Catalyst for preparation of propylene and ethylene from mixed C4 alkenes and application thereof

A catalyst, ethylene technology, applied in molecular sieve catalysts, physical/chemical process catalysts, hydrocarbon cracking to produce hydrocarbons, etc., can solve the problem of not giving a low degree of hydrogen transfer reaction, and cannot have high propylene yield and low degree of hydrogen transfer reaction at the same time. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

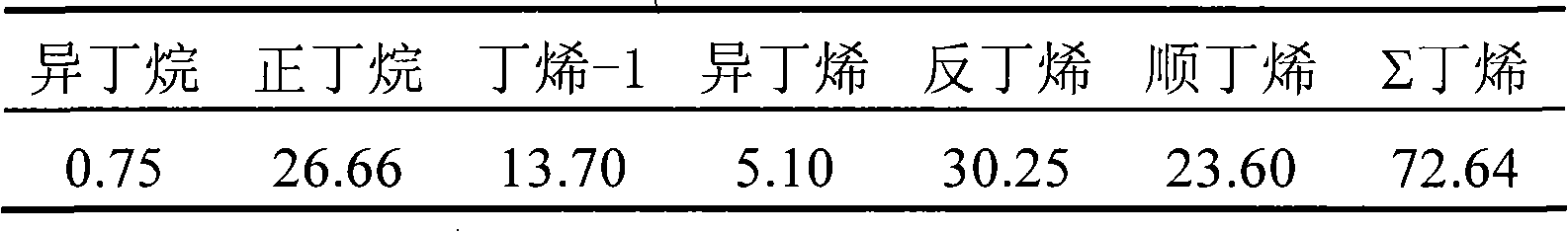

Image

Examples

Embodiment 1

[0030] Catalyst preparation: HZSM-5 molecular sieve (purchased from the market, silicon-aluminum molar ratio of 200) and alumina (weight ratio of 3:1) are mixed uniformly, stirred and kneaded, and extruded. Drying at 100°C for 10 hours, and baking at 560°C for 4 hours. The strips were placed in an aqueous solution containing potassium nitrate, diammonium hydrogen phosphate and lanthanum nitrate for 2 hours, filtered, dried at 100°C for 10 hours, and calcined at 560°C for 4 hours. Based on the weight percentage of the catalyst, the catalyst contains 74.0% ZSM-5 molecular sieve, 23.8% alumina, 0.2% potassium oxide, 1.0% phosphorus oxide and 1.0% lanthanum oxide.

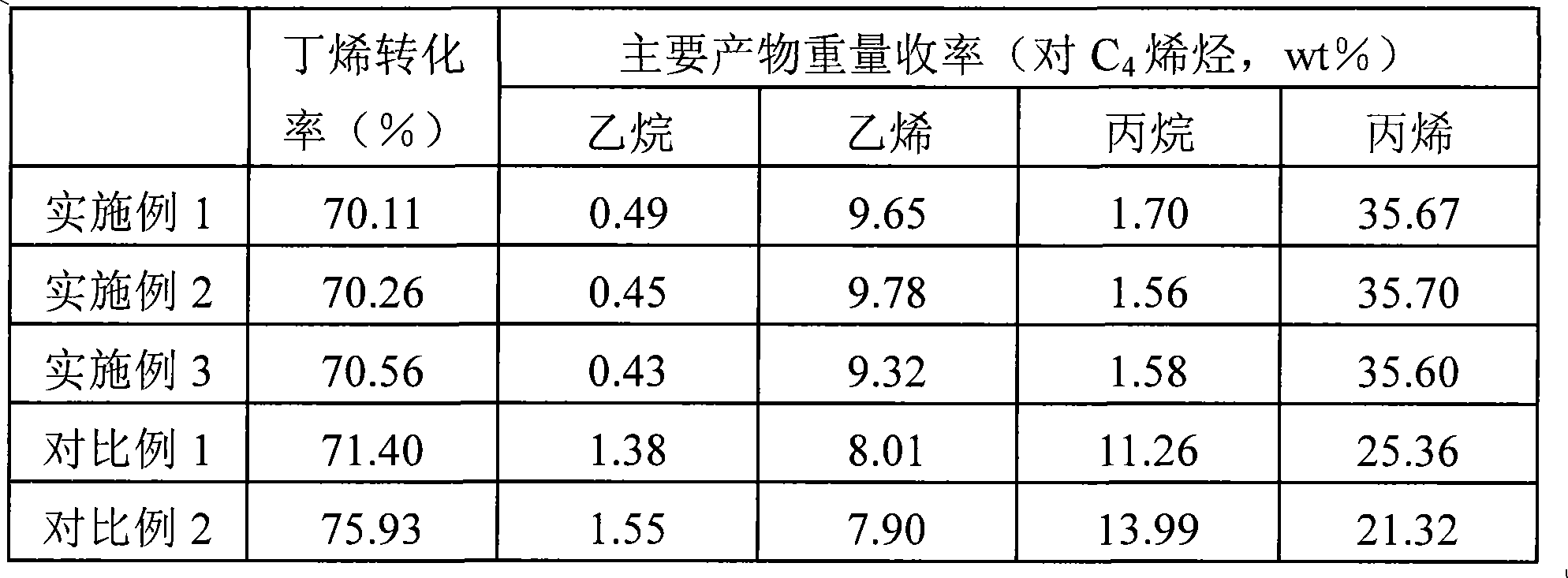

[0031] The catalyst evaluation conditions are: reaction temperature 520℃, pressure 0.1MPa, weight ratio of water in the feed to feed C4 is 0.5, and feed weight space velocity is 2.5h -1 . The results of the reaction are shown in Table 2.

Embodiment 2

[0033] Catalyst preparation: HZSM-5 molecular sieve (purchased from the market, silicon-aluminum molar ratio of 200) and alumina (weight ratio of 3:1) are mixed uniformly, stirred and kneaded, and extruded. Dry at 100°C for 10 hours, and calcinate at 560°C for 4 hours. The strips were placed in an aqueous solution containing potassium nitrate, diammonium hydrogen phosphate and cerium nitrate for 2 hours, filtered, dried at 100°C for 10 hours, and calcined at 560°C for 4 hours. The catalyst contains 74.0% ZSM-5 molecular sieve, 23.8% alumina, 0.2% potassium oxide, 1.0% phosphorus oxide and 1.0% cerium oxide based on the weight percentage content of the catalyst. The catalyst evaluation conditions were the same as in Example 1. The results of the reaction are shown in Table 2.

Embodiment 3

[0035] Catalyst preparation: HZSM-5 molecular sieve (purchased from the market, silicon-aluminum molar ratio of 200) and alumina (weight ratio of 3:1) are mixed uniformly, stirred and kneaded, and extruded. Dry at 100°C for 10 hours, and calcinate at 560°C for 4 hours. The strips were placed in an aqueous solution containing potassium nitrate and diammonium hydrogen phosphate for 2 hours, filtered, dried at 100°C for 10 hours, and calcined at 560°C for 4 hours. Based on the weight percentage of the catalyst, the catalyst contains 74.1% ZSM-5 molecular sieve, 24.75% alumina, 0.15% potassium oxide and 1.0% phosphorus oxide. The catalyst evaluation conditions were the same as in Example 1. The results of the reaction are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com