Patents

Literature

145results about How to "Improve intergranular corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intergranular corrosion resistant high-strength full austenite welding rod

InactiveCN1927528ADoes not affect mechanical propertiesReduce manufacturing costWelding/cutting media/materialsSoldering mediaSlag (welding)Adhesive

The invention relates to an anti-inter-crystal-corrosion high-strength austenite welding bar. Wherein, it is formed by CaO-CaF2-SiO2 alkali coat slag and Cr-Ni-Mo-Mn-N alloy austenite coat, while its coat comprises marble at 45-55%, 45-55% at 16-25%, ferrotitanium at 8-12%, ferrosilicium at 1-5%, manganese metal at 2-8%, titanium dioxide at 1-6%, soda at 1-3% and fluoride rare earth at 0.5-2.0%; and the welding bar comprises C at 0.03-0.12%, Si at 0.2-0.7%, Mn at 2.0-7.0%, S and P<=0.030%, Cr at 15.0-19.5%, Ni at 20-25%, Mo at 4.0-7.0%, N at 0.15-0.25%, V at 0.15-0.3%, and the left is iron, then the mixed powder is coated on the welding core via soldium-water glass as adhesive.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

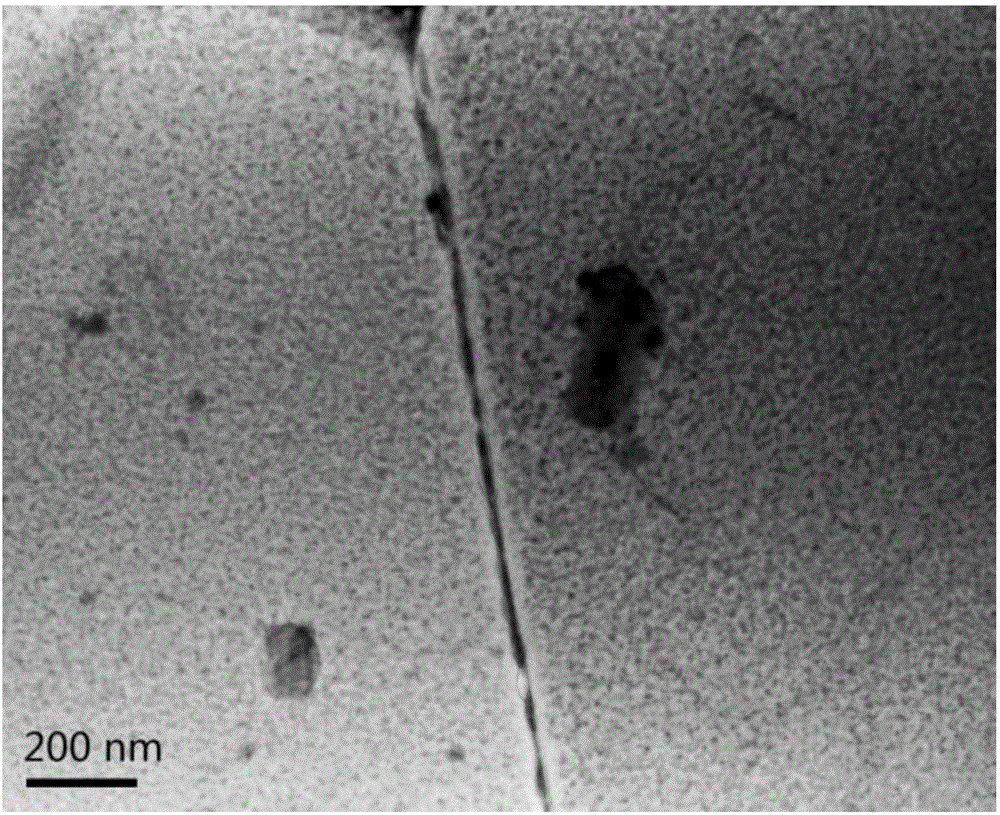

Heating processing process for improving ageing strengthening type Al-Mg-Zn alloy intergranular corrosion performance

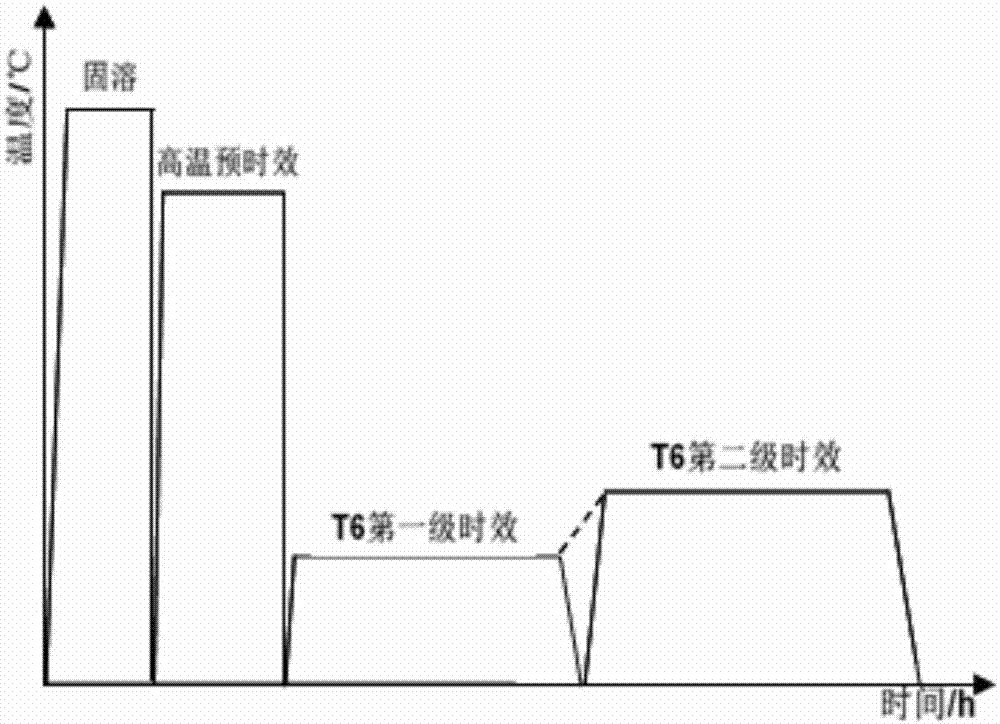

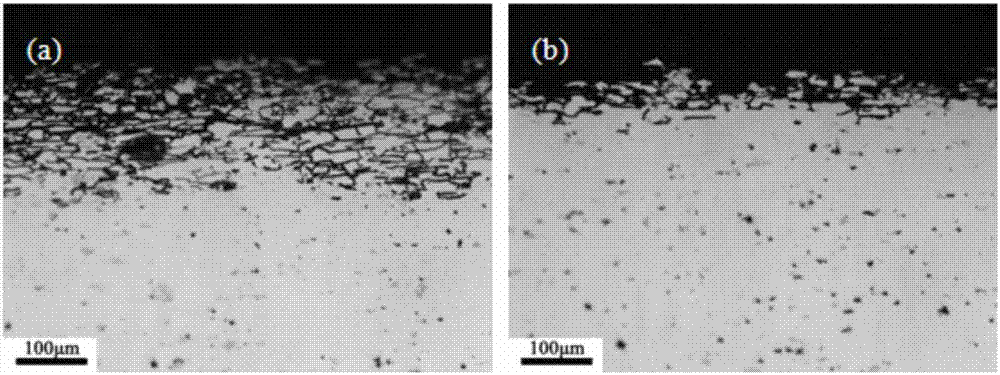

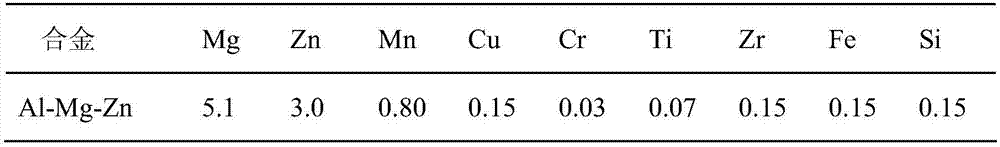

The invention relates to a heating processing process for improving ageing strengthening type Al-Mg-Zn alloy intergranular corrosion performance, and belongs to the field of nonferrous metal and preparation of the nonferrous metal. According to the heating processing process, after an ageing strengthening type Al-Mg-Zn alloy is subject to solution hardening treatment, high temperature preageing treatment is carried out, in other words, heat preservation is carried out for 10 min to 3 h at the temperature ranging from 380 DEG C to 450 DEG C, quick quenching is carried out to the room temperature, then T6 peak aging treatment is carried out, two-step aging is carried out, heat preservation is firstly carried out for 12 h to 36 h at the temperature ranging from 60 DEG C to 100 DEG C, then heat preservation is carried out for 10 h to 40 h at the temperature ranging from 110 DEG C to 160 DEG C, and cooling is carried out to the room temperature. According to the heating processing process, alloy crystal boundary and crystal interior microstructures are changed, on the premise that the alloy strength and the extending rate are basically not lost, and the alloy intergranular corrosion resistance is remarkably improved; and in addition, compared with a traditional retrogression and reaging process, the process flow is greatly shortened, and industrial production is facilitated. The heating processing process has the important reference value on developing the novel high-strength corrosion-resistant ship and armored vehicle ageing strengthening type Al-Mg-Zn alloy.

Owner:UNIV OF SCI & TECH BEIJING

Low-nickel austenite gas valve alloy and preparation method thereof

The invention discloses low-nickel austenite gas valve alloy and a preparation method thereof. The low-nickel austenite gas valve alloy comprises the following ingredients in percentage by weight: 0.02-0.08% of C, 28.0-35.0% of Ni, 12.0-17.0% of Cr, 1.5-2.5% of Al, 2.5-3.5% of Ti, 0.4-1.02% of W and Mo, 0.3-0.9% of Nb and Cu, 0.05-0.2% of Y, 0.05-0.3% of Hf, 0.001-0.005% of B, smaller than or equal to 0.4% of Mn, smaller than or equal to 0.3% of Si, smaller than or equal to 0.02% of S, smaller than or equal to 0.02% of P, smaller than or equal to 0.02% of O, smaller than or equal to 0,02% of N and the balanced Fe and unavoidable impurities. Cu is smaller than or equal to 0.3%. The alloy has the advantages of high strength, excellent corrosion resisting property and good high-temperature performance.

Owner:JIANGSU SHENYUAN SPECIAL STEEL +1

Composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt and preparation method of flux cored wire

ActiveCN102935559AImprove cleanlinessImprove intergranular corrosion resistanceWelding/cutting media/materialsSoldering mediaRare-earth elementAluminum fluoride

The invention discloses a composite zinc-aluminum flux cored wire containing beryllium and magnesium and rubidium salt. The composite zinc-aluminum flux cored wire comprises a wire body consisting of an outer metal skin and core brazing flux powder, wherein the outer metal skin is prepared by the following raw materials by weight percent: 80.5 to 98.5% of zinc, 0.01 to 6.5% of silver, 0.01 to 3% of copper, 0.001 to 2% of nickel, 0.001 to 0.5% of beryllium, 0.001 to 1.2% of magnesium, 0.001 to 0.5% of rare earth element and the balance of aluminum; and the brazing flux powder is prepared by the following raw materials by weight percent: 15 to 35% of aluminum fluoride, 30 to 75% of cesium fluoride, 2.5 to 10% of rubidium fluoride, and the balance of potassium fluoride. The invention also provides a preparation method of the composite zinc-aluminum flux cored wire. The preparation method has the advantages that trace Be and Mg are introduced based on the conventional Zn-Al-Ag-Cu alloy system in the brazing filed, so that the cleanness of the wire can be improved, the quality and the reliability of a brazing joint are ensured, and the intercrystalline corrosion resistance of the wire can be greatly improved, and as a result, the phenomenon of 'embrittlement' can be delayed or inhibited.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

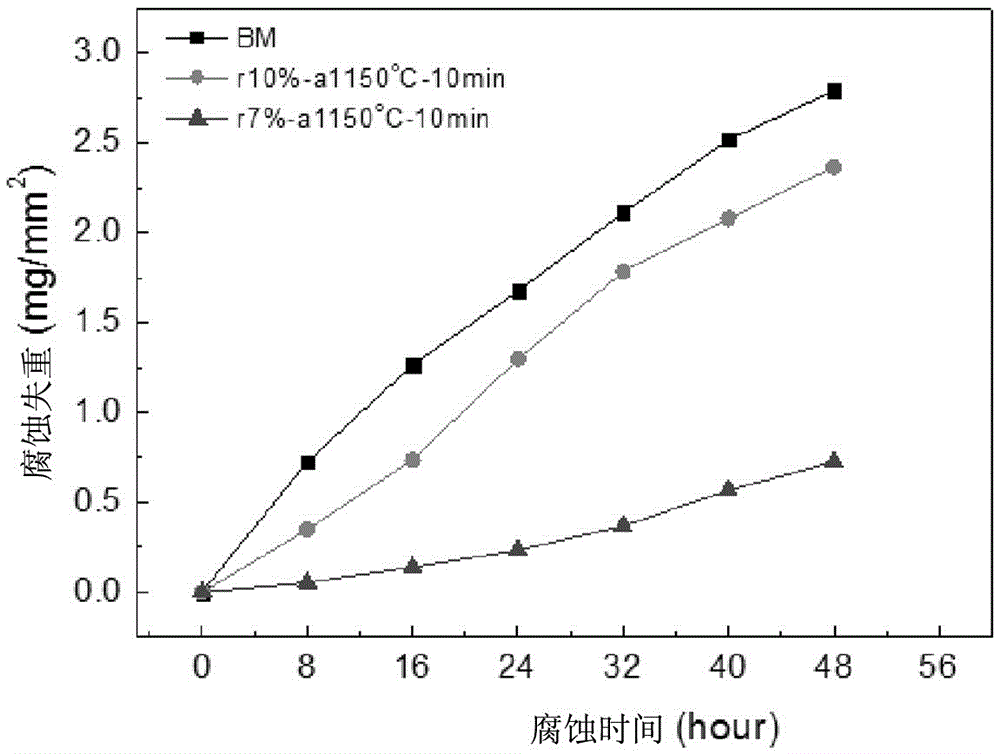

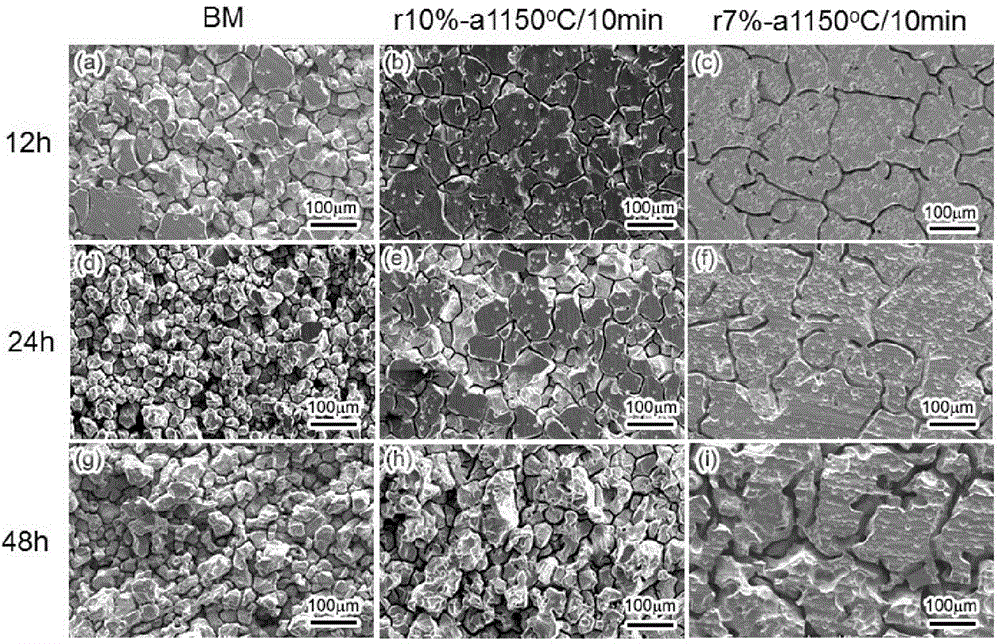

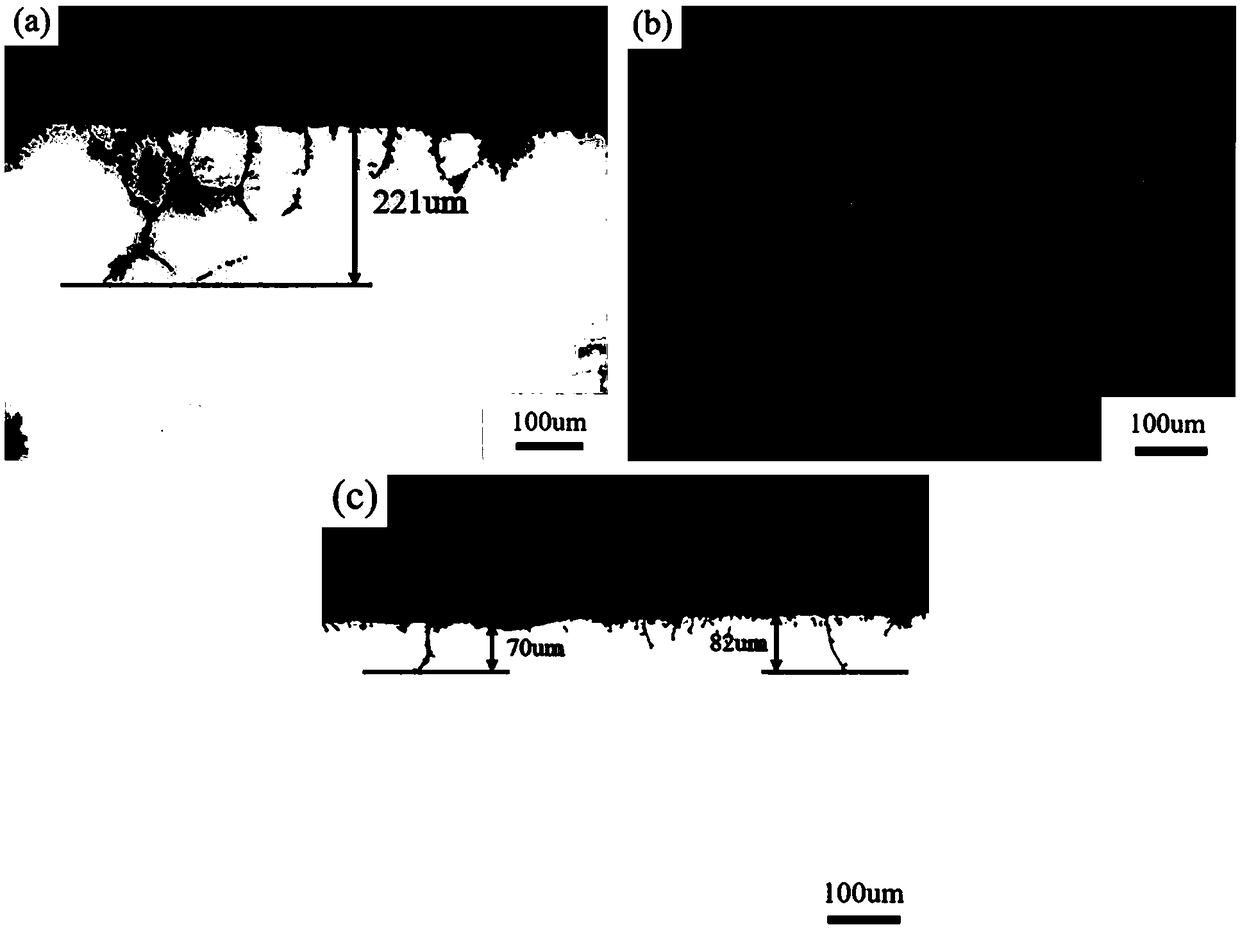

High-nitrogen nickel-free austenitic stainless steel intergranular-corrosion-prevention processing technology

InactiveCN105177257AImprove intergranular corrosion resistanceExcellent corrosion fatigue performanceSolution treatmentSS - Stainless steel

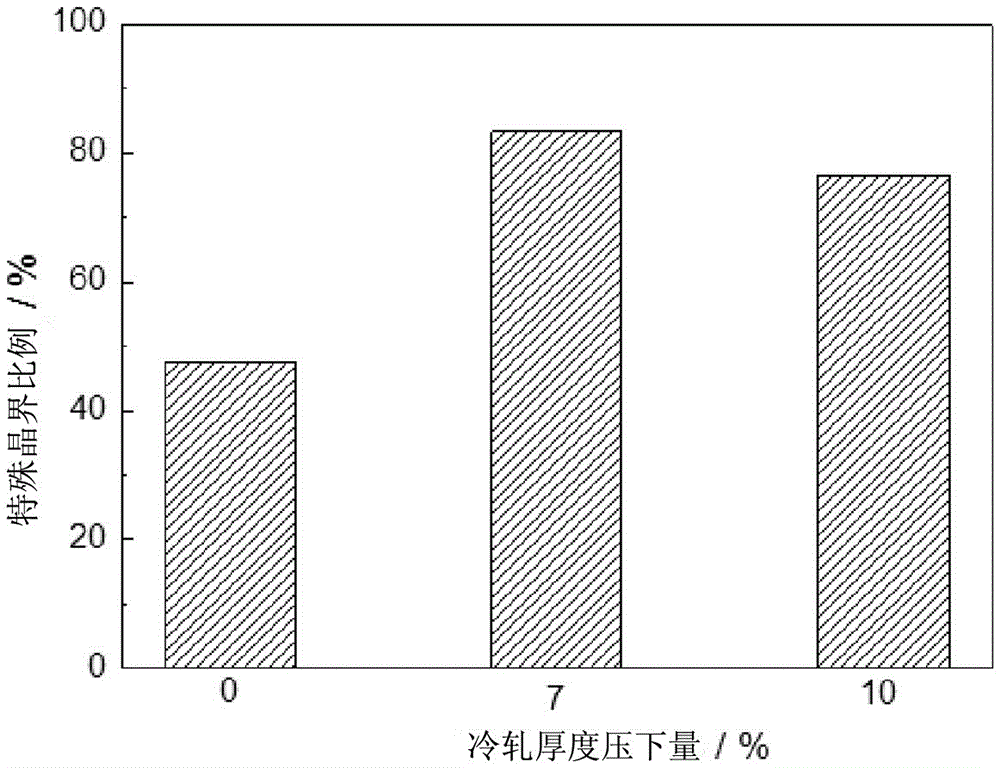

The invention relates to a high-nitrogen nickel-free austenitic stainless steel intergranular-corrosion-prevention processing technology. Solution treatment is firstly carried out on materials; and then cold rolling deformation and recrystallization annealing technological treatment is carried to enable the proportion of the special grain boundary in high-nitrogen nickel-free austenitic stainless steel to be improved, and therefore the aim of improving the decay resistance of the materials is accordingly achieved. The high-nitrogen nickel-free austenitic stainless steel intergranular-corrosion-prevention performance can be obviously improved through technological treatment.

Owner:NORTHEASTERN UNIV LIAONING

Ferritic stainless steel and preparation method thereof

InactiveCN101158007AImprove intergranular corrosion resistanceImprove corrosion resistanceMetal rolling arrangementsImpurityFerric

The invention is a ferrite stainless steel plate and a preparation method. The stainless steel plate consists of (in weight percentage): C is less than or equal to 0.03, Si is less than or equal to 1.00, Mn is less than or equal to 1.00, Cr:15-25, P is less than or equal to 0.035, S is less than or equal to 0.03, N is less than or equal to 0.03, 0.20 is less than or equal to Cu and Cu is less than or equal to1.5%, Ti+Nb0.2+4 multiplied by (C+N)-0.75, the rest being Fe and unavoidable impurity. The preparation method for the stainless steel plate is as follows: (1) the casting billet is smelted, the casting billet comprises (in weight percentage):C is less than or equal to 0.03, Si is less than or equal to 1.00, Mn is less than or equal to 1.00, Cr:15-25, P is less than or equal to 0.035, S is less than or equal to 0.03, N is less than or equal to 0.03, 0.20 is less than or equal to Cu and Cu is less than or equal to1.5%, Ti+Nb 0.2+4 multiplied by (C+N)-0.75, the rest being Fe and unavoidable impurity;(2) the casting billet is heated;(3) hot the casting billet is hot-rolled; (4)cold roll and anneal. The ferrite stainless steel plate has the anti-corrosion performance and the weldability close to the anti-corrosion performance and the weldability of stainless steel 304, the preparation method of the ferrite stainless steel can be just general preparation method.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

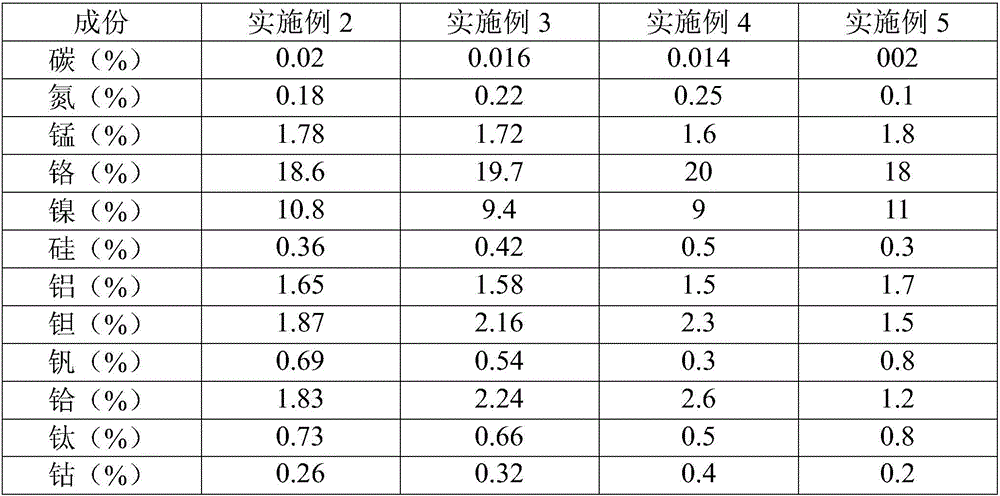

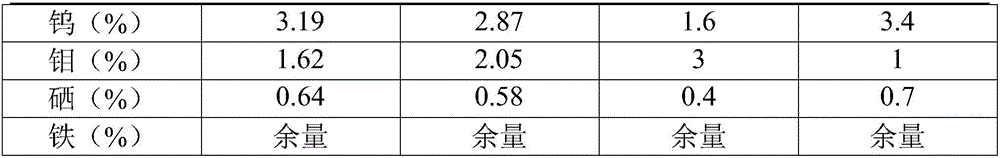

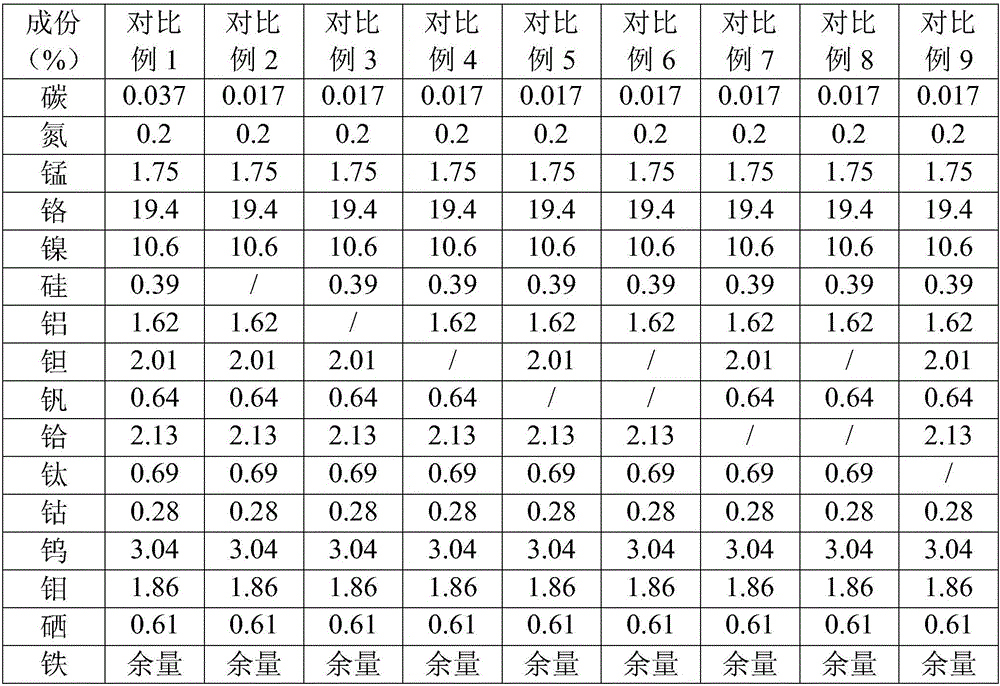

Corrosion-resistance seamless stainless steel pipe and preparation method thereof

InactiveCN106282845AMake up for the lack of strengthImprove corrosion resistanceFurnace typesHeat treatment furnacesManganeseHafnium

The invention discloses a corrosion-resistance seamless stainless steel pipe and a preparation method thereof. The corrosion-resistance seamless stainless steel pipe comprises the following chemical components in percentage by mass: carbon not more than 0.02%, 0.1-0.25% of nitrogen, 1.6-1.8% of manganese, 18-20% of chromium, 9-11% of nickel, 0.3-0.5% of silicon, 1.5-1.7% of aluminum, 1.5-2.3% of tantalum, 0.3-0.8% of vanadium, 1.2-2.6% of hafnium, 0.5-0.8% of titanium, 0.2-0.4% of cobalt, 1.6-3.4% of tungsten, 1-3% of molybdenum, 0.4-0.7% of selenium, and the balance of iron. Tantalum, hafnium and tungsten are added in austenitic stainless steel, and the chemical components can improve the performances of corrosion resistance, hardness, strength and high-temperature resistance of the austenitic stainless steel, so that the austenitic stainless steel is rich in high ductility and toughness.

Owner:ZHEJIANG HENGYUAN STEEL CO LTD

Aluminum alloy tube resistant to seawater corrosion and preparation method thereof

ActiveCN102465221AImprove seawater corrosion resistanceGood resistance to seawater corrosionRigid pipesDistillationMulti effect

The invention relates to an aluminum alloy tube resistant to seawater corrosion, in particular to an aluminum alloy tube with high seawater corrosion resistance. The aluminum alloy tube is manufactured from magnesium, aluminum and other raw materials through the steps of: melting, stirring, in-furnace modification treatment, impurity removal, fining treatment, online argon refining, purification treatment, casting, homogenization treatment, extrusion, cold drawing and the like. The aluminum alloy tube has the advantages of good seawater corrosion resistance and long service life, is particularly suitable for equipment for low-temperature multi-effect seawater distillation and seawater desalination treatment.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

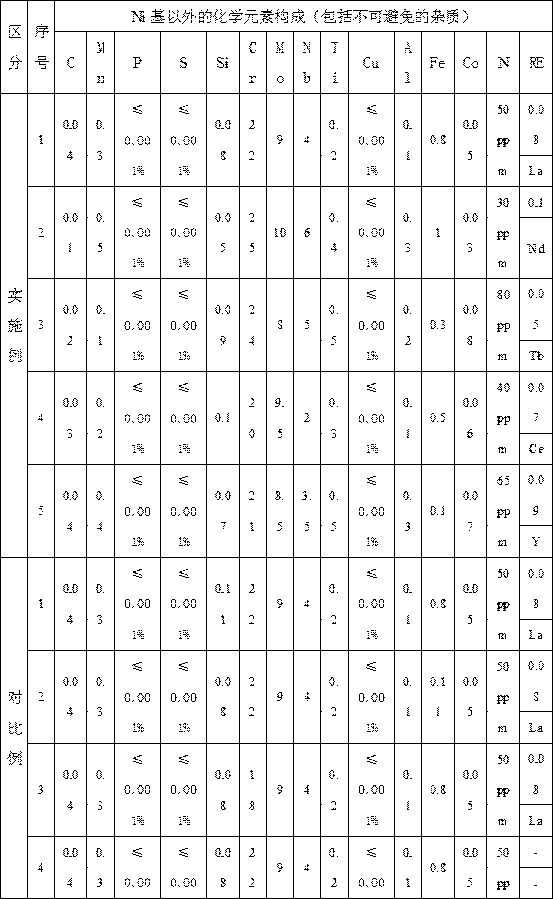

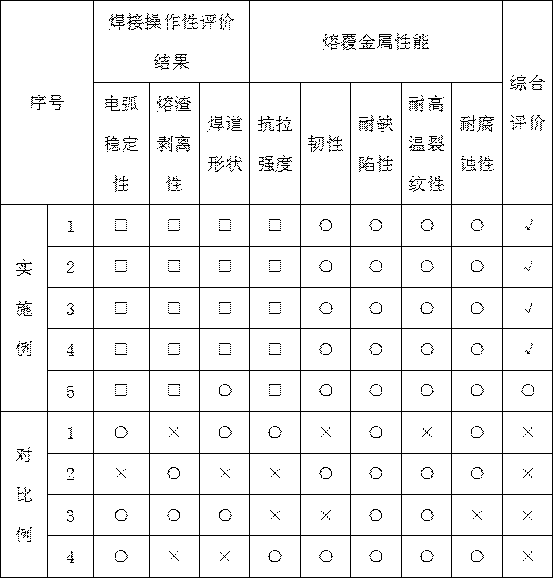

High-performance stainless steel surfacing nickel-based special welding wire and preparation method thereof

InactiveCN108406164AHigh tensile strengthImprove intergranular corrosion resistanceWelding/cutting media/materialsSoldering mediaRare-earth elementCrack resistance

The invention belongs to the field of welding materials and particularly relates to a high-performance stainless steel surfacing nickel-based special welding wire and a preparation method thereof. Thewelding wire comprises chemical elements including, by mass, not greater than 0.04% of C, 0.1-0.5% of Mn, not greater than 0.001% of P, not greater than 0.001% of S, 0.05-0.1% of Si, 20-25% of Cr, 8-12% of Mo, 2-6% of Nb, 0.2-0.5% of Ti, not greater than 0.001% of Cu, 0.1-0.3% of Al, not greater than 1% of Fe, 0.03-0.08% of Co, 0.05-0.1% of the rare earth element RE, 30-80 ppm of N and the balance Ni and inevitable impurity elements. The preparation method comprises the steps of (1) vacuum electric-furnace smelting; (2) VOD external refining; (3) horizontal continuous casting; (4) tandem rolling; and (5) tandem drawing. The welding wire provided by the invention has the good properties of active gas resistance and reducing acid medium corrosion resistance, the electric arc stability and slag stripping performance are excellent during welding, and welding metal with high strength, good tenacity, flaw resistance, high temperature cracking resistance and corrosion resistance is obtained;and the preparation technology is simple, the raw material and manufacturing cost is low, environmental friendliness is achieved, no pollution is generated, and the welding wire and the preparation method are suitable for industrial volume production and remarkable in economic benefit.

Owner:DANYANG HUALONG SUPERIOR STEEL

All-position niobium -contained stainless steel flux-cored wire

ActiveCN101690996AGood slag removalReduce splashWelding/cutting media/materialsSoldering mediaSlagNiobium

The invention belongs to the technical field of welding materials, which relates to an all-position niobium-contained stainless steel flux-cored wire. The flux-cored composition comprises the following components in percentage by weight: 2-10% of manganese, 8-15% of nickel, 20-35% of chromium, 2-9% of niobium-iron alloy in which the quantity of the niobium accounts for 70-80%, 20-45% of titanium dioxide, 2-6% of fluoride, 0.5-8% of magnesium oxide, 0.5-8% of silicon dioxide, 5-10% of titanium-iron alloy in which the percentage content of the titanium is 40-45%, 1-8% of Al2O3 and the balance iron powder. The flux-cored composition accounts for 16-30% of the total weight proportion of the flux-cored wire. The self-shielded flux-cored wire of the invention has excellent toughness and plasticity of weld metals, small splashing and good all-position welding performance, and obviously improves the slag removing performance and seam forming performance.

Owner:HEBEI YICHEN INDAL GROUP

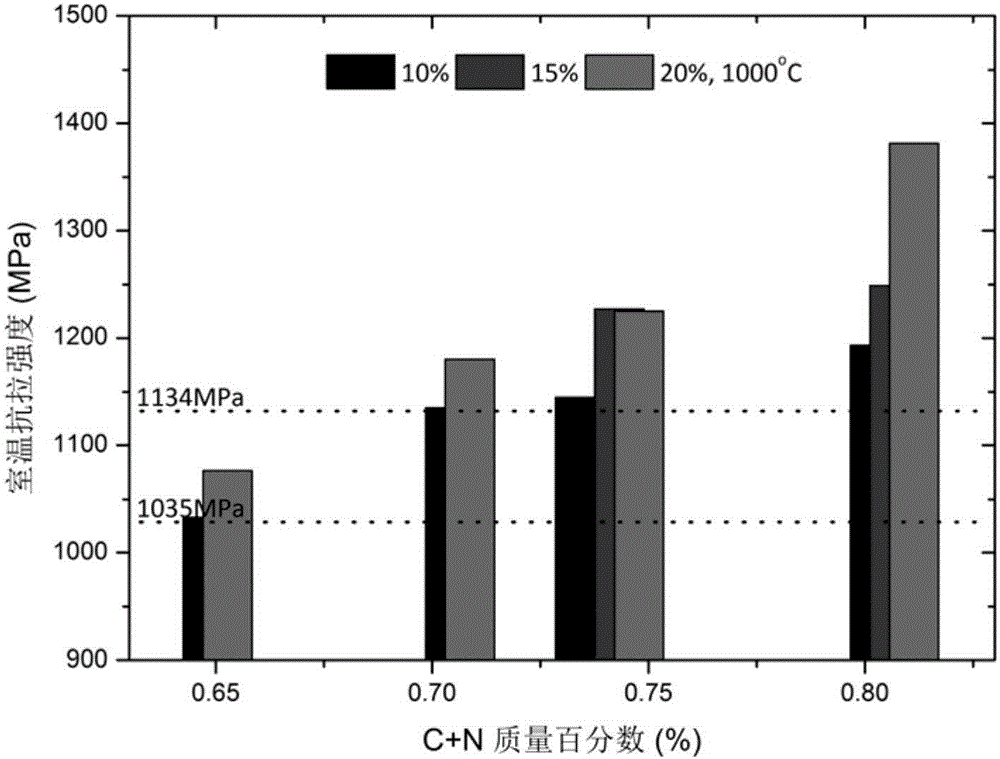

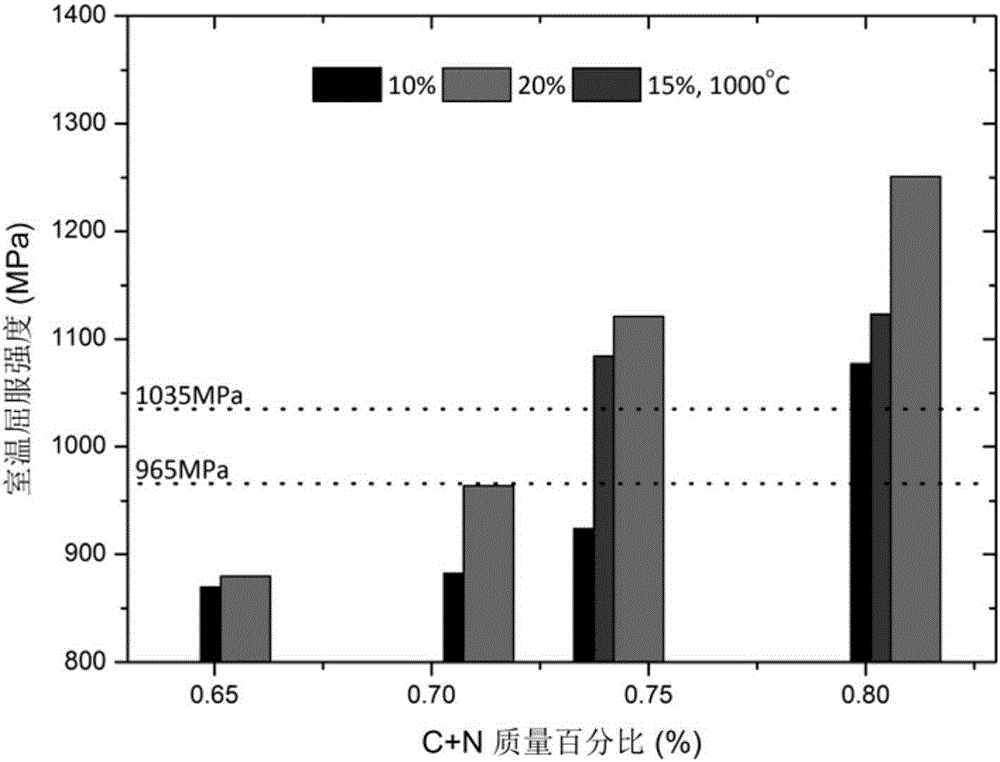

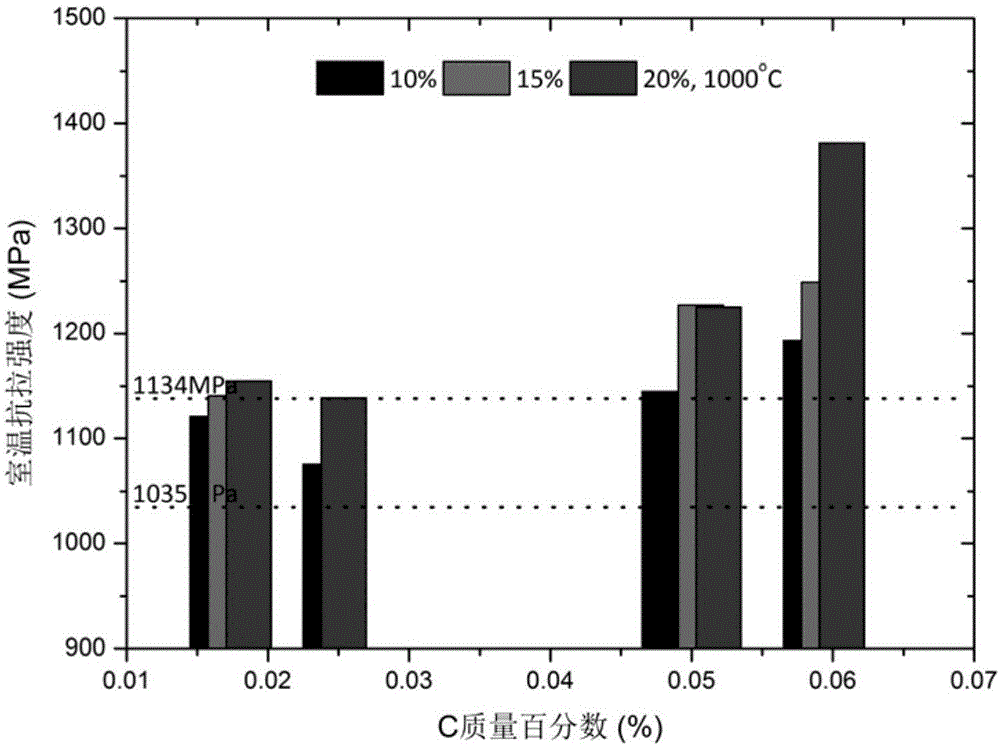

Novel high-nitrogen austenitic stainless steel for non-magnetic drill collar and manufacturing method of novel high-nitrogen austenitic stainless steel

ActiveCN106702290AAvoid the sensitive temperature range that is easy to generateImprove intergranular corrosion resistanceNon magneticWater cooling

The invention relates to novel high-nitrogen austenitic stainless steel for a non-magnetic drill collar and a manufacturing method of the novel high-nitrogen austenitic stainless steel, and belongs to the technical field of stainless steel materials. The stainless steel comprises, by weight, 22.15-23.50% of Cr, 0.56-0.68% of Mo, 0.047-0.060% of C, 0.70-0.81% of N, 0.95-2.14% of Ni, 16.20-16.94% of Mn, 0.17-0.24% of Si, 0.008-0.010% of P, 0.008-0.012% of S, and the balance Fe, wherein the C+N is greater than or equal to 0.747% but smaller than or equal to 0.836% by weight, and Cr+3.3*Mo+16.0*N is greater than or equal to 35.0% by weight. The manufacturing method comprises the steps of non-vacuum induction melting, argon oxygen decarburization external refining, cogging by a quick forging press, molding by a radial forging machine, and water-cooling treatment. The novel high-nitrogen austenitic stainless steel for the non-magnetic drill collar has the advantages of excellent indoor temperature strength and intercrystalline corrosion resistance.

Owner:CENT IRON & STEEL RES INST

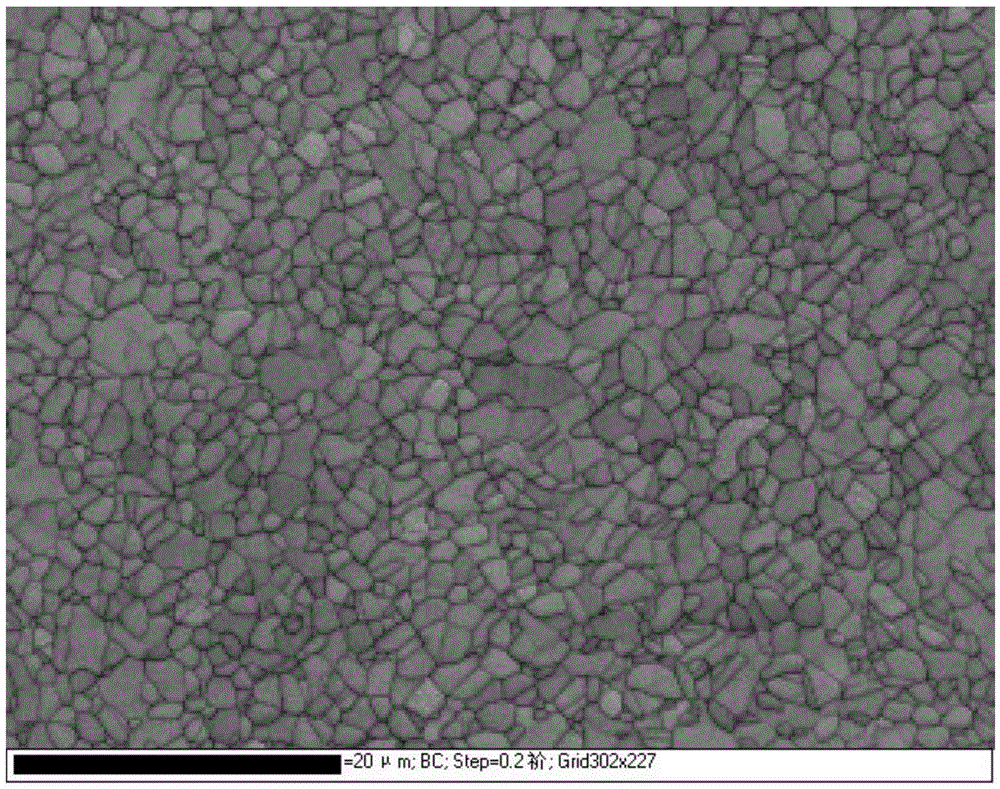

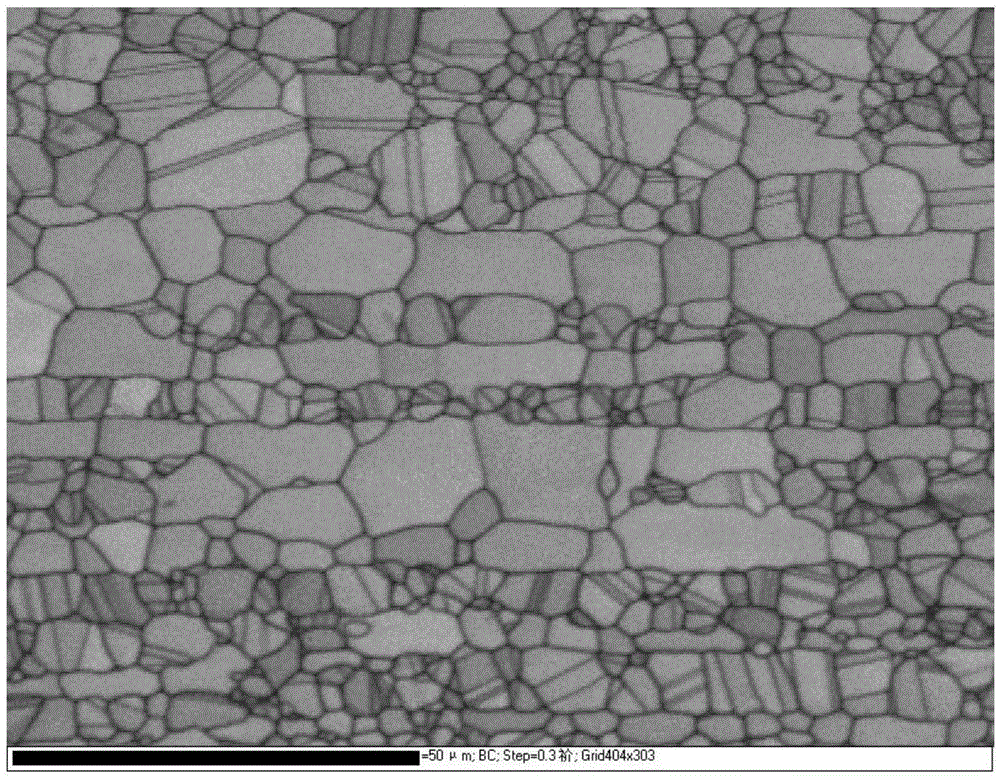

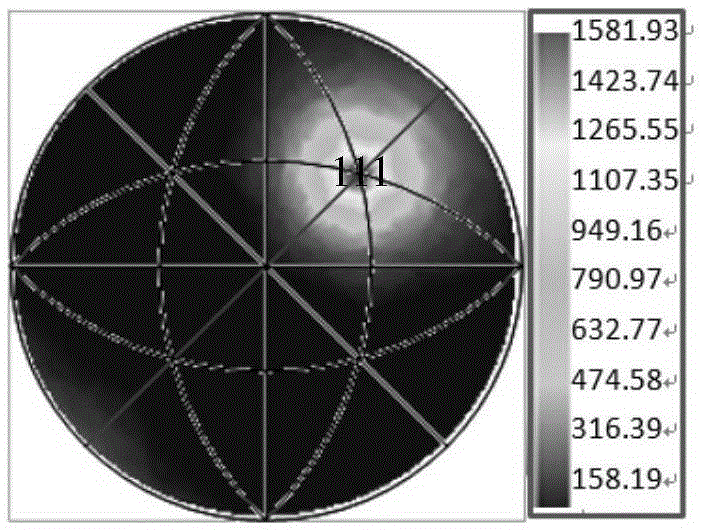

Dual-phase anti-corrosion stainless steel and corrosion resistance optimizing treatment process thereof

The invention discloses dual-phase anti-corrosion stainless steel and a corrosion resistance optimizing treatment process thereof and belongs to the technical field of metallurgy. The process is characterized in that an initial alloy solid solution process is clearly determined and then large-deformation cold rolling and annealing treatments for the stainless steel are performed. Low-angle grain boundary proportion of ferrites in the dual-phase stainless steel which is already subjected to optimizing treatment is increased obviously, low-angle grain boundaries are mostly located in the {111} position, twin boundaries inside austenite are {111} coherent twin boundaries, the proportion of phase boundaries satisfying a specific orientation relationship (K-S and N-W) is substantially increased, and the alloy intercrystalline corrosion resistance is improved through increase of the low-energy boundary density. On the basis of achieving alloy microstructure ultrafining (smaller than five micrometers), the corrosion resistance of the stainless steel is improved synchronously.

Owner:SHANDONG UNIV OF TECH

Active solder for welding ferritic stainless steel with fined grains and preparation method of active solder

ActiveCN103418938AHigh strengthHigh hardnessWelding/cutting media/materialsSoldering mediaWeld seamMechanical property

The invention belongs to the field of welding materials, and discloses an active solder for welding ferritic stainless steel with fined grains and a preparation method of the active solder. The active solder is formed by the following components of 8.77-9.77 mass percentage of Cr2O3, 5.27-6.27 mass percentage of TiO2, 6.53-7.53 mass percentage of SiO2, 49.33-53.33 mass percentage of CaF2, 14.60-16.60 mass percentage of NaF, 4.50-5.50 mass percentage of Ni, 4.50-5.50 mass percentage of TiFe and 0.80-1.20 mass percentage of Zr. By using the active solder disclosed by the invention, the fined grains at the welding seam of the ferritic stainless steel can be obviously fined, the mechanical properties of the welding seams can be improved, the intergranular corrosion-resistant capacity of the welding seams can be improved and the cost is low.

Owner:HUBEI HONGLU STEEL STRUCTURE

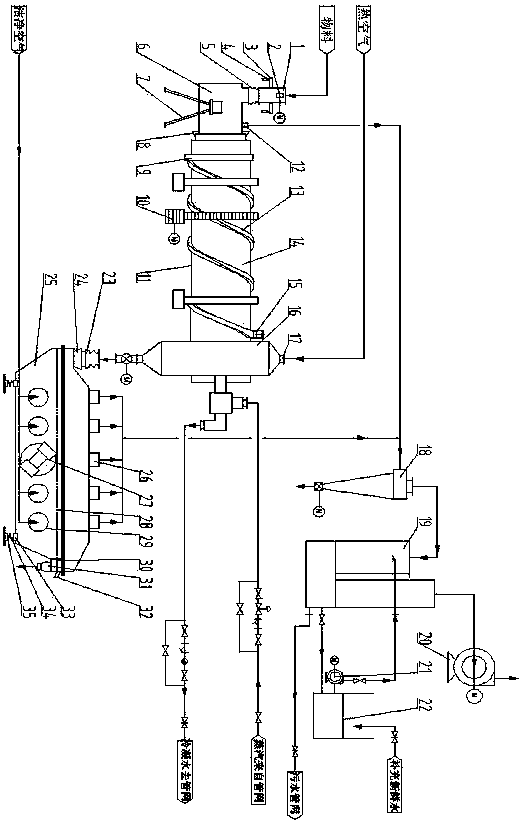

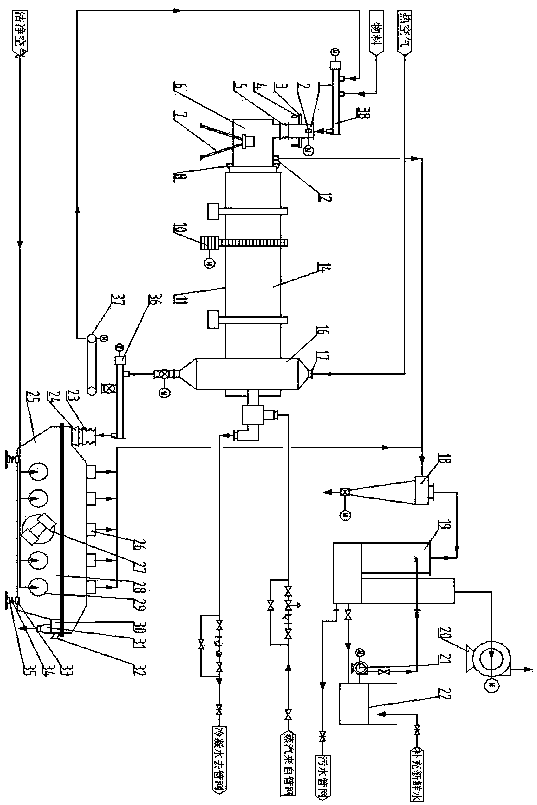

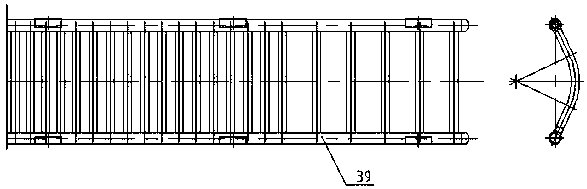

Steam rotary drying system for ammonium salt and method for preparing ammonium salt

PendingCN108592611APrevent moisture absorption and cakingExtended staySievingScreeningEnvironmental resistanceProcess engineering

The invention provides a steam rotary drying system for ammonium salt and a method for preparing the ammonium salt. The steam rotary drying system is used in an ammonium salt drying process for the first time, a novel energy-saving and environmental-friendly ammonium salt drying technology is proposed, and the ammonium salt steam rotary drying system with the less moisture, low product breakage rate, high thermal efficiency, low power consumption, stable operation and energy conservation and the method for preparing the ammonium salt are provided. The steam rotary drying system for the ammonium salt comprises a feeding device, a steam rotary dryer, a conveying device, a vibration conveying cooling sieving machine and a tail gas dedusting device. The steam rotary dryer comprises a feeding cover, a rotary cylinder, a discharge cover, a transmission device and multiple heat exchange tubes arranged in the rotary cylinder. The hot air inlet of the steam rotary dryer is in a countercurrent mode.

Owner:SHANDONG KEYUAN TIANLI ENERGY CONSERVATION ENG

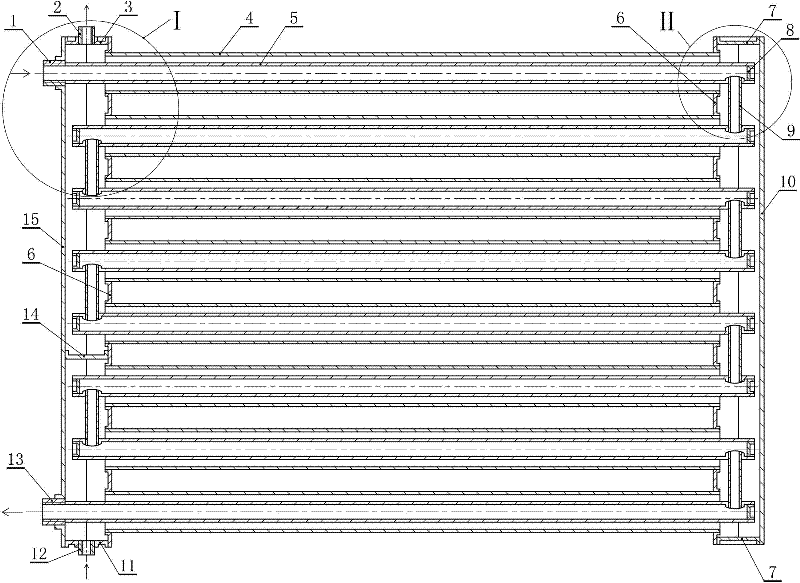

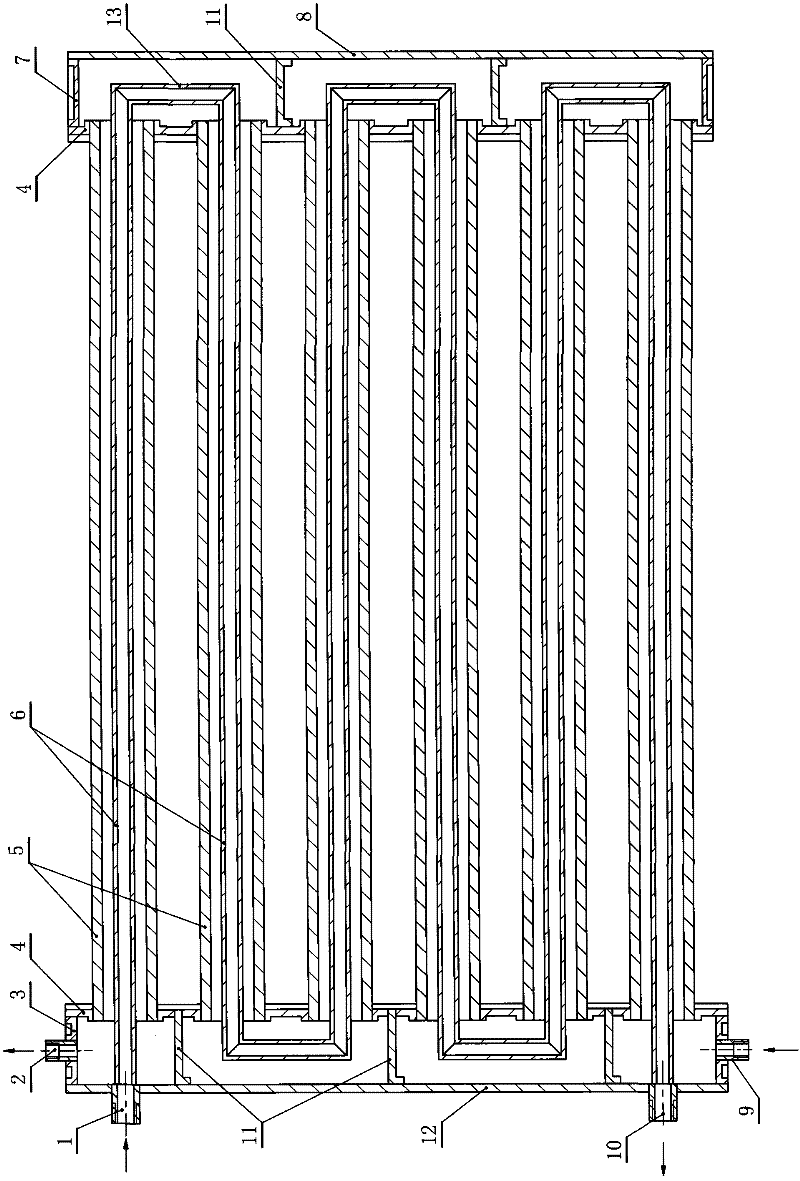

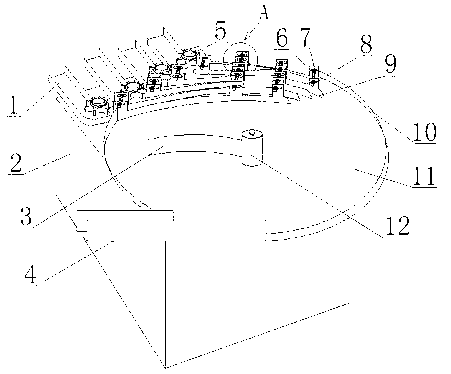

Circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and manufacturing process thereof

ActiveCN102418956ASolve the problem of water leakage under pressureReduce difficultySpace heating and ventilation detailsHeat exchanger casingsPlate heat exchangerWater leakage

The invention discloses a circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and a manufacturing process thereof. The heat exchanger comprises two headers, wherein a tap water communication pipe is fixedly connected between the two headers; a hot air heat supply pipe passes through the tap water communication pipe; each header is formed by welding two arc plates; the plate edges of the arc plates are flanged outwards; the plate edges of the two arc plates are aligned with each other and are subjected to edge-pinching and self-fluxing welding to form a circular tubular header cylinder body; head blocking plates of the headers are flanged outwards and are embedded at two ports of the circular tubular headers; and the two edges are aligned with a pipe wall surface, are spliced and are subjected to the edge-pinching and the self-fluxing welding to form the headers. An installation hole is punched on each arc plate; the installation hole is stretched inward an arc to form an edge; the aperture and the height of are stretched according to the arc plates; and the end surfaces of the two ends of the tap water communication pipe are subjected to R-angle cutting according to the stretching hole diameter and the stretching height of the arc plates, and then the tap water communication pipe is inserted into the installation holes stretched from the arc plates, are matched with each other, are spliced and are subjected to edge-pinching and self-fluxing welding connection. In the heat exchanger, welding seams are spliced, the edge-pinching welding is easy to realize, and water leakage is avoided; and the heat exchanger is good in pressure-bearing performance, and low in maintenance cost.

Owner:张伟

Super wear-resistant steel with hardness not smaller than 400 HBW and production method

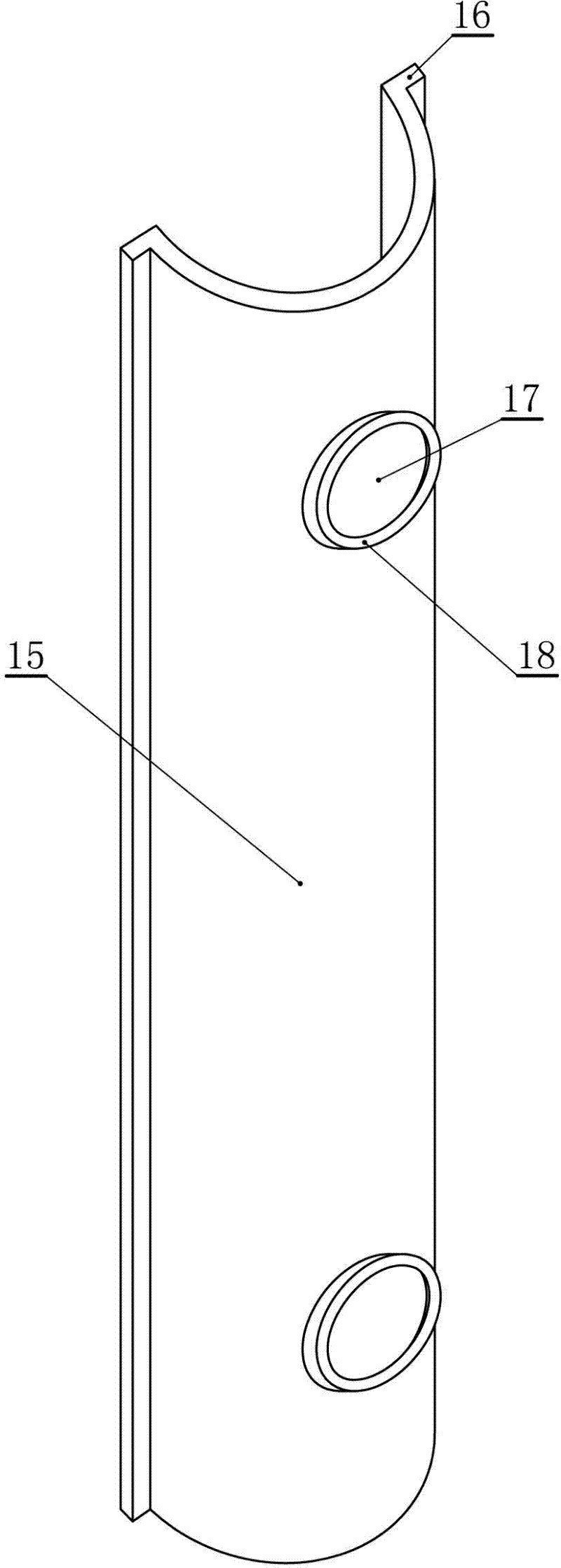

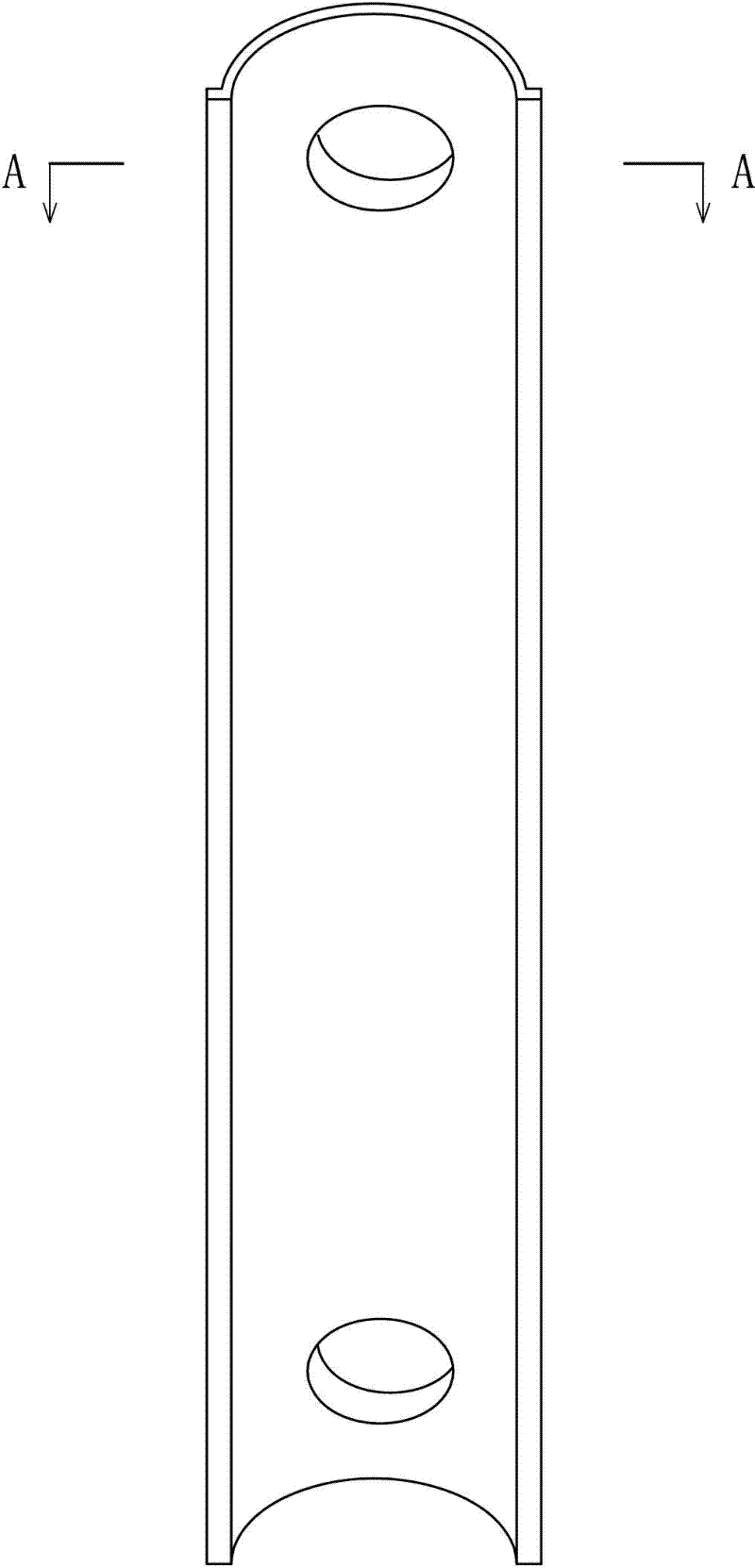

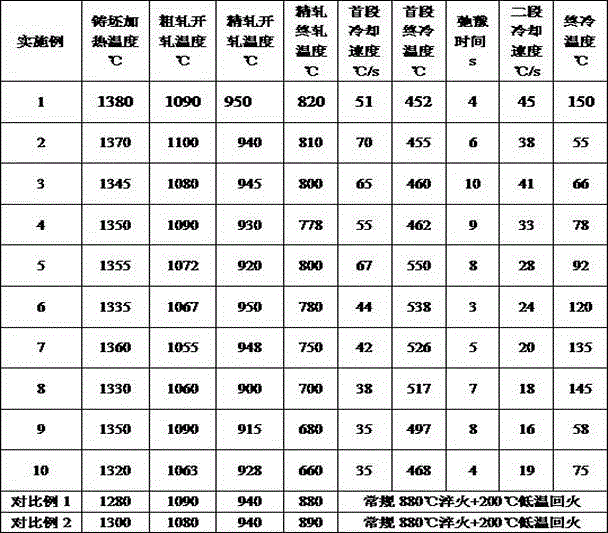

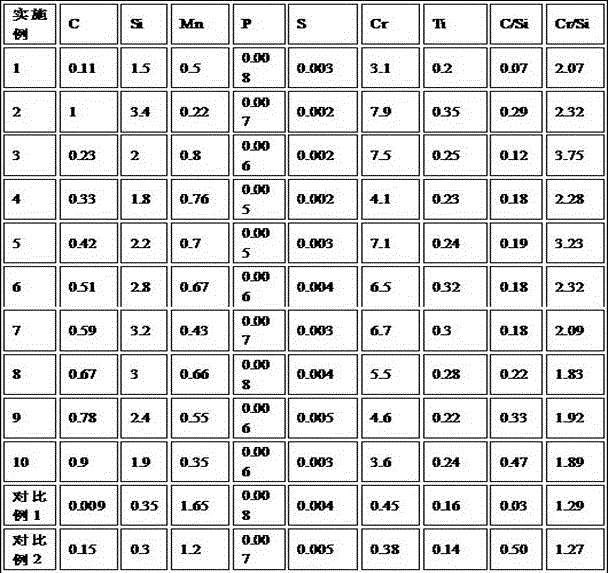

Super wear-resistant steel with hardness not smaller than 400 HBW is prepared from, by weight percent, 0.10%-1.00% of C, 1.5%-3.5% of Si, 0.2%-0.8% of Mn, 0.20%-0.35% of Ti and 3.0%-8.0% of Cr. According to the production steps, a casting blank is heated after being formed through conventional smelting and pouring; double-pass high-pressure descaling is conducted till the surface is clean; hot rolling is conducted, and single-piece rolling is adopted; two-segment type cooling is adopted; and pit cooling is conducted till the room temperature. According to the super wear-resistant steel, by obtaining the metallographic structure of tempered martensite and ferrite, the brinell hardness can be larger than 400 HBW; and the corrosion rate does not exceed 0.04 mm / a under seawater soaking.

Owner:武汉钢铁有限公司

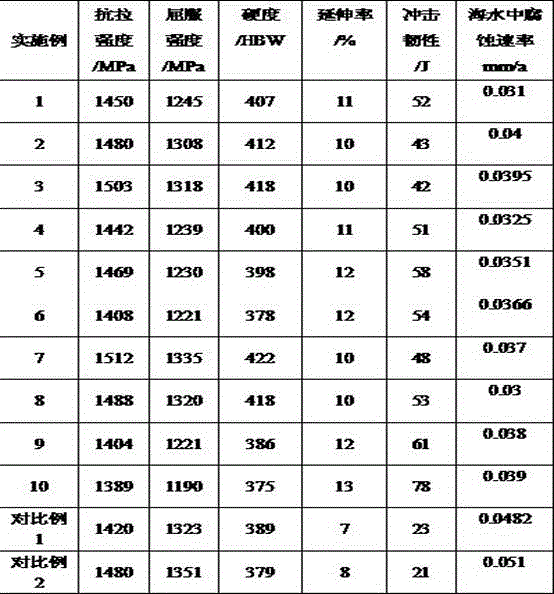

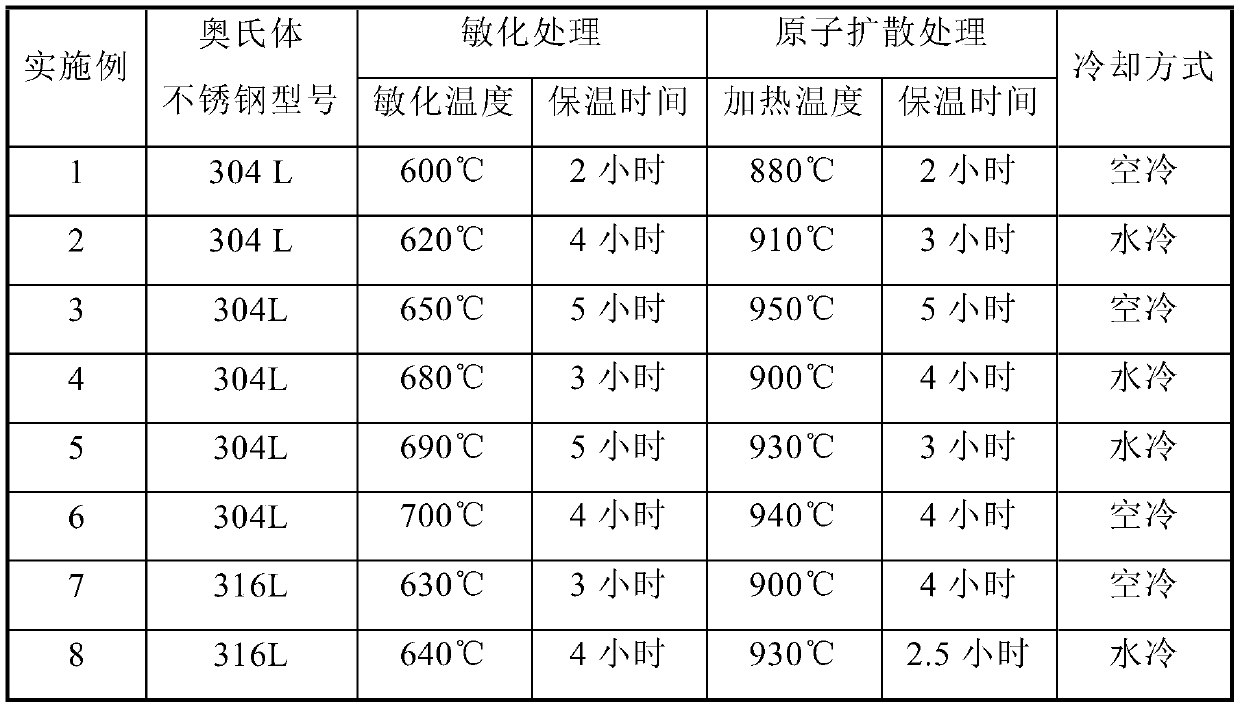

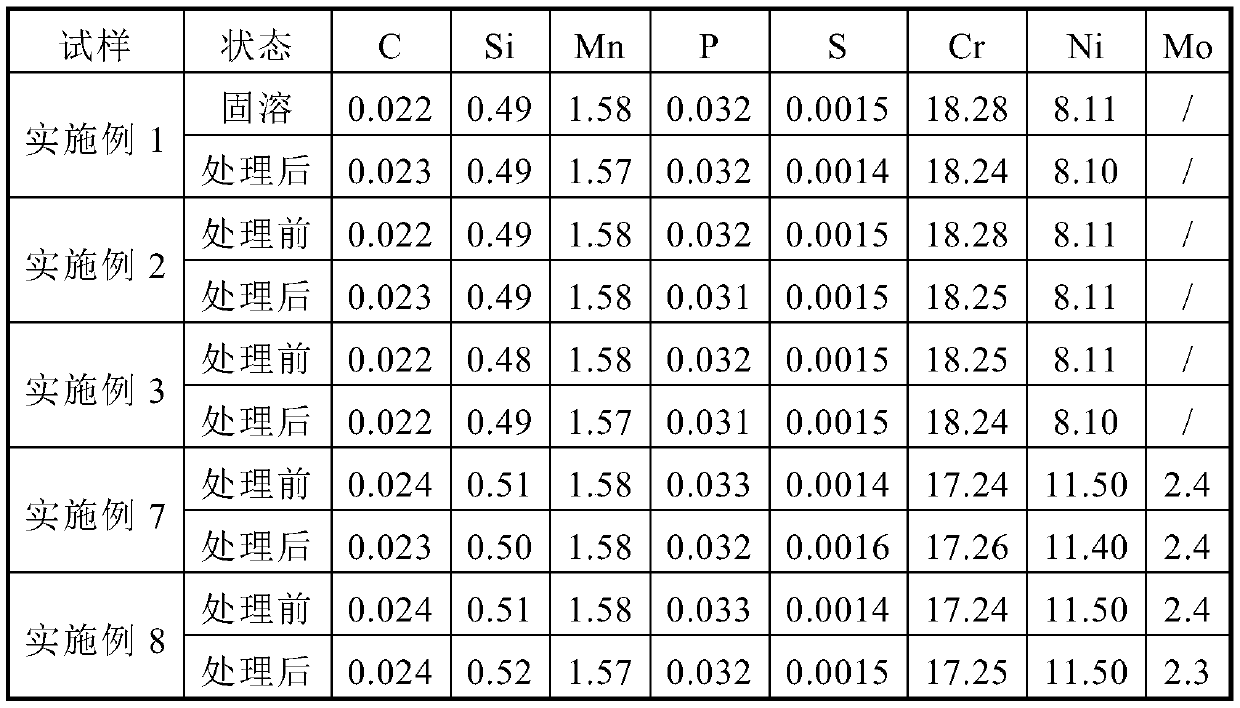

Method for improving intergranular corrosion resistance capacity of austenitic stainless steel

The invention provides a method for improving the intergranular corrosion resistance capacity of austenitic stainless steel. The method comprises the following steps that sensitization treatment is carried out, specifically, heating treatment and sensitization treatment are carried out on the austenitic stainless steel, so that chromium carbide is separated out between crystal particles, and the sensitized stainless steel is obtained; the sensitized stainless steel is continuously heated to 880 DEG C-950 DEG C through atomic diffusion treatment, and the stainless steel is subjected to heat preservation; and then the stainless steel is cooled to the room temperature. According to the method, the chromium carbide is separated out between the crystal particles of the austenitic stainless steel through sensitization treatment firstly, so that the content of chromium between the crystal particles is low; then chromium atoms in the austenitic stainless steel crystal particles are diffused tothe crystal boundary through atomic diffusion treatment, so that the intergranular barren chromium phenomenon is eliminated, and the intergranular corrosion resistance is achieved in a stable state;and the method has the advantages that the heating temperature is low, the fuel consumption is low, the thermal forming process does not need to avoid a sensitization region, the equipment requirementis low, normalizing treatment can be carried out with a carbon steel material at the same time, the cost is low, and chemical components of an austenitic stainless steel material do not need to be changed.

Owner:HENAN SHENZHOU PRECISION MFG CO LTD

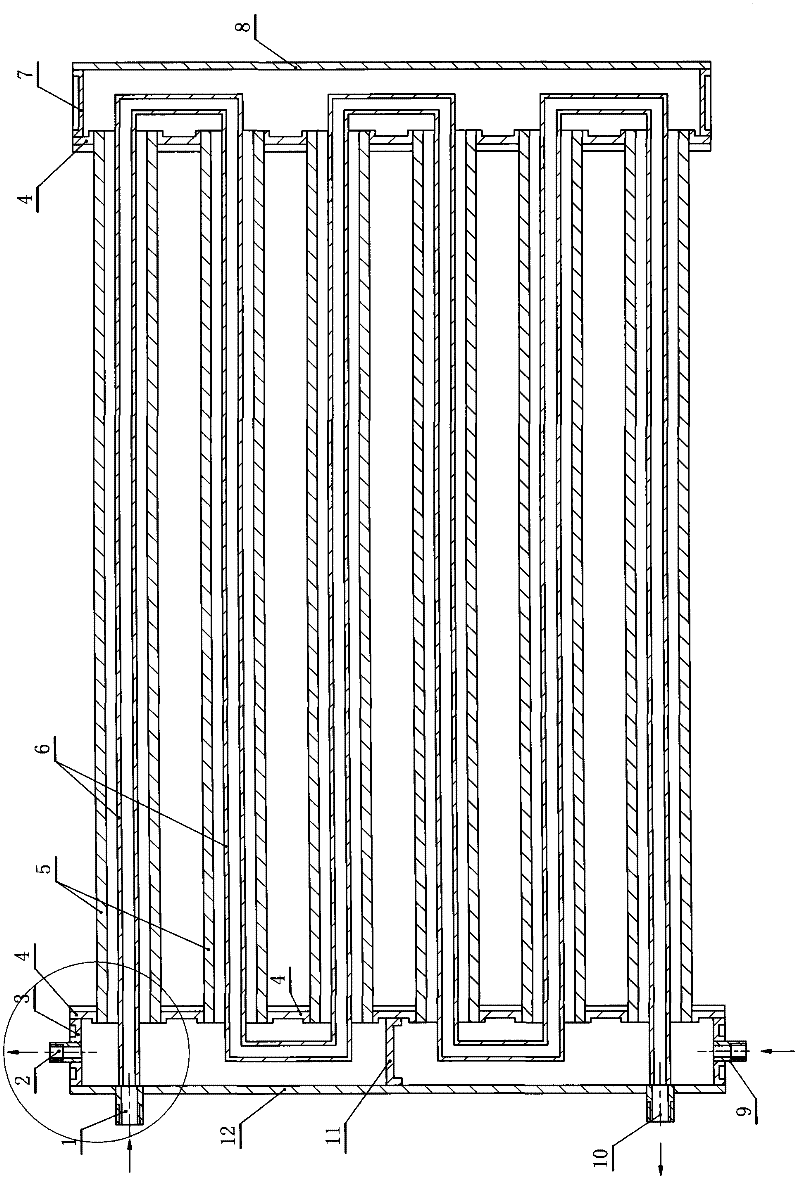

Header pressure heat exchanger

InactiveCN102297613ASolve the bend angleReduce bend angleSpace heating and ventilation detailsStationary conduit assembliesGusset plateEngineering

The utility model relates to a pressure-bearing header heat exchanger, which utilizes heating water for heat exchange to obtain hot tap water. Including: two headers, the header includes header shell, orifice plate and cover plate. Two or more tap water heat-absorbing pipes are fixedly connected between the two headers. The tap water heat-absorbing pipes are pierced with heating pipes. The heating pipes are connected. One end of the heating pipes is connected to the The heating water inlet is connected to the heating water outlet at the other end; one or more water blocking plates are arranged in one of the headers, and one or more water blocking plates are arranged in the other header. There are flanges around the water blocking plate, one side is welded on the orifice plate, and the other side is stuck or welded on the header shell. There are flanges around the cover plate, and the edges on both sides of the orifice plate are folded outwards, and the outwards folded edges on both sides of the orifice plate are welded and connected with the edge of the header shell plate. In the invention, the welded seam of the joint of the tube plate of the header shell is under pressure, the weld seam does not leak water, and the countercurrent heat exchange can also be realized.

Owner:张伟

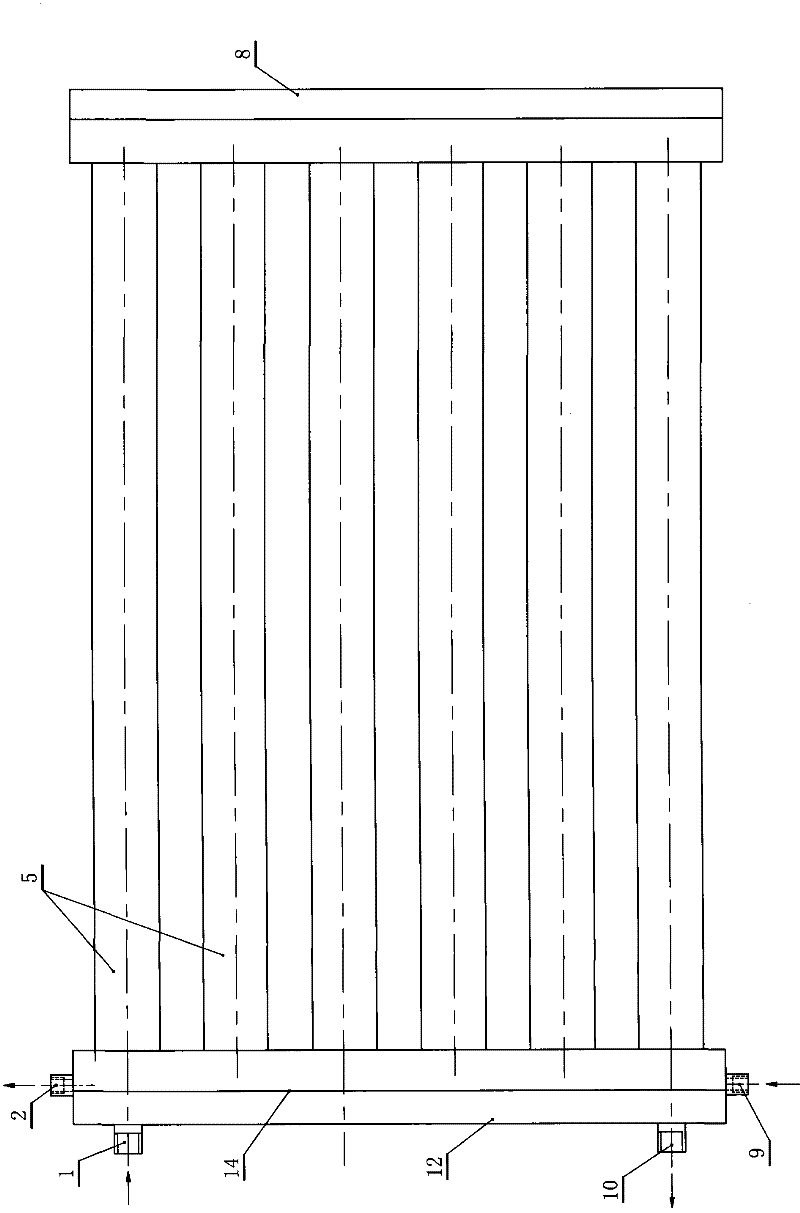

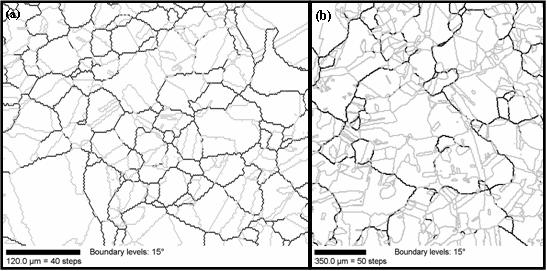

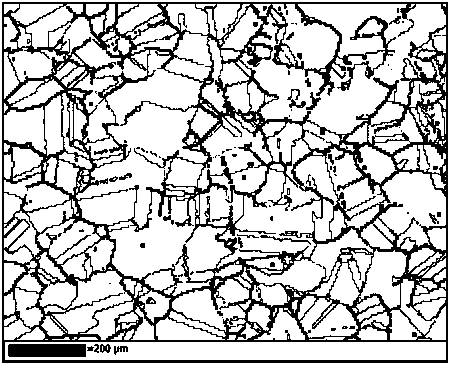

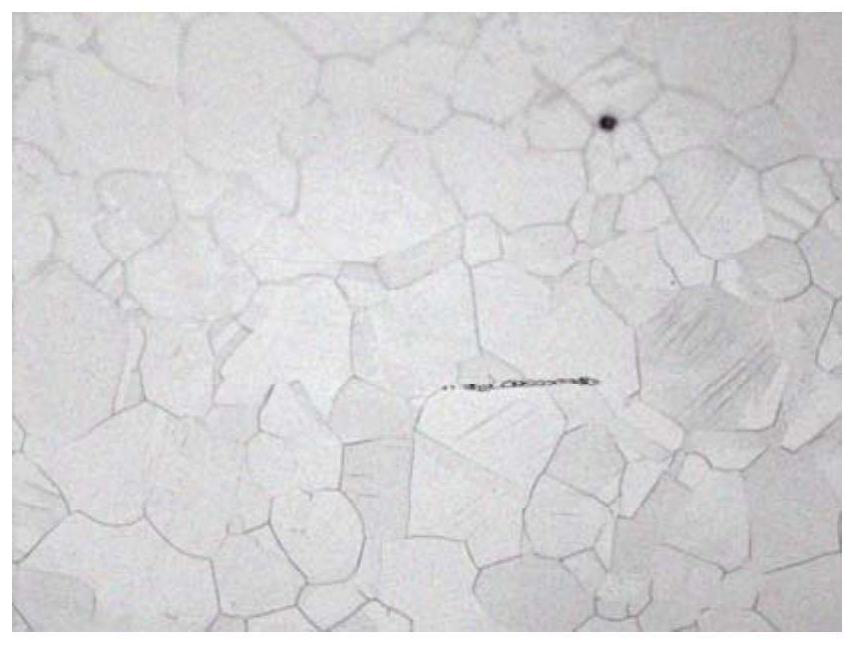

Method for controlling grain boundary characteristics of austenitic stainless steel

InactiveCN102031344AImprove intergranular corrosion resistanceAccelerated corrosionErbium lasersAustenitic stainless steel

The invention relates to a method for controlling grain boundary characteristics of austenitic stainless steel. The method comprises the following steps of: pre-processing the austenitic stainless steel, cutting the austenitic stainless steel into square blocks of the size of 40*40mm, and polishing the blocks with sand paper gradually to obtain No.800; then placing the pre-processed material on a laser processing workbench, regulating the output power, pulse width, light spot size and overlap ratio of a laser device, and carrying out laser impact processing on the surface of the material; and finally placing the material processed by laser impact in a heat treatment furnace, taking the material out of the furnace after warm preservation for water quenching so as to realize the control over the grain boundary characteristics of the austenitic stainless steel. The method can increase the intergranular corrosion resistance of the austenitic stainless steel, and can perform in-situ repair on an austenitic stainless steel member.

Owner:NANJING UNIV OF SCI & TECH

Repair welding method of austenite stainless steel casted nuclear pump shell

InactiveCN106808058APrevention of stomataInhibition of segregationArc welding apparatusEngineeringWelding defect

The invention provides a repair welding method of an austenite stainless steel casted nuclear pump shell. The repair welding method comprises the specific steps of defect detection and treatment; welding slot treatment; welding rod treatment: baking a welding rod at the temperature of 150 DEG C, and keeping the temperature for standby application; preheating of a to-be-welded zone; repair welding of the to-be-welded zone: carrying out repair welding layer by layer and pass by pass; confirmation of the repair welding effect: carrying out flaw detection on a repair welding zone of a pump body through rays, confirming the repair welding effect, and guaranteeing that the repair welding zone does not have weld defects; and solution treatment: carrying out solution treatment on workpieces subjected to repair welding. According to the repair welding method, samples do not have relatively large welding deformation through adoption of symmetrical arc-shaped welding slots, pre-welding preheating and postwelding thermal treatment; stress after repair welding is reasonably distributed through requirements on shape and radian of the welding slots and pre-welding thermal treatment; the content of impurity elements can be controlled and weld joints do not have obvious defects through surface roughness control and cleaning for the welding slots, and baking treatment for the welding rod; and intergranular corrosion resistance of austenite of the repair welding zone of a nuclear pump can be improved through postwelding solution treatment for a corresponding zone of the nuclear pump body.

Owner:DALIAN UNIV OF TECH

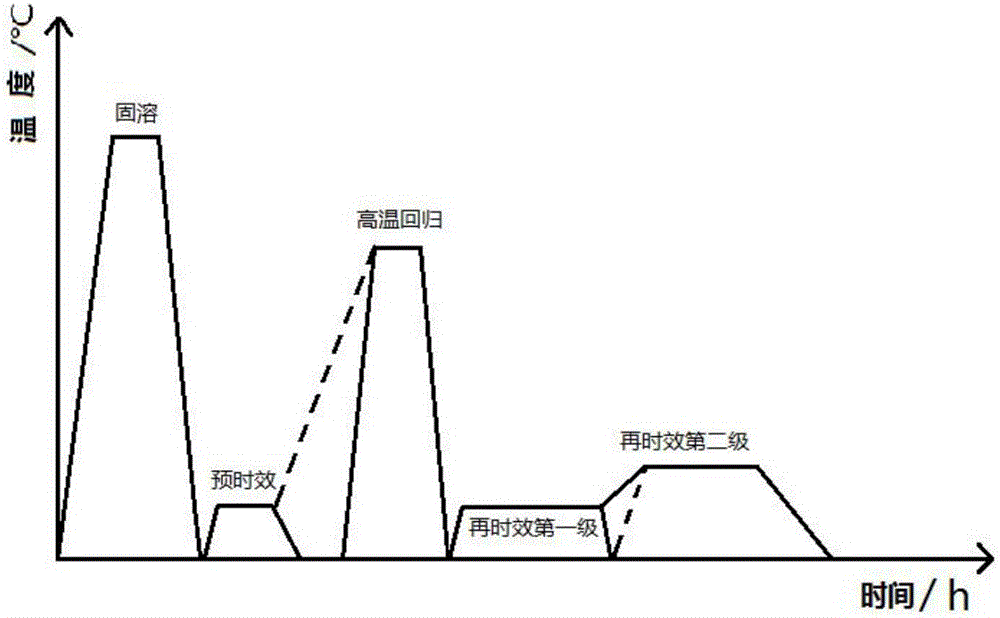

Aging heat treatment method for Al-Mg-Zn alloy

ActiveCN106148865AImprove microstructureImprove corrosion resistanceHigh intensityCorrosion resistant alloy

The invention discloses a retrogression re-aging heat treatment technique suitable for Al-Mg-Zn alloy. The retrogression re-aging heat treatment technique suitable for the Al-Mg-Zn alloy comprises the steps that according to a pre-aging rule, heat preservation is conducted at the temperature of 80-220 DEG C for 15-50 h for one-stage or two-stage aging treatment, and cooling is conducted till the room temperature is reached, or furnace heating is conducted for retrogression aging; according to a retrogression aging rule, heat preservation is conducted at the temperature of 380-460 DEG C for 10 min-6 h, cooling is conducted till the room temperature is reached, and re-aging is conducted immediately; and re-aging is achieved through two sub-steps, heat preservation is conducted on the alloy at the temperature of 50-100 DEG C for 10-80 h in the first sub-step, heat preservation is conducted on the alloy at the temperature of 110-180 DEG C for 10-50 h in the second sub-step, and the alloy is cooled to the room temperature. According to the retrogression re-aging heat treatment technique suitable for the Al-Mg-Zn alloy, through the heat treatment way including pre-aging, high-temperature short-time retrogression and re-aging, the microstructure of the Al-Mg-Zn alloy can be obviously improved, a dispersing T-Mg32(AlZn)49 phase can be evenly separated out from the crystal of the alloy, the T-Mg32(AlZn)49 phase on the crystal boundary is distributed in an interrupted mode, and thus high strength is maintained; meanwhile, the intercrystalline corrosion resistance of the alloy is greatly improved, and the retrogression re-aging heat treatment technique has important reference value for developing novel high-strength and corrosion-resistant alloy for ships and armors.

Owner:UNIV OF SCI & TECH BEIJING

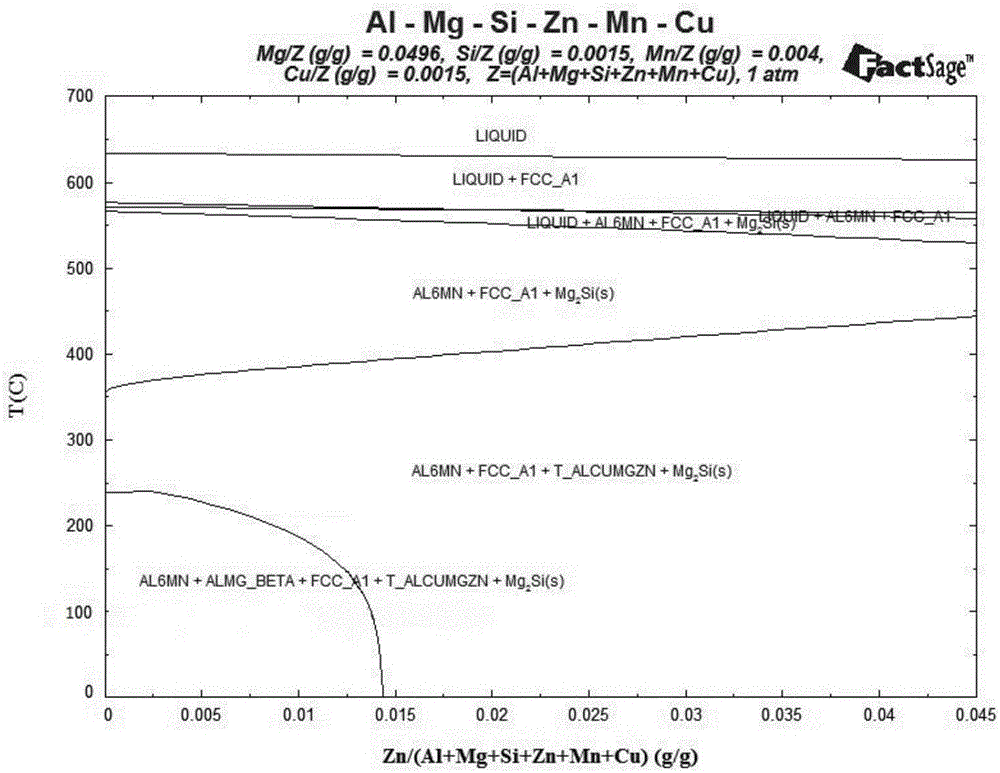

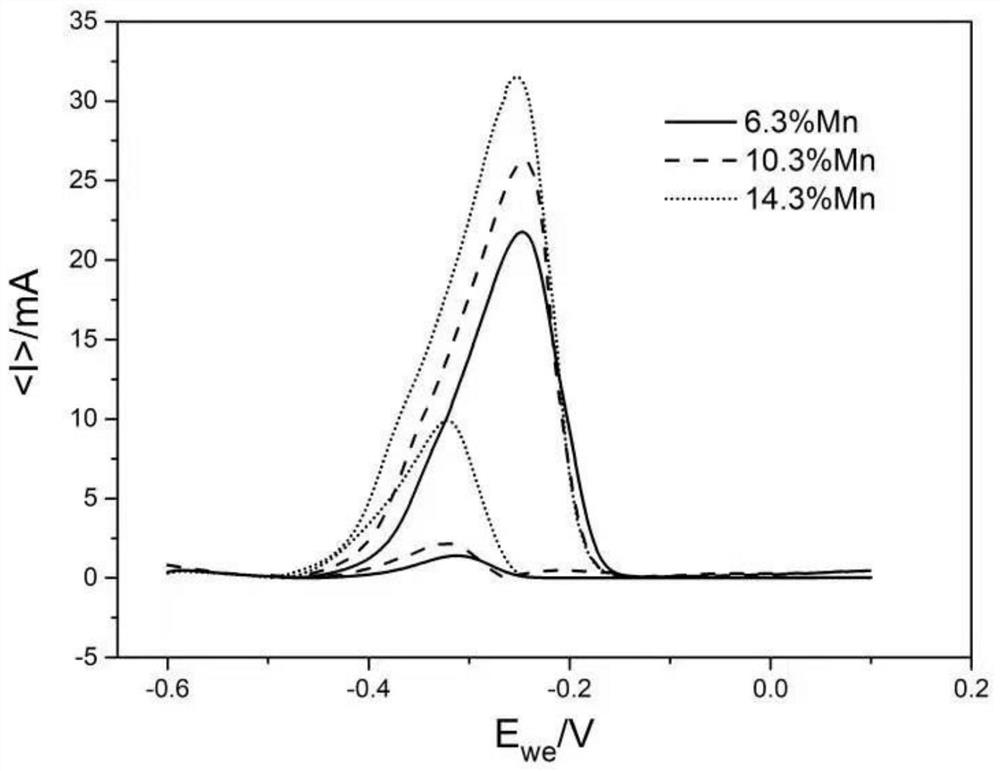

Intergranular corrosion resistant Ni-saving type duplex stainless steel and preparation method thereof

PendingCN113355594AImprove intergranular corrosion resistanceFurnace typesHeat treatment furnacesManganeseSS - Stainless steel

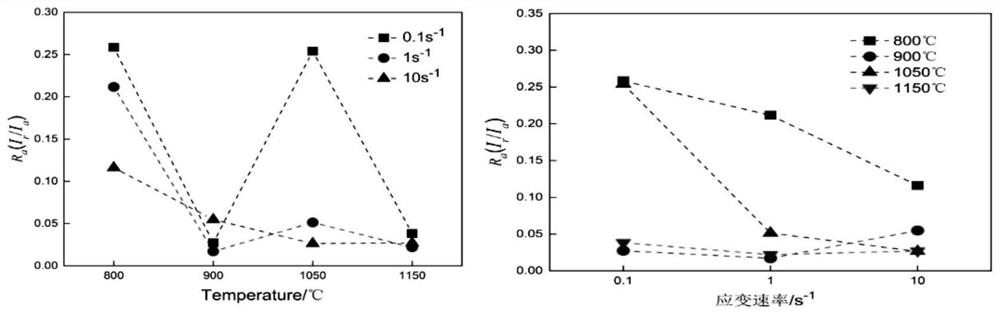

The invention provides intergranular corrosion resistant Ni-saving type duplex stainless steel. The intergranular corrosion resistant Ni-saving type duplex stainless steel is prepared from the following chemical components in percentage by mass: 0.034 to 0.04 percent of C, 0.20 to 0.26 percent of Si, 5.9 to 14.6 percent of Mn, 22.30 to 23.69 percent of Cr, 2.12 to 2.40 percent of Ni, 1.20 to 1.41 percent of Mo, 0.10 to 0.14 percent of Cu, 0.26 to 0.28 percent of N, less than or equal to 0.008 percent of P, less than or equal to 0.006 percent of S and the balance of Fe and inevitable impurities. The invention further provides a preparation method of the intergranular corrosion resistant Ni-saving type duplex stainless steel, experimental steel is obtained through vacuum smelting and hot compression experiments, and the intergranular corrosion sensitivity of 23% Cr Ni-saving type duplex stainless steel solid solution state and hot compression samples with different Mn contents is tested through a double-ring potentiodynamic reactivation (DL-EPR). The relationship between the manganese content and the strain rate and the deformation temperature is regulated and controlled, the change trend of the corresponding intergranular corrosion sensitivity is analyzed, the influence rule of the deformation temperature, the strain rate and the Mn content change on the intergranular corrosion sensitivity is analyzed, and then the duplex stainless steel with good intergranular corrosion resistance under the condition of different Mn contents is obtained.

Owner:KUNMING UNIV OF SCI & TECH

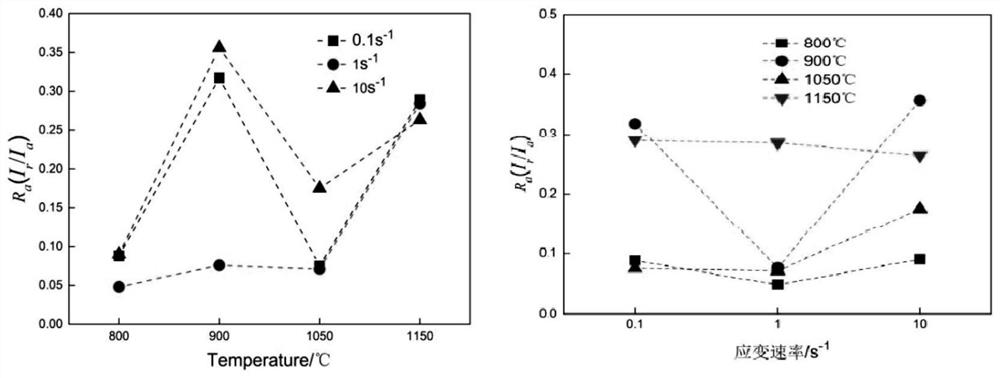

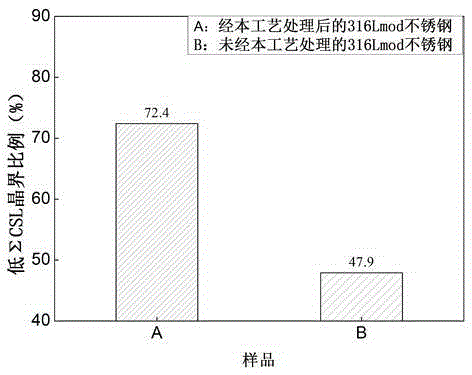

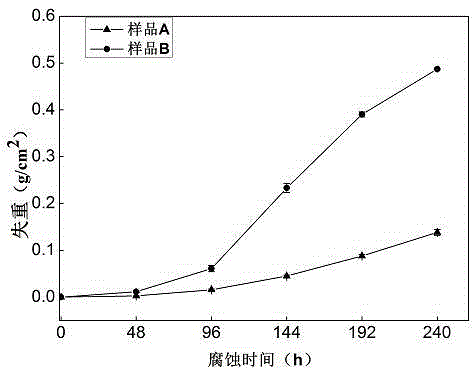

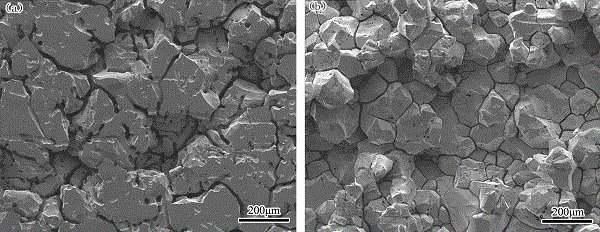

Grain boundary engineering technique for improving corrosion resistance of 316Lmod stainless steel

InactiveCN105420472AImprove intergranular corrosion resistanceImprove fatigue resistanceCorrosion resistantMetallic materials

The invention discloses a grain boundary engineering technique for improving the corrosion resistance of 316Lmod stainless steel. The grain boundary engineering technique for improving the corrosion resistance of the 316Lmod stainless steel comprises the steps that heat preservation is conducted on the 316Lmod stainless steel at the temperature of 1050-1150 DEG C for 5-60 min; machining deformation with the deformation quantity being 3%-15% is conducted at the indoor temperature after water cooling; then annealing is conducted at the temperature of 1020-1150 DEG C for 3-12 min; and finally, the 316Lmod stainless steel with high corrosion resistance can be obtained after water cooling. According to the grain boundary engineering technique for improving the corrosion resistance of the 316Lmod stainless steel, the low sigma CSL grain boundary of the 316Lmod stainless steel can be improved remarkably; the components of materials do not need to be changed, and compared with an existing similar technique, long-time annealing is not needed, repeated machining and repeated annealing are not needed either, the technique is simpler, and operation is easy; the technique can also be referred and used for other several low-stacking fault energy face-centered cubic metal materials, cost control in industrial production is facilitated, popularization is easy, and extremely remarkable economic benefits are achieved.

Owner:SHANGHAI UNIV

Method for performing surface treatment on golf head by forming carbon, nitrogen, titanium, chromium composite coating

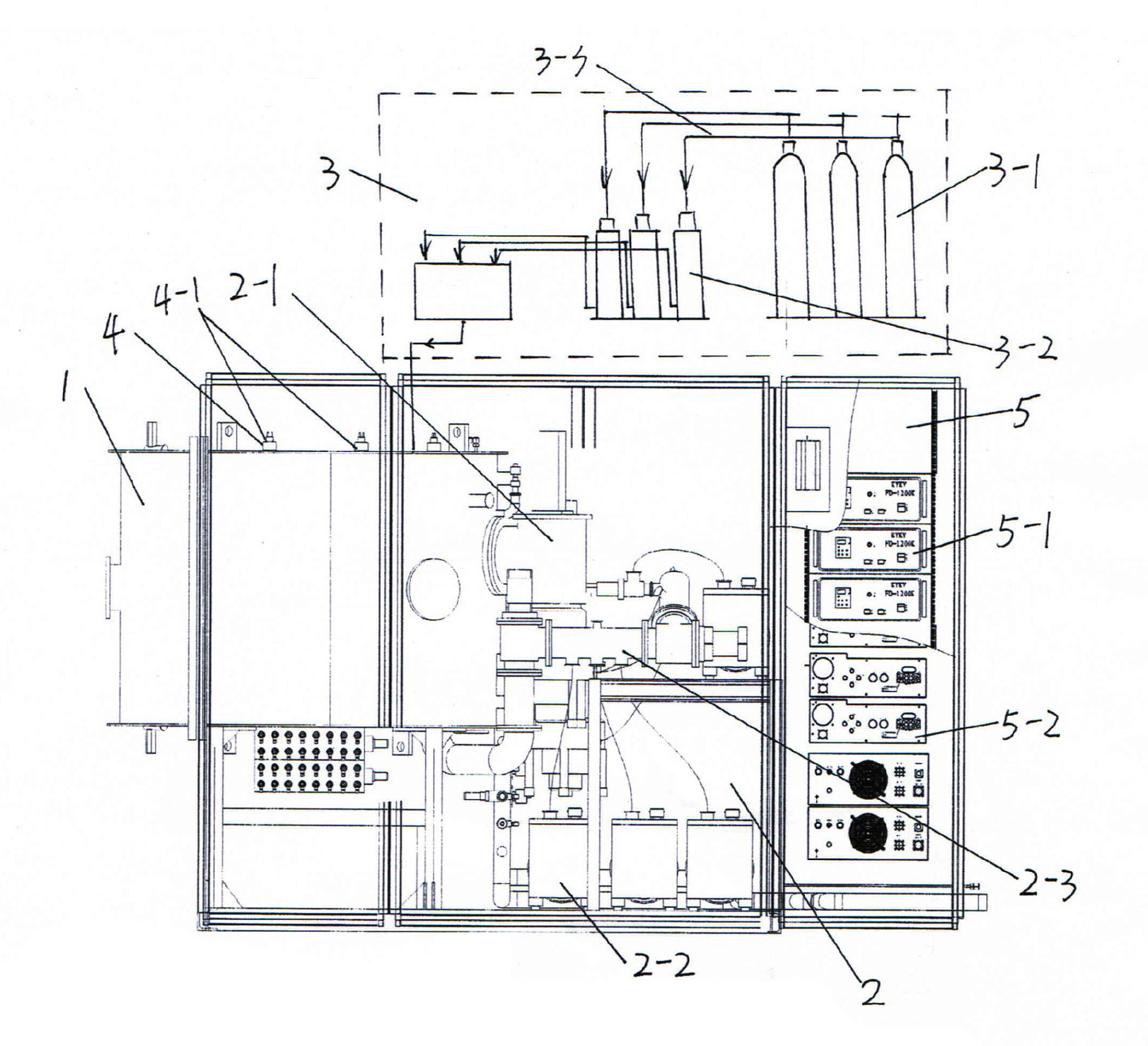

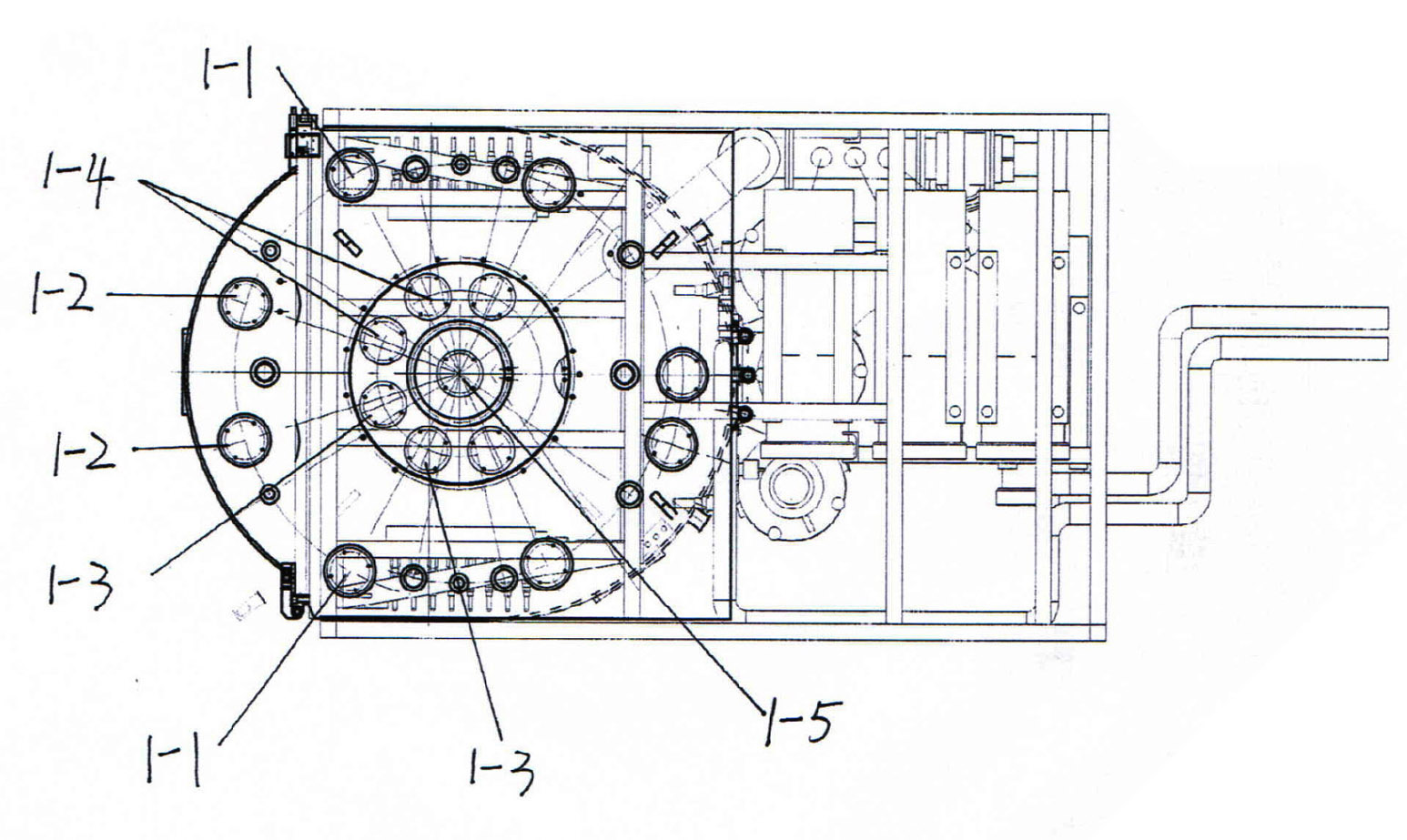

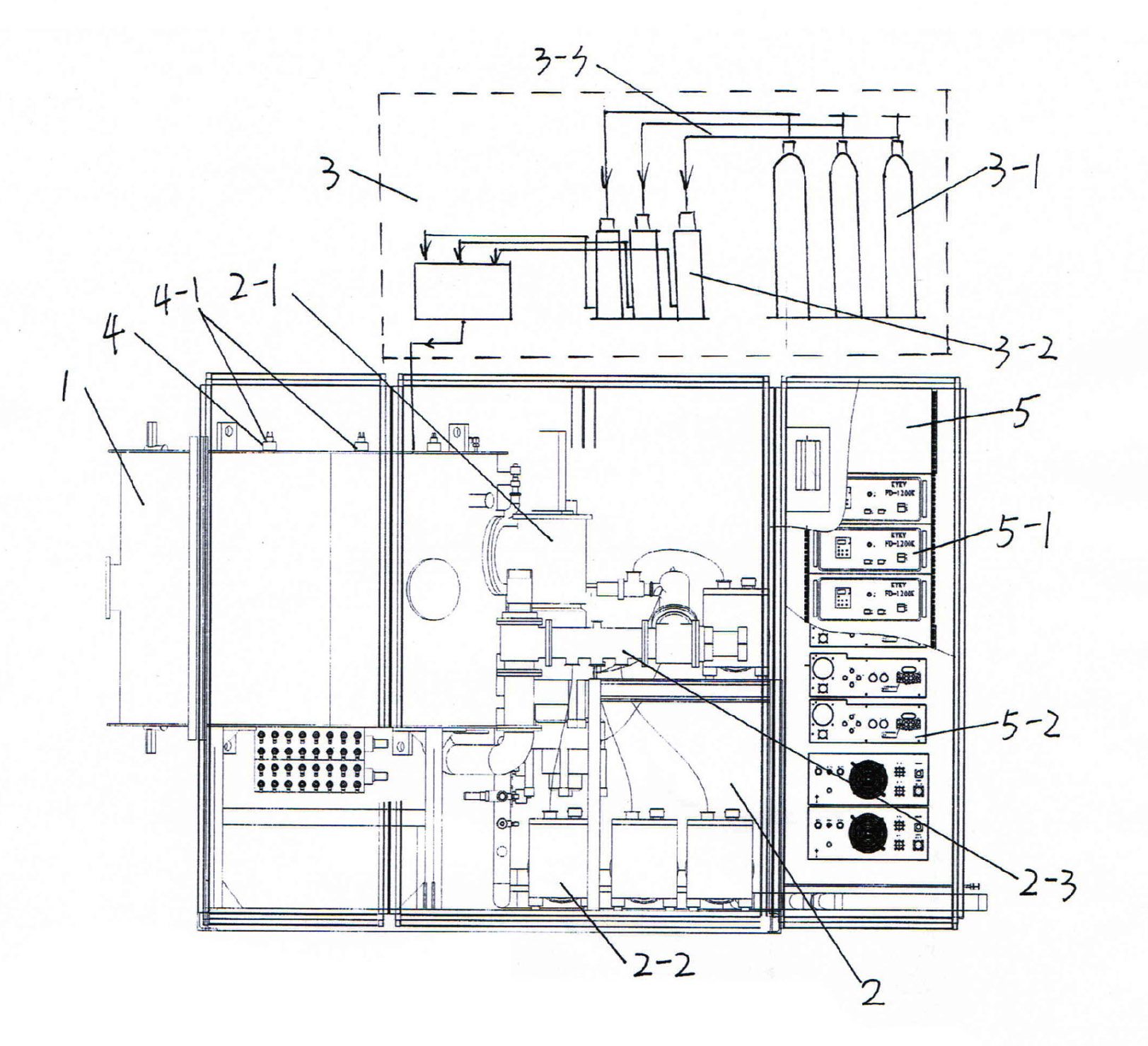

ActiveCN102031483AReduce coefficient of frictionMeet quality requirementsVacuum evaporation coatingSputtering coatingGas phaseGolf Ball

The invention discloses a method for performing surface treatment on a golf head by forming a carbon, nitrogen, titanium and chromium composite coating. Under the vacuum condition, the pure metal such as titanium and chromium, and graphite are gasified and argon, nitrogen and acetylene gas are introduced so as to form plasma, and the carbon, nitrogen, titanium and chromium composite coating is formed on the surface of the golf head by a physical vapor deposition method according to an alloying principle. The golf head treated by the method has a pearlescent glossy black appearance, and high solvent resistance, corrosion resistance, impact resistance and metal adhesion firmness. Simultaneously, the coating has high comprehensive mechanical property, and certain hardness and toughness and completely meets the surface quality requirement of the golf head.

Owner:范文波

Method for optimizing grain boundary characteristic distribution of 316L austenitic stainless steel

InactiveCN108193036AImprove intergranular corrosion resistanceShape is unlimitedQuenchingCharacteristic distribution

Provided is a method for optimizing grain boundary characteristic distribution of 316L austenitic stainless steel. The method includes the following steps that (1), the shape of a 316L stainless steelmember is adjusted, the upper and lower sides of the member need to be repaired to be flat and symmetrical; (2), the member is placed in a resistance furnace with the temperature being 1050-1150 DEGC for heat preservation for 60-90 minutes, and then material is taken out and subjected to water quenching; (3), the member is subjected to unidirectional compression deformation at room temperature,the deformation rate is 0.1-10 s<1>, and the deformation amount is 3%-6%; and (4), the deformed member is subjected to subsequent annealing treatment, the annealing temperature is controlled to 1080-1150 DEG C, and the annealing time is 90-110 min, and after the annealing is completed, the member is taken out and subjected to the water quenching. The optimized 316L austenitic stainless steel has alow [sigma] coincidence site lattice grain boundary ratio more than 80%, and the increase amplitude is significant; and multiple low [sigma] coincidence site lattice grain boundary clusters are formed, and the intergranular corrosion resistance performance of the material is significantly improved.

Owner:NANCHANG UNIV

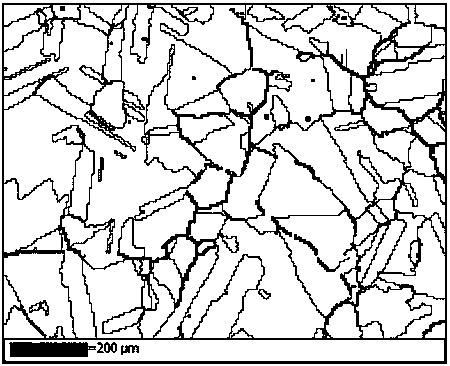

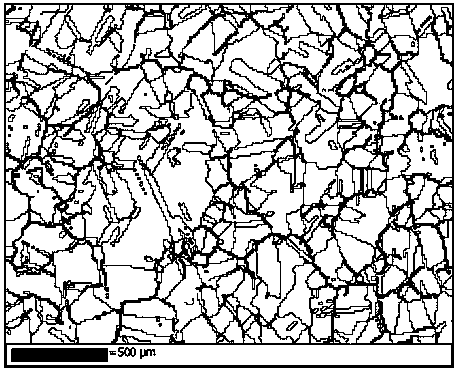

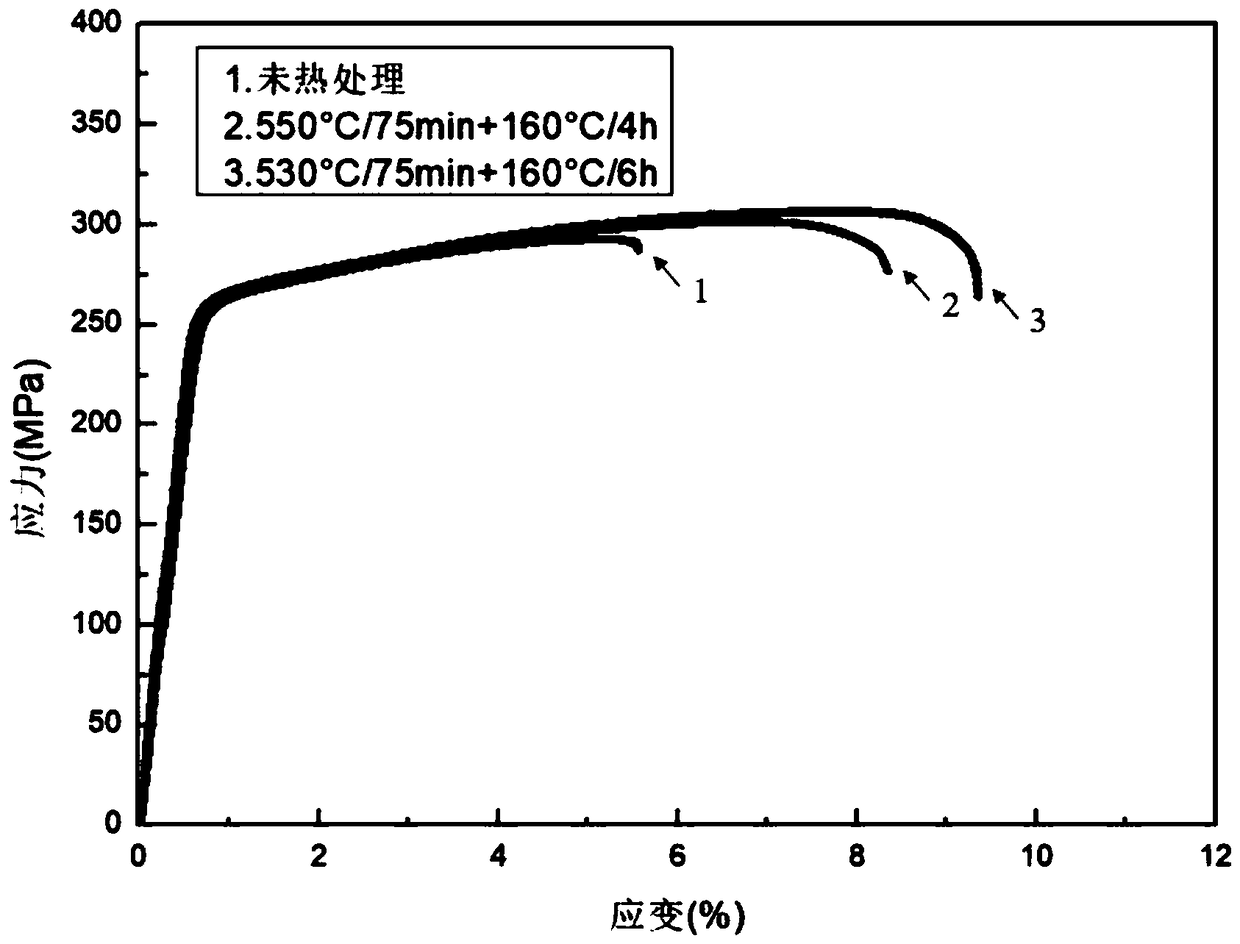

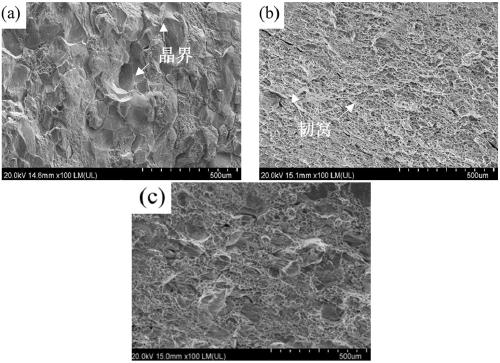

Thermal treatment method for improving performance of aluminum alloy and welding connector thereof

InactiveCN109136803AImprove plastic toughnessReduce the depth of intergranular corrosionSolution treatmentRoom temperature

The invention discloses a thermal treatment method for improving performance of an aluminum alloy and a welding connector thereof. The thermal treatment method comprises the following step: sequentially carrying out solid dissolving treatment, water quenching and aging treatment on an aluminum alloy or a welding connector of the aluminum alloy. The thermal treatment method is characterized in thatthe aluminum alloy is a 6N01 aluminum alloy; the solid dissolving treatment temperature is 530-550 DEG C, the solid dissolving treatment time is 50-90 minutes, the aging treatment temperature is 155-180 DEG C, the aging treatment time is 2-13 hours, and the aluminum alloy is placed in the air for air cooling to the room temperature after the aging treatment. By adopting the method, thermal treatment modification is carried out on the 6N01 system aluminum alloys and welding connectors thereof, and on premise that the strength is not degraded, a breakage mode of the aluminum alloys is changed,and in addition, the intercrystalline corrosion resistance of the aluminum alloy can be improved.

Owner:SOUTHWEST JIAOTONG UNIV

High-strength wear-resistant nonmagnetic stainless steel and preparation method thereof

The invention discloses a high-strength wear-resistant nonmagnetic stainless steel and a preparation method thereof. The high-strength wear-resistant nonmagnetic stainless steel is composed of the following components in percentage by weight: 0.1%-0.18% of carbon, 8%-11% of nickel, 19%-21% of chromium, 1%-2% of manganese, 0.5%-1% of silicon, 0.48%-0.65% of niobium, 0.11%-0.14% of vanadium, 1.2%-2.0% of molybdenum, 0.021%-0.03% of titanium, 0.01%-0.1% of aluminum, 0.8%-2% of nitrogen, 0.2%-0.3% of rare earth, not more than 0.035% of phosphorus and sulfur, and the balance of iron thereof inevitable impurities. The high-strength wear-resistant nonmagnetic stainless steel has the advantages of favorable corrosion resistance, favorable intercrystalline corrosion resistance, favorable oxidation resistance, favorable acid / alkali resistance, high strength and high hardness.

Owner:何鹏

Heat treatment method of aluminum alloy

InactiveCN106319408AImprove intergranular corrosion resistanceHigh strengthThree levelHigh intensity

The invention discloses a heat treatment method of an aluminum alloy. The heat treatment method comprises the steps that (1) an aluminum alloy plate is used as a raw material to be subjected to solid solution and quenching, the solid solution treatment temperature is 560 DEG C, and the solid solution holding time is 40 min; and (2) after solid solution and quenching, primary aging under the conditions of 135 DEG C and 6 h, secondary aging under the conditions of 170 DEG C and 8 h and tertiary aging under the conditions of 150 DEG C and 8 h are sequentially carried out, and aging is carried out in an air circulation furnace. The aluminum alloy plate is subjected to three levels of aging heat treatment, and the aluminum alloy with high intergranular corrosion resisting performance and strength can be obtained.

Owner:张家港市丰乐汽车设备有限公司

Multi-channel medicine bottle separating device

InactiveCN103241530AImprove intergranular corrosion resistanceImprove heat resistanceConveyor partsCircular discBiomedical engineering

The invention discloses a multi-channel medicine bottle separating device. The device comprises a transmission box (2), wherein a disk (11) is connected with the upper end of the transmission box (2), a guardrail (10) is arranged on the circumferential face of the disk (11), a rotating shaft (12) is arranged in the middle of the disk (11) and connected with a blocking plate (3), a medicine bottle inlet groove (4) and a plurality of guide blocking plates (9) are arranged at the edge portion of the disk (11), the plurality of guide blocking plates (9) are communicated with a plurality of medicine bottle outlet grooves (1) outside the disk (11), auxiliary rotating wheels (5) are arranged on connection portions of guide blocking plates (9) and the disk (11), and lower portions of auxiliary rotating wheels (5) are connected with the transmission box (2). The multi-channel medicine bottle separating device is simple and reasonable in structure, high in practicability and capable of improving the medicine bottle separating efficiency and separating medicine bottle orderly.

Owner:CHINA CHENGDU ANIMAL HUSBANDRY IND BIOPHARM

High-carbon low-ferrite-content austenitic stainless steel plate and production method thereof

ActiveCN113549820AImprove intergranular corrosion resistanceAccelerated corrosionNuclear energy generationNuclear powerElectro-slag remelting

The invention provides a high-carbon low-ferrite-content austenitic stainless steel plate and a production method thereof. The steel plate comprises, by weight, 0.15%-0.20% of C, 0.4%-0.6% of Si, 1.20%-1.40% of Mn, less than or equal to 0.010% of P, less than or equal to 0.002% of S, 21.0%-22.0% of Cr, 10.5%-11.5% of Ni, 2.0%-3.0% of Mo, 0.035%-0.055% of N and the balance Fe and inevitable impurities. The content of delta-ferrite in the steel plate is less than 1%. The manufacturing method comprises the steps of smelting, casting, electroslag remelting, heating, forging, homogenizing heat treatment, rolling and grain boundary engineering control. The steel plate produced through the method has good mechanical properties and good comprehensive properties and is suitable for a long-term service environment of nuclear power station core components, and high efficiency and safety of nuclear power equipment operation are ensured.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com