Preparation method of 3-chloropyridine

A technology of chloropyridine and trichloropyridine, which is applied in the field of preparation of important fine chemical intermediate 3-chloropyridine, can solve the problems of multiple synthesis steps, complex reaction types, and high raw material prices, and achieve high-efficiency separation and recovery technology and novel process routes simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

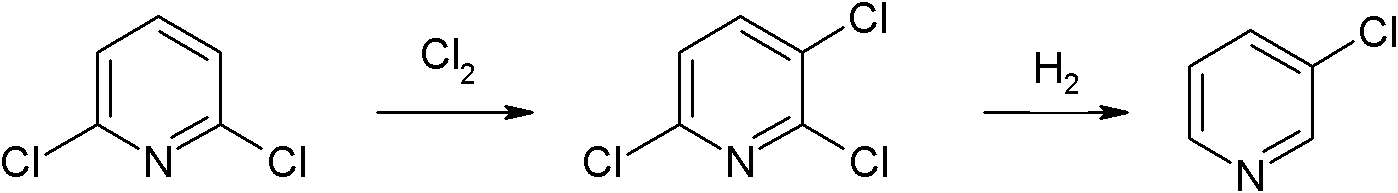

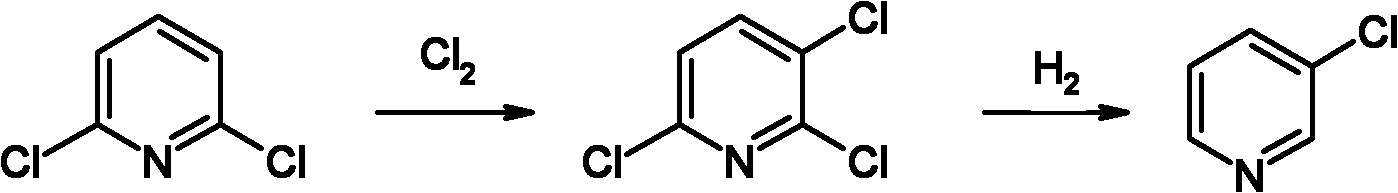

Image

Examples

Embodiment 1

[0032] Chlorination

[0033] Weigh 1480.0g of 2,6-dichloropyridine and anhydrous FeCl 3 89.2g was placed in a 2000ml four-necked flask and mixed and heated up. When the temperature reached 120~140℃, chlorine gas was introduced. After the reaction was complete, the temperature was lowered to 100℃, and vacuum distillation was carried out at -0.1MPa, the top temperature was 118~ The product fractions are collected at 124°C, and the low-concentration distillate produced during the rectification process can be applied to the next batch for re-reaction or applied to the next batch for re-rectification and purification. After the application, 1715.0 g of 2,3,6-trichloropyridine is finally obtained, the total yield after the application is 94.0%, and the purity is ≥99.5%.

[0034] Hydrogenation reaction

[0035] Put 557.8g of 2,3,6-trichloropyridine prepared in the chlorination reaction, 232.0g of triethylamine, 8.5g of palladium on carbon, and 1675g of toluene into the reactor at one time...

Embodiment 2

[0039] Chlorination

[0040] Weigh 299.2g of 2,6-dichloropyridine and 533.7g of the recovered fraction (of which 2,6-dichloropyridine accounts for 86.1%, 2,3,6-trichloropyridine accounts for 9%), and anhydrous AlCl 3 36.5g is placed in the reactor and mixed, and when the temperature is raised to 120~140℃, chlorine gas is introduced. After the reaction is completed, the temperature is lowered to 100℃, and vacuum distillation is carried out. The product fraction is collected at -0.1MPa and the top temperature is 118~124℃. , The low-concentration product steamed out can be applied to the next batch for re-reaction or applied to the next batch for re-rectification and purification; after the application, 890.7g of 2,3,6-trichloropyridine is finally obtained, and the total yield after application is 95.2%, with purity ≥99.5%.

[0041] Hydrogenation reaction

[0042] 1340g of the toluene solution containing 2,3,6-trichloropyridine recovered in Example 1 can be added with 410.5g of 2,3,6-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com