Circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and manufacturing process thereof

A technology of pressure-bearing heat exchangers, which is applied in the fields of kneading welding pressure-bearing water heaters, stainless steel water storage or instant heating round pipes to achieve the effects of reducing use costs, high thermal efficiency, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

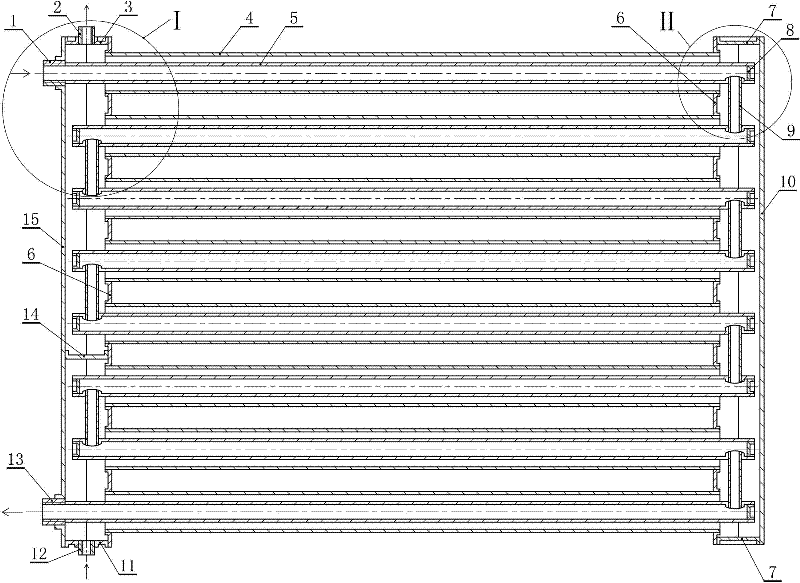

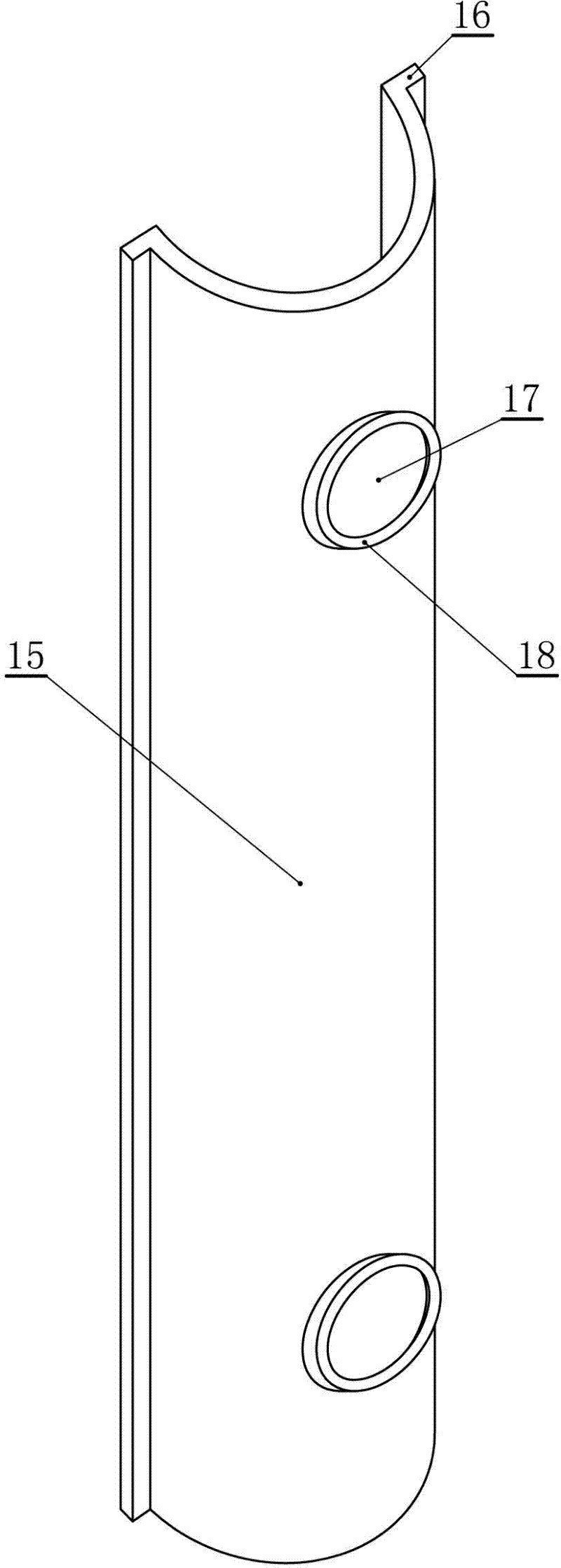

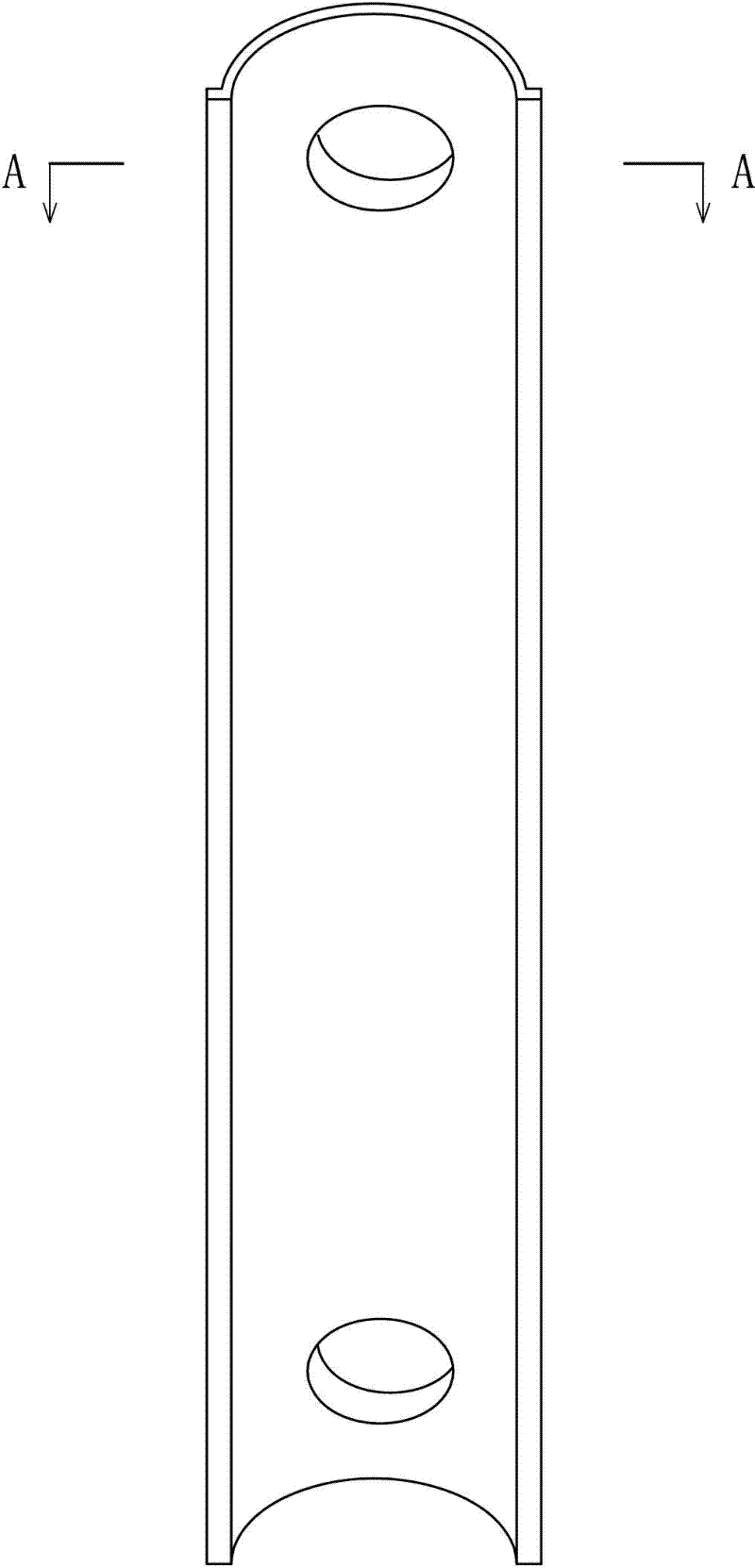

[0052] Such as figure 1 , Figure 5 As shown, in the present invention, the two D-shaped headers of the original patent are updated into 4 arc plates, and the two arc plates are punched at the center of the arc and stretched 2 to 2.5 mm inwards, and the edges of the arc plates face outwards. Flanging 1~1.5mm, tap water connecting pipe according to the drawing hole diameter and drawing height of the circular arc plate, the end faces of the two ends are cut at R angle, inserted into the drawing hole of the circular arc plate, consistent and connected, pinched edge self-fluxing flat welding The heating pipe is inserted into the tap water connecting pipe, the two ends of the heating pipe are punched on one side at a distance of 8mm from the end, and the other end is punched below the corresponding surface, and the two corresponding holes are stretched inward by 1.5-2mm to connect the heat The straight pipe is cut according to the drawing hole diameter and drawing height of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com