Patents

Literature

3195results about "Hydrocarbon by hydrocarbon cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

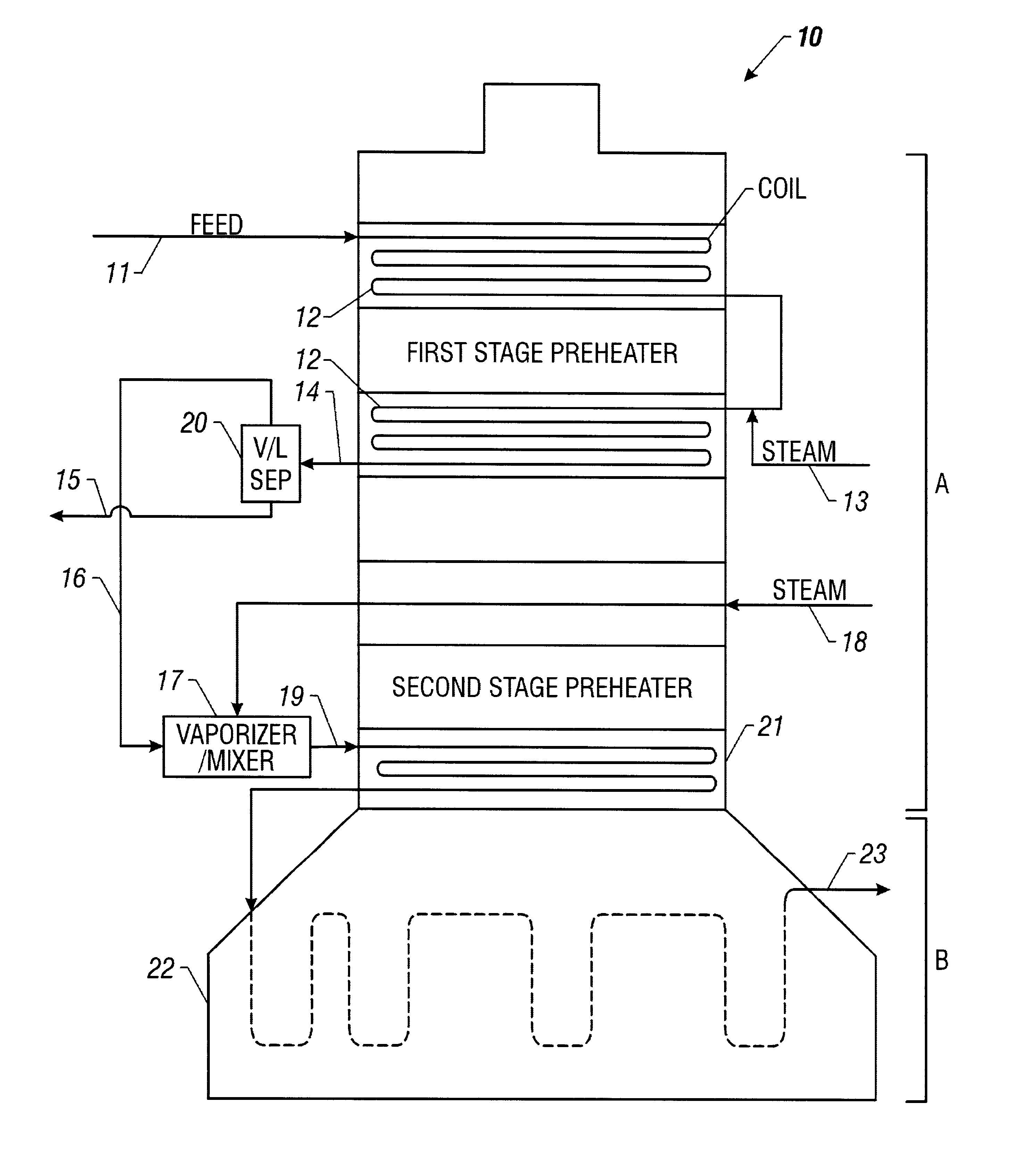

Thermal cracking of crude oil and crude oil fractions containing pitch in an ethylene furnace

InactiveUS6632351B1Cheap sourceMinimizing coke formationThermal non-catalytic crackingHydrocarbonsEthyleneChemistry

Owner:SHELL OIL CO

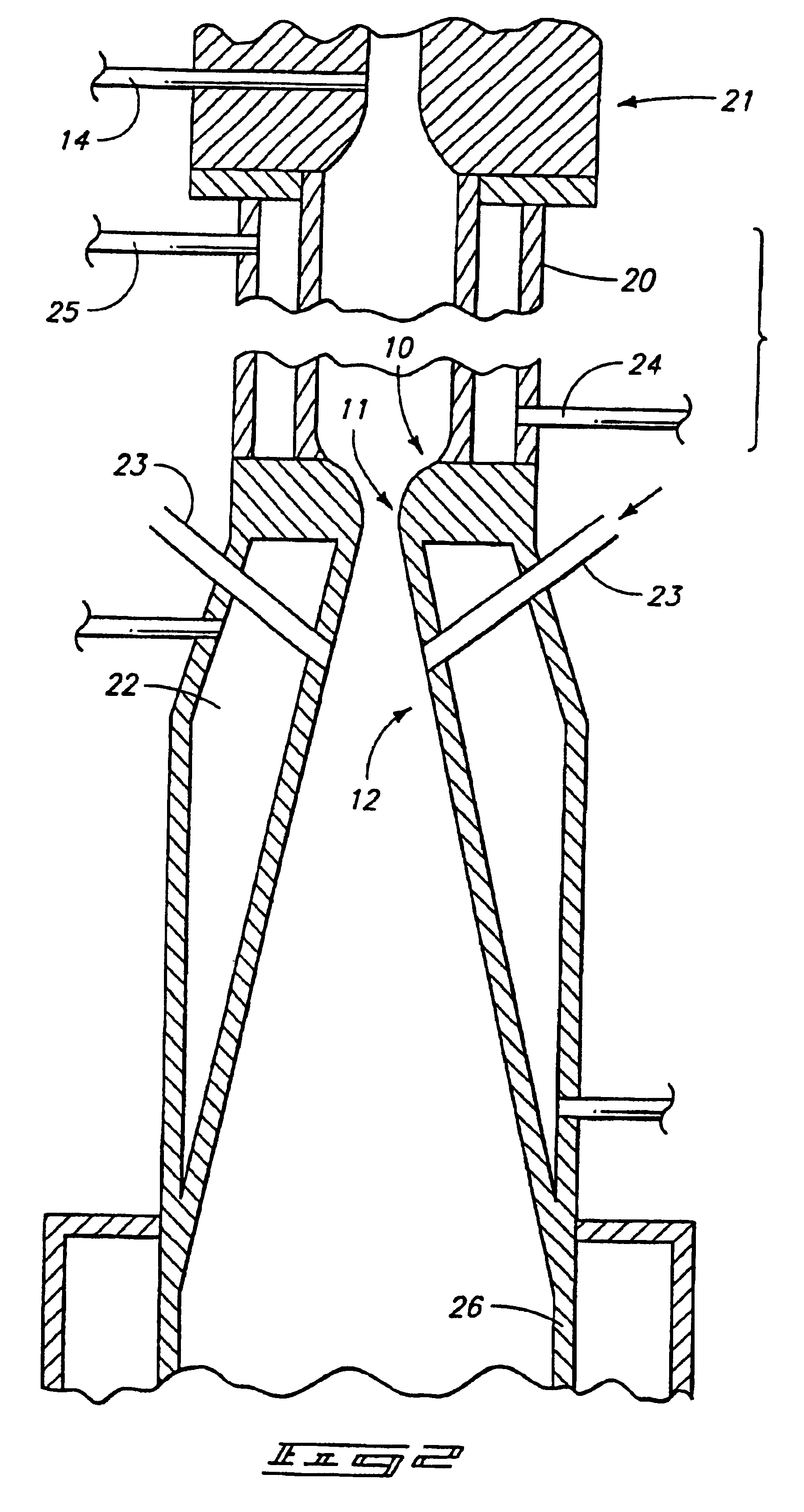

Pyrolytic reactor

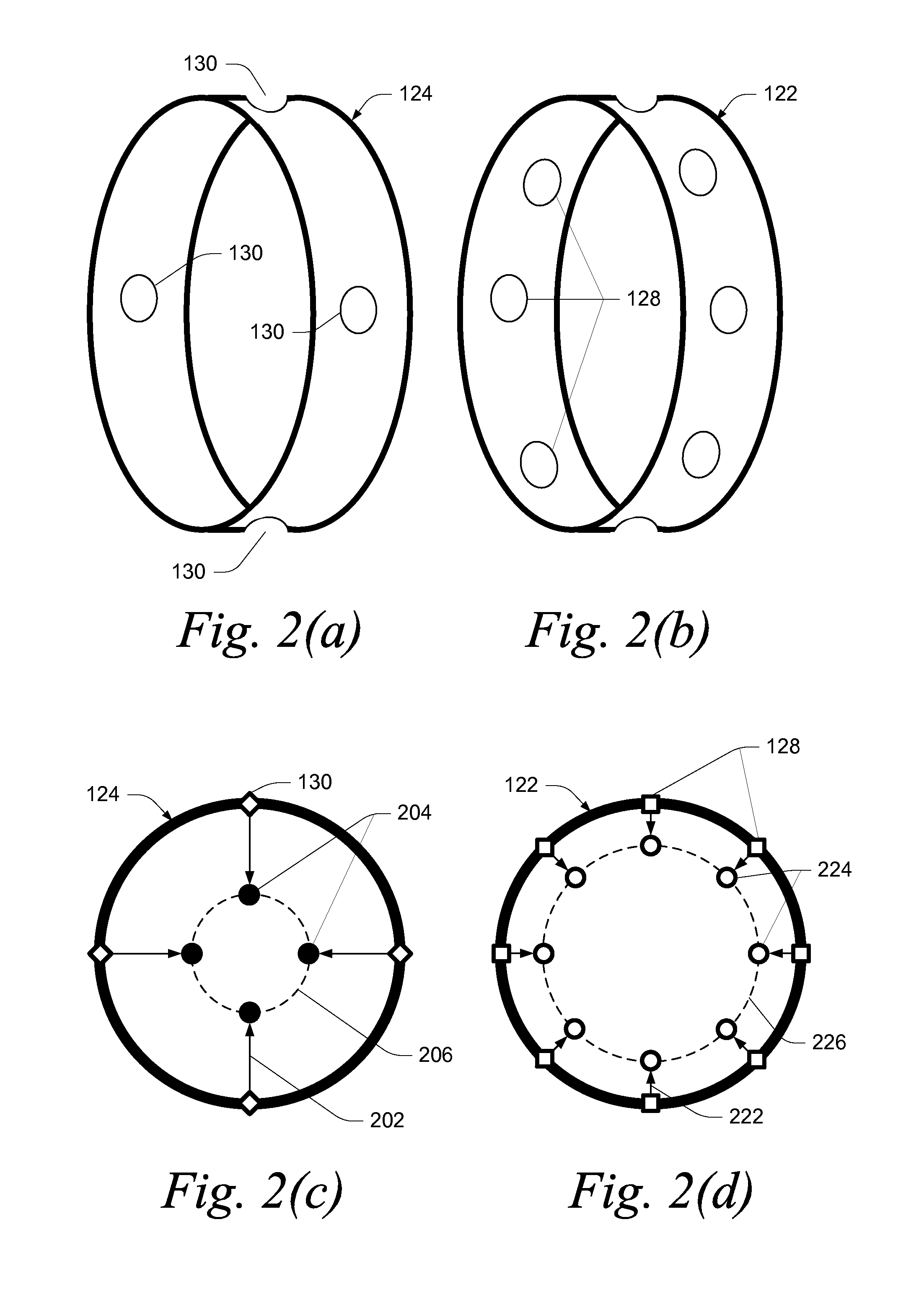

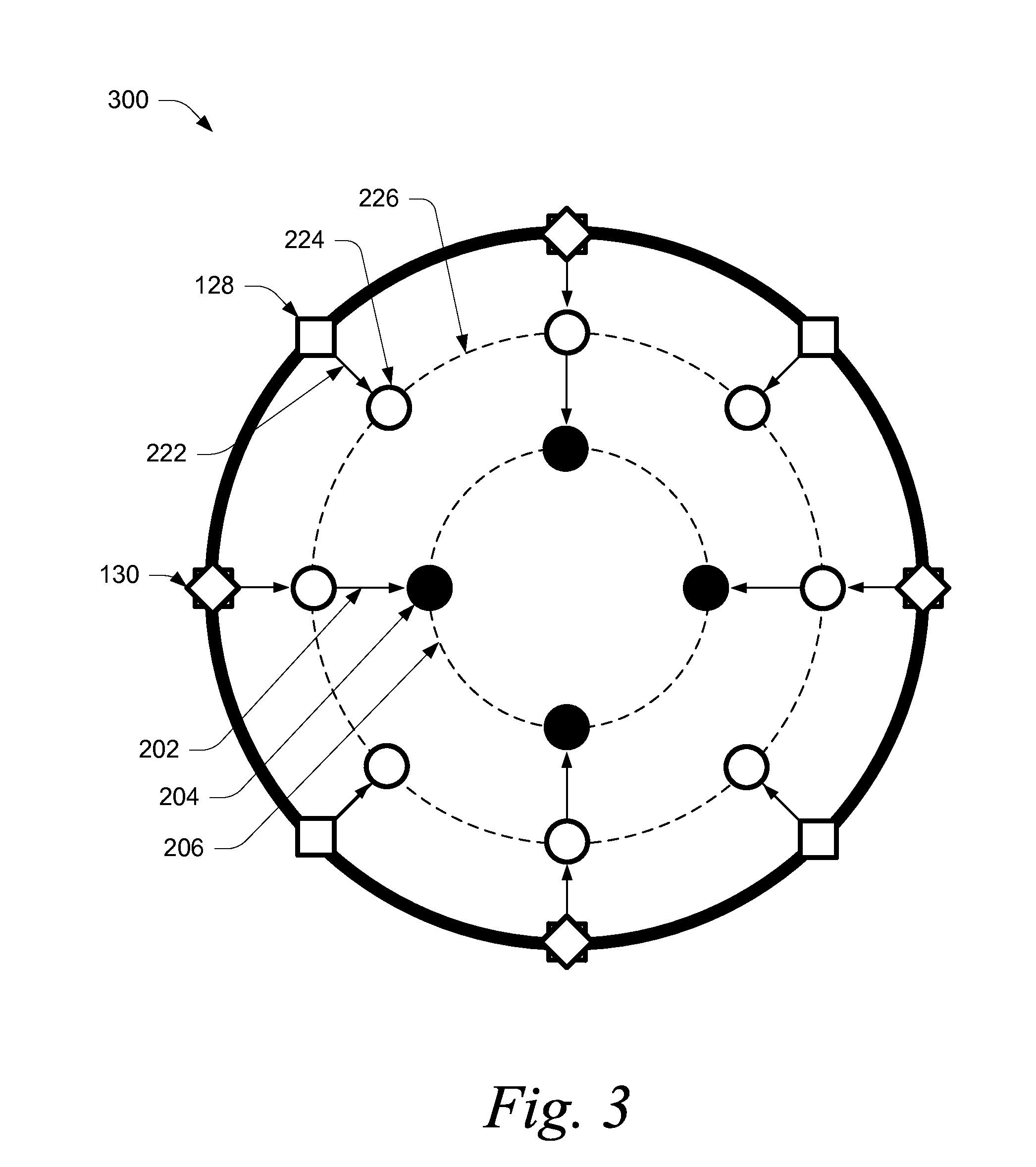

A pyrolytic reactor comprising a fuel injection zone, a combustion zone adjacent to the fuel injections zone, an expansion zone adjacent to the combustion zone, a feedstock injection zone comprising a plurality of injection nozzles and disposed adjacent to the expansion zone, a mixing zone configured to mix a carrier stream and feed material and disposed adjacent to the feedstock injection zone, and a reaction zone adjacent to the mixing zone. The plurality of injection nozzles are radially distributed in a first assembly defining a first plane transverse to the feedstock injection zone and in a second assembly transverse to the feedstock injection zone.

Owner:UOP LLC

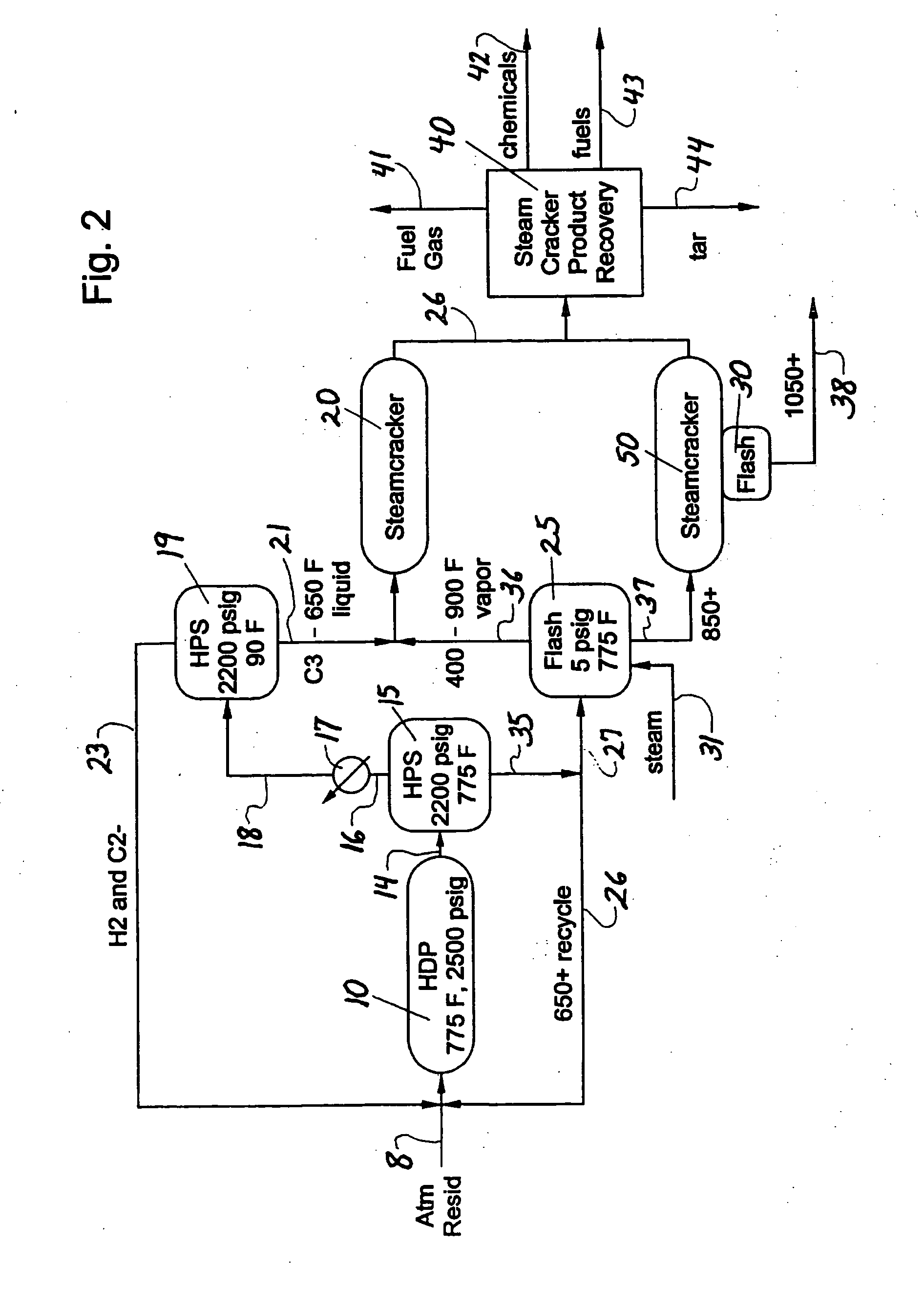

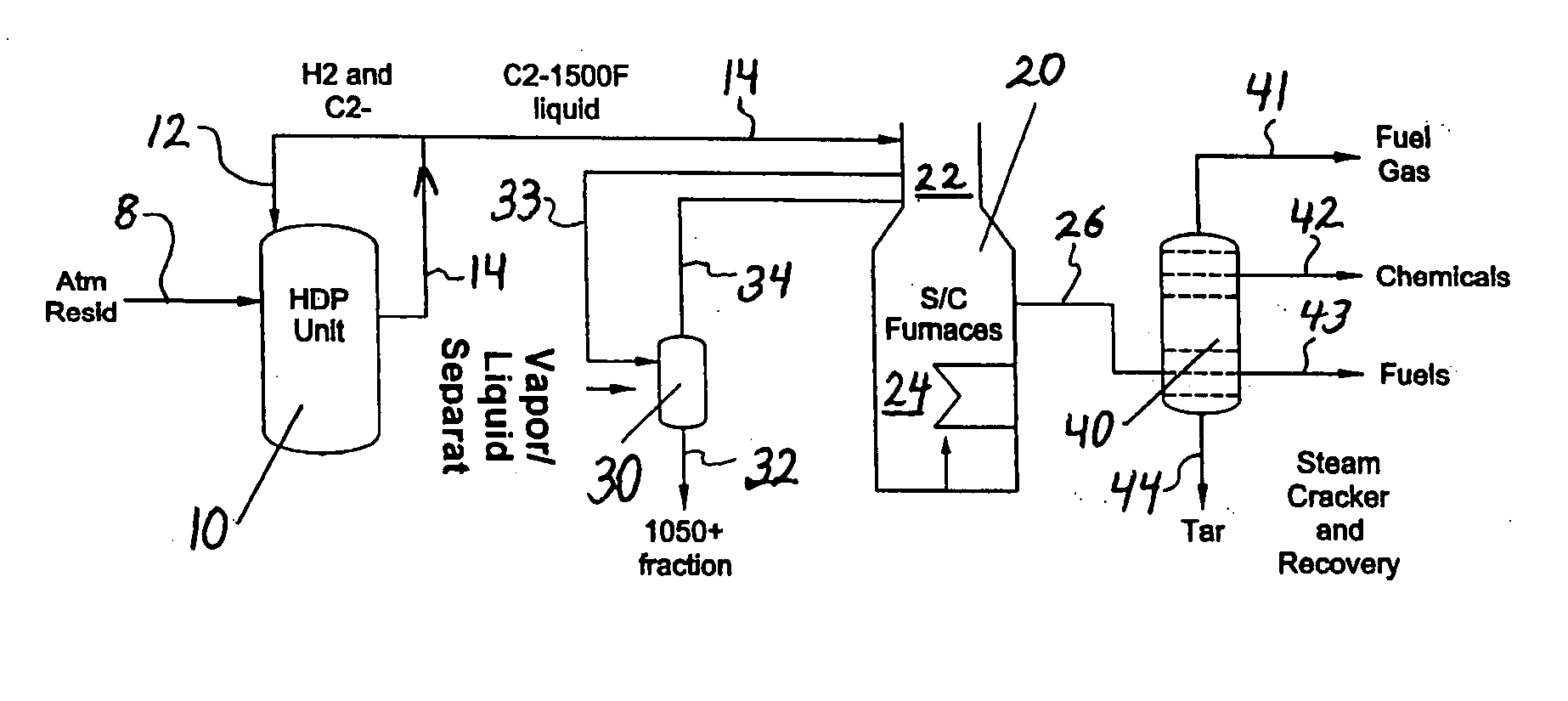

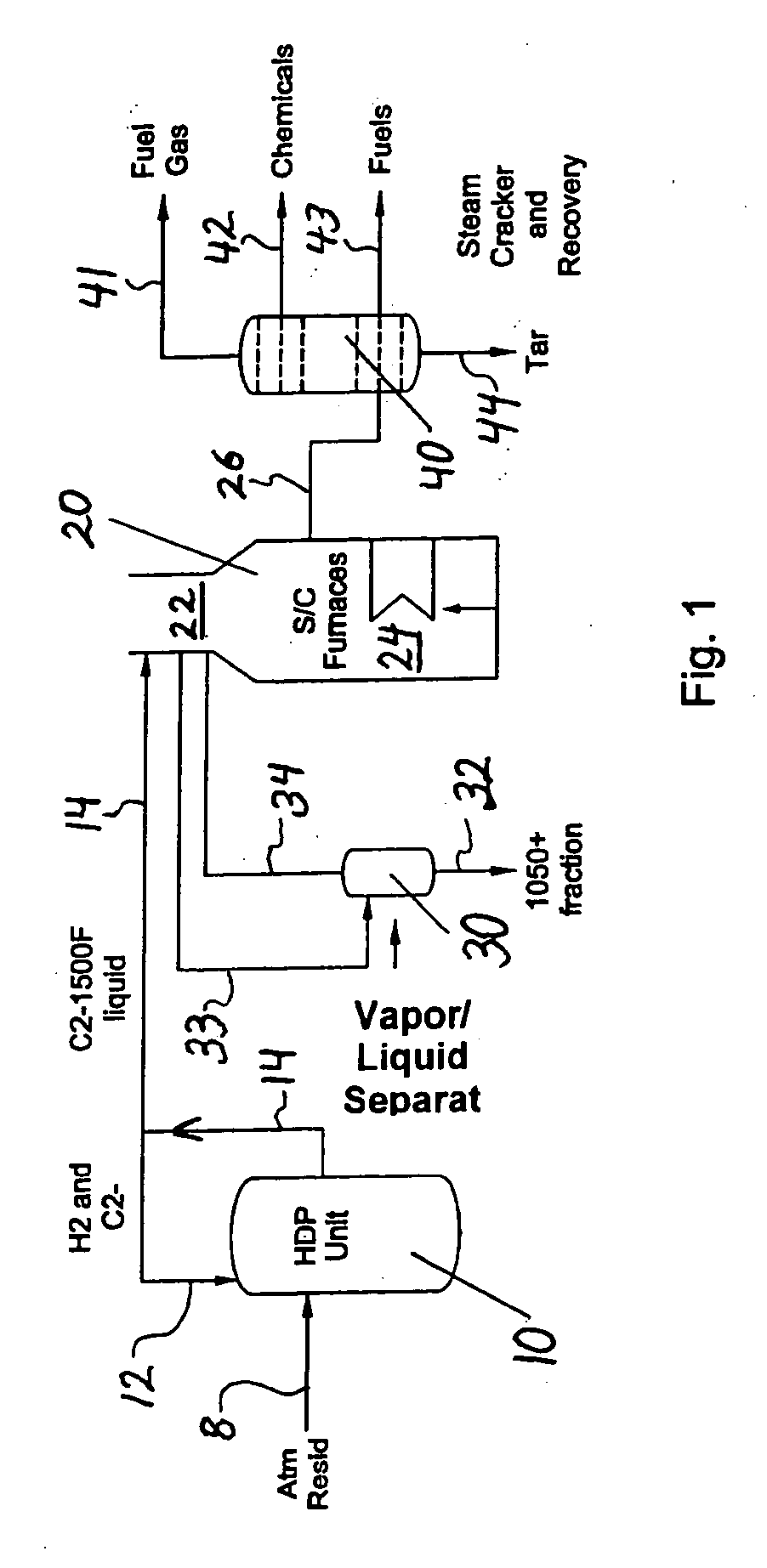

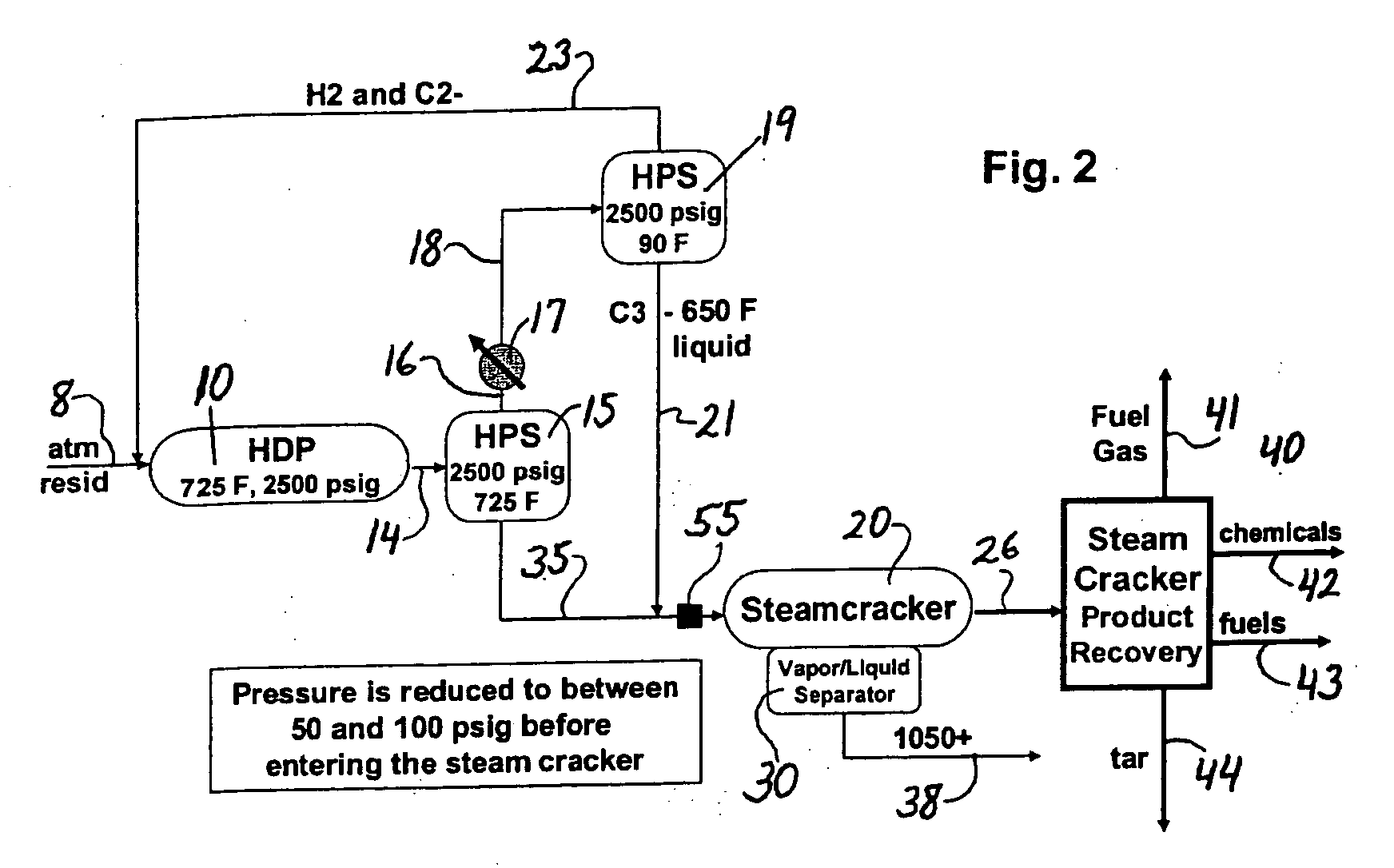

Hydrocarbon resid processing

ActiveUS20070090018A1Increase in severityReduce pressureThermal non-catalytic crackingHydrocarbon oil cracking processHydrocarbonChemistry

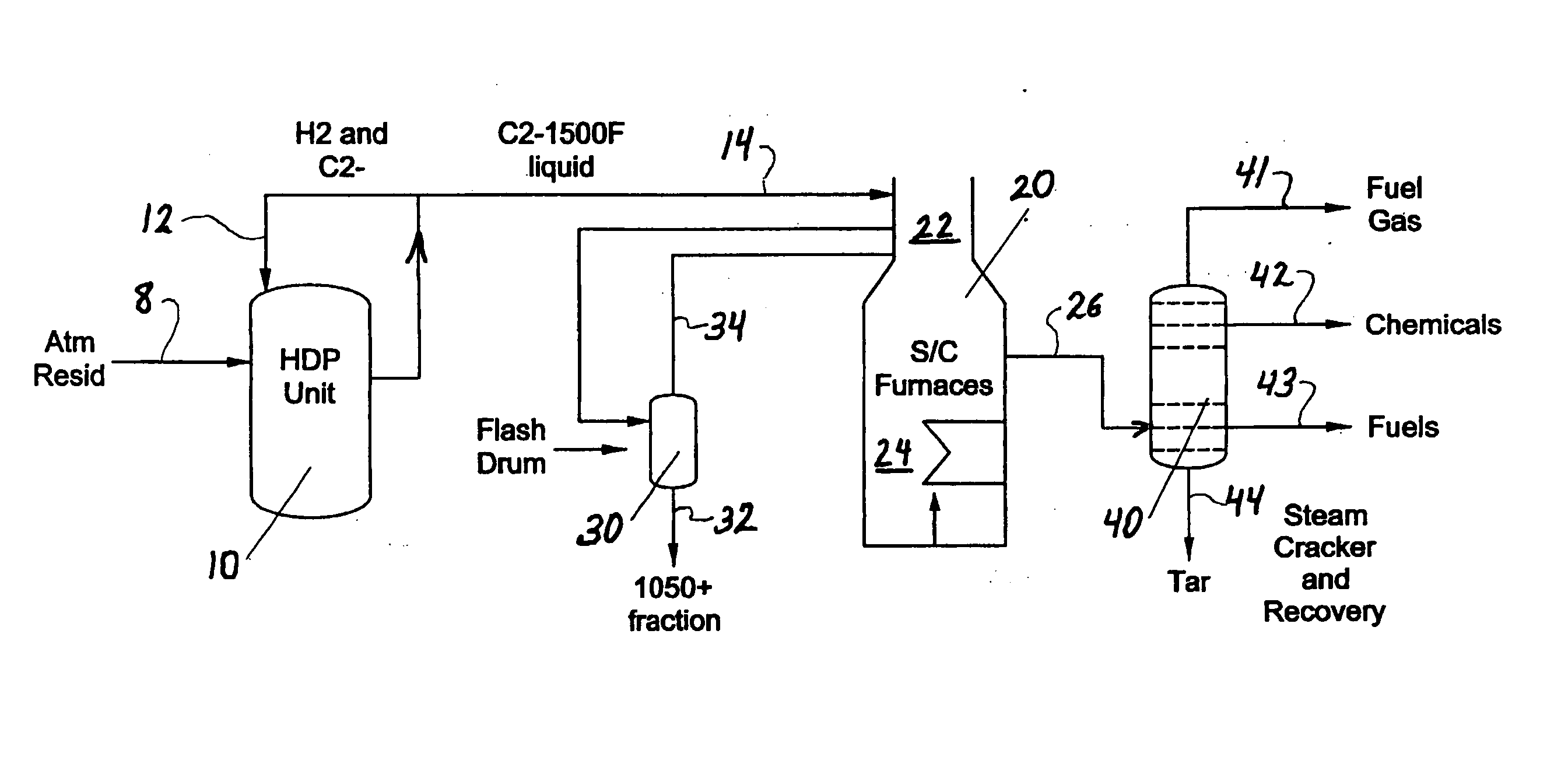

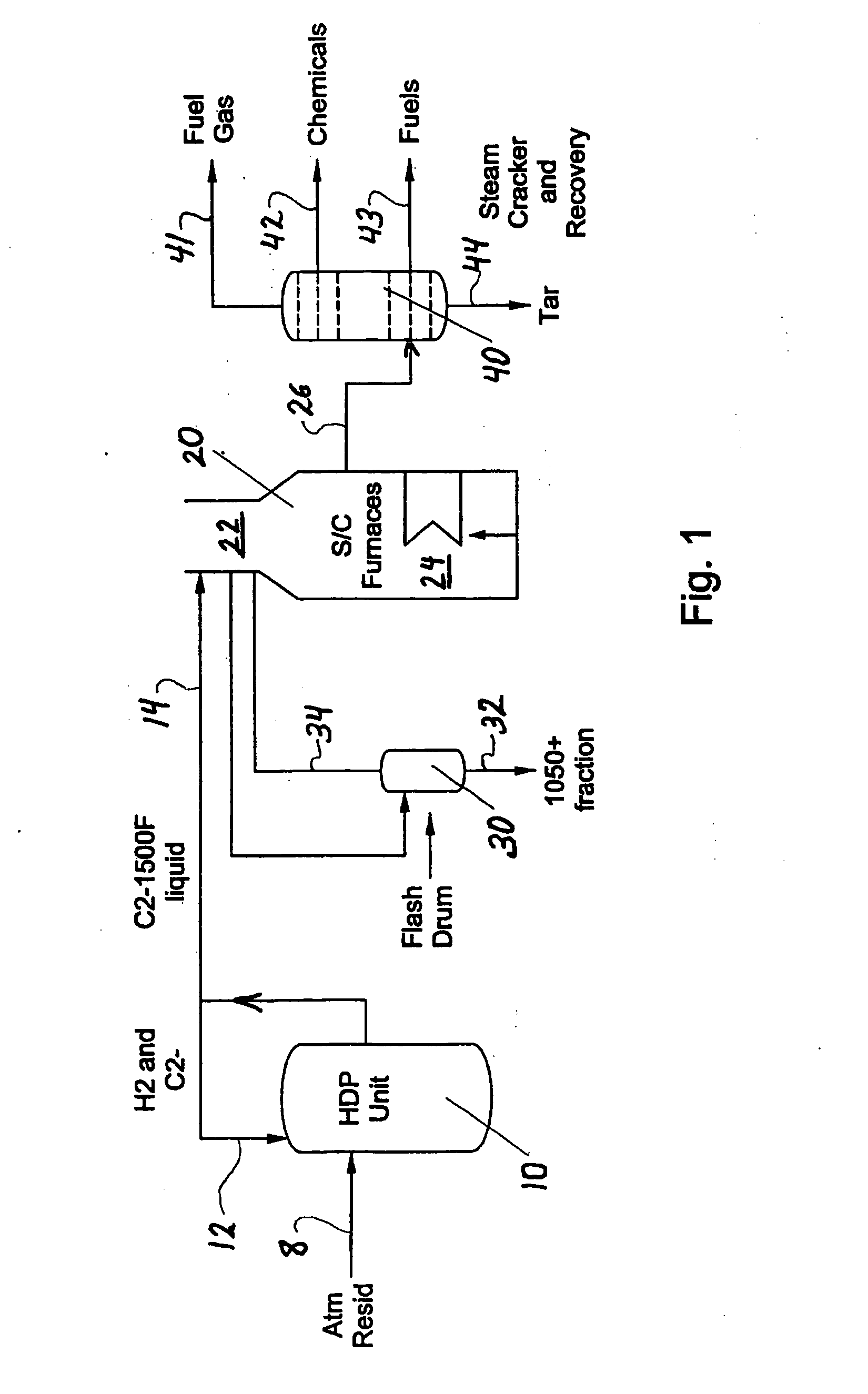

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is severely hydrotreated and passed to a steam cracker to obtain an olefins product.

Owner:EXXONMOBIL CHEM PAT INC

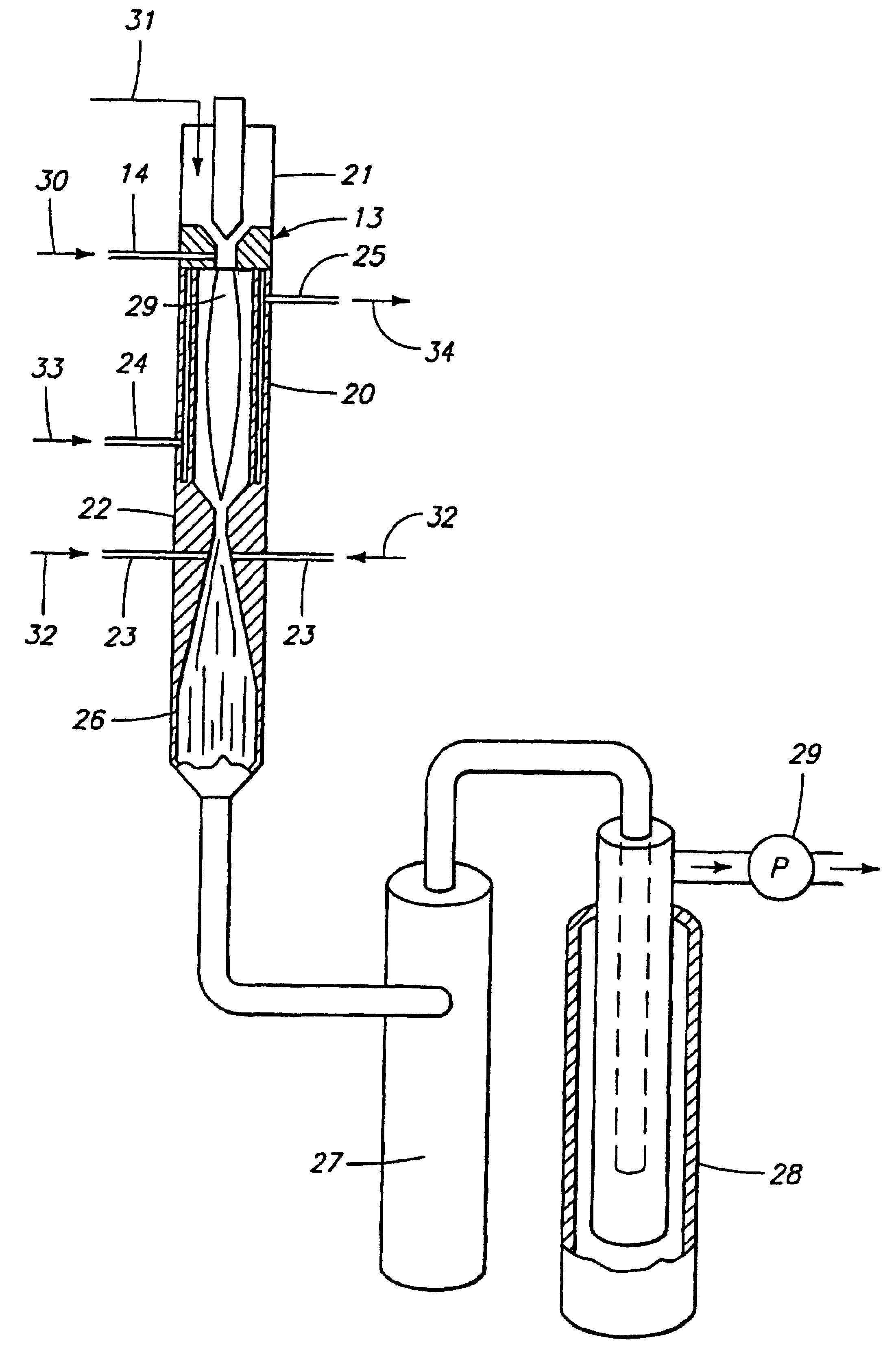

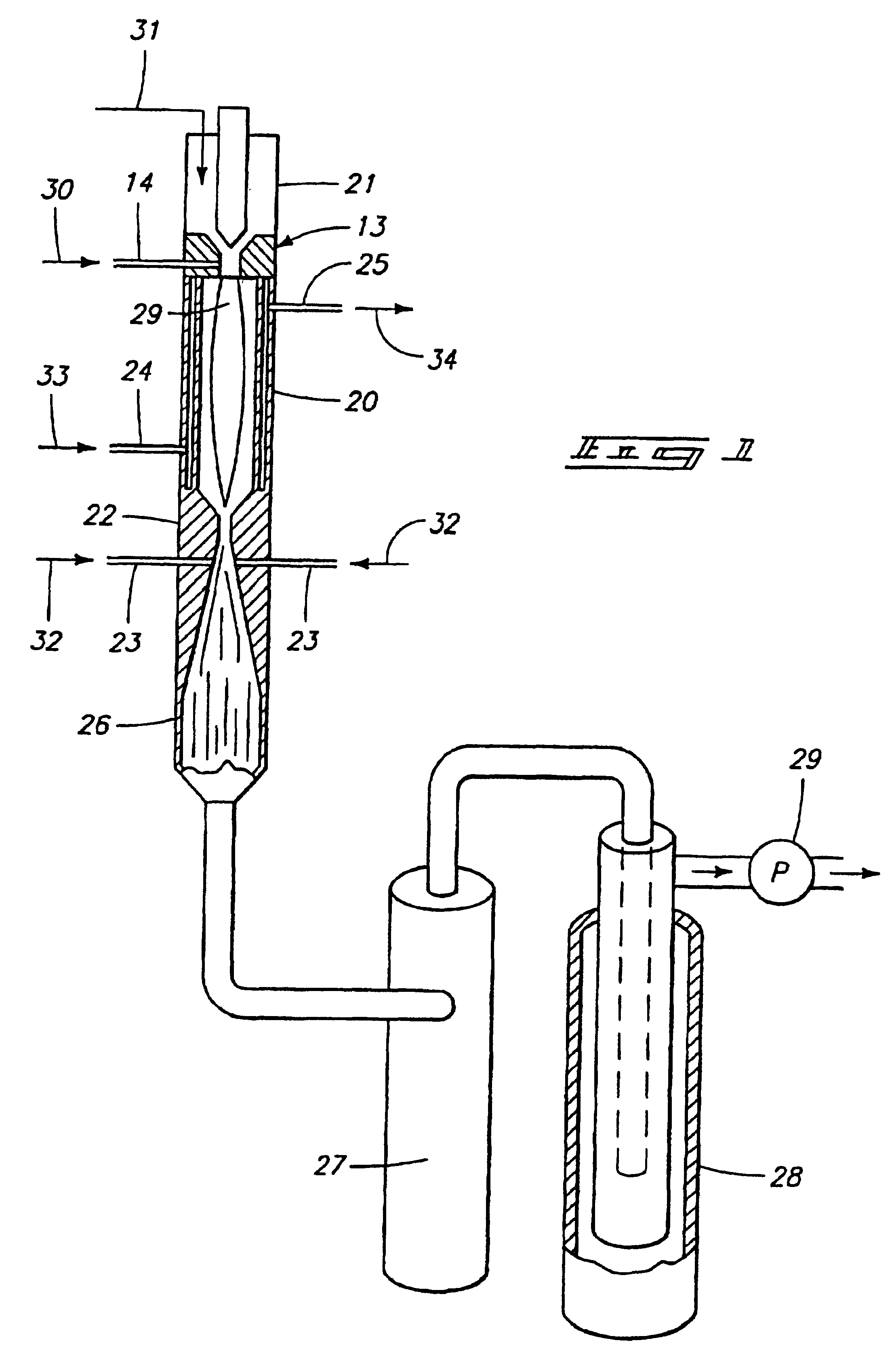

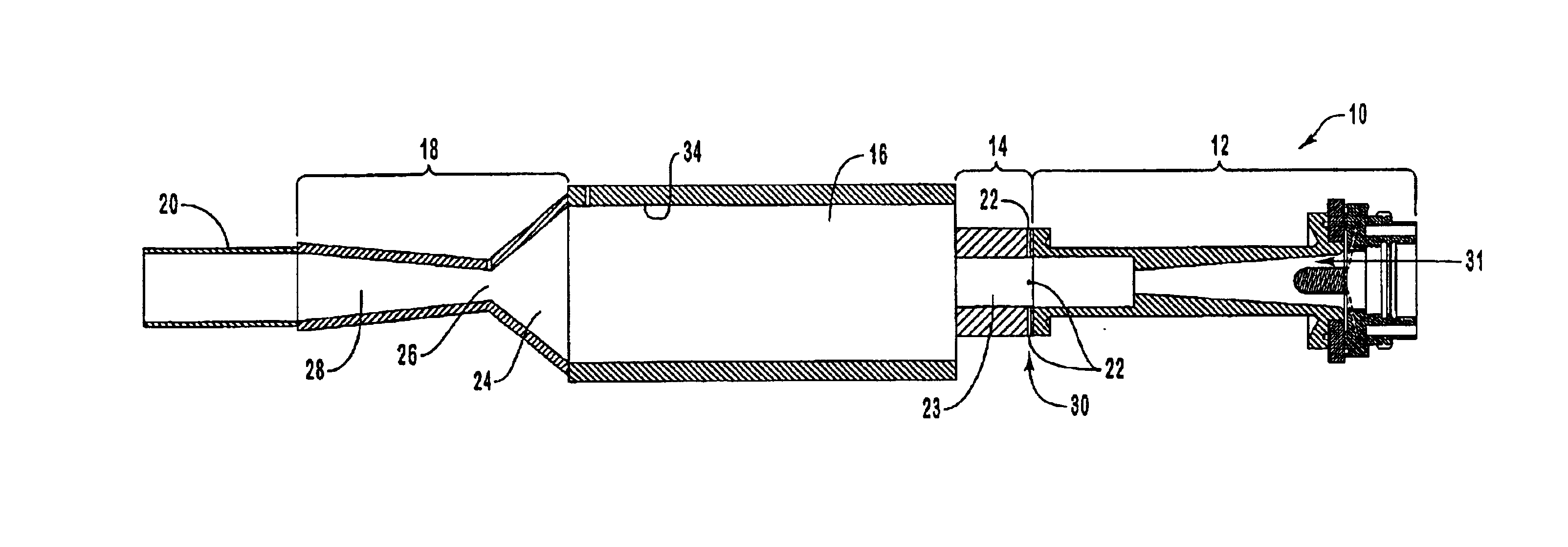

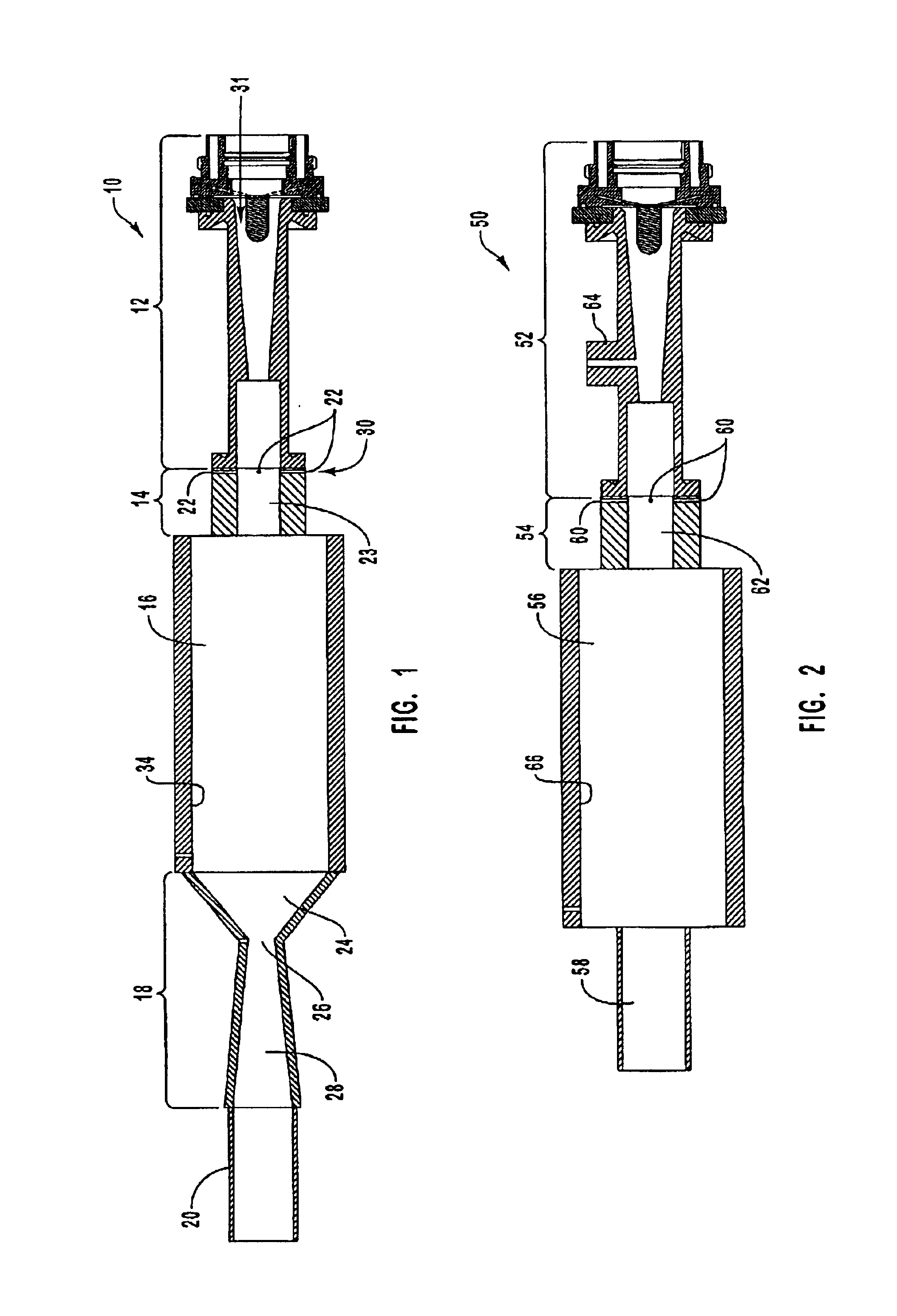

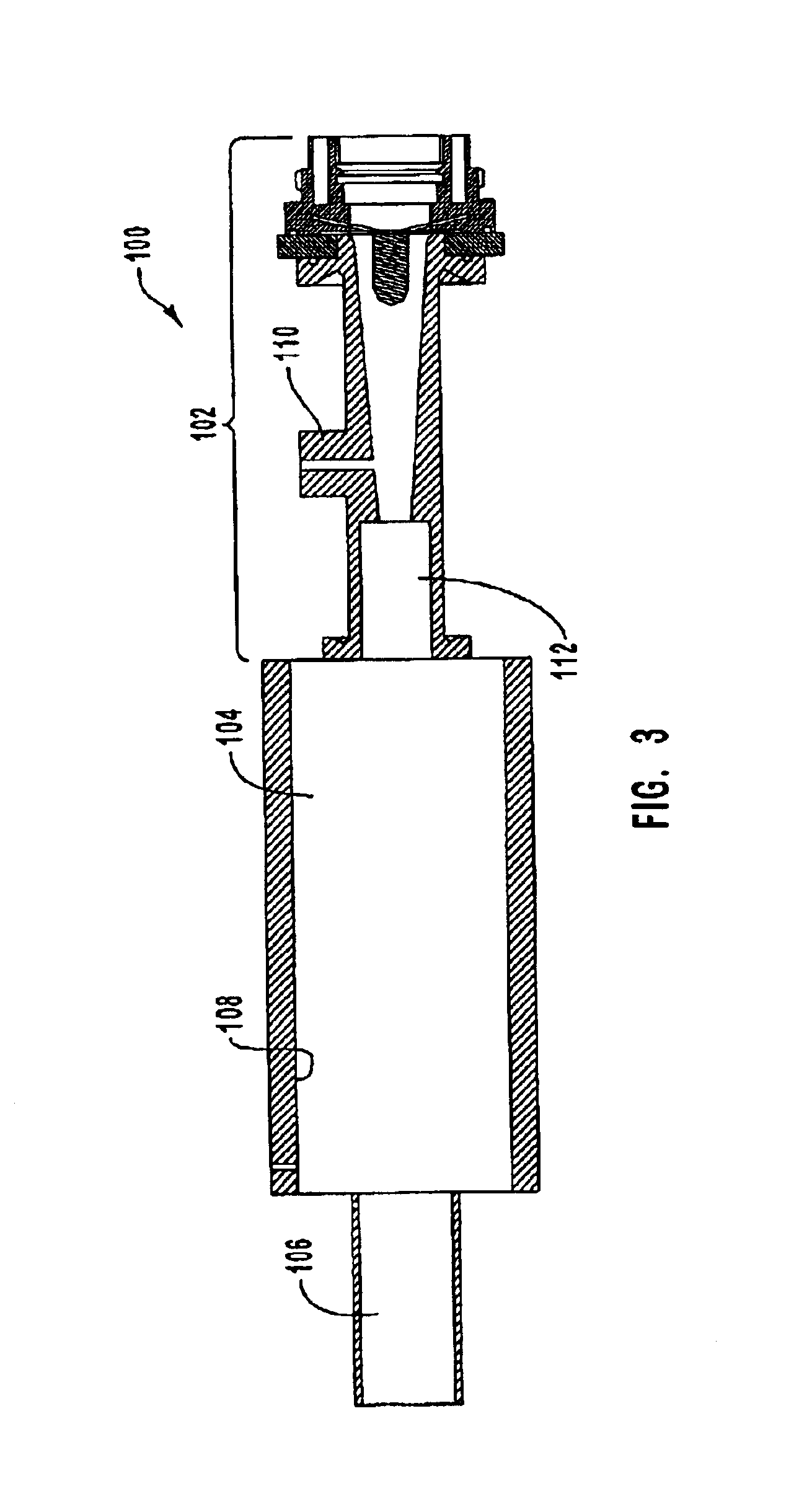

Fast quench reactor and method

InactiveUSRE37853E1Minimizing back reactionRapid coolingMaterial nanotechnologyIndirect heat exchangersThermodynamicsProcess engineering

A fast quench reaction includes a reactor chamber having a high temperature heating means such as a plasma torch at its inlet and a restrictive convergent-divergent nozzle at its outlet end. Reactants are injected into the reactor chamber. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle. This "freezes" the desired end product(s) in the heated equilibrium reaction stage.

Owner:BATTELLE ENERGY ALLIANCE LLC

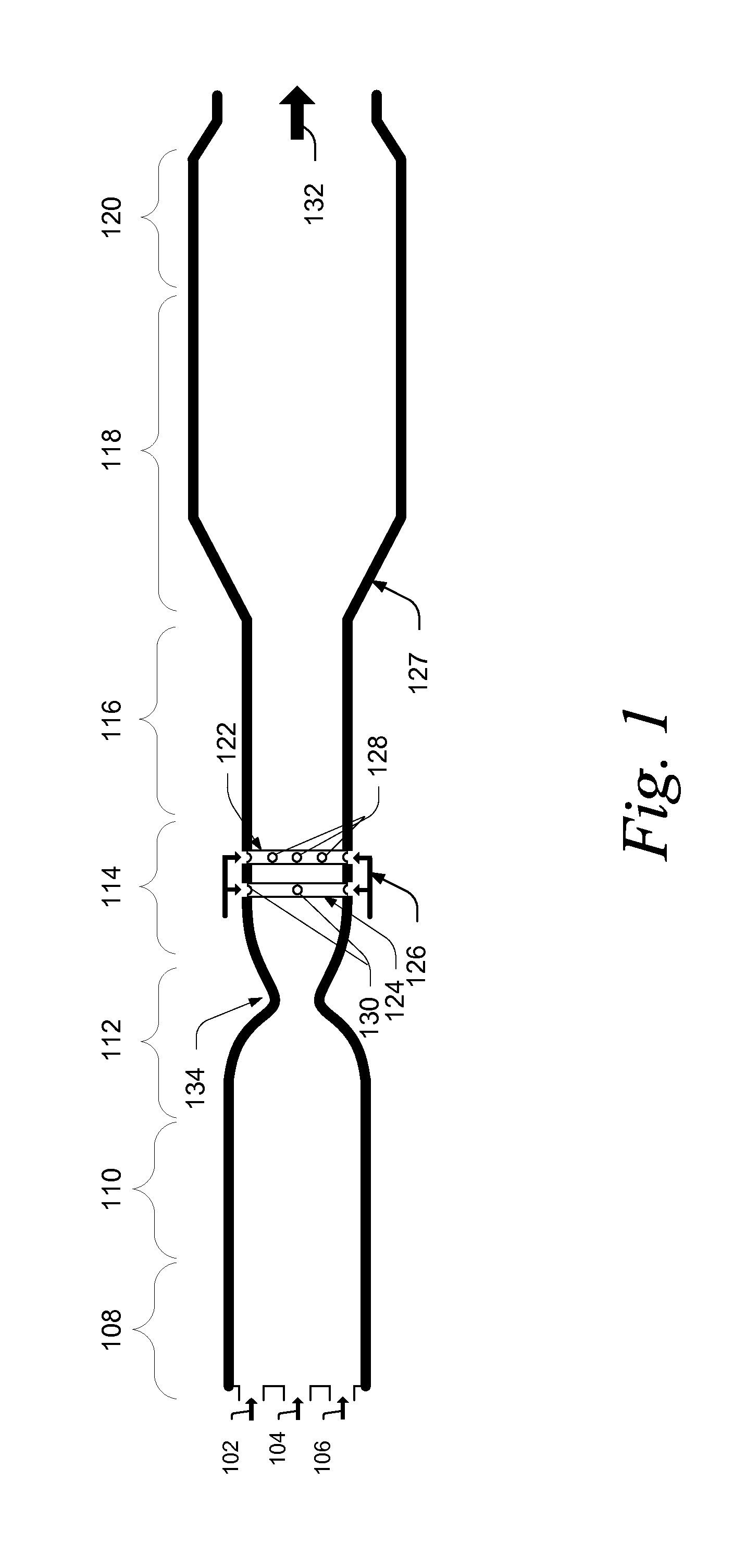

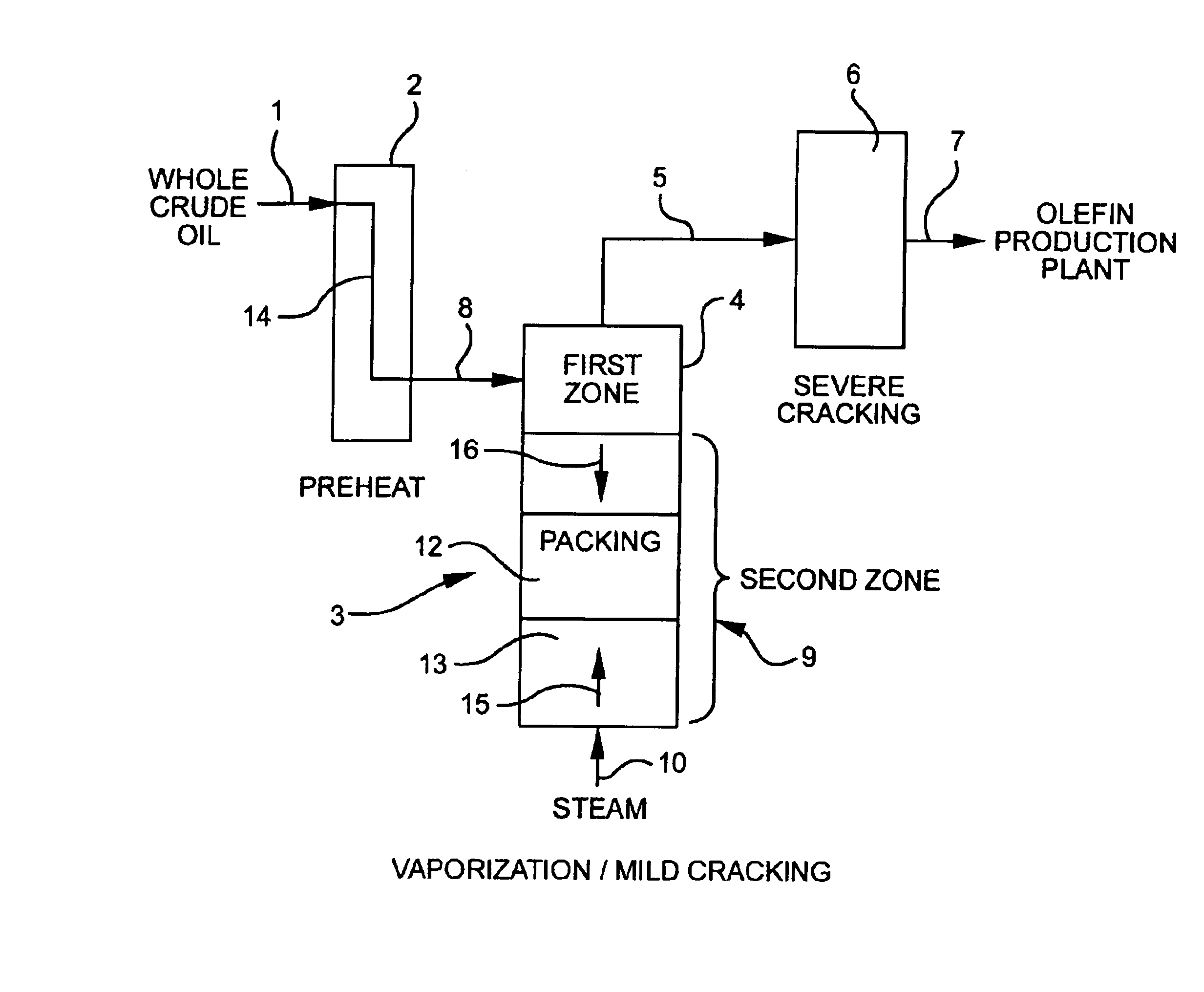

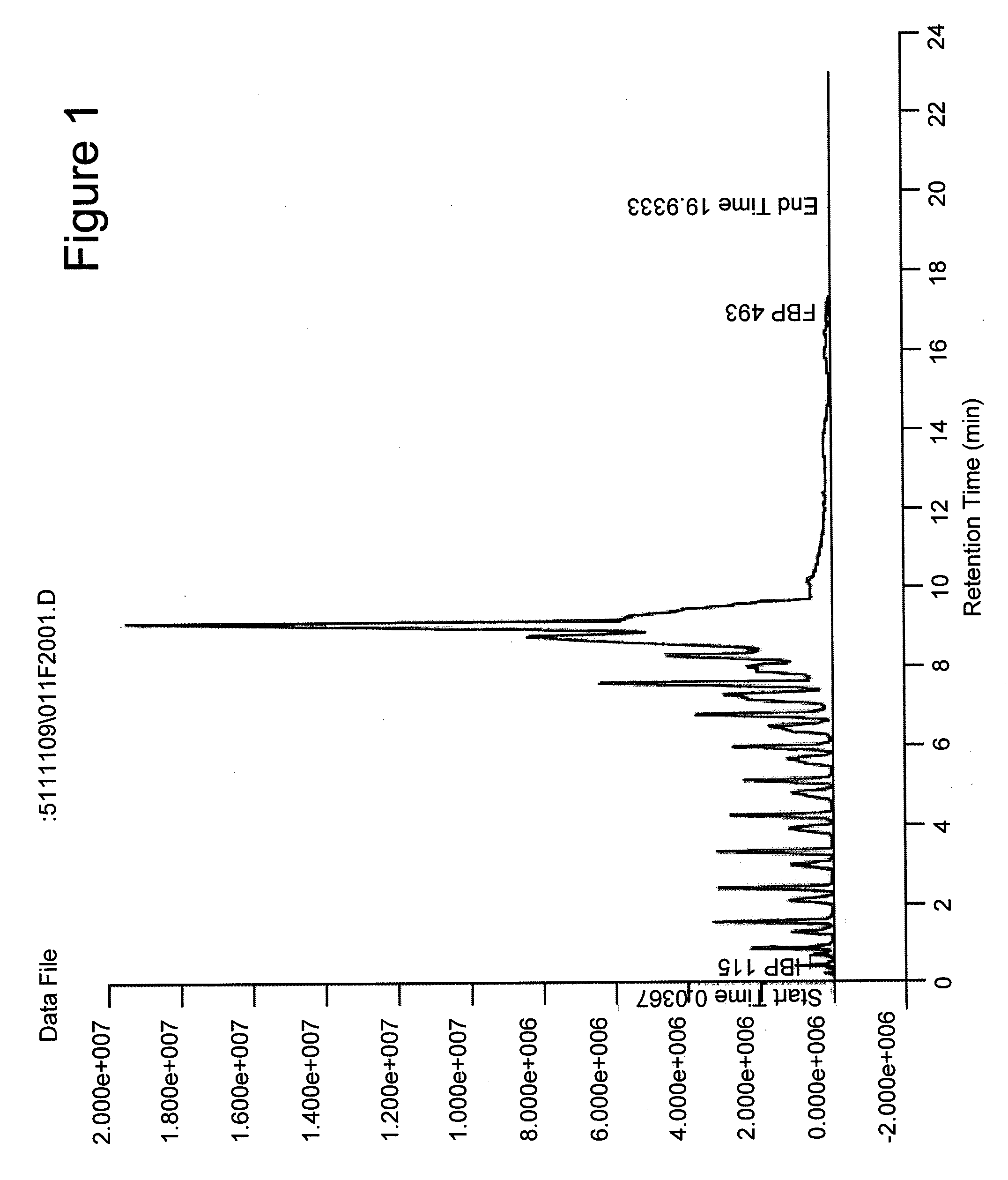

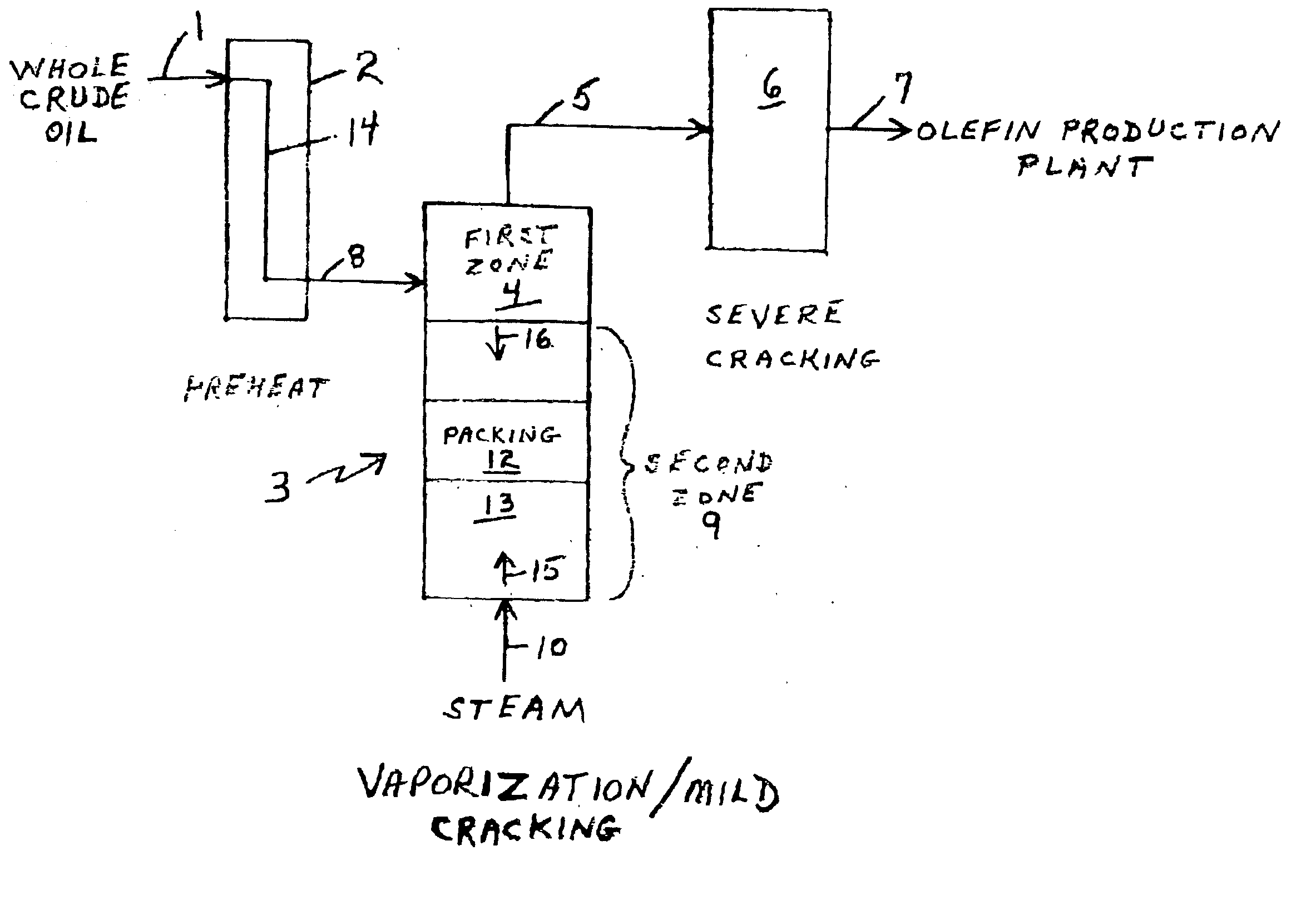

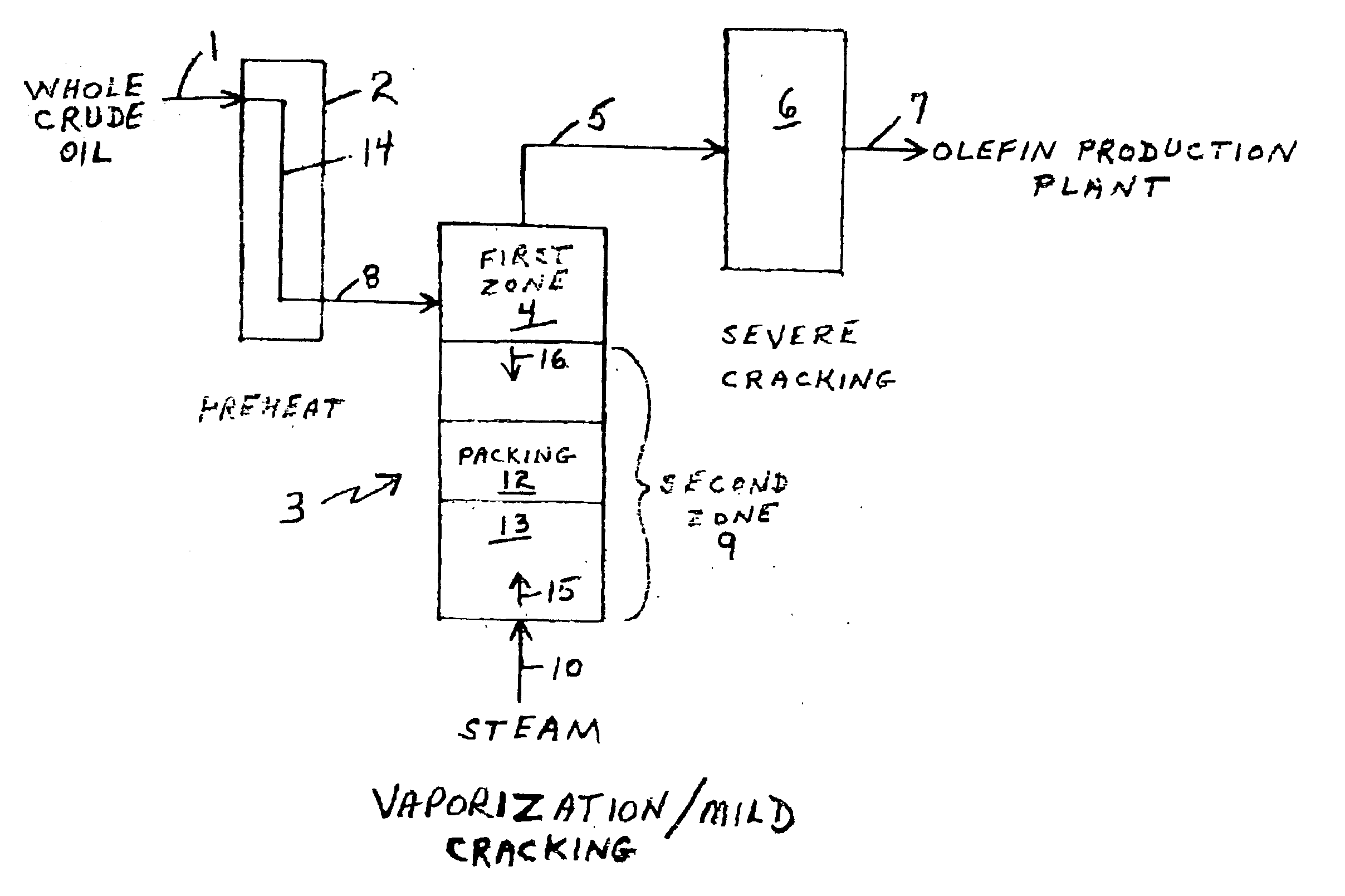

Olefin production utilizing whole crude oil

InactiveUS6743961B2Lower temperature rangeReduce molecular weightThermal non-catalytic crackingHydrocarbonsOil productionAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild cracking conditions until substantially vaporized, the vapors from mild cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

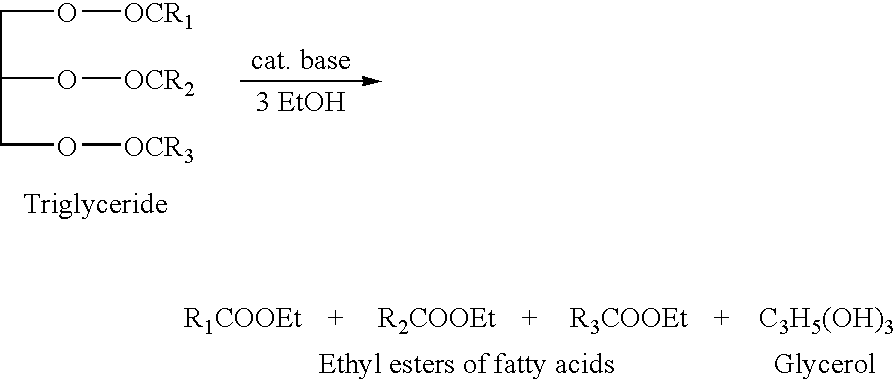

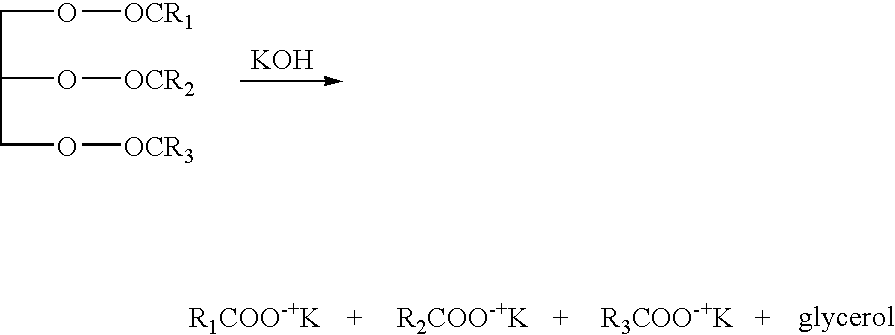

Hydroprocessing Microalgal Oils

InactiveUS20100170144A1Improve efficiencyLow costHydrocarbon by isomerisationHydrocarbon purification/separationChemical treatmentAlkaline hydrolysis

Fuels and other valuable compositions and compounds can be made from oil extracted from microbial biomass and from oil-bearing microbial biomass via hydroprocessing and / or other chemical treatments, including the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts.

Owner:TERRAVIA HLDG INC

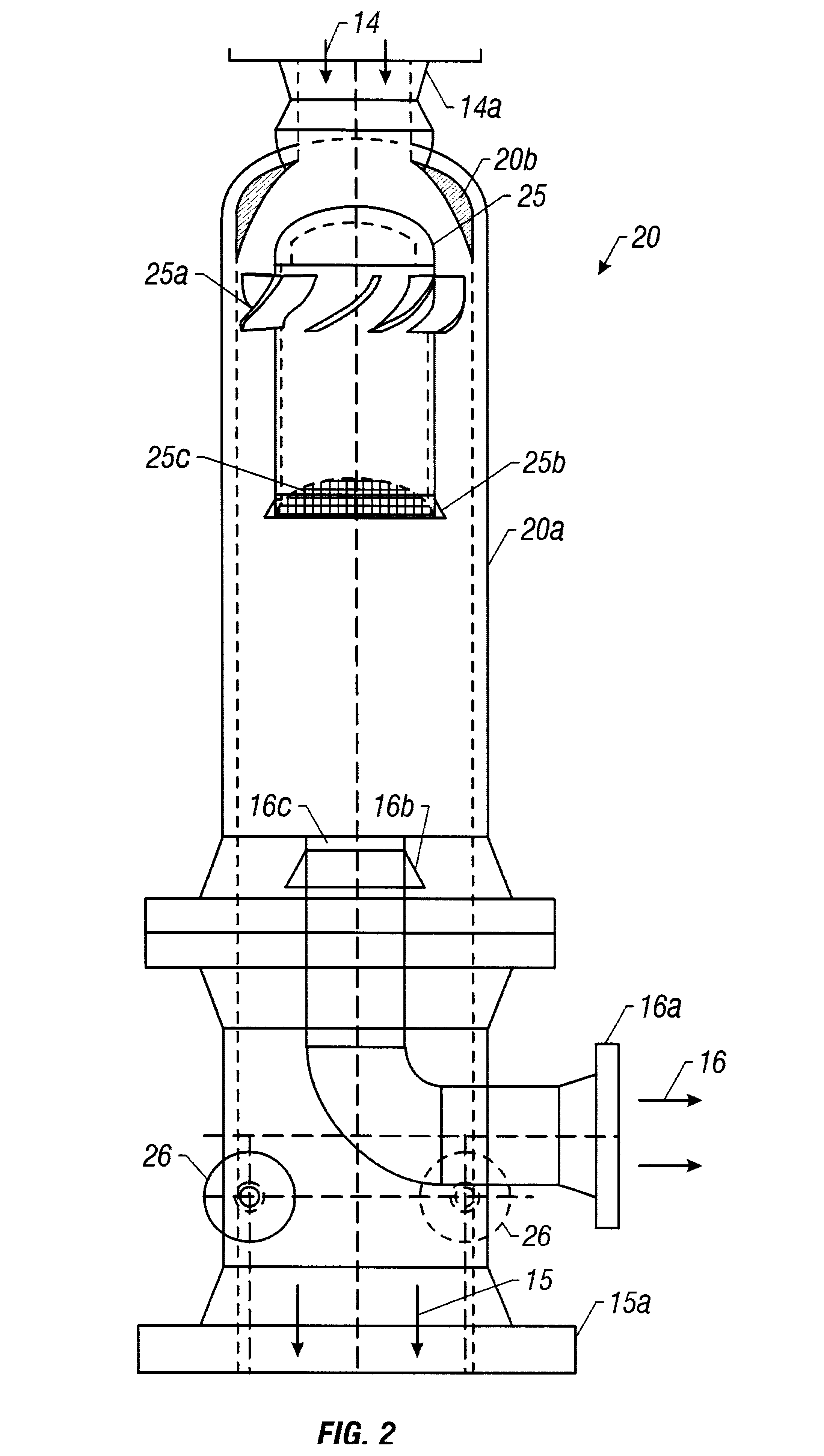

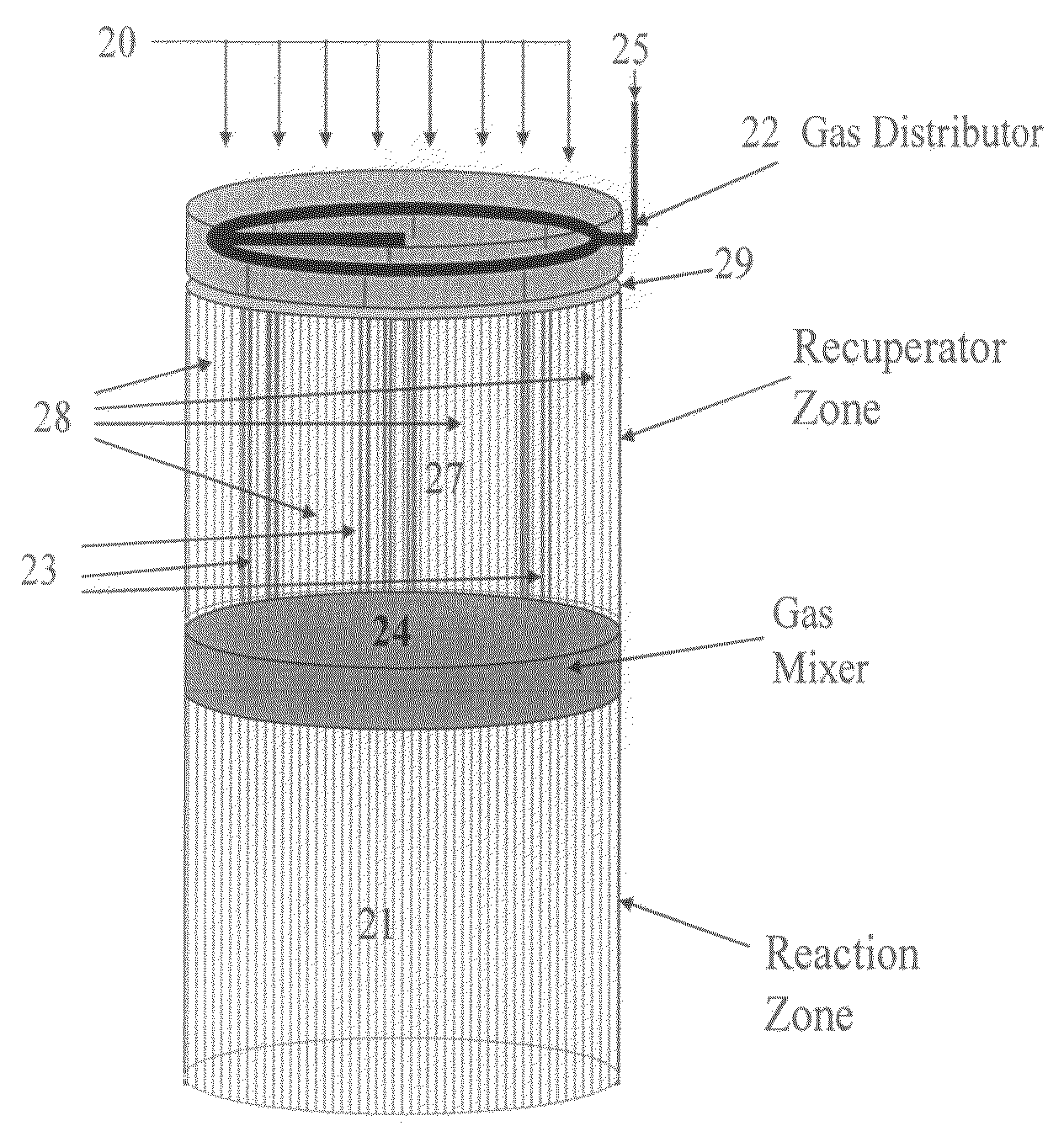

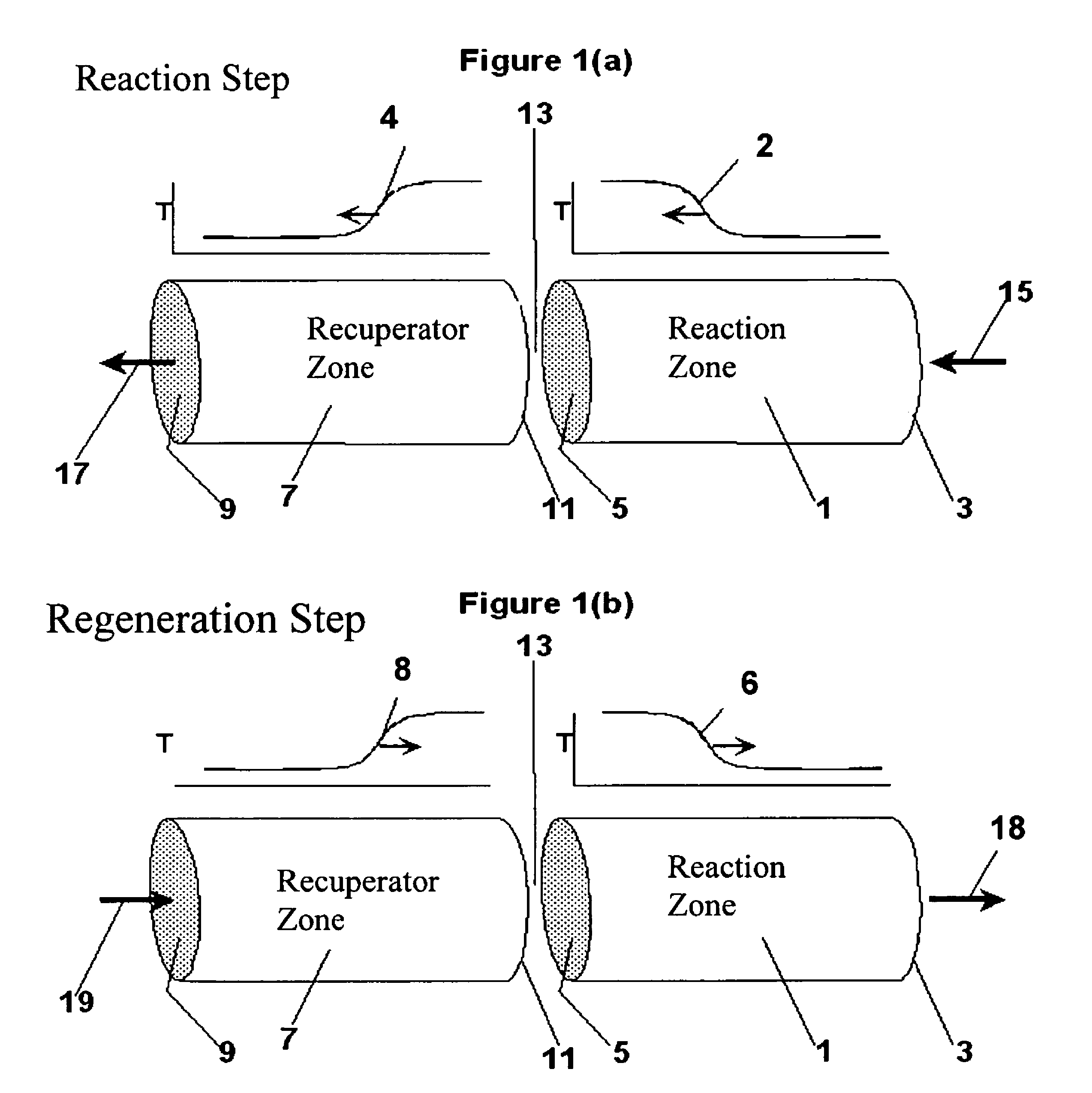

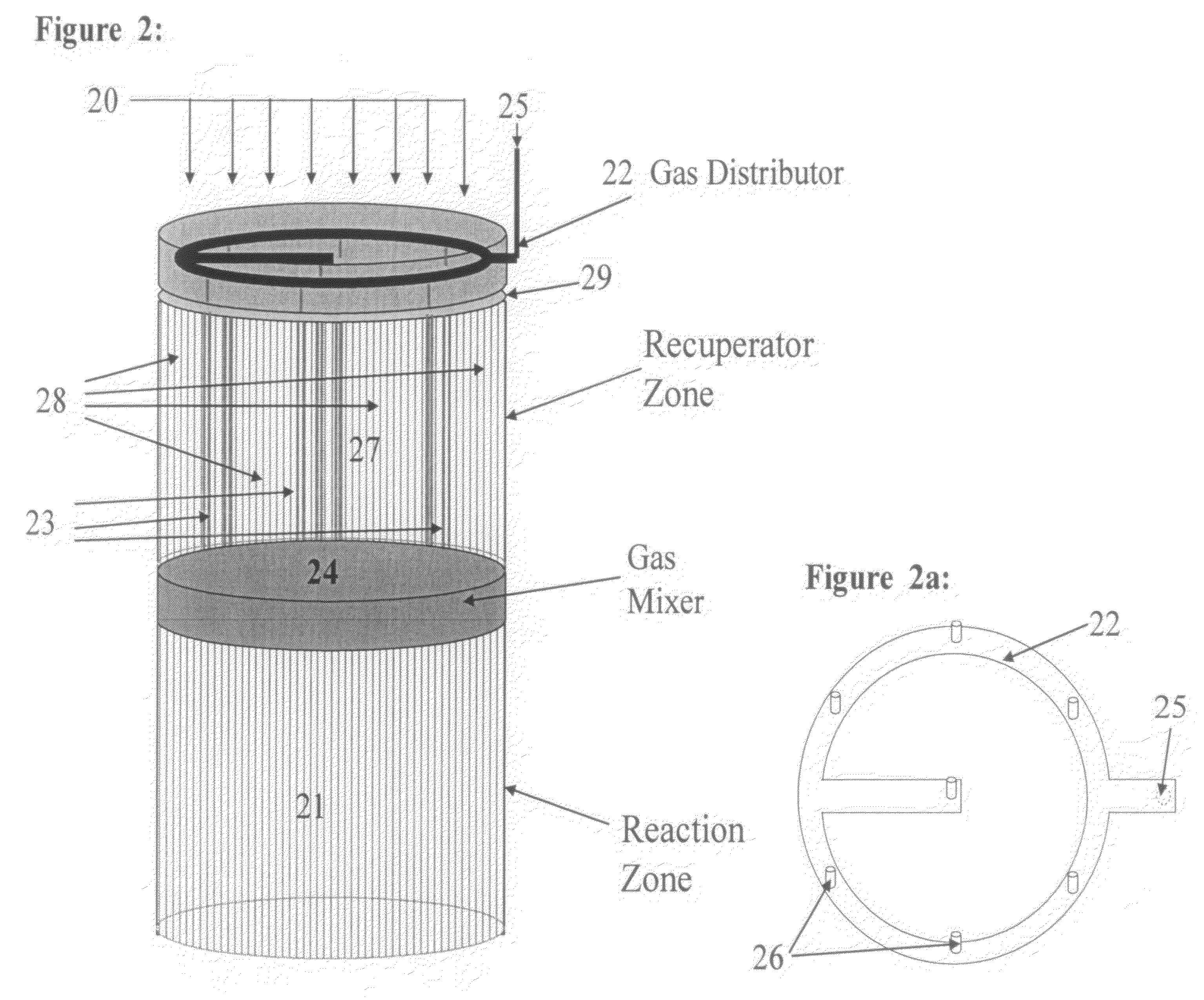

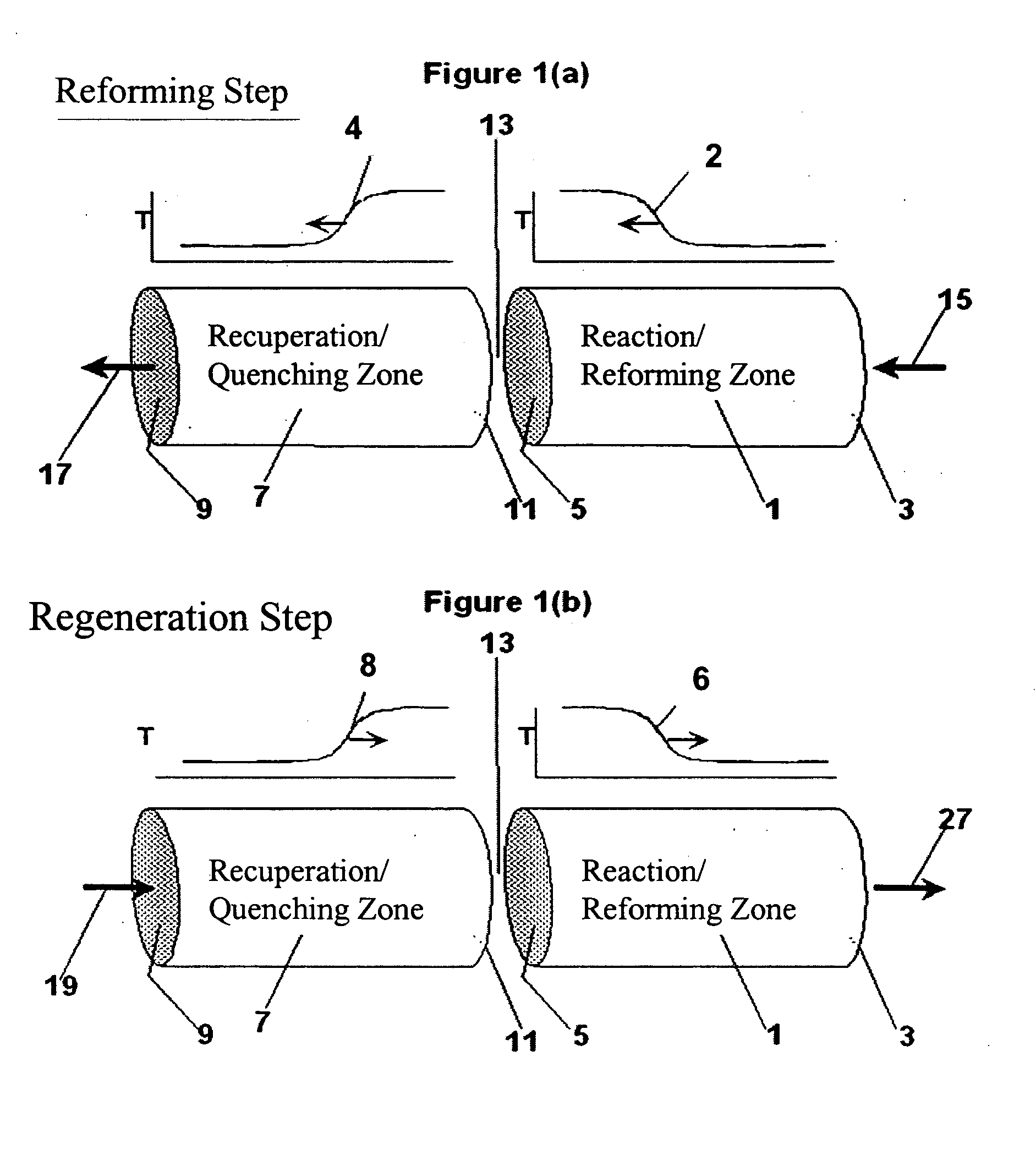

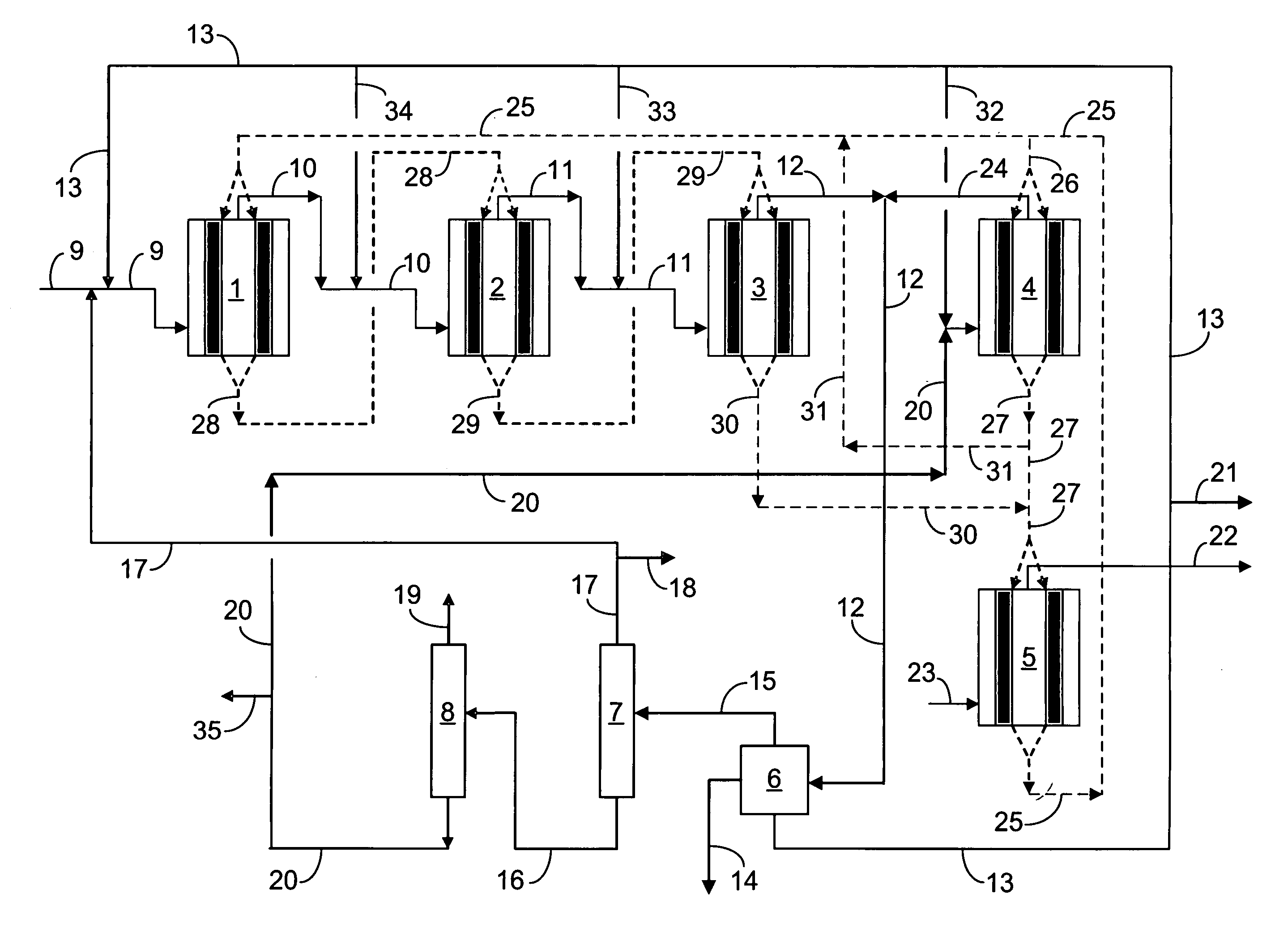

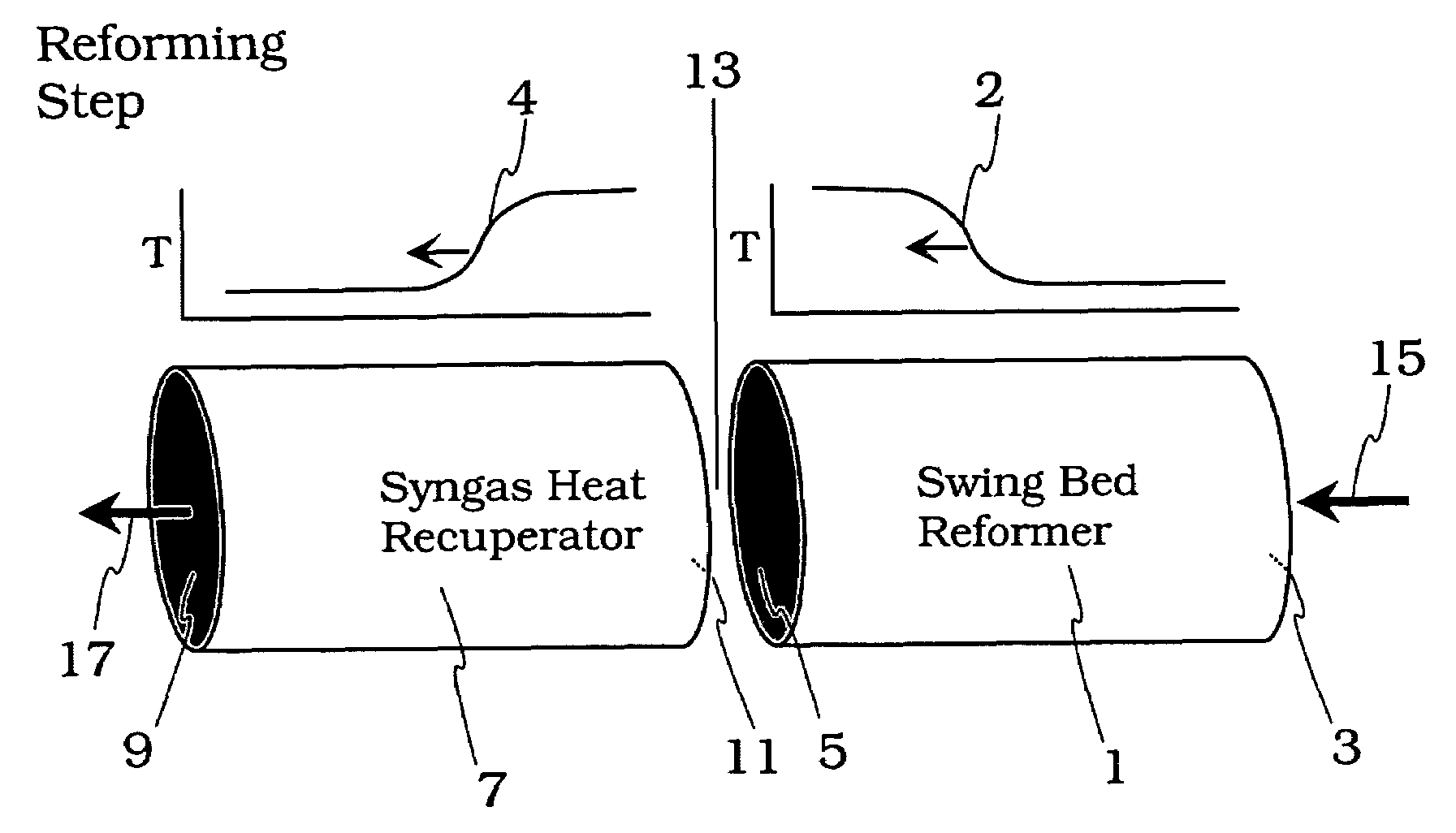

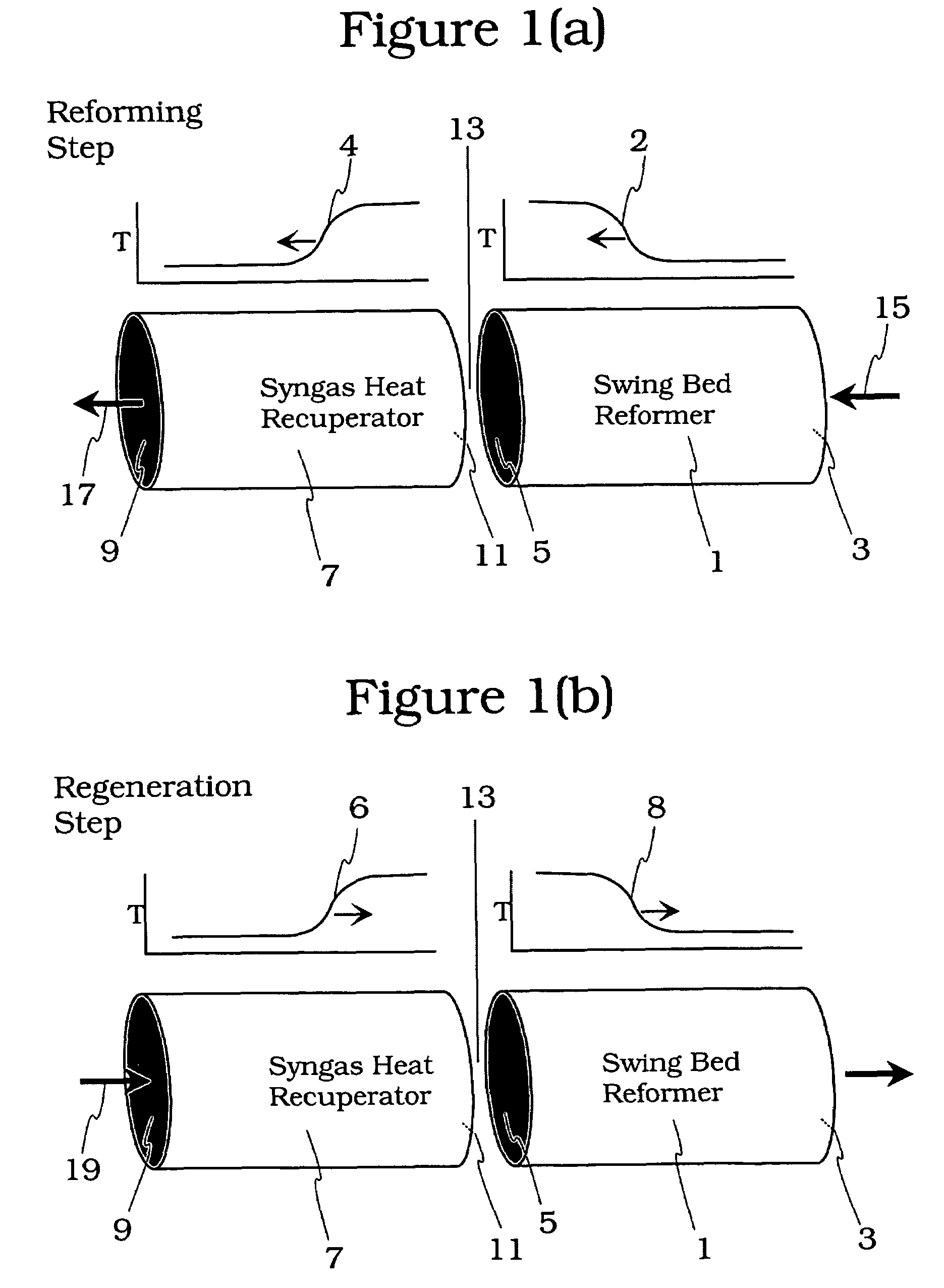

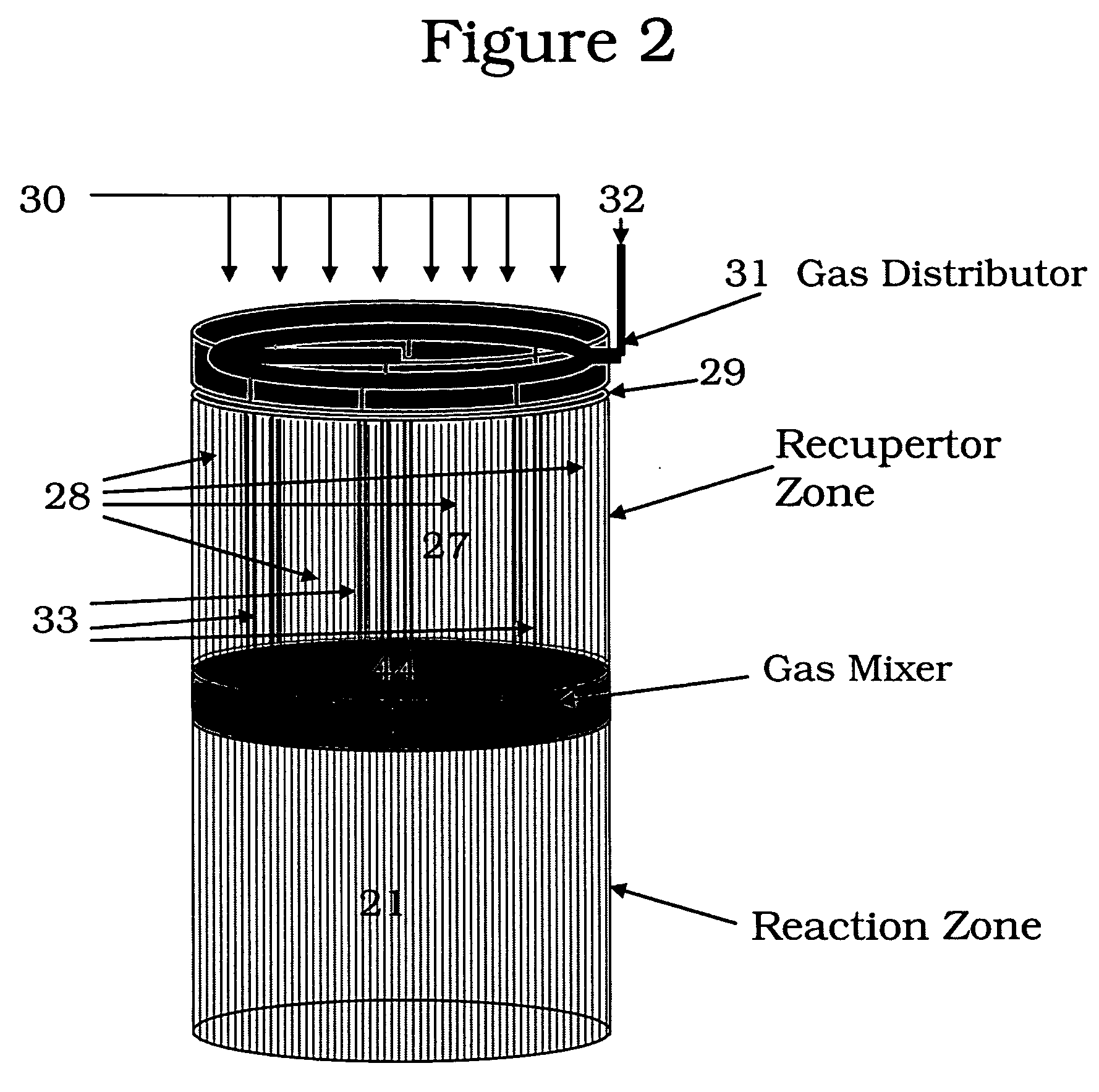

Controlled combustion for regenerative reactors with mixer/flow distributor

ActiveUS7815873B2Efficient transferEvenly distributedHydrocarbon by dehydrogenationFlow mixersReactor systemCombustion

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

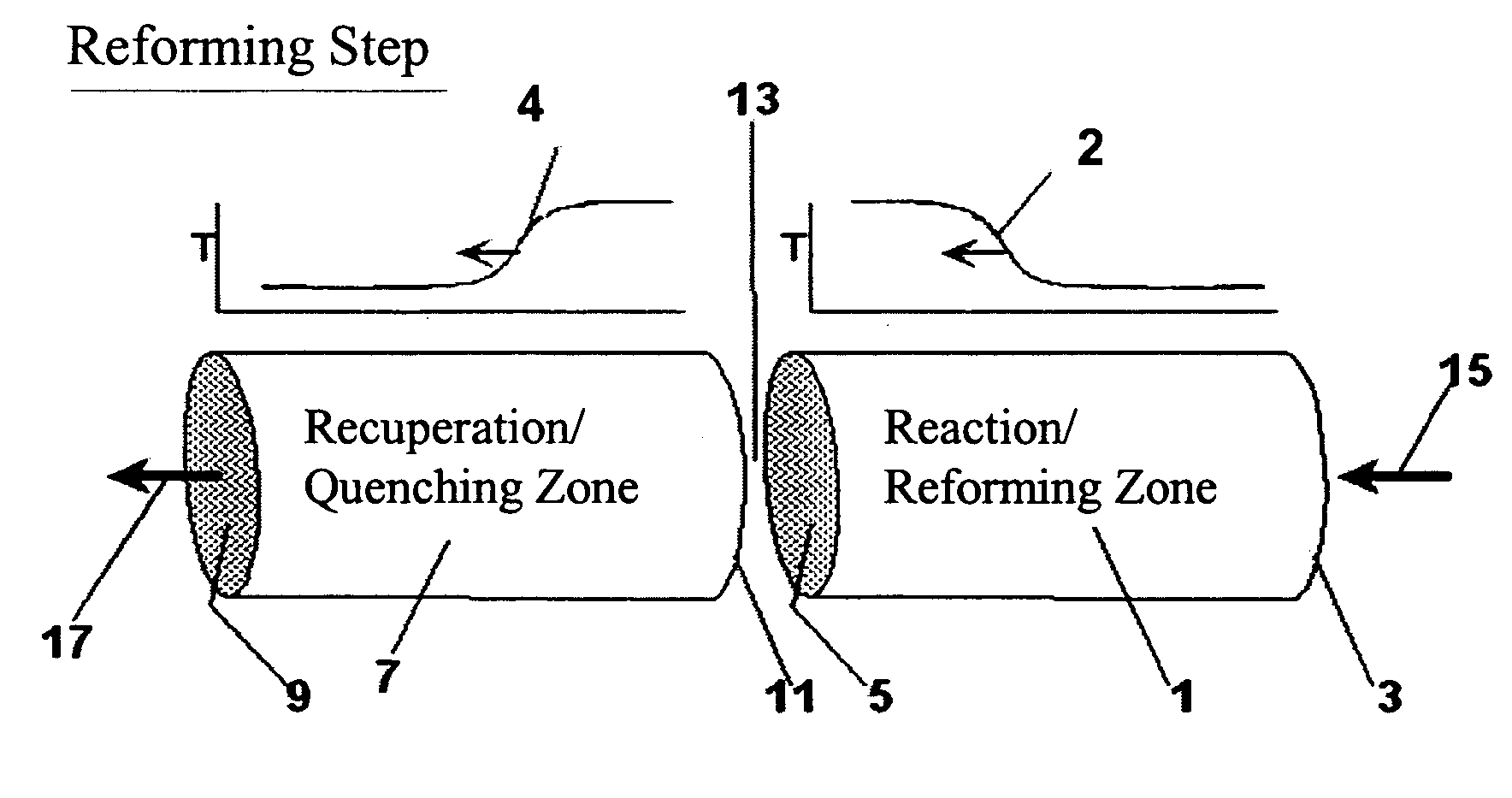

Methane conversion to higher hydrocarbons

ActiveUS20070191664A1Efficient preparationValid conversionGenerators with non-automatic water feedFlow mixersReactor systemReagent

The present invention provides a process for the manufacture of acetylene and other higher hydrocarbons from methane feed using a reverse-flow reactor system, wherein the reactor system includes (i) a first reactor and (ii) a second reactor, the first and second reactors oriented in a series relationship with respect to each other, the process comprising supplying each of first and second reactant through separate channels in the first reactor bed of a reverse-flow reactor such that both of the first and second reactants serve to quench the first reactor bed, without the first and second reactants substantially reacting with each other until reaching the core of the reactor system.

Owner:EXXONMOBIL CHEM PAT INC

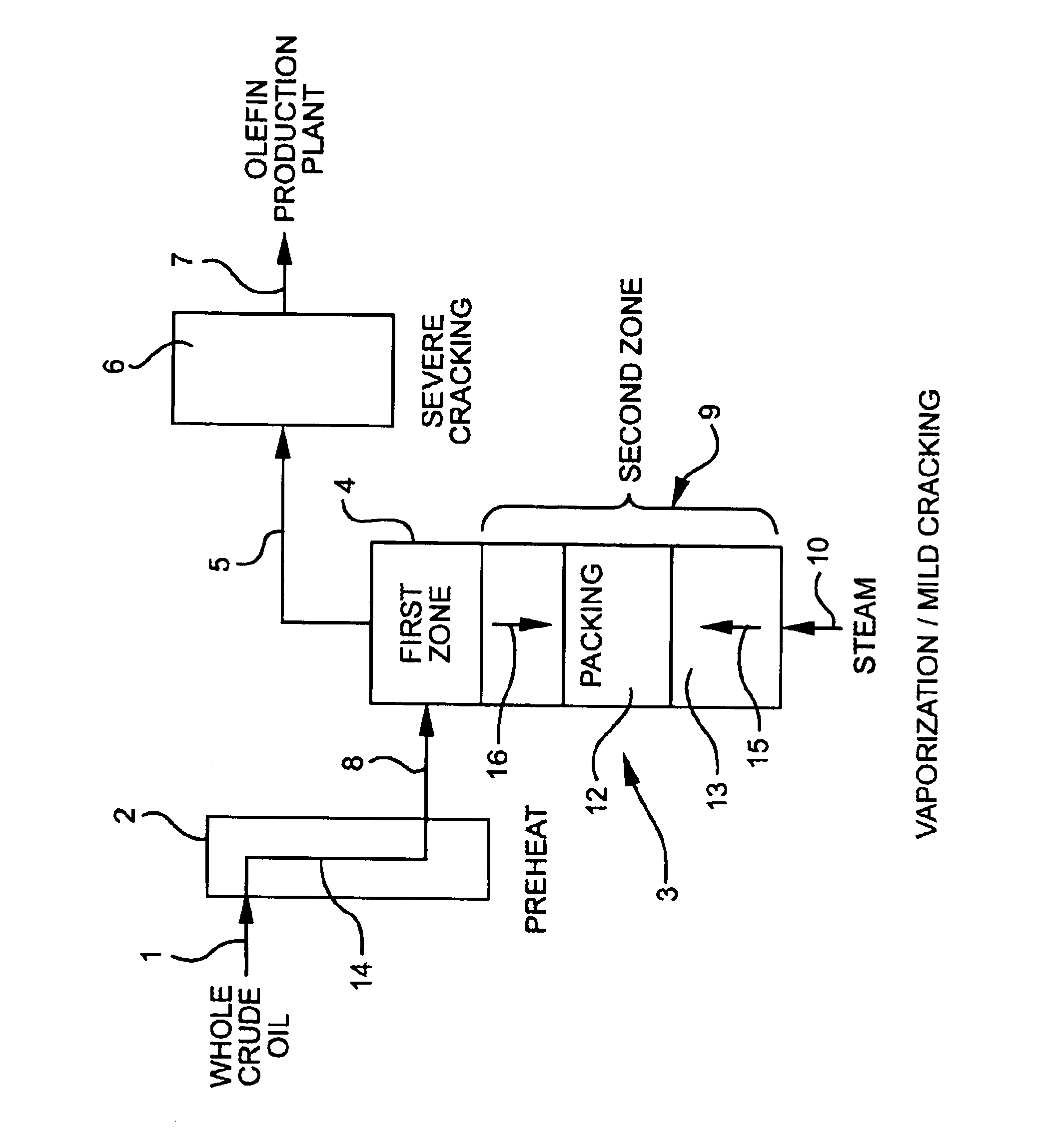

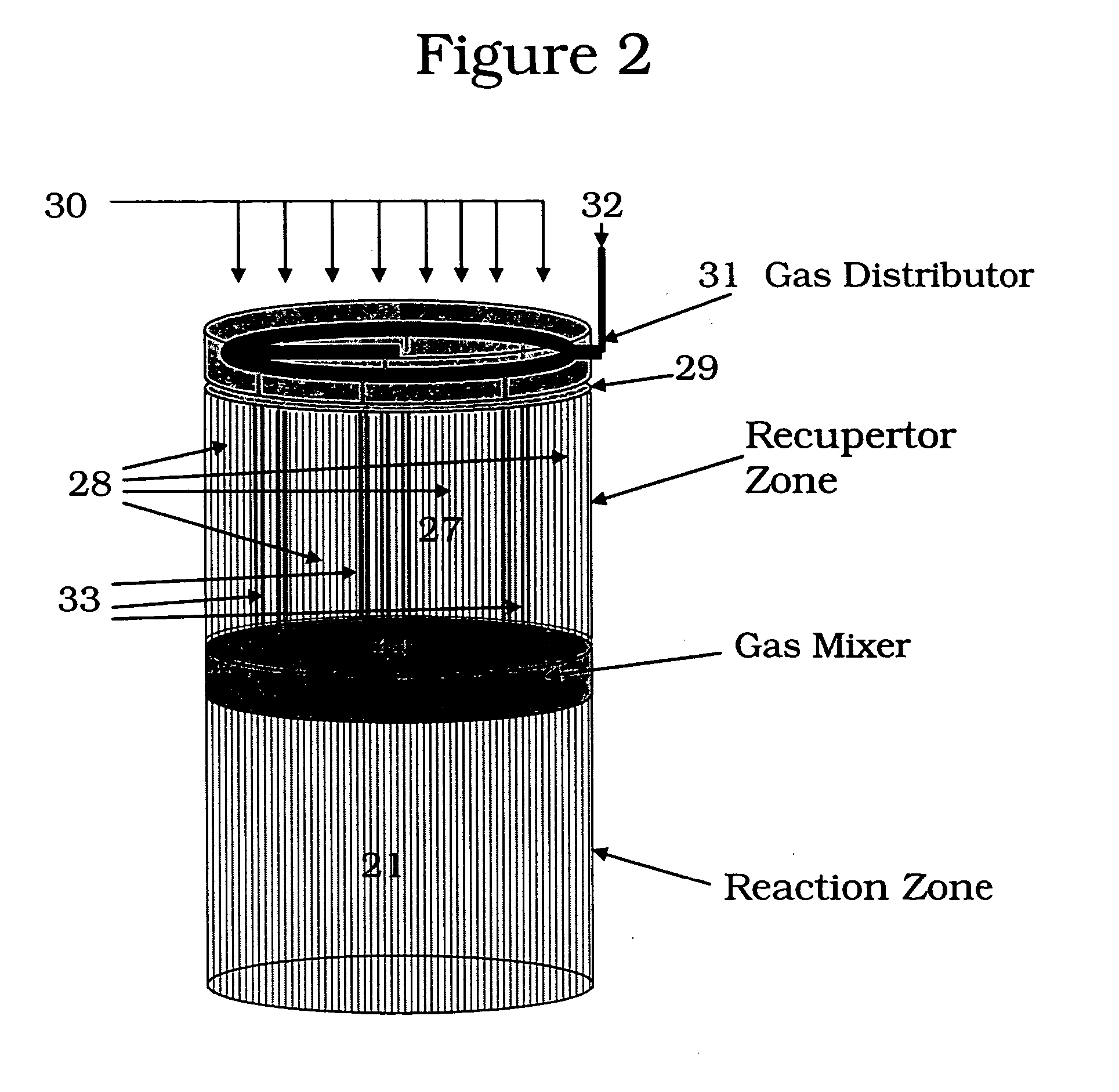

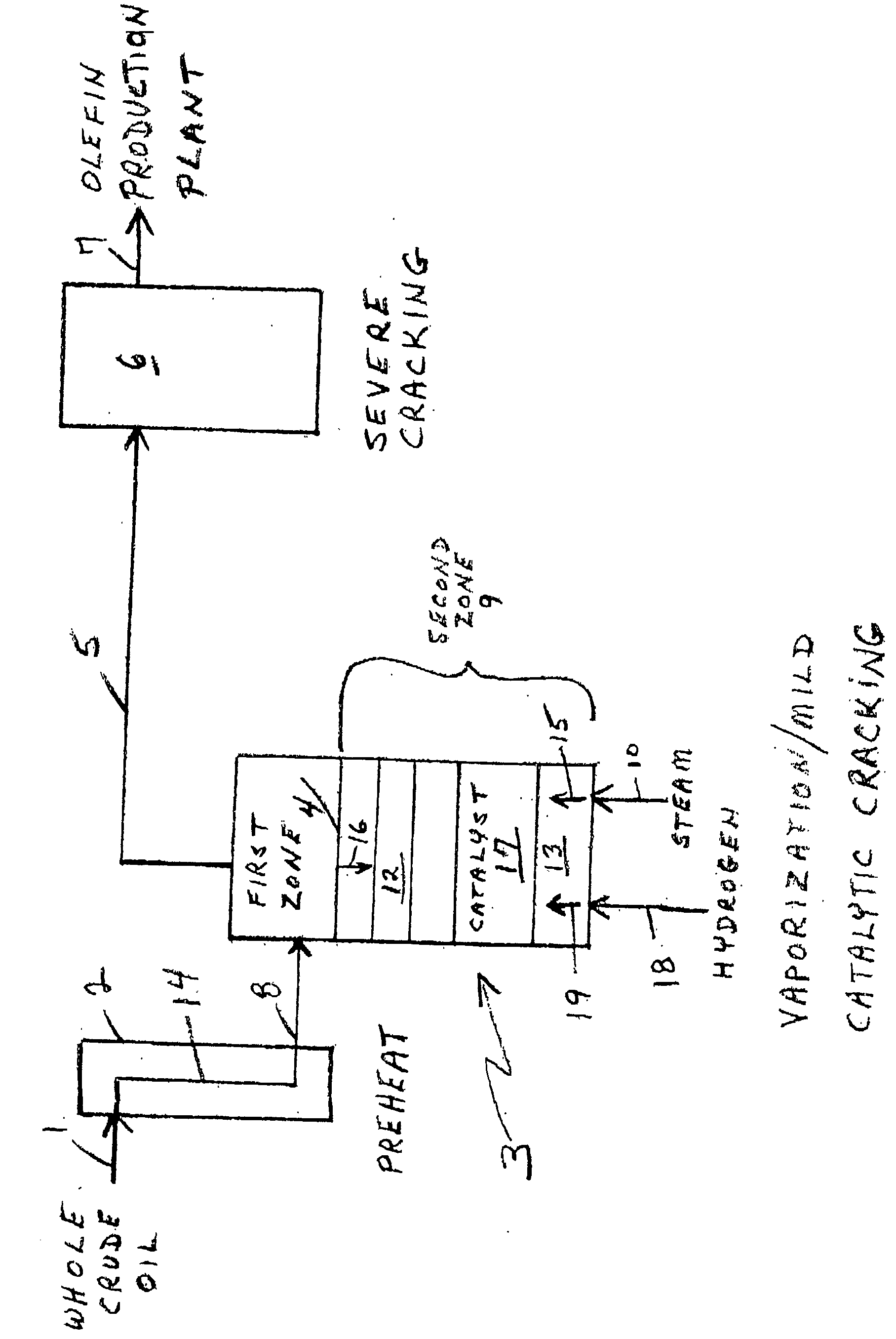

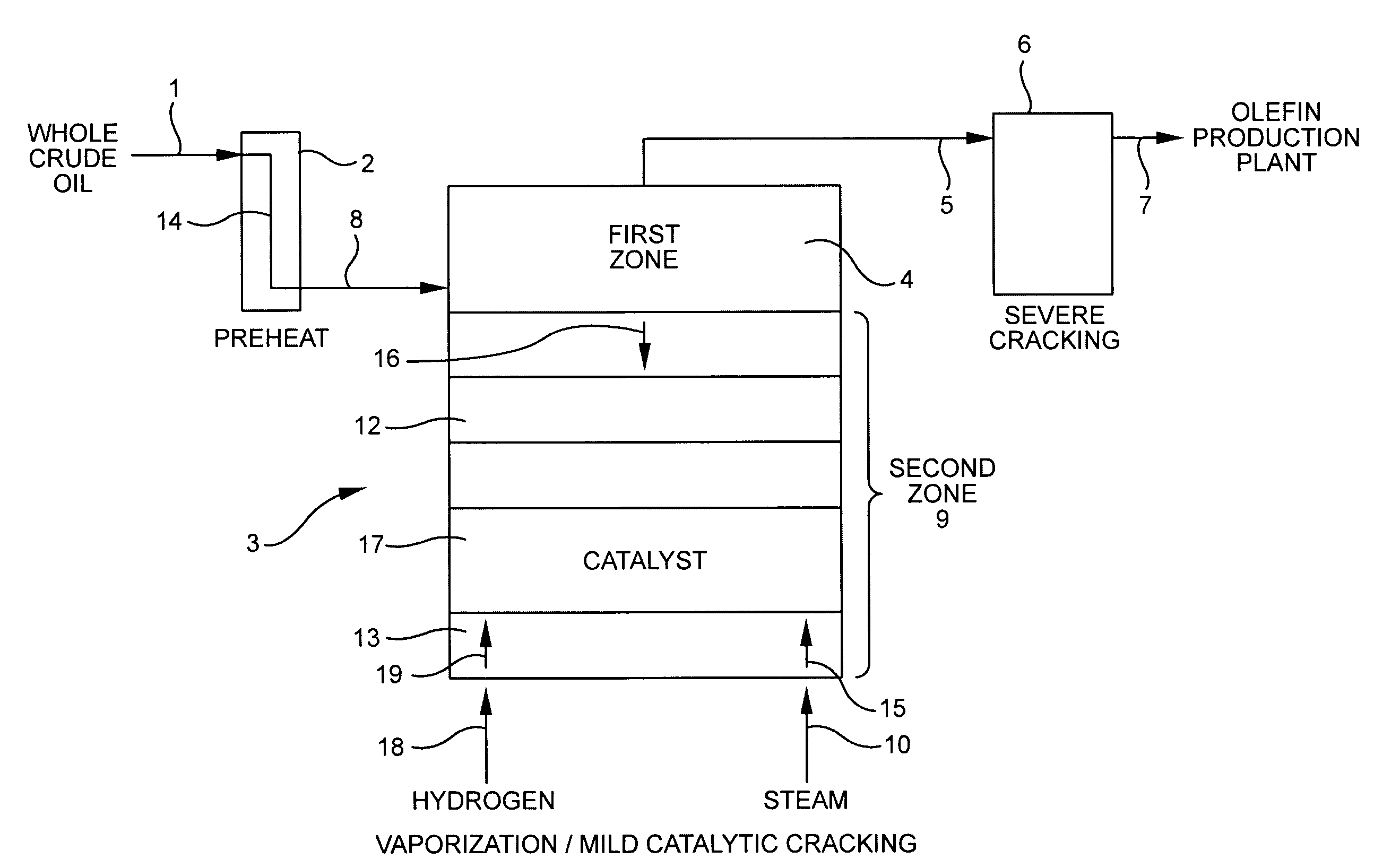

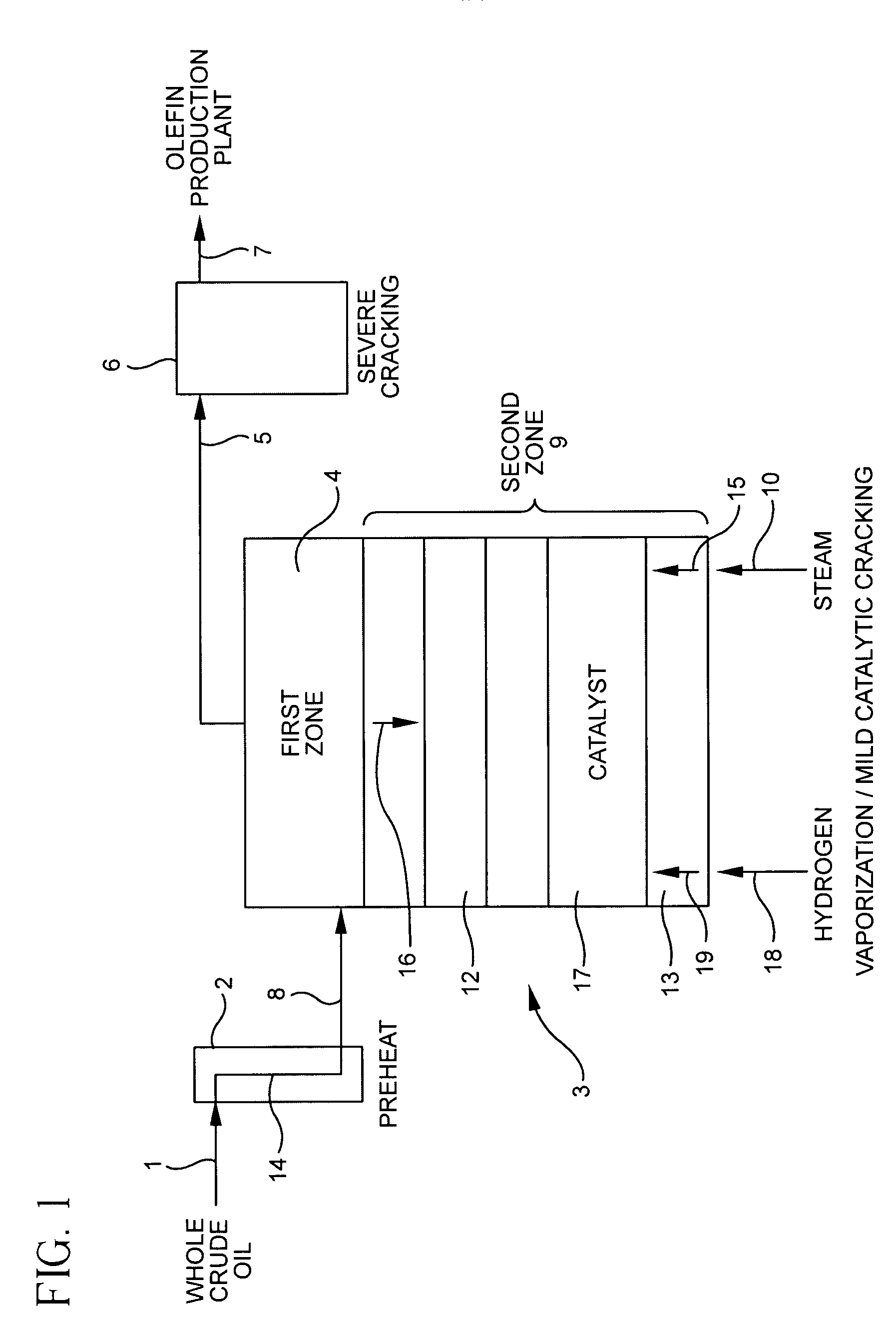

Olefin production utilizing whole crude oil and mild catalytic cracking

InactiveUS20040054247A1Lower temperature rangeImproved vaporizationThermal non-catalytic crackingCatalytic crackingChemistryPyrolysis

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild catalytic cracking conditions until substantially vaporized, the vapors from the mild catalytic cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

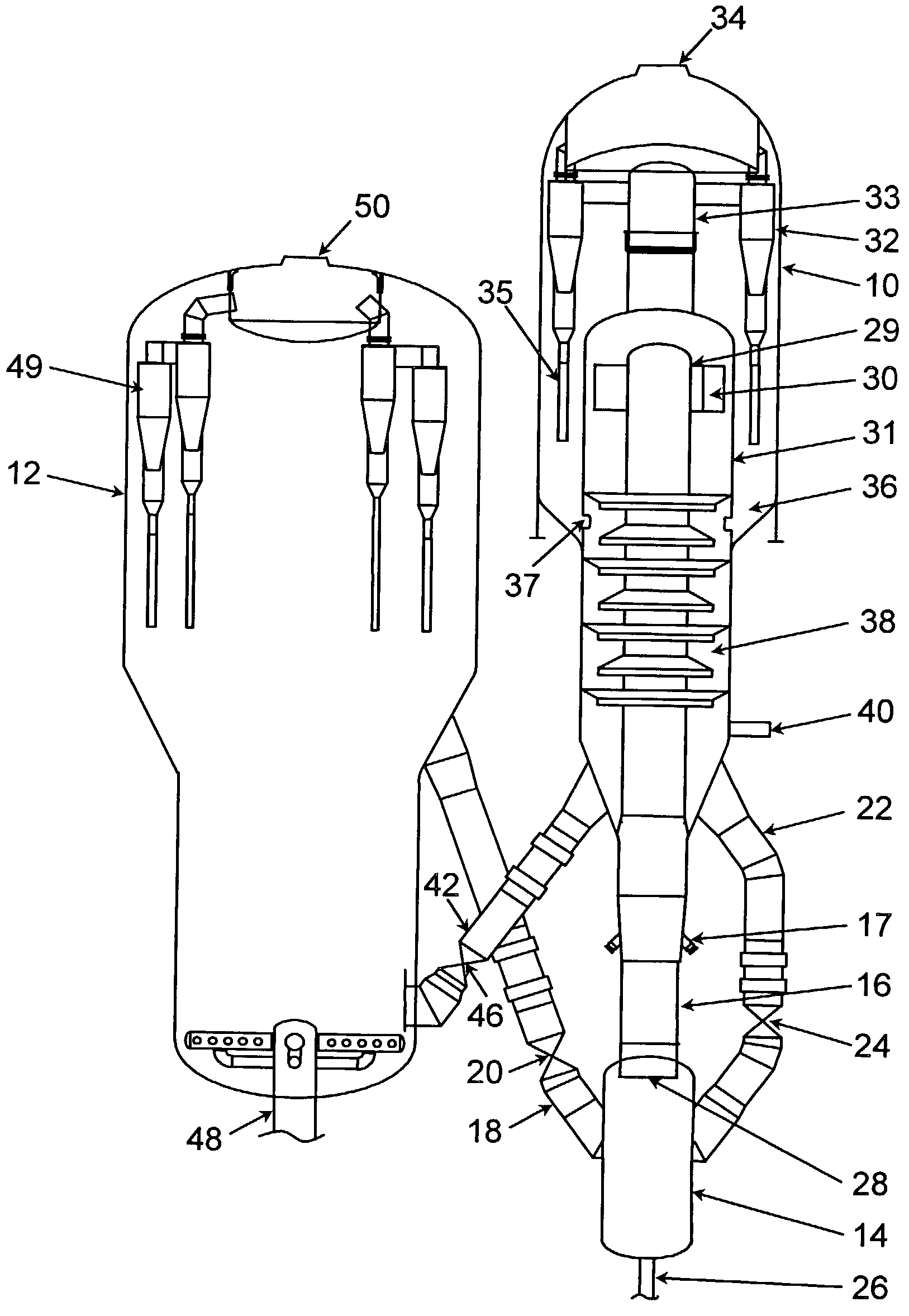

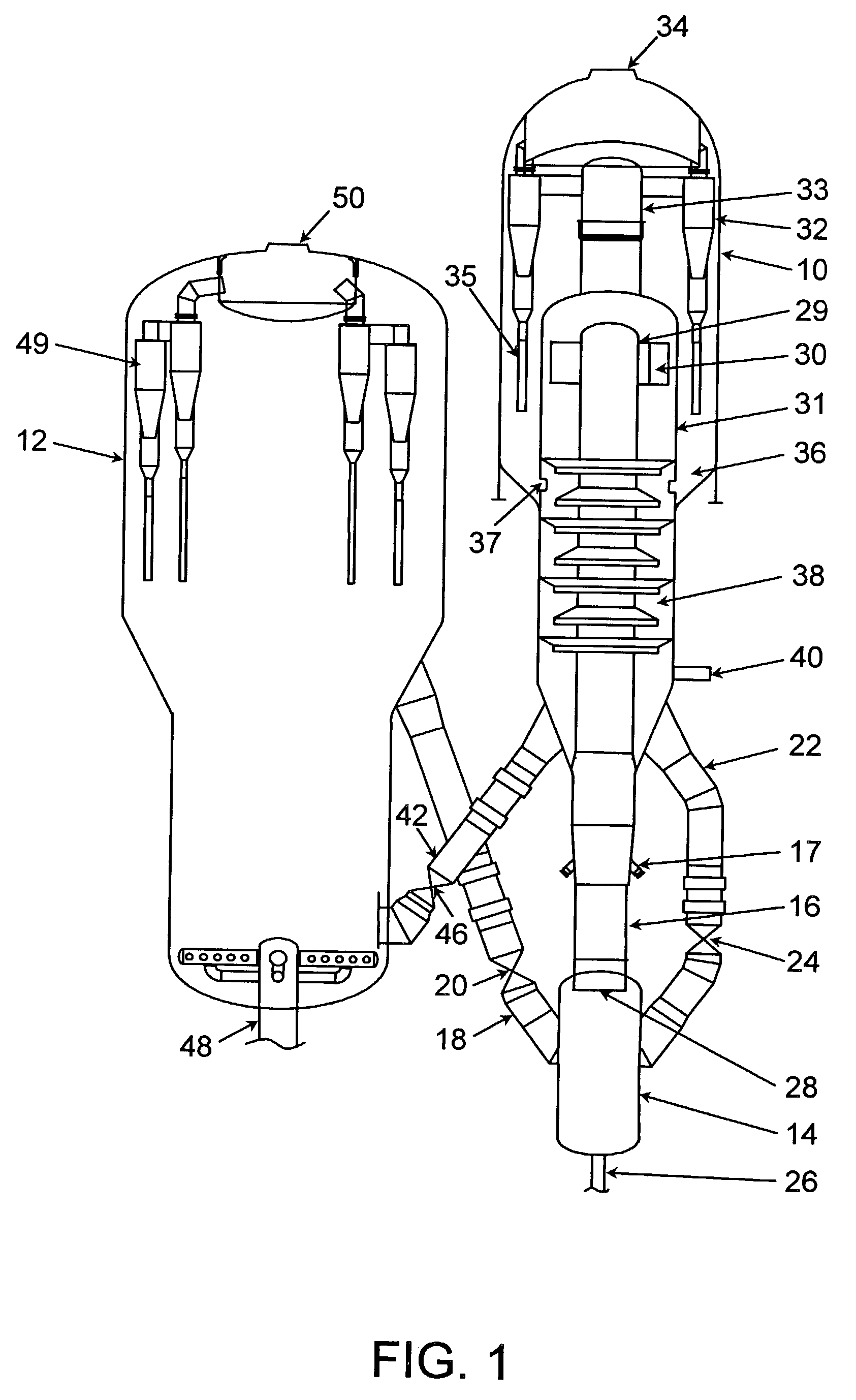

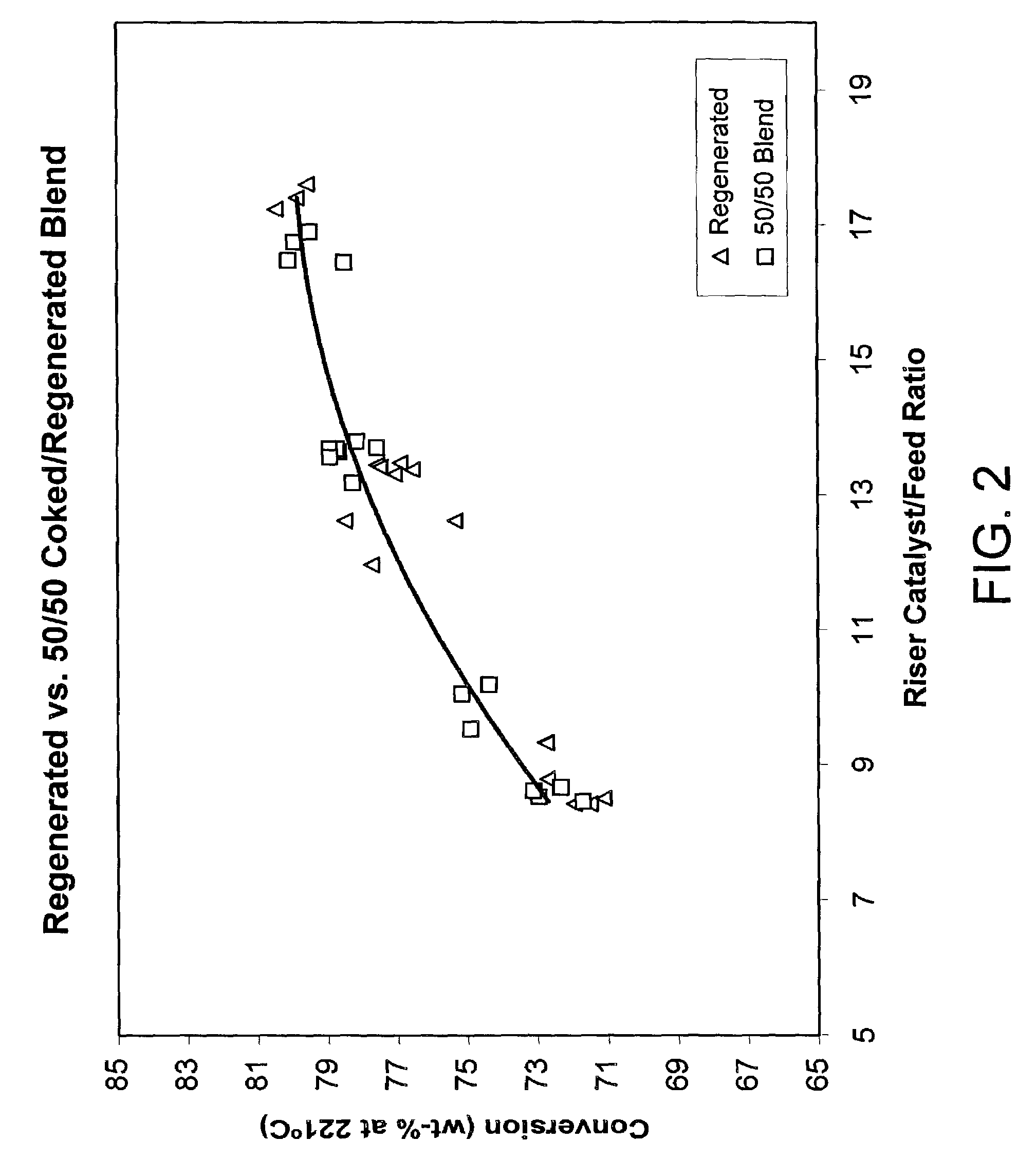

FCC process with improved yield of light olefins

InactiveUS7312370B2Increase productionImprove olefin selectivityCatalytic crackingHydrocarbonsHydrocarbonZeolite

An FCC process for obtaining light olefins comprises contacting a hydrocarbon feed stream with blended catalyst comprising regenerated catalyst and coked catalyst. The catalyst has a composition including a first component and a second component. The second component comprises a zeolite with no greater than medium pore size wherein the zeolite comprises at least 1 wt-% of the catalyst composition. The contacting occurs in a riser to crack hydrocarbons in the feed stream and obtain a cracked stream containing hydrocarbon products including light olefins and coked catalyst. The cracked stream is passed out of an end of the riser such that the hydrocarbon feed stream is in contact with the blended catalyst in the riser for less than or equal to 2 seconds on average. The hydrocarbon products including light olefins are separated from the coked catalyst. The first portion of the coked catalyst is passed to a regeneration zone in which coke is combusted from the catalyst to produce a regenerated catalyst. A second portion of the coked catalyst is blended with the regenerated catalyst and introduced to the riser. The regenerated catalyst has substantially the same relative proportions of the first component and the second component as the blended catalyst that contact the hydrocarbon feed stream.

Owner:UOP LLC

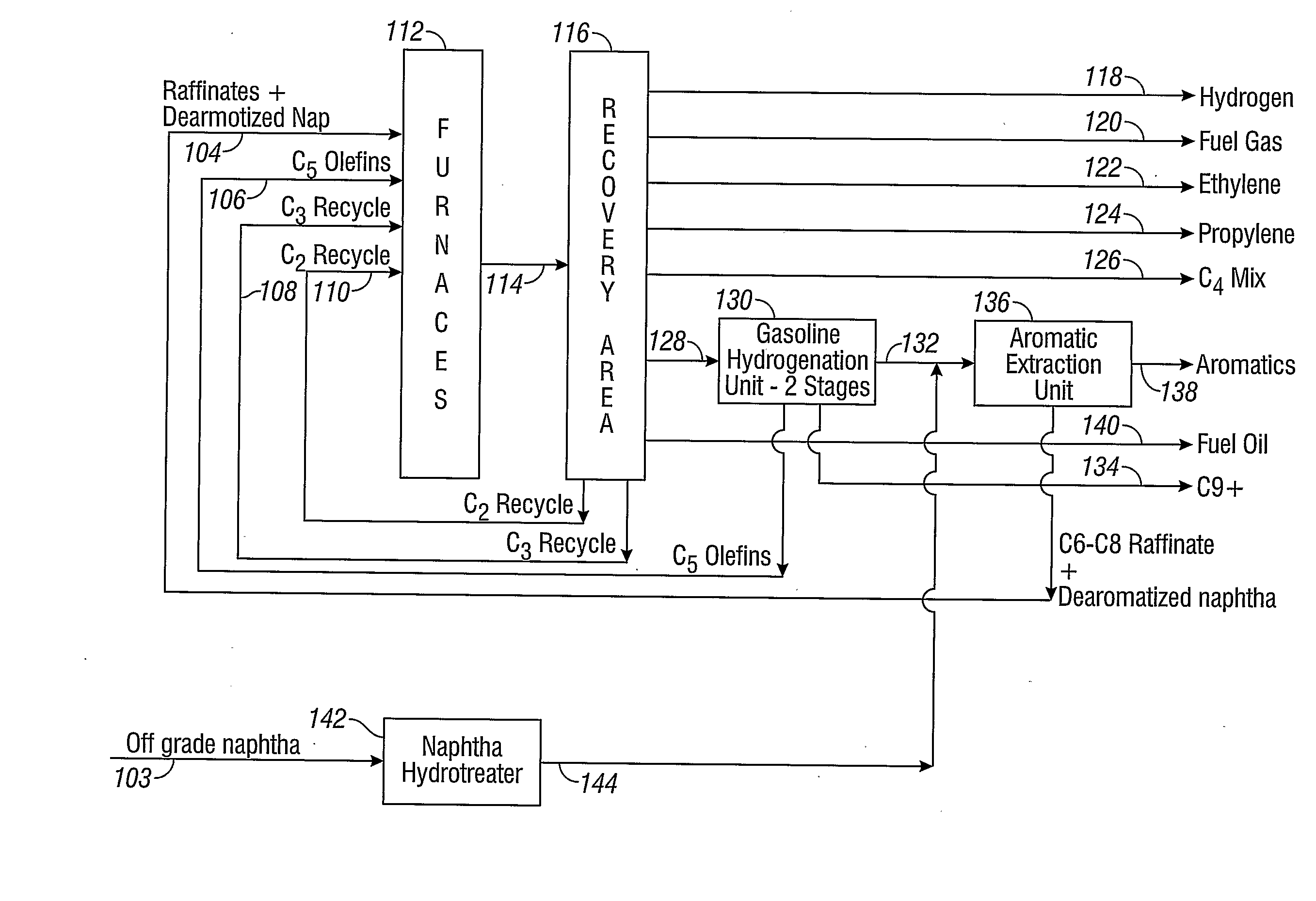

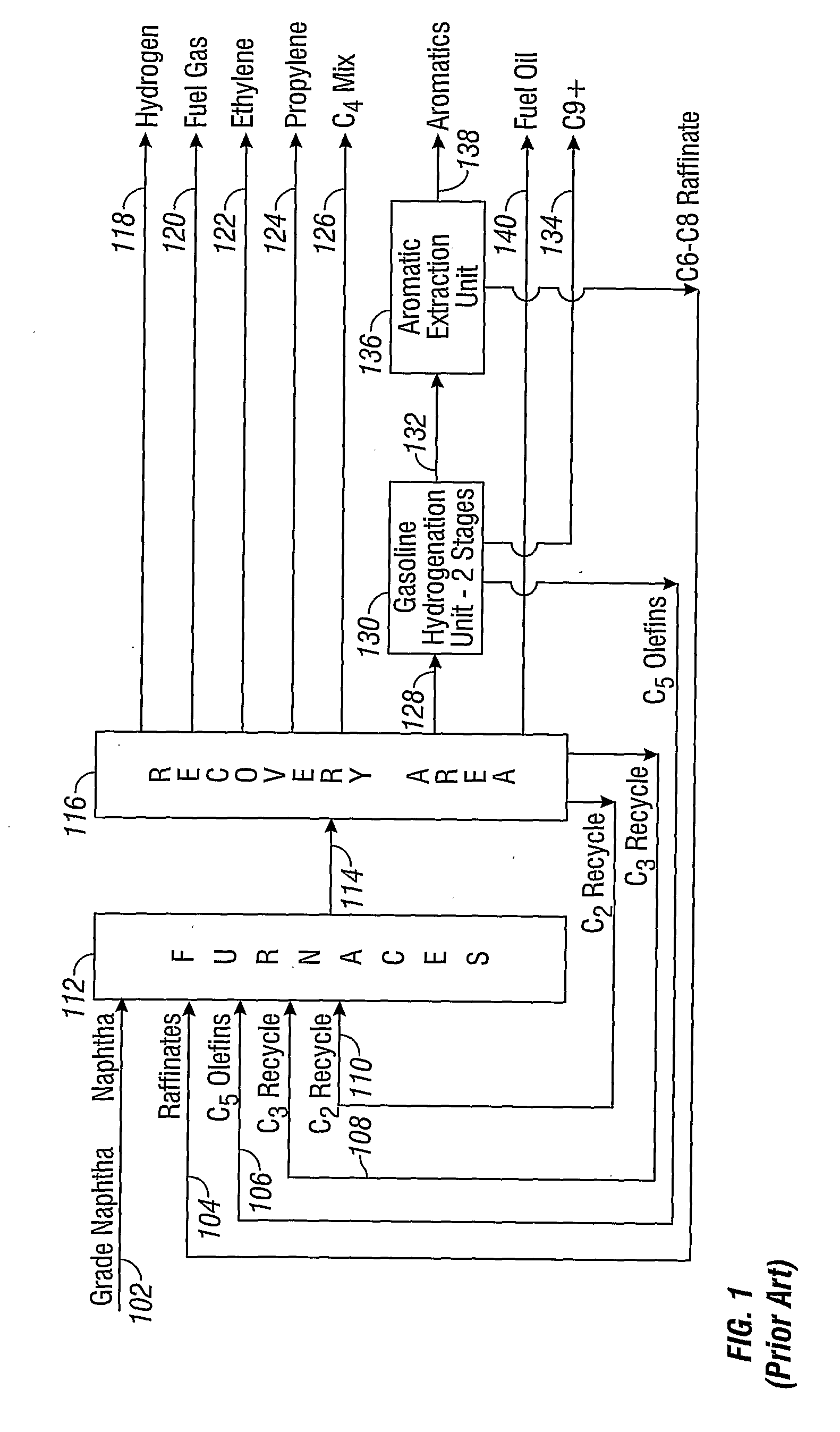

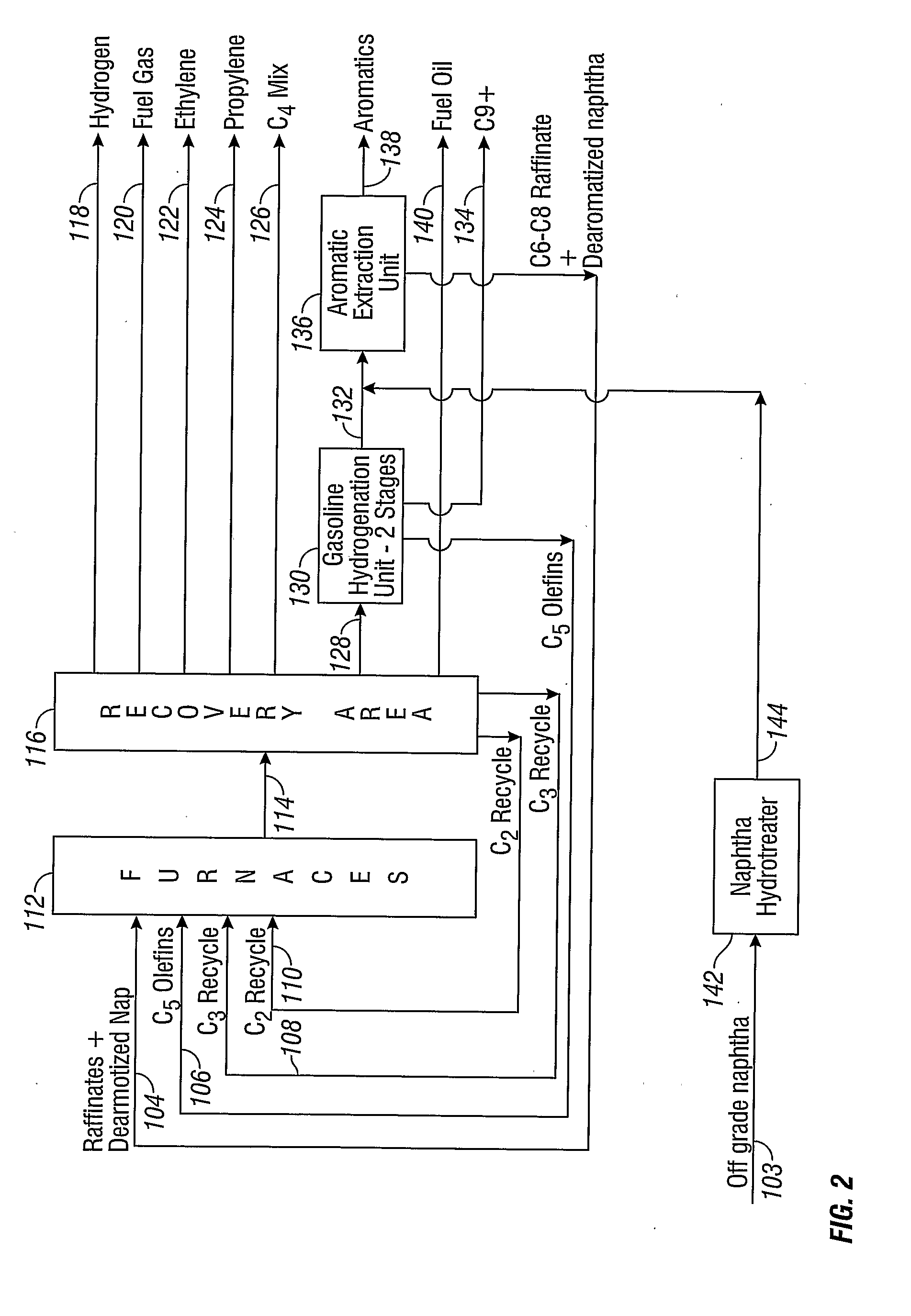

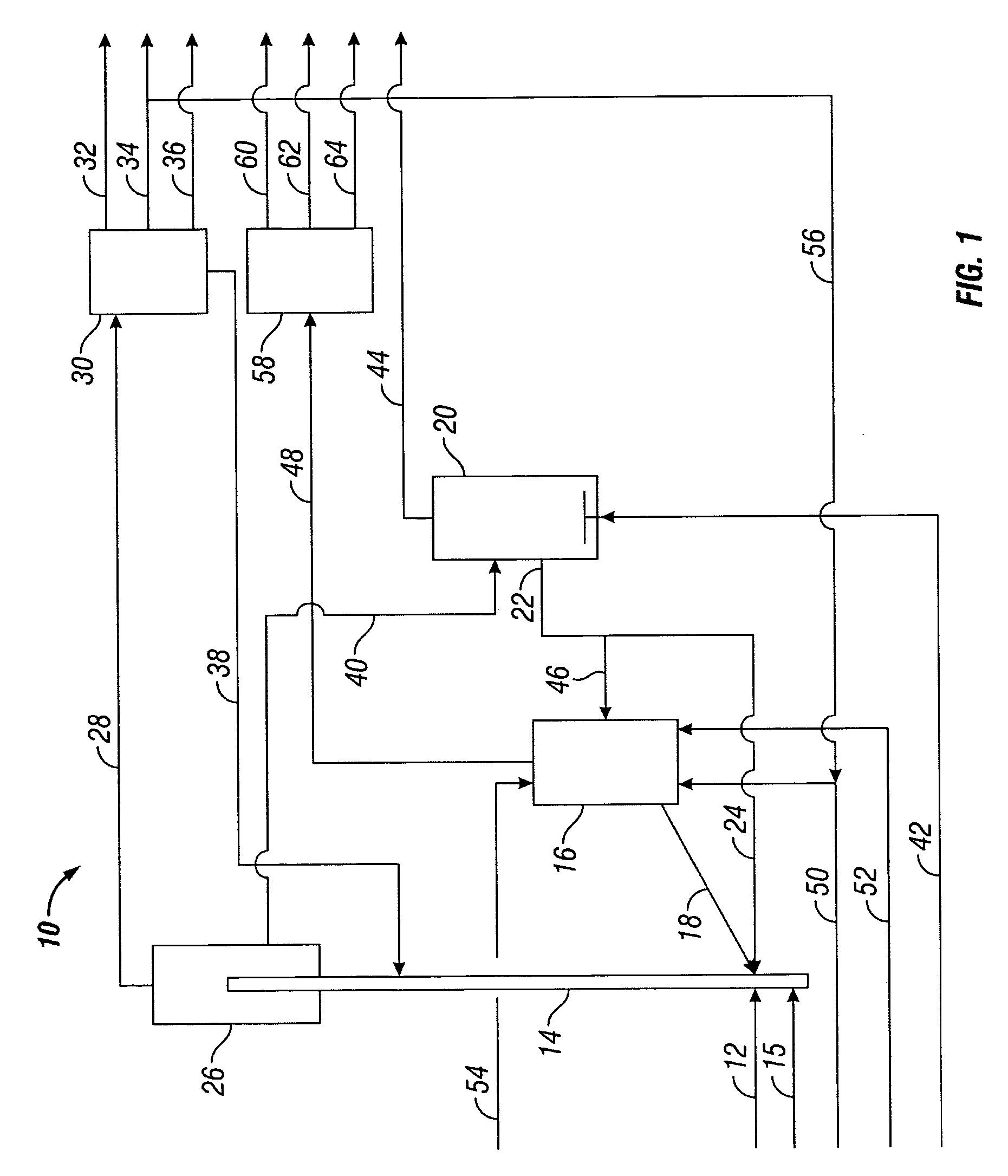

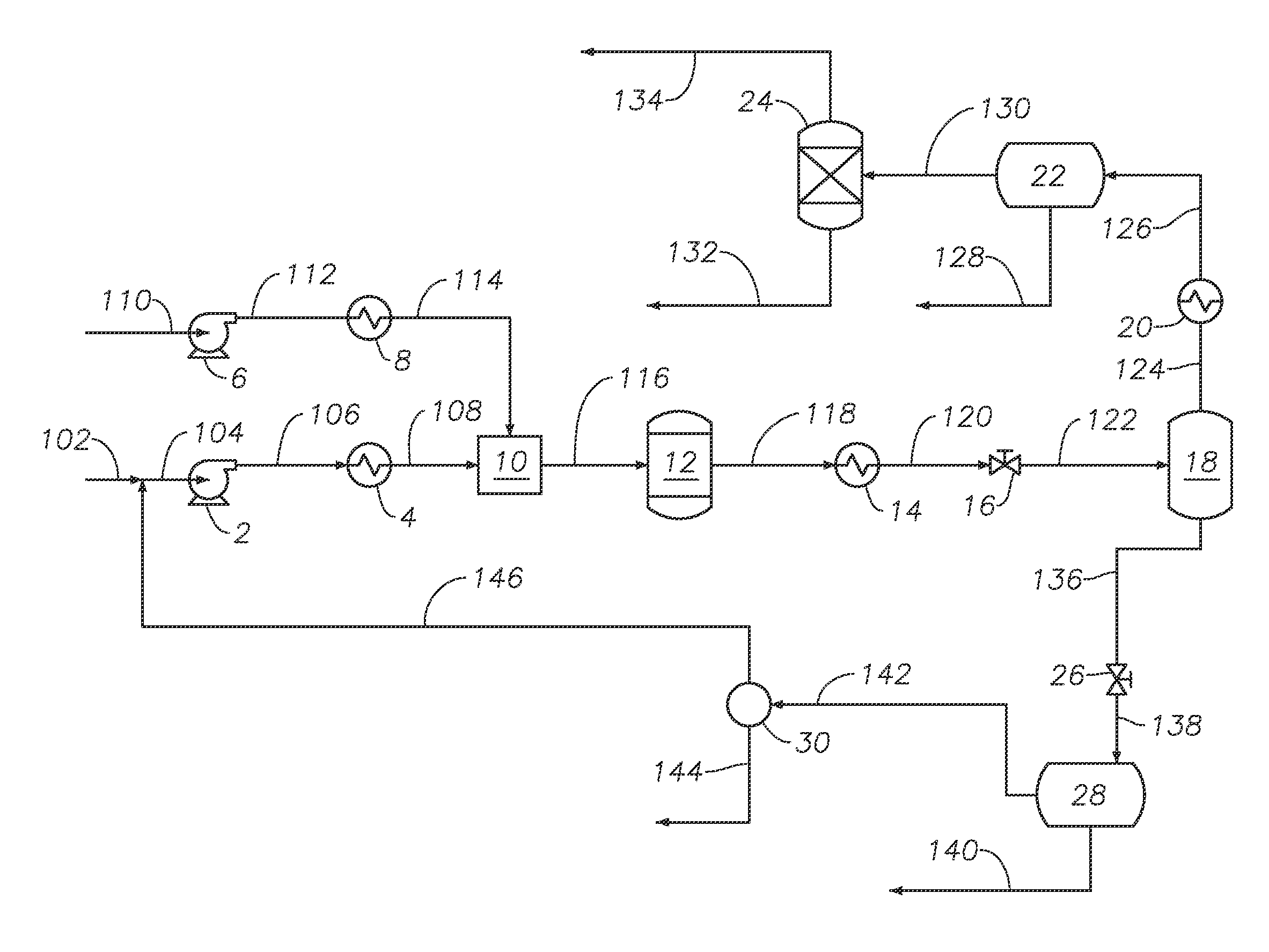

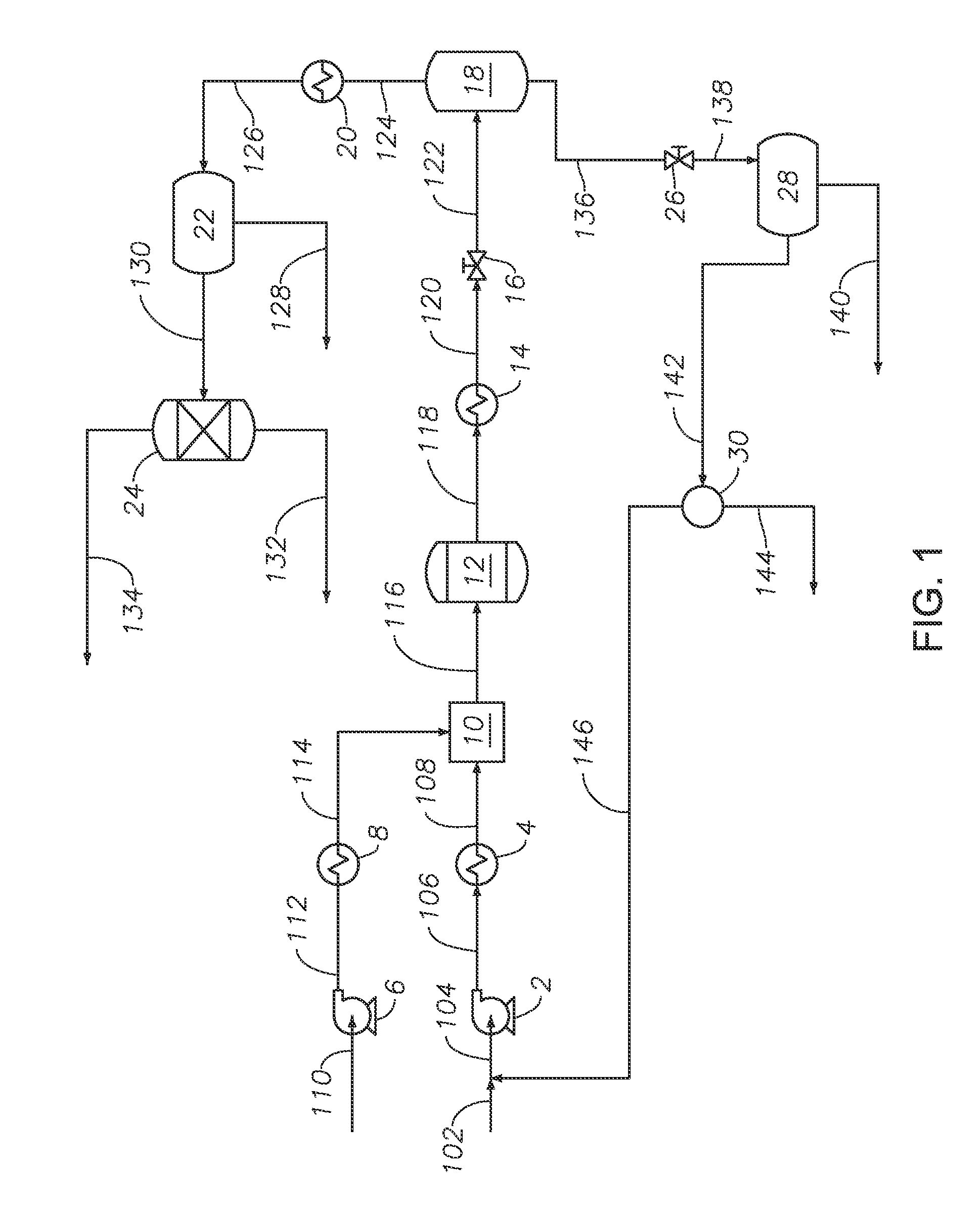

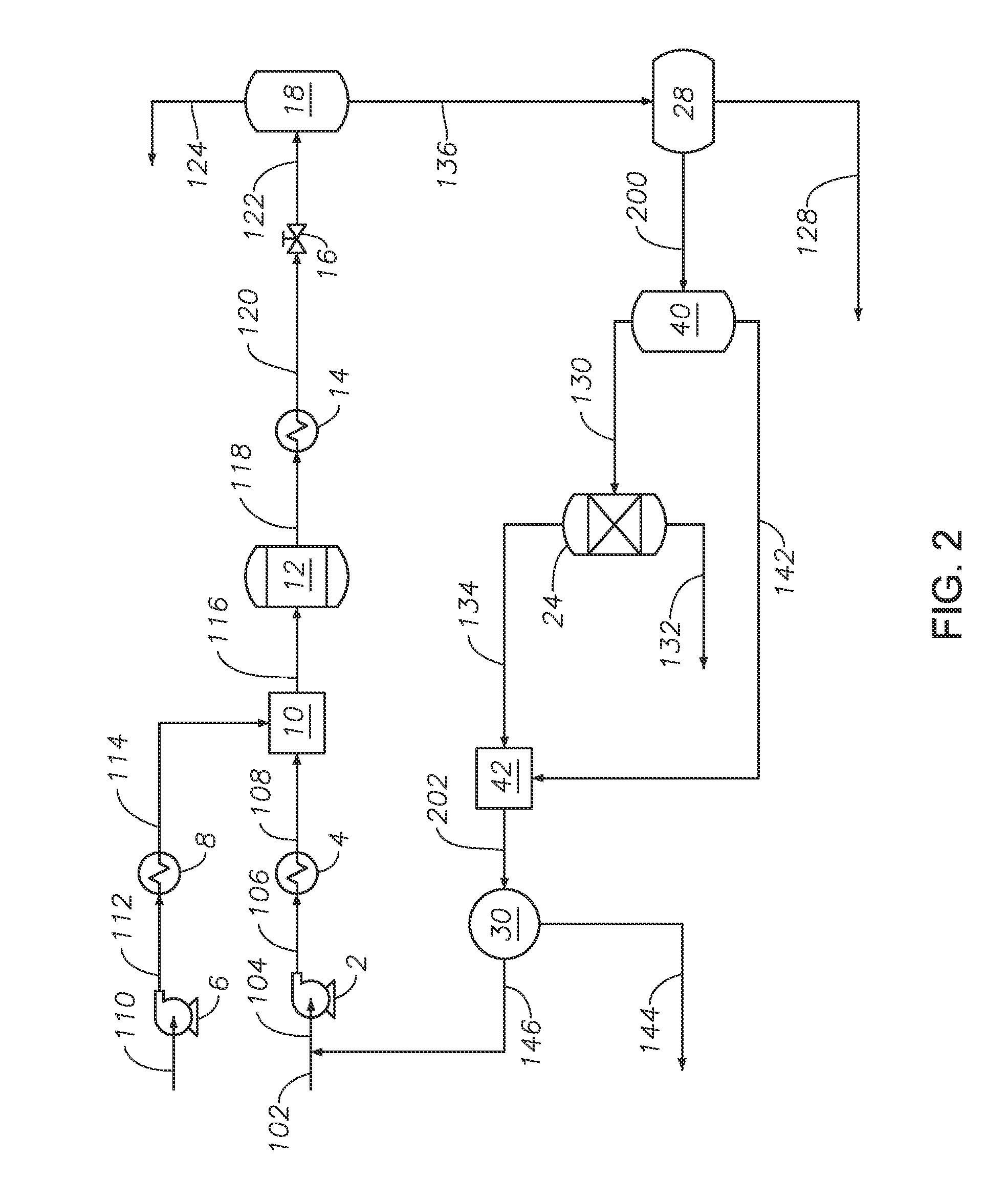

Steam Cracking with Naphtha Dearomatization

Disclosed is a process for upgrading a naphtha feed stream comprising light naphtha, heavy naphtha, or a combination thereof, for supplying to a cracking process. A naphtha feed stream can be supplied to a hydrotreater 142 to remove impurities, followed by dearomatization in an aromatics extraction unit 136. A dearomatized naphtha stream 104 can be supplied to a cracking process 112 and a recovery process 116 to produce various streams including ethylene 122 and propylene 124 for collection, ethane 110 and propane 108 for recycle to the cracking process 112, and a pyrolysis gas stream 128 which can be further treated to produce a C5 olefins stream 106, a C6-C8 stream 104, a C9+ stream 134, and a fuel oil stream 140.

Owner:BHIRUD VASANT L

Thermal synthesis apparatus and process

InactiveUS6821500B2Improve efficiencyHigh yieldCarbon monoxideIndirect heat exchangersNuclear engineeringReaction zone

An apparatus for thermal conversion of one or more reactants to desired end products includes an insulated reactor chamber having a high temperature heater such as a plasma torch at its inlet end and, optionally, a restrictive convergent-divergent nozzle at its outlet end. In a thermal conversion method, reactants are injected upstream from the reactor chamber and thoroughly mixed with the plasma stream before entering the reactor chamber. The reactor chamber has a reaction zone that is maintained at a substantially uniform temperature. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle, which "freezes" the desired end product(s) in the heated equilibrium reaction stage, or is discharged through an outlet pipe without the convergent-divergent nozzle. The desired end products are then separated from the gaseous stream.

Owner:BATTELLE ENERGY ALLIANCE LLC

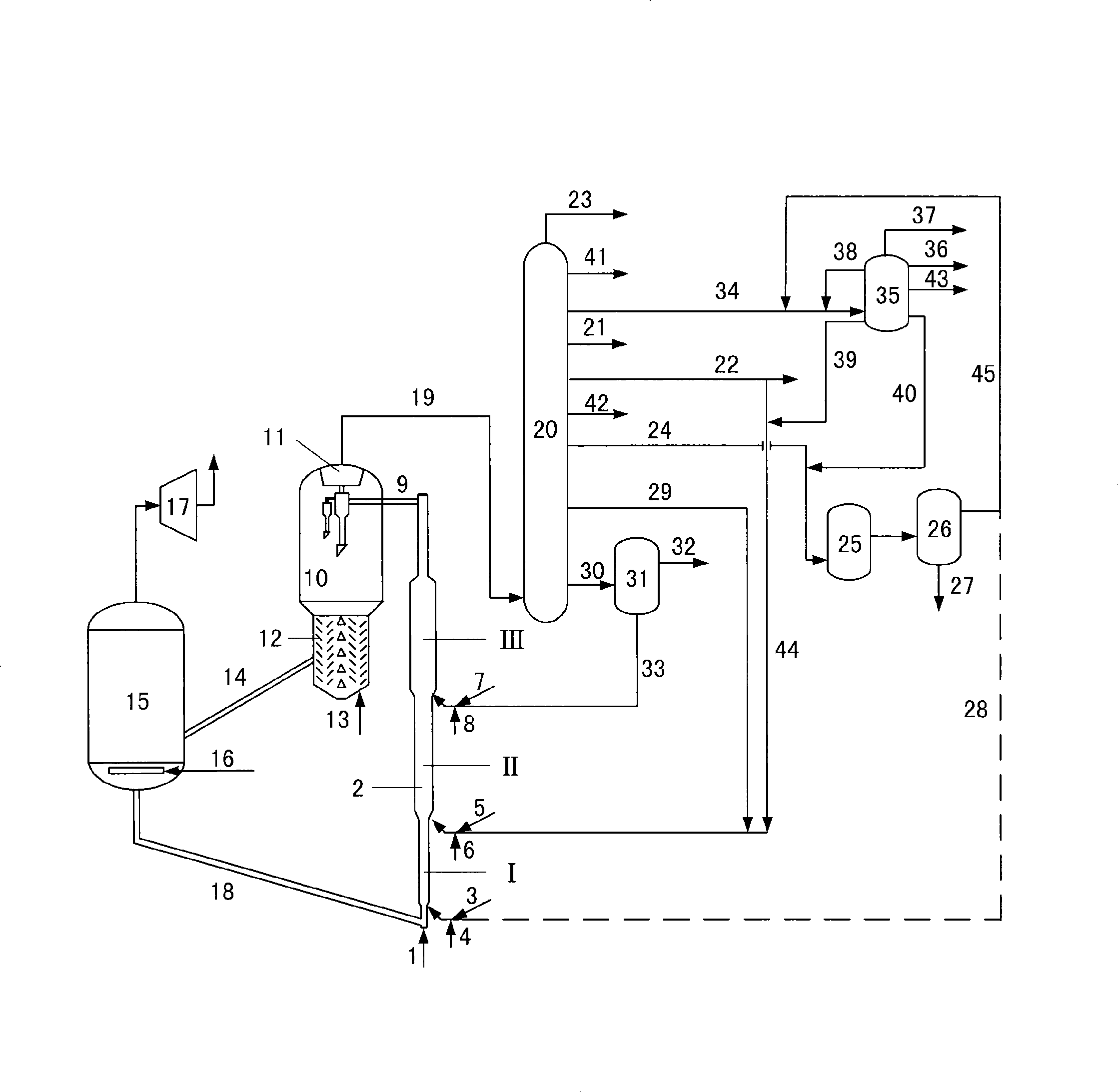

Method and apparatus for making a middle distillate product and lower olefins from a hydrocarbon feedstock

ActiveUS20060178546A1Yield maximizationCatalytic crackingCatalytic naphtha reformingPetroleum productGasoline

Disclosed is a process for making middle distillate and lower olefins. The process includes catalytically cracking a gas oil feedstock within a riser reactor zone by contacting under suitable catalytic cracking conditions within the riser reactor zone the gas oil feedstock with a middle distillate selective cracking catalyst that comprises amorphous silica alumina and a zeolite to yield a cracked gas oil product and a spent cracking catalyst. The spent cracking catalyst is regenerated to yield a regenerated cracking catalyst. Within an intermediate cracking reactor such as a dense bed reactor zone and under suitable high severity cracking conditions a gasoline feedstock is contacted with the regenerated cracking catalyst to yield a cracked gasoline product and a used regenerated cracking catalyst. The used regenerated cracking catalyst is utilized as the middle distillate selective catalyst.

Owner:SHELL USA INC

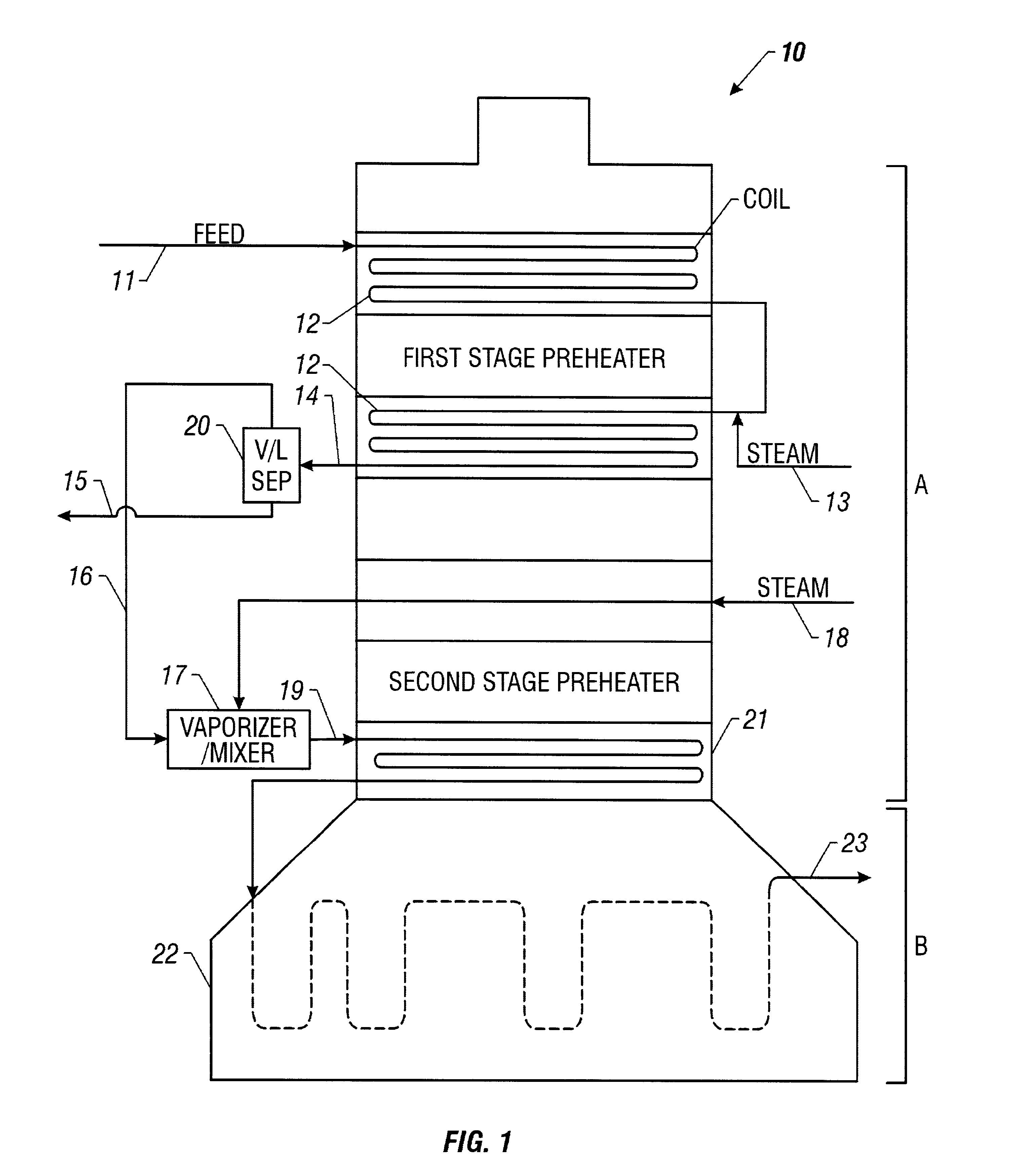

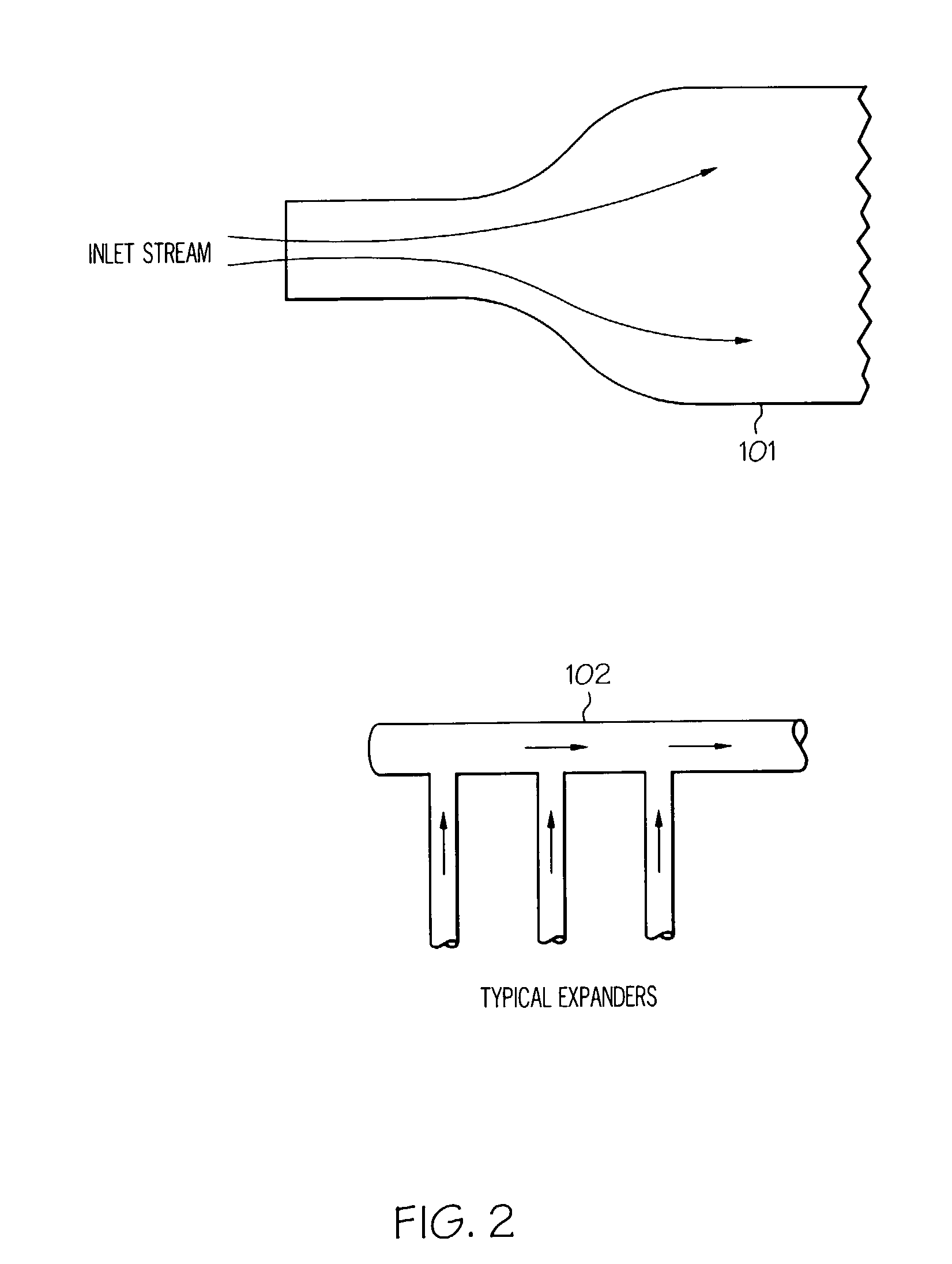

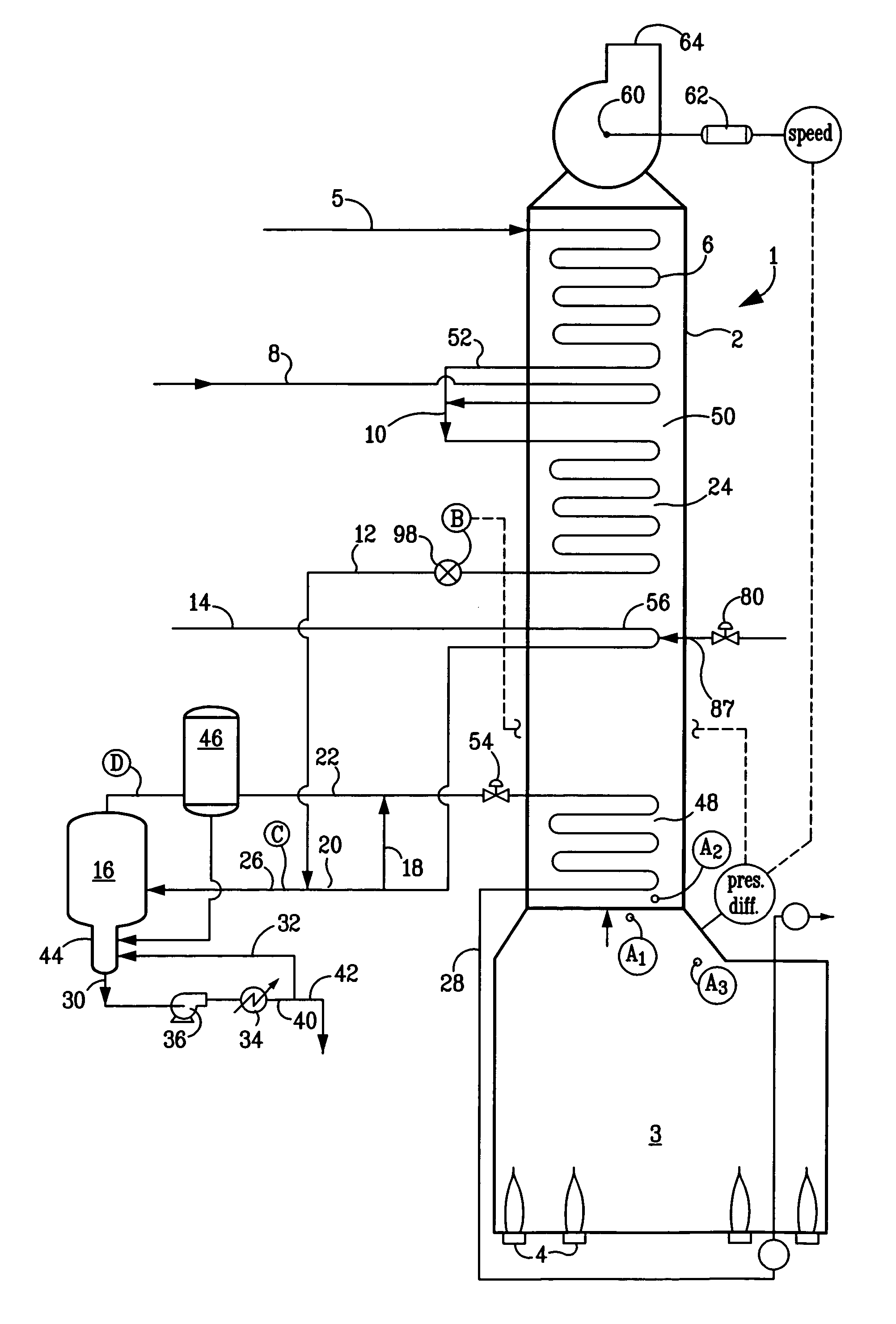

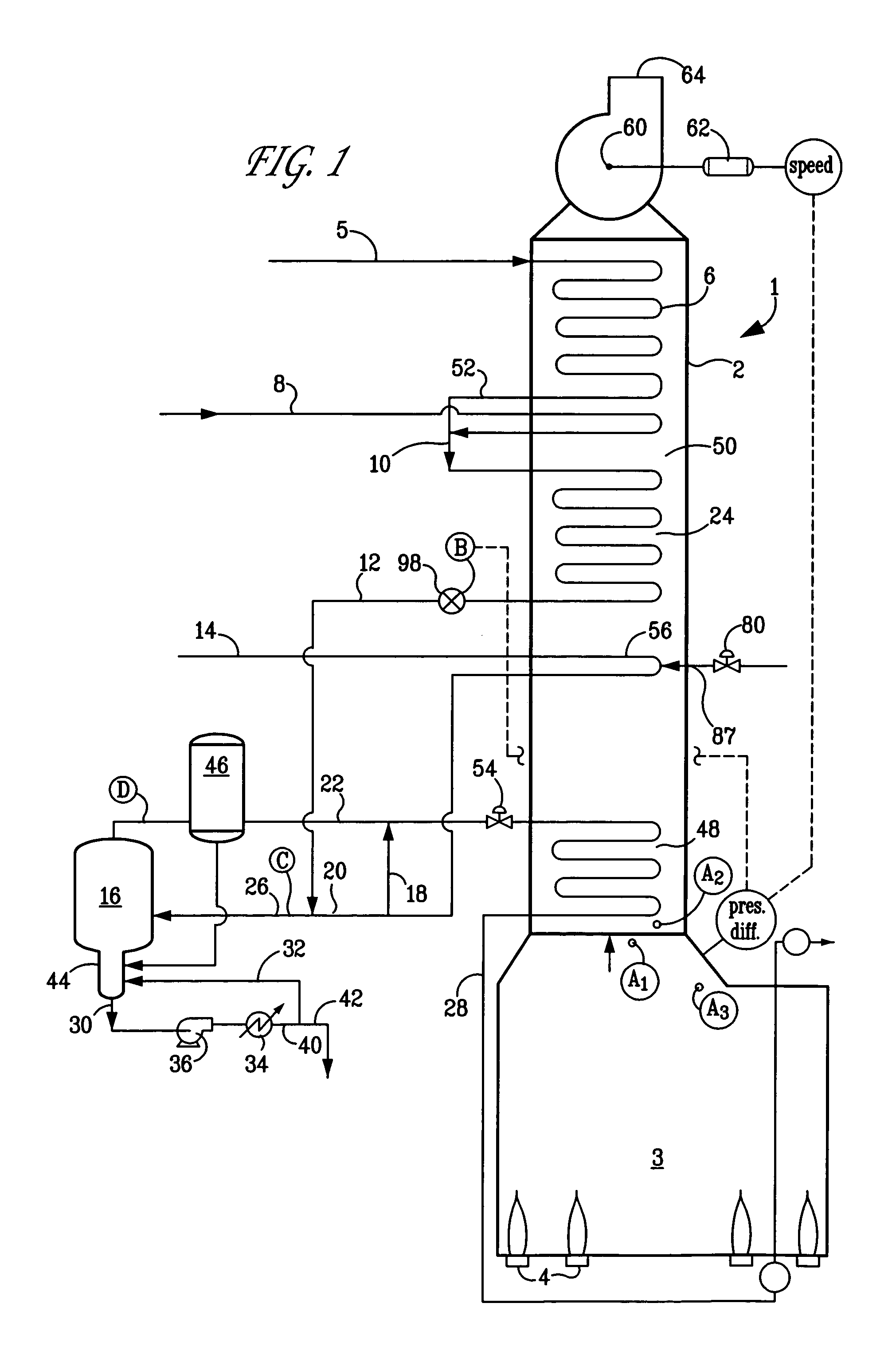

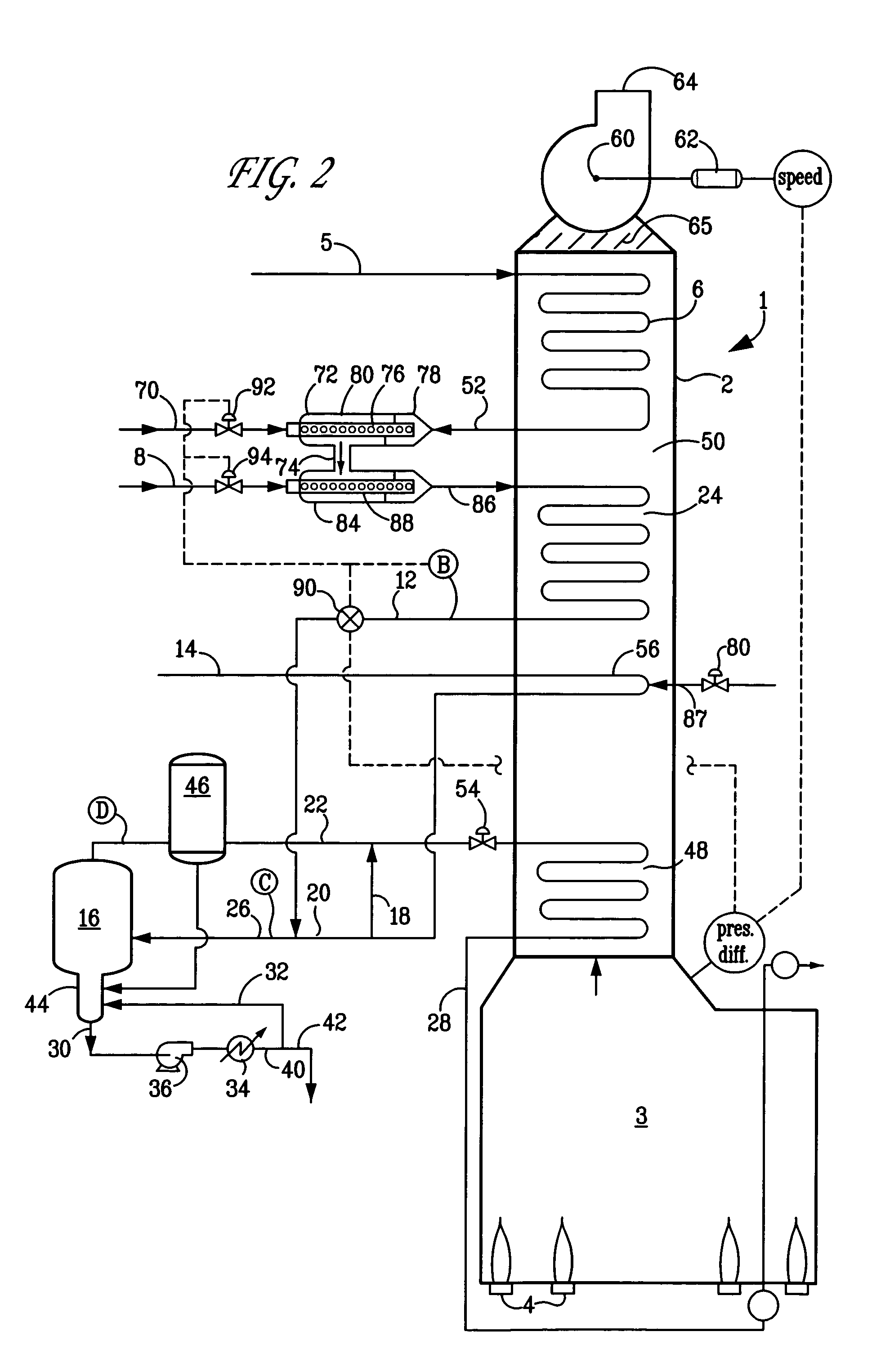

Converting mist flow to annular flow in thermal cracking application

ActiveUS7097758B2Reduce flow rateShorten speedThermal non-catalytic crackingHydrocarbon oil cracking processGas phaseEngineering

A process to increase the non-volatile removal efficiency in a flash drum in the steam cracking system. The gas flow from the convection section is converted from mist flow to annular flow before entering the flash drum to increase the removal efficiency. The conversion of gas flow from mist flow to annular flow is accomplished by subjecting the gas flow first to at least one expander and then to bends of various degrees and force the flow to change directions at least once. The change of gas flow from mist to annular helps coalesce fine liquid droplets and thus being removed from the vapor phase.

Owner:EXXONMOBIL CHEM PAT INC

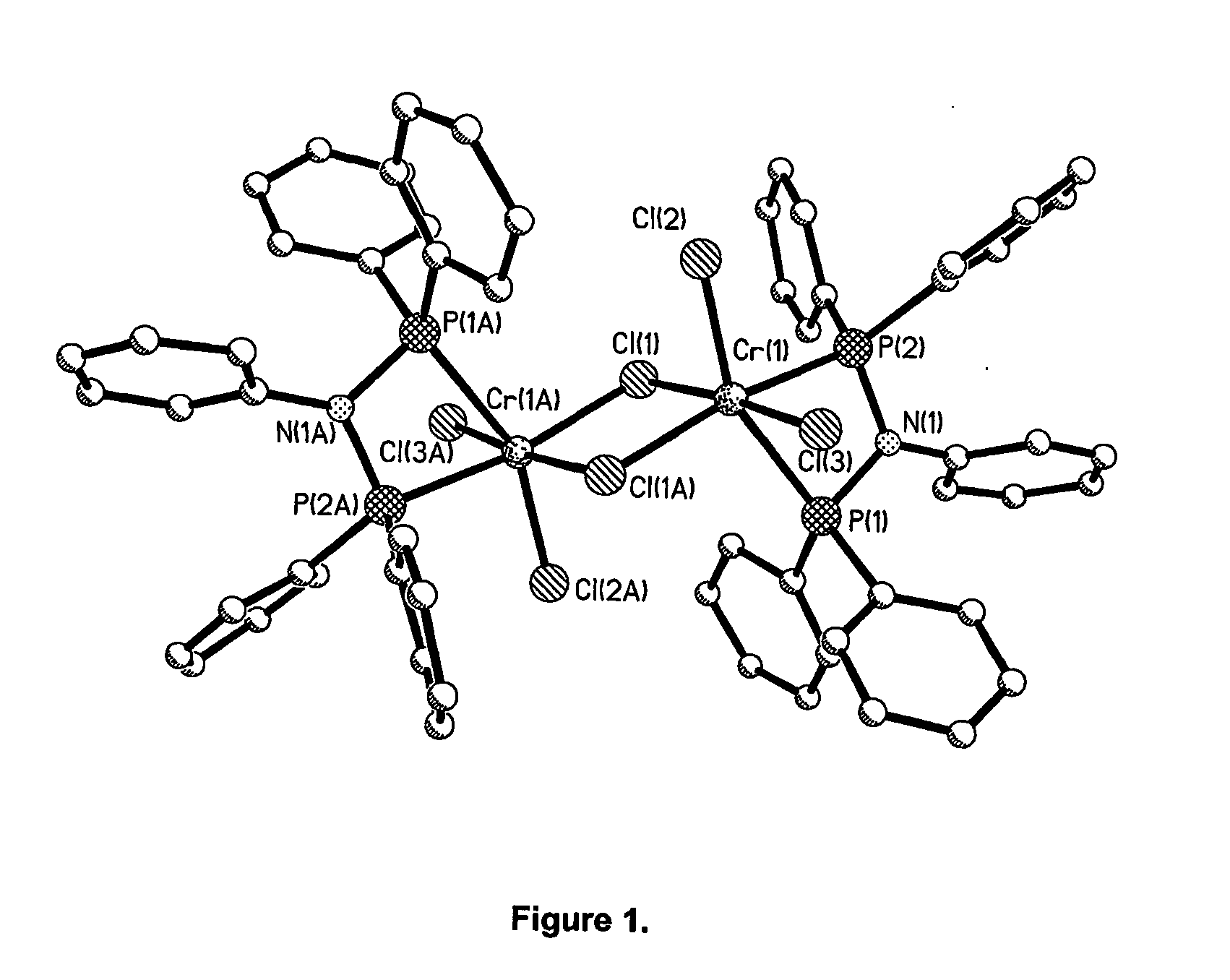

Tetramerization of olefins

ActiveUS20060229480A1Stabilise the catalyst systemImprove catalytic performanceHydrocarbon by dehydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsAlkeneTetramer

The invention describes a process for tetramerisation of olefins wherein the product stream of the process contains more than 30% of the tetramer olefin. The process includes the step of contacting an olefinic feedstream with a catalyst system containing a transition metal compound and a heteroatomic ligand.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

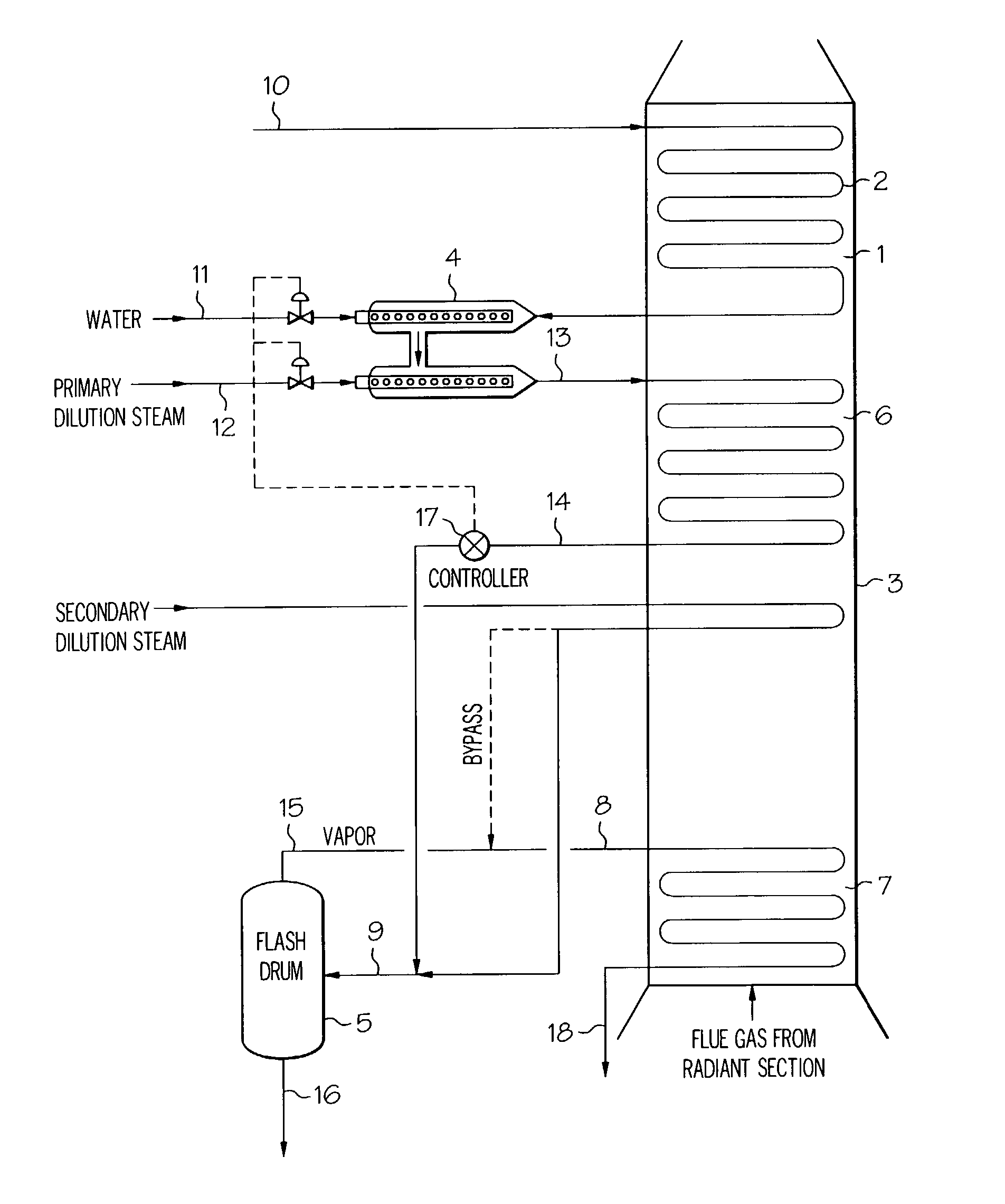

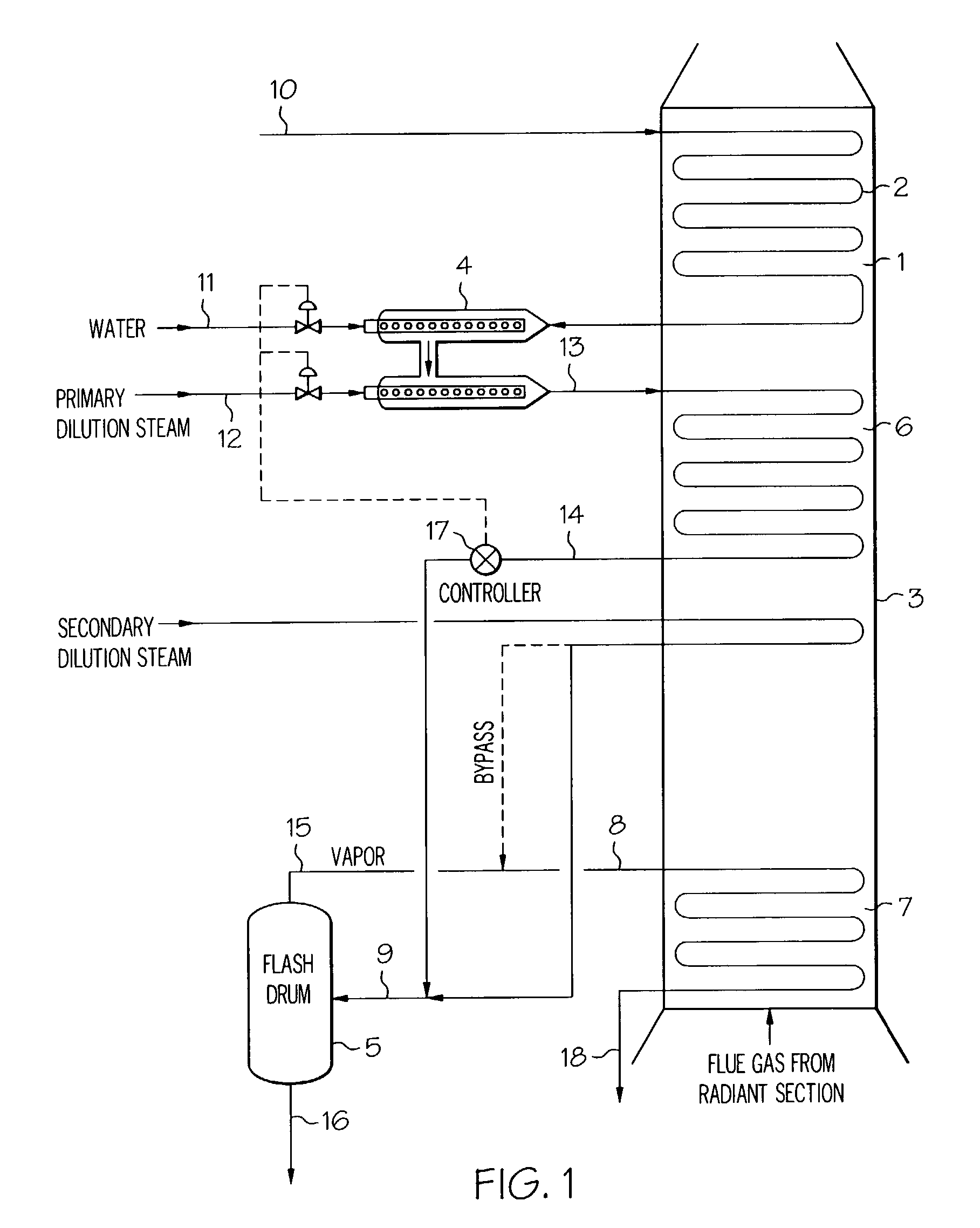

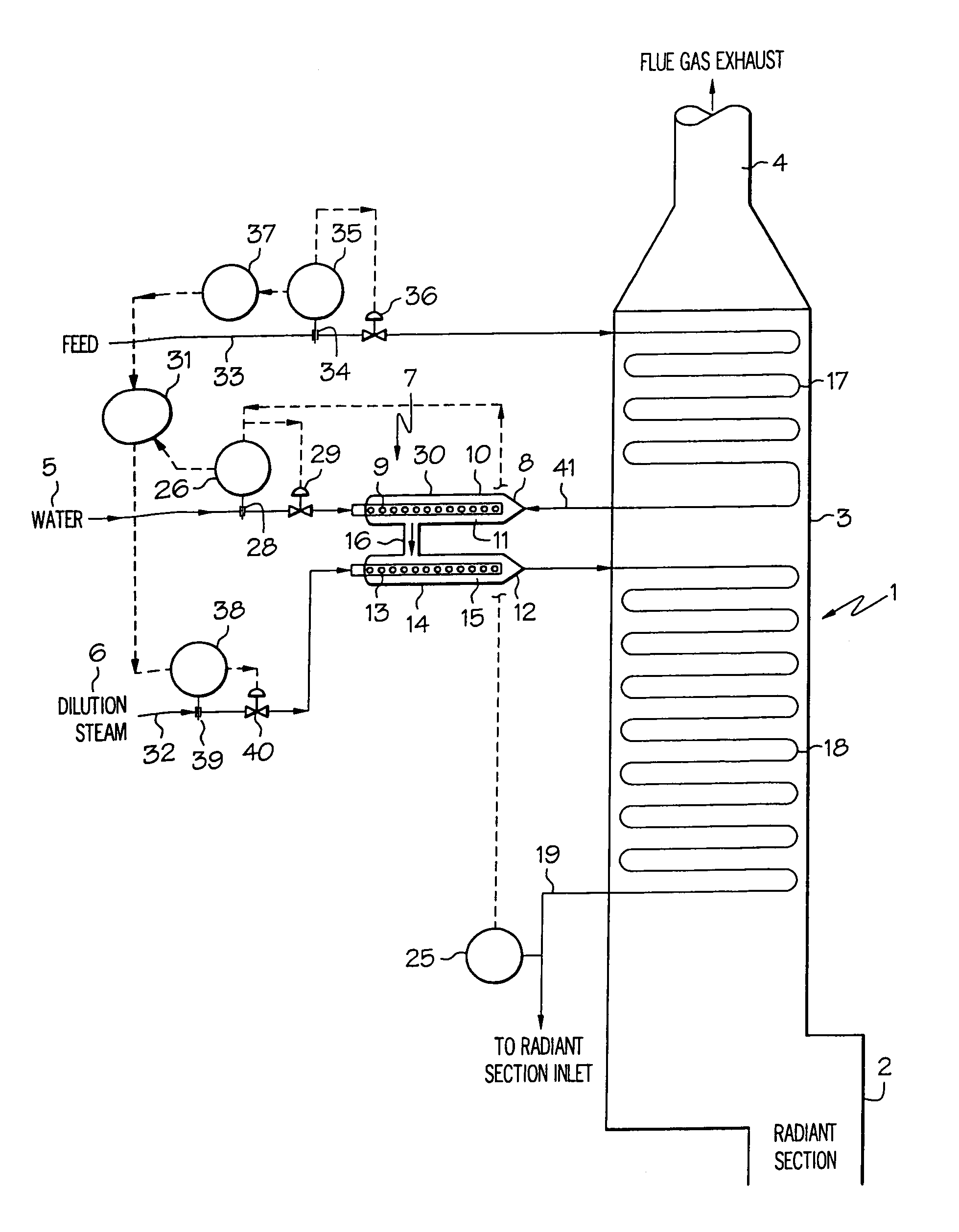

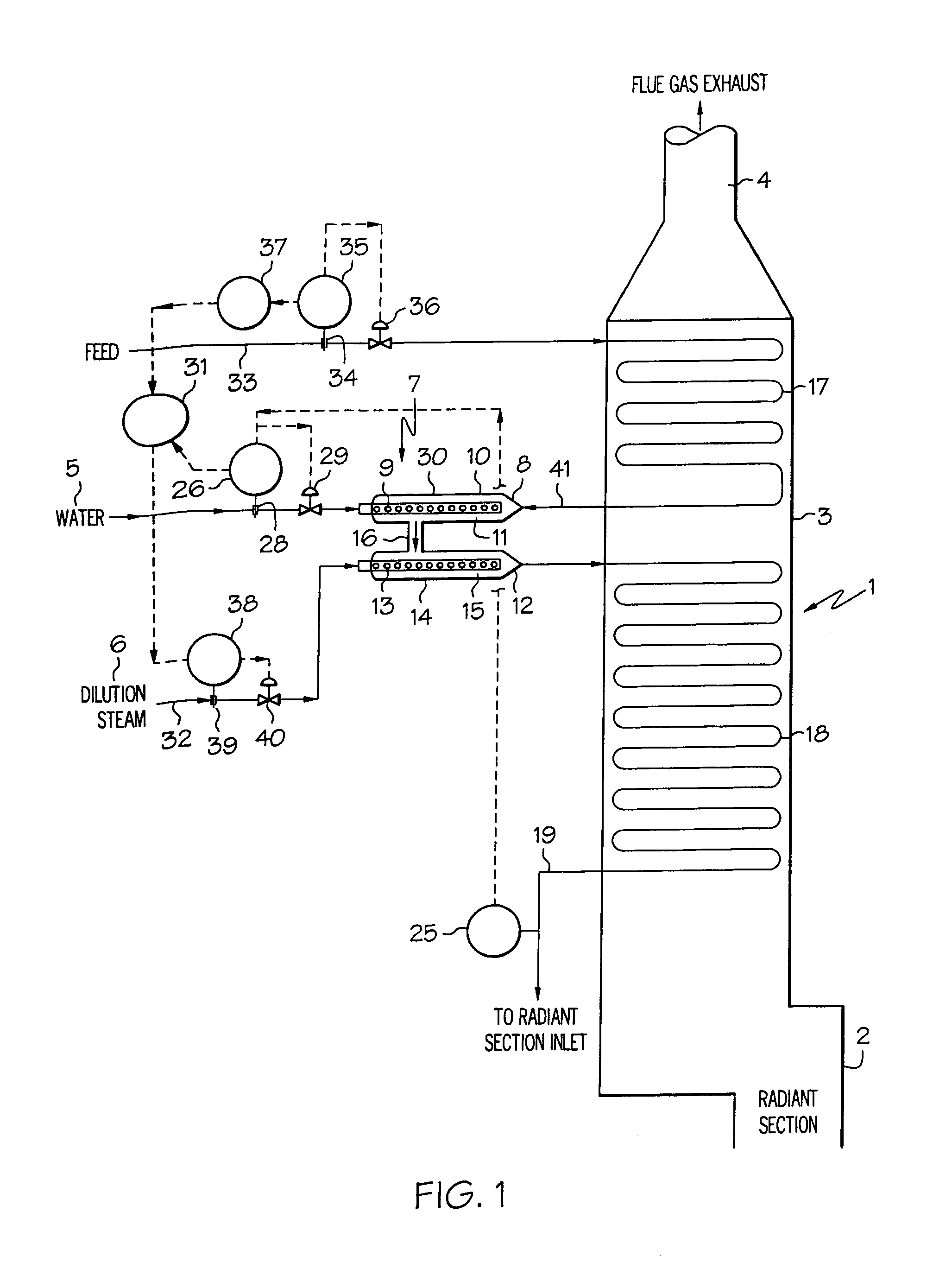

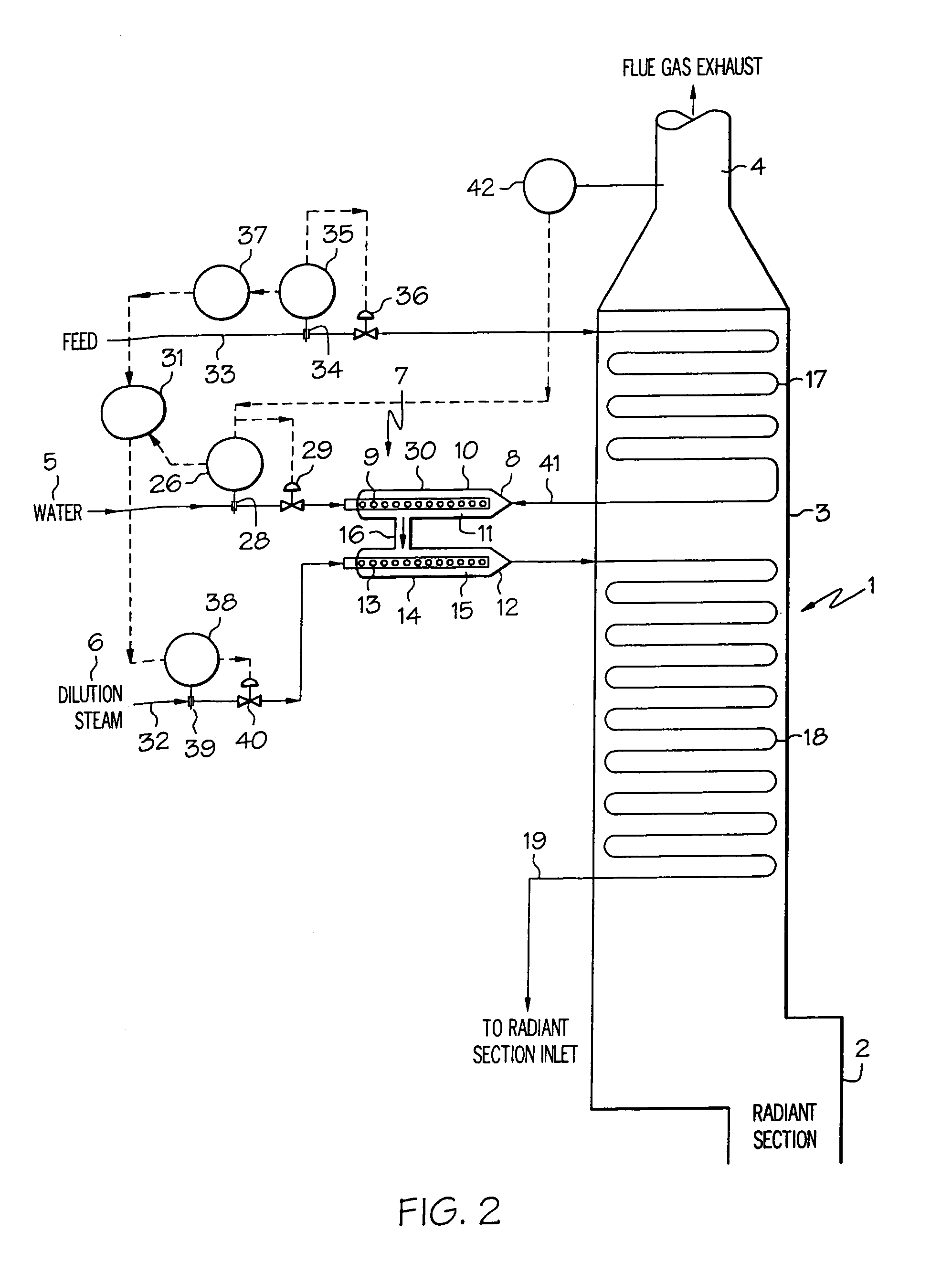

Process for cracking hydrocarbon feed with water substitution

InactiveUS7090765B2Thermal non-catalytic crackingHydrocarbon oil cracking processHydrocarbonHydrocotyle bowlesioides

A process for treating hydrocarbon feed in a furnace, the process comprising: (a) heating hydrocarbon feed, (b) adding water to the heated feed, (c) adding dilution steam to the heated feed to form a mixture, (d) heating the resulting mixture and feeding the resulting heated mixture to the furnace, wherein the water in (b) is added in an amount of from at least about 1% to 100% based on water and dilution steam by weight.

Owner:EXXONMOBIL CHEM PAT INC

Resid processing for steam cracker feed and catalytic cracking

ActiveUS20070090020A1High hydrogen contentEliminate needThermal non-catalytic crackingHydrocarbon oil cracking processProcess engineeringAlkene

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is treated by hydroprocessing and visbreaking and then passed to a steam cracker to obtain a product comprising olefins.

Owner:EXXONMOBIL CHEM PAT INC

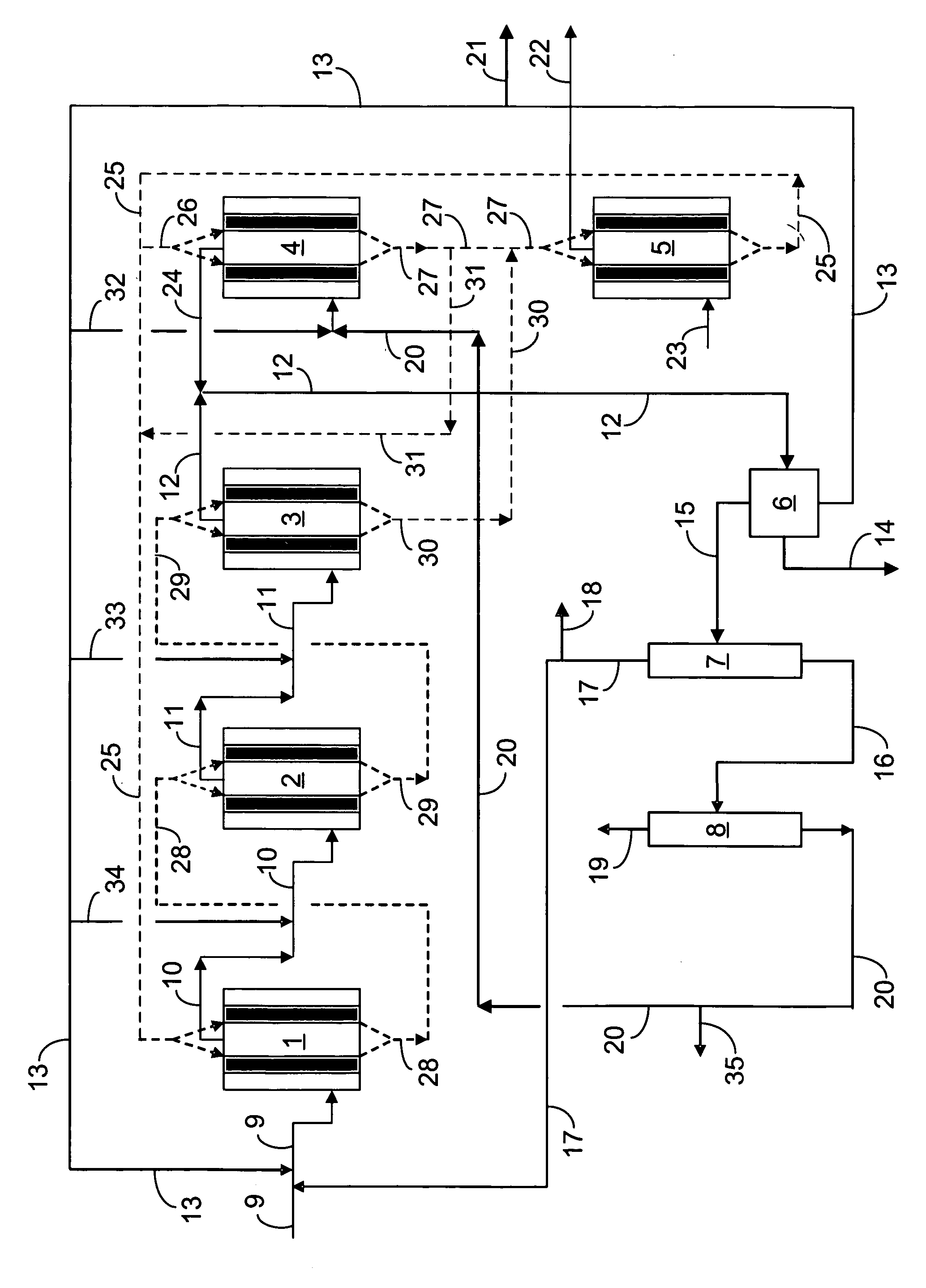

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS20060161035A1Improve economyEfficient OTP processMolecular sieve catalystCatalystsFixed bedOxygenate

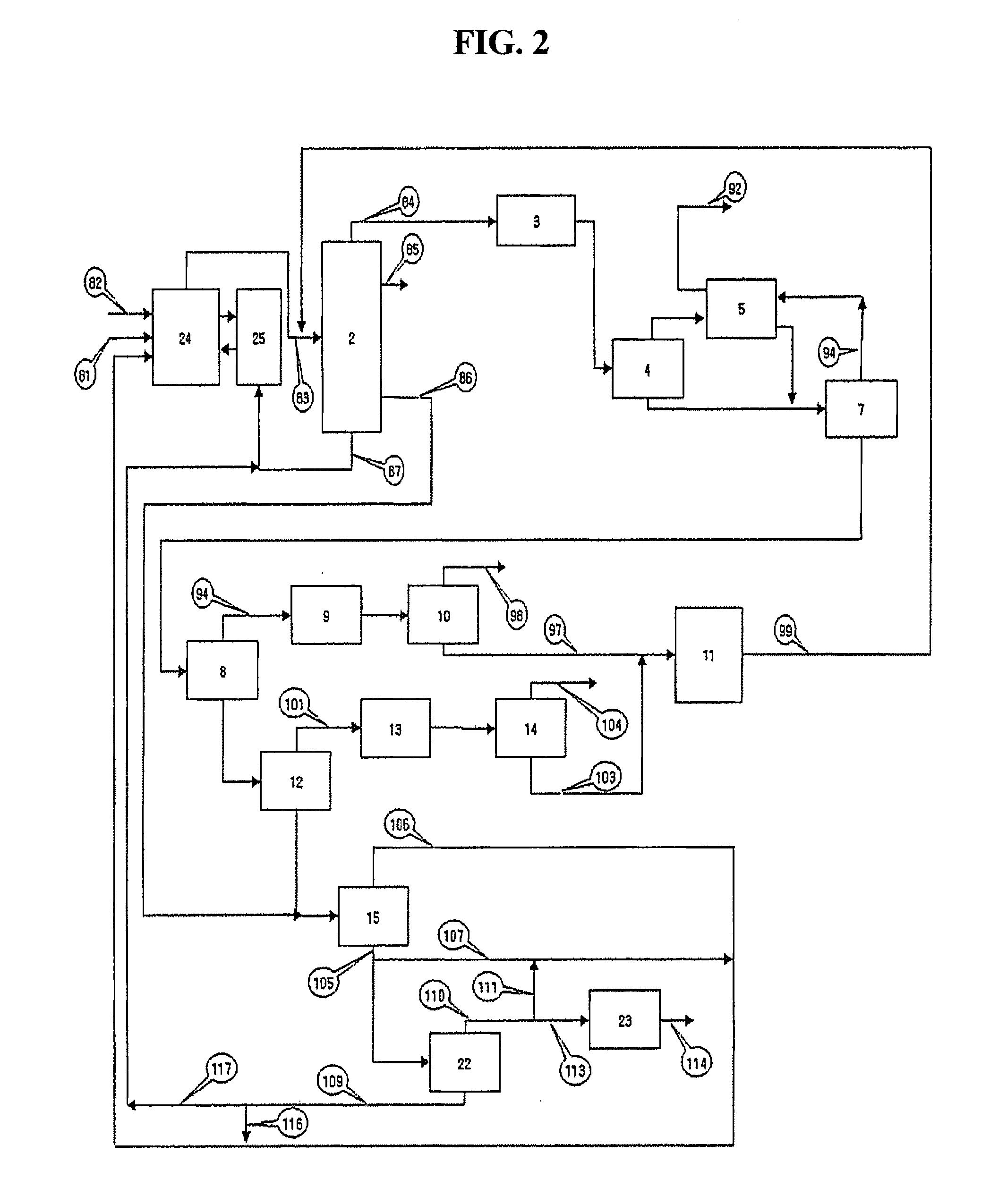

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

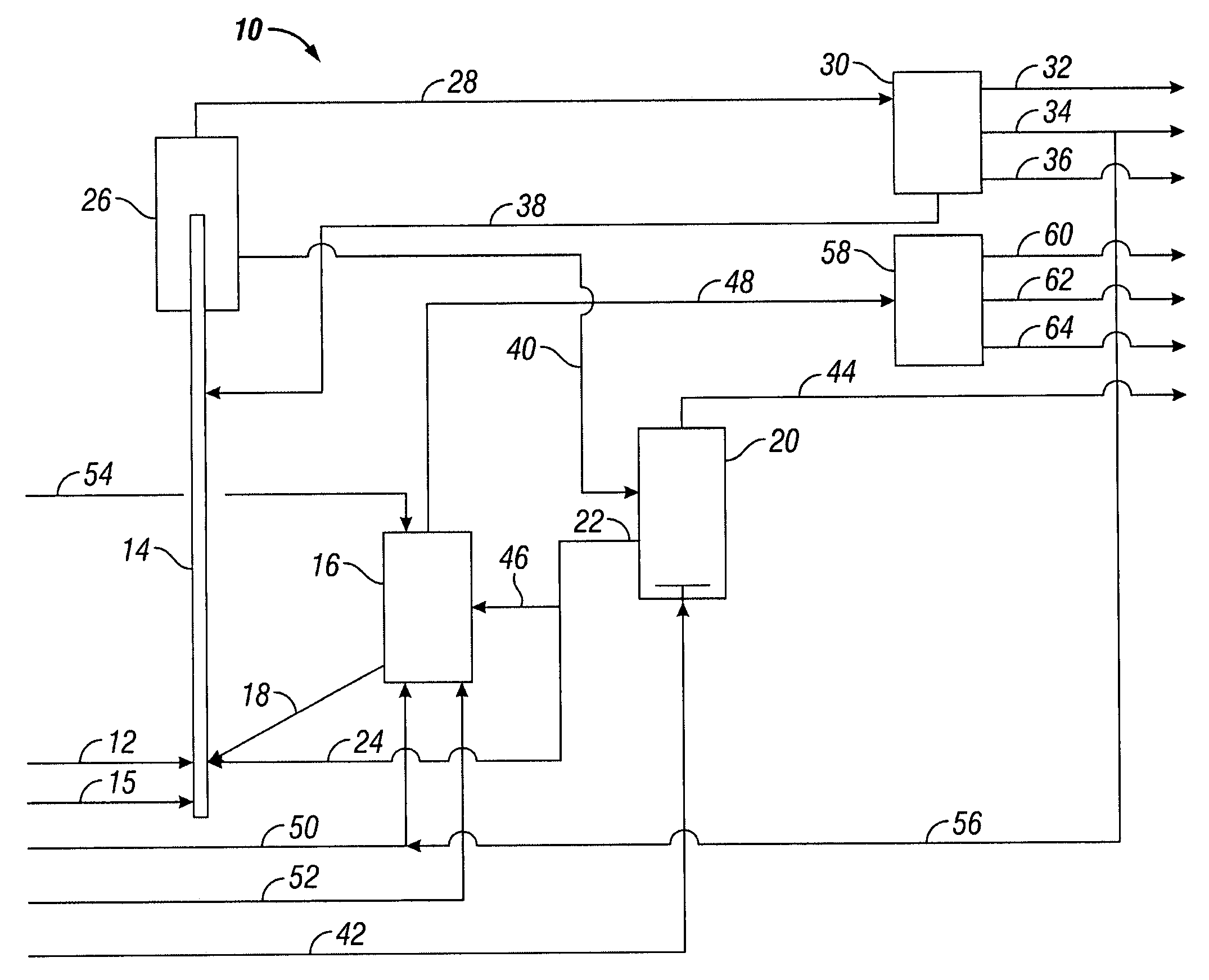

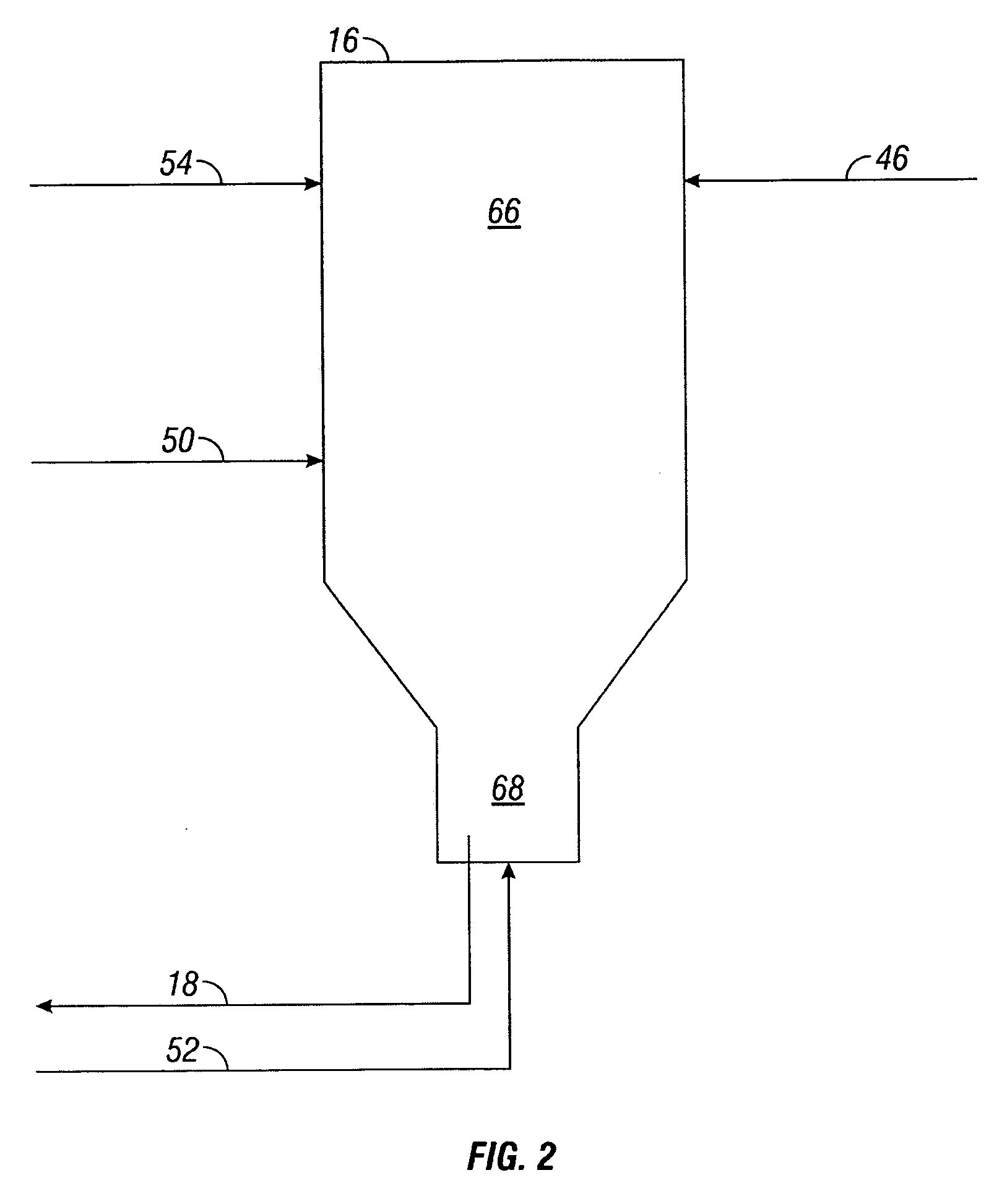

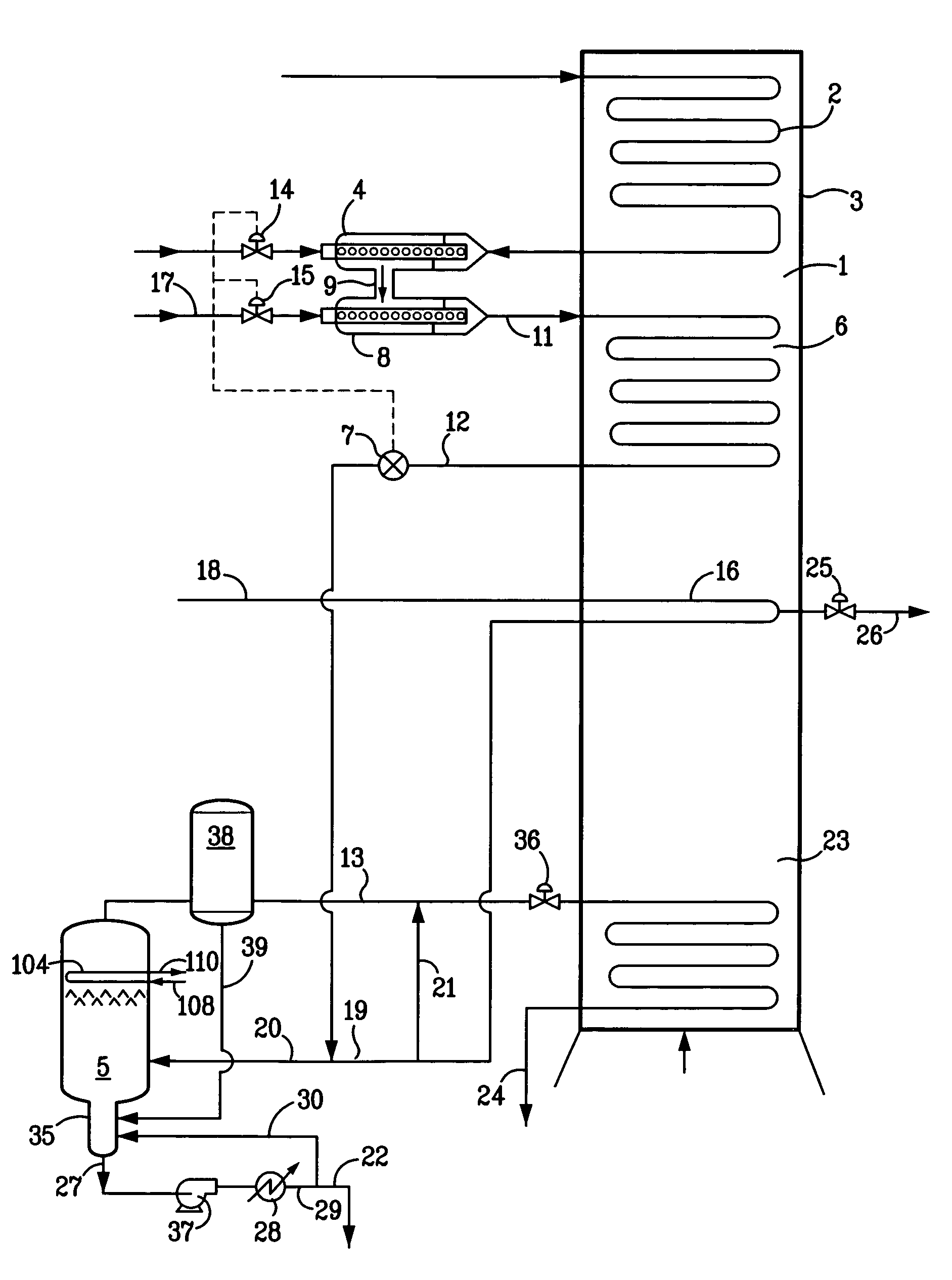

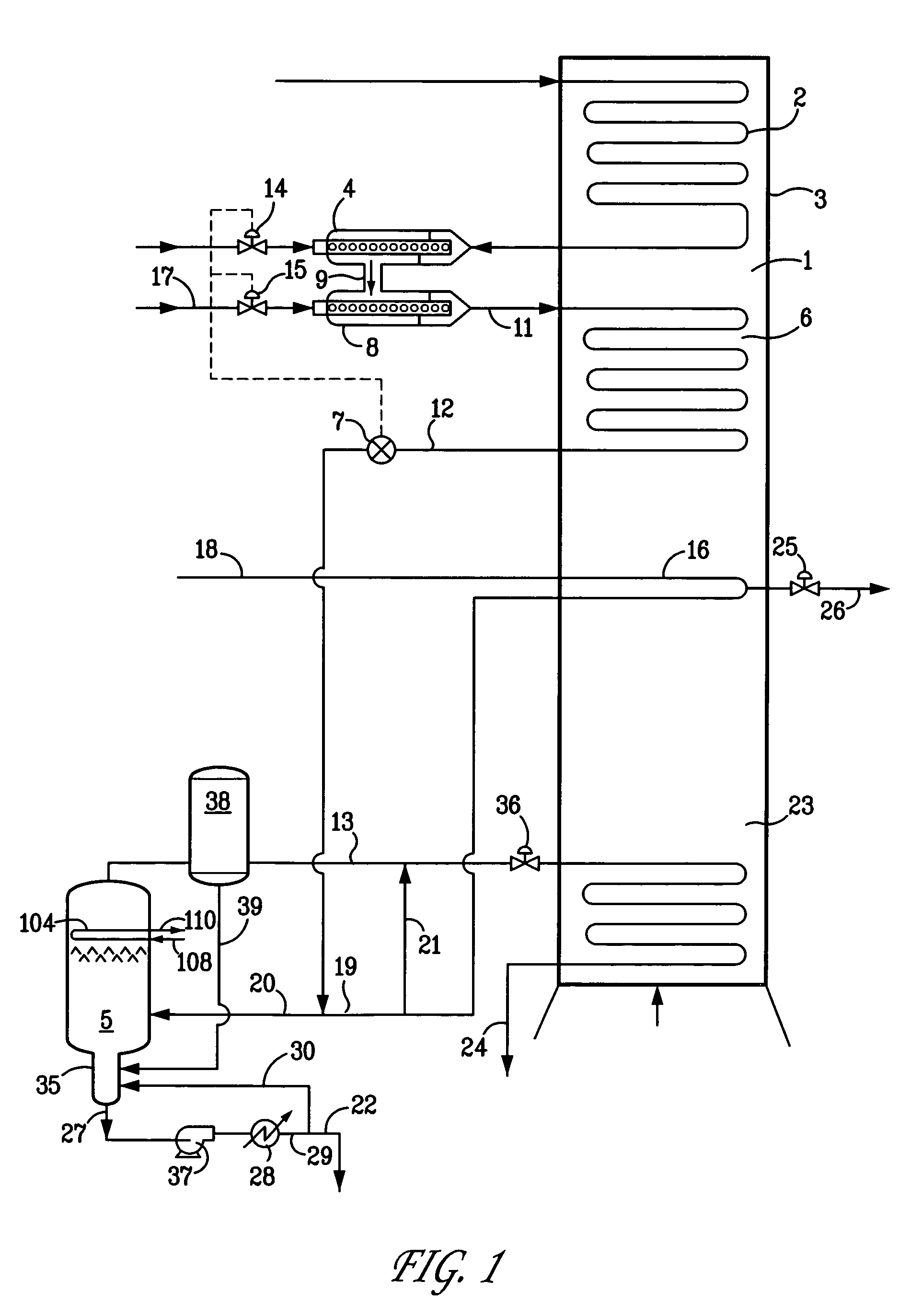

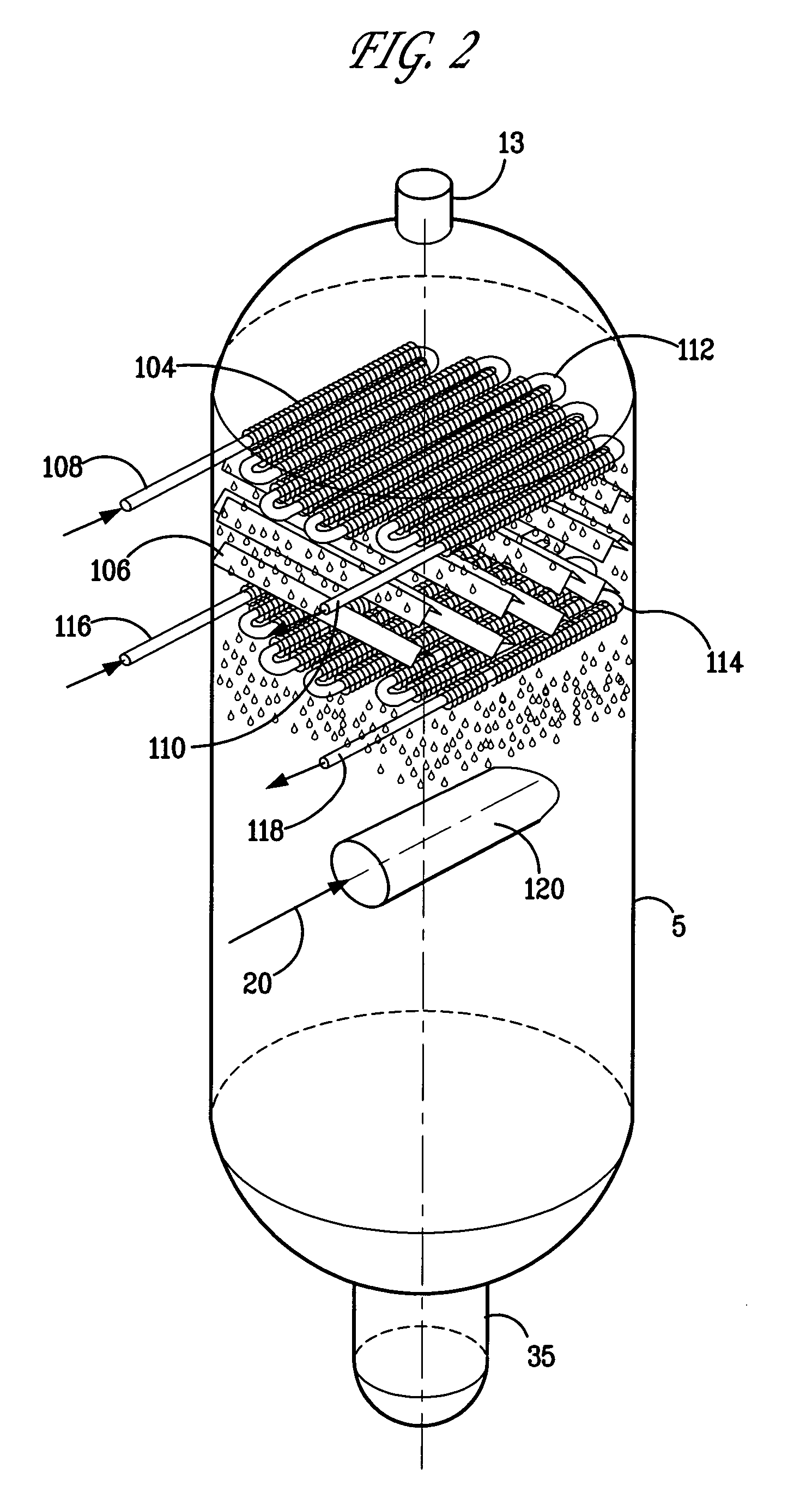

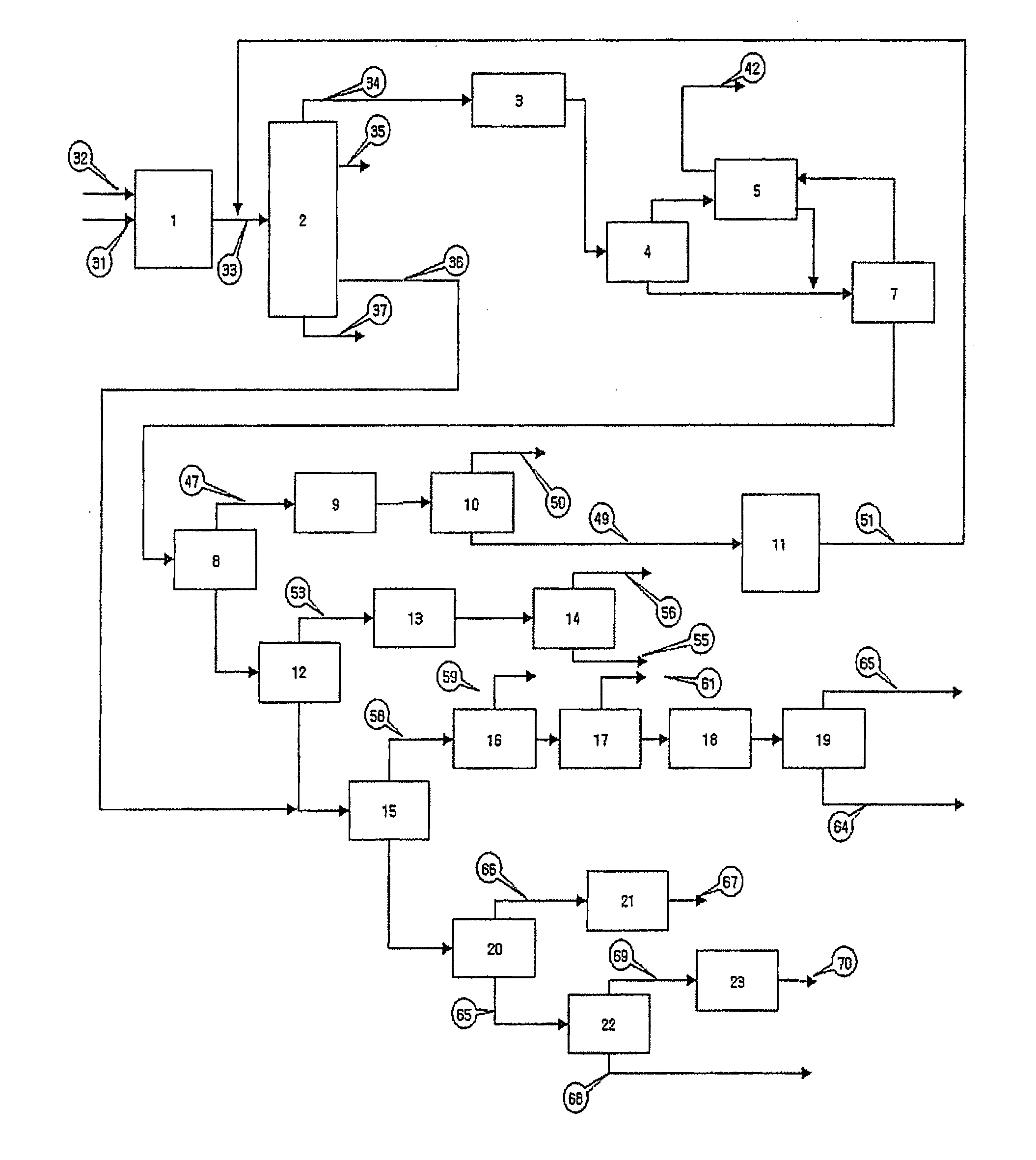

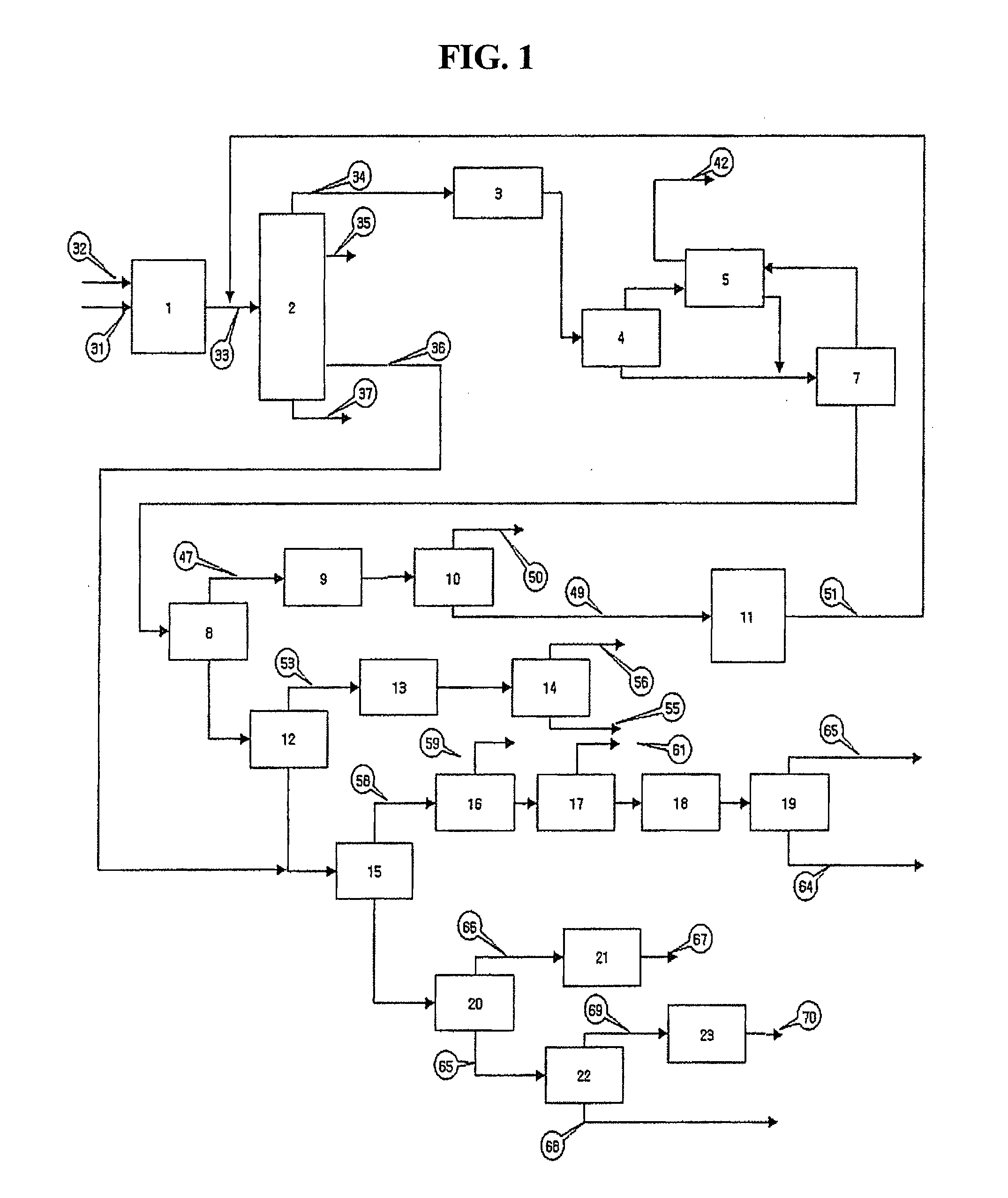

Cracking hydrocarbon feedstock containing resid utilizing partial condensation of vapor phase from vapor/liquid separation to mitigate fouling in a flash/separation vessel

A process is provided for cracking hydrocarbon feedstock containing resid comprising: heating the feedstock, mixing the heated feedstock with a fluid and / or a primary dilution steam stream to form a mixture, optionally further heating the mixture, flashing the mixture within a flash / separation vessel to form a vapor phase and a liquid phase, partially condensing the vapor phase by contacting with a condenser within the vessel, to condense at least some coke precursors within the vapor while providing condensates which add to the liquid phase, removing the vapor phase of reduced coke precursors content as overhead and the liquid phase as bottoms, heating the vapor phase, cracking the vapor phase in a radiant section of a pyrolysis furnace to produce an effluent comprising olefins, and quenching the effluent and recovering cracked product therefrom. An apparatus for carrying out the process is also provided.

Owner:EXXONMOBIL CHEM PAT INC

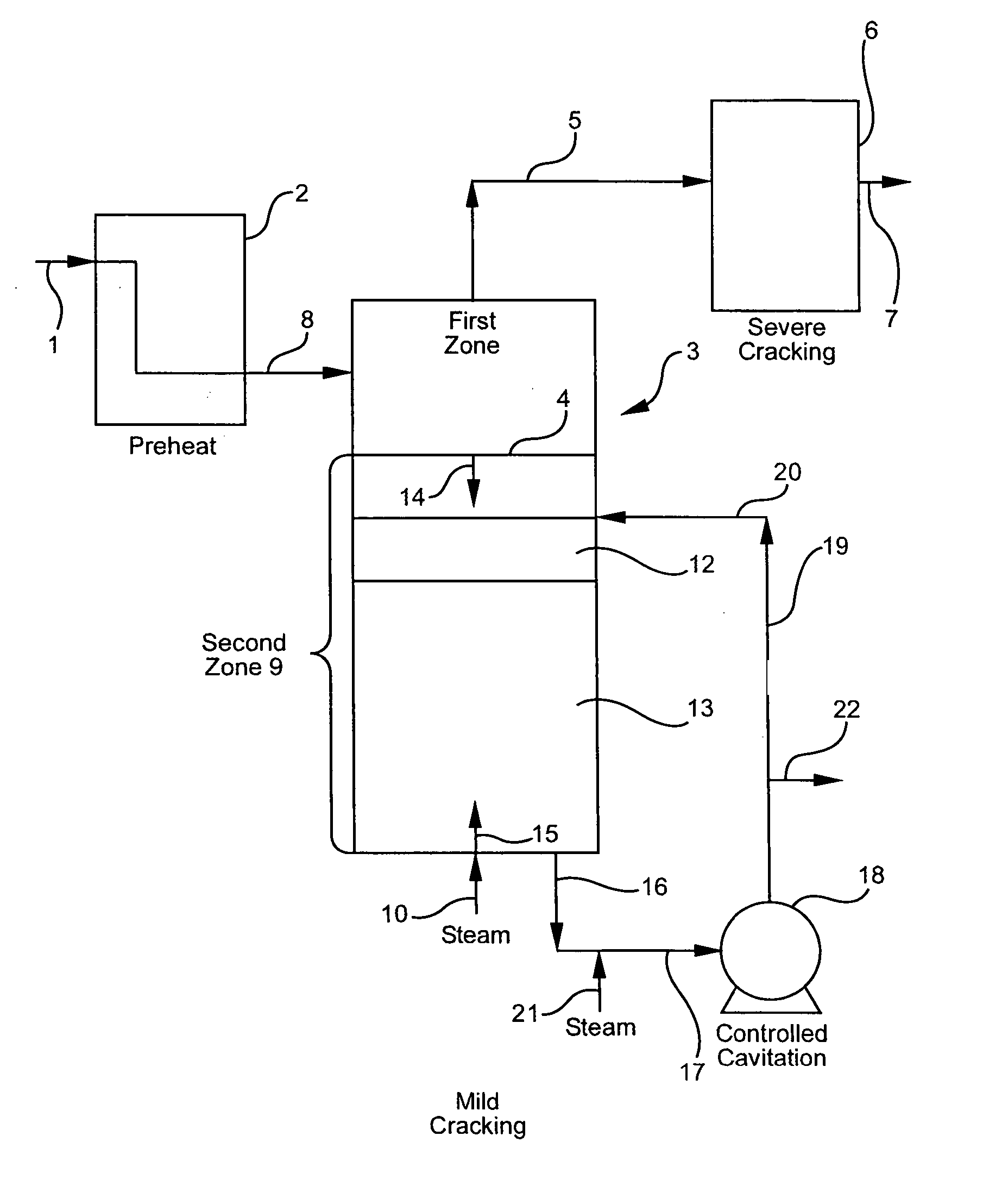

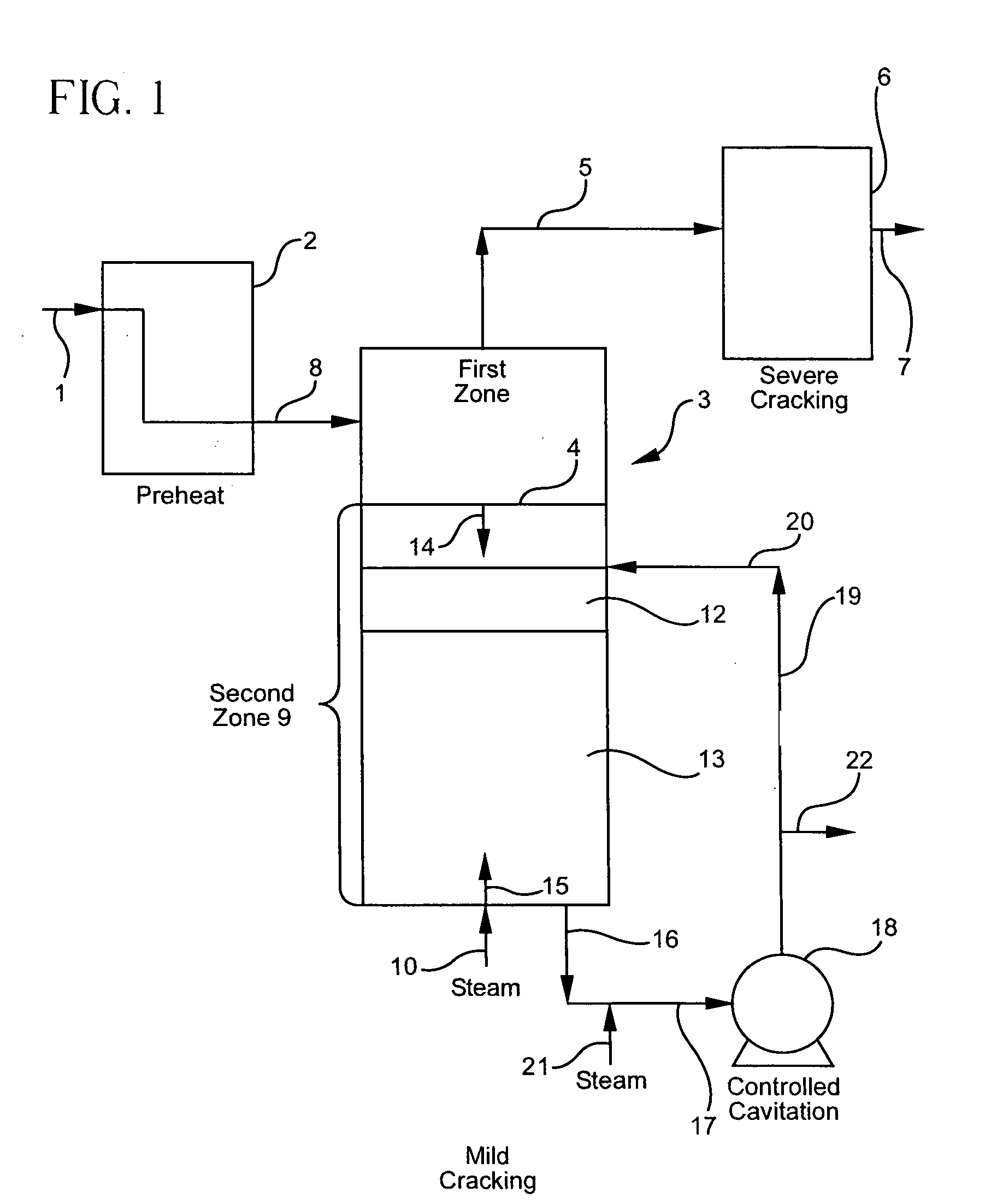

Olefin production utilizing whole crude oil and mild controlled cavitation assisted cracking

InactiveUS20050010075A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyCavitationAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild thermal cracking assisted with controlled cavitation conditions until substantially vaporized, the vapors being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

Controlled combustion for regenerative reactors

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

Olefin production utilizing whole crude oil

InactiveUS20040039240A1Lower temperature rangeReduce molecular weightThermal non-catalytic crackingHydrocarbonsOil productionAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild cracking conditions until substantially vaporized, the vapors from mild cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

Process and draft control system for use in cracking a heavy hydrocarbon feedstock in a pyrolysis furnace

Owner:EXXONMOBIL CHEM PAT INC

Process for increasing production of light olefins from hydrocarbon feedstock in catalytic cracking

ActiveUS20070083071A1Increase productionEconomical efficiencyTreatment with plural serial cracking stages onlyCatalytic crackingProduction ratePhotochemistry

Disclosed is a process for increasing production of light olefinic hydrocarbons from hydrocarbon feedstock by catalytic cracking. In the process, an effective separation process structure and recycle method of light olefins are used not only to increase the productivity and efficiency of an overall process, thus effectively increasing the production of light olefins, but also to simplify the overall process.

Owner:SK INNOVATION CO LTD

Catalytic conversion method of ethylene, propylene and aromatic hydrocarbon preparation

The invention discloses a catalytic conversion method for preparing ethylene, propylene and aromatic hydrocarbon. Hydrocarbon raw material with different cracking performances is contacted with a catalytic cracking catalyst, and cracking reaction is carried out in a fluidized bed reactor under the conditions that the temperature is 550 DEG C to 800 DEG C, the weight hourly space velocity is 0.1-800h<-1>, the reaction pressure is 0.10MPa to 1.0MPa, the weight ratio of the catalytic cracking catalyst and the raw material is 10-150, and the weight ratio of steam and the raw material is 0.15-1.0.Then a spent catalyst and reaction oil gas are separated, the spent catalyst returns to the reactor after regeneration, and the target products comprising low carbon olefin and the aromatic hydrocarbon are obtained by separating the reaction oil gas, wherein, fraction with the temperature to be 160 DEG C to 260 DEG C returns for catalytic cracking as circulating material, and the ethylene and the propylene are further obtained by cracking of ethane, propane, butane, and the steam entered. Low carbon olefin such as ethylene, propylene, and the like, is produced from heavy feedstock to the utmost extent in the method, and the yield of the ethylene and the propylene is over 20% by weight, in addition, the aromatic hydrocarbon such as toluene, xylene, and the like, are produced in an integrated way.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process to produce aromatics from crude oil

ActiveUS20150321975A1Low impurity contentHigh API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyVapor–liquid separatorWater flow

A process for producing aromatics from a hydrocarbon source in the presence of supercritical water comprising the steps of mixing a pressurized, pre-heated water stream with a pressurized, pre-heated petroleum feedstock, the pressurized, pre-heated water stream at a pressure above the critical pressure of water and a temperature above the critical temperature of water, feeding the combined stream to a supercritical water reactor to create a modified stream, cooling and depressurizing the modified stream, separating the depressurized stream in a vapor-liquid separator, condensing the vapor stream, separating the condensed stream into a water recovery stream and a light product recovery stream, extracting the aromatics from the light product recovery stream, depressurizing the liquid stream, separating the depressurized liquid stream in a heavy separator into an upgraded product stream, and recycling part of the upgraded product stream to the pressurized, pre-heated petroleum feedstock as a product recycle.

Owner:SAUDI ARABIAN OIL CO

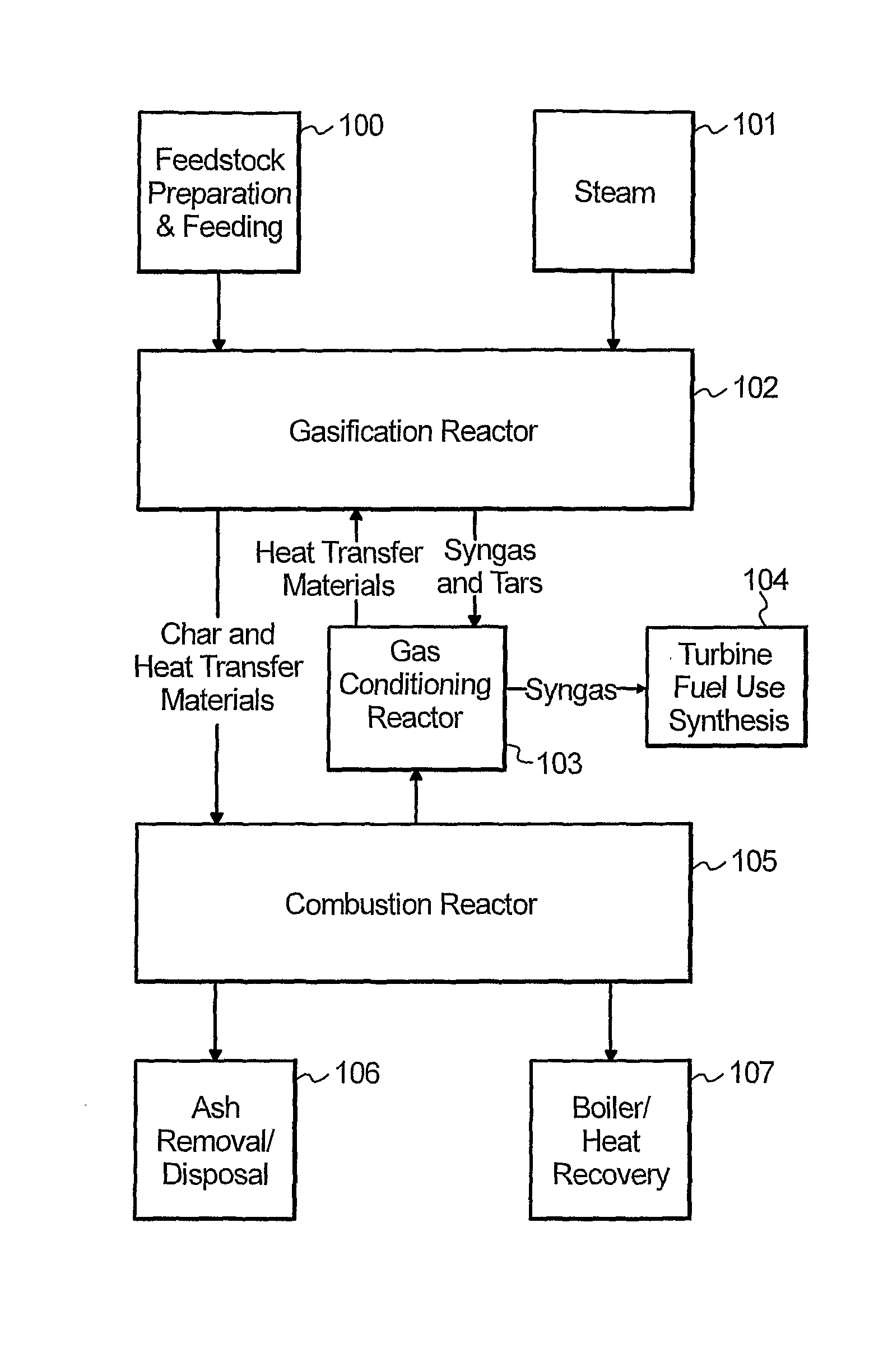

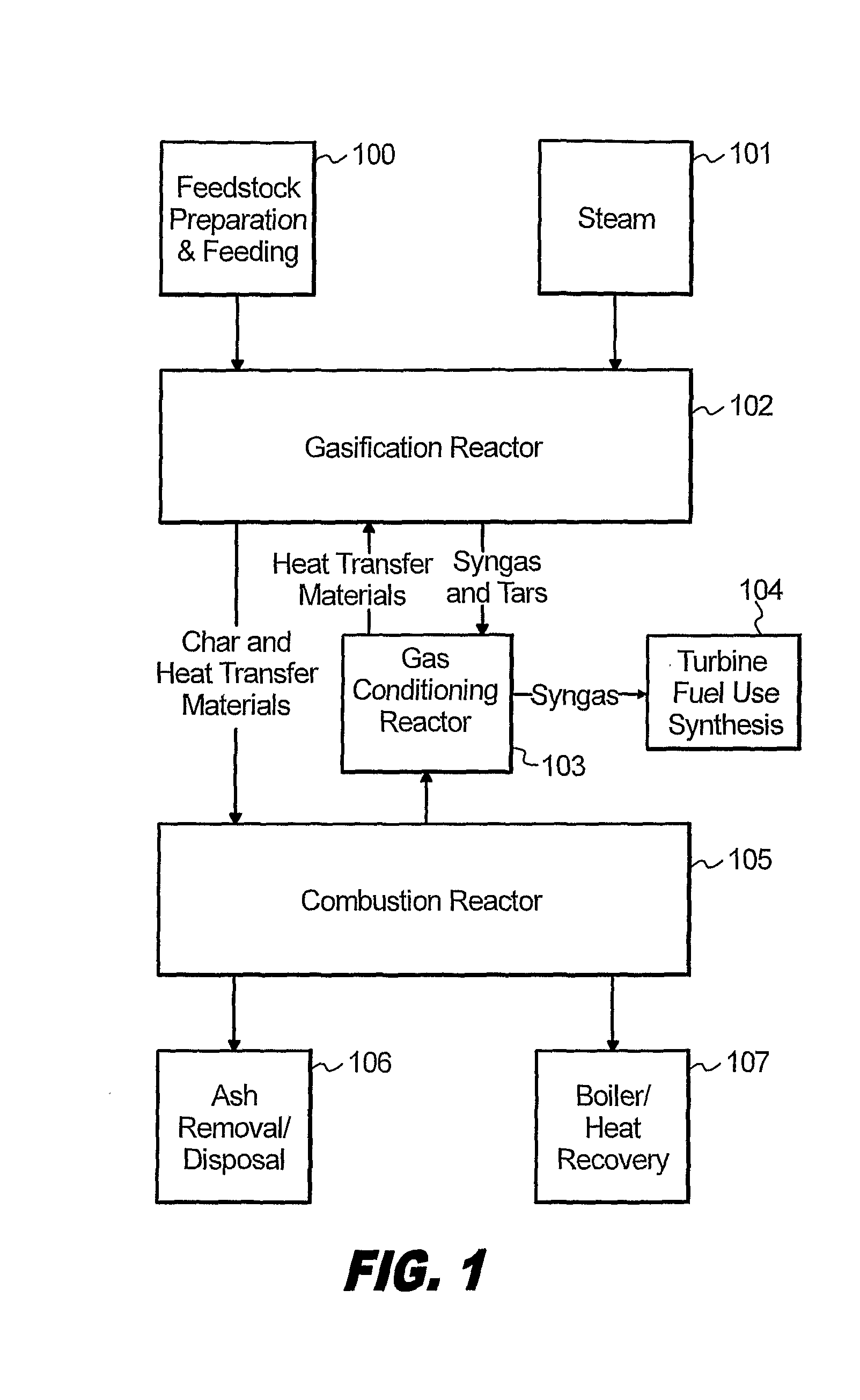

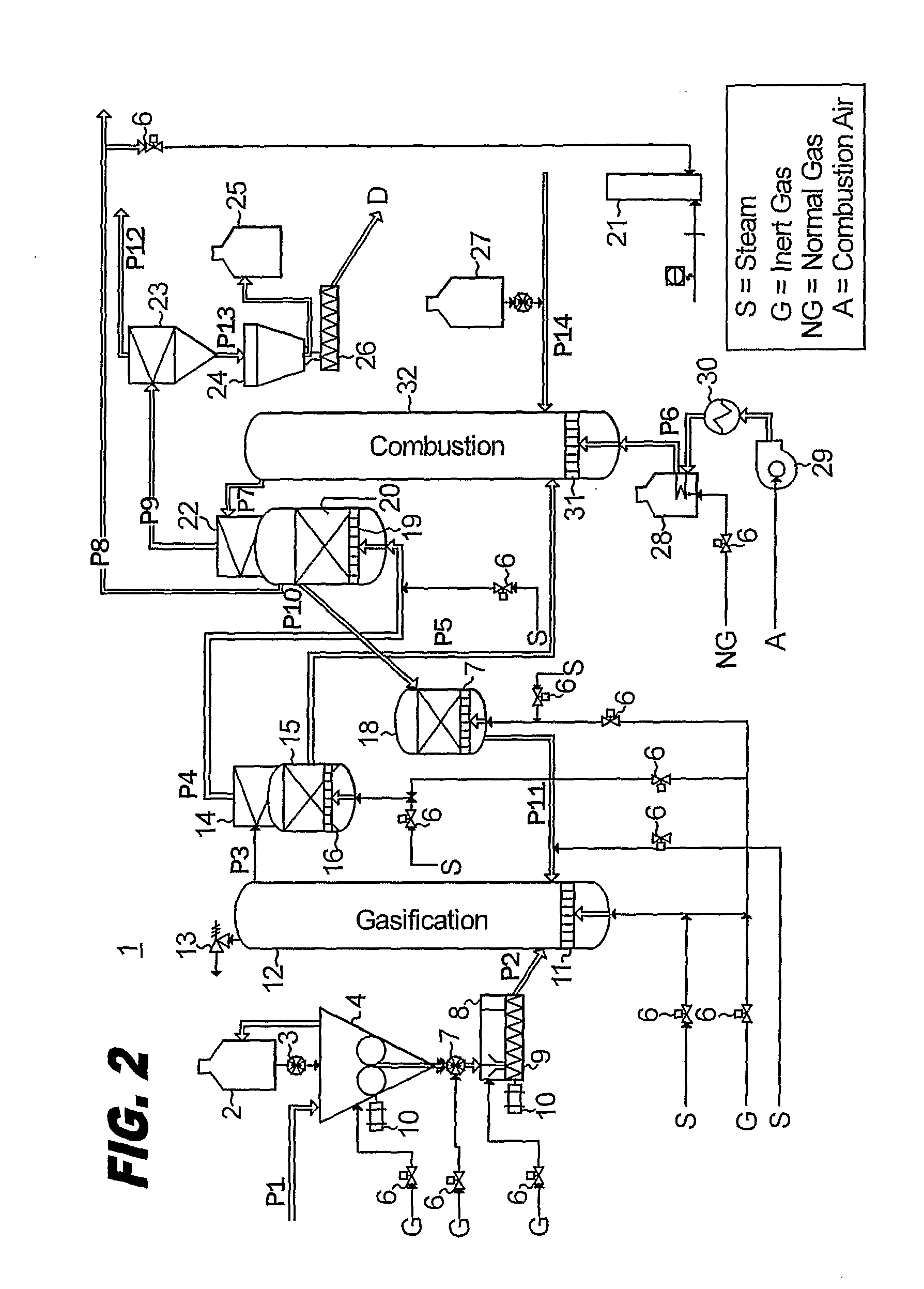

Process and System for Gasification with In-Situ Tar Removal

ActiveUS20080244976A1Simplifying downstream heat recoveryIncreased hydrogenCombustible gas catalytic treatmentCombustible gas thermal treatmentHeat carrierTar

The present invention relates to a process and system for gasifying biomass or other carbonaceous feedstocks in an indirectly heated gasifier and provides a method for the elimination of condensable organic materials (tars) from the resulting product gas with an integrated tar removal step. More specifically, this tar removal step utilizes the circulating heat carrier to crack the organics and produce additional product gas. As a benefit of the above process, and because the heat carrier circulates through alternating steam and oxidizing zones in the process, deactivation of the cracking reactions is eliminated.

Owner:TAYLOR BIOMASS ENERGY

Olefin production utilizing whole crude oil and mild catalytic cracking

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild catalytic cracking conditions until substantially vaporized, the vapors from the mild catalytic cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

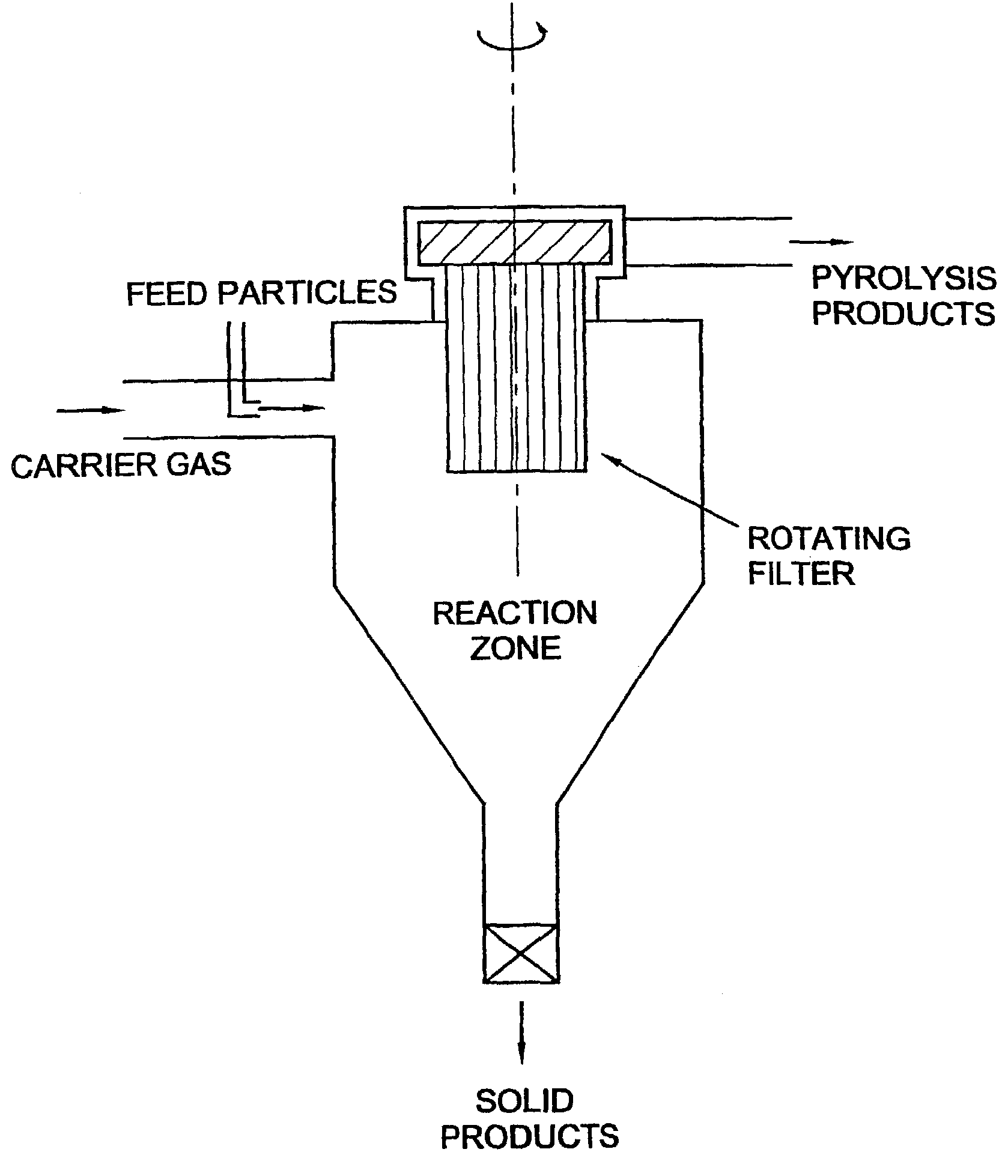

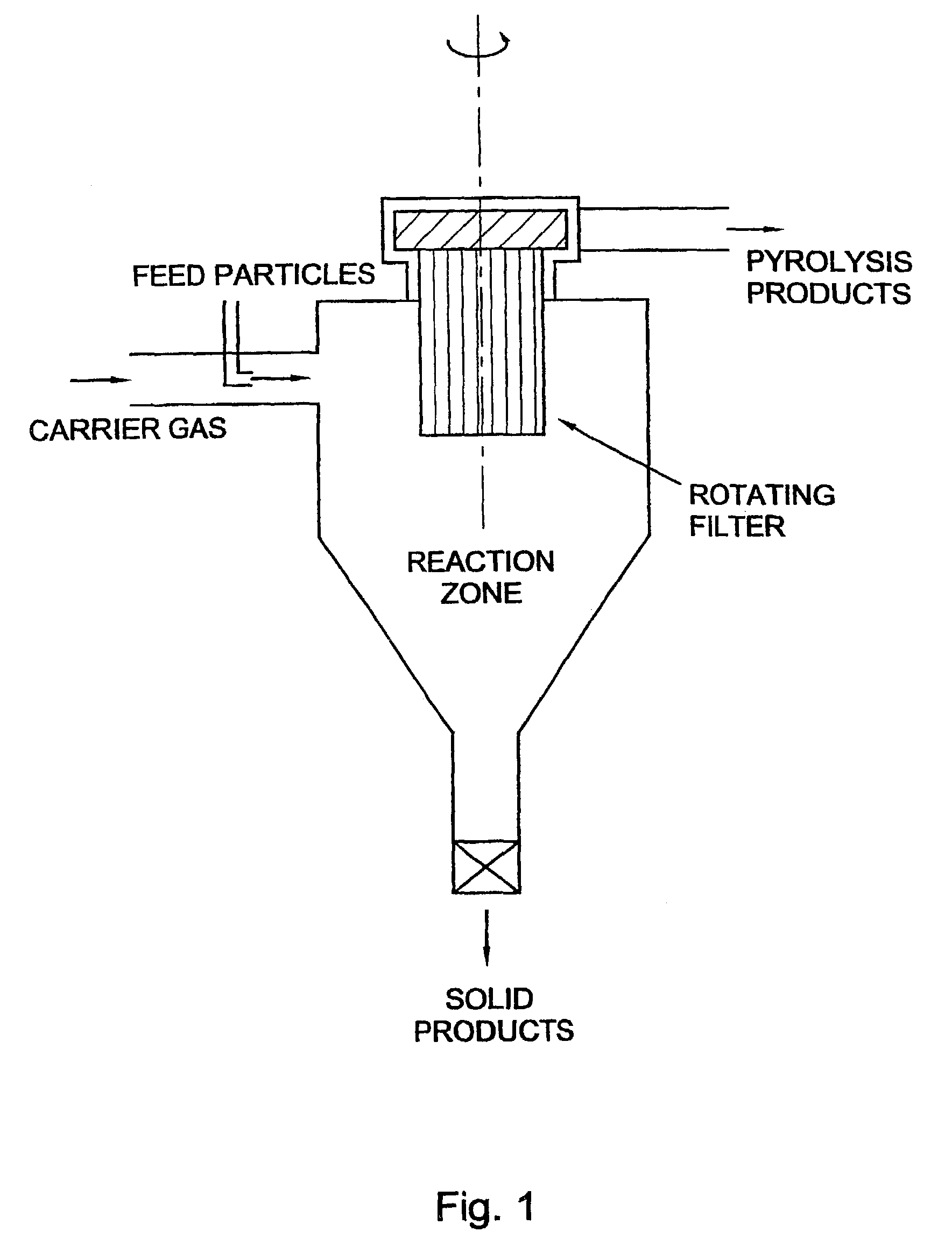

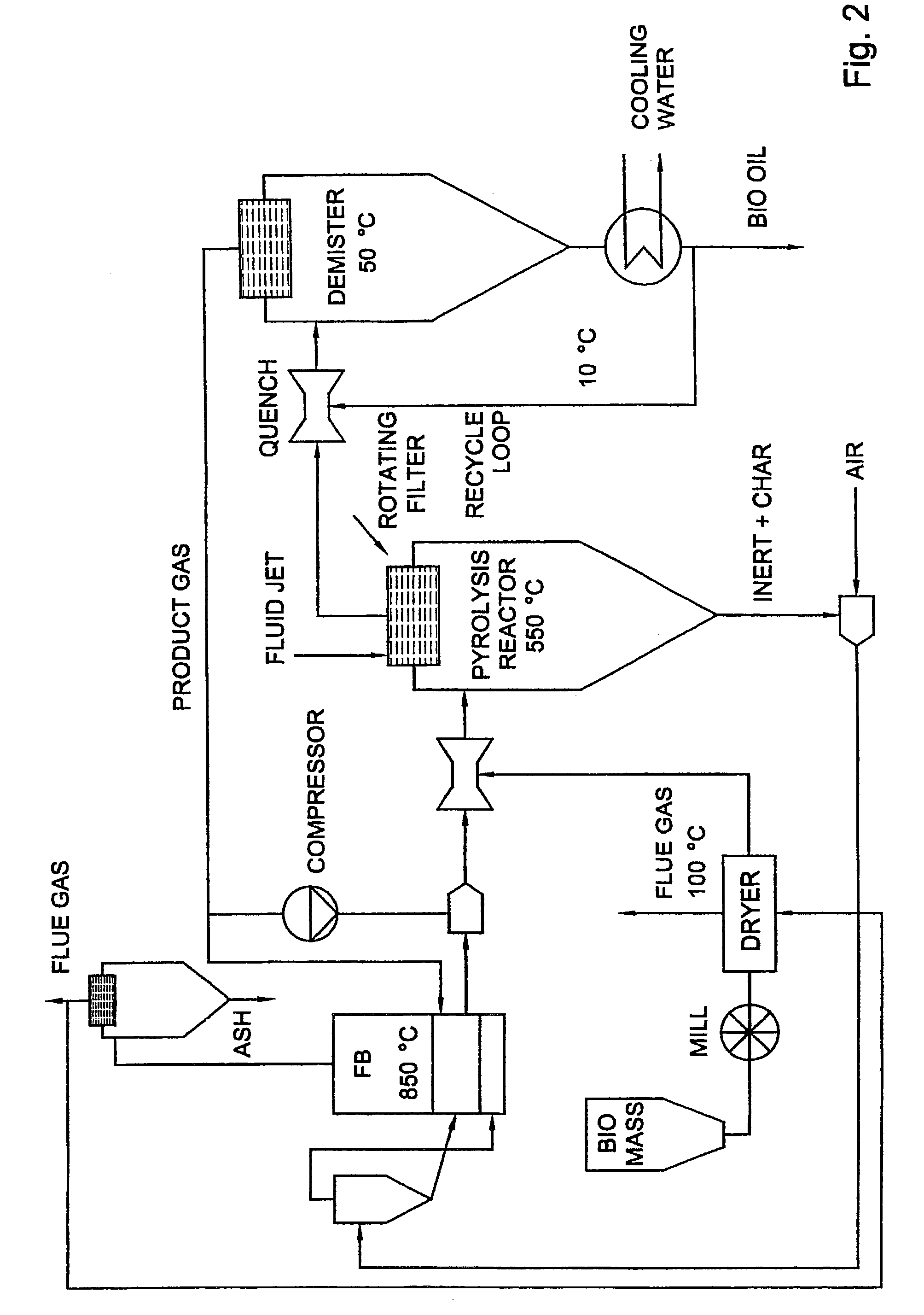

Flash-pyrolysis in a cyclone

InactiveUS7202389B1Excessive crackingCombination devicesDispersed particle filtrationParticulatesCyclone

A process for the pyrolysis of carbonaceous material is carried out in a cyclone reactor which is fitted with enhanced filtering equipment. In addition the invention relates to the use of a cyclone fitted with a rotating filter as a pyrolysis reactor. By using a cyclone of the rotating separator type as a pyrolysis reactor, carbonaceous material, such as biomass, can effectively be converted in a product having excellent chemical properties and which product is free from particulate matter.

Owner:UNIVERSITY OF TWENTE

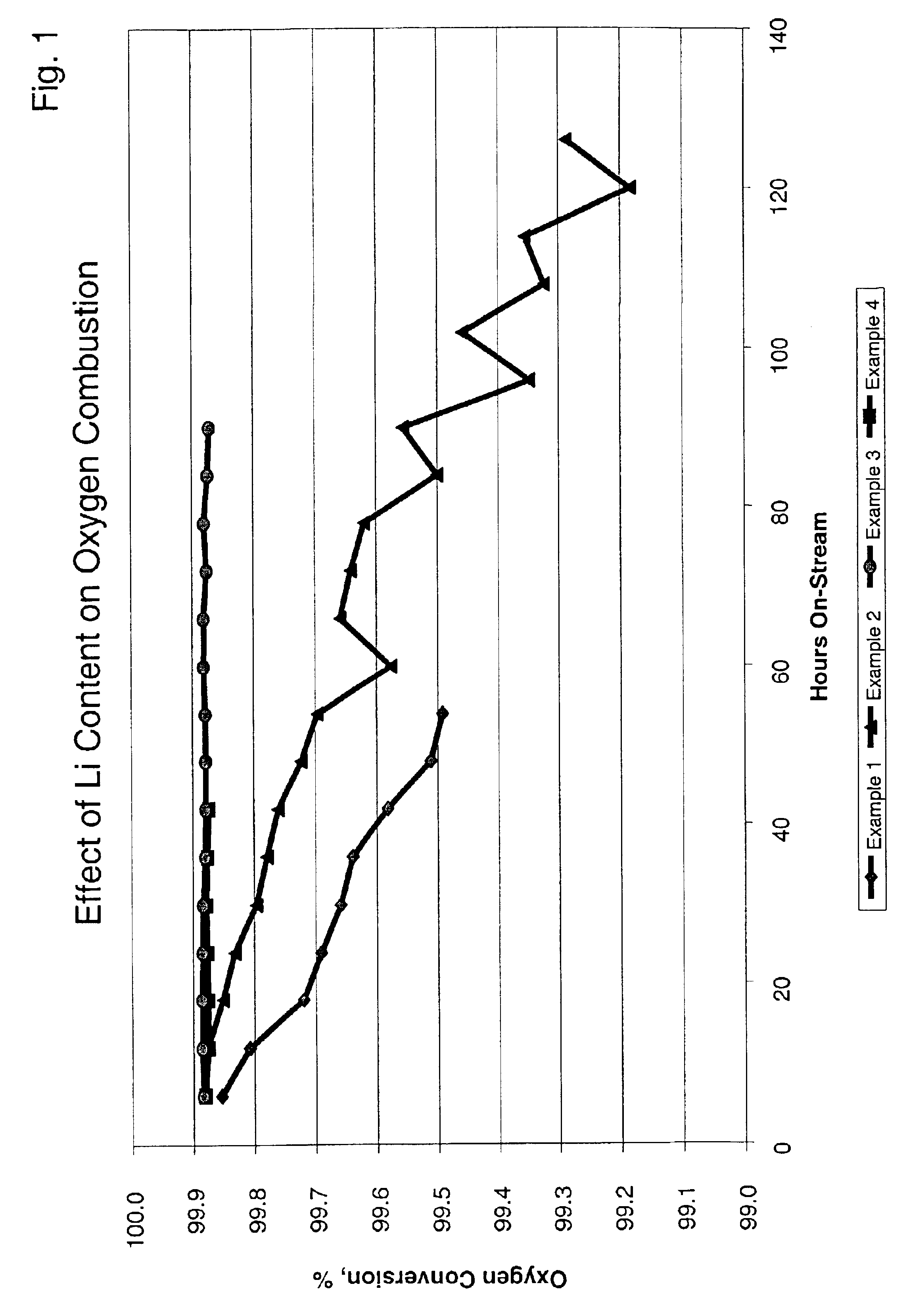

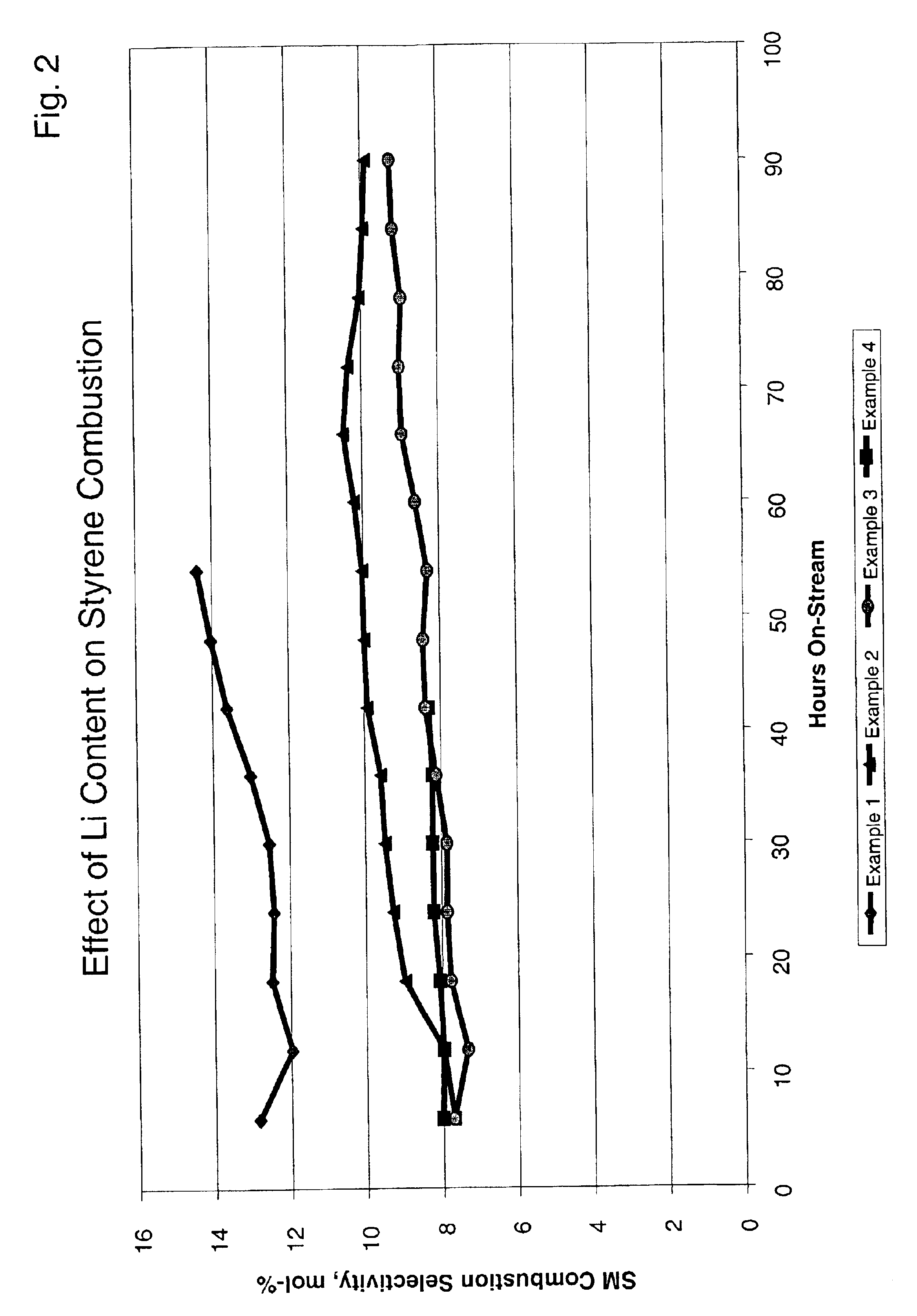

Lithium aluminate layered catalyst and a selective oxidation process using the catalyst

InactiveUS6858769B2Thermal non-catalytic crackingHydrocarbon by isomerisationHydrogenDehydrogenation

A catalyst for the selective oxidation of hydrogen has been developed. It comprises an inert core such as cordierite and an outer layer comprising a lithium aluminate support. The support has dispersed thereon a platinum group metal and a promoter metal, e.g. platinum and tin respectively. This catalyst is particularly effective in the selective oxidation of hydrogen in a dehydrogenation process.

Owner:UOP LLC

Popular searches

Hydrocarbon by hydrocarbon cracking Pyrolysis reactions Hydrocarbon by hydrocarbon condensation Chemical/physical/physico-chemical nozzle-type rreactors Feed devices Supercritical condition processes Treatment with hydrotreatment processes Distillation separation Liquid-gas reaction processes Refining by aromatic hydrocarbon hydrogenation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com