Patents

Literature

774 results about "Aluminum fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reduction of reactive gas attack on substrate heater

InactiveUS20060005856A1Reduce harmReduce the amount requiredElectric discharge tubesHollow article cleaningAluminum fluorideReactive gas

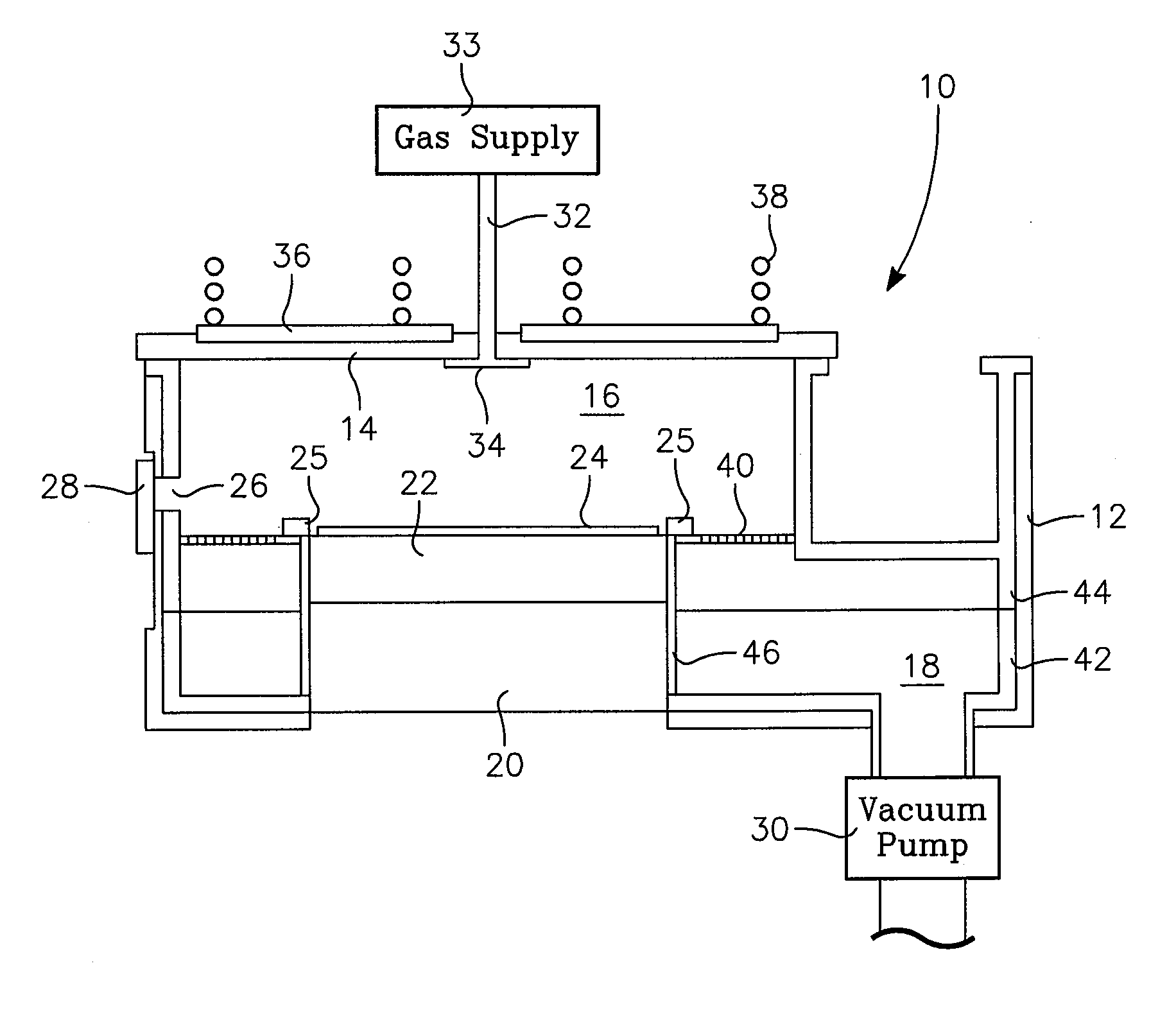

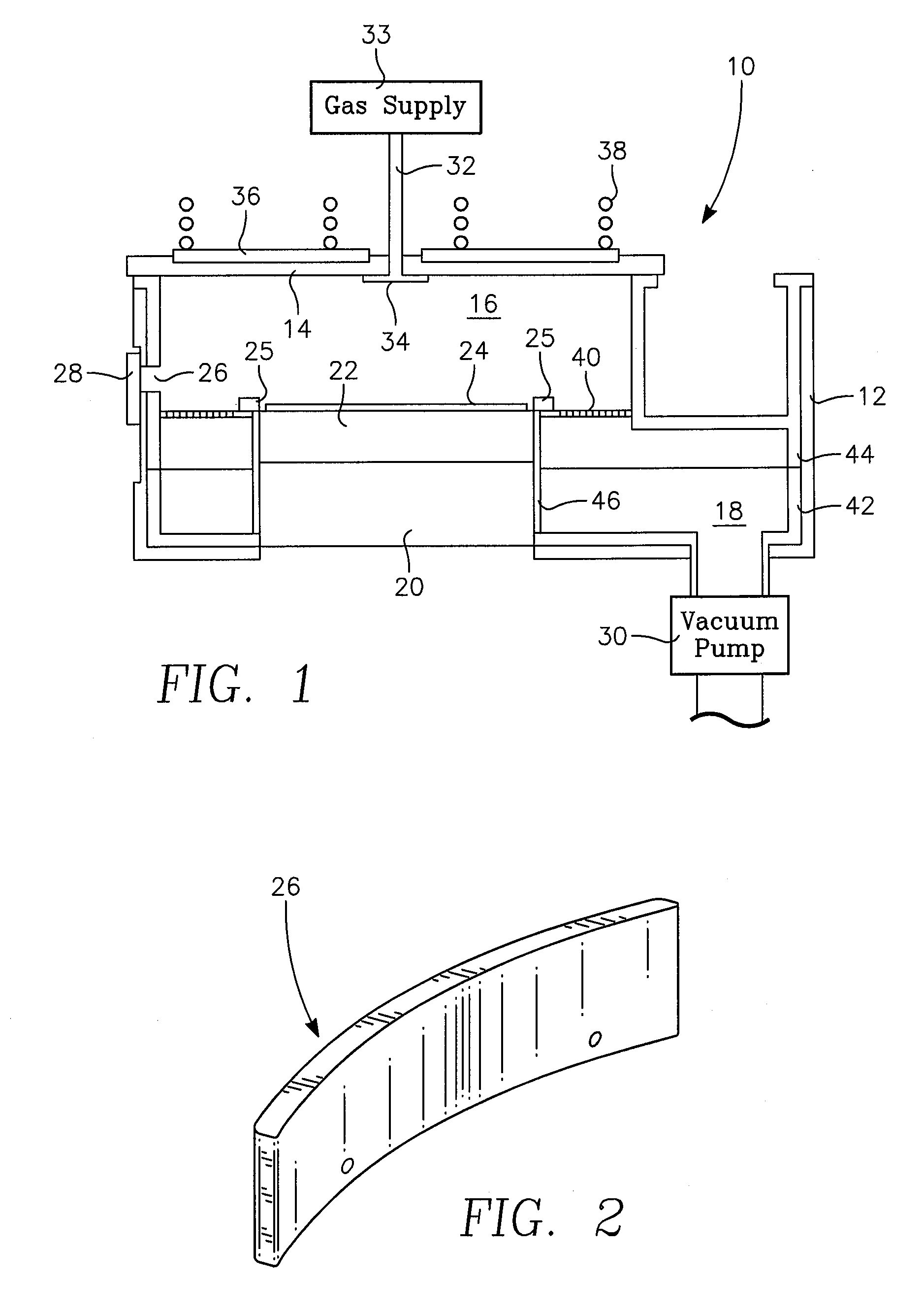

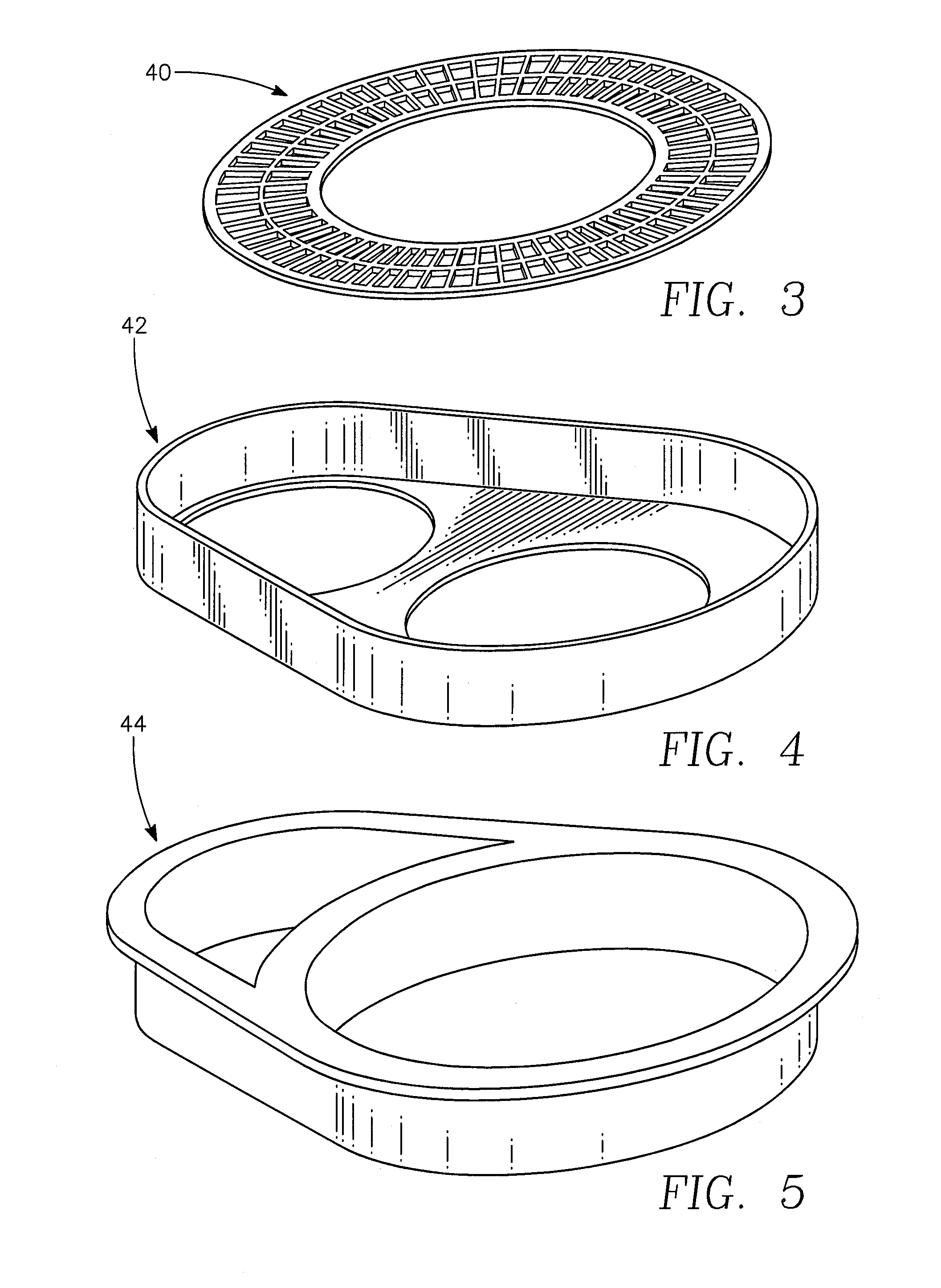

Embodiments of the present invention provide a method of reducing damage to the substrate support by the cleaning gas during a cleaning process of the processing chamber, such as by reducing aluminum fluoride formation on the substrate support. In one embodiment, a method of cleaning a semiconductor process chamber which is used for processing a substrate disposed on a surface of a substrate support comprises introducing a cleaning gas into a process chamber through an inlet facing a surface of a substrate support. The inlet is spaced from the surface of the substrate support by a clean spacing. Reactive species are provided from the cleaning gas to clean the process chamber. The clean spacing is substantially greater than a process spacing between the inlet and the surface of the substrate support during processing of a substrate on the substrate support in the process chamber.

Owner:APPLIED MATERIALS INC

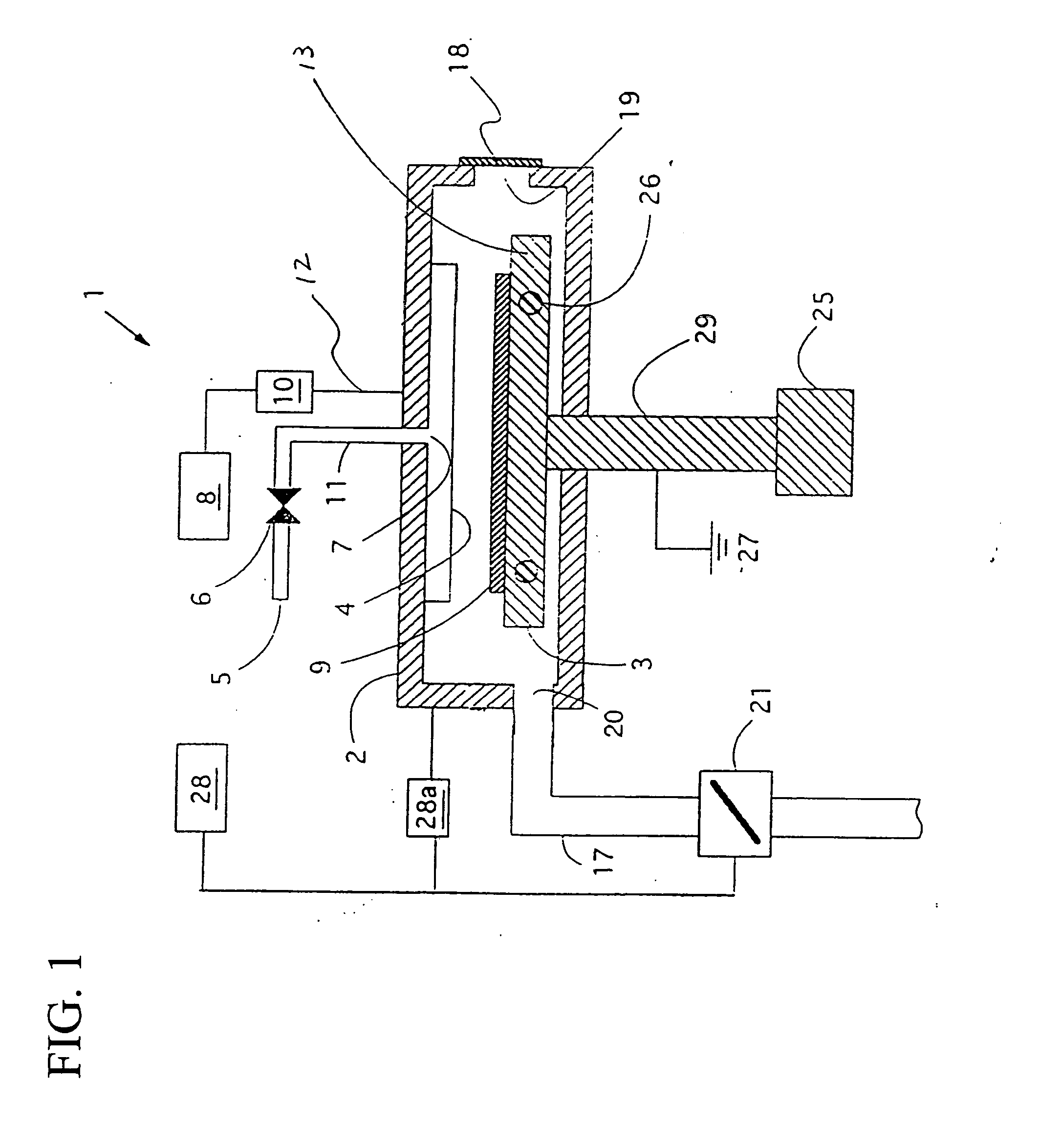

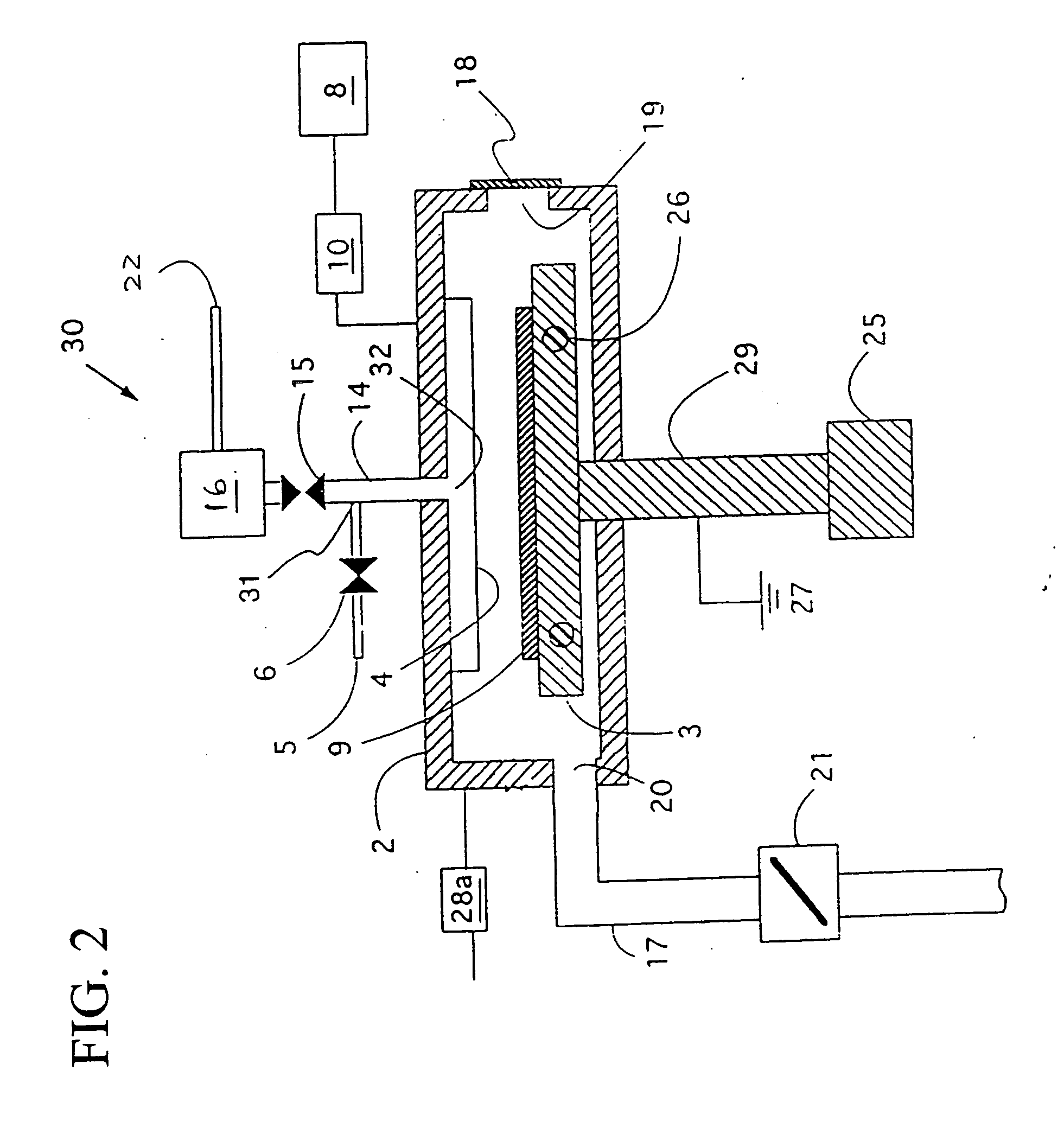

Thin-film forming apparatus having an automatic cleaning function for cleaning the inside

InactiveUS20050139578A1Good reproducibilityReduces non-working hourDecorative surface effectsSemiconductor/solid-state device manufacturingAluminum fluorideSusceptor

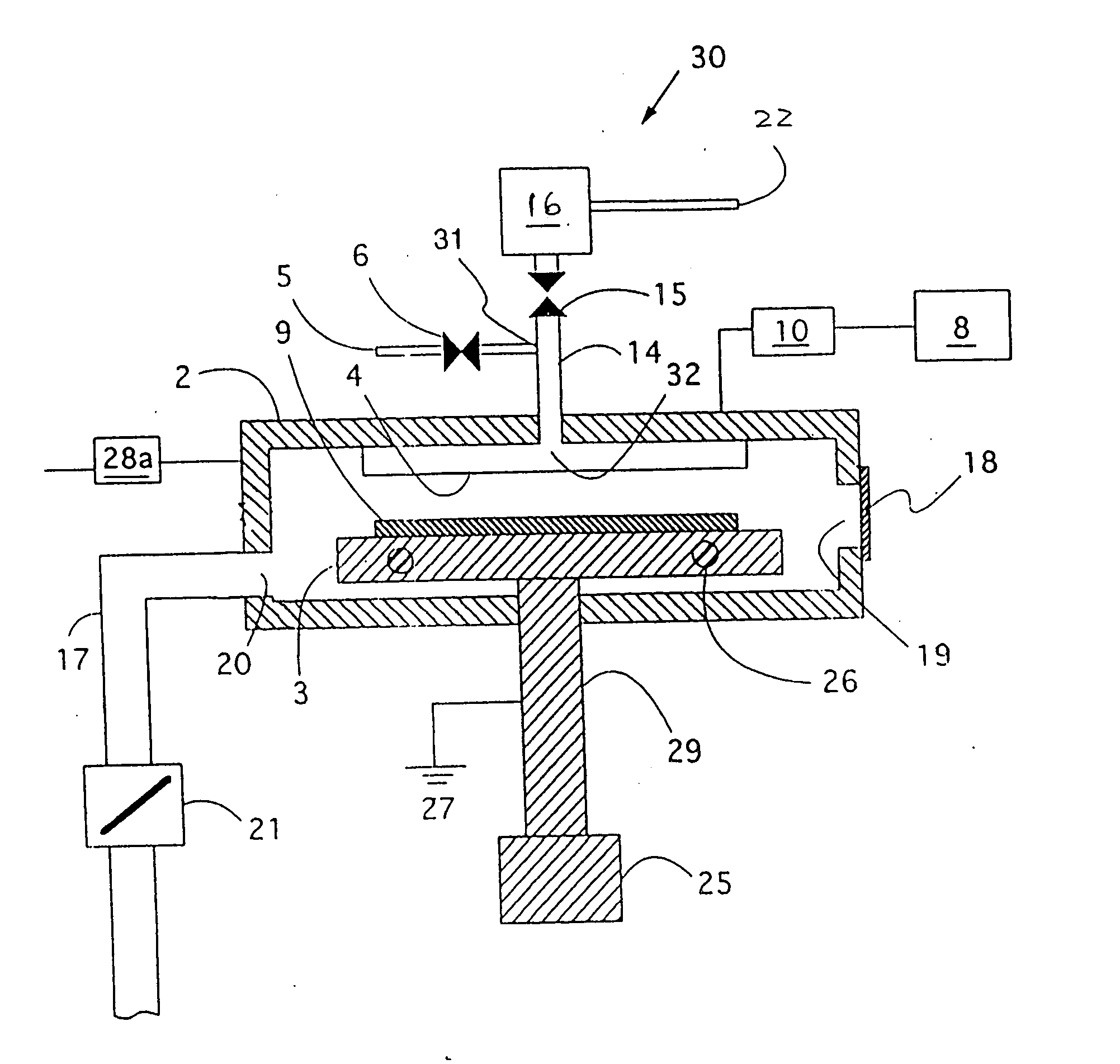

A method of cleaning the inside of a reaction chamber includes reducing the temperature of a susceptor to 470° C. or lower for cleaning; contacting the inside of the reaction chamber including the showerhead with fluorine radicals; cleaning the unwanted deposits by the fluorine radicals, wherein gaseous aluminum fluoride is inhibited from being emitted from the susceptor and solidified on the showerhead by maintaining the temperature of the susceptor at 470° C. or lower; and raising the temperature of the susceptor to 500-650° C. for film formation.

Owner:ASM JAPAN

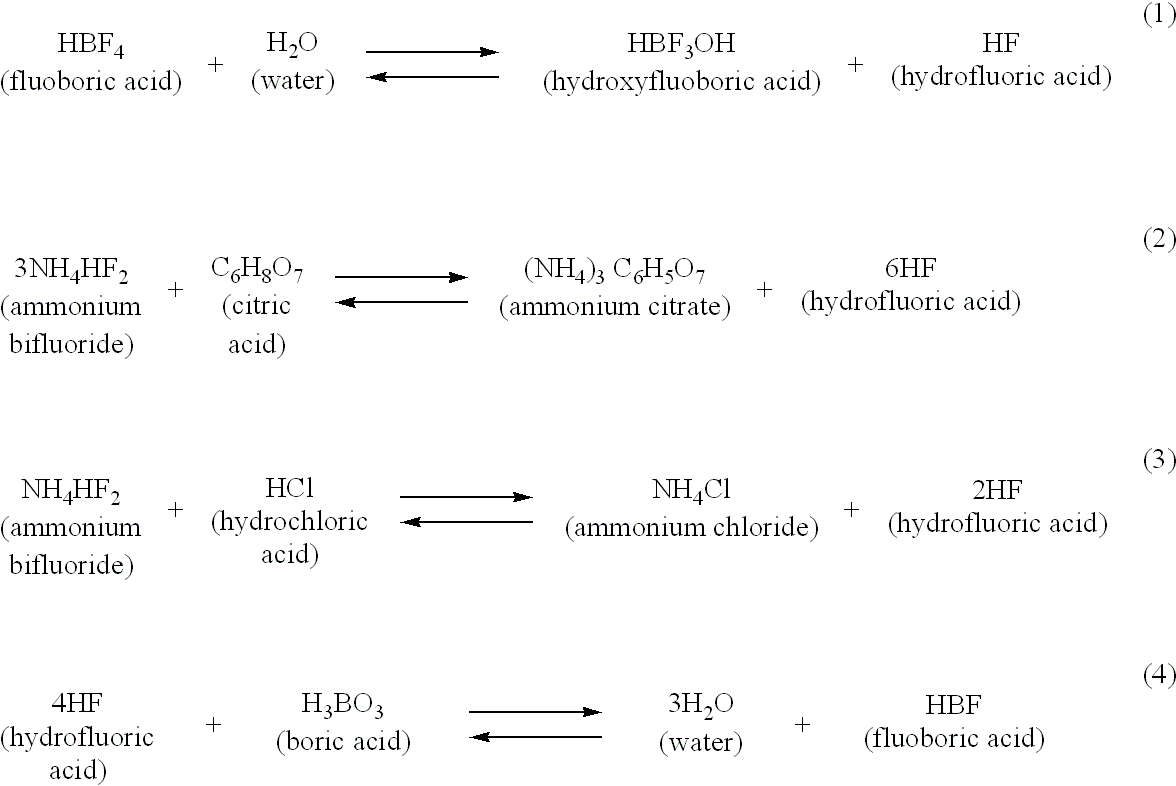

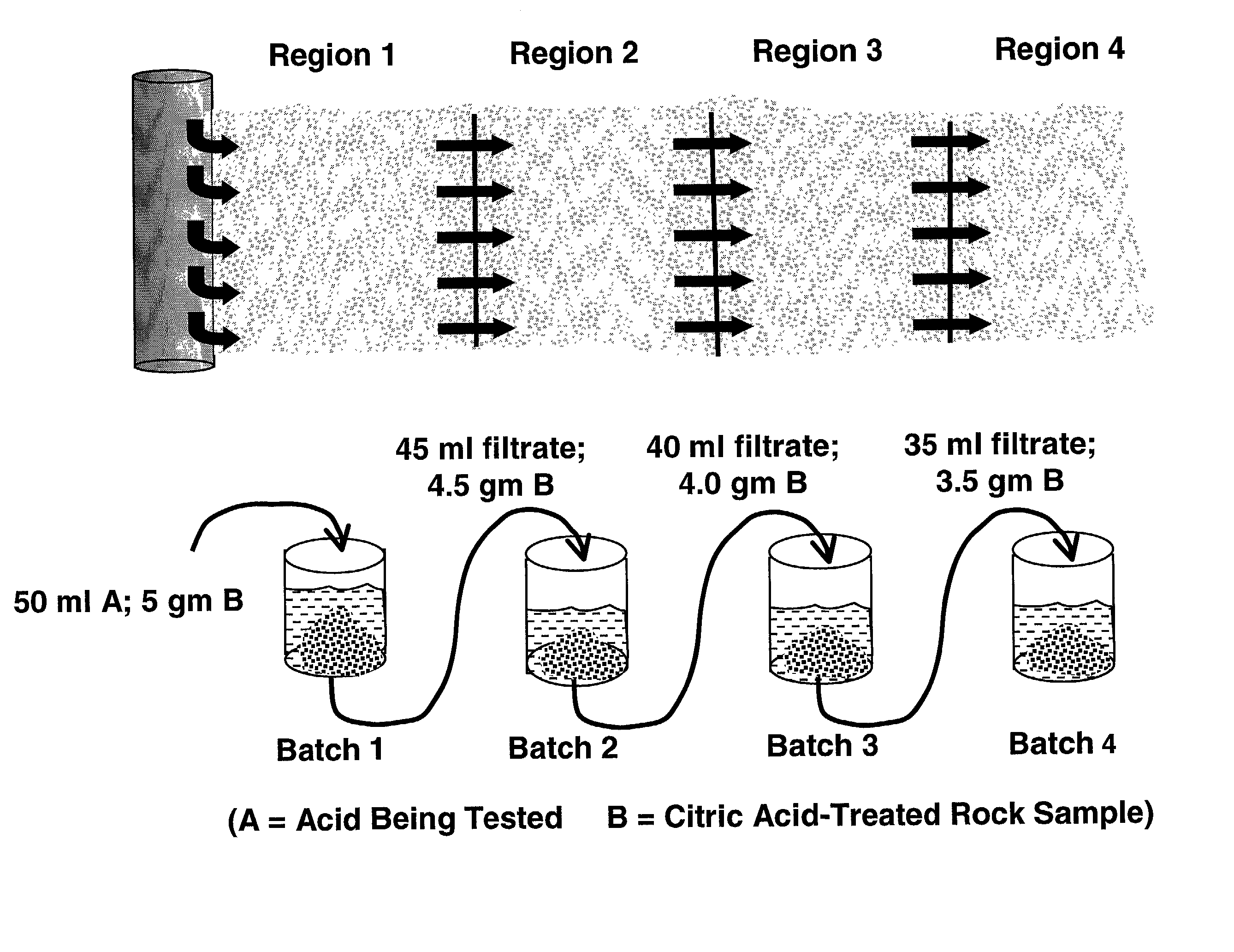

Composition and method for treating a subterranean formation

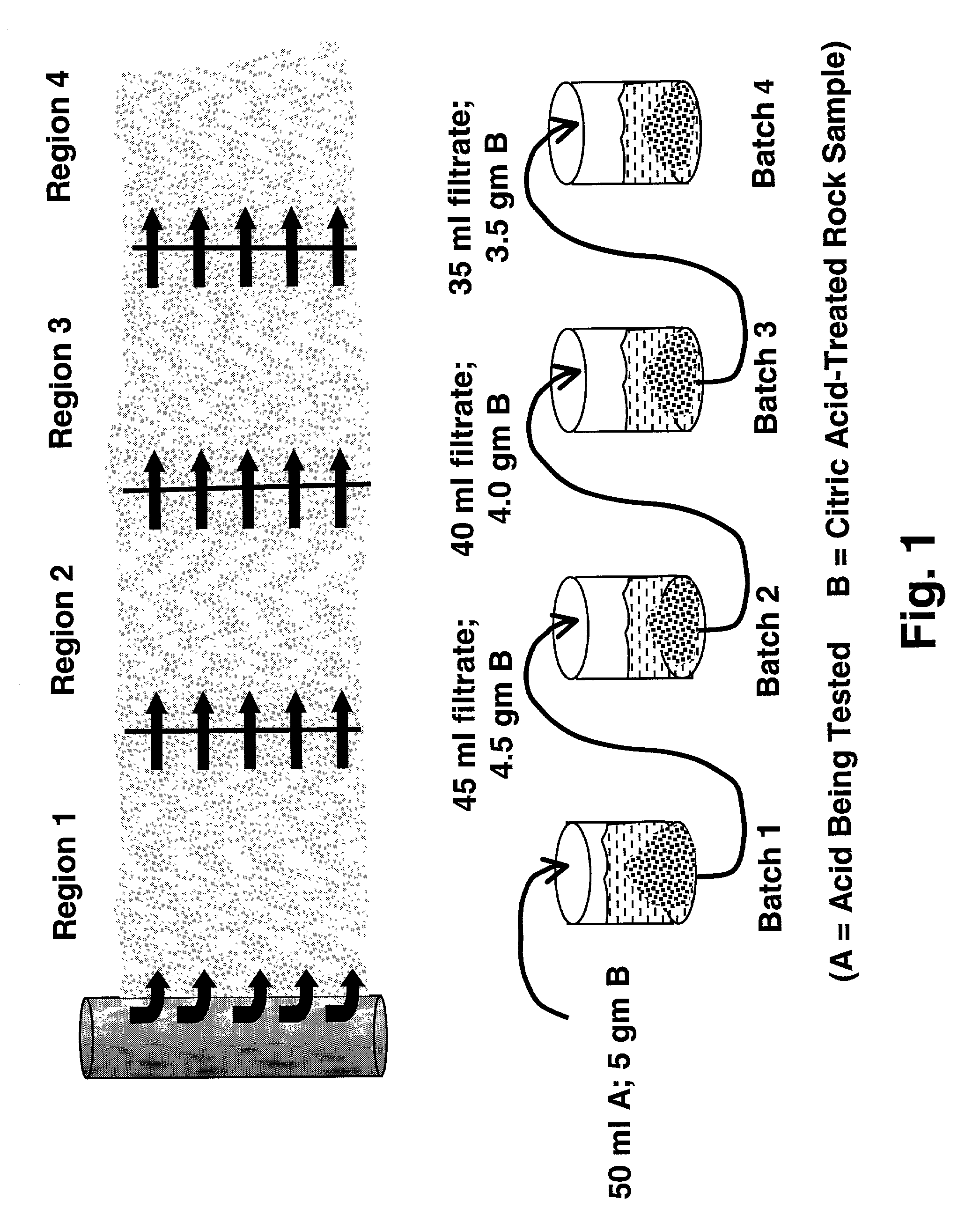

Aqueous liquid compositions for increasing the permeability of a subterranean formation are disclosed, the compositions being characterized by provision of fluoborate anion (fluoboric acid) and a specified compound or compounds, or mixture thereof, which chelate aluminum ions and aluminum fluoride species. Methods of treating a subterranean formation by injection of the composition(s) into the formation are also described.

Owner:SCHLUMBERGER TECH CORP

Method and apparatus for testing material utilizing differential temperature measurements

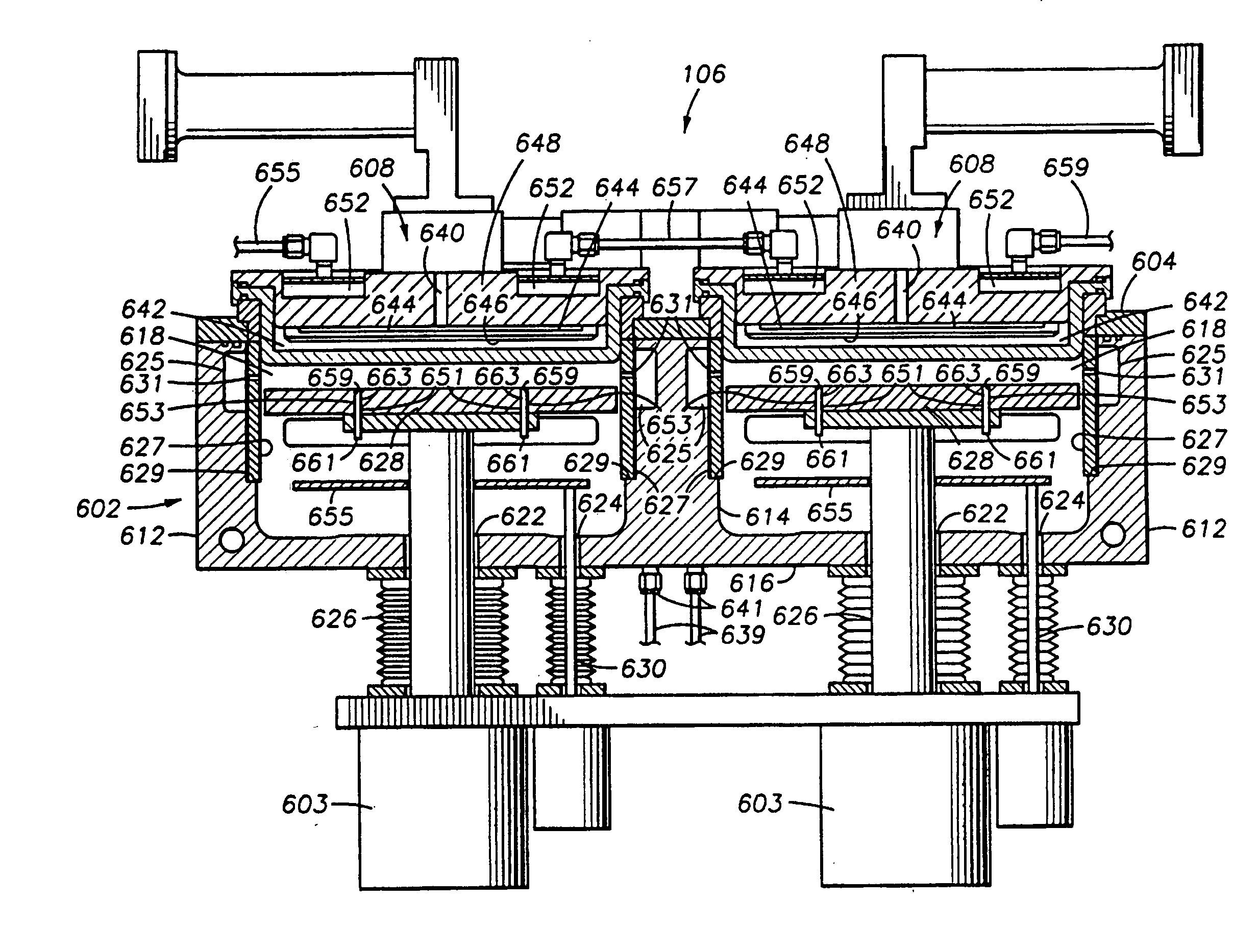

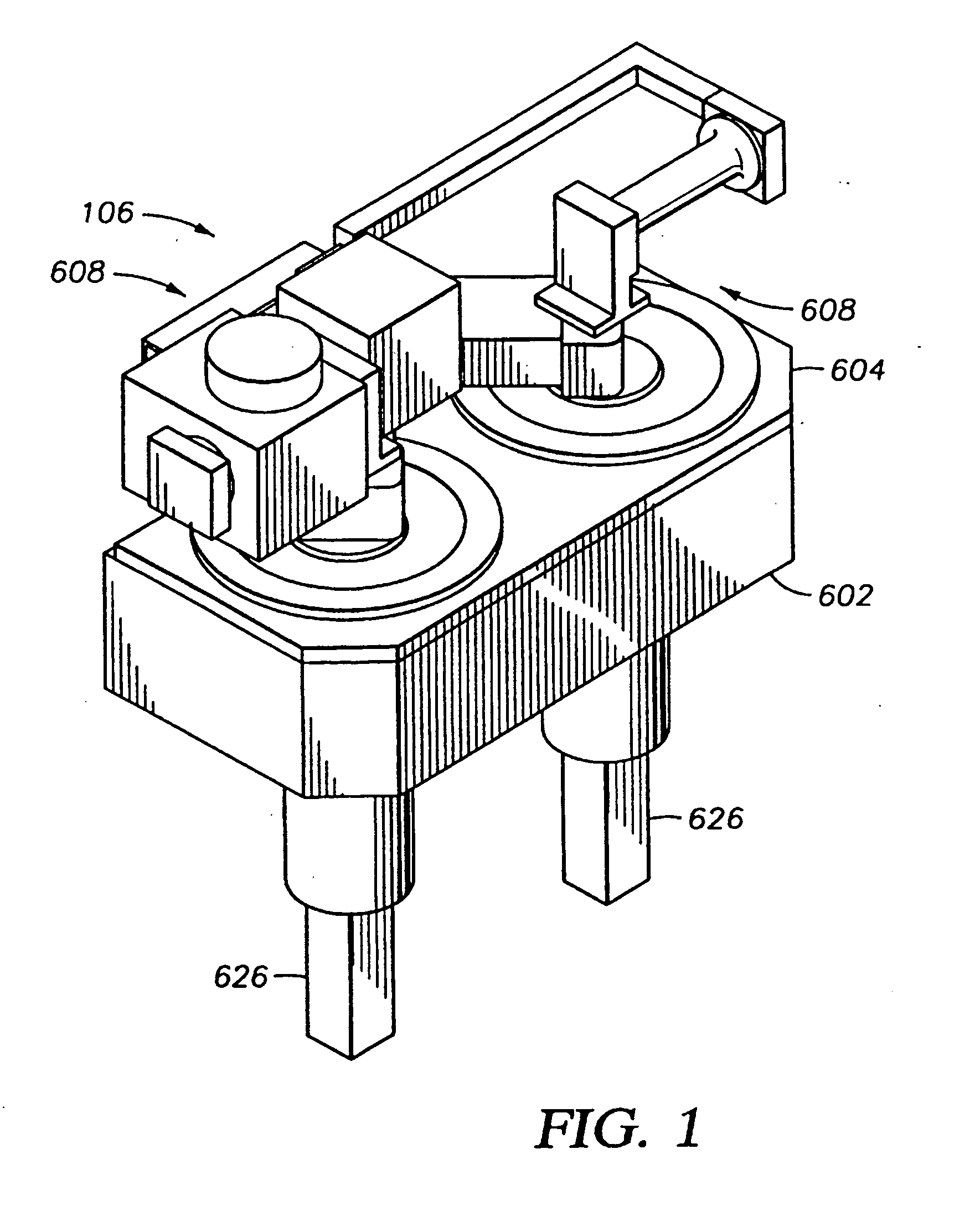

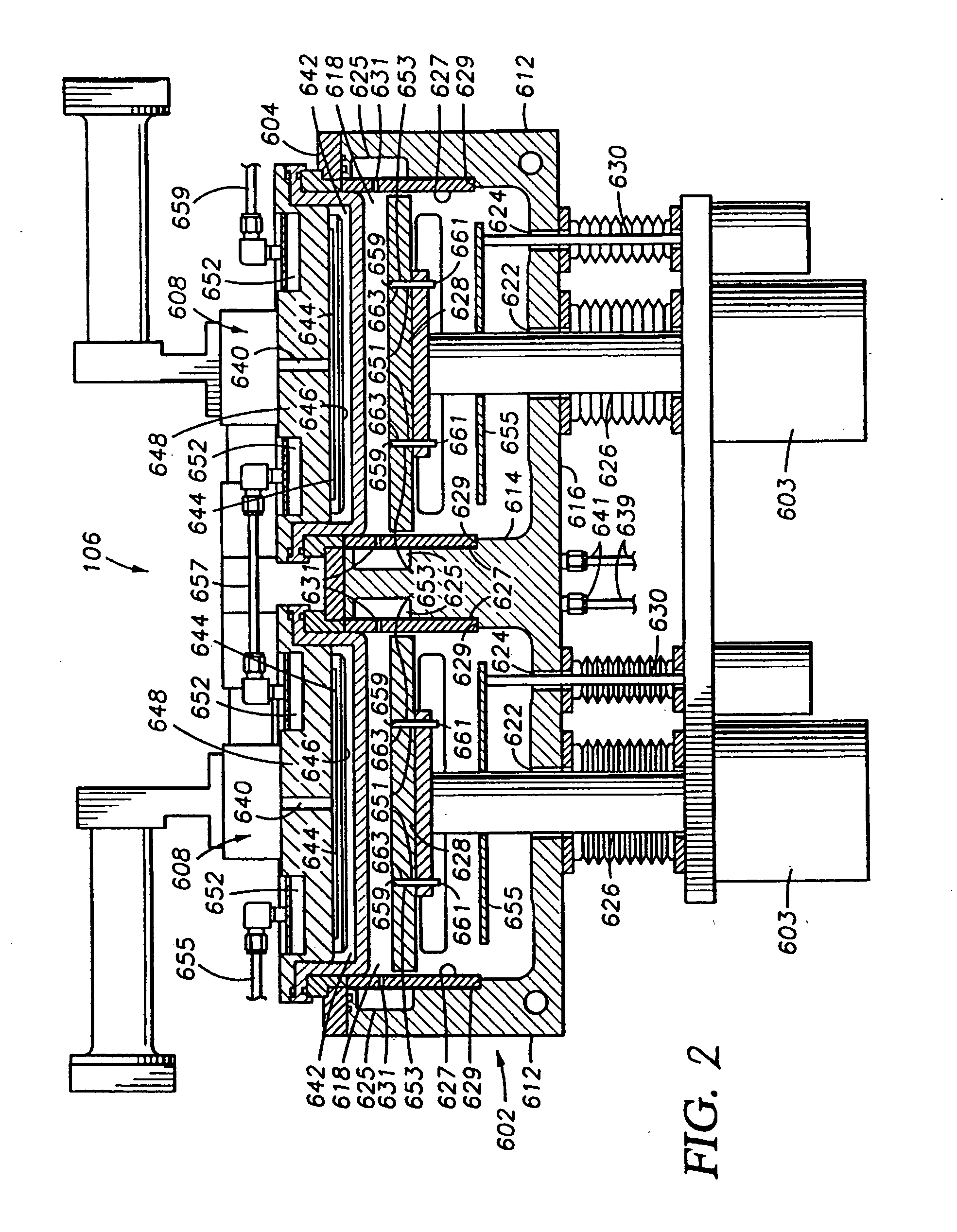

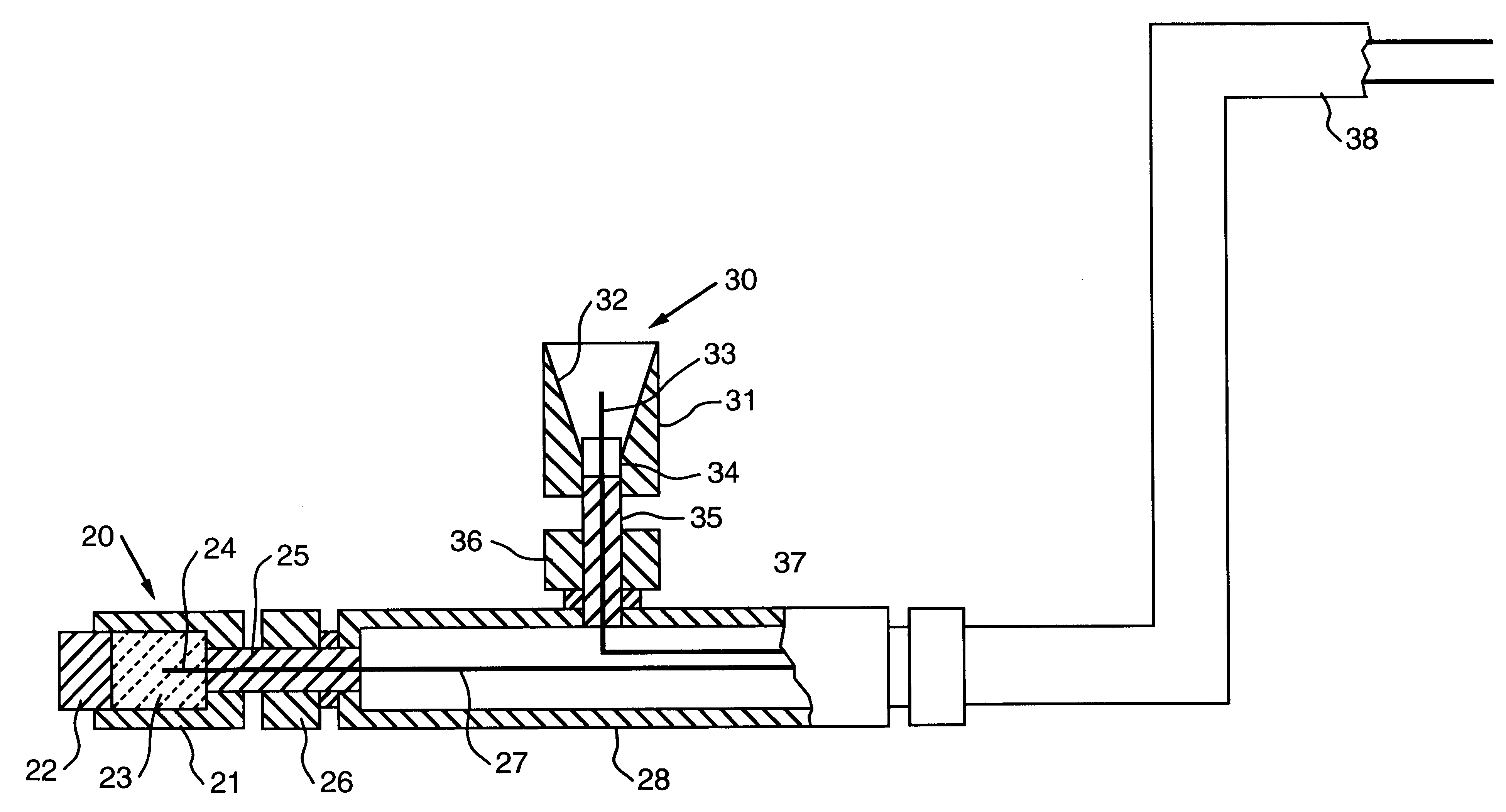

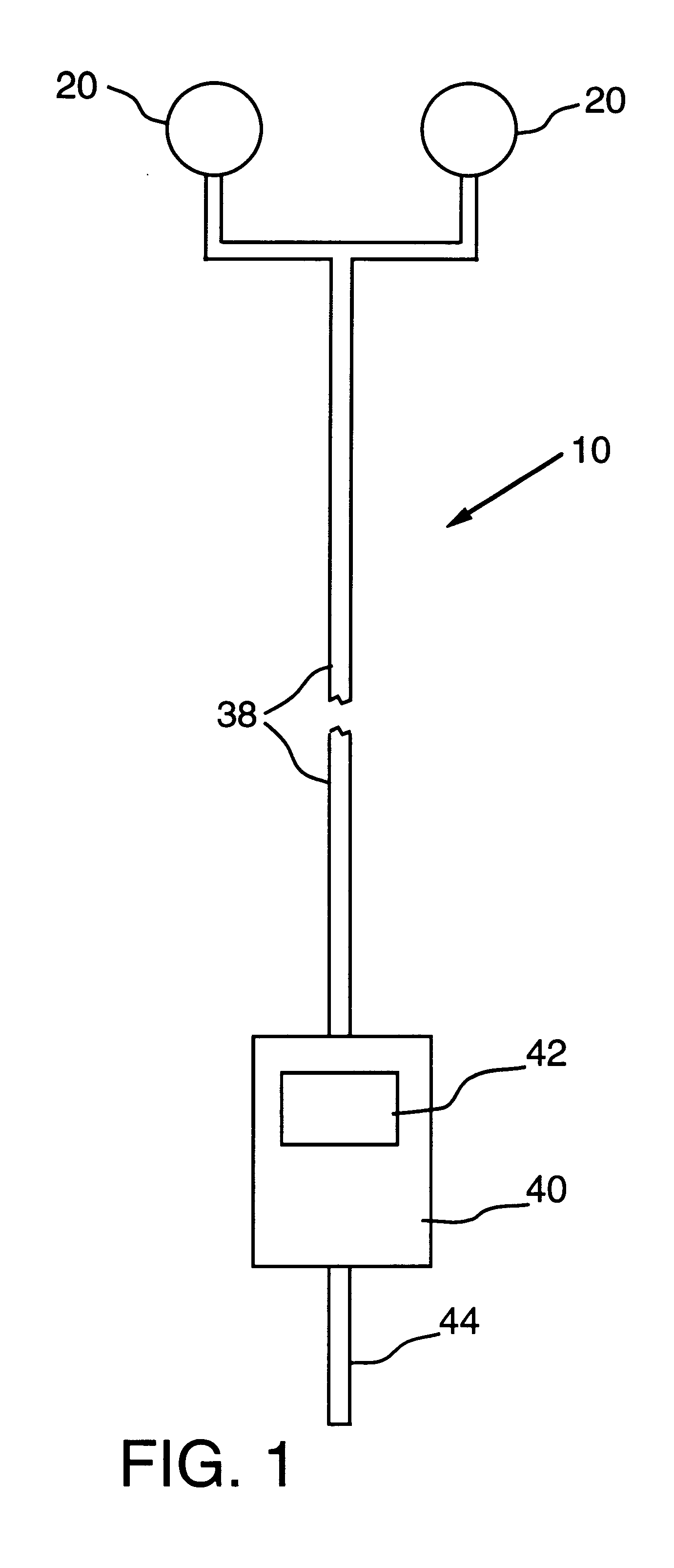

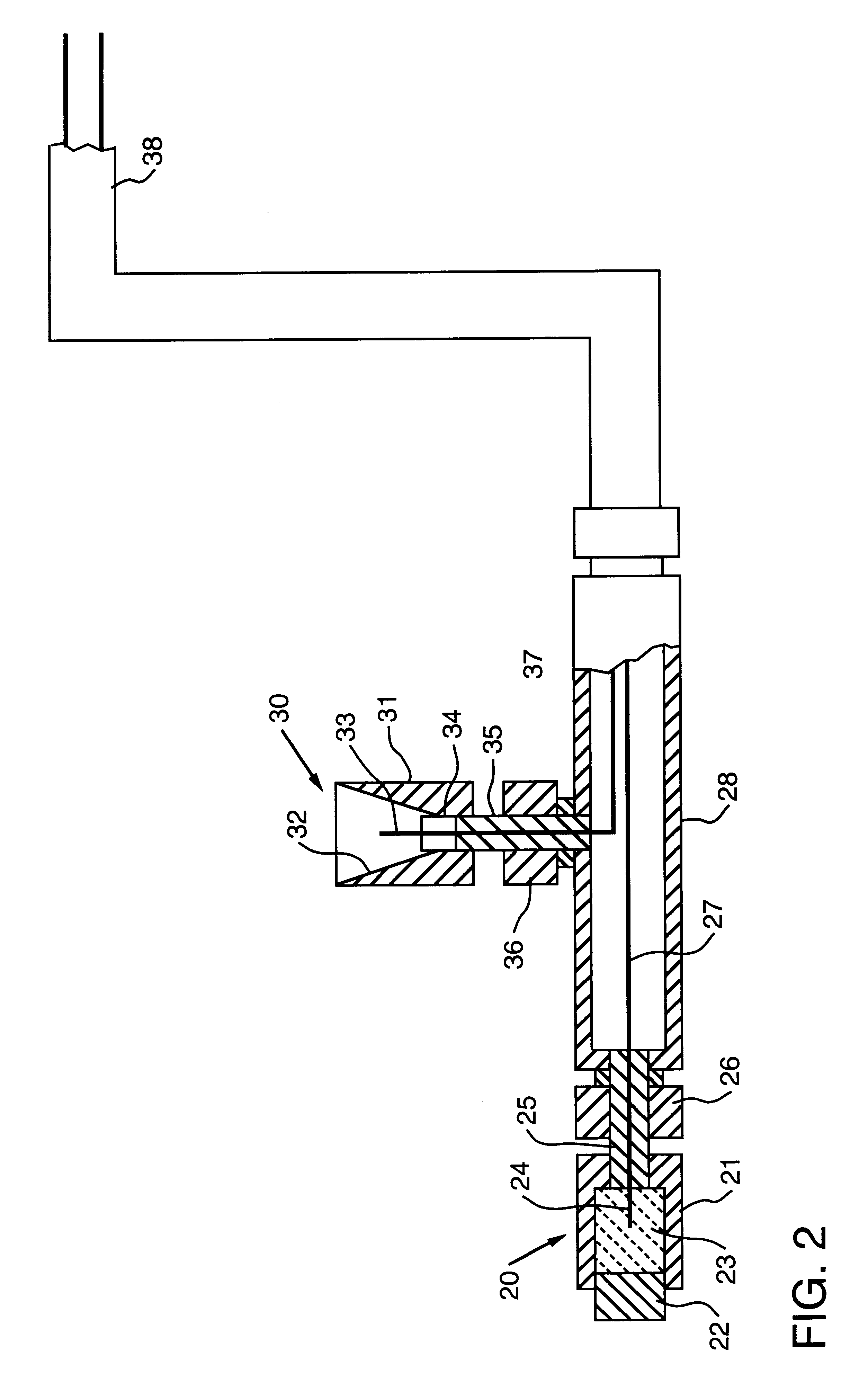

A method and apparatus for timely and accurate measurement of material parameters are disclosed. A test sensor measures the temperature of a sample of material as it is heated up and / or cooled down. A reference sensor is used to obtain differential temperature measurements as the temperature of the test sample is varied. A differential temperature trace is generated and analyzed in order to determine various characteristics of the material being tested. In one embodiment, the sodium fluoride to aluminum fluoride ratio (NaF:AlF3) and alumina concentration in a Hall bath aluminum smelting operation are determined in order to efficiently control smelting of aluminum metal. In this embodiment, bath temperature and liquidus temperature may be measured and compared in order to determine the amount of superheat of the bath and to prevent the operation of smelters at higher temperatures than necessary.

Owner:ARCONIC INC

Coproduction of hydrofluoroolefins

InactiveUS7687670B2Preparation by hydrogen halide split-offHalogenated hydrocarbon separation/purificationCeriumCobalt

Disclosed is a process for the co-manufacture of the hydrofluoroolefins HFC-1225ye and HFC-1234yf. The process comprises contacting a blend of 1,1,1,2,3,3-hexafluoropropane and 1,1,1,2,3-pentafluoropropane at a temperature of from about 200° C. to about 500° C. with a catalyst, optionally in the presence of an inert gas. The catalyst includes, but is not limited to, aluminum fluoride; fluorided alumina; metals on aluminum fluoride; metals on fluorided alumina; oxides, fluorides, and oxyfluorides of magnesium, zinc and mixtures of magnesium and zinc and / or aluminum; lanthanum oxide and fluorided lanthanum oxide; chromium oxides, fluorided chromium oxides, and cubic chromium trifluoride; carbon, acid-washed carbon, activated carbon, three dimensional matrix carbonaceous materials; and metal compounds supported on carbon. The metal compounds are oxides, fluorides, and oxyfluorides of at least one metal selected from the group consisting of sodium, potassium, rubidium, cesium, yttrium, lanthanum, cerium, praseodymium, neodymium, samarium, chromium, iron, cobalt, rhodium, nickel, copper, zinc, and mixtures thereof. The product hydrofluoroolefins are separated from unreacted hydrofluorocarbons and hydrogen fluoride. In another embodiment, the unreacted hydrofluorocarbons optionally may be recirculated back through the process.

Owner:EI DU PONT DE NEMOURS & CO

Method for recycling waste cathode carbon blocks of aluminum electrolysis cell

InactiveCN107282598ASave chemical processing raw materialsUse allSolid waste disposalAluminium sulfateAluminum fluoride

The invention discloses a method for recycling waste cathode carbon blocks of an aluminum electrolysis cell. The method comprises the following steps: 1, grinding the waste cathode carbon blocks into powder of 100-200 meshes through superfine grinding, and then winnowing the powder to separate the carbon powder from aluminum and aluminum carbide; 2, adding the fine carbon powder into water, stirring the fine carbon powder, then filtering the obtained solution, and preparing filtrate and filter residues for later use; 3, adding the filter residues in the step 2 into an aluminum sulfate solution, leaving the mixed solution to stand at normal temperature for 20-30 hours, then filtering the mixed solution, washing obtained filter residues to obtain the carbon powder with the carbon content higher than 90% and preparing filtrate for later use; 4, mixing the filtrate obtained in the step 2 and the filtrate obtained in the step 3, adjusting the pH value to be 5.5, increasing the temperature to 90 DEG C, then carrying out reaction for 3 hours to obtain flocculent hydroxyl aluminum fluoride, and carrying out filtering to obtain filter residues; and 5, calcining the filter residues obtained in the step 3 at 485 DEG C to obtain AlF3 and Na5Al3F14 and using AlF3 and Na5Al3F14 as raw materials of aluminum electrolysis. Through the method, the waste cathode carbon blocks of the aluminum electrolysis cell can be efficiently recycled.

Owner:李立安

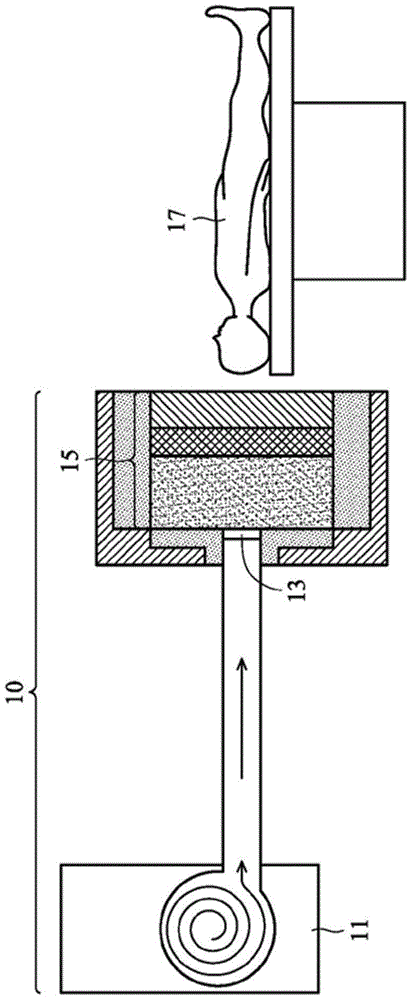

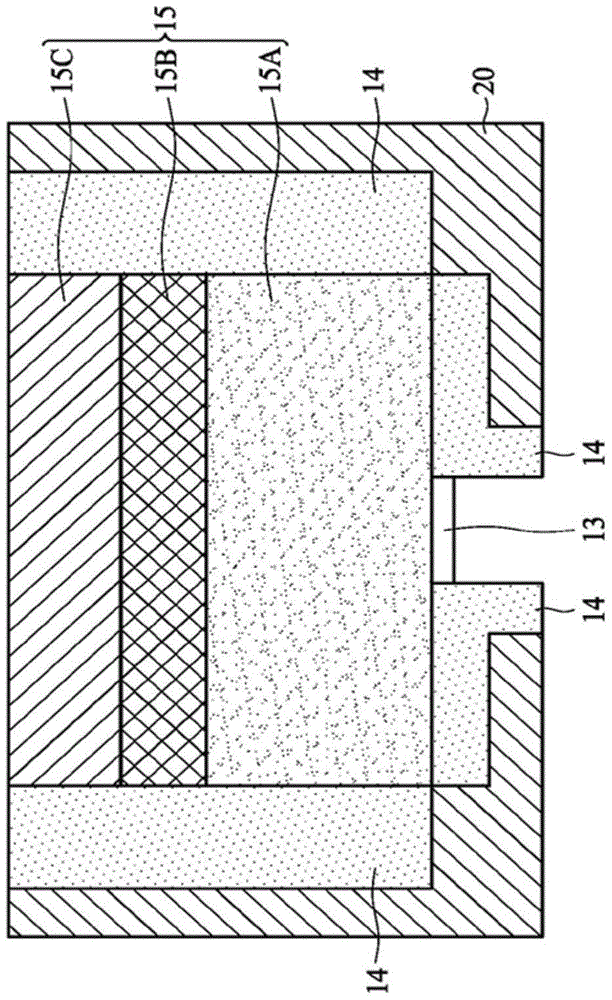

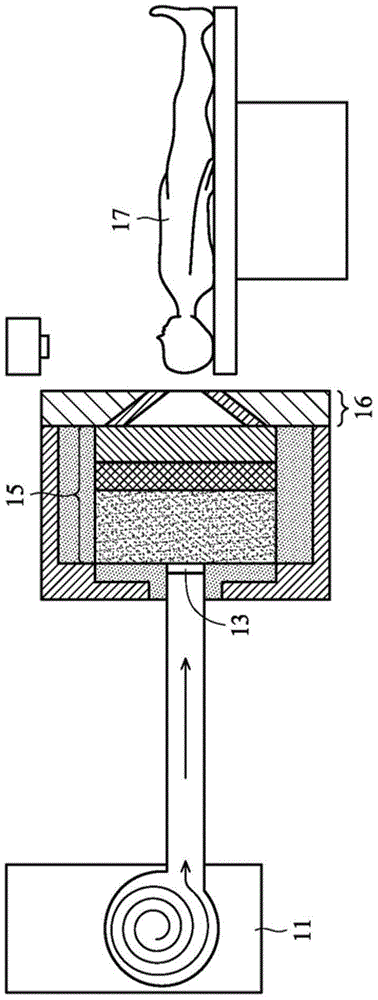

Filter and neutron beam source

Disclosed is a filter including a second layer disposed between a first layer and a third layer. The first layer is composed of iron. The second layer is composed of 1 part by volume of lithium fluoride, 20 to 50 parts by volume of aluminum, and 50 to 80 parts by volume of aluminum fluoride. The third layer is composed of 1 part by weight of lithium fluoride and 99 to 100 parts by weight of magnesium fluoride.

Owner:HERON NEUTRON MEDICAL CORP

Method for determining element of aluminum fluoride using X ray fluorescence spectrophotometry

InactiveCN101059456AAccurate measurementRapid determinationMaterial analysis using wave/particle radiationAluminum fluorideSoft x ray

The invention relates to a method for using X-ray fluorescence spectrum method to measure the components of aluminum fluoride, characterized in that the test process comprises that a, fusing a standard sample and a sample borate mixture solvent into a glass sample at 980-1000Deg. C, b, using X-ray fluorescence spectrum method to measure the fluorescence strength of standard sample to make a correct curvature, c, using a X-ray fluorescence spectrometer to measure the strength and the component contents of the sample. The invention can accurately and quickly measure the component contents of aluminum fluoride, to improve measurement accuracy, meet the demands of aluminum fluoride industry and user, improve working efficiency and save test cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

High-heat resistance shock resistant mullite bearing burning plate and preparation thereof

The invention discloses a mullite setter plate with high thermal shock resistance and a preparation method thereof. The preparation method comprises the following steps: mixing sillimanite, alpha-Al2O3 powder, micro-silicon powder, clay and aluminum fluoride in a ball mill according to mass percentages; then evenly mixing andalusite particles, sheet-like corundum particles and mullite particles in a mixer based on mass percentages, adding a binding agent yellow dextrin solution for stirring, and then adding powder evenly mixed in the ball mill for even stirring, sealing material package, and shock shaping by double-surface pressurization on a shock press, and obtaining the mullite setter plate by high-temperature burning. The setter plate prepared in the high-temperature mullitization process by adopting andalusite aggregate and the sillimanite has the advantages of good stability and high strength of thermal shock resistance, good temperature resistance, long service life, simple preparation process and low cost, and is suitable for mass production; and when high-grade electronic components are calcined by the setter plate, the setter plate has stable performance, the sintered electronic components have higher yields and better electrical property.

Owner:ZHEJIANG UNIV

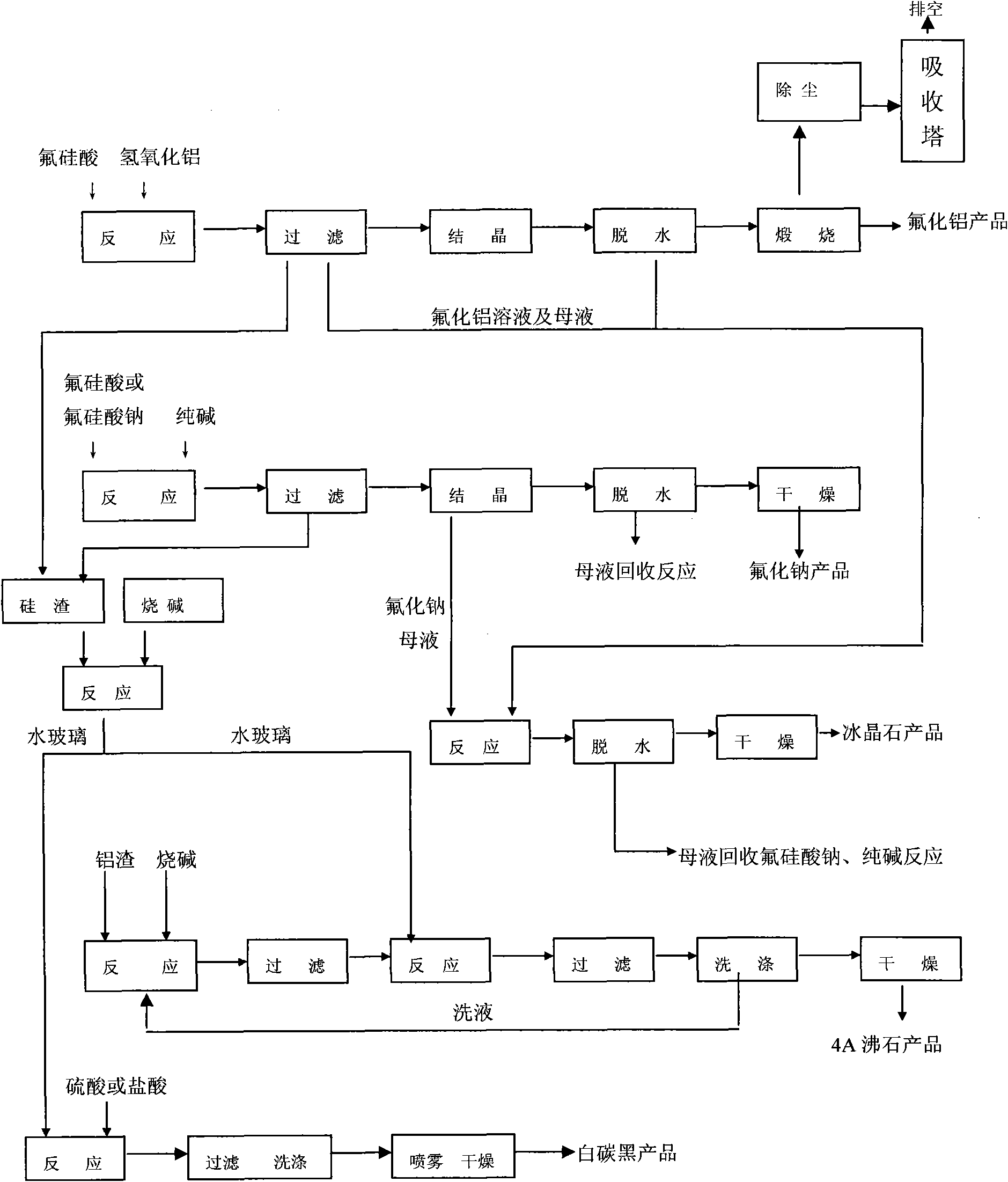

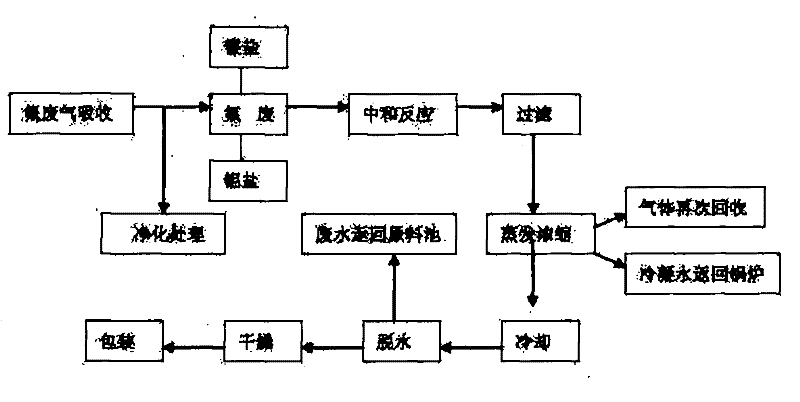

Process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid

ActiveCN101913637AHigh recovery rateTake advantage ofSilicaAlkali metal silicatesChemical industrySlag

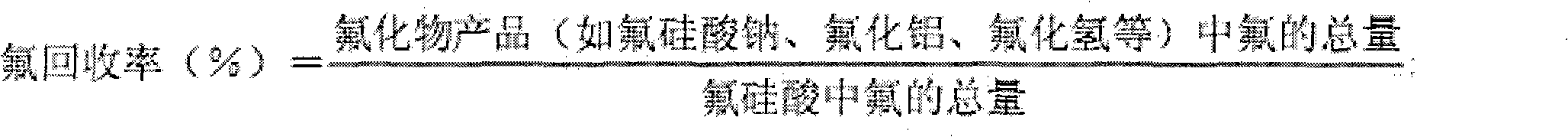

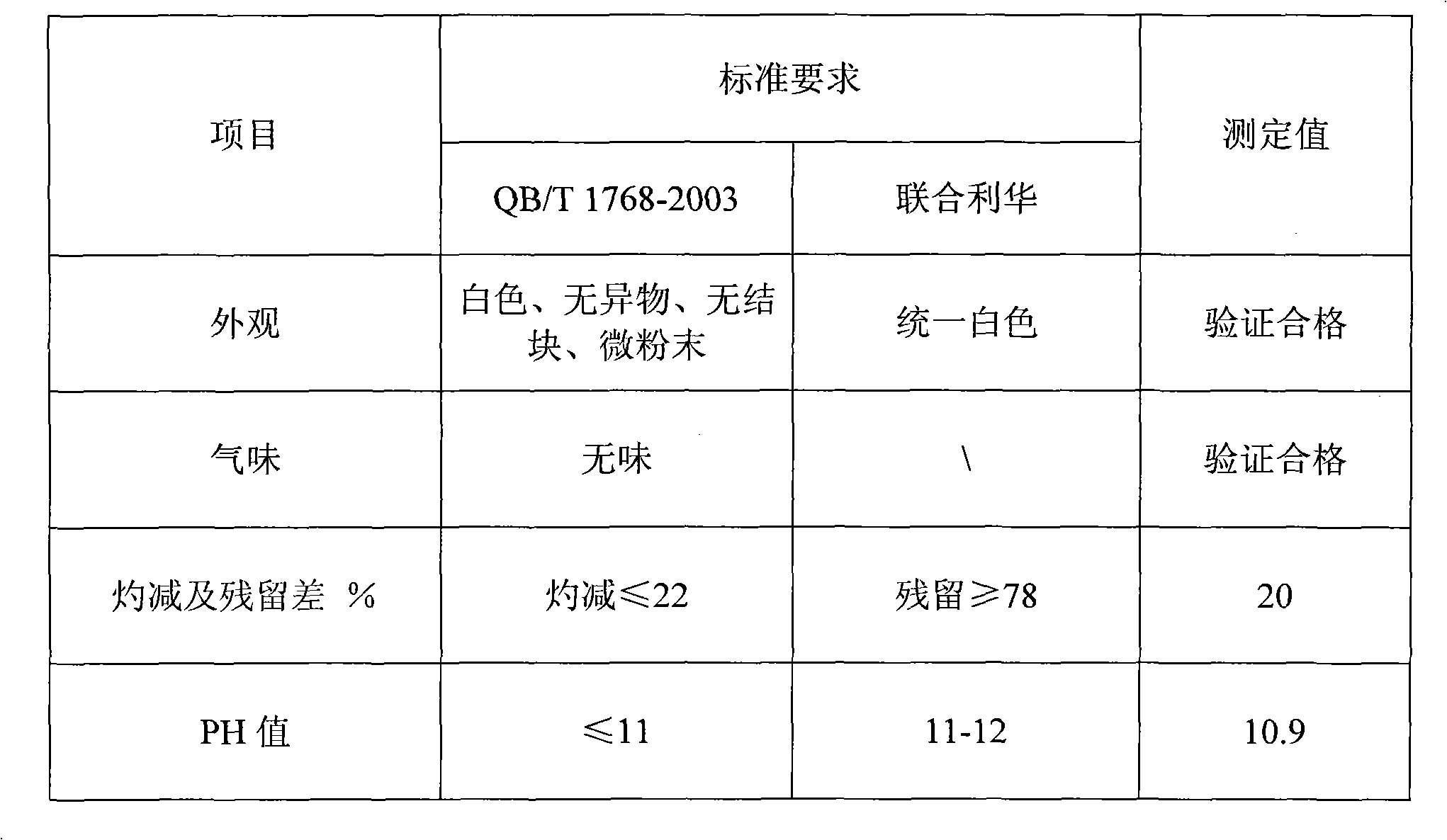

The invention discloses a process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid. The process method comprises the following steps of: preparing fluosilicic acid as a phosphorus chemical by-product into an anhydrous aluminum fluoride product, a sodium fluoride product and a cryolite product, and combining with other industrial waste silicon slags and aluminum slags to prepare a 4A zeolite product. The process method comprehensively utilizes the fluosilicic acid and has high resource recovery rate, wherein the recovery rate of the fluorine element reaches higher than 90 percent. Waste silicon dioxide slags generated in the process can be recycled to produce white carbon black and the 4A zeolite, and a mother liquor, a cleaning solution and waste gas which are generated in the production process are all recycled, thereby the environmental pollution is reduced, and the purposes of zero emission and no pollution are truly achieved, thus the method completely meets the requirement for clean production. The invention has the advantages of advanced production process, good product quality and high value, wherein the fluorine content of the aluminum fluoride is high and between 63-65 percent; the quality index of the obtained white carbon black meets the requirement on the standard of the chemical industry; and the quality of the 4A zeolite product meets the requirements on the national standard and the standard of European and American developed countries.

Owner:四川励志环保科技有限公司

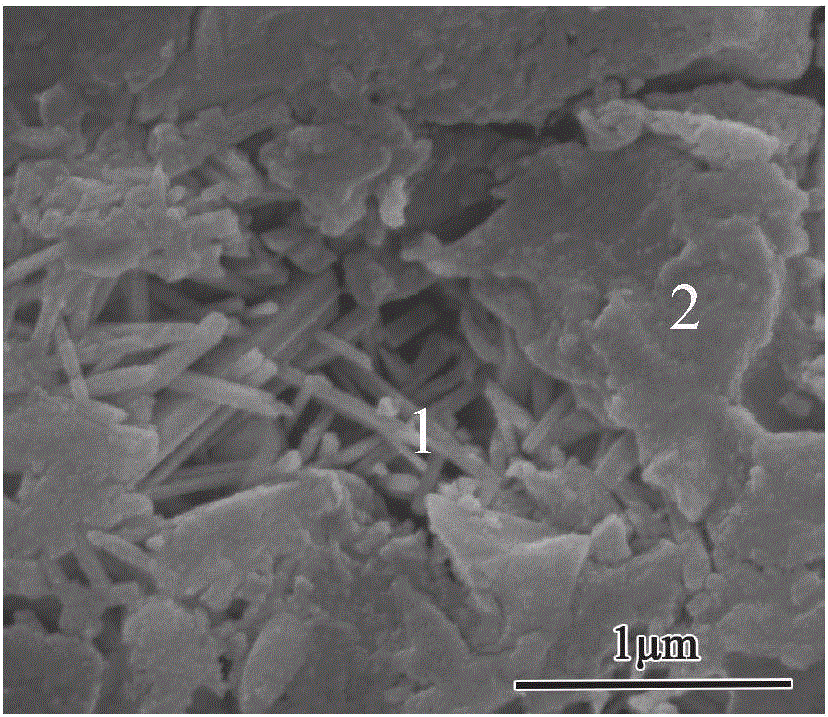

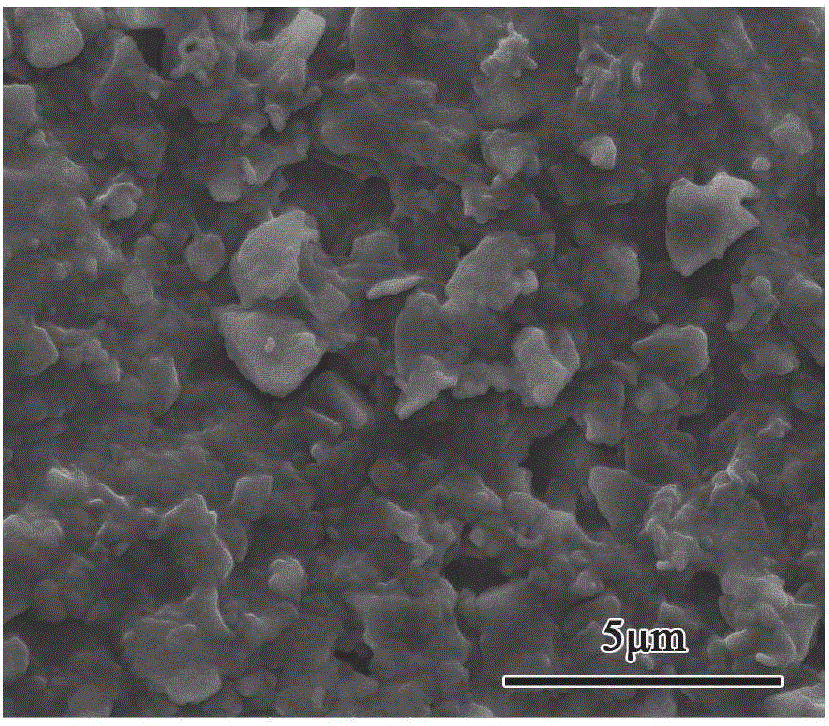

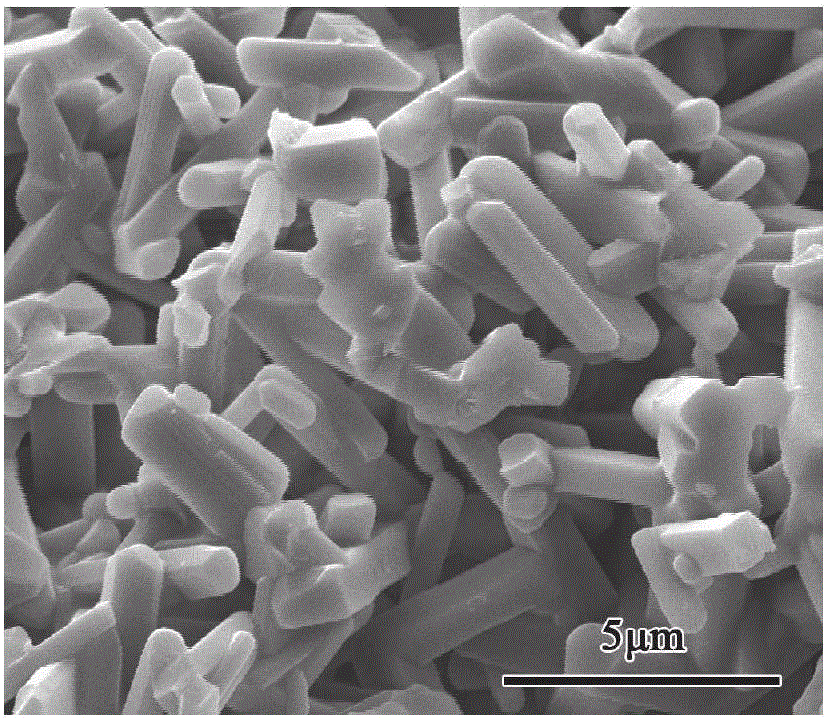

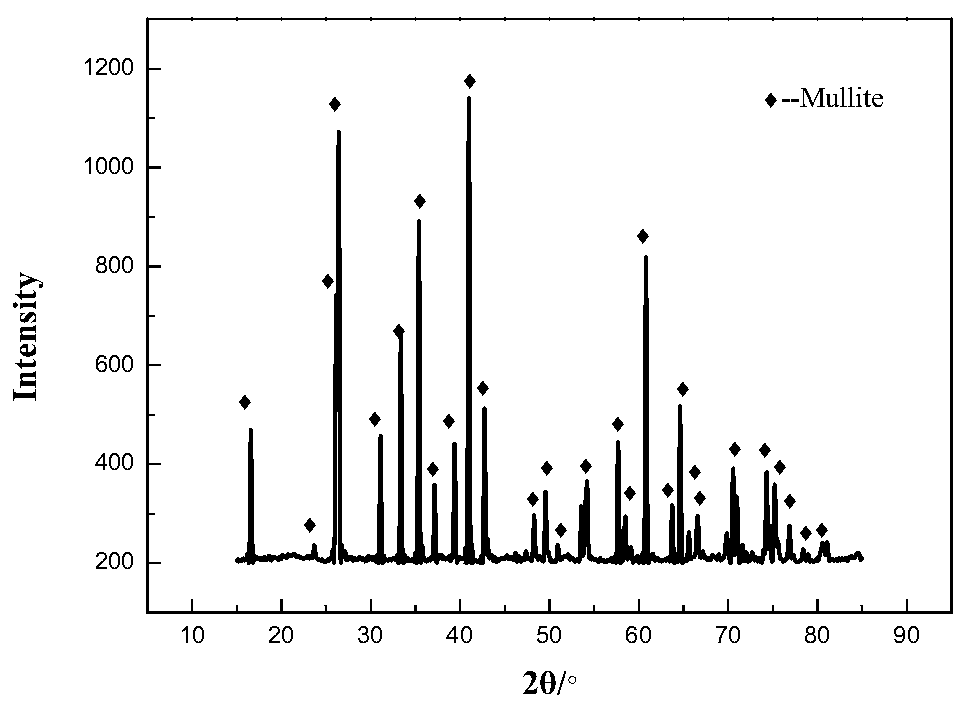

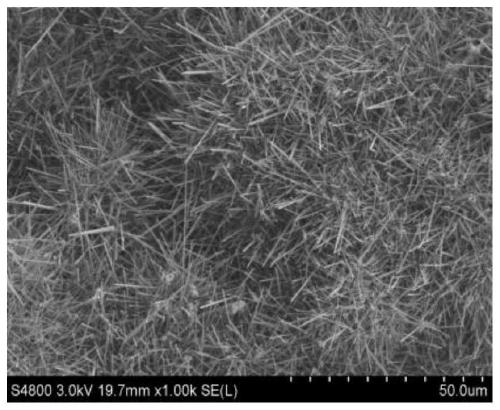

Method for in-situ synthesizing mullite whisker self-toughened mullite ceramics

The invention discloses a method for in-situ synthesizing mullite whisker self-toughened mullite ceramics. The method comprises the following steps: mixing 55-70 parts by weight of aluminum oxide, 20-30 parts by weight of silicon dioxide, 5-18 parts by weight of mullite whisker seed crystal, and 2-5 parts by weight of aluminum fluoride in a manner of wet grinding; pouring and curing to obtain a green body; sintering the green body at the temperature of 500 to 600 DEG C for the first time; sintering at the temperature of 900 to 1000 DEG C for the second time; sintering at the temperature of 1350-1550 DEG C for the third time so as to obtain the mullite ceramics. In addition, the invention also discloses the mullite ceramics prepared by the abovementioned method. According to the method, the raw materials, namely, aluminum oxide and silicon dioxide based on the ratio, conduct reaction under the synergistic effect of mullite whisker seed crystal and aluminum fluoride in parts by weight through the sectional sintering technology under the abovementioned temperature to obtain the high-toughness in-situ self-growth mullite whisker mullite ceramics; the high-activity seed crystal is added, so that the in-site uniform and dispersed distribution of the mullite whiskers in a substance can be realized, and thus the toughness of the ceramics can be effectively improved.

Owner:CENT SOUTH UNIV

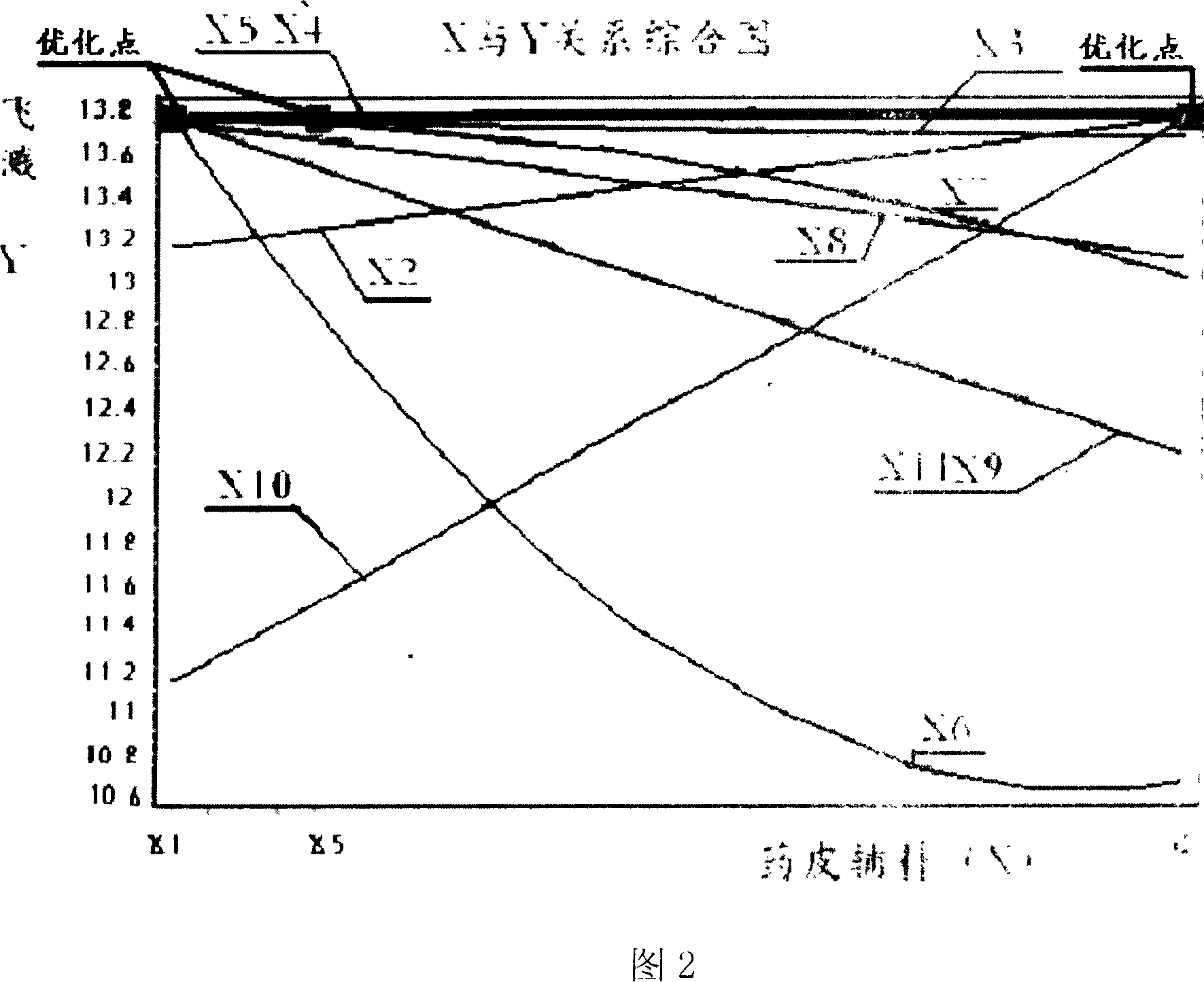

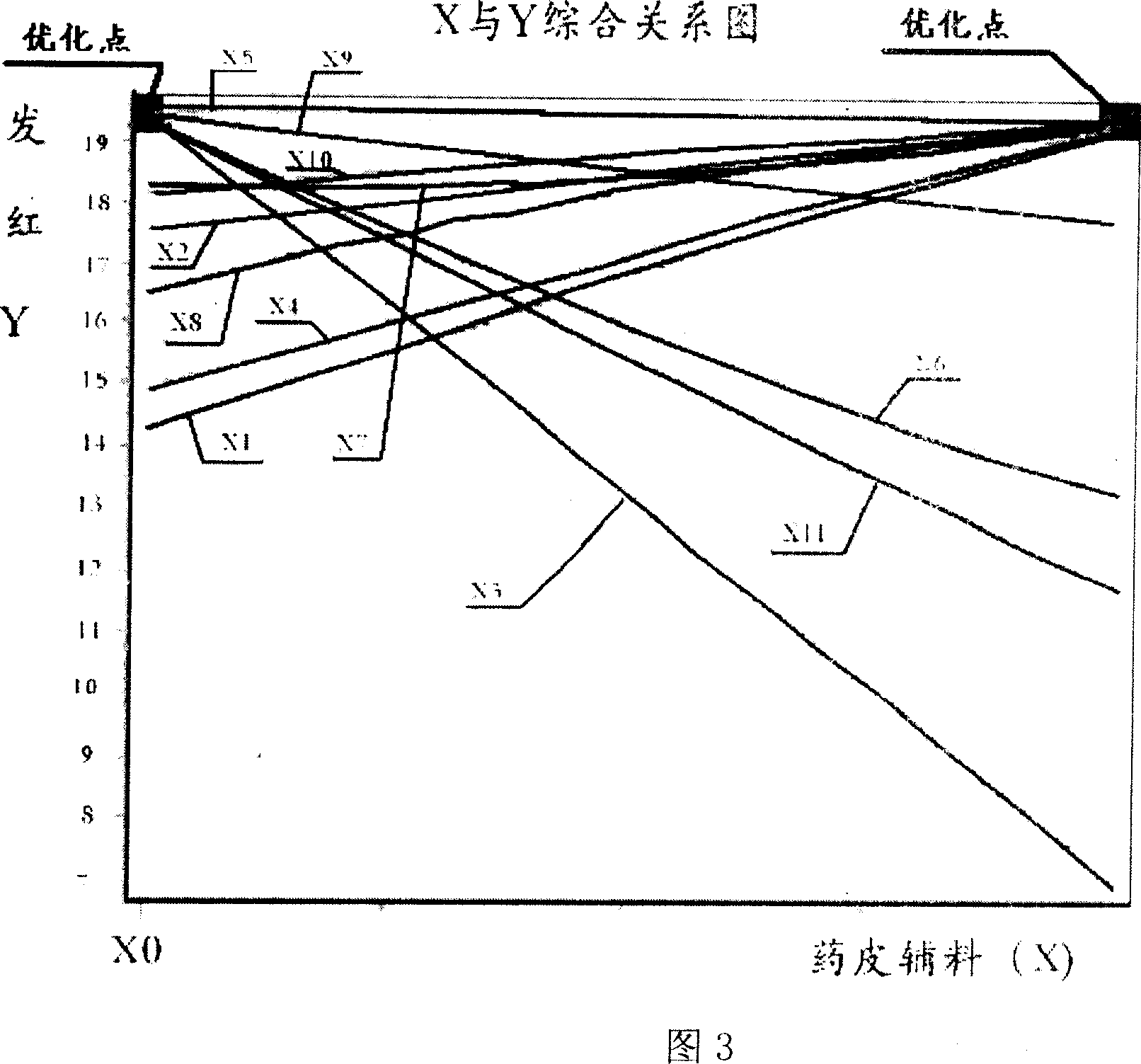

Stainless steel welding rod of new dregs series

InactiveCN1958213AReduce slag viscosityImprove conductivityWelding/cutting media/materialsSoldering mediaArc stabilitySlag

A welding stainless steel electrode with improved slag detachability and welding quality is composed of a core and a coated flux layer prepared proportionally from rutile, feldspar, marble, fluorite, wollastonite, megnesite, titaniunm oxide powder, hematite, aluminum fluoride, mice, barium carbonate, Cr, Ni, sodium carbonate, electrolytic manganese and ferrotitanium.

Owner:HARBIN UNIV OF SCI & TECH

Harmlessness and reclamation treatment method of aluminum scrap electrolyte

ActiveCN108677020AEfficient decompositionSolve environmental problemsSulfate/bisulfate preparationAlkali metal nitrate preparationAluminum fluorideElectrolysis

The invention discloses a harmlessness and reclamation treatment method of aluminum scrap electrolyte and belongs to the technical field of inorganic chemistry. The method comprises the main steps that 1, aluminum scraps are electrolyzed and subjected to crushing and screening, and aluminum electrolyte particles are obtained; 2, acid liquor with the concentration of 1 mol / L and an aluminum salt solution with the concentration of 1 mol / L are prepared for standby application; 3, the aluminum electrolyte particles obtained in the step 1 are placed in the acid liquor prepared in the step 2 and leached on the heating and stirring conditions, the PH of the solution is controlled to be smaller than 5, when the fluorinion leaching rate is higher than 94%, leaching is finished, impurities are filtered, and a leaching solution is obtained; 4, the aluminum salt solution prepared in the step 2 is added to the leaching solution in the step 3, the mixture is heated and stirred, Al3+ / Na+ is controlled to be larger than 0.3, when sediment is generated in the solution, the solution is filtered, filter residues and filter liquor are obtained, and the filter residues are washed and dried to obtain alkali type aluminum fluoride products; and 5, the filter liquor in the step 4 is evaporated and crystallized to obtain sodium salt products.

Owner:NORTHEASTERN UNIV

Novel brazing flux-containing aluminum alloy soldering wire and preparation method thereof

InactiveCN101947702AIncrease profitReduce processingWelding/cutting media/materialsSoldering mediaAluminum fluoridePotassium

Owner:BEIJING UNIV OF TECH

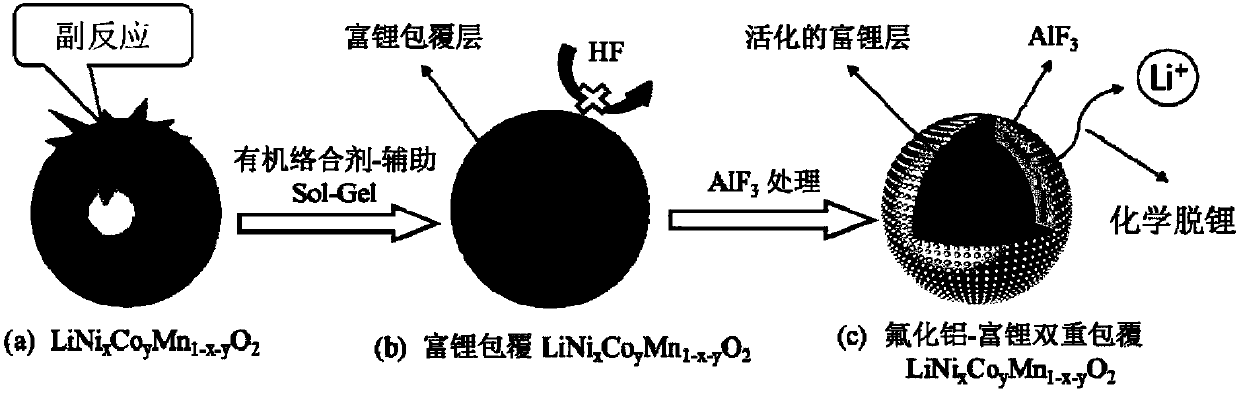

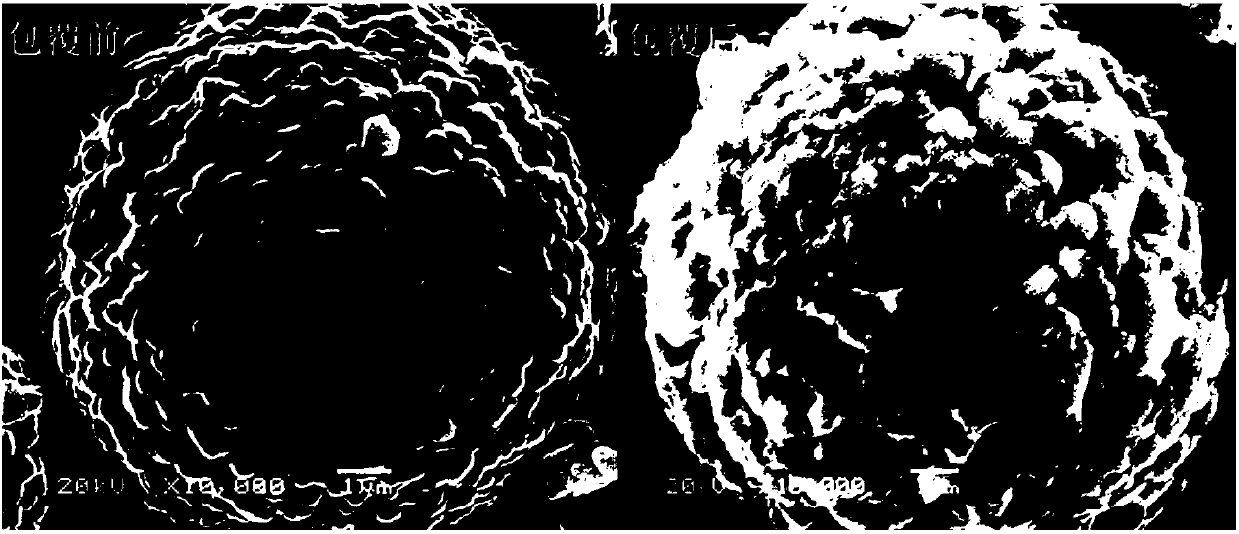

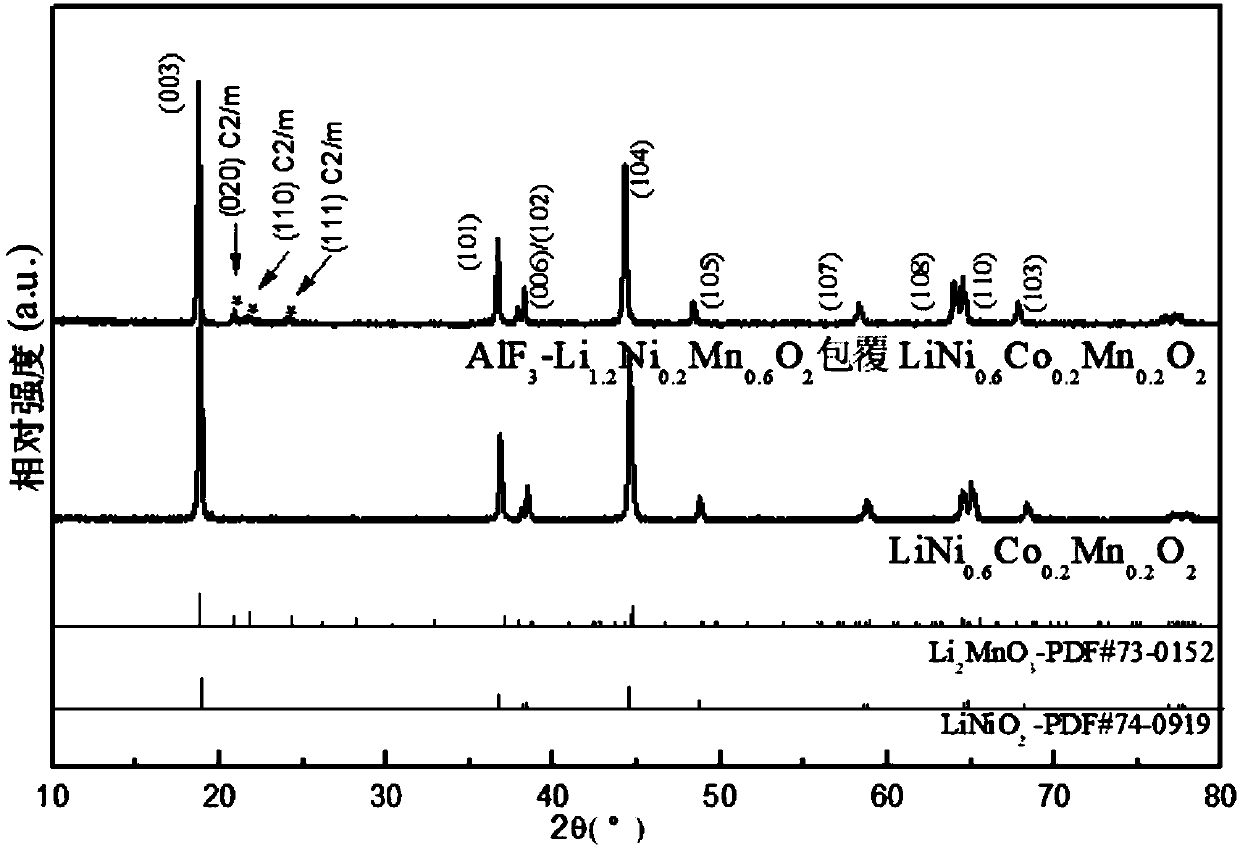

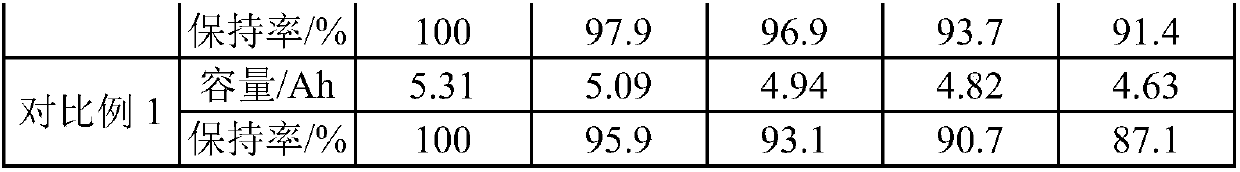

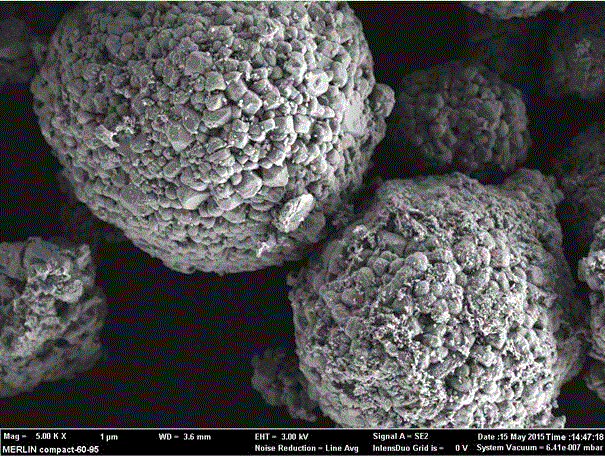

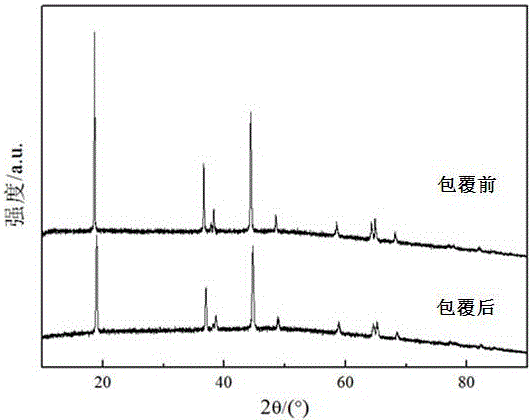

Lithium ion battery ternary material with double-coated surface and preparation method thereof

InactiveCN107768642AHigh Capacity FeaturesImprove protectionCell electrodesSecondary cellsManganeseCobalt

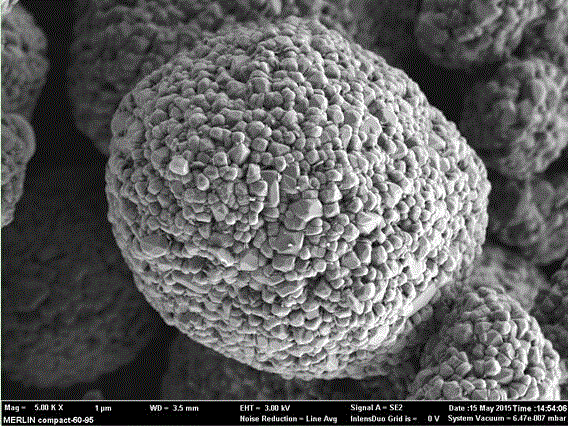

The invention discloses a lithium ion battery ternary material with a double-coated surface. The lithium ion battery ternary material with the double-coated surface comprises a nickel-cobalt-manganeseternary material, wherein a lithium-rich layered oxide coating layer is covered on a surface of the nickel-cobalt-manganese ternary material; an aluminum fluoride coating layer is covered on a surface of the lithium-rich layered oxide coating layer; the lithium ion battery ternary material with the double-coated surface is not easy to fall off, and has good chemical stability and high capacity. The invention also discloses a preparation method of the lithium ion battery ternary material. The method comprises the steps of firstly adopting an organic complexing agent-auxiliary sol-gel method for covering lithium-rich layered oxide on the surface of the ternary material so as to form the lithium-rich coating layer; then using a liquid phase method for coating aluminum fluoride on the surfaceof the lithium-rich layered oxide coating layer, and obtaining the double-coated lithium ion battery ternary material. The preparation method is simple in process, high in operation feasibility, andhigh in element utilization rate.

Owner:CENT SOUTH UNIV

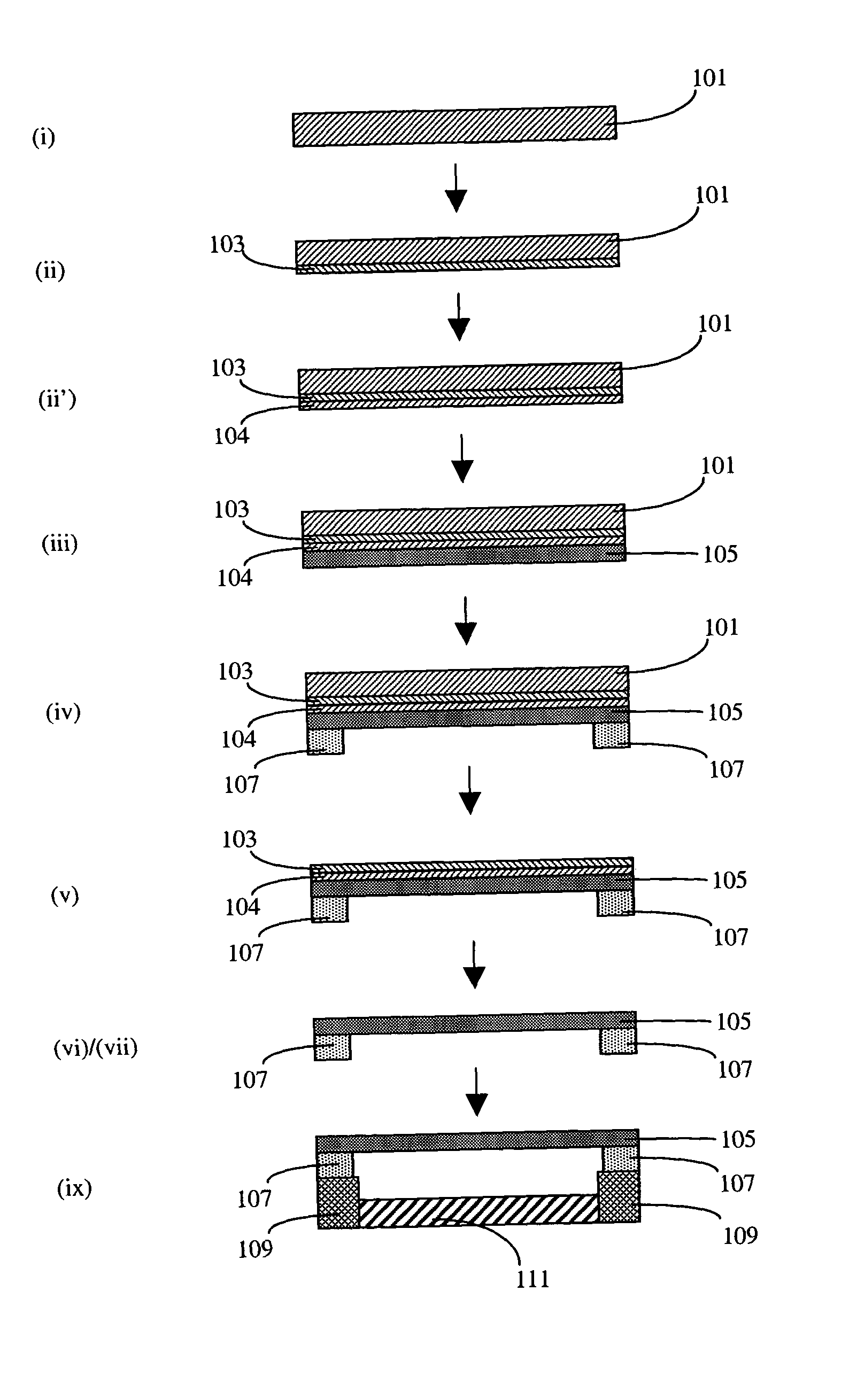

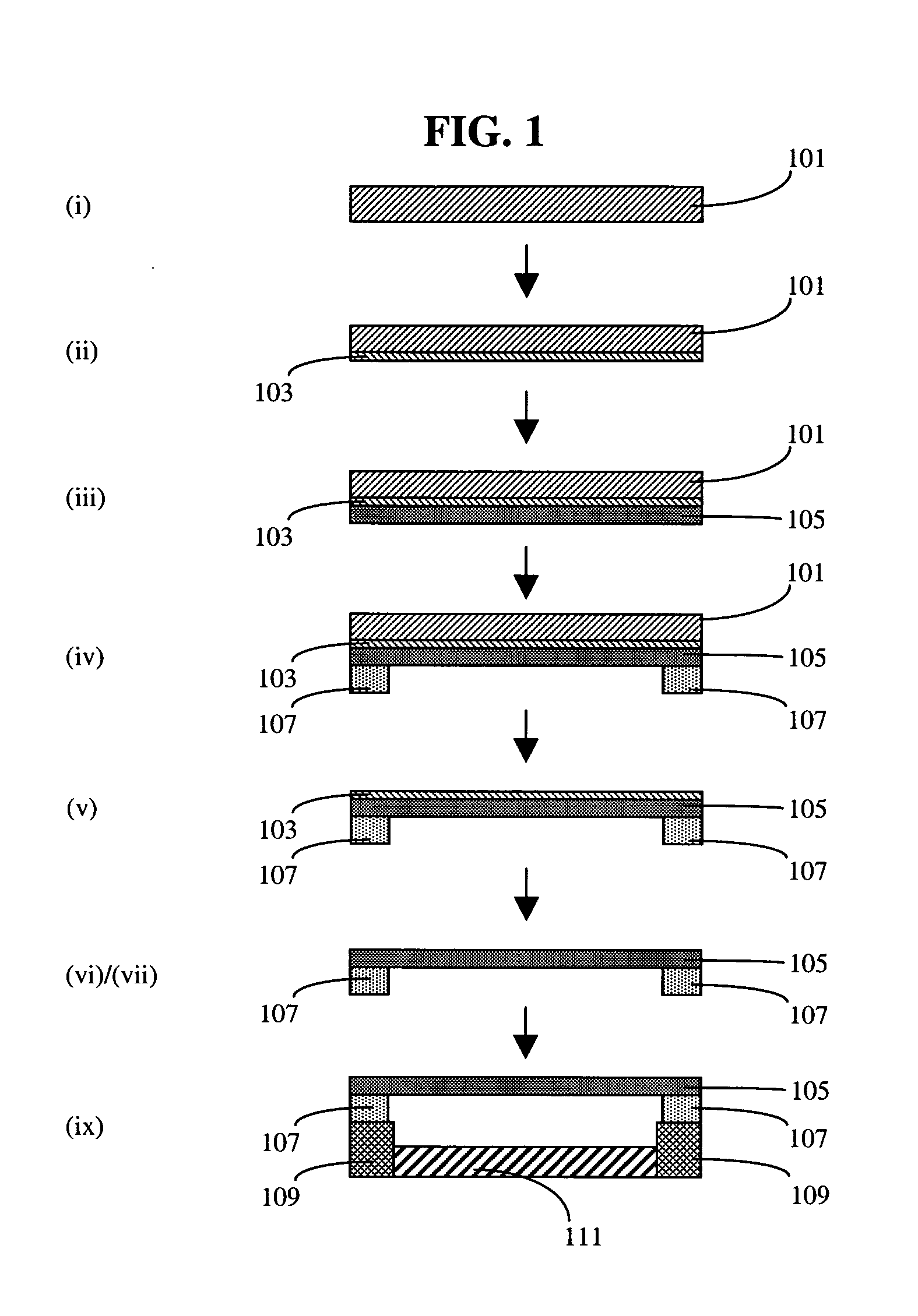

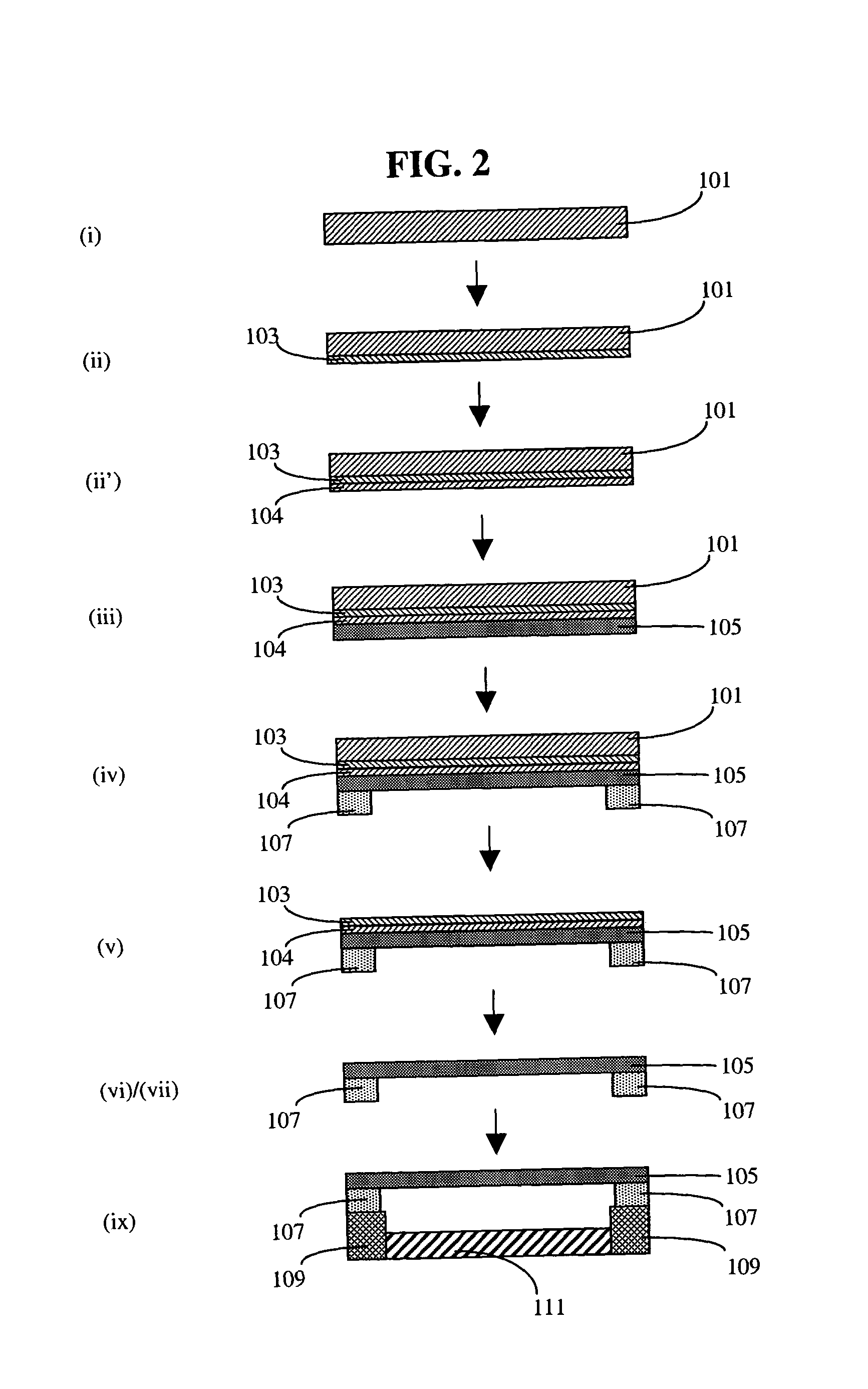

Process for making hard pellicles

Disclosed is a process for making thin hard pellicle for photomasks used in projection photolithography. The process can be used for making thin hard pellicles comprising a pellicle layer having a thickness in the range of about 5 to 120 μm and a mount frame attached to the peripheral area of a surface of the pellicle layer. The pellicle layer can consist essentially of a material selected from silica, fluorine doped silica, aluminum doped silica, methylated silica, fluorinated and methylated silica, fluorinated aluminum doped silica, CaF2, MgF2, BaF2 and SiC. The mount frame is preferred to have substantially the same CTE of the pellicle layer to minimize stress caused by temperature change. The mount frame is preferred to be porous to the purging gas. The process for making the hard pellicle involves deposition of an intermediate layer comprising a hydrogenated amorphous silicon layer on a flat substrate, deposition of the pellicle layer on the intermediate layer, mounting the frame to the pellicle layer and the separation of the pellicle from the substrate by heat treatment.

Owner:CORNING INC

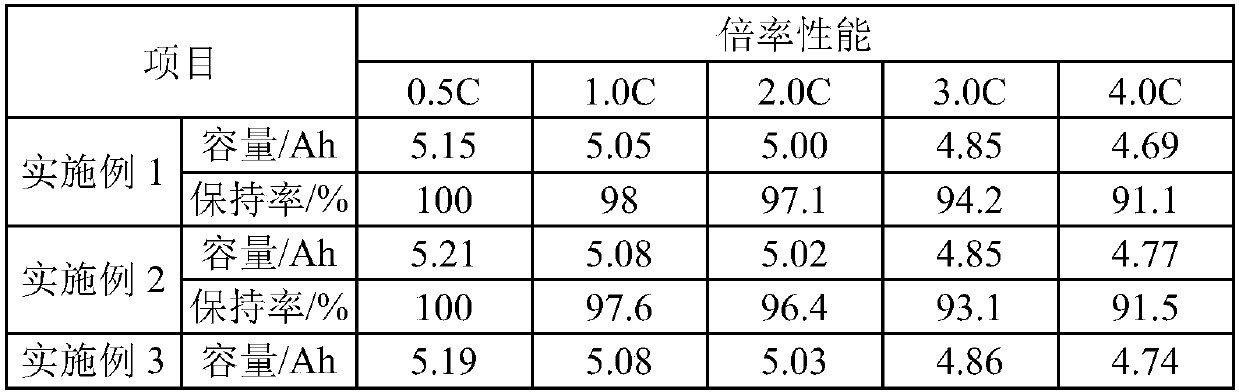

Aluminum fluoride/silver double-coated lithium nickel cobalt manganese oxide positive electrode material and preparation method thereof

ActiveCN107591532AImprove cooling effectImprove conductivityCell electrodesDischarge efficiencyAluminum fluoride

The invention relates to an aluminum fluoride / silver double-coated lithium nickel cobalt manganese oxide positive electrode material and a preparation method thereof and belongs to the technical fieldof positive electrode materials for lithium-ion batteries. The aluminum fluoride / silver double-coated lithium nickel cobalt manganese oxide positive electrode material has a core-shell structure; a core is lithium nickel cobalt manganese oxide LiNixCoyMn(1-x-y)O2, wherein x smaller than or equal to 1.0 and greater than or equal to 0.5 and y is smaller than or equal to 0.23 and greater than or equal to 0; and a shell of the core-shell structure comprises an inner shell and an outer shell, wherein the inner shell is aluminum fluoride and the outer shell is silver. The aluminum fluoride / silver double-coated lithium nickel cobalt manganese oxide positive electrode material has excellent cycle performance, high initial charge-discharge efficiency and excellent safety performance.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

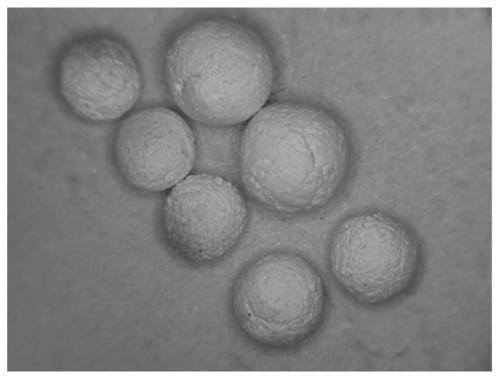

Hollow spheroidal mullite material and preparation method thereof

The invention provides a hollow spheroidal mullite whisker material and a preparation method thereof. The preparation method comprises steps as follows: silica sol, water and ethanol are added to a container and stirred uniformly, the pH value is regulated to 2, and silica sol is formed; alumina powder, aluminum fluoride trihydrate and ethanol are mixed and subjected to ball milling, and mixed slurry is obtained; the silica sol and the mixed slurry are mixed uniformly in a volume ratio of 1:(0.5-1.4), the pH value is regulated to 7-9, gelatinization is performed, and precursor powder is obtained; a polyvinyl alcohol solution is uniformly sprayed to the surfaces of polystyrene spheres, starch spheres, phenol-formaldehyde resin spheres or urea spheres, then the spheres are put in the precursor powder to adhere to the precursor powder, the operation is repeated multiple times, then ball milling, drying and calcining are performed in sequence, and the hollow spheroidal mullite whisker material is obtained. According to the hollow spheroidal mullite whisker material, the volume density is 0.34-0.85 g / cm<3>, the room-temperature thermal conductivity is 0.184-0.485 W / (m<-1>.K<-1>), and the open porosity is 62.33%-81.86%.

Owner:CHANGAN UNIV

Wet clean process for recovery of anodized chamber parts

InactiveUS20090056745A1Detergent mixture composition preparationSemiconductor/solid-state device manufacturingAluminum fluorideFluoride

A cleaning process for recovering an anodized aluminum part is particularly useful when the part has been exposed to a fluorine-containing plasma in etch reactor. The part is bathed in an agitated solution of a fluoride acid, such as ammonium fluoride, which converts aluminum fluoride to a soluble fluoride. The part is rinsed in water. The pores of the cleaned anodization may be resealed by a submerging the part in hot agitated deionized water.

Owner:APPLIED MATERIALS INC

Composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt and preparation method of flux cored wire

ActiveCN102935559AImprove cleanlinessImprove intergranular corrosion resistanceWelding/cutting media/materialsSoldering mediaRare-earth elementAluminum fluoride

The invention discloses a composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt. The composite zinc-aluminum flux cored wire comprises a wire body consisting of an outer metal skin and core brazing flux powder, wherein the outer metal skin is prepared by the following raw materials by weight percent: 80.5 to 98.5% of zinc, 0.01 to 6.5% of silver, 0.01 to 3% of copper, 0.001 to 2% of nickel, 0.001 to 0.5% of beryllium, 0.001 to 1.2% of magnesium, 0.001 to 0.5% of rare earth element and the balance of aluminum; and the brazing flux powder is prepared by the following raw materials by weight percent: 15 to 35% of aluminum fluoride, 30 to 75% of cesium fluoride, 2.5 to 10% of rubidium fluoride, and the balance of potassium fluoride. The invention also provides a preparation method of the composite zinc-aluminum flux cored wire. The preparation method has the advantages that trace Be and Mg are introduced based on the conventional Zn-Al-Ag-Cu alloy system in the brazing filed, so that the cleanness of the wire can be improved, the quality and the reliability of a brazing joint are ensured, and the intercrystalline corrosion resistance of the wire can be greatly improved, and as a result, the phenomenon of 'embrittlement' can be delayed or inhibited.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

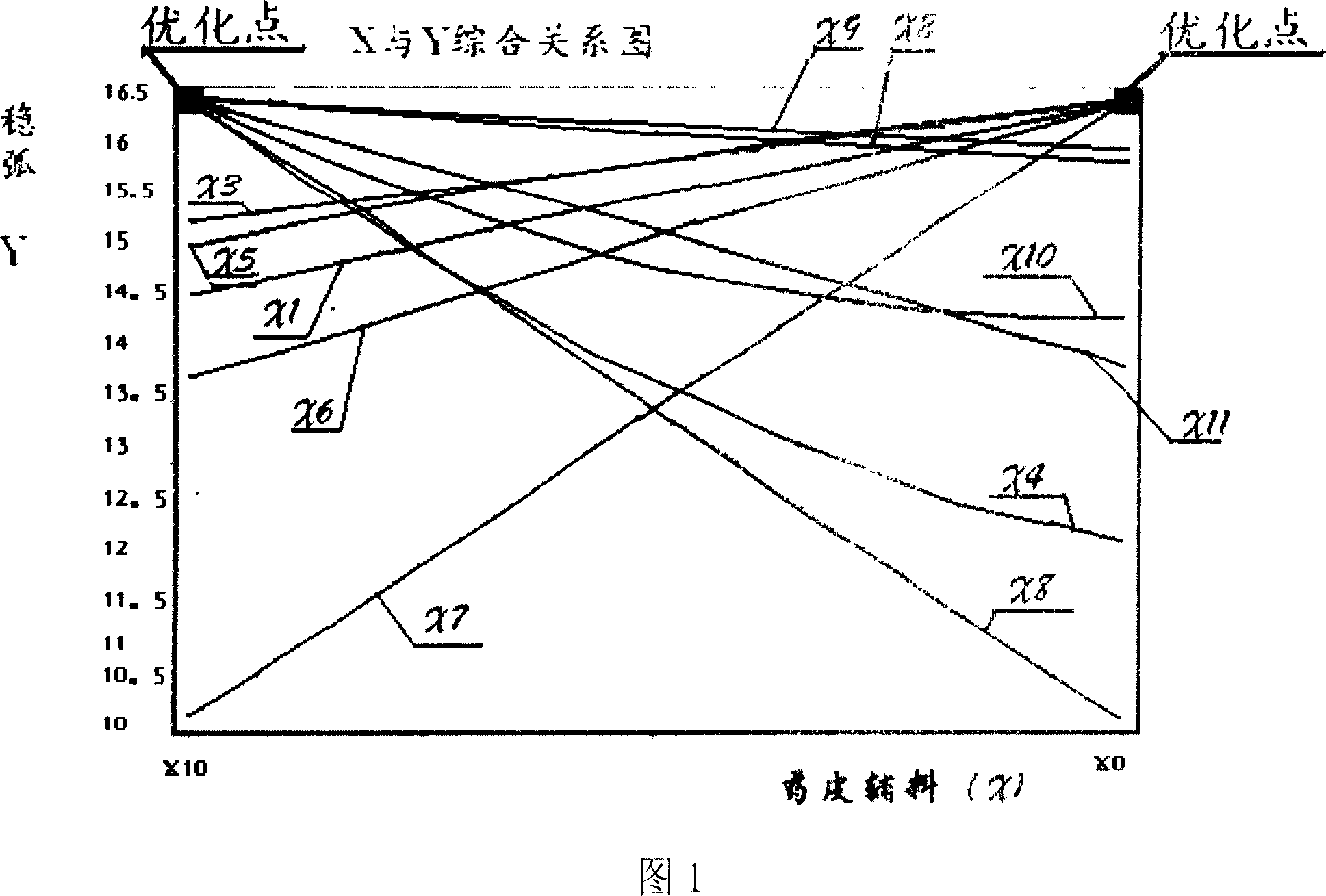

Energy equilibrium control method for aluminum cell

InactiveCN101109092AEnergy balance control effective controlReduced DC power consumptionAluminum fluorideCelsius Degree

The invention relates to a production process for the aluminum electrolytic industry, in particular to an energy balance controlling way for aluminum electrolytic tanks, which comprises a tank controller and an up-level unit. The process comprises: 1) the adjusting of the operation voltage of the tank; 2) the adjusting of the concentration or addition volume of aluminum fluoride. The benefits with the invention are: 1. that the balance controlling of the energy for the pre-baked aluminum electrolytic tank is efficiently controlled; 2. that the controlling accuracy of plus or minus 5 Celsius system for the electrolyte temperature, the primary crystal temperature of the electrolyte and the overheat rate is up to 80% above; 3. that the average thickness of the side furnace ledge of the aluminum electrolytic tank is 120 swung dash 150 mm, a regular structure in the inside of the furnace chamber is formed; 4. that the operation voltage of the aluminum electrolytic tank is controlled to be 4.04 swung dash 4.06V, the average voltage drop for the cathode is 390 mV, and the DC consumption reduces 50kWh / t is multiplied by Al. The invention is applicable for energy-balancing control for pre-baked aluminum electrolytic tanks.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Preparation method for aluminum-fluoride-coated lithium nickel cobalt manganate positive electrode material

InactiveCN105958017AImprove cycle stabilityImprove cycle lifeCell electrodesSecondary cellsManganateNitrogen gas

The invention relates to the technical field of the positive electrode material of a lithium ion battery, and particularly to a preparation method for an aluminum-fluoride-coated lithium nickel cobalt manganate positive electrode material. The preparation method for the aluminum-fluoride-coated lithium nickel cobalt manganate positive electrode material comprises the following steps of (1) adding the lithium nickel cobalt manganate positive electrode material into a prepared aluminium salt compound solution to be stirred at a uniform speed; (2) adding a fluorine source compound solution to the mixed solution in a dropwise manner, evaporating the solution after the dropwise adding is finished until the solution is in an evaporated state, then allowing the solution to age and drying the solution; and crushing the sample and sieving the sample by a 400-mesh screen to obtain solid powder; and (3) putting the solid powder obtained in the step (2) in a tubular furnace, roasting the solid powder under a nitrogen atmosphere, and naturally cooling to the room temperature to obtain the aluminum-fluoride-coated lithium nickel cobalt manganate positive electrode material. By adoption of the preparation method, the cycling stability and the rate capability of lithium nickel cobalt manganate are improved; the preparation method is simple in process; and compared with the common coating process, the preparation method provided by the invention is environment-friendly and less in time consumption, low in energy consumption and low in cost, and industrialized production is facilitated.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

Novel anti-radiation material and gloves made from novel anti-radiation material

The invention belongs to the technical field of novel materials, particularly relates to a novel anti-radiation material and gloves made from the novel anti-radiation material, wherein the novel anti-radiation material comprises components with weight by percentage: nanometer bismuth oxide 55-73%, aluminum fluoride 20-35%, lanthanum trioxide 3-10%, nano tungsten trioxide 3-10%, fuller alcohol nanoparticles 1-2%. Anti-radiation gloves are prepared by adding the novel anti-radiation material into raw materials of latex gloves, and the novel anti-radiation material can keep flexibility and malleability of the latex gloves, and guarantees operation elaboration and safety of operators.

Owner:SUZHOU COLOR WAY ENTERPRISE DEV

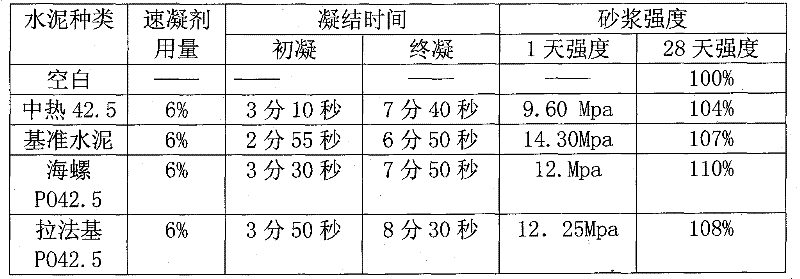

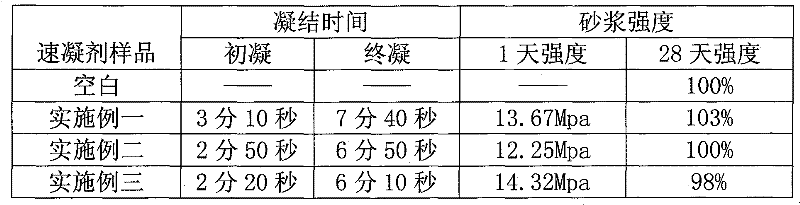

High-performance chlorine-free alkali-free liquid accelerating agent

The invention discloses a high-performance chlorine-free alkali-free liquid accelerating agent which is prepared from the following materials by weight percent: 6 to 15 percent of magnesium aluminum fluoride, 20 to 50 percent of aluminum sulfate, 2 to 6 percent of organic amines, 0 to 2 percent of stabilizer, and the balance of water. The production process comprises the following steps of: adding water at the given weight percent to a stirring drum, adding magnesium aluminum fluoride and stirring to dissolve, adding organic amines and stirring to dissolve, adding aluminum sulfate and stirring to dissolve, and making the final product. The high-performance chlorine-free alkali-free liquid accelerating agent is free of chlorine and alkali and non-corrosive to human beings and steel-bar-made machines, and has the advantages of long holding period, low addition amount, quick setting action, low rebound rate, high one-day strength, substantially no loss of long-term strength and good material compatibility. The production process is simple, pollution-free and noise-free, does not produce gas discharge or waste water, and is safe and environment-friendly. The materials are abundant, the production cost is low, and the social and economic benefits are extremely good.

Owner:昆明合起工贸有限公司

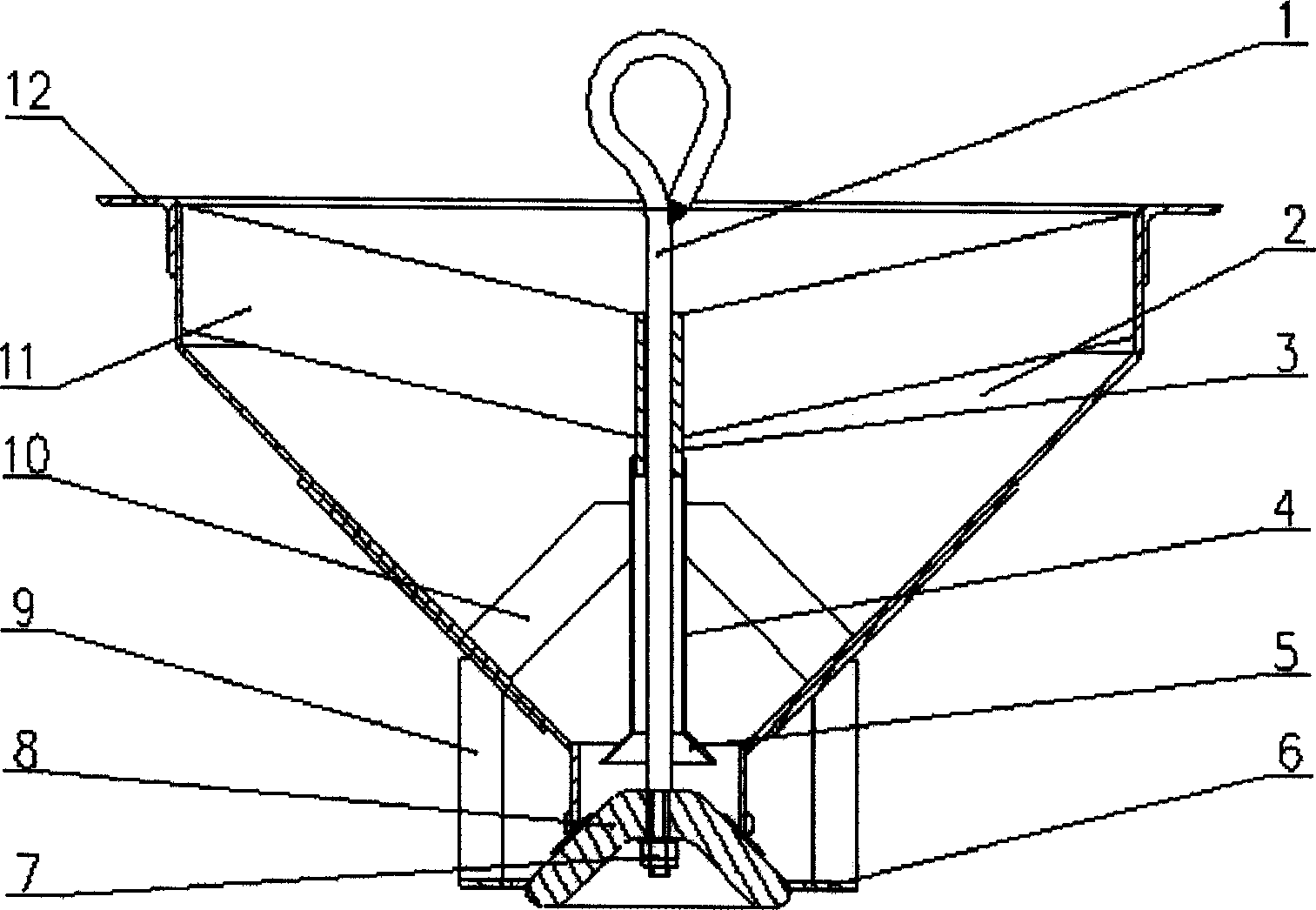

Simple aluminum fluoride charging hopper

This invention exposed a kind of simple hopper of aluminium fluoride. The structure is: there is pull- rod (1) in taper hopper (2). The pull- rod (1) is placed in guiding device and connected with sealed end cover (8). The guiding device is composed by guidance set (3), sleeve (4), and trumpet end (5). The guidance set (3) is connected with taper hopper (2) by ribbed plate (11), and the Sleeves (4) are connected with taper hopper (2) by ribbed plate (10). The lower part of taper hopper (2) is jointed with ring-form base (6) by supporting plate (9). The upper part of taper hopper (2) is jointed by enforcing ring (12). The upper part of pull- rod (1) is bent to ring form hook, the head of which is connected with neck part. The lower part of pull- rod (1) is screw threaded, and connected with sealed end cover (8) by nut. This invention used to produce electrolytic aluminium, and compact, easy to use and maintain.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method for producing aluminun fluoride

The present invention relates to process of producing aluminum fluoride with fluorosilicic acid and aluminum hydroxide as material. The process includes the following steps: 1. reacting fluorosilicic acid solution and sodium sulfate for 10-60 min, filtering to obtain solid sodium fluorosilicate and waste sulfuric acid solution to be treated and drained; 2. decomposing aluminum fluorosilicate at 300-800 deg.c for 1-5 hr to produce solid sodium fluoride and silicon tetrafluoride gas; 3. absorbing silicon tetrafluoride gas with water and hydrolyzing, filtering to obtain fluorosilicic acid solution to be returned to the step 1 and solid silica, and washing and drying silica to obtain carbon white; 4. reacting solid sodium fluoride and sulfuric acid, condensing, rectifying to obtain anhydrous hydrofluoric acid and solid sodium sulfate returned to the step 1; and 5. reacting anhydrous hydrofluoric acid and aluminum hydroxide to produce aluminum fluoride product. The process is environment friendly.

Owner:DO FLUORIDE CHEM CO LTD

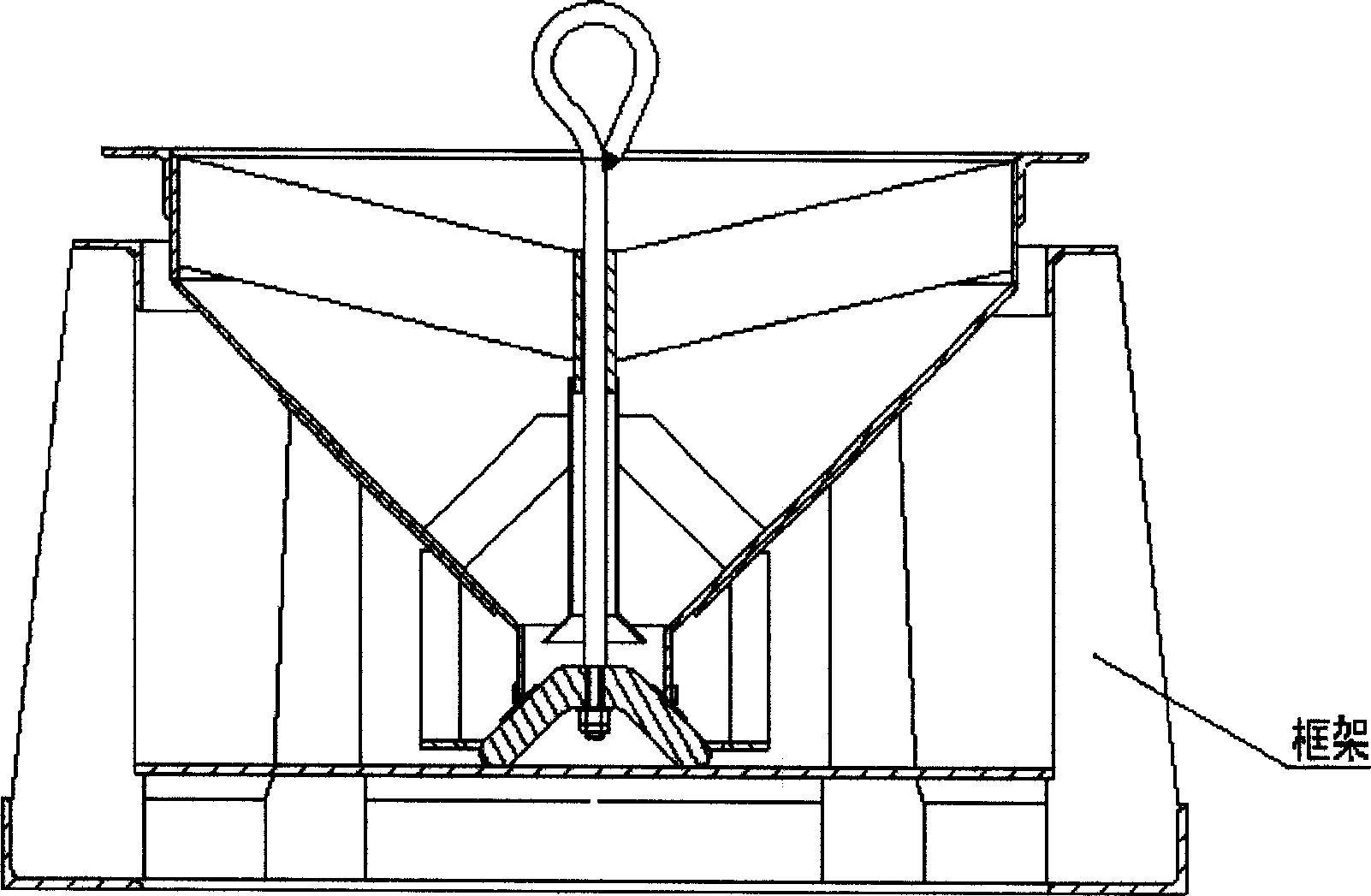

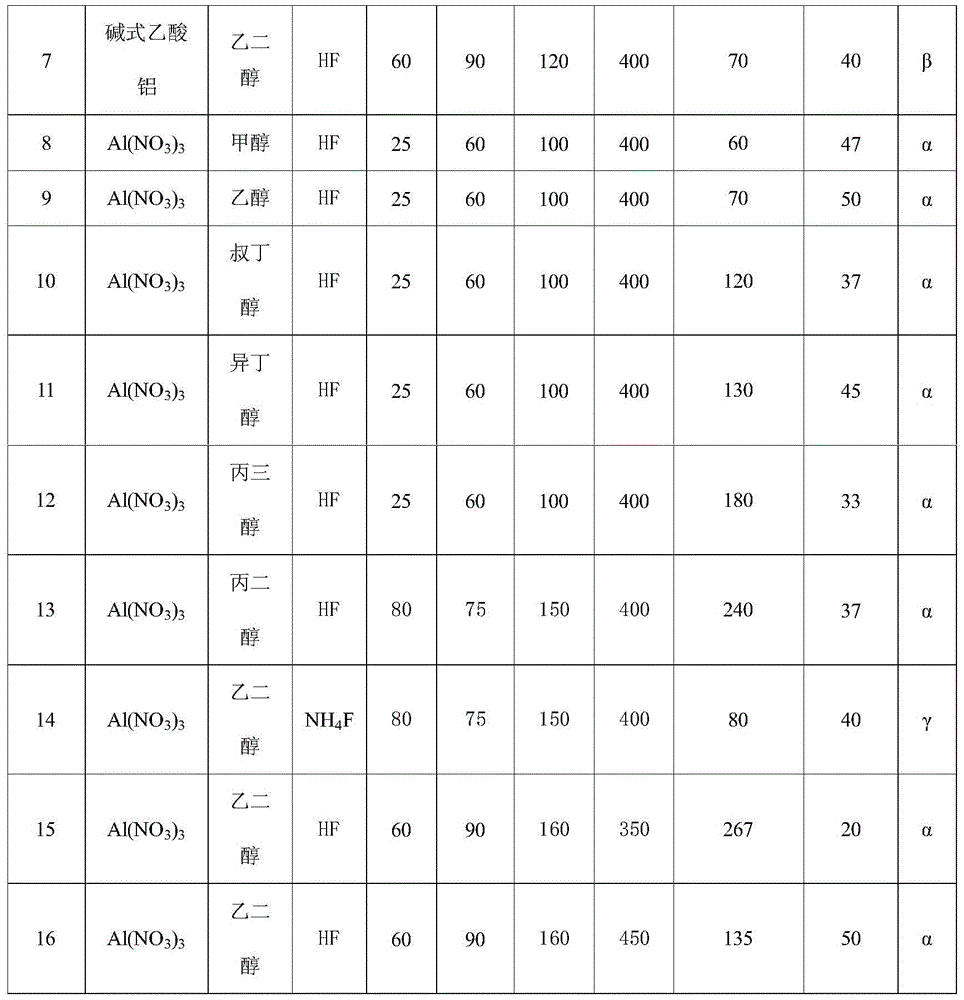

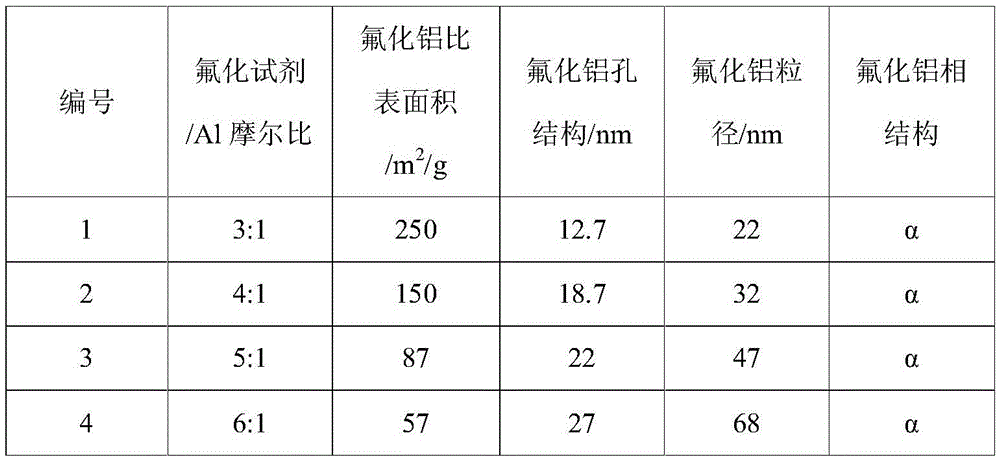

Preparation method of nanometer aluminum fluoride-based catalyst

ActiveCN105597795ARaw materials are easy to getEasy to operatePhysical/chemical process catalystsAluminum fluorideOrganic solvent

The invention discloses a nanometer aluminum fluoride-based catalyst with large specific surface area, and a preparation method and applications thereof. The preparation method is used for solving problems in conventional preparation methods of aluminum fluoride-based catalysts that high temperature specific area is small, thermal stability is poor, and the conventional preparation method is complex, and is high in cost. The preparation method comprises following steps: (1) a solution containing an aluminium source precursor, an organic solvent, and a doping ingredient is prepared, and is subjected to refluxing at 20 to 80 DEG C; (2 ) an aqueous solution of a fluorinating reagent is added into the solution obtained in (1) dropwise for fluorination, and a liquid sol is obtained via aging at 60 to 90 DEG C; and (3) the liquid sol is dried at 100 to 160 DEG C so as to obtain a solid gel, and roasting is carried out at 350 to 450 DEG C so as to obtain the nanometer aluminum fluoride-based catalyst.

Owner:XIAN MODERN CHEM RES INST

LiF-coated doped and undoped yttrium oxide

ActiveUS7449238B1Prevent peelingAvoid boilingMaterial nanotechnologySynthetic resin layered productsAluminum fluorideYttrium

An embodiment of the invention includes a particle. The particle includes a first yttria core; and a fluoride salt coating on the first yttria core. The coating is sufficiently continuous to prevent a large number of sites where a second yttria core may come into contact with the first yttria core. Optionally, the particle has been heated in an oxidizing atmosphere to a temperature in the range of about 400° C. to about 750° C. Optionally, the particle is substantially free of at least one of carbon-containing species and water. Optionally, the fluoride salt is lithium fluoride. Optionally, the fluoride salt is aluminum fluoride.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

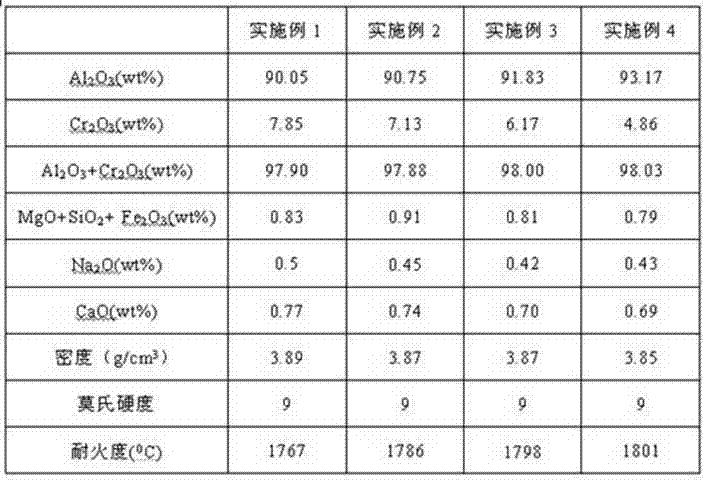

Chromium corundum material and production method thereof

The invention relates to a chromium corundum material and a production method thereof. The chromium corundum material consists of 90wt%-94.5wt% of aluminum oxide, 3wt%-8wt% of chromic oxide and less than and equal to 2.5wt% of total impurities. The production method comprises the steps of uniformly mixing aluminum-chromium slag having a particle size less than and equal to 20mm, aluminum oxide having a particle size less than and equal to 1mm, petroleum coke having a particle size less than and equal to 20mm and aluminum fluoride, heating bitumen and spraying to the mixture, pressing into ball materials, drying, and adding the dried ball materials to an electric-arc furnace; smelting, pouring smelted liquid in a slag pot, removing the calcium fluoride floating on the upper part of the liquid material and standing; and separating from the slag pot, crushing, selecting chromium metal reduced by carbon and finishing to obtain the chromium corundum material. The chromium corundum material has the advantages that the problem of aluminum chromium slag solid waste is solved by taking aluminum chromium slag as raw materials, environmental friendliness is achieved, the raw material cost is lowered, the contents of Al2O3 and Cr2O3 are improved and the high-temperature performance, slag resistance and corrosion resistance of the chromium corundum material are ensured.

Owner:锦州集信高温材料有限公司

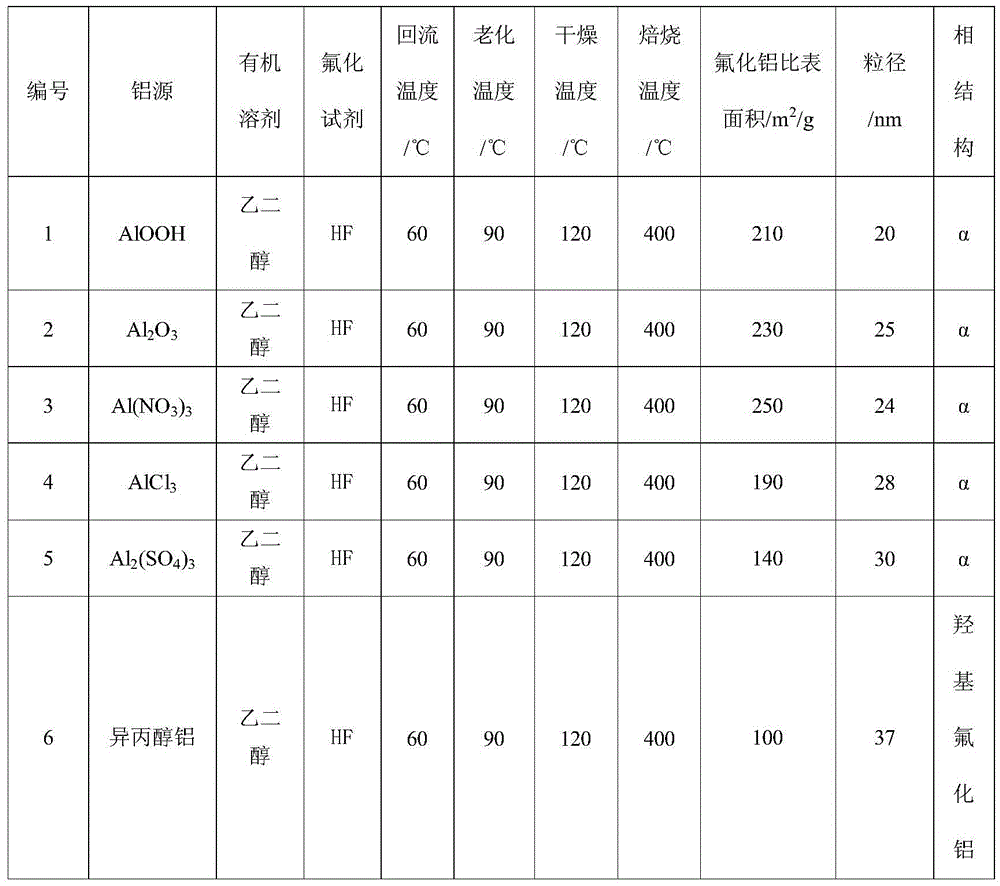

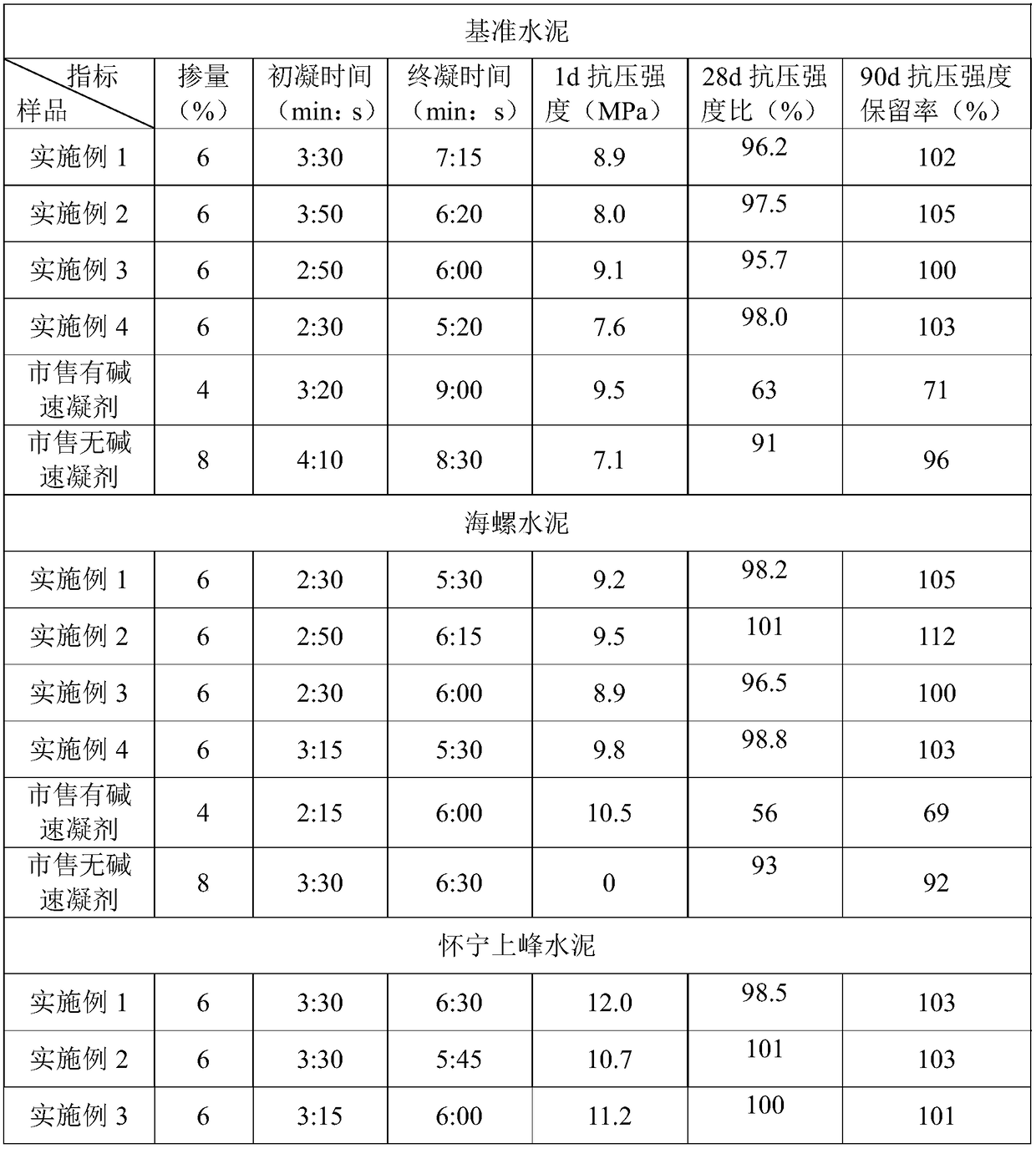

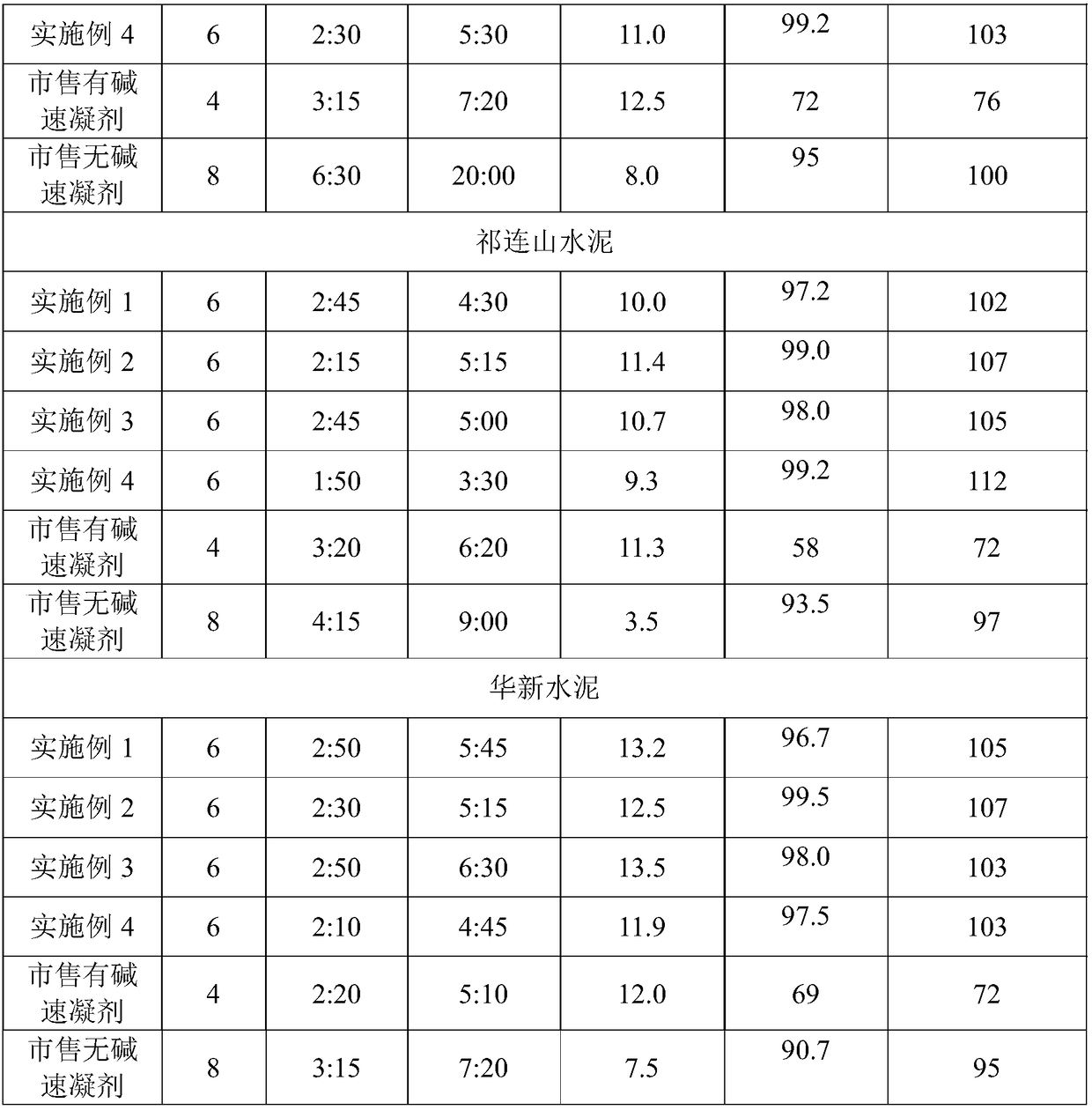

Liquid alkali-free setting accelerator widely applicable to various types of cement

The invention provides a liquid alkali-free setting accelerator widely applicable to various types of cement, wherein the liquid alkali-free setting accelerator includes 35-60 parts by weight of water, 40-50 parts by weight of polyaluminum sulfate or aluminum sulfate, 0-5 parts by weight of iron sulfate, 0-3 parts by weight of a complexing agent, 2-5 parts by weight of organic amine, 2-5 parts byweight of an early strength agent, 0-2 parts by weight of a pH regulator, 0.5-1 part by weight of a slag activator, 0.1-0.3 part by weight of a defoamer, and 2-8 part by weight of aluminum fluoride. The invention also provides a preparation and application of the liquid alkali-free setting accelerator. The liquid alkali-free setting accelerator provided by the invention is especially suitable forshotcrete, has wide adaptability to various kinds of cement, can improve the applicability of the alkali-free setting accelerator to cement, improves the strength of the shotcrete, and is more widelyapplied in various projects.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com