Patents

Literature

235 results about "Thermodynamic equilibrium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermodynamic equilibrium is an axiomatic concept of thermodynamics. It is an internal state of a single thermodynamic system, or a relation between several thermodynamic systems connected by more or less permeable or impermeable walls. In thermodynamic equilibrium there are no net macroscopic flows of matter or of energy, either within a system or between systems.

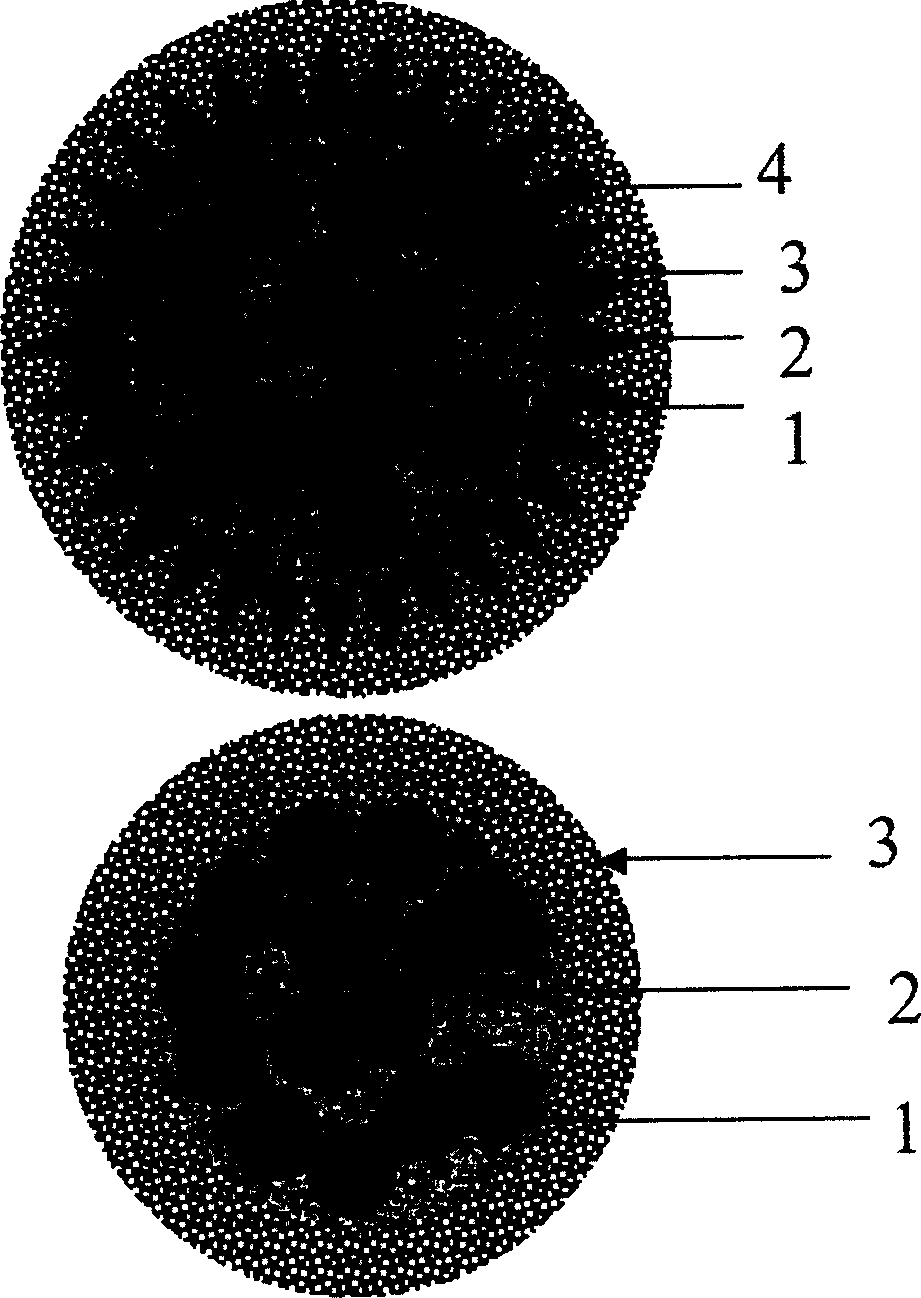

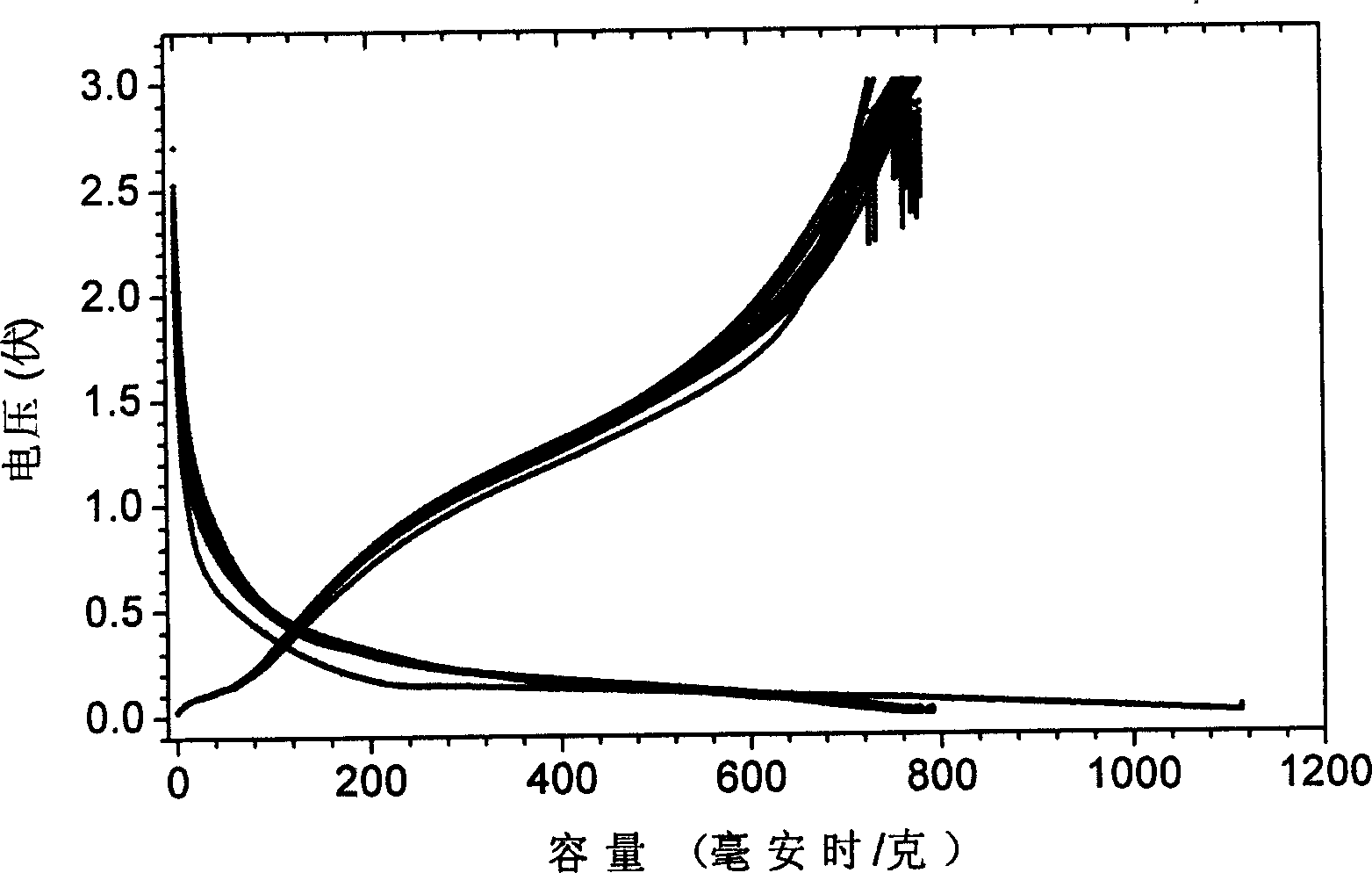

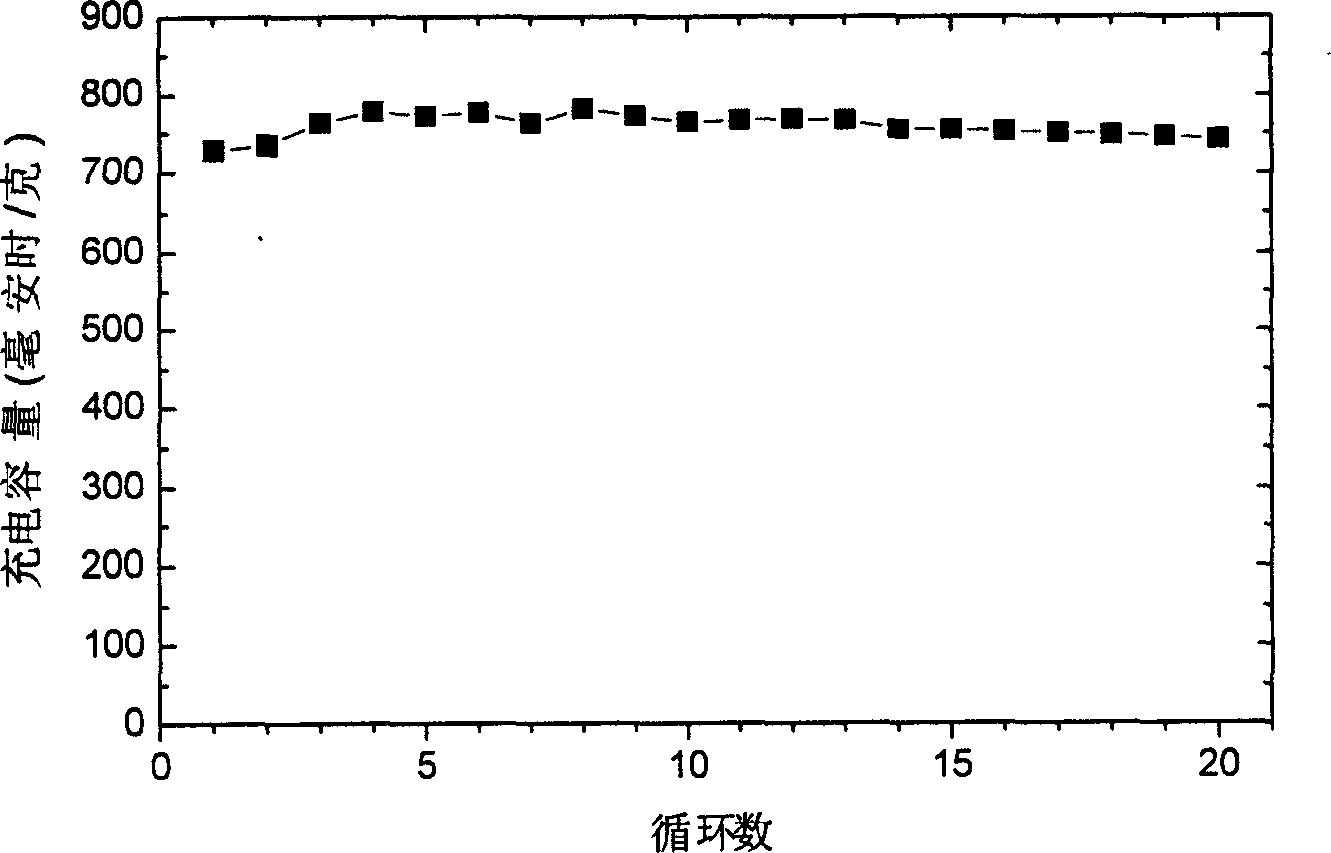

Negative electrode active material and use of secondary lithium battery

The invention has a grain structure with an outer shell and several inner cores. The grain size is from 100 nanometers to 100 microns. The inner cores are compound grain that includes active substance and conducting additive. The outer shell is a carbon layer. The active substance takes 20-95wt% of total cathode active material, and is mixture of one or several transition metallic compound selected from silicon and lithium storage whose thermodynamic equilibrium potential is less than 1.5v. The cathode material can be made by using mechanical process or thermal method, and can be directly used as cathode material or used with other existing cathode material.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

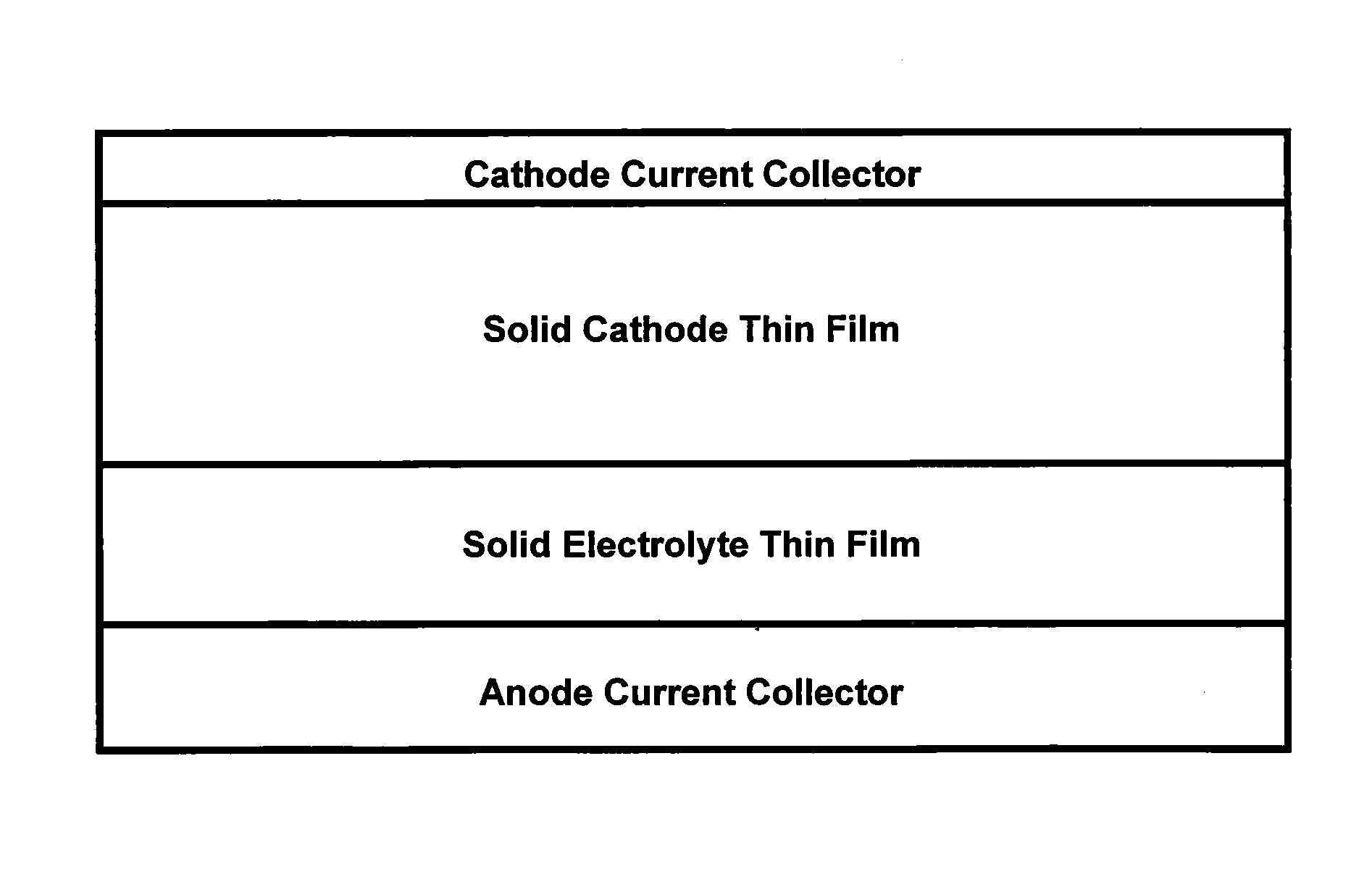

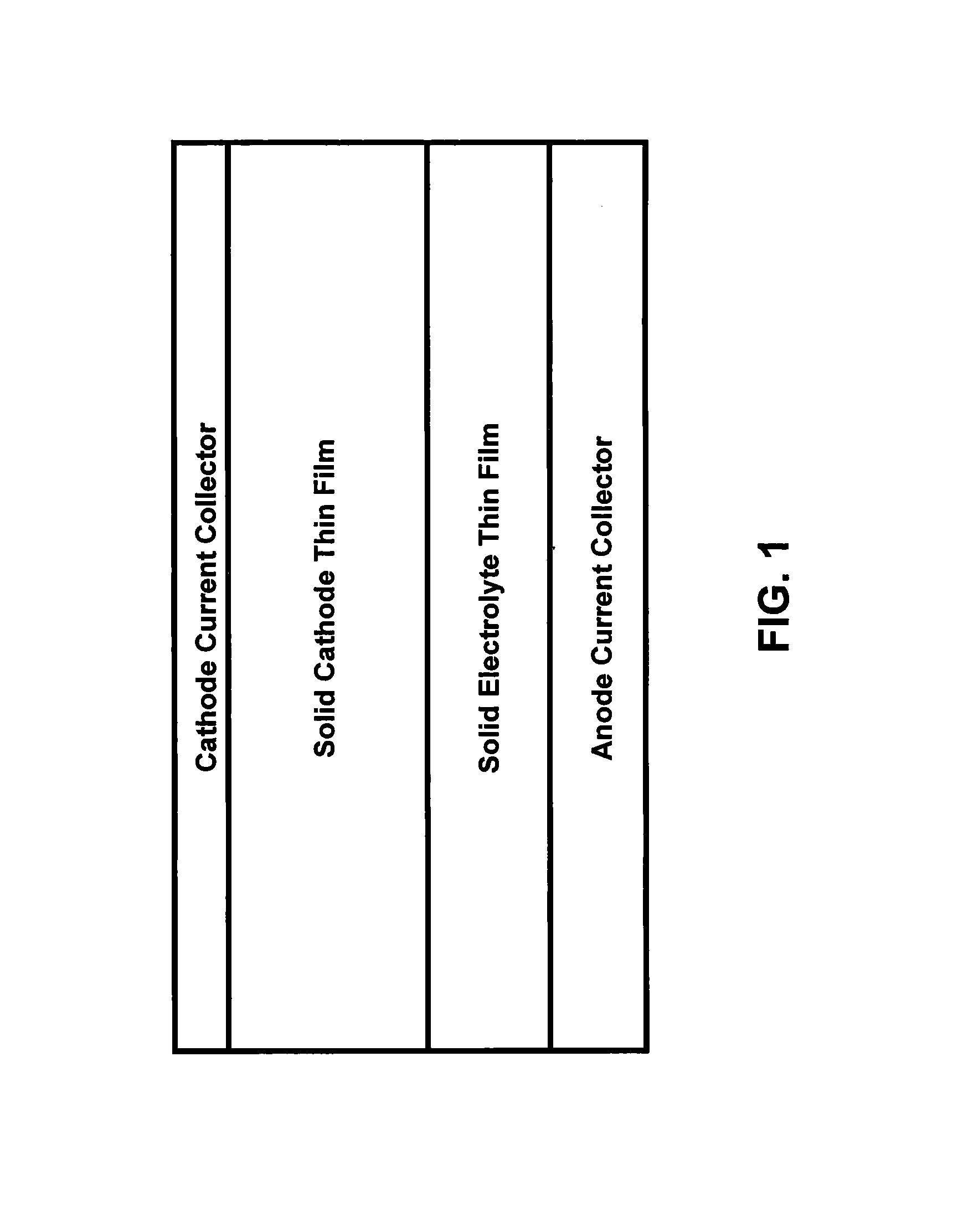

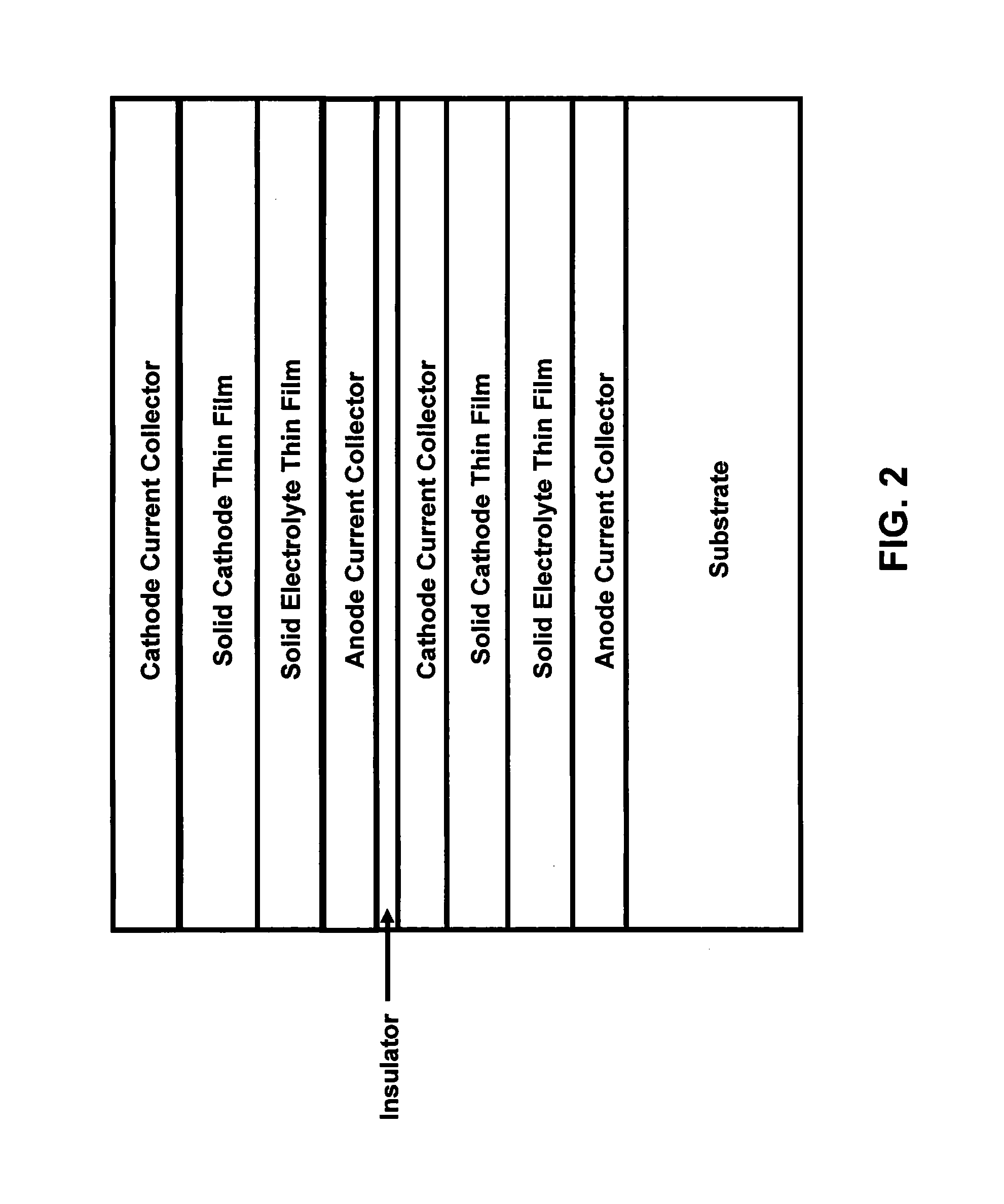

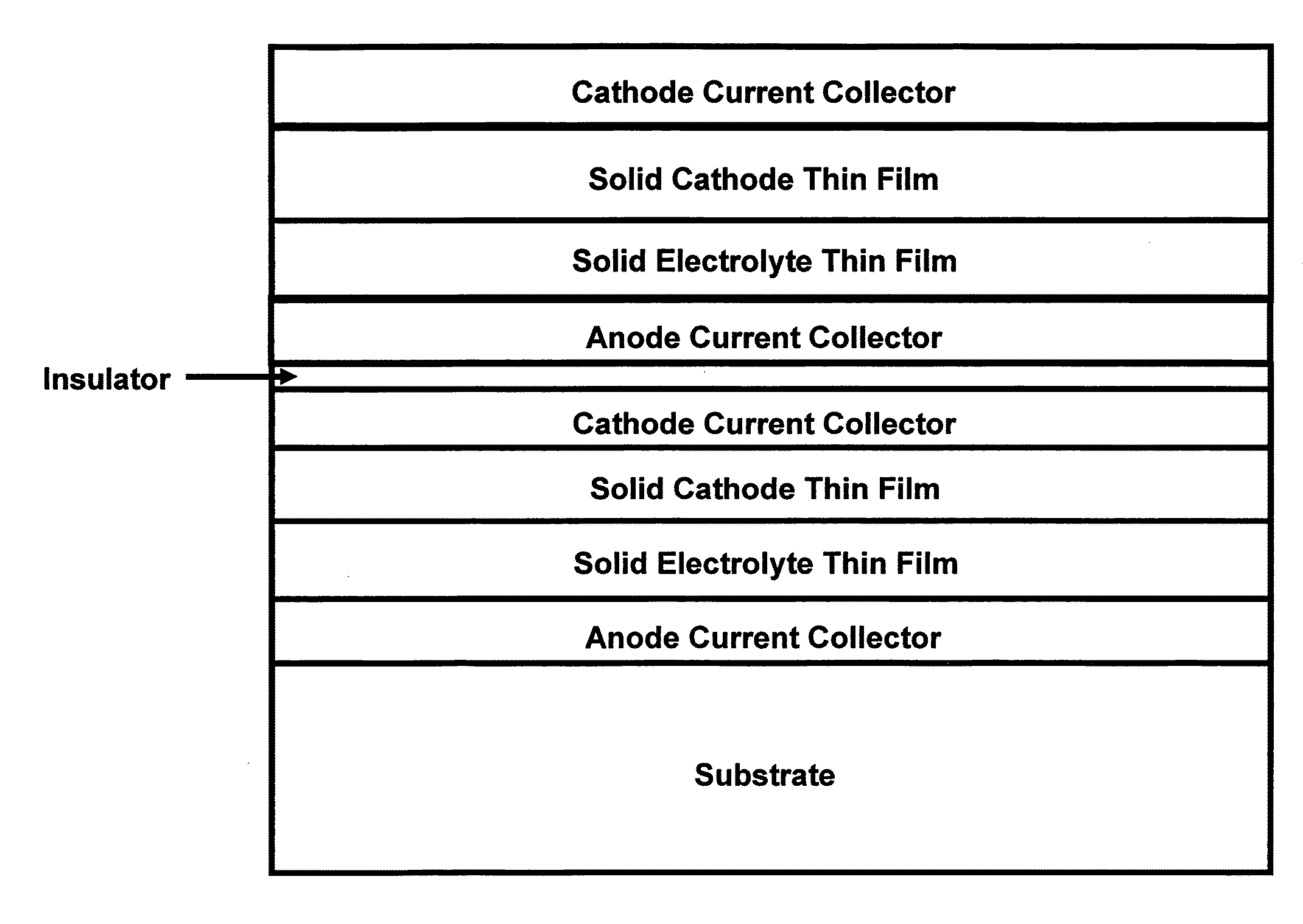

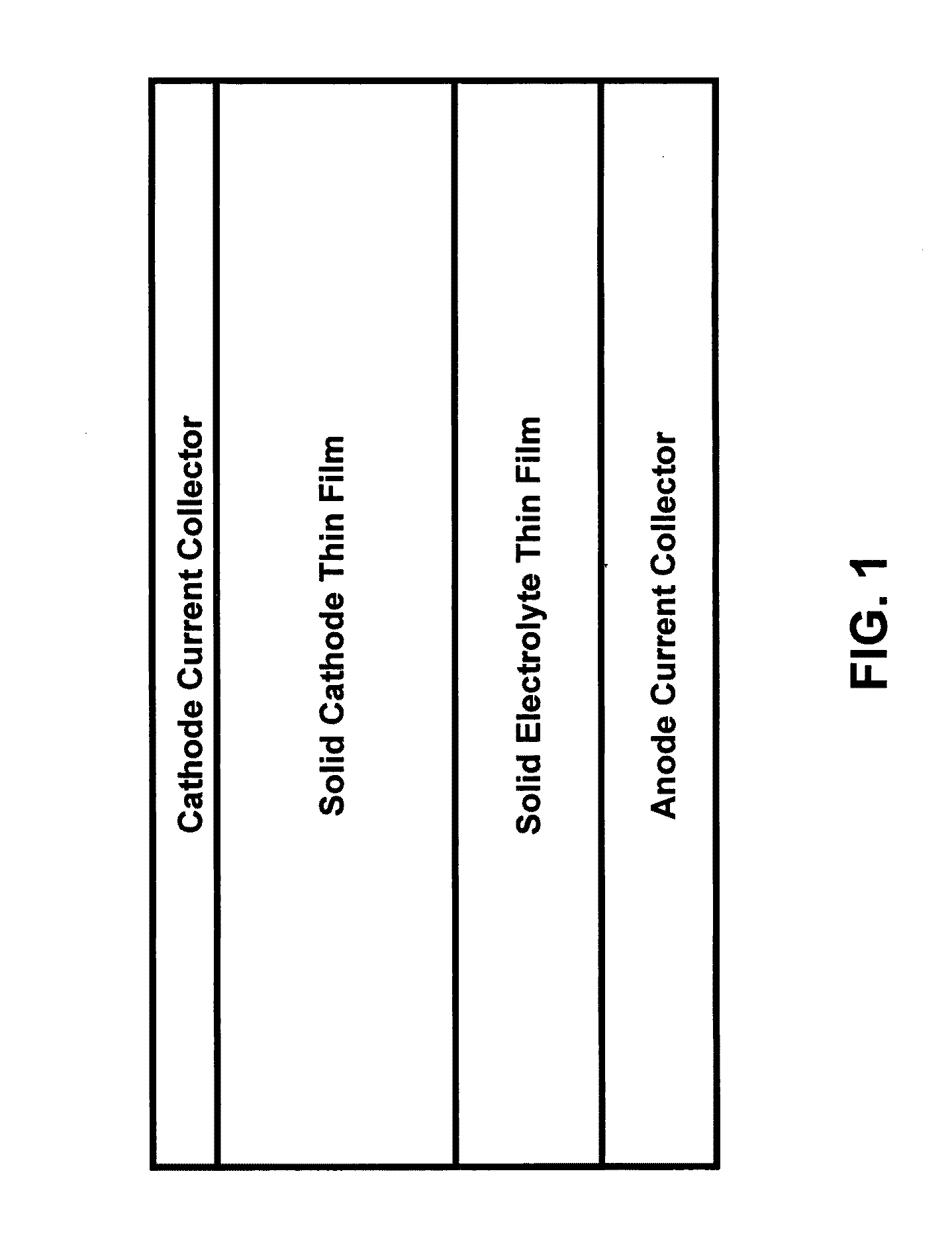

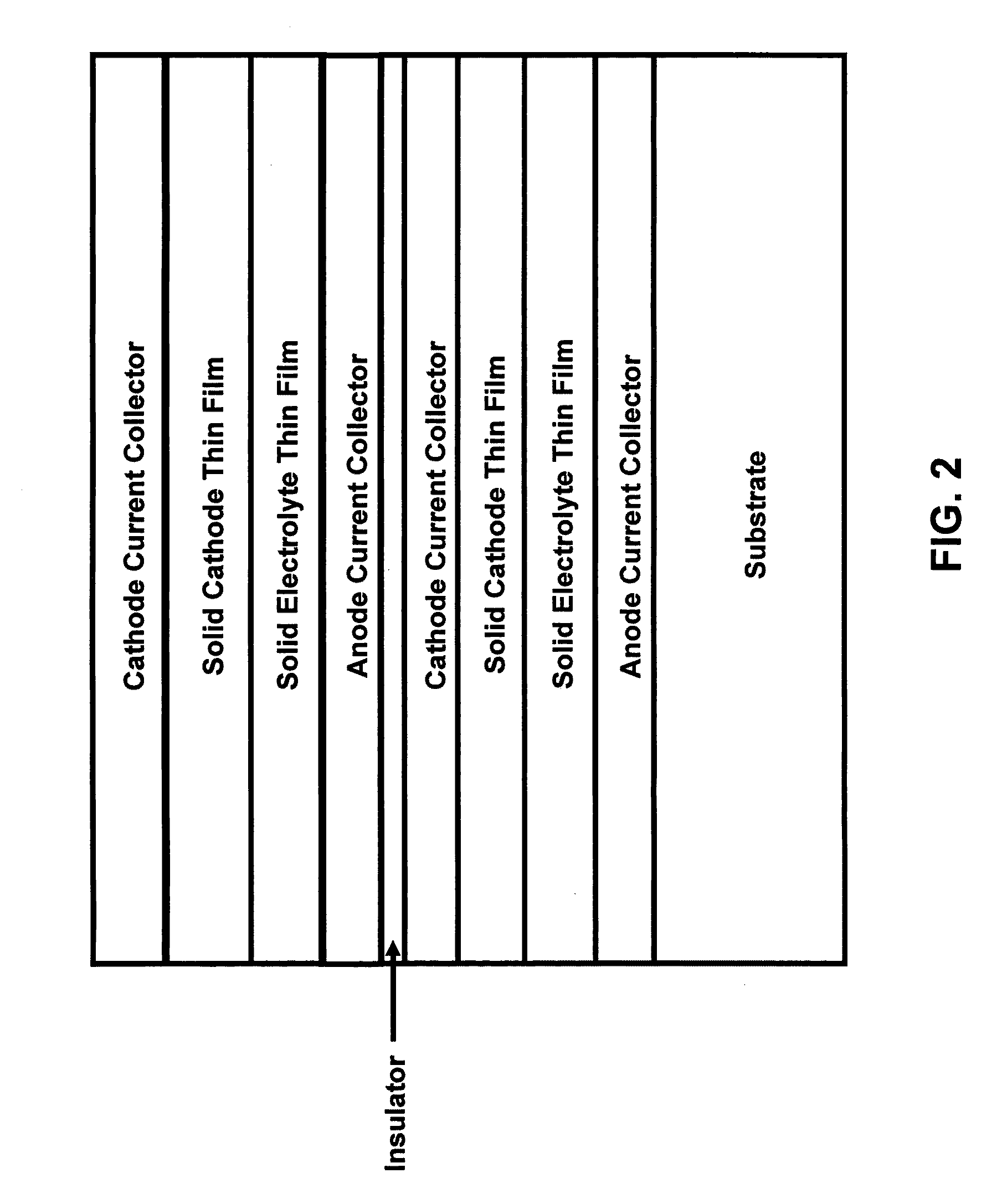

Solid-state lithium battery

ActiveUS8877388B1Low form factor requirementsIncrease powerTantalum compoundsPrinted batteriesLanthanumLithium.free

The present invention is directed to a higher power, thin film lithium-ion electrolyte on a metallic substrate, enabling mass-produced solid-state lithium batteries. High-temperature thermodynamic equilibrium processing enables co-firing of oxides and base metals, providing a means to integrate the crystalline, lithium-stable, fast lithium-ion conductor lanthanum lithium tantalate (La1 / 3-xLi3xTaO3) directly with a thin metal foil current collector appropriate for a lithium-free solid-state battery.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

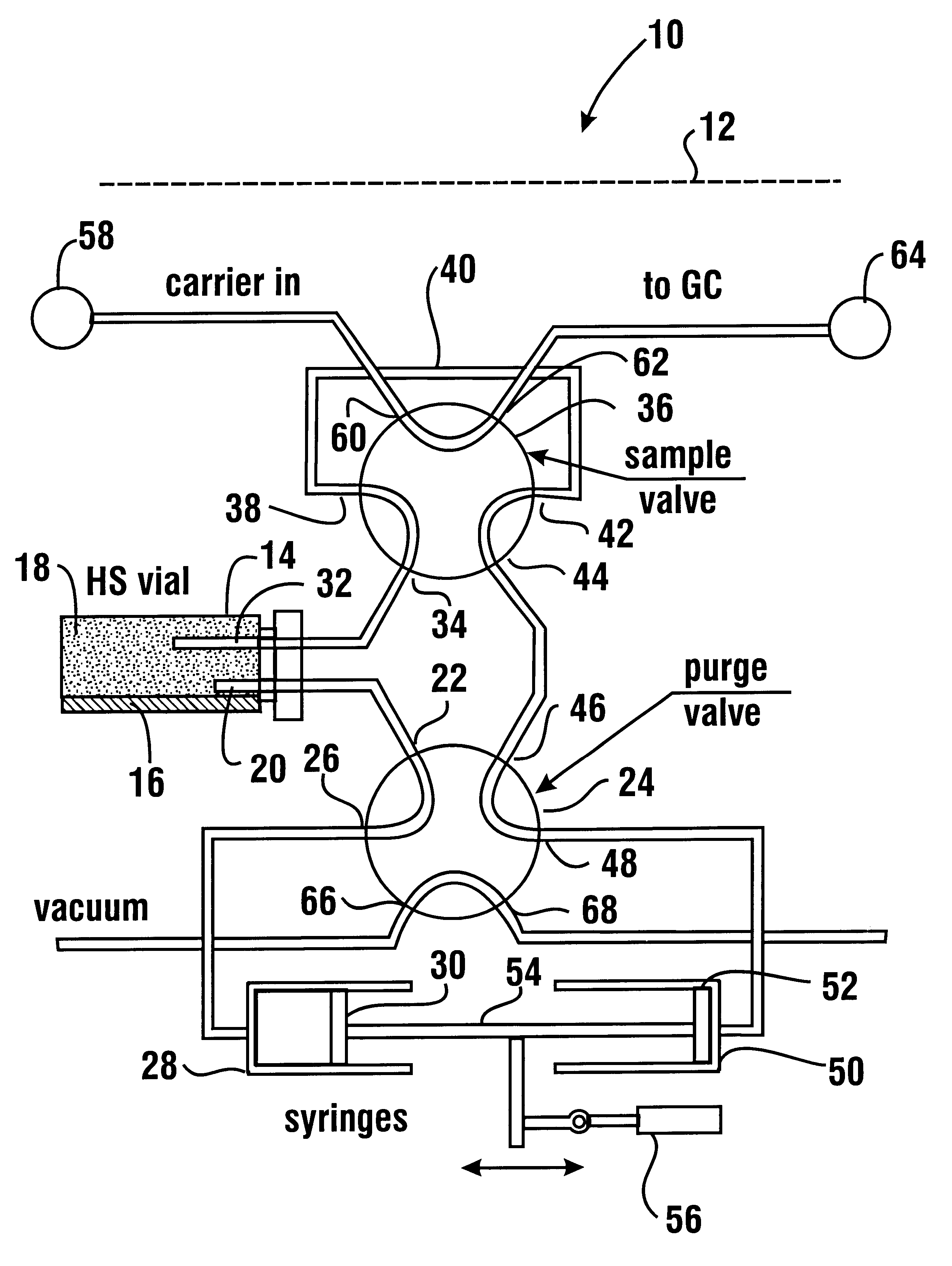

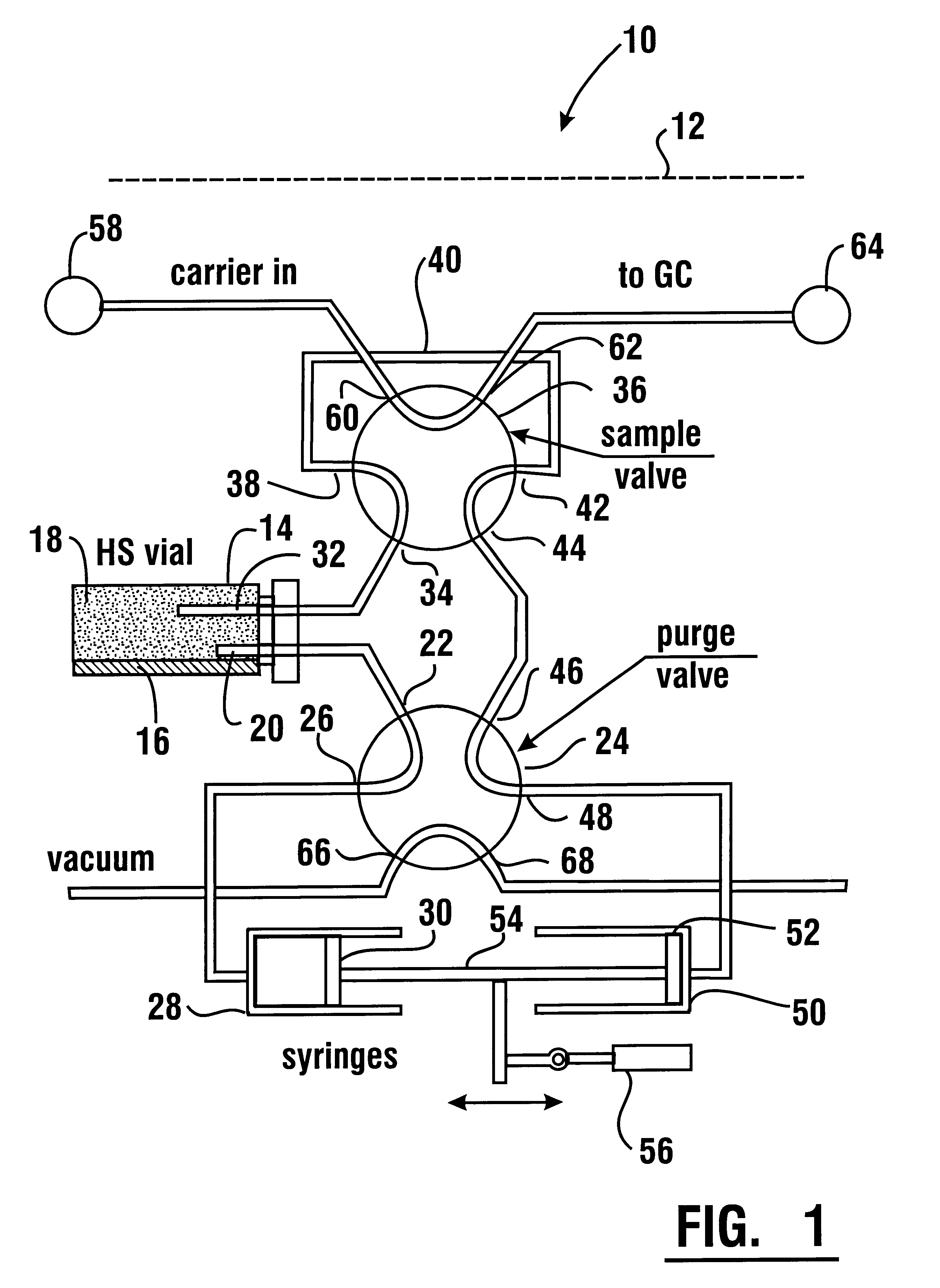

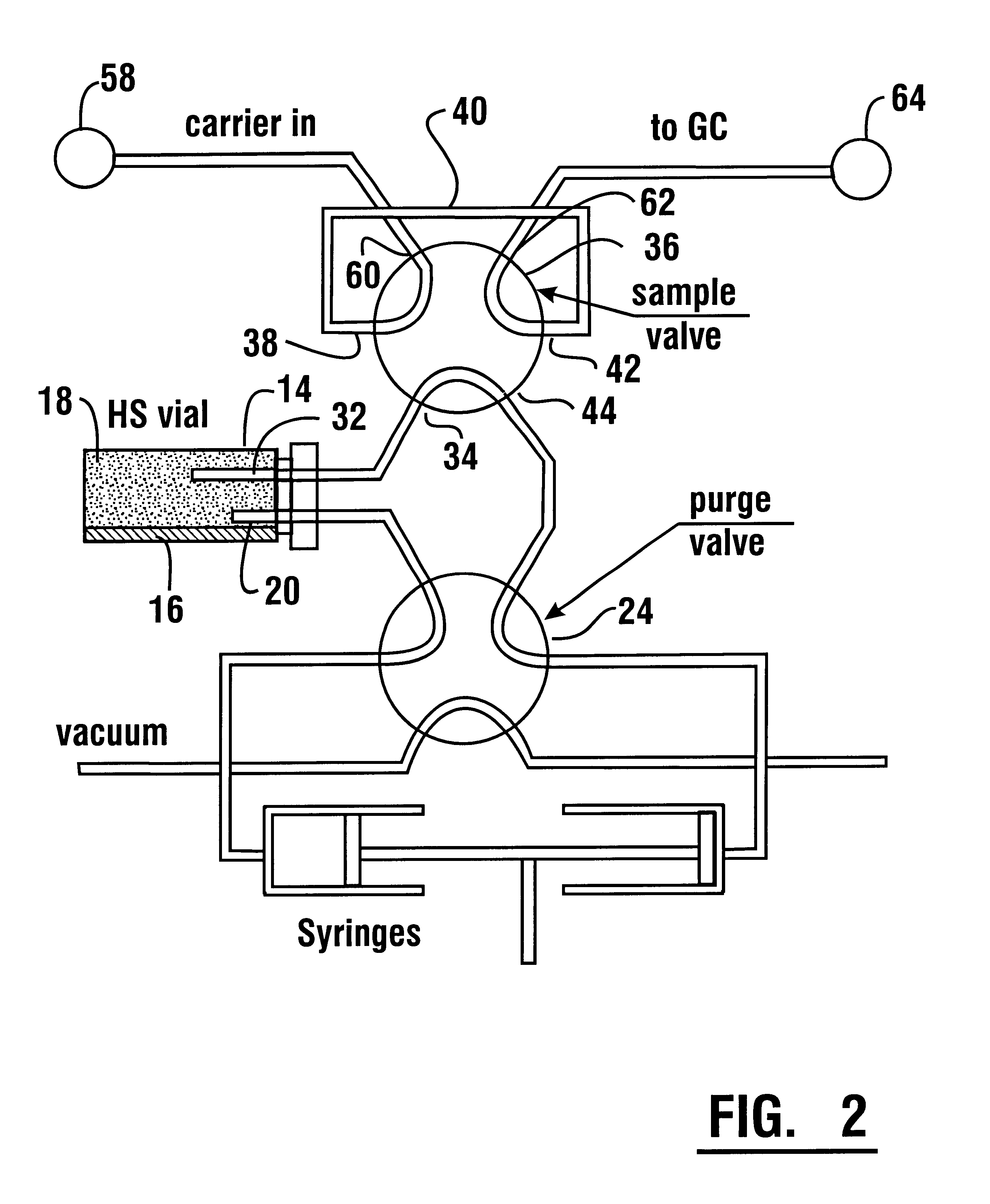

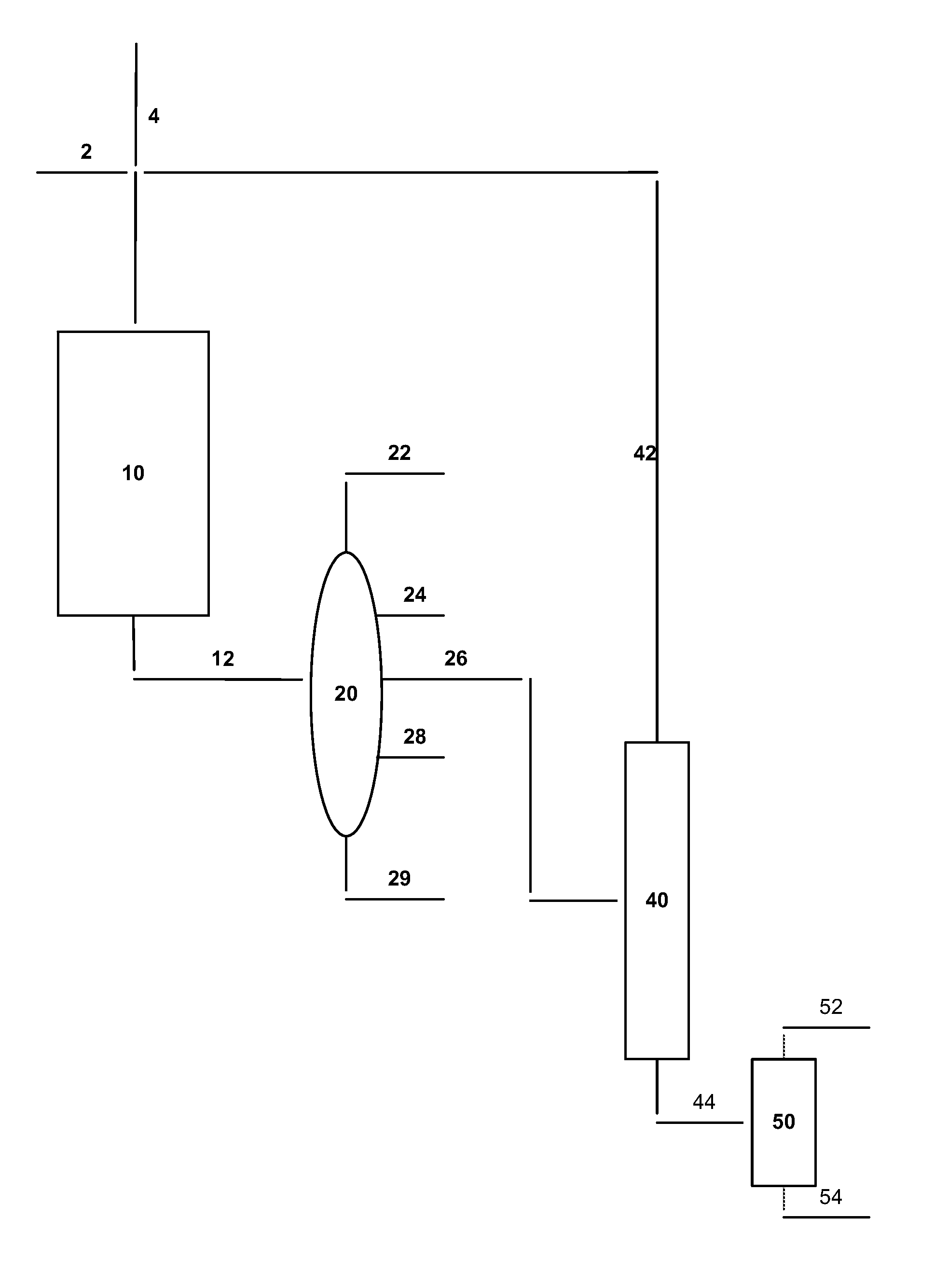

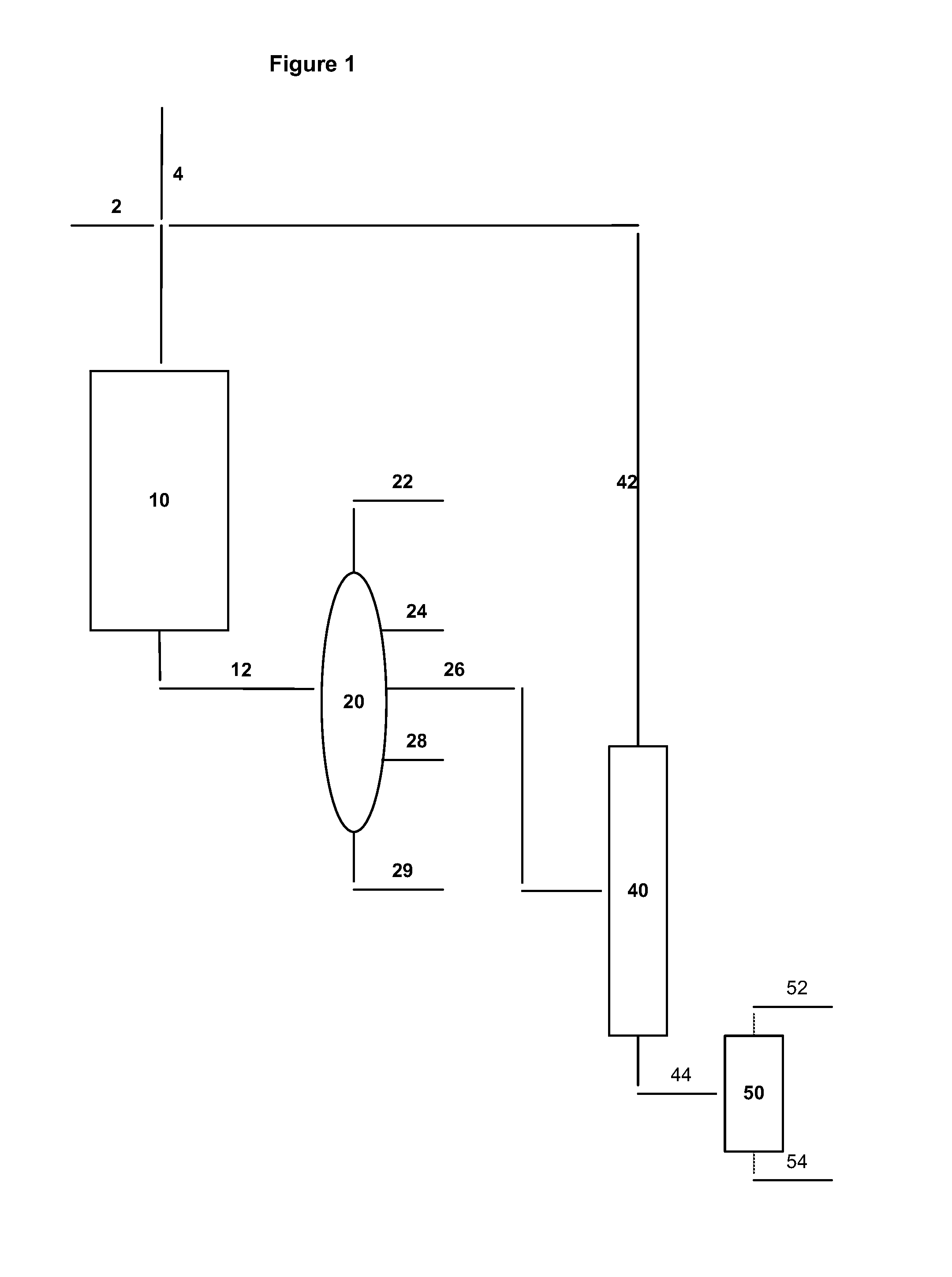

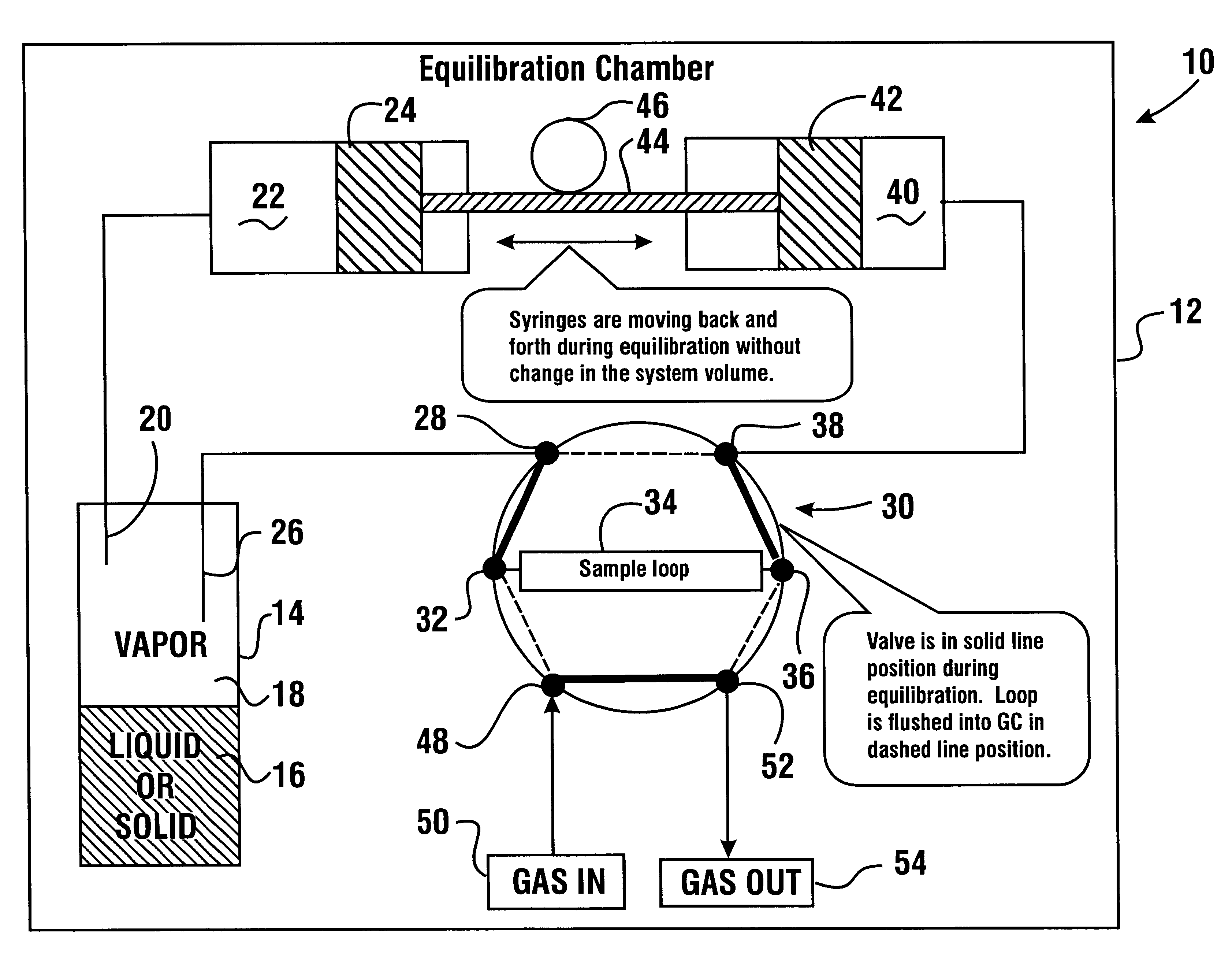

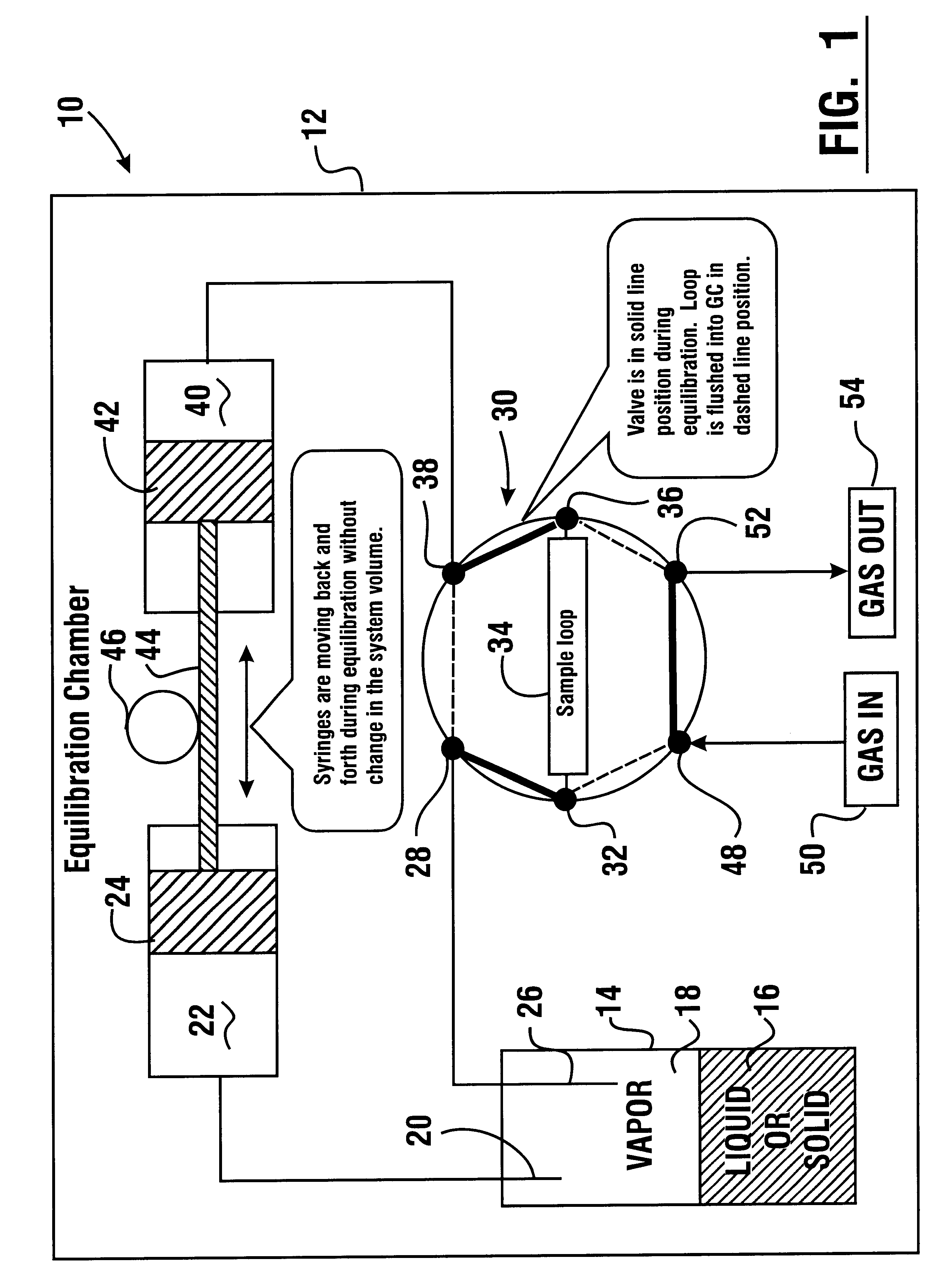

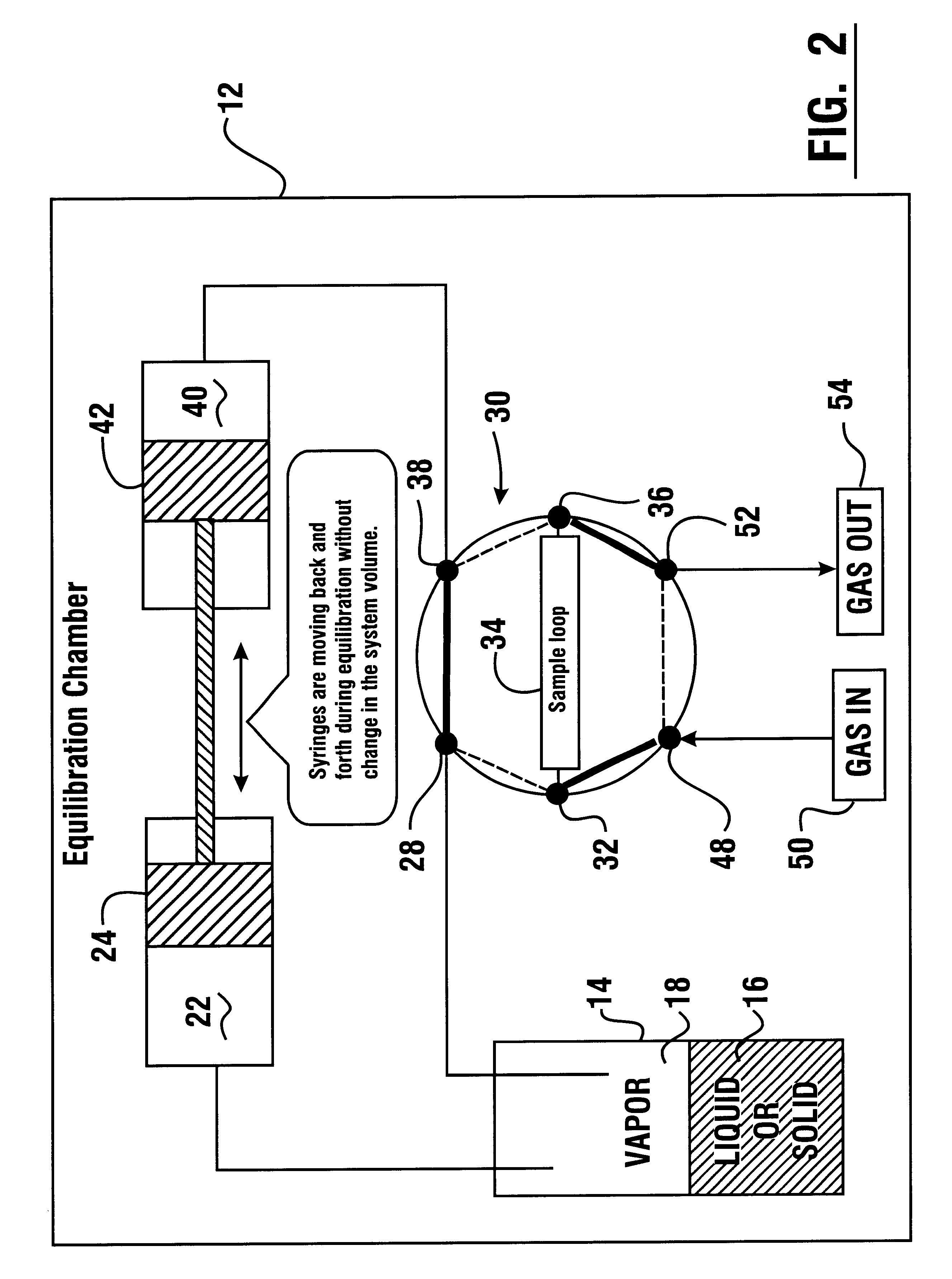

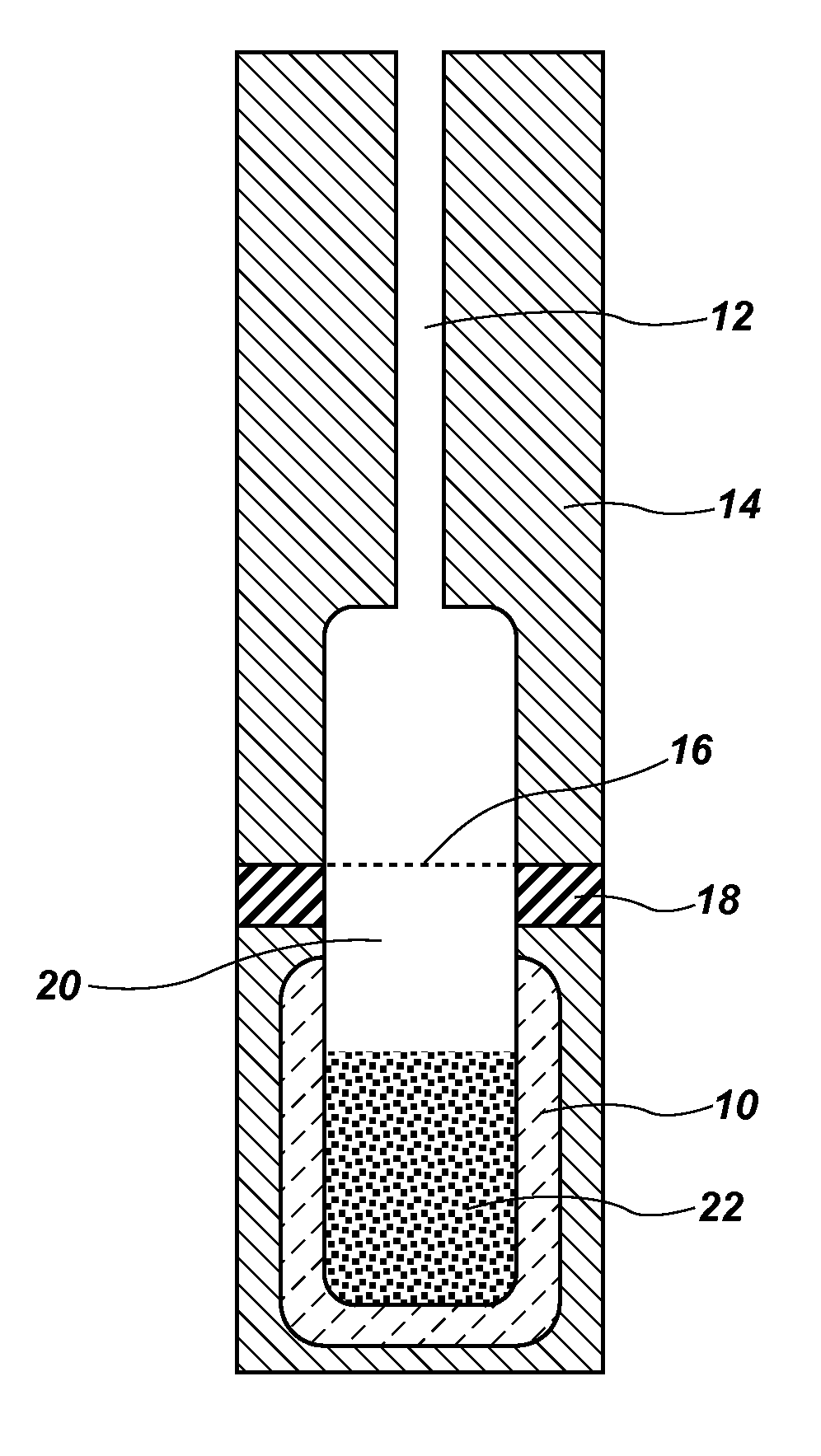

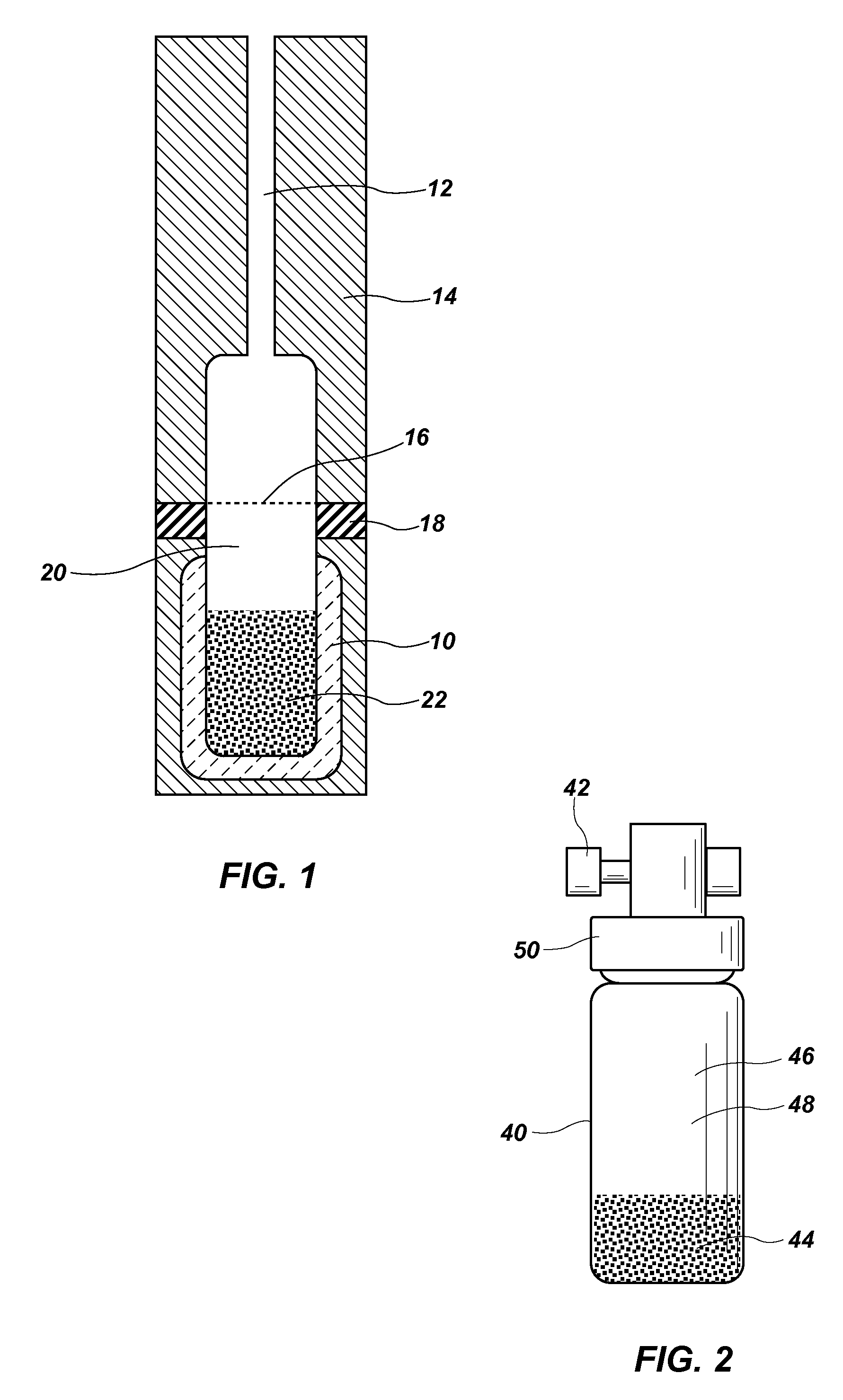

Headspace instrument

InactiveUS6365107B1Minimize disturbanceRisk minimizationChemical analysis using combustionComponent separationDesorptionGas phase

A headspace instrument (10, 70) operates to equilibrate a vapor phase of a headspace sample in a sample loop (40, 74). The sample is equilibrated by flow through the headspace between variable volume chambers (28, 50, 86, 90). The volume of the variable volume chambers are changed in coordinated relation so that a constant total volume is always maintained. An aliquot of the equilibrated sample in the sample loop is delivered to an analytical instrument. The headspace instrument enables delivering a vapor sample from a headspace under conditions which do not disturb the thermodynamic equilibrium between the vapor phase and the non-vapor phase of the sample and avoids having the sampling process impact the results of the analysis. Alternative forms of the headspace instrument enable the conduct of concentration dependent processes and absorption and desorption experiments.

Owner:MARKELOV MICHAEL +1

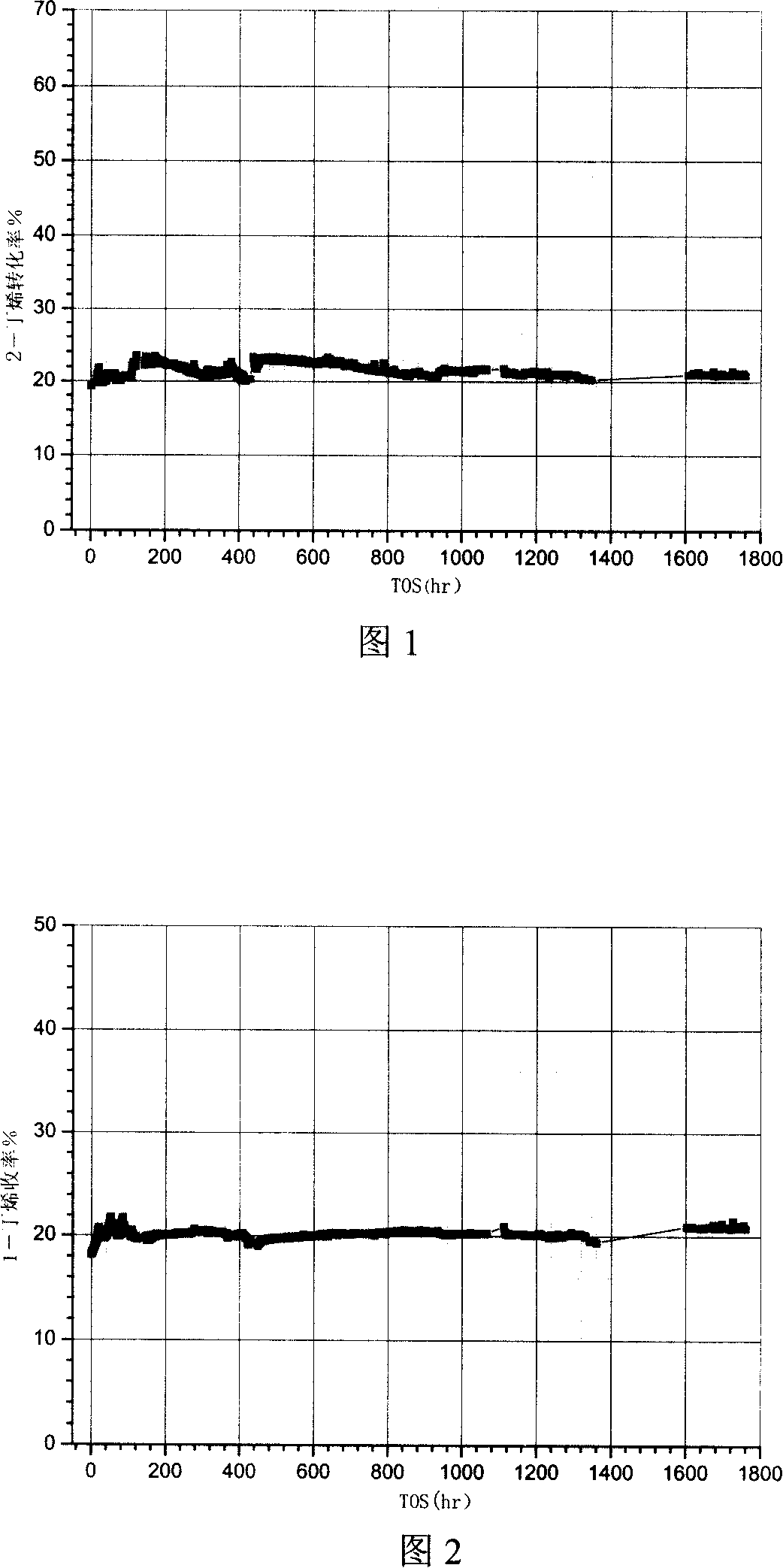

Method for improving butene double bond isomerization reaction

ActiveCN101475432AHigh selectivityImprove technical effectHydrocarbon by isomerisationMolecular sieve catalystsButeneIsomerization

The invention relates to a method for improving reaction selectivity of isomerization of double bonds of butylene. The method mainly solves the problem of poor reaction selectivity in the prior art. Through a technical proposal that butylenes-1, butylenes-2 or a mixture which contains the butylenes-1 and butylenes-2 and does not meet a thermodynamic equilibrium value is used as a raw material; carbon-predeposited aluminosilicate is used as a catalyst, wherein the amount of predeposited carbon is 0.01 to 5 percent counted by the weight of the catalyst; and under the conditions of reaction temperature of between 50 and 480 DEG C, reaction pressure of between -0.08 and 10MPa and weight space velocity of between 0.1 and 100 hours<-1>, the raw material and the catalyst contact and have the isomerization reaction of the double bonds of the butylene to generate an effluent substance with the molar ratio of butylenes-1 to butylenes-2 close to the thermodynamic equilibrium value, and the method well solves the problems and can be applied to industrial production of isomerization of double bonds of butylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for butylenes double-bond isomerization

ActiveCN101121623AExtended regeneration cycleShort regeneration periodHydrocarbon by isomerisationMolecular sieveButene

The invention relates to a method for isomerizing butene double bonds. It mainly solves the technical problems of narrow application range of raw materials and short catalyst regeneration period existing in the prior art. The present invention solves this problem well by adopting the technical scheme of contacting the raw material containing butene with the molecular sieve catalyst to generate the effluent containing the molar ratio of butene-1 and butene-2 close to the thermodynamic equilibrium value, and can be used for butene In the industrial production of double bond isomerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

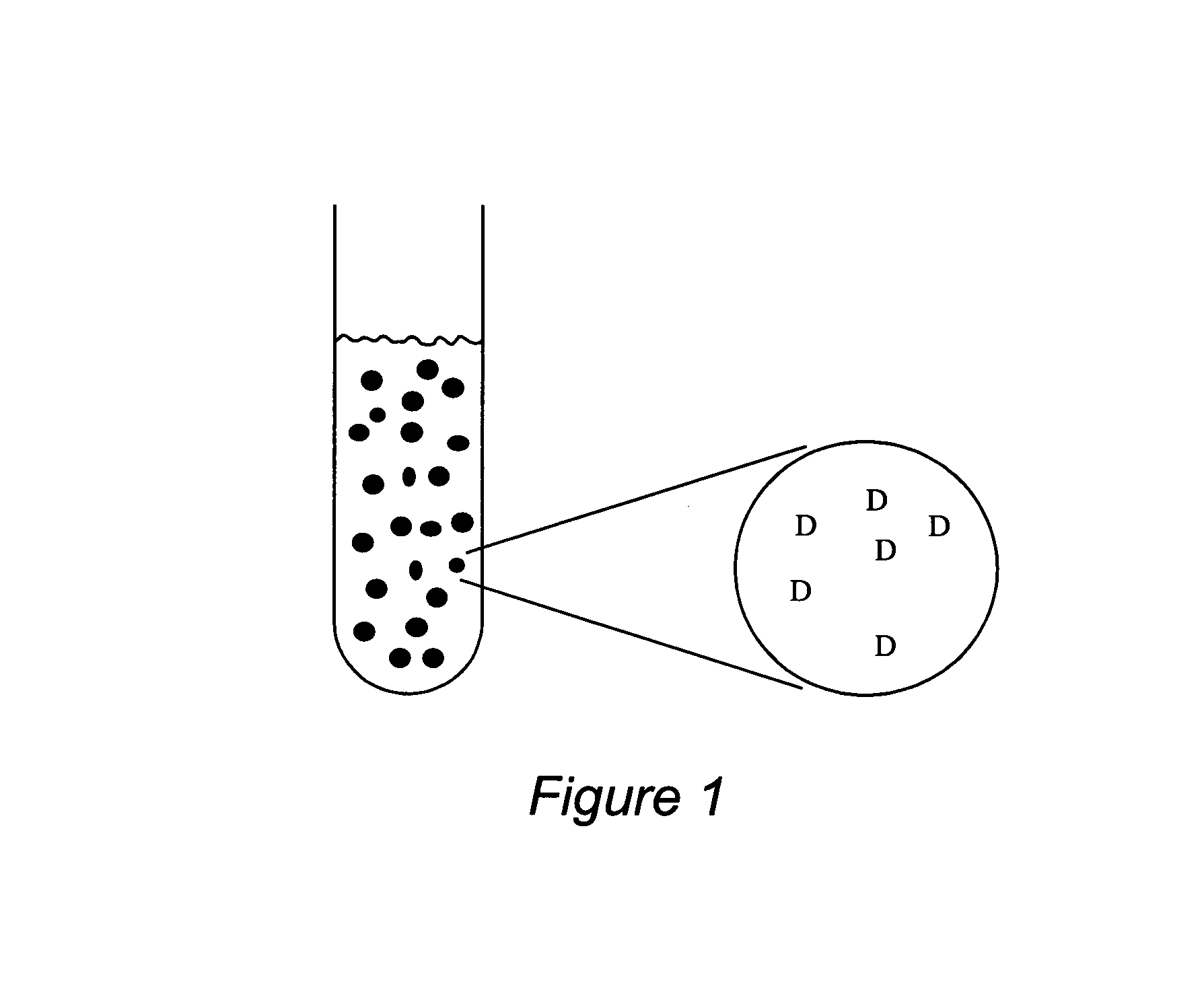

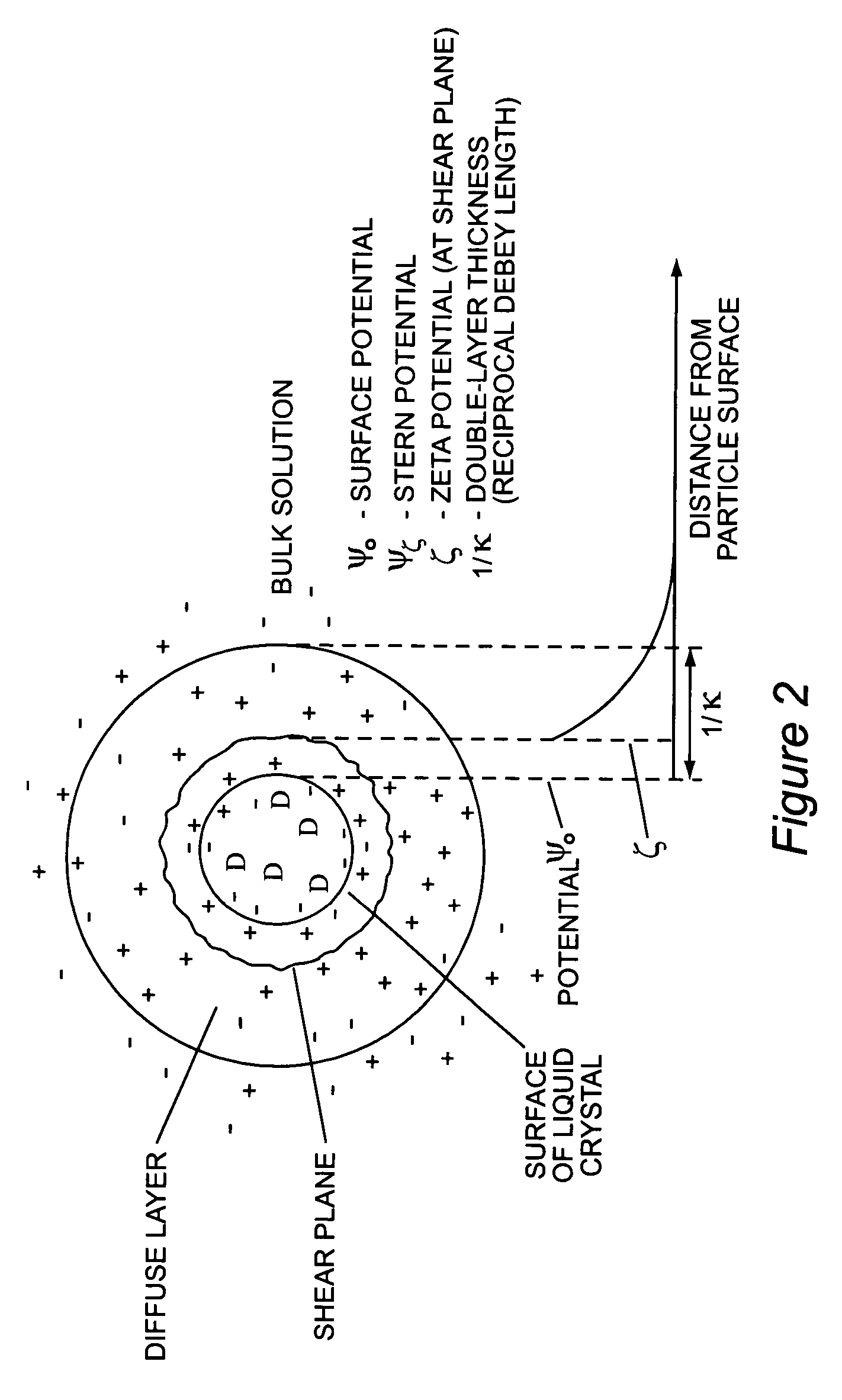

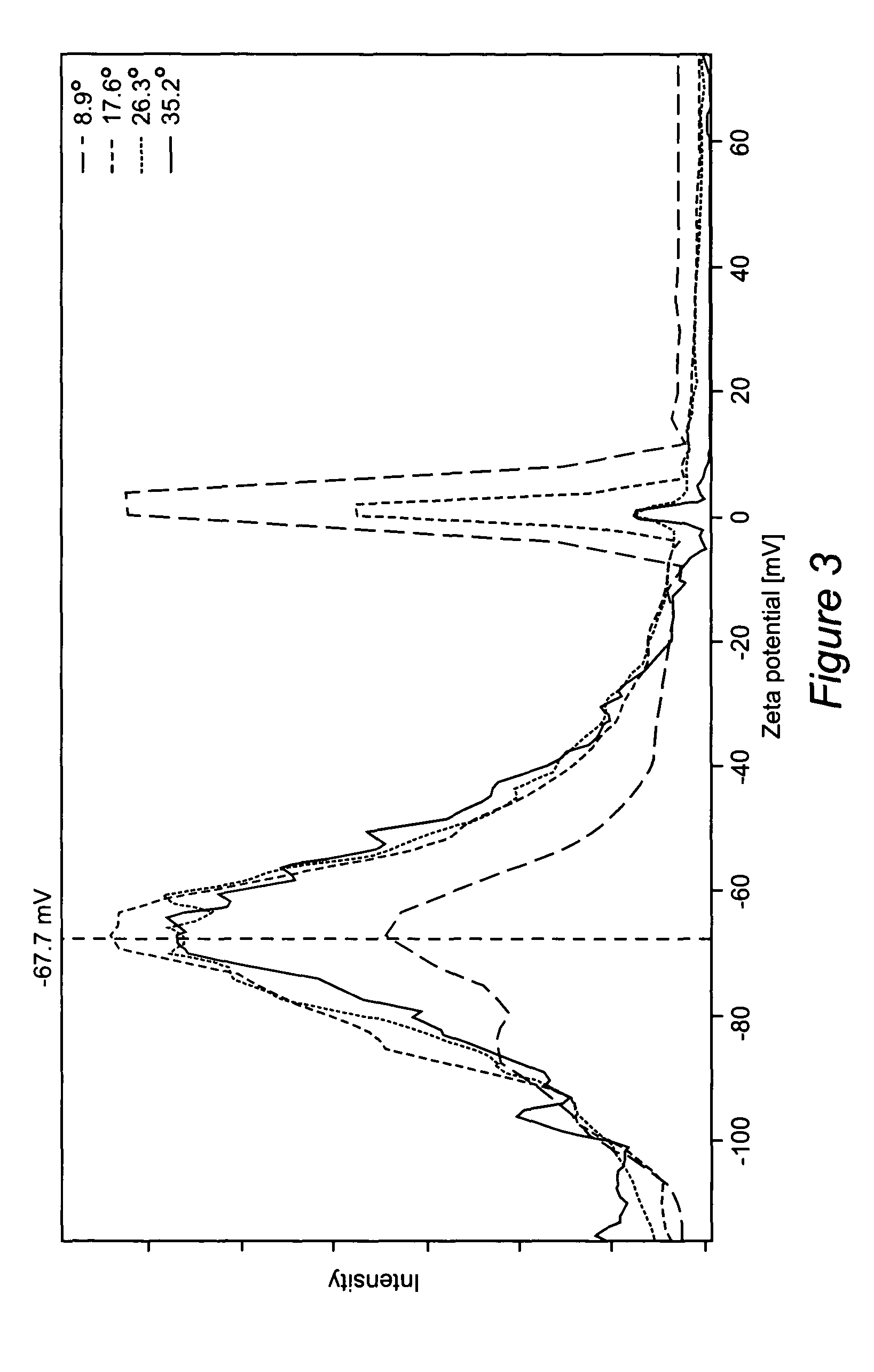

Stabilized uncoated particles of reversed liquid crystalline phase materials

ActiveUS7713440B2Raise the potentialLow water solubilityLiquid crystal compositionsPowder deliveryCrystallographyLiquid crystalline

A pharmaceutical composition comprises uncoated particles of a single thermodynamic equilibrium reversed cubic phase material containing an active agent disposed within. The uncoated particles have an anionic charge that is sufficient to stabilize them in dispersion in a liquid, e.g. a polar solvent.

Owner:LYOTROPICS THERAPEUTICS INC

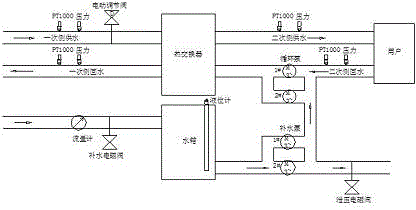

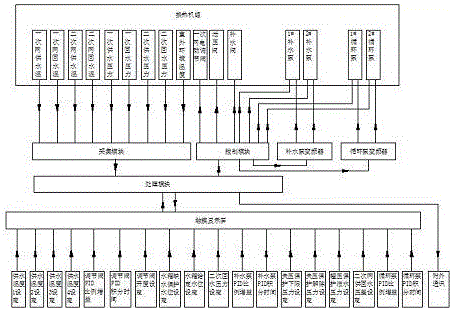

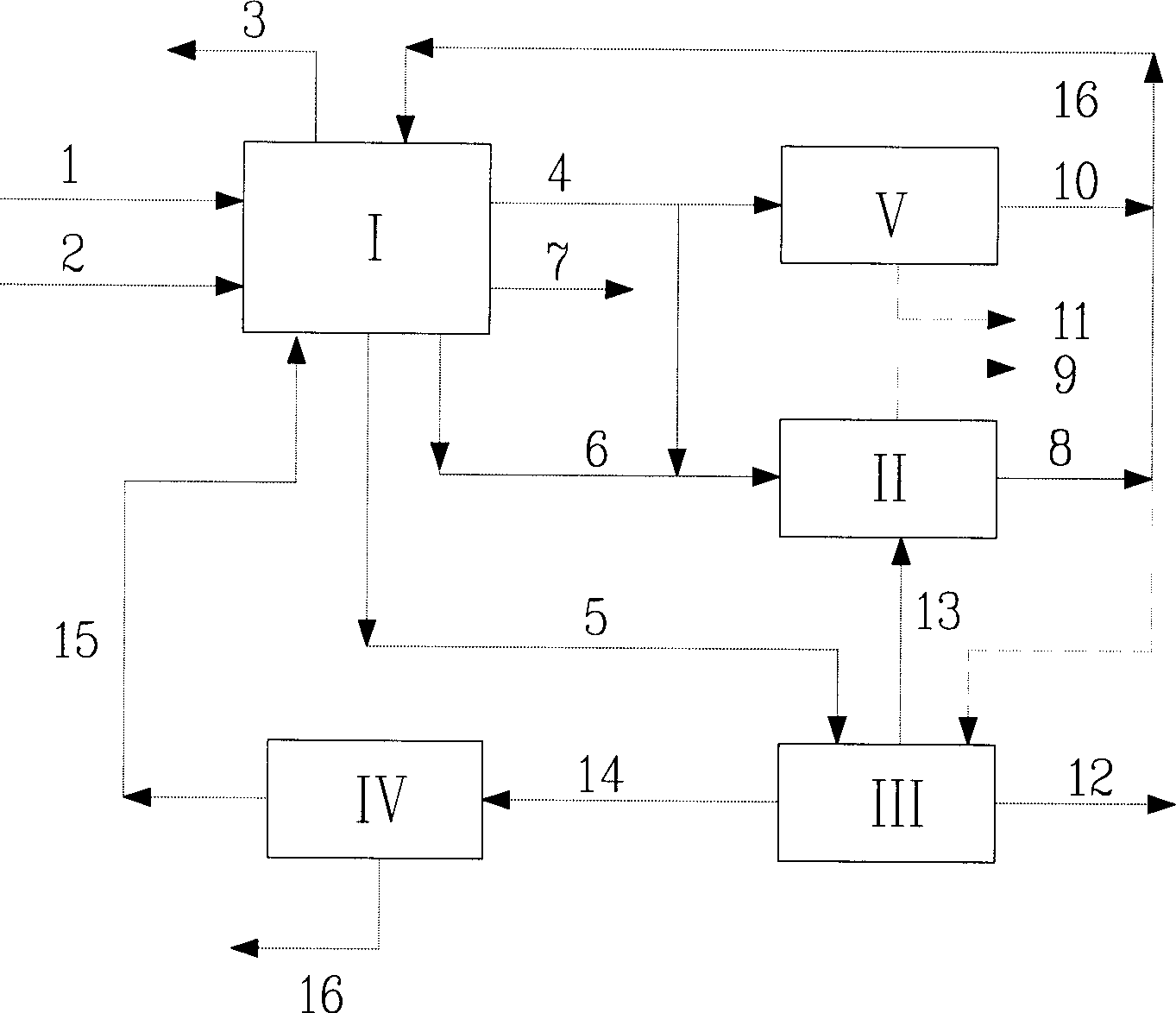

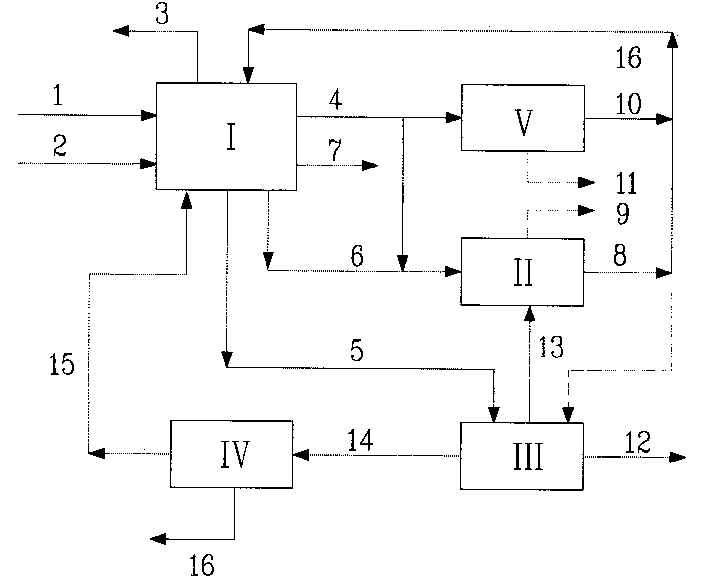

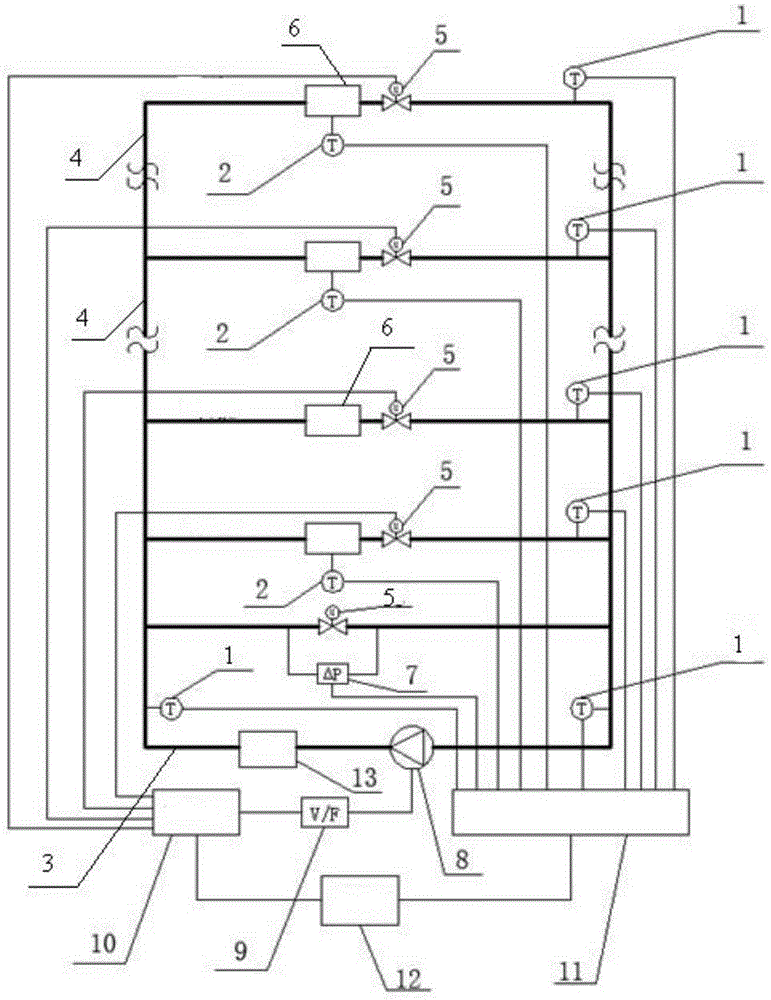

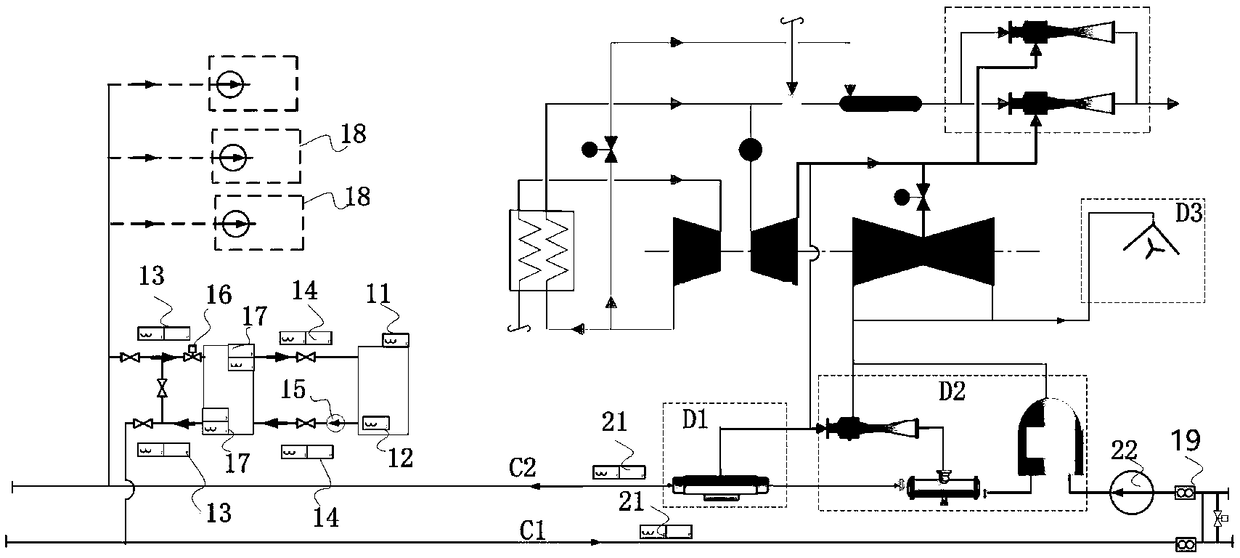

Automatic control system and method of heat exchange station

InactiveCN106123110AImplementation failureEnsure thermal balanceLighting and heating apparatusAuxillary controllers with auxillary heating devicesAutomatic controlAutomatic train control

The invention belongs to the technical field of control systems of heat exchange stations, and discloses an automatic control system and method of a heat exchange station. The control system used in the method comprises a temperature regulation and control device, a circulating system automatic control device and a water replenishing regulation and control loop automatic control device of the heat exchange station, wherein temperature ends of information acquisition modules of the three control devices are connected with temperature sensors on a heat exchange unit; pressure ends of the information acquisition modules are connected with pressure sensors on the heat exchange unit; output ends of the information acquisition modules are connected with a touch display screen through an analytical processing module; the analytical processing module is connected with a primary side electric regulation valve, a pressure release valve and a water replenishing valve through control modules; pump actuating ends of the control modules are connected with circulating water pumps on the heat exchange unit; and frequency conversion ends of the control modules are connected with water replenishing pump frequency converters and circulating water pump frequency converters. Thermodynamic equilibrium of a heat supply network is guaranteed, a heat supply system can run safely and reliably, and remote monitoring under the unattended condition is realized.

Owner:HENAN DIESEL ENGINE IND

Process for the production of para-xylene

InactiveUS20120029257A1Increase productionRaise the ratioMolecular sieve catalystHydrocarbons from unsaturated hydrocarbon additionAlkaneXylene

A reforming process using a medium pore zeolite under conditions to facilitate the conversion of C8 paraffinic compounds to para-xylene is provided. Para-xylene is produced at greater than thermodynamic equilibrium concentrations using the process.

Owner:CHEVROU USA INC

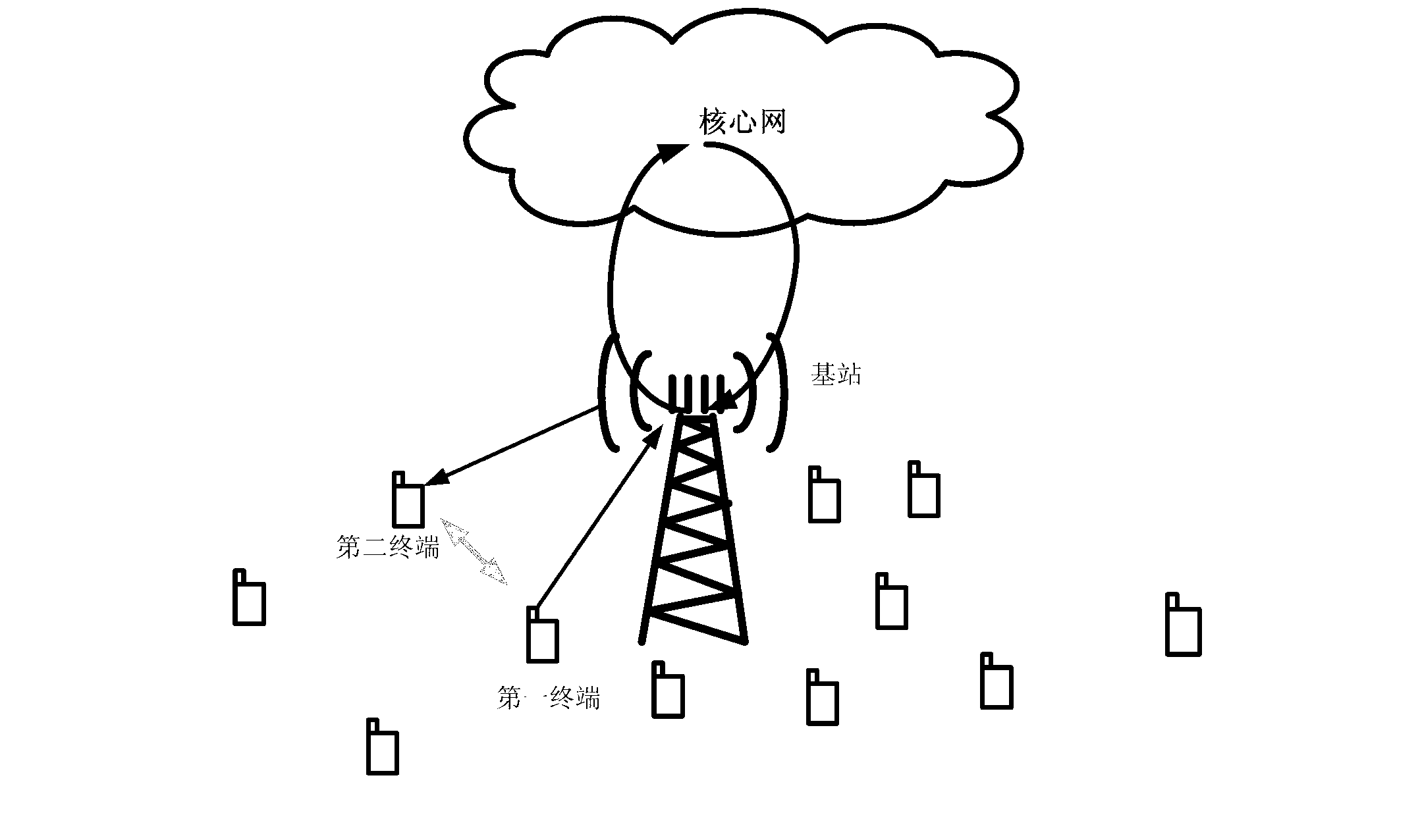

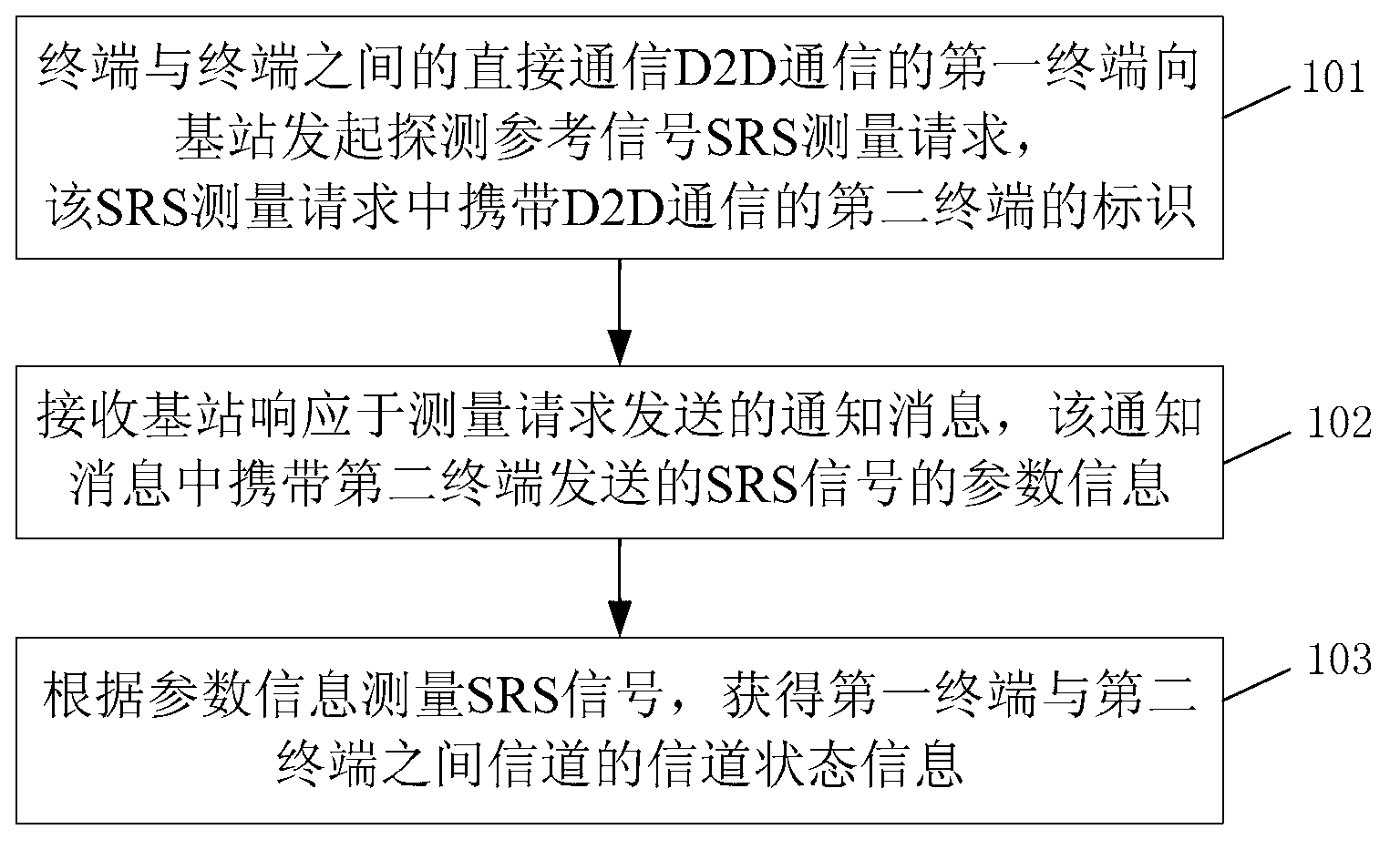

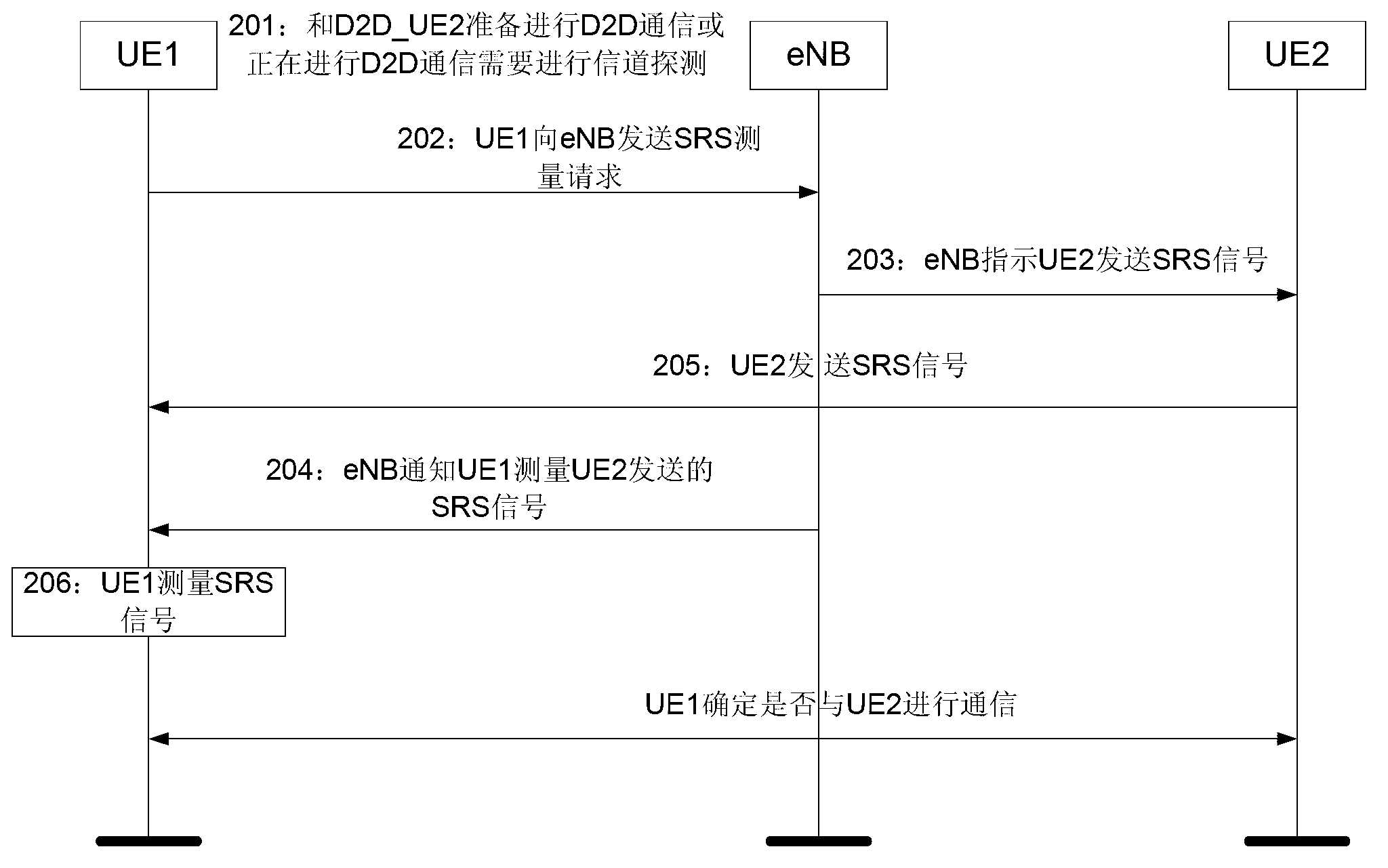

Channel detection method, communication method, terminal and system

InactiveCN103067132ANo added complexityLow costError preventionCriteria allocationChannel state informationChannel sounding

The invention discloses a channel detection method, a communication method, a terminal and a system, and belongs to the field of communication. The channel detection method includes that a first terminal of device-to-device (D2D) communication sends a supplemental restrgint system (SRS) measuring requirement to a base station, and identifications of a second terminal of the D2D communication are carried by the SRS measuring requirement; notification information sent by the base station is received, and parameter information of SRS signals sent by the second terminal is carried by the notification information; and the SRS signals are measured by the parameter information, and channel state information of a channel between the first terminal and the second terminal is obtained. The communication terminal comprises a sending module, a receiving module, a measuring module and a communication module. Channel detection is conducted for the a SRS signals in a local thermodynamic equilibrium (LTE) cellular system is well achieved, and unity scheduling and communication of the D2D communication and the LET cellular system are achieved.

Owner:HUNAN CHAIRMAN IND INTELLIGENT SYST CO LTD

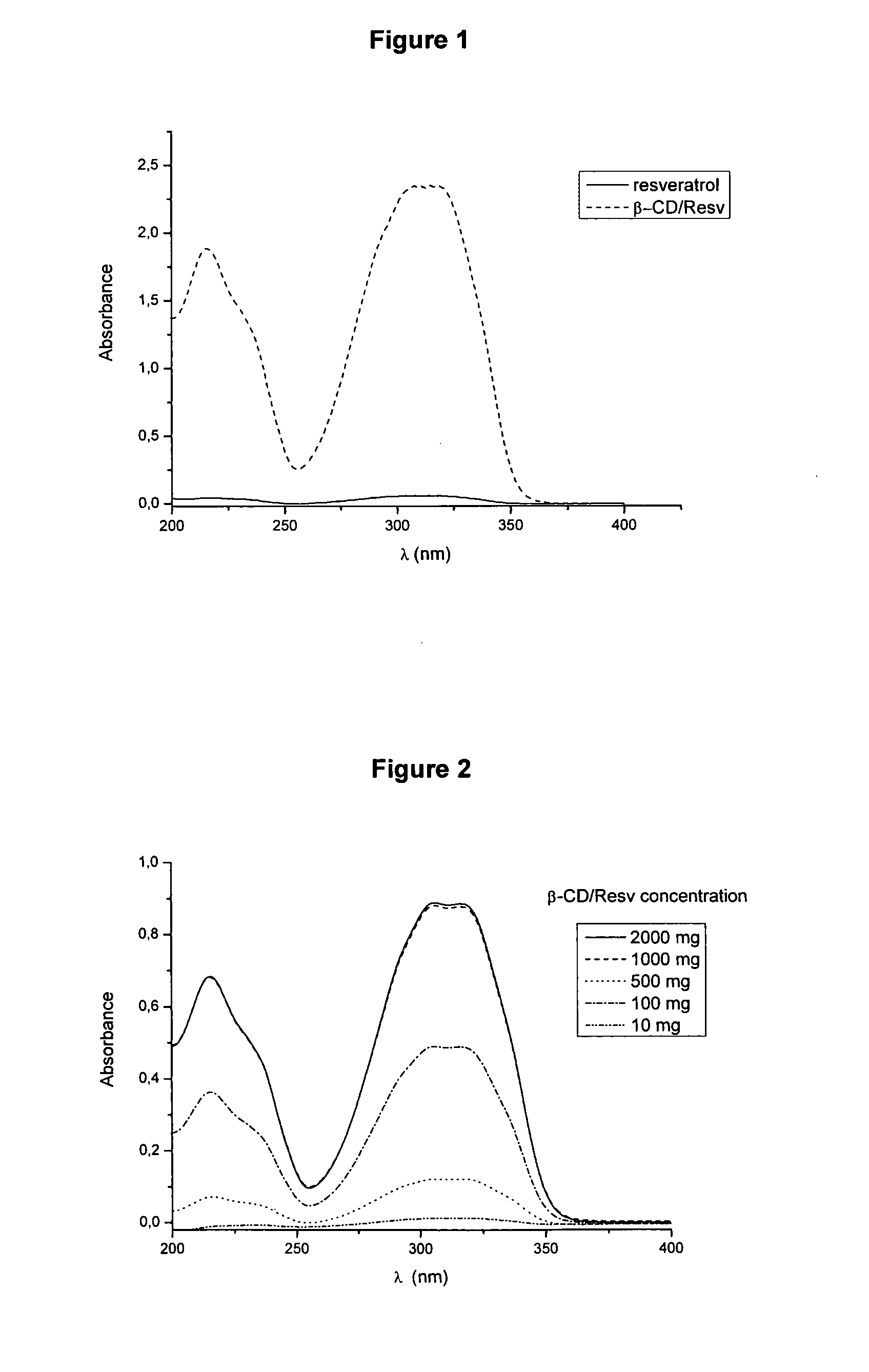

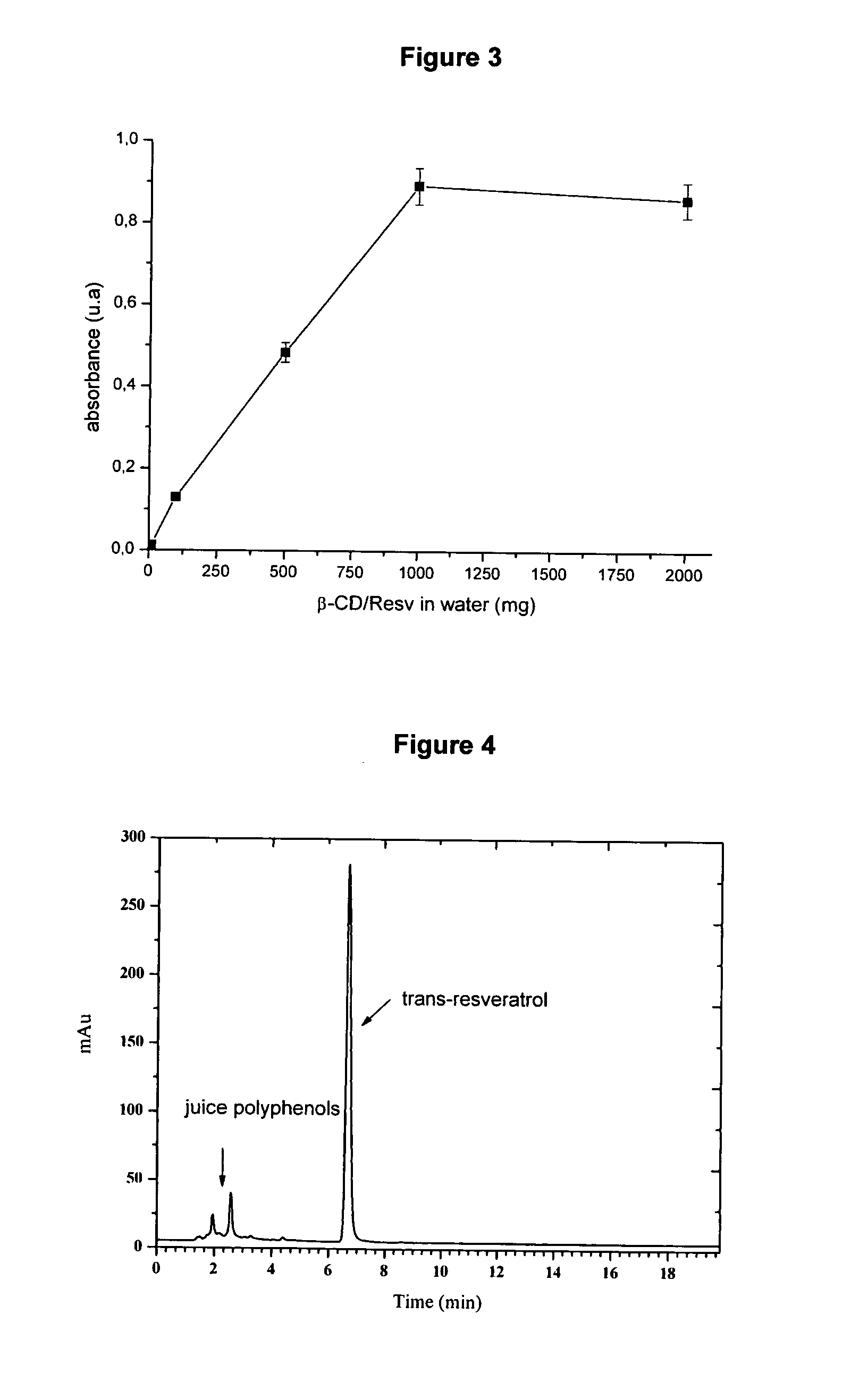

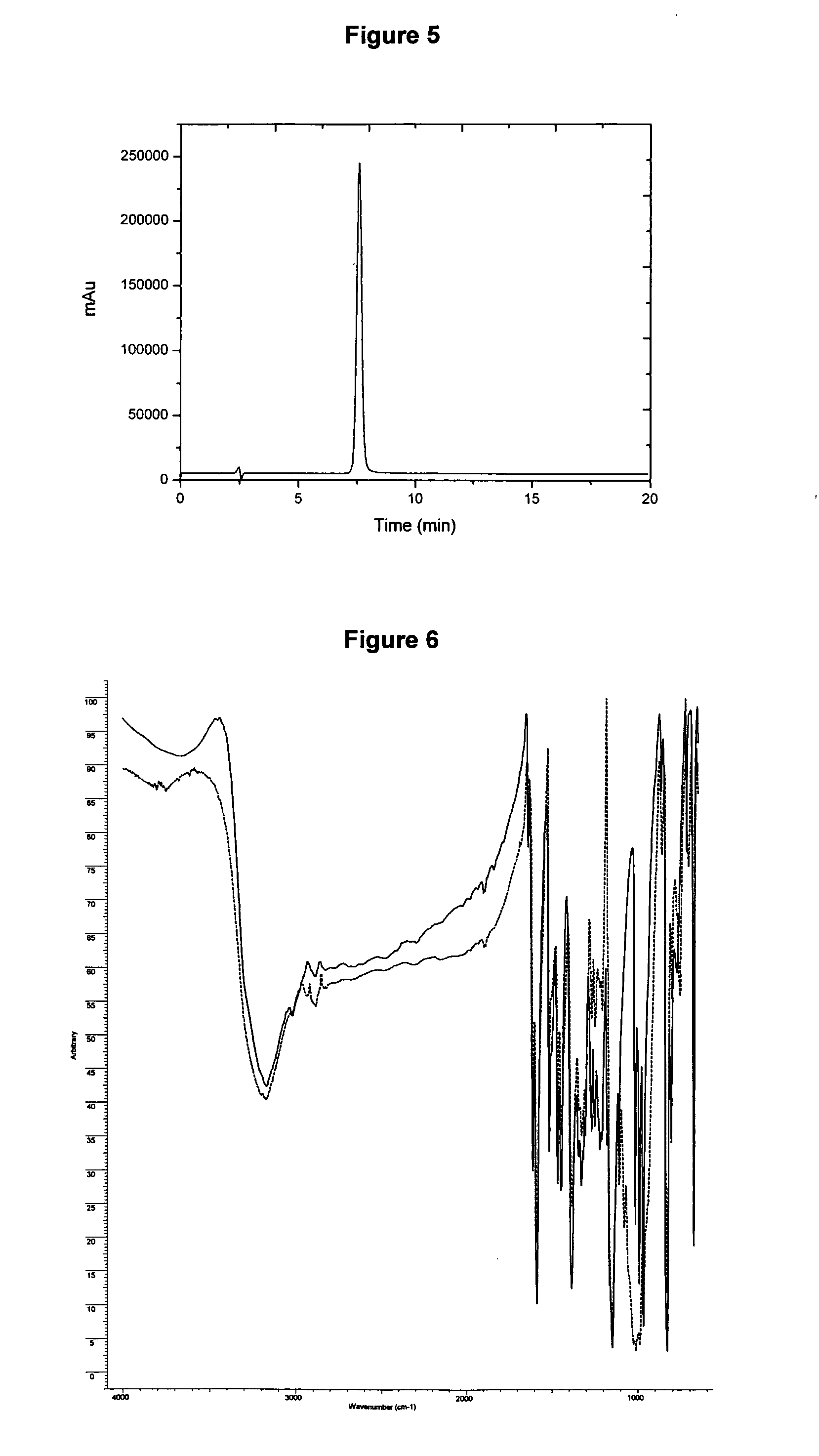

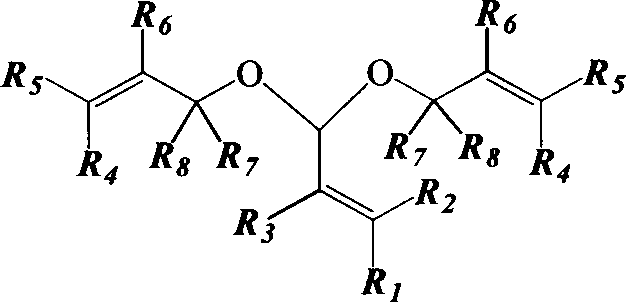

Resveratrol complex and process for the preperation

The present invention provides products having resveratrol with high water solubility and nutraceutical and / or phytotherapic compositions having said substances. The processes for obtaining them include the solubility increase of the polyphenol corresponding to a resveratrol compound, preferably trans-resveratrol in water, by its complexation with cyclodextrin under specific conditions that favor thermodynamic equilibrium. The products of the invention present high solubility and purity in aqueous medium, being, therefore, useful to prepare nutraceutical compositions (pharmaceutical and / or alimentary) with antioxidant, anti-inflammatory, antiviral, antidiabetics, cardioprotective, neuroprotective, chemoprotective activities; besides protecting against infections and ischemia, reducing obesity, and preventing aging. Phytotherapic compositions useful to the same therapeutical activities, prepared from the complex of resveratrol and cyclodextrin compound, preferably beta-cyclodextrin / trans-resveratrol, are also provided.

Owner:UNIAO BRASILEIRA DE EDUCACAO E ASSISTENCIA MANTENEDORA DA PUC RS

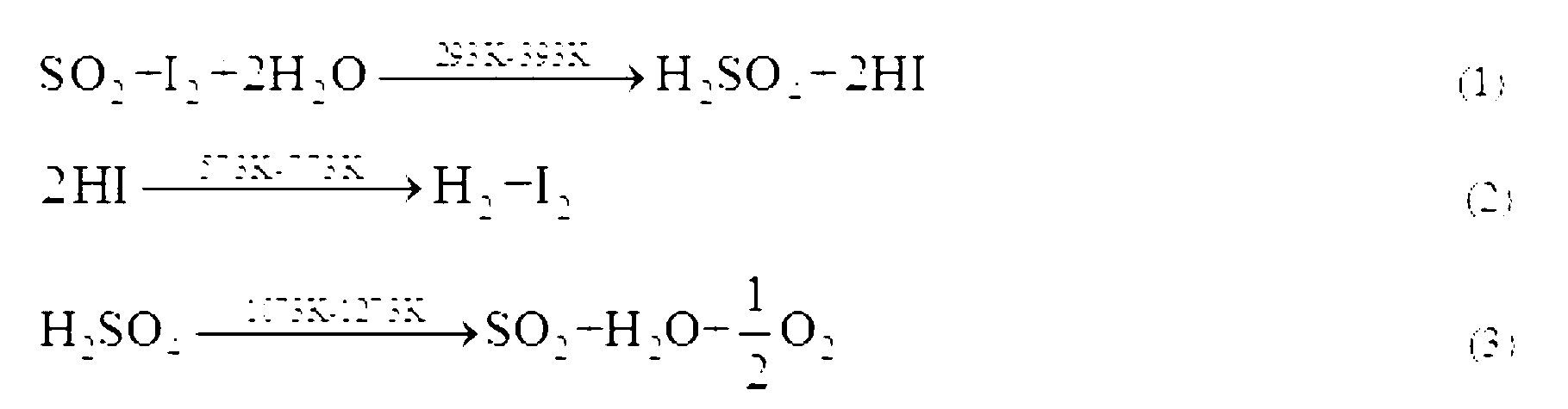

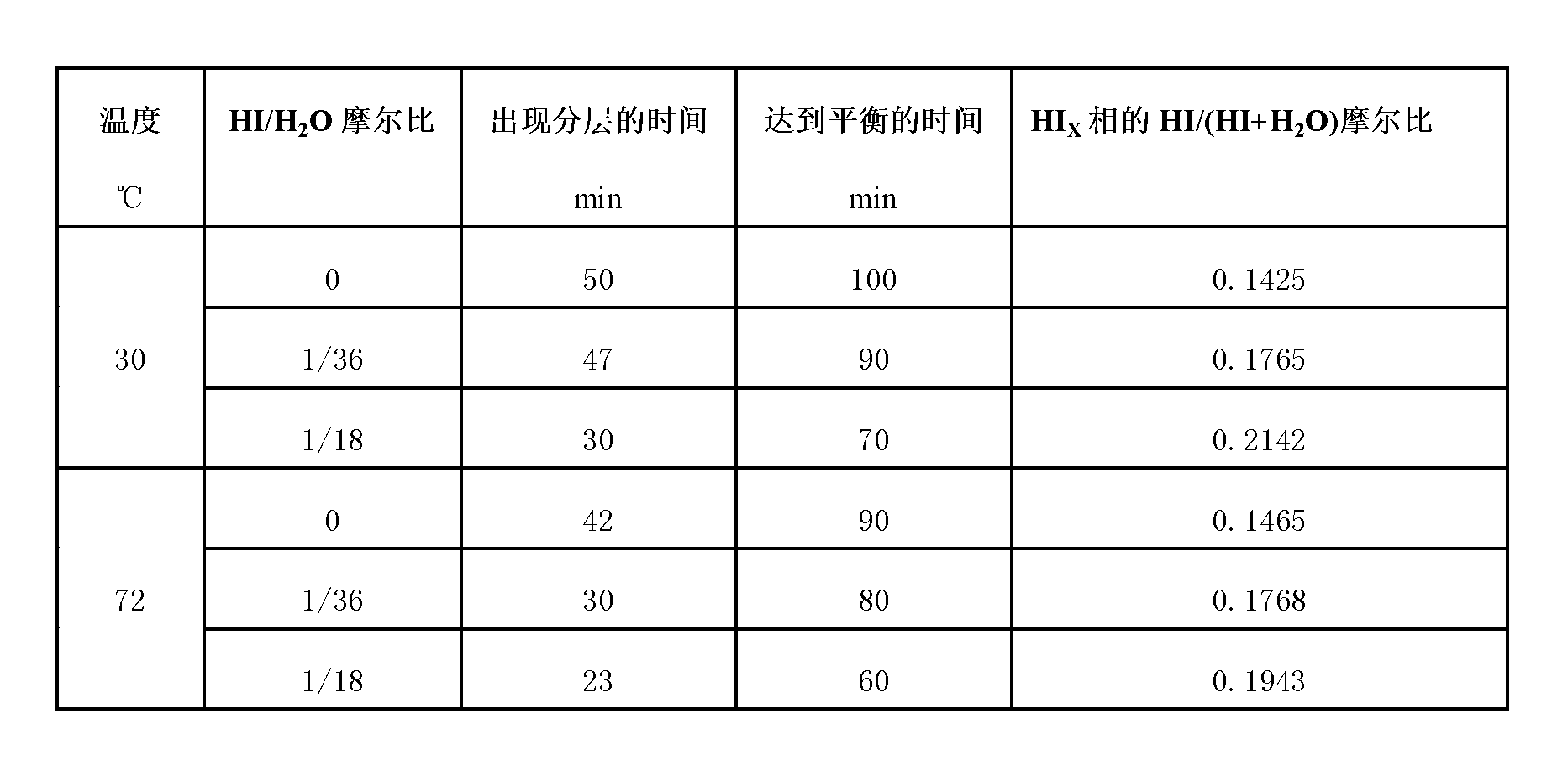

Method for promoting Bunsen reaction in thermochemical iodine-sulfur cycle for hydrogen manufacturing

ActiveCN103213945AOmit the concentration stepIncreased reaction kinetic rateHydrogen productionMass ratioDistillation

The invention relates to a technique of iodine cycles for hydrogen manufacturing, and aims to provide a method for promoting a Bunsen reaction in a thermochemical iodine-sulfur cycle for hydrogen manufacturing. The method comprises the following steps: adding I2 and H2O in a reactor, and heating a reaction solution to 30-72 DEG C; adding hydroiodic acid under the condition that the mass ratio of HI / H2O is 1 / 36-1 / 18: 1, and mixing the reaction solution at a uniform speed so as to ensure I2 is completely dissolved; feeding SO2 at a constant flow rate, and spontaneously carrying out the Bunsen reaction so as to obtain H2SO4 and HI; and in the presence of excessive iodine, carrying out the separation of liquid-liquid phases, so that the reaction achieves a liquid-liquid equilibrium state finally. According to the invention, the original gas-liquid-solid three-phase reaction is transferred into a gas-liquid reaction, and then the kinetic velocity of the Bunsen reaction is improved; and added HI has certain contribution to the improvement of the concentration of HI in a HIx phase in a thermodynamic equilibrium state, and HI achieves a super azeotropic concentration, so that the situation that pure HI steam is obtained through subsequent distillation is facilitated, and a HI concentration step can be cancelled, therefore, the method is extremely advantageous to the simplification of a whole SI circulation system and the improvement of the thermal efficiency of the system.

Owner:ZHEJIANG UNIV

Headspace sampling apparatus and method

InactiveUS6395229B1Minimize disturbanceHigh sensitivityComponent separationMicrobiological testing/measurementGas phaseVapor phase

A headspace sampling apparatus (10) operates to provide a sample of a vapor phase of a substance being analyzed under conditions of thermodynamic equilibrium. The substance is held in a vial (14). The vapor phase of the substance (18) is moved through a sample loop (34) between a first variable volume chamber (22) and a second variable volume chamber (40). A constant volume and temperature is maintained within the variable volume chambers, the sample loop and the headspace of the vial. An aliquot of the equilibrated vapor in the sample loop is passed to an analytical instrument (54) for analysis. The sample is obtained under conditions in which the sampling process does not affect the makeup of the sample because thermodynamic equilibrium is maintained.

Owner:MARKELOV MICHAEL

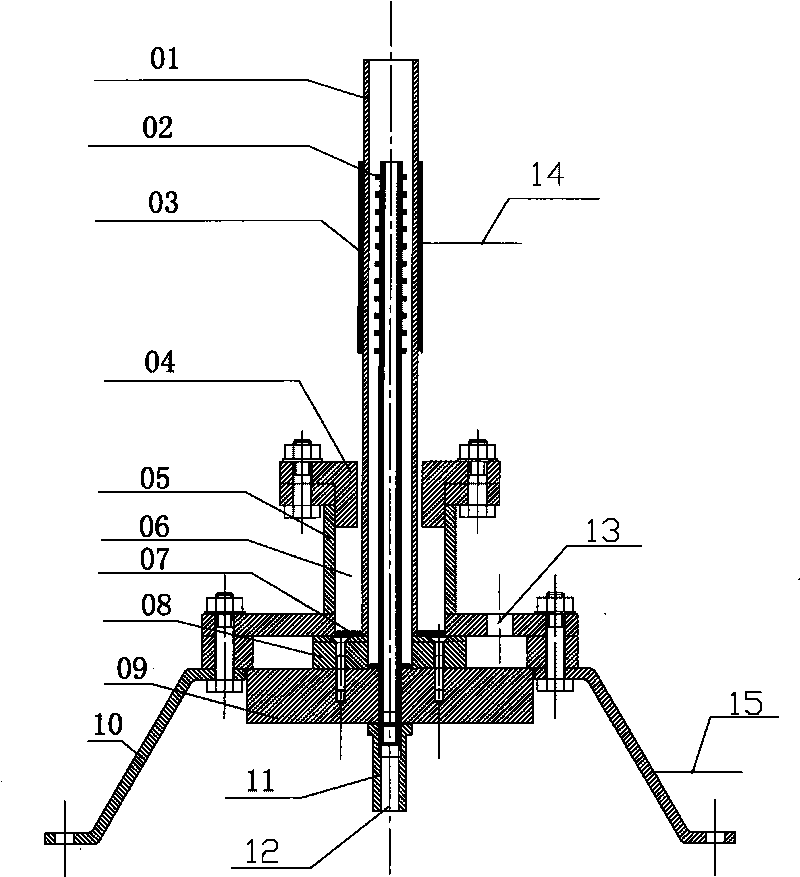

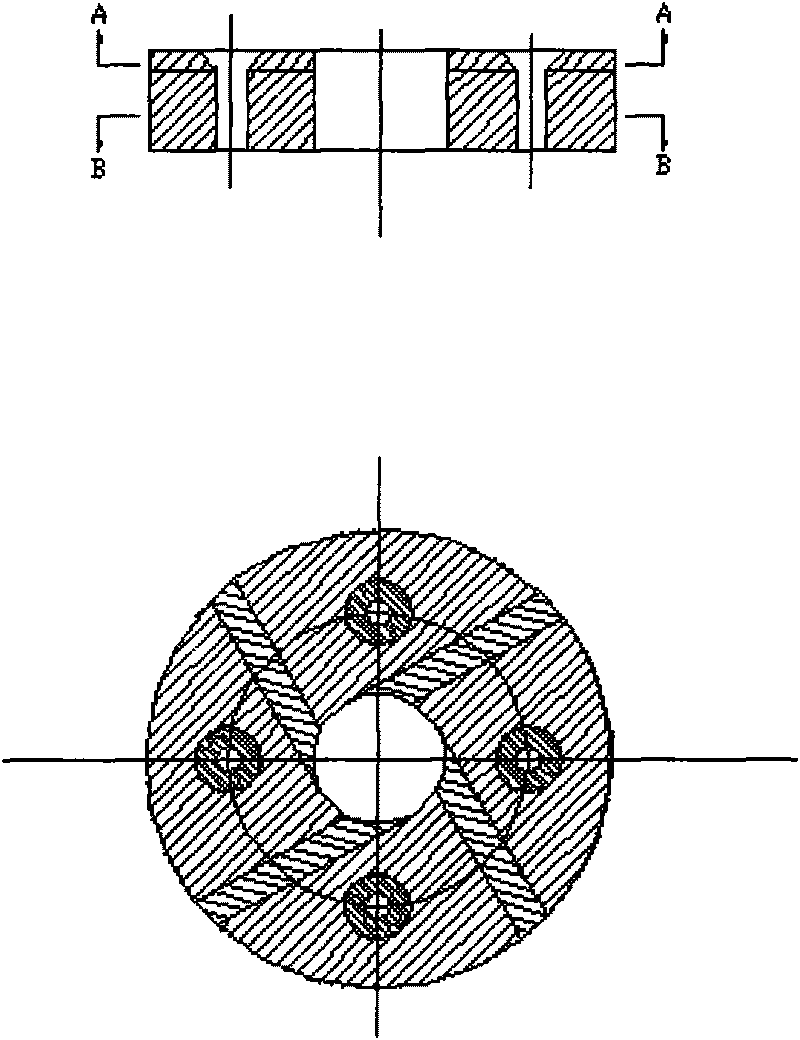

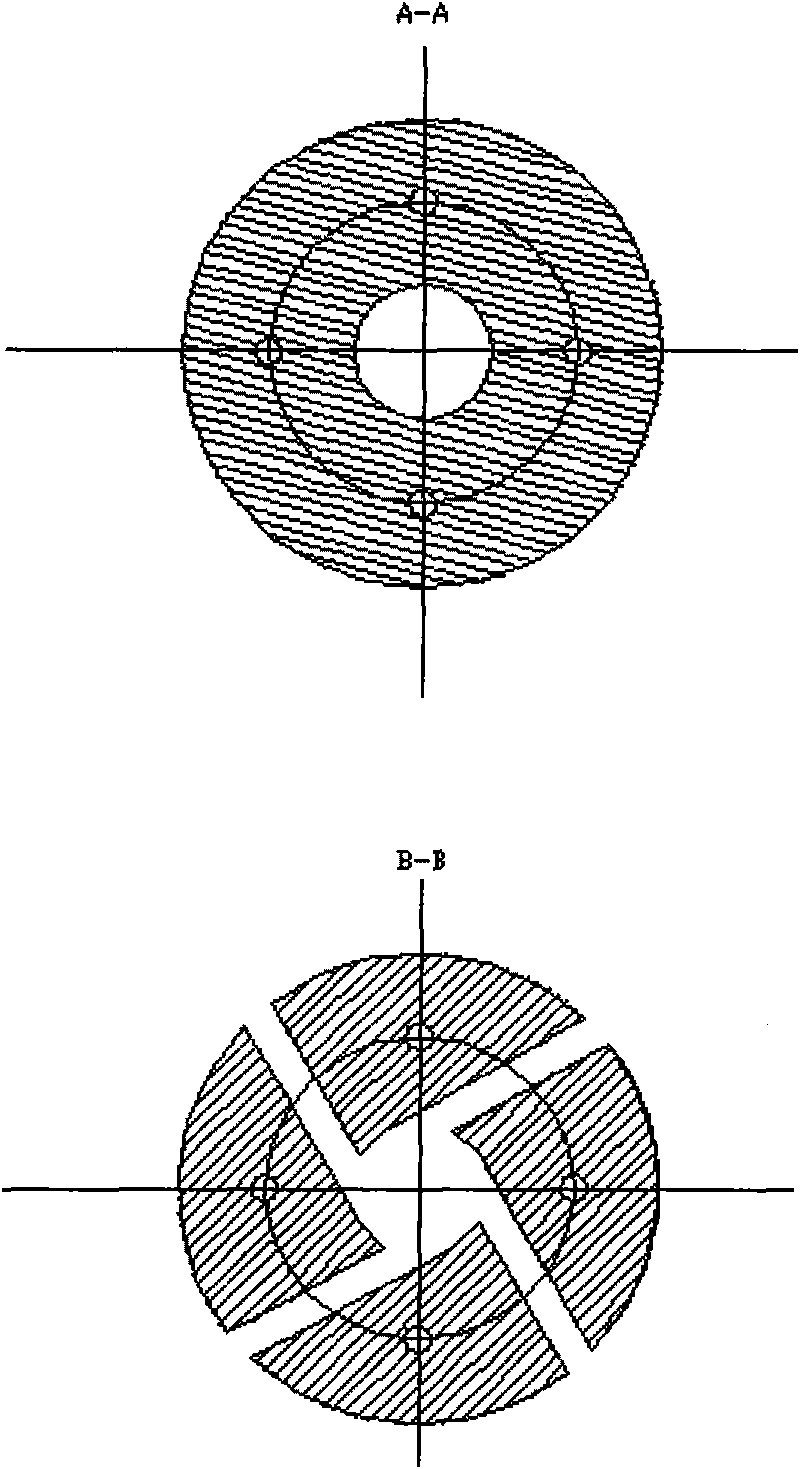

Non-equilibrium thermodynamics plasma igniting and combustion-supporting device

The invention discloses a non-equilibrium thermodynamics plasma igniting and combustion-supporting device, which comprises an inner electrode, an outer electrode, an insulating barrier medium and high-pressure AC power supply, wherein the inner electrode is a hollow metal pipe; the inner electrode passes through the inner metal pipe; the outer electrode is made from metal net; the insulating barrier medium is inserted between the inner electrode and the outer electrode, and is coaxially arranged with the inner electrode and the outer electrode; and the high-pressure AC power supply is connected with the outer electrode to apply AC voltage between the inner electrode and the outer electrode, so that gas in a gap between the inner electrode and the outer electrode is broken down. Compared with the existing plasma igniting device, the non-equilibrium thermodynamics plasma igniting and combustion-supporting device has the advantages that the temperature of the non-equilibrium plasma is low, the power consumption is low, the chemical activity is good, the temperature of the electrode is low, and the device can run for a long term without cooling.

Owner:CENT FOR CLEAN ENERGY TECH OF SHANGHAI +1

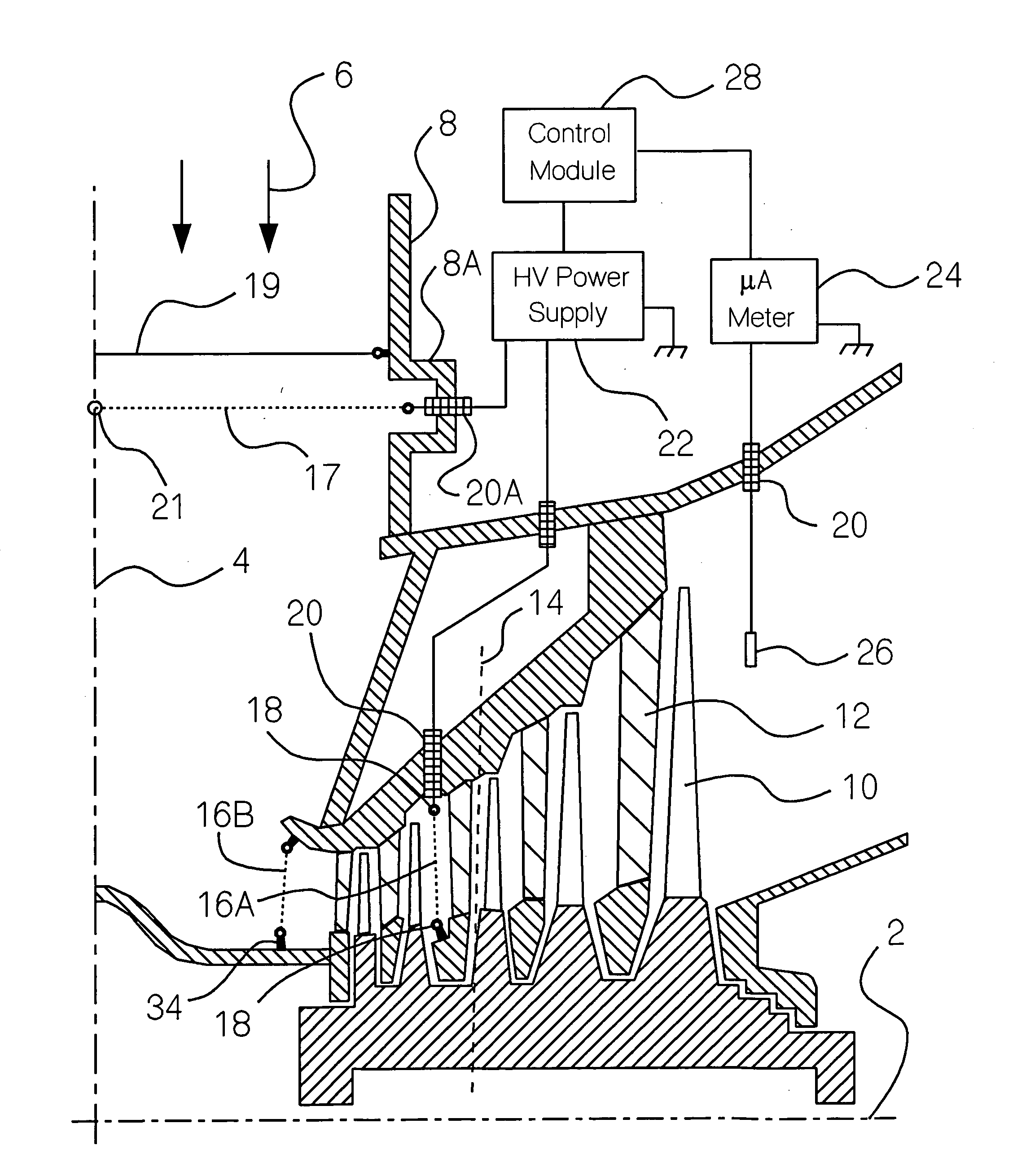

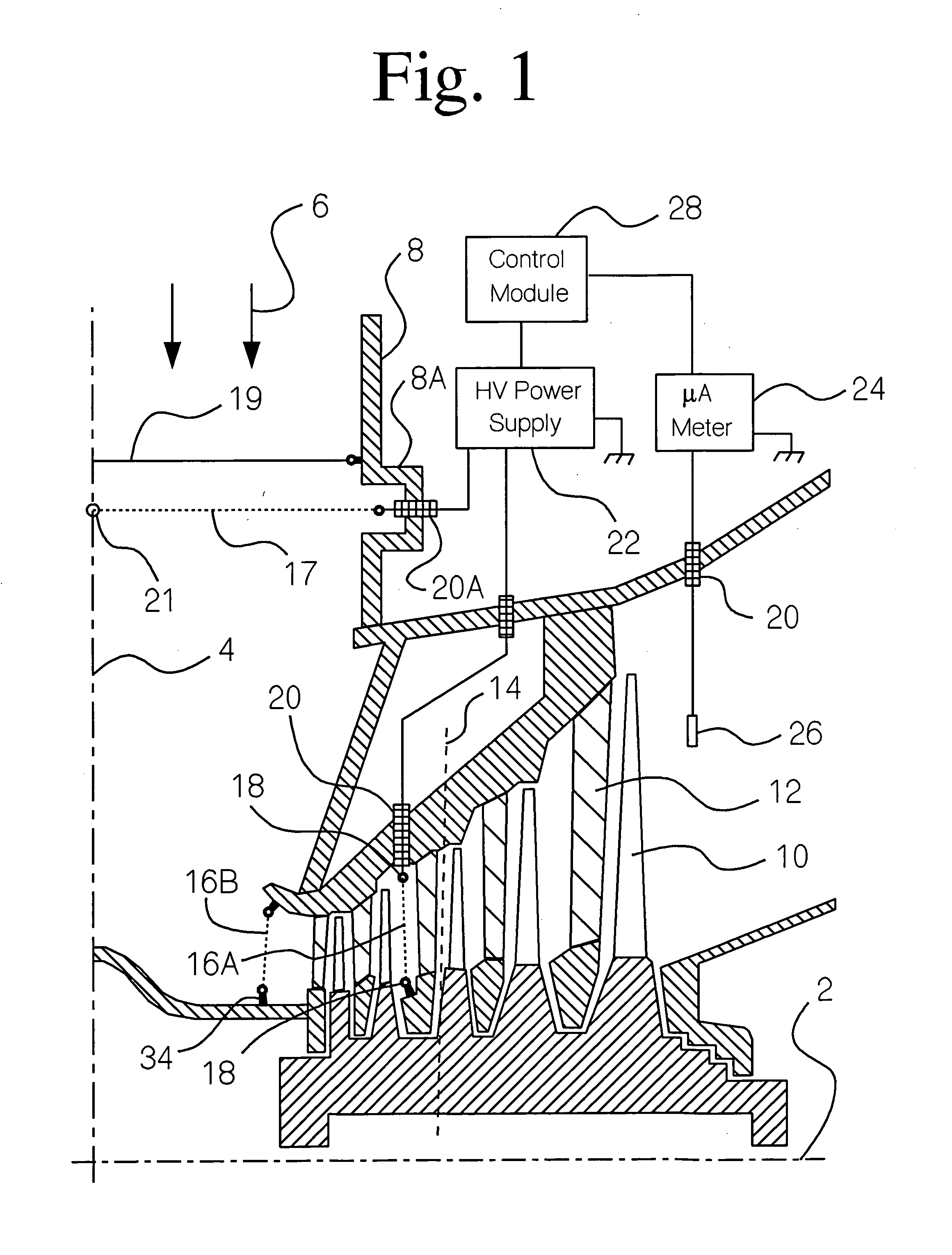

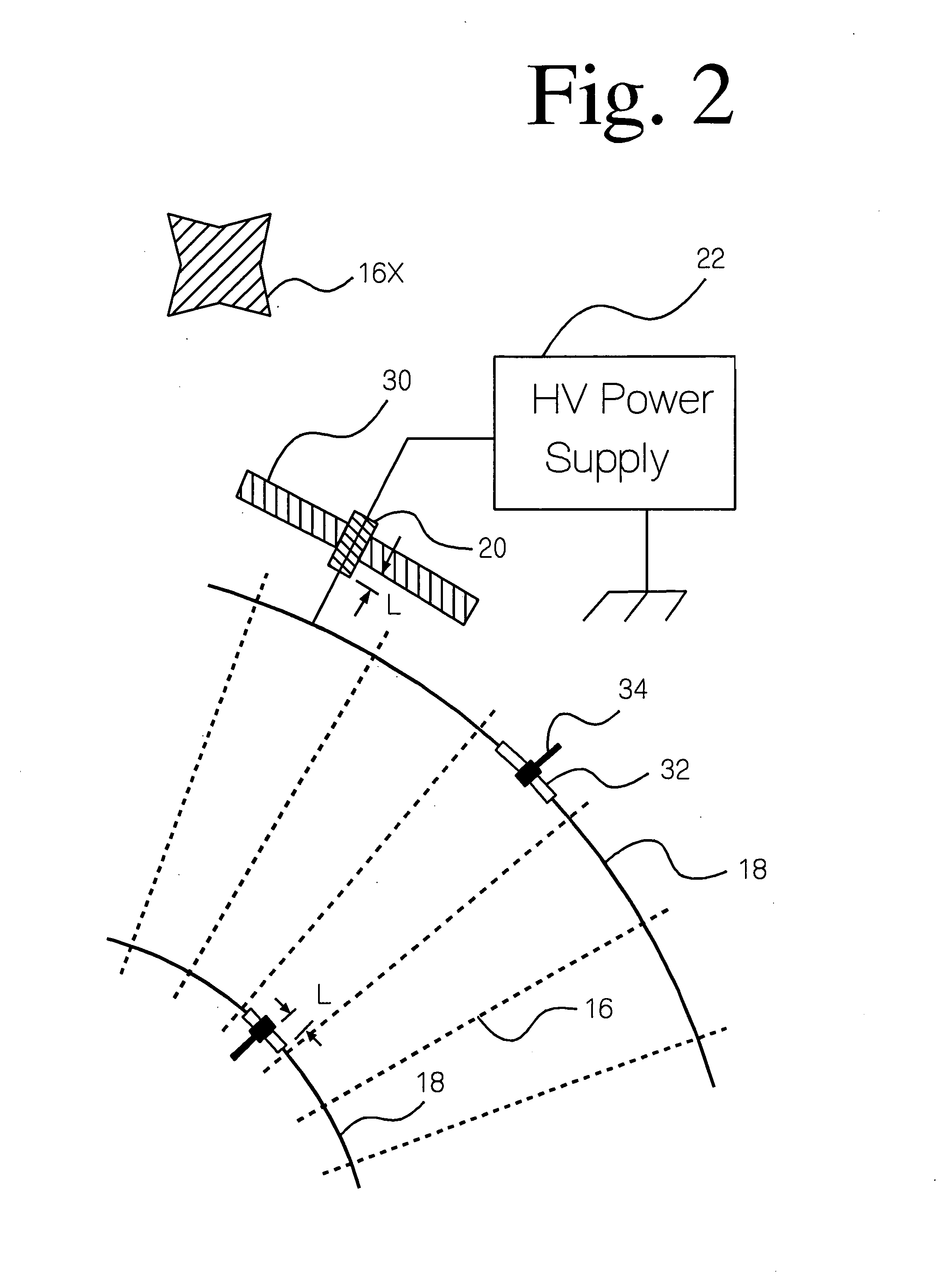

Electrostatic method and device to increase power output and decrease erosion in steam turbines

InactiveUS20050207880A1Easy to condenseSubcooling is decreasedPump componentsWorking fluid for enginesLiquid waterEngineering

The wet steam exiting a low pressure steam turbine does not rapidly attain thermodynamic equilibrium because insufficient condensation nuclei are present in the phase transition zone inside the turbine. Therefore, the steam is subcooled, decreasing the power generated by the turbine, and the liquid water carried by the steam consists of relatively coarse droplets which strike the surface of the turbine blades causing erosion. Corona electrodes installed inside the turbine before the saturation line create electrically charged particles which serve as condensation nuclei, decreasing subcooling, and producing a large number of fine droplets. Thereby, thermodynamic equilibrium is more closely approached, more power is generated, and smaller water droplets cause less erosion inside the turbine.

Owner:TARELIN ANATOLY OLEKSIOVYCH +2

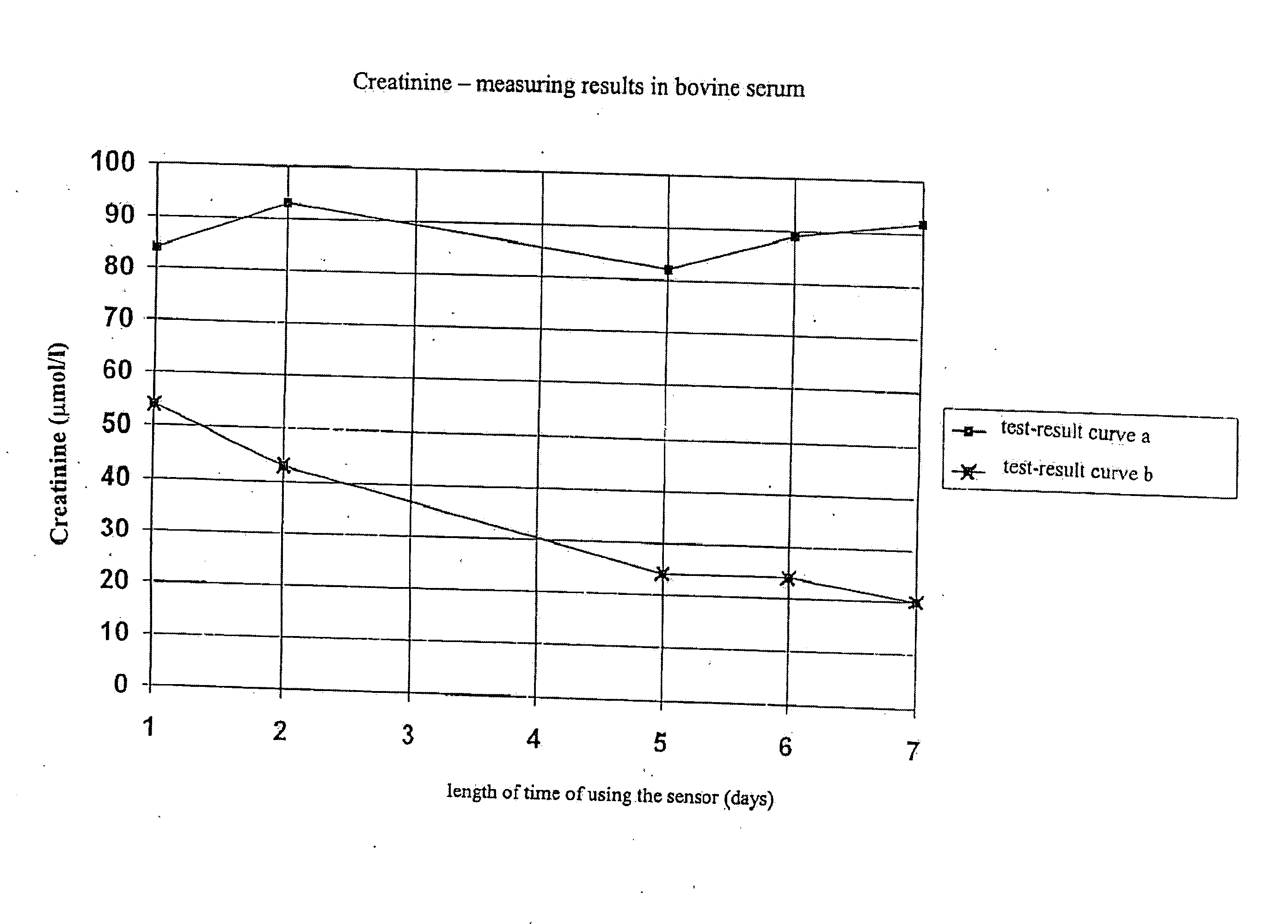

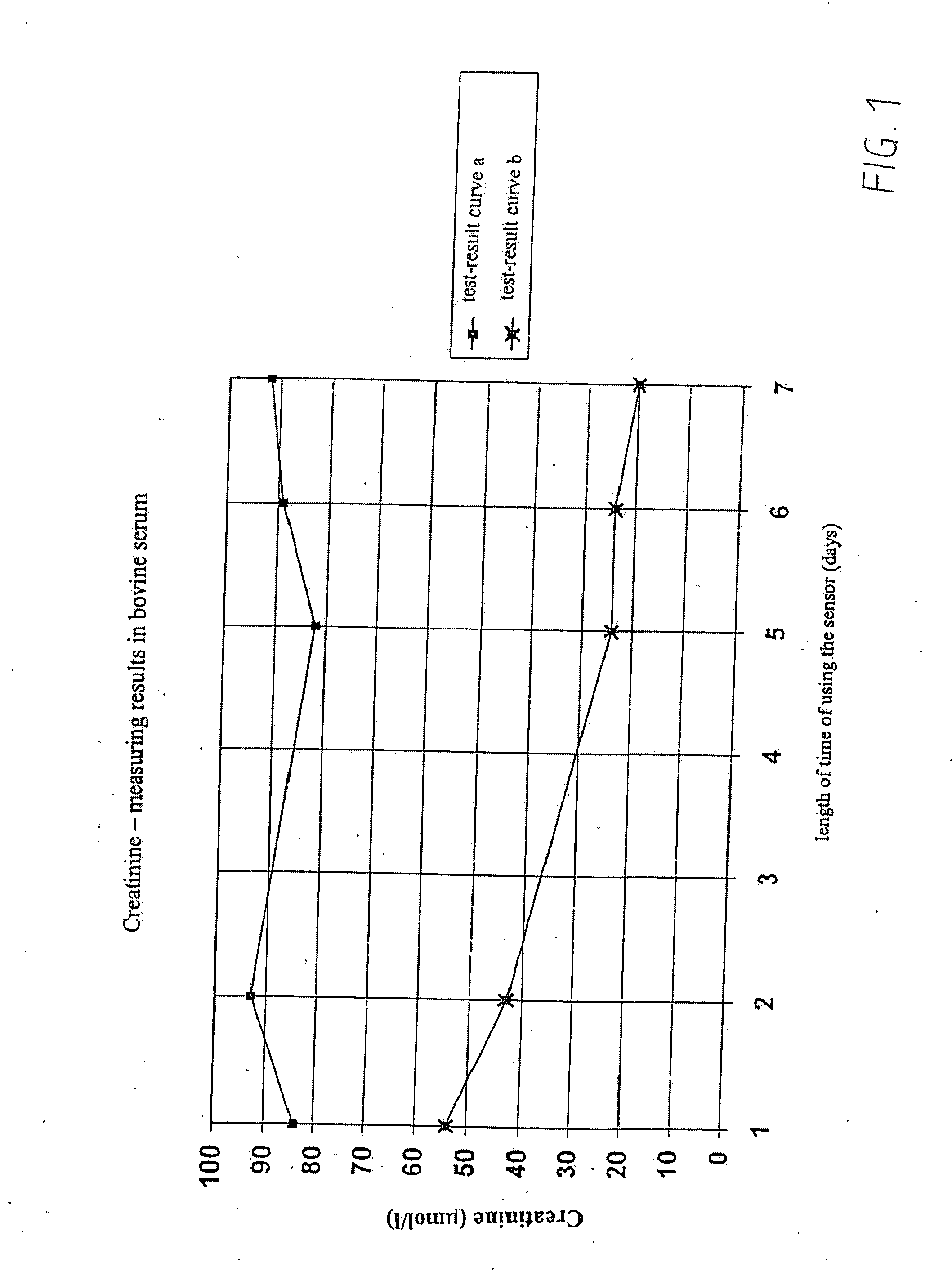

Creatinine Sensor Calibration

InactiveUS20080173064A1Weather/light/corrosion resistanceMicrobiological testing/measurementCreatinine riseAmperometry

In a method for calibrating a biosensor for the amperometric determination of creatinine in biological liquids, consisting of one electrode system each for measuring the concentrations of creatinine and creatine, with at least two calibration solutions being used, the electrode system for measuring the creatinine concentration is calibrated with a creatinine solution which, prior to the calibration measurement, was mixed in the form of an acidic solution with an alkaline buffer solution, and the electrode system for measuring the creatine concentration is calibrated with a solution in which creatinine and creatine are at a thermodynamic equilibrium.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

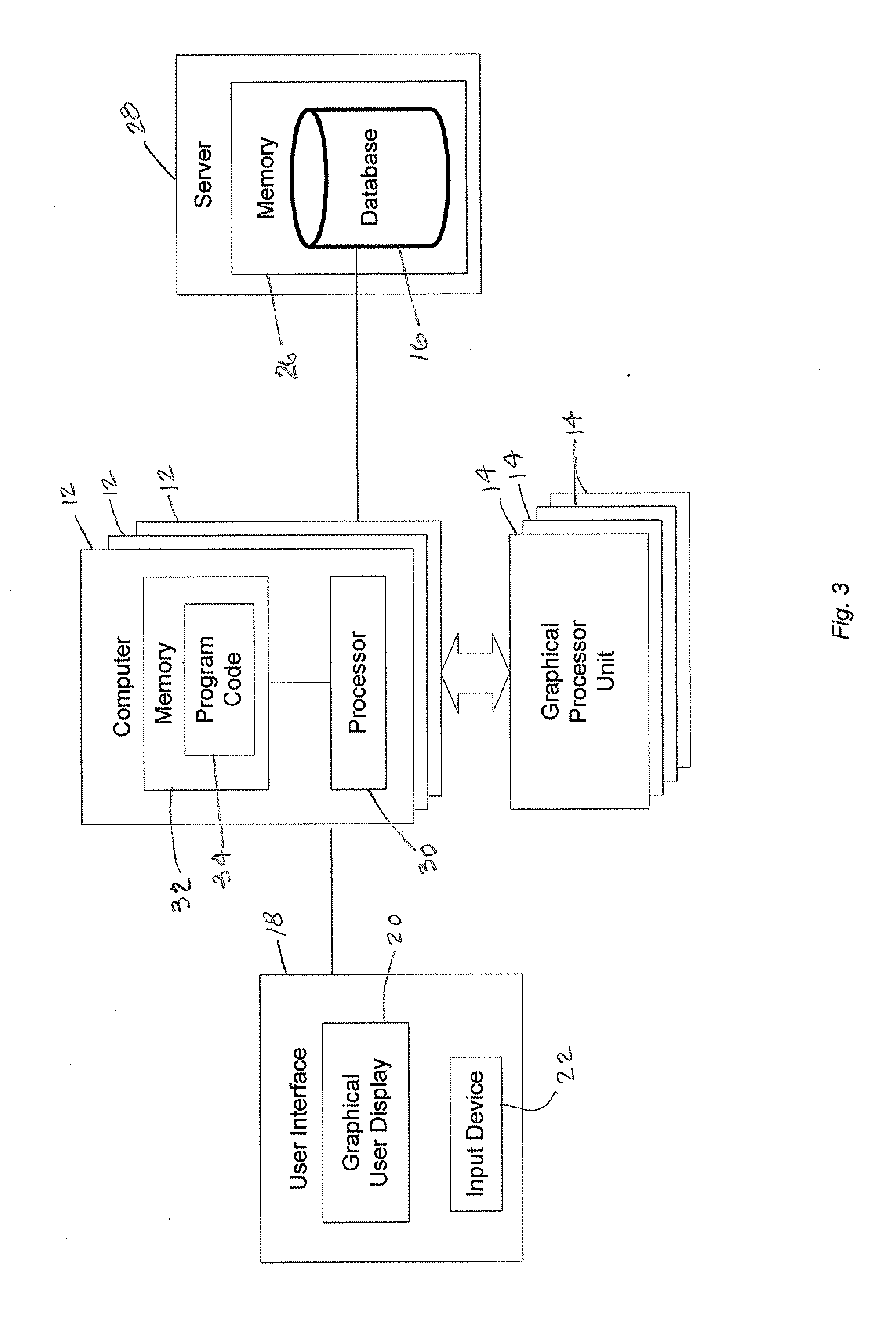

Reservoir Simulation of Giant Subsurface Reservoirs With Accelerated Phase Equilibrium Determination

Owner:SAUDI ARABIAN OIL CO

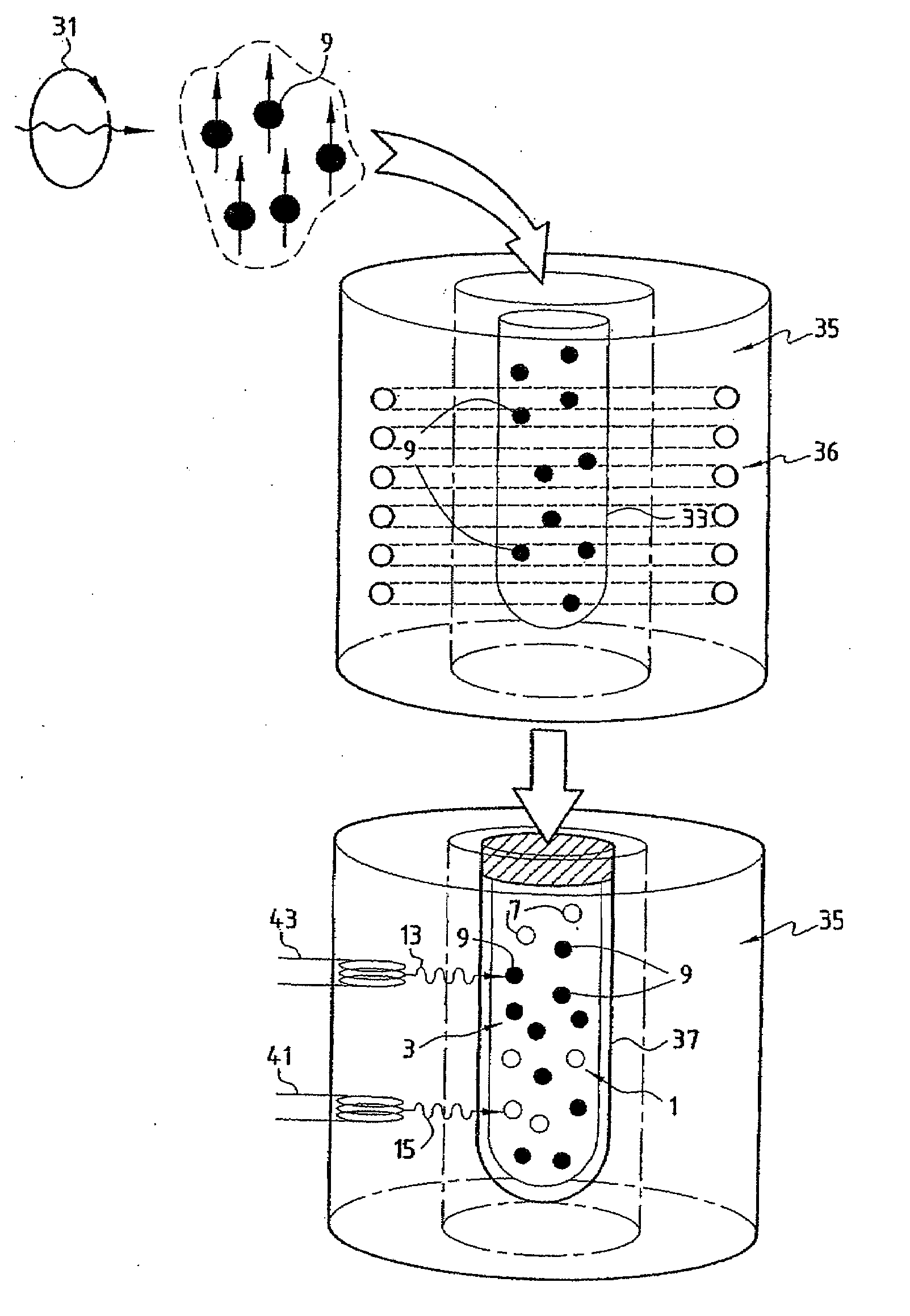

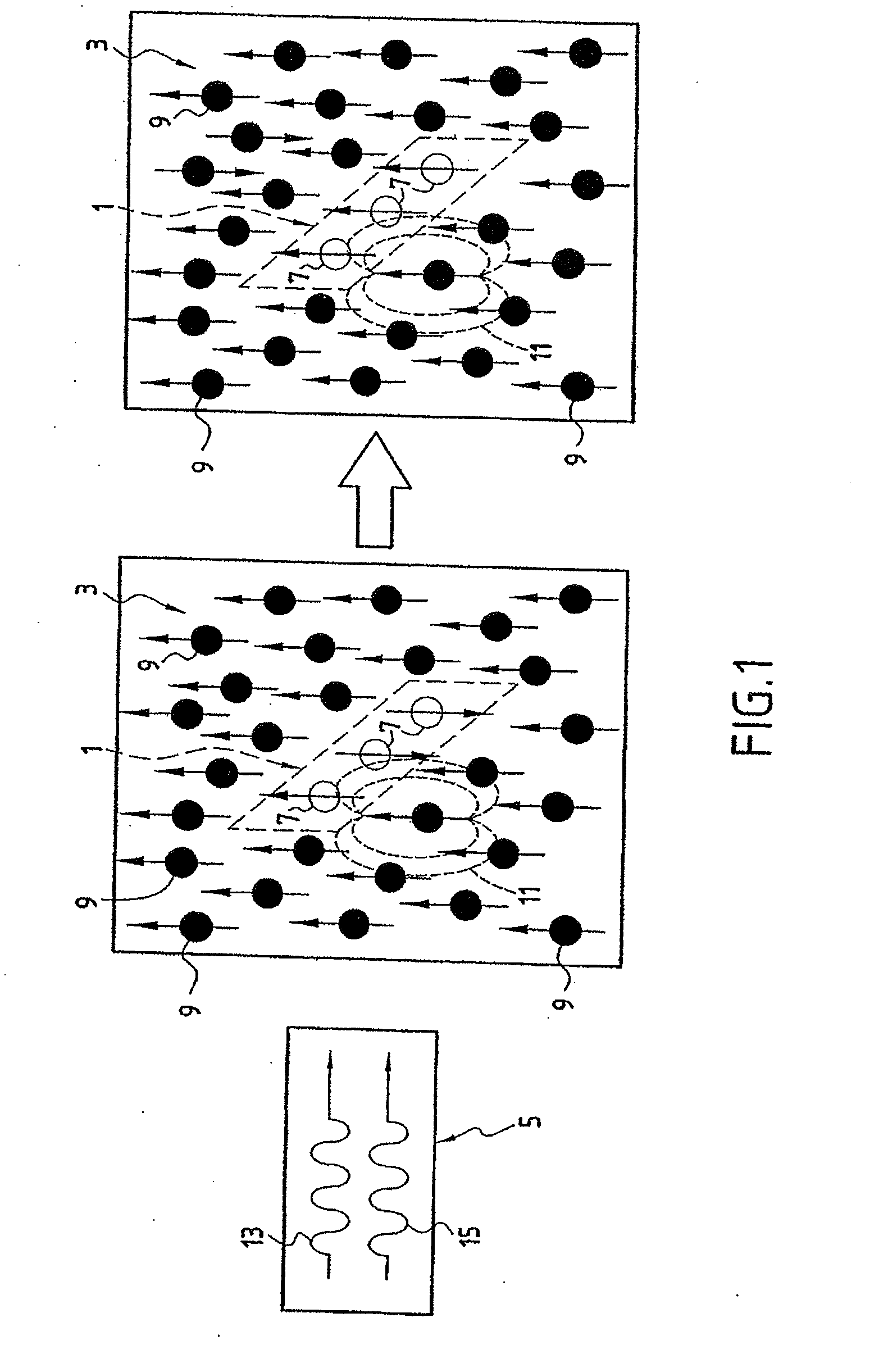

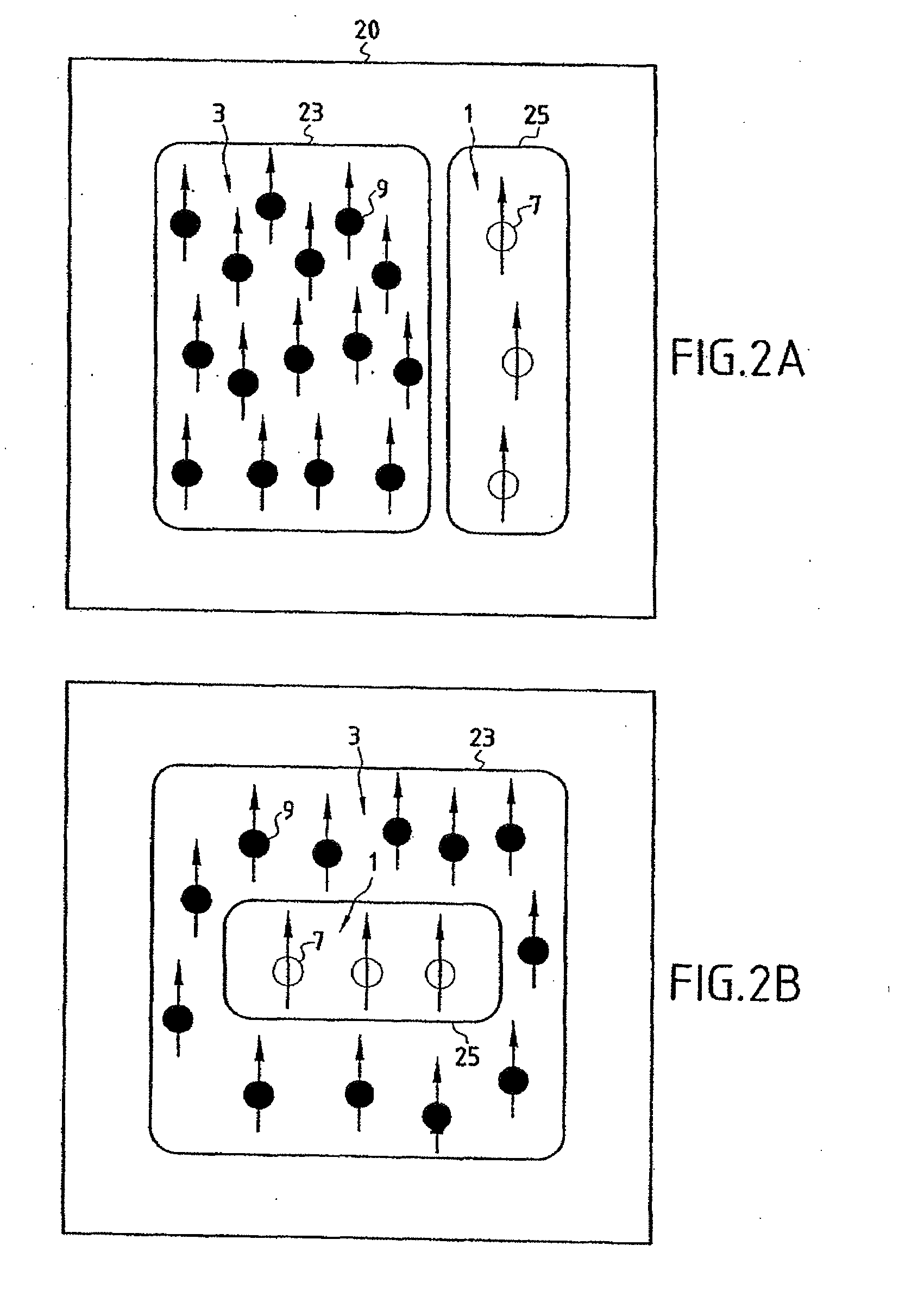

Method for Enhancing the Nmr Signal of a Liquid Solution

InactiveUS20080204014A1Increased polarizationEnhanced signalMeasurements using NMR spectroscopyElectric/magnetic detectionCouplingSpins

The invention relates to an NMR analysis system and method for obtaining an NMR signal from a liquid solution enhanced in relation to the value that it would have on the basis of the thermodynamic equilibrium. It has been discovered in a surprising manner that if the spins of the cores of a highly-polarised polarisation source and the spins of the cores of the liquid solution are irradiated such that a polarisation transfer, such as a Hartmann-Hahn transfer, of the spins of the cores of the source to the spins of the cores of the liquid solution is carried out by means of a coherent coupling resulting from the dipolar field created by the cores of the source, an NMR signal of the liquid solution is obtained, said signal being significantly enhanced in relation to the value it would have on the basis of the thermodynamic equilibrium.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Toluene selective disproportion and toluene and C9 and its above aromatic disproportion and alkyl transfusion method

InactiveCN1413968AReduce difficultyEliminate harsh requirementsHydrocarbon by isomerisationMolecular sieve catalystsHigh concentrationAlkyl transfer

The toluene is selectively disproportionated to obtain the mixed xylene containing high-concentration p-xylene. Then the C9 and C9+x arylhydrocarbon and toluene take part in disproportionation and alkyl transfer reaction to prepare benzene and thermodynamically balanced mixed xylene. The advantages are less circulation of arylhydrocarbon, low energy consumption, and low requirement to raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

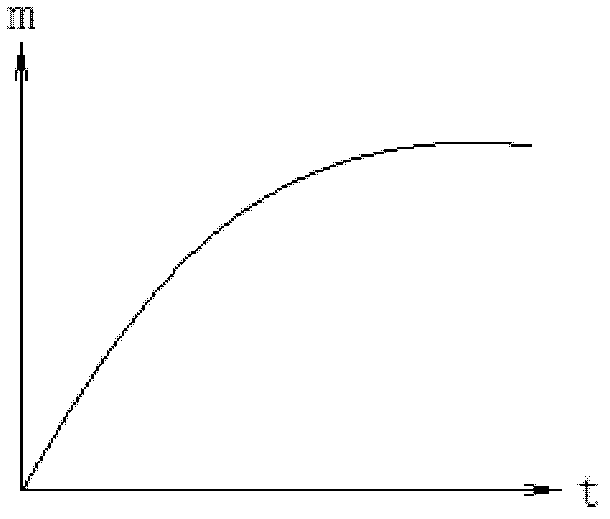

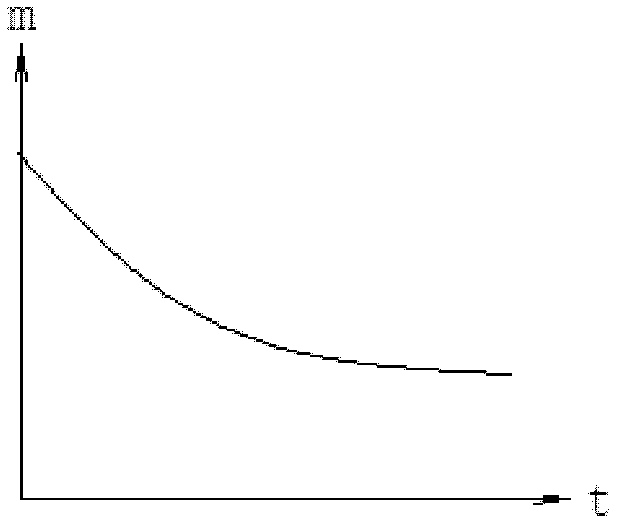

Preparation method of rock test samples with different water ratios

InactiveCN102393320AUniform moisture contentReduce moisture contentPreparing sample for investigationCooking & bakingTest sample

The invention discloses a preparation method of rock test samples with different water ratios and relates to the technical field of tests about rock mechanics. The preparation method comprises the following steps of: setting a test environment with a certain humidity in a hygrostat; weighing a sample to be prepared to obtain an original sample; marking the quality of the original sample as m1; feeding the original sample with the quality being m1 in a baking oven; drying the original sample at the temperature of 105-110DEG C and then weighing to obtain a dried sample; making the quality of the dried sample as m2 and feeding the dried sample with the quality being m2 in the hygrostat for preserving moisture; saturating the original sample with the quality being m1 with water and weighing to obtain a saturated sample; marking the quality of the saturated sample as m3; feeding the saturated sample with the quality being m3 into the hygrostat for preserving moisture; periodically weighing the sample in the hygrostat until the weight of the sample is constant to obtain a sample with constant weight; and marking the quality of the sample as m4. The solving method of the water ratio is shown in the description. The water content of the sample prepared in the invention is quite uniform and reaches a thermodynamic equilibrium state; and samples with little difference in the water ratio can be prepared.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

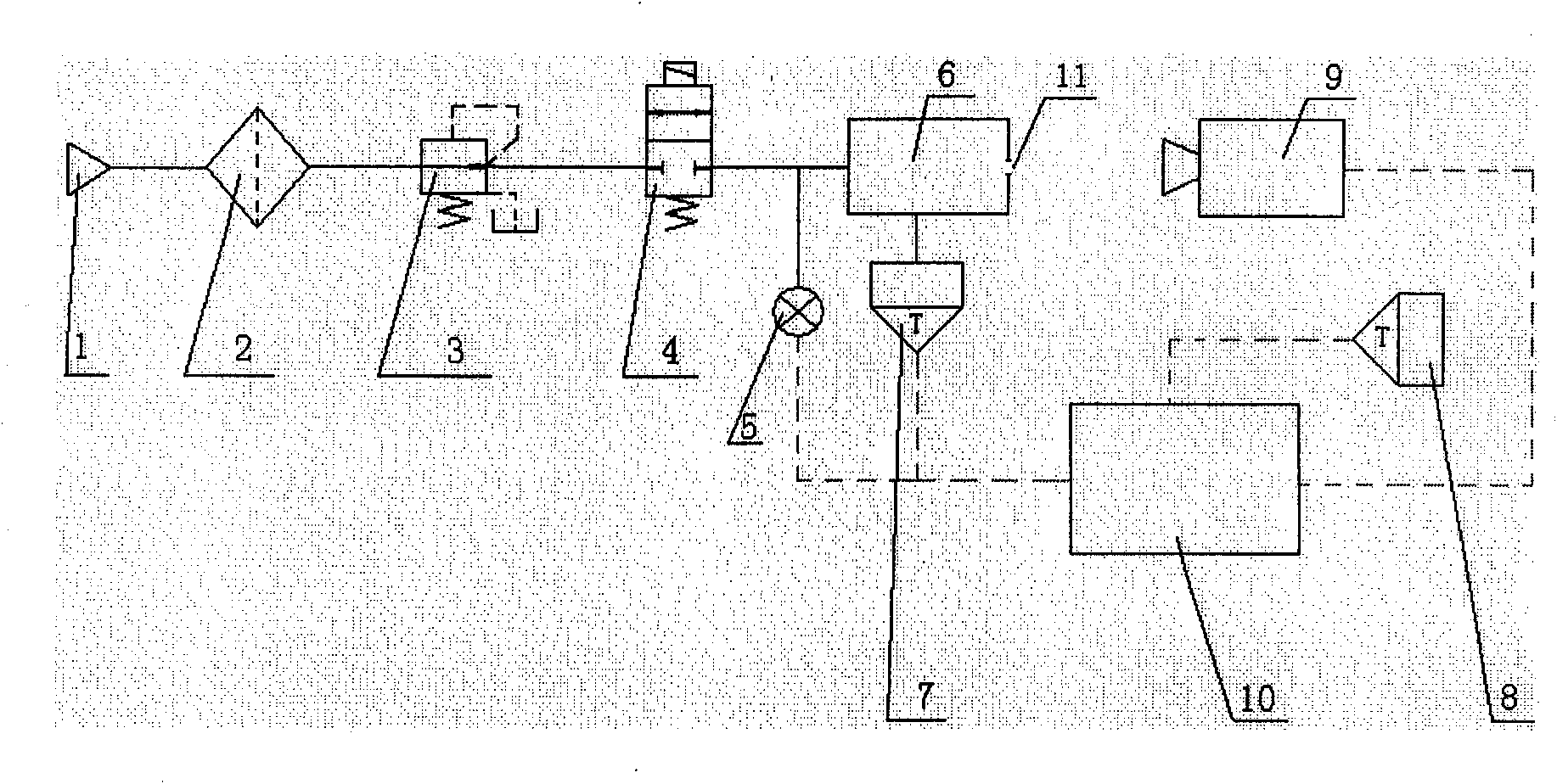

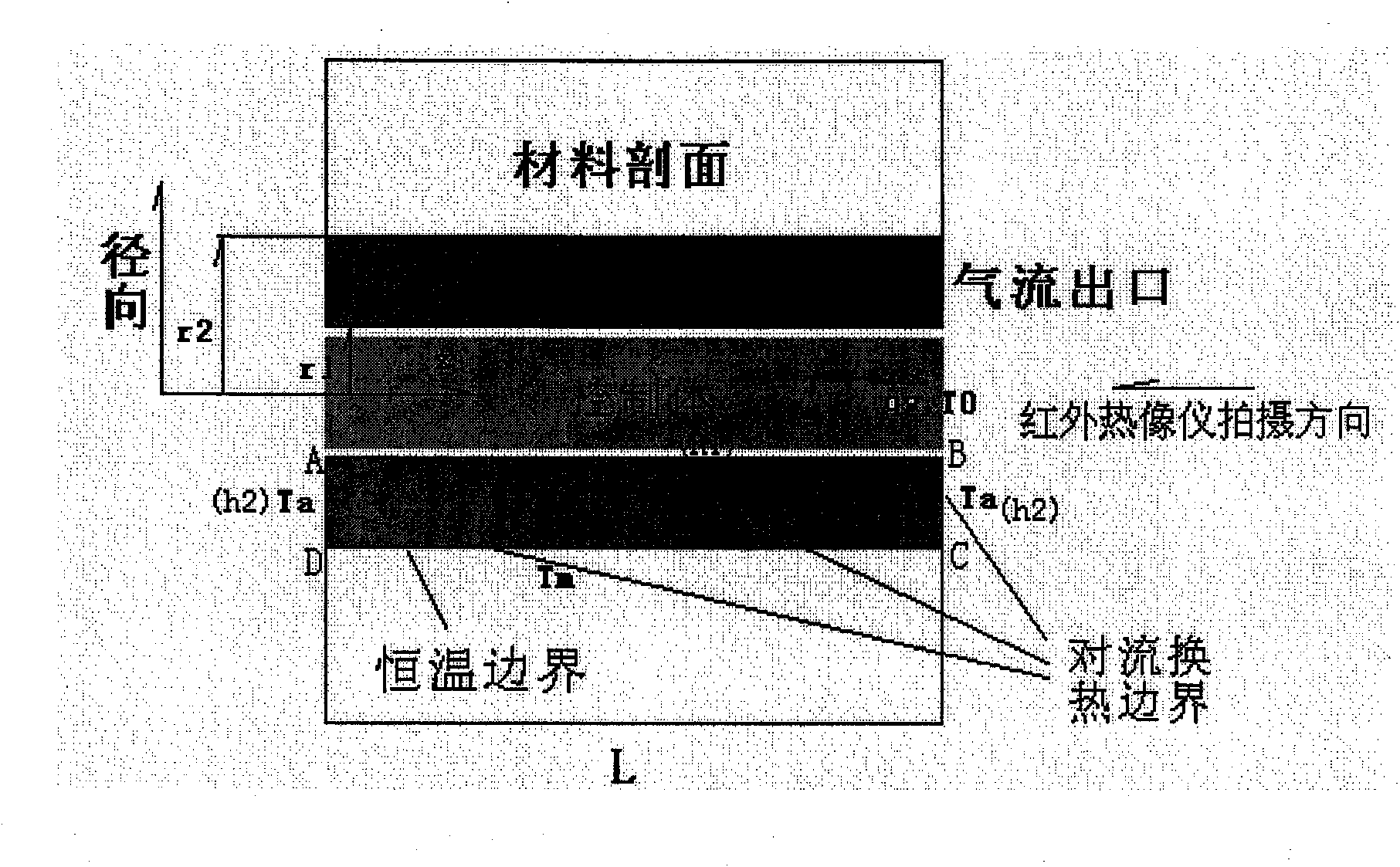

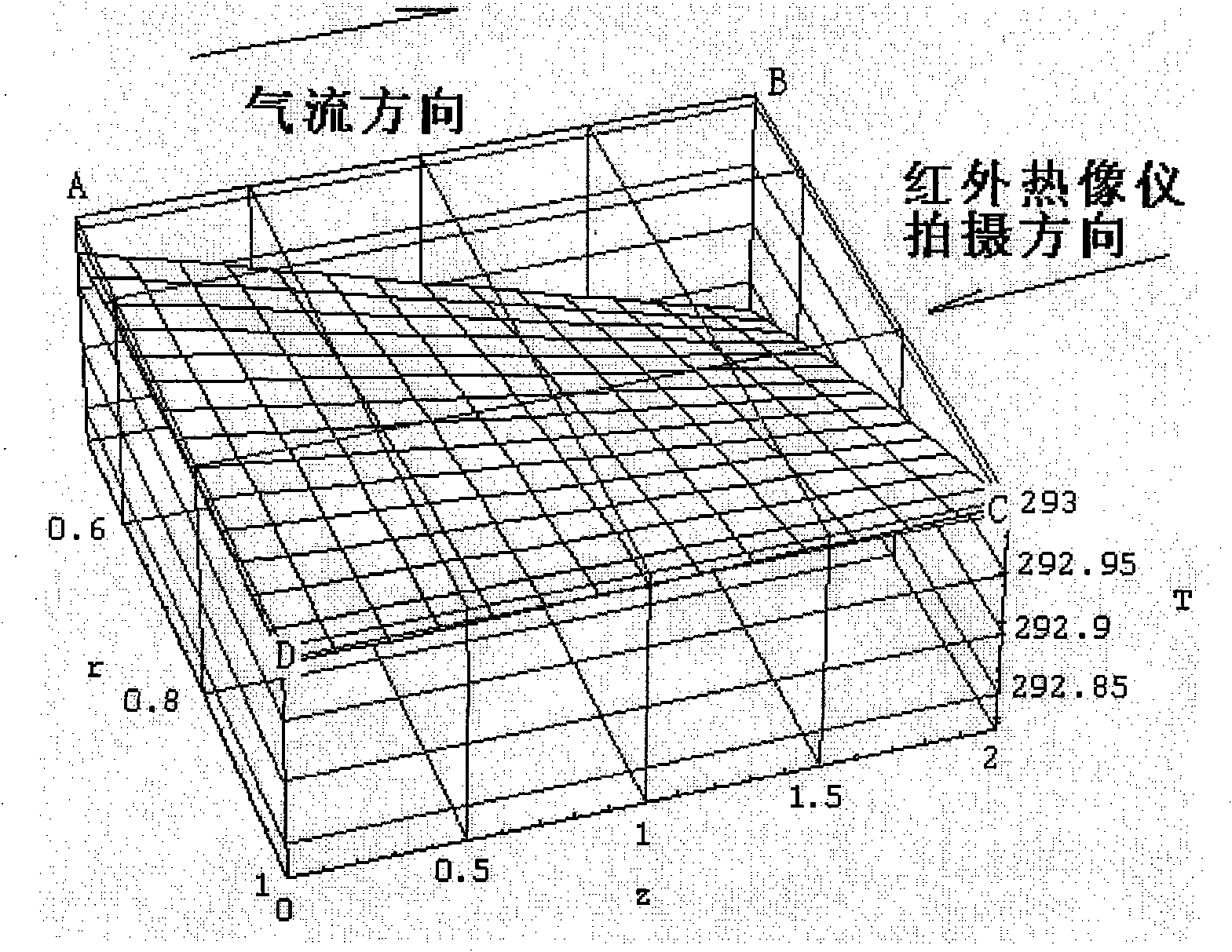

Device and method for detecting leakage of seal chamber by infrared imaging technology

ActiveCN101592544ASimple structureEasy to operateDetection of fluid at leakage pointAtmospheric airControl system

The invention provides a device for detecting leakage of a seal chamber by infrared imaging technology. The device comprises a gas source, a filter, a pressure regulating valve, an electromagnetic valve, a pressure sensor, a temperature sensor, a thermal infrared imager and a control system, wherein the pressure sensor, the temperature sensor and the thermal infrared imager are connected with the control system through lead wires respectively. A method for detecting the leakage of the seal chamber by the device comprises the following steps that a device to be detected reaches a thermodynamical equilibrium state after inflation, namely heat of a material around a vent released to airflow in unit time is equal to that of the material absorbed from atmosphere around the vent, and a leakage point can be determined through the position with reduced temperature detected by the thermal infrared imager; and the leakage amount can be determined through calculation of a computer in the control system. The device and the method have the advantages that the detecting device has simple structure, easy operation and low cost; the detecting method is practical, has small detection error, and can quickly and accurately detect the leakage point and the leakage amount of a chamber to be detected; and the detecting device and the method have strong applicability and wide application prospect.

Owner:BOYI TIANJIN PNEUMATIC TECH INST

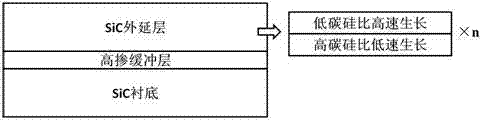

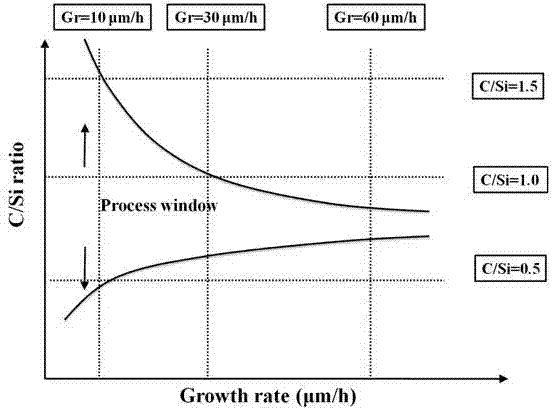

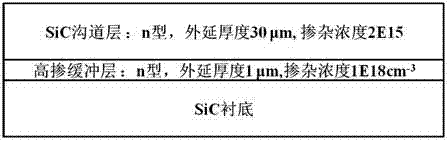

Method for prolonging lifetime of carriers of silicon carbide epitaxial layer

ActiveCN107492482AIncrease growth rateExtend your lifeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEpitaxial materialChemical vapor deposition

The invention discloses a method for prolonging lifetime of carriers of a silicon carbide epitaxial layer. By mainly adoption of a combination of a low-speed high-carbon-silicon ratio process and a high-speed low-carbon-silicon-ratio process, a required thick layer silicon carbide epitaxial layer is grown periodically; compared with the single low-speed high-carbon-silicon ratio process, the growth rate of the epitaxial layer is improved effectively by the method disclosed in the invention; and meanwhile, by combination with high-temperature annealing treatment, carbon vacancy is eliminated by carbon element migration in a chemical vapor deposition thermodynamic equilibrium condition, so that carbon vacancy effective restoration in the in-situ growth process is realized, and the lifetime of the carriers of the silicon carbide epitaxial layer is prolonged. The epitaxial material grown by the epitaxial method provided by the invention does not need ion implantation or high-temperature oxidization post treatment after epitaxy completeness, and the method is compatible with the existing commercial silicon carbide epitaxial furnace base process, so that the method has extremely high popularization value.

Owner:李哲洋

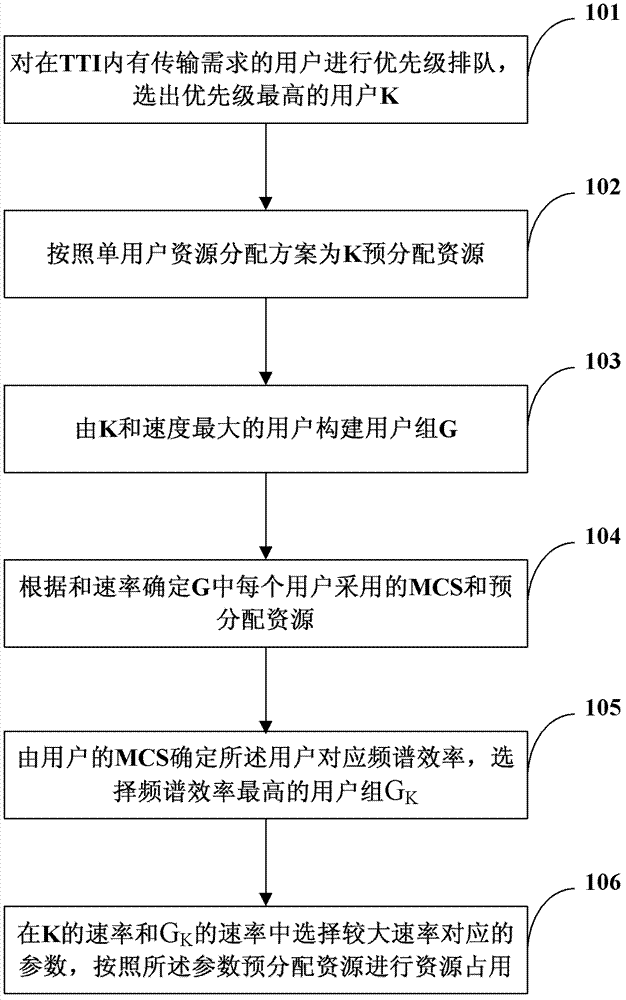

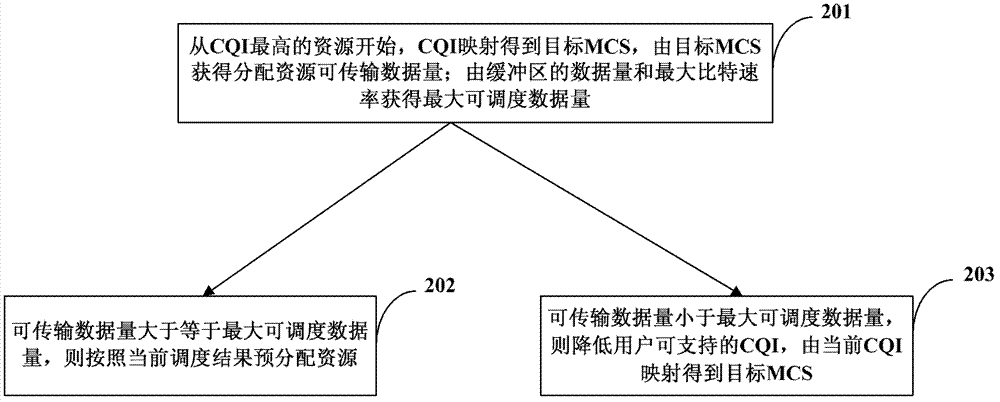

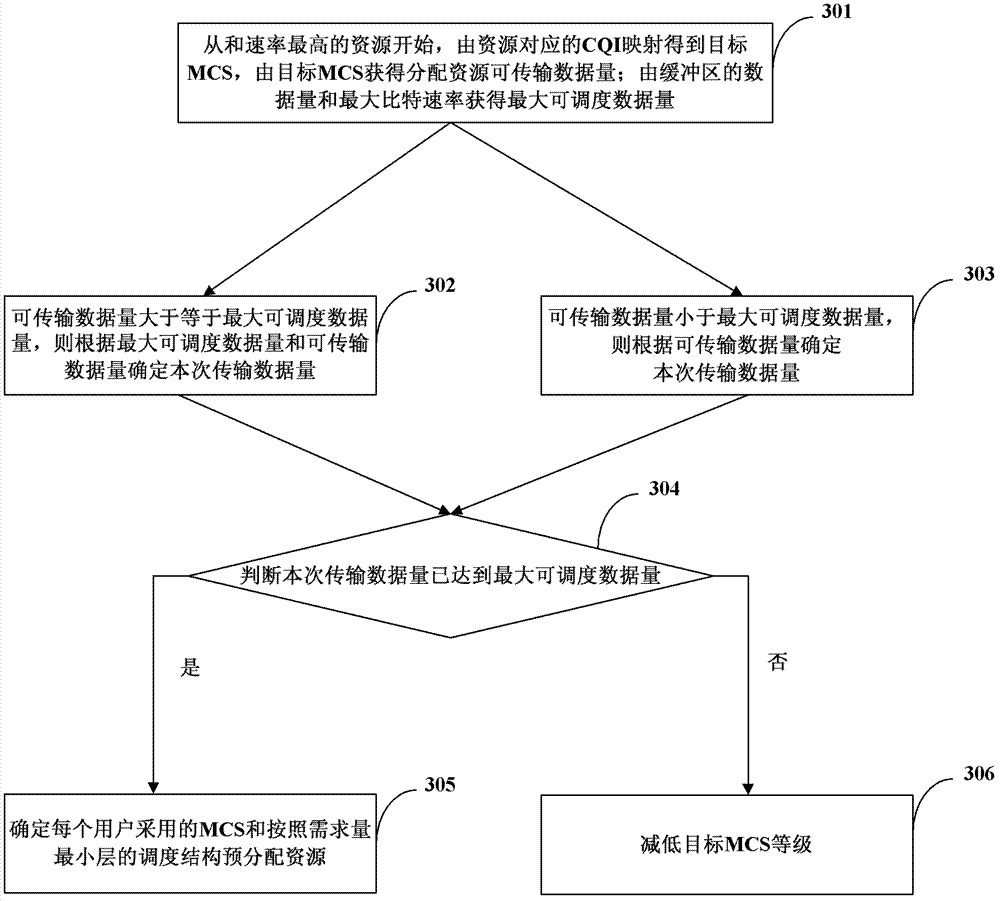

Method of multi-user multi-input multi-output frequency selection scheduling of local thermodynamic equilibrium (LTE) system

A method of multi-user multi-input multi-output frequency selection scheduling of a local thermodynamic equilibrium (LTE) system is characterized by including that: users having transmission requirements are lined up according to priority in a transmission time interval (TTI), a user K having the highest priority is chosen; resources are distributed in advance for the user K according to a single user resource distribution scheme; and a user group G is built for the user K on each pre-distributed resource; modulating control system (MCS) regulation is conducted according to user group MCS regulation scheme, single user transmission or multi-user transmission and pre-distribute resource occupation are confirmed according to the user group G and user transmission data quantity. After the method is applied, maximization of user groups and speed is achieved, and waste of resources is avoided.

Owner:POTEVIO INFORMATION TECH

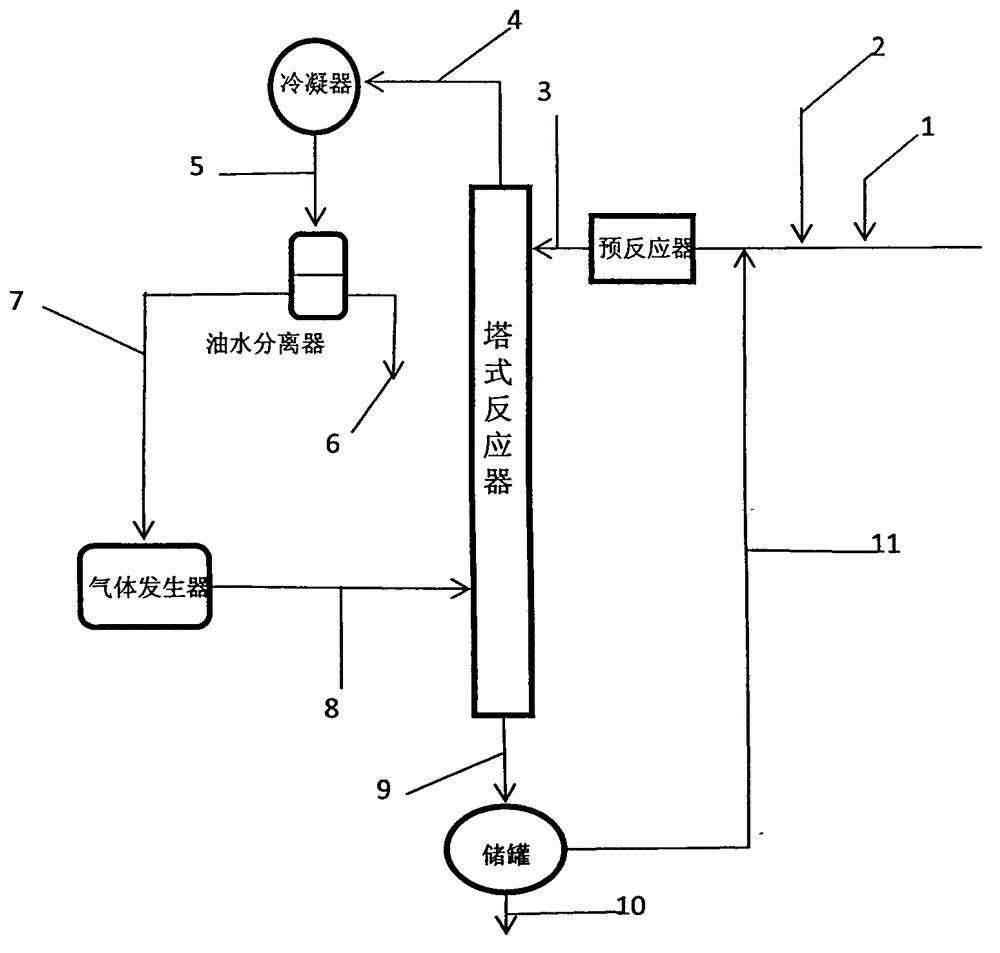

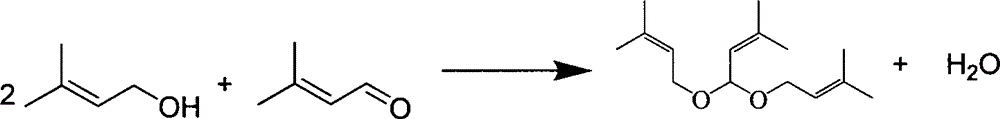

Unsaturated acetal preparation method

ActiveCN102942460AEvenly distributedSmooth responseOrganic chemistryOrganic compound preparationButene3-methyl-2-buten-1-ol

The present invention discloses an unsaturated acetal preparation method. According to the preparation method, an unsaturated alcohol and an unsaturated aldehyde are subjected to a reaction in a pre-reactor to achieve a thermodynamic equilibrium, and then enter a tower type reactor, a water carrying agent is subjected to gasification through a gas generator, and then is subjected to reverse contact with a reaction liquid, and the water generated from the reaction is removed, such that the unsaturated alcohol and the unsaturated aldehyde are subjected to a continuous condensation reaction to prepare the unsaturated acetal. The preparation method has the following characteristics that: the method can be performed under a normal pressure condition, the reaction temperature is constant, low cost synthesis of the unsaturated acetal can be achieved, particularly 3-methyl-2-buten-1-ol and 3-methyl-2-butenal can be adopted as raw materials to synthesize 3-methyl-2-butenal-1 diisopentenyl acetal, wherein the compound is an important intermediate of a synthetic perfume citral.

Owner:WANHUA CHEM GRP CO LTD +1

Method for preparing salt of hydroxylamine by using 'coupling' technique of reactive extraction

This invention provides a method for preparing hydroxylamine salt by reaction-extraction 'coupled' technique. The method utilizes hydroxylamine hydrochloride and HNO3, H2SO4 or H3PO4 as the reactants to prepare hydroxylamine nitrate, hydroxylamine sulfate or hydroxylamine phosphate. During the reaction, a mixture of amide and diluting agent is utilized as the extraction phase to extract byproduct HCl generated during the reaction to obtain high-concentration hydroxylamine salt mother liquor. Then multi-stage cross-flow or vacuum distillation is performed to obtain concentrated hydroxylamine salt solution or crystal. During the reaction, byproduct inorganic acid can be extracted into the organic phase, which can reduce the amount of inorganic acid in aqueous phase, and break the previous thermodynamic equilibrium limit so that the reaction advances toward the positive reaction direction, and the yield is increased. The method has such advantages as simple process, few buproducts and easy operation, and is suitable for industrialization production.

Owner:BEIJING UNIV OF CHEM TECH

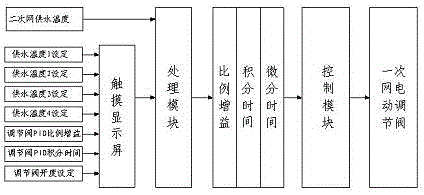

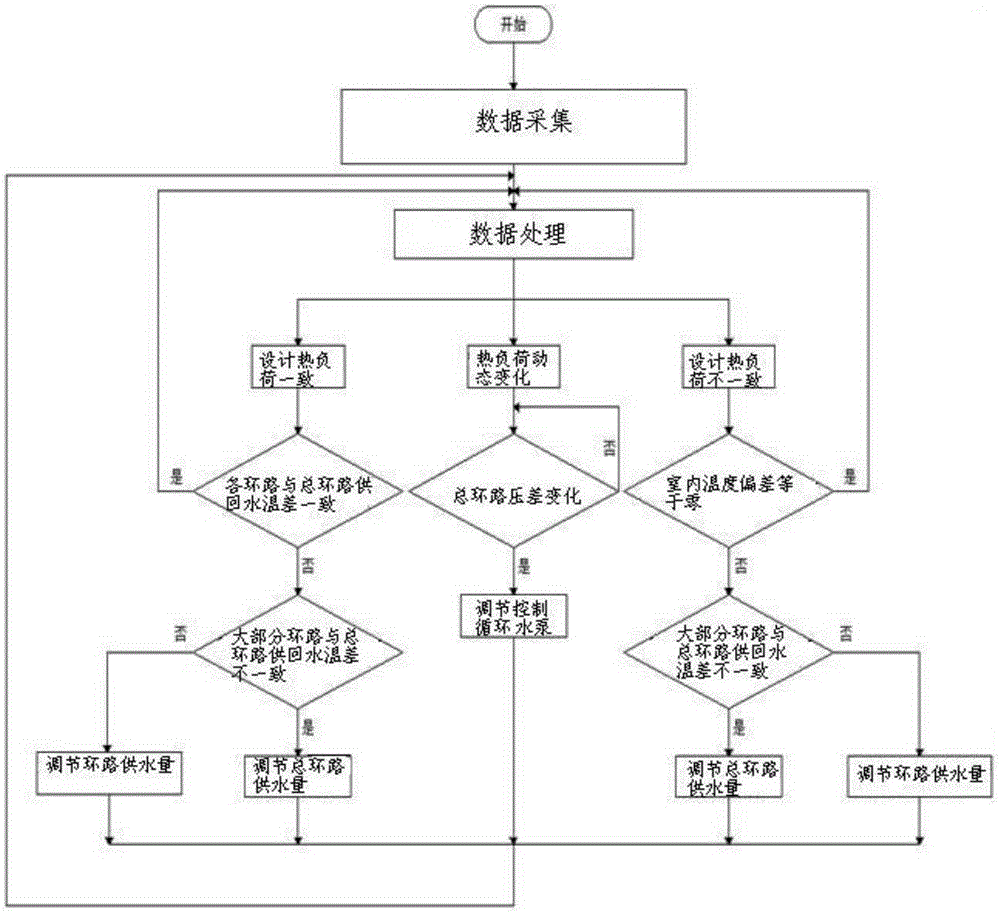

A constant-temperature difference and variable-flow hydraulic equilibrium adjusting method and system

ActiveCN106610052AEasy accessReduce transmission and distribution energy consumptionLighting and heating apparatusEfficient regulation technologiesDifferential pressureProcess engineering

The invention relates to the technical field of heat supply adjustment and in particular relates to a constant-temperature difference and variable-flow hydraulic equilibrium adjusting method. The method comprises the steps of: S1, collecting the indoor temperature ts of users on each loop, the water supply temperature tg of a total loop, the water return temperature ti of each loop and the water return temperature th of the total loop and collecting the data parameters of the pressure difference delta p between a water supply pipe and a water return pipe of the total loop; S2, calculating the indoor temperature deviation delta ts of the users on each loop, the water supply and water return temperature difference delta t of the total loop and the water supply and water return temperature difference delta ti of each loop; S3, performing analytic comparison on the data parameters collected in the step S1 and the data results obtained in the S2 to obtained the required control quantity for the water supply quantity of the total loop and the control quantity for the water supply quantity of each loop; S4, adjusting and controlling the water supply quantity of the total loop according to the control quantity for the water supply quantity of the total loop obtained in the S3 and adjusting and controlling the water supply quantity of each loop according to the control quantity for the water supply quantity of each loop obtained in the S3. The water supply quantities can be controlled in real time by using a dynamic adjusting method, so that hydraulic dynamic equilibrium and thermodynamic equilibrium are achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Solid-State Lithium Battery

InactiveUS20150030909A1Low form factorSimple materialTantalum compoundsPrinted batteriesLanthanumLithium.free

The present invention is directed to a higher power, thin film lithium-ion electrolyte on a metallic substrate, enabling mass-produced solid-state lithium batteries. High-temperature thermodynamic equilibrium processing enables co-firing of oxides and base metals, providing a means to integrate the crystalline, lithium-stable, fast lithium-ion conductor lanthanum lithium tantalate (La1 / 3-xLi3xTaO3) directly with a thin metal foil current collector appropriate for a lithium-free solid-state battery.

Owner:SANDIA

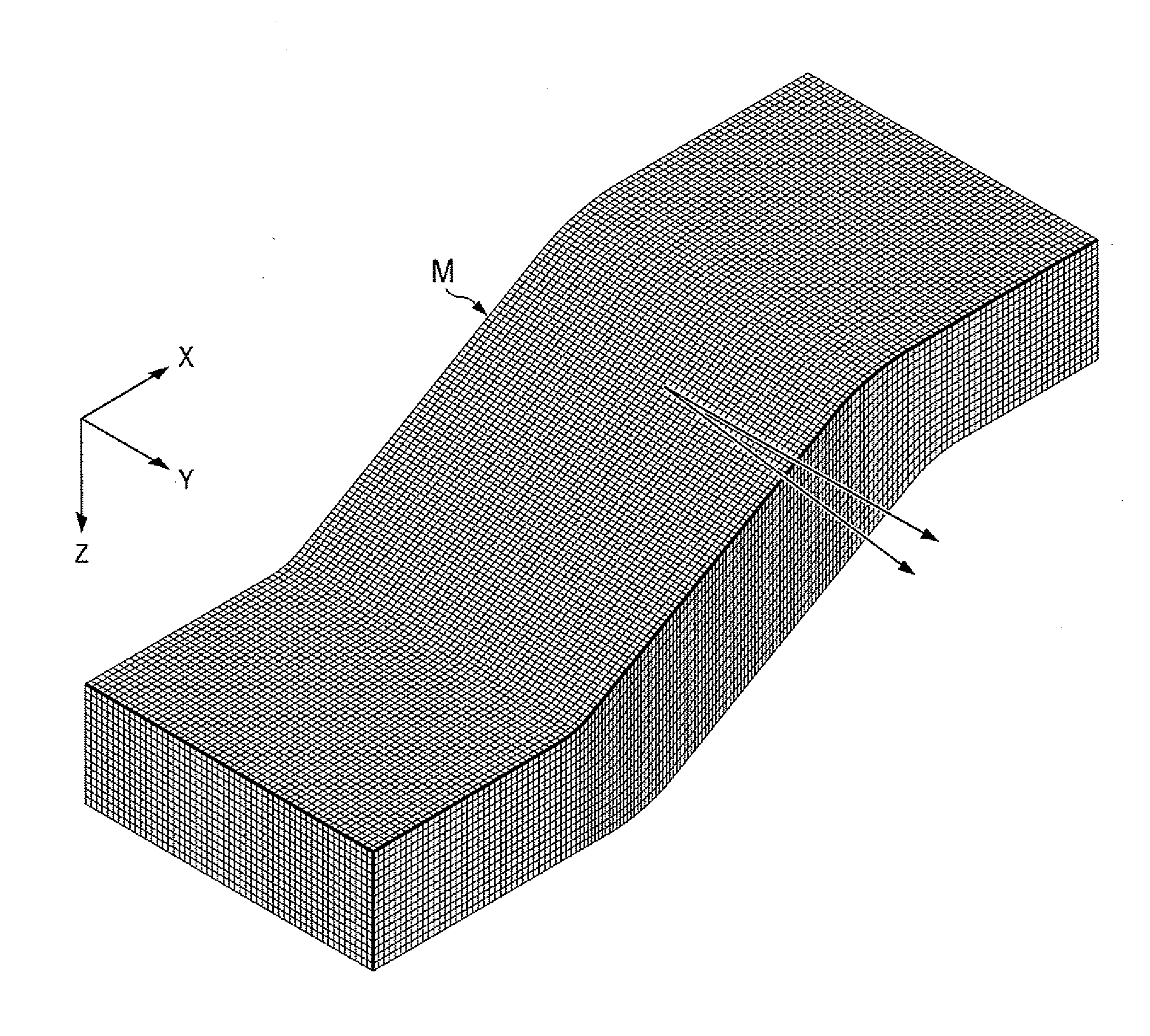

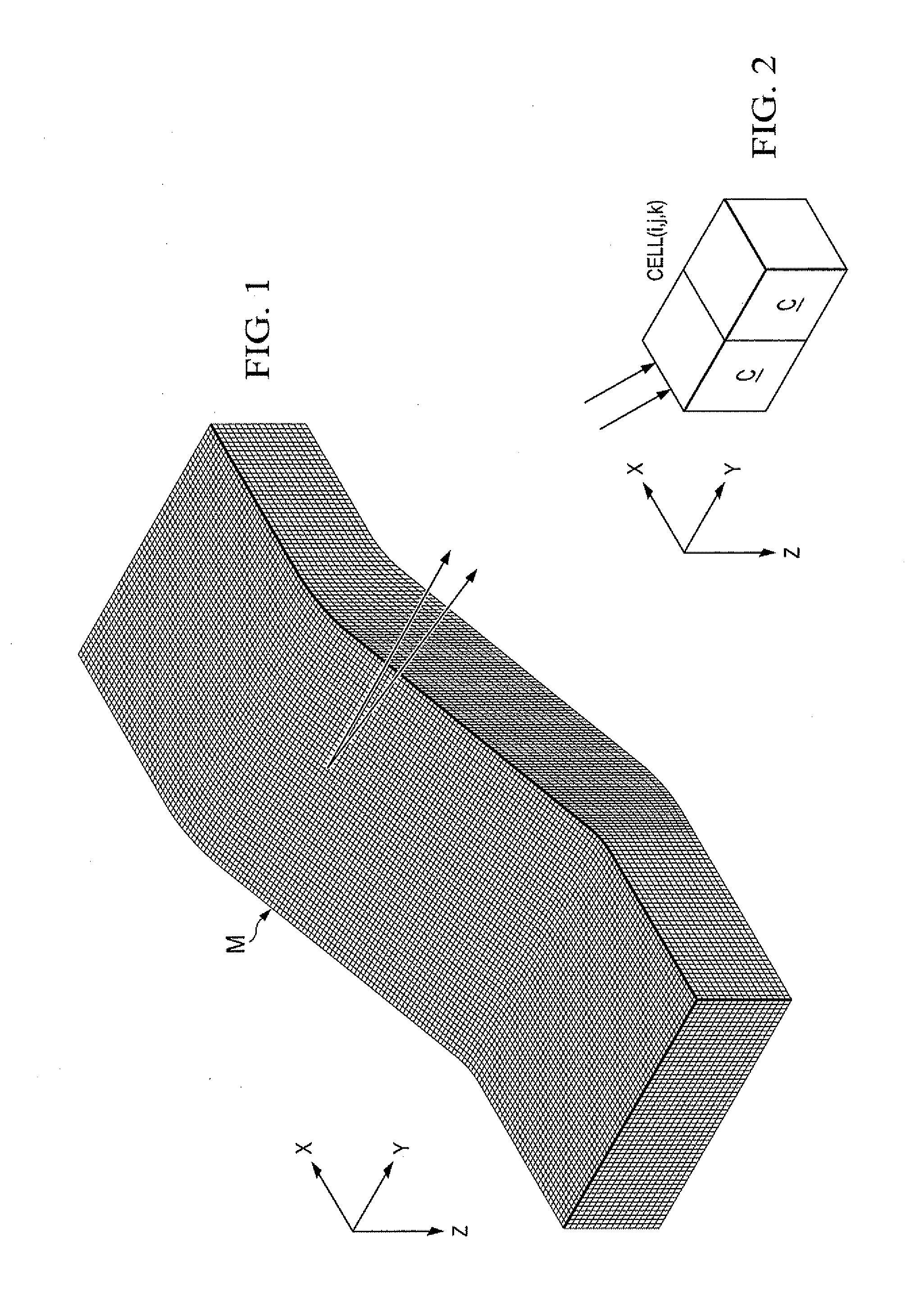

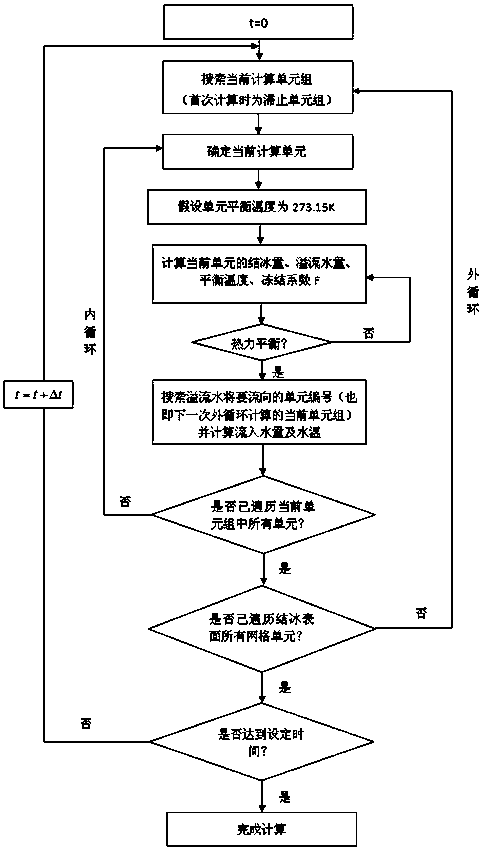

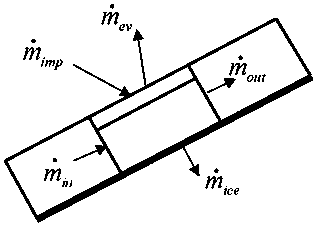

Unsteady three-dimensional icing numerical-simulation method

The invention discloses an unsteady three-dimensional icing numerical-simulation method, and belongs to the field of aircraft flight safety design. An N-S equation is used for calculating an air field, a Lagrangian method is used for calculating movement trajectory of water droplets, icing quantity and overflow water quantity are calculated according to mass conservation and energy conservation, aflowing direction of overflow water and flow distribution of different directions are calculated and obtained by a velocity vector of local air and position vectors of a current unit and adjacent units. By using the unsteady calculation method, icing calculation starts from a stagnation unit group in each time step, thermodynamic equilibrium calculation is carried out for each grid unit therein,the icing quantity, the overflow water quantity and the number of a next grid unit to which the overflow water flows are obtained, calculation advances backwards according to the flow direction of theoverflow water until all the grid units on an icing surface are traversed, and then calculation of a next time step is entered. Through comparison of a calculation example and the prior art, it is proved that the unsteady three-dimensional icing numerical-simulation method provided by the invention is effective.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

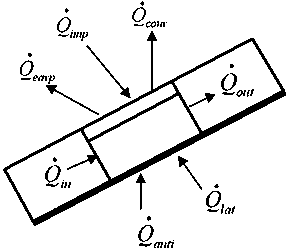

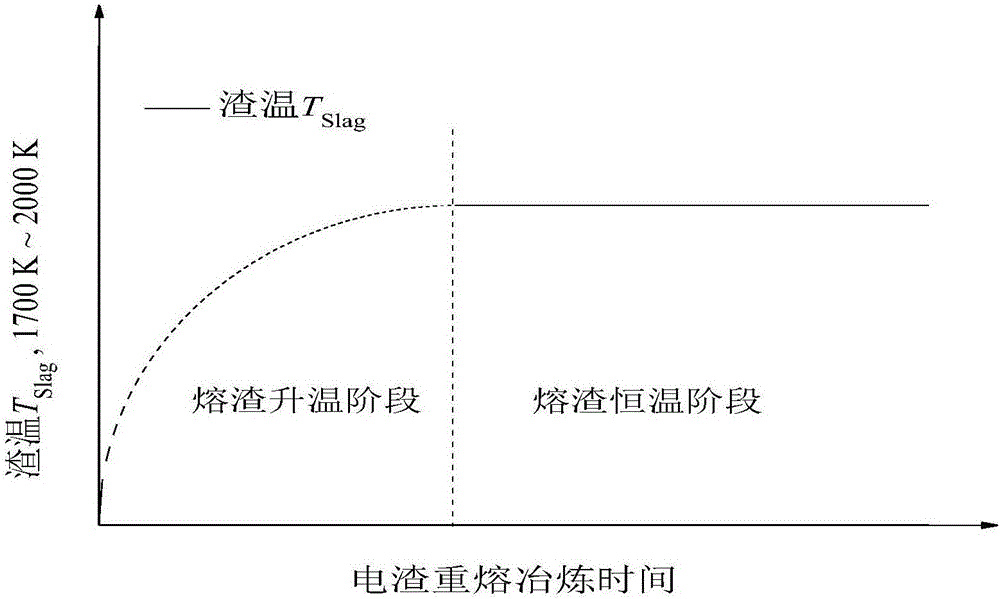

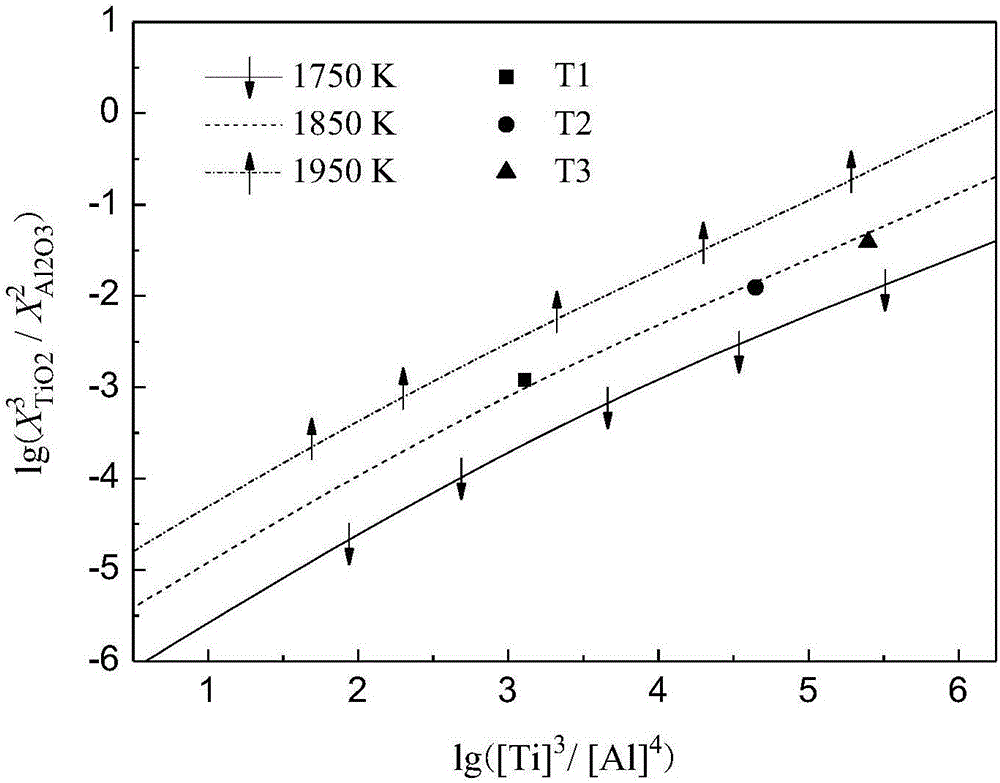

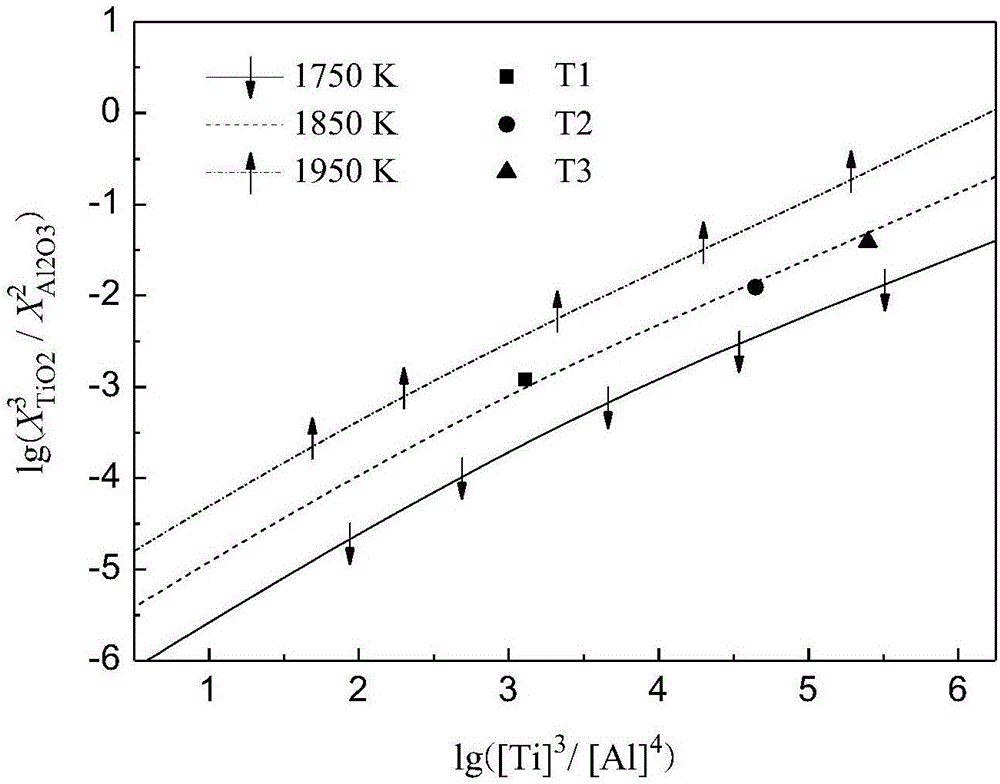

Re-melting slag system used for electroslag re-melting high-titanium low-aluminum type steel type and smelting technique

The invention discloses a re-melting slag system used for electroslag re-melting high-titanium low-aluminum type steel type and a smelting technique. The problem of unevenness of components, in the electroslag ingot axial direction, of aluminum and titanium in electroslag re-melting is solved. Base slag adopts a TiO2-free low-CaO slag system; and according to the component range of the base slag, CaF2:Al2O3:CaO:MgO is equal to (65-70%):(18-22%):(0-5%):(6-10%), wherein SiO2 is less than 0.8%, and FeO is less than 0.2%. Firstly, in an initial slag system, through the balancing principle of molten slag and Ai and Ti in molten steel, the TiO2 content of initial slag is determined under the liquidus temperature of a target steel type; and then in the molten slag temperature rising stage of a re-melting initial stage, extra TiO2 is continuously and evenly replenished into the slag, and the total replenishing quantity is the difference value of the TiO2 contents obtained through calculation in balancing under the temperature of 1677 DEG C and the liquidus temperature of the target steel type. According to the re-melting slag system used for the electroslag re-melting high-titanium low-aluminum type steel type and the smelting technique, the Ai and Ti in the molten steel in the temperature rising stage of the re-melting initial stage and the molten slag approach a thermodynamic equilibrium state, interreaction between the aluminum and the titanium is lowered, evenness of the components, in the electroslag ingot axial direction, of the aluminum and the titanium is improved, and the component qualification rate and the finishing product rate of a product are increased.

Owner:NORTHEASTERN UNIV

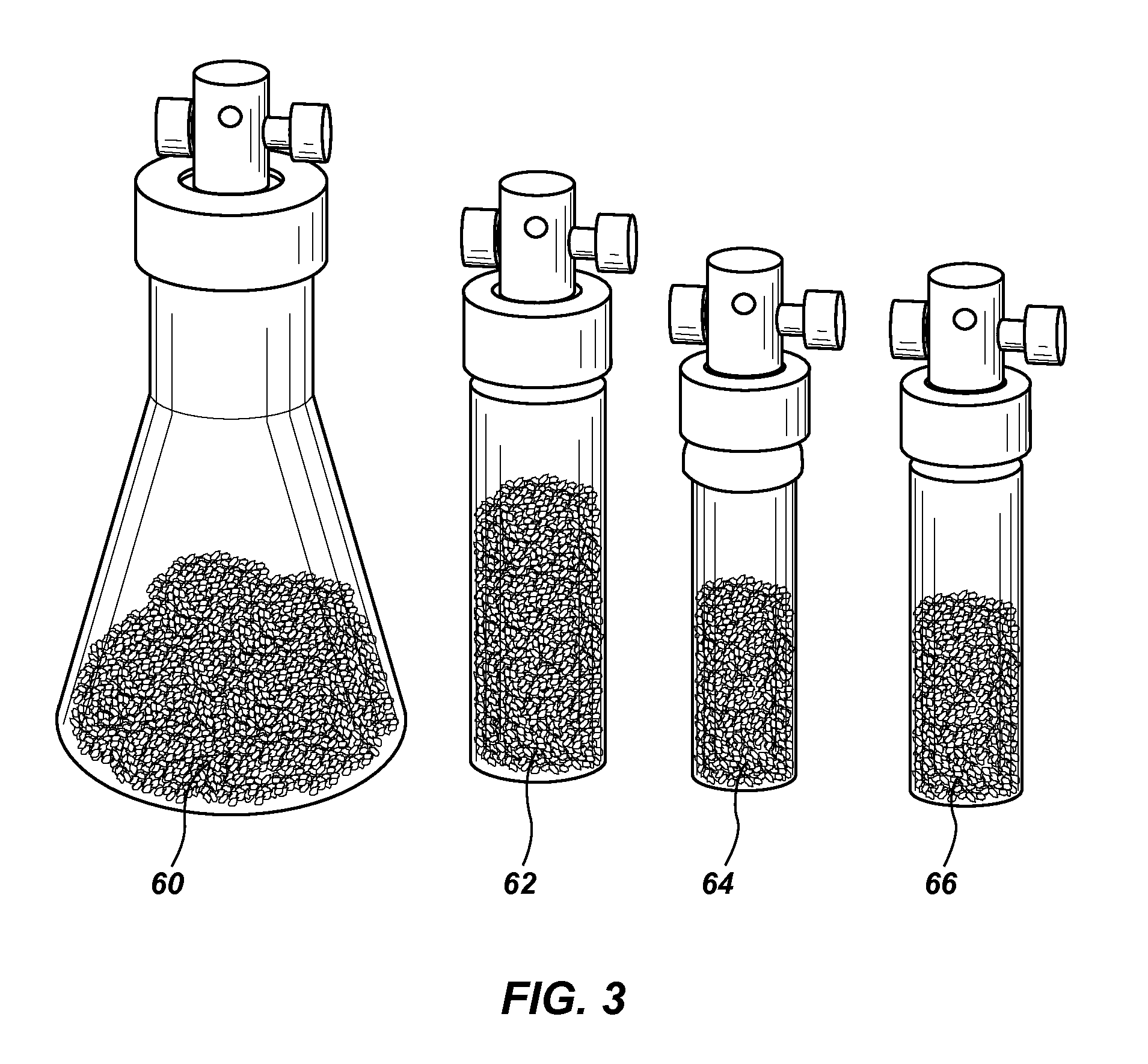

Simple equilibrium distribution sampling device for gc-ms calibration

A system for providing standard mixtures of volatile and semi-volatile organic compounds for simultaneous CC and MS calibration in a calibration vial, wherein calibration mixtures are prepared by diluting calibration analytes in granular PDMS such that most of the analytes are in the PDMS phase and the sample can then be taken from the analytes in the headspace vapor in the calibration vial, wherein a reliable calibration sample can be taken from the calibration vial because the analytes in the PDMS phase and the headspace vapor are in thermodynamic equilibrium, and wherein the method provides solvent-less sampling, long-time stability, ease of use, is quantifiable, and related to temperature.

Owner:BRIGHAM YOUNG UNIV

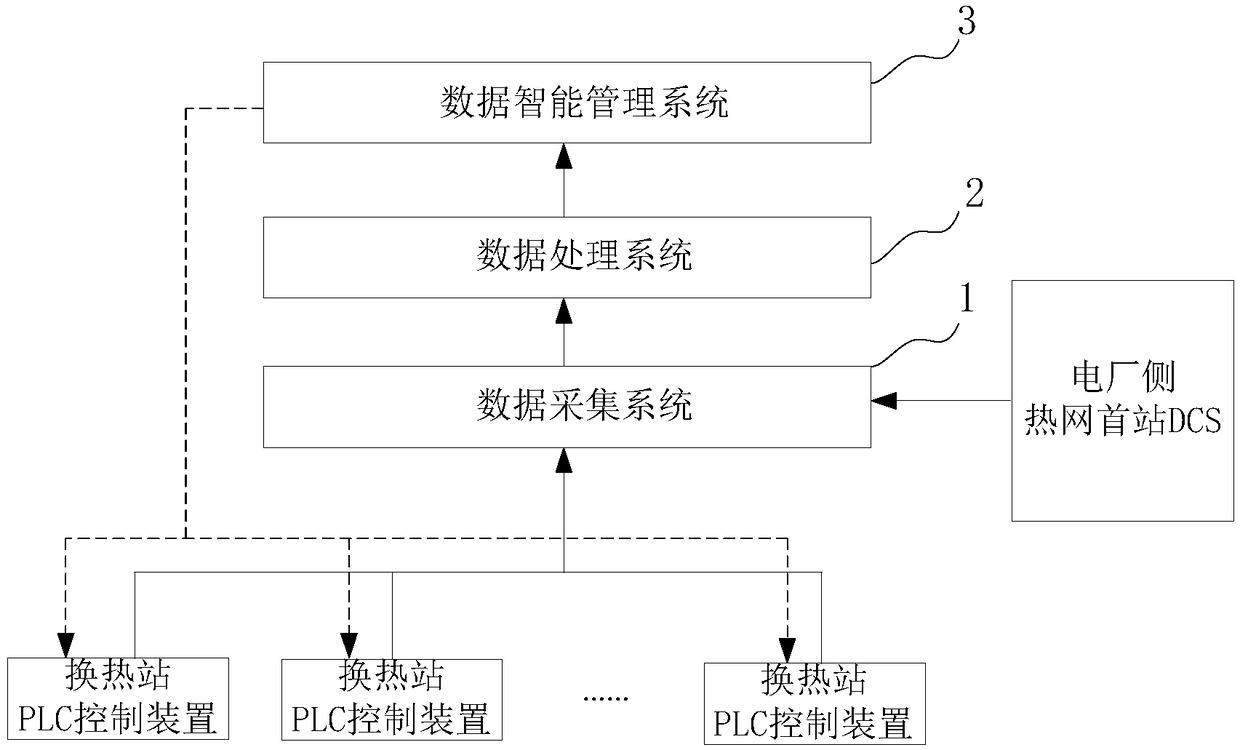

Heating network energy management system and processing method thereof

InactiveCN109373441AIntelligent control of heating loadMaximize utilizationLighting and heating apparatusSpace heating and ventilation detailsData acquisitionEngineering

The invention provides a heating network energy management system and a processing method thereof. The heating network energy management system comprises a plurality of PLC control devices of user side heat exchanging stations, a power plant side heating network origin station DCS, a data acquisition system, a data processing system and an intelligent data management system, wherein each of the PLC control devices is connected with all measure points of the heat exchanging station in which the PLC control device is in; the data acquisition system is connected with all PLC control devices and the power plant side heating network origin station DCS; the data processing system is connected with the data acquisition system and is used for processing according to the data received by the data acquisition system; and the intelligent data management system is connected with the data processing system and obtains the optimization and adjustment results for optimizing and adjusting the flow rate, water supply and return water temperature of the primary network and / or secondary network of each heat exchanging station. The heating network energy management system can realize thermodynamic equilibrium, hydraulic equilibrium and heat distribution according to the demand, so that the energy is utilized to the maximum, and energy consumption is reduced during the transmission process.

Owner:普瑞森能源科技(北京)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com