Patents

Literature

372 results about "Weight space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A weight of the representation V is a linear functional λ such that the corresponding weight space is nonzero. Nonzero elements of the weight space are called weight vectors. That is to say, a weight vector is a simultaneous eigenvector for the action of the elements of , with the corresponding eigenvalues given by λ.

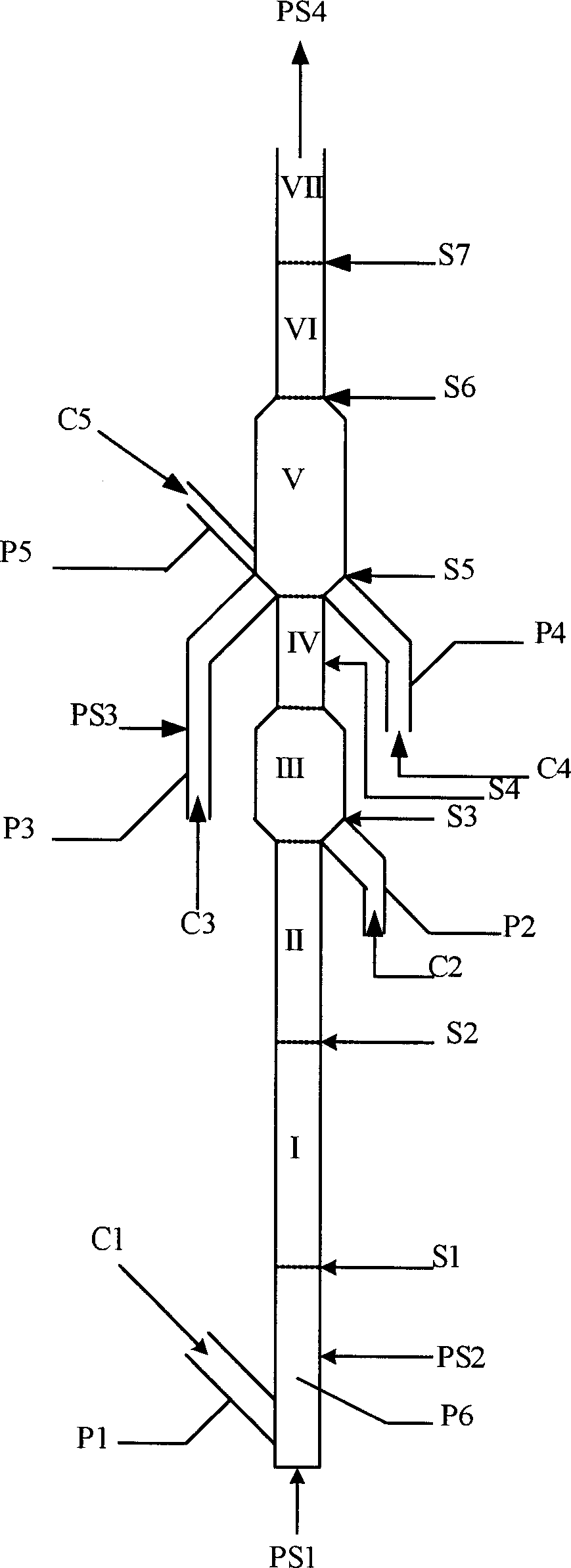

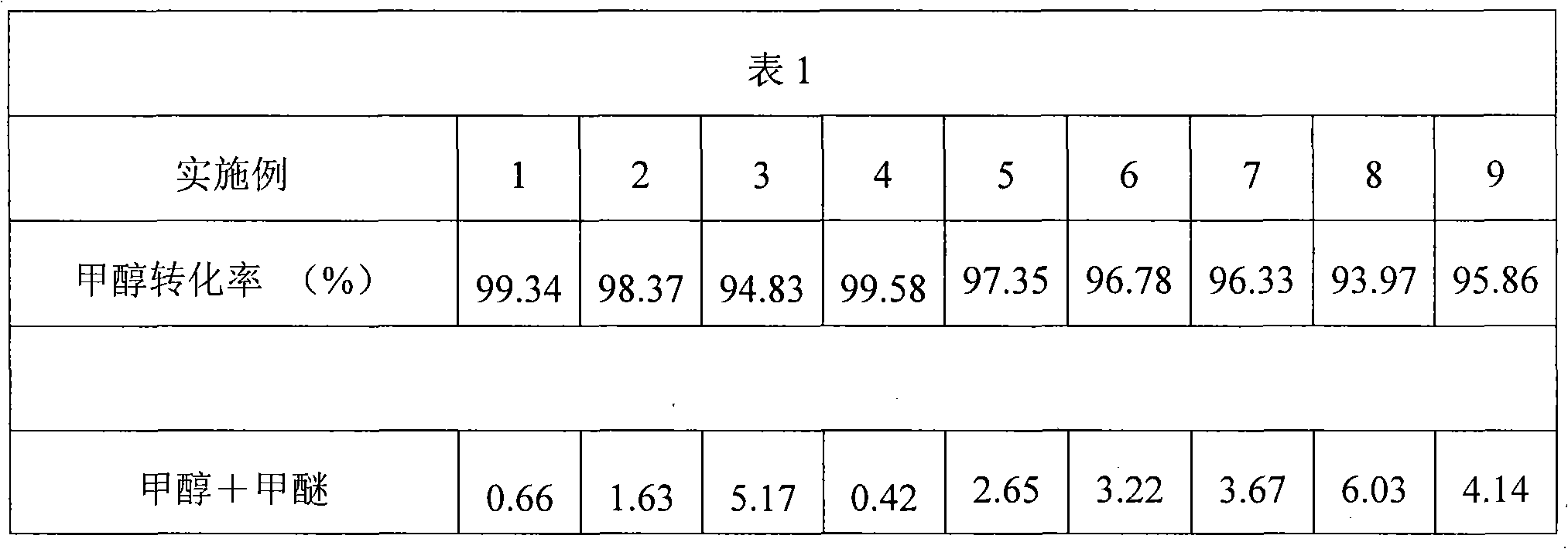

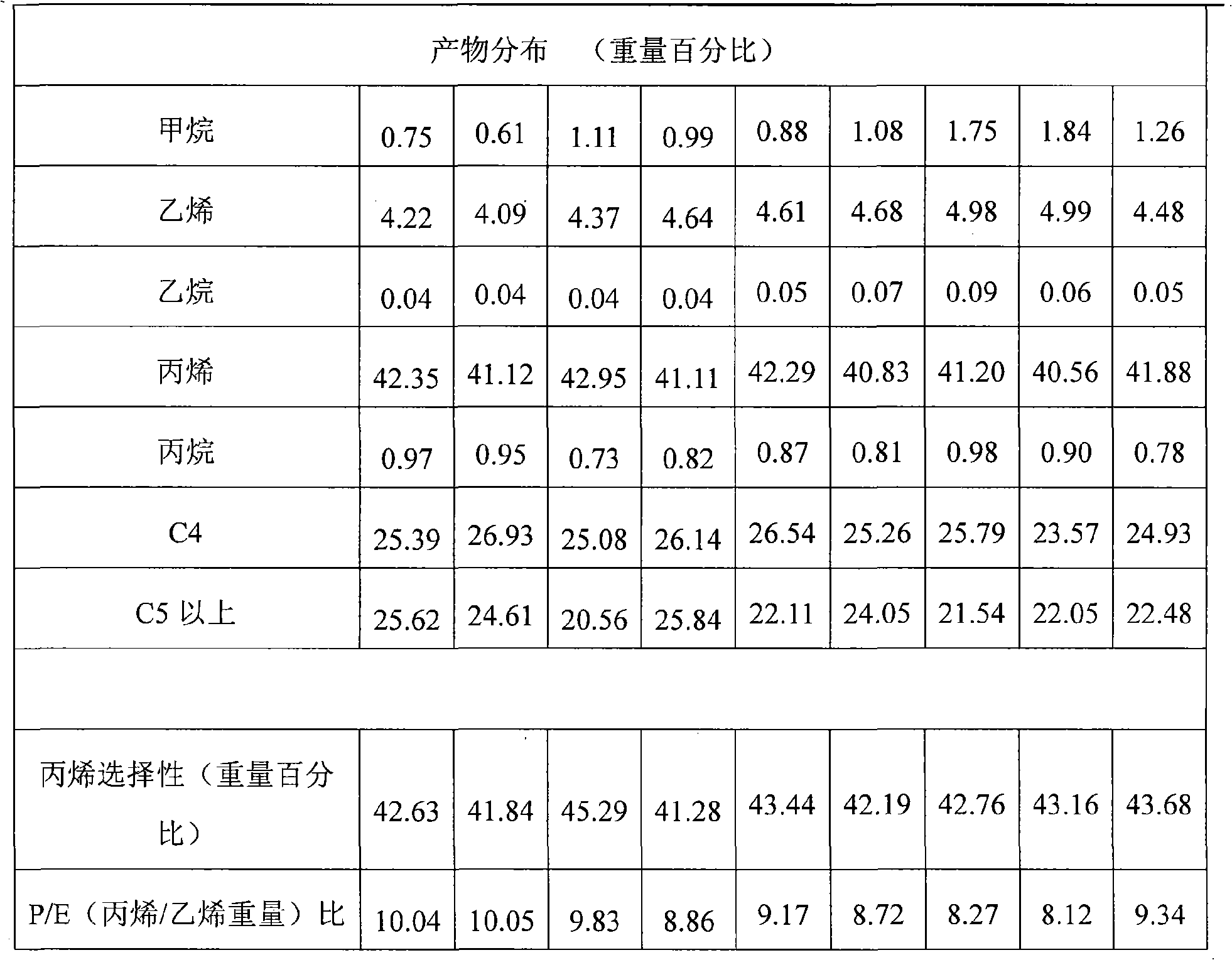

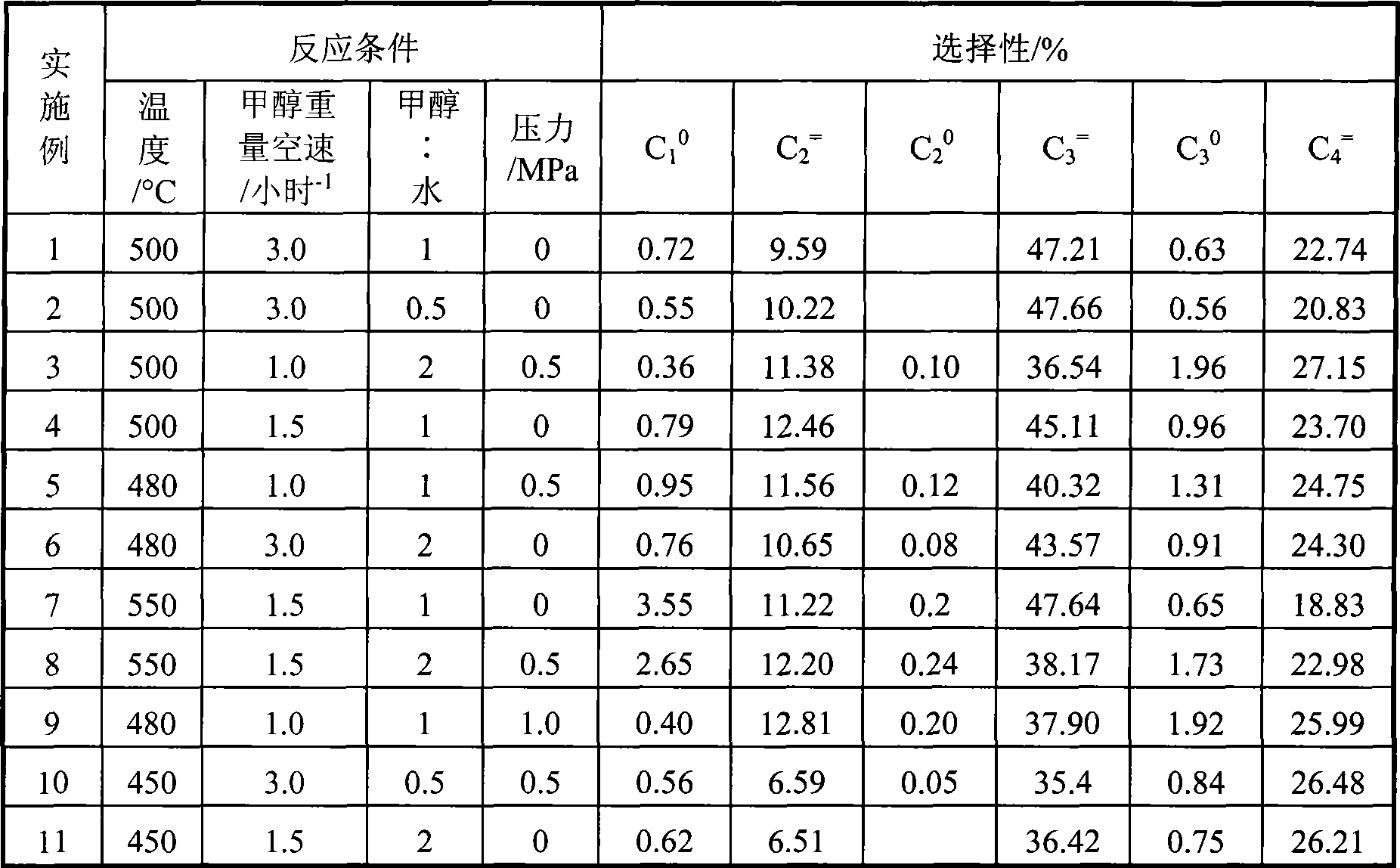

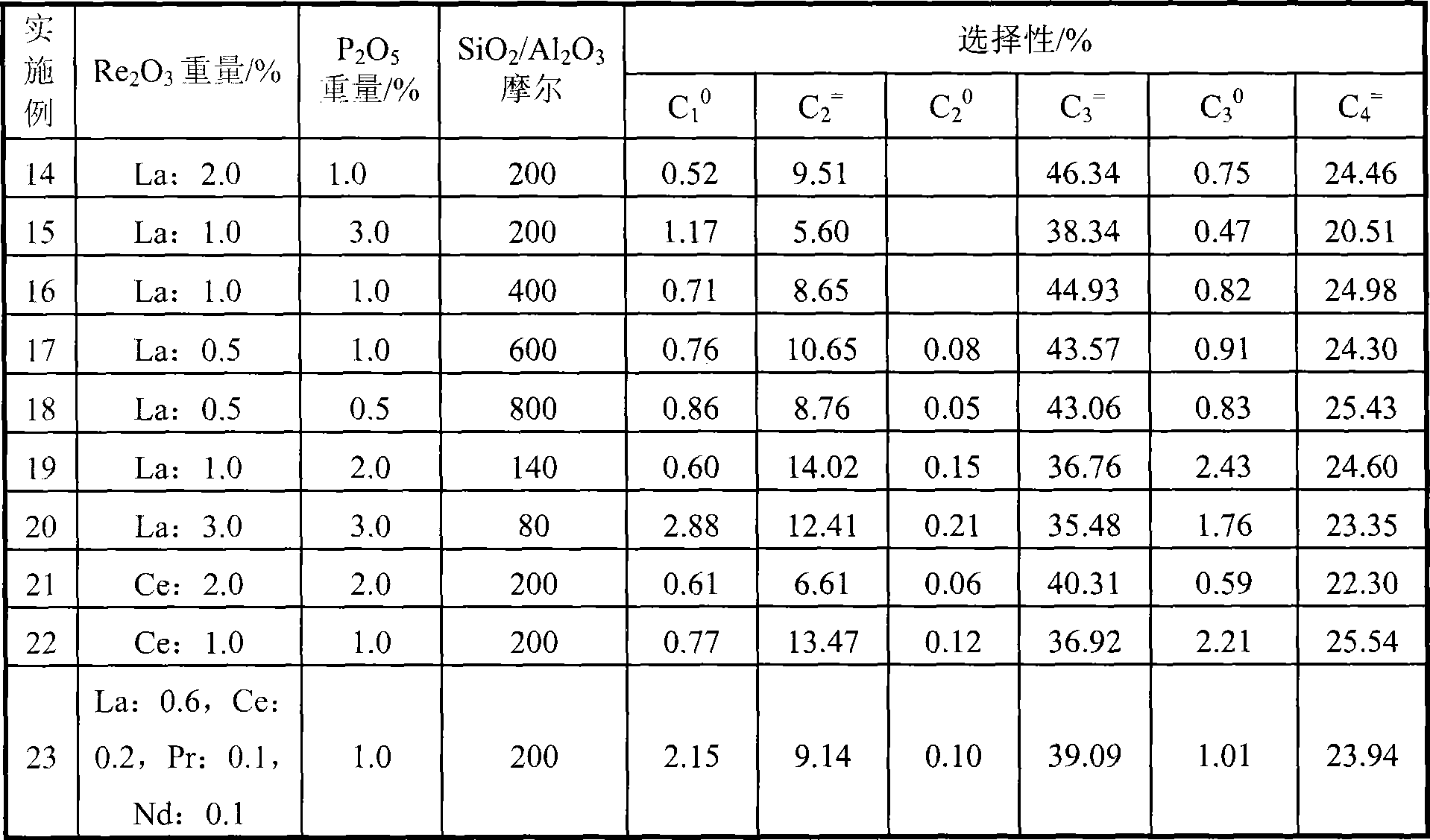

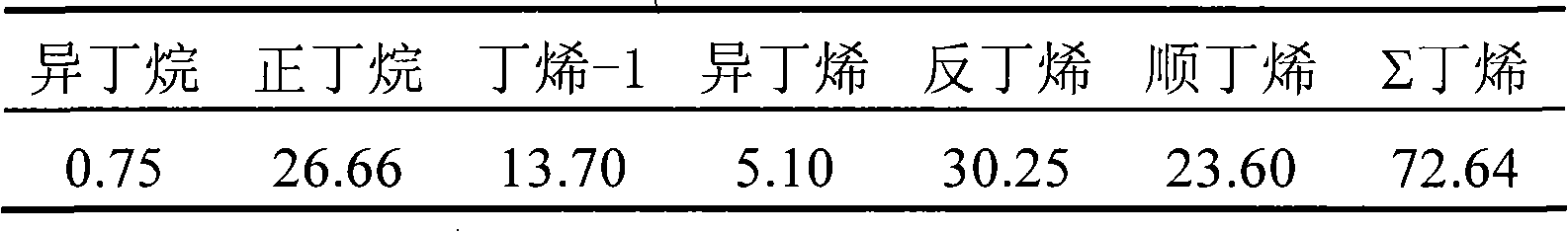

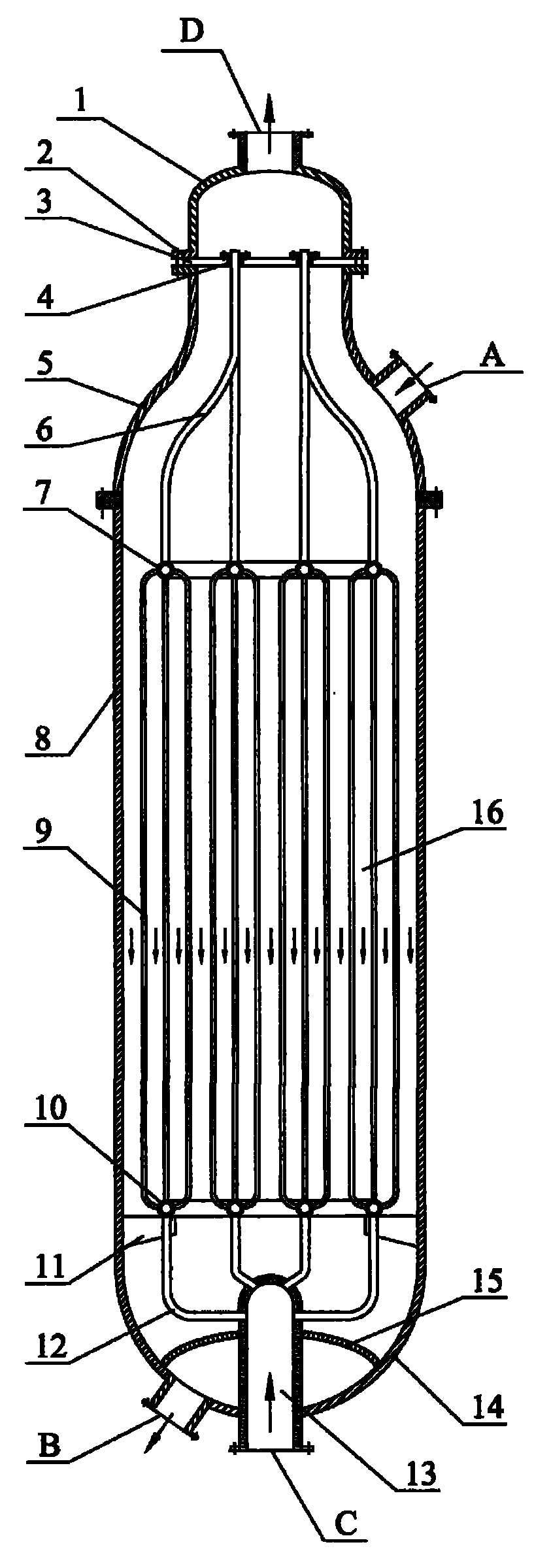

Method for preparing olefin by conversion of methanol

ActiveCN1704390AHigh selectivityImprove catalytic performanceHydrocarbon from oxygen organic compoundsEthylene productionMolecular sieveReaction temperature

The invention relates to a method for preparing olefin by conversion of methanol by using Zn-SAPO-34 molecular sieve and bonding agent as the catalyst for alkene production through methanol converstion, and employing a reaction temperature of 300-500 deg. C, a reaction pressure of atmospheric pressure, methanol weight space velocity of 1.0-10hr-1, the prepared low carbon alkene can be used in the industrial production of alkene from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

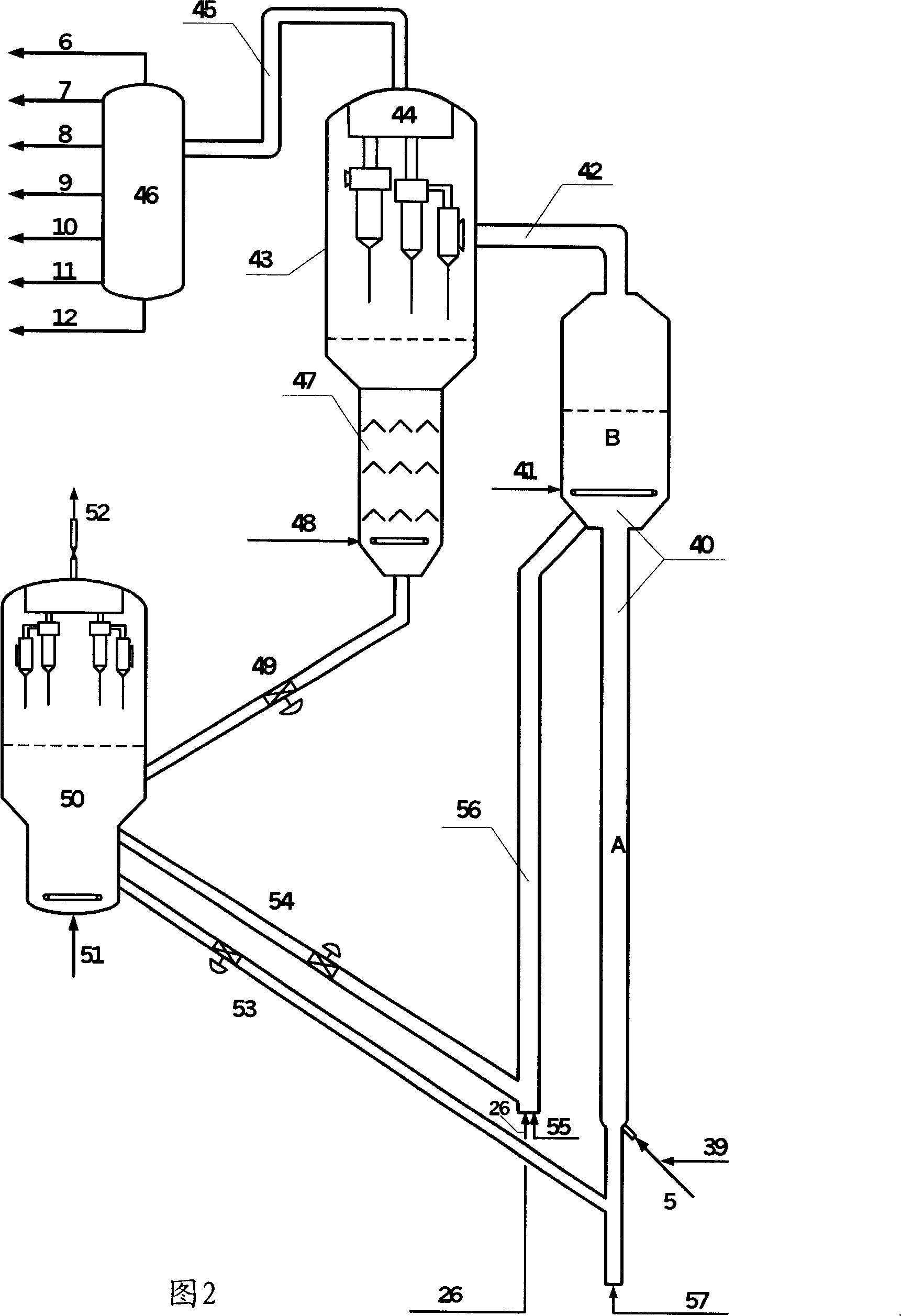

Production of low-carbon olefine and arene

A process of production of lower olefins and aromatics involves contacting the feeds with a catalytic pyrolyzing catalyst. There are at least two reaction zones, the temperature of at least one reaction zone in the downstream of the first reaction zone is higher than that of the first one, but the weight space velocity is lower. The oil gas after reaction is separated from the catalyst, and the catalyst is recycled to the reactor after regeneration. The oil gas is separated and the required products of lower olefins and aromatics are obtained. This process can acquire maximum lower olefins such as propylene, ethylene from the heavy feeds, and the yield of the propylene exceeds 20wt. %, at the same time, aromatics such as toluene, xylene is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

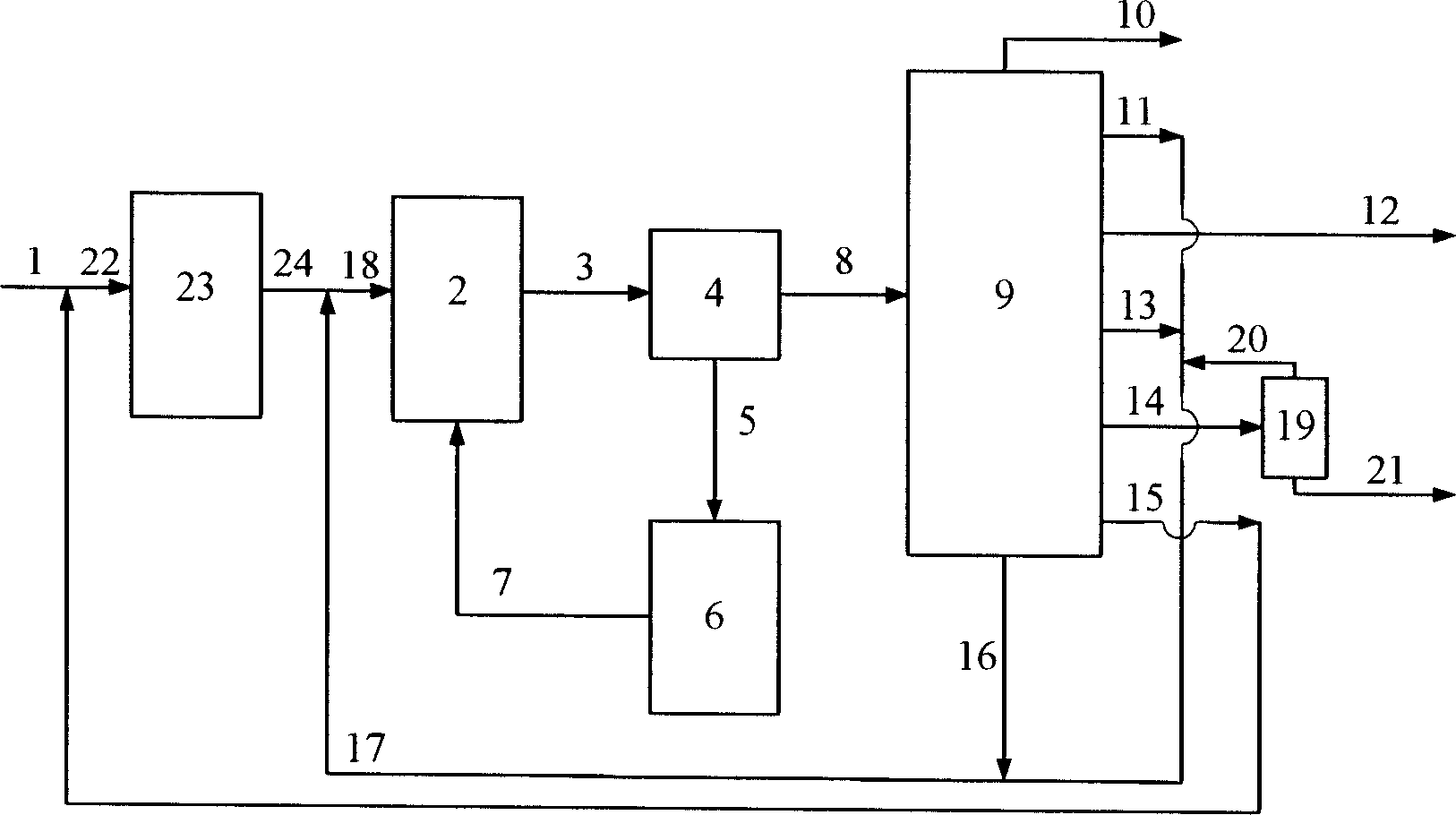

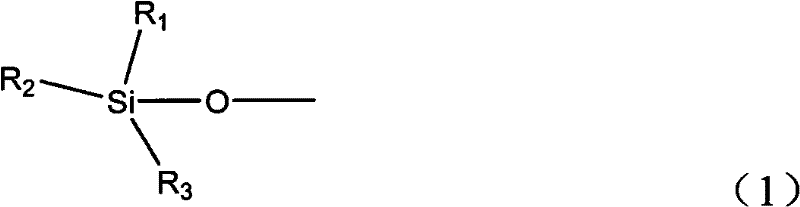

Method for preparing alcohols by selectively hydrogenating aldehydes

ActiveCN102408304AHigh selectivityHydrophobicOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSilanesReaction temperature

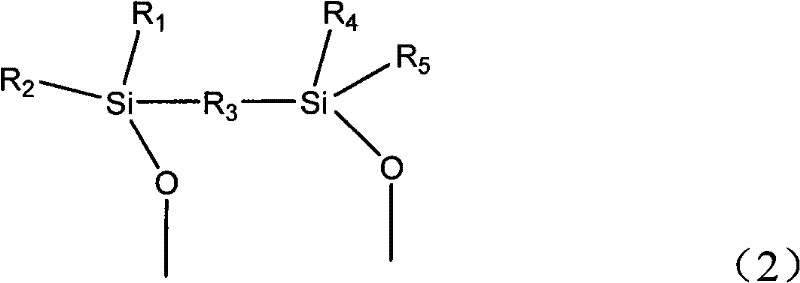

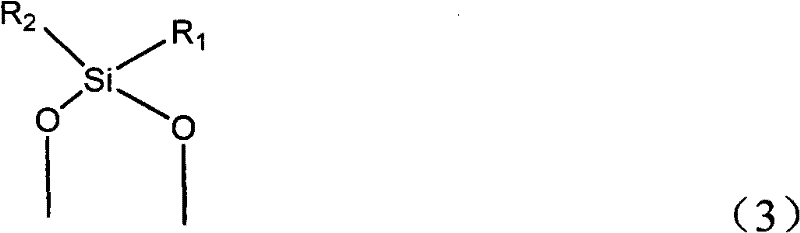

The invention relates to a method for preparing alcohols by selectively hydrogenating aldehydes, belonging to hydrogenation technologies. In order to meet the requirements of people on two aspects, i.e. the improving of the selectivity on preparing the alcohols by hydrogenating the aldehydes and the prolonging of the service life of a catalyst currently, the method proposes that: the aldehydes are taken as raw materials; the reaction temperature is 20-300 DEG C; the reaction pressure is 0.1-7.0 MPa; the weight space velocity of the aldehydes is 0.02-20 h<-1>; the aldehydes and hydrogen gas are in contact with a hydrogenation catalyst; and the aldehydes are produced into corresponding alcohols through selectively hydrogenating. In the method, the hydrogenation catalyst comprises a carrier, a metal active component and silane groups; the silane groups are grafted through a silylanizing treatment; and the content of the silane groups in the total weight of the catalyst is 0.05 wt% to 25 wt%. Compared with the existing method, with the adoption of the catalyst in the method provided by the invention, the selectivity is high, the amount of byproducts, such as ethers, esters and acetals is greatly lowered; and meanwhile, the generation amount of carbon deposit is little, so that the catalyst has longer service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving butene double bond isomerization reaction

ActiveCN101475432AHigh selectivityImprove technical effectHydrocarbon by isomerisationMolecular sieve catalystsButeneIsomerization

The invention relates to a method for improving reaction selectivity of isomerization of double bonds of butylene. The method mainly solves the problem of poor reaction selectivity in the prior art. Through a technical proposal that butylenes-1, butylenes-2 or a mixture which contains the butylenes-1 and butylenes-2 and does not meet a thermodynamic equilibrium value is used as a raw material; carbon-predeposited aluminosilicate is used as a catalyst, wherein the amount of predeposited carbon is 0.01 to 5 percent counted by the weight of the catalyst; and under the conditions of reaction temperature of between 50 and 480 DEG C, reaction pressure of between -0.08 and 10MPa and weight space velocity of between 0.1 and 100 hours<-1>, the raw material and the catalyst contact and have the isomerization reaction of the double bonds of the butylene to generate an effluent substance with the molar ratio of butylenes-1 to butylenes-2 close to the thermodynamic equilibrium value, and the method well solves the problems and can be applied to industrial production of isomerization of double bonds of butylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene and propylene by benzin naphtha catalytic pyrolysis

ActiveCN101279881AHigh yieldMolecular sieve catalystsBulk chemical productionCatalytic pyrolysisWater vapor

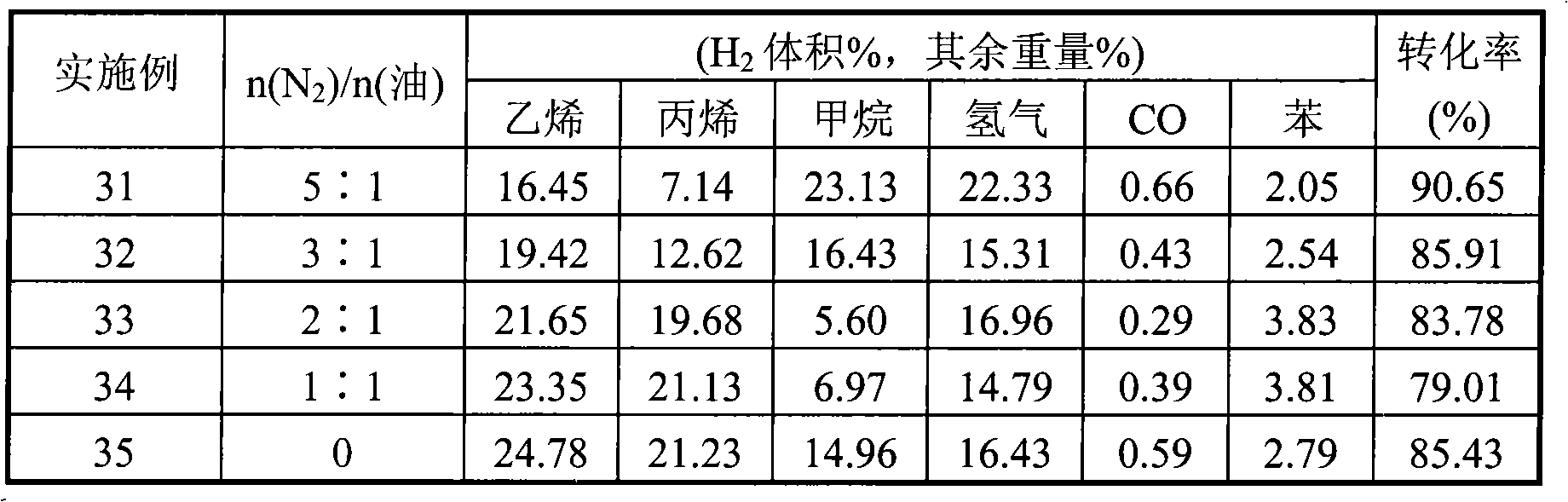

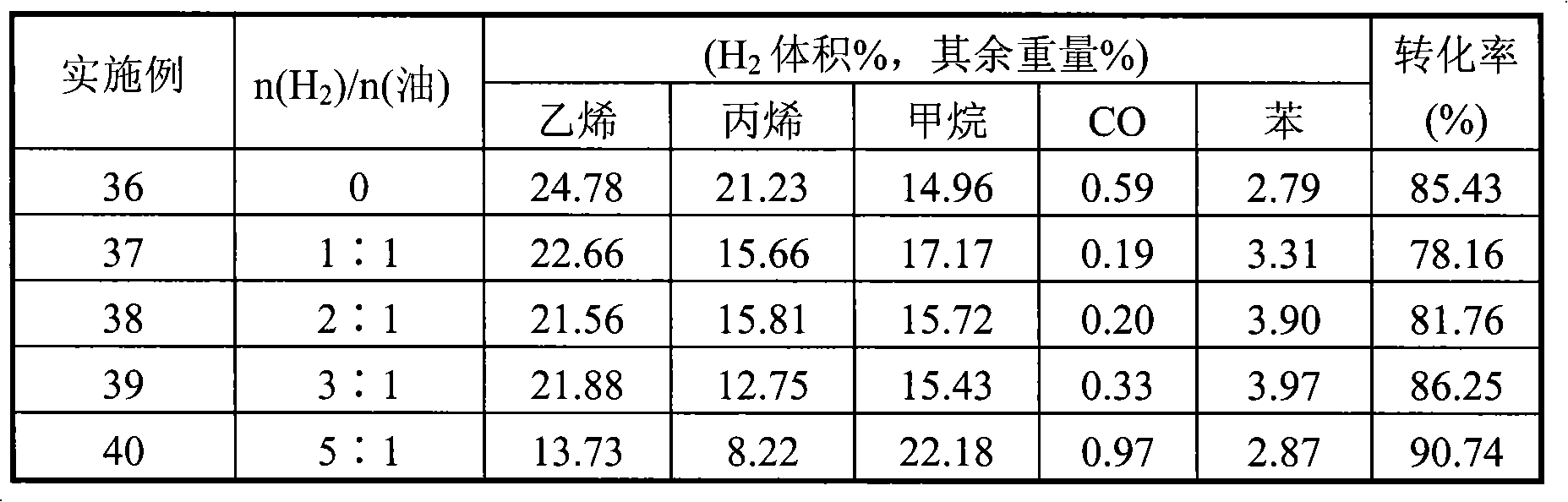

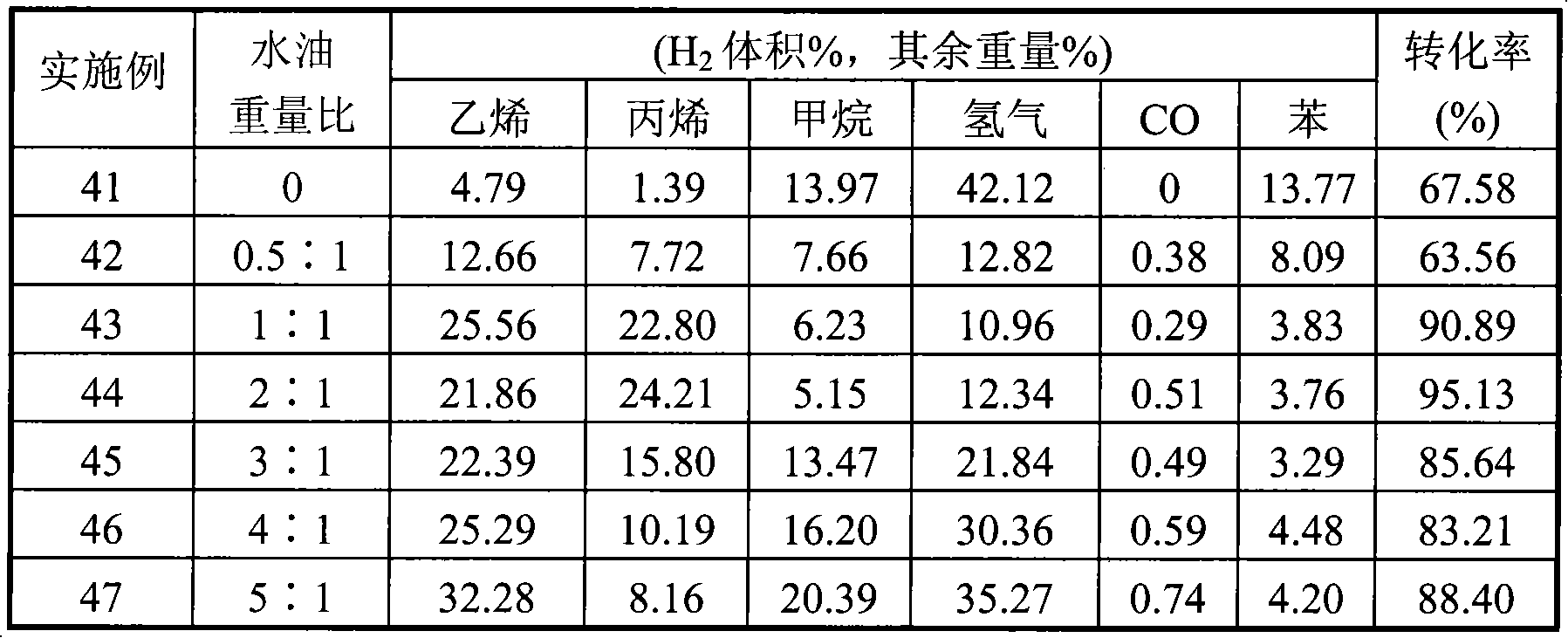

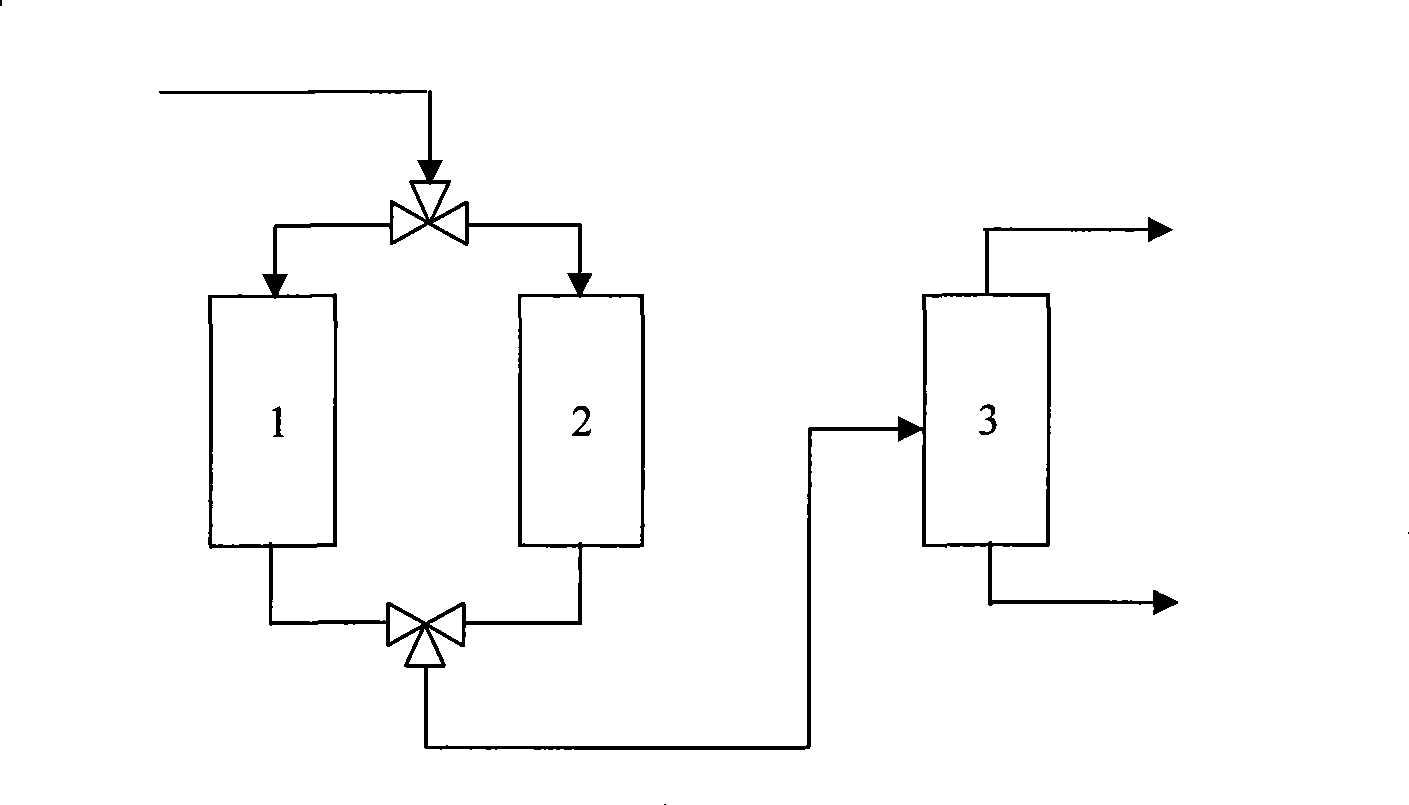

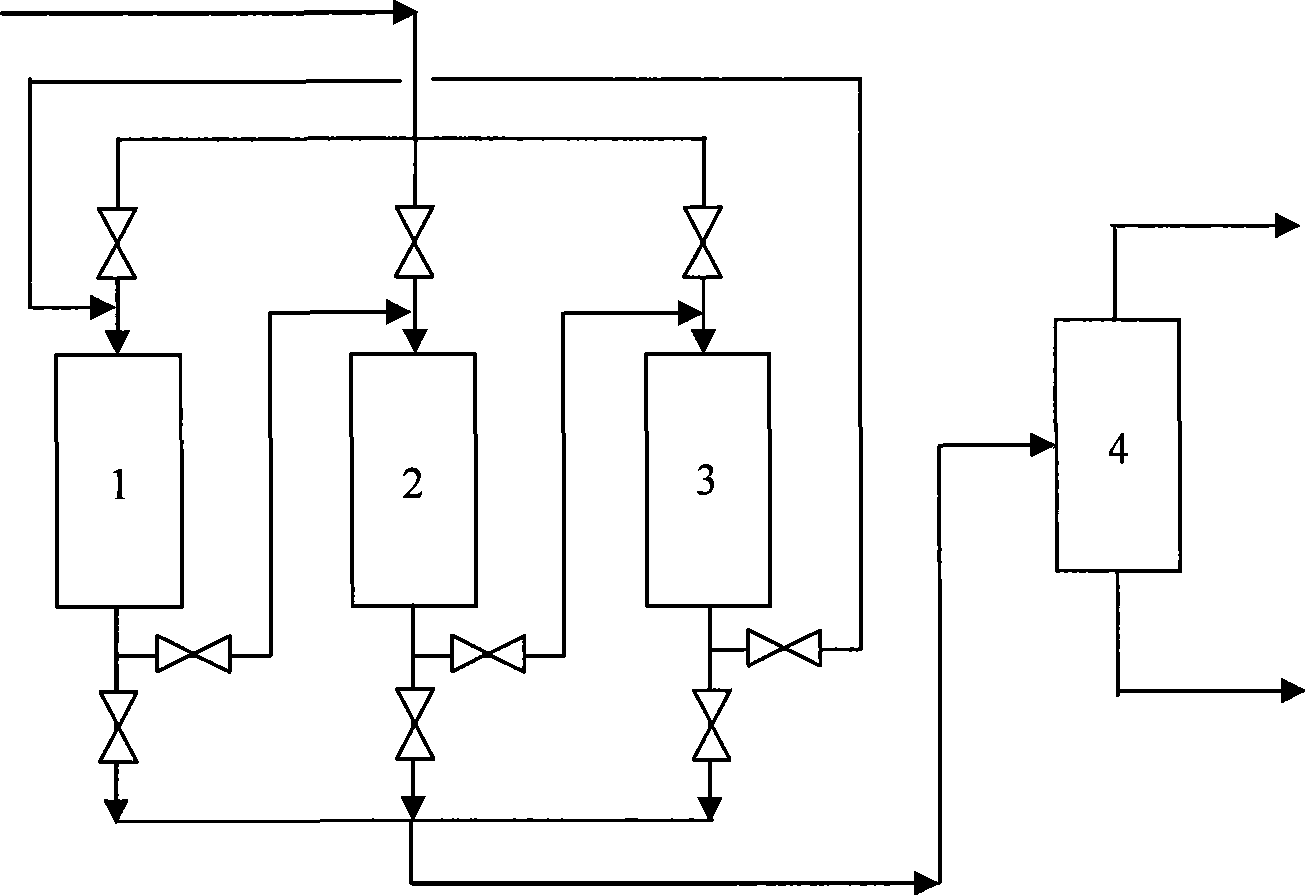

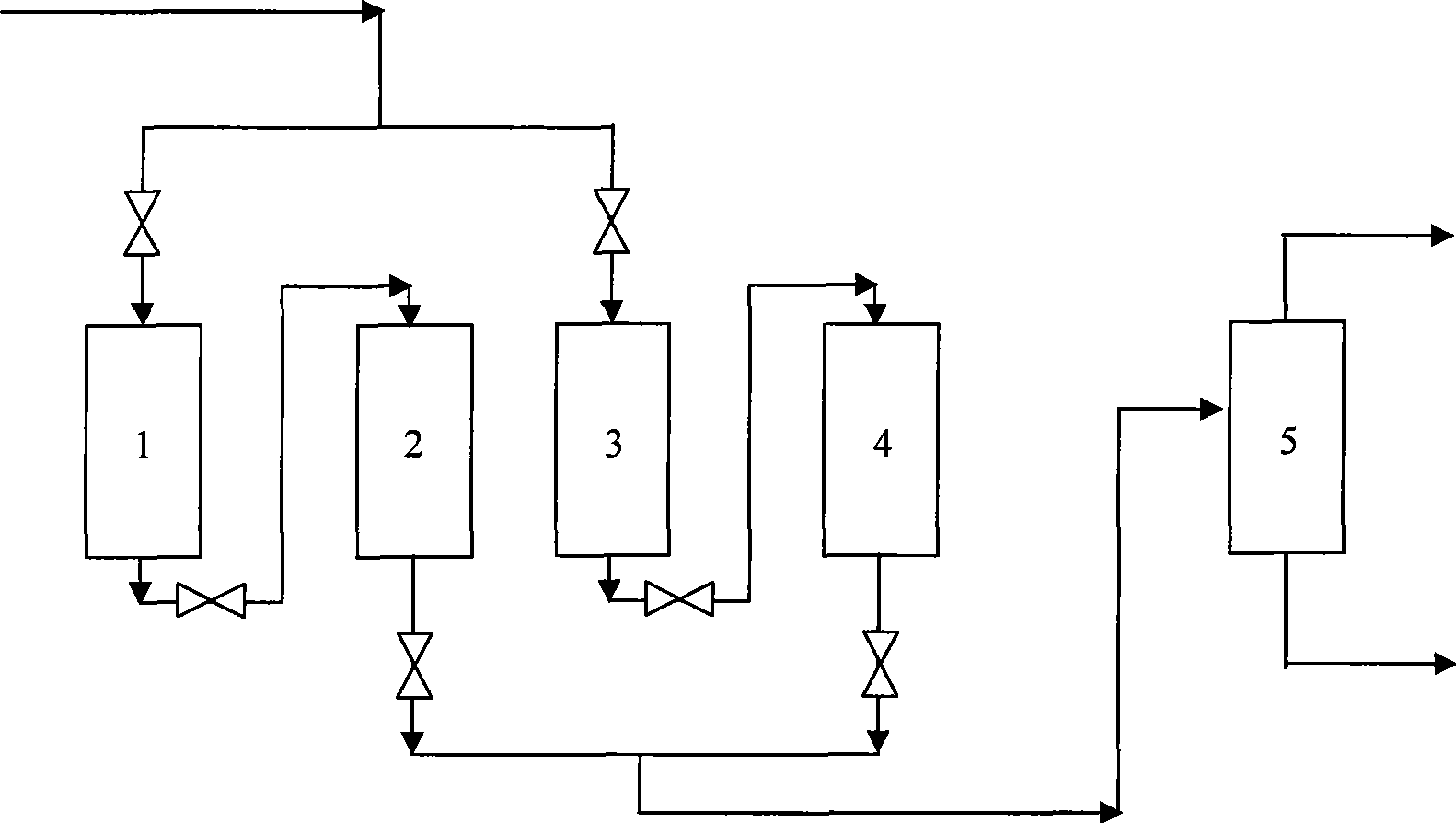

The invention relates to a method for producing ethylene propylene by catalytic cracking naphtha, which mainly solves the problems of short service life caused by coking of the catalyst and high consumption of vapor in the reaction of ethylene propylene preparation by catalytic cracking the naphtha. The invention properly solves the problems by adopting the technical proposals that: a naphtha of C4 to C10 hydrocarbon is taken as a raw material, the material hydrocarbon is firstly mixed with a gas inert to reaction after the vaporization, wherein the inert gas and the naphtha are present in a mole ratio of more than 0-5.0: 1, the material mixed gas contacts with a catalyst to generate an ethylene propylene under the conditions of a reaction temperature of between 580 and 750 DEG C, a pressure gauge reaction pressure of more than 0 to 0.5MPa, a weight space velocity of between 0.5 and 3 / h, and water / naphtha being present in a weight ratio of 0-5: 1, wherein the adopted catalyst is selected from at least one of ZSM-5 / mordenite intergrown molecular sieve, ZSM-5 / zeolite beta intergrown molecular sieve or ZSM-5 / zeolite Y intergrown molecular sieve, and the method of preparation can be used for the industrial production of preparing the ethylene propylene by catalytic cracking the naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high-octane gasoline

ActiveCN101429452AReduce gasoline olefin contentHigh aromatic contentCatalytic naphtha reformingRare-earth elementSimulated moving bed

The invention provides a method for producing high octane gasoline by aromatization reaction of a mixed raw material of catalytic gasoline and C4, and catalyst on an aromatization reactor after the mixed raw material contacts the catalyst. The method is as follows: the catalytic gasoline is mixed with the C4 olefin, and the mixed raw material enters into a fixed bed aromatization reactor or a simulated moving bed aromatization reactor which is filled with the molecular sieve catalyst, contacts the aromatizing catalyst, and undergoes olefin aromatization reaction, wherein the reaction conditions are as follows: the reaction temperature is between 250 and 340 DEG C; the pressure is between 0.5 and 3.0 MPa; the weight space velocity is between 0.5 and 10h<-1>; the mass ratio of the C4 olefin to the catalytic gasoline is between 90 to 10 and 2 to 98; and active ingredients of a molecular sieve carrier of the catalyst are one or more than one among rare earth element, No. 4B element and No. 8 element, and the weight of the active ingredients is 0.01 to 10 percent of that of the carrier. The method can obviously reduce the olefin content of the raw gasoline, effectively improve the octane number, and achieve the aim of production of the clean high-octane gasoline.

Owner:PETROCHINA CO LTD

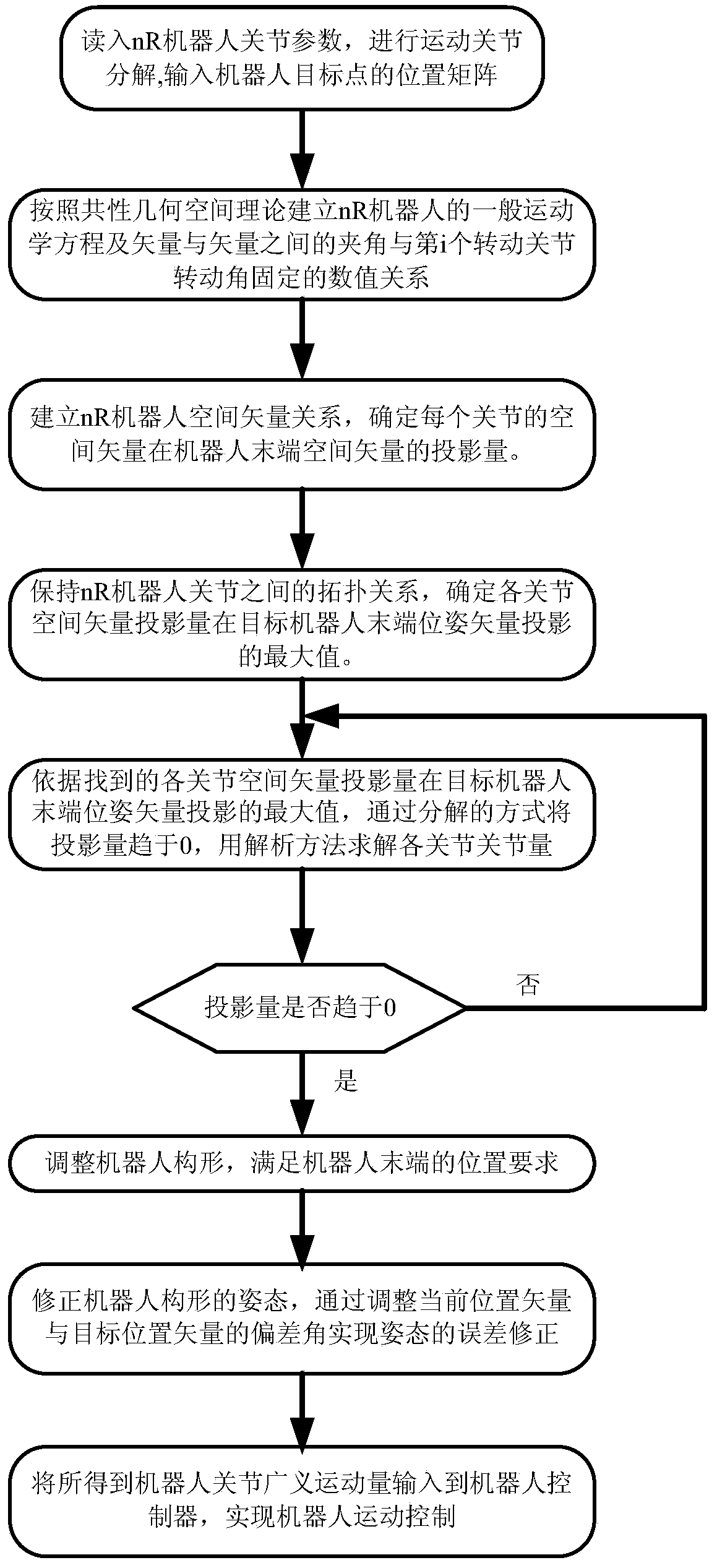

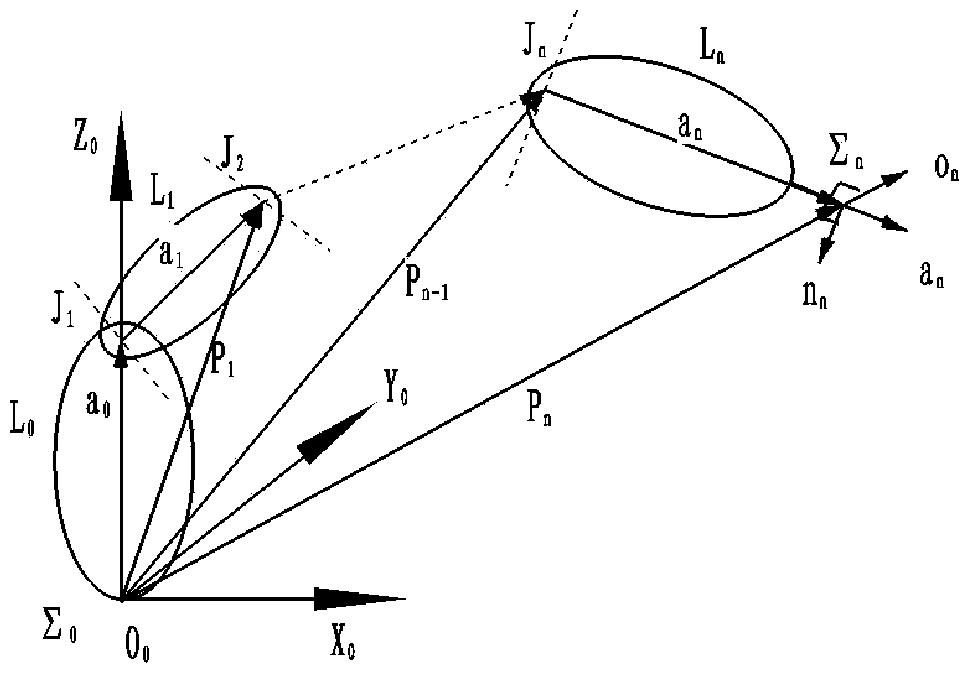

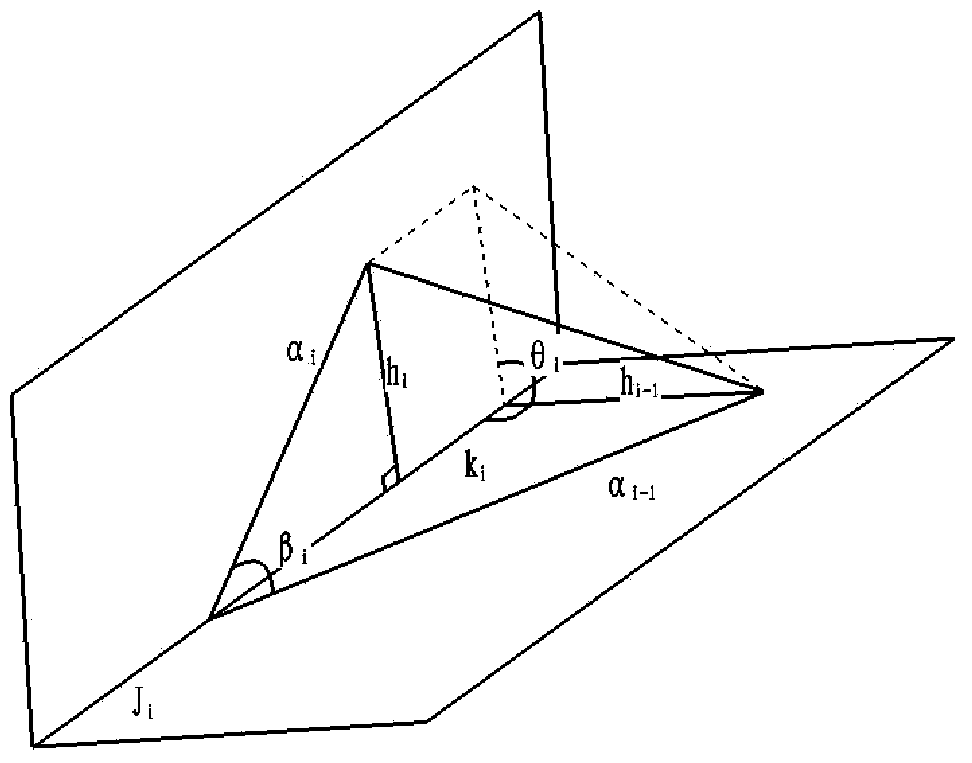

Inverse-kinematics universal solving method of robot with multi-degree of freedom

InactiveCN103901898AOvercome limitationsOvercoming real-timePosition/direction controlWeighted spaceKinematics equations

The invention provides an inverse-kinematics universal solving method of a robot with multi-degree of freedom. The common space theory is used for setting a universal kinematical equation of an nR robot, the weighted space vector projection method is used for analyzing the relationship between space vector projection values and revolute joint angles of a space robot, projection weighted values of joint vectors on robot tail end vectors are used as the basis for regulating the tail end pose of the robot, and projection weighted values of joint vectors are determined to achieve half-analytic solution of the inverse kinematics. The method achieves kinematical salvation of the nR robot and also finishes the space obstacle avoidance task. The method can be widely applied to series type space nR robots, has the advantages of being high in calculation speed and high in solving precision, provides control input parameters for series type robots, and meets the requirement for robot kinematics solving operation on industrial sites.

Owner:HARBIN ENG UNIV

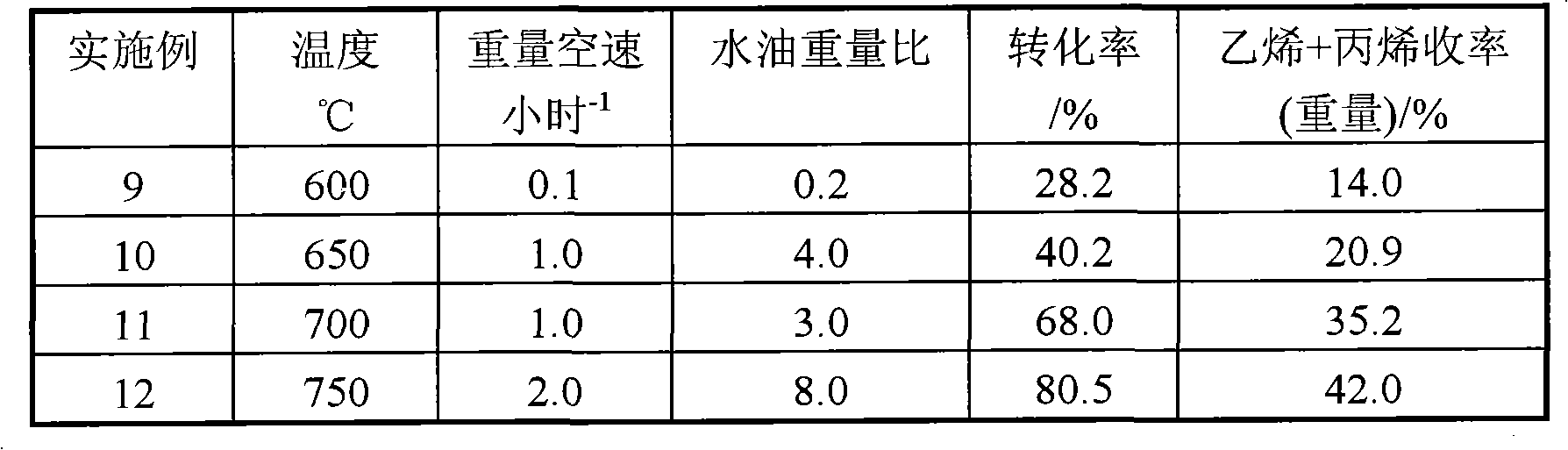

Method for preparing light olefins through fluid catalytic cracking of naphtha

ActiveCN102372555AHigh selectivityHigh yieldMolecular sieve catalystsBulk chemical productionAlkaline earth metalRare earth

The invention relates to a method for preparing light olefins through the fluid catalytic cracking of naphtha and mainly solves the technical problems of the existing catalytic cracking method such as low conversation rate of naphtha and low yields of ethylene and propylene. The method uses naphtha and water as raw materials and comprises the following step: contacting the raw materials and a catalyst under the conditions that the temperature is 600-750 DEG C, the weight space velocity is 0.1-2.0h<-1> and the weight ratio of water to oil is 0.2-8.0:1, to react and obtain ethylene and propylene, wherein the catalyst comprises the following components by weight percent: 15.0-60.0% of kaolin, 10.0-30.0% of at least one of silicon oxide and aluminum oxide, 0.5-15% of at least one of phosphorus and rare earth oxide or alkaline earth metal oxide and 25.0-70.0% of 200-1000nm of ZSM-5 zeolite. The technical scheme in the invention better solves the problems and can be used in the catalytic cracking industrial production for preparing ethylene and propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene glycol

ActiveCN101475443AImprove technical effectOrganic compound preparationHydroxy compound preparationOxalateHydrogen

The invention relates to a method for producing glycol, which mainly solves the problem that catalysts in the prior art are poor in stability and short in regeneration period. By adopting a technical proposal of taking oxalate as raw material, taking polar or nonpolar solvent as thinner and allowing the raw material to be in contact with and react with a copper-bearing catalyst so as to form glycol-containing effluent at a temperature between 120 and 300 DEG C, at a weight space velocity between 0.01 and 10 hours, with the hydrogen / ester molar ratio of 5-300:1, under the reaction pressure between 0.1 and 10.0 MPa, under the condition that the mass fraction of the oxalate is between 0.1 and 100 percent, the method solves the problem well, and can be used in the industrial production of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

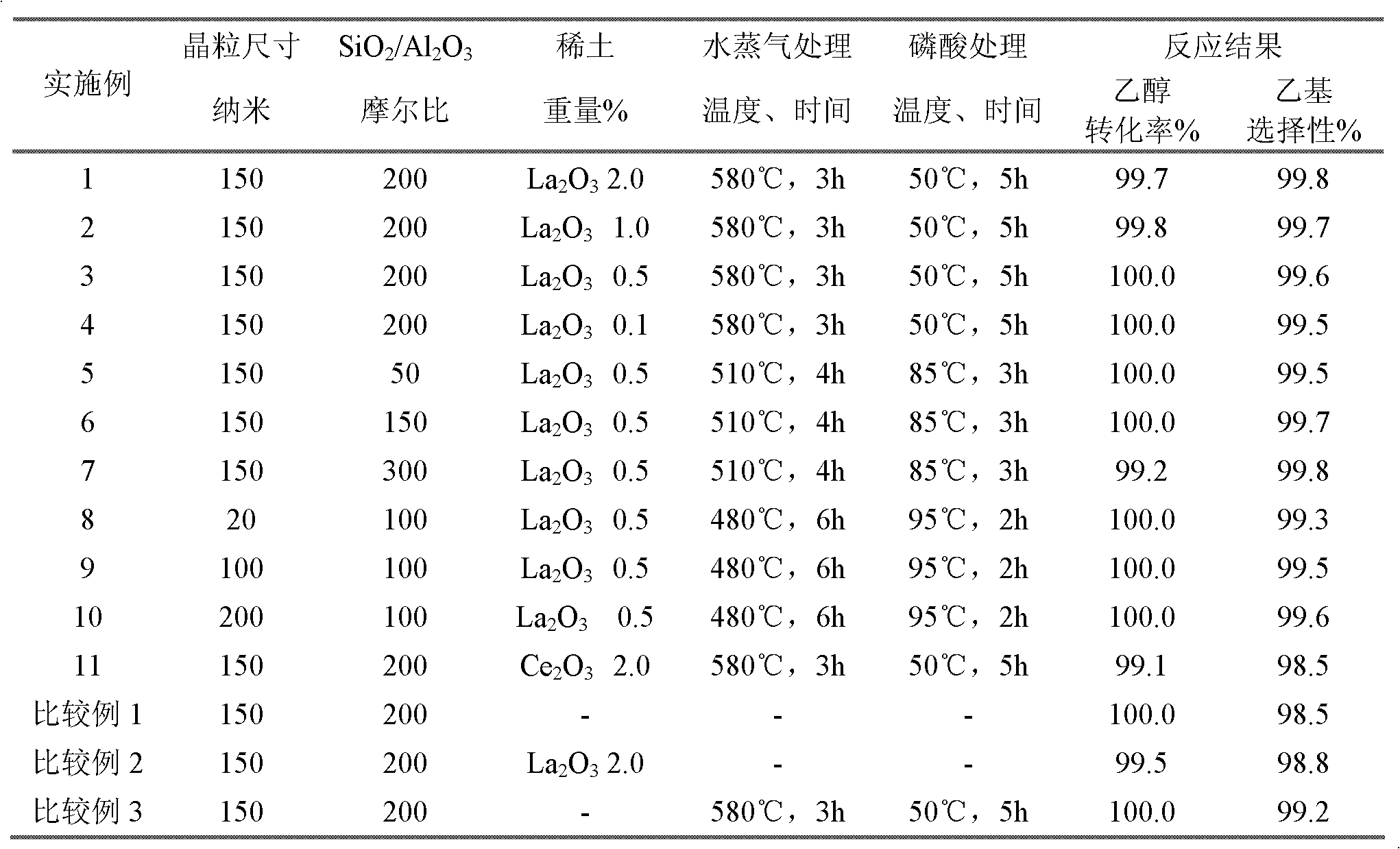

Process for producing catalyst for producing propylene with methanol

InactiveCN101402049AReduced Diffusion Path LengthImprove diffusivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsReaction temperaturePhosphoric acid

The invention relates to a catalyst for preparing propylene from methanol and a method for preparing the same, which mainly solve the problems that in the prior art, the objective product propylene has low yield and the ratio of P / E (mass ratio of the propylene to ethylene) is low. The method adopts a technical proposal in which small-grain high silicon ZSM-5 zeolite synthesized in an extremely-dense system is used, and an inorganic acid selected from nitric acid, hydrochloric acid, phosphoric acid or sulfuric acid is adopted for exchange and calcination to prepare obtain the required catalyst, and the technical proposal better solves the problems. The obtained catalyst has partial pressure of 50 kPa in the methanol and reaction temperature of 470 DEG C; under the condition that the weight space velocity of the methanol is 1, the yield of the propylene reaches 42 weight percent, and the weight ratio of the propylene to the ethylene reaches more than 8, thus the catalyst can be used in the industrial production of preparing the propylene from the methanol.

Owner:CHINA ENERGY GRP NINGXIA COAL IND CO LTD +1

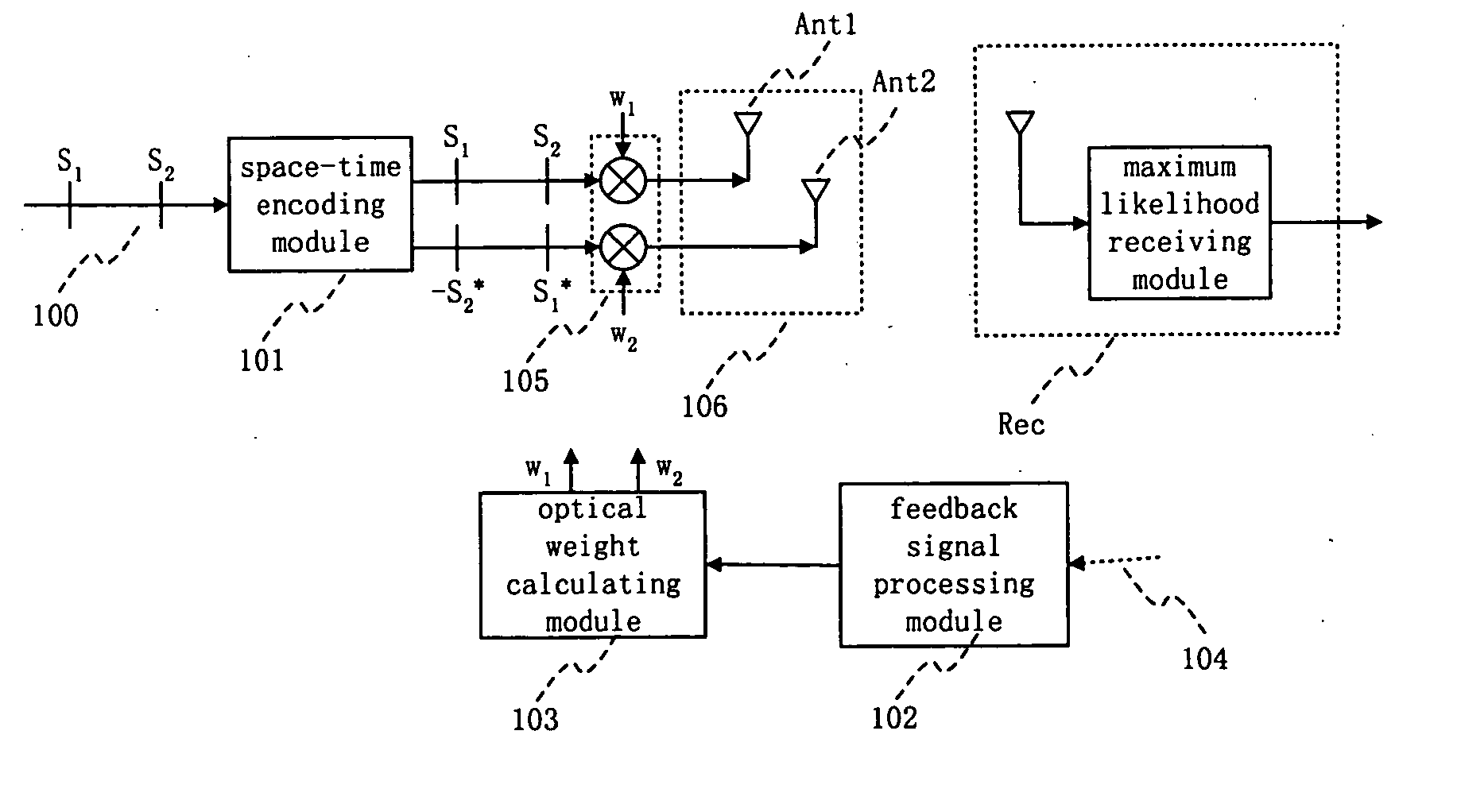

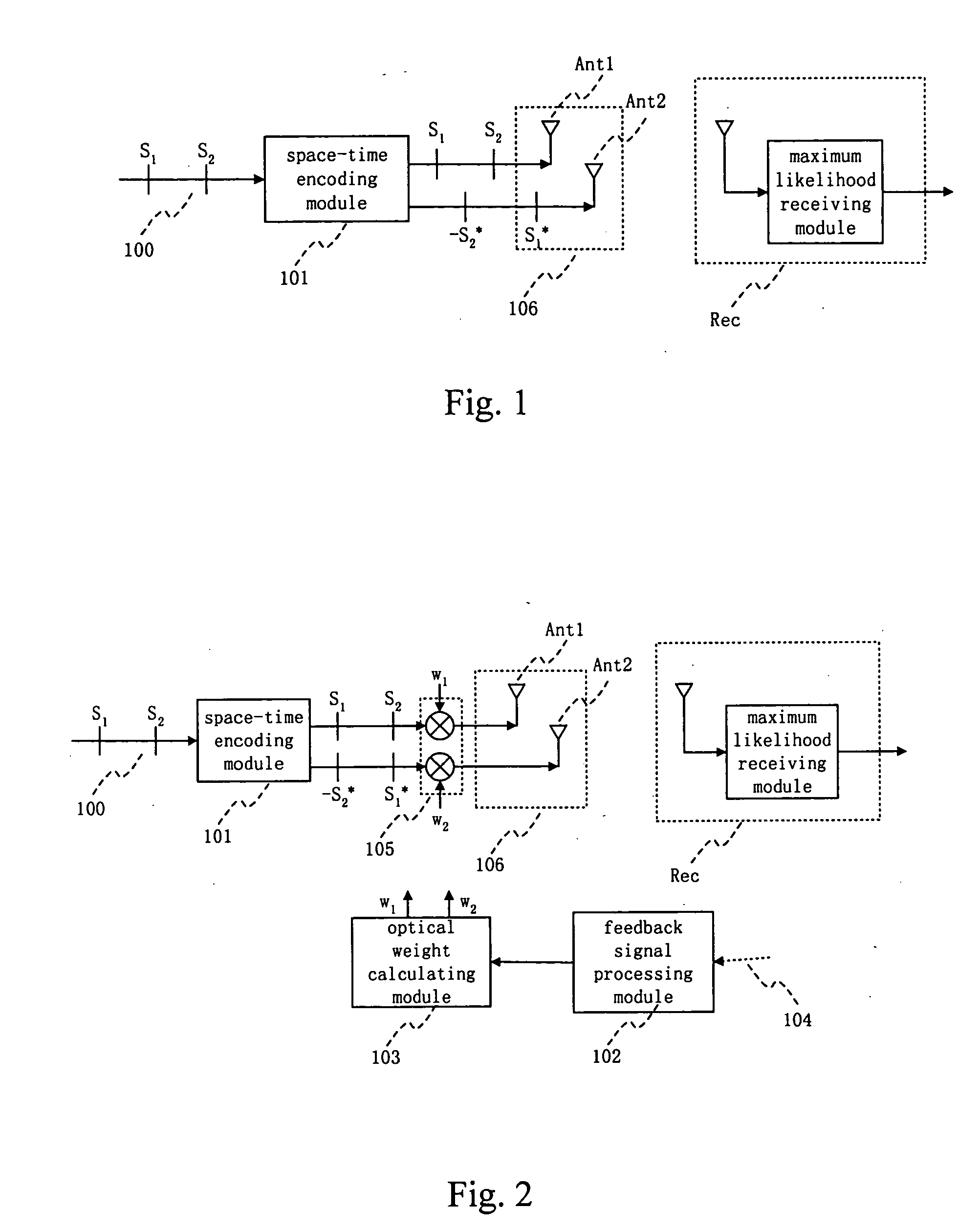

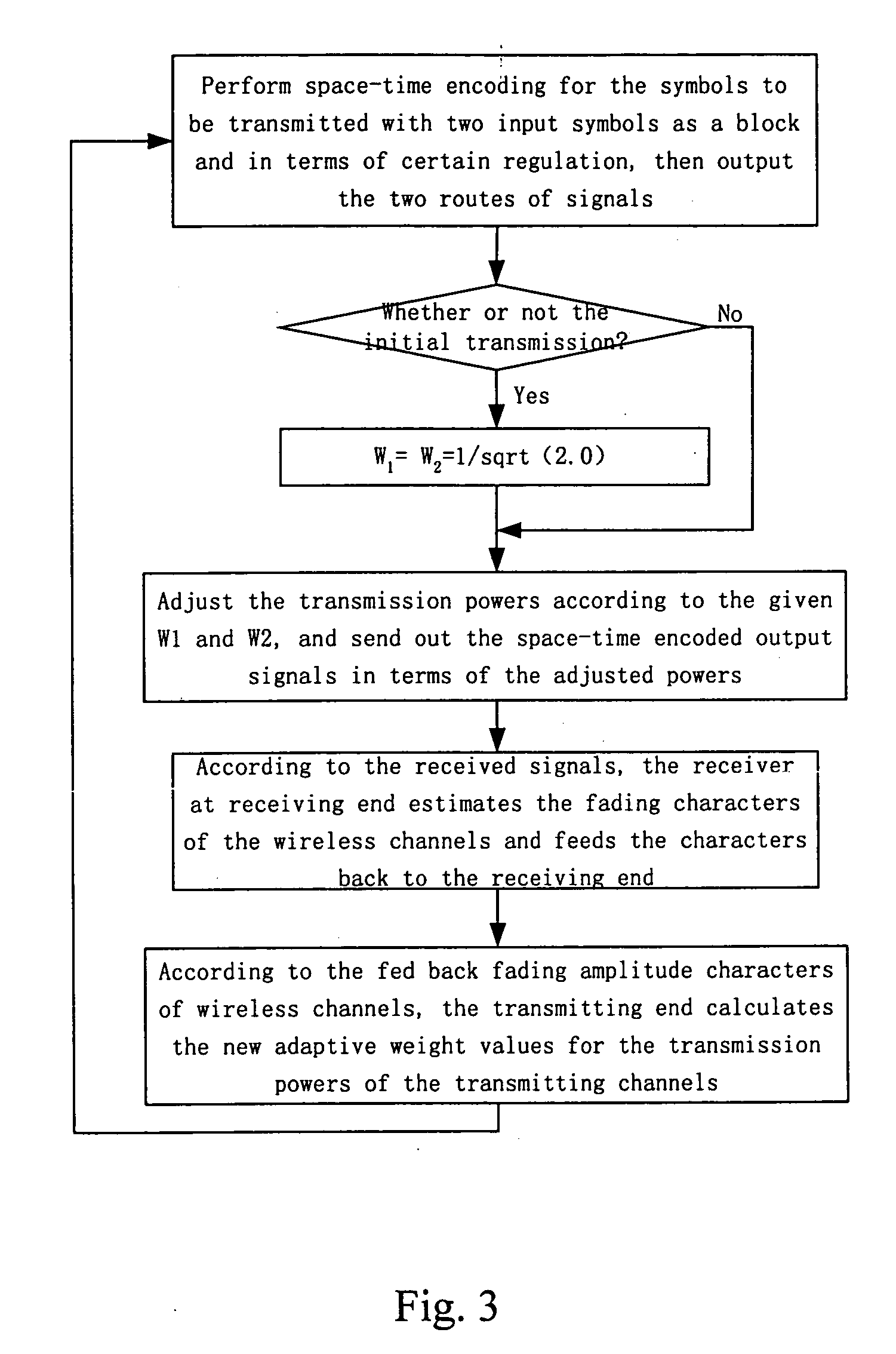

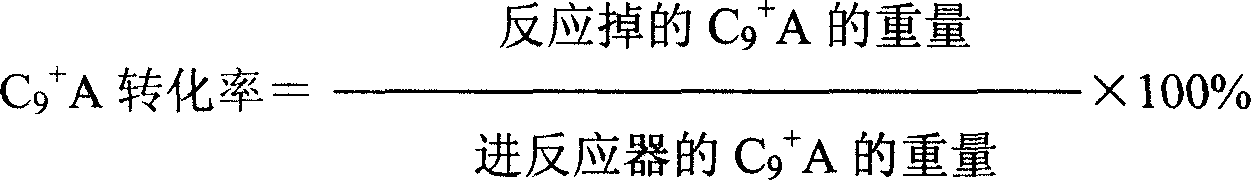

Self & minus; adaptive weighted space time transmitting diversity method and system thereof

InactiveUS20050181736A1Improve system performanceEasily flexiblePower managementResonant long antennasSpace time transmit diversityWeighted space

The present invention discloses a method of adaptive weighting space-time transmit diversity, comprising: symbols to be transmitted at a transmitting end being output after being space-time encoded according to certain regulation, and the current transmission powers of the two antennae being real-timely adjusted according to the given transmission power weight values; after the transmission powers are determined, the space-time encoded output signals being sent out at two independent antennas by transmitting antenna array in terms of the current transmission power; the fading characters of two wireless channels being estimated by the receiver at a receiving end according to the present received signals and then fed back to the transmitting end; the transmitting end receiving and obtaining the fading amplitude characters of two wireless channels through feedback channel, calculating new adaptive weight values of transmission powers, and adjusting transmission powers according to these weight values. The present invention also discloses a system for implementing the above method of adaptive weighting Space-time Transmit Diversity. In term of the method and structure, the transmission powers can be dynamically adjusted in adaptive weighting manner, in order to boost system performance gain.

Owner:HUAWEI TECH CO LTD

Selective hydrogenation method for phenylacetylene in the presence of phenylethylene

ActiveCN101475438AMolecular sieve catalystsHydrocarbon by hydrogenationLoss rateReaction temperature

The invention relates to a method for selective hydrogenation of phenylacetylene in the presence of styrene, which mainly solves the problem of high loss rate of the styrene in the prior art. The method adopts a technical proposal that hydrocarbon fractions containing the phenylacetylene are taken as raw materials, the raw materials are contacted with carbonic oxide catalyst under the condition that the reaction temperature is between 15 and 100 DEG C, the weight space velocity is between 0.01 and 100 h, the mol ratio of hydrogen to the phenylacetylene is 1-30:1, and the reaction pressure is between -0.08 and 5.0 MPa, the phenylacetylene in reaction effluent is hydrogenated into styrene, wherein carbon content in the carbonic oxide catalyst is between 0.02 and 8 in percentage by weight. The method better solves the problem, and can be applied in industrial production for removing the phenylacetylene by hydrogenation in the presence of the styrene.

Owner:CHINA PETROLEUM & CHEM CORP +1

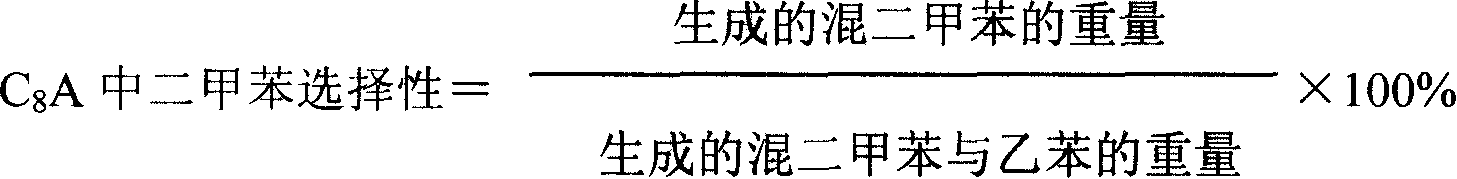

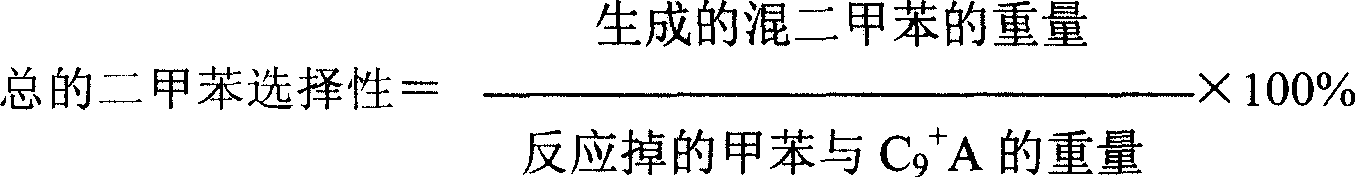

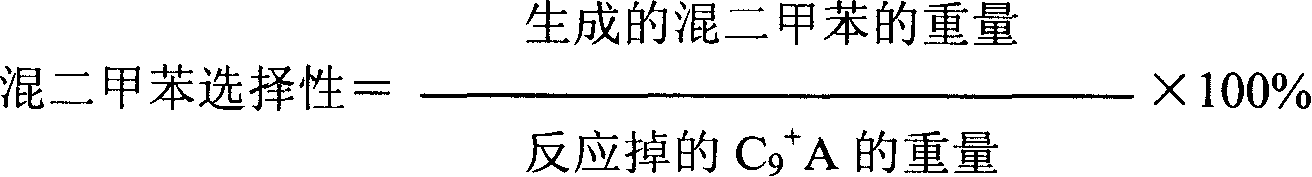

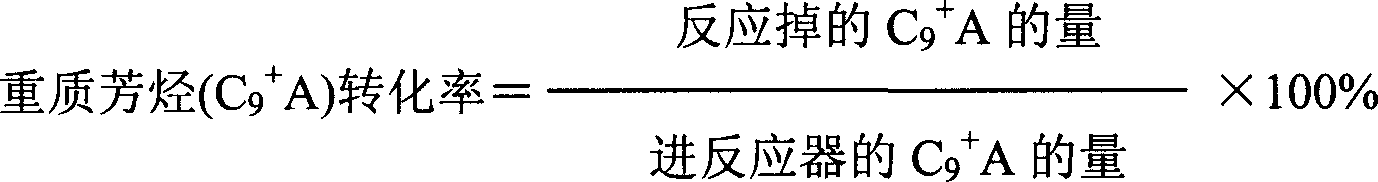

High selectivity arene alkyl transfer and dealkylation xylol production increase reaction method

ActiveCN101172924AImprove efficiencyHigh selectivityMolecular sieve catalystsHydrocarbonsSide chainReaction temperature

The invention relates to a reaction method for transferring high selectivity alkyl aromatic hydrocarbon and increasing the yield of xylene through dealkylation. The invention mainly solves the problems that the reaction product has high content of by-product of phenylethane, thereby causing that the xylene of compound C6 product has low selectivity, and has no selection to the dealkylation of lateral chain alkyl aromatic hydrocarbon in the prior art. The invention has the technical proposal that the catalyst is made of 40 to 90 proportions of hydrogen zeolite with the SiO2AL2O3 mole ratio of 12 to 70, 10 to 60 proportions of adhesive agent, oxide which is selected from at least one of molybdenum, palladium or nickel, zeolite which is selected from at least one of iron, bismuth, stannum ormolybdenum and oxide which is selected from at least one of lanthanum, cerium, magnesium or titanuium; the xylene product is generated through a catalytic reaction at the weight space velocity of 1.0to 3.5 hours<-1>, the reaction temperature of 350 to 460 DEG C, the reaction pressure of 1.5 to 3.5 MPa and the hydrogen-hydrocarbon molecule rate of 2.0 to 8.0. The invention preferably solves the technical problems mentioned above, and the invention can be applied to the industrial production of transferring C9 and more than C9 heavy aromatic hydrocarbon and toluol alkyl and the dealkylation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

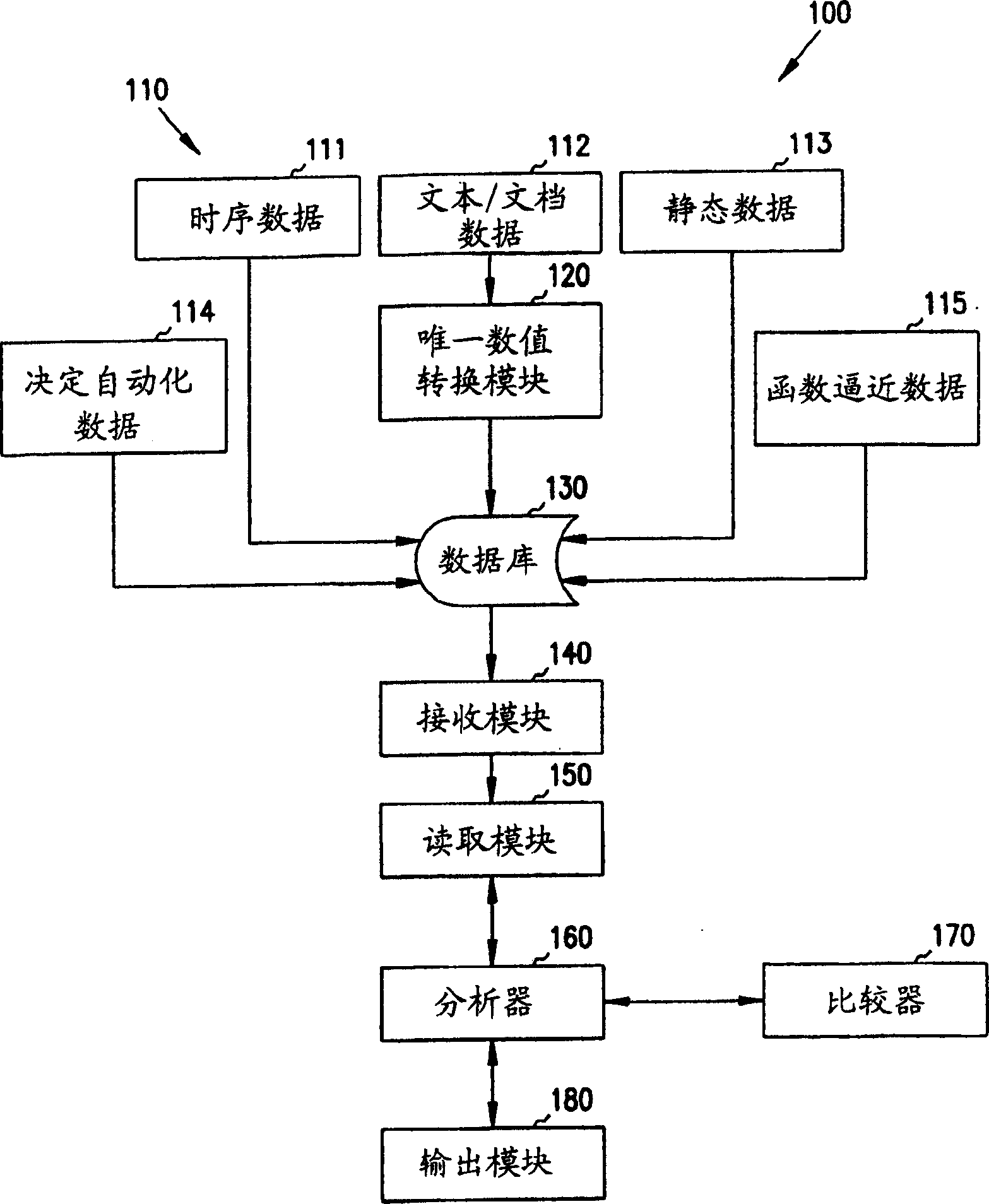

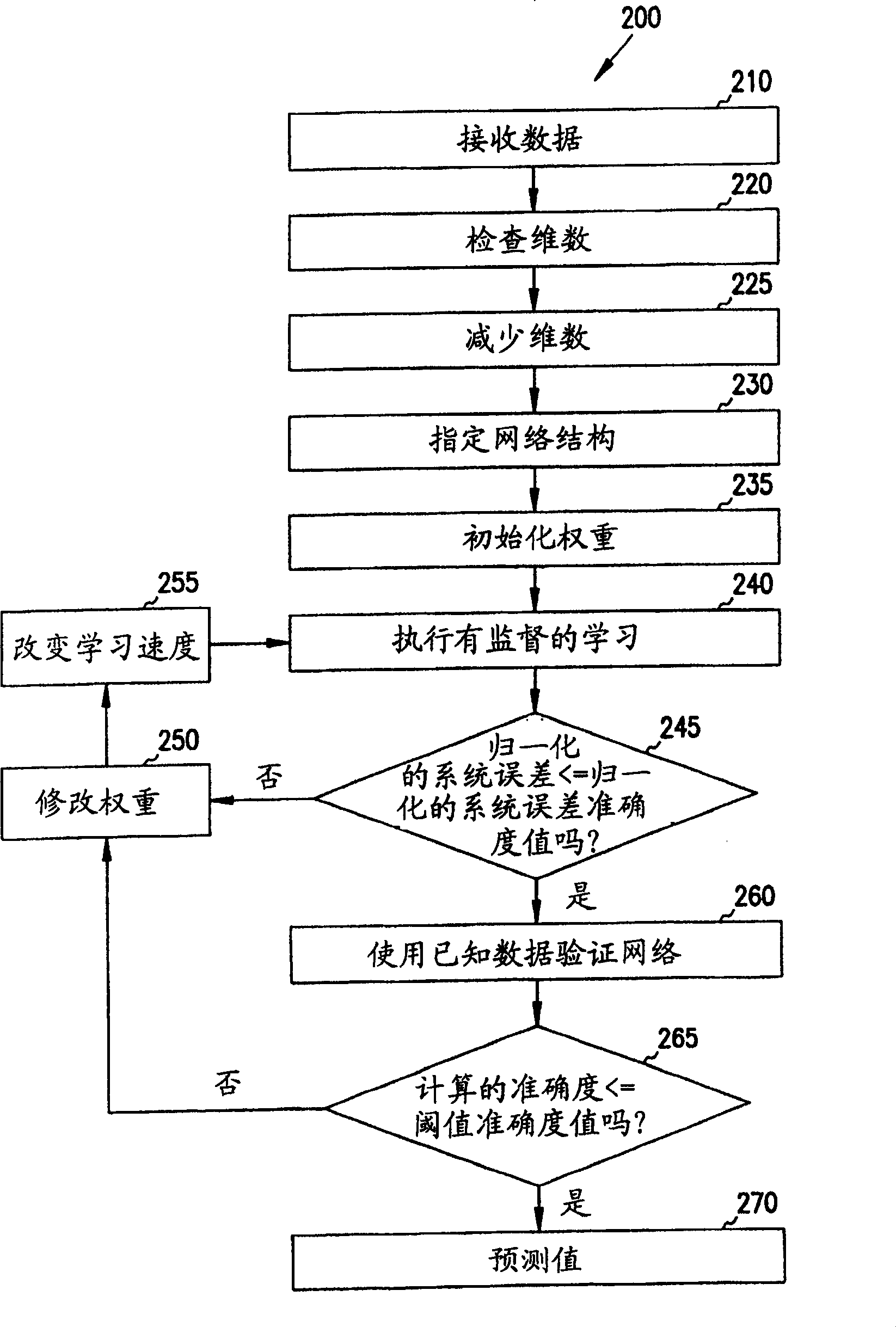

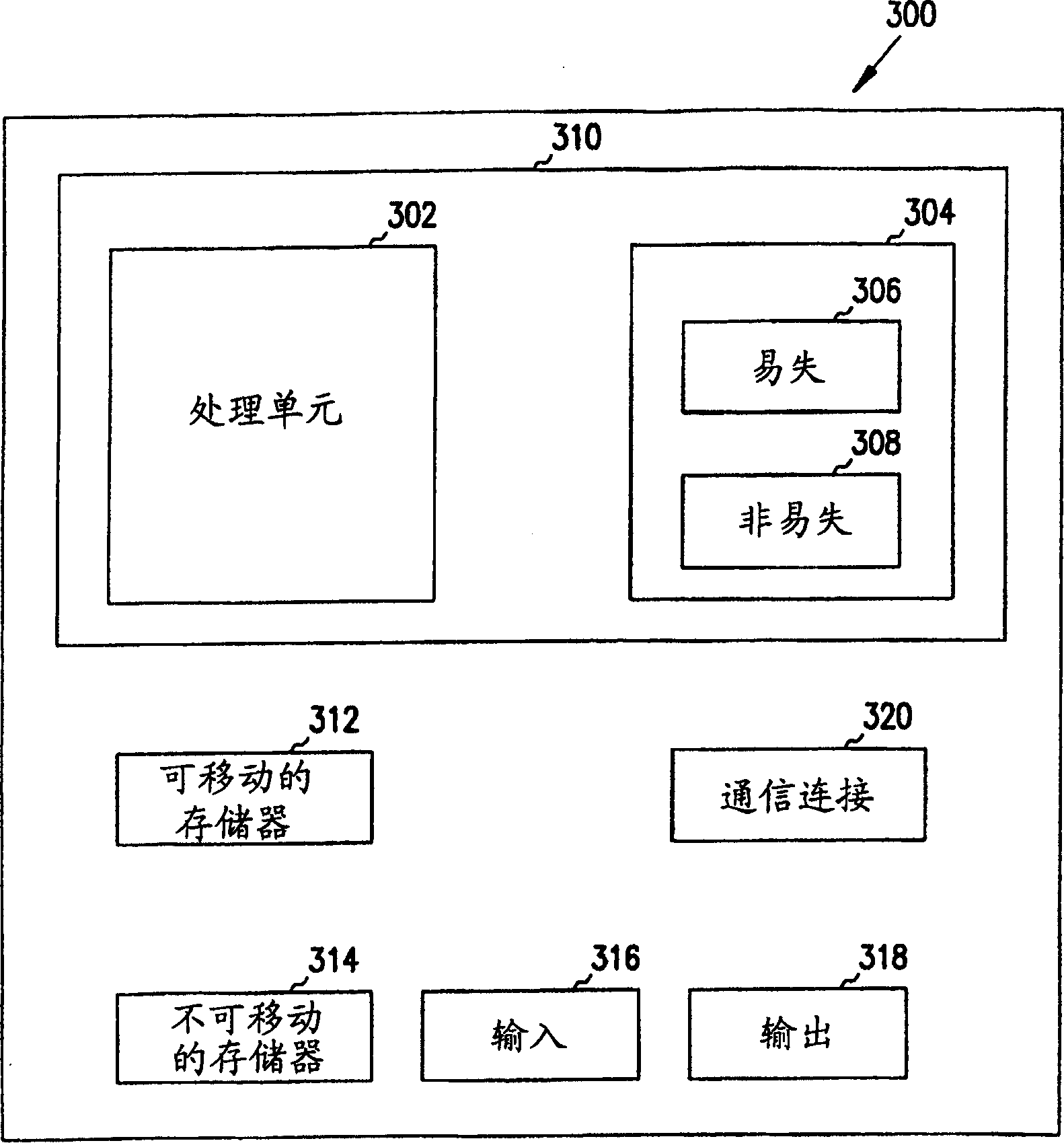

A combinatorial approach for supervised neural network learning

A technique for machine learning, such as supervised artificial neural network learning includes receiving data and checking the dimensionality of the read data and reducing the dimensionality to enhance machine learning performance using Principal Component Analysis methodology. The technique further includes specifying the neural network architecture and initializing weights to establish a connection between read data including the reduced dimensionality and the predicted values. The technique also includes performing supervised machine learning using the specified neural network architecture, initialized weights, and the read data including the reduced dimensionality to predict values. Predicted values are then compared to a normalized system error threshold value and the initialized weights are revised based on the outcome of the comparison to generate a learnt neural network having a reduced error in weight space. The learnt neural network is validated using known values and is then used for predicting values.

Owner:HONEYWELL INT INC

Vehicle brand model fine identification method and system based on depth learning

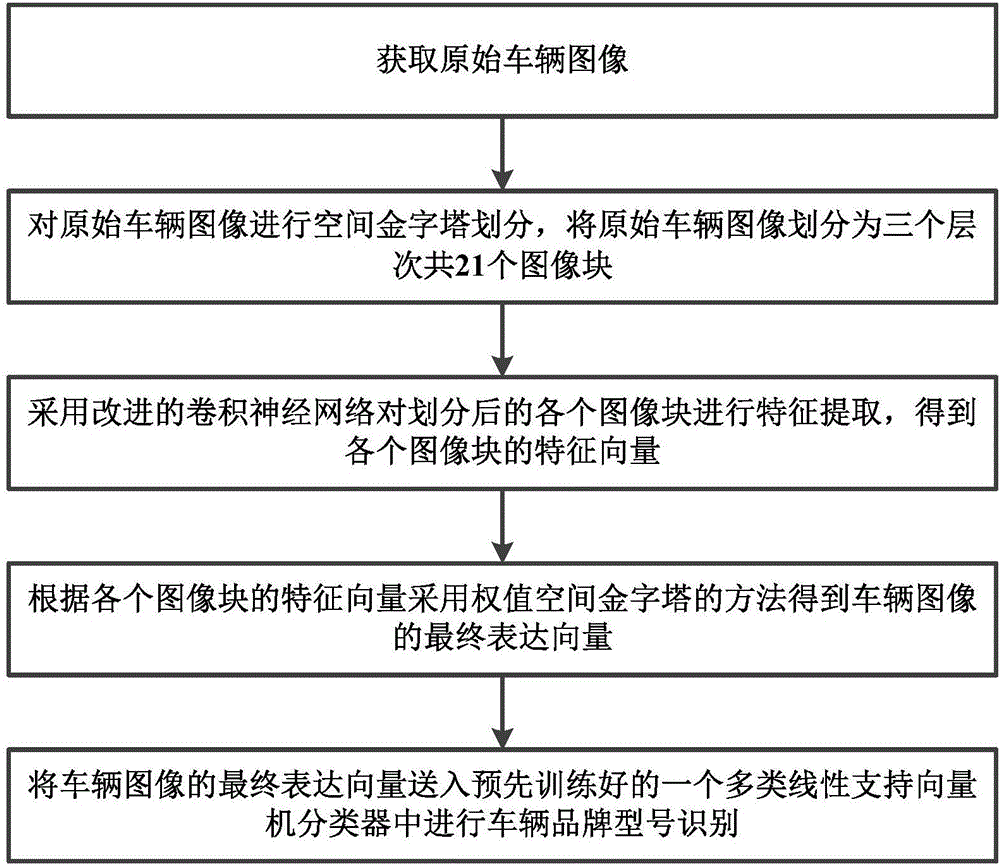

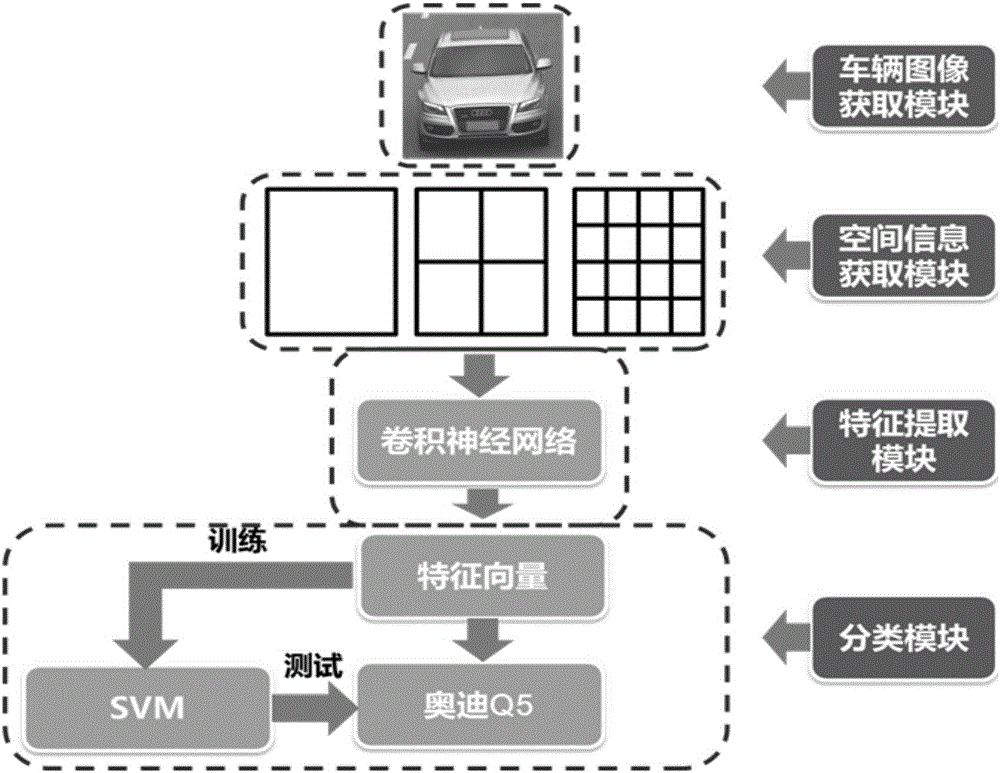

InactiveCN106529578ALow costImprove robustnessCharacter and pattern recognitionFeature vectorImaging processing

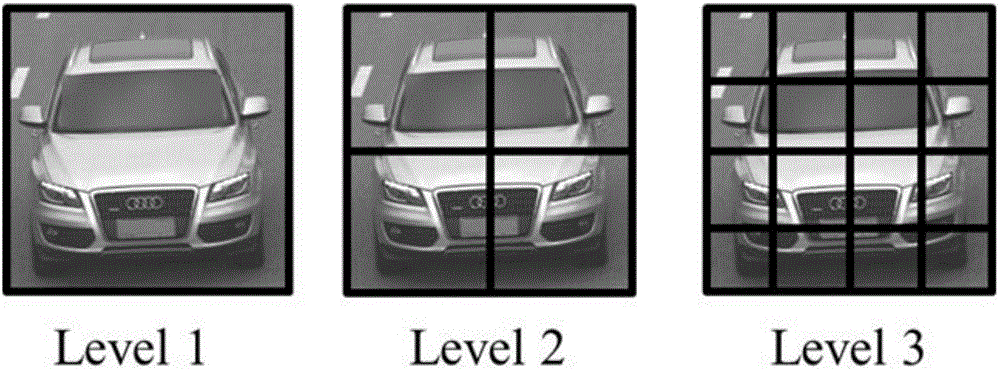

The invention discloses a vehicle brand model fine identification method and system based on depth learning. The vehicle brand model fine identification method based on depth learning includes the steps: acquiring an original vehicle image; performing spatial pyramid dividing on the original vehicle image to divide the original vehicle image into three layers and 21 image blocks, wherein the number of the image blocks in the three layers is respectively 1, 4 and 16; utilizing an improved convolution neural network to perform characteristic extraction on each divided image block to obtain the characteristic vector of each image block, wherein the improved convolution neural network includes a convolution layer, a maximum pooling layer, a configuration layer and an average pooling layer; according to the characteristic vector of each image block, utilizing the method of weight space pyramid to obtain the final expression vector of the vehicle image; and sending the final expression vector of the vehicle image to a pre-trained multi-class linear support vector machine classifier to perform vehicle brand model identification. The vehicle brand model fine identification method and system based on depth learning have the advantages of high robustness and high identification accuracy, and can be widely applied to the image processing field.

Owner:SUN YAT SEN UNIV +1

Arene alkyl transferring and dealkylation reaction method of low ethyl benzene by-product

ActiveCN101190866AImprove efficiencyHigh selectivityMolecular sieve catalystsHydrocarbonsSide chainCerium

The invention relates to a transalkylation of aromatics and dealkylation method that produces low content of ethyl benzene by-product, and mainly solves the problem that reaction products have high content of the ethyl benzene by-product in the prior art, thus causing low selectivity to target product of dimethyl benzene among mixed carbon-eight products and no selectivity to dealkylation of side chains of arene alkylation. The invention adopts the technical proposal of producing target product of dimethyl benzene through reaction in the fixed reaction bed by adopting carbon-nine and above heavy aromatics and methyl benzene as raw material or adopting carbon-nine and the heavy aromatics as raw material, adopting catalyst containing zeolite with SiO2 / Al2O3 mole ratio of 12-70 by weight proportion, oxide that is selected from at least one of molybdenum, palladium or nickel, oxide that is selected from at least one of ferrum, bismuth, tin or platinum and oxide that is selected from at least one of cerium, lanthanum, magnesium or titanium, and in reaction conditions of weight space velocity of 1.0 to 3.5h<-1>, reaction temperature of 350 - 460 DEG C, reaction pressure of 1.5 to 3.5MPa and molecular proportion of hydrogen / hydrocarbon of 2.0 to 80, thereby properly solving the problem. The method can be used for industrial production of carbon-nine and above heavy aromatics or transalkylation of phenylmethane and dealkylation to reduce content of the ethyl benzene by-product and increase content of the dimethyl benzene product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Benzene and C9 and more than that arene transalkylation method

InactiveCN1443736AIncrease moistureHigh activityHydrocarbon by hydrogenationHydrocarbonsFixed bedWeight space

The present invention adopts benzene and C9 and higher aromatic hydrocarbons as raw material for reaction, in the fixed bed reactor and under the condition of hydrogenation uses the composition formed from zeolite in which the silicon-aluminium ratio is 3-500 and alumina as catalyst, on the zeolite metal molybdenum or / and its oxide and non-forced-added at least one metal selected from Fe, Co, Ni,Cr, W, Bi, La, Zr and Ag or / and oxide are loaded, under the conditions of that reaction temp. is 300-600 deg.C, pressure is 1.0-6.0 MPa, hydrogen and hydrocarbon mole ratio of 1-15 and weight space velocity WHSV is 0.5-5.0 hr.(-1) makes the above-mentioned materials produce reaction to produce methylbenzene and C8 aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

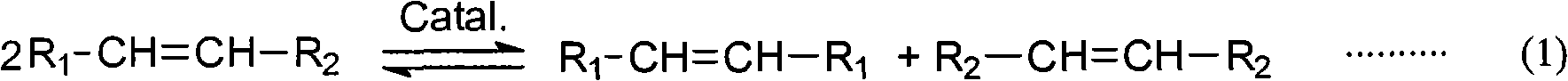

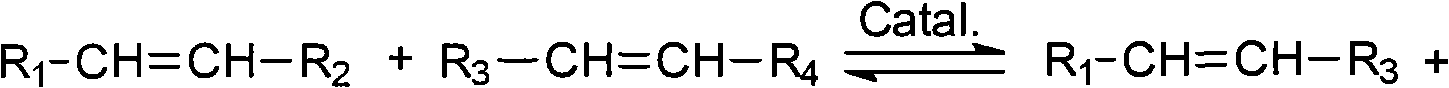

Method for preparing propylene through C4 disproportionation

ActiveCN102372572AToxic reductionAdjust the ratioHydrocarbon by metathesis reactionMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureDisproportionation

The invention relates to a method for preparing propylene through C4 disproportionation and mainly solves the problems of the past technologies such as the consumption of ethylene and low catalyst activity. In the technical scheme in the method, C4 is used as the raw material and the method comprises the following step: under the conditions that the reaction temperature is 300-520 DEG C, the reaction pressure is 0-2MPa and the weight space velocity is 1-10h<-1>, the raw material passes through a catalyst bed to generate propylene. The catalyst used in the method comprises the following components in parts by weight: 4-30 parts of at least one of tungsten oxide, molybdenum oxide and rhenium oxide and 70-96 parts of SiO2 carrier. By adopting the technical scheme, the problems can be better solved and the method can be used in the propylene industrial production adopting C4 disproportionation.

Owner:CHINA PETROLEUM & CHEM CORP +1

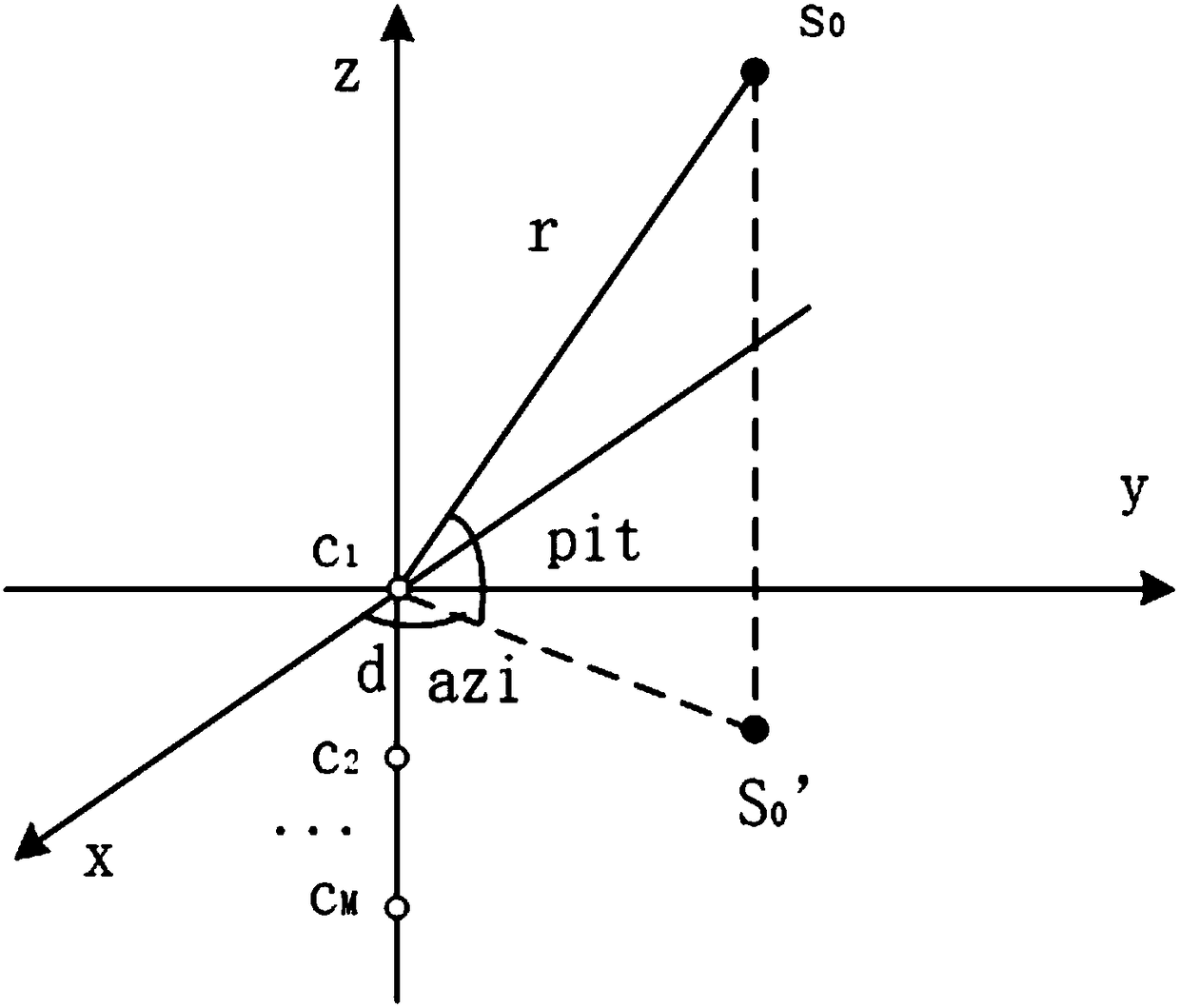

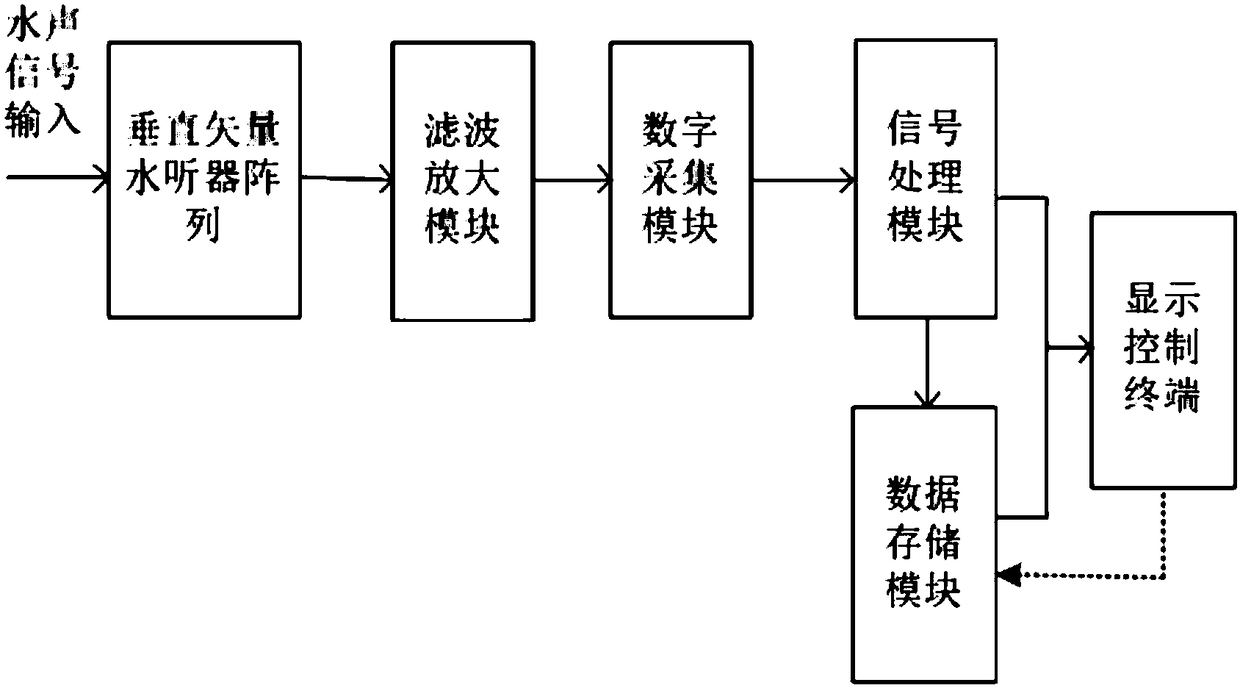

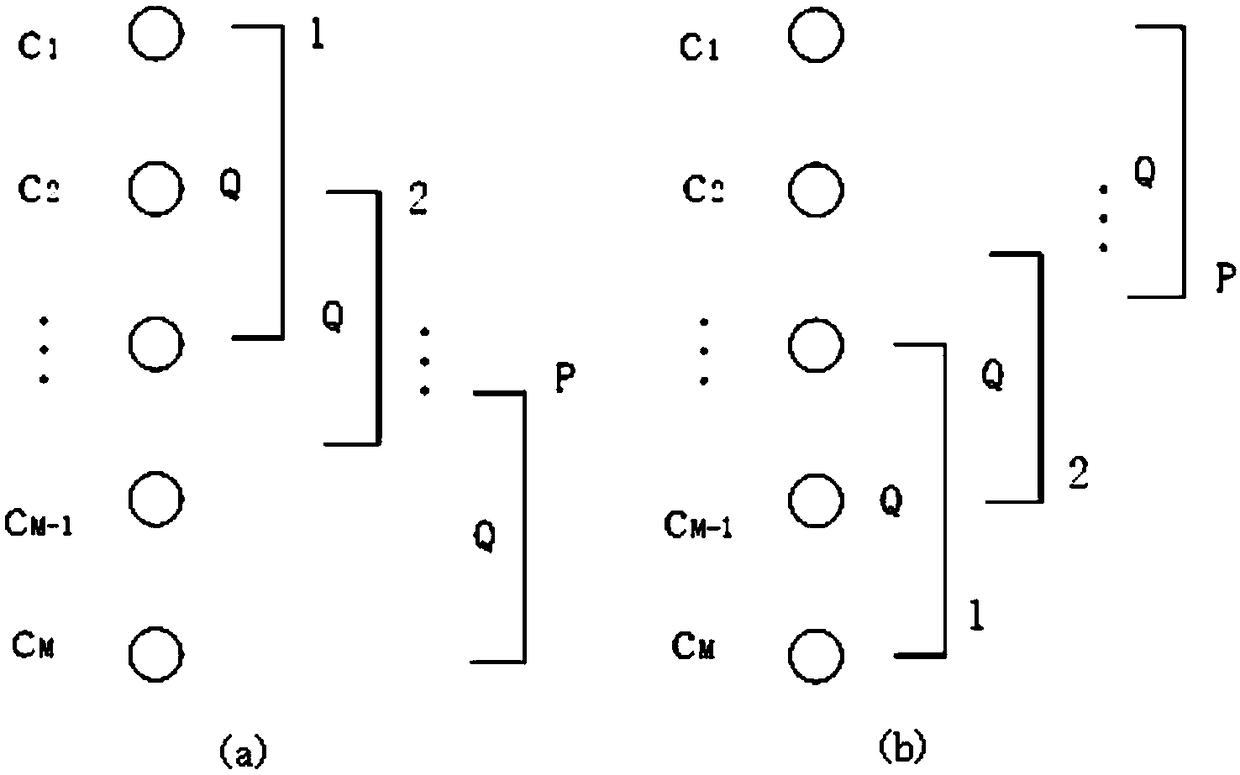

Multi-target DOA estimation method and underwater sound vertical vector array system

ActiveCN109283492ARealize a full range of estimatesImprove position estimation accuracyPosition fixationWeighted spaceFrequency spectrum

The invention relates to a multi-target DOA estimation method and an underwater sound vertical vector array system; the method comprises the following steps: receiving a multi-target signal based on the vertical vector hydrophone array; converting the received multi-target signal to obtain a frequency spectrum and a power spectrum, and extracting a line spectrum; using a vector regular correlationalgorithm to estimate a target sound source number; using a vector weighted space smooth algorithm to obtain a MUSIC space spectrum according to the extracted line spectrum; carrying out two dimensional searching decision for a space spectrum peak corresponding to the multi-target according to the estimation result of the target sound source number and the MUSIC space spectrum, and respectively obtaining a multi-target horizontal angle and a pitching angle; step6, integrating the horizontal angles and pitching angles calculated for each line spectrum, thus obtaining the multi-target DOA estimation result. The method uses the three-dimensional vertical vector hydrophone array to realize all-dimensional estimation of the target signal horizontal angle and pitching angle, thus improving theDOA estimation accuracy of the coherent multi-target signal.

Owner:THE THIRD RES INST OF CHINA ELECTRONICS TECH GRP CORP

Method for producing ethylbenzene by performing vapor phase alkylation on ethanol and benzene

ActiveCN103121909AImprove technical effectMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationRare earthReaction temperature

The invention relates to a method for producing ethylbenzene by performing vapor phase alkylation on ethanol and benzene and mainly solves the problem of low ethylbenzene selectivity in the prior art. The problem is solved by adopting the technical scheme that ethanol and benzene which are used as reaction raw materials and a catalyst contact under the conditions that the reaction temperature is 300 to 460 DEG C, the reaction pressure is 0.5 to 2.8MPa, the weight space velocity of ethanol is 0.1 to 5.0 hours<-1>, and the molar ratio of benzene to ethanol is 2 to 10 to perform vapor phase alkylation reaction so as to generate ethylbenzene; the used catalyst contains the following components in percentage by weight: 90 to 99.9 percent of adhesive-free ZSM-5 molecular sieve of which the silicon-to-aluminum (SiO2 / Al2O3) molar ratio is 30 to 400 and the grain diameter is 5 to 350 nanometers, and 0.1 to 10 percent of rare-earth metallic oxide. The method can be used for industrial production of preparing ethylbenzene by performing vapor phase alkylation on ethanol and benzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene propylene by catalytic pyrolysis of light oil

ActiveCN101279880AIncrease acidityHigh acid strengthMolecular sieve catalystsBulk chemical productionCatalytic pyrolysisMordenite

The invention relates to a method for preparing ethylene propylene by light oil through catalytic cracking, which mainly solves the problems of low catalyst activity, low ethylene propylene yield and high reaction temperature of the current ethylene propylene preparing technique by catalytic cracking. The invention properly solves the problems by adopting the technical proposals that: a ZSM-5 / mordenite / analcime intergrown molecular sieve, a ZSM-5 / mordenite / zeolite beta intergrown molecular sieve, a ZSM-5 / mordenite / zeolite Y intergrown molecular sieve, a ZSM-5 / mordenite / MCM-22intergrown molecular sieve or a mixture thereof serves as a catalyst, the light oil with the compositions of C4 to C10 hydrocarbon is adopted as a raw material, and the material is in contact reaction with a catalyst under the conditions of a reaction temperature of between 600 and 700 DEG C, a reaction pressure of between 0.001 and 0.5MPa, a reaction weight space velocity of between 0.1 and 4 / h, and water / light oil being present in a weight ratio of 0.5-6: 1, and the method of preparation can be used for the industrial production of preparing the ethylene propylene by the light oil through catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

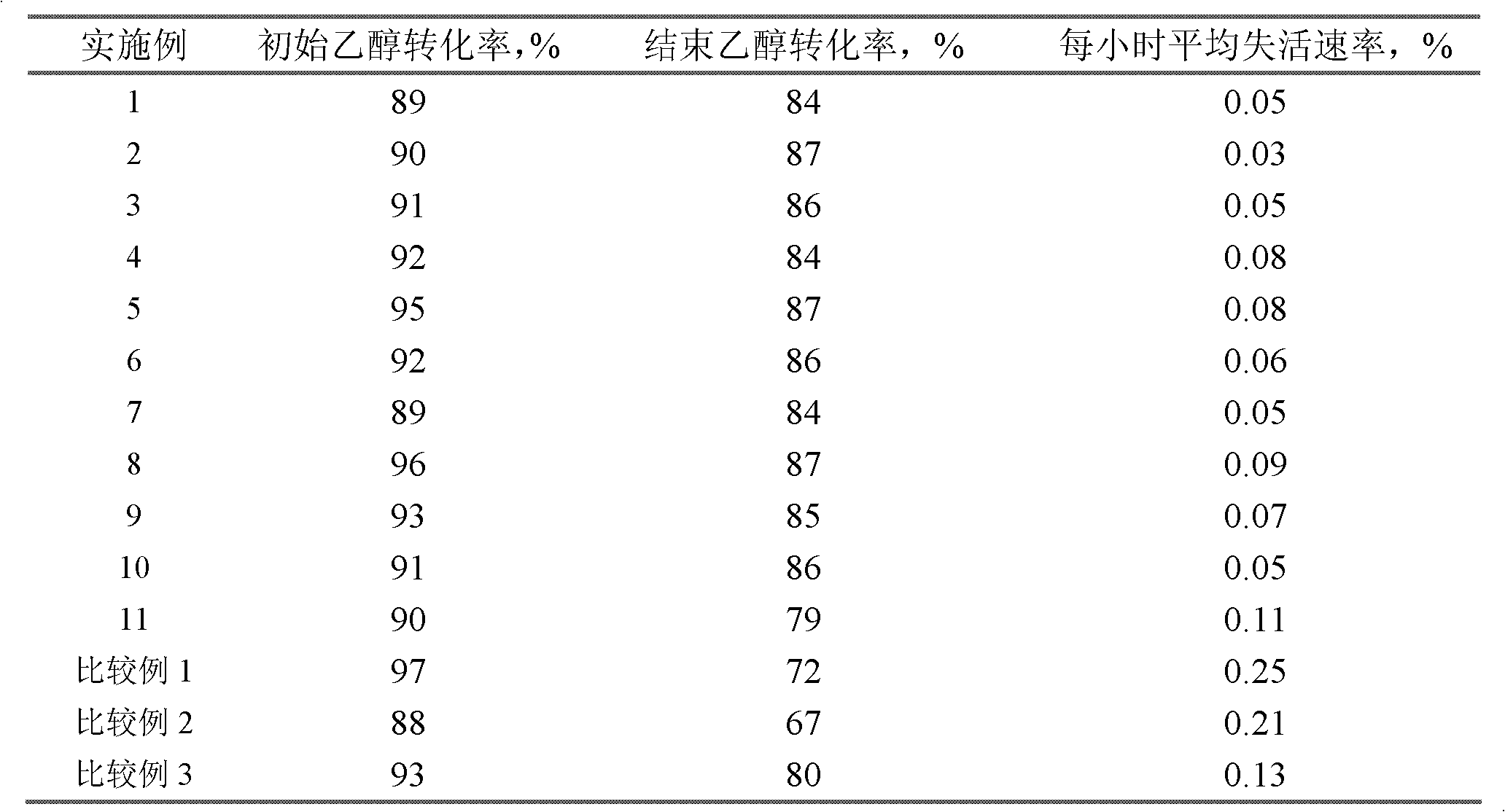

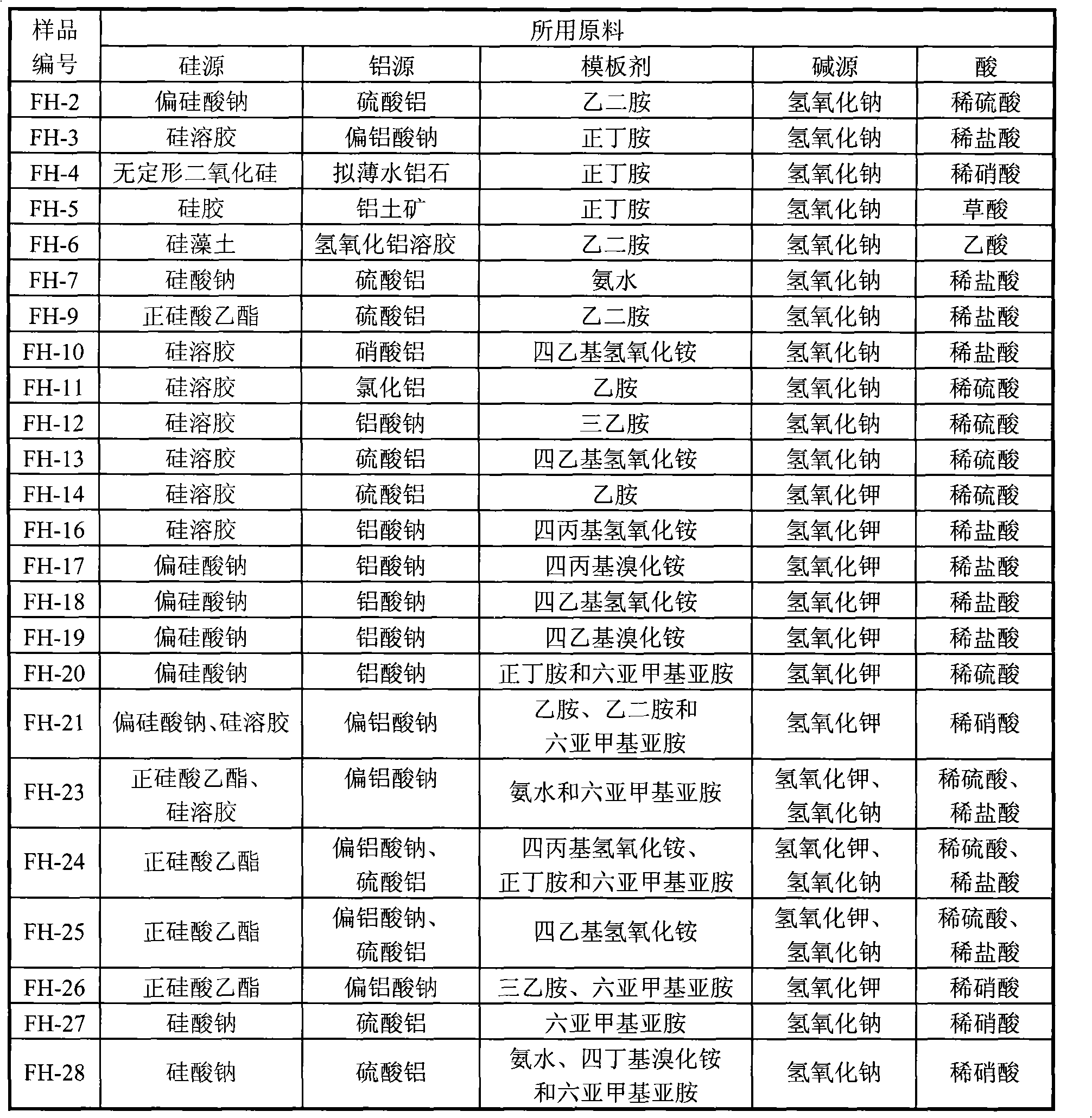

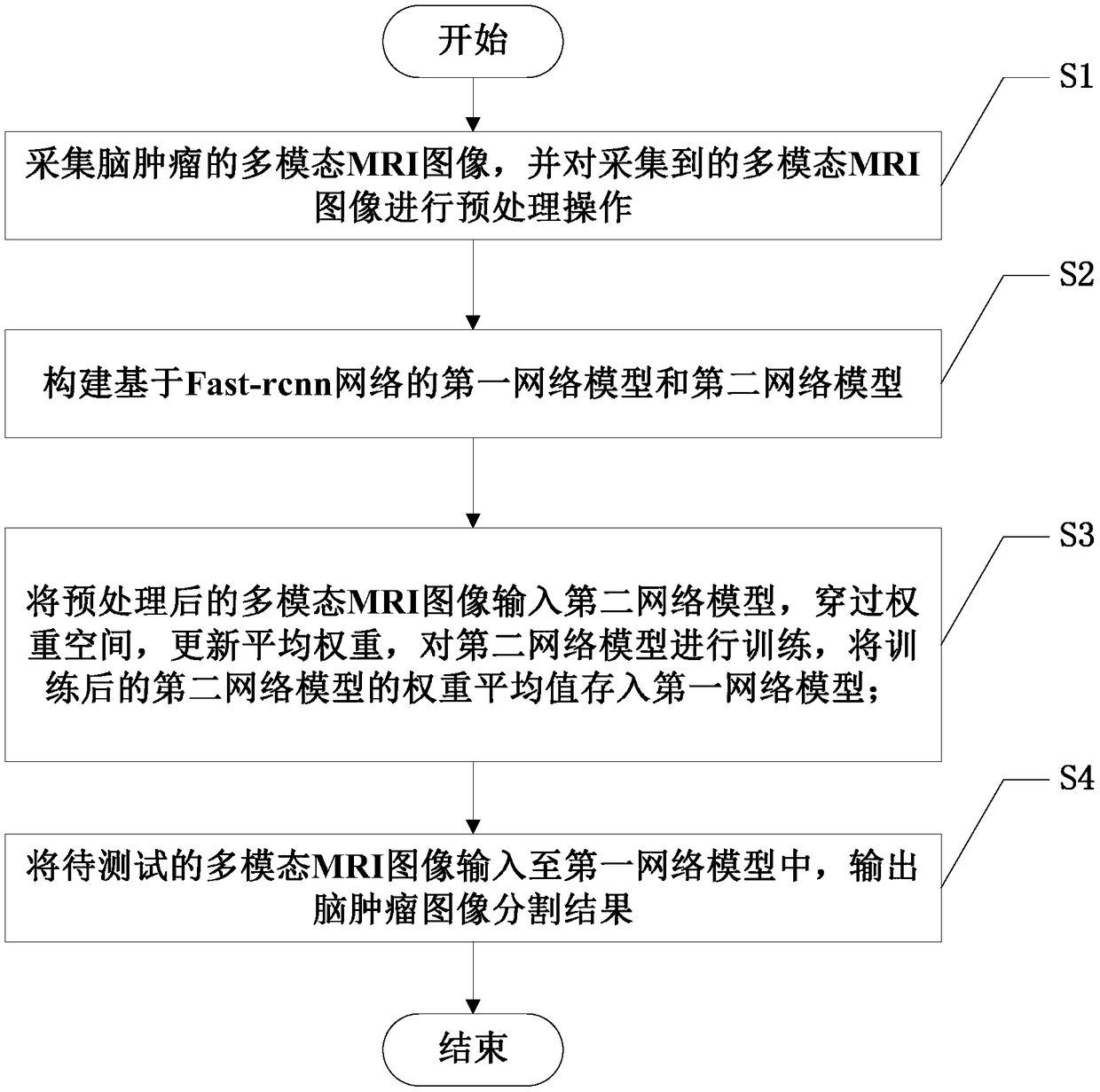

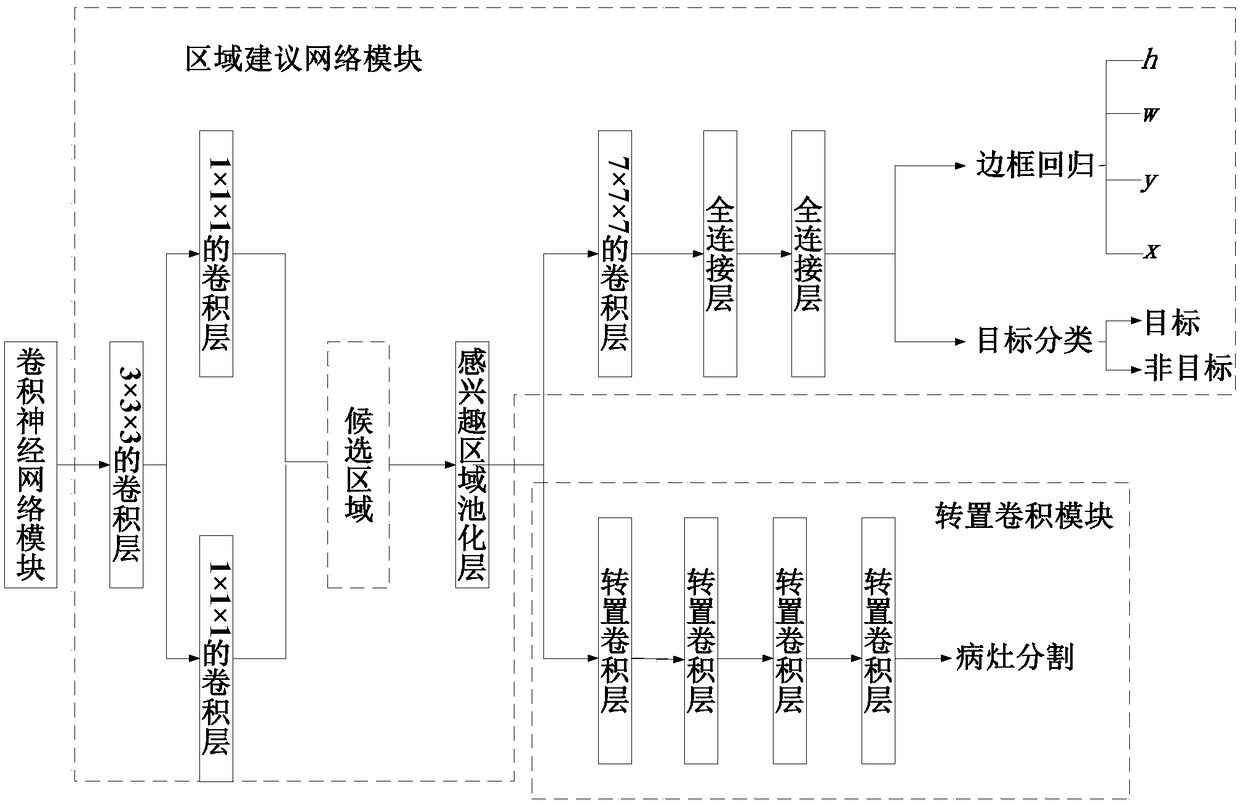

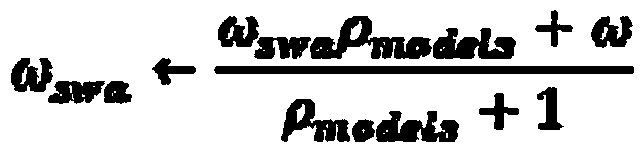

Brain tumor image segmentation method based on depth learning and weight space integration

ActiveCN109242860AEasy to identifyImprove final performanceImage enhancementImage analysisBrain tumorNetwork model

The invention discloses a brain tumor image segmentation method based on depth learning and weight space integration, comprising the following steps: S1, acquiring a multimodal MRI image of the braintumor, and preprocessing the acquired multimodal MRI image; S2, constructing a first network model and a second network model; S3, inputting the preprocessed multimodal MRI image into the second network model, passing through the weight space, and updating the average weight; training it and storing the average value of weights into the first network model; S4, inputting the multimodal MRI image to be tested into the first network model, and outputting the segmentation result of the brain tumor image. The segmentation method of the invention is conducive to improving the accuracy and reliability of the brain tumor segmentation result, and the parallel network can obtain the positioning information while segmenting the lesion, and meanwhile, the method integrates the weight space collection, thereby improving the efficiency and the accuracy of the brain tumor segmentation.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for producing propylene, ethylene light olefin hydrocarbon

ActiveCN101429085ARaise the ratioImprove reaction stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveReaction temperature

The invention relates to a method for producing propylene and ethane light olefin by using methanol and / or dimethyl ether as raw materials so as to mainly solve the problems of poor high temperature hydrothermal stability and quick inactivation of a catalyst in the prior reaction process. The method well solves the problems through adopting the technical proposal of using reaction conditions of a molecular sieve containing rare earth and phosphorous oxides as catalysts, at a temperature of between 350 and 650 DEG C, at a pressure of between minus 0.05 and 1.0MPa, according to the weight space velocity of the methanol and / or the dimethyl ether of between 0.2 and 20 hours<-1>, and the weight ratio of water and raw materials of between 0 to 1 and 5 to 1. The method can be used in industrial production of light olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

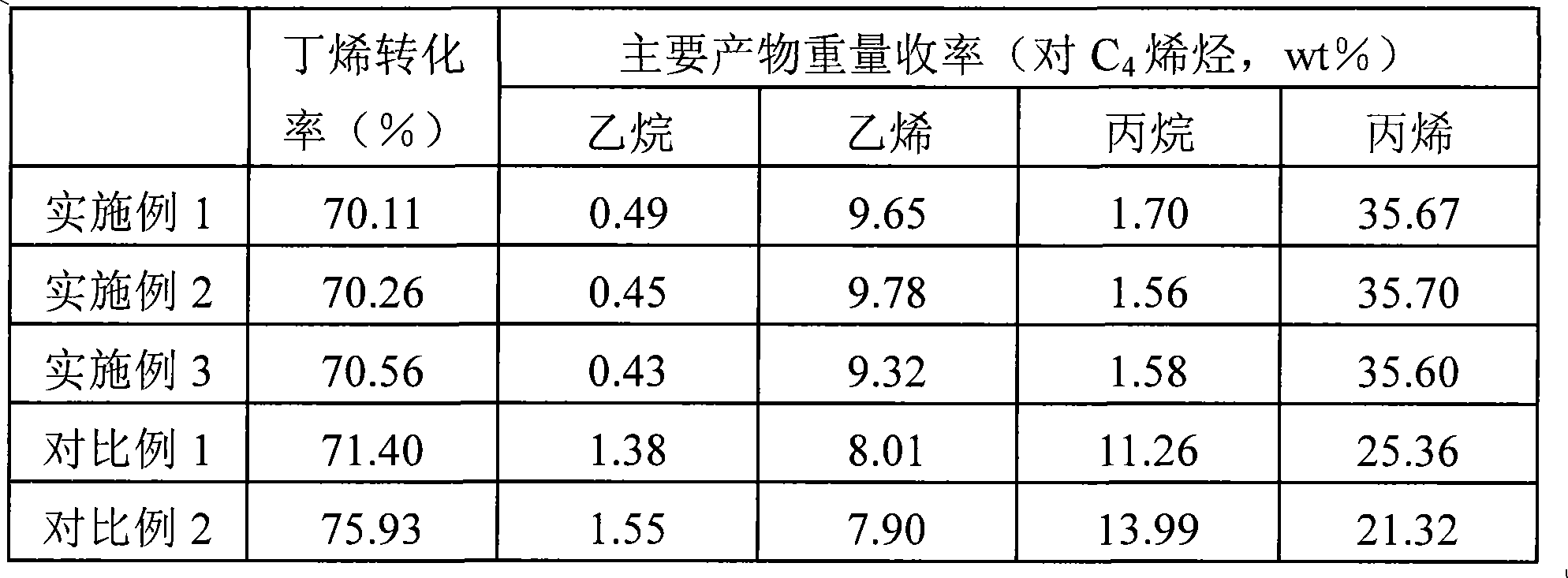

Catalyst for preparation of propylene and ethylene from mixed C4 alkenes and application thereof

ActiveCN101664692AReduced responseMolecular sieve catalystsBulk chemical productionAlkali metal oxideReaction temperature

The invention discloses a catalyst for preparation of propylene and ethylene by transforming mixed C4 alkenes and application thereof. The modified components including lanthanide metal oxides, alkalimetal oxides and phosphorus oxides are introduced into the catalyst so that the catalyst has high propylene yield and low hydrogen transfer degree. The catalyst catalyzes the reactions of preparing the propylene and the ethylene by transforming the mixed C4 alkenes under the following reaction conditions that: the reaction temperature is between 460 and 600 DEG C, the pressure is between -0.05 and 0.3 MPa, the weight ratio of feed water to feed C4 is 0 to 1, and the weight space velocity is 1-20 h<-1>. By using the catalyst in the process of catalyzing the reaction of preparing the propyleneand the ethylene by transforming the mixed C4 alkenes, compared with an unmodified molecular sieve, the catalyst can obviously improve the yield of the propylene and the ethylene. Simultaneously, theyield of byproducts C1-C3 alkanes is obviously reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

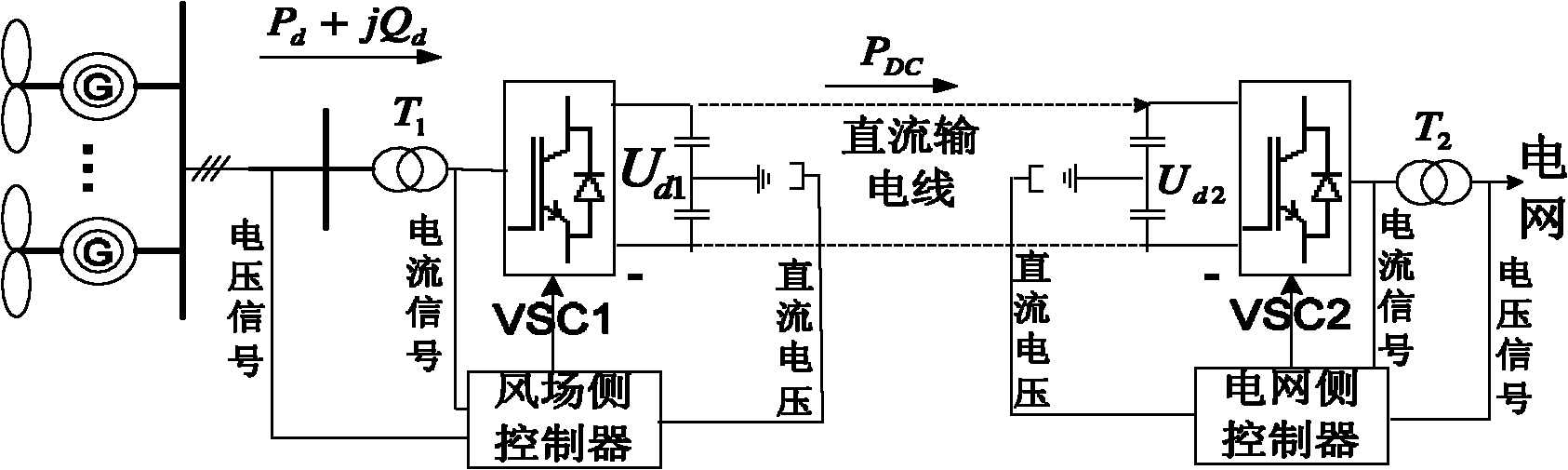

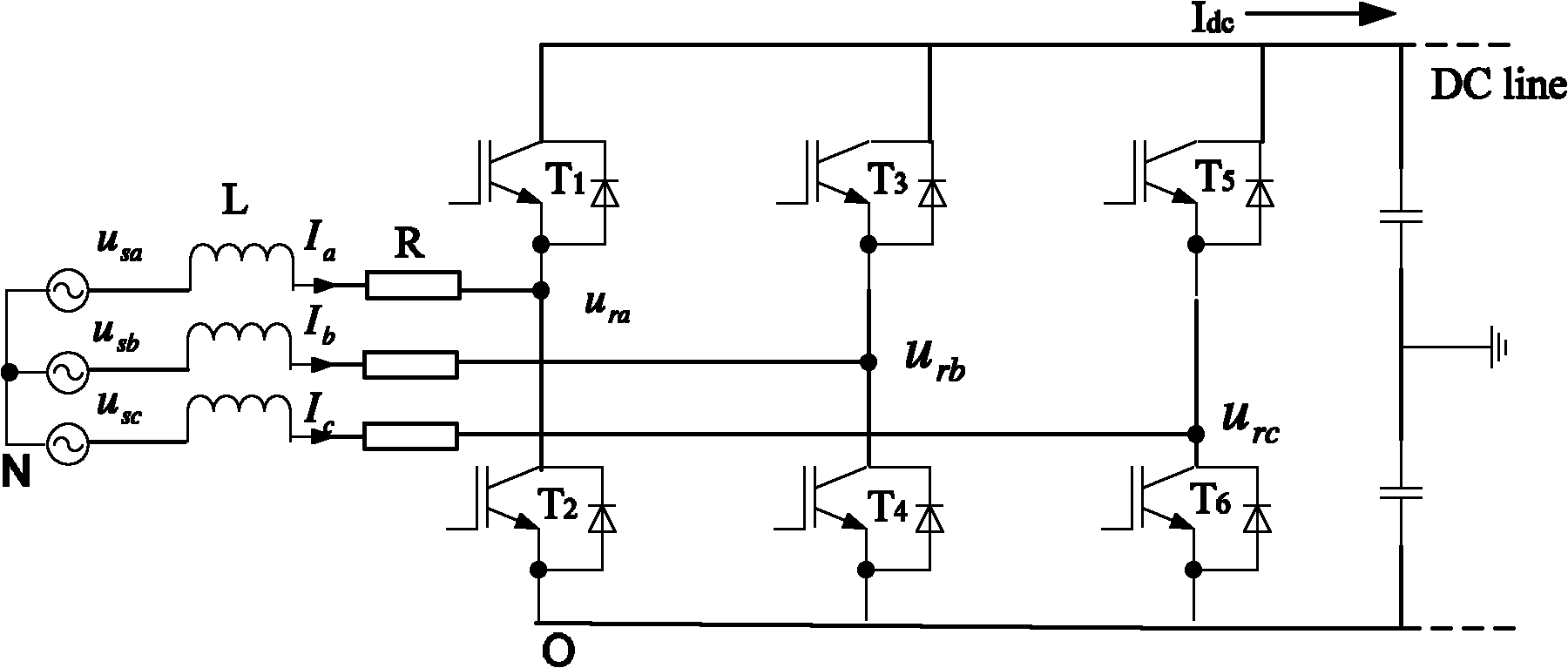

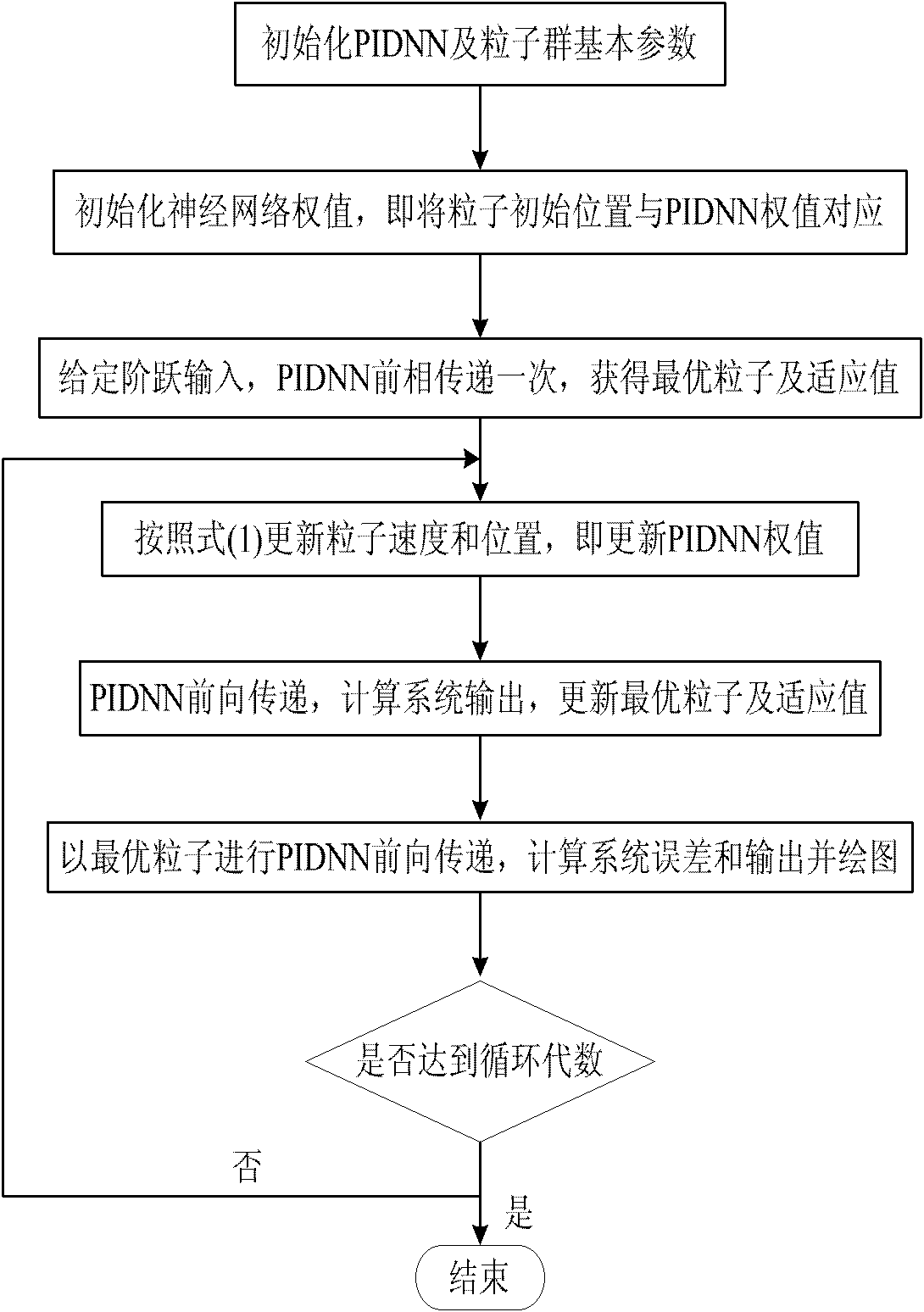

Control method of light-type direct-current transmission system converter of offshore wind power station

InactiveCN101895125AImprove transient response performanceAvoid uncertaintyElectric power transfer ac networkElectric power transmissionNonlinear model

The invention relates to a control method of a light-type direct-current transmission system converter of an offshore wind power station, belonging to the technical field of power transmission. In the invention, a PID (Piping and Instruments Diagram) neural network controller is designed based on a particle group optimizing method, the traditional PI (Piping and Instruments) regulator is substituted, step input is used to train a neural network, that is to say, multi-group particles are set to search in the neural network weight space of searching, and the position and speed of the particles are continuously updated according to an adaptive value function of the neural network to obtain the optimum weight of the neural network. The invention adopts the method of using the optimum weight value obtained by training in combination with the error forward broadcast of the neural network to substitute the traditional PI regulator to control the operation of the system, thereby reducing the parameter to be regulated and improving the transient response performance of the system; the neural network weight value is obtained by training a nonlinear model of a controlled system so as to approach to a true system. Only the forward broadcast process of the PID neural network is controlled in the operation process of the system. The method is relatively simple and is easy to achieve.

Owner:SHANGHAI JIAO TONG UNIV

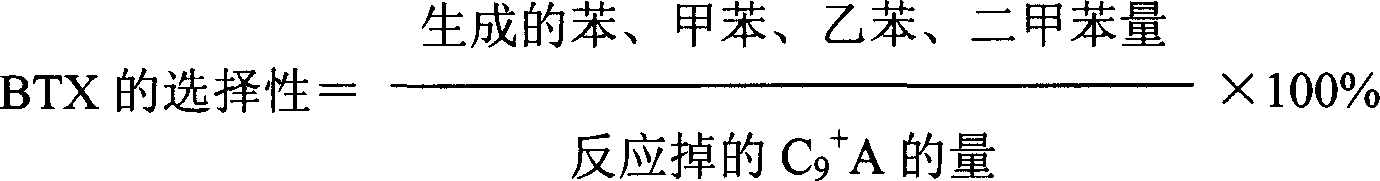

Method used for heavy arene light formation and alkyl transfer

ActiveCN100999433AHigh acid strengthIncrease acidityMolecular sieve catalystsBulk chemical productionSodium BentoniteFixed bed

This invention relates to a method of lighting heavy aromatic hydrocarbon and alkyl transfer. Mainly to solve existing technologies problems, such as low conversion rate and needing precious metal when use solo pure zeolite molecular sieve catalyst, and raw materials and components demanding. This invention takes carbon 9 and above aromatic hydrocarbon as raw material, in the fixed-bed reactor, use symbiotic molecular sieve that contains 10 ~ 80% (weight) of beta zeolite and Mordenite, and 20 ~ 90% (weight) inorganic binder composition of the catalyst that at least one selected from the gamma-Al2O3, thin diaspore, silica, silicon oxide, alumina oxide, bentonite, kaolin, diatomite or montmorillonite. Take reaction under the conditions of the reaction temperature 300 to 500 deg, pressure of 1.0 to 3.5MPa, raw materials weight space velocity of 1.5 ~ 6 .0 per hour, hydrogen and hydrocarbon molar ratio of 2.0 to 6.0 to obtain product containing benzene, toluene and xylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene and propylene by catalytic pyrolysis

ActiveCN101348407AHigh hydrothermal stabilityIncrease acidityMolecular sieve catalystsBulk chemical productionCatalytic pyrolysisRare-earth element

The invention relates to a method for preparing ethylene and propylene through catalytic cracking, mainly solving the problems of the prior catalyst used for preparing ethylene and propylene through catalytic cracking of high service temperature and low yields of ethylene and propylene. Through taking naphtha the compositions of which are C4 to C10 hydrocarbons as raw material, catalytic cracking reaction of the raw material is carried out through a catalyst bed so as to generate ethylene and propylene at a temperature of between 550 and 700 DEG C, under the pressure of between 0.001 and 0.5MPa, at the weight space velocity of between 0.1 and 4 hour<-1> and in the water / naphtha weight ratio of between 0.5 and 4 to 1, wherein the catalyst is at least two of rare earth elements, VA group elements, IIIA group elements, IB group elements or IIB group elements, IA group elements or IIA group elements loaded on ZSM-5 / mordenite intergrowth molecular sieve, ZSM-5 / Beta zeolite intergrowth molecular sieve or ZSM-5 / Y zeolite intergrowth molecular sieve; and the technical proposal solves the problems better, and can be used in the industrial production for preparing ethylene and propylene through catalytic cracking of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing glycol from oxalate

ActiveCN101993348AImprove technical effectOrganic compound preparationHydroxy compound preparationOxalateHydrogen

The invention relates to a method for preparing glycol from oxalate, which mainly solves the problems of easy catalyst deactivation and low selectivity of glycol serving as a target product caused by large temperature difference in a reactor in the prior art. The technical scheme of the invention is that: oxalate and hydrogen are used as raw materials, a molar ratio of the hydrogen to the oxalateis 40-200:1, fatty alcohol having 1 to 4 carbon atoms is used as a solvent, the weight ratio of the solvent to the oxalate in the raw materials is 0-0.9:1, and at least one of the oxalate, hydrogen, solvent and water is used as a cooling medium; and the cooling medium passes through a tube nest in a shell and tube fixed bed reactor at the temperature of 160 and 280 DEG C, under the pressure of between 1.0 and 6.0 MPa and under the conditions that the weight space velocity is between 0.1 and 10 hours<-1> on the basis of the weight of a mixture of the oxalate and the solvent and the molar ratioof the hydrogen to the oxalate is 40-200:1, a catalyst bed is positioned outside the tube nest, and after entering the reactor, the mixture of the raw materials and the solvent contacts a copper-containing catalyst outside the tube nest for reacting to form the glycol, wherein the flow direction of the cooling medium is the same or opposite to that of the mixture of the raw materials and the solvent, and the oxalate accounts for more than or equal to 10 weight percent of the mixture. By adopting the technical scheme, the problems are solved better. The method can be used for the industrial production of the glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing dimethylbenzene through methylation and transalkylation

ActiveCN103121912AMaximizeHydrocarbon by metathesis reactionHydrocarbon by hydrocarbon and non-hydrocarbon condensationMethyl benzeneReaction temperature

The invention relates to a method for preparing dimethylbenzene through methylation and transalkylation, and mainly aims to solve the problems that the yield of dimethylbenzene is determined by the link relative ratio of methyl benzene in raw materials, and when a heavy aromatic raw material is insufficient, the output of the dimethylbenzene is low and a lot of byproduct benzene is generated at the same time in the existing toluene disproportionation or toluene disproportionation and transalkylation technologies. The problems are well solved by adopting the technical scheme which is s follows: the method comprises the following steps of: by using a methylation agent and aromatic hydrocarbons which has less than 12 Cs and does not contain or only contains a small amount of dimethylbenzene as raw materials, under the condition that the reaction temperature is 300-500 DEG C, the reaction pressure is between the normal pressure and 10.0MPa and the weight space velocity of the raw materials is 0.3-10h<-1>, contacting the raw materials with a solid acid catalyst to ensure that an alkylation reaction is performed on methanol and the aromatic hydrocarbons, and performing transalkylation among the aromatic hydrocarbons to obtain the dimethylbenzene. The method can be used in industrial production of dimethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

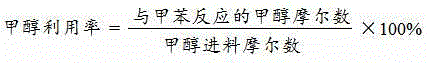

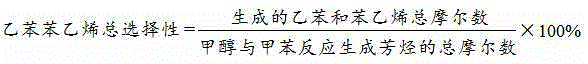

Toluene/methanol side chain alkylation method

ActiveCN104557374AMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationRare-earth elementSide chain

The invention relates to a toluene / methanol side chain alkylation method and mainly aims at solving the problems of low styrene selectivity and poor stability of catalysts in the prior art. The problems are well solved by virtue of the following technical scheme: toluene and methanol are taken as raw materials; the raw materials are in contact with a catalyst and react to generate ethylbenzene and styrene under the conditions of a reaction temperature of 200-600 DEG C, a reaction pressure of 0-0.5MPa and a raw material weight space velocity of 0.5-10 h<-1>; the molar ratio of the toluene to the methanol in the raw materials is 0.1-10; the catalyst is prepared from the following components in percentage by weight: a) 93-99.8% of alkali metal ion exchange molecular sieve, b) 0.1-0.5% of rare earth element, and c) 0.1-2% of at least one of boron or phosphorus; and the toluene / methanol side chain alkylation method is applicable to the industrial production of preparing the ethylbenzene and the styrene by virtue of toluene / methanol side chain alkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com