Patents

Literature

481results about How to "Prevent popping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ceramsite by utilizing dried sludge and burnt fly ash

InactiveCN102060426AAchieving simultaneous reductionAchieving processing powerSludge treatment by de-watering/drying/thickeningSodium BentoniteExpanded clay aggregate

The invention discloses a method for preparing ceramsite by utilizing dried sludge and burnt fly ash, belonging to the technology of reduction, harmless treatment and disposal and recycling of dangerous solid waste. The method comprises the following steps of: drying dewatered sludge with moisture content of 75-85% to obtain dry sludge; crushing the dry sludge, and then screening; mixing the screened dry sludge, burnt fly ash and bentonite uniformly according to a certain proportion to obtain a mixture; injecting the mixture into a powder pressing machine for extruding and forming to obtain a blank; preheating the blank at certain time; roasting the blank at high temperature at certain time; and naturally cooling to room temperature to obtain a ceramsite product. Simultaneous reduction, harmless treatment and disposal and recycling of two dangerous wastes of the burnt fly ash and municipal sludge are realized with the method, and the produced ceramsite product conforms to the standard of toxic leaching and meets the requirement of lightweight aggregate of buildings. The method has the advantages of simplicity in process, less investment, low operating cost, large required quantity of the produced ceramsite products and the like.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION +1

Powder coatings containing symmetrical additives

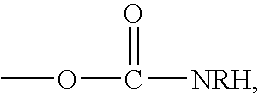

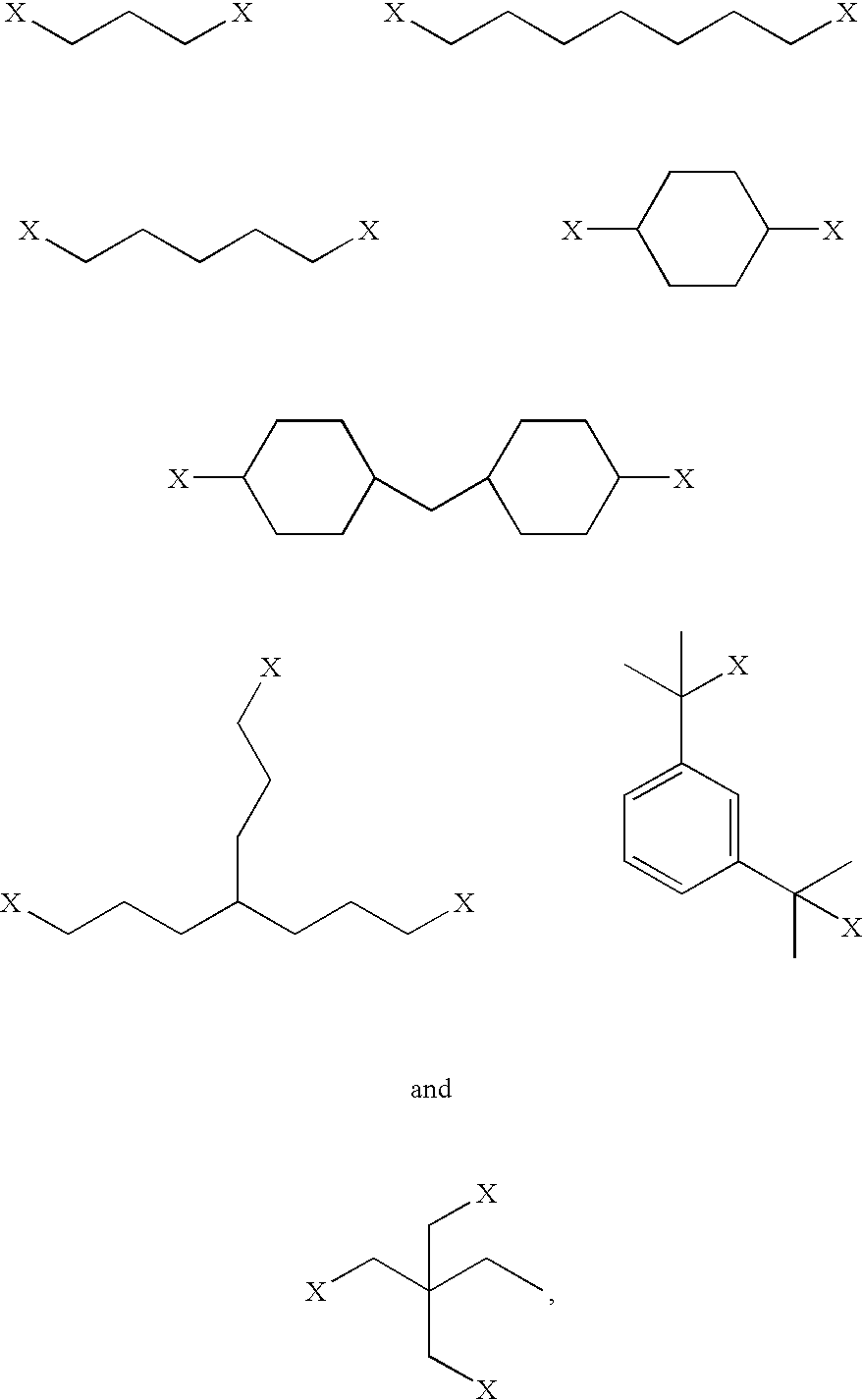

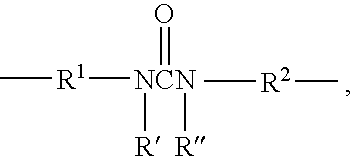

InactiveUS7060357B2Excellent leveling and smoothnessHigh trafficSynthetic resin layered productsPowdery paintsPolymer scienceCarbamate

A coating composition contains solid particulates of a mixture of an aminoplast crosslinking agent, a solid polymer having functionality reactive with the aminoplast crosslinking agent, and a crystalline, carbamate-functional additive. The crystalline, carbamate-functional additive has a melting point of at least about 30° C. and is up to about 15% by weight of the powder coating composition.

Owner:BASF CORP

Method for preparing haydite from wet sludge and incineration fly ash

The invention discloses a method for preparing haydite from wet sludge and incineration fly ash, belonging to solid hazardous waste treatment and recycling technology. The method comprises the following steps: proportionally and uniformly mixing municipal sludge of which the water content is 75-85%, incineration fly ash and bentonite; carrying out extrusion forming on the mixture to obtain a haydite blank; drying the blank for a period of time; preheating the blank for a period of time; roasting the blank at high temperature for a period of time; and naturally cooling to room temperature to obtain the haydite product. In the invention, the wet sludge (municipal sludge of which the water content is 75-85%) and other raw materials are directly mixed, formed and granulated; and thus, the invention avoids the problem of sludge drying, and facilitates forming and granulation based on the viscosity of the wet sludge. The invention has the advantages of simple process, low investment, low operating cost, high demand for the haydite product and the like, thereby having wide development prospects and high popularization value.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION +1

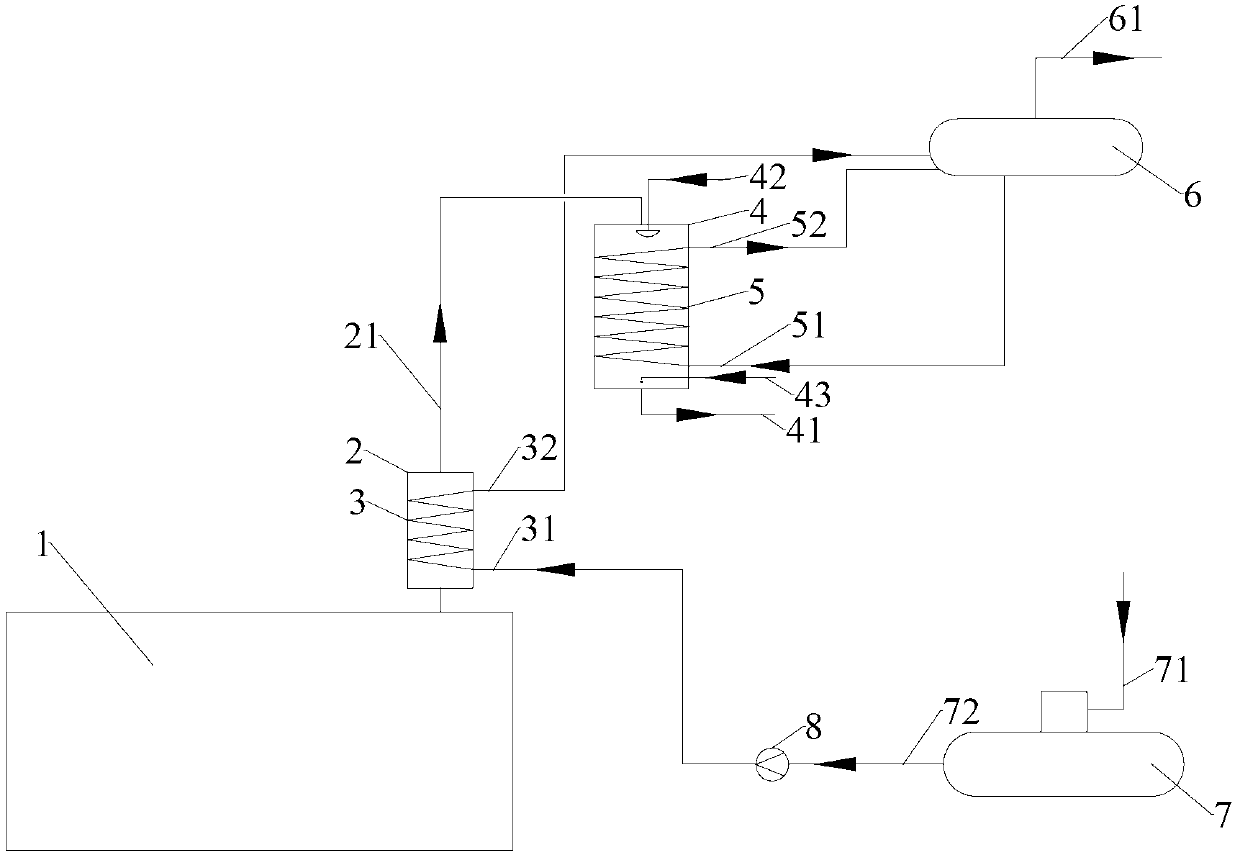

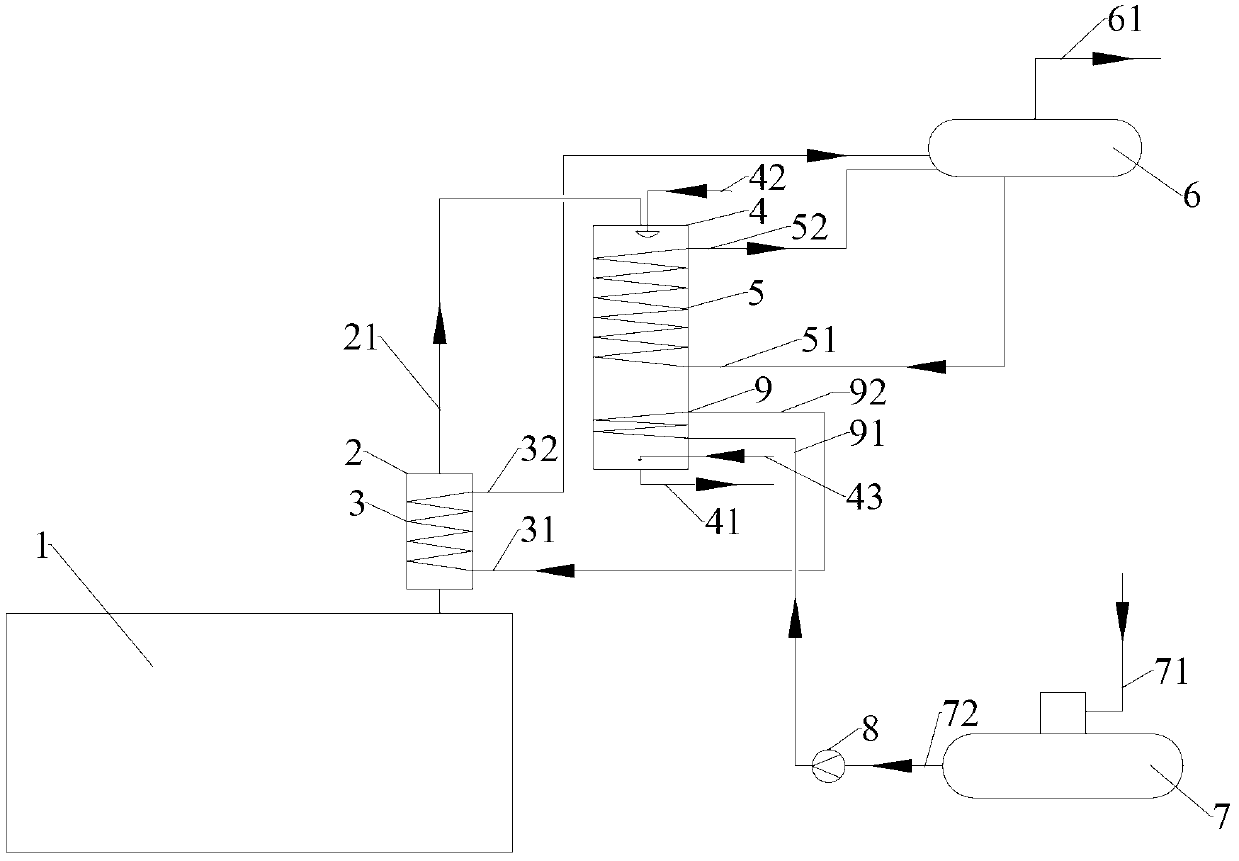

Method for recovering waste heat from coke oven raw gas

ActiveCN103131432AQuality assurancePrevent poppingCoke oven safety devicesEnergy inputWater vaporCoke oven

The invention relates to a method for recovering waste heat from a coke oven raw gas. The method utilizes water as a heat exchange medium, water exchanges heat with the raw gas having a temperature of about 650-750DEG C in a riser heat exchanger, the temperature of the raw gas subjected to the heat exchange decreases to 480-550DEG C, the heat exchange medium forms a vapor-water mixture after heating, and enters a vapor bag, and the vapor-water mixture is separated to form high temperature water and saturated vapor by a vapor-water separator in the vapor bag; the raw gas discharged from the riser heat exchanger undergoes heat exchange in a bridge tube heat exchanger, the temperature of the raw gas subjected to the heat exchange decreases to 280-350DEG C, and the high temperature water obtained after the separation of the vapor-water separator undergoes heat exchange by the bridge tube heat exchanger, enters the vapor bag and generates saturated vapor, wherein the outer wall of the heat exchanger is cleaned through high-pressure ammonia water intermittent spray or water vapor intermittent blow in the bridge tube; and finally the temperature of the raw gas is reduced to 80-85DEG C by adopting ammonia water, and then the raw gas enters a gas collection tube. The method furthest recovers the waste heat of the raw gas and guarantees the continuous normal work of the heat exchangers under a complex condition.

Owner:BEIJING RISUN TECH CO LTD

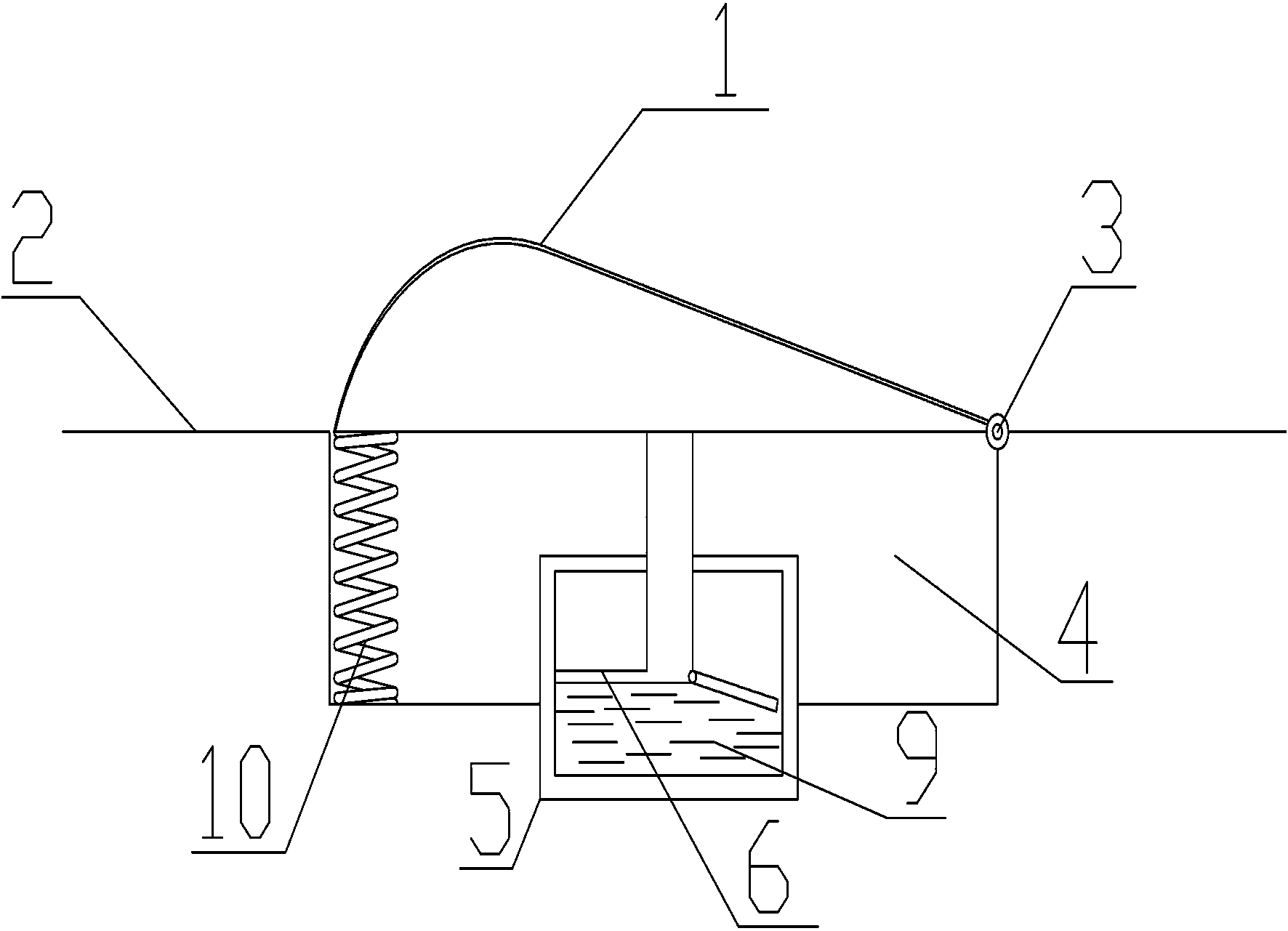

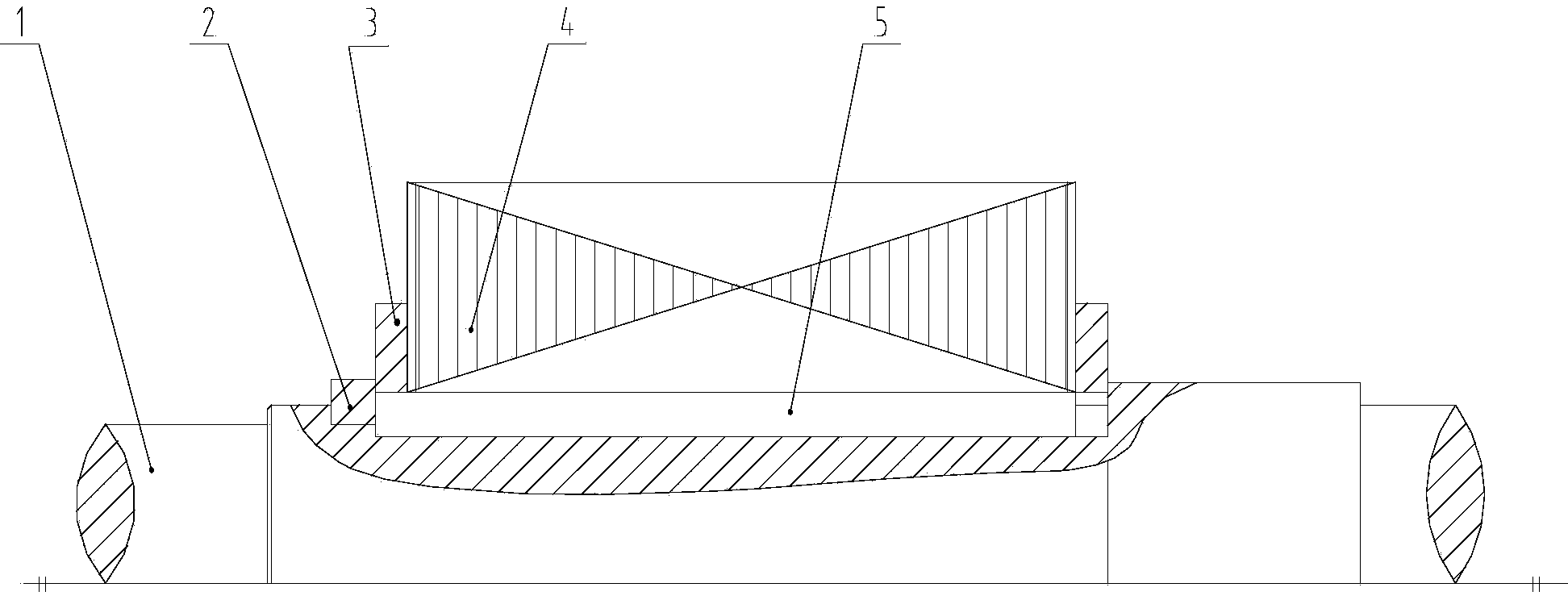

Automatic adjustment deceleration strip with vehicle speed identification function

ActiveCN103628426ATorque maximizationIncrease vehicle weight rangeTraffic signalsRoad signsEngineeringPermeation

The invention discloses an automatic adjustment deceleration strip with a vehicle speed identification function. The automatic adjustment deceleration strip comprises a deceleration strip panel, an adhesive cylinder and a piston plate, wherein one end of the deceleration strip panel is movably fixed on the ground, and the other end of the deceleration strip panel is in contact with the ground through an elastic part; a connection rod is fixed on the deceleration strip panel; the non-fixed end of the connection rod is provided with the piston plate; water permeation holes are formed in the piston plate; the adhesive cylinder is fixed in a groove in the ground; the adhesive cylinder is filled with liquid; the piston plate can do perpendicular motion in the adhesive cylinder; the liquid can only overflow or flow back to the adhesive cylinder through the water permeation holes. The automatic adjustment deceleration strip has the advantages that the stopping force of the deceleration strip can be adjusted and controlled according to vehicle speeds, and the deceleration strip can be self-adjusted to adapt to different traffic environments.

Owner:泰州市海通资产管理有限公司

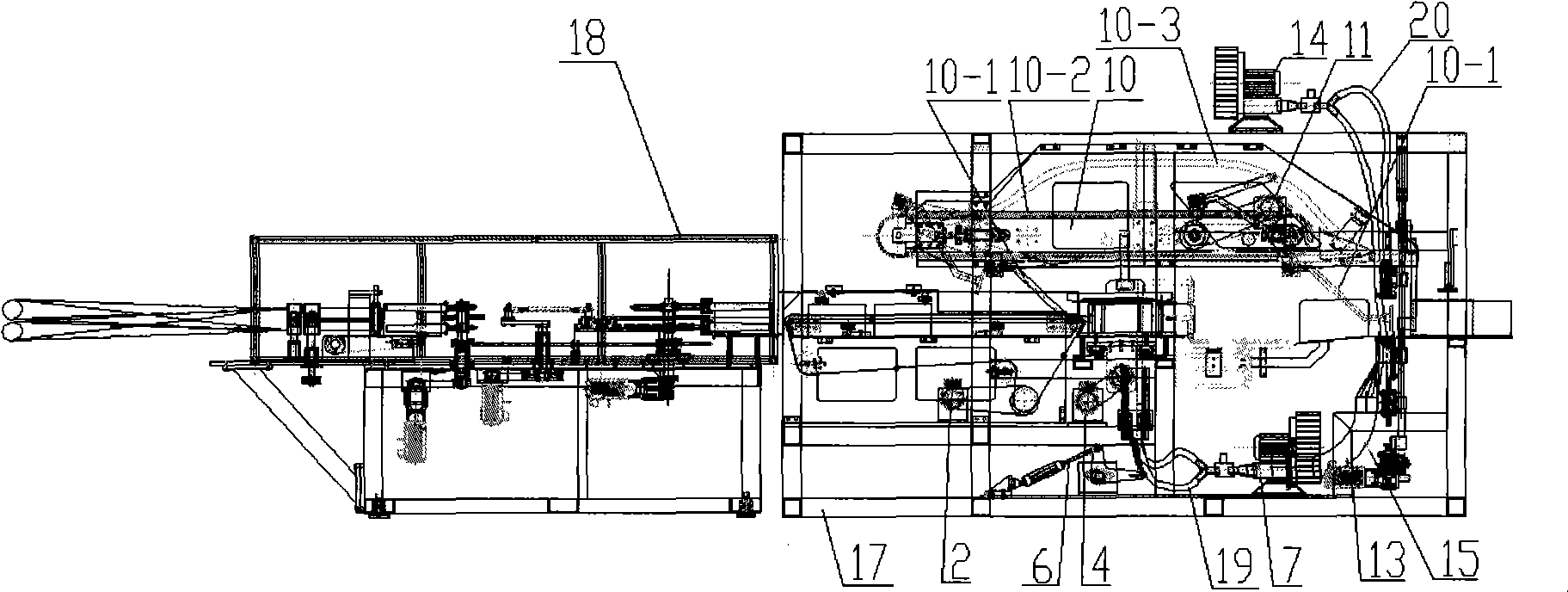

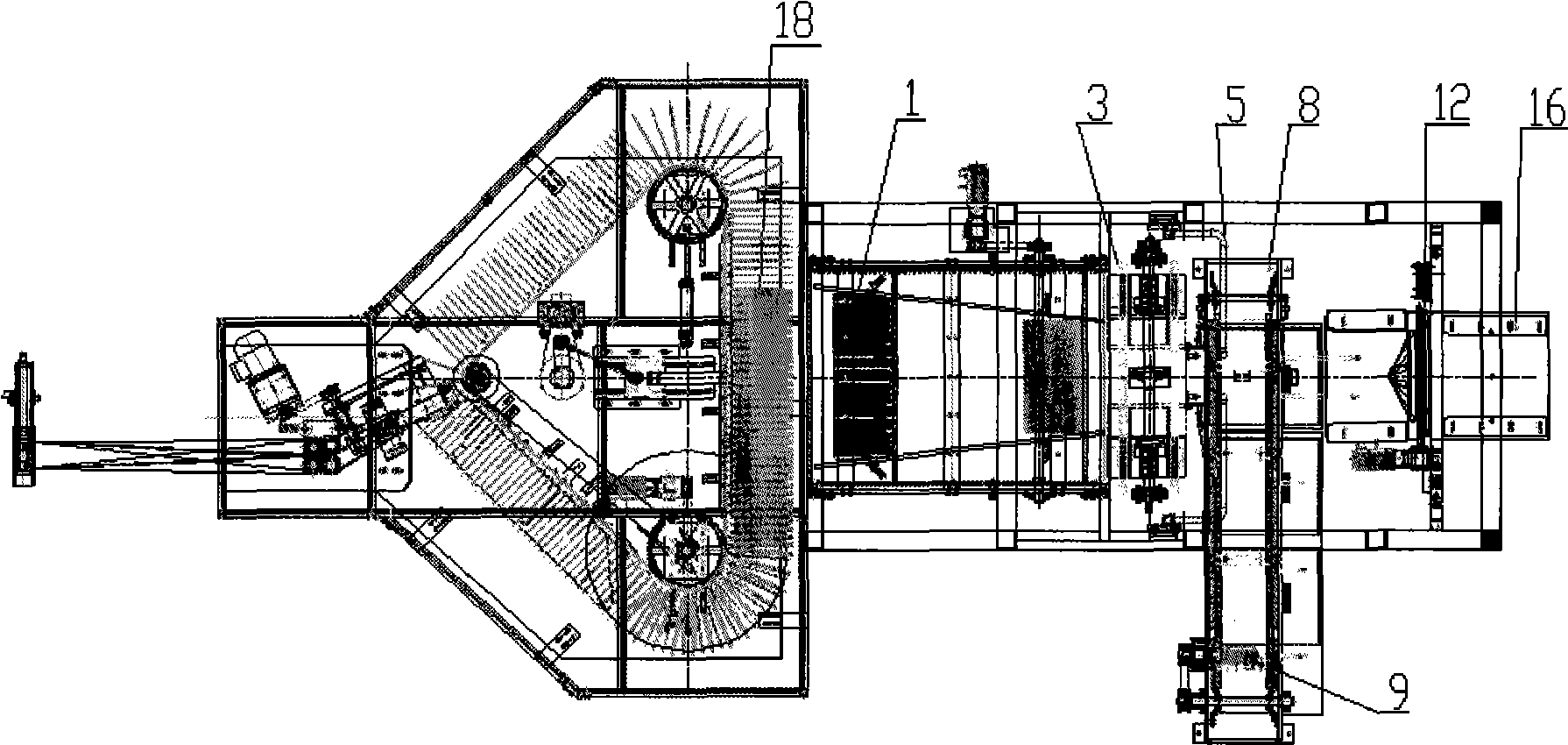

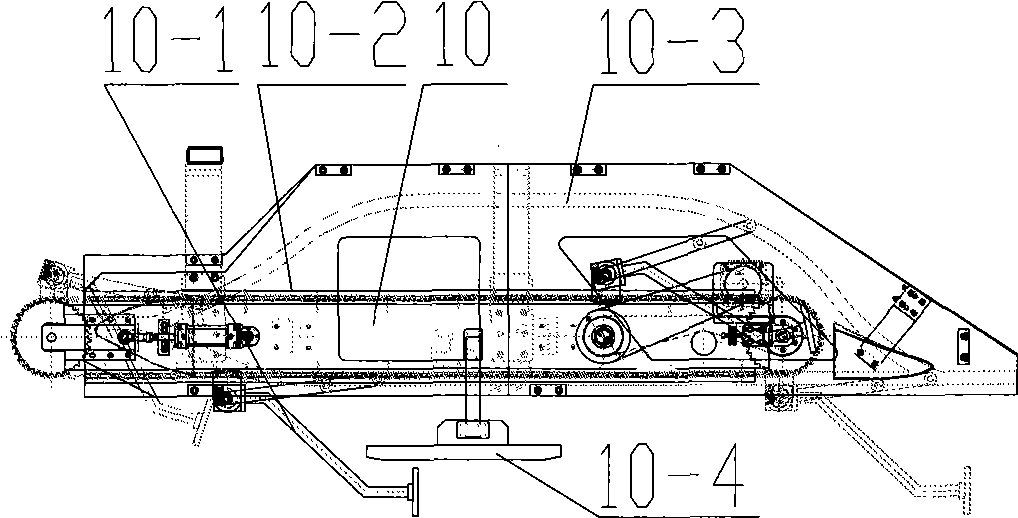

Pants products packing device and method

ActiveCN101508351APrevent poppingReliable heat sealingWrapper twisting/gatheringPackaging automatic controlEngineeringRelative motion

The invention relates to a pants-type product packing machine capable of packaging and sealing a plurality of pants-type products after precompression gas exhaust and rapid compression, and a packing method. The packing machine comprises a stander, a sealing cutting device and a waste material recovery device, wherein a movable precompression device is in shape of a contraction passage of which two sides are provided with two sets of mutually symmetrical annular chain driving mechanisms driven by a precompression servomotor; a product compressor is positioned at an outlet of the contraction passage 1, and the precompression servomotor drives a double-ended guide screw which drives two compression plates thereon to perform quick relative motions so as to compress the pants-type products; product bag-opening devices are positioned at the outlet of the product compressor and packaging bags are conveyed to the outlet of the compressor through a movable cylinder, and the product bag-opening devices at two sides of the outlet of the contraction passage suck the bag openings of the packaging bags open; a bag conveyor is positioned at the outlet of the product bag-opening device and is driven to move by a bag conveying servomotor; and the sealing cutting device is positioned at the outlet of the bag conveyor.

Owner:ZHEJIANG YONGCHUANG MACHINERY

Pressure filter and pressing filtering method thereof

ActiveCN102836581AEasy resetGood pressure holding effectFiltration separationStructural reliabilityWater filter

The invention discloses a pressure filter comprising a plurality of filtering plate sets which are connected in sequence, wherein each filtering plate set comprises a main plate, an auxiliary plate, and an auxiliary frame, the auxiliary plate is fixed on one side of the main plate and on the same side of the main plate, the auxiliary frame is sleeved on the periphery of the auxiliary plate in a sliding mode, and the other side of the main plate is connected with the auxiliary frame of the adjacent filtering plate sets. Moreover, volume-changeable pressing filtering space used for containing materials is arranged between the adjacent filtering plate sets. Each filtering plate set is provided with a material channel which is communicated with the pressing filtering space. The other side of the main plate, opposite to the contact face of the auxiliary plate, is provided with a filtering mesh. Filter cloth wraps outside the filtering mesh. Each filtering plate set is also provided with a gas channel and a liquid channel which are communicated with the outside to the pressing filtering space. The pressure filter is high in structure reliability, has no leakage of the materials, and is convenient to maintain. The invention further provides a pressing filtering method. As pressing filtering and drying above the third level are adopted, water-filtering effect is better, size of the pressed and filtered material is larger, water containing rate of the materials is lower, work efficiency is higher, and production is higher.

Owner:FOSHAN JINKAIDI FILTRATION EQUIP CO LTD

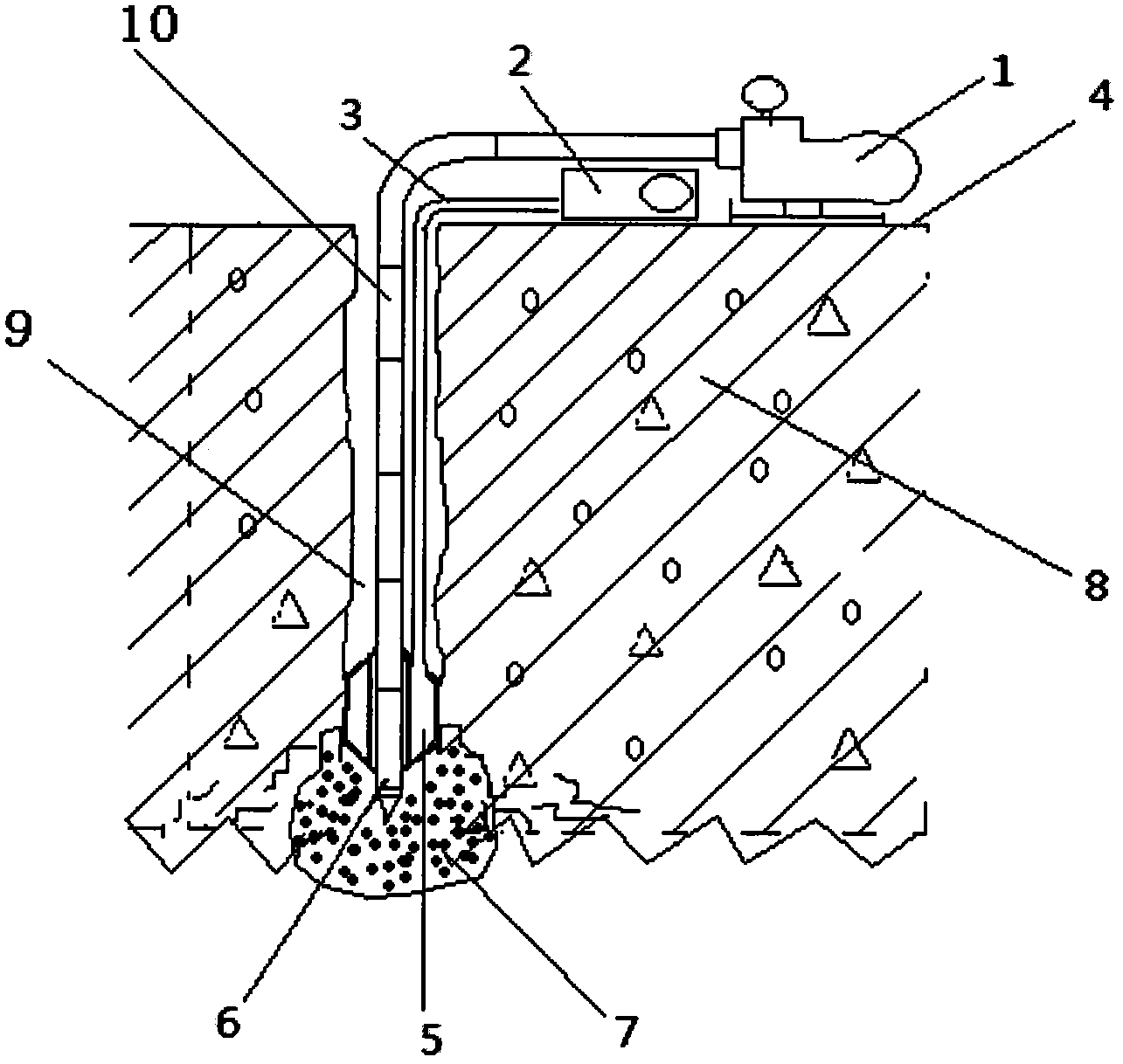

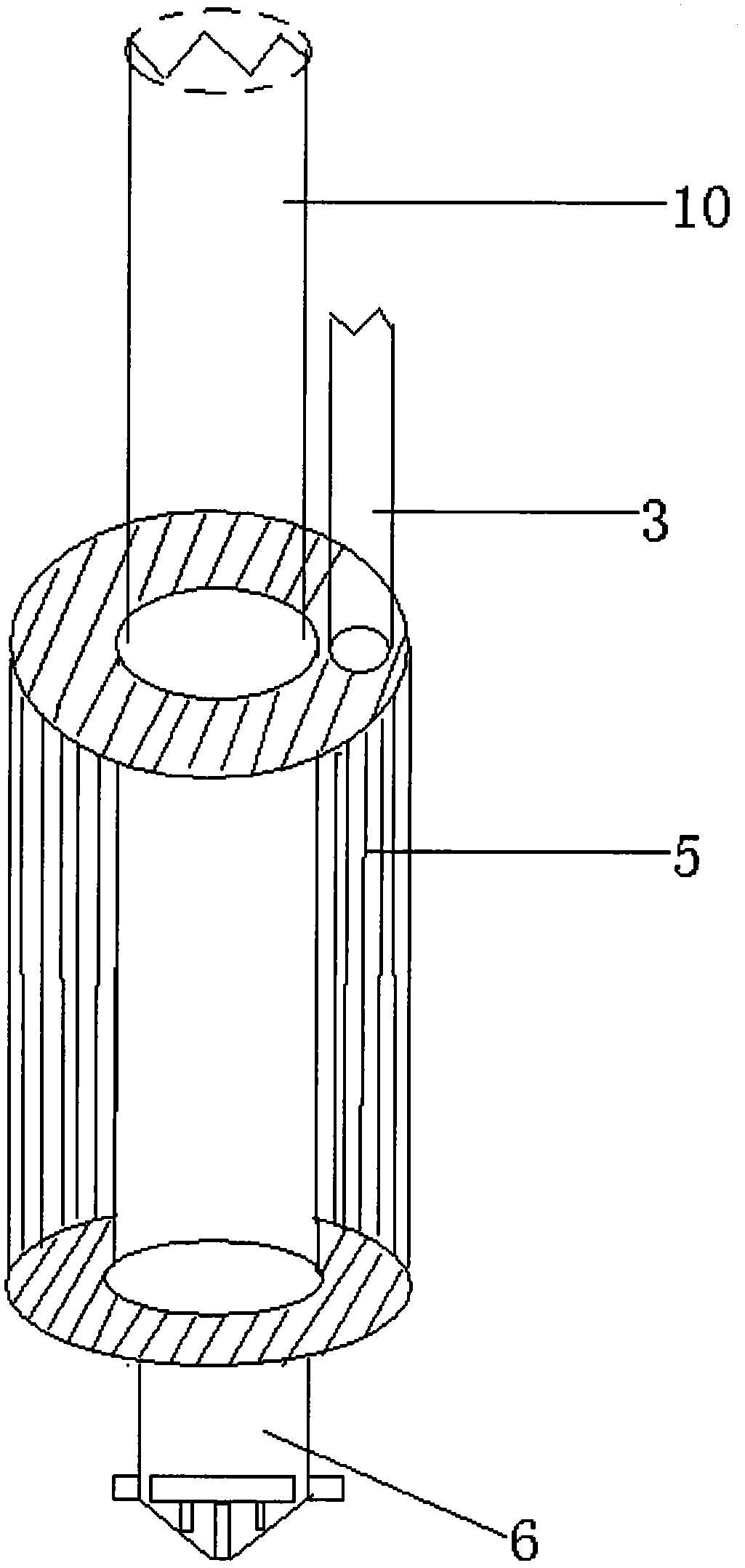

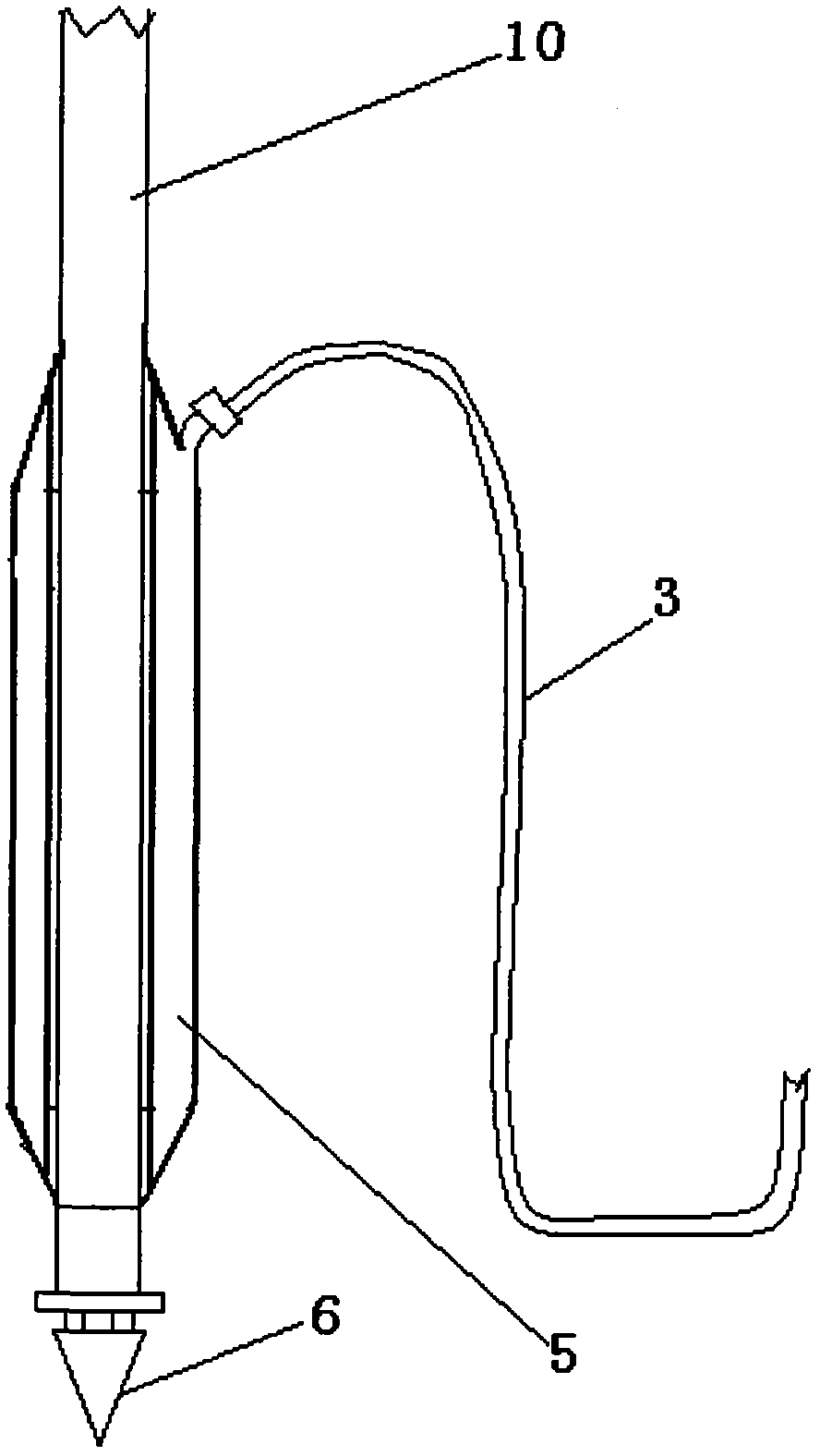

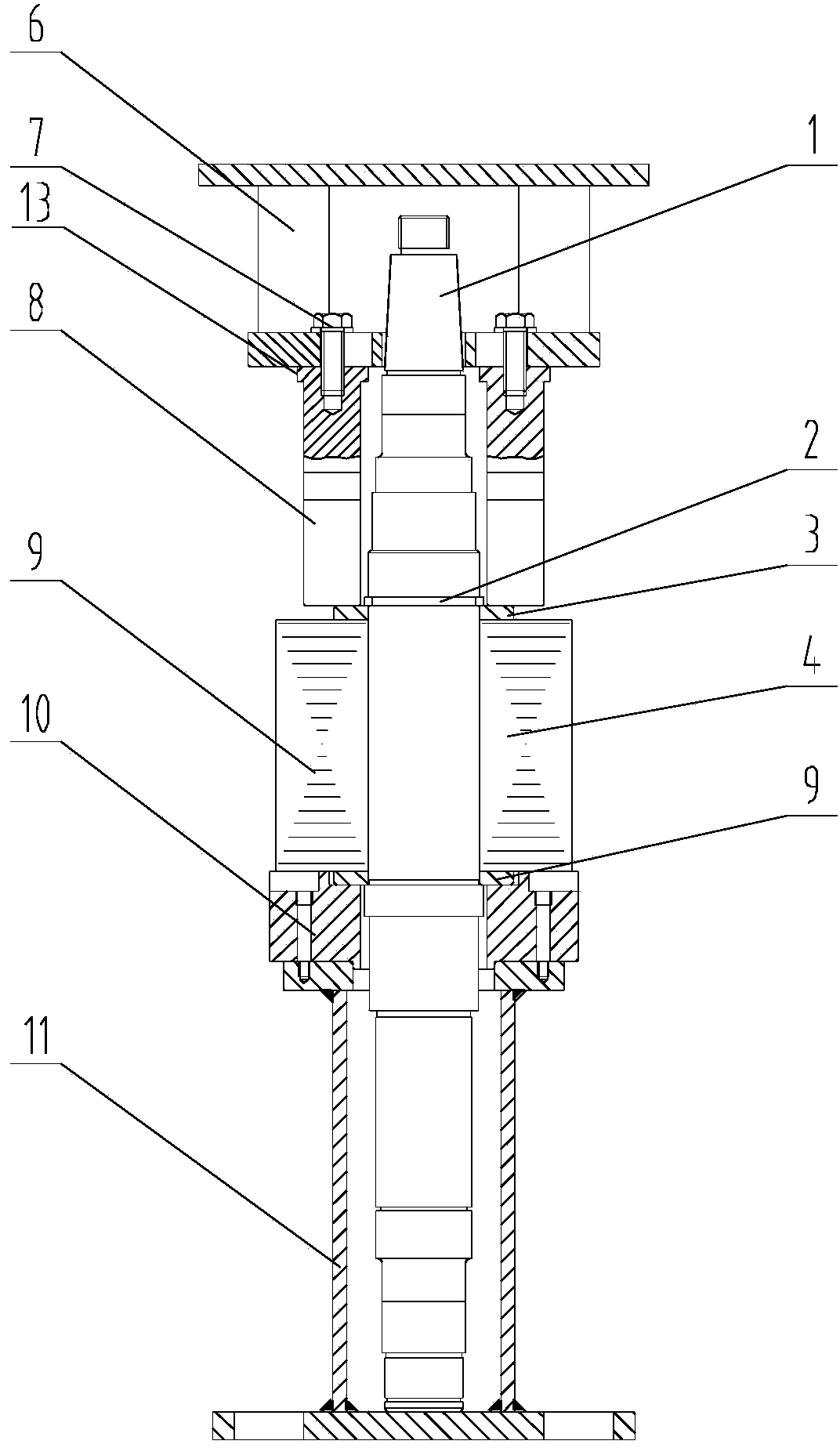

Grouting air cushion plug

ActiveCN104164865APrevent poppingPrevent slurrySealing/packingSoil preservationPressure decreaseGas compressor

A grouting air cushion plug comprises a grouting pump, a slurry conveying pipe, a guniting head, an air cushion sealing plug body, an air compressor and the like, wherein the air cushion sealing plug body is placed on the periphery of the pipe wall of the joint between the guniting head and the slurry conveying pipe, and the air cushion sealing plug body is connected with the air compressor through an air pipe. Because the air cushion sealing plug body is additionally added between the a grouting pipe and a hole wall, slurry can be prevented from overflowing, and the grouting air cushion plug is used for preventing the phenomenon of slurry overflowing caused by the fact that because a gap exists between the grouting pipe and the hole wall, pressure decreases. After the grouting pipe stretches underground, the air cushion sealing plug body is inflated by the air compressor to seal the gap, the inflated air cushion sealing plug body blocks off the gap so that back pressure can be formed, and the slurry is forced to evenly permeate to the periphery of a bottom layer. After grouting is completed, the air cushion sealing plug body is deflated and made to ascend by 0.5 meter together with the guniting head, grouting is carried out after the air cushion sealing plug body is inflated again, operation is carried out repeatedly and so forth till the slurry reaches a hole opening, the whole grouting process is segmented, and reinforcement is uniform. The size of the air cushion plug needs to be decided according to the size of the gap between the grouting pipe and the hole wall. Therefore, grouting quality can be guaranteed.

Owner:苏州云企易站科技服务有限公司

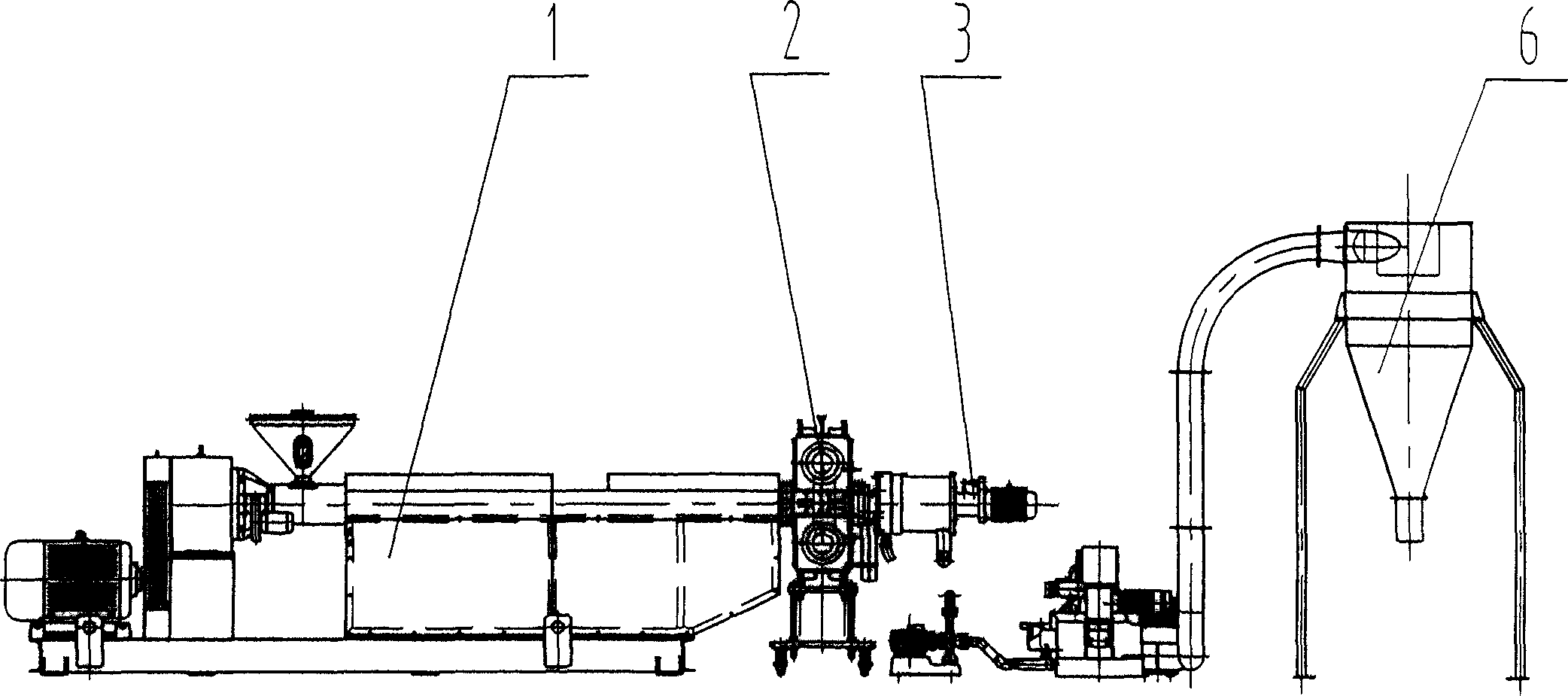

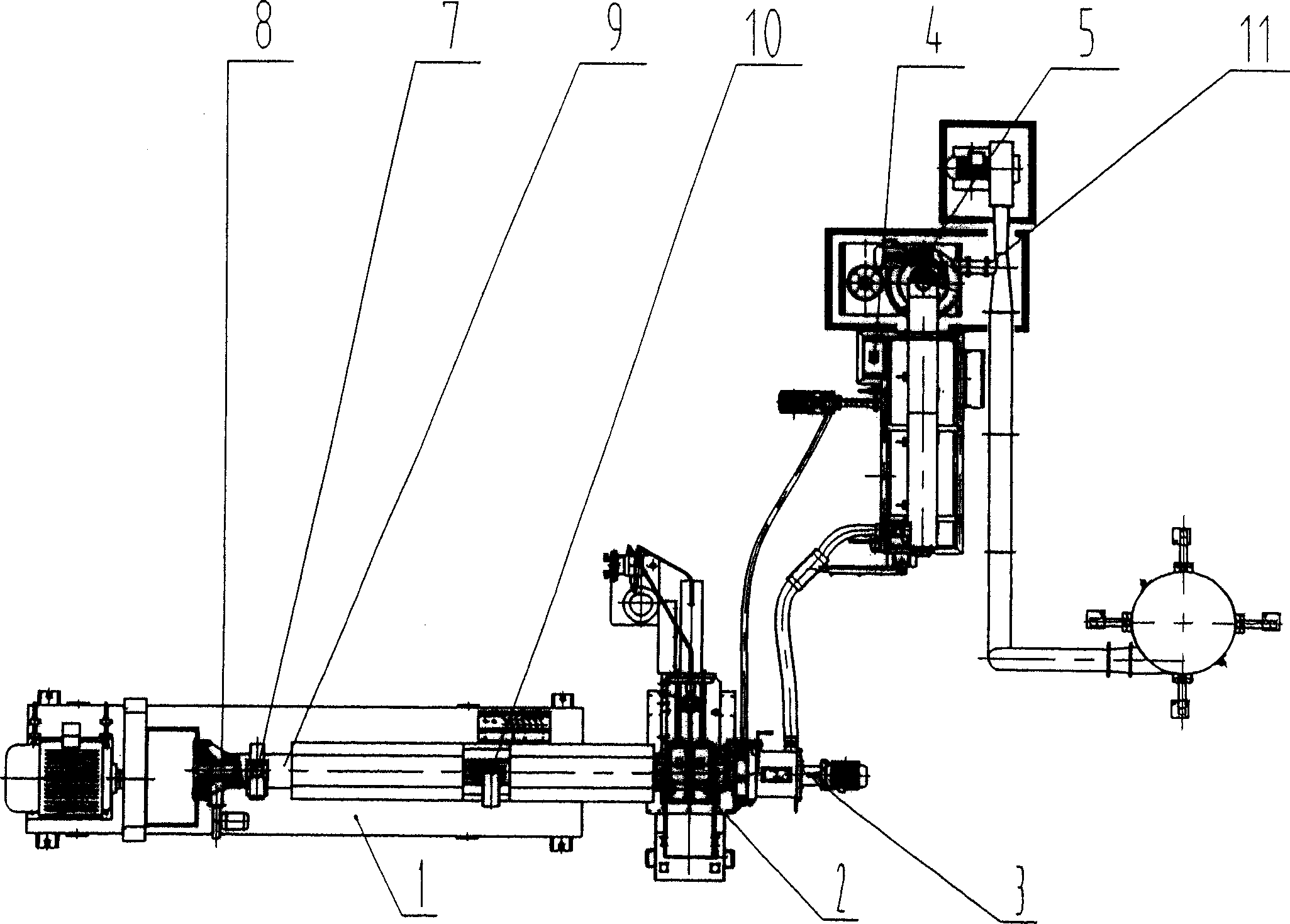

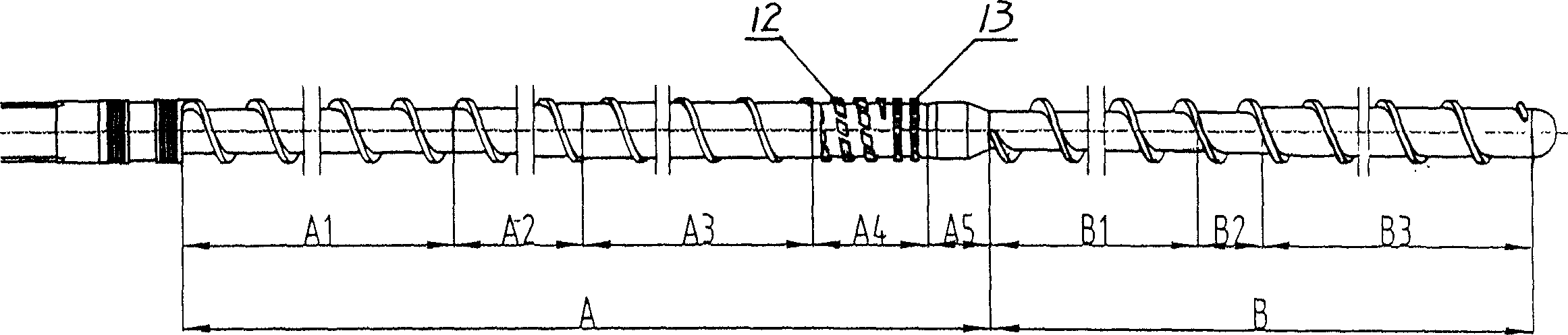

Regeneration pelletizer for worn-out plastic

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

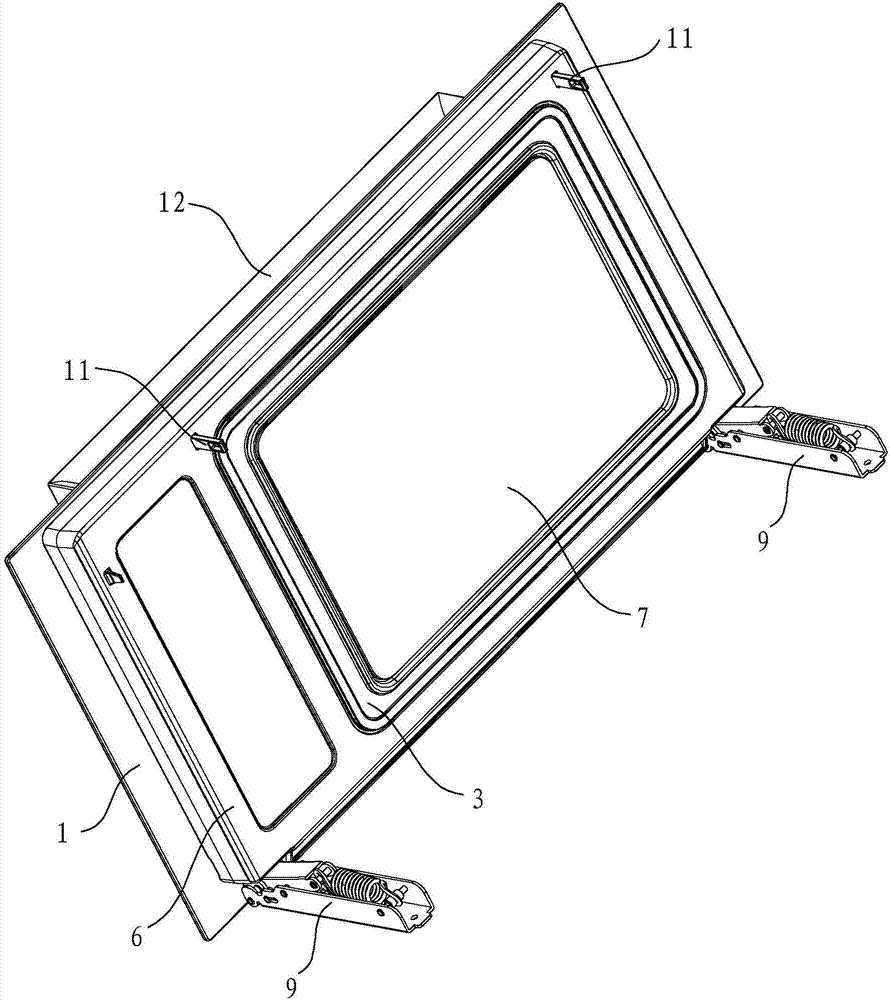

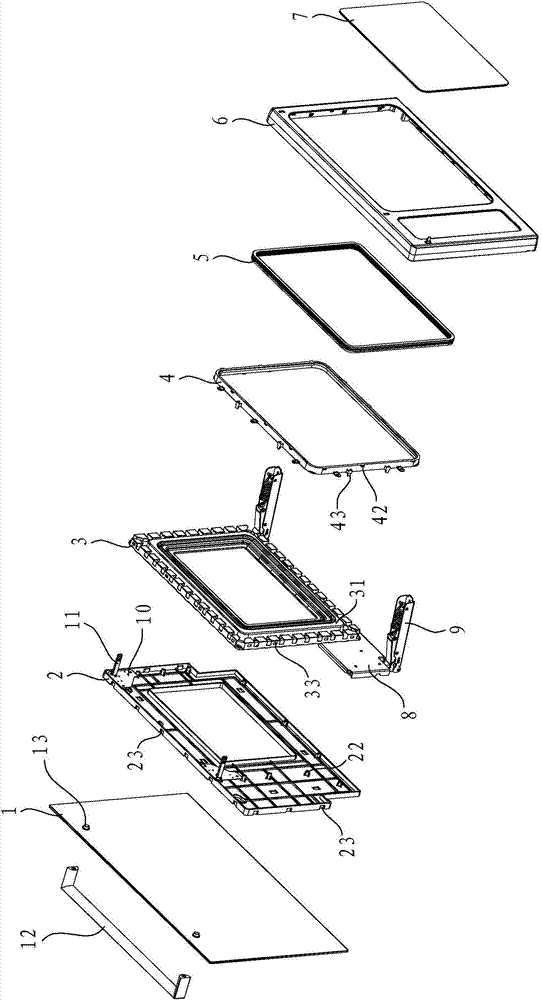

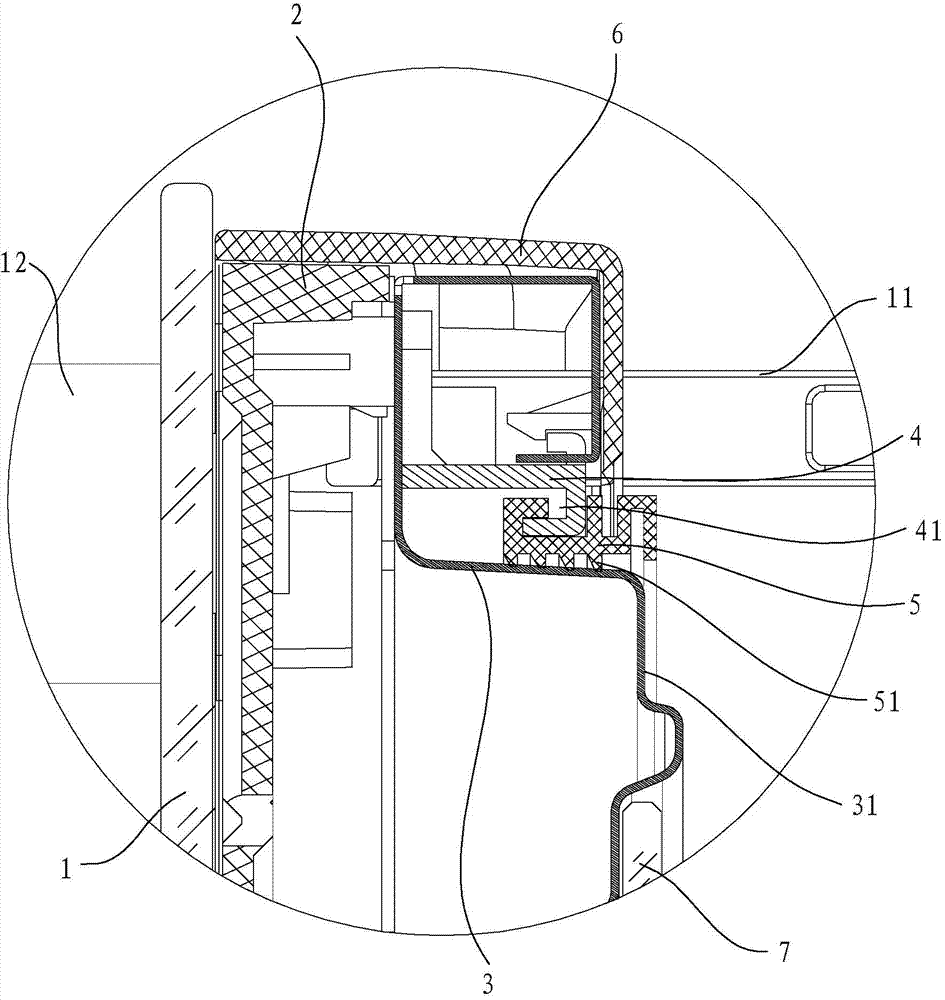

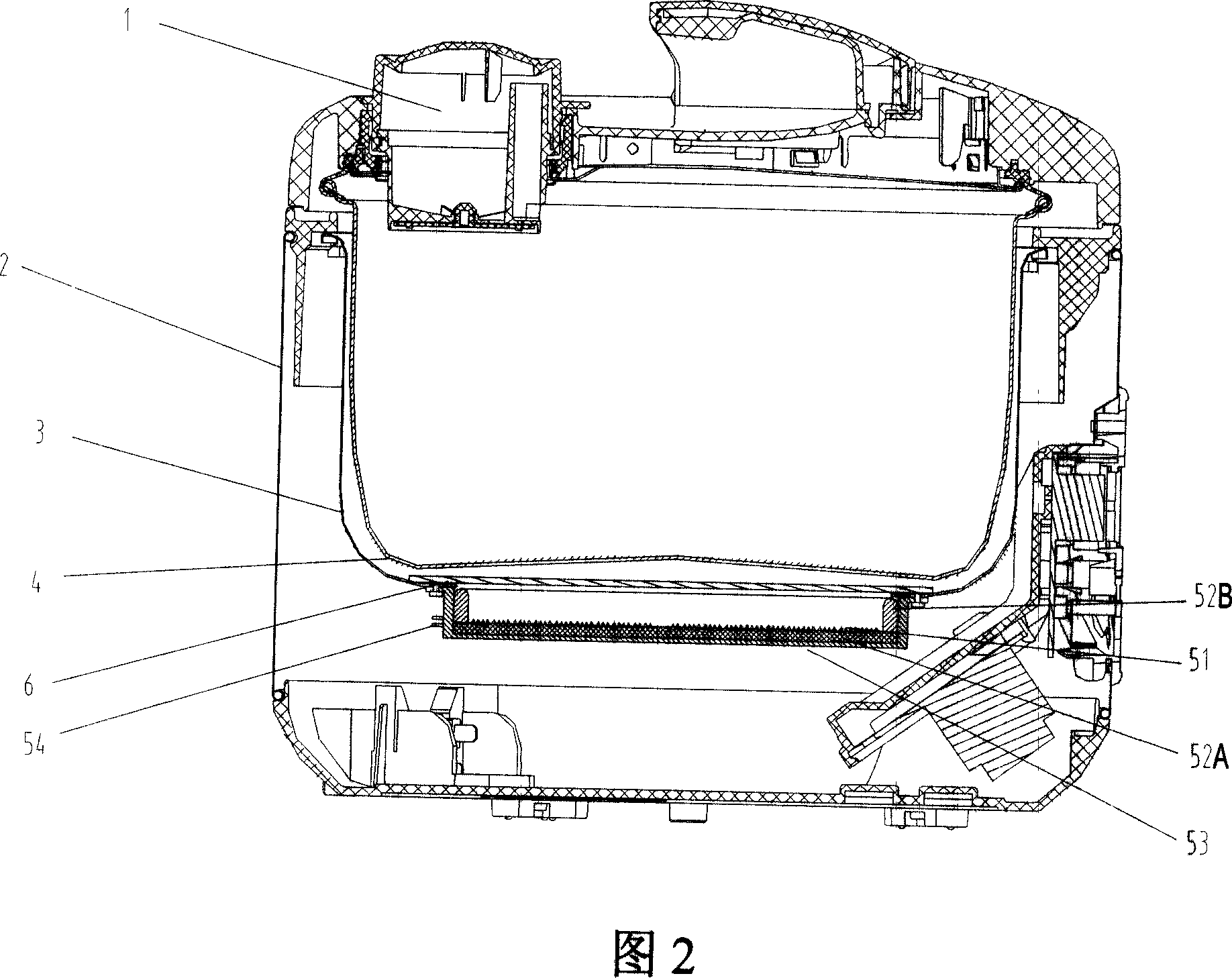

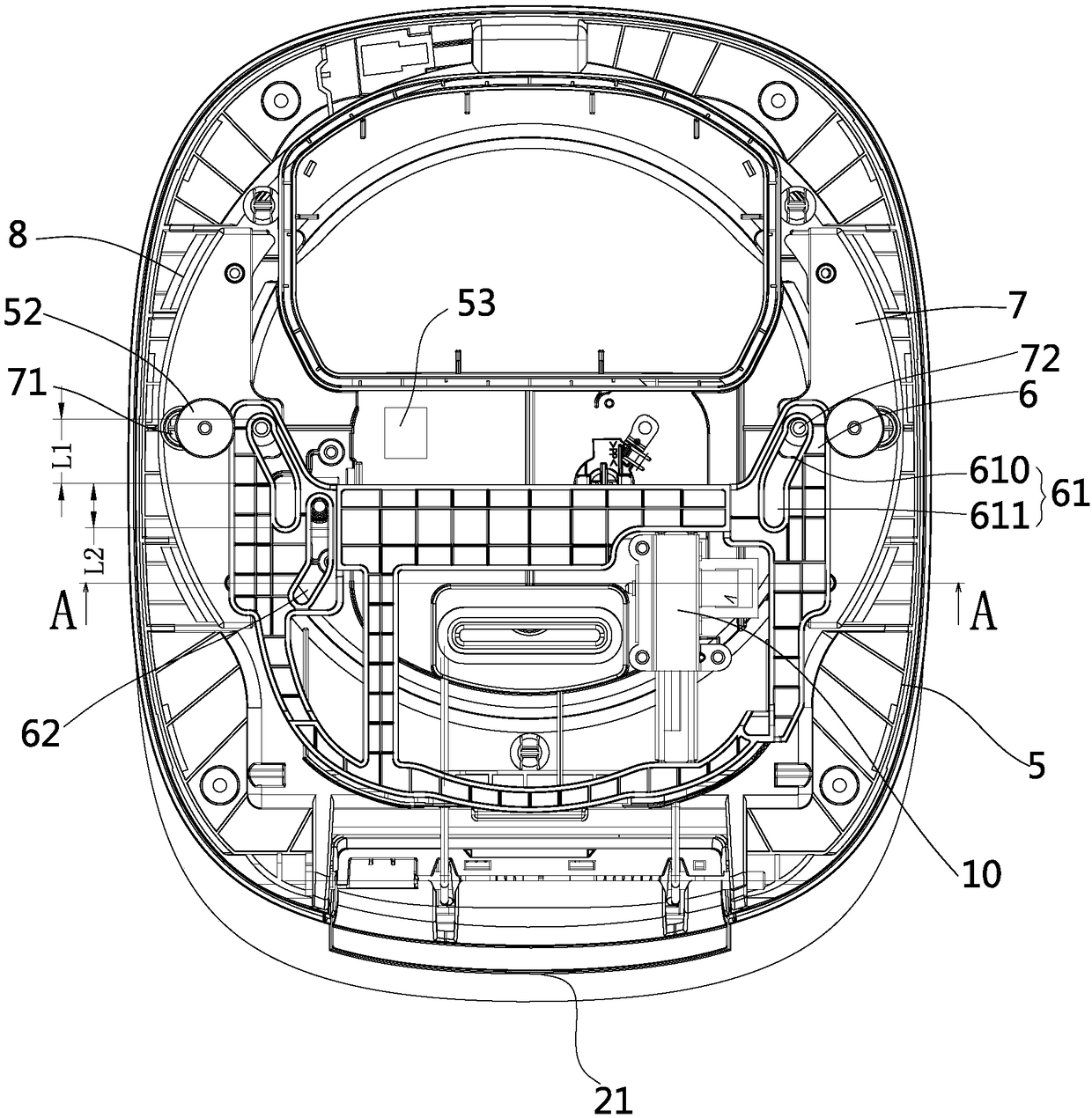

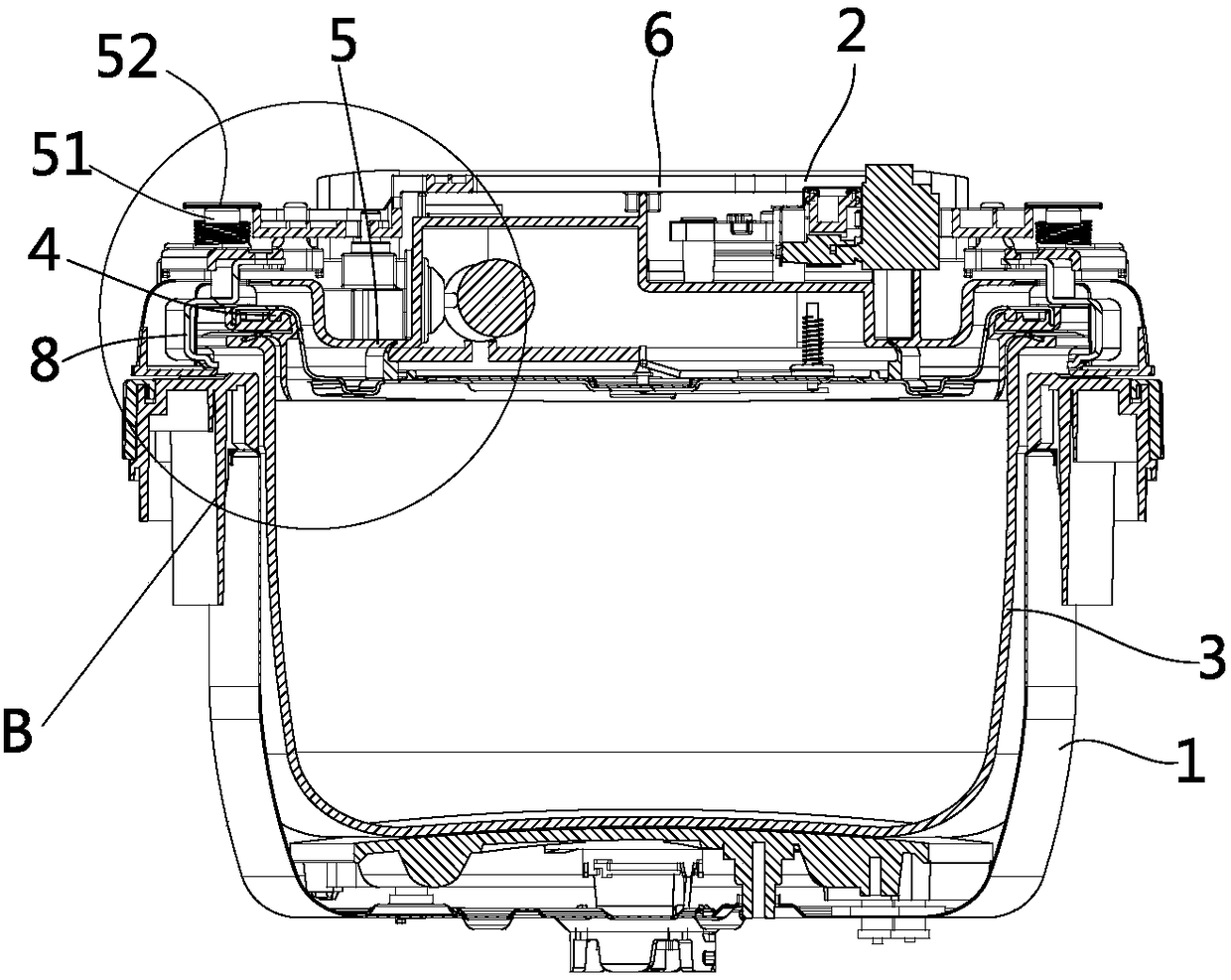

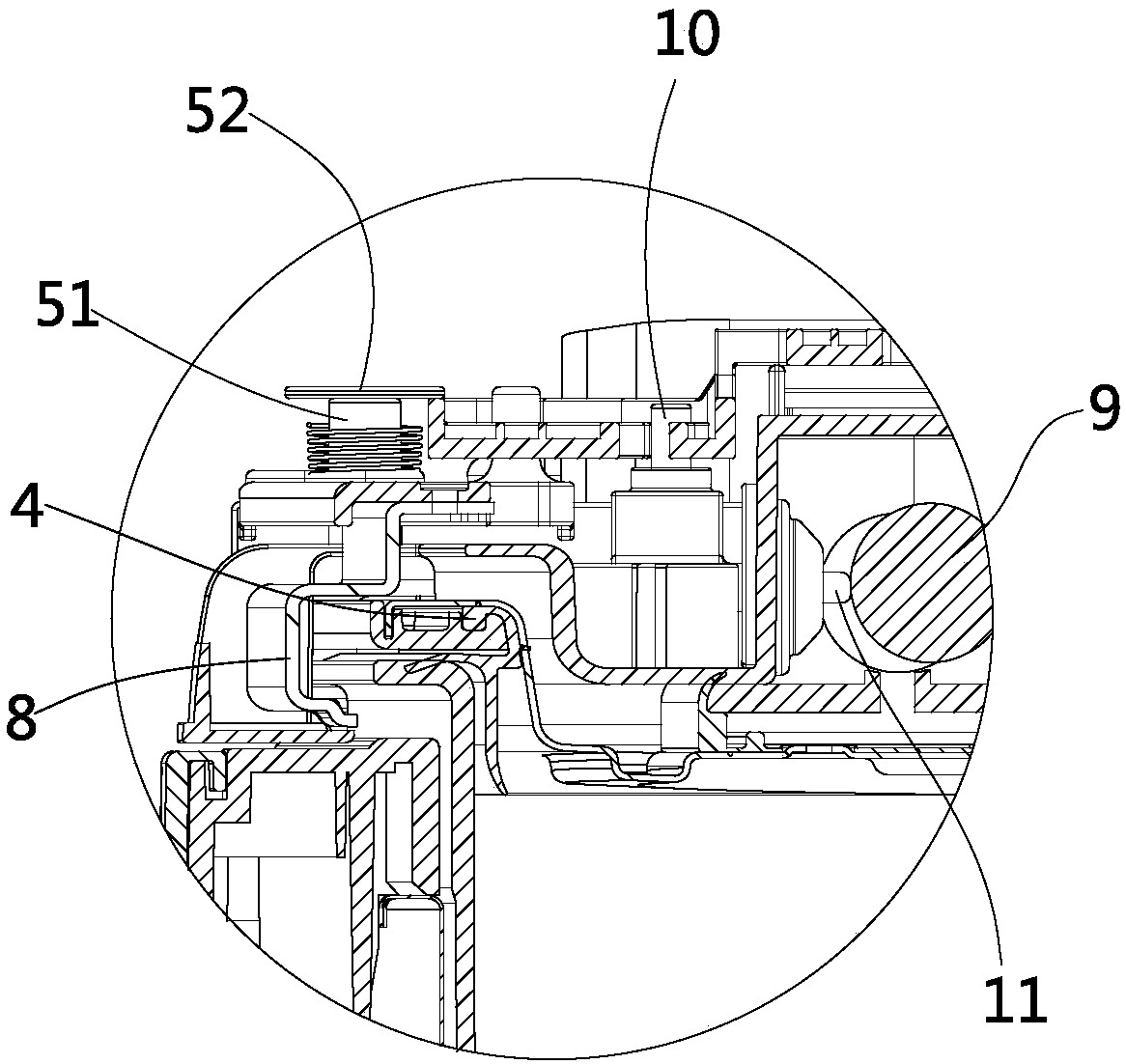

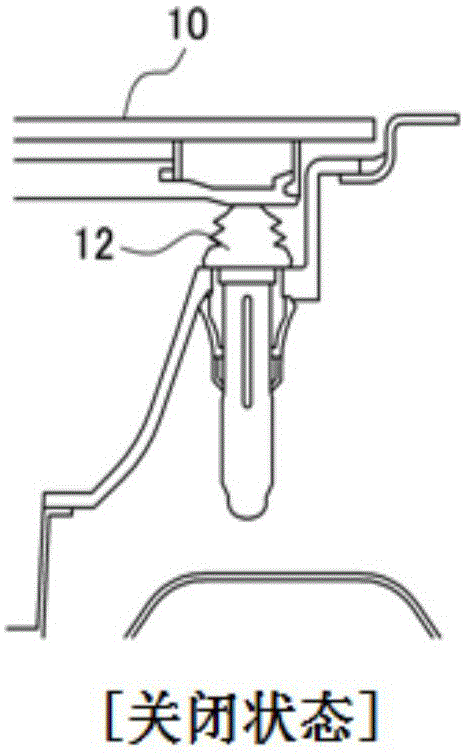

Door of steamer and microwave oven all-in-one machine

ActiveCN104848274AGuaranteed tightnessPrevent poppingDomestic stoves or rangesDoors for stoves/rangesMicrowave ovenEngineering

The invention relates to a door of a steamer and microwave oven all-in-one machine. The door of the steamer and microwave oven all-in-one machine comprises a face plate, a face frame, a door body, a door sealing ring support, a door sealing ring, a door seal and a back plate. The door of the steamer and microwave oven all-in-one machine is characterized in that both the back plate and the door sealing ring support are sealed with the door body, the door sealing ring is simultaneously sealed with the door body and a chamber front plate, and the part, facing to the chamber front plate, of the back surface of the door body forms a microwave sealing surface. The door of the steamer and microwave oven all-in-one machine has the advantages that since the back plate and the door sealing ring support are respectively sealed with the door body and the door sealing ring is simultaneously sealed with the door body and the chamber front plate, steam can be very favorably prevented from leaking, and the microwave sealing surface formed between the back surface of the door body and the chamber front plate can effectively prevent microwaves from leaking; since a compression spring mechanism and a tension spring of a hinge jointly control the force for opening and closing the door, the hand feeling during opening and closing of the door is guaranteed to be moderate, the compression spring mechanism can continuously apply certain closing force to the door after the door is closed, the door is prevented from being popped up during cooking, and thus the steam and microwave sealing effect is guaranteed.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

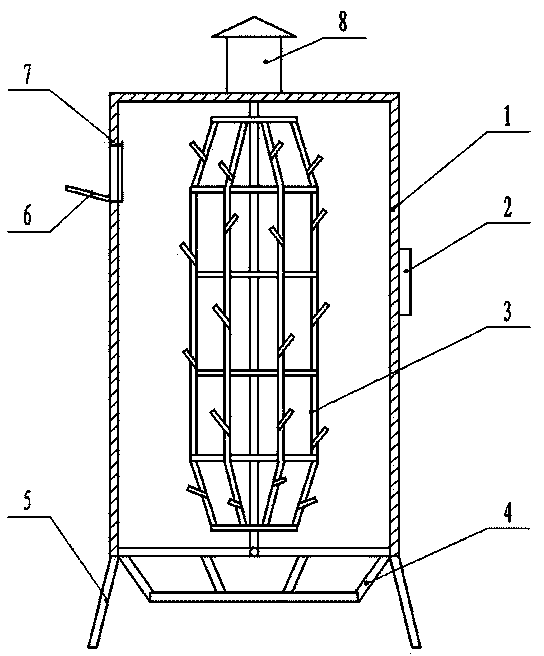

Garbage incinerator

InactiveCN103939910AIncrease temperatureAvoid fightingIncinerator apparatusCombustorCombustion chamber

The invention discloses a garbage incinerator which comprises an incinerator body, a combustor, a feeding notch, a movable baffle, fire bars, a chimney and incinerator legs. The inner wall of the incinerator body is provided with refractory bricks. The incinerator body is hollow to form the combustor. The top of the incinerator body is provided with the chimney. The upper portion of the incinerator body is provided with the feeding notch and the movable baffle. The bottom of the incinerator body is provided with the fire bars. The bottom end of the incinerator body is open to form an ash outlet. The bottom end of the incinerator body is provided with the incinerator legs. The combustor of the incinerator body is provided with a support used for distributing garbage. The support is arranged in the center area of the incinerator body. As the support used for supporting the garbage thrown into the incinerator body is arranged in the incinerator body, in the combusting process, when the garbage is thrown, flames of the lower layer are prevented from being put out, high temperature in the incinerator body can be kept continuously, various materials in the garbage can be fully combusted, the combustion rate is increased, and harmful gas can be effectively prevented from being generated.

Owner:蓝宜建

Portable disinfection device for anesthesiology department

PendingCN112755221ASolid clampingReduce labor intensityLavatory sanitoryChemicalsAnesthetic departmentMedical staff

The invention relates to a disinfection device, and particularly relates to a portable disinfection device for the anesthesiology department. The portable disinfection device for the anesthesiology department can replace the disinfection position of a medical instrument, meanwhile, the medical instrument can be fixed and prevented from shaking, and an existing disinfection cabinet is small in size and convenient for medical staff to carry. The portable disinfection device for the anesthesiology department comprises supporting legs, a box body, a box cover and a handle, wherein the four supporting legs are placed on the ground, the box body is connected among the four supporting legs, the box cover is arranged on the upper portion of the box body in a sliding mode, the handle is fixedly connected to the middle of the top of the box cover, a fixing mechanism is installed at the bottom of the inner wall of the box body, and a disinfection mechanism is arranged on the upper portion of the inner wall of the box body in a sliding mode. According to the portable disinfection device for the anesthesiology department, the fixing mechanism is arranged, the fixing mechanism is matched with the disinfection mechanism, so that the medical instrument can be clamped and fixed, and meanwhile, the medical instrument can be disinfected; and a switch mechanism is matched with an auxiliary mechanism, so that a first rack does not need to be manually loosened at intervals by the medical staff.

Owner:王琳

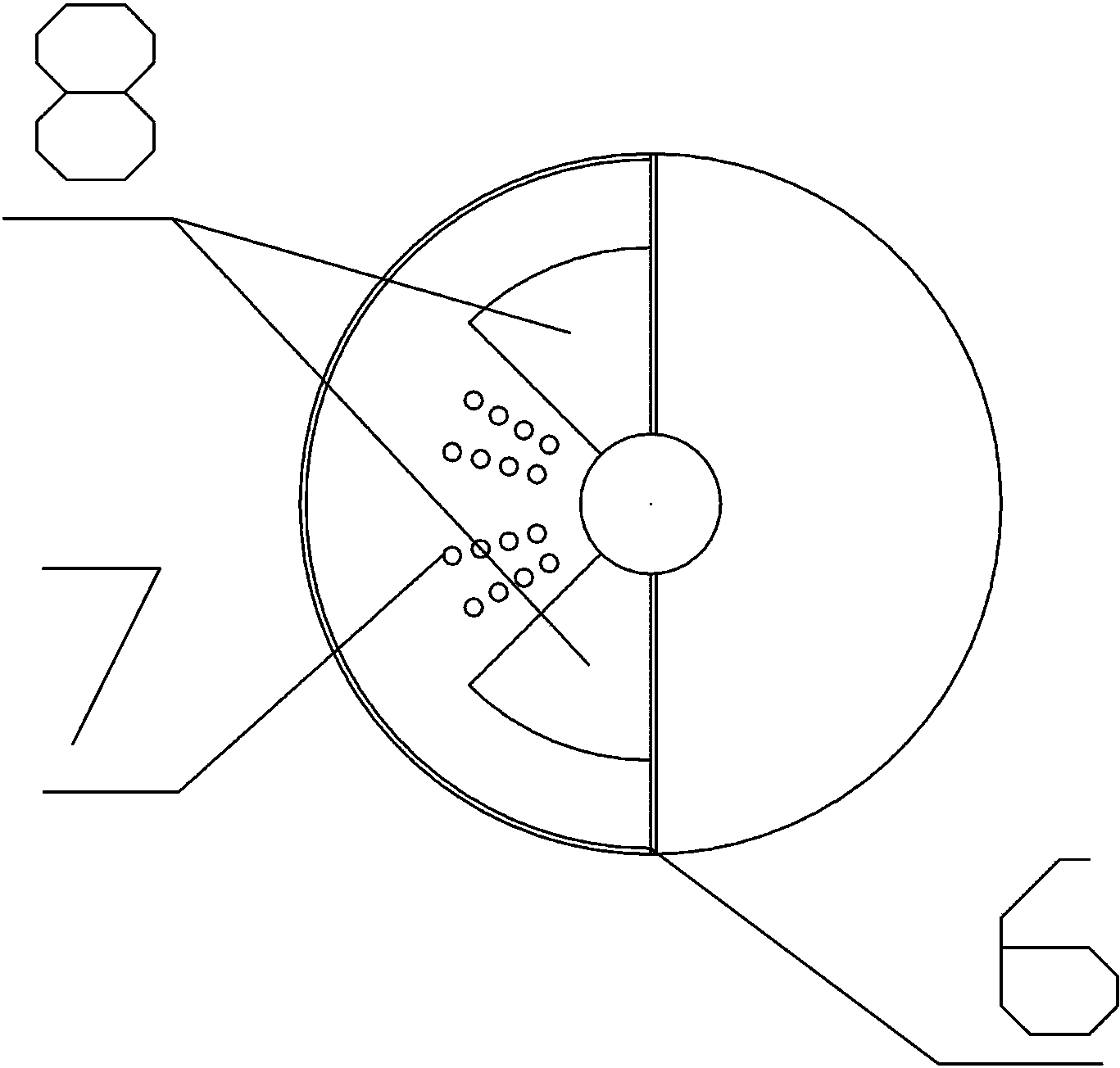

Steel ball screening device

The invention provides a steel ball screening device. The steel ball screening device comprises a body. An annular slide is arranged on the right side of the body. A screening groove is formed in the joint of the slide and the body. An air pump is installed at the tail end of the slide. Because the screening groove is formed in the joint of the body and the slide and unsuitable steel balls can be screened out through the screening groove, manual screening is reduced; because the air pump arranged at the tail end of the slide will be stopped every time when a preset number of steel balls pass and namely the steel balls are controlled to pass through start or stop of the air pump, manual control is reduced; because a plastic plate is arranged on the body to prevent the steel balls from jumping out when workers work, the safety of the workers is improved.

Owner:NEXTEER LINGYUN DRIVELINE WUHU

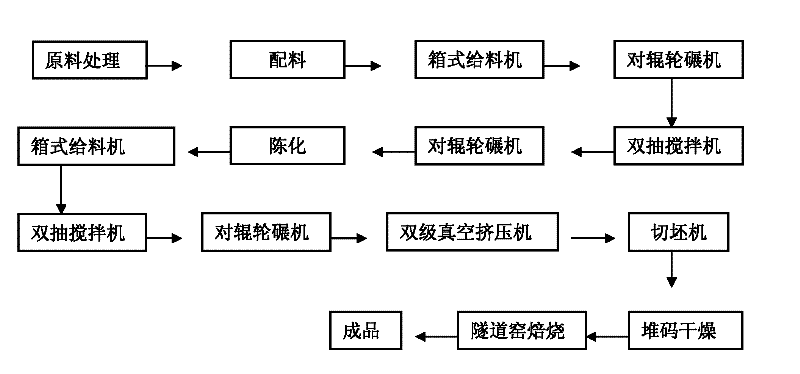

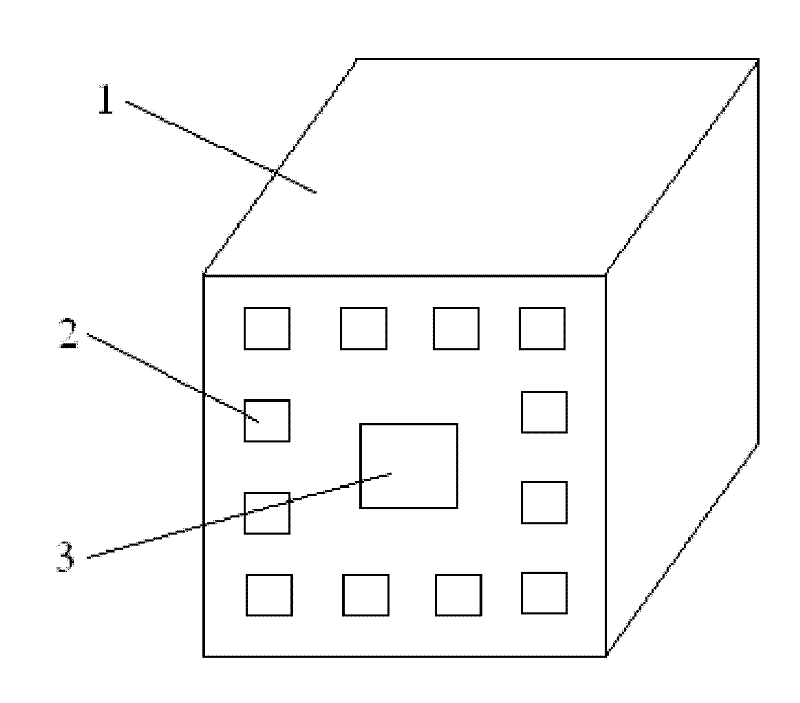

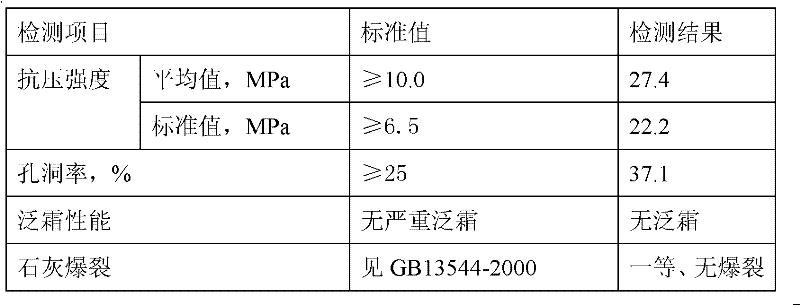

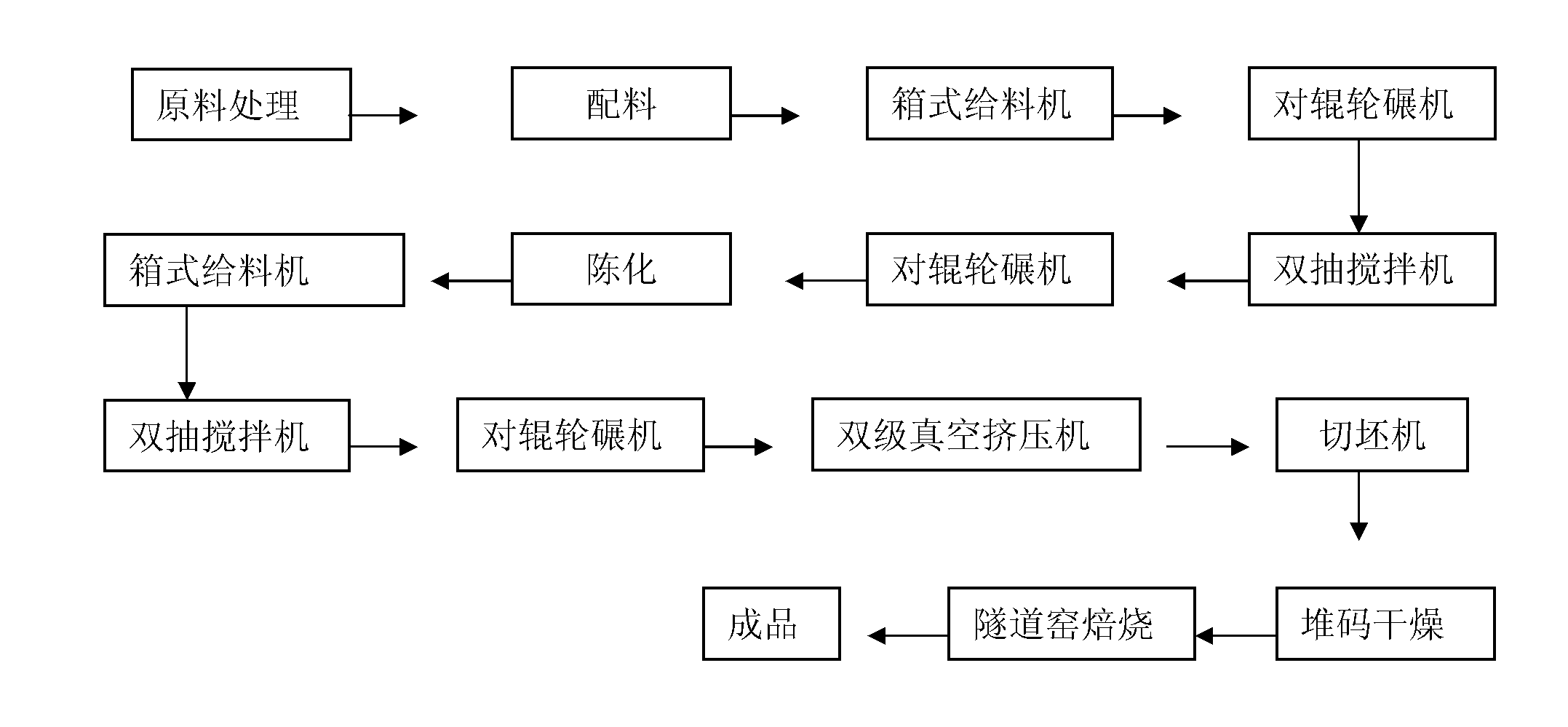

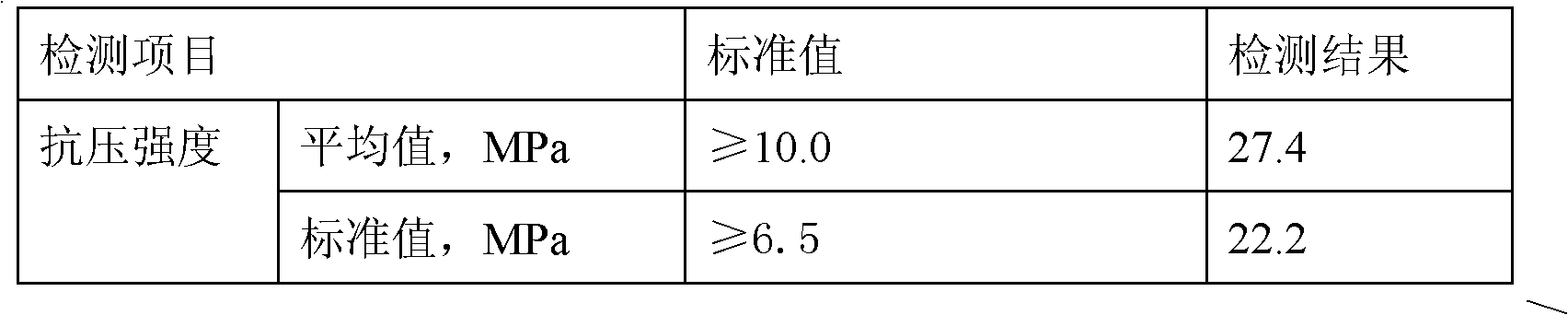

Slickens baked brick and production method thereof

The invention relates to a braked brick, specifically a braked brick prepared from slickens and a preparation process thereof. The sintering material of the slickens baked brisk, in terms of oven dry weight, comprises the following components in part by weight: 35 to 45 parts of slickens by weight, 30 to 45 parts of coal gangue or coal cinder by weight, 10 to 25 parts of engineering dregs or shale by weight, 5 to 10 parts of clinker by weight and 3 to 8 parts of fine sawdust or rice husks by weight. The material source of slickens baked brisk is extensive, so that the waste slickens is recycled to save the land resources and protect the cultivated land, thus the large-surface yield slickens waste which easily generates raise dust is sufficiently used for changing waste into valuable and purifying the environment. The acquired slickens baked brisk is thermally insulated and heat-insulated, shock and pressure resistant, free of decrustation and distortion, and difficult to break and burst; the yield can be more than 99%, thus the slickens baked brick is suitable for the large-scale industrial production.

Owner:上海鑫晶山建材开发有限公司 +1

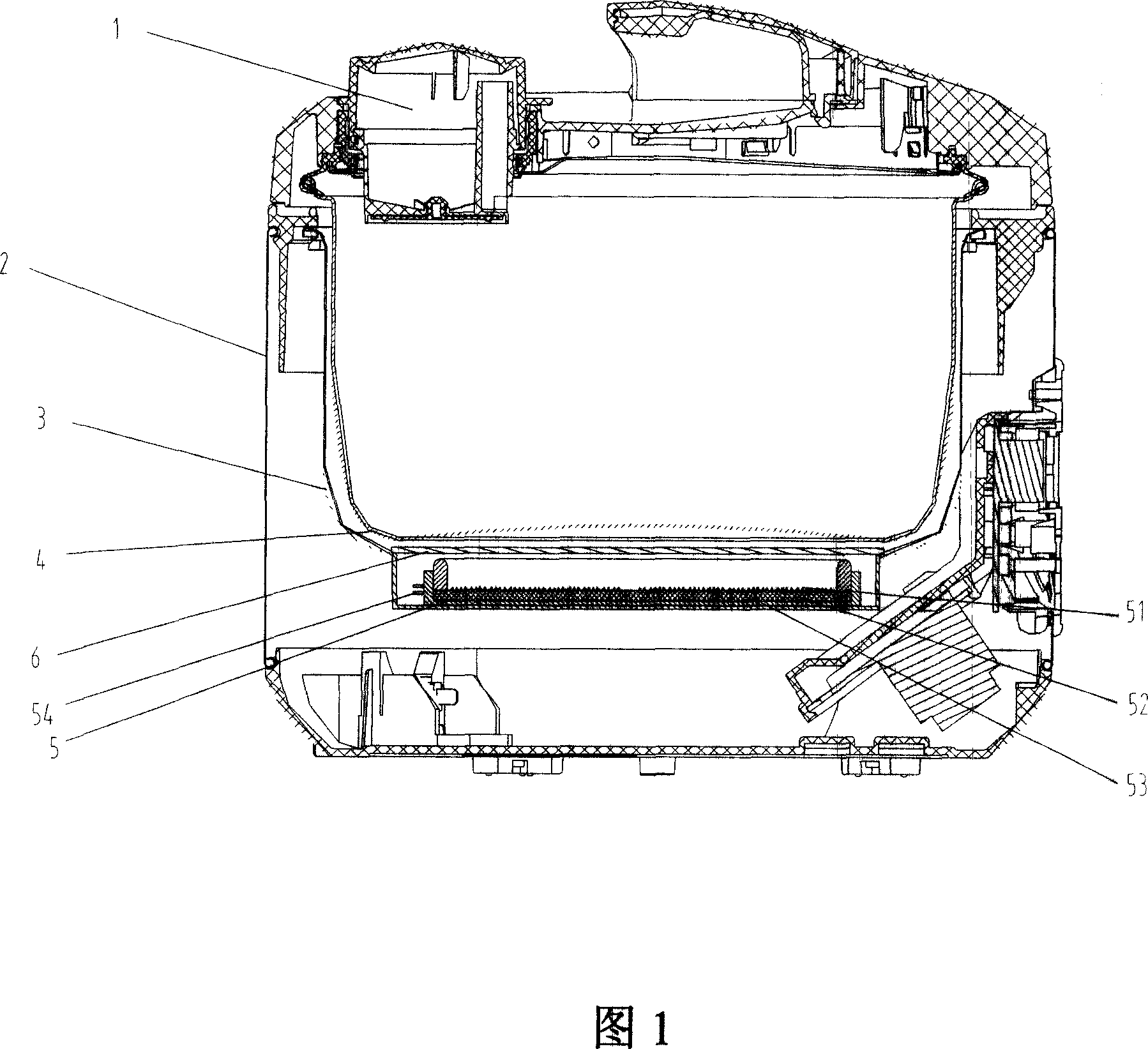

Electric cooker

InactiveCN1935066AEvenly heatedReduce material requirementsCooking vesselsOhmic-resistance heatingBrickEngineering

The present invention provides an electric rice cooker. It is characterized by that said electric rice cooker includes the following several portions: external shell, cooker body placed in the external shell interior, internal container placed in the cooker body interior, upper cover placed on the upper portion of external shell and can be formed into relatively-closed structure together with the internal container and infrared heater placed in the bottom portion and / or side portion of said external shell. Said electric rice cooker not only has high heating efficiency, but also can effectively save energy.

Owner:MIDEA GRP CO LTD

Fault detection method for electric cooker

InactiveCN109393956APrevent poppingReduce potential safety hazardsPressure-cookersElectricityReciprocating motion

The invention discloses a fault detection method for an electric cooker, and belongs to the technical field of kitchen appliances, for solving the technical problem that in the prior art, whether a drive part for driving a caliper assembly to move breaks down or not can not be detected. For the fault detection method for the electric cooker provided by the invention, the electric cooker comprisesa cooker body, a cooker cover and a master controller, wherein an inner pot is accommodated in the cooker body, the cooker cover comprises an inner cover, a caliper assembly and a drive part, the master controller controls the drive part to drive the caliper assembly to perform radial reciprocating motion, so that the locking or unlocking of the inner cover and the inner pot is completed, the cooker cover further comprises a detection switch used for detecting that whether the caliper assembly realizes the in-place locking or not, and the detection switch is connected with the master controller. For the fault detection method for the electric cooker, after the electric cooker is powered on, the master controller judges that whether the caliper assembly realizes the in-place locking or notaccording to a detection signal sent by the detection switch, and if judging that the caliper assembly dose not realize in-place locking, the master controller controls the electric cooker to stop operation.

Owner:PANASONIC HOME APPLIANCES R&D CENT HANGZHOU

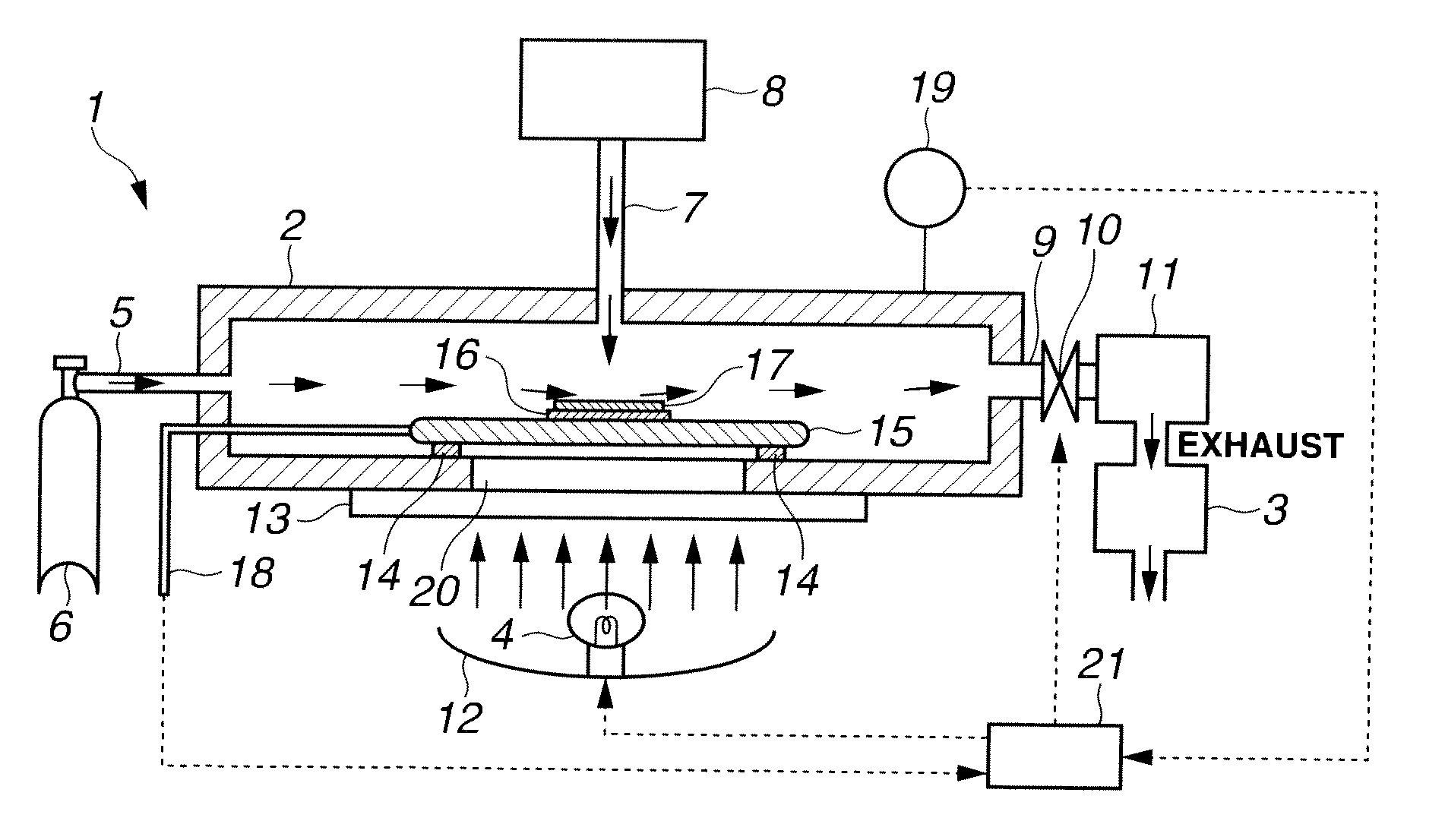

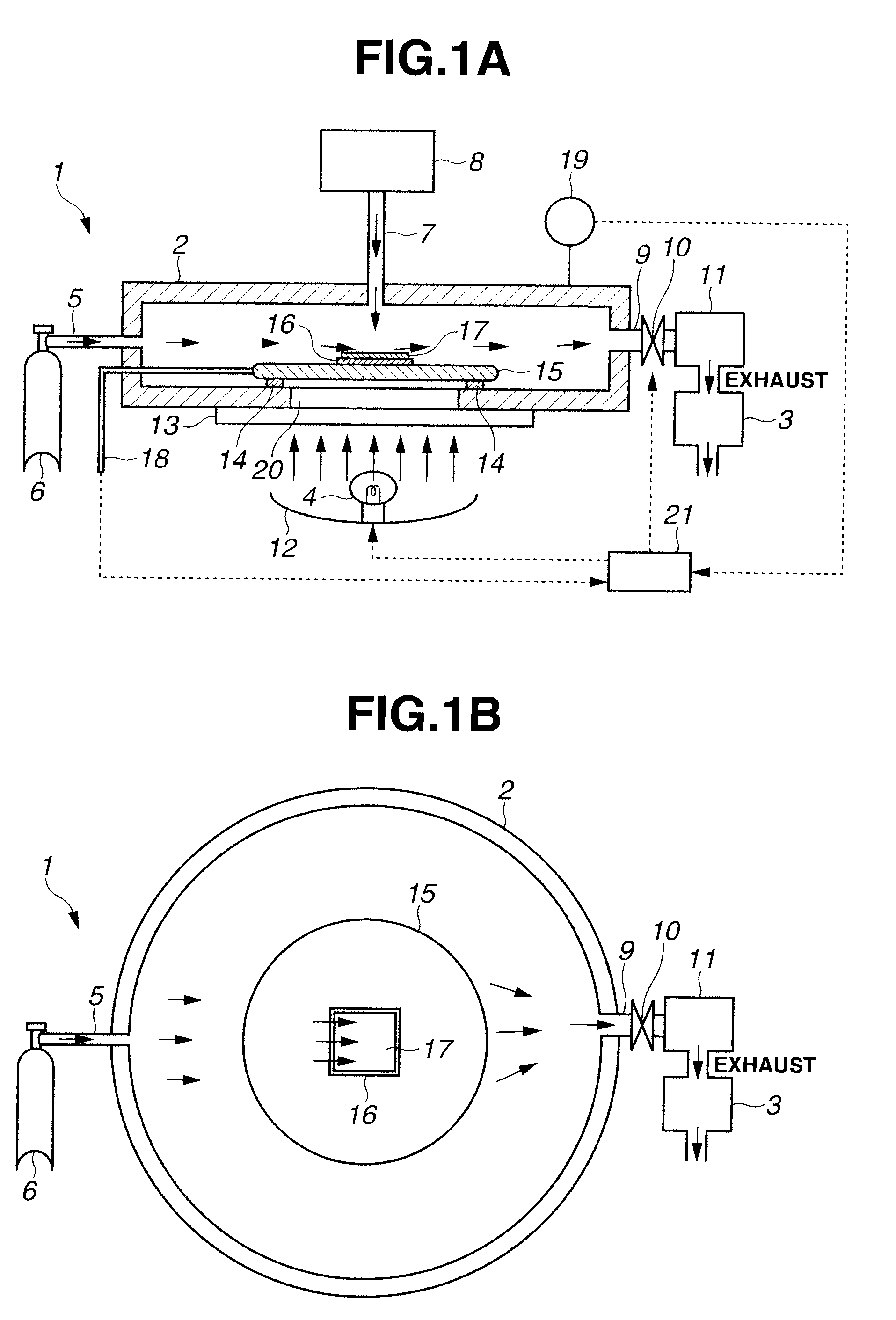

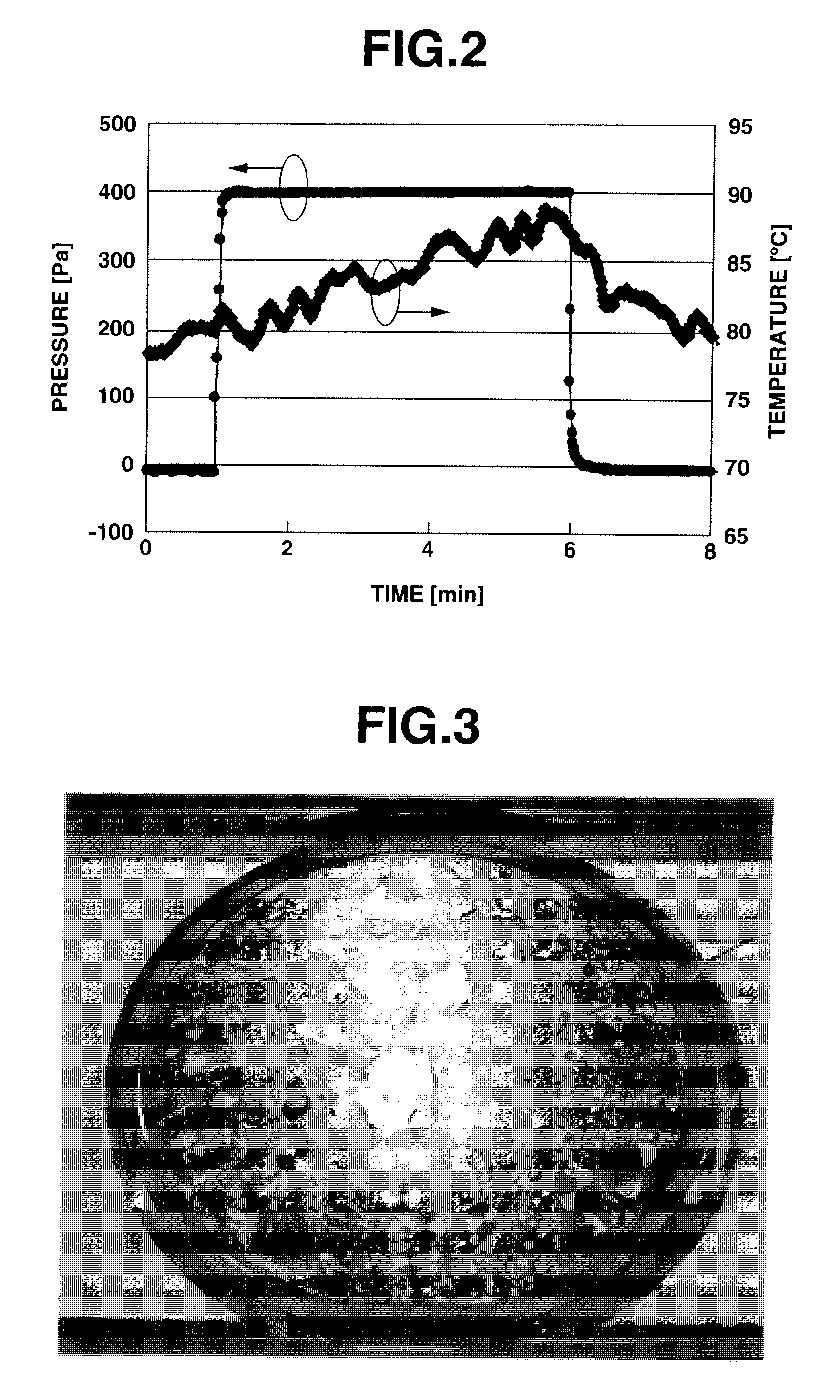

Method of removing resist and apparatus therefor

ActiveUS20100300482A1Simple systemAvoid it happening againDecorative surface effectsSemiconductor/solid-state device manufacturingResistHigh concentration

A resist removal apparatus 1 can remove a resist on a substrate at a low temperature of 90° C. or less. That is, the resist removal apparatus 1 has a chamber 2 which holds a substrate 16 coated with a resist 17 that is going to be removed, and can heat the substrate 16, also into which unsaturated hydrocarbon gas or fluorine substitution product gas of unsaturated hydrocarbon together with ozone gas are supplied at a lower pressure than an atmospheric pressure. An internal pressure of the chamber 2 is controlled so that a temperature of the substrate 16 is 90° C. or less. As the ozone gas, ultra-high concentration ozone gas that is obtained by separating only ozone from ozone-containing gas by a difference of vapor pressure through liquefaction separation and by vaporizing the above ozone again, is given. It is preferable to supply ultrapure water to a treated substrate 16 for cleaning. The chamber 2 is provided with a susceptor 15 that holds the substrate 16. The susceptor 15 is heated by a light source 4 that emits infrared light.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

Phosphogypsum sintered brick and production process thereof

ActiveCN102503517AWide variety of sourcesSave land resourcesSolid waste disposalCeramicwareDistortionCoal gangue

The invention relates to a sintered brick, and concretely relates to a sintered brick prepared by using phosphogypsum and a preparation process thereof. The phosphogypsum sintered brick comprises the following sintering raw materials, by oven dry weight, 17-29.75 parts of phosphogypsum, 27.6-41.4 parts of coal gangue or 25.5-38.25 parts of coal slag, 22.5-30 parts of river silt, and 5-15 parts ofa dry powder additive. The phosphogypsum sintered brick of the invention has the advantages of wide raw material source, realization of the resource recovery of the waste phosphogypsum, land resourcesaving, cultivated land protection, full utilization of the phosphogypsum waste which is extensive and easily generates pollution, and environment purification through changing wastes into valuables The obtained phosphogypsum sintered brick which has the advantages of thermal insulation, earthquake resistance and stress resistance, no peeling or distortion, non-frangibility, non-explosion, and high yield of above 99%, is suitable for the industrial production.

Owner:上海鑫晶山建材开发有限公司 +1

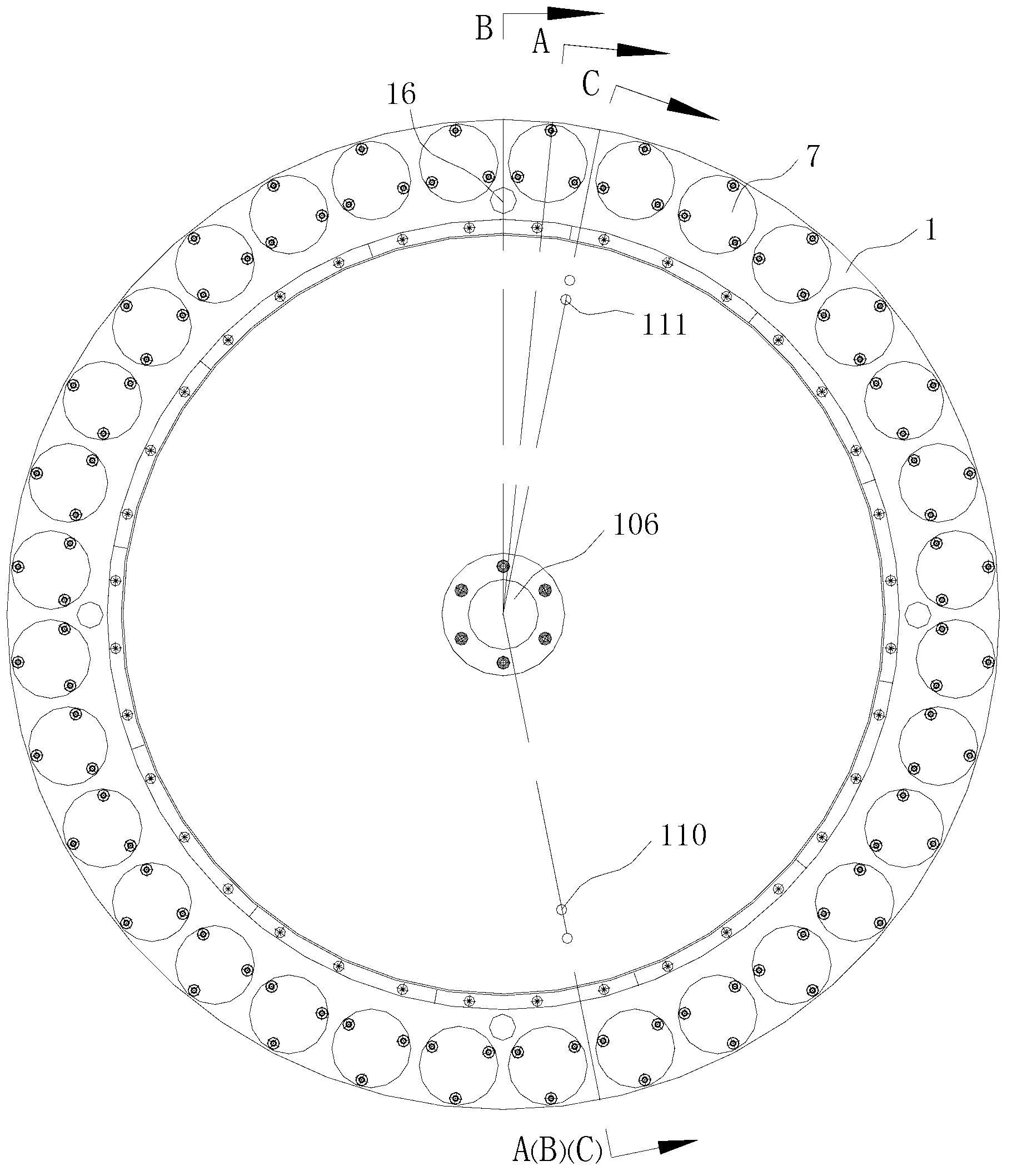

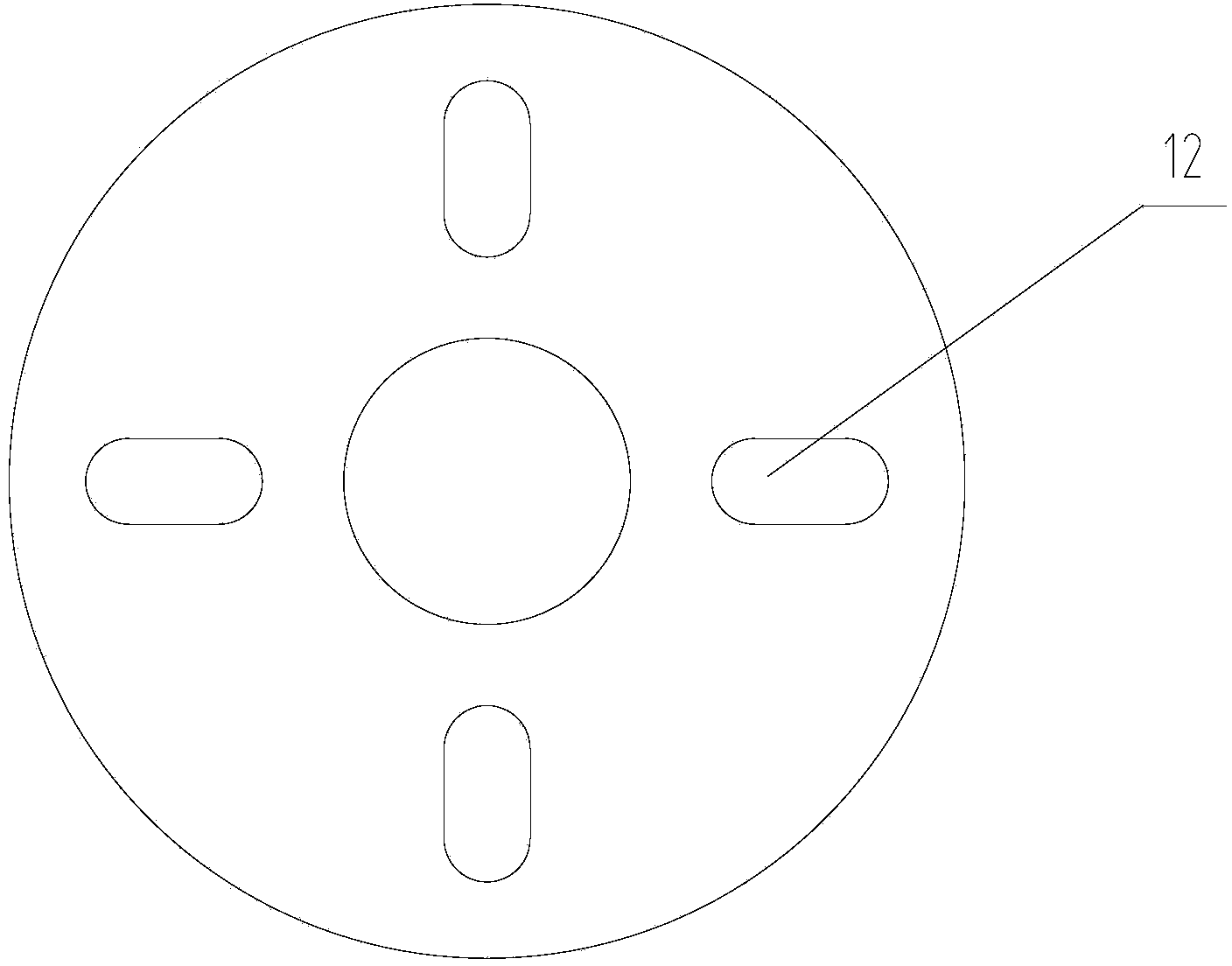

Universal type rotor core overlaying tool and method

ActiveCN104242568AImprove securityReduce the impactManufacturing stator/rotor bodiesEngineeringRadial clearance

The invention discloses a universal type rotor core overlaying tool which comprises a platen, a base and a mandrel. The mandrel is sleeved with rotor cores in an overlaid mode. The rotor cores are located between the platen and the base, and core laminations are overlaid through the platen and the base jointly. The universal type rotor core overlaying tool is characterized in that a plurality of pressing columns are connected with the lower portion of the platen and are evenly and annularly distributed at intervals, and the platen drives the pressing columns to enable the iron laminations to be overlaid. According to the universal type rotor core overlaying tool, the pressing column structure is adopted, and radial clearances exist between the pressing columns; compared with a traditional closed overlaying tool, rotor core end fixing keys can be installed when the rotor cores are compressed, the influences of the oil press stroke on rotor core overlaying specifications can be lowered, the security coefficients in the rotor core overlaying process are increased, working procedure tome is shortened, and production efficiency is improved by about 30%.

Owner:安徽金箔机电产业集团股份有限公司

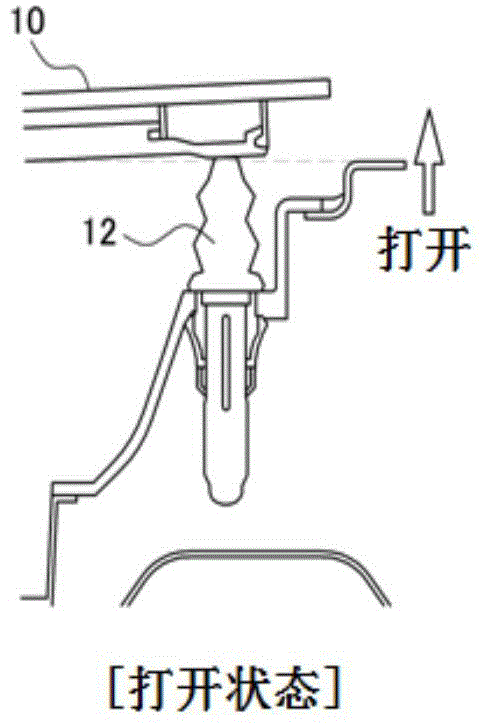

Device for opening and closing push open type fuel door for vehicle

InactiveCN105082986AReduce in quantityImprove assembly processabilityPower transmission/actuator featuresElectrical locking actuatorsEngineeringElectric motor

Owner:HYUNDAI MOTOR CO LTD +2

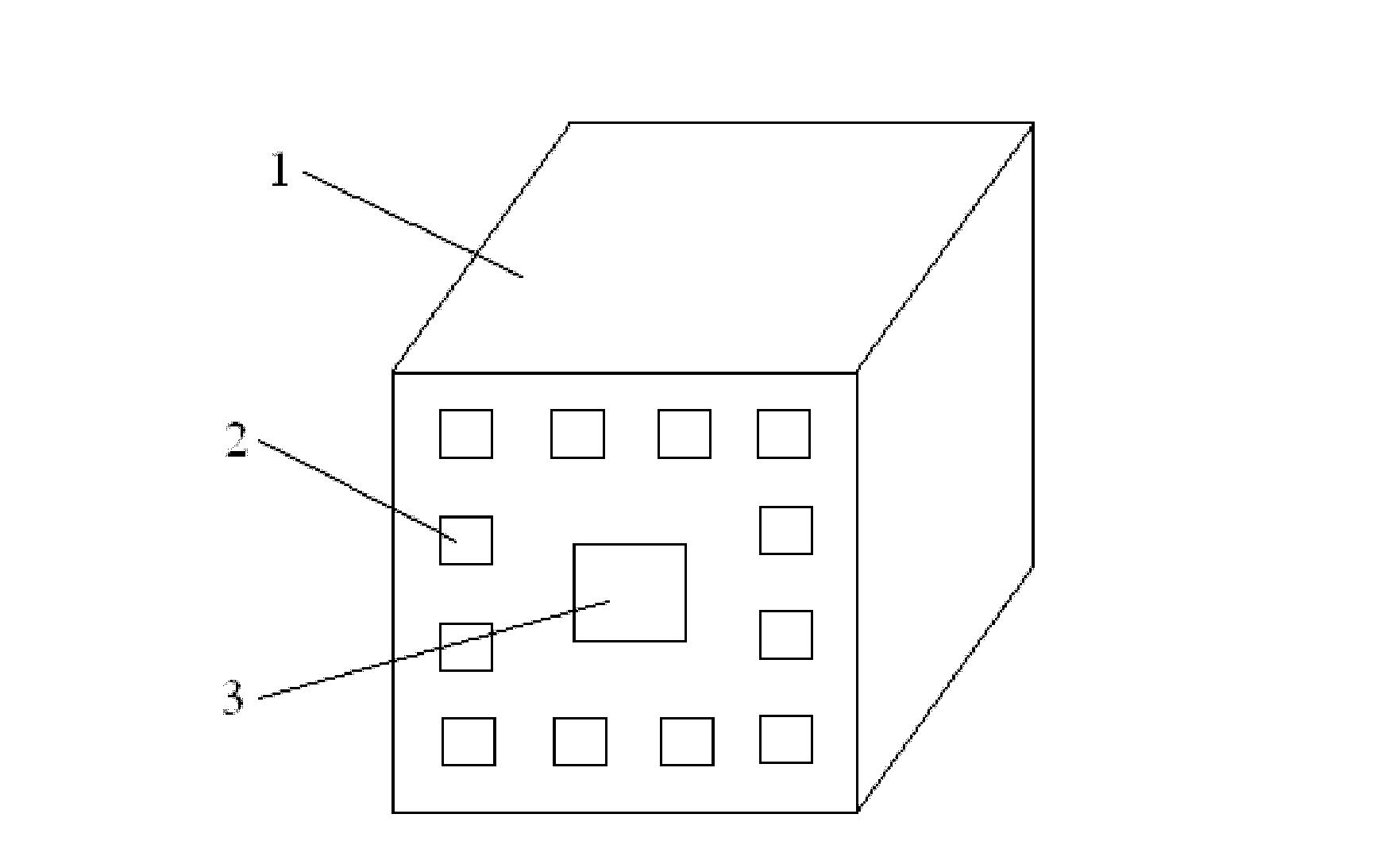

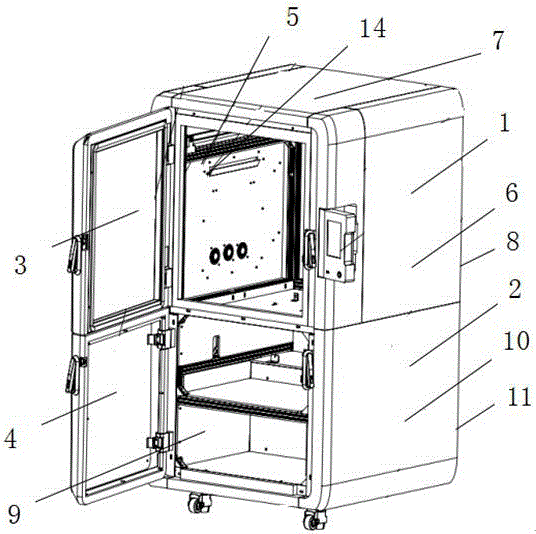

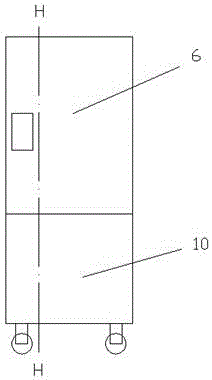

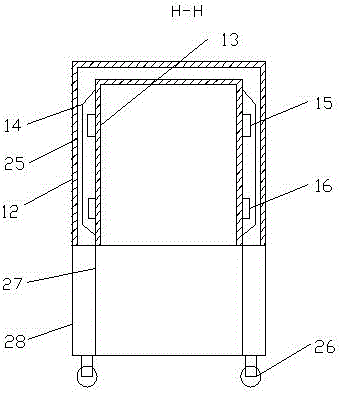

FDM 3D printer with heating thermal insulation property

InactiveCN106003736ABeautiful structureLow priceAdditive manufacturing apparatusThermal insulationFlue

The invention discloses a FDM3D printer with heating and heat preservation performance, which comprises a casing, the casing includes a lower casing and an upper casing fixedly connected above the lower casing; an upper front door is installed directly in front of the upper casing, and the lower casing The lower front door is installed directly in front of the front; the upper shell and the lower shell are set as a rectangular parallelepiped structure without a front face; The double-layer structure, the double-layer structure includes the outer sheet metal shell and the inner sheet metal plate; the double-layer structure on the upper left side and the upper right side is equipped with an air duct; the upper end of the air duct is equipped with a heater, and the lower end is It is equipped with a turbo fan; it reduces the heat exchange between the printer's printing chamber and the outside air, so that the hot air in the printer is not easy to flow out from the sheet metal gap; and heats the air in the upper casing, and makes the printing chamber reach the preset goal After the temperature value, it is in a state of constant temperature and uniformity.

Owner:JIANGSU OURING THREE DIMENSIONAL SCI & TECH CO LTD

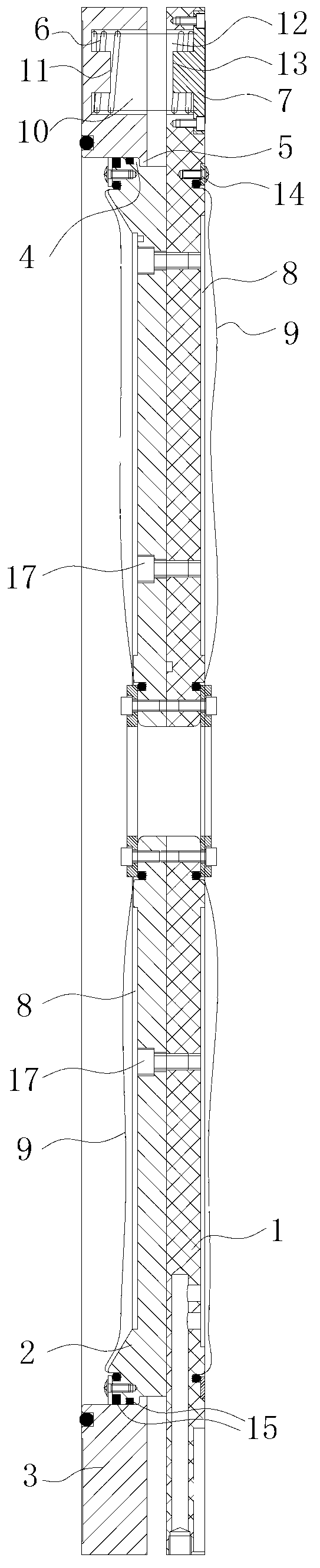

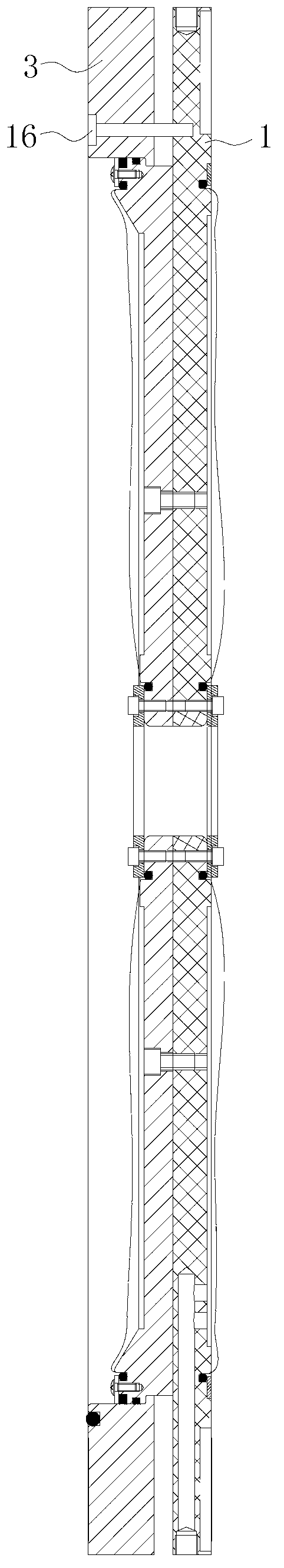

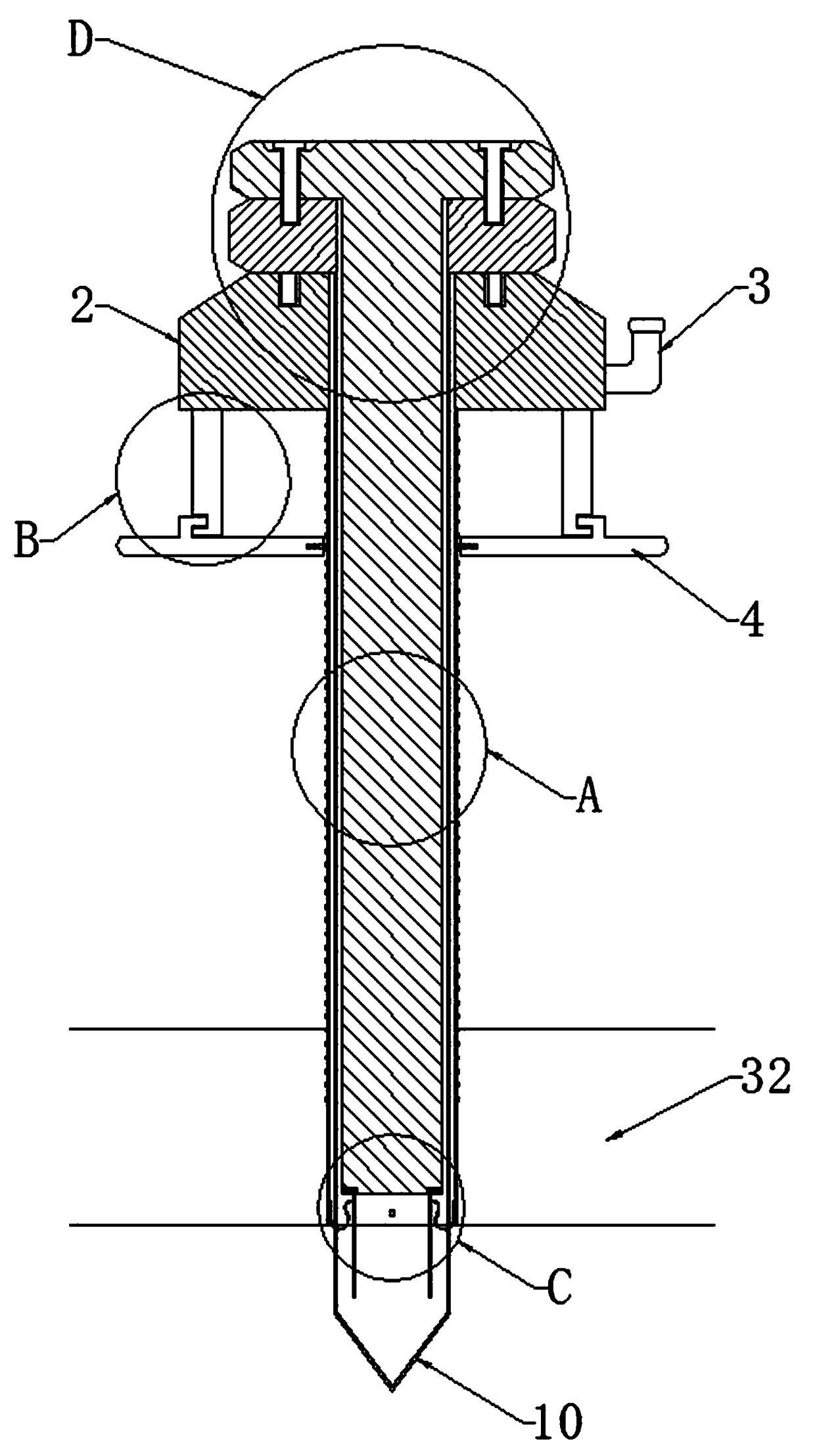

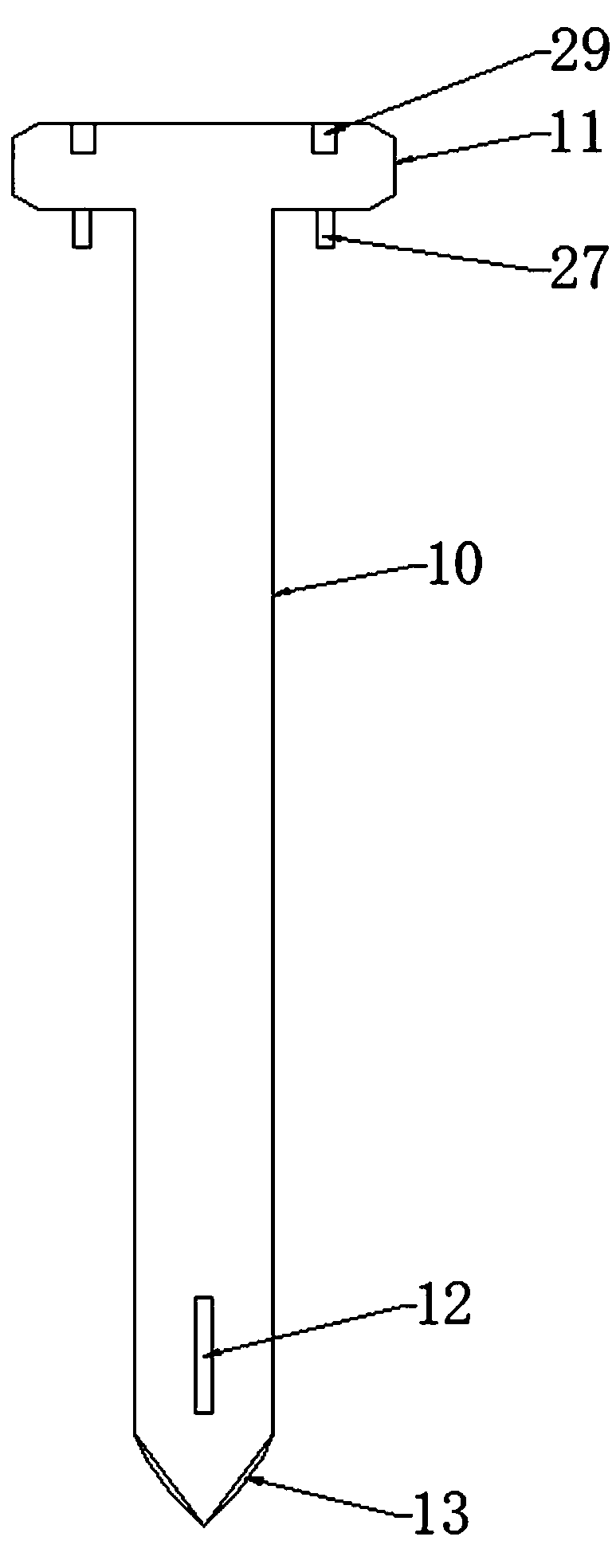

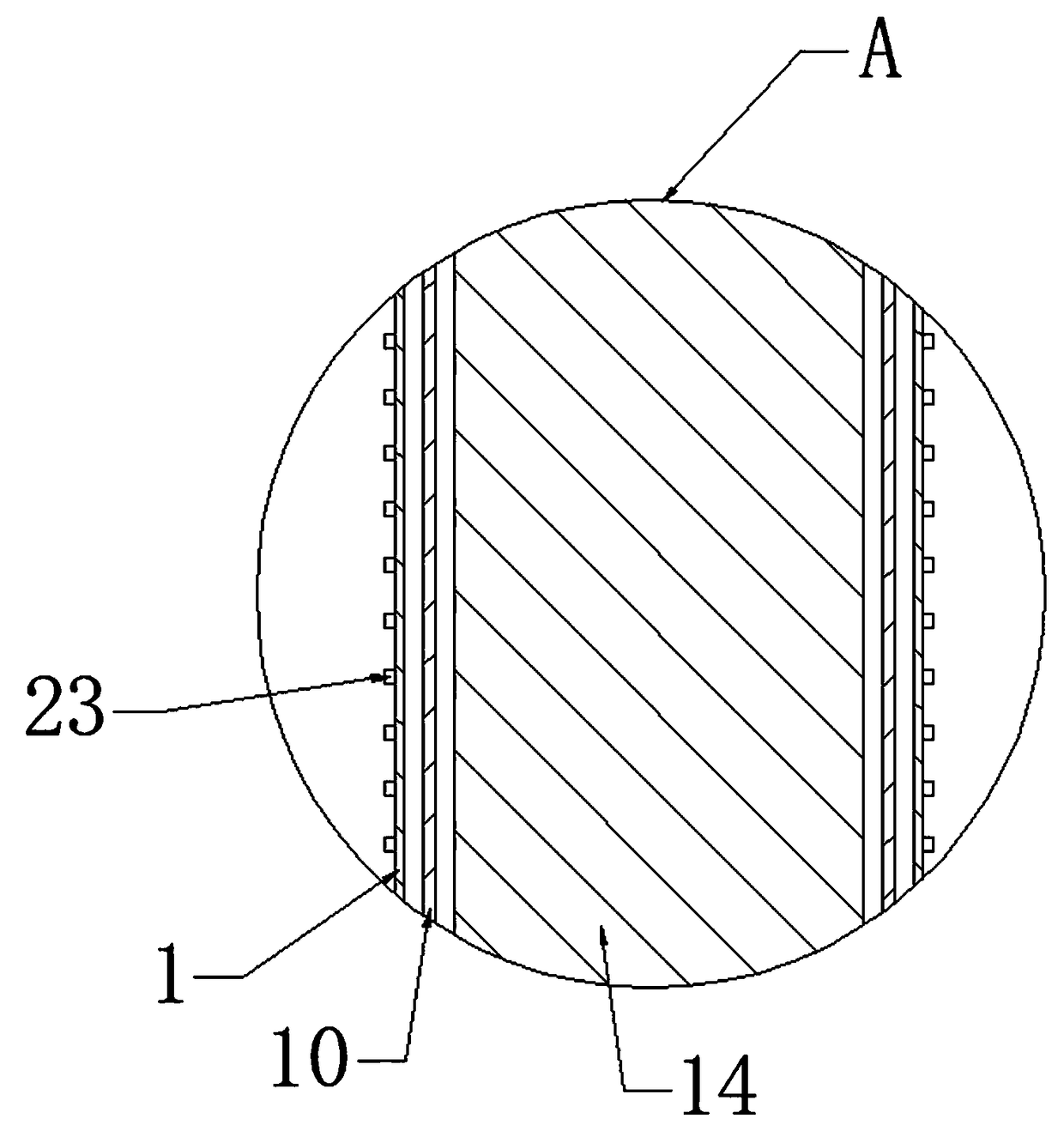

Telescopic and fixation-type endoscope puncture device

PendingCN108938056APrevent slipping outAvoid situations where it slips out of the abdominal wallCannulasSurgical needlesAbdominal cavityAbdominal wall

The invention discloses a telescopic and fixation-type endoscope puncture device. The telescopic and fixation-type endoscope puncture device comprises a tube cavity, a tube cavity base, a pneumoperitoneum port, a base sheet, M upper rotary buckles, M lower rotary buckles, N arc strutting pillars, N strutting petals, N strutting petal buckles, an outer core, an outer core base, N groove holes, a cutting part, an inner core, an inner core base and N rotary clamping grooves; the tube cavity comprises a tube cavity telescoping section and a tube cavity fixing section, the top of the tube cavity isconnected with the tube cavity base, and the two ends of the tube cavity telescoping section are connected with the tube cavity base and the tube cavity fixing section respectively. According to thetelescopic and fixation-type endoscope puncture device, through the arrangement of the tube cavity, the outer core, the inner core, the N arc strutting pillars, the N strutting petals, the N struttingpetal buckles and the N rotary clamping grooves, firm fixation of the interiors of the abdominal wall and the chest wall by the puncture device is achieved, and slip is avoided; meanwhile, the puncture length of the puncture device can be shortened, the situation that redundant tube cavity parts are left in the abdominal cavity and the chest cavity is avoided, convenience is brought to surgical operation, and precious time is saved.

Owner:张云峰

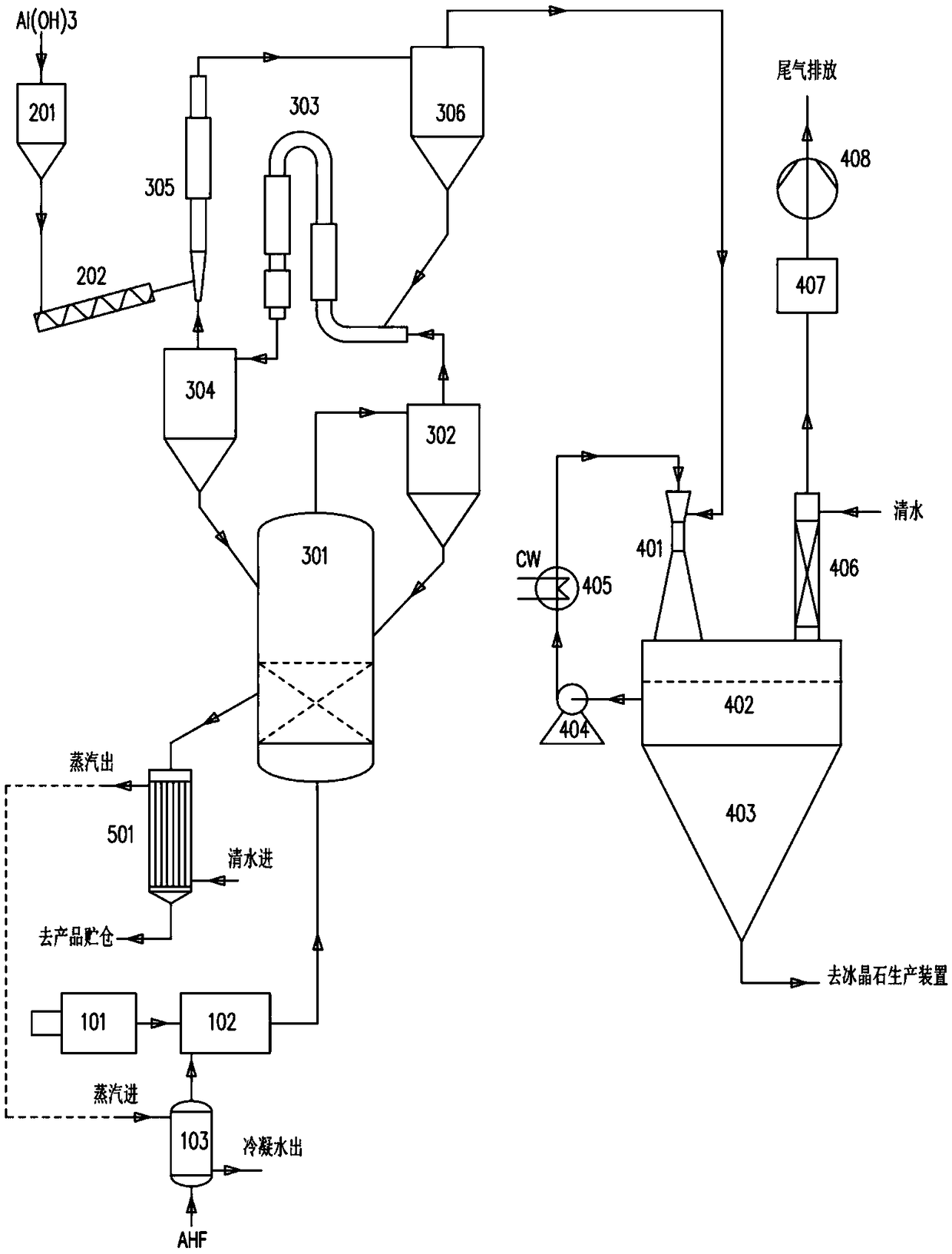

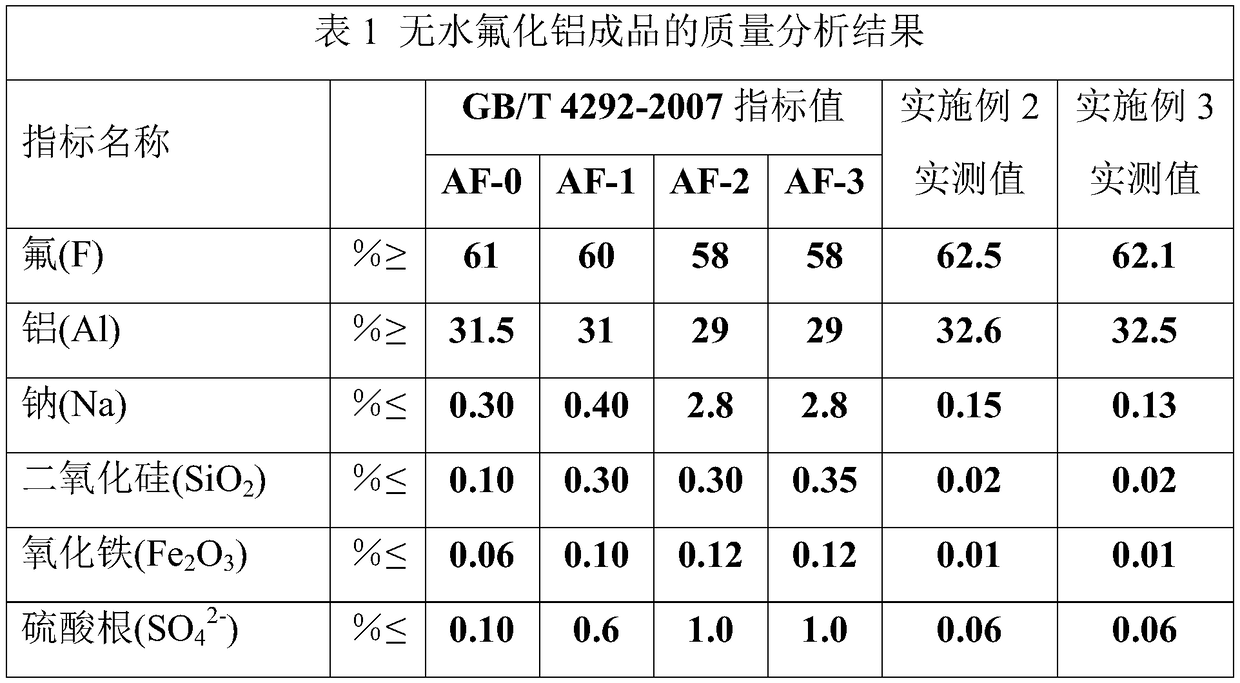

Device and method for preparing anhydrous aluminum fluoride

ActiveCN108840358APlay the effect of saving energy and reducing consumptionPrevent poppingAluminium fluoridesAluminum fluorideHydrogen fluoride

The invention relates to a device and a method for preparing anhydrous aluminum fluoride. The device comprises a gas inlet device, a wet aluminum hydroxide metering and feeding device, a single-layerfluidized bed reactor (301), an aluminum fluoride gas-solid separator (302), an aluminum oxide reactor (303), an aluminum oxide gas-solid separator (304), an aluminum hydroxide dryer (305), an aluminum hydroxide gas-solid separator (306), an aluminum fluoride static cooler (501) and a tail gas treatment device, wherein the gas inlet device comprises an air heater (101), a hydrogen fluoride vaporizer (103) and a hydrogen fluoride mixer (102); the air heater (101) and the hydrogen fluoride vaporizer (103) are connected with the hydrogen fluoride mixer (102) respectively; the hydrogen fluoride mixer (102) is connected with the single-layer fluidized bed reactor (301). Through the device and the method, a prepared product has better quality, namely high content, low impurity, large specific gravity and good fluidity, and the energy consumption is low.

Owner:衢州市鼎盛化工科技有限公司

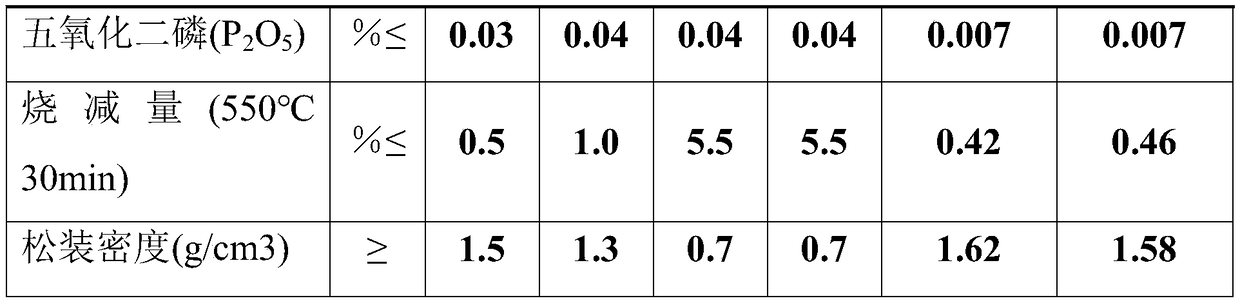

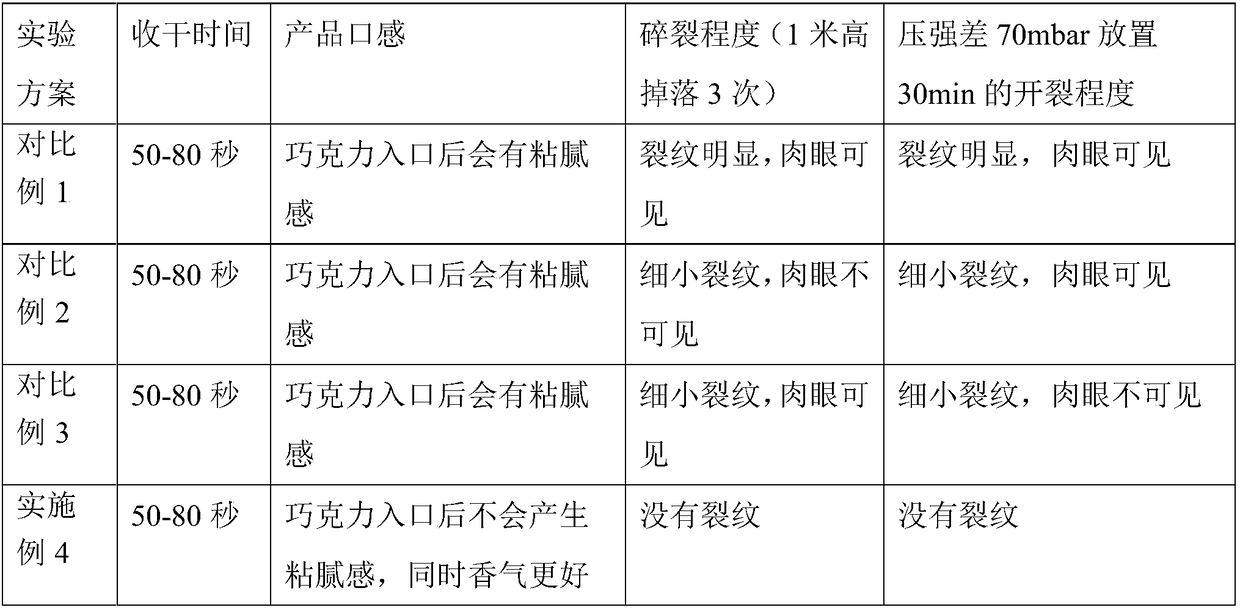

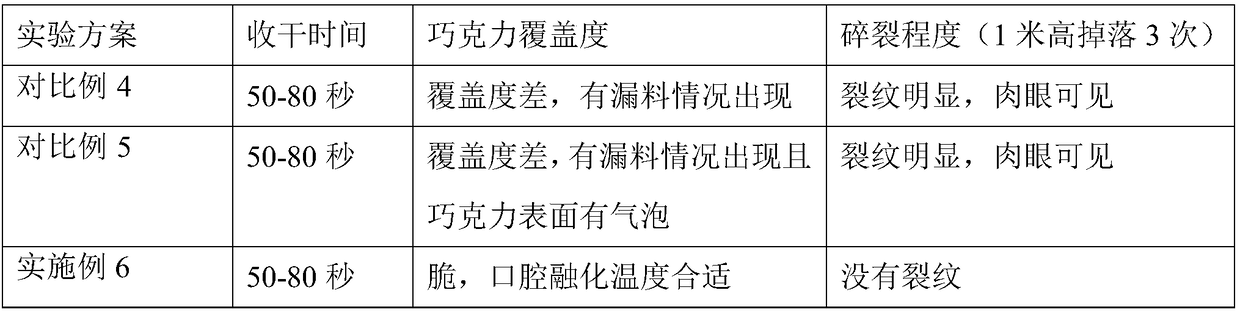

Brittle-failure-resistant chocolate coating and method for coating frozen beverage with brittle-failure-resistant chocolate coating

The invention discloses a brittle-failure-resistant chocolate coating, which comprises the following raw materials by weight: 330-400 parts of white granulated sugar, 130-170 parts of milk powder, 120-160 parts of cocoa liquid block, 40-60 parts of natural anhydrous cream, 260-300 parts of cocoa butter, 1-3 parts of lecithin, and 1-3 parts of polyglyceryl-3 polyricinoleate. The invention further discloses a method for coating a frozen beverage with the brittle-failure-resistant chocolate coating. According to the present invention, by adjusting the ratio of various raw materials of the chocolate coating and optimizing the method for coating the frozen beverage with the chocolate coating, the brittleness of the chocolate coating is ensured, and no cracking is generated within pressure difference of 70 mbar, such that the quality of the product is enhanced, and the market is easily broadened.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

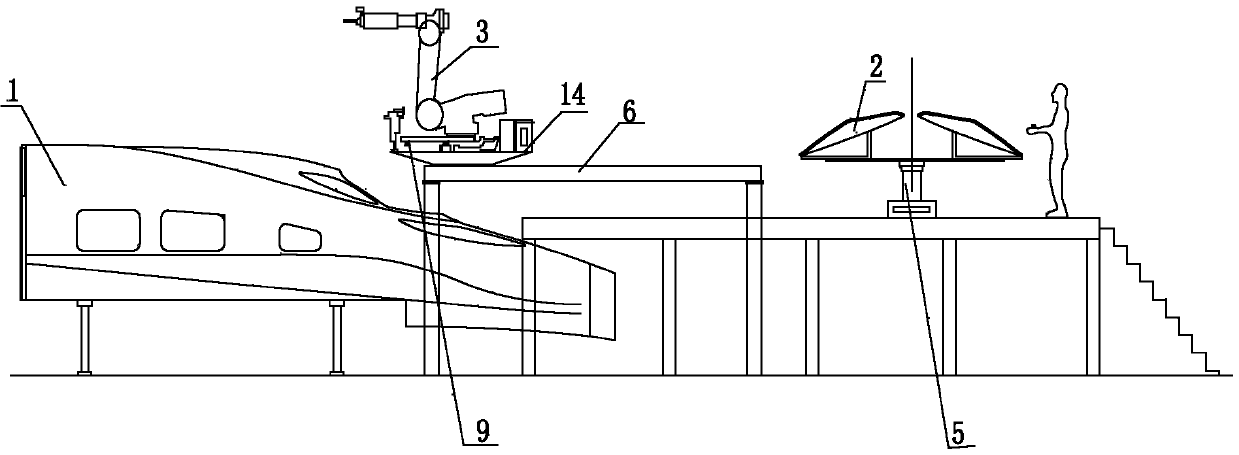

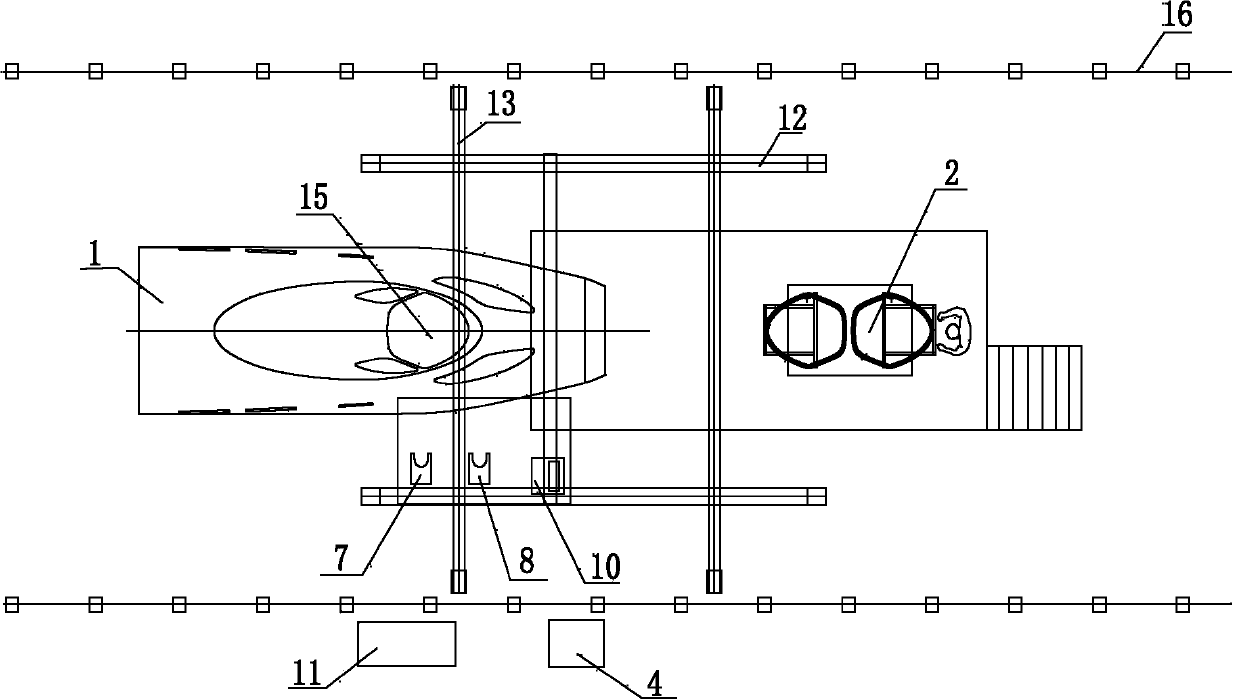

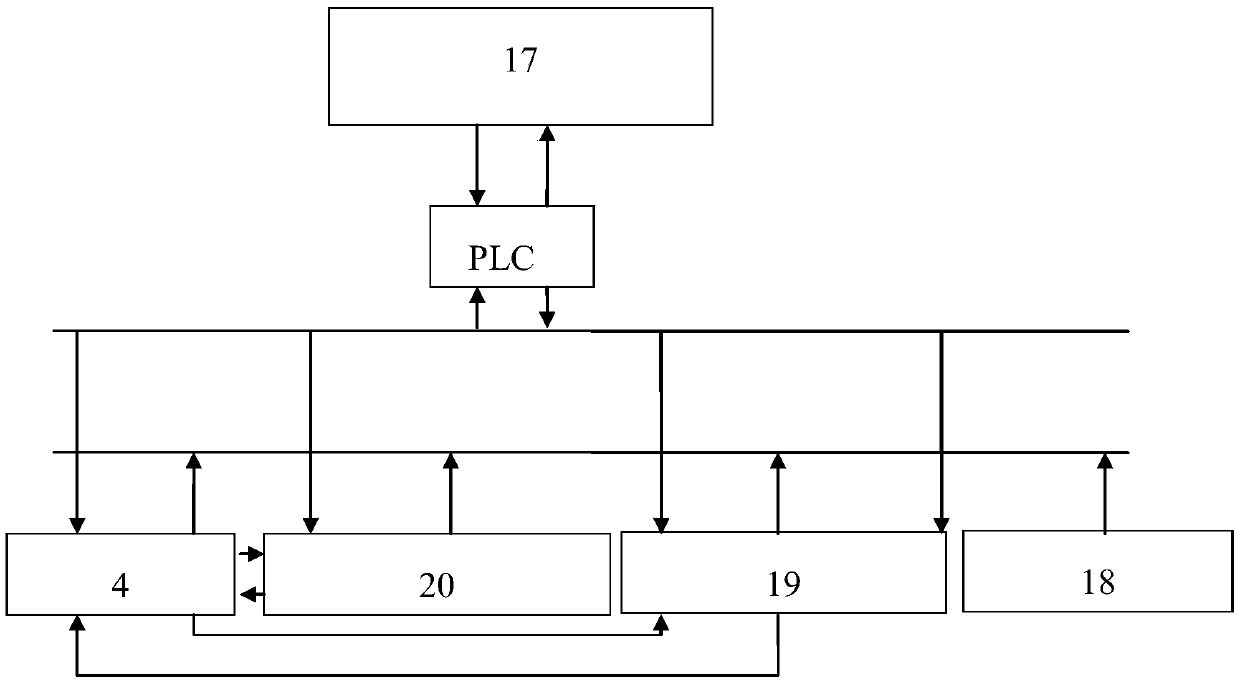

High-speed train front window glass installation device and method

ActiveCN103624514AReasonable layoutHigh degree of mechanizationLiquid surface applicatorsGrinding machinesRobot controlEngineering

The invention relates to a high-speed train front window glass installation device and method. The high-speed train front window glass installation device comprises a robot body, a robot control device, a glass feeding platform and a traveling device. The robot body is installed on the traveling device. The high-speed train front window glass installation device further comprises a measuring locating device used for collecting spatial position information of a train body window, a polishing device used for polishing the train body window, a grabbing device used for grabbing front window glass, a gluing device used for coating sealant and a central control system. The robot control device, the measuring locating device, the polishing device, the grabbing device, the gluing device and the traveling device are all connected with the central control system. The robot body is selectively connected with the measuring locating device, the polishing device, the grabbing device and the gluing device. The high-speed train front window glass installation device and method have the advantages that the layout is reasonable, the degree of mechanization is high, all the installation operations, from locating and polishing to gluing, of the train front window glass can be realized quickly and accurately, the installation quality is guaranteed and not limited by human factors, the production efficiency is greatly improved, the labor intensity is lowered, meanwhile, an ideal matching state between the front window glass and the train body window can be realized and stress is prevented from being generated during glass installation.

Owner:CHINA RAILWAYS CORPORATION +1

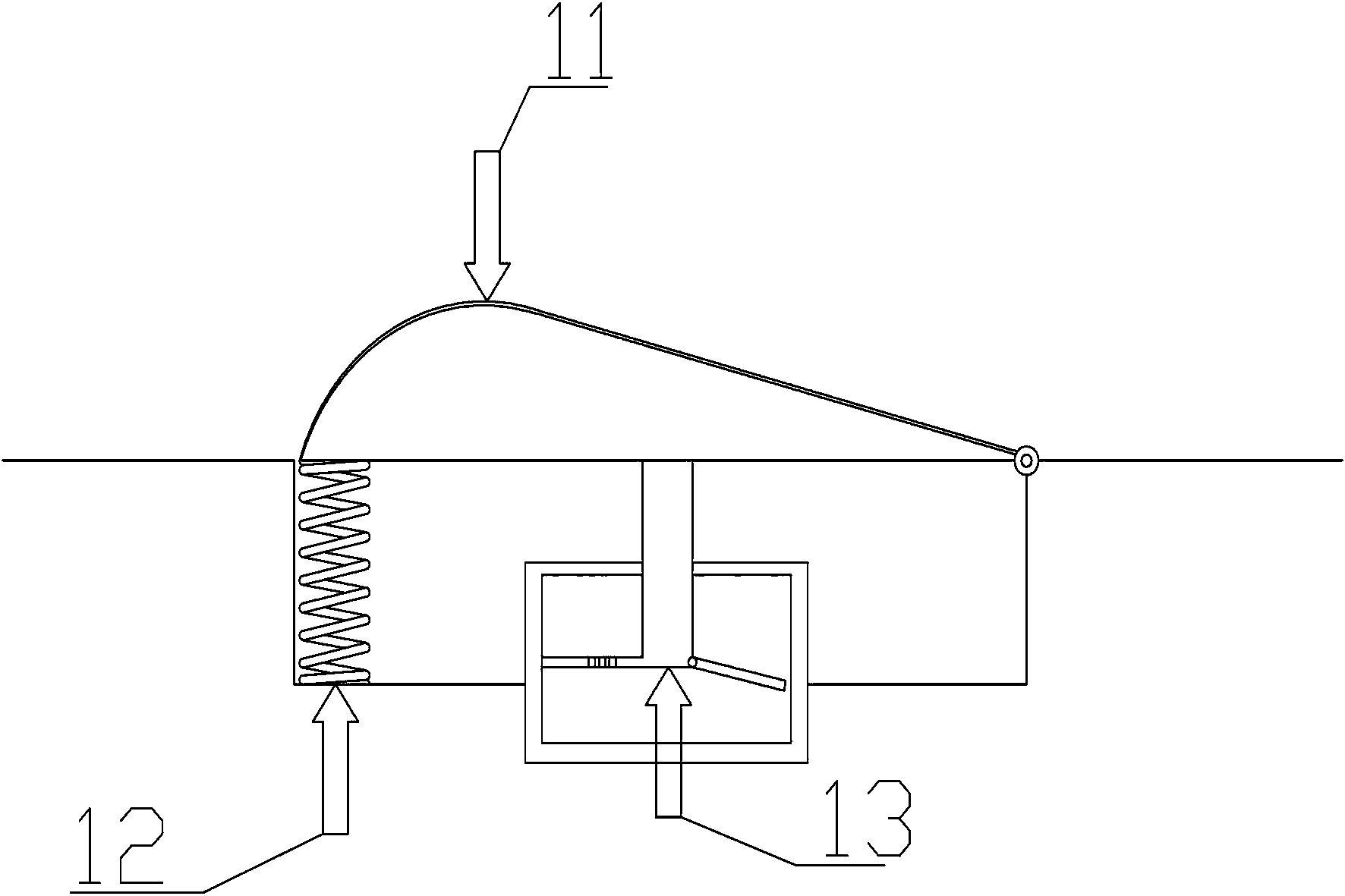

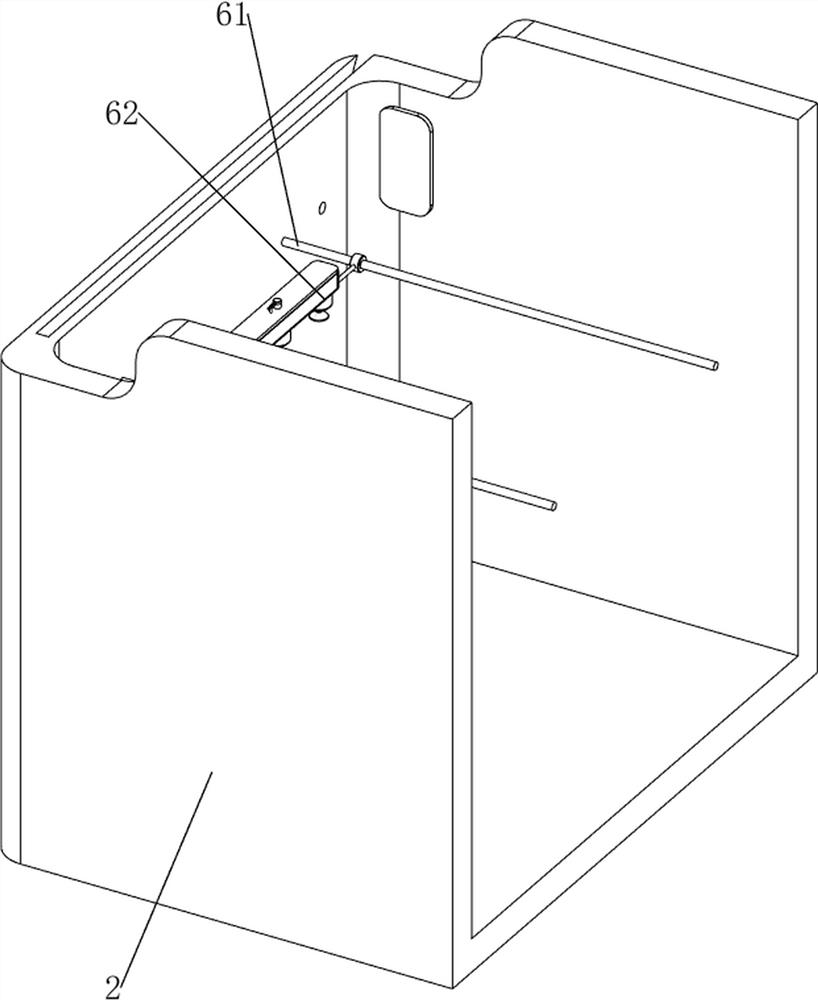

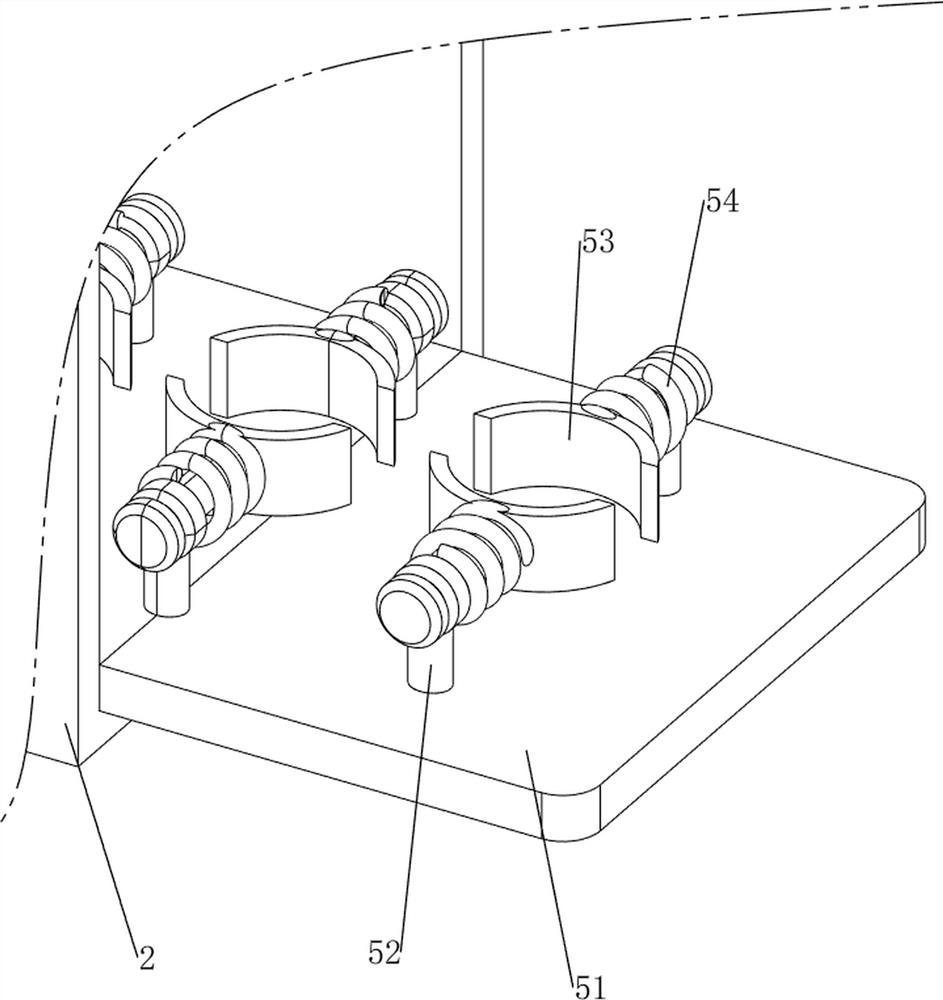

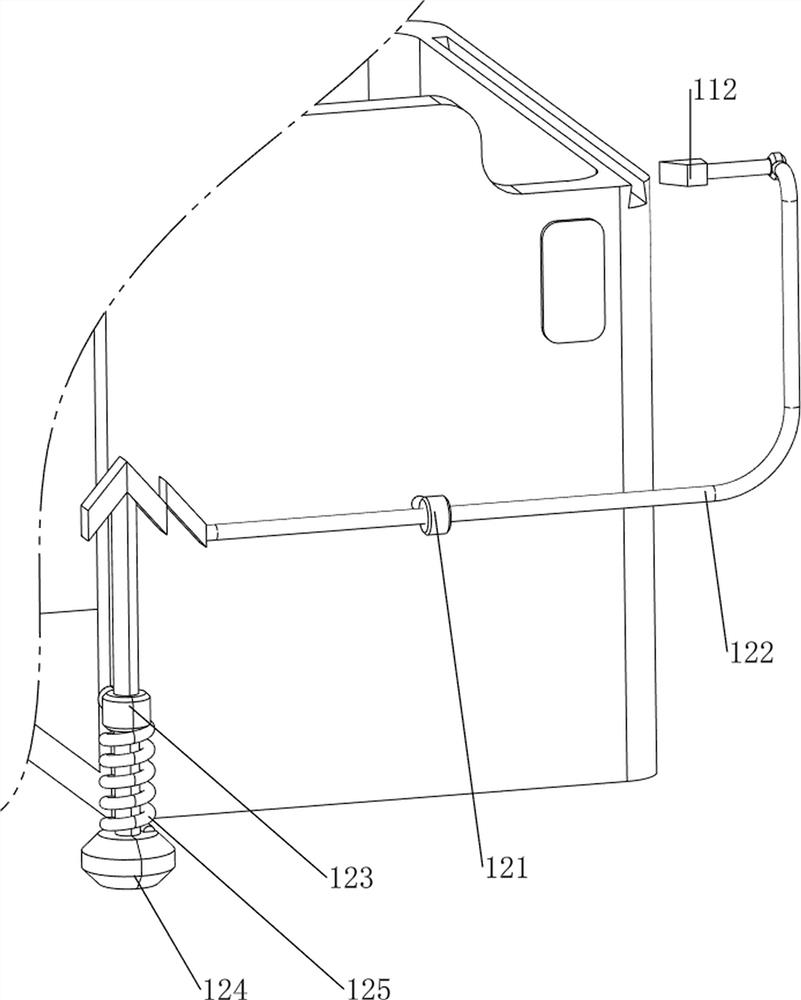

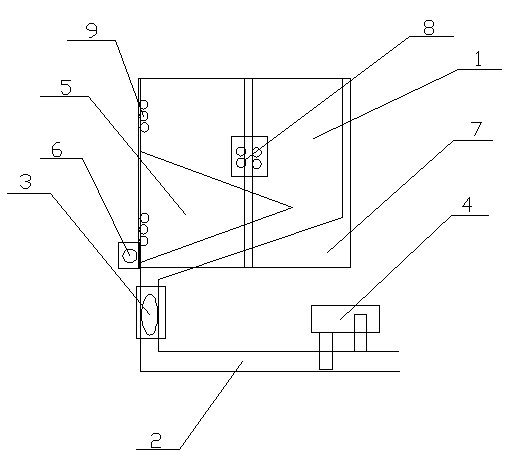

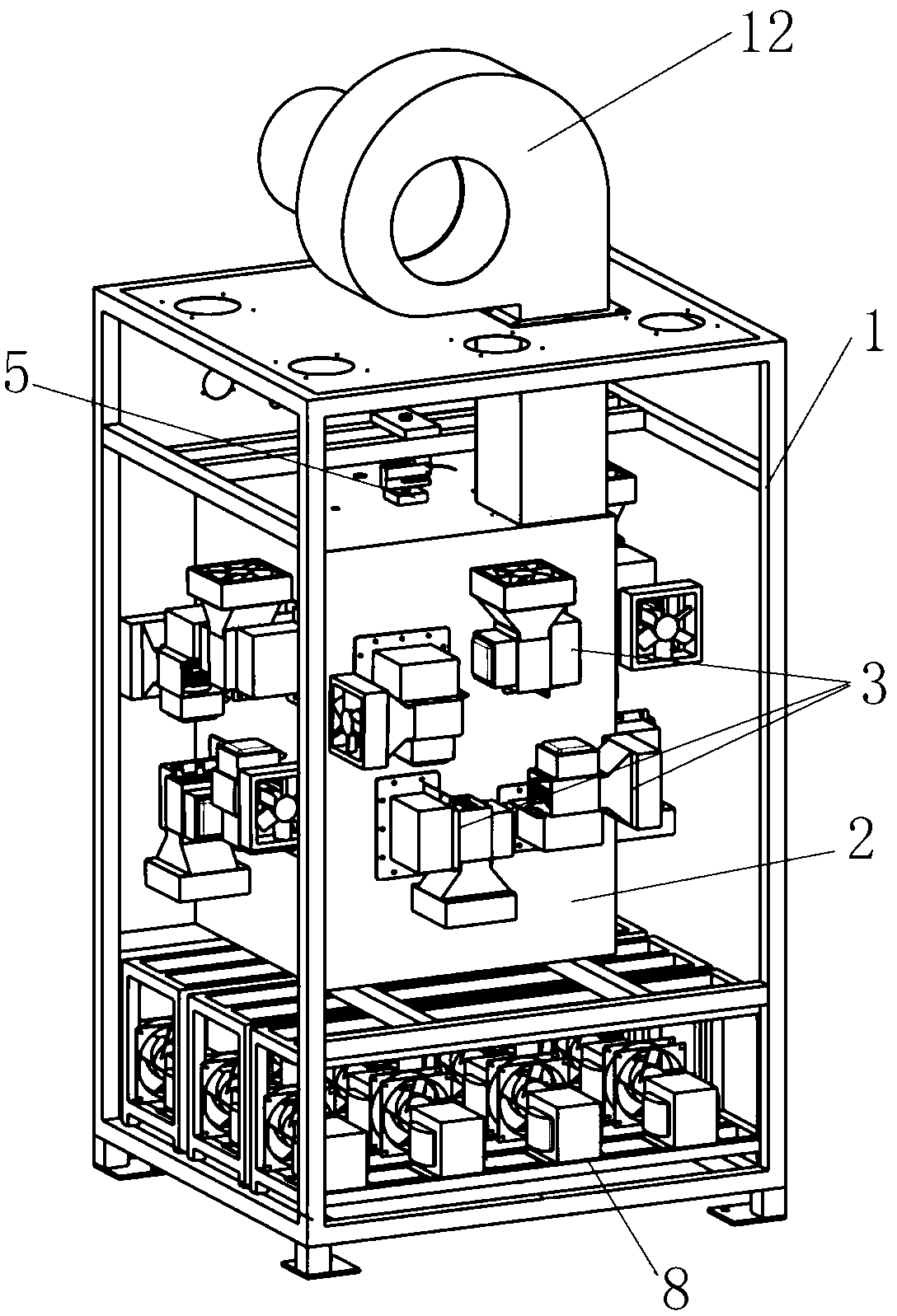

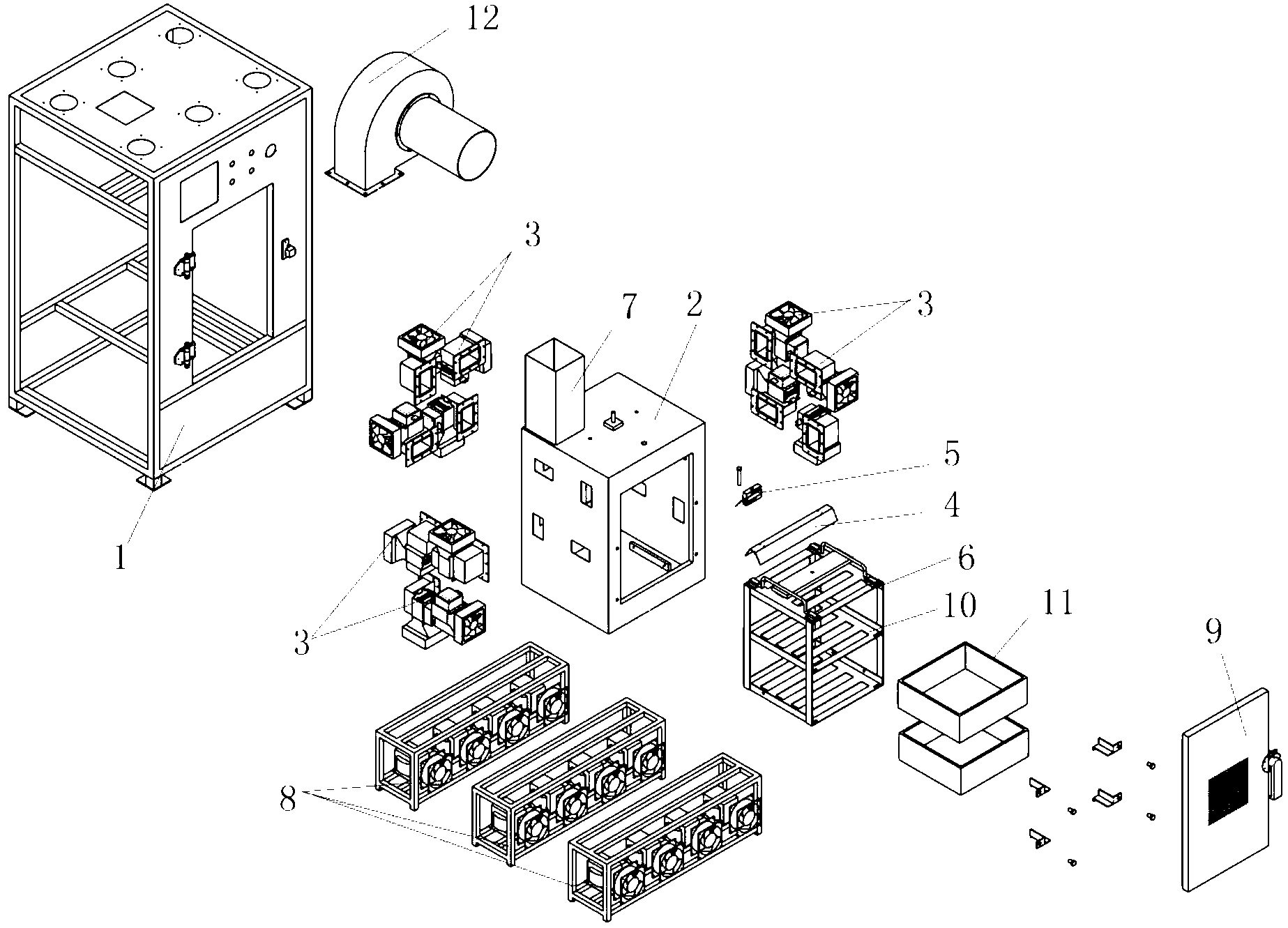

Fast detector of soil water content and detection method therefor

InactiveCN103267702APrevent poppingIntegrity guaranteedWeighing by removing componentInfrared lampEngineering

The invention discloses a tool for detection of soil water content and especially relates to a fast detector of soil water content and a detection method therefor. The fast detector comprises a stainless steel housing (1). A receiving chamber (2), magnetrons (3), an infrared lamp (4), an automatic weighing device (5) and a weighing support (6) are installed in the stainless steel housing (1). The weighing support (6) is installed in the receiving chamber (2), passes through the top of the receiving chamber (2) and is connected to the stainless steel housing (1) by a connection rod. The automatic weighing device (5) is arranged on the connection rod. The magnetrons (3) are installed at outer side walls of the receiving chamber (2). The fast detector avoids the influence produced by factors such as natural water loss in transport on detection accuracy, avoids the influence on the whole engineering progress, effectively prevents soil sample burst in heating, guarantees soil sample integrity and improves detection accuracy.

Owner:SINOHYDRO BUREAU 5

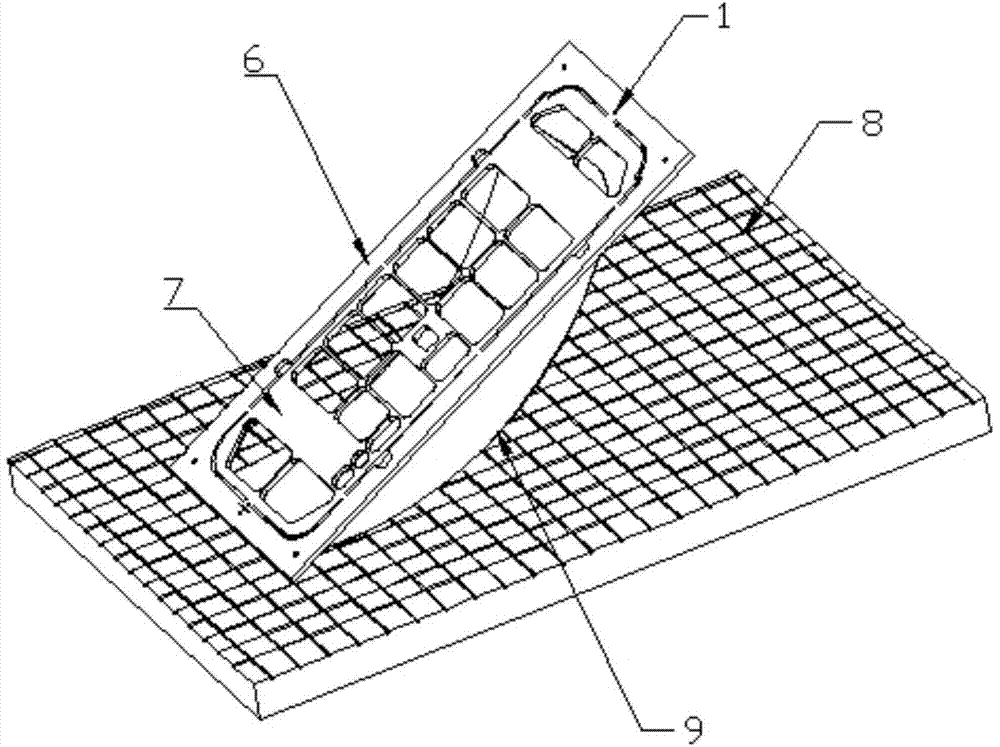

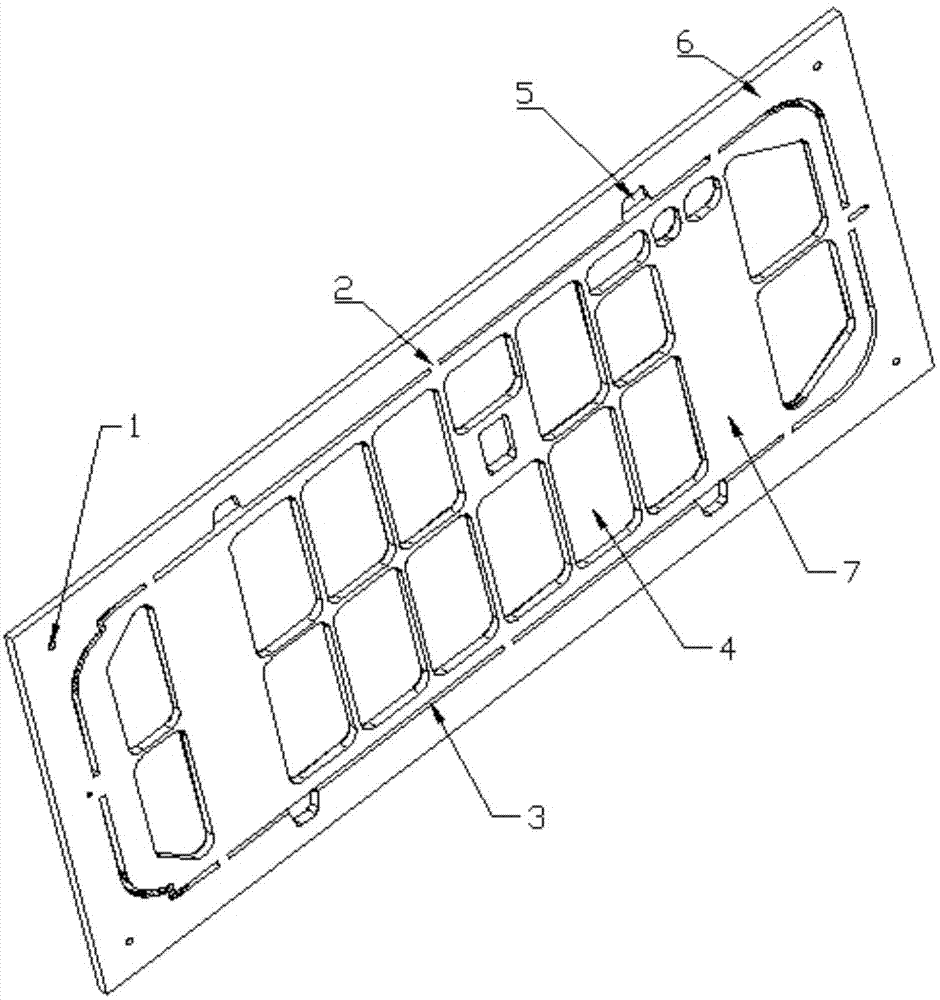

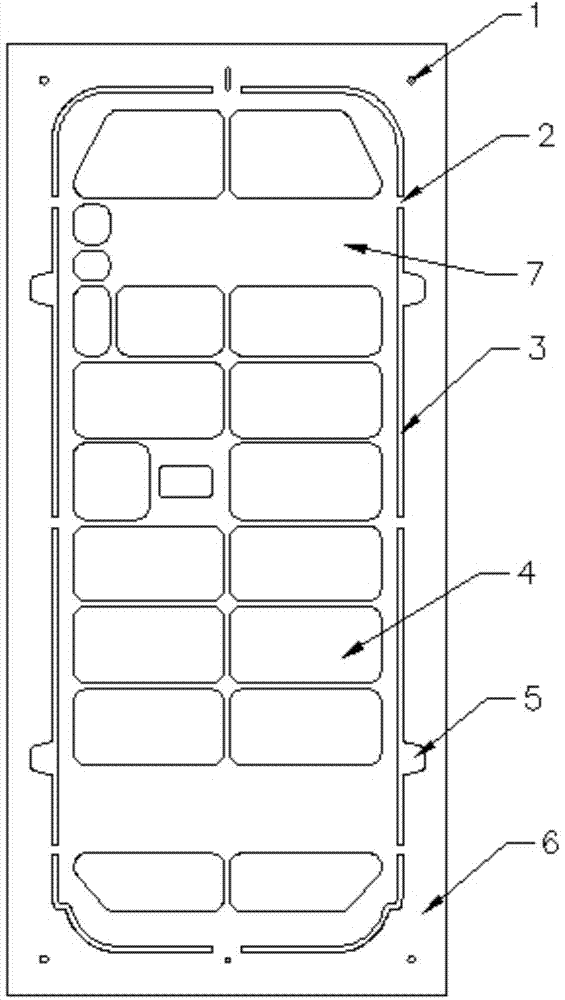

Thin skin milling device and method for milling by utilizing device

InactiveCN103920915AImprove machining accuracyReduce usage timeMilling equipment detailsPositioning apparatusThinning skinBiomedical engineering

The invention relates to a thin skin milling device. The thin skin milling device comprises a vacuum platform, thin skin and a profiling compression clamp, wherein the thin skin is arranged on the vacuum platform, the profiling compression clamp is arranged on the thin skin, the surface area of the vacuum platform is larger than that of the profiling compression clamp, and the surface area of the profiling compression clamp is larger than that of the thin skin; the profiling compression clamp is a rectangular thick aluminum plate, cutting troughs matched with the outer contour of the thin skin are formed in the periphery, close to the edge, of a surface plane of the thick aluminum plate, sunken milling regions matched with sunken regions of the thin skin are formed in the surface of the thick aluminum plate, an outer contour compression region is arranged at the region, outside of the cutting troughs, on the profiling compression clamp, and an interior compression region is arranged at the region, inside the cutting troughs, on the profiling compression clamp. By milling the skin by virtue of the thin skin milling device, the phenomenon that skin is scrapped due to the overcutting as the skin is intermittently desorbed from the vacuum platform and looses and shakes in a milling process can be effectively avoided.

Owner:AVIC SAC COMML AIRCRAFT

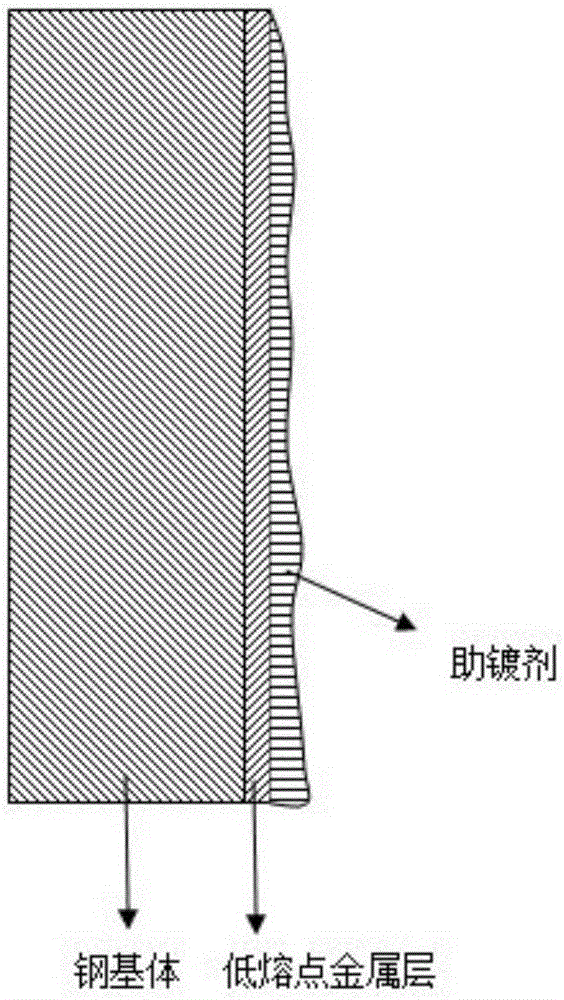

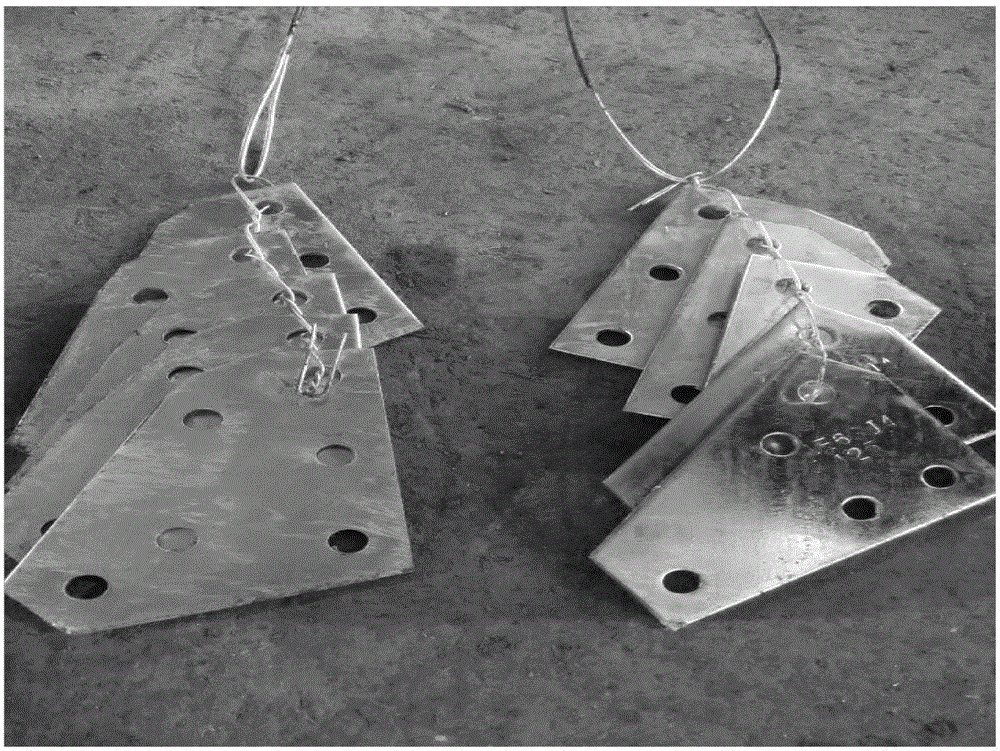

Plating assisting agent for batch hot-dip coating of Galfan and preparation method of plating assisting agent

ActiveCN105220099ASolve the problem of missing plating that is easy to occurSolving Missing Plating ProblemsHot-dipping/immersion processesCeriumLanthanum

The invention relates to a plating assisting agent for batch hot-dip coating of Galfan and a preparation method of the plating assisting agent. The plating assisting agent is characterized in that according to the formula of calculation of each liter of plating assisting agent, the plating assisting agent comprises 80-180 g of ZnCl2, 10-30 g of alkali chloride, 10-30 g of bismuth chloride and / or tin chloride, 2-10 g of transition metal element chloride which does not contain rear earth elements or zinc chloride and can be dissolved in water, 5-25 g of calcium chloride, 1-10 g of rare earth chloride, 15-25 ml of industrial hydrochloric acid and the balance water, wherein the rare earth chloride comprises at least one of lanthanum chloride and cerium chloride.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

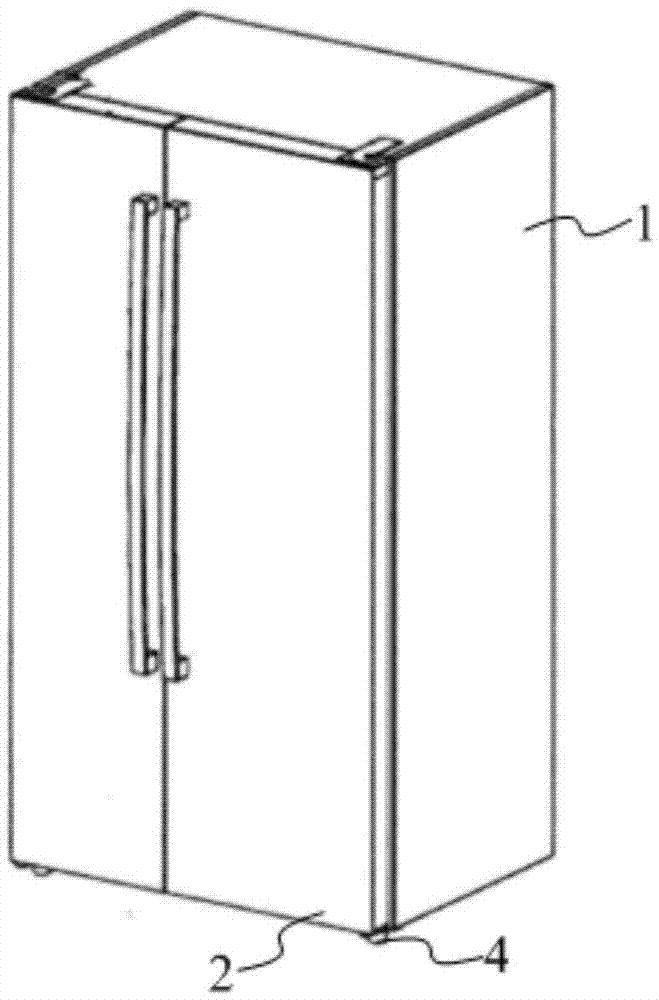

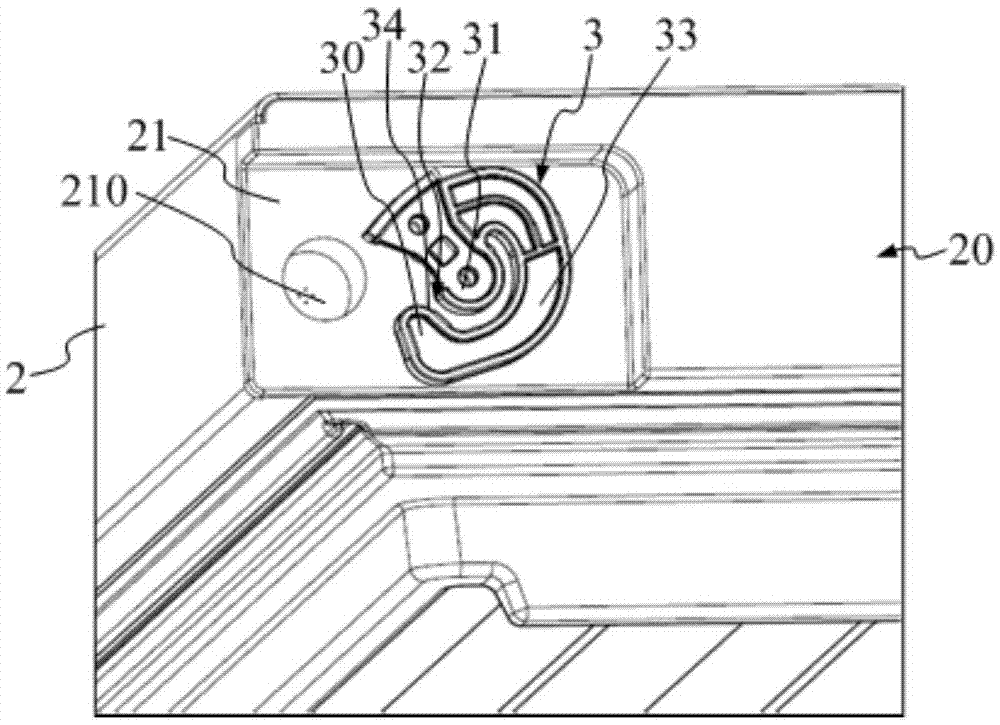

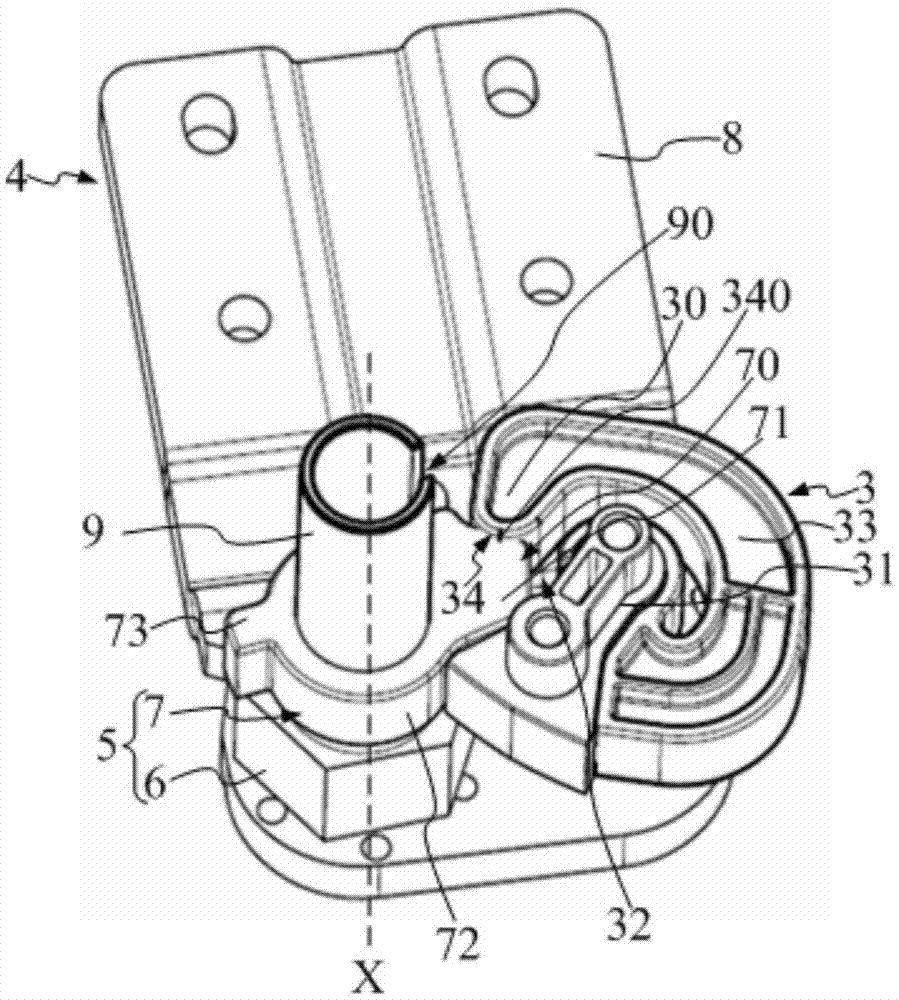

Refrigerating appliance

ActiveCN106907897ANice appearanceImprove stabilityLighting and heating apparatusWing accessoriesElectrical and Electronics engineeringTransportation safety

A refrigerating appliance comprises a cabinet body (1), a door (2), door closers (3) and hinge assemblies (4). Each hinge assembly (4) comprises an adjusting unit (5).Each adjusting unit (5) comprises an adjusting element (6) and a supporting element (7)which can be driven by the adjusting element (6) to move in the vertical direction within an adjusting range and to support the door (2). The cabinet body (1) can rotate around the supporting elements (7). Each supporting element (7) comprises a door closing part (70) used for being matched with the corresponding door closer (3) in the following manner that at any height within the adjusting range, the door closing parts (70) and the corresponding door closers (3) are at least partially overlapped in the horizontal direction, when the door (2) is to be closed, the door closing parts (70) and the door closers (3) are matched to prevent the door (2) from being bounced off, and the door closing parts (70) are disengaged from the door closers (3) when the door (2) is opened. According to the technical scheme, the refrigerating appliance is attractive in appearance, beneficial to transportation safety, and the upper side gap of the door (2) is small.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

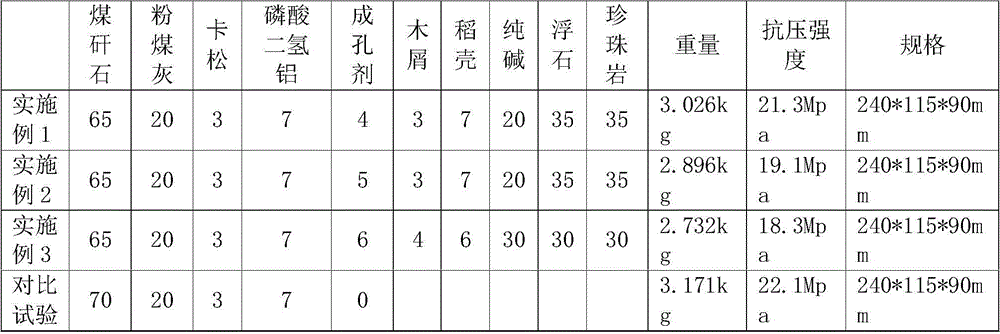

Coal gangue brick and preparation method thereof

The invention discloses a coal gangue brick and a preparation method thereof. According to the technical scheme, the coal gangue brick comprises the following components in parts by weight: 60-70 parts of coal gangue with a calorific value of 1800kJ / mol-2000kJ / mol, 20-30 parts of coal ash, 2-3 parts of Kathon, 5-8 parts of aluminum dihydrogen phosphate and 4-6 parts of a pore-forming agent, wherein the pore-forming agent comprises the following components in parts by weight: 2-5 parts of saw dust, 6-10 parts of rice husk, 20-30 parts of sodium carbonate, 30-40 parts of float stone and 30-40 parts of perlite. According to the coal gangue brick and the preparation method thereof, by adding the pore-forming agent, the purpose of increasing porosity in a brick body is achieved; meanwhile, by changing the components and processing process of the pore-forming agent, a lime blowing phenomenon of the brick body is avoided.

Owner:重庆市合川区狮滩矸砖厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com