Patents

Literature

912 results about "Self-consolidating concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

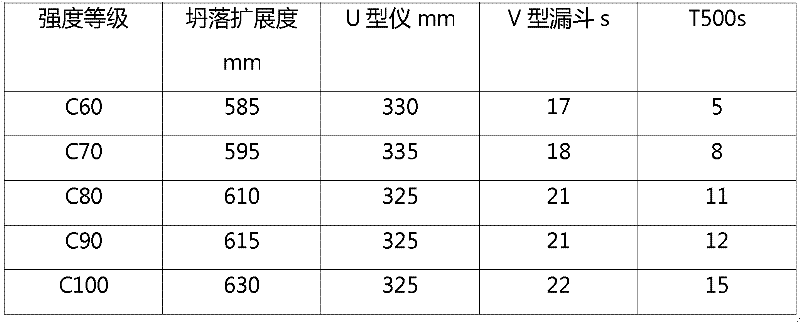

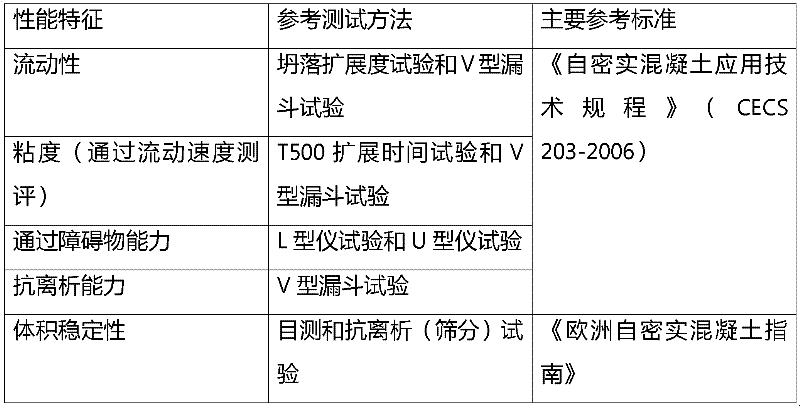

Self-consolidating concrete or self-compacting concrete (commonly abbreviated to SCC) is a concrete mix which has a low yield stress, high deformability, good segregation resistance (prevents separation of particles in the mix), and moderate viscosity (necessary to ensure uniform suspension of solid particles during transportation, placement (without external compaction), and thereafter until the concrete sets).

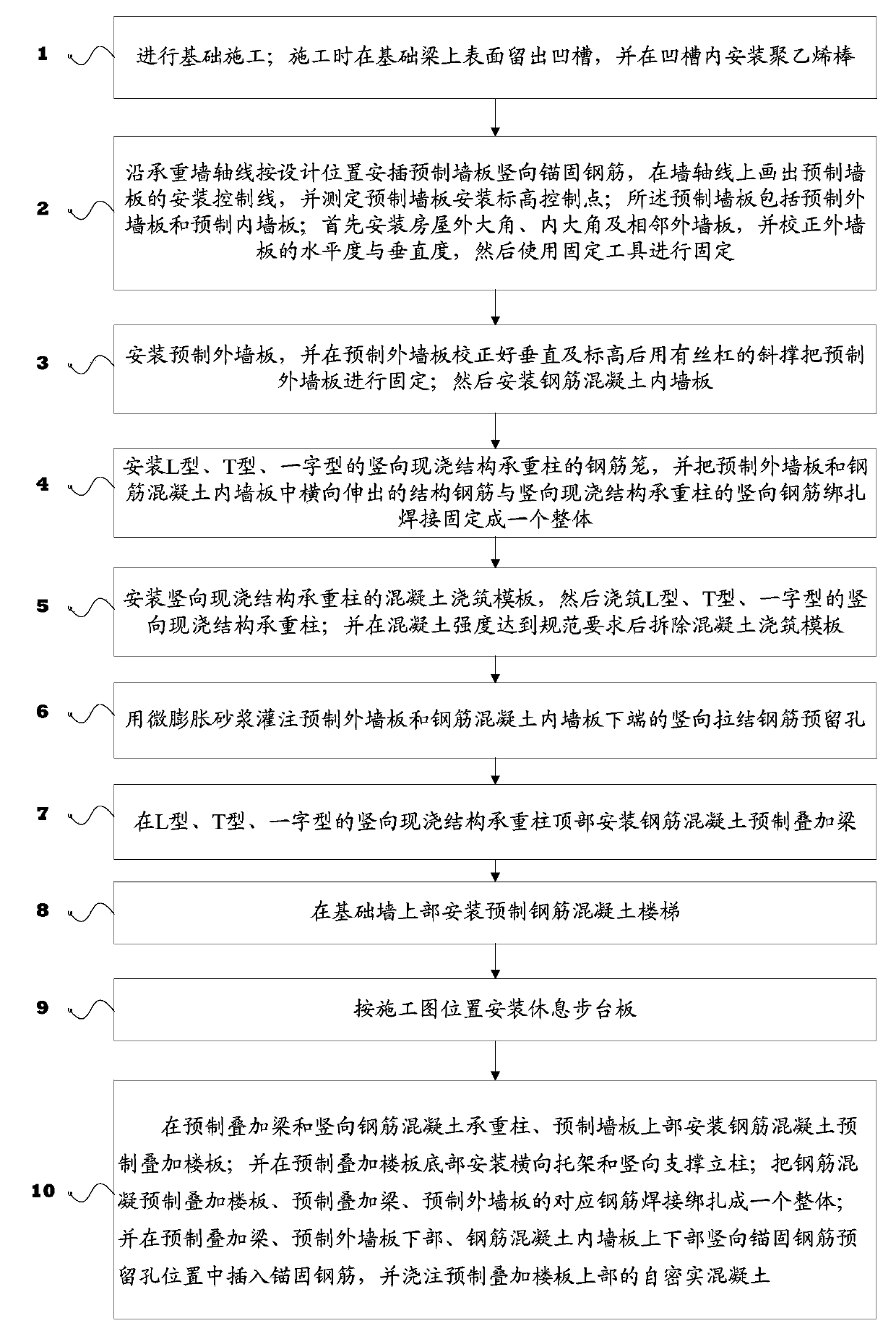

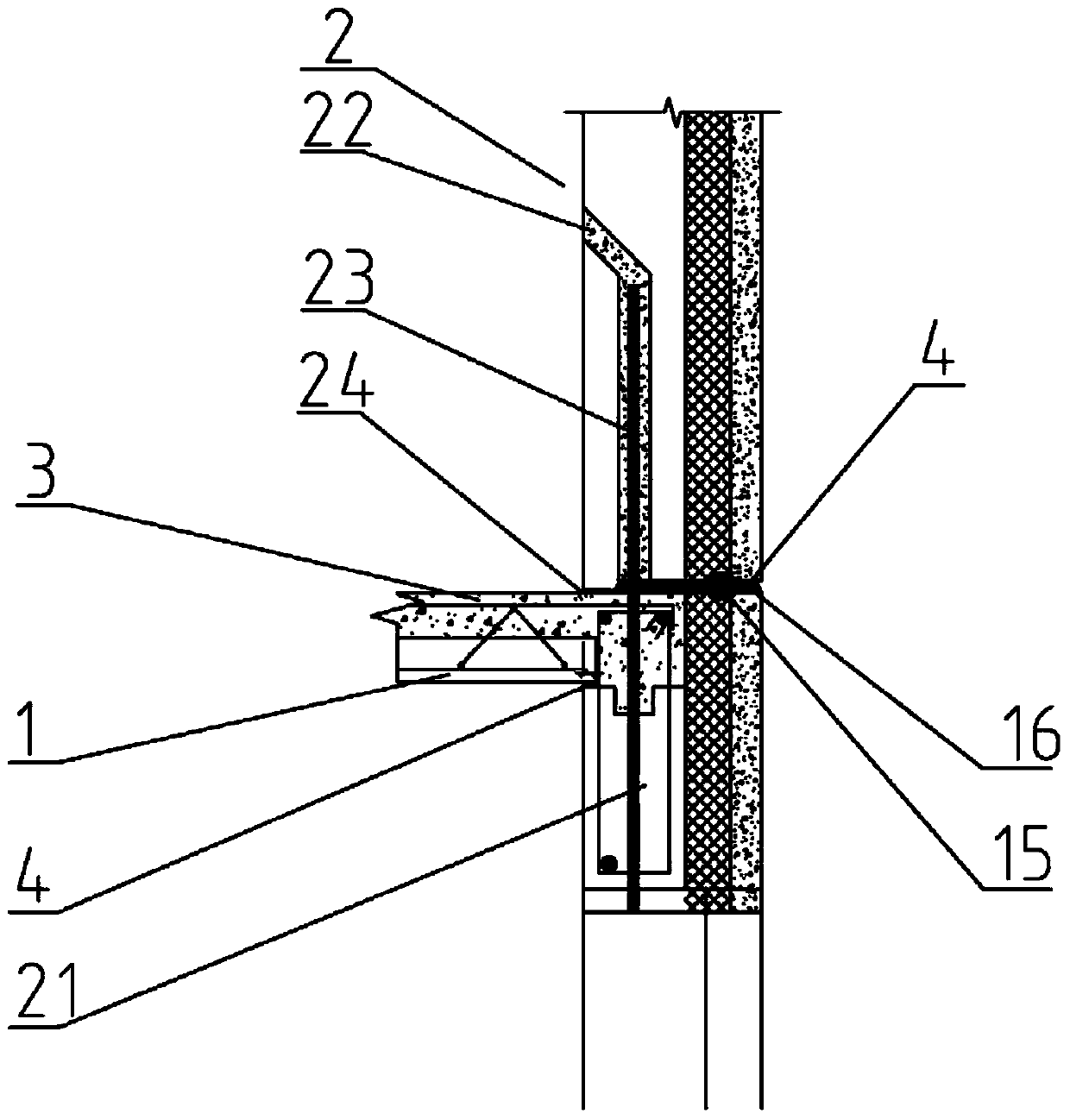

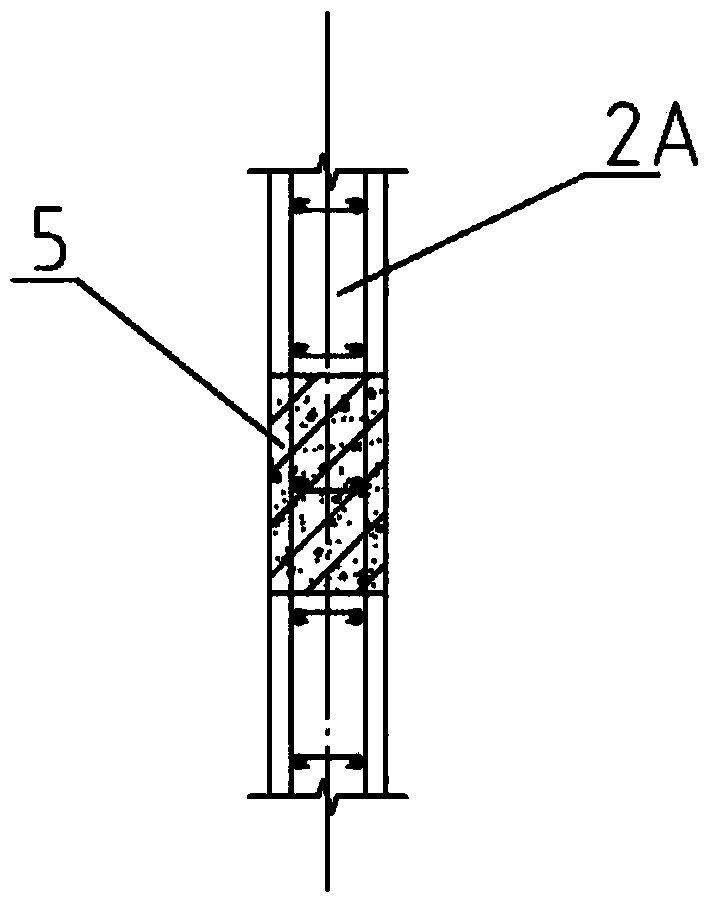

Construction method for reinforced concrete prefabricated house

ActiveCN103422672AImprove construction efficiencyReduce engineering costsBuilding material handlingFloor slabReinforced concrete

The invention provides a construction method for a reinforced concrete prefabricated house. The method comprises the following steps of constructing a foundation; mounting prefabricated wallboards; casting in situ T-shaped, L-shaped and inline vertical heel posts; pouring micro-expansion mortar into vertical steel tie preformed holes in the upper and lower ends of the prefabricated wallboards; mounting reinforced concrete prefabricated superimposed beams; mounting reinforced concrete prefabricated stairs and flat stepping plates; mounting prefabricated superimposed floor slabs on the prefabricated superimposed beams; welding and binding corresponding reinforcements exposed from the prefabricated superimposed floor slabs, the upper ends of the prefabricated superimposed beams and the prefabricated wallboards into a whole, and inserting vertical anchor bars for fixing the upper and lower end parts of the prefabricated superimposed beams and the wallboards, and casting self-compacting concrete on the upper parts of the prefabricated superimposed floor slabs. A 100m-high building can be constructed in an 8 earthquake fortification region such as Beijing by sequential and cyclic construction to a design top layer from bottom to top. According to the method, a technical index of building energy efficiency of 75 percent can be achieved, and the development of a prefabricated house construction technology can be accelerated.

Owner:洪都建设集团有限公司

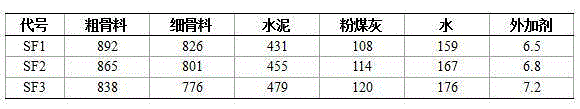

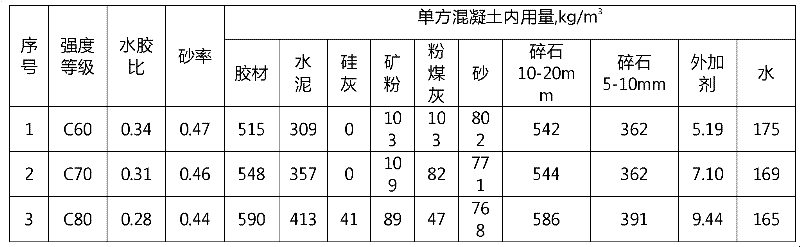

Design method for mixing proportion of self-compacting concrete mixture

ActiveCN105224727AQuick lockPrevent disengagementSpecial data processing applicationsParticulatesVoid ratio

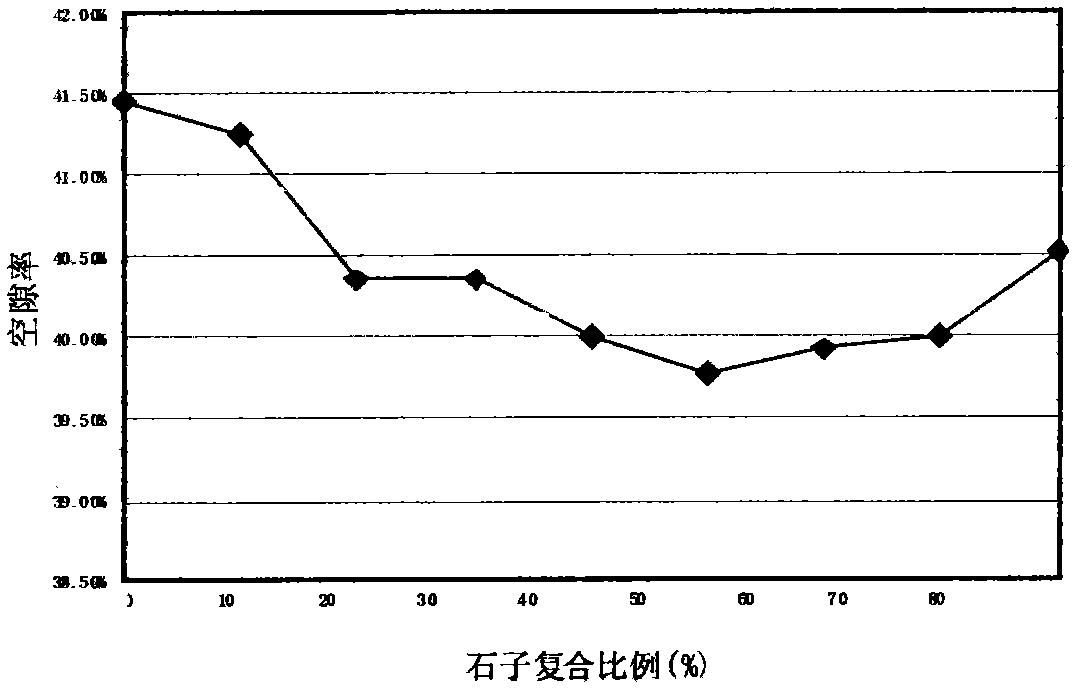

The present invention belongs to the technical field of concrete construction and particularly relates to a design method for a mixing proportion of a self-compacting concrete mixture. The method comprises the steps of: determining a performance design target; determining mixing strength and a water-binder ratio; determining densest gradation (or a sand rate) of aggregates and void ratios of different packing states; determining the usage amount of binding materials and mixing water; determining the usage amount of the aggregates; determining the usage amount of additives; determining the actual adding amount of the mixing water; and the like. According to the method provided by the present invention, aimed at blindness of material selection during self-compacting concrete mixing proportion design in the prior art, based on a fundamental theory of particulate dense packing and a composition rule of reaching a densest packing state of solid particulate materials with different particulate diameters, a mixing proportion of different materials is determined by an actually measured densest packing state, and relationships are established between the material mixing proportions corresponding to different densest packing states and expected self-compacting performance grades of the mixture, so that the design method used for the mixing proportion of the self-compacting high-performance concrete mixture and based on a use performance as a target is constructed.

Owner:ZHENGZHOU UNIV

Machine-made sand self-compacting concrete

A self-compacting concrete with high affinity, strength and durability is proportionally prepared from cement, powdered coal ash, wollastonite, other mineral additives, polycarboxylic acid type water-reducing agent, viscosity increaser, defoaming agent, mechanically prepared sand and broken stone.

Owner:GUIZHOU HIGHWAY ENG GRP

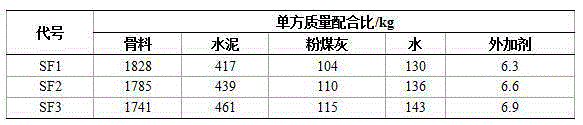

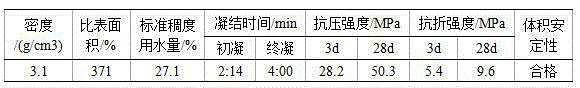

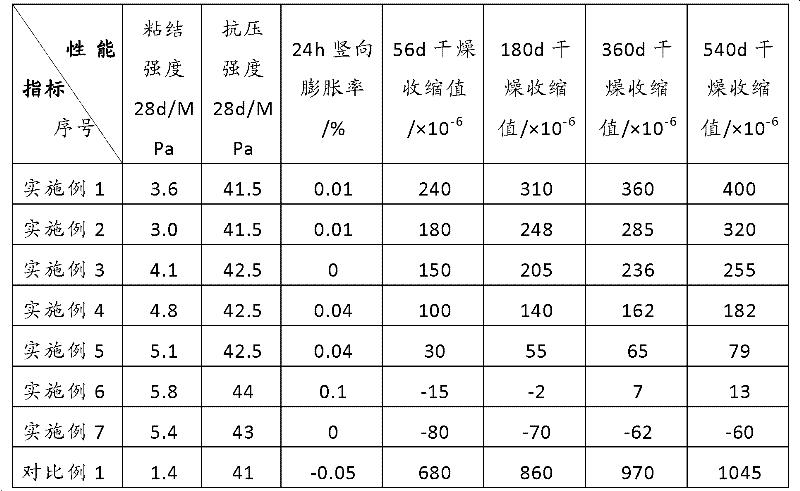

Self-compacting concrete mixture for plate-type ballastless track of railway

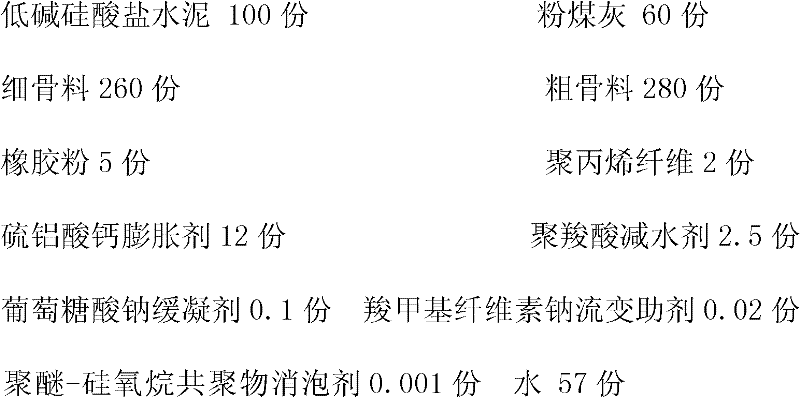

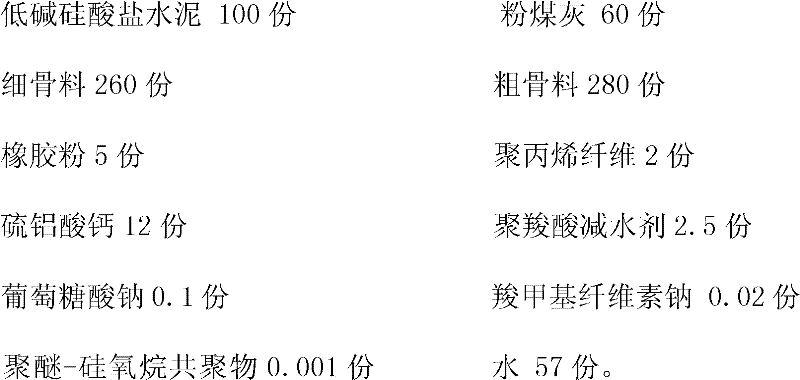

The invention discloses a self-compacting concrete mixture for a plate-type ballastless track of a railway, which is composed of the following ingredients in part by weight: 100 parts of cement, 20-80 parts of mineral admixture, 200-300 parts of fine aggregate, 250-350 parts of coarse aggregate, 2-10 parts of parts of rubber powder, 1-3 parts of polypropylene fiber, 10-25 parts of expansion agent, 1.0-3.0 parts of water reducing agent, 0.1-1 part of retarder, 0.01-0.05 parts of rheology accessory agent, 0.001 part of antifoaming agent and 60-80 parts of water; and the self-compacting concretemixture is prepared by blending and stirring the materials. The self-compacting concrete mixture disclosed by the invention has the advantages of large flow state, self-compacting property, non-segregation, low shrinkage, high anti-cracking property and vibration adsorption, and the like, so that the self-compacting concrete mixture can be used as filler between a rail board and a soleplate in a plate-type ballastless track and can also be used as filler between a turnout board and the soleplate in a turnout structure.

Owner:SOUTHWEST JIAOTONG UNIV

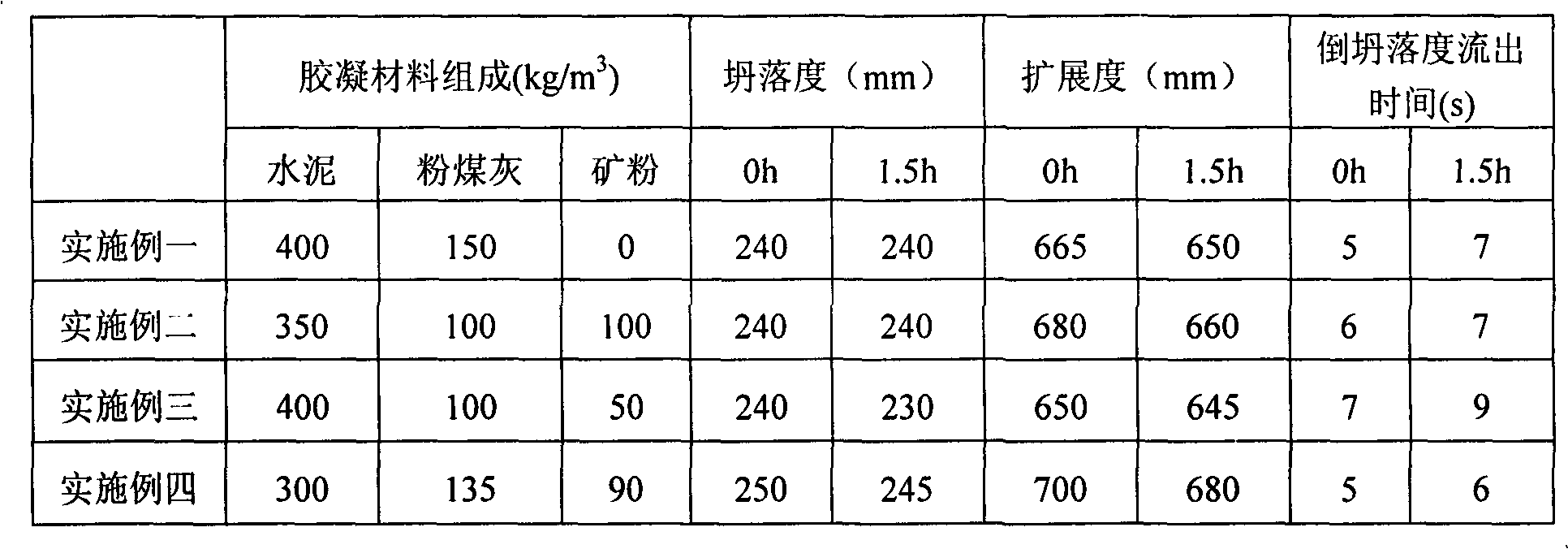

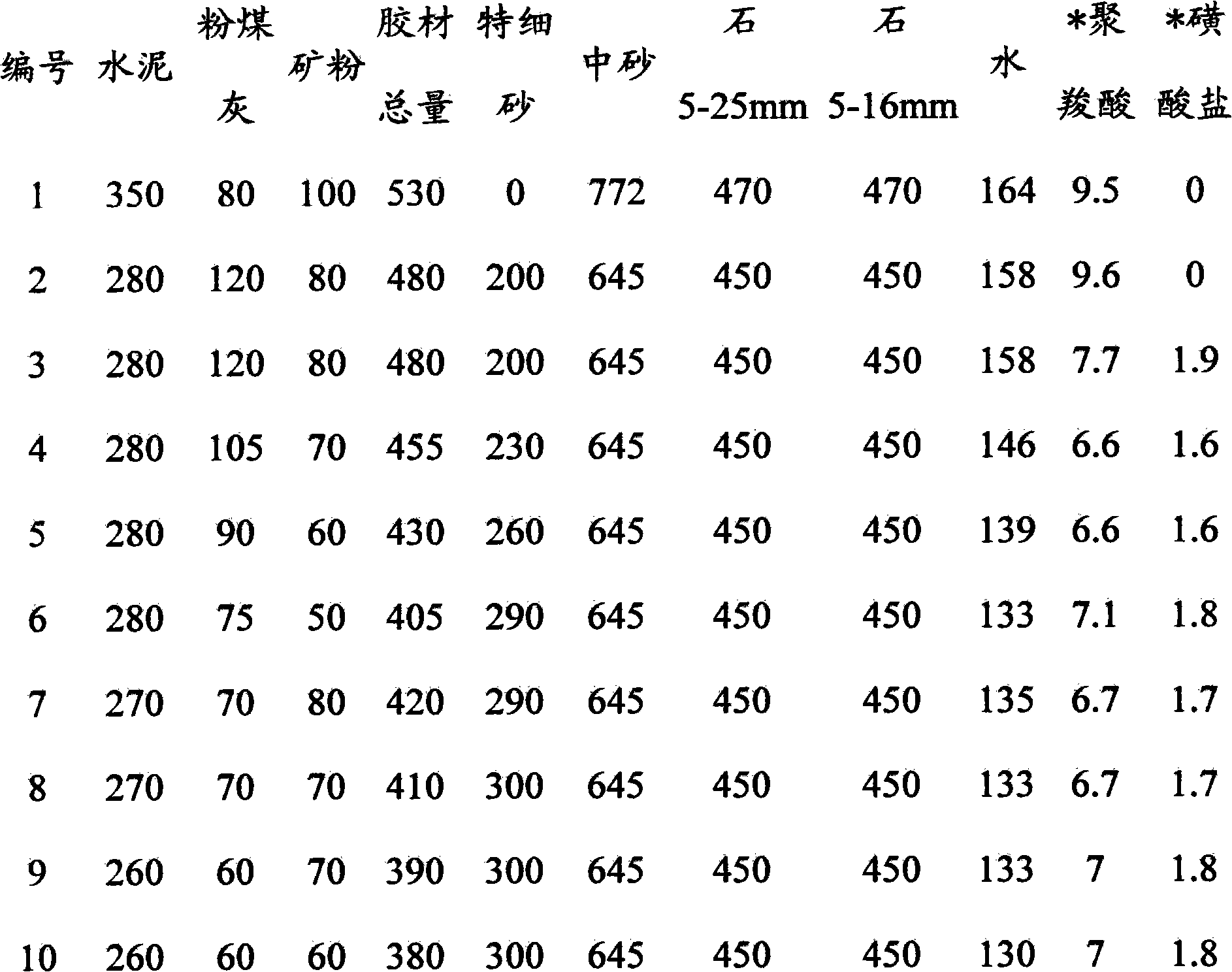

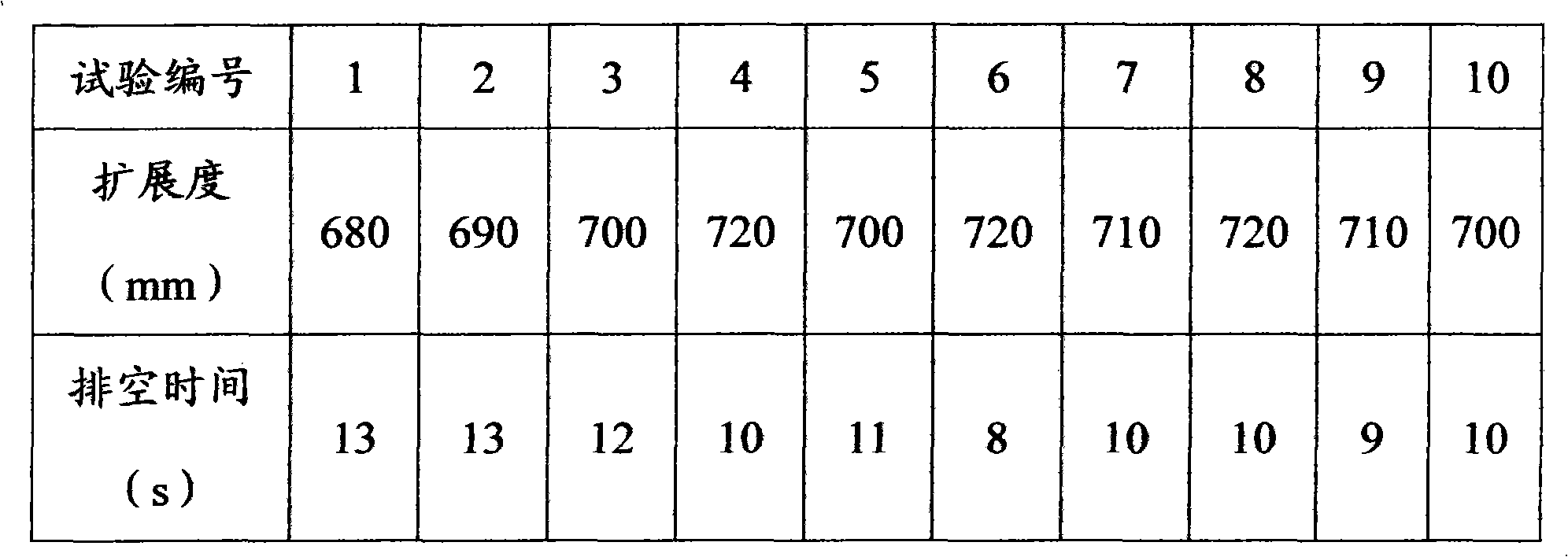

Self-compacting concrete and design method of mixing proportion thereof

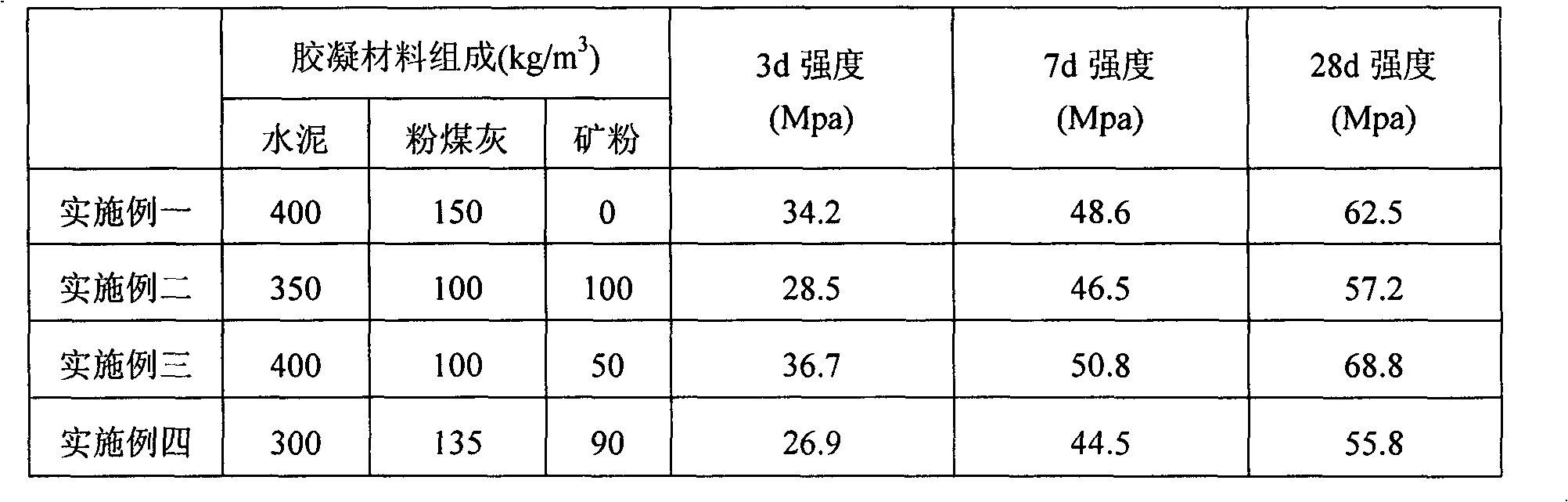

The invention relates to the technical field of concrete for building casting, specifically to self-compacting concrete and a design method of the mixing proportion of the concrete. The invention is characterized in that the self-compacting concrete is prepared by uniformly stirring the following raw materials in mixing proportion: 300-400kg / m<3> of cement, 70-150kg / m<3> of fly ash, 70-150kg / m<3> of mineral powder, 0-50kg / m<3> of silicon powder, 750-850kg / m<3> of sand, 850-1050kg / m<3> of stone, 4.4-28kg / m<3> of additive and 150-175kg / m<3> of water. Compared with the prior art, the self-compacting concrete disclosed by the invention has obviously improved flowing property, self-compacting property and durability of the concrete mixture, and is particularly applicable to the engineering structures limited by the construction operation space such as the structures with high casting quantity, large casting depth and height, complex shape, densely arranged reinforcing bars, thin walls, concrete-filled steel tubes and the like.

Owner:HEFEI TIANZHU BAOHE SPECIAL CONCRETE

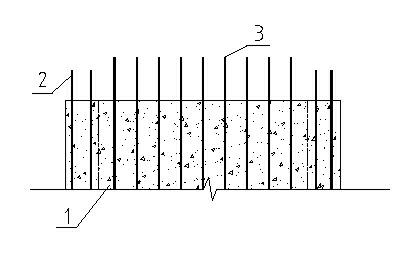

Assembly-type residential shear wall structural wall body vertical connection construction method

ActiveCN102425310AReduce the number of connectionsReduce construction costsBuilding material handlingHigh pressureRebar

The invention relates to a prefabricated shear wall body vertical connection construction method, in particular to an assembly-type residential shear wall structural wall body vertical connection construction method, which is characterized in that: when a prefabricated lower layer wall body is connected with a prefabricated upper layer wall body, supporting leg parts on two ends of the bottom part of a shear wall body are connected with each other through a reinforced bushing anchoring grouting method, and preformed steel reinforced parts on the middle part of the shear wall are connected with each other through a binding and overlapping method. When an upper layer wall body is prefabricated, anchoring connection bushings are respectively embedded on the supporting leg parts on two ends of the shear wall, the middle part of the shear wall is produced into a feeding passage for pouring concrete at a later period by embedding a steel bushing, self-compacting concrete is poured towards the middle part of the shear wall from a feeding port on the top part of the feeding passage, and high-strength grouting materials are fulfilled into the anchoring connection bushing at high pressure through a high-pressure grouting machine. Due to the adoption of the method, the quantity of the connection bushing can be reduced, the cost can be saved, and the connection quality and the connection speed can be improved. The weaknesses of the traditional shear wall vertical connection installation process that the cost is high, the construction speed is slow, the quality is difficult to control, and the like can be overcome.

Owner:CHINA 22MCC GROUP CORP +1

Self-densifying concrete as well as preparation method and application thereof

The invention provides self-densifying concrete, which is prepared from 100 parts by weight of cement, 20-100 parts by weight of coal ash, 20-120 parts by weight of porous fine aggregate, 150-250 parts by weight of non-porous fine aggregate, 150-300 parts by weight of coarse aggregate, 0.1-3 parts by weight of water-absorbing resin, 5-40 parts by weight of polymer emulsion, 1-12 parts by weight of expanding agent, 0.5-3 parts of water reducing agent, 10-90 parts by weight of water, 5-50 parts by weight of steel slag, 0-2 parts by weight of air entraining agent and 0-2 parts by weight of defoaming agent. The invention also provides a method for preparing the self-densifying concrete and the application of the self-densifying concrete in preparing a filling layer which is laid under plates of ballastless tracks.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +1

Preparation and application of two-component self-compacting concrete for slab ballastless track

The invention relates to a preparation and an application of two-component self-compacting concrete for a slab ballastless track. The preparation of the two-component self-compacting concrete is characterized in that the two-component self-compacting concrete is formed by mixing a dry mixture with a liquid in the ratio of 1:(0.05-0.15), wherein the dry mixture is formed by mixing components in parts by mass as follows: 100 parts of a bonding component, 0-30 parts of an inert mineral additive, 150-400 parts of fine aggregate, 150-300 parts of coarse aggregate, 0-2.0 parts of a water reducing agent, 5-20 parts of an expansion component, 0-10 parts of a viscosity regulating component, 0-0.5 parts of fiber and the like; and the liquid is formed by mixing components in parts by mass as follows: 100 parts of water, 0-4.0 parts of the water reducing agent, 0-3 parts of the viscosity regulating component and the like. According to the preparation and the application of the two-component self-compacting concrete for the slab ballastless track, the sensibility of the self-compacting concrete can be reduced, loss of the self-compacting concrete is reduced, and environment-friendly construction is realized. The two-component self-compacting concrete is applicable to the slab ballastless track of a high speed railway and is also applicable to the field of bridges, civil buildings, repair and strengthening and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

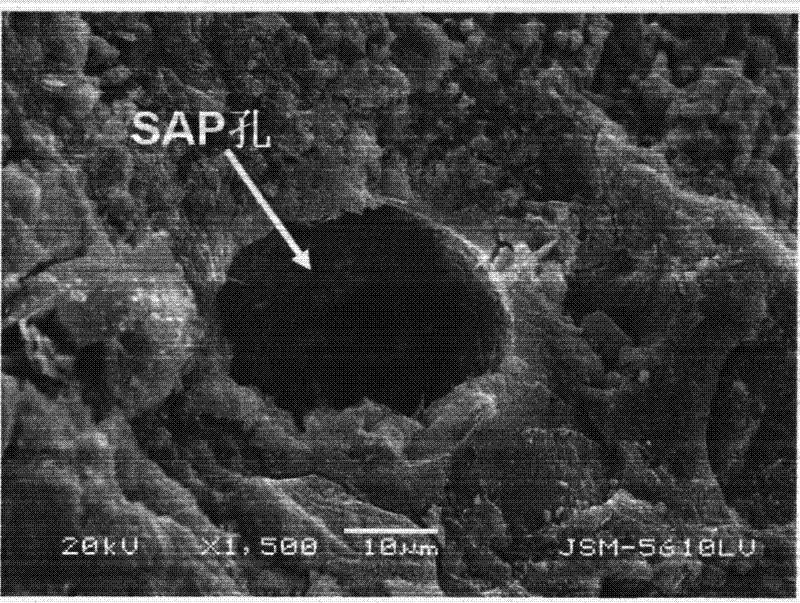

Preparation method for water-preserving and salt-tolerant alkaline concrete internal curing agent

The present invention discloses a preparation method for a water-preserving and salt-tolerant alkaline concrete internal curing agent. According to the method, plant starch, inorganic powder with a layered structure, an anionic monomer, a non-ionic monomer and water are adopted as main raw materials; under effects of an initiator, a cross-linking agent and a certain temperature, treatments of dissolving, reacting, filtering, washing, drying and crushing are performed to obtain the internal curing agent. The internal curing agent of the present invention has the following advantages that: the internal curing agent of the present invention provides the stronger deionized water absorbency than the existing internal curing agent, wherein the deionized water absorbency is increased by 200-500 times; the saline solution absorbency and the alkaline solution absorbency are 35-55% of the deionized water absorbency; the water-preserving rate of the internal curing agent of the present invention is 55-65% after the internal curing agent absorbs the alkaline solution; with adopting the low mixing amount of 0.05-0.5% of the internal curing agent, the strength of the silica fume-doped C60-C100 high-performance concretes is not reduced while the 7-day autogenous shrinkage rates of the concretes are reduced by 65-85%; the internal curing agent of the present invention is applicable for the high strength and early strength concrete pavement, steel pipe concrete under the closed environment, self-compacting concrete and other engineering fields, wherein the fields adopt the design with a low water-cement ratio and a high cementing material content, and adopt a large amount of high activity mineral admixtures.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Eco-friendly self-compacting concrete prepared through complete recycling of waste concrete

InactiveCN104788054AWorkability is goodExcellent and workability (liquiditySolid waste managementSuperplasticizerFly ash

The invention discloses eco-friendly self-compacting concrete prepared through complete recycling of waste concrete. The eco-friendly self-compacting concrete comprises components in parts by weight as follows: 100 parts of cement, 10-25 parts of fly ash, 10-25 parts of mineral powder, 20-40 parts of recycled micro-powder, 1-2 parts of a polycarboxylate superplasticizer, 230-380 parts of recycled fine aggregate, 240-400 parts of recycled coarse aggregate and 45-60 parts of water which are mixed. The coarse aggregate only adopts the recycled coarse aggregate, the fine aggregate only adopts the recycled fine aggregate, the recycled micro-powder formed by grinding waste materials produced in production of the recycled aggregate is blended into a mineral admixture, so that complete recycling of the waste concrete is realized, and the eco-friendly self-compacting concrete has a very good eco-friendly effect.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

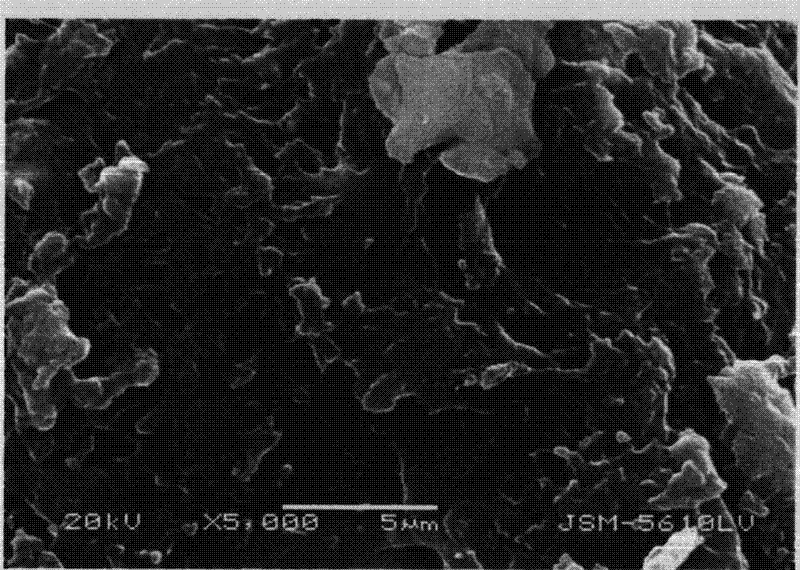

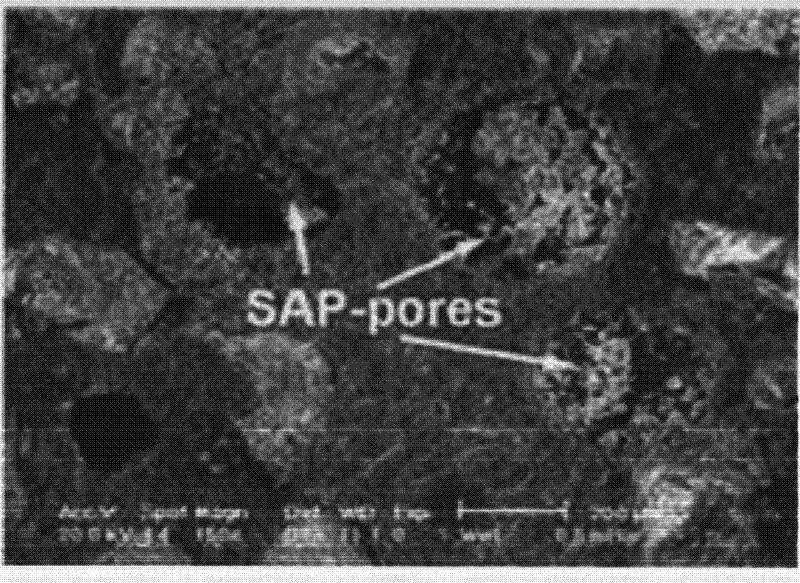

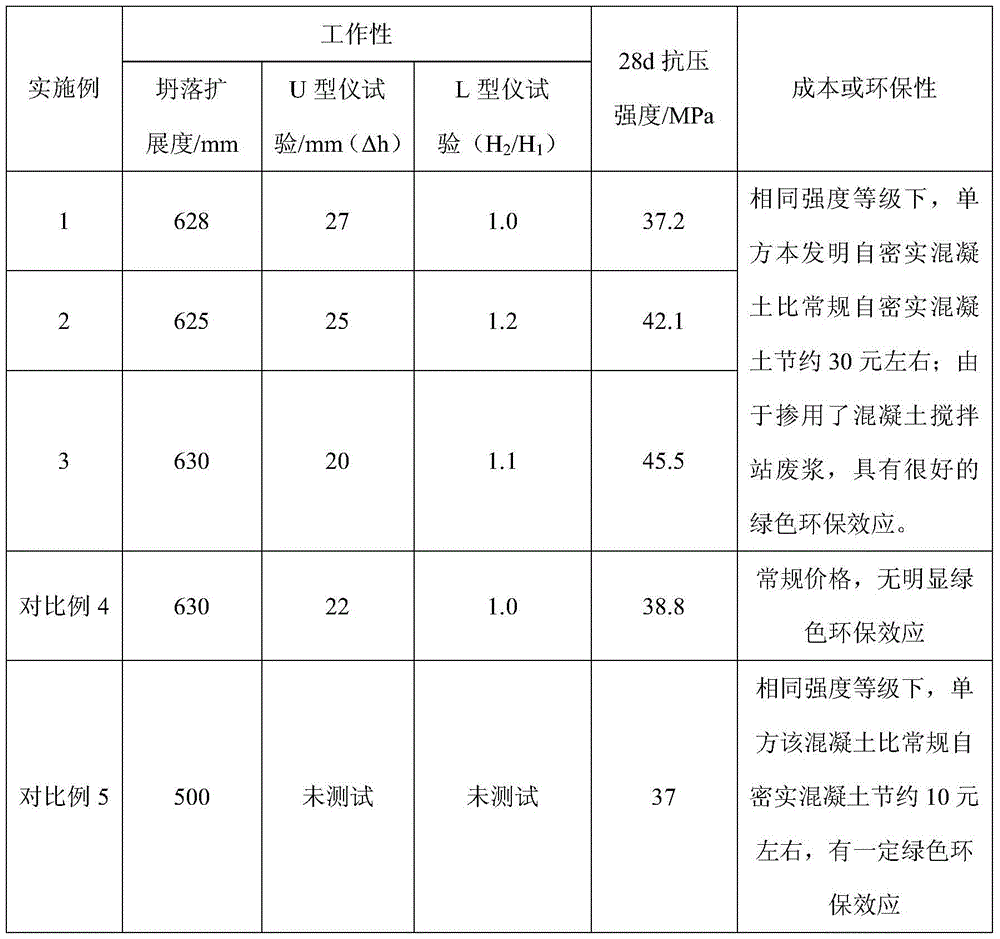

Self-compacting concrete prepared from concrete mixing station waste slurry

ActiveCN105776994AIncrease profitHigh value-added utilizationSolid waste managementWastewaterAdditional values

The invention discloses self-compacting concrete prepared from concrete mixing station waste slurry.The self-compacting concrete is prepared by mixing, by weight, 270-330 parts of cement, 135-165 parts of pulverized fuel ash, 90-110 parts of the concrete mixing station waste slurry, 770-840 parts of river sand, 875-940 parts of gravels, 4.5-5.5 parts of a water reducing agent and 100-150 parts of water, wherein the concrete mixing station waste slurry is formed by precipitating concrete mixing station wastewater, the water content of the concrete mixing station waste slurry is 45%-50%, and the concrete mixing station waste slurry is generated in 24 hours.Accordingly, the self-compacting concrete is prepared from the waste slurry obtained by precipitating the concrete mixing station wastewater, therefore, the dosage of the cementing material and the water is decreased, the cost of the self-compacting concrete is greatly reduced, harmless high-additional value utilization of the concrete mixing station waste slurry is achieved, the very good environmental protection effect is achieved, and a green sustainable development road is achieved.

Owner:浙江华滋奔腾建材有限公司

Method for constructing normal piled concrete

ActiveCN101074560APouring is flexible and fastReduce usageFoundation engineeringUltimate tensile strengthWater temperature

The invention relates to a construction method to pour the natural moraine by the concrete. The invention transforms the scree or rock block with 15cm particle to the storehouse, then to pour the compact concrete into the moraine from the surface. The invention has the simple construction and improved the efficiency and saved cost. The moraine concrete uses little cement and low water temperature, good volume stability.

Owner:TSINGHUA UNIV +1

Machine-made sand self-compaction concrete

The invention discloses a machine-made sand self-compacting concrete. The concrete is made from the following components according to parts by weight: 100 parts of cement, 25-45 parts of fly ash, 0-30 parts of mineral powder, 0.8-1.5 parts of a polycarboxylic acid water reducing agent, 220-250 parts of machine-made sand, 130-150 parts of cobble and 130-150 parts of crushed stone. The concrete saves natural resource as well as has high fluidity, high stability and low slump loss; compared with equivalent effects, the concrete has the advantages of lower cost and simpler production, meanwhile, silicon dust is not applied to the concrete, therefore, the health of operators is better guaranteed.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

Self-compacting concrete

InactiveCN102060482AImprove volume stabilityIncreased durabilitySolid waste managementSuperplasticizerCoal

The invention relates to self-compacting concrete which is used for overcoming the contradiction between flowability and stability, early strength and delayed coagulation, contraction and expansion and the like of the self-compacting concrete in the prior art. In the invention, by means of combination of an aliphatic (hydroxyl) sulfonate superplasticizer and a polycarboxylic acid superplasticizer, selection and collocation of a cementing material and coarse and fine aggregates as well as specific mix design, the self-compacting concrete (more than C40) with low consumption of the cementing material is prepared from coal ash, mineral powder and tailings, wherein, a ketoaldehyde condensate is taken as the main component of the aliphatic (hydroxyl) sulfonate superplasticizer; and when the superplasticizer is added to cement paste, the mixed concrete has the advantages of good construction workability, less possibility of bleeding and segregation, no crystallization precipitate at low temperature and the like. Compared with the prior art, the self-compacting concrete prepared by the method provided by the invention has the advantages of lowering cement consumption by at least 70kg / m<3>, reducing consumption of the cementing material by at least 70kg / m<3>, comprehensively utilizing at least 470kg / m<3> of solid waste, and lowering concrete cost by at least **yuan / m<3>.

Owner:北京中联新航建材有限公司 +1

Preparation and application of dry-mixed mortar for plate-type ballastless track self-compacting concrete

The invention relates to preparation and application of dry-mixed mortar for plate-type ballastless track self-compacting concrete. The dry-mixed mortar is prepared by mixing cement, a mineral additive, fine aggregate, a water-reducing and collapse-preventing component, an expanding component, a viscosity adjusting component and fiber according to a certain ratio, wherein 100 parts of cement, 50-120 parts of the mineral additive, 150-400 parts of the fine aggregate, 0.2-3 parts of the water-reducing and collapse-preventing component, 5-20 parts of the expanding component, 1-10 parts of the viscosity adjusting component and 0-0.5 part of the fiber are included. The invention further provides preparation and application of the dry-mixed mortar. The dry-mixed mortar is prepared by a high-speed mixer in a factory; the dry-mixed mortar is transported by a bulk truck or by an automobile in a bagged way; the dry-mixed mortar, coarse aggregate and water are weighed on a construction site in parts by weight and uniformly stirred for use. According to the technical scheme, the sensitivity of the self-compacting concrete to quality fluctuation of the raw materials can be greatly reduced and the loss of the self-compacting concrete can be significantly reduced; the dry-mixed mortar is suitable for a plate-type ballastless track of a high-speed railway, and can also be applied to bridges, civil buildings and the repairing and strengthening field.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Rubber elastic self-compaction concrete for plate-type ballastless tracks

InactiveCN104030638AHigh compressive strengthImprove impact resistancePolyvinyl alcoholUltimate tensile strength

The invention relates to a rubber elastic self-compaction concrete for plate-type ballastless tracks, which is used for obviously enhancing the compression strength of the self-compaction concrete and enabling the self-compaction concrete to have favorable shock absorption and damping capacities. The rubber elastic self-compaction concrete for plate-type ballastless tracks can be used as a filler between the track plate and the bottom plate in a CRTS III plate-type ballastless track structure, and can also be used as a filler between a switch plate and the bottom plate in a switch structure. The self-compaction concrete is composed of the following components in parts by weight: 100 parts of cement, 4-10 parts of rubber powder, 30-60 parts of mineral admixture, 250-300 parts of fine aggregate, 250-300 parts of coarse aggregate, 1-2 parts of basalt fiber, 5-15 parts of expanding agent, 1.0-2.0 parts of water reducing agent, 0.01-0.05 part of rheologic assistant, 0.001 part of defoaming agent and 40-60 parts of water. The grain fineness of the rubber is 30-50 meshes, and the surface of the rubber is previously treated with polyvinyl alcohol and a silane coupling agent.

Owner:SOUTHWEST JIAOTONG UNIV +1

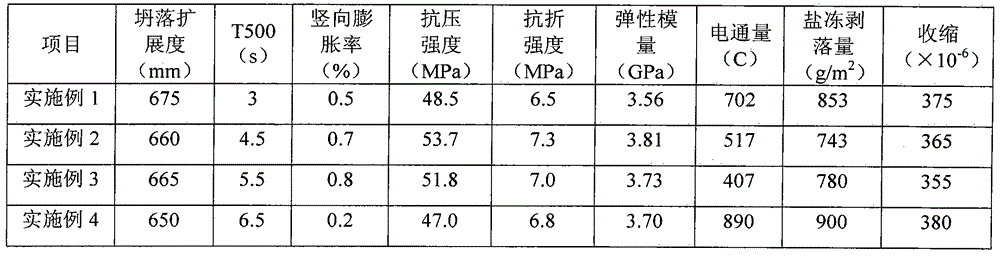

Self-compacting concrete for rapid transit railway III-type plate ballastless tracks and preparation method of self-compacting concrete

The invention discloses a self-compacting concrete for rapid transit railway III-type plate ballastless tracks and a preparation method of the self-compacting concrete. The self-compacting concrete can effectively eliminate bleeding in a pouring process, has low contractibility rate and good durability, and is beneficial to improving of pavement quality of track plates and prolonging of service life of the ballastless tracks. The self-compacting concrete is prepared by stirring and mixing cement, sand, stone, an expanding agent, a water reducing agent, a shrinkage reducing agent, a thickening agent, a water reducing agent, a collapse preventing agent and water as raw materials, wherein the raw materials comprise the following components in parts by weight: 100 parts of common silicate 425# cement, 11 parts of an expanding agent, 38.5 parts of coal ash, 20.5 parts of mineral powder, 261-277 parts of sand with fineness modulus of 2.4-2.8, 235-251 parts of stone with a grain size of 5-10mm, 0.04 part of a thickening agent, 56-60 parts of water, 1.3 parts of a shrinkage reducing agent, 2.3 parts of a water reducing agent and 0.37 part of a collapse preventing agent.

Owner:中铁八局集团第四工程有限公司

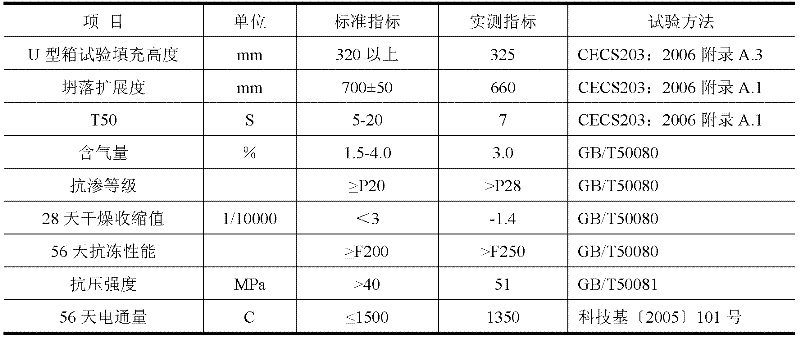

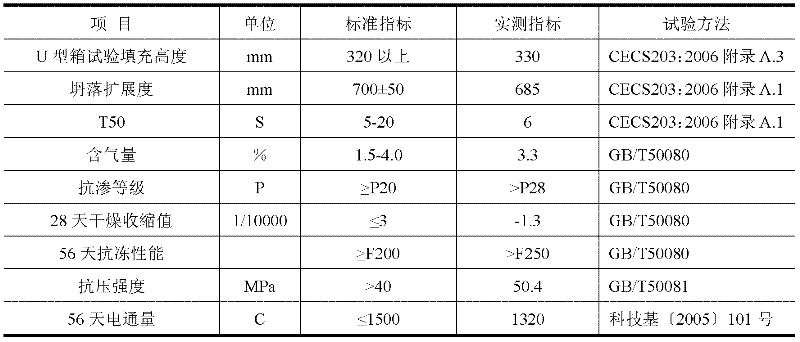

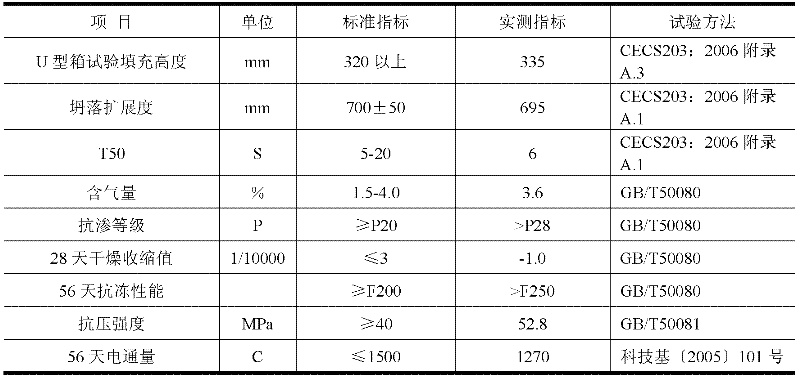

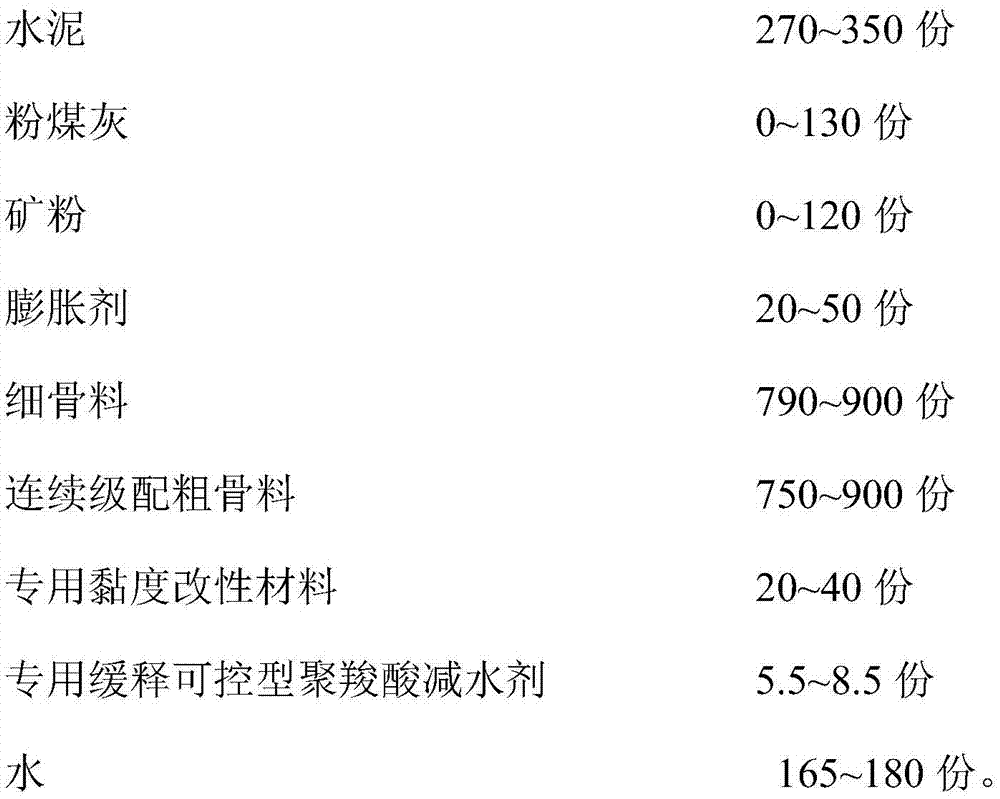

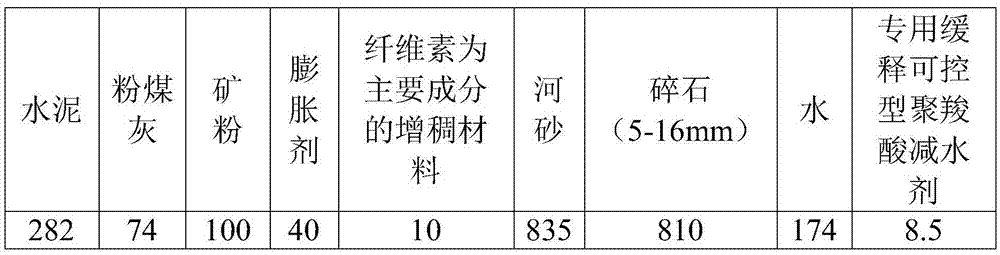

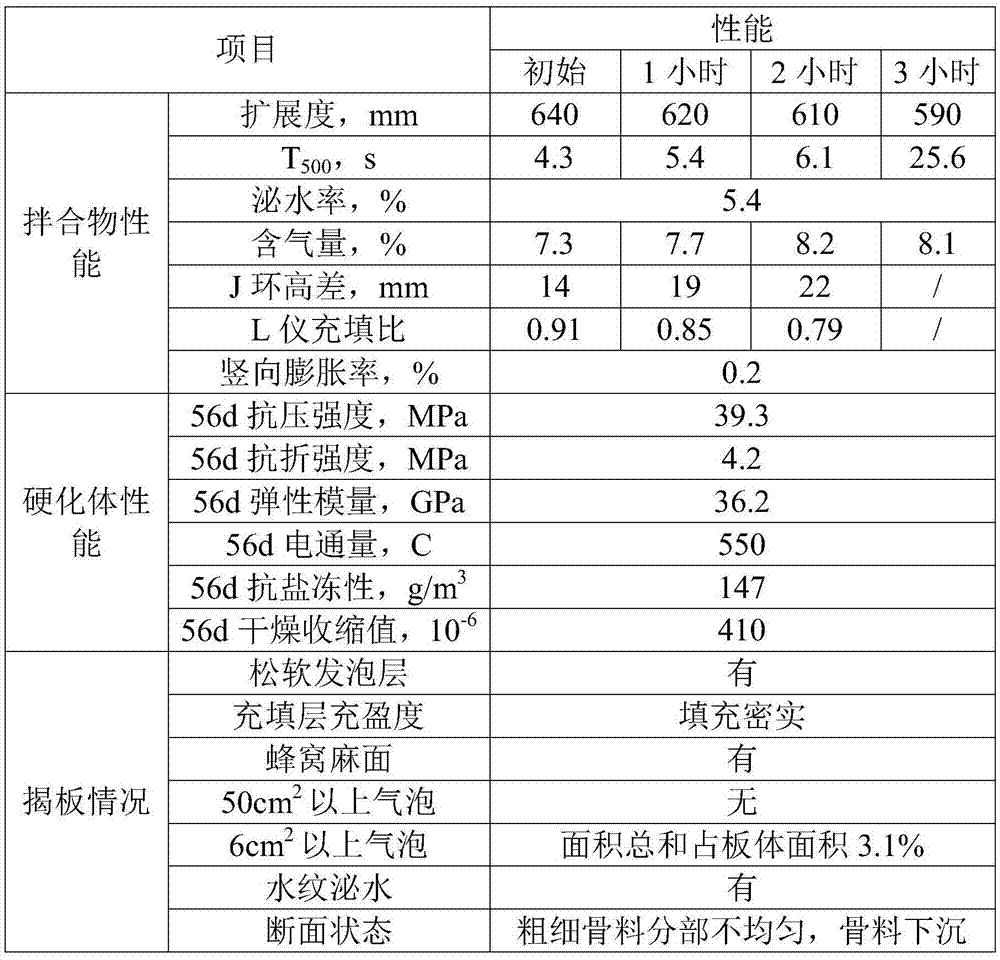

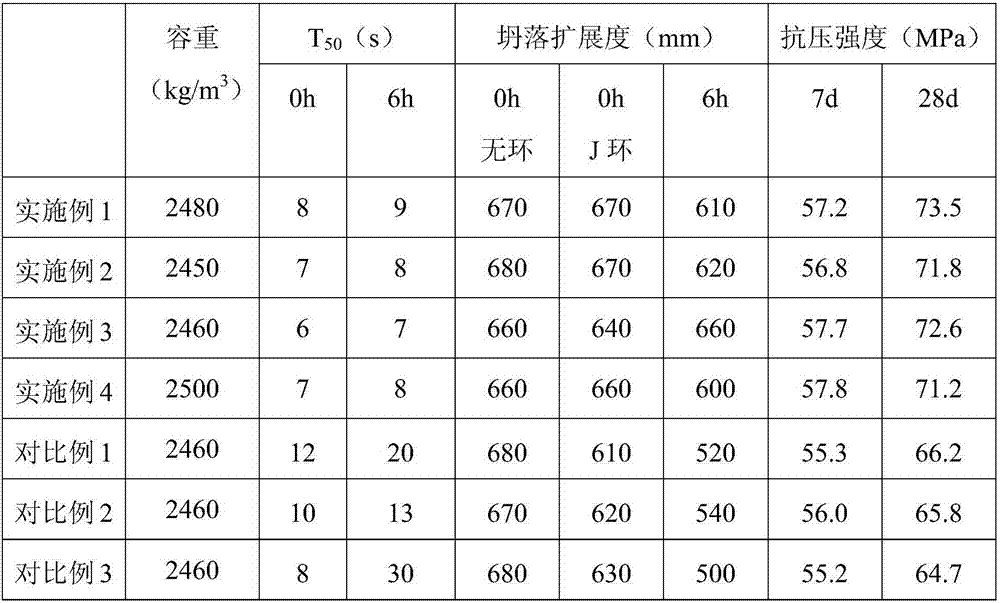

Self-compacting concrete for CRTS III plate-type ballastless track filling layer and preparation method for self-compacting concrete

The present invention discloses a self-compacting concrete for CRTS III plate-type ballastless track filling layer. The concrete is prepared from the following raw materials in parts by weight: 270-350 parts of cement, 0-130 parts of coal fly ash, 0-120 parts of mineral powder, 20-50 parts of an expanding agent, 790-900 parts of fine aggregate, 750-900 parts of continuous gradation coarse aggregate, 20-40 parts specific viscosity modified materials, 5.5-8.5 parts of a specific sustained release controllable polycarboxylic acid water reducing agent and 165-180 parts of water. According to the invention, the specific viscosity modified materials and specific sustained release controllable polycarboxylic acid water reducing agent are used in combination to prepare the specific self-compacting concrete for filling layer with good flowability, strong volume stability, low sensitivity for water consumption, small thixotropic time change, low shrinkage and good longevity, thereby reducing theconstruction difficulty of the CRTS III plate-type filling layer and prolonging the sevice life of the ballastless track structure.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

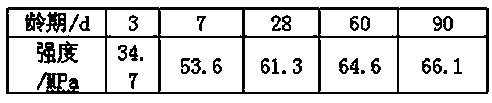

Self-compacting concrete

The invention discloses a self-compacting concrete and belongs to the technical field of concrete. The self-compacting concrete comprises the following components in parts by weight: 350-400 parts of cement, 54-80 parts of coal ash, 52-60 parts of slag powder, 50-62 parts of expanding agent, 9-13 parts of silica powder, 748-800 parts of mixed sand, 948-1020 parts of macadam, 140-165 parts of drinking water, 0-10 parts of compound additive and high-performance additive being 1-2% of the binding material in mass fraction. The concrete acquired according to the invention has excellent self-compacting property, fluidity, collapse prevention, cohesiveness and separation resistance, and meanwhile, a test proves that the compressive strength after 7 days is about 57MPa and the compressive strength after 28 days is about 70MPa, so that the concrete provided by the invention has higher compressive strength.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

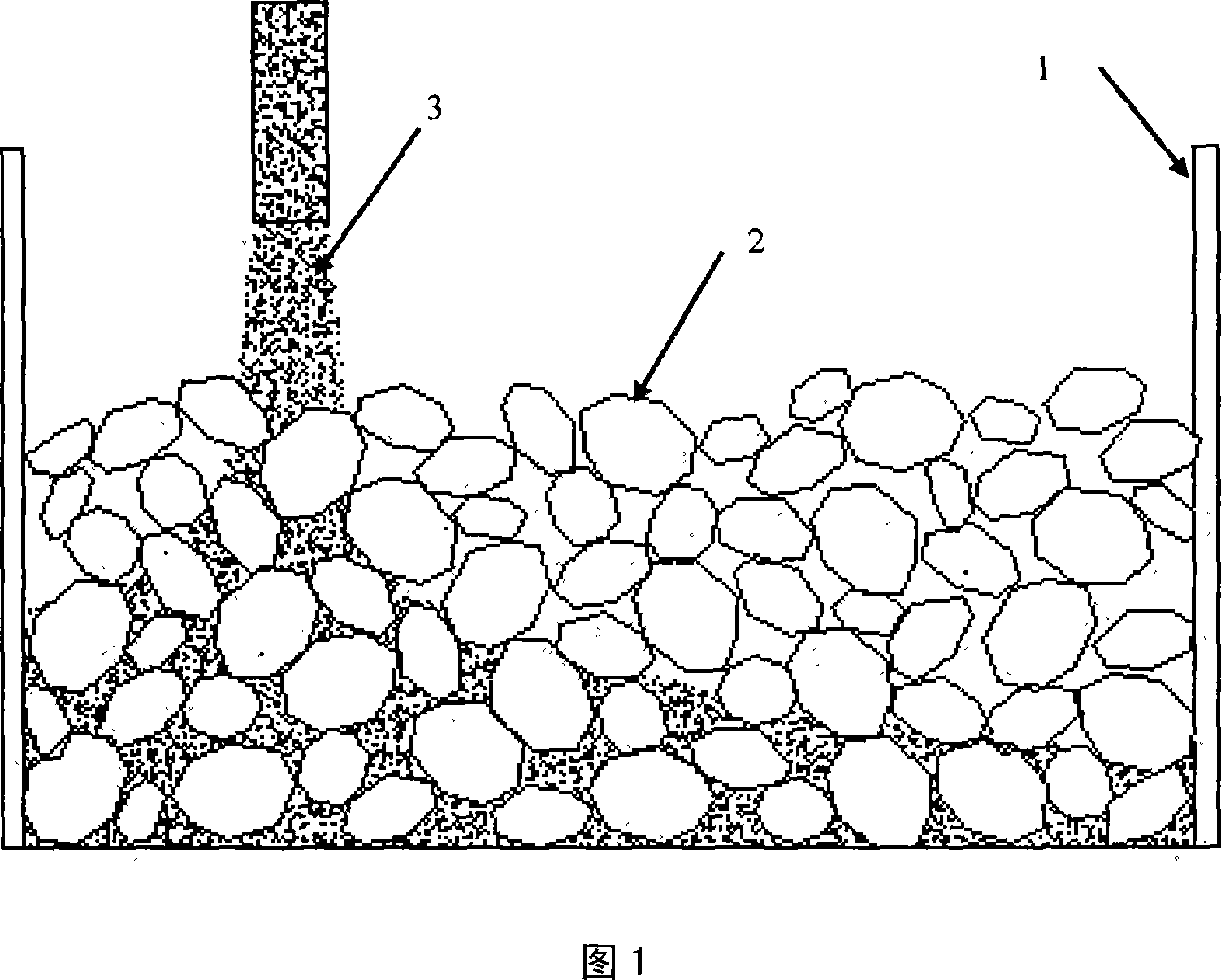

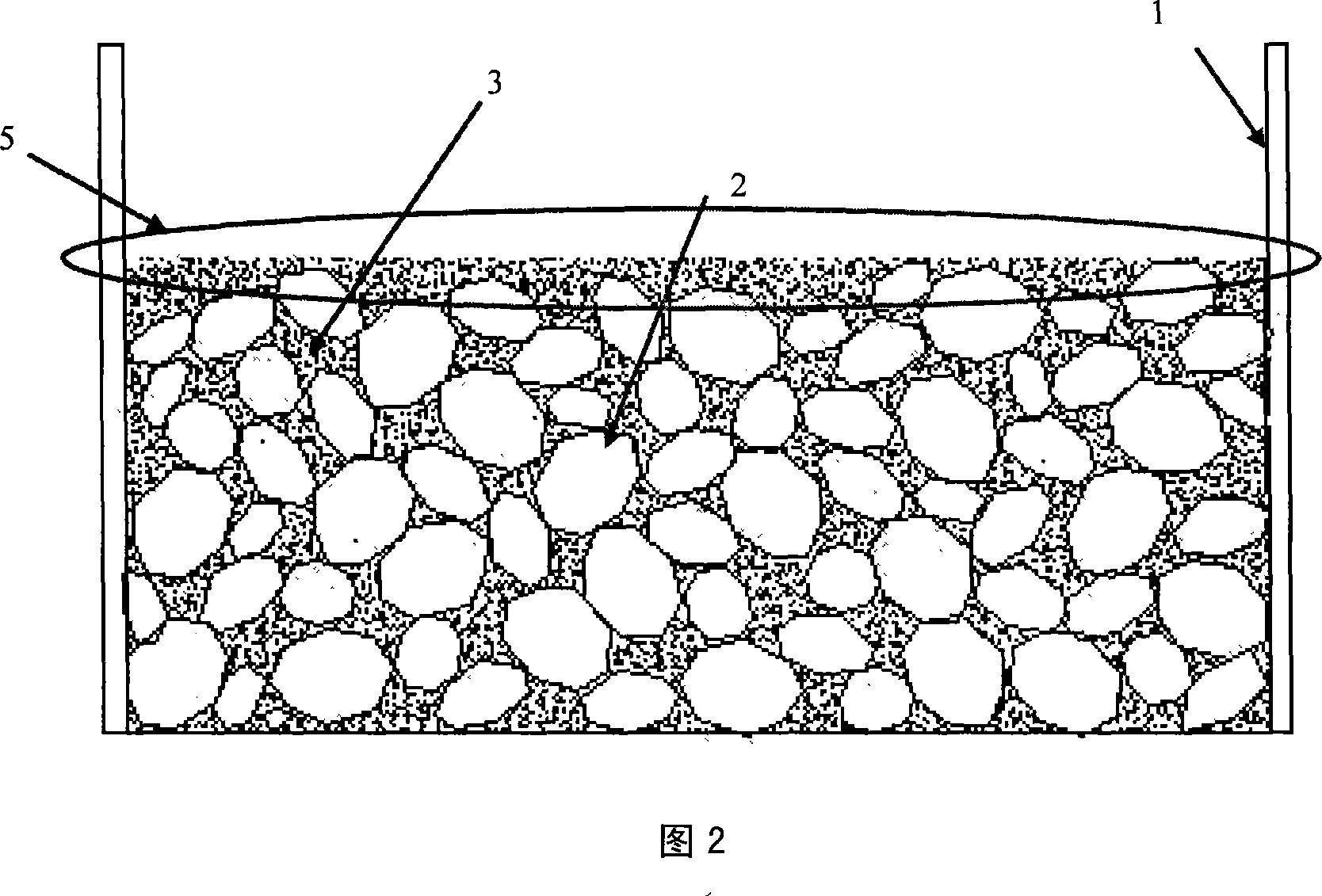

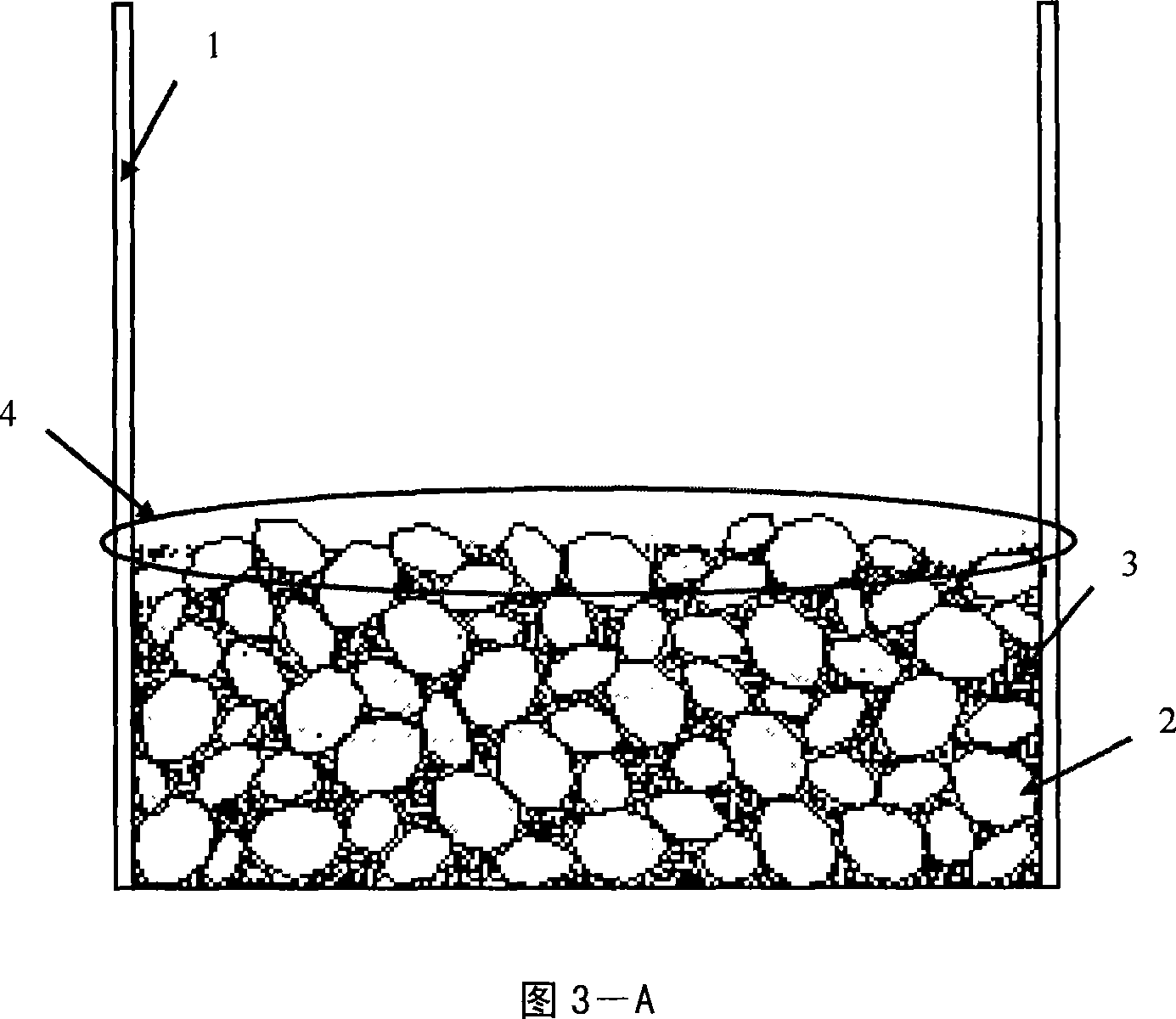

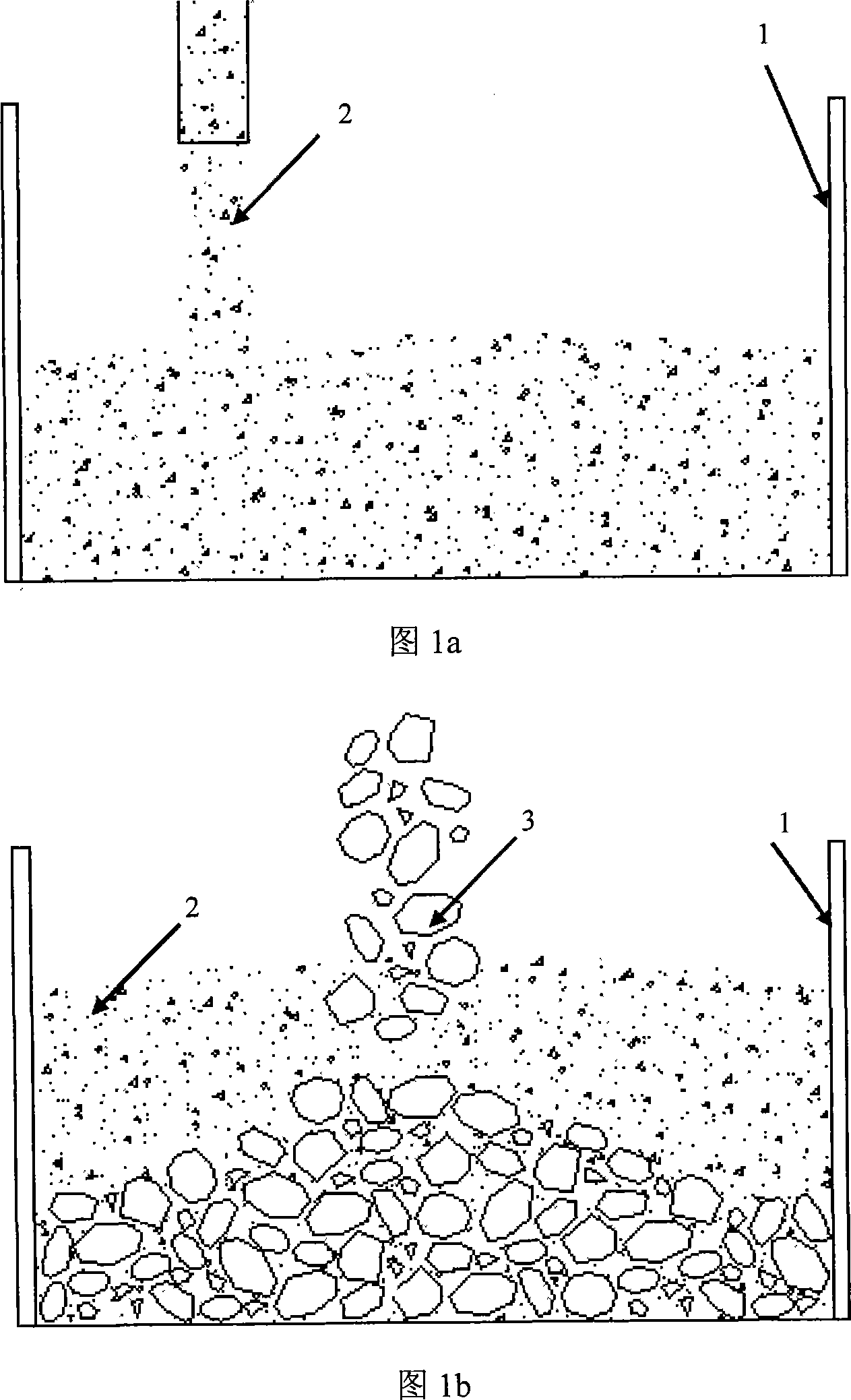

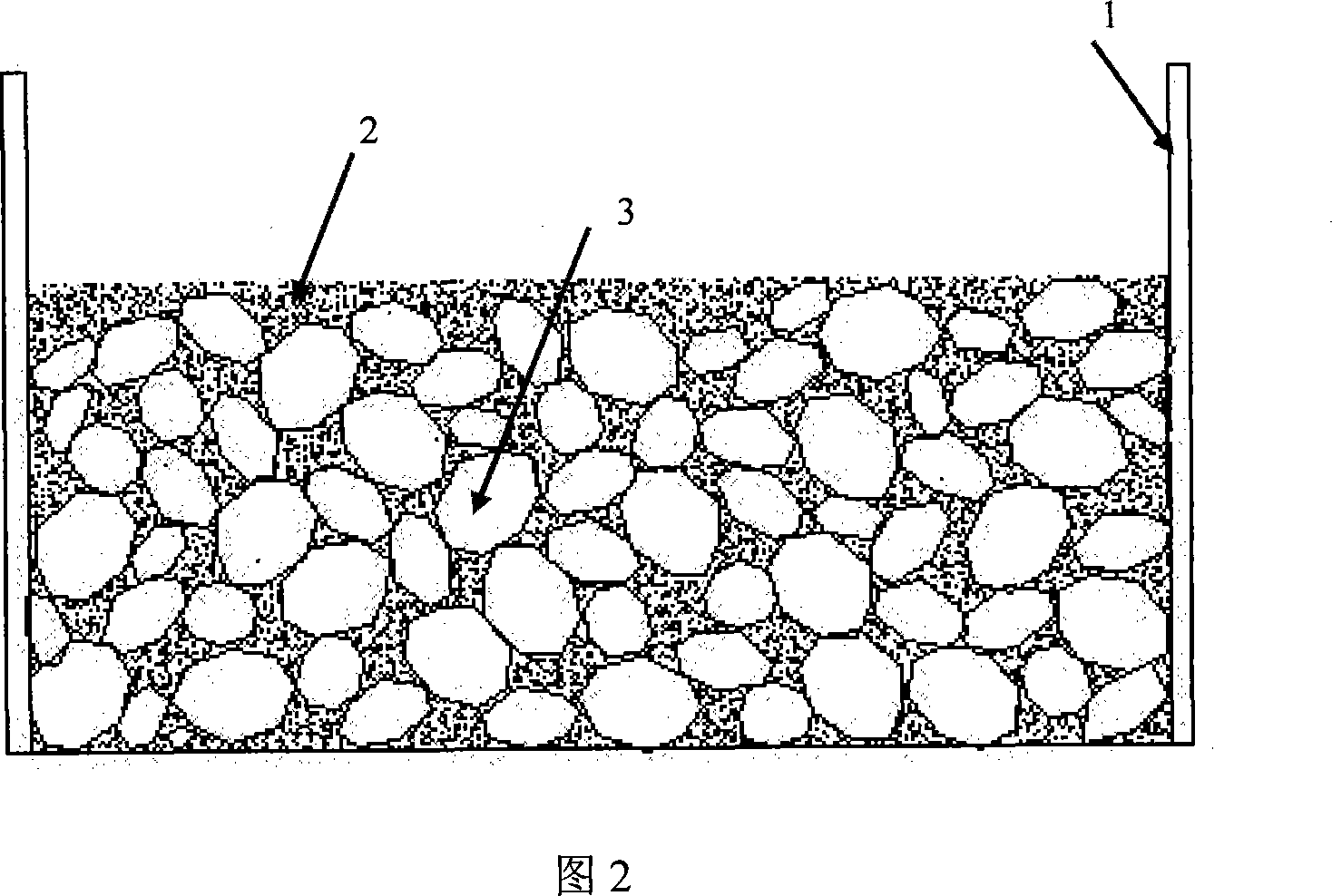

Jackstone-type rockfill concrete construction method

ActiveCN101144279APouring is flexible and fastReduce usageFoundation engineeringEarth-fill damsHigh intensityUltimate tensile strength

The present invention discloses a riprap rock-fill concrete construction method, which relates to a construction method for the large volume concrete. The present invention adopts self-compacting concrete having superior anti-segregation performance and good plasticity-retention performance, and firstly the concrete is poured into a bin, and then block stones or pebbles with the particle size smaller than 4 cm are poured into the poured self-compacting concrete in a mechanical way or a manual way, and the self-compacting concrete can fill up and compact the vacancies caused in the block stone settlement path at any time, the high anti-segregation performance ensures that the self-compacting concrete does not segregate and bleed water under the impact of the block stones, and finally the self-compacted rock-fill concrete with high intensity is formed. The method has the advantages that the construction is convenient, and the present invention has significant effects on the aspects of improving the construction efficiency and saving the construction cost, and the rock-fill concrete formed has high degree of compaction, the cement used is less, the hydration temperature rise is low, the volume stability is good, and the comprehensive performance is excellent, meanwhile, the present invention also has the advantages of energy-saving, environmental protection and being easy for continuous construction.

Owner:TSINGHUA UNIV +1

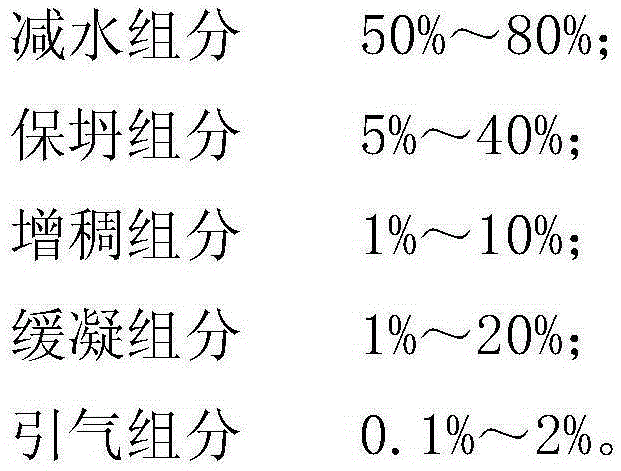

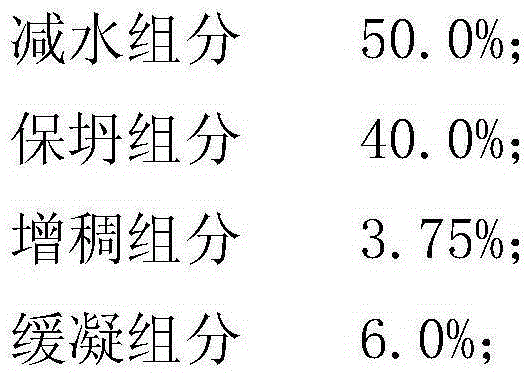

Poly carboxylic acid series compound water reducing agent used for hydraulic self-compacting concrete and preparation method and application

The present invention discloses a poly carboxylic acid series compound water reducing agent used for hydraulic self-compacting concrete and a preparation method and application, the poly carboxylic acid series compound water reducing agent comprises the following components by weight: 50 % to 80% of a water-reducing component; 5% to 40% of a slump retaining component; 1% to 10% of a thickening component; 1% to 20% of a retarding component; and 0.1% to 2% of an air entraining component. The poly carboxylic acid series compound water reducing agent improves the workability, fluidity, segregation resistance and slump retaining properties of the self-compacting concrete.

Owner:CHINA BUILDING MATERIALS ACAD

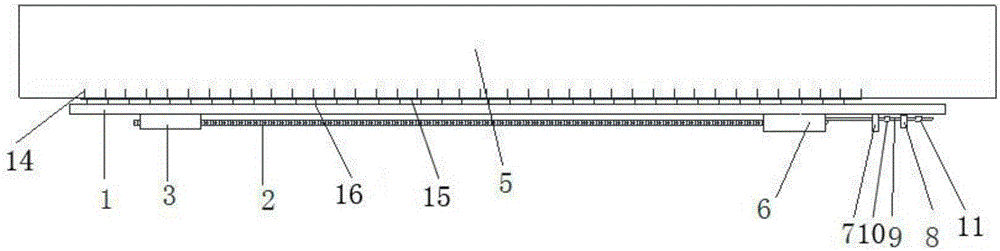

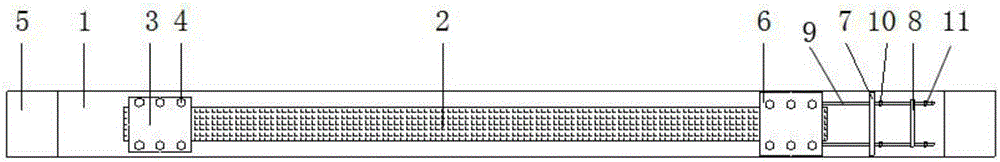

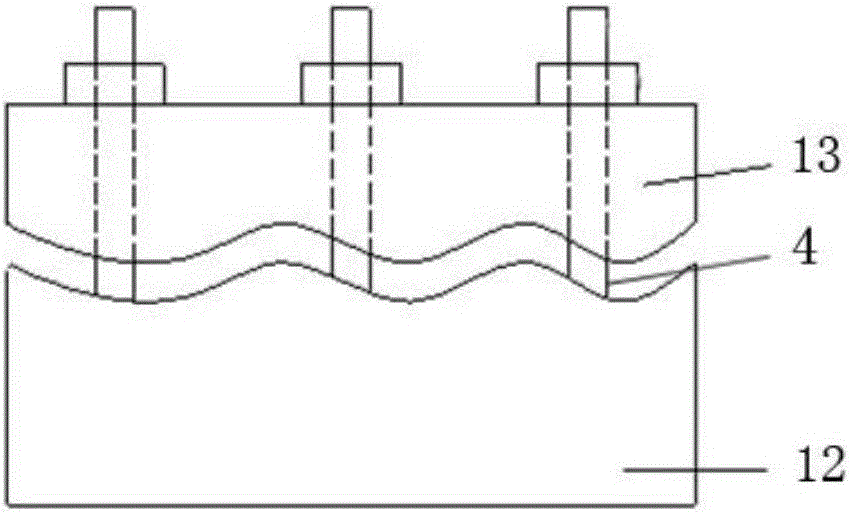

Method for reinforcing concrete beam by prestressed carbon fiber plate and steel-concrete

ActiveCN105887702AImprove bearing capacitySolve the problem of difficult anchoringBridge erection/assemblyBridge strengtheningSheet steelCement composites

The invention provides a method for reinforcing concrete beam by a prestressed carbon fiber plate and steel-concrete. The method comprises the following main steps of firstly, chiseling off a concrete protecting layer on the bottom surface of the concrete beam, drilling and embedding steel bars, and arranging a layer of a steel bar mesh; secondly, blanking a steel plate, and respectively welding waved toothed plates at an anchoring end and a tensioning end of the steel plate for constraining the carbon fiber plate; thirdly, fixing the steel plate on the steel bar mesh, and taking the reinforcing steel plate as a bottom die to prepare and cast self-compacting concrete; fourthly, applying prestress by adopting a jack, tensioning the carbon fiber plate and anchoring; finally, varnishing cement composite mortar on the surface of the prestressed carbon fiber plate and the waved toothed plates as protecting layers to finish the bending resistance and reinforcing of concrete. According to the reinforcing method provided by the invention, the convenience in construction is realized, and the required equipment is simple; the bending capacity, rigidity and the durability of the existing concrete beam can be remarkably improved, and the service life is prolonged; the reinforcing method is particularly suitable for conditions of concrete spalling, carbonization and other damages at the bottom of the concrete beam.

Owner:WUHAN UNIV OF TECH

Self compact concrete

The invention relates to self compact concrete, and belongs to the technical field of constructional engineering materials. The self compact concrete comprises the following components by weight: concrete 250-300 kg / m<3>, pulverized fuel ash 120-200 kg / m<3>, coarse aggregate 820-950 kg / m<3>, fine aggregate 700-850 kg / m<3>, water reducer 5-12 kg / m<3>, and water supply volume 145-160 kg / m<3>; the particle size of the coarse aggregate is 5-25 mm, and the fineness modulus of the fine aggregate is 2.5-2.8. The optimal proportion of the self compact concrete is concrete 290 kg / m<3>, pulverized fuel ash 160 kg / m<3>, coarse aggregate 891 kg / m<3>, fine aggregate 754 kg / m<3>, and water reducer 5.29 kg / m<3>. Compared with the prior art, the self compact concrete has the advantages that concrete consumption is about 35-55 kg / m<3>, the varieties of additives and admixtures are few, the preparation is simple, and the cost can be lowered to 30 yuan / m<3> at least.

Owner:KUNMING UNIV OF SCI & TECH

Self-compacted concrete of resisting erosion of sulfate and its preparing method

The invention relates to a sulfate corrosion-resistant self-compacted concrete and the preparing method, adopting fly ash, slag and siliceous dust and cement as concrete cementitous material and adding in water reducer and thickening agent to prepare a high-fluidity self-compacted concrete. And the components in the concrete which are corroded by sulfate are remarkably reduced so as to reduce possibility of corrosion to the concrete. And the concrete has high fluidity, slump above 25 cm, extensibility above 60 cm, and blocking ratio above 0.8; and the corrosion test of above 9 months with 10% sodium sulfate solution shows that compressive ratio is above 0.8 and the surface is complete. And the preparing method is simple, and has low cost and wide application.

Owner:TONGJI UNIV

Ground limestone powder full-manufactured sand high-strength recycled self-compacting concrete and application thereof

ActiveCN104724989AHigh strengthImprove workabilitySolid waste managementSuperplasticizerUltimate tensile strength

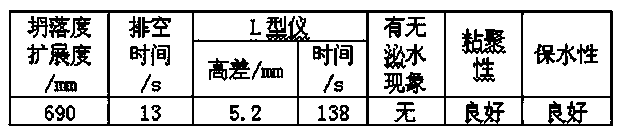

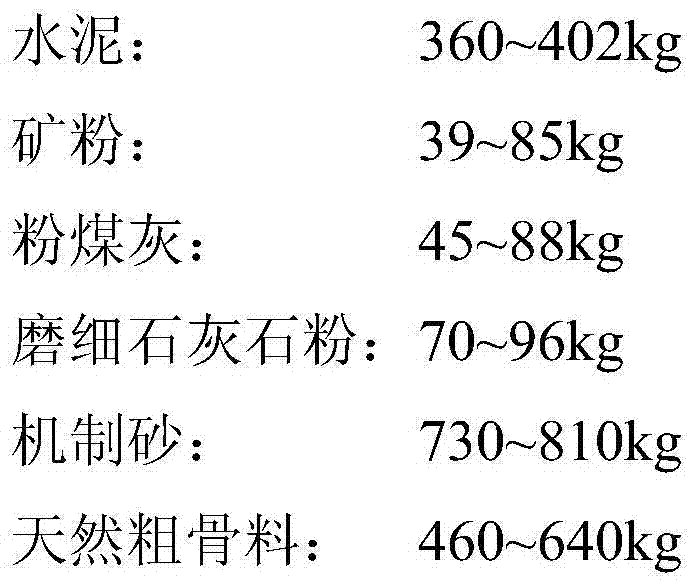

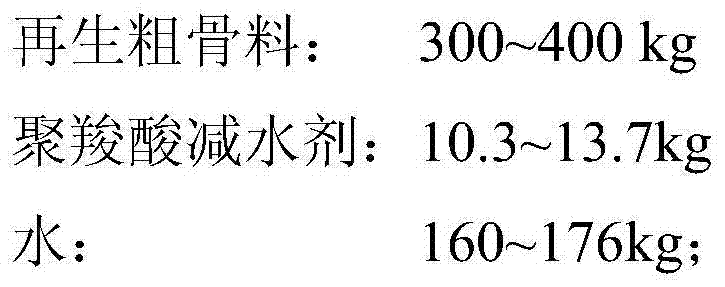

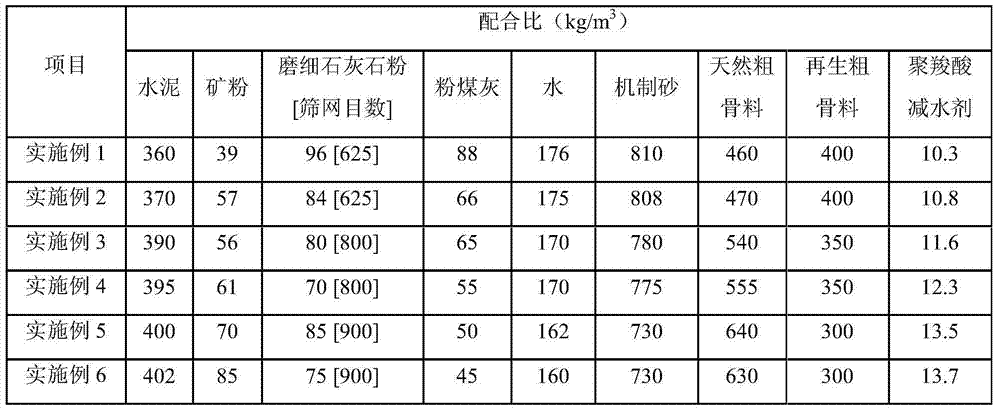

The invention discloses ground limestone powder full-manufactured sand high-strength recycled self-compacting concrete and application thereof. Per cubic meter of concrete contains 360-402kg of cement, 39-85kg of mineral powder, 45-88kg of fly ash, 70-96kg of ground limestone powder, 730-810kg of manufactured sand, 460-640kg of natural coarse aggregate, 300-400kg of recycled coarse aggregate, 10.3-13.7kg of polycarboxylate superplasticizer and 160-176kg of water. According to the full-manufactured sand high-strength recycled aggregate self-compacting concrete prepared from three additives including the ground limestone powder, the fly ash and the mineral powder, the fine aggregate is totally manufactured sand, and 31-46% of recycled coarse aggregate is added to the coarse aggregate, so that an effective path is provided for reducing exploitation and utilization of natural sand and sufficiently recycling concrete wastes, and a technical reference is provided for preparing the ground limestone powder full-manufactured sand self-compacting concrete.

Owner:华润水泥技术研发(广西)有限公司

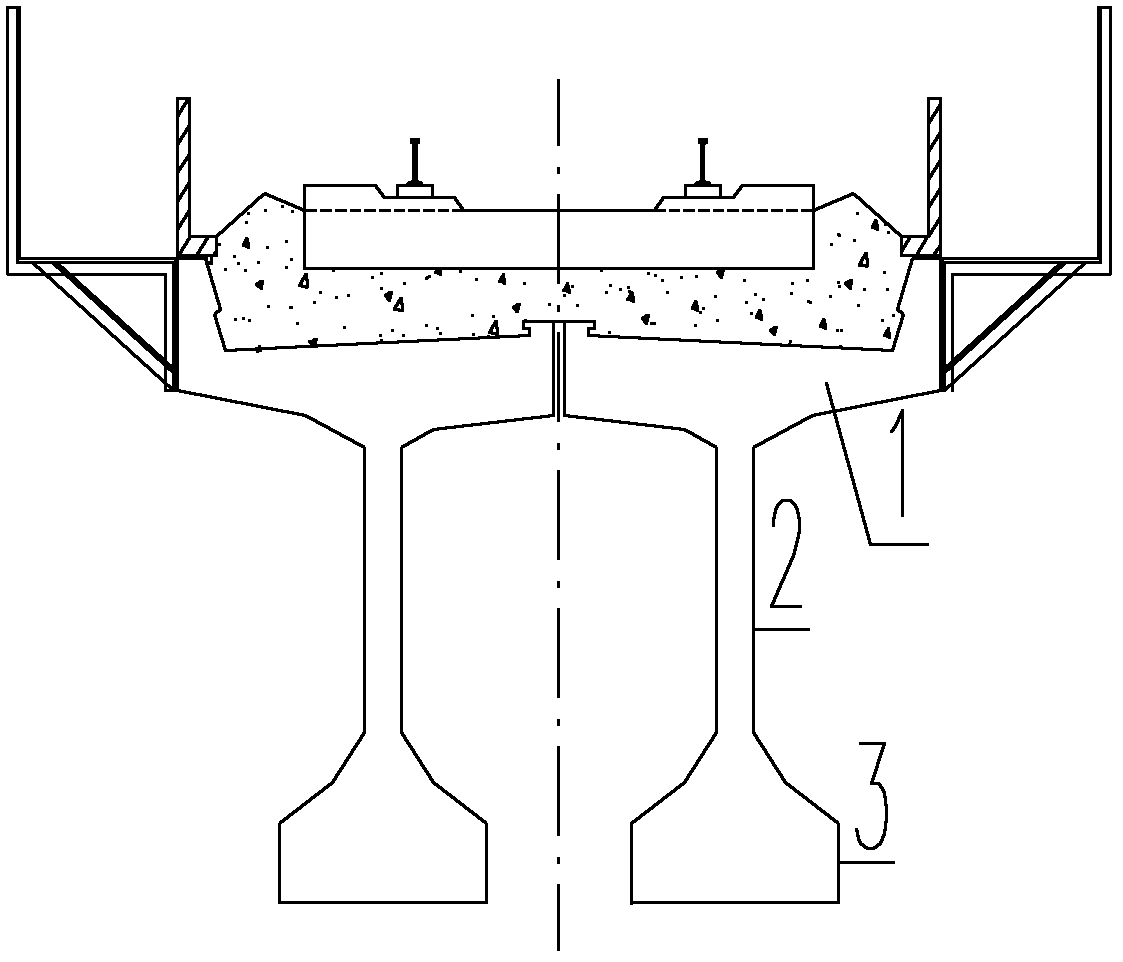

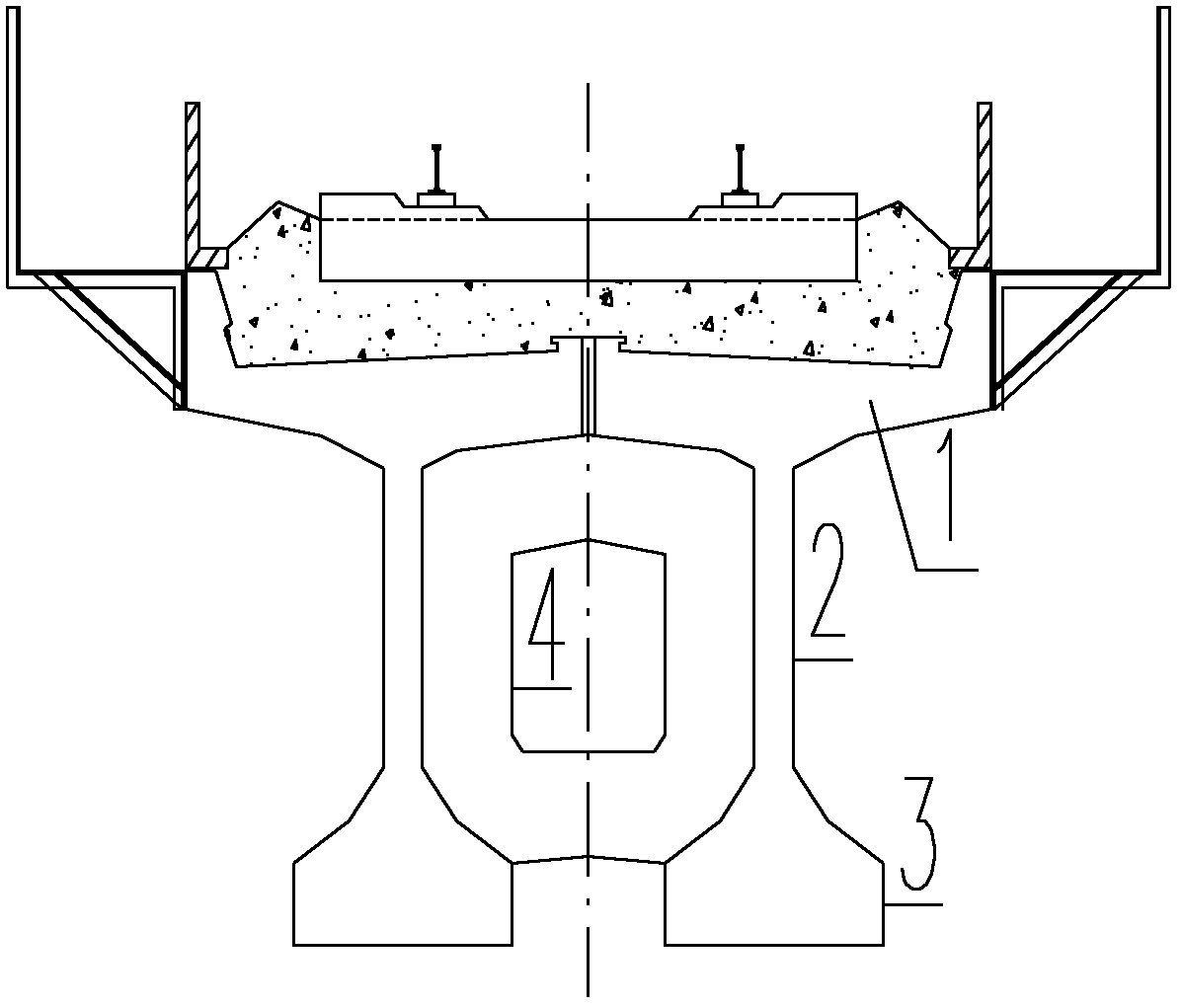

Self-balancing external prestressing strengthening method for bridge structure

ActiveCN102587296AReduce the burden onGive full play to the role of reinforcementBridge erection/assemblyBridge strengtheningConcrete beamsT-beam

The invention relates to a self-balancing external prestressing strengthening method for a bridge structure. The self-balancing external prestressing strengthening method is characterized by comprising the following steps of: carrying out interface processing at a connecting place (5) of a top flange of a concrete beam; (2) inserting reinforced bars at the connecting place (5) of the top flange of the concrete beam; (3) installing the reinforced bars at the connecting place (5) of the top flange of the concrete beam; (4) installing the reinforced bar of a steering block (6) and a diverter (9) at the bottom of the beam; (5) symmetrically adding diaphragm plates at a place far away from the end of the beam by 2-3m, and installing an anchorage device (10); (6) concreting the connecting place (5) of the top flange of the beam, the steering block (6) and the newly added diaphragm plates (8); and (7) installing and tensioning an anchoring external cable, thus obtaining a self-balancing external prestressing strengthening structure. An external prestressing system can be used for detecting and adjusting the stress of the cable at any time, inspecting the corrosion condition of the cable and can also be used for maintaining and replacing the cable when necessary. The self-compacting concrete solves the problems of dense reinforcement assembly, complex structure, narrow space of formworks and traditional structural members, cavities caused by the blocking of aggregates and the like, effectively ensures the dense degree of placing concrete and increases the strengthening effect. The self-balancing external prestressing strengthening method can be used for strengthening heavy railroad brides, concrete box girders and T beams.

Owner:SHUOHUANG RAILWAY DEV +3

Water-retaining polycarboxylic acid type water reducer containing beta-cyclodextrin, preparation method thereof and usage method thereof

The invention discloses a water-retaining polycarboxylic acid type water reducer containing beta-cyclodextrin, a preparation method thereof and a usage method thereof. The water-retaining polycarboxylic acid type water reducer containing beta-cyclodextrin is prepared through a method of free-radical polymerization in an aqueous solution with treating allyl polyethylene glycol, acrylic acid, sodium methyl allyl sulfonate, beta-cyclodextrin, maleic anhydride, dimethyl formamide, sodium hydroxide, ammonium persulfate and azobis (isobutylamidine hydrochloride) as raw materials. The polycarboxylic acid type water reducer, which allows water reducing rate to be high, enhancement effect to be good and water retention and cohesiveness of concrete to be greatly improved, has large technical advantages in high fluidity concrete, self-compacting concrete, grouting materials and lean concrete, so the reducer provided by the invention has a broad market prospect.

Owner:河北红墙新材料有限公司

Vibration-free self-compacting concrete composition

The invention relates to infrastructure construction materials, particularly to a concrete composition. A vibration-free self-compacting concrete composition is formed by mixing of the following components by weight: 100 parts of cement, 10-30 parts of fly ash, 20-50 parts of limestone powder, 0.8-2 parts of a polycarboxylic acid water reducer, 250-350 parts of machine-made sand obtained by crushing gravel, and 250-350 parts of gravel. The limestone powder is made by processing the waste material generated in the gravel and machine-made sand production process. The invention realizes complete utilization of limestone resources, not only reduces the project cost, but also realizes the energy saving and environmental protection, thus being in line with the development requirements of green concrete.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

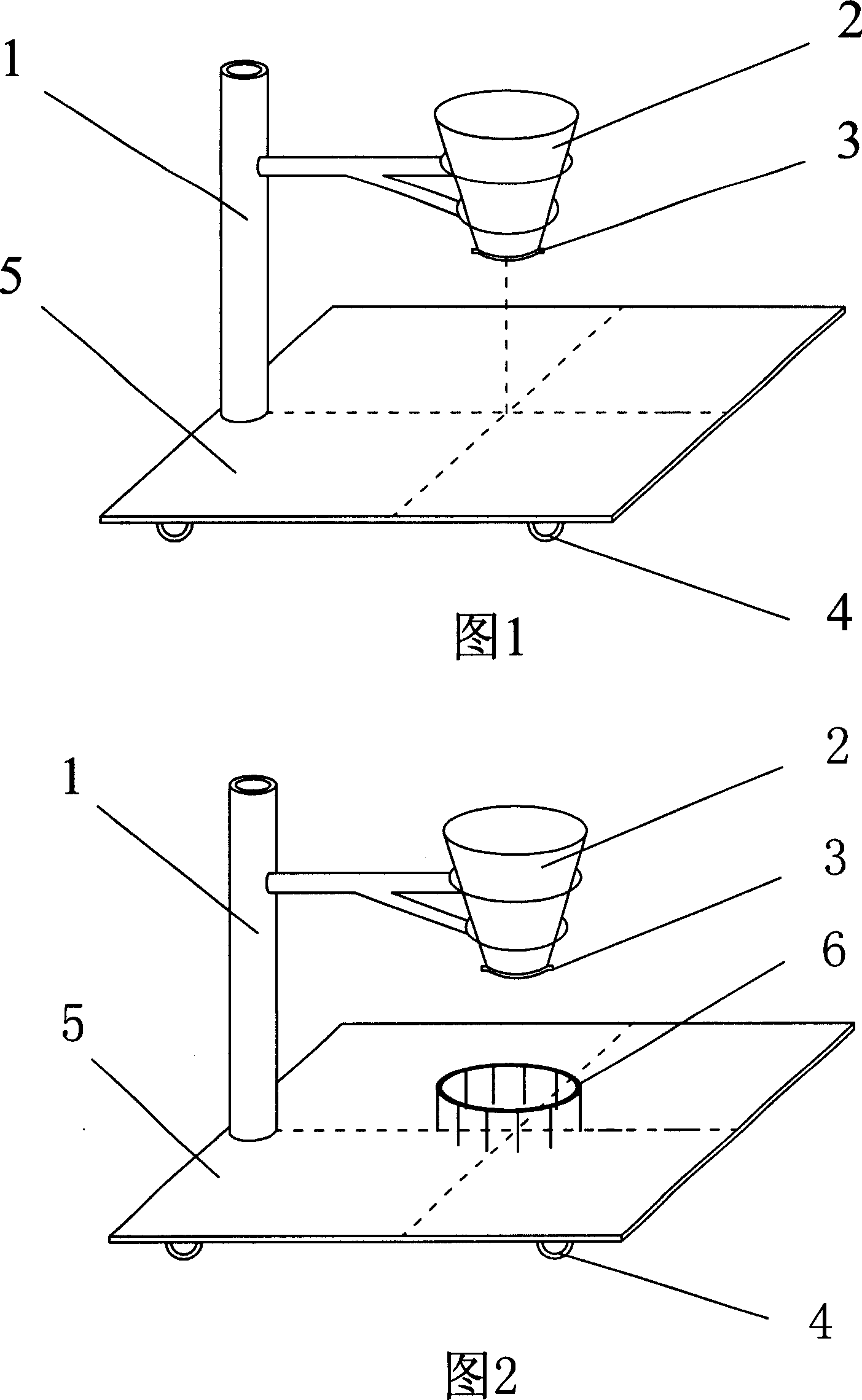

Integrated device for measurement and evaluation of workability of self-compacting concrete

InactiveCN101008640AReflective self-consolidationHuman subjective influence factors are reducedFlow propertiesUsing mechanical meansEngineeringMechanical engineering

This invention discloses one self-impacting concrete work property test and evaluation integration device, wherein, the rack supports and fixes switch head tamper cylinder with axis central line vertical to level surface with small diameter facing down; the said small diameter end is set with valve is set with plane board in certain distance; the said rack, plane board are fixed on band wheel cargo. This invention is one integration device to realize work property test.

Owner:CENT SOUTH UNIV

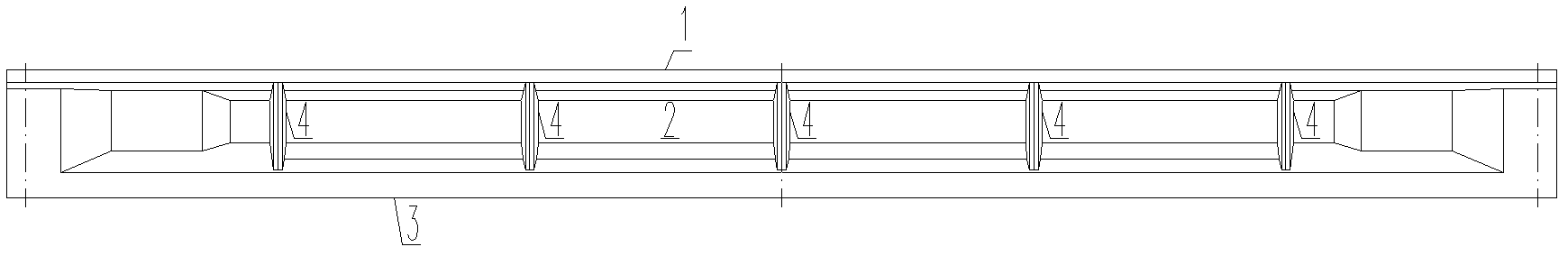

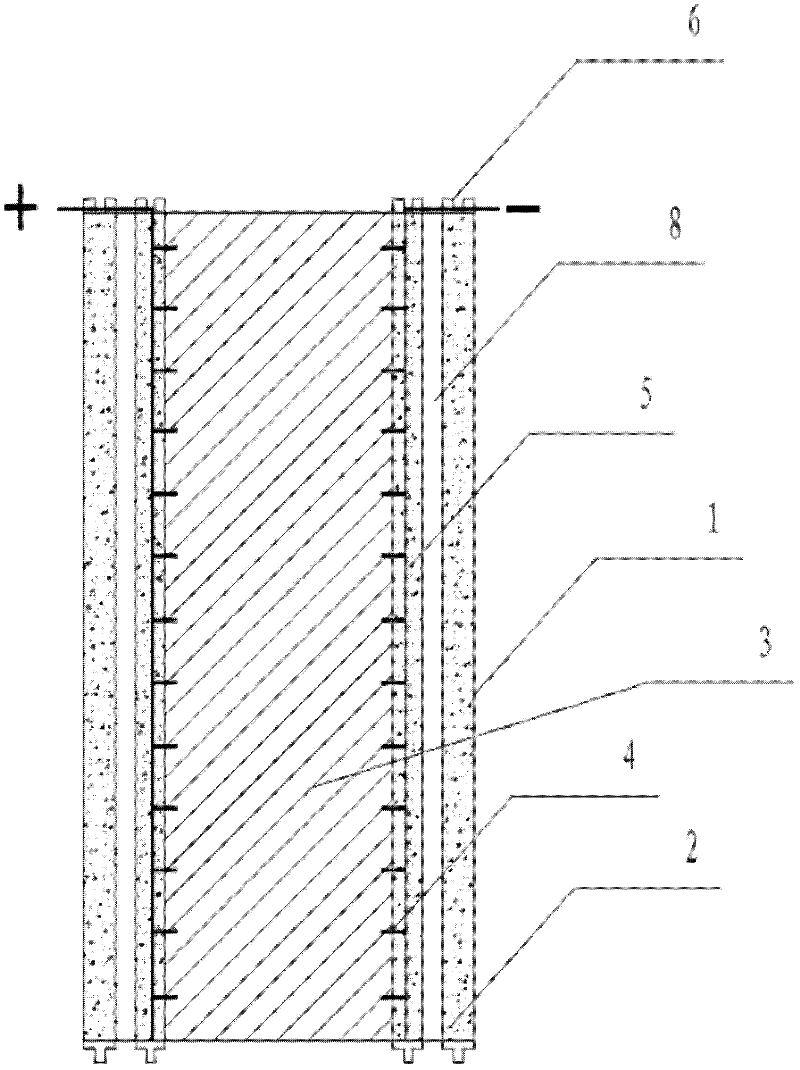

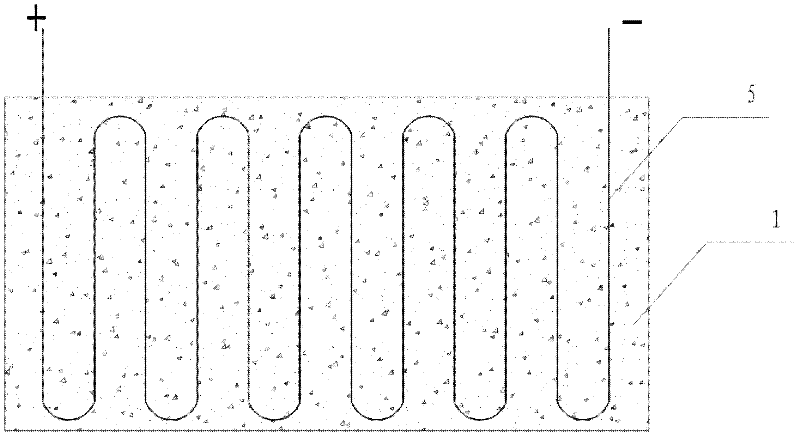

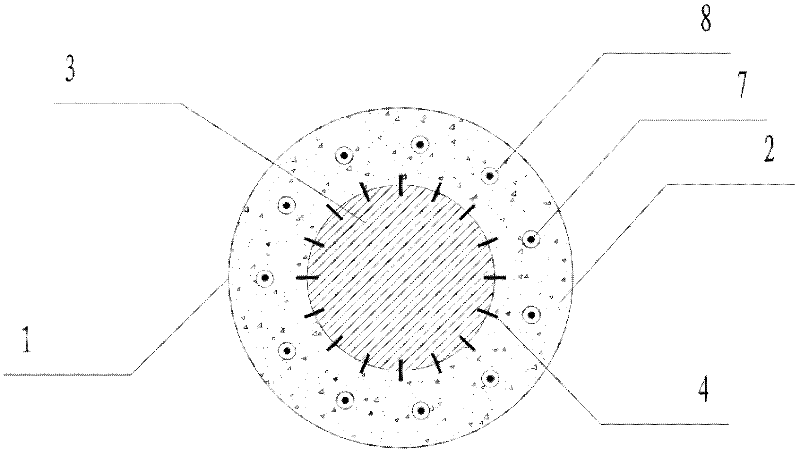

Novel precast concrete pipe die and construction method thereof

InactiveCN102373803ARealize the use functionReduce usageStrutsForms/shuttering/falseworksPre stressEngineering

The invention discloses a novel precast concrete pipe die, which is a precast concrete pipe pile of a hollow structure. The wall of the precast concrete pipe die is internally provided with annular and vertical reinforcing steel bars, the inner surface of the pipe die is provided with dowel bars connected with post-poured concrete into a whole and an electric heating wire for heating, the upper end and the lower end of the pipe die are provided with tooth-shaped connectors which are mutually matched, the wall of the pipe die is internally provided with preset pore canals for prestress reinforcing steel bars, and the pore canals are through longitudinally. A construction method of the novel precast concrete pipe die comprises the steps of: after positioning the precast concrete pipe die, switching on a power supply of the electric heating wire, and performing high-dropping self-compacting concrete pouring on the middle of the concrete pipe die; and after a first section of cylinder core of the pipe die is poured, performing hoisting positioning and concrete pouring on a second section of the concrete pipe die. The invention has the advantages that by precasting the concrete pipe die, the special requirement on the use functions of a concrete column surface and a column template can be met, and the heating functions of the novel precast pipe die can also ensure the smooth construction in winter; and the novel precast concrete pipe die and the construction method thereof have the advantages of simplicity and rapidness for construction, less required construction equipment, and capability of greatly reducing the construction cost and the comprehensive manufacturing cost.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com