Sludge fuel stick and its prepn

A fuel rod and sludge technology is applied in the field of solid waste treatment and disposal, which can solve the problems of unfavorable comprehensive promotion and high cost, and achieve the effects of realizing social and economic benefits, saving costs and improving combustion conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

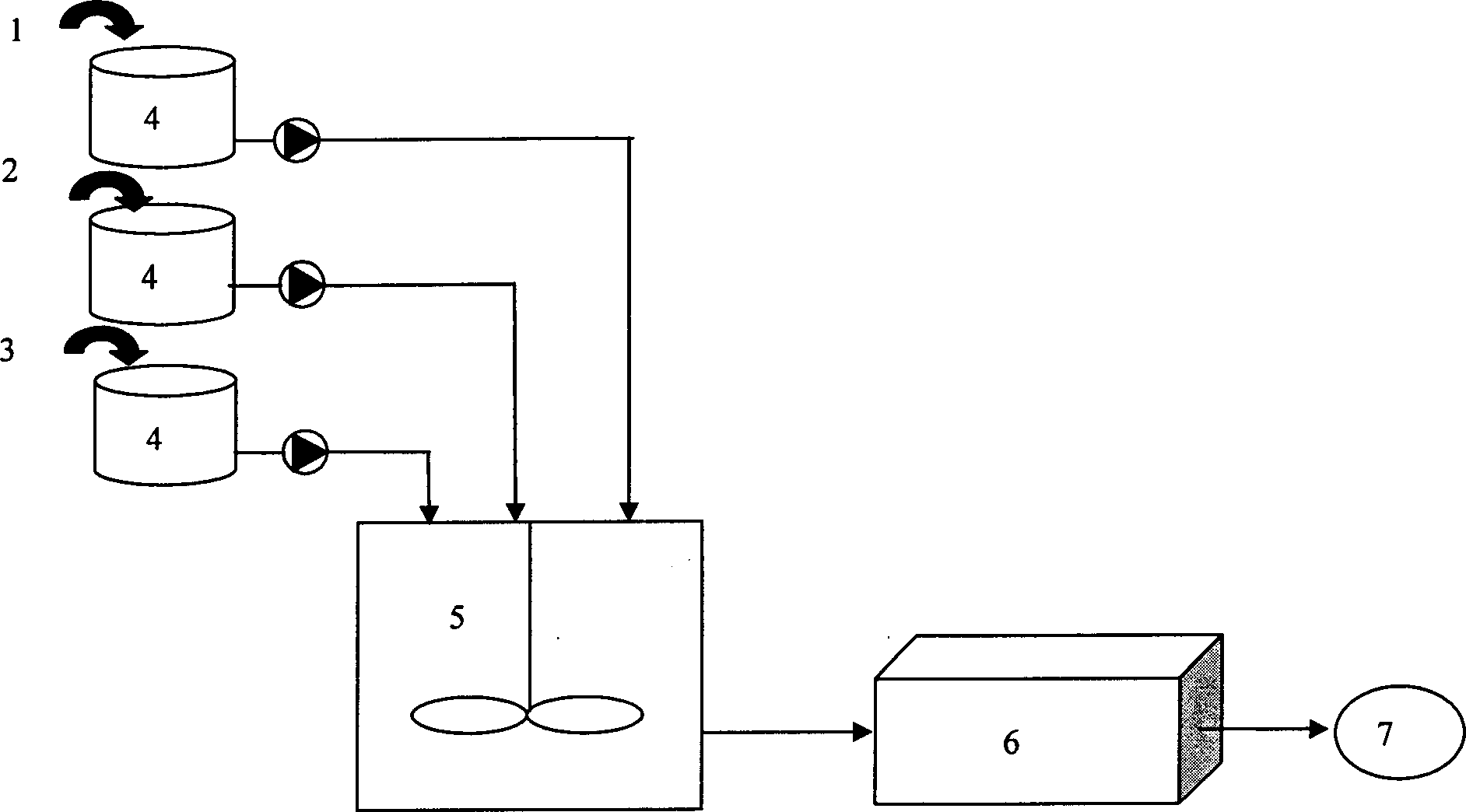

Method used

Image

Examples

Embodiment 1

147

8.77

78.94

[0033] The productive test scale is 30,000T / D of sewage treatment capacity, and the dewatered sludge produced daily can produce 24T of fuel rods.

[0034] The fuel rods are used to generate electricity after burning and heating. The combustion efficiency and generator efficiency are calculated as 50% and 30% respectively, so the total daily power generation is:

[0035] 4.8×10 7 kcal×4.2kJ / kcal×50%×30%=3.0×10 7 kJ = 8400 degrees

[0036] The entire dehydration and fuel rod production process consumes about 336 degrees of electricity per day.

[0037] Then the net electricity generated per day is:

[0038] 8400-336 = 8064 degrees

[0039] According to the current grid-connected electricity price policy for renewable energy power generation, each kilowatt-hour of electricity is calculated at 0.50 yuan, and the economic benefits of annual power generation are:

[0040] 8064 degrees × 365 days × 0.5 = 1471680 yuan

[0041] If the daily...

Embodiment 2

153

7.32

80.02

[0048] The scale of this productive test is 50,000T / D sewage treatment capacity, and the dewatered sludge produced every day can produce 40T fuel rods.

[0049] The fuel rods are used to generate electricity after burning and heating. The combustion efficiency and generator efficiency are calculated as 50% and 30% respectively, so the total daily power generation is:

[0050] 9.0×107kcal×4.2kJ / kcal×50%×30%=5.0×107kJ=14000 degrees

[0051] The entire dehydration and fuel rod production process consumes about 600 degrees of electricity per day.

[0052] Then the net electricity generated per day is:

[0053] 14000-600 = 13400 degrees

[0054] According to the current grid-connected electricity price policy for renewable energy power generation, each kilowatt-hour of electricity is calculated at 0.50 yuan, and the economic benefits of annual power generation are:

[0055]13400 degrees × 365 days × 0.5 = 2445500 yuan

[0056] The daily c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com