Patents

Literature

132results about How to "Does not affect liquidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

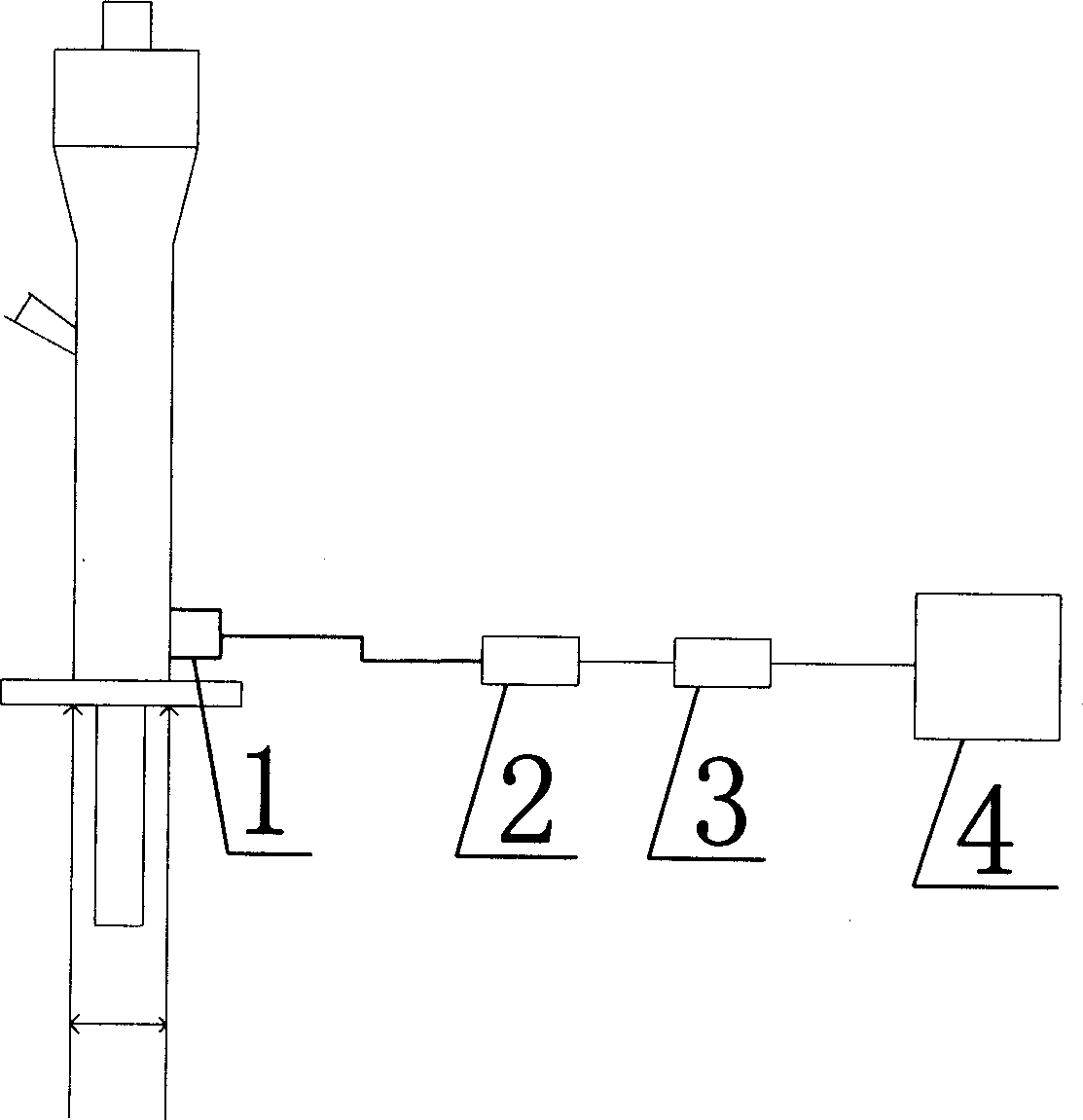

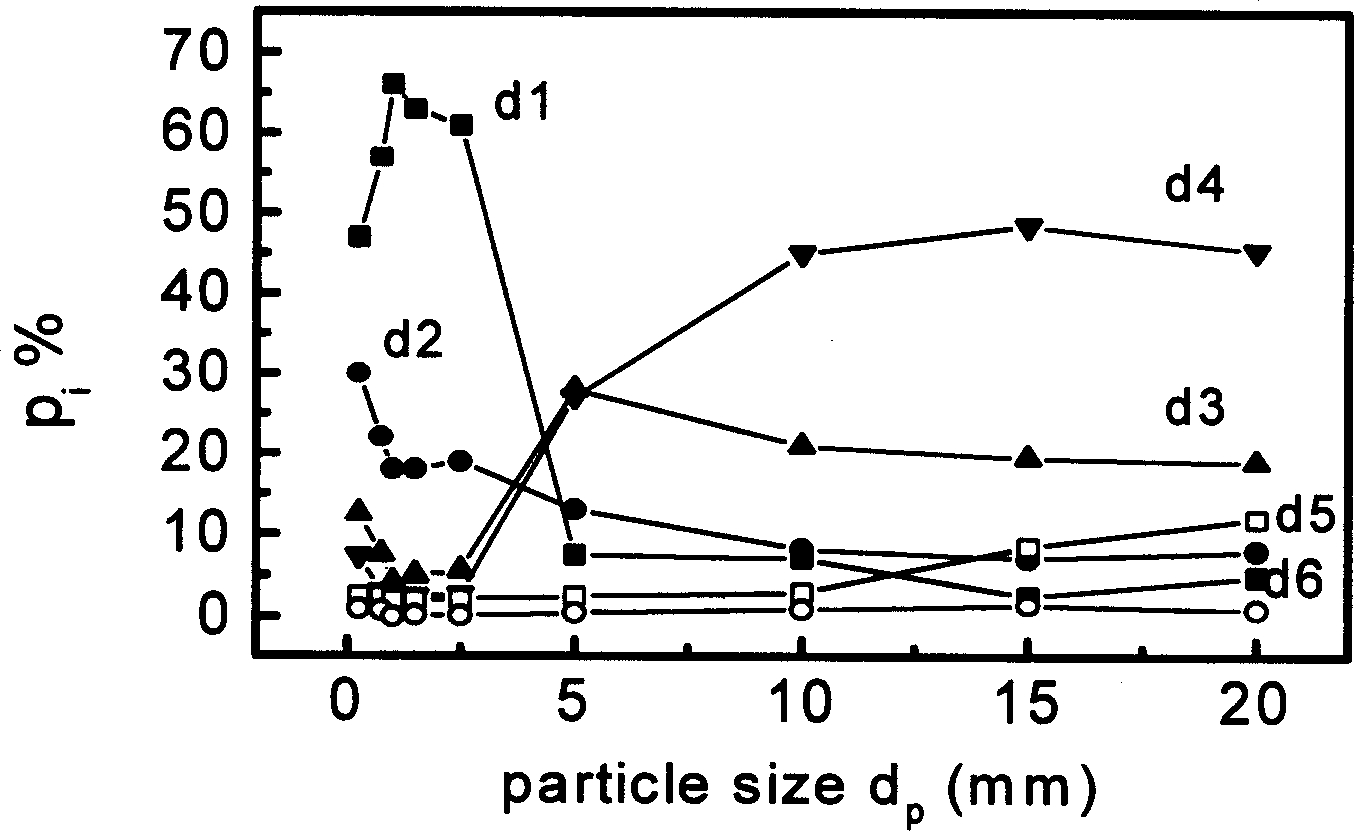

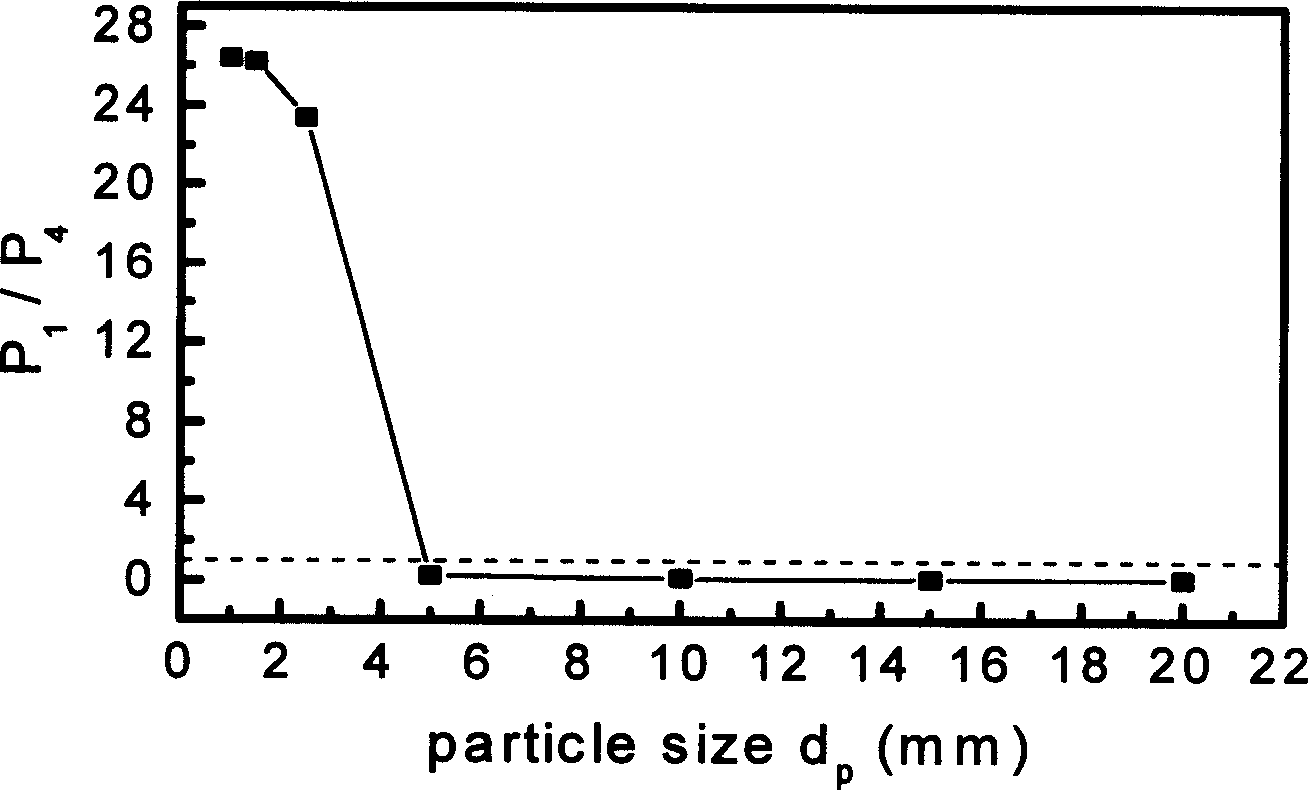

Sound wave monitoring device and method for fluidized bed reactor

ActiveCN1544140ASensitive fault monitoringThe phenomenon of reunion is obviousMaterial analysis using sonic/ultrasonic/infrasonic wavesChemical/physical processesFluidized bedAcoustic wave

The invention discloses a fluid bed reactor sound-wave monitoring device and method, where the device includes receiving device, amplifying device, signal collecting device and signal processing device; the method includes the following steps: a, receiving sound signal transmitted in the fluid bed reactor; b, analyzing the sound signal, to select the parameters like frequency f, amplitude A, energy E, energy partition Pi in each frequency segment, etc; the practice proves that it has characters of sensitivity, safety and environmental protection, facility and shortcut, etc, can in time and accurately make on-line analysis on the information in the fluid bed (fluid situation, reaction situation, particle size distribution, flow pattern distribution, etc) during the producing practice, and can control production parameters by analyzing result.

Owner:CHINA PETROLEUM & CHEM CORP +1

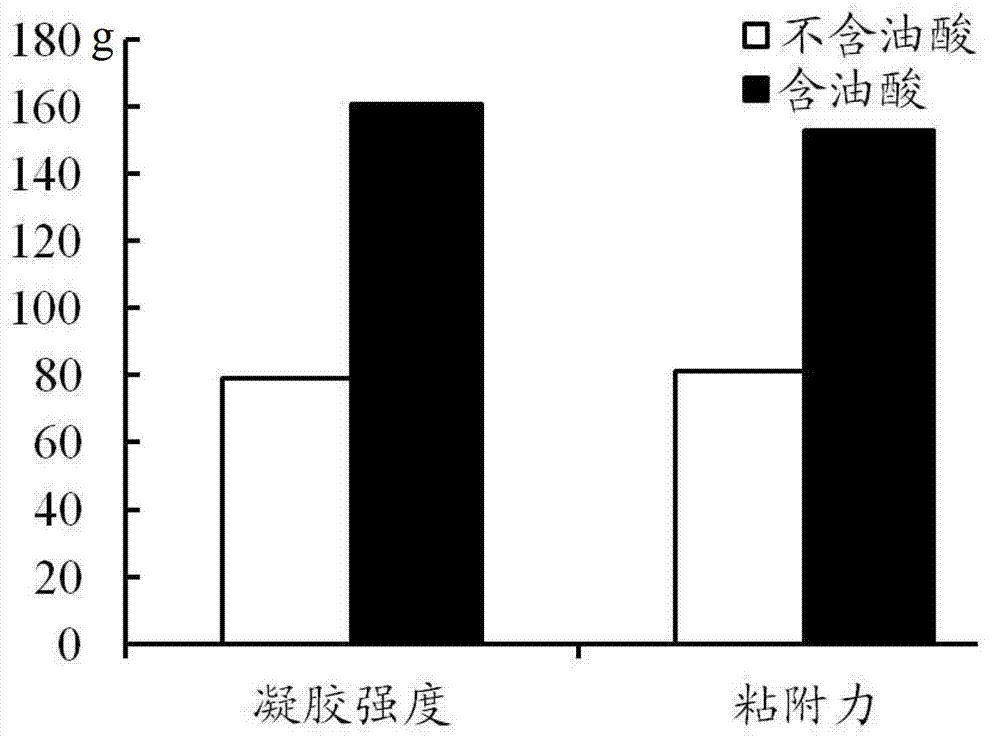

Precursor suspension of lyotropic liquid crystal and preparation method thereof

ActiveCN103040741AHigh viscosityHigh strengthSolution deliveryEmulsion deliveryOrganic solventUltimate tensile strength

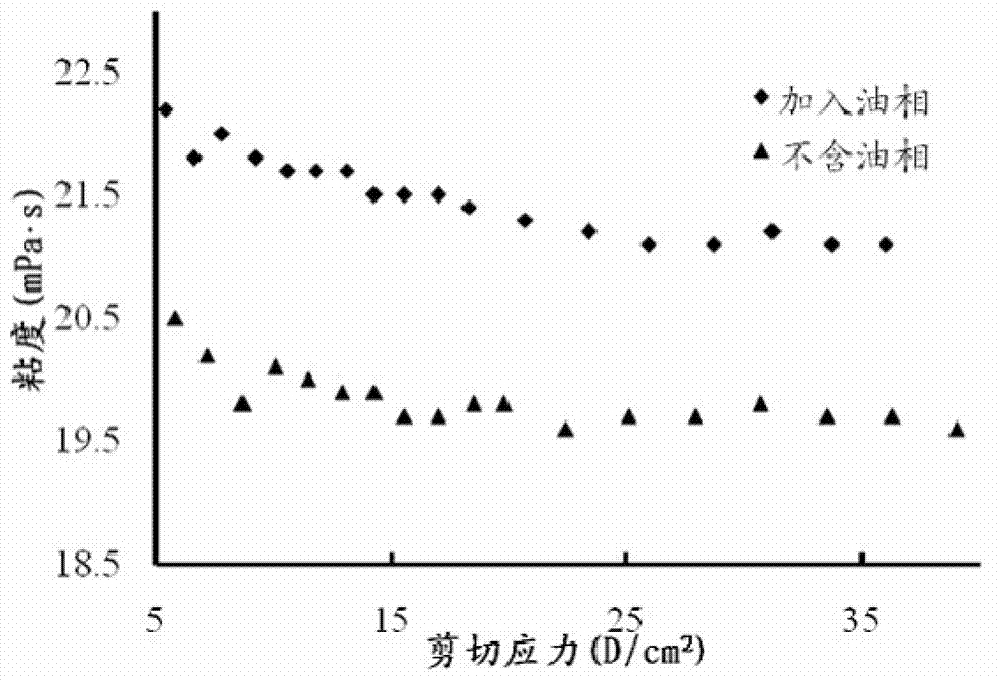

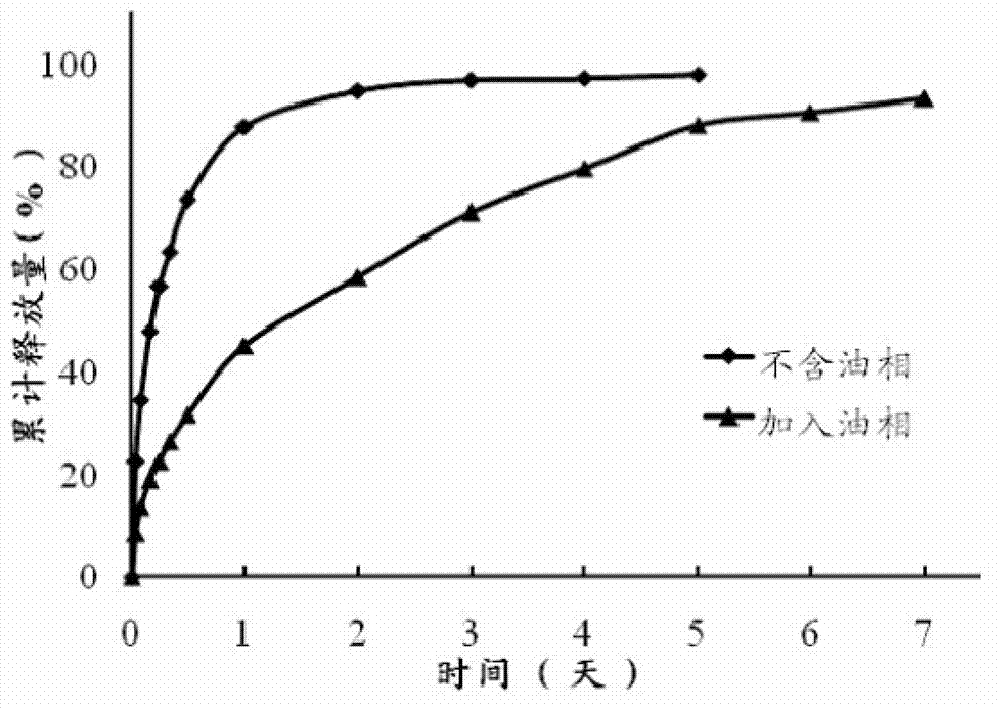

The invention discloses a precursor suspension of a lyotropic liquid crystal. The precursor suspension comprises lyotropic liquid crystal material, organic solvent, oil phase and a drug, wherein the weight percentage of the oil phase in the precursor suspension is 2-50 percent, the weight percentage of the drug in the precursor suspension is 1-30 percent, and the weight ratio of the lyotropic liquid crystal material and the organic solvent in the precursor suspension is 2-9:1. According to the invention, through the adding of the oil phase into the precursor suspension, the stability of the suspension is improved, the sedimentation rate is reduced, and the strength and the adhesive force of the gel formed are enhanced at the same time; the gel formed in the body is more liable to stay at a lesion location and less liable to be relocated and the shape is less liable to be damaged by the mechanical motion of the body, so that the drug therapy can be located effectively; and the preparation technology is simple and the precursor suspension of the lyotropic liquid crystal is a partial slow-release drug delivering system provided with a favorable perspective.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD

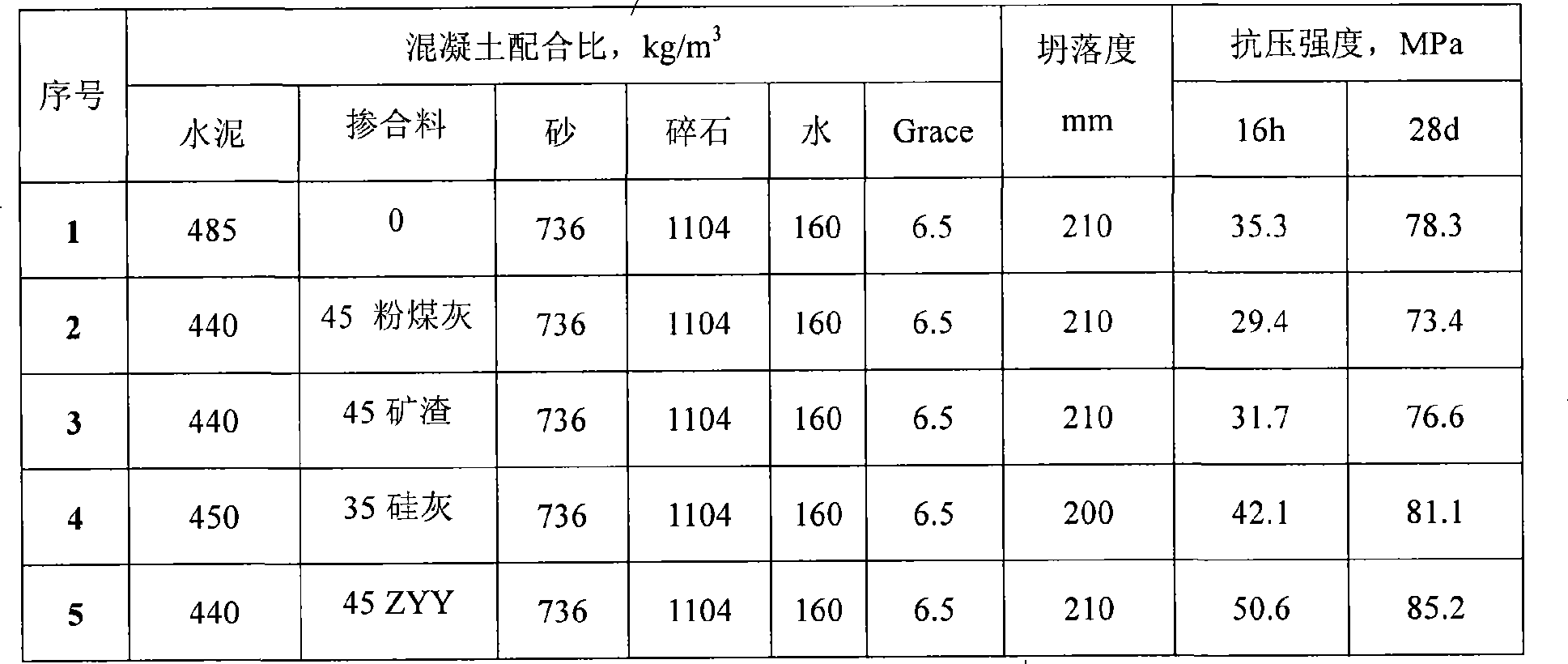

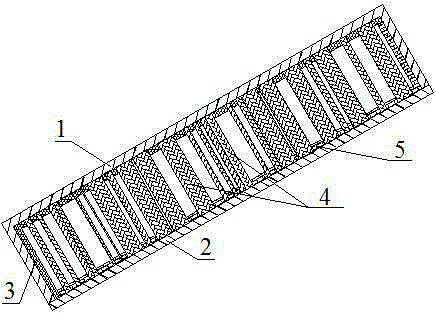

Composite high-early strength blending material for unballasted track plate and use thereof

ActiveCN101475330AAccelerated hydration condensationDoes not affect liquiditySolid waste managementBallastwayFilling materialsBuilding material

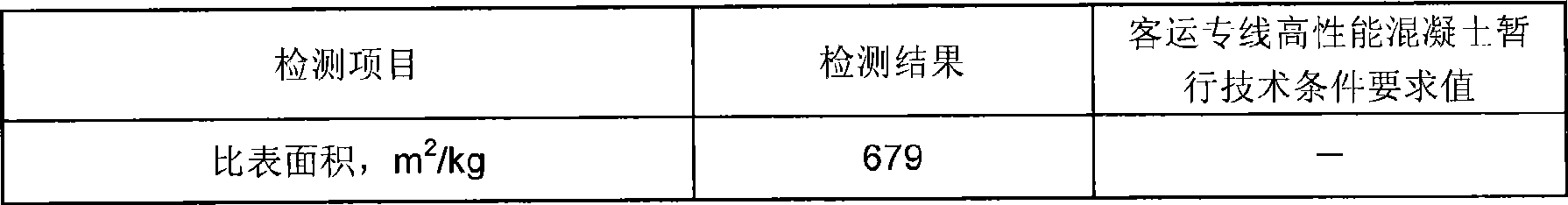

The invention discloses a composite early strength admixture for an unballasted track plate and application of the admixture and relates to the field of building material. The admixture consists of 50 to 70 weight percent of a silicon reinforcing material (A), 0 to 20 weight percent of a carbonate reinforcing material (B), 0 to 20 weight percent of an aluminium-silicon reinforcing material (C), 0to 20 weight percent of a silicon filling material (D), 0 to 20 weight percent of an aluminum filling material (E) and an excitant (F) in combined preparation, wherein B, C, D and E are not zero simultaneously; and the use amount of the excitant (F) is 0 to 5 weight percent of gross weight of (A+B+C+D+E). The admixture is applied to the manufacture of the unballasted track plate, can offset the insufficiency of concrete performance brought by the replacement of ultrafine cement by common silicate or silicate cement; collapse degree of the applied concrete is between 140 and 200 mm; 16h compressive strength is more than 48 MPa; and the high-performance concrete for the unballasted track plate fully meets the technical requirement of a provisional technical condition for high performance concrete in a passenger transportation dedicated line.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

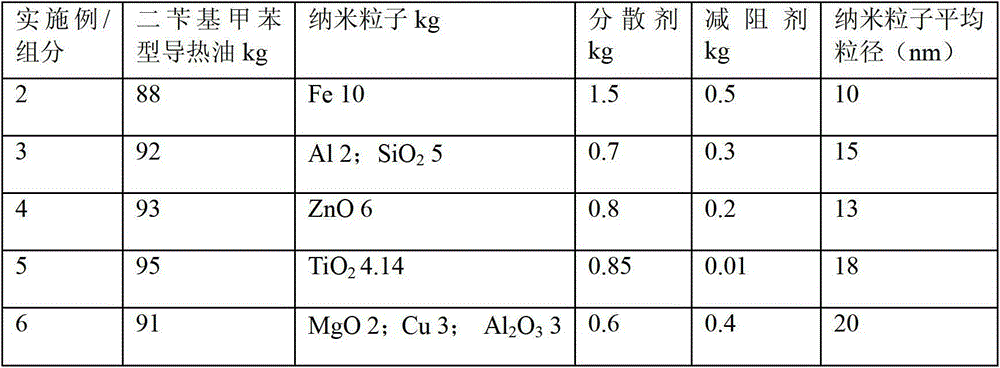

Dibenzyltoluene type high-temperature nanometer heat-conducting oil, and preparation method and application thereof

InactiveCN103937463AImprove suspension stabilityGood dispersionSolar heat devicesHeat-exchange elementsDibenzyltolueneHeat conducting

The invention provides dibenzyltoluene type high-temperature nanometer heat-conducting oil, and a preparation method and application thereof. The heat-conducting oil comprises dibenzyltoluene heat-conducting oil, nanometer particles, a drag reducer and a dispersant. The surfaces of the nanometer particles are coated with the dispersant for forming modified nanometer particles, the modified nanometer particles are dispersed in heat-conducting oil to form suspension type heat-conducting oil, and the nanometer particles are metals, metal oxides, non-metals and / or non-metal oxides. The heat-conducting oil provided by the invention has the advantages of good heat stability, fast heat conducting speed, uniform heating and large energy storage amount in heat conducting mediums, and has the highest usage temperature of 500 DEG C and the service life of 3 years or more.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

Water reducing agent with concrete workability adjusting function and synthetic method thereof

ActiveCN103819628AHas water retention capacityReduce surface tensionPotassium persulfateUltimate tensile strength

The invention discloses a water reducing agent with a concrete workability adjusting function. The water reducing agent is prepared from the following components: a. isopentenol polyoxyethylene ether, b. acrylic acid or methylacrylic acid or a mixture of the acrylic acid and the methylacrylic, c. maleic anhydride, d. sodium p-styrenesulfonate, e. ammonium persulfate or potassium persulfate or a mixture of the ammonium persulfate and the potassium persulfate, and f. sodium methallyl sulfonate, wherein the molar ratio of the using amount of a to b to c to d to f is 1:(1-1.5):(1.5-2.5):(0.2-0.25):(0.3-0.6); the using amount of e is 0.5 to 1.0 percent of the total weight of a, b and c. The water reducing agent provided by the invention has water retention capacity and has the function of reducing the surface tension of concrete so as not to influence the viscosity and the flowability of the concrete, and also can guarantee normal condensation and strength development of the concrete.

Owner:大连市铭源全科技开发有限公司

Extinction type thermoplastic elastomer for preparation of wire and cable

ActiveCN102304266ADoes not affect mechanicsDoes not affect liquidityPlastic/resin/waxes insulatorsElastomerAntioxidant

The invention discloses an extinction type thermoplastic elastomer for preparation of a wire and a cable. The extinction type thermoplastic elastomer is characterized by being preparing from the following raw material components by weight percent: 20-60% of styrene elastomer, 20-50% of mineral oil, 0-40% of reinforcing agent, 5-40% of extinction modification material, 0.1-1% of antioxidant, 0.1-1% of processing aid and 5-20% of mineral filling material, wherein the reinforcing agent is at least one of allyl resin and styryl resin, and the extinction modification material is dynamically-vulcanized thermoplastic elastomer or crosslinkable resin / crosslinking agent composition. The extinction type thermoplastic elastomer has the advantages that the crosslinkable resin / crosslinking agent composition or thermoplastic vulcanized rubber is adopted in a basic material, thus the matt effect is good, and the mechanical property and flowability of the material are not influenced.

Owner:NINGBO QINGHU ELASTOMER SCI & TECH

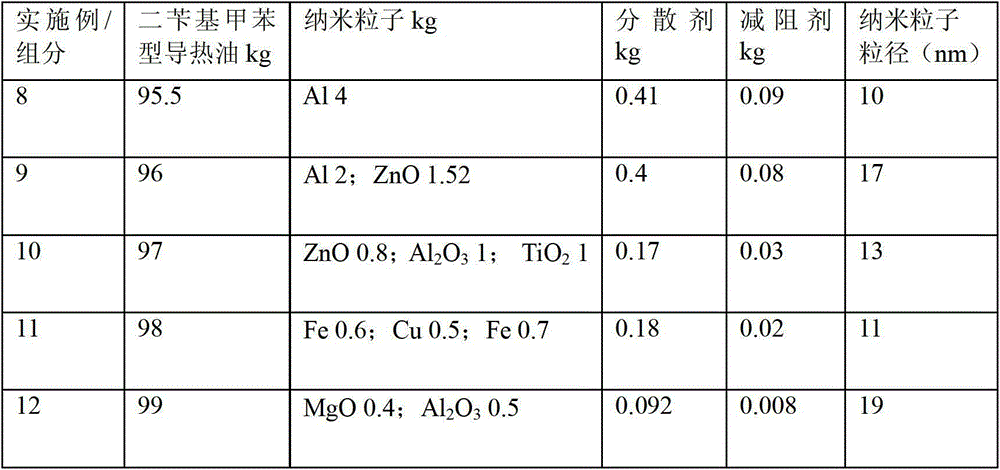

Pre-stressed duct grouting agent, and preparation and application methods thereof

The invention provides a pre-stressed duct grouting agent which has the characteristics of high fluidity, bleeding prevention and the like. The pre-stressed duct grouting agent comprises the following components: 2 to 10 percent of a water reducing agent, 0.1 to 10 percent of a viscosity modifying agent, 0 to 1 percent of a defoaming agent, and 35 to 78 percent of a coagulation time regulating agent; the coagulation time regulating agent comprises the following components: 28 to 52 percent of clinker, 42 to 68 percent of plaster, 4 to 30 percent of fillers, and 0 to 3 percent of a coagulation accelerator. The invention further provides a preparation method and an application method of the pre-stressed duct grouting agent. The invention has the advantages that the pre-stressed duct grouting agent contains the cement coagulation time regulating agent, so that the coagulation time of a cement-based composite material can be regulated based on external temperature changes to guarantee the normal use and normal strength growth of the cement-based composite material; meanwhile, the cement-based composite material achieves micro-expansion at the later stage due to the addition of the cement coagulation time regulating agent.

Owner:WUHAN BILLION TECH DEV CO LTD

Mud-resistant polycarboxylate superplasticizer as well as preparation method and application thereof

InactiveCN110002784AGood water reduction effectGood collapsibilityMaterials preparationThermal insulation

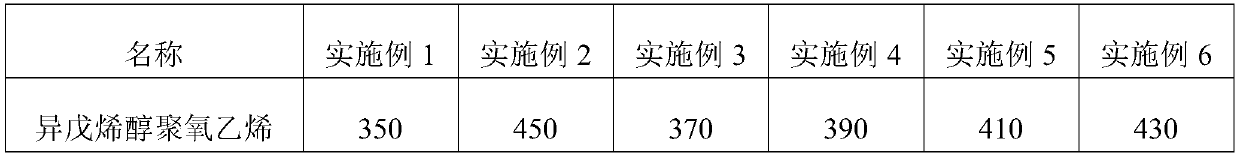

The invention belongs to the technical field of concrete and proposes a mud-resistant polycarboxylate superplasticizer. The mud-resistant polycarboxylate superplasticizer is prepared from components in parts by weight as follows: 350-450 parts of isoamyl alcohol polyoxyethylene ether, 40-70 parts of acrylic acid, 18-36 parts of hydroxyethyl acrylate, 6-16 parts of an initiator, 1-5 parts of a chain transfer agent, 4-15 parts of a cationic monomer and 10-50 parts of a coagulation adjusting component. The preparation method of the mud-resistant polycarboxylate superplasticizer comprises steps asfollows: material preparation, preparation of materials A and B, dissolution, droplet adding of the materials A and B, thermal insulation ageing, neutralization and the like. The mud-resistant polycarboxylate superplasticizer is applied to preparation of concrete. With the adoption of the technical scheme, the problem that application of the polycarboxylate superplasticizer is affected due to massive adsorption by mud in the prior art is solved.

Owner:兰州同邦建材有限公司

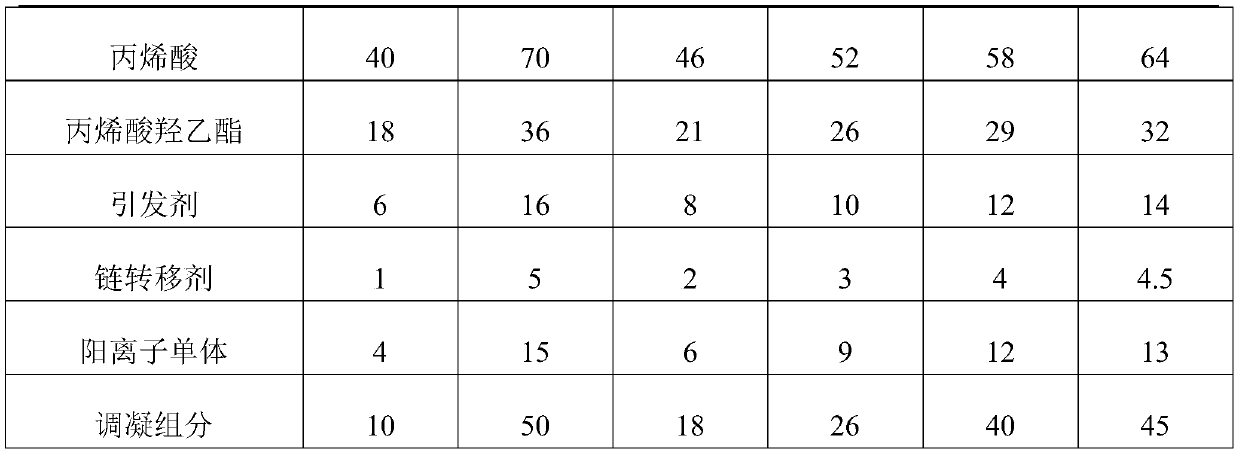

Waterproof pulverized coal and preparation method thereof

The invention discloses a waterproof pulverized coal and a preparation method thereof, wherein the waterproof pulverized coal comprises components with parts by weight: calcium salt or calcium hydroxide (Ca(OH)2) 5-30 parts, stearic acid or stearate 1-10 parts or pulverized coal 60-94 parts. The method for preparing the waterproof pulverized coal comprises steps: firstly, the components with parts by weight are weighted, are added into a roller type reaction kettle to be kept to heat for 20-60 min after being heated to 110-140 DEG C, thereby obtaining the waterproof pulverized coal. The method for preparing the waterproof pulverized coal can convert pulverized coal to be a hydrophobic substance from a hydrotropic substance, greatly reduces hydrophilic performance of the pulverized coal, and can prevent volatile components in the pulverized coal from volatilizing, thereby preventing the autoignition problem of the pulverized coal during storing, prolonging service life, improving safety during storage and transportation, and having excellent application prospect.

Owner:重庆四季金标科技有限公司

Original gravel additive for preventing castings stria defect

ActiveCN101036932ASmall expansion coefficientRelax grain boundary stressFoundry mouldsFoundry coresKaoliniteCalcite

The invention discloses a raw sand additive for preventing casting rattail defect, including following weight compositions: transparent quartz 8%, calcite 1%, sepiolite 1%, kaolinite 70%, pyrophyllite 10%, magnetite 10%; without affecting functional performance of mixture and sand mould, and mainly preventing casting rattail defect, while with assistant curative effect for the casting air-hole and the burnt-on sand (sintering) and so on defects.

Owner:SUZHOU XINGYE MATERIALS TECH

Environment-friendly low-smoke fire-retardant acrylonitrile-butadiene-styrene (ABS) resin and preparation method thereof

InactiveCN103509309AImprove flame retardant performanceHigh smoke suppression effectHalogenCombustion

The invention relates to the technical field of fire-retardant resins, and discloses an acrylonitrile-butadiene-styrene (ABS) resin and a preparation method thereof. The resin is prepared from the following components in parts by weight: 1000 parts of ABS resin, 150-350 parts of halogen flame retardants, 30-70 parts of synergistic fire retardant, 30-70 parts of smoke suppressant, 1-10 parts of antioxidant, and 1-10 parts of lubricant. The preparation method comprises the following steps: fully and evenly mixing the 1000 parts of ABS resin, 150-350 parts of halogen flame retardants, 30-70 parts of synergistic fire retardant, 30-70 parts of smoke suppressant, 1-10 parts of antioxidant and 1-10 parts of lubricant; feeding the materials to a double-screw extruder through a precise metering feeder after completely mixing; fully fusing the materials under the conditions of shearing, mixing and conveying of screws; and finally preparing granules after extruding, bracing and cooling. The ABS resin disclosed by the invention is low in smoke generation in combustion, does not generate harmful gases such as dioxin, does not generate molten droplets, accords with the instruction of restriction of hazardous substances (ROHS) of the European Union, and is low in cost and convenient to process.

Owner:HEFEI GENIUS NEW MATERIALS

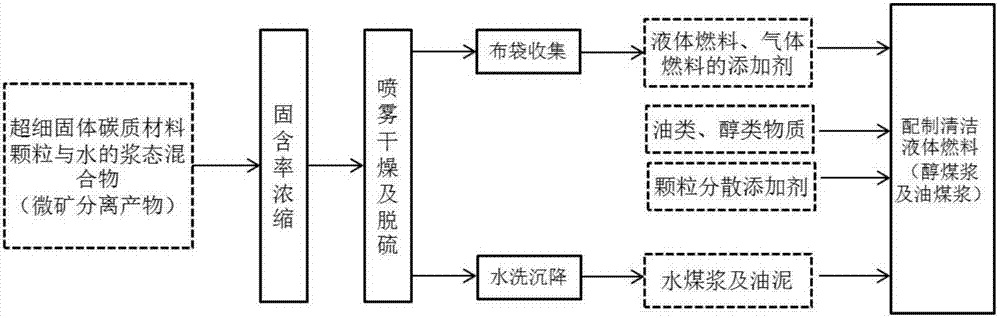

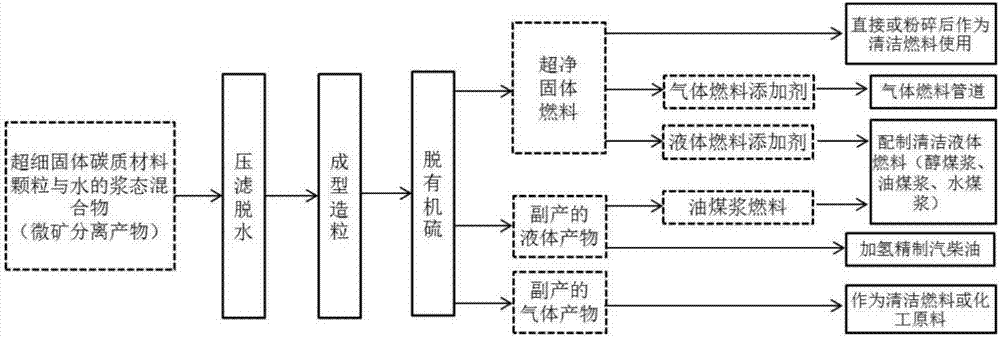

Method of increasing energy density of liquid fuel or gaseous fuel

ActiveCN107446632AIncrease energy densityLow costGaseous fuelsLiquid carbonaceous fuelsSolid carbonMicrometer

The invention discloses a method of increasing energy density of liquid fuel or gaseous fuel. The method is characterized in that low-sulfur and low-ash superfine solid carbon material particles with an ash content of less than 3wt%, a total sulfur content of less than 0.6wt% and an average particle size of less than 500 micrometers are doped into the liquid fuel or the gaseous fuel. The low-sulfur and low-ash superfine solid carbon material particles are obtained by separating low-ash superfine solid carbon material particles from a carbon material source via a micro mineral separation technology and performing desulfuration via a desulfuration technology as appropriate. The method can increase the energy density of the liquid fuel in unit volume by 1.4 times and a calorific value of the gaseous fuel in the unit volume by 4 times maximally.

Owner:SHENZHEN REVELATION TECH CO LTD

Special material for injection grade non-halogen flame-retardant wire plug and preparation method thereof

ActiveCN101161719AGood physical and mechanical propertiesFlat surfaceCouplings bases/casesHalogenSmooth surface

The invention discloses special material and preparation method for injection molding level halogen-free flame retardation wire plug. The special material adopts elastic body and polyolefin resin as base material with expansion type flame retardant, flame retarding synergist, compatilizer, antioxidant and processing agent added. After intensive mixing, the special material is obtained through extrusion and pelleting by a BUSS mixing roll with autoweighing blanking device. The method has good mixing effect, stable compounding formula and high processing efficiency and the particles prepared via the method have even size and bright appearance. The flame retardation rating of produces prepared via the method reaches UL94V-0 level, the tiptop fusion index reaches 55g / 10min, and Shore hardness is from 65A to 95A in case of qualified flame retardation level and high fusion index. The composite material provided by the invention is environmental-friendly material which completely meets current international environmental requirements on halogen-free material. The material which not only has good flame retardation performance and flowing property but also enables smooth surface and good felt of products is suitable for manufacturing various injection molding level wire plugs with high flame retardation requirements.

Owner:SHANGHAI KINGFA SCI & TECH +1

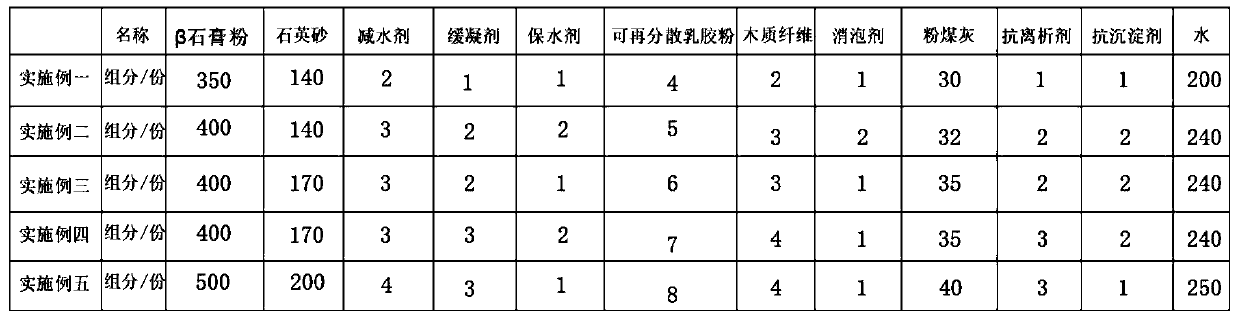

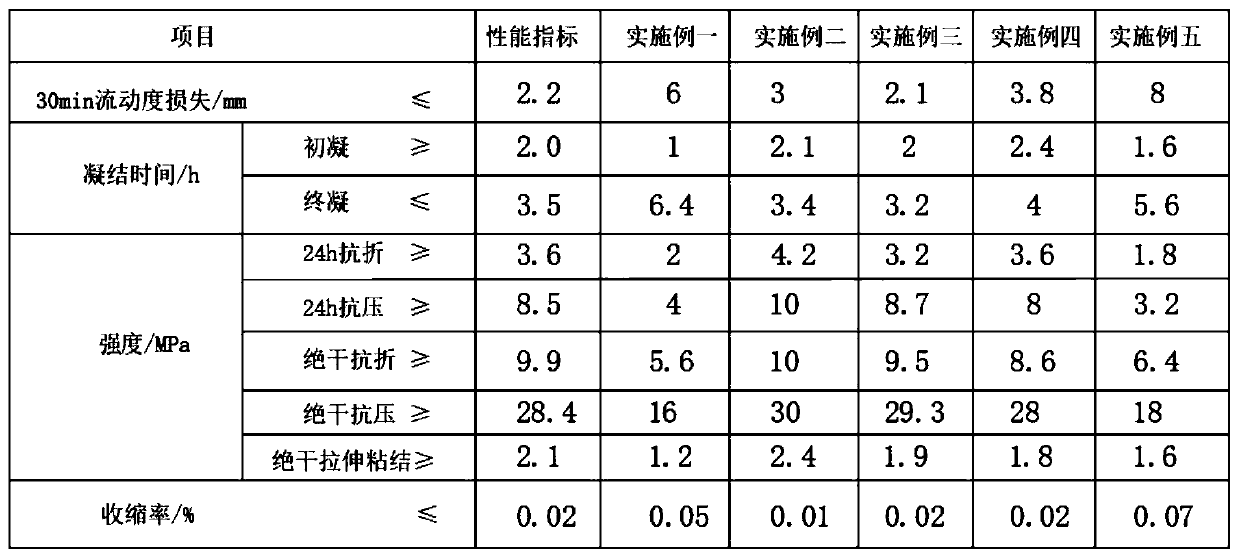

Gypsum-based self-leveling mortar special for floor heating backfill

InactiveCN110330302AReasonable optimization of the promotion formulaImprove flexural strengthFiberDefoaming Agents

The invention discloses gypsum-based self-leveling mortar special for floor heating backfill, belonging to the technical field of building materials. The gypsum-based self-leveling mortar comprises the following components in parts by weight: 350-500 parts of beta gypsum powder, 140-200 parts of quartz sand, 2-4 parts of a water reducing agent, 1-3 parts of a retarder, 1-2 parts of a water retaining agent, 4-8 parts of redispersible latex powder, 2-4 parts of wood fiber, 1-2 parts of a defoaming agent, 30-40 parts of fly ash, 1-3 parts of an anti-precipitant agent, 1-2 parts of an anti-segregation agent and 200-250 parts of water, has the characteristics of good fluidity, short curing time, high strength, smooth surface, small shrinkage deformation, high bonding strength and low cost, andexpands application fields of alpha high-strength microcrystalline gypsum and iron tailing sand.

Owner:李山

Anti-crack plastering mortar and preparation method thereof

ActiveCN110482893AIncreased durabilityDoes not affect liquidityPlastic recyclingGrain treatmentsPolymer scienceResin-Based Composite

The invention discloses anti-cracking plastering mortar and a preparation method thereof, wherein the anti-cracking plastering mortar comprises an anti-cracking agent and plastering mortar; the mass of the anti-cracking agent is 1%-10% of the mass of the plastering mortar; the anti-cracking agent comprises 60%-95% of polymer composite fibers, 5%-10% of a surfactant and the balance of filler; the polymer composite fiber is formed by processing a resin-based composite material of a fiber reinforcement, and the polymer composite fiber is a composite fiber of which the surface of the fiber reinforcement is coated with at least one layer of resin. The anti-cracking plastering mortar disclosed by the invention is good in anti-cracking performance and good in durability.

Owner:南通生材科技有限公司

Binding agent powder for magnesian castable and preparation method thereof

The invention relates to binding agent powder for a magnesian castable and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: firstly, uniformly stirring 30-65wt% of silicon oxide fine powder and 35-70wt% of magnesian fine powder as raw materials, putting the powder in a ball-milling tank, and then adding 2-10wt% of an additive and 150-300wt% of water based on the weight of the raw materials into the ball-milling tank to be ball-milled for 1-3h to prepare pulp; conserving the pulp for 12-84h at 25-80 DEG C, and grinding the pulp till the grain size is smaller than 75mu m to prepare pre-prepared powder; and keeping the temperature of the pre-prepared powder at 150-650 DEG C for 2-8h to obtain the binding agent powder for magnesian castable. The application result of the binding agent powder for magnesian castable prepared by the preparation method shows that the strength of the magnesian castable is improved remarkably, and the burst resistance and slag resistance of the magnesian castable are enhanced remarkably.

Owner:WUHAN UNIV OF SCI & TECH

Synthetic resin polymer for pouring of fire-proof medium-voltage bus

InactiveCN105623195AIncrease or decrease ratioFeatures do not affectPlastic/resin/waxes insulatorsCopper conductorEpoxy

The invention relates to a synthetic resin polymer for pouring of a fire-proof medium-voltage bus. The synthetic resin polymer comprises epoxy resin, a polyamide curing agent, a modified amine curing agent, quartz sand and ceramic zinc borate, wherein epoxy resin accounts for 42 to 48 percent of the polymer by weight; the polyamide curing agent accounts for 6 to 12 percent of the polymer by weight; the modified amine curing agent accounts for 4 to 6 percent of the polymer by weight; the granularities of the quartz sand are 10 to 150 meshes; quartz sand which is 10 to 50-mesh accounts for 12 to 16 percent of the polymer by weight; quartz sand which is 50 to 80-mesh accounts for 8 to 12 percent of the polymer by weight; quartz sandwhich is 80 to 150-mesh accounts for 8 to 12 percent of the polymer by weight; ceramic zinc borate accounts for 8 to 10 percent of the polymer by weight. The synthetic resin polymer can be poured outside a copper conductor, and cured into an insulating layer, and a glass ceramic layer starts to be formed when the temperature is 550 to 600 DEG C. Therefore, flame retardancy, smoke suppression, dripping resistance and ash firing inhibiting effect are high.

Owner:镇江西门子母线有限公司

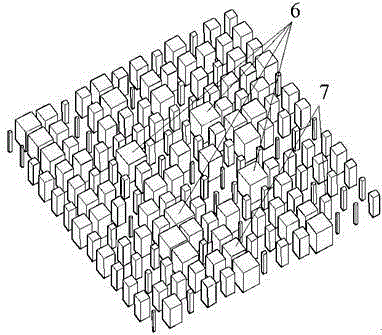

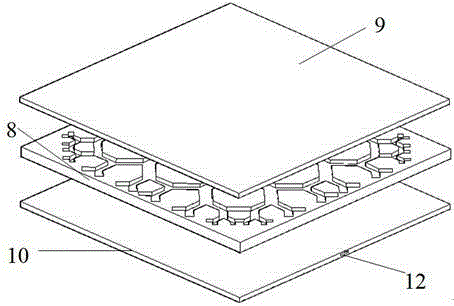

Anti-deformation pressure resistant temperature-uniforming plate

ActiveCN105280583AImprove heat transfer coefficientIncrease the heat exchange areaSemiconductor/solid-state device detailsSolid-state devicesChannel networkEngineering

Owner:安徽瀚程机械制造有限公司

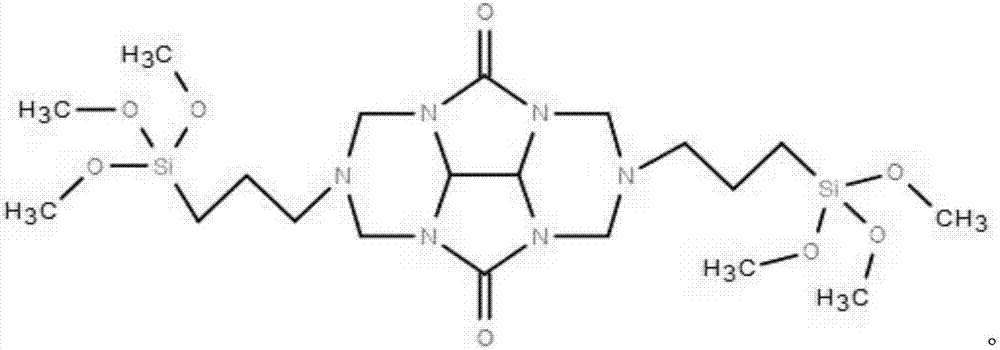

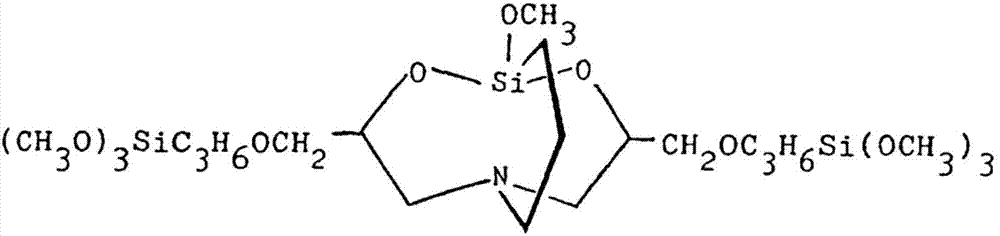

Two-component organosilicon pouring sealant and preparation method thereof

ActiveCN106947428AAdd lessDoes not affect liquidityNon-macromolecular adhesive additivesNitrogenSealant

The invention provides a two-component organosilicon pouring sealant. The two-component organosilicon pouring sealant comprises a component A and a component B with equal mass, wherein the component A comprises 100 parts of a base material, a platinum catalyst with the mass of platinum accounting for 1 to 500 ppm of the mass of the component A, and 1 to 5 parts of an adhesion promoter; the component B comprises 100 parts of a base material, 0.2 to 20 parts of a crosslinking agent and 0.002 to 0.5 part of an inhibitor; and the adhesion promoter is nitrogen heterocycle containing polycyclic siloxane. The invention belongs to the technical field of pouring sealants. The two-component organosilicon pouring sealant provided by the invention has the advantages of good flame-retardant performance, adhesion properties with a substrate, excellent fluidity, no poisoning caused by a platinum catalyst, environmental protection, safety, and easy operation.

Owner:广东皓明有机硅材料有限公司

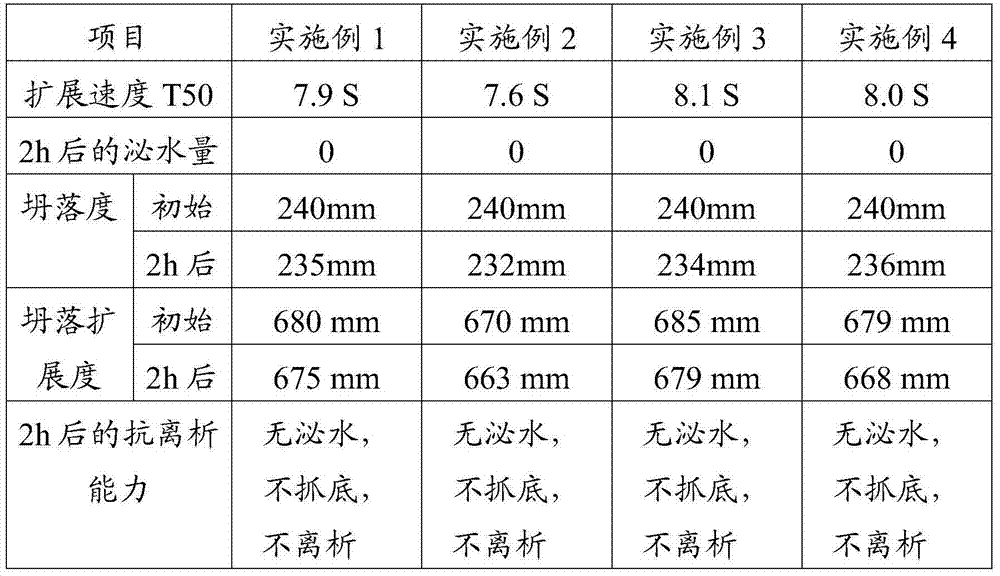

Viscosity regulator and preparation method thereof and self-leveling self-compacting concrete

The invention discloses a viscosity regulator which is exclusively applied to the self-leveling self-compacting concrete. The viscosity regulator is prepared mainly from the following raw materials in parts by weight: 15-85 parts of starch, 160-550 parts of epoxybutane and 0.1-2.0 parts of alkali. Correspondingly, the invention also discloses a preparation method of the viscosity regulator, which comprises the steps of grinding the alkali into fine powder, and adding the fine powder together with the starch into epoxybutane; stirring for two days at room temperature so that the epoxybutane sufficiently permeates into the starch particles to realize sufficient wetting and swelling; heating to 45-50 DEG C, and continuously reacting for 48 hours; filtering and drying to obtain a reaction product, namely hydroxybutyl starch ether. Meanwhile, the invention also discloses self-leveling self-compacting concrete using the viscosity regulator. By adopting the viscosity regulator disclosed by the invention, the viscosity of concrete slurry can be improved, a thickening effect is realized, and the separation and bleeding of the concrete are prevented without influencing the fluidity of the concrete.

Owner:GUANGDONG REDWALL NEW MATERIALS +1

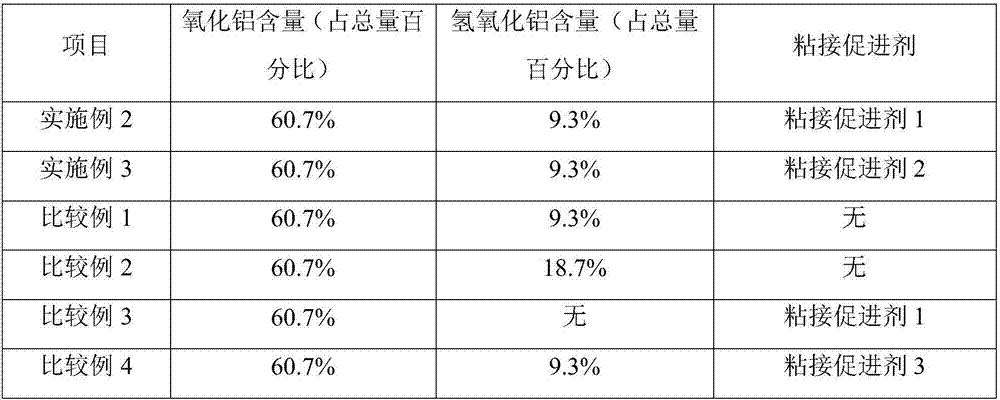

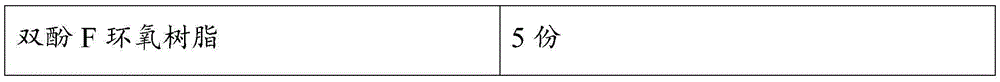

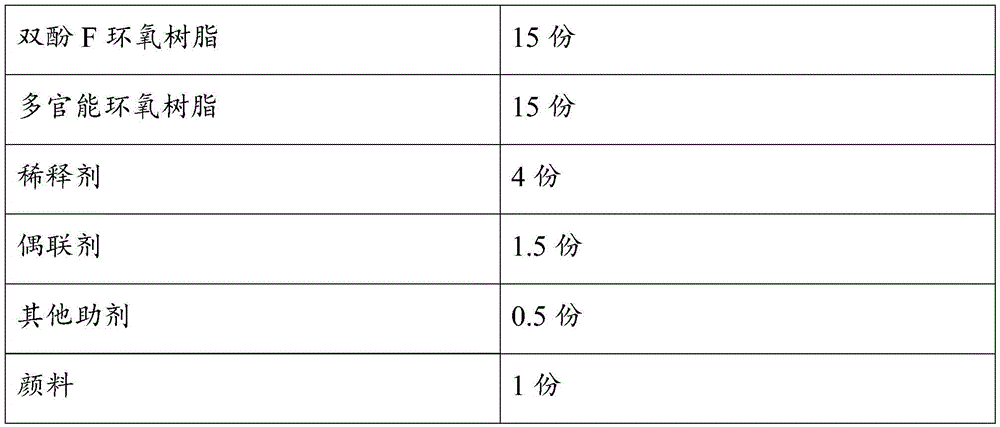

Medium-and-low-temperature curing single-component epoxy adhesive low in linear expansion coefficient and preparation method thereof

InactiveCN105670542ASave resourcesLow costNon-macromolecular adhesive additivesEpoxy resin adhesivesLow temperature curingDiluent

The invention provides a medium-and-low-temperature curing single-component epoxy adhesive low in linear expansion coefficient.The single-component epoxy adhesive is formed by bisphenol F epoxy resin, multifunctional epoxy resin, silica micropowder, diluent, latent curing agent, coupling agent, and / or surfactant and / or other auxiliaries through reaction.Medium-and-low-temperature curing is adopted, the advantages of medium-and-low-temperature curing enable the single-component epoxy adhesive to be more used for application materials, resources can be saved, cost can be lowered, and internal stress generated during curing can be reduced.

Owner:上海拜高高分子材料有限公司

High temperature resistant organosilicone pouring sealant for PCB (Printed Circuit Board)

InactiveCN106833508AHigh tensile strengthHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesSodium stearateMetallurgy

The invention discloses a high temperature resistant organosilicone pouring sealant for a PCB (Printed Circuit Board). The high temperature resistant organosilicone pouring sealant for the PCB is prepared from the following raw materials in parts by weight: 40 to 50 parts of vinyl-terminated silicone oil-1, 50 to 60 parts of vinyl-terminated silicone oil-2, 0.38 to 0.5 part of 12 percent platinum catalyst, 0.02 to 0.04 part of ethynylcyclohexanol, 25 to 30 parts of vinyl silicone resin, 14.8 to 16.8 parts of 1-allyloxy-2,3-propylene oxide, 23 to 25 parts of 1,3,5,7-tetramethylcyclotetrasiloxane, 2.7 to 3.6 parts of silane coupling agent A171, a suitable amount of hydrogen-containing silicone oil, 3 to 3.8 parts of sepiolite fibres, 1.7 to 3 parts of aluminium nitride, 2 to 2.5 parts of sodium stearate, 1.5 to 2 parts of dodecylamine and a suitable amount of deionized water. The pouring sealant prepared by the preparation method is simple in preparation process, low in cost and wide in raw material source, has good performance in the aspects of radiating, high temperature resistance, stability, insulating and the like, is wide in application field, and is worth being popularized.

Owner:铜陵安博电路板有限公司

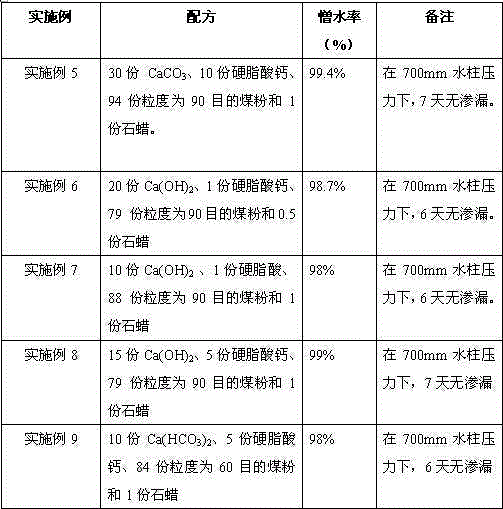

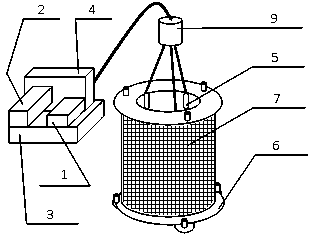

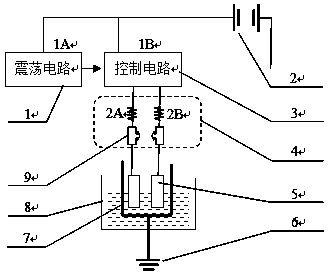

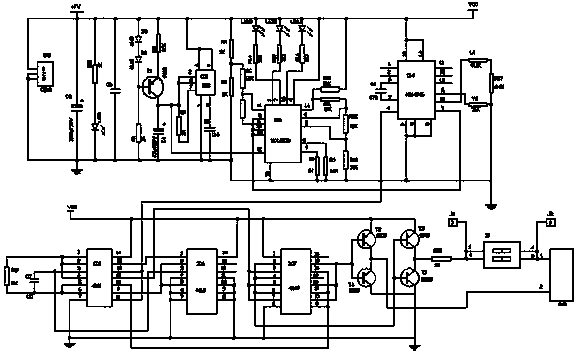

Electrical method treatment apparatus for increasing concentration multiple of circulation water

InactiveCN104163503AReduce corrosionAvoid secondary pollutionScale removal and water softeningIonCorrosion

The invention relates to an electrical method treatment apparatus for increasing the concentration multiple of circulation water. According to the electrical method treatment apparatus, electrode members contain alternating electrodes (5), a grounding electrode (6) and a grounding protection cover (7), wherein a group comprising at least the two alternating electrodes (5) is arranged inside the barrel-like grounding protection cover (7), and the grounding protection cover (7) is connected with the grounding electrode (6); and control members contain an oscillation circuit module (1), a power supply (2), a control circuit module (3) and an output module (4), wherein the power supply (2) and the control circuit module (3) are connected, and the control circuit module (3), the oscillation circuit module (1) and the output module (4) are connected. With the electrical method treatment apparatus, the concentration multiple of the circulation water in the prior art can be increased to more than 1 time; the pollution discharge of the circulation water is reduced by more than 1 / 2; the hardness, the conductivity and the turbidity of the circulation water are reduced by more than 30%; and the chloride ions are always less than the standard of 300 mg / L so as to substantially reduce the corrosion caused by increase of the chloride ions.

Owner:杨林丰

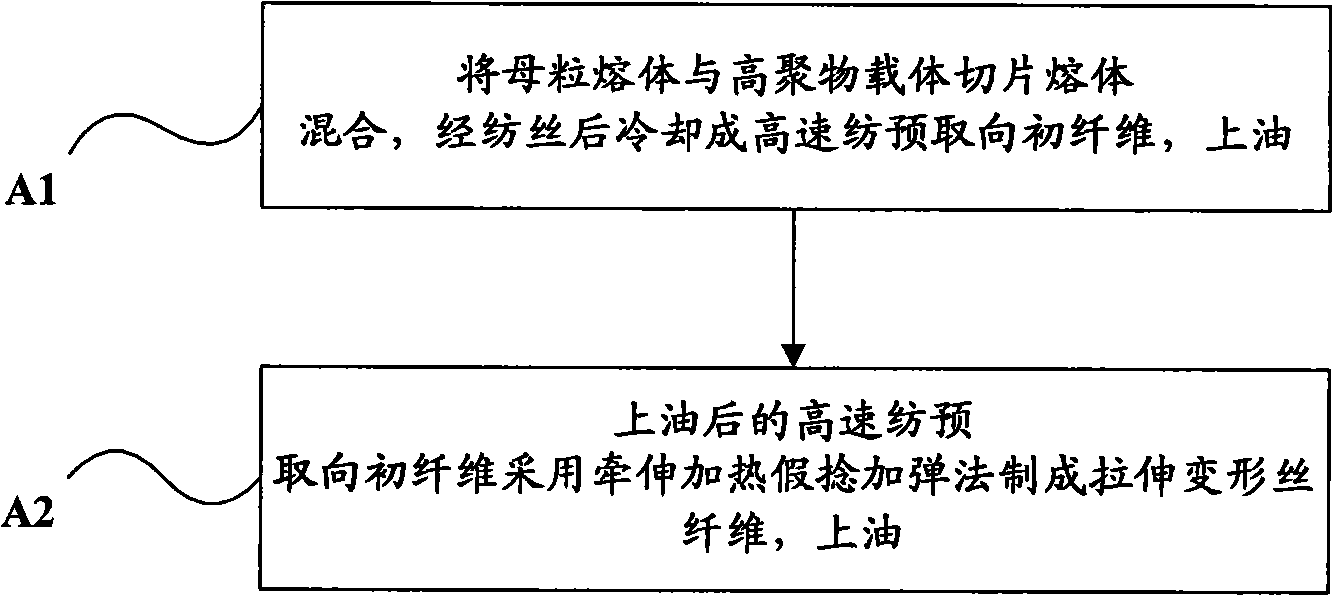

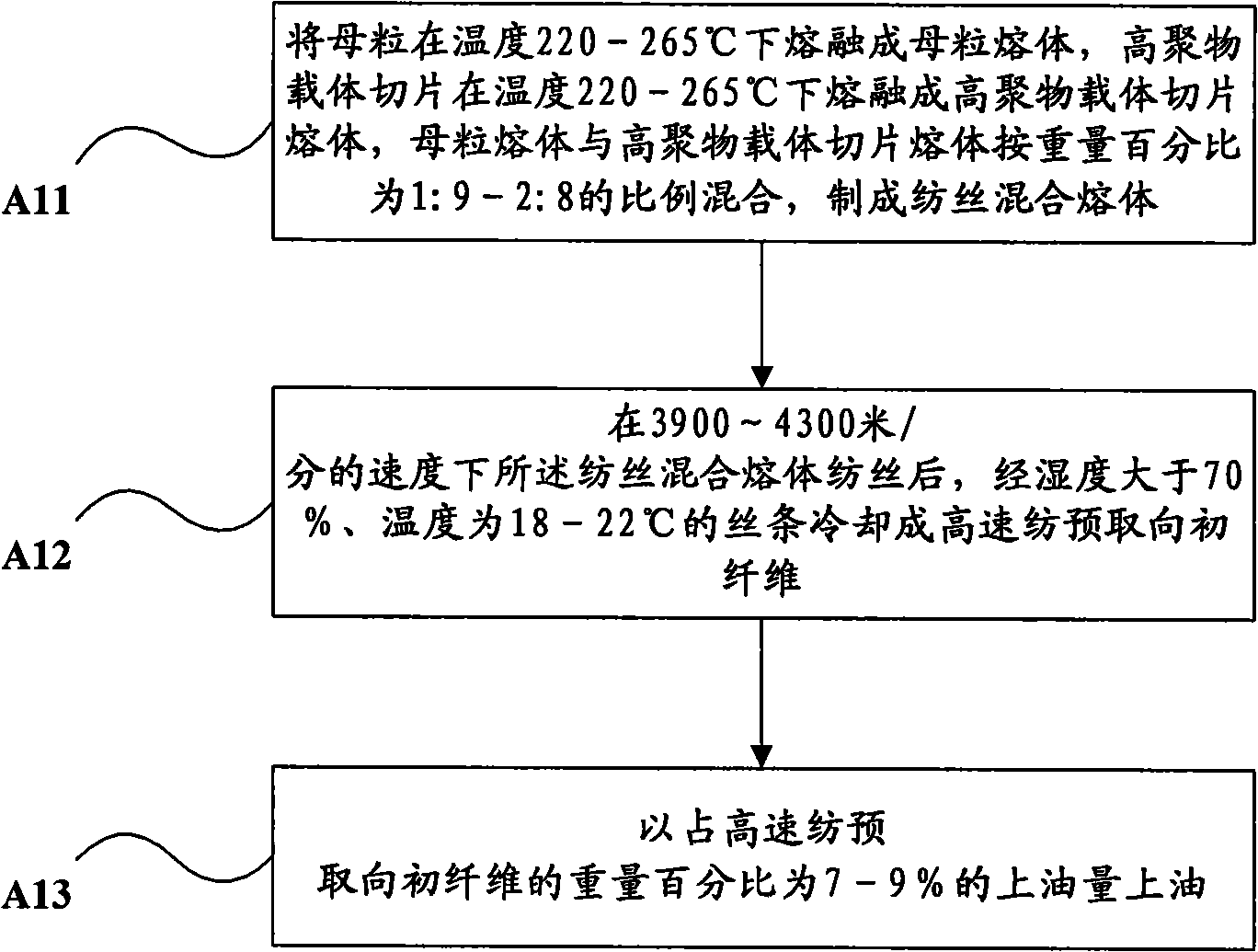

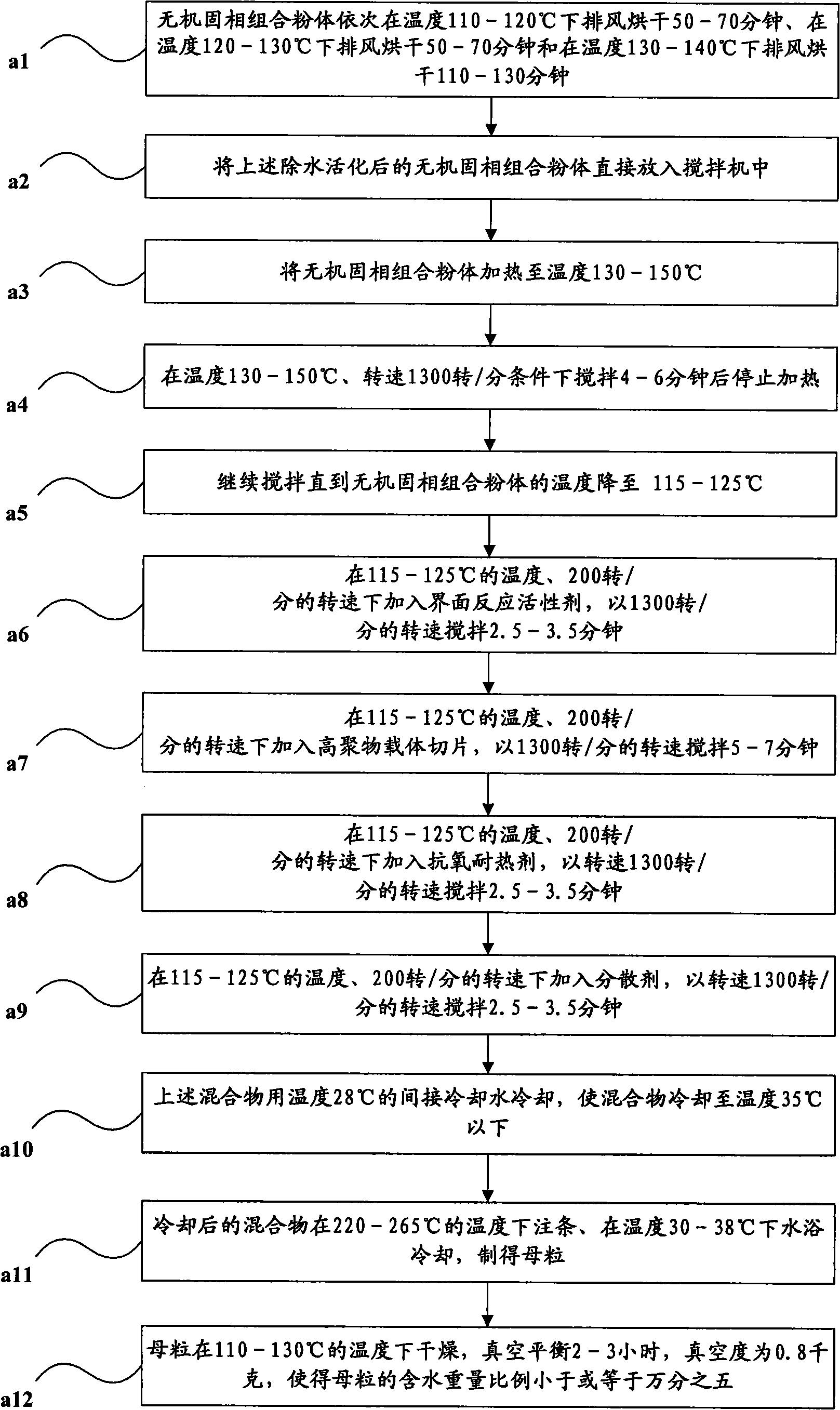

Method for preparing fibre

ActiveCN101314870AGood effectHigh sterilization rateMonocomponent polypropylene artificial filamentMelt spinning methodsMaterials scienceFiber size

The invention relates to a fiber manufacturing method which comprises the following steps: a master batch melt and a polymer support section melt are mixed and are cooled into a high-speed spinning pre-oriented embryo fiber after spinning, and then oiling is carried out; the high-speed spinning pre-oriented embryo fiber after oiling is made into a draw texturing silk fiber by adopting an intra-drawing heating fast-twist method, and then is oiled. The silver content of the fiber of the invention can reach 3-10 percent, the sterilizing rate is high, the ultraviolet blocking rate is high, the efficacy is lasting and safe, and no toxic or side effects exist; the fiber spinnability is good, and the indexes such as the fiber size, etc. accord with the first order standards of the national fiber; the water absorbability, the air permeability, the dying uniformity and the electric conductivity of the fiber are greatly improved, thereby increasing the drapability and the comfortableness of the fiber fabrics.

Owner:天津益康世纪抗菌新材料科技股份有限公司

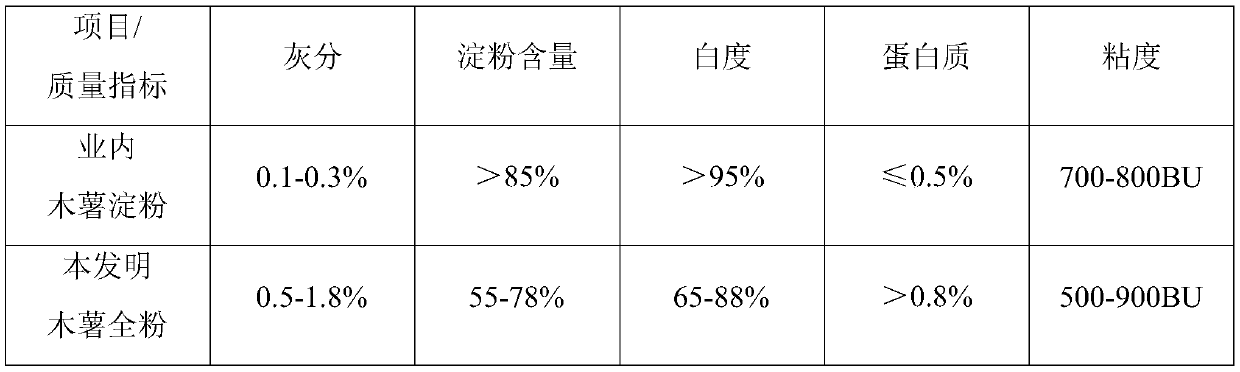

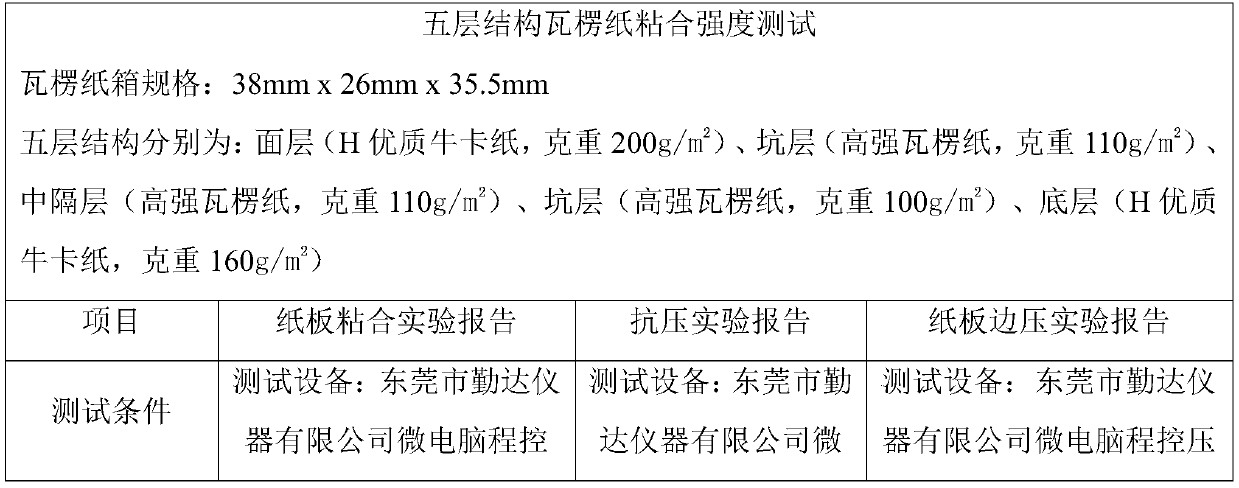

Application and processing method of cassava whole flour

ActiveCN110527458ADoes not affect liquidityHigh bonding strengthStarch adhesivesMacromolecular adhesive additivesBonding strengthMoisture

The invention relates to the technical field of glue, and in particular relates to application and a processing method of cassava whole flour. According to the method, cassava whole flour is used forreplacing traditional pure starch; the whole cassava flour containing the fibers is used for preparing glue, the prepared whole cassava flour glue is high in bonding strength, steam is saved, when thewhole cassava flour glue is used for producing paperboards, the phenomenon of false bonding or glue failure can be avoided, the fiber in the whole cassava flour is capable of effectively improving the compression resistance of corrugated paperboards, machine speed is increased, and paperboard processing quality is stable. A processing method of whole cassava flour comprises the following steps: impurity removing, wherein, cleaning and removing impurities on the surface of fresh cassava; slicing or shredding, and drying in the sun or baking, so that the moisture of the cassava is controlled within 15%; and crushing, wherein crushing the dry cassava or the dry cassava slices by using a crusher to obtain the whole cassava flour. The processing method of the whole cassava flour is simple andhigh in production efficiency, it is not needed to remove cassava residues in the whole cassava flour, waste is turned into valuables, the use amount of glue preparation raw materials is greatly reduced, and the processing cost of corrugated board production lines is reduced.

Owner:东莞市田园淀粉有限公司

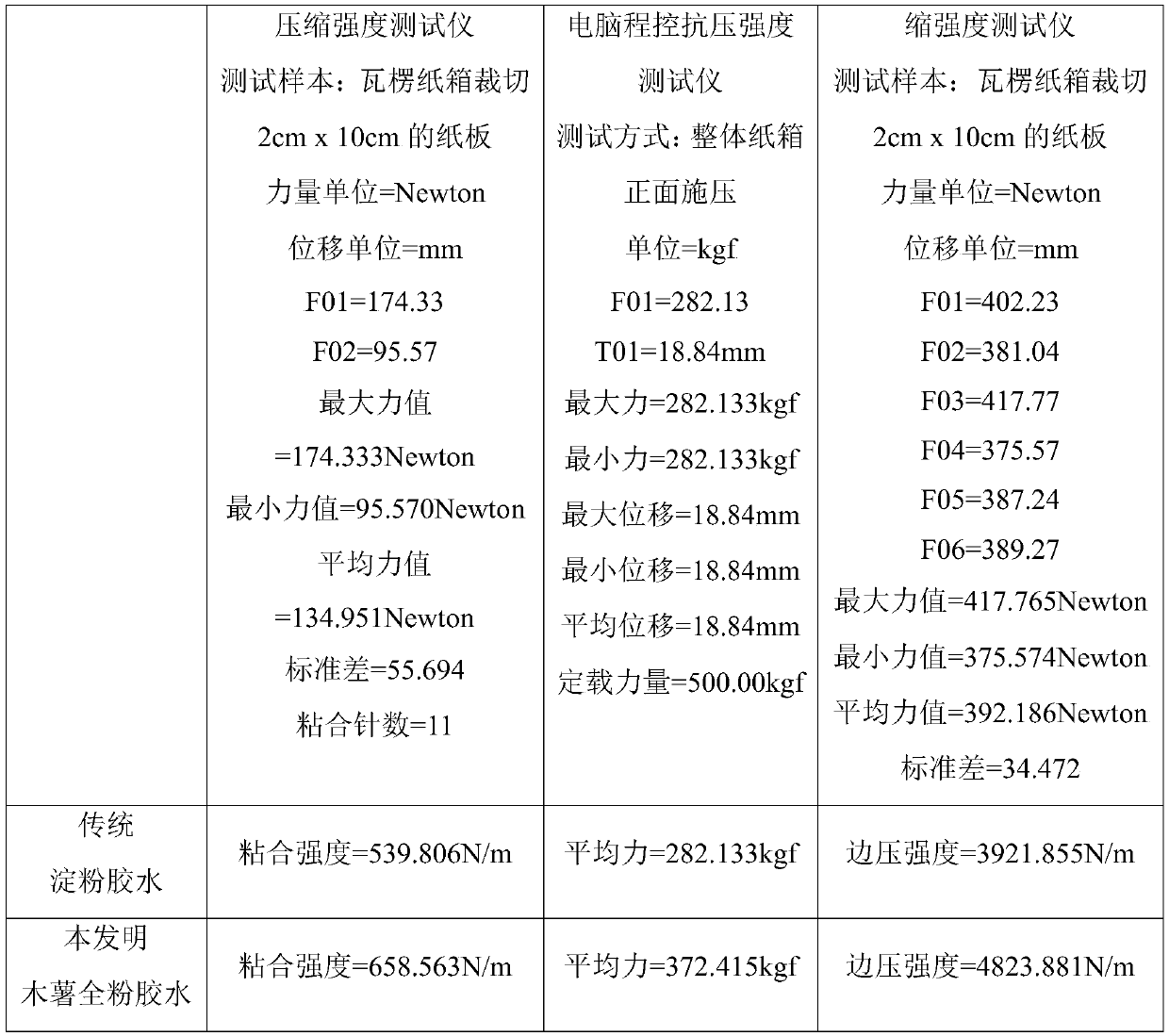

High-rigidity and high-toughness polypropylene composite material and preparation method thereof

InactiveCN109575450ADoes not affect liquidityPlay a role in heterogeneous nucleationThin walledAntioxidant

The invention discloses a high-rigidity and high-toughness polypropylene composite material which comprises, by weight, 40-80 parts of co-polypropylene, 5-20 parts of mineral fillers, 3-10 parts of reinforcing agents, 10-25 parts of toughening agents, 0-3 parts of compatilizers, 02-1 parts of nucleation master batch, 0.1-0.5 part of coupling agents, 0.1-0.5 part of antioxidants and 0.1-0.5 part oflubricating agents and light stability agents. The materials are mixed and extruded to prepare the composite material, the nucleation master batch is provided with mixture of nano-scale rare earth oxide Y2O3 and arylamine TMB (tetramethylbenzidine)-5, and the blending weigh ratio is 1:1-1:4. According to the composite material, the co-polypropylene and the mineral fillers, the reinforcing agentsand the toughening agents are compounded, the strength of the composite material is improved, the contraction rate of a resin substrate is reduced, dimensional stability of the material is ensured, and the modified polypropylene composite material can be widely applied to thin-walled automotive interior and exterior decoration products.

Owner:HEFEI GENIUS NEW MATERIALS

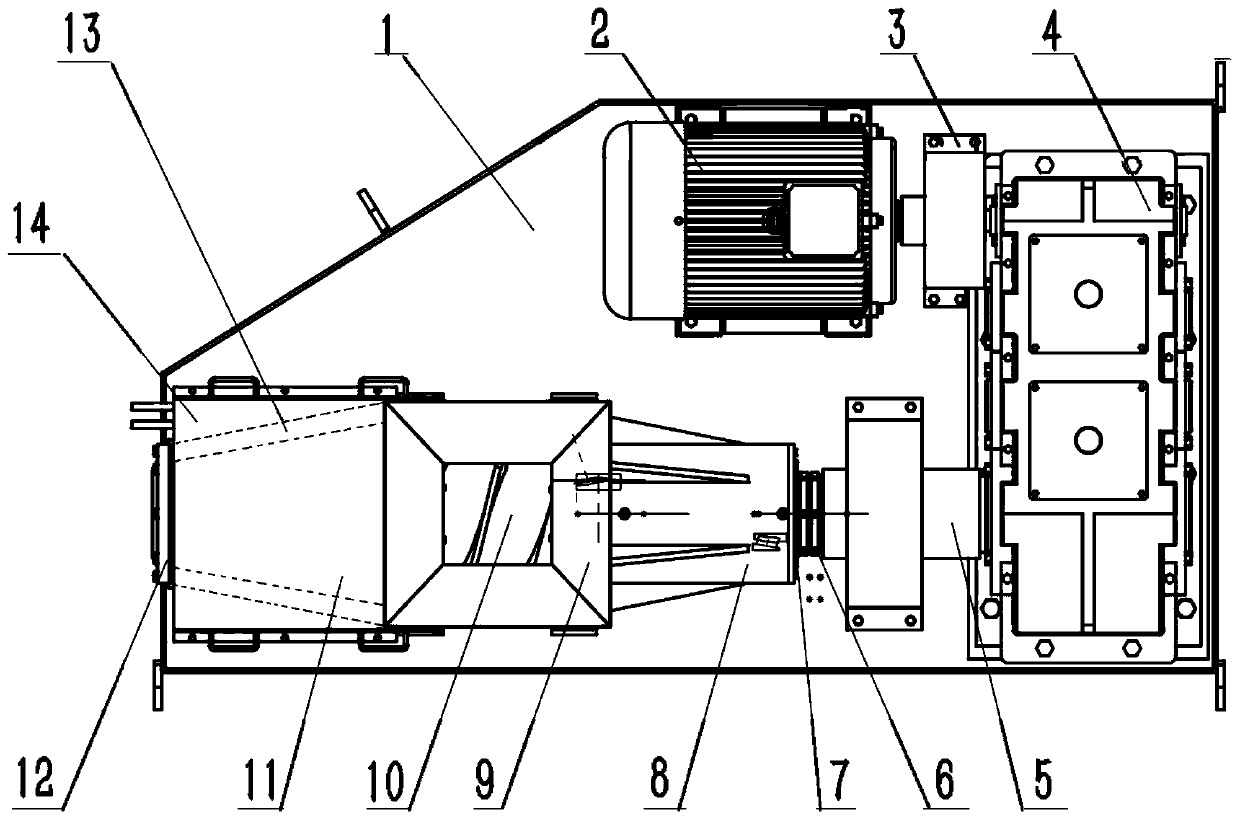

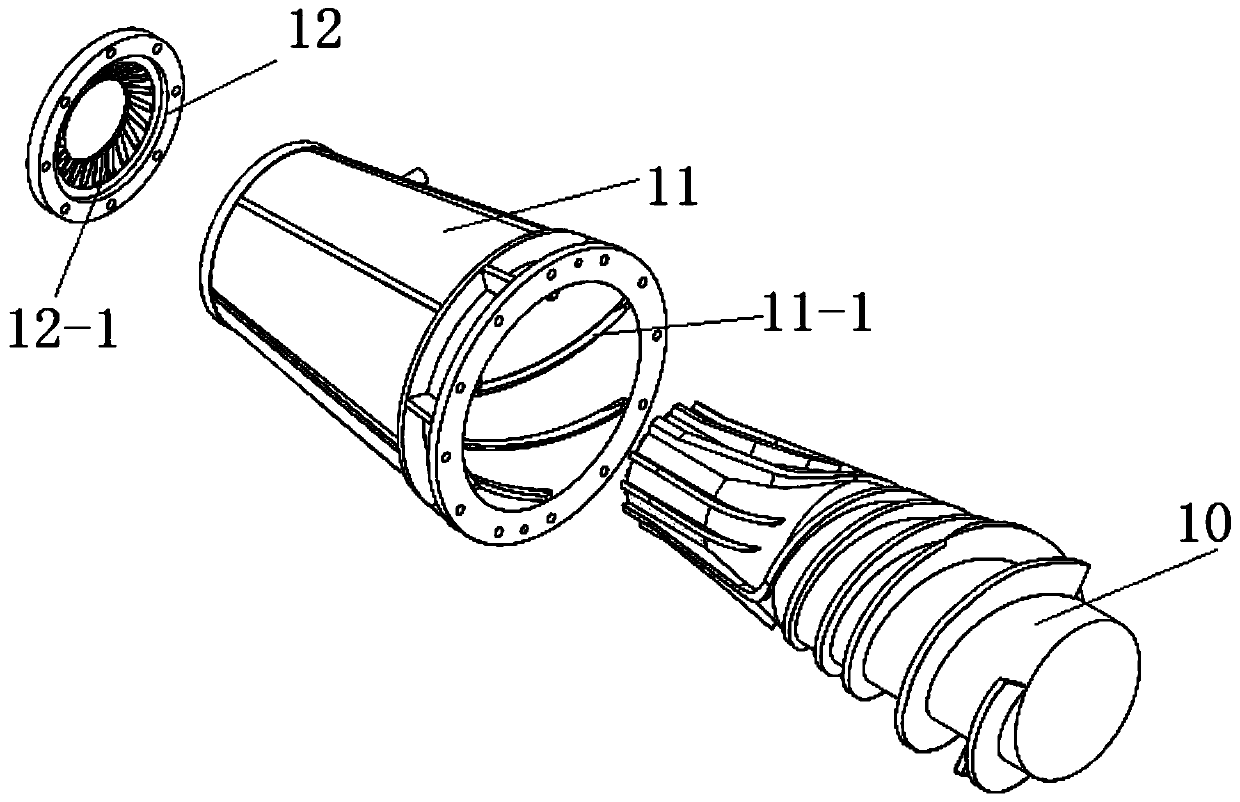

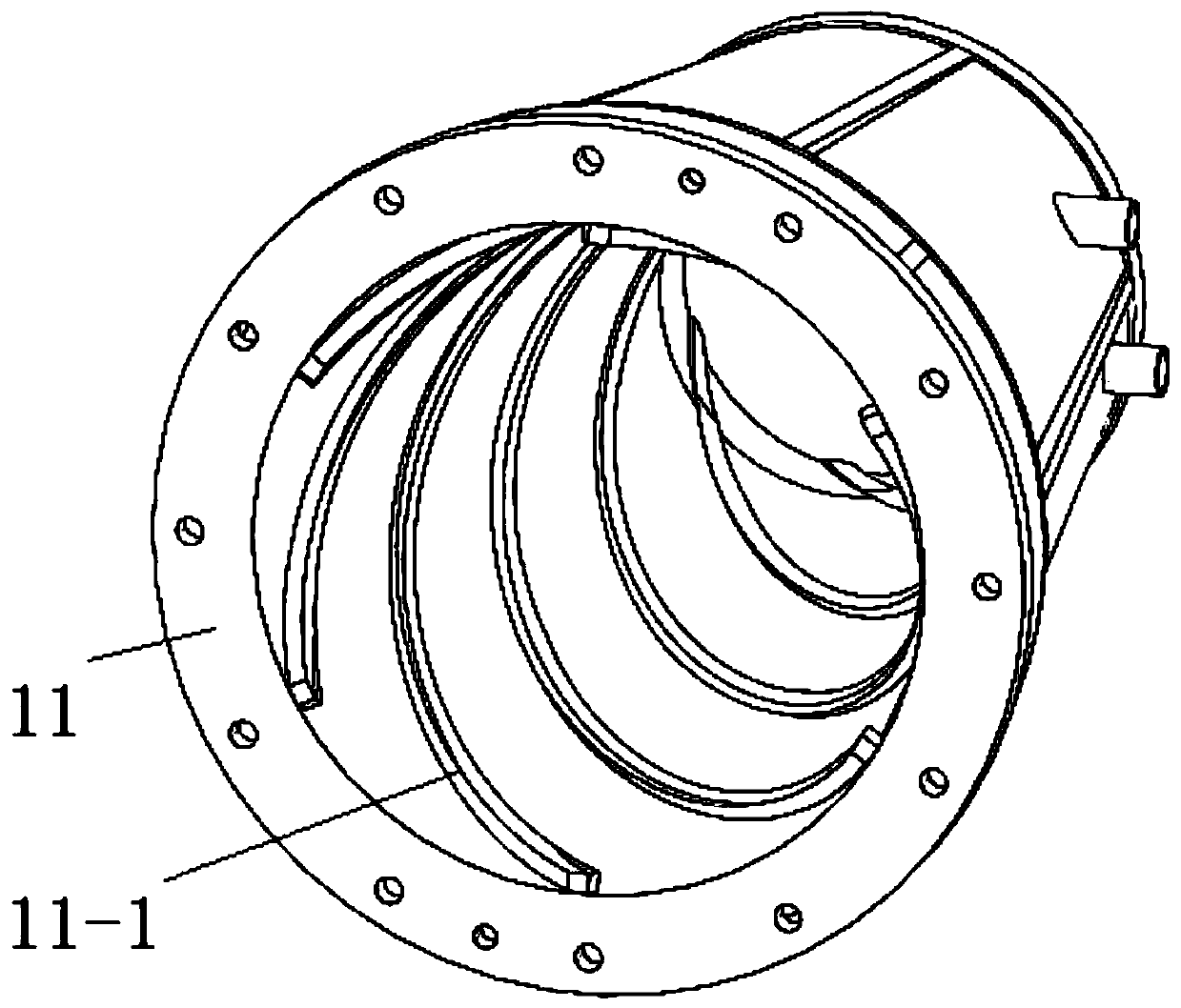

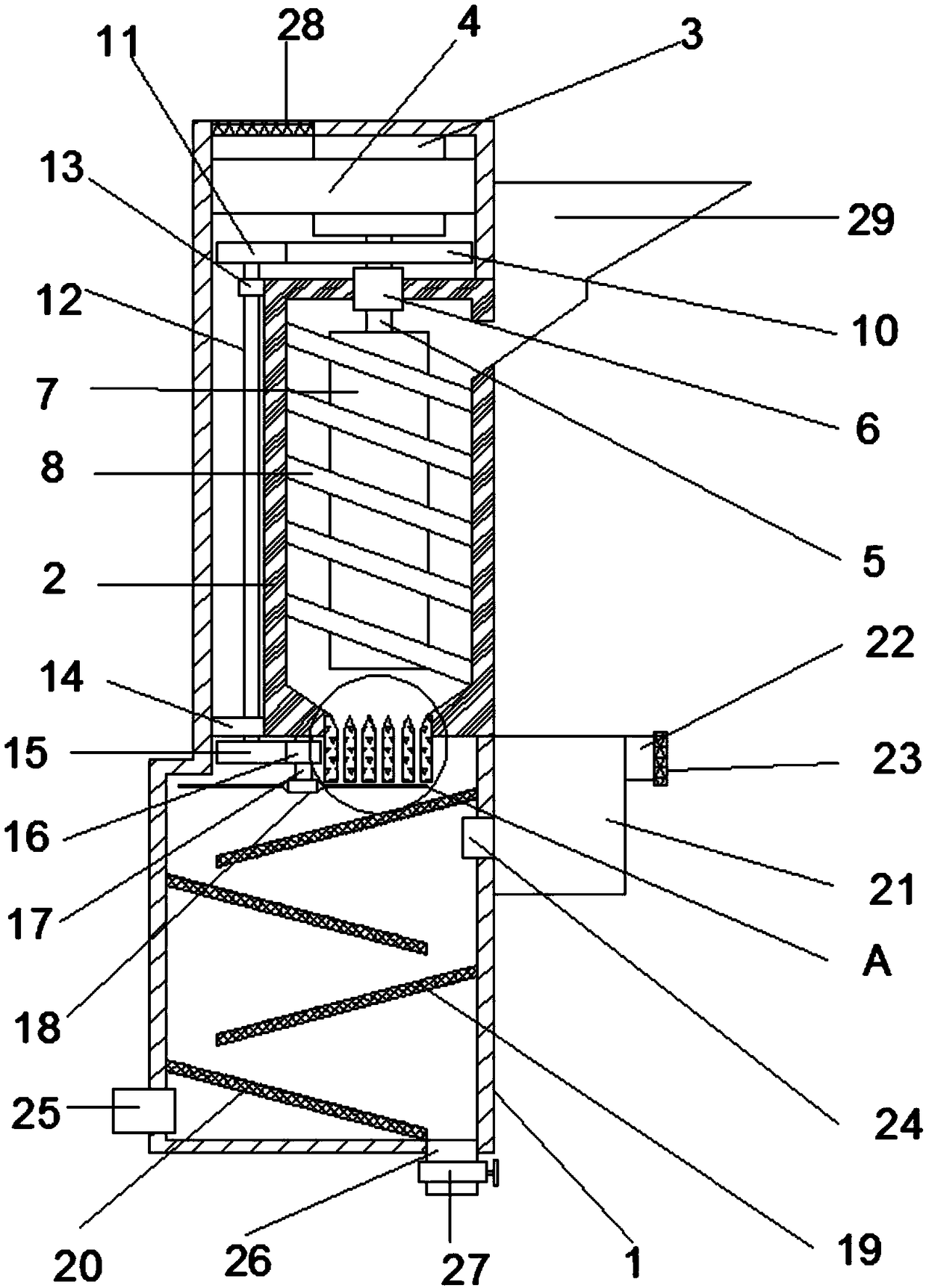

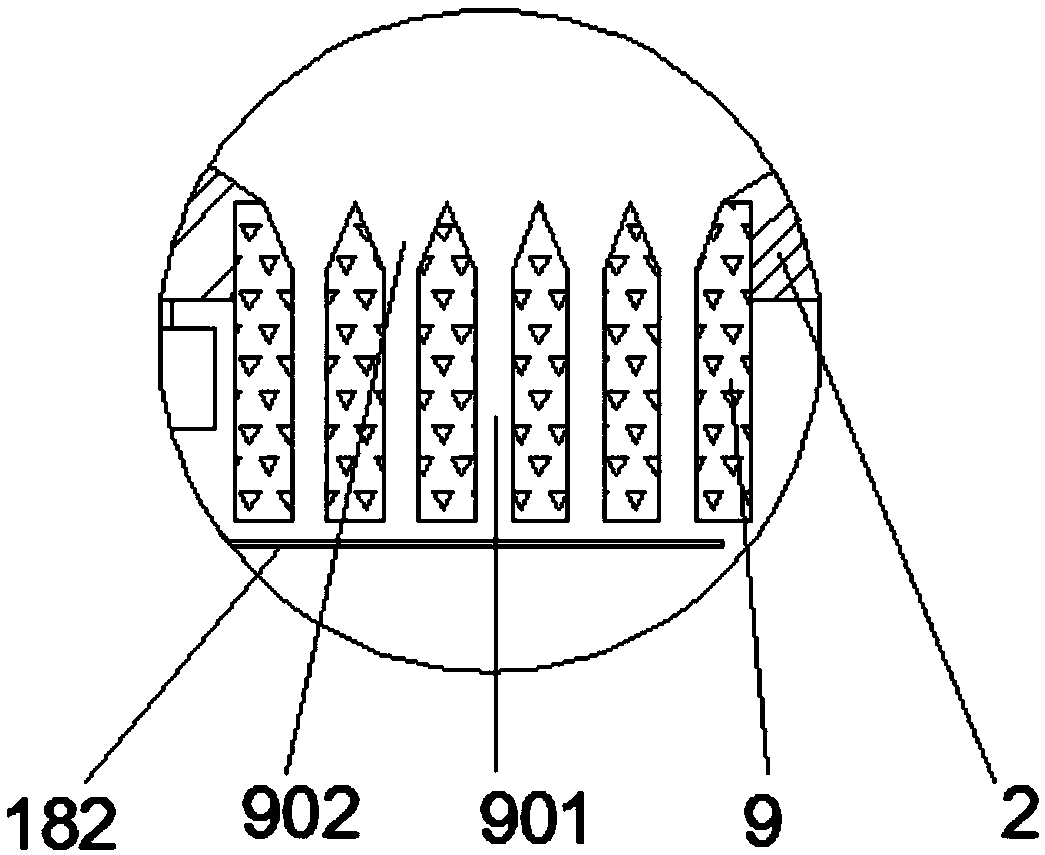

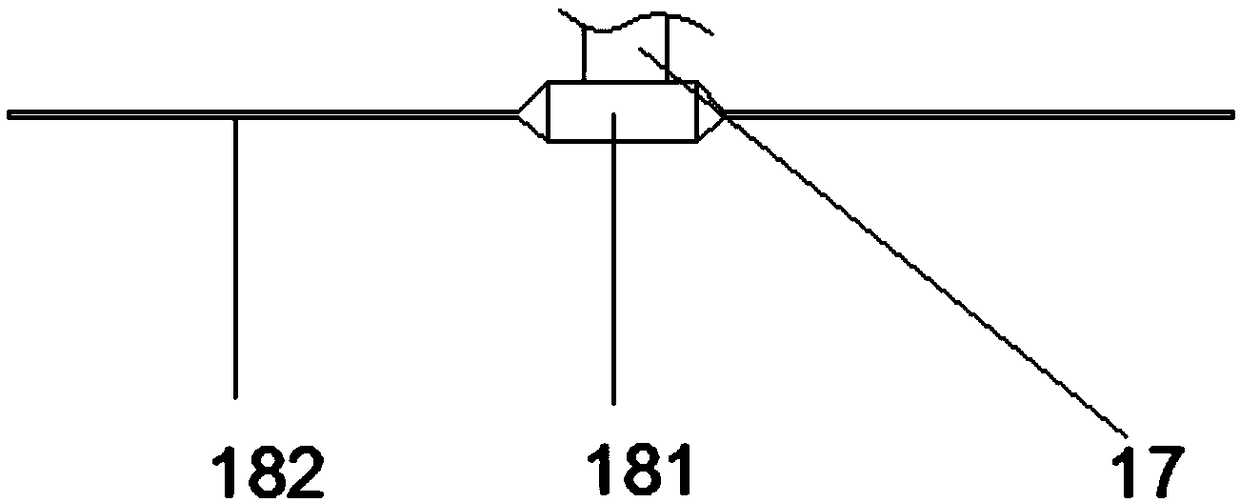

Feed granulation device

InactiveCN109007926AAchieve uninterrupted productionIncrease productivityFeeding-stuffEngineeringMechanical engineering

The present invention discloses a feed granulation device. The feed granulation device comprises an outer shell, a pressurized box, a motor, molding parts and a hot air fan; the upper part inside theouter shell is provided with the pressurized box; the right side of the top end inside the outer shell is provided with the motor; besides, the motor is fixedly connected with the inner side wall of the outer shell via a first fixing frame; a first rotating shaft is arranged at the lower end of the motor; the lower end of the motor passes through the top end of the pressurized box and is connectedwith a rotating wheel column; and the outside of the rotating wheel column is provided with a compression spiral disk. The motor is started to drive the first rotating shaft to rotate; the first rotating shaft drives the rotating wheel column to rotate; the rotating wheel column is then drives the compression spiral disk to rotate, thereby pressing a feed mixture downward, generating high-strength pressure and thereby realizing the extruding of the feed into tight strips; and the first rotating shaft then drives a rotating blade assembly to rotate at a high speed through various gears, thereby cutting the strips into the granular feed, realizing the uninterrupted production of the granular feed and improving the production efficiency of the feed granulation device.

Owner:WANGJIANG YUANYUAN AGRI CO LTD

Shrinkage-reducing compound additive capable of effectively reducing CA (cement and asphalt) mortar bleeding, and CA mortar dry material and CA mortar containing same

ActiveCN102173628ADoes not significantly increase water demandImprove bleedingAsphaltMaterials science

The invention discloses a shrinkage-reducing compound additive capable of effectively reducing CA (cement and asphalt) mortar bleeding, and a CA mortar containing the same. The shrinkage-reducing compound additive capable of effectively reducing CA mortar bleeding comprises the following components in percentage by mass: 45-75% of CaO clinker and 25-55% of low-temperature calcined MgO. The shrinkage-reducing compound additive capable of effectively reducing CA mortar bleeding accounts for 1-4% by mass of the CA mortar dry material. The CA mortar containing the additive has the advantages of low bleeding rate, small degree of separation, and favorable freezing resistance, and has an obvious compensation action on volume shrinkage of the CA mortar in medium and later periods.

Owner:JIANGSU SOBUTE NEW MATERIALS

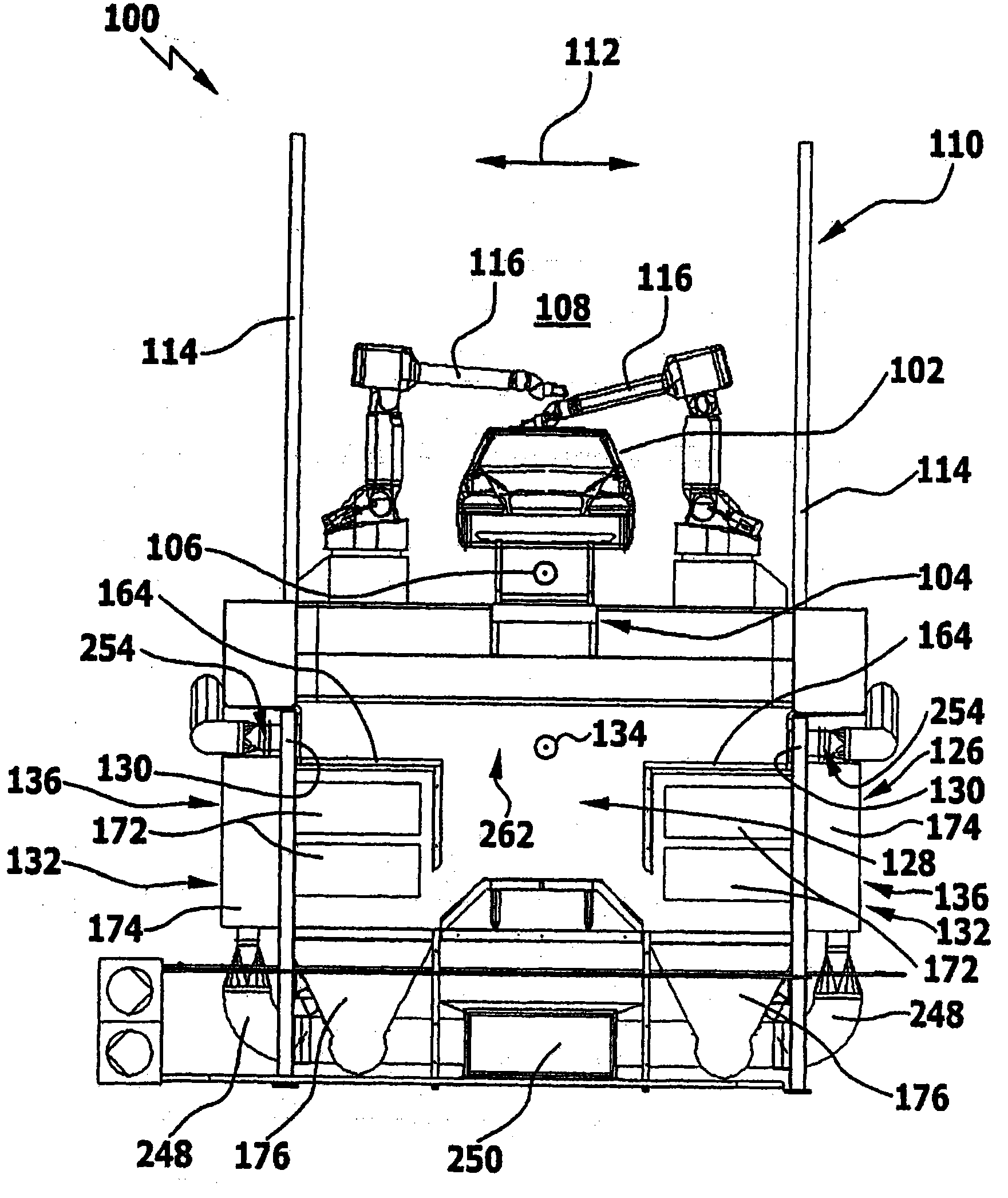

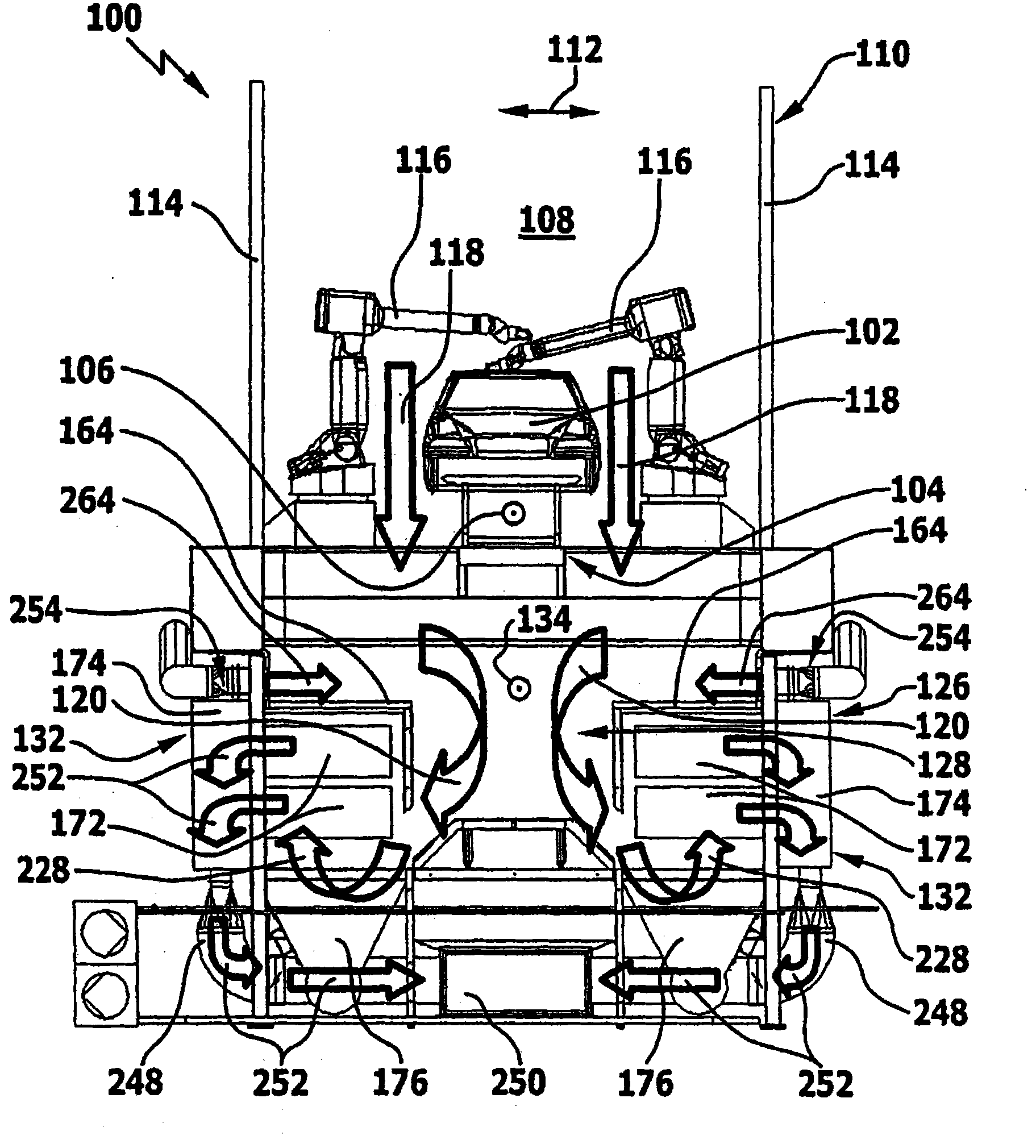

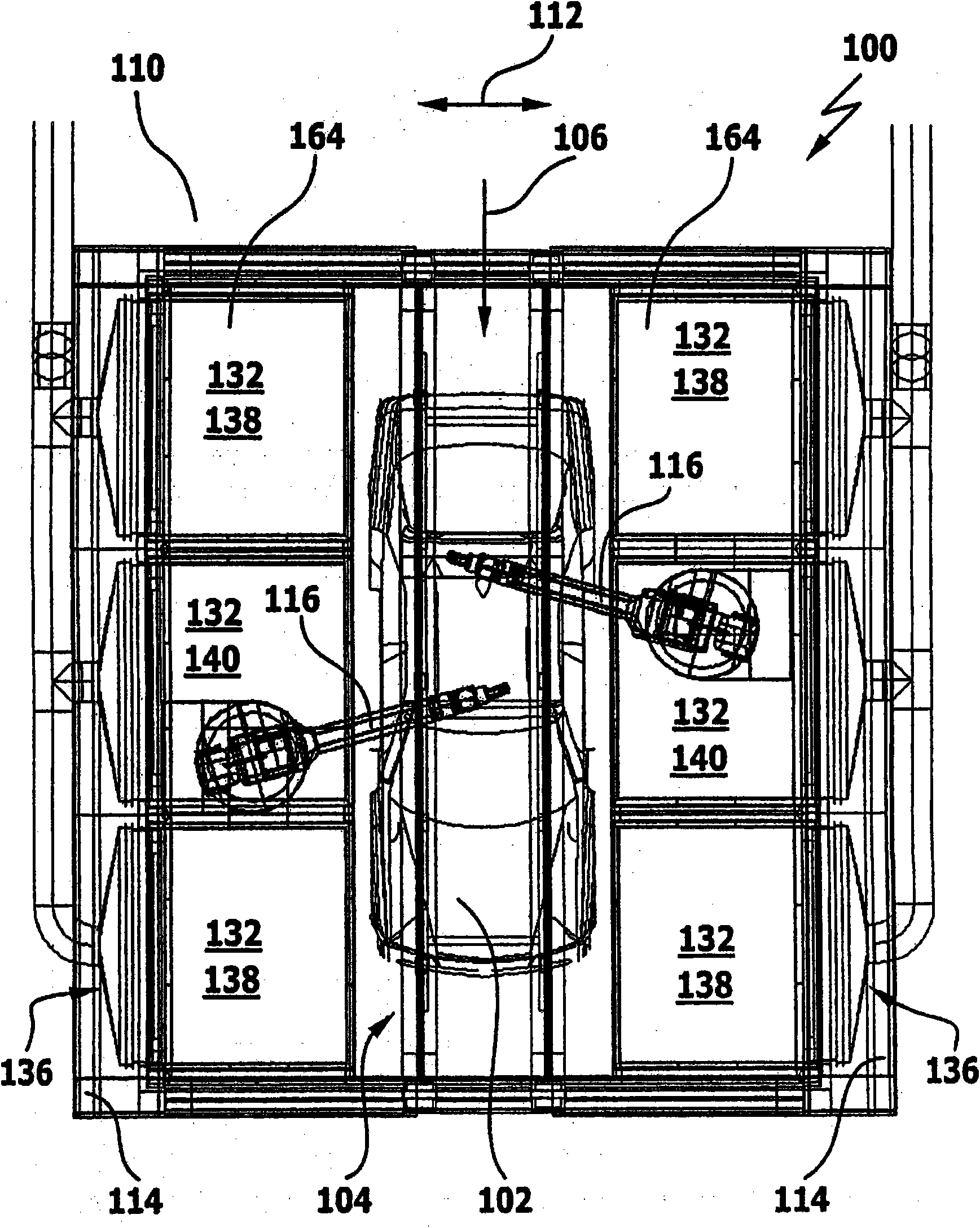

Apparatus and method for separating wet paint overspray

ActiveCN101952046ASmall structural expensesLarge internal spaceLiquid surface applicatorsDispersed particle filtrationLacquerProcess engineering

The invention relates to an apparatus for separating wet paint overspray from a stream of untreated gas containing overspray particles, comprising at least two filter devices which respectively comprise an inlet opening, through which a partial stream of the untreated gas enters the filter device concerned, and in each case at least one filter element for separating the overspray from the partial stream of untreated gas. To provide such an apparatus which makes it possible to maintain the flowability of the mixture of filter-aiding material and wet-paint overspray, cleaned off from the filter elements, easily and efficiently in the containers for receiving filter-aiding material, it is proposed that the apparatus comprises at least one receiving container for receiving a material cleaned off from filter elements of a number of filter devices and a mixing device for mechanically mixing the cleaned-off material from a number of filter devices.

Owner:DUERR SYST GMBH

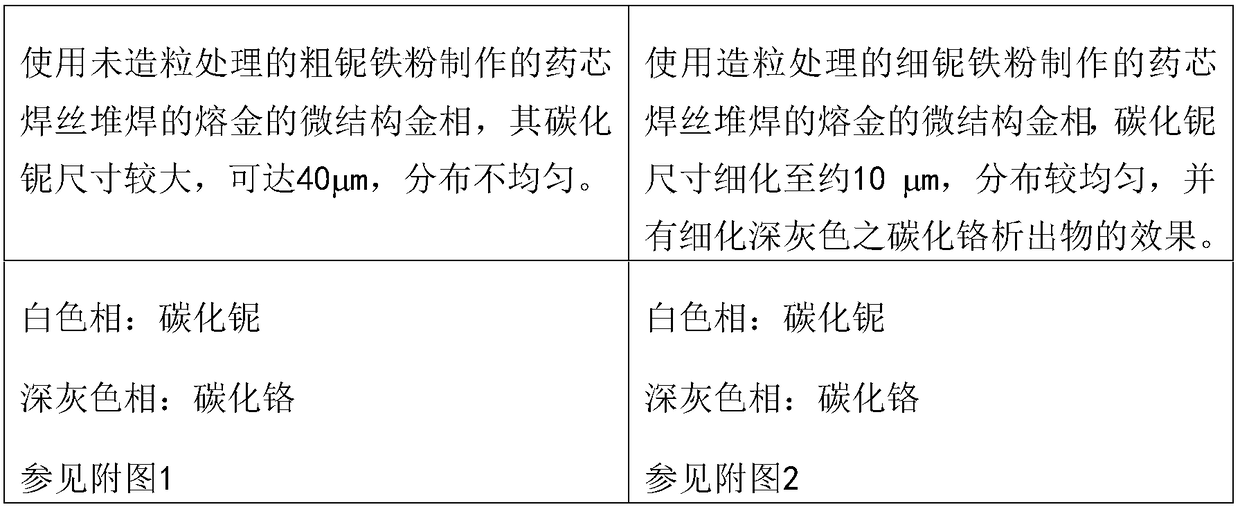

Alloy powder homogenizing treatment method for flux-cored wire

InactiveCN109317867AEvenly dispersedEasy to useTransportation and packagingWelding/cutting media/materialsAdhesiveAlloy

The invention discloses an alloy powder homogenizing treatment method for a flux-cored wire. The alloy powder homogenizing treatment method comprises the following steps of: S1, keeping the basic requirements for the grain size of used primary raw material powder, and keeping the grain size of a to-be-added little secondary powder raw material to be smaller than 100 meshes, thereby forming a powdered raw material; S2, adopting a pelletizing adhesive which is a sodium silicate solution diluted by adding water, wherein the pelletizing adhesive needs to add with 20-70% of water to dilute for use;S3, adding the adhesive and the powdered raw material into a stirrer to stir, wherein adding amount of the adhesive and weight percentage of the powdered raw material are smaller than 30%; S4, uniformly mixing the adhesive with the powdered raw material to obtain a mixture, then, taking out the mixture to spread on a heat-resistant steel disc to sinter and dry; and S5, crushing and sieving to a required mesh number, using a 40-50-mesh screen to screen, thereby completing a pelletizing process for the screened powder. The alloy powder homogenizing treatment method realizes modifying flux-coredwire powder, and further improves uniformity of the added alloy, so that the expected grain refinement or other metallurgical effects are achieved.

Owner:SUZHOU U P WEAR RESISTANCE COMPOUND MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com