Patents

Literature

251 results about "Activity index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

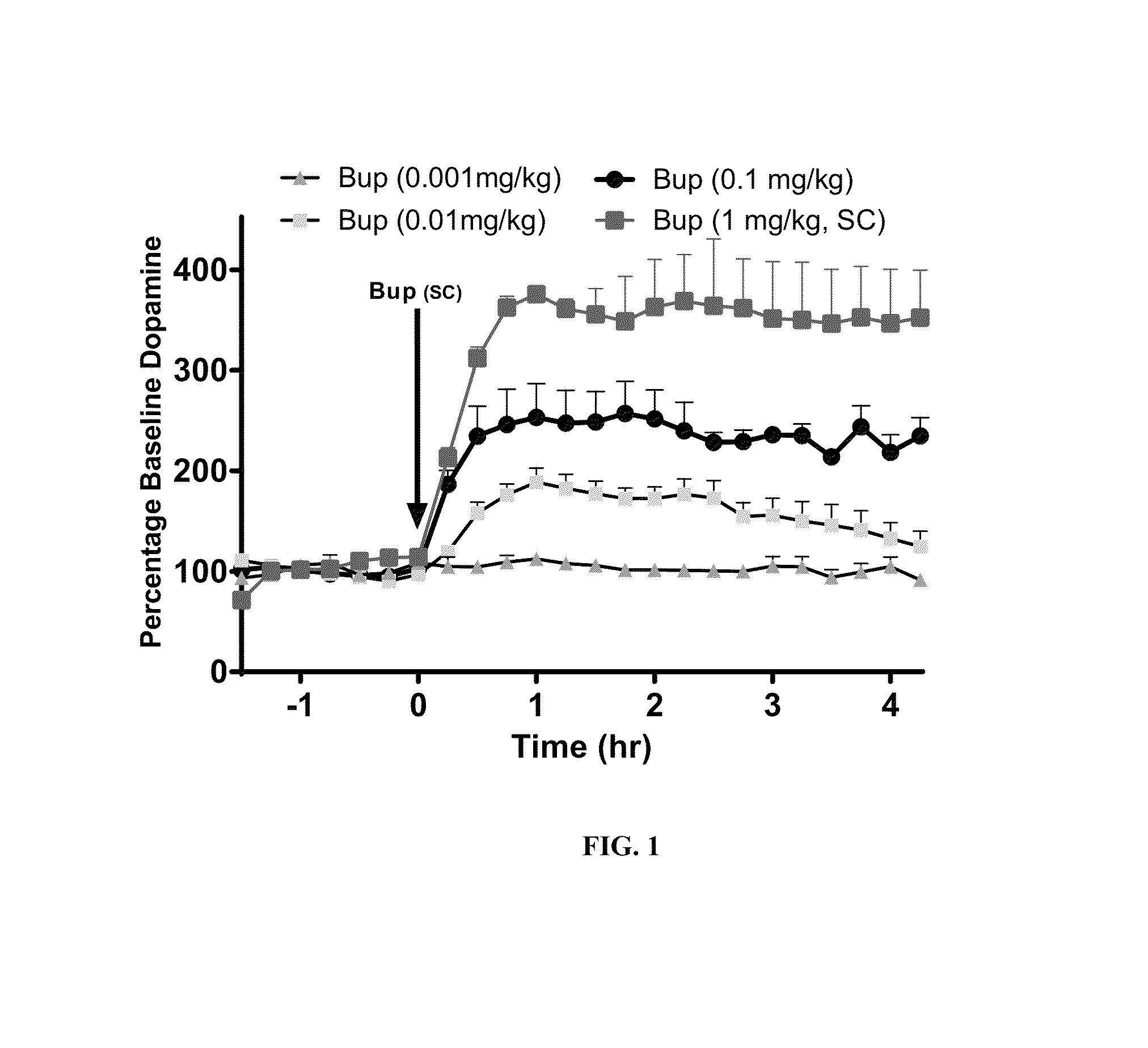

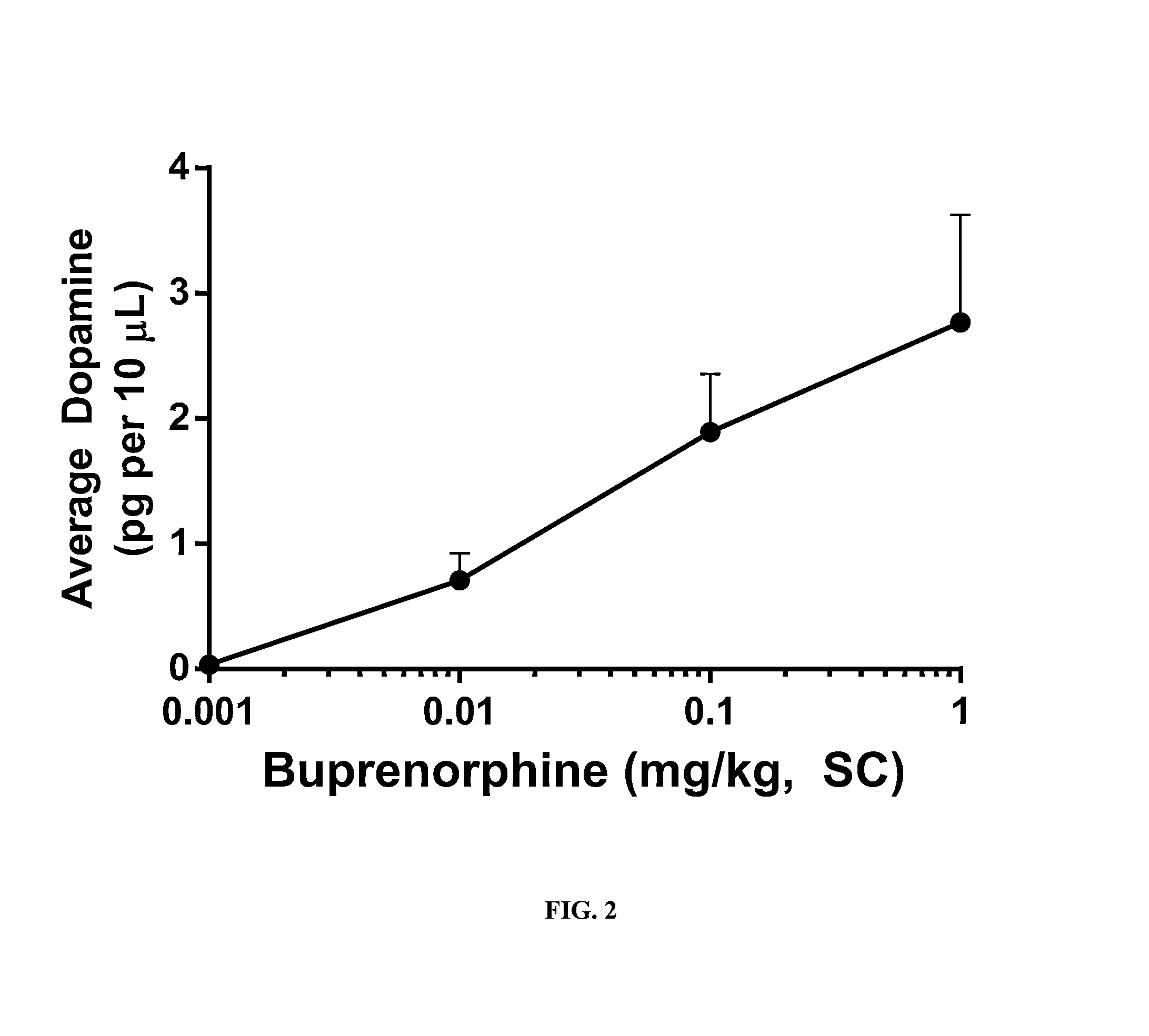

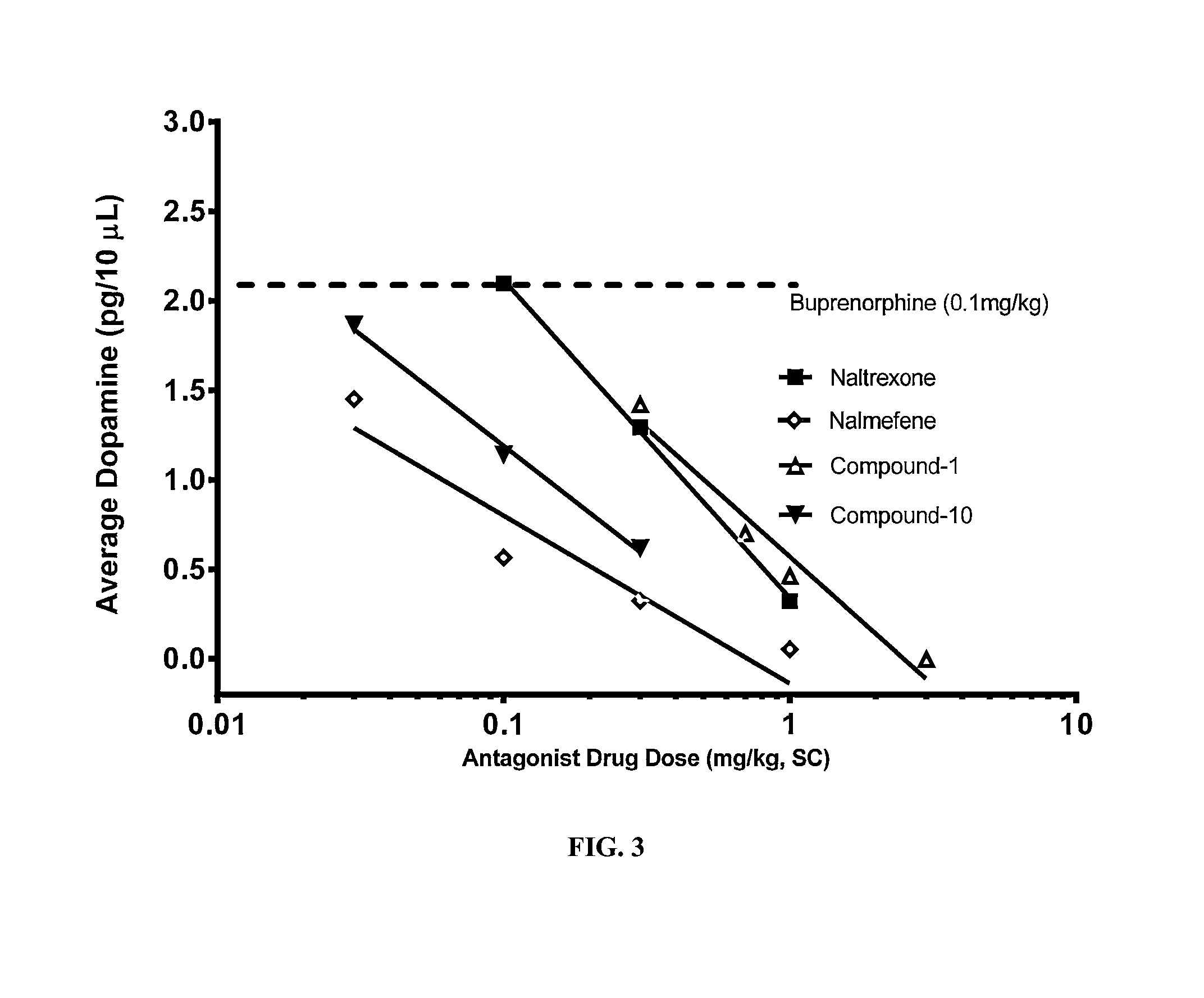

Compositions of buprenorphine and μ antagonists

Owner:ALKERMES PHARMA IRELAND LTD

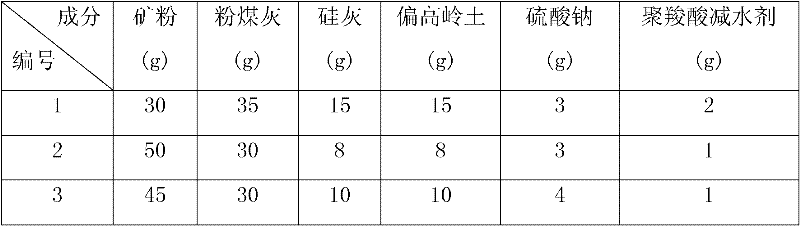

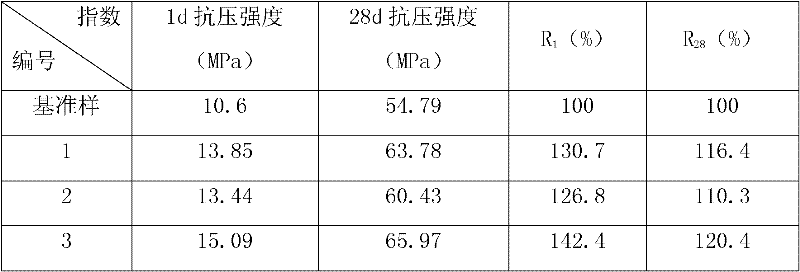

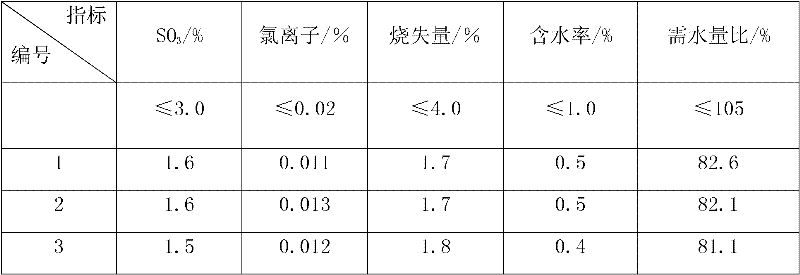

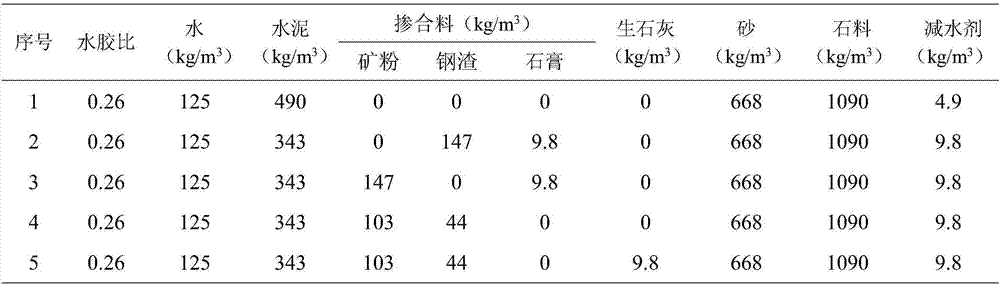

High-early-strength mineral additive for concrete

The invention relates to a high-early-strength mineral additive for concrete, which is characterized in that the high-early-strength mineral additive consists of the following ingredients which are mixed by mass percent: 30-50 percent of mineral powder, 20-35 percent of pulverized coal ash, 5-15 percent of silicon ash, 5-15 percent of metakaolin, 2-5 percent of sodium sulfate and 1-2 percent of polycarboxylate water reducing agent The high-early-strength mineral additive provided by the invention can be used for concrete prefabricated members, grouting materials, patching materials and the like. When 10 percent of high-early-strength mineral additive is added to replace cement to prepare the concrete, the water demand is small, the early activity index is high, the strength development situation is good, and compared with common cement and mineral additives, the dry shrinkage resistance is improved greatly.

Owner:赖斌

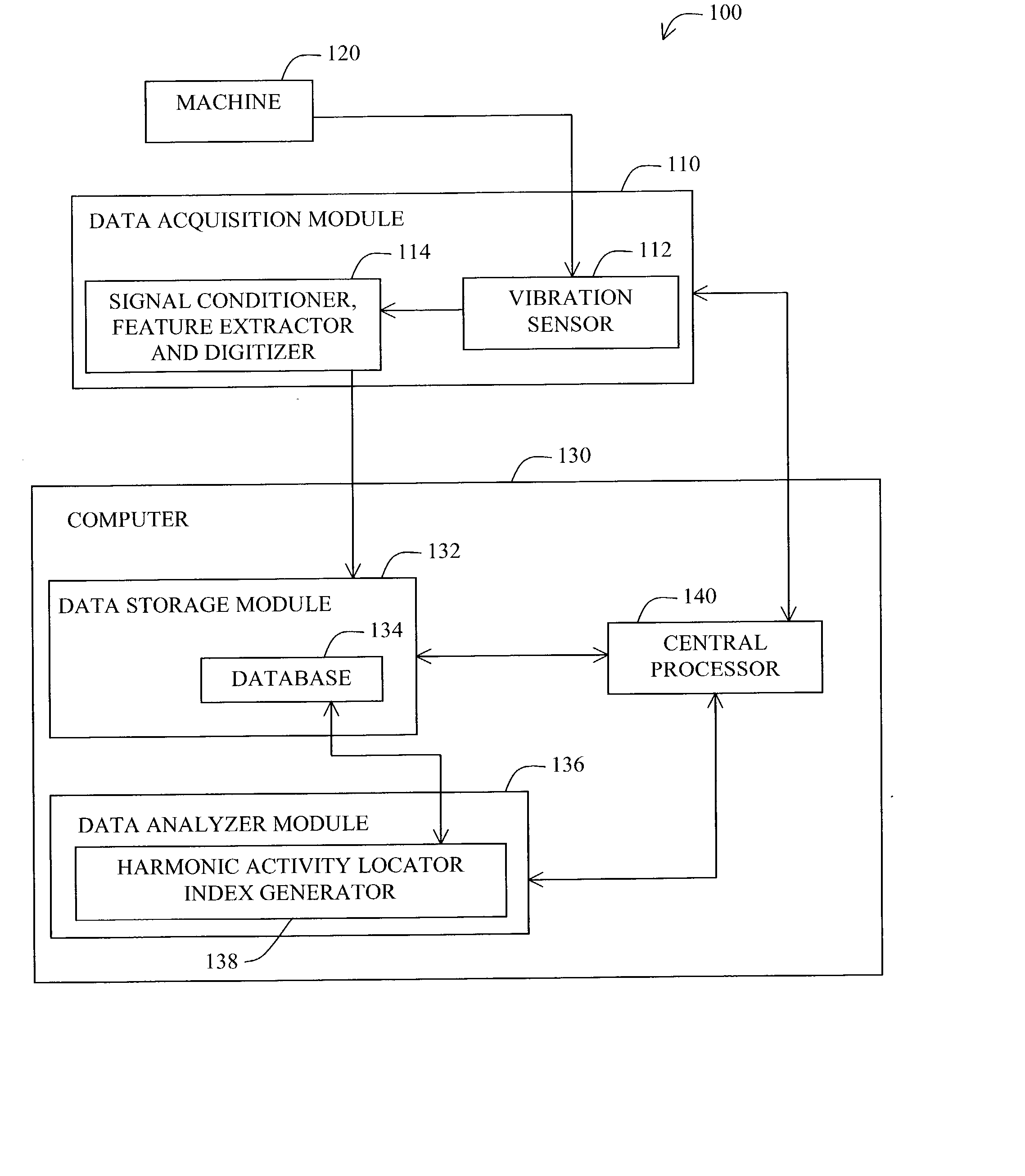

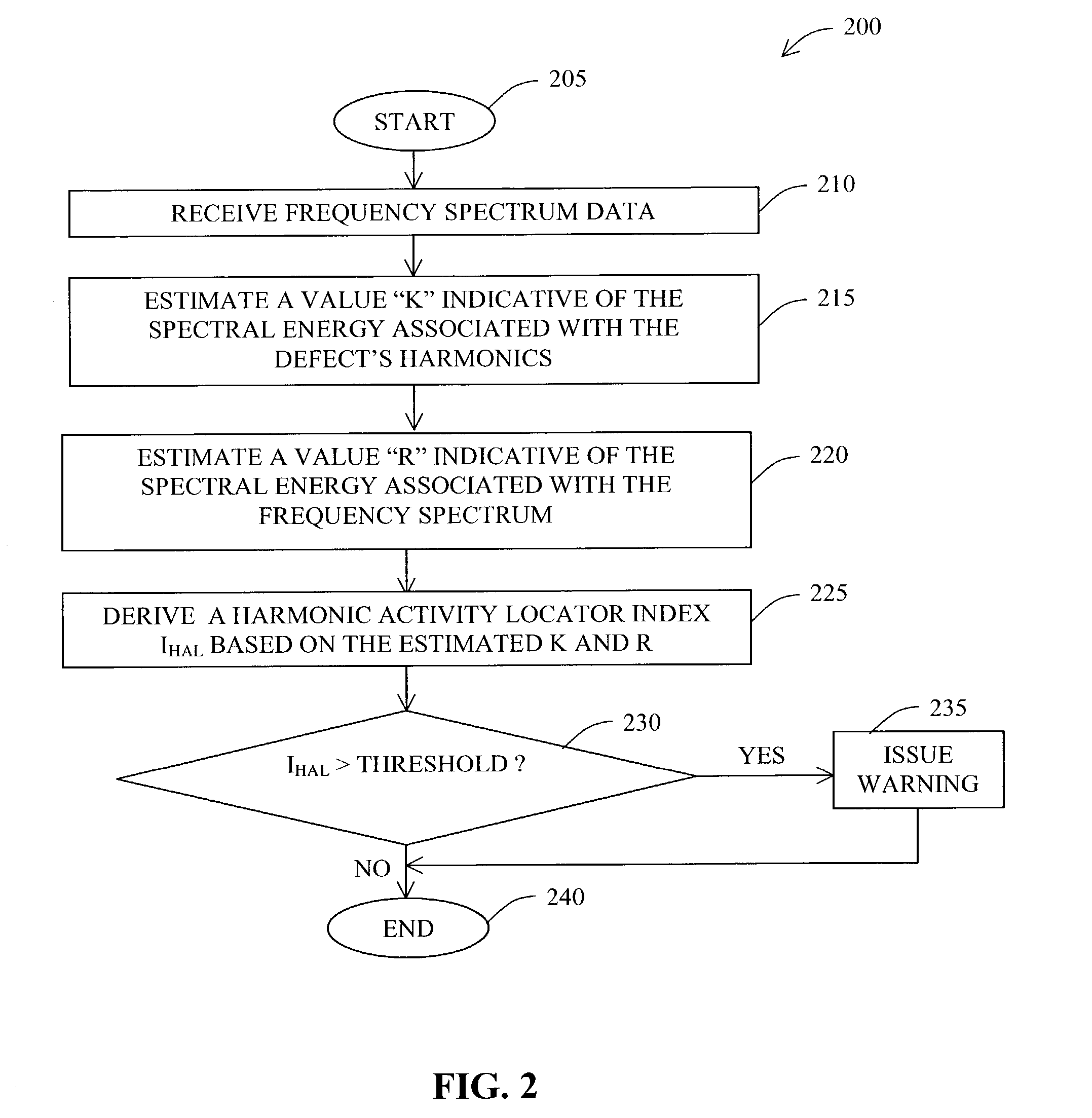

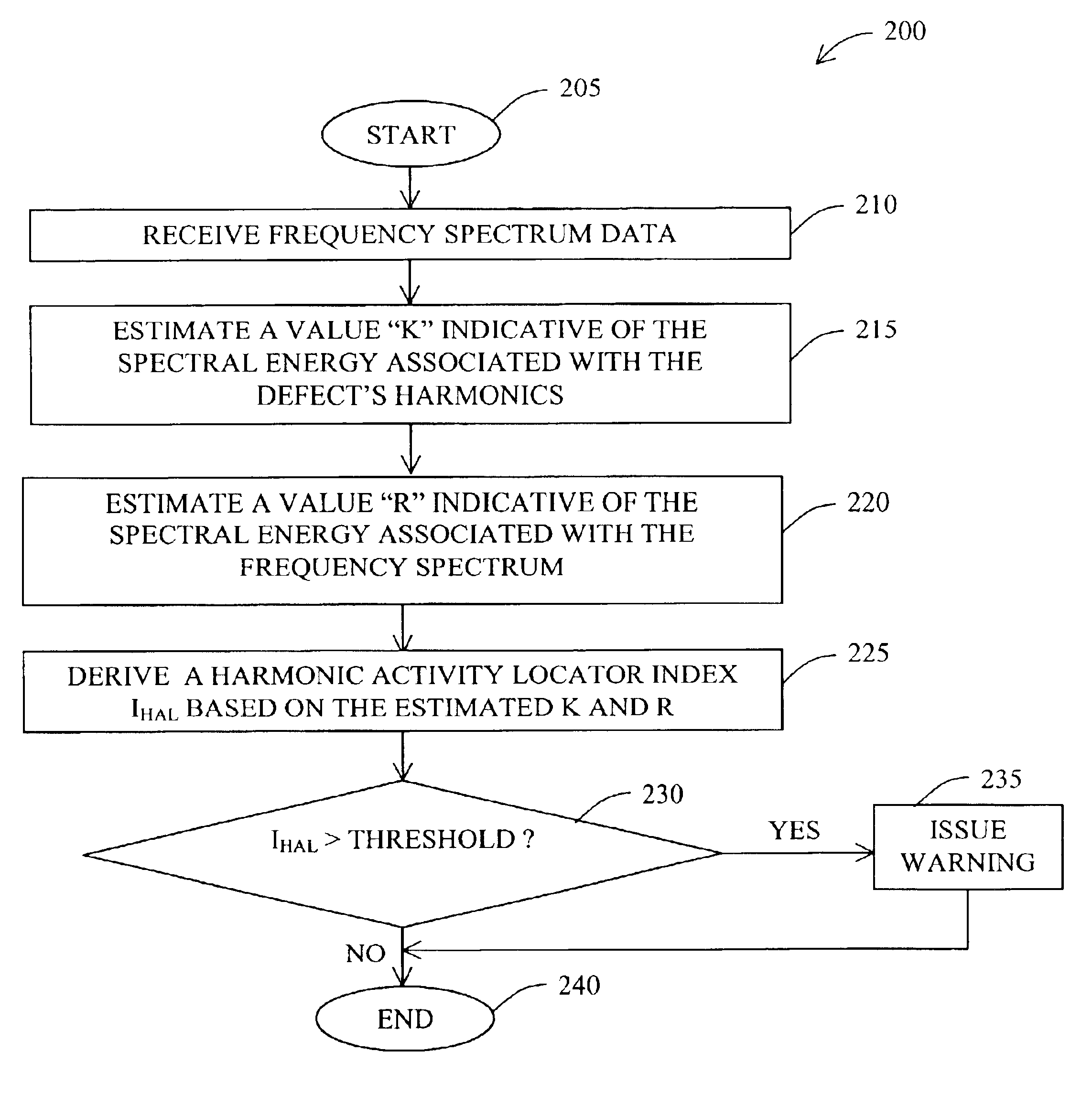

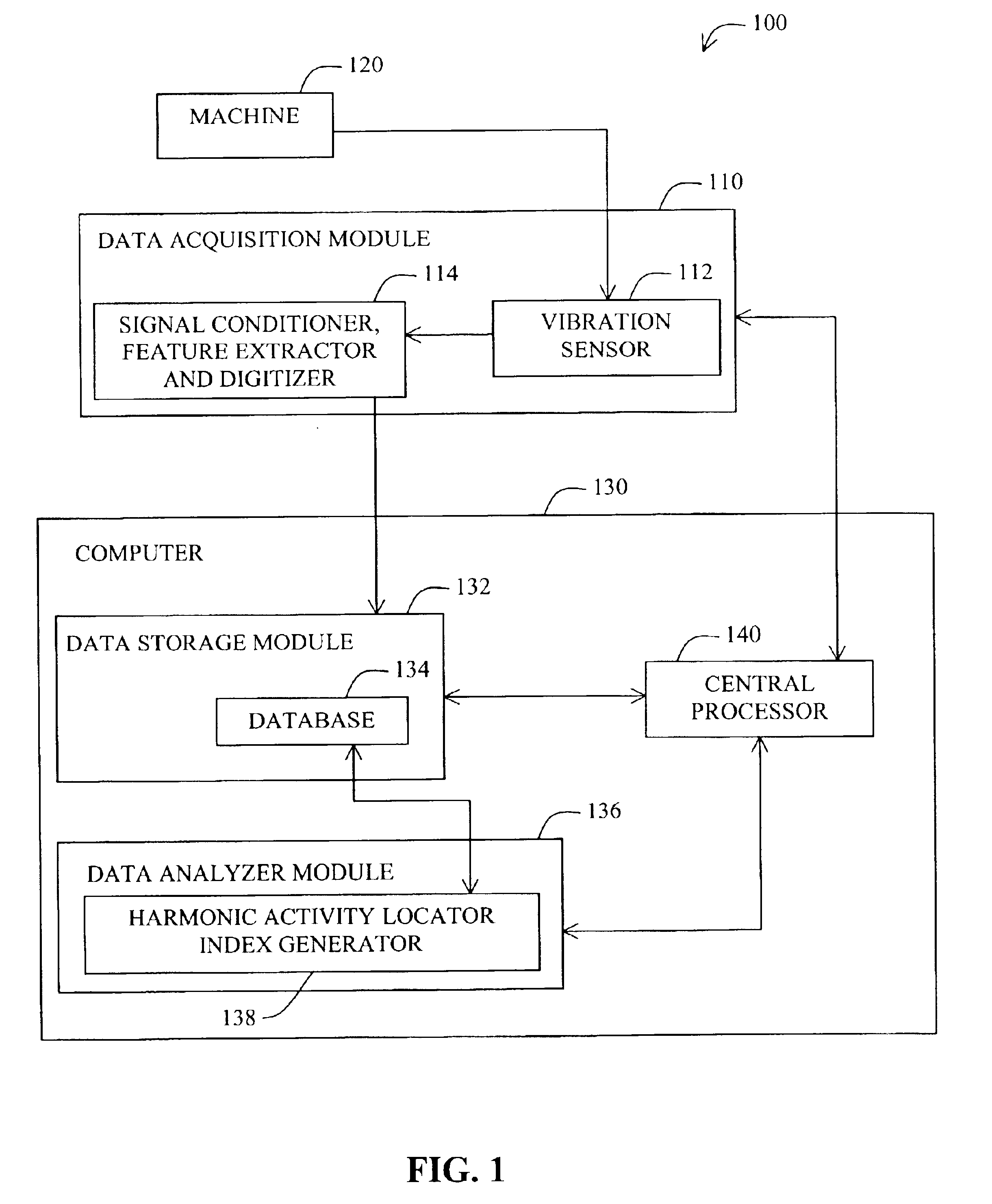

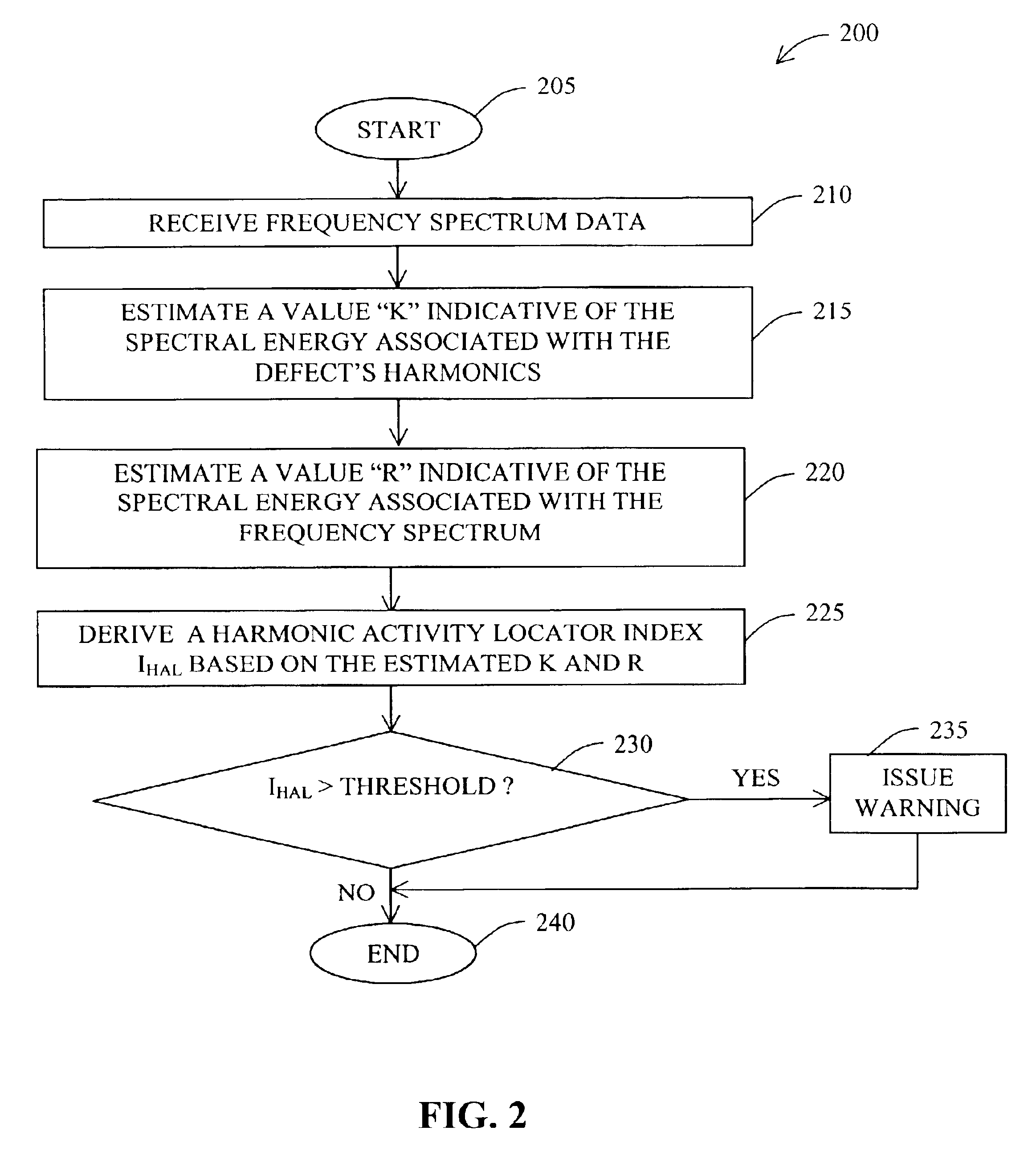

Harmonic activity locator

InactiveUS20030130810A1Vibration measurement in solidsMachine part testingFrequency spectrumHarmonic

Systems and methods for identifying the presence of a defect in vibrating machinery. An exemplary method comprises analysis of frequency spectrum vibration data of the machine. The method comprises deriving a harmonic activity index based on estimates of the energy associated with the frequency spectrum and the energy associated with the defect's harmonic series. The method may comprise deriving a value K by estimating a value M indicative of the energy of the defect's harmonic series and dividing M by the number of spectral lines corresponding to the defect's harmonic series. The method may further comprise deriving a value R by estimating a value Q indicative of the energy in the frequency spectrum data and dividing Q by the number of spectral lines of the frequency spectrum data. The method further comprises deriving the harmonic activity index based on the estimated K and R. Related systems for executing the methods are also disclosed.

Owner:SKF USA INC

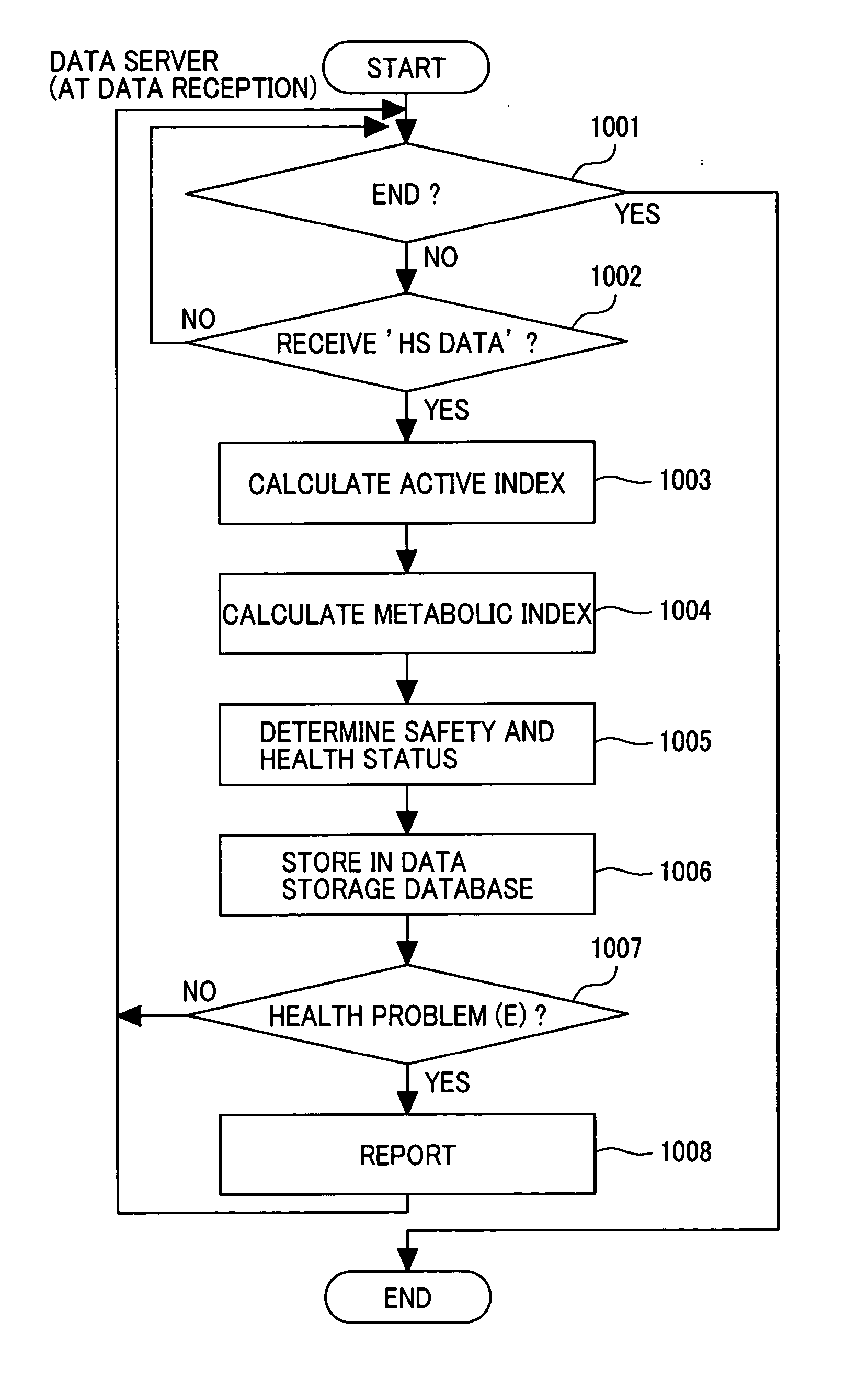

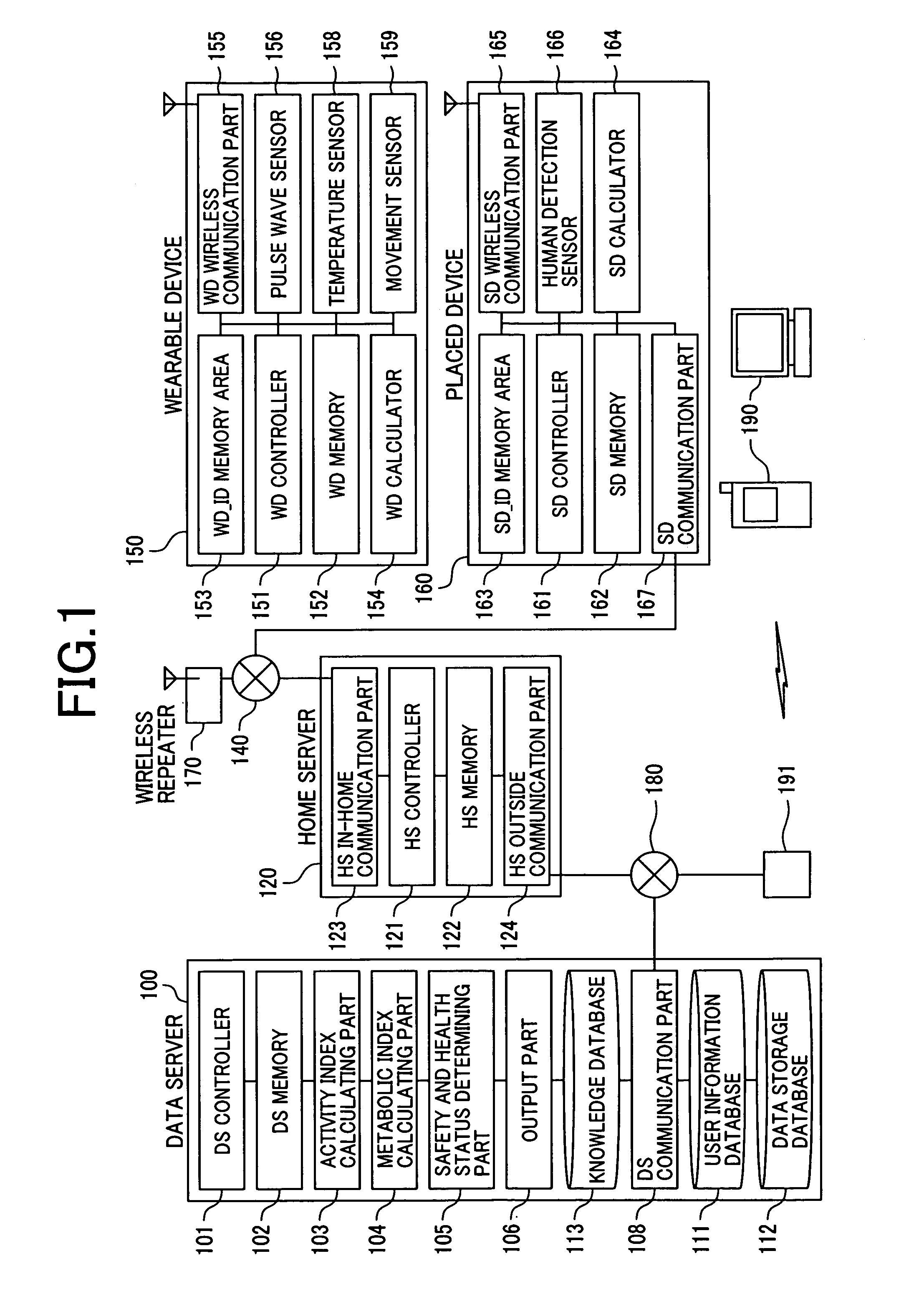

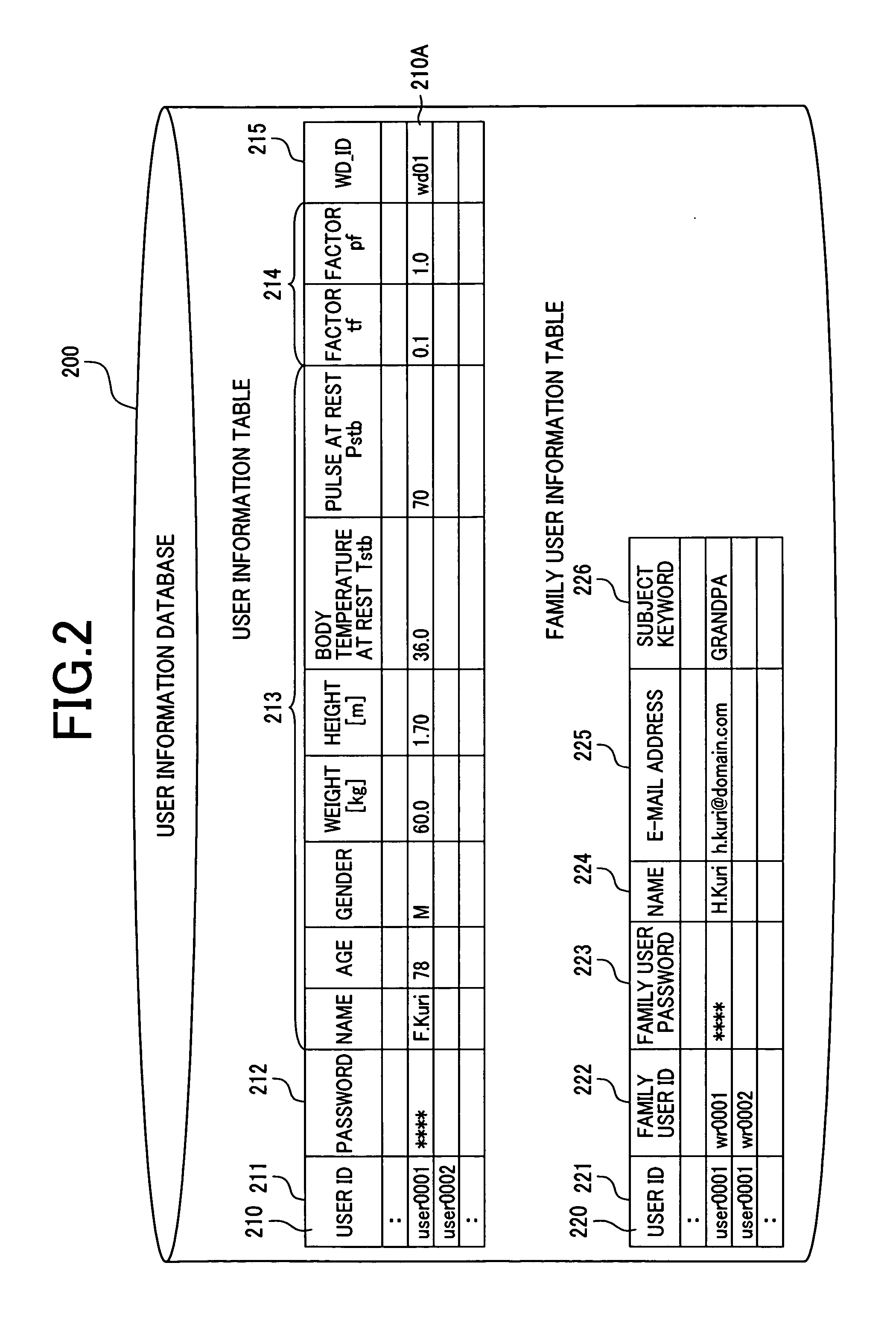

Safety and health information reporting system

ActiveUS20060094938A1Easy to understandWithout anxietyData processing applicationsInertial sensorsActivity indexEngineering

A safety and health information reporting system including a wearable device, a metabolic index calculating part, an activity index calculating part, a safety and health status determining part and a determination result output part. The wearable device is worn by a living body. The metabolic index calculating part calculates a metabolic index which represents energy consumption of the living body, based on a detection signal of the wearable device. The activity index calculating part calculates an activity index representing an activity amount of the living body on a daily basis. The safety and health status determining part which determines a safety and health status of the living body, based on a comparison of the metabolic index and the activity index. The determination result output part outputs a determination result of the safety and health status determining part.

Owner:HITACHI LTD

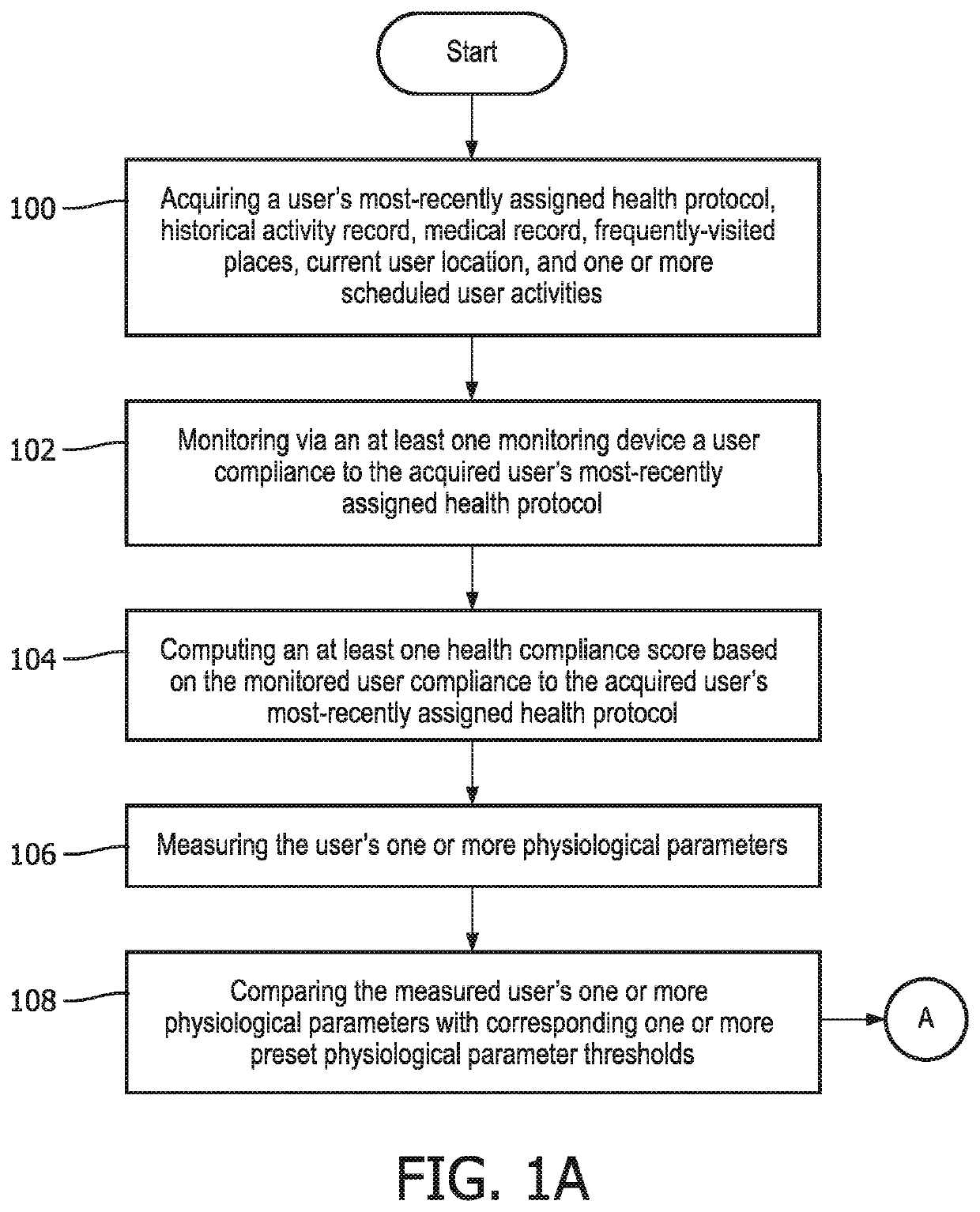

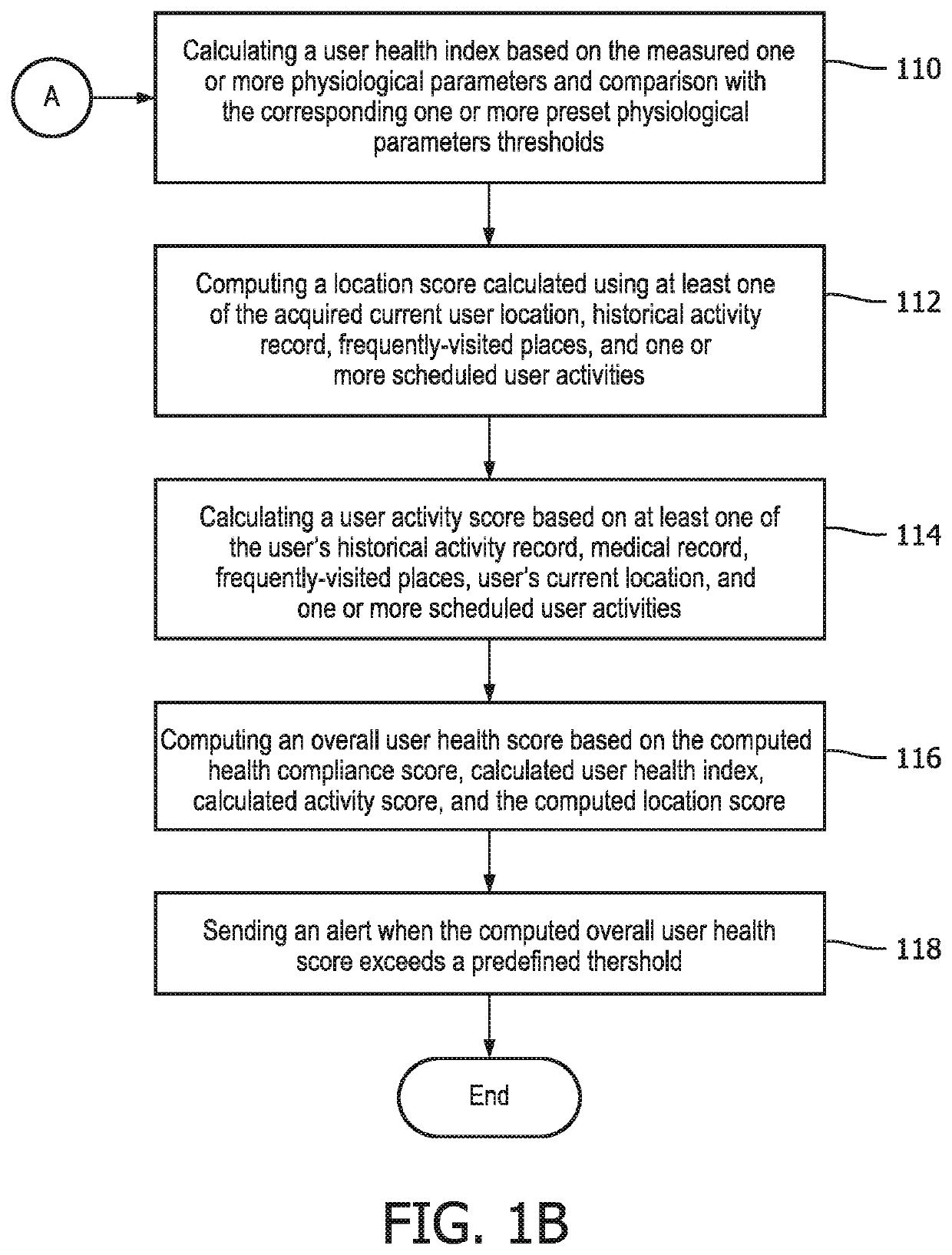

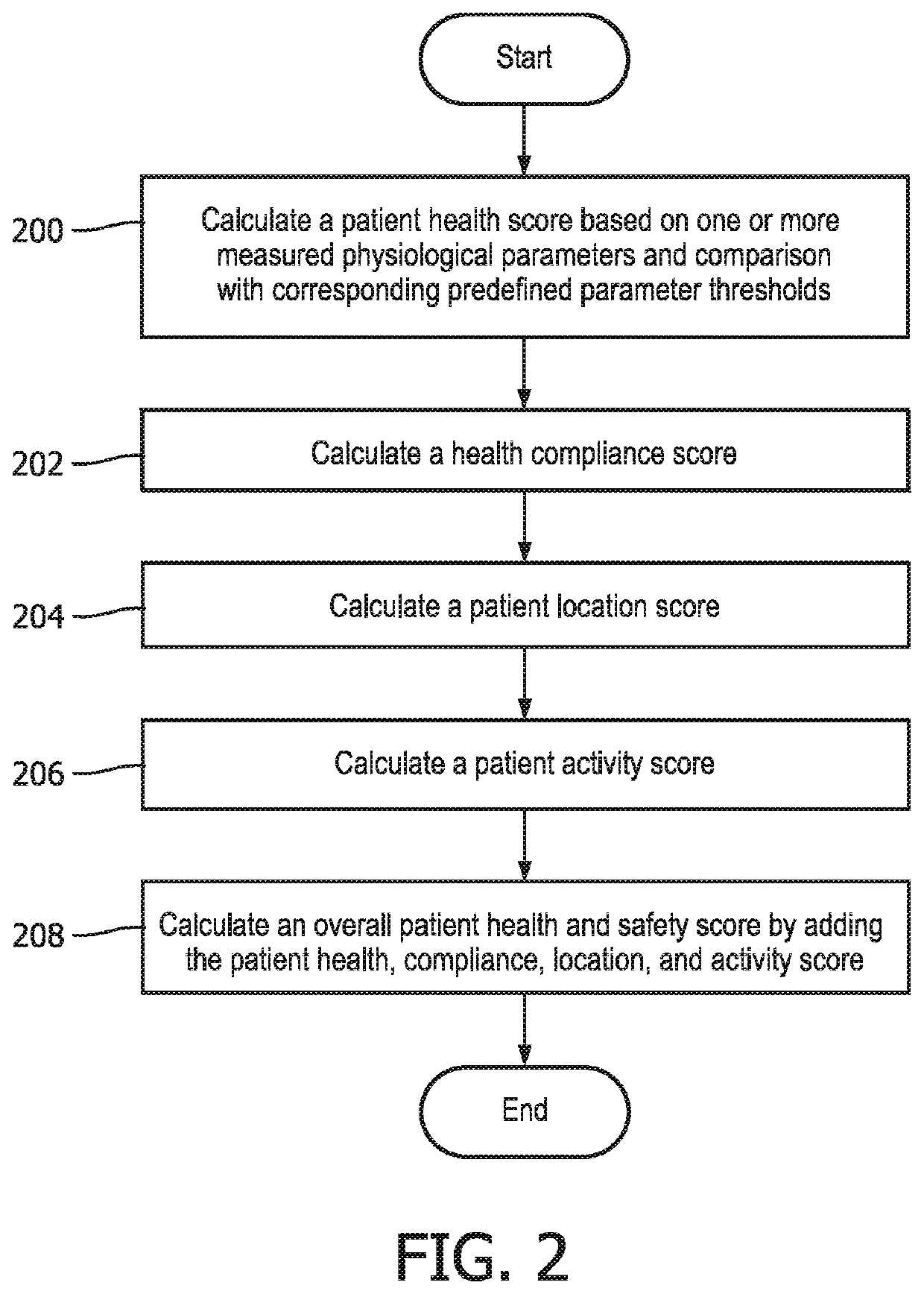

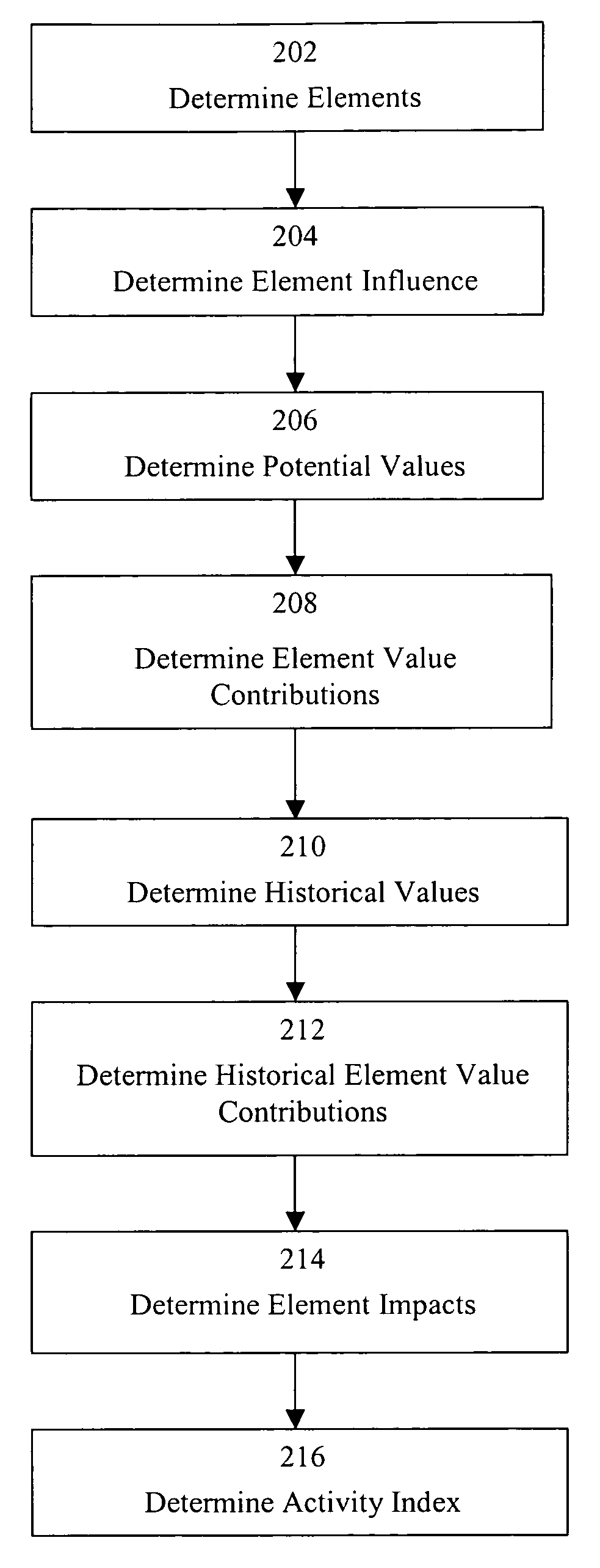

Location, activity, and health compliance monitoring using multidimensional context analysis

ActiveUS10602964B2Improve accuracy and reliabilityPhysical therapies and activitiesHealth-index calculationHealth indexActivity index

A system and method for monitoring patient activity, location, present health status, and health protocol compliance. The present invention provides a more complete and accurate picture of a patient's health and safety context through a multi-dimensional user health and safety context analysis. Based on the combined computed health compliance score, calculated activity index, the computed location score, and calculated user health index, an overall user health and safety score is calculated. If the computed overall user health and safety score violates a predefined threshold or threshold range, an alert is transmitted to one or more persons.

Owner:KONINKLJIJKE PHILIPS NV

Method of determining a climate-based activity index and best-time-to recommendation

ActiveUS7212922B1Affect desirabilityIncrease weightWeather condition predictionMarketingActivity indexData mining

A method of using climate data to determine activity index values for a given activity. One embodiment provides a method of more objectively determining the desirability of an activity based on climate data by determining an activity index value using a weighted-element type analysis. Multiple activity index values may be determined for different time periods and used to provide information useful in comparing the desirability of the different time periods for a given activity. The activity index values may be used to answer questions such as “what is the best month to visit Kingston, Jamaica” and “what is the worst season for allergies in Atlanta.”

Owner:DTN LLC

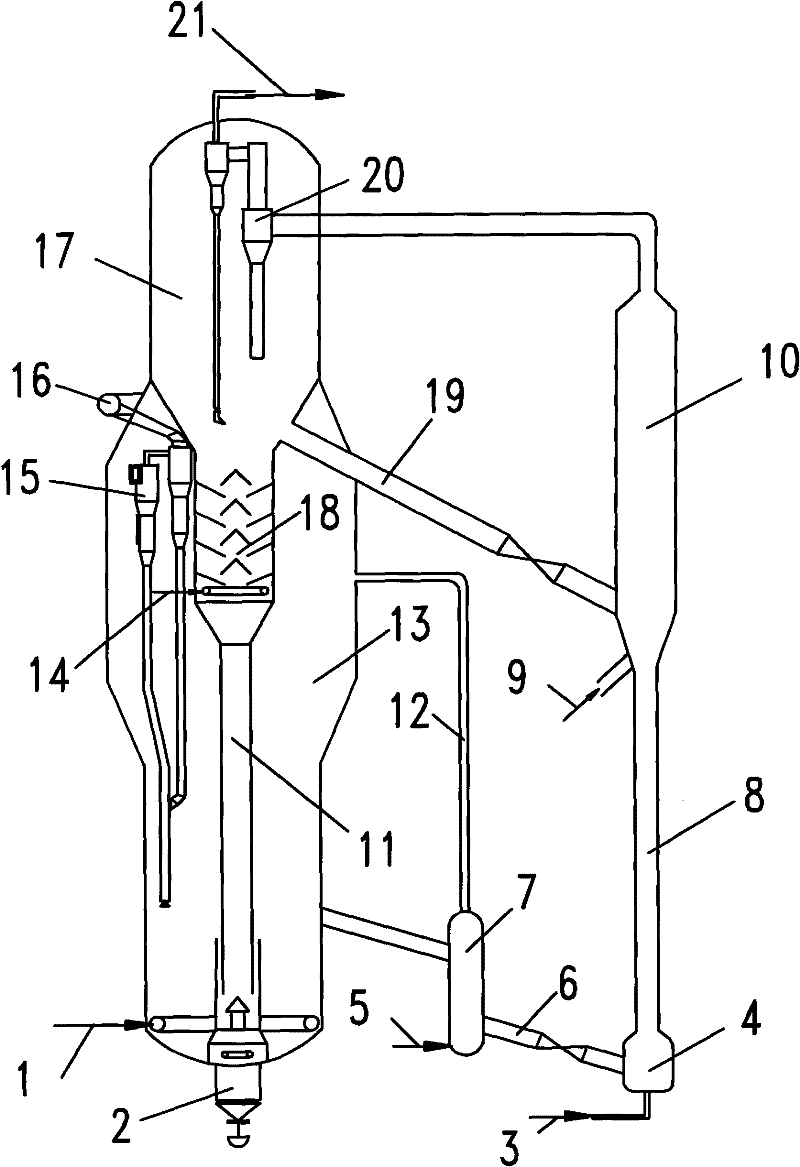

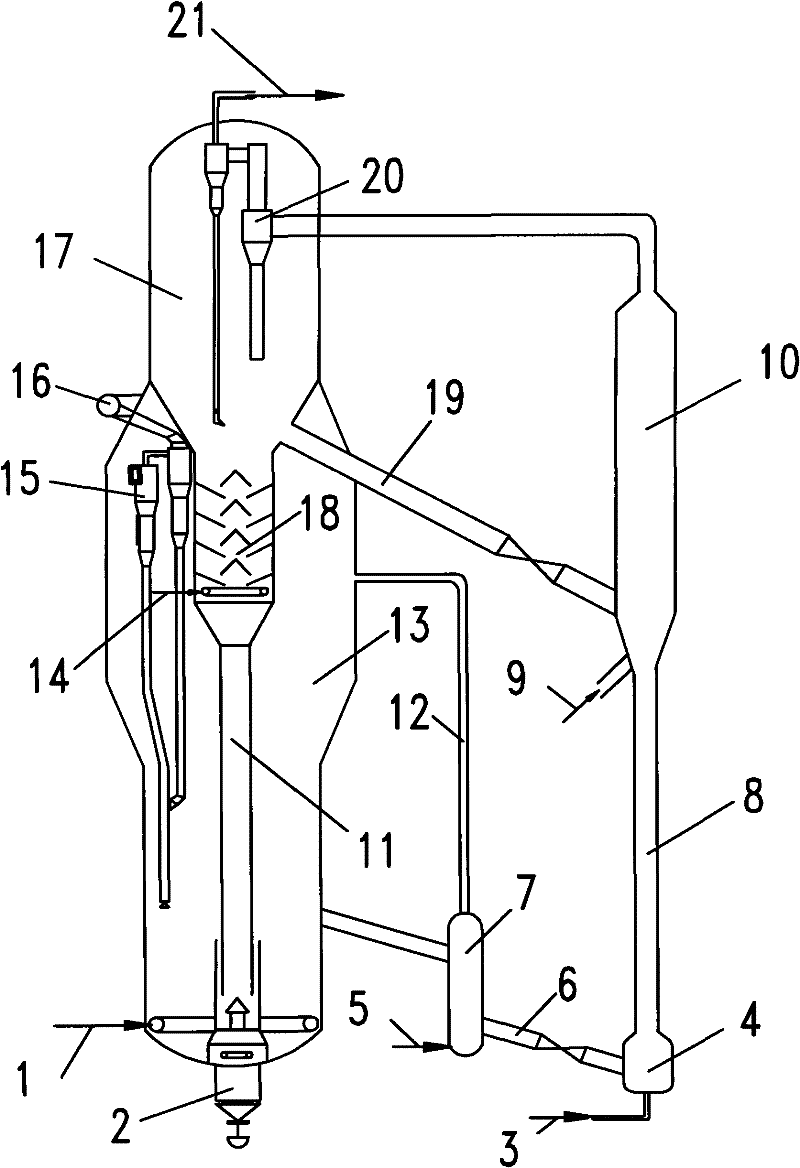

Method for catalytically converting naphtha into light olefins

The invention relates to a method for catalytically converting naphtha into low-carbon olefins, which mainly solves the problem of low yield of low-carbon olefins in the prior art. The present invention comprises the following steps by adopting a naphtha catalytic conversion method for light olefins: (a) providing a reaction device comprising a naphtha conversion reactor, a regenerator, a settling stripper, and a gas-solid cyclone Separator; (b) The main raw material of naphtha is contacted with the catalyst in the naphtha conversion reactor to generate products, and at the same time form a carbon deposition catalyst, which enters the settling stripper above the regenerator; (c) carbon deposition catalyst After entering the stripping zone, part of the carbon-deposited catalyst after stripping returns to the upper section of the naphtha conversion reactor, and a part enters the regenerator for regeneration to form a regenerated catalyst; (d) the regenerated catalyst enters the lower section of the naphtha conversion reactor; wherein, the regeneration The technical solution with a catalyst activity index greater than 0.8 better solves the above problems and can be used in the industrial production of light olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

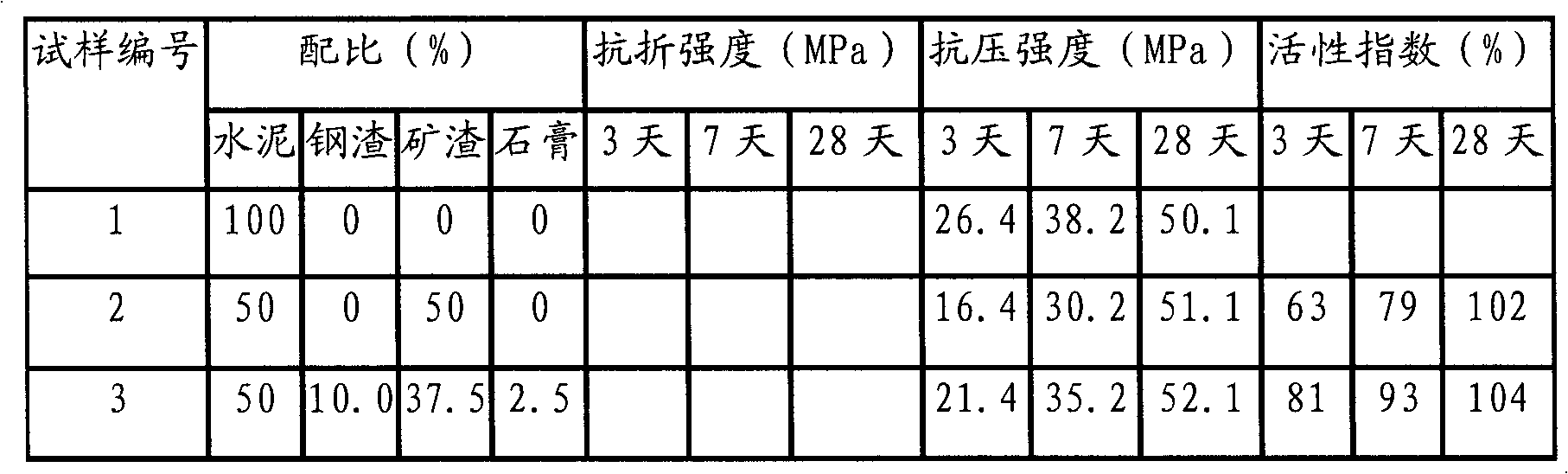

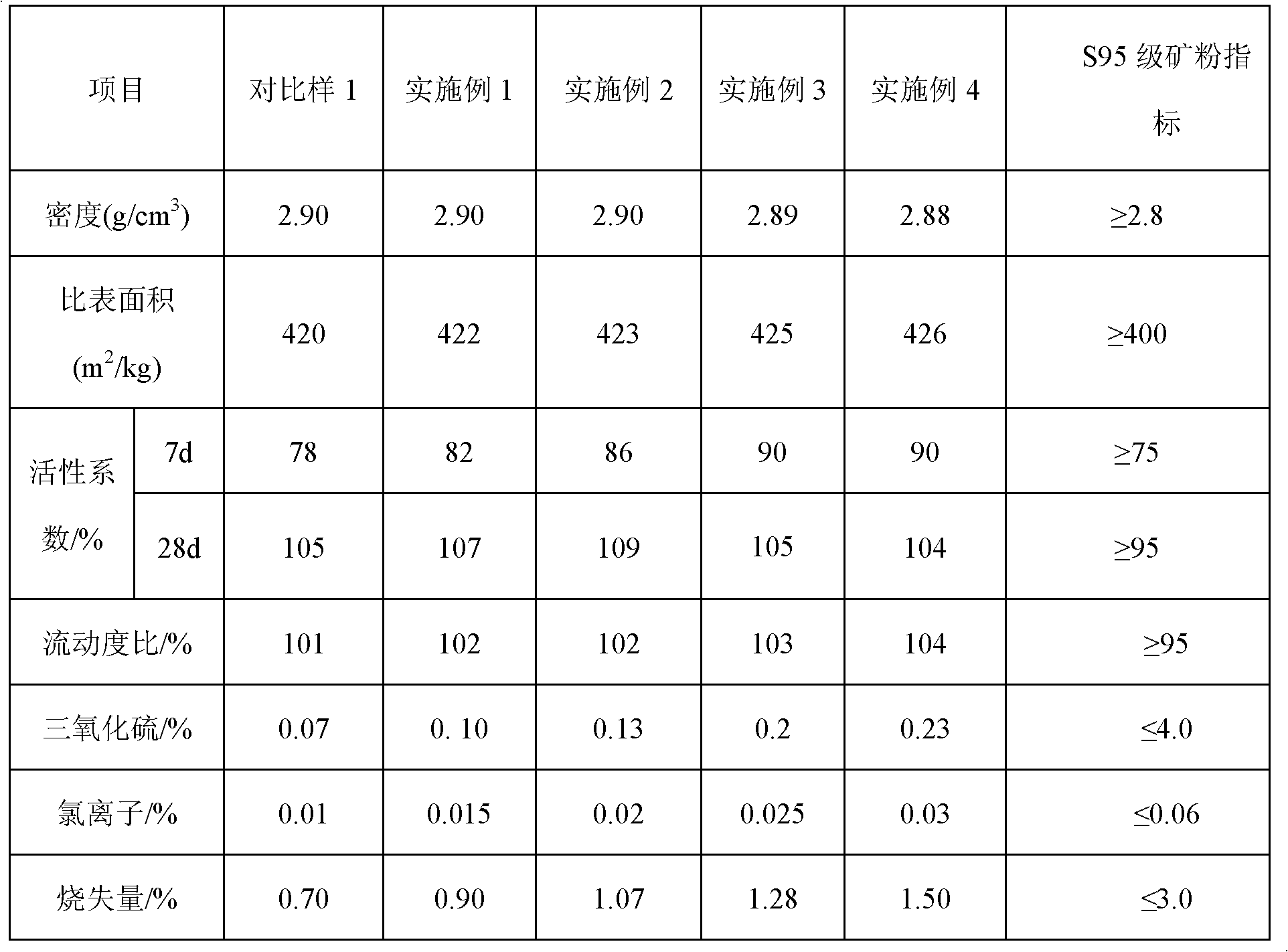

Preparation method of modified S95-grade slag powder

ActiveCN101805142AOvercome the disadvantage of low early strengthHigh strengthSolid waste managementSlagActivity index

The invention relates to a preparation method of modified S95-grade slag powder, belonging to the technical field of building materials. The modified S95-grade slag powder comprises the following raw materials in percentage by weight: 50%-85% of S95-grade slag powder, 10%-40% of superfine slag micropowder and 3%-15% of semi-hydrated gypsum. The modified S95-grade slag micropowder has a three-day activity index between 70% and 80%, a seven-day activity index between 85% and 90% and a twenty-eight-day activity index between 100% and 115%. The invention not only overcomes the shortage of low three-day early strength of the S95-grade slag powder, but also can obviously reduce the drying of concrete and decrease early contraction cracks of the concrete when applied to premixed concrete and also can effectively enhance the durability performance of the concrete.

Owner:SHANGHAI HAILI NEW ENVIRONMENTAL PROTECTION BUILDING MATERIAL CO LTD

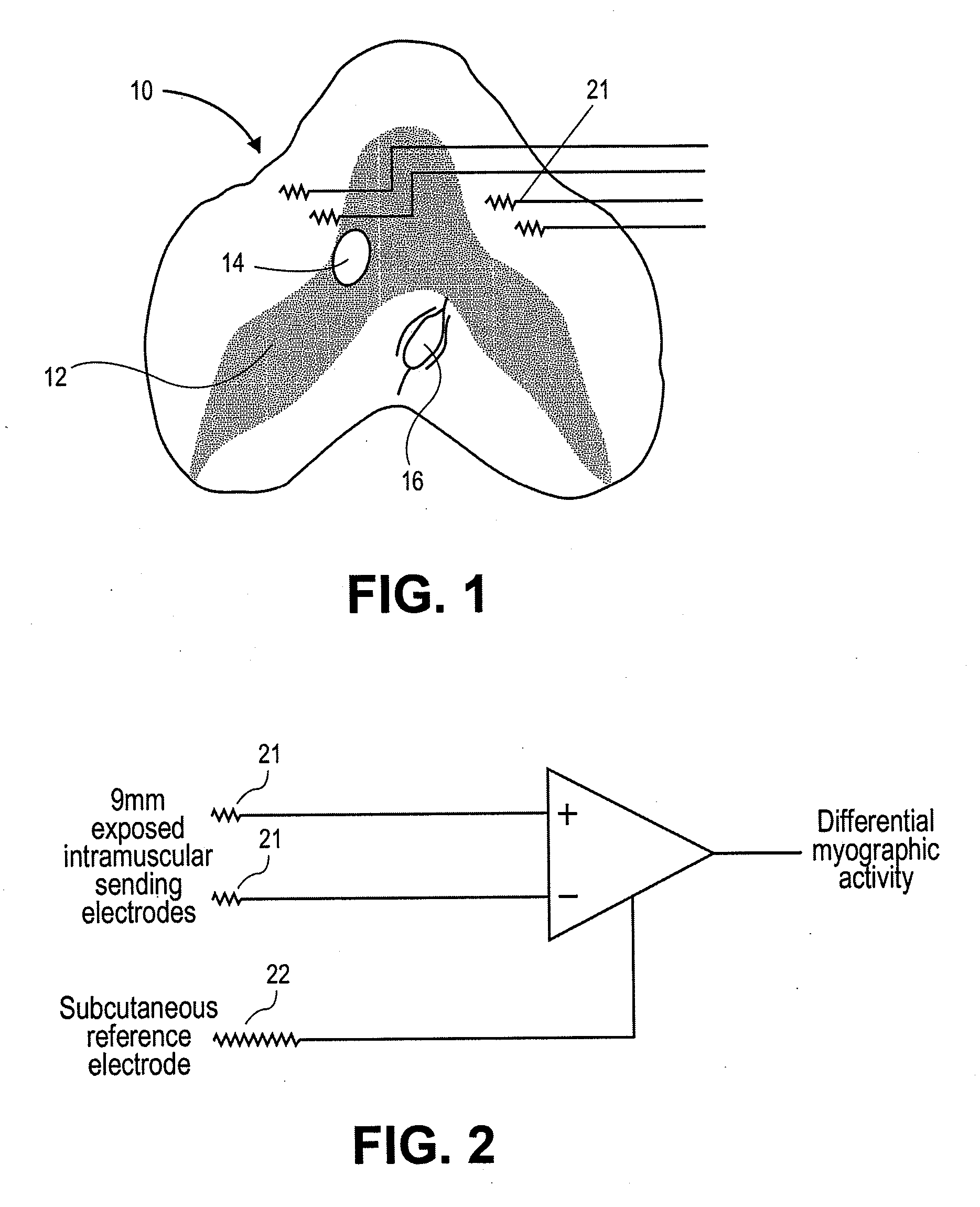

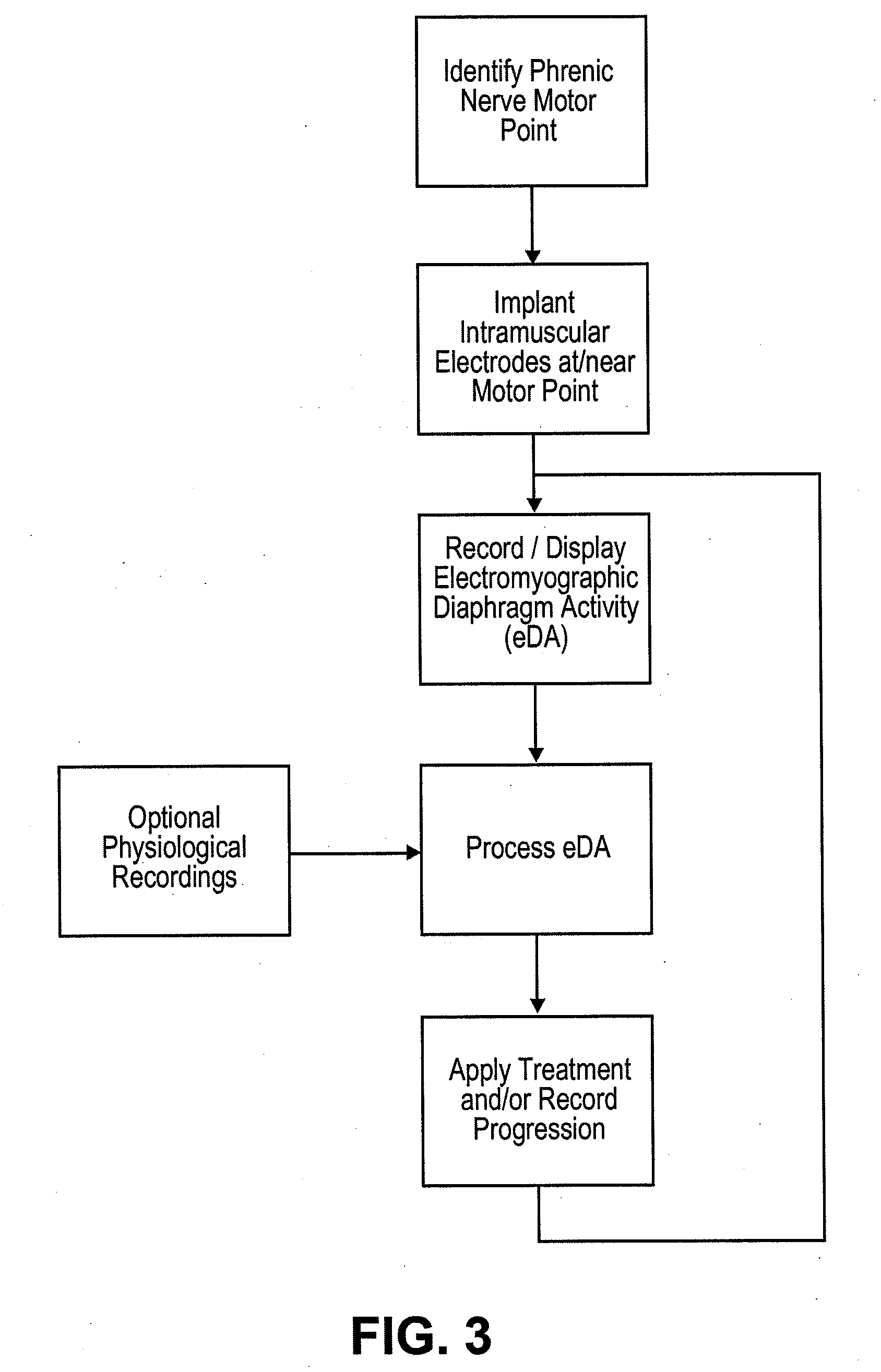

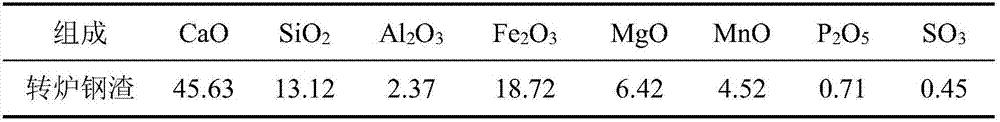

Devices and methods for assessing motor point electromyogram as a biomarker

ActiveUS20080287820A1Effectiveness of treatmentWeakening of the diaphragmElectrotherapyElectromyographyActivity indexPhysical therapy

Owner:SYNAPSE BIOMEDICAL INC

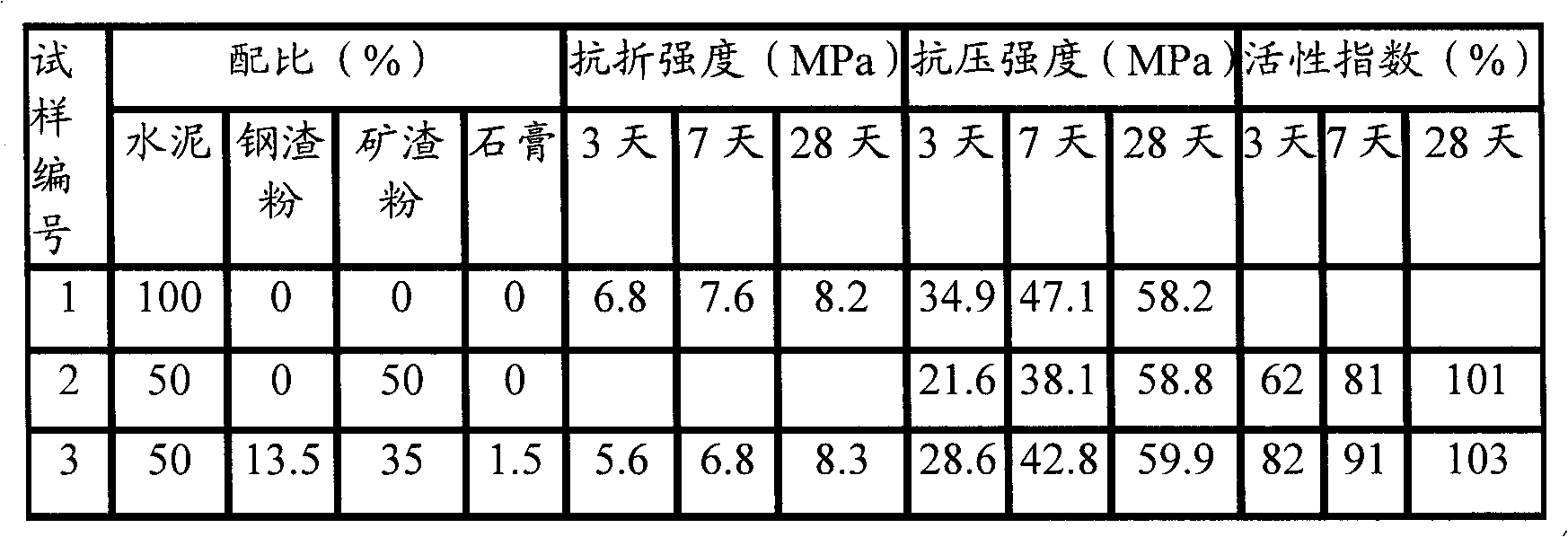

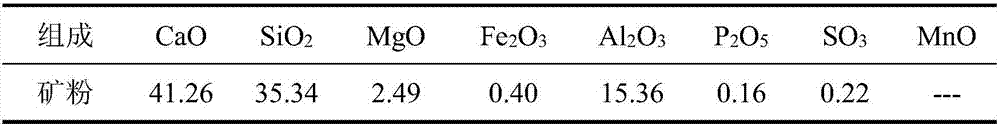

Admixture prepared from gypsum activation steel slag and ore powder and high-performance concrete prepared from admixture

The invention discloses an admixture prepared from gypsum activation steel slag and ore powder and high-performance concrete prepared from the admixture. The admixture is prepared by mixing steel slag, ore powder and gypsum according to the weight ratio of (8 to 10):(20 to 22):(1 to 3). The high-performance concrete is prepared from the following ingredients of 300 to 500 parts of gelled materials, 1000 to 1200 parts of stone materials, 600 to 700 parts of sand, 100 to 150 parts of water and 3 to 10 parts of water reducing agents, wherein the admixture accounts for 25 to 35 percent of total amount of the gel material. The gypsum is used for activating the activity of the steel slag; the mutual activation effect between the steel slag and the ore powder is utilized; the activity after the steel slag and the ore powder are mixed is improved; the high-activity admixture is used for replacing partial cement to prepare the concrete; the work performance of the concrete can be ensured; meanwhile, the early stage intensity and the later stage intensity of the concrete can be obviously improved; the activity index of the concrete is improved.

Owner:JINAN UNIVERSITY

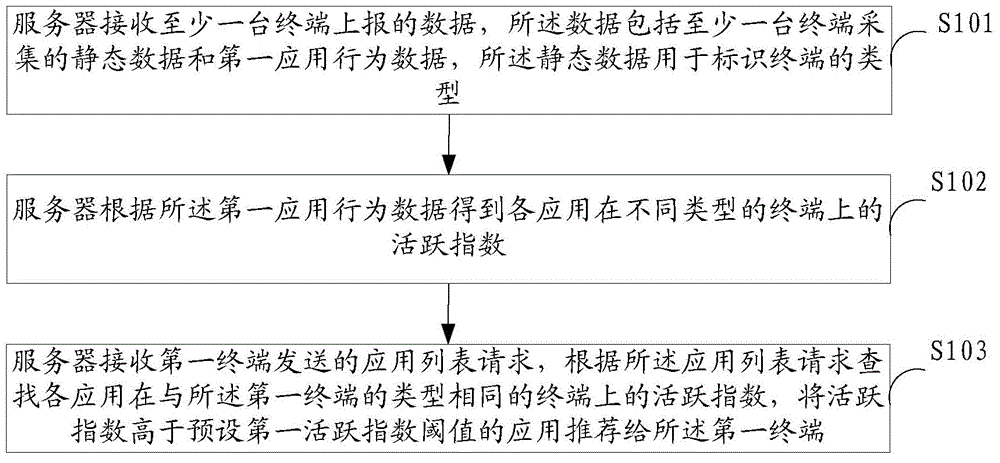

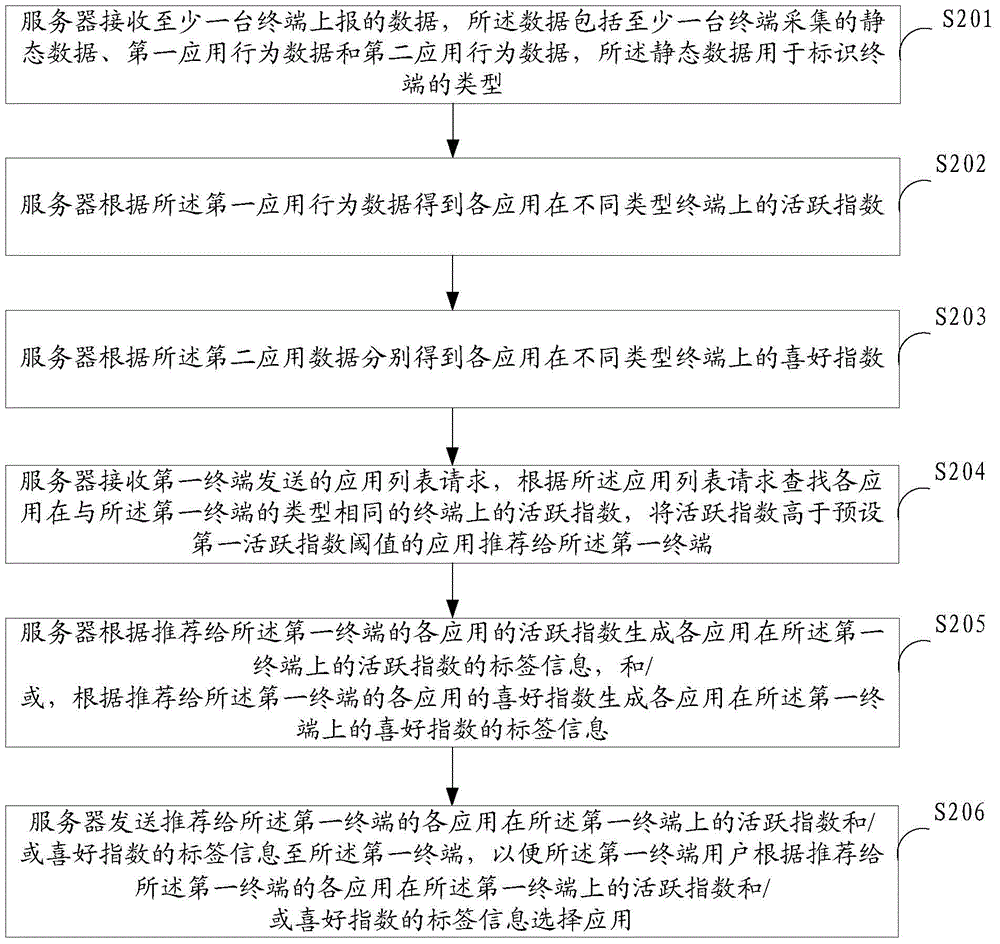

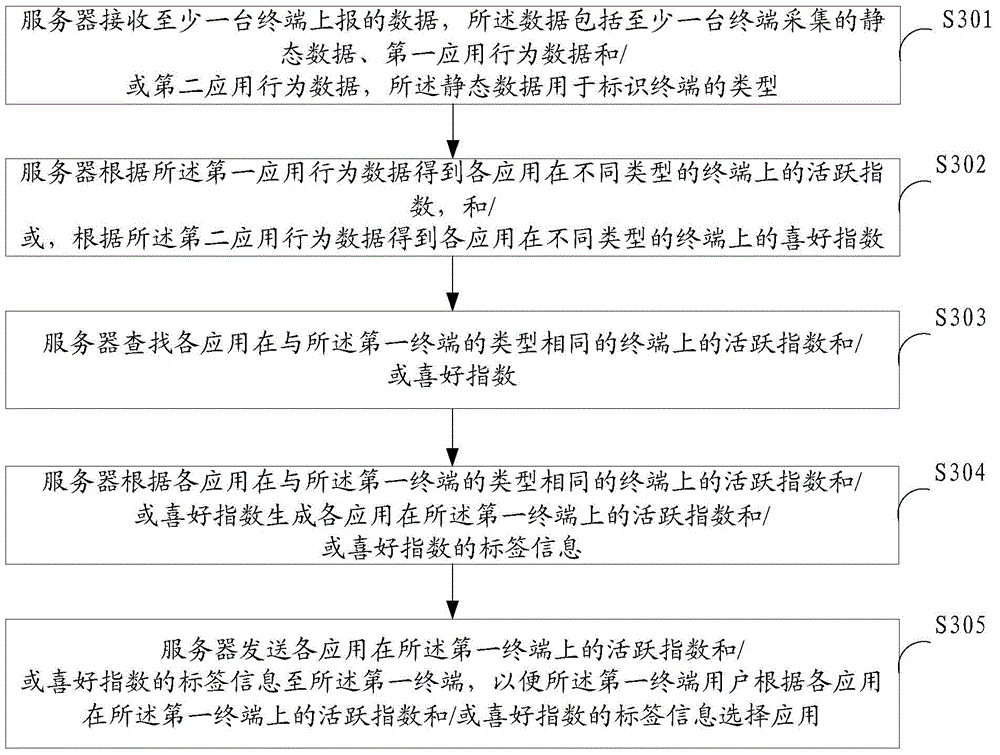

Method, system and server for recommending application

ActiveCN104603753AHigh activity indexImprove compatibilityHardware monitoringCommerceActivity indexComputer compatibility

Embodiments of the invention are applicable to the technical field of communication and provide a method, a system and a server for recommending an application. The method comprises: data reported by at least one terminal are received, and the data include static data and first application behavior data collected by the at least one terminal, the static data being used for marking the type of the terminal; activity indices of each application on different types of terminals are obtained according to the first application behavior data; an application list request sent by a first terminal is received, the activity index of each application on the terminal of the same type as the first terminal is queried according to the application list request, and the application with the activity index higher than a preset first activity index threshold is recommended to the first terminal. According to the embodiments, the application recommended to the terminal by a server has the highest activity index. The method is good in compatibility with regard to the terminals.

Owner:HUAWEI TECH CO LTD

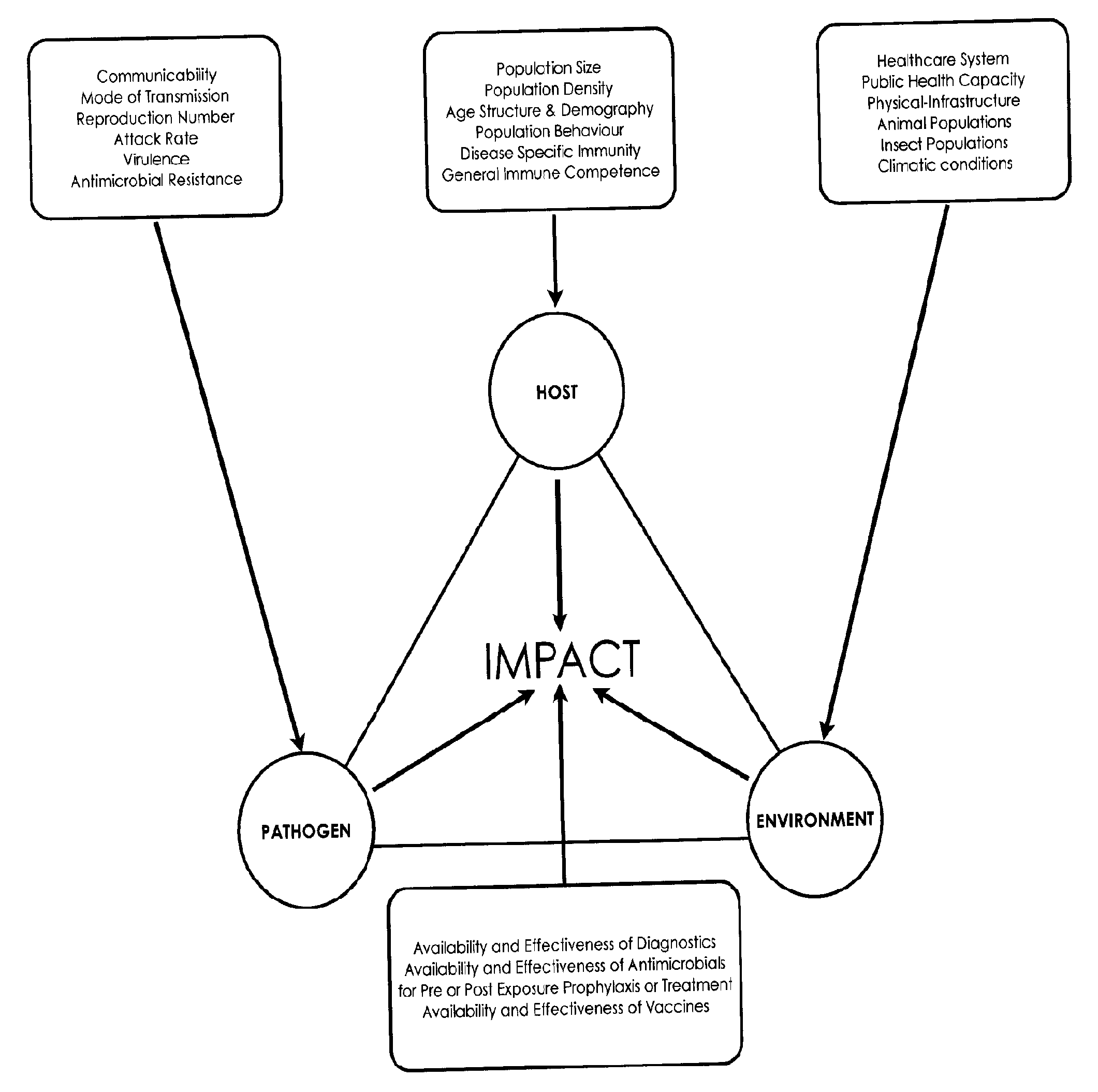

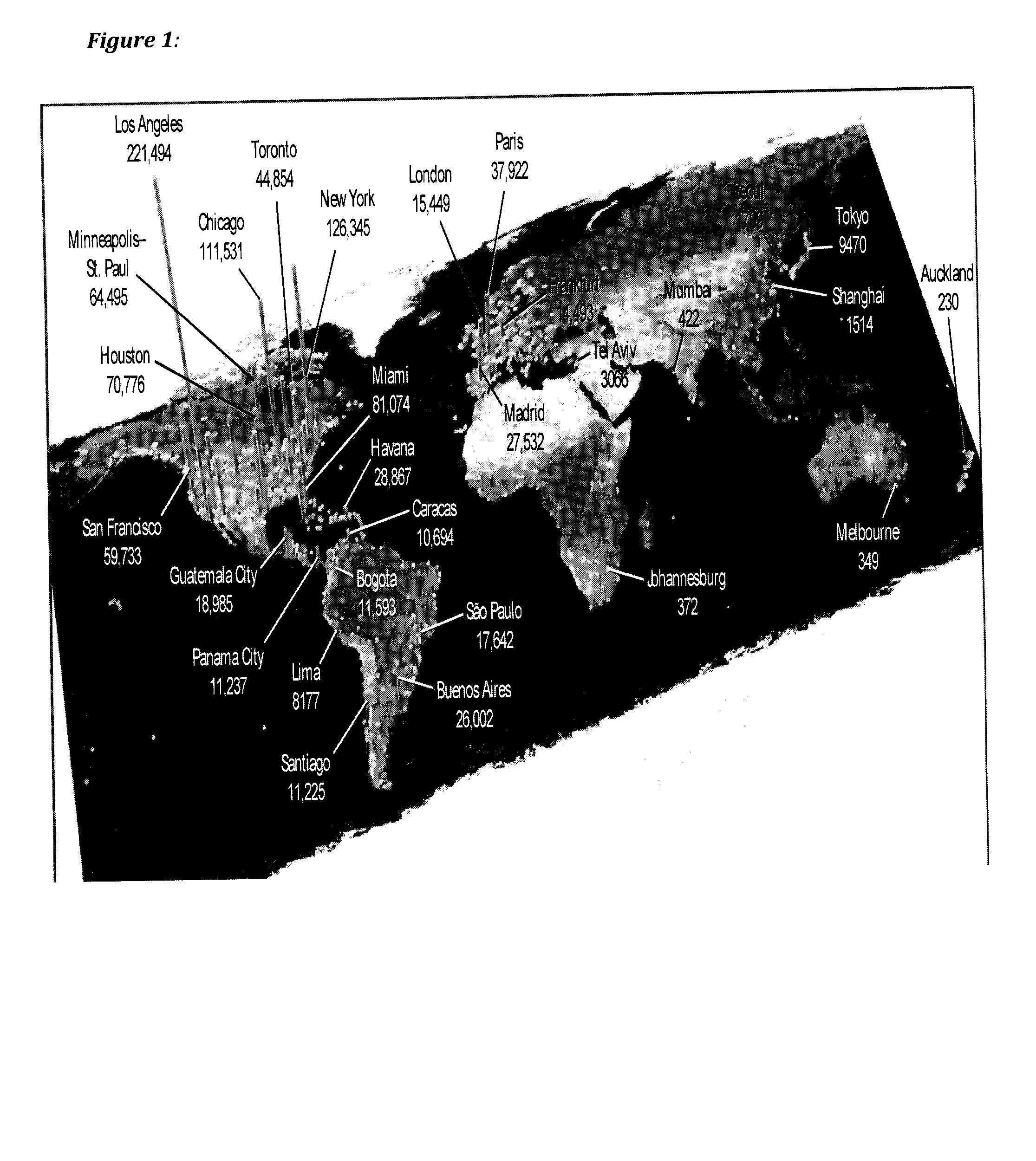

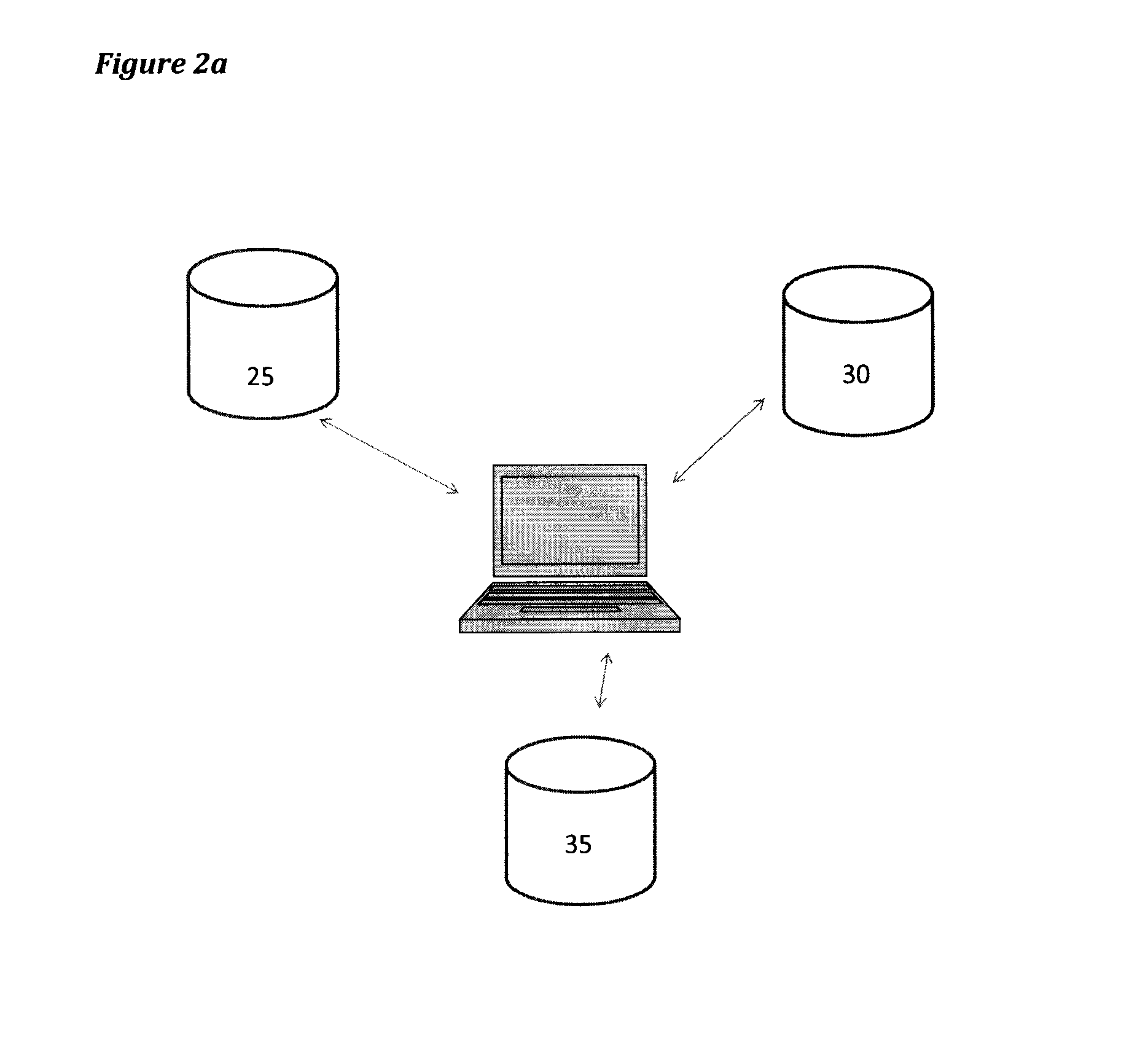

Warning System For Infectious Diseases And Method Therefor

A computer implemented method for predicting the local area impact of the spread of global infectious diseases including the steps of providing on a computer readable medium a global pathogen risk factors database having data stored therein related to local area vulnerability of a group of human pathogens across a plurality of areas, providing on a computer readable medium a global pathogen activity database having data stored therein related to the activity of the group of human pathogens in said plurality of geographies, providing on a computer readable medium a global transport database having data stored therein related to travel patterns in and / or between the plurality of areas, processing by a computer system data on each of the global pathogen risk factors database, the global pathogen activity database and the global transport database to generate a pathogen vulnerability index, a pathogen activity index and a transportability index, and processing by the computer system each of the pathogen vulnerability index, the pathogen activity index and the transportability index to generate a risk indicator indicative of the local area impact of individual global infectious diseases.

Owner:BLUEDOT INC

Mineral admixture as well as preparation method and application thereof

The invention discloses a mineral admixture as well as preparation and application thereof. The mineral admixture contains superfine solid sulfur ash, the D50 of the superfine solid sulfur ash is 0.5 to 15mum, and the D90 of the superfine solid sulfur ash is less than or equal to 30mum. The invention also provides a preparation method for the mineral admixture. The method comprises the following step of: mixing the superfine solid sulfur ash, fly ash and slag powder, wherein the mineral admixture contains 50-70wt% of superfine solid sulfur ash, 10-30wt% of fly ash and 10-30wt% of slag powder, the D50 of the superfine solid sulfur ash is 0.5 to 15mum, the D90 of the superfine solid sulfur ash is less than or equal to 30mum, the specific surface area is 450 to 1,500m<2> / kg, the 28d activity index is more than or equal to 75 percent, and the 28d self-hardening compressive strength is 7 to 15MPa. Compared with the common fly ash or slag powder in the prior art, the mineral admixture has the advantages that when concrete is prepared, the filling effect of fine particles can be fully exerted, the internal structure of the concrete is optimized, micro cracks produced by dry shrinkage or chemical shrinkage are inhibited to a certain degree, and the durability such as freezing resistance of the concrete can also be improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

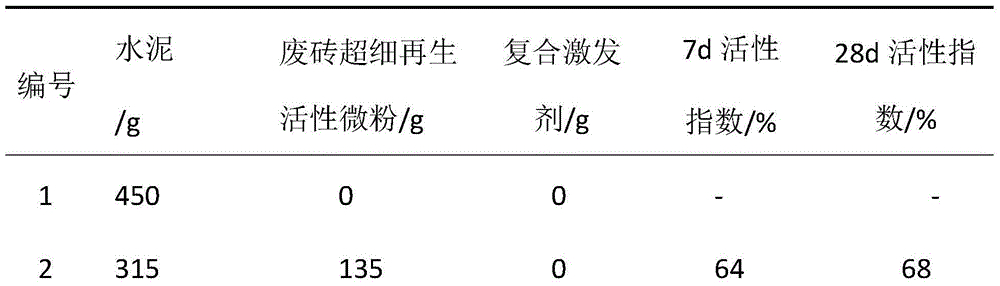

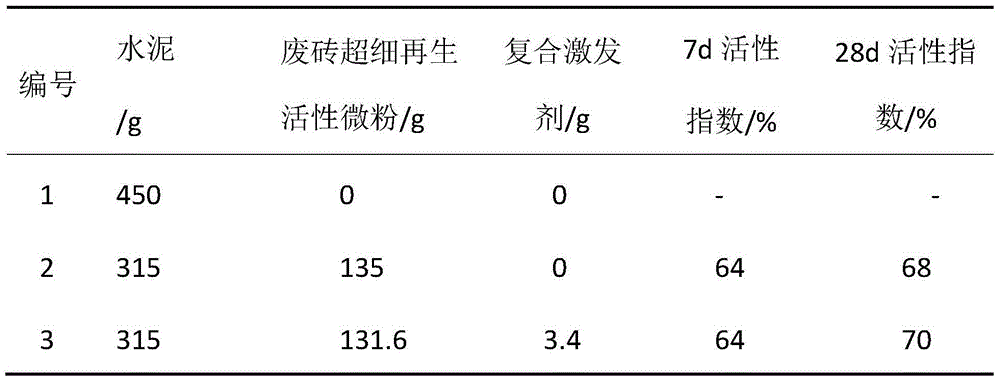

Waste brick superfine regenerated active micro-powder and preparation method thereof

The invention discloses a waste brick superfine regenerated active micro-powder and a preparation method thereof. The micro-powder has a specific surface area of more than 600m<2> / kg and a 28d activity index of more than 70%, and can be used as a mortar and concrete admixture. The micro-powder is prepared by taking waste bricks, which have grain diameters of about 3-10cm and are selected from the building waste generated during a house building removal and construction process, as raw materials, and processing through grinding and composite chemical excitation processes. According to the micro-powder and the preparation method disclosed by the invention, superfine grinding and efficient activation for the waste bricks are realized, and a utilization mode with high additional value is provided for the waste bricks.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

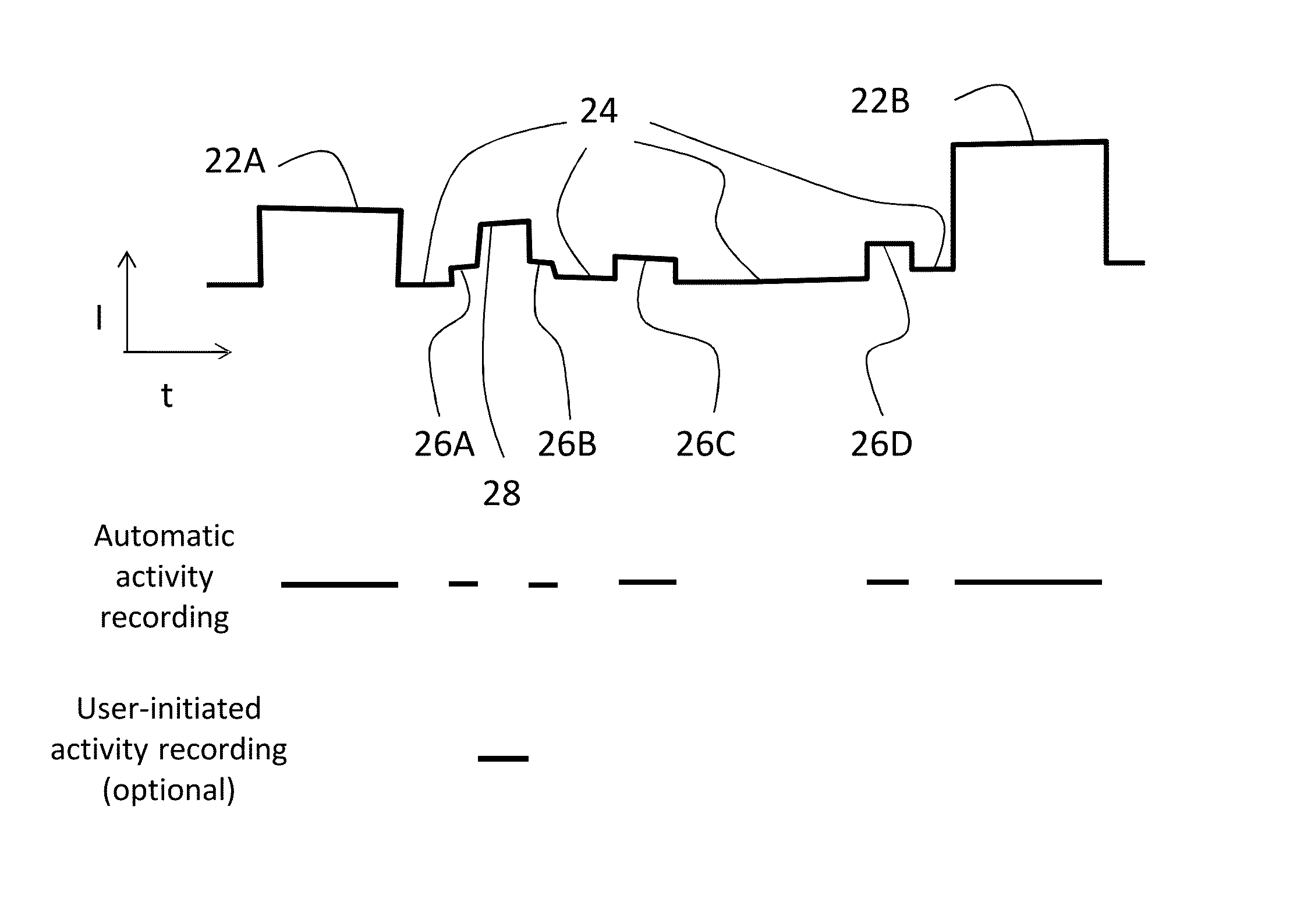

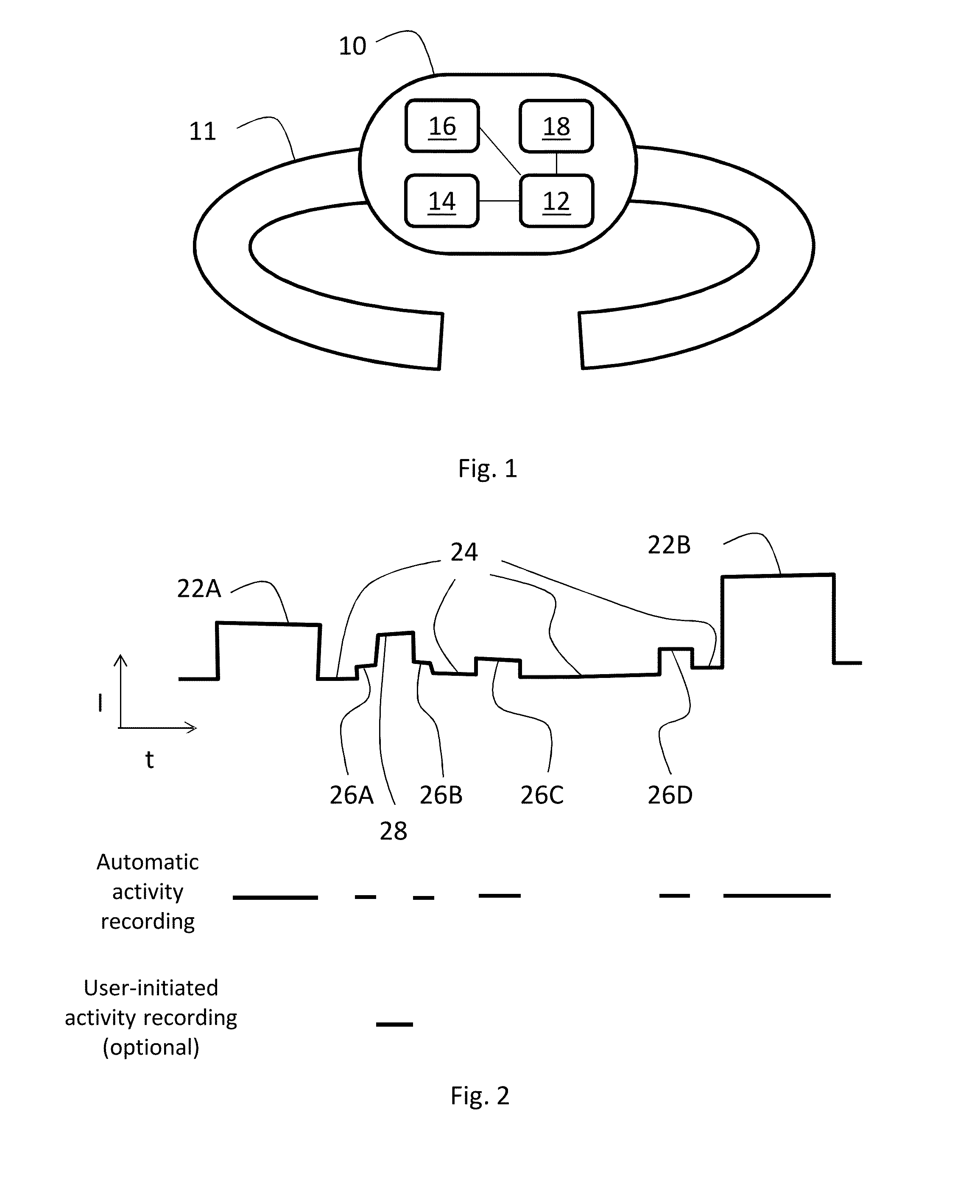

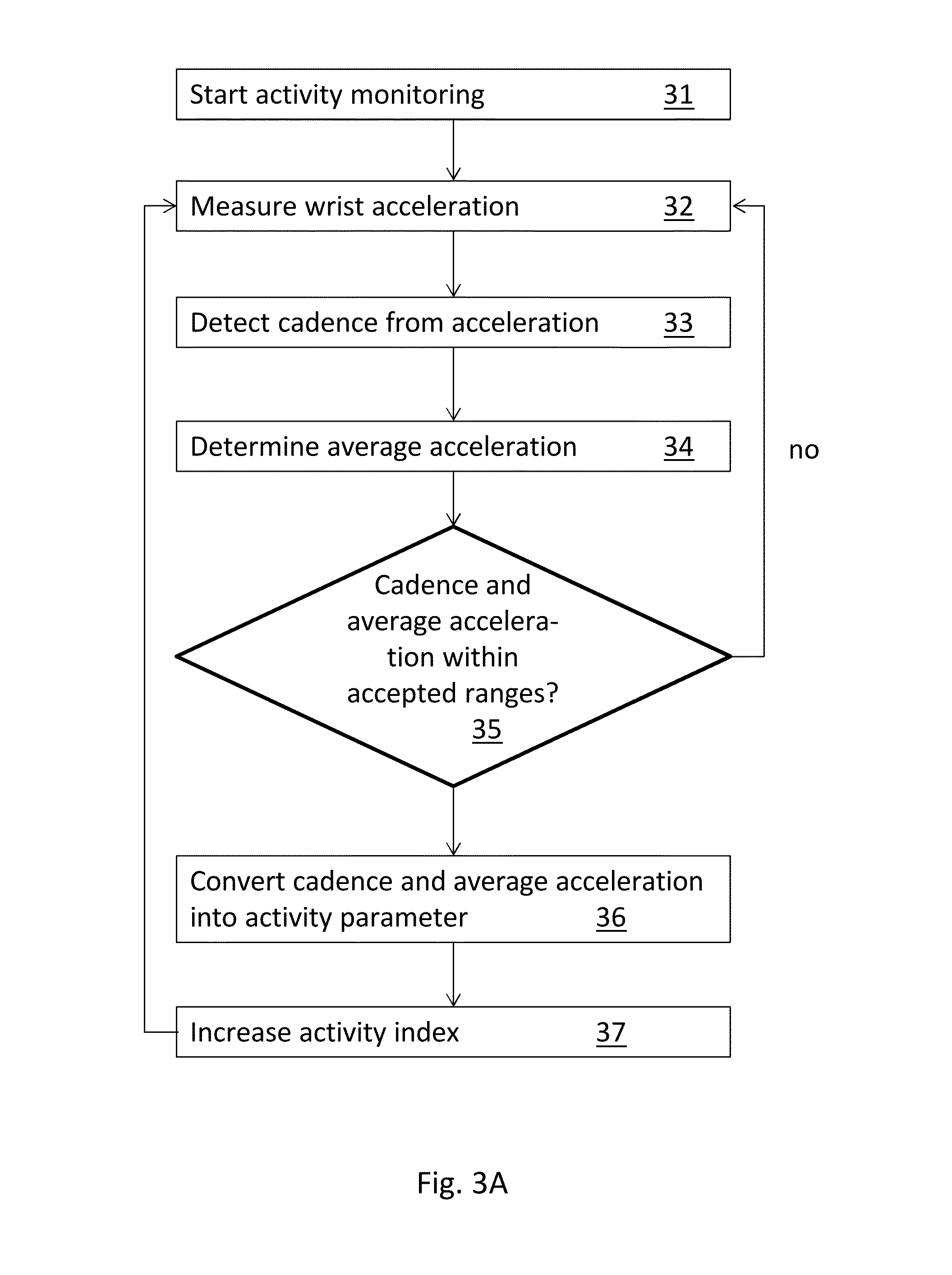

Wearable activity monitoring device and related method

PendingUS20160007888A1Accurate activityPositive effect fitnessGymnastic exercisingPerson identificationActivity indexActivity monitoring

The invention relates to a device and method for monitoring physical activity of a person. The device comprises an acceleration sensor for providing acceleration data corresponding to movements of the person, a memory unit capable of storing an activity index value describing cumulative physical activity of the person, and data processing unit capable of being operated in at least a first activity monitoring mode in which the data processing unit is adapted to update the activity index value based on the acceleration data. In addition, the processing unit is, in the first activity monitoring mode, configured to determine if, and to update the activity index value only if, the acceleration data corresponds to walking- and / or running-related movements of the person. The invention allows for robust monitoring of activities that have an impact on fitness and health of individuals and reduce the risk of incorrect activity recordings.

Owner:SUUNTO OY

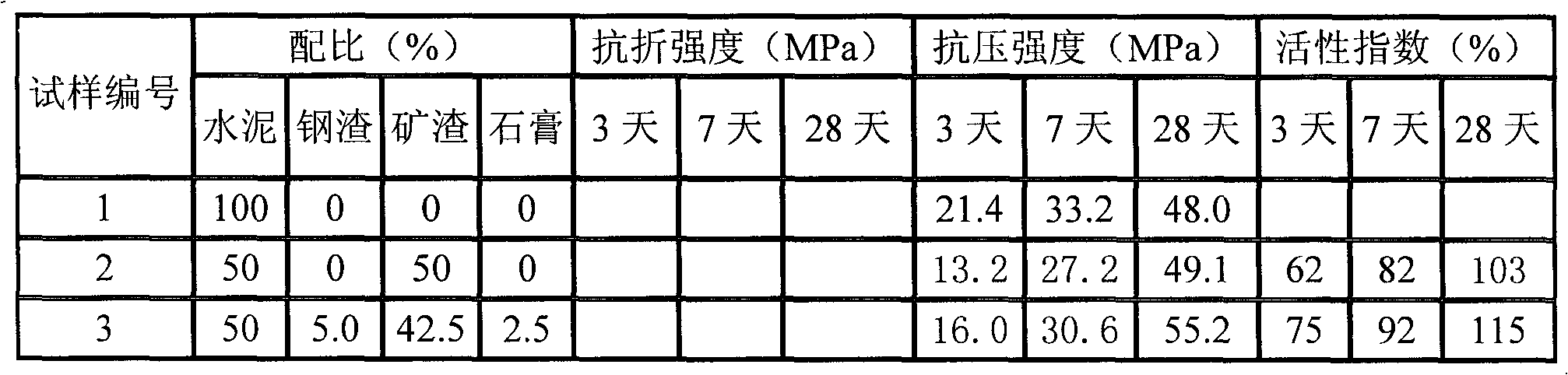

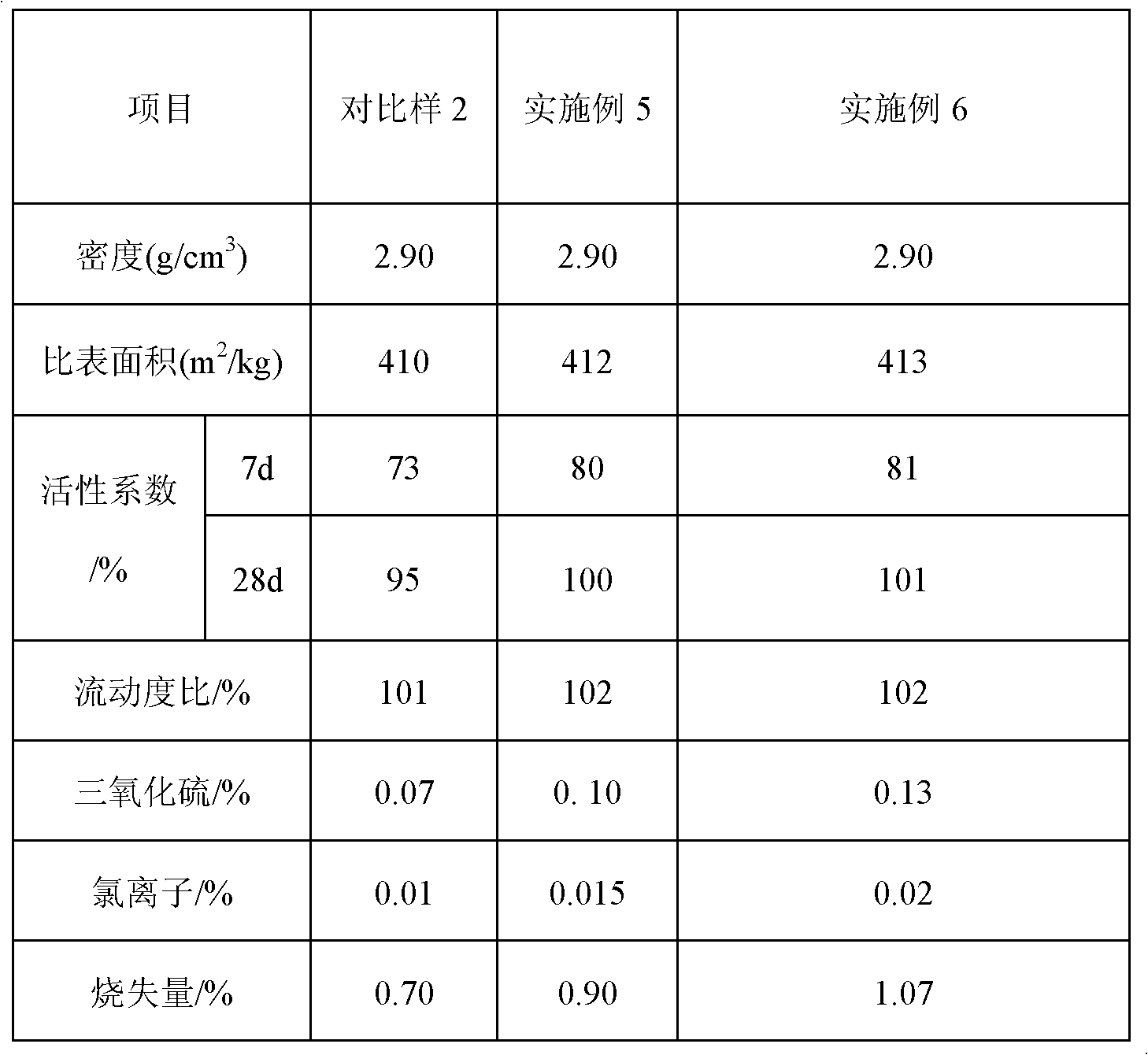

Mineral powder modified by sintering dry desulphurization ash and preparation method thereof

InactiveCN102584062ASmall specific surface areaImprove early shrinkage crack resistanceSolid waste managementCrack resistanceWork performance

The invention discloses a mineral powder modified by sintering dry desulphurization ash and a preparation method thereof. The 7-day activity index of the mineral powder modified by sintering dry desulphurization ash is more than 80%, the 28-day activity index is more than 100%, the specific surface area is more than or equal to 400 m2 / kg, the sulfur trioxide content is less than or equal to 4.0%, the chloride ion content is less than or equal to 0.06%, the loss on ignition is less than or equal to 3.0% and the motility ratio is more than or equal to 100%. The mineral powder is made from the following raw materials in percentage by weight: 95 to 99% of blast-furnace slag powders and 1 to 5% of sintering dry desulphurization ash. The 7-day activity index and 28-day activity index of the modified mineral powder are greatly increased as compared with the common mineral powders, the requirement for specific surface area is reduced, and the energy consumption for milling slag powders can be reduced effectively. When applied to premixed concrete, the modified mineral powder is excellent in durability indices such as carbonization resistance, freeze resistance and chloride ion infiltration resistance, can effectively improve the working performance of concrete and improve the early-stage shrinkage crack resistance of hardened concrete.

Owner:BAOSHAN IRON & STEEL CO LTD +1

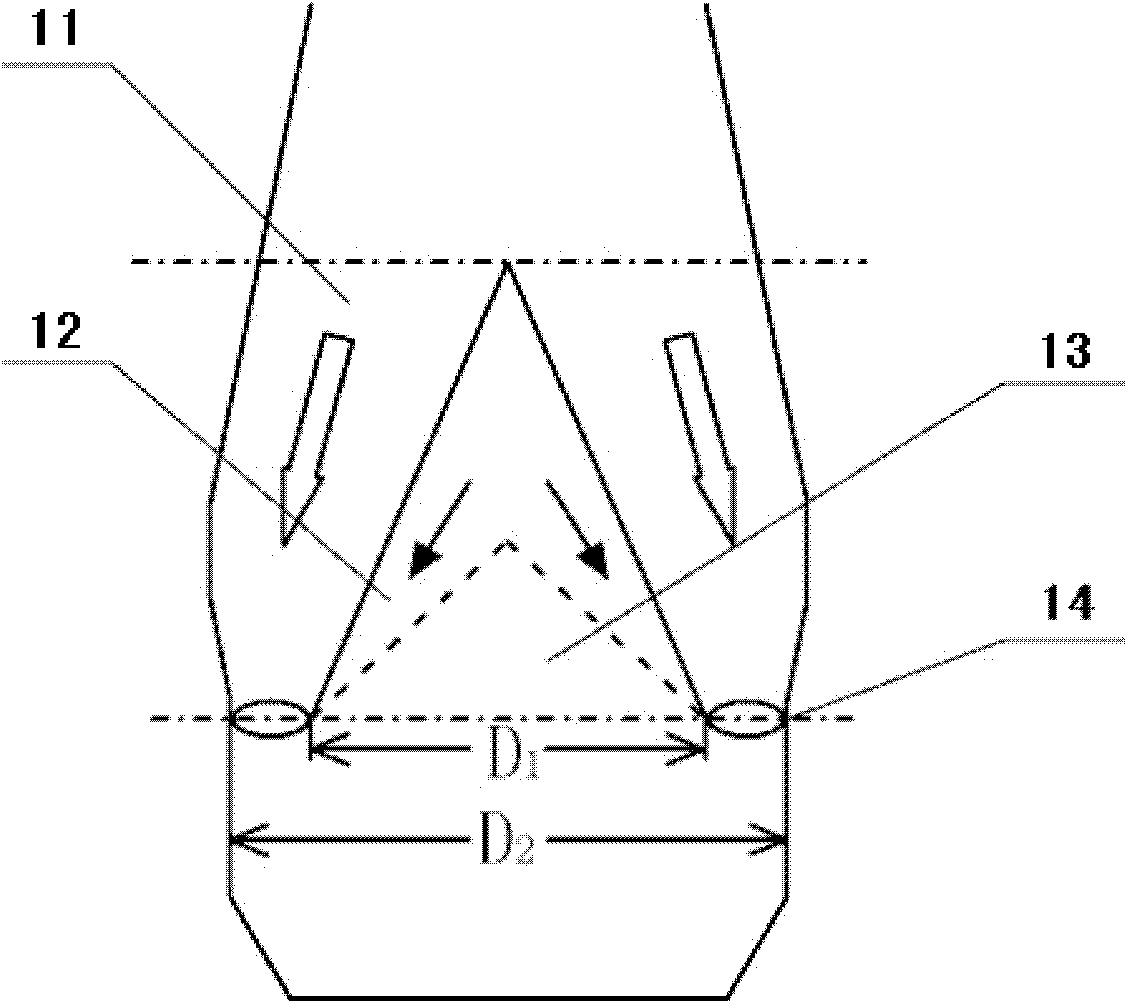

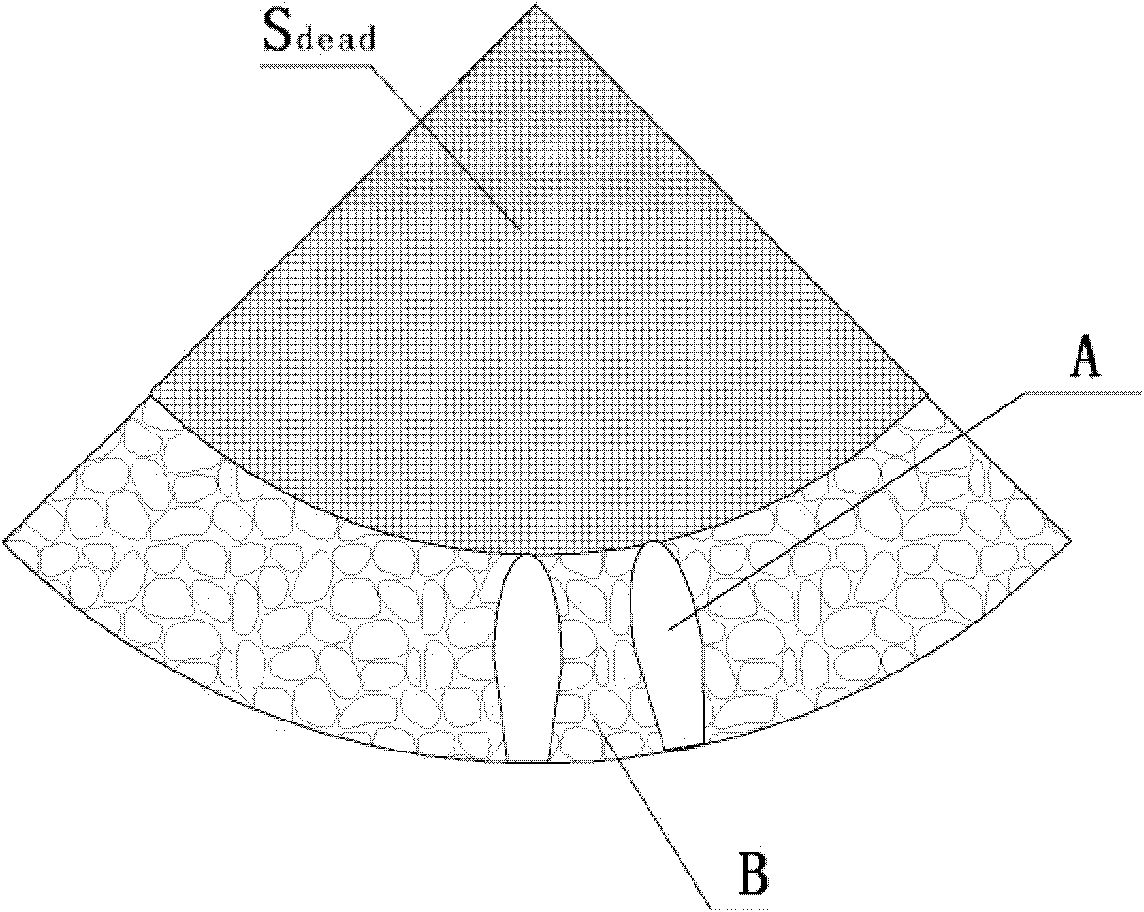

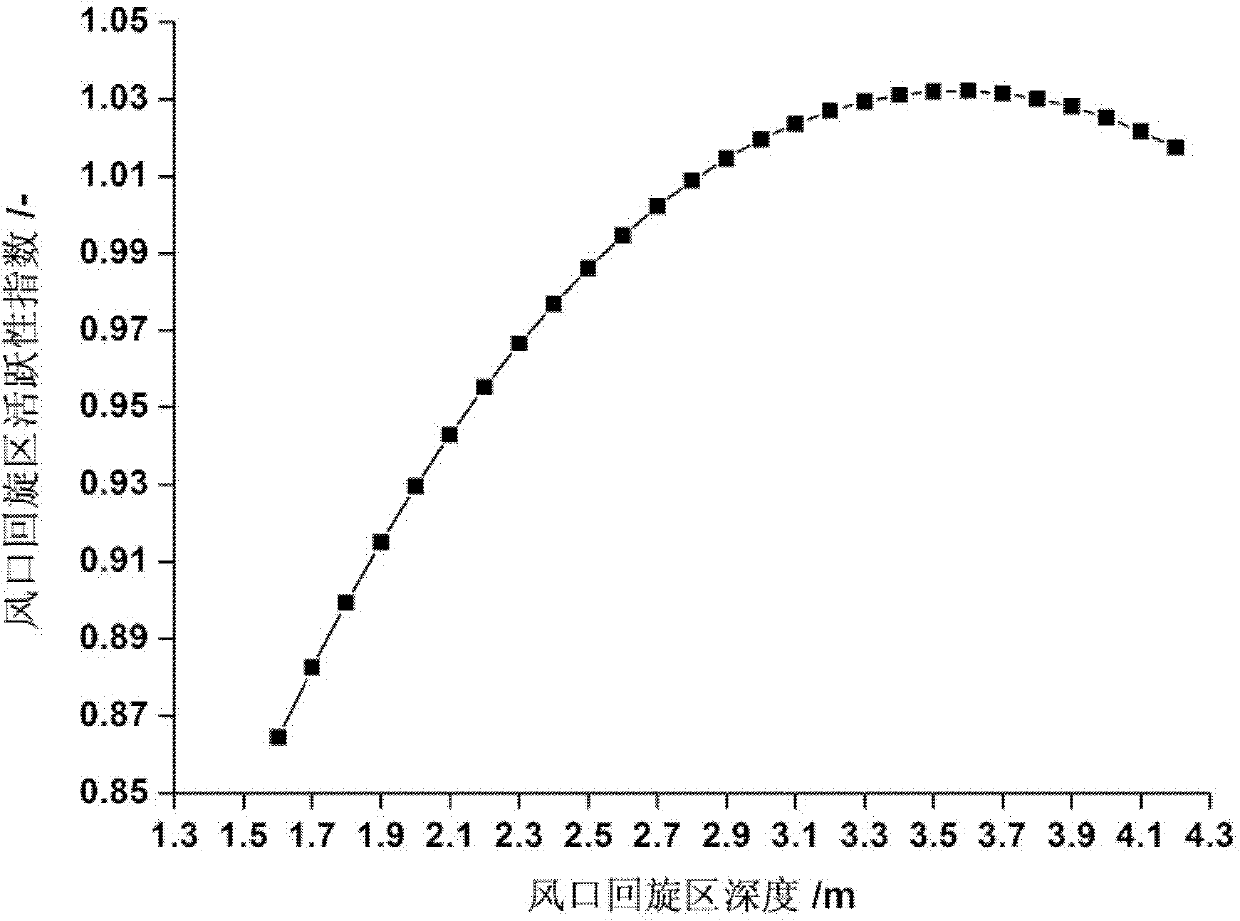

Method for quantitatively evaluating activity of tuyere convolute region

The invention relates to a method for quantitatively evaluating activity of a tuyere convolute region. In the method, the depth DR of the tuyere convolute region, the width WR of the tuyere convolute region, the sectional area A of the convolute region, the sectional area B of the adjacent tuyere and the sectional area Sdead of a dead material column are calculated through the basic parameters of the tuyere convolute region of a blast furnace; and the activity index AIR of the tuyere convolute region of the blast furnace is calculated through a formula. According to the method, the defect of mismatch of the original 'blasting kinetic energy' index and the shape characteristic of the convolute region is overcome; the activity index of the tuyere convolute region and the depth of the convolute region basically form a one-to-one correspondence relationship; the active degree and the existing state of the tuyere convolute region and an air-permeating and liquid-permeating channel on the lower part are reflected accurately, reasonably and effectively; and important judgment basis and technical basis are provided for a regulating agent on the lower part of the blast furnace.

Owner:BAOSHAN IRON & STEEL CO LTD

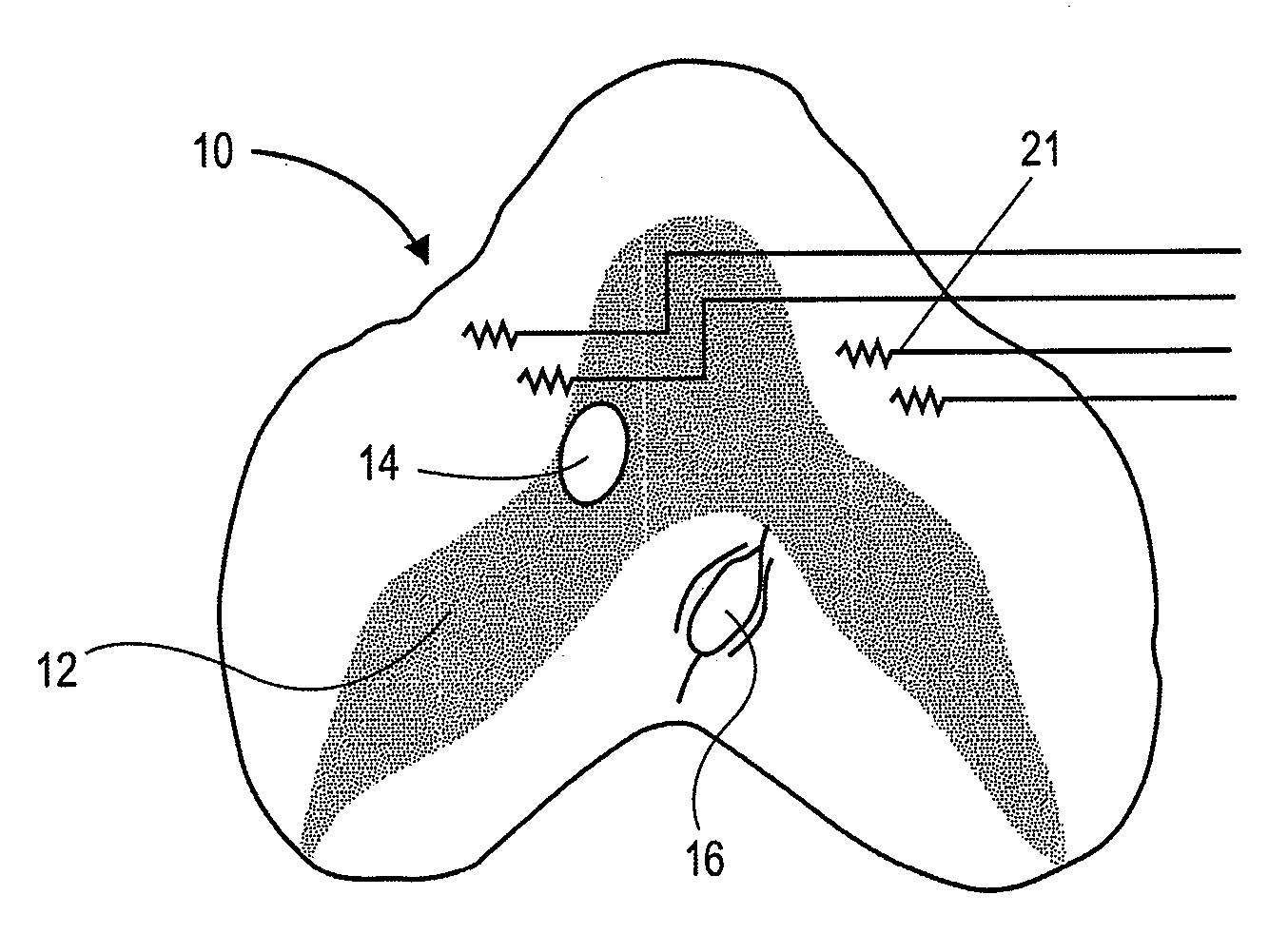

Harmonic activity locator

InactiveUS6792360B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesFrequency spectrumHarmonic

Systems and methods for identifying the presence of a defect in vibrating machinery. An exemplary method comprises analysis of frequency spectrum vibration data of the machine. The method comprises deriving a harmonic activity index based on estimates of the energy associated with the frequency spectrum and the energy associated with the defect's harmonic series. The method may comprise deriving a value K by estimating a value M indicative of the energy of the defect's harmonic series and dividing M by the number of spectral lines corresponding to the defect's harmonic series. The method may further comprise deriving a value R by estimating a value Q indicative of the energy in the frequency spectrum data and dividing Q by the number of spectral lines of the frequency spectrum data. The method further comprises deriving the harmonic activity index based on the estimated K and R. Related systems for executing the methods are also disclosed.

Owner:SKF USA INC

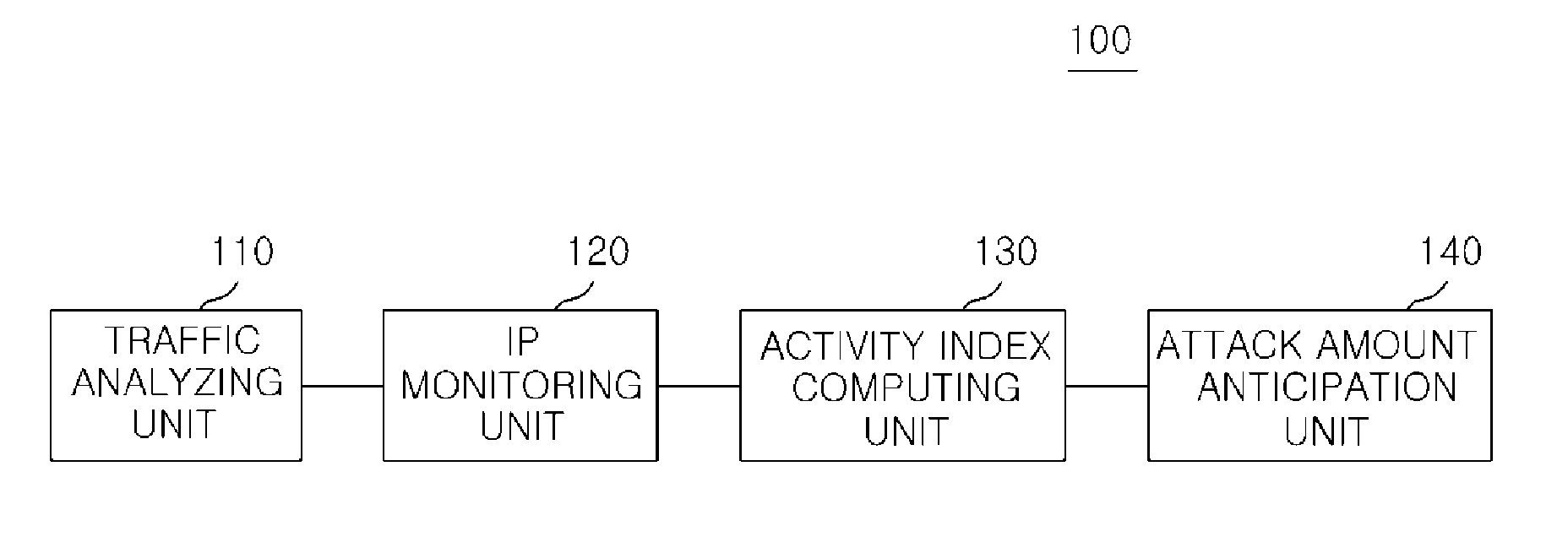

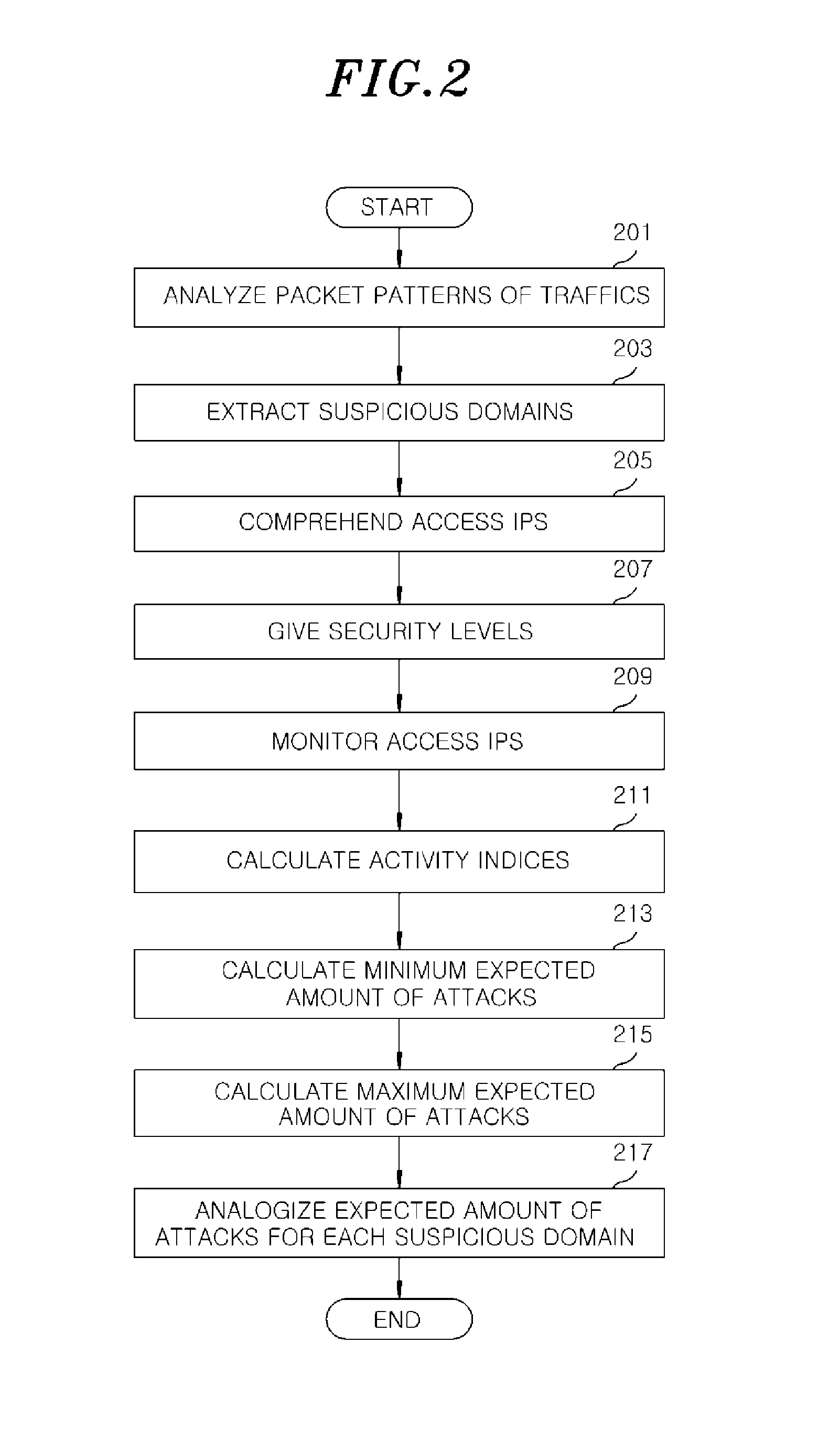

Method and apparatus for quantifying threat situations to recognize network threat in advance

An apparatus for quantifying network threat situations includes a traffic analyzing unit to analyze packet patterns of traffics occurring on a target network being monitored to extract one or more suspicious domains. An IP monitoring unit gives security levels among a plurality of security levels to the suspicious domains according to the number of access IPs accessing the suspicious domains. An activity index computing unit computes activity indices for the suspicious domains from activity indices according to the access times to the suspicious domains of the access IPs. An attack amount anticipation unit analogizes an expected amount of attacks for each suspicious domain according to an expected amount of attacks for each zombie computer, the security level and the activity index of the suspicious domain.

Owner:ELECTRONICS & TELECOMM RES INST

Method for producing low-carbon olefins by using methanol and naphtha

InactiveCN102875299AHigh yieldCatalytic crackingHydrocarbon from oxygen organic compoundsMolecular sieveNaphtha

The invention relates to a method for preparing low-carbon olefins by using methanol and naphtha, mainly solving the problem of low yield of low-carbon olefins in the prior art. The method disclosed herein is characterized by letting a raw material containing methanol and naphtha enter into a fluidized bed reactor in a circulating fluidized bed reaction-regeneration system to contact with a catalyst to generate a product containing low-carbon olefins and simultaneously form a regeneration catalyst, letting the regeneration catalyst enter into a regenerator for regenerating to form a regenerated catalyst, letting the regenerated catalyst return to the reactor to continue participating in reaction, wherein the catalyst comprises a SAPO-34 catalyst and a ZSM-5 catalyst, the weight ratio of the SAPO-34 catalyst to the ZSM-5 catalyst is 0.1-10:1, the mass content of the SAPO-34 molecular sieves in the SAPO-34 catalyst is 10-70%, the mass content of the ZSM-5 molecular sieves in the ZSM-5 catalyst is 15-70%, and the activity index of the regenerated catalyst is larger than 0.75. The method disclosed herein well solves the problem and can be used in the industrial production of low-carbon olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Non-calcinated solid waste high-activity mineral admixture and preparation method therefor

The invention discloses a non-calcinated method produced high-activity regenerated mineral admixture by utilizing multiple solid wastes such as waste building mortar, fine grinded steel slag, desulphurized gypsum and waste stone dust as well as a preparation method therefor. The mineral admixture comprises the following components in doped percentages: 32-60% of waste mortar powder, 15-25% of fine grinded steel slag, 4-8% of desulphurized gypsum and 20-35% of waste stone dust. The water demand ratio of the regenerated high-activity mineral admixture is 70-90%; the initial working performance of the concrete can be improved; the activity index is 80-100%; the specific surface area is 350-450 sq. / kg; and the mineral admixture has the characteristics of a coagulation time controllability, high early strength, stable volume performance and the like.

Owner:WUHAN TIANYICHENG RENEWABLE RESOURCES CO LTD

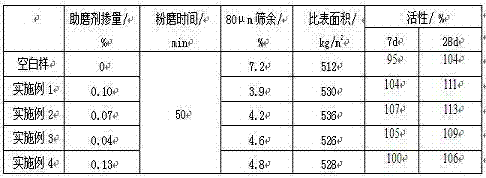

Liquid composite grinding aid for granulated blast-furnace slag and preparation method thereof

InactiveCN102923982ASieve reductionLarge specific surface areaSolid waste managementCement productionSodium acetateSlag

The invention relates to liquid composite grinding aid for granulated blast-furnace slag and a preparation method thereof. The grinding aid is prepared by triethanolamine 1-30 parts, mixed alcohol 15-20 parts, glycerin 5-10 parts, molasses 5-10 parts, sodium acetate 1-10 parts, sodium tripolyphosphate 1-10 parts, sodium sulfate 1-10 parts and water 40-50 parts. The liquid composite grinding aid is low in toxicity, non-volatile, stable in source, sufficient in supply, simple in processing and preparation and low in cost. Can improve distribution and morphology of powder particles after doped into the granulated blast-furnace slag, has no adverse effects on mineral powder quality, has the good advantages of improving the yield and the mineral powder quality, and simultaneously reduces energy consumption greatly. The liquid composite grinding aid is stable in performance, low in price and high in cost performance, wide in adaptability and low in admixture amount, improves the grinding effect, increases specific surface area of the mineral powder and improves activity index of the mineral powder under the condition of same grinding time.

Owner:SHENYANG JIANZHU UNIVERSITY

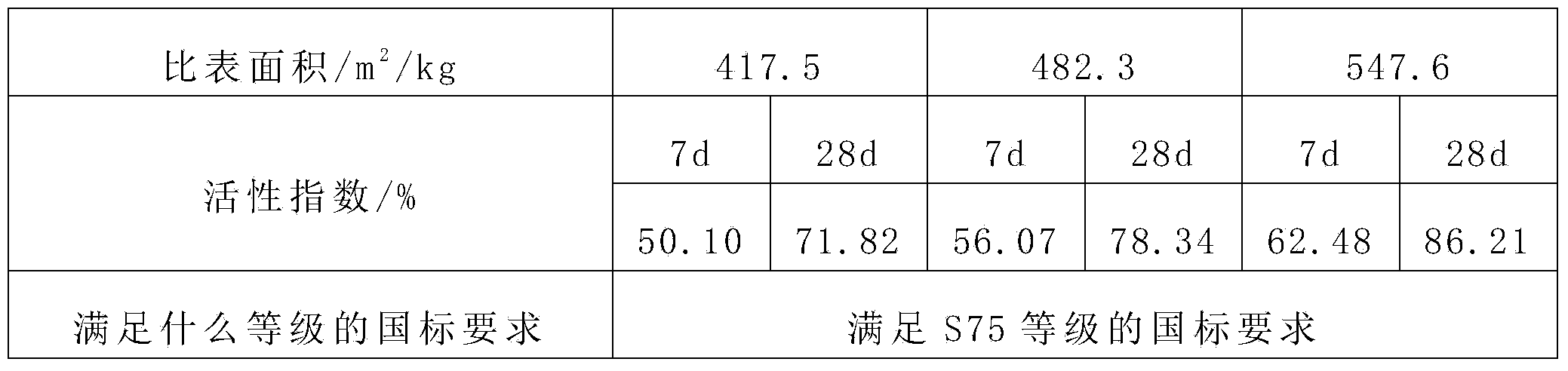

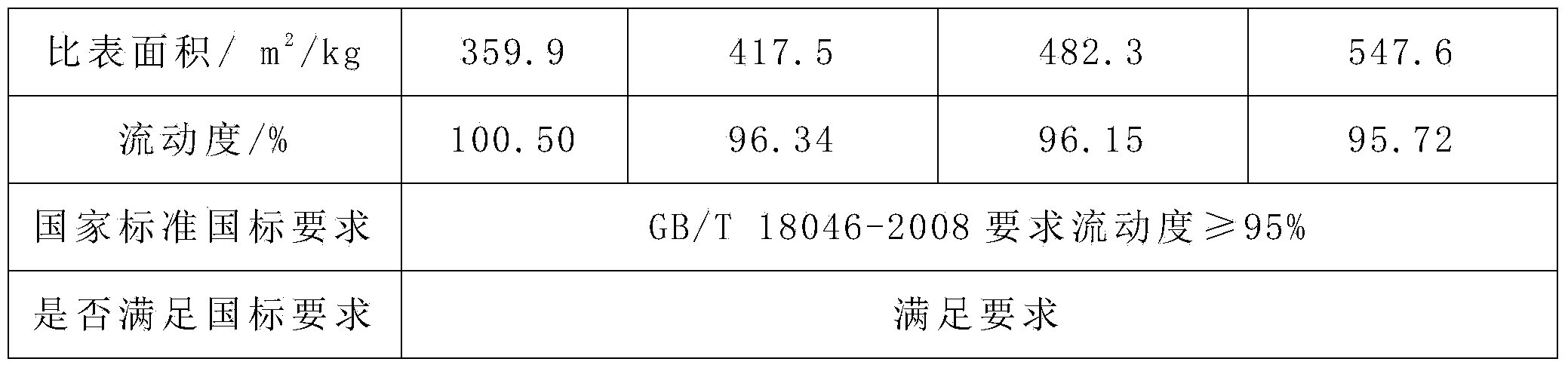

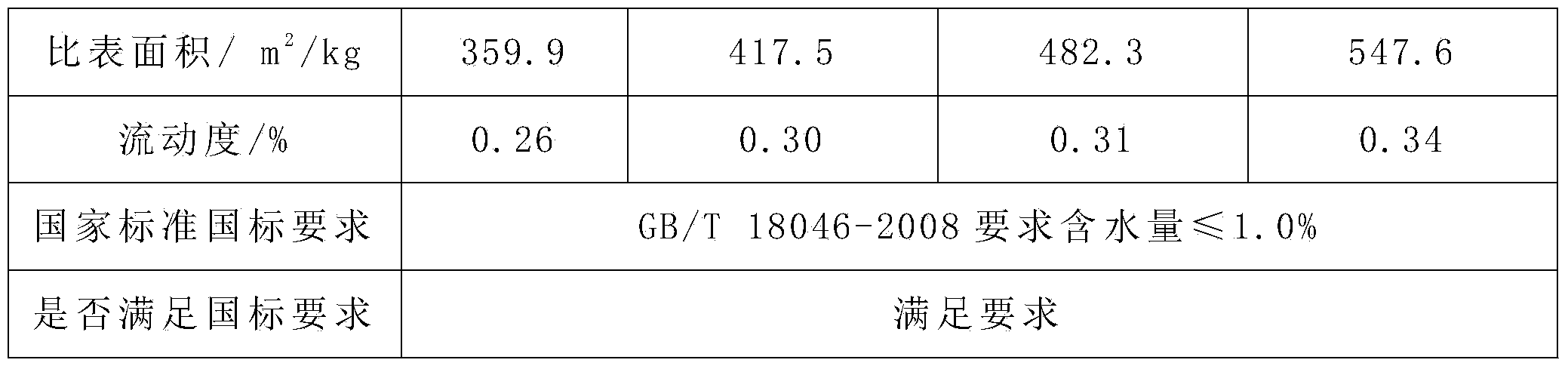

Nickel iron slag micropowder and preparation method thereof

InactiveCN103771739AUniform surface area distributionImprove activity indexSolid waste managementSocial benefitsEcological environment

The invention relates to nickel iron slag micropowder and a preparation method thereof. The method comprises the following steps: performing magnetic separation on nickel iron slag taken as a raw material and grinding the nickel iron slag so as to obtain the nickel iron slag micropowder with the specific surface area being 359.9m<2> / kg to 550m<2> / kg. The specific surface area of the nickel iron slag micropowder is uniformly in distribution; the nickel iron slag micropowder with the certain specific surface area has a good activity index, thereby conforming to the international S75-level standard. In addition, the water content, the ignition loss and the like of the nickel iron slag micropowder all conform to rules in 'Granulated Blast Furnace Slag Powder Used in Cement and Concrete' of GB / T18046-2008. The prepared nickel iron slag micropowder can be taken as a blending stock of the cement and the concrete. Meanwhile, after the nickel iron slag micropowder is prepared from the nickel iron slag, the purposes of recycling wastes and turning wastes into wealth are realized. Thus, pollutions to atmosphere, soil and water, which are caused by the nickel iron slag, are lightened, namely, the ecological environment is optimized; the high added-value is obtained while the cost is low. As a result, the significant economic and social benefits are achieved.

Owner:SHANDONG WEIYE NEW BUILDING MATERIAL

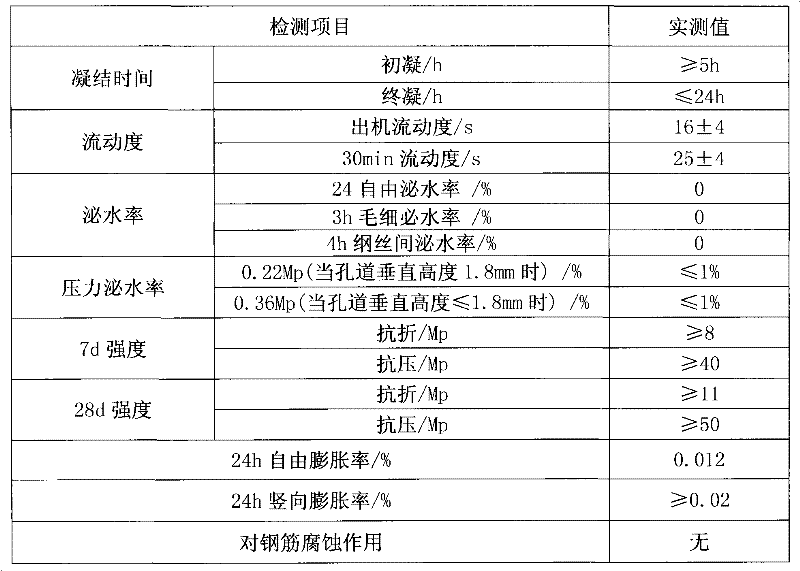

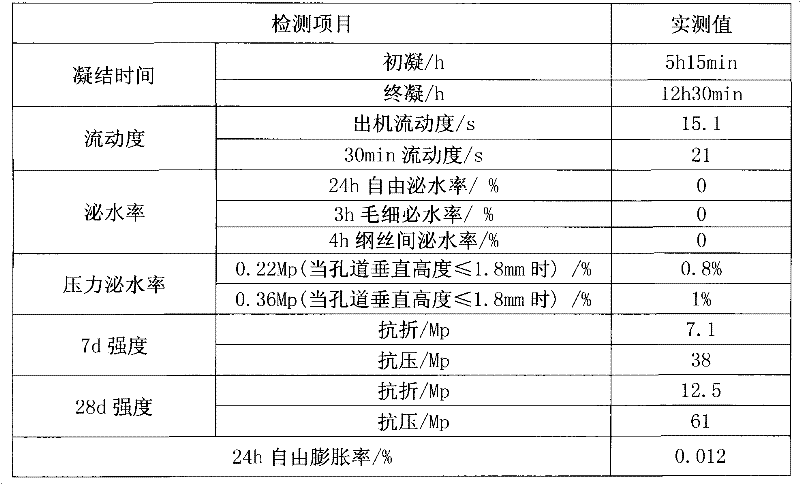

Grouting material, premix of grouting material, and preparation method of premix

The invention relates to a premix of a grouting material. The premix is characterized in that the premix comprises the following components, by weight, 65-90% of ordinary portland cement with the strength level of 42.5MPa or low alkaline cement with the strength level of greater than 42.5MPa, wherein the water demand for normal consistency is less than 25%, and the tricalcium aluminate content is lower than 8%; 2-29.696% of an ultrafine mineral admixture with a specific surface area of greater than 450m<2> / kg, a water demand ratio of less than 95%, and a 28d activity index of greater than 90%; 5-15% of calcium sulphoaluminate; 0.1-1.5% of a melamine water reducer; 0.002-0.2% of a cellulose polymer, an acrylic polymer or polyoxyethylene; 0.1-1.0% of a carbohydrate, a hydroxycarboxylic acid compound and salts thereof, a sulfate, a carbonate, or calcium formate; 0.002-0.1% of vinyl acetate-ethylene copolymerized rubber powder; and 0.1-1.0% of a chromate or a borate.

Owner:王小清

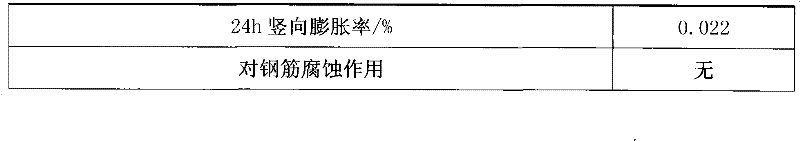

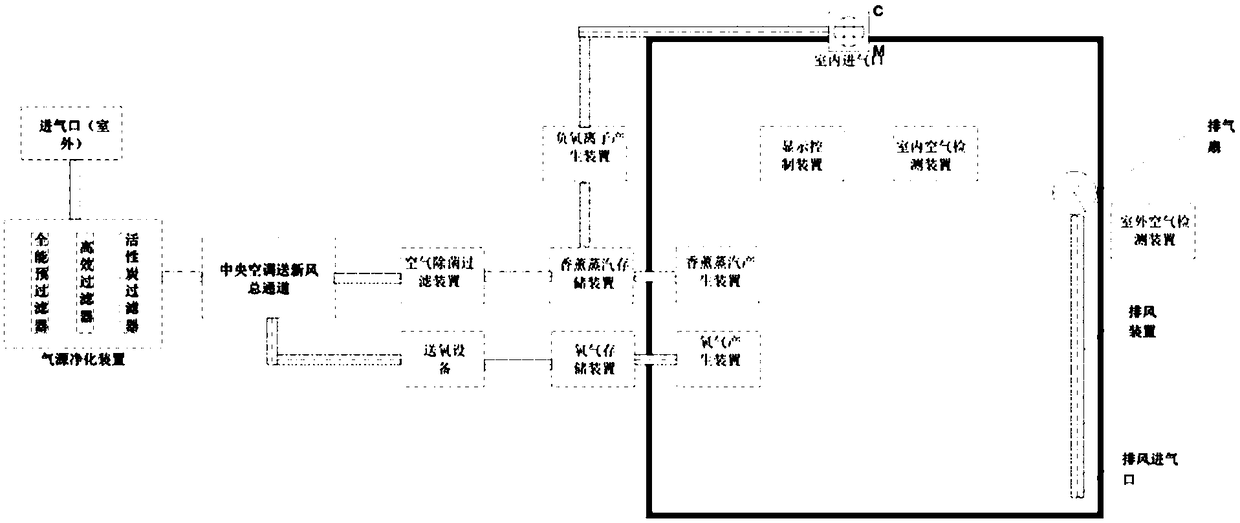

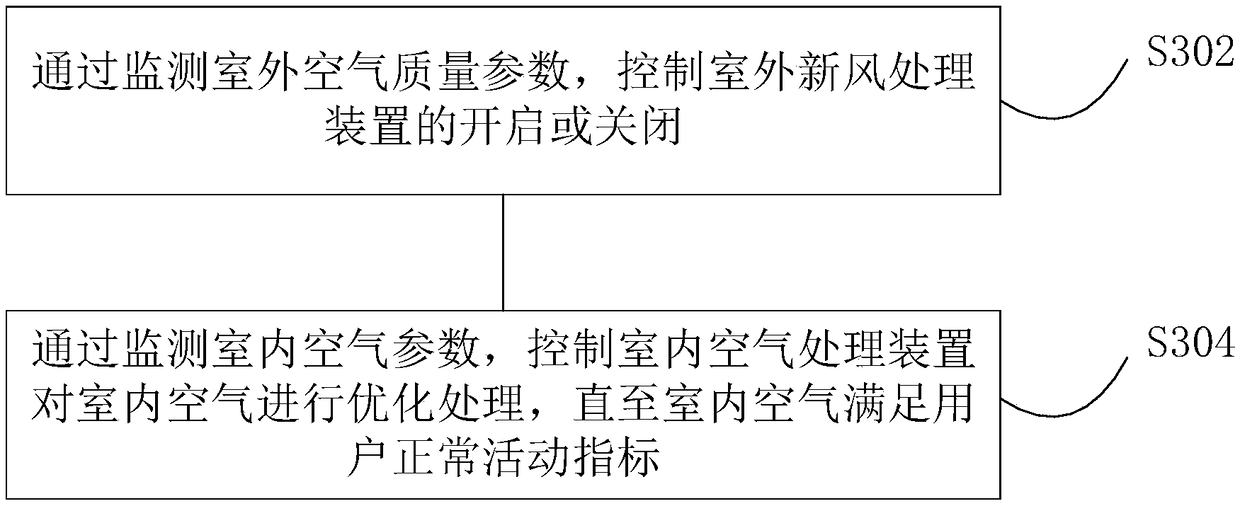

Air conditioning system, adjusting method and air conditioner adopting air conditioning system

InactiveCN109405151AEasy to adjustSolve the problem that the air conditioning effect is not idealMechanical apparatusSpace heating and ventilation safety systemsActivity indexFresh air

The invention discloses an air conditioning system, an adjusting method and an air conditioner adopting the air conditioning system. The air conditioning system comprises a control device, an outdoorfresh air processing device and an indoor air processing device. The control device is connected with the outdoor fresh air processing device and the indoor air processing device. The control device is used for controlling the opening or closing of the outdoor fresh air processing device by monitoring the outdoor air quality parameters, and is used for controlling the indoor air processing deviceto carry out optimization processing on indoor air by monitoring indoor air parameters, until the indoor air meets the normal activity index of the user. The air conditioning system solves the problemthat the air conditioning effect of an air conditioning system in the prior art is not ideal, and improves the conditioning effect of the air conditioning effect.

Owner:GREE ELECTRIC APPLIANCES INC

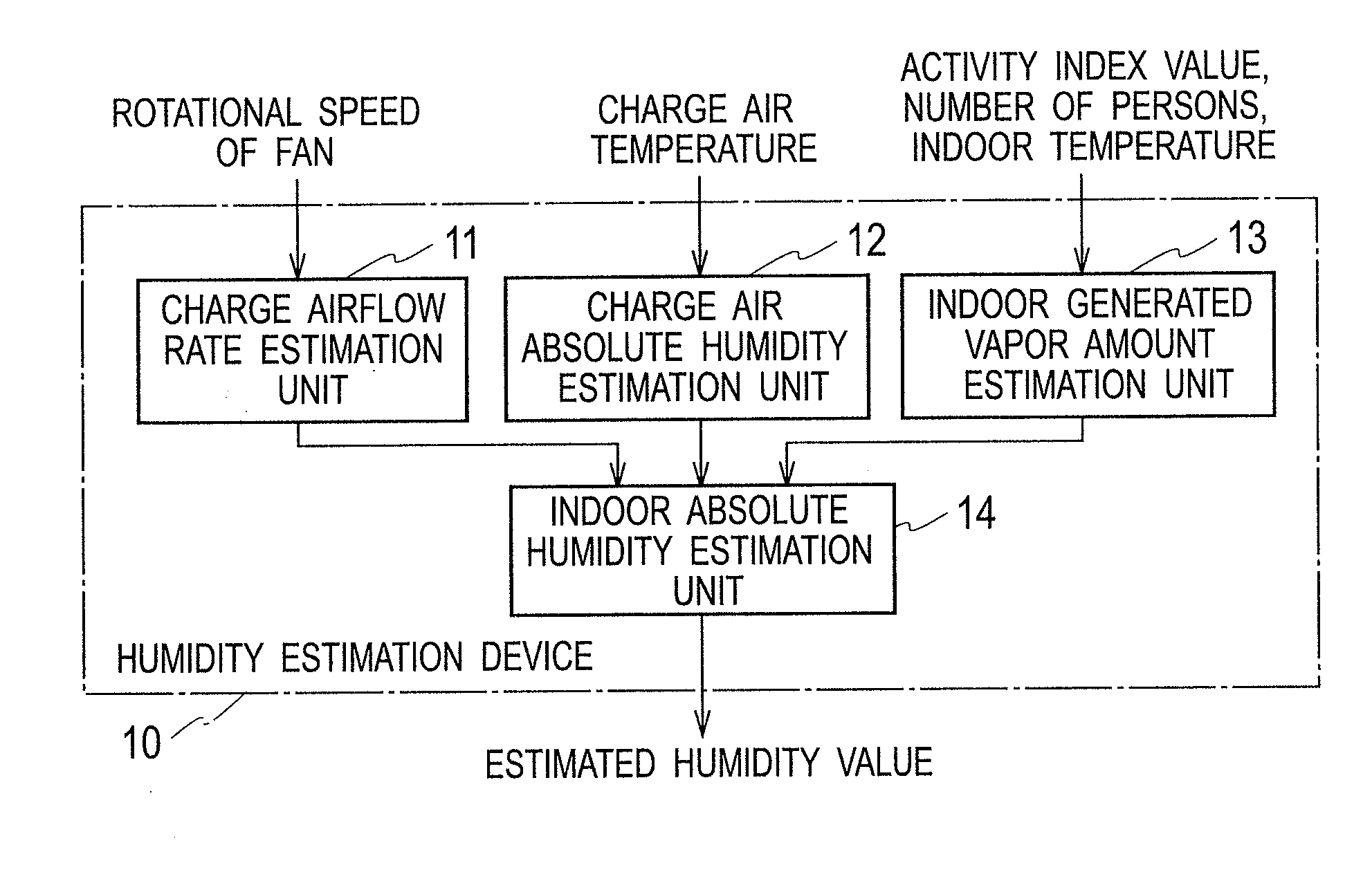

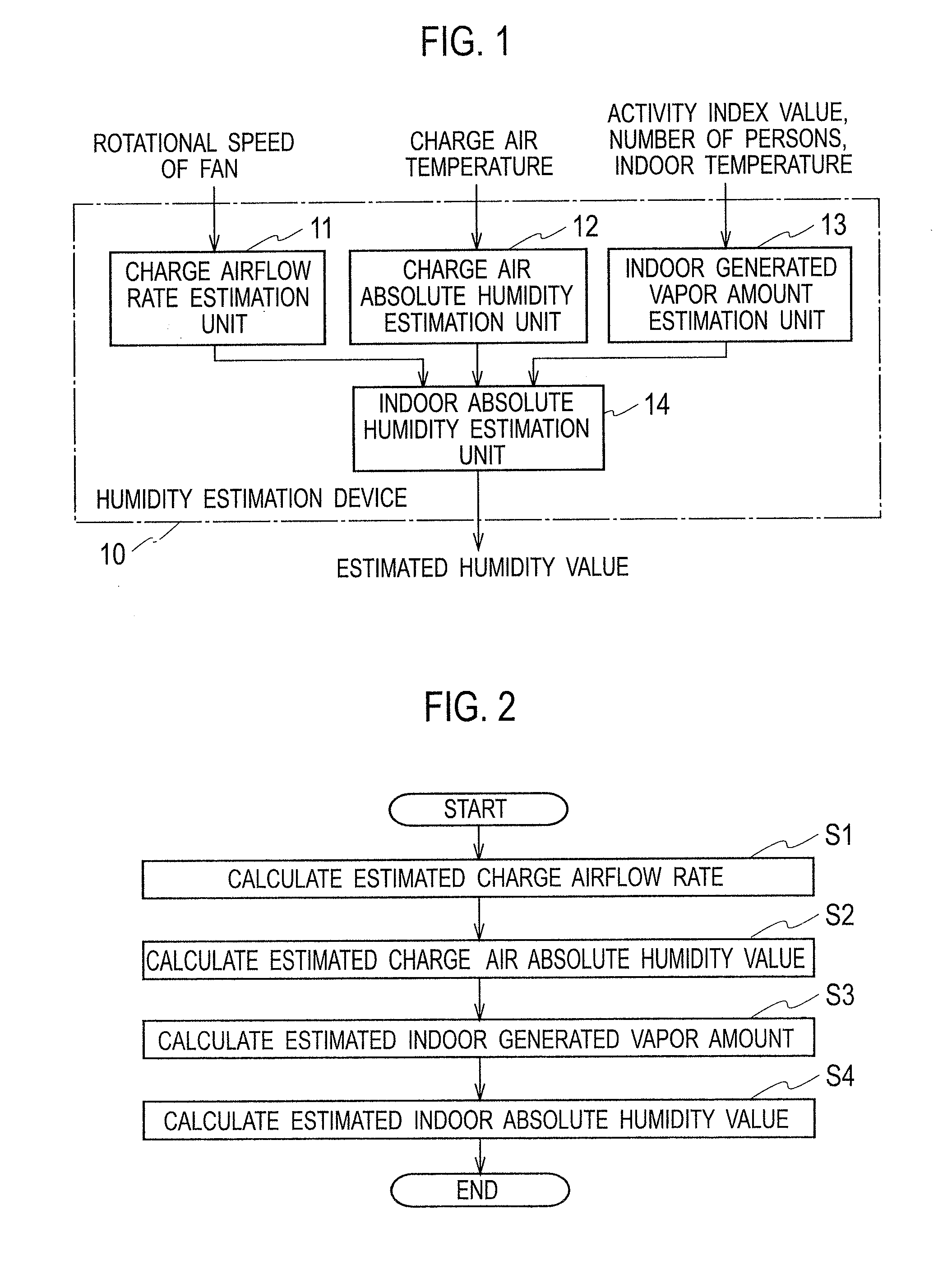

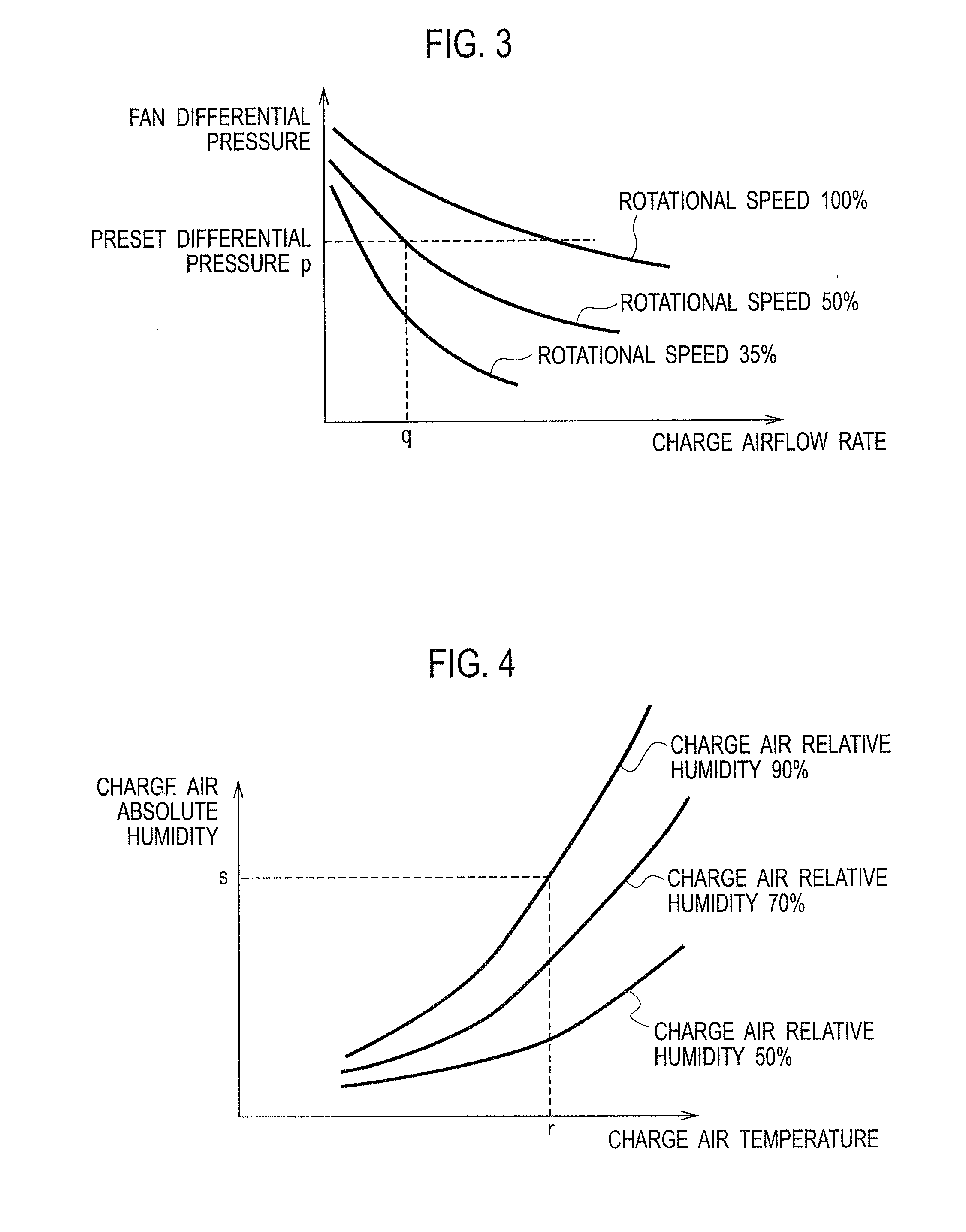

Device and method for humidity estimation

A humidity estimation device connected with an air-conditioner includes a charge airflow rate estimation (CARE) unit, a charge air absolute humidity estimation (CAAHE) unit, an indoor generated vapor amount estimation (IGVAE) unit, and an indoor absolute humidity estimation (IAHE) unit. The CARE unit calculates an estimated charge airflow rate (ECAR) of the air-conditioner based on operation control information of the charge fan and a preset fan differential pressure. The CAAHE unit calculates an estimated charge air absolute humidity (ECAAH) of the air-conditioner based on a charge air temperature and a preset charge air relative humidity. The IGVAE unit calculates an estimated indoor generated vapor amount (EIGVA) based on an indoor temperature, the number of persons in the room and activity index values of the persons. The IAHE unit calculates an estimated absolute humidity in the room based on the ECAR, the ECAAH and the EIGVA.

Owner:KK TOSHIBA

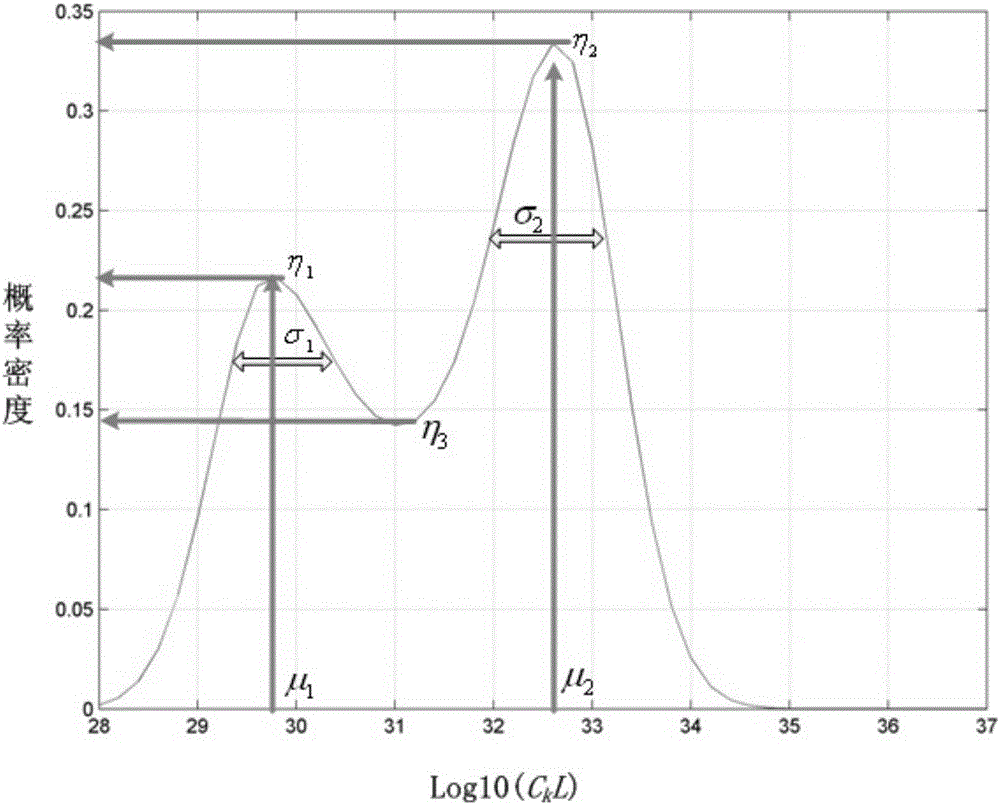

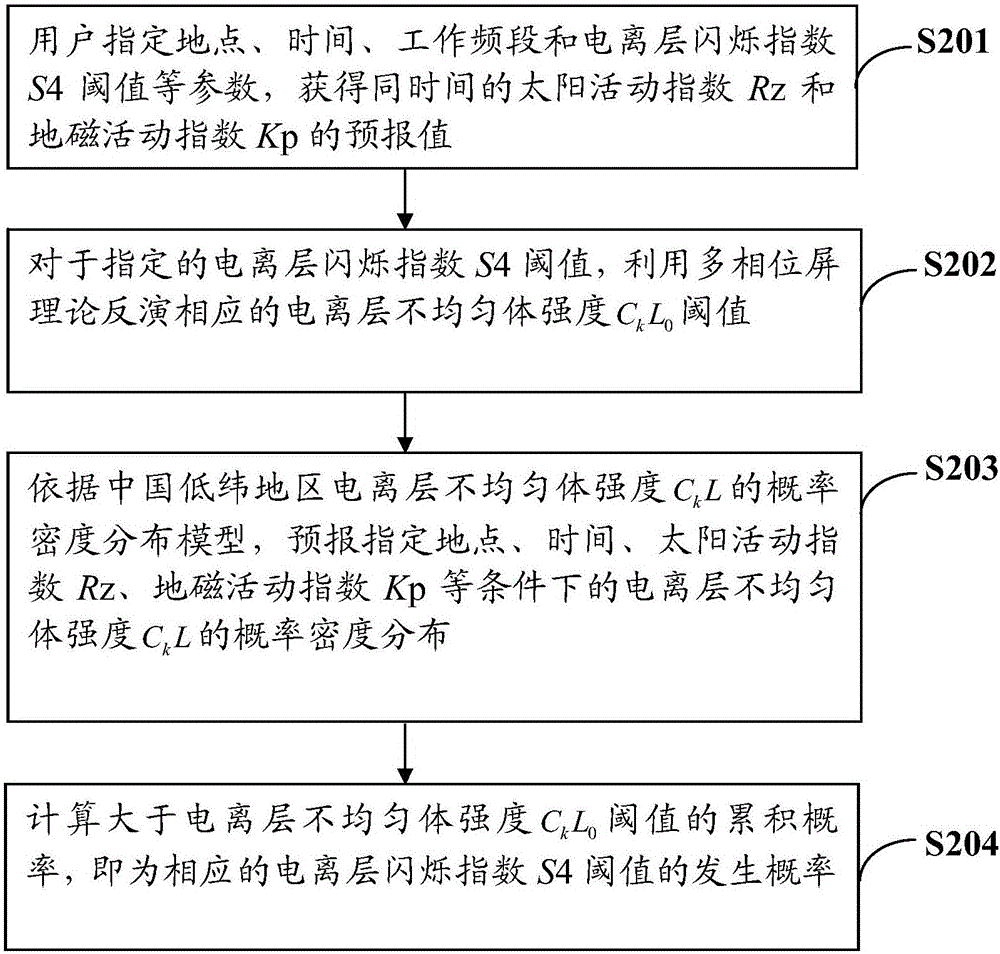

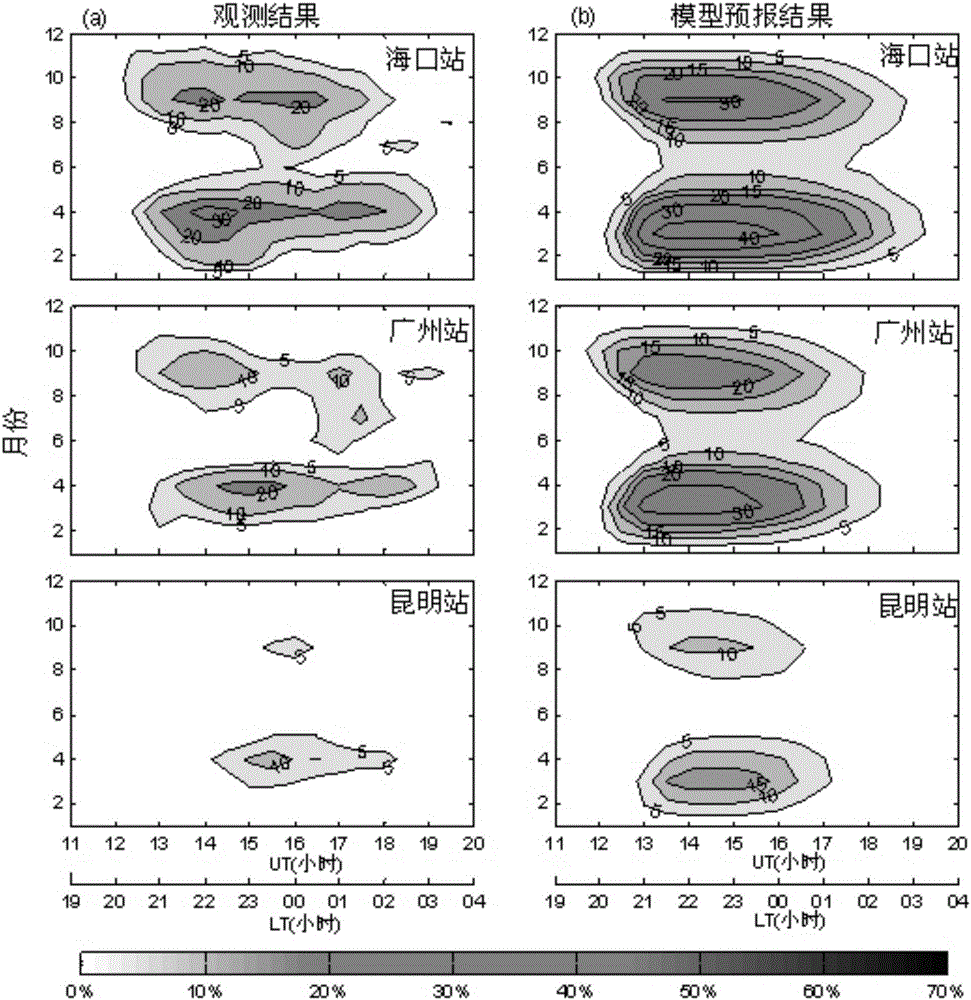

Method for forecasting occurrence probability of ionospheric scintillation in low-latitude areas of China

The invention discloses a method for forecasting the occurrence probability of ionospheric scintillation in low-latitude areas of China. The method includes: an ionospheric irregularity intensity CkL inversion method based on an ionospheric scintillation index S4, a probability density distribution model of ionospheric irregularity intensity CkL of low-latitude areas of China which changes with solar activity index Rz, geomagnetic activity index Kp, geographical position, season and time, and an ionospheric scintillation occurrence probability calculation method. The method provided by the invention can calculate the occurrence probability of an ionospheric scintillation event under conditions of designated place, time, solar activity index Rz, geomagnetic activity index Kp, working frequency band, ionospheric scintillation index S4 threshold value and the like according to user demands.

Owner:THE 22ND RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Production method of novel ureaformaldehyde slow-release nitrogen fertilizer and composite fertilizers of novel ureaformaldehyde slow-release nitrogen fertilizer

InactiveCN104761324ATake advantage ofUnrestricted contentFertilizer mixturesActivity indexProcess conditions

The invention discloses a production method of a novel ureaformaldehyde slow-release nitrogen fertilizer and composite fertilizers of the novel ureaformaldehyde slow-release nitrogen fertilizer. The production method comprises following steps: urea is dissolved in formaldehyde solutions with common concentrations at a urea / formaldehyde molar ratio of 1.5-2.5:1; under alkaline conditions, an obtained mixture is subjected to hydroxymethylation reaction; and then under acidic conditions, methylenenation of an obtained product is realized quickly. According to the preparation method, technical conditions such as molar ratio of urea to formaldehyde are controlled, so that the pure powdery or granular ureaformaldehyde slow-release nitrogen fertilizer with an activity index (AI value) ranging from 40 to 65 is obtained, and the composite fertilizers of the ureaformaldehyde slow-release nitrogen fertilizer can be obtained via traditional composite fertilizer production methods. The production method comprises following characteristics: technology is simple; reaction time is short; heat energy released by reaction is fully used; energy consumption is low; quality of the obtained products is reliable; slow release performance is excellent; particles are uniform; strength is high; caking is not easily caused; and production cost is low.

Owner:ZHENGZHOU GAOFU FERTILIZER CO LTD

Inorganic high performance fiber composite material and preparation method thereof

The invention discloses an inorganic high performance fiber composite material, prepared from the following raw materials in parts by weight: 450-900 parts of cement with the mean grain size of 30-60 mu. m and strength grade not less than 42.5, 180-360 parts of active mineral admixture with the mean grain size of 0.1-60 mu. m, loss on ignition being less than or equal to 3.0 percent, and a 28-day activity index not lower than 90 percent, 70-120 parts of inert admixture with the mean grain size of 0.1-60 mu. m, 850-1250 parts of sand with the continuous grading grain size of 0.16-4.75mm, 25-32 parts of water reducer with a water reducing rate greater than 30 percent, 130-150 parts of water, and 50-120 parts of copper plating end hook-shape steel fiber with the diameter less than 0.20mm and length of 12-14mm. The composite material is relatively low in overall price, uniform in fiber distribution, high in compressive strength and flexural strength, good in tenacity and suitable for being popularized and used in the constructional engineering industry.

Owner:黄贺明

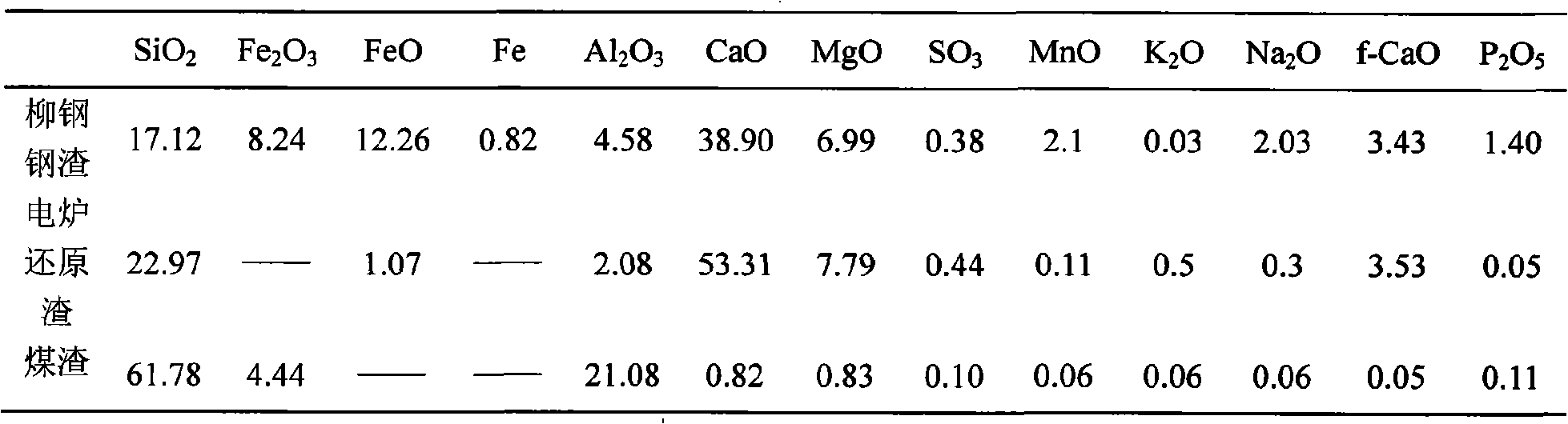

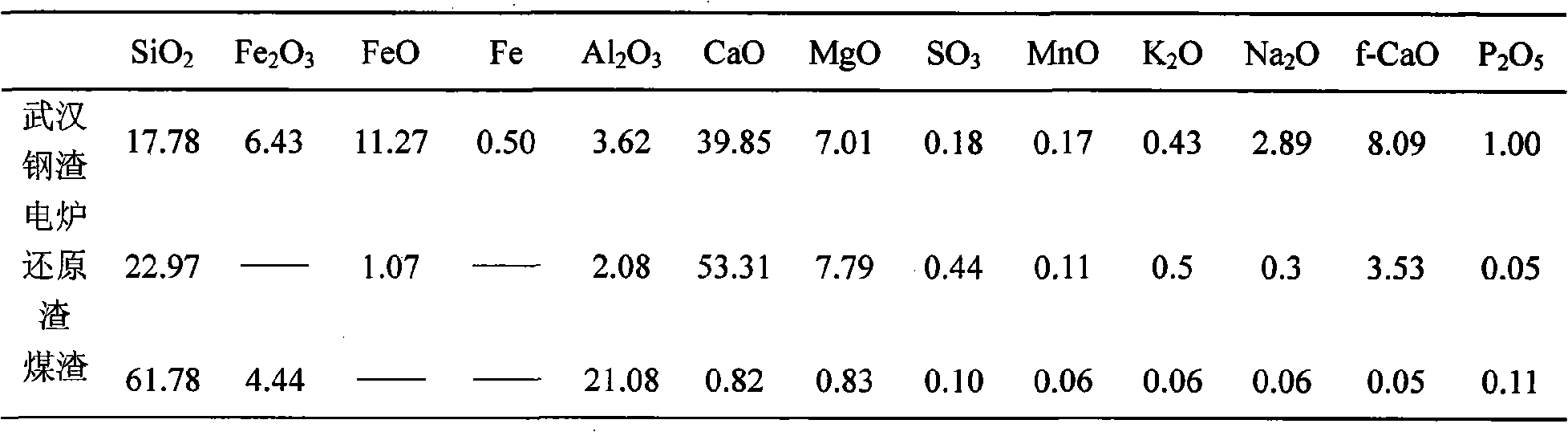

Performance adjustment material for activating steel slag at high temperature and application thereof

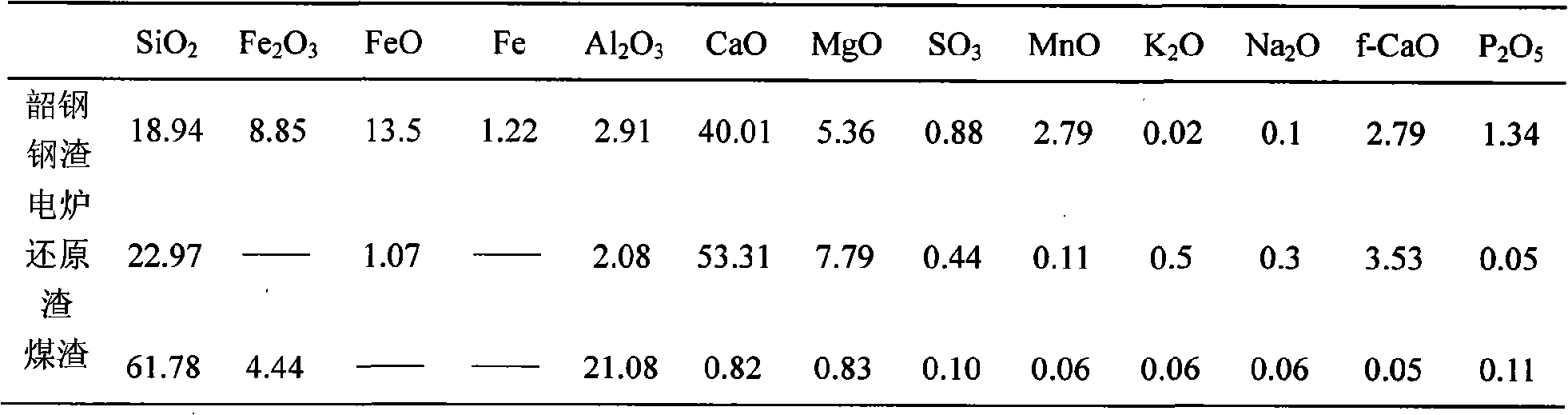

InactiveCN101560578AImprove hydrationHigh activityRecycling and recovery technologiesChemical reactionElectric arc furnace

The invention discloses a performance adjustment material for activating steel slag at high temperature and the application thereof. The performance adjustment material is prepared by mixing electric arc furnace restored slag, coal slag and starch polymer or poval. The application of the material is as follows: after being mixed, the performance adjustment material and the steel slag chemically react under the action of high temperature so as to improve the hydration and the cohesive activity of the steel slag. The invention utilizes the electric arc furnace restored slag, the coal slag and a small quantity of starch polymer or poval to prepare the performance adjustment material; and the performance adjustment material and the steel slag are mixed and chemically react at the certain temperature so as to improve the hydration and the cohesive activity of the converter steel slag. After reaction, the content of free calcium oxide in the steel slag is lower than 2 percent; and when the specific surface area of steel slag powder ranges from 400 to 500m / kg after activation, the 28d activity index is higher than 85 percent. The activated steel slag powder prepared by the invention can be used as cement admixture or concrete admixture, and can be widely applied to the construction projects of industrial and civil architecture, water conservancy, roads, airports, etc.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com