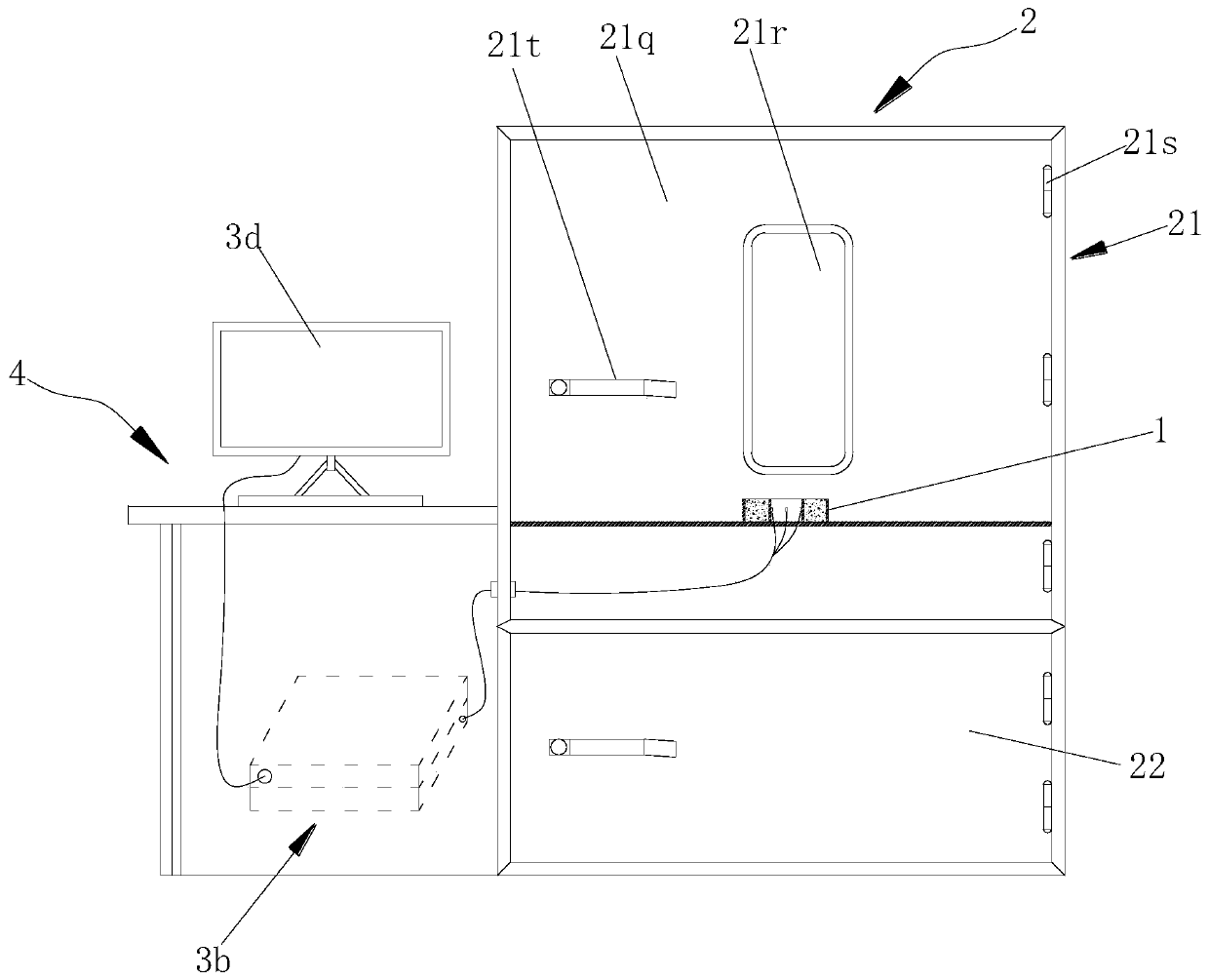

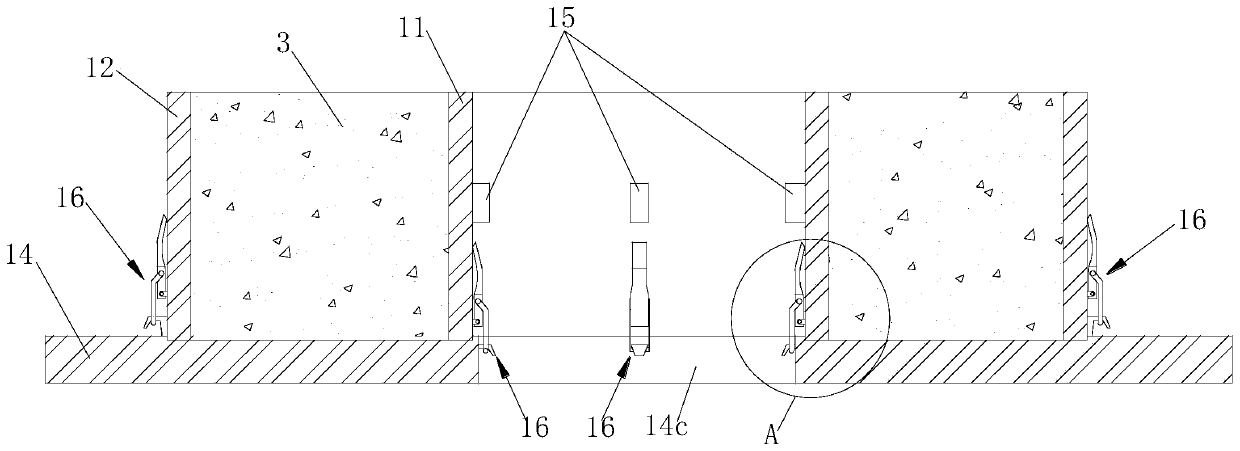

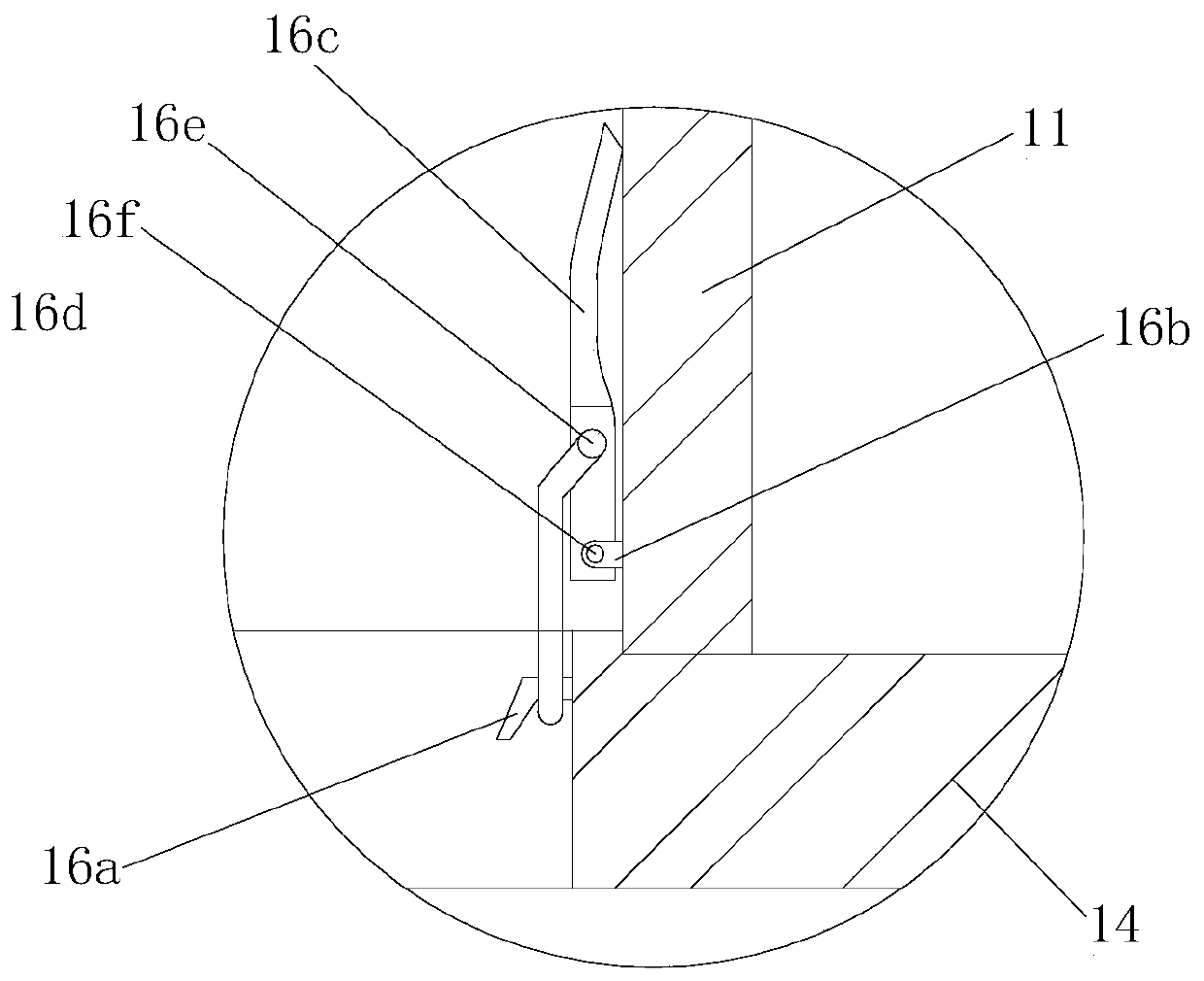

Comprehensive test device and comprehensive test method for primary power distribution device

InactiveCN113219270AReasonable designSimple and reliable external connectionEnvironmental/reliability testsTest efficiencyPower switching

The invention belongs to the technical field of power distribution tests, and particularly relates to a comprehensive test device and method for a primary power distribution device, the comprehensive test device comprises a control unit, a power supply unit and a load unit, and the control unit comprises a KVM assembly, a test host and an interface conditioning box which are in communication connection in sequence; the interface conditioning box is electrically connected with a signal interface box used for providing a signal acquisition interface and a power switching device used for supporting common loading of a plurality of channels, and the output end of the power switching device is electrically connected with a power interface box used for providing a power supply / load interface. According to the invention, functions and performance of a tested product can be comprehensively tested, whether each test item is qualified or not can be rapidly judged, the test mode is efficient and accurate, the safety and reliability of use of a primary power distribution device are better guaranteed, the direct installation of a fault product is avoided, the system test efficiency and quality of aircraft assembly are improved, and the aircraft accident rate is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Concrete sample temperature anti-crack test device and test method

PendingCN109975346AIncreased and accelerated crackingRapid cracking responseMaterial thermal analysisMonitoring systemEngineering

The invention discloses a concrete sample temperature anti-crack test device. The device comprises a temperature expansion loading assembly for shaping concrete samples, a maintenance device for maintaining the concrete samples, and an intelligent detection and monitoring system for detecting anti-crack performance of the concrete samples and monitoring the maintenance device. The temperature expansion loading assembly comprises a temperature expansion annular inner mold, an annular outer mold and a base plate. An annular space is formed between the temperature expansion annular inner mold andthe annular outer die mold. According to the test device, through setting of the temperature expansion loading assembly, the maintenance device and the intelligent detection and monitoring system, aconcrete sample temperature anti-crack test under a temperature effect condition can be carried out effectively and rapidly. The invention also discloses a concrete sample temperature anti-crack testmethod. According to the test method, the anti-crack test of the concrete samples under the effect of the temperature can be carried out accurately and reliably.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

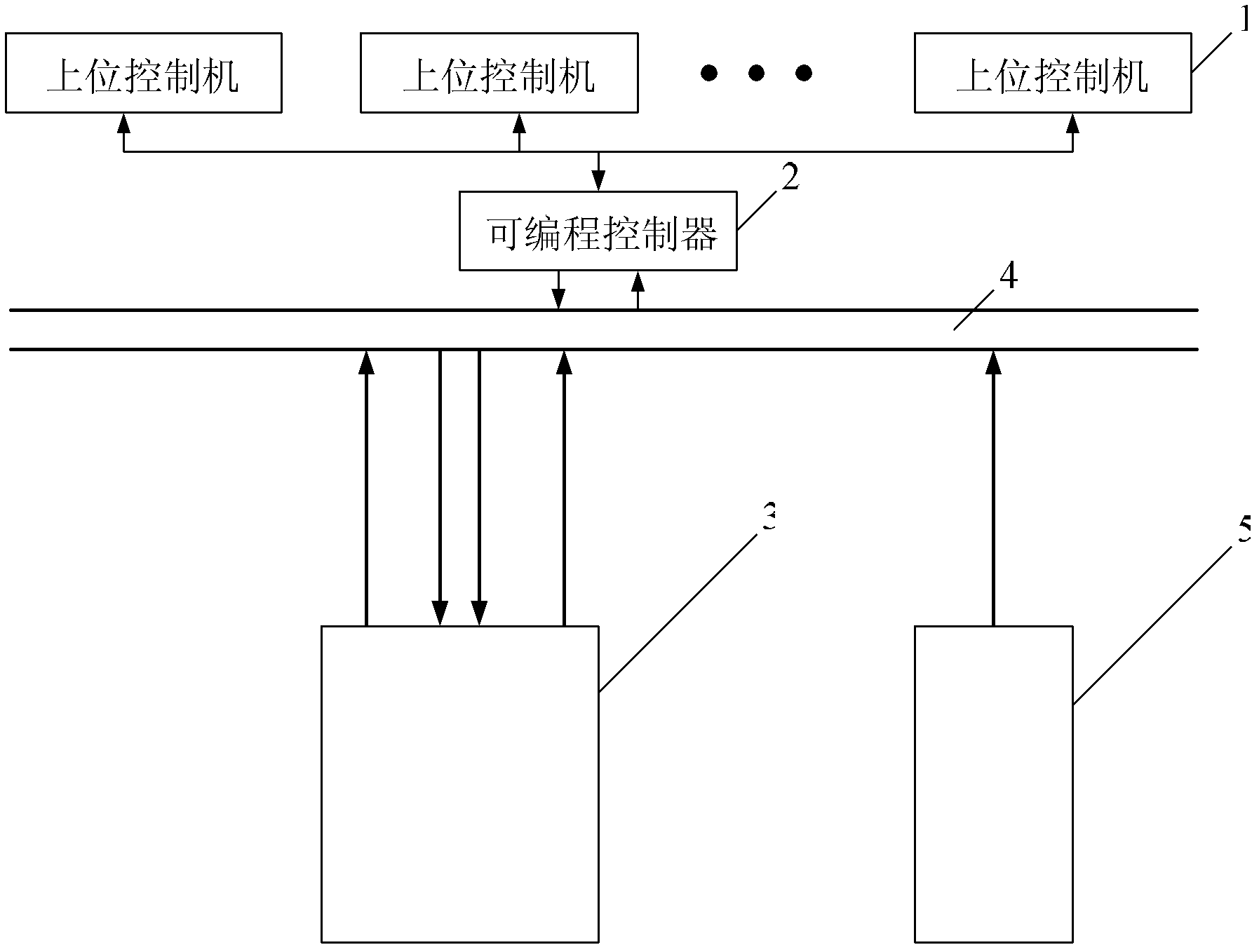

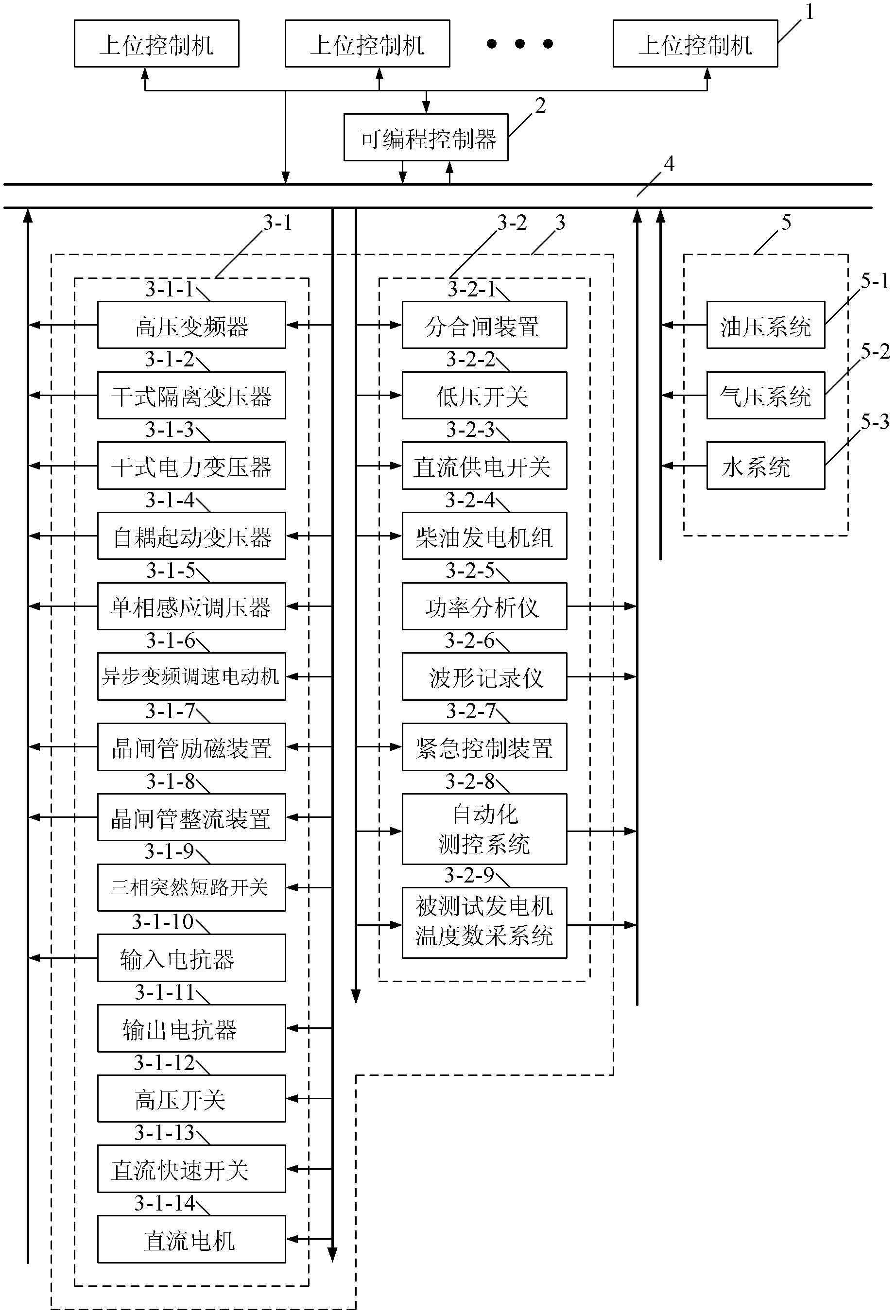

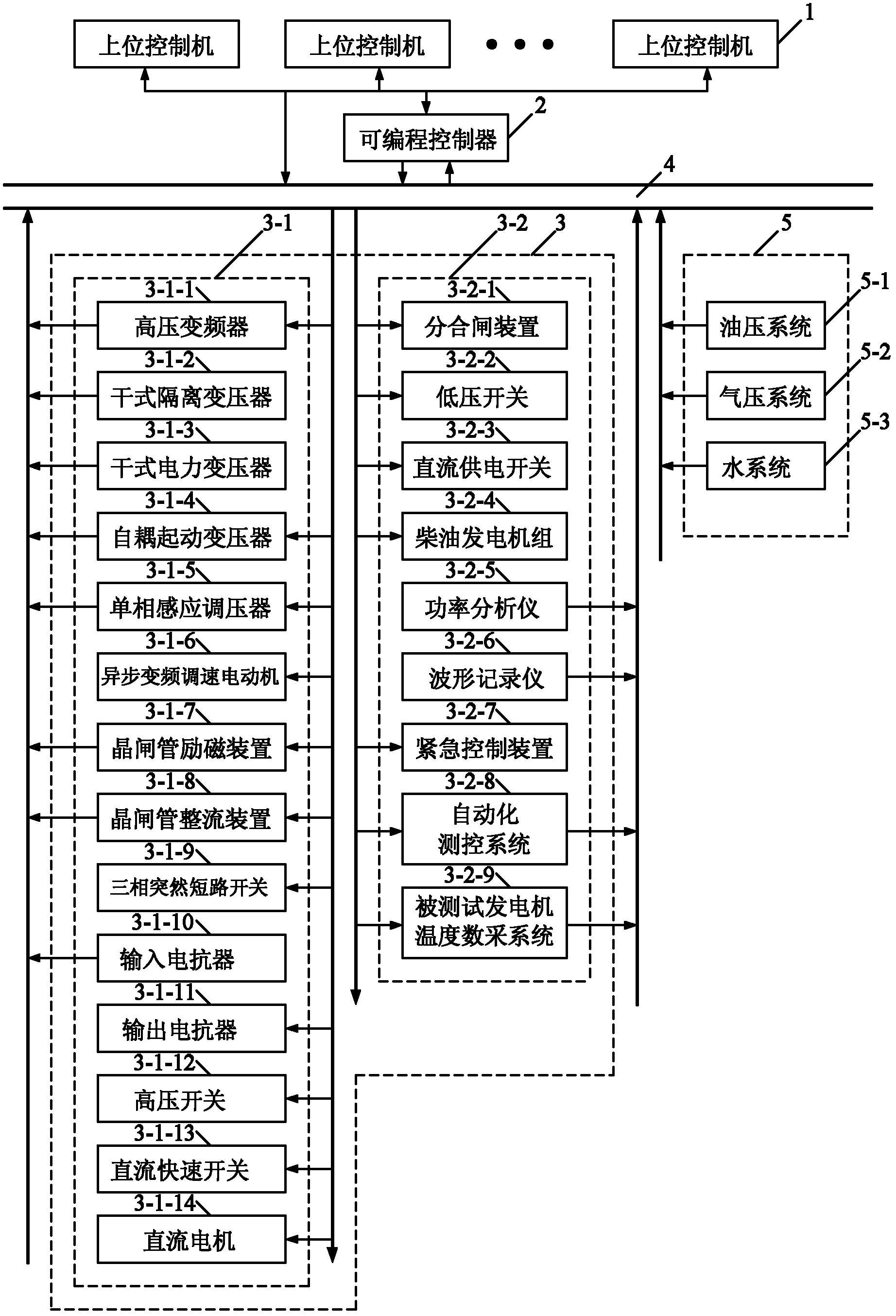

Nuclear power generator test device

ActiveCN102520704AFast controlAccurate controlTotal factory controlProgramme total factory controlNuclear powerFrequency conversion

The invention provides a nuclear power generator test device and relates to a nuclear power generator test device, which is provided by aiming at solving the problems that in the existing ten million megawatt level generator test process, the regulation of a frequency conversion unit is realized through the regulation of a slide rheostat, the manual reading of the thermotechnical quantity value by work personnel is need for the detection and the collection aiming at the thermotechnical quantity in the test process, the regulation precision of the frequency conversion unit is low, the precision of the artificial measurement sampling value is low, and the time synchronism is poor. The sampling data and control signal input and output end of a host machine is connected with the sampling data and control signal output and input end of a programmable controller, the sampling data input end of the programmable controller is simultaneously connected with a first sampling data output end and a second sampling data output end of an electric monitoring system and a sampling data output end of a non-electric monitoring system, and the control signal output end of the programmable controller is simultaneously connected with the first control signal input end and the second control signal input end of the electric monitoring system and the control signal input end of the non-electric monitoring system. The nuclear power generator test device has the advantages that the regulation precision is high, the thermotechnical quantity is detected and collected in real time, and the data precision is high.

Owner:哈尔滨五联电气设备有限责任公司

Micron-nano scale in-situ nano indentation and scratching test system

InactiveCN101876609BThe test method is accurateAccurate and effective research and testing methodsUsing optical meansInvestigating material hardnessImage resolutionEngineering

Owner:赵宏伟

Split type micro extensometer for measuring tensile deformation of small in-situ tension tester

PendingCN108020466AFulfil requirementsCompact structureMaterial strength using tensile/compressive forcesElectrical/magnetic solid deformation measurementScanning electron microscopeMicroscopic scale

The invention relates to a split type micro extensometer for measuring tensile deformation of a small in-situ tension tester and belongs to the technical field of precise sensors and precise instruments. Fixing clips are close to the side surface of a sample, clamping clips are fixedly connected with the fixing clips through rotary shafts, the clamping clips provided with cutting edges clamp the sample and are tightened with the fixing clips through rubber bands, and a capacitive displacement sensor and a measuring plate fixing rack are connected with the fixing clips through screws. The wholeextensometer is very compact in size due to adoption of tiny sensing elements and can be applied to micro tension samples with 8-20 mm long gauge length sections, and the gauge length sections of thesamples cannot be shielded and in-situ imaging of the samples in the experiment process is not affected by the aid of the split type structure. The extensometer has the advantages as follows: the extensometer is compact in structure, small in size, high in precision and particularly applicable to deformation measurement of in-situ tension tests for material micro-mechanical properties under a scanning electron microscope.

Owner:JILIN UNIV

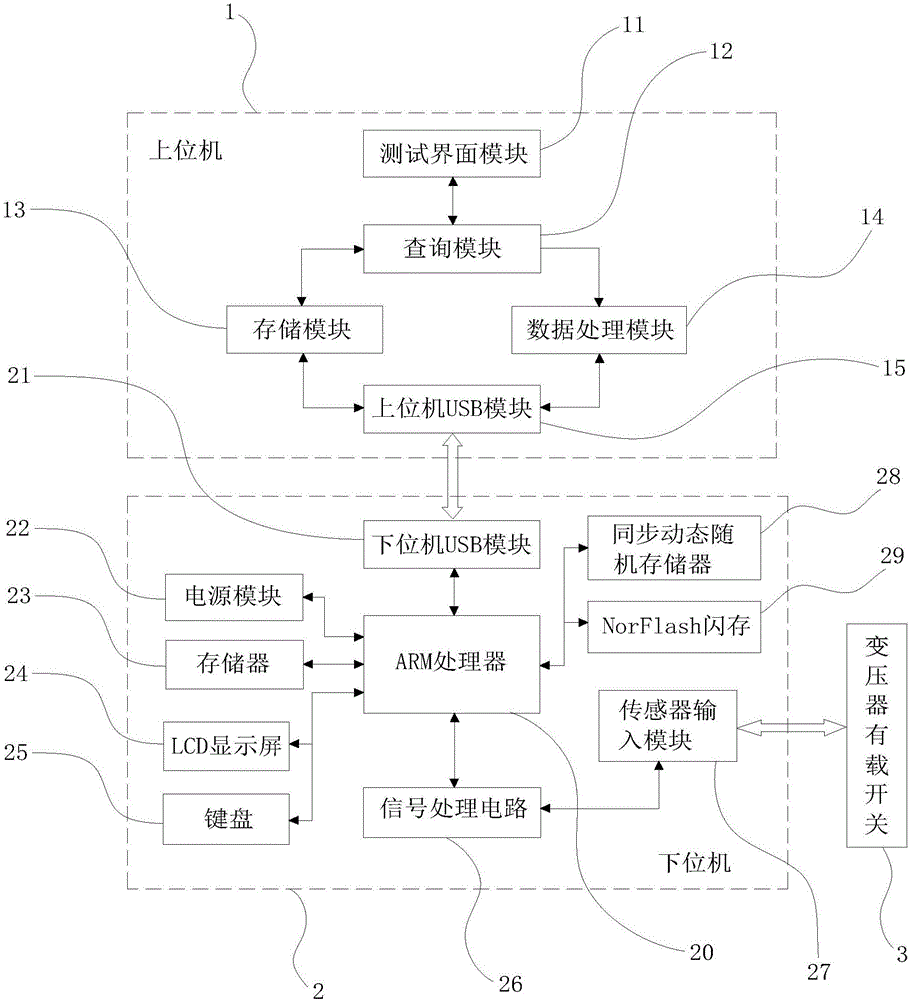

Transformer on-load switch testing system and method

The invention relates to a transformer on-load switch testing system and method. The system comprises an upper computer and a lower computer. The upper computer comprises a test interface module, a query module, a storage module, a data processing module, and an upper computer USB module. The lower computer comprises an ARM processor, a lower computer USB module, a power supply module, a memory, an LCD display, a keyboard, a signal processing circuit, a sensor access module, a synchronous dynamic random access memory, and a NorFlash. According to the method, the tests of the upper computer and the lower computer are employed, the lower computer can communicate with the upper computer through the lower computer USB module, the upper computer and the lower computer carry out analysis processing and displaying on a signal so as to judge the performance of a high voltage switch, and the normal operation of a grid is protected. The transformer on-load switch testing system and method have the advantages of a reasonable conception and simple and fast testing, through the simultaneous comparison of a DC waveform and an AC wave form and mutual reference, a more accurate testing result is given, and the testing result is more comprehensive.

Owner:WUHAN ORIG TECH CO LTD

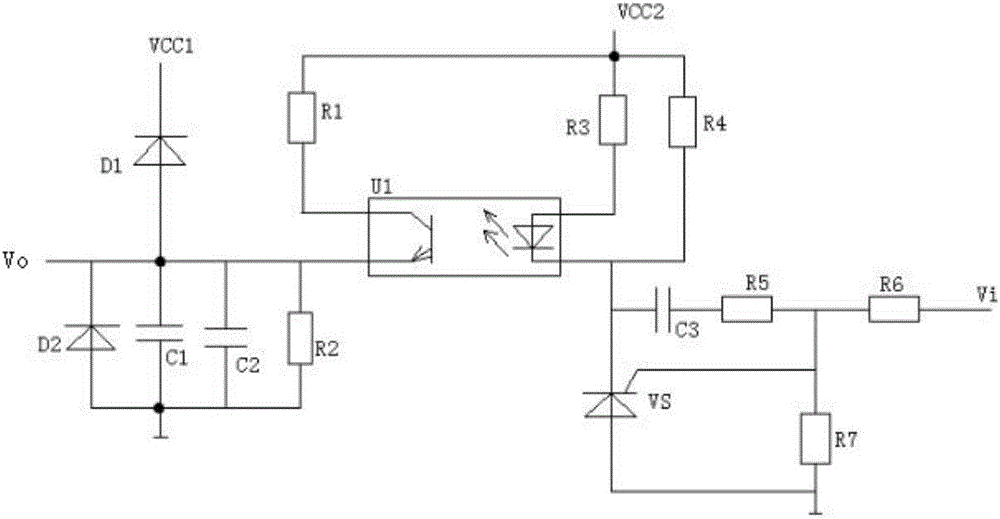

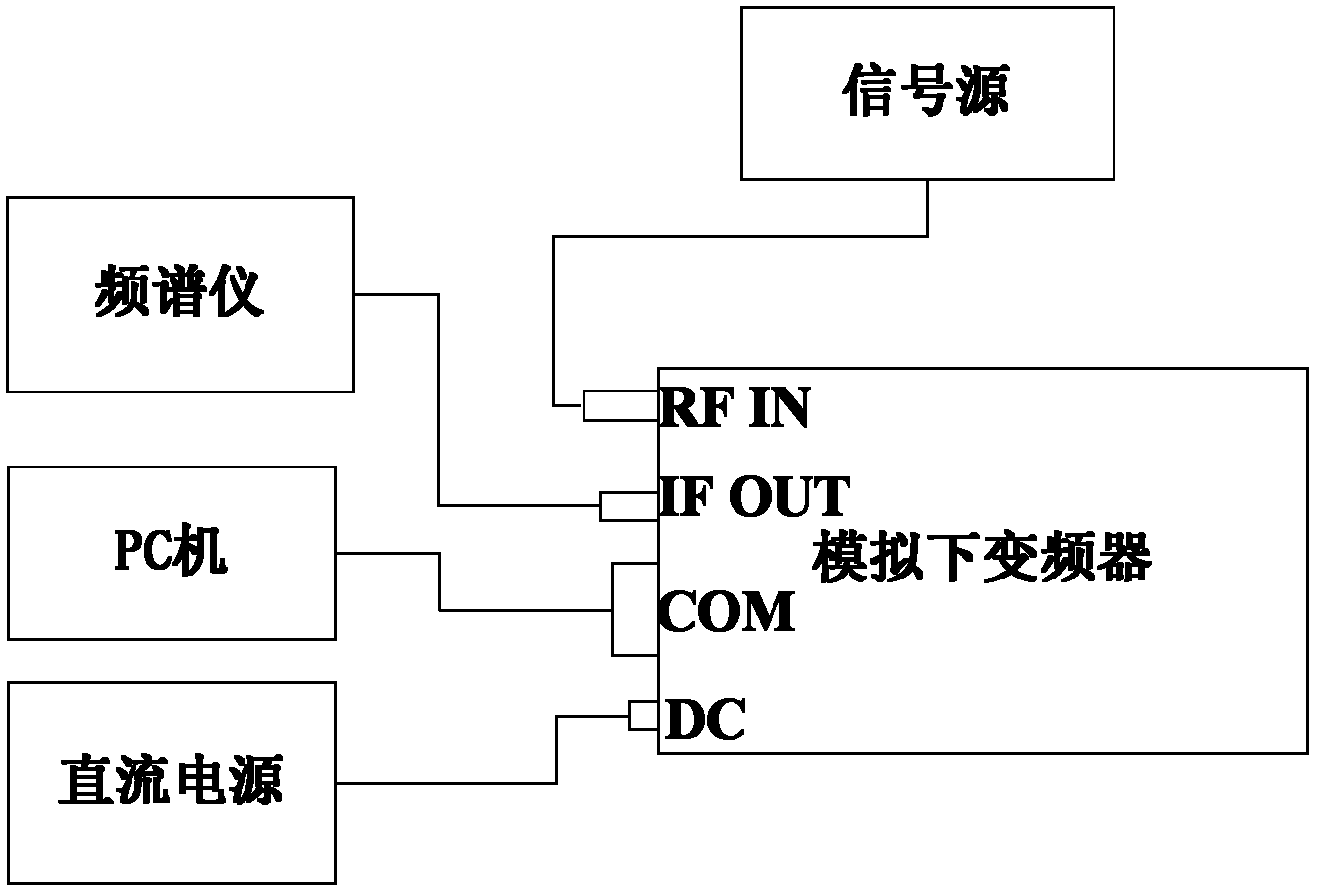

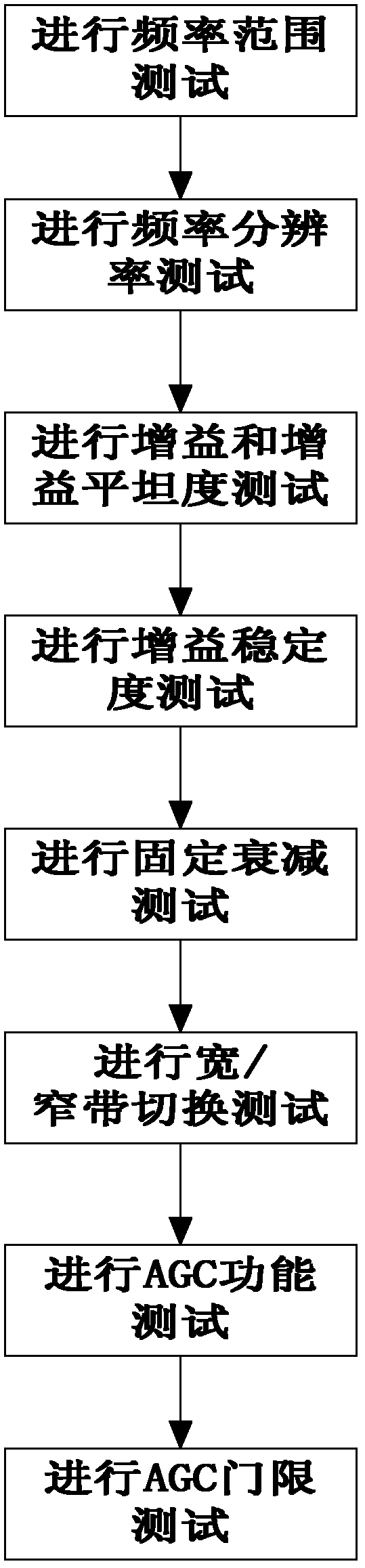

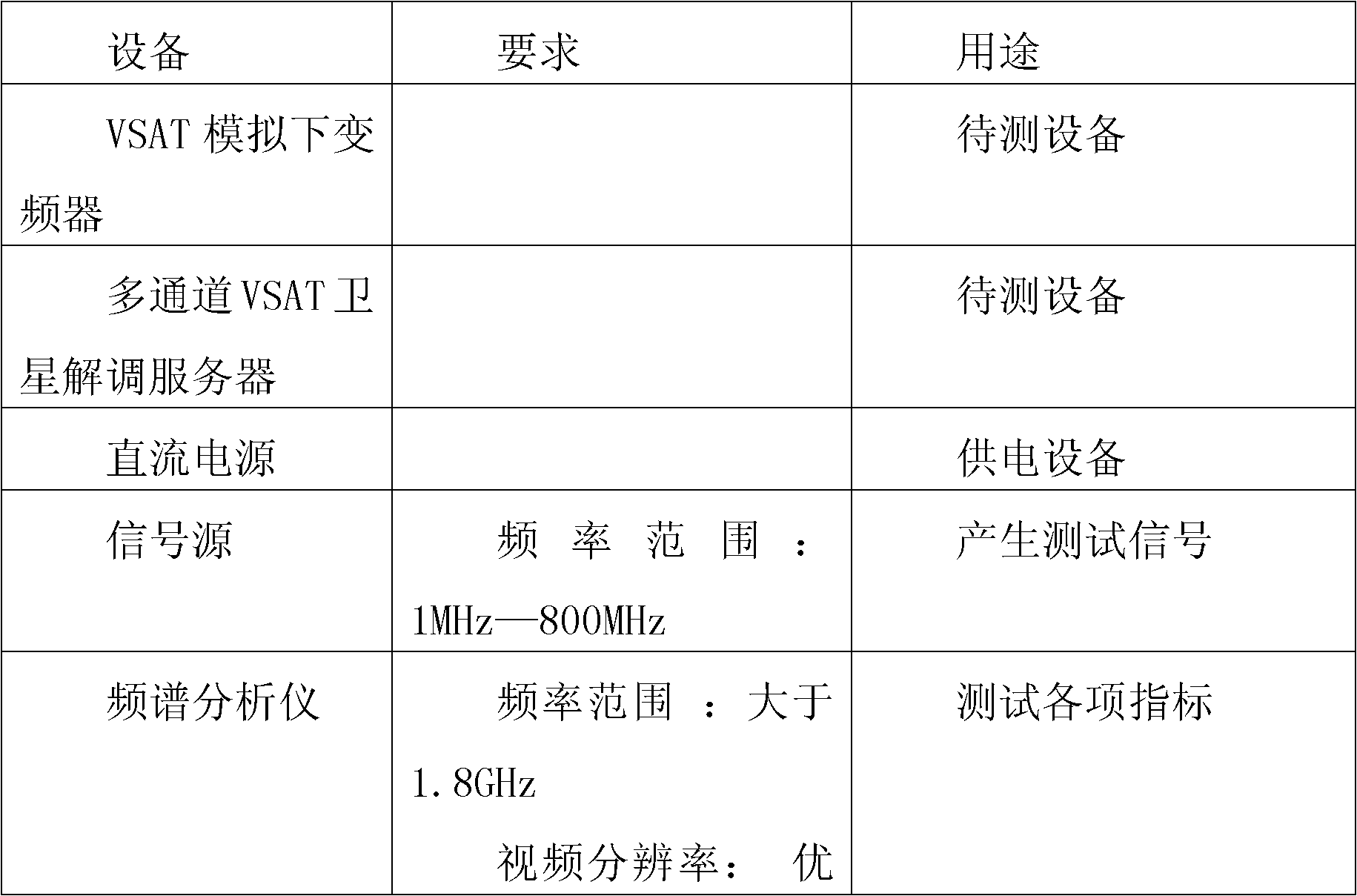

Test method for simulated down-converter in satellite demodulator

InactiveCN102571244AThe test method is accurateRelay systems monitoringFrequency changerSpectrograph

The invention discloses a test method for a simulated down-converter in a satellite demodulator. The test method is used for testing various parameters of the simulated down-converter. The simulated down-converter comprises an input interface, an output interface, a control interface and a power interface, wherein a signal source, a frequency spectrograph, a PC (Personal Computer) machine and a direct current power supply are connected with the input interface, the output interface, the control interface and the power interface of the simulated down-converter in turn. The frequency range test, the frequency resolution test, the gain and gain flatness test, the gain stability test, the fixed attenuation test, the wide / narrow band switching test, the AGC (Automatic Gain Control) function test and the AGC threshold test are performed in turn. The test method provided by the invention is accurate, stable and reliable. After all the parameters of a VSAT (Very Small Aperture Terminal) simulated down-converter meet the demand, the satellite demodulator is switched on.

Owner:CHENGDU LINHAI ELECTRONICS

Steel solidus-liquidus temperature measurement method

ActiveCN103235001BThe test method is accurateHigh degree of automationInvestigating phase/state changeMetallic materialsMaterials science

The invention relates to a steel solidus-liquidus temperature measurement method, and belongs to the technical field of metal material detection. The specific method comprises sample preparation, equipment calibration, experiment testing, and result analysis so as to complete the measurement. The results show that: an extrapolated onset temperature is consistent with a thermodynamic equilibrium temperature, such that a temperature corresponding to an extrapolated onset point of the first endothermic peak on a differential thermal curve during sample heating melting is judged as a liquidus temperature TL, and a temperature corresponding to an extrapolated onset point of the first exothermic peak on a differential thermal curve during sample cooling solidification is judged as a solidus temperature Ts. The measurement method has advantages of rapidness, accuracy, high automation degree, and good reproducibility.

Owner:SHOUGANG CORPORATION

Asphalt mortar forming, measuring device and test method for dynamic shear parameters of asphalt mortar

ActiveCN105300758BWon't hurtEnsure accuracy andPreparing sample for investigationMaterial strength using steady shearing forcesMeasurement deviceMaterials science

The invention relates to an asphalt mortar forming and measuring device and a test method for the dynamic shear parameter of the asphalt mortar, belonging to the field of testing the dynamic shear parameter of the asphalt mortar. Asphalt mortar specimens produced by existing molding methods are easily damaged, and the existing measuring devices and methods for asphalt mortar specimens cannot meet the requirements of high temperature performance testing. Asphalt mortar forming device, one end of the test mold (3) is oppositely provided with a guide rod (1), and the other end is matched with the base (4) for insertion. Asphalt mortar dynamic shear parameter testing device, a detachable fixture (9) and a fixture loading body (20) arranged opposite to each other are respectively installed in cooperation with a connection base (16). Asphalt mortar dynamic shear parameter testing method, preparing asphalt mortar specimen (19), performing inertia moment correction, zeroing, and geometric correction operations on the uninstalled specimen connection base (16), starting the DHR-II rheometer environment box for testing. The invention has the advantages of simple operation and accurate test results.

Owner:HARBIN INST OF TECH

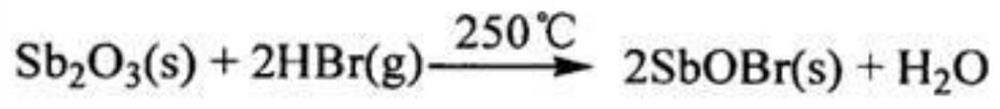

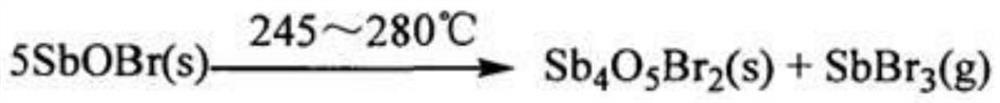

Efficient flame-retardant master batch for high-density polyethylene

InactiveCN111662502ASmall particle sizeGood compatibilityFlame-proof filament manufactureMonocomponent polyolefin artificial filamentElastomerPolymer science

The invention provides an efficient flame-retardant master batch for high-density polyethylene. The efficient flame-retardant master batch is prepared from components through a double-screw extruder,and the components comprise, by weight, 28-34 parts of a powdery polyolefin elastomer, 65-70 parts of a compound flame retardant, 0.5-1 part of an auxiliary agent and 0.5-1 part of a coupling agent; the coupling agent is an aluminate coupling agent; and the auxiliary agent is an antioxidant. According to the efficient flame-retardant master batch for the high-density polyethylene, the flame retardant adopted in the formula is a compound flame retardant of decabromodiphenyl ethane and antimonous oxide, the bromine-antimony ratio is 1: 1.055, and the proportion is accurate and reasonable; and all the components in the formula have a synergistic effect, so that a very good flame-retardant effect can be achieved under the condition of a very small addition amount. The efficient flame-retardantmaster batch is applied to spinning and film blowing production of HDPE materials under the condition of hardly influencing mechanical properties; and the preparation method is simple, the used equipment is a common water brace twin-screw extruder with very wide applicability, and large-scale production is easy to realize.

Owner:太仓市华鼎塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com