Patents

Literature

191 results about "Cetyltrimethylammonium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber modified asphalt warm-mixing agent, preparation method and application

InactiveCN101831187ALow viscosityLow softening pointClimate change adaptationBuilding insulationsSurface-active agentsFatty alcohol

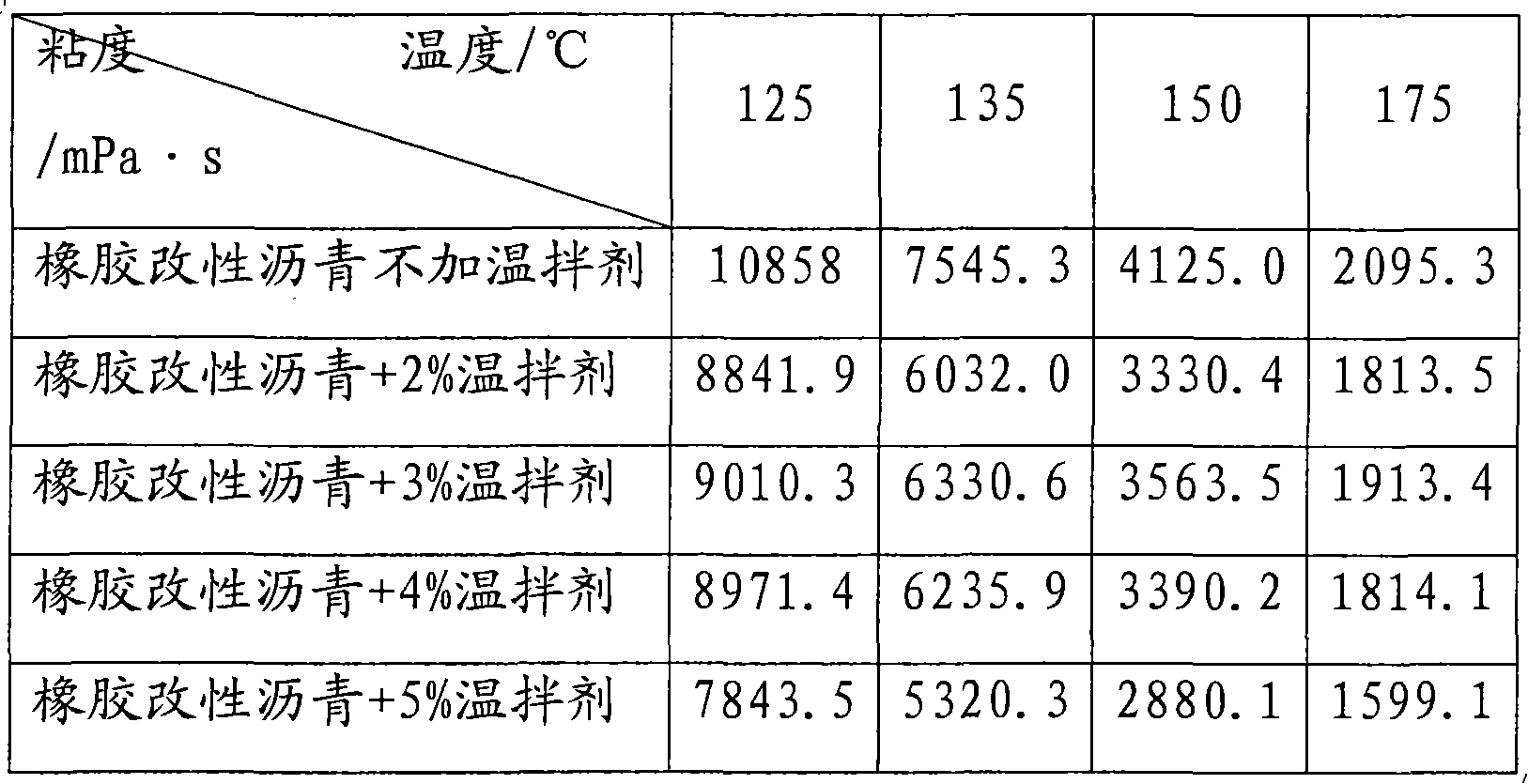

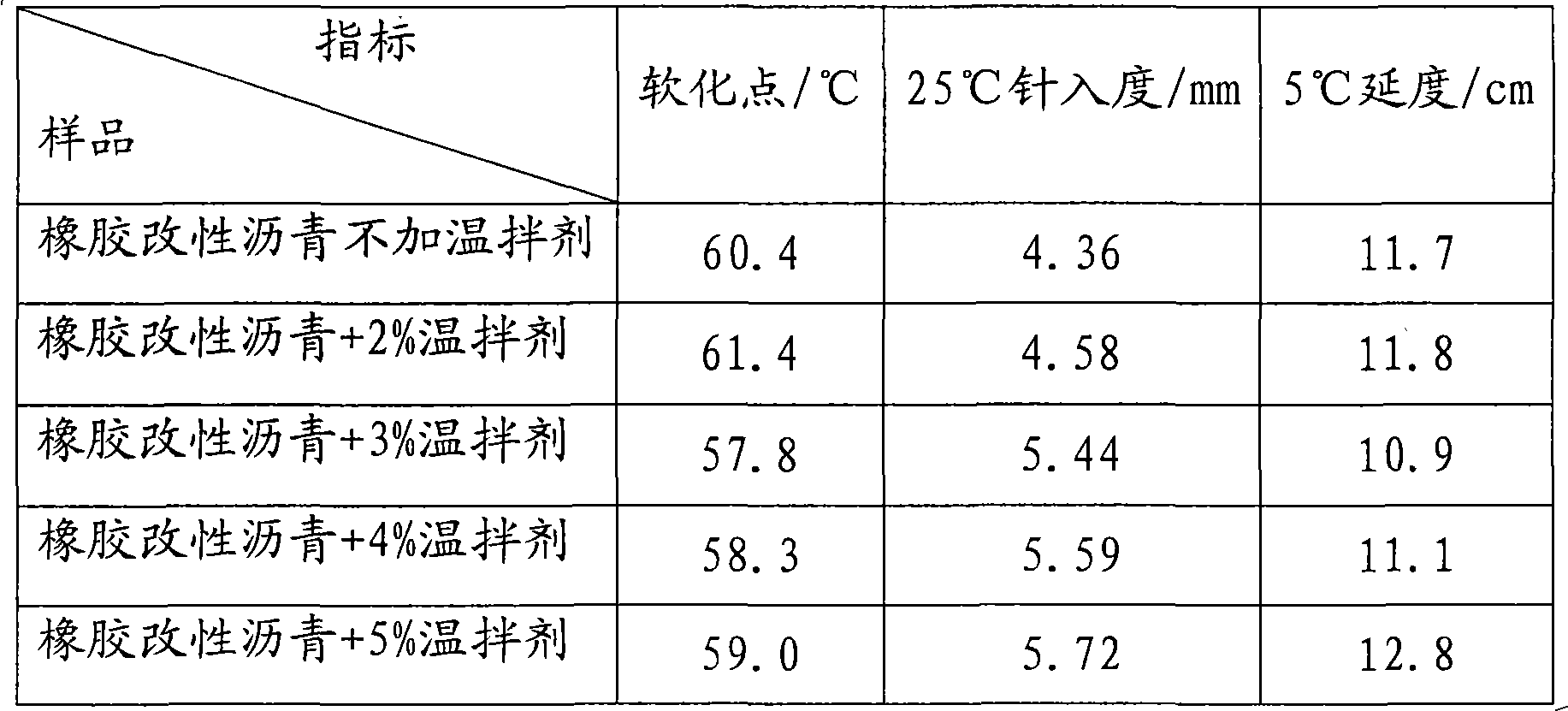

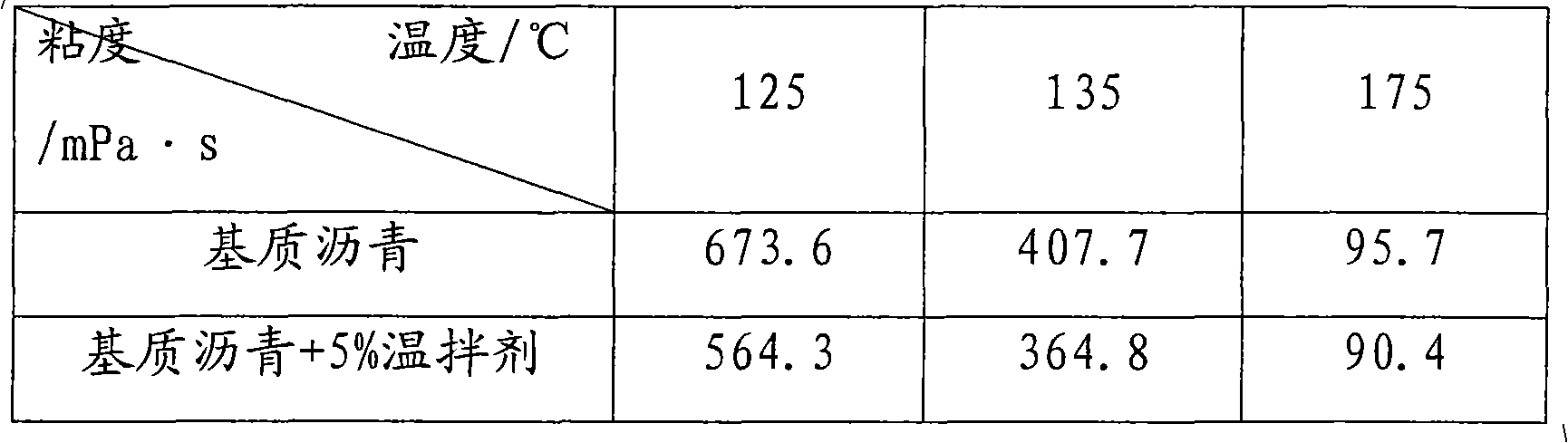

The invention discloses a rubber modified asphalt warm-mixing agent, a preparation method and application thereof. The warm-mixing agent comprises the following components in parts by weight: 100 parts of water, 5-30 parts of fatty alcohol sodium sulfate, 15-30 parts of palmitic acid, 5-30 parts of oleic acid, 1-20 parts of sodium dodecyl benzene sulfonate, 1-15 parts of cetyltrimethylammonium chloride and 10-30 parts of imidazoline-type cationic surface active agent ODD. The preparation method comprises the following steps of: adding the water in a container at the temperature of 65 DEG C, and then adding the following substances under the condition of stirring: the fatty alcohol sodium sulfate, the palmitic acid, the oleic acid, the sodium dodecyl benzene sulfonate, the cetyltrimethylammonium chloride and the imidazoline-type cationic surface active agent ODD, and stirring for 15 min to obtain the warm-mixing agent. The warm-mixing agent is directly applied to rubber asphalt or matrix asphalt to reduce the viscosity of the asphalt. The kinematic viscosity of the rubber powder asphalt added with the warm-mixing agent at the temperature of 150 DEG C can reach less than 3.0Pa.s of the kinematic viscosity at the temperature of 180 DEG C, and the production temperature can be reduced by about 30 DEG C, thereby not only preventing the rubber asphalt from being aged but also saving energy and reducing equipment loss.

Owner:BEIJING UNIV OF CHEM TECH

Hair conditioning composition containing a salt of cetyl trimethyl ammonium chloride, and having higher yield point

InactiveUS20090324532A1Conditioning benefits to hairCosmetic preparationsCationic surface-active compoundsSURFACTANT BLENDPolymer

Disclosed is a hair conditioning composition comprising: (a) a cationic surfactant being cetyltrimethylammonium chloride; (b) a high melting point fatty compound; and (c) an aqueous carrier; wherein the composition has a yield point of at least 9 Pa, and the yield point meeting the following mathematical expression: Y≧3.50X−7.80, wherein Y is yield point of the composition, X is a total amount (percentage by weigh of the composition) of the cationic surfactant and the high melting point fatty compound; and wherein the composition is substantially free of thickening polymers. The composition of the present invention effectively delivers conditioning benefits to hair.

Owner:THE PROCTER & GAMBLE COMPANY

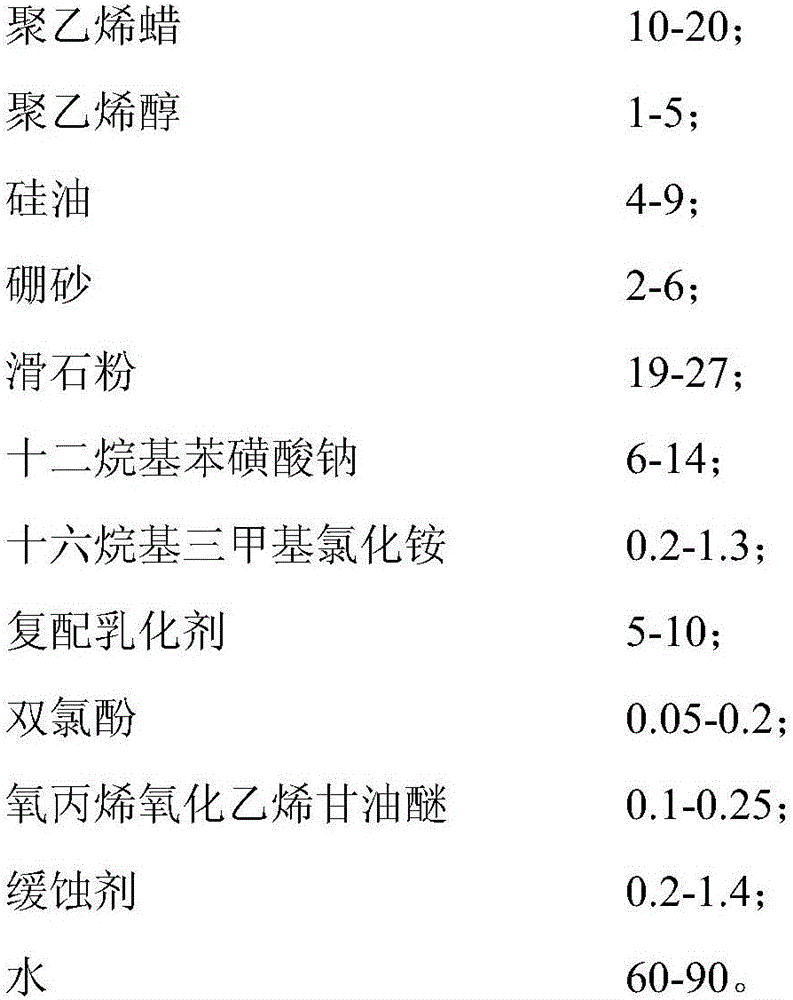

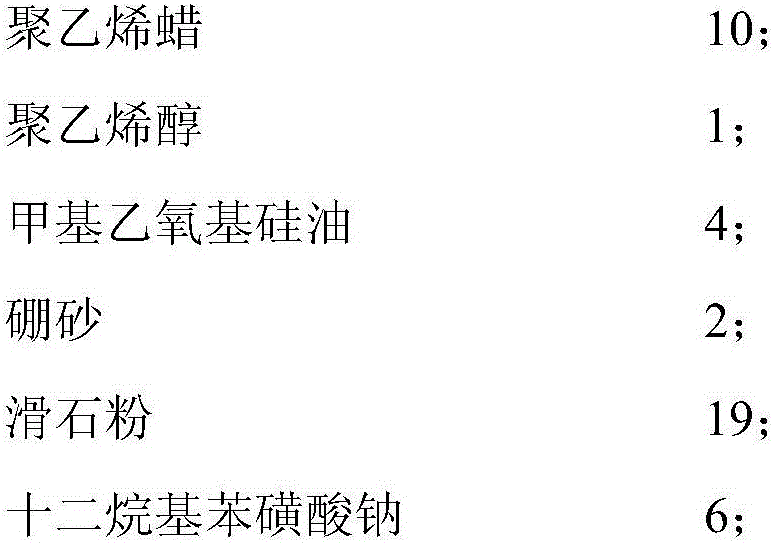

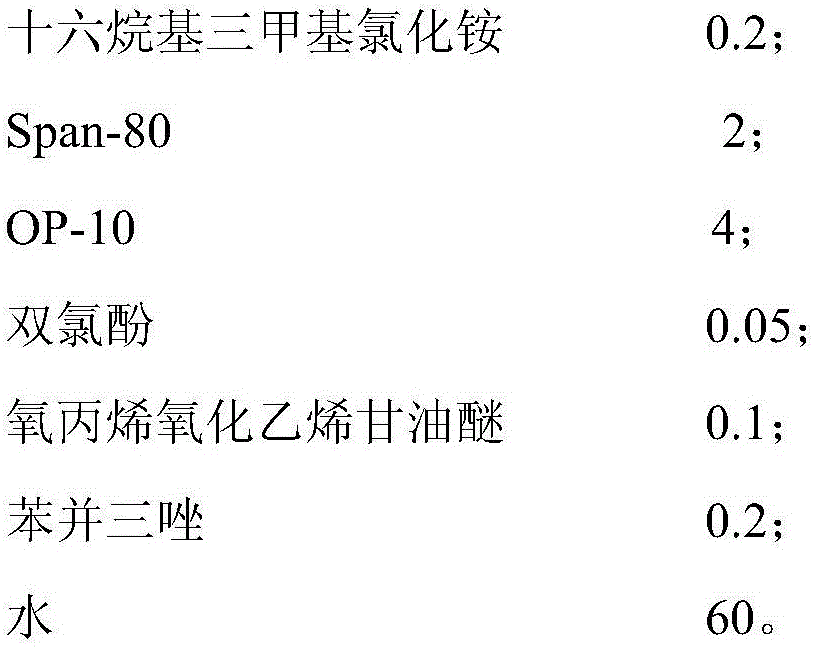

Release agent for aluminum alloy mold and preparation method of release agent

InactiveCN106311968AEasy to prepareNo pollution in the processFoundry mouldsFoundry coresCooling effectOxygen

The invention provides a release agent for an aluminum alloy mold and a preparation method of the release agent. The release agent comprises, by weight, 10-20 parts of polyethylene wax, 1-5 parts of polyving akohol, 4-9 parts of silicone oil, 2-6 parts of boraxes, 19-27 parts of talcum powder, 6-14 parts of sodium dodecyl benzene sulfonate, 0.2-1.3 parts of cetyltrimethylammonium chloride, 5-10 parts of compound emulsifiers, 0.05-0.2 part of dichlorophen, 0.1-0.25 part of oxygen propylene ethylene oxide glyceryl ether, 0.2-1.4 parts of inhibiters, and 60-90 parts of water. The preparation method of the release agent comprises the steps that the raw materials are weighed according to the formula, and then stirred and cooled, and thus the release agent for the aluminum alloy mold is obtained. The release agent prepared through the method is safer, clean and free of pollution; compared with a traditional oil-based release agent, the release agent has the advantages that the cooling effect is good, accumulation is avoided, and the surface quality of castings is good; and compared with a powdery release agent, the release agent has the advantage of being low in cost.

Owner:天津可喜涂料有限公司

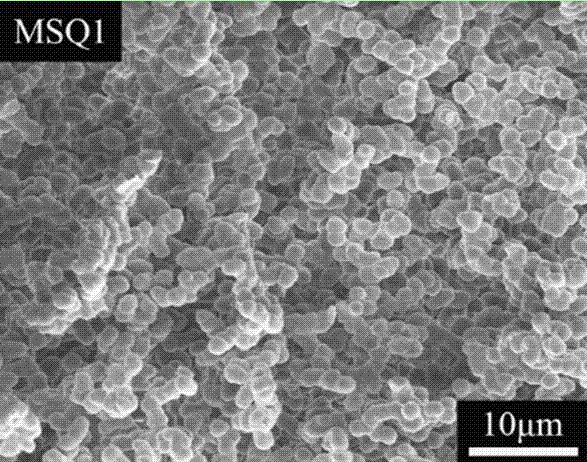

Hydrophobic high-elasticity methylsilsesquioxane aerogel block and preparation method thereof

The invention discloses a hydrophobic high-elasticity methylsilsesquioxane aerogel block and a preparation method thereof. The aerogel block is a compound with methyltrimethoxysilane and dimethoxydimethylsilane as a co-precursor, a hydrochloric acid solution HCl as a solvent and a catalyst and cetyltrimethylammonium chloride as a dispersant. The preparation method includes the following steps: adding cetyltrimethylammonium chloride into the hydrochloric acid solution, then adding the precursor, carrying out magnetic stirring under a closed condition, adding a gel accelerator, then stirring again, placing in a drying oven, gelling and aging; carrying out solvent replacement of the gel formed in the step 1) with isopropanol for at least two times, to obtain a gel after solvent replacement; and placing the gel after solvent replacement in a drying oven, and drying to obtain the complete hydrophobic high-elasticity methylsilsesquioxane aerogel block. Through the way, the methylsilsesquioxane aerogel block with good hydrophobicity and high elasticity can be obtained under the condition of ambient pressure drying.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

Organic montmorillonite-aqueous polyurethane compound leather finishing agent and method for preparing same

InactiveCN101544820ARestricted free movementImprove mechanical propertiesEthylene diaminePolymer science

The invention discloses an organic montmorillonite-aqueous polyurethane compound leather finishing agent and a method for preparing the same. The method comprises the following steps: firstly using quaternary ammonium salt such as cetyl trimethyl ammonium chloride, octadecyl dihydroxyethyl methyl ammonium bromide and the like, organic amine such as ethylene diamine, octadecylamine and the like, or a silane coupler, polyisocyanate and the like to organically modify montmorillonite to prepare organic montmorillonite; and secondly, performing intercalation reaction of emulsion of a polyurethane resin finishing agent and the organic montmorillonite to obtain the finished product of the organic montmorillonite-aqueous polyurethane compound leather finishing agent. In the method, the quaternary ammonium salt, the organic amine, the silane coupler or the polyisocyanate are used for organically modifying the montmorillonite, so that the interlamellar spacing of the montmorillonite is increased, the micro environment among the lamellas is improved, the compatibility of the montmorillonite and the organic phase is improved, and the intercalation reaction of the polyurethane molecules and the montmorillonite is easily performed; moreover, due to the interlamellar compound of the organic montmorillonite on the polyurethane resin finishing agent, the mechanical property, the thermal resistant stability, the water resistance and the water vapor permeability of the finishing material are improved. When the leather finishing material is applied to leather finishing, the leather finishing material has the advantages of greatly improving the mechanical strength and thermal resistant stability of the coating and having active effects on water resistance, sanitary property and the like of the coating.

Owner:SICHUAN UNIV

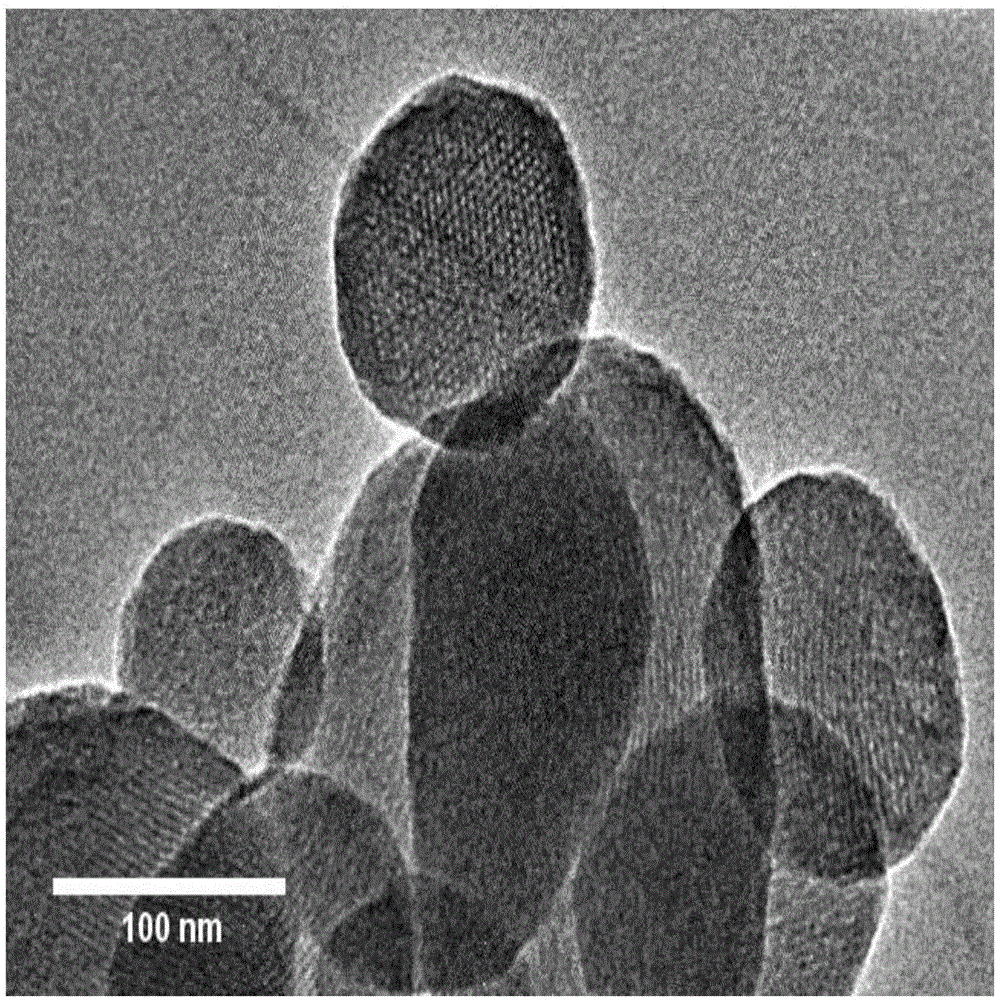

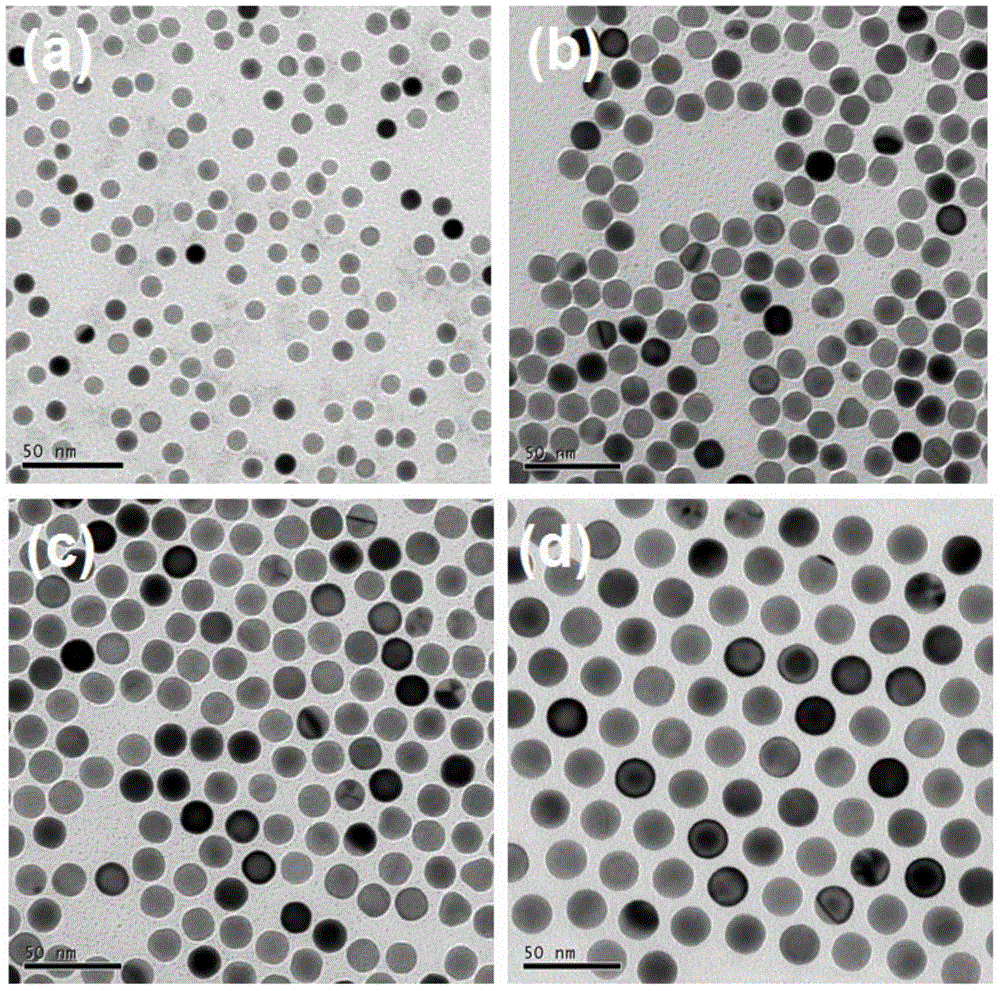

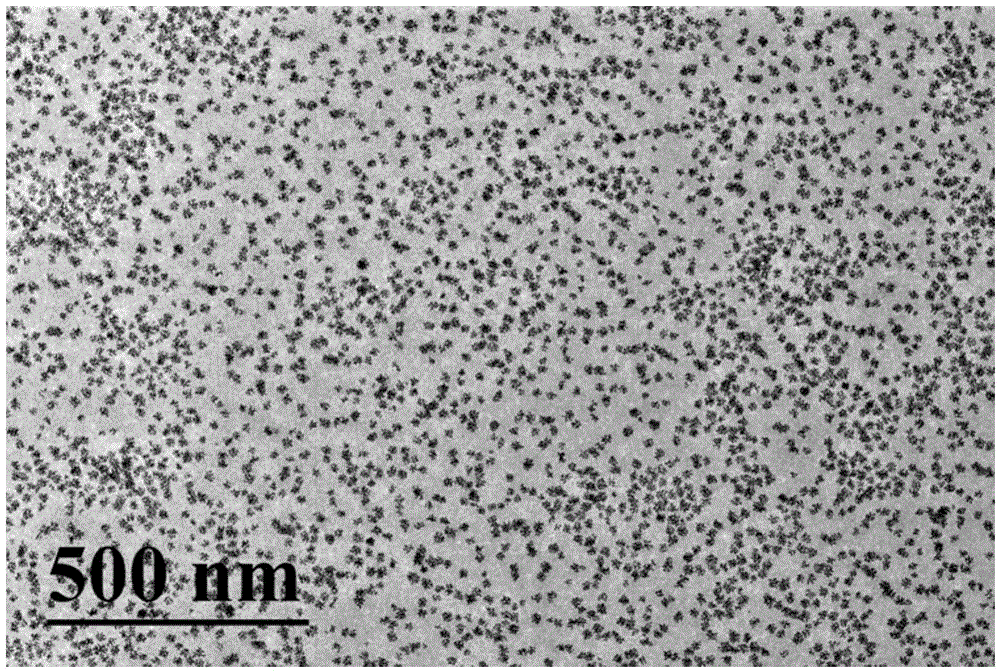

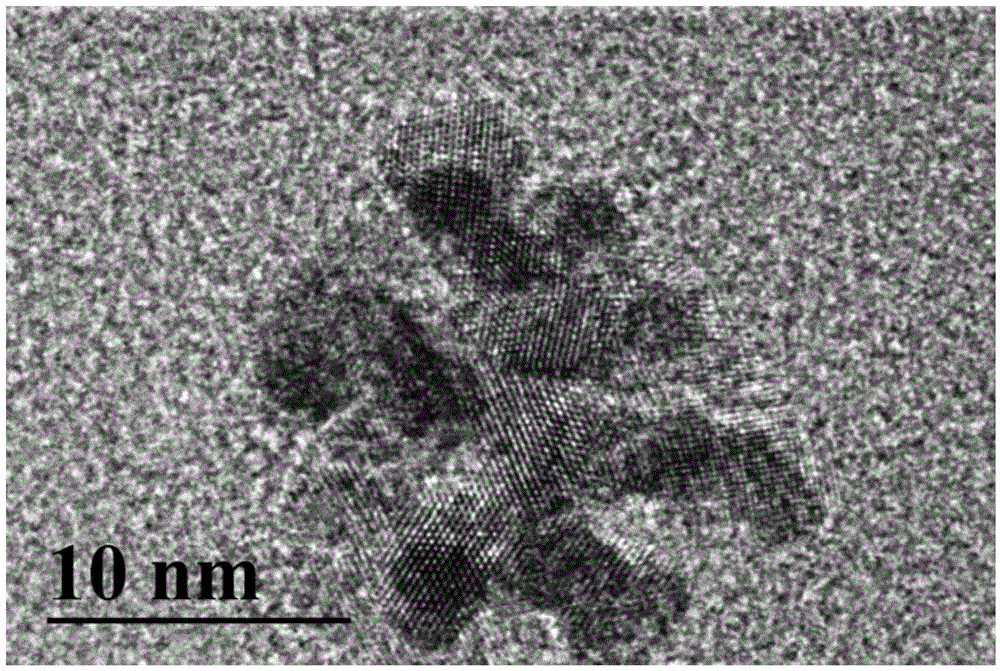

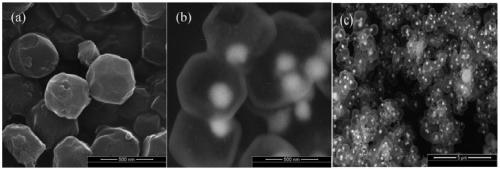

Preparation method of meso-porous silica nanoparticles

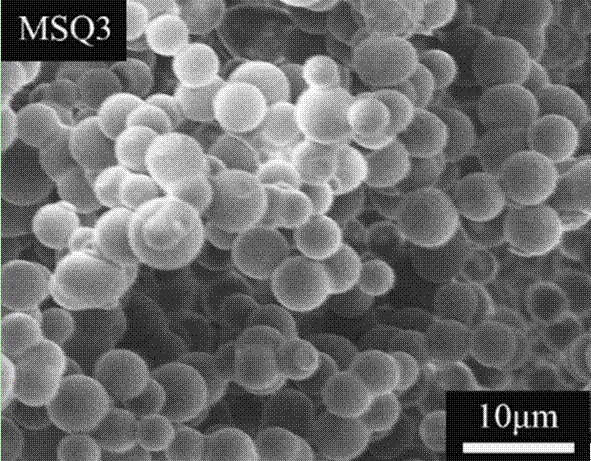

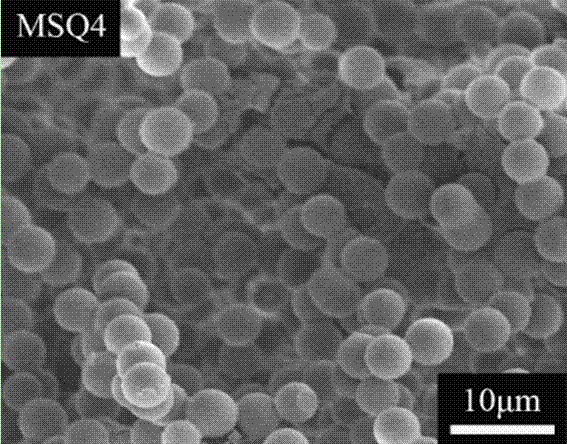

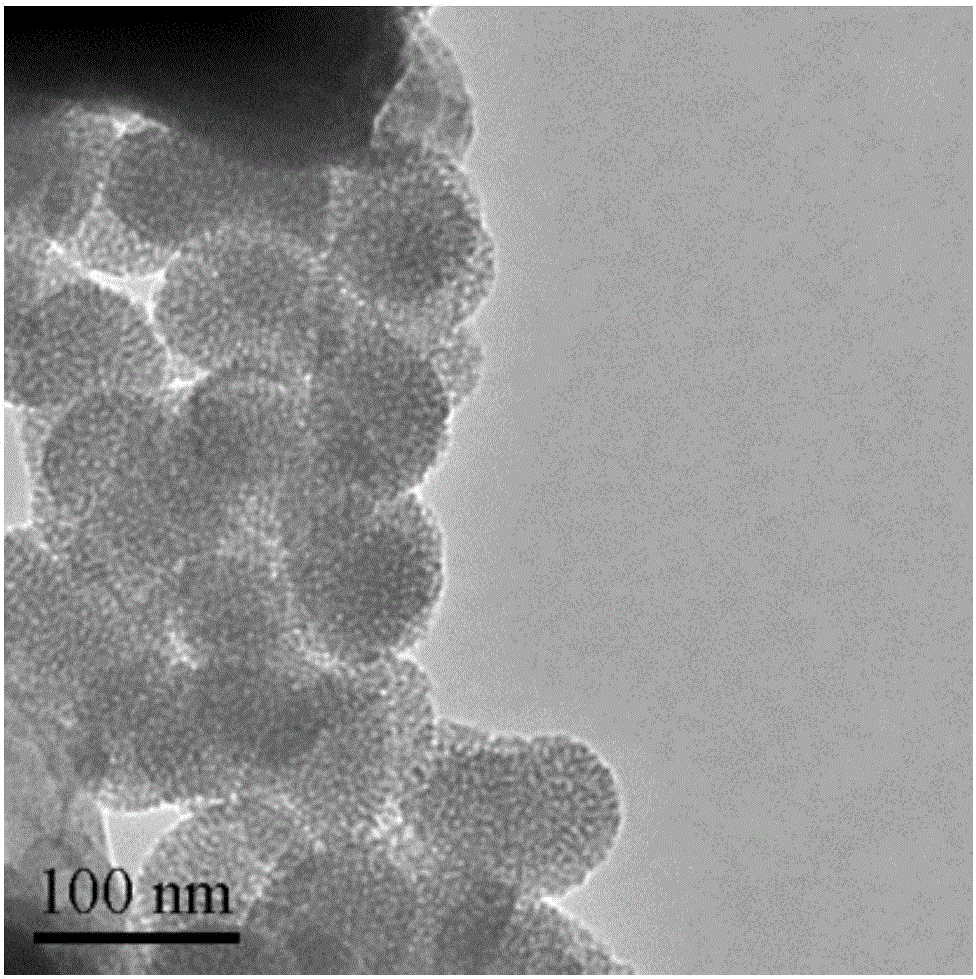

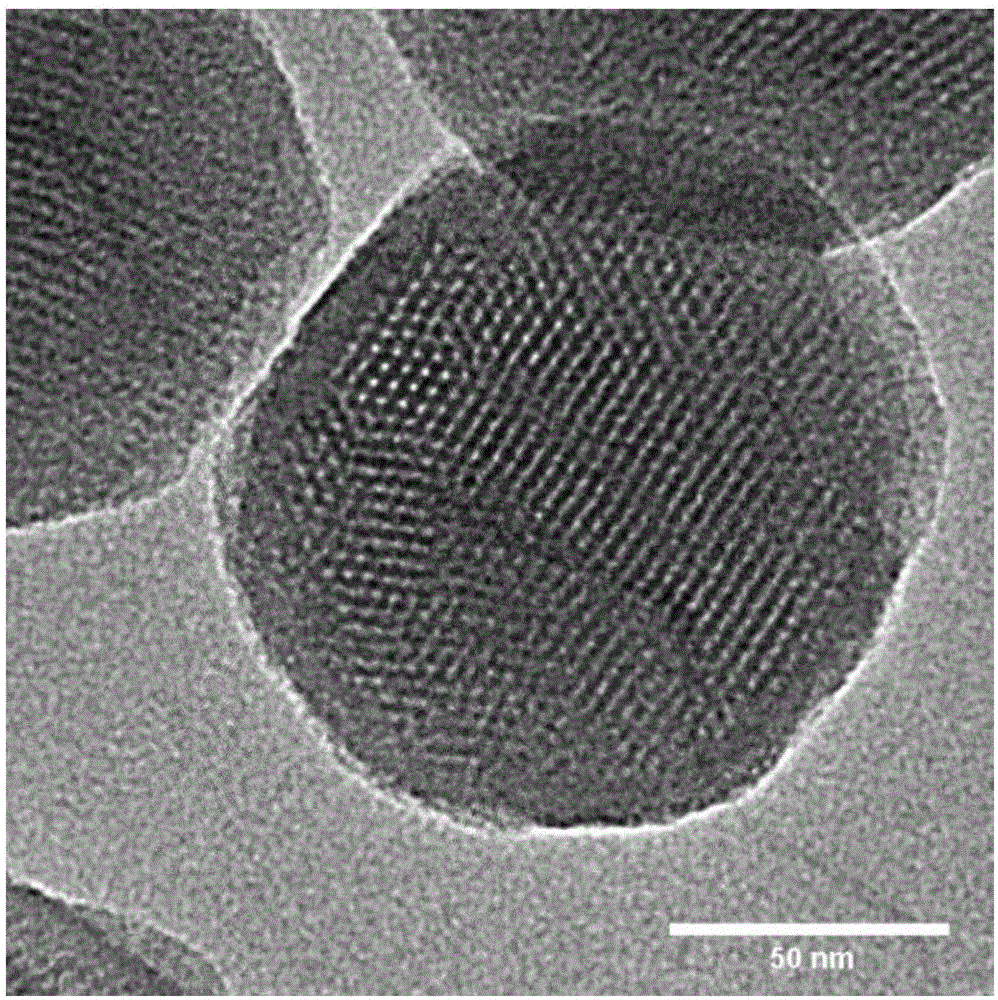

InactiveCN106587078AThe synthesis method is simpleMild reaction conditionsSilicaNanotechnologySilica nanoparticlesMesoporous silica

The invention discloses a preparation method of meso-porous silica nanoparticles. The method comprises the following steps: mixing ethanol with distilled water according to a certain ratio in order to obtain a solvent, adding triethanolamine used an alkali and a chelating agent, adding cetyltrimethylammonium chloride used as a template, heating the above obtained solution to 25-80 DEG C, adding ethyl orthosilicate within 2-3 min, stirring and reacting the above substances for 0.5-6 h, carrying out solid-liquid separation on a product obtained after the above reaction solution cools to room temperature, washing obtained solid with water and ethanol, removing the template, respectively washing the above obtained material with distilled and anhydrous ethanol multiple times, and dispersing obtained meso-porous silica nanoparticles in 25 mL of water to form a colloid. The colloid has high stability, is degradable and can be applied to the field of biomedicines. The preparation method has the advantages of simple process, easiness in operation, good repeatability and cheap and easily available raw materials, and the prepared meso-porous silica nanoparticles has the advantages of monodispersion, controllable morphology and large specific surface area.

Owner:HUBEI UNIV OF TECH

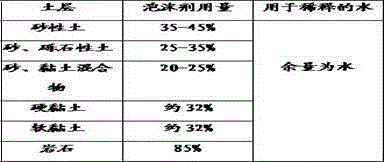

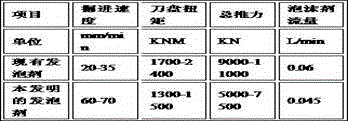

Earth pressure balance shield foaming agent

ActiveCN104946263AImprove plasticityImprove liquidityBuilding constructionsOrganic fertilisersBetaineCocamidopropyl betaine

The invention relates to an earth pressure balance shield foaming agent and a preparation technology thereof. The earth pressure balance shield foaming agent is prepared from 4-15% by weight of sodium dodecyl sulfate, 1-10% by weight of cetyltrimethylammonium chloride, 2-8% by weight of cocamidopropyl betaine, 1-5% by weight of dodecyldimethylamine oxide, 0.1-0.5% by weight of disodium ethylene diamine tetraacetate, 0.1-2.0% by weight of a tackifier and the balance water. The earth pressure balance shield foaming agent has a simple formula and high effects, and utilizes cetyltrimethylammonium chloride with excellent permeability, flexibility, emulsification effects and sterilization performances as a cationic surfactant which can be mixed with other surfactants. The earth pressure balance shield foaming agent is environmentally friendly, has excellent permeability and lubricity and can effectively improve excavated soil fluidity and watertightness.

Owner:XIAMEN NORNS TECH

Corrosion-prevention, waterproof and antifouling paint containing polymer asphalt and preparation method thereof

The invention relates to a corrosion-prevention, waterproof and antifouling paint containing polymer asphalt and a preparation method thereof. The paint comprises the following components in parts by weight: 30 to 50 parts of 10# asphalt, 0.8 to 2 parts of soluble polytetrafluoroethylene resin, 3 to 4.5 parts of poval, 1 to 3 parts of cetyltrimethylammonium chloride, 3 to 12 parts of neoprene rubber latex, 2 to 6 parts of organic silicon milk, 5 to 20 parts of calcium carbonate superfine powder, 2 to 5 parts of mica superfine powder, 1 to 3 parts of hydroxymethyl cellulose, 0.3 to 0.7 part of defoaming agent and 80 to 120 parts of water. The corrosion-prevention, waterproof and antifouling paint containing polymer asphalt of the invention has the advantages of wide temperature adaptability, no flowing at the high temperature of 180 DEG C, no cracking at the low temperature of below 30 DEG C, good film forming toughness, short film forming time, shortened waterproof construction time, no sediment in use, clean film forming and easy washing.

Owner:北京立高科技股份有限公司 +1

Method for preparing adhesive abamectin polydopamine microcapsule by employing emulsion interface polymerization method

The invention relates to a method for preparing an adhesive abamectin polydopamine microcapsule by employing an emulsion interface polymerization method, and aims at solving the problems that abamectin is easy to decompose in light, and most of dosage forms cannot effectively remain on a plant leaf surface. The method comprises the following steps: with a Tris-HCl buffer liquid containing cetyltrimethylammonium chloride (1.5%m / v of water phase) as a water solution, and an n-butyl alcohol solution containing abamectin as an oil phase, carrying out oxidizing auto-polymerization on an emulsion interface through polydopamine (the density is 1mg / mL); carrying out mechanical agitation at room temperature for 24 hours; and centrifugally washing to obtain the abamectin polydopamine microcapsule with stickiness and light stability, wherein the microcapsule has temperature and pH control-release property. The abamectin polydopamine microcapsule which is uniform in size, high in loading capacity and high in stickiness can be prepared by the method disclosed by the invention; and the method is high in yield and simple in steps, and can be applied to industrialization.

Owner:SHIHEZI UNIVERSITY

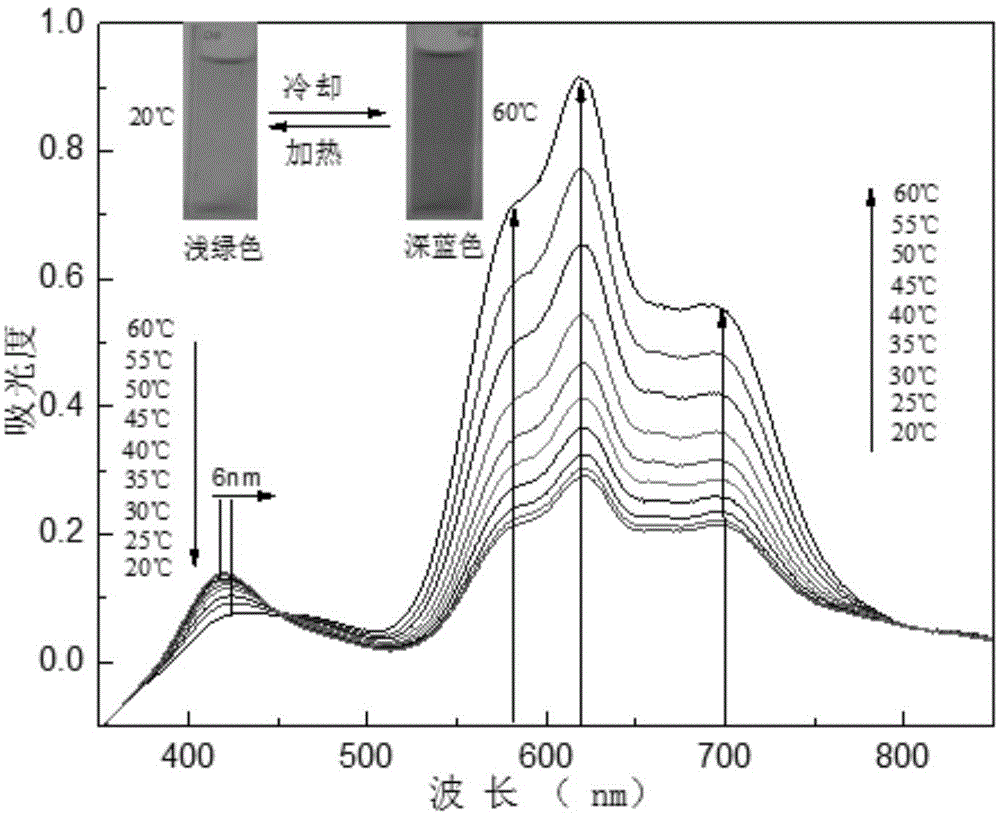

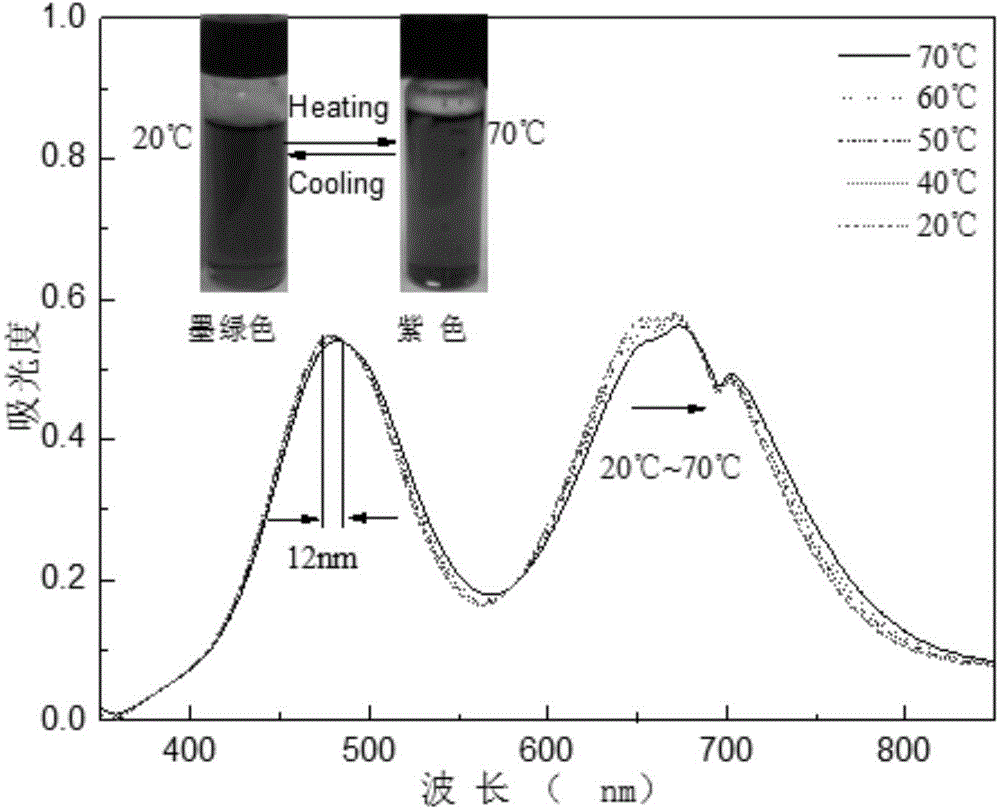

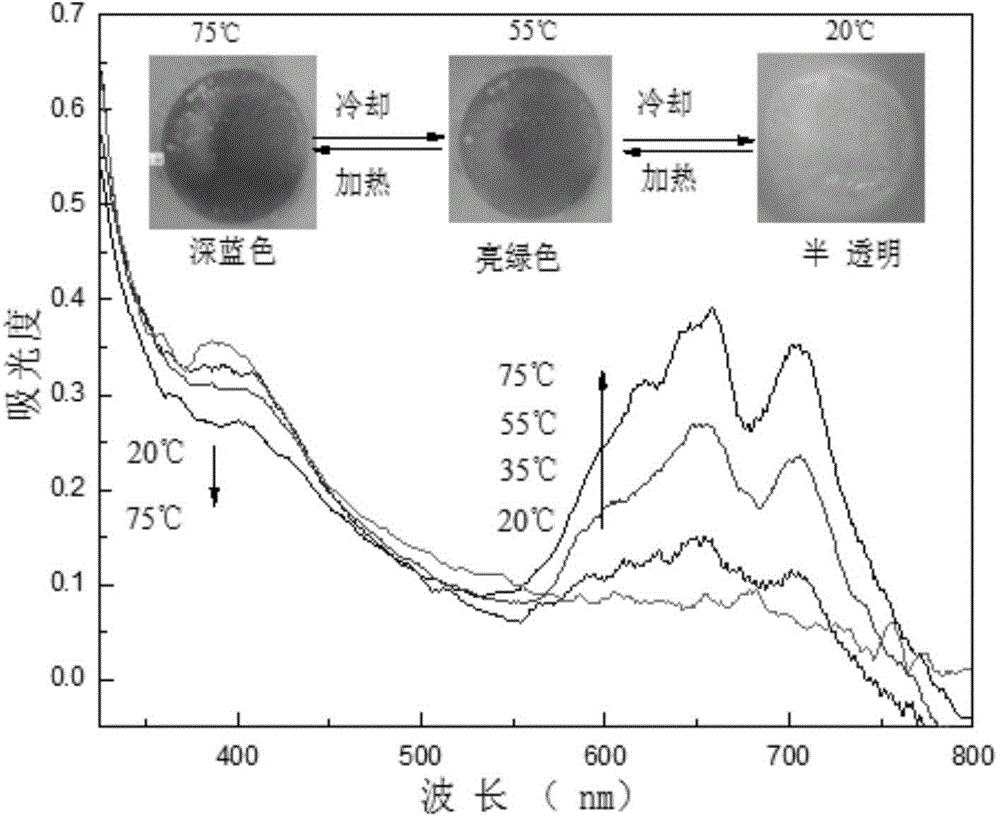

Preparation of reversible thermo-color material, and preparation and applications of thermo-color solution system thereof

InactiveCN104830309AEasy to makeVivid color changeInksTenebresent compositionsColor changesMole ratio

The invention discloses preparation of a reversible thermo-color material, and preparation and applications of a thermo-color solution system of the reversible thermo-color material. The reversible thermo-color material is prepared by the following steps: mixing cetyl trimethyl ammonium chloride (C19H42ClN) and metal salts according to a mole ratio of 2:1-5:1 in a solvent (water or ethanol), stirring to completely dissolving C19H42ClN and metal salts under heating to obtain a colloidal solid namely the reversible thermo-color material having a thermochromic temperature of 50 to 75 DEG C. The preparation of the reversible thermo-color material is simple, the reversible thermo-color material is green, environment-friendly, stable, and reliable, the color change is clear, the raw materials are easily available, and the preparation is easy. The reversible thermo-color material can be dissolved in N,N-dimethyl formamide to form a thermo-color solution system, the system has the advantages of high sensitivity and adjustable temperature, moreover, the color change is reversible, the effect can last for a long time, and the thermochromic temperature is in a range of 20 to 100 DEG C.

Owner:SUN YAT SEN UNIV

Quaternized zinc oxide sol as textile finishing agent and preparation method thereof

InactiveCN102505450AImprove bonding fastnessStrong adhesionFibre treatmentPolymer scienceAmmonium bromide

The invention relates to a preparation method of quaternized zinc oxide sol as a textile finishing agent. In the preparation method, the quaternized zinc oxide sol is respectively prepared by taking diallyl dimethyl ammonium chloride, diallyl methyl dodecyl, myristyl, hexadecyl, octadecylselyl ammonium bromide and cetyltrimethyl ammonium chloride as additives and taking diallyl methyl alkyl quaternary ammonium as an additive, the monomers not only have a certain regulating function for the shape of the zinc oxide sol, but also can be used for remarkably improving the dispersion degree of the nano ZnO and reducing the grain size of the nano ZnO and can also be used for improving the performance of a finished textile; meanwhile, the quaternized zinc oxide sol can be subjected to cyclopolymerization with other monomers because of containing non-conjugated diene bonds. The quaternized zinc oxide sol has the bacteriostasis rate of 62-83% and the strength loss rate of 22-29% when being applied to the antimicrobial finishing of a cotton textile, and meanwhile, the quaternized zinc oxide sol has certain ultraviolet resistance.

Owner:SHAANXI UNIV OF SCI & TECH

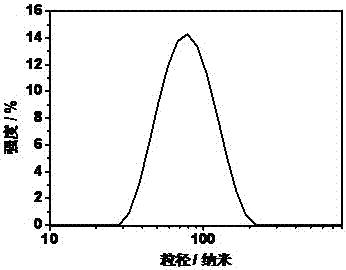

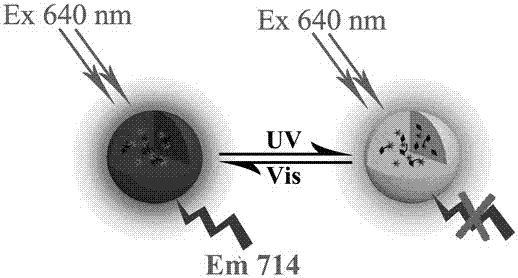

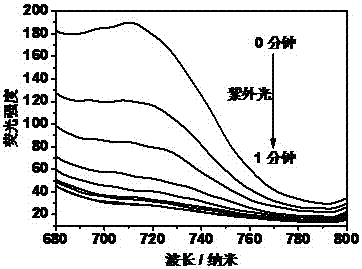

Preparation method for near-infrared light switch fluorescent polymer nanoparticle, and application thereof

The invention discloses a preparation method for a near-infrared light switch fluorescent polymer nanoparticle, and application thereof. A FRET (Fluorescence Resonance Energy Transfer) principle is used, MMA (Methyl MethAcrylate) is taken as a polymerizable monomer, polymerizable near infrared fluorescent dye (TEGTPPDI-Aly) is taken as an energy donor, a polymerizable photochromic compound (STPMA) is taken as an energy receptor, hexadecane (HD) is taken as a hydrophobic substance, CTAC (Cetyltrimethylammonium Chloride) is taken as surfactant, and a one-step simple miniemulsion polymerization method is adopted to prepare the near-infrared light switch fluorescent polymer nanoparticle. The near-infrared light switch fluorescent polymer nanoparticle prepared with the predation method has the advantages of near-infrared light switch ability, low cytotoxicity, good water dispersibility, low input cost, simple synthetic route and the like, is suitable for amplification synthesis and practical production and application, and has a huge application prospect in technical field including super-resolution imaging, life science and the like.

Owner:HUNAN UNIV OF SCI & TECH

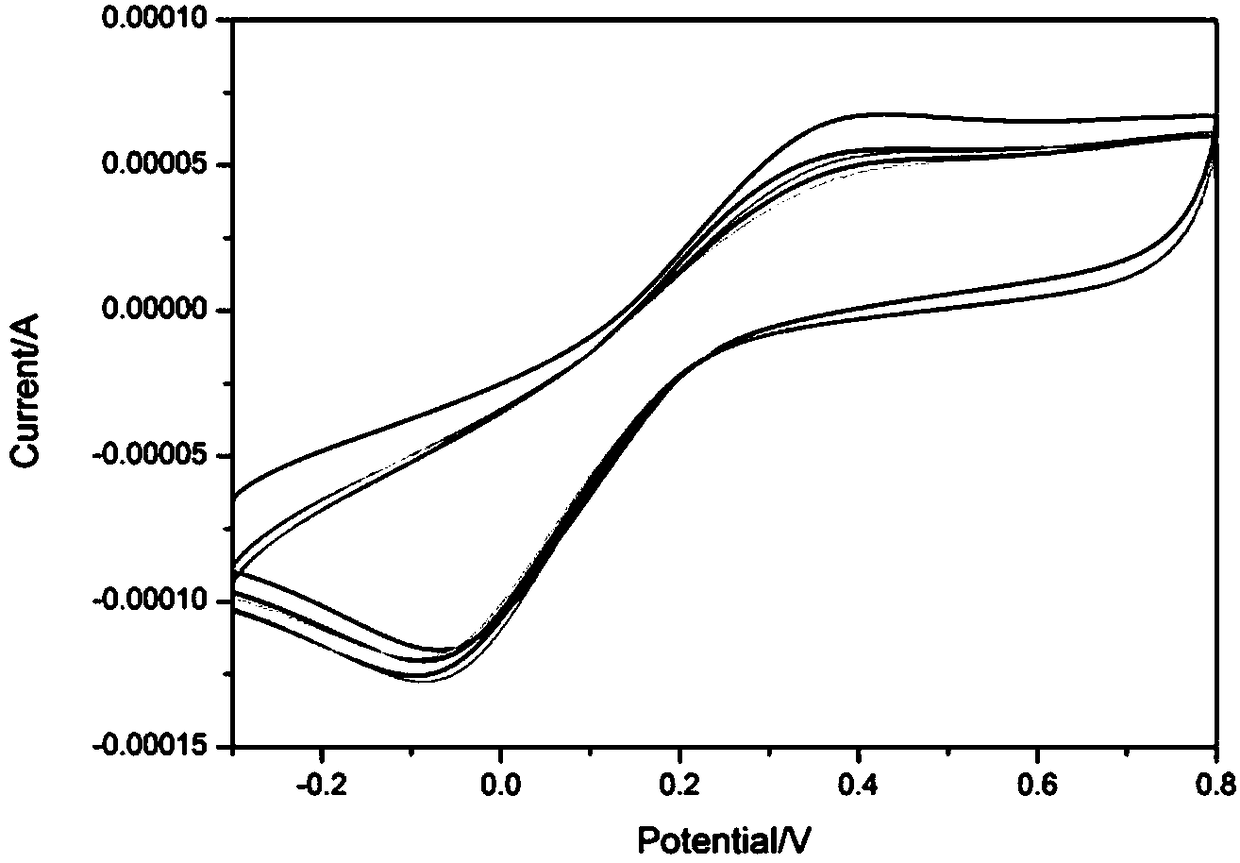

Preparation method and application of electrochemical biosensor based on gold nanocage

ActiveCN108344788AIncrease the areaIncrease its electrochemical performanceMaterial analysis by electric/magnetic meansElectrochemical biosensorTG - Triglyceride

The invention discloses a preparation method and application of an electrochemical biosensor based on a gold nanocage. A gold-sulfur covalent bond is used for fixing the gold nanocage on a substrate conductive glass sheet immersed in a mercaptosilylating reagent, and electrostatic adsorption force is sequentially utilized for adsorption of dopamine and lipase on the surface of nanoparticles to further modify gold nanocage particles on the substrate conductive glass sheet; the gold nanocage is the gold nanocage particles formed by using a seed growth method to prepare a gold core-silver shell nanocubic structure and finally using chloroauric acid to convert a silver shell under the condition of using cetyltrimethylammonium chloride as a surfactant. The high-performance electrochemical biosensor effectively increases the surface area of an electrode and the electrochemical performance while the maximum biological activity of enzyme is reserved; the high-performance electrochemical biosensor can be used for highly sensitive detection of triglyceride in a water sample and can also be applicable to human serum samples.

Owner:NANJING UNIV OF POSTS & TELECOMM

Attapulgite-level paper-making additive

InactiveCN104343051AImprove fiber structureIncreased ring compressive strengthInorganic compound additionPaper forming aids additionSodium BentonitePolyethylene glycol

The invention discloses an attapulgite-level paper-making additive. The attapulgite-level paper-making additive comprises the following materials in parts by weight: 60-70 parts of attapulgite, 2-3 parts of aluminum fluoride, 10-20 parts of sea-foam stone powder, 20-30 parts of bentonite, 2-3 parts of polyoxyethylene glyceryl ether, 0.3-1 part of calendula soaking oil, 1-2 parts of sodium borohydride, 3-4 parts of hydroxy ethylidene diphosphate, 0.3-0.5 part of silver nitrate, 0.5-2 parts of dibromo-5,5-dimethylhydantoin, 1-2 parts of cetyltrimethylammonium chloride, 0.4-1 part of ammonium metavanadate, 1-2 parts of casein, 3-4 parts of calcium lignosulphonate and 2-3 parts of polyethylene glycol 1000. The attapulgite-level paper-making additive can be uniformly distributed in paper pulp, so that the favorableness to bonding among paper-pulp materials is achieved, the used amount of the materials of the paper pulp is reduced, the fiber structure of the paper pulp is improved, the ring crush compression resistance, the glossiness, the softness, the whiteness and the flatness of the paper are improved, and the linting and the fluffing of the paper in the use process are avoided, the quality of the paper is improved, and the decontaminating and environment-friendly effects are achieved.

Owner:ANHUI BOSHUO TECH

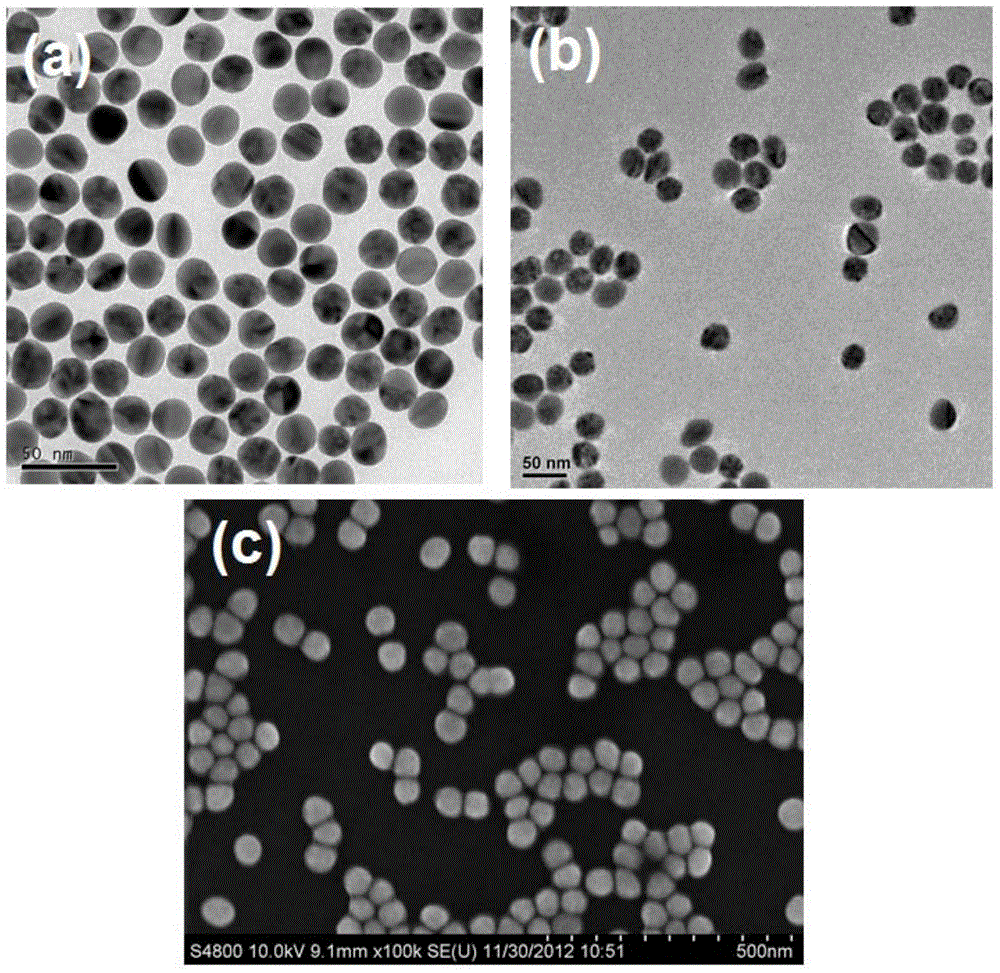

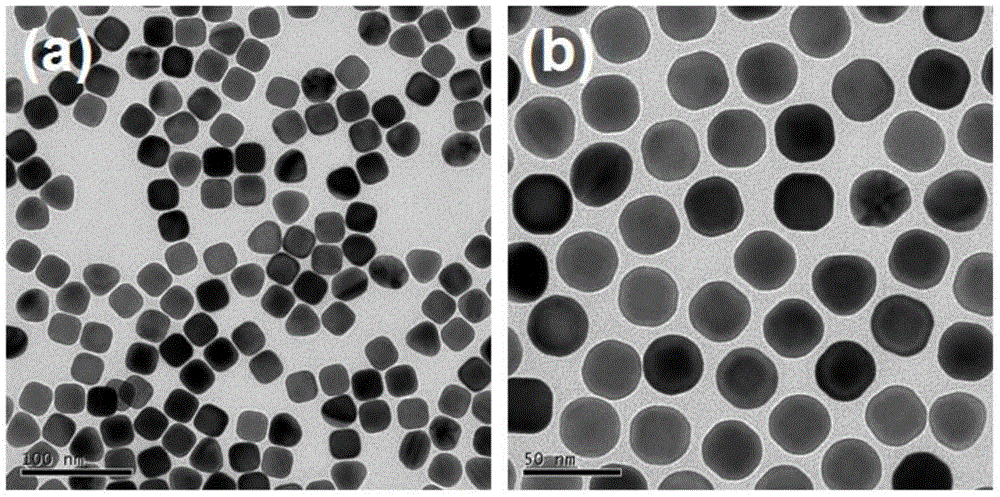

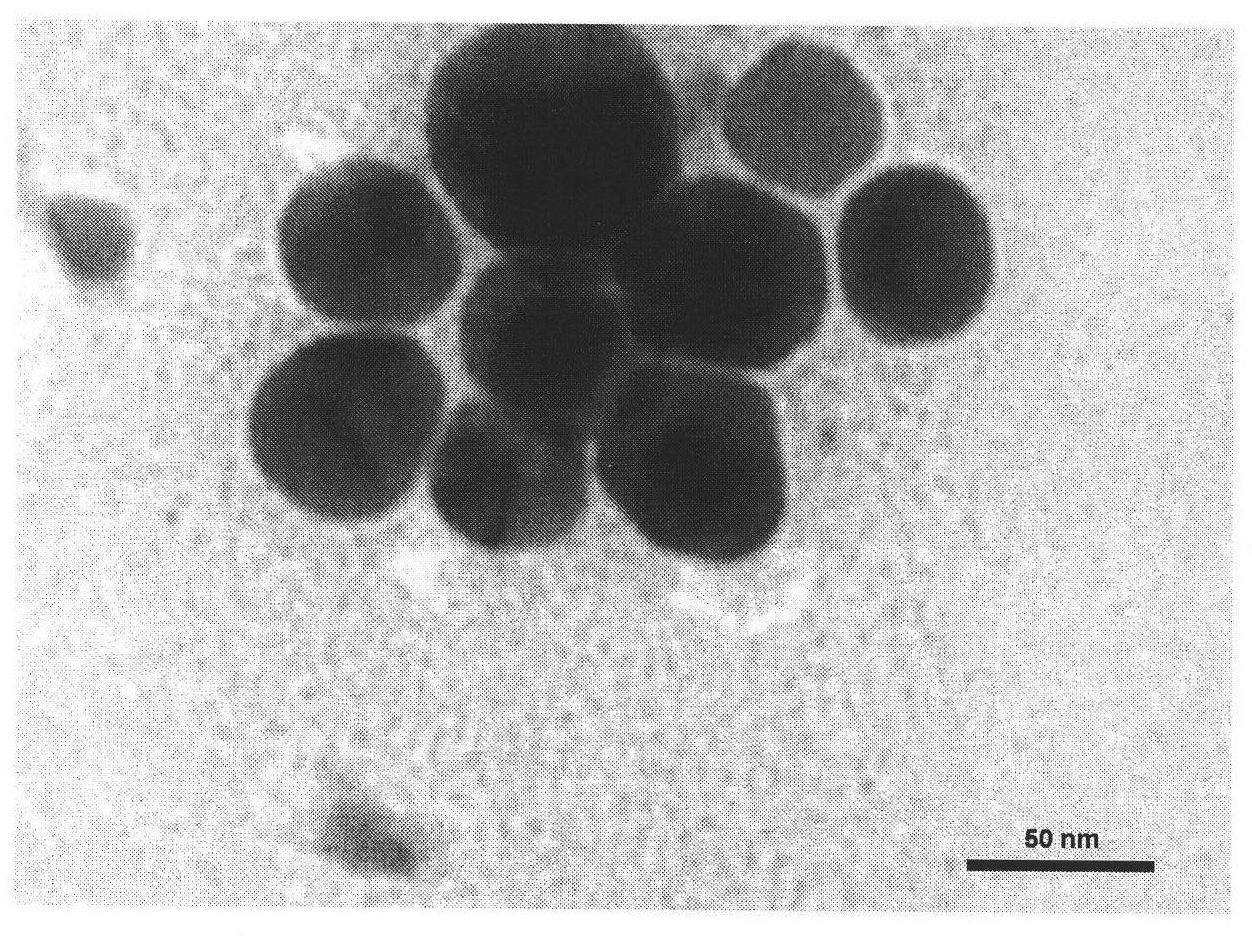

Spheroidal gold particle and step-by-step rapid synthesis method thereof

The invention relates to a spheroidal gold particle and a step-by-step rapid synthesis method thereof. The method includes the following steps: soluble gold salt, surfactant and reducer are prepared into mixed solution, and gold particle seeds are added in the process of rapid agitation, and thereby react to grow into spheroidal gold particles, the grain size of which is 5nm to 100nm; the surfactant is the mixed surfactant of cetyltrimethylammonium bromide or cetyltrimethylammonium chloride and cetyltrimethylammonium bromide, the reducer is ascorbic acid, and the gold particle seeds are spheroidal gold particles, the grain size of which is 2nm to 60nm. The gold particle seeds can be monocrystalline or polycrystalline, and the synthesized spheroidal gold particles have the same crystal form as the gold particle seeds. Since the invention adopts the surfactant and the reducer and the gold particle seeds are added in the process of rapid agitation, reaction is rapid enough, consequently, the gold salt can rapidly and uniformly grow on the surfaces of the gold particle seeds, and the obtained spheroidal gold particles is narrow in grain size and has a good degree of sphericity.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for preparing hydrophobic white carbon black

InactiveCN103360798ANo pollution in the processImprove hydrophobicityPigment treatment with non-polymer organic compoundsPolymer scienceBiological activation

The invention discloses a method for preparing hydrophobic white carbon black. The method comprises the steps of drying precipitated white carbon black to constant weight, then mixing with a modifier solution, adjusting a pH value to 8; and at a temperature of 30-90 DEG C, stirring for a reaction for 20-100 min with a stirring speed of 250-450 rpm, then filtering, and drying to obtain the hydrophobic white carbon black. The modifier is selected from one or more of cetyltrimethylammonium chloride, hexadecyltrimethylammonium bromide, dodecyltrimethylammonium chloride, and dodecyltrimethylammonium bromide. The activation degree of the modified white carbon black is obviously improved and can reach 95% or more, and the modified white carbon black is the hydrophobic white carbon black. The method of the invention is simple in process, has the solvent with cleanliness and no pollution; and the modified white carbon black has the hydrophobic property improved significantly, and thereby being beneficial to improving compatibility when adding into rubber and plastics.

Owner:HEFEI UNIV OF TECH

Compound gas hydrate anti-agglomerant and application thereof

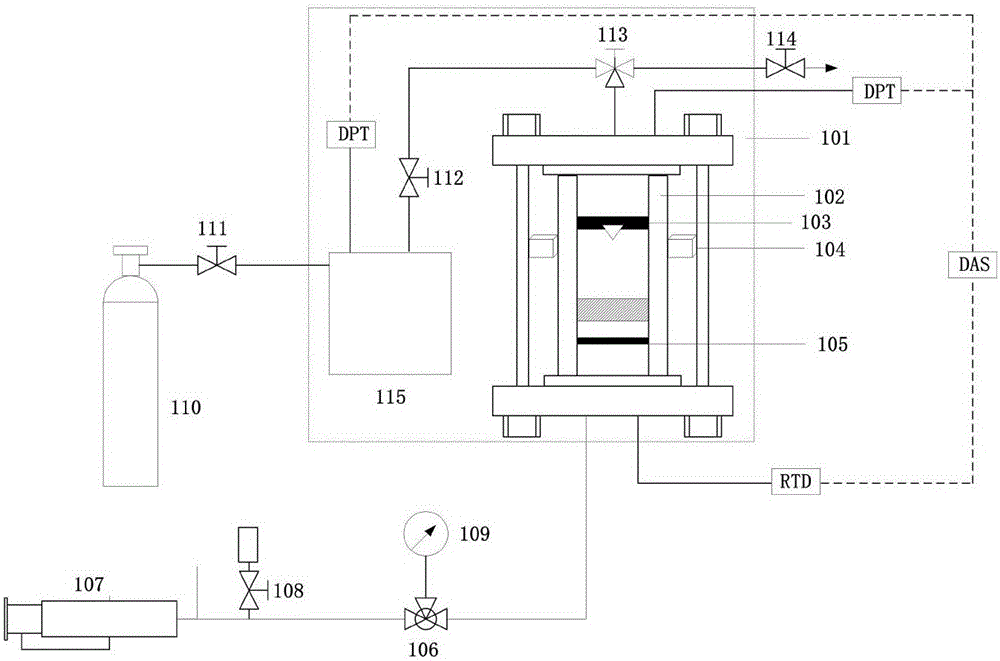

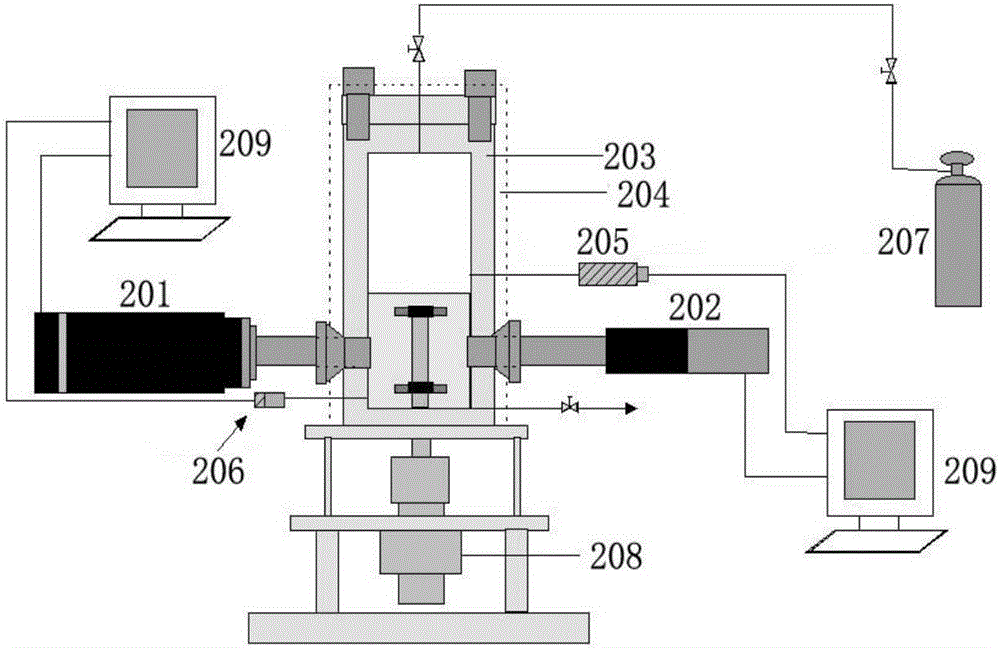

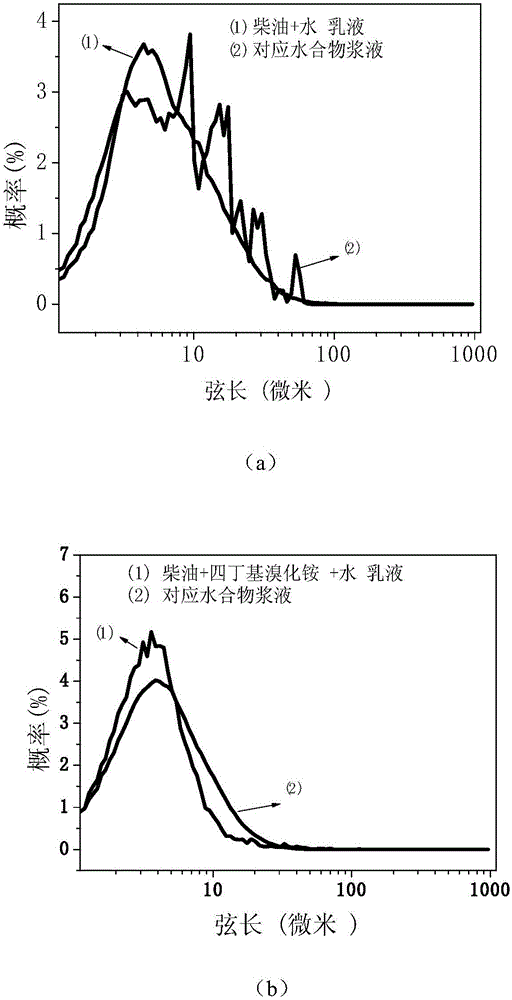

ActiveCN105733539AGood inhibition effectHas polymerization inhibition propertiesDispersed particle separationPipeline systemsOil emulsionMixed gas

The invention discloses a compound gas hydrate anti-agglomerant and an application thereof. The anti-agglomerant is prepared by compounding a polyalcohol nonionic surfactant and a quaternary ammonium salt compound, wherein the polyalcohol nonionic surfactant is one or a combination of more of span-20, span-40, span-60, span-65, span-80 and span-85; and the quaternary ammonium salt compound is one or a combination of more of tetrabutylammonium bromide, tetraamylammonium bromide, dodecyltrimethylammonium bromide, dodecyltrimethylammonium chloride, tetradecyltrimethylammonium chloride, cetyltrimethylammonium chloride, dioctyldimethyl ammonium chloride and didecyldimethyl ammonium chloride. The anti-agglomerant is applied to a separation process of a mixed gas by a water / oil emulsion system in the conditions of mixed transportation of an oil-gas-water three-phase system and hydrate generation. Under the influence of supercooling degree and operation conditions, the compound gas hydrate anti-agglomerant disclosed by the invention has the advantages of small dosage, good performance, economy and environmental friendliness, wide application range, good recycling property and the like and has a broad market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

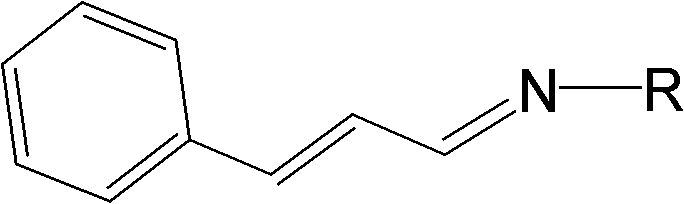

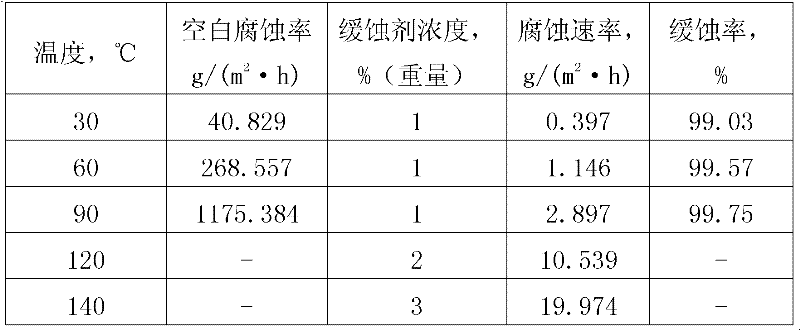

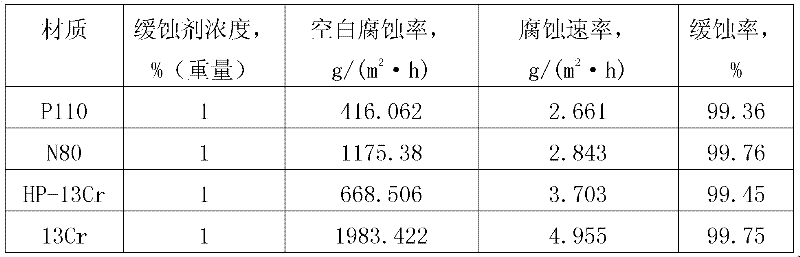

Novel preparation method of schiff base oil well acidification corrosion inhibitor and application of preparation method

InactiveCN102559167AImprove adsorption capacityImprove protectionDrilling compositionChemical industryAcid washing

The invention relates to a novel preparation method of a schiff base oil well acidification corrosion inhibitor and application of the preparation method. The corrosion inhibitor comprises the following components in percentage by weight: 5-20 percent of schiff base compound, 0.5-2 percent of cyclohexylamine, 1-3 percent of methoxy amine, 3-5 percent of hexadecyl trimethyl ammonium chloride, 15-20 percent of N'N-dimethyl formamide and 50-75.5 percent of solvent. The corrosion inhibitor has extremely strong adsorption, can form a compact protective film on a metal surface and is extremely suitable for corrosion resistance of different oil pipe steel in acid fracturing construction of petroleum exploitation industry. The acidification corrosion inhibitor used for the oil pipe steel can also be promoted and used in pipeline acid washing of industries of chemical industry, water supply and drainage, boilers, steel mill and the like. The application temperature of the corrosion inhibitor in an acidification process can reach 140 DEG C; and the corrosion inhibitor is suitable for hydrochloric acid with concentration of reaching up to 25 percent, and has the characteristics of less using amount, high efficiency, wide application temperature range, suitability for oil pipes of different materials, good dispersion in acid solution, easiness and convenience for production and the like.

Owner:XIAN SANHUAN TECH DEV GENERAL

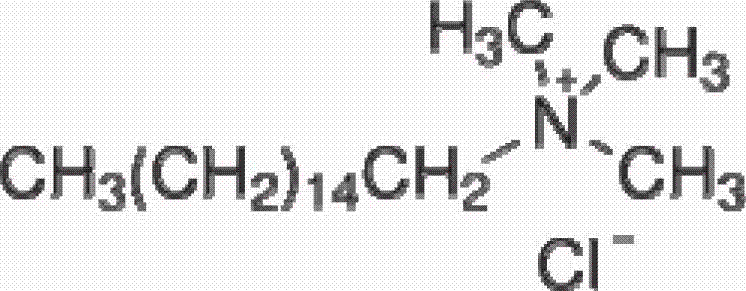

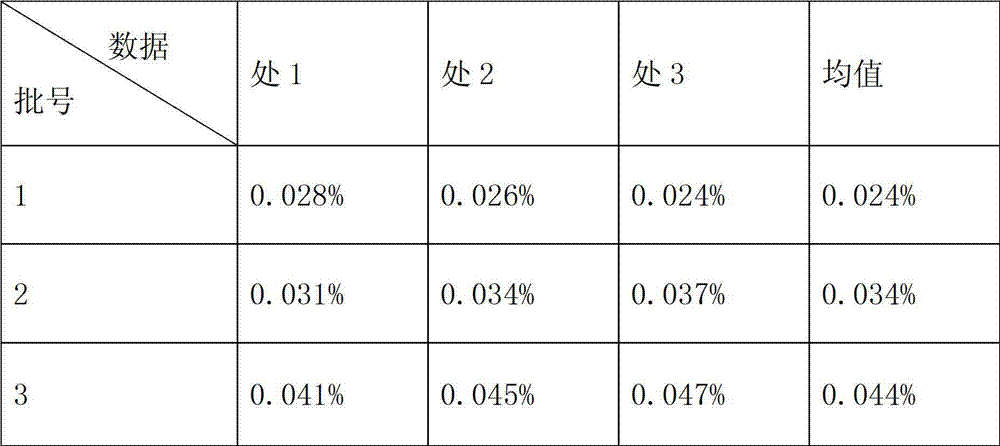

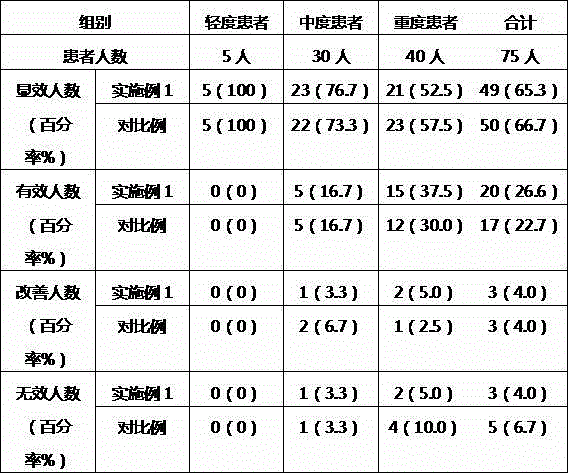

Method for detecting residual disinfecting Cetyltrimethylammonium Chloride used in production process of sodium hyaluronate

ActiveCN103048319AShorten detection timeReduce testing costsMaterial analysis by observing effect on chemical indicatorDisinfectantLinear regression

The invention relates to a method for detecting residual disinfecting Cetyltrimethylammonium Chloride (CTAC) used in the production process of sodium hyaluronate. The method comprises the following steps: preparing a CTAC standard solution to structure a linear regression equation; preparing a sample solution, using an improved bismuth potassium iodide test solution for developing and measuring the absorbency value; and calculating the content of the CTAC with the linear regression equation. The structuring method of the linear regression equation is as follows: after using the improved bismuth potassium iodide test solution for developing of the prepared 2 Mug / ml, 4 Mug / ml, 8 Mug / ml, 10 Mug / ml and 20 Mug / ml standard solutions, measuring the absorbency under 290nm. By adopting the method to detect the content of the CTAC, the shortcoming that the content and the residue of the CTAC serving as a disinfectant or a reaction agent can not be monitored at present can be overcome, the detection time is greatly shortened, and the detection cost is lowered. The method provided by the invention is particularly suitable for detecting CTAC in labs.

Owner:SHANGHAI JINGFENG PHARMA

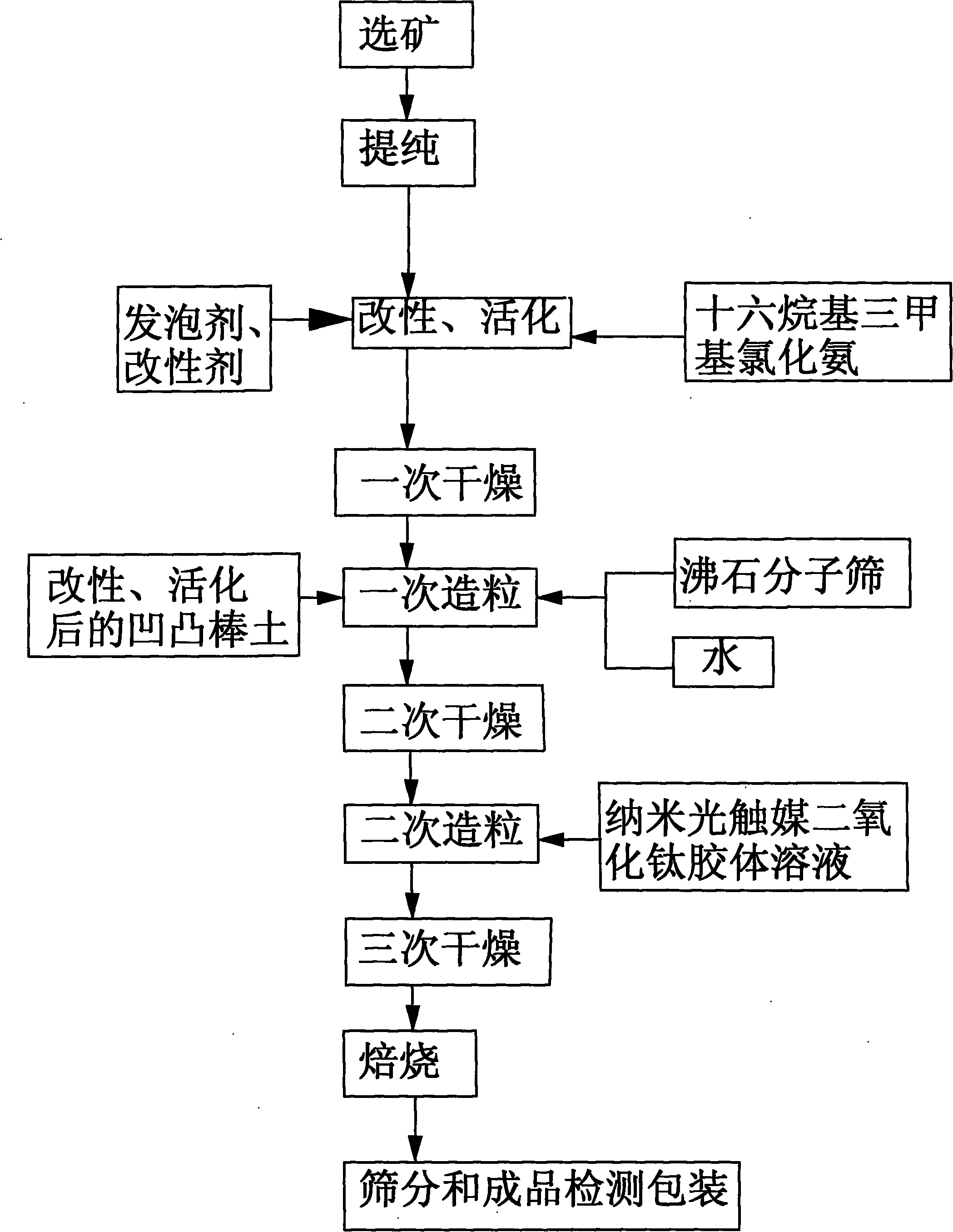

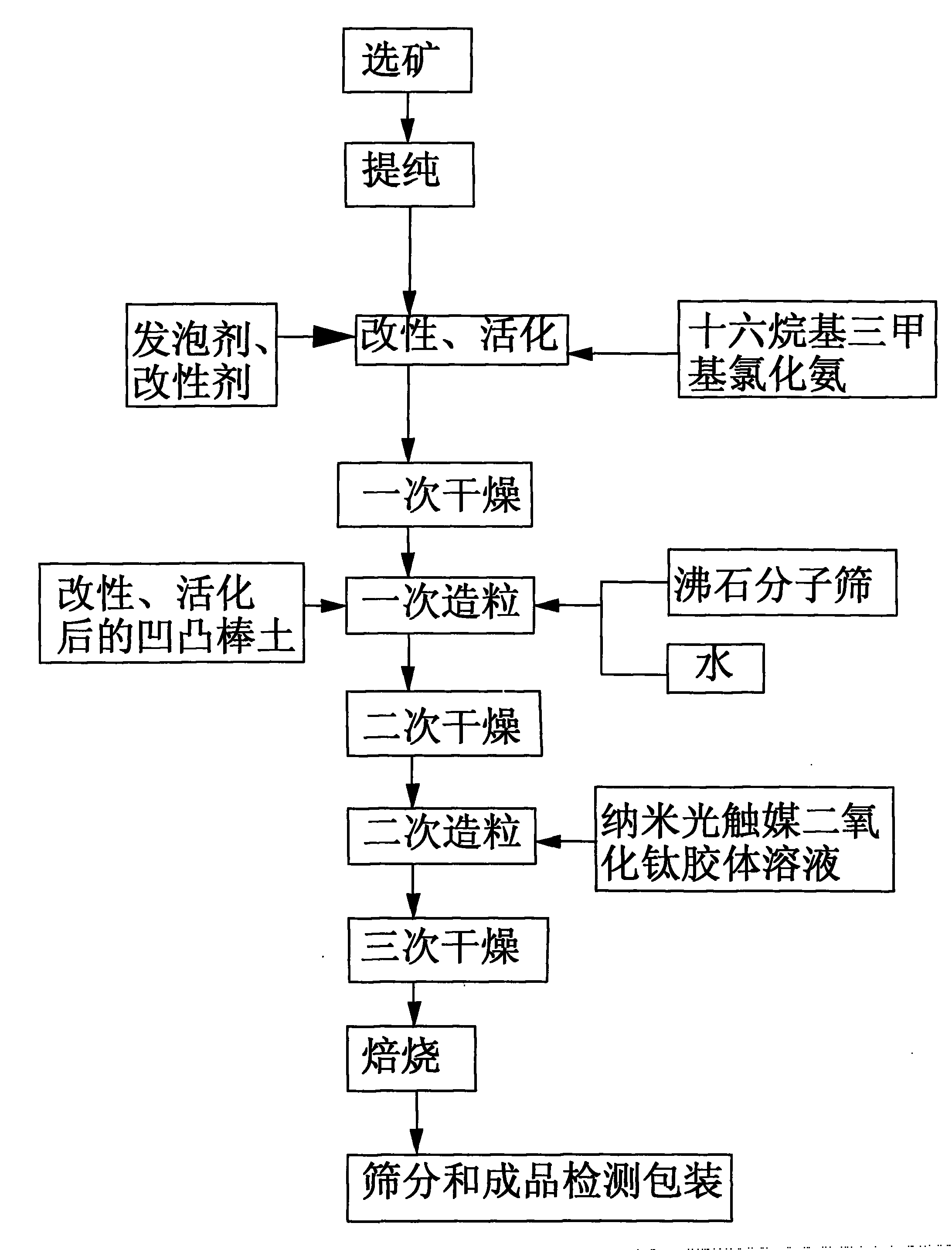

Composite air purifying preparation containing nanometer mineral substance and preparation method thereof

InactiveCN101780289AWill not polluteProcess environmental protectionPhysical/chemical process catalystsDispersed particle separationDecompositionBiological activation

The invention provides a composite air purifying preparation containing nanometer mineral substances, which comprises the following components in percentage by weight: 47-78% of attapulgite as natural mineral, 20-50% of artificial zeolite molecular sieve as molecular sieve, 0.5-5% of sodium hydrogensulfite as a modifier, 0.5-5% of aluminum sulfate as foaming agents and 0.5-2% of cetyltrimethylammonium chloride as surfactants, 0.2-2% of nanometer photocatalyst titanium dioxide colloidal solution as a photochemical catalyst; and the air purifying preparation is prepared by the method comprising the following steps: purification, modification, activation, primary drying, primary pelleting, secondary drying, secondary pelleting, third drying, roasting, sieving and inspection of the finished product and packaging. The product of the invention has extremely selective adsorption capability of organic pollutants in the air, and has the advantages of strong preferential adsorption capability and high decomposition efficiency, environment-friendly craft, low cost, volume production fitness and the like.

Owner:赵溶

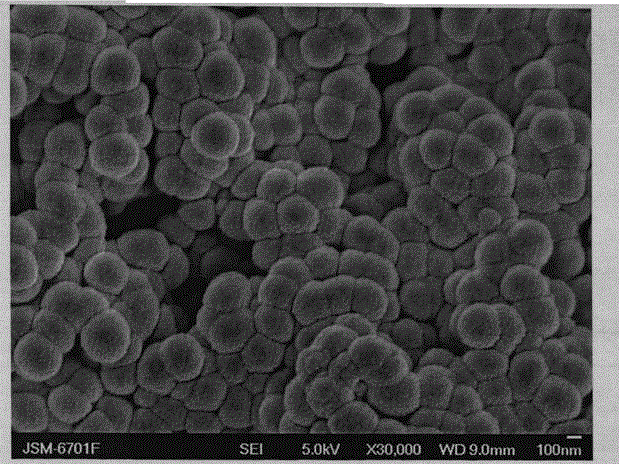

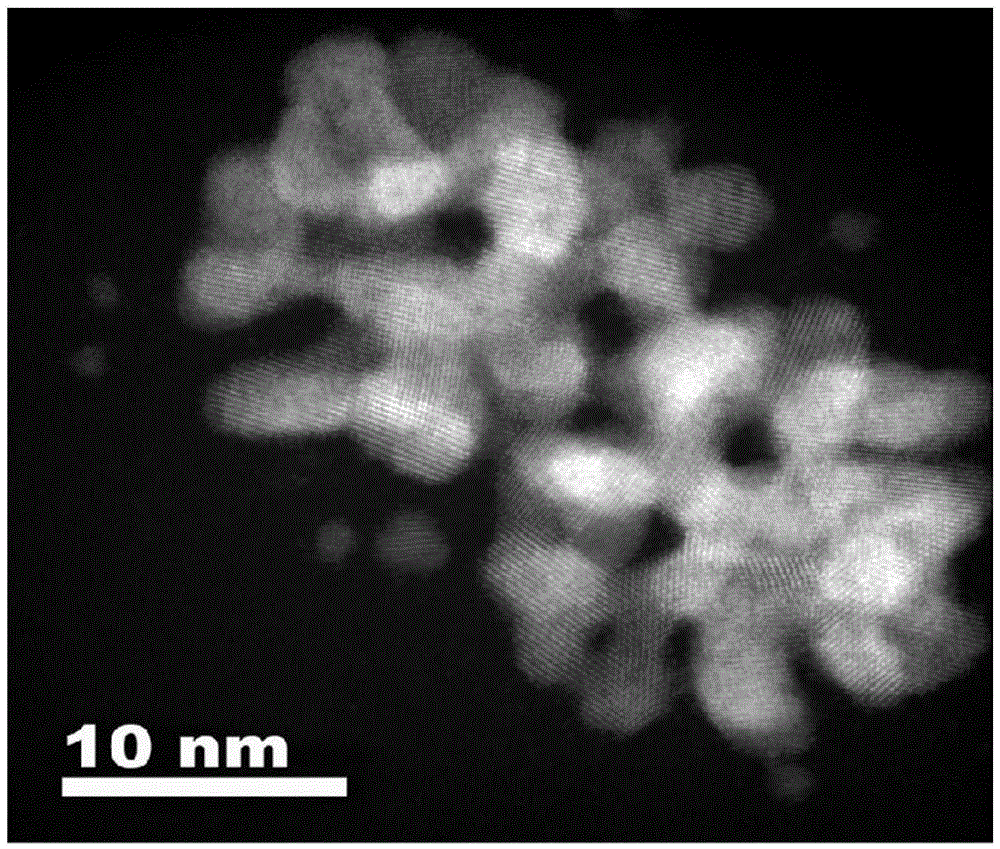

Coralline platinum-copper alloy nano-particle and preparing method thereof

InactiveCN105537611AMild reaction conditionsLess harshTransportation and packagingMetal-working apparatusWater bathsSurface-active agents

The embodiment of the invention provides a preparing method of a coralline platinum-copper alloy nano-particle. The preparing method includes the following steps that (1) a mixed aqueous solution containing chloroplatinate, soluble copper salt and a surface active agent is prepared, wherein the surface active agent is cetyltrimethylammonium chloride; and (2) a reducing agent is added into the mixed aqueous solution, the mixed aqueous and the reducing agent are stirred in a water bath at the temperature of 60 DEG C to 90 DEG C to react for 1 hour to 3 hours, after the reaction is finished, a solution obtained after the reaction is subject to centrifugation, liquid supernatant is removed, a solid product is obtained, and the coralline platinum-copper alloy nano-particle is obtained after the solid product is washed. The preparing method is simple in process, soft in reaction condition, short in reaction time and low in cost; and the obtained coralline platinum-copper alloy nano-particle is quite uniform in size, easy to separate and good in monodispersity. The embodiment of the invention further provides the coralline platinum-copper alloy nano-particle prepared from the preparing method.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Ultrasonic cleaning agent and ultrasonic cleaning method

ActiveCN103289828AEfficient removalEasy to recycleCationic surface-active compoundsCleaning using liquidsMagnesium stearateCleansing Agents

The invention discloses an ultrasonic cleaning agent which comprises the following components: sodium dodecyl benzene sulfonate, calcium dodecyl benzene sulfonate, dodecyl dimethyl benzyl ammonium chloride, magnesium stearate, cetyltrimethylammonium chloride, disodium EDTA (Ethylene Diamine Tetraacetic Acid), polyacrylamide, NaOH, NH3, H2O, NH4Cl and an organic solvent. Aiming at the characteristics of shell of electronic products, for the ultrasonic cleaning agent disclosed by the invention, cetyltrimethylammonium chloride is added to remove negative charges on the surface of the shell. The three anionic surfactants sodium dodecyl benzene sulfonate, calcium dodecyl benzene sulfonate, dodecyl dimethyl benzyl ammonium chloride can effectively remove dirt carried by the shells of the electronic products, and magnesium stearate is used as a supplement for the three anionic surfactants so as to thoroughly clean various dirt on the shells of the products. Meanwhile, various medicaments provided by the invention have the characteristics of easiness in recovery, low toxicity, easiness in treatment and the like, so that the damage to the environment and human body in the production process is reduced.

Owner:HUIZHOU WEK PRECISION PART

Nano-clay added foaming polypropylene and high-molecular absorbent composite material and preparation method thereof

InactiveCN104987588AHigh hole densityLarge specific surface areaOther chemical processesLow-density polyethylenePolyvinyl alcohol

The invention discloses a nano-clay added foaming polypropylene and high-molecular absorbent composite material. The nano-clay added foaming polypropylene and high-molecular absorbent composite material is characterized by being prepared by, by weight, 95-98 parts of high-melt-strength polypropylene, 2-3 parts of low-density polyethylene, 5-7 parts of nano clay, 1-2 parts of polyvinyl akohol, 2-3 parts of calcium carbonate, 4-6 parts of ammonium bicarbonate, 0.1-0.2 part of cetyltrimethylammonium chloride, an appropriate amount of deionized water, 4-5 parts of methylcellulose, 13-15 parts of butyl acrylate, 7.5-9 parts of dodecyl methacrylate, 0.08-0.1 part of N,N,-methylene bisacrylamide, 0.5-0.6 part of azodiisobutyronitrile, 11-12.5 parts of ethyl acetate and 2-3 parts of di-cotyl phosphoric acid. The composite foaming material is relatively compact in appearance, small in particles and good in lustrousness, meets the environmental protection requirement, can be prepared by adopting a simple injection molding process, the preparation process of a micro-foaming material is simplified, and comprehensive performance is excellent.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

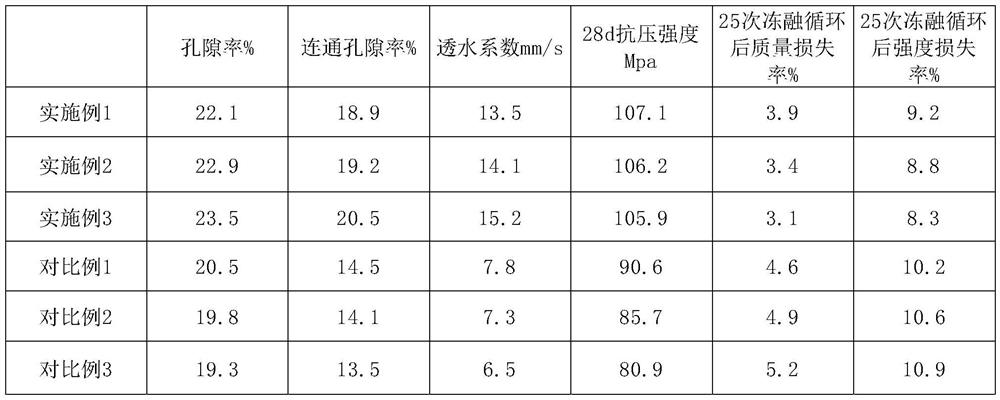

Recycled aggregate pervious concrete and preparation method thereof

The invention discloses recycled aggregate pervious concrete and a preparation method thereof, and belongs to the technical field of concrete. The pervious concrete is prepared from the following raw materials: cement, pretreated recycled aggregate, superfine slag powder, fly ash, toughened modified polypropylene fibers, redispersible latex powder, a silane coupling agent, hydroxypropyl methyl cellulose, a water reducing agent and water. According to the invention, the recycled aggregate is pretreated by chitosan, and then the toughening modified polypropylene fiber is modified by nano silicon dioxide and cetyltrimethylammonium chloride, so that the bonding force between the fiber and recycled aggregate particles is improved, and the strength of the material is greatly improved on the whole. The raw materials are scientifically proportioned, recycled aggregate is used for preparing the pervious concrete, recycling of waste resources is achieved, and the obtained recycled aggregate pervious concrete is high in compressive strength, high in water permeability, high in frost resistance and high in adaptability to the environment and has wide economic benefits and social benefits.

Owner:日照联汇建材有限公司

Preparation method of dandruff removing and itching relieving plant shampoo

InactiveCN104352392AHigh glossImprove flexibilityCosmetic preparationsHair cosmeticsStearic acidGlyceryl monostearate

The invention discloses a preparation method of dandruff removing and itching relieving plant shampoo. Effective components of the shampoo consist of the following components in percentage by mass: 5-8 percent of a cacumen biotae extracting solution, 3-5 percent of a herba andrographitis extracting solution, 5-8 percent of wheat protein subjected to quaternization, 2.0-5.0 percent of N-hexadecyltrimethylammonium chloride, 7.0-15.0 percent of sodium alcohol ether sulphate, 0.5-1.5 percent of coconut monoethanol amide, 0.5-1.5 percent of hexadecanol, 0.5-1.5 percent of glyceryl monostearate, 0.5-1 percent of a preservative and the balance of deionized water. According to the preparation method, the plant extracting solutions are good in compounding and cooperating effect with a hair washing system, so that the dandruff removing and itching relieving plant shampoo has obvious dandruff removing and itching relieving effects; furthermore, by the adoption of pure natural additives, the dandruff removing and itching relieving plant shampoo does not have dependency or side effects; moreover, the wet combing property of hair and the softness, the brightness and the smoothness of dried hair can be obviously improved. In addition, as the compounded system has other effects, the shampoo has rich foam, glossiness, high flexibility and higher anti-static electricity capacity.

Owner:王越

Preparing method for high-whiteness potash feldspar powder

InactiveCN109127152AHigh whitenessRelieve stressHigh gradient magnetic separationHigh gradient magnetic separatorsHigh concentrationSulfonate

The invention provides a preparing method for high-whiteness potash feldspar powder. The preparing method comprises beneficiation and ore washing, preliminary screening, ball milling, magnetic separation, primary flotation, secondary flotation and water removal. Petroleum sodium sulfonate and sodium oleate are selected as a collecting agent of primary flotation, and lauryl amine, dodecyl trimethylammonium chloride and cetyltrimethylammonium chloride serve as a collecting agent of secondary flotation; and compared with a single collecting agent, the flotation effect can be improved, and the whiteness is improved. Treatment is conducted in a physical method and chemical method combination manner, the whitening efficiency is improved, and the high-whiteness potash feldspar powder is obtained; and the pressure brought to the environment due to usage of high-concentration sulfuric acid is avoided.

Owner:贺州市骏鑫矿产品有限责任公司

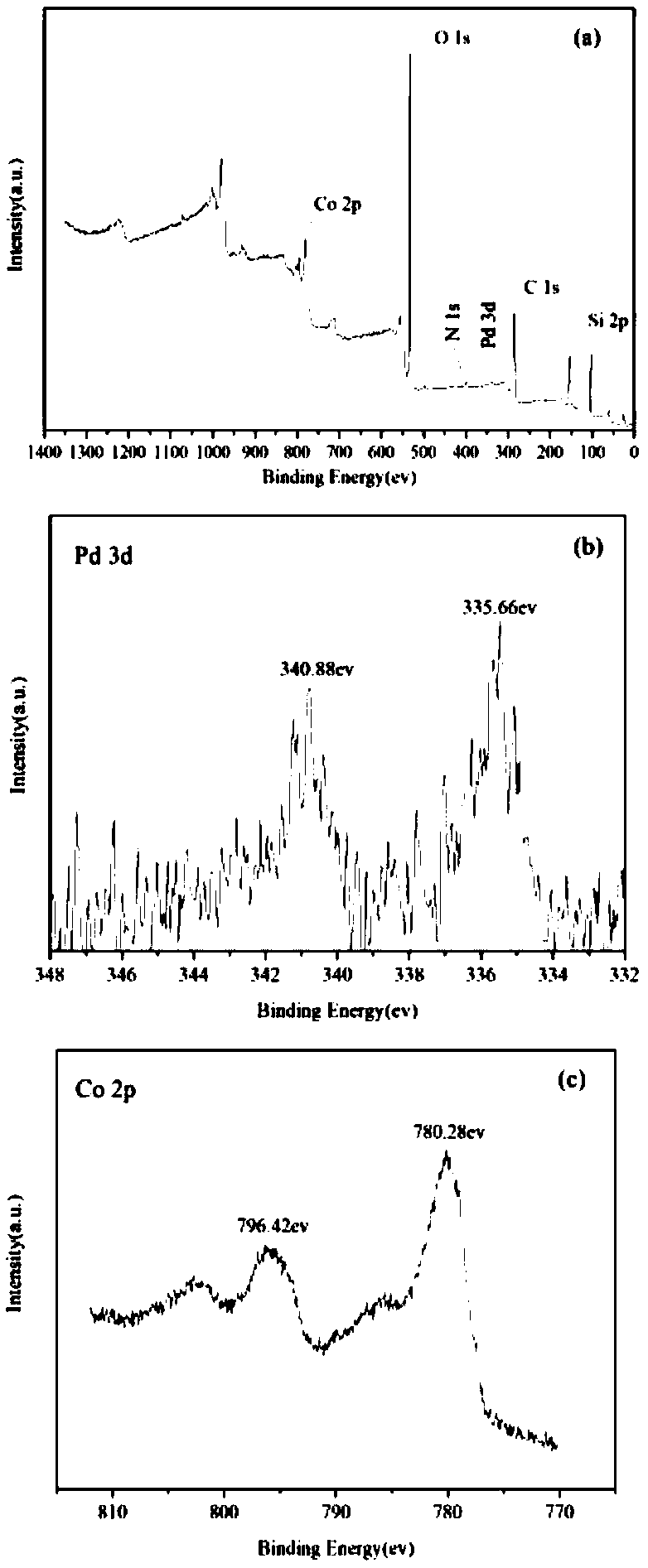

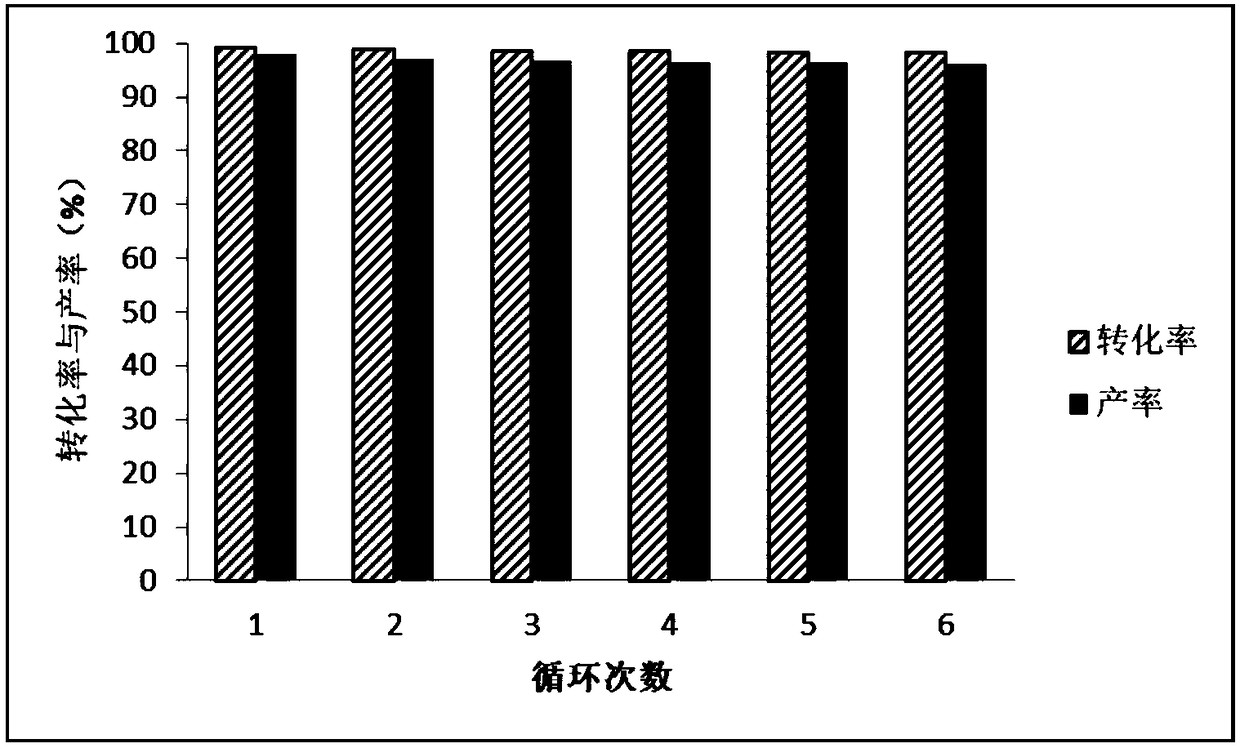

Preparation method of core-shell structured Pd-Co/CN@SiO2 nano-catalyst

InactiveCN109012723AAvoid reunionAvoid churnPhysical/chemical process catalystsOrganic compound preparationNano catalystNitro compound

The invention discloses a preparation method of a core-shell structured Pd-Co / CN@SiO2 nano-catalyst. The method comprises the following steps: mixing and reacting cobalt nitrate hexahydrate, potassiumchloropalladate and 2-methylimidazole to prepare a palladium-supported cobalt-based metal organic framework Pd<2+> / ZIF-67, then reacting the Pd<2+> / ZIF-67 with 2-methylimidazole, cetyltrimethylammonium chloride and tetraethyl orthosilicate to make the surface of the Pd<2+> / ZIF-67 wrapped with silica, and performing calcination to obtain the Pd-Co / CN@SiO2 catalyst. SiO2 shell coating can effectively prevent the agglomeration of Pd-Co nanoparticles and prevent the loss of metal particles in a catalytic reaction, so the catalytic activity is improved, and the hydrogenation reduction of nitro compounds under normal temperature and normal pressure conditions is realized; the method has the advantages of mild conditions, strong practicability, and easiness in operation; and the catalyst has theadvantage of magnetism, easiness in recovery, and realization of cycle use.

Owner:NANJING UNIV OF SCI & TECH +1

High-hardness boiler scale corrosion inhibiting cleaning agent and preparation method thereof

The invention discloses a high-hardness boiler scale corrosion inhibiting cleaning agent and a preparation method thereof. The cleaning agent comprises cetyltrimethylammonium chloride glycine betaine, carboxymethylcellulose, fatty alcohol polyoxyethylene (9) ether, disodium of 1-hydroxy ethylidene-1,1-diphosphonic acid, glycollic acid, oxalic acid, essence and water. The preparation method comprises the following steps: weighing the components according to a formula; stirring and mixing evenly; and adding the carboxymethylcellulose. The prepared high-hardness boiler scale corrosion cleaning agent is good in stability, weak in corrosivity, high in dispersion force, high in decontaminating and descaling capabilities, easy to clean, and simple and convenient to operate, has good dissolving capacity on watermarks, does not endanger the health of an operator.

Owner:SUZHOU FUQINUO WATER TREATMENT EQUIP

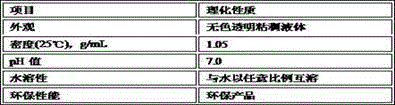

Easy-to-foam shield foam additive

PendingCN111978964AHigh viscosityImprove structural stabilityBuilding constructionsOrganic fertilisersPolymer sciencePtru catalyst

The invention discloses an easy-to-foam shield foam additive. The easy-to-foam shield foam additive specifically comprises the following components in parts by mass: 15-20 parts of sodium dodecyl sulfate, 10-18 parts of cetyltrimethylammonium chloride, 8-15 parts of fatty alcohol polyoxyethylene ether sulfate, 5-8 parts of an amphiphilic polymer, 25-40 parts of expanded polystyrene, 4-12 parts ofmodified cellulose, 80-90 parts of water, 3-6 parts of polyethylene glycol, 3-5 parts of a blowing promoter, 10-26 parts of a foaming additive, 3-7 parts of a foam stabilizer, 5-8 parts of a dispersant, 3-8 parts of an acid catalyst, 10-25 parts of a coagulant and 2-8 parts of a hydrophilic additive.

Owner:南京睿盾工程科技有限公司

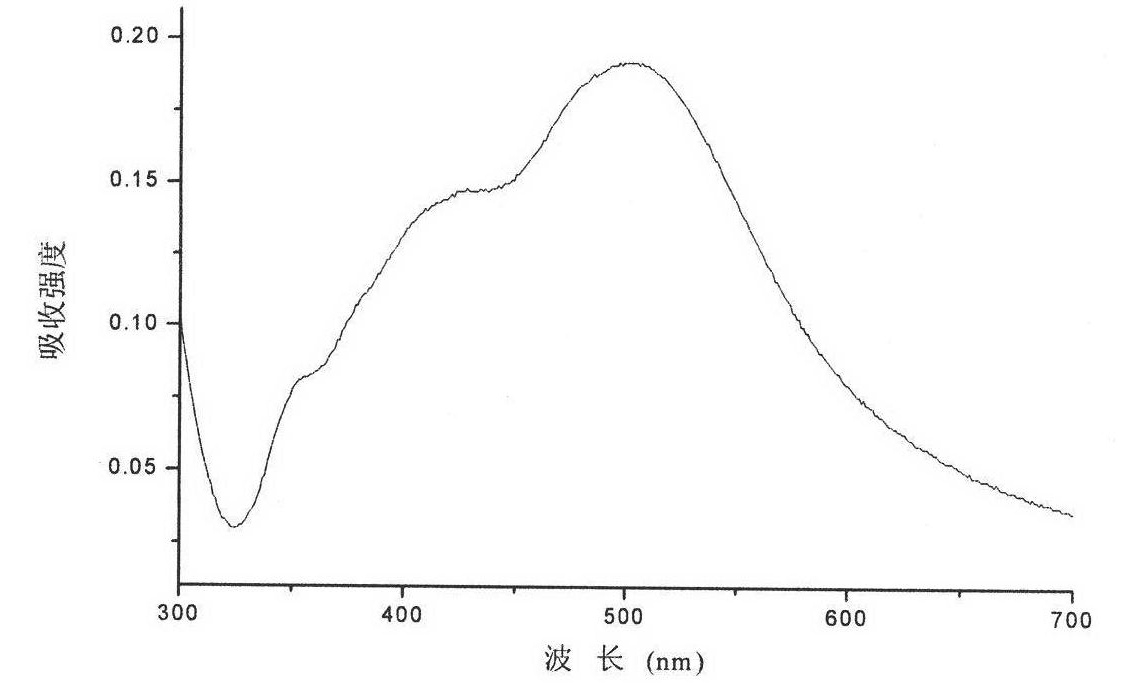

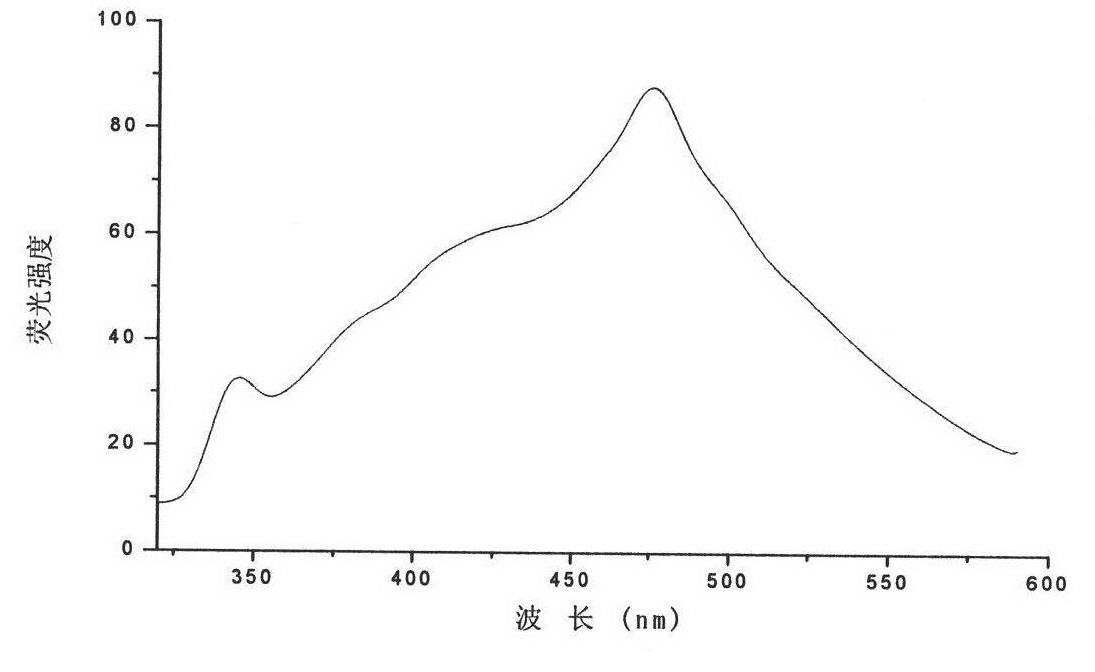

Fluorescent silver nanoparticle and preparation method thereof

The invention discloses a fluorescent silver nanoparticle and a preparation method thereof. The fluorescent silver nanoparticle is prepared according to the following steps: mixing a mixed aqueous solution of a wrapping agent and a reducing agent with a soluble silver salt, and reacting under the light-resistant or the irradiant condition to obtain the fluorescent silver nanoparticle; wherein thewrapping agent is cetyltrimethyl ammonium chloride or cetyltrimethyl ammonium bromide, and the reducing agent is ascorbic acid. The particle fluoresces under natural light, the yield of the fluorescent quantum is over 0.5%, and the particle can be fully settled out at the rotating speed of 4000-6000 rpm through the centrifugation. When the particle is kept in dark place at 4 DEG C, the fluorescence of the particle can be stable for more than 4 months. The fluorescent particles of different emission wavelengths (420-480 nm) can be obtained by controlling the reaction conditions (such as keeping out of the sun or irradiation of natural light, stirring or static placing and the like). The method is simple and rapid, and provides a new path for the synthesis of the fluorescent noble metal nanoparticles.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com