Patents

Literature

5278 results about "Reaction step" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A reaction step of a chemical reaction is defined as: "An elementary reaction, constituting one of the stages of a stepwise reaction in which a reaction intermediate (or, for the first step, the reactants) is converted into the next reaction intermediate (or, for the last step, the products) in the sequence of intermediates between reactants and products".

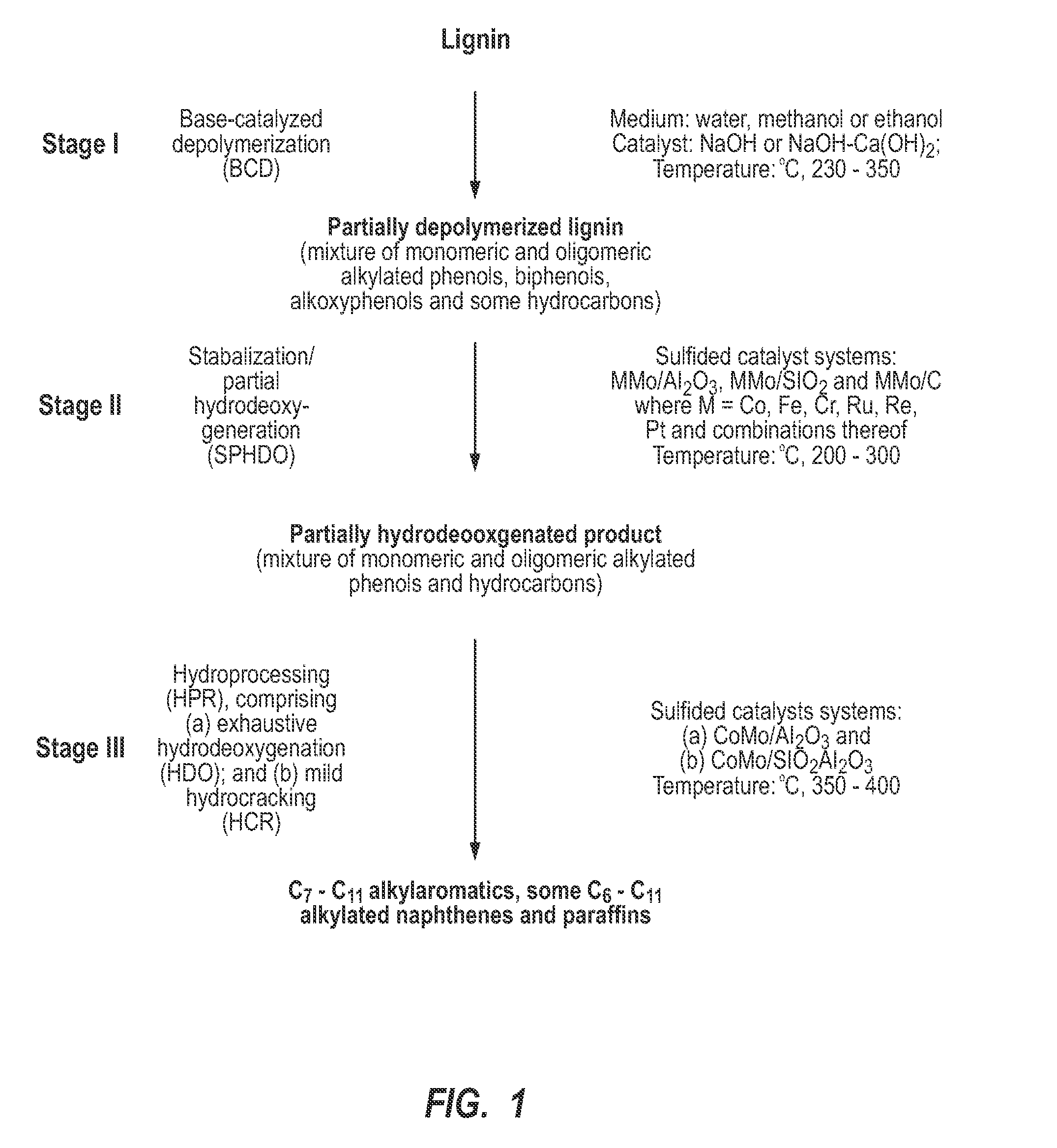

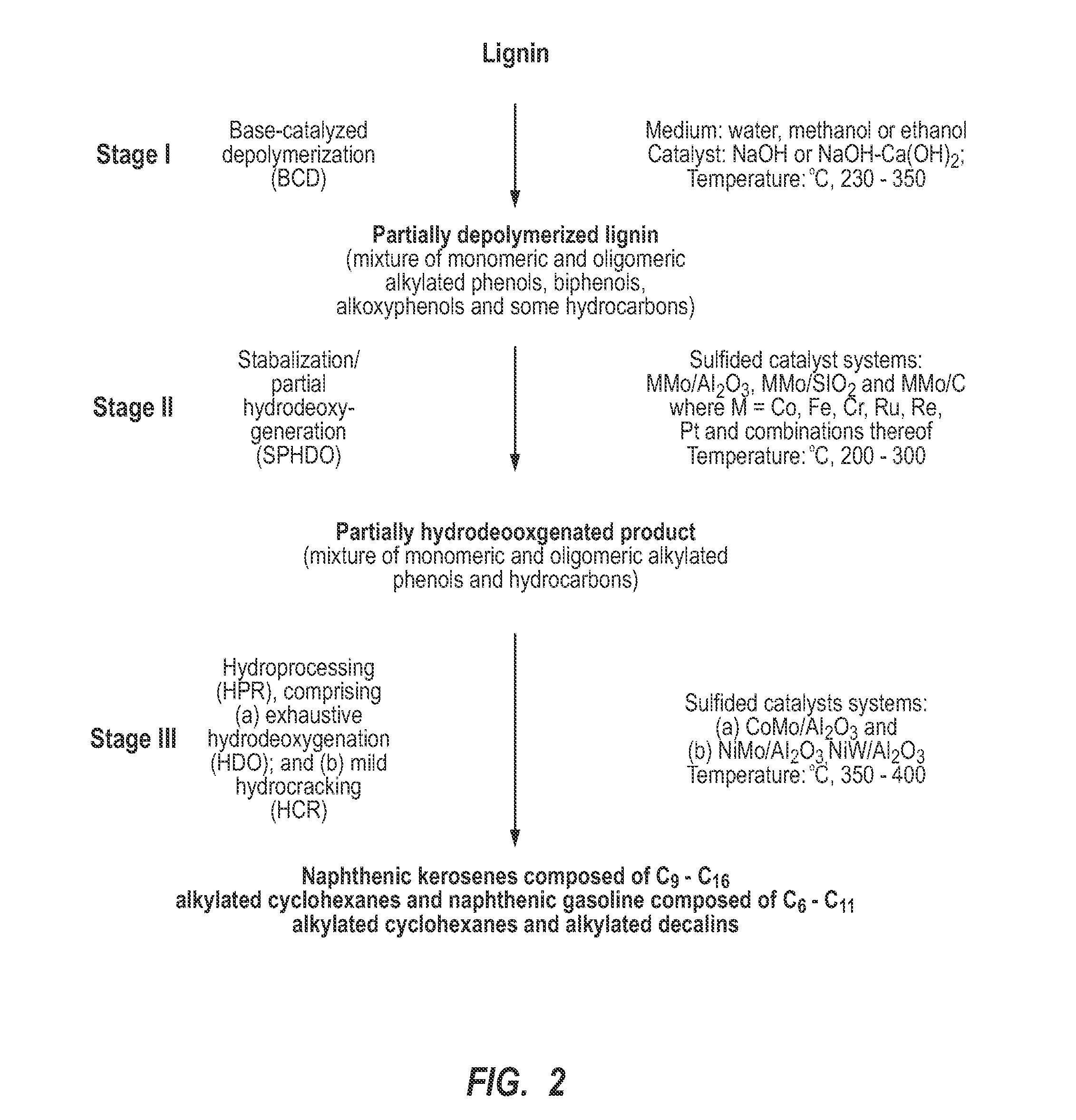

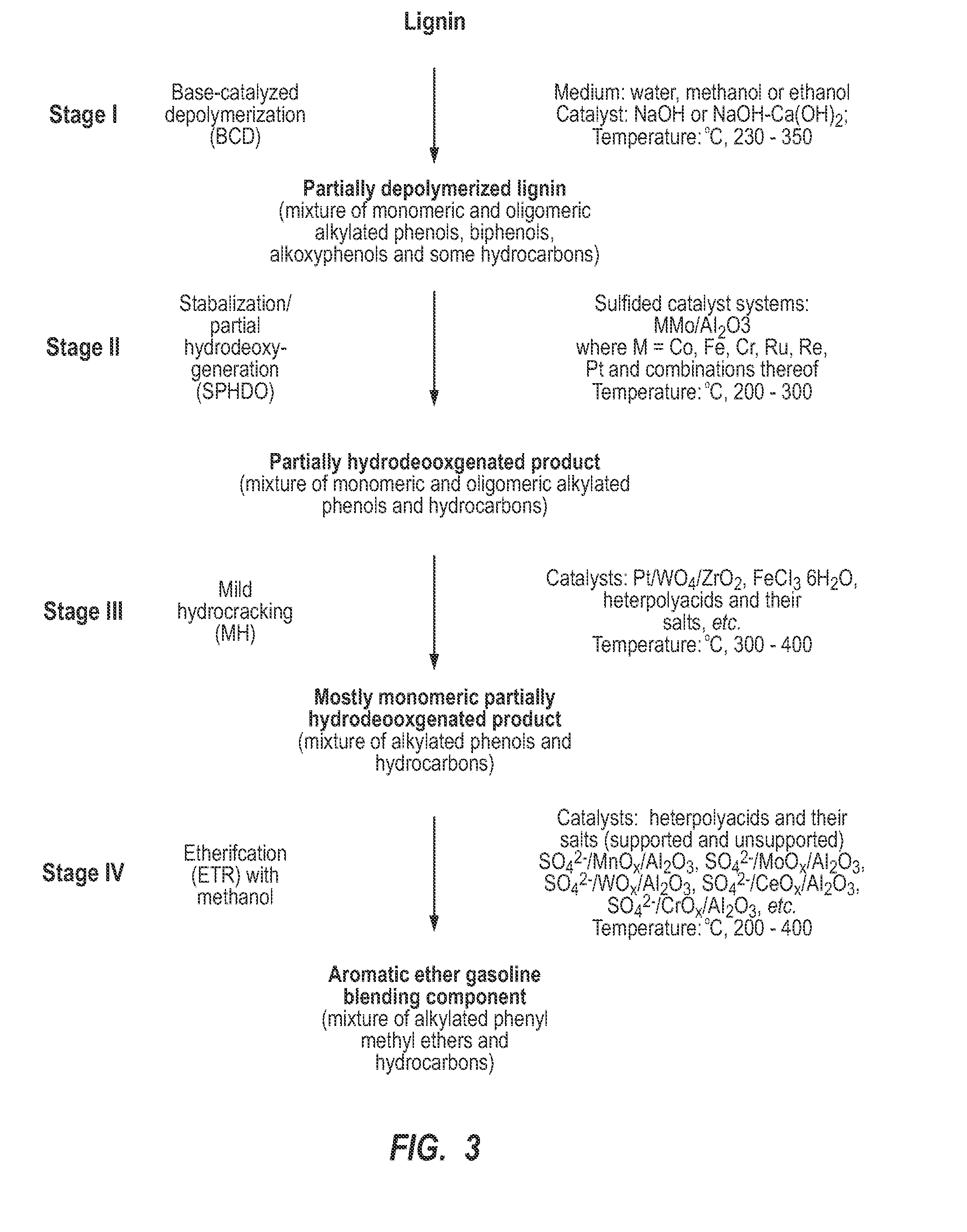

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS20080050792A1Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productLignin degradation

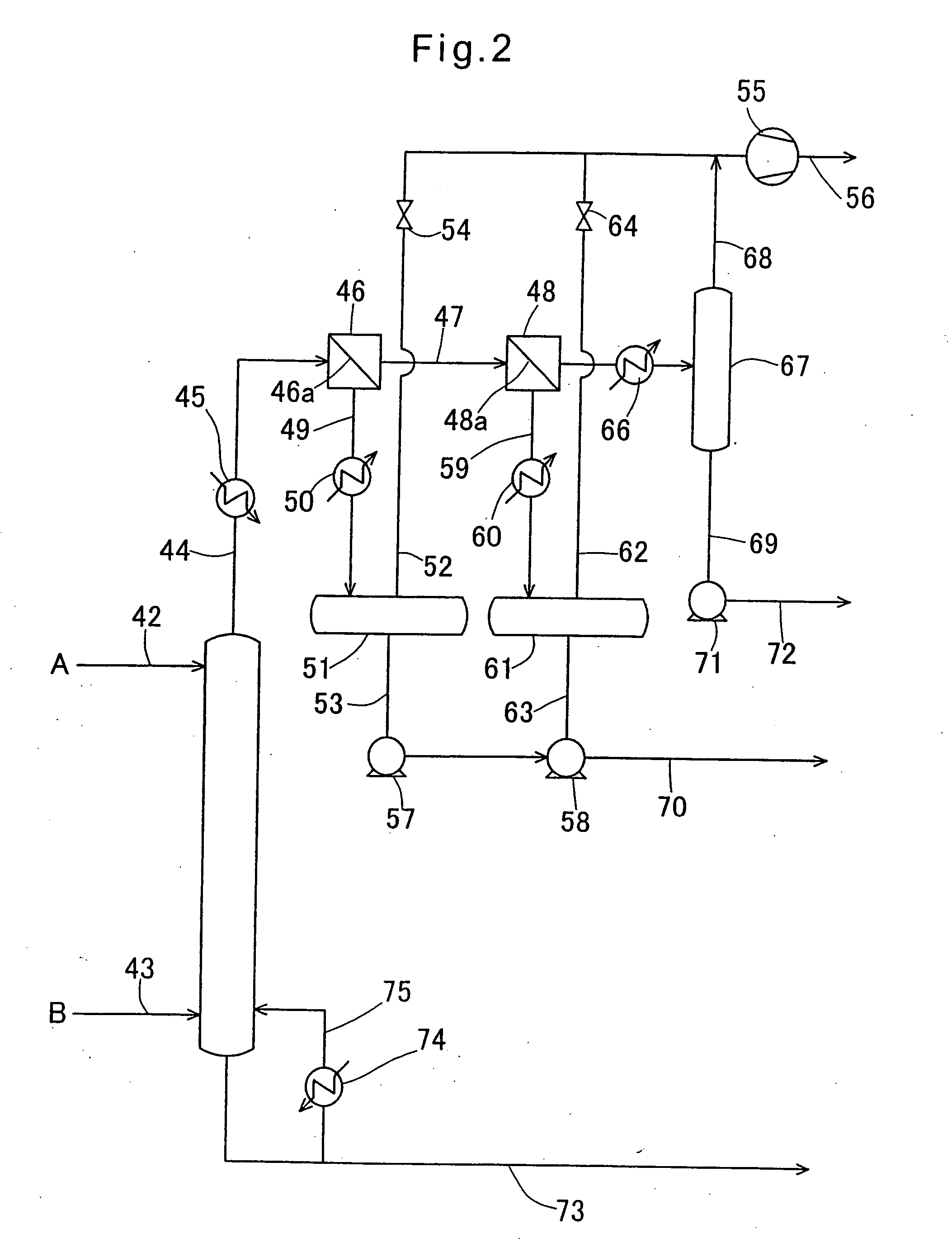

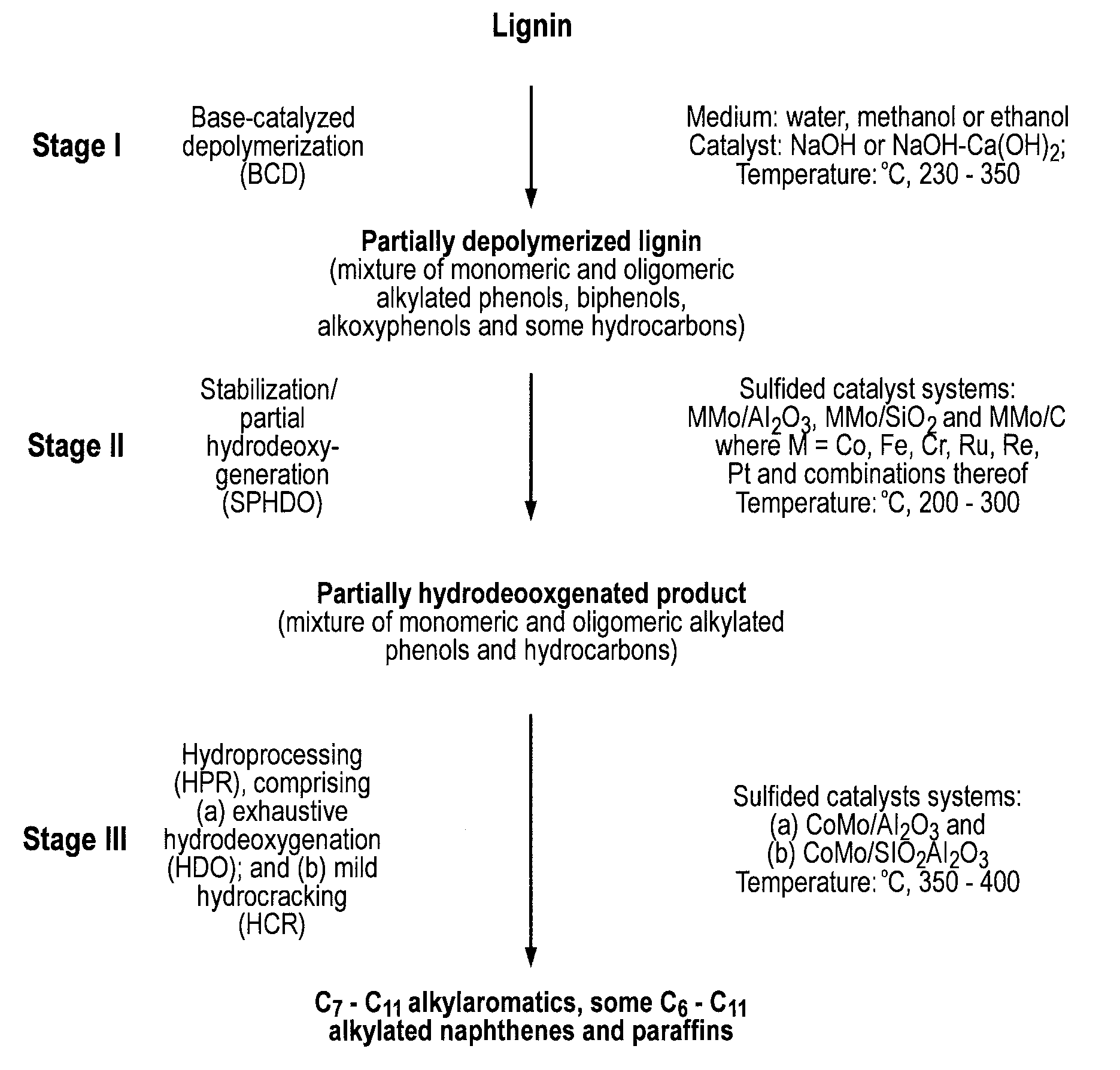

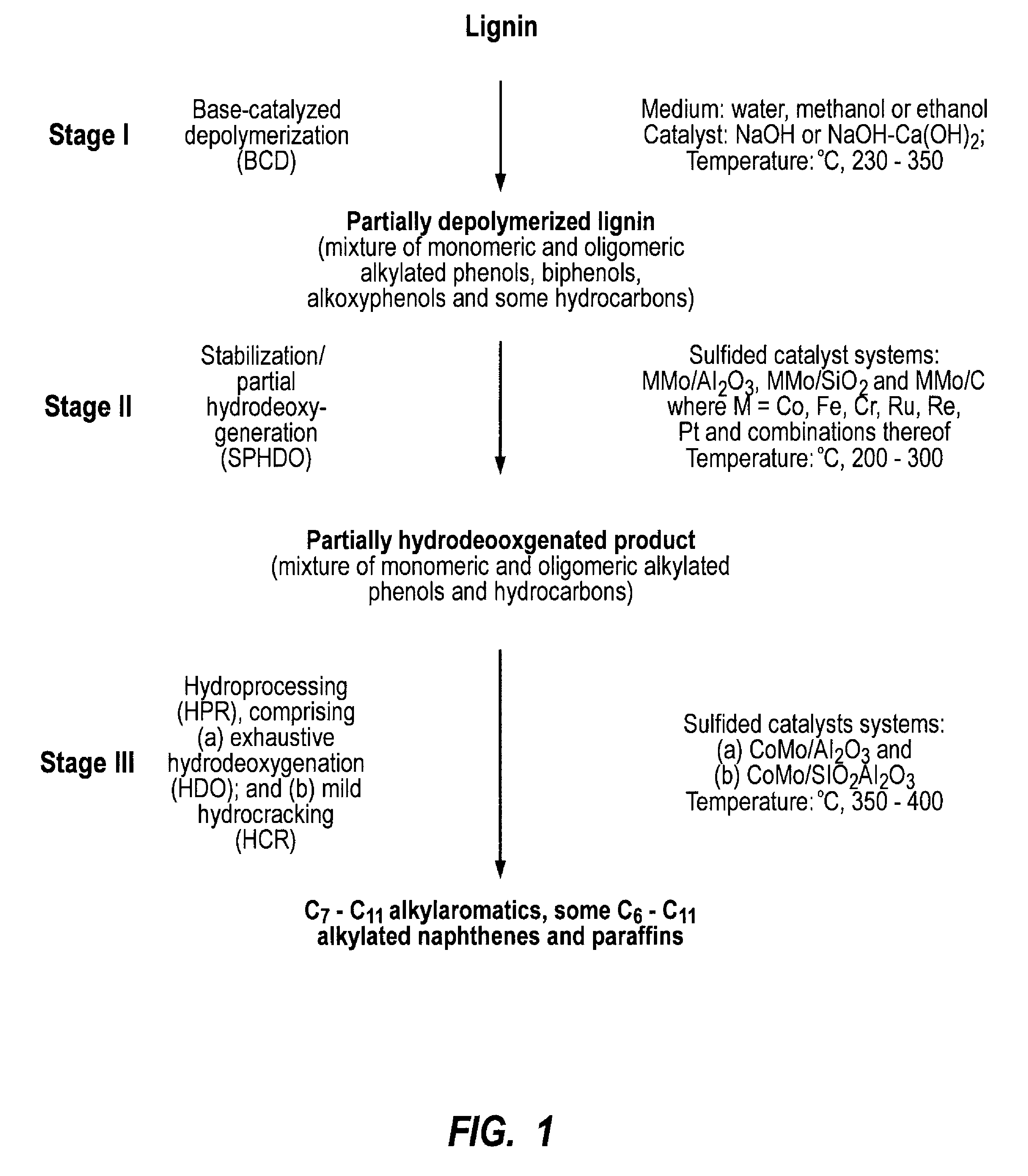

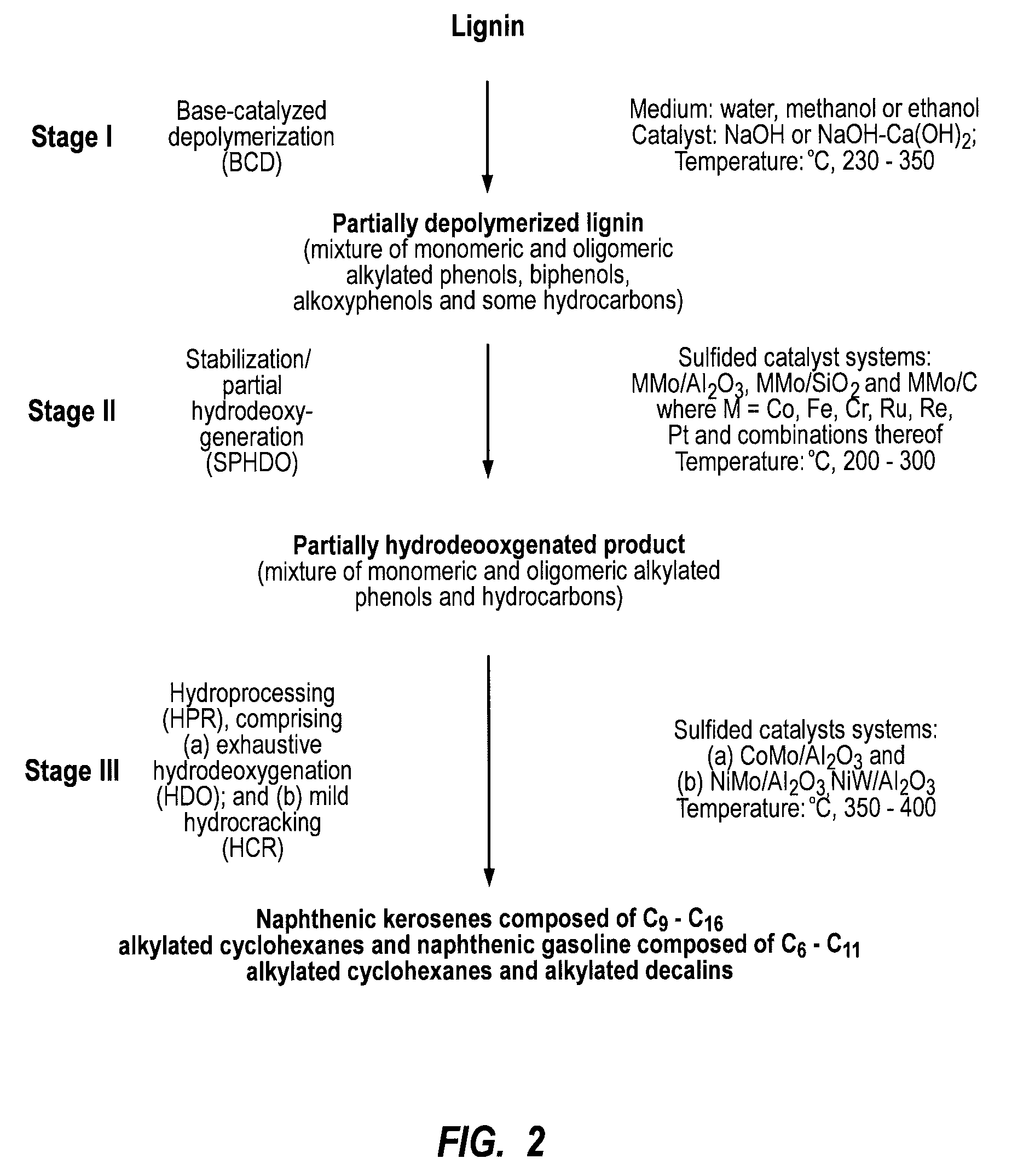

Processes for conversion of lignin to liquid products such as bio-fuels and fuel additives are disclosed and described. A process for conversion of a lignin material to bio-fuels can include subjecting the lignin material to a base catalyzed depolymerization reaction to produce a partially depolymerized lignin. The partially depolymerized lignin can then be subjected to a stabilization / partial hydrodeoxygenation reaction to form a partially hydrodeoxygenated product. Following partial hydrodeoxygenation, the partially hydrodeoxygenated product can be reacted in a hydroprocessing step to form a bio-fuel. Each of these reaction steps can be performed in single or multiple steps, depending on the design of the process. The production of an intermediate partially hydrodeoxygenation product and subsequent reaction thereof can significantly reduce or eliminate reactor plugging and catalyst coking. A variety of useful bio-fuels such as fuels, fuel additives, and the like, including gasoline and jet or rocket fuels are describe which can be readily produced from renewable lignin materials in an improved conversion process.

Owner:UNIV OF UTAH RES FOUND

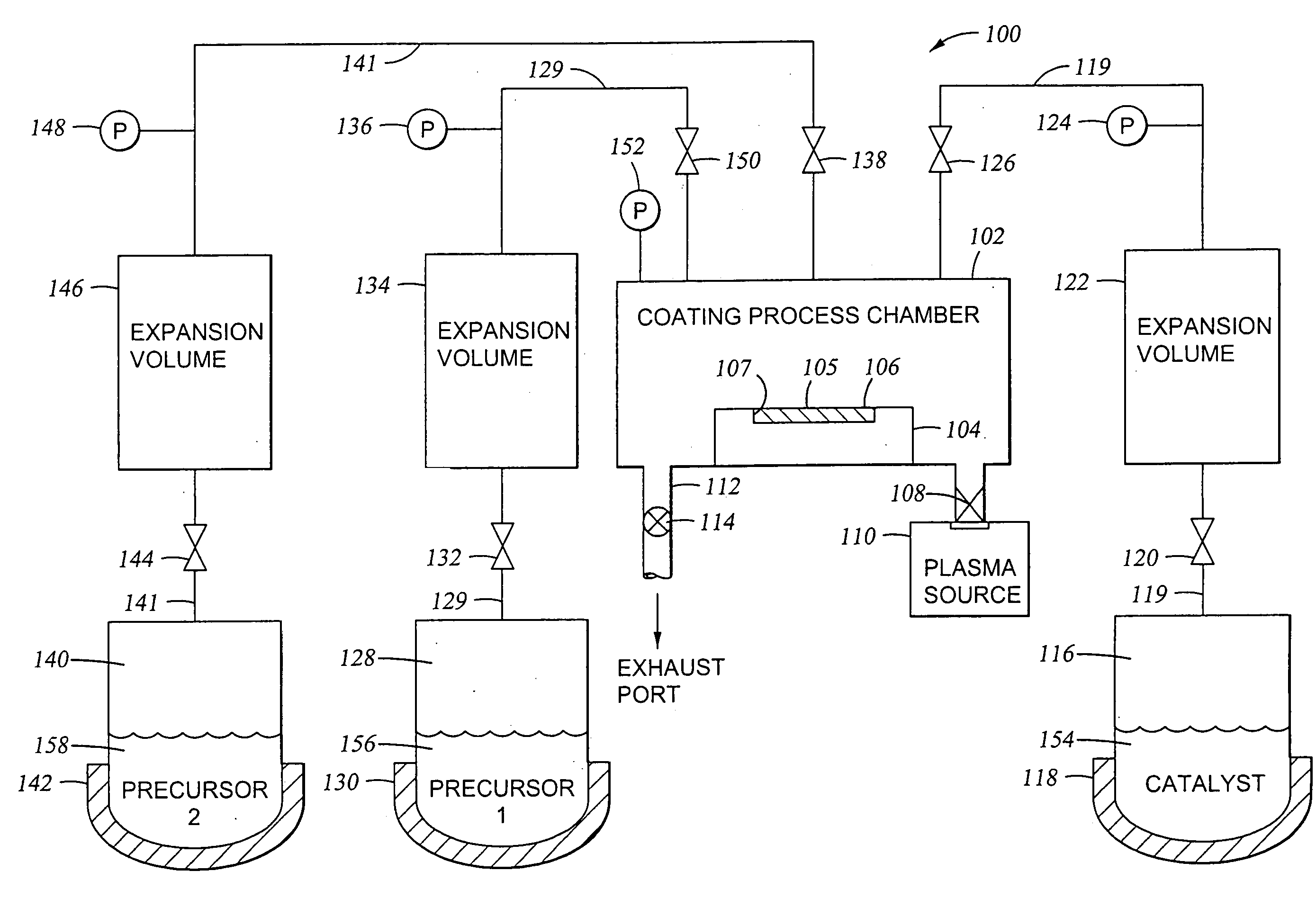

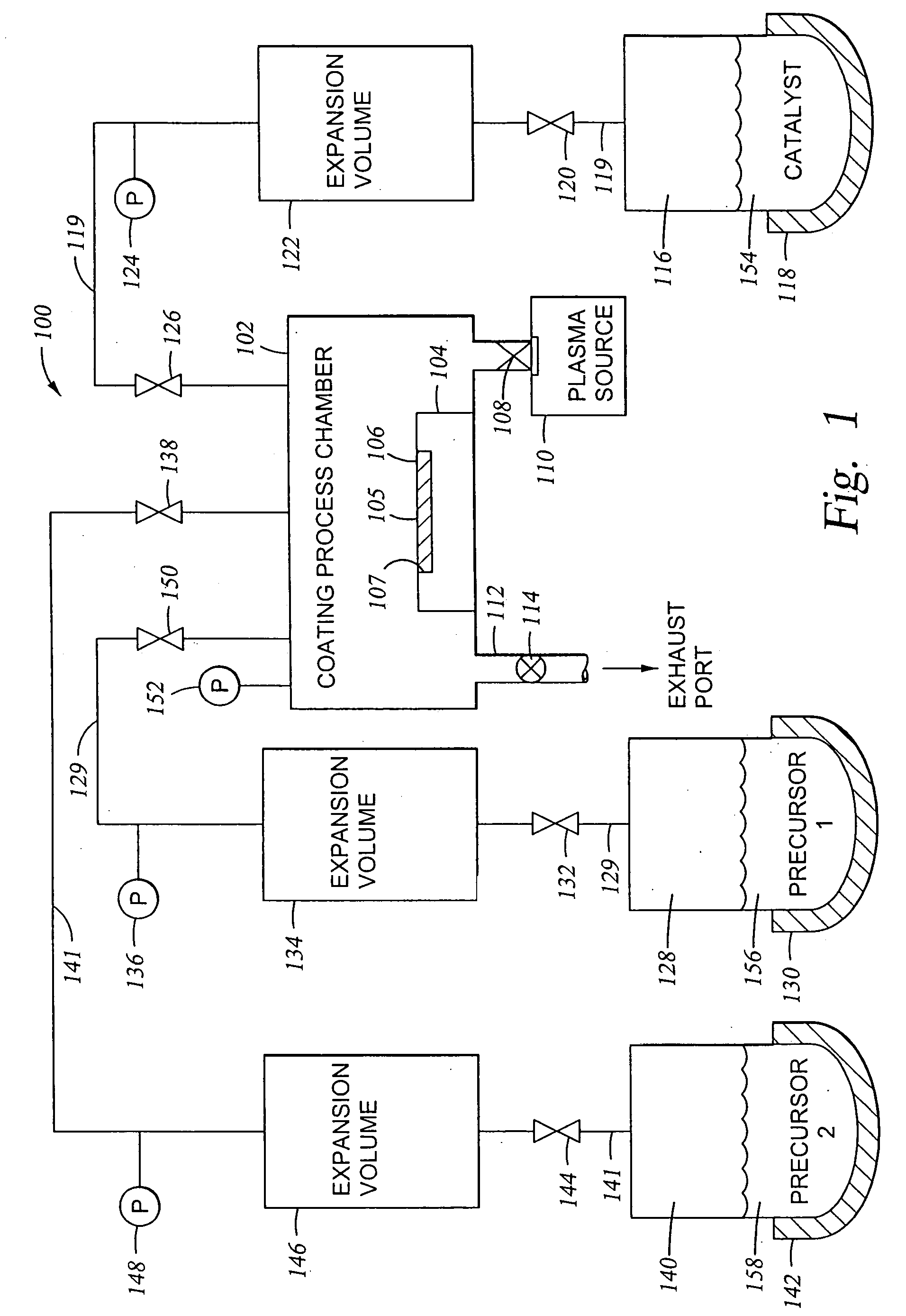

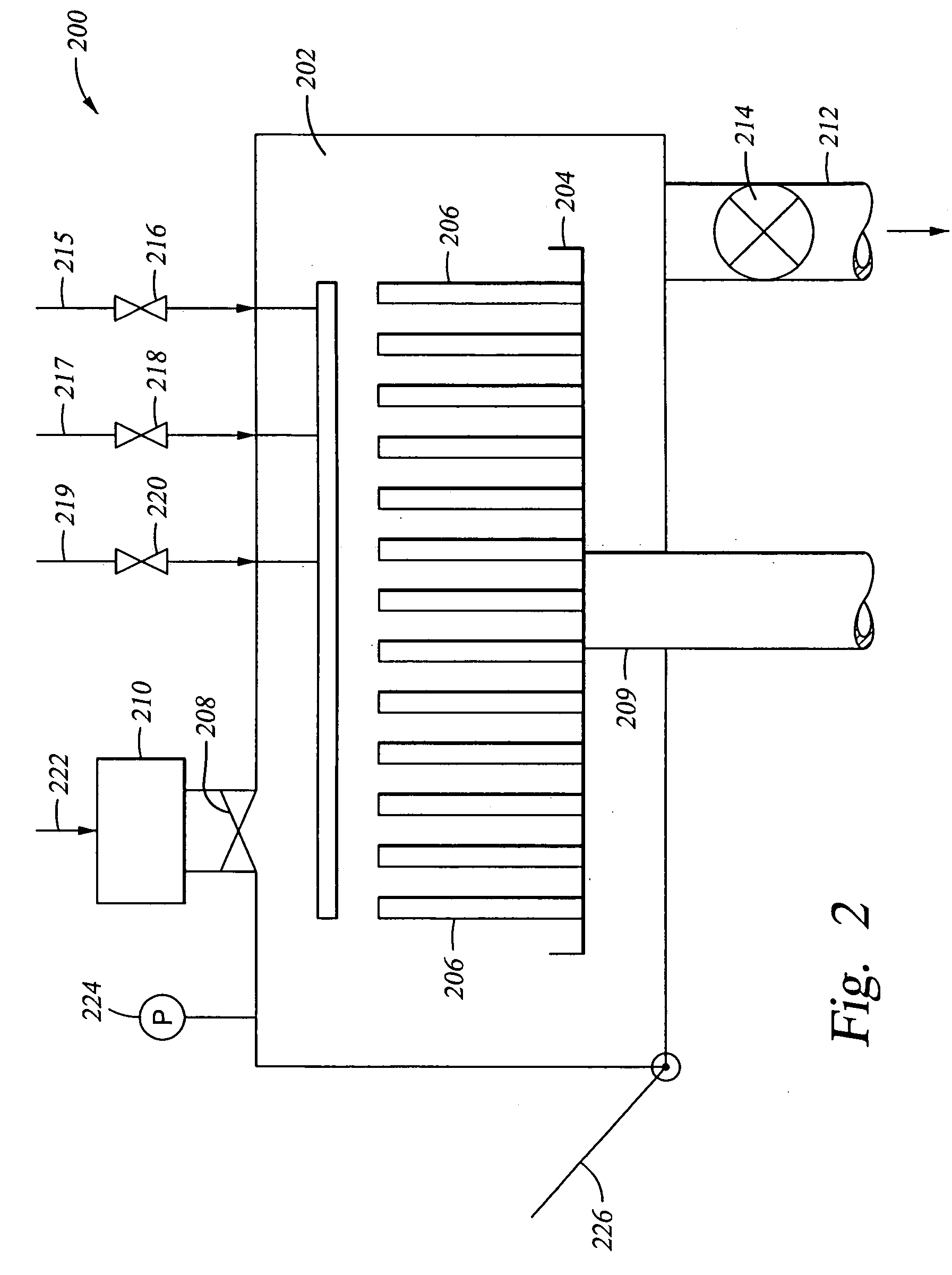

Apparatus and method for controlled application of reactive vapors to produce thin films and coatings

ActiveUS20060213441A1Highly accurate amountSimple methodMaterial nanotechnologyPretreated surfacesGas phaseThin layer

A vapor phase deposition method and apparatus for the application of thin layers and coatings on substrates. The method and apparatus are useful in the fabrication of electronic devices, micro-electromechanical systems (MEMS), Bio-MEMS devices, micro and nano imprinting lithography, and microfluidic devices. The apparatus used to carry out the method provides for the addition of a precise amount of each of the reactants to be consumed in a single reaction step of the coating formation process. The apparatus provides for precise addition of quantities of different combinations of reactants during a single step or when there are a number of different individual steps in the coating formation process. The precise addition of each of the reactants in vapor form is metered into a predetermined set volume at a specified temperature to a specified pressure, to provide a highly accurate amount of reactant.

Owner:JEFFREY D CHINN & ROMUALD NOWAK +1

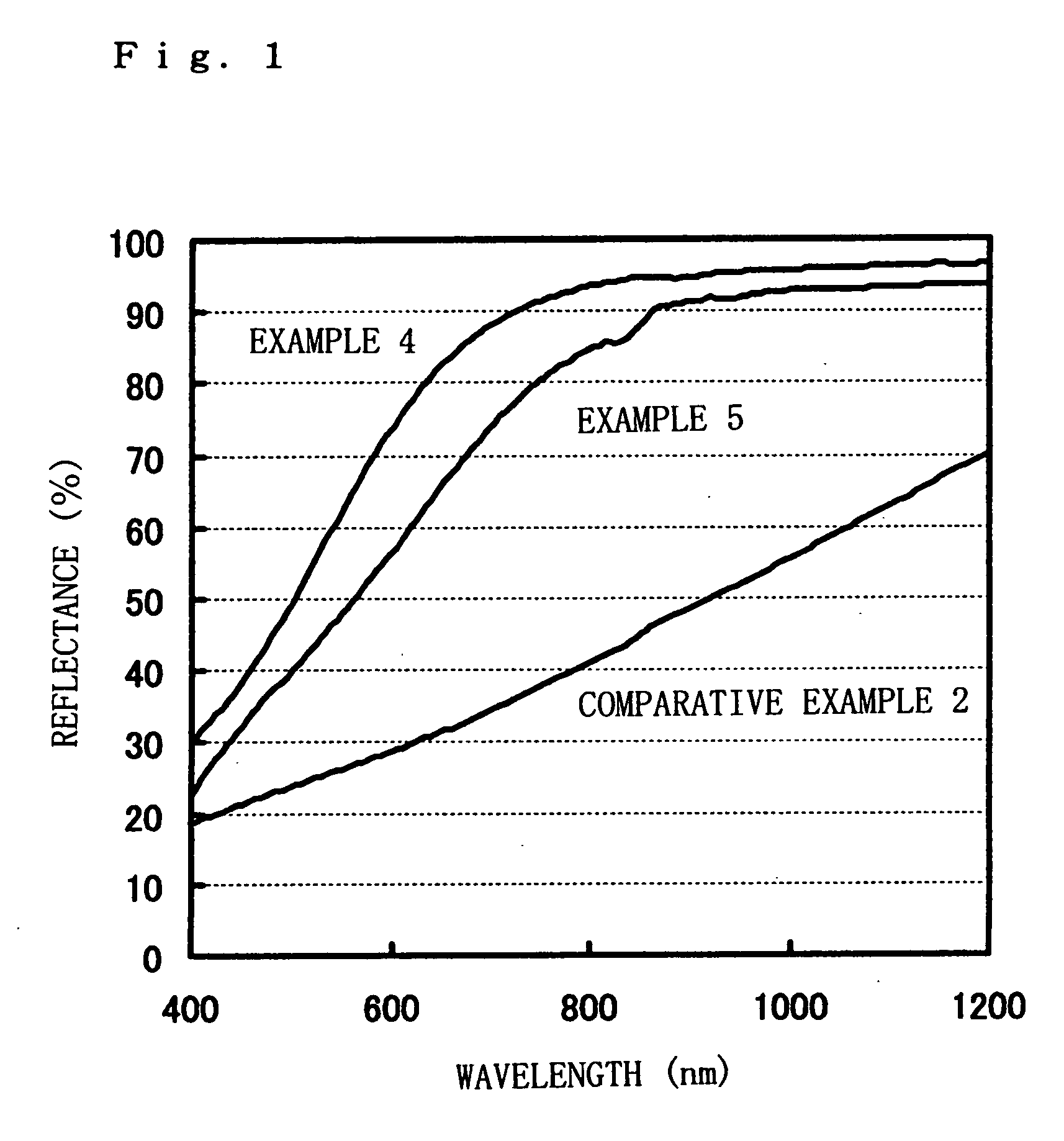

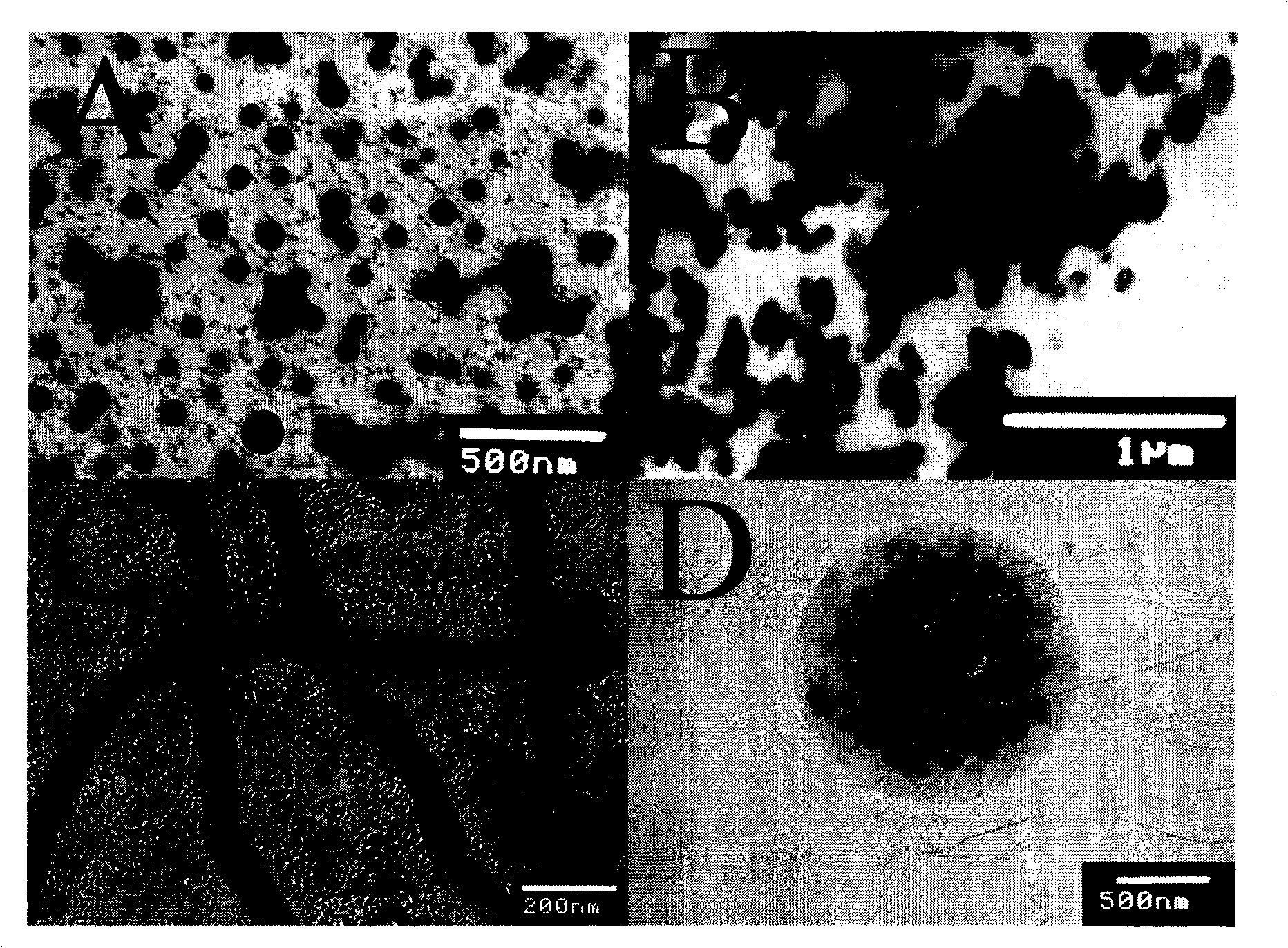

Method for preparing liquid colloidal dispersion of silver particles, liquid colloidal dispersion of silver particles, and silver conductive film

InactiveUS20060264518A1Good dispersionHighly conductive filmMaterial nanotechnologyOther chemical processesScreen printingFiltration

A process for producing a fine silver particle colloidal dispersion which can simply form conductive silver layers and antimicrobial coatings by screen printing or the like. The process is characterized by having a reaction step of allowing an aqueous silver nitrate solution to react with a mixed solution of an aqueous iron(II) sulfate solution and an aqueous sodium citrate solution to form an agglomerate of fine silver particles, a filtration step of filtering the resultant agglomerate of fine silver particles to obtain a cake of the agglomerate of fine silver particles, a dispersion step of adding pure water to the cake to obtain a first fine silver particle colloidal dispersion of a water system in which dispersion the fine silver particles have been dispersed in the pure water, and a concentration and washing step of concentrating and washing the first fine silver particle colloidal dispersion of a water system.

Owner:SUMITOMO METAL MINING CO LTD

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS20060161035A1Improve economyEfficient OTP processMolecular sieve catalystCatalystsFixed bedOxygenate

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

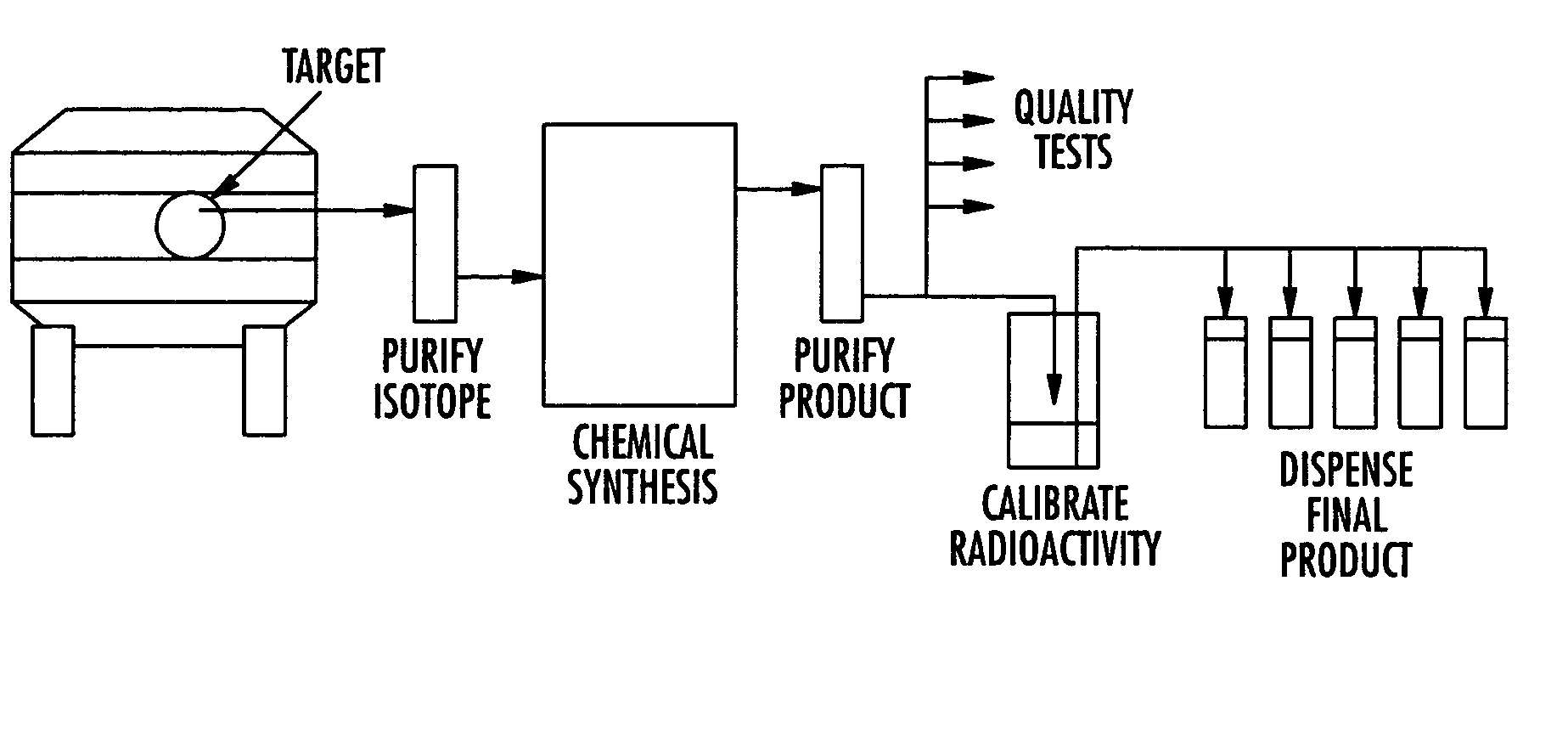

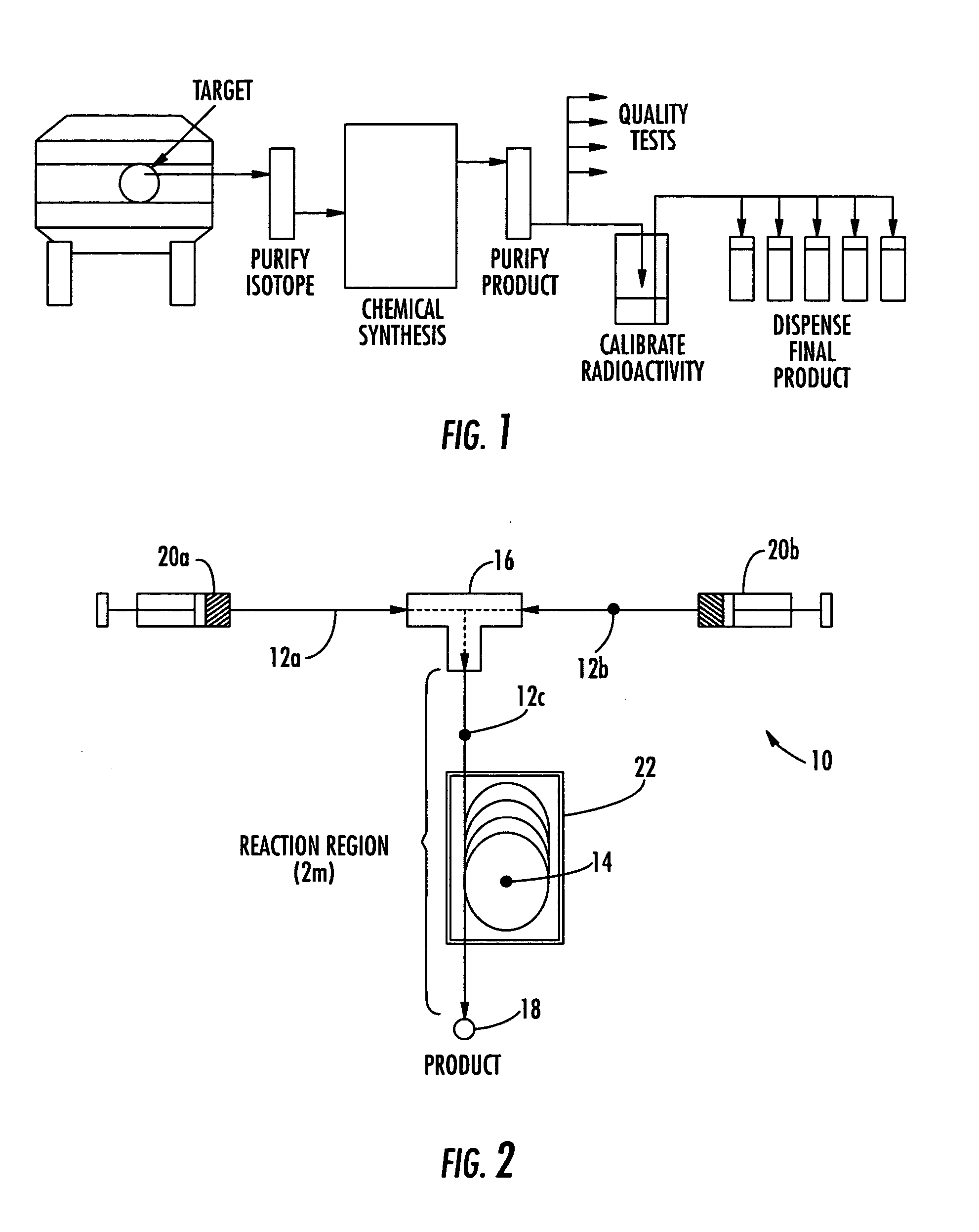

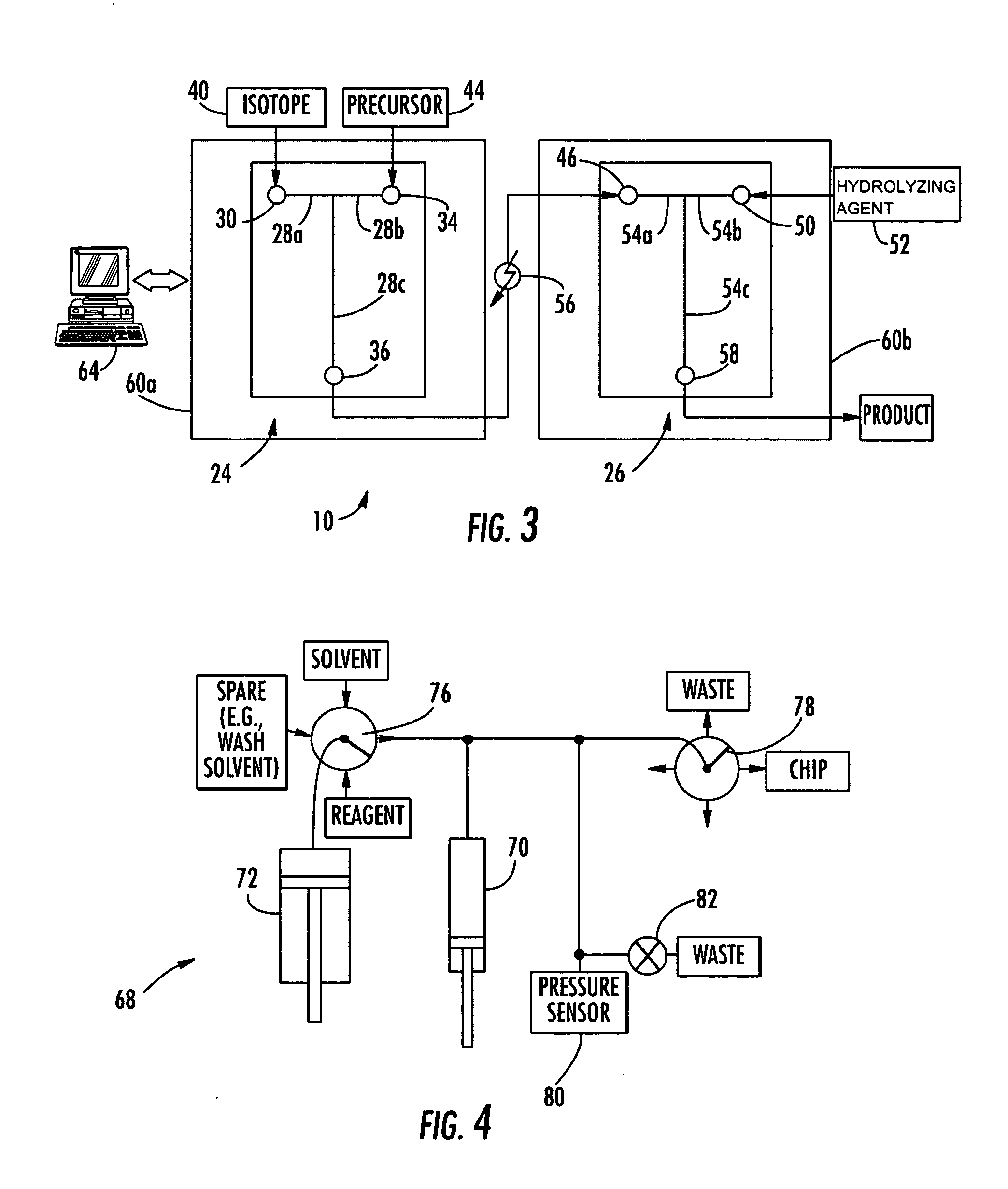

Microfluidic apparatus and method for synthesis of molecular imaging probes

InactiveUS20050232387A1Fast synthesis timeHigh synthetic yieldIn-vivo radioactive preparationsConversion outside reactor/acceleratorsMicroreactorMolecular imaging

The invention provides a method and apparatus for preparation of radiochemicals, such as PET molecular imaging probes, wherein the reaction step or steps that couple the radioactive isotope to an organic or inorganic compound to form a positron-emitting molecular imaging probe are performed in a microfluidic environment. The method for synthesizing a radiochemical in a microfluidic environment comprises: i) providing a micro reactor comprising a first inlet port, a second inlet port, an outlet port, and at least one microchannel in fluid communication with the first and second inlet ports and the outlet port; ii) introducing a reactive precursor into the first inlet port of the micro reactor, the reactive precursor adapted for reaction with a radioactive isotope to form a radiochemical; iii) introducing a solution comprising a radioactive isotope into the second inlet port of the micro reactor; iv) contacting the reactive precursor with the isotope-containing solution in the microchannel of the micro reactor; v) reacting the reactive precursor with the isotope-containing solution as the reactive precursor and isotope-containing solution flow through the microchannel of the micro reactor, the reacting step resulting in formation of a radiochemical; and vi) collecting the radiochemical from the outlet port of the micro reactor.

Owner:MOLECULAR TECH

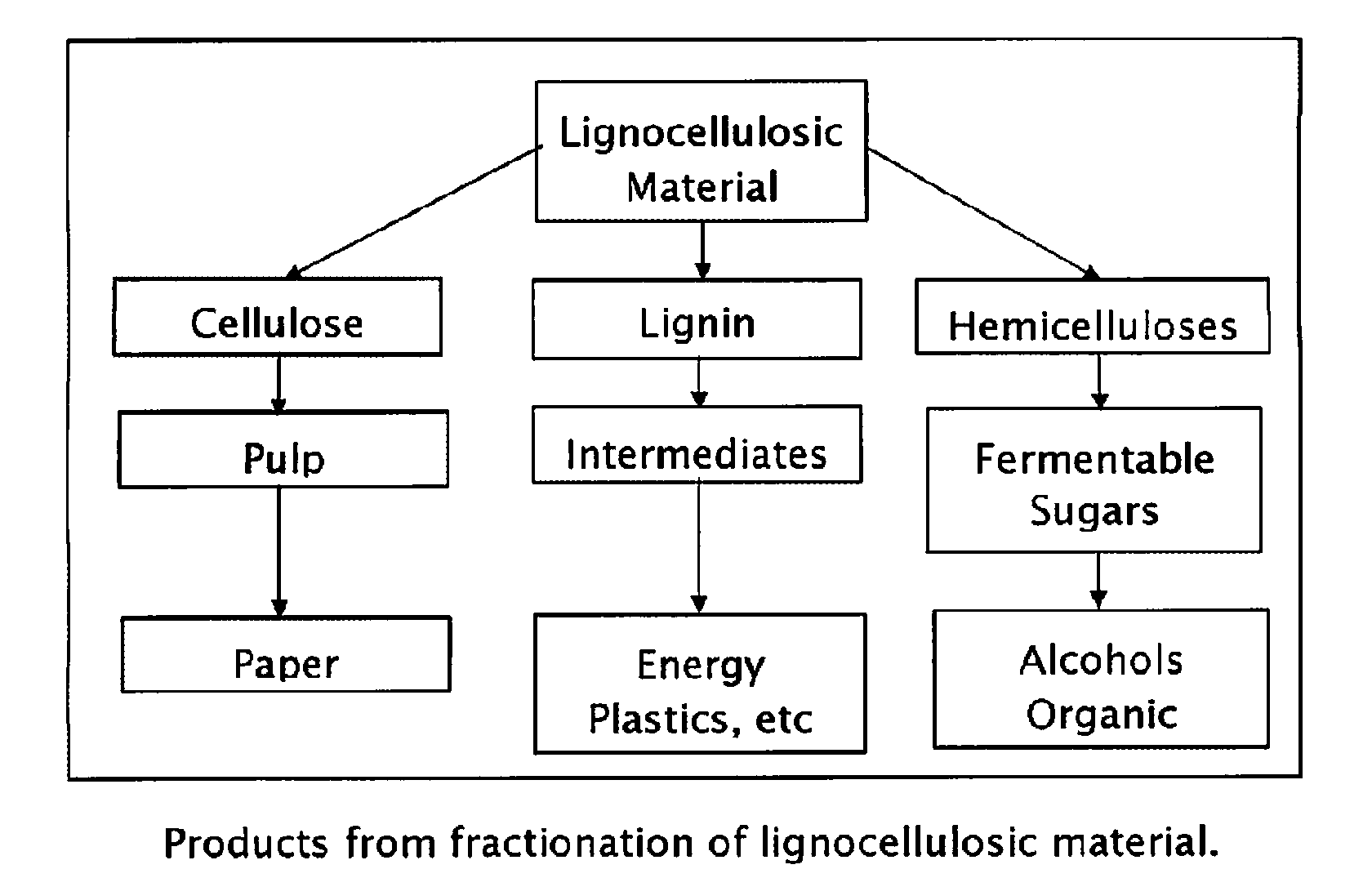

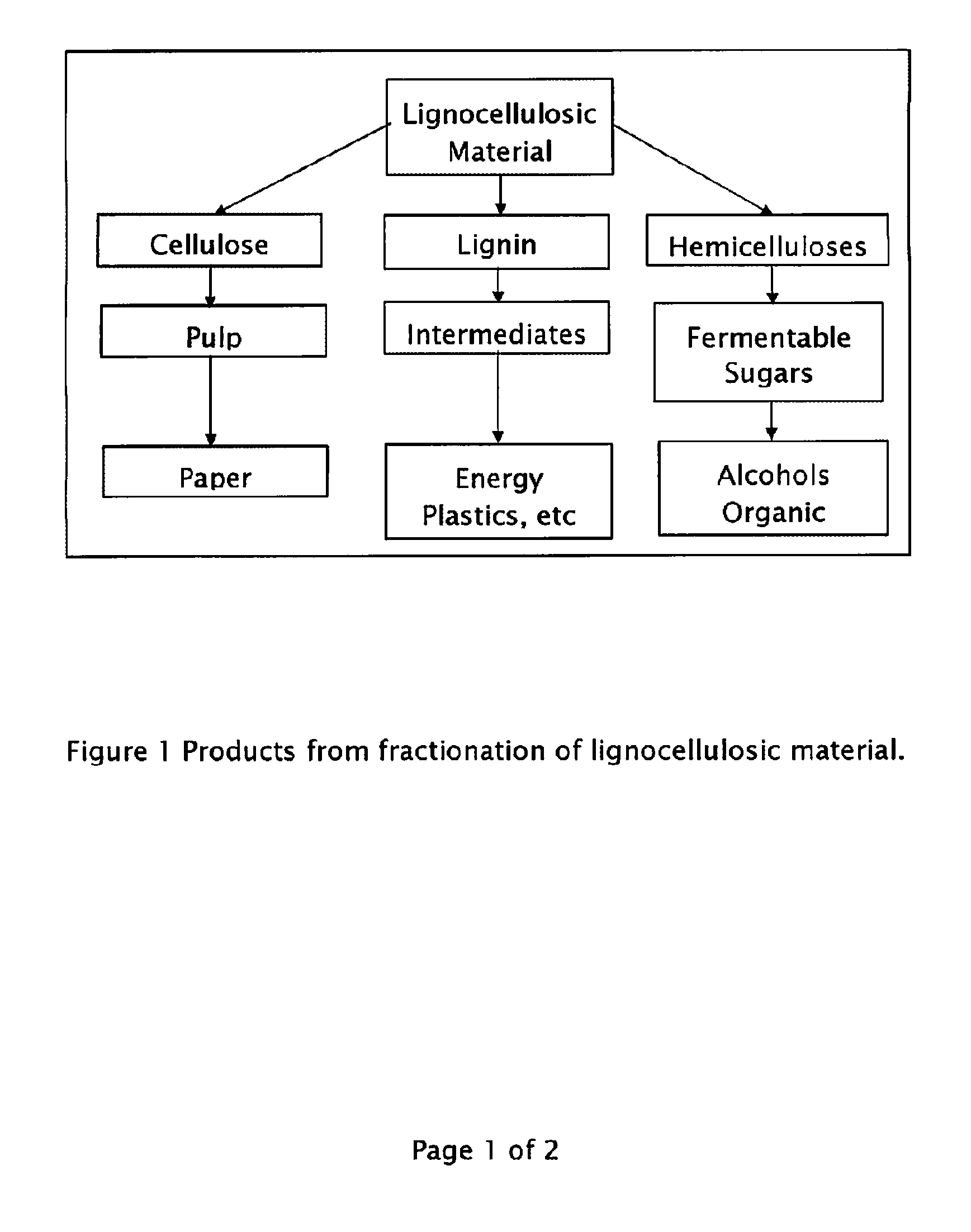

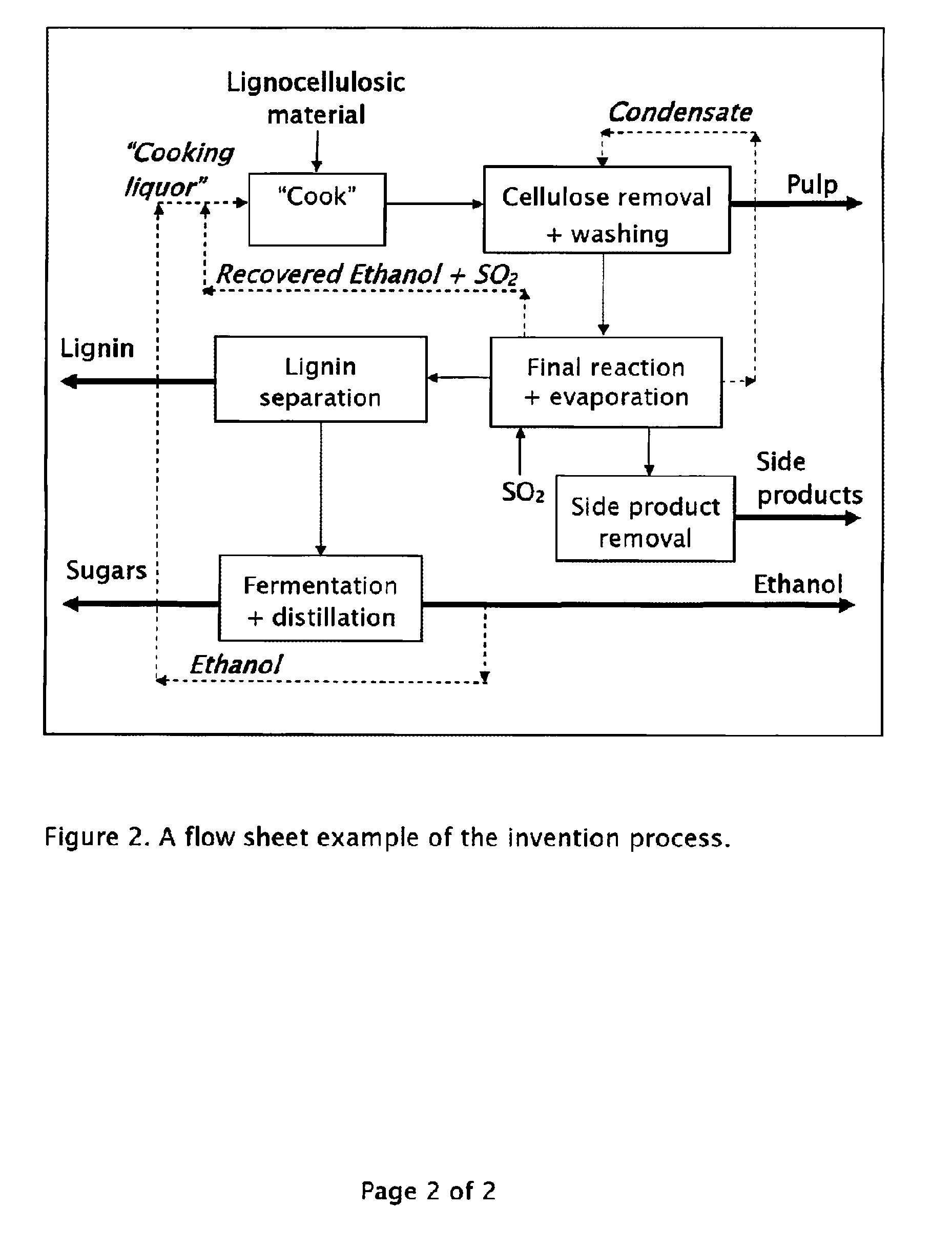

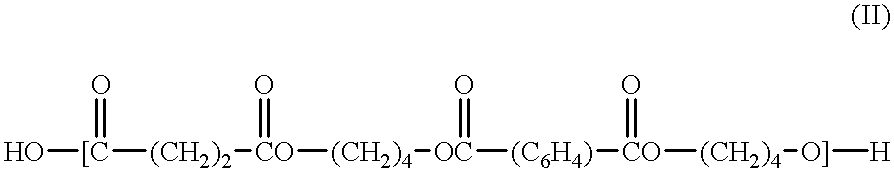

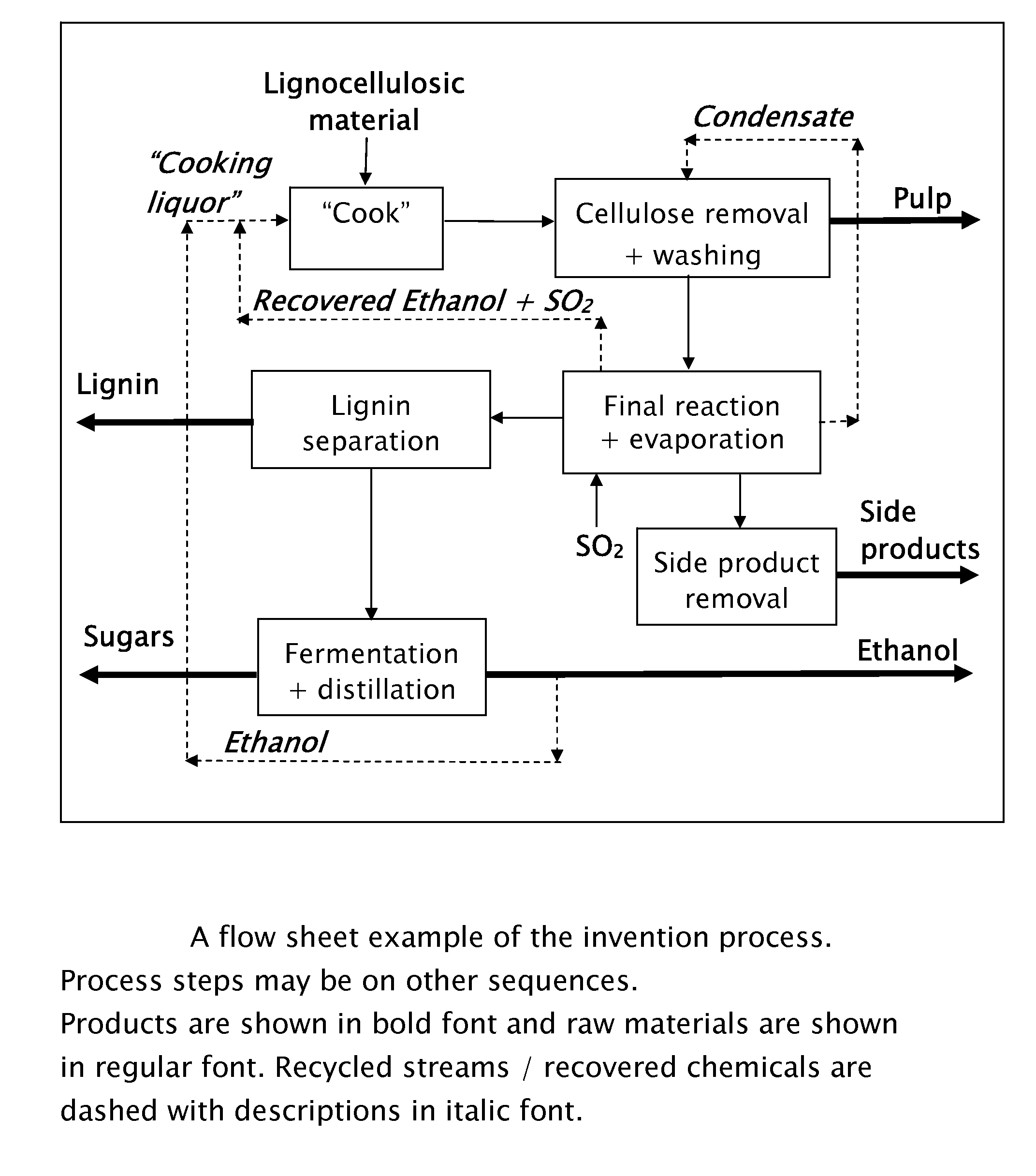

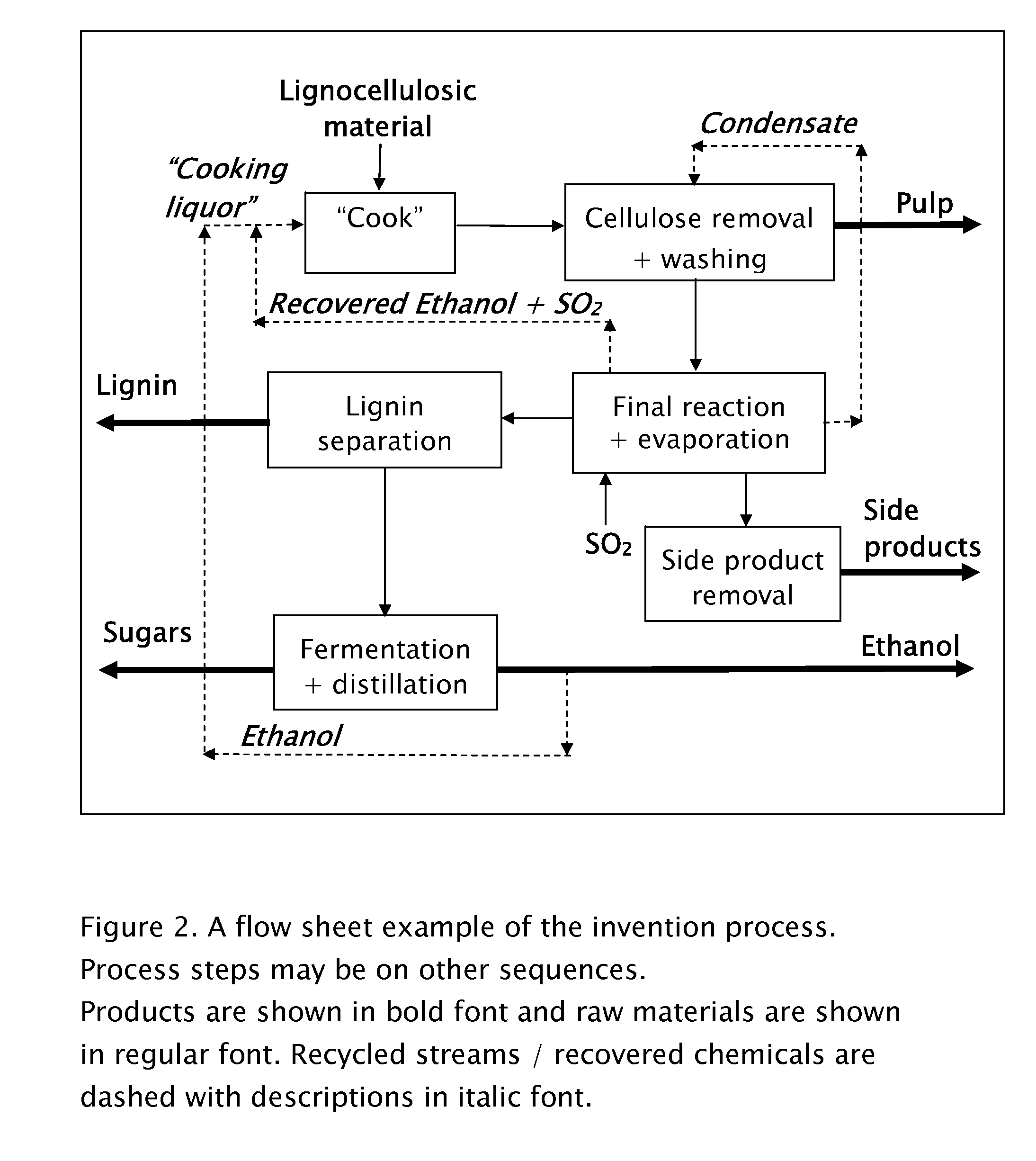

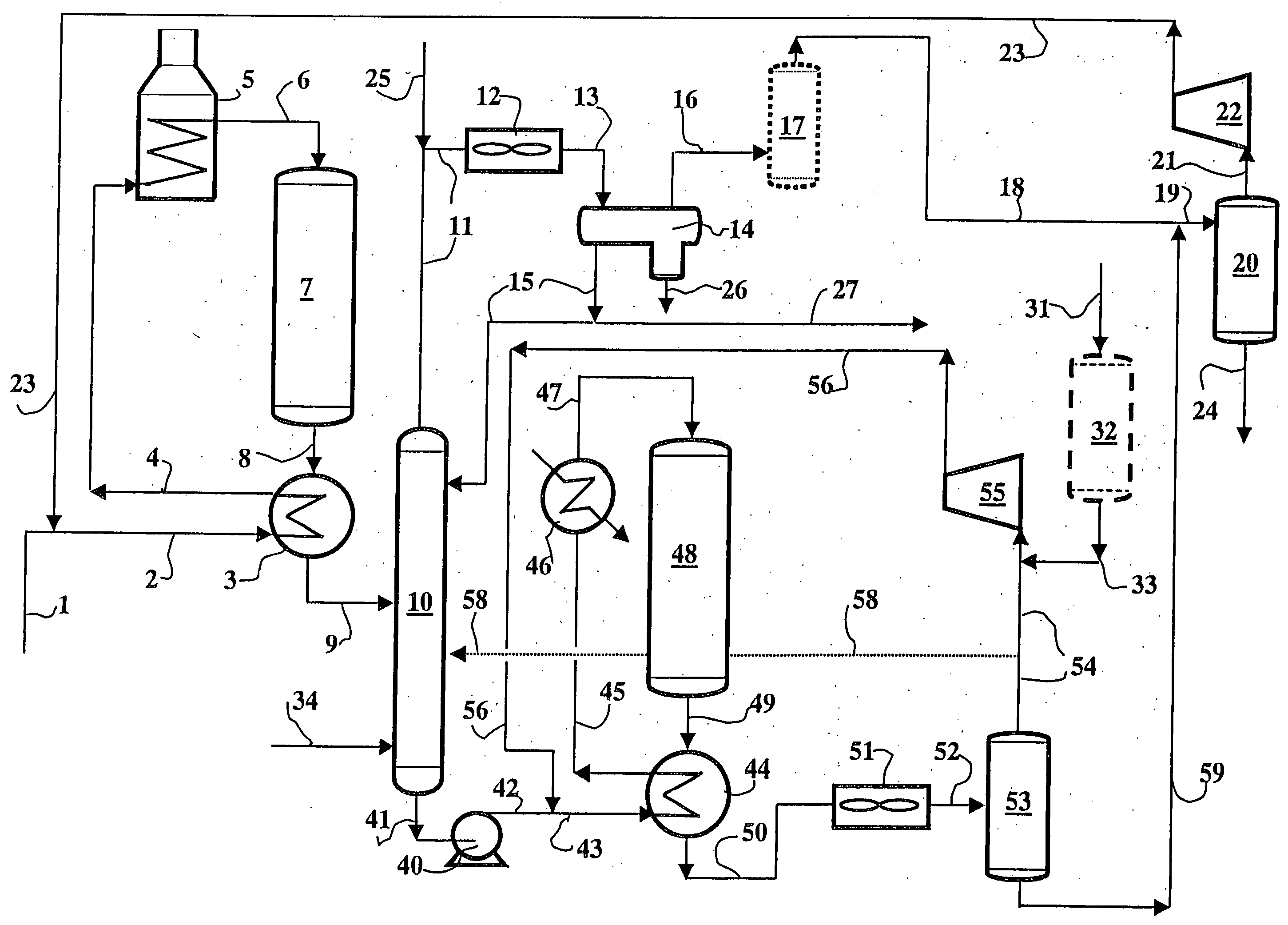

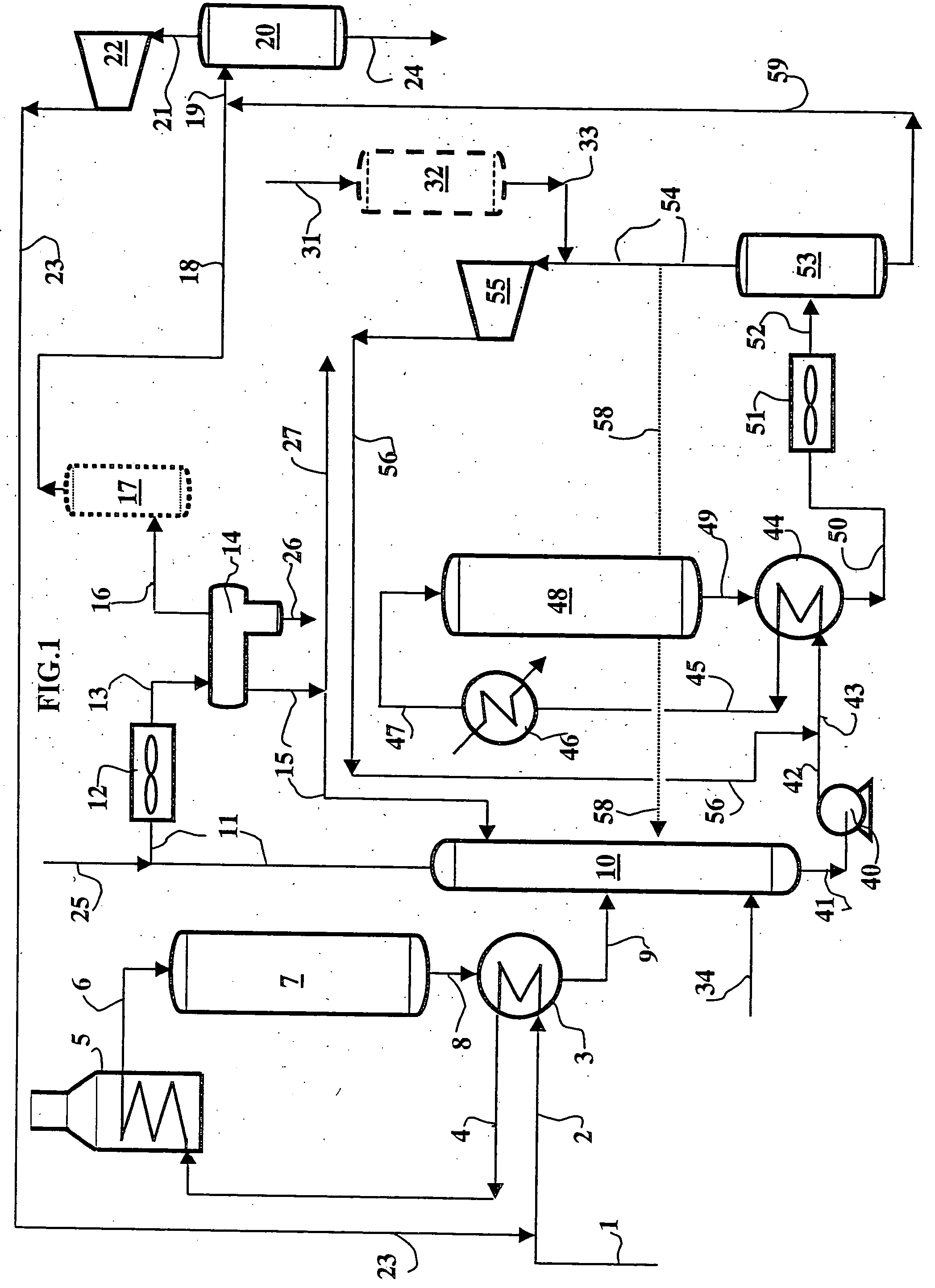

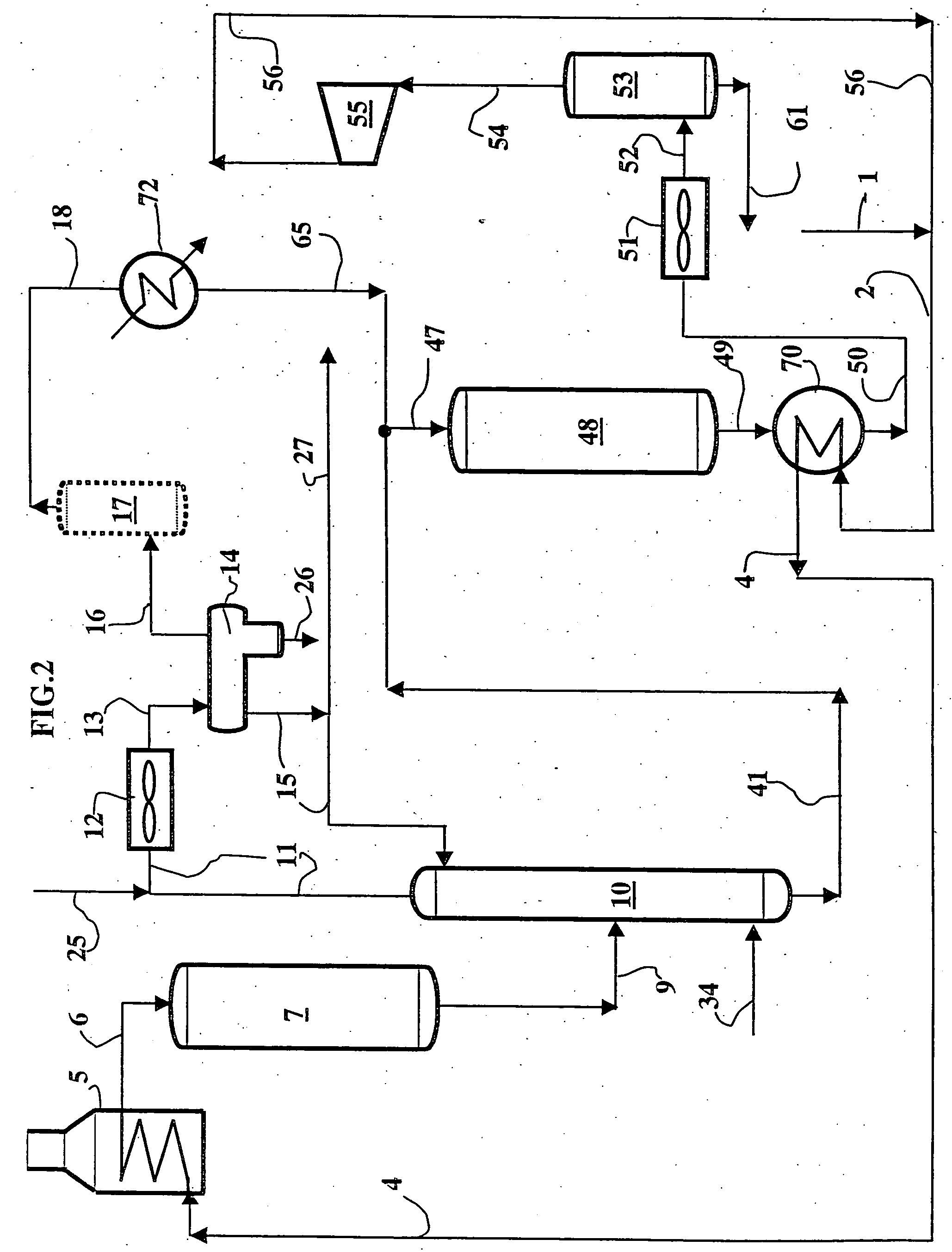

Method for the production of fermentable sugars and cellulose from lignocellulosic material

ActiveUS8030039B1High yieldIncreased ethanol yieldFats/resins/pitch/waxes removal in pulpPulping with organic compoundsOrganic acidAlcohol

A method for the production of fermentable sugars and high viscosity cellulose from lignocellulosic material in a batch or continuous process is provided. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, cooking chemicals can be reused, lignin is separated for the production of process energy, and hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. High yield production of alcohols or organic acids can be obtained from this method using the final reaction step.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Recording sheet for ink jet printing

InactiveUS20060078696A1Improve image qualityImprove water fastnessMaterial nanotechnologyPigmenting treatmentCompound (substance)Silicon dioxide

A method for the preparation of silicon dioxide dispersions is described, wherein the surface of the silicon dioxide is modified by a treatment with the reaction products of a compound of trivalent aluminum with least one aminoorganosilane. These reaction products are formed in a separate reaction step. The present invention also relates to recording sheets for ink jet printing having such a dispersion incorporated in an ink-receiving layer.

Owner:WIFAG POLYTPE HLDG AG

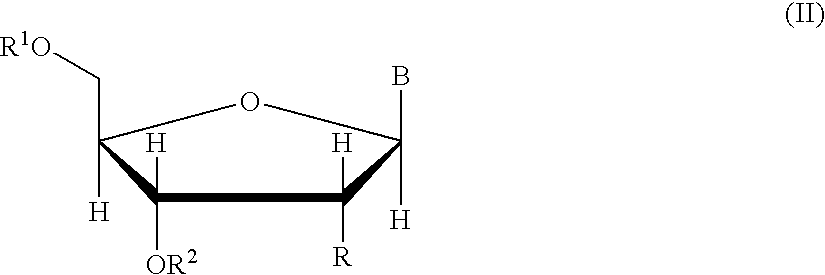

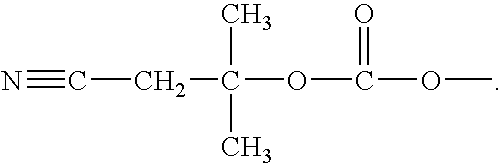

Methods of synthesizing oligonucleotides using carbonate protecting groups and alpha-effect nucleophile deprotection

The invention provides methods for synthesizing oligonucleotides using nucleoside monomers having carbonate protected hydroxyl groups that are deprotected with α-effect nucleophiles. The α-effect nucleophile irreversibly cleave the carbonate protecting groups while simultaneously oxidizing the internucleotide phosphite triester linkage to a phosphodiester linkage. The procedure may be carried out in aqueous solution at neutral to mildly basic pH. The method eliminates the need for separate deprotection and oxidation steps, and, since the use of acid to remove protecting groups is unnecessary, acid-induced depurination is avoided. Fluorescent or other readily detectable carbonate protecting groups can be used, enabling monitoring of individual reaction steps during oligonucleotide synthesis. The invention is particularly useful in the highly parallel, microscale synthesis of oligonucleotides.

Owner:AGILENT TECH INC +1

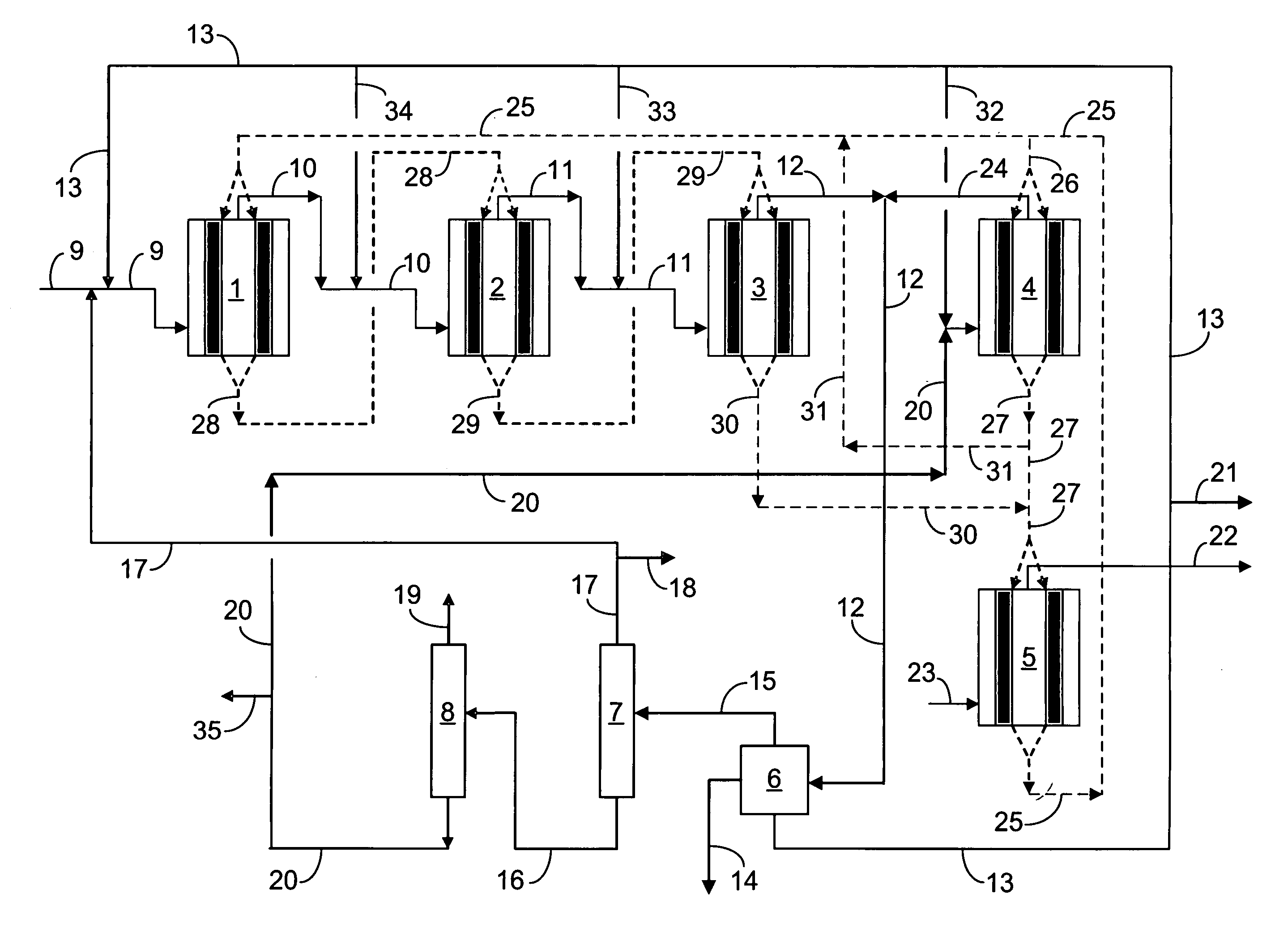

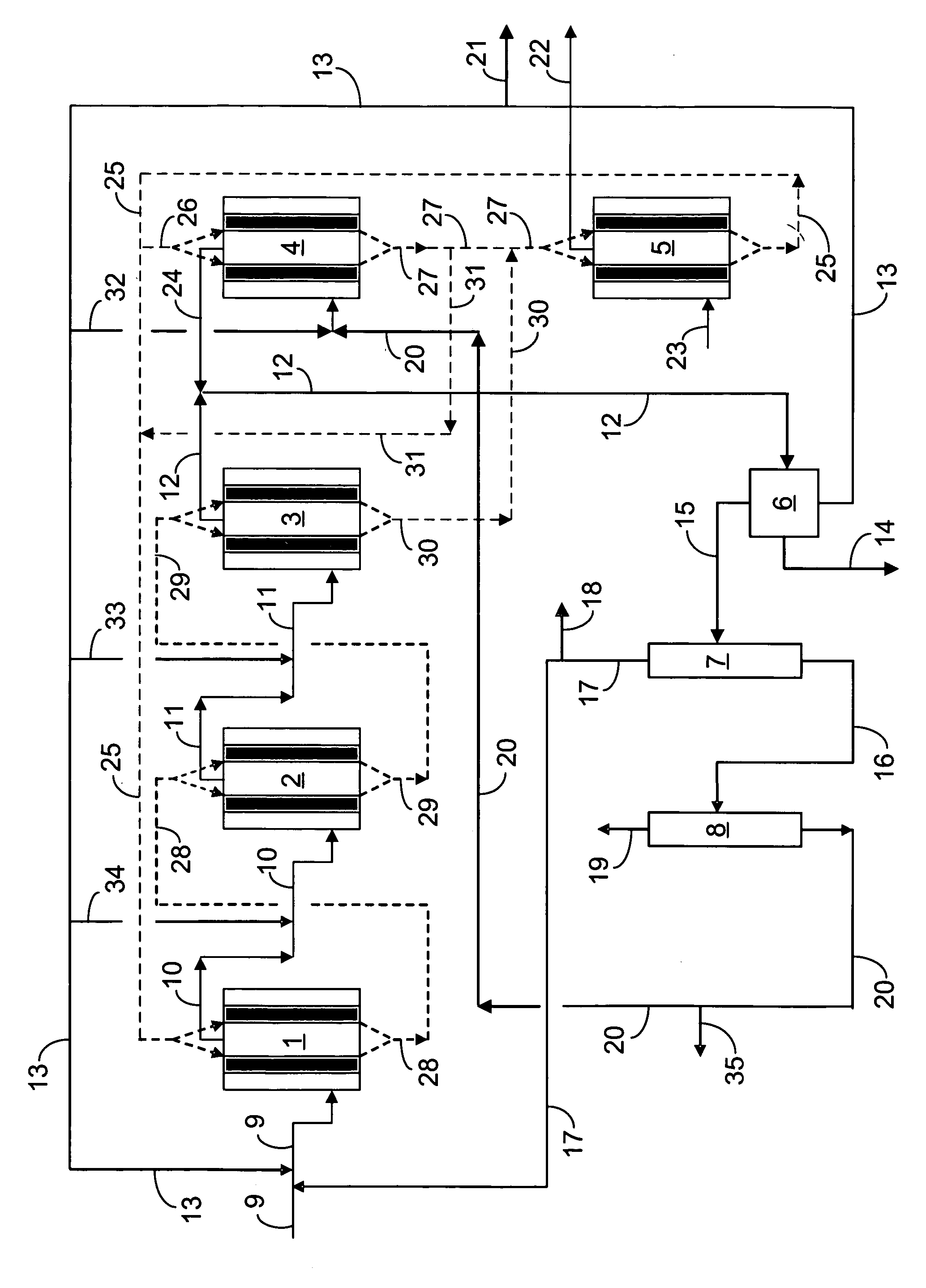

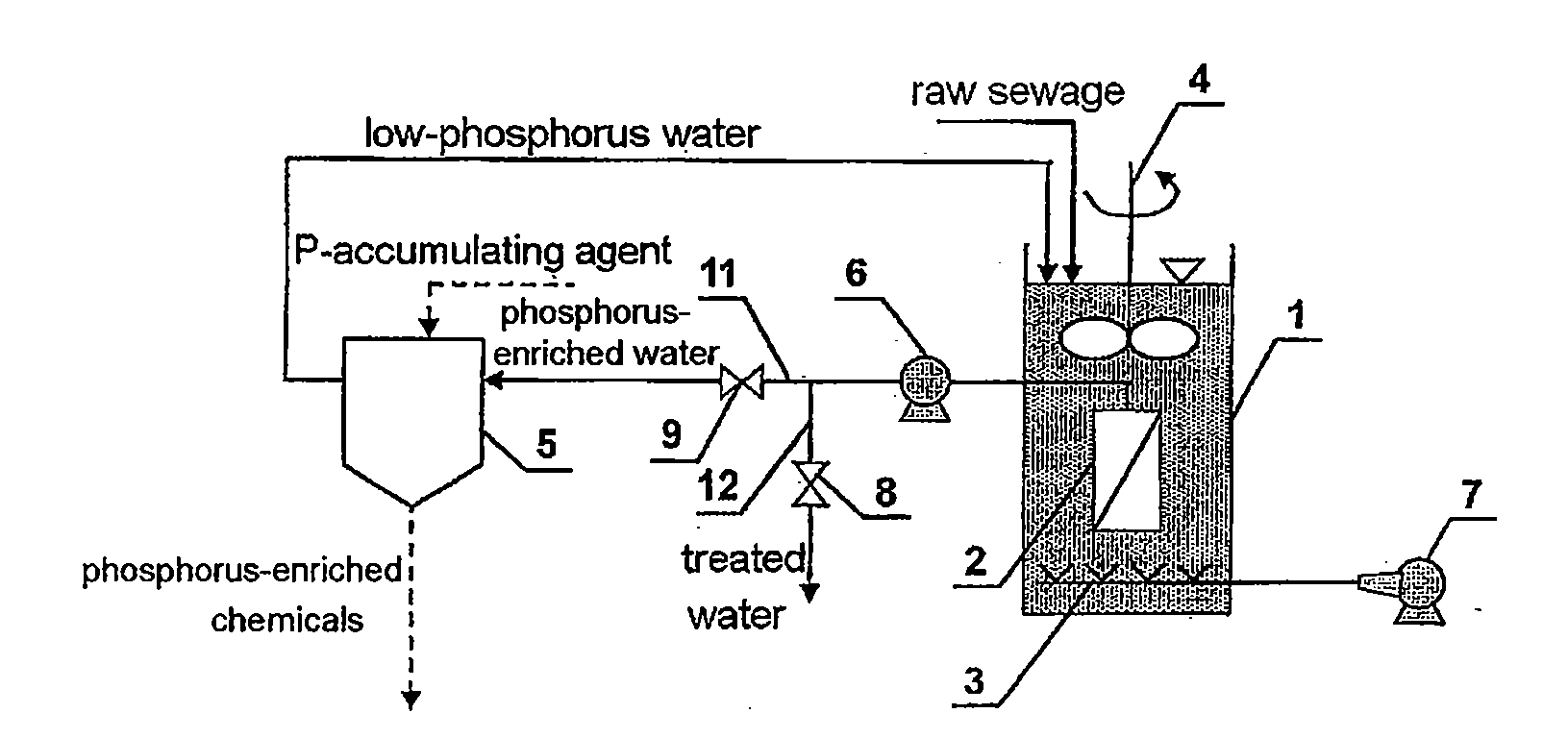

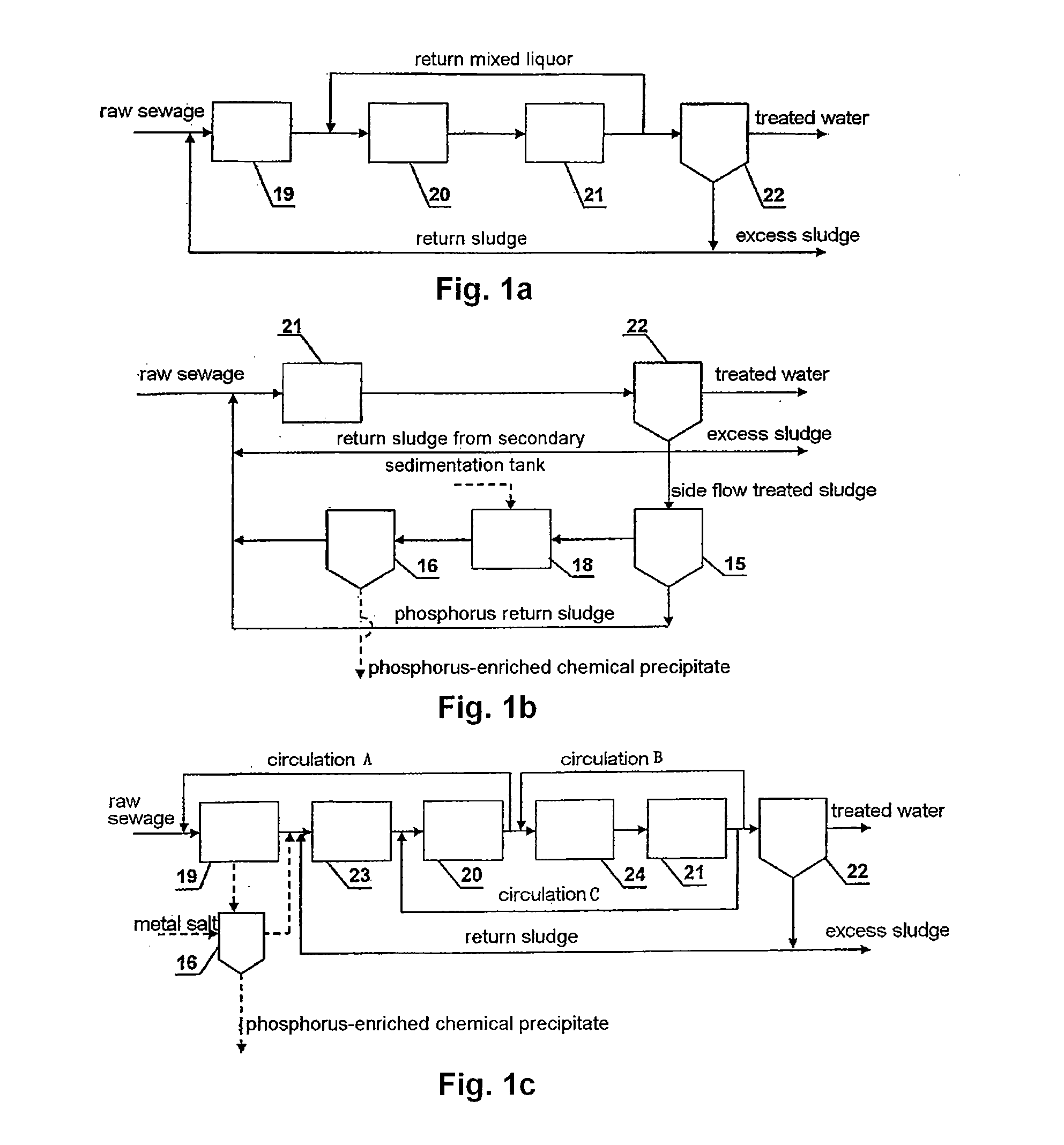

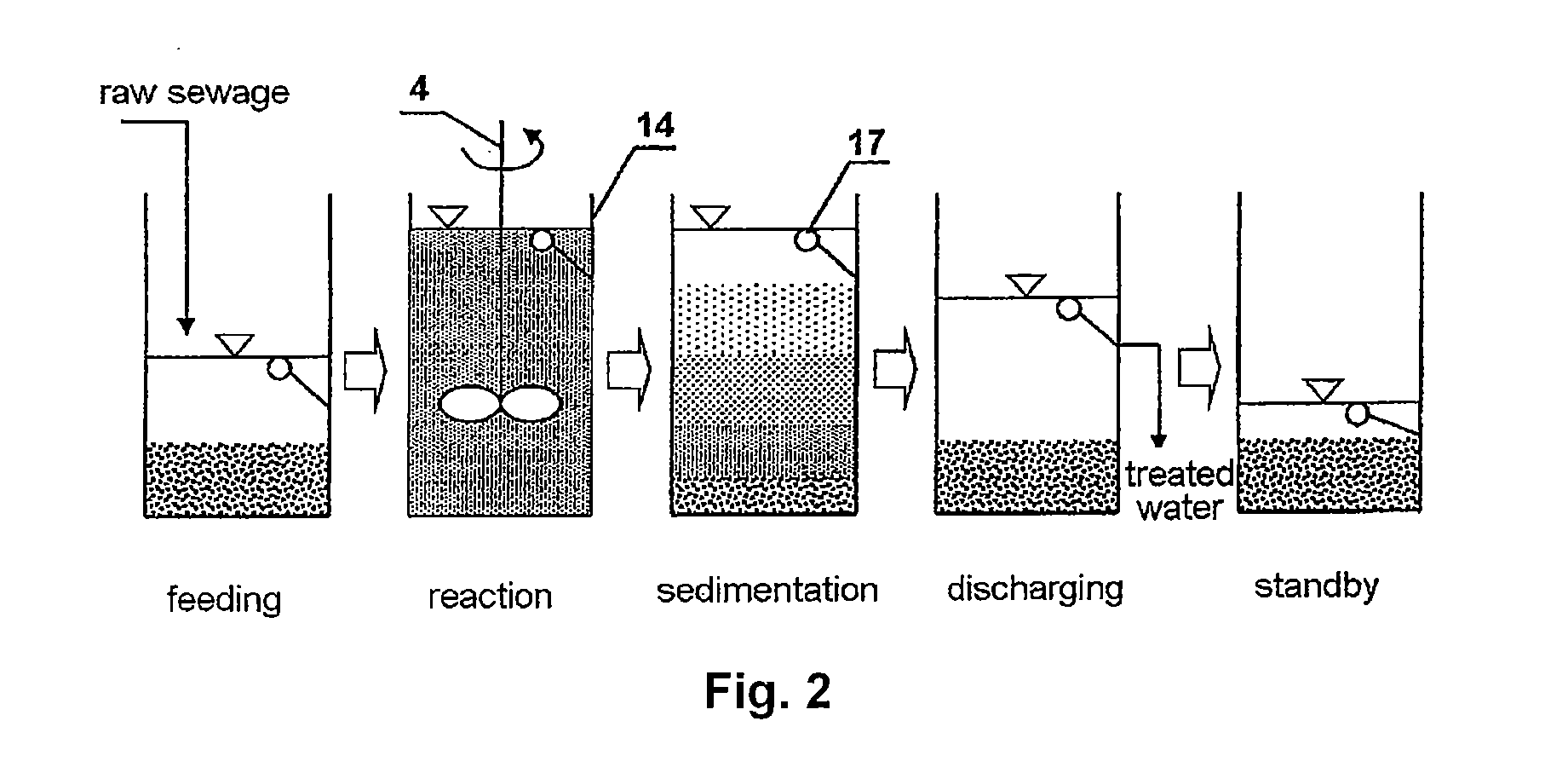

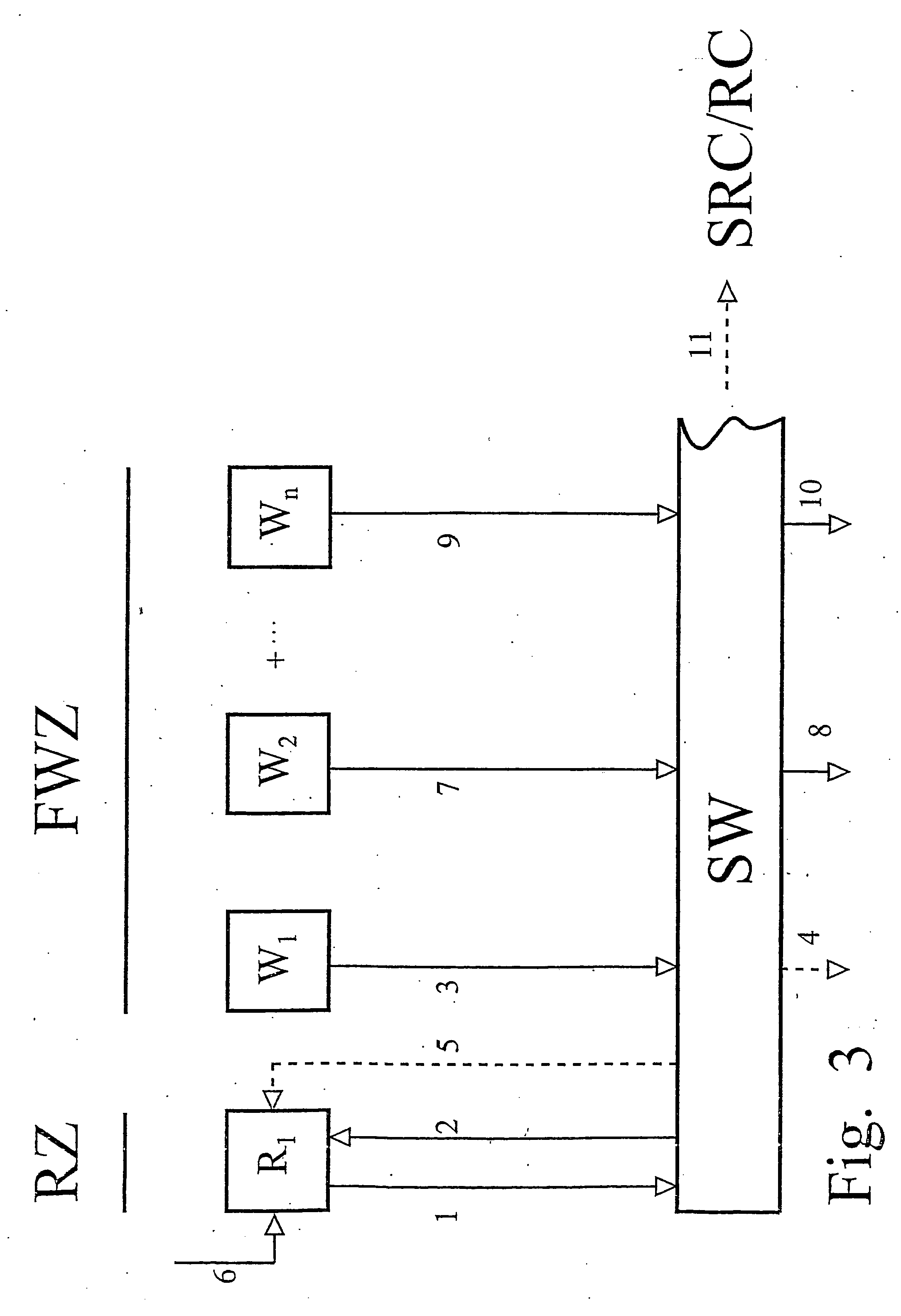

Sewage Treatment Process and System

InactiveUS20120018374A1Reduce space utilizationEfficient removalDialysis systemsTreatment with aerobic and anaerobic processesWater flowSewage

A sewage treatment process is provided, which includes the following steps: a) sewage feeding step, comprising introducing raw sewage into a biological reaction tank (1) to a predetermined time or liquid level; b) reaction step comprising performing aeration and stirring intermittently in the biological reaction tank (1); c) treated water discharging step, comprising performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a first permeate, which is taken as the final treated water; d) standby step comprising stopping aeration in the biological reaction tank (1); and e) phosphorus-enriched water discharging step, comprising keeping anaerobic condition in the biological reaction tank (1) and performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a second permeate, the second permeate entering inside a phosphorus recycling unit (5) which is set independent from the biological reaction tank (1), the phosphorus recycling unit (5) removing phosphorus from water, the second permeate becoming low-phosphorus water, and the low-phosphorous water flowing back to the biological reaction tank (1); the sewage treatment process runs in cycle by repeating above steps. A corresponding treatment system is also provided.

Owner:SUN YOUFENG

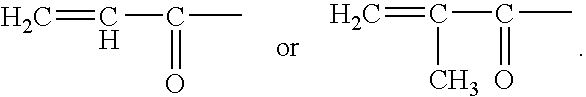

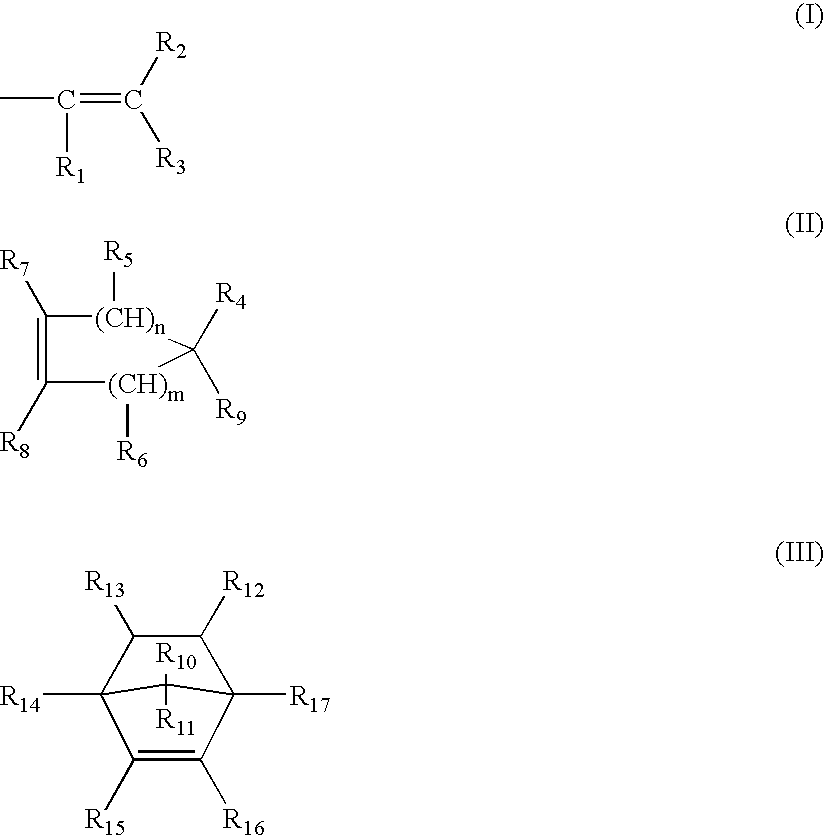

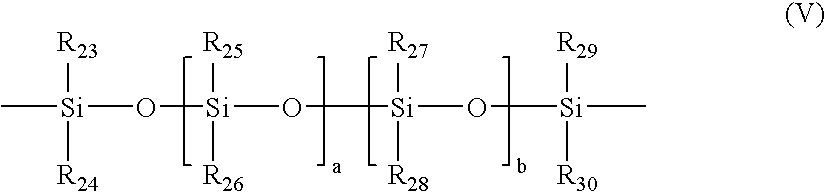

Actinically-crosslinkable silicone-containing block copolymers

The invention provide a new class of silicone-containing prepolymers containing poly(oxyalkylene) blocks, polysiloxane blocks, and actinically-crosslinkable groups which are acryl groups, thiol groups, ene-containing groups or combinations thereof. A preopolymr of the invention is prepared in a one-pot procedure according to the Micahel addition of thiol to electron deficient alkenes, such as α,β-unsaturated carbonyl compounds, without need for additional reaction step(s) to introduce actinically crosslinkable groups. The present invention is also related to silicone hydrogel contact lenses made from this class of silicone-containing prepolymers and to methods for making the silicone hydrogel contact lenses.

Owner:ALCON INC

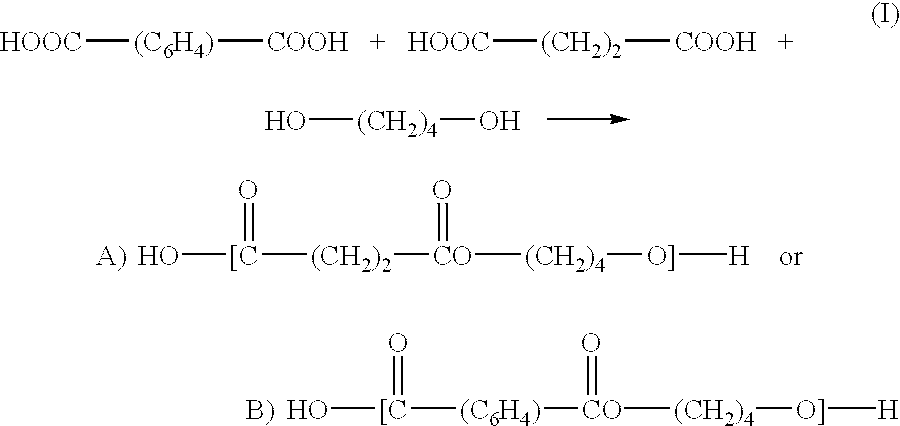

Copolyester resin composition and a process of preparation thereof

The present invention provides a copolyester resin composition which has good physical properties, biodegradability and processability and a process for preparing and / or producing the same. To improve the biodegradability and physical properties of the copolyester, the present invention applied multi-stage reaction step, and copolyester resin having number average molecular weight of from 30,000 to 70,000, weight average molecular weight of from 100,000 to 600,000, melting point of from 55° C. to 120° C., and melt index of from 0.1 to 30 g / 10 minute (190° C., 2,160 g) is obtained. The processability and physical properties of the copolyester resin of the present invention has been greatly enhanced by incorporating (i) an "aromatic-aliphatic prepolymers" having number average molecular weight of from 300 to 30,000 and the contiguous repeating unit of aromatic group in the dicarboxylic acid position of "aromatic-aliphatic prepolymers" is less than 5. Thus it can be processed by using the conventional processing equipment for polyethylene and polypropylene without any modification.

Owner:ANKOR BIOPLASTICS CO LTD

Process for producing aromatic hydrocarbon

InactiveUS20100185034A1Simple and economical procedureHigh reaction yieldMolecular sieve catalystsMolecular sieve catalystHydrogenReaction temperature

Provided is a process for producing an aromatic hydrocarbon using a molybdenum-containing solid catalyst, more specifically a process for producing an aromatic hydrocarbon efficiently from a lower hydrocarbon gas essentially containing methane by activating the molybdenum-containing solid catalyst with maintaining a high yield for a long period of time.The process comprises a pre-contacting step of allowing a molybdenum-containing solid catalyst to contact with a pre-contacting gas comprising at least one selected from a lower hydrocarbon and a hydrogen gas; and a reaction step of allowing the pre-contacted catalyst to contact with a raw material gas essentially containing methane, to generate an aromatic hydrocarbon, wherein the starting temperature in the pre-contacting step is lower than the reaction temperature, and the temperature during the pre-contacting step from the beginning to the end is not over the reaction temperature.

Owner:MITSUI CHEM INC +1

Method for the production of fermentable sugars and cellulose from lignocellulosic material

InactiveUS20070254348A1Pulping with acid salts/anhydridesPulp by-products recoveryOrganic acidAlcohol

A method for the production of fermentable sugars and cellulose from lignocellulosic material in a batch or continuous process. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, cooking chemicals reused, lignin is separated for the production of process energy, hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. High yield production of alcohols or organic acids can be obtained from this method using the final reaction step.

Owner:RETABINA THEODORA +1

Two-step method for hydrotreating of a hydrocarbon feedstock comprising intermediate fractionation by rectification stripping

InactiveUS20060118466A1Reduce sulfur contentReduce nitrogen contentHydrocarbon distillation control/regulationTreatment with hydrotreatment processesPtru catalystPhysical chemistry

A process for hydrotreatment of a hydrocarbon feed comprises at least two reaction steps with intermediate fractionation of the effluent from the first step to eliminate unwanted impurities for the catalyst of the second step and to produce a desulphurized light liquid fraction. The intermediate fractionation comprises stripping the liquid effluent from the first step using low pressure hydrogen with rectification of the stripping vapours using a substantially desulphurized liquid reflux. The conditions for said fractionation and for the first hydrotreatment step can produce a substantially desulphurized light liquid fraction which is not supplied to the second step.

Owner:INST FR DU PETROLE

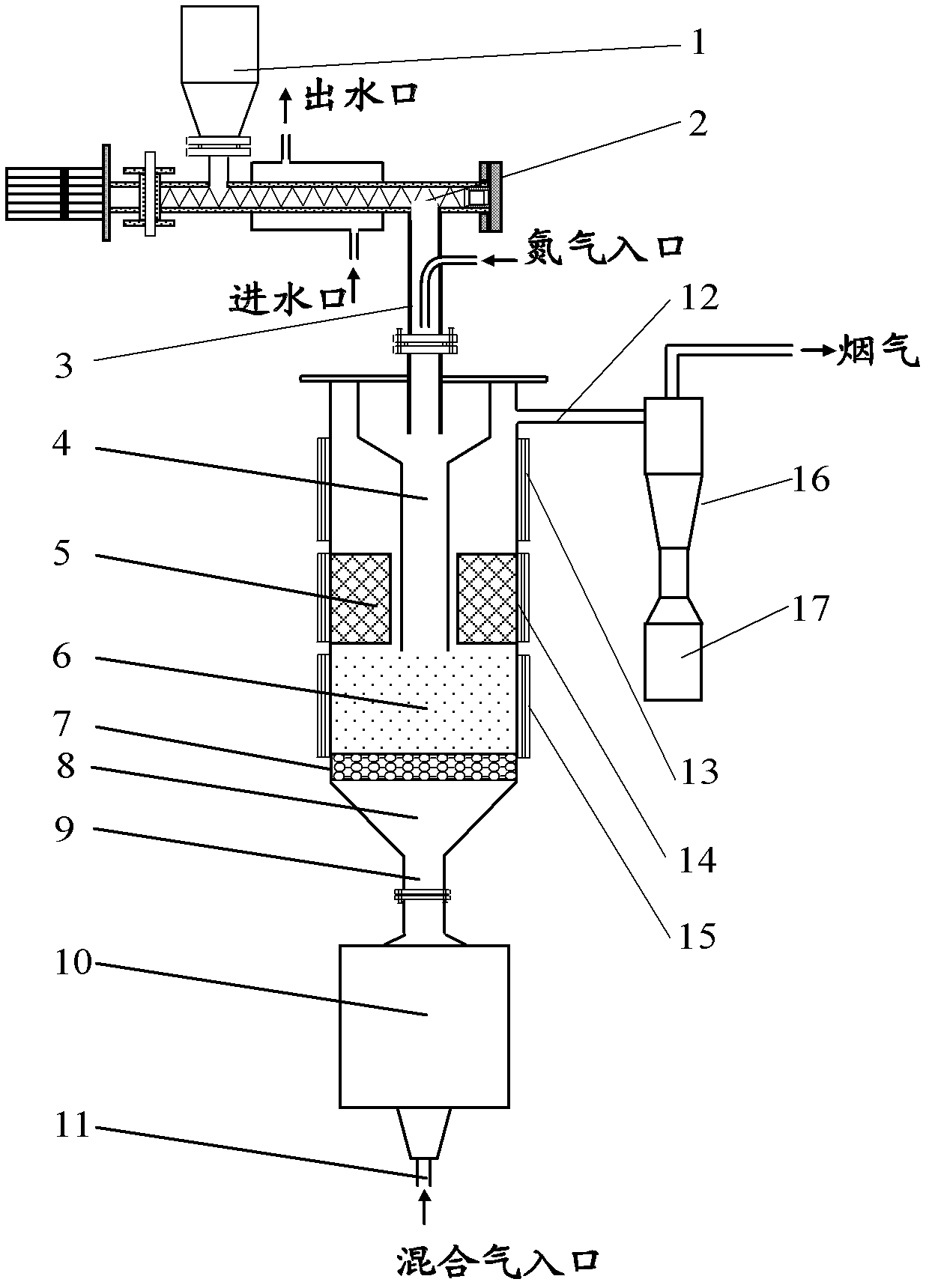

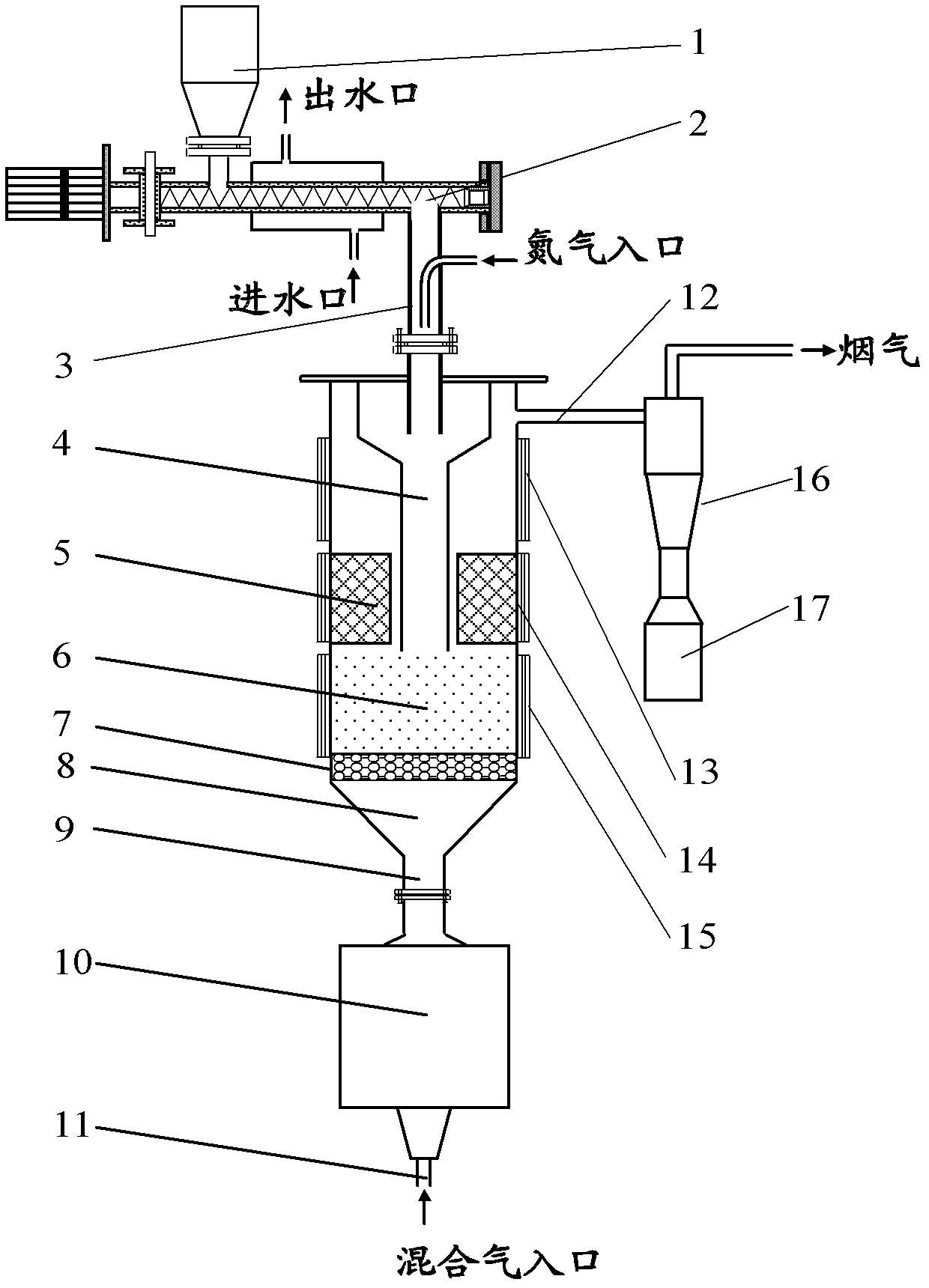

Method for preparing synthetic gas by three-phase type biomass pyrolysis-gasification-catalytic reforming

ActiveCN102424359AImprove conversion utilizationHigh yieldHydrogenWaste based fuelCatalytic reformingChemical industry

The invention belongs to the technical field of energy chemical industry. The process for preparing synthetic gas by biomass pyrolysis and gasification is divided into three steps of biomass low-temperature pyrolysis, coke or semi-coke high-temperature gasification and crude synthetic gas / tar catalytic reforming. The three reaction steps are successively and continuously carried out in three relatively independent spaces of an upper pyrolysis hearth, a lower gasification hearth and a catalyst bed inside the same gasification reaction device so as to finally obtain the high-quality synthetic gas. The method provided by the invention has high carbon conversion rate, produces no secondary pollution and is simple to realize. In addition, required biomass is rich in reserves and can be regenerated, thus realizing integrated sustainable utilization of resource, energy and environment.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

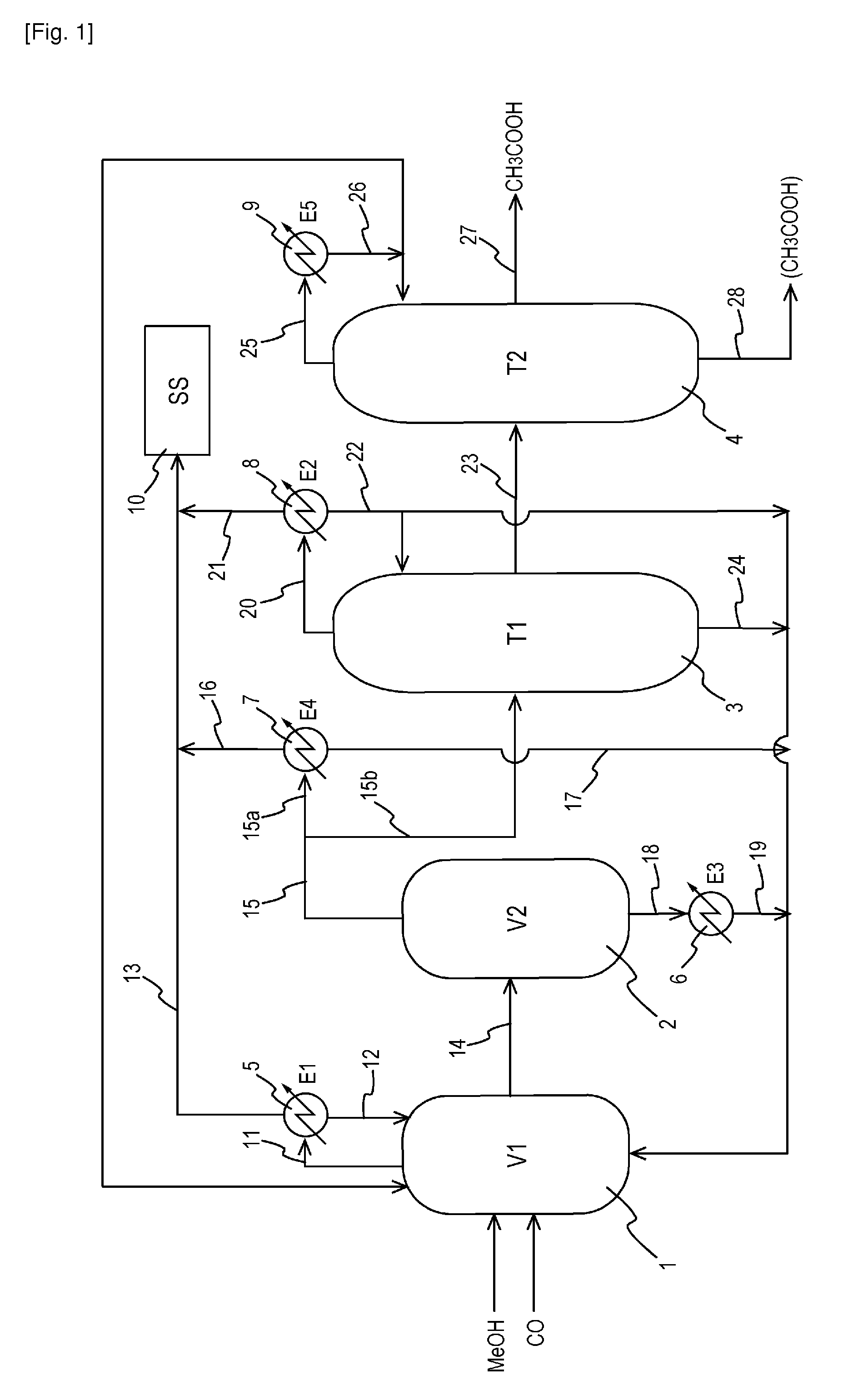

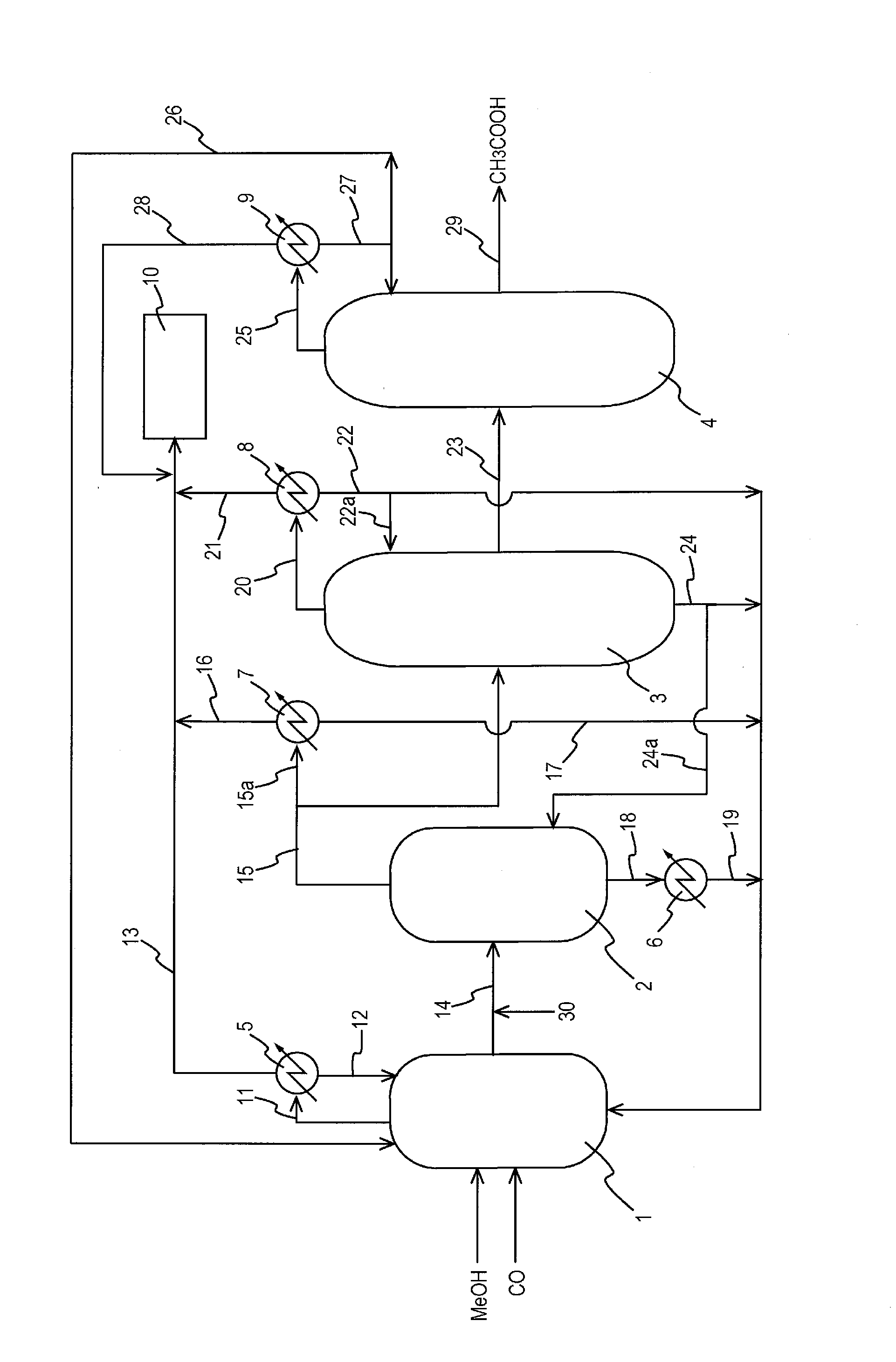

Process for producing acetic acid

ActiveUS20130310603A1Efficient productionEasy to save energyOrganic compound preparationOrganic chemistry methodsIodideReaction step

Acetic acid is produced while inhibiting an increased concentration or production of hydrogen iodide in a carbonylation reactor or corrosion of the carbonylation reactor.A production process of acetic acid comprises a reaction step for continuously allowing methanol to react with carbon monoxide in the presence of a catalyst system comprising a metal catalyst (e.g., a rhodium catalyst), an ionic iodide (e.g., lithium iodide), and methyl iodide in a carbonylation reactor; and in the process, (i) the concentration of the metal catalyst is maintained at not less than 860 ppm on the basis of weight, the concentration of water is maintained at 0.8 to 15% by weight, the concentration of methyl iodide is maintained at not more than 13.9% by weight, and the concentration of methyl acetate is maintained at not less than 0.1% by weight, in a whole liquid phase in the reactor, and / or (ii) the concentration of the metal catalyst is maintained at not less than 660 ppm on the basis of weight, the concentration of water is maintained at 0.8 to 3.9% by weight, the concentration of the ionic iodide is maintained at not more than 13% by weight, the concentration of methyl iodide is maintained at not more than 13.9% by weight, and the concentration of methyl acetate is maintained at not less than 0.1% by weight, in a whole liquid phase in the reactor.

Owner:DAICEL CHEM IND LTD

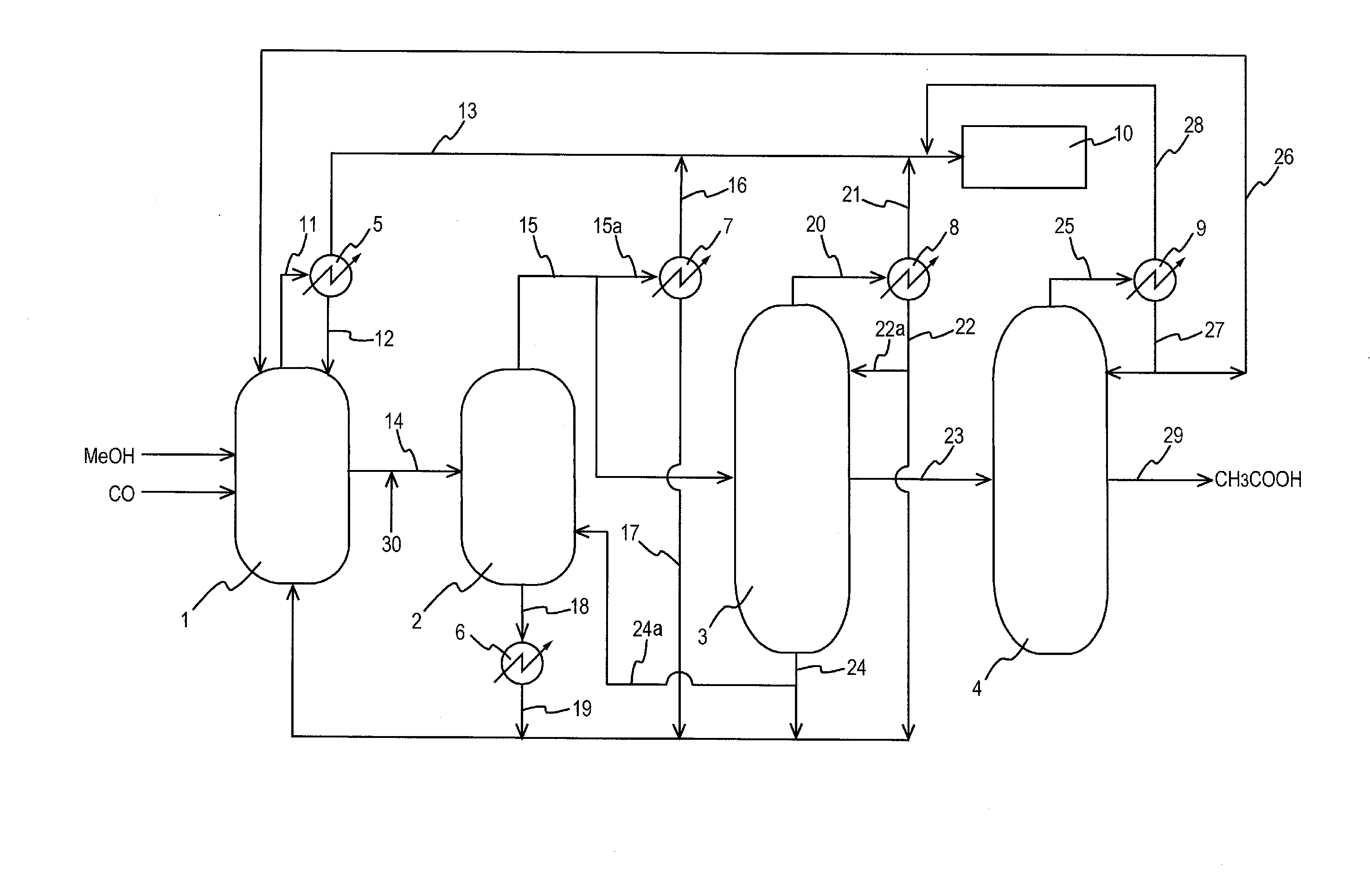

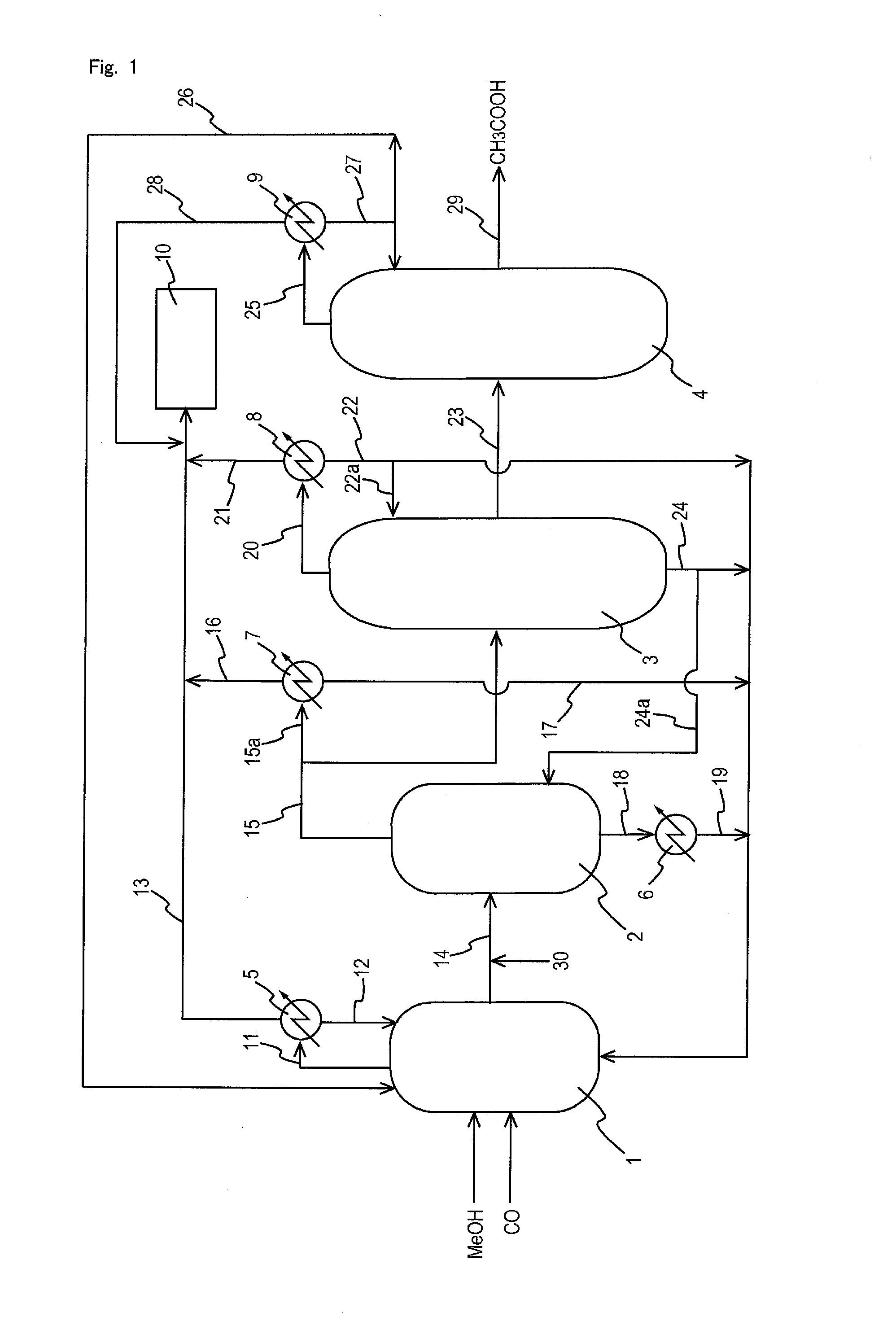

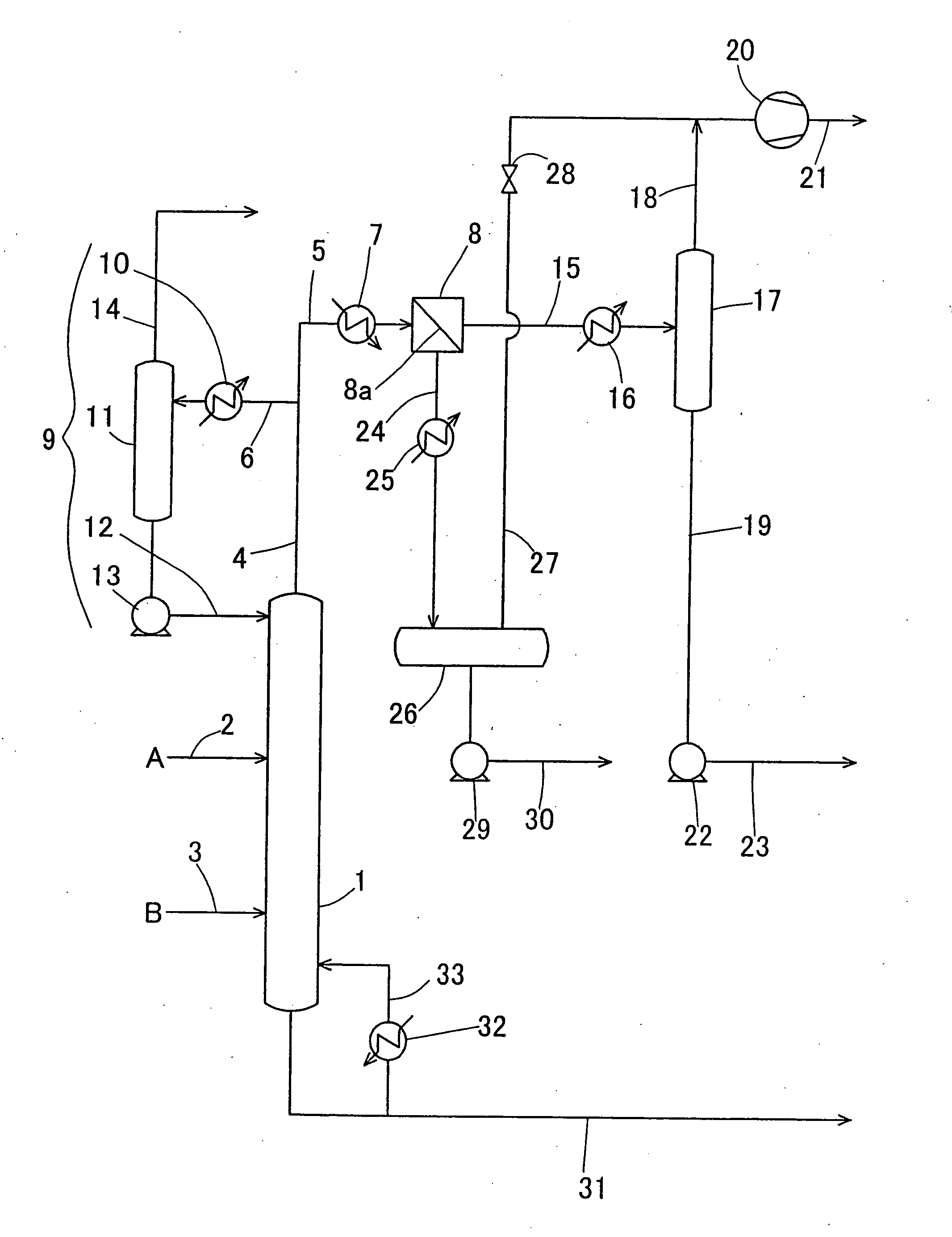

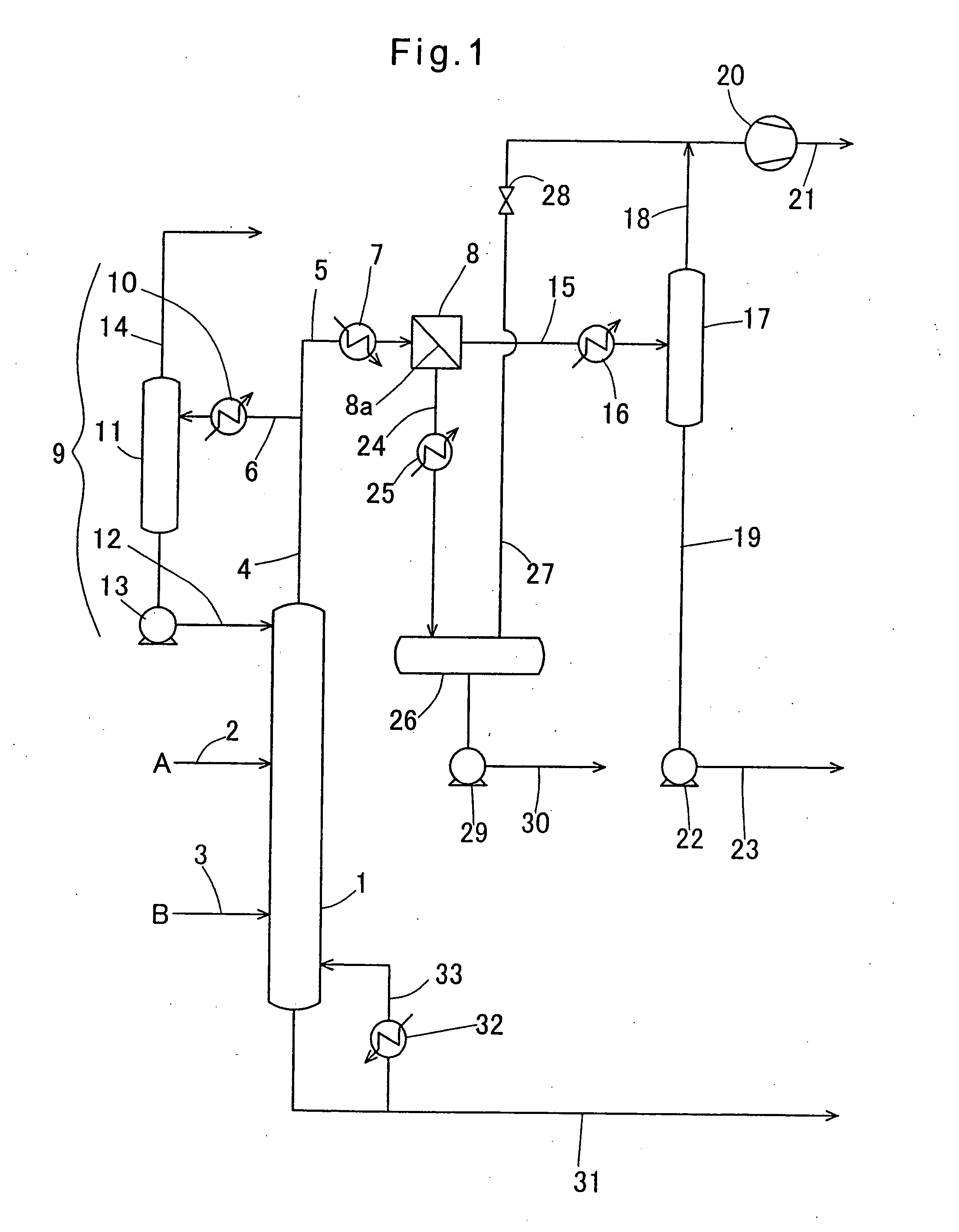

Process for producing acetic acid

ActiveUS20130116470A1High purityHigh yieldOrganic compound preparationChemical industryDistillationResource saving

A production process of acetic acid comprises a reaction step for continuously allowing at least one member selected from the group consisting of methanol, dimethyl ether, and methyl acetate to react with carbon monoxide in a catalyst system comprising a rhodium catalyst, an iodide salt, and methyl iodide in the presence of acetic acid and water in a plant compromising a reactor 1; a flasher 2; and a distillation column 3; wherein part of the vaporized stream is introduced into a heat exchanger 7. The process achieves a production of acetic acid with a high purity in a resource-saving and energy-saving equipment by efficiently removing a reaction heat even in a large-sized plant.

Owner:DAICEL CHEM IND LTD

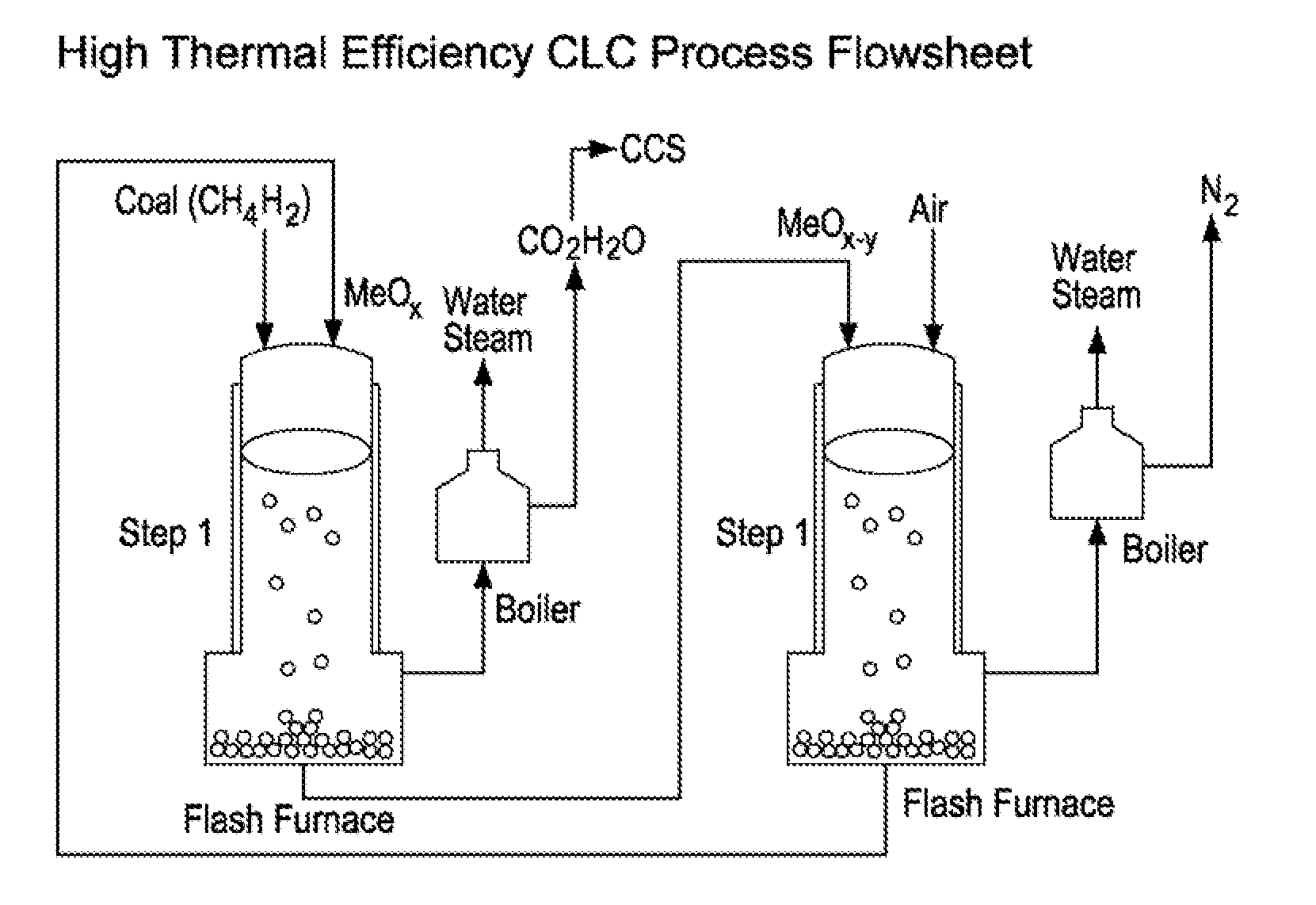

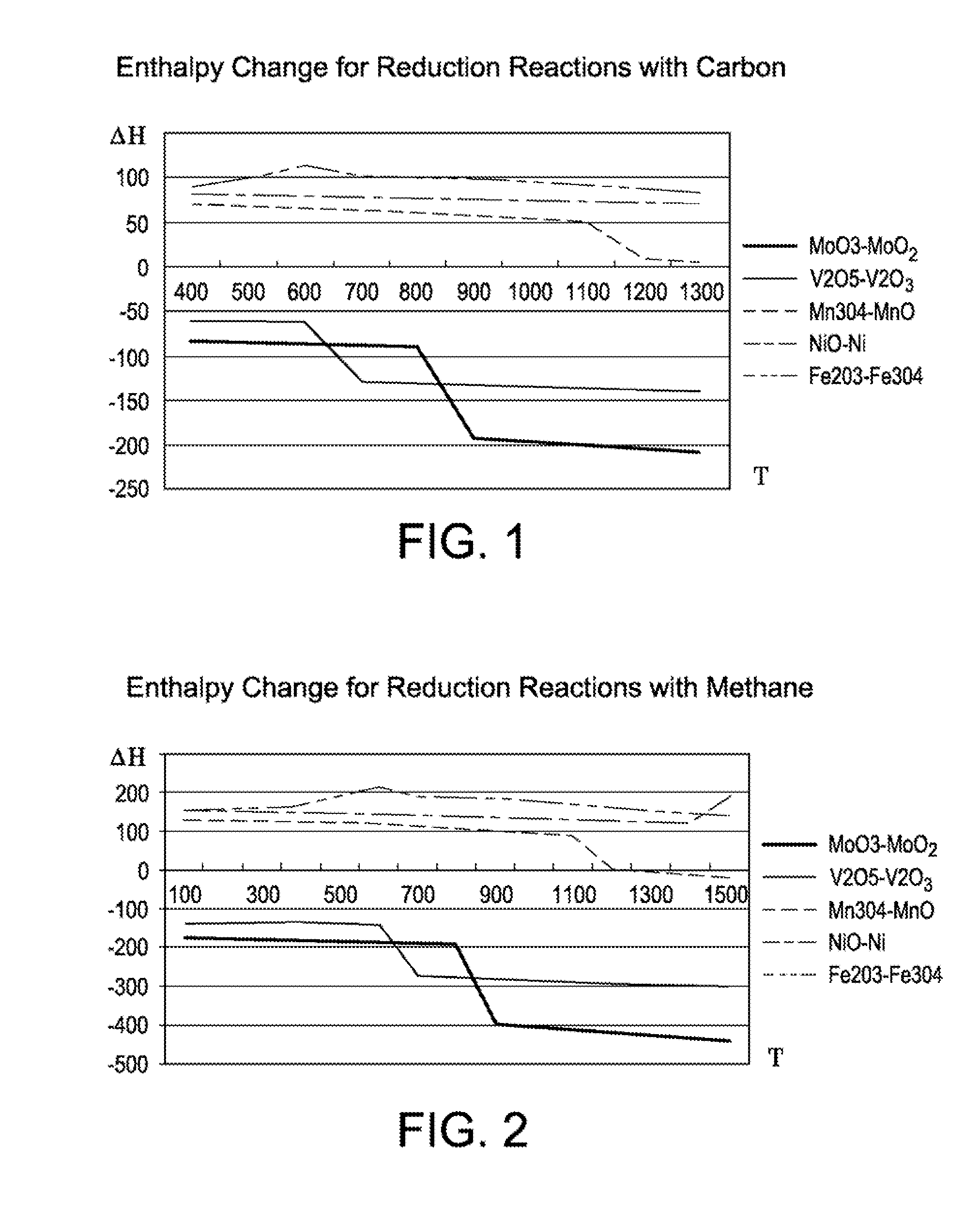

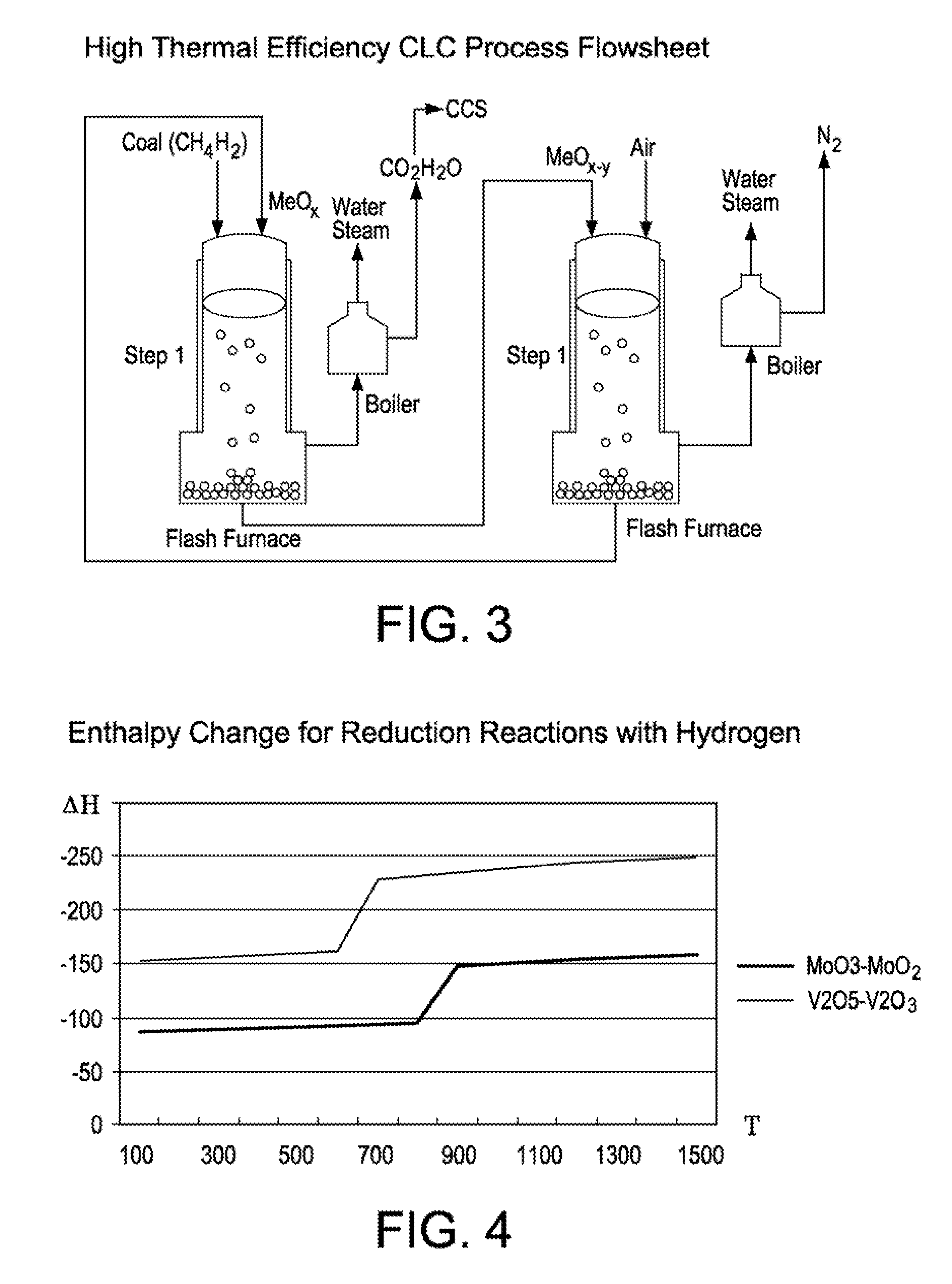

Process and apparatus for high energy efficiency chemical looping combustion

InactiveUS20110094226A1Liquid carbonaceous fuelsDirect carbon-dioxide mitigationHigh energyChemical measurement

Process and apparatus are provided for a high energy efficiency chemical combustion process. The process provides two reaction steps, both of which are exothermic. First, a reduced oxygen carrier is contacted with oxygen in a reactor to form an oxidized oxygen carrier, such as metal oxide or metal suboxide, and then the oxidized oxygen carrier is fed to a second reactor and combusted with a fuel. The reaction produces the reduced oxygen carrier and carbon dioxide. The reduced oxygen carrier from the second reactor is recycled back to said first reactor. Carbon monoxide can also be produced during the process depending on stoichiometric amounts of the reactants. Though the process can be performed in various types of reactor systems, one preferred embodiment is the flash furnace with the production of fly ash during combustion. The process is highly efficient and produces a large amount of usable work.

Owner:ORCHARD MATERIAL TECH

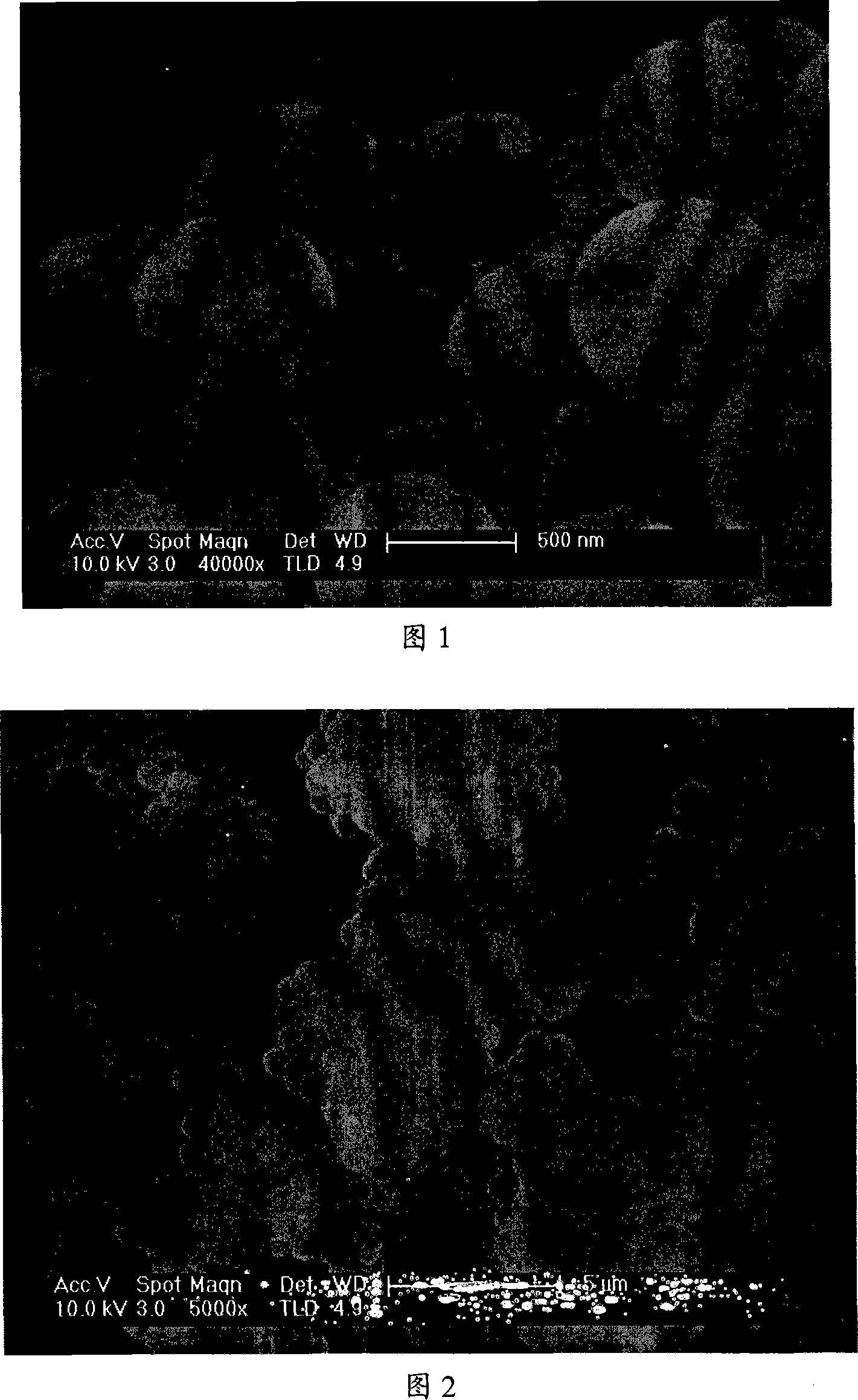

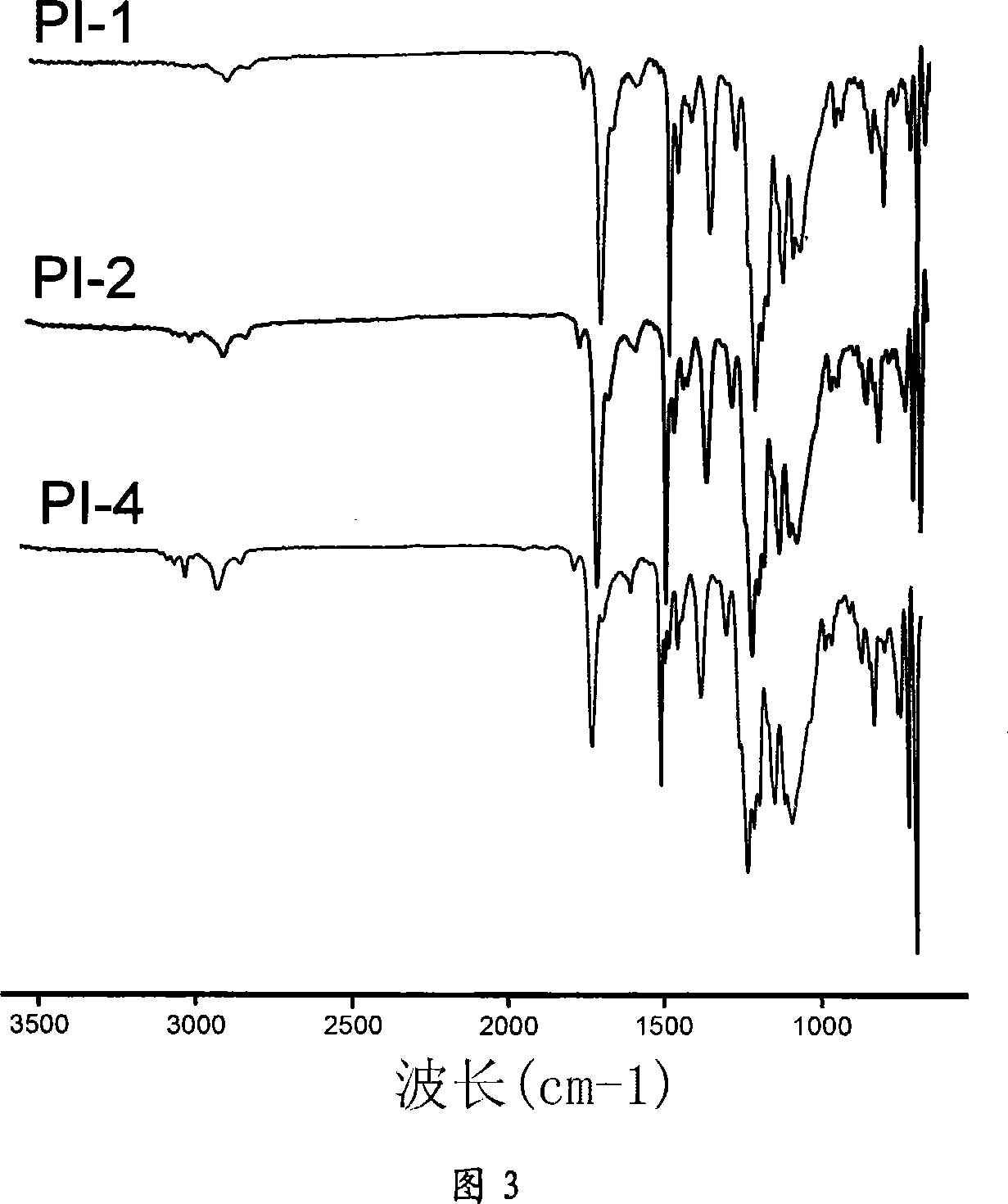

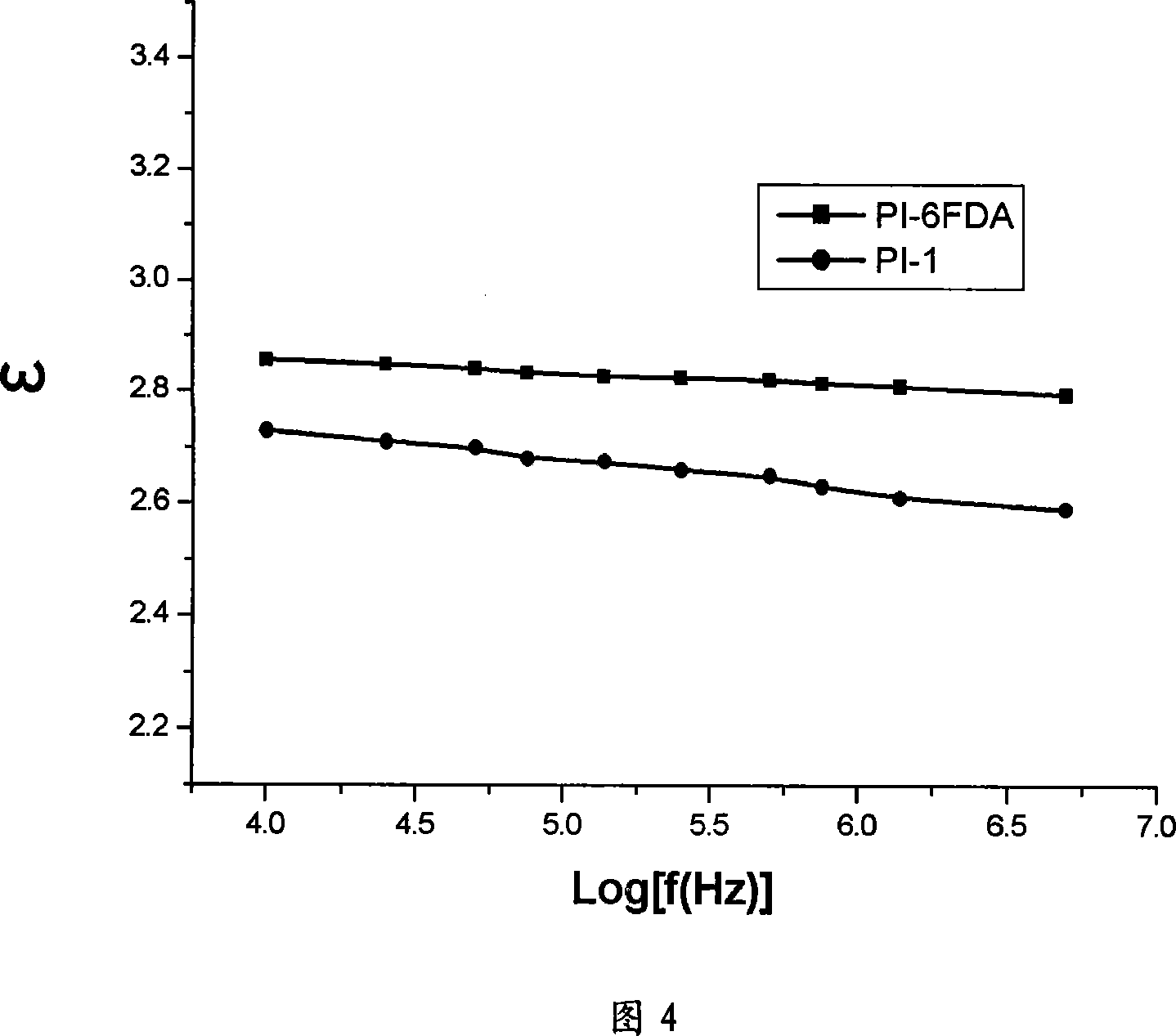

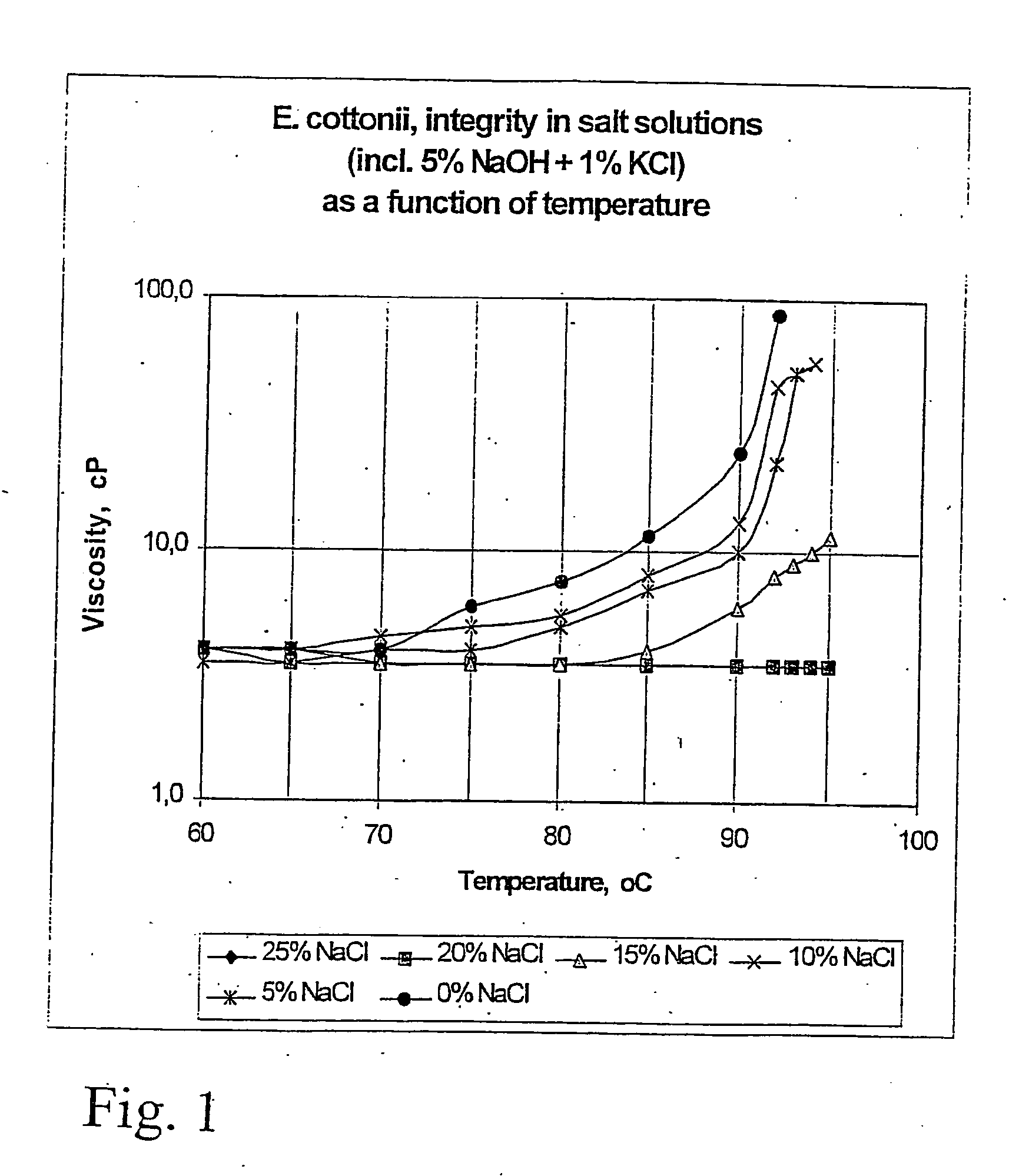

Method for preparing polyimide/ silicon dioxide hollow micro-sphere composite film

The invention discloses a method for preparing polyimide / silicon dioxide hollow microballoon laminated film which has low dielectric constant and keeps thermal property, and steps of reaction are that: silicon dioxide hollow microballoon is put into ethanol solution, amino-containing silane coupling agent is added after ultra sonic dispersion, stirred for reaction, separated centrifugally, washed and dried; then under the protection of nitrogen flow, the dianhydride and the diamine with a mole-ratio 1:1 are added into the high boiling polarity aprotic solvent to prepare solvent containing 10 percent (wt / wt) of solid-content; the silicon dioxide hollow microballoon modified by silane coupling agent is put into the solvent, and the weight of the silicon dioxide hollow microballoon modified by the silane coupling agent is 2-50 percent of the weight of laminated film, the polyamide acid viscous fluid is prepared upon ultra sonic dispersion and a reaction of twenty-four hours at room temperature; the polyamide acid viscous fluid is taken and poured into the glass plate mould; finally the mould is put in vacuum to dry, the temperature is heated up continuously after the solvent is removed for cyclic reaction. Thus, the polyimide / silicon dioxide hollow microballoon laminated film is prepared..

Owner:SOUTHEAST UNIV

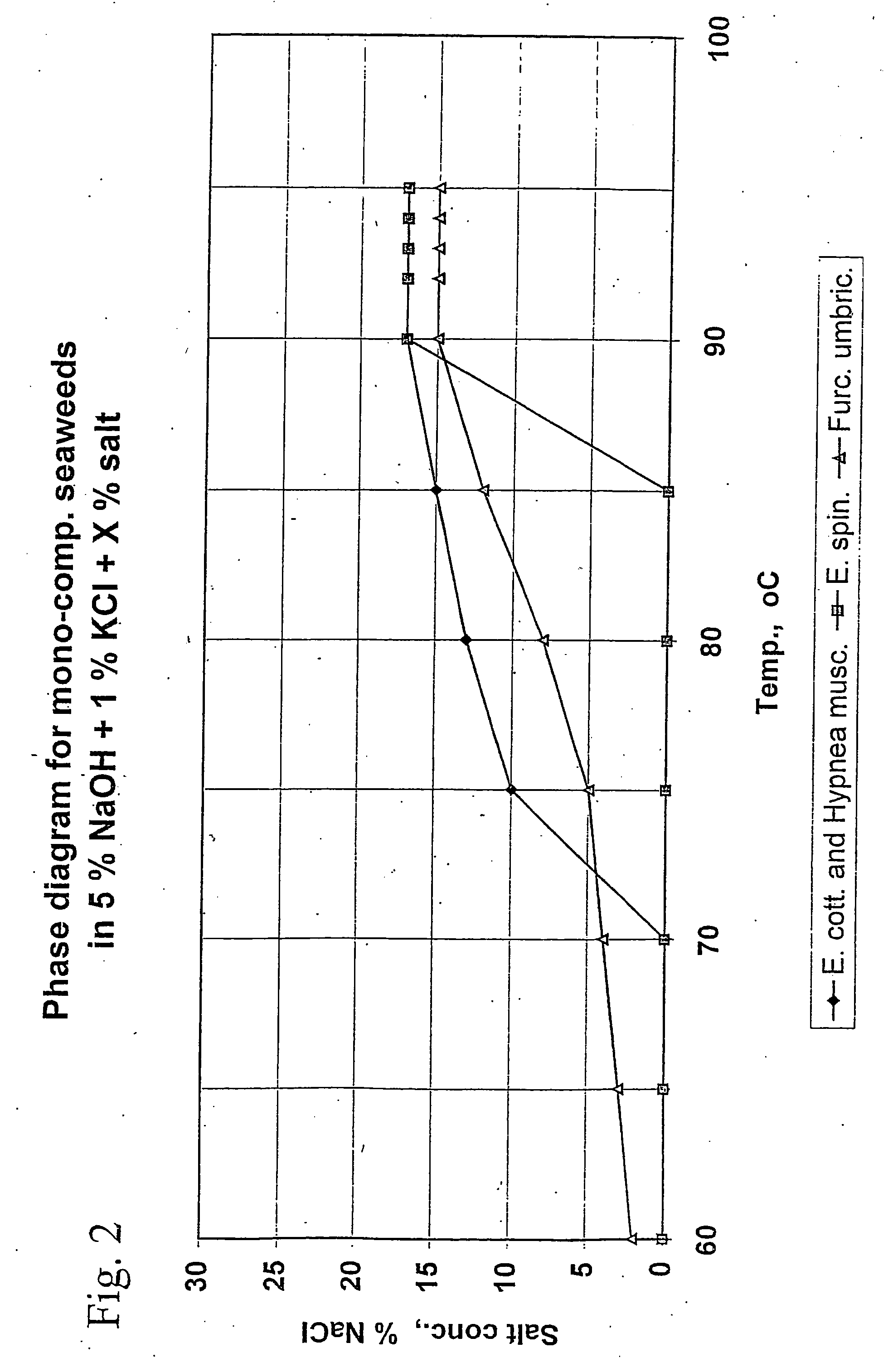

Heterogeneous carrageenan manufacturing process from mono component seaweed with reduced use of level of koh

InactiveUS20050020828A1Reduction in alkali costReduce the amount requiredEsterified saccharide compoundsSugar derivativesCarrageenanPhosphate

An improved method for the manufacture of gelling carrageenens from seaweed, wherein mono-component seaweed is subjected to a heterogeneous reaction step, one or more washing step (s), and further workup provides for substantial savings in alkali costs as non-expensive alkalis, such as NaOH, Na2CO3,Na-phosphates, K2CO3, K-phosphates, ammonia may be used in the heterogeneous reaction step.

Owner:CP KELCO

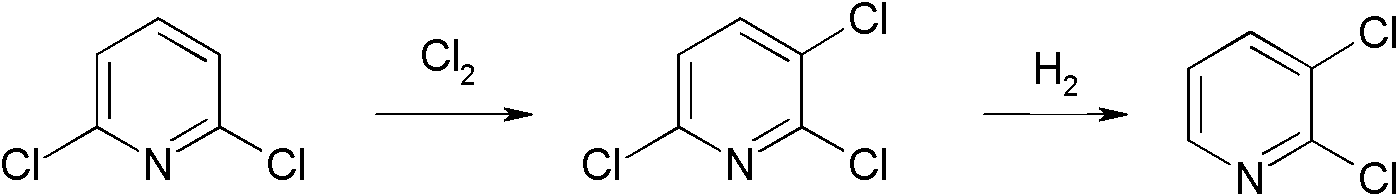

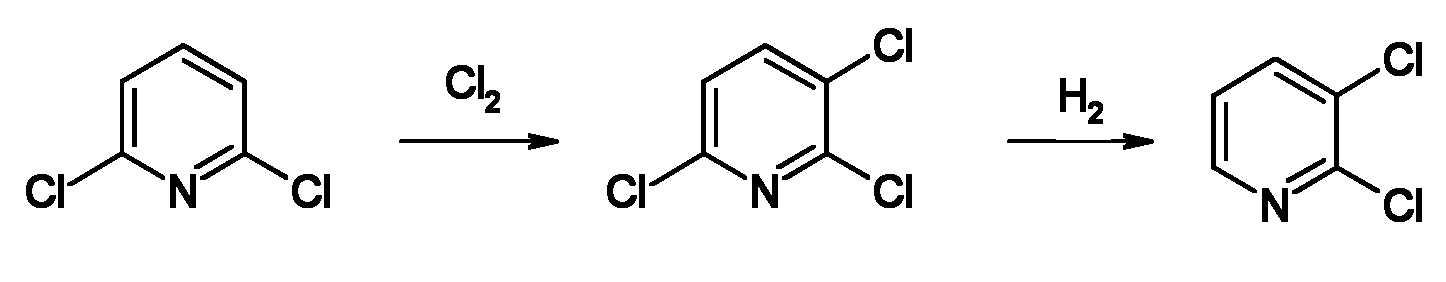

Preparation method of 2,3-dichloropyridine

ActiveCN102153507ANovel process routeReduce manufacturing costOrganic chemistryOrganic solventMetal catalyst

The invention discloses a preparation method of 2,3-dichloropyridine. 2,3-dichloropyridine is an intermediate in fine chemical industry, which is widely used in the fields of medicine and pesticide. The method comprises the following steps: carrying out chlorination reaction on 2,6-dichloropyridine, which is used as a raw material, to obtain 2,3,6-trichloropyridine; adding the 2,3,6-trichloropyridine, an acid binding agent, a metal catalyst and an organic solvent into a reactor, and carrying out hydrogenation reaction, wherein the mol ratio of 2,3,6-trichloropyridine to acid binding agent is 1:(0.1-0.5); and cooling the hydrogenation reaction liquid, adding water to dissolve the acid binding agent hydrochloride, filtering, standing, separating out the water layer, extracting the organic solvent layer with water-containing acid at least three times, merging the water-containing acid layers after extraction, diluting by adding water, precipitating a solid, filtering, and drying to obtain the 2,3-dichloropyridine product. The invention has the advantages of novel process route, short reaction steps, high yield, low production cost and environmental friendliness, is simple to operate, and is suitable for industrial production.

Owner:LIANHE CHEM TECH +1

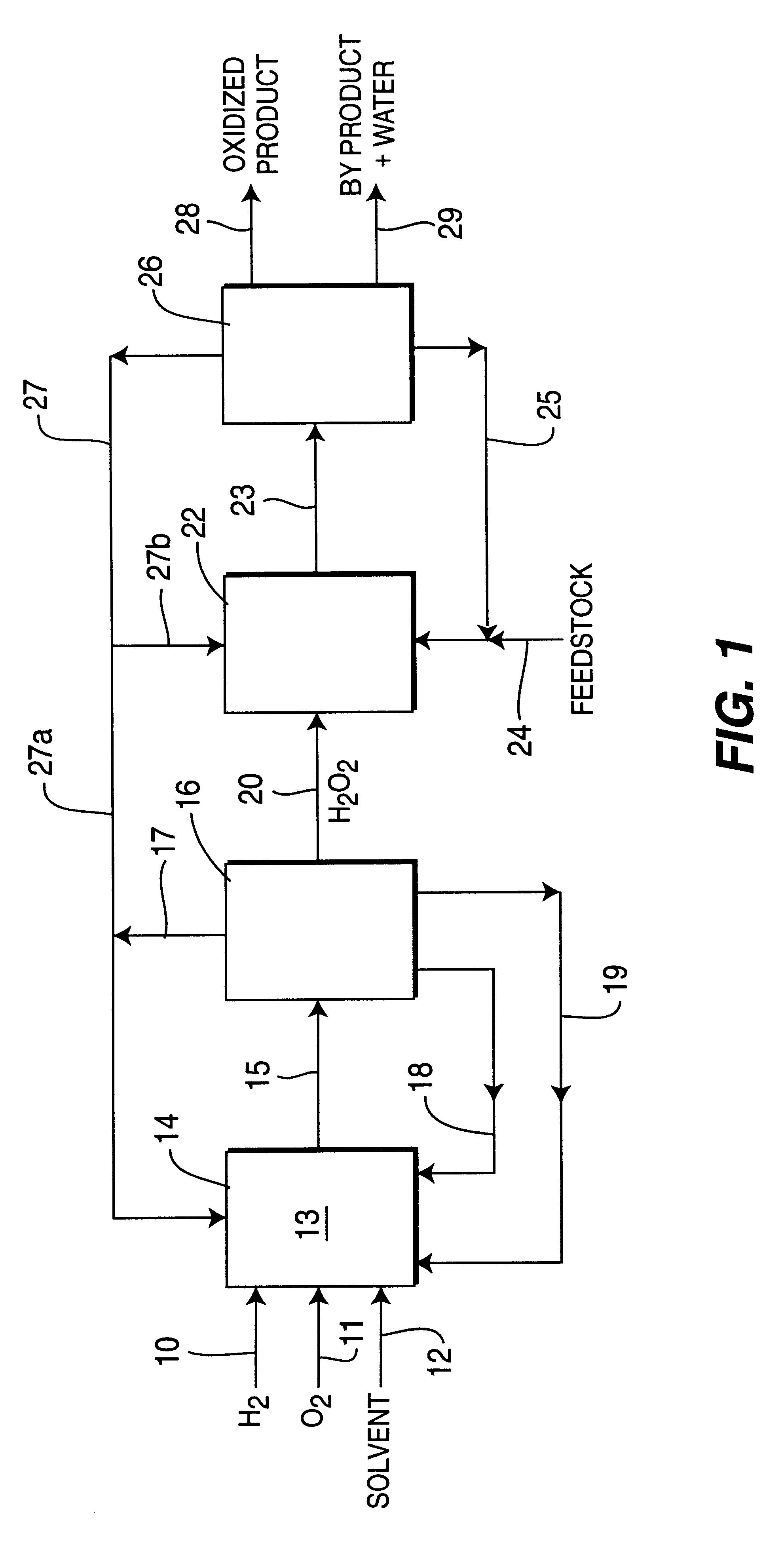

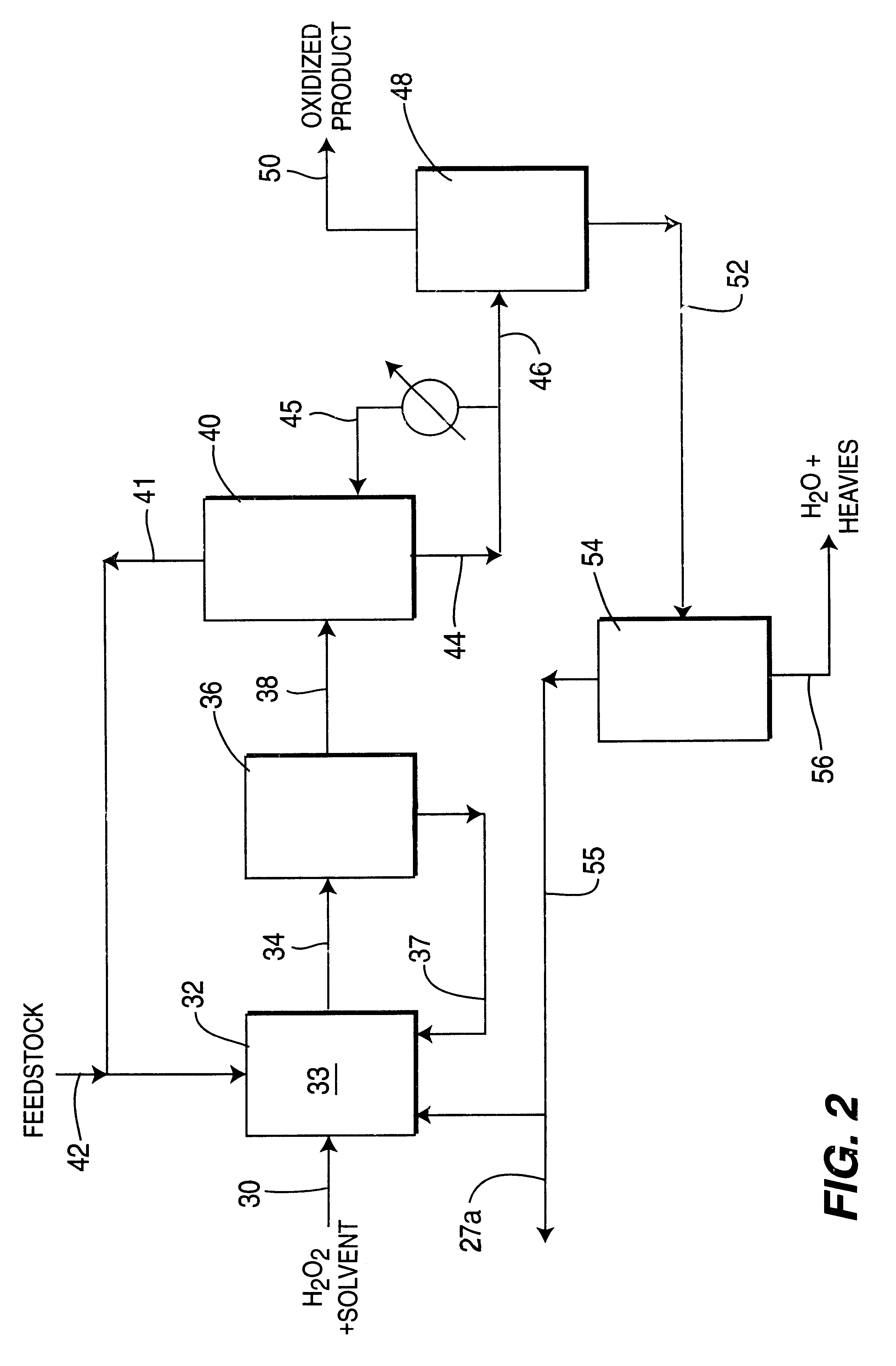

Process for selective oxidation of organic feedstocks with hydrogen peroxide

InactiveUS6500968B2Increase productionLow costOrganic chemistryPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDistillationActive support

A process for producing oxidized organic chemical products such as propylene oxide from various organic chemical feedstocks utilizing as oxidant directly produced hydrogen peroxide (H2O2) intermediate oxidizing agent. The hydrogen peroxide intermediate is directly produced from hydrogen and oxygen feeds plus a suitable solvent in a first catalytic reaction step utilizing an active supported phase-controlled noble metal catalyst at reaction conditions of 0-100° C. temperature and 300-3,000 psig pressure. An organic chemical feedstock such as propylene together with the hydrogen peroxide intermediate and solvent solution are fed into a second catalytic reactor maintained at 0-150° C. temperature and 15-1,500 psig pressure and oxidized to produce a desired crude oxidized organic product such as propylene oxide, which is purified by distillation steps and recovered from the solvent solution.

Owner:HEADWATERS TECH INNOVATION LLC

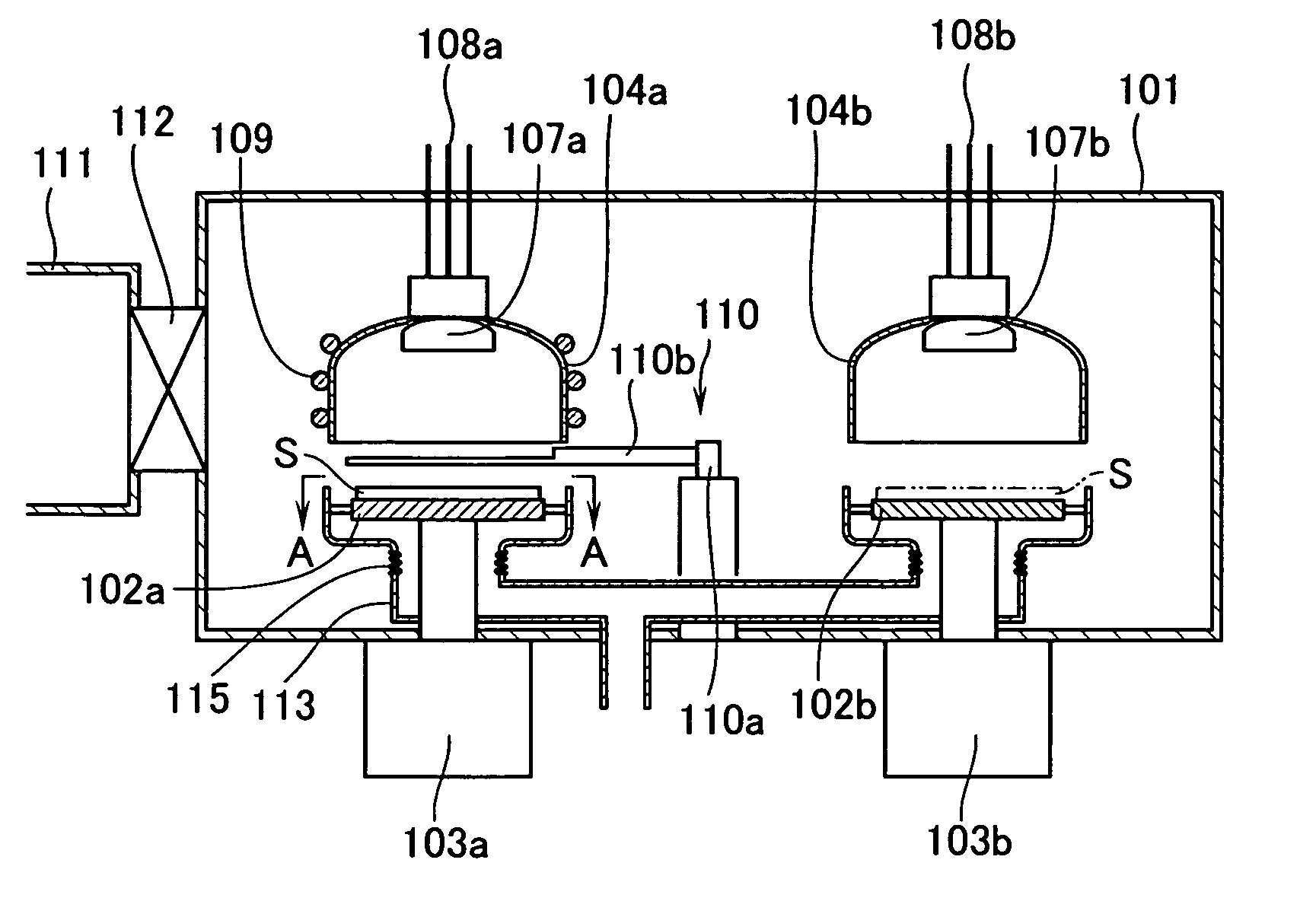

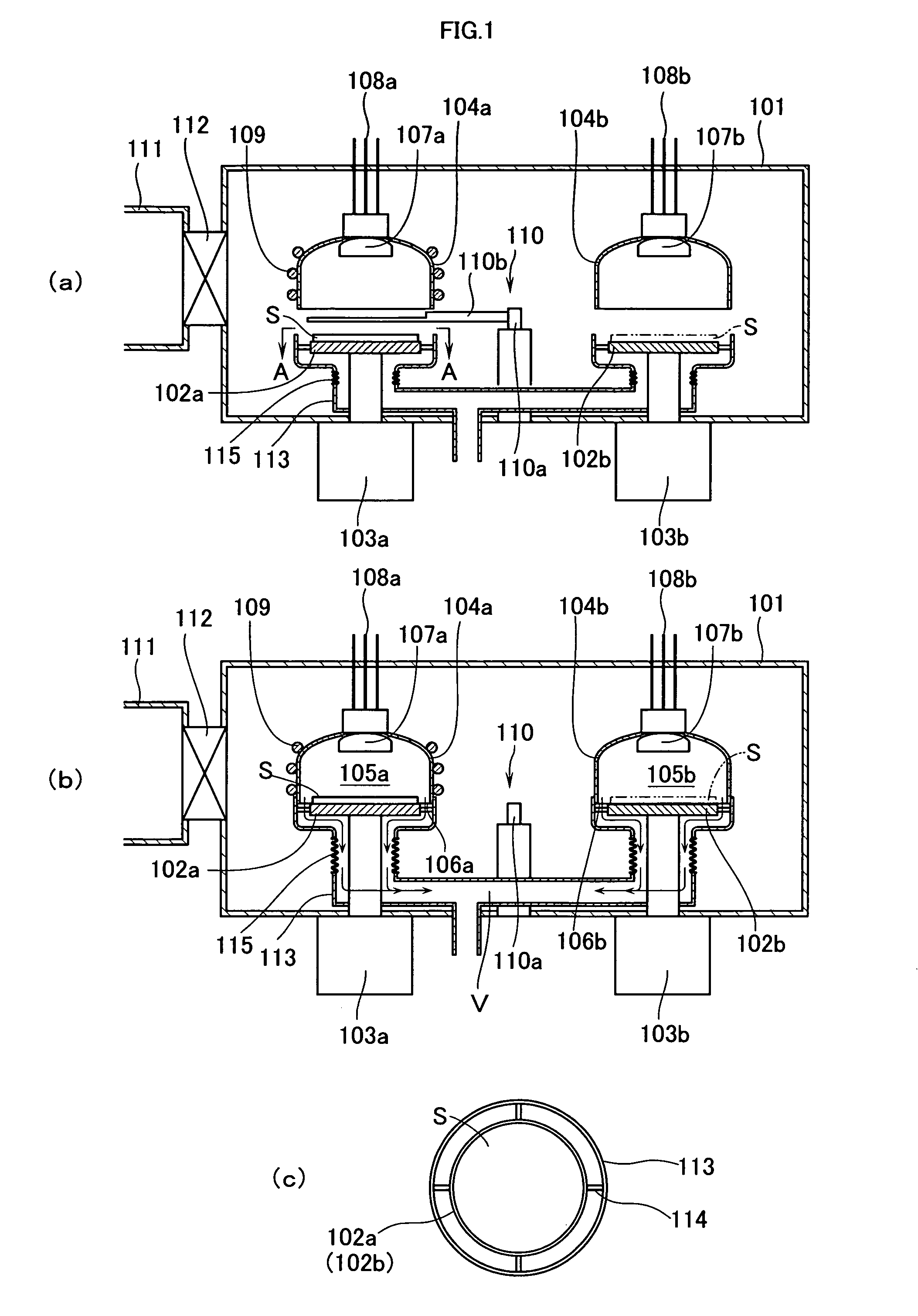

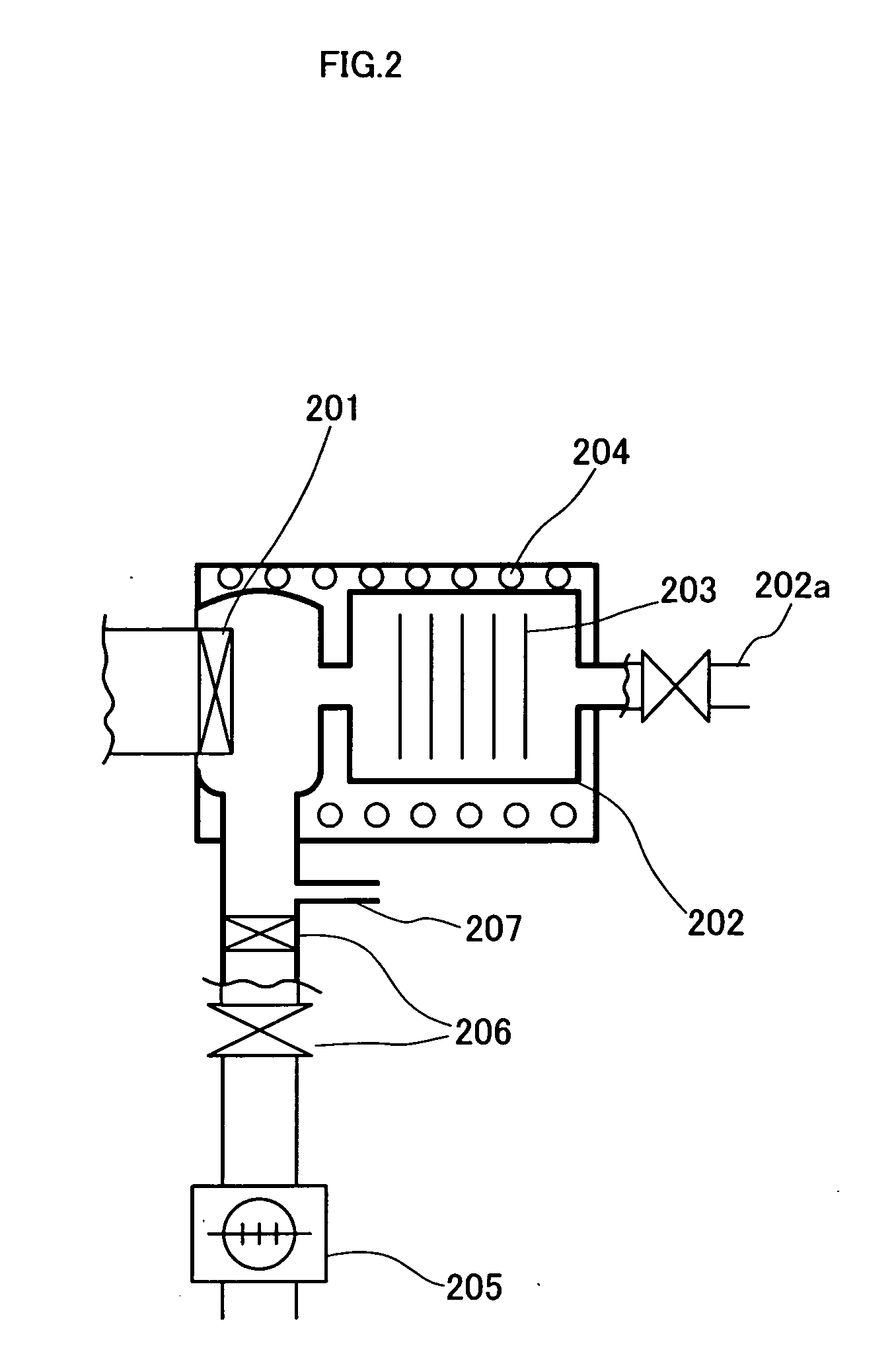

Vaccum film-forming apparatus

ActiveUS20050268852A1Improve film qualityReduce manufacturing costVacuum evaporation coatingSputtering coatingEngineeringProcess conditions

A vacuum film-forming apparatus comprising substrate stages; vacuum chamber-forming containers opposed to the stages; a means for moving the substrate between the stages; and gas-introduction means connected to every containers, wherein one of the stage and the container is ascended or descended towards the other to bring the upper face of the stage and the opening of the container into contact with one another so that vacuum chambers can be formed and that a raw gas and / or a reactant gas can be introduced into each space of the chamber through each gas-introduction means to carry out either the adsorption or reaction step for allowing the raw gas to react with the reactant gas. The apparatus permits the independent establishment of process conditions for the adsorption and reaction processes and the better acceleration of the reaction between raw and reactant gases to give a film having excellent quality and the apparatus can be manufactured at a low cost.

Owner:ULVAC INC

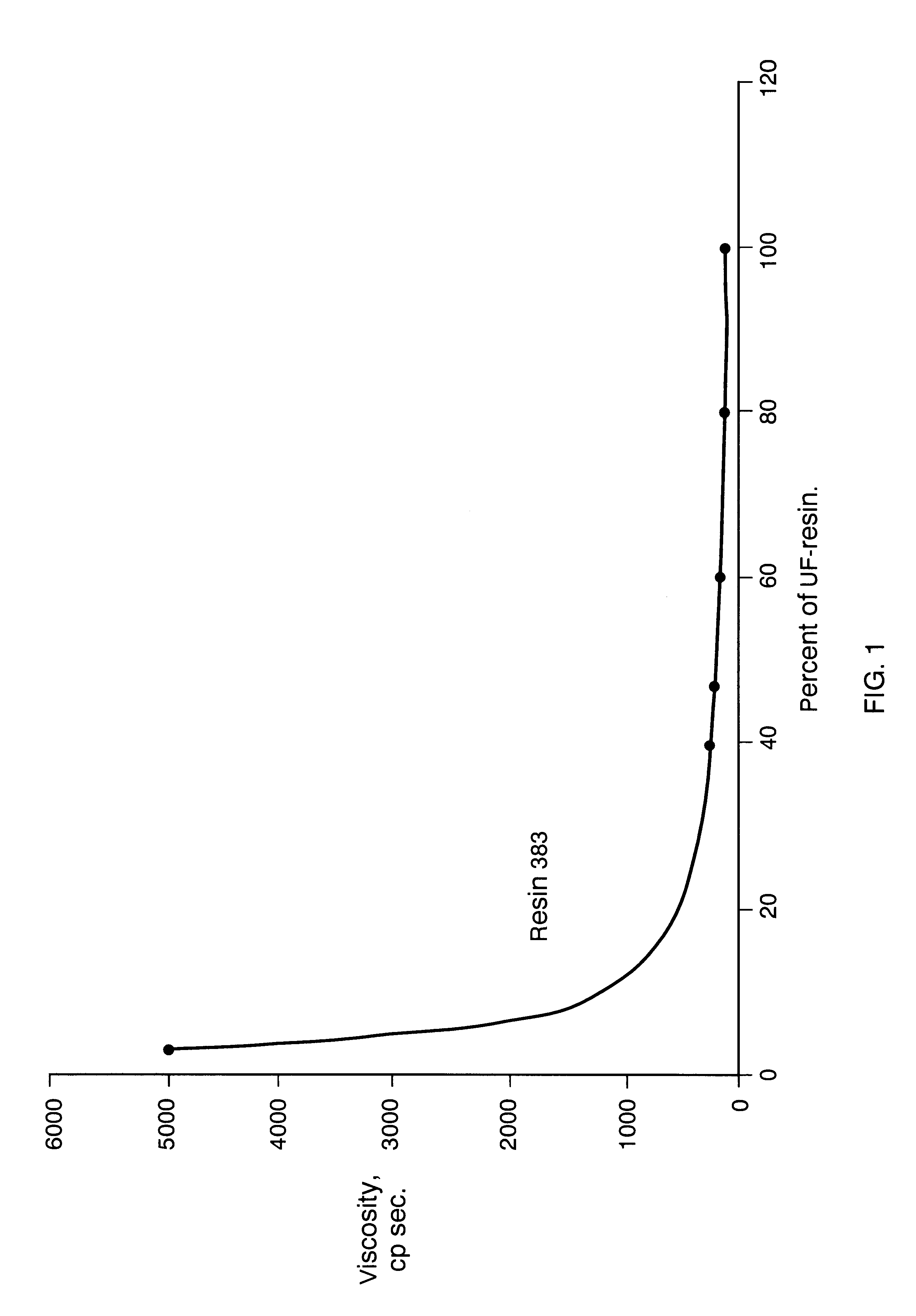

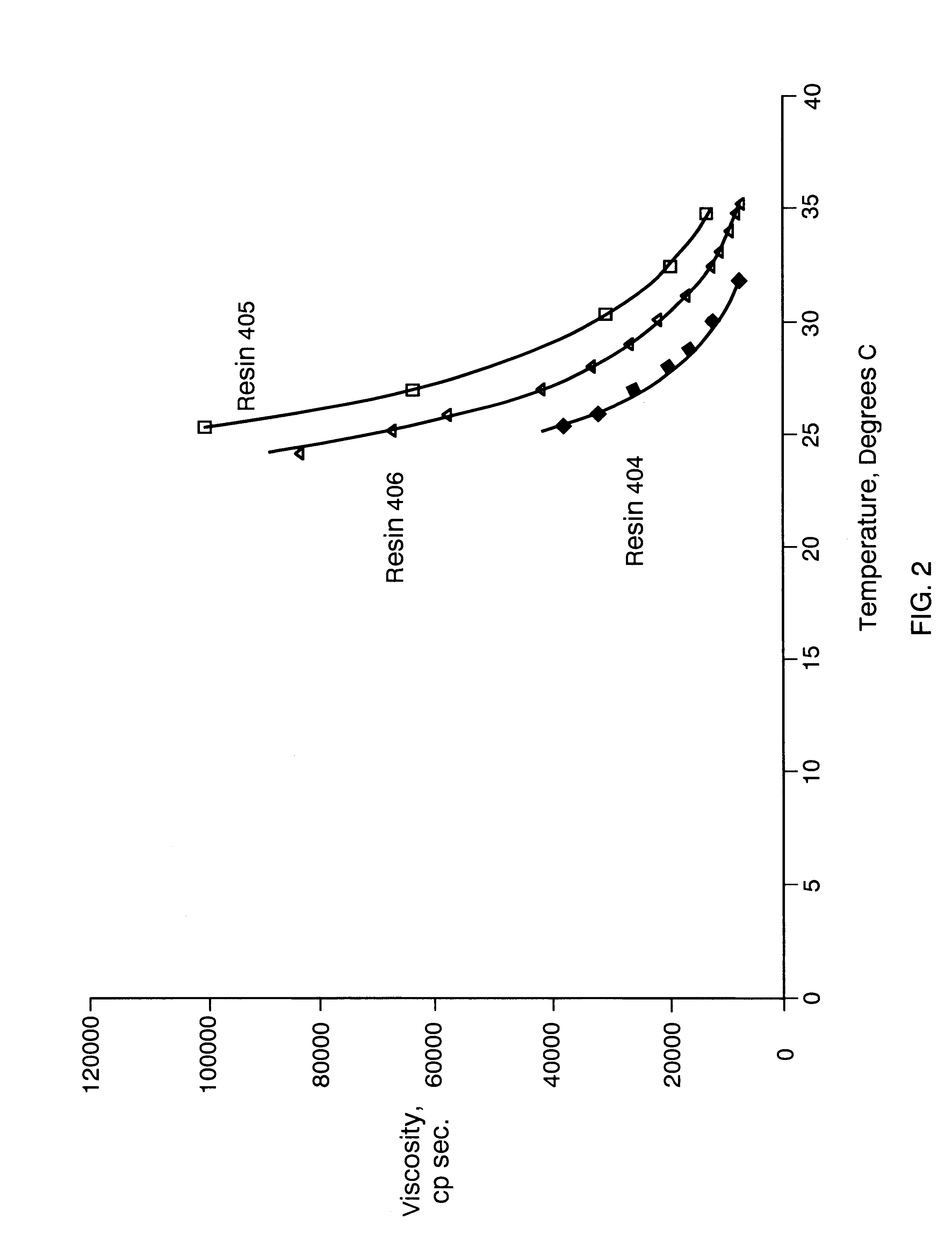

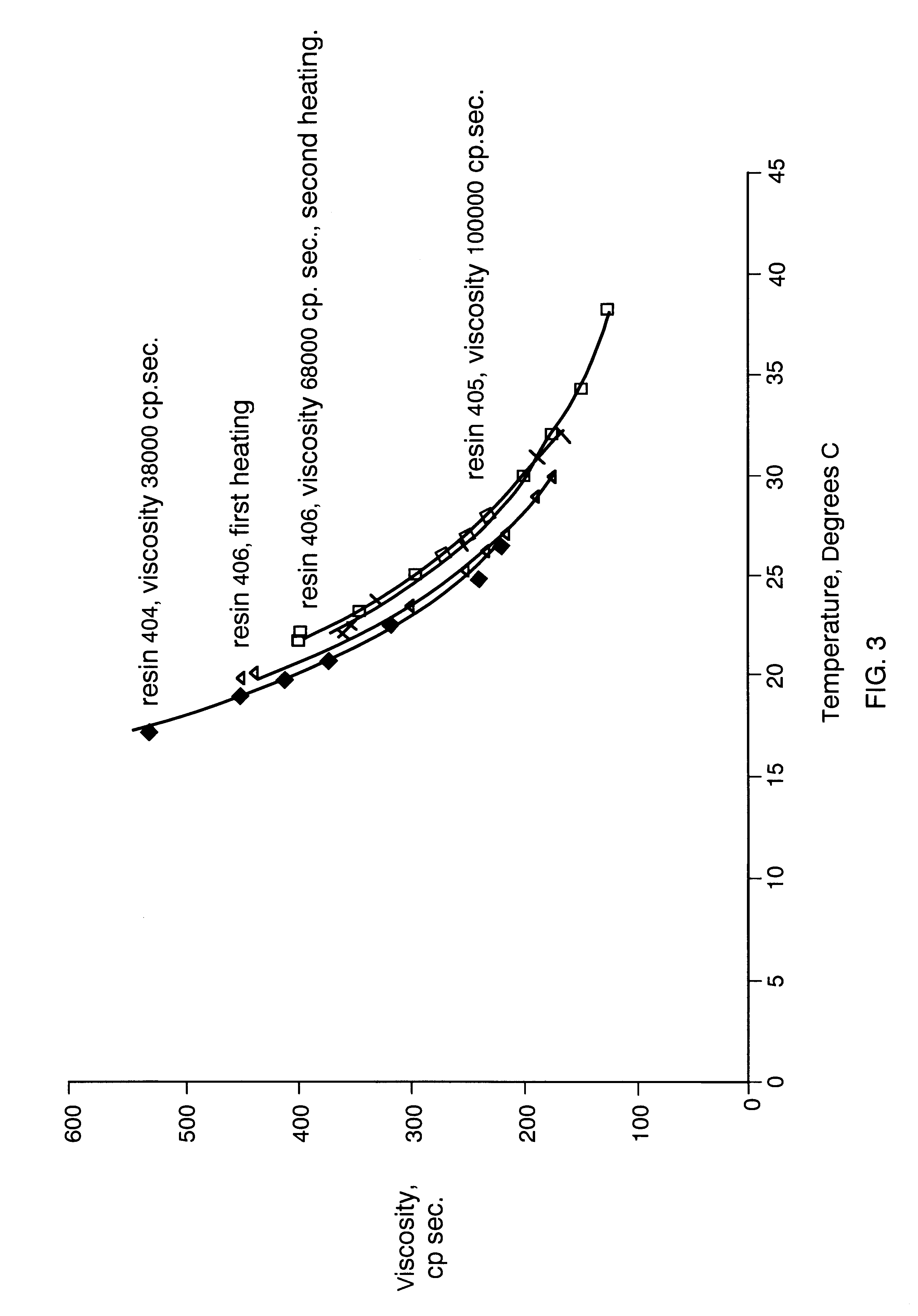

Composition board binding material

InactiveUS6291558B1Good dispersibilityImprove stabilityInksLignin derivativesLignosulfonatesReaction step

This invention features a graft copolymer of lignosulfonates reacted with an unsaturated carbonyl compound and an aldehyde, in two separate reaction steps. The resin can be used as a substitute for a majority of pure urea formaldehyde resin in the manufacture of composite board products. The resin can also be introduced directly into the urea formaldehyde resin production process.

Owner:CELLUTECH

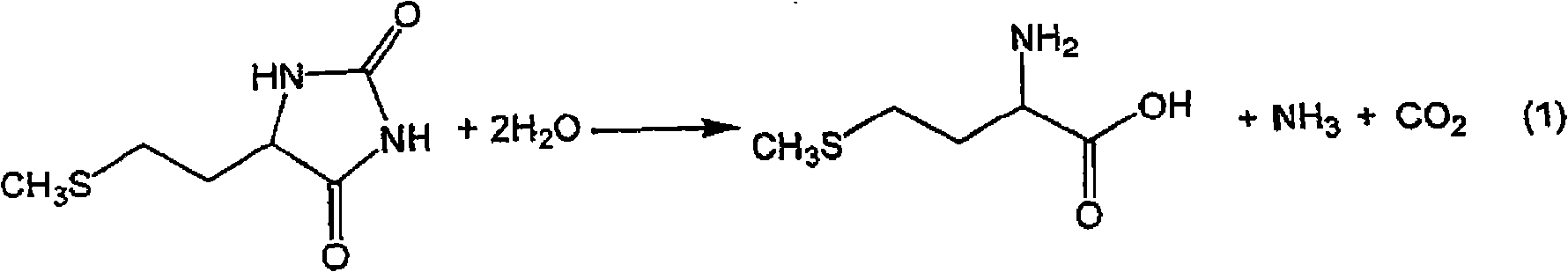

Process for producing methionine

InactiveCN101602700AEfficient recyclingEfficient productionOrganic compound preparationSulfide preparationPotassiumSlurry

The present invention provides a process for producing methionine which is advantageous from the viewpoints of cost and wastewater disposal, and which comprises the following steps (1) to (5): (1) a reaction step comprising hydrolysis of 5-[2-(methylthio)ethyl]imidazolidine-2,4-dione in the presence of a basic potassium compound; (2) a first crystallization step comprising introduction of carbon dioxide into the reaction solution obtained in step (1) to precipitate methionine, and separation of the resultant slurry into a precipitate and a mother liquor; (3) a second crystallization step comprising concentration of the mother liquor obtained in step (2), mixing with a lower alcohol, introduction of carbon dioxide into the mixture to precipitate methionine and potassium hydrogen carbonate, and separation of the resultant slurry into a precipitate and a mother liquor; (4) a heating step comprising concentration of the mother liquor obtained in step (3) followed by a heating treatment at 150 to 200 DEG C; and (5) a third crystallization step comprising introduction of carbon dioxide into the heated mother liquor obtained in step (4) to precipitate methionine and potassium hydrogen carbonate, and separation of the resultant slurry into a precipitate and a mother liquor.

Owner:SUMITOMO CHEM CO LTD

Diblock copolymer containing full-fluorine cyclobutyl aryl aether block and uses thereof

InactiveCN101492520AThe synthesis method is simpleMixingPharmaceutical non-active ingredientsMethacrylateAtom-transfer radical-polymerization

The invention provides a bi-block polymer containing perfluorocyclobutyl aryl ether-based polymer, a preparation method thereof and application thereof. The preparation method comprises two reaction steps: firstly, a macroinitiator formed through atom transfer radical polymerization is prepared; and then the macroinitiator is used for initiating an acrylic ester monomer and a metacrylic acid ester monomer, which contain perfluorocyclobutyl aryl ether structures, to carry out the atom transfer radical polymerization, thus obtaining the diblock polymer containing the perfluorocyclobutyl aryl ether-based polymer. The obtained diblock polymer can be used for preparing an aggregate with microscopic shape and can be potentially applied to such fields as a pollution-resistant reagent, a surfactant, an emulsifier, a drug carrier, photoconductive materials, photonic crystals, etc.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

Magnetic bead-based sample treatment and nucleic acid automatic extraction system

InactiveCN104232469AImplement automatic removalEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsSiphonPeriodic alternating

The invention discloses a magnetic bead-based sample treatment and nucleic acid automatic extraction system, comprising a micro-fluidic chip and a micro motor drive device, wherein the micro-fluidic chip comprises a layer of cover plate, two layers of bottom plates and two layers of structure plates, wherein the chip can automatically finish the operation processes such as cell lysis, nucleic acid purification, nucleic acid eluting and the like, and finally a nucleic acid sample is obtained. Based on siphon principle or micro-fluidic surface tension properties, a driven drive pump without external drive force is designed by the chip, so as to achieve flowing and transferring of a detection sample, a reaction reagent and reaction liquid waste. Under mixed hardening of a micro vibration motor, through a periodic alternating magnetic field and a constant magnetic field provided by an external magnet, effective mixing between the magnetic bead and the reaction sample and the reaction reagent in a reaction cavity, and fixing of the magnetic bead in the liquid waste discharge process are achieved; and the chip is matched with a full-automatic micro motor drive device to automatically finish a plurality of reaction steps, so that a high-purity nucleic acid sample template is provided for gene amplification reaction.

Owner:BEIJING UNIV OF CHEM TECH +1

Process for producing acetic acid

ActiveUS20130261334A1Increase concentrationEfficient executionOrganic compound preparationOrganic chemistry methodsIodideDistillation

A process for producing acetic acid by: a reaction step for continuously allowing methanol to react with carbon monoxide in the presence of a catalyst system comprising a metal catalyst, an ionic iodide, and methyl iodide in a carbonylation reactor, a flash distillation step for continuously feeding a flasher with a reaction mixture from the reactor and evaporating a volatile component at least containing product acetic acid, methyl acetate, and methyl iodide by flash distillation to separate the volatile component and a liquid catalyst mixture at least containing the metal catalyst and the ionic iodide, and an acetic acid collection step for separating a stream containing acetic acid from the volatile component to collect acetic acid; wherein, in the flash distillation step, the flash distillation is conducted under the condition that the concentration of methyl acetate in the liquid catalyst mixture is not less than 0.6% by weight.

Owner:DAICEL CHEM IND LTD

Separator, reactor, and method for producing aromatic carboxylic acids

InactiveUS20070213557A1Reduce lossesReduce system sizeOrganic compound preparationDistillation regulation/controlAcetic acidCarboxylic acid

In a process for producing an aromatic carboxylic acid, it is a dehydrating process which can achieve compactification of a step for removing water from a mixture of acetic acid and water produced in the production process, and which can reduce the consumed energy. In a production process of an aromatic carboxylic acid having an oxidation reaction step for producing a slurry of an aromatic carboxylic acid by carrying out liquid-phase oxidation reaction of an alkyl aromatic compound with an oxygen-containing gas in a solvent containing acetic acid in the presence of an oxidation catalyst, at least a portion of a mixture containing acetic acid and water produced in the production steps is separated into a permeable gas mainly comprising water and nonpermeable substances mainly comprising acetic acid, using a separation membrane having water selectivity.

Owner:SEIKI YOSHIO +7

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS7964761B2Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productDepolymerization

Owner:UNIV OF UTAH RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com