Patents

Literature

969 results about "Water exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recirculating marine aquaculture process

A high efficiency recirculating marine aquaculture process for producing fish at variable yield densities of up to 60 kg / meter3 of the aquaculture tank, including fish that spawn under short photoperiods such as gilthead seabream (Sparus aurata) as well as fish that spawn under long photoperiods such as striped bass (Morone saxatilis). The process involves broodstock conditioning, spawning / reproduction, larval growth, nursery, and adult grow-out operations. The process is characterized by high-rate growth at optimal process conditions requiring less than 10% daily water exchange, thereby enabling effluent waste from the system to be discharged to a municipal sewer after disinfection treatment, which in turn permits siting of the aquaculture process facility in urban / suburban locations where aquaculture processes have been previously infeasible.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

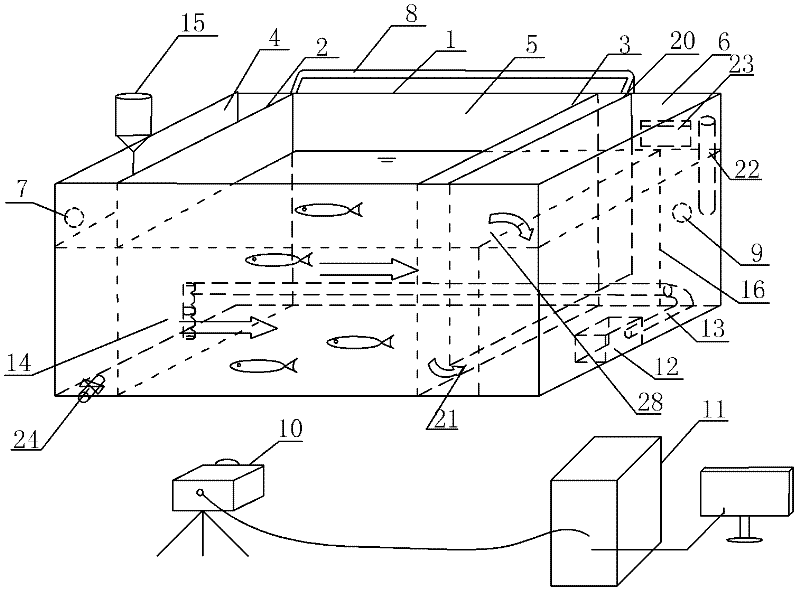

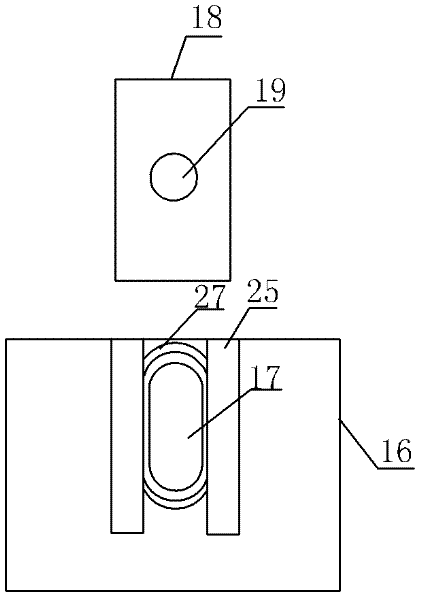

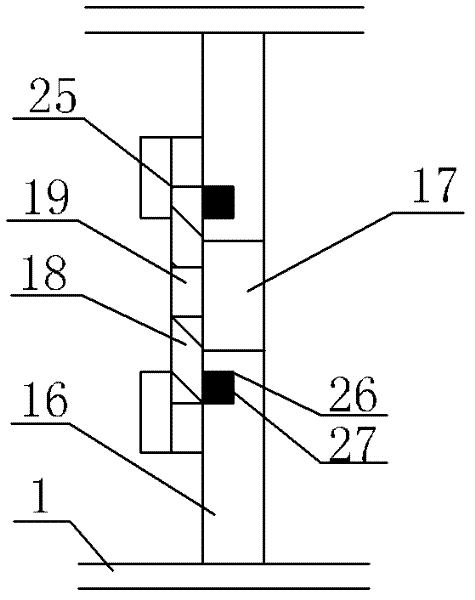

A biological water quality monitoring system and monitoring method for fish behavior

InactiveCN102297865ARealize water change testJudging pollutionMaterial analysis by optical meansFiltrationData acquisition

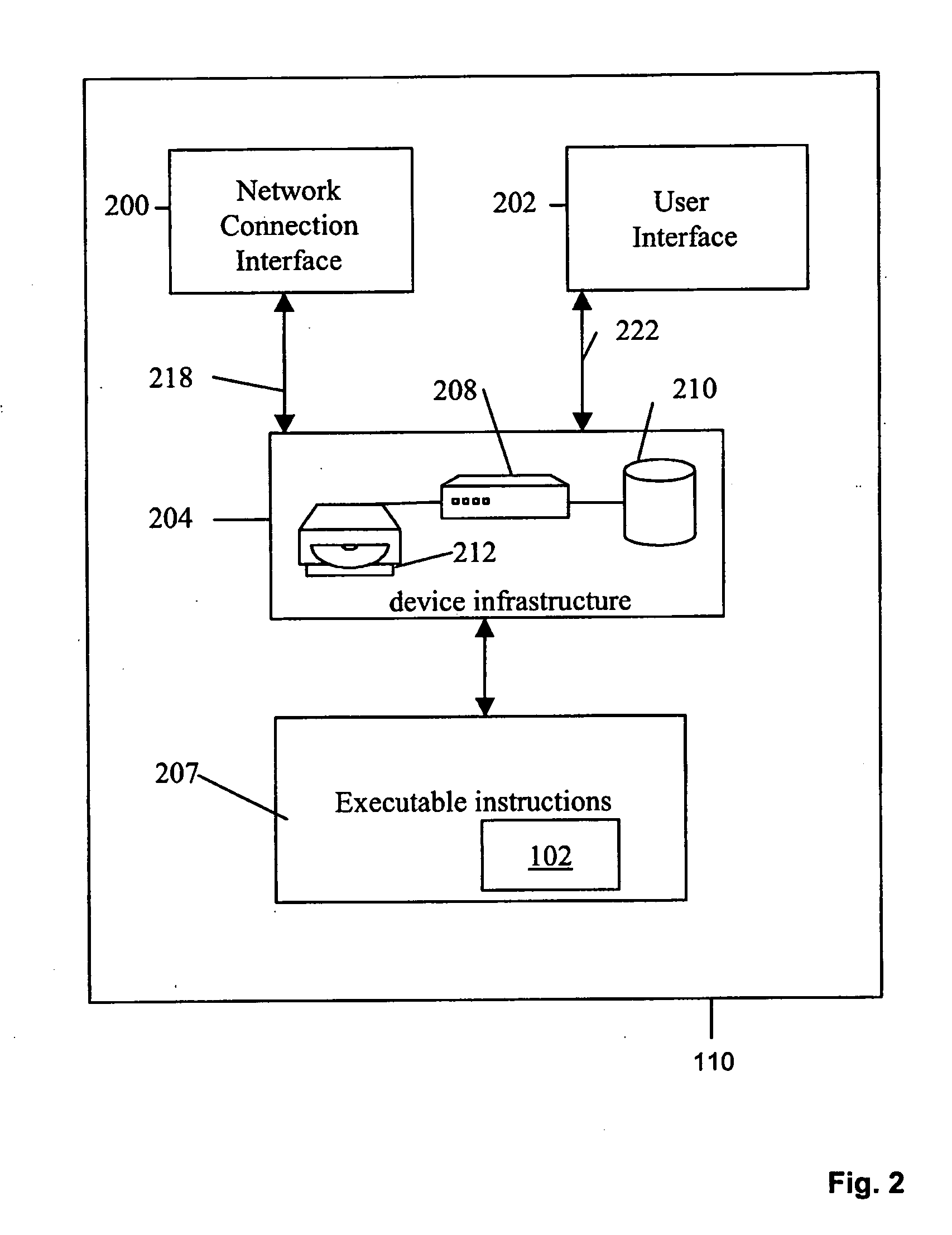

The invention relates to a biological water quality monitoring system by fish behaviors and a monitoring method thereof. The monitoring system provided by the invention comprises a data acquisition device, a data analysis device and a transparent water tank, and is characterized in that the water tank is successively divided into a pipelining buffer area, a fish shoal observation area and a filtration adjusting area by netted fish baffle plates; the sidewall of the pipelining buffer area is provided with a water inlet pipe; the outer portion of the fish shoal observation area is equipped witha light source; the sidewall of the filtration adjusting area is provided with a water outlet pipe; the filtration adjusting area is provided with a circulating pump; and the sidewall near the bottomof the water tank is equipped with a draining valve. The monitoring method provided by the invention comprises the following steps of: shooting the behaviors of the tested fish shoal by the use of a camera to obtain an image sequence, sending into a computer for real time image processing and data analysis, comparing obtained average moving speed, dispersion and the like and a preset threshold value, and determining whether the water quality is polluted or not. According to the invention, parametric records of fish behaviors in hydrostatic, pipelining and water-exchanging tests can be simultaneously realized, and the behaviors of individual and colonial organism can be simultaneously measured.

Owner:NINGBO UNIV

Pool temperature controller

ActiveUS20090204263A1Less electricityUse minimizedFlow control using electric meansTemperature control using electric meansTemperature controlAutomatic control

A device for controlling the temperature of a swimming pool is disclosed. The device measures the temperature of the water as well as other environmental conditions (such as air temperature). The device controls a circulation pump, which circulates water throughout the pool. The pool water exchanges heat with the surfaces of the water (including the side walls, ground and surface air) when a heat differential exists between the water and the surfaces. When the water is circulated throughout the pool it increases the volume of water that exchanges heat with the surfaces, thus cooling or heating the water depending on the temperature of the surfaces. A target temperature is entered into the device and using this target temperature the device automatically controls the pump in order to take advantage of the heat exchange between the water and the water's surfaces to alter the water temperature in the direction of the target temperature. Additionally a heating element may be used to supplement the heating operation of the circulation pump.

Owner:CARIBBEAN HEATERS

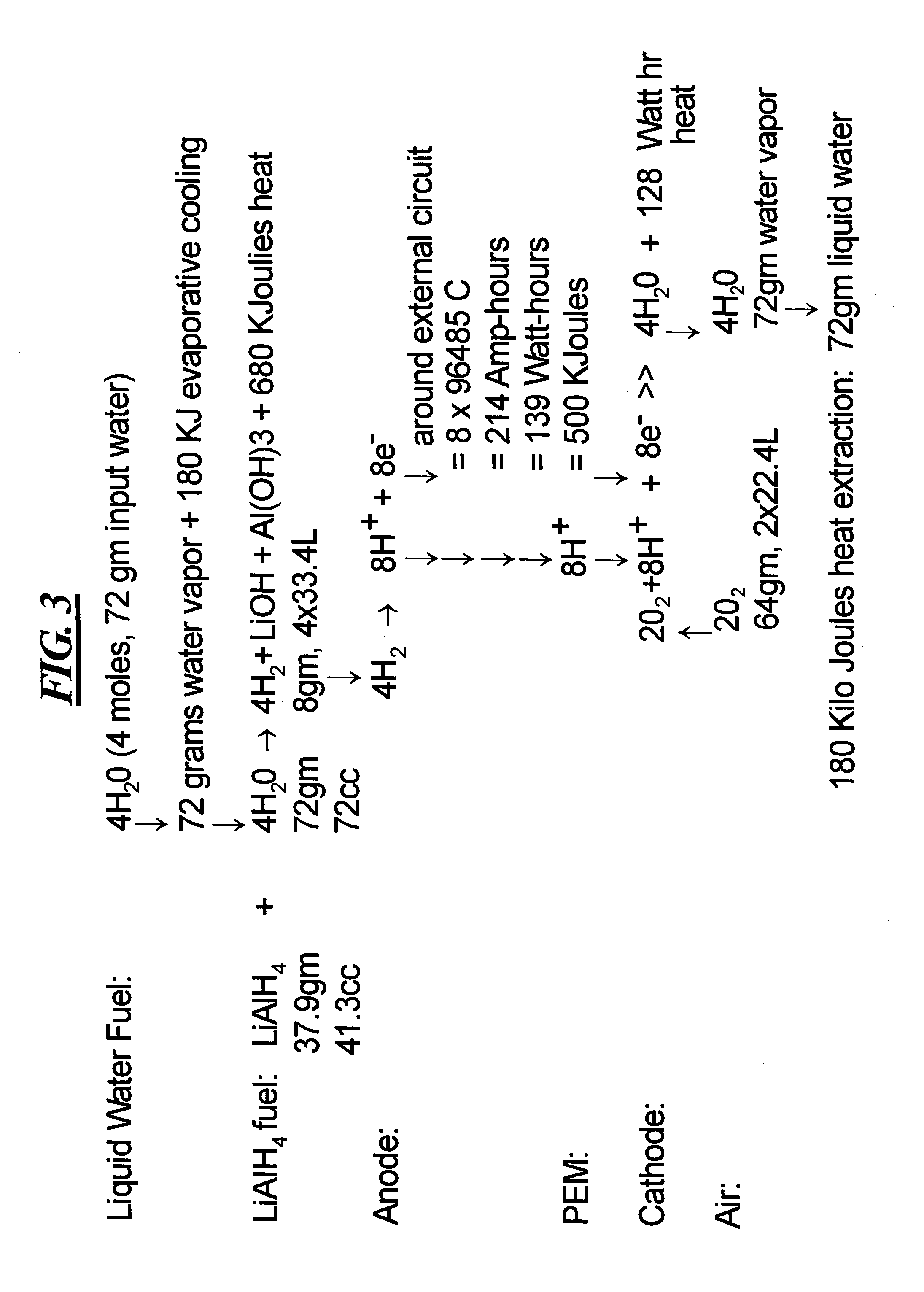

Electrical power generator

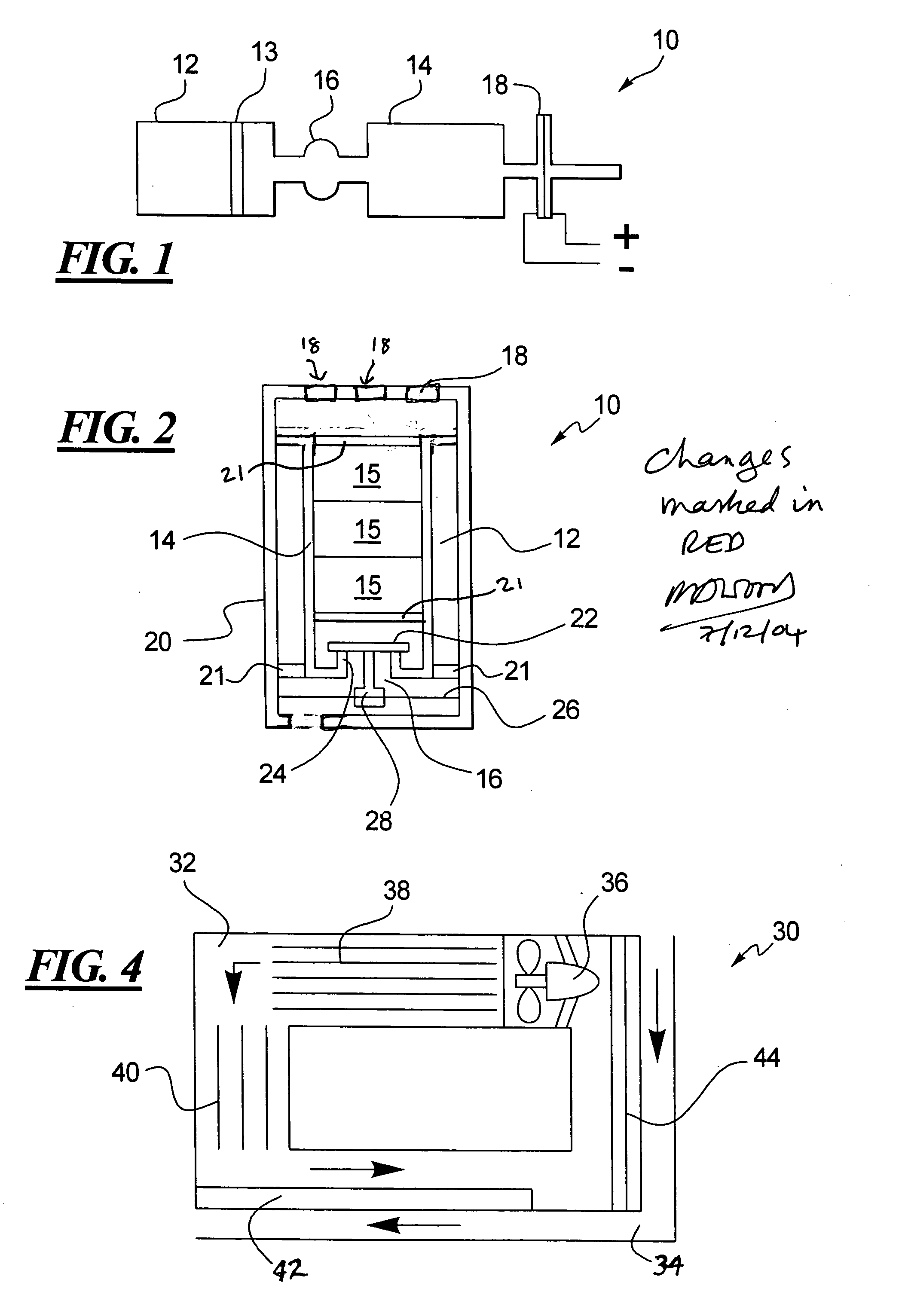

A power generator has a hydrogen flow path through which moisture is induced to flow to a hydrogen-containing fuel that reacts with the moisture to produce hydrogen. The moisture passes to the hydrogen flow path through a water exchange membrane from a water vapor flow path. A fuel cell between the hydrogen flow path and the water vapor flow path reacts with the hydrogen in the hydrogen flow path to produce electricity, and to also principally produce the moisture in the water vapor flow path.

Owner:HONEYWELL INT INC

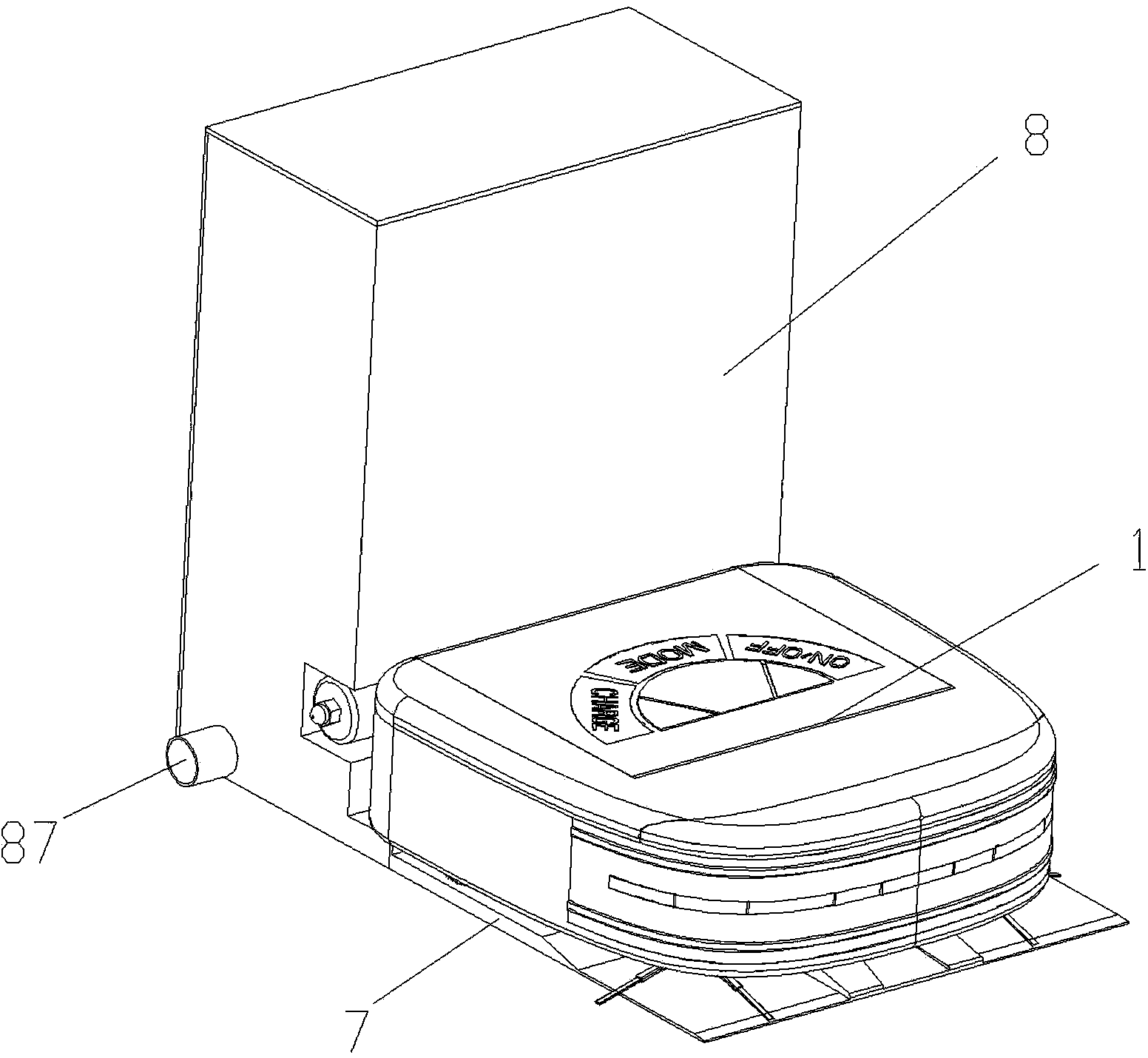

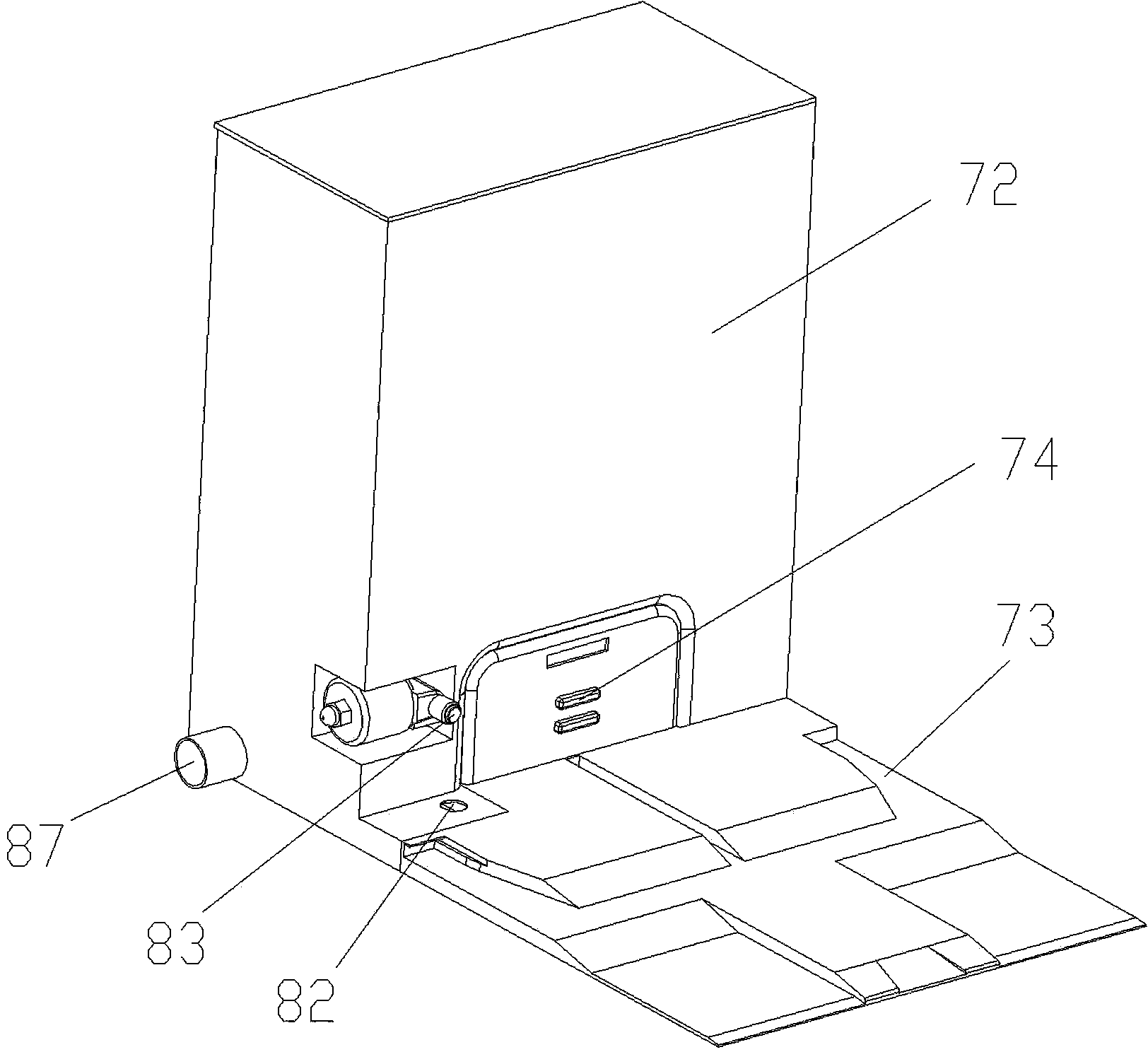

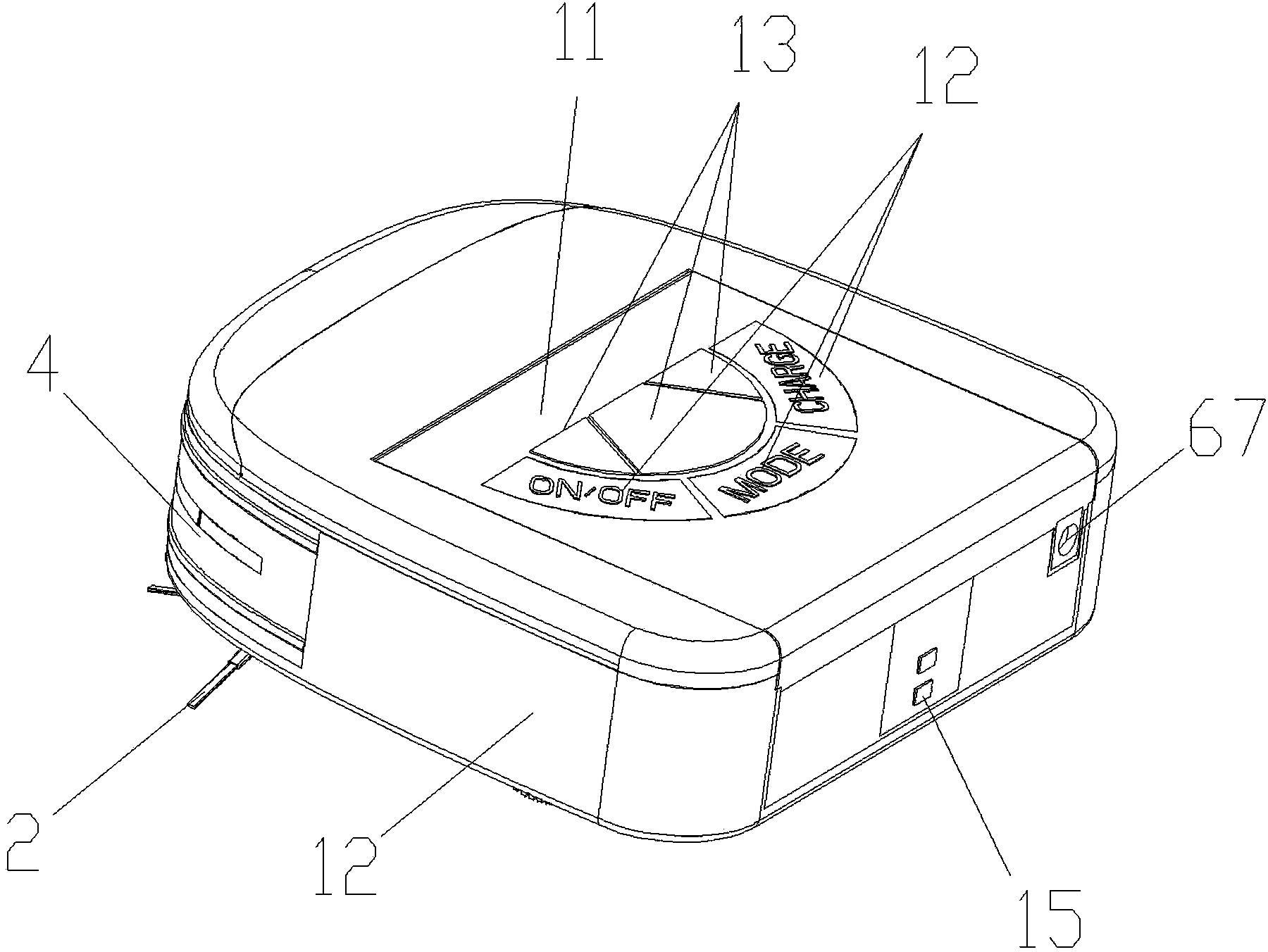

Intelligent mopping machine

ActiveCN104257330ARealize high intelligenceMeet the needs of automatic cleaning indoor sanitationMachine detailsFloor-scrubbing machinesDrive wheelControl system

The invention discloses an intelligent mopping machine. The intelligent mopping machine comprises a main machine and a recharging station for automatically recharging the main machine, a sweeping component, a driving wheel component, an obstacle avoiding device, a mopping component, a power system and a control system are arranged inside the main machine, the mopping component comprises a wiping unit and an internal water tank, and the recharging station is also provided with an external water tank which can automatically exchange water with the internal water tank. When the main machine returns to the recharging station for recharging, the control system opens the water exchange between the internal water tank and the external water tank. The intelligent mopping machine can achieve automatic recharging through the recharging station, achieve automatic water circulation through the internal water tank and the external water tank, achieve automatic and synchronous sweeping and mopping through the sweeping component and the mopping component, truly achieve intelligent control of the mopping machine in combination with the driving wheel component and the obstacle avoiding device arranged inside the main machine and meet the demand for automatic indoor cleaning by machines.

Owner:陈国英

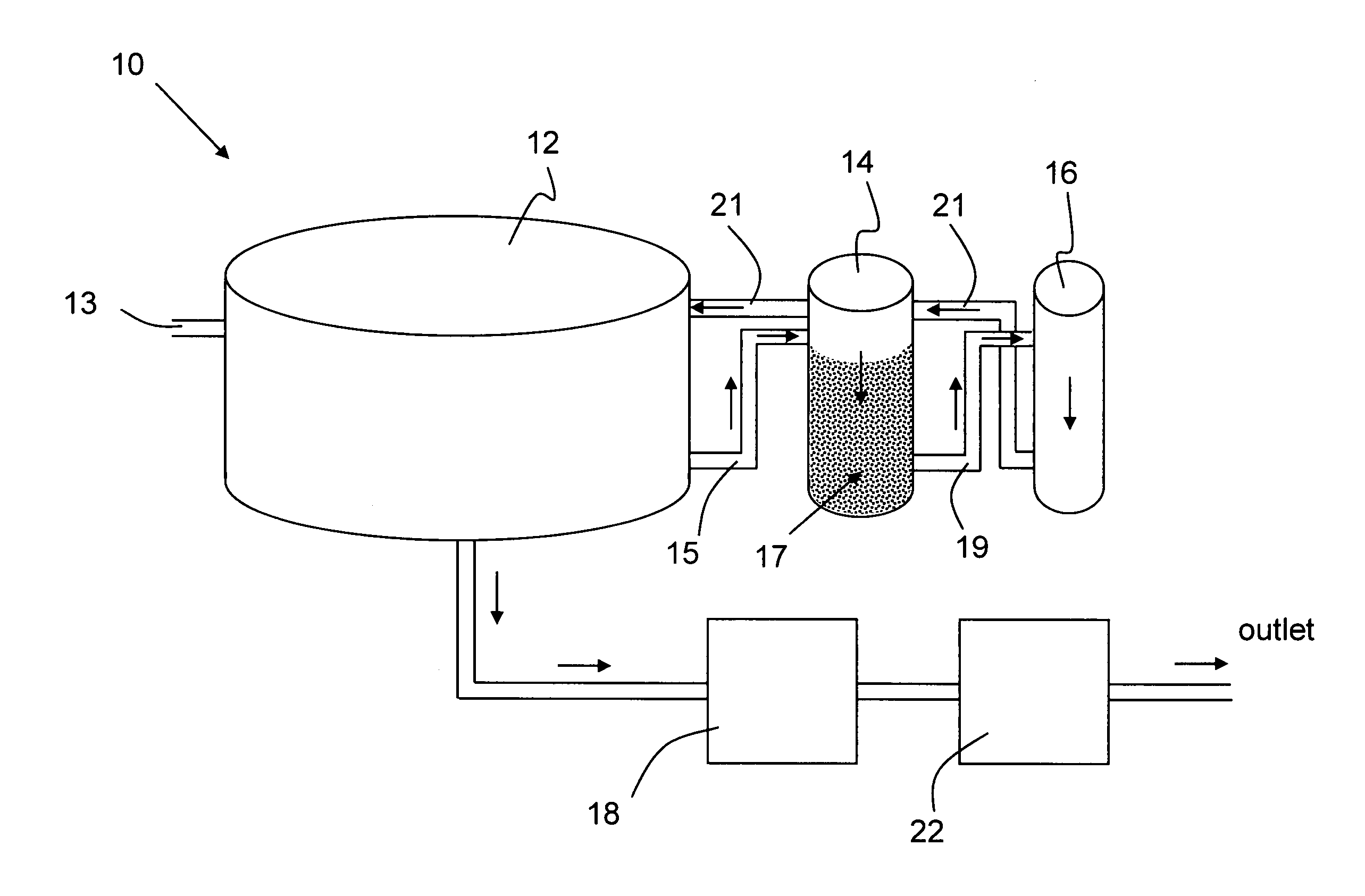

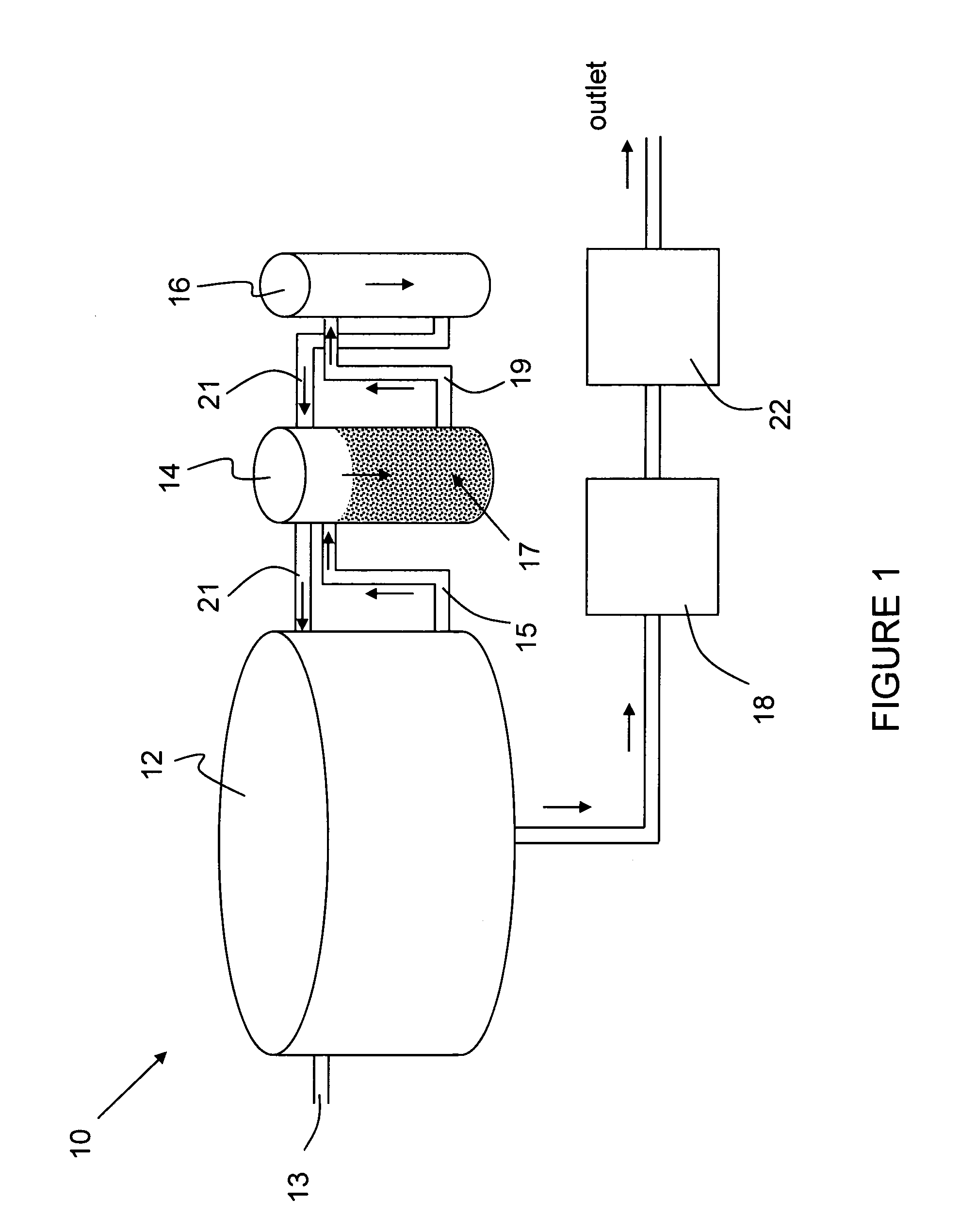

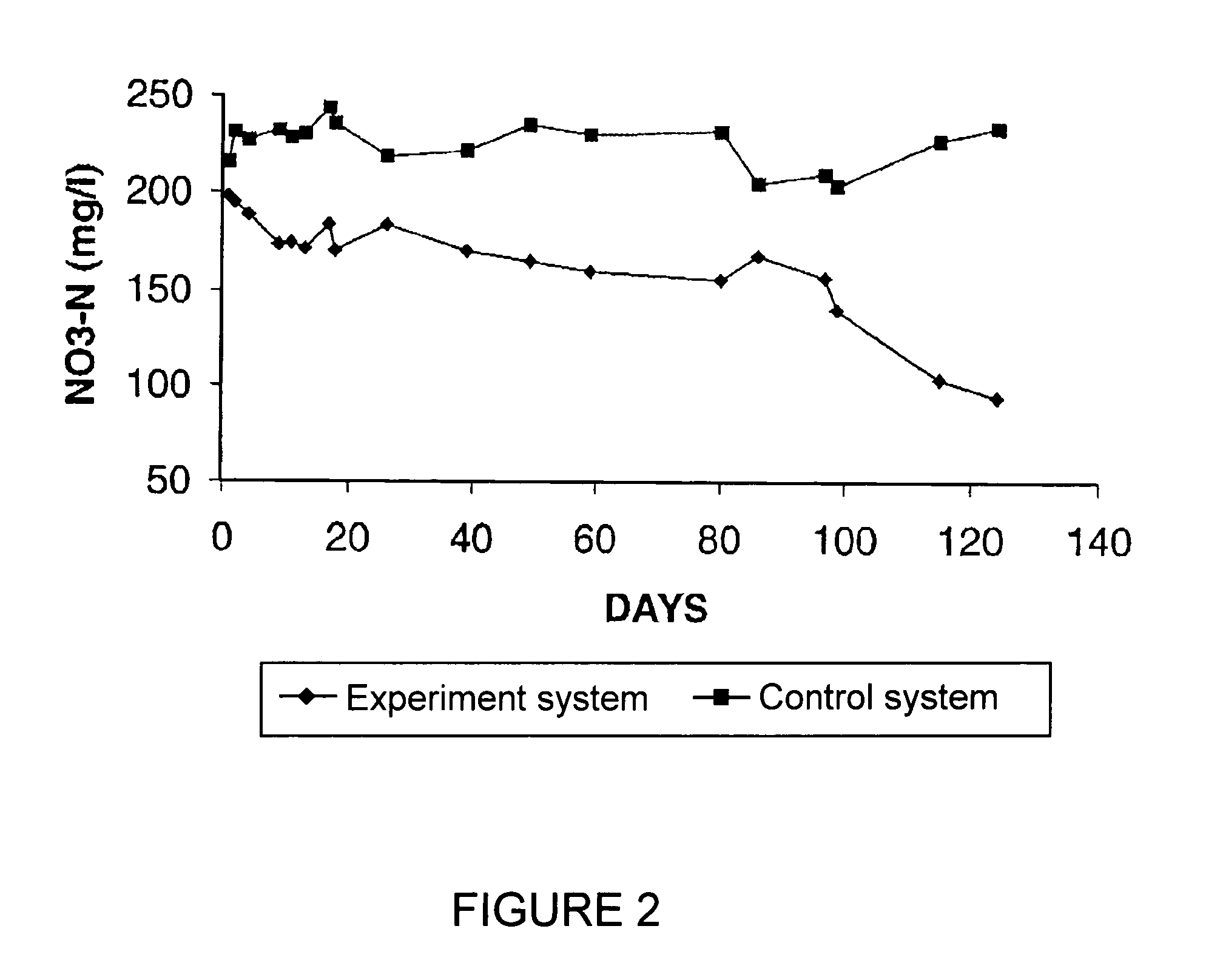

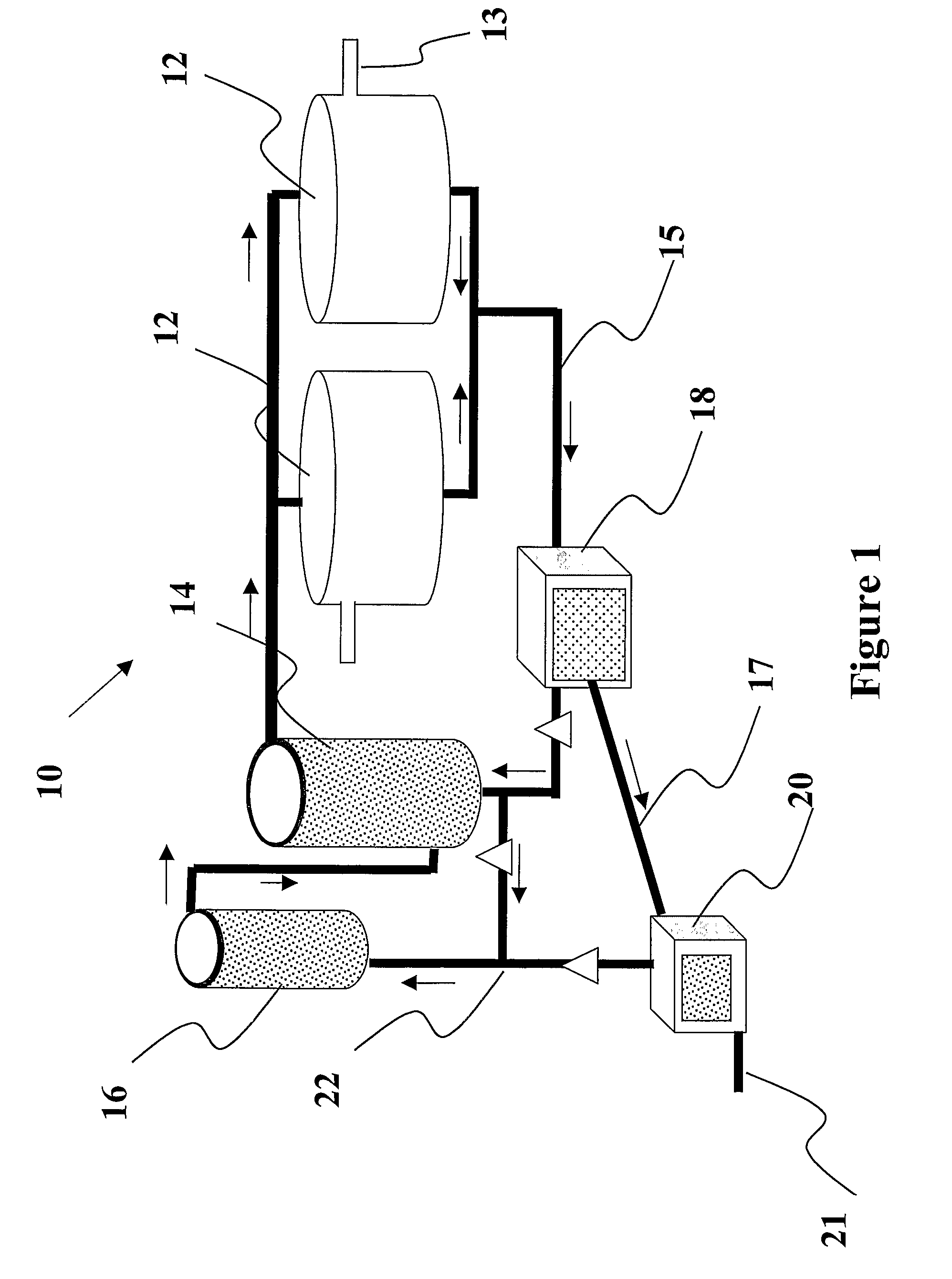

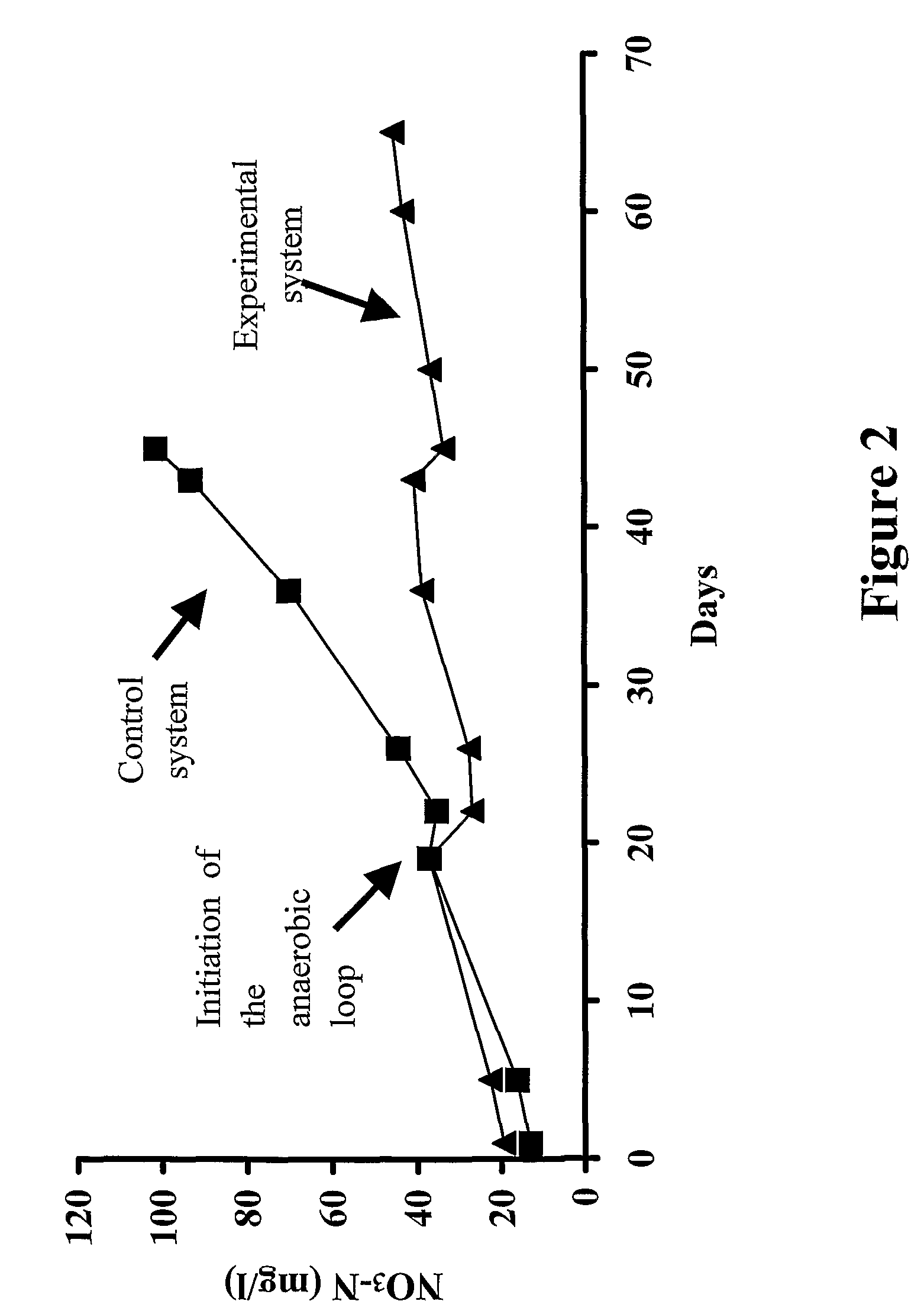

Aquaculture nitrogen waste removal

ActiveUS7082893B2Treatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesNitrateReactor system

The present invention relates to a two-stage biofilter reactor system for removing nitrogenous compounds from a recirculating aquaculture system. The system includes a aerobic nitrification unit and a downstream anaerobic denitrification unit, wherein both units have a mobile bed of suspended media whereon bacteria can grow and reduce nitrate and / or ammonia levels in the recirculating aquaculture system. Use of the two-stage system has the advantage of reducing the water exchange rates and consumption of salt when maintaining a saline effluent.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

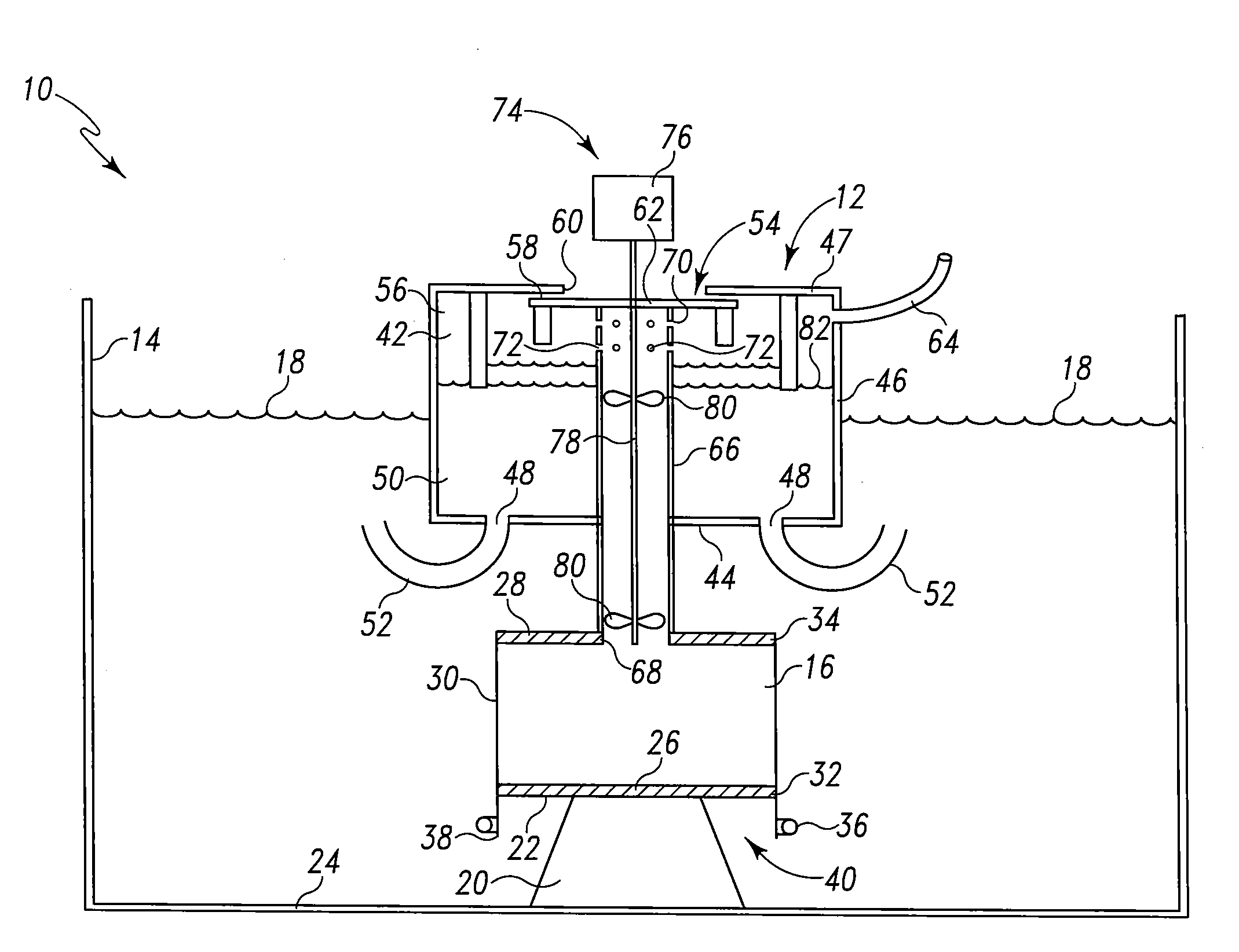

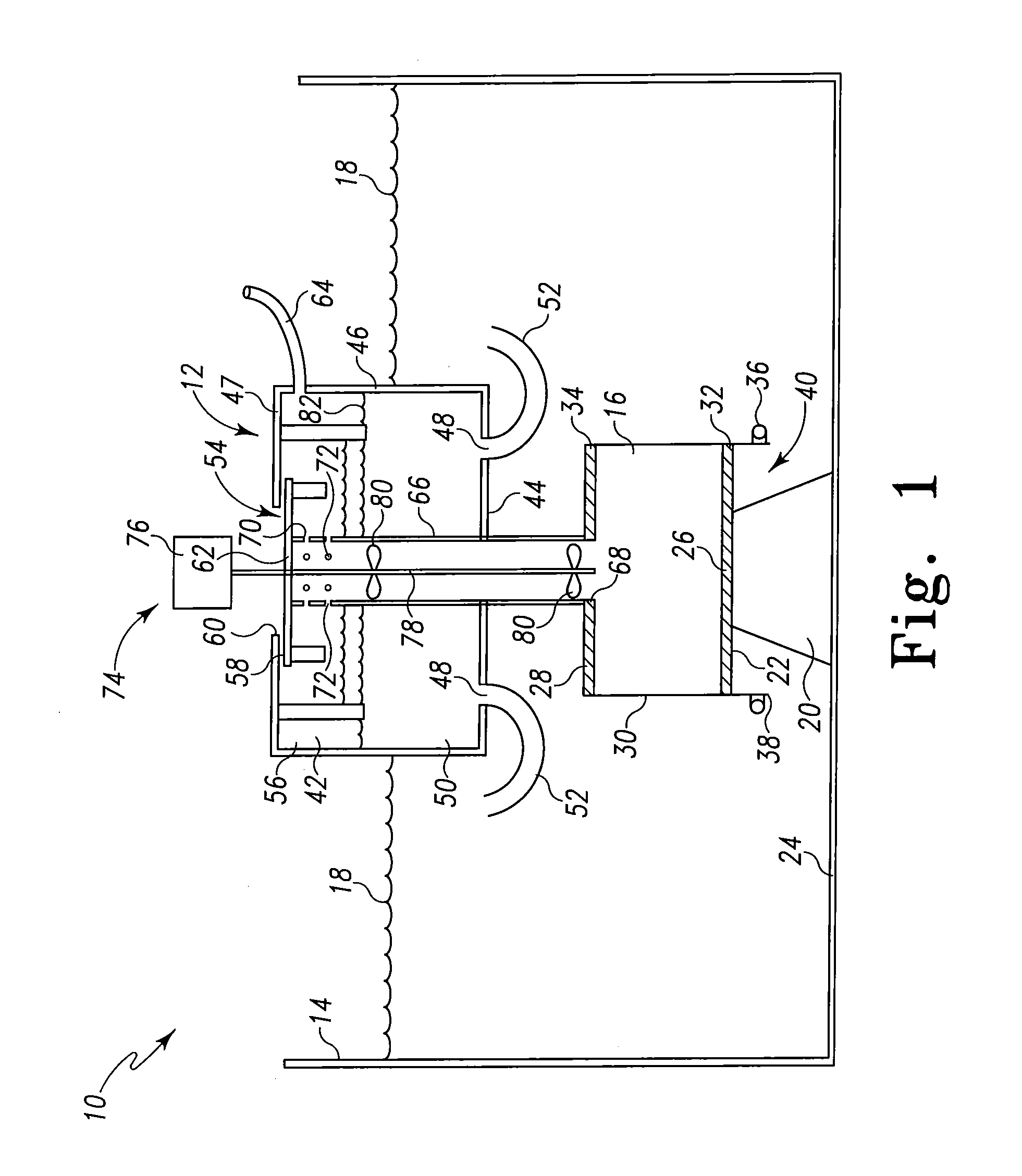

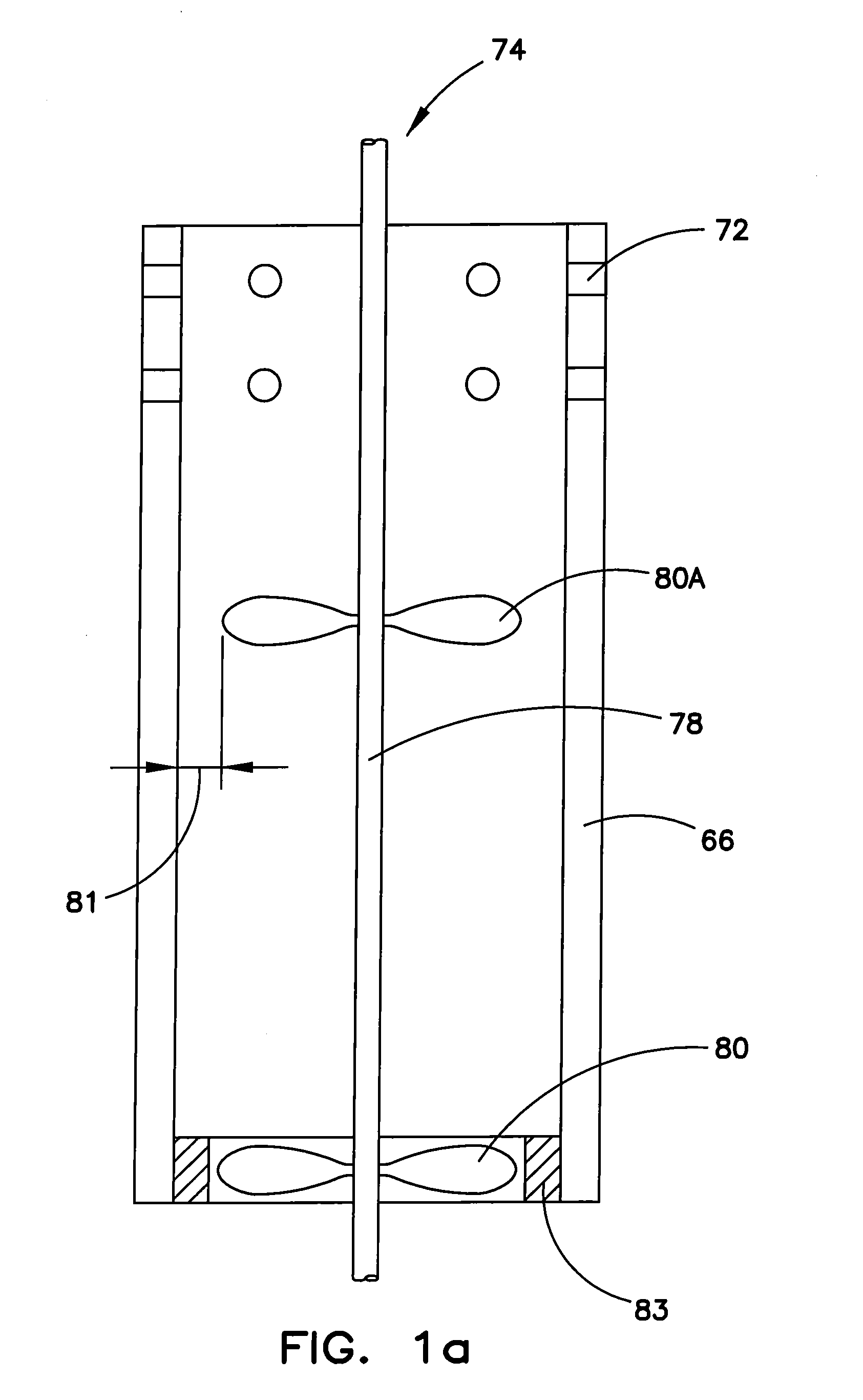

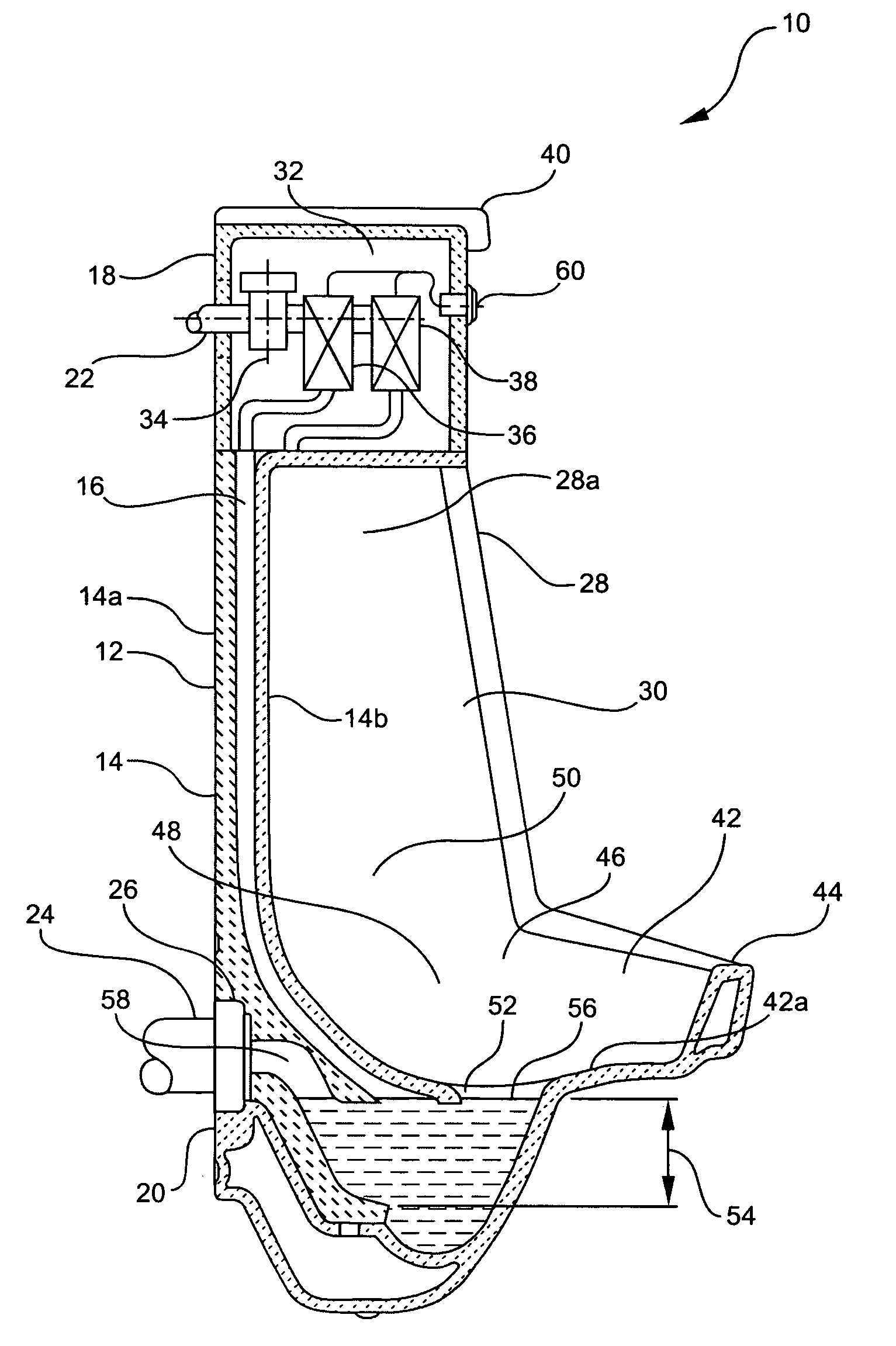

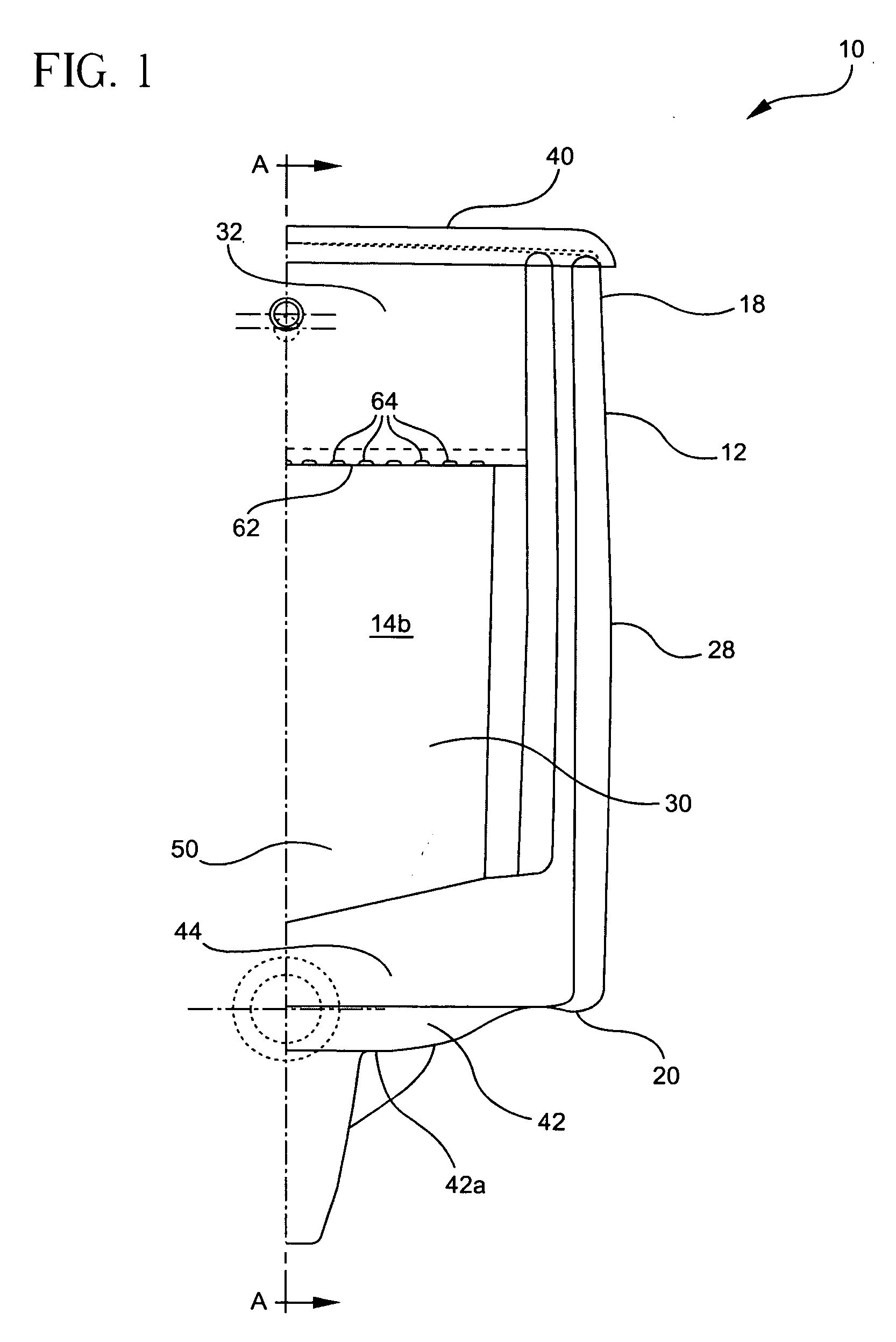

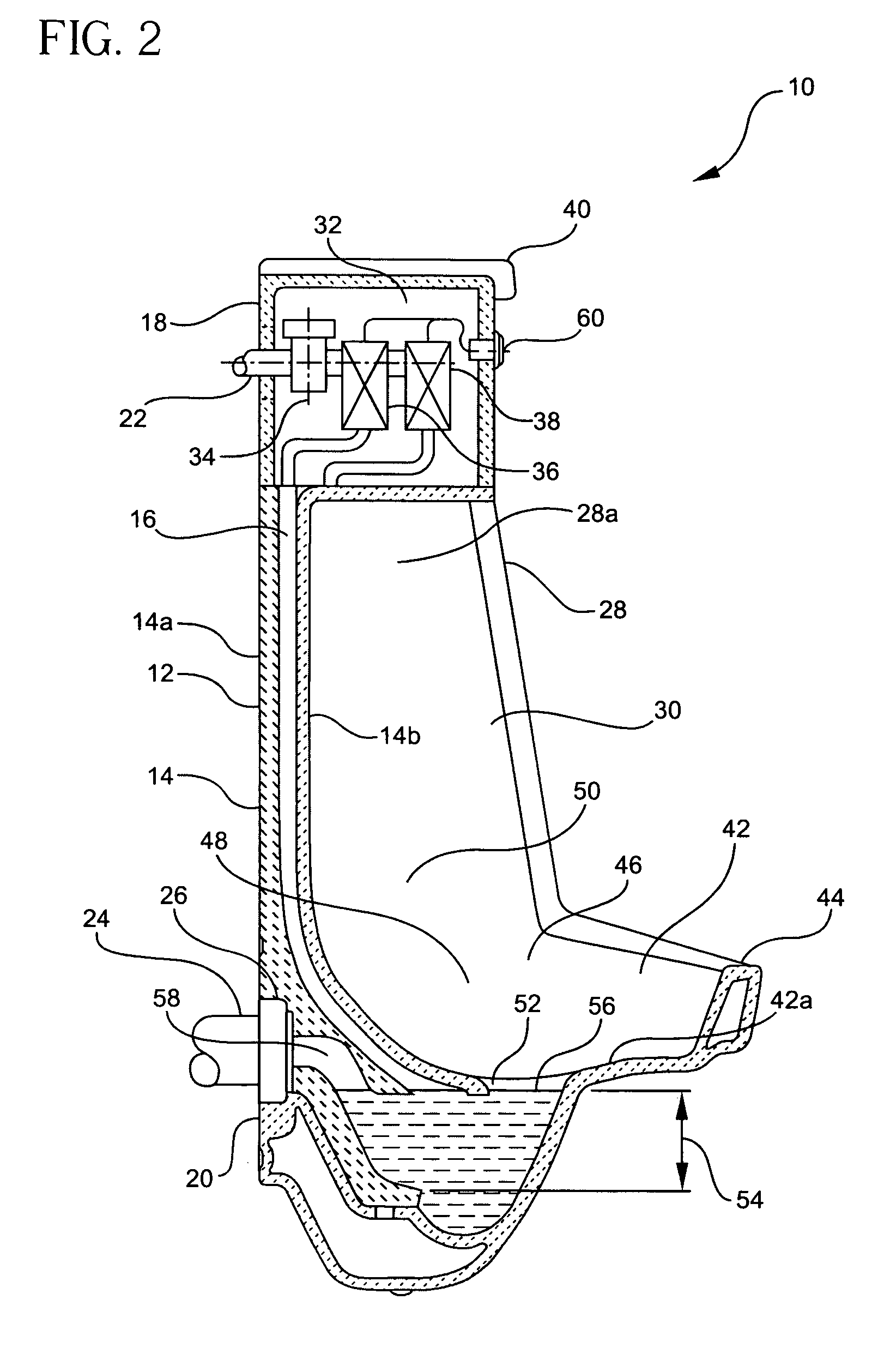

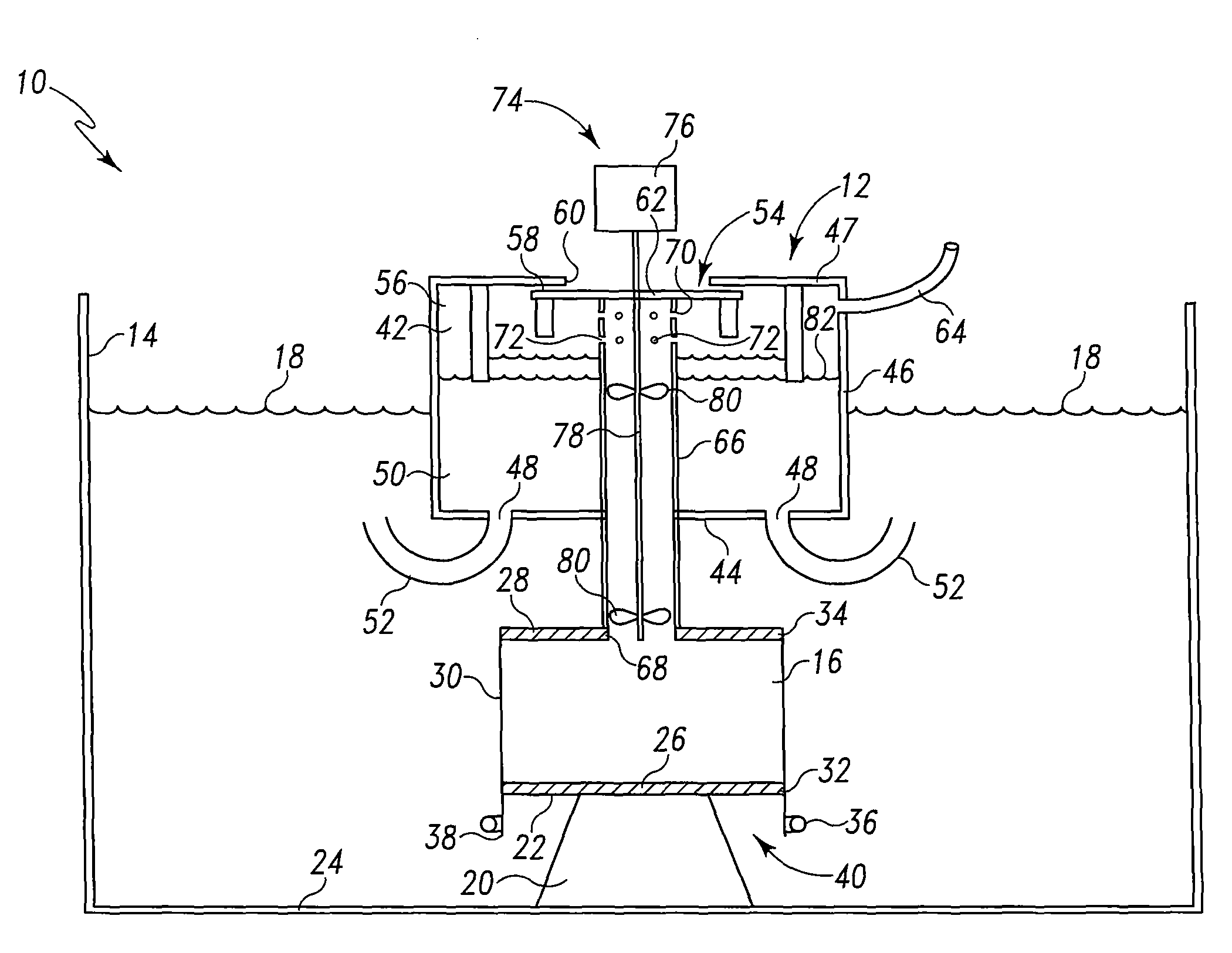

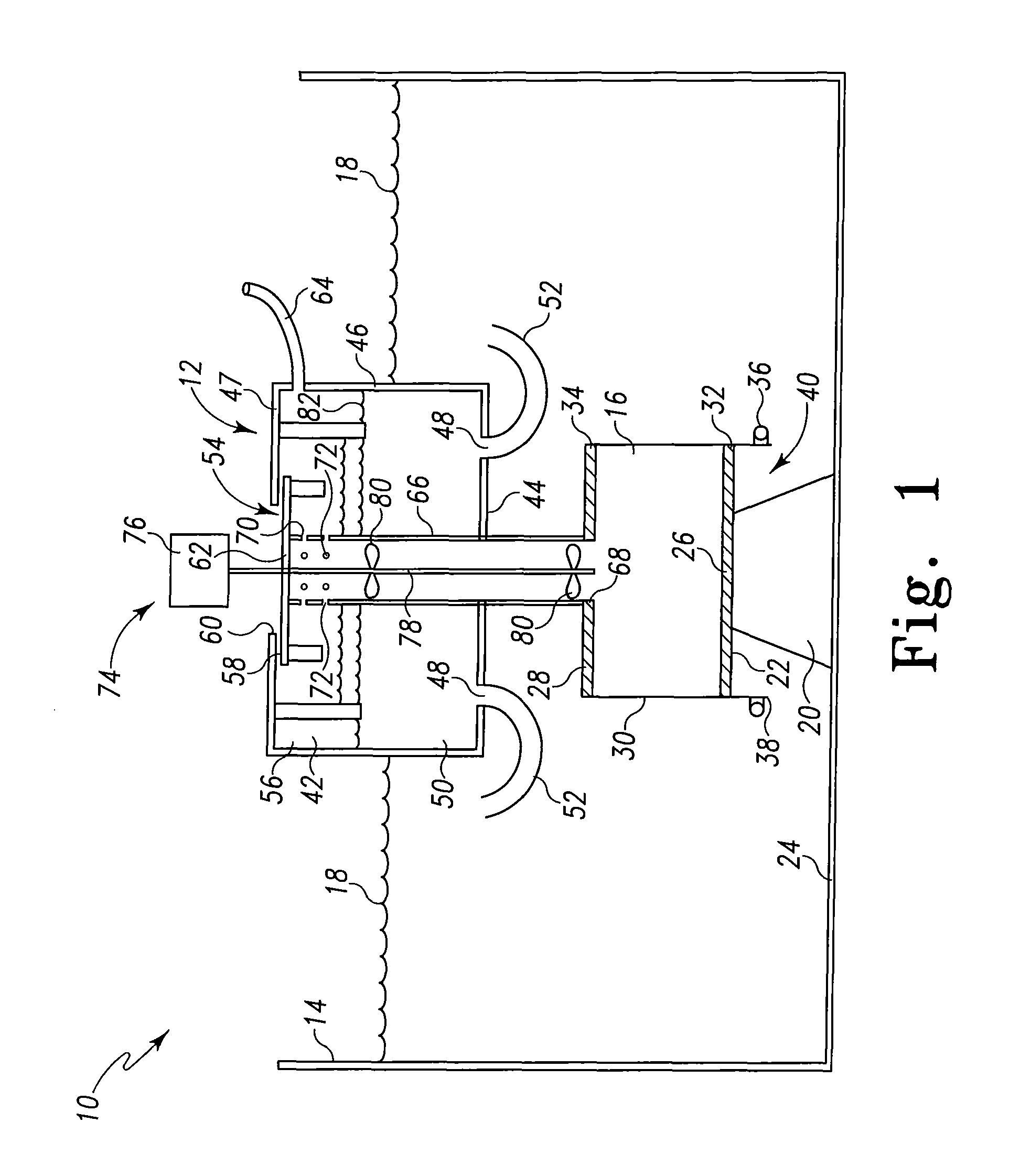

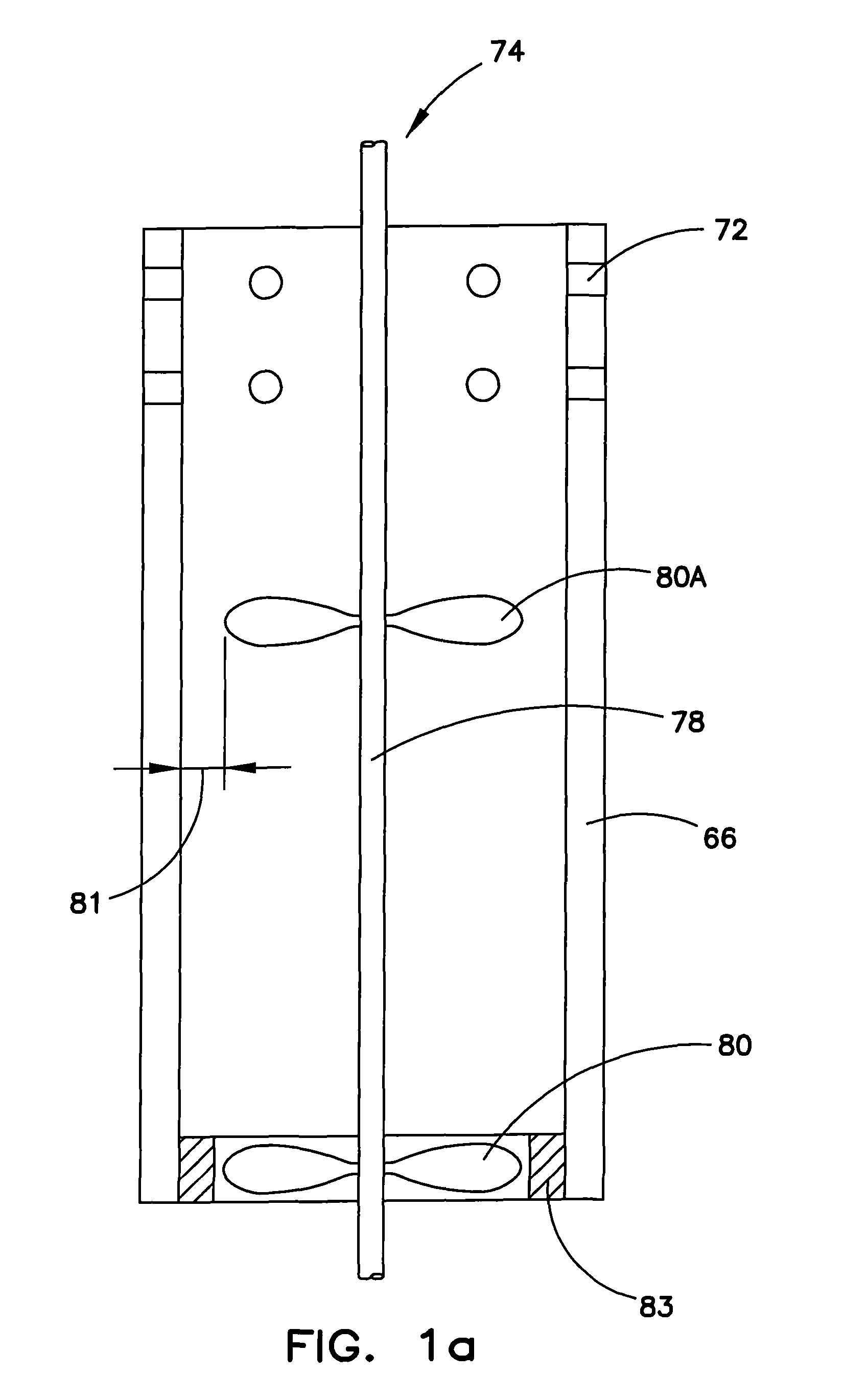

Process and system for growing crustaceans and other fish

InactiveUS20100170450A1Reduce the ratioTreatment using aerobic processesTransportation and packagingMarine aquacultureCavitation

A recirculated marine aquaculture system and process for growing crustaceans or other fish within a body of water. Water from the body of water is treated by stripping carbon dioxide and biological byproducts and by oxygenating the water. A water treatment unit may be provided to treat the water and provide movement to the body water. The water treatment unit can be configured to provide cavitation to the water, which aids in the removal of carbon dioxide and biological byproducts. Water may also be cycled through a deflocculation tank to reduce the floc of bacteria within the body of water to acceptable levels for optimal growth of crustaceans or other fish within a body of water. Using the system and the deflocculation tank has the advantage of significantly reducing the water exchange rates and even the water effluent, while maintaining acceptable water quality for growing crustaceans or other fish.

Owner:AQUA MANNA

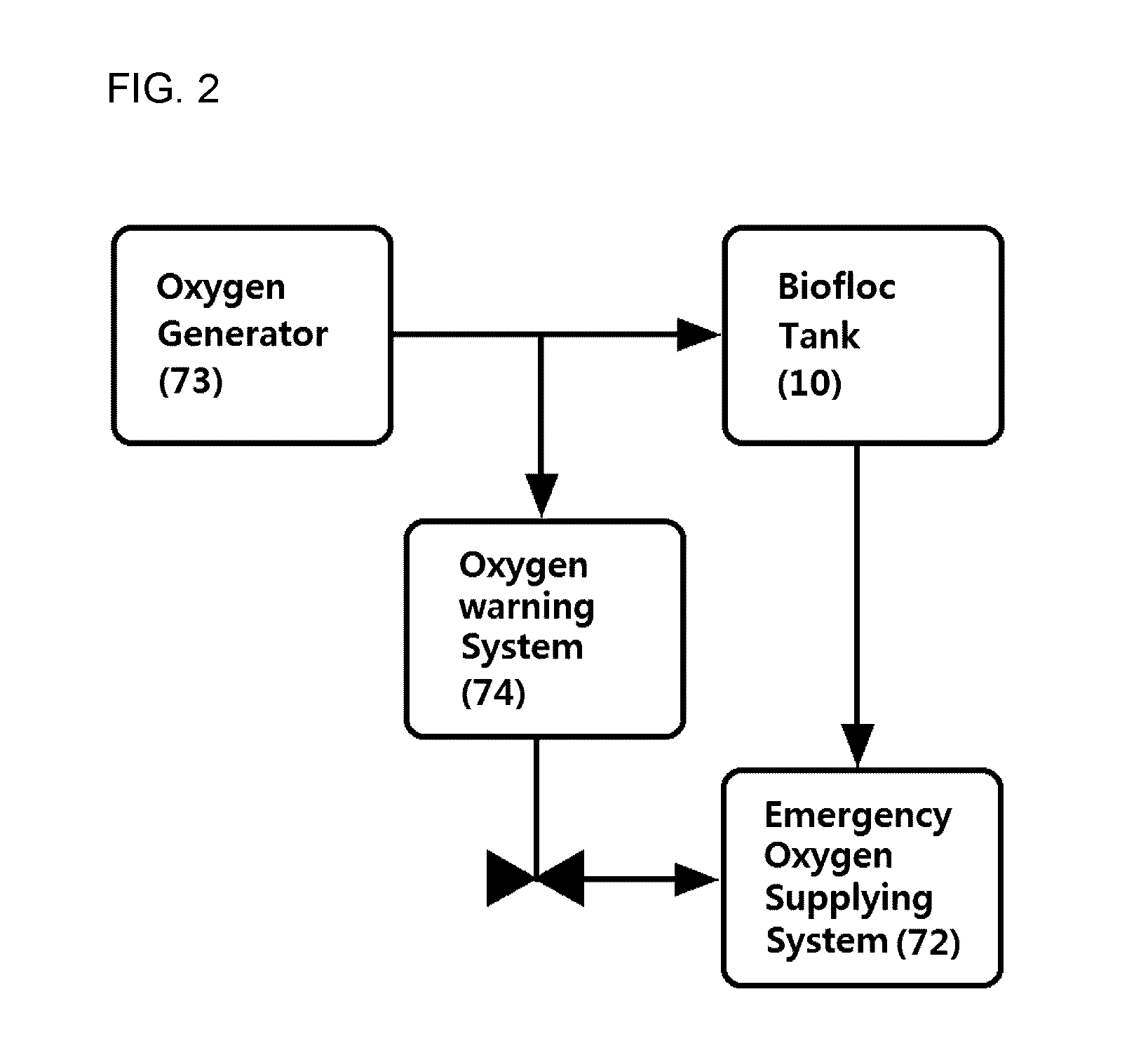

Inland aquaponics system using biofloc technology

InactiveUS20170049082A1Low production costMaximize production efficiencySelf-acting watering devicesClimate change adaptationAquaponicsGrowth plant

A closed recirculating aquaponics system combined with a biofloc tank for symbiotic breeding of aquatic species and plant species, wherein the culture water for growing aquatic species is transferred to a plant growing apparatus, organic material in the culture water is used as nutrients for plant species and the water is purified in the plant growing apparatus, and purified water is reused as culture water for aquatic species to facilitate symbiotic breeding of aquatic species and plant species without any need of culture water exchange, reducing cost for production and enhancing production efficiency.

Owner:REPUBLIC OF KOREA (NAT FISHERIES RES & DEV INST)

Dual phase flush urinal

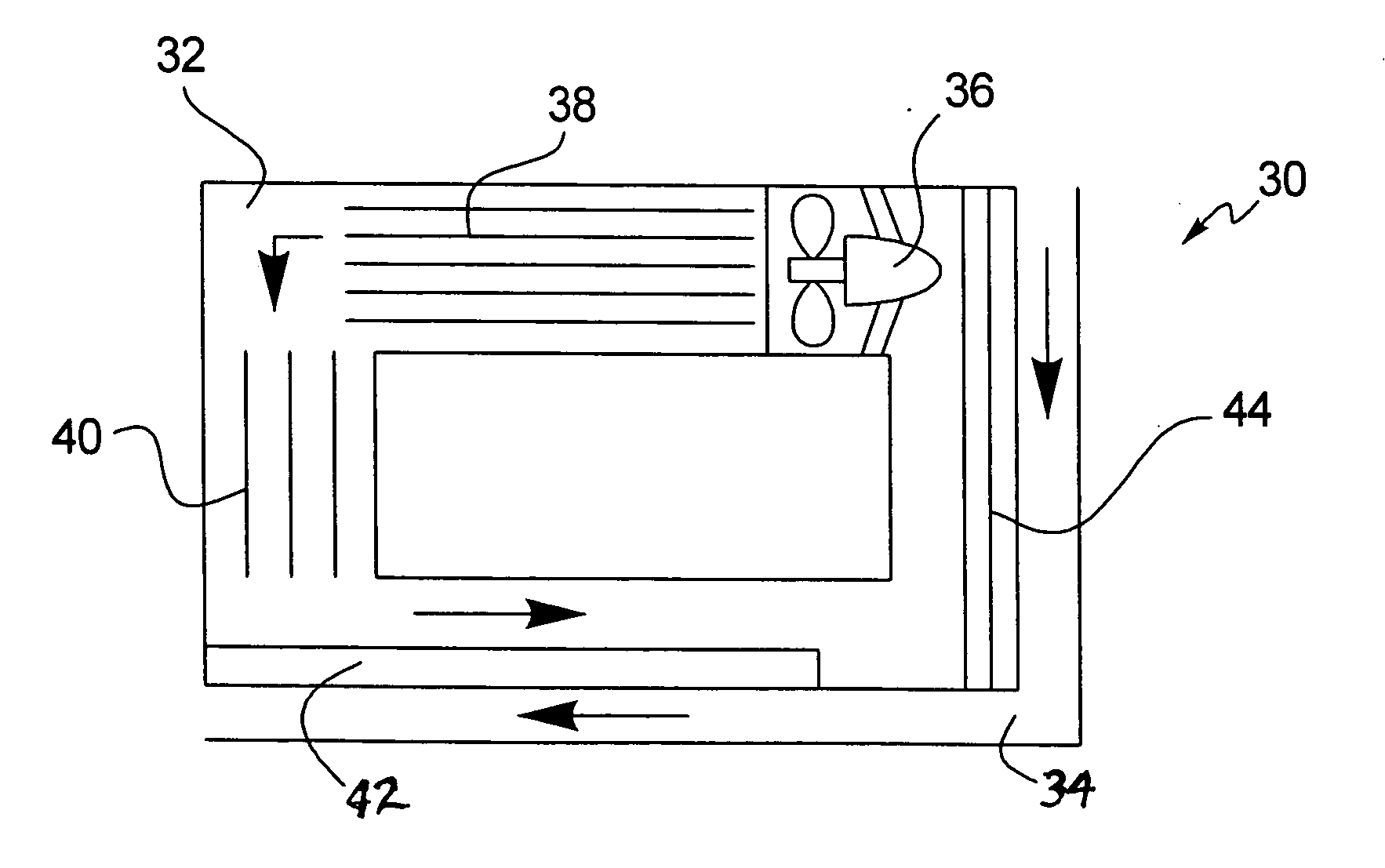

A dual-phase flush urinal that maintains itself in a sufficiently sanitary condition with minimal water consumption. The urinal includes a piece of chinaware having a rear wall with a pair of sidewalls depending normally outward therefrom. A bottom extent of the sidewalls terminates in a curved bowl portion having a fluid well and a water drain therewithin. The sidewalls and rear wall together define a containment area in which an atmospheric vacuum breaker and valve means are disposed. The valve means is in electrical communication with a sensor that detects the presence of a user and has a first fluid discharge port in fluid communication with the bowl portion and a second fluid discharge port. Upon detection of the user, the sensor transmits a first signal to the valve means to initiate a first water exchange phase of the flush cycle. The first fluid discharge port provides water along an elongate channel to remove waste from the bowl portion. After a preprogrammed delay, the sensor transmits a second signal to the valve means to initiate a subsequent, time-delayed wall-scouring phase of the flush cycle. The second fluid discharge port provides water through a urinal spreader to ensure rinsing of the back surface subsequent to actuation of the jet. The valve means operates according to a desired preprogrammed schedule to ensure delivery of adequate water to the urinal jet and expulsion of waste from the urinal to an exterior sewage system.

Owner:AS IP HOLDCO LLC

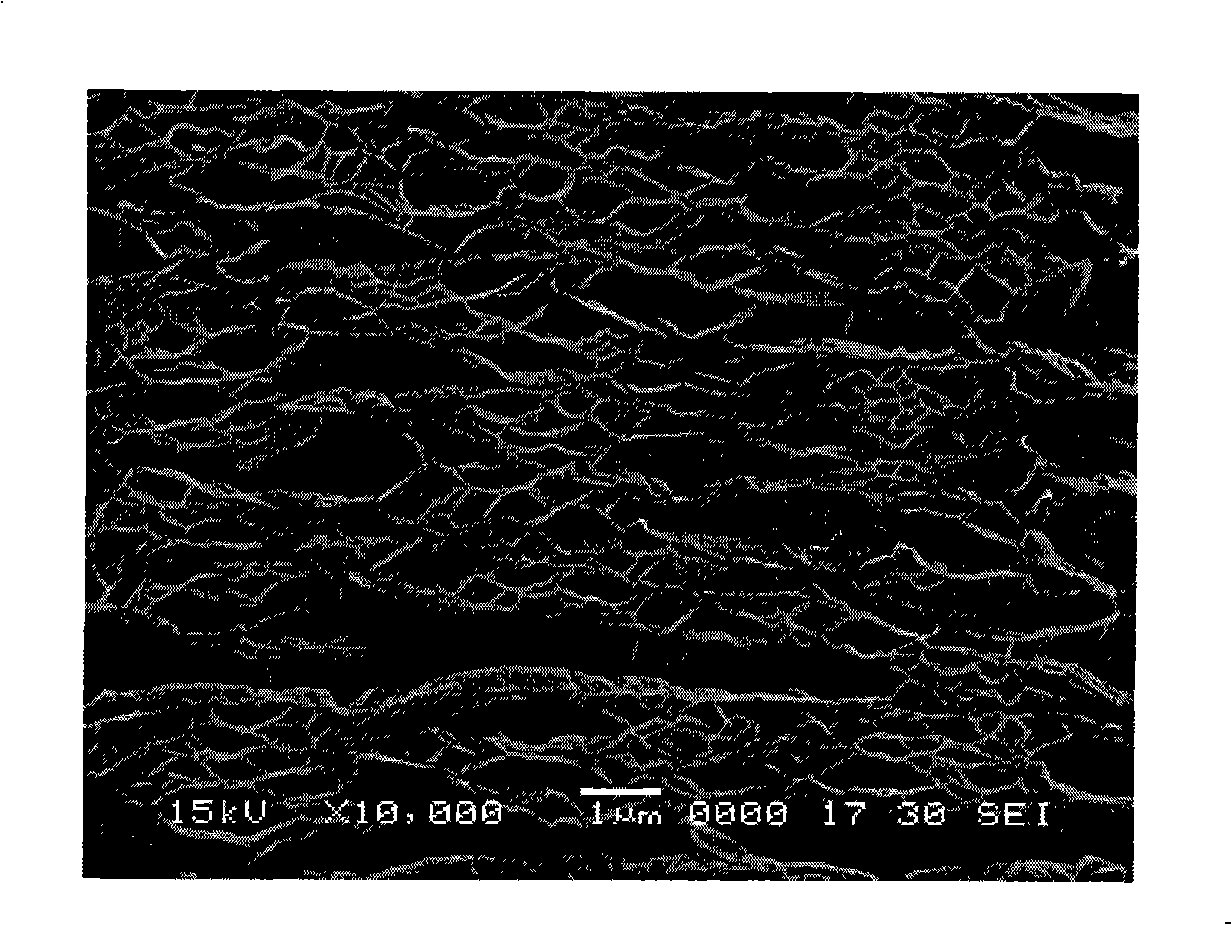

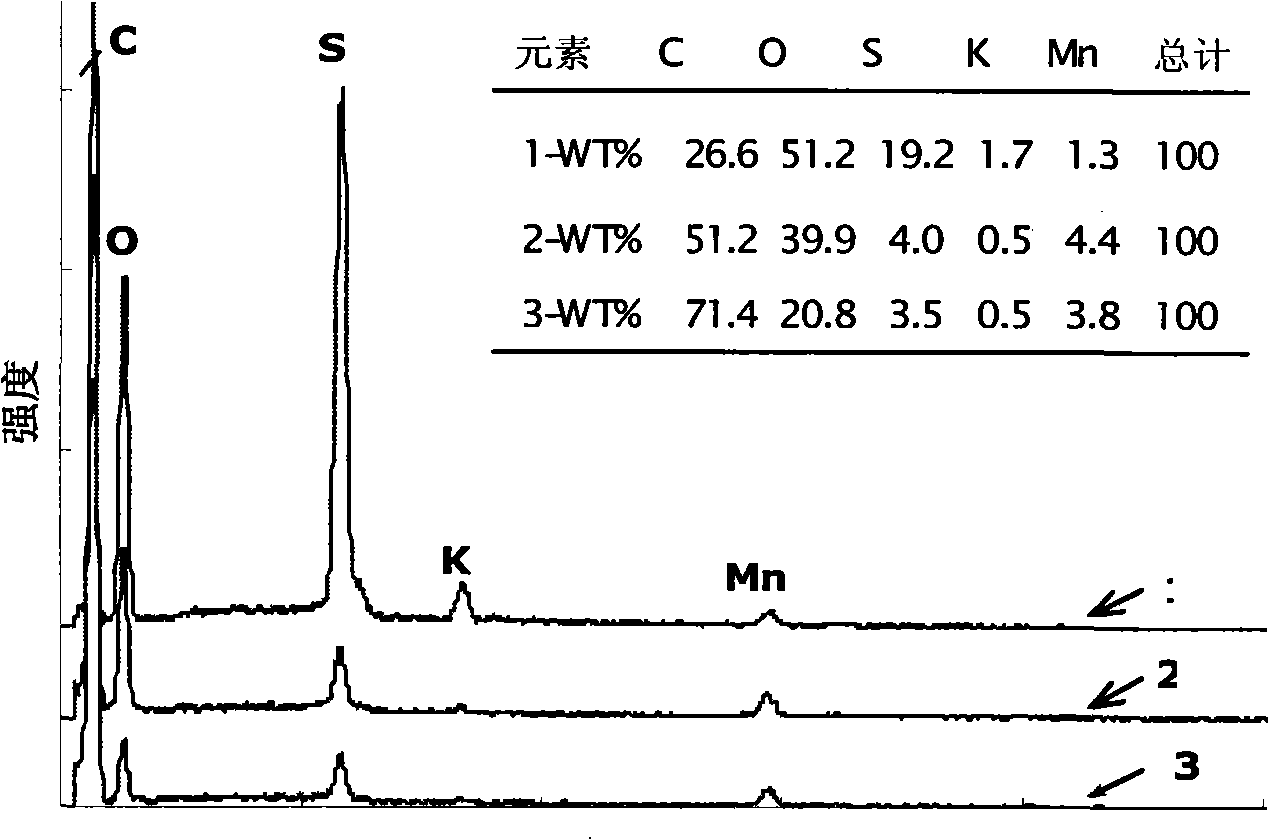

Preparation of low temperature expandable graphite

The invention relates to a preparation method of an expansible graphite (expansible graphite intercalation compound) which comprises the following steps: dipping a flake graphite in a solution mainly formed by oxidant and intercalation agent for intercalation reaction, replacing the intercalation compound between the graphite layers by water exchange method after filtration, drying the obtained solid formation to obtain target compounds. The invention has advantages of low energy consumption, environment friendly, and the prepared expansible graphite is capable of expansion at a low temperature.

Owner:EAST CHINA UNIV OF SCI & TECH

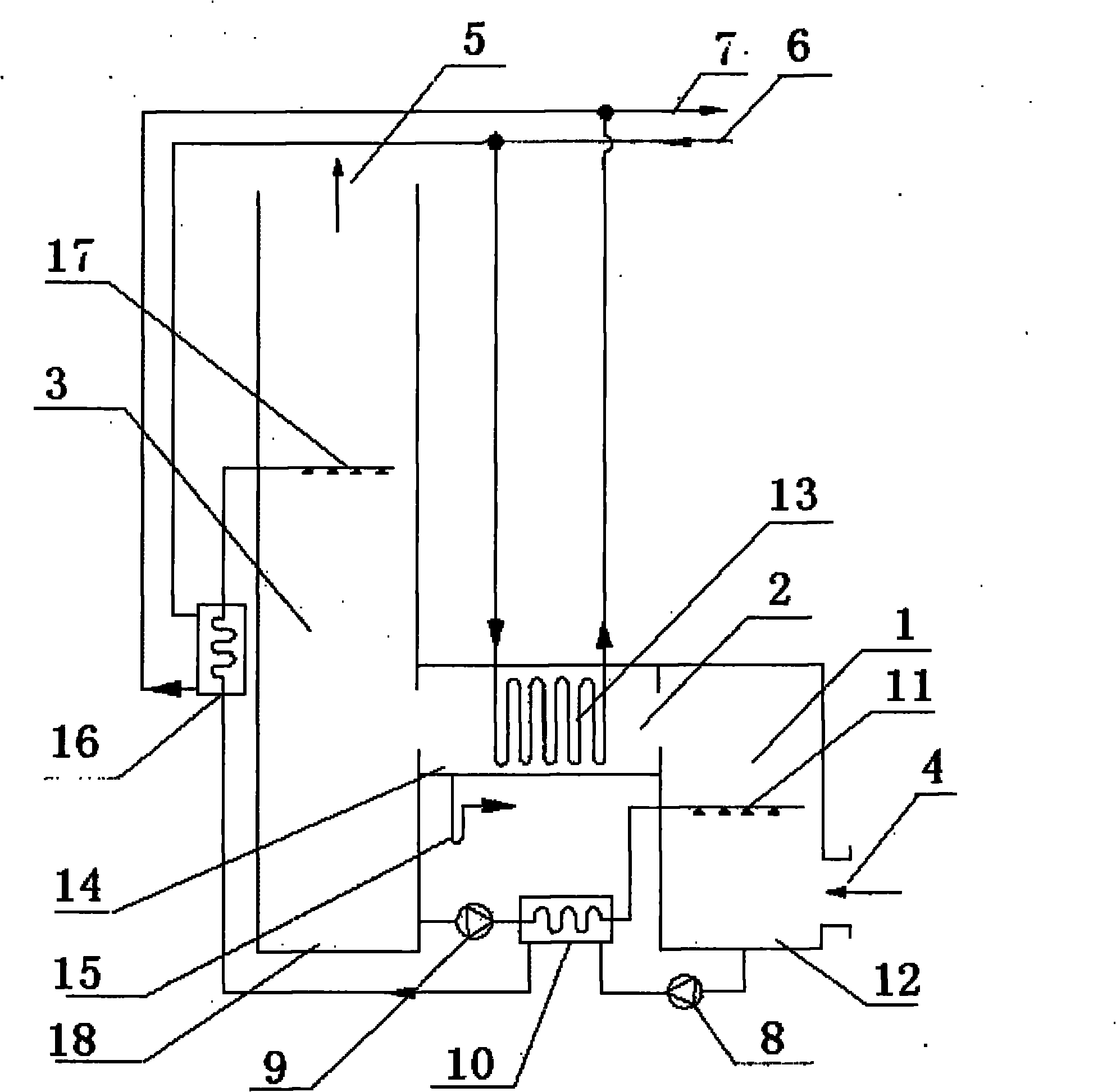

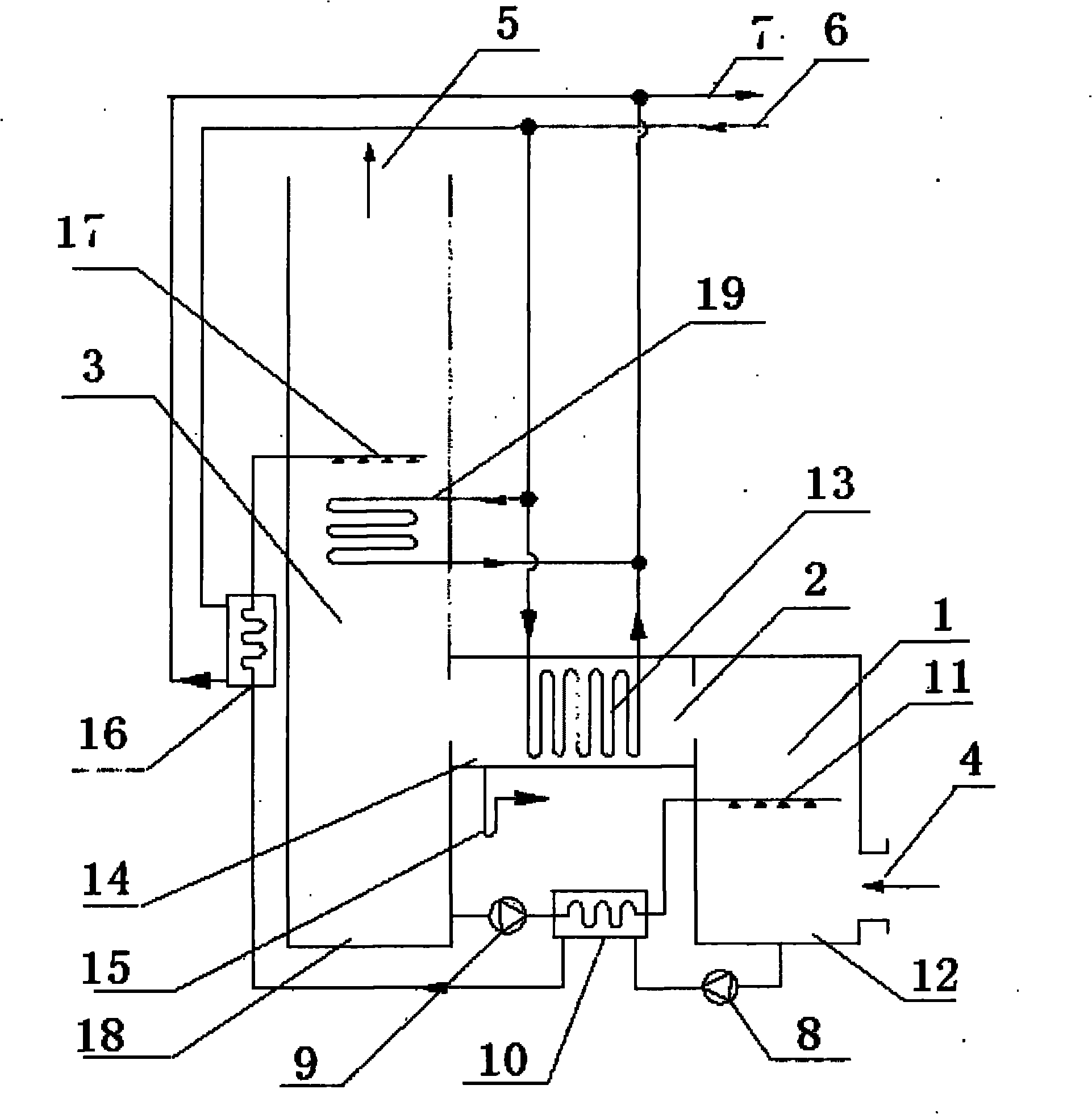

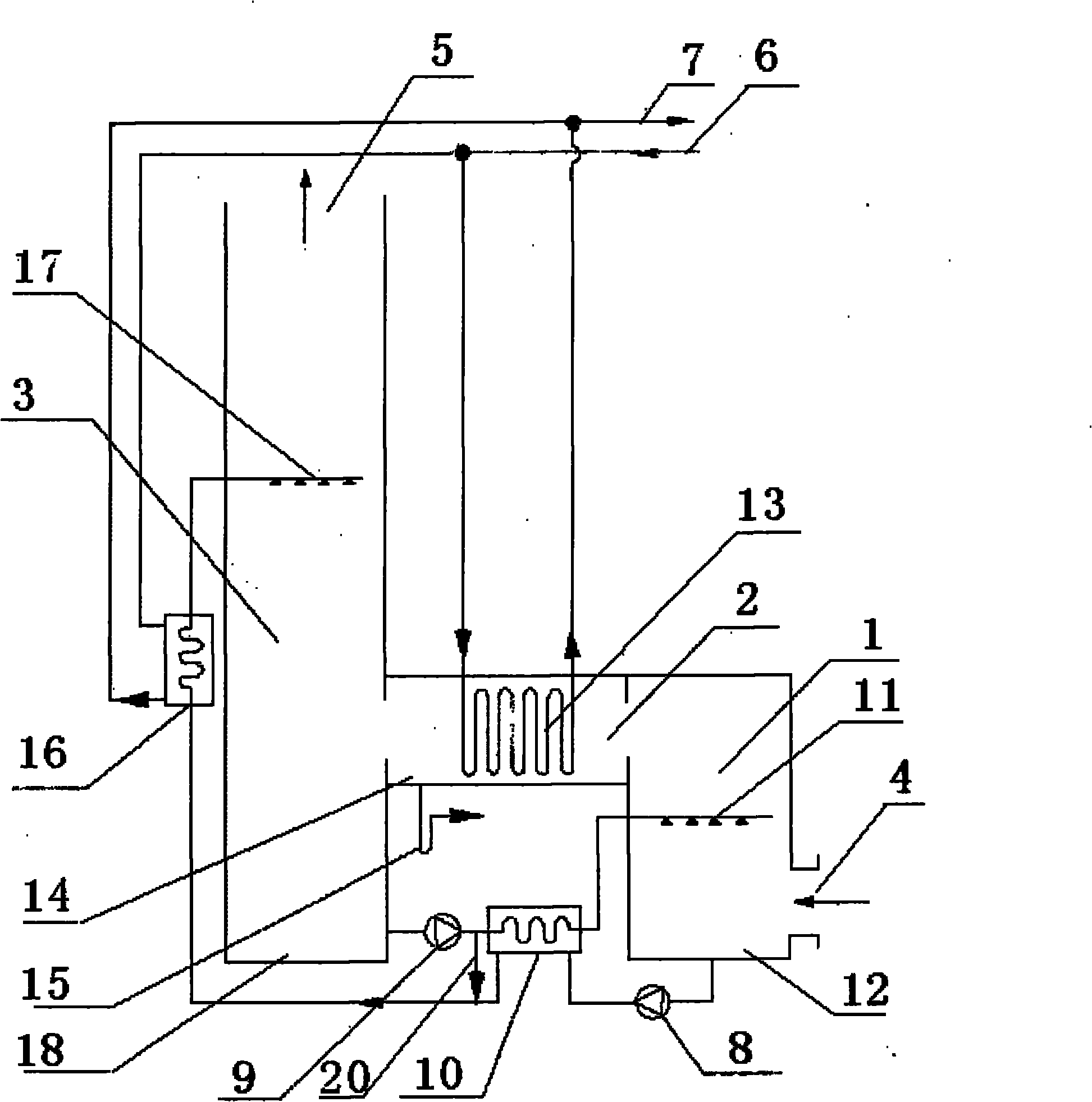

Flue gas waste heat recovery system based on solution absorption cycle

ActiveCN101922799ALower dew point temperatureDiffusion of influenceClimate change adaptationEnergy efficient heating/coolingWater vaporMoisture

The invention belongs to the technical field of energy resources, in particular to a flue gas waste heat recovery system based on solution absorption cycle, which is used for recovering flue gas waste heat and moisture in natural gas. The system consists of a generator, a condenser and an absorber, and the absorber is a one-level absorber or multiple-level serial absorber. High temperature flue gas from a boiler or a gas engine is used for heating a dilute solution in the generator, moisture in the solution is absorbed, the high temperature flue gas becomes high humidity fuel gas, and the dilute solution becomes a concentrated solution. The high humidity fuel gas and cooling water exchange heat in the condenser, the high humidity fuel gas is cooled to below dew point temperature, condensate water is separated out, after being cooled through a solution / solution heat exchanger and a solution / water heat exchanger, the concentrated solution sprays in the absorber and flows downwards, the flue gas flows from bottom to top in the direction opposite to that of the solution, water vapor in the flue gas is absorbed by the solution, and simultaneously, latent heat is discharged and the flue gas is discharged from a chimney. Heating backwater absorbs heat from the condenser, the absorber and the solution / water heat exchanger, and after being heated, the heating backwater can supply heat to a city heating net directly or after being heated by the boiler.

Owner:TSINGHUA UNIV +1

Artificial culture method for Portunus trituberculatus

InactiveCN101790965AEasy to hideCarnage fromClimate change adaptationPisciculture and aquariaSludgeWater quality

The invention relates to an artificial culture method for Portunus trituberculatus in mariculture, and belongs to the technical field of agricultural mariculture. The artificial culture method consists of two parts of technology: 1, an integrated culture regulation method is carried out; and 2, anti-slaughter nets are arranged at the bottom of a pond, 300 nets are arranged in each mu and the slaughter on unshelled crabs by shelled crabs is reduced. The integrated culture regulation method comprises steps of: 1, performing pond regulation: dredging, sterilizing, drying sludge, fertilizing the fond, and laying pipelines at the bottom of the pond and sterilizing the water; 2, performing finite amount of water exchange; 3, regulating the water quality of the culture pond by using composite microorganism agents; 4, reasonable configuring and using aeration facilities; and 5, preparing feeds and reasonably feeding the feeds. Due to the application of the technology, the water quality of the culture pond is improved; the slaughter between the unshelled crabs and the shelled crabs is prevented; and the yield and economic benefit of the portunus trituberculatus are improved.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Integrated apparatus for researching sediment sampling and laminated gradient

InactiveCN101441207AStructural damage is smallKeep the original shapeEarth material testingBiological propertyLight irradiation

The invention provides an integrated device for sampling and layered-gradient research of lake or stream sediments, mainly comprising a sampling and layered-gradient research integrated tube, a constant-temperature lighting system, an exchange system for inlet water and outlet water, a dissolved oxygen control system, an online monitoring system, and a hydropower disturbance system. The invention has the advantages that the sampling tube and the layered-gradient research device are integrated into a whole, thus reducing the artificial disturbance as much as possible to keep the original characters of overlying water and sediments; and the real-time, layered, and non-disturbance observation and sampling can be realized by using the sediment simulator. The device of the invention can be applicable to the research on the change rules of physicochemical characteristics and biological properties of sediments and overlying water in various layers under the condition that the aquatic environment, like simulation temperature, light irradiation, and water body exchange, varies.

Owner:ZHEJIANG UNIV

Integrated process of furfural production as well as wastewater, waste slag and waste gas treatment

InactiveCN101481189ACurb emissionsPollution suppressionOrganic chemistryEnergy inputWater vaporDistillation

The invention belongs to the technical field of the chemical production, and relates to a technology for optimizing energy saving and integrating treatment of waste water, waste slag and waste gas in a furfural production process, which is suitable for the energy saving and the three-waste treatment and reformation of furfural production enterprises. The technology is characterized in that limestone and dolomite are used for neutralizing furfural waste water to convert acetic acid into calcium magnesium acetate, and then the water exchanges heat with high-temperature aldehyde gas generated by a hydrolysis kettle to enter an evaporator; high-temperature vapor generated by the vaporization of the waste water enters the hydrolysis kettle to be used as a reaction medium, the residual concentrated liquid is decolorized for extracting calcium magnesium acetate salt, and the residual liquid is used for smoke desulfurization and denitration. After the low-pressure automatic heating and vaporization of high-temperature aldehyde slag for furfural recovery, the high-temperature aldehyde slag is dried at a low temperature to reduce the water content of the aldehyde slag to be lower than 20 percent. The invention has the advantages that the utilization rates of materials and energy are greatly increased, the zero discharge of three wastes is realized without additional energy consumption, and the calcium magnesium acetate salt of high value is also prepared. After the automatic heating distillation and low-temperature drying of the aldehyde slag, the aldehyde slag is used for active carbon and is effectively and cleanly burnt.

Owner:DALIAN UNIV OF TECH

Method for recovering waste heat from coke oven raw gas

ActiveCN103131432AQuality assurancePrevent poppingCoke oven safety devicesEnergy inputWater vaporCoke oven

The invention relates to a method for recovering waste heat from a coke oven raw gas. The method utilizes water as a heat exchange medium, water exchanges heat with the raw gas having a temperature of about 650-750DEG C in a riser heat exchanger, the temperature of the raw gas subjected to the heat exchange decreases to 480-550DEG C, the heat exchange medium forms a vapor-water mixture after heating, and enters a vapor bag, and the vapor-water mixture is separated to form high temperature water and saturated vapor by a vapor-water separator in the vapor bag; the raw gas discharged from the riser heat exchanger undergoes heat exchange in a bridge tube heat exchanger, the temperature of the raw gas subjected to the heat exchange decreases to 280-350DEG C, and the high temperature water obtained after the separation of the vapor-water separator undergoes heat exchange by the bridge tube heat exchanger, enters the vapor bag and generates saturated vapor, wherein the outer wall of the heat exchanger is cleaned through high-pressure ammonia water intermittent spray or water vapor intermittent blow in the bridge tube; and finally the temperature of the raw gas is reduced to 80-85DEG C by adopting ammonia water, and then the raw gas enters a gas collection tube. The method furthest recovers the waste heat of the raw gas and guarantees the continuous normal work of the heat exchangers under a complex condition.

Owner:BEIJING RISUN TECH CO LTD

Storage tank for hot water systems

InactiveUS6907923B2Reduce heat transferLevel controlHeat storage plantsWater dischargePlate heat exchanger

A heat pump system includes a compressor, a heat rejecting heat exchanger, an expansion device, and a heat accepting heat exchanger. A storage tank stores the water that cools the refrigerant in the heat rejecting heat exchanger. A mechanical interface plate positioned between a hot water reservoir and a cold water reservoir in the storage tank reduces heat transfer between the hot water and the cold water. During a water heating mode, cold water from the cold reservoir flows into the heat sink to cool the refrigerant in the heat rejecting heat exchanger. As the water exchanges heat with the refrigerant, the water is heated in the heat sink, exits the heat sink, and flows into the hot reservoir of the storage tank. During a water discharge mode, the hot water in the hot reservoir is removed from the storage tank and flows into a hot water discharge. Cold water from a water source flows into the cold reservoir of the storage tank to refill the storage tank.

Owner:CARRIER CORP

Dual phase flush urinal

InactiveUS20050039248A1Consumes substantially less waterOvercome deficienciesUrinalsElectricityTime delays

The present invention provides a dual-phase flush urinal that maintains itself in a sufficiently sanitary condition with minimal water consumption. The urinal includes a piece of chinaware having a rear wall with a pair of sidewalls depending normally outward therefrom. A bottom extent of the sidewalls terminates in a curved bowl portion having a fluid well and a water drain therewithin. The sidewalls and rear wall together define a containment area in which an atmospheric vacuum breaker and valve means are disposed. The valve means is in electrical communication with a sensor that detects the presence of a user and has a first fluid discharge port in fluid communication with the bowl portion and a second fluid discharge port. Upon detection of the user, the sensor transmits a first signal to the valve means to initiate a first water exchange phase of the flush cycle. The first fluid discharge port provides water along an elongate channel to remove waste from the bowl portion. After a preprogrammed delay, the sensor transmits a second signal to the valve means to initiate a subsequent, time-delayed wall-scouring phase of the flush cycle. The second fluid discharge port provides water through a urinal spreader to ensure rinsing of the back surface subsequent to actuation of the jet. The valve means operates according to a desired preprogrammed schedule to ensure delivery of adequate water to the urinal jet and expulsion of waste from the urinal to an exterior sewage system.

Owner:AS IP HOLDCO LLC

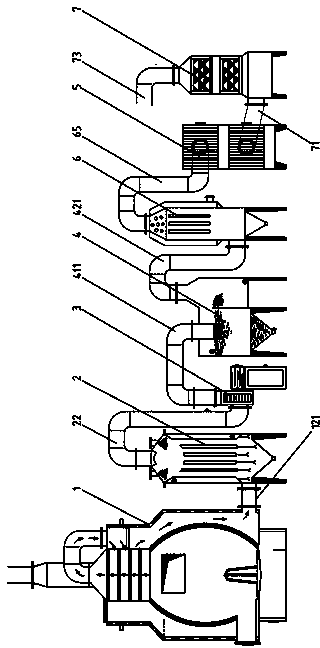

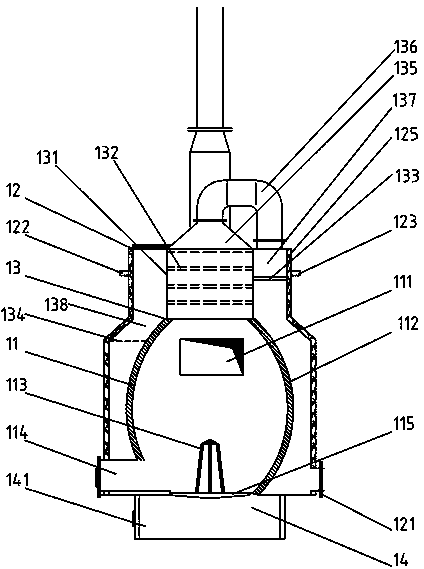

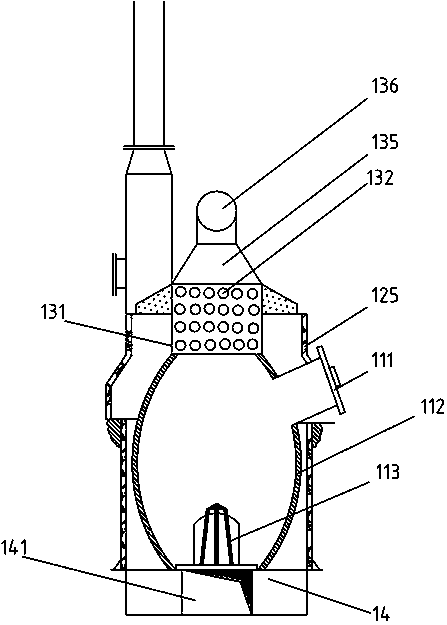

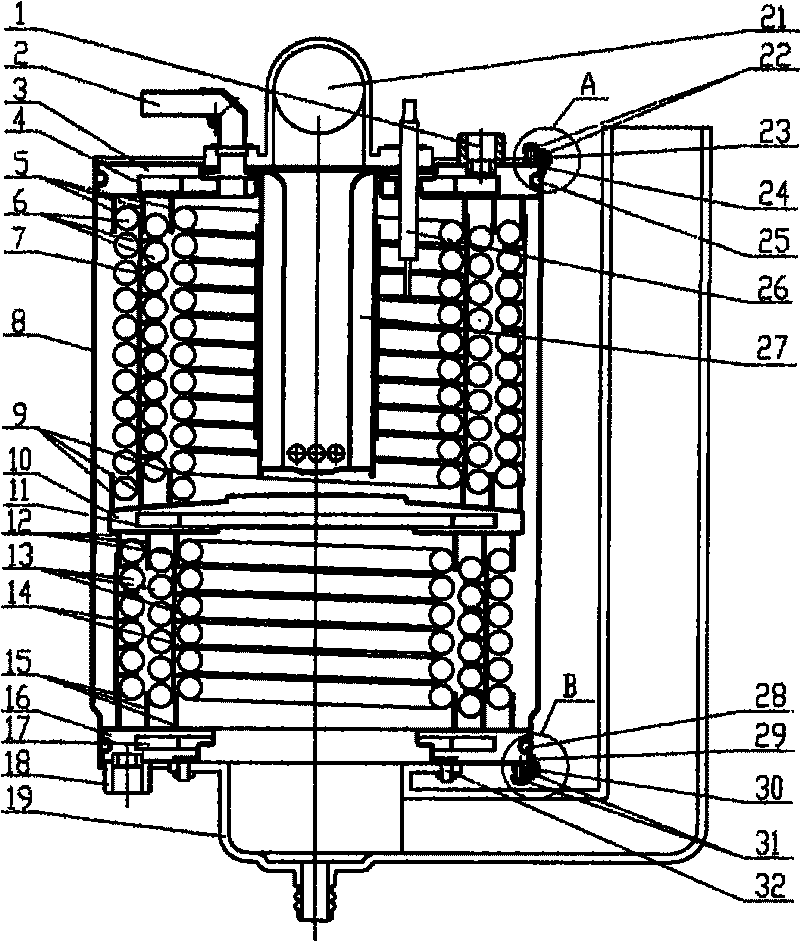

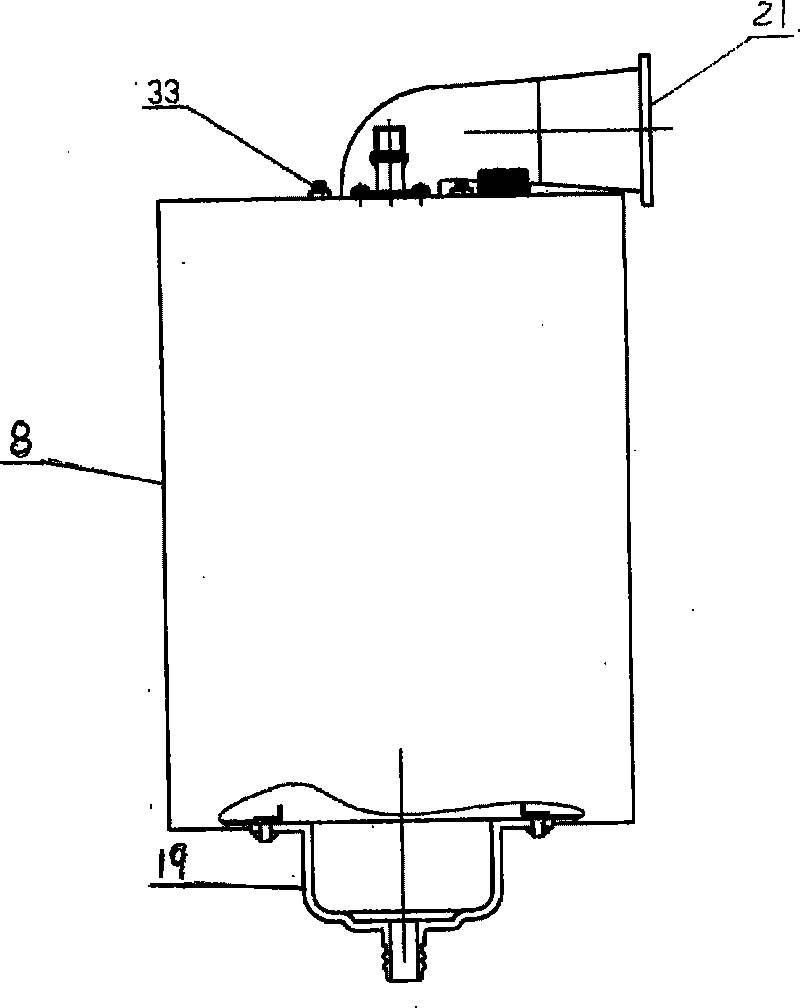

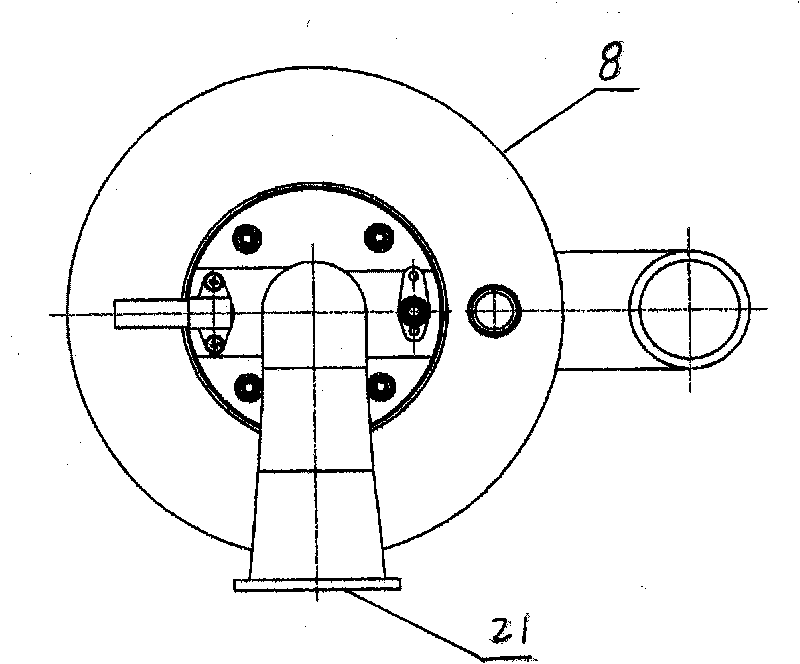

Garbage incineration disposal device

ActiveCN104165365AImprove utilizationHigh interception effectIncinerator apparatusActivated carbonCombustor

The invention discloses a garbage incineration disposal device which comprises an incinerator, a shock cooling type high-pressure spraying dust collection device, an induced draft fan, a smoke and melt water exchange treatment device, a smoke treatment condenser, a winding plate combination ash-sticking dust remover and an activated carbon adsorption chamber, wherein the incinerator, the shock cooling type high-pressure spraying dust collection device, the induced draft fan, the smoke and melt water exchange treatment device, the smoke treatment condenser, the winding plate combination ash-sticking dust remover and the activated carbon adsorption chamber are sequentially connected. The incinerator comprises an incinerator body, a hearth combustor, two combustors and an incinerator body base. The shock cooling type high-pressure spraying dust collection device comprises a spraying case, a smoke inlet pipe joint, a spraying water gathering hopper and a smoke outlet pipe joint. The smoke and melt water exchange treatment device comprises a smoke and melted water exchange treatment action tank, a water and smoke passing tank and an overflow gap water line control sideboard. The smoke treatment condenser comprises a condenser case, a smoke outlet pipe joint and a second smoke inlet pipe joint. The winding plate combination ash-sticking dust remover comprises an upper dust remover body and a lower dust remover body. The activated carbon adsorption chamber comprises an adsorption chamber case, a third smoke outlet pipe joint and a third smoke inlet pipe joint. The device saves energy, is environmentally friendly, generation of dioxin can be effectively restrained, garbage is combusted fully, and the maintenance cost is low.

Owner:SHE COUNTY LVYUAN ENVIRONMENTAL PROTECTION EQUIP CO LTD

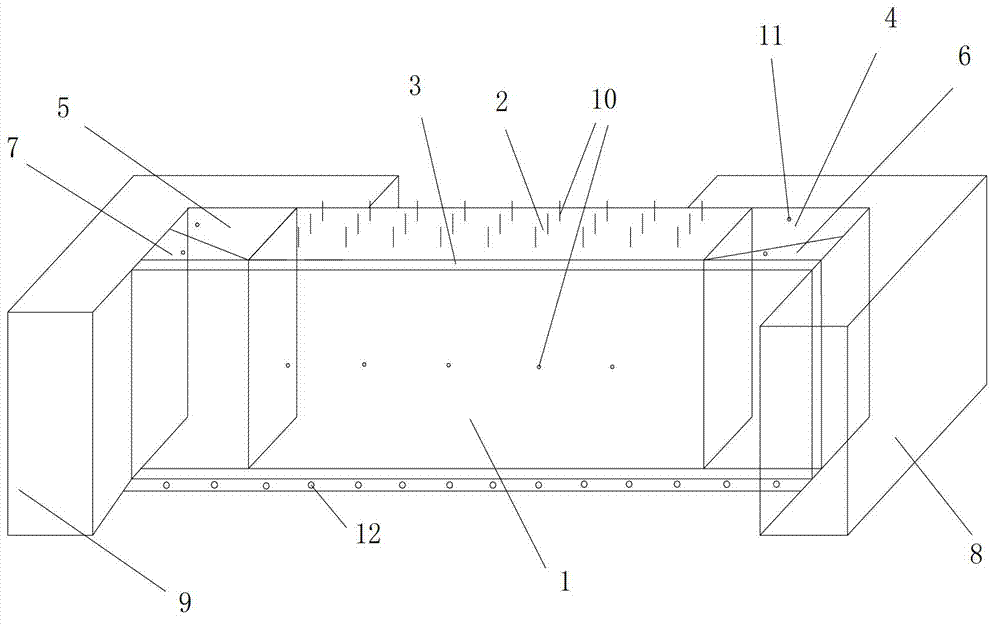

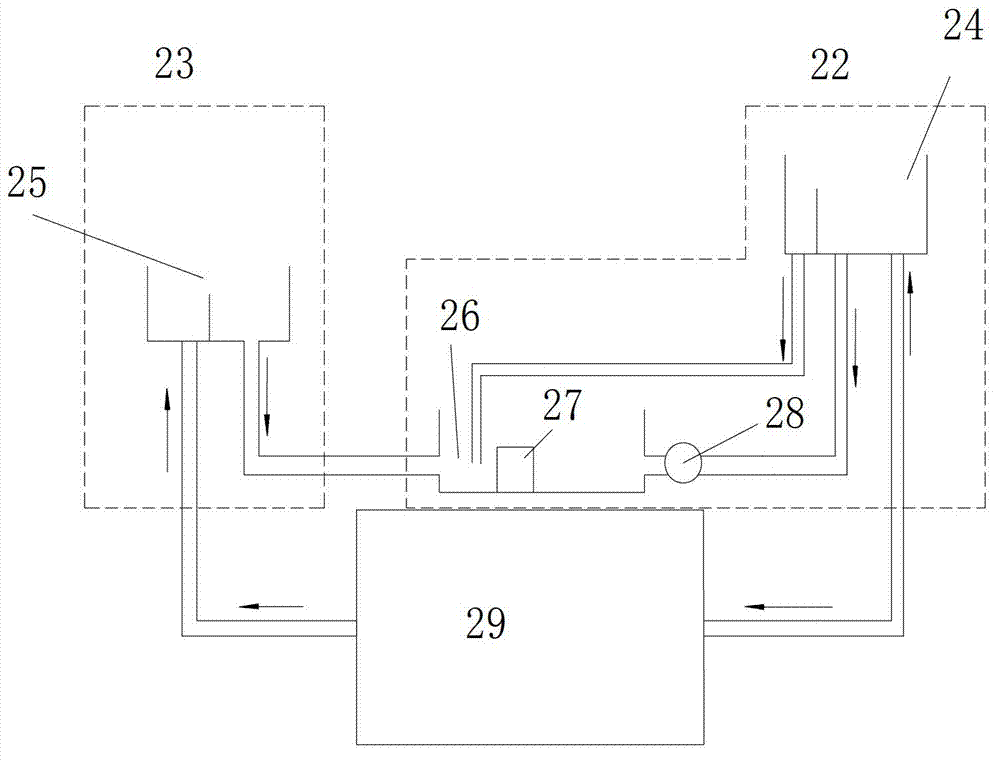

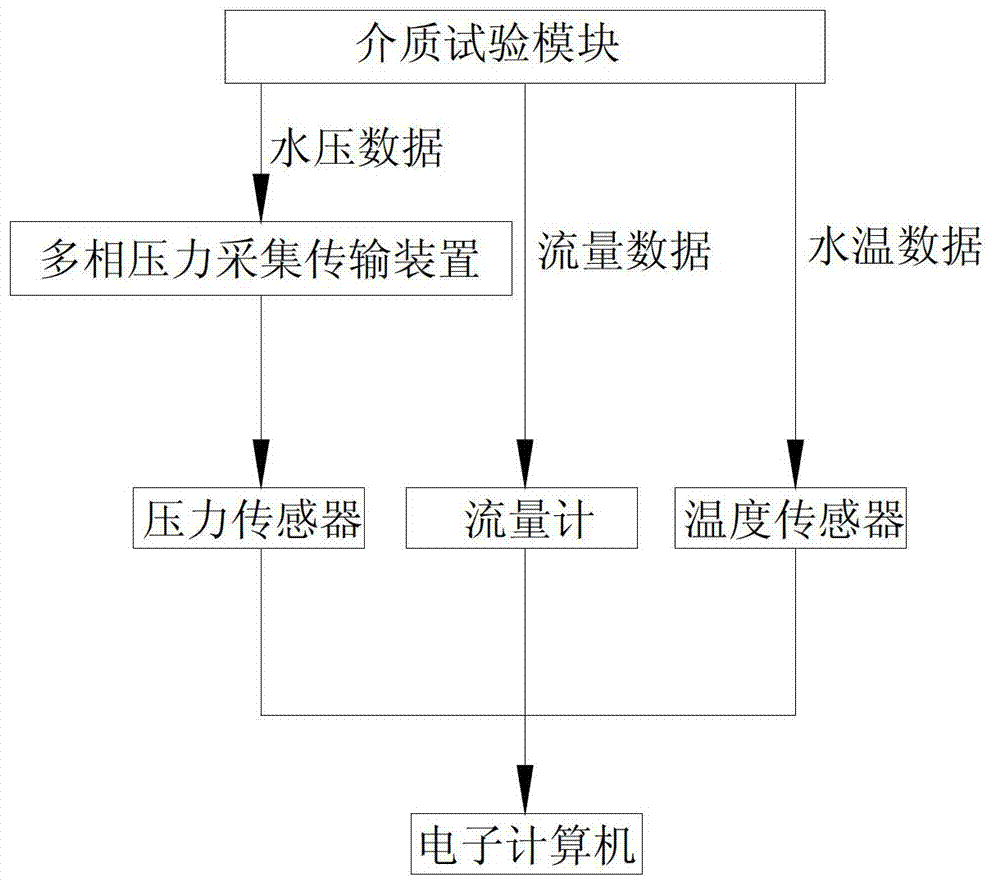

Test system for simulating pore-fissure double-medium seepage hydraulic characteristics

InactiveCN102890147AReal-time acquisitionReal-time collection of mutual permeability of water flow between two mediaEarth material testingData acquisitionWater circulation

The invention discloses a test method for simulating pore-fissure double-medium seepage hydraulic characteristics. The test method comprises a medium experiment module, a water circulation control module and a data acquisition module, wherein the medium experiment module comprises a box body and a pore medium which is arranged in the middle of the box body; an interval-adjustable fissure medium is formed between the pore medium and the inner wall of the box body; two ends of the pore medium in the box body are provided with a pore medium water inlet tank and a pore medium water outlet tank respectively; two ends of the fissure medium in the box body are provided with a fissure medium water inlet tank and a fissure medium water outlet tank respectively; the water circulation control module comprises a water supply system and a water return system; and the data acquisition module comprises a temperature sensor, a flow meter and a pressure sensor. By the experiment system, the defects that in the conventional fissure seepage test system, the permeability of the pore medium is ignored, double-medium water exchange information can not be obtained, and the like are overcome, and the test system is better matched with the practical situation.

Owner:HOHAI UNIV

High-efficiency condensing type heat exchanger

InactiveCN101726109AImprove heat transfer efficiencySafety devices for heat exchange apparatusEnergy efficient heating/coolingEngineeringWater vapor condensation

The invention relates to a high-efficiency condensing type heat exchanger which comprises a tubular shell, an upper-layer water tank, an upper spiral sleeve pipe, a middle-layer water tank, a lower spiral sleeve pipe, a lower-layer water tank and a U-shaped condensed water collection smoke exhauster. The heat energy generated in the combustion process of water exchange is used for lowering the temperature of the smoke generated in the combustion process, and the water vapor in the smoke is condensed into the liquid state from the gaseous state to generate condensed water, thereby absorbing the latent heat emitted in the condensation process and improving the heat exchange efficiency of the heat exchanger. In the invention, the shell has a dismountable internal structure, can be cleared and maintained easily, improves the heat exchange efficiency of the heat exchanger, is suitable for various products of gas-fired hot water, and is suitable for domestic gas-fired hot water heating equipment and the like.

Owner:GUANGDONG ROC COOLING & HEATING EQUIP

Water soluble preservative film for fruits and vegetables and preparation method of preservative film

ActiveCN102898668ASuitable for freshnessSuitable for storageFruits/vegetable preservation by coatingPolymer sciencePolyvinyl alcohol

The invention relates to a water soluble preservative film for fruits and vegetables and a preparation method of the preservative film. The water soluble preservative film for the fruits and vegetables is mainly prepared by the following materials in percentage in weight: 50 to 80% of polyvinyl alcohol with alcoholysis degree of less than 90%; 10 to 30% of polyhydroxy plasticizer, 1 to 5% of auxiliary film forming agent, 3 to 8% of low temperature antifreeze agent, 3 to 10% of adsorbent filling agent and 0.3 to 2% of film-forming adding additive. The preparation method comprises the following two steps of: 1, after metering contents of components of the preservative film in the formula, obtaining a uniform aqueous solution with concentration of 15 to 25% in water; and 2, uniformly casting the prepared solution on a clear steel band, and drying the solution to obtain the film through a dried drying tunnel with temperature of 120 to 180 DEG C. The preservative film has a high barrier property against oxygen, carbon dioxide and nitrogen and the like, and has a high bidirectional permeable exchange capacity for steam, thereby guaranteeing free breathing and water exchange of the fruits and vegetables in a preserving process.

Owner:深圳市乾健科技有限公司

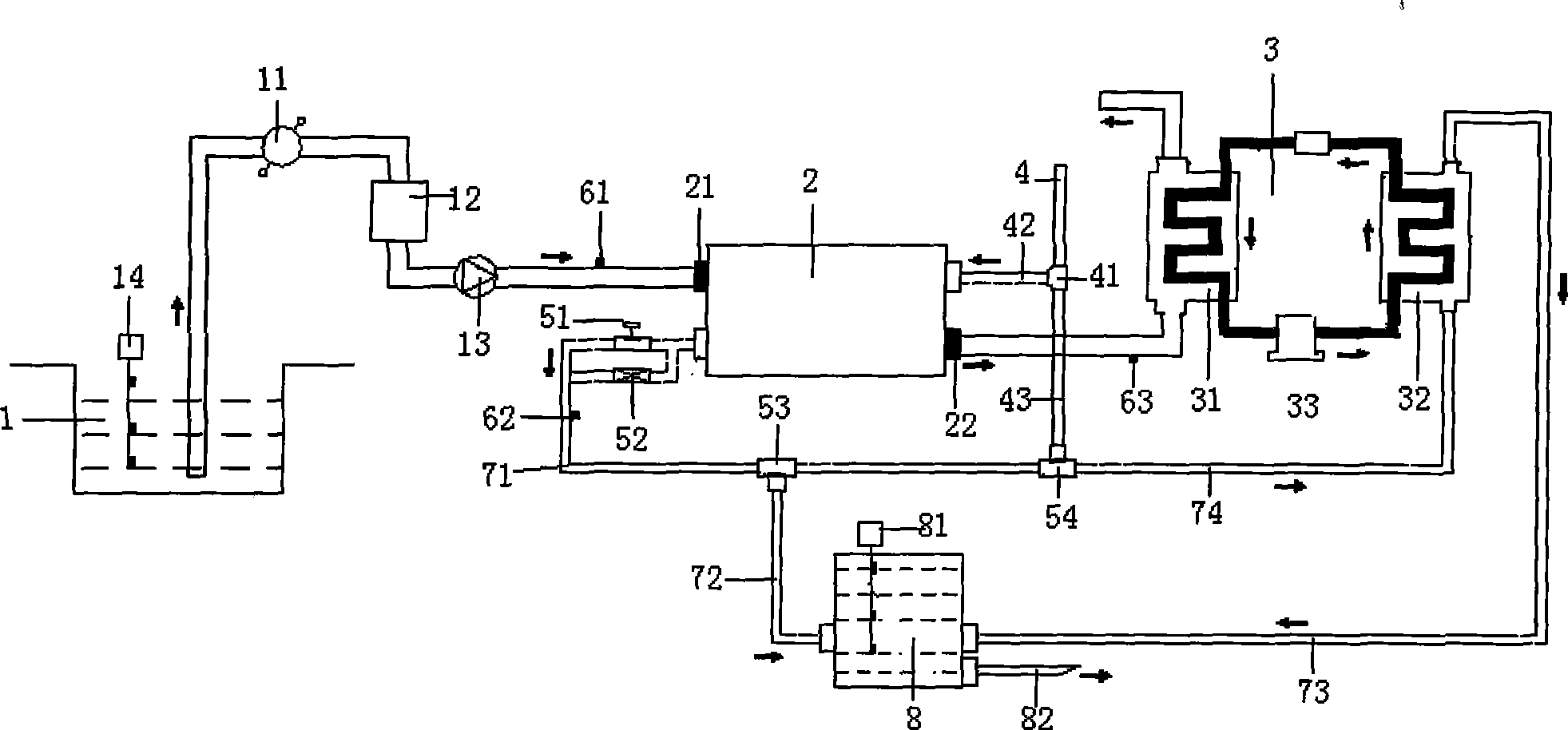

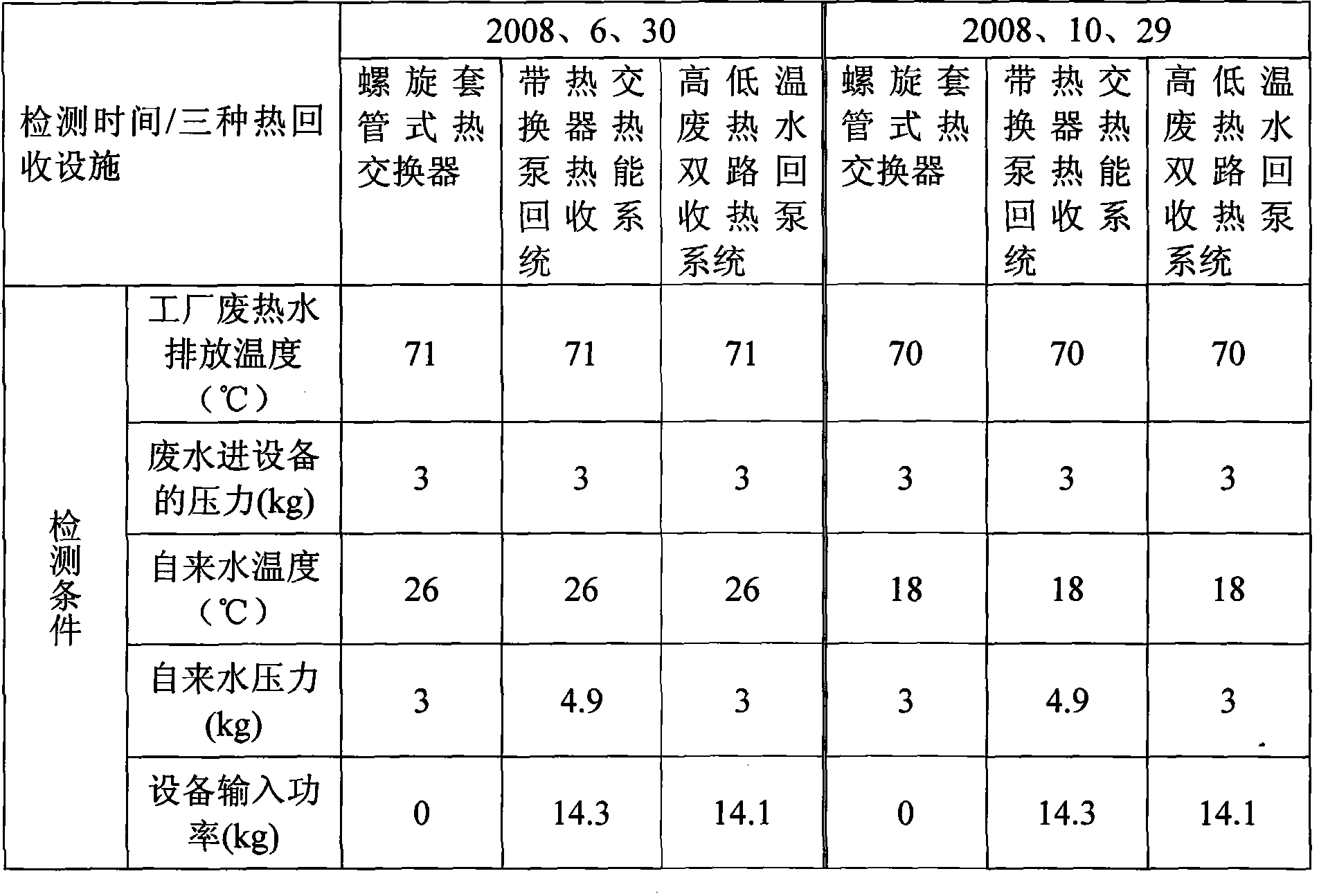

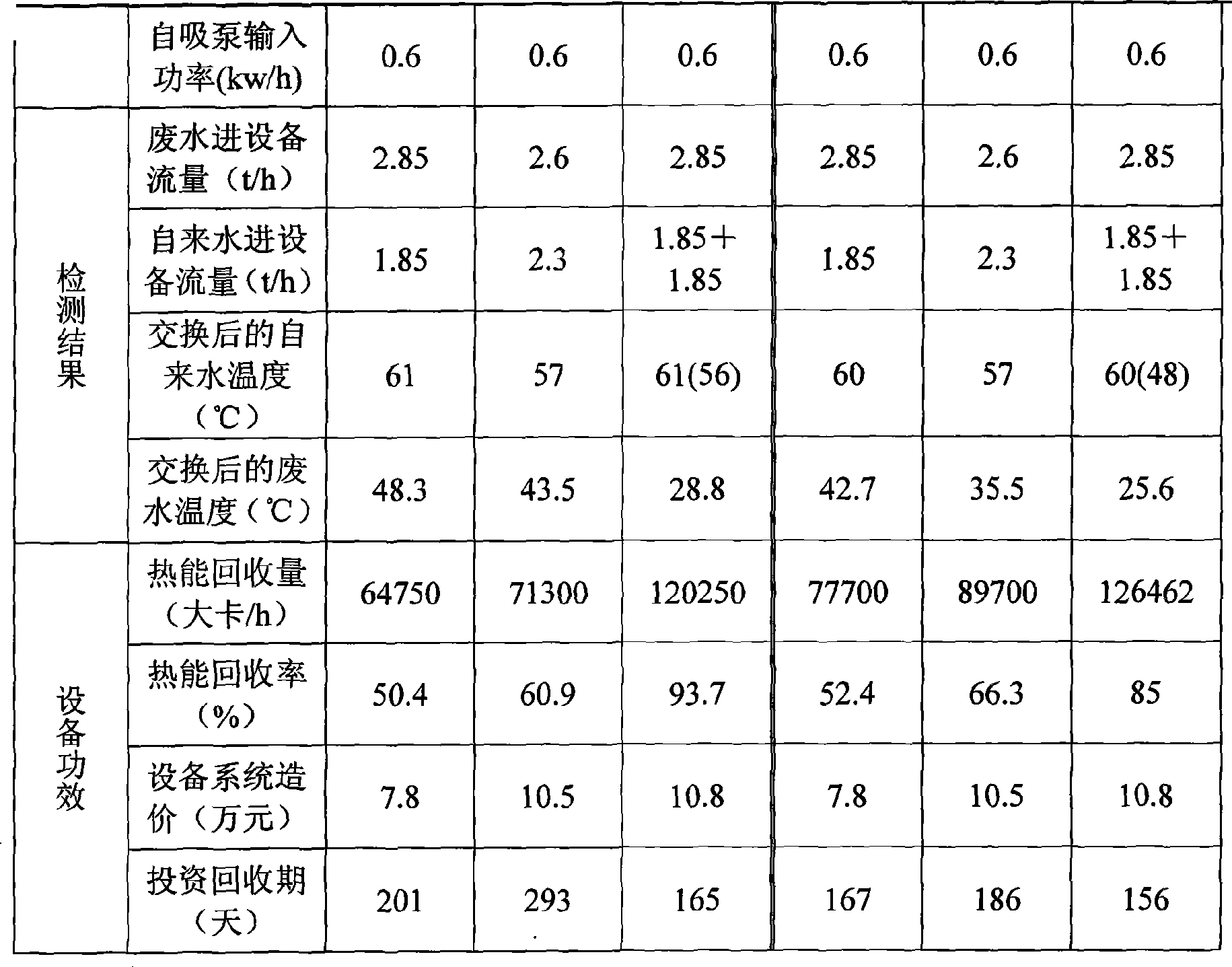

High-low temperature waste water double-channel heat recovery heat pump system

ActiveCN101520257ASolve the problem of fully recovering heat energyGuaranteed uptimeFluid heatersHeat pumpsThermal energyAutomatic control

The invention relates to a high-low temperature waste water double-channel heat recovery heat pump system. The high-temperature waste water heat recovery of the system is designed with single-channel waste water input and double-channel heat output. Through operation adjustment, one of two heat double-channel output routes is that running water exchanges heat with waste water through a heat exchanger, and after temperature rise, the running water transmits the recovered heat to a heat storage water tank; meanwhile, the other route is that under the automatic control of the system, part of running water is added to enter a condenser of a hot water source heat pump to exchange heat with a refrigerant gas and outputs recovered heat to the heat storage tank. The system radically solves the problem of recovery and use of high-temperature waste hot water, recovers heat of high-low temperature waste water with one set of system equipment, protects the heat pump from overheat protection to maintain the normal operation of the system and is wide in application ranges; after heat recovery, the temperature of the wasted water is reduced greatly, and the heat recovery amount and rate of the system are more than 40 percent higher than other heat recovery modes; and the system has the advantages of high efficiency, energy conservation, high input-output ratio, low operation cost, obvious economic benefits and so on.

Owner:江苏恒信诺金科技股份有限公司

High-density cultural method of loaches

InactiveCN101574067AHigh densityImprove efficiencyClimate change adaptationPisciculture and aquariaBiological propertyHigh density

The invention relates to a high-density cultural method of loaches, which is exclusively used for cultivating the loaches and comprises the steps of designing and building ponds, using a high-density cultural technique and designing a water supply and drainage system to perform water quality management. The method can satisfy the biological characteristics of benthonic property, thermophily and shallow water of the loaches, solve the problems that the loaches are good at escaping, are fond of burrowing and are easy to be harmed by natural enemies of mice, snakes and the like, and also solve the problems of water exchange, feedstuff feeding, upper layer algae, oil pollution, discharging of bottom layer impurities and the like. The method has the advantages of high density of the loaches, more increase in yield, low risk, high benefit and wide practicability.

Owner:GANYU LOACH BREEDING IND ASSOC

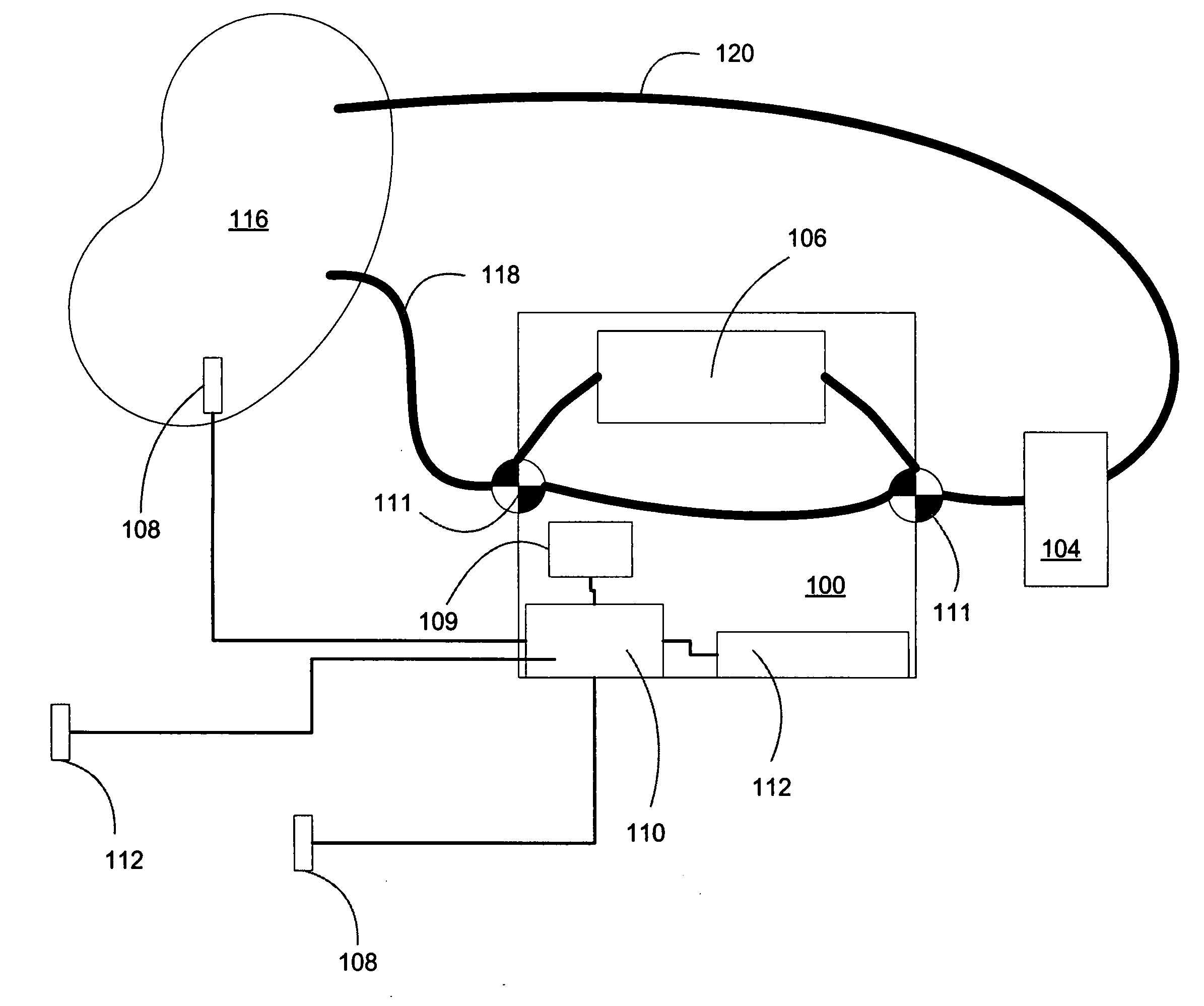

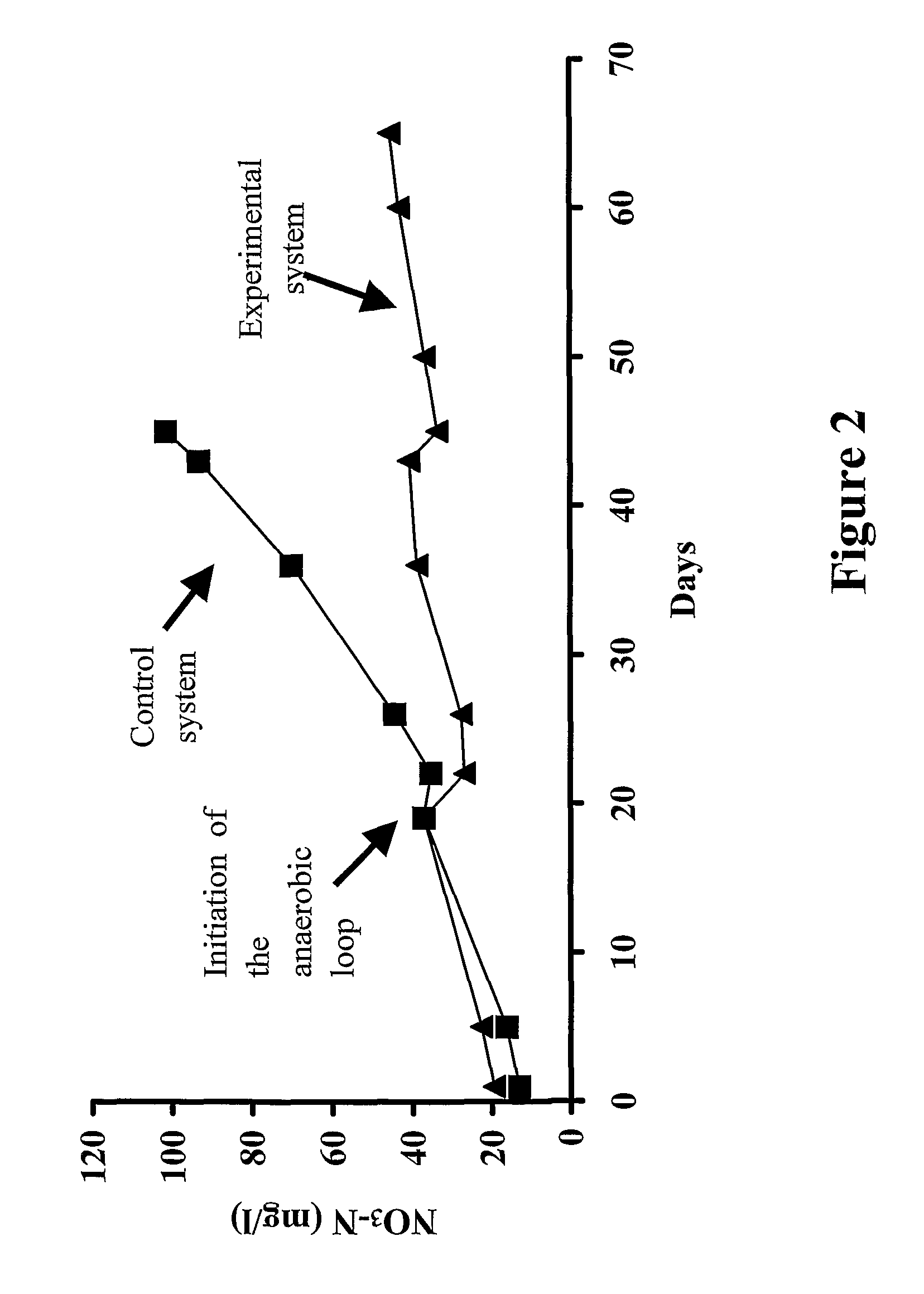

Dissimilatory sulfate reduction as a process to promote denitrification in marine recirculating aquaculture systems

InactiveUS7462284B2Promote autotrophic denitrificationPromote dissimilatory sulfate reductionWater treatment parameter controlWater contaminantsHigh concentrationSludge

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

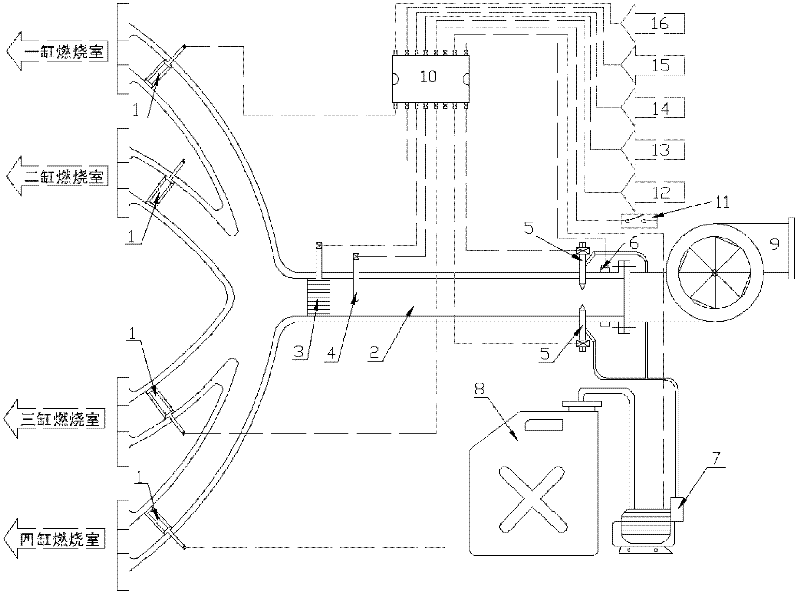

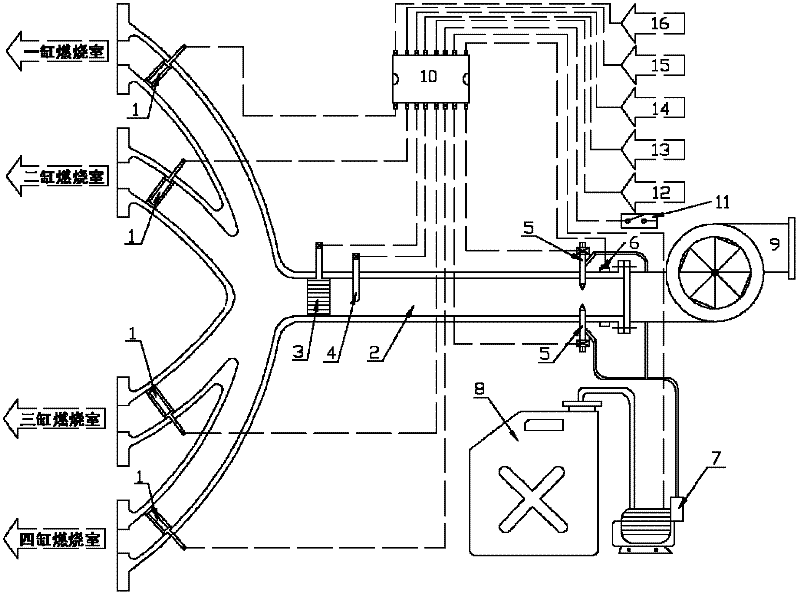

Engine intake pipe water injection system

InactiveCN102269081AAdjustable water supplyEasy to modifyNon-fuel substance addition to fuelMachines/enginesPower sensorCombustion chamber

The invention discloses an air intake tube water spray system of an engine. Each intake manifold leading to a combustion chamber is internally provided with a convex evaporation belt; an air intake duct general pipe is sequentially provided with a grate-type liquid drop evaporator, an air intake temperature sensor, an electromagnetic high-pressure water atomizing nozzle and an air intake flow rate sensor; the electromagnetic high-pressure water atomizing nozzle is sequentially connected with a high-pressure water pump and a water storage pump in series; an inlet end of the air intake duct general pipe is provided with a gas compressor; and a main control chip in an air intake pipe water spray electric control subsystem is respectively connected to the components above through a light beam, as well as is connected to a manual / automatic water spray water exchange switch, a cooling water temperature sensor, a power sensor, a fuel oil consumption sensor, an exhaust temperature sensor, a rotation speed sensor and the like. The intake air is ensured to have favorable water atomization under the condition of no improvement of air intake temperature as far as possible to achieve the optimal temperature control effect; and the system provided by the invention can be controlled full-automatically and exchanged manually, the system is easy to modify on the existing engine, and the control accuracy is high, and the air intake pipe water spray strategy can be regulated appropriately as the working conditions of the engine.

Owner:TIANJIN UNIV

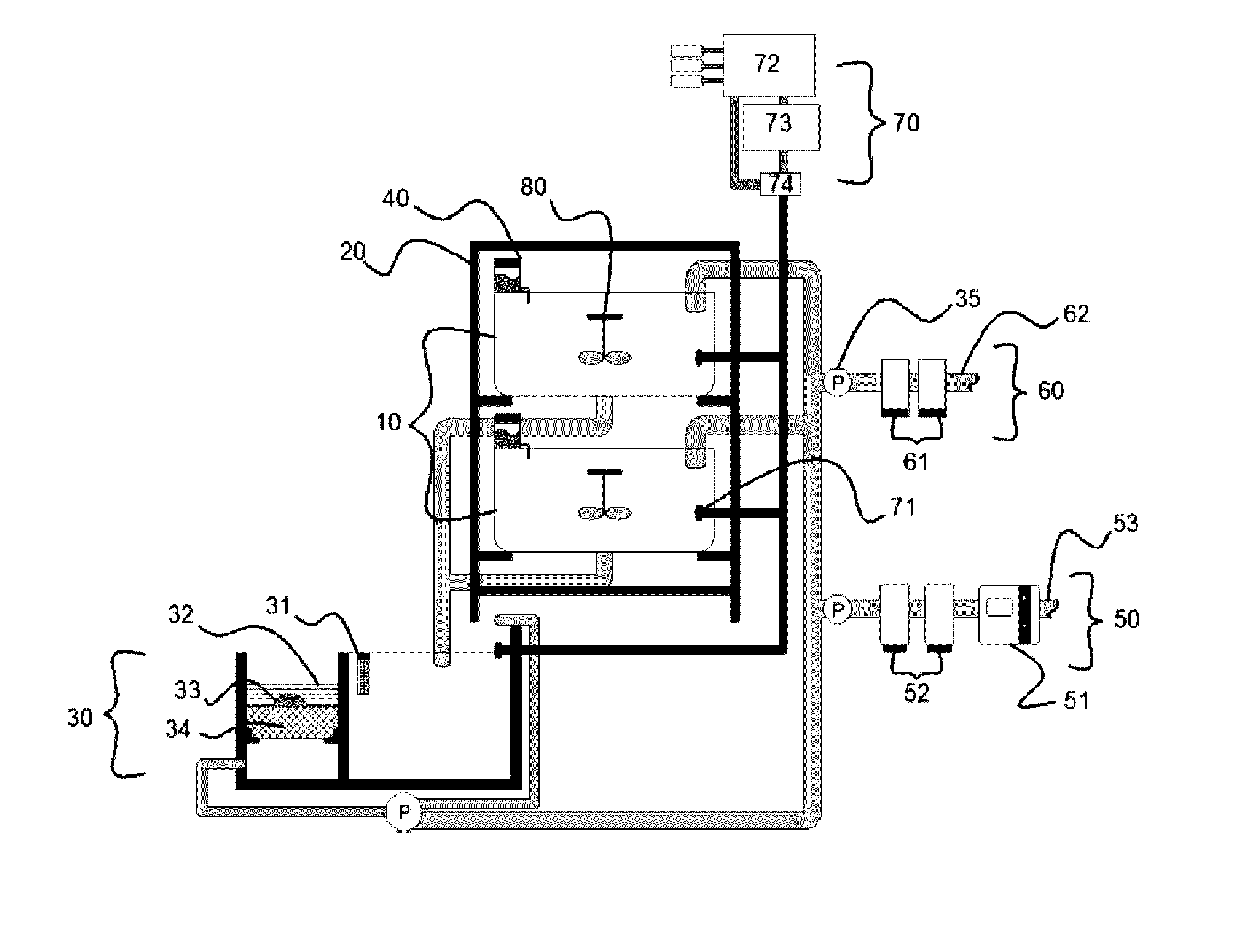

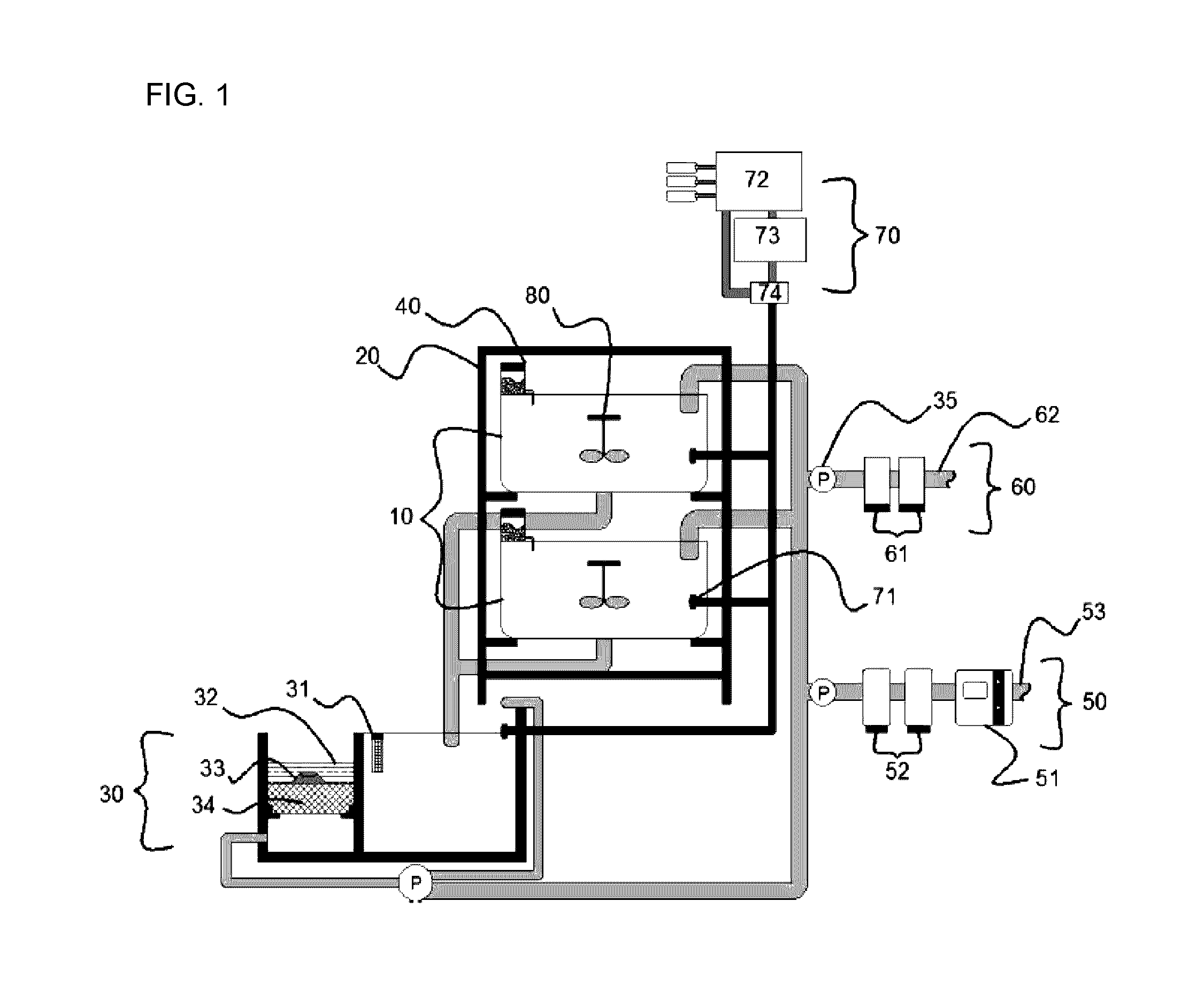

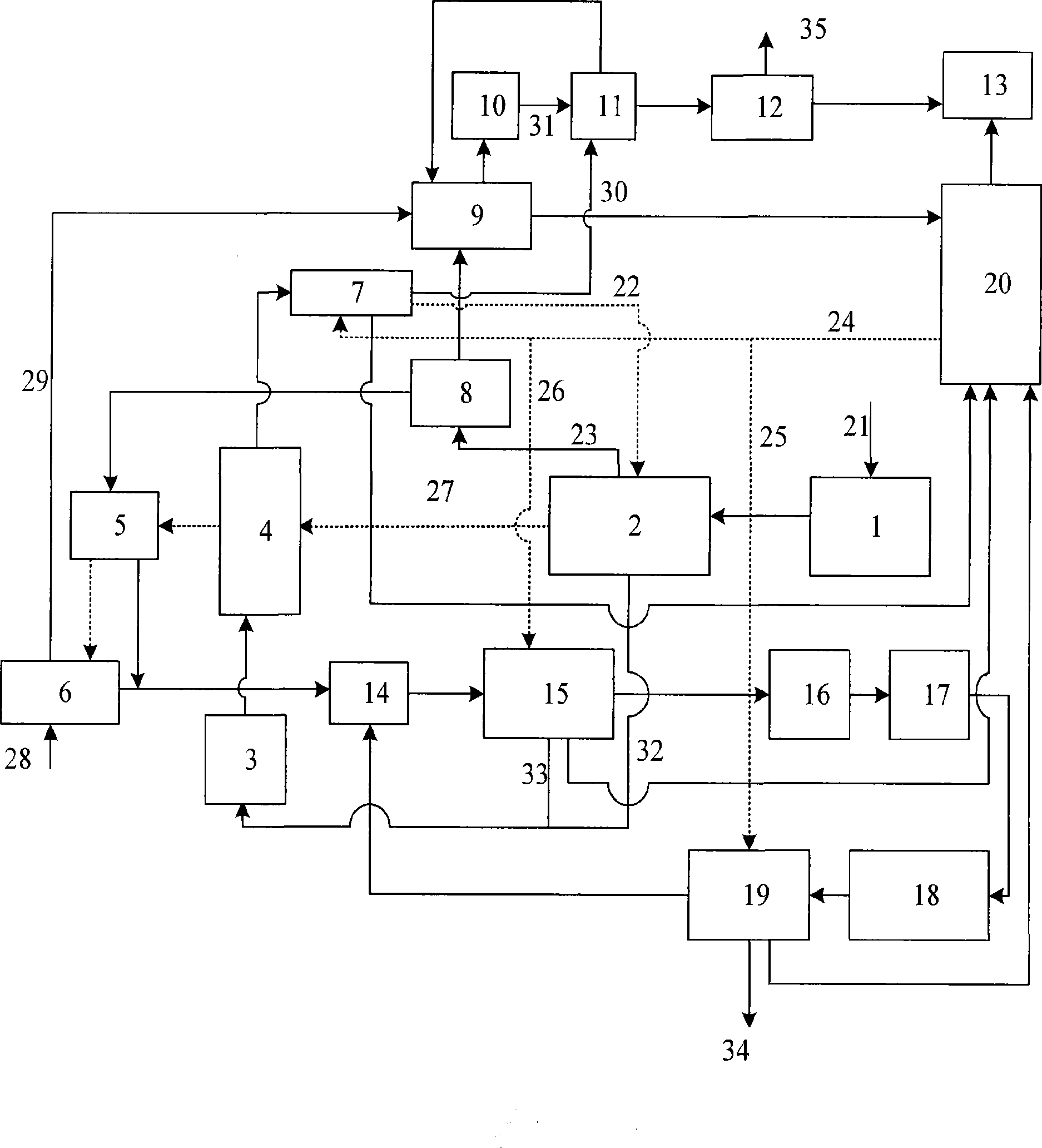

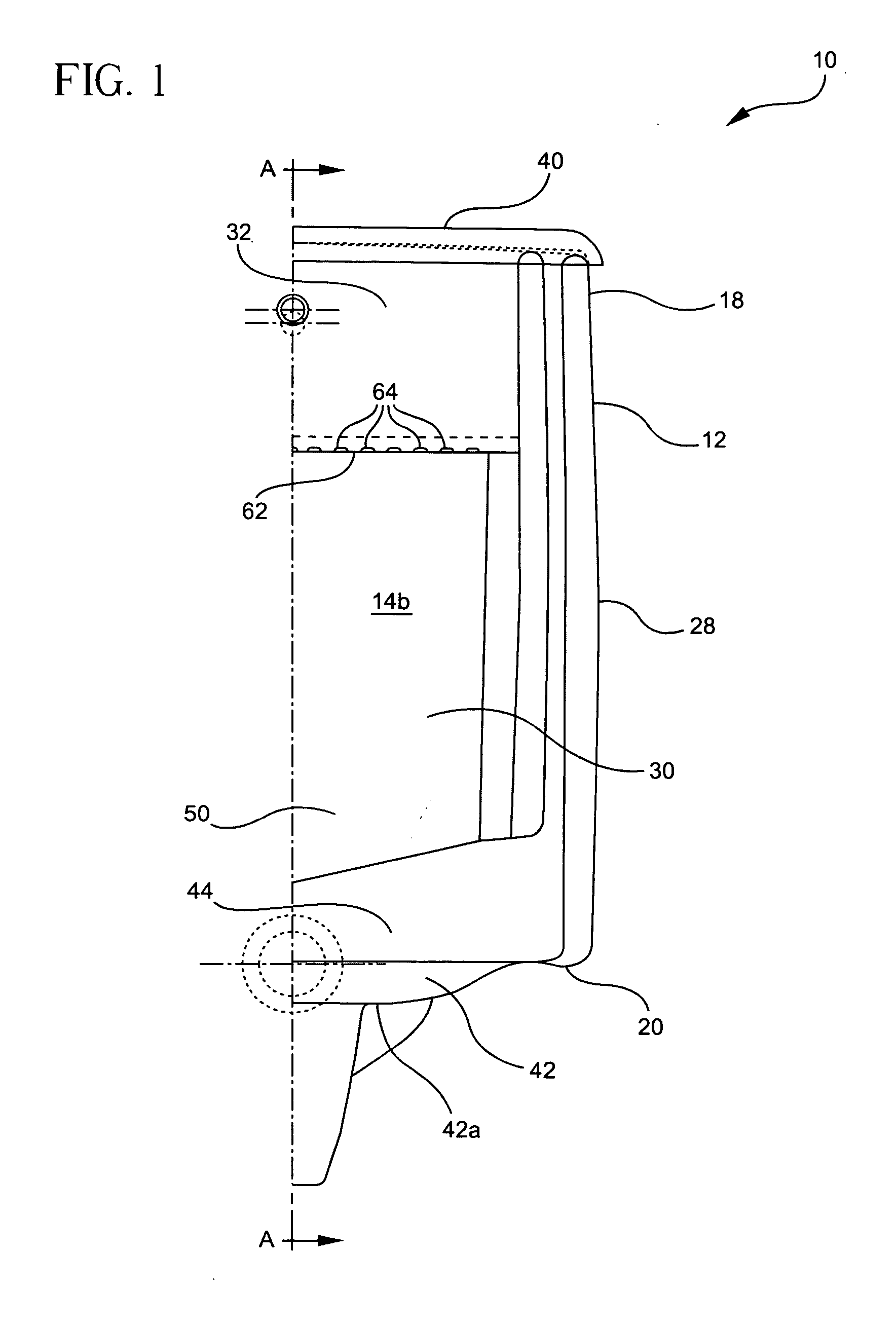

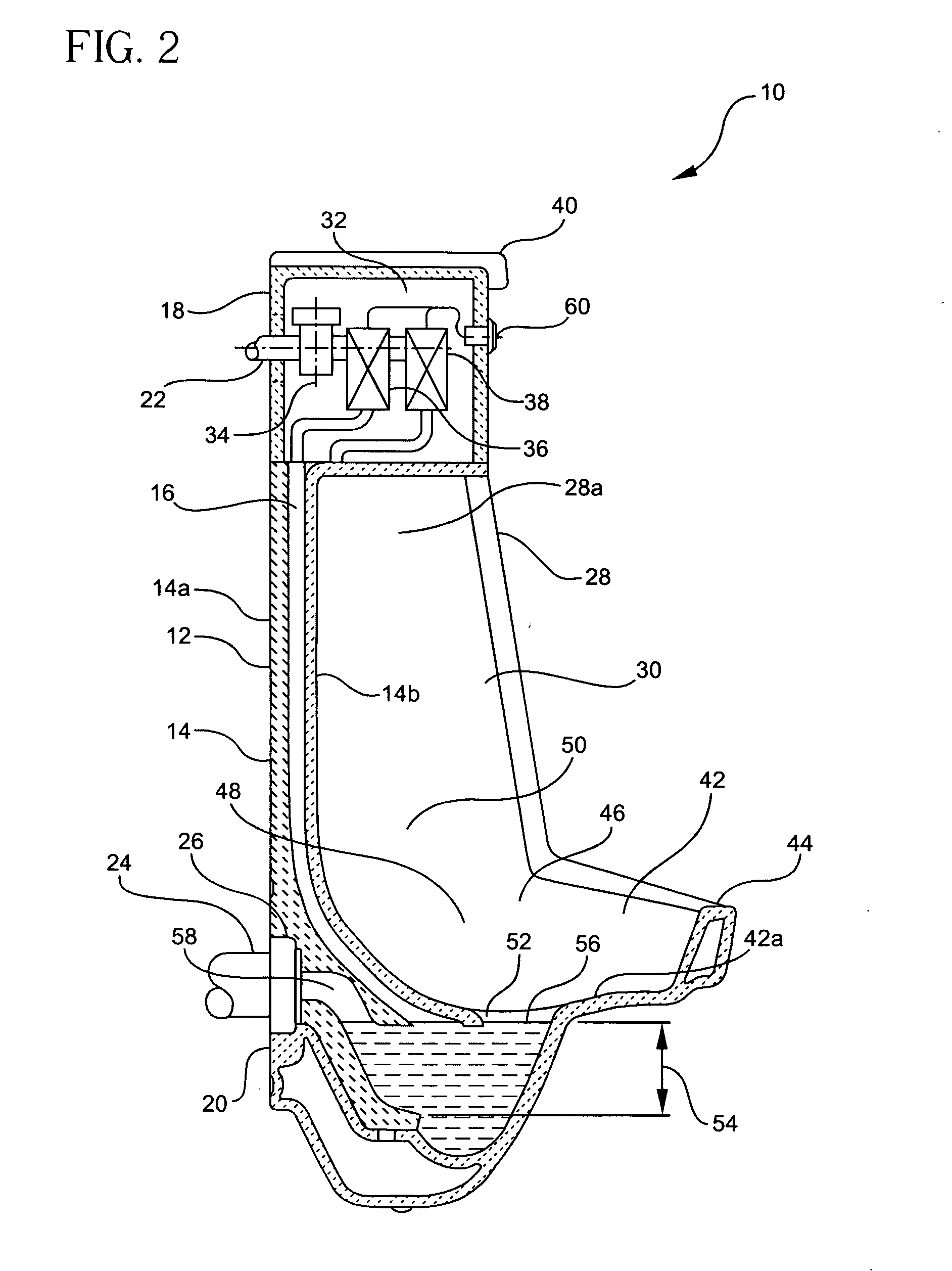

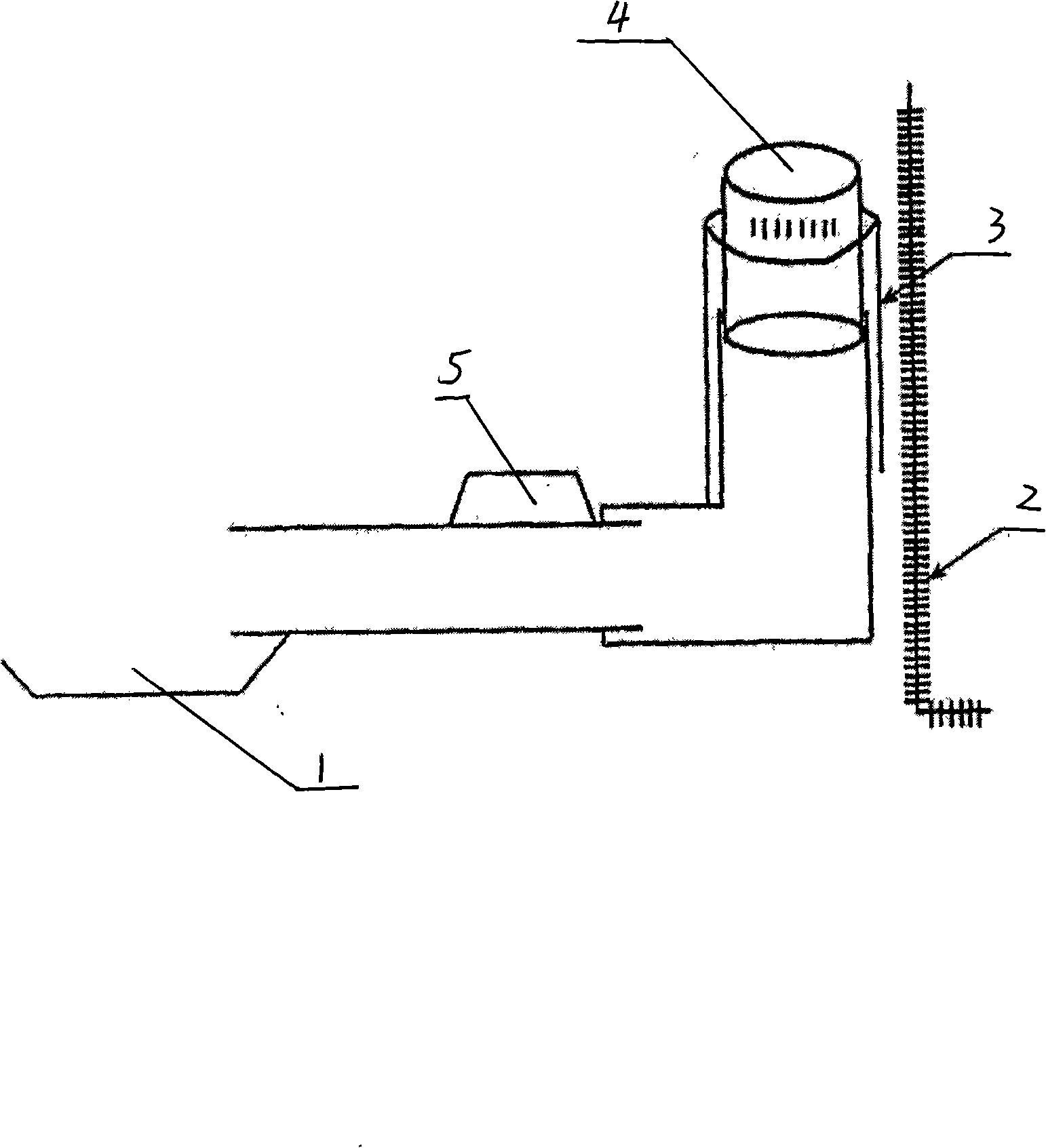

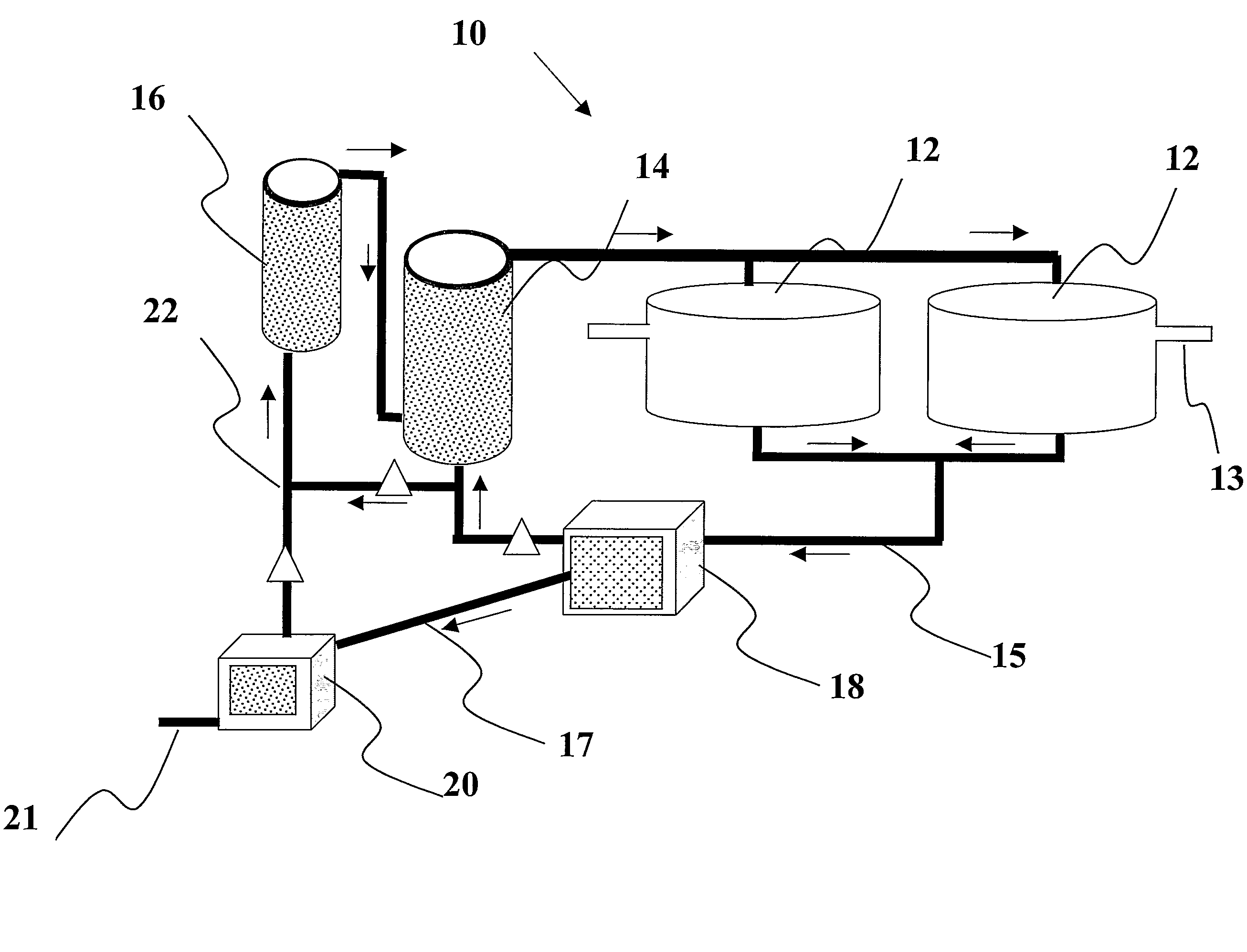

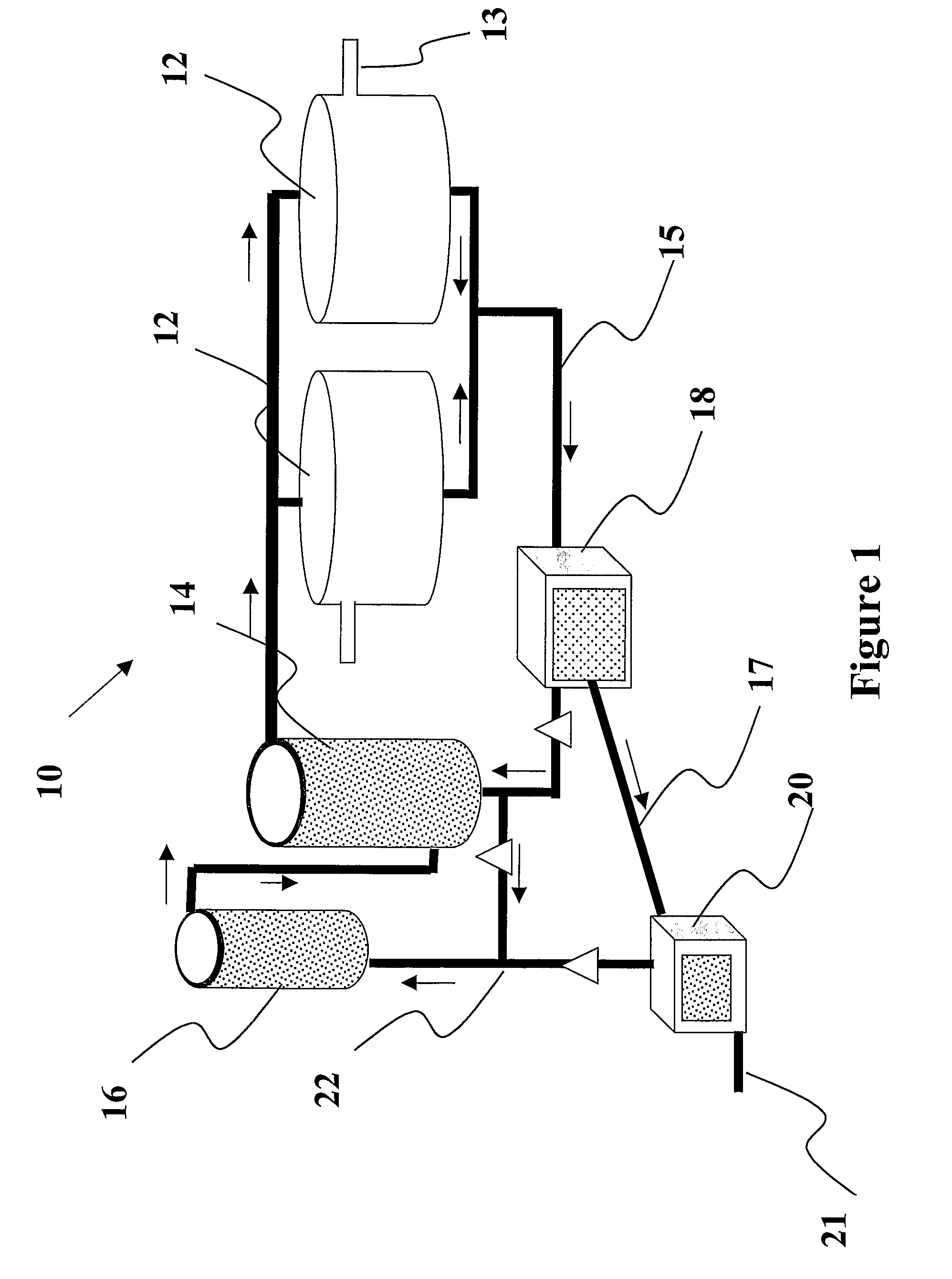

Dissimilatory sulfate reduction as a process to promote denitrification in marine recirculating aquaculture systems

InactiveUS20070163952A1Promote dissimilatory sulfate reductionReduce water exchangeWater treatment parameter controlWater contaminantsHigh concentrationSludge

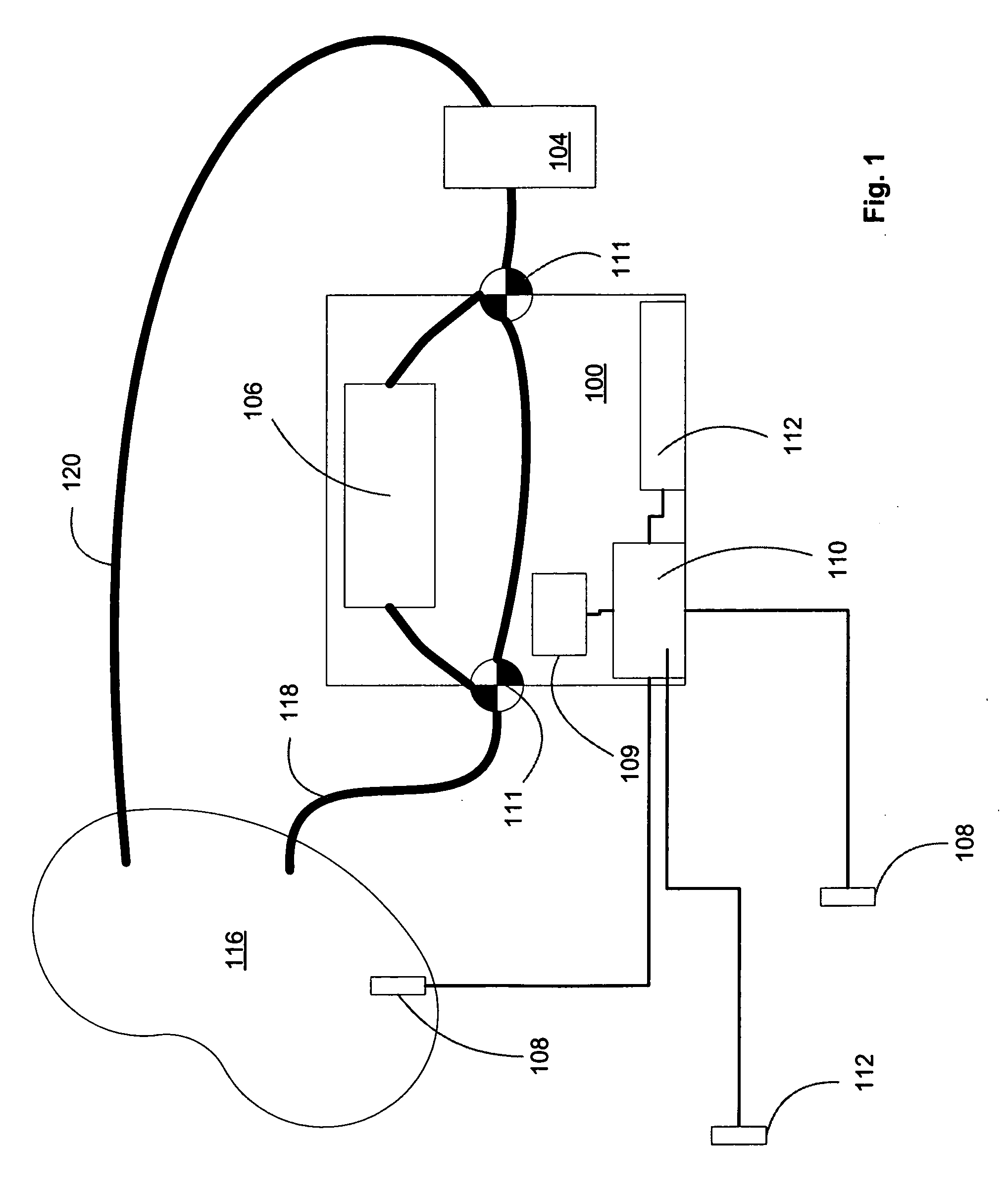

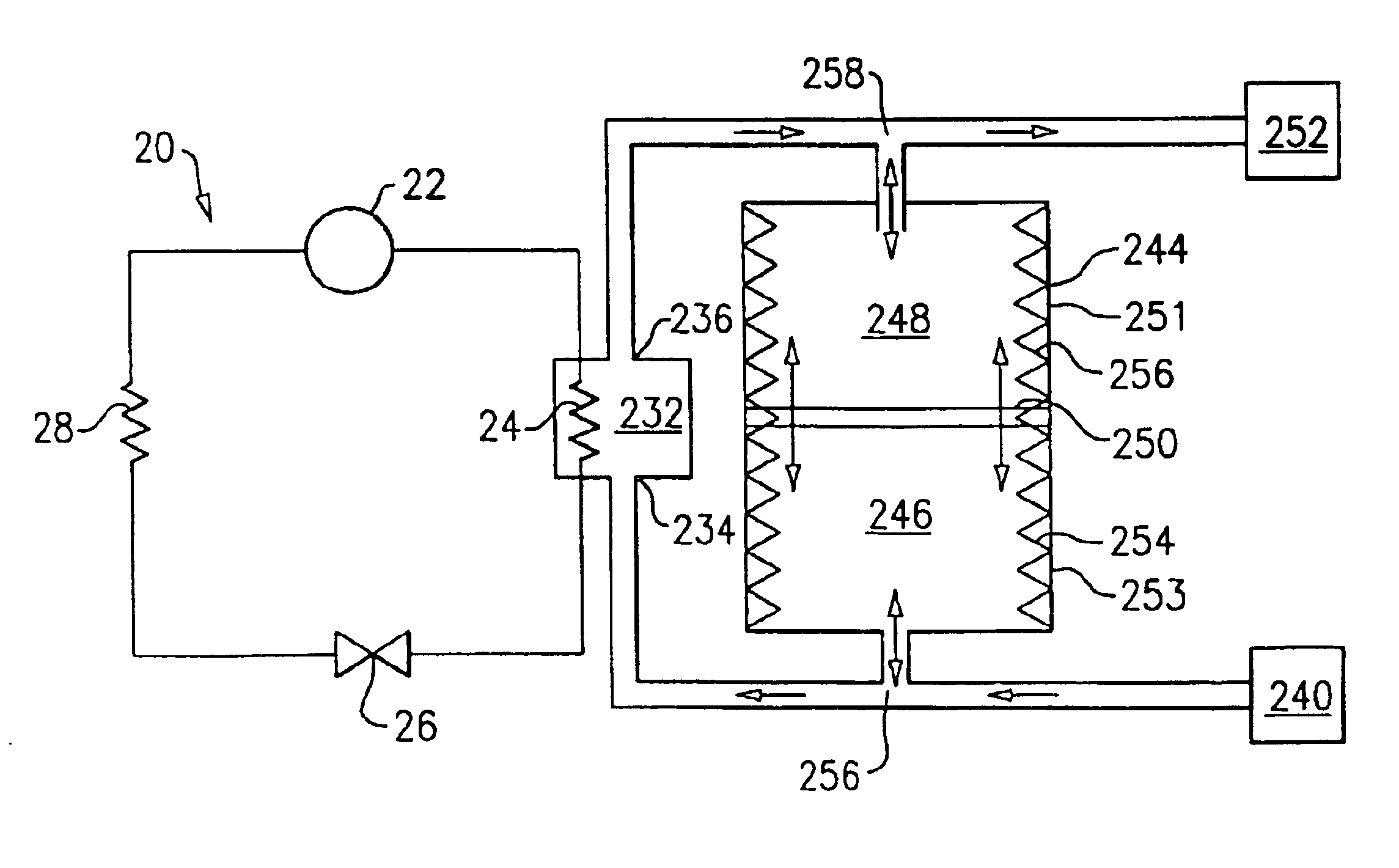

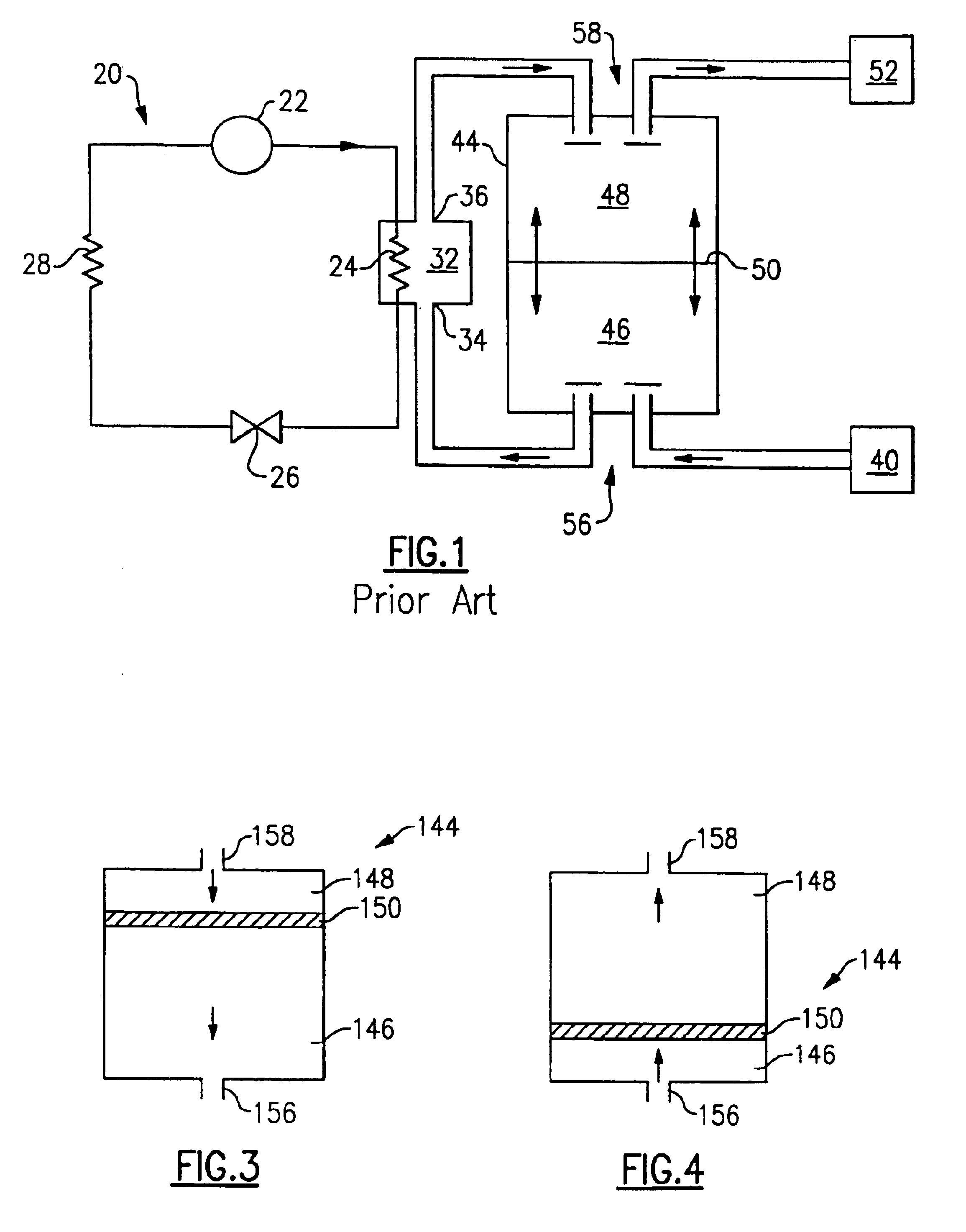

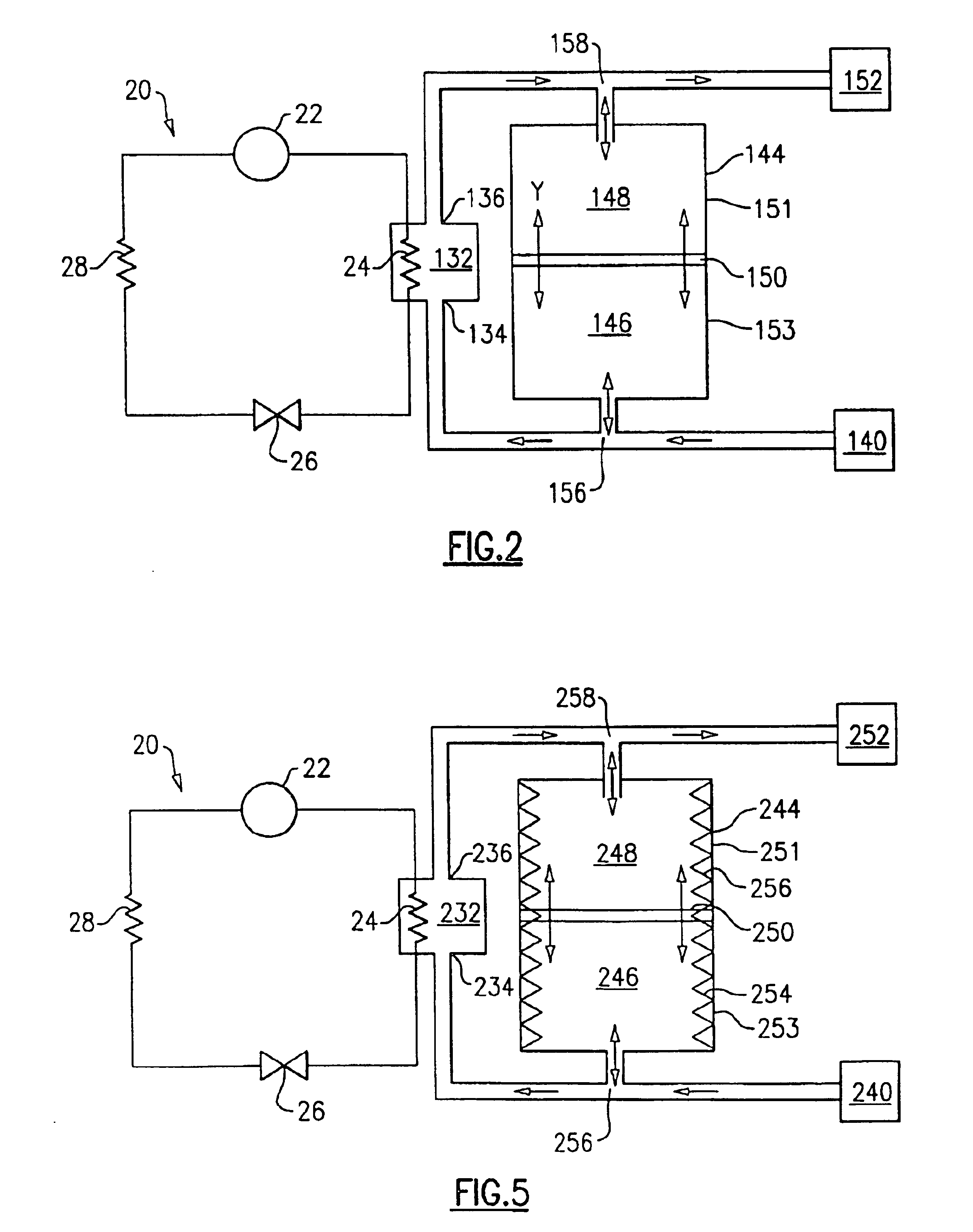

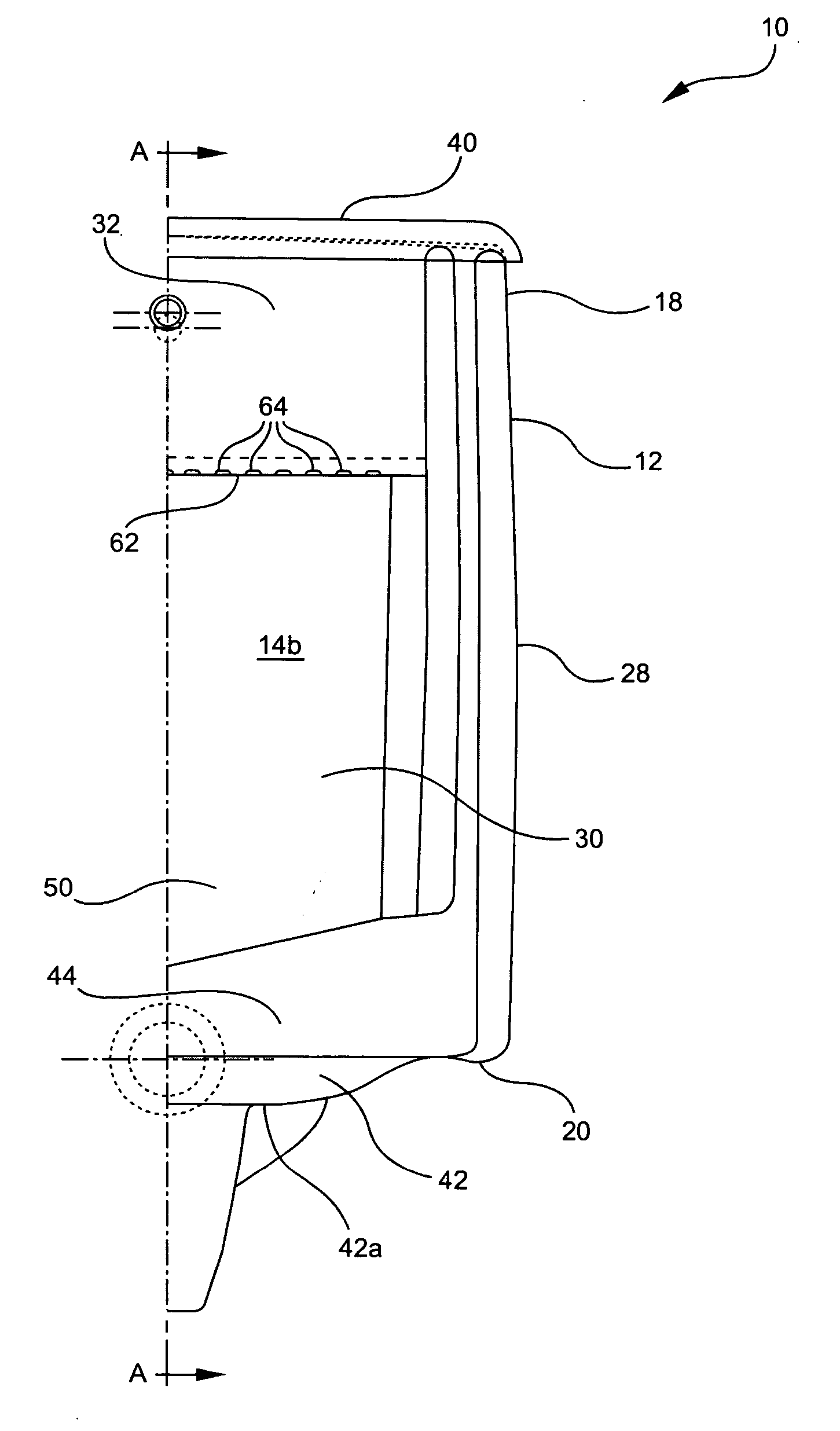

The present invention relates to a novel approach for nitrate removal from a marine recirculating system (10) wherein high concentrations of sulfate found in seawater is used in combination with sludge (20) collected from fish growing tanks (12) to promote dissimilatory sulfate reduction to hydrogen sulfide. The sulfide is used as an electron source to promote autotrophic denitrification in an up-flow fix bed bioreactor (16), followed by nitrification in a nitrification unit (14). By utilizing the symbiotic relationship between the sulfate-reducing and sulfide-oxidizing bacterial community, nitrate accumulation is controlled in the recirculating water of the system thereby reducing water exchange in the marine recirculating system.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

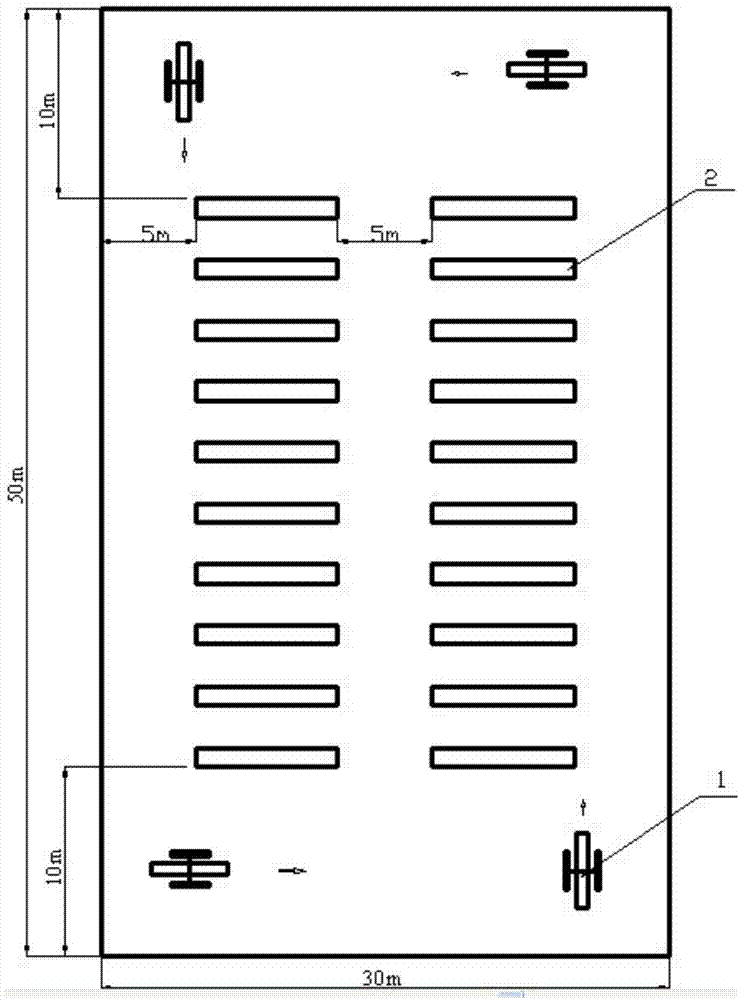

Method for cultivating loach larvae by arranging net cages in pond

ActiveCN103583428AUnobstructed exchangeAvoid harmClimate change adaptationPisciculture and aquariaAquatic insectWater flow

The invention discloses a method for cultivating loach larvae by arranging net cages in a pond to improve the rate of survival. The method mainly comprises the steps that firstly, the pond which is appropriate in area and water depth is selected, water is injected into the pond to clean and disinfect the pond, and palatable bait is prepared; secondly, the net cages with the total area being 10% of the area of the pond are arranged inside the pond, wherein each net cage conforms to the standard of (5-8)m*1m*0.7m, the net mesh is 60, the net cages are evenly arranged along the long edges of the pond in a multi-line and two-row mode, and the cage bottoms are close to the bottom of the pond but not make contact with the bottom mud when the net cages are fixed; thirdly, four submerged pumps are installed at the four corners of the pond, and pond circulating small-flow water is formed by adjusting the direction of a water outlet; fourthly, loach larvae are thrown into the net cages according to the demand of 2250-3000 loach larvae per square meter, the submerged pumps are started, and wheel animalcule and other palatable bait enter the net cages along water flow to be eaten by the loach larvae; fifthly, unobstructed exchanging of water inside and outside the net cages is guaranteed, and the bait is thrown into the net cages in due time to ensure adequate bait; sixthly, the loach larvae are moved out of the net cages when growing to be 2 centimeters long, the net is dragged out, aquatic insects in water are removed, then the loach larvae are moved to the pond to be bred, the bait is thrown into the pond in due time, and the loach larvae are bred to be larvae being 4 centimeters to 5 centimeters long.

Owner:HUAZHONG AGRI UNIV

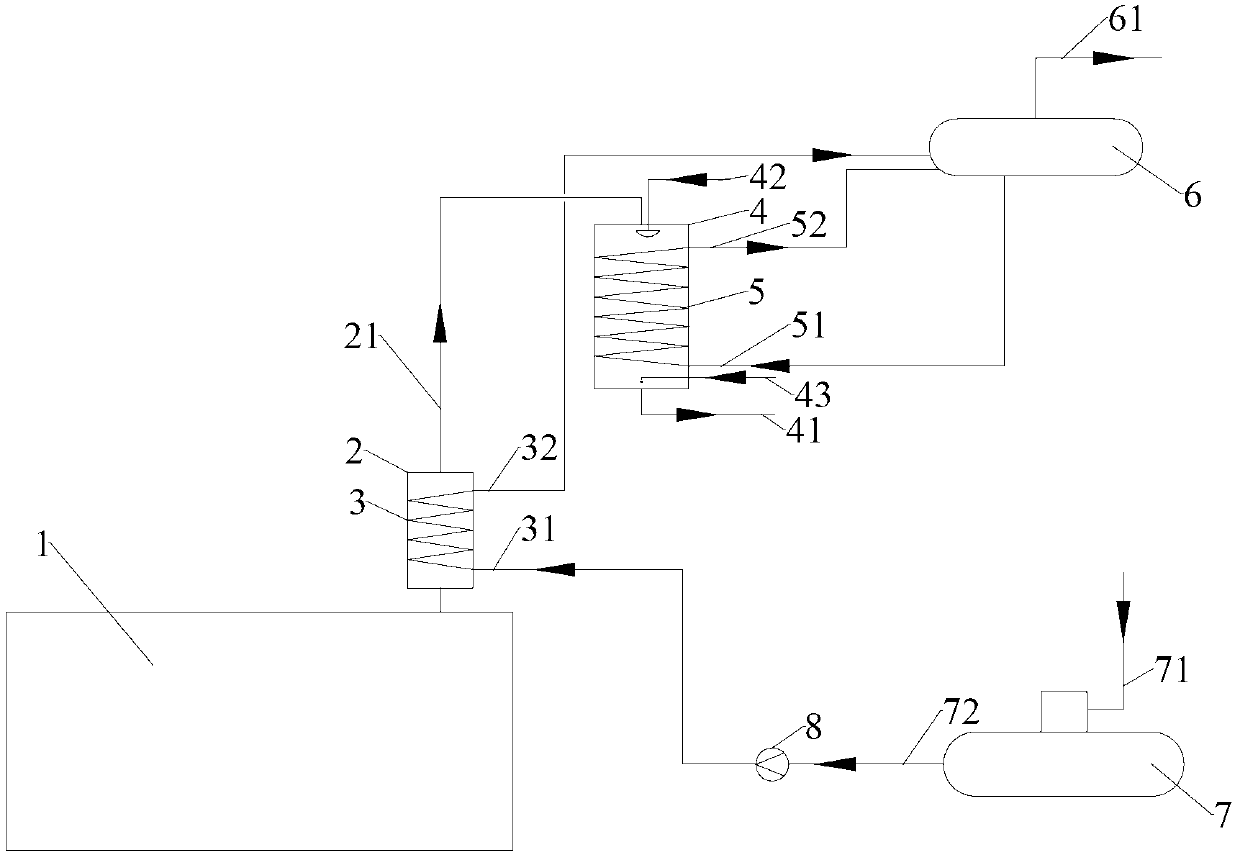

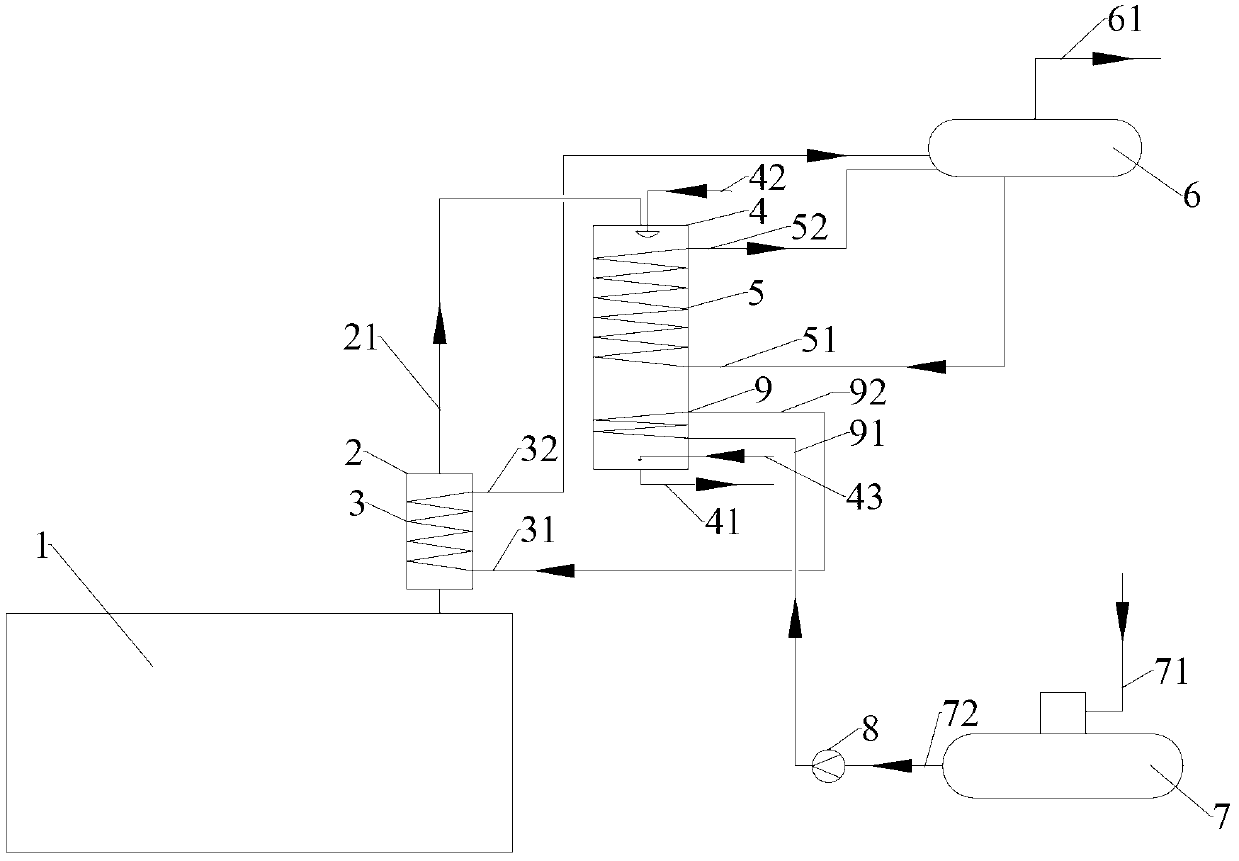

Process and system for growing crustaceans and other fish

InactiveUS8506811B2Reduce the ratioTreatment using aerobic processesTransportation and packagingMarine aquacultureCavitation

A recirculated marine aquaculture system and process for growing crustaceans or other fish within a body of water. Water from the body of water is treated by stripping carbon dioxide and biological byproducts and by oxygenating the water. A water treatment unit may be provided to treat the water and provide movement to the body water. The water treatment unit can be configured to provide cavitation to the water, which aids in the removal of carbon dioxide and biological byproducts. Water may also be cycled through a deflocculation tank to reduce the floc of bacteria within the body of water to acceptable levels for optimal growth of crustaceans or other fish within a body of water. Using the system and the deflocculation tank has the advantage of significantly reducing the water exchange rates and even the water effluent, while maintaining acceptable water quality for growing crustaceans or other fish.

Owner:AQUA MANNA

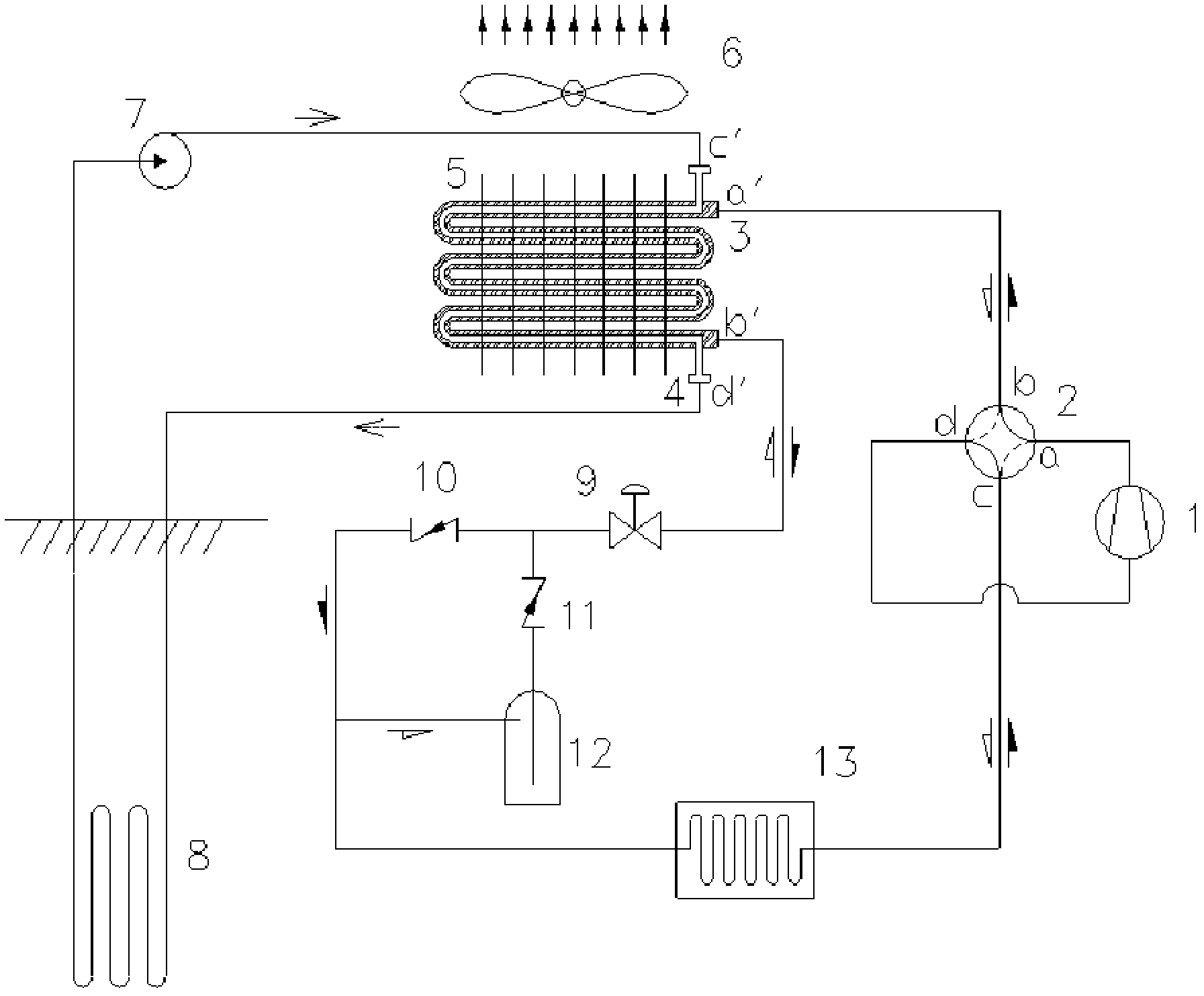

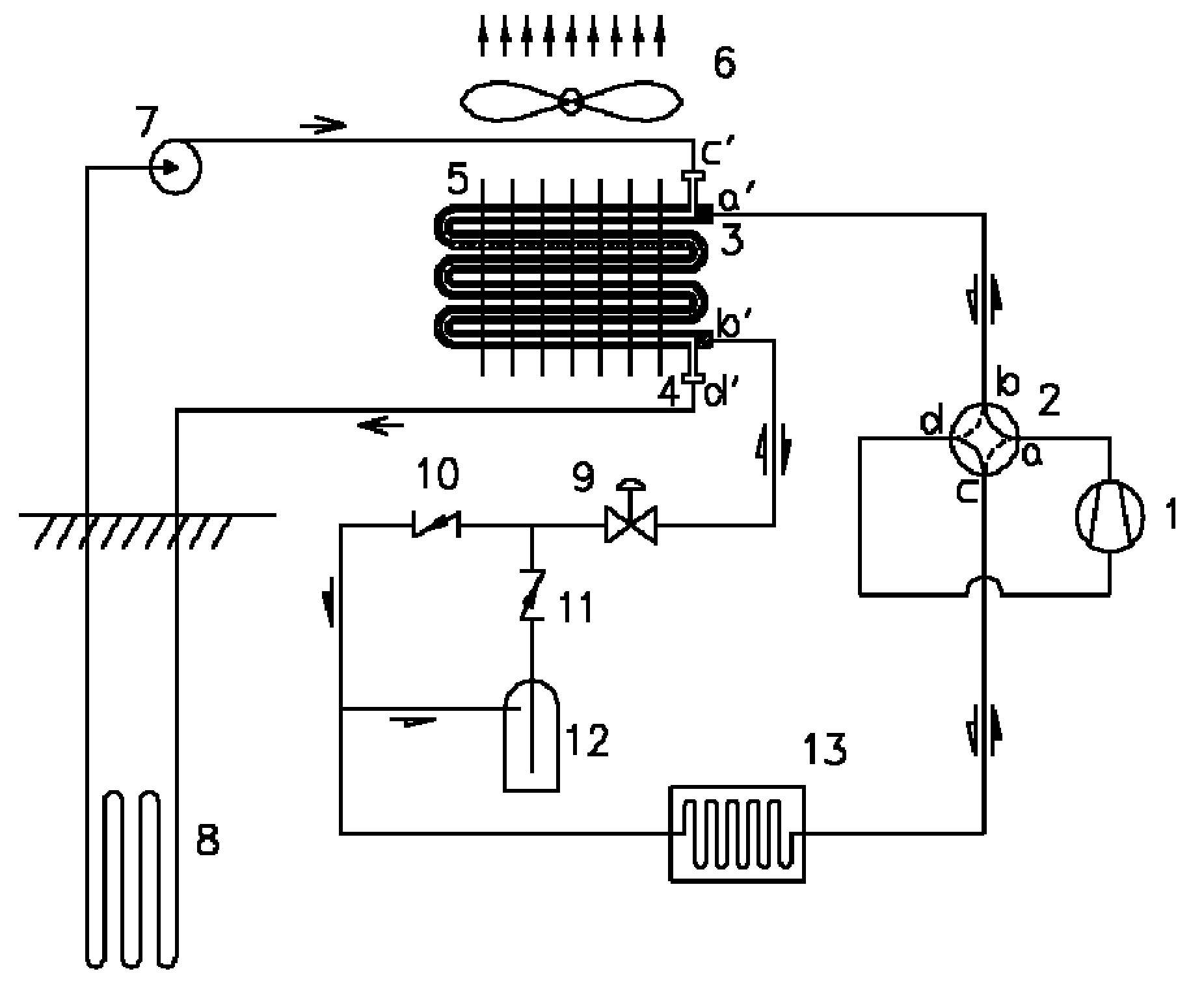

Integral air source and ground source composite heat pump device

InactiveCN102418969ALong runSustainable operationHeat pumpsSpace heating and ventilation detailsEnvironmental resistanceFour-way valve

The invention discloses an integral air source and ground source composite heat pump device. During mixed use of a heat pump, air and soil serve as cold and heat sources for refrigerating / heating. The heat pump mainly comprises a compressor, a four-way valve, an outdoor heat exchanger, a fan, a circulating water pump, a ground source heat exchanger, a throttling mechanism, a one-way valve, a reservoir and an indoor heat exchanger, wherein the outdoor heat exchanger consists of a refrigerant pipe, a water pipe and fins; and the water pipe is arranged on the inner side of the refrigerant pipe, so that circulating water exchanges heat with refrigerants, and the refrigerant pipe comprising the water pipe passes through the fins to realize heat exchange between the refrigerants and the air. The device is a heat pump system, low-energy-consumption environment-friendly shallow soil is used as a cold and heat source, a feasible scheme is provided for solving the problem of hot soil stack caused by long-term use of a ground source heat pump, and the heat pump device has a simple structure, low cost, reliable performance and a high energy efficiency ratio.

Owner:SOUTHEAST UNIV +1

Method for realizing ecological larval culture on rapana venosa

InactiveCN102160529AIncrease emergenceReduce manufacturing costClimate change adaptationAnimal feeding stuffWater qualityOrganism

The invention relates to a method for realizing ecological larval culture on rapana venosa. The method is characterized by comprising the following steps of: firstly selecting a pond which is convenient in water exchange, takes lithoherm and stone bottom as a substrate and is in the size of 2-5Mu; then placing mature rapana venosa with the length of 7-10cm into the pond in the quantity of 100kg per Mu, mating and spawning after the rapana venosa eats ruditapes and mussel for 2-3 days, when enough oocysts are obtained, removing the rapana venosa away, incubating the oocysts for 20-22 days at the water temperature of 20-25 DEG C to obtain planktonic larva, growing the planktonic larva by eating the planktonic larva in the pond, starting to throwing polyethylene corrugated plate adherence ortile under the condition that the water temperature is 22-25 DEG C after 15-16 days, sticking benthic diatom and the planktonic larva onto the polyethylene corrugated plate or tile, transfigurating the planktonic larva of the rapana venosa into young spiral shell after 5-6 days, growing the transfigurated young spiral shell by eating the planktonic larva and benthic diatom on the corrugated plate, wherein the survival rate of the transfigurated young spiral shell on the corrugated plate can reach more than 50%, and feeding small low-value bivalve to the young spiral shell with the length morethan or equal to 3mm. By applying the method provided by the invention, the defects that the survival rate is low and the larval yield is low as bait conversion is difficult and water is polluted when carnivorous fish mice are used as feed in indoor artificial larval culture can be overcome, and the larval yield is improved by more than 50% compared with the indoor artificial larval culture. Meanwhile, the production cost is saved as no bait is thrown into the pond, thus the method is environment-friendly, and the produced larval is strong.

Owner:OCEAN UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com