Patents

Literature

74results about How to "Novel process route" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

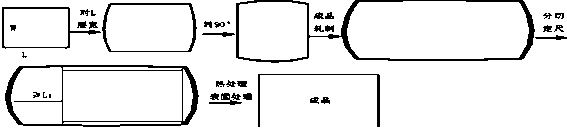

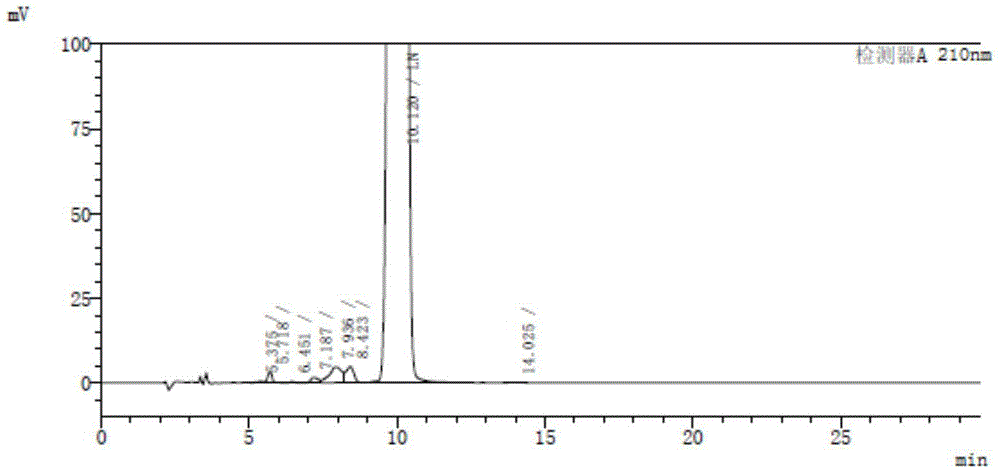

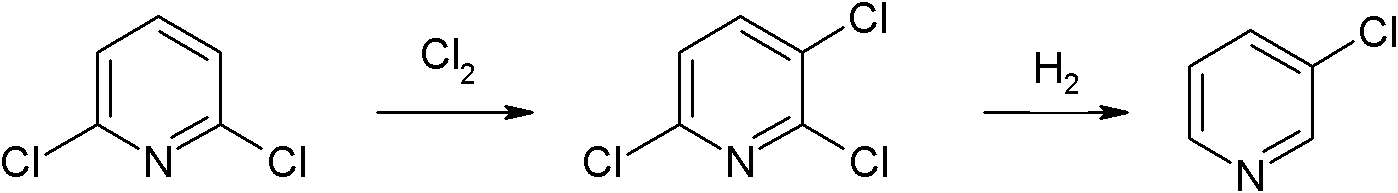

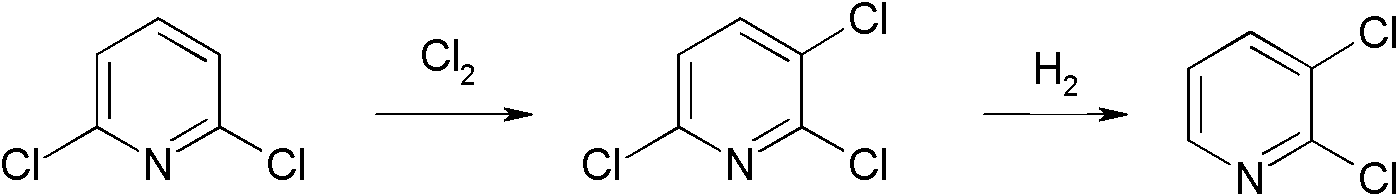

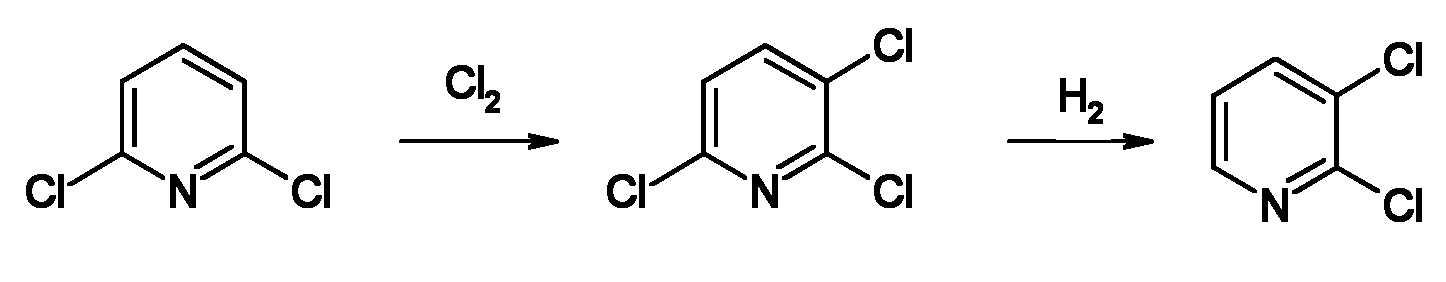

Preparation method of 2,3-dichloropyridine

ActiveCN102153507ANovel process routeReduce manufacturing costOrganic chemistryOrganic solventMetal catalyst

The invention discloses a preparation method of 2,3-dichloropyridine. 2,3-dichloropyridine is an intermediate in fine chemical industry, which is widely used in the fields of medicine and pesticide. The method comprises the following steps: carrying out chlorination reaction on 2,6-dichloropyridine, which is used as a raw material, to obtain 2,3,6-trichloropyridine; adding the 2,3,6-trichloropyridine, an acid binding agent, a metal catalyst and an organic solvent into a reactor, and carrying out hydrogenation reaction, wherein the mol ratio of 2,3,6-trichloropyridine to acid binding agent is 1:(0.1-0.5); and cooling the hydrogenation reaction liquid, adding water to dissolve the acid binding agent hydrochloride, filtering, standing, separating out the water layer, extracting the organic solvent layer with water-containing acid at least three times, merging the water-containing acid layers after extraction, diluting by adding water, precipitating a solid, filtering, and drying to obtain the 2,3-dichloropyridine product. The invention has the advantages of novel process route, short reaction steps, high yield, low production cost and environmental friendliness, is simple to operate, and is suitable for industrial production.

Owner:LIANHE CHEM TECH +1

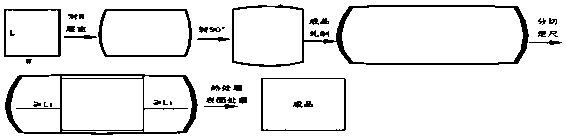

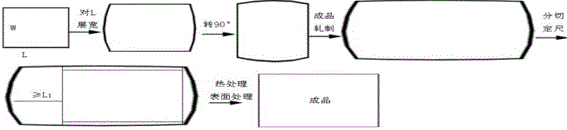

Process method of producing high-grade TC4 alloy hot rolled plate with high material-obtaining rate and low cost

ActiveCN103045906ANovel process routeGood product performanceMetal rolling arrangementsHot rolledAtmosphere

The invention presents a process method of producing a high-grade TC4 alloy hot rolled plate with a high material-obtaining rate and low cost, which comprises the following steps: slab ingot preparation through an EB, grinding, heat rolling, atmosphere annealing, sand blasting, pickling, grinding and sizing to obtain an annealed TC4 hot rolled plate, wherein a coloring and inspection technology is applied for the surface detection of a cogging bland and for the surface quality detection of a fire rolling blank. According to the invention, the EB is adopted to smelt and roll blank; the material-obtaining rate from the raw materials to slabs is improved to 92 percent, and the material-obtaining rate from the raw materials to finished products is improved to 69-73.6 percent; cracks are ensured to be removed completely, so as to achieve the purpose of no grinding or less grinding in follow-up rolling, and accordingly the labor and material cost for grinding is greatly reduced; and the prepared plate has the tensile strength of 950-1100 MPa, the yield strength of 880-980 MPa, and the elongation percentage among 14-20 percent, and meets the standard requirements of GB / T3621-2007, GT / B14845-2007 and ASTMB265-2006.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

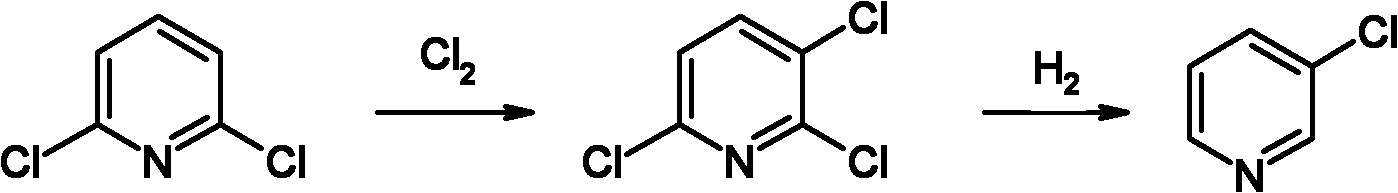

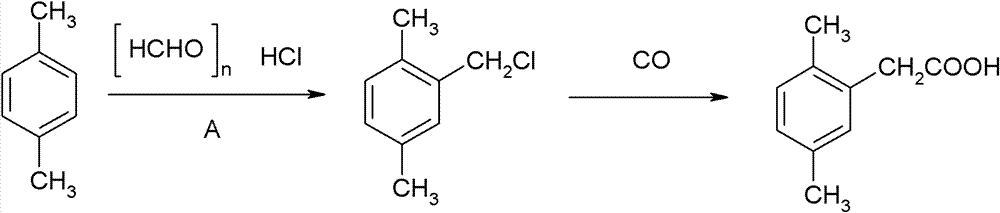

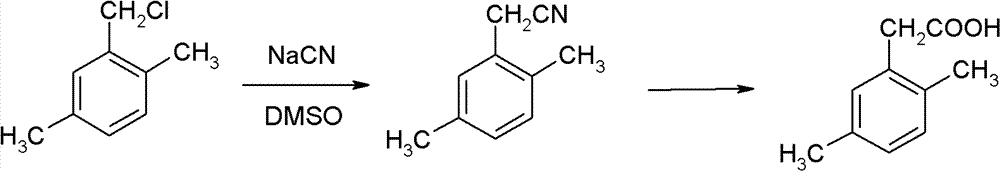

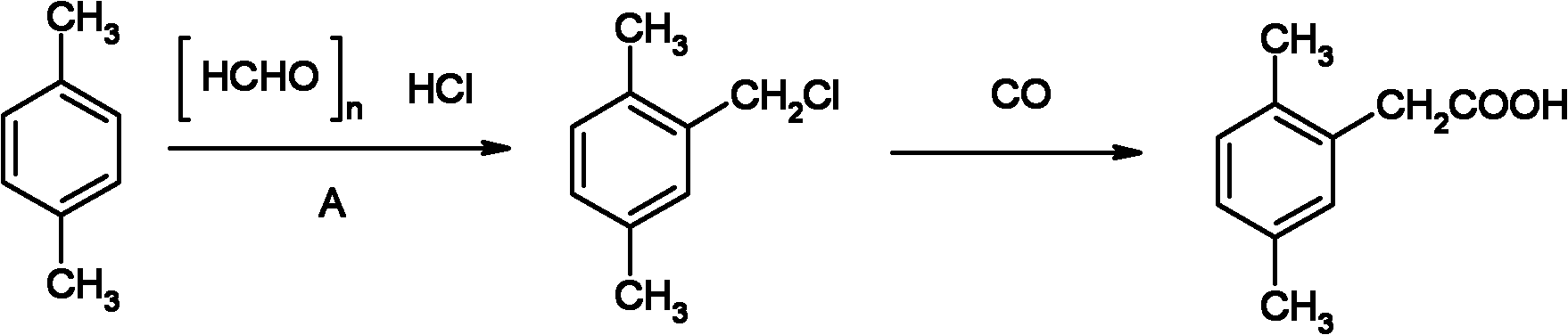

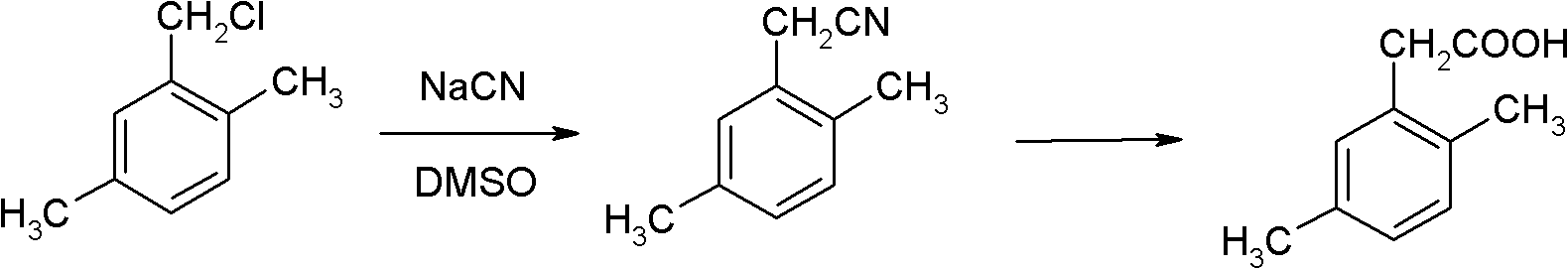

Method for preparing 2,5-dimethyl phenylacetic acid

ActiveCN102140062ANovel process routeReasonable process conditionsCarboxylic preparation from carbon monoxide reactionHalogenated hydrocarbon preparationSolventBenzyl chloride

The invention discloses a method for preparing 2,5-dimethyl phenylacetic acid. The 2,5-dimethyl phenylacetic acid is a fine chemical engineering intermediate which is widely applied in fields of medicines and pesticides, and particularly is a key intermediate of spirotetramat serving as a novel insecticide. The method comprises the following steps of: mixing paraxylene serving as a raw material and ionic liquid serving as solvent with paraformaldehyde and concentrated hydrochloric acid, and performing a chloromethylation reaction to obtain 2, 5-dimethyl benzyl chloride; and performing a carbonylation reaction and a hydrolysis reaction of the 2, 5-dimethyl benzyl chloride and an acid-binding agent and the solvent in a reactor under the action of a catalyst to obtain the 2,5-dimethyl phenylacetic acid. The method has a novel process, short synthetic reaction steps, simplicity of operation, low production cost, high reaction yield, and environmental friendliness, and is suitable for industrial production.

Owner:LIANHE CHEM TECH +1

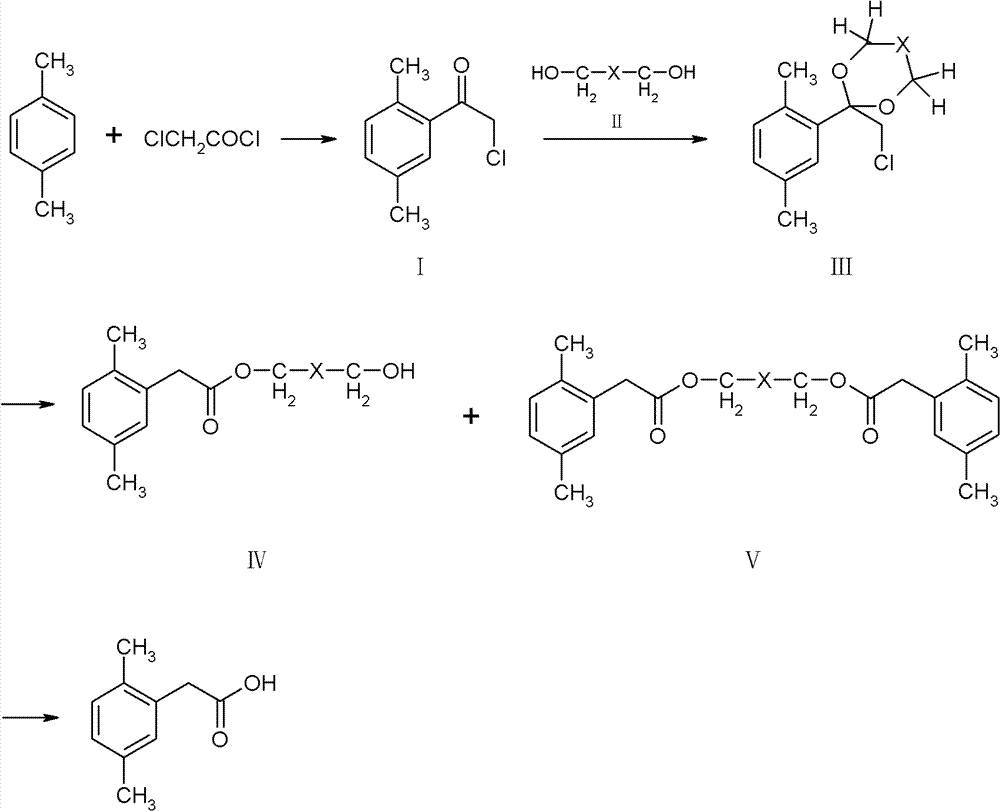

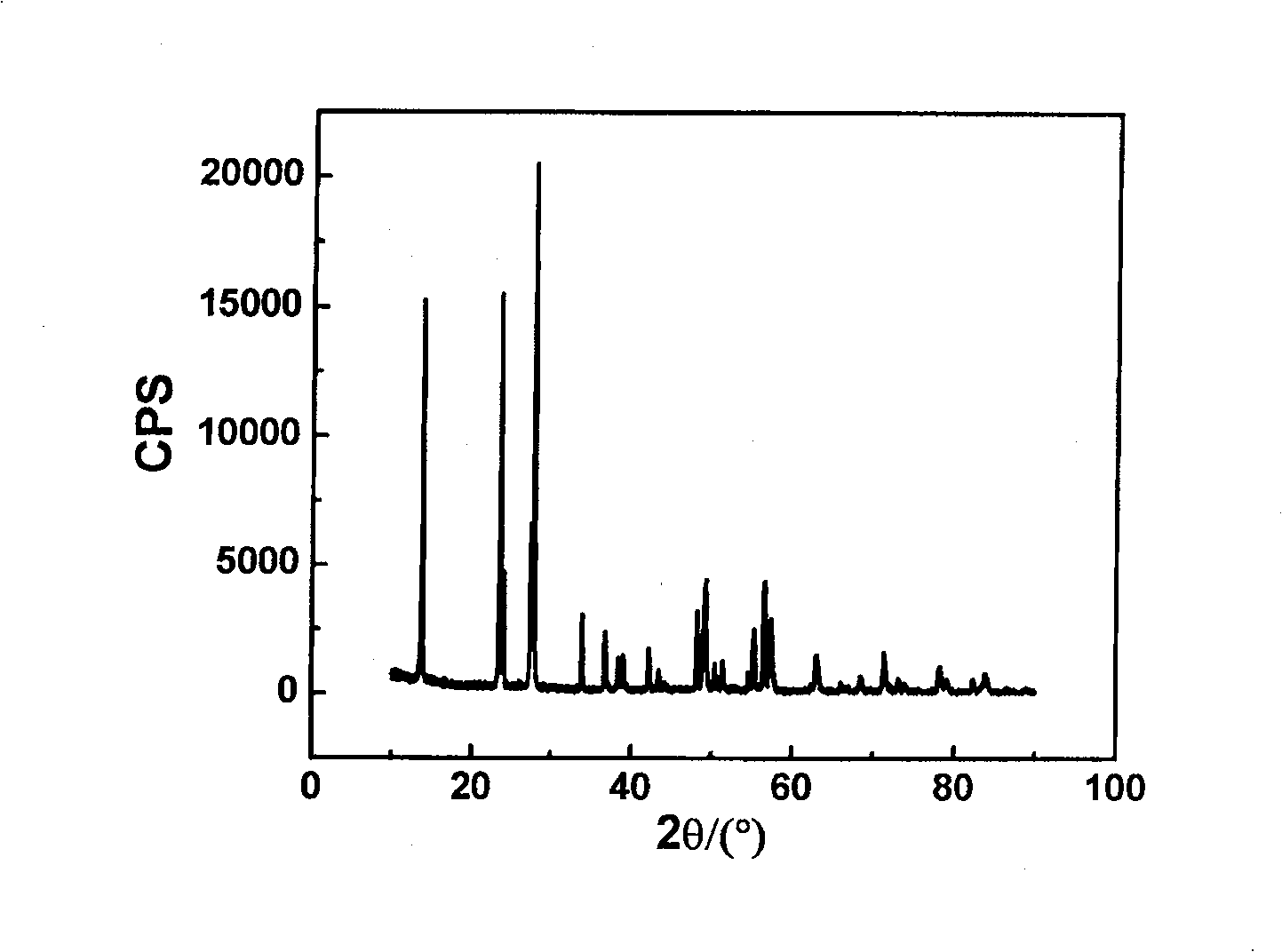

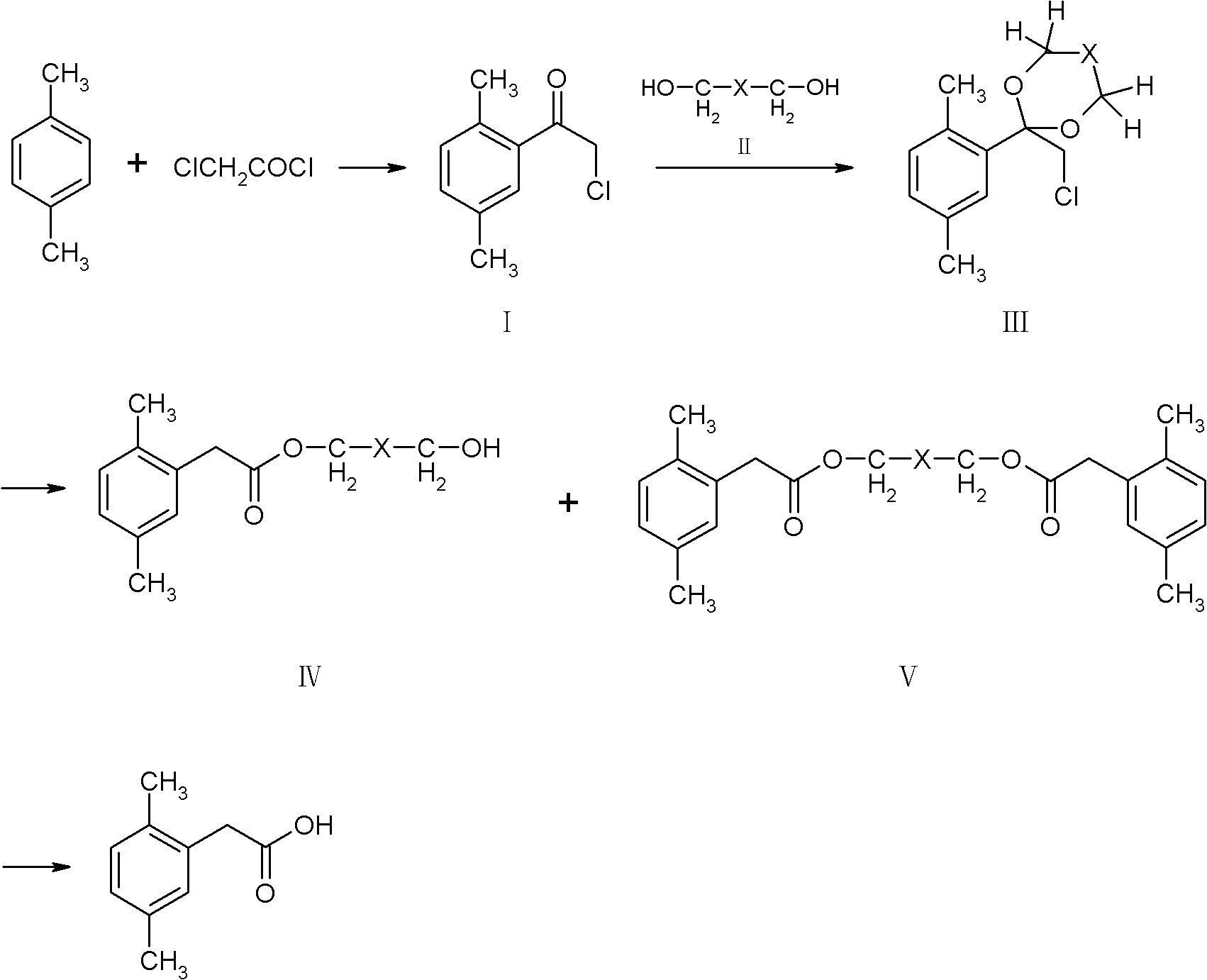

Ferric fluoride nano material and preparation method thereof

The invention discloses a ferric fluoride nano material and a preparation method thereof. The preparation method comprises the following steps of: dissolving inorganic ferric salt in an alcohol solvent to obtain alcohol solution containing iron; dispersing an inorganic fluorine source into the alcohol solution containing iron and adding the solution into a hydrothermal reaction kettle; carrying out the hydrothermal reaction kettle solution for 1 hour to 7 days at a temperature of 40 to 140 DEG C, naturally cooling, carrying out centrifugal separation, washing by ethanol and carrying out vacuum drying to obtain the ferric fluoride nano material. According to the preparation method of ferric fluoride, a volatile hydrofluoric acid fluorine source does not need to be used as a raw material, low-toxicity fluoride is used as the fluorine source, common ferric salt is used as a ferric source, the FeF3.0.33H2O nano material containing trace moisture is obtained by the simple solvent heat treatment, the preparation process is simple, the yield is high and the obtained material has high crystallinity. The method disclosed by the invention is a novel and practical process route for preparing the ferric fluoride nano material and has high actual application value.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

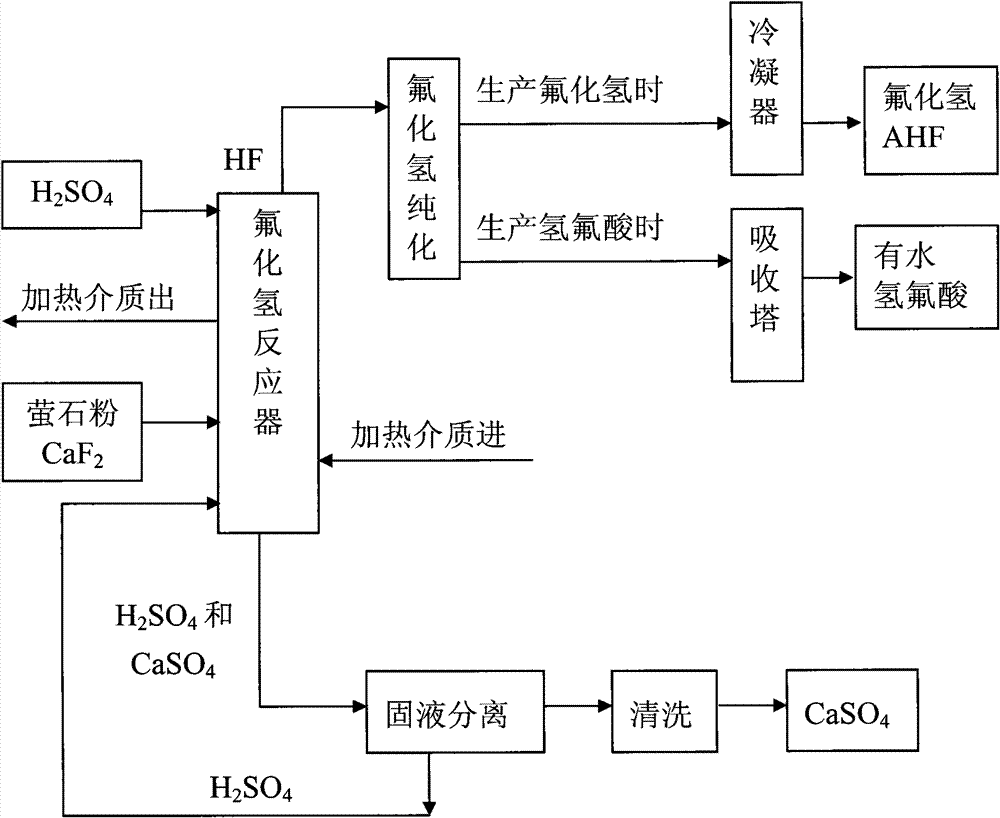

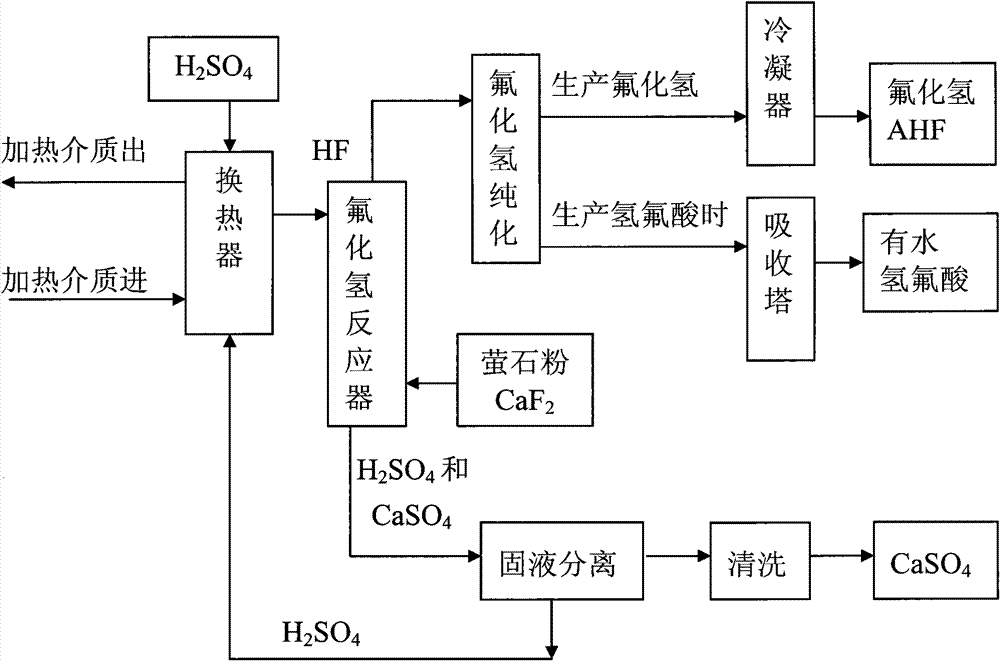

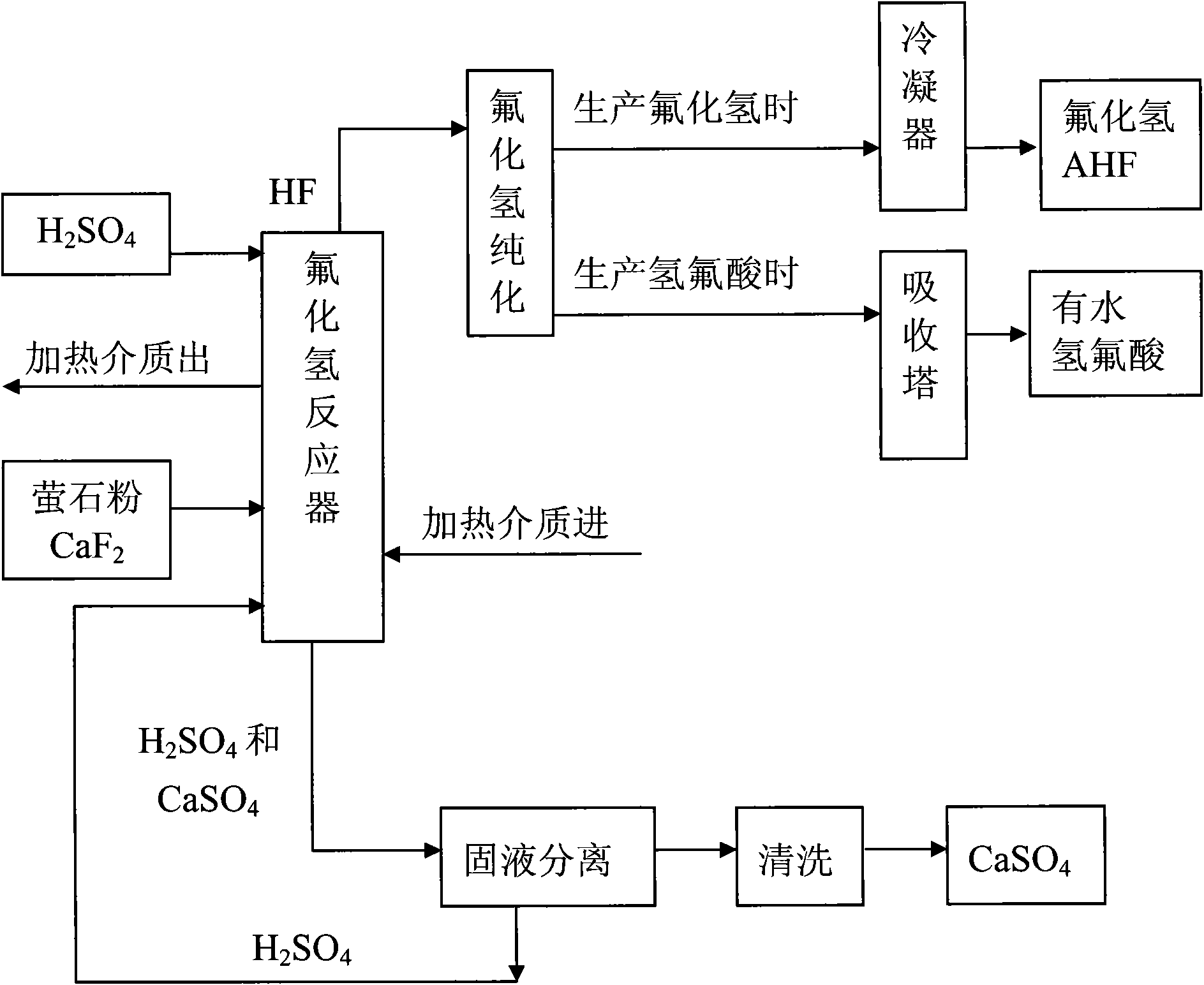

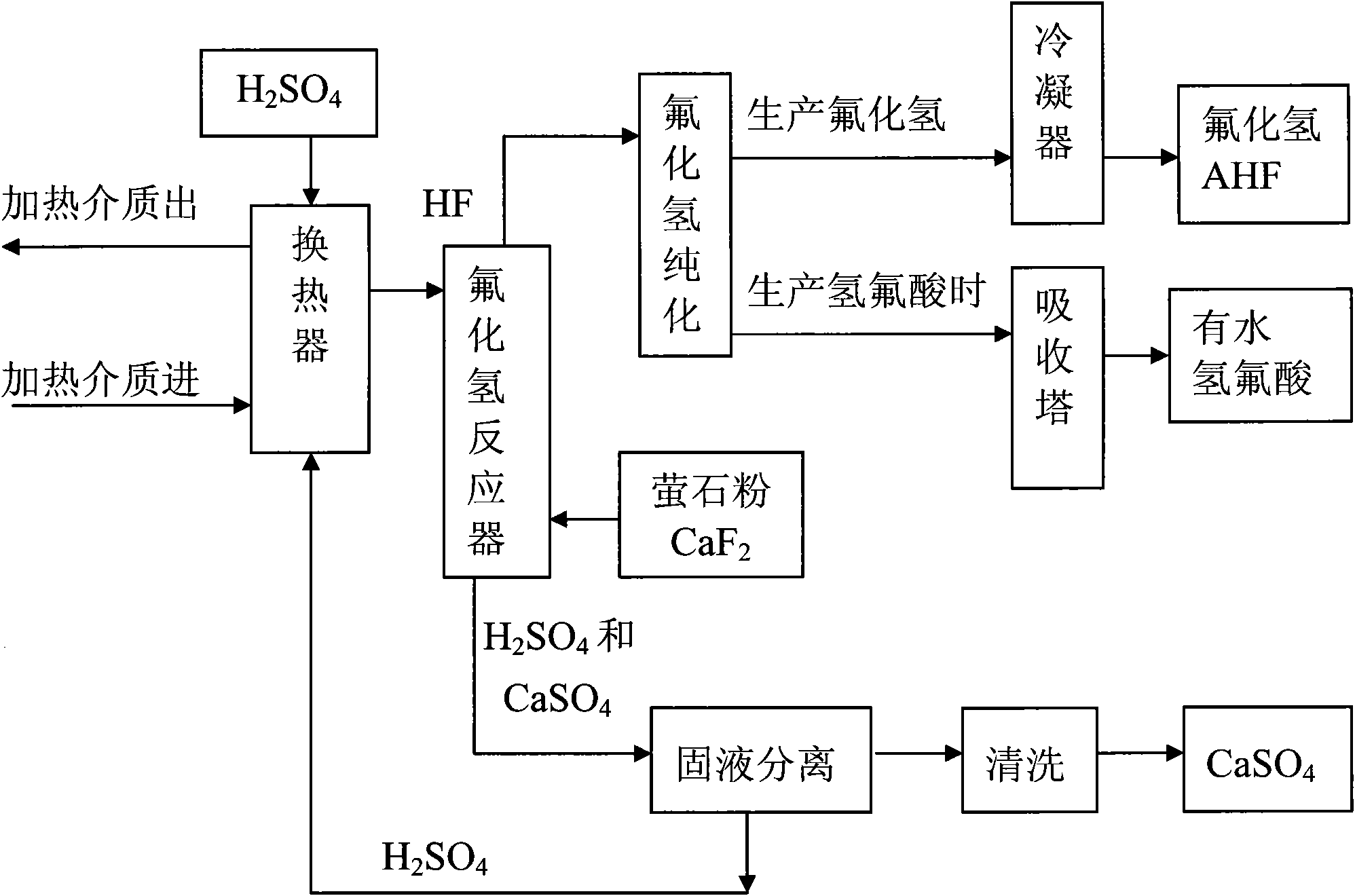

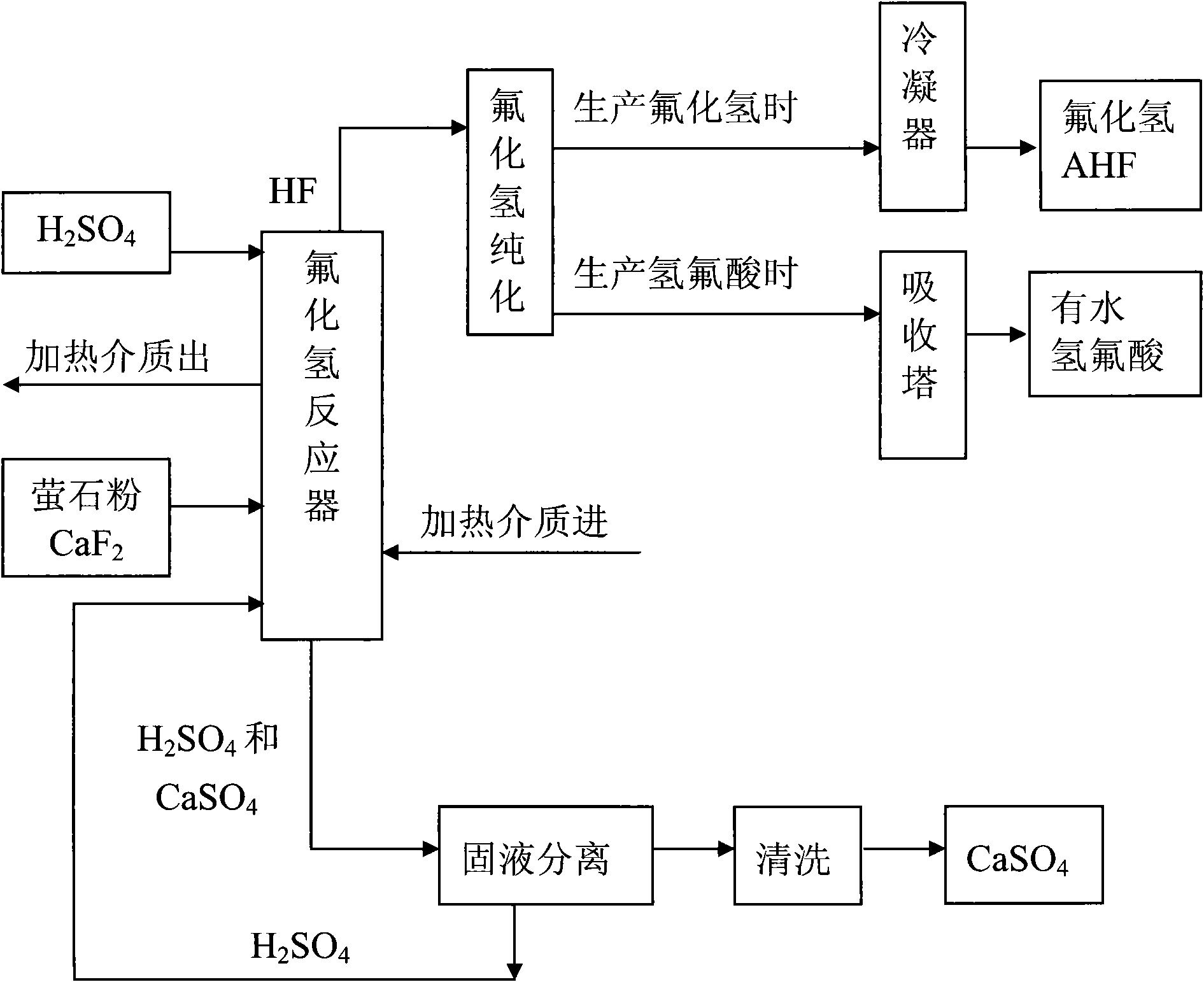

Method for preparing hydrogen fluoride from flousper powder and sulfuric acid

ActiveCN101913565ANovel process routeEasy to operateCalcium/strontium/barium sulfatesFluorine/hydrogen-fluorideHydrofluoric acidHydrogen fluoride

The invention discloses a method for preparing hydrogen fluoride from flousper powder and sulfuric acid. The method comprises the following specific steps of: adding solution of sulfuric acid and the flousper powder into a reactor with a stirrer respectively, wherein the molar ratio of calcium fluoride to the sulfuric acid is 1:3-1:30, the granularity of the flousper powder is 280 to 1,220 meshes, and the reaction temperature is controlled to between 90 and 300 DEG C; generating hydrogen fluoride gas and calcium sulfate solid after the reaction; purifying, condensing and rectifying the hydrogen fluoride gas to obtain anhydrous hydrogen fluoride, or purifying and absorbing the hydrogen fluoride gas to obtain hydrofluoric acid; transferring the calcium sulfate solid and the sulfuric acid toa filtering system from the reactor to perform solid-liquid separation; returning the separated solution of sulfuric acid to the reactor; and washing and drying the calcium sulfate solid separated from the sulfuric acid to form a by-product. The method has the advantages of simple equipment, high reaction efficiency, low cost and easy industrialized production.

Owner:衢州市鼎盛化工科技有限公司

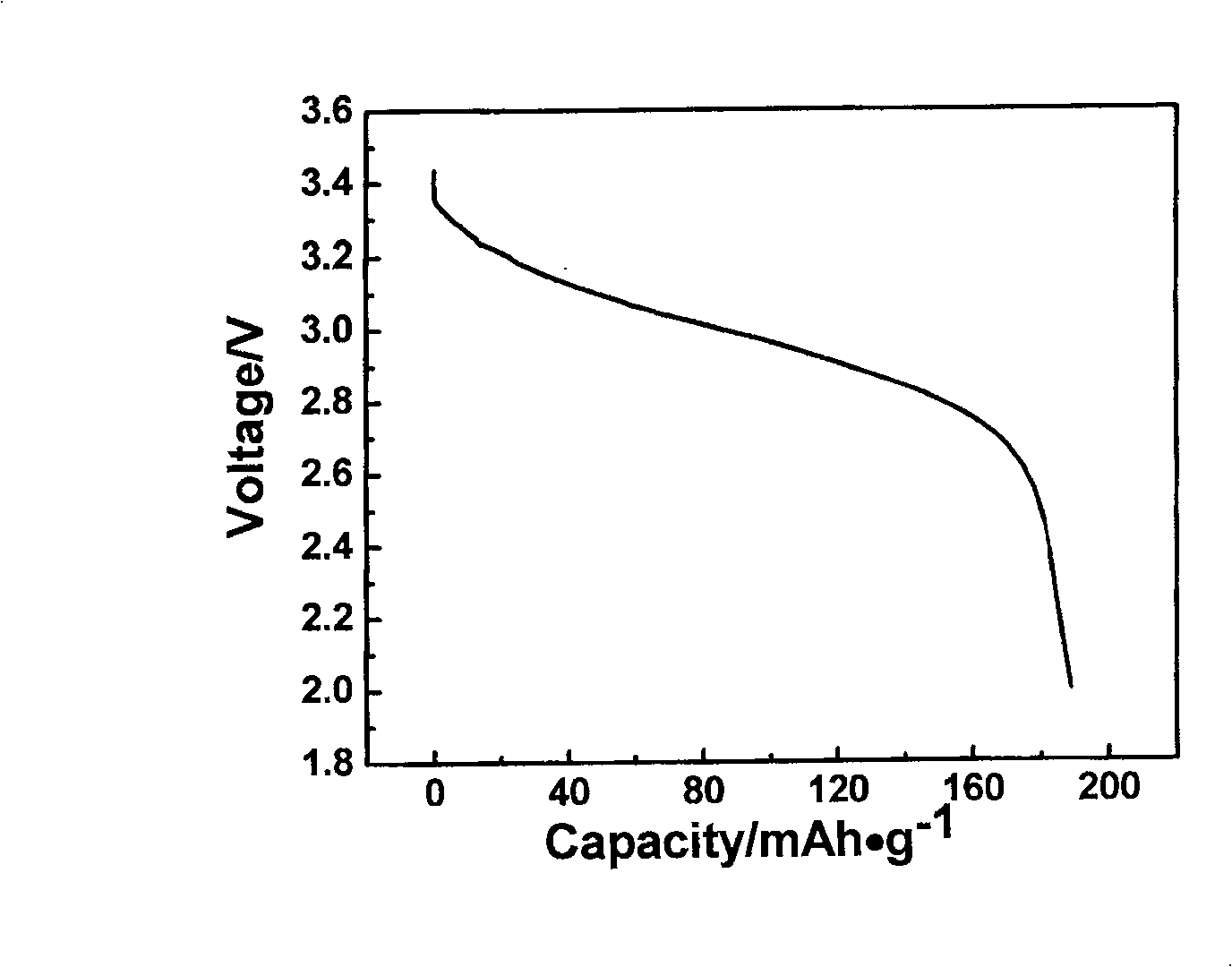

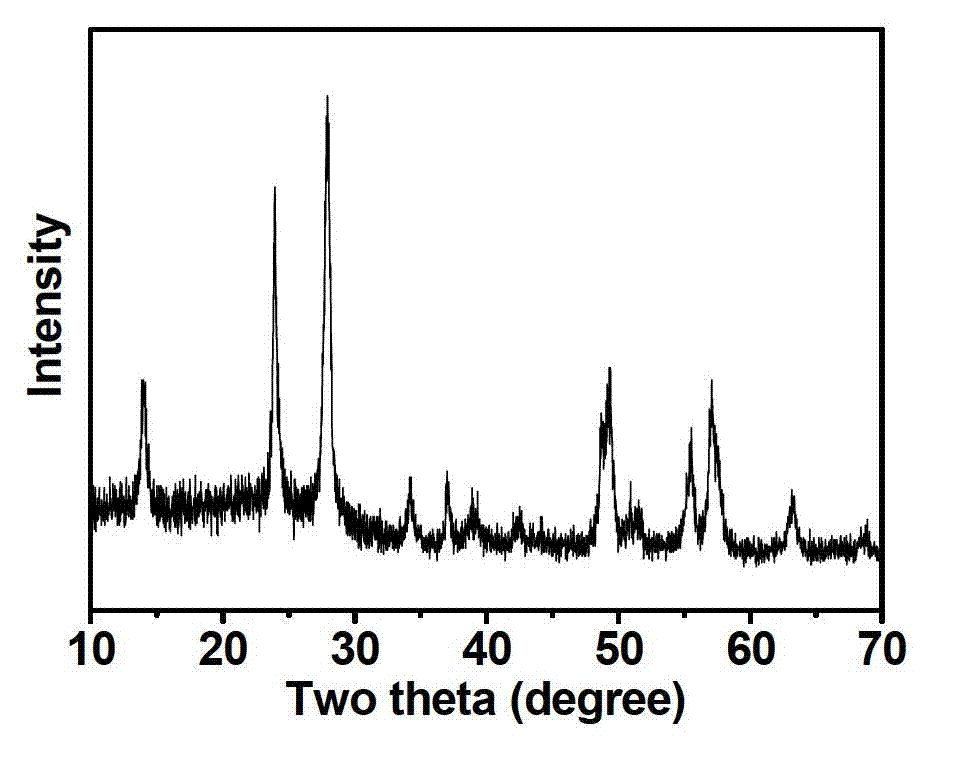

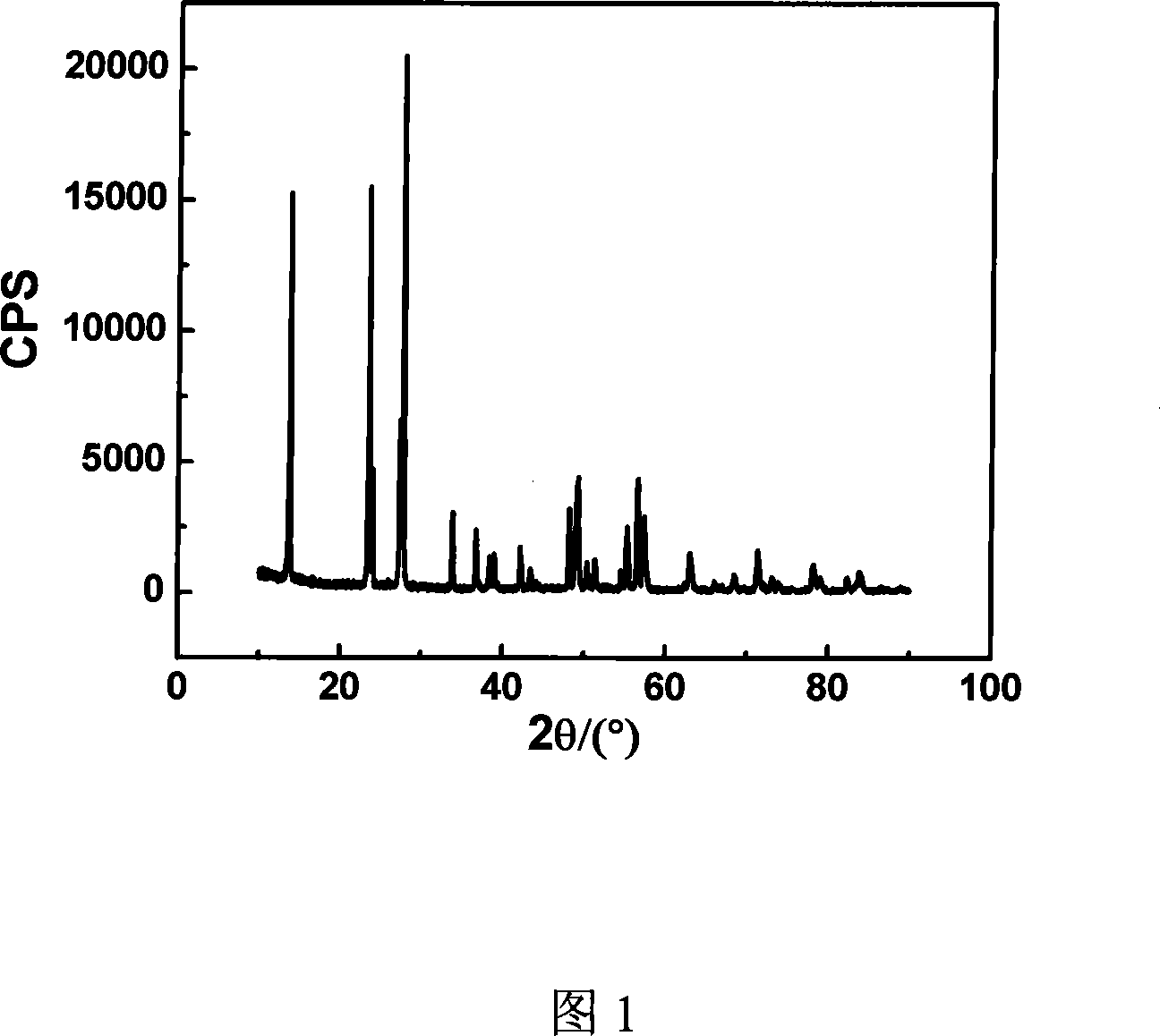

Production method of lithium secondary battery drop water ferric fluoride anode material

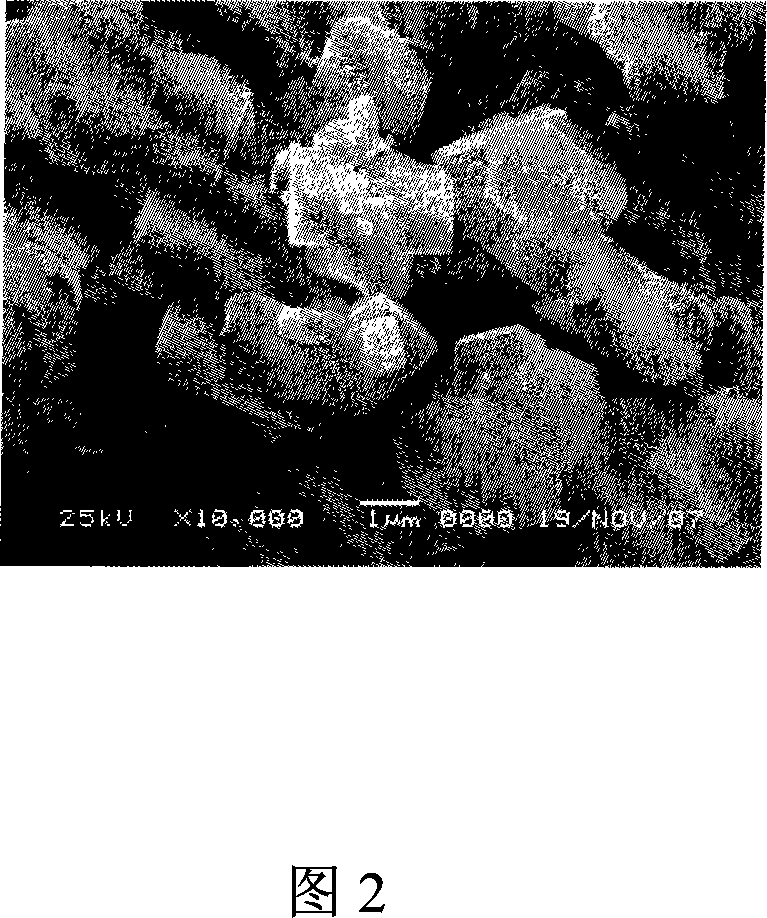

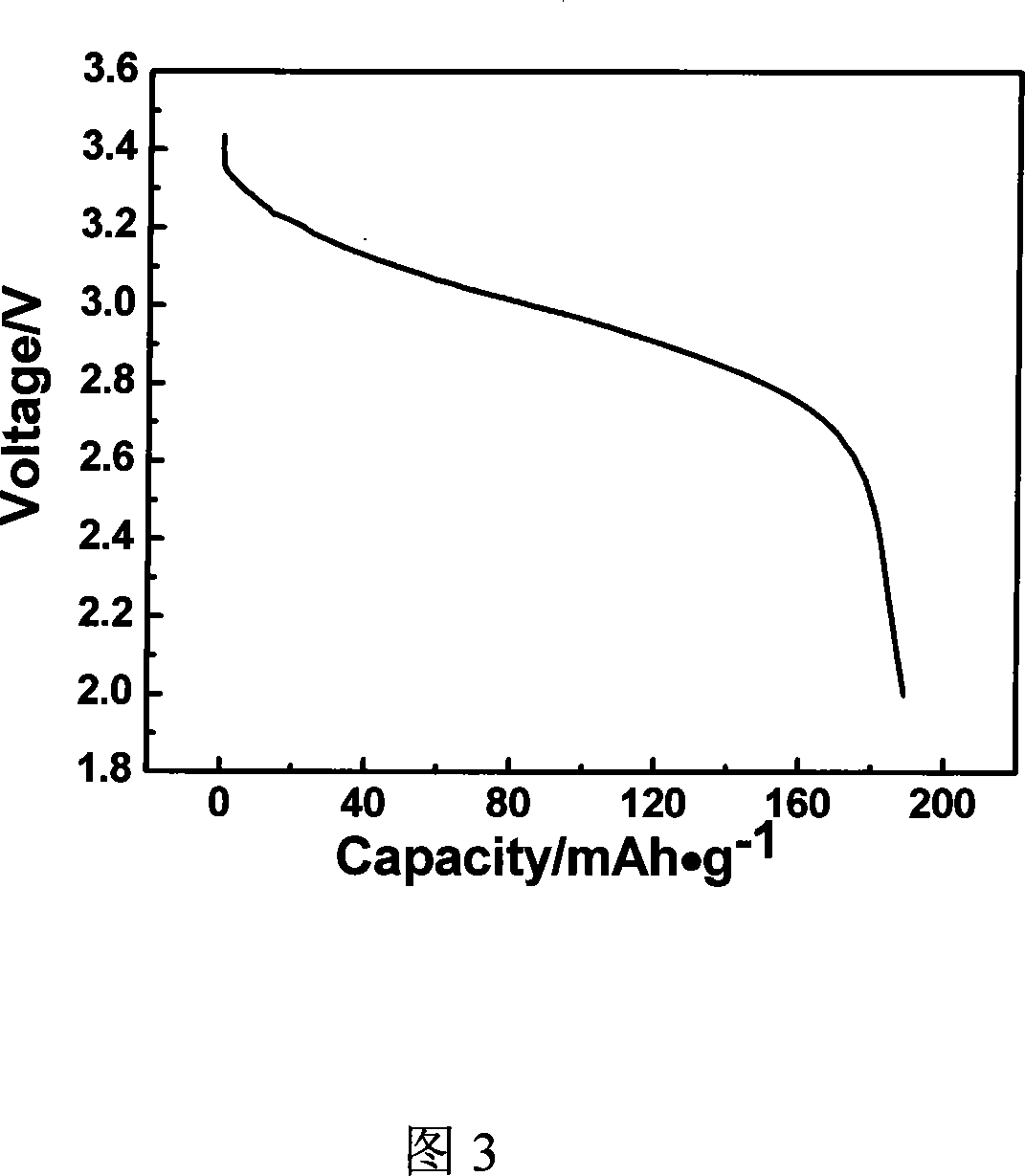

InactiveCN101222037AHigh yieldSurface Topography RulesElectrode manufacturing processesFluoride preparationAutomatic controlChemistry

The invention discloses a preparation method for lithium secondary battery micro water ferric fluoride anode materials, wherein, firstly, teracidic malysite and alkali are uniformly mixed in an aqueous solution under normal temperature in proportion from 1 to 1 - 1 to 10; water is removed after sucking filtration; iron-alkali mixture is obtained after drying for 1 to 48 hours; secondly, the iron-alkali mixture and 5 to 40 percent hydrofluoric acids are uniformly reacted in a plastic sealed container in proportion from 1 to 1 - 1 to 10, and heat preservation is performed for 1 to 48 hours under the temperature of 40 to 100 DEG C; thirdly, mixture is filtered, cleaned by utilization of ethanol and dried for 1 to 36 hours in the air; fourthly, the mixture is dried for 1 to 72 hours under vacuum state of 50 to 250 DEG C; fifthly, the mixture is crushed in a ball mill and passes through a 100 to 400 mesh sieve, and then a ferric fluoride product is obtained. The invention has the advantages that: firstly, systematic temperature is automatically controlled, and technological parameters are determined through precise calculation on the basis; secondly, yield of the method is high and product purity is larger than 95 percent. Obtained FeF3 (H2O) 0.33 has an integrated orthorhombic system structure, regular surface topography, small grain diameter and uniform distribution, and good discharge performance. The method is a novel and practical technological line for preparation of the FeF3 (H2O) 0.33.

Owner:XIANGTAN UNIV

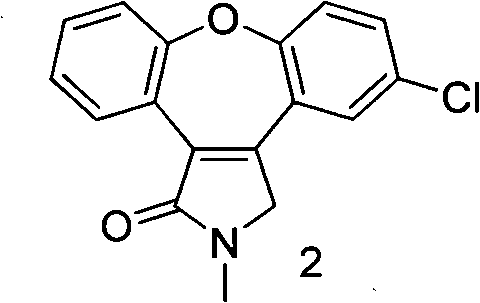

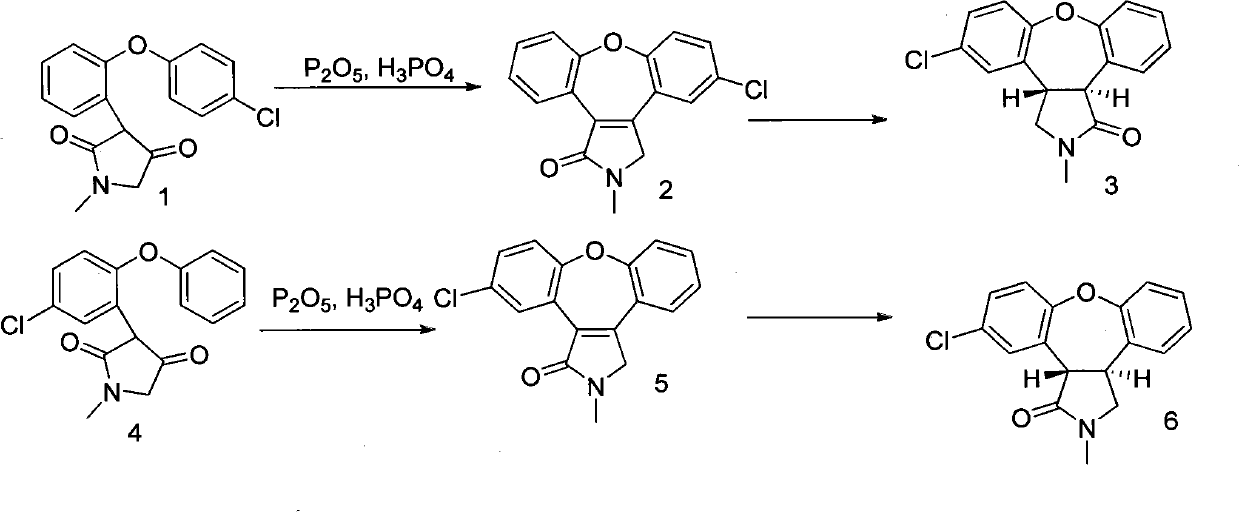

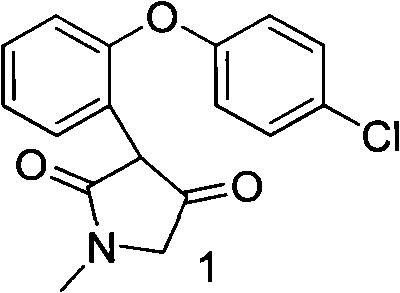

Preparation method of asenapine intermediate

ActiveCN101851242ANovel process routeReasonable process conditionsOrganic chemistryTriflic acidKetone

The invention discloses a novel preparation method of an asenapine intermediate, comprising the following steps of: carrying out cyclization in protonic acid including trifloromethanesulfonic acid by taking 3-(2-(4- chlorophenoxyl)-phenyl-4-hydroxyl-1-methyl-1H-pyrrole-2(5H)-ketone (compound 1) or 3-(5-chlorine-2-phenoxyl phenyl)-1-methyl-1H-pyrrole-2(4H)-ketone (compound 4) as a raw material to generate key intermediate compounds 2 and 4 of asenapine; and carrying out reduction reaction to obtain asenapine. The invention has the advantages of novel process route, high reaction yield and low production cost, and has greater application value and social economic effect.

Owner:SHANGHAI HAOYUAN MEDCHEMEXPRESS CO LTD

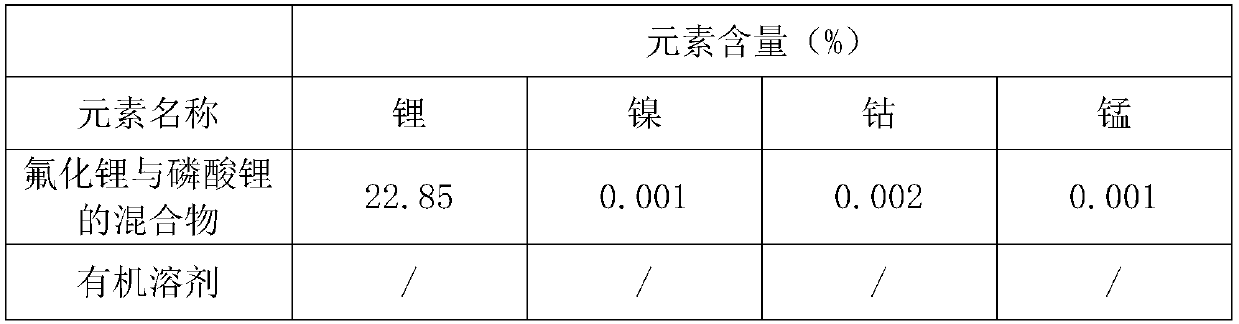

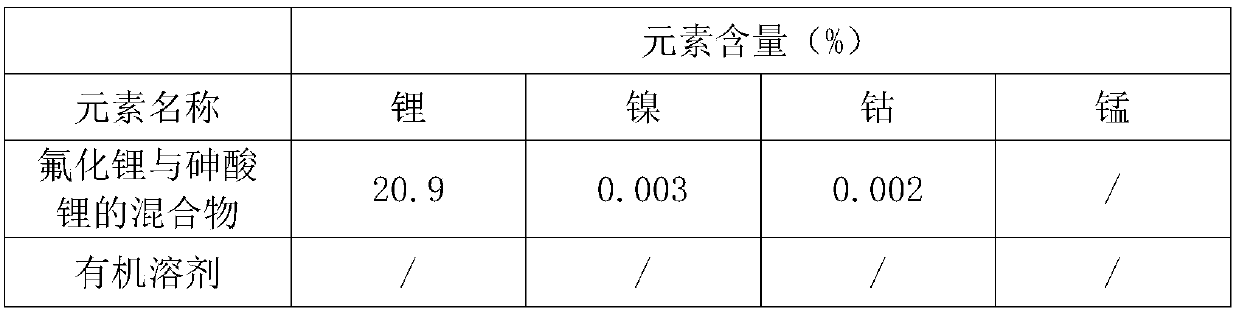

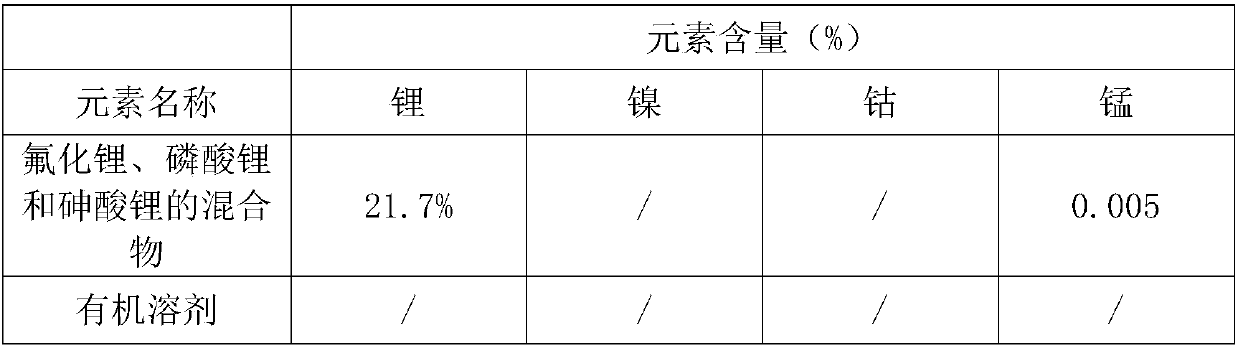

Waste lithium ion battery electrolyte solution recovery treatment method

ActiveCN109585963AAvoid secondary pollutionAchieve recyclingWaste accumulators reclaimingBattery recyclingOrganic solventLithium carbonate

The invention provides a waste lithium ion battery electrolyte solution recovery treatment method comprising freezing a waste lithium ion battery in liquid nitrogen; taking out the waste lithium ion battery and pulverizing the waste lithium ion battery by a low-temperature pulverizer to obtain a pulverized mixture; fully immersing the pulverized mixture in a container filled with a saturated lithium carbonate solution for a certain period of time according to certain proportion; successively filtering a reaction product by a coarse sieve and a fine sieve to obtain an oversized product and a filtrate; and finally separating an organic solvent and a lithium carbonate solution from the filtrate in an oil-water separation device under the effect of gravity; and collecting the organic solvent from the upper liquid outlet of the oil-water separation device, and collecting the lithium carbonate solution from the lower liquid outlet of the oil-water separation device. The method of the invention is simple in process, separates the electrolyte, the organic solvent and other components of the battery from the electrolyte solution, and is small in pollution and high in safety.

Owner:先进储能材料国家工程研究中心有限责任公司

Extracting method of gamma-polyglutamic acid

The invention discloses an extracting method of gamma-polyglutamic acid (gamma-PGA), in particular to an extracting method, which comprises the following steps: adjusting the pH value to be 3.0-5.0 with dilute acid; filtering and degermming; adding protease and lysozyme to remove protein; adding 2-3 times of volume of ethanol and precipitating; filtering and dissolving with distillated water; filtering by using an ultrafiltration membrane to remove impurities and condensing; and spraying and drying to obtain a finished product of the gamma-polyglutamic acid. The invention has the advantages of novel and simple process route, low production cost, high yield and high suitability for industrial production.

Owner:郸城财鑫糖业有限责任公司

Preparation method of posaconazole intermediate

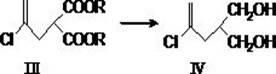

InactiveCN102643194ANovel process routeReasonable process conditionsOrganic compound preparationCarboxylic acid esters preparationBiochemical engineeringPharmaceutical drug

The invention belongs to the technical field of pharmacochemistry and in particular relates to a preparation method of a posaconazole intermediate. The method comprises four steps of alkylation, reduction, acylation and cross-coupling, so that a target compound (I) is obtained. Compared with the existing synthetic method, the synthetic method provided by the invention has the characteristics of low price and easiness in obtainment of raw materials, simple and convenient technology, high yield and the like.

Owner:FUZHOU UNIV

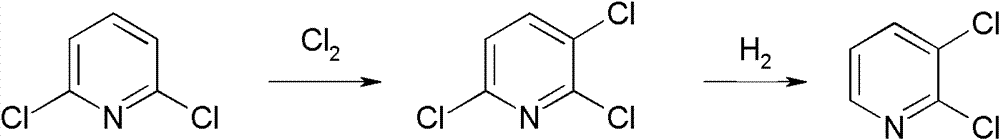

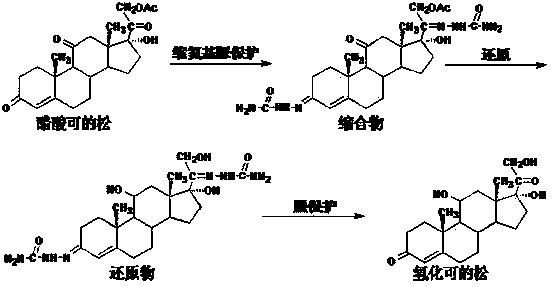

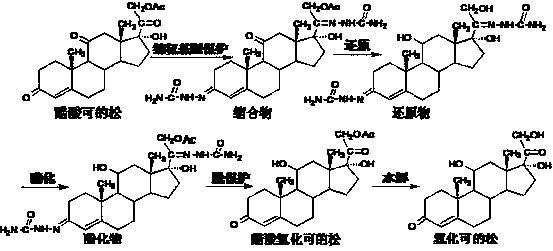

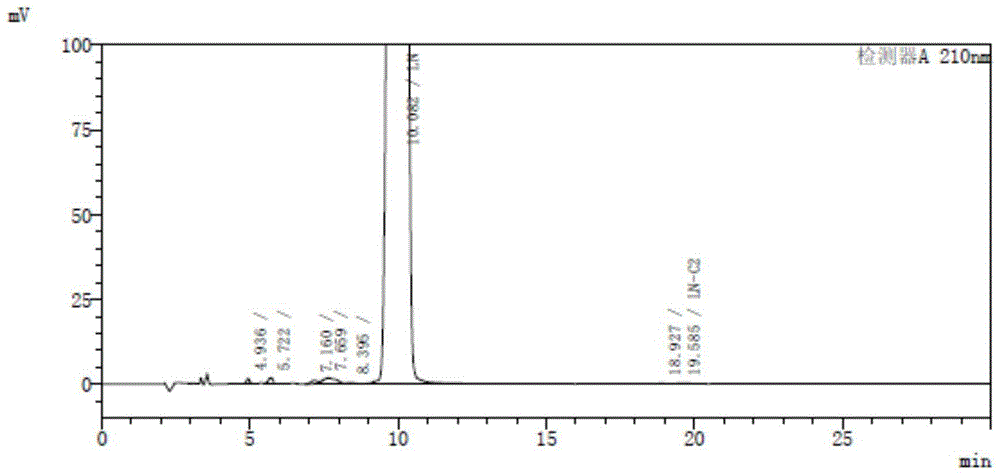

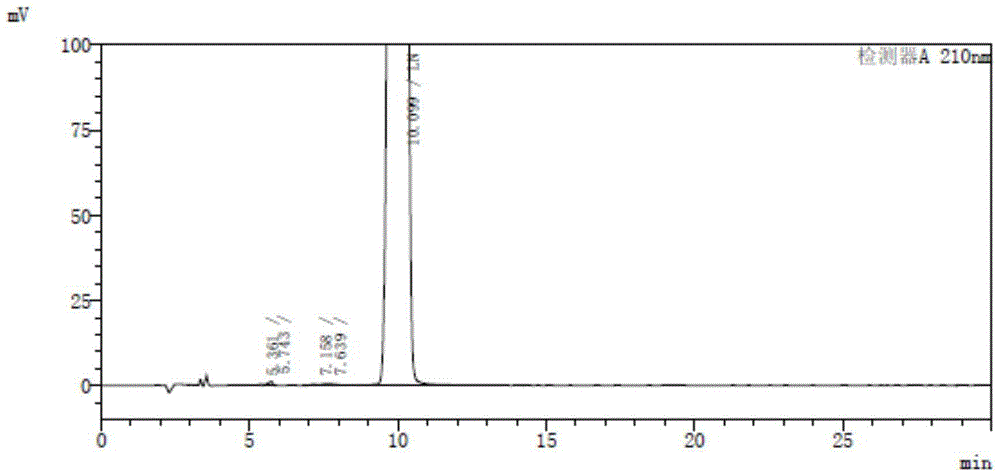

Preparation method of prednisolone

The invention relates to a preparation method of prednisolone. The preparation method comprises the steps of sequentially carrying out 3, 20-keto protective reaction, 11-keto reduction reaction, 21-hydroxyl esterification reaction, 3, 20-keto deprotection reaction and 21-acetic ester hydrolysis reaction by taking prednisone acetate as a raw material to obtain prednisolone. The invention provides a novel synthesis route sequentially comprising the steps of esterifying and deprotecting; nitrosification quenching reaction and resin hydrolysis reaction are omitted in the deprotection process; and ester hydrolysis reaction is finished under the protection of a mixed solvent and inert gases, so that the condition that byproducts are produced by hydrolysis reaction is avoided. The preparation method is novel in process route, simple and rapid in operation process, low in production cost and suitable for large-scale industrial production.

Owner:HUAZHONG PHARMA

Method for purifying and separating gamma-polyglutamic acid from fermentation liquor

The invention discloses a method for purifying and separating gamma-polyglutamic acid from fermentation liquor. Through the utilization of the characteristic that only the gamma-polyglutamic acid can be separated out in a fermentation liquor filtrate with low pH value, the purpose of separating and purifying high-purity gamma-polyglutamic acid is achieved. The method comprises the following steps: adjusting the pH value to be 3.0-6.0 with acid, performing filtration sterilization, then, decolorizing with activated carbon, adjusting the pH value to be 2.0-5.0 with acid, leaving to stand, separating out sediments, performing solid-liquid separation, dissolving the sediments in purified water to obtain a high-concentration water solution, finally, performing band drying, and smashing, so as to obtain the gamma-polyglutamic acid finished product. According to the invention, the process route is novel and simple, an organic solve is completely avoided, the product has no organic solvent residue, the production cost is low, the cost is reduced by 30% or above, the yield is as high as 85% or above, the product quality is excellent, the purity reaches 95% or above, and the method is more suitable for industrial production.

Owner:SHANDONG FREDA BIOTECH

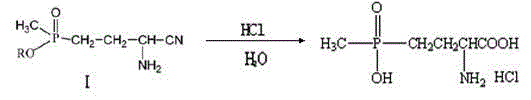

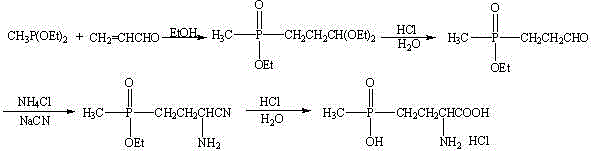

Glufosinate-ammonium separating and purifying method

ActiveCN105315303AHigh recovery rateHigh purityGroup 5/15 element organic compoundsPhosphoric Acid EstersAlcohol

The invention discloses a glufosinate-ammonium separating and purifying method. The method includes the steps of conducting ammoniation on a glufosinate-ammonium acidolysis solution or solid glufosinate-ammonium hydrochloride, conducting drying to obtain a glufosinate-ammonium crude product A, adding the glufosinate-ammonium crude product A to alcohol, conducting filtering to obtain a glufosinate-ammonium crude product B, adding the glufosinate-ammonium crude product B to phosphate ester, conducting filtering to obtain filtrate, washing a filter cake through phosphate ester, combining filtrate with washing liquid to obtain a glufosinate-ammonium crude product C, adding the glufosinate-ammonium crude product C to water to be extracted, and taking a water layer which can be directly used as a glufosinate-ammonium aqueous solution or obtaining high-purity glufosinate-ammonium active compounds after the water layer is spray-dried. The method is simple in step, the content of chloride impurities in the obtained glufosinate-ammonium aqueous solution or glufosinate-ammonium active compounds is extremely low, basically no organic impurities exist, the purity of the separated glufosinate-ammonium active compounds can reach 98% or higher, and the recovery rate of glufosinate-ammonium reaches up to 98% or higher. Compared with the traditional process, the method has the higher advantages of cost, safety, environmental friendliness and quality and has extremely-high social value and economic value.

Owner:SHANDONG WEIFANG RAINBOW CHEM

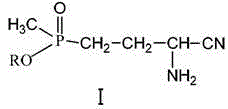

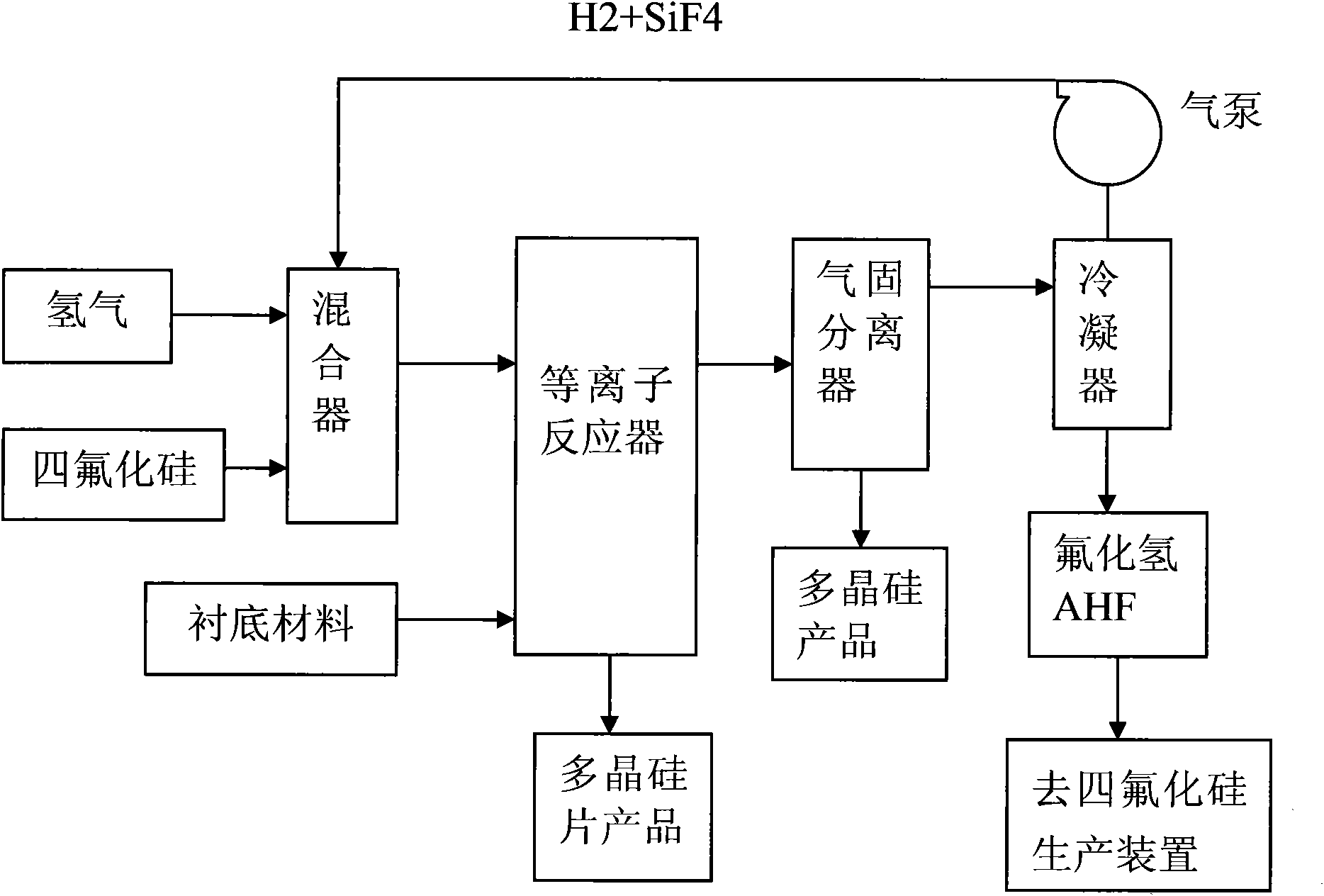

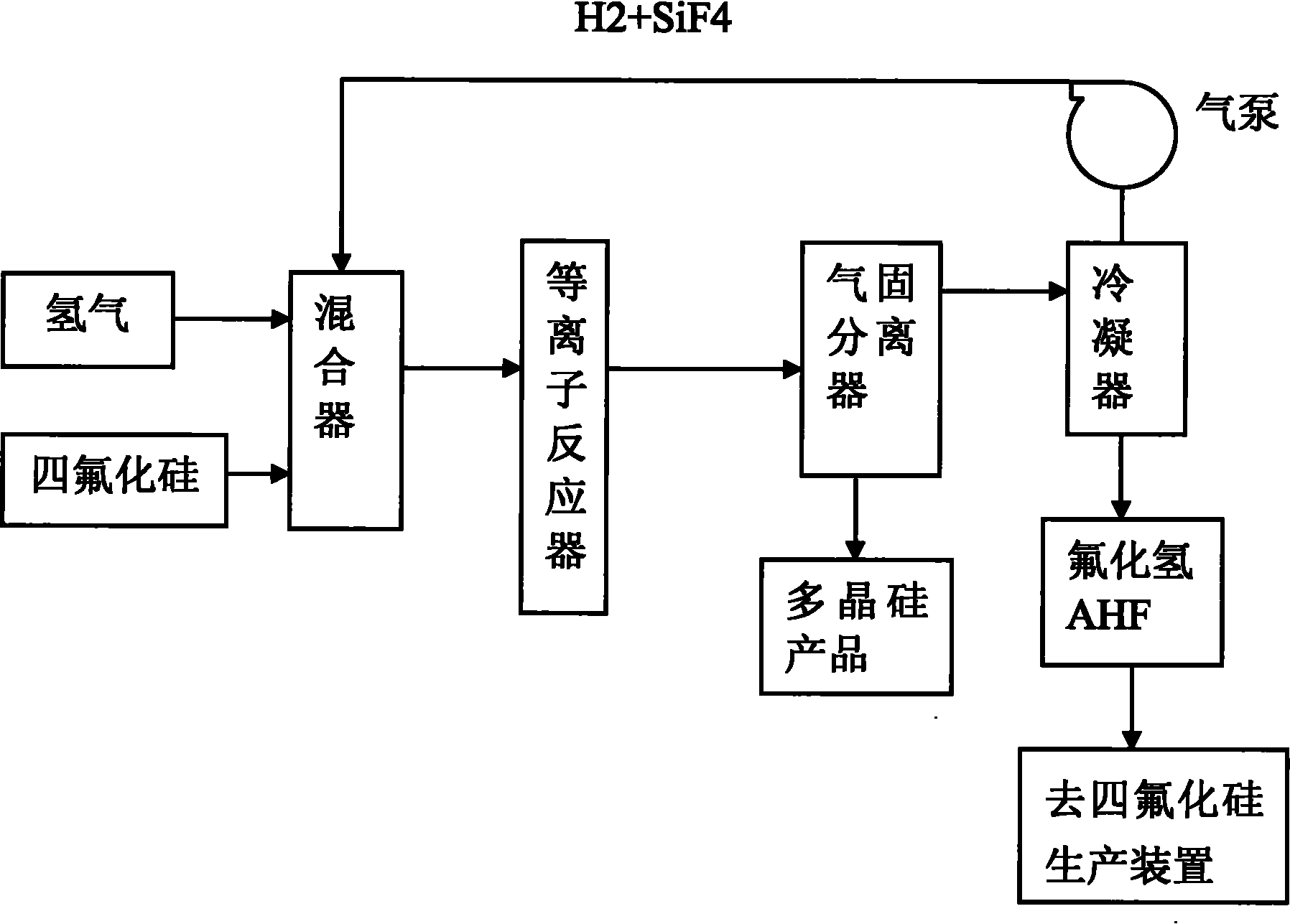

Method for producing polysilicon with silicon tetrafluoride reduced by plasmas

The invention discloses a method for producing polysilicon with silicon tetrafluoride reduced by plasmas, specifically comprising the following steps: pumping the mixture of the silicon tetrafluoride gas and hydrogen as the raw materials into a plasma reactor filled with hydrogen, heating the silicon tetrafluoride gas and hydrogen to 1200-3500 DEG C instantaneously under the action of the plasmas and the silicon tetrafluoride gas and hydrogen carrying out chemical reaction to produce the polysilicon solid and the hydrogen fluoride gas; the produced polysilicon solid and hydrogen fluoride gas and the unreacted silicon tetrafluoride gas and hydrogen jointly entering into a gas-solid separation device, separating the polysilicon solid from the gases, the purity being more than 99.9999% and producing the finished product; and the hydrogen fluoride gas and the unreacted silicon tetrafluoride gas and hydrogen jointly entering into a condenser, condensing the hydrogen fluoride gas to liquid and the silicon tetrafluoride gas and hydrogen returning to the plasma reactor. The method has the advantages of novel and reasonable process routes, low equipment requirements, easy industrialization realization and low energy consumption.

Owner:应盛荣

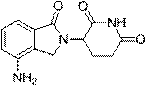

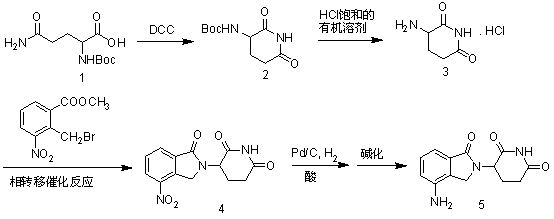

Novel preparation method of lenalidomide

ActiveCN103193763ANovel process routeReasonable process conditionsOrganic chemistryIsoindoleIntramolecular cyclization

The invention discloses a method for preparing lenalidomide (3-(7-amino-3-oxo-1H-isoindazole-2-yl) piperidine-2,6-diketone). The method comprises the steps of: intramolecular cyclization, deprotection, phase-transfer catalytic reaction, catalytic hydrogenation, alkalization and the like. The technology is novel in path, short in step, high in reaction yield, and low in production cost, and has large implementation value and social and economic benefits.

Owner:HANGZHOU BIO SINCERITY PHARMA TECH CO LTD

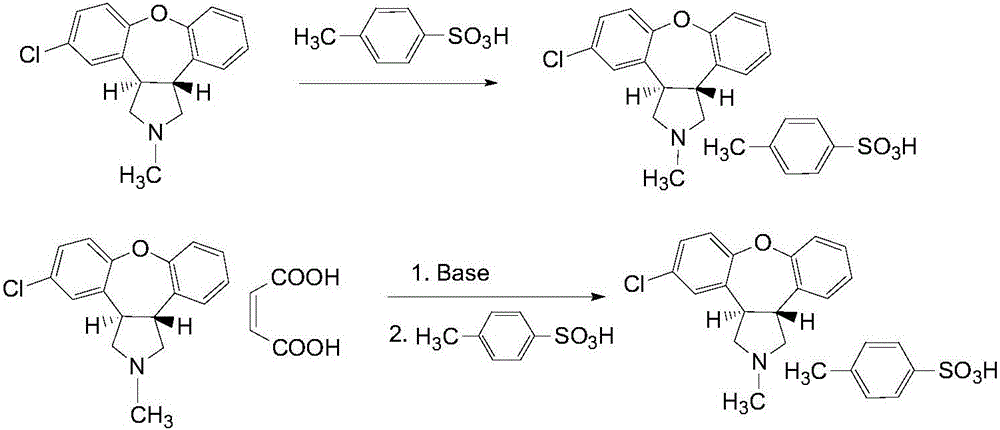

The preparation method of asenapine maleate

ActiveCN103864802BNovel process routeMild process conditionsCarboxylic acid salt preparationOrganic acidEconomic benefits

The invention discloses a preparation method of high-purity asenapine maleate. The preparation method comprises the following steps: by taking an asenapine free alkali crude product and a asenapine maleate crude product as an initial raw material, reacting the asenapine free alkali crude product with an organic acid to generate salt or carrying out alkalifying dissociation on the asenapine maleate crude product to asenapine free alkali to be reacted with the organic acid to generate salt so as to obtain asenapine para-benzyl benzyl; crystallizing, filtering and carrying out alkalifying dissociation to obtain asenapine free alkali; then reacting the product obtained from the former step with maleic acid to obtain asenapine maleate; and crystallizing and filtering. The preparation method of high purity asenapine maleate is novel in process route, mild in process condition and simple to operate, and an acceptable product with the purity greater than or equal to 99% can be obtained by just one time without repeatedly recrystallizing operations. Meanwhile, the preparation method further improves the reaction yield, lowers the production cost, is suitable for being applied to industrial production on a large scale, and has good practical value and social and economic benefits.

Owner:SICHUAN KELUN PHARMA CO LTD

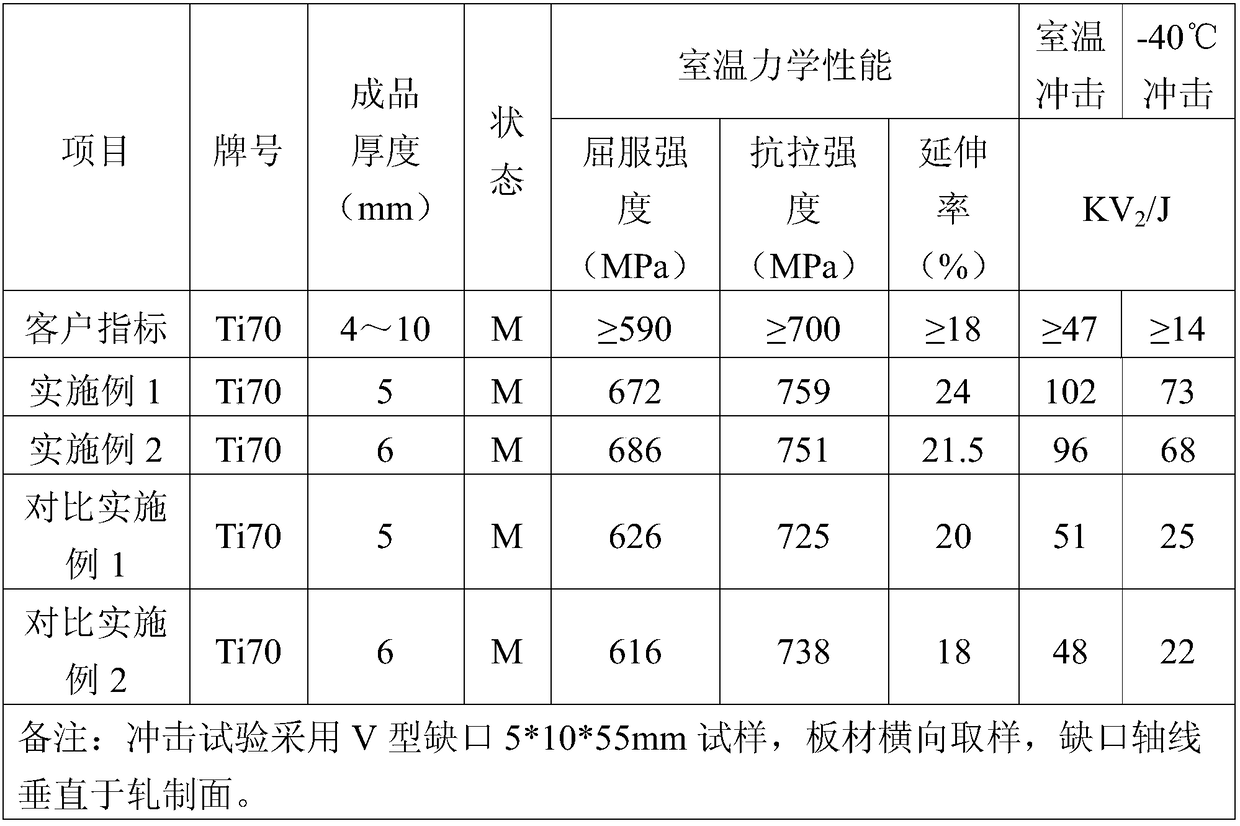

TA23 alloy plate with high impact toughness and high plasticity and preparation and application

The invention belongs to the field of non-ferrous metal processing, and specifically relates to a TA23 alloy plate with high impact toughness and high plasticity and preparation and an application. According to the TA23 alloy plate, a whole process design concept is adopted, and key processes of cast ingot components, forging processes, rolling and heat treatment and the like are controlled in alldirections, so that the TA23 alloy plate with high impact toughness and high plasticity is prepared. The tensile strength Rm of the TA23 alloy plate is greater than or equal to 740 Mpa, the yield strength Rp0.2 is greater than or equal to 630 Mpa, the elongation A is greater than or equal to 19%, the room temperature impact KV2 is greater than or equal to 80 J, the low temperature impact at -40 DEG C is greater than or equal to 30 J, the overall performance is good, wherein the room temperature impact toughness is increased by more than 100%, the low temperature impact toughness is increasedby more than 190%, the elongation is increased by more than 3%, all indexes meet the customer standard, enough performance allowance is left, the safety factor of the product is greatly increased, andthe TA23 alloy plate is used for manufacturing ship structural parts and has the advantages of high impact resistant capability and high safety.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

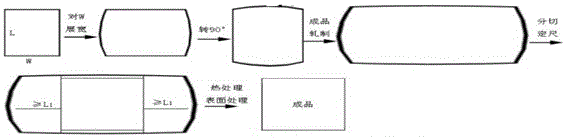

Short-flow preparation method of TA5 titanium alloy medium-thickness plate for ship

ActiveCN105951016AAvoid causing production abnormalitiesNovel process routeThick plateTitanium alloy

The invention discloses a short-flow preparation method of a TA5 titanium alloy medium-thickness plate for a ship. According to the short-flow preparation method, the design concept of a whole-flow technology is adopted, and the edge crack, the plate shape, the structure and the property of the TA5 titanium alloy medium-thickness plate are comprehensively controlled from the aspects of slab selection, broadening reversing rolling, heat treatment technology design and the like; According to the method, the slab used for a thick plate in the production is smaller, the production is convenient and flexible, and the requirement for the capability of equipment is lower.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

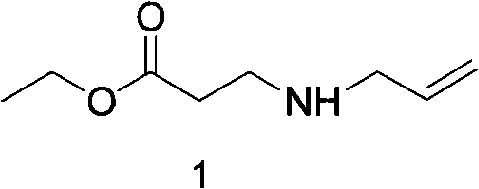

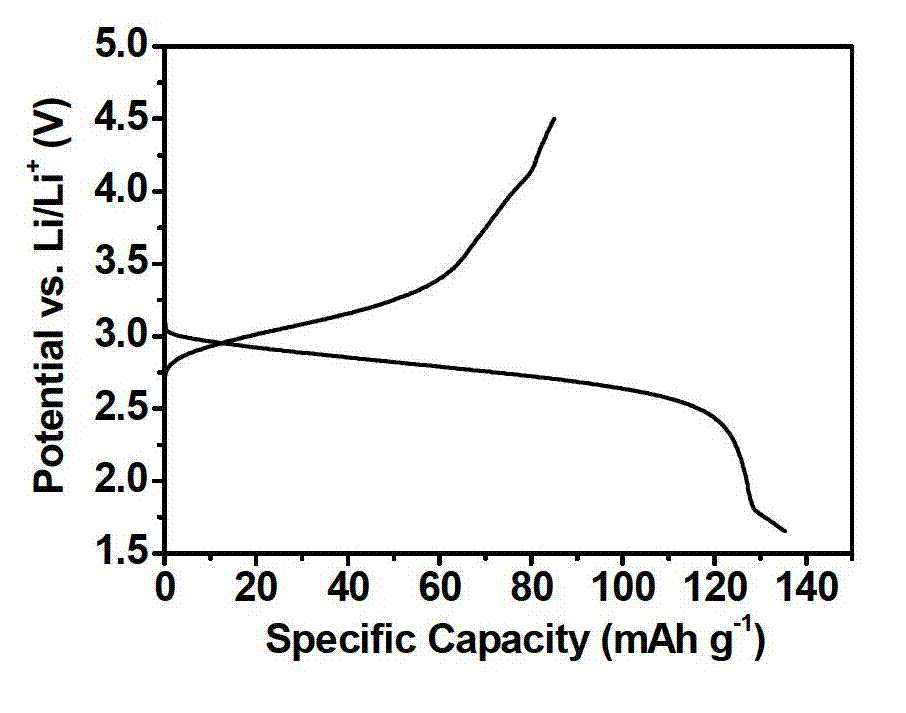

Method for preparing (2s, 3s)-3-amino-bicyclo [2.2. 2] octane-2-formate

ActiveCN111454166ANovel process routeMild reaction conditionsOrganic compound preparationOrganic chemistry methodsFormateBiochemical engineering

The invention discloses a method for synthesizing (2S,3S)-3-amino-bicyclo[2.2.2] octane-2-formate and belongs to the field of pharmaceutical intermediate synthesis. The purposes of the invention are to solve the problems of high preparation cost, low material safety and the like of (2S, 3S)-3-amino-bicyclo[2.2.2] octane-2-formate, further improve the productivity and reduce the production cost. According to the method disclosed by the invention, 3-carbonyl-bicyclo[2.2.2] octane-2-formate is used as a starting material, and reductive amination, basic configuration inversion, hydrogenation protection group removal and the like are sequentially carried out, so that the target product is obtained. According to the invention, the (2S, 3S)-3-amino-bicyclo [2.2. 2] octane-2-formate is synthesizedby using the synthesis method, the novel process route is used, the yield is more than 65%, and the method has characteristics of novel route, mild reaction condition, low cost and the like.

Owner:RAFFLES PHAMRMATECH CO LTD

A short-process preparation method of ta5 titanium alloy medium-thick plate for ships

ActiveCN105951016BAvoid causing production abnormalitiesNovel process routeThick plateTitanium alloy

A short-process preparation method of TA5 titanium alloy medium-thick plate for ships, which adopts the whole-process process design concept, and comprehensively controls the edge of TA5 medium-thick plate from the aspects of slab selection, widening and reversing rolling, heat treatment process design, etc. Cracks, plate shape, structure and performance, the slab used in the production of medium and thick plates by this method is small, the production is convenient and flexible, and the requirements for equipment capacity are low.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Forming method for large thin-walled skin-coated ribbed plate titanium castings

The invention discloses a forming method for large thin-walled skin-coated ribbed plate titanium castings. According to the forming method, several skin-coated ribbed plate units are bonded by means of casting to obtain finished titanium casting products after being processed from titanium alloy raw materials; and processing steps for the skin-coated ribbed plate units are material selection, skin production, graphite die processing, graphite die degassing, and pouring and mould assembly. The forming method disclosed by the invention is novel in process route, and a forming process for large thin-walled skin-coated ribbed plate titanium alloy products is comprehensively controlled in the three aspects of titanium alloy rolled plate skin design, graphite model design and titanium alloy melting pouring; and therefore, the problems of insufficient pouring and deformation of the conventional large thin-walled titanium castings can be avoided, and the conditions of slag inclusion and surface cracks in casting of a conventional method for large thin-walled titanium castings can also be avoided.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Preparation method of 2,3-dichloropyridine

ActiveCN102153507BNovel process routeReduce manufacturing costOrganic chemistryOrganic solventMetal catalyst

The invention discloses a preparation method of 2,3-dichloropyridine. 2,3-dichloropyridine is an intermediate in fine chemical industry, which is widely used in the fields of medicine and pesticide. The method comprises the following steps: carrying out chlorination reaction on 2,6-dichloropyridine, which is used as a raw material, to obtain 2,3,6-trichloropyridine; adding the 2,3,6-trichloropyridine, an acid binding agent, a metal catalyst and an organic solvent into a reactor, and carrying out hydrogenation reaction, wherein the mol ratio of 2,3,6-trichloropyridine to acid binding agent is 1:(0.1-0.5); and cooling the hydrogenation reaction liquid, adding water to dissolve the acid binding agent hydrochloride, filtering, standing, separating out the water layer, extracting the organic solvent layer with water-containing acid at least three times, merging the water-containing acid layers after extraction, diluting by adding water, precipitating a solid, filtering, and drying to obtain the 2,3-dichloropyridine product. The invention has the advantages of novel process route, short reaction steps, high yield, low production cost and environmental friendliness, is simple to operate,and is suitable for industrial production.

Owner:LIANHE CHEM TECH +1

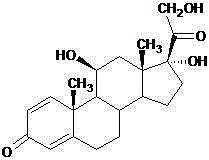

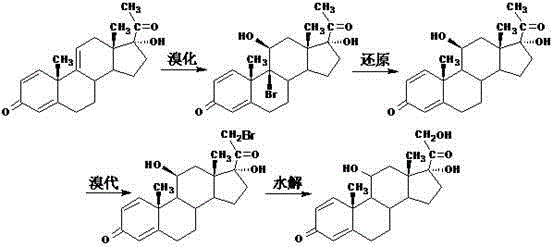

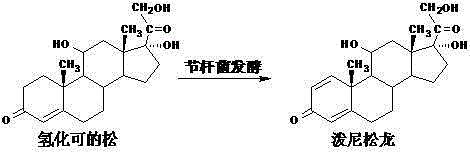

Method for preparing hydrocortisone

The invention relates to a method for preparing hydrocortisone. The method includes: subjecting a cortisone acetate raw material to sites No. 3,20-keto protective reaction, site No.11-keto reduction reaction, site No.21-hydroxy esterification reaction, sites No. 3,20-ketone deprotection reaction, and site No. 21-acetate hydrolysis to obtain hydrocortisone. The method provides a new synthetic route containing esterification and deprotection in order, greatly improves the reaction selectivity, easily separates deprotection reaction products and avoids the posttreatment of tedious several times of extraction of a large amount of solvents in the traditional deprotection reaction process, and also avoids the side reaction caused by quenching reaction in the posttreatment of the traditional process; and the ester hydrolysis reaction is carried out under protection of inert gases in a mixed solvent, so as to avoid by-products produced in the hydrolysis reaction. The process route of the invention is novel, simple for operation, low in production cost, and applicable to industrial scale production.

Owner:HUAZHONG PHARMA

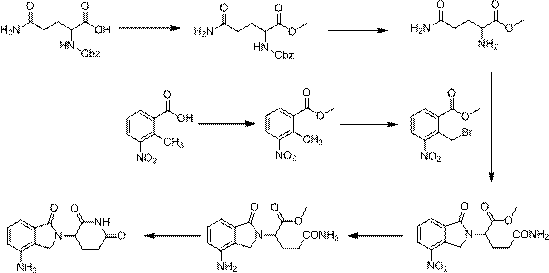

Preparation method of lenalidomide

ActiveCN105440014ANovel process routeReasonable process conditionsOrganic chemistryGlutaric acidL glutamate

A preparation method of lenalidomide comprises the following steps: 1, reacting a raw material methyl 2-methyl-3-nitro-benzoate with a halogenating reagent to obtain methyl 2-halomethyl-3-nitro-benzoate represented by formula (I); 2, reacting the methyl 2-halomethyl-3-nitro-benzoate with dimethyl D,L-glutamate hydrochloride in the presence of an alkaline compound to obtain dimethyl 3-(7-nitro-1-oxo-1,3-dihydroisoindole-2-yl)glutarate represented by formula (II); 3, hydrolyzing the above compound of formula (II) to obtain 3-(7-nitro-1-oxo-1,3-dihydroisoindole-2-yl)glutaric acid represented by formula (III); 4, reducing the above compound of formula (III) to obtain 3-(7-amino-1-oxo-1,3-dihydroisoindole-2-yl)glutaric acid represented by formula (IV); and 5, carrying out ring closure on the above compound of formula (IV) to obtain lenalidomide represented by formula (V). The method has the advantages of simple process, high safety, cheap and easily available raw materials, good quality of the above product, and suitableness for industrial production.

Owner:HANGZHOU HEZE PHARMA TECH

Preparation method of 3-chloropyridine

ActiveCN102174014ANovel process routeEfficient separation and recovery technologyOrganic chemistryChemical recyclingPesticideChemistry

The invention discloses a preparation method of 3-chloropyridine. 3-chloropyridine is a fine chemical engineering intermediate extensively used in the fields of medicine and pesticides. The preparation method comprises the following steps of: taking 2,6-dichloropyridine as a raw material and performing chlorination reaction to obtain 2,3,6-trichloropyridine; putting the 2,3,6-trichloropyridine, an acid-binding agent, a metal catalyst and an organic solvent into a reactor for performing hydrogenation reaction, wherein the mol ratio of the 2,3,6-trichloropyridine to the acid-binding agent is 1:(0.5-1.0); cooling the hydrogenation reaction liquid, adding water to dissolve the hydrochlorate of the acid-binding agent, filtering and standing to separate the water layer; extracting the organic solvent layer by aqueous acid at least more than three times; combining the extracted aqueous acid layers, thinning up with water, alkalizing for adjusting the pH value of the filtrate to be 7; and layering the filtrate to obtain the liquid product of 3-chloropyridine. The preparation method of 3-chloropyridine has a novel process route, short reaction steps, simplicity of operation, high yield, low production cost and environmental friendliness, and is suitable for industrialized production.

Owner:LIANHE CHEM TECH +1

Method for preparing 2,5-dimethyl phenylacetic acid

ActiveCN102140062BNovel process routeReasonable process conditionsCarboxylic preparation from carbon monoxide reactionHalogenated hydrocarbon preparationPhenylacetic acidBenzyl chloride

The invention discloses a method for preparing 2,5-dimethyl phenylacetic acid. The 2,5-dimethyl phenylacetic acid is a fine chemical engineering intermediate which is widely applied in fields of medicines and pesticides, and particularly is a key intermediate of spirotetramat serving as a novel insecticide. The method comprises the following steps of: mixing paraxylene serving as a raw material and ionic liquid serving as solvent with paraformaldehyde and concentrated hydrochloric acid, and performing a chloromethylation reaction to obtain 2, 5-dimethyl benzyl chloride; and performing a carbonylation reaction and a hydrolysis reaction of the 2, 5-dimethyl benzyl chloride and an acid-binding agent and the solvent in a reactor under the action of a catalyst to obtain the 2,5-dimethyl phenylacetic acid. The method has a novel process, short synthetic reaction steps, simplicity of operation, low production cost, high reaction yield, and environmental friendliness, and is suitable for industrial production.

Owner:LIANHE CHEM TECH +1

Production method of lithium secondary battery drop water ferric fluoride anode material

InactiveCN100517812CComplete structureHigh yieldElectrode manufacturing processesFluoride preparationAutomatic controlFiltration

The invention discloses a preparation method for lithium secondary battery micro water ferric fluoride anode materials, wherein, firstly, teracidic malysite and alkali are uniformly mixed in an aqueous solution under normal temperature in proportion from 1 to 1 - 1 to 10; water is removed after sucking filtration; iron-alkali mixture is obtained after drying for 1 to 48 hours; secondly, the iron-alkali mixture and 5 to 40 percent hydrofluoric acids are uniformly reacted in a plastic sealed container in proportion from 1 to 1 - 1 to 10, and heat preservation is performed for 1 to 48 hours under the temperature of 40 to 100 DEG C; thirdly, mixture is filtered, cleaned by utilization of ethanol and dried for 1 to 36 hours in the air; fourthly, the mixture is dried for 1 to 72 hours under vacuum state of 50 to 250 DEG C; fifthly, the mixture is crushed in a ball mill and passes through a 100 to 400 mesh sieve, and then a ferric fluoride product is obtained. The invention has the advantages that: firstly, systematic temperature is automatically controlled, and technological parameters are determined through precise calculation on the basis; secondly, yield of the method is high and product purity is larger than 95 percent. Obtained FeF3 (H2O) 0.33 has an integrated orthorhombic system structure, regular surface topography, small grain diameter and uniform distribution, and good discharge performance. The method is a novel and practical technological line for preparation of the FeF3 (H2O) 0.33.

Owner:XIANGTAN UNIV

Method for preparing hydrogen fluoride from flousper powder and sulfuric acid

ActiveCN101913565BNovel process routeEasy to operateCalcium/strontium/barium sulfatesFluorine/hydrogen-fluorideHydrofluoric acidHydrogen fluoride

The invention discloses a method for preparing hydrogen fluoride from flousper powder and sulfuric acid. The method comprises the following specific steps of: adding solution of sulfuric acid and the flousper powder into a reactor with a stirrer respectively, wherein the molar ratio of calcium fluoride to the sulfuric acid is 1:3-1:30, the granularity of the flousper powder is 280 to 1,220 meshes, and the reaction temperature is controlled to between 90 and 300 DEG C; generating hydrogen fluoride gas and calcium sulfate solid after the reaction; purifying, condensing and rectifying the hydrogen fluoride gas to obtain anhydrous hydrogen fluoride, or purifying and absorbing the hydrogen fluoride gas to obtain hydrofluoric acid; transferring the calcium sulfate solid and the sulfuric acid toa filtering system from the reactor to perform solid-liquid separation; returning the separated solution of sulfuric acid to the reactor; and washing and drying the calcium sulfate solid separated from the sulfuric acid to form a by-product. The method has the advantages of simple equipment, high reaction efficiency, low cost and easy industrialized production.

Owner:衢州市鼎盛化工科技有限公司

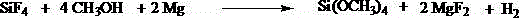

Method for preparing ethyl silicate and magnesium fluoride from silicon tetrafluoride, ethanol and magnesium

InactiveCN103059057ANovel process routeSimple stepsMagnesium fluoridesSilicon organic compoundsChemical industryBoiling point

The invention relates to the technical field of chemical industry and in particular relates to a method for preparing ethyl silicate and magnesium fluoride by utilizing reactions of silicon tetrafluoride, ethanol and magnesium. The method comprises the following steps of: a. adding ethanol and magnesium powder to a reaction kettle; b. raising the temperature of the reaction system to a preset temperature to react; c. after reaction is completed, cooling the reaction system, adding prepared ethanol solution of silicon tetrafluoride to the reaction kettle until the reaction system is neutral; d. separating solid from liquid through filtration; e. washing the solid obtained in step d with ethanol and drying the washed solid to obtain the target product magnesium fluoride; and f. distilling the filtrate obtained in step d to remove ethanol, thus obtaining ethyl silicate with high boiling point. The method can be used for producing by-product silicon tetrafluoride by efficiently utilizing phosphate fertilizers.

Owner:云天化集团有限责任公司 +1

Method for preparing talipexole

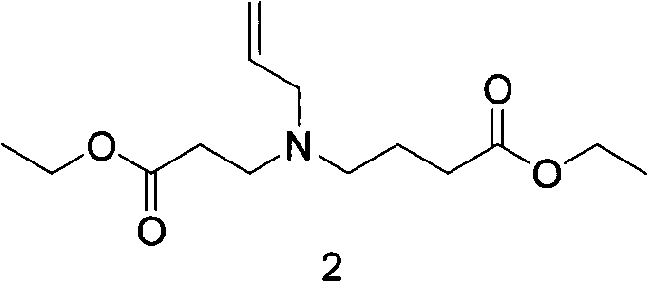

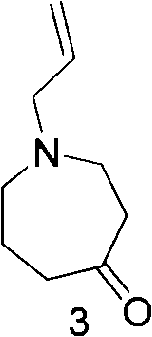

ActiveCN101665501ANovel process routeReasonable process conditionsNervous disorderOrganic chemistryThioureaStrong acids

The invention discloses a method for preparing talipexole (6-allyl-2-amino-5,6,7,8-tetrahydro-4H-thiazole [4,5-d]-aza-dihydrochloride). The method comprises the following steps: using ethyl acrylate as starting raw materials; firstly, carrying out addition reaction on the ethyl acrylate and allyl to generate 3-allylamine base ethyl propionate, then reacting with 4-bromobutyrate to generate 4-(allyl(3-ethoxyl-3-oxopropyl)amino) ethyl butyrate; performing the ring closing reaction under the condition of strong base, decarboxylasing under strong acid to generate 1-allyl azacycloheptane-4-ketone;then performing the nuclear bromination to generate 1-allyl-5-bromine azacycloheptane-4-ketone, and finally, reacting with thiourea to generate a target product (formula I). The invention has novel process, short procedures, high reaction yield, low production cost, and larger implementation value and social and economic benefits.

Owner:SHANGHAI HAOYUAN MEDCHEMEXPRESS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing (2s, 3s)-3-amino-bicyclo [2.2. 2] octane-2-formate Method for preparing (2s, 3s)-3-amino-bicyclo [2.2. 2] octane-2-formate](https://images-eureka.patsnap.com/patent_img/5748ab0f-4e7f-4c7e-9b82-6f7b3d1014a5/FDA0002348060530000031.png)

![Method for preparing (2s, 3s)-3-amino-bicyclo [2.2. 2] octane-2-formate Method for preparing (2s, 3s)-3-amino-bicyclo [2.2. 2] octane-2-formate](https://images-eureka.patsnap.com/patent_img/5748ab0f-4e7f-4c7e-9b82-6f7b3d1014a5/FDA0002348060530000032.png)

![Method for preparing (2s, 3s)-3-amino-bicyclo [2.2. 2] octane-2-formate Method for preparing (2s, 3s)-3-amino-bicyclo [2.2. 2] octane-2-formate](https://images-eureka.patsnap.com/patent_img/5748ab0f-4e7f-4c7e-9b82-6f7b3d1014a5/BDA0002348060540000011.png)