Method for preparing hollow microsphere with hydrogel microsphere as stencil

A technology of hydrogel microspheres and microspheres, which is applied in the preparation of microspheres and microcapsule preparations, etc., which can solve the problems of many steps and long time, and achieve the effect of safe preparation process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

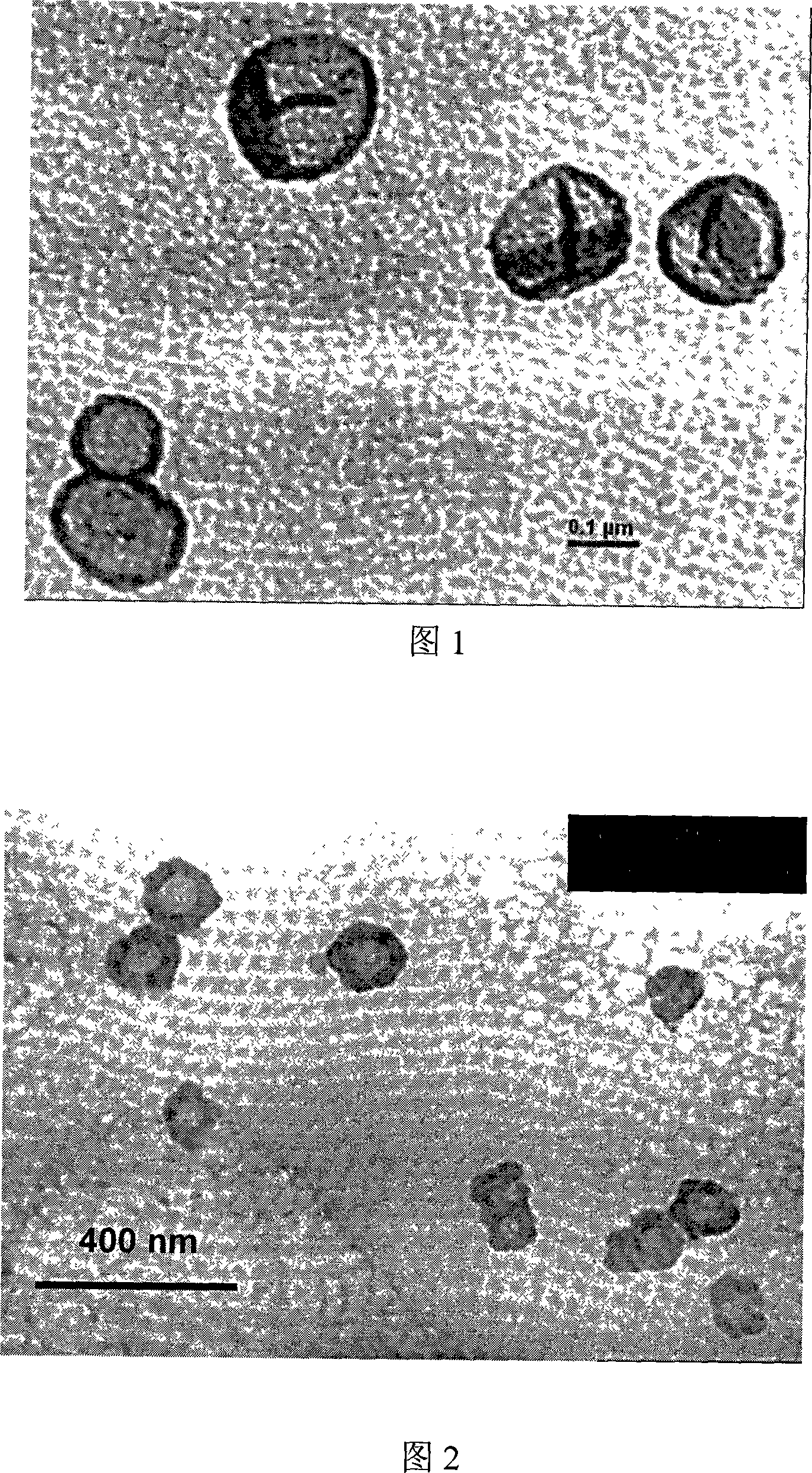

Embodiment 1

[0028] Put 5.0g of N-isopropylacrylamide (NIPAAm), 0.05g of N,N'-methylenebisacrylamide (BIS) and 50g of deionized water into a 100ml flask and stir to dissolve, add 0.005g of hexadecyltri Methyl ammonium chloride, 0.25g methacryloyloxyethyltrimethylammonium chloride (DMC), after nitrogen gas for 60 minutes, add 0.05g N,N'-azobisisobutylamidine hydrochloride (AIBA) Heat the oil bath to 75°C, turn on the condensing reflux device to react for 8 hours, naturally cool to room temperature and let stand for half an hour until it swells completely. After purification by dialysis and drying, 0.3 g of the product was taken in 50 ml of deionized water and redispersed by ultrasonic vibration to obtain a suspension of hydrogel microspheres. Put the hydrogel microsphere suspension into a 250ml Erlenmeyer flask as a seed, add 150ml ionized water, 0.05g sodium dodecyl sulfate (SDS) successively, stir and ventilate nitrogen for 60 minutes, then add 0.3g styrene ( St), 0.005g divinylbenzene (...

Embodiment 2

[0030] Put 4.0g of N-isopropylacrylamide (NIPAAm), 0.04g of BIS and 800g of deionized water into a 1000ml flask and stir to dissolve, add 0.4g of cetyltrimethylammonium chloride, 0.2g of styrene benzyl trimethyl Methyl ammonium chloride, after nitrogen gas for 60 minutes, then add 0.02g AIBA to raise the temperature of the oil bath to 60°C, turn on the condensing reflux device to react for 72 hours, naturally cool to room temperature and let it stand for half an hour until it is completely swollen, after dialysis and purification, After drying, 0.3 g of the product was taken and dispersed in 100 ml of deionized water to obtain a suspension of hydrogel microspheres. Put the hydrogel microsphere suspension into a 250ml Erlenmeyer flask as a seed, add 150ml ion water, 0.15g sodium bis(2-ethylhexyl) sulfosuccinate, 2.0g St, 0.05gDVB and 0.05 gKPS, stirred and passed nitrogen for 10 minutes, then added 0.024g SSA to react for 1 hour, and obtained polystyrene hollow microspheres aft...

Embodiment 3

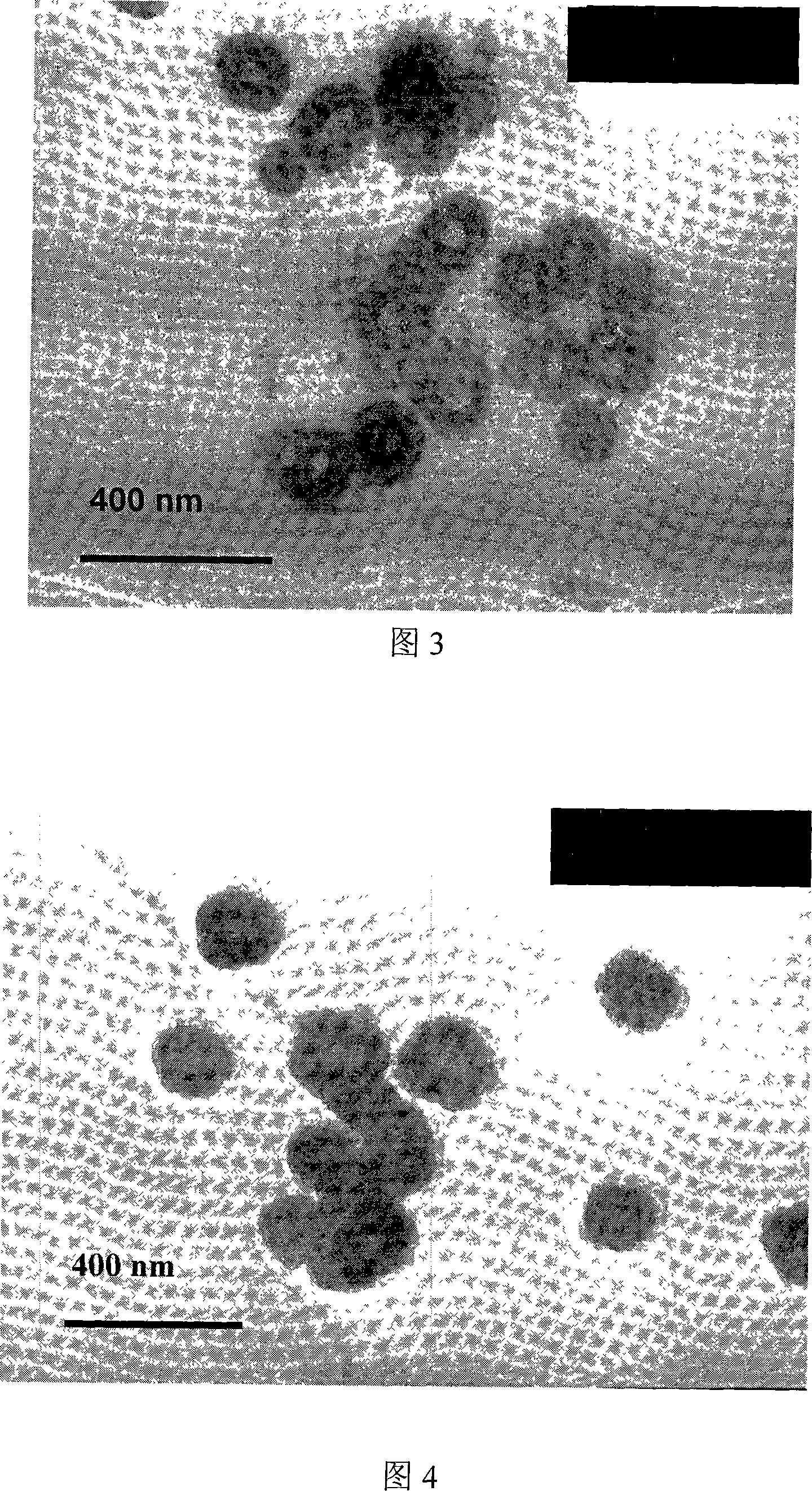

[0032] Put 5.0g of N-isopropylacrylamide (NIPAAm), 0.01g of BIS and 500g of deionized water in a 1000ml flask and stir to dissolve, add 1g of styrene benzyltrimethylammonium chloride, and after nitrogen gas for 60 minutes, add 0.005g AIBA Heat the oil bath to 60°C, turn on the condensing reflux device to react for 72 hours, naturally cool to room temperature and let stand for half an hour until it swells completely. After purification by dialysis and drying, 0.3 g of the product was taken and dispersed in deionized water to obtain a suspension of hydrogel microspheres. Take 50ml of the hydrogel microsphere suspension and put it into a 250ml Erlenmeyer flask as a seed, add 150ml of ionized water, 0.057gSDS, 10.0g styrene (St), 0.5g divinylbenzene (DVB) and 0.12gKPS successively, stir Nitrogen was passed for 10 minutes, and then 0.06 g of sodium sulfite (SSA) was added to react for 1 hour. After drying, polystyrene hollow microspheres were obtained ( FIG. 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com