Patents

Literature

323results about How to "Reduce water demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

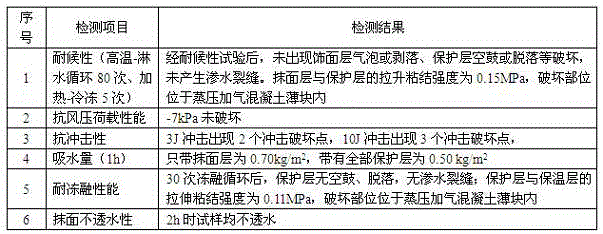

Exterior wall composite insulation heat-proof plastering material

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

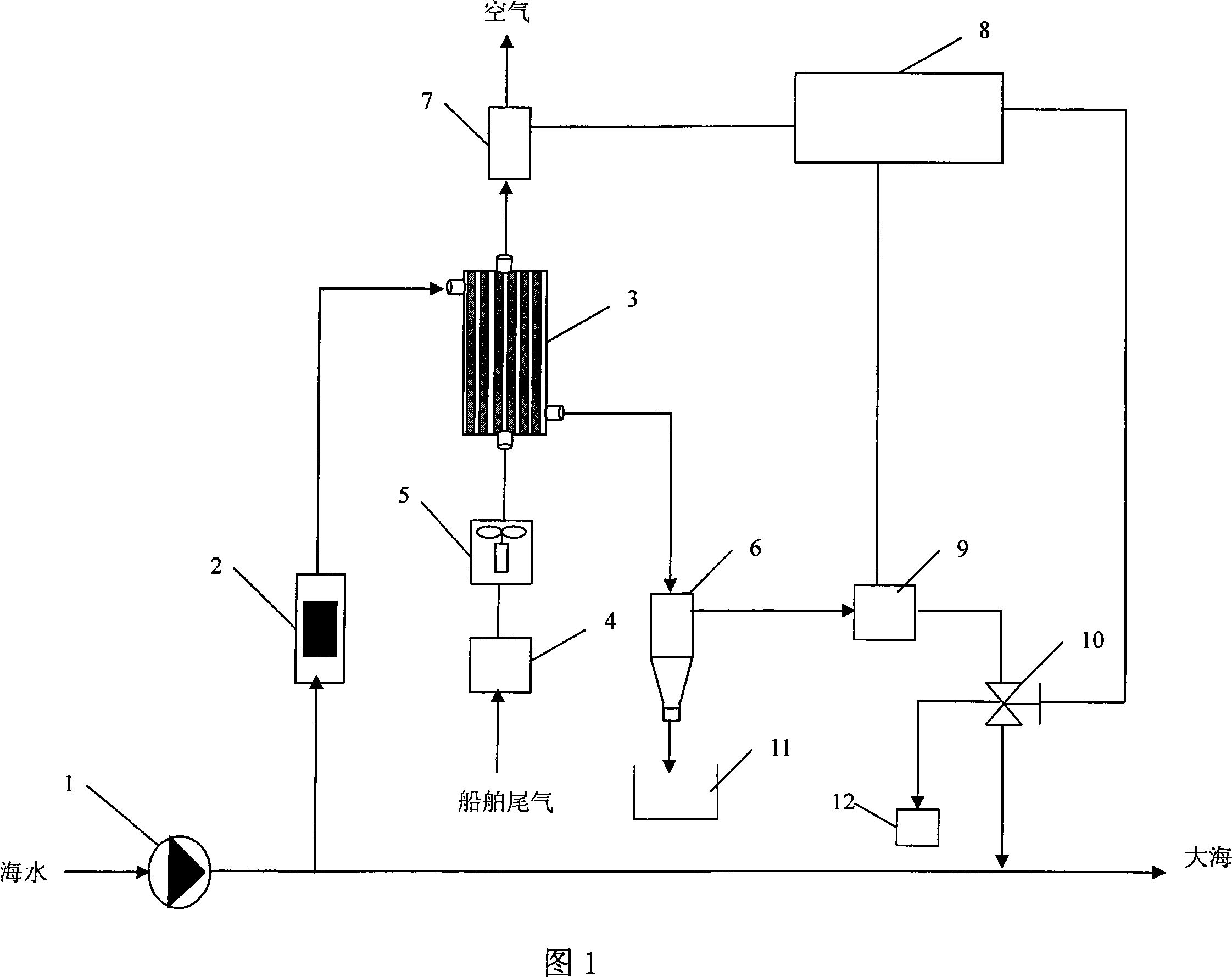

Device and method for treating ship tail gas with sea water washing

InactiveCN101104130AEfficient removalEasy to checkDispersed particle separationWater dischargeWater quality

The invention is a device and the method conducting seawater washing treatment to the ship exhaust gas which belongs to the ship exhaust gas treatment technical field. The ship exhaust gas after the dust-removing pretreatment is treated by seawater washing in a hollow fiber membrane contactor which serves as a syringe, a control system comprising an SO2 density monitor, a water quality monitor and a PLC programmable controller conducts real-time detection and storage to the SO2 density and waste water quality in the ship exhaust gas after treatment, as well as the control to the water discharging. The invention has beneficial effects that: water requirement is little by adopting the hollow fiber membrane contactor as the syringe, and the oxysulfide and particle substances in the ship exhaust gas can be effectively eliminated; and real-time monitoring, collection and storage of treatment effects of the ship exhaust gas and the seawater by adopting the PLC programmable controller facilitate the inspections of port states.

Owner:DALIAN MARITIME UNIVERSITY

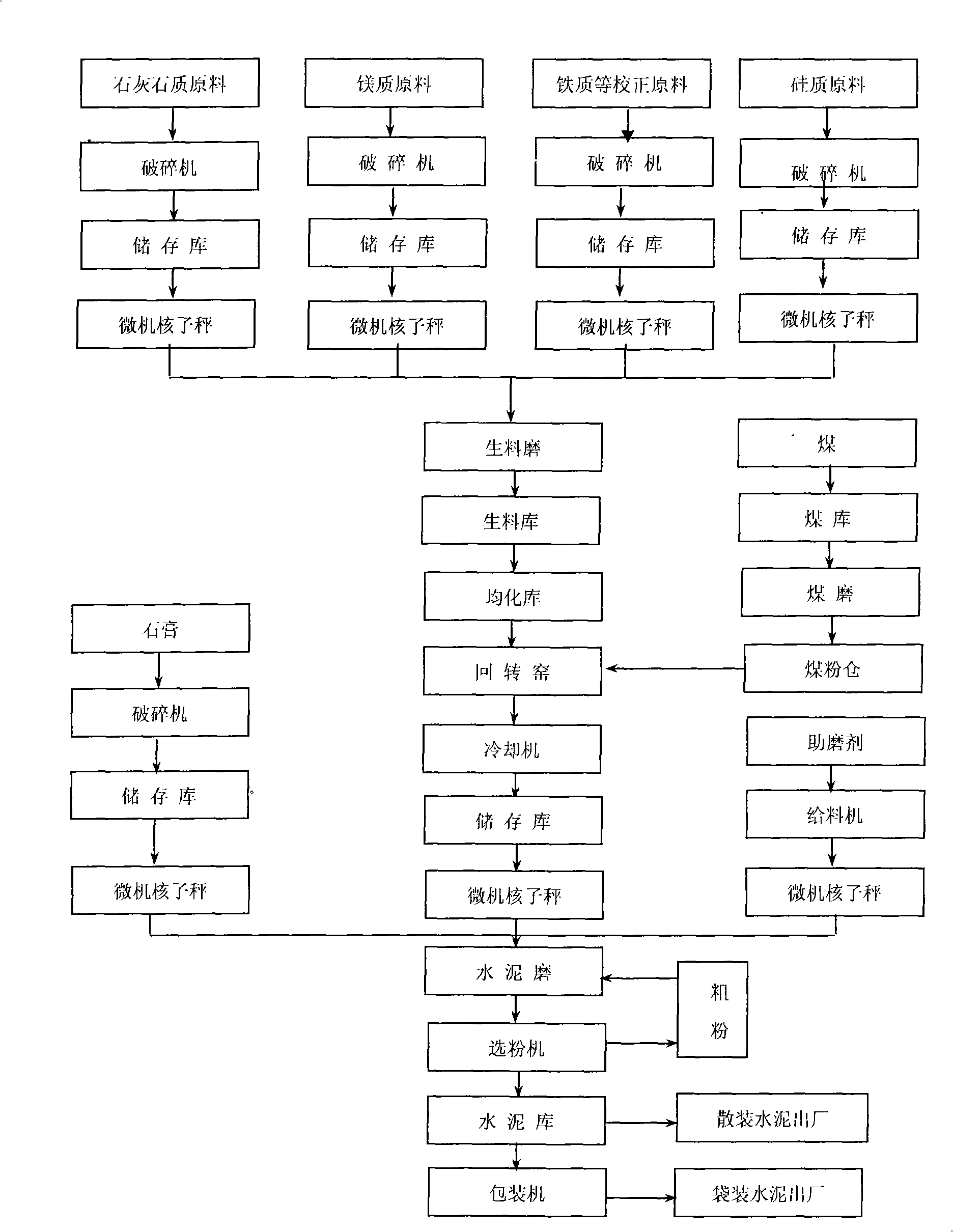

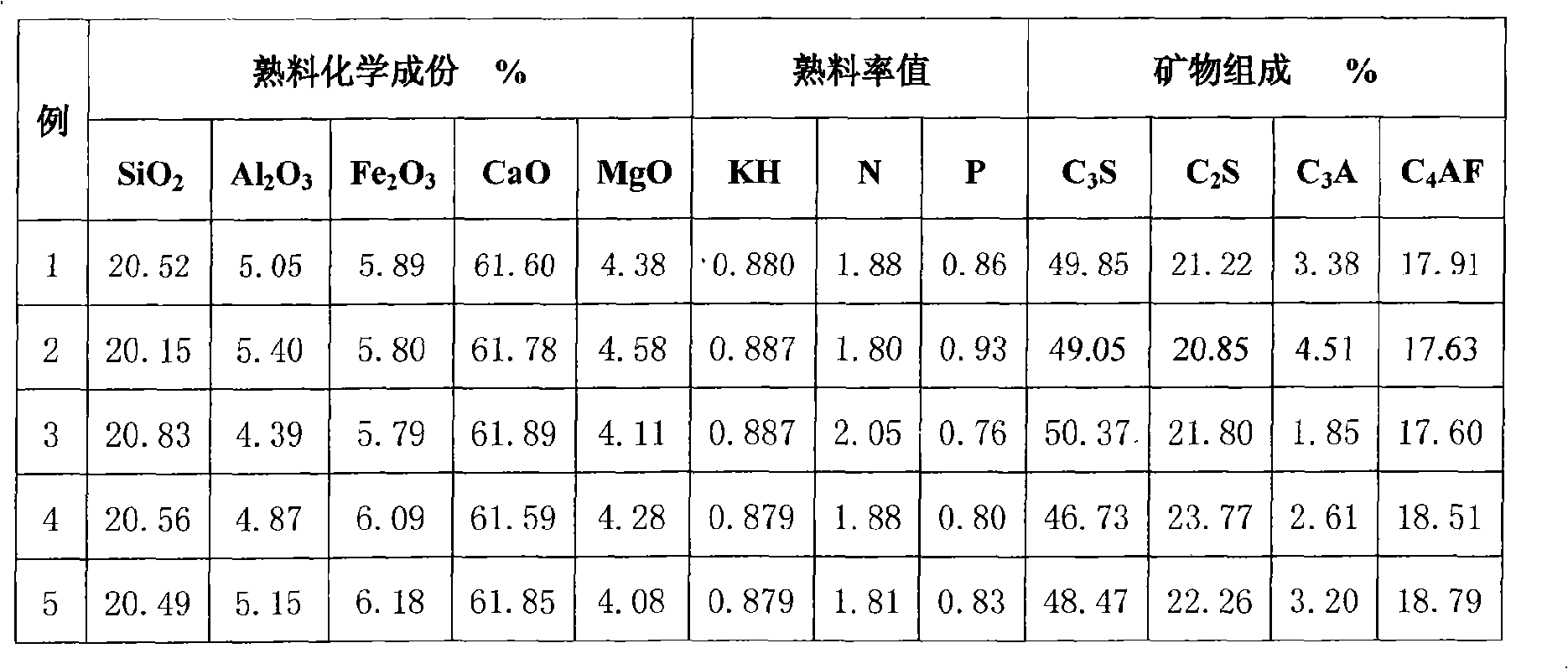

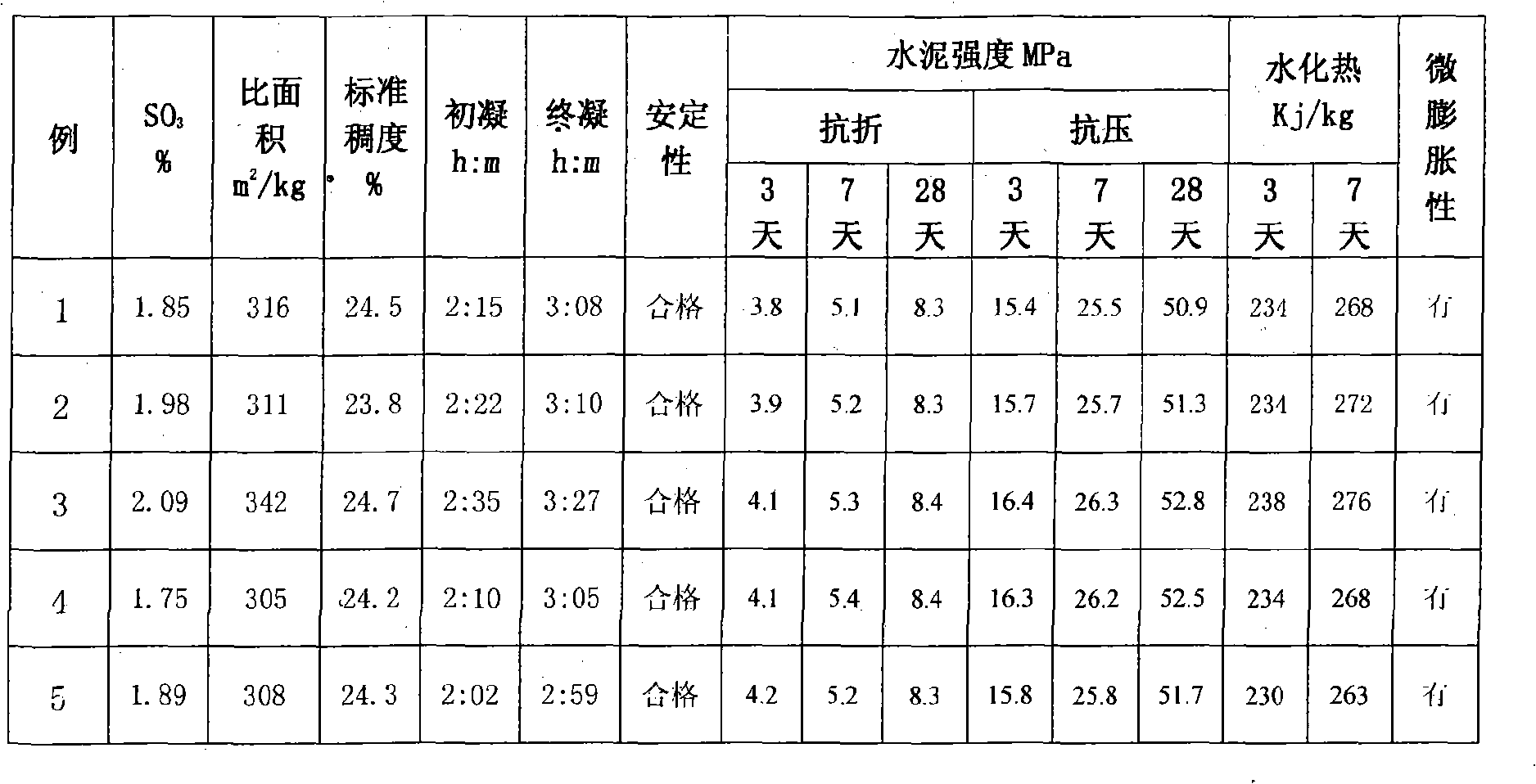

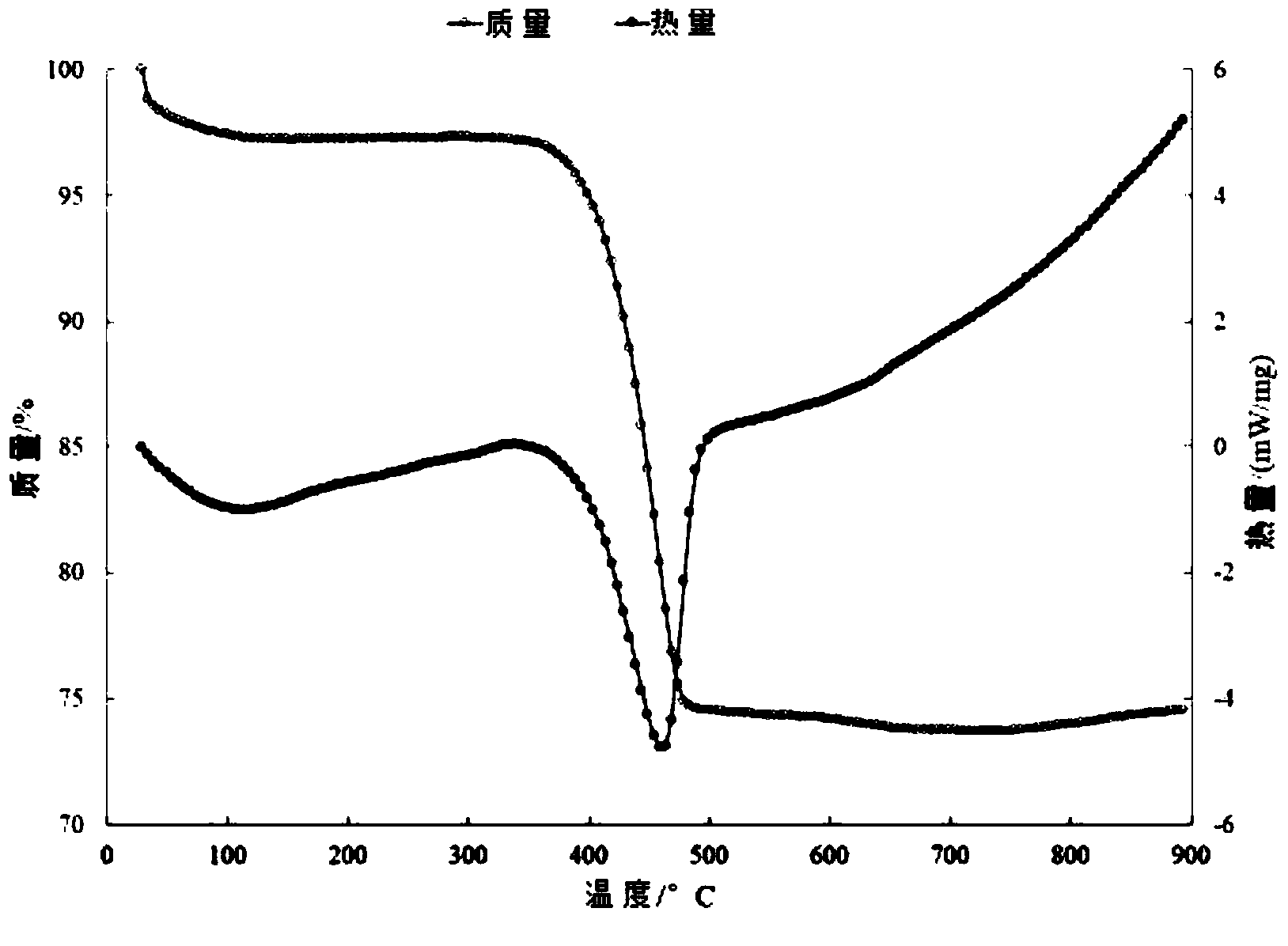

High-magnesium moderate-heat portland cement and production method thereof

InactiveCN101353231AReduce water demandThe micro-expansion property hasClinker productionHigh magnesiumPortland cement

The invention relates to a high-magnesium moderate heat portland cement, which is characterized in that (1) the contents of MgO and SO3 in the cement are 3.0-6.5% and 1.4-2.2% respectively; (2) the weight percentages of the mineral composition for grinding cement clinker are 35-55% of C3S, 15-35% of C2S, 1-6% of C3A and 10-25% of C4AF; and the content of MgO in the cement clinker is 3.0-6.5%; (3) in the raw materials for calcining the clinker, the contents of MgO, CaO and Fe2O3 are respectively controlled at a certain value within the ranges of 2.5-3.8%, 38.0-42.0% and 3.5-4.5%, and the variation ranges thereof are respectively controlled within plus or minus 0.10%, plus or minus 0.20% and plus or minus 0.15%. The production method of the cement mainly comprises three procedures of raw material milling, clinker calcining and cement grinding, namely, 'two grinding and one calcining'. The concrete made from the cement is characterized by good fluidity, low water requirement, moderate cement heat, high later strength, good durability, microdilatancy performance, and the like; compared with the conventional portland cement and moderate heat portland cement, the high-magnesium moderate heat portland cement is more favorable for realizing high performance of the concrete.

Owner:湖南石门特种水泥有限公司

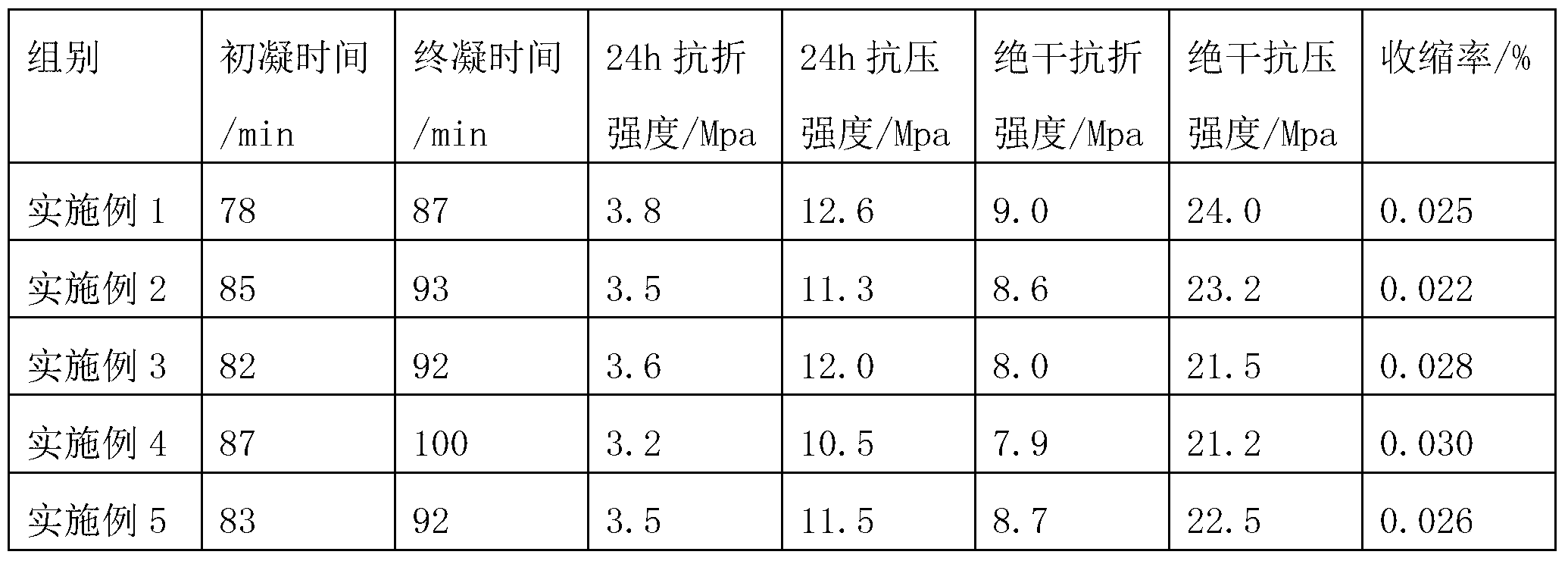

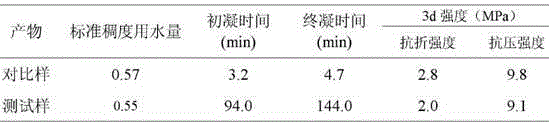

Alpha high-strength gypsum based self-leveling material prepared by adopting phosphogypsum and production process thereof

The invention relates to an alpha high-strength gypsum based self-leveling material prepared by adopting phosphogypsum and a production process thereof. The material comprises the following components in percentage by weight: 40-60% of alpha high-strength gypsum powder, 30-50% of aggregates, 1-4% of cement, 1-4% of fly ash, 2-4% of re-dispersible rubber powder, 0.1-0.3% of retarder, 0.2-0.75% of water reducing agent, 0.1-0.25% of water-retaining agent, 0.1-0.4% of air entraining agent and 0.05-0.15% of antifoaming agent. The production process comprises the steps of uniformly mixing the components and obtaining the alpha high-strength gypsum based self-leveling material. The alpha high-strength gypsum based self-leveling material disclosed by the invention has the advantages that the requirements of JC / T1023-2007 Gypsum based Self-leveling Mortar are met and the requirements on the 30min fluidity loss, the initial setting time, the final setting time, the breaking strength, the compressive strength and the shrinking rate are met.

Owner:WUHAN UNIV OF TECH

Cement grinding aid

InactiveCN101898878AIncrease productionReduce power consumptionCement productionCalcium formateGlycerol

The invention discloses a cement grinding aid, comprising calcium formate solution, compound glycerol distilled residue solution, triethanolamine, diols and molasses. While the product reutilizes the industrial wastes, the components of the product synergistically act to optimize the efficacy of the grinding process and the product modifies the cement particles, thus improving the quality and performance of the cement while improving the cement yield and saving electricity, and the product does not only have grinding function.

Owner:宜兴市宏伟科技有限公司

Ultrahigh-strength concrete and preparation method thereof

The invention discloses ultrahigh-strength concrete which comprises the following components in parts by weight: 300-350 parts of cement, 270-315 parts of composite mineral admixture, 30-35 parts of composite expanding agent, 96-112 parts of water, 680-720 parts of river sand, 1012-1080 parts of gravel, 13.2-14.0 parts of polycarboxylic acid high-efficiency water reducing agent, 4.4-4.7 parts of plastic retaining agent and 0.18-0.21 part of defoaming agent, wherein the composite mineral admixture is prepared from 42-49 parts of ore powder, 150-175 parts of fly ash, 30-35 parts of silica fume, 18-21 parts of zeolite powder and 30-35 parts of wollastonite powder. The invention is characterized in that the 60d concrete compression strength is 140-160 MPa, the 60d splitting tensile strength is 9.2-10.2 MPa, extruded concrete can achieve self-compaction effect within 3 hours, and the 14d self-shrinkage value is less than 0.05%.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

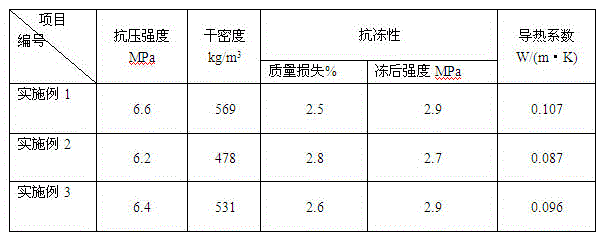

Ardealite-based high-strength light building blocks prepared from ardealite and production process thereof

The invention relates to an ardealite-based high-strength light building block prepared from ardealite and a production process thereof. The ardealite-based high-strength light building block is prepared from the following raw material components by weight percent: 50-70% of dry basis of alpha high-strength gypsum, 3-10% of cement, 10-20% of coal ash, 10-20% of glass beads and 0.1-0.4% of air entraining agent. The raw materials are mixed together evenly in a water-material ratio from 0.4 to 0.6 and stirred into slurry; then the slurry is moulded to form the ardealite-based high-strength light building block. The ardealite-based high-strength light building block produced through the production process provided by the invention is found by detection that the apparent density of the solid building block is not higher than 1000 kg / m<3>, the strength grade is above MU10, the softening coefficient is not lower than 0.6 and the utilization rate of the solid waste is more than 70%.

Owner:WUHAN UNIV OF TECH

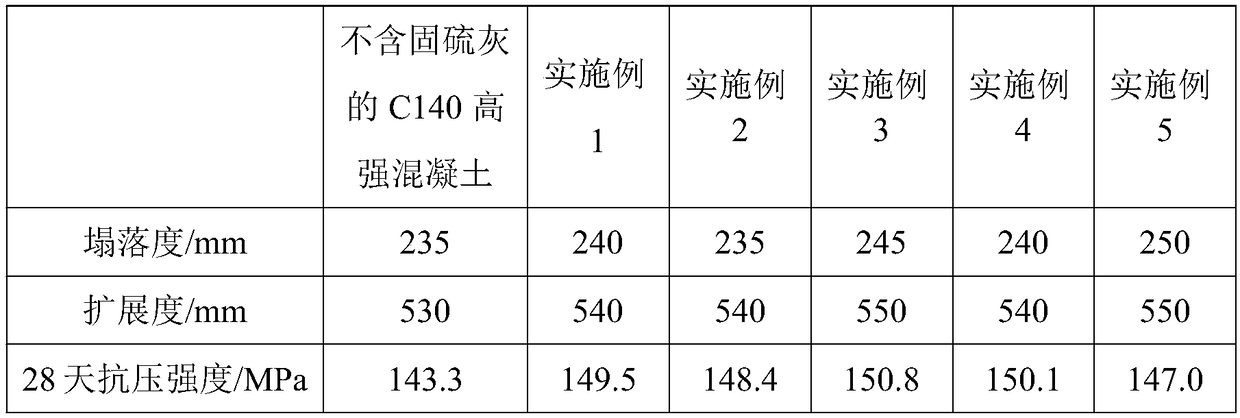

C140 high-strength concrete and preparation method thereof

The invention belongs to the field of concrete, and particularly discloses C140 high-strength concrete and a preparation method thereof. The concrete is prepared from the following materials in partsby weight: 490-570 parts of cement, 45-65 parts of coal ash, 100-120 parts of mineral powder, 65-85 parts of desulphurization ash, 20-40 parts of silica fume, 750-950 parts of coarse aggregate, 400-600 parts of fine aggregate, 5.5-7.5 parts of a water reducer, 10-20 parts of a corrosion inhibitor, 60-100 parts of fibers and 145-160 parts of water. The invention provides the C140 high-strength concrete; the concrete has a good slump, good extended degree, good compressive strength, and excellent comprehensive performance, and meanwhile, the problems of resource shortage of traditional cement admixtures of the mineral powder, the coal ash, the silica fume and the like, and limited resourced approaches and a low utilization rate of the desulphurization ash are solved.

Owner:成都宏基建材股份有限公司

Autoclaving-free prestressed high-strength tube pile concrete and tube pile manufacturing method

The invention relates to autoclaving-free prestressed high-strength tube pile concrete and a tube pile manufacturing method. The concrete is prepared from the following components in parts by mass: 300-420 parts of PI or PII 52.5 cement, 5-80 parts of mineral powder, 5-100 parts of lithium slag powder, 5-40 parts of glass microbead powder, 680-720 parts of sand, 1125-1170 parts of broken stones, 125-135 parts of water, 4-5 parts of a polyocarboxy acid water reducing agent and 2-5 parts of an exciting agent. After stirring and shaping are performed, only constant-pressure steaming is performed for 6-8 hours, the strength requirement of C80 can be met, the energy consumption is reduced, and besides, the lithium slag powder which is industrial waste is utilized for the autoclaving-free concrete tube pile, so that the problem of resource wasting and the problem of environmental pollution are solved to a certain extent.

Owner:SOUTHEAST UNIV

Phosphogypsum-base wall material for cast-in-place wall

The invention discloses a phosphogypsum-base wall material for a cast-in-place wall. The invention is characterized in that the material is prepared from the following raw materials in percentage by weight: 60-80% of beta-phosphogypsum, 10-20% of mineral admixture, 5-25% of cement, 0.25-0.5% of retarder, 0.05-0.15% of defoaming agent, 0.05-0.2% of thickener and 0.5-1% of water reducer. The raw materials are uniformly mixed to obtain the phosphogypsum-base cast-in-place wall material; and the material and water are mixed uniformly in a water / material ratio of 0.4-0.5 to obtain a slurry, and the slurry is cast in place and molded. The phosphogypsum-base wall material has the advantages of controllable setting time, low flowing loss rate, high utilization ratio of solid waste, low material cost and high strength, is convenient for construction, and can be widely used for frame-structure infilled internal walls of commercial and civil buildings.

Owner:WUHAN UNIV OF TECH

Preparation method and application of gypsum retarder

The invention discloses a preparation method and an application of a gypsum retarder. The gypsum retarder is prepared from a diacid or anhydride material and an ammoniacal material or L-aspartic acid; the retarder prepared by use of the preparation method is added to gypsum so as to increase the setting time of a gypsum building material and reduce the strength loss of a hardened gypsum body. The retarder is a water-soluble amino acid degradable polymer, has excellent biodegradability and is a green and environment-friendly polymer material. The molecular structure of the retarder contains a large number of groups such as carboxyl, carbonyl and acyl, and the groups can be combined with Ca<2+> into complexes so that the dissolution velocity of the gypsum can be reduced, the diffusion of Ca<2+> to gypsum crystals can be restricted and hydration of gypsum particles can be hindered, and therefore, the retarding effect of the retarder is realized. Meanwhile, the strength loss caused by structural degradation of gypsum holes due to a high water-gypsum ratio is reduced.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

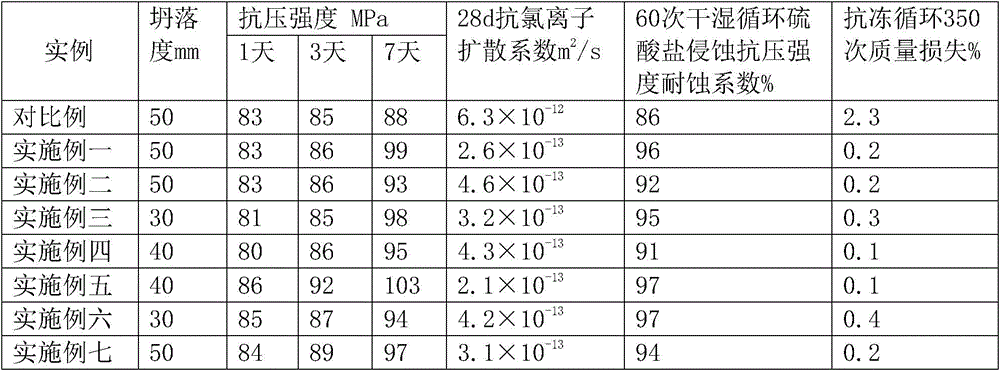

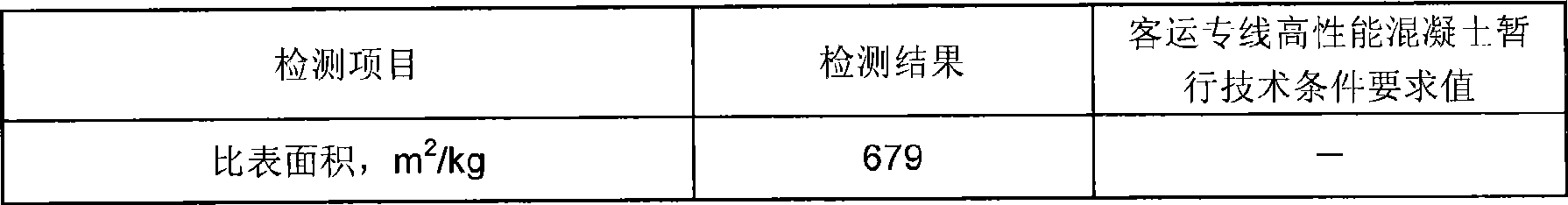

Composite high-early strength blending material for unballasted track plate and use thereof

ActiveCN101475330AAccelerated hydration condensationDoes not affect liquiditySolid waste managementBallastwayFilling materialsBuilding material

The invention discloses a composite early strength admixture for an unballasted track plate and application of the admixture and relates to the field of building material. The admixture consists of 50 to 70 weight percent of a silicon reinforcing material (A), 0 to 20 weight percent of a carbonate reinforcing material (B), 0 to 20 weight percent of an aluminium-silicon reinforcing material (C), 0to 20 weight percent of a silicon filling material (D), 0 to 20 weight percent of an aluminum filling material (E) and an excitant (F) in combined preparation, wherein B, C, D and E are not zero simultaneously; and the use amount of the excitant (F) is 0 to 5 weight percent of gross weight of (A+B+C+D+E). The admixture is applied to the manufacture of the unballasted track plate, can offset the insufficiency of concrete performance brought by the replacement of ultrafine cement by common silicate or silicate cement; collapse degree of the applied concrete is between 140 and 200 mm; 16h compressive strength is more than 48 MPa; and the high-performance concrete for the unballasted track plate fully meets the technical requirement of a provisional technical condition for high performance concrete in a passenger transportation dedicated line.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

Minimum inflation low heat silicate cement

ActiveCN102173700AWith micro expansionReduce water demandSolid waste managementCement productionTemperature stressSlag

The invention discloses minimum inflation low heat silicate cement. The cement comprises the following components in percentage by weight: 75 to 95 percent of low heat silicate clinker, 1 to 10 percent of gypsum, 0.01 to 6 percent of lightly-burnt MgO, and 5 to 15 percent of steel slag. The minimum inflation low heat silicate cement can effectively reduce early concrete plastic cracking and temperature stress cracking generated by later hydrating adiabatic temperature rise, caused by adverse construction and maintenance conditions when the concrete is constructed. The prepared concrete has the advantages of high flowing performance, small dry shrinkage, little temperature contraction joint and the like, and can be applied in the fields of mass concrete, hydraulic concrete, high performance concrete engineering and the like which have high requirement on anti-cracking performance.

Owner:JIAHUA SPECIAL CEMENT

Method for comprehensively utilizing fine coal gasification slag

ActiveCN107857496AHigh activityImprove adsorption capacityOther chemical processesSolid waste managementCycloneSlag

The invention discloses a method for preparing an adsorption material from fine coal gasification slag. The method comprises the following steps: 1, taking a proper amount of the fine coal gasification slag, and adding water to prepare a fine coal gasification slag slurry with the solid content being 10-30 wt%; 2, fully stirring the slurry prepared in step 1, performing gravity cyclone separation,collecting the obtained heavy separation product to obtain a silicon-rich composite slurry, and collecting the obtained light separation product to obtain a carbon-rich composite slurry; and 3, carrying out solid-liquid separation and drying on the carbon-rich composite slurry to obtain the carbon-rich adsorption material, and further preparing other products from the remaining silicon-rich composite slurry. The method realizes the high-added value recycling of the fine coal gasification slag.

Owner:鄂尔多斯市慧恒科技有限责任公司

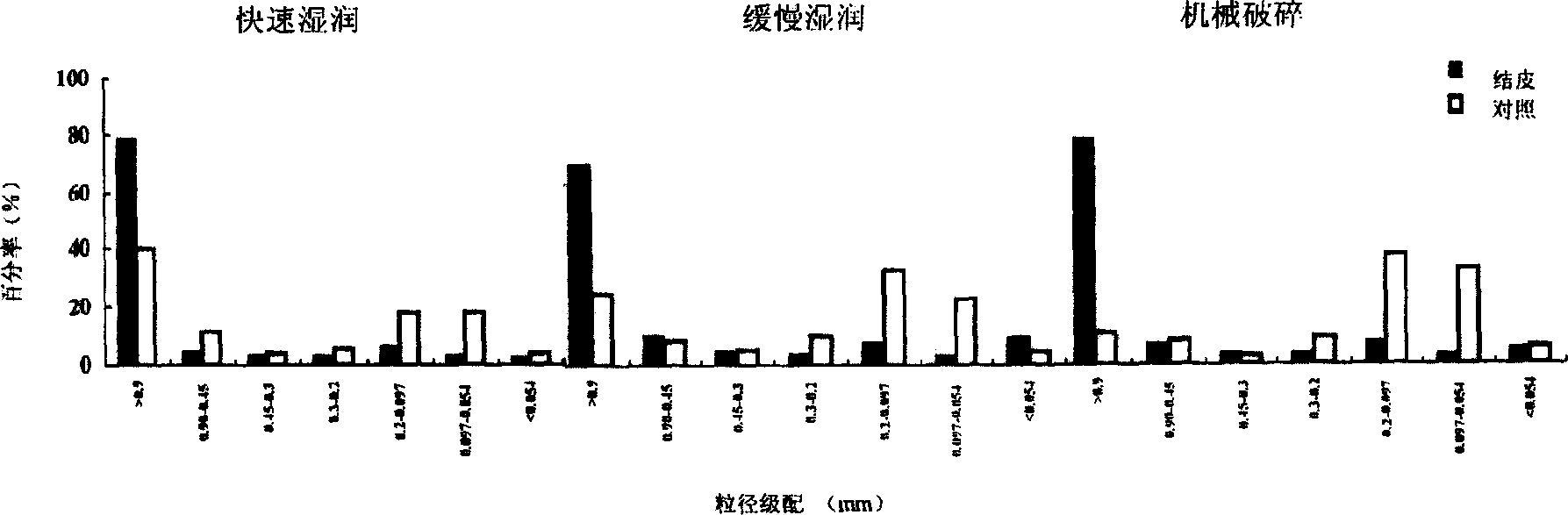

Method for improving desert and semi-desert soil by soil algae

InactiveCN1654596ARestore physiological activityGet biomassOrganic fertilisersSoil conditioning compositionsSheet mulchingPlastic mulch

The process of improving desert soil and semi-desert soil with soil algae includes the steps of: 1. separating algae from soil crust and performing solid plate culture for purifying; 2. inoculating algae seed to liquid and ventilating to culture, selecting algae seed with practical value, centrifugally collecting and drying for storage; 3. re-compounding dried algae with water to restore activity for spread culture; 4. exercising via simulating field environment to make algae suit to varying environment; 5. inoculating the algae to desert soil and semi-desert soil, covering with mulching and spraying nutritious liquid for culture; and 6. field management. By means of the growth, propagation and cell secretion of algae in soil surface, the present invention raises the organic matter content in soil and water content in soil, promotes soil structure stability and improves the physical, chemical and biological characteristics of soil effectively.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Modified glutinous rice mortar for perfusion and preparation method of modified glutinous rice mortar

The invention discloses modified glutinous rice mortar for perfusion and a preparation method of the modified glutinous rice mortar. The glutinous rice mortar comprises the following raw materials in parts by weight: 100 parts of calcium hydroxide powder, 220-400 parts of calcium carbonate particles, 5-54 parts of metakaolin, 5-18 parts of pre-gelatinized glutinous rice powder, 0.5-1.5 parts of a water-reducing agent and 80-150 parts of water. By adopting the modified glutinous rice mortar for perfusion, the problems of complicated preparation process, slow curing, great shrinkage and relatively low strength of traditional glutinous rice mortar are solved and a novel grouting and reinforcing material is provided for protection and maintenance of heritage.

Owner:ZHEJIANG UNIV

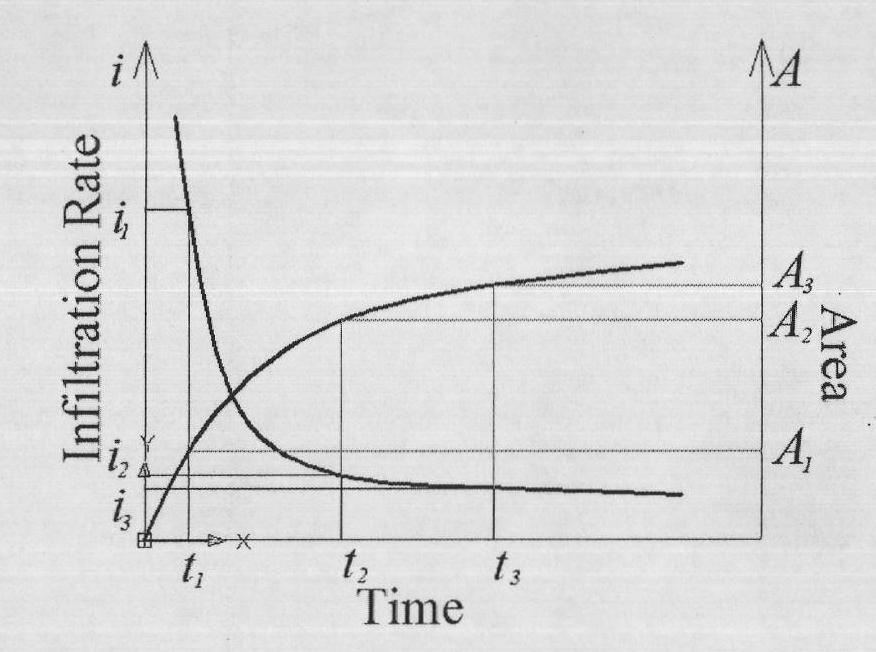

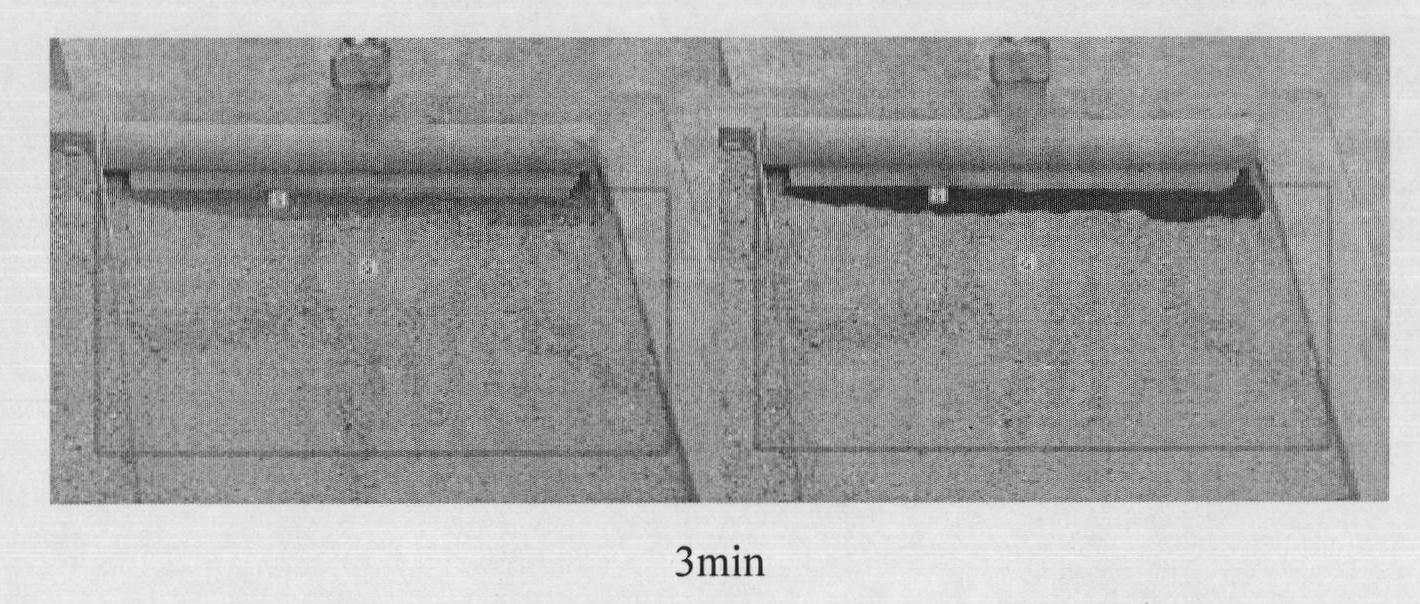

Method and system for measuring soil infiltration capability

InactiveCN101806700AHigh precisionVerification accuracyImage analysisMaterial analysis by optical meansSoil scienceWater requirement

The invention discloses a method for measuring soil infiltration capability, which comprises the following steps of: S1, acquiring an earth surface image of each frame with a camera; S2, extracting an earth surface humid area in the image acquired by the S1; S3, calculating the area of the earth surface humid area extracted by the S2; S4, correcting the earth surface humid area acquired by the S3; and S5, calculating the soil infiltration capability through the corrected earth surface humid area. The method has the advantages of less water requirement and high precision in the process of measuring, and wide popularization and application value, and can provide an effective, time-saving, labor-saving and precise tool for research on the measurement of the soil infiltration capability, and research in the related aspects such as earth surface runoff formation and soil erosion and the like.

Owner:CHINA AGRI UNIV

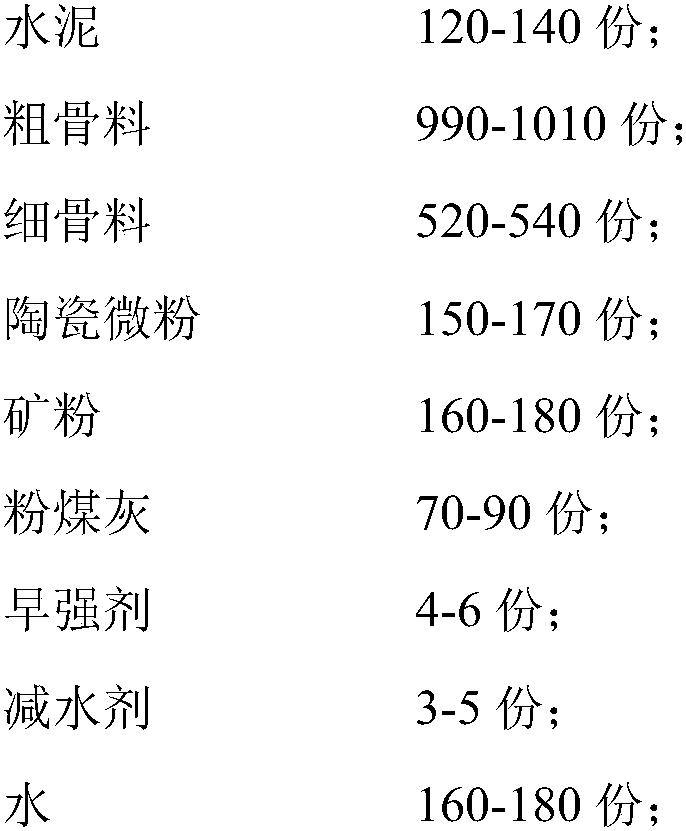

Heat-resistant concrete and preparation method thereof

The invention discloses heat-resistant concrete and a preparation method thereof and belongs to the technical field of concrete. According to key points of the technical scheme, the heat-resistant concrete comprises the following components in parts by weight: cement, coarse aggregate, fine aggregate, ceramic ultrafine powder, mineral powder, fly ash, an early strength agent, a water reducing agent and water. The coarse aggregate refers to basalt gravel and barite gravel; the fine aggregate refers to grain slag; the early strength agent comprises calcium formate and sodium silicate; the waterreducing agent comprises an early strength polycarboxylic water reducer. By replacing medium sand with grain slag, the grain slag can be effectively utilized, the long-term strength of the concrete can be improved, the heat resistance of the concrete is improved by the basalt gravel, the barite gravel and the ceramic ultrafine powder, the defects that low early strength of the concrete is broughtby the grain slag and the water demand is large can be overcome through the early strength agent and the water reducing agent, the compactness of the concrete is improved, and the compressive strengthof the concrete is improved.

Owner:北京建工新型建材有限责任公司

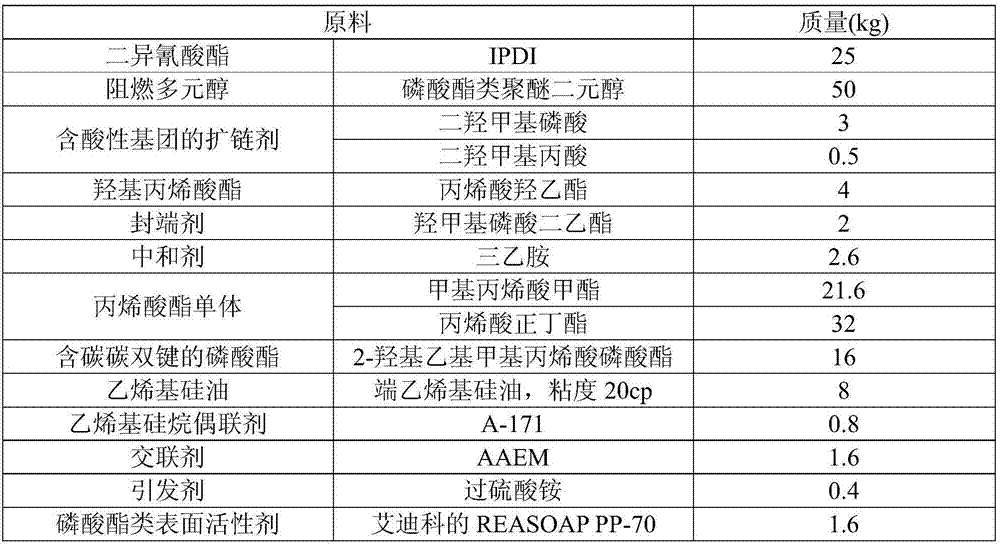

A waterborne polyurethane-acrylate copolymer emulsion and a preparing method thereof

A waterborne polyurethane-acrylate copolymer emulsion and a preparing method thereof are disclosed. The emulsion is prepared by preparing a phosphorus containing waterborne polyurethane emulsion containing carbon-carbon double bonds from diisocyanate, a flame-retardant polyol, a non-flame-retardant polyol, a chain extender containing an acidic group, hydroxyl acrylate and an end-capping agent through a chemical grafting method; and then subjecting acrylate, phosphate containing a carbon-carbon double bond, vinyl silicone oil, a vinyl silane coupling agent and an acrylic acid type crosslinking agent which are adopted as raw materials to emulsion polymerization under protection of a phosphate surfactant. The copolymer emulsion has a high solid content, time for drying the copolymer emulsion is short, and a product after the copolymer emulsion is dried has good flame retardance and resistance to thermal decomposition.

Owner:DONGGUAN CTL NEW MATERIAL TECH

Pretreatment method of phosphogypsum and paper gypsum board and preparation method thereof

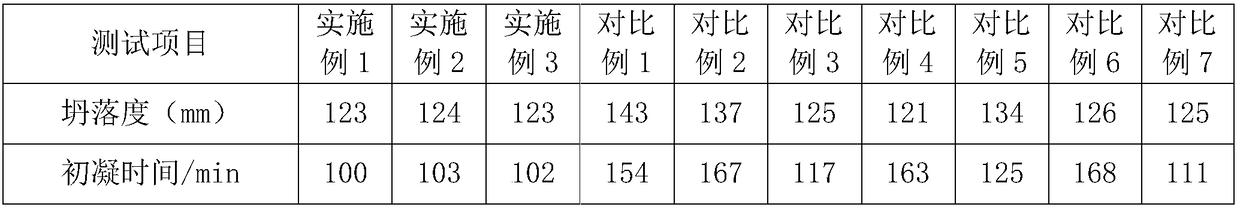

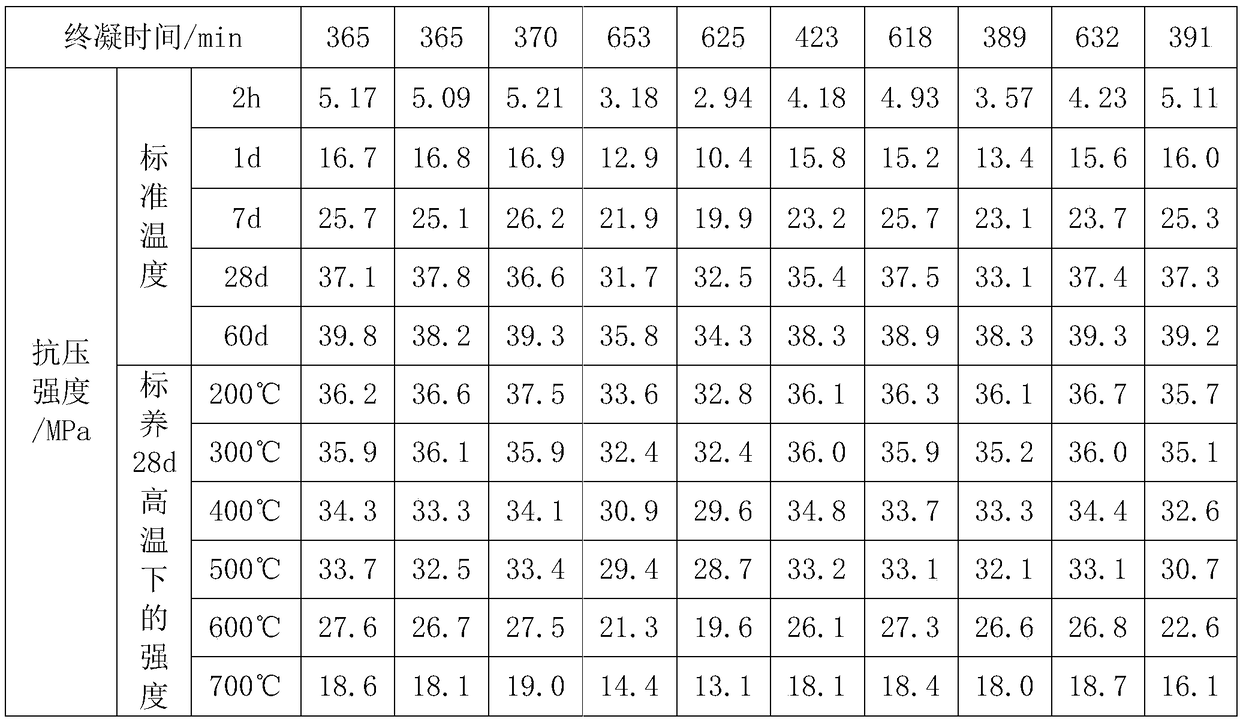

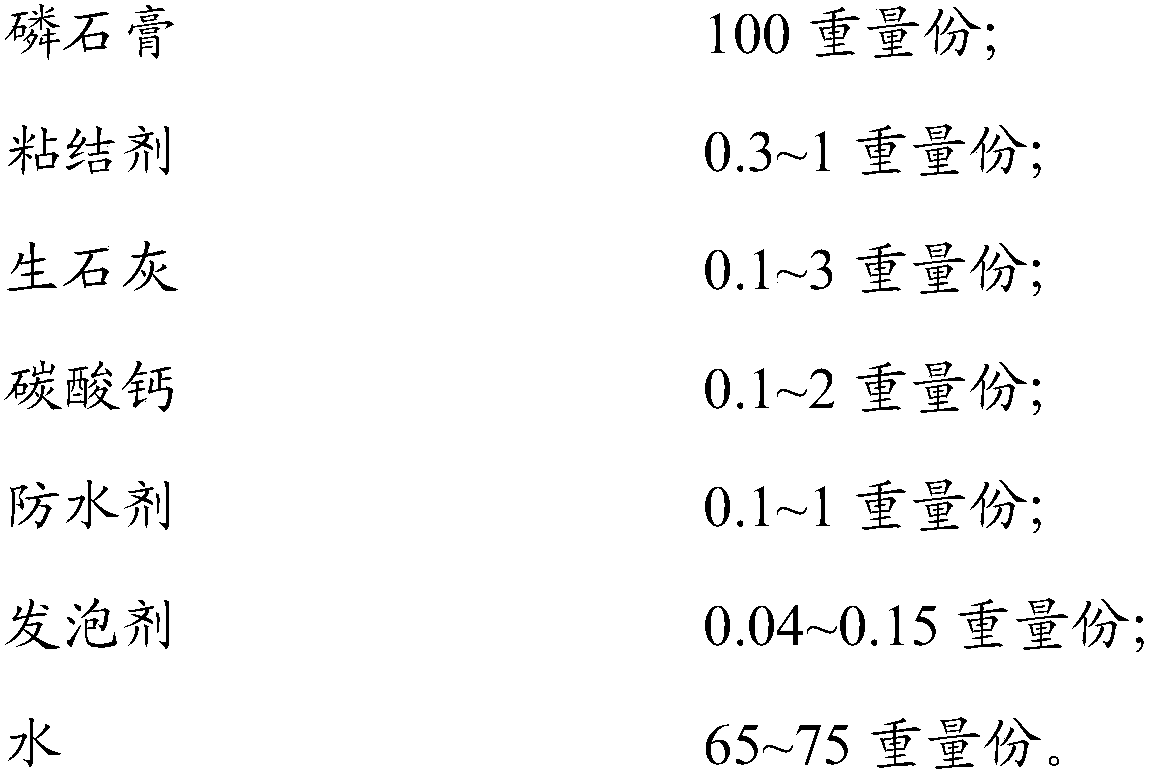

InactiveCN109133687AReduce water demandShort setting timeSurface layering apparatusCeramicwareGypsumPre treatment

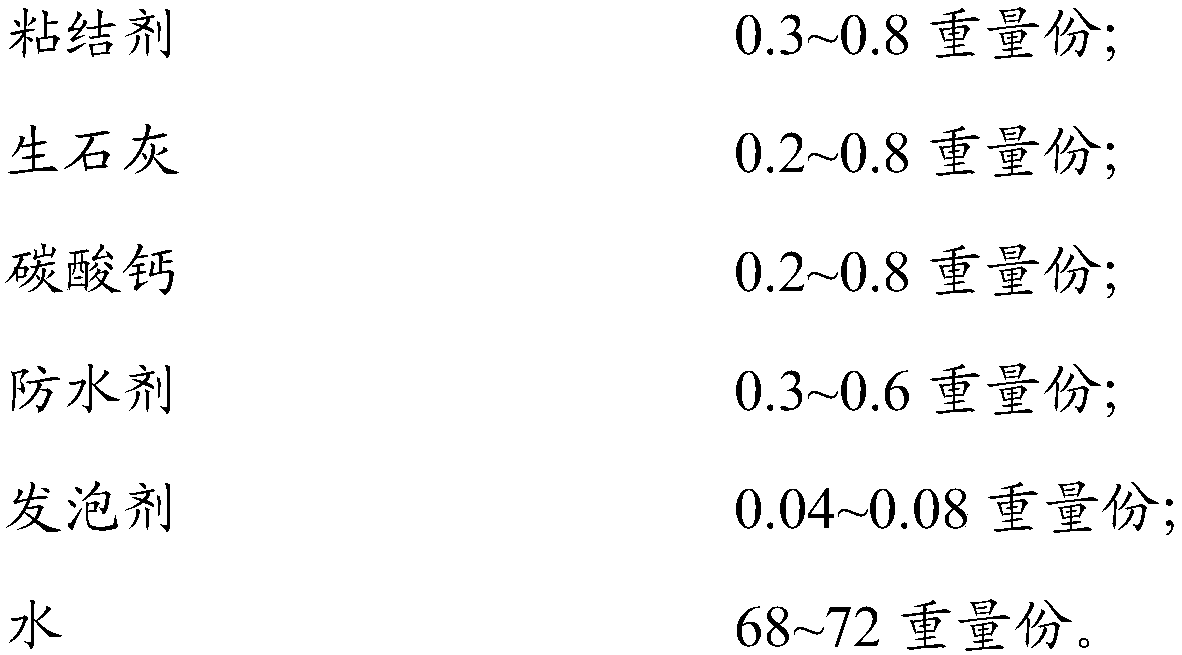

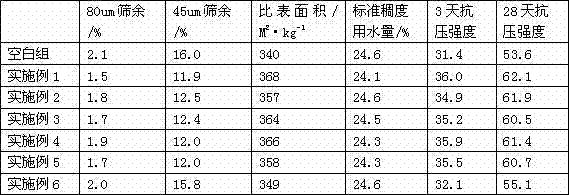

Provided are a pretreatment method of phosphogypsum and a paper gypsum board prepared by using the treated phosphogypsum and a preparation method thereof. The pretreatment method of the phosphogypsumcomprises the steps of drying and mixing the phosphogypsum with quicklime by 100:0.1-3, by weight, grounding, calcining at 140-180 DEG C, and aging; the paper gypsum board comprises, by weight, 100 parts of phosphogypsum, 0.3-1 part of binder, 0.1-3 parts of raw lime, 0.1-2 parts of calcium carbonate, 0.1-1 part of water repellent, 0.04-0.15 part of foaming agent and 65-75 parts of water; the method comprises the steps of mixing the pretreated phosphogypsum with other raw materials, stirring to form a slurry, forming upper and lower protective papers, drying, and cutting according to sizes. The method achieves the comprehensive utilization of the phosphogypsum, and the performance of the prepared paper gypsum board meets the requirements of national standards.

Owner:BEIJING NEW BUILDING MATERIAL

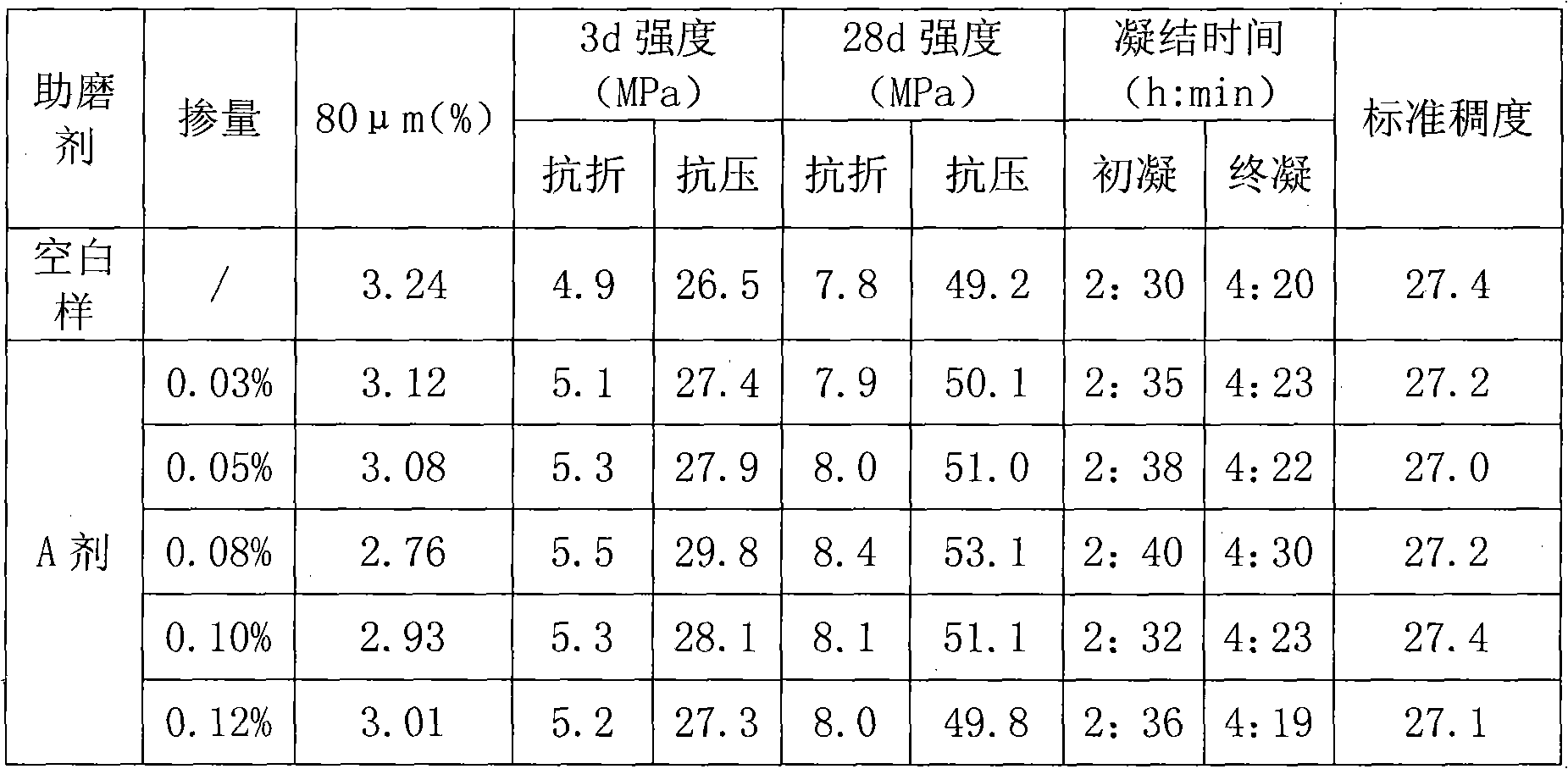

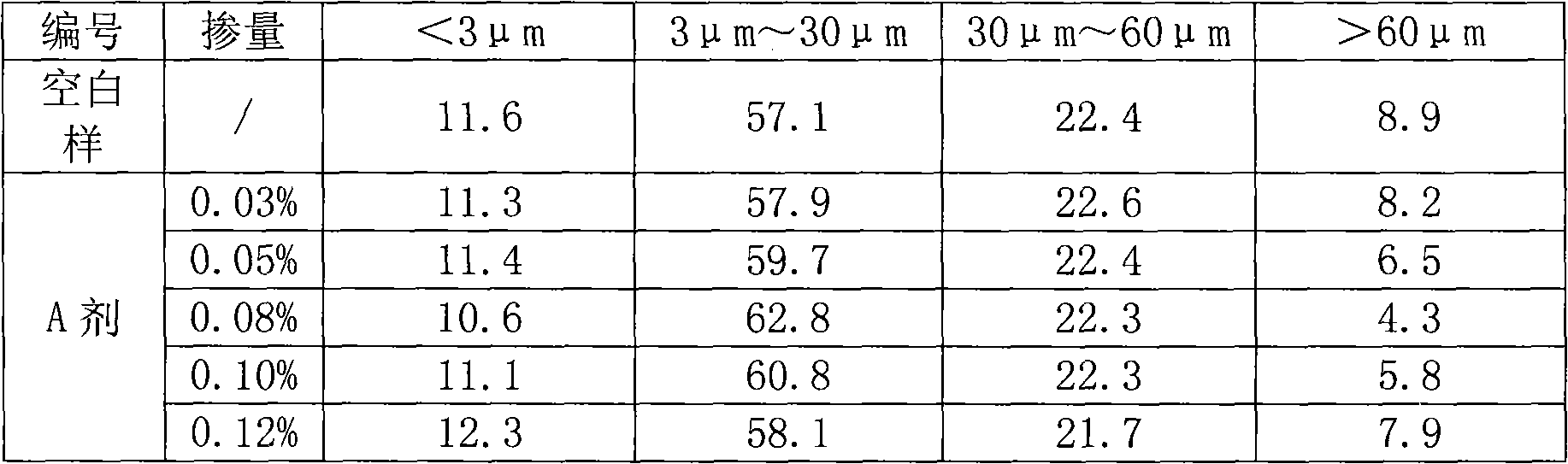

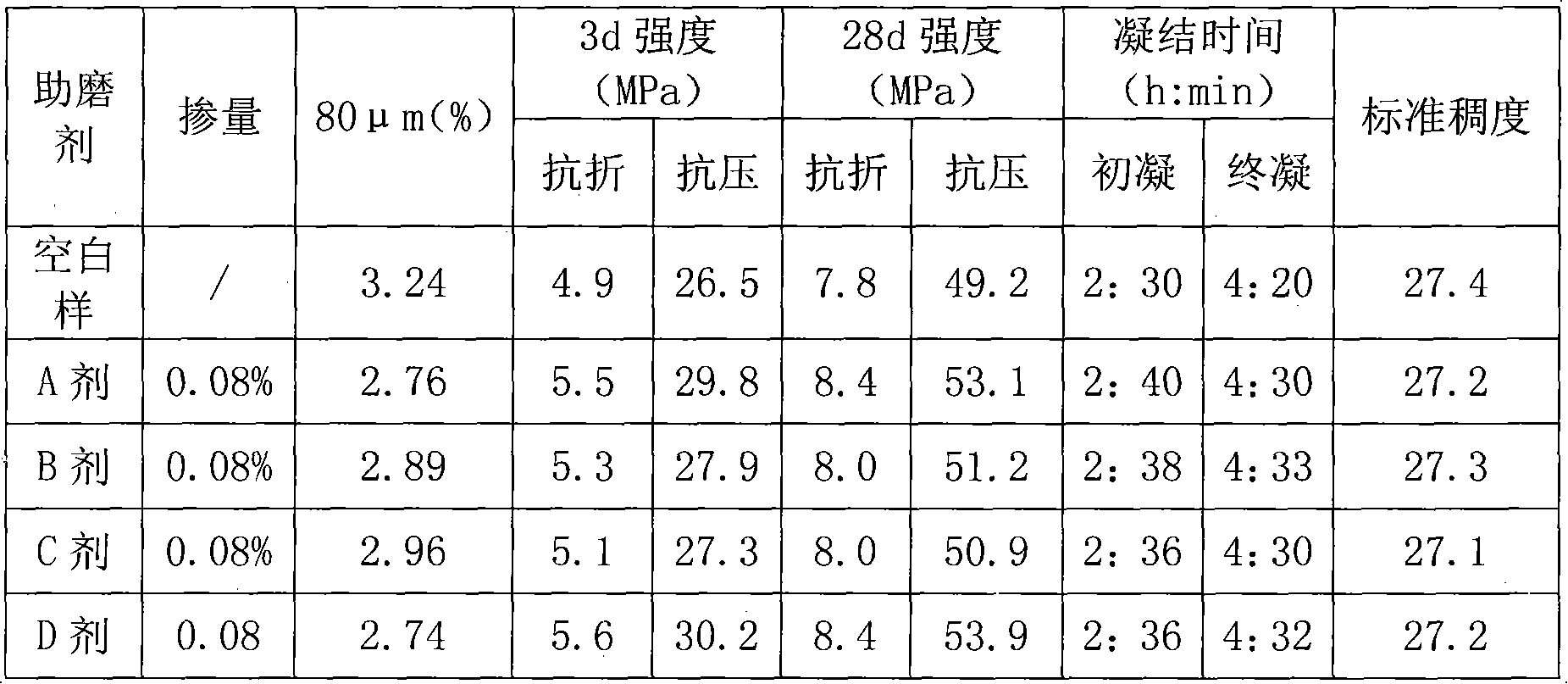

Cement composite grinding aid

The invention discloses a cement composite grinding aid which is characterized by comprising the following components in parts by weight: 10-30 parts of polyol amine, 10-30 parts of polyol, 5-15 parts of molasses, 5-15 parts of lignosulphonate, 2-6 parts of sodium metasilicate pentahydrate, 3-7 parts of sodium hexametaphosphate and 20-30 parts of water. The cement composite grinding aid disclosed by the invention is stable in raw material source, environmental-friendly, low in toxicity and easy to produce, and ensures that the components achieve preferable synergistic effect by confirming the components and a content range, thus optimizing the efficacy of a powder grinding process and improving the power granule distribution and morphology of cement without adverse effect on cement quality. The cement composite grinding aid disclosed by the invention has the advantages of preferably increasing the yield increase and enhancing the cement quality and has the effects of saving the electricity consumption, improving the powder efficiency and the cement strength, reducing the free calcium oxide contained in the cement and enhancing the early strength and later strength of the cement.

Owner:湖州华仑助剂科技有限公司

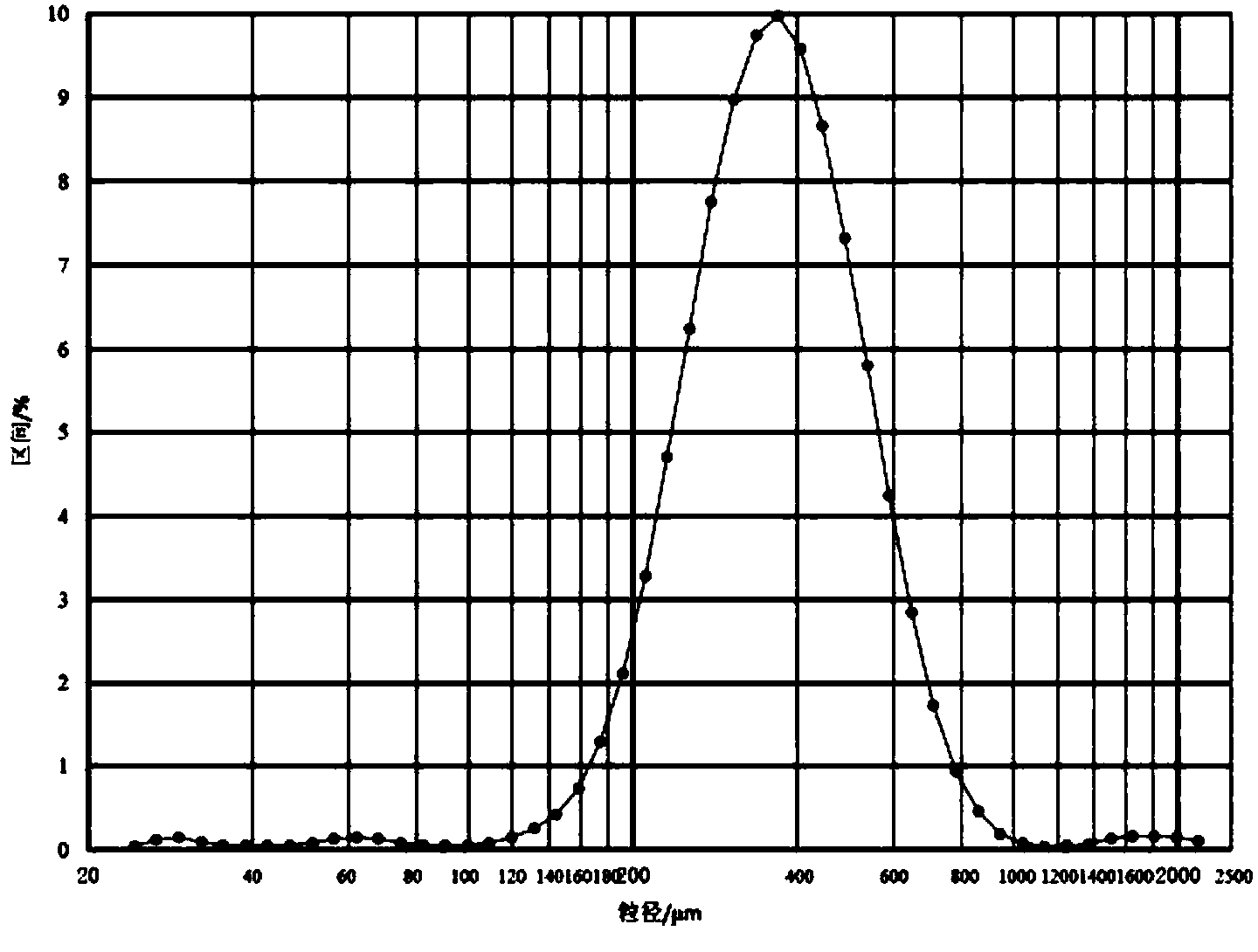

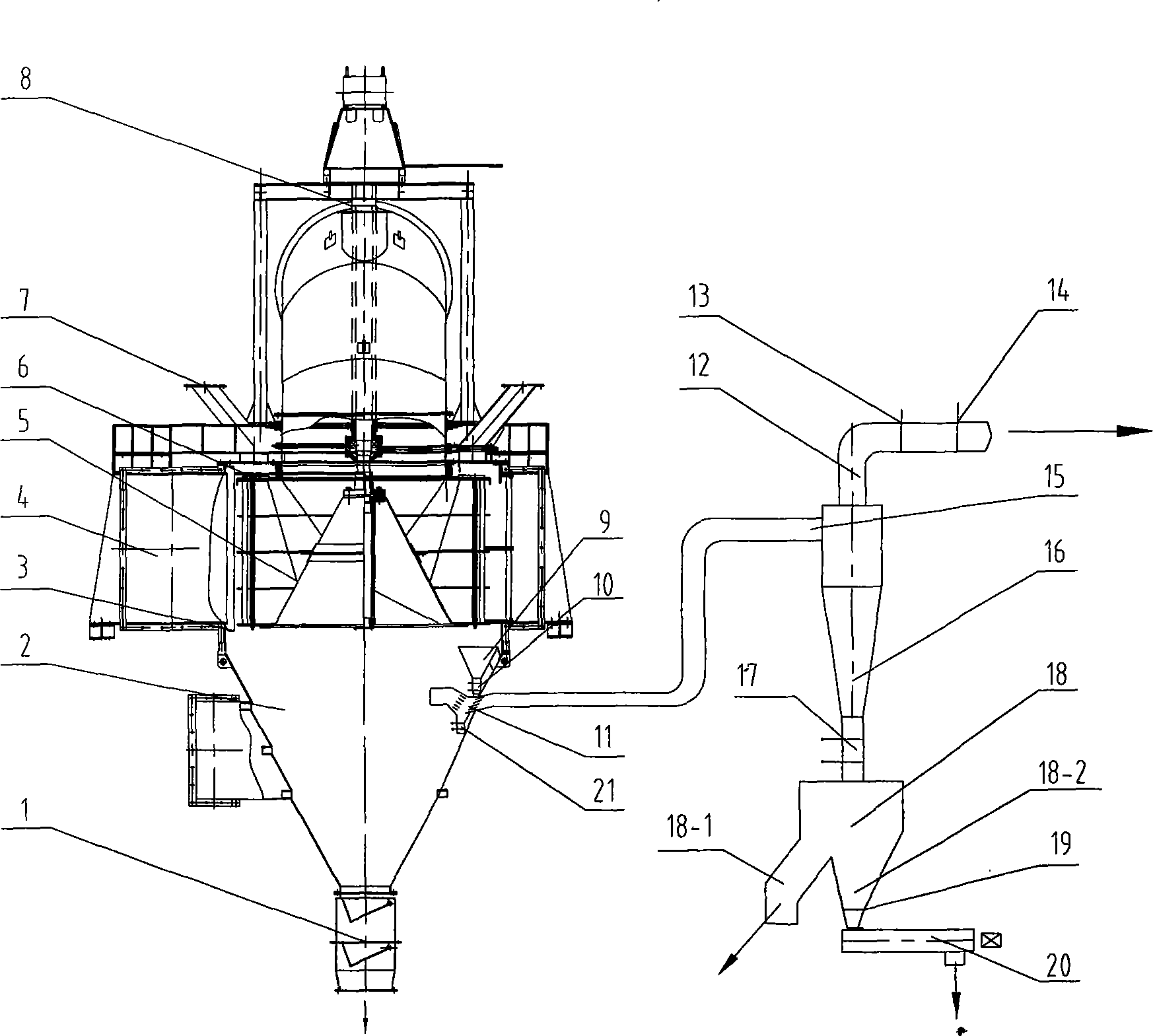

High-effective flour screening machine with wide size distribution of particles

ActiveCN101433897AImprove particle distributionGood compatibilityGas current separationGrain treatmentsWork performanceEngineering

The invention provides a high-efficiency powder-selecting machine with wide particle diameter distribution. The powder-selecting machine comprises a shell body, a cage-type rotor, a feed spreading tray, a central wind pipe and a coarse powder cone; the central wind pipe is arranged on the upper part of the shell body; the lower part of the shell body is provided with the feed spreading tray and the rotor; a wind inlet and a feed inlet are arranged on the shell body; the lower part of the rotor is provided with the coarse powder cone; a semiannular collecting hopper of a secondary sorting device is arranged on the upper part of the coarse powder cone; a lower mouth of the collecting hopper is communicated with an upper mouth of a four-way joint through a wind locking valve; two side mouths of the four-way joint are connected with a separator and secondary wind respectively; a lower mouth of the four-way joint is connected with the wind locking valve; an upper mouth of the separator is connected with a wind outlet pipe; and a lower mouth of the separator is communicated with an overflow valve through the wind locking valve. The high-efficiency powder-selecting machine can once sort out fine powder, finer powder and coarser powder needed by cement with wide particle diameter distribution, and improve the particle distribution of a sorted powder body so that water amount needed by the cement is reduced, improve the compatibility between the cement and an additive and the working performance of the cement and reduce energy consumption and production cost.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

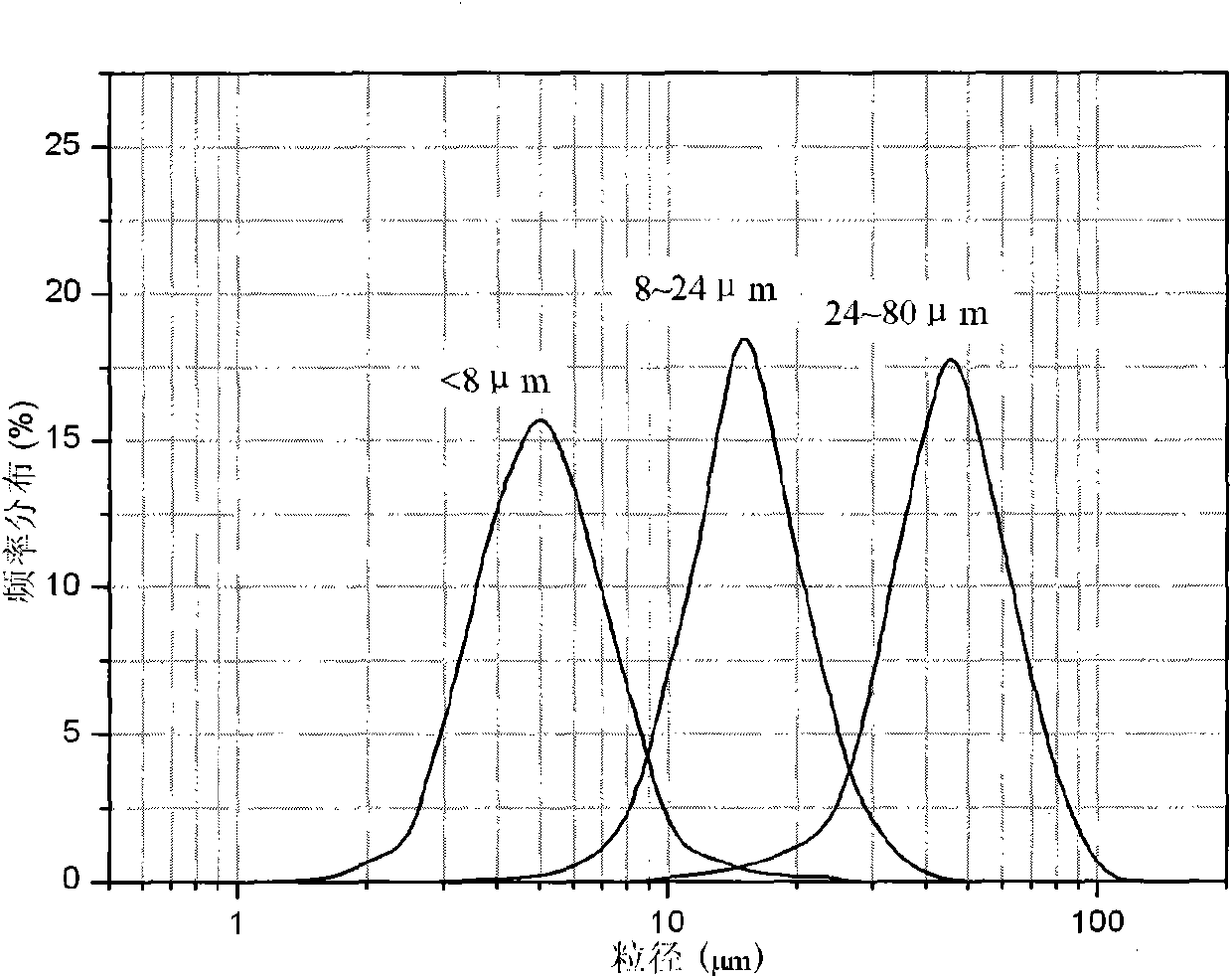

Preparation method of composite cement with low clinker dosage and high flexural compression ratio

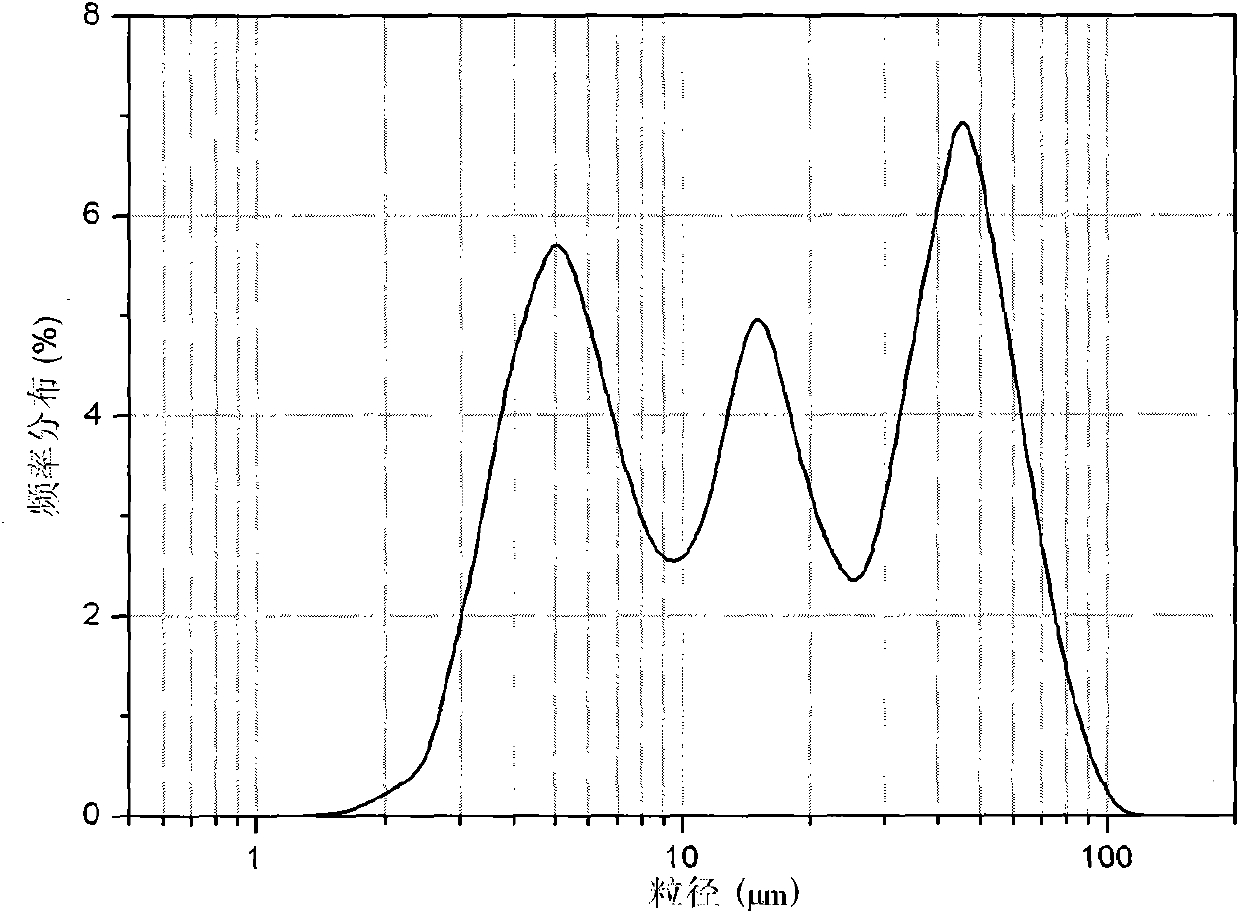

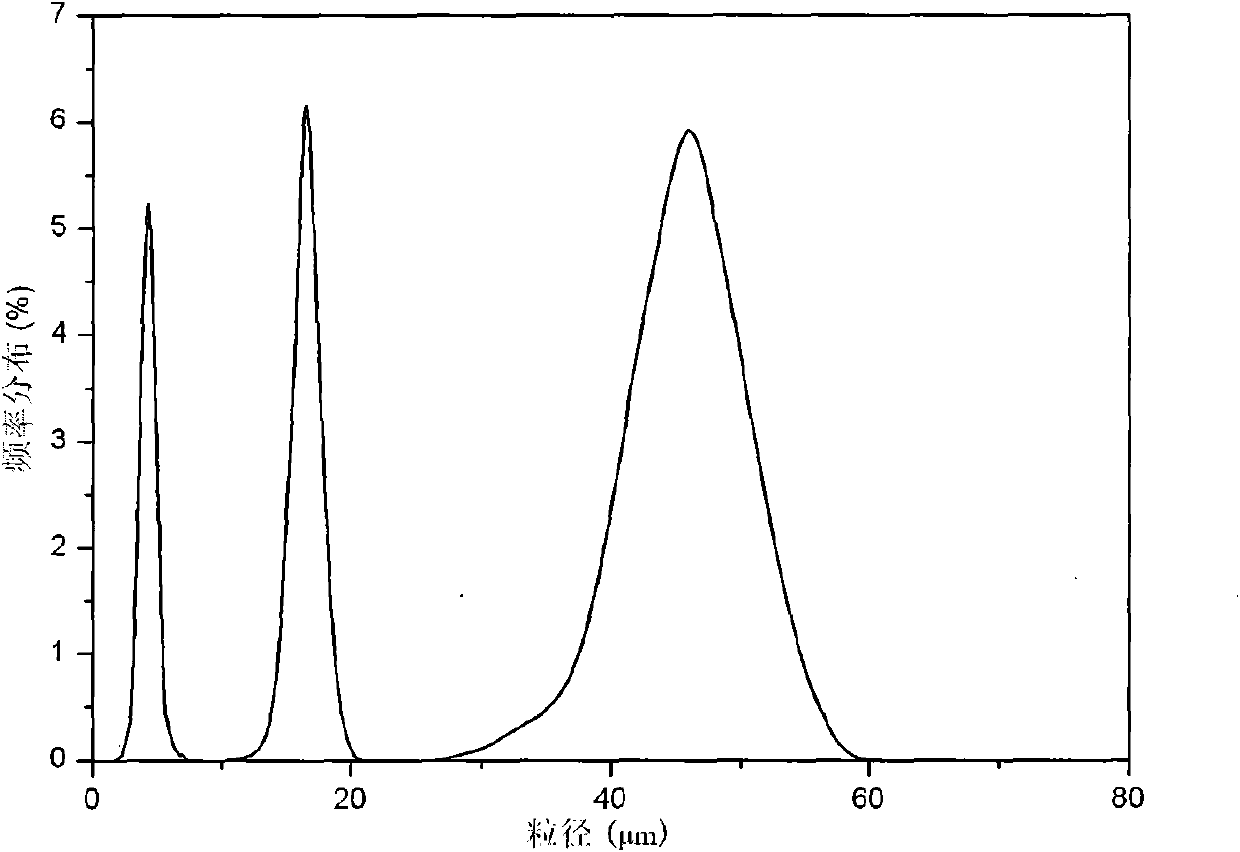

The invention discloses a preparation method of composite cement with low clinker dosage and high flexural compression ratio. The preparation method is to mix three size ranges of powder particles and obtain the composite cement. The three size ranges of powder particles are as follows: 1) the grain size of particles is less than 8mu m, the particles are composed of high-activity supplementary cementing material with the grain size; 2) the grain size of particles is 8-24mu m, the particles are composed of cement clinker particles with the grain size; and 3) the grain size of particles is 24-80mu m, and the particles are composed of low-activity supplementary cementing material or inert filler. The volume percentages of the three size ranges of powder particles are 25-40%, 25-30% and 30-45% respectively. The clinker volume percentage of the composite cement is 25-30%, the 28-day compressive strength is up to 35-50MPa, the flexural strength is up to 10-12Mpa, the flexural compression ratio is 1 / 3-1 / 4; and the composite cement has low hydration heat and good anti-cracking capability and can be used in the civil construction / engineering with the demand on the anti-cracking capability.

Owner:SOUTH CHINA UNIV OF TECH

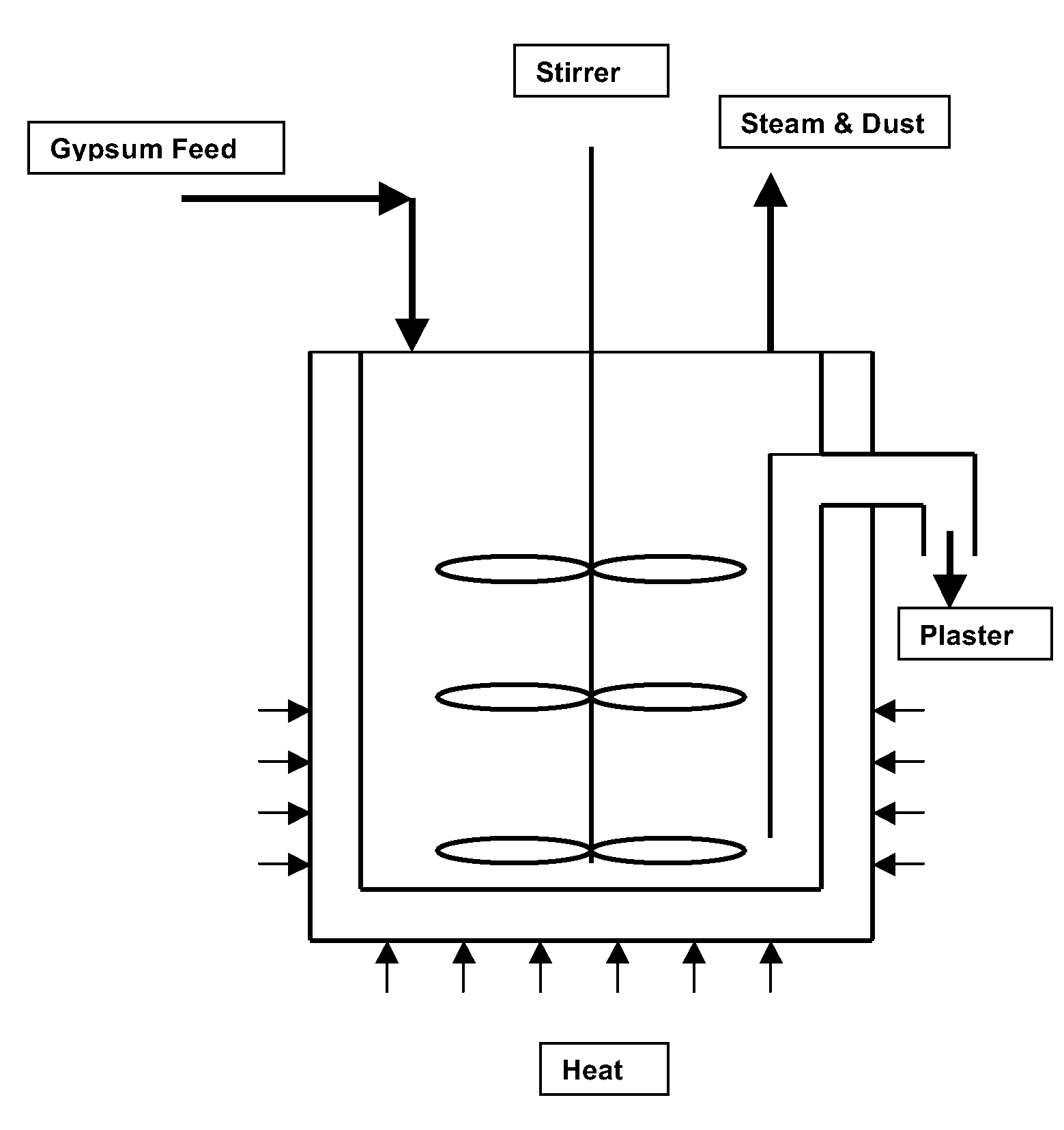

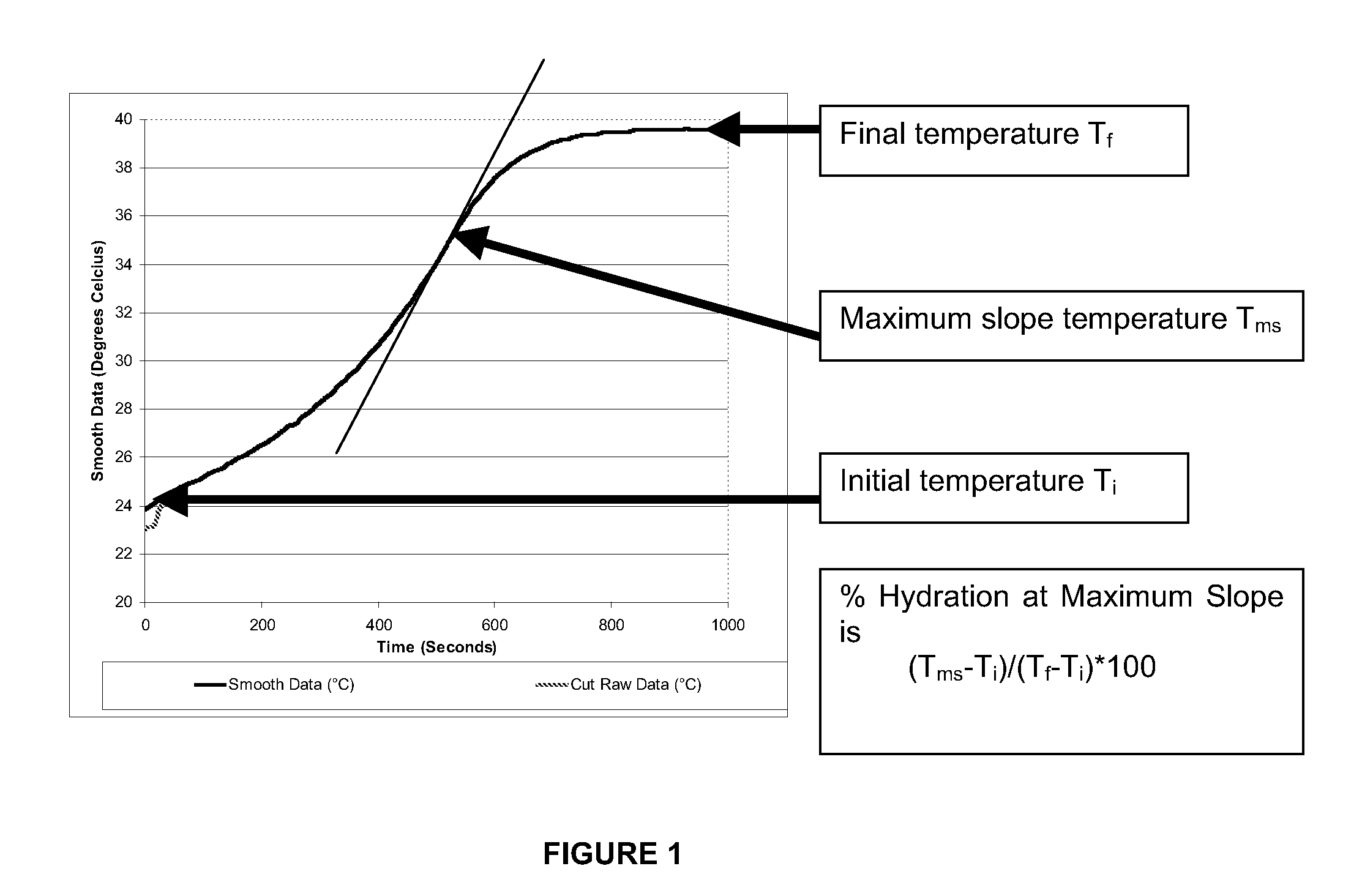

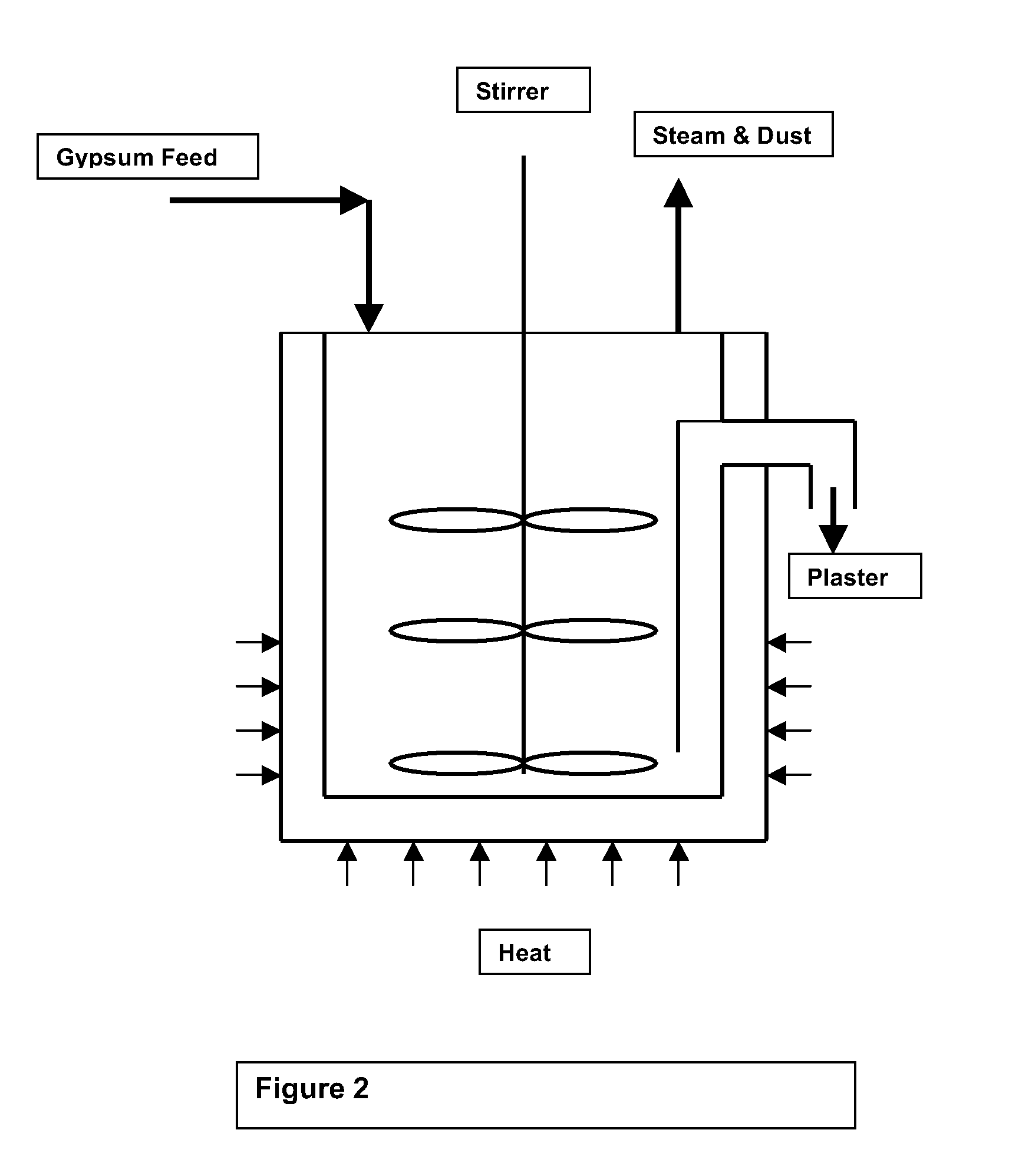

Calcium sulfate hemihydrate treatment process

ActiveUS20080148998A1Reduced compressive strengthReduced water demandCalcium/strontium/barium sulfatesAtmospheric pressureHemihydrate

A process for treating beta calcium sulfate hemihydrate is disclosed. The process comprises exposing beta calcium sulfate hemihydrate to steam at a pressure above atmospheric pressure.

Owner:GYPSUM THECHNOLOGIES INC

Round granule ore fertilizer pelleting process and device

ActiveCN106495811AAvoid cloggingHigh ball rateCalcareous fertilisersMagnesium fertilisersEngineeringUltimate tensile strength

The invention discloses a round granule ore fertilizer pelleting process which comprises the following steps: I) preparing raw materials; II) performing stirring mixing; III) performing pelleting; IV) screening wet granules; V) performing first-stage drying; VI) performing second-stage drying; VII) cooling; VIII) screening a finished product; IX) packaging the finished product. The invention further discloses a pelleting device with the process. The pelleting device comprises a mixing machine, a disc pelleting machine, a staged rotary screen, a rotary drying machine, a vibration fluid bed dryer, a rotary cooling machine and a vibration screen. The round granular ore fertilizer pelleting process is high in pelleting disc balling yield, low in granule crushing rate in the drying procedure, high in yield of the whole system, advanced in pelleting process, low in drying cost, small in water amount, high in granule strength of a round granule ore fertilizer product, good in sphericity degree and high in market acceptance degree.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

Low-heat anti-cracking portland cement

The invention discloses low-heat anti-cracking Portland cement. The cement clinker of the cement consists of the following minerals in percentage by weight: 40 to 70 percent of dicalcium silicate, 10 to 35 percent of tricalcium silicate, 1 to 4 percent of tricalcium aluminate, 15 to 30 percent of tetra calcium aluminoferrite, and 0.1 to 0.8 percent of free calcium oxide, wherein the content of magnesium oxide in the cement is between 3.5 and 5.0 percent, the content of alkali is not more than 0.55 percent, and the content of sulfur trioxide is not more than 3.5 percent. The cement has the main technical indexes that the ignition loss is less than or equal to 3wt%, the specific area is less than or equal to 340m<2> / kg, the stability is qualified, 3-day tensile strength is not required, the 7-day tensile strength is more than or equal to 13MPa, the 28-day tensile strength is between 42.5MPa and 52.5MPa, the 3-day breaking strength is not required, the 7-day breaking strength is more than or equal to 3.5MPa, the 28-day breaking strength is more than or equal to 7.0MPa, the 3-day hydration heat is less than or equal to 220KJ / kg, and the 7-day tensile strength is less than or equal to 250KJ / kg. The cement can be used for remarkably improving the cracking resistance of hydraulic concrete.

Owner:CHINA THREE GORGES CORPORATION

Aerated concrete prepared from copper smelting water quenching slag and titanium white slag and preparation method thereof

The invention discloses an aerated concrete prepared from copper smelting water quenching slag and titanium white slag. The invention is characterized in that the aerated concrete is composed of the following components in percentage by mass: 20-50% of copper smelting water quenching slag, 14-17% of quicklime powder, 15-45% of quartz sand, 10-15% of cement clinker, 3-6% of titanium white slag, 0.06-0.1% of aluminum powder, 0.05-0.1% of foam stabilizer, 0.3-1% of water reducing agent, 1-2% of modifier, and water which is 0.3-0.5 time of the total components above. The invention aims to successfully apply the industrial waste residue copper smelting water quenching slag, titanium white slag and other industrial wastes to the aerated concrete industry, thereby solving the problems of waste of resources and environmental pollution to some extent.

Owner:HUAIAN TESTING CENT FOR CONSTR ENG

Non-combustible rubber powder polyphenyl-granule fire-retardant thermal-insulation paste with high water resistance

The invention discloses a non-combustible rubber powder polyphenyl-granule fire-retardant thermal-insulation paste with high water resistance. 100 parts of the non-combustible rubber powder polyphenyl-granule fire-retardant thermal-insulation paste comprise, by weight, 65 to 70 parts of cement, 2 to 10 parts of fly ash, 8 to 10 parts of a high activity mineral admixture, 5 to 10 parts of an alkali activator, 3 to 5 parts of a sulfate activator, 2 to 4 parts of a redispersible latex powder, 0.5 to 1 part of modified cellulose ether, 0.3 to 0.7 part of a high efficiency water reducing agent, 0.02 to 0.05 part of an accessory ingredient with drop resistance, 0.3 to 0.5 part of fiber, 0.3 to 0.5 part of a stearate water repellent, 0.5 to 1 part of a silylation water repellent, 0.01 to 0.02 part of an air entraining agent, and 4.5 to 5 parts of a B1-grade native-level polyphenyl granule. The non-combustible rubber powder polyphenyl-granule fire-retardant thermal-insulation paste is low in heat conductivity coefficient, high in thermal insulation performance, high in compression strength, low in volume water absorption rate, high in softening coefficient, and high in fire-protection rating.

Owner:BEIJING YUEZHU XINTIAN ENERGY SAVING TECH

Light high-strength external wall inner thermal gypsum and preparing method thereof

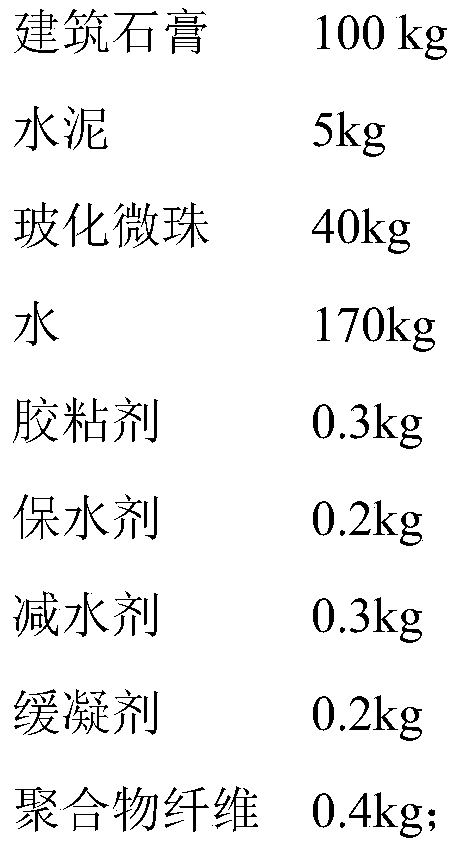

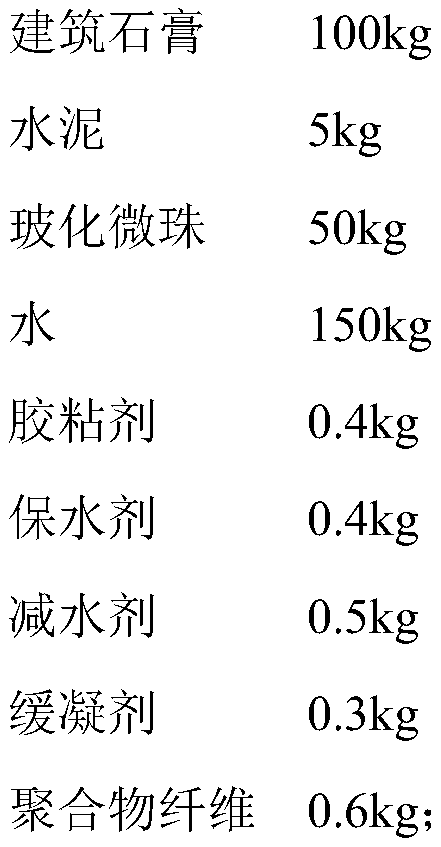

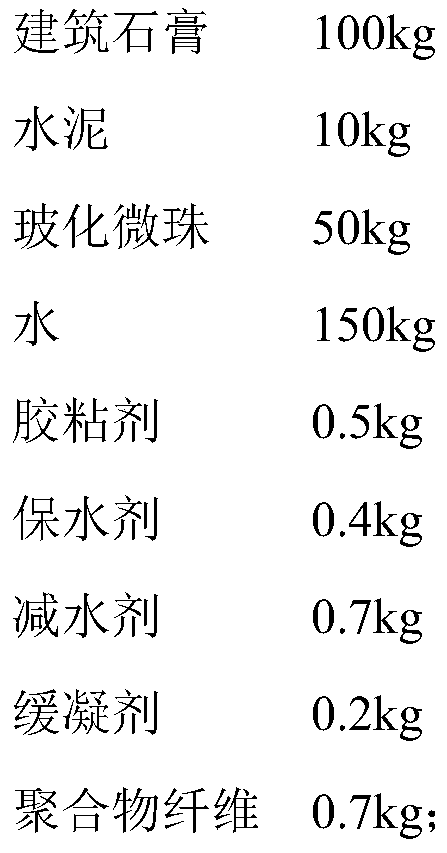

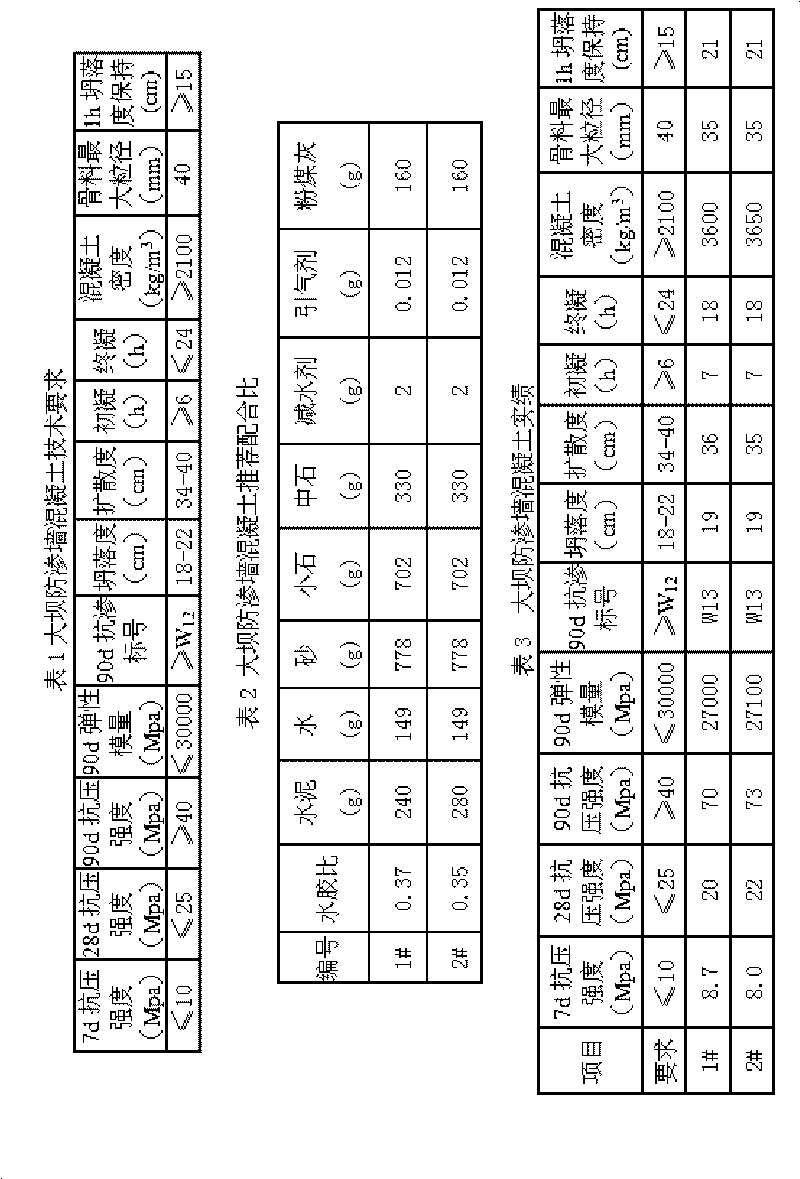

The invention relates to light high-strength external wall inner thermal gypsum. The external wall inner thermal gypsum is prepared from, by mass, 100 parts of building plaster, 5-15 parts of cement,40-60 parts of glass beads, 120-170 parts of water, 0.2-0.6 part of an adhesive, 0.2-0.5 part of a water-retaining agent, 0.3-0.9 part of a water reducing agent, 0.2-0.5 part of a retarder and 0.4-1.2parts of polymer fiber. The overall particle grading optimization, the water reducing agent and the like are adopted for reducing the water demand under the standard working thickness, the reinforcing and modifying treatment is conducted on the external wall inner thermal gypsum through various measures of increasing hydration products through the cement, compounding the retarder and the like, and the prepared light high-strength external wall inner thermal gypsum has excellent thermal insulation performance, can greatly reduce the operation energy consumption of a building, and meanwhile hashigh strength. The strength problem and workability problem of the thermal gypsum on the basis of low density and good thermal insulation performance are solved.

Owner:CHONGQING JIANDA BUILDING MATERIAL

Cement clinker and hydraulic engineering cement for impervious wall of dam and application thereof

ActiveCN101723606AMeet the design requirementsImprove compactnessBarrages/weirsPortland cementEnvironmental engineering

The invention belongs to the field of buildings, in particular to a cement clinker, hydraulic engineering cement for an impervious wall of a dam and application thereof. The invention provides a cement clinker with optimized mixture ratio, wherein the cement clinker is prepared into cement which is applied to the hydraulic engineering cement for the impervious wall of the dam and has the characteristics of low strength at early stage and high strength at late stage. The cement clink comprises the following minerals in percentage by weight: 25-40 percent of C3S, 42-63 percent of C2S, 1-3.5 percent of C3A, 11-16 percent of C4AF and 0-2 percent of inevitable impurities. The concrete prepared from the cement clinker and the cement as raw materials has the characteristics of low hydration heat, low strength at early stage, high strength at late stage, non-hanging strength and the like, is suitable for hydraulic engineering of the impervious wall of the dam and can replace special hydraulic engineering cement for the concrete prepared from the traditional moderate-heat cement, low-heat cement or general purpose portland cement.

Owner:JIAHUA SPECIAL CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com