Patents

Literature

1465 results about "Cinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cinder is a pyroclastic material. Cinders are extrusive igneous rocks. Cinders are similar to pumice, which has so many cavities that its low density of 0.641g/cm^3 allows it to float in water. Cinder is typically brown, black, or red depending on its chemical content.

Burning-free block brick prepared from bulky industrial waste residues

The invention relates to a burning-free block brick prepared from bulky industrial waste residues. The burning-free block brick is characterized in that the block brick comprises the following raw materials in parts by weight or volume: 10-80 parts of at least one of tailing, magnesium slag, basic slag, mountain flour, cinder, fly ash, coal gangue, oil shale waste and sulfuric acid slag, 0-80 parts of at least one of gravel, waste sand, construction waste, garbage to be burnt, steel slag, mineral slag, copper slag, iron slag with gold, ardealite, phosphorous slag and carbide slag, 0-50 parts of active cementing material, 0-30 parts of cement clinker, 2-15 parts of cement and a defined amount of water. The preparation method of all types of burning-free and steaming-free standard bricks, perforated bricks, hollow blocks, paving tiles, road edge bricks and fence railings which have low cost and high strength, is as follows: proportioning, stirring for 1-6 minutes, adding a defined amount of water to stir, placing in moulds to form in a machine and performing natural curing for 7-28 days. The burning-free block brick has high raw material selectability, simple technology and wide development and application prospects, and is environmental-friendly.

Owner:司密花 +2

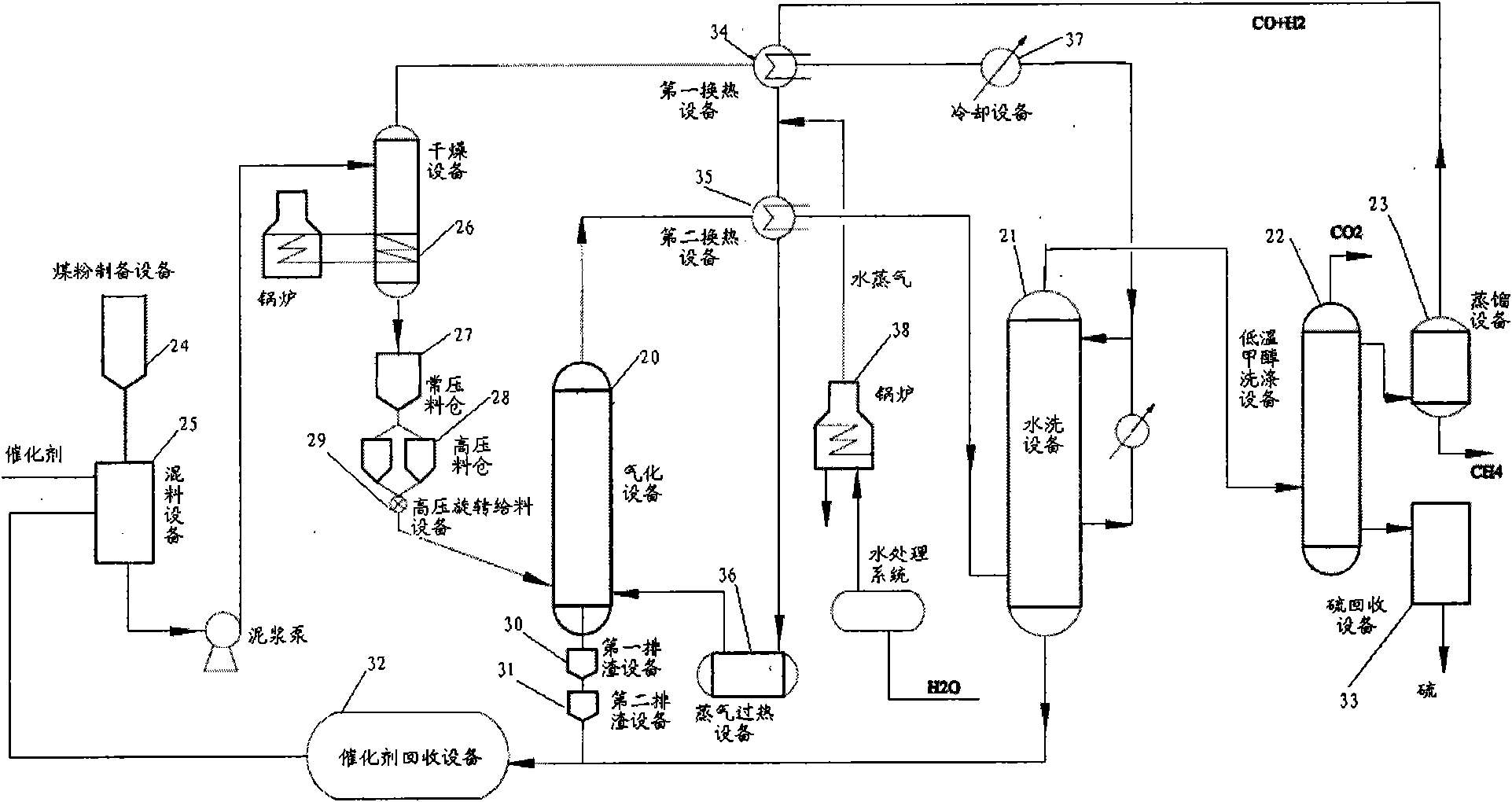

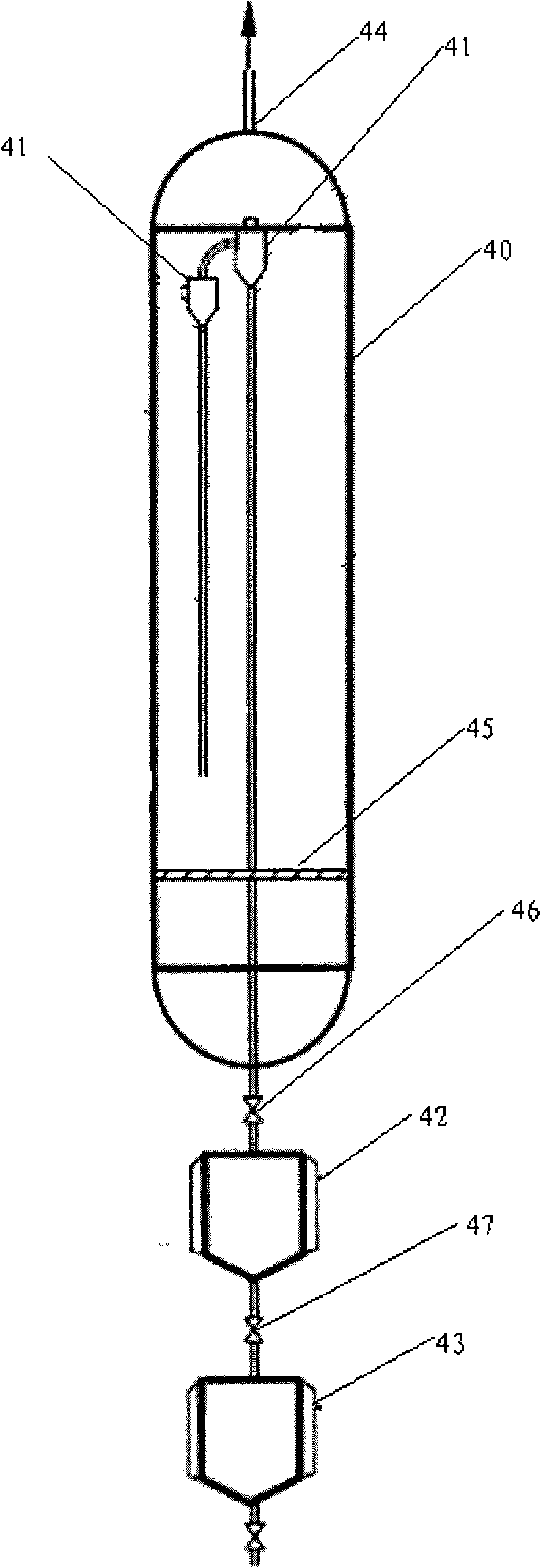

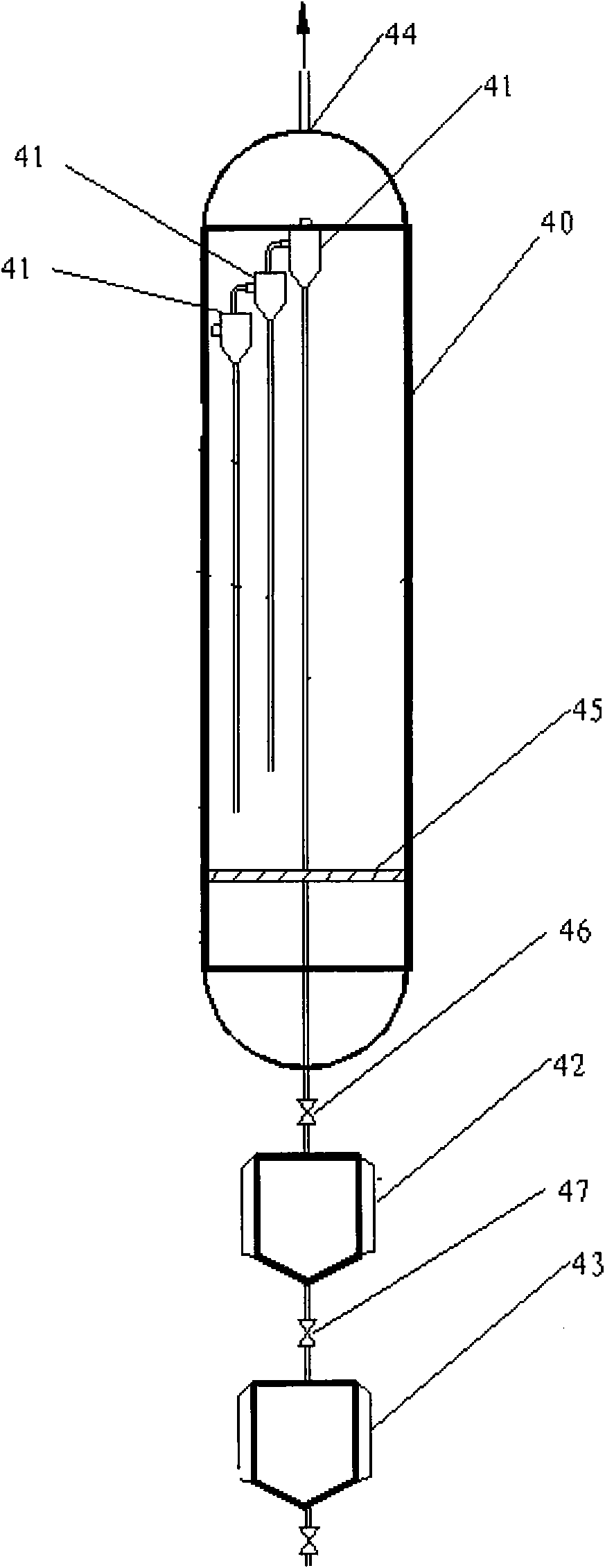

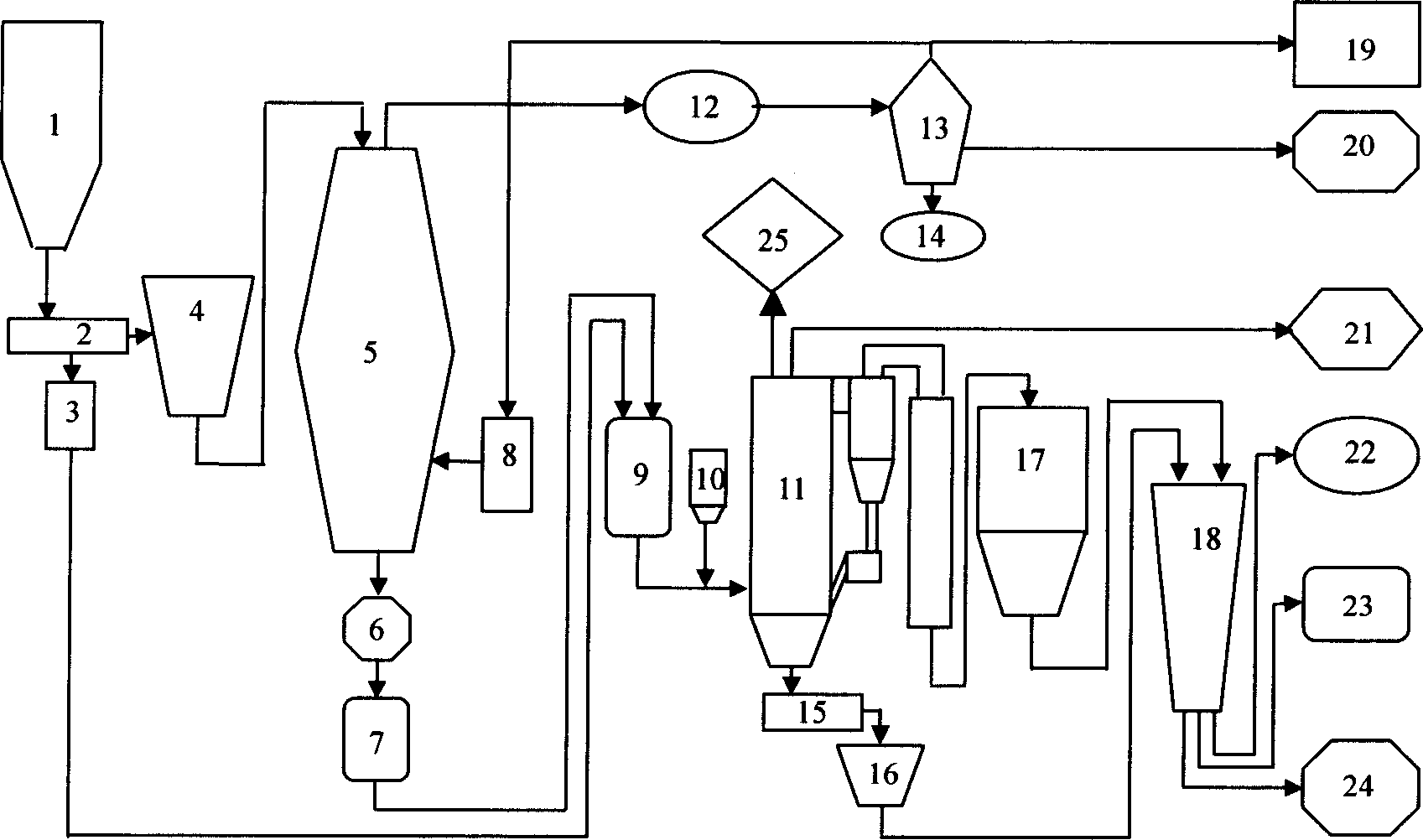

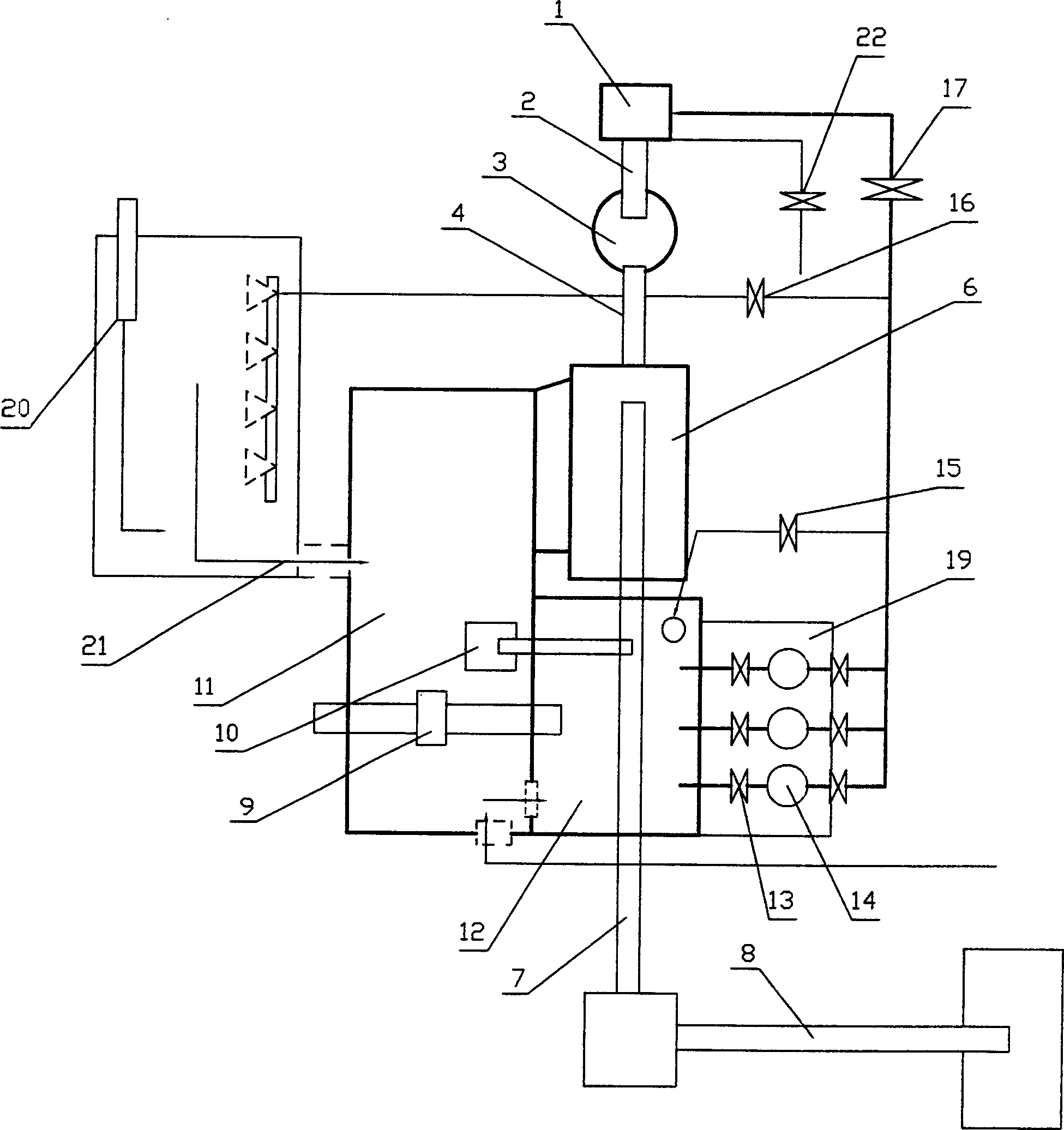

Method, system and equipment for catalytic coal gasification

ActiveCN101555420AContinuous slaggingCombined combustion mitigationGasification with fuel pre-distillationHydrogenProduct gas

The embodiment of the invention discloses a method for catalytic coal gasification. The method comprises the following steps: delivering pulverized coal to gasification equipment under high pressure of high-pressure rotating equipment, allowing a gasification reaction of the coal and a gasification agent in the presence of a catalyst in the gasification equipment, performing gas-solid separation on substances from the gasification reaction, delivering solid obtained from the gas-solid separation to first cinder discharge equipment, and delivering the solid from the first cinder discharge equipment to second cinder discharge equipment; and washing gases obtained from the gas-solid separation to obtain acidic water and purified gases, performing low temperature methanol washing on the purified gases to obtain a mixed gas of methane, hydrogen and carbon monoxide, distilling the mixed gas at low temperature to obtain the methane, delivering the acidic water to a catalyst recovery plant, and returning the recovered catalyst to mixing equipment. The embodiment of the invention further discloses a system and equipment for catalytic coal gasification. The method, the system and the equipment can help realize continuous cinder discharge under high pressure.

Owner:ENN SCI & TECH DEV

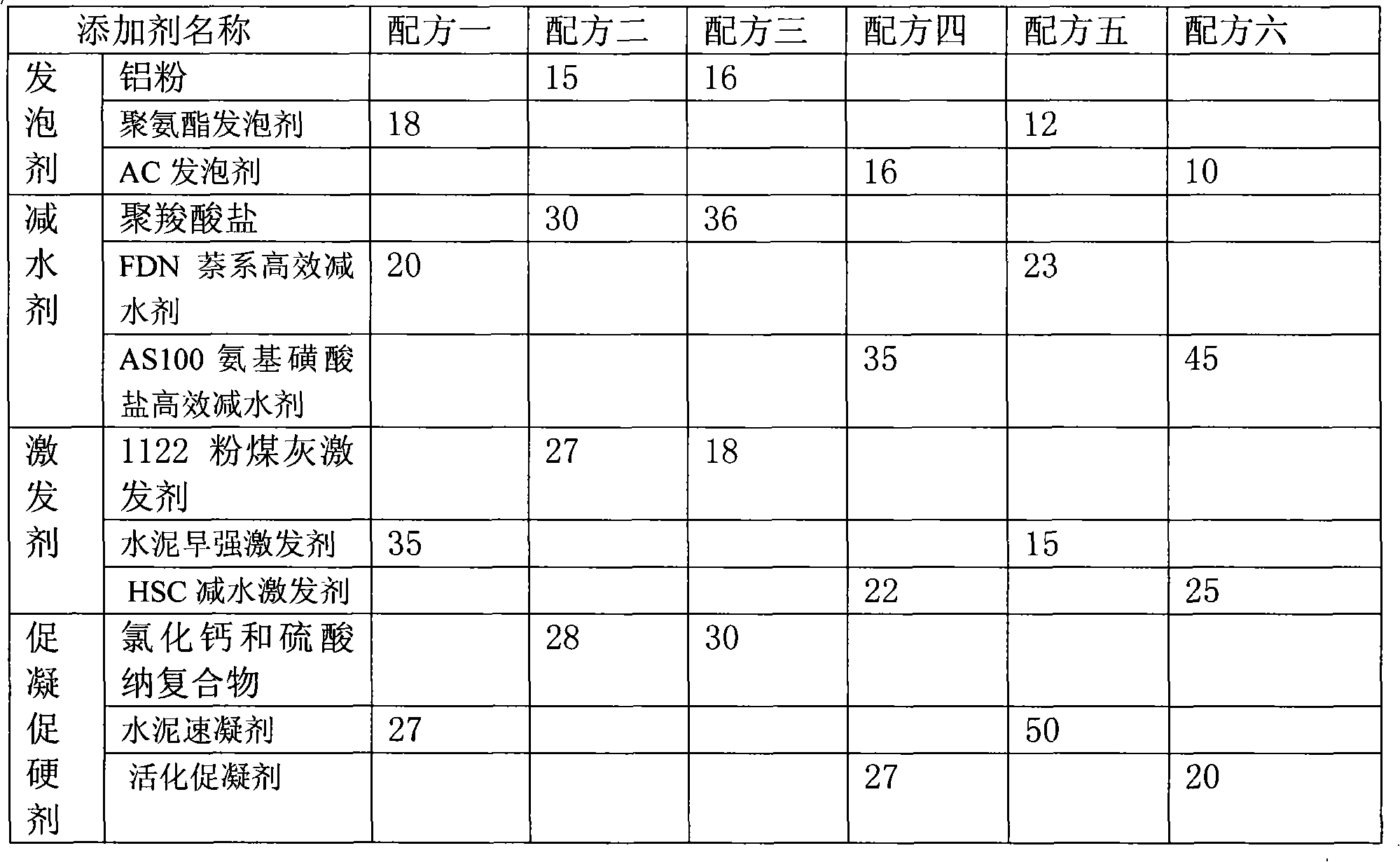

Haydite aerated concrete block and method for manufacturing same

InactiveCN101306934AImprove performanceIntegrity guaranteedSolid waste managementCeramic shaping plantsBrickSlag

The invention discloses a formula of a ceramic aggregate aerated concrete brick and a method for making the concrete brick. The compositions in portion by weight of the concrete brick are: 12 to 26 portions of cement, 26 to 46 portions of fly ash, 16 to 28 portions of ceramic aggregate, 2 to 6 portions of slag, 2 to 6 portions of cinder, 16 to 26 portions of water and 2 portions of addition agent, wherein the concrete matters in percentage by weight of the addition agent are: 10 to 18 percent of aluminum powder (a foaming agent), 20 to 45 percent of polycarboxylate (a water reducing agent), 15 to 35 percent of 1122 fly ash excitant and 20 to 50 percent of coagulant hardening accelerator in which calcium chloride and sodium sulfate compounds respectively occupies 50 percent. The concrete steps for making the ceramic aggregate aerated concrete brick are as follows: raw materials are weighed; the weighed raw materials are placed in a stirring machine to carry out stirring and mixing in advance; an addition agent is added in the stirring machine to carry out full stirring; a brick die is prepared, and stirred raw materials are cast in the brick die; initial set and forming are carried out; stripping is carried out; a water-proofing agent is sprinkled on a stripped brick; and natural curing is carried out. Moreover, the obtained brick has light dead weight, low density, high strength, low water absorption rate and excellent sound insulation performance and heat-shielding performance.

Owner:胡宗芳 +1

Method of treating refractory pollutants through catalyzing H2O2 oxidation by pyrite cinder

ActiveCN101745197AApplicable to a wide range of pHImprove responseSolid waste disposalWater contaminantsCinderPollutant

A method of treating refractory pollutants utilizes the pyrite cinder as catalyst which forms a heterogeneous Fenton system with H2O2 to catalyze H2O2 to generate hydroxyl radical (.OH) with strong oxidability and degrade the organic pollutants efficiently and quickly. The method comprises the following steps: (1) after the waste water is added in a reactor, a given amount of pyrite cinder original sample or activated and pretreated cinder is added in the waste water; (2) H2O2 solution is added in a mixed liquid of the waste water and the pyrite cinder so as to form an analogous Fenton reagent with the pyrite cinder; (3) stirring is carried out so as to lead the pyrite cinder, the H2O2 solution and the waste water to be mixed for reaction, and the stirring is stopped at the set reaction time; and (4) standing is carried out, the pyrite cinder is quickly precipitated and the supernate is discharged, so that the pyrite cinder can be reused. The invention discovers a novel analogous Fenton oxidation catalyst, extends the resource utilization ways of the pyrite cinder, achieves the purpose of controlling waste by waste and realizes the comprehensive utilization of the waste.

Owner:TONGJI UNIV

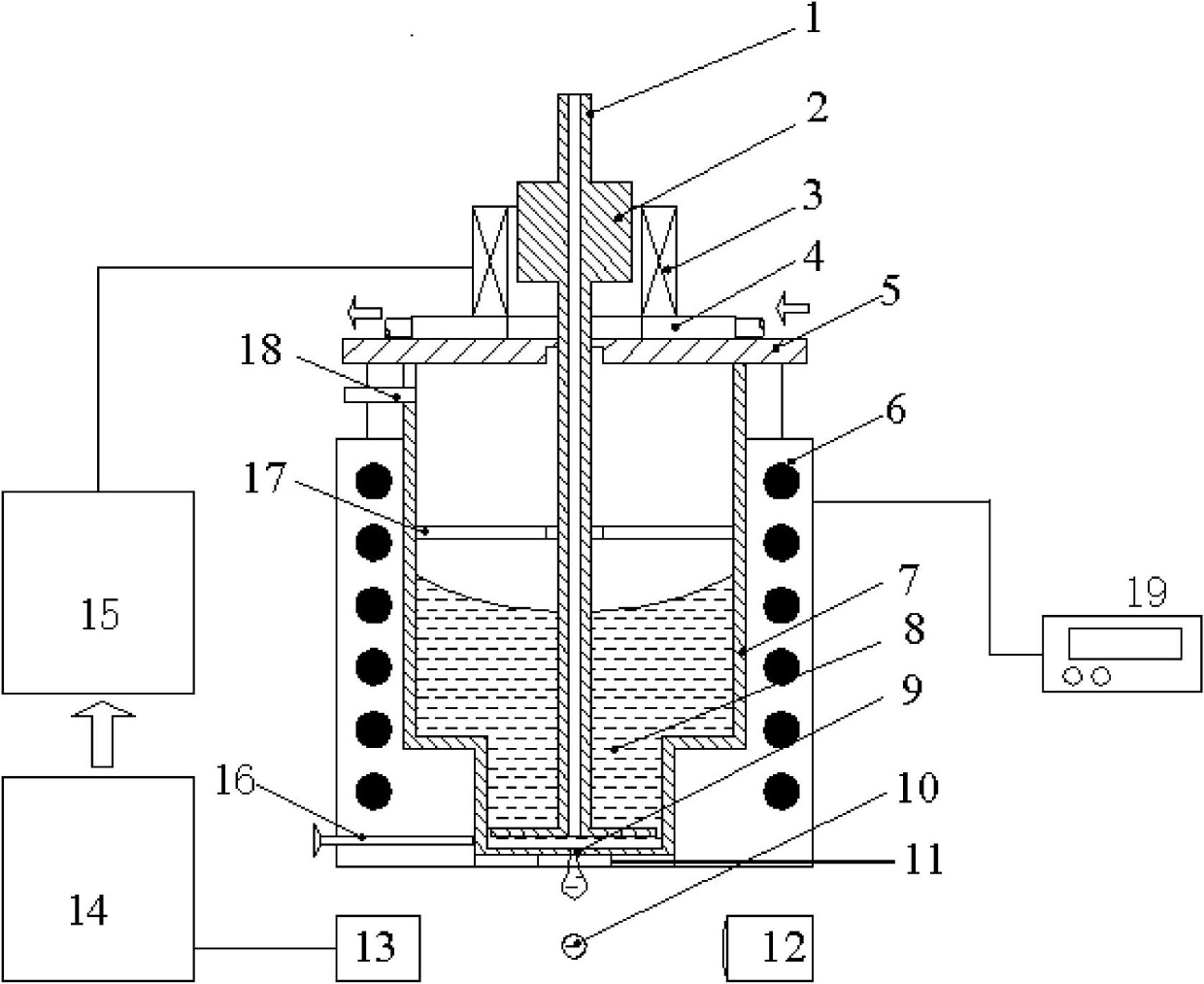

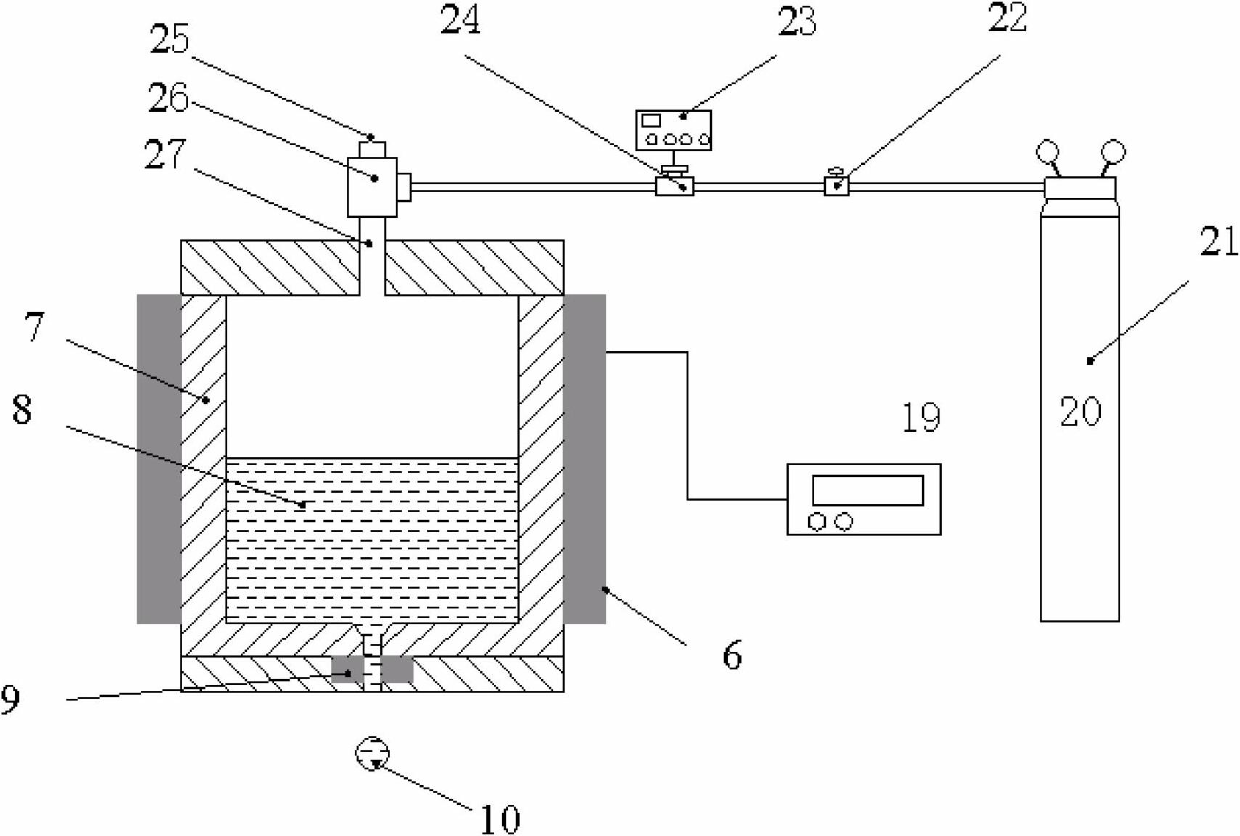

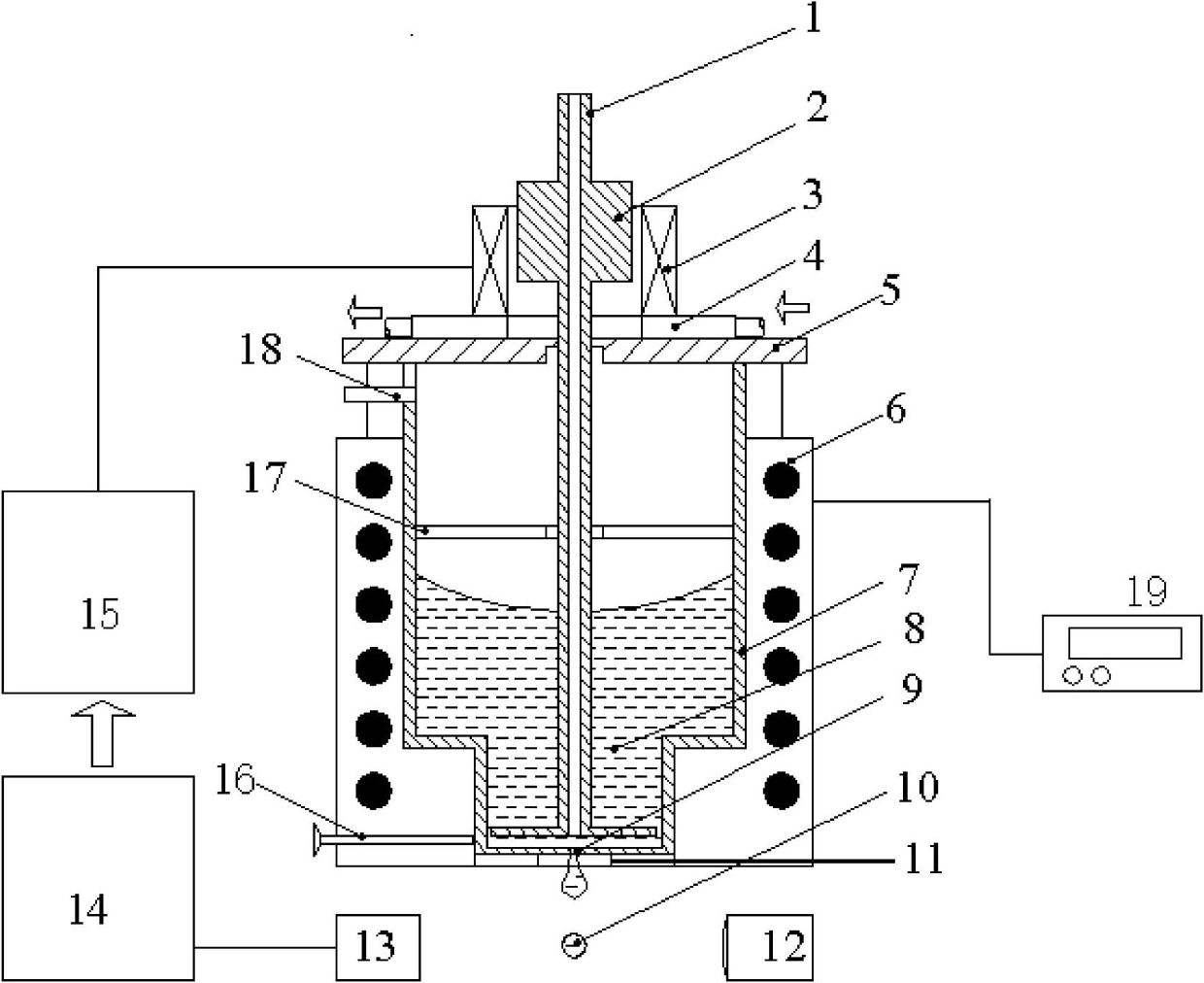

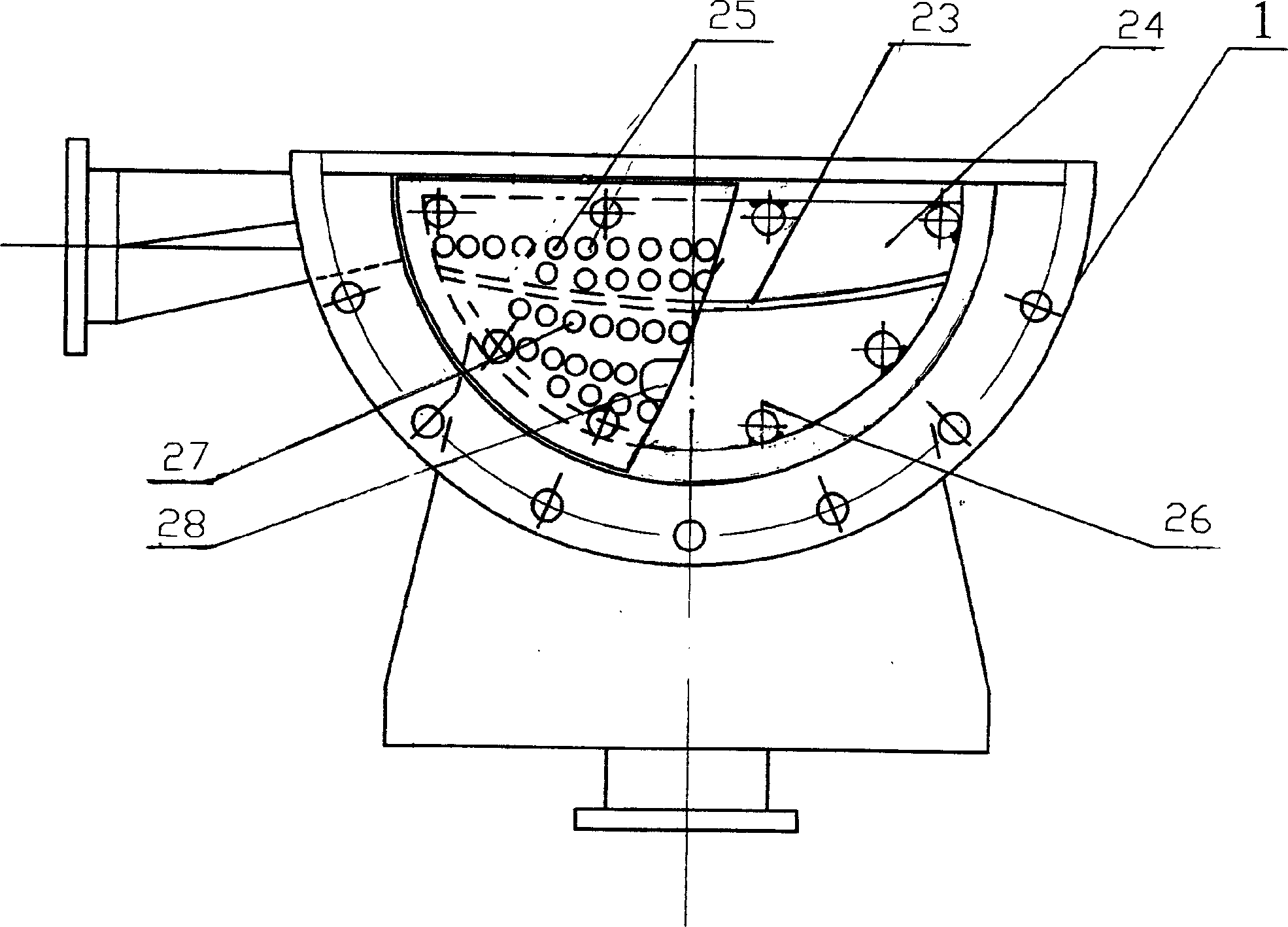

Metal molten drop ejecting device and method for ejecting high-melting-point metal molten drops using same

The invention discloses a metal molten drop ejecting device and a method for ejecting high-melting-point metal molten drops using the same. The metal molten drop ejecting device is used for solving the technical problem that the existing metal molten drop ejecting device is poor in stability in the ejecting forming process when ejecting high-melting-point light reactive metal molten drops. The metal molten drop ejecting device maintains stable ejecting of the high-melting-point metal molten drops by means of a nozzle automatic dredge device and an ejecting state detection system. The nozzle dredge device and a metal molten drop ejecting state monitoring and feedback system for high-melting-point metal ejecting are adopted; when the molten drop ejecting state monitoring and feedback systemdetects unstable ejecting state and transmits cleaning signals, an excitation rod is lowered, large positive or negative pressure is led into an inner channel of the excitation rod instantly, so thatmolten metal or gas at the position of a nozzle flows fast to bring out scale cinder or impurities adhered onto the inner wall of the spraying orifices, the aim of cleaning and dredging tiny nozzles can be achieved, and accordingly the ejecting forming process of high-melting-point metal molten drops is stable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

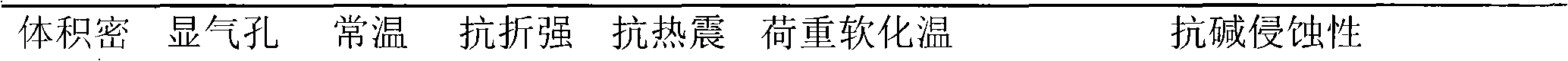

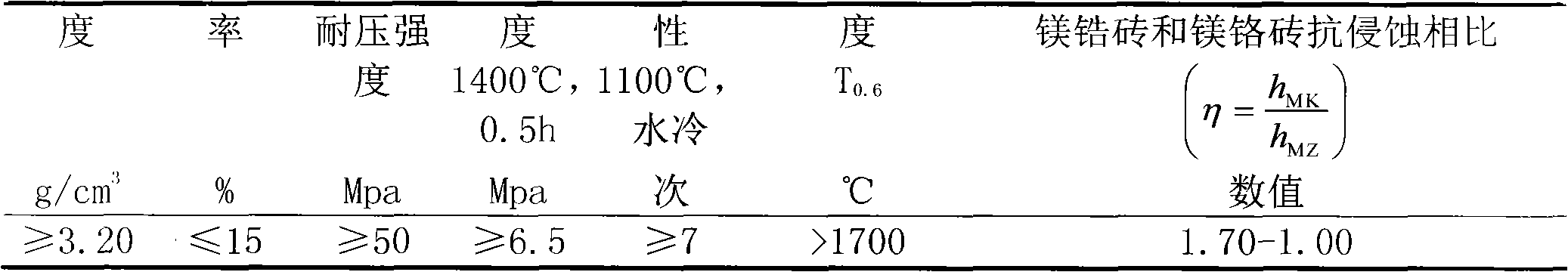

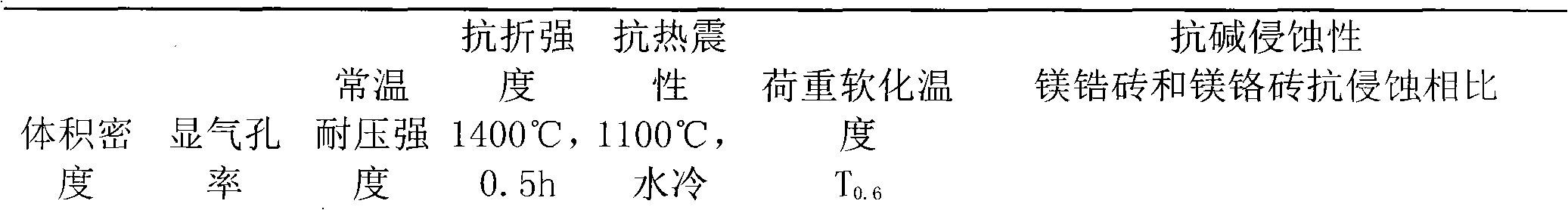

Magnesium-zirconium brick with high erosion resistance and thermal shock resistance for RH furnace and production technology thereof

The invention relates to a magnesium-zirconium brick with high erosion resistance and thermal shock resistance for an RH furnace and a production technology thereof. The brick comprises the following components by weight percent: 76-90% of MgO and 5-21% of ZrO2; and the firing temperature of the brick is 1680-1840 DEG C. The production technology comprises the following steps: pretreating magnesia and zirconia, synthesizing the magnesia and zirconia into magnesium-zirconium sand; crushing synthesized magnesium-zirconium sand and fused magnesia to 5-3mm, 3-1mm and 1-0mm particles; homogenizing under strong force and mixing the granular materials, 150-200 mesh magnesia and magnesium-zirconium sand powder, 200-250 mesh zirconia powder, additives CaO and Y2O3 and binder paper pulp water liquid and performing compression moulding; baking at 120 DEG C for 24-72 hours; and heating to 1680-1840 DEG C and maintaining the temperature for 3-5 hours. The linear change of the finished brick is within the range of + / -0.5%; and after being baked, the brick has no surface chap defect caused by the phase change of zirconia and has excellent refinery cinder erosion resistance and thermal shock resistance.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

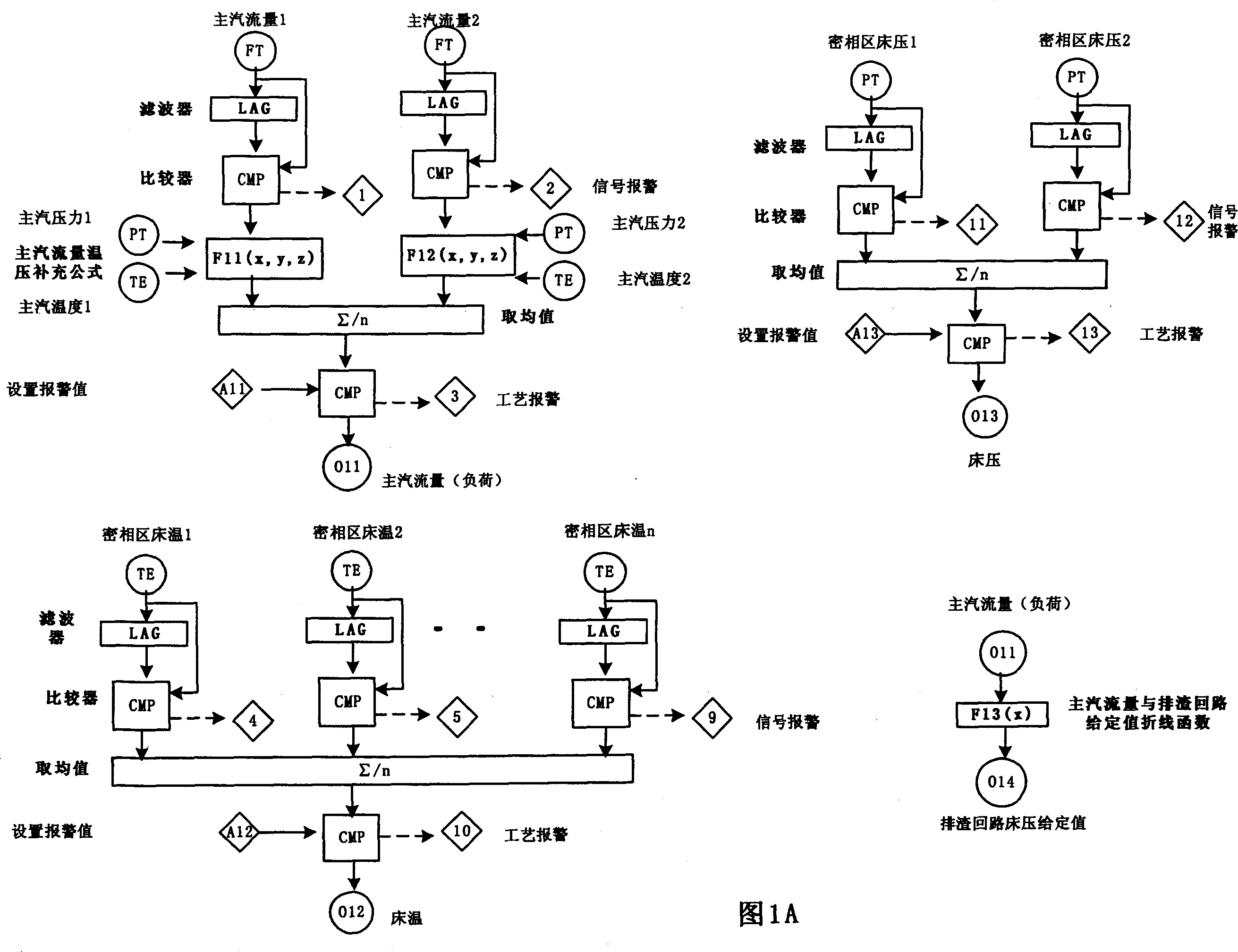

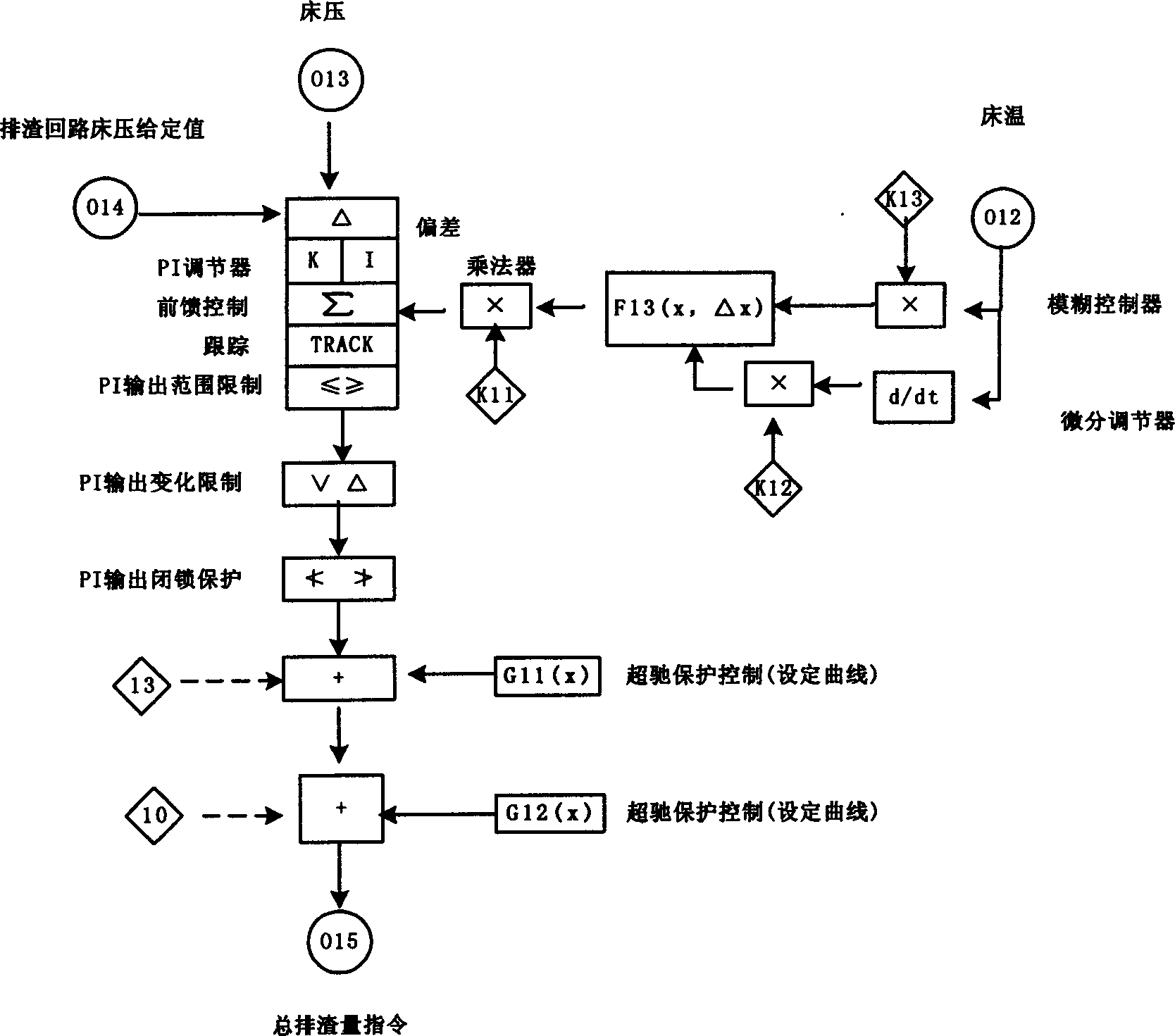

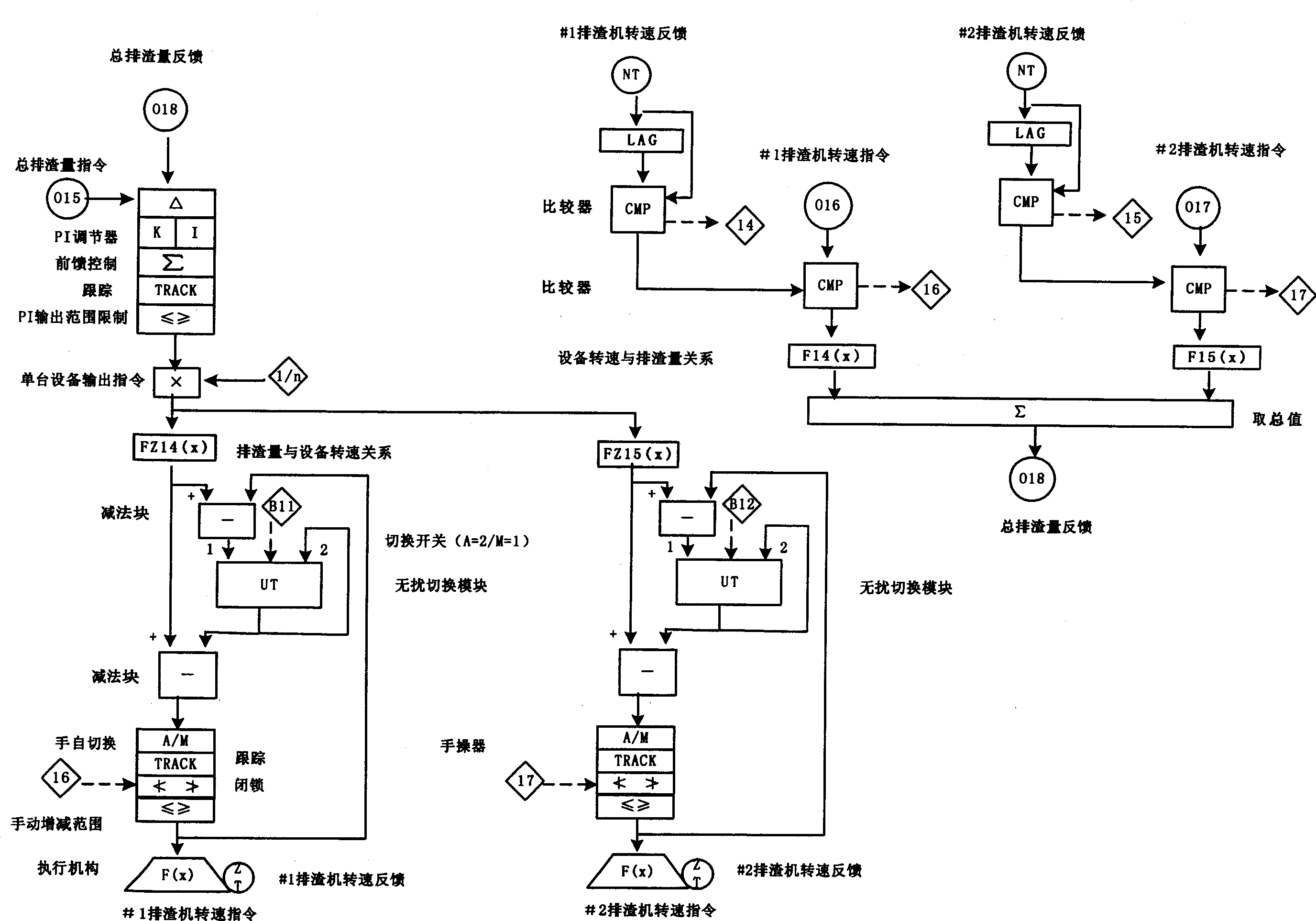

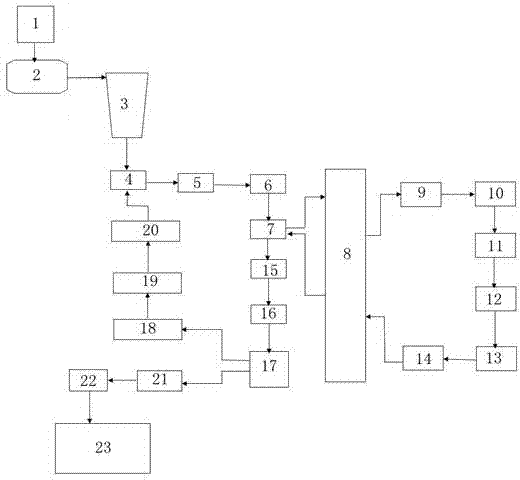

Automatic regulating system for combustion process of circulating fluid bed in boiler

InactiveCN1480682ATake full advantage of precisionContinuous and stable investmentFluidized bed combustionApparatus for fluidised bed combustionAuto regulationCombustion system

An automatic regulation system for the combustion of circulating fluidized-bed boiler (CFBB) features that it has several regulation loops for the discharged cinder quantity, primary blowing rate, supplied coal quantity, secondary blowing rate and draught air volume, which are based on the coordination between fluidizing, combustion and heat exchange, the expert system, fuzzy control and composite cascaded PI regulation are combined, and the protecting tactics such as override protection, output restriction and lock distribution choosing and tracking are used.

Owner:BEIJING HOLLYSYS

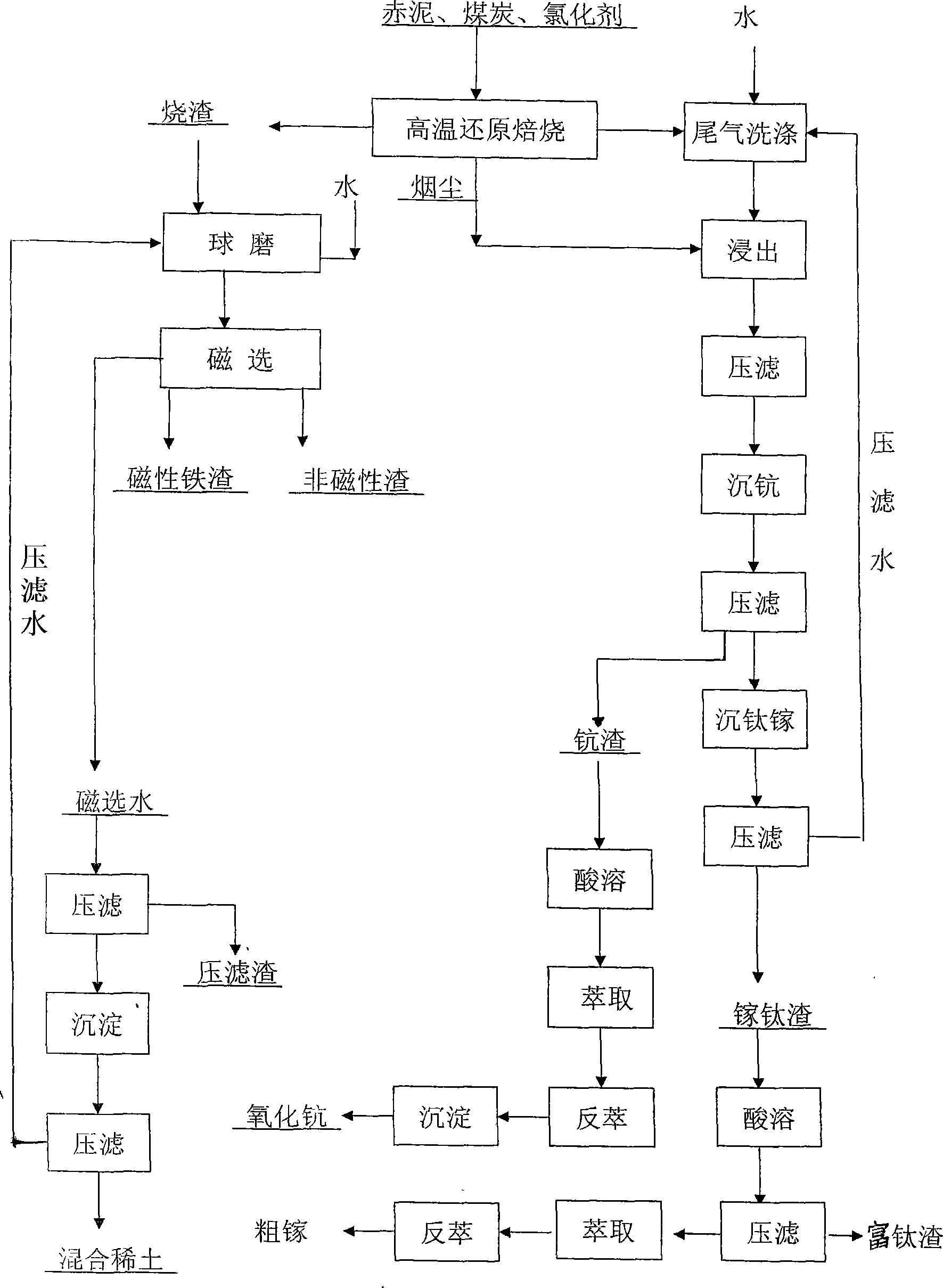

Comprehensive utilization method for red mud

InactiveCN101463426APromote environmental protectionGood benefitSolid waste managementProcess efficiency improvementWash waterRed mud

The invention discloses a method for comprehensively utilizing red mud, comprising the following steps: chloridizing roasting, namely roasting the mixture of the red mud, coal and calcium chloride; cinder treatment, namely obtaining magnetic iron slag and non-magnetic slag after magnetic separation is carried out to levigated cinder, and then separating the magnetic iron slag and non-magnetic slag; adding calcined soda or oxalic acid after levigation liquid and wash water are rich in mischmetal due to cyclic use, and then precipitating mischmetal slag; treatment of dry dust and circulation liquid, namely, after dry powder for roasting dust collection is collected, mixing the dry powder with scouring water which is used for tail gas circulation and then leaching soluble ScCl3 and GaCl3; after filter pressing, precipitating scandium by adding oxalic acid crystal in filtrate; carrying out filter pressing again, precipitating gallium and Ti(OH)4 by adding ammonia into the filtrate, dissolving obtained gallium-titanium slag with acid and then using P2O4 extractant to extract the gallium; and using extractant to extract the scandium after scandium precipitate is dissolved by acid, carrying out precipitation again by adopting back-extraction acid dissolving, and obtaining Sc2O3 by means of roasting. The method can realize recovery of valuable metals from the red mud, and secondary residual slag is totally used for building material production; and the method has environment protection effects and economic benefits, plays an important role in the development of recycling economy and is applicable to enterprises generating red mud.

Owner:张钦

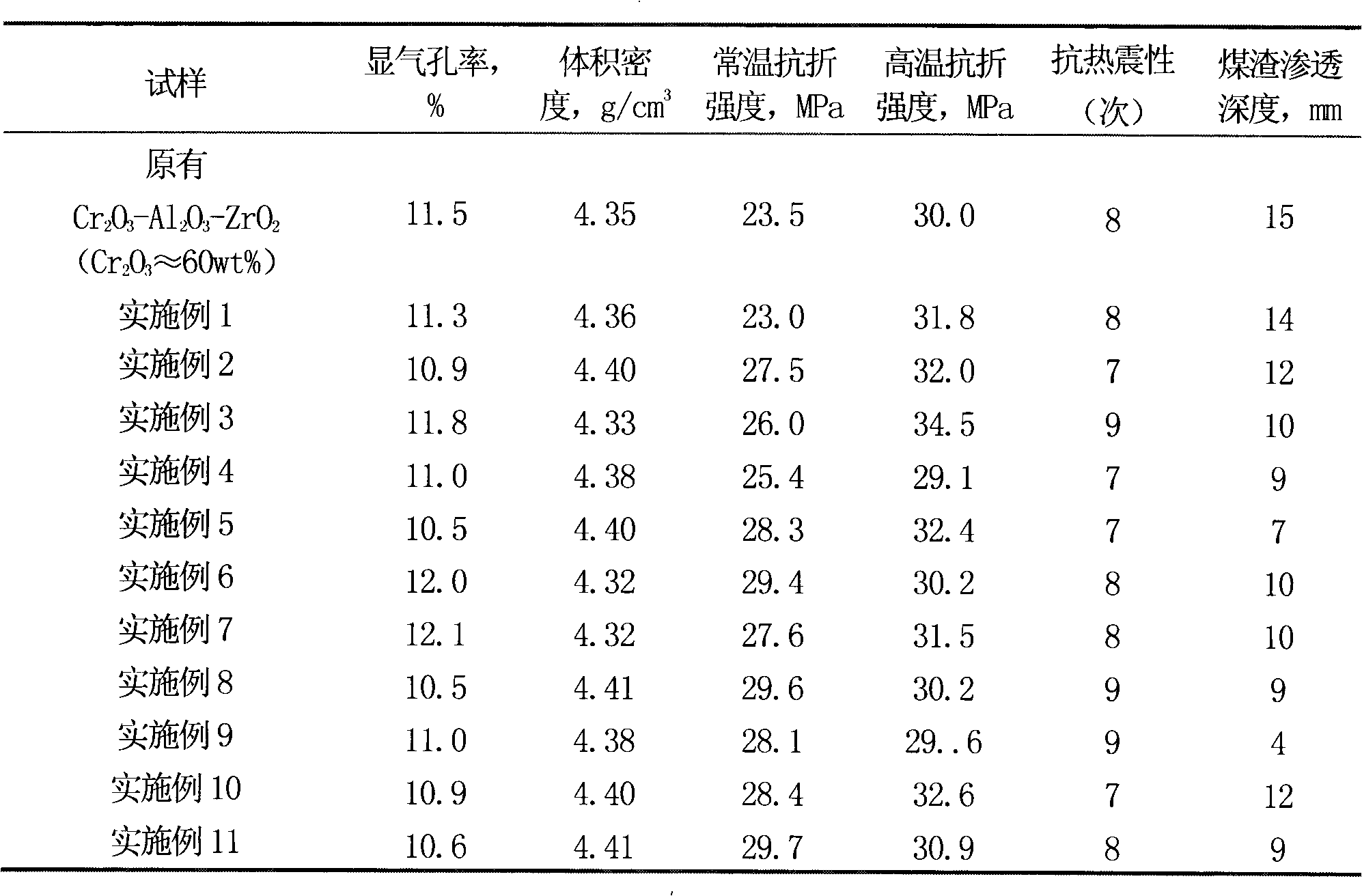

Preparation method of high-chrome brick

ActiveCN101648812AImprove thermal shock resistanceSolve the problem of reduced permeability resistancePorosityBreaking strength

The invention provides a preparation method of a high-chrome brick, belonging to the field of fireproof material. The high-chrome brick is a key lining material of a water-coal-slurry gasification furnace. Compared with the prior high-chrome brick product, the invention does not influence the apparent porosity, the breaking strength and the thermal shock resistance of the prior high-chrome brick and can obviously enhance the coal cinder permeability resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Novel high sulfur-resistant cement

The invention discloses a new-type cement with a high resistance to the sulfur which comprises 20-70 wt.% of common silicate grog, 3-10 wt.% of gesso kind, 0-10 wt.% of microdilatancy component, 20-70 wt.% of functionality mineral admixture and 0-2 wt.% of grinding aid. The mineral admixture is composed of grammite, flyash, graining blast-furnace cinder, slag, steel slag, graining blast-furnace phosphorus slag, limestone, kiln dust or other eruption. The cost of the new-type cement with a high resistance to the sulfur is equal to the cement with a medium resistance and cement with a high resistance to the sulfur. The strength is equal to the common silicate cement. But the resistance to sulfate and the resistance to seawater is obviously better than former cement with a medium resistance and cement with a high resistance to the sulfur. The invention can improve the quality of the ocean engineering and beton resists to erosion, prolongs the service life of the beton and has an outstanding technique, economy and community benefit. The new-type cement with a high resistance to the sulfur is widely applied in the ocean engineering.

Owner:CHINA BUILDING MATERIALS ACAD

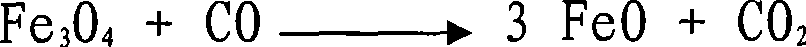

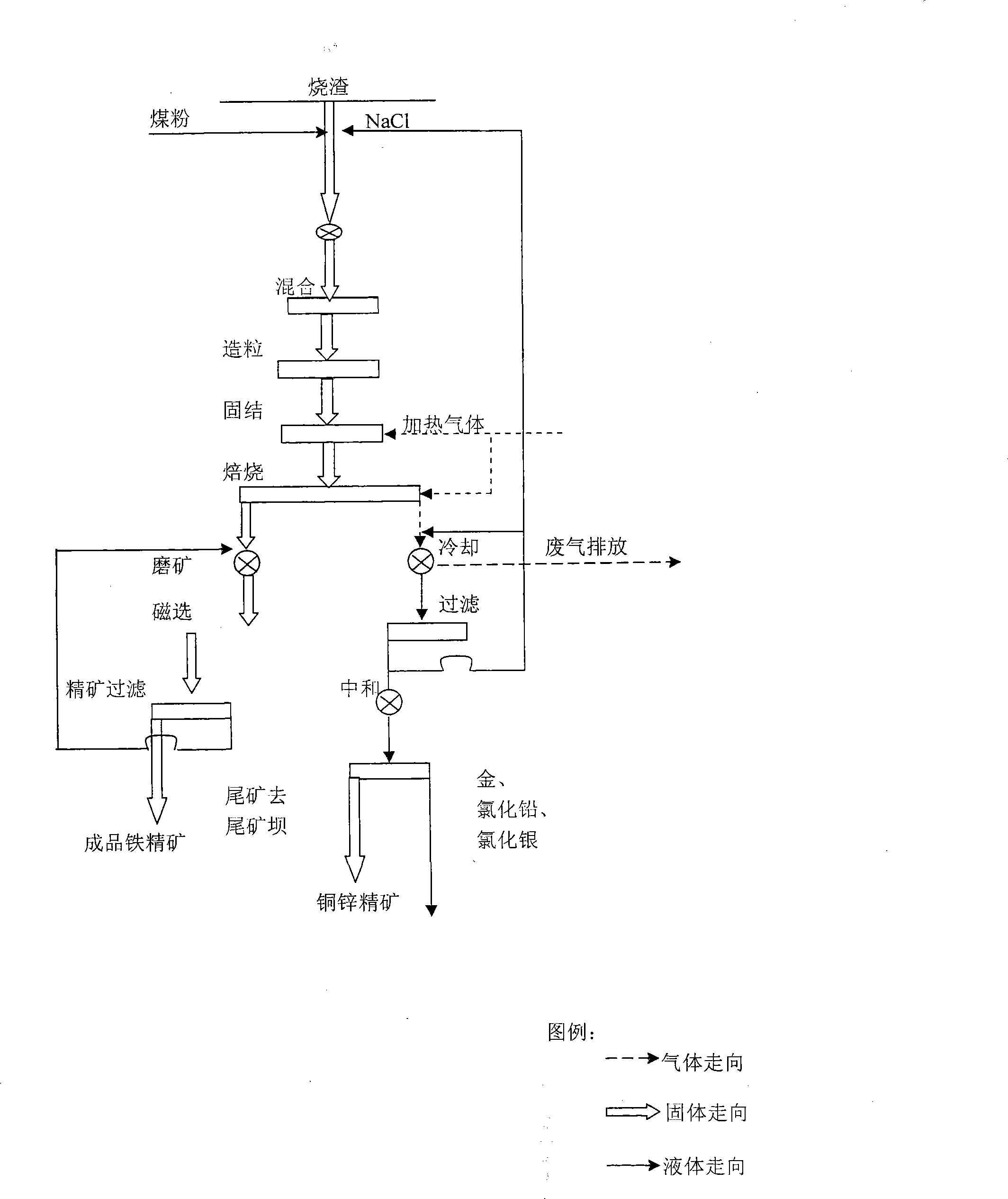

Method for recovering gold, silver, iron and lead from acid calcination slag by magnetization chlorination process

InactiveCN101225468AEliminate pollutionReduce wasteProcess efficiency improvementLimited resourcesSlag

The invention discloses a method to recover the gold, silver, iron and lead from the acidiation roasted cinder by a magnetic chlorination method, which is characterized in that the method comprises two sections, one is that the gold, silver, lead, and copper in the cinder are volatilized as a chloride gas through the high temperature chlorination roasting, and the gold, silver, copper and lead are recovered through the condensed gas; the other is that the iron is recovered by the process that the coal dust is filled during the granulation of the cinder, the magnetic reduction roasting is done with the chlorination roasting, the ferric oxide is reduced to the ferroferric oxide, and the processed cinder is ground and selected magnetically. Thanks to the recovering method, the recovery rate of the gold and silver is above 95%, the iron recovery rate is above 85%, and the lead recovery rate is above 90%, the production cost is about 300 RMB per ton, the profit is over 700 RMB per ton, so that a multiple billion RMB profit is harvested, and the waste of the limited resource is reduced. The method to recover the gold, silver, iron and lead from the acidiation roasted cinder by a magnetic chlorination method has the advantages of simple process, high efficiency, low smelting cost, comprehensive utilization of the ore resources, elimination of the environment pollution, and economic benefit growth of enterprise.

Owner:张伟晓

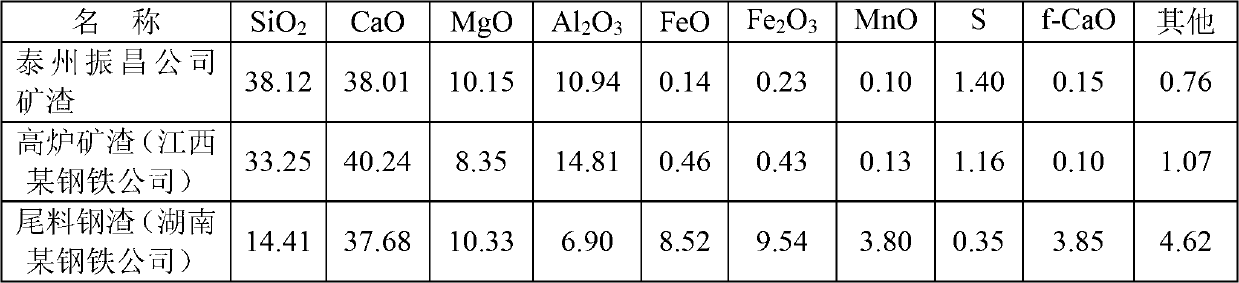

Aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and production method of aerated concrete block

The invention provides an aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and a production method of the aerated concrete block. The aerated concrete block is produced through the following steps: adding an additive A, an additive B and water in components as follows: 40 to 50% of specially-made mineral waste residue obtained in a such way that cinder is obtained through the production process of recycling steel slag discharged from Taizhou Zhenchang Industrial Waste Residue Comprehensive Utilization LTD and metallurgical and chemicalferrous waste residue, and then is water-quenched, 35 to 45% of tailings steel slag, 2 to 4% of cement clinker, 1 to 3% of gypsum, and 8 to 12% of modified wood, wherein the grain size of the specially-made mineral waste residue is less than or equal to 5 mm, the grain size of the tailings steel slag is less than or equal to 20 mm, the additive A accounts for 1% of the total weight of the components, the additive B accounts for 0.05% of the total weight of the components, and water accounts for 0.5 to 0.6 times of the total weight of the components; and conducting mixing, heating, air-entrapping, steaming and pressing, and curing in sequence. The aerated concrete block produced by adopting the production method is high in strength, and small in drying shrinkage value, and can meet the block standards of the A3.5 grade and the B09 grade in the JC1062-2007 foam concrete block standard.

Owner:TAIZHOU ZHENCHANG IND RESIDUE COMPREHENSIVE UTILIZATION +1

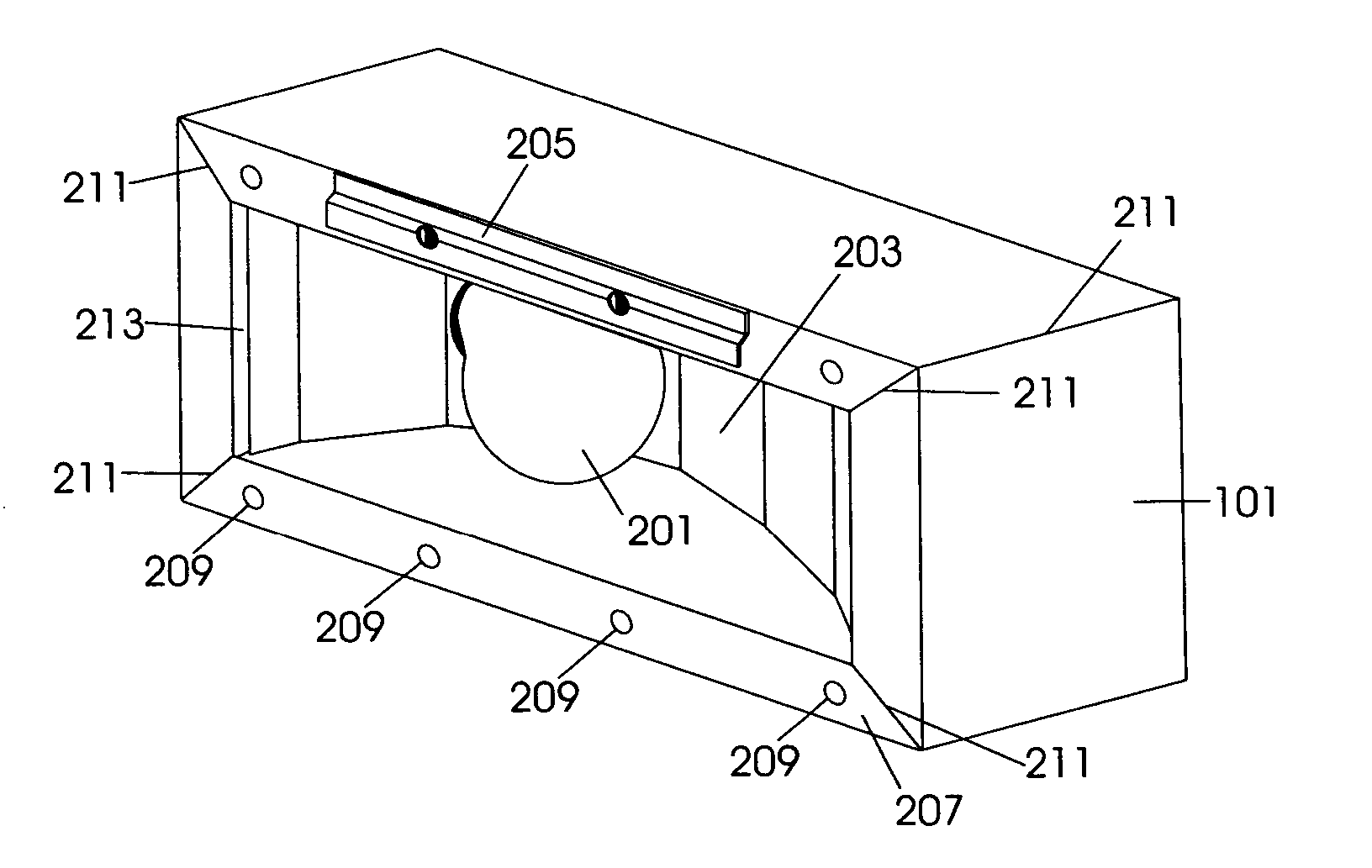

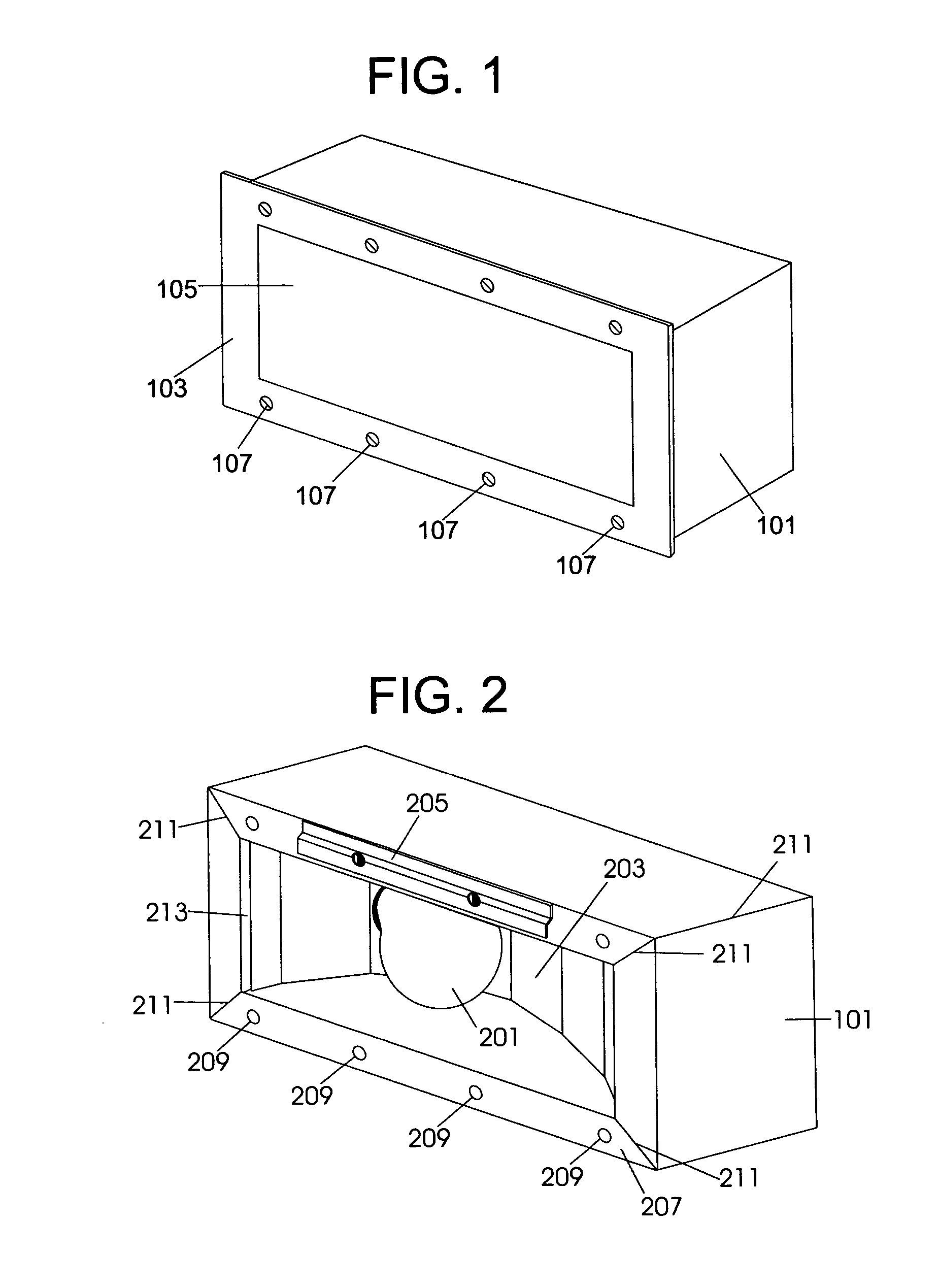

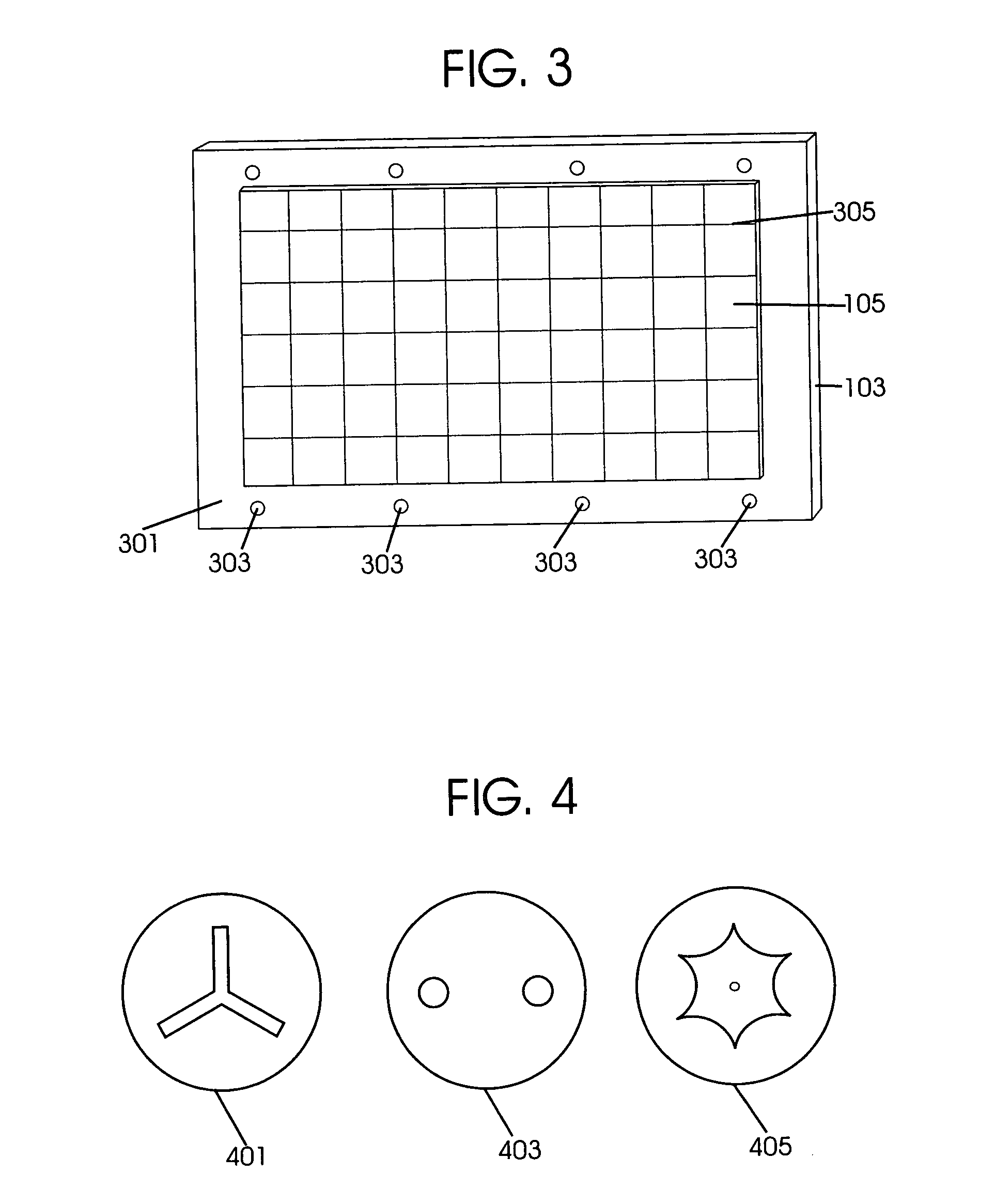

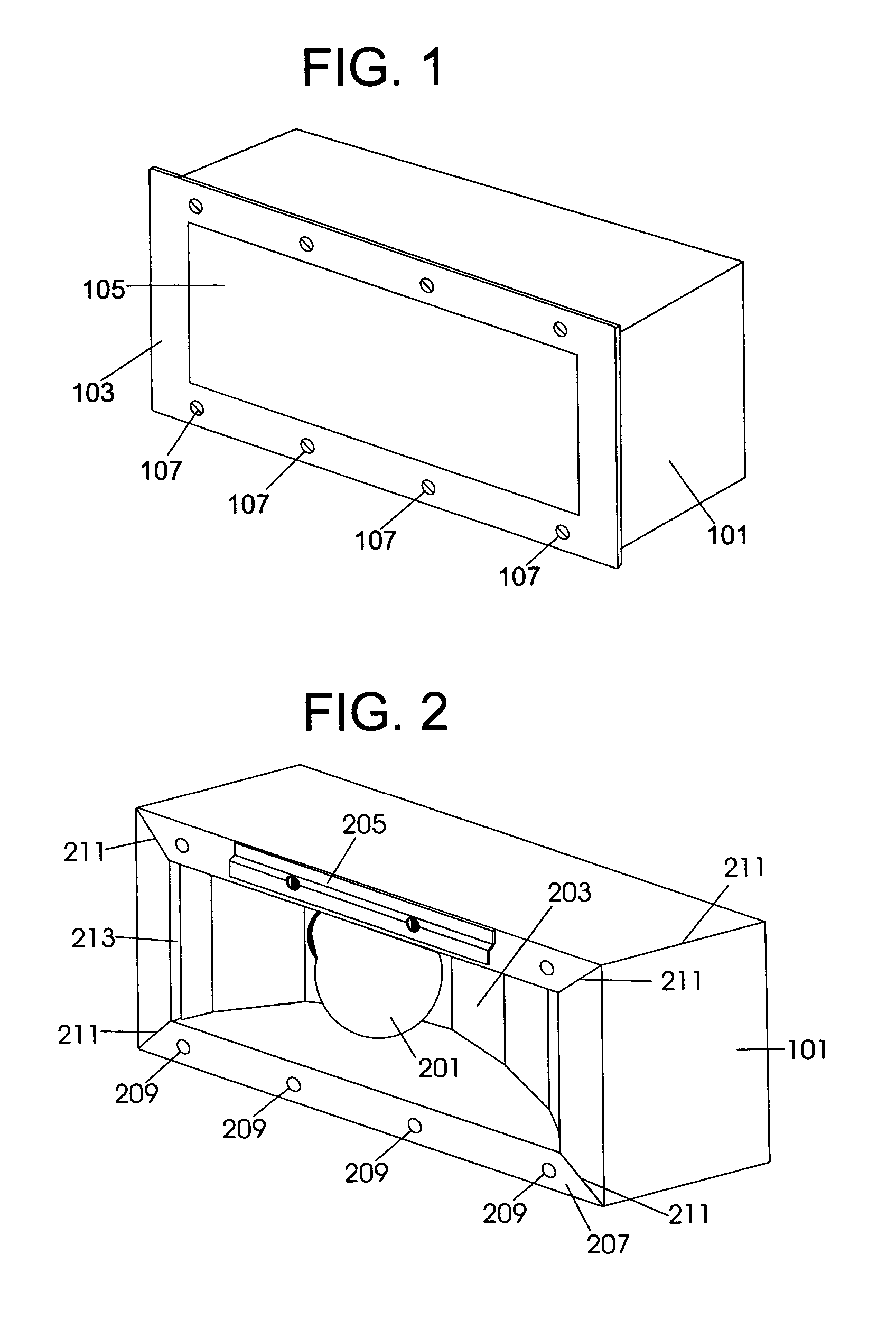

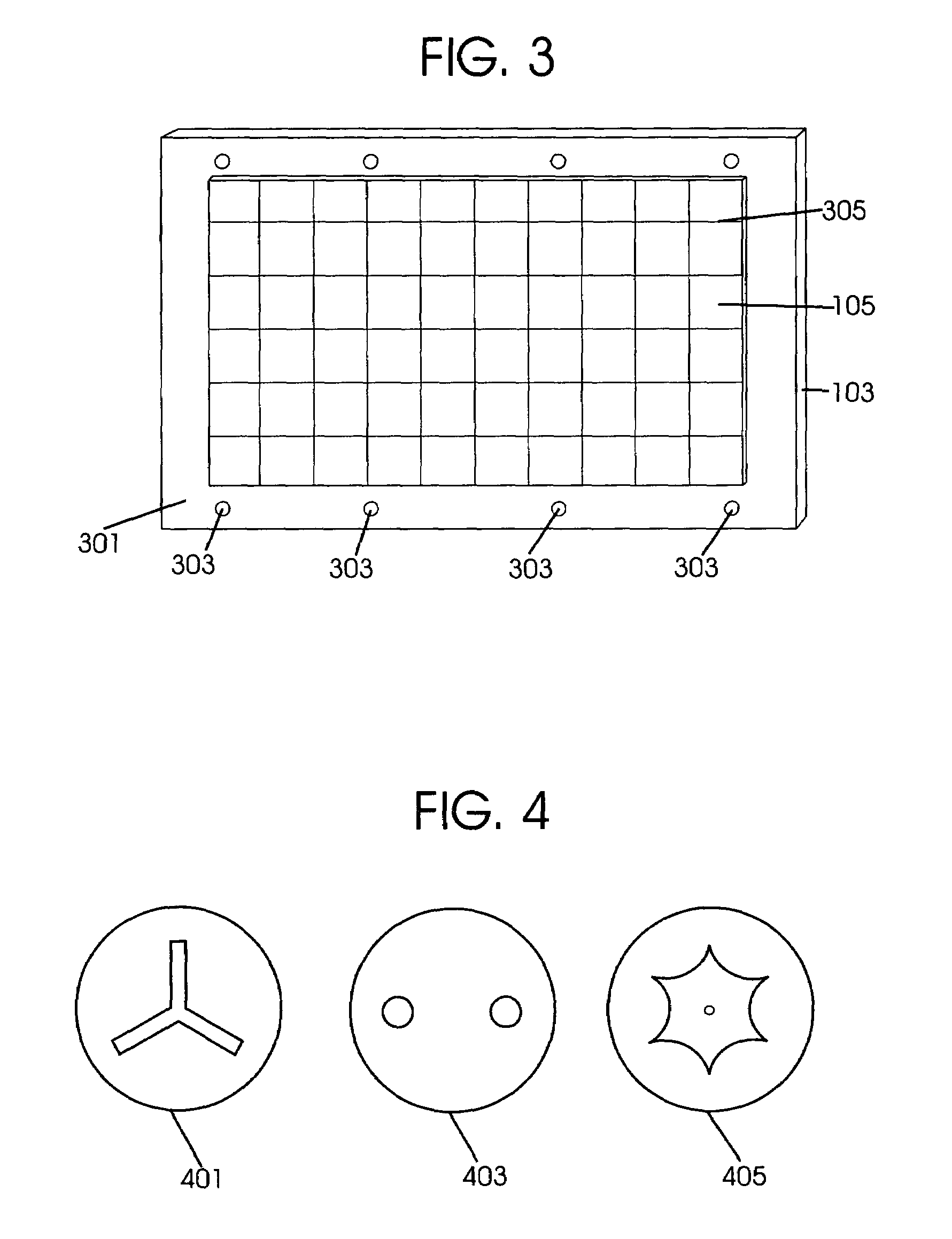

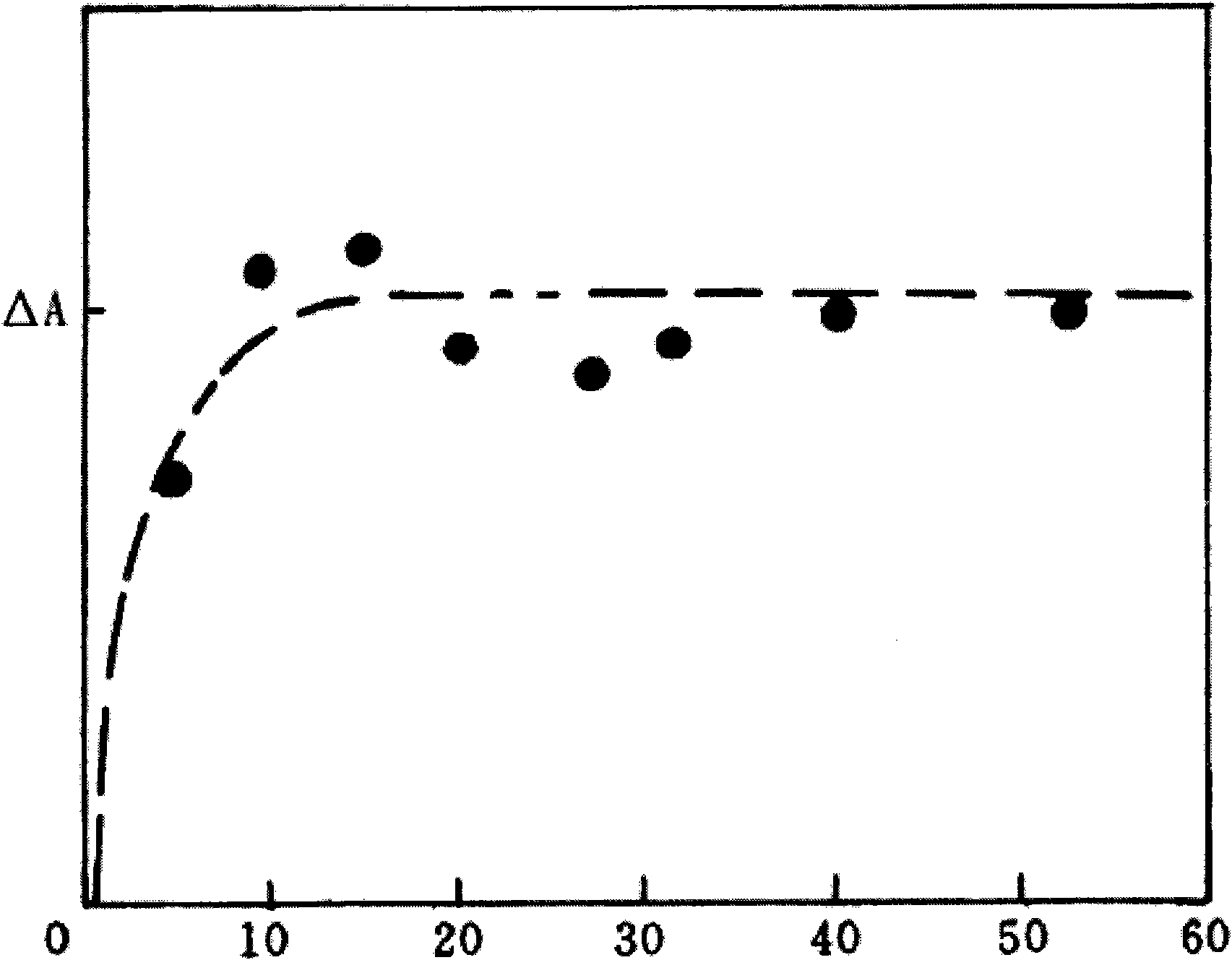

Enclosure for a light source

ActiveUS20050024856A1Light would become directionalPoint-like light sourceElongate light sourcesBrickEngineering

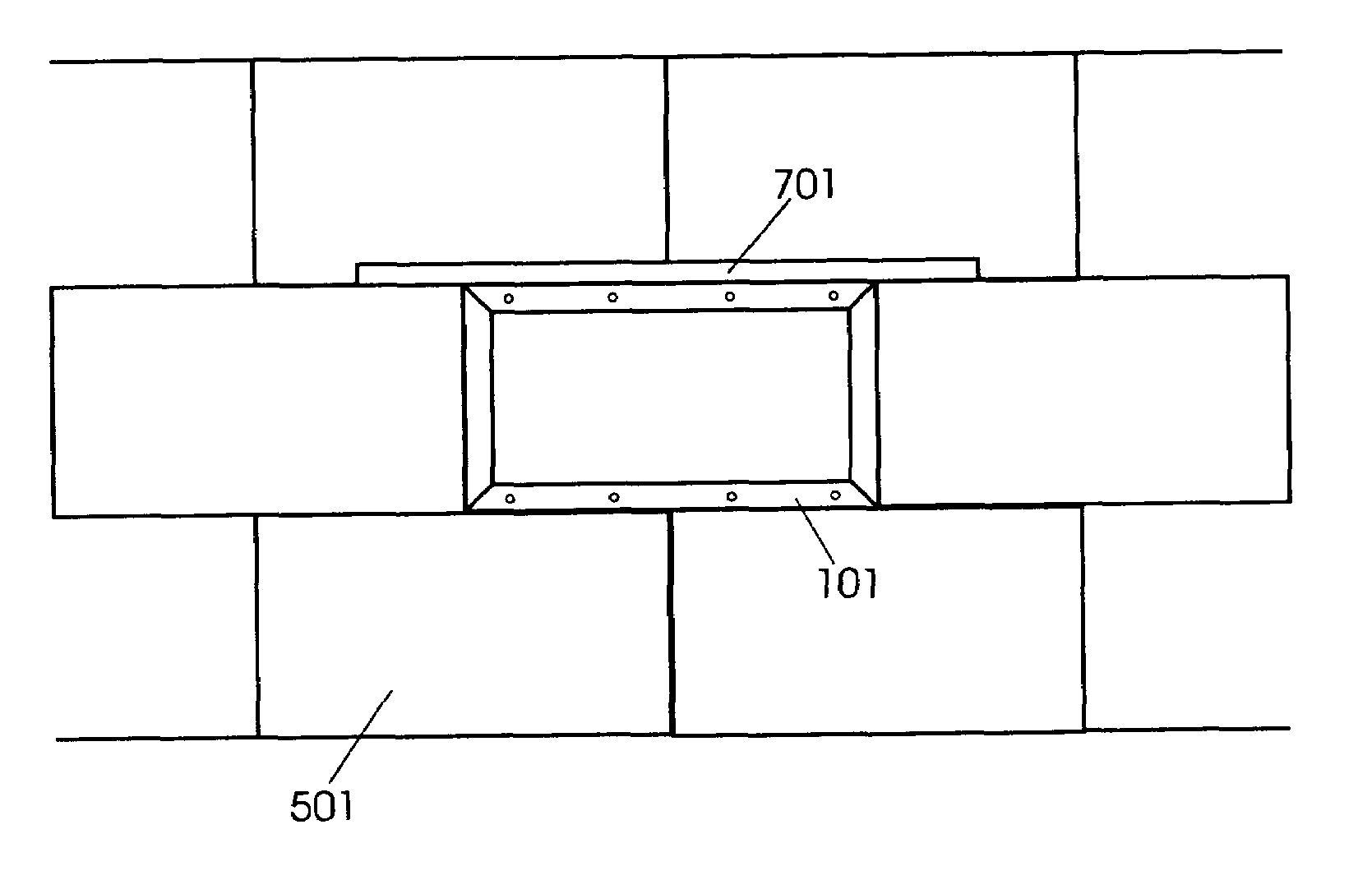

A light source is disposed in a cavity in an enclosure that supports a part of the wall. The enclosure may be disposed substantially within the wall, such that the enclosure does not provide an obstacle to those moving near the wall. Because the enclosure is capable of supporting a part of the wall, the enclosure may be substituted for one or more substructures of the wall, including, but not limited to, concrete blocks, cement blocks, bricks, cinder blocks, and combinations thereof. The enclosure may be disposed at most any height in the wall.

Owner:HELENOWSKI JACEK

Method for complex optimum using oil shale

InactiveCN1683472AAchieve optimal utilizationIncrease profitLiquid hydrocarbon mixture productionSpecial form destructive distillationFluidized bedOil shale gas

The comprehensive optimized oil shale utilizing method includes crushing and sieving oil shale ore, dry distilling the 8-80 mm size component in retort furnace to produce shale oil and fuel gas, crushing the semicoke waste into 8 mm below size, mixing the crushed semicoke waste and 8 mm below size waste grain from oil refining to form mixed fuel for the circulating fluidized bed boiler, using the produced steam partially for externally supplying and partially to drive turbine generator, and using the cinder in producing cement, haydite and building block. The present invention provides one new way for comprehensive utilization of giant oil shale resource.

Owner:SHANGHAI JIAO TONG UNIV

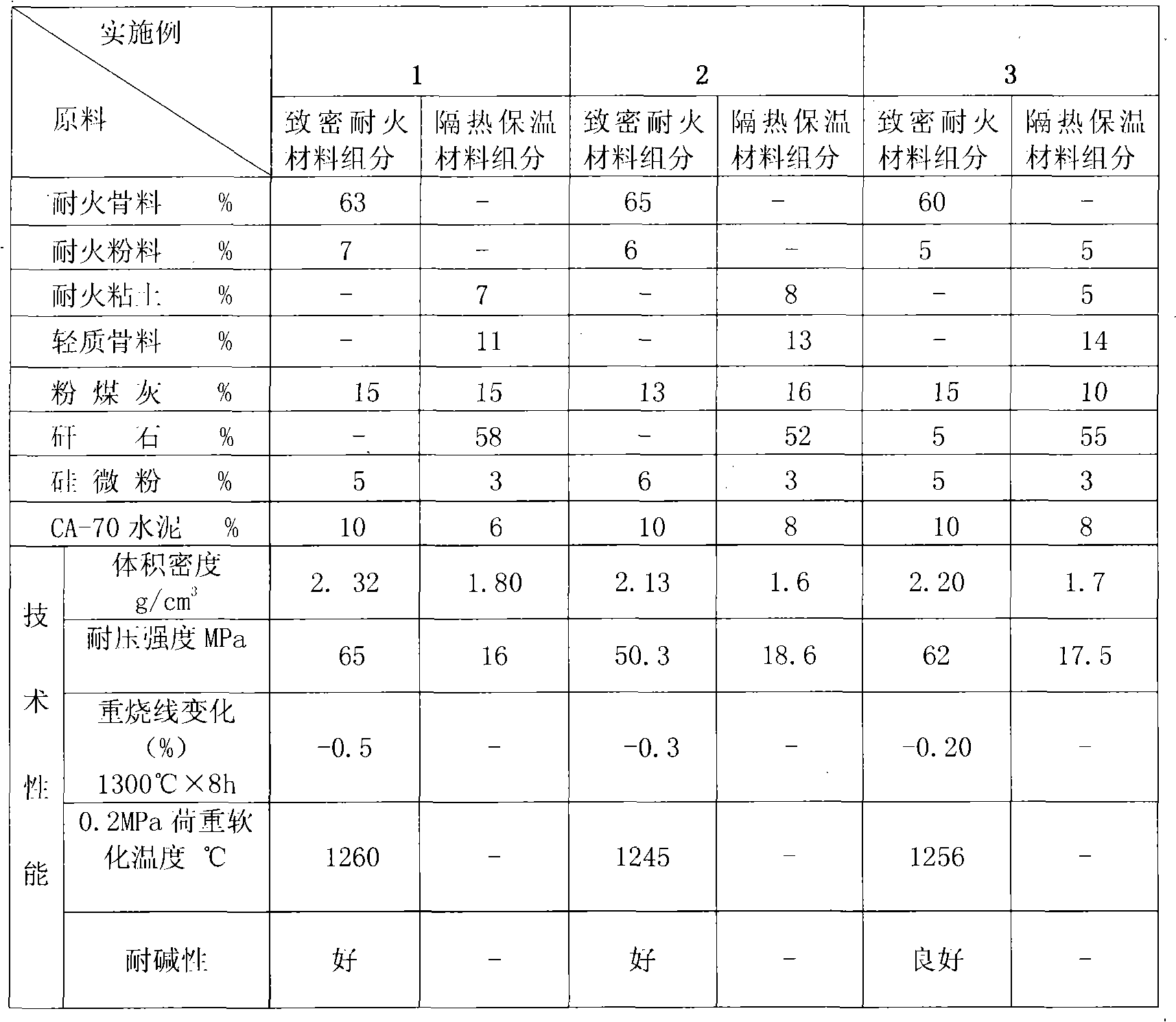

Composite alkali-resistant refractory brick of pulverized fuel ash

The invention provides a composite alkali-resistant refractory brick of pulverized fuel ash, wherein the composite brick is applied to the inner lining of an industrial kiln and is prepared by providing refractory aggregate, refractory powder, light aggregate, refractory clay, aluminate cement and silica micropowder to the pulverized fuel ash of solid wastes of a fuel electric plant and the coal cinder after burning, then adding water into the same and mixing, and then pressing and drying. The composite alkali-resistant refractory brick of pulverized fuel ash is composed of compact refractory material components and heat insulation material components. The percentages by weight of the compact refractory material components are as follows: the refractory aggregate is 55 to 65 %, the pulverized fuel ash is 5 to 8 %, the refractory powder is 10 to 15 %, the silica micropowder is 4 to 6 % and the aluminate cement is 8 to11 %; the percentages by weight of the heat insulation material components are as follows: the coal cinder is 50 to 65 %, the pulverized fuel ash is 5 to 10 %, the light aggregate is 5 to 10 %, the refractory clay is 5 to 8 %, the refractory powder is 10 to 16 %, the silica micropowder is 3 to 5 % and the aluminate cement is 7 to 10 %; and the compact refractory material components and the heat insulation material components of the composite alkali-resistant refractory brick of pulverized fuel ash provided by the invention are pressed into a tightly combined compound. Compared with common refractory brick, the composite alkali-resistant refractory brick of pulverized fuel ash provided by the invention has the advantages that a heat insulation layer is increased, the temperature for the skin of the rotary kiln can be reduced, a great quantity of energy can be saved and the service life of the kiln is prolonged.

Owner:阮克胜

Sludge fuel stick and its prepn

InactiveCN1810940ALow costSolve the way outSludge treatment by de-watering/drying/thickeningBiofuelsCombustionPlant stalk

The present invention is one kind of sludge fuel stick and its preparation process, and belongs to the field of solid waste treating technology. The sludge fuel stick is prepared with dewatered sludge 50-70 wt%, combustion improver 20-50 wt%, adhesive 3-5 wt% and desulfurizing agent 5-10 wt%. The preparation process includes mixing the said materials in a stirrer, pelletizing in a pelletizer, forming and stoving. The present invention can treating sludge as well as plant stalk, furnace slag, coal slag, flyash and other solid waste and utilize heat in sludge.

Owner:TSINGHUA UNIV

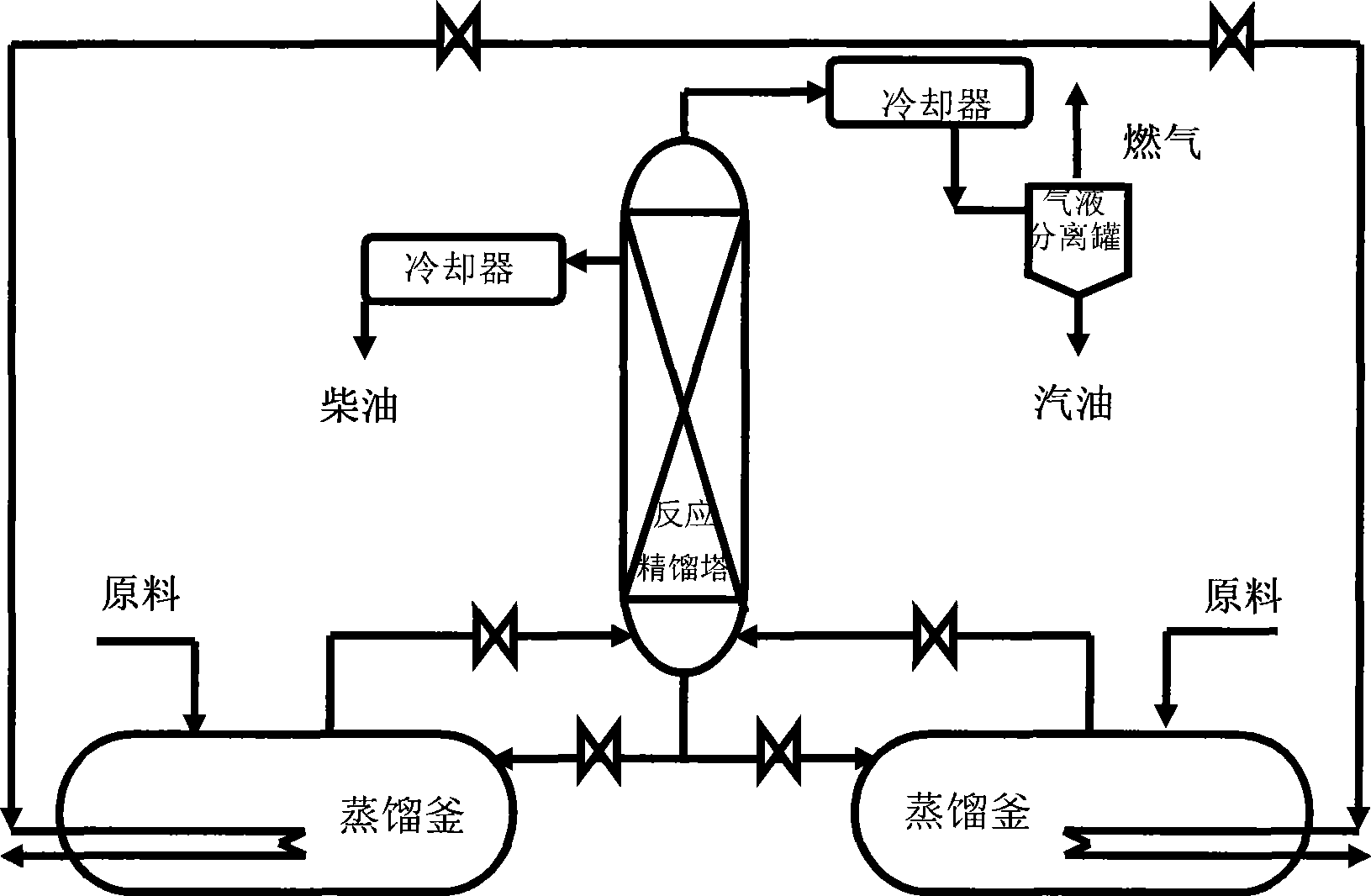

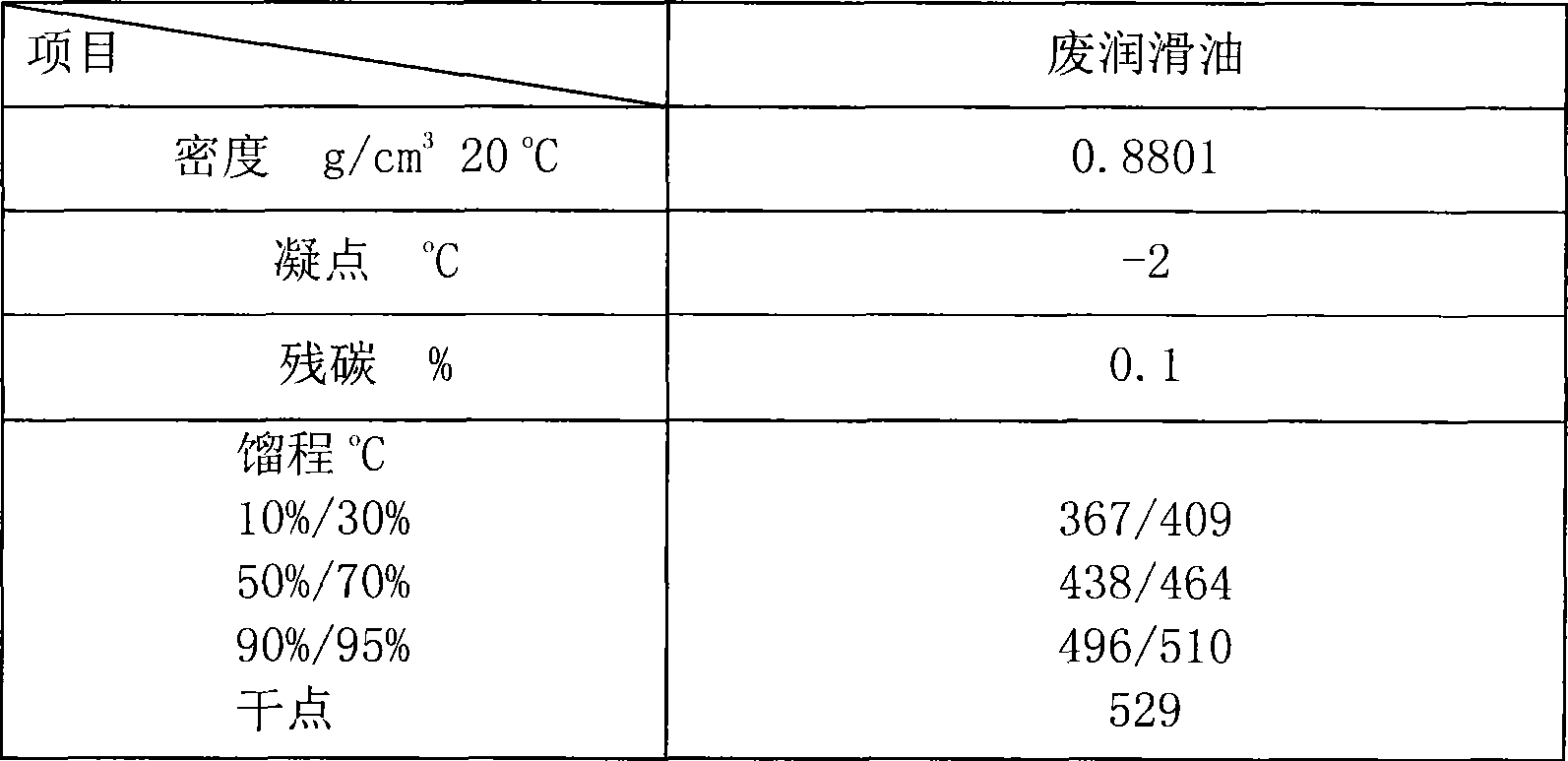

Method for producing petrol and diesel oil by recycling waste lubricant oil

ActiveCN101475870ASimple processLow costHydrocarbon distillationLubricant compositionDistilled oilGas phase

The invention relates to a method for producing gasoline and diesel fuel through resource utilization of waste lubricant oil, which belongs to the technical field of environmental protection and energy resources. The method comprises: integrally performing the vapor phase catalytic cracking process on molecular sieve / alumina catalyst of the waste lubricant oil and the fractionation and separation process of reaction products in a reaction fractionator; injecting crude waste oil into a distillation kettle, and adopting waste residue and fuel gas generated during conversion of the waste lubricant oil for heating, wherein the temperature of the distillation kettle is controlled to be between 250 and 500 DEG C; making distilled oil gas enter the reaction fractionator which is filled with the molecular sieve / alumina catalyst for reaction and rectification when the distillation kettle is heated to 250 DEG C, wherein the ratio of the catalyst to oil is controlled to be between 1 and 20; and cutting the oil into the gasoline and the diesel fuel according to the distilled temperature, wherein fuel gas generated by reaction and residual cinder can be used for heating the distillation kettle, and generated fuel gas can be used for heating the distillation kettle. The method has the advantages of wide range of raw materials, normal-pressure reaction and separation, simple technological flow, high conversion and selectivity of products, long service life of the catalyst, comprehensive utilization of the fuel gas and the cinder, no secondary pollution, large operating flexibility of a production apparatus, and small investment.

Owner:DALIAN UNIV OF TECH

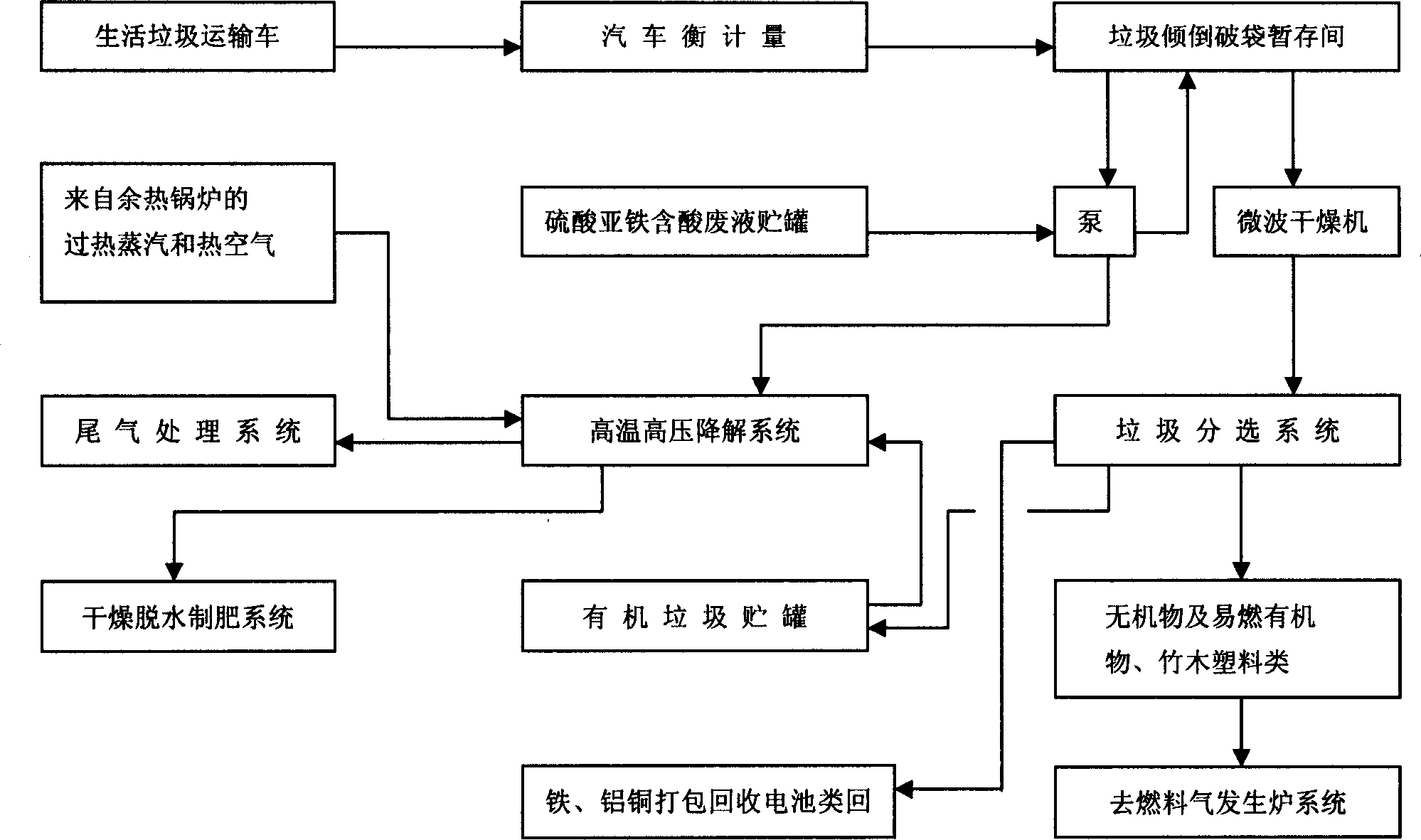

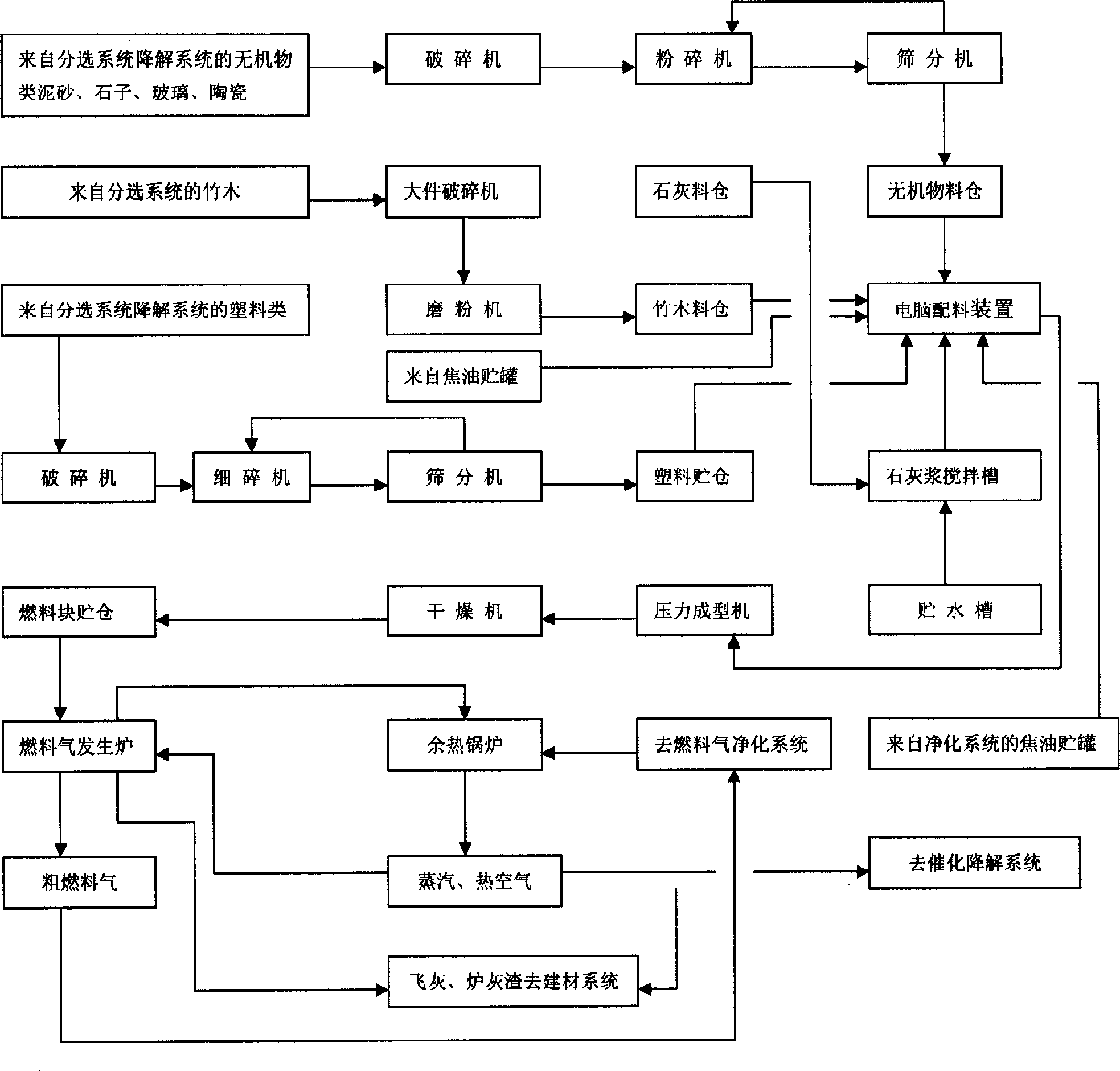

Cleansed handling domestic garbage

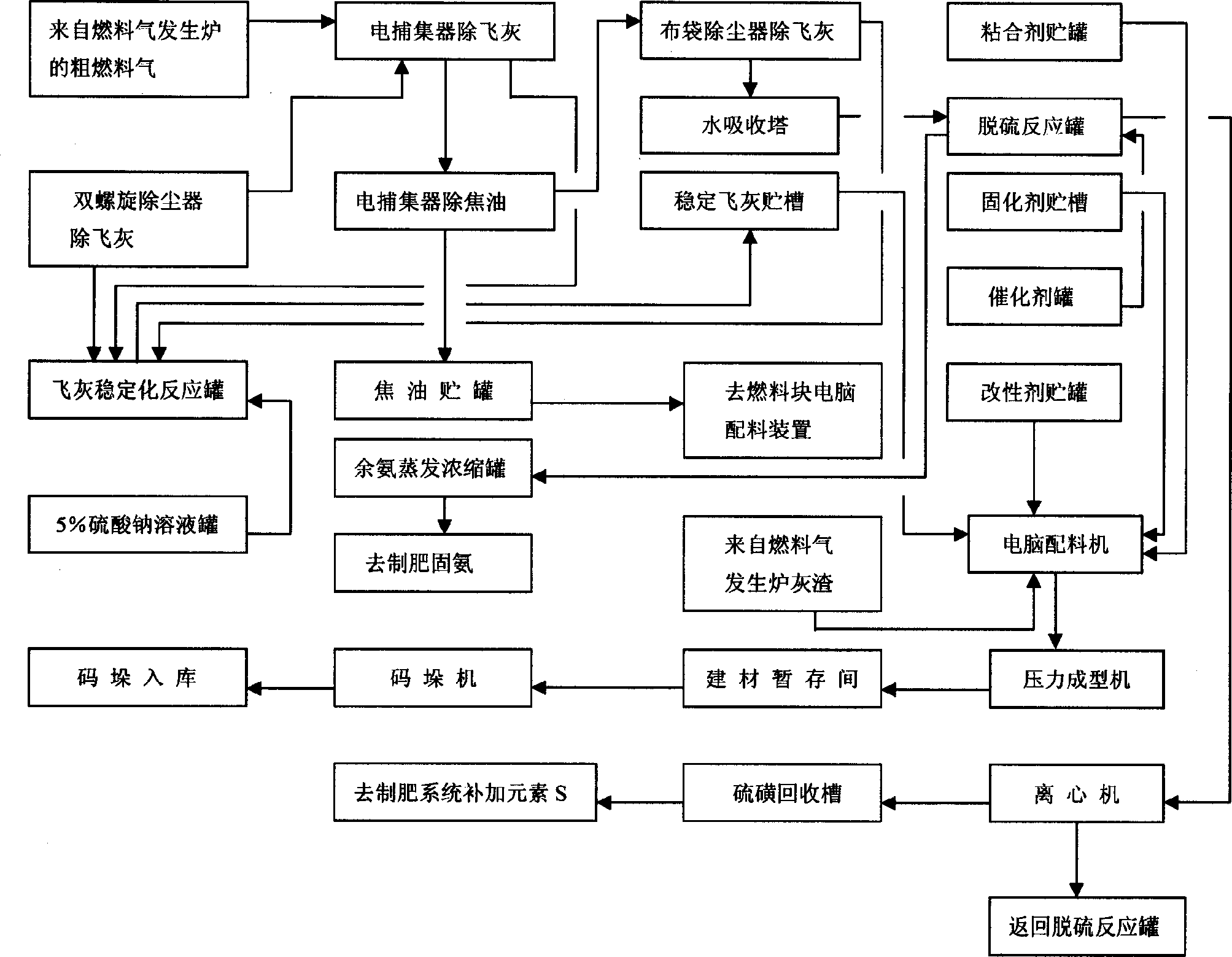

A technique for treating life garbage without environmental pollution includes such steps as using deodoring agent and microwave for removing odor smell and killing bacteria, cyclically treating the seeped liquid, separating organic substance from inorganic one, high-temp high-pressure degradation of organic substance to kill microbes and obtain clean raw material, preparing fuel blocks from the inorganic substance, stabilizing fly ash, mixing it with fuel cinder, making building material, treating sewage by magnetized biologic filter pool and magnetized chemical flocculating pool for cyclic use, and reclaiming sludge.

Owner:刘文治 +2

Lightweight ceramicite and preparation method thereof

InactiveCN101224972AHigh porosityLarge specific surface areaCeramic materials productionCeramicwareSlagAdhesive

The invention relates to a light ceramisite and a preparation method, comprising processes such as modification treatment of the raw material, the biological preparation, granulation, drying, baking and roasting etc. The invention is characterized in that the component and volume percent of the raw materials comprise: 30-70 percent of tailing of tungsten mine; 15-22.5 percent of cinder; 15-22.5 percent of fly ash; 10-14.5 percent of clay; 0.1-3 percent of pore-forming material; 0.2-1 percent of modified adhesive of biological material; the preparation technology is that after subject to modification treatment using 15-25 percent of HC1, the tailing of tungsten mine is prepared to be the ceramisite together with materials with different melting temperatures such as the cinder, the fly ash, the clay etc., as well as the pore forming agent and adhesive; then the tailing of tungsten mine is put into an oven below normal temperature for baking below 120 DEG C for 1 hour, and placed into a muffle furnace for gradually heating up to 500 DEG C within 1 hour; presintered after kept constant temperature for 10 min; then entered into a furnace up to 800 - 1120 DEG C for burning for 30 minutes, finally discharged to be naturally cooled down to normal temperature.

Owner:JIANGXI UNIV OF SCI & TECH

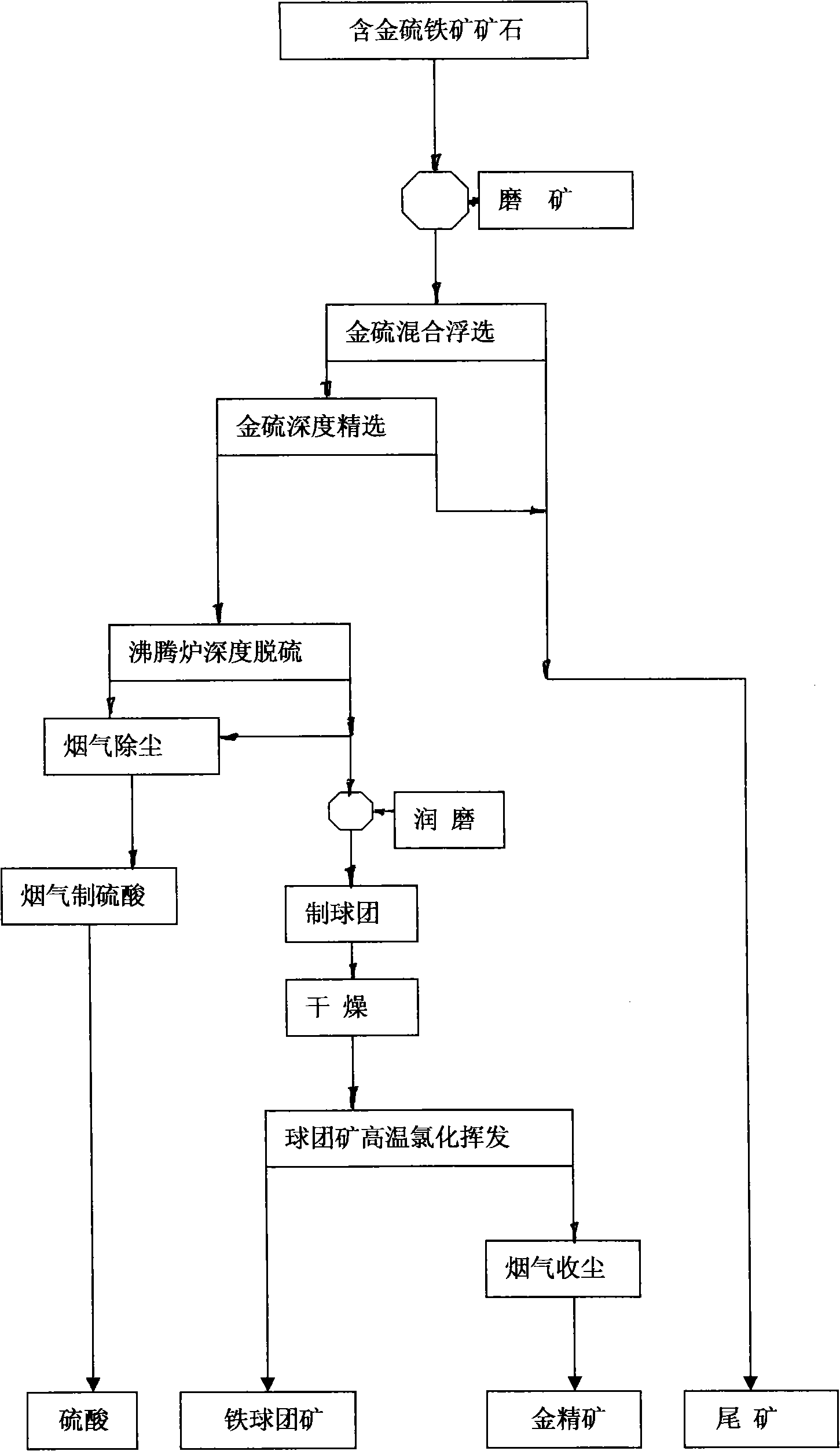

Method for comprehensively recovering gold, iron and sulphur resource from gold-containing sulfurous iron ore

The invention discloses a method for comprehensively recovering gold sulfurous iron resources from gold-bearing sulfurous iron ore, comprising the following steps: middle and low-grade sulfurous iron ore containing micro-gold and enclosed gold is grinded, and gold-bearing high-grade sulfur ore concentrate is obtained after sulfate dipping, mixture, floatation and concentration for a plurality of times; the ore concentrate undergoes high-temperature overoxidation roasting in a fluid-bed furnace to prepare sulfuric acid after flue gas undergoes dust removal and purification, and cinder becomes high-iron low-sulfur gold-bearing slag; the cinder is added with a pellet adhesive and a chlorating agent for grinding, and a pellet is prepared; the pellet is dried and then undergoes high-temperature chlorination-evaporation roasting; the flue gas is roasted and gold concentrate is obtained after dust collection; and the roasted pellet ore is a high-quality iron-making raw material the iron content of which is more than 60 percent and the gold content of which is less than 0.2 grams per ton. The technology highly efficiently recovers a large amount of gold resources which is lost in the sulfurous iron ore due to difficult cyanidation and leaching caused by containing the micro-gold and the enclosed gold through mixture and floatation of gold and sulfur, concentrate for a plurality of times, high-temperature overoxidation roasting deep desulfurization and high-temperature chlorination roasting degolding, obtains high-quality iron pellet ore while obtaining the sulfuric acid, and highly efficiently utilizes iron resources.

Owner:KUNMING UNIV OF SCI & TECH

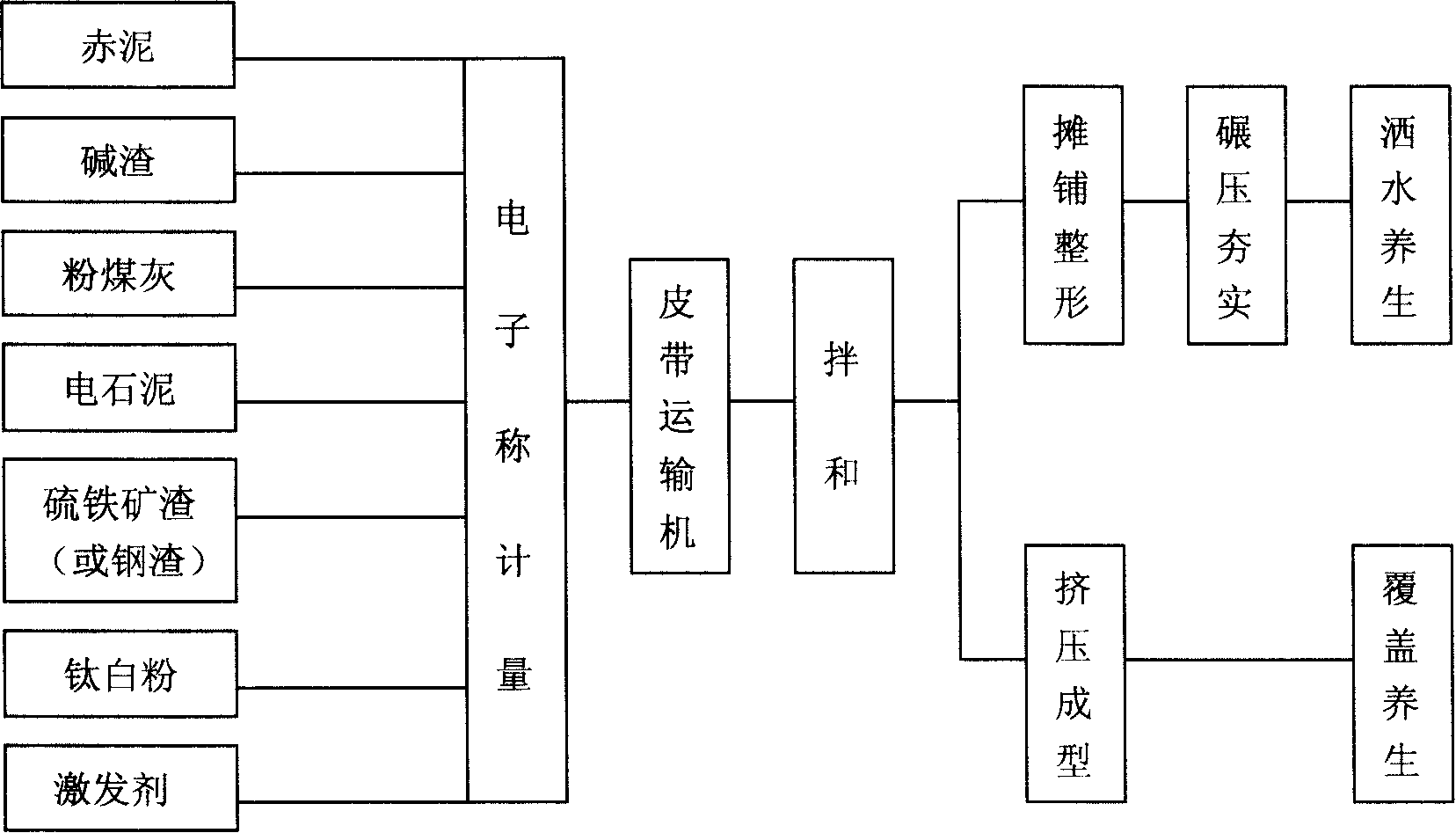

Method for preparing low-grade rolled concrete by using multiple industrial waste slag

This invention relates to a method for preparing low-grade concrete by utilizing industrial-residues, such as: red mud (from sintering process aluminium production), residue from chlorine-alkali process for producing alkali, carbide slag, pyrite cinder, waste slag of titanium oxide and coal ash and the like. The water content of these residues is regulated and they are proportioned, mixed evenly by mechanical agitation and added no binder suchas cement, lime or asphalt to produce this inventive products. This product can be used as basic material under road structure, foundation earth; or for producing low grade concrete, baking-free bricks, building-blocks with the strength being up to 13MPa. Advantages are: simple process, low cost, wide use, high utilization rate of industrial wastes, no secondary pollution.

Owner:王文举

Gear thermal precision forging machining process adopting carburizing steel 20CrMnTi as material

InactiveCN102764838AOvercome concentrated stressOvercome the defect of easily broken teethMetal-working apparatusWheelsSand blastingMachining process

The invention discloses a gear thermal precision forging machining process adopting carburizing steel 20CrMnTi as a material. The process especially comprises the following steps of: upsetting prolonging, blank manufacturing, die forging, burring, forging aftert-reatment (including quenching, tempering thermal treatment; accomplishing the gear thermal treatment through nitriding, surface quenching and normalizing; and finally carrying out sand blasting to remove a scale cinder and the surface acid treatment), and tooth profile cold-finish. By utilizing the process, the fogging process is simplified, the procedures are reduced; the processed product is good in quality; the production in scale can be realized so as to achieve the purposes of good quality, material conservation, energy conservation and time saving; and meanwhile the service life of a mold can be improved greatly, so that the wear resistance of the manufactured gear is enhanced greatly; the gear point-corrosion spalling is overcome; the strength is improved greatly; the service life is prolonged; and the cost is reduced.

Owner:无锡市钻通工程机械有限公司

Enclosure for a light source

ActiveUS6976765B2Light would become directionalPoint-like light sourceElongate light sourcesBrickEngineering

A light source is disposed in a cavity in an enclosure that supports a part of the wall. The enclosure may be disposed substantially within the wall, such that the enclosure does not provide an obstacle to those moving near the wall. Because the enclosure is capable of supporting a part of the wall, the enclosure may be substituted for one or more substructures of the wall, including, but not limited to, concrete blocks, cement blocks, bricks, cinder blocks, and combinations thereof. The enclosure may be disposed at most any height in the wall.

Owner:HELENOWSKI JACEK

Process of compounding and roasting desulfurized cinder and potash ore to produce composite K-Ca-Si-S fertilizer

InactiveCN1974494AEmbody the scientific conceptLower activation energyCalcareous fertilisersPotassium fertilisersTrace elementCinder

The present invention discloses process of compounding and roasting desulfurized cinder and potash ore to produce composite K-Ca-Si-S fertilizer. The composite K-Ca-Si-S fertilizer is produced with potash ore 25-55 wt%, desulfurized cinder 15-50 wt%, limestone 5-55 wt% and additive 2-5 wt%, and through mixing, milling, roasting at 1000-1050 deg.c for 2-3 hr, cooling and ball milling. The production process has desulfurized cinder as one kind of solid waste utilized and potash ore heat decomposed to produce the fertilizer with soluble potassium oxide, soluble Ca, Si and S compounds and trace elements. The additive can lower the potash ore decomposing temperature from 1100-1150 deg.c to 1000-1050 deg.c.

Owner:广州康沣农业科技有限公司

Mold powder for continuous casting of high aluminium-titanium-rare earth steel

The invention discloses a mold powder for continuous casting of high aluminium-titanium-rare earth steel, which comprises the following compositions in percentage by weight: 20 to 40 percent of CaO, 30 to 50 percent of SiO2, 3 to 8 percent of F, 5 to 9 percent of Na2O, 0 to 5 percent of Li, 0.5 to 5 percent of C, less than 8 percent of Al2O3, less than 5 percent of MgO and the balance of inevitable impurities; and the alkalinity range of CaO / SiO2 is R+ / -0.05, wherein R is alkalinity and is equal to between 0.917 and 0.333M; and M is the sum of mass percent of Al, Ti and rare earth elements in molten steel. The mold powder improves the performance, can meet the requirement of the continuous casting of steel types such as Al, Ti, rare earth and the like, fully guarantees the thickness, lubrication and consumption of a melt cinder layer, avoids causing surface defects of casting blanks such as cinder inclusion, cracks and the like or causing steel leakage due to too big withdrawal resistance, and effectively guarantees smooth continuous casting process and the surface quality of the casting blanks so as to produce high-quality casting blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

Crystallizer protecting cinder for continuous casting of crack sensitive steel and its prepn process

InactiveCN1974062AReduce crystallization rateLower crystallization temperatureProcess efficiency improvementManganese(II) carbonateWollastonite

The present invention provides one kind of crystallizer protecting cinder for continuous casting of crack sensitive steel and its preparation process. The protecting cinder is compounded with wollastonite, limestone, quartz sand, fluorite, industrial soda, manganese carbonate and carbon material. Chemically, it consists of CaO 28-42 wt%, SiO2 26-40 wt%, CaF2 10-20 wt%, Na2O 4-10 wt%, MnO2 2-8 wt%, Al2O3 0-6 wt%, and C 2-10 wt%, and has the weight ratio between CaO and SiO 2in 1.0-1.2. The crystallizer protecting cinder can reduce the heat transfer, maintain the crystallization rate and the crystallization temperature of protecting cinder, reduce longitudinal cracks in the surface of cast billet, and raise continuous casting efficiency and quality.

Owner:CHONGQING UNIV

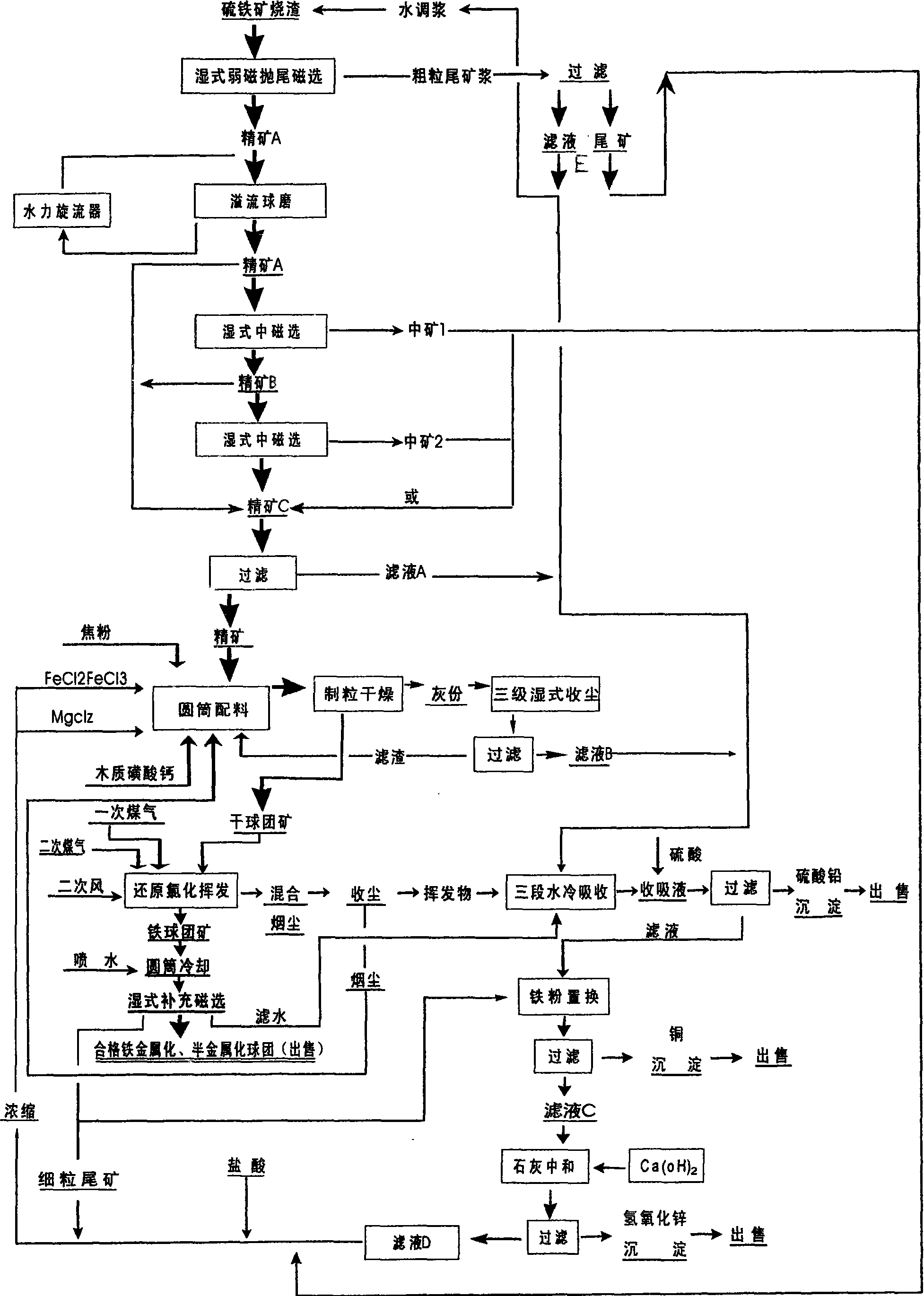

Comprehensive reclaiming method for pyrite slag

InactiveCN101157985AHigh in ironHigh softening temperatureProcess efficiency improvementMagnetic separationSlagPollution

The invention provides a comprehensive recycle method for pyrite cinder. The steps are to, obtain concentrate by conducting a 3-phase wet magnetic separation, mix the concentrate with coke powder, ferric chloride, magnesium chloride and wood calcium sulfonate, granulize and dry to obtain dry pellet mine and ash, deoxidize, chloridize and volatilize the dry pellet mine to obtain qualified metallized and semi-metallized pellet and ash. In the meanwhile, conduct dust collection and water-cool absorption respectively to ash and soot. In the final step, lead, copper and zinc are extracted. The mill run can increase the iron content by 8%-12%, produce qualified metallized and semi-metallized pellet with the iron content of 70%-90%, lead a recycle rate of iron to be no less than 70% and the iron content of coarse tailing to be no greater than 15%, and in the meanwhile, lead the recycle rate of the valuable metals to be greater than 90%, effectively deal with the pollution, turn wastes into values, which is good for sustaining of resources, has important meaning for the countermeasure of the lack of iron resource and the dealing with low grade iron ore. The method is suitable for the comprehensive recycle of pyrite cinder of different grades.

Owner:池煊庆

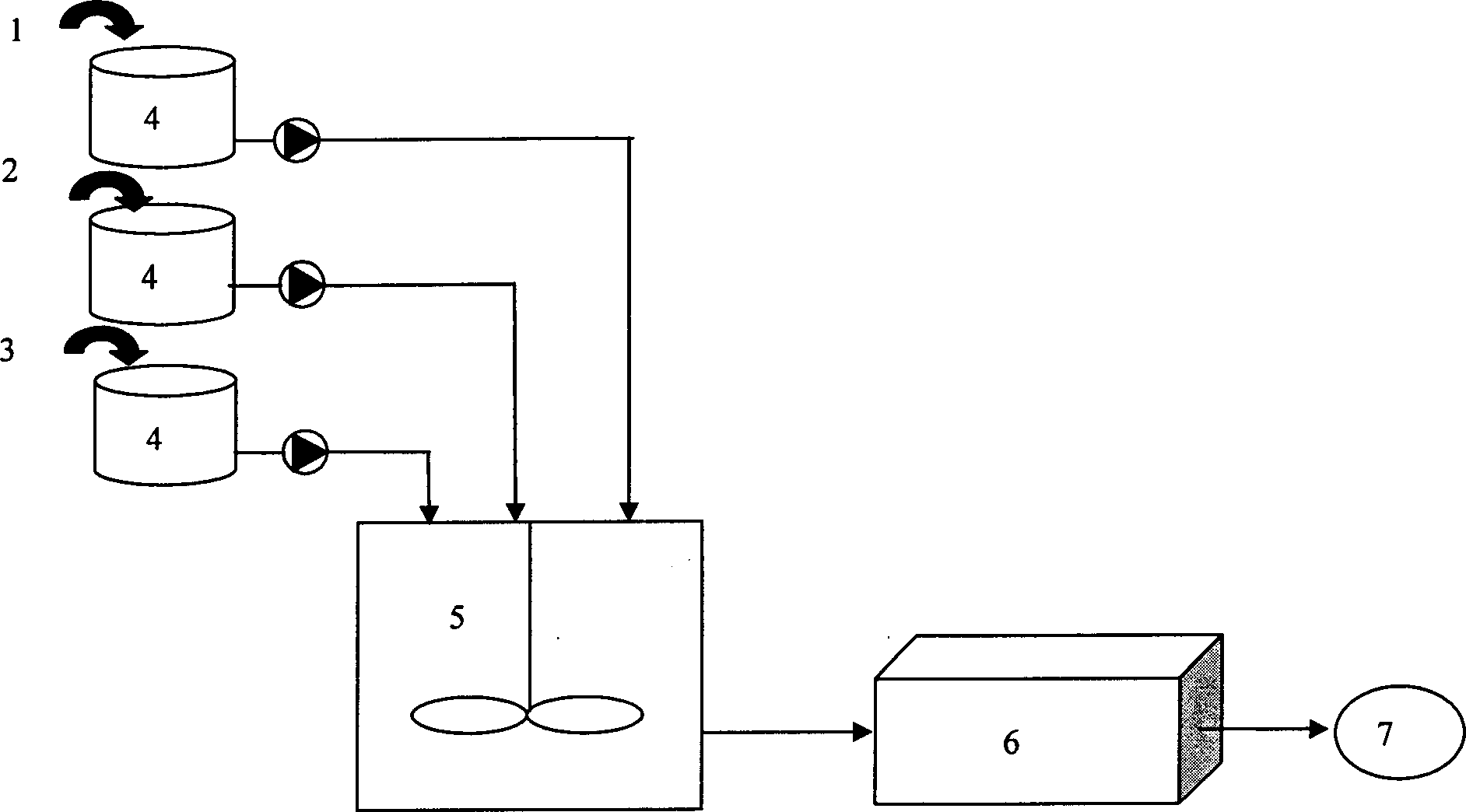

Full-automatic composite self-insulation building block production method

InactiveCN103612318AIncrease profitImprove thermal insulation performanceMixing operation control apparatusCeramic shaping plantsSocial benefitsFoaming agent

The invention discloses a full-automatic composite self-insulation building block production method. The full-automatic composite self-insulation building block production method includes distributing, building block forming, maintenance, supporting plate returning and product conveying. Distributing includes shell material distribution and thermal insulation material distribution. Shell materials are made of 15% of cement, 50% of coal cinders, 18% of sand, 10% of rubble and 7% of water. Thermal insulation materials are made of, by mass, 54% of PO42.5 cement, 10% of fly ash, 0.5% of foam stabilizer and fortifiers, 31.5% of water and 4% of foaming agents. The stirred raw materials are conveyed into a forming machine (4) so that forming can be carried out; a formed building block shell is conveyed into a maintenance kiln (8) to be maintained four hours; filling cores are poured, and the building block shell is conveyed into the maintenance kiln again to be maintained five to eight hours; maintained building blocks are piled, packaged and stacked. All the steps of the production method are coordinated, automatic control is achieved, and production efficiency is improved; the full-automatic composite self-insulation building block production method has good ecological benefit and social benefit.

Owner:连太吉 +3

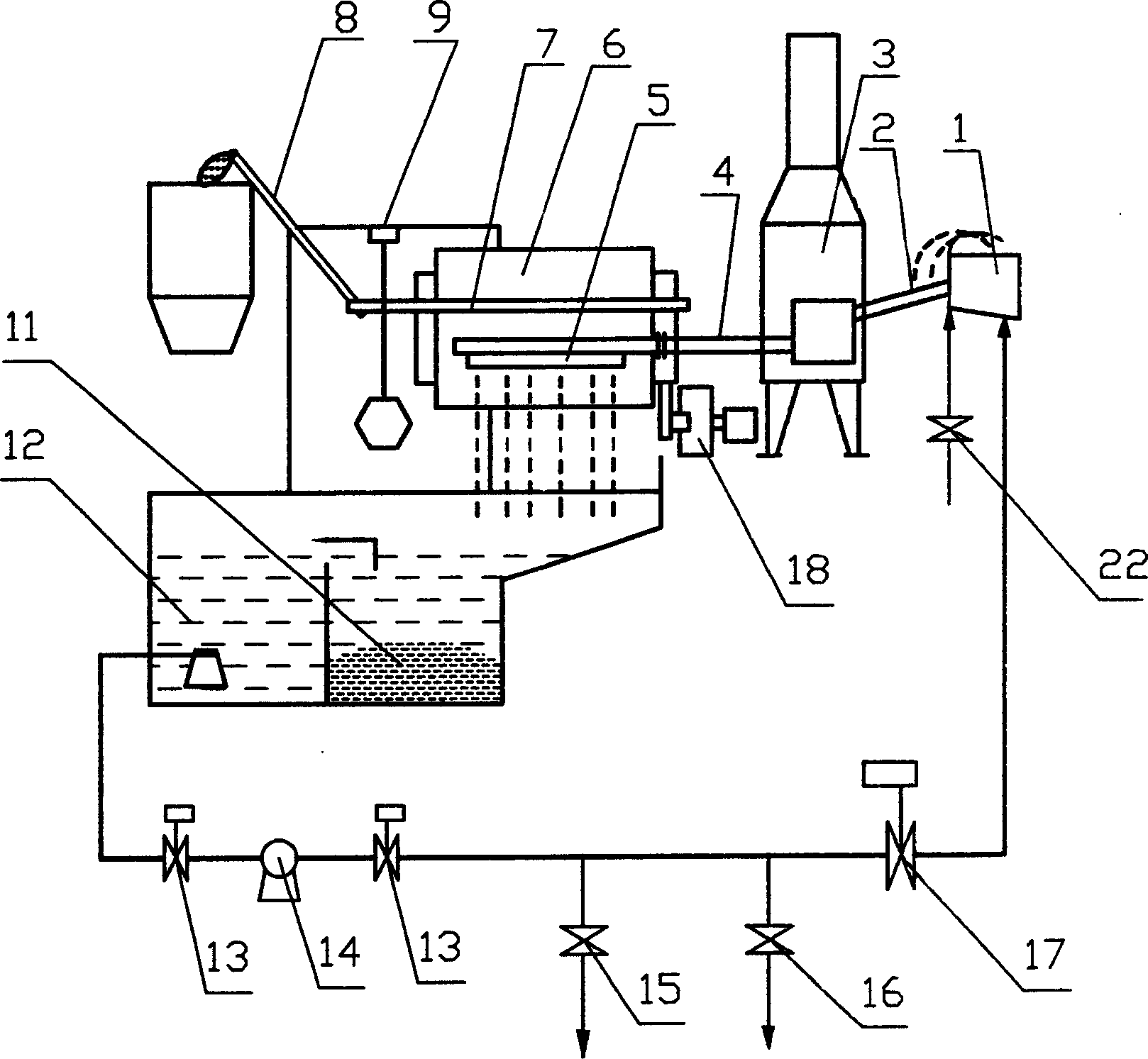

Blast furnace cinder water quenching processing unit

ActiveCN1769498ASimple configurationReasonable configurationRecycling and recovery technologiesCooling towerQuenching

This invention belongs to the molten slag treatment, especially relates to the blast furnace molten slag treating apparatus. The slag ditch connects with the granulating device and slag flume, the down part of the slag flume connects with the communicating pipe, the distributing trough that connects with the communicating pipe extends into the rotating drum filter, the belt device in the canister connects with the rotating belt device to form a finished articles warehouse; the down part of the rotating filter is arranged with the storage cabinet, laying-up basin, which are connected by the overflow on the pool wall, the dregs cleaning device is arranged on the storage cabinet the laying-up basin connects with the granulating device by the tube connector, valve and dregs cleaning pump. The device fault rate is low, the dregs punching out rate reaches up to more than 99úÑ, which is propitious to the operation and steady production of the blast furnace. And the dreg cleaning water and the sewage is used in closed cycle, so it can save a lot of pure water.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com