Patents

Literature

6569 results about "Strong acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The strong acids are hydrochloric acid, nitric acid, sulfuric acid, hydrobromic acid, hydroiodic acid, perchloric acid, and chloric acid. The only weak acid formed by the reaction between hydrogen and a halogen is hydrofluoric acid (HF).

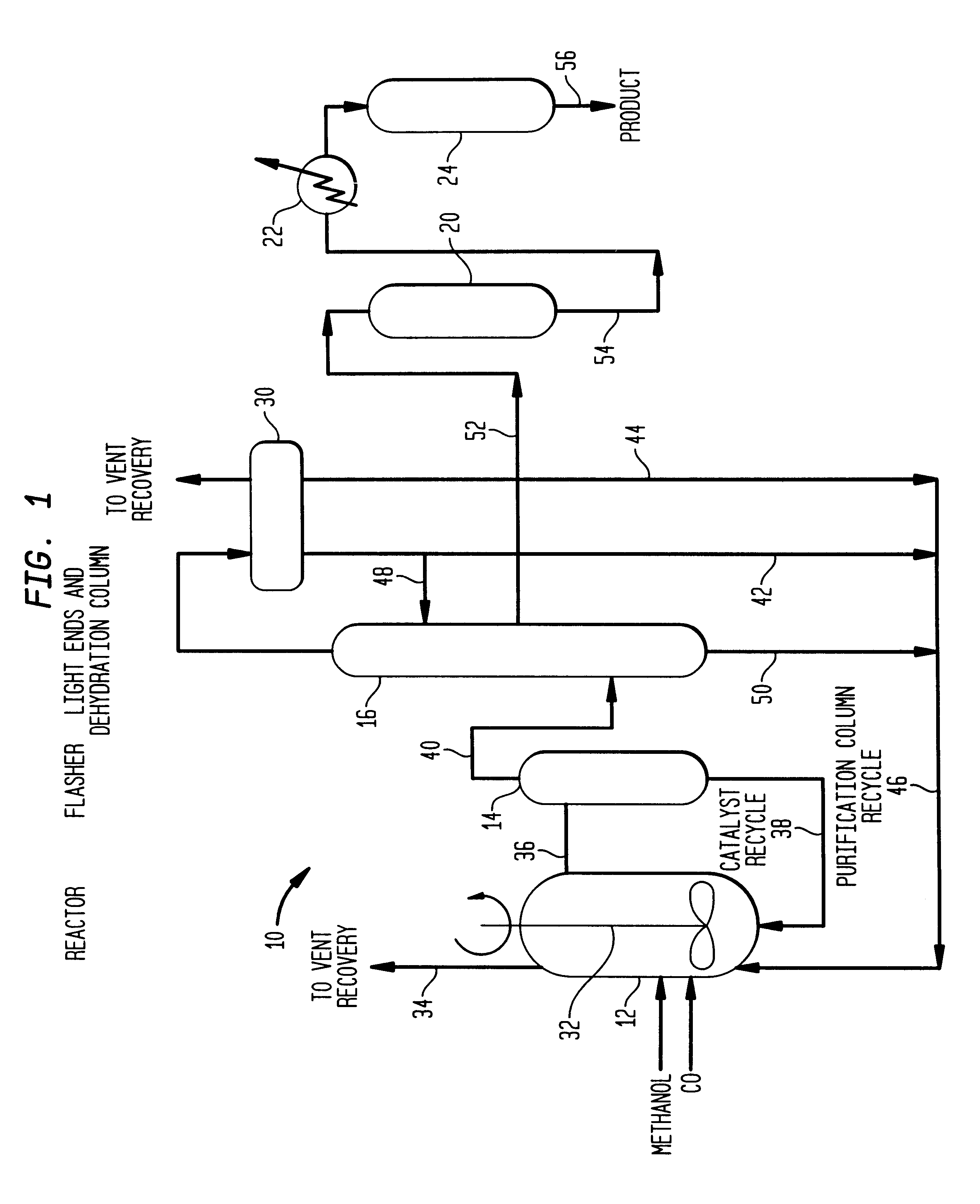

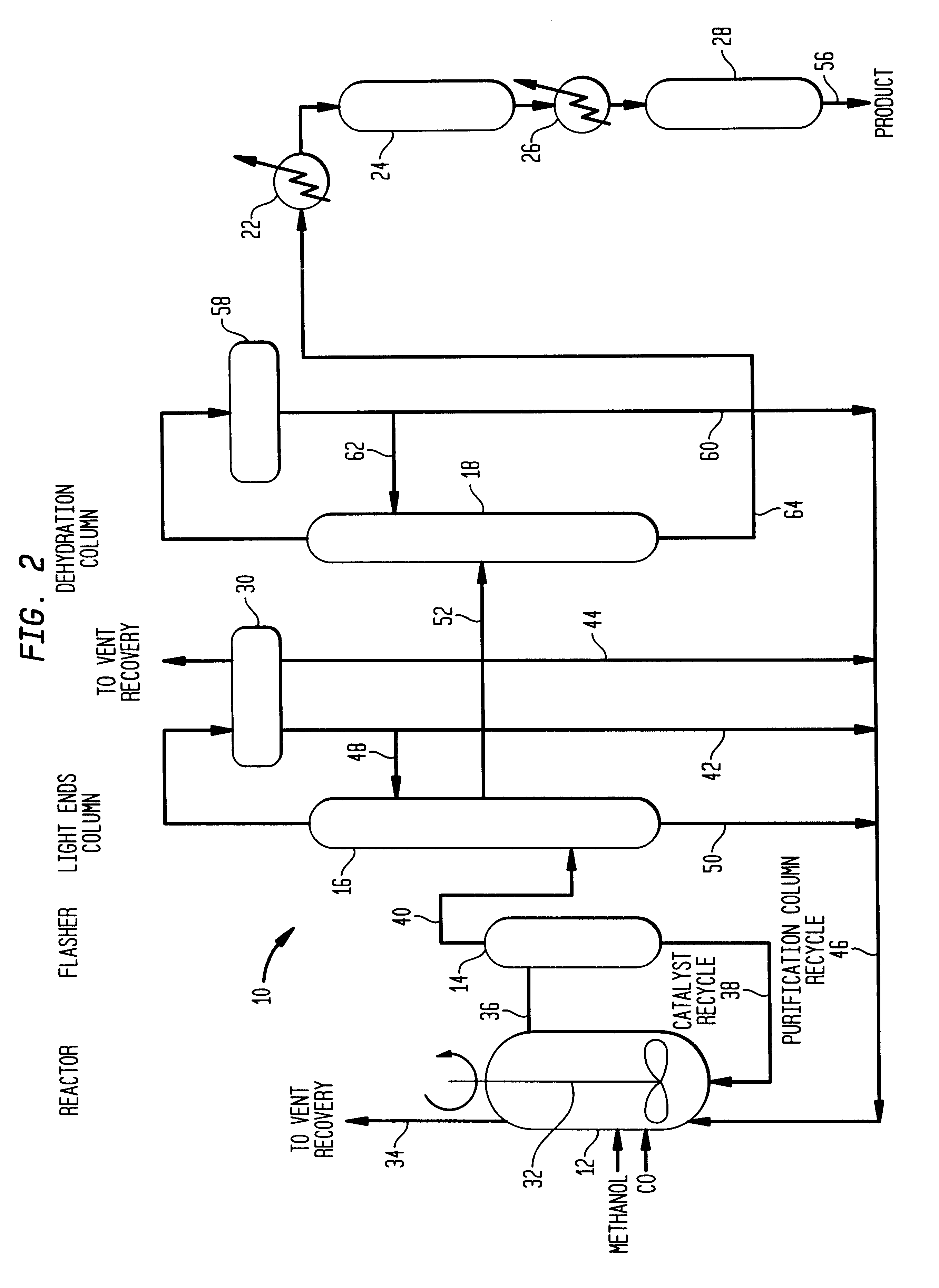

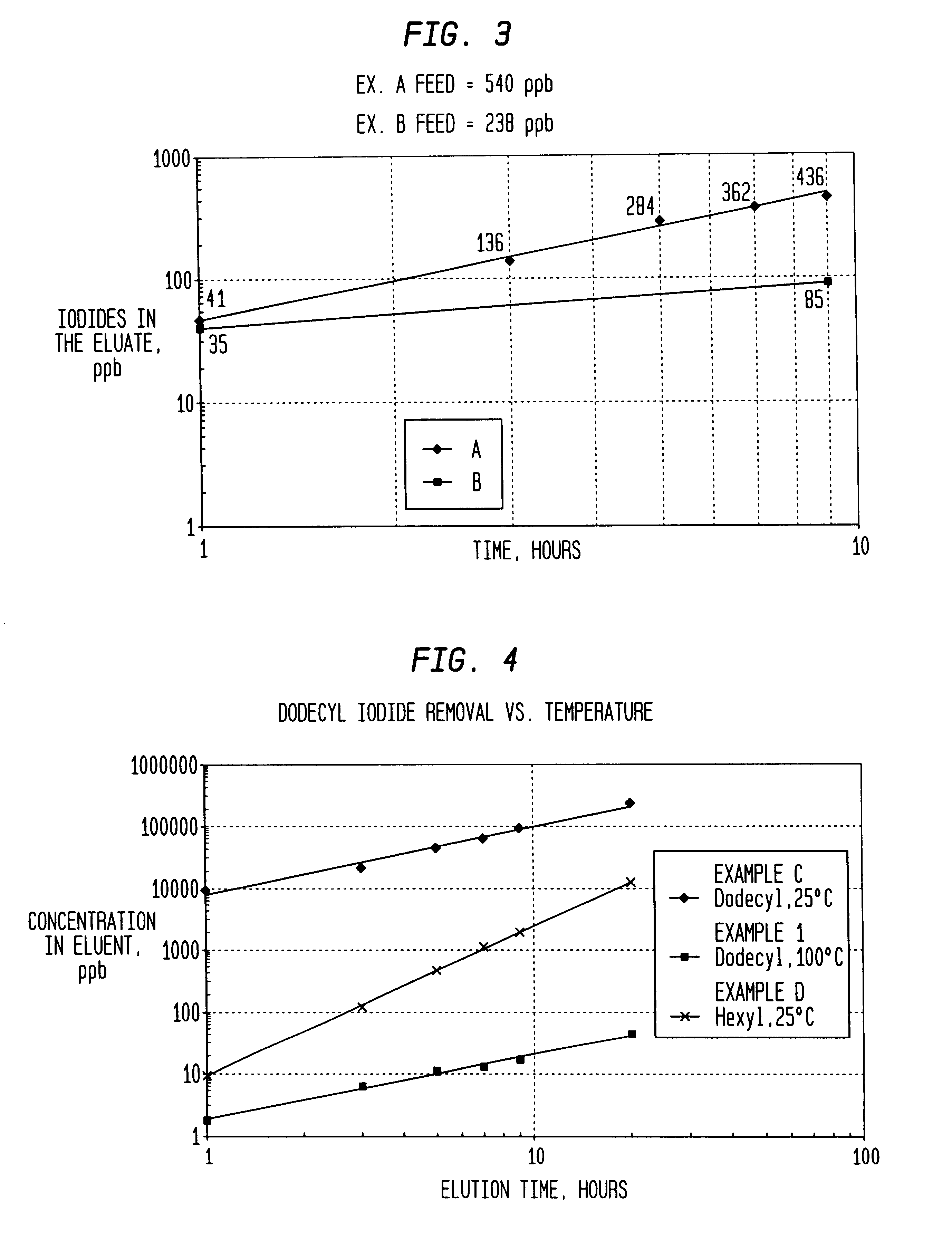

Low energy carbonylation process

InactiveUS6657078B2Weaken energyHigh purityOrganic compound preparationOrganic chemistry methodsPropanoic acidIodide

A low energy process for producing acetic acid by the carbonylation of methanol is disclosed. The process involves a rhodium-catalyzed system operated at less than about 14% water utilizing up to 2 distillation columns. The process is preferably controlled such that the product stream has a low level of propionic acid impurity and the level of aldehyde impurities is minimized by way of aldehyde removal or minimizing aldehyde generation. The level of iodides is controlled by contacting the product, at elevated temperatures, with ion exchange resins. In preferred embodiments, at least one silver or mercury exchanged macroreticular strong acid ion exchange resin is used to purify the product. The high temperature treatment provides the added benefit of controlling the Color Value (Pt-Co units) of the product stream.

Owner:CELANESE INT CORP

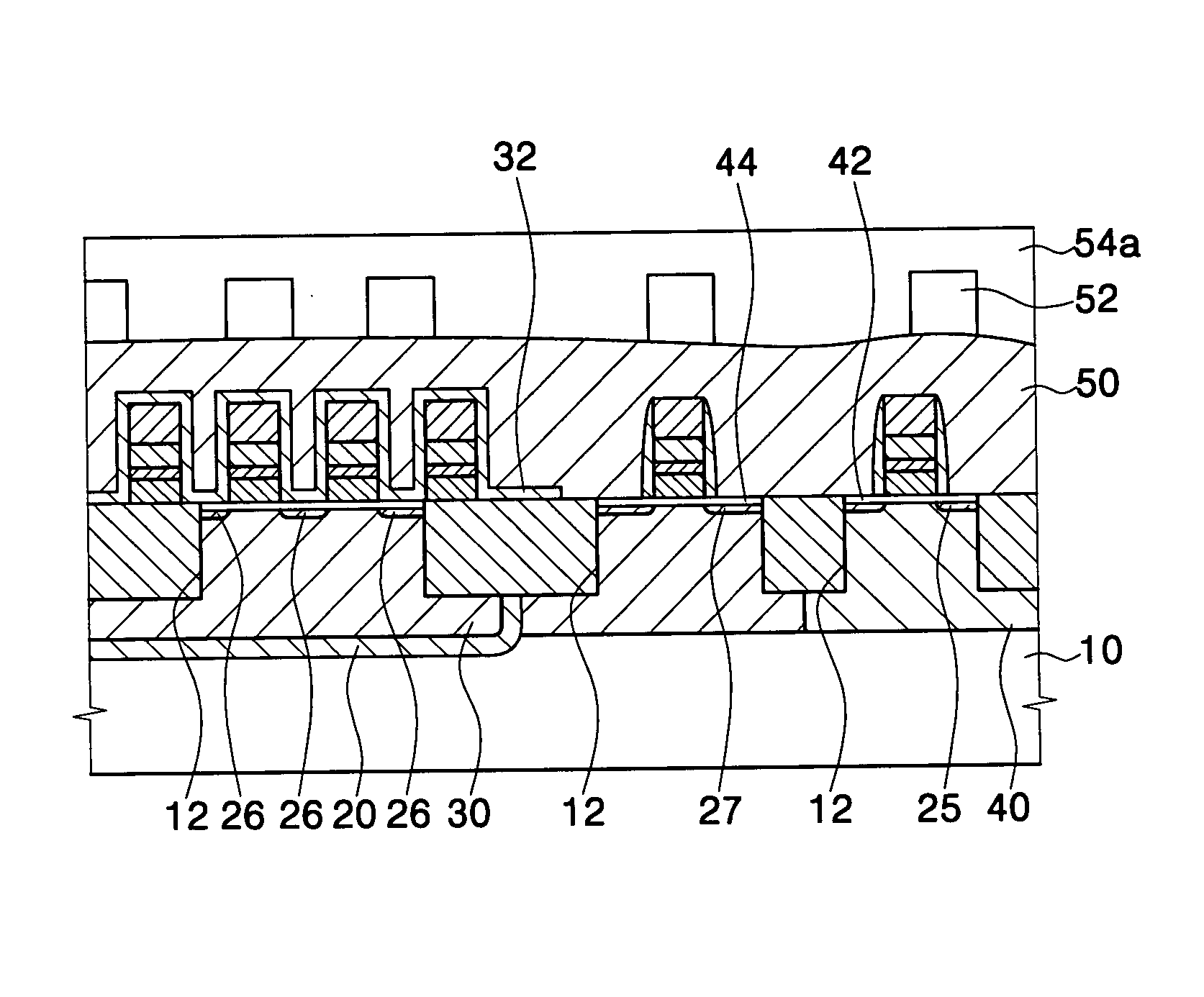

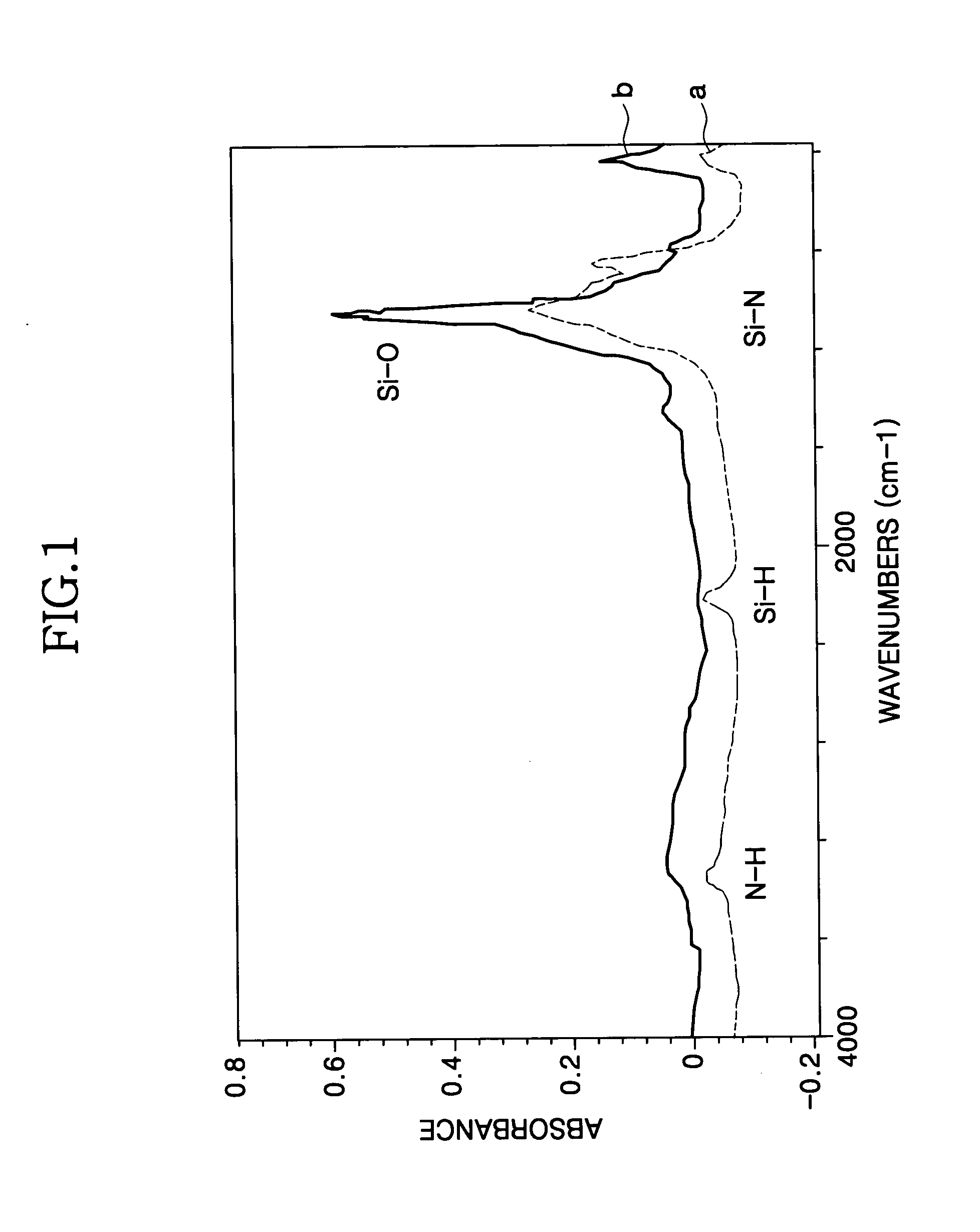

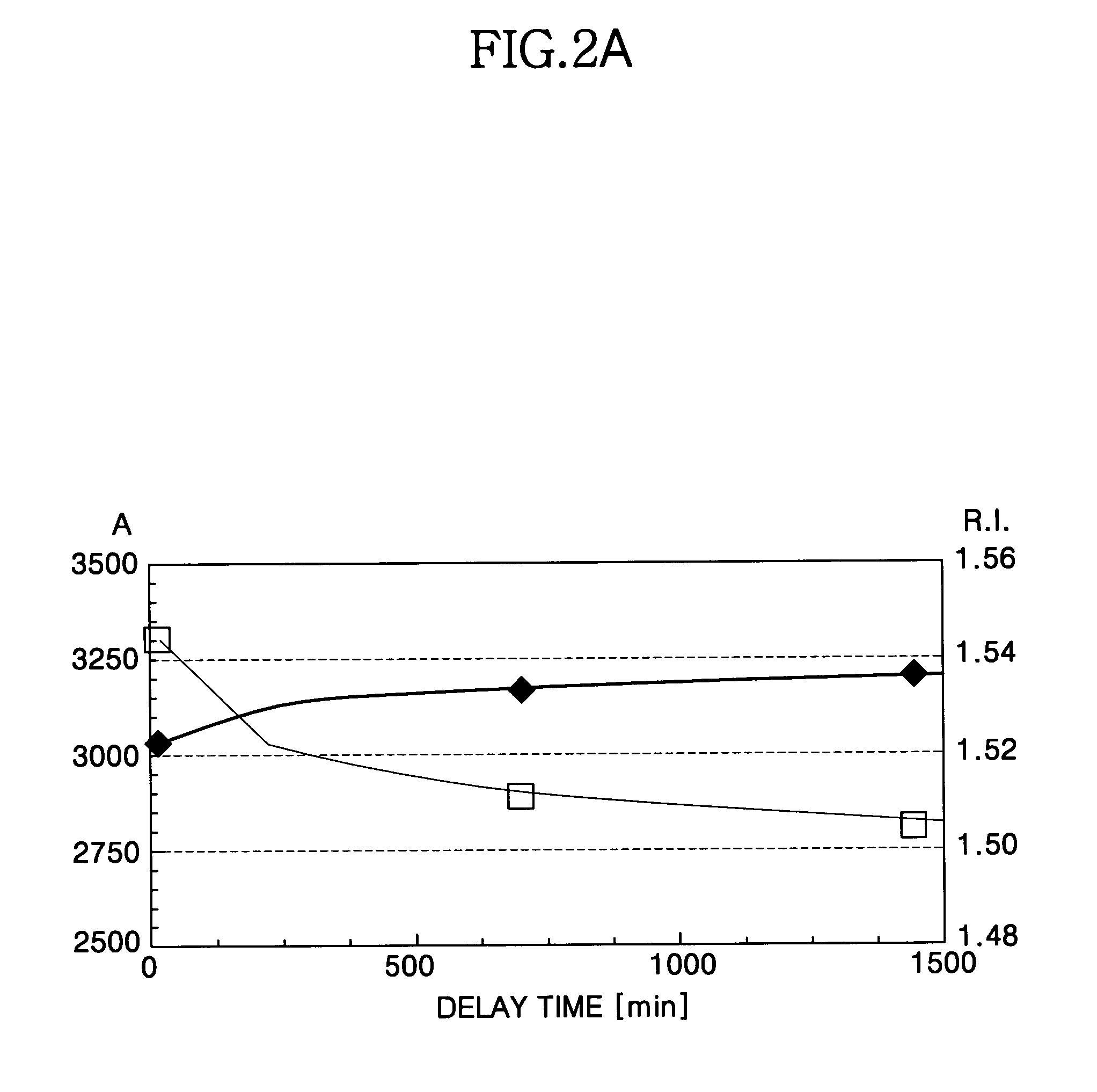

Method for forming a silicon oxide layer using spin-on glass

A method is provided for forming silicon oxide layers during the processing of semiconductor devices by applying a SOG layer including polysilazane to a substrate and then substantially converting the SOG layer to a silicon oxide layer using an oxidant solution. The oxidant solution may include one or more oxidants including, for example, ozone, peroxides, permanganates, hypochlorites, chlorites, chlorates, perchlorates, hypobromites, bromites, bromates, hypoiodites, iodites, iodates and strong acids.

Owner:SAMSUNG ELECTRONICS CO LTD

Process for production of steviosides from stevia rebaudiana bertoni

A process for the production of steviosides from Stevia rebaudiana Bertoni includes extraction of comminuted plant material by directly injecting steam into the extractor followed by filtration to get aqueous extract and alkali treatment to remove unwanted compounds in the form of precipitate. The treated aqueous extracted was filtered and the filtrate was first treated with gel or macroporous strong acid cation exchange resin and then with gel or macroporous weak base anion exchange resin. The aqueous eluant containing steviosides was concentrated to obtain purified steviosides.

Owner:COUNCIL OF SCI & IND RES

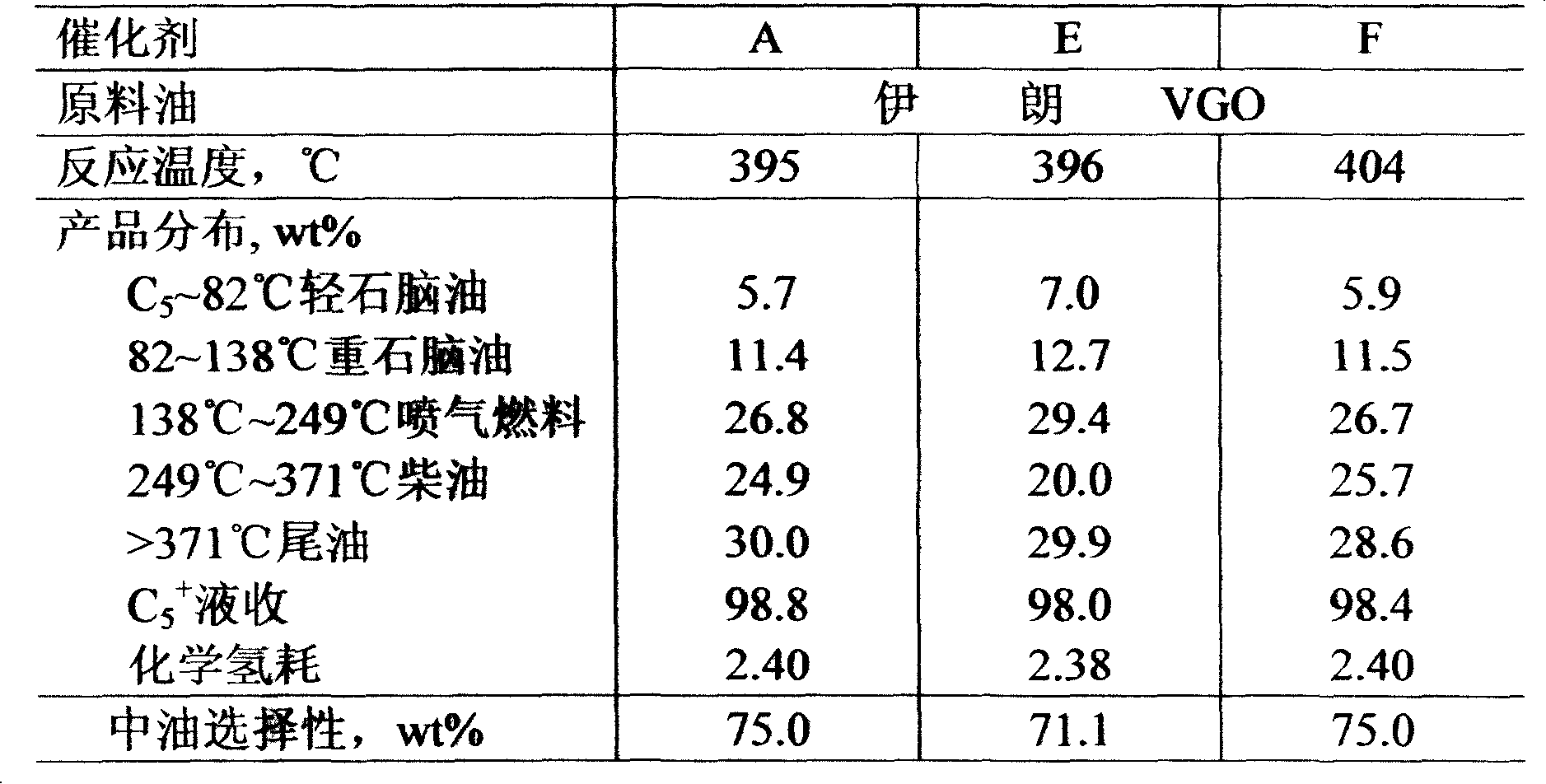

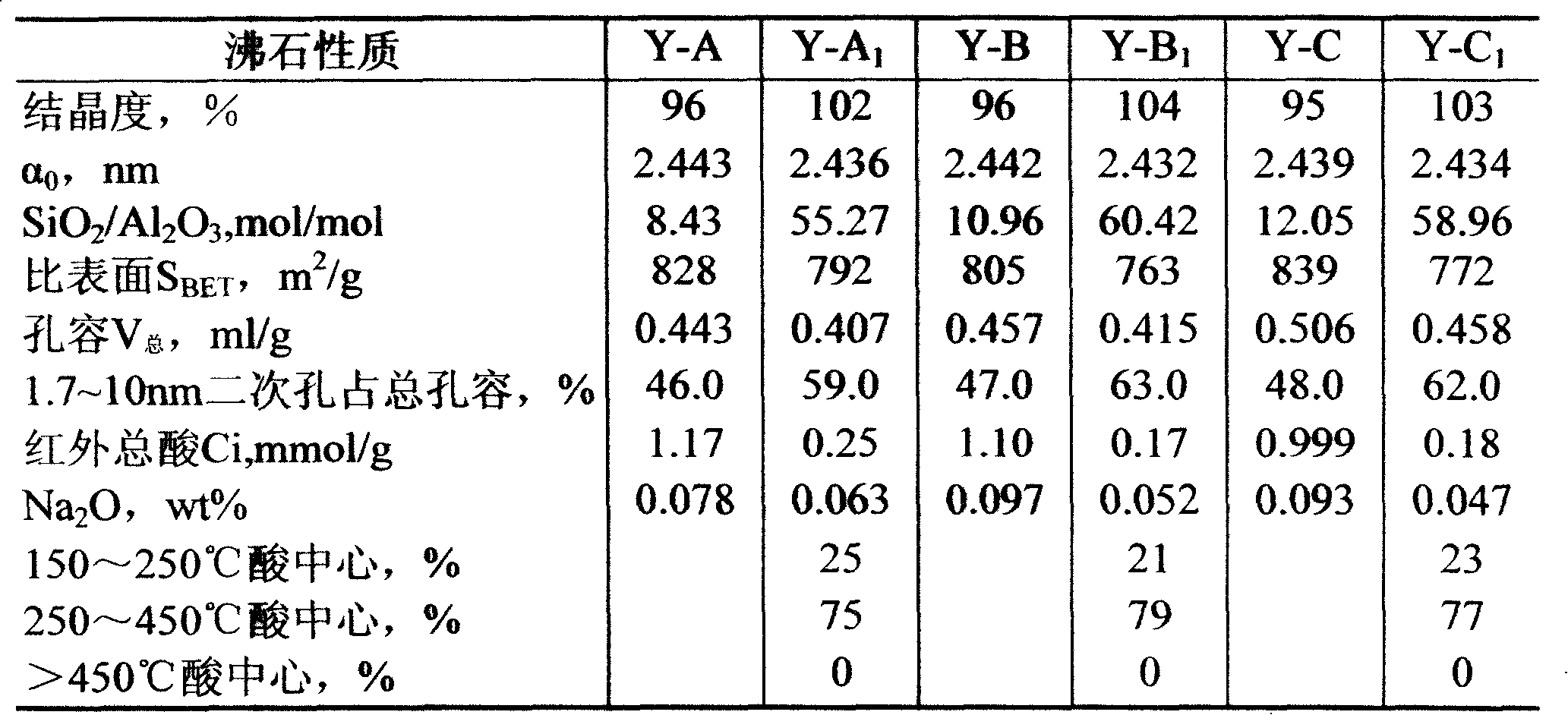

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

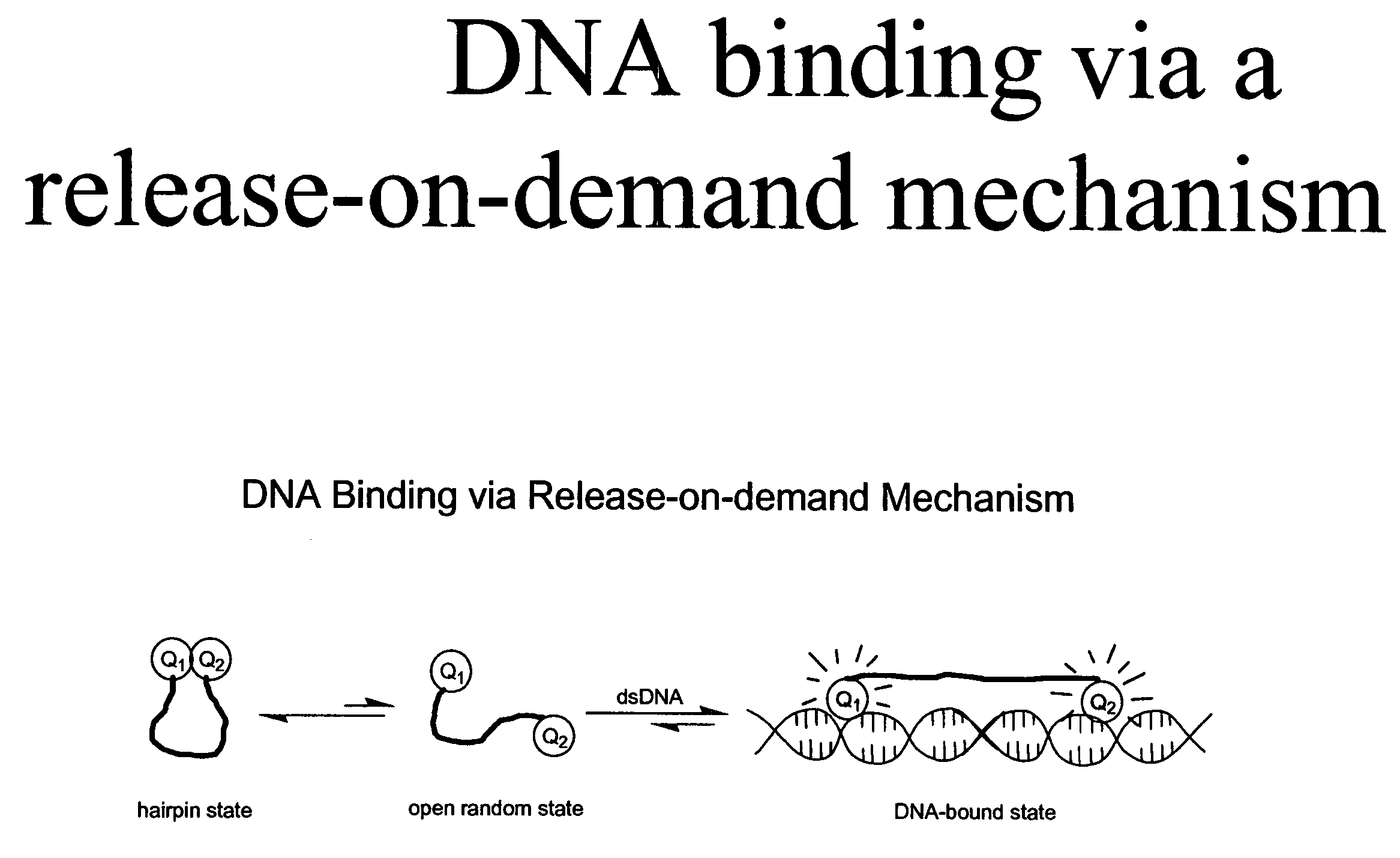

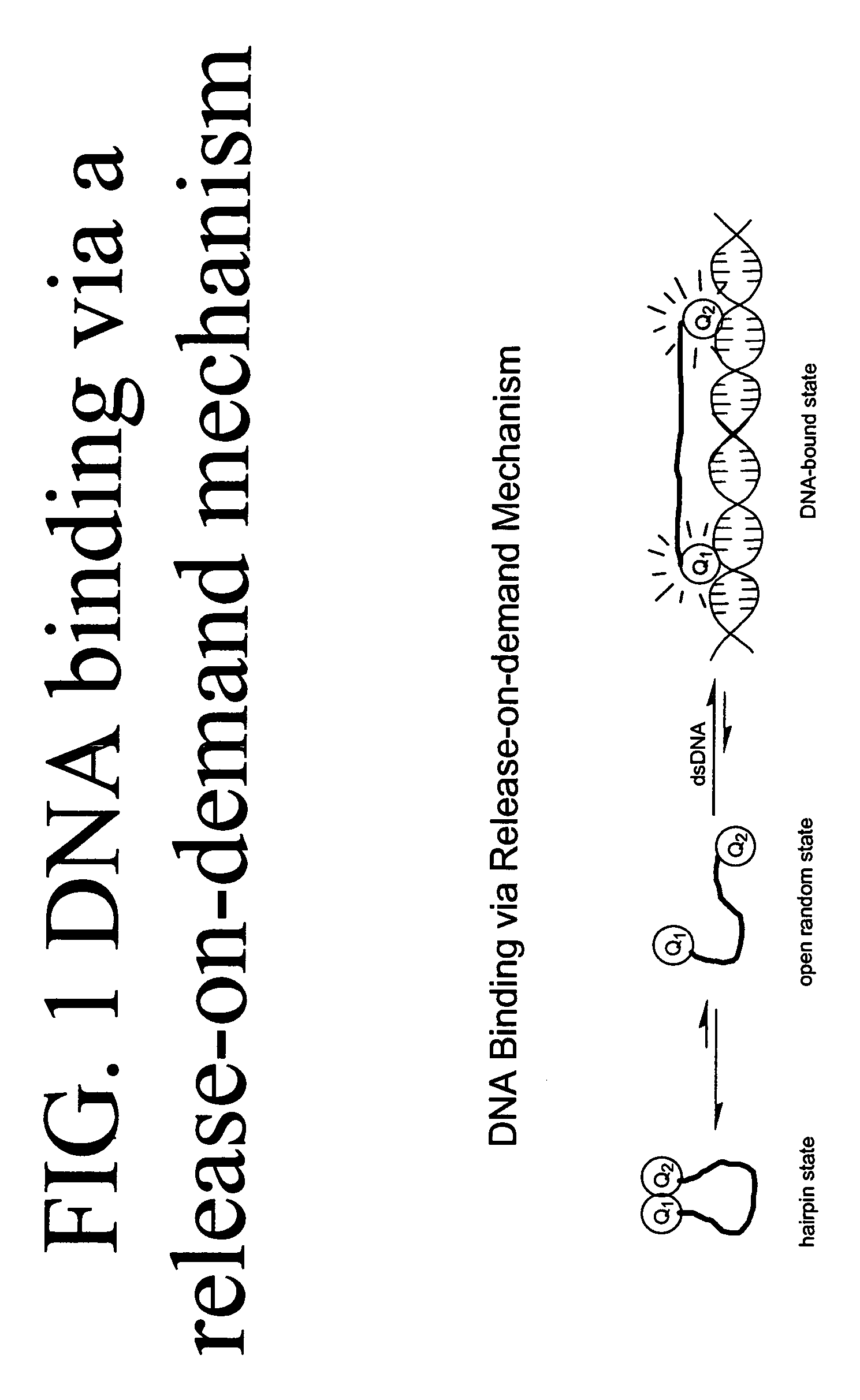

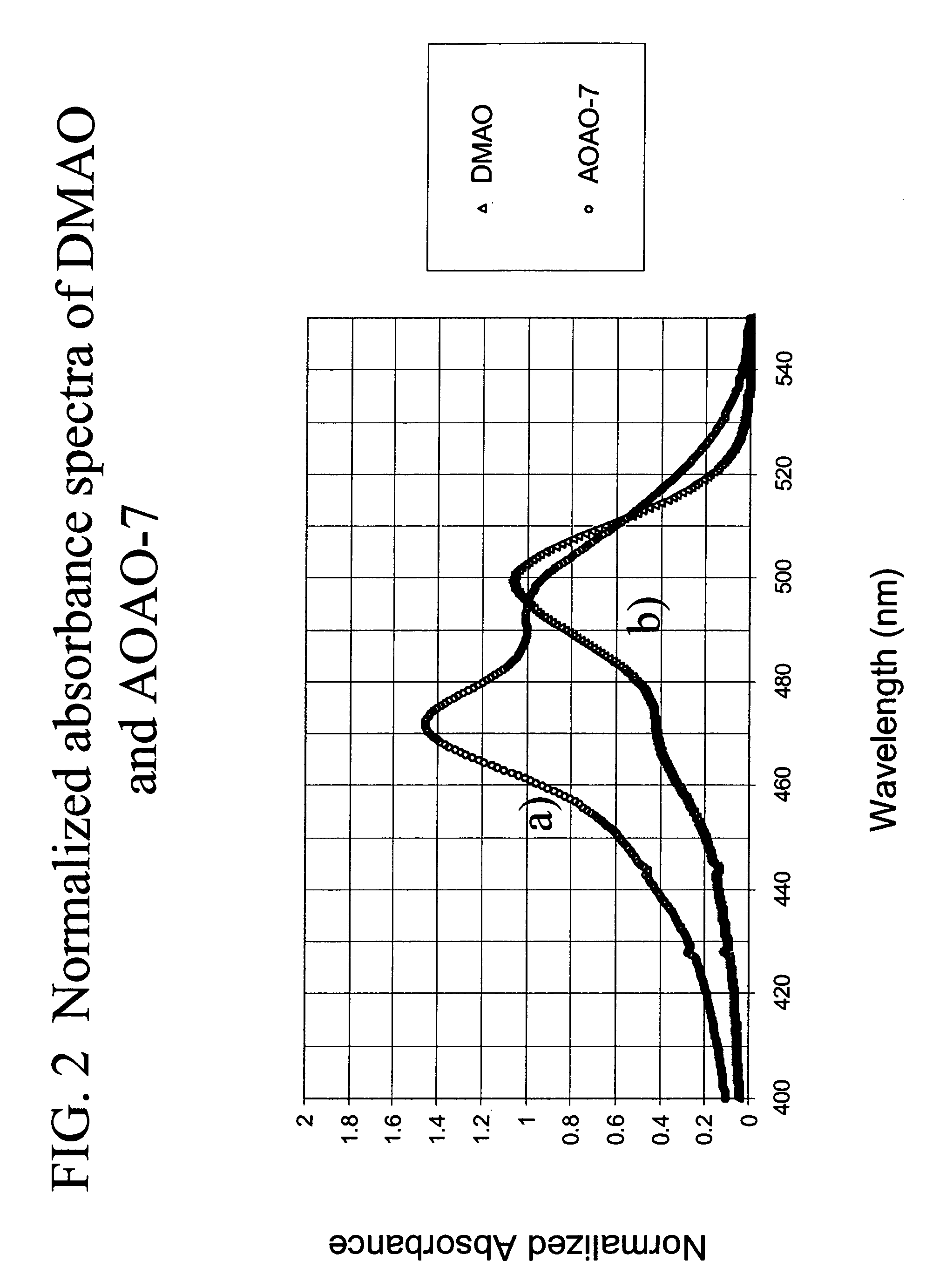

Methods of using dyes in association with nucleic acid staining or detection and associated technology

ActiveUS7601498B2Low toxicityIncrease signal strengthMethine/polymethine dyesSugar derivativesNucleic acid detectionStaining

Methods of using dyes and associated technology are provided. A dye, such as a monomeric dye or a dimeric dye, may be used in a nucleic acid gel staining application and / or a nucleic acid detection application. Such a dye and a salt that comprises an anion that is associated with a strong acid and a cation that is associated with a strong base may be used in such an application. A dimeric dye, such as a dimeric dye capable of forming a hairpin-like structure, may be used to stain and / or detect nucleic acids via a release-on-demand mechanism. A dimeric dye having low background fluorescence in the absence of nucleic acids and high fluorescence in the presence of nucleic acids, upon binding therewith, may be used to stain and / or detect nucleic acids.

Owner:BIOTIUM INC

Preparation method for aluminum oxide by direct forming method

InactiveCN102923744AReduce drynessReduce stepsAluminium oxide/hydroxide preparationAluminium hydroxide preparationHydrated aluminaAluminium hydroxide

The invention discloses a preparation method for aluminum oxide by a direct forming method. The method is characterized in that the aluminum oxide is directly formed by a wet filter cake, wherein pore volume is 0.3-0.8ml / g; a specific surface area is 150-300 m<2> / g; and crushing strength is 30-120 N / particle; the preparation process comprises the steps: a) meta-aluminate containing aluminum or a strong acid salt compound is neutralized with a precipitator solution at a temperature of 30-80 DEG C and pH of 6-9; accessory ingredient is added in a neutralizing process; mixture is aged for at least 10min after neutralizing; b) prepared aluminium hydroxide gel is washed by de-ionized water for 4-10 times; dosage of the de-ionized water for each time is 10-40 times of mass of a dried substrate of prepared aluminium hydroxide; a hydrated alumina filter cake is obtained after washing and filtering; content of the aluminium hydroxide in the filter cake is controlled to be 5-50%; and c) the accessory ingredient is added into one or various liquid in the step a) and step b); the filter cake after washing is formed by a normal forming method; and the formed filter cake is dried at a temperature of 80-120 DEG C and calcined at a temperature of 450-1000 DEG C to obtain a finished product of the aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Environment-friendly metal surface treating agent and using method thereof

InactiveCN101701336ALarge specific surface areaStrong corrosion resistanceMetallic material coating processesStrong acidsFluoride

The invention discloses an environment-friendly metal surface treating agent and a using method thereof. The treating agent comprises fluoride, zircon salt, silane, silicon dioxide, accelerating agent, dispersing agent and stabilizing agent. A conversion coating having the advantages of being compact and even, strong in corrosion resistance and excellent in adhesive force of the coating is respectively formed on the metal surface of steel and zinc; a treatment method of the metal surface treating agent is simple and is operated at the normal temperature; the original phosphating treatment equipment can be used without any change; and strong acid and strong base are not used as the treating agent; therefore, the environment-friendly metal surface treating agent is safe in production without emission, and is the best substitute product of the phosphating treatment technique and an energy-saving type environment-friendly product.

Owner:芜湖市瑞杰环保材料科技有限公司

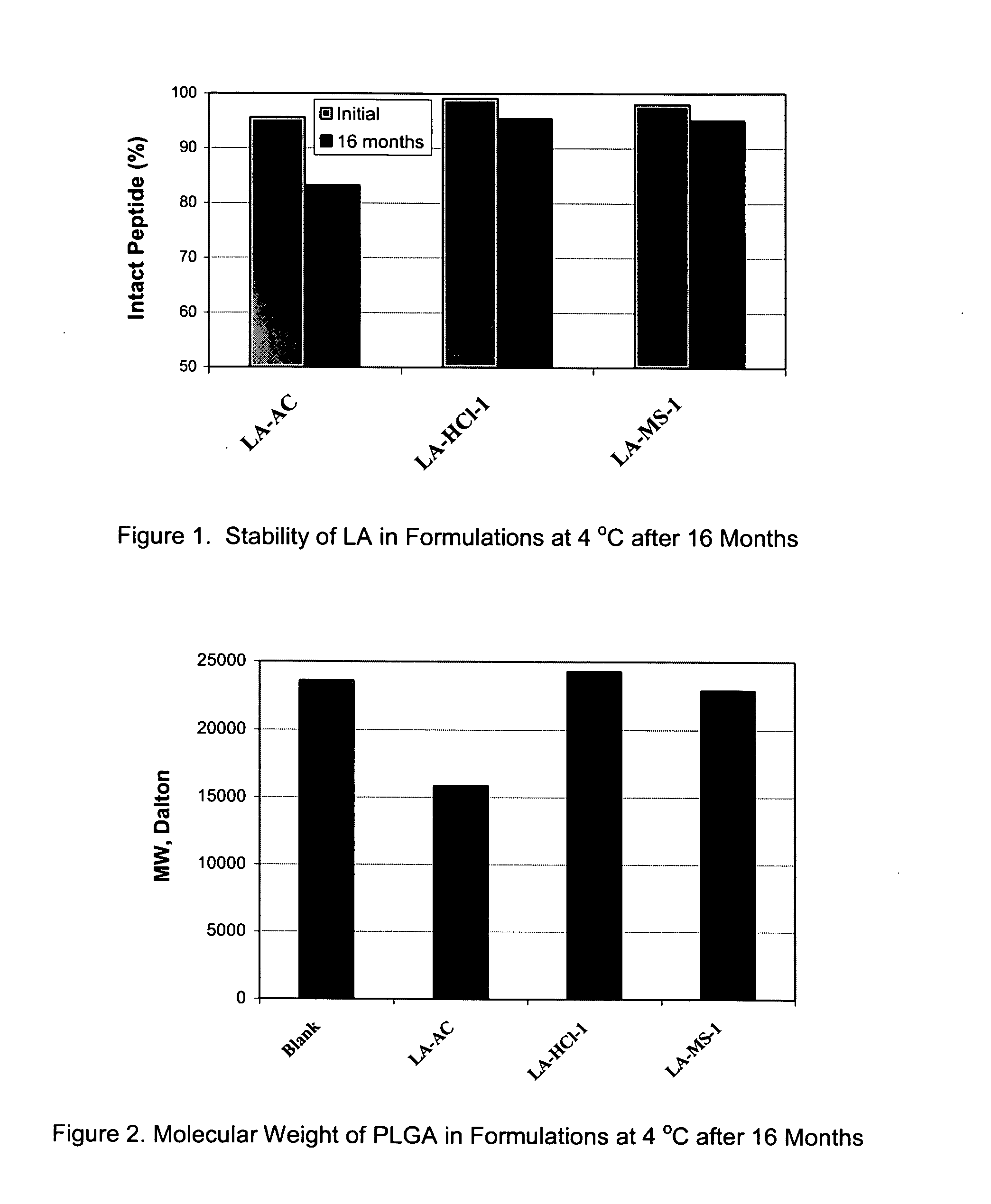

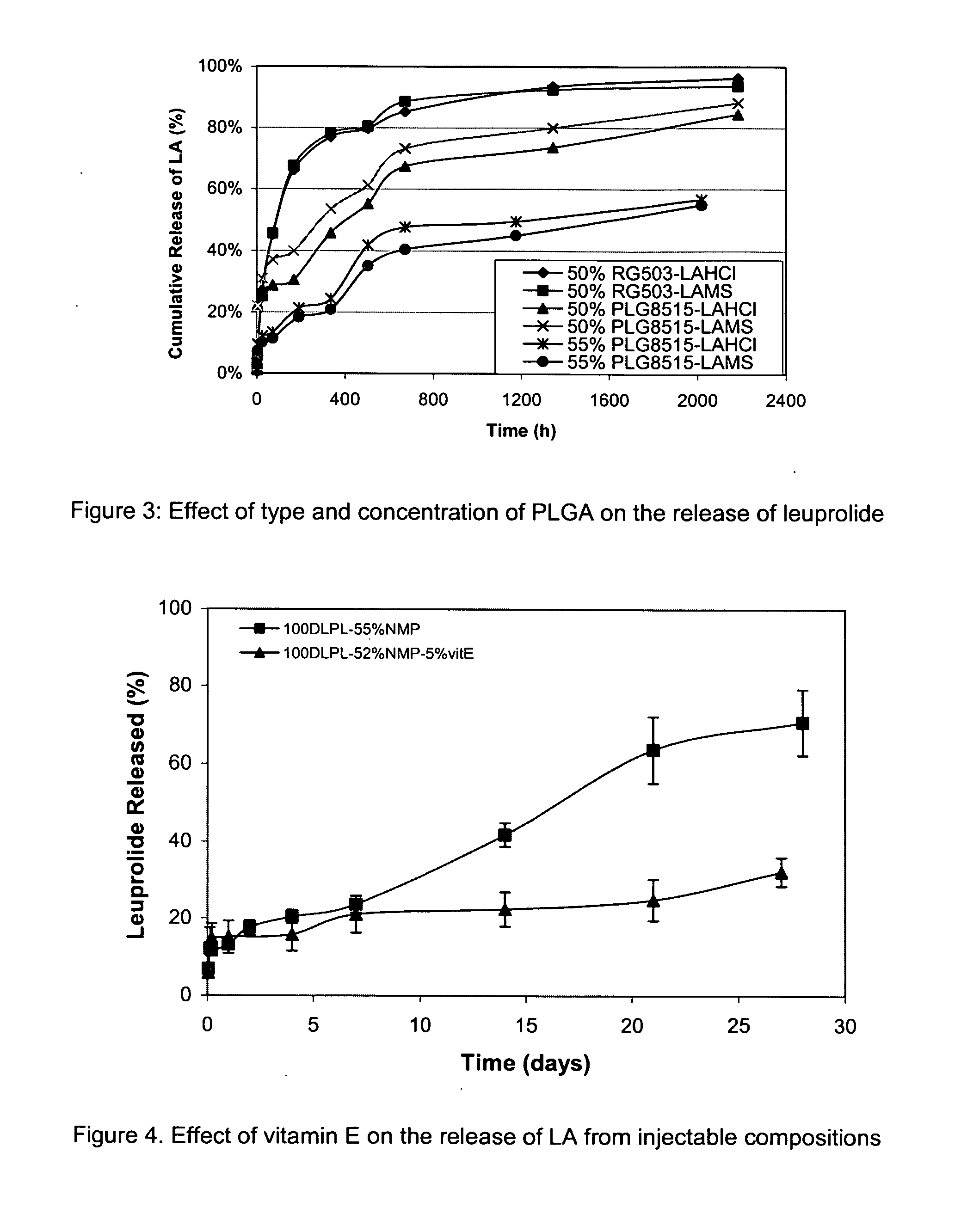

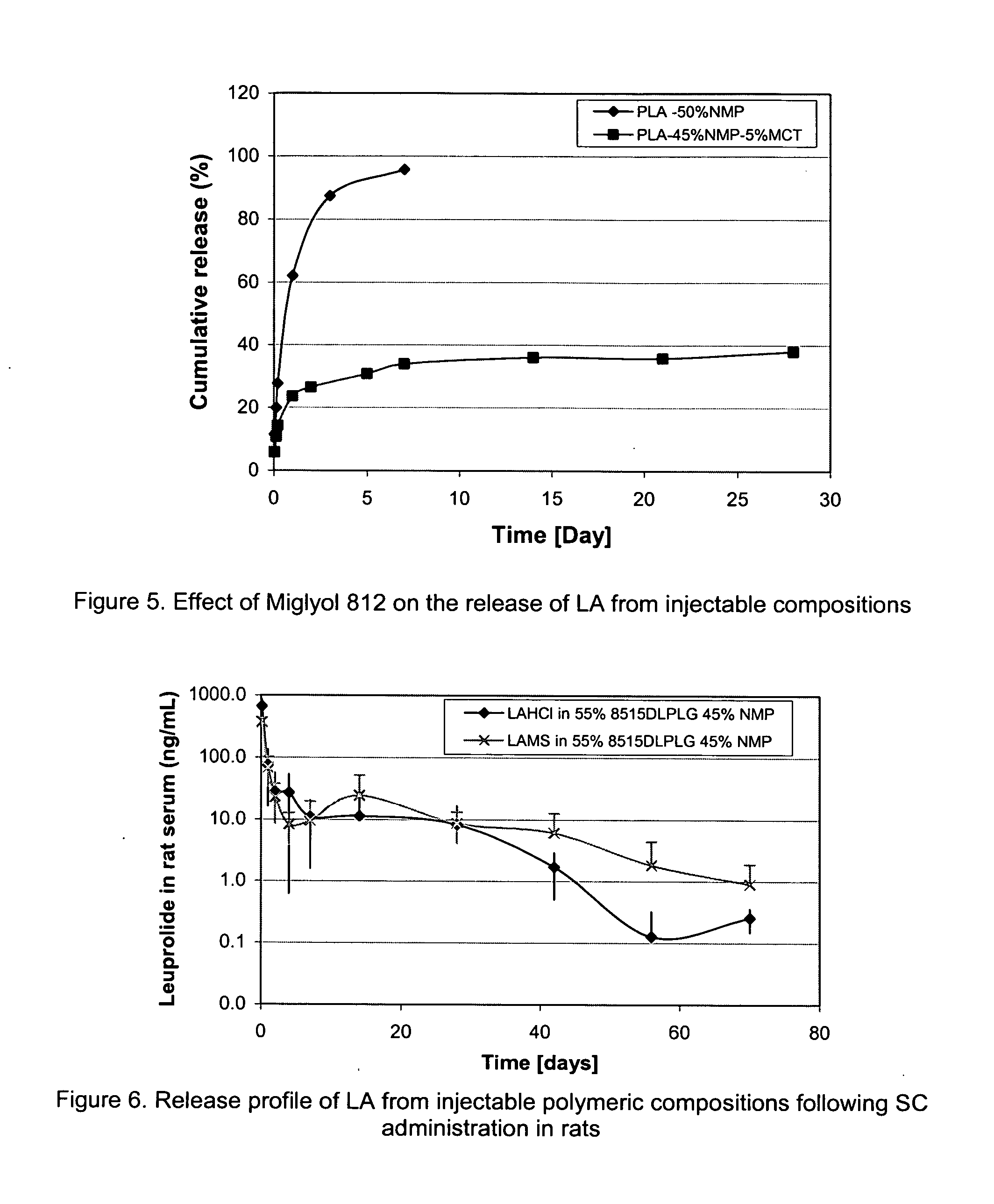

Pharmaceutical compositions with enhanced stability

InactiveUS20070196416A1Improve stabilitySatisfied with stabilityPowder deliveryPeptide/protein ingredientsOrganic solventControl release

The present invention provides for a stabilized biodegradable polymeric composition useful as a controlled release delivery system for peptide agents. The compositions of the present invention comprise a) a beneficial salt of a peptide agent formed with a strong acid that minimizes or prevents the interaction / reaction between the peptide agent and the polymer in an organic solution; b) a biodegradable polymer; c) a pharmaceutically acceptable organic solvent; and d) optionally one or more excipients. The present invention also relates to a method of manufacturing and a method of use thereof.

Owner:FORESEE PHARMA CO LTD

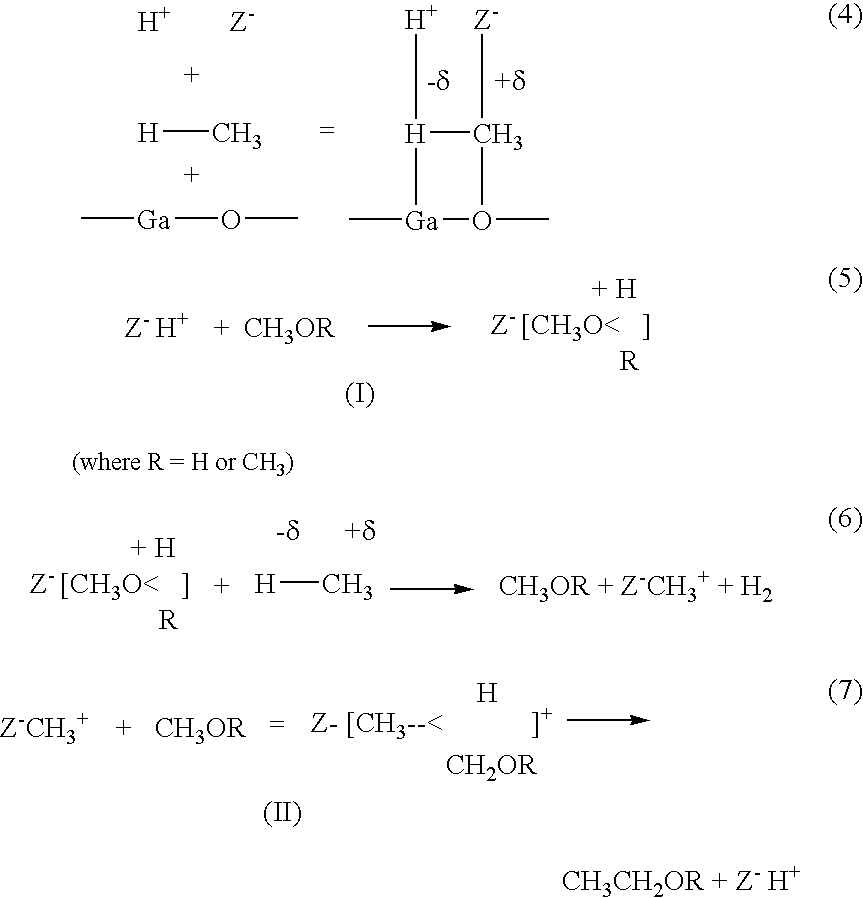

Process for the simultaneous conversion of methane and organic oxygenate to C2 to C10 hydrocarbons

A process for the non-oxidative conversion of methane simultaneously with the conversion of an organic oxygenate, represented by a general formula: CnH2n+1OCmH2m+1, wherein C, H and O are carbon, hydrogen and oxygen elements, respectively; n is an integer having a value between 1 and 4; and m is an integer having a value between zero and 4, to C2+ hydrocarbons, particularly to gasoline range C6–C10 hydrocarbons and hydrogen, using a bifunctional pentasil zeolite catalyst, having strong acid and dehydrogenation functions, at a temperature below 700° C. is disclosed. In this process the moles of methane converted per mole of oxygenate converted is above 1.0, depending upon the process conditions.

Owner:COUNCIL OF SCI & IND RES

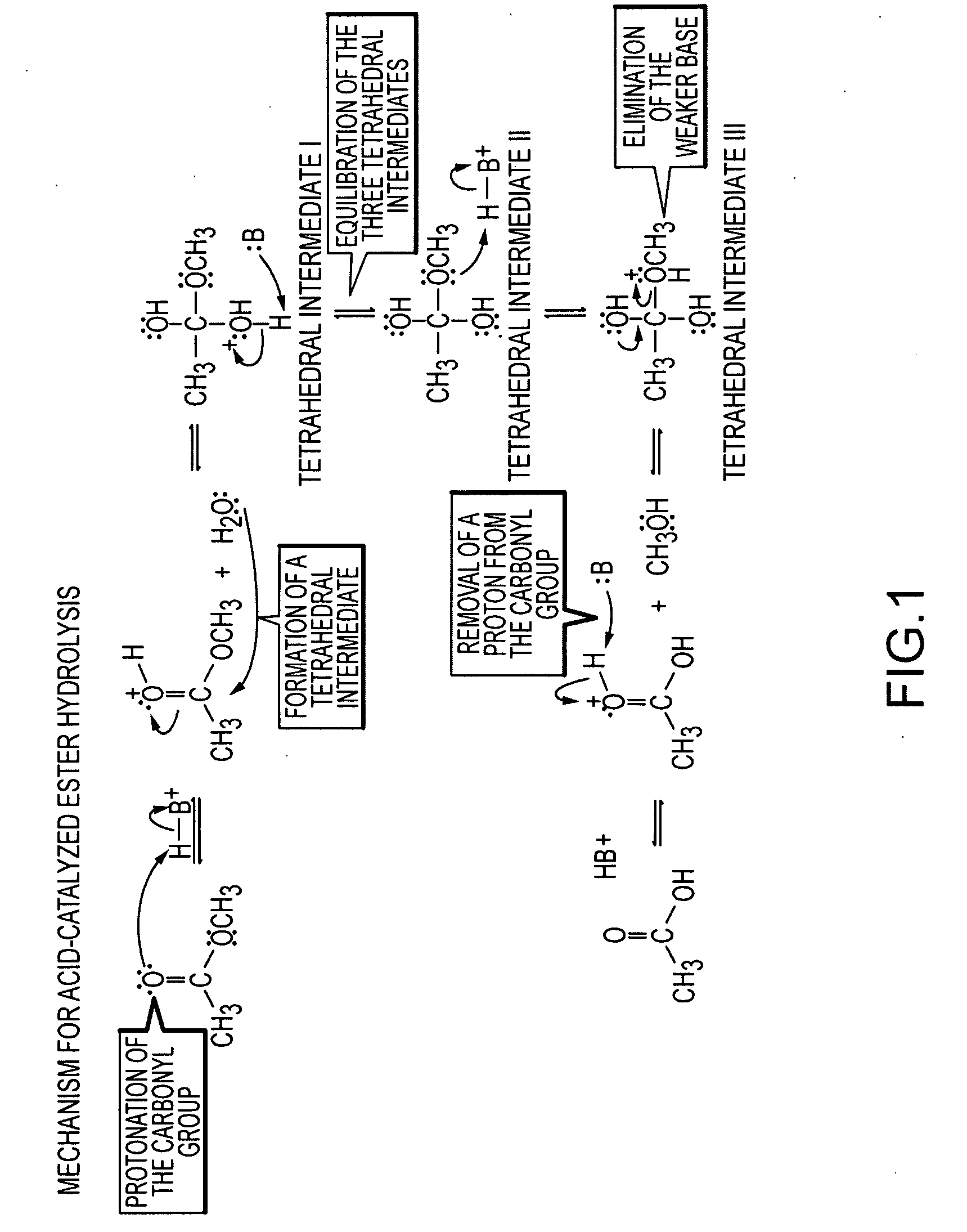

Continuous algal biodiesel production facility

Embodiments of the present invention concern methods, compositions, and apparatus for the continuous conversion of algal lipids into biodiesel. In some embodiments, the biodiesel is formed in a multi-step sequence, the first steps occurring in the presence of water and a strong acid wherein the lipids are released from the algae by means of mechanical and chemical action and are then hydrolyzed to free fatty acids. In a subsequent step, this free fatty acid mixture is reacted with methanol to generate fatty acid methyl esters (also known as biodiesel). Such methods produce biodiesel from algal lipids without the requirement for separate algal cell lysis or lipid extraction or purification prior to the acid catalysis sequence. In other embodiments, the multi-step acid catalysis sequence occurs at 100° C. at two atmospheres of pressure.

Owner:COLORADO STATE UNIVERSITY +1

Method for extracting tungsten, titanium and vanadium from waste SCR (selective catalytic reduction) catalyst

InactiveCN102936049ASolve the pollution of the environmentLow equipment requirementsTungsten oxides/hydroxidesTitanium dioxideSlagStrong acids

The invention discloses a method for extracting tungsten, titanium and vanadium from a waste SCR (selective catalytic reduction) catalyst, which comprises the following steps: crushing the waste SCR catalyst, adding a strongly alkaline solution, and reacting; filtering, separating, then adding strong acid into the sodium tungstate and sodium vanadate mixed solution, and reacting to obtain tungstic acid and a sodium salt and vanadic acid mixed solution; regulating the pH value of the sodium salt and vanadic acid mixed solution until precipitate is separated out, thus obtaining ammonium vanadate; then adding sulfuric acid into the tungsten-and-vanadium-removed SCR catalyst, and reacting to obtain a titanyl sulfate solution and solids such as aluminum slag and the like; then adding water into the titanyl sulfate solution, and hydrolyzing to obtain titanic acid and a waste acid solution; and finally, respectively calcining the obtained ammonium vanadate, tungstic acid and titanic acid to obtain vanadium pentoxide, tungsten trioxide and titanium dioxide. According to the invention, tungsten, titanium and vanadium can be extracted from the SCR catalyst through the reaction with strong alkali and strong acid at a low temperature, the equipment requirement is low, the energy consumption is low, some products having added values can be coproduced, and no secondary pollution is generated, thereby facilitating popularization and application.

Owner:成都新智金森环保科技有限公司

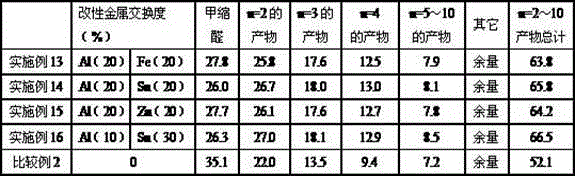

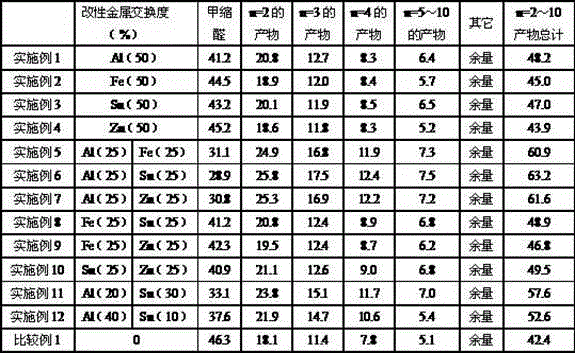

Catalyst for synthesis of polyoxymethylene dimethyl ether and application of catalyst

ActiveCN104549502AHigh yieldEasy to separateOrganic chemistryOrganic compound preparationIon exchangeStrong acids

The invention relates to a catalyst for synthesis of polyoxymethylene dimethyl ether, application of the catalyst in synthesis of polyoxymethylene dimethyl ether and a method for synthesizing polyoxymethylene dimethyl ether, and mainly aims to solve the problem that the catalyst has low selectivity and low yield for polyoxymethylene dimethyl ether which has a polymierization degree n of 2-10 in the prior art. The technical problem can be well solved by adopting a technical scheme that the catalyst is a metal ion modified hydrogenous strong-acid ion exchange resin, wherein the modifying metal is at least one of Al, Fe, Sn and Zn; and the ion exchange degree of the modifying metal in the catalyst is more than zero and less than or equal to 50 percent. The catalyst can be used in industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

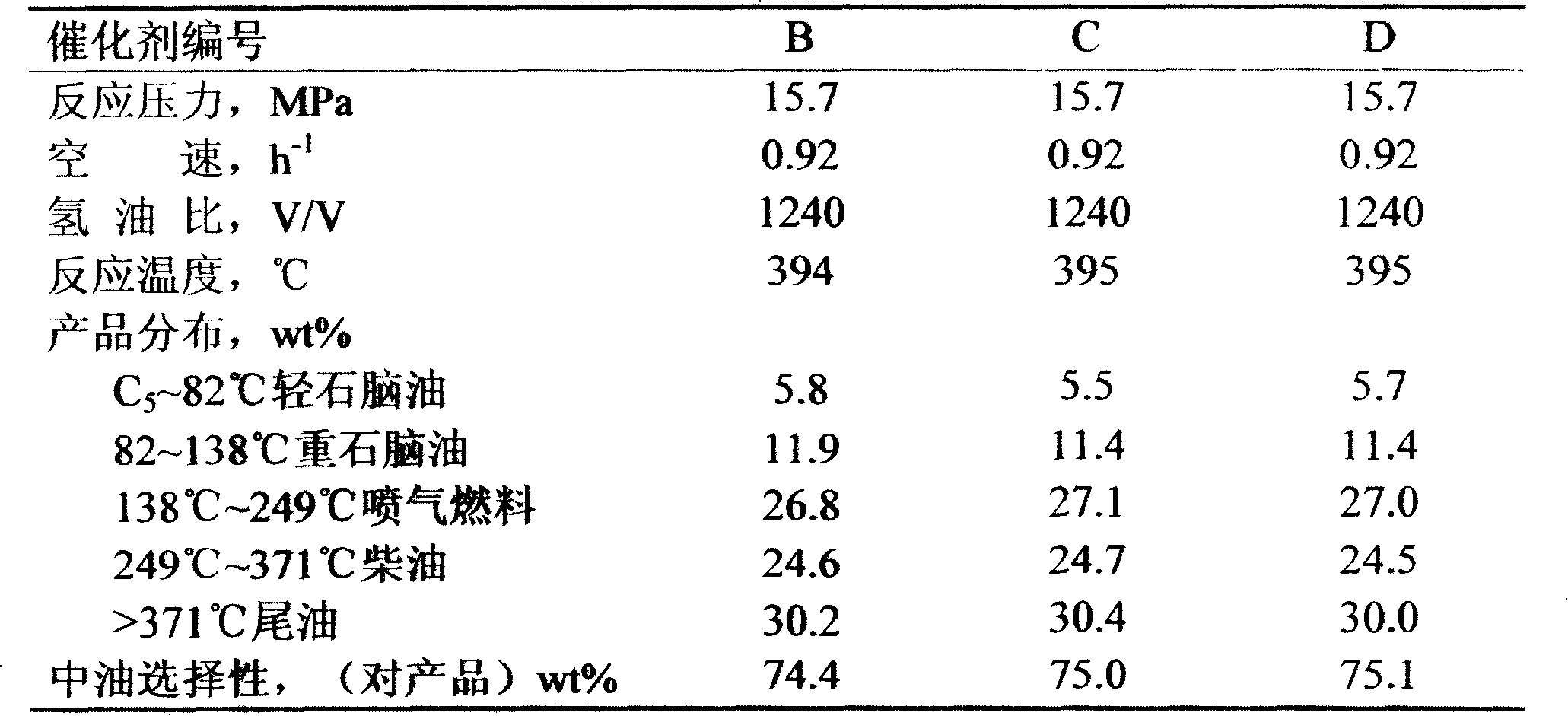

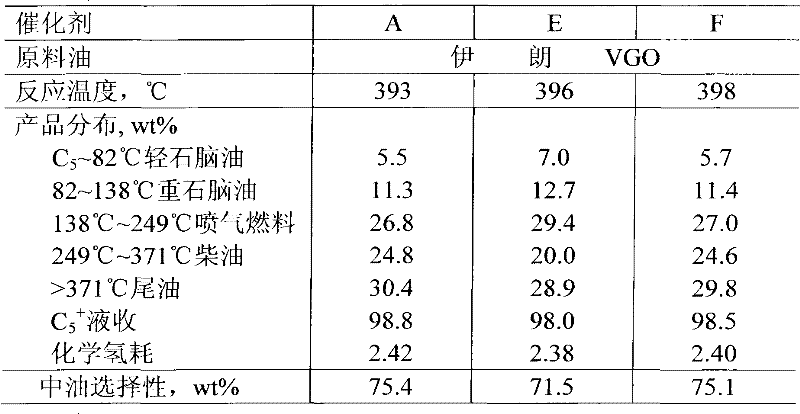

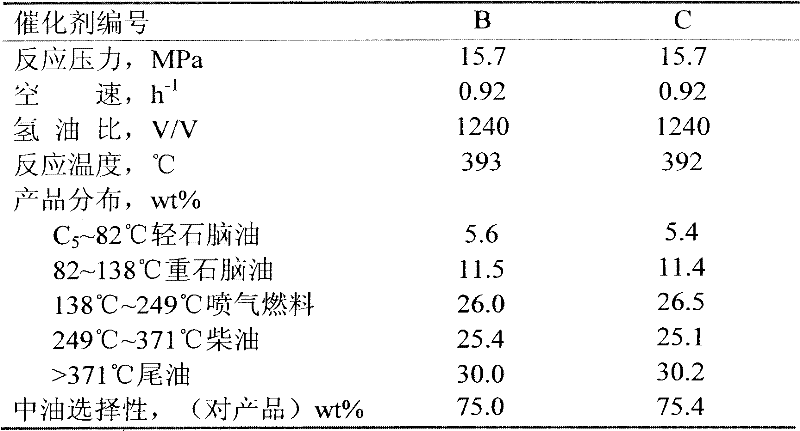

Hydrocracking catalyst with high activity and high-medium oil selectivity and preparation method of hydrocracking catalyst

ActiveCN102441411AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitrogen

The invention relates to a hydrocracking catalyst with high activity and high-medium oil selectivity. According to the hydrocracking catalyst, amorphous silicon aluminum is used as a carrier, and a specially-modified Y-type molecular sieve is used as acid component, the molecular sieve has high degree of crystallization and low cell parameters, rich secondary holes, large surface area, less uniformly-distributed acid sites, no strong acid center, and most of medium-strength acid centers, and also has strong nitrogen-resisting performance and better damage capacity; and the hydrocracking catalyst using the molecular sieve has high hydrocracking activity and high middle oil selectivity, and stronger nitrogen resisting capacity. The catalyst provided by the invention is used in the process of producing an intermediate distillate product by adopting a heavy hydrocarbon single-section or one-section hydrocracking process, and has better activity and middle oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Shelf stable, reduced corrosion, ready to use peroxycarboxylic acid antimicrobial compositions

ActiveUS20090061017A1Advantageous sporicidal activityBiocidePeroxide active ingredientsSporeProtonation

The present invention relates to shelf stable and / or less corrosive peroxycarboxylic acid antimicrobial compositions, including ready-to-use compositions. Shelf stable compositions can include defined ratios of hydrogen peroxide to peroxycarboxylic acid and / or hydrogen peroxide to protonated carboxylic acid, but need not include strong acid. Reduced corrosion compositions can include carboxylic acid and corrosion inhibitor at acid pH. Compositions of the invention can have advantageous activity against spores.

Owner:ECOLAB USA INC

Large-area ultra-thin carbon nanotube film and its preparation process

The large-area untrathin nano carbon tube film with well feature in microcosmic level comprises nano carbon tubes with centimeter-level length and more then 90wt% purity. Wherein, the least thickness of single-layer film can achieve 20nm with near transparent color and more then 10cm2 film area; there are multiple functional groups on tube surface. It also discloses the opposite preparation technique: with the macroscopic body of nano carbon tube, oxidating the macroscopic body in air; then, dipping into hydroperoxide; adding strong acid to poach till the liquid shows neutrality; finally, adding alcohol or acetone into the liquid to float the tube and form the film.

Owner:TSINGHUA UNIV +1

Method of producing a crosslinked coating in the manufacture of integrated circuits

InactiveUS20050215713A1Photosensitive materialsSemiconductor/solid-state device manufacturingResistAnti-reflective coating

The present invention is directed to a method of providing a thermally curable coating composition for to provide positive photoresists layers, underlayers for multiple layer resists, antireflective coatings, bottom layer antireflective coatins, dielectric layers, photoresist layers, hard mask etch stops, in the manufacture of integrated circuits. More particularly, the present invention is directed to a method of using a thermally activable latent acid or a thermal acid generator, a N-benzylpyridinium or N-benzylanilinium salt of a strong acid, as a catalyst in a polymerizable composition suitable for preparing such coatings and layers. The present invention is also directed to novel compositions comprising benzylpyridinium and benzylanilinium salts of a strong acid, such as sulfonic acid or disulfonic acid as thermal acid generators.

Owner:KING INDUSTRIES INC

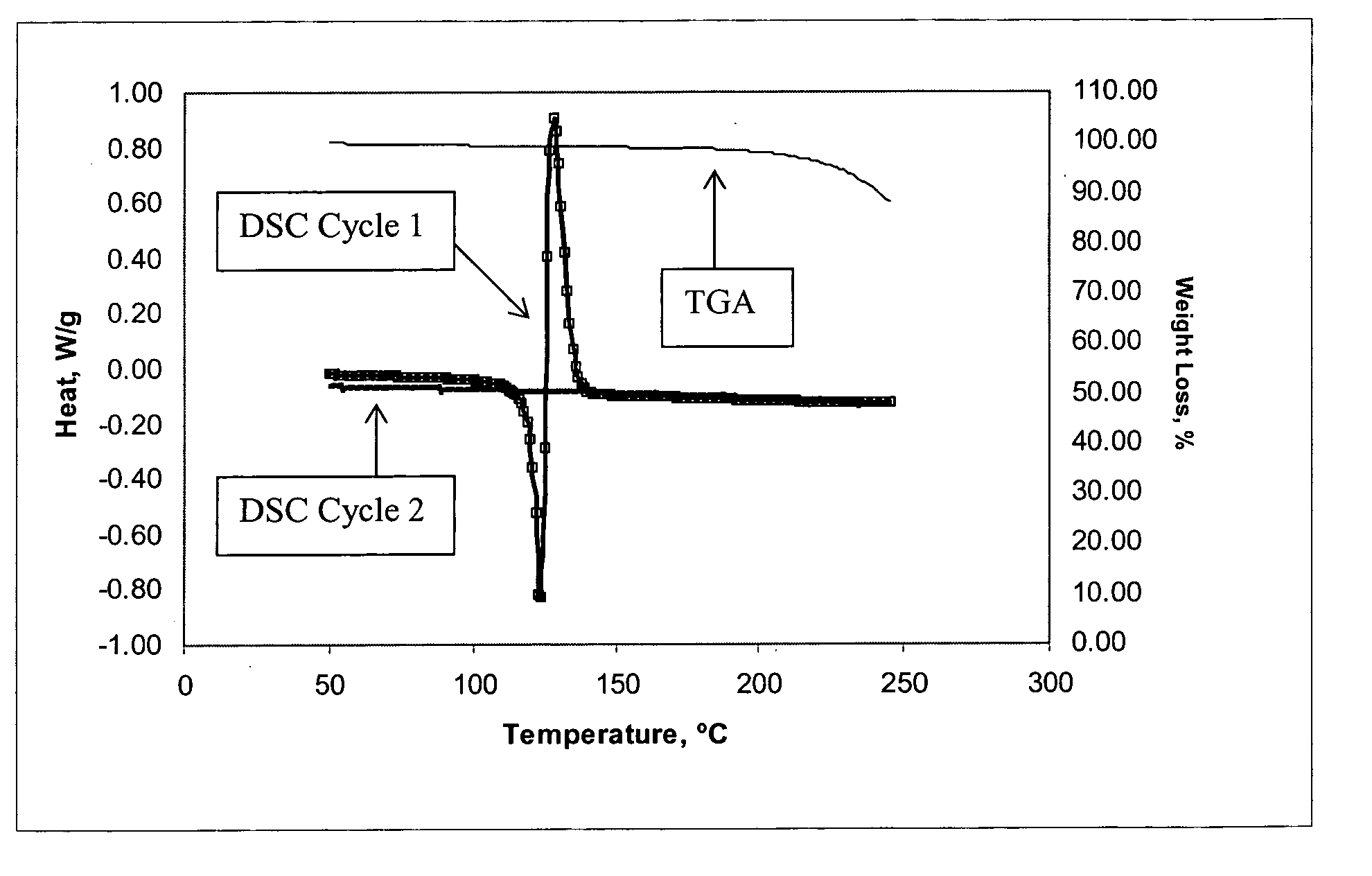

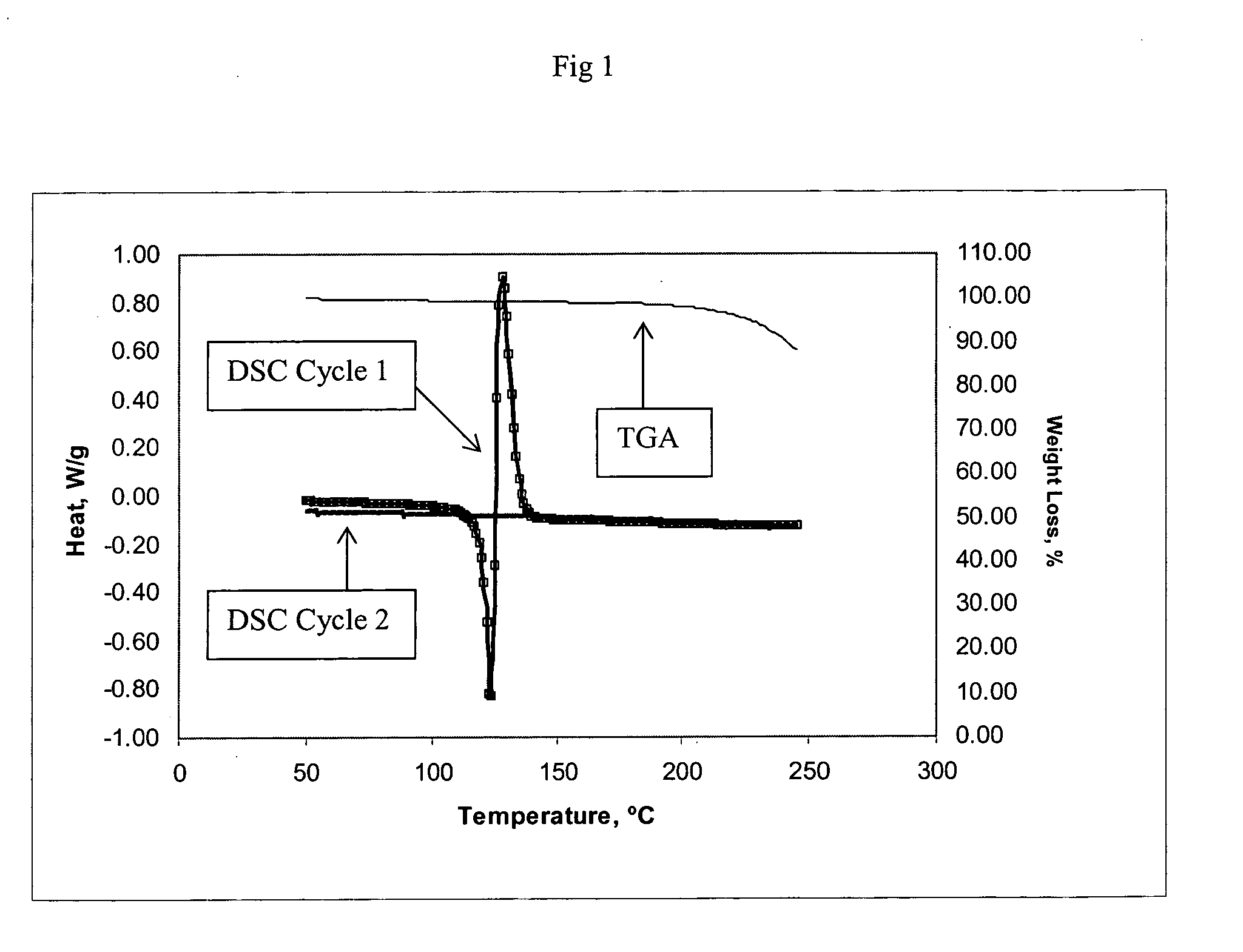

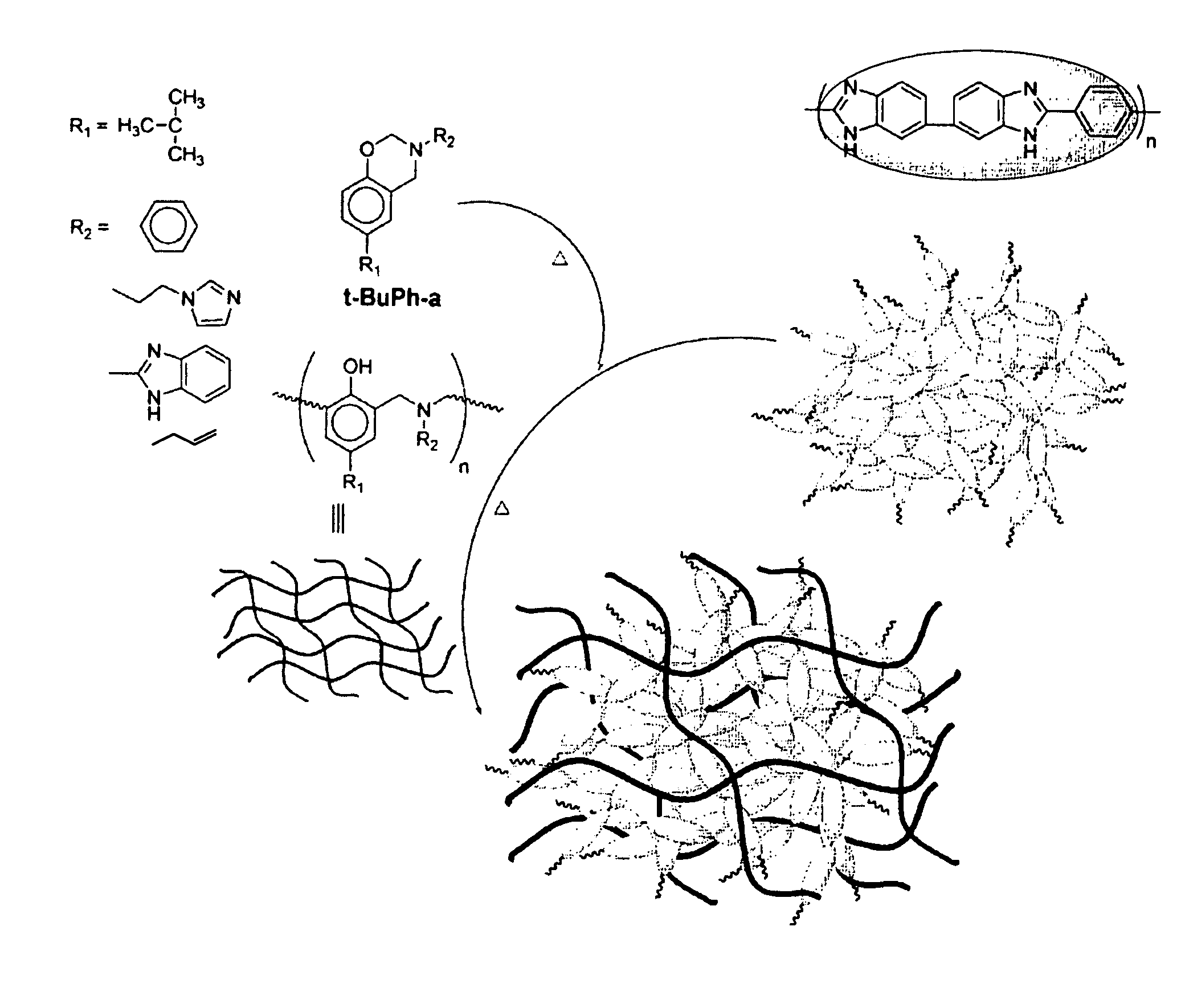

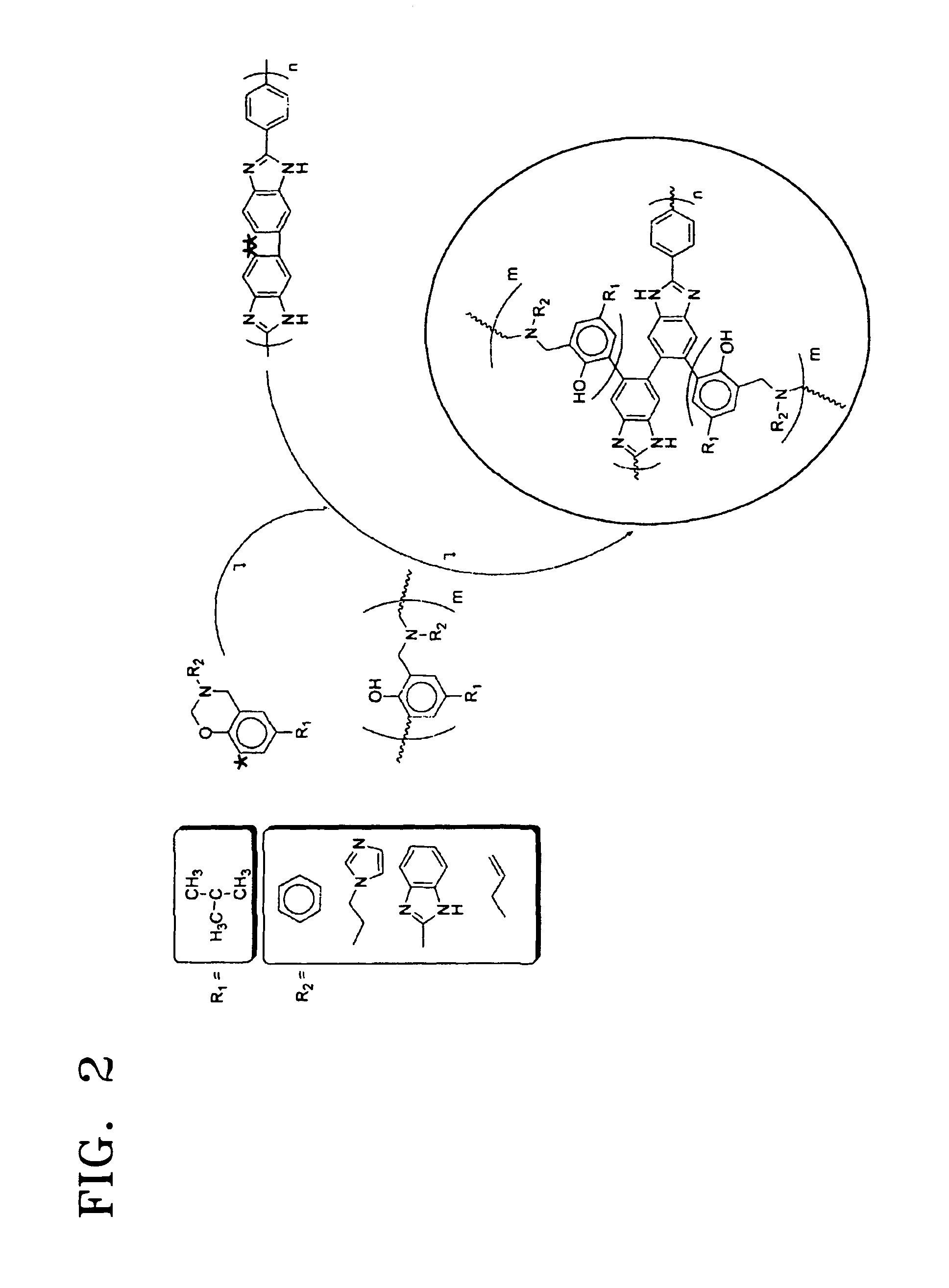

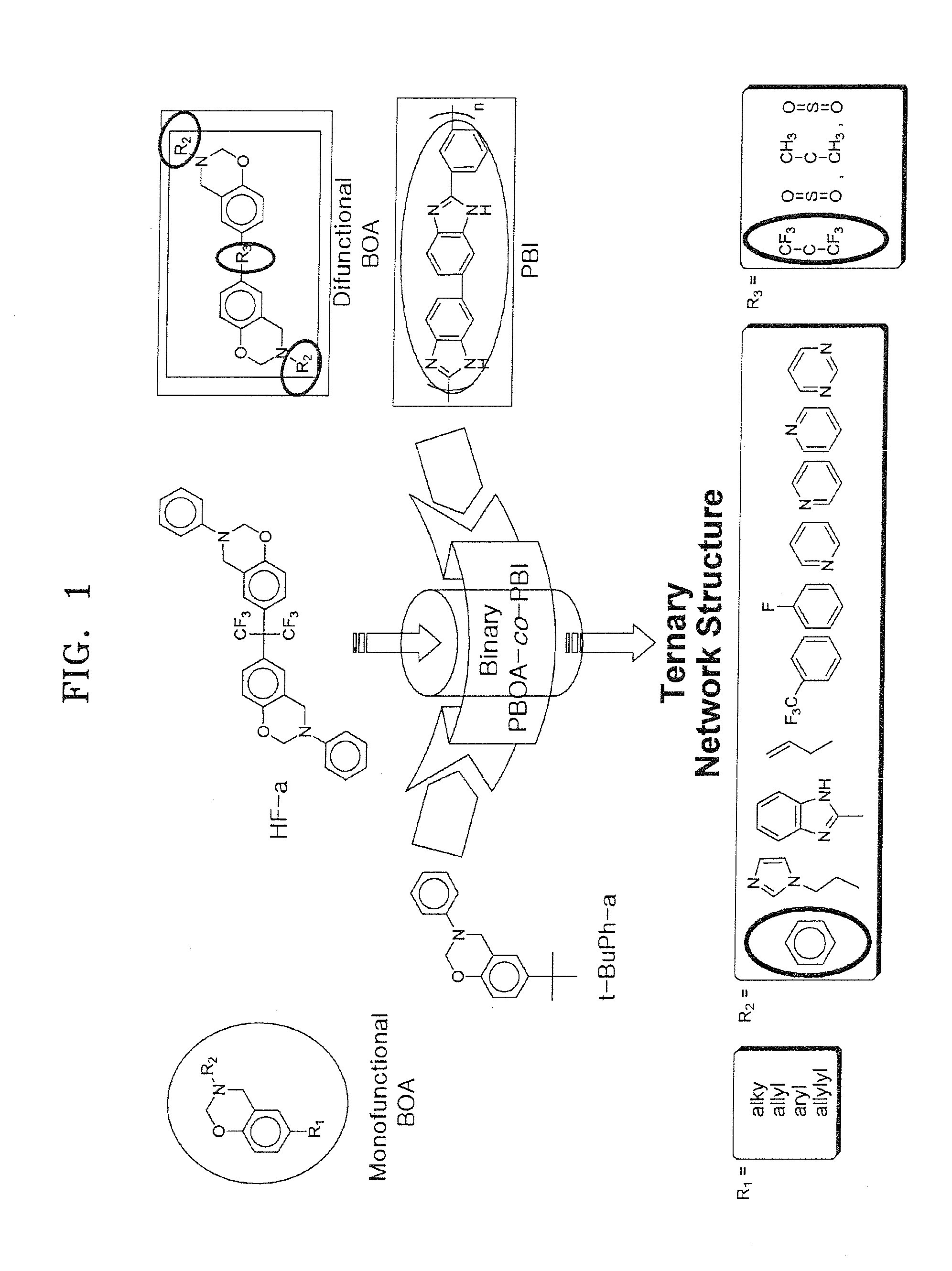

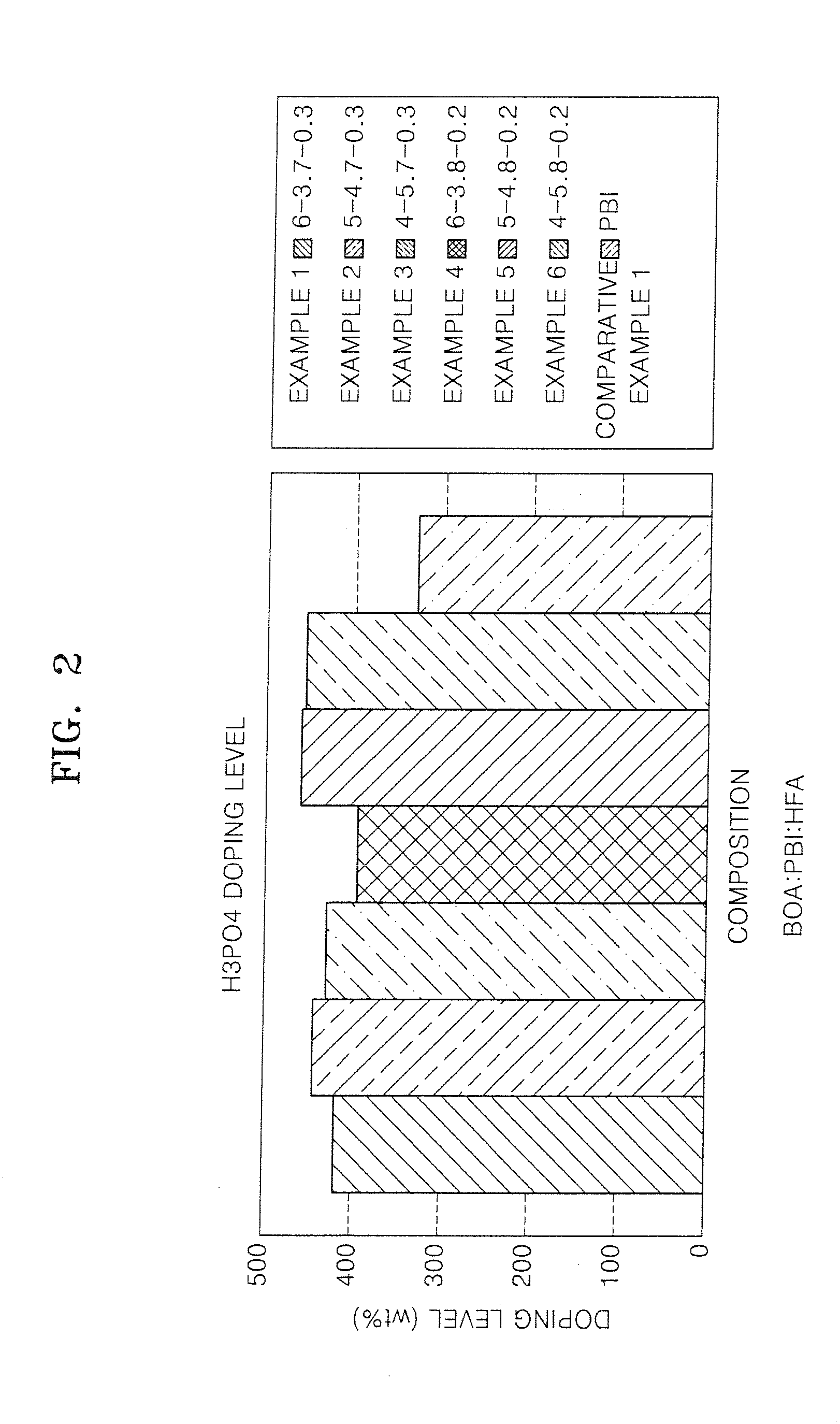

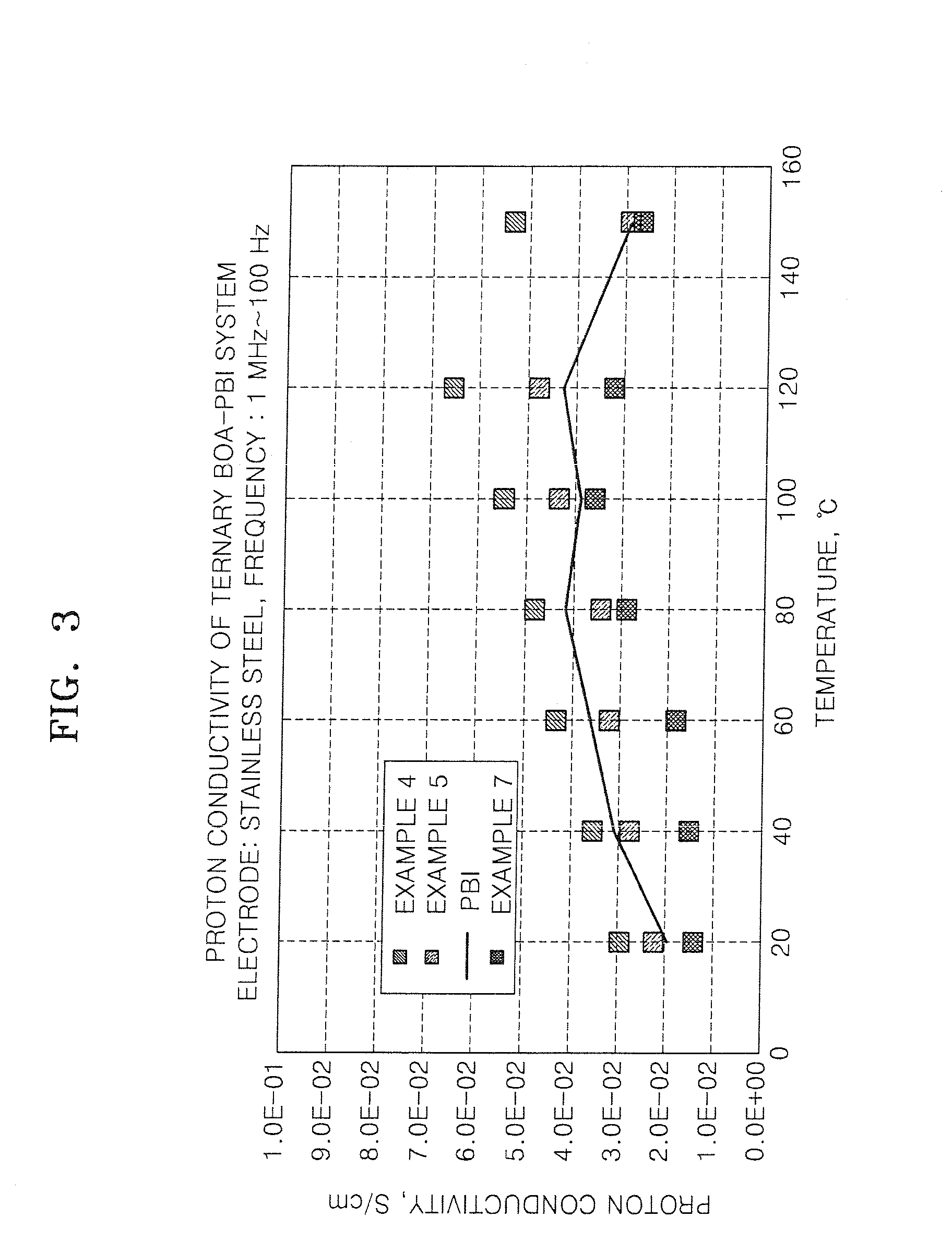

Electrolyte membrane using polybenzoxazine based compound and method of manufacturing the same

An electrolyte membrane includes a cross-linked reaction product of a benzoxazine monomer and a cross-linkable compound. The electrolyte membrane is impregnated with 300 to 600 parts by weight of phosphoric acid based on 100 parts by weight of the electrolyte membrane, and has a yield strain 0.5% or less, and a yield stress 0.3 Mpa or less. The cross-linked material has a strong acid trapping ability with respect to the benzoxazine compound and excellent mechanical properties due to a cross-linkage. Also, the solubility of the cross-linked material in polyphosphoric acid is low, thereby showing excellent chemical stability. Accordingly, when the cross-linked material is used, an electrolyte membrane having an excellent liquid supplementing ability and excellent mechanical and chemical stability at a high temperature can be obtained. The cross-linked material can be obtained by a simple polymerization process by combining a benzoxazine monomer and a crosslinkable compound and by using heat instead of using a polymerization initiator or a cross-linking agent.

Owner:SAMSUNG ELECTRONICS CO LTD +1

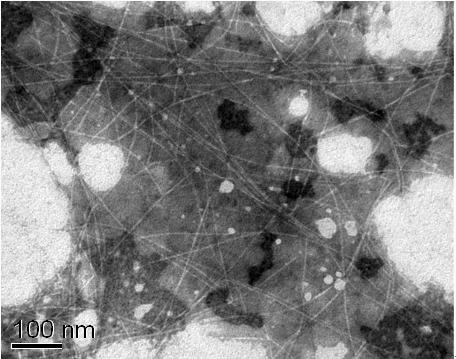

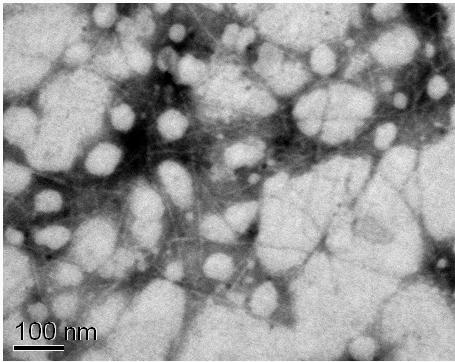

Preparation method of homogenized fine nano-cellulose fiber

InactiveCN101851295ALow degree of mutual aggregationEvenly dispersedArtificial filaments from cellulose solutionsStrong acidsCatalytic oxidation

The invention relates to a preparation method of a homogenized fine nano-cellulose fiber. The preparation method can solve the problems of uniform diameter distributor of biomass nano-cellulose prepared by the existing strong acid hydrolysis method and the high-strength mechanical shearing method, easy gathering among the nano-fiber and a narrow range of applications of the TEMPO catalytic oxidation method. The preparation method comprises the following steps: 1) extracting biomass fiber with benzyl alcohol solution; 2) carrying out treatment by using acidified sodium chlorite; 3) carrying out gradient treatment with alkaline liquor; 4) using TEMPO, sodium bromide and sodium hypochlorite for catalytic oxidation treatment; 5) using sodium chlorite for treatment; and 6) carrying out nano-scale processing by using the long-term stirring method, the ultrasonic method or the high-pressure homogenization method, drying, and then obtaining the homogenized fine nano-cellulose fiber. The fiber has the uniform diameter distribution, the diameter is 3-5nm, the length-diameter ratio is not less than 500, the fiber is mutually interwoven into a mesh snarling structure, and the method is applicable to preparing the nano-cellulose fiber by using wood pulp, paper-making pulp, wood, bamboo and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

Thermostable strong acid cation resin catalyst and its preparing method

ActiveCN1569334ARaise the partial pressure of the gas phaseImprove uniformityOrganic-compounds/hydrides/coordination-complexes catalystsAlkanePurification methods

The present invention solves the problem that the existing strong acid resin catalyst has bad high temperature mechanical intensity and complex hole purification technics, brings forward a simple preparing method for pressurization polymerization and hole purification method, the pressurization polymerization improves the uniformity of polymer bead body structure and the high temperature mechanical stability for resin, the extraction is executed by solvent naphtha first and the boiling is executed by halogeno-alkane, the hole purification method is simplified. The prepared strong acid cation resin catalyst has high temperature resistant and excellent catalytic activity and its high temperature stability is better than same kind of product.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Method for preparing hollow microsphere with hydrogel microsphere as stencil

InactiveCN101121112ASafe preparationSimple and fast operationMicroballoon preparationMicrocapsule preparationStrong acidsSilicon dioxide

The present invention discloses a hollow microsphere preparation method, which uses a hydrogel microsphere as a template. The preparation method is that an emulsion or inverse emulsion polymeric method is adopted to synthesize the hydrogel microsphere with electric charge. A surfactant with inverse electric charge and hydrophobic monomer are added into the hydrogel microsphere suspension, and the hydrogel microsphere is coated by a polymer crust layer of the hydrophobic monomer by a seed emulsion polymerization method to form a core-shell microsphere with an inner layer of hydrogel and an outer layer of polymer; a hydrolyzation of a silicon dioxide or titanium dioxide precursor is used to form the core-shell microsphere with the outer layer of inorganic matter and the inner layer of hydrogel. The core-shell microsphere is dried to obtain the hollow microsphere. The method of the present invention does not need removing the template by organic impregnant dissolving, strong acid or strong alkali etching or high temperature calcining; the preparation process is safe and the operation is simple; and the hollow microsphere with different chemical components can be obtained by changing core or shell.

Owner:ZHEJIANG UNIV

Cmp polishing slurry and method of polishing substrate

InactiveUS20070218811A1Decrease of residual film thicknessGreat polishing pressurePigmenting treatmentOther chemical processesStrong acidsSlurry

A CMP polishing slurry of the present invention, contains cerium oxide particles, a dispersant, a polycarboxylic acid, a strong acid having a pKa of its first dissociable acidic group at 3.2 or less, and water, the pH of the polishing slurry is 4.0 or more and 7.5 or less, wherein the strong acid is contained 100 to 1,000 ppm or 50 to 1,000 ppm, or the strong acid is a monovalent strong acid contained 50 to 500 ppm or is a bivalent strong acid contained 100 to 1,000 ppm. The preferable polycarboxylic acid is a polyacrylic acid. The present invention allows polishing in the CMP methods of surface-smoothening an interlayer dielectric film, a BPSG film and a shallow-trench-isolation insulation film with high speed operation efficiently and easier process management and cause smaller fluctuation in film thickness due to difference in pattern density.

Owner:HITACHI CHEM CO LTD

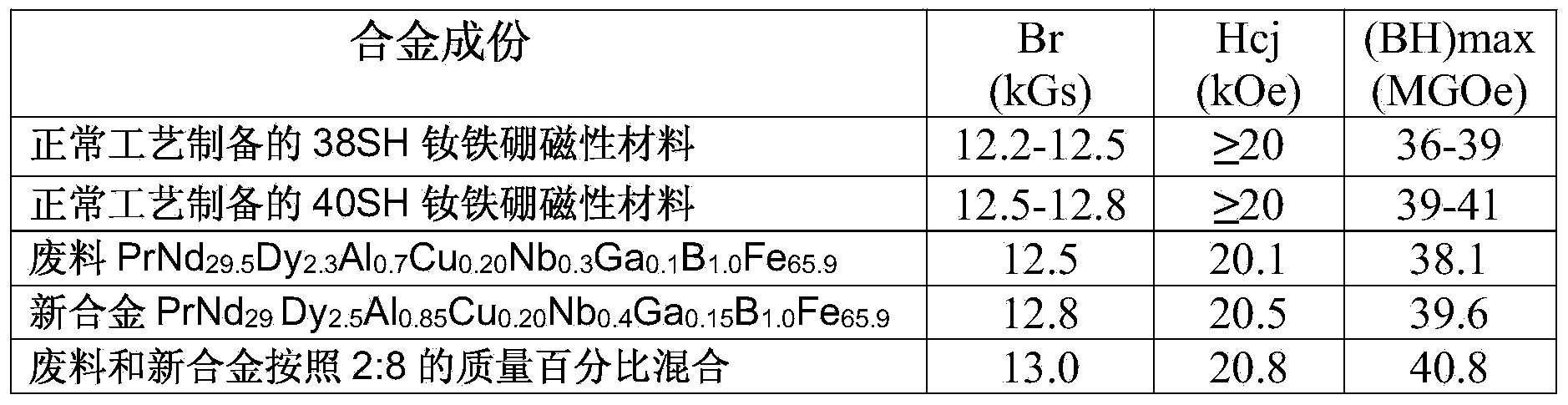

Method for preparing neodymium iron boron through regenerating waste material containing neodymium, iron and boron

ActiveCN103866127AFully absorb hydrogenImprove recycling ratesMagnetic materialsProcess efficiency improvementMetallurgyEconomic benefits

The invention provides a method for preparing neodymium iron boron through regenerating a waste material containing neodymium, iron and boron. The method comprises steps of (1) preprocessing the waste material; (2) correcting the components of the waste material; (3) crushing by hydrogen; (4) preparing into powder; (5) molding under a magnetic field; and (6) vacuum sintering. The method fully uses the waste material recycled in a production process, has high recovery rate of the waste material, can produce high performance product, has a simple and controllable flow, has high operability, uses no strong acid and strong base polluting the environment, is environment-friendly and energy-saving, and has high social and economic benefits.

Owner:CHINALCO JINYUAN RARE EARTH

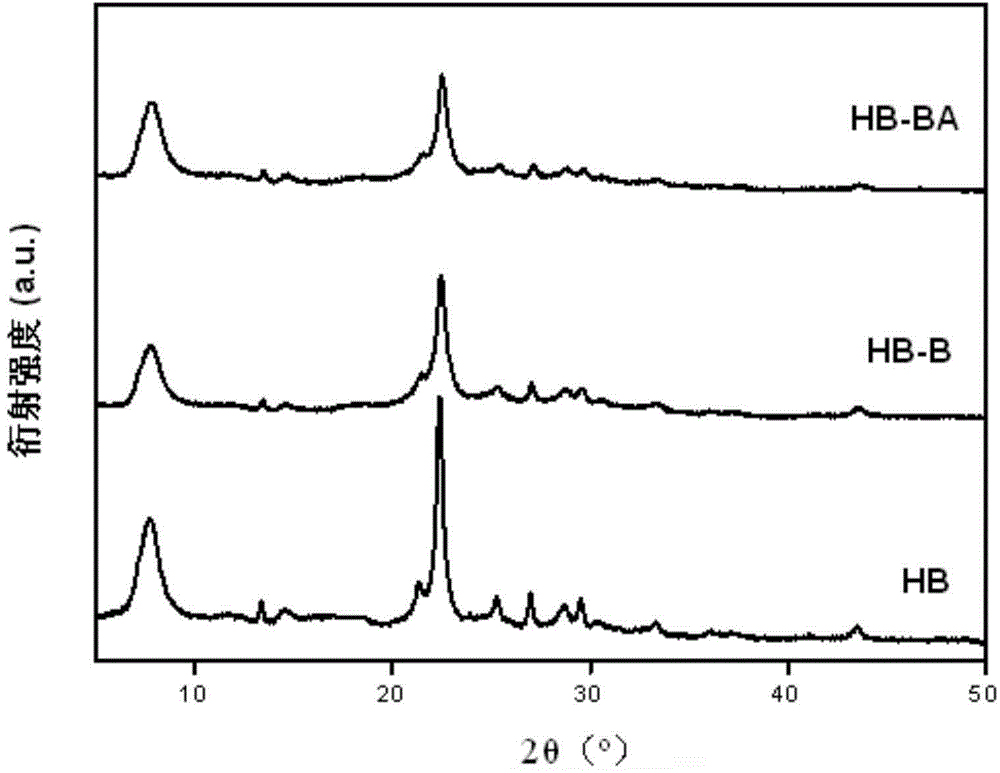

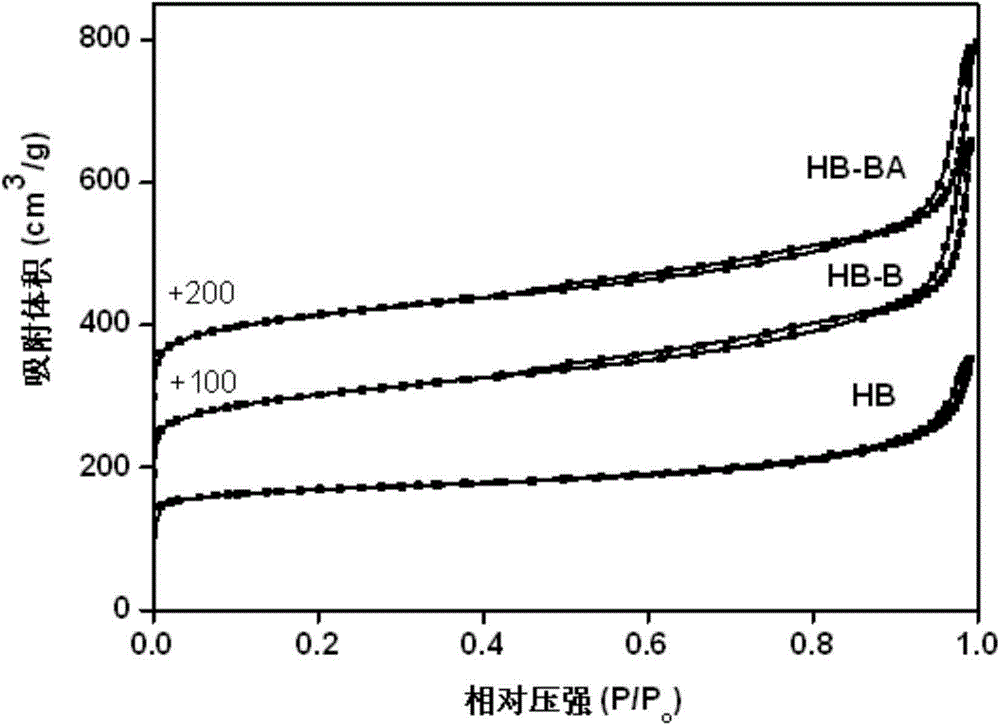

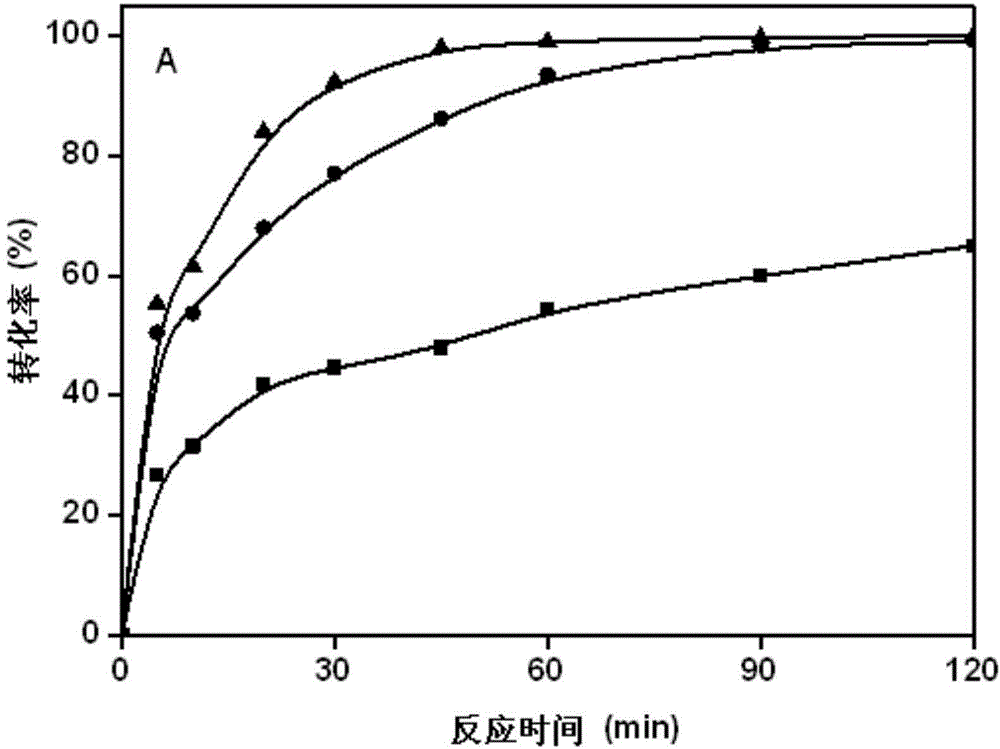

Preparation method of low-cost strong-acid hierarchical-pore Beta zeolite

The invention discloses a preparation method of low-cost strong-acid hierarchical-pore Beta zeolite, and relates to a preparation method of hierarchical-pore Beta zeolite. The problem that the acidity of an existing desilicication post-treatment hierarchical-pore Beta zeolite molecular sieve is weakened is solved. The preparation method comprises the steps of 1. calcining Beta zeolite to obtain microporous hydrogen type Beta zeolite; 2. adding the microporous hydrogen type Beta zeolite into an alkaline solution, stirring, and washing and drying to obtain sodium type desilicication hierarchical-pore Beta zeolite; 3. adding the sodium type desilicication hierarchical-pore Beta zeolite into an ammonium nitrate aqueous solution for exchange, and calcining to obtain hydrogen type desilicication hierarchical-pore Beta zeolite; and 4. adding the hydrogen type desilicication hierarchical-pore Beta zeolite into an acidic solution, stirring, washing and drying, and repeating the step 3 to obtain the strong-acid hierarchical-pore Beta zeolite.

Owner:HARBIN INST OF TECH

Polybenzoxazines, electrolyte membrane comprising the same, and fuel cell employing the electrolyte membrane

ActiveUS20070275285A1Efficiency electric power generationEfficiency fuel useSolid electrolytesFinal product manufactureFuel cellsTrapping

Crosslinked polybenzoxazines obtained by crosslinking a monofunctional first benzoxazine monomer and a multifunctional second benzoxazine monomer with a crosslinkable compound, an electrolyte membrane including the same, a method of preparing the electrolyte membrane, a fuel cell including the electrolyte membrane having the crosslinked polybenzoxazines using the method. The crosslinked polybenzoxazines have strong acid trapping capability, improved mechanical properties, and excellent chemical stability as it does not melt in polyphosphoric acid. Even as the amount of impregnated proton carrier and the temperature are increased, mechanical and chemical stability is highly maintained, and thus the electrolyte membrane can be effectively used for fuel cells at a high temperature.

Owner:SAMSUNG SDI CO LTD

Production method of biodiesel oil using high acid ralue animal and vegetable grease

InactiveCN1556174AAchieve cycleAchieve recyclingBiofuelsLiquid hydrocarbon mixture productionOil and greaseAlcohol

A process for preparing the biological diesel oil from the animal fat or vegetative oil with high acid number includes esterifying by glycerine under existance of strong acid catalyst, distilling in azeotropic solvent for removing water, mixing with methanol, transesterifying reacting to remove glycerine, water washing, and low-temp treating for removing high-smelting-point substances to obtain methyl ester of fatty acid, which is just the biological diesel oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Ester production method by transesterification reaction using solid acid catalyst

Owner:JAPAN ENERGY CORP

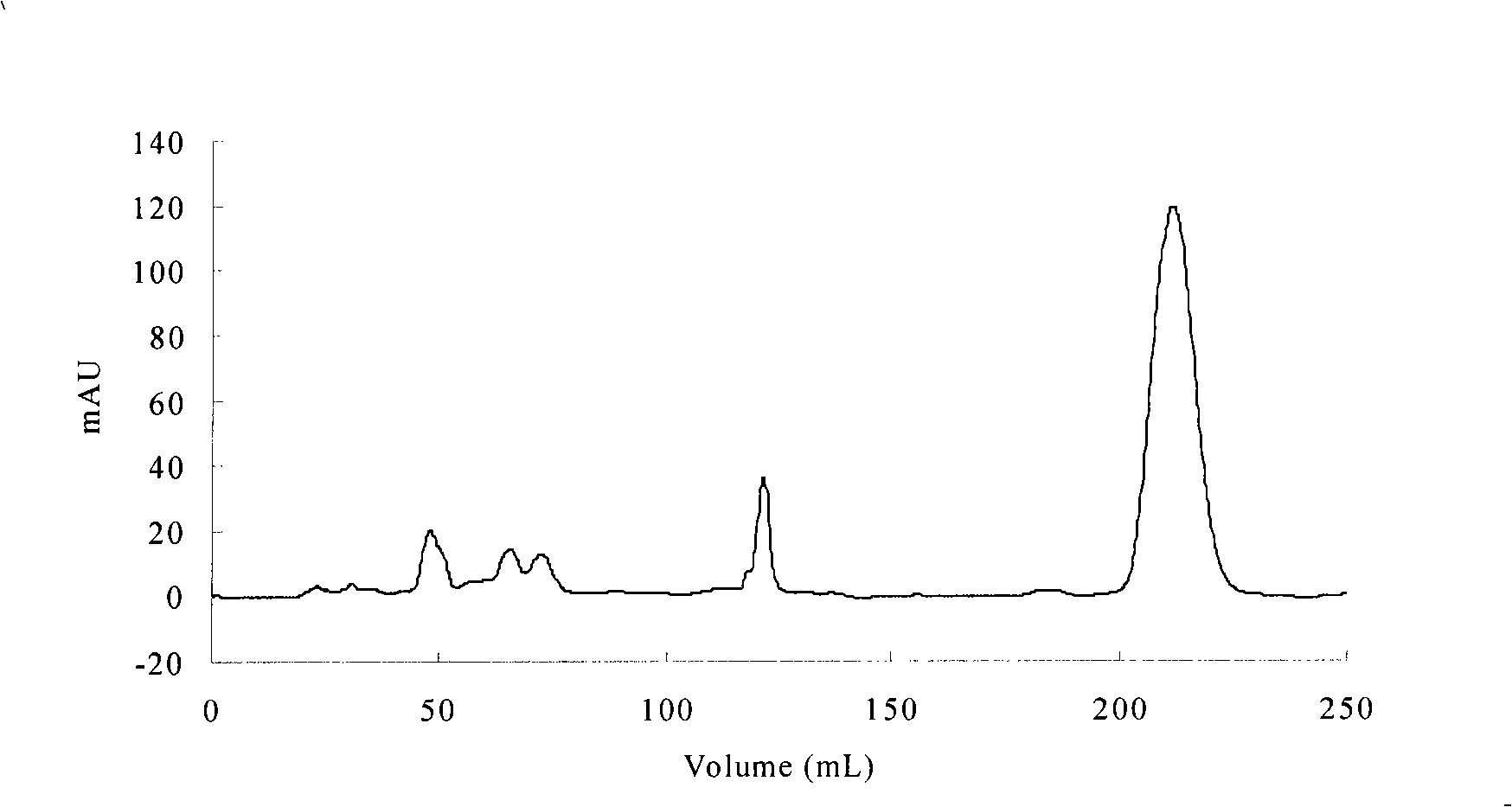

Method for separating and purifying sea-mussel mucin by using mixing adsorption chromatography

ActiveCN101348520AOvercoming the problem of low yieldHigh yieldPeptide preparation methodsAnimals/human peptidesHigh concentrationChromatographic separation

The invention relates to a method for separating and purifying mussel mucin by using a mixed adsorption chromatography. Mussel mucin contains a group of L-3,4- -Dihydroxyphenylalanine (L-DOPA), a phenohydroxyl group thereof can act as the supplier for hydrogen bond, the benzene ring thereof can generate a hydrophobic effect, and the lysine thereof with strong positive charges is capable of forming a static bond. On the basis of the properties of mussel mucin, a mixed adsorption chromatography (i.e. the adsorption chromatography based on three principles of adsorption with hydrogen bond, adsorption with hydrophobic effect, and static adsorption) is adopted to overcome the problem of low yielding rate of mussel mucin in the prior art for separating and purifying mussel mucin. An strong acid extraction is adopted to eliminate small-molecular compounds from a desalting column, an argar medium with high concentration and high cross-linking degree to separate and purify mussel mucin, and an acetic acid-urea- polyacrylamide gel electrophoresis is used to differentiate mussel mucin through specific chromogenesis with nitro blue tetrazolium. Three principles adopted with one separation medium to separate mussel mucin achieve high selectivity, simplify the purification technology, and decrease production cost.

Owner:JIANGYIN USUN BIOCHEMICAL TECH CO LTD

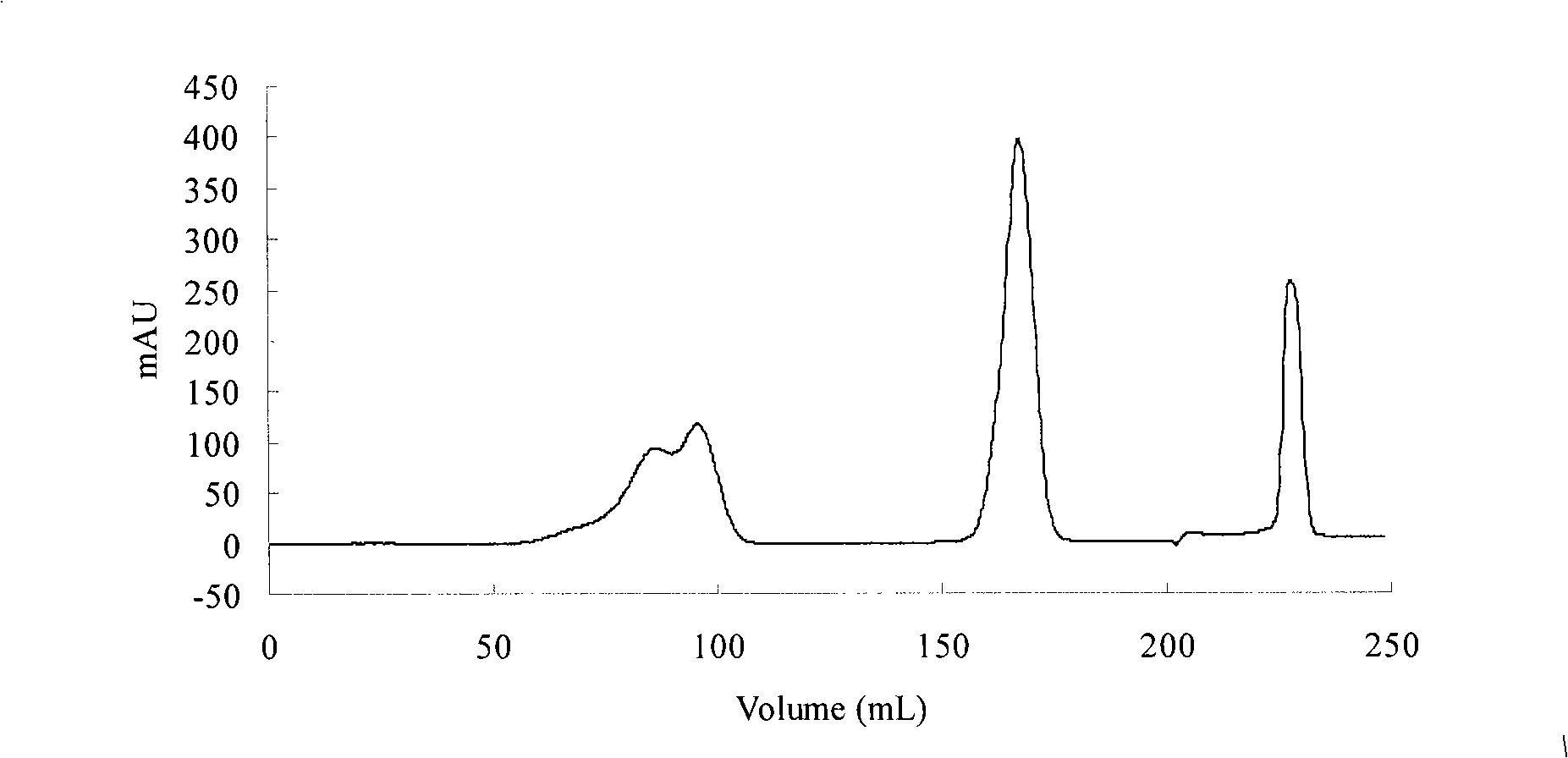

Method for separating and purifying sea-mussel mucin by using salting out and dialyzing

ActiveCN101585874ALow costIncrease concentrationPeptide preparation methodsAnimals/human peptidesHigh concentrationPurification methods

The invention relates to a method for separating and purifying the sea-mussel mucin by using salting out and dialyzing, the salting out and the dialyzing utilizes the proteinaceous physicochemical character to purify by a non- chromatograph method, and solves the problem of high apparatus and material cost in the chromatograph method for purifying the sea-mussel mucin, a quick, low-cost and high-concentration method for separating and purifying the sea-mussel mucin is provided. The strong acid is used for extracting, the salting out and the dialyzing are used for purifying, the sea-mussel mucin is determined by adopting the acetic acid-carbamide- polyacrylamide gel electrophoresis via the blue tetrazolium specificity colour development, and the purity is determined by the inversed phase chromatography quantitatively.

Owner:JIANGYIN USUN BIOCHEMICAL TECH CO LTD

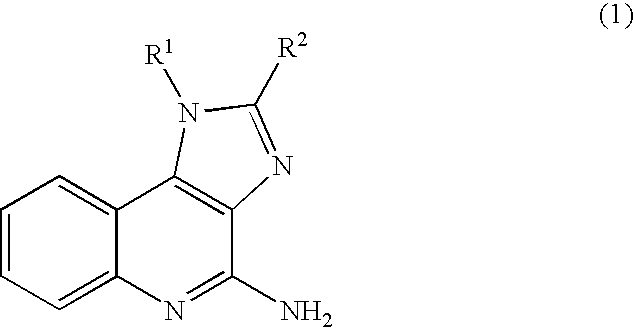

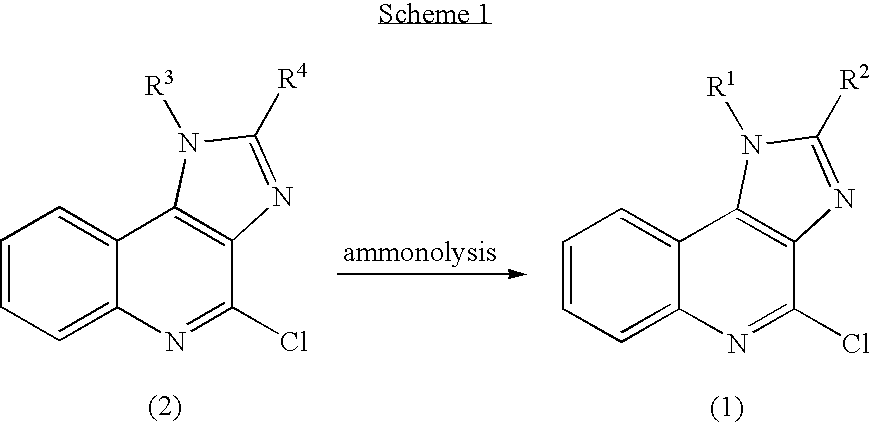

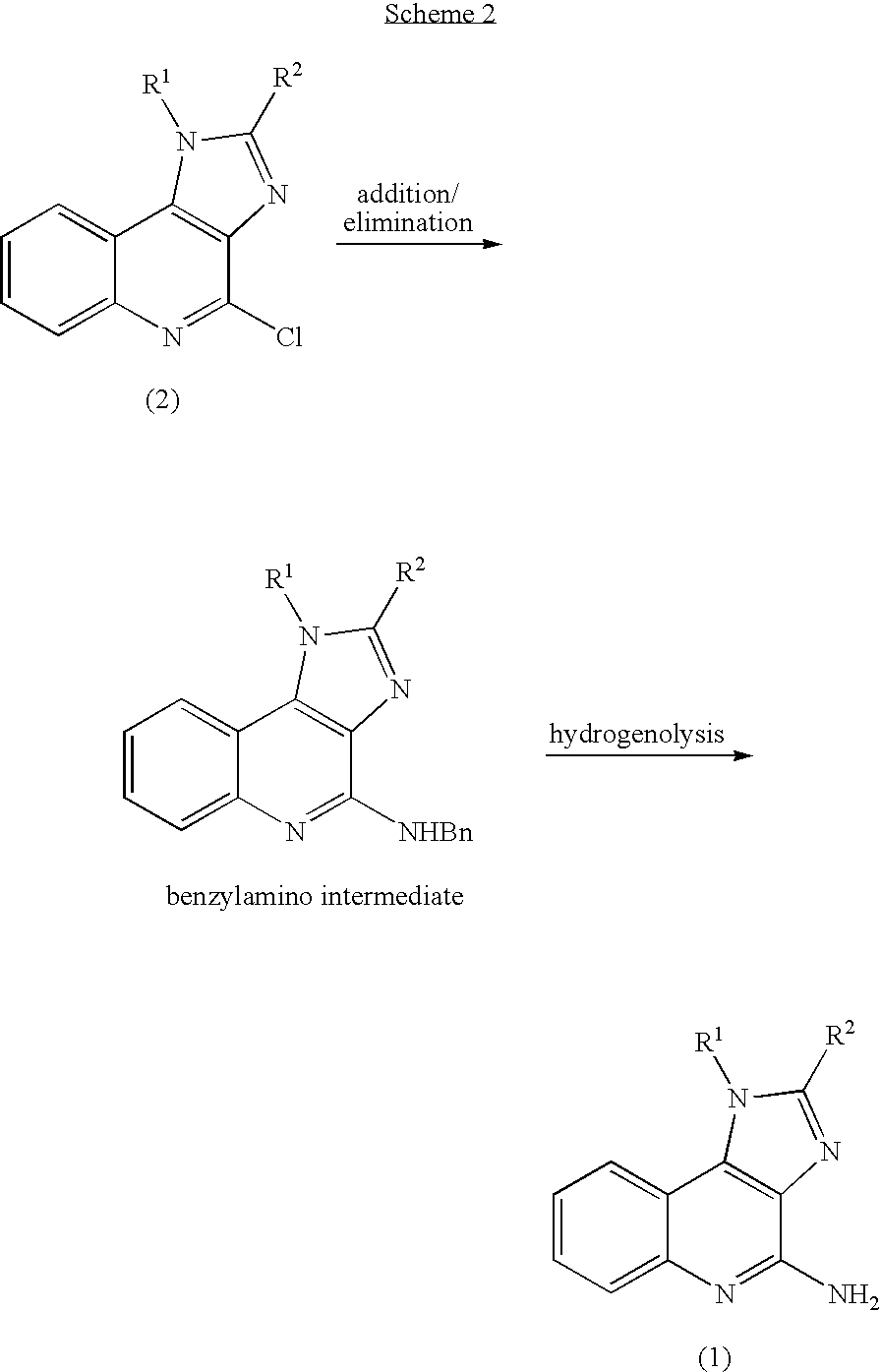

Method of preparing 4-amino-1H- imidazo(4,5-c)quinolines and acid addition salts thereof

The present invention provides a method of preparing a 4-(arylmethyl)amino-1H-imidazo(4,5-c)quinoline of formula (4) by reacting an arylmethylamine of formula (3) with a 4-chloro-1H-imidazo(4,5-c)quinoline of formula (2). The present invention further provides a method of preparing an acid addition salt of formula (5) comprising the step of hydrolyzing a 4-(arylmethyl)amino-1H-imidazo(4,5-c)quinoline of formula (4) with a strong acid, HX. The present invention further provides a method of preparing a 4-amino-1H-imidazo(4,5-c)quinoline of formula (1) comprising the step of treating an acid addition salt of formula (5) with a base.

Owner:TARO PHARMA US INC

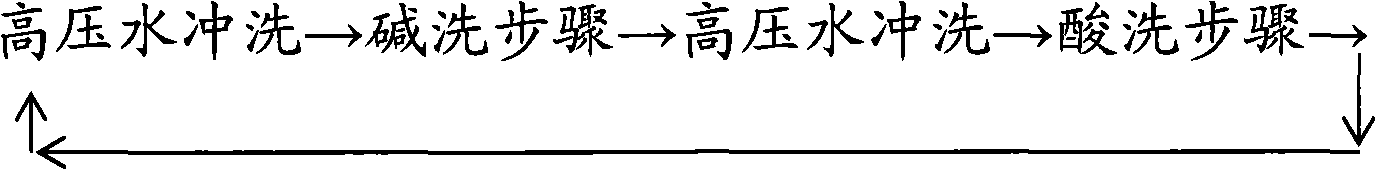

Cleaning agent and cleaning process of GGH heat exchange component

ActiveCN101555441AQuick washWash thoroughlyDispersed particle separationInorganic non-surface-active detergent compositionsStrong acidsHigh pressure water

The invention provides a cleaning agent and a cleaning method of a GGH heat exchange component applying the same. The cleaning agent comprises alkaline cleaning solution and acidic cleaning solution, wherein the alkaline cleaning solution contains 1.6 weight percent to 11.0 weight percent (wt, same below) of alkali, 0.7 to 2.4 of penetrating agent, 1.2 to 3.5 of scale dissolver, 0.3 to 1.2 of surfactant, 0.2 to 1.3 of remover b and the balance of water; and the acidic cleaning solution contains 2.6 to 5.5 of strong acid, 0.7 to 2.4 of penetrating agent, 0.3 to 1.2 of latent solvent, 0.2 to 0.6 of inhibitor, 0.2 to 1.3 of remover a, and the balance of water. The washing process comprises an alkaline cleaning step, an acid cleaning step and a high-pressure water flushing step between the alkaline cleaning step and the acid cleaning step. The cleaning process and the cleaning agent of the GHH heat exchange component have the advantages of quick and thorough cleaning, low cost, environmental protection, and the like.

Owner:CHINA SHENHUA ENERGY CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com