Viscosity regulator and preparation method thereof and self-leveling self-compacting concrete

A technology of viscosity modifier and dense concrete, applied in the field of concrete, can solve the problems that the thickener cannot meet the requirements at the same time, affect the fluidity and filling property of concrete, and the concrete has no effect on segregation and bleeding, so as to prevent segregation and bleeding. , Increase viscosity, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

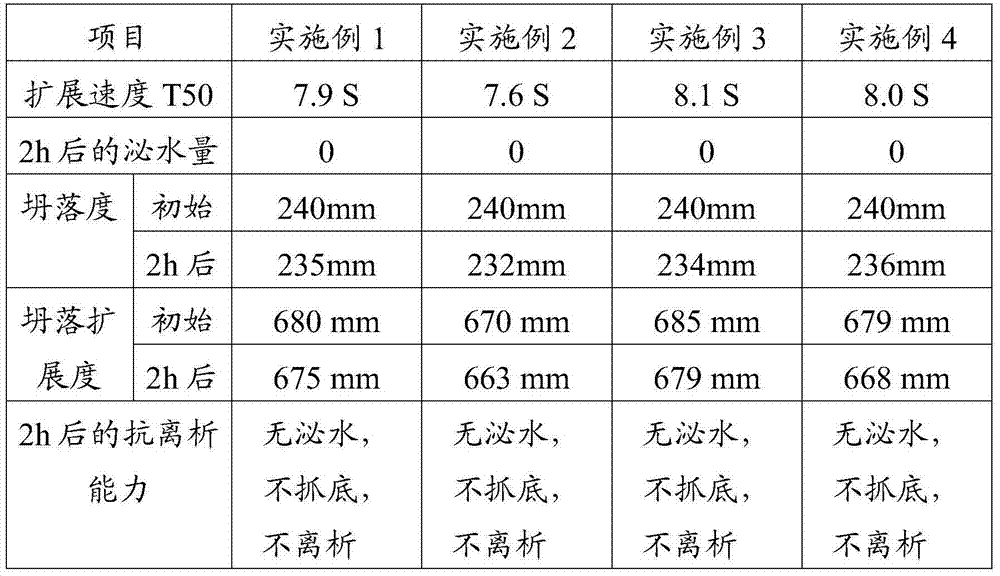

Examples

Embodiment 1

[0113] 1. Preparation of viscosity modifier

[0114] Grind 0.45g KOH into fine powder, add 60g of starch into 300ml of butylene oxide, stir at room temperature for 2 days, make the butylene oxide fully penetrate into the starch granules, make them fully wet and swell; heat up to Continue to react at 45-50°C for 48 hours, filter, and dry to obtain the reaction product hydroxybutyl starch ether, that is, the viscosity modifier.

[0115] 2. Apply the viscosity modifier to the preparation of concrete

[0116] First add 400kg of cement, 150kg of fly ash, 832kg of sand and 768kg of gravel, then add 25kg of slag powder, then add 86kg of water, then add 5.75kg of 20% solid content polycarboxylate superplasticizer and 0.4kg of viscosity modifier, Finally, add the remaining 86kg of water and stir evenly to obtain concrete.

Embodiment 2

[0118] 1. Preparation of viscosity modifier

[0119] Grind 0.3g KOH into fine powder, add 45g of starch into 260ml of butylene oxide, stir at room temperature for 2 days, make the butylene oxide fully penetrate into the starch granules, make them fully wet and swell; heat up to Continue to react at 45-50°C for 48 hours, filter, and dry to obtain the reaction product hydroxybutyl starch ether, that is, the viscosity modifier.

[0120] 2. Apply the viscosity modifier to the preparation of concrete

[0121] First add 400kg of cement, 150kg of fly ash, 832kg of sand and 768kg of gravel, then add 25kg of slag powder, then add 86kg of water, then add 5.75kg of 20% solid content polycarboxylate superplasticizer and 0.3kg of viscosity modifier, Finally, add the remaining 86kg of water and stir evenly to obtain concrete.

Embodiment 3

[0123] 1. Preparation of viscosity modifier

[0124] Grind 0.6g KOH into fine powder, add 75g of starch into 380ml of butylene oxide, stir at room temperature for 2 days, make the butylene oxide fully penetrate into the starch granules, make them fully wet and swell; heat up to Continue to react at 45-50°C for 48 hours, filter, and dry to obtain the reaction product hydroxybutyl starch ether, that is, the viscosity modifier.

[0125] 2. Apply the viscosity modifier to the preparation of concrete

[0126] First add 400kg of cement, 150kg of fly ash, 832kg of sand and 768kg of gravel, then add 25kg of slag powder, then add 86kg of water, then add 5.75kg of 20% solid content polycarboxylate superplasticizer and 0.5kg of viscosity modifier, Finally, add the remaining 86kg of water and stir evenly to obtain concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com