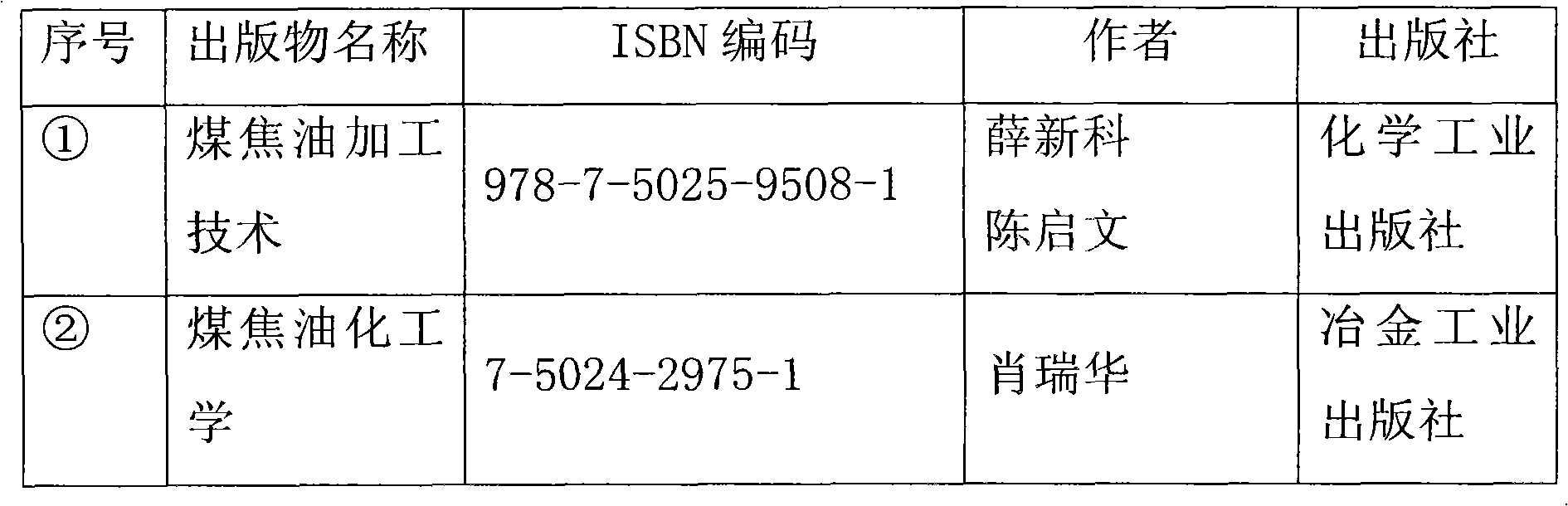

Patents

Literature

757 results about "Coal waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste coal is a byproduct of coal processing, containing coal, along with trace minerals, dirt, and other materials.

Burning-free block brick prepared from bulky industrial waste residues

The invention relates to a burning-free block brick prepared from bulky industrial waste residues. The burning-free block brick is characterized in that the block brick comprises the following raw materials in parts by weight or volume: 10-80 parts of at least one of tailing, magnesium slag, basic slag, mountain flour, cinder, fly ash, coal gangue, oil shale waste and sulfuric acid slag, 0-80 parts of at least one of gravel, waste sand, construction waste, garbage to be burnt, steel slag, mineral slag, copper slag, iron slag with gold, ardealite, phosphorous slag and carbide slag, 0-50 parts of active cementing material, 0-30 parts of cement clinker, 2-15 parts of cement and a defined amount of water. The preparation method of all types of burning-free and steaming-free standard bricks, perforated bricks, hollow blocks, paving tiles, road edge bricks and fence railings which have low cost and high strength, is as follows: proportioning, stirring for 1-6 minutes, adding a defined amount of water to stir, placing in moulds to form in a machine and performing natural curing for 7-28 days. The burning-free block brick has high raw material selectability, simple technology and wide development and application prospects, and is environmental-friendly.

Owner:司密花 +2

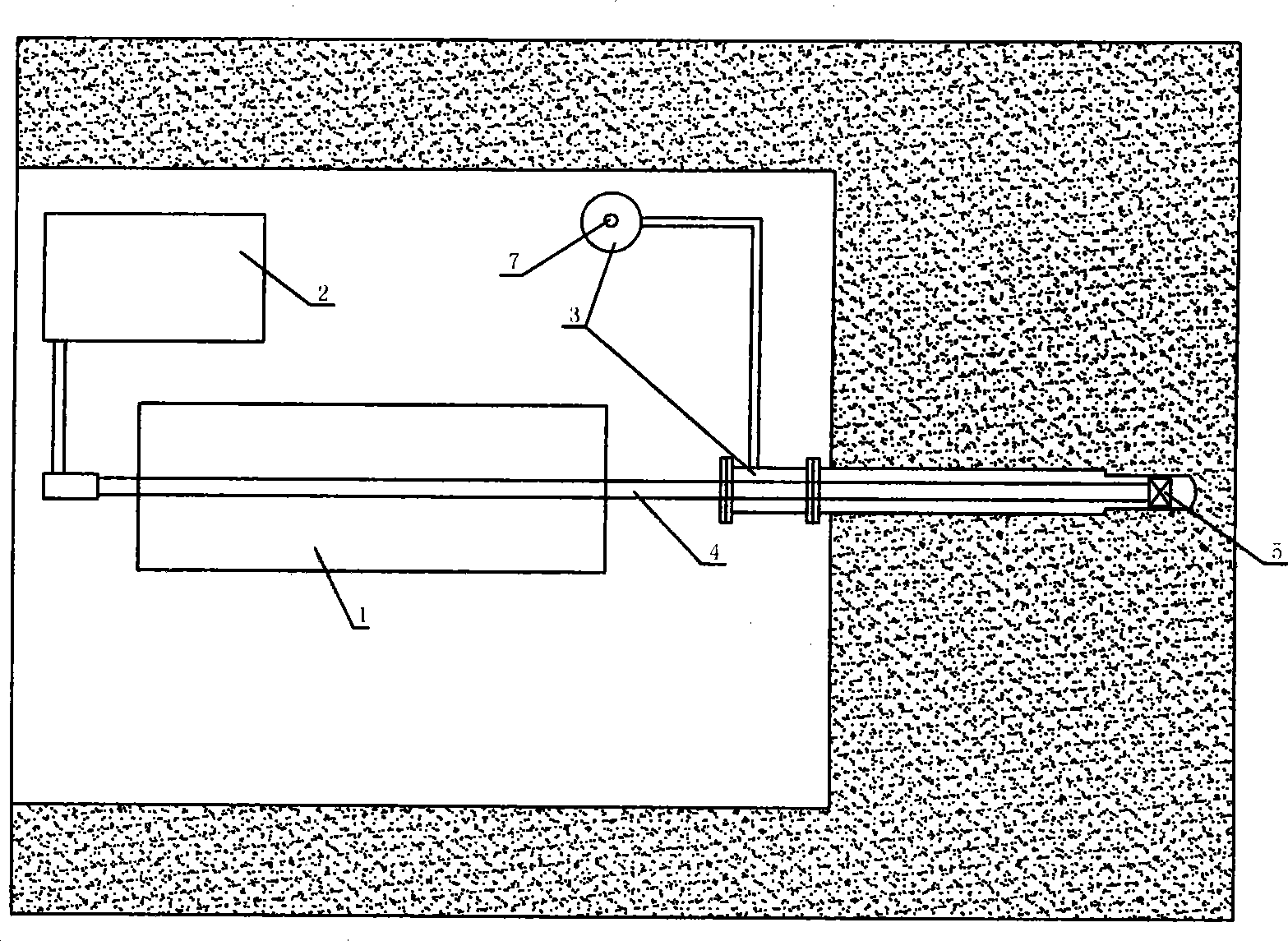

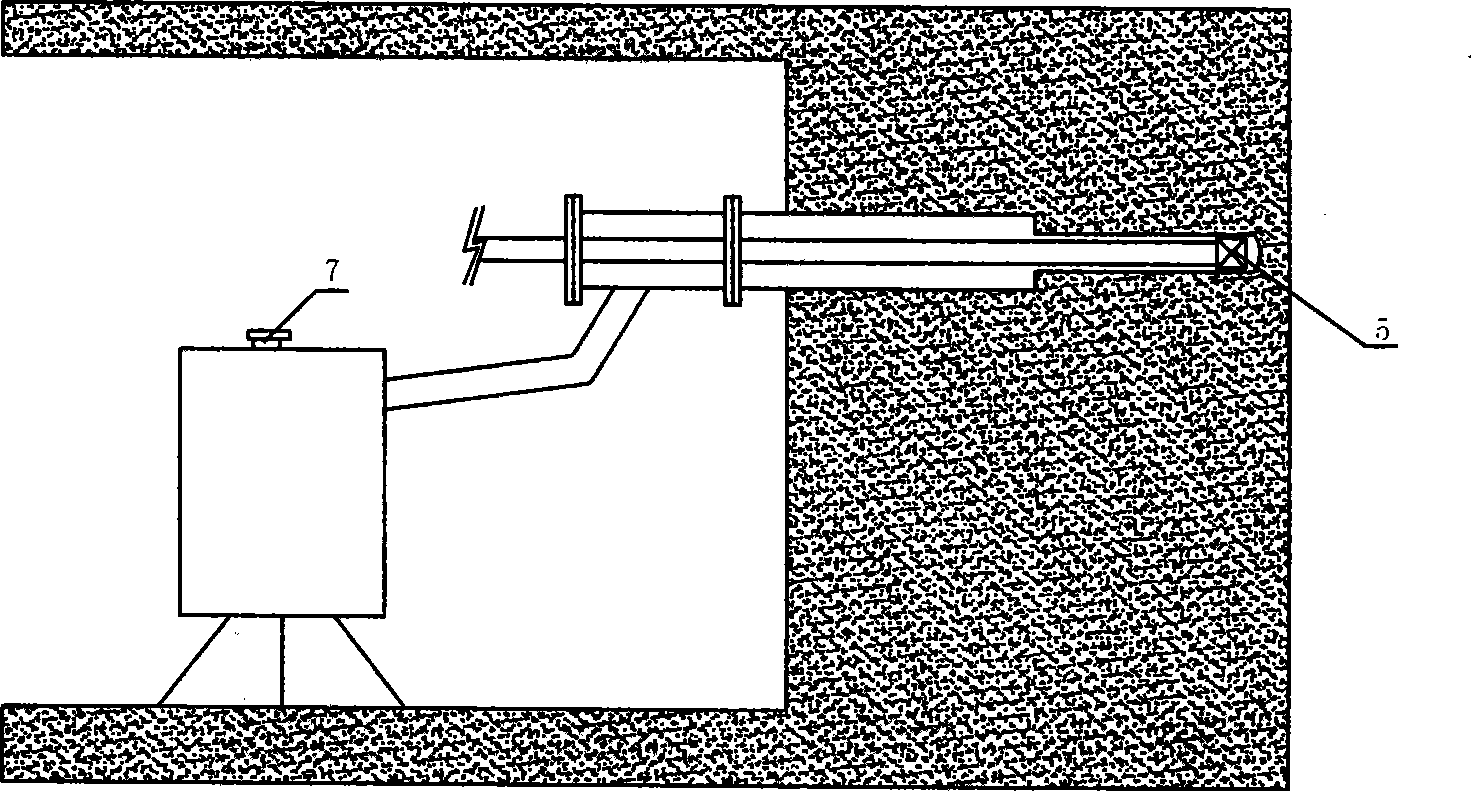

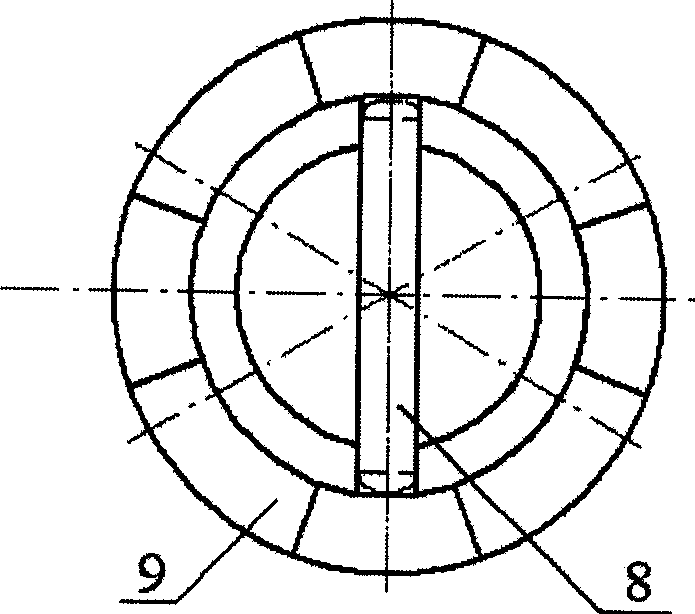

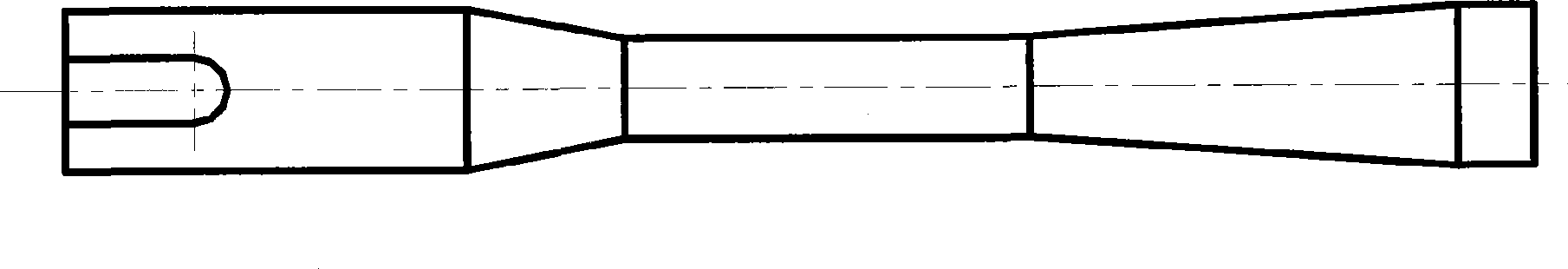

Wind pressure air drilling equipment in downhole soft outbursting coal bed and process matched therewith

ActiveCN101446178ADrill normalImprove governance efficiencyGas removalDrilling machines and methodsExplosion protectionHigh intensity

The invention relates to wind pressure air drilling equipment in a downhole soft outbursting coal bed and a process matched therewith. At present, as the consequent layer drilling characterized by high construction speed, low cost and high gas extraction efficiency becomes the primary option for coal control and gas control in coal mines, for soft outbursting coal beds, the gas extraction efficiency is directly dependant upon the pore-forming rate of the consequent layer drilling. The equipment comprises a boring machine, an air compressor, an orifice dust collection and dust removal device, a high-strength large through-hole drill rod, a drill bit with an inner core which can automatically fall off, and an antistatic explosion-protection PVC sieve tube; the boring machine which has large power and large torque supplies power to drilling construction; the orifice dust collection and dust removal device collects and eliminates slack carried out by wind from the orifice during drilling; and the antistatic explosion-protection PVC sieve tube is transferred from the interior of the high-strength large through-hole drill rod to the bottom of the orifice without lifting a drill on the completion of drilling, and at last remains in the orifice, thereby ensuring the completeness of drilling. The equipment and the process matched therewith provided by the invention has the advantages of increasing the pore-forming rate of the consequent layer drilling in soft outbursting coal beds, improving the effect of gas extraction, improving the working atmosphere of downhole air drilling, and protecting the production safety of outbursting coal mines.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Organic flower and tree culture substrate and production method thereof

InactiveCN101417903AConvenient sourceImprove fertilizer efficiencyBio-organic fraction processingOrganic fertiliser preparationSlagMicrobial agent

The invention discloses an organic cultural substrate for flowers and trees and a preparation method thereof. The method has the following steps: carrying out anaerobic fermentation to organic maturity fertilizer, plant growth inhibitor, sustained-release agent, microbial agent and coal slag according to a certain proportion, and reversing chopping the above substances after the temperature to a certain range; fermenting and ripening raw materials for 25 days, and condensing the raw materials in vacuum to obtain organic maturity fertilizer; and mixing all the cultural substrates for flowers and trees according to a certain proportion, and producing cultural substrate for flowers and trees by grain production line and then packed and sold out. The invention overcomes the difficulty of sludge treatment, recycles sludge, makes use of such wastes as straws and avoids environmental pollution caused by incinerating.

Owner:如皋市天寿生物科技开发有限公司

Ecological glass-ceramic and preparation method thereof

The invention relates to ecological glass ceramics and a preparation method thereof. The ecological glass ceramics adopts coal gangue of coal wastes as main raw material, quartz sand, limestone, waste glass, etc., as auxiliary raw materials and rich cebaite gangue as raw material of a nucleating agent. The compositions and weight percentage contents are as follows: 40-70 percent of SiO2, 10-20 percent of CaO, 5-15 percent of Al2O3, 1-10 percent of Fe2O3, 1-5 percent of BaO, 0.1-3 percent of F, 0.5-3 percent of TiO2 and 1-5 percent of rear earth oxides. The invention comprehensively utilizes the coal wastes such as the coal gangue, the rich cebaite gangue, etc., as raw material to prepare the glass ceramics, which not only saves cost and improves the usage efficiency of mineral wastes but also settles environmental pollution and safety problems caused by pile-up mineral mining wastes. The ecological glass ceramics of resource recycling can be used as the materials of high-grade building decoration and industry.

Owner:ZHEJIANG UNIV

Drilling, pumping and discharging integrated coal seam pressure relief and permeability improvement device and using method thereof

InactiveCN103470297APrevent overrunningPrevent overrun accidentsDrainageGas removalThermodynamicsSlag

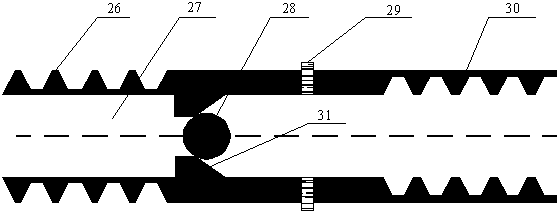

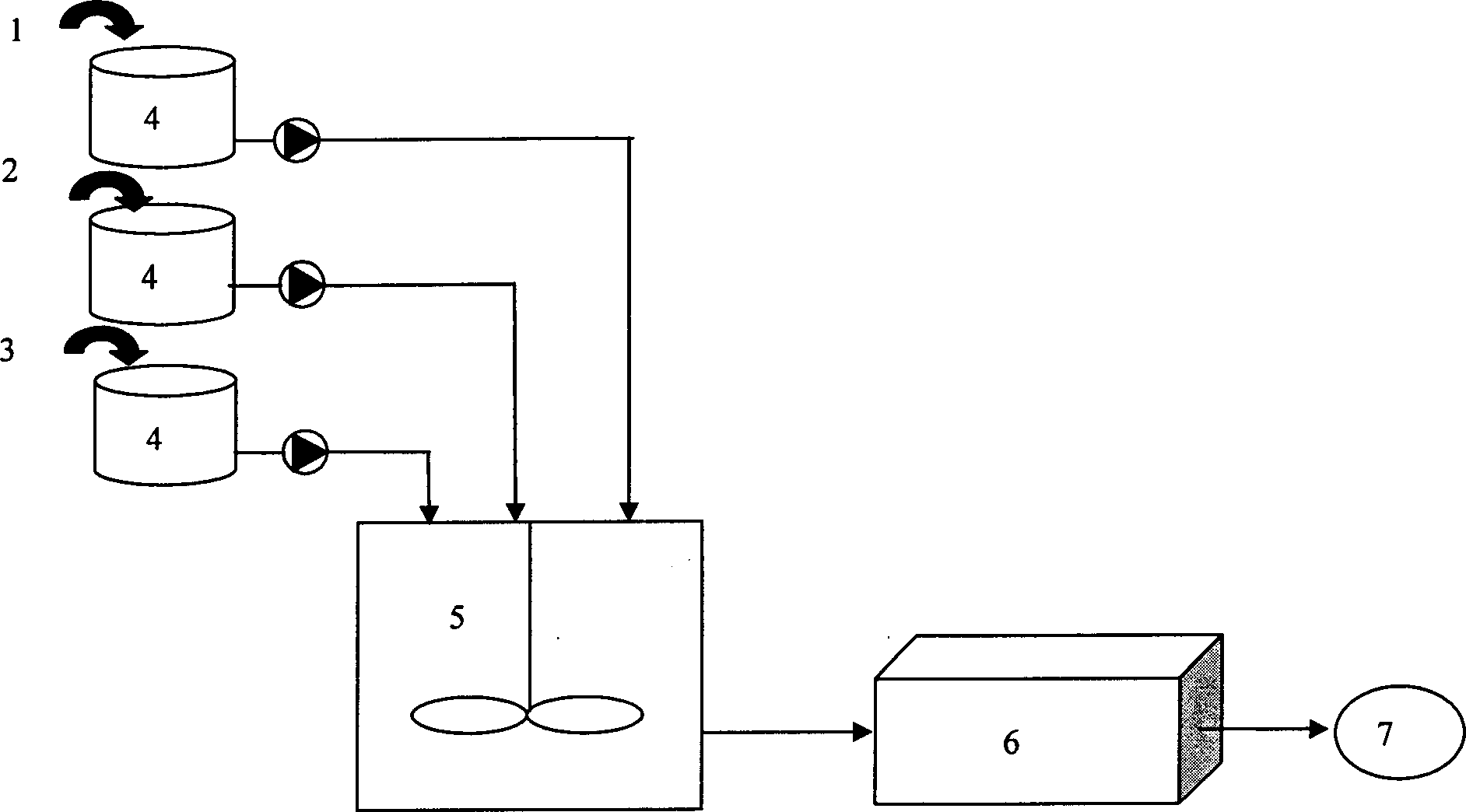

The invention discloses a drilling, pumping and discharging integrated coal seam pressure relief and permeability improvement device and a using method thereof. The drilling, pumping and discharging integrated coal seam pressure relief and permeability improvement device comprises a water jet high and low pressure switching device, a blowout control hole guide device and a gas and slag separation discharge device. The water jet high and low pressure switching device is positioned between a drill bit and a drill stem and can achieve flexible switching between low-pressure drilling and high-pressure water jet slotting and punching. The blowout control hole guide device is positioned between the drill stem and a drill hole and used for guiding water coal slag and gas sprayed out of the drill hole into the gas and slag separation discharge device. The gas and slag separation discharge device is connected with the blowout control hole guide device through a pipeline and used for separating and discharging the coal slag and the gas in a sealed environment. The complete drilling, pumping and discharging integrated coal seam pressure relief and permeability improvement device can achieve flexible switching of high and low pressure drilling, timely collects, separates and discharges the gas and slag, and is simple, reliable, easy to assemble and disassemble, capable of being used for multiple times conveniently and especially suitable for performing multiple drill hole operation at the same workplace.

Owner:HUNAN COAL SCI INST

Sludge fuel stick and its prepn

InactiveCN1810940ALow costSolve the way outSludge treatment by de-watering/drying/thickeningBiofuelsCombustionPlant stalk

The present invention is one kind of sludge fuel stick and its preparation process, and belongs to the field of solid waste treating technology. The sludge fuel stick is prepared with dewatered sludge 50-70 wt%, combustion improver 20-50 wt%, adhesive 3-5 wt% and desulfurizing agent 5-10 wt%. The preparation process includes mixing the said materials in a stirrer, pelletizing in a pelletizer, forming and stoving. The present invention can treating sludge as well as plant stalk, furnace slag, coal slag, flyash and other solid waste and utilize heat in sludge.

Owner:TSINGHUA UNIV

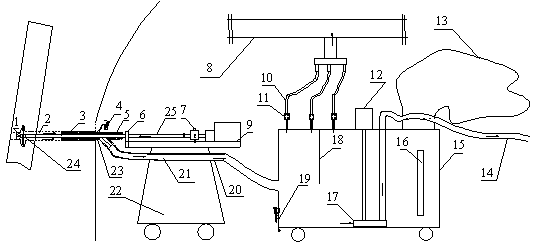

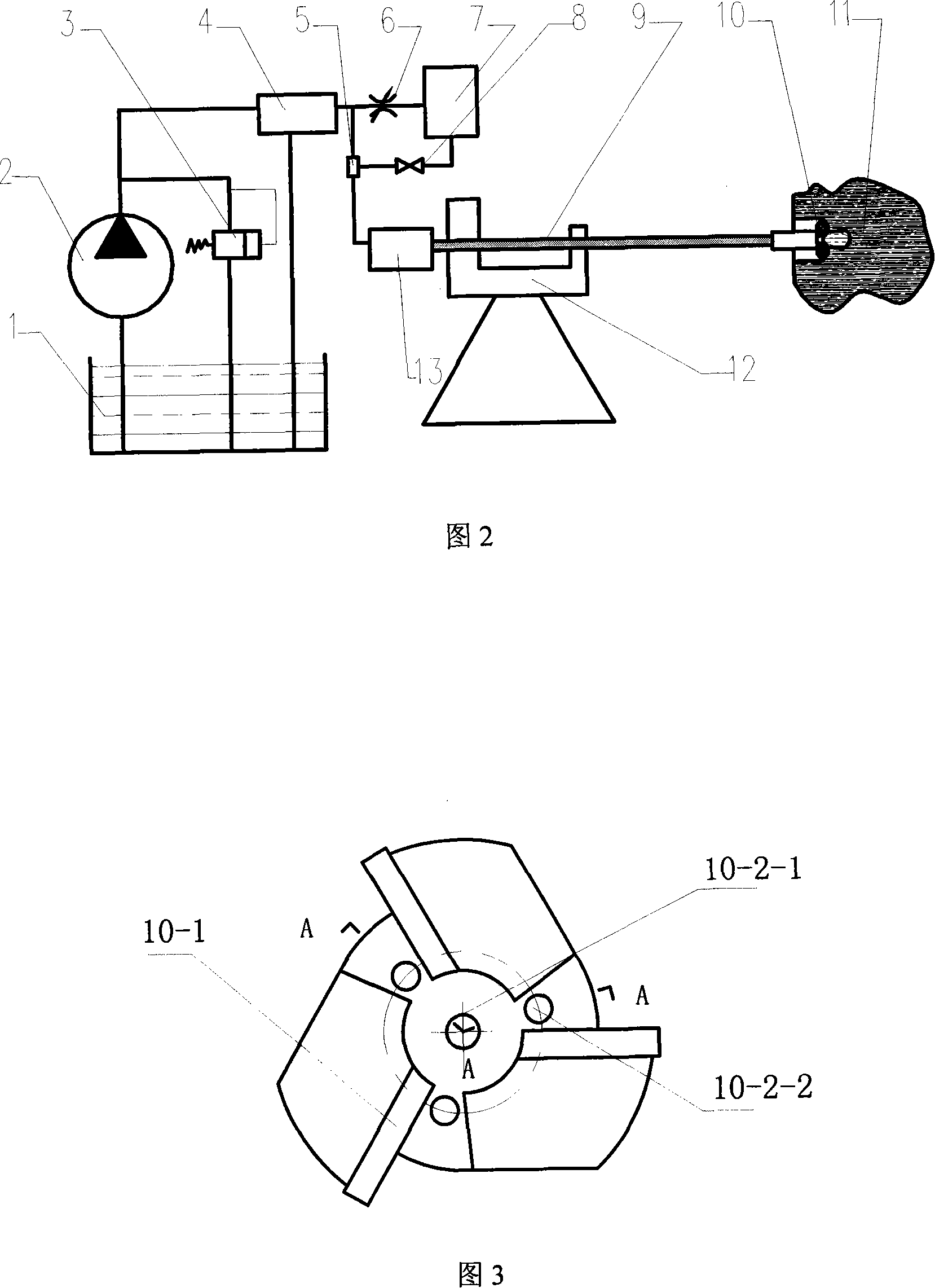

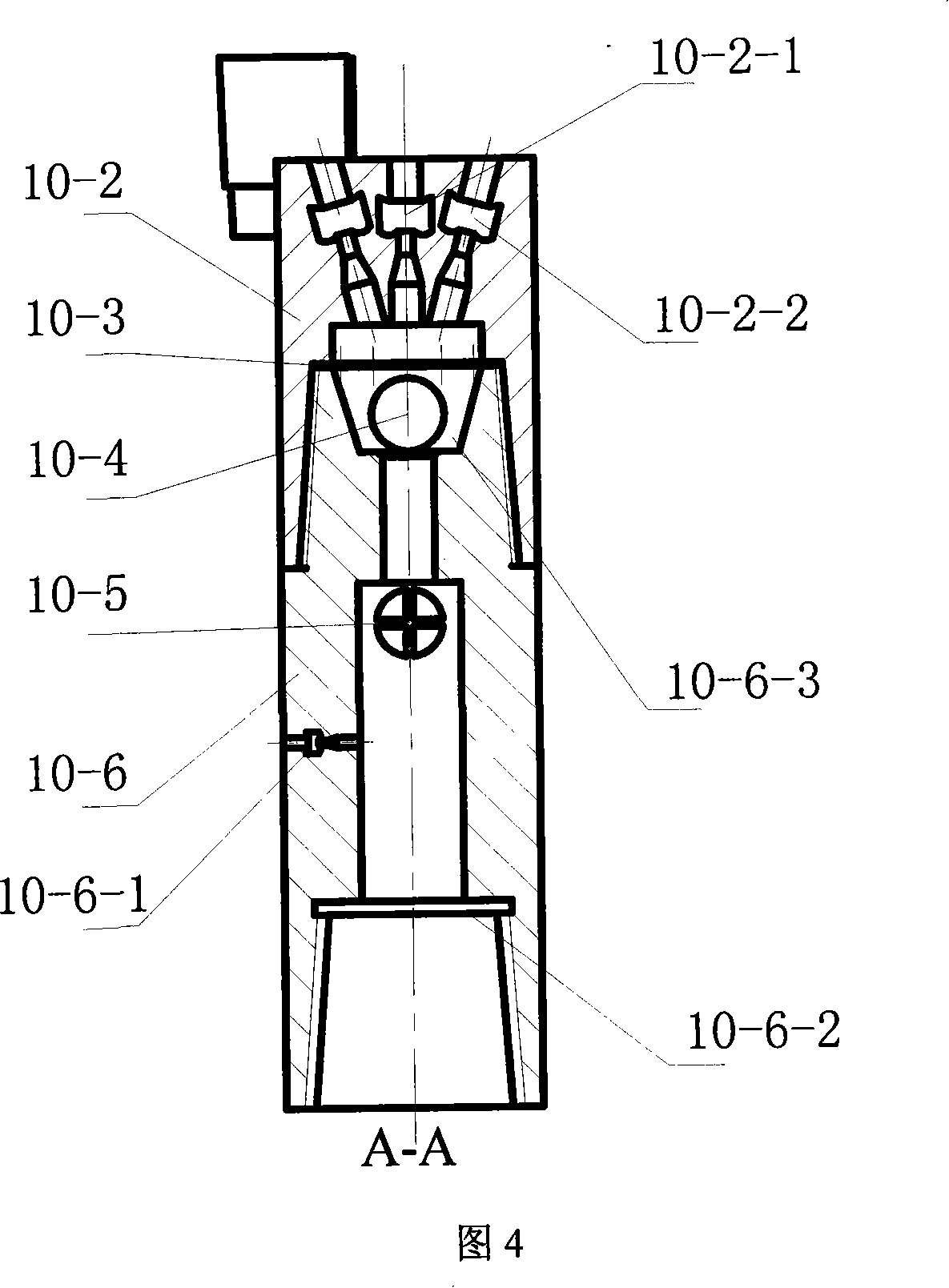

Coal bed gas drainage method and device

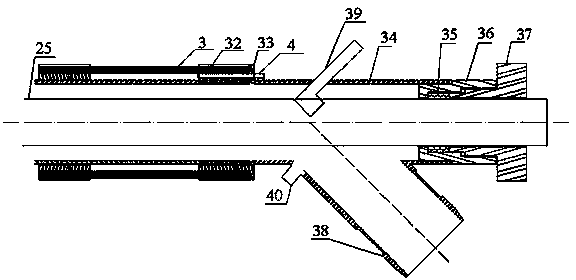

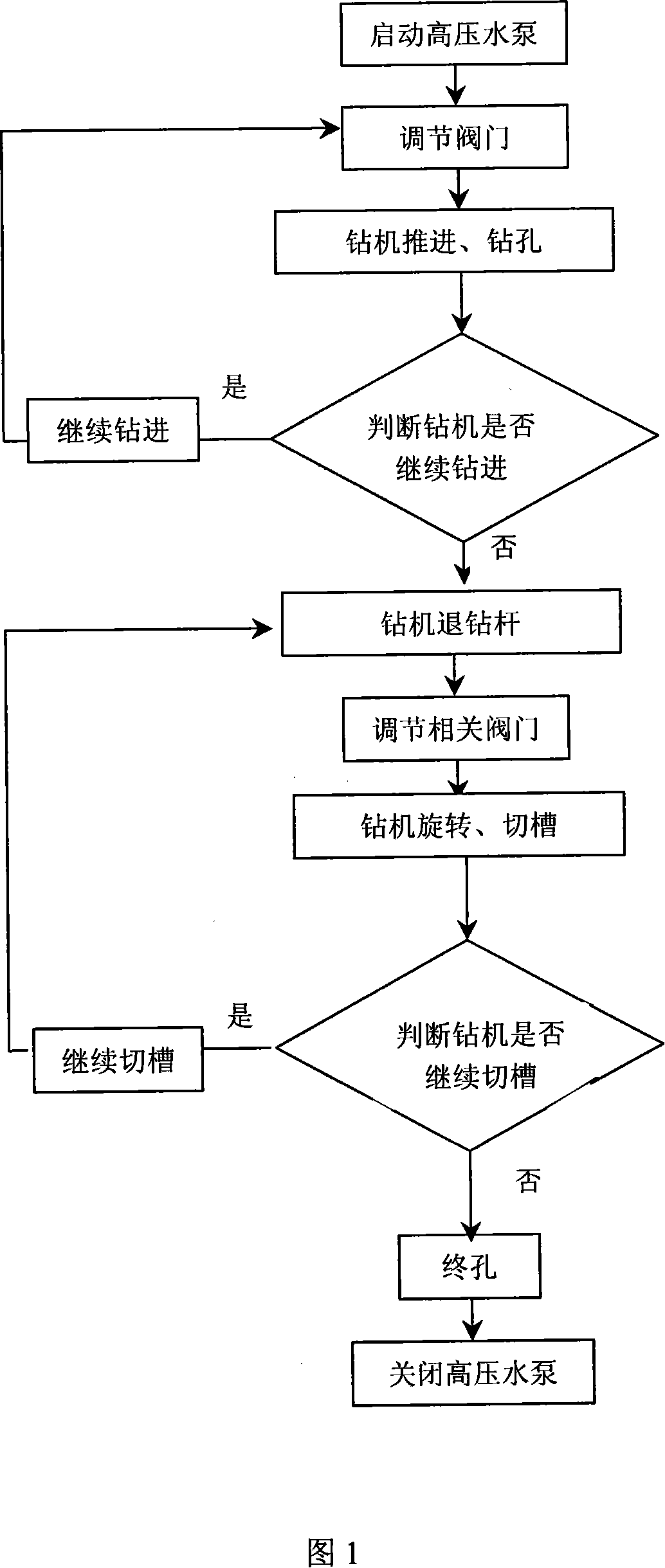

The present invention relates to a gas pumping and exchanging method and devices in a coal mine and coal seam, and belongs to the coal mine security field; the present invention aims to prolong the service life of the drill and improve the drilling depth and the drilling speed, and to enhance the safety during pumping gas and to improve the validation of the coal seam. The present invention is characterized in that the method is performed by following steps: starting a high-voltage water pump, adjusting a valve, drill pushing, hole drilling, adjusting the valve drill rotating, grooving, and shutting down the high-voltage water pump. The devices involved in the method mainly comprises the high-voltage water pump, a mixing chamber, abrasive cans, a high-voltage sealed rotator, a drill, drill pipes and a multifunctional drill; the method uses the multiphase oscillation jet to cut off and break the coal seam and also to drill holes and cut grooves; the power effect leads to the evolution of the coal seam fractured field, thereby improving the validation of the coal seam. And the cinder produced is wee and can flow away with water, thereby avoiding the drill holding and the hole bursting; the method can be used to pump and exchange gas in different quality coal mines and to improve the pumping and exchanging capability of the gas.

Owner:CHONGQING UNIV

Method for producing bricks from silt and sludge

InactiveCN101830687AWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primary stirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

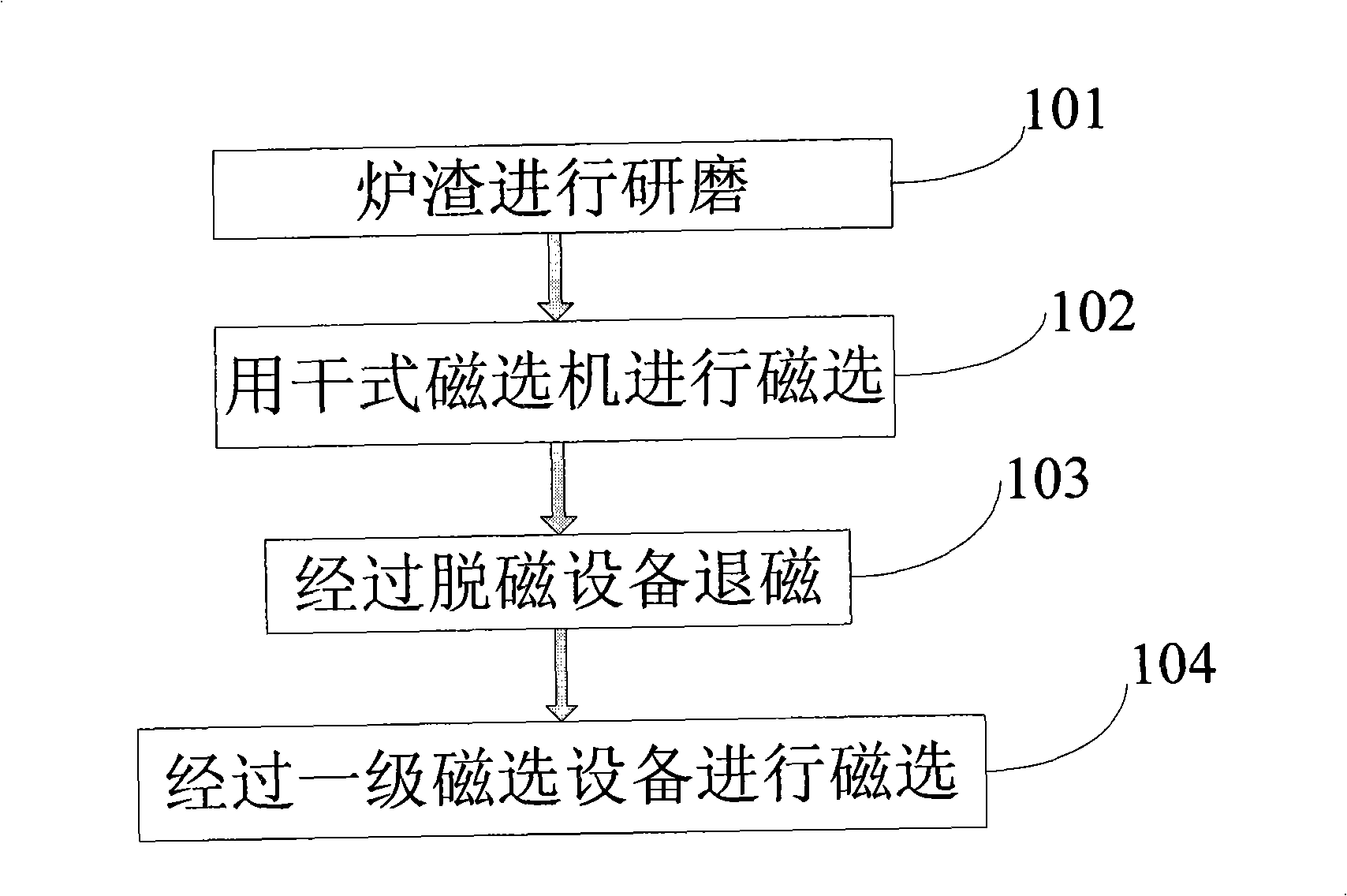

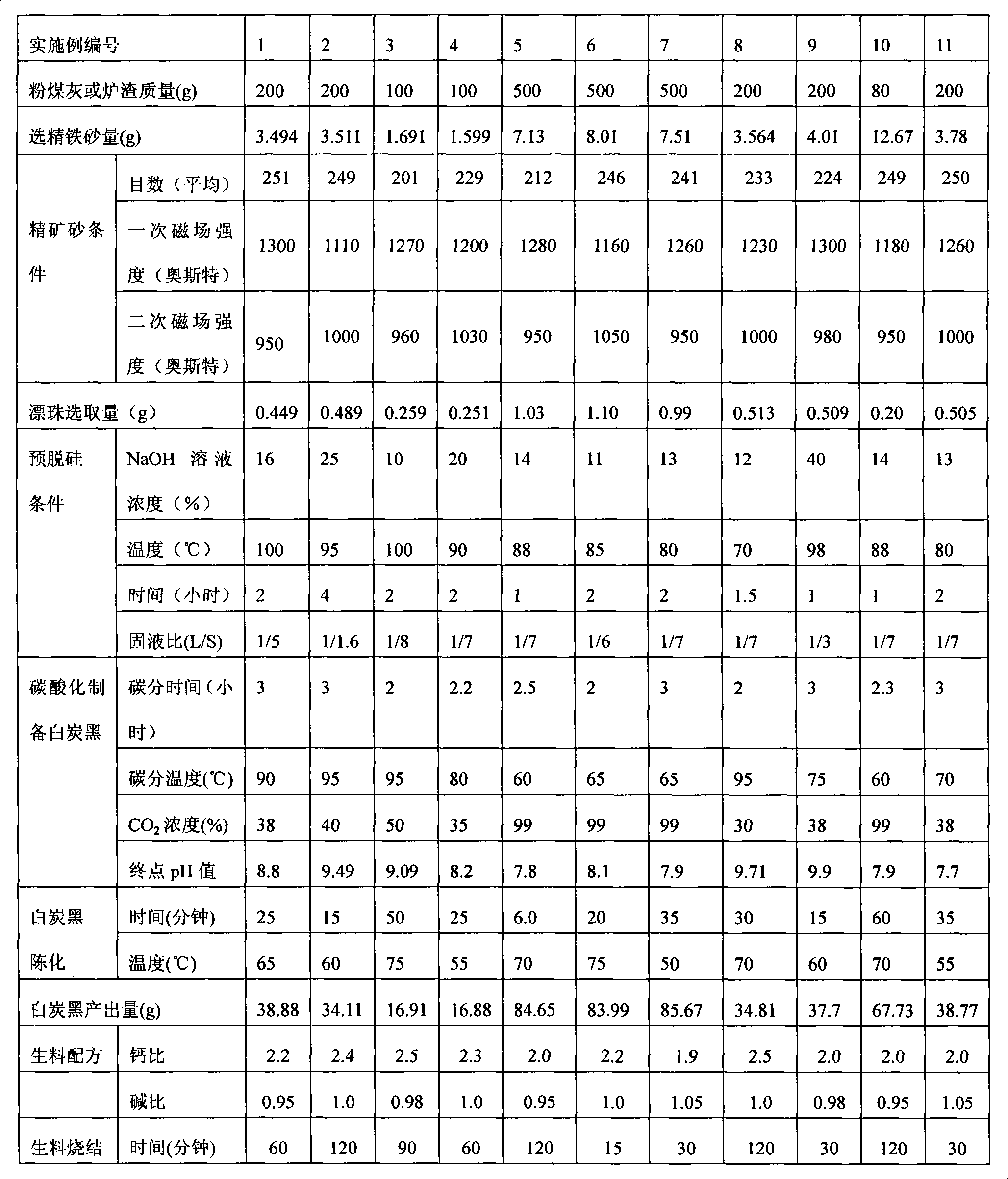

Method for extracting iron washed ore from fly ash or slag

ActiveCN101306426ARealize selectionIncrease added valueSolid waste disposalMagnetic separationSlagBall mill

The invention relates to a method for the comprehensive utilization of fly ash and slag, in particular to a method for extracting the iron concentrate ore from the fly ash or the slag. The method comprises the technological processes as follows: a screening process of the iron concentrate ore in the fly ash or the slag, a flotation process of floating beads, a pre-desiliconization process, a technological process of white carbon black production, a technological process of alumina production and a technological process of cement production by adopting the slag. Since the element Fe in the fly ash or the slag is not uniformly distributed, the fly ash or the slag is ground by a ball mill so as to allow the extracted iron ore to meet certain requirements for the quality and the purity; and the purity of the iron ore can be further improved after dry magnetic separation of two levels. Moreover, after the iron concentrate ore is extracted, the floating beads, the white carbon black, alumina and joint cement can also be extracted from the fly ash or the slag organically and continuously step by step.

Owner:北京世纪地和控股有限公司

Composite artificial wet land denitrifying and dephosphorizing method for living waste water vertical fluid-horizontal fluid

ActiveCN1583604ATreatment with aerobic and anaerobic processesSustainable biological treatmentConstructed wetlandEngineering

The vertical flow of artificial humid land which is filled with cider including the much oxidation of Te, Ca, Si, Al and so on, is working in the way of interchange of dry and humid; The horizontal flow of artificial humid land which is filled with marble or limestone and cinder including Ca, is working continuously, but the partial untreatment waste water and flow into the 'C' source of horizontal flow of artificial humid land to improve its efficient of 'N' removal. The flower such as cannas, china rose, rose and chrysanthemum, can be planted in the vertical flow of artificial humid land, and vegetables such as leek, lettuce, cucumber, tomato arrowhead can be planted in the horizontal flow of artificial humid land.

Owner:SOUTH CHINA AGRI UNIV

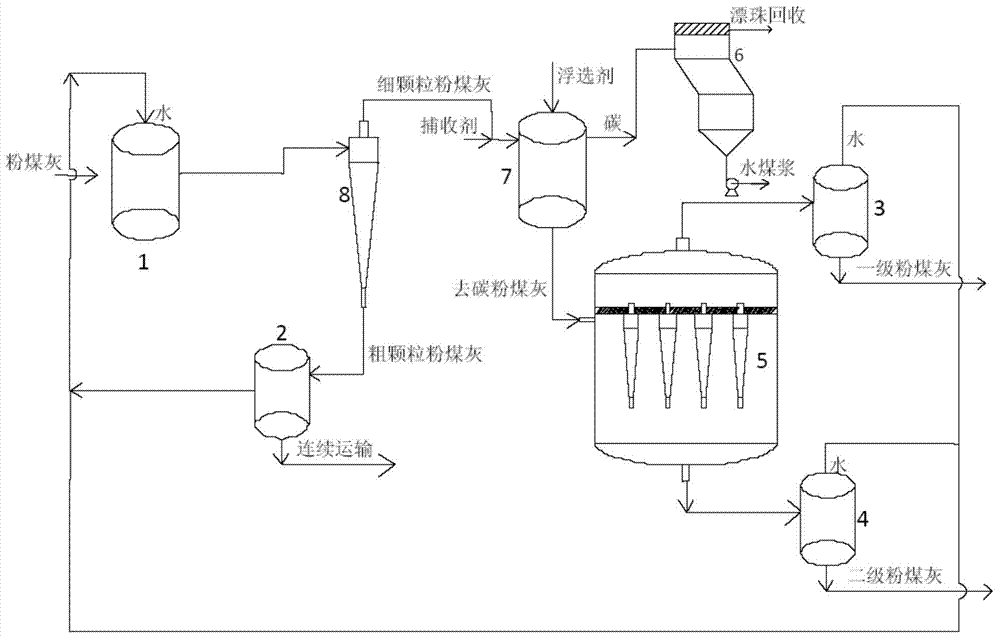

High-carbon pulverized coal ash/coal slag decarbonization and classification method and device

The invention relates to a high-carbon pulverized coal ash / coal slag decarbonization and classification method and device and provides a high-carbon pulverized coal ash / coal slag decarbonization and classification method. The method comprises the following steps of 1 mixing coal ash / coal slag with water, utilizing solid-liquid rotational flows to remove large particles in coal slag and obtain coal ash / coal slag subjected to pre-deslagging treatment; 2 adding a collector agent into the coal ash / coal slag subjected to pre-deslagging treatment, performing ore pulp pretreatment, performing even stirring, feeding the mixture into a flotation column for flotation, recovering floating carbon powder, and discharging out the coal ash / coal slag; 3 performing classified whirling on the coal ash / coal slag deposited in the flotation column, collecting first-grade pulverized coal ash, discharging out second-grade pulverized coal ash and third-grade pulverized coal ash; 4 performing dehydration treatment on the large particles obtained in the step 1, the carbon powder obtained in the step 2 and the pulverized coal ash obtained in the step 3 and recovering water for recycle. The invention further provides a high-carbon pulverized coal ash / coal slag decarbonization and classification device.

Owner:EAST CHINA UNIV OF SCI & TECH

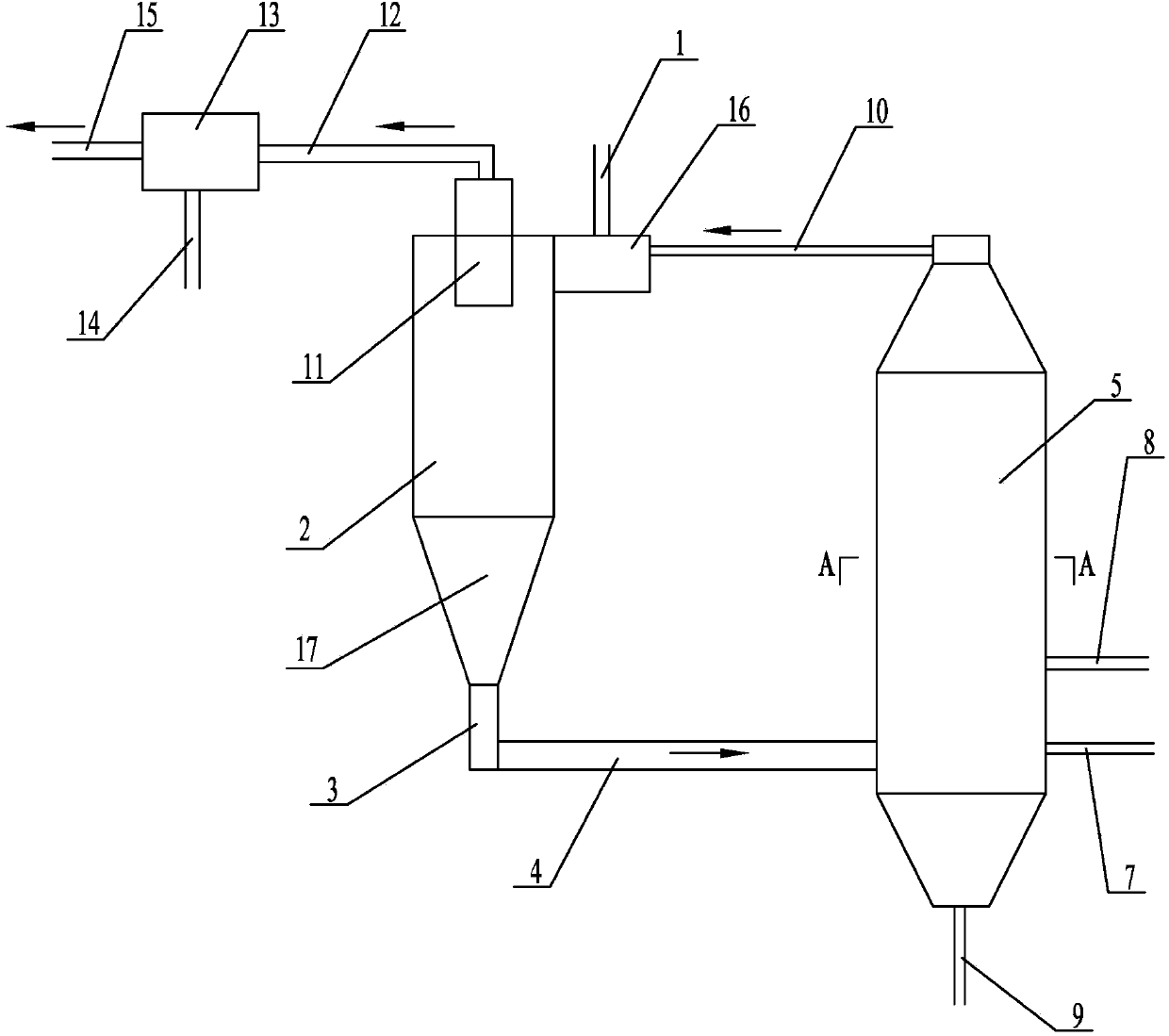

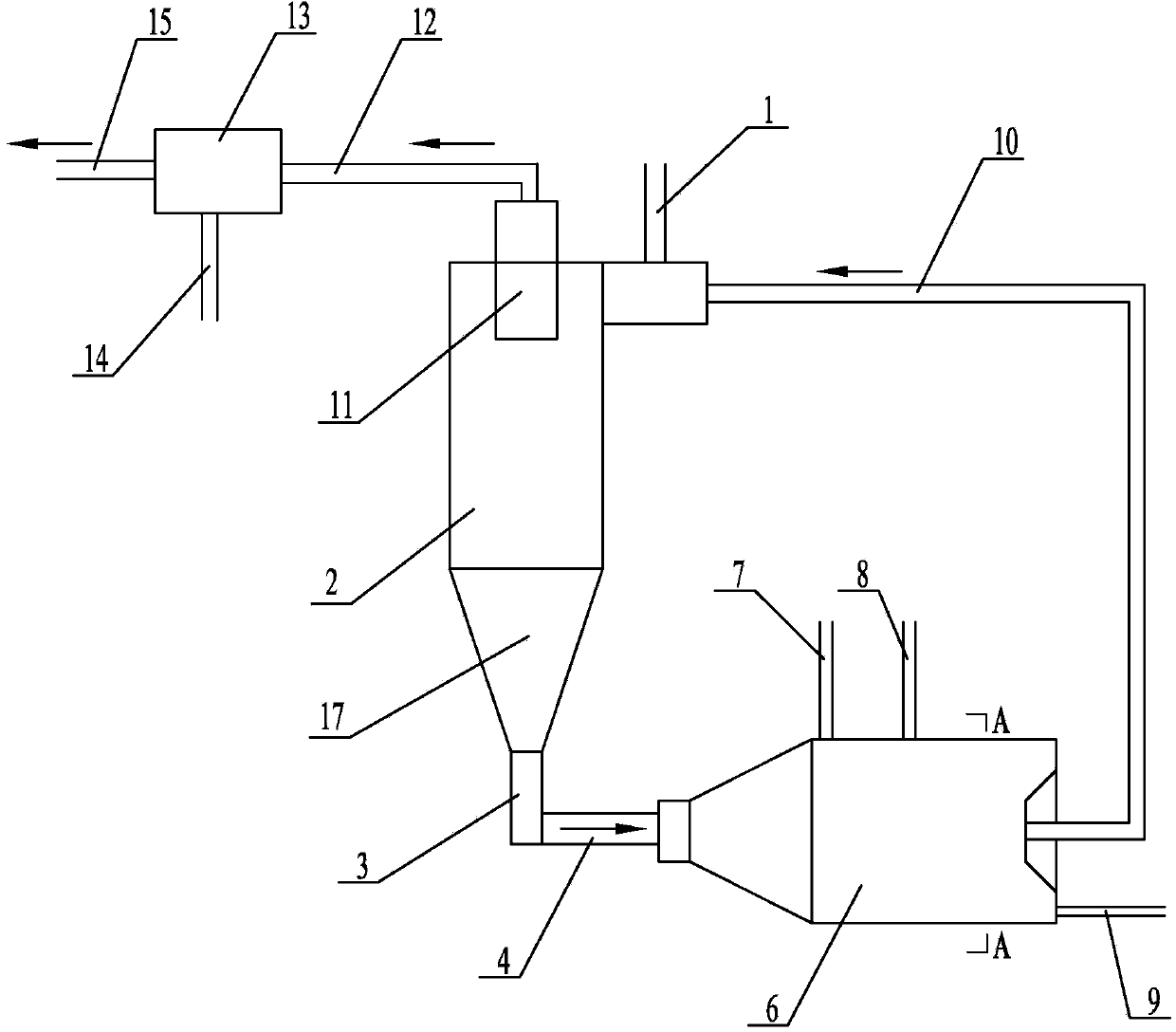

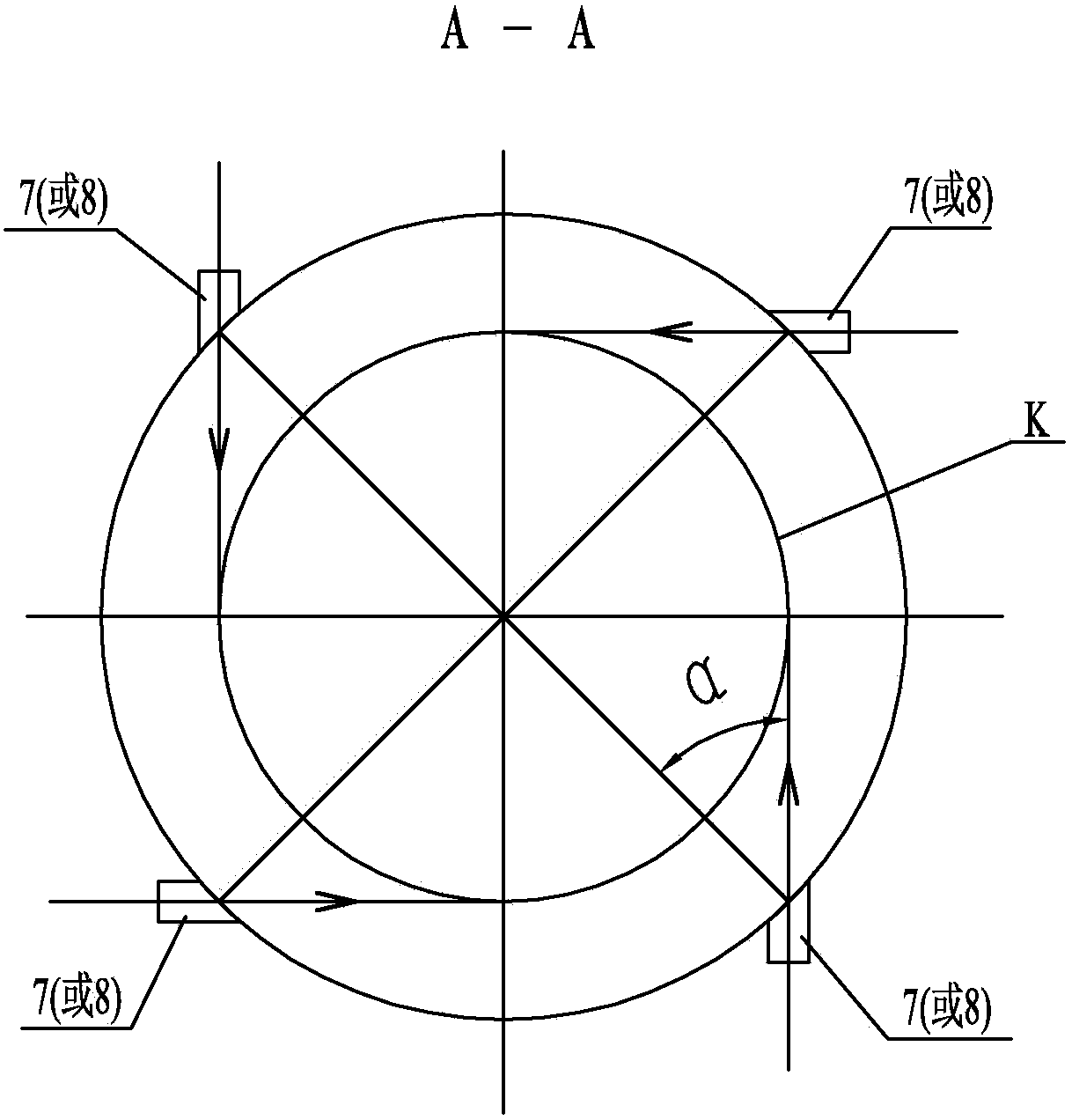

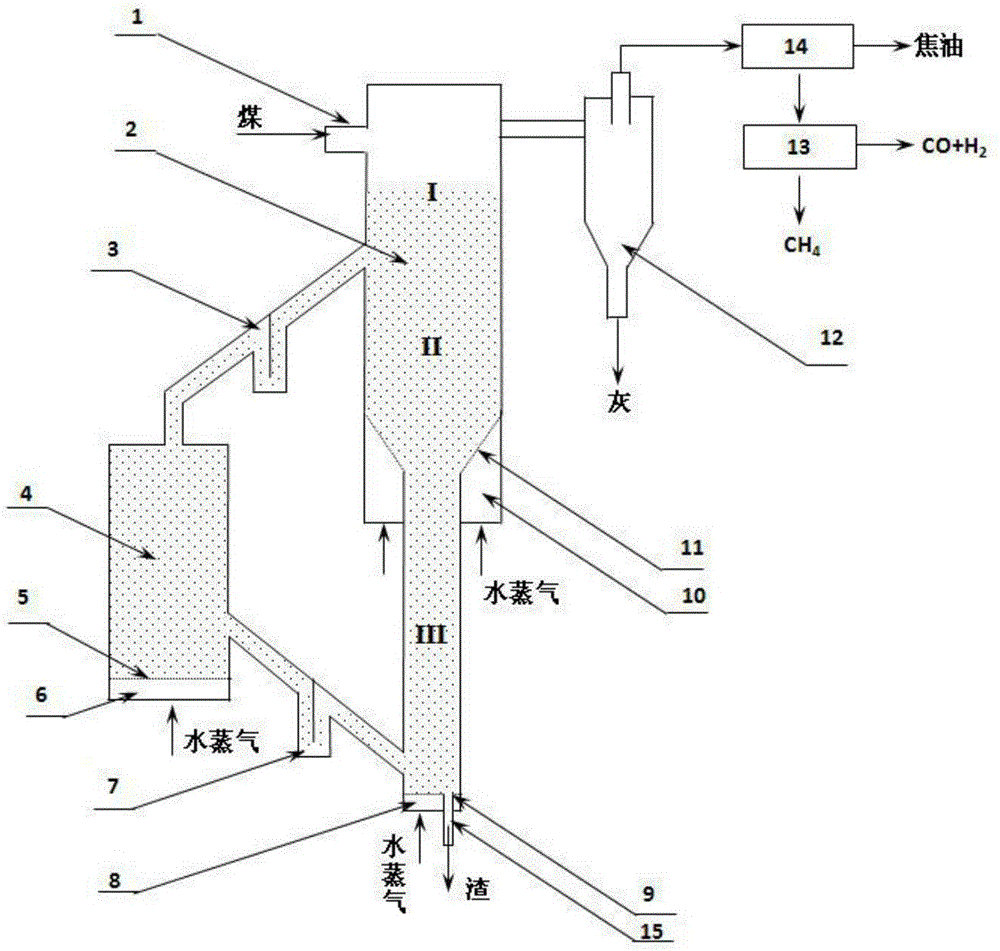

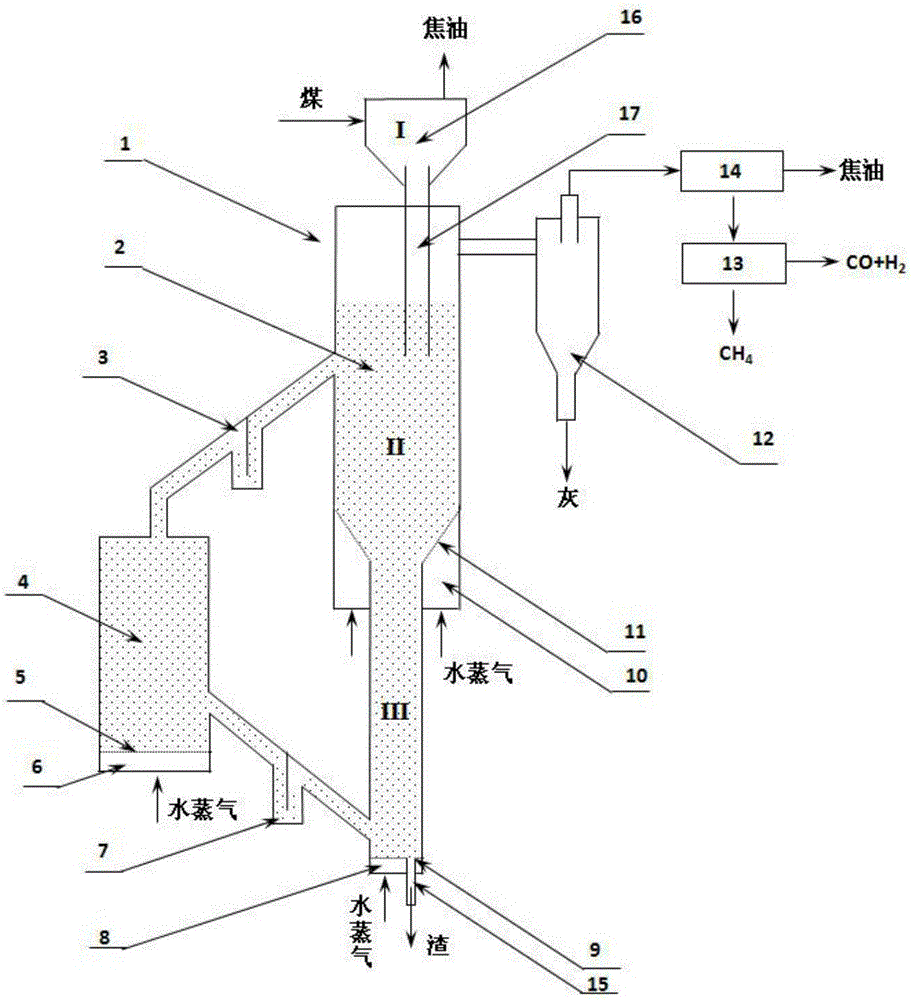

Double-cyclone coal pyrolysis gasification step converting device and double-cyclone coal pyrolysis gasification step converting method

ActiveCN103992824AIncrease profitFully pyrolyzedGranular/pulverulent flues gasificationCycloneWater vapor

The invention discloses a double-cyclone coal pyrolysis gasification step converting device and a double-cyclone coal pyrolysis gasification step converting method, and relates to a combusting device and a combusting method. The device is characterized in that a cyclone pyrolyzing furnace is communicated with a cyclone gasifying furnace by a material backing device and a pyrolyzing semi-coke channel; the cyclone gasifying furnace is communicated with the cyclone pyrolyzing furnace by a high-temperature raw coal gas channel; the cyclone pyrolyzing furnace is communicated with a cooling device by a pyrolyzing gas-mixing channel; an oxidant spray nozzle and a vapor spray nozzle are arranged on the outer wall of the cyclone gasifying furnace. The method is as follows: firstly, feeding coal dust into the cyclone pyrolyzing furnace under blocking and feeding of the high-temperature raw coal gas; secondly, pyrolyzing the coal dust in the cyclone pyrolyzing furnace, exhausting the pyrolyzed gas mixture into the cooling device, cooling, and conveying back the pyrolyzed semi-coke to the cyclone gasifying furnace; thirdly, spraying the oxidant and the vapor into the cyclone pyrolyzing furnace by the oxidant spray nozzle and the vapor spray nozzle at the same time, wherein the produced high-temperature raw coal gas is re-fed into the cyclone pyrolyzing furnace as a coal pyrolyzing gas heater carrier; coal residue in the cyclone gasifying furnace is exhausted through an ash residue discharge hole in the form of solid or liquid. The double-cyclone coal pyrolysis gasification step converting device and the double-cyclone coal pyrolysis gasification step converting method are used for gasifying clean coal gas.

Owner:HARBIN INST OF TECH

Device and method for directly preparing methane based on coal chemical chain gasification

ActiveCN106220461AReduce consumptionReduce generationHydrocarbon from carbon oxidesCatalystsMethanationSlag

The invention belongs to the technical field of preparation of substitutive natural gas from coal, and relates to a device and method for directly preparing methane based on coal chemical chain gasification. Pulverized coal particles pass through the upper portion of a chemical chain gasification reactor and enter a chemical chain gasification reactor, oxidation state multifunctional composite oxygen carrier particles and unreacted carbon in the pulverized coal particles enter a regeneration reactor on the upper portion of a coal methanation section through a first flowing control device, coal slag obtained after reacting is discharged through a slag discharging opening, gas separated by a cyclone separator sequentially passes through a gas purifying unit and a gas separation unit, methane gas is obtained, and coal ash obtained after separation of the cyclone separator, part of unreacted carbon and the oxidation state multifunctional composite oxygen carrier particles return to the chemical chain gasification reactor or the regeneration reactor again to be recycled. The device is simple in structure and convenient to operate, the process theory is scientific, the raw materials are easy to obtain, cost is low, thermal efficiency is high, the carbon utilization efficiency is high, fewer pollutants are generated, and environmental friendliness is achieved.

Owner:QINGDAO UNIV OF SCI & TECH

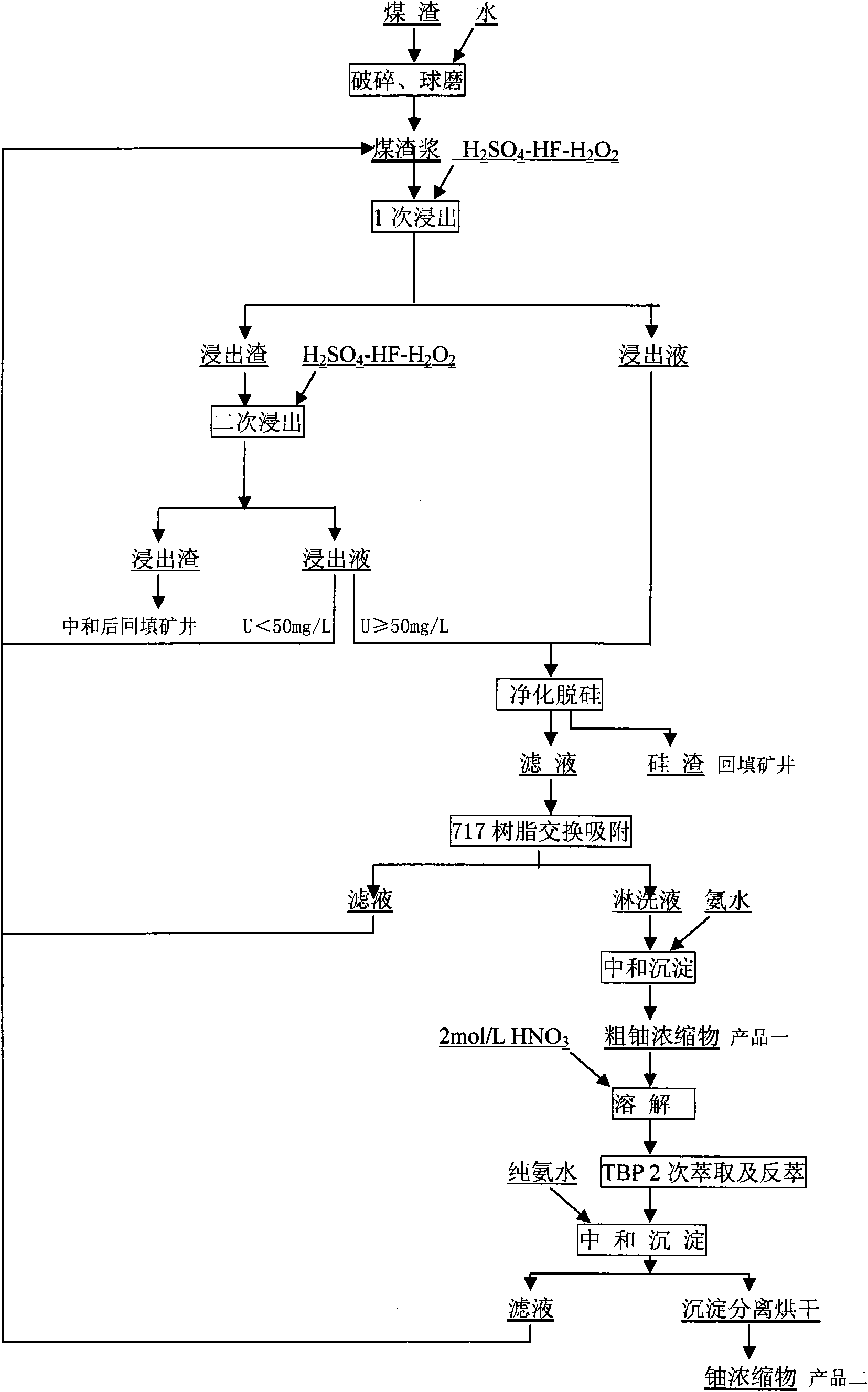

Method for recycling uranium from uranium extraction coal residue with wet method

InactiveCN101619397AHigh recovery rateLow costProcess efficiency improvementEcological environmentSilicic acid

The invention discloses a method for recycling uranium from uranium extraction coal residue with a wet method, which comprising the following steps: (1) particle size requirements: crashing the coal residue below 200 meshes; (2) oxidation and acid leaching: in a dilute sulphuric acid-hydrofluoric acid medium, using peroxide as an oxidizer to carry out reverse oxidation leaching twice; (3) desilicification and purification: using ammonia to adjust the pH value of once leaching filtering liquid of the uranium to 9.8-10.2, enabling the silicon in the solution to become silicic acid sediments, after filtering, carrying out ion exchange on the filtering liquid, desilicificating slag and stockpiling; (4) ion exchange: using a 717 type ion exchange resin to carry out exchange absorption by the filtering liquid, and then using 1 mol / L of NaCl-0.1 mol / LH2SO4 of mixed solution to elute the resin, after using tributyl phosphate to carry out extraction and back-extraction on eluent, obtaining uranium concentrates containing about 65% of the uranium. The invention successfully extracts and separates the uranium from the uranium extraction coal residue to produce the uranium concentrates, has t high recycling rate of uranium as high as 80-85% and low cost, and comprehensively utilizes the uranium extraction waste, thereby eliminating the influence of the radiation wastes on the ecological environment.

Owner:JIUJIANG BAIDUN VANADIUM TECH TRADING

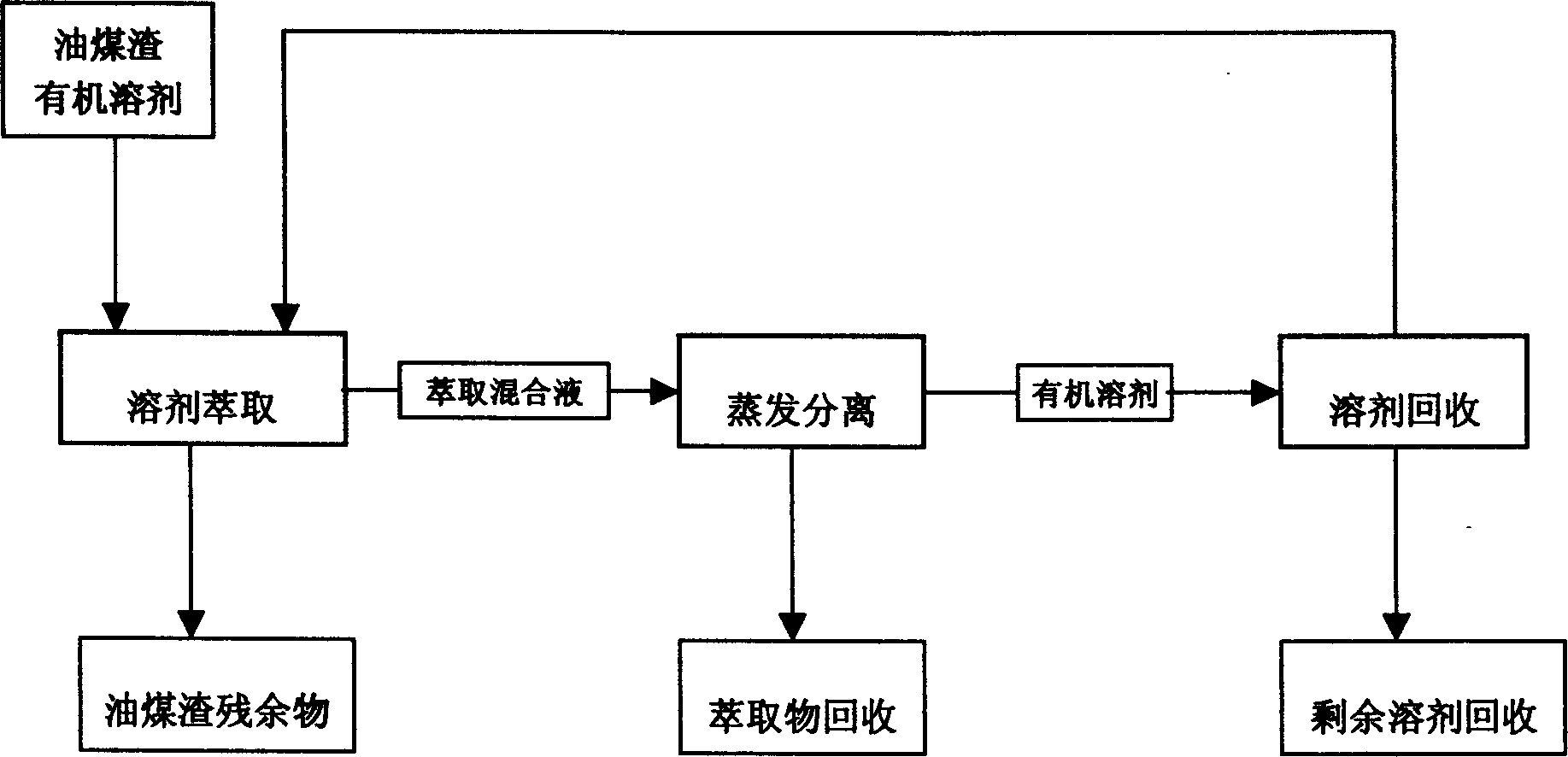

Oil coal cinder extracting process and equipment

InactiveCN1775914AHigh recovery rateImprove cooling effectSolvent extractionHydrocarbon oils refiningCooling effectEvaporation

The invention relates to oil cinder extraction process and the device that adopts extraction kettle, evaporation kettle, solvent recycle kettle, solvent condenser, cooling water circulatory system, magnetic stirrer, and valve pipeline and controller platform. The extraction could take place of petrol and diesel oil after post process, or further separating into organic chemicals. It is low cost, safe to operation, low energy consumption, and has good cooling effect, high recycling ratio and could save solvent and water resource. The invention has great social and economic benefits.

Owner:CHINA UNIV OF MINING & TECH

Ventilation property test method and device for hypergolic coal waste pile isolating layer

InactiveCN101393100AImprove featuresIncrease volumePermeability/surface area analysisSpontaneous combustionEcological environment

The invention relates to a method and a device for testing the gas permeability of an isolating layer of a self inflammable coal refuse heap, which belongs to the technical field of treatment and utilization of environmental, ecological and solid waste. The method comprises the following steps: the device is hermetically connected by a gas injection chamber, a test chamber and an exhaust chamber in turn along the direction of the gas paths, so as to form an enclosed gas chamber; the gas paths of the upstream section and the downstream section are isolated by an isolating layer sample in the test chamber; constant-pressure air flow is injected on the upstream section; a downstream instrument is communicated with the atmosphere; and the gas permeability of the isolating layer sample is determined after the positive pressure difference on both sides of the sample is stabilized. The test method is simple and convenient; the dimension of the sample is large; the test process well simulates the objective reality; and the method can detect the gas permeability of the isolating layer for treating the self inflammable coal refuse heap, and guarantee that the configuration of the isolating layer has the function of air barrier, thereby preventing spontaneous combustion of the coal refuse heap, reducing the hazard of the coal refuse heap on the environment, and improving the ecological environment of mining areas.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Magnetic separation device and method for ash agglomerating cinder during coal gasification course

InactiveCN101214463ANo pollution in the processIncrease the magnetic field strengthMagnetic separationJigging conveyorsWear resistantMagnetization

The invention relates to a magnetic separation device and a method used in ash gathering slack during the course of gas generation. The magnetic separation device of the invention comprises a feed device, a flexible connecting piece, a shaker feeder, a rubber roll, a ultra-thin wear-resistant transmission belt, a plate pole pretreatment device, a high field intensity permanent magnetism roll, a distribution plate, a case body, a low-magnetic agent blanking hopper, a high-magnetic agent blanking hopper and a frequency conversion retarding machine. The invention is characterized in that the feed device is connected with the shaker feeder through the flexible connecting piece. A first-stage pre-magnetization and magnetic separation structure consists of the frequency conversion retarding machine, the driving high field intensity permanent magnetism roll, the rubber roll, the transmission belt, the plate pole pretreatment device and the adjustable distribution plate. The plate pole pretreatment device is merely arranged at a middle position between the permanent magnetism roll and the rubber roll. The structure of a second-stage and a third-stage pre-magnetization and magnetic separation is the same with the structure of the first-stage pre-magnetization and magnetic separation. But the second-stage and the third-stage pre-magnetization and magnetic separation have not the plate pole pretreatment device. The invention has the multiple advantages of high magnetic density, low energy consumption and no environment pollution and is environment-friendly, consumption-reducing and benefit-increasing.

Owner:BEIJING LIKONPEC TECH

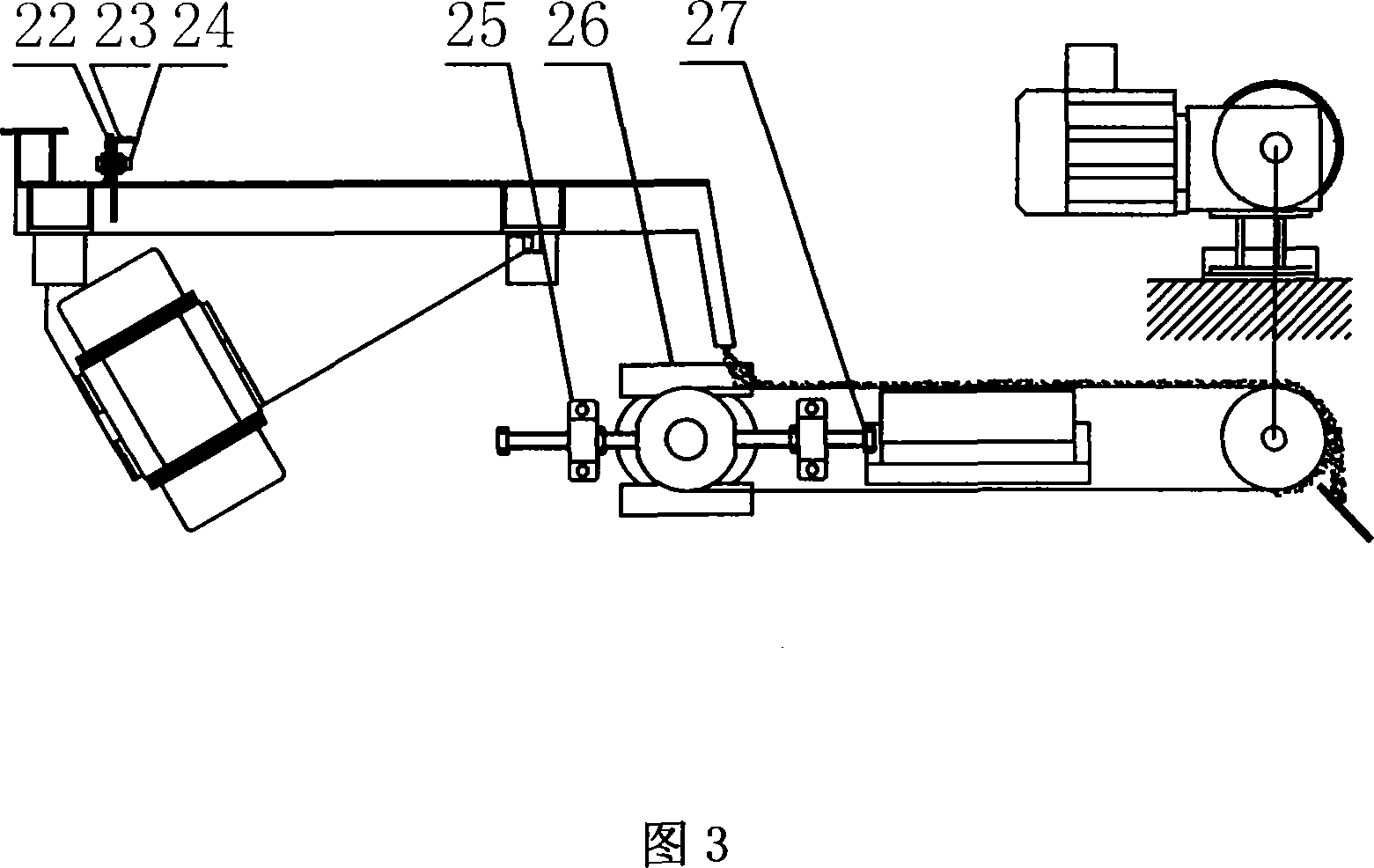

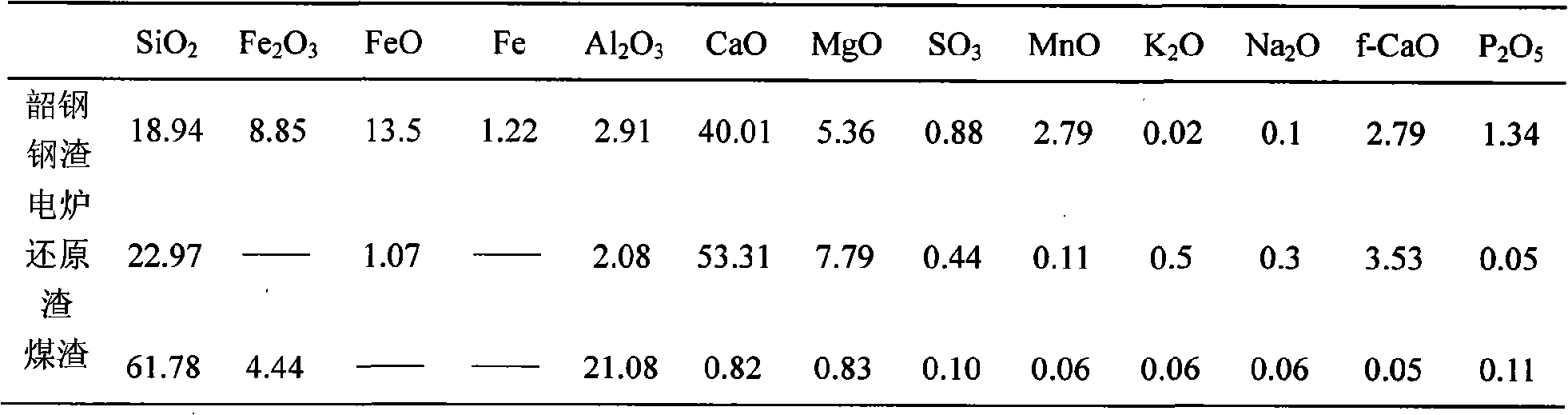

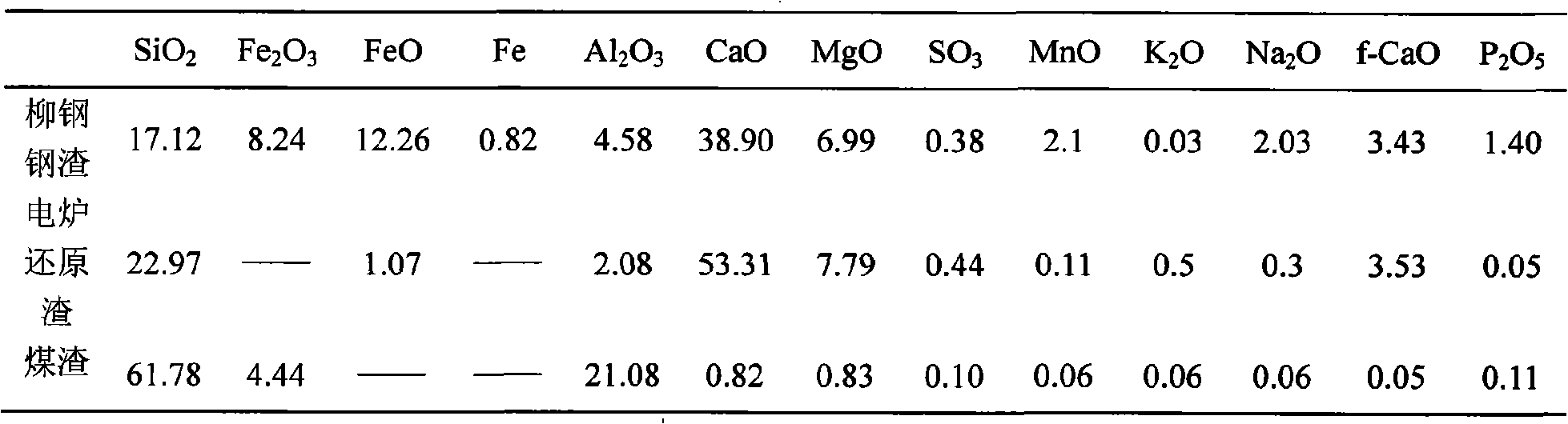

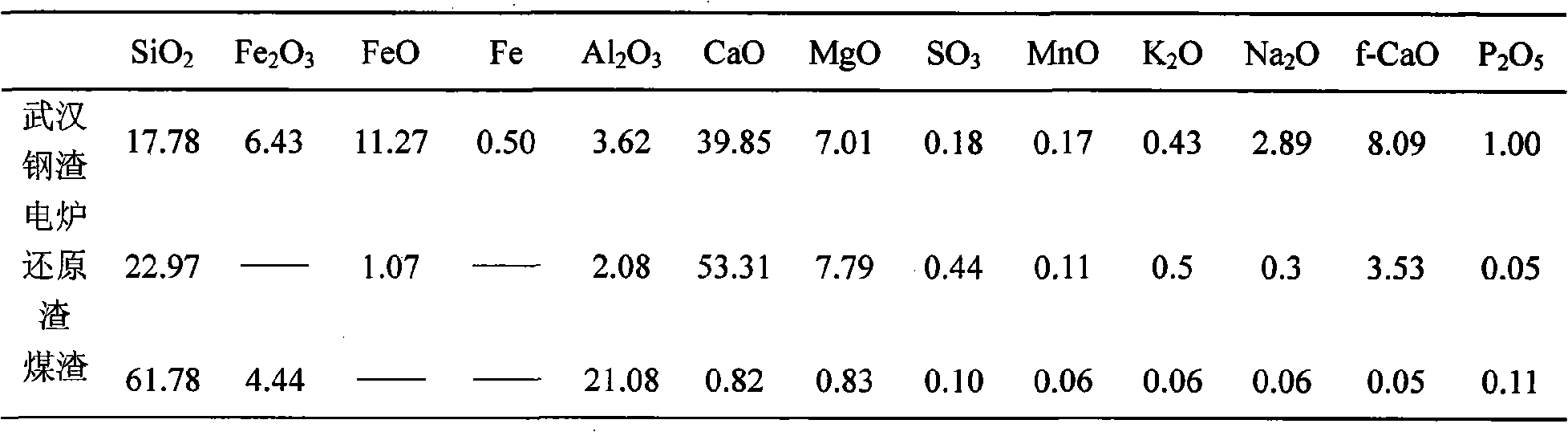

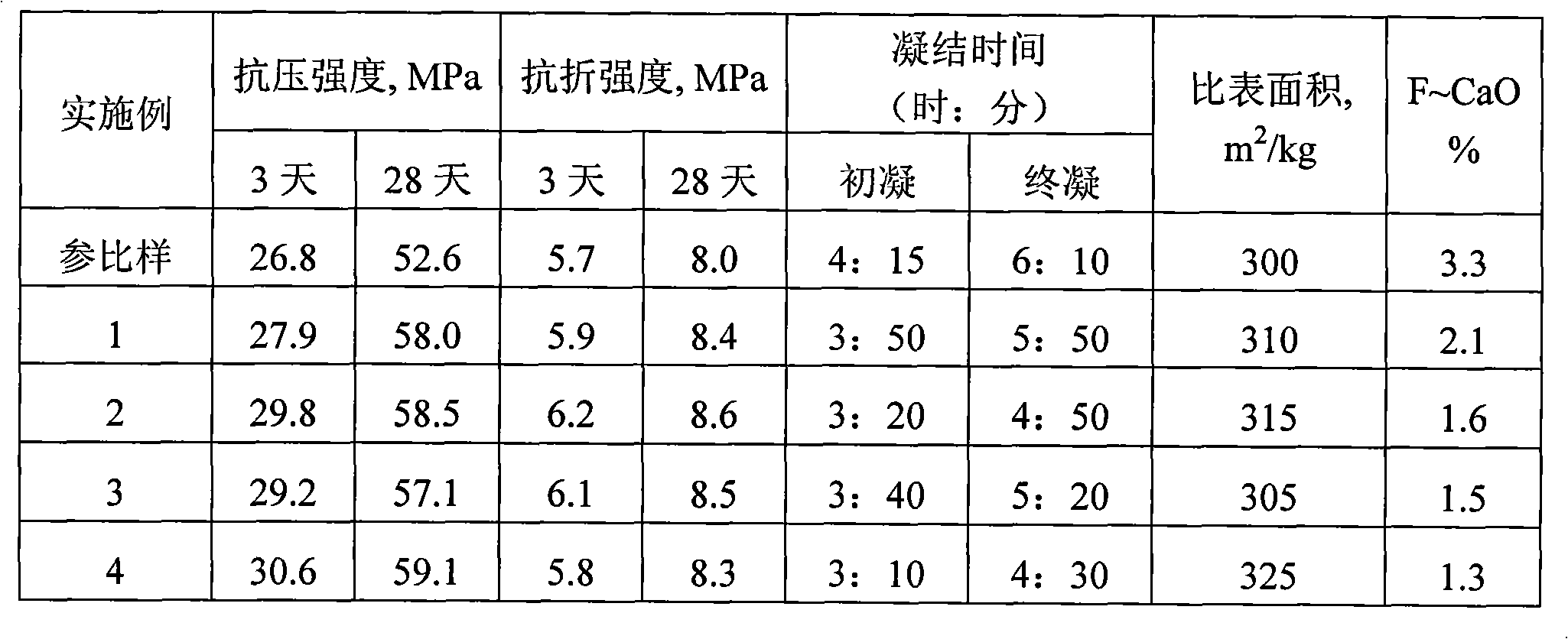

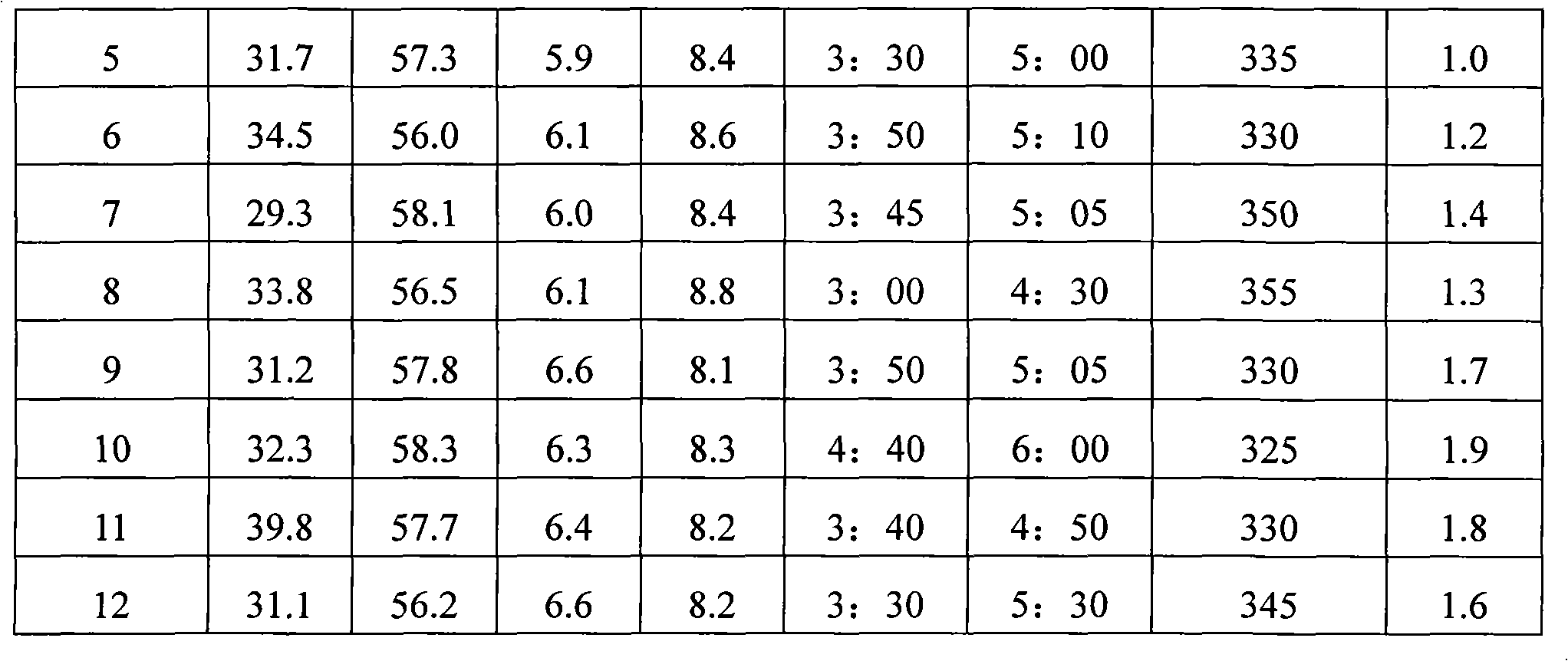

Performance adjustment material for activating steel slag at high temperature and application thereof

InactiveCN101560578AImprove hydrationHigh activityRecycling and recovery technologiesChemical reactionElectric arc furnace

The invention discloses a performance adjustment material for activating steel slag at high temperature and the application thereof. The performance adjustment material is prepared by mixing electric arc furnace restored slag, coal slag and starch polymer or poval. The application of the material is as follows: after being mixed, the performance adjustment material and the steel slag chemically react under the action of high temperature so as to improve the hydration and the cohesive activity of the steel slag. The invention utilizes the electric arc furnace restored slag, the coal slag and a small quantity of starch polymer or poval to prepare the performance adjustment material; and the performance adjustment material and the steel slag are mixed and chemically react at the certain temperature so as to improve the hydration and the cohesive activity of the converter steel slag. After reaction, the content of free calcium oxide in the steel slag is lower than 2 percent; and when the specific surface area of steel slag powder ranges from 400 to 500m / kg after activation, the 28d activity index is higher than 85 percent. The activated steel slag powder prepared by the invention can be used as cement admixture or concrete admixture, and can be widely applied to the construction projects of industrial and civil architecture, water conservancy, roads, airports, etc.

Owner:SOUTH CHINA UNIV OF TECH

Renewable unfired filter material and preparation method, application and regeneration method thereof

ActiveCN110342862AAchieve consumptionAchieve porosityOther chemical processesAluminium silicatesBrickSludge

The invention belongs to the technical field of resource reuse, and particularly relates to a renewable unfired filter material and a preparation method, application and regeneration method thereof. The invention provides a filter material, which is mainly prepared from the following components: sal industrial solid waste, construction waste, sludges, alkali activators and foaming agent; the sal industrial solid waste is selected from one or more kinds of flyash, metakaolin, solid sulfur ash, coal gangue, cinder, slag, zeolite slag, red mud, waste gypsum, desulfurization ash, carbide slag andindustrial dust; the construction waste is selected from one or more kinds of waste concrete blocks, waste cement mortar, crushed stones, waste slag soil, waste bricks and waste tiles. According to the renewable unfired filter material and the preparation method, application and regeneration method thereof, the consumption of the construction waste, the sludge and the industrial solid waste is realized simultaneously, and the resource utilization of the construction waste, the sludge and the industrial solid waste is achieved, and great economic and social values are brought.

Owner:GUANGDONG UNIV OF TECH

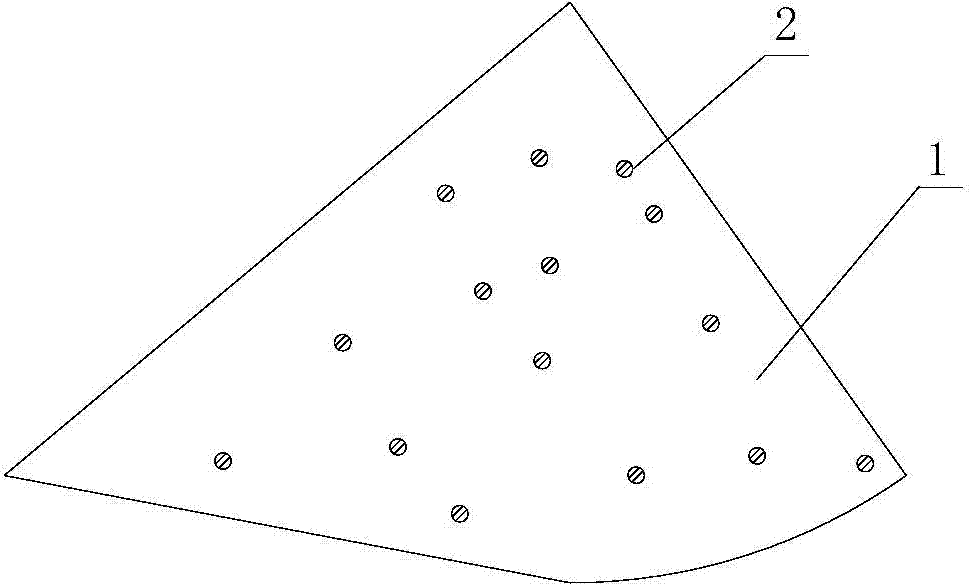

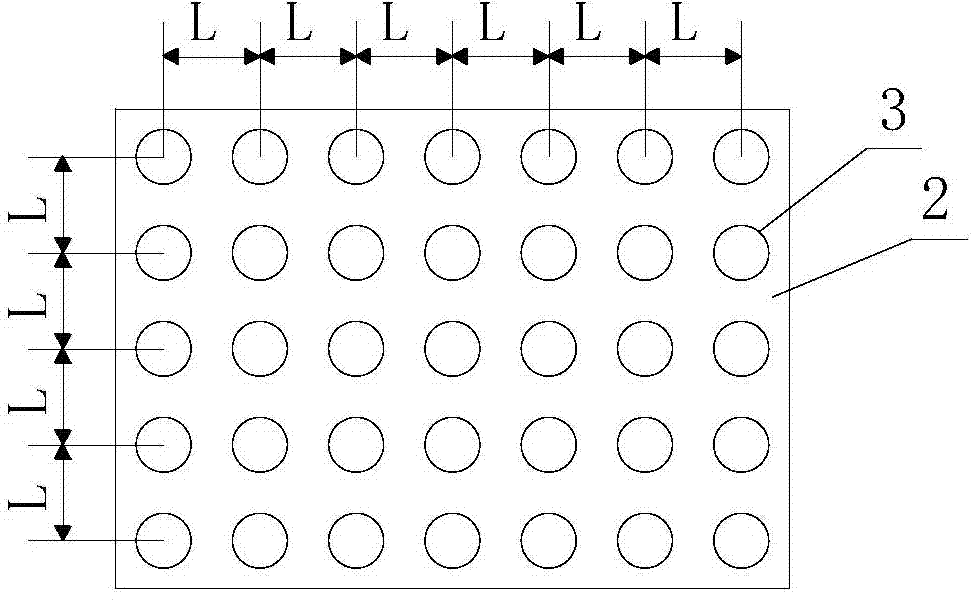

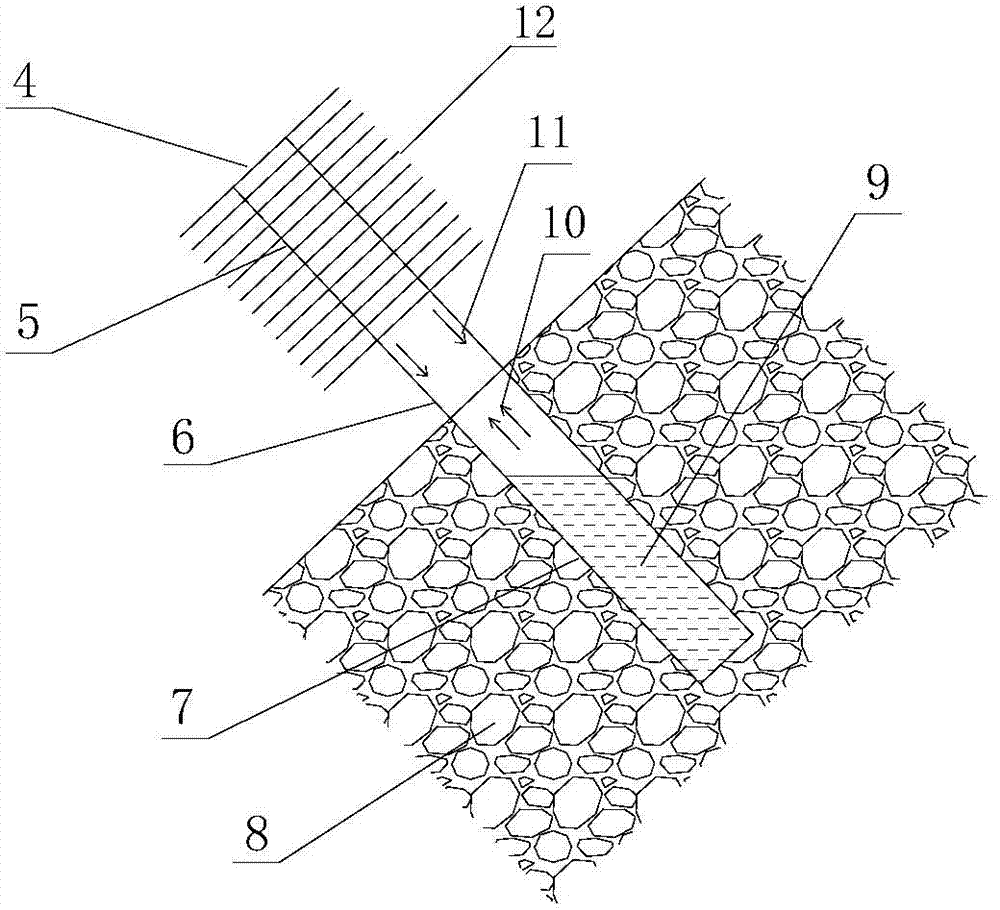

Method for preventing coal waste piles from spontaneous combustion

InactiveCN104492004APrevent spontaneous combustionSmall amount of workFire rescueBoring toolsSpontaneous combustionCooling effect

A method for preventing coal waste piles from spontaneous combustion is disclosed. According to the method, construction of drill-hole groups is carried out by a grid arrangement method in temperature anomaly regions of coal waste piles; one-dimensional heat transfer sealed pipes are embedded into each drill hole; by high-efficiency heat transfer performance of the one-dimensional heat transfer sealed pipes, heat inside the coal waste piles is continuously transferred to the outside air such that heat is hard to gather; and by synergistic effect of the multiple one-dimensional heat transfer sealed pipes, grid heat-absorption and cooling regions are formed, and temperature of high temperature anomaly regions decreases continuously. By synergy of the multiple grid heat-absorption and cooling regions, internal heat storage conditions of the coal waste piles are destructed, and temperature decreases continuously. Thus, spontaneous combustion is avoided, and the coal waste piles are prevented from spontaneous combustion. The invention brings forward a coal waste piles spontaneous combustion prevention method which is simple to construct and is safe, reliable, economical and efficient. The method provided by the invention has advantages of remarkable cooling effect, small work amount, recycling, low maintenance cost and the like, and has good popularization and application value.

Owner:CHINA UNIV OF MINING & TECH

Planting method suitable for blueberries in south China regions and soil conditioner

InactiveCN107306724AMeet planting requirementsImprove soil conditionsSuperphosphatesBioloigcal waste fertilisersPlant SourcesToxic industrial waste

The invention provides a planting method suitable for blueberries in south China regions and a soil conditioner, and belongs to the field of plant cultivation. The planting method suitable for the blueberries comprises the steps of adopting the soil conditioner and organic material mixtures to conduct soil improvement on a blueberry planting field, wherein after the soil improvement, the pH value of the soil is 4.4-4.8, and the organic matter in the soil is 17-24%; after laying drop irrigation pipelines in the blueberry planting field and digging planting holes, laying padding on the bottoms of the planting holes, laying basic fertilizer on the padding, and then transplanting blueberry seedlings and conducting water irrigation to fixing the seedlings; conducting field management in the later period. The soil conditioner is obtained by mixing coal waste after flue gas desulfurization, acid industrial waste of plant sources and controlled-release starch balls containing carbonic acid. According to the planting method for the blueberries, the soil of the blueberry planting field is improved, and then the later soil management is conducted, so that the survival rate of the blueberries planted in the south China regions is substantially improved, and meanwhile, the quality of the produced blueberry fruits is high.

Owner:ZHONGKAI UNIV OF AGRI & ENG

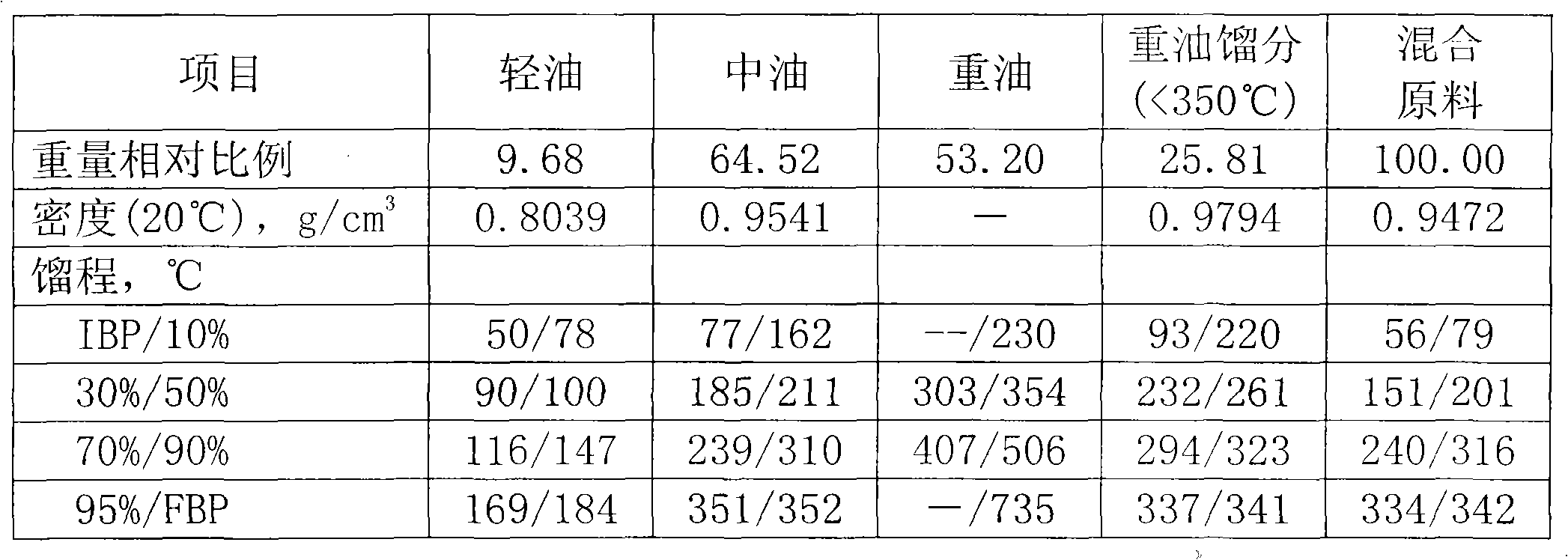

Processing method of middle and low temperature coal tar

InactiveCN102021010AReduce the amount of higher phenolsReduce in quantityTreatment with hydrotreatment processesTar working-up by distillationIonChemistry

The invention relates to a processing method of middle and low temperature coal tar. The processing method comprises the following steps: completing countercurrent contact wash and separation at least twice on narrow fraction phenol oil PO and alkali liquid SHW which are obtained by fractionating raw coal tar to obtain a water solution of oil-containing sodium phenolate and dephenolized phenol oil; washing the dephenolized phenol oil with washing water to obtain washed dephenolized phenol oil DPO and oil washing water, wherein at least part of the oil washing water is circulated to be used as the washing water, and the residual oil washing water enters an alkali washing process for the phenol oil; and further, fractionating the washed dephenolized phenol oil to obtain tower bottom residual liquid DLO the yield of which is lower than 5% and refined dephenolized phenol oil, wherein the washed dephenolized phenol oil DPO or the refined dephenolized phenol oil TDPO enters a hydro-upgrading process of the raw coal tar distillate oil, and the tower bottom residual liquid DLO enters a coking unit of raw coal tar residual oil to complete the coking process and recycle the coke products. The processing method provided by the invention has the advantages of reducing the consumption of the alkali liquid, reducing the quantity of alkali metal ions in the dephenolized phenol oil, and the like, integrates the coal tar hydro-upgrading process and the coal residual oil coking process into a combined technique, and is especially suitable for the comprehensive utilization of the middle and low temperature coal tar.

Owner:何巨堂

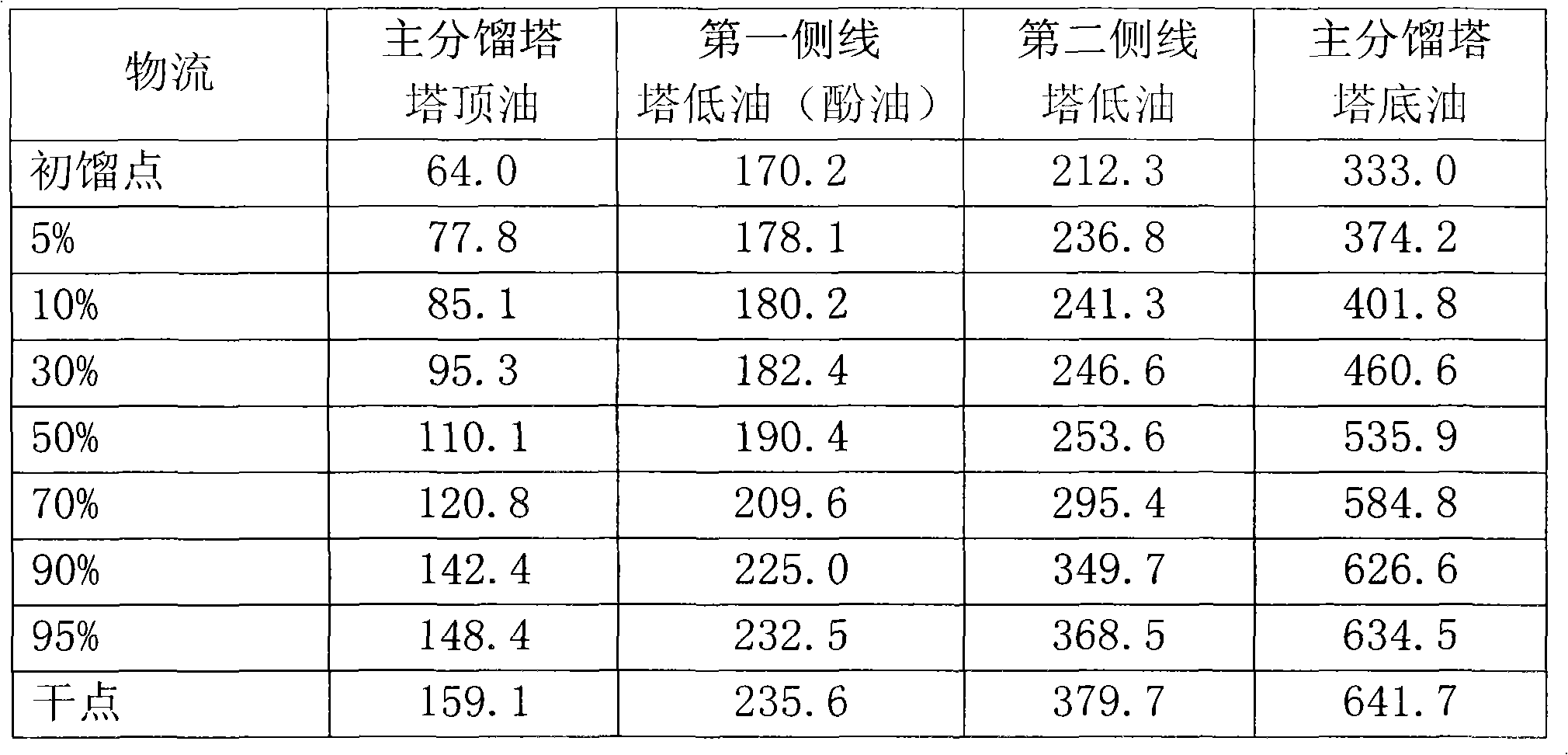

Hydraulic-loom wastewater treatment recycling method

InactiveCN104045178ASolutionEliminate secondary pollutionSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentGratingFiltration

A hydraulic-loom wastewater treatment recycling method belongs to the field of a wastewater treatment recycling technology. By a method of ''oil removal+ coal slag adsorption+ coagulating sedimentation+ air floatation +mechanical filtration + recycling'', hydraulic-loom wastewater enters a grating well, an oil removal device and a gang-type coal slag oil-absorption device to carry out oil-removal pretreatment; the hydraulic-loom wastewater flows into a homogeneous regulating tank; a pump is used for lifting; sodium hydroxide, polyaluminum chloride and polyacrylamide are respectively poured into three pipeline mixers; hydraulic-loom wastewater is sent into a coagulating sedimentation device and a high-efficiency air floatation device to carry out physicochemical treatment, and an effluent flows into a middle water tank; the pump is used for lifting and the effluent is sent into a multimedium filter, a microstrainer and a security filter to carry out physical treatment, an effluent flows into a recycling clean-water basin, and the pump is used for lifting and the effluent is sent into a hydraulic-loom for recycling; separated floating oil, granular colloid and foreign materials can be doped with fire coal and the mixture is sent into a furnace to be burned; physicochemical float sludge, physicochemical mud and wash water are collected and flow into a sludge thickener; and sludge is sent through a screw pump into a sludge dewaterer for dehydration. Hydraulic-loom wastewater treatment recycling rate can reach more than 95%.

Owner:SHAOXING SHENSHUI ENVIRONMENTAL PROTECTION EQUIP

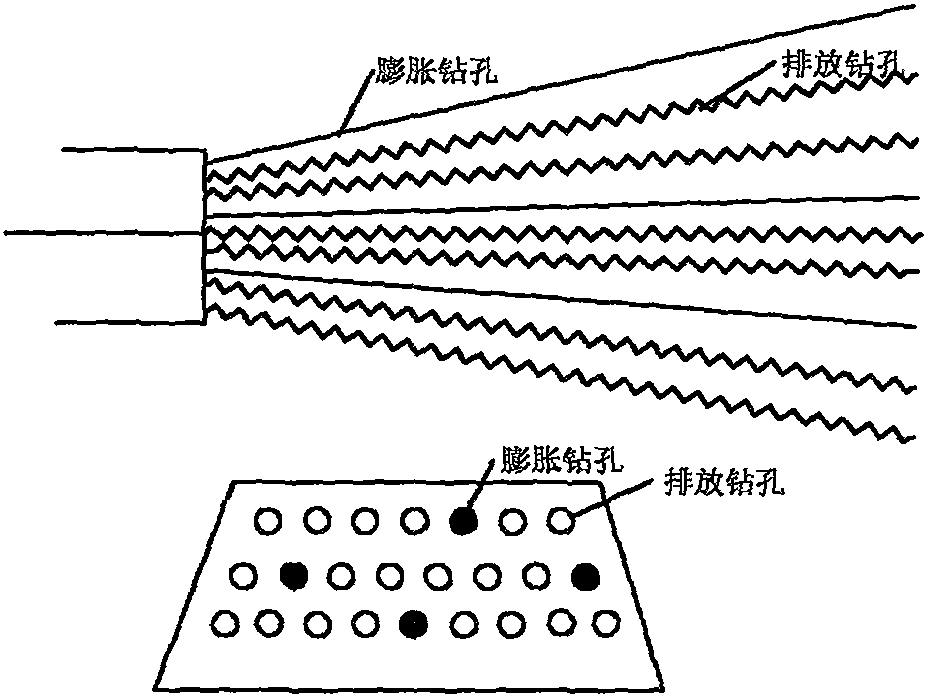

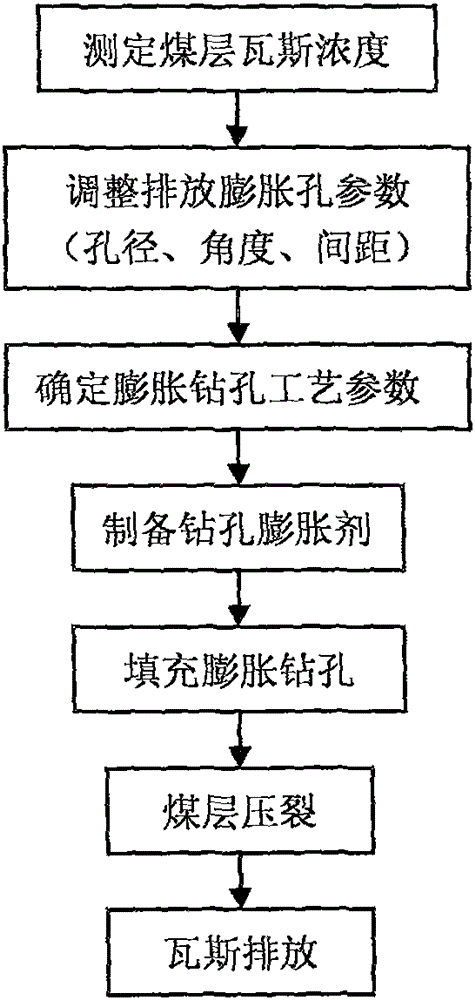

Method for treating low air permeability coal seam gas discharge

The invention discloses a method for treating low air permeability coal seam gas discharge. According to the method, holes are bored in a coal seam of a coal face, and coal seam fracturing is carried out through a borehole expansion agent to increase the coal seam air permeability for gas discharge. The method comprises the following steps: firstly, forming the boreholes in the coal seam according to the degree of freedom and the hardness of the coal seam; secondly, preparing the borehole expansion agent according to different coal seam temperatures and the characteristics of the borehole expansion agent; thirdly, purging residual coal slag and water in the boreholes in the coal seam to be clean through high-pressure air, and pressing the expansion agent into the boreholes through an extrusion pump or a grout pump to break the coal seam after the reaction of the expansion agent; finally, fracturing the coal seam through the explosion agent to increase the coal seam air permeability, thereby reducing the gas concentration.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

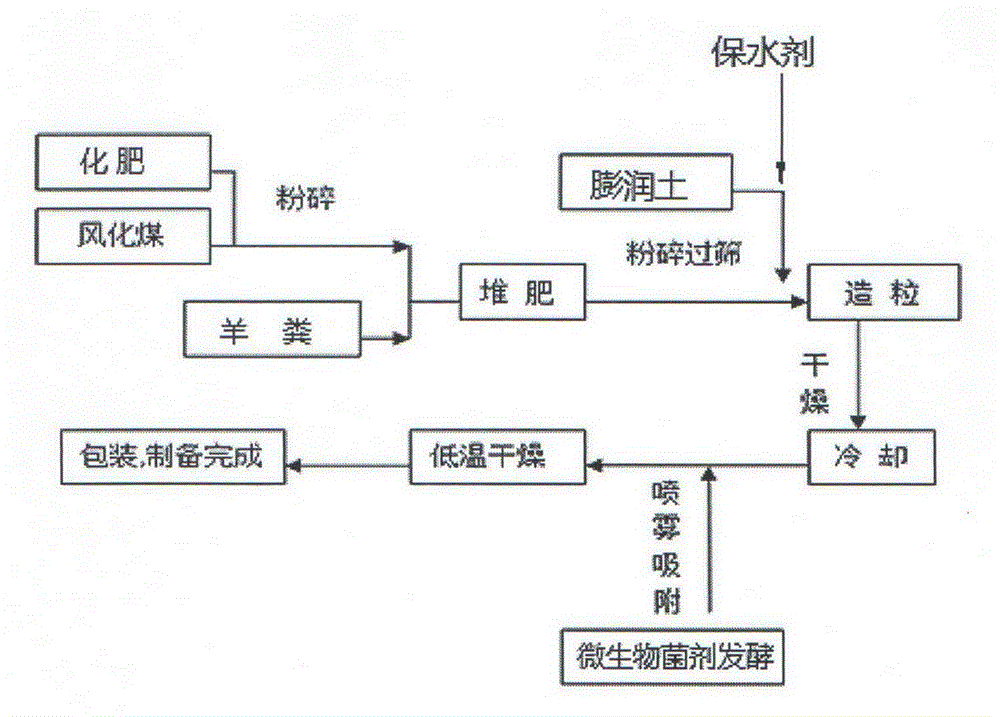

Water retention type humic acid bio-organic fertilizer and preparation method

InactiveCN105016929APromote growthImprove water retentionBio-organic fraction processingOrganic fertiliser preparationSodium BentoniteMicrobial agent

The invention relates to water retention type humic acid bio-organic fertilizer and a preparation method. The raw materials of the fertilizer comprise decomposed coal, dried sheep manure, chemical fertilizer, bentonite, water-retaining agents and mixed microbial agents, the fertilizer is prepared through the composting process, granulation process, spray absorption functional bacteria agent process and low temperature drying process, and according to the decomposed coal in the fertilizer, by utilizing coal wastes, the recycle of the wastes is achieved; meanwhile, by using the fertilizer, the soil can be fertilized, and the drought resistance capacity of crops and yield can be improved. The water retention type humic acid bio-organic fertilizer contains abundant humic acid and functional microorganisms; the soil can be improved, and meanwhile the crop yield, the crop quality and the drought resistance capacity of the crops can be improved.

Owner:INST OF SOIL & FERTILIZER XINJIANG ACAD OF AGRI SCI

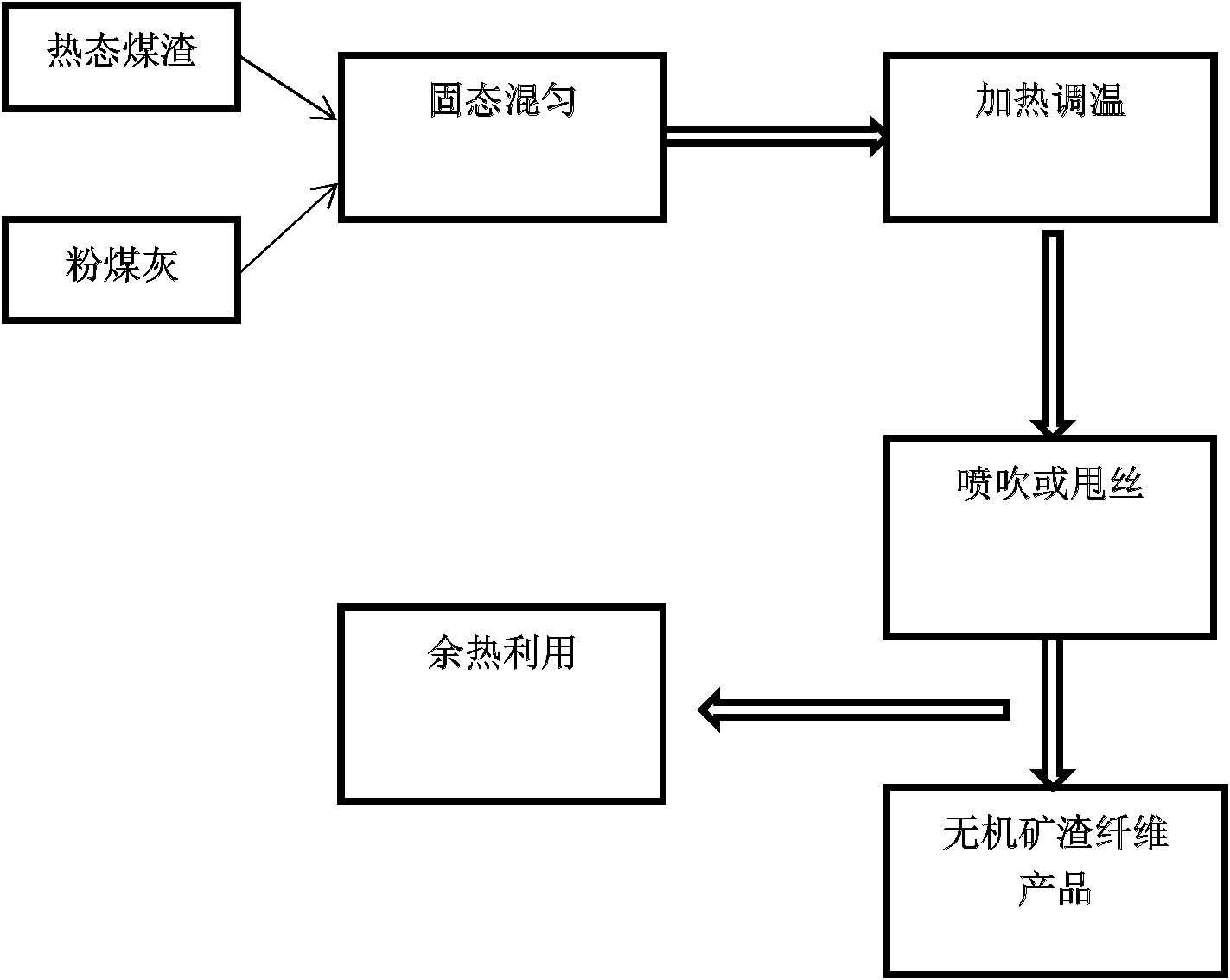

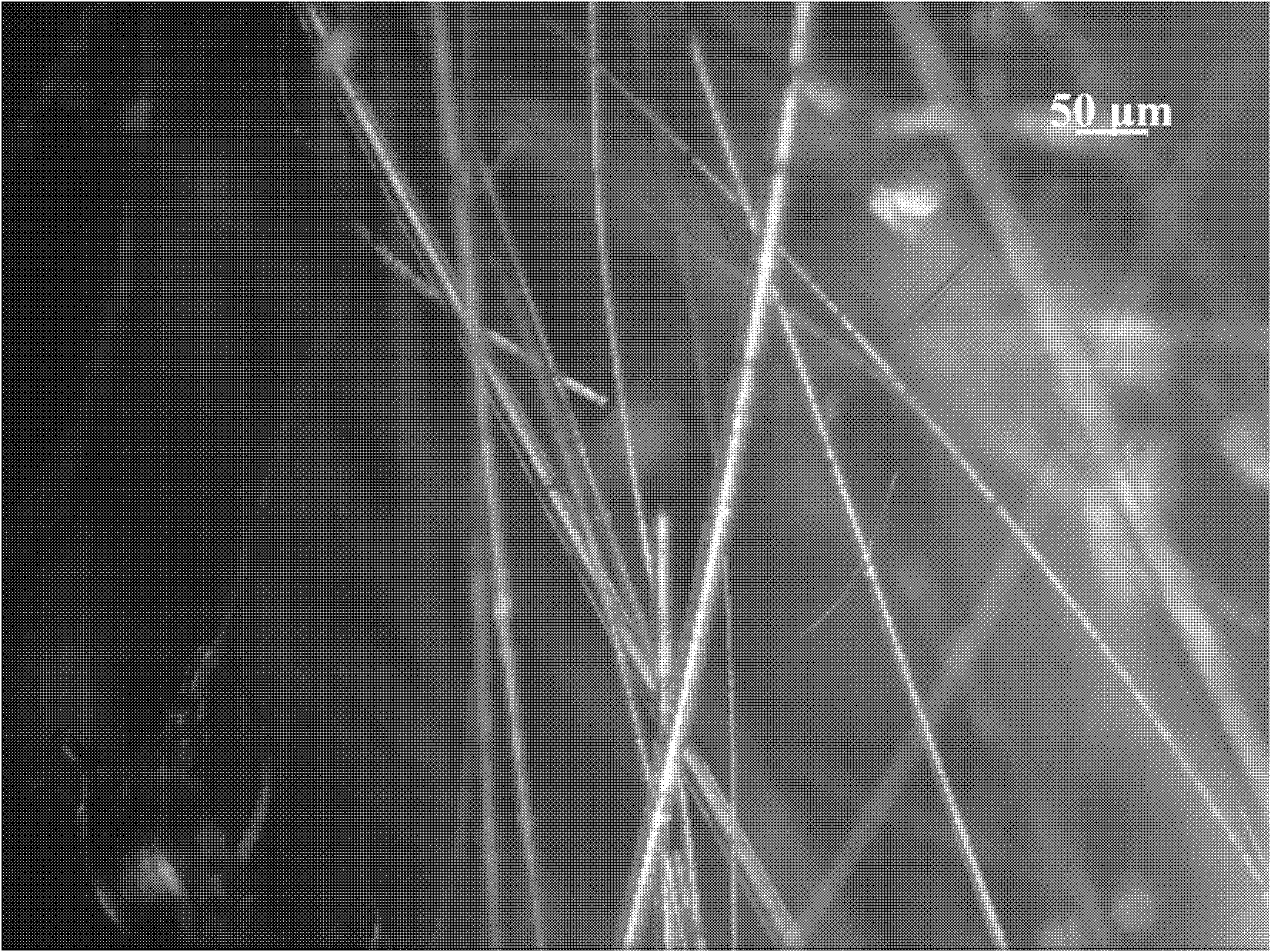

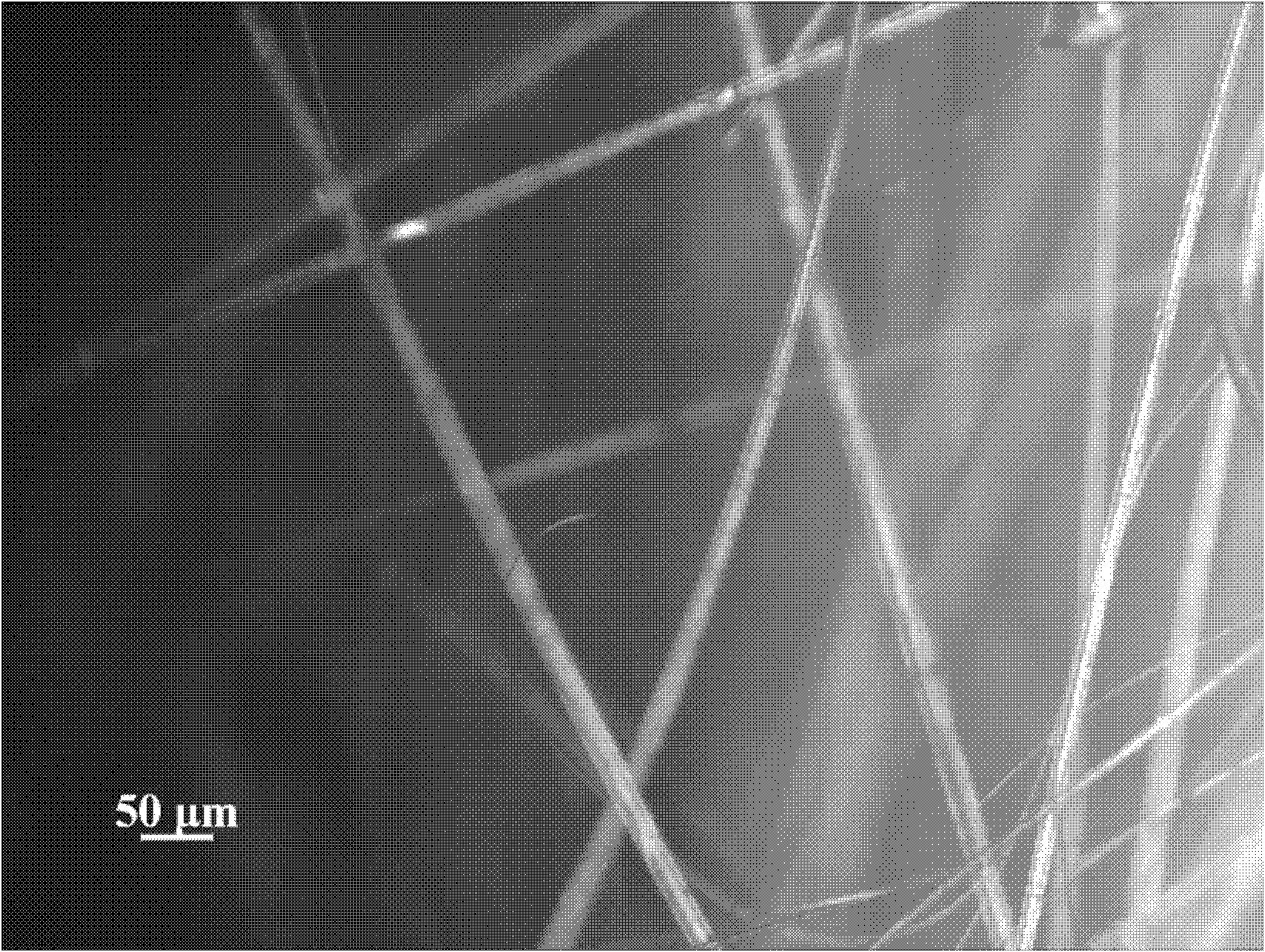

Method for preparing inorganic slag fibers by using thermal state coal slag

The invention provides a method for preparing inorganic slag fibers by using thermal state coal slag. According to the invention, thermal state coal slag and fly ash are produced through solid state well-mixing, and the mixture is heated to a melted state, such that melt water is obtained; the melt water is produced into filaments, such that the inorganic slag fibers are obtained. The invention is advantaged in that: the method is simple and easy to apply; the method is convenient to be put into practice; prepared inorganic slag fibers have relatively high flexibility and strength; simultaneous utilization of energy and material is realized; production cost is greatly reduced; energy consumption is low; no pollution is caused; circulation and high-efficiency utilization of resources are realized in a maximal degree. Therefore, the method provided by the invention has wide application prospect, positive social significance and positive environmental significance.

Owner:PEKING UNIV

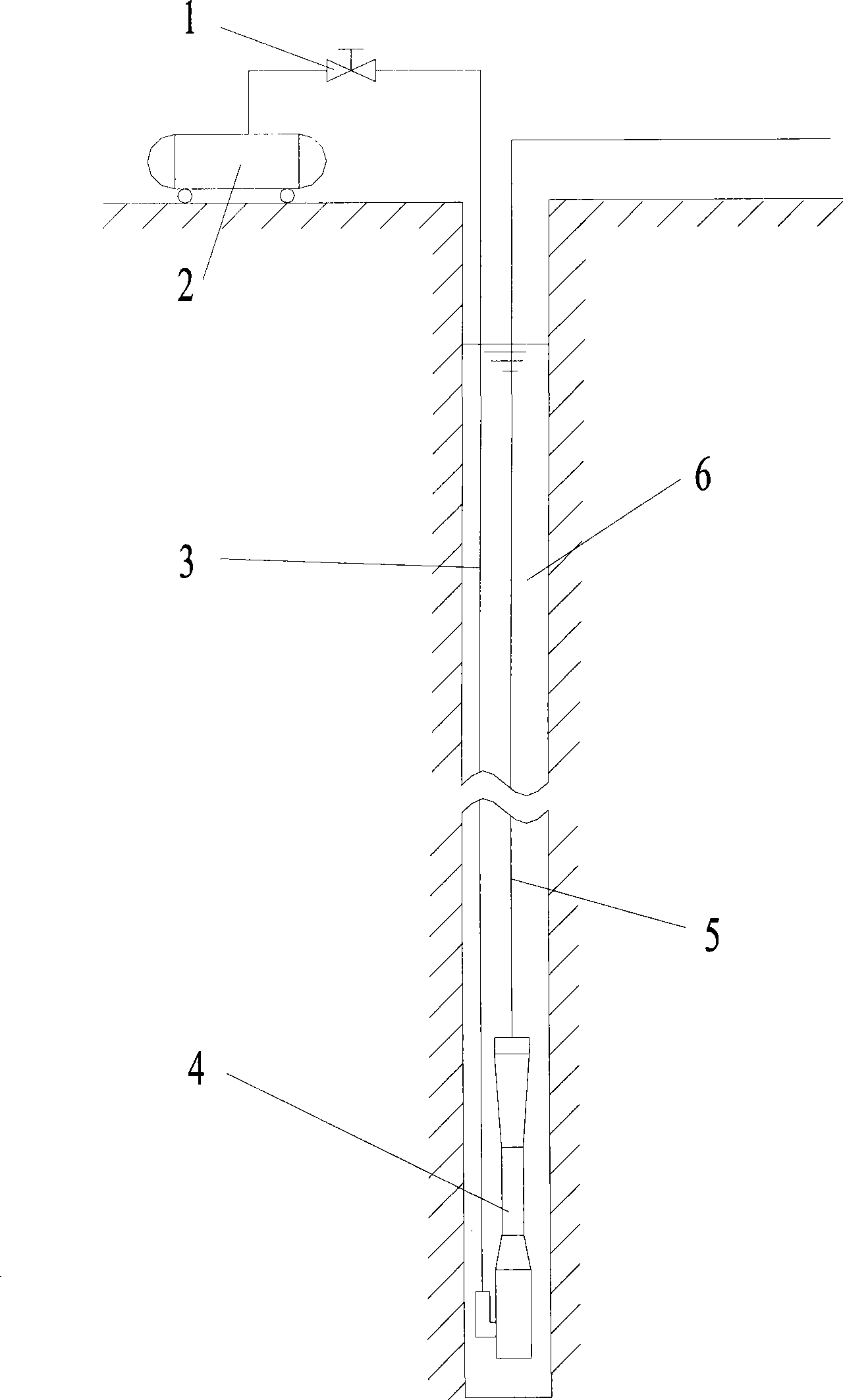

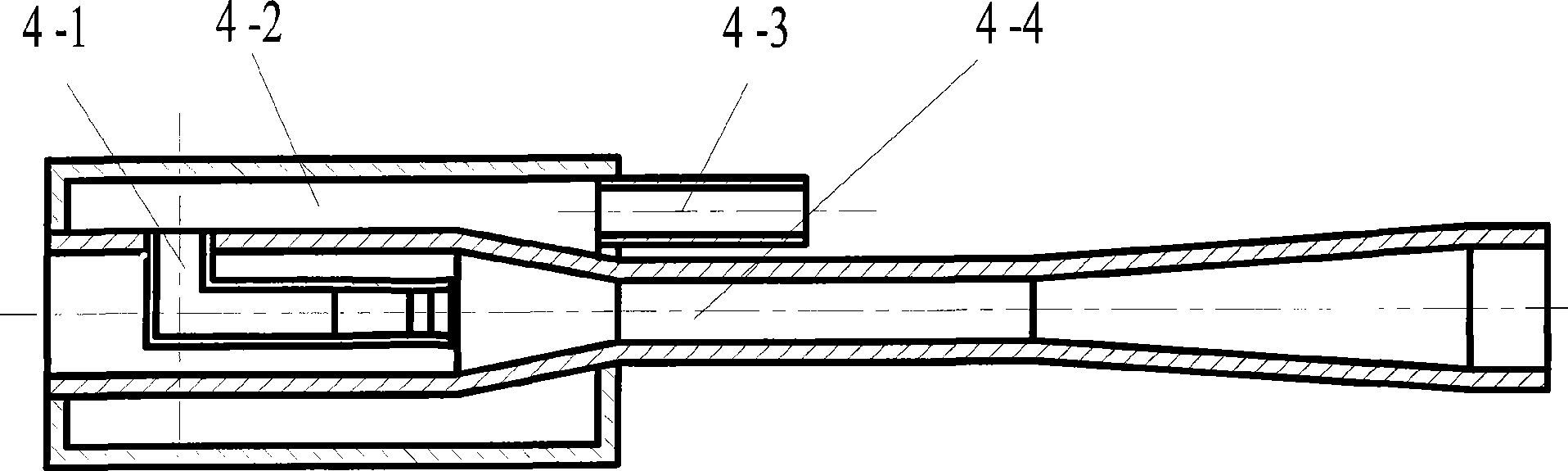

Method and apparatus for discharging water and slag of coal mine deep hole

InactiveCN101413401ATo achieve the purpose of pumping and draining accumulated waterImprove drainageDrainageSlagSpray nozzle

The invention discloses a coal mine deep hole water and slag drainage method and a device thereof. The method comprises the following steps: firmly connecting a drain pipe and an outlet of the body of a drainage pump and firmly connecting an outlet of a compressed air station and a compressed air spray nozzle of the drainage pump through a compressed air pipe; placing the connected drainage pump in an overhead bore hole and opening a compressed air valve; after the drainage water works normally, observing the water in the overhead bore hole on site, closing the compressed air valve when observing on water or coal slag is discharged from the drain pipe, which means water is completely drained, and taking out the drainage pump after water drainage in a deep hole is finished and placing the connected drainage pump into another overhead bore hole; and repeating the former steps. Based on turbulent dispersion of gas, liquid and solid three-phrase jet flow, the device uses compressed air supplied by a coal mine compressed air station to drainage, transmit and discharge water and coal slag in coal mine deep overhead bore hole. The device is simple, convenient and easy in operation and light and smart, and overcomes difficulties in discharge water and coal slag in coal mine deep overhead bore holes.

Owner:CHONGQING UNIV

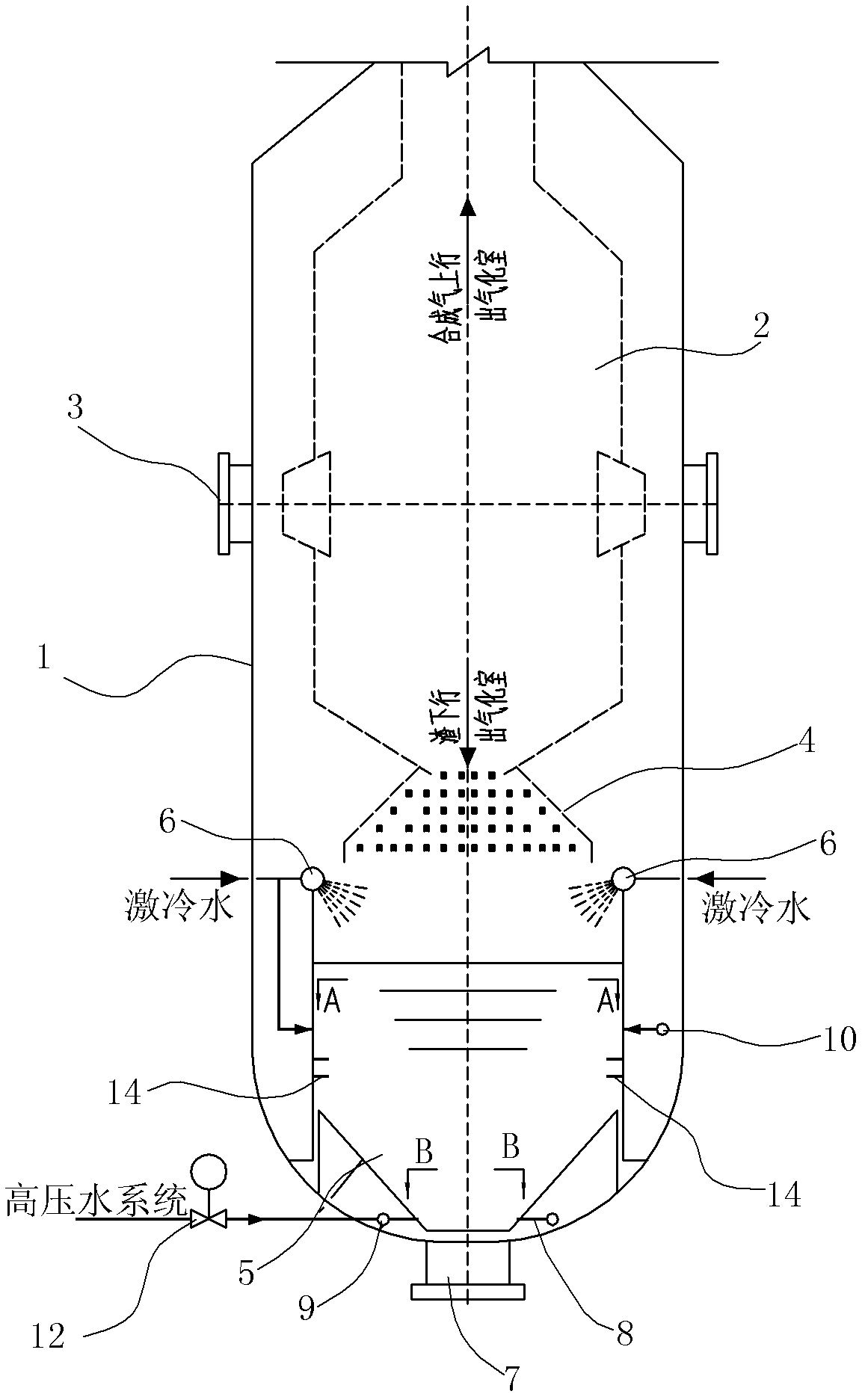

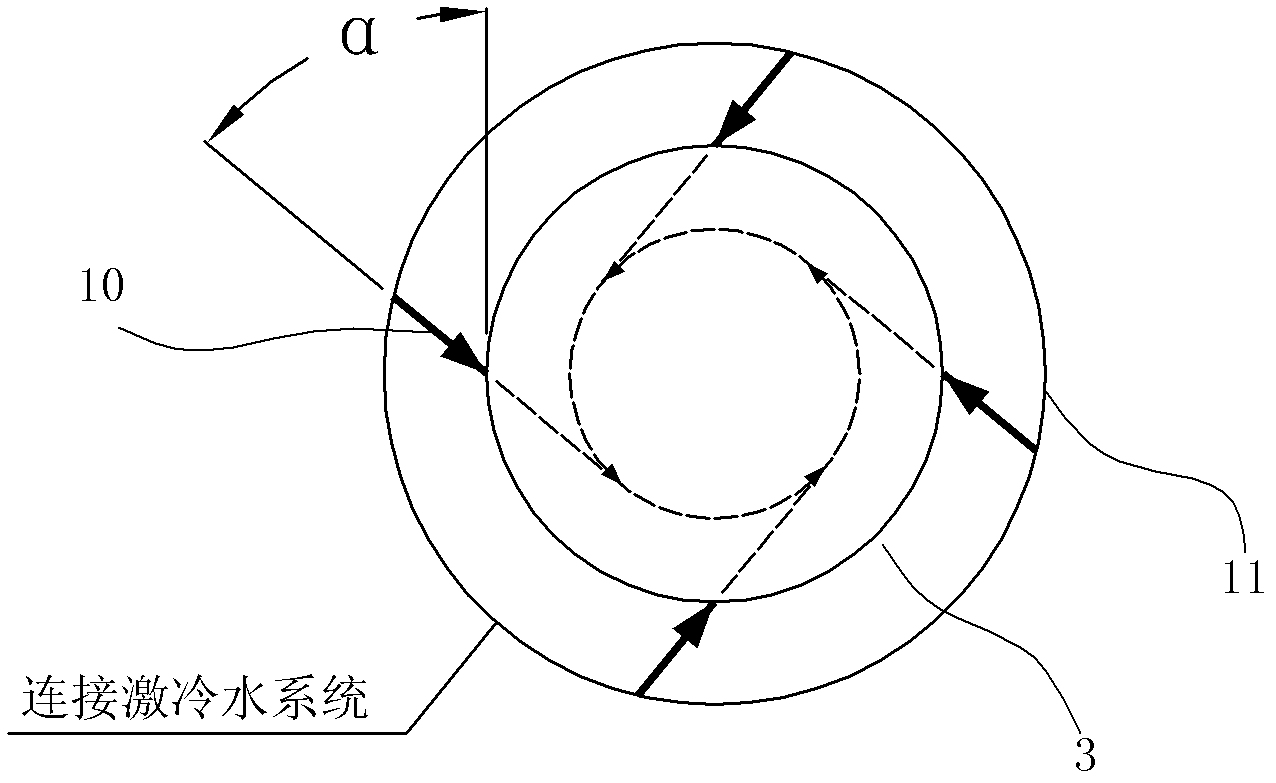

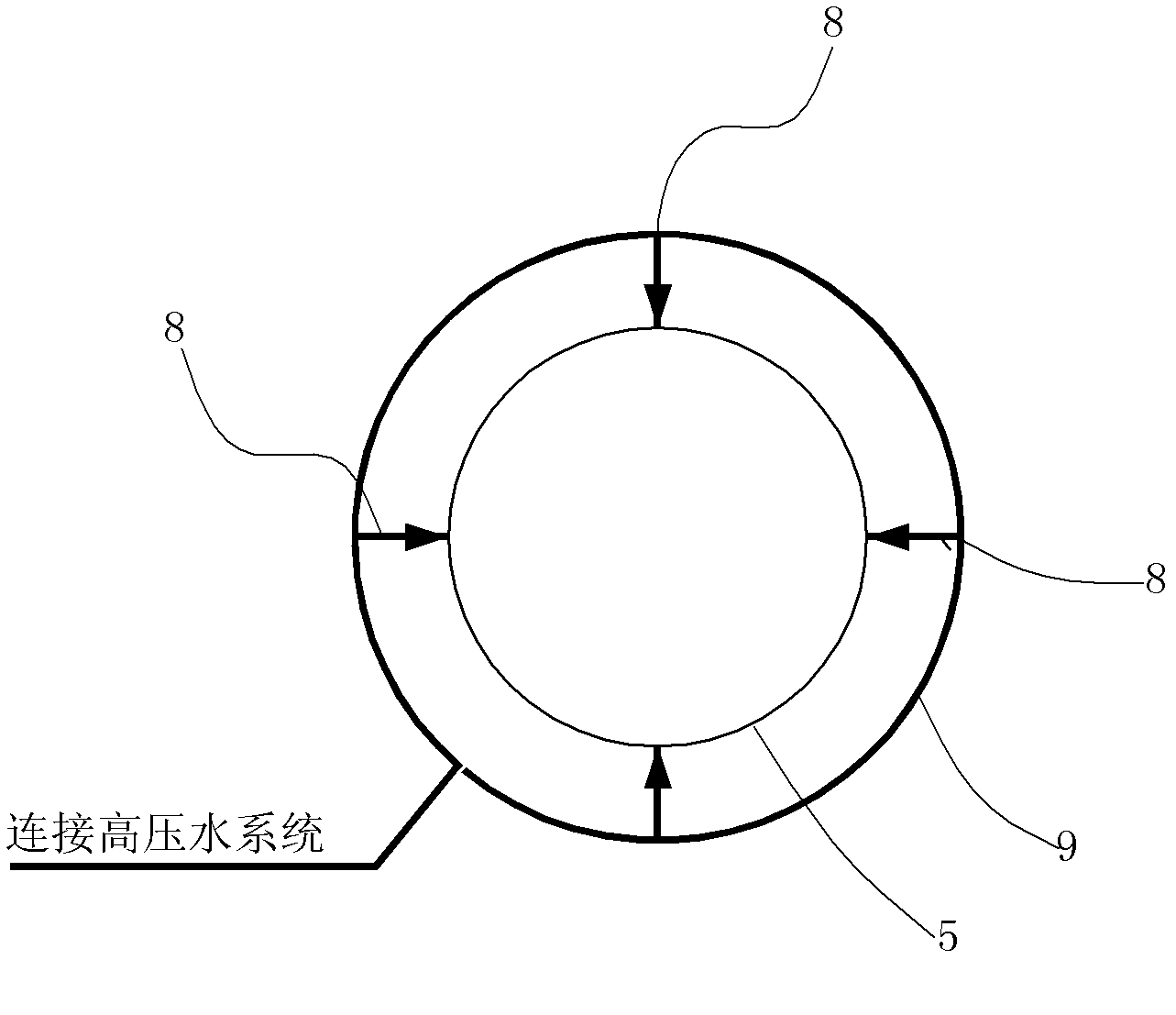

Slag-discharge system of pulverized coal gasification furnace

ActiveCN102634379ABroken GuaranteeImprove crushing effectGranular/pulverulent flues gasificationSlagChilled water

The invention relates to a slag-discharging system of a pulverized coal gasification furnace. A gasification chamber communicated with a feed port is arranged in the shell of the pulverized coal gasification furnace. A slag chamber is positioned below the gasification chamber and is communicated with the gasification chamber through a slag screen. The upper end of the slag chamber is provided with a chilling circular pipe for spraying chilling water towards coal slag entering the slag chamber, and the lower end of the slag chamber is communicated with a slag hole arranged at the bottom of the shell through a tapered slag hopper. The slagging system of the pulverized coal gasification furnace is characterized in that the peripheral wall of the slag chamber is provided with a plurality of water injection nozzles connected with a chilling water system. Compared with the prior art, the slagging system of the pulverized coal gasification furnace can effectively avoid slag blockage in the slag chamber, therefore, the gasification furnace can stably operate for a long term, the maintenance cost is saved, and the production efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

Composite industrial residue mineralizer cement clinker and preparation method thereof

The invention relates to a composite industrial residue mineralizer cement clinker and a preparation method thereof. The mineralizer doped into a cement green stock is between 5 and 20 percent by weight, and the cement clinker is characterized in that raw materials consist of 50 to 80 percent of metallic slag and 20 to 50 percent of inorganic non-metallic slag, wherein the metallic slag comprises the following components in portion by weight: 25 to 45 portions of steel slag, 15 to 40 portions of barium slag, 15 to 35 portions of chromium slag, 5 to 30 portions of zinc slag, 5 to 15 portions of copper slag, and 5 to 10 portions of tungsten slag; and the inorganic non-metallic slag comprises the following components in portion by weight: 25 to 45 portions of sulfuric acid slag; 25 to 40 portions of iron purite slag, 5 to 15 portions of phosphogypsum slag, 5 to 15 portions of coal slag, 5 to 10 portions of coal gangue slag, and 5 to 10 portions of rare-earth slag. The preparation method comprises the following steps: (1) mixing the metallic slag and grinding the metallic slag into fine powder; (2) mixing the inorganic non-metallic slag and grinding the inorganic non-metallic slag into fine powder; (3) mixing the metallic slag with the inorganic non-metallic slag evenly according to weight proportion; (4) activating the fine powder; and (5) blending the clinker fine powder into cement green stock.

Owner:常熟紫金知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com